Patents

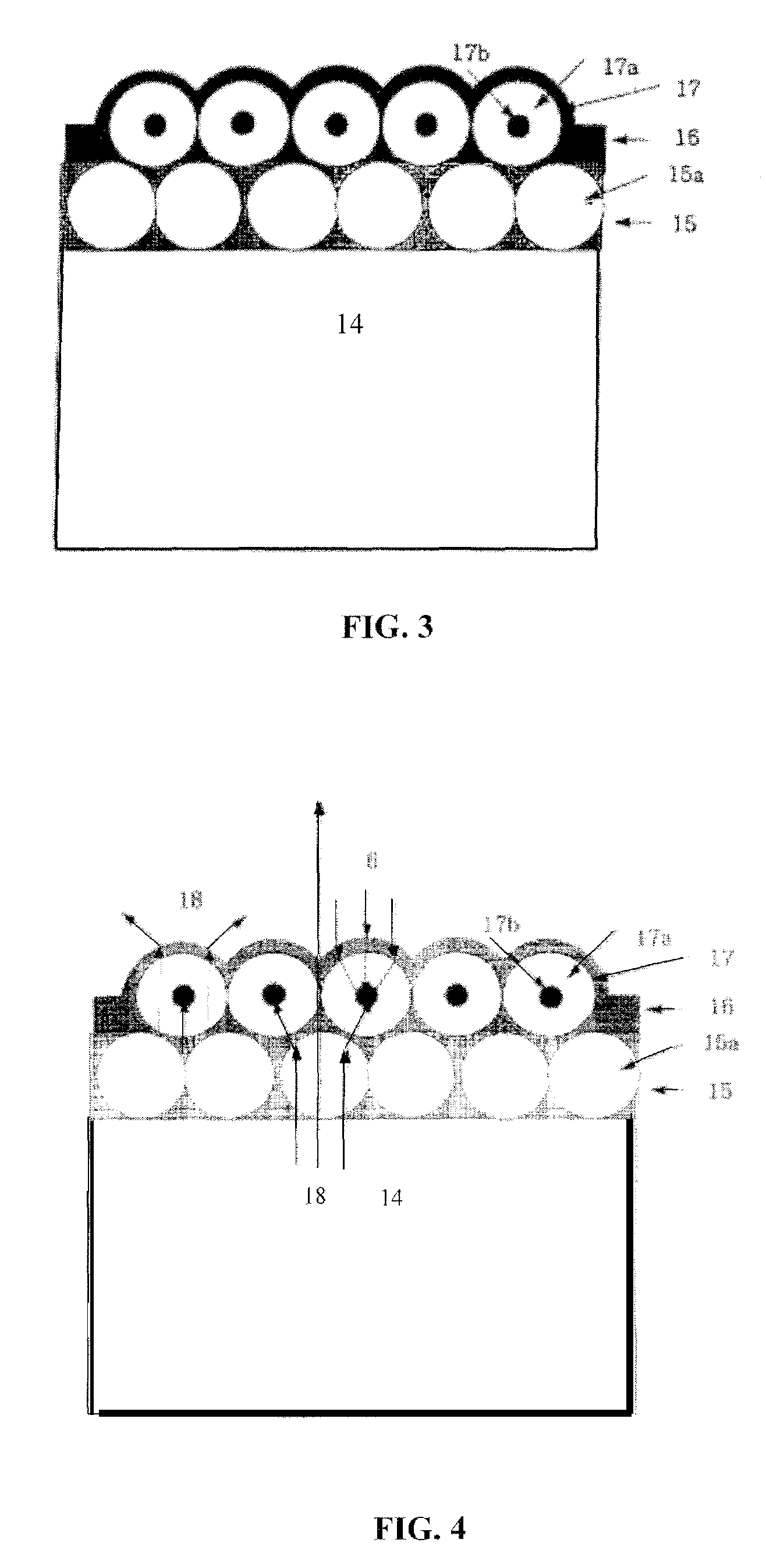

Literature

8273 results about "Optical film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

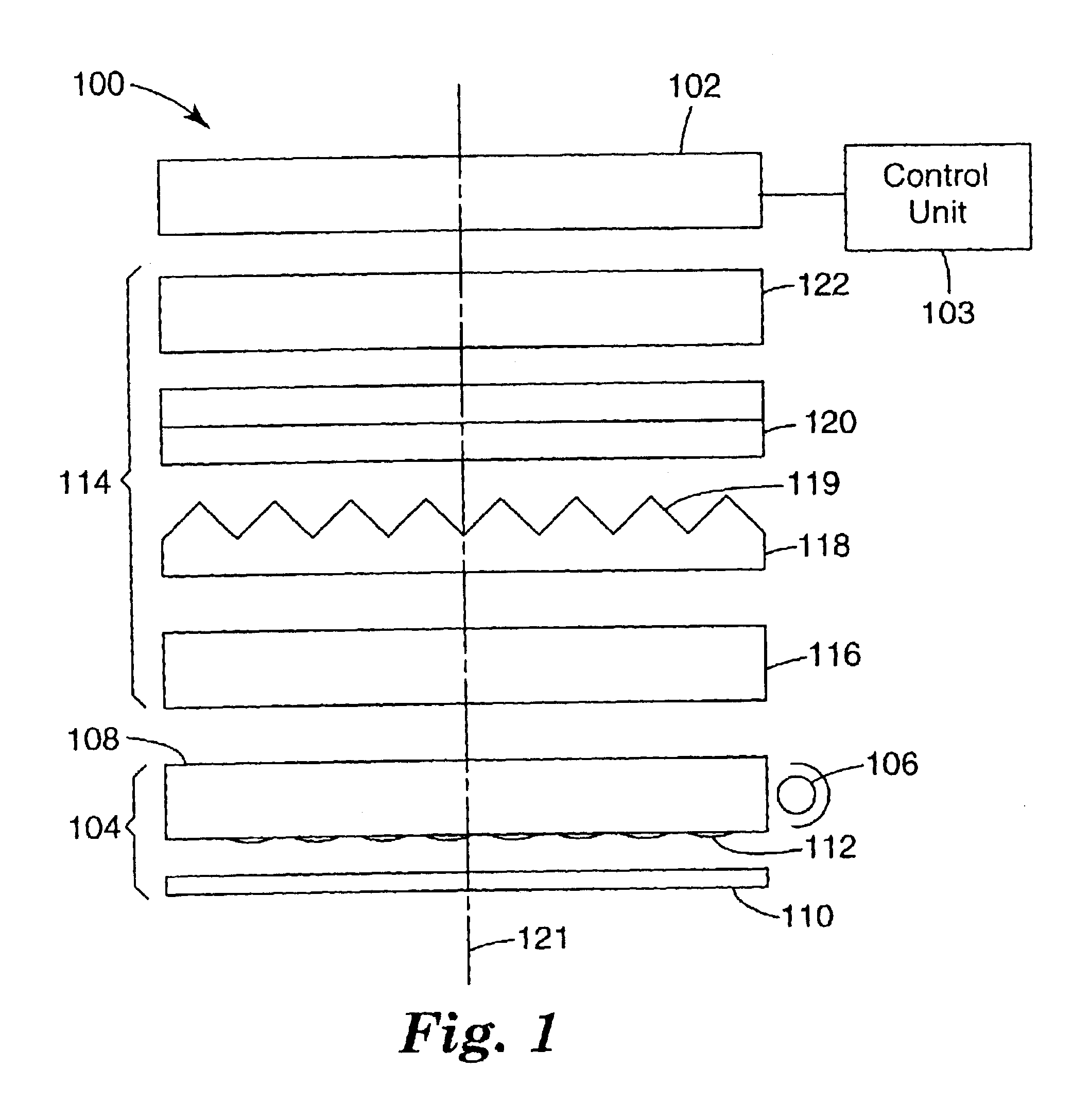

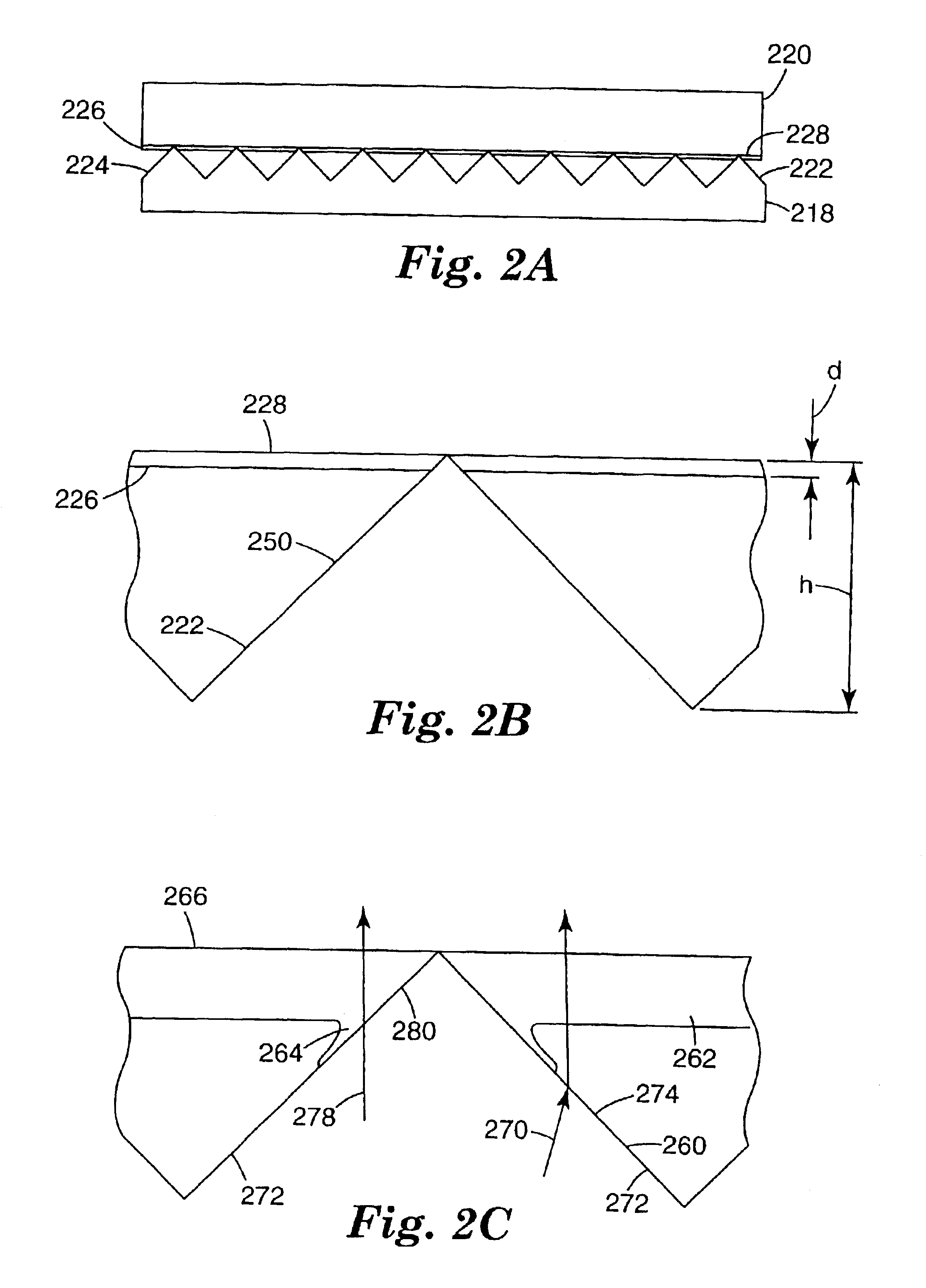

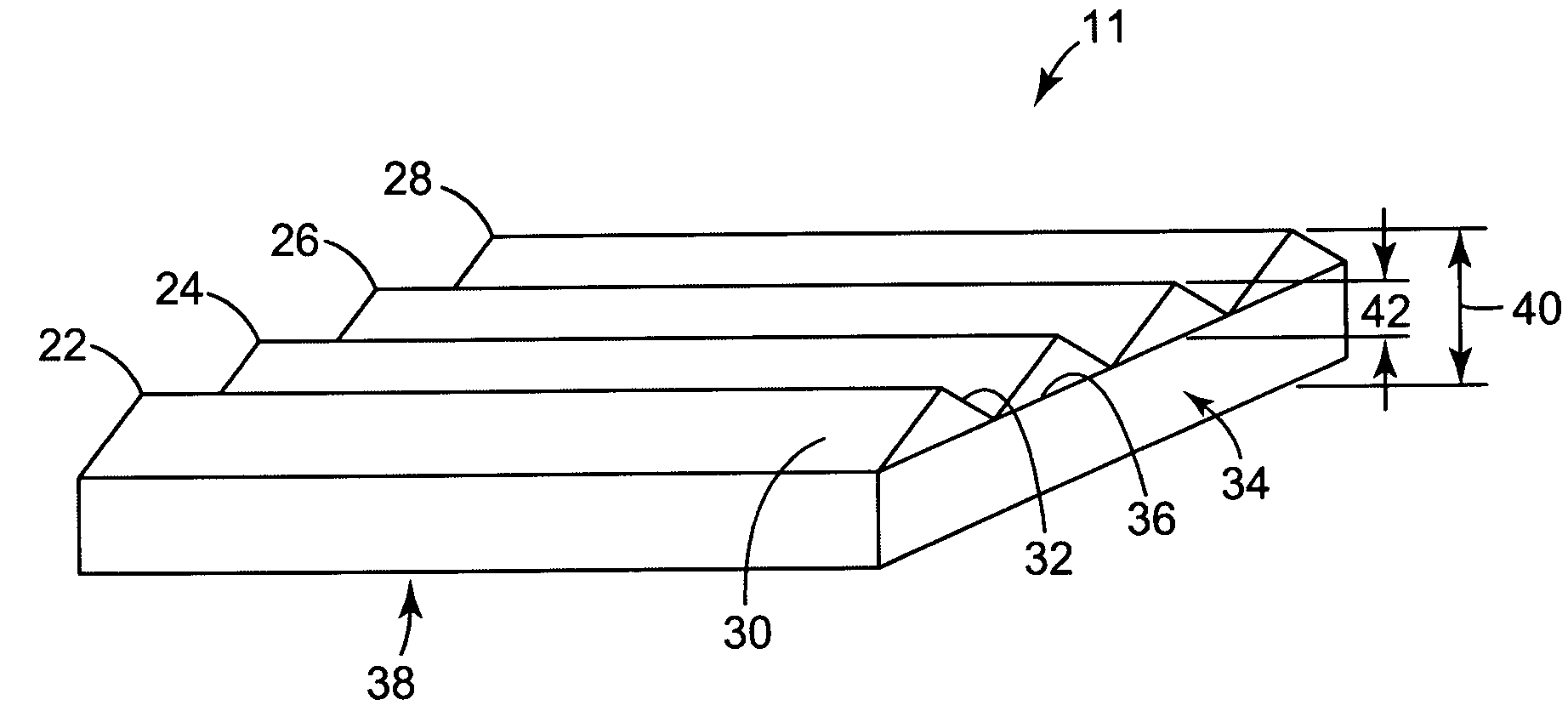

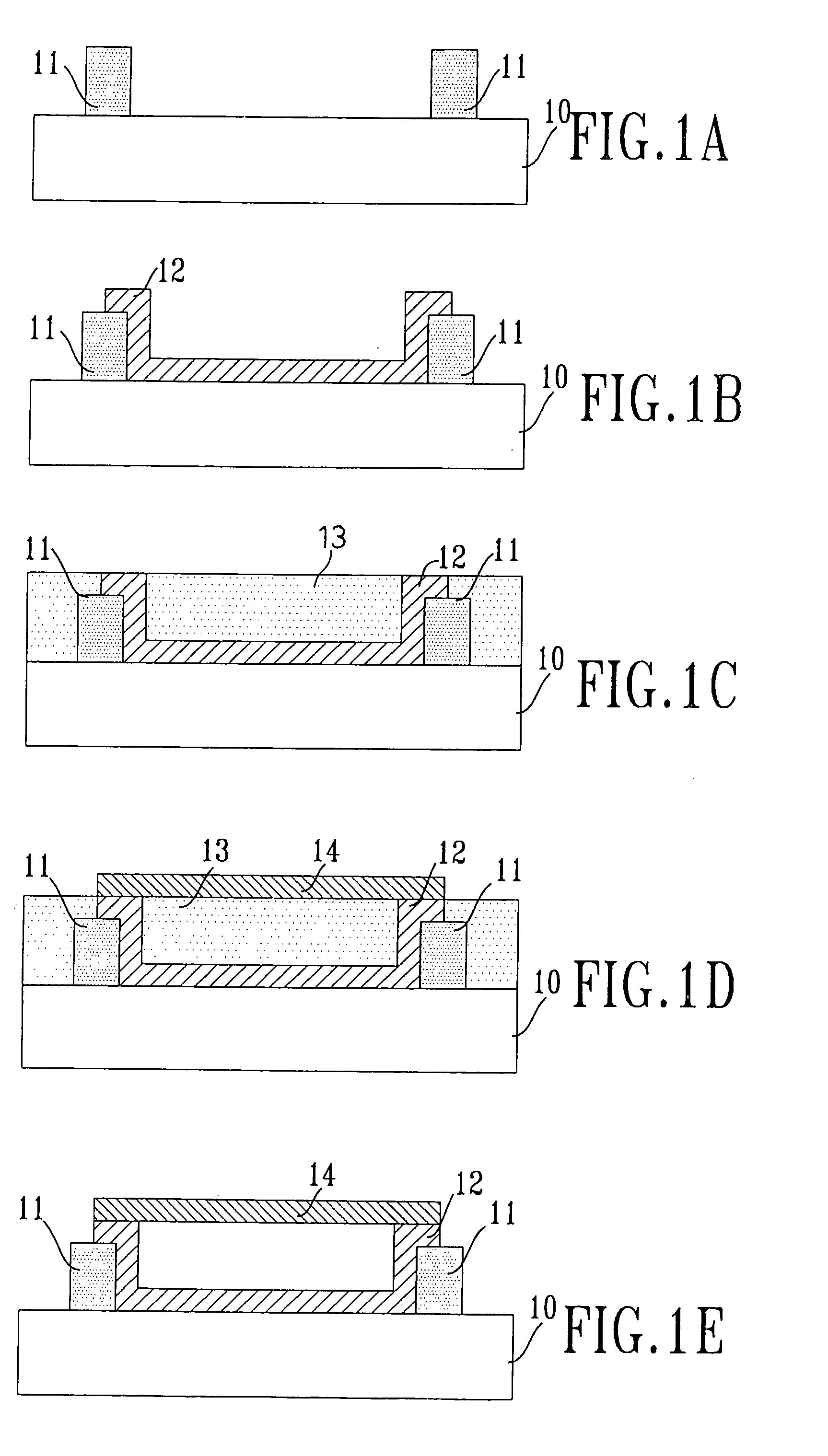

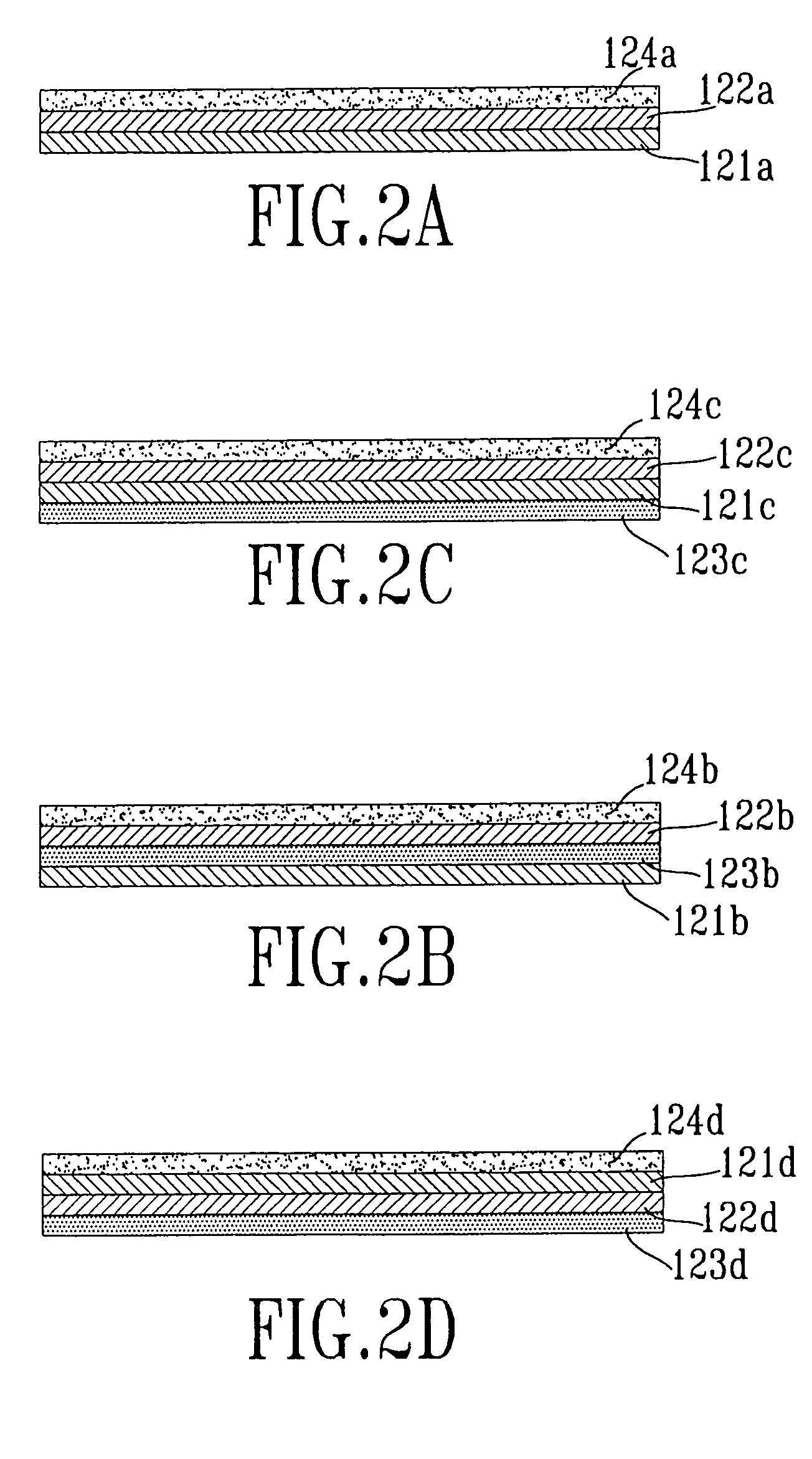

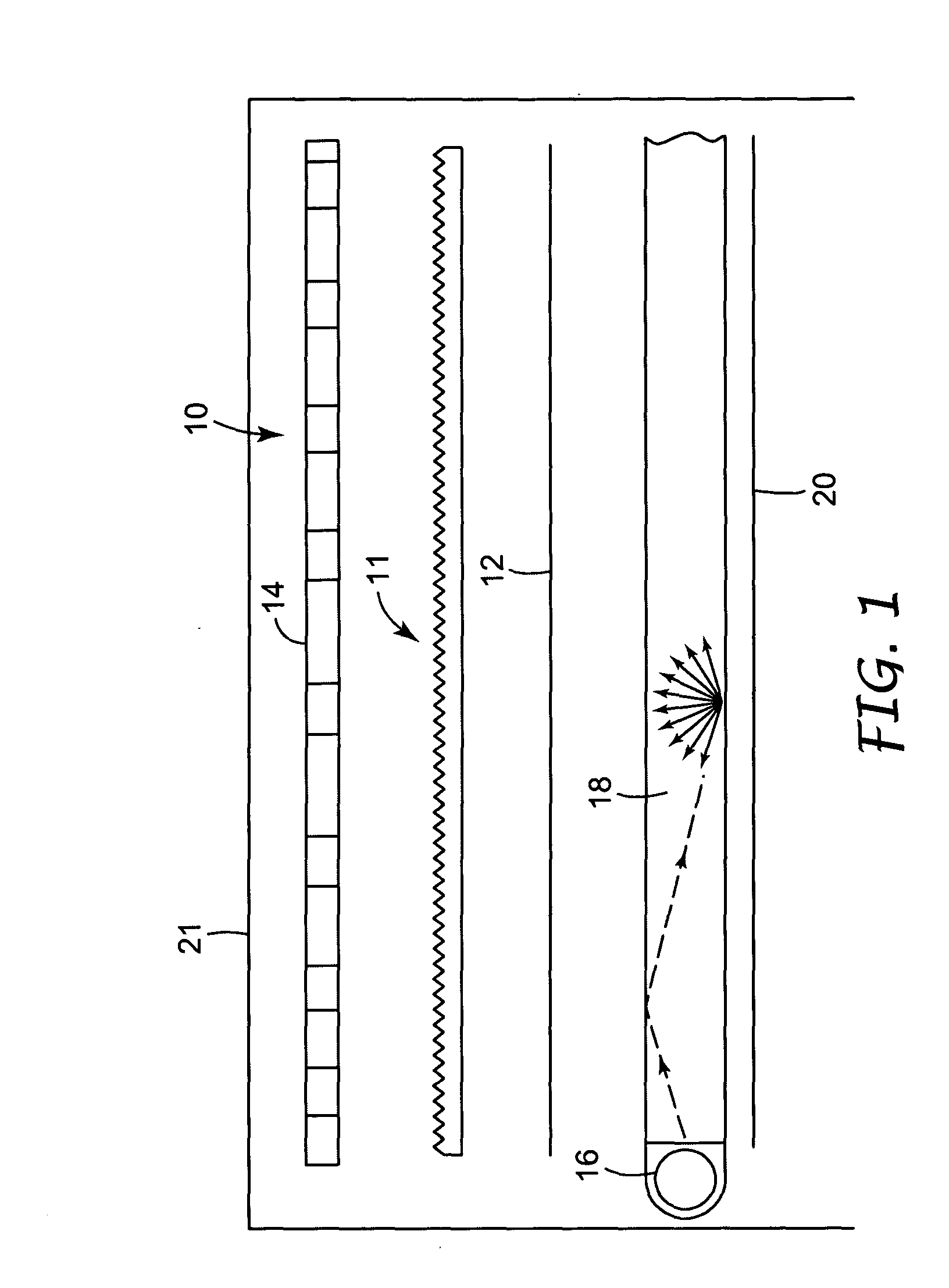

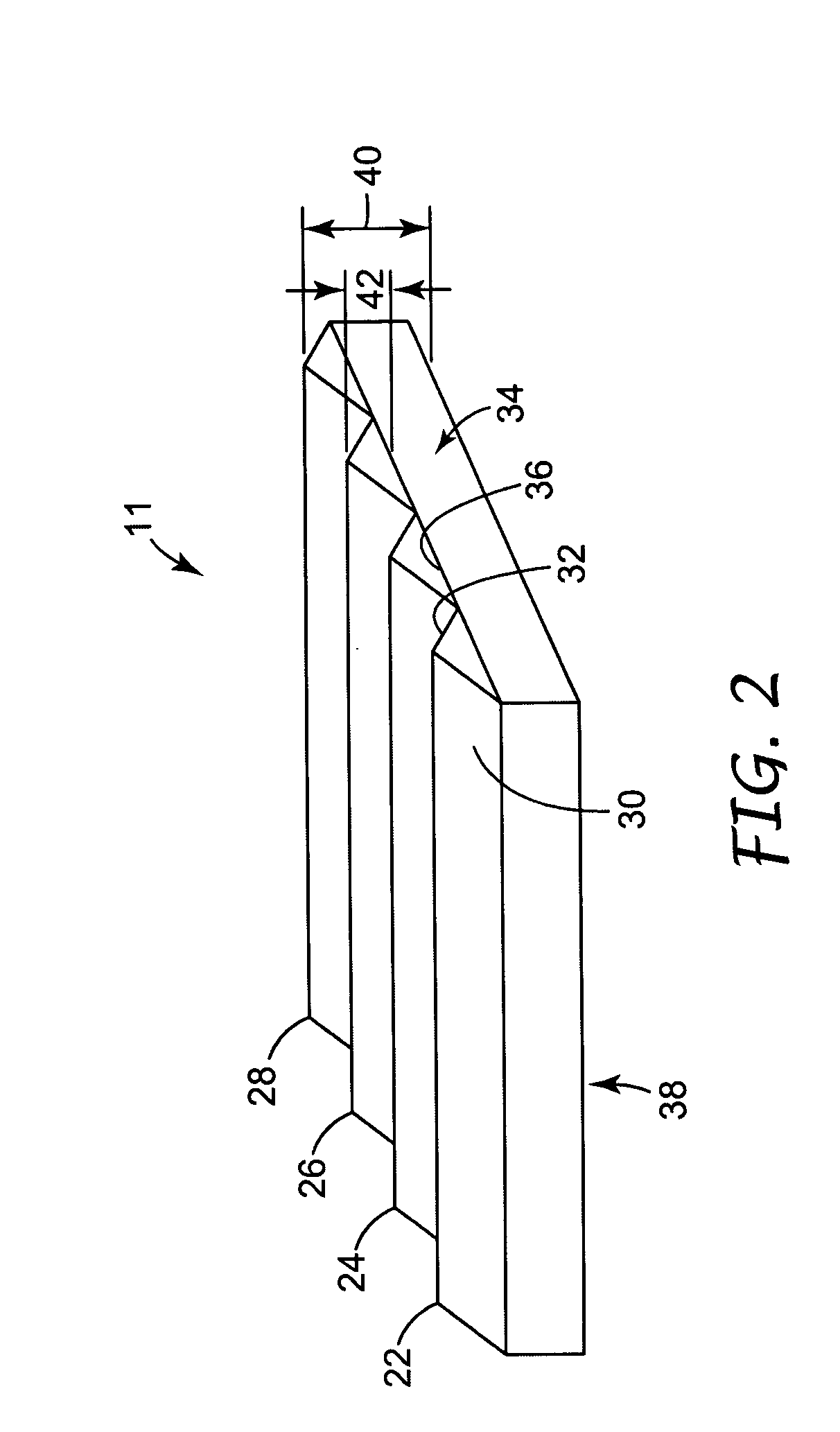

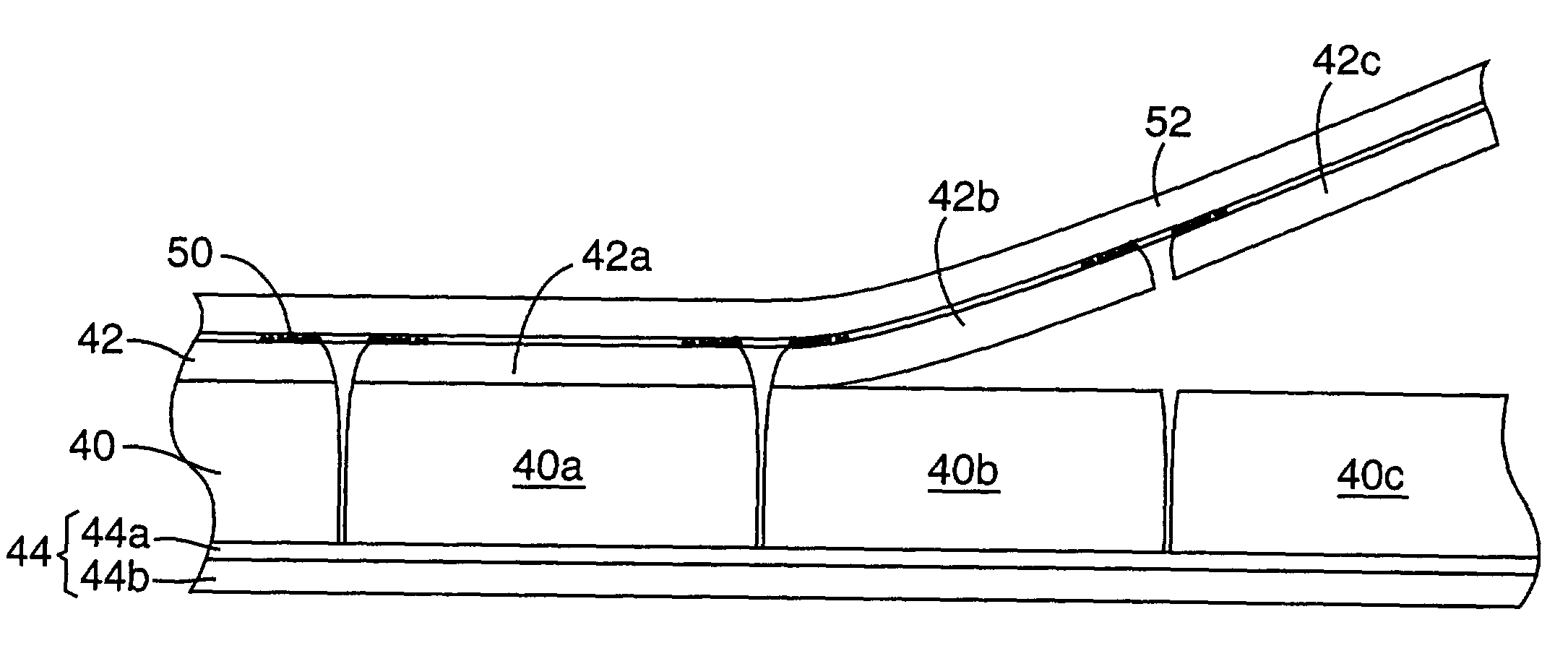

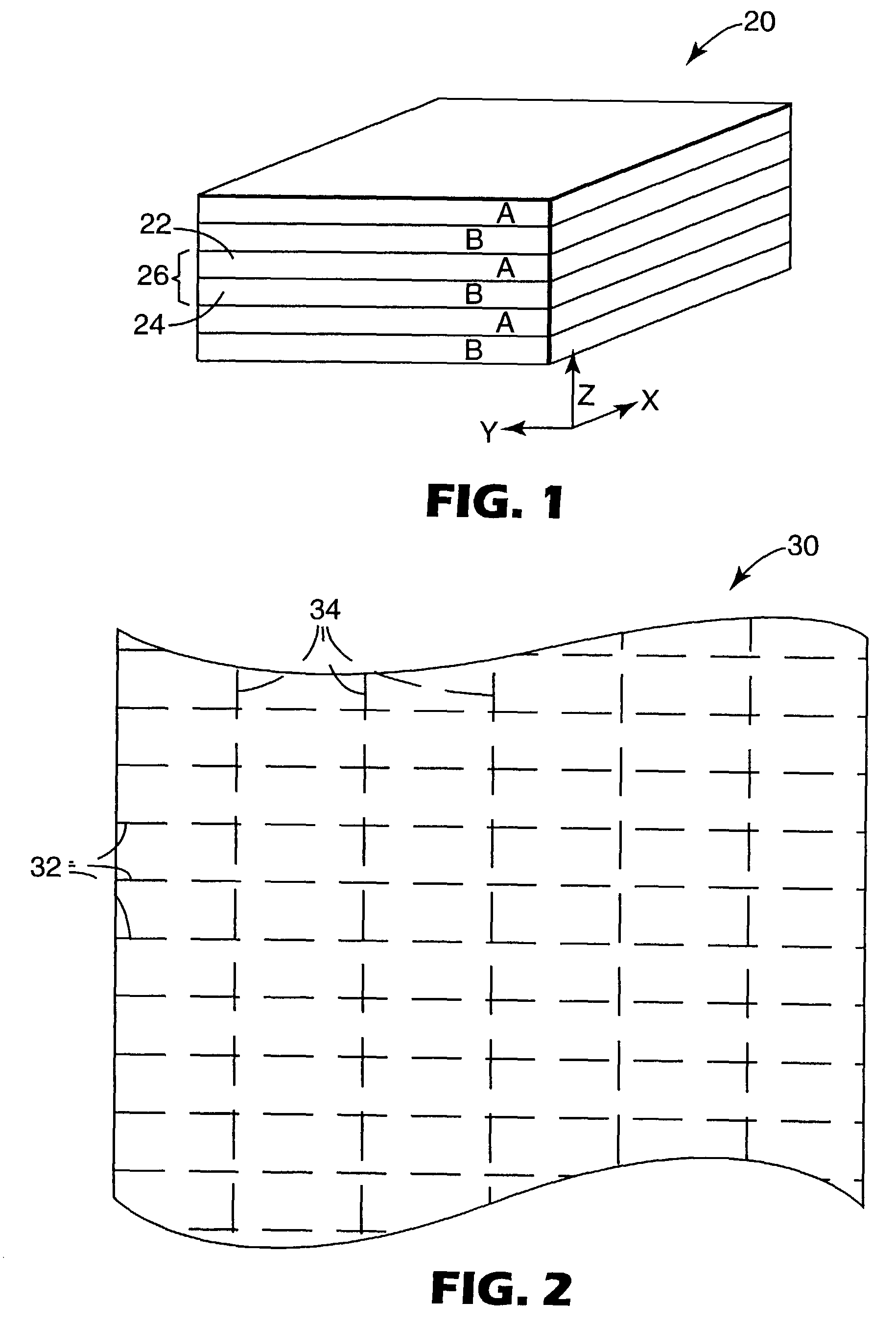

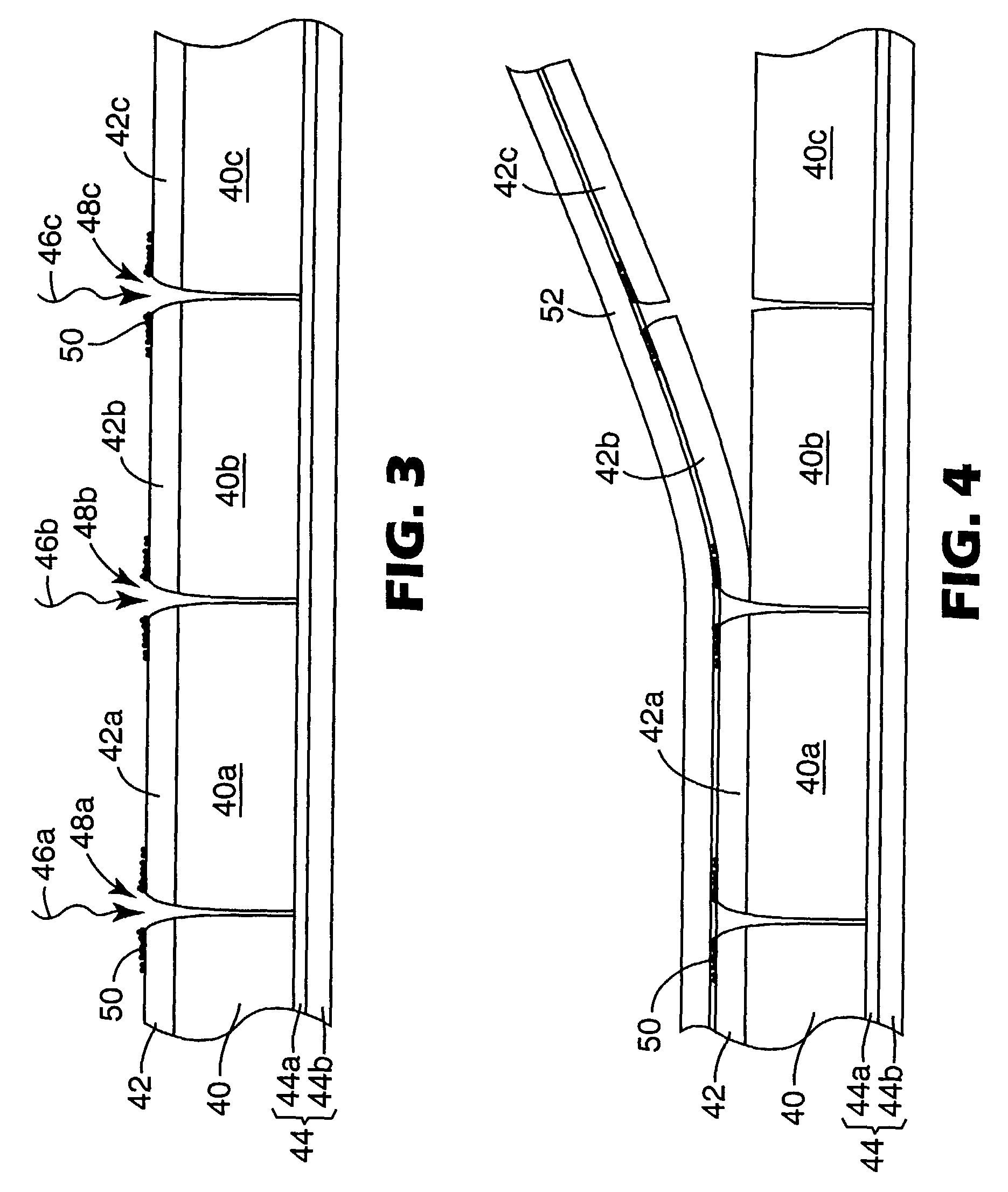

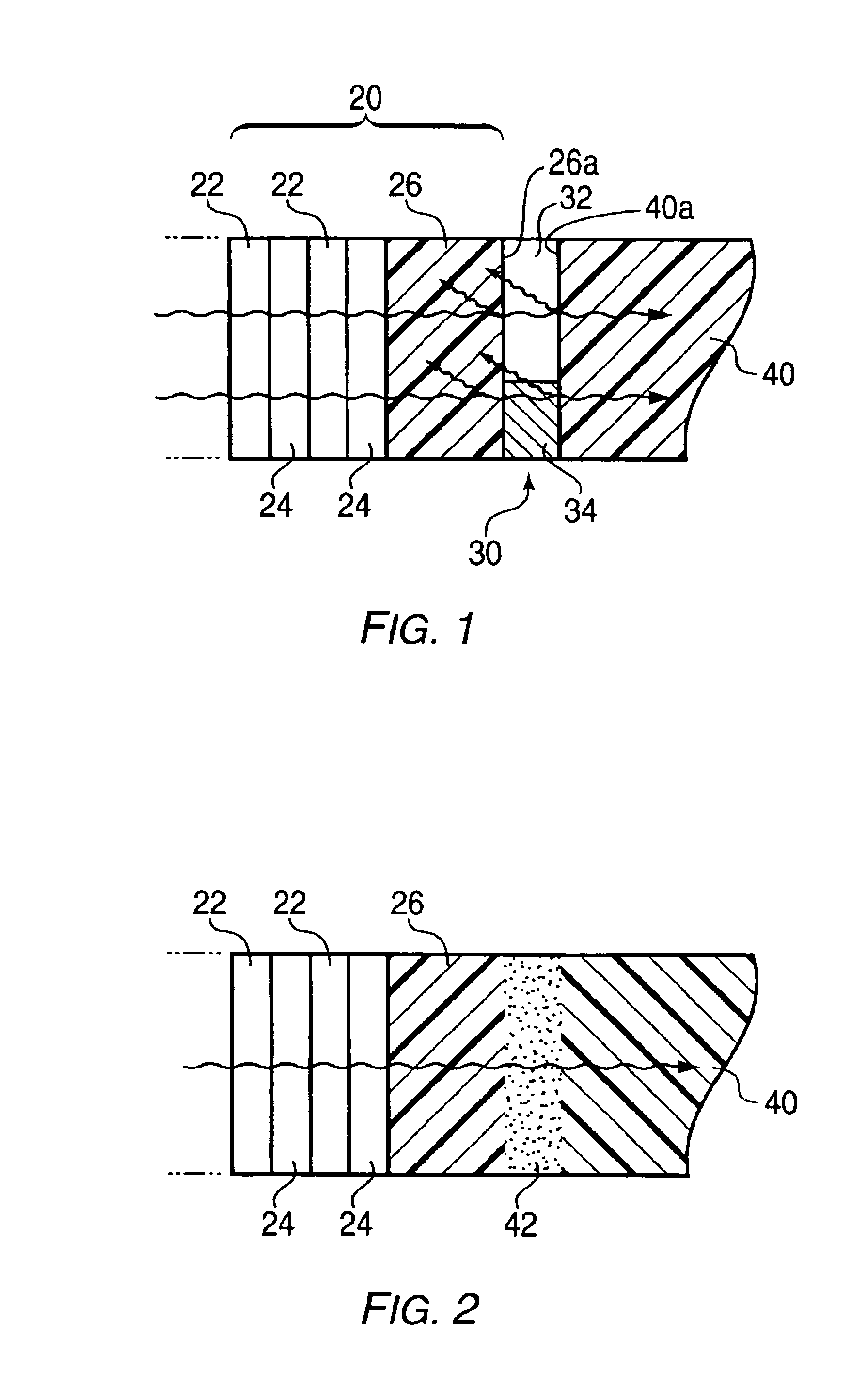

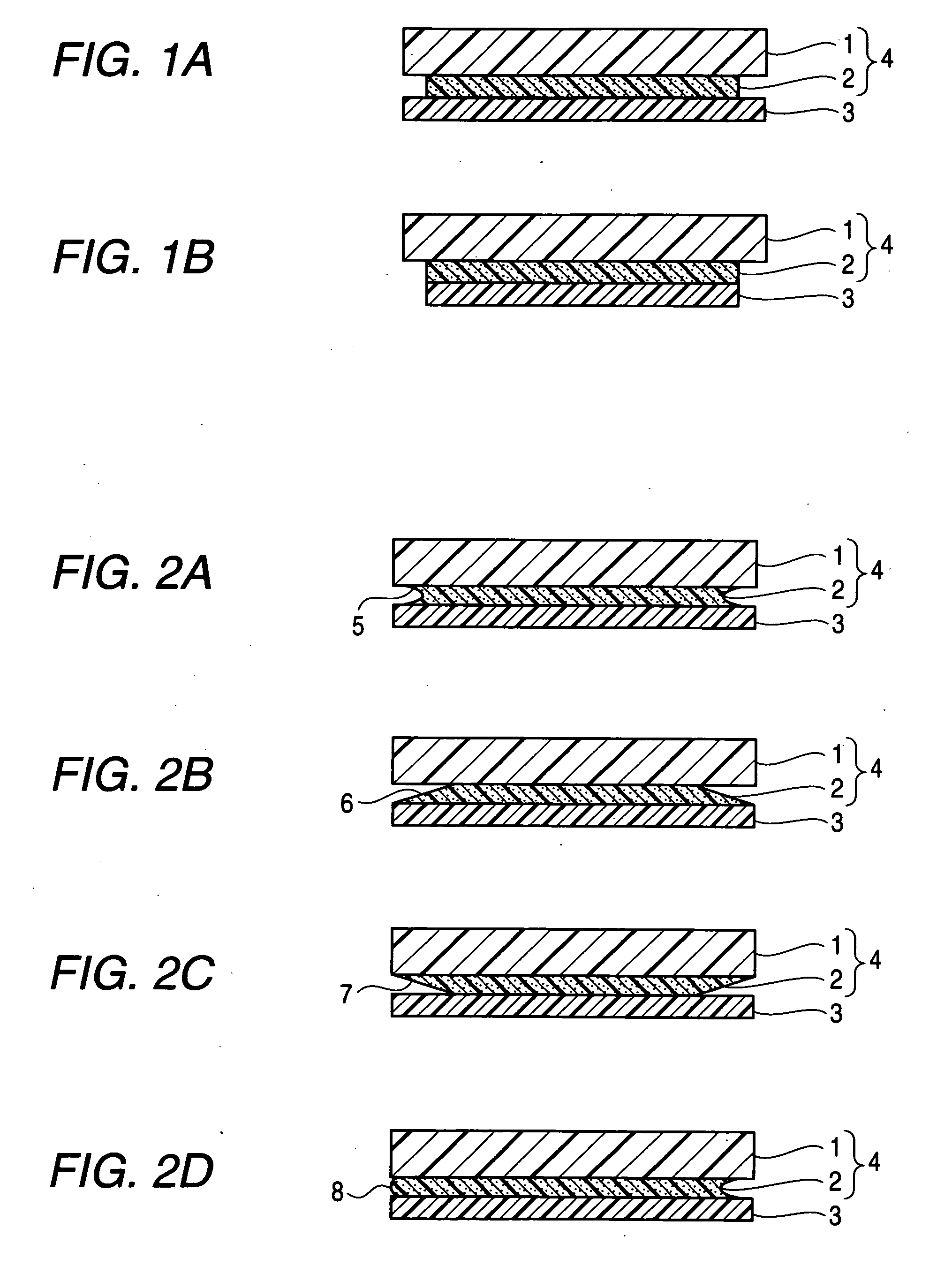

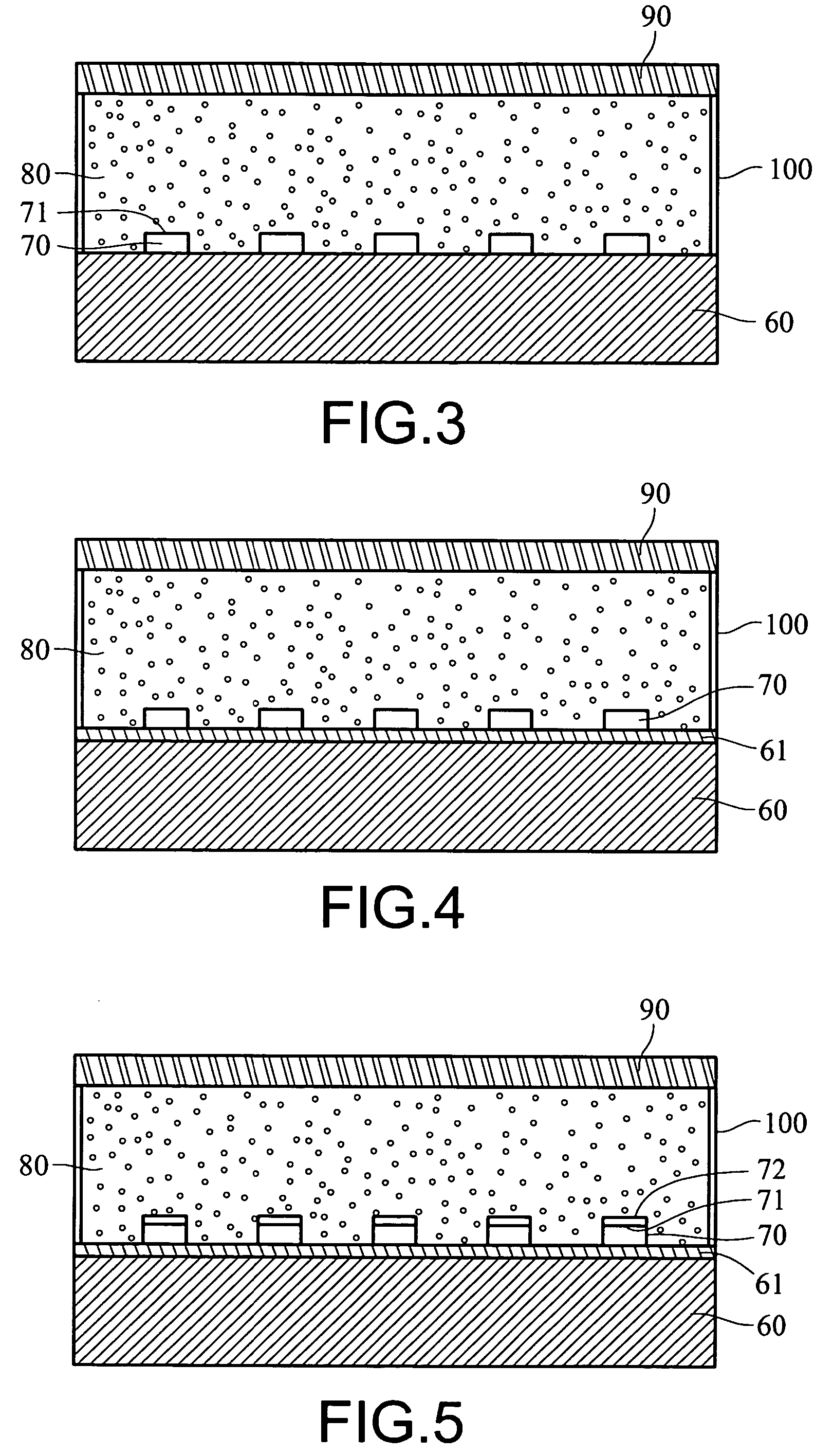

Method for stacking surface structured optical films

InactiveUS6846089B2Reduce the number of stepsIncrease productionShow cabinetsImpedence networksAdhesiveDisplay device

A display includes an optical film that has a surface structure, such as a prismatically structured surface for increasing the brightness of the display. The structured surface is bonded to an opposing surface of a second film using a layer of adhesive, by penetrating the structured surface into the adhesive layer to a depth less than a feature height of the structured surface. The bonded film structure provides additional strength to the films and reduces the possibility of film damage during display assembly.

Owner:3M INNOVATIVE PROPERTIES CO

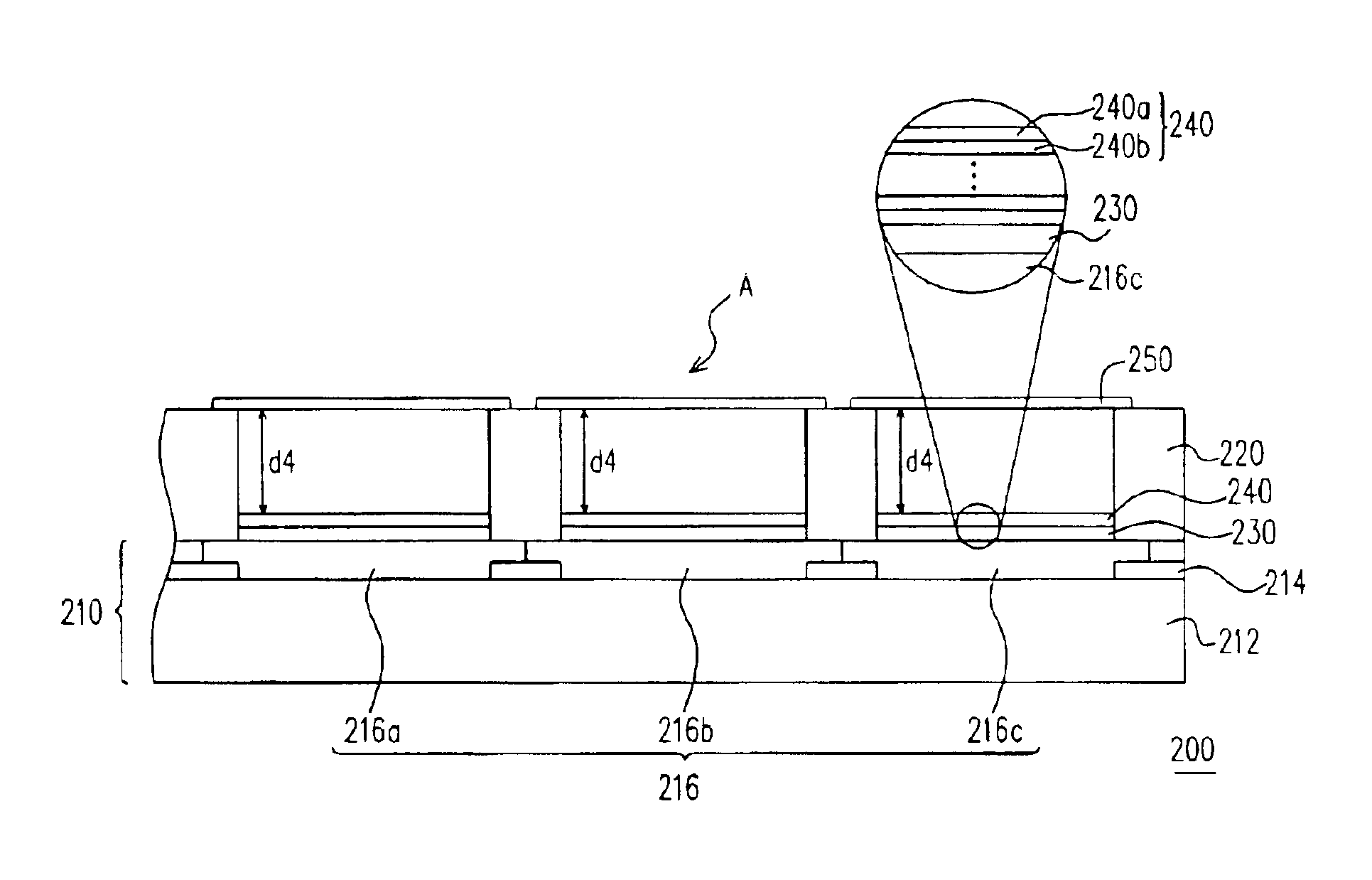

Optical interference color display and optical interference modulator

An optical interference color display is provided. The optical interference color display comprises a color filtering substrate, a patterned support layer, a plurality of first electrodes, a plurality of optical films and a plurality of second electrodes. The patterned support layer and the first electrodes are positioned on the color filtering substrate with the patterned support layer between the first electrodes. The optical films are positioned on the first electrodes. The second electrodes is positioned over the first electrodes and supported through the patterned support layer such that an air gap with identical thickness is produce between every pair of second electrode and first electrode. Using the color filtering substrate to show color images, air gap between the first electrodes and the second electrodes are identical and hence simplifies the manufacturing process.

Owner:SNAPTRACK

Durable optical element

ActiveUS7074463B2Liquid crystal compositionsTelevision system detailsDisplay deviceColloidal nanoparticles

A durable optical film or element includes a polymerized structure having a microstructured surface and a plurality of surface modified colloidal nanoparticles of silica, zirconia, or mixtures thereof. Display devices including the durable microstructured film are also described.

Owner:3M INNOVATIVE PROPERTIES CO

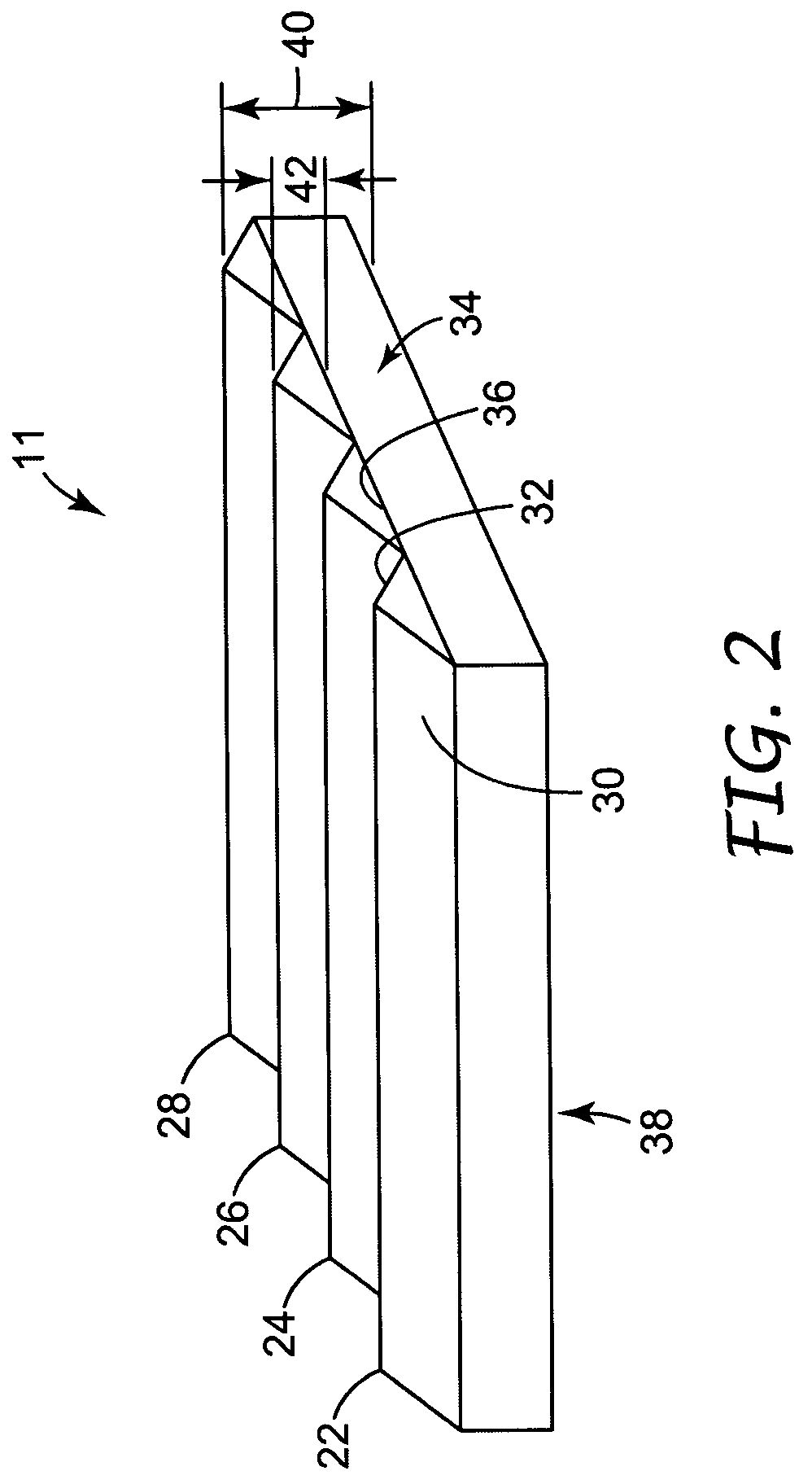

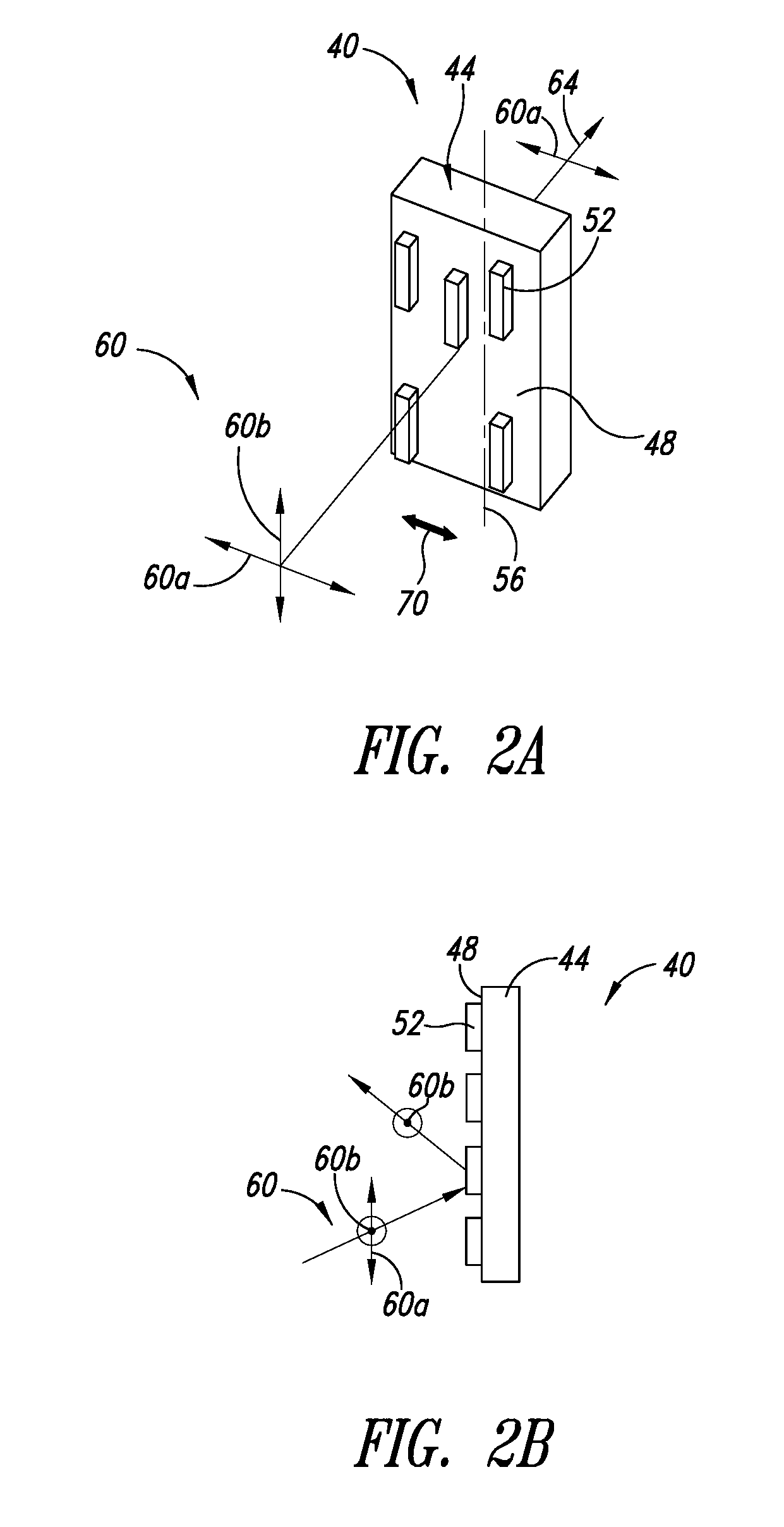

Methods of cutting or forming cavities in a substrate for use in making optical films, components or wave guides

InactiveUS20050024849A1Small in in lengthSmall in widthMechanical apparatusFlat articlesEngineeringRidge

The methods involve using a tool to cut or form multiple optical element shaped cavities in a surface of a substrate without rotating the tool or substrate during the cutting or forming process. At least some of the cavities are cut or formed to have at least two surfaces that come together to form a ridge and that are quite small relative to the length and width of the substrate. Thereafter the substrate is used to form optical films, components or wave guides having multiple optical elements on at least one surface corresponding to the cavities in the substrate.

Owner:SOLID STATE OPTO

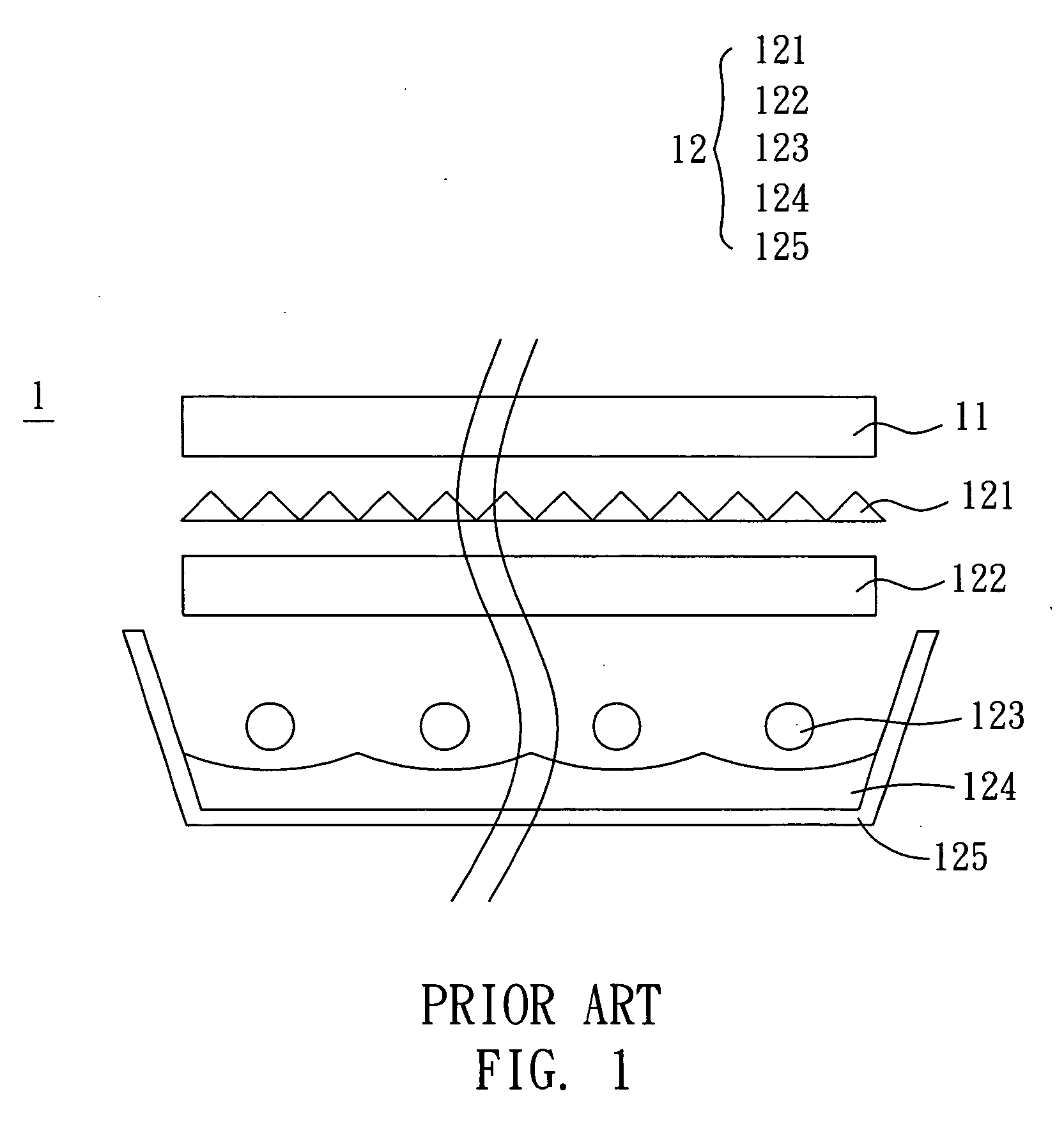

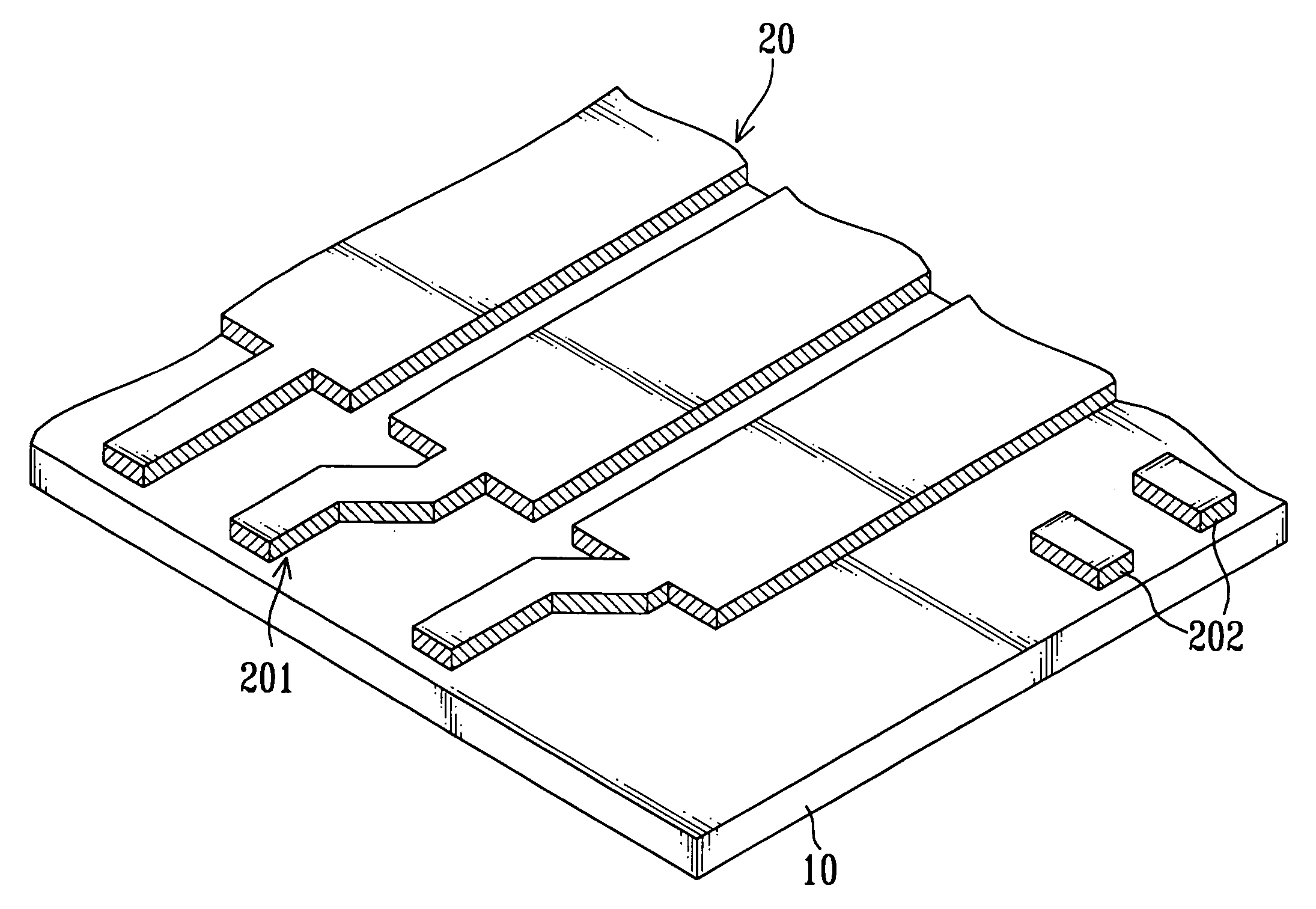

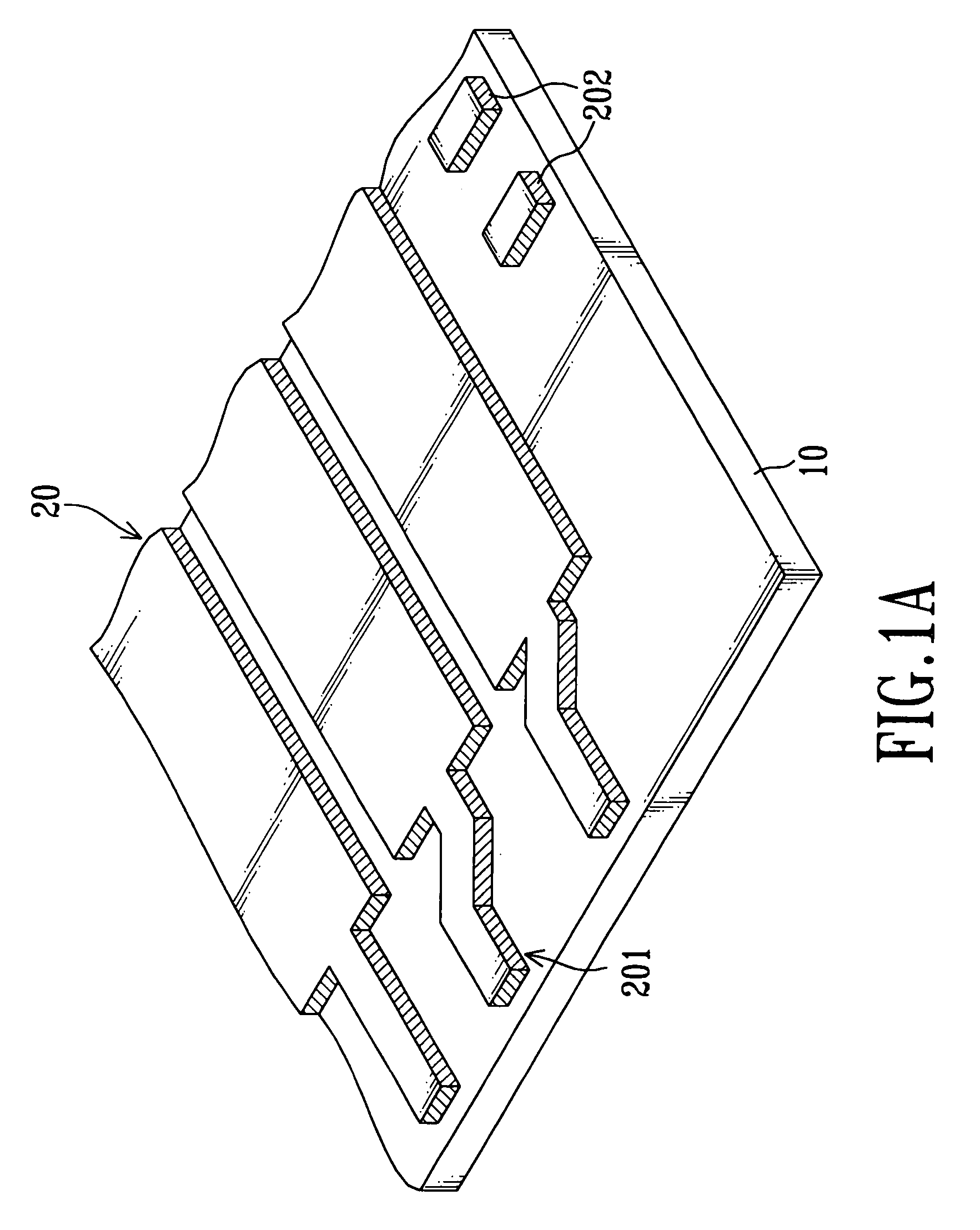

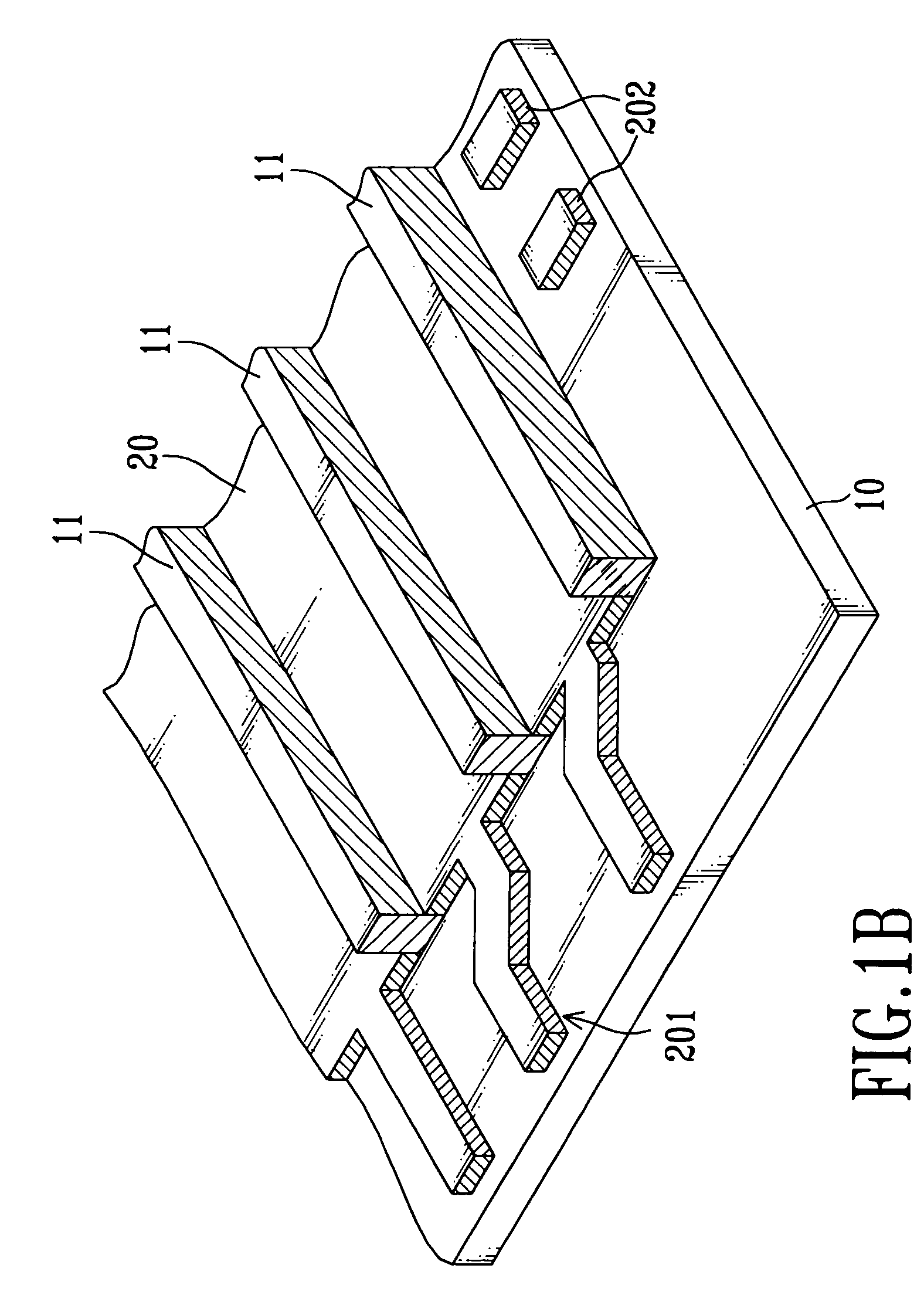

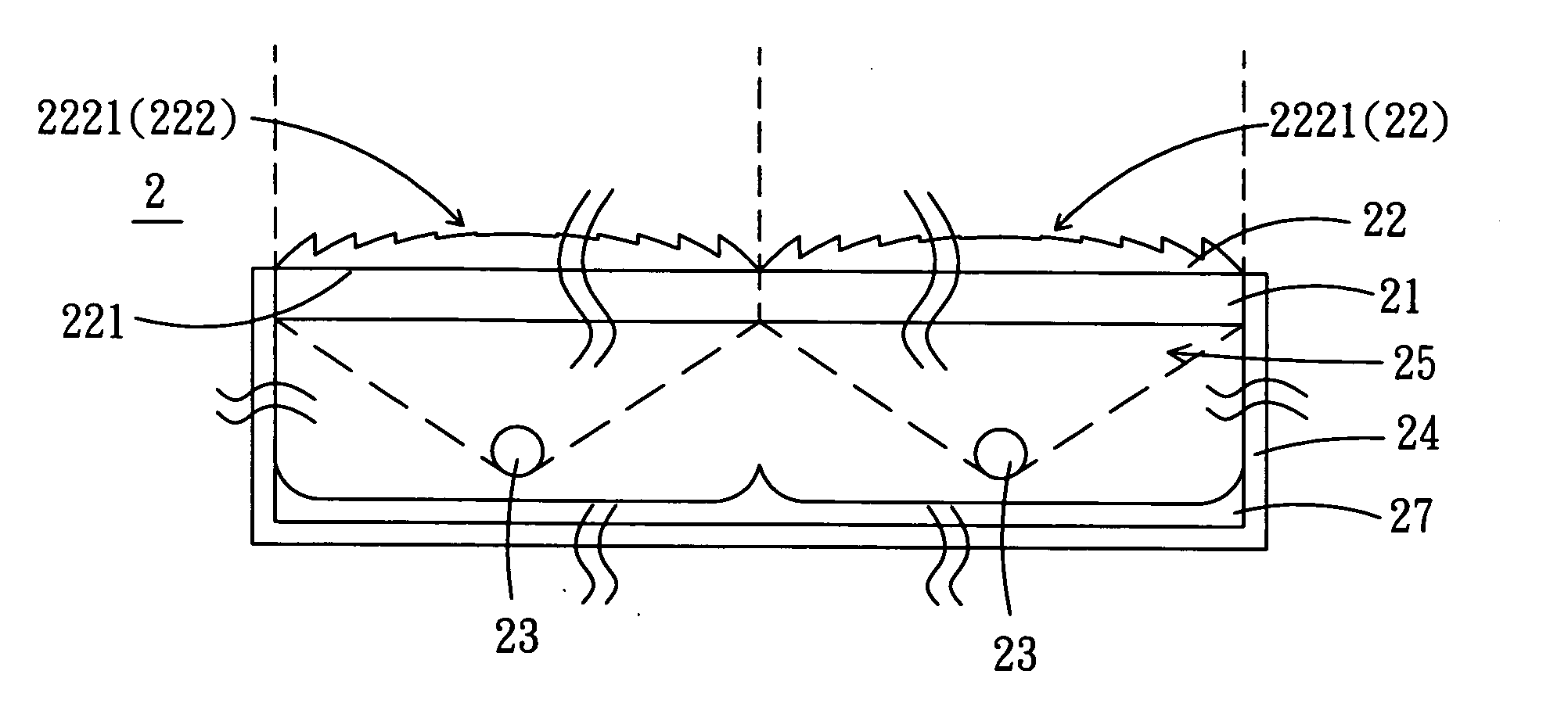

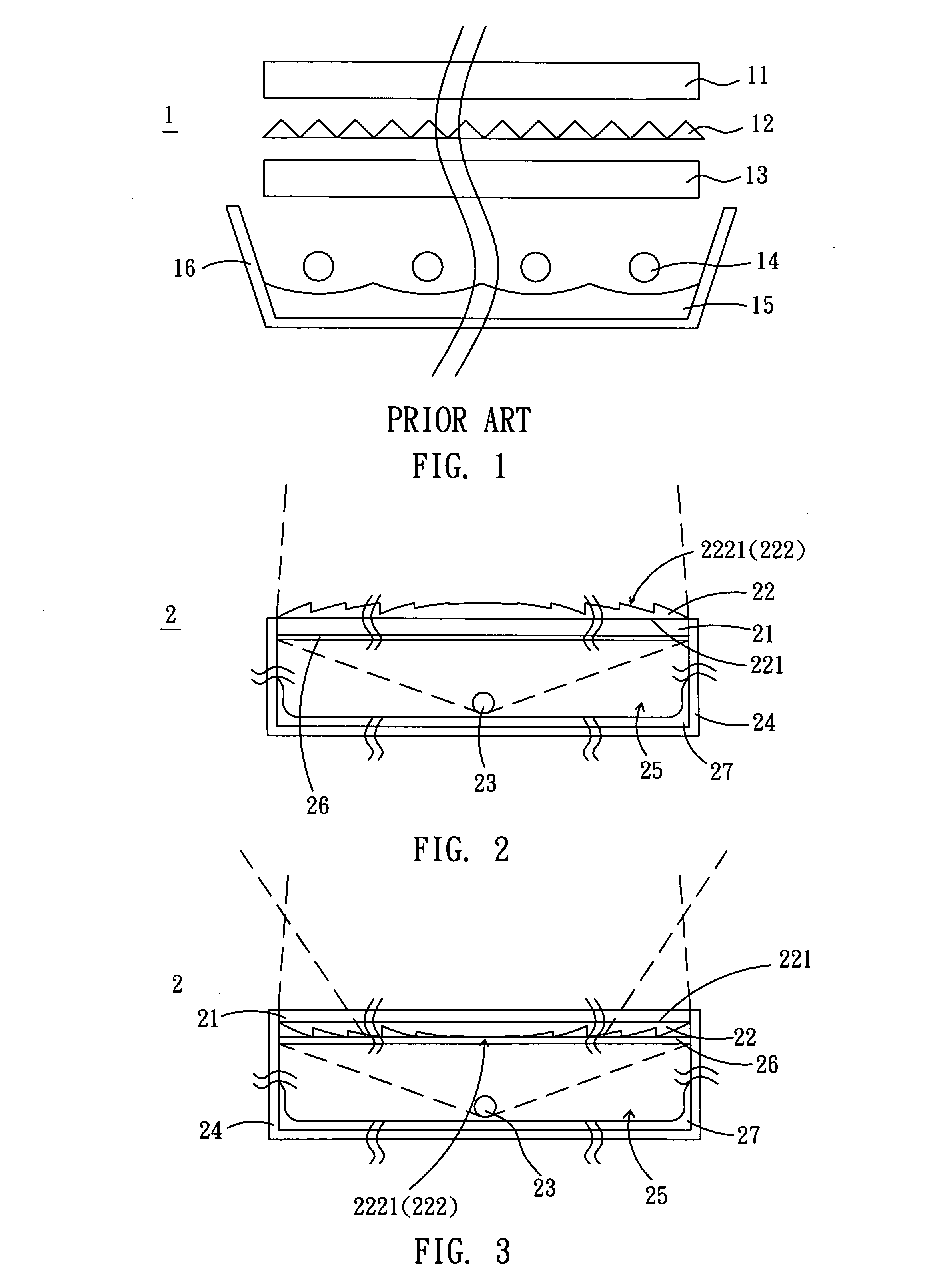

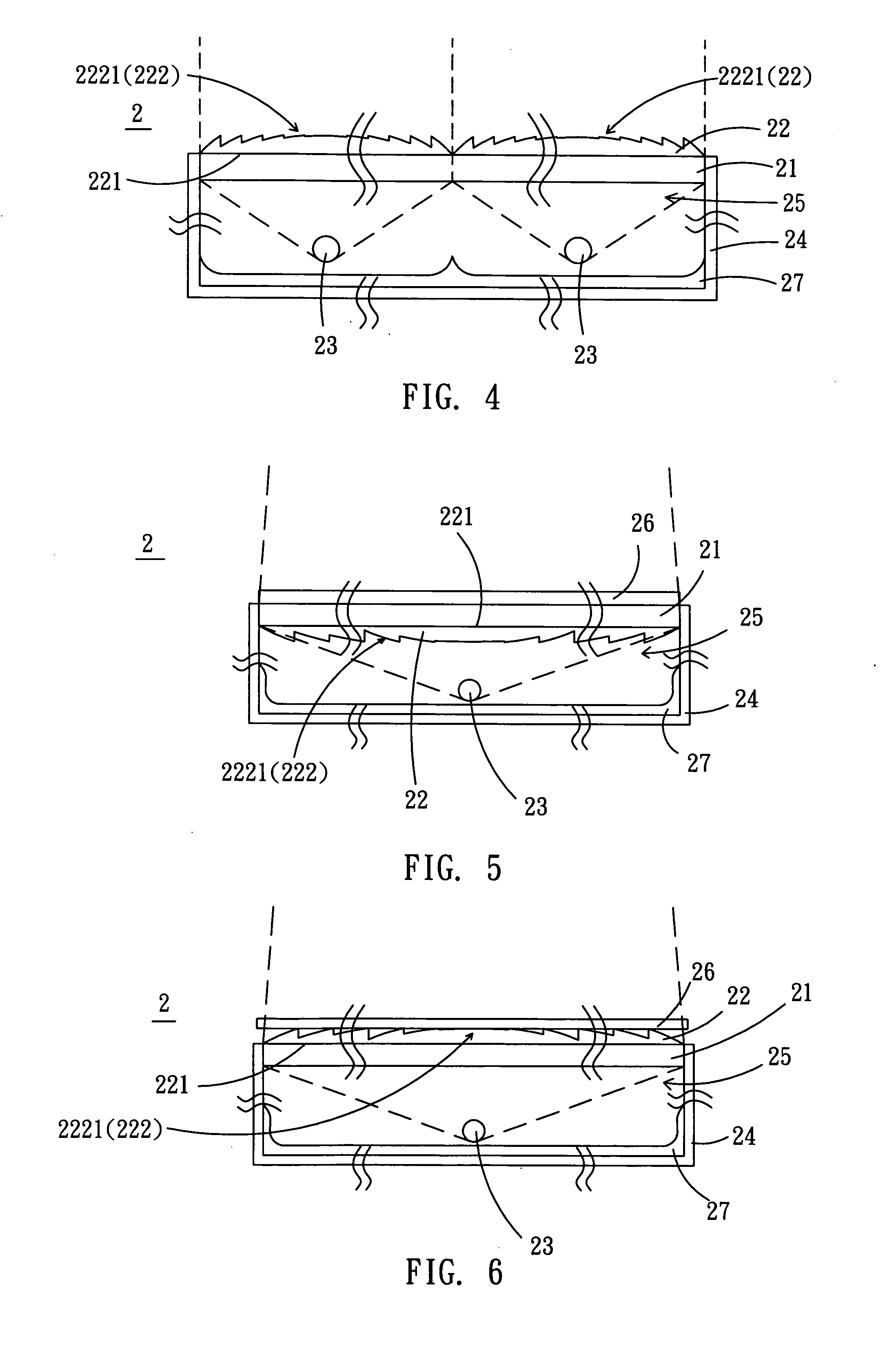

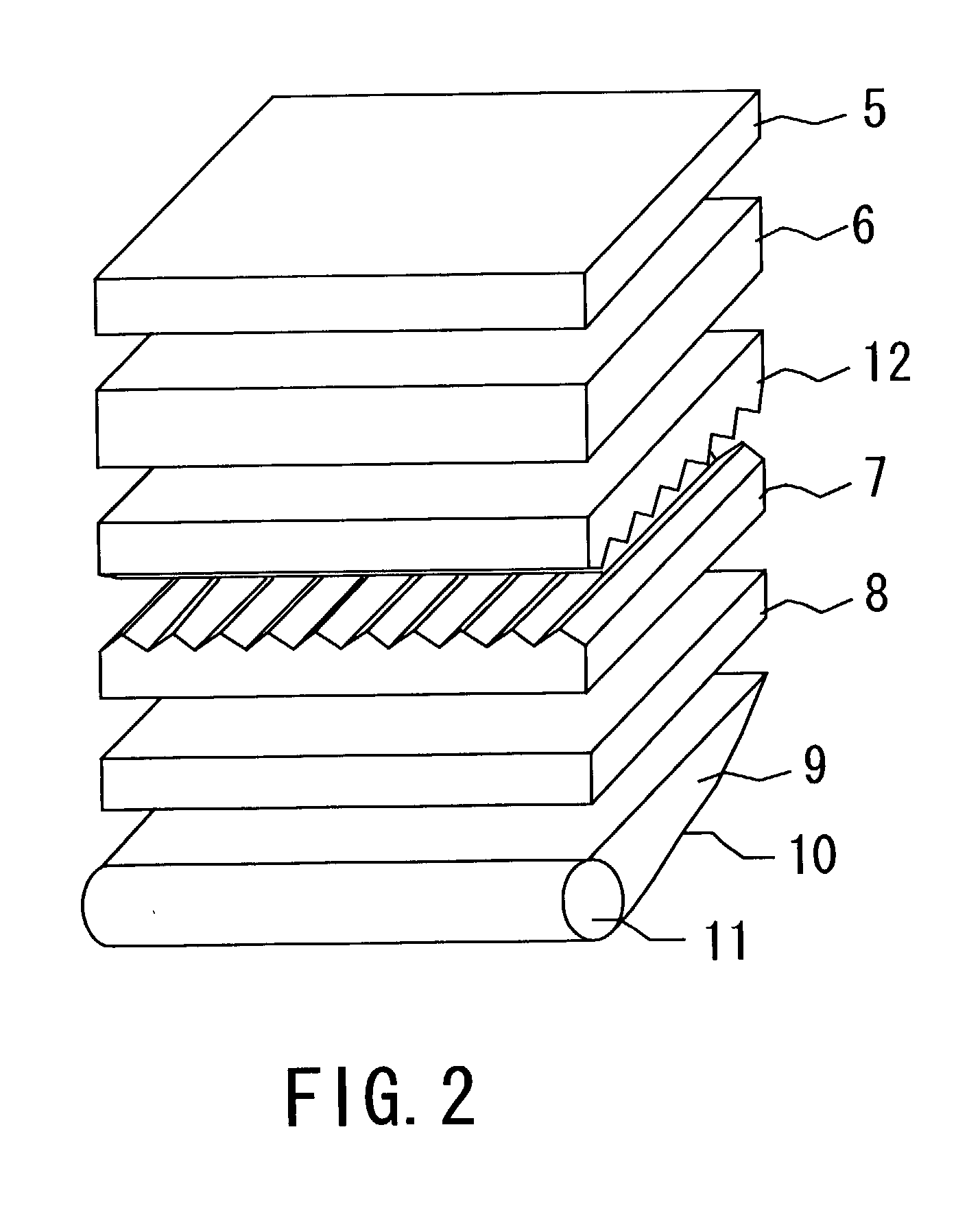

Liquid crystal display and backlight module thereof

InactiveUS20060139953A1Wide viewing angleIncrease brightnessNon-linear opticsLensLiquid-crystal displayLight source

A backlight module includes an optical film substrate and a plurality of light sources. The optical film substrate has a first surface and a second surface opposite to the first surface. The first surface of the optical film substrate has a plurality of Fresnel areas. The Fresnel areas are disposed on the first surface in an array arrangement. The light sources are disposed at one side of the optical film substrate. In addition, a liquid crystal display including the backlight module is provided.

Owner:PRODISC TECH INC

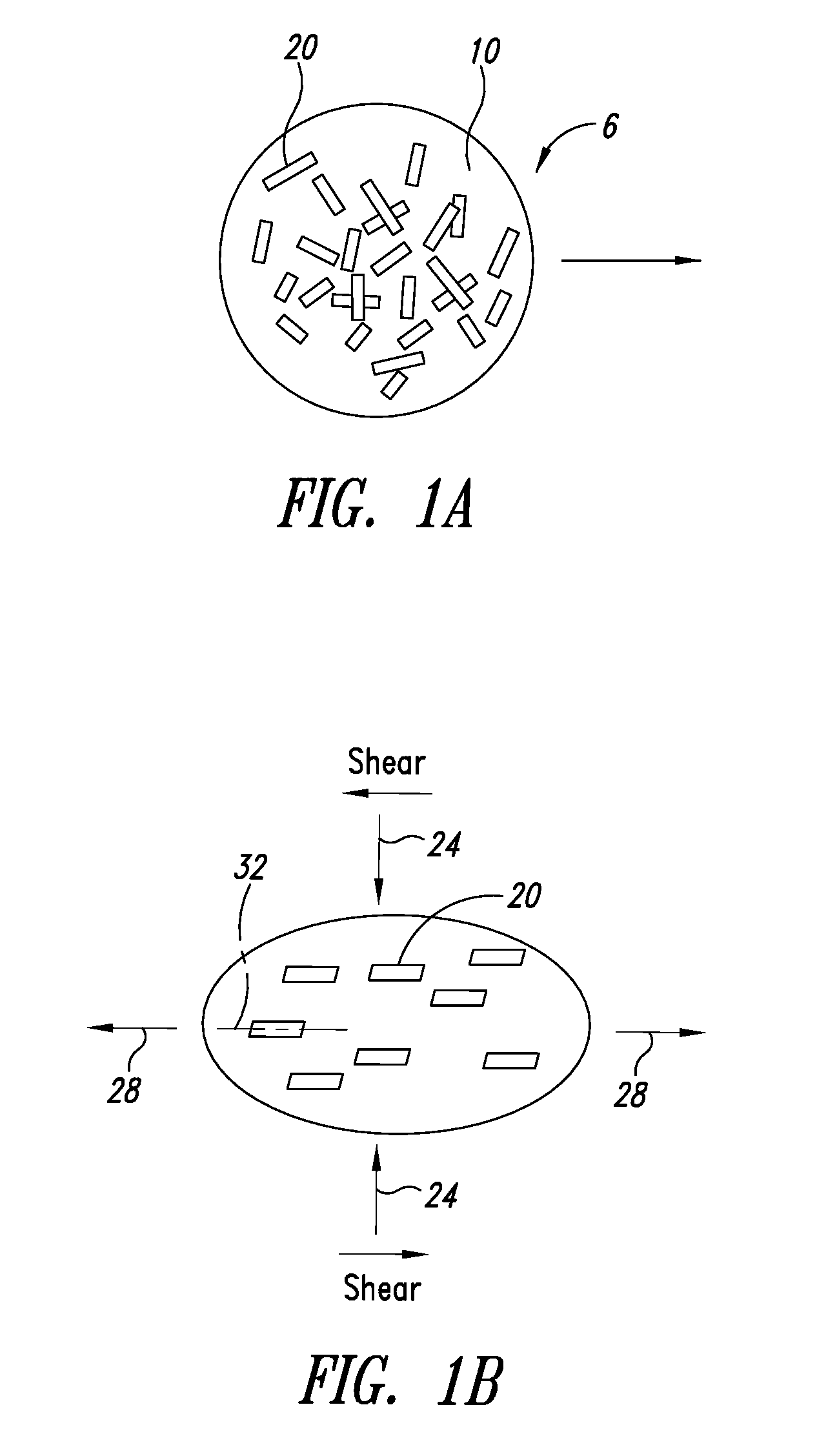

Functional films formed by highly oriented deposition of nanowires

InactiveUS20090052029A1Reduce manufacturing costIncreased durabilityMaterial nanotechnologyNon-insulated conductorsNanowireNanometre

Optical films formed by deposition of highly oriented nanowires and methods of aligning suspended nanowires in a desired direction by flow-induced shear force are described.

Owner:CAMBRIOS TECH +1

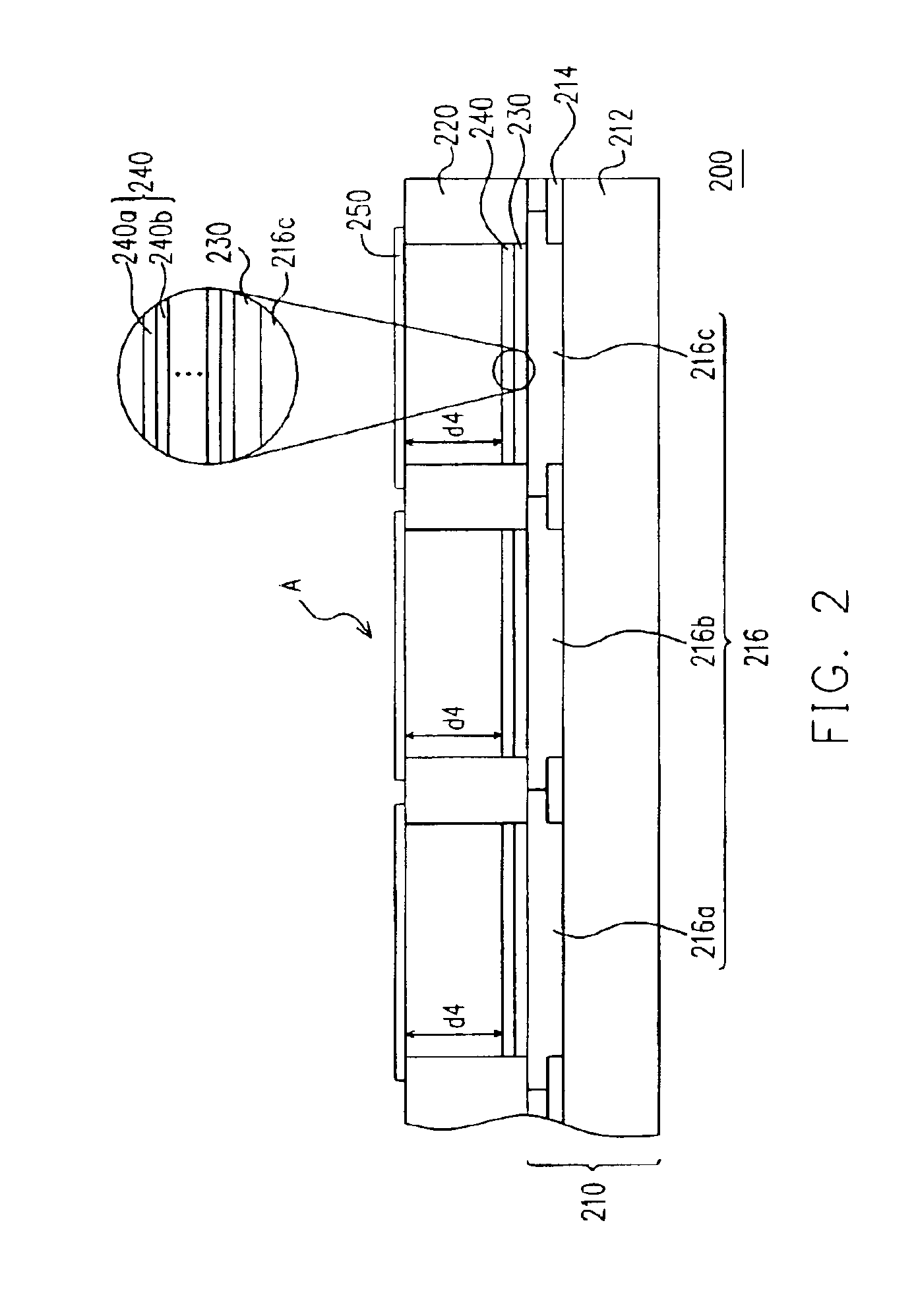

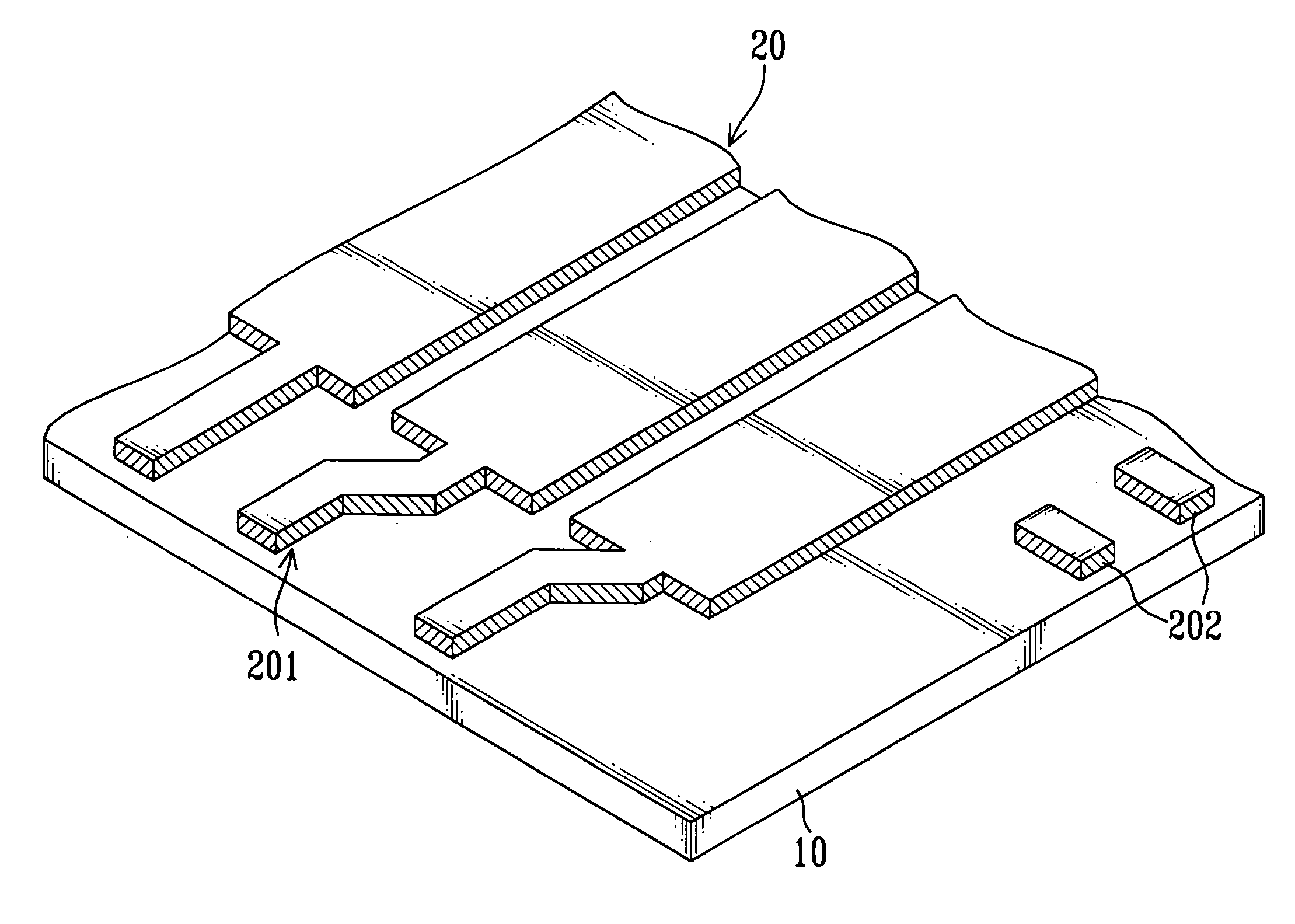

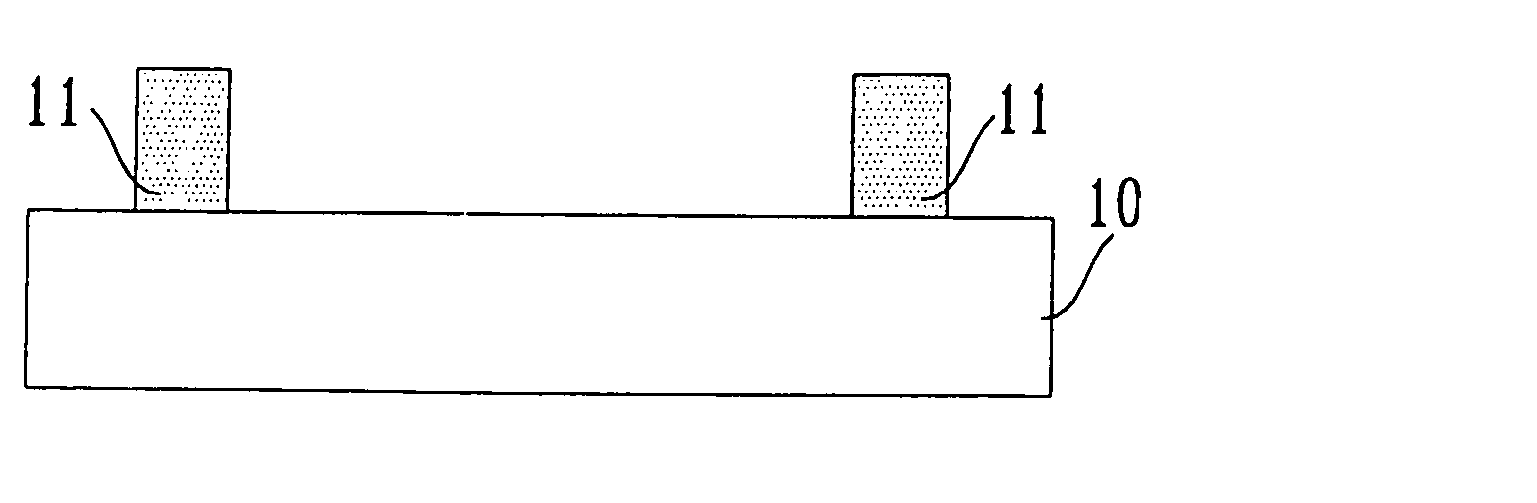

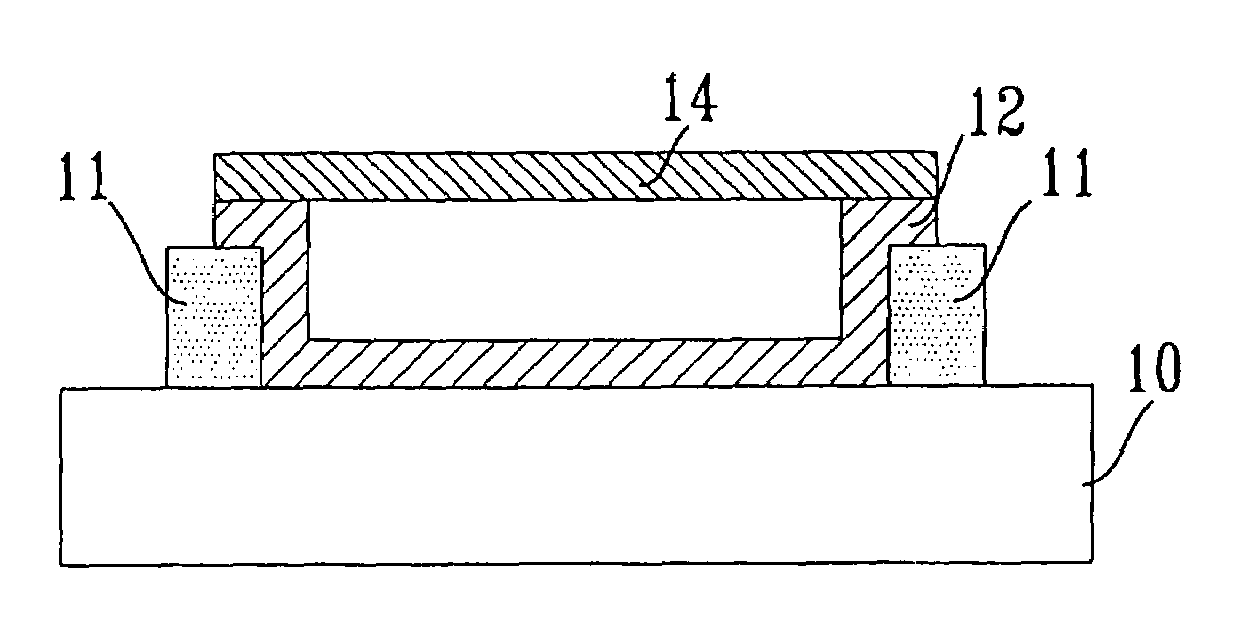

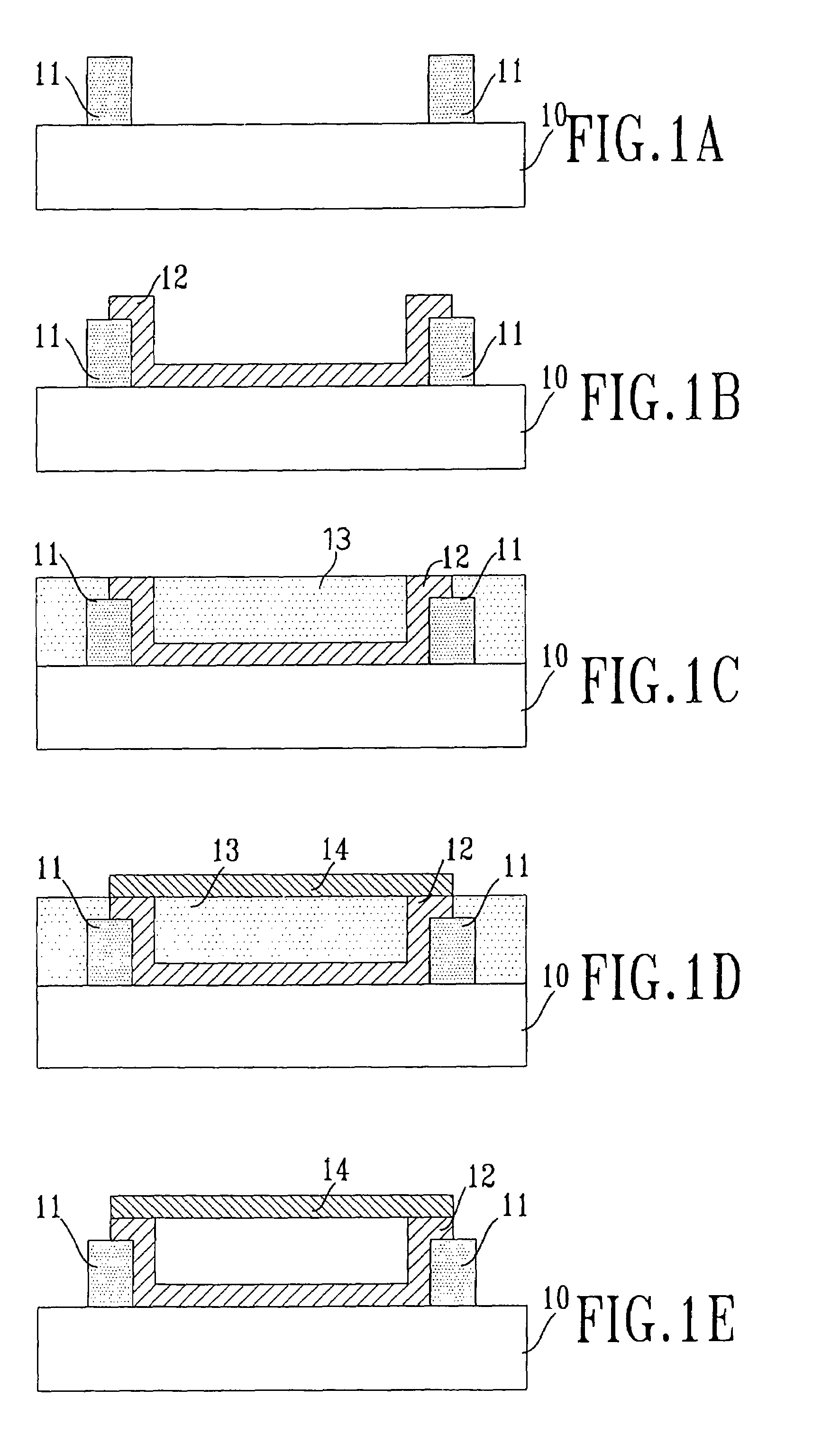

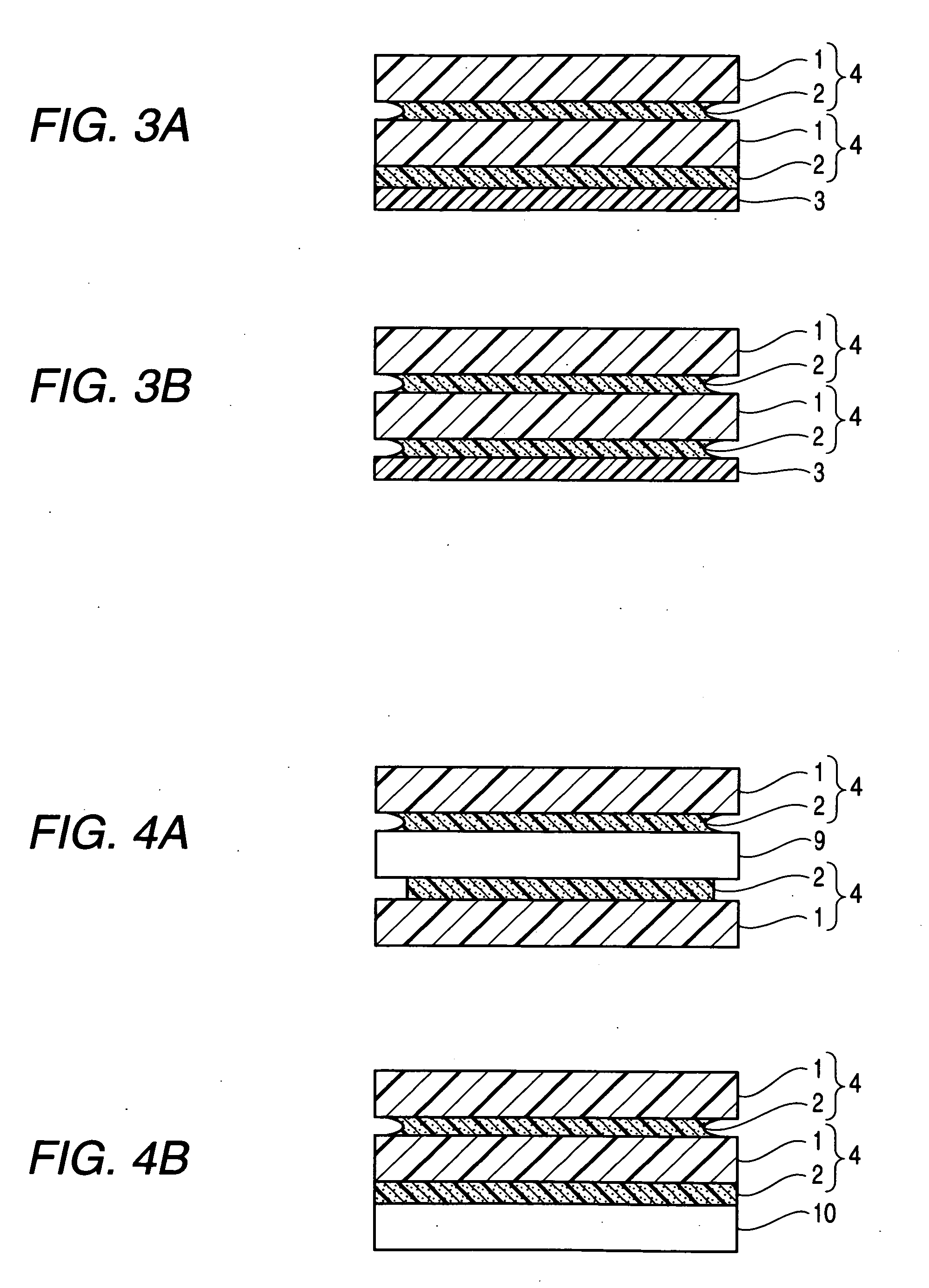

Optical-interference type display panel and method for making the same

InactiveUS20040147198A1Semiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

An optical-interference type display panel and a method for making the same are disclosed, wherein the display panel has a substrate on which multiple first conductive optical film stacks, supporting layers and multiple second conductive optical film stacks are formed. The substrate further has a plurality of connecting pads consisting of a transparent conductive film of the first conductive optical film stacks. Since the transparent conductive film is made of indium tin oxide, these connecting pads have the excellent anti-oxidation ability at their surface.

Owner:SNAPTRACK

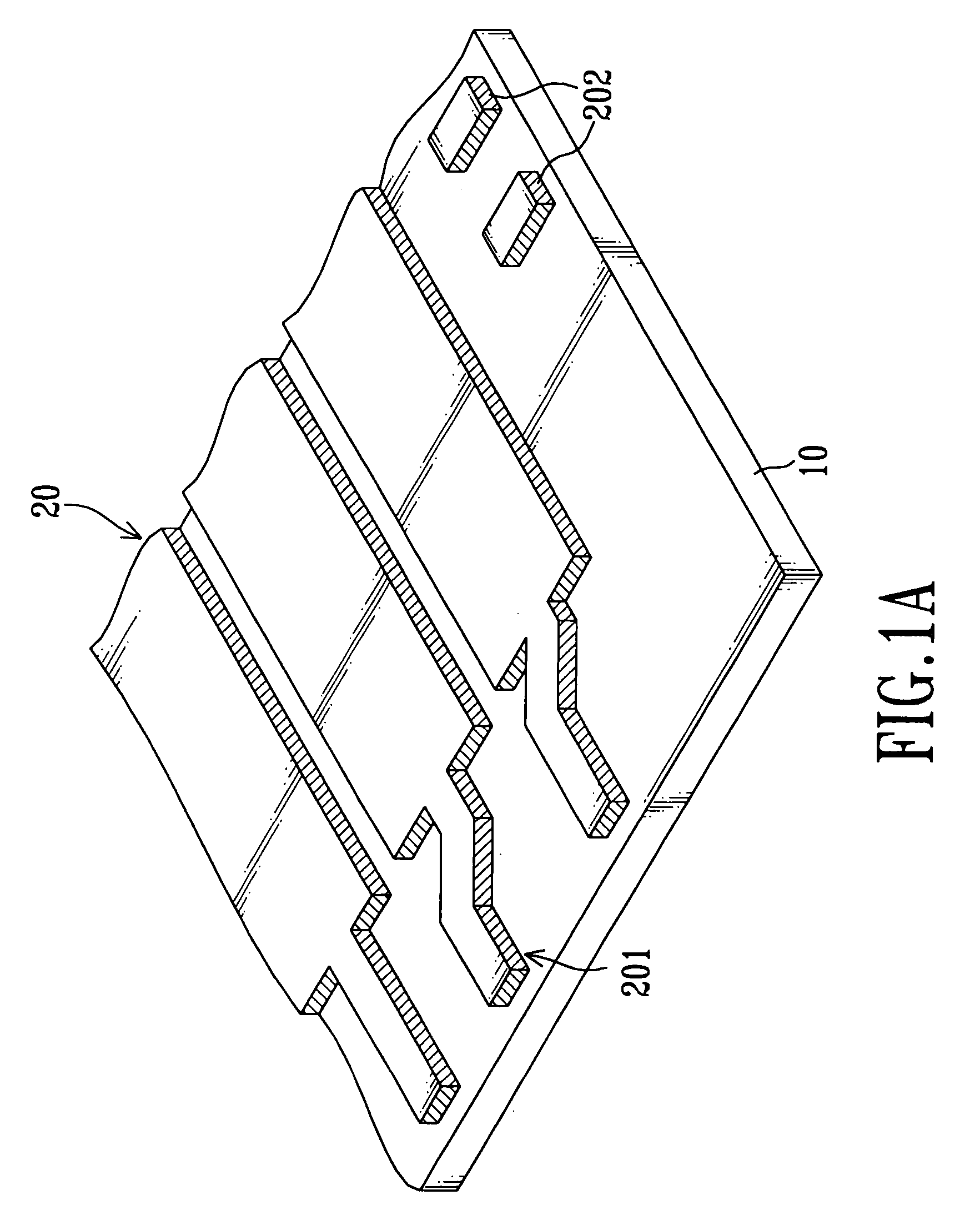

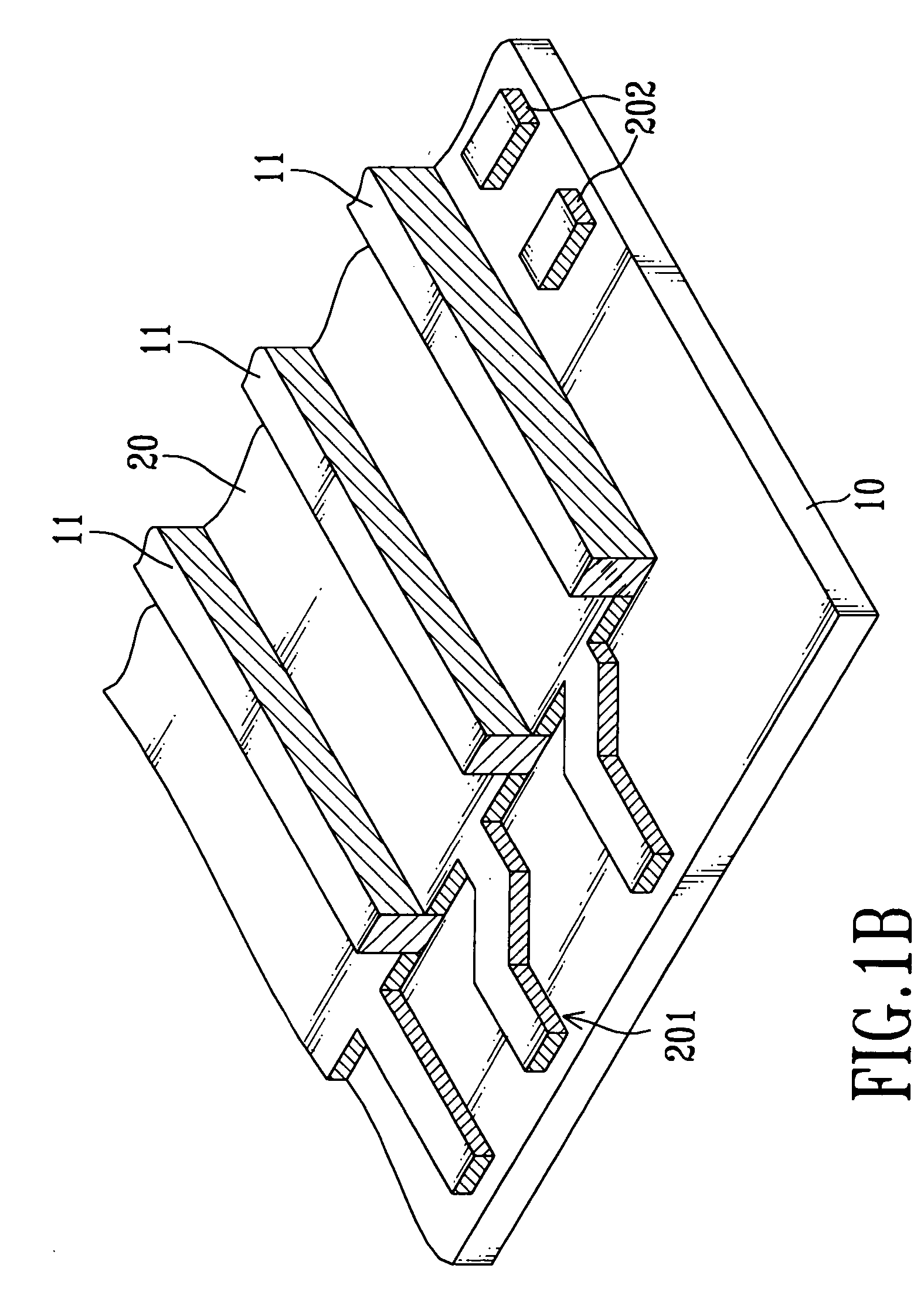

Optical-interference type reflective panel and method for making the same

An optical-interference type reflective panel and a method for making the same are disclosed, wherein the display panel has a substrate on which multiple supporting layers are firstly formed. Then, a plurality of first conductive optical film stacks, spacing layers and multiple second conductive optical film stacks are sequentially formed on the substrate. Finally, once the spacing layers are removed, optical-interference regulators are formed. Since said supporting layers forming step is prior to the first conductive optical film stacks, a precise back-side exposing step is not necessary so that the making procedure of the panel is simplified.

Owner:SNAPTRACK

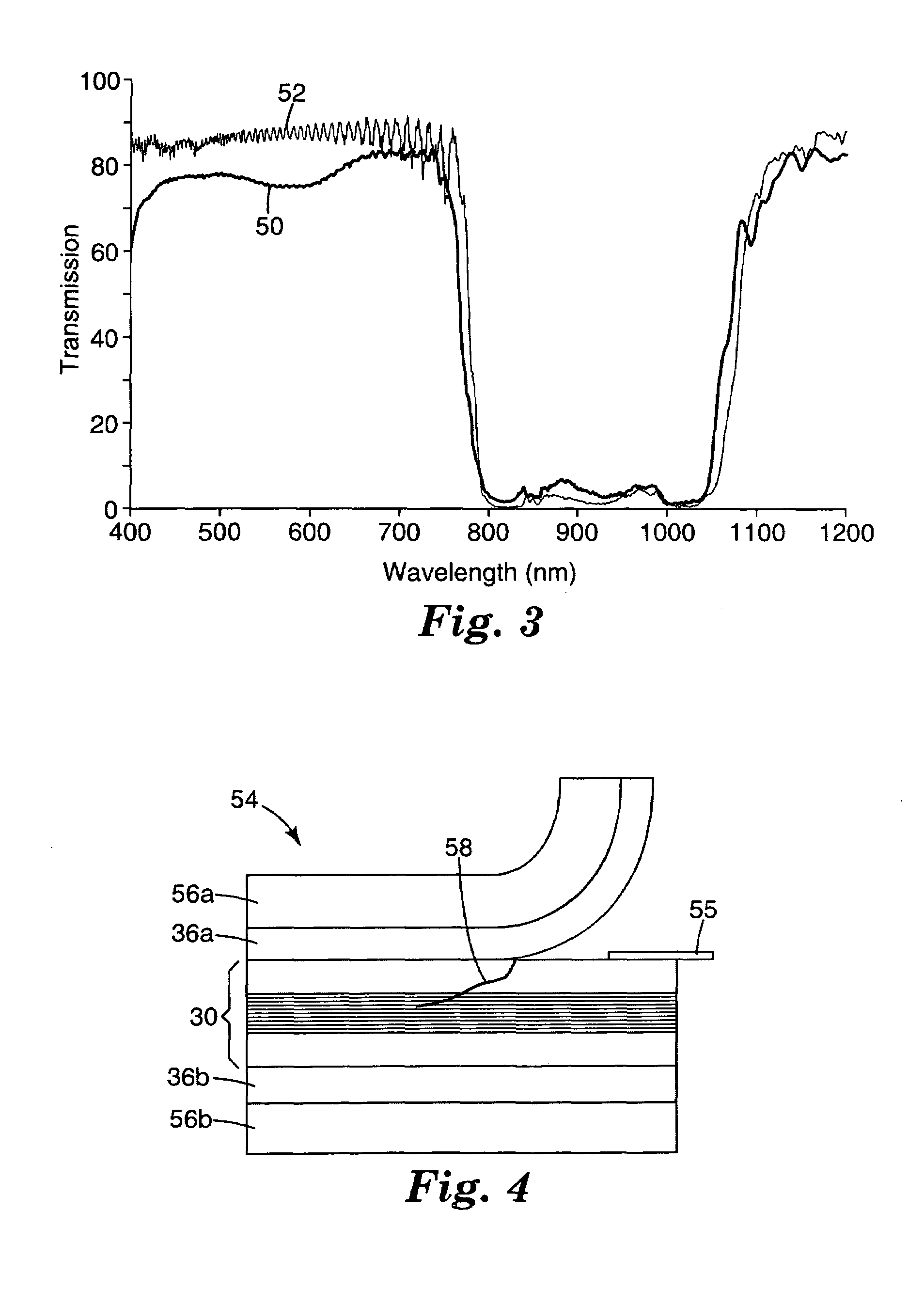

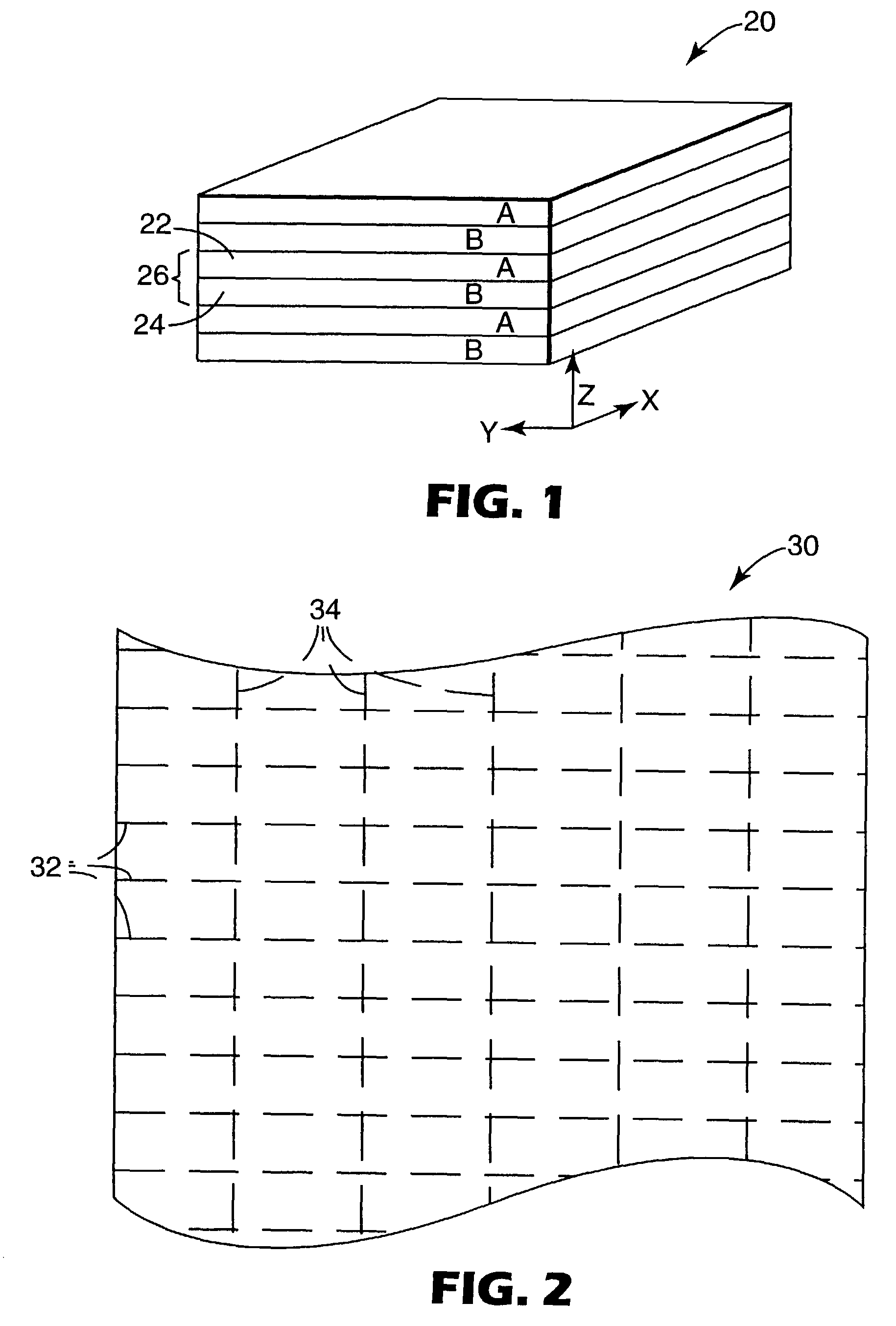

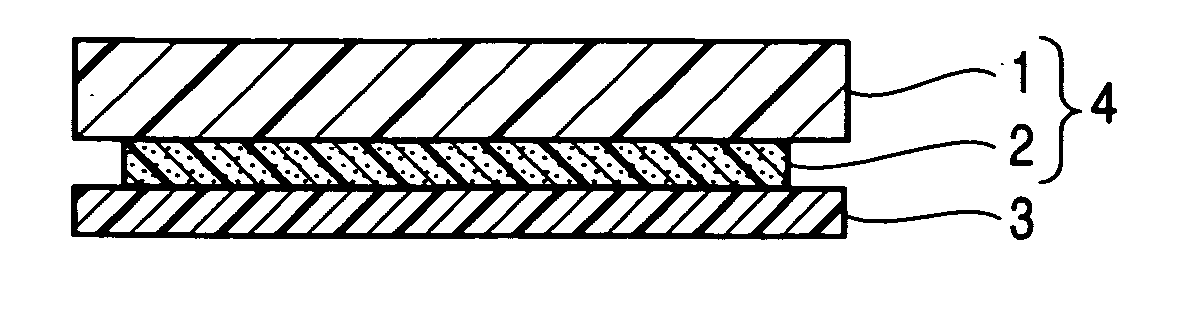

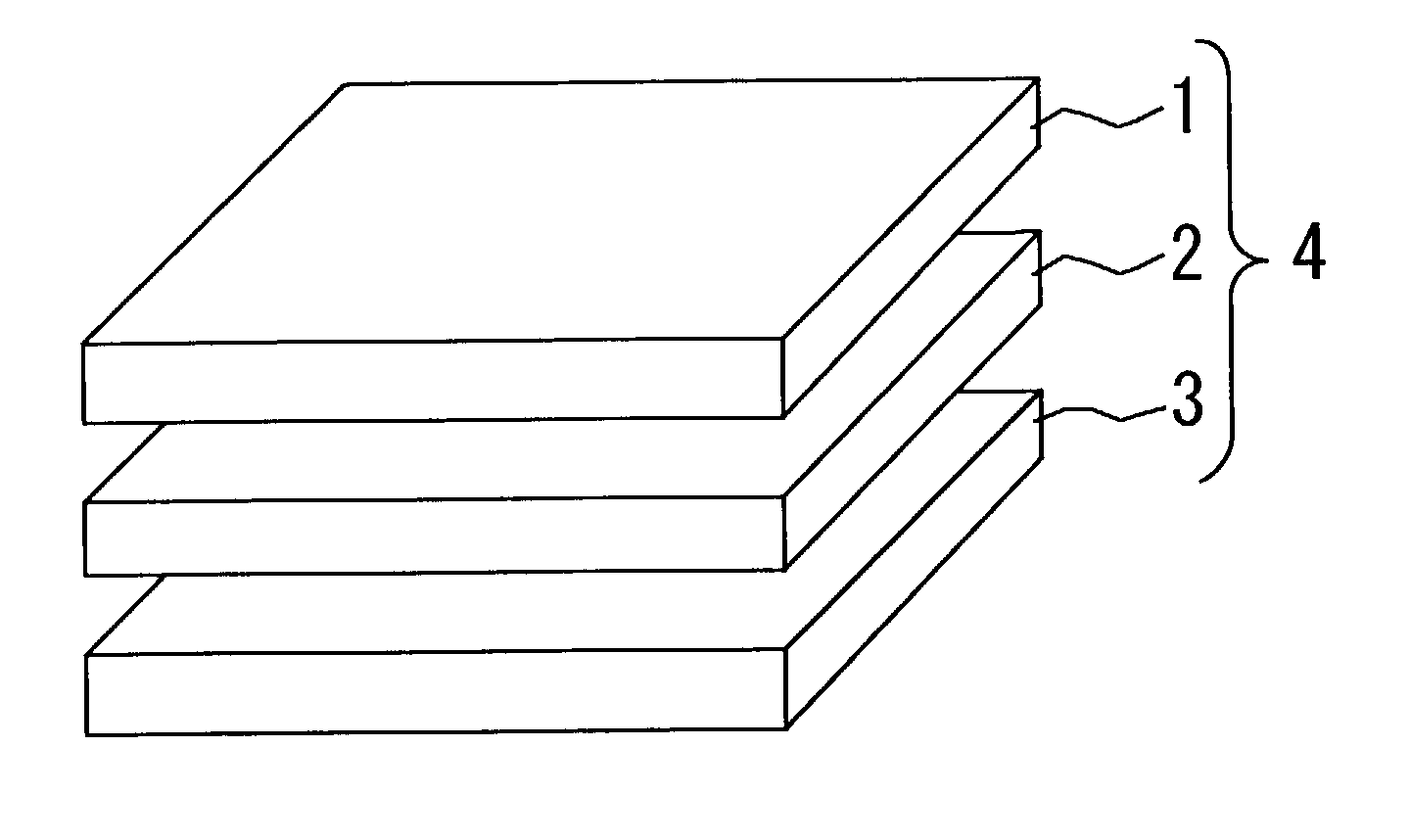

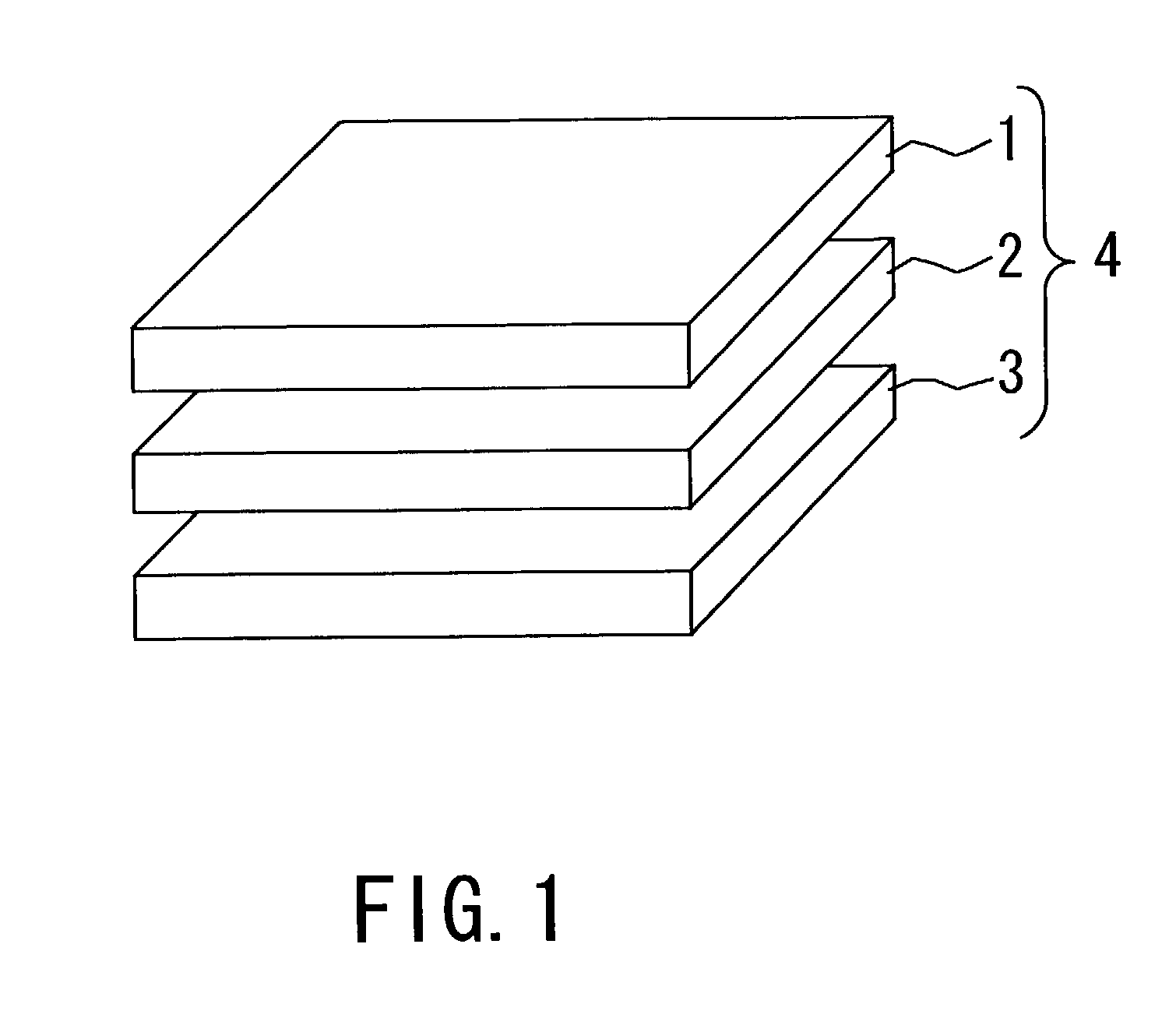

Cards and laminates incorporating multilayer optical films

New constructions of multilayer optical films, laminates thereof, and cards incorporating same are disclosed. In a card, the multilayer optical film can be sandwiched between relatively thick polymer layers using adhesive layers that are at least 0.5 mils thick but that may collectively account for no more than 3 mils of thickness. The cards can if desired be highly transmissive in the visible yet highly opaque in portions of the infrared. The resulting cards can have reduced angel hair formation during card stamping, increased resistance to delamination, and reduced haze.

Owner:3M INNOVATIVE PROPERTIES CO

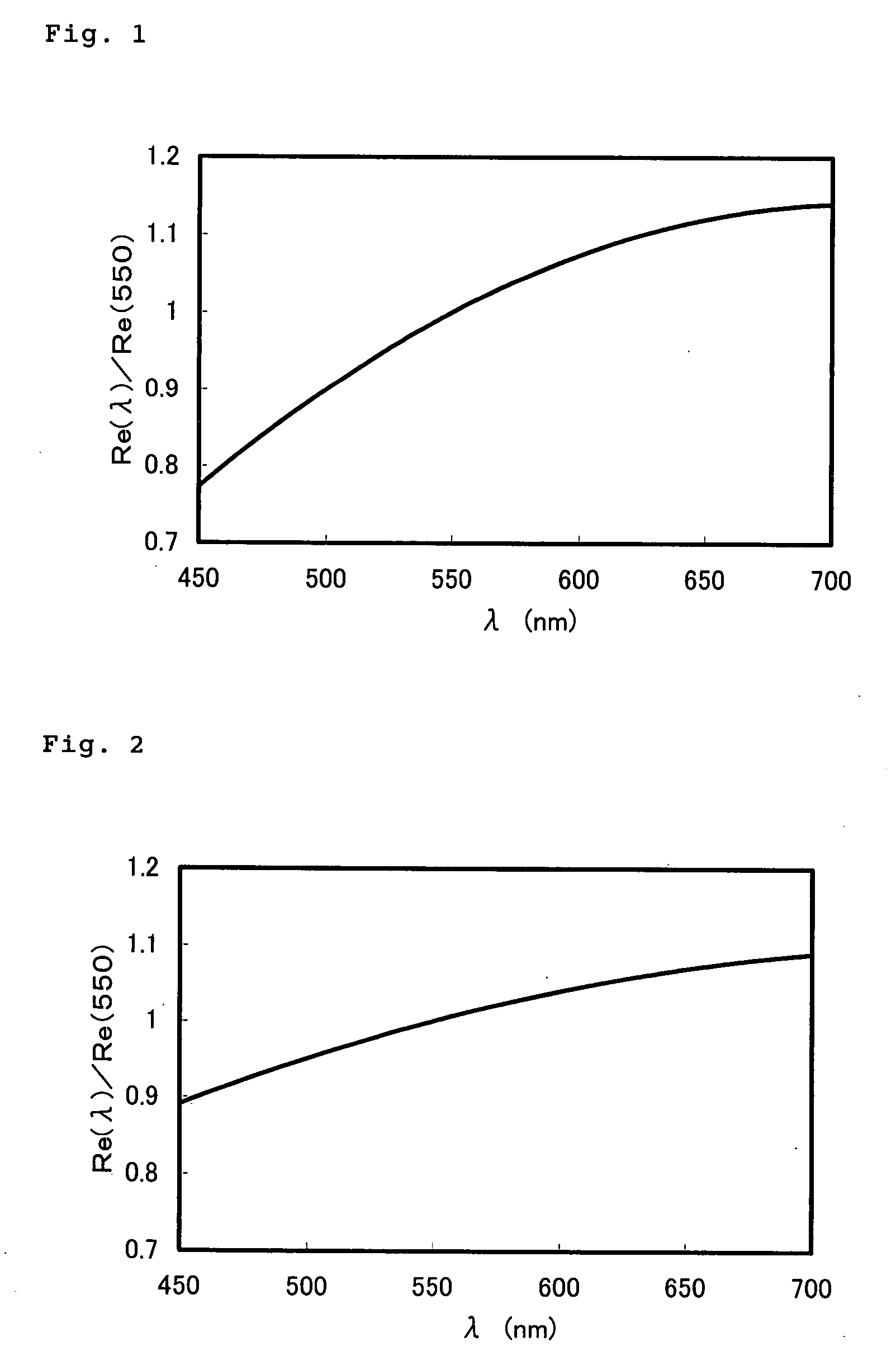

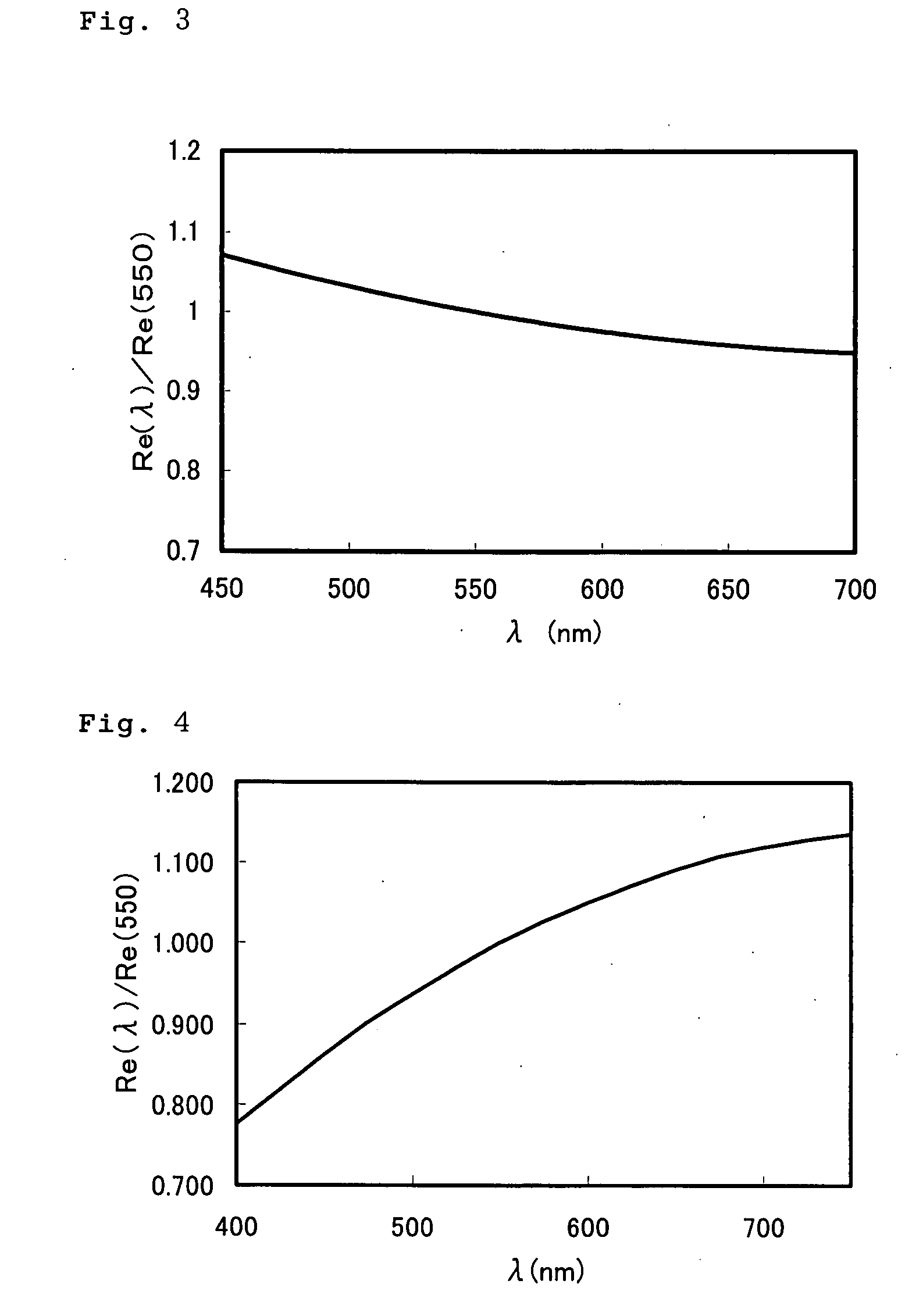

Optical Film

A composition comprising a polymerizable compound of the formula (1) and a rod-shaped polymerizable liquid crystal compound: P2-E2-X2-B2-A2-(G2)t-Y-(G1)s-A1-B1-X1-E1-P1 (1) (in the formula (1), Y represents a di-valent group, s and t represent each independently an integer of 0 or 1, G1 and G2 when s and t are 1 represent each independently —CR1R2—, R1 and R2 represent each independently an alkyl group having 1 to 4 carbon atoms, halogen atom or hydrogen atom, A1 and A2 represent each independently a di-valent cyclic hydrocarbon group, di-valent heterocyclic group, methylenephenylene group, oxyphenylene group or thiophenylene group, B1 and B2 represent each independently a di-valent group, X1 and X2 represent each independently a di-valent group, E1 and E2 represent each independently an alkylene group having 2 to 25 carbon atoms, and P1 and P2 represent a hydrogen atom or polymerizable group, at least one of P1 and P2 being a polymerizable group.).

Owner:SUMITOMO CHEM CO LTD

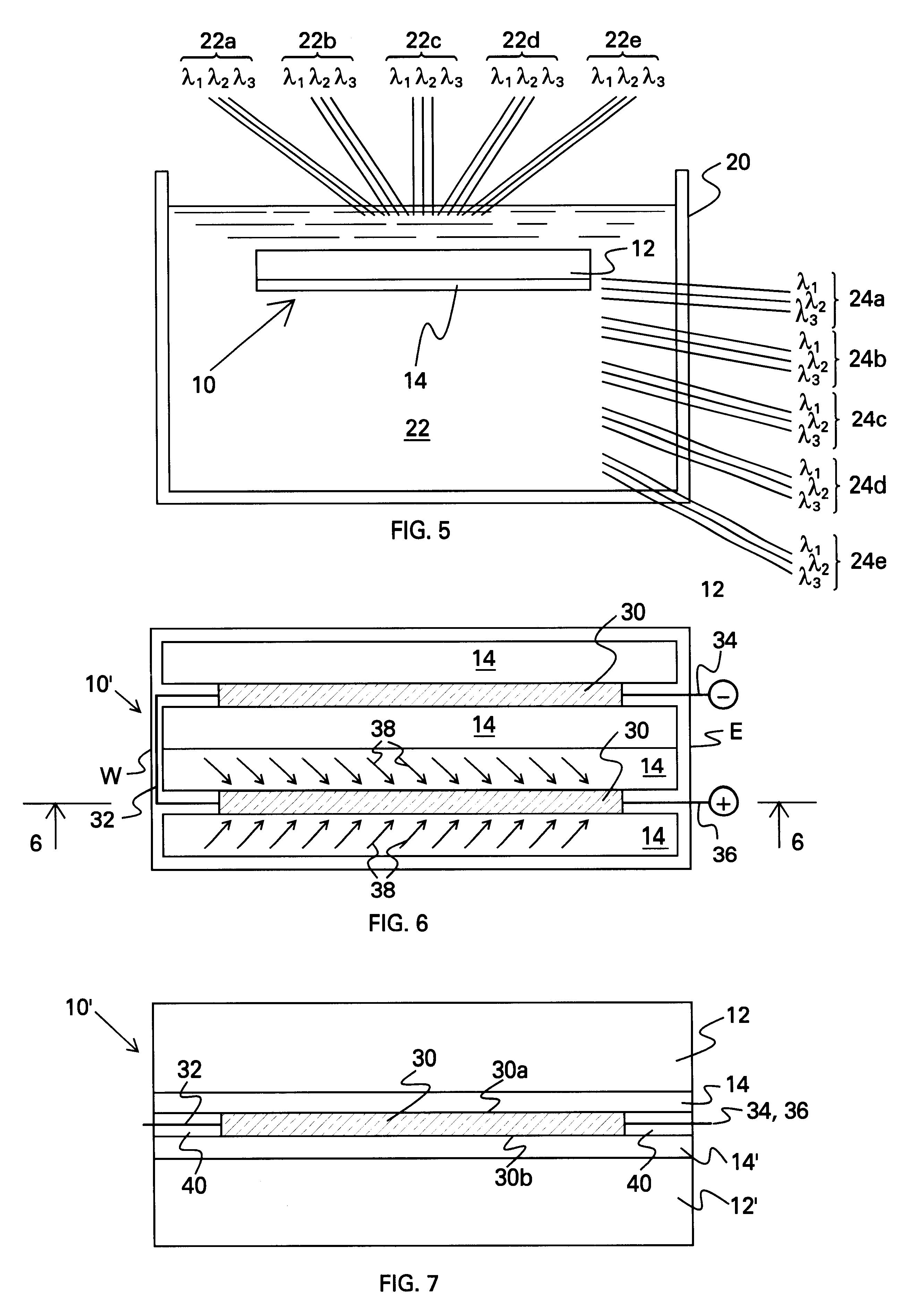

Device for concentrating optical radiation

InactiveUS6274860B1Minimizes waste heatLow costSolar heating energyPhotometry using reference valueOptical radiationFiber

A holographic planar concentrator (HPC) for collecting and concentrating optical radiation is provided. The holographic planar concentrator comprises a planar highly transparent plate and at least one multiplexed holographic optical film mounted on a surface thereof. The multiplexed holographic optical film has recorded therein a plurality of diffractive structures having one or more regions which are angularly and spectrally multiplexed. Two or more of the regions may be configured to provide spatial multiplexing. The HPC is fabricated by: (a) recording the plurality of diffractive structures in the multiplexed holographic optical film employing angular, spectral, and, optionally, spatial multiplexing techniques; and (b) mounting the multiplexed holographic optical film on one surface of the highly transparent plate. The recording of the plurality of diffractive structures is tailored to the intended orientation of the holographic planar concentrator to solar energy. The HPC is mounted in the intended orientation for collecting solar energy and at least one solar energy-collecting device is mounted along at least one edge of the holographic planar concentrator. Examples of suitable solar energy-collecting devices include photovoltaic cells and fiber optic light guides for transmitting collected light into an interior of a building for illumination purposes and for transmitting collected solar radiation into a hot water tank for heating. The HPC permits efficient collection of solar energy without expensive requirements, while minimizing energy losses.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Optical-interference type reflective panel and method for making the same

ActiveUS6999236B2The production process is simpleEasy to manufactureLayered productsDecorative surface effectsEngineeringElectrically conductive

Owner:SNAPTRACK

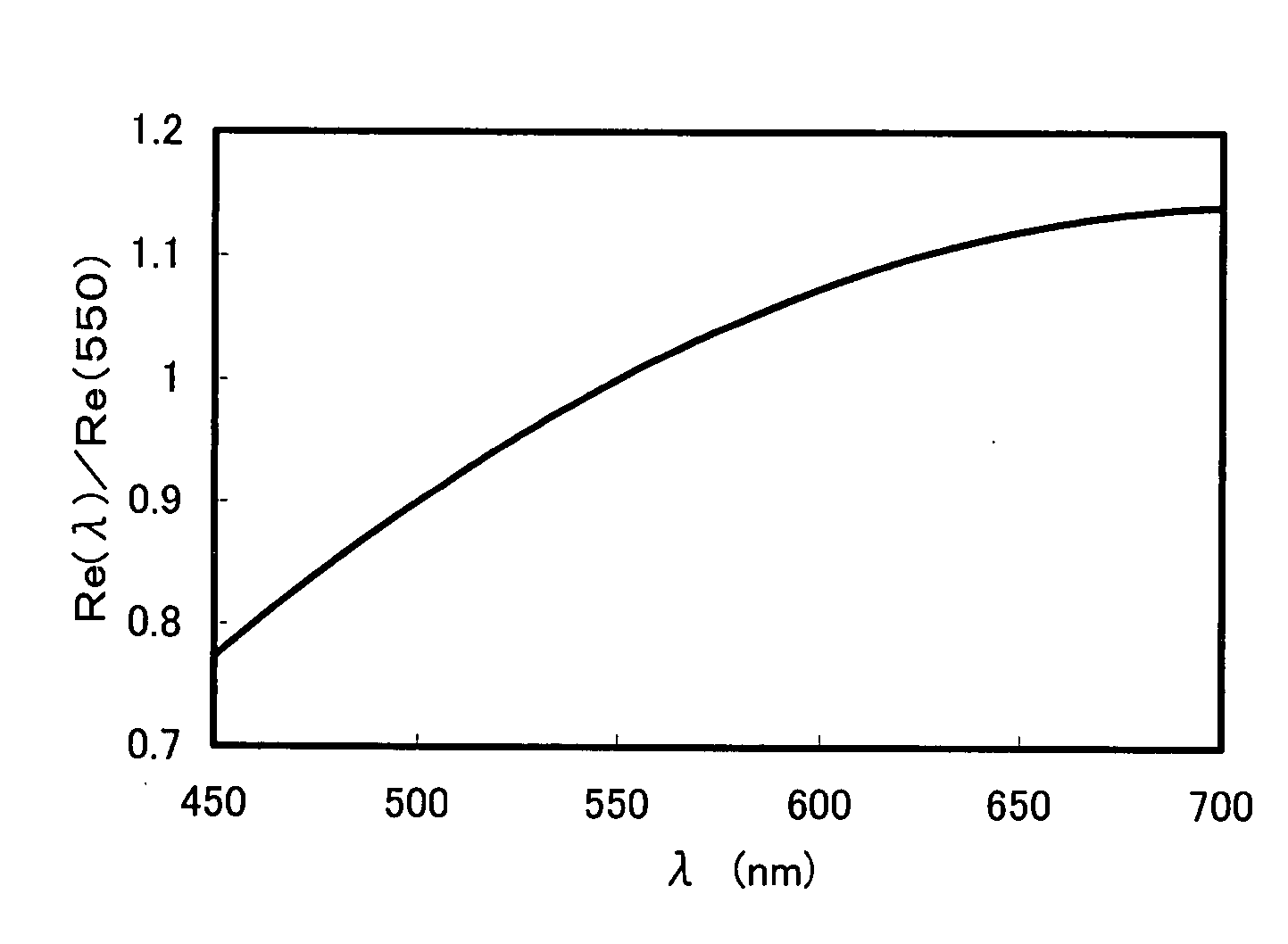

Polarizing film, optical film and liquid crystal display using polarizing film

InactiveUS6961178B2Solve the real problemImprove adhesionSynthetic resin layered productsLaminationTectorial membraneLiquid-crystal display

Owner:NITTO DENKO CORP

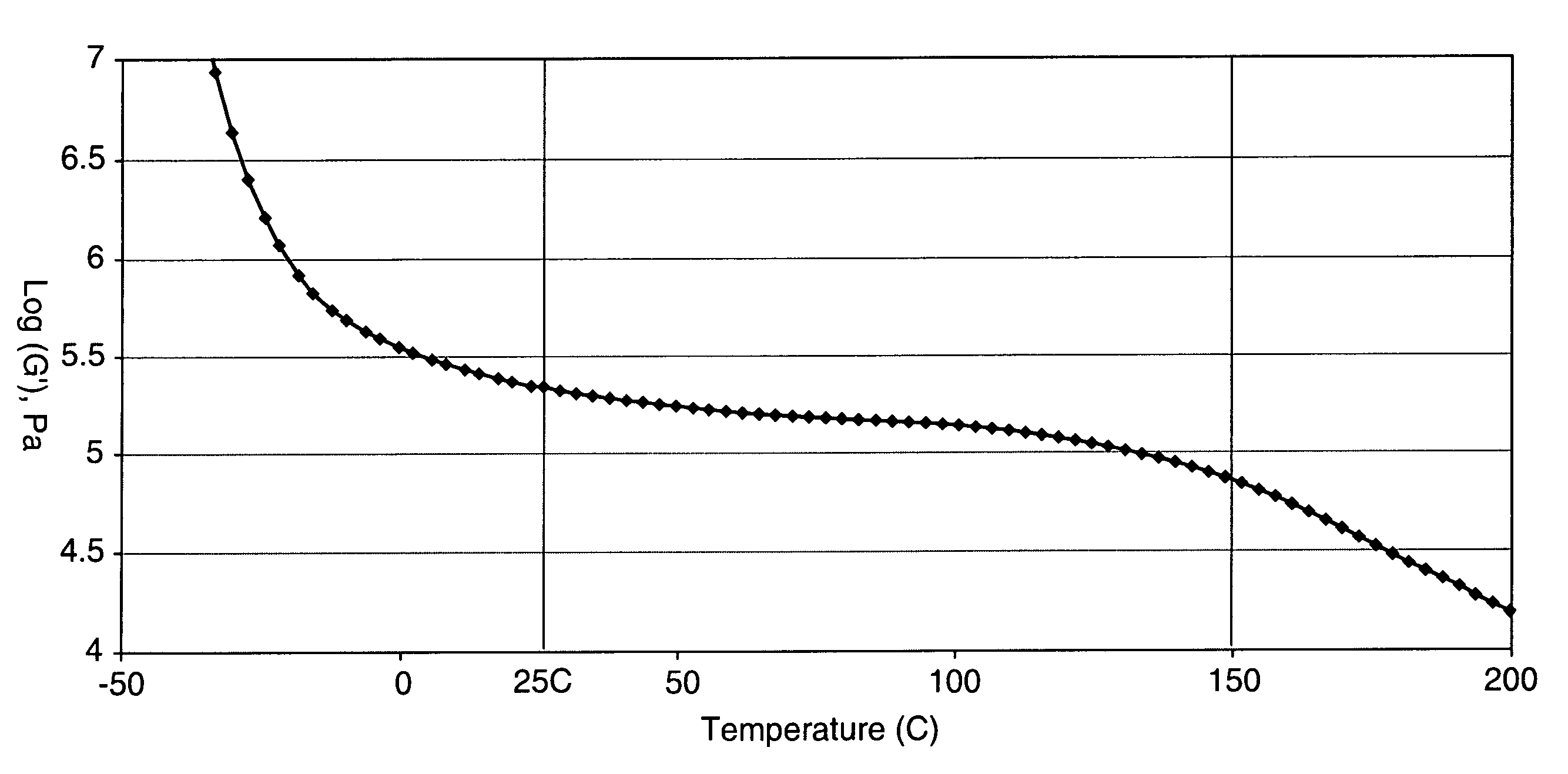

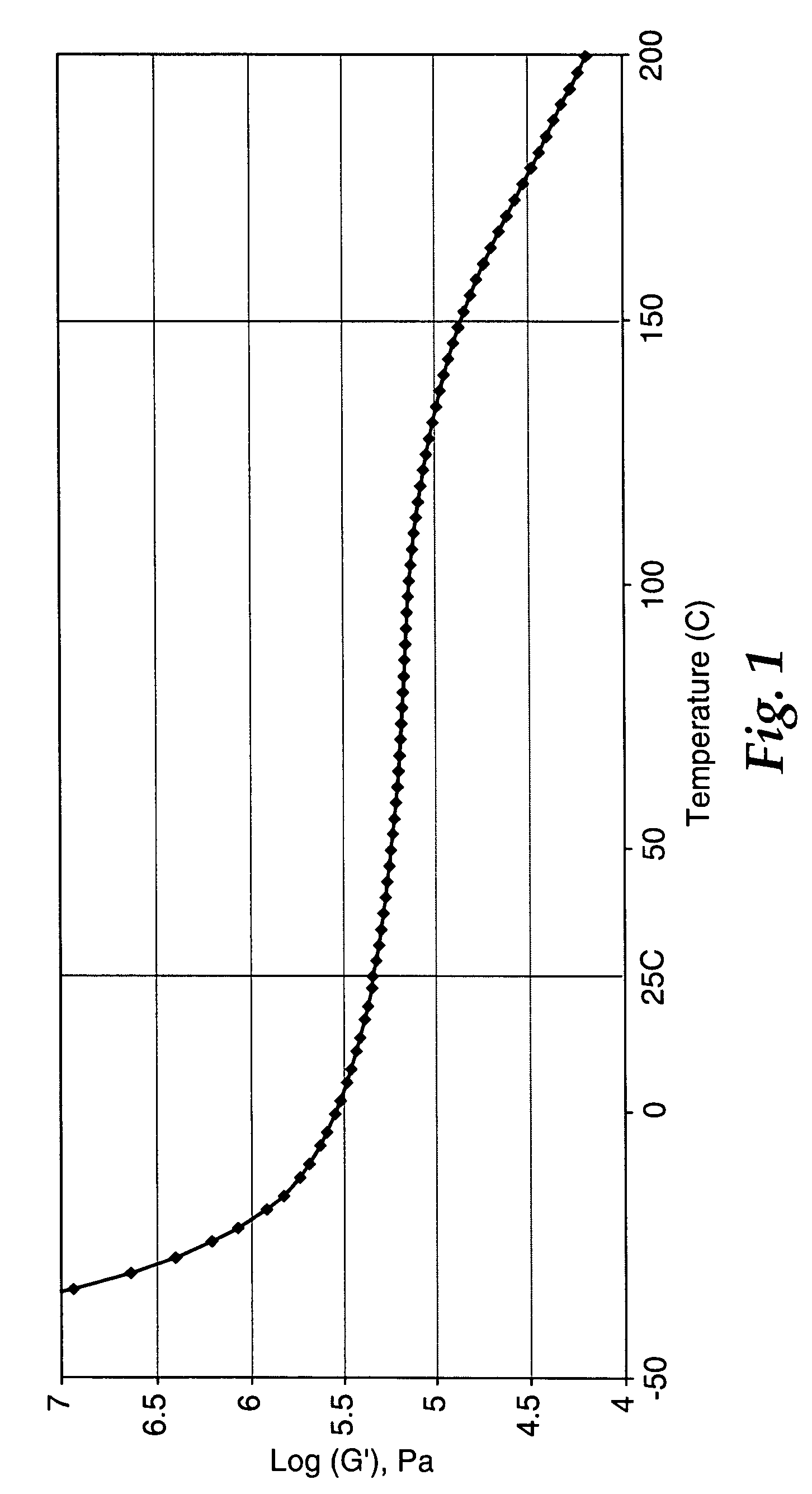

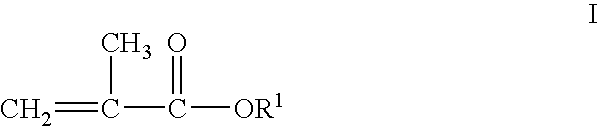

(Meth)acrylate block copolymer pressure sensitive adhesives

Articles are provided that include an optical film and an optically clear pressure sensitive adhesive layer on at least one outer surface of the optical film. Additionally, articles are provided that include a pressure sensitive adhesive layer that resists bubble formation when adhered to an outgassing substrate. The pressure sensitive adhesive layer in the various articles contain a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

Durable optical element

A durable optical film or element includes a polymerized structure having a microstructured surface and a plurality of surface modified colloidal nanoparticles of silica, zirconia, or mixtures thereof. Display devices including the durable microstructured film are also described.

Owner:3M INNOVATIVE PROPERTIES CO

Method for subdividing multilayer optical film cleanly and rapidly

InactiveUS6991695B2Reduce electrostatic attractionPaper/cardboard articlesOptical articlesPolymerLaser

Owner:3M INNOVATIVE PROPERTIES CO

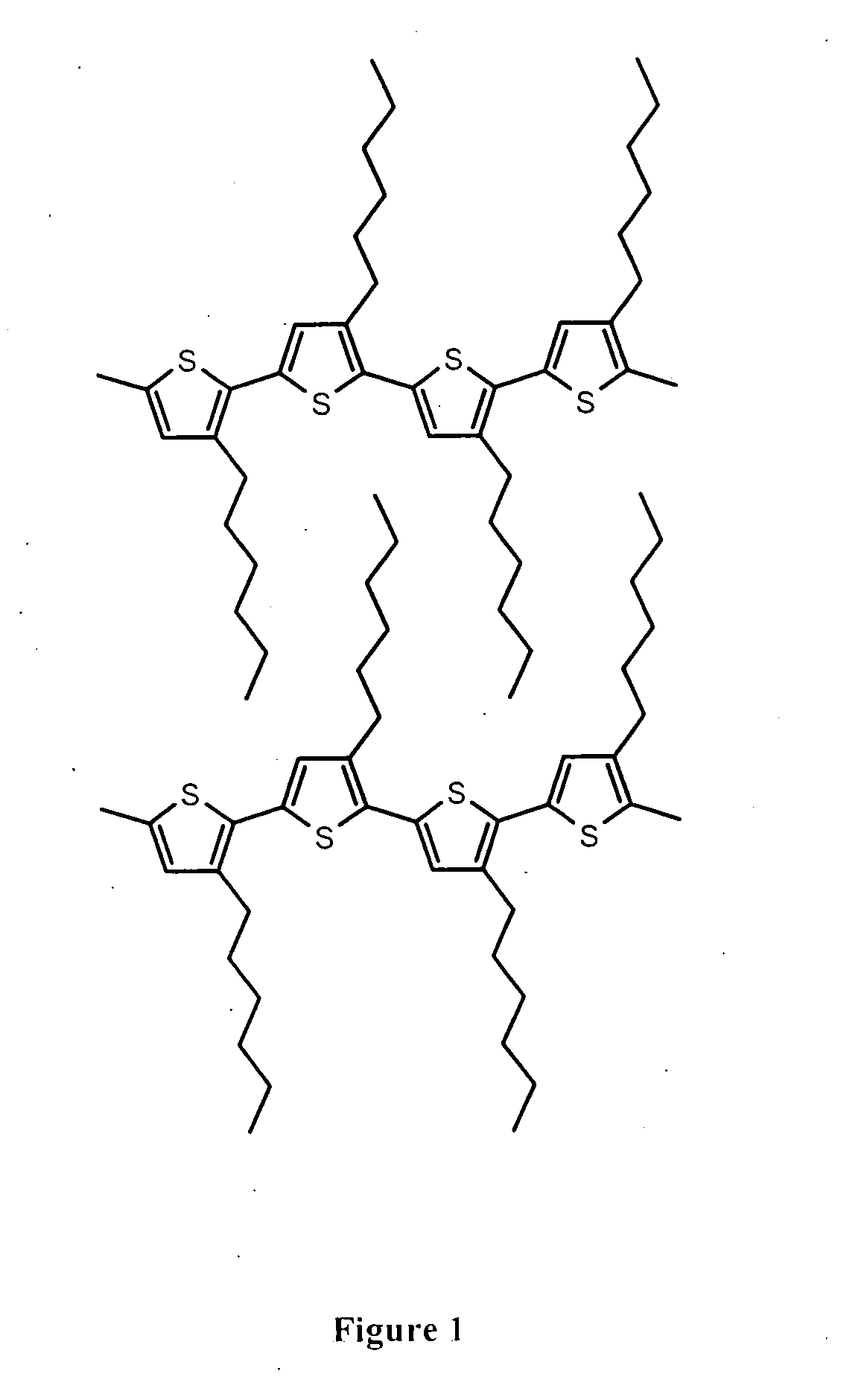

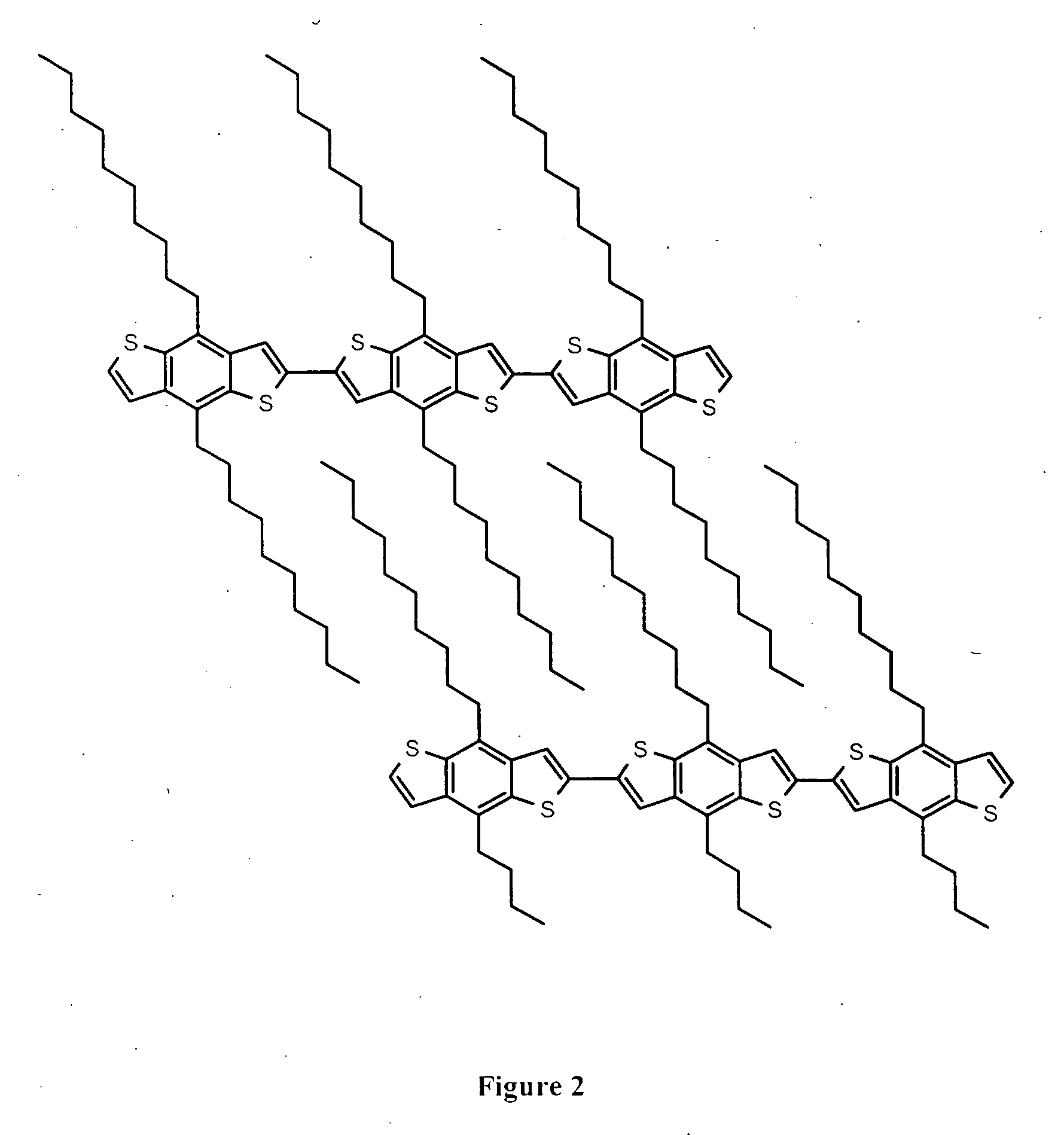

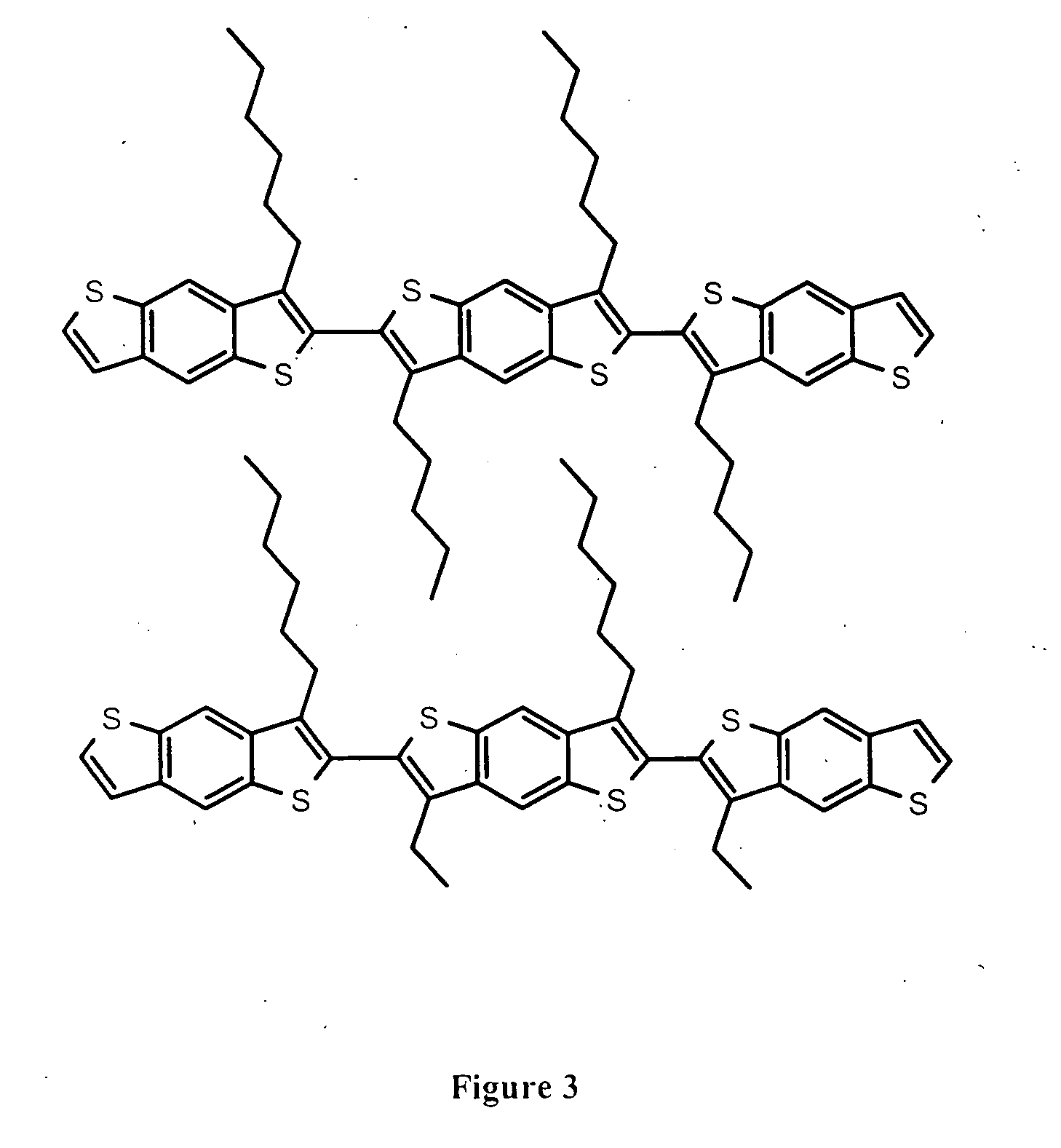

Poly(benzodithiophenes)

InactiveUS20050082525A1Liquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

Disclosed are novel poly(benzodithiophenes), their use as semiconductors or charge transport materials in optical, electro-optical or electronic devices, for example, liquid crystal displays, optical films, organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag.

Owner:RAYNERGY TEK INC

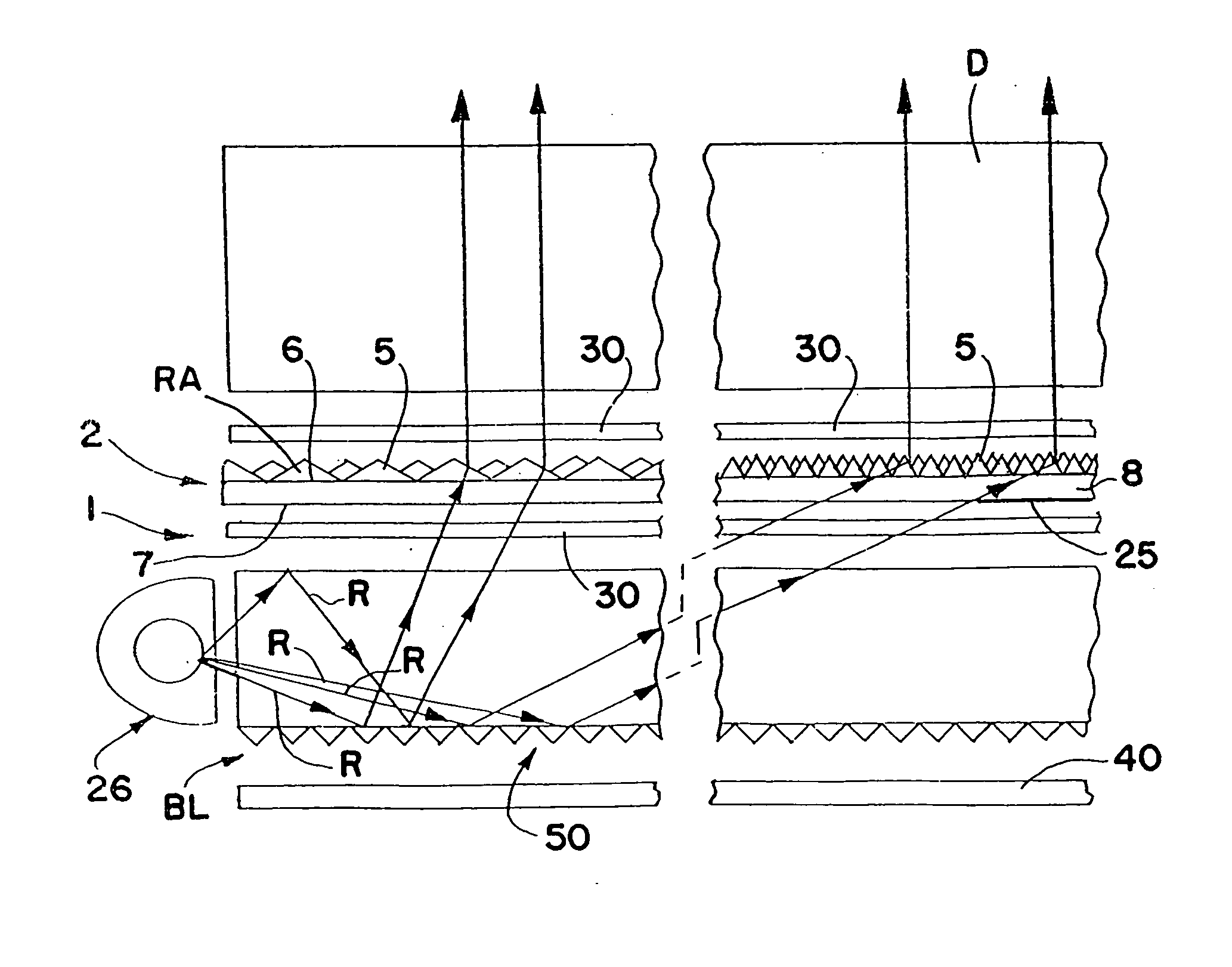

Backlight system with multilayer optical film reflector

InactiveUS6905220B2Efficiently reflecting lightReduce weightMechanical apparatusMeasurement apparatus componentsBack reflectorOptical film

The present invention includes a backlight system incorporating a back reflector and / or a lamp cavity reflector constructed of a multilayer optical film.

Owner:3M INNOVATIVE PROPERTIES CO

Optical-interference type display panel and method for making the same

InactiveUS7172915B2Improve antioxidant capacityConnecting qualitySemiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

Owner:SNAPTRACK

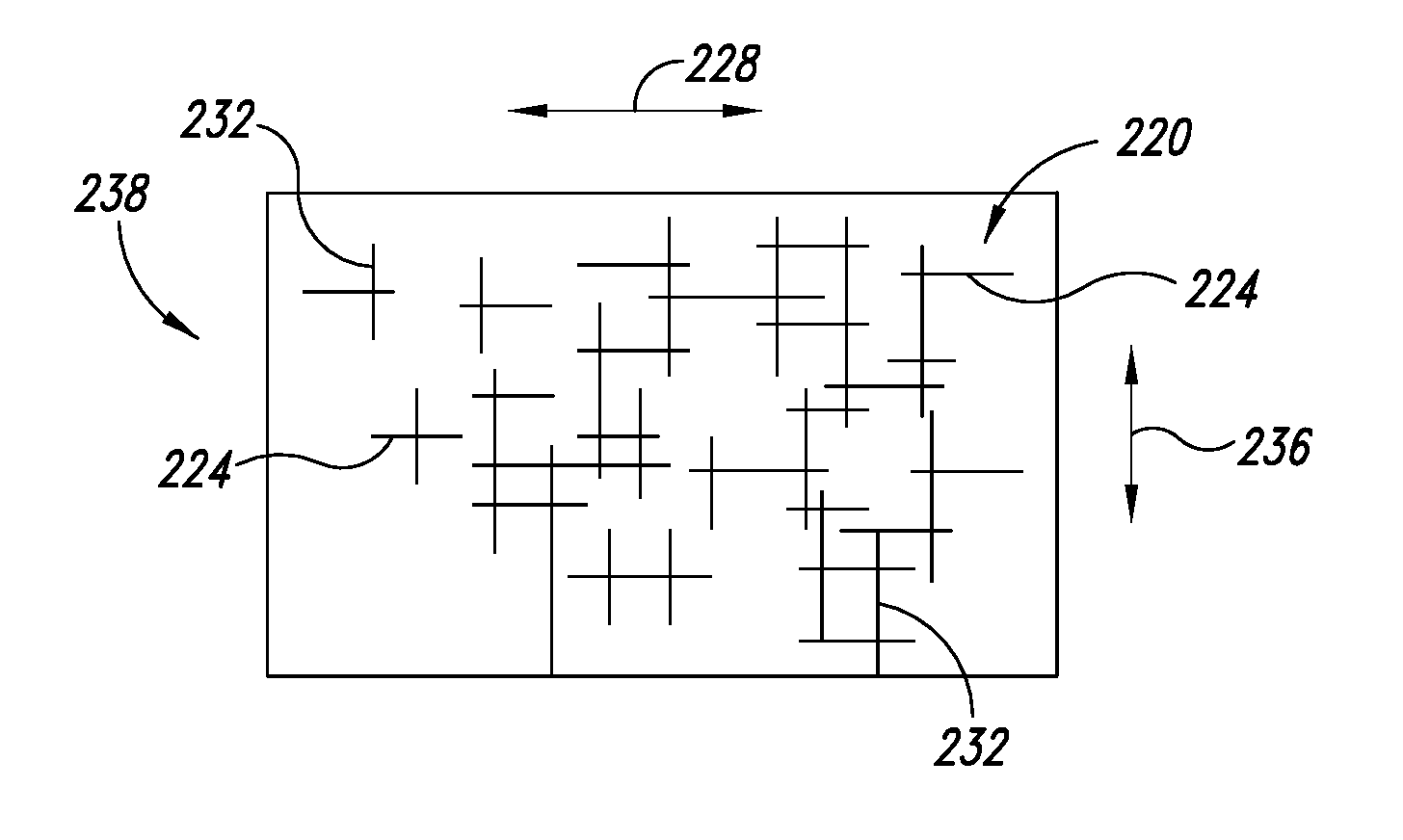

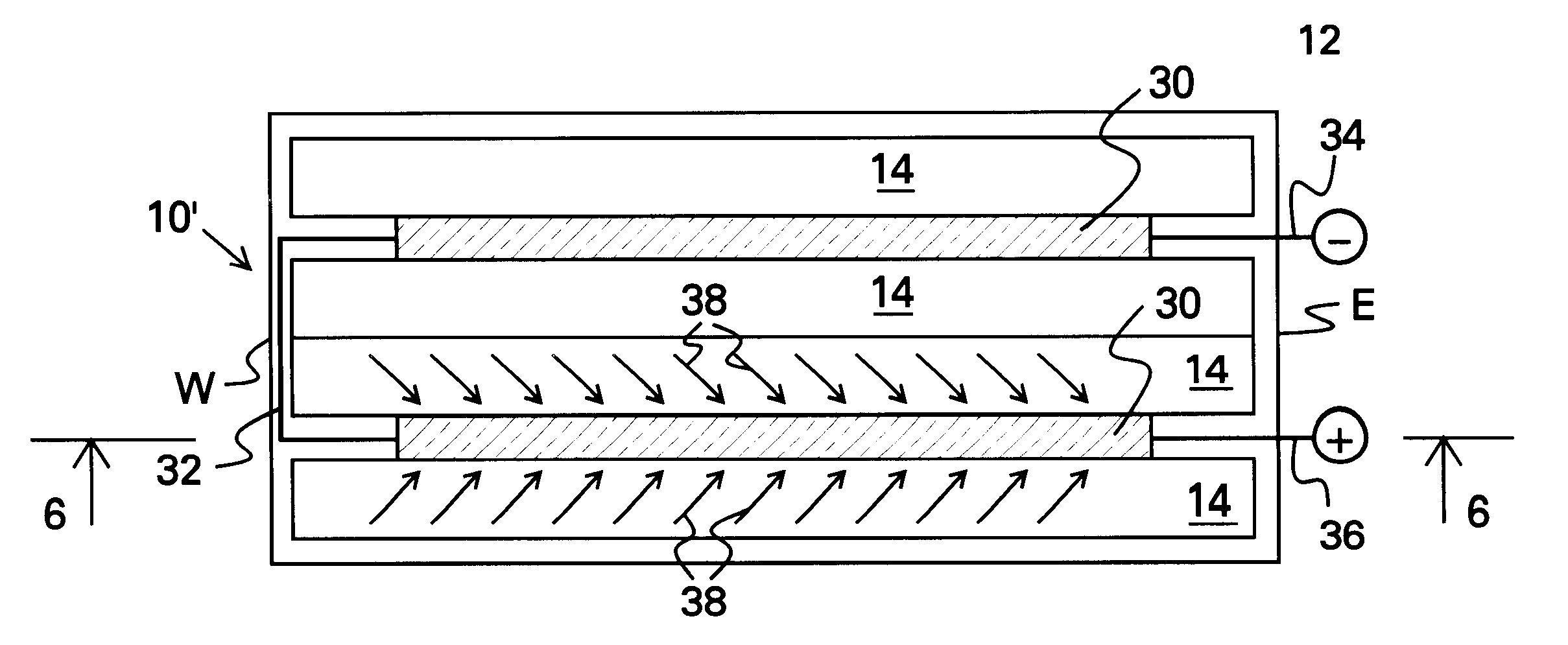

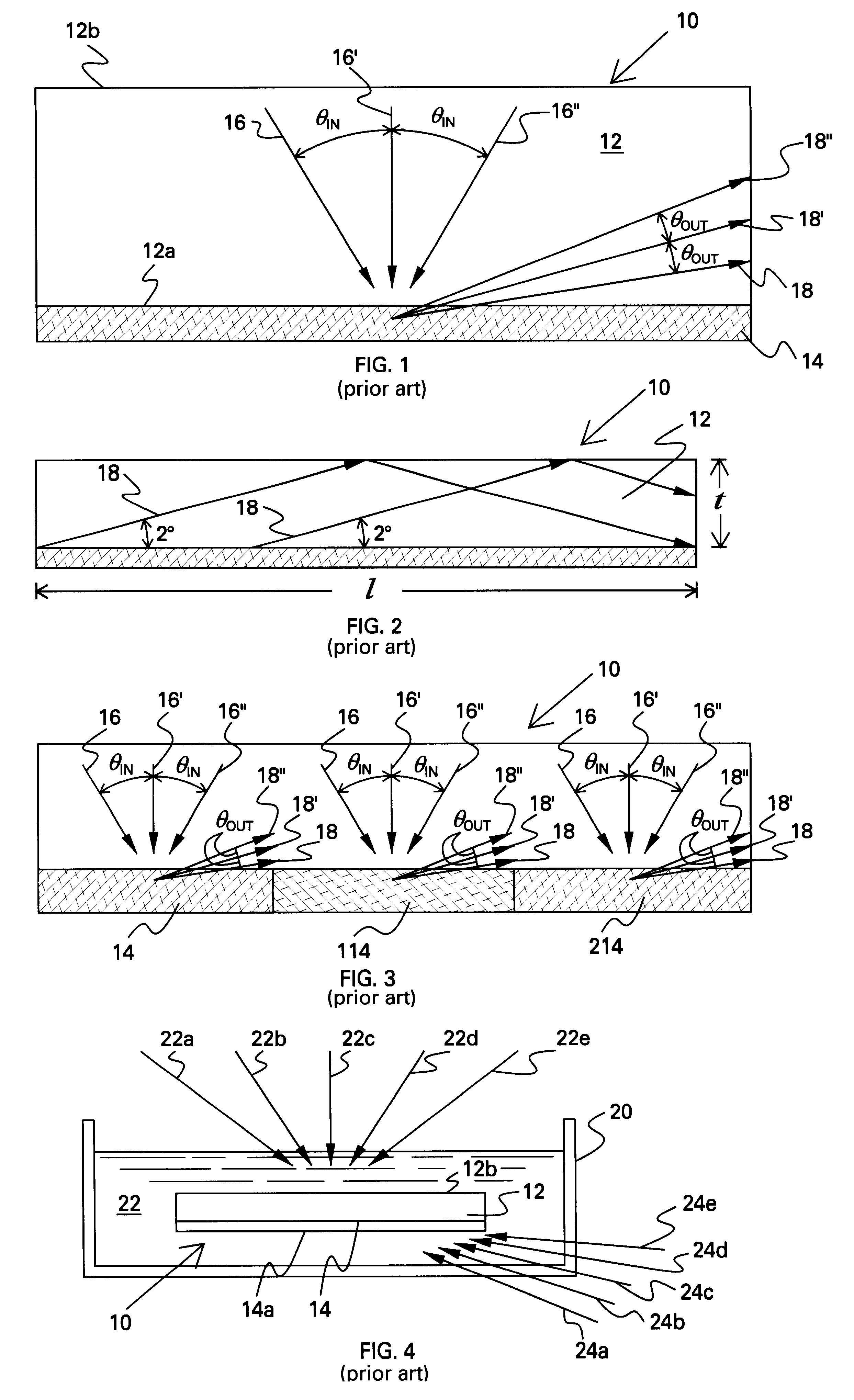

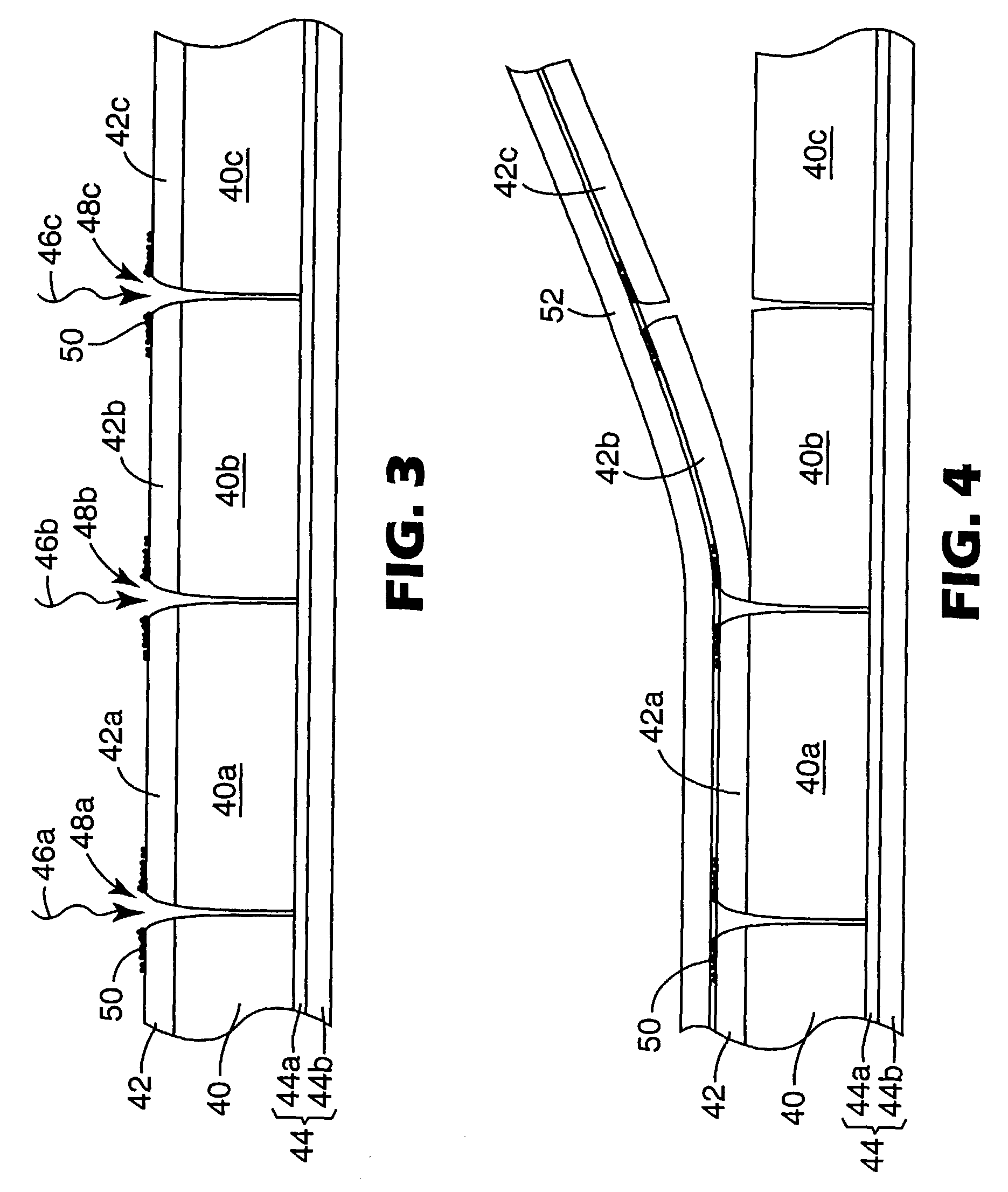

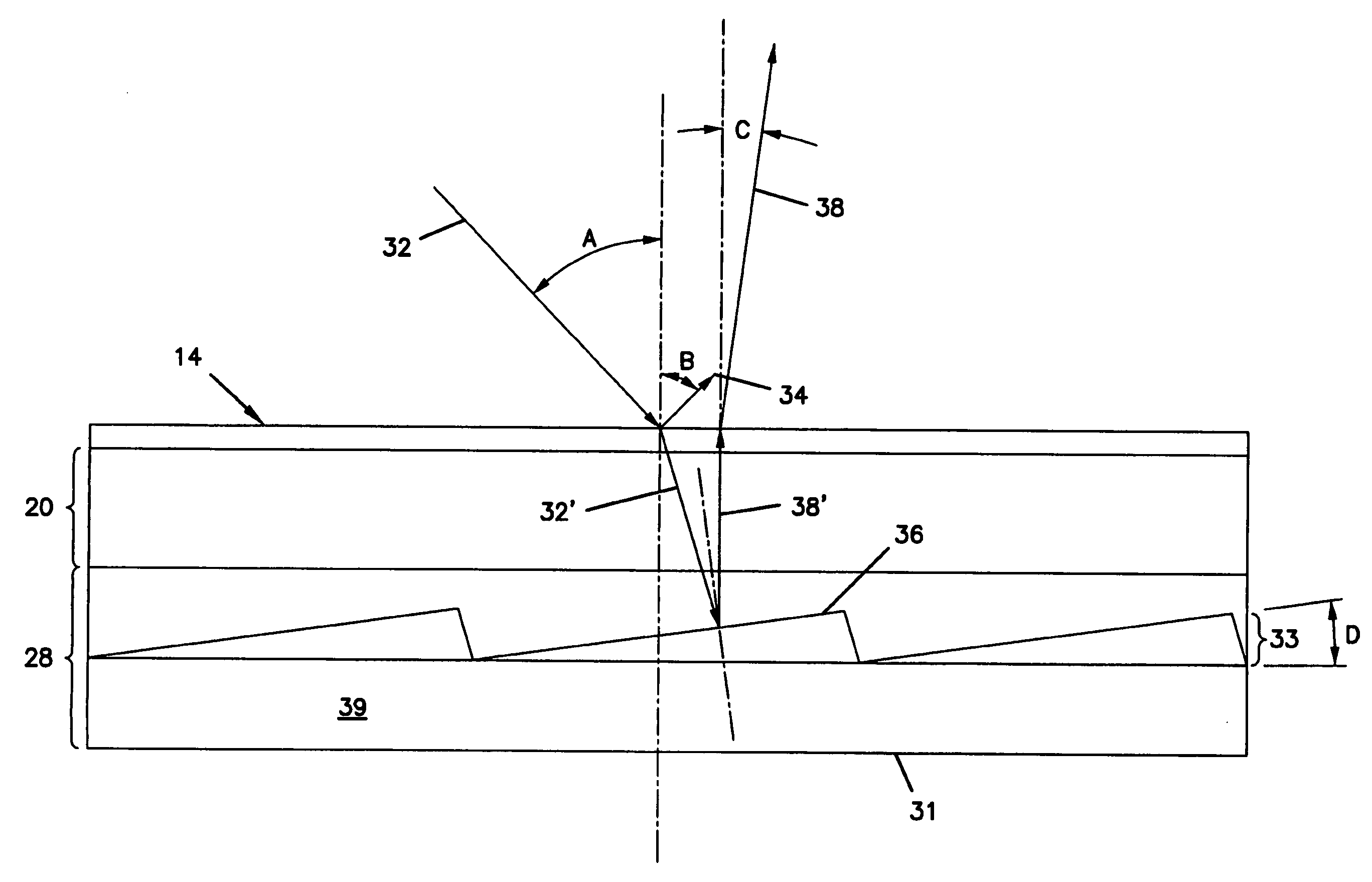

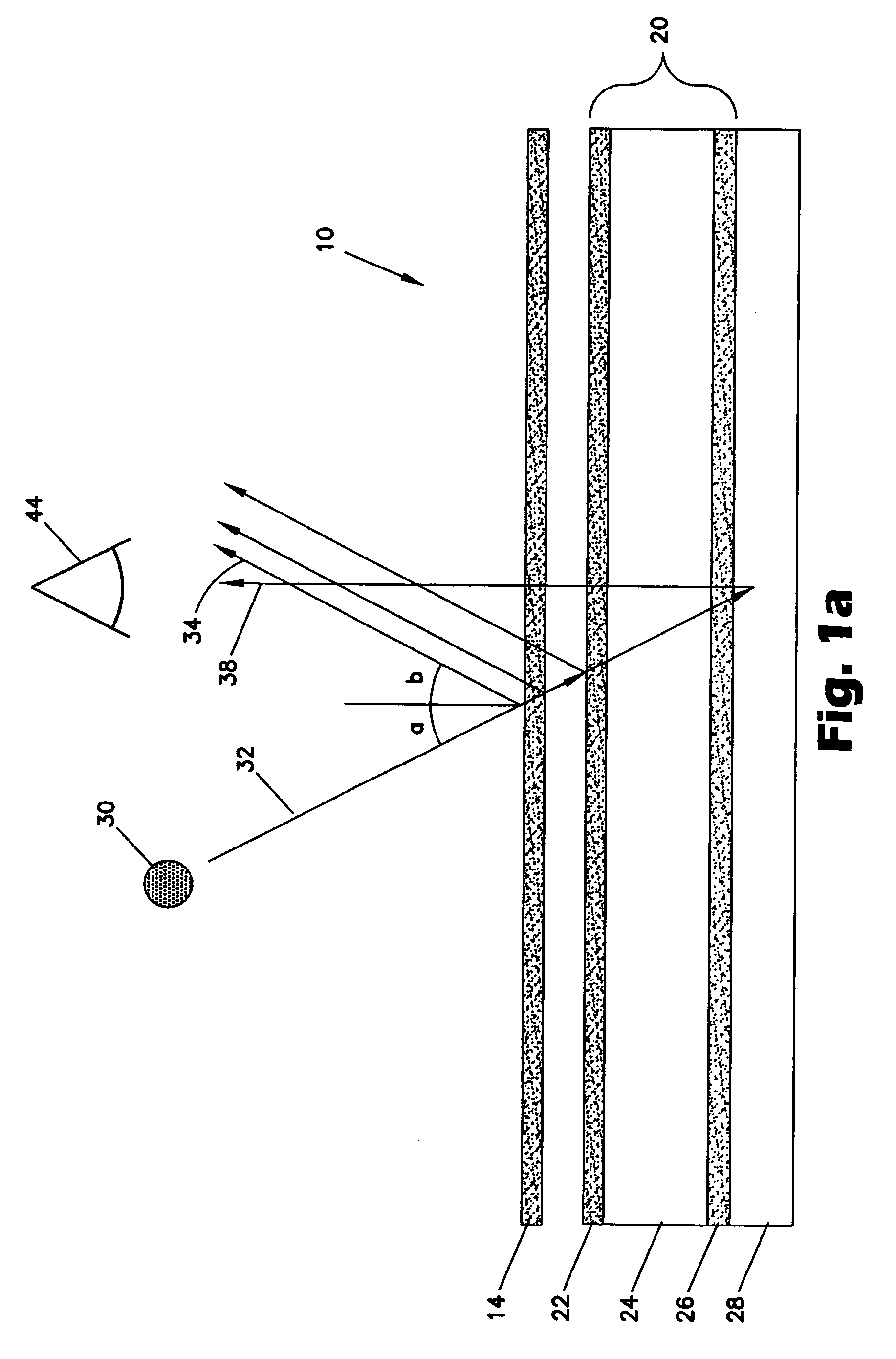

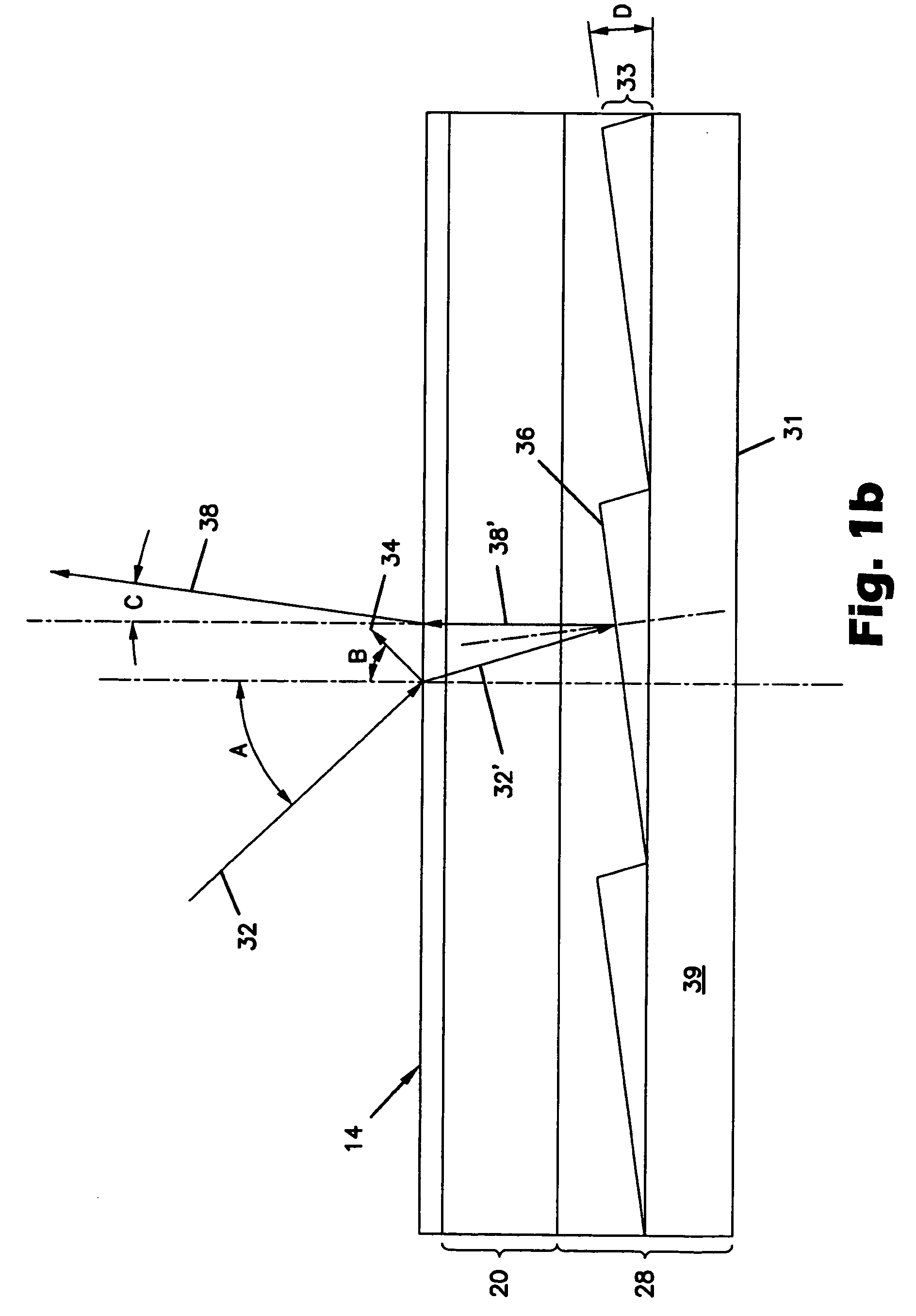

Thin illumination system

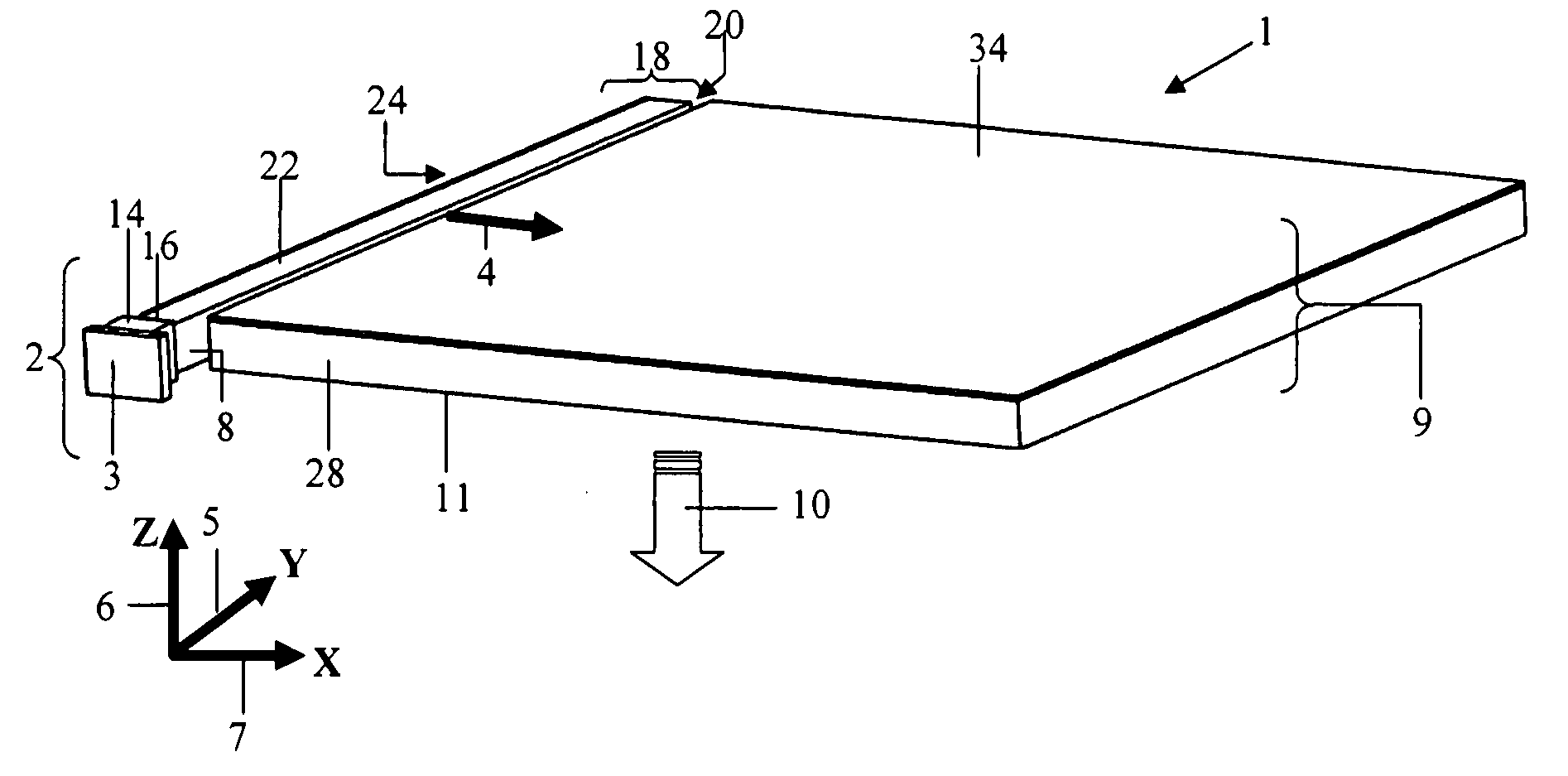

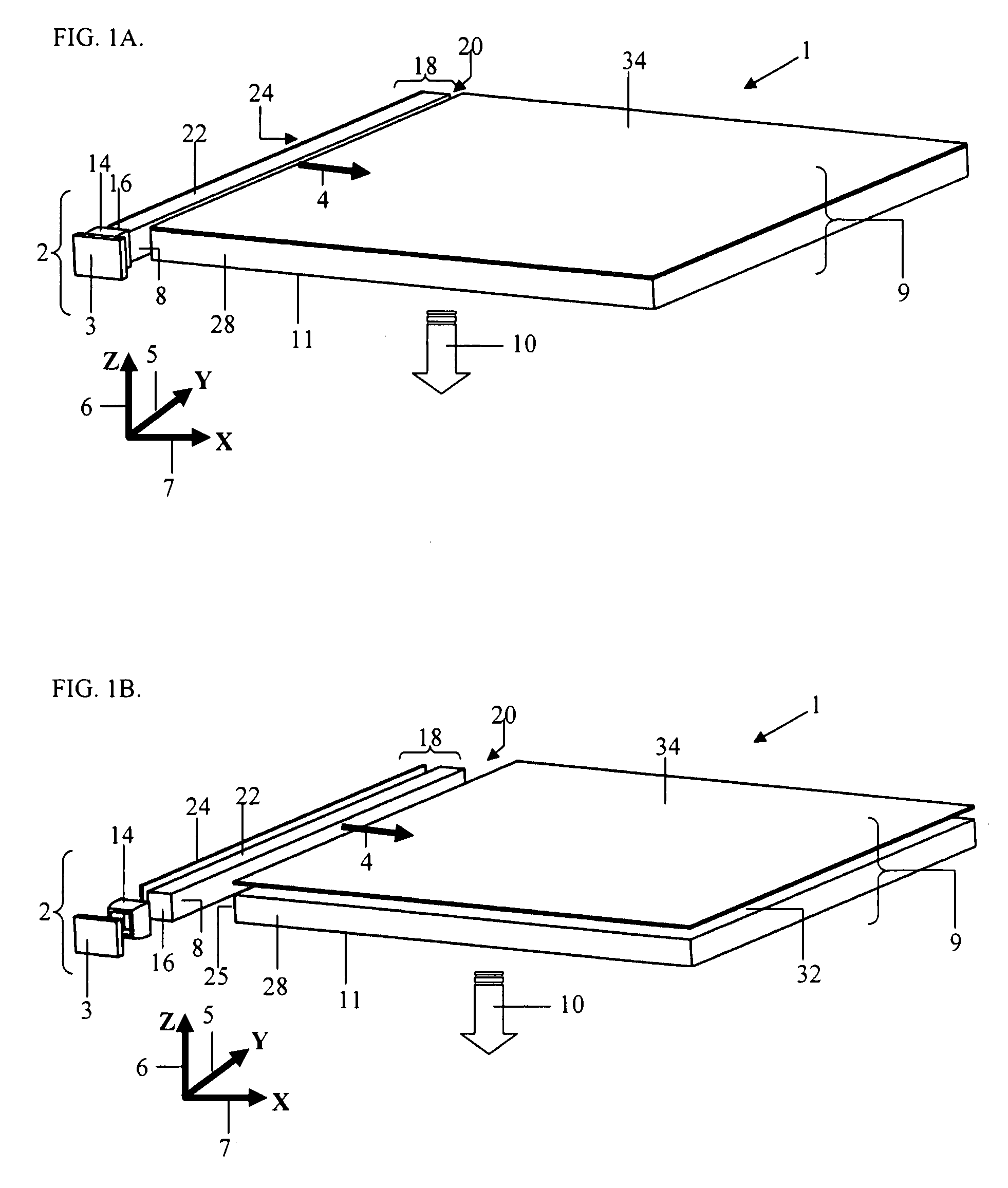

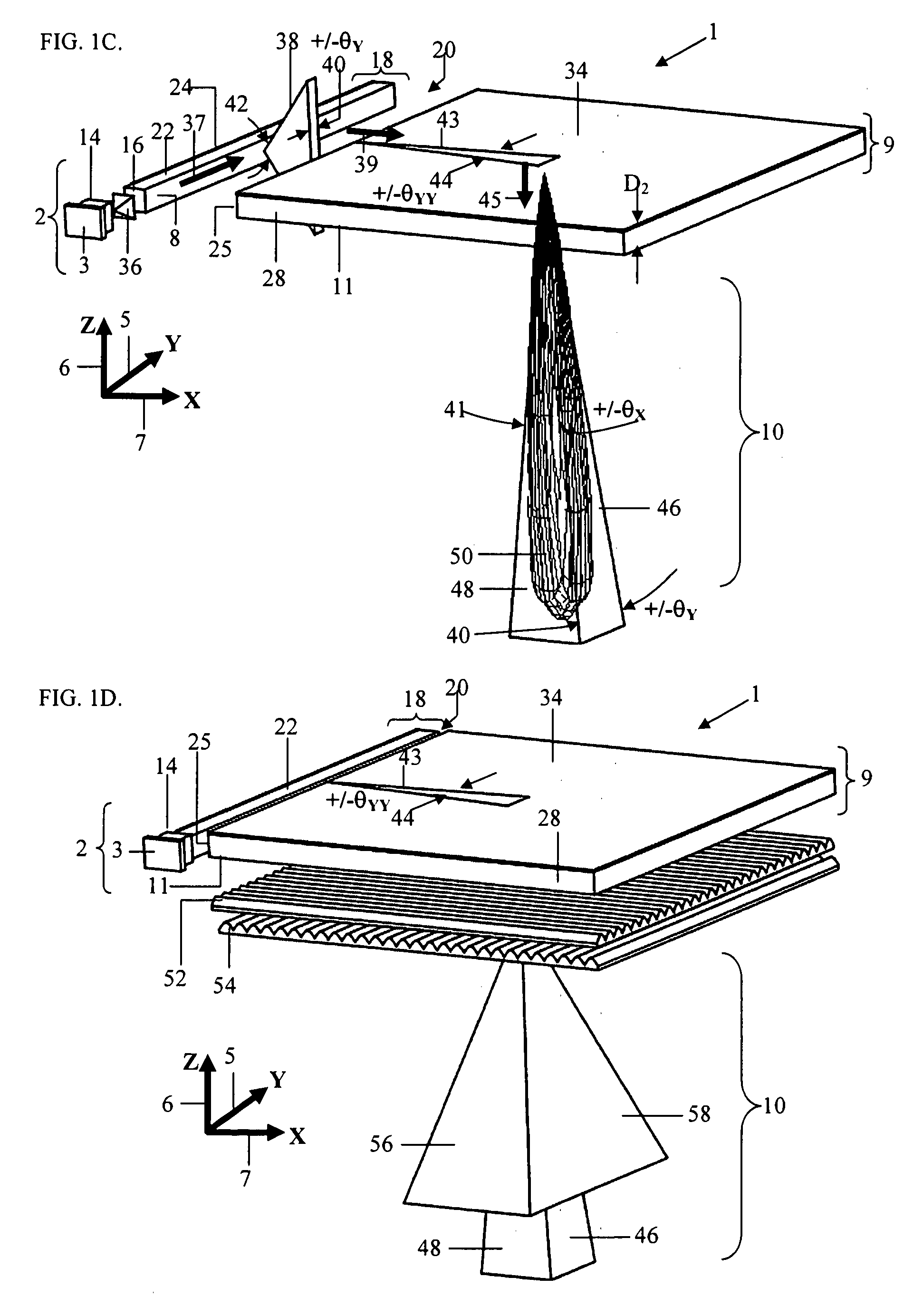

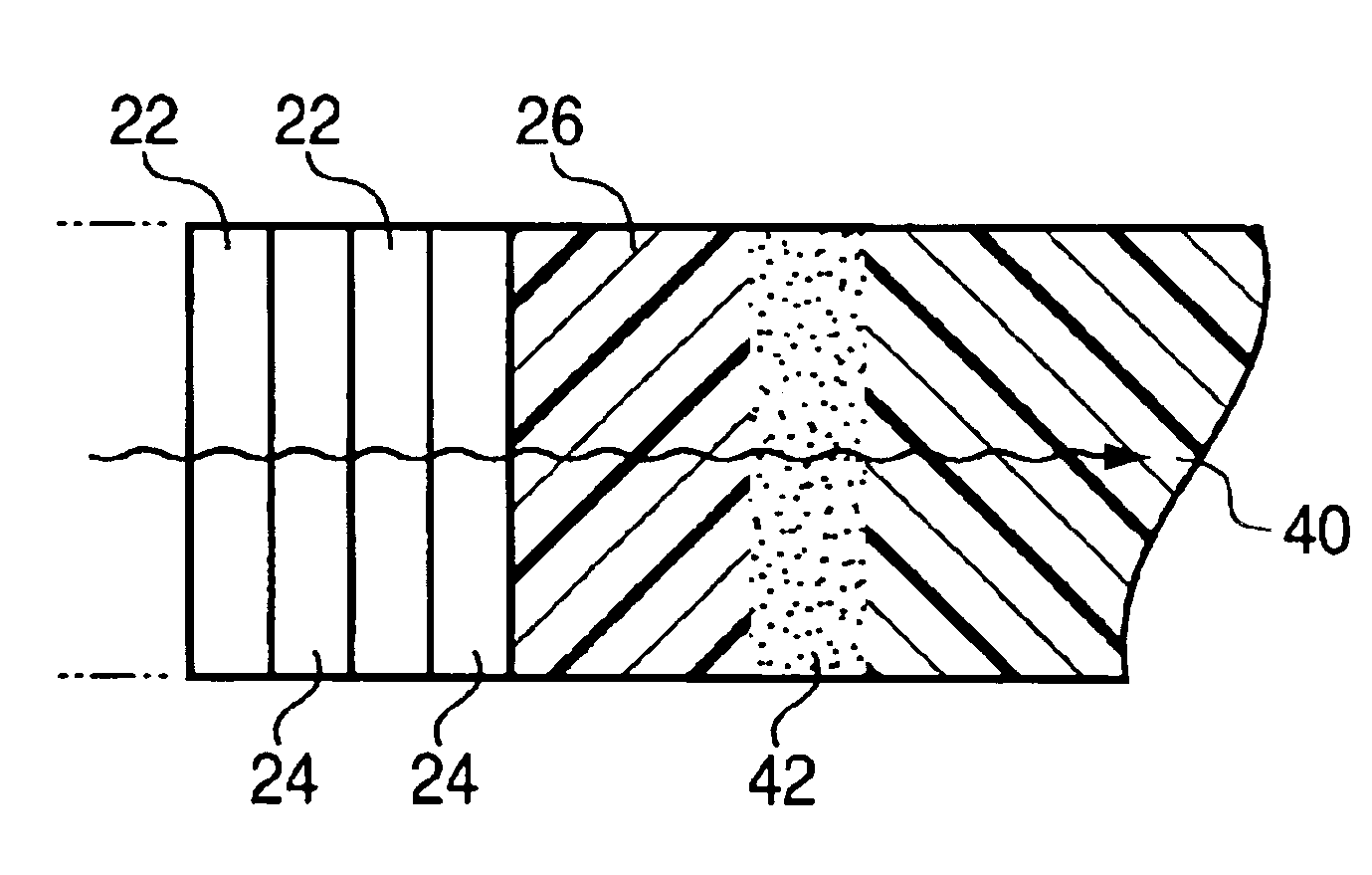

ActiveUS20100315833A1Without compromise in sharpnessModerate brightnessPlanar light sourcesMechanical apparatusLight beamEffect light

The present invention introduces a new class of thin doubly collimating light distributing engines for use in a variety of general lighting applications, especially those benefiting from thinness. Output illumination from these slim-profile illumination systems whether square, rectangular or circular in physical aperture shape is directional, square, rectangular or circular in beam cross-section, and spatially uniform and sharply cutoff outside the system's adjustable far-field angular cone. Field coverage extends from + / −5- to + / −60-degrees and more in each meridian, including all asymmetric combinations in between, both by internal design, by addition of angle spreading film sheets, and angular tilts. Engine brightness is held to safe levels by expanding the size of the engine's output-aperture without sacrifice in the directionality of illumination. One form of the present invention has a single input light emitter, a square output aperture and the capacity to supply hundreds of lumens per engine. A second multi-segment form of the invention deploys one light emitter in each engine segment, so that total output lumens is determined by the number of segments. Both types of thin light distributing engines provide input light collimated in one meridian and a light distributing element that maintains input collimation while collimating output light in the un-collimated orthogonal meridian, in such a manner that the system's far-field output light is collimated in both its orthogonal output meridians. The present invention also includes especially structured optical films that process the engine's doubly collimated output illumination so as to increase its angular extent one or both output meridians without changing beam shape or uniformity.

Owner:SNAPTRACK +1

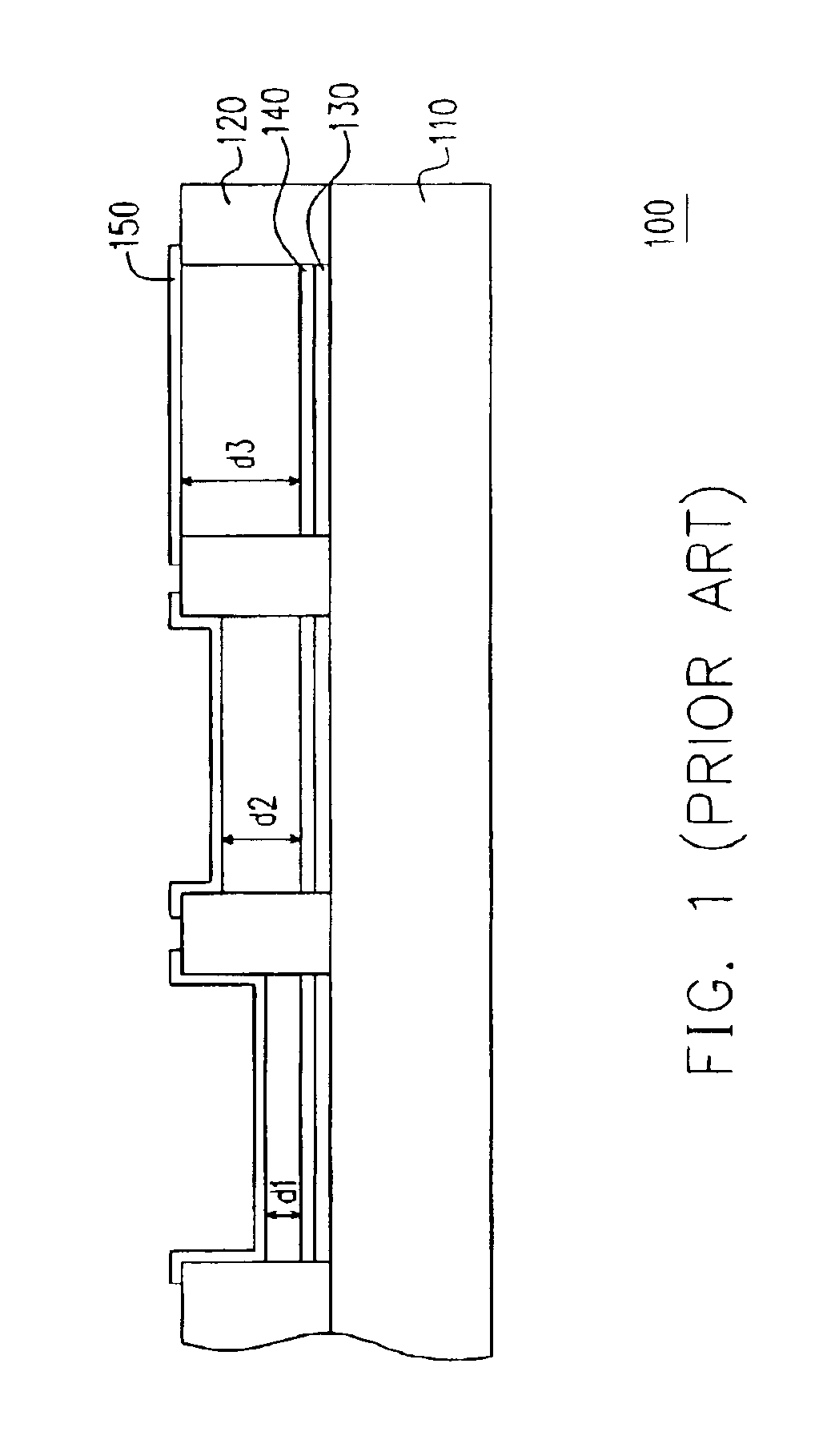

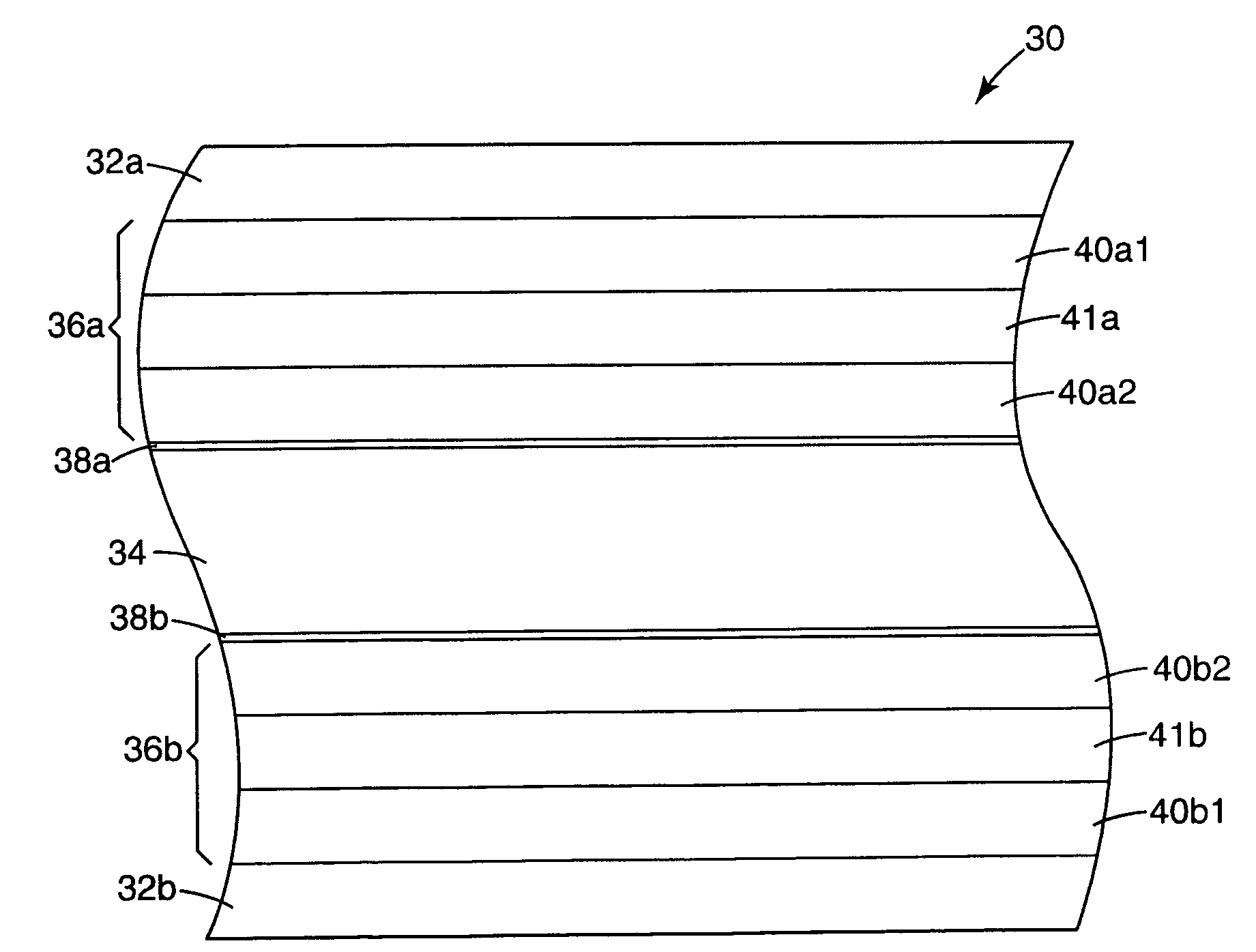

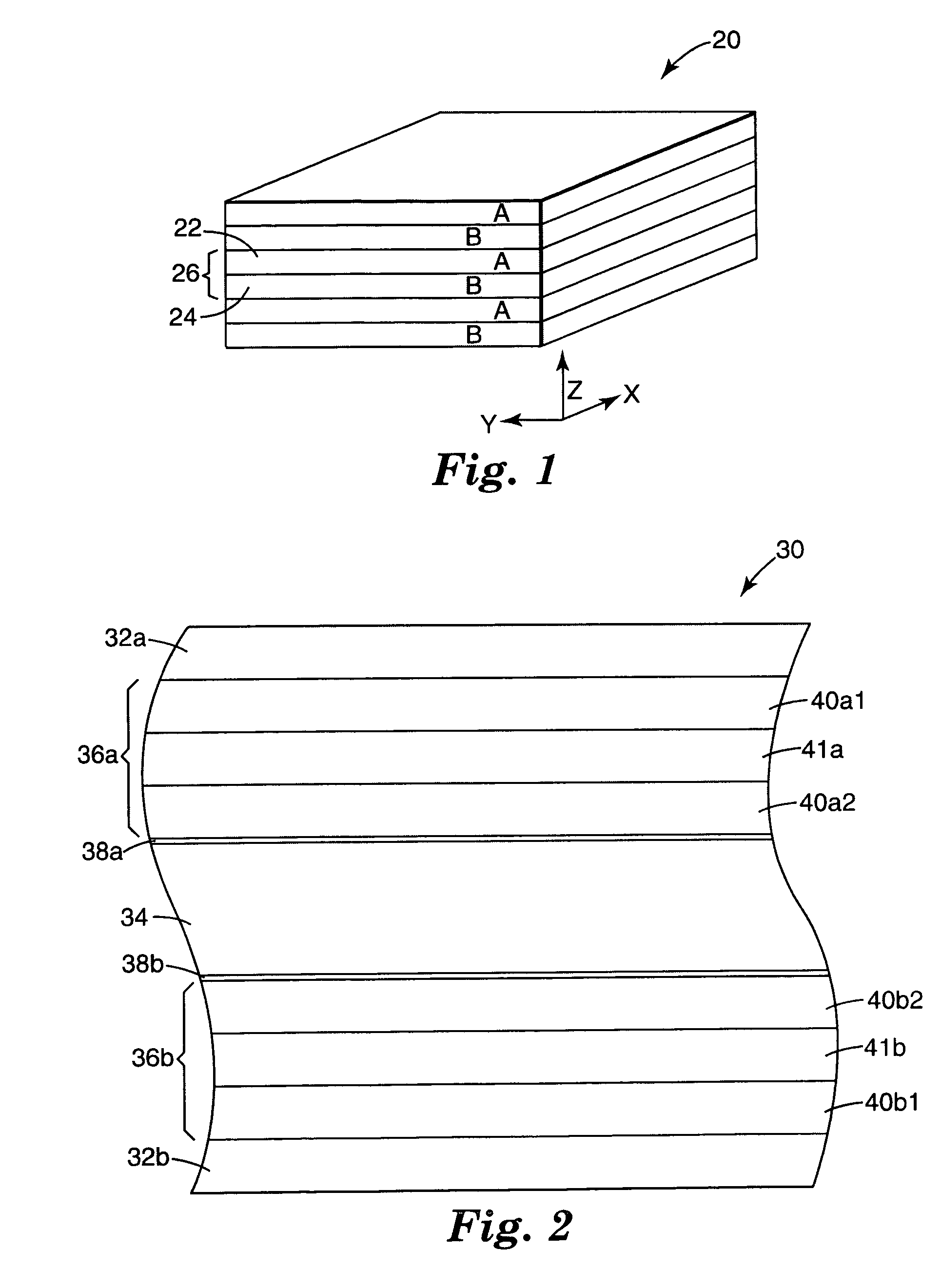

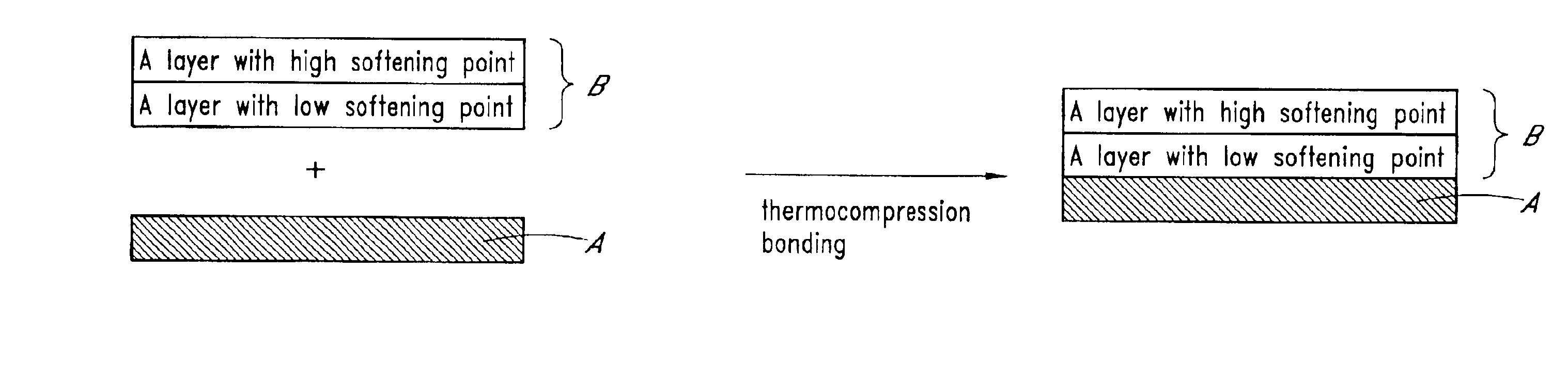

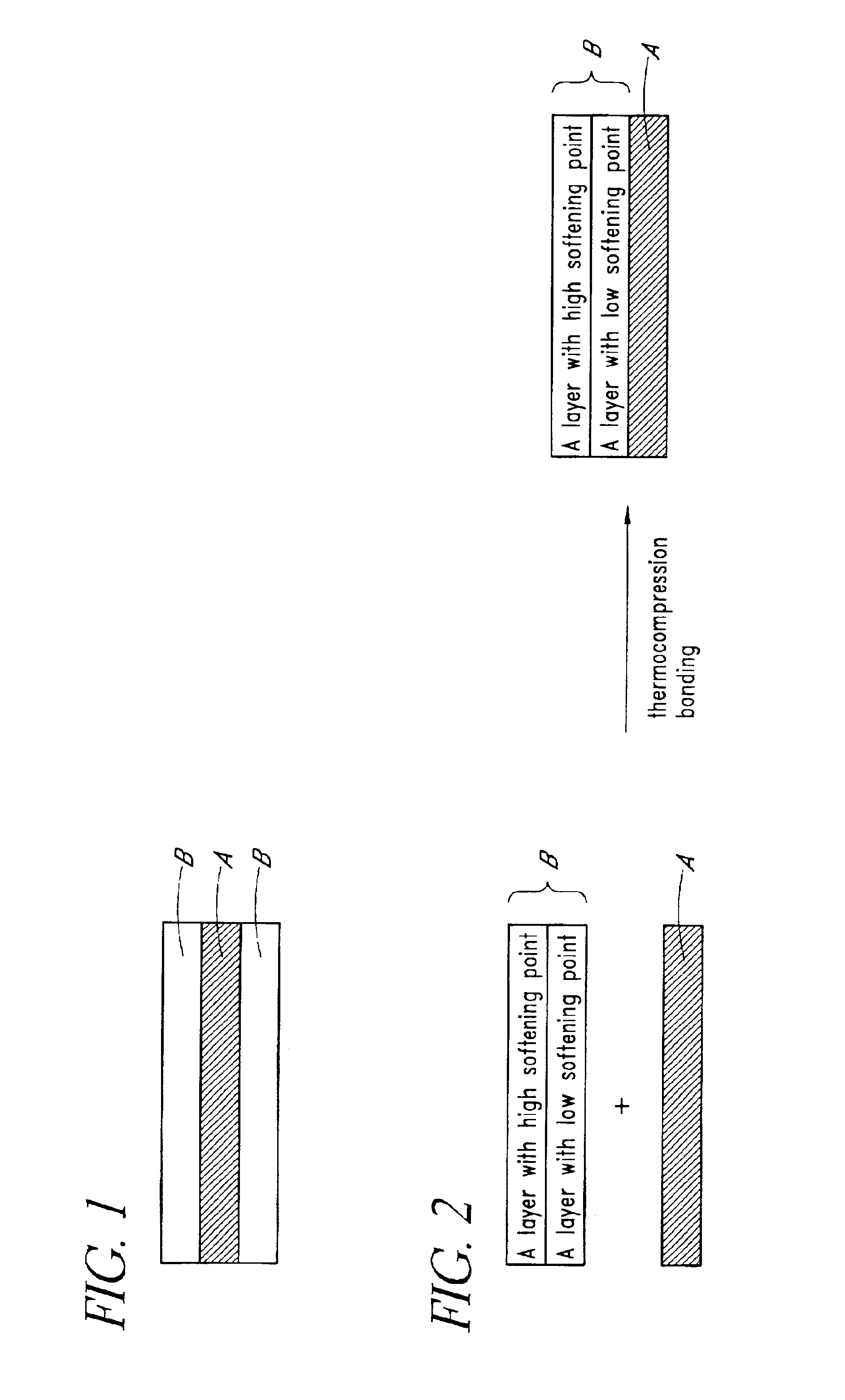

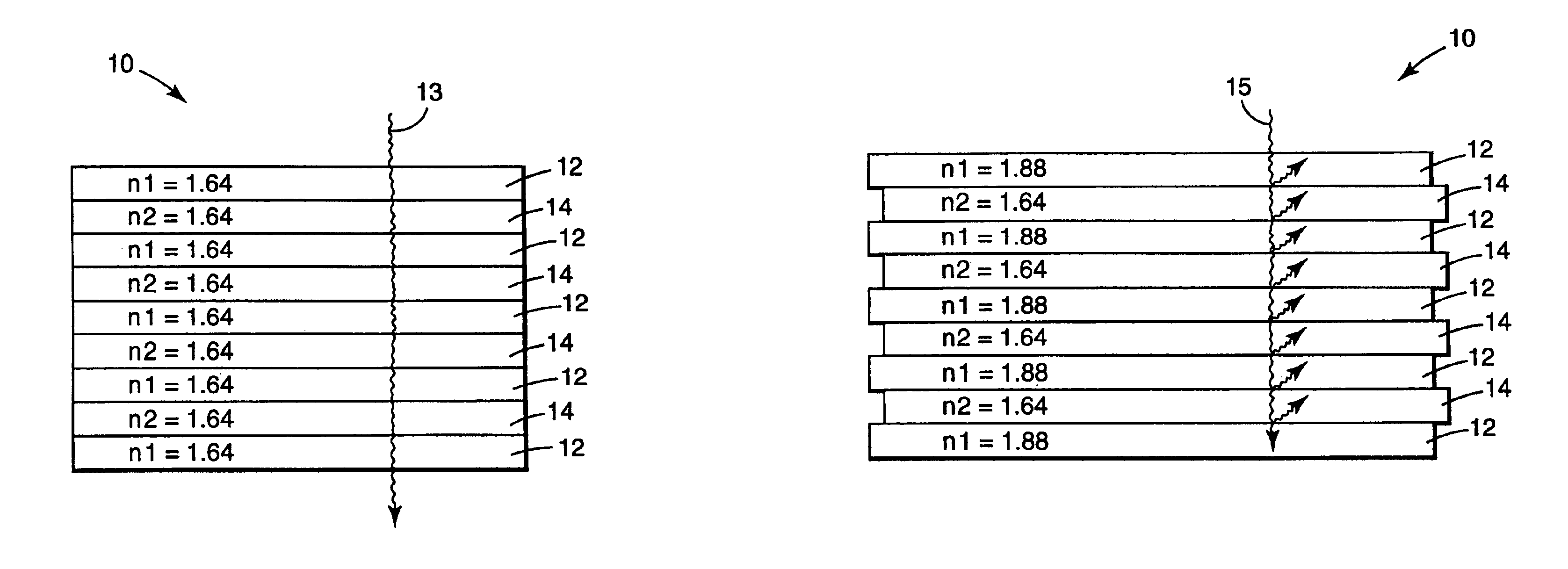

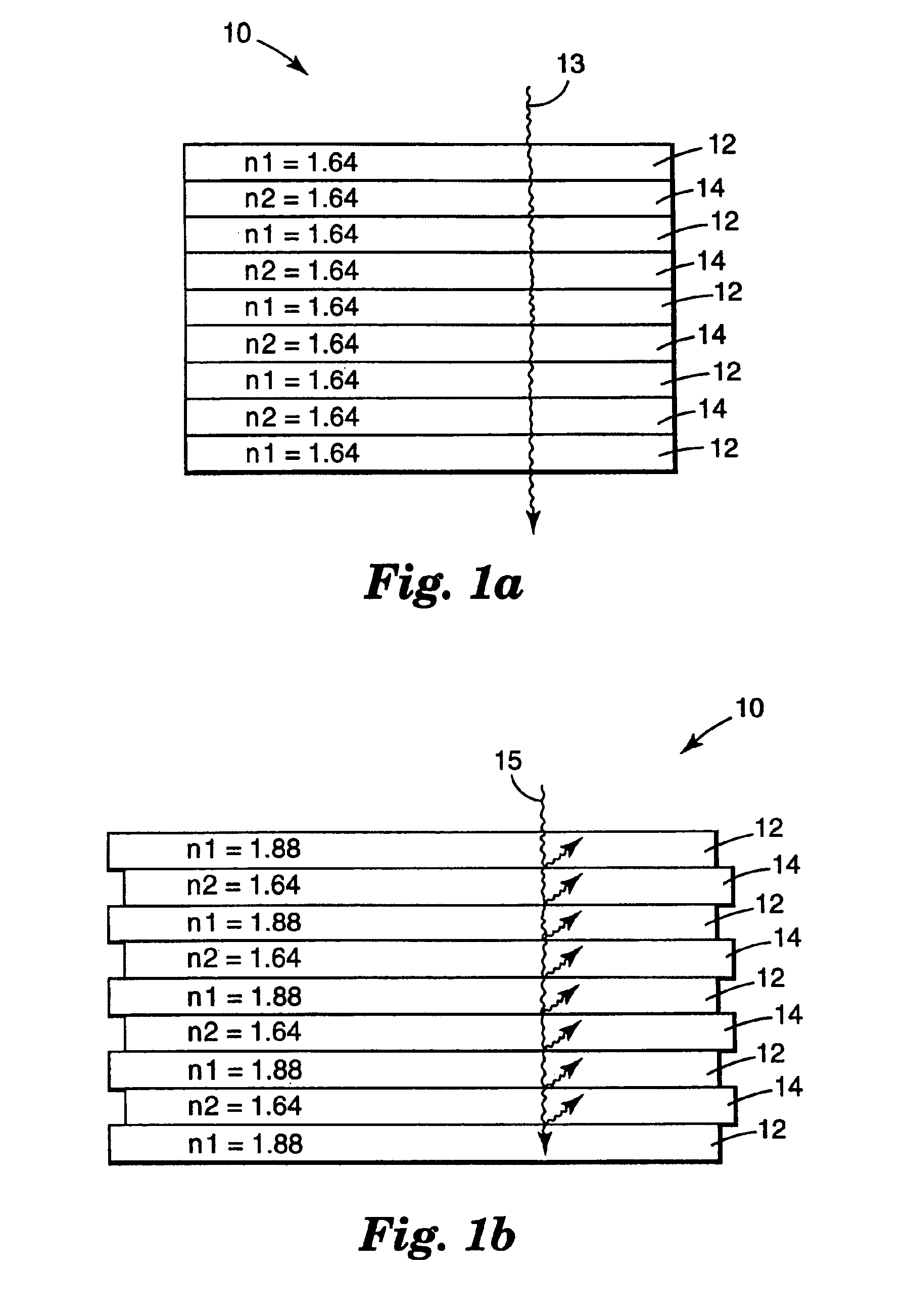

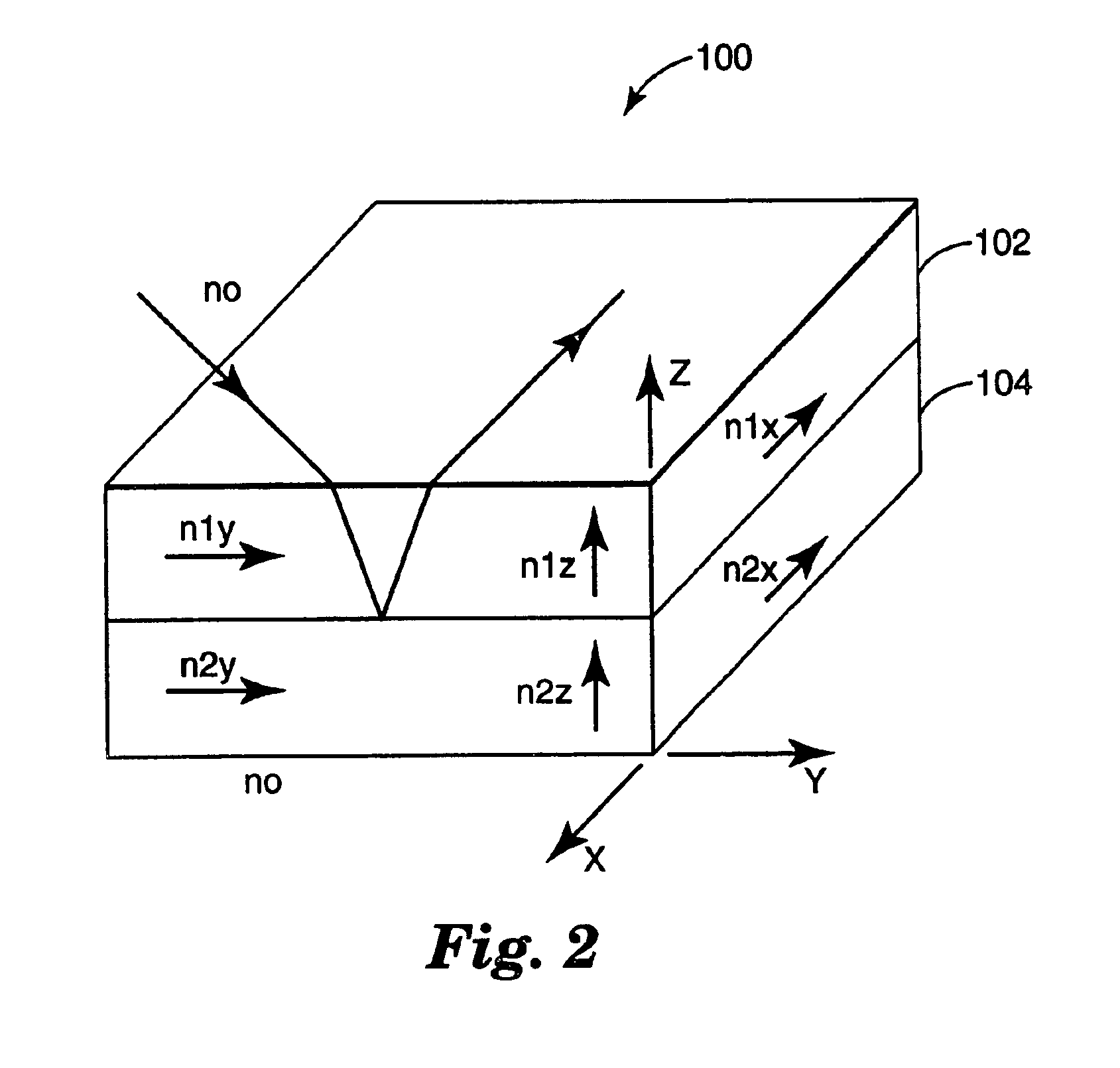

Substrate mounting for organic, dielectric, optical film

A method for optically coupling a thermoplastic material to an outer surface layer of an organic, dielectric, optical film and the resulting optical filter. Initially, a dielectric film is selected that includes (i) repeating optical layers of at least two polymers having different refractive indexes from each other, (ii) an exterior film surface, (iii) a refractive boundary along the exterior film surface, and (iv) a delamination threshold based on total thermal energy delivered to the film. A thermoplastic material which is miscible with the exterior film surface is fused to the refractive boundary with thermal energy below the delamination threshold to form a polydisperse region having a higher optical transmission than the refractive boundary. Add-on filters in the form of hardcoat layers, anti-reflection layers, holograms, metal dielectric stacks and combinations of these may be combined with the thermoplastic-film construct.

Owner:GENTEX CORP

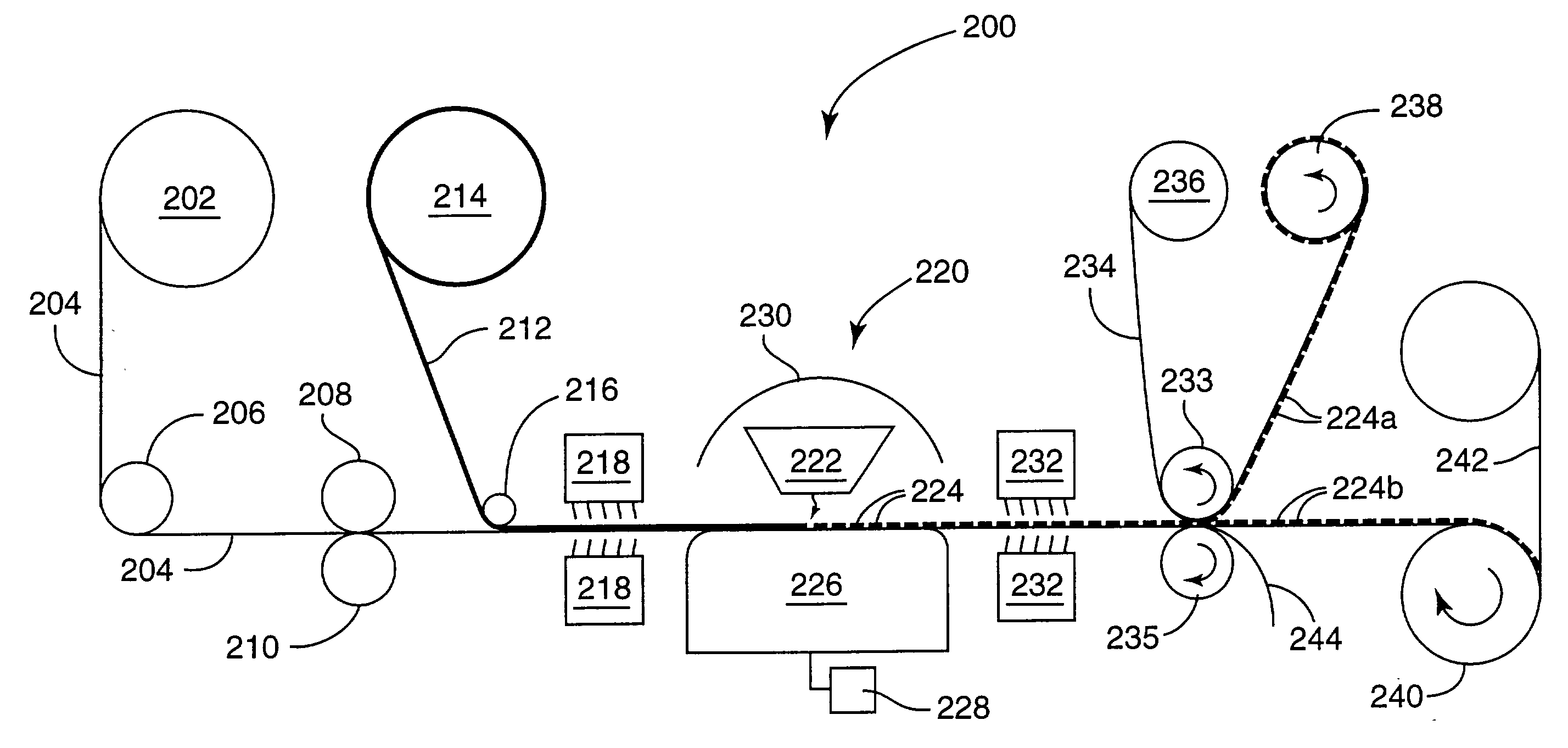

Method for subdividing multilayer optical film cleanly and rapidly

Polymeric multilayer optical films, and laminate bodies that include such films, are cut or subdivided into one or more discrete pieces by removably applying a first and second liner to opposed major surfaces of the multilayer optical film. Laser radiation is then directed at the multilayer optical film through the first liner in such a way as to produce cut lines that define a plurality of pieces of the first liner and of the multilayer optical film. Thereafter, the plurality of pieces of the first liner are removed from the plurality of pieces of the multilayer optical film while the pieces of multilayer optical film are supported by the second liner. Application of the first liner to the multilayer optical film can be accomplished with electrostatics.

Owner:3M INNOVATIVE PROPERTIES CO

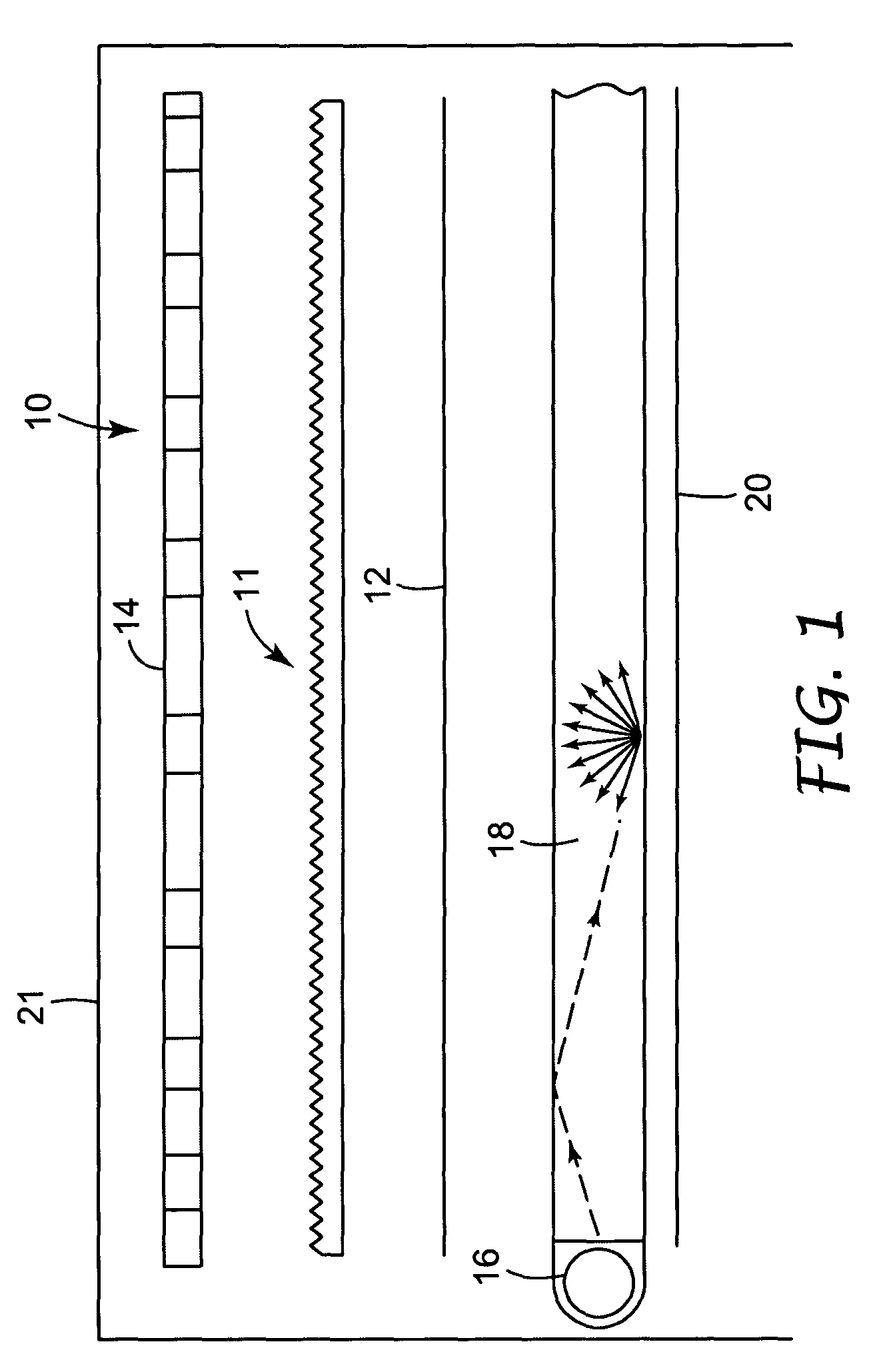

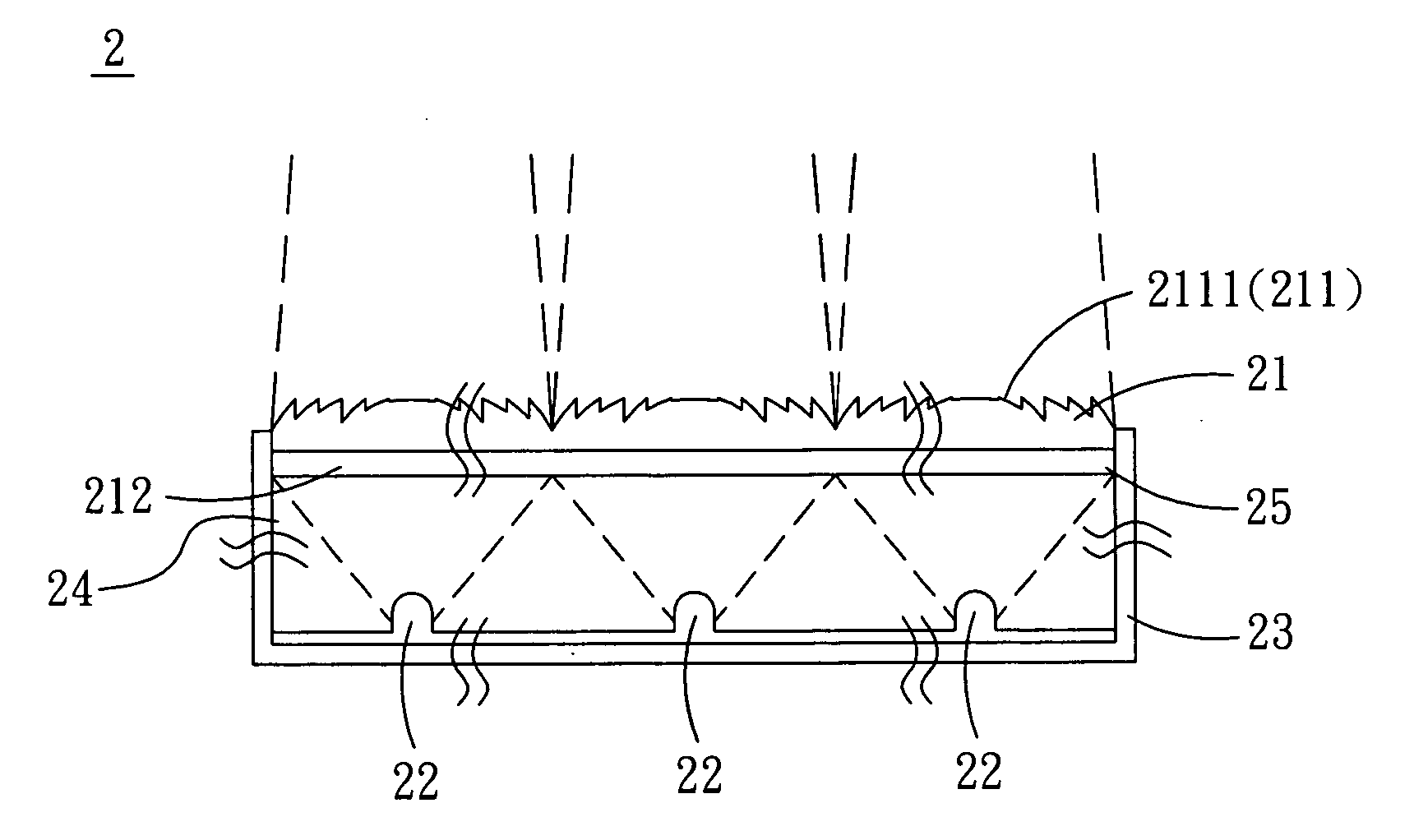

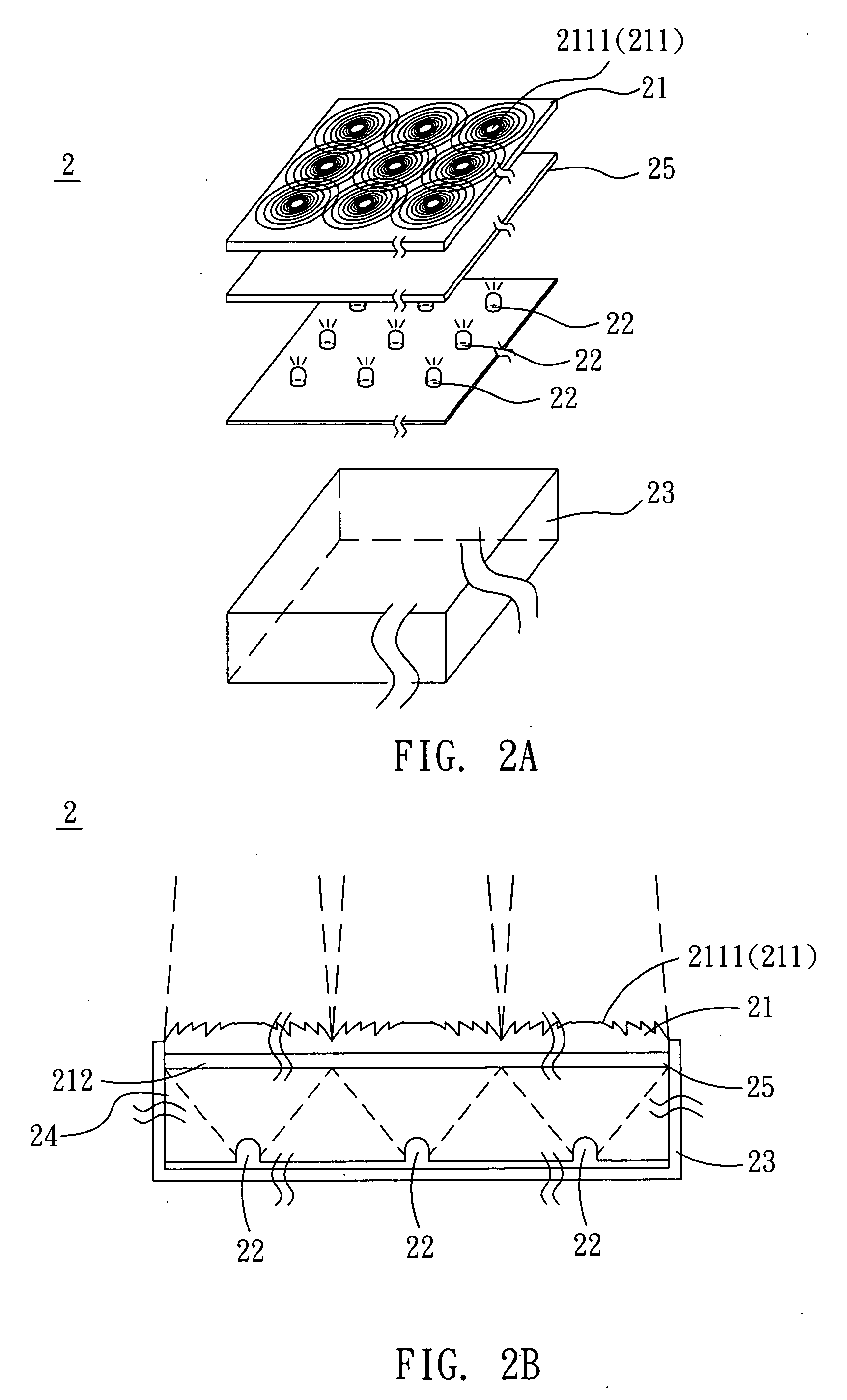

Liquid crystal display device and backlight module thereof

InactiveUS20050270766A1Improve uniformityIncrease brightnessNon-electric lightingPoint-like light sourceLiquid-crystal displayOptical thin film

A backlight module comprises a light transmissive substrate, an optical film, and at least one light source. In this case, the optical film has a first surface and a second surface opposite to the first surface. The first surface of the optical film is connected to the transparent surface, and the second surface of the optical film has at least one fresnel area. The light source is disposed at one side of the light transmissive substrate.

Owner:PRODISC TECH INC

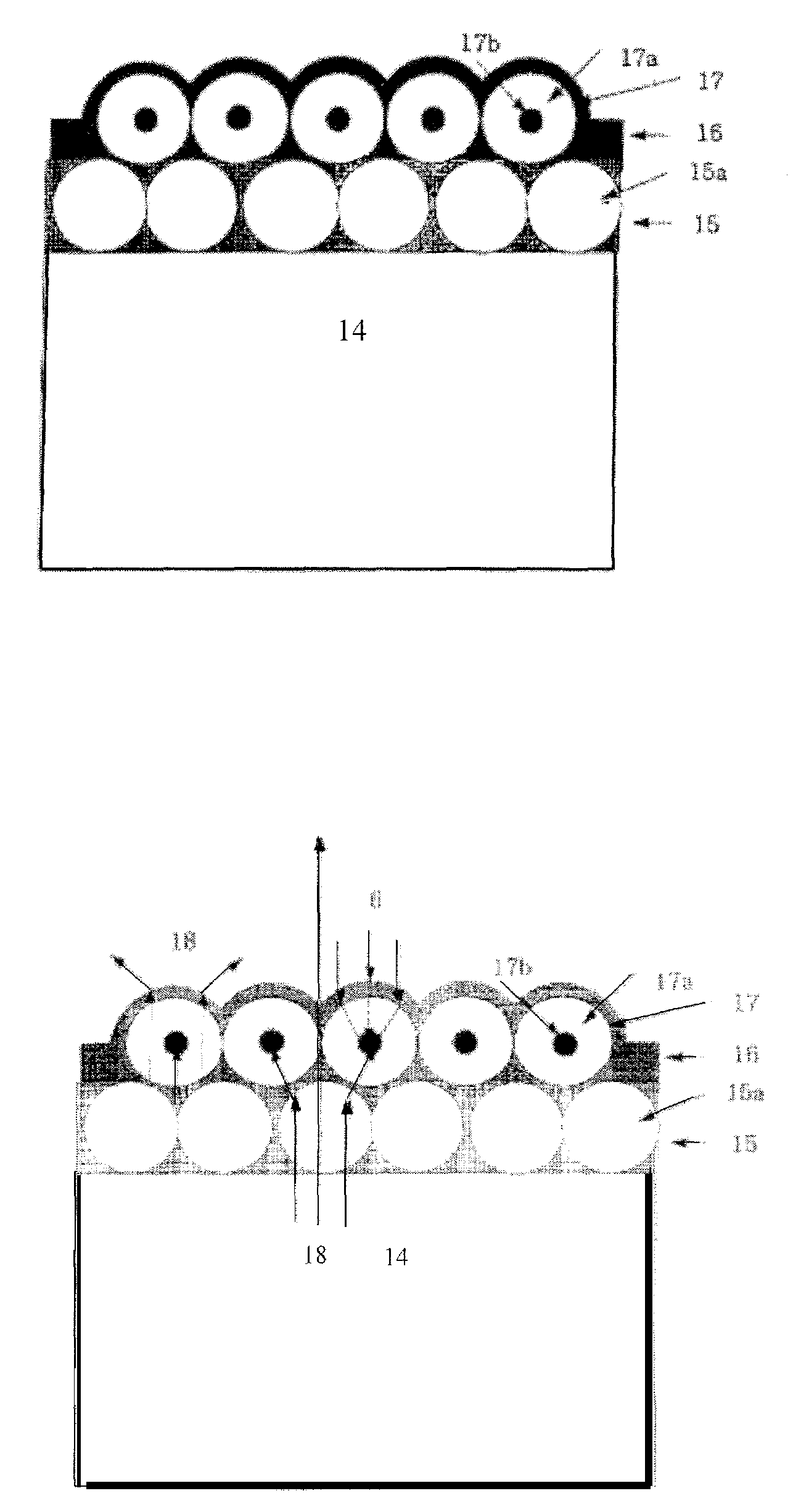

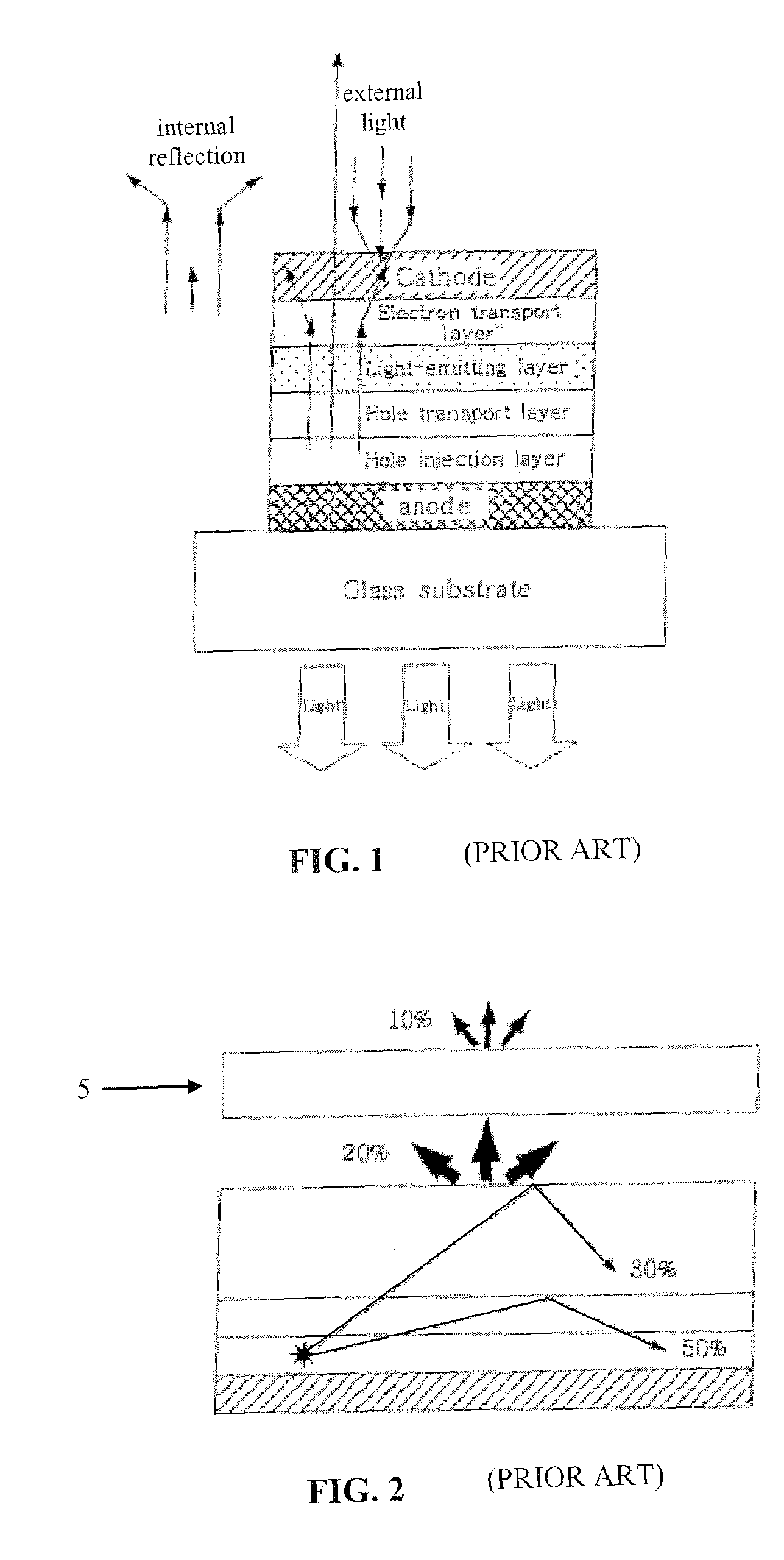

Brightness-enhanced multilayer optical film with low reflectivity for display and organic light emitting diode display using the same

ActiveUS7446462B2Reduce reflectivityImprove output efficiencyIncadescent screens/filtersDischarge tube luminescnet screensDisplay deviceLight-emitting diode

The subject invention features a low-reflectivity, brightness-enhancing multilayer optical film for enhancing the brightness of an organic light emission diode (OLED) display and imparting anti-reflection performance to the display.

Owner:CHEIL IND INC

Adhesive optical film, method for manufacturing adhesive optical film and image display

ActiveUS20060108050A1More easilySimply easilyAdhesive articlesSolid-state devicesAdhesiveEngineering

An adhesive layer included in an adhesive-type optical film forms a portion located on the inside of a edge line of an optical film.

Owner:NITTO DENKO CORP

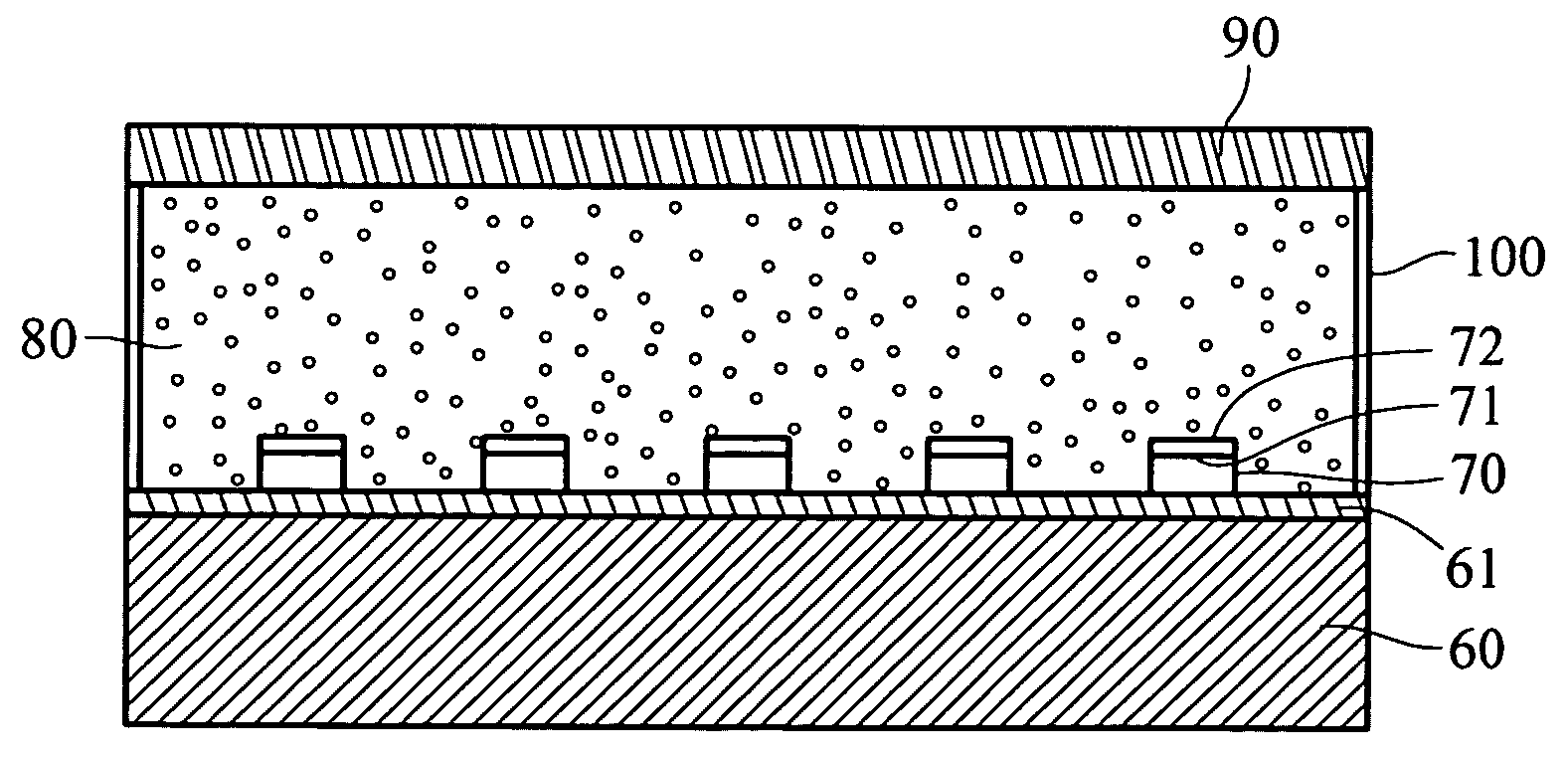

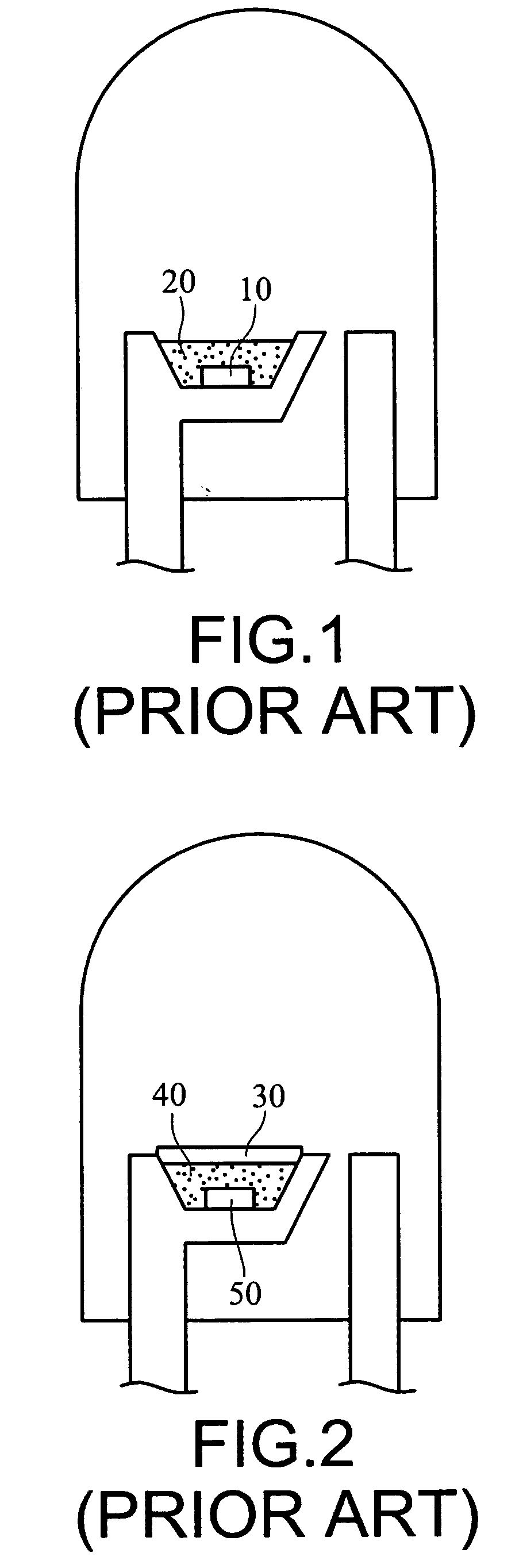

Light emitting diode with a quasi-omnidirectional reflector

InactiveUS20060145172A1Improve conversion efficiencyStrong penetrating powerSemiconductor devicesLight-emitting diodeLuminescent material

A light emitting diode with a quasi-omnidirectional reflector comprises a luminescent gel which is coated surrounding a UV light LED chip and a quasi-omnidirectional reflector which is disposed above the luminescent gel. The quasi-omnidirectional reflector is a wild angle cut-off filter which is made by a cooperation of a method for an optical film coating and a property of a total reflection. According to the property of the optical film coating, a light with an incident angle smaller than a critical angle can be reflected, such that a light form the LED chip is confined in the luminescent gel, which makes the luminescent material is excited as much as possible for improving the conversion efficiency of the light. When this LED chip co-works with different colors of the luminescent gels, different colors of lights are excited and produced.

Owner:IND TECH RES INST

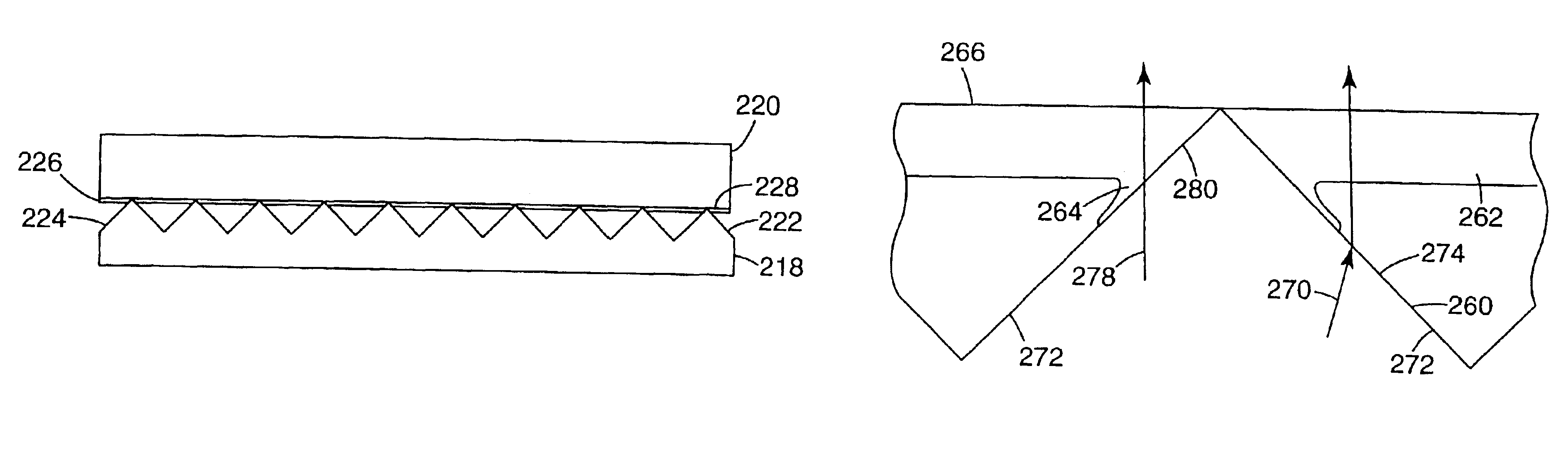

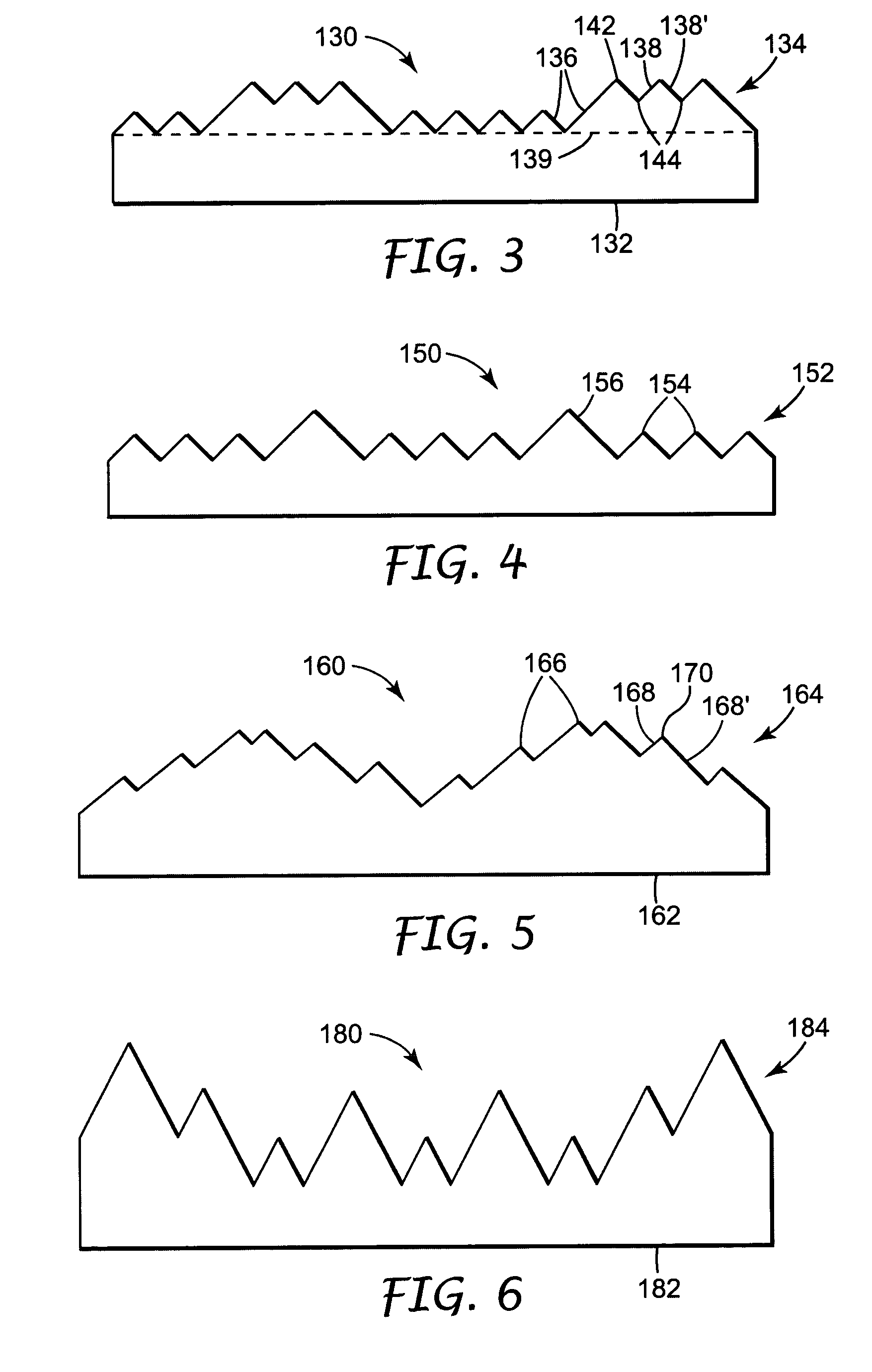

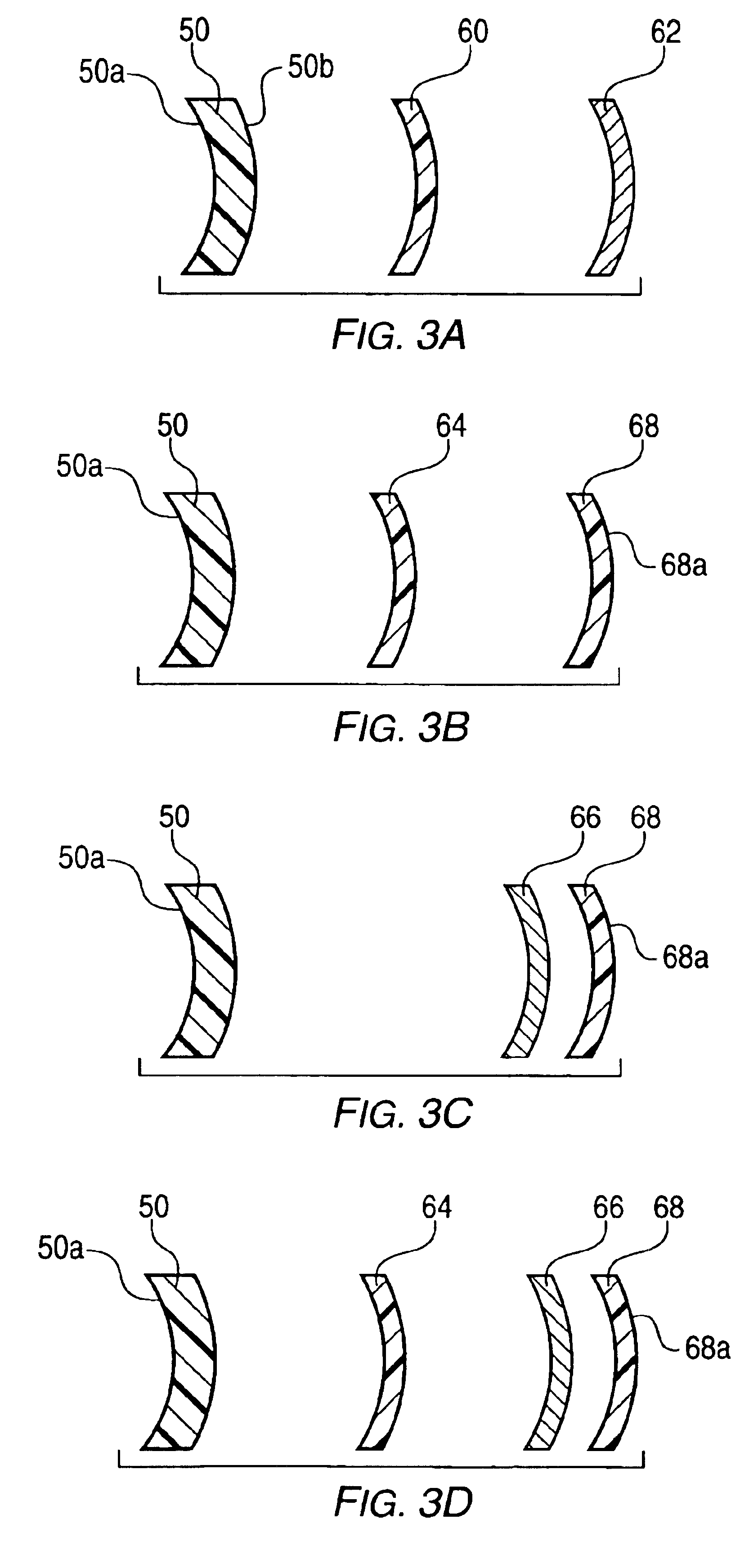

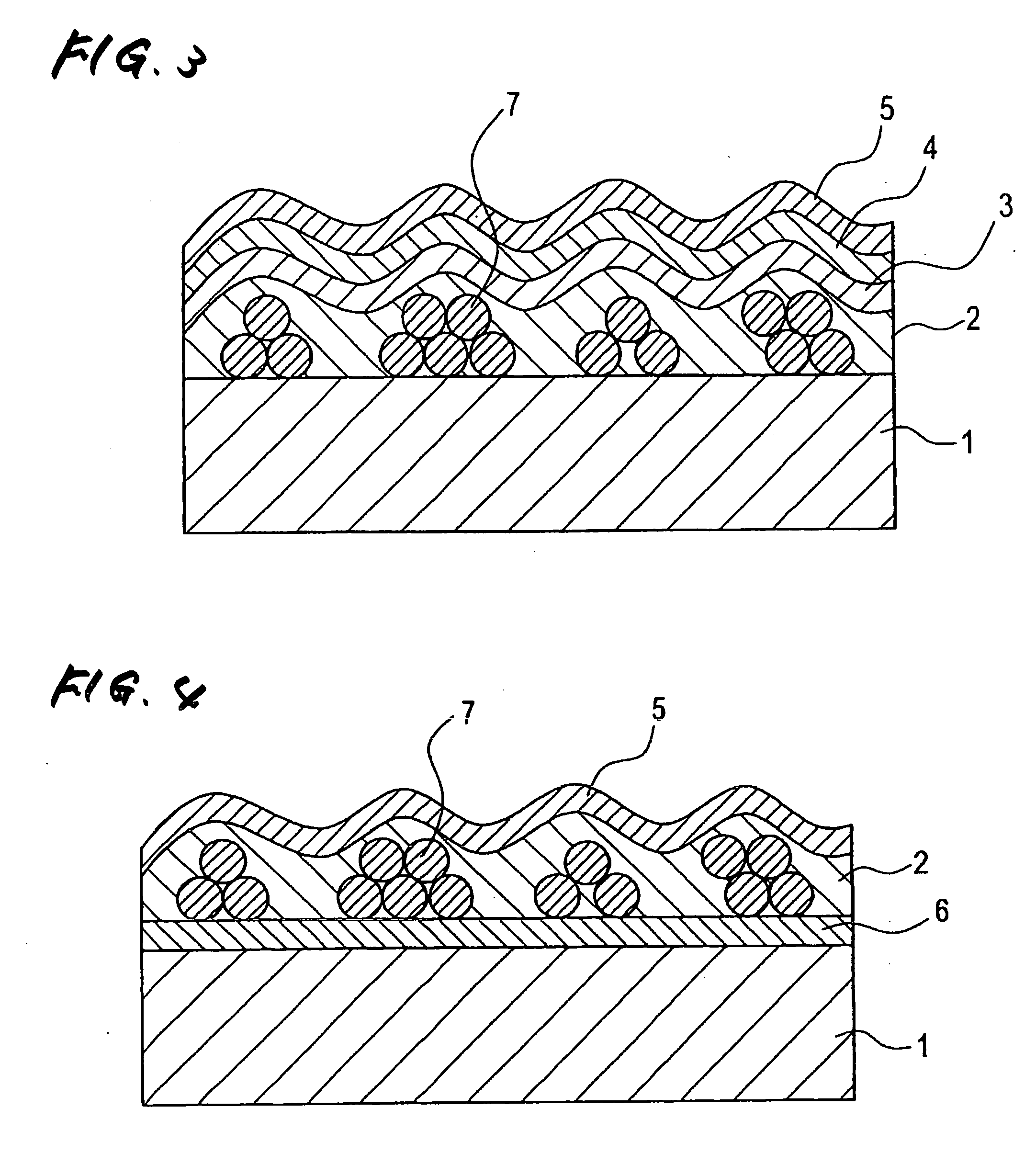

Optical film having microeplicated structures; and methods

An optical film for use in transparent displays, such as reflective LCDs. The optical film has three-dimensional, prismatic structures that reflect incoming light. The prismatic structures are configured so that the reflecting facets orient the reflected light in desired reflective light pattern. The pattern shape and intensity can be controlled by the shape and dimensions of the various reflecting facets. In one embodiment, the height of the prismatic structure varies along two dimensions of the structure.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure-sensitive adhesive sheet

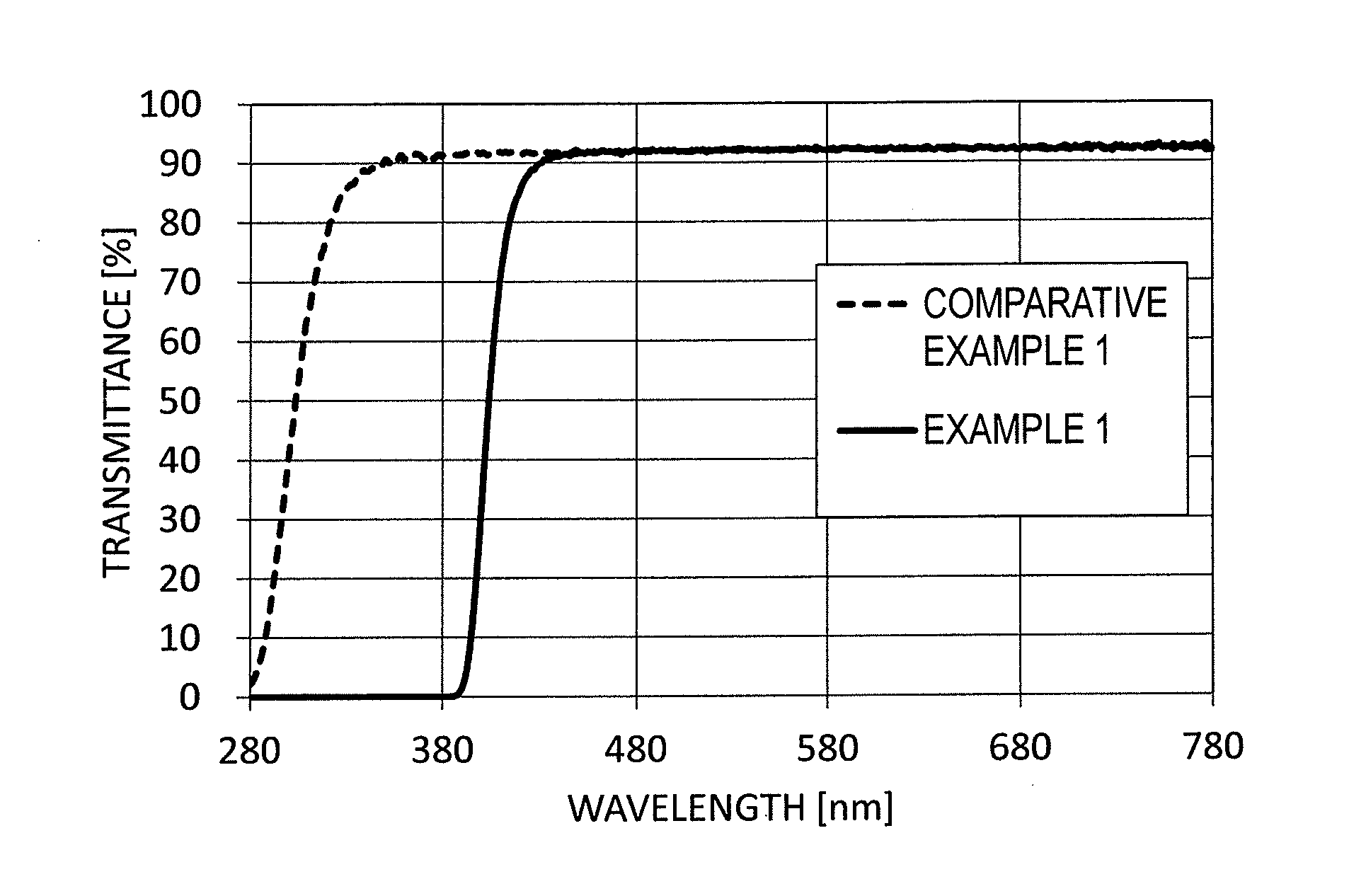

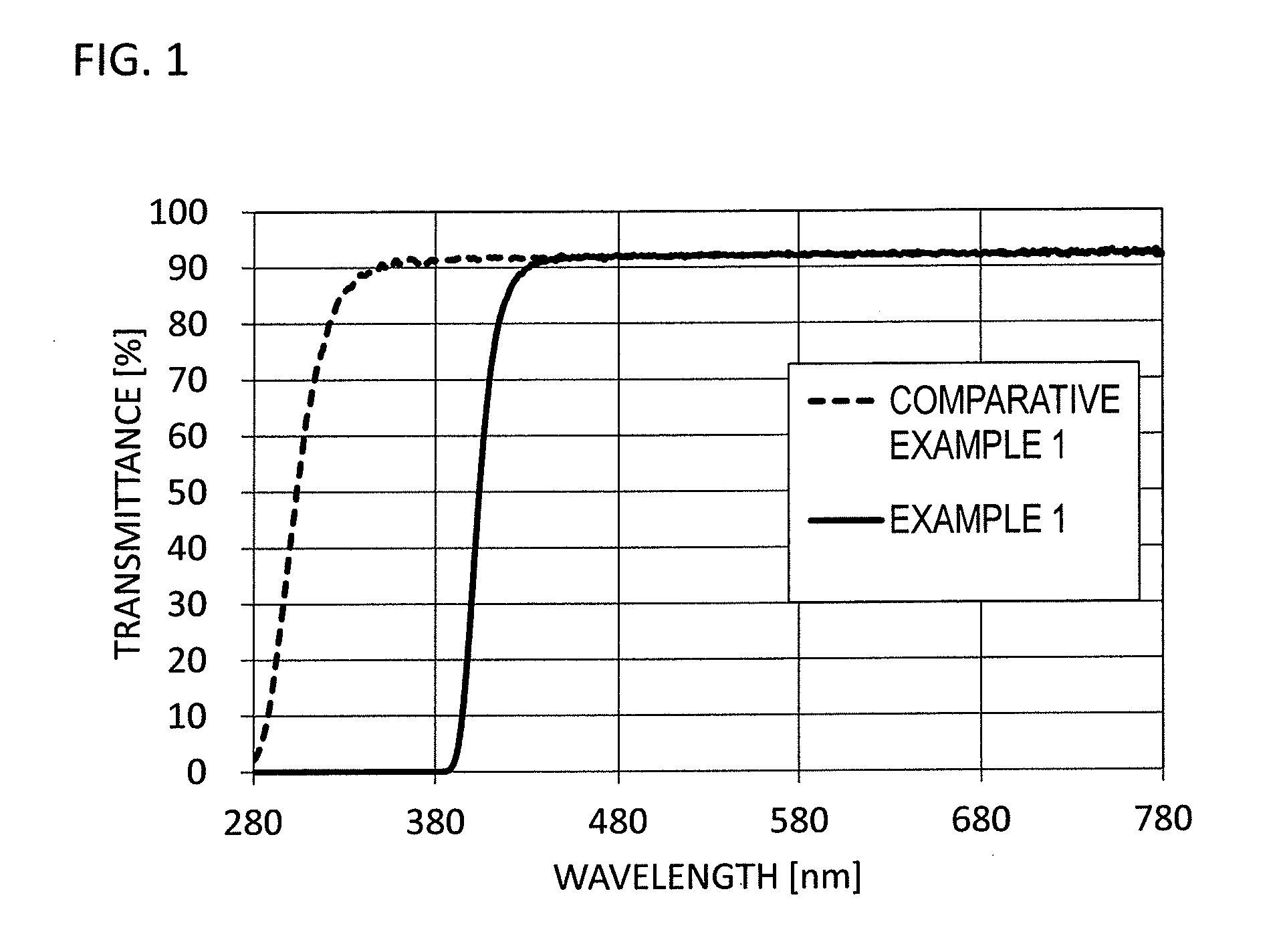

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

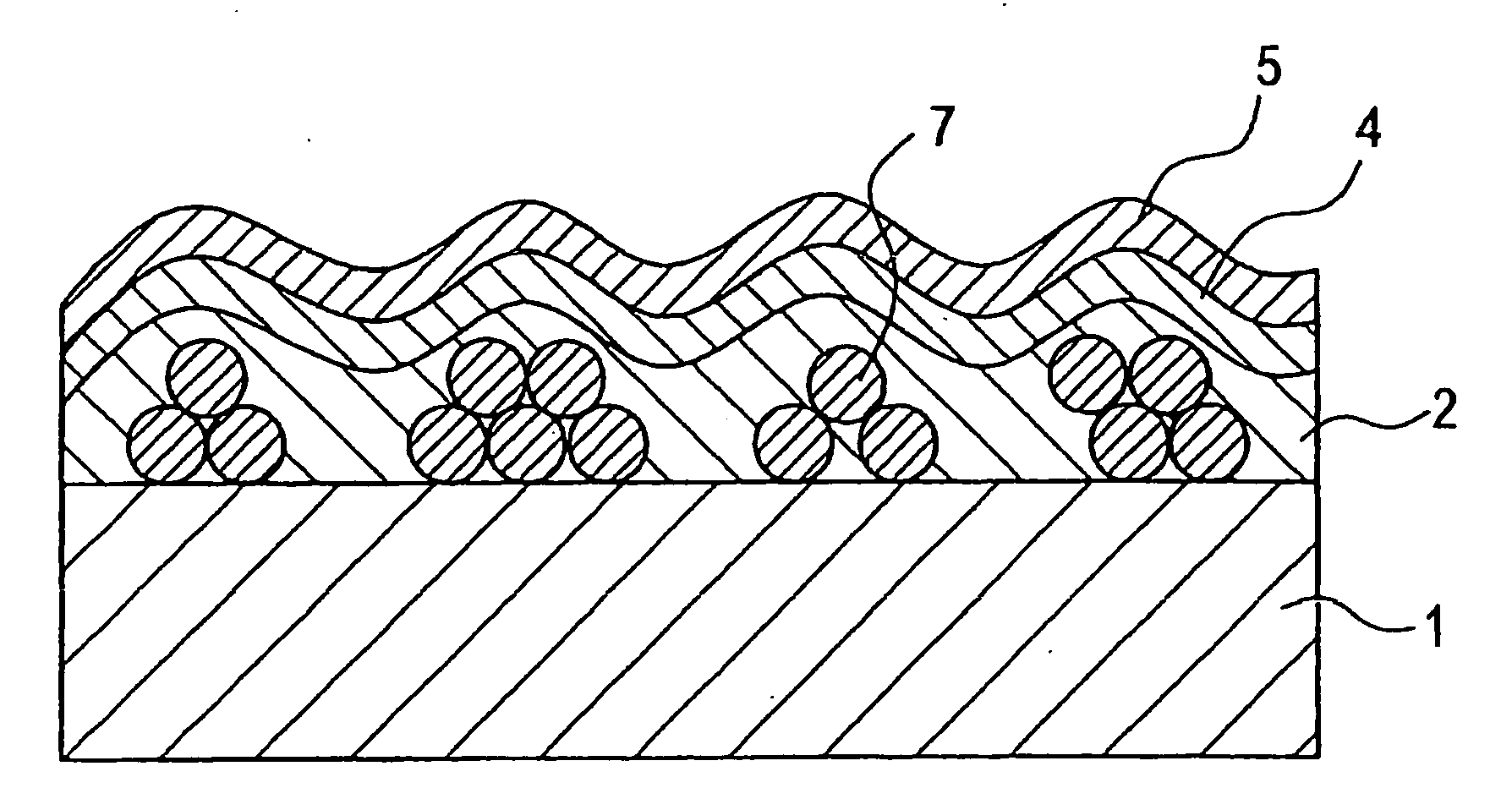

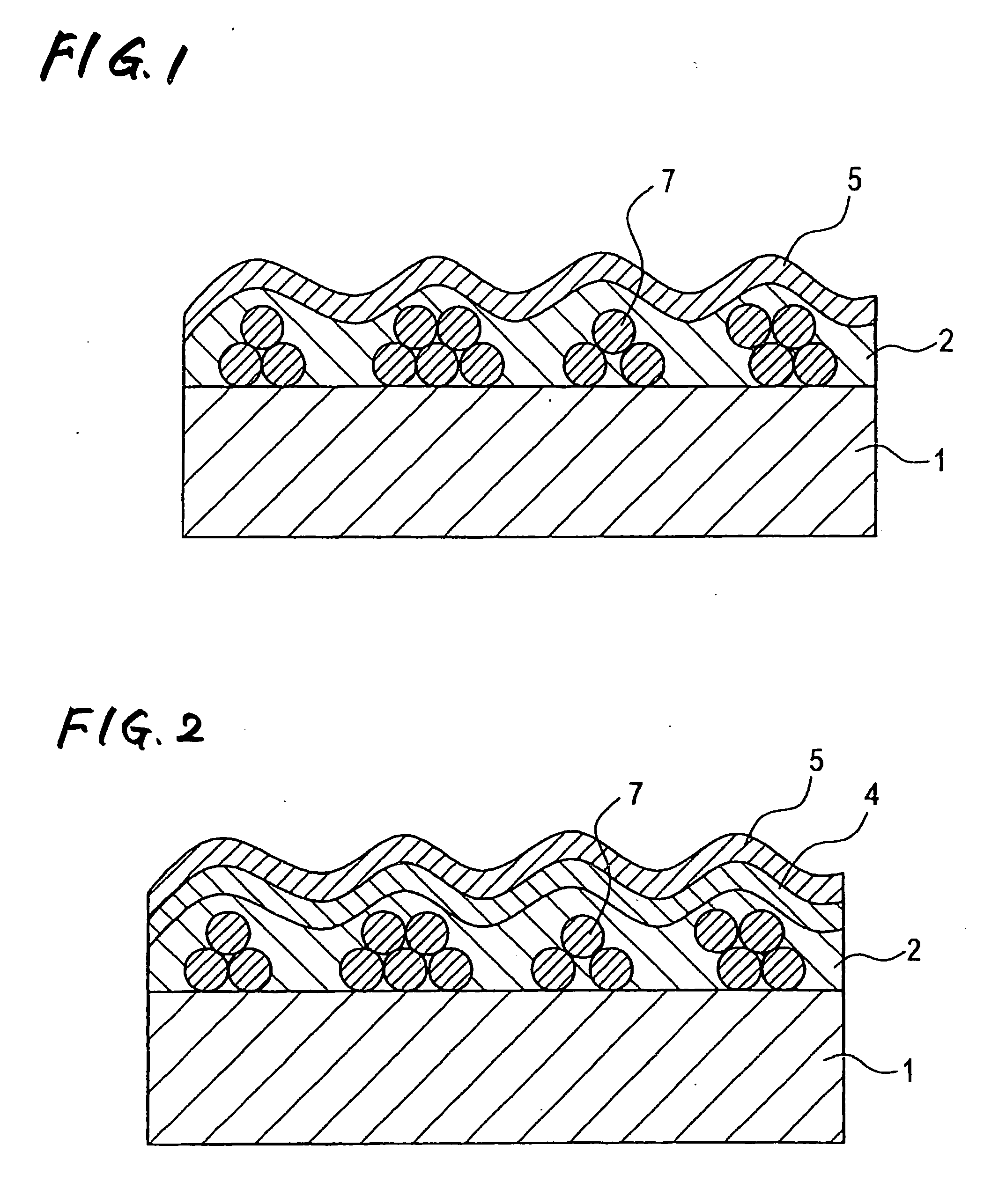

Optical film, antireflection film, polarizing plate and image display device

ActiveUS20070195431A1High film strengthExcellent optical propertiesDiffusing elementsDisplay deviceDiffusion layer

An optical film is provided and includes: a transparent support; and a light diffusion layer containing light-transmitting particles and a binder. The light diffusion layer has an average thickness of from 7.5 to 30 μm, and the average thickness of the light diffusion layer is from 1.4 to 3.5 times as large as an average particle diameter of the light-transmitting particles.

Owner:FUJIFILM CORP

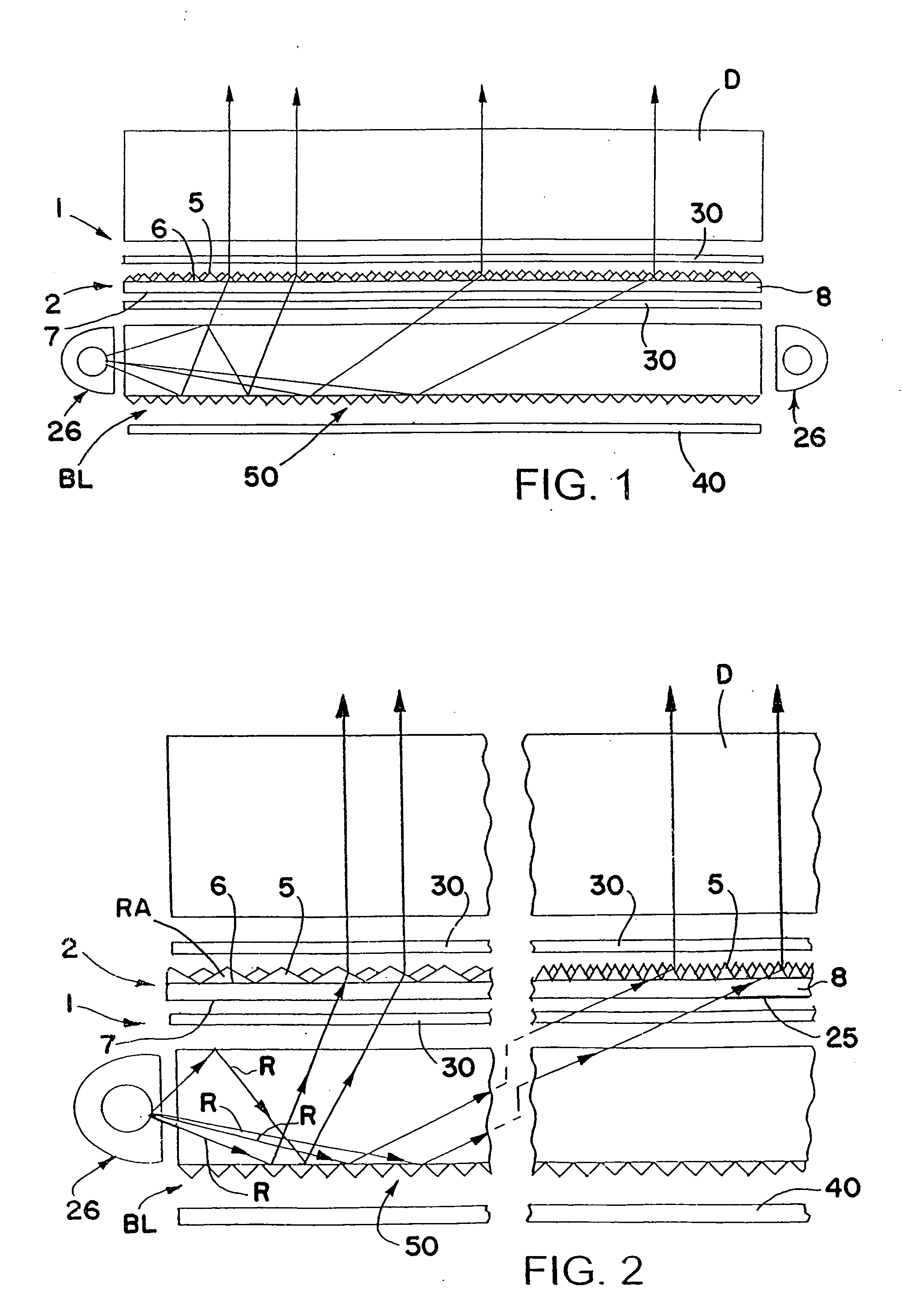

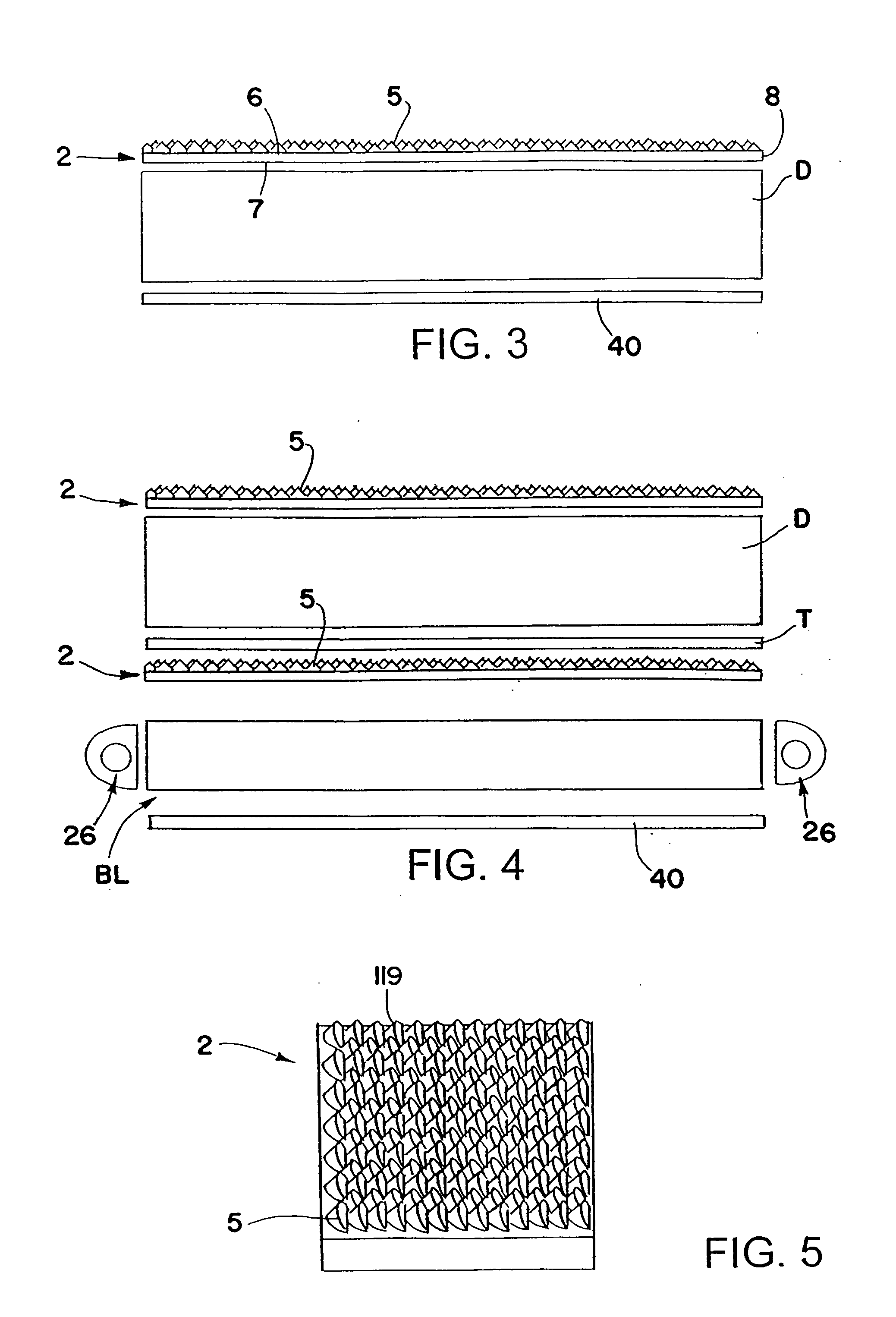

Optical film and a liquid crystal display using the same

InactiveUS20030071947A1Mechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayDisplay device

An optical film having excellent light utilization efficiency and high brightness, and a liquid crystal display using the optical film. The optical film is formed by laminating integrally a brightness enhancement film (A) that separates natural light into transmitted light and reflected light and a collimating film (B) having an uneven portion on a surface thereof. Since an air interface is eliminated by the integral lamination of the brightness enhancement film and the collimating film, stray light is reduced, and the brightness enhancement film has an improved efficiency in reflecting and polarizing light; thereby, enhancing the brightness.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com