Patents

Literature

3516 results about "Transparent conducting film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent conducting films (TCFs) are thin films of optically transparent and electrically conductive material. They are an important component in a number of electronic devices including liquid-crystal displays, OLEDs, touchscreens and photovoltaics. While indium tin oxide (ITO) is the most widely used, alternatives include wider-spectrum transparent conductive oxides (TCOs), conductive polymers, metal grids and random metallic networks, carbon nanotubes (CNT), graphene, nanowire meshes and ultra thin metal films.

Transparent conductive film and method for manufacturing the same

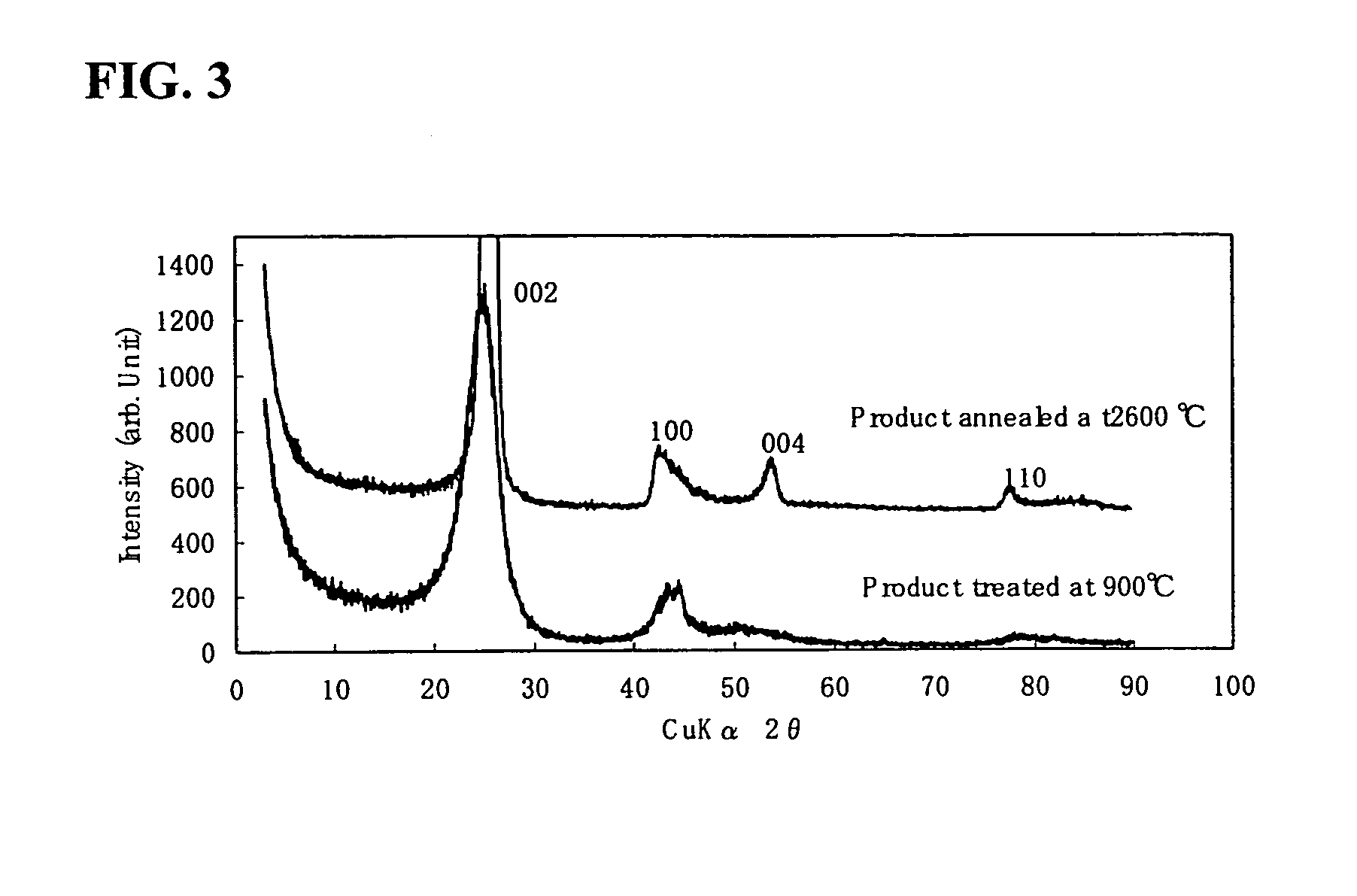

ActiveUS20080050595A1Improve economyConductive layers on insulating-supportsSynthetic resin layered productsRocking curveFull width at half maximum

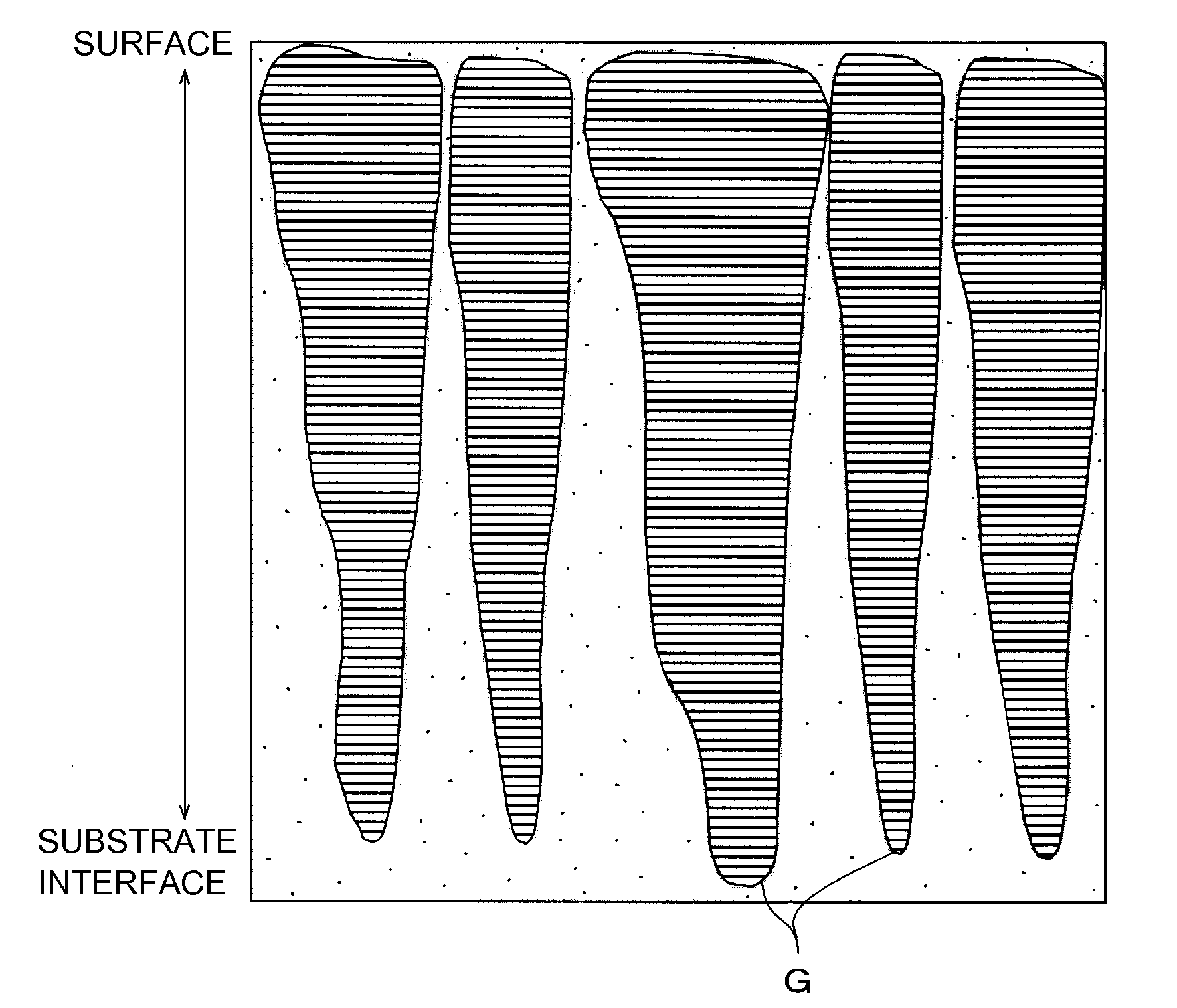

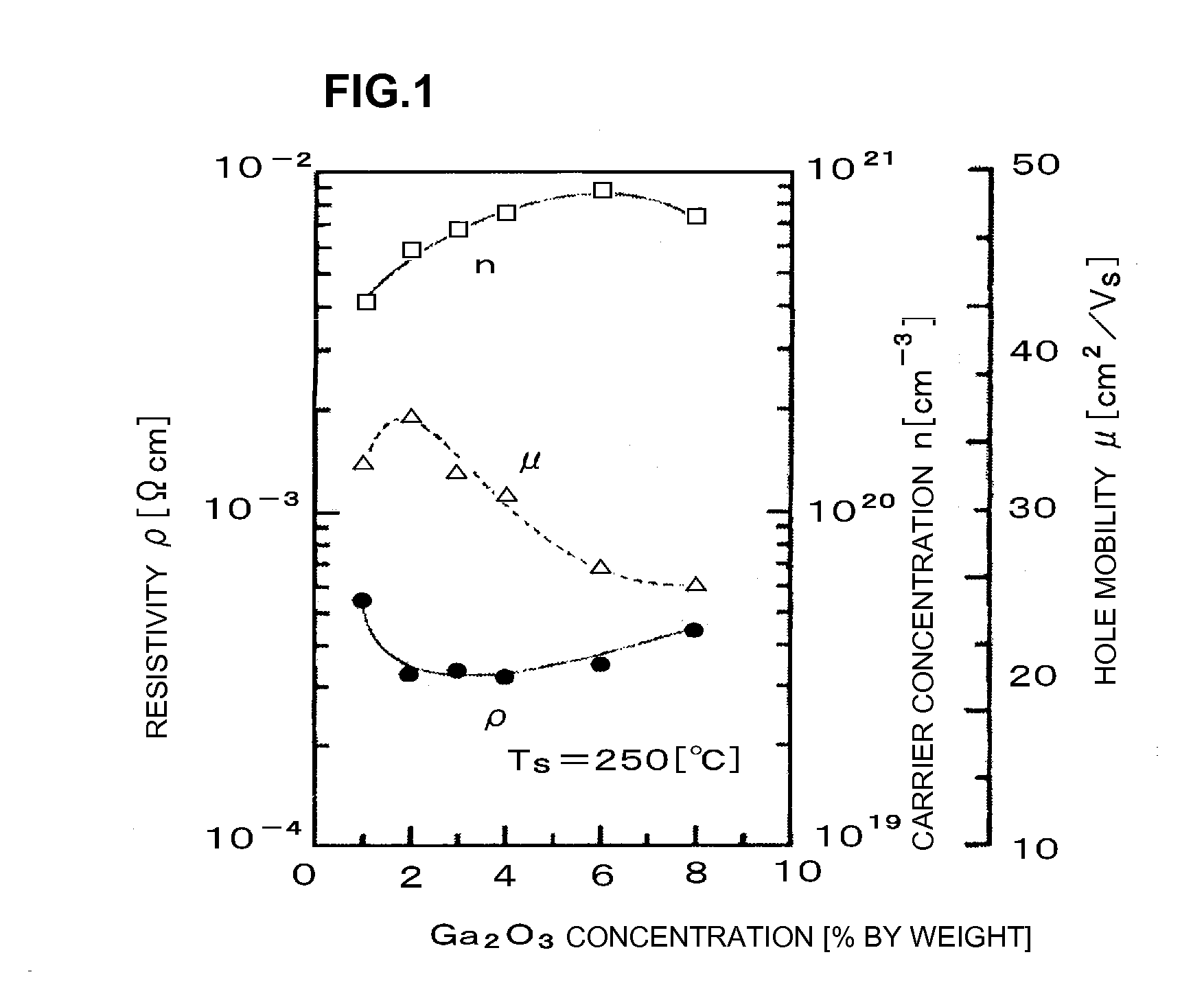

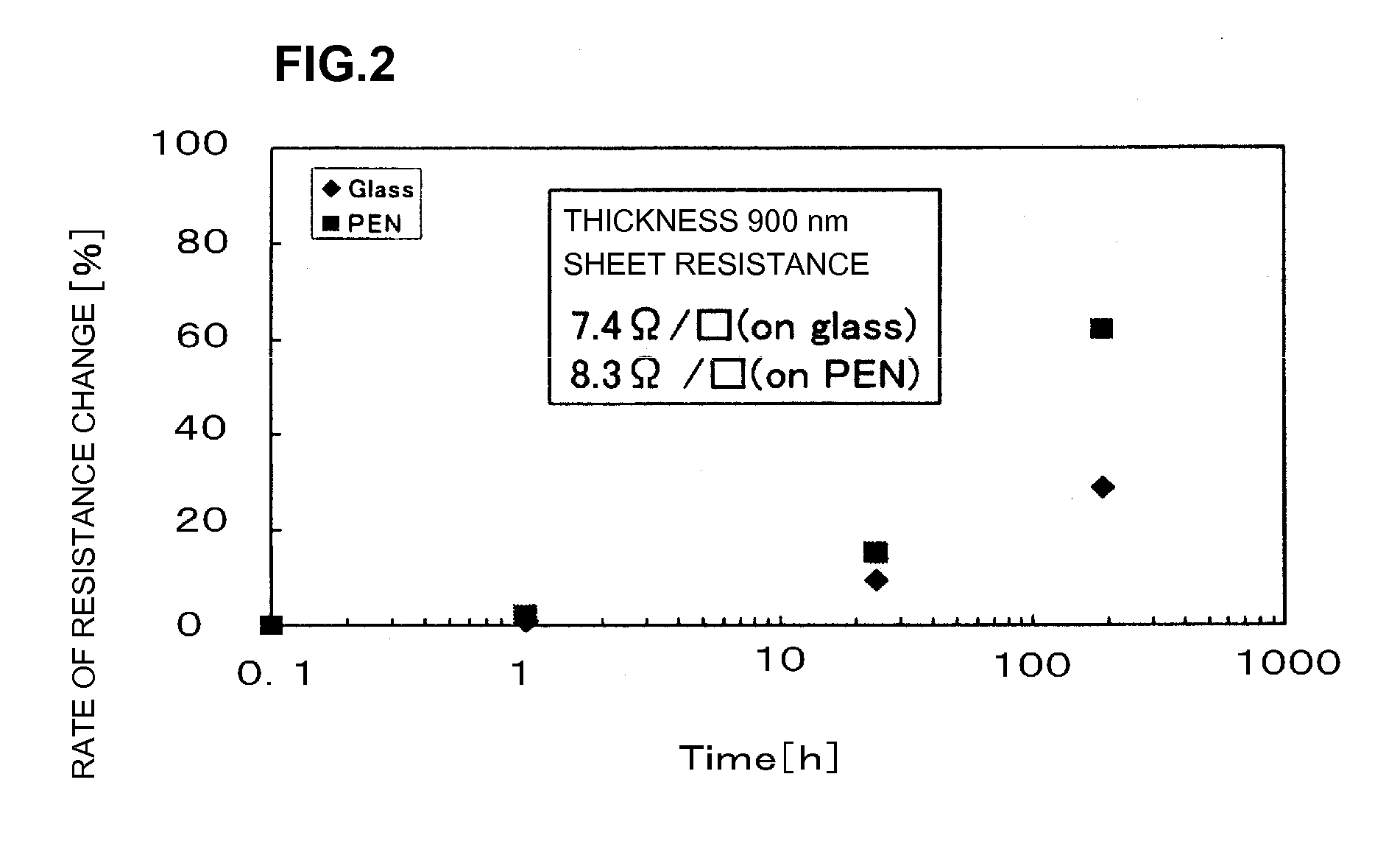

A ZnO-based transparent conductive film has practicable moisture resistance, desired characteristics of a transparent conductive film, and excellent economy. The transparent conductive film is produced by growing ZnO doped with a group III element oxide on a substrate and has a region with a crystal structure in which a c-axis grows along a plurality of different directions. The transparent conductive film produced by growing ZnO doped with a group III element oxide on a substrate has a ZnO (002) rocking curve full width at half maximum of about 13.5° or more.ZnO is doped with a group III element oxide so that the ratio of the group III element oxide in the transparent conductive film is about 7% to about 40% by weight.The transparent conductive film is formed on the substrate with a SiNx thin film provided therebetween.The transparent conductive film is formed on the substrate by a thin film formation method with a bias voltage applied to the substrate.

Owner:MURATA MFG CO LTD

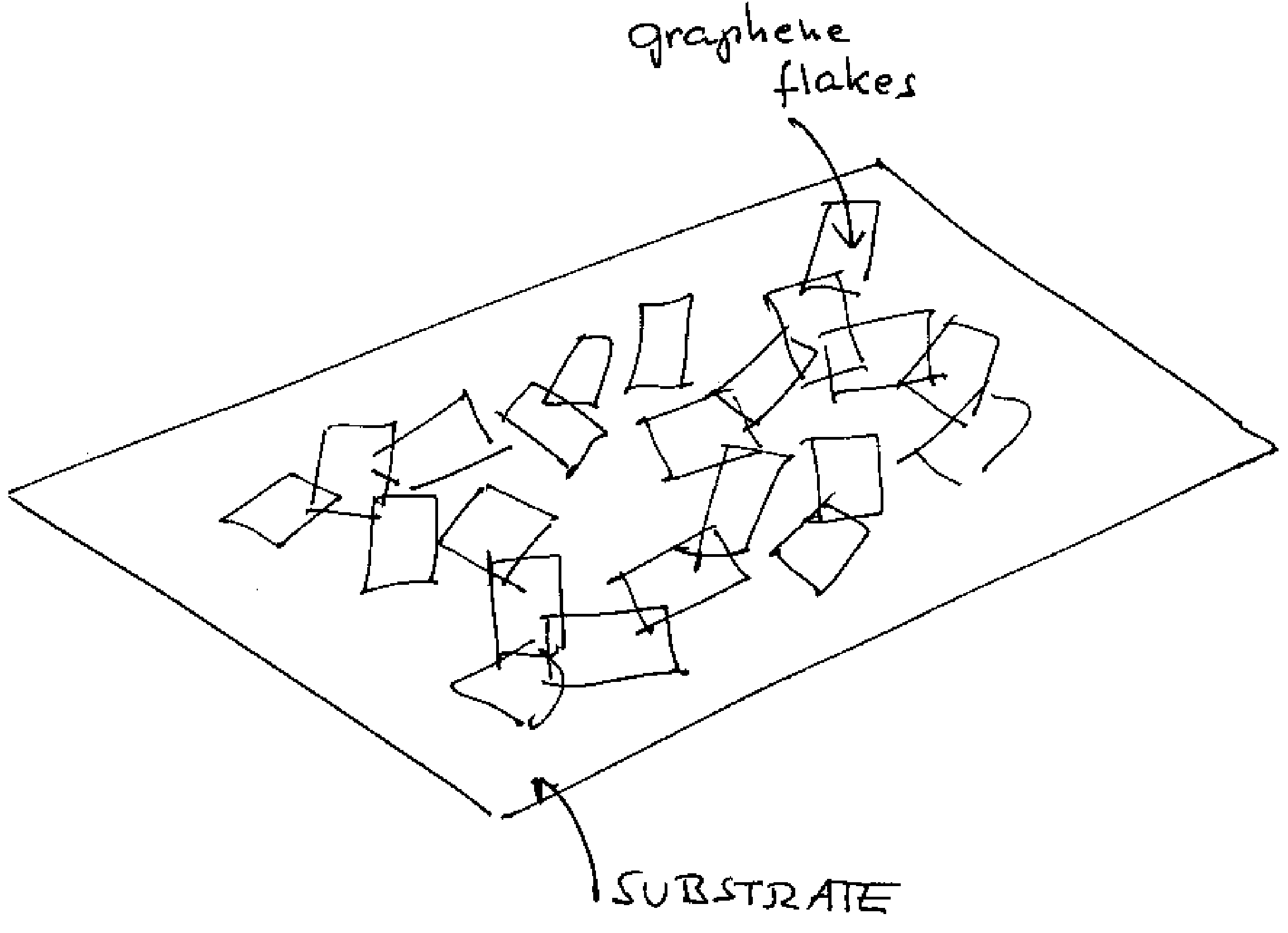

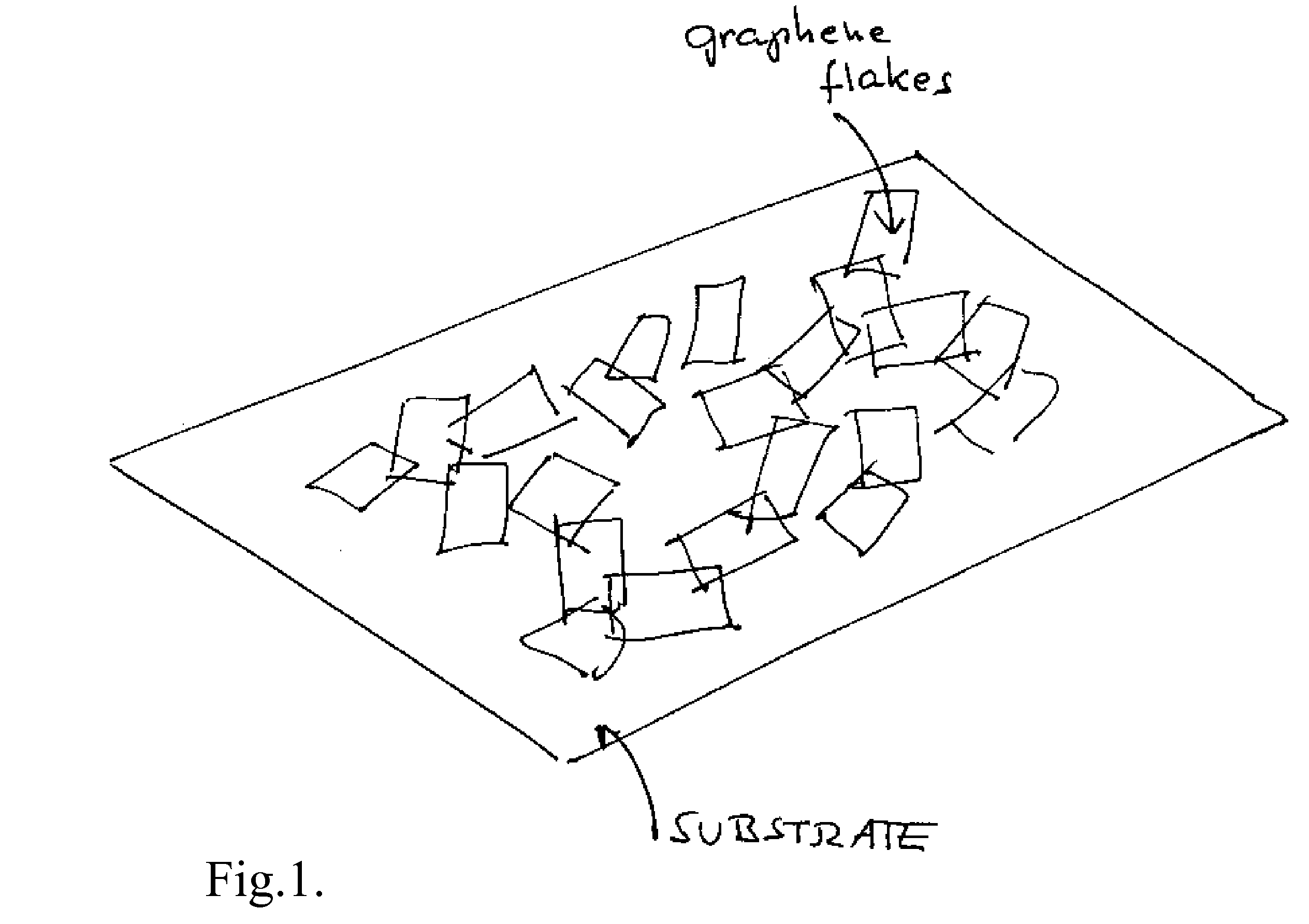

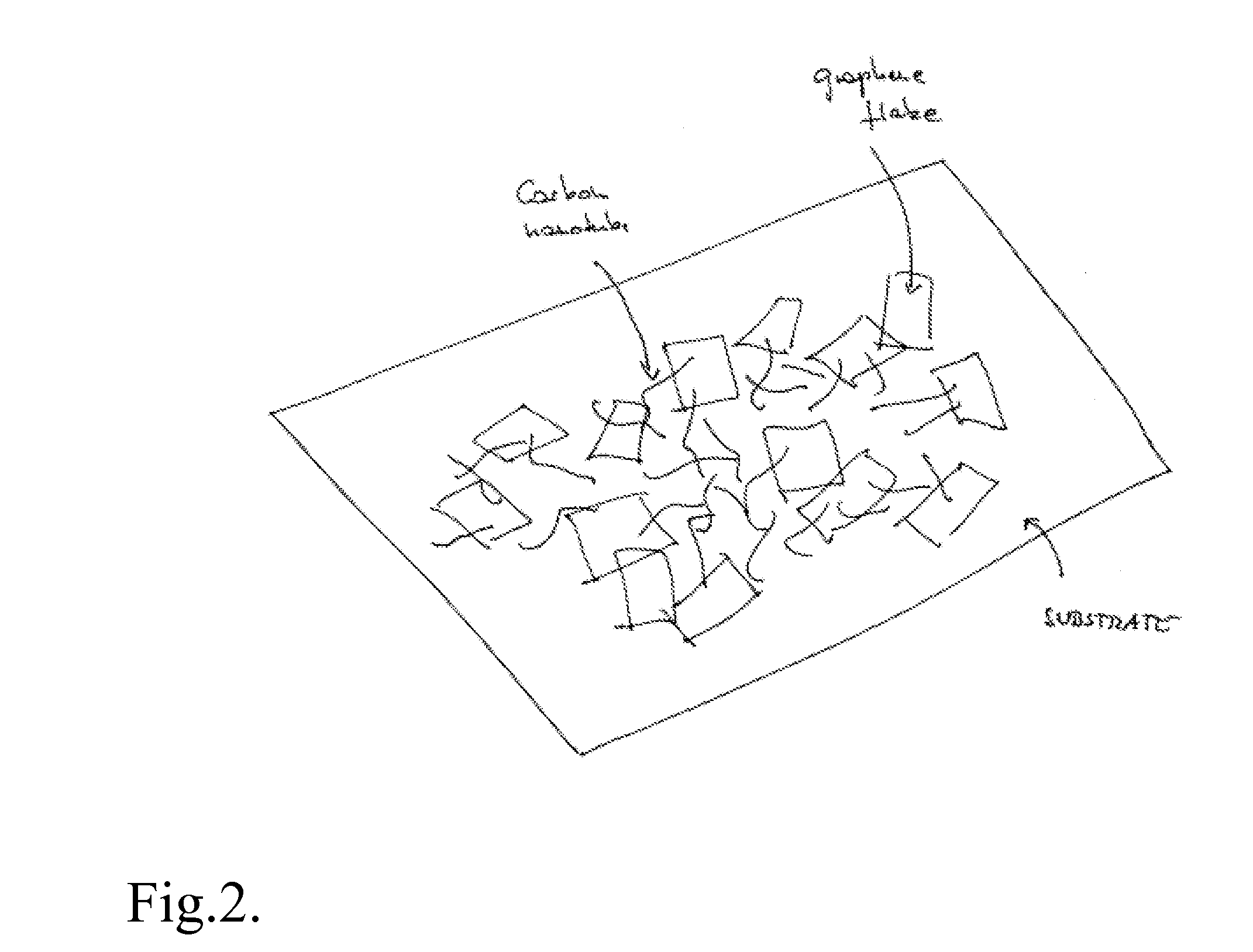

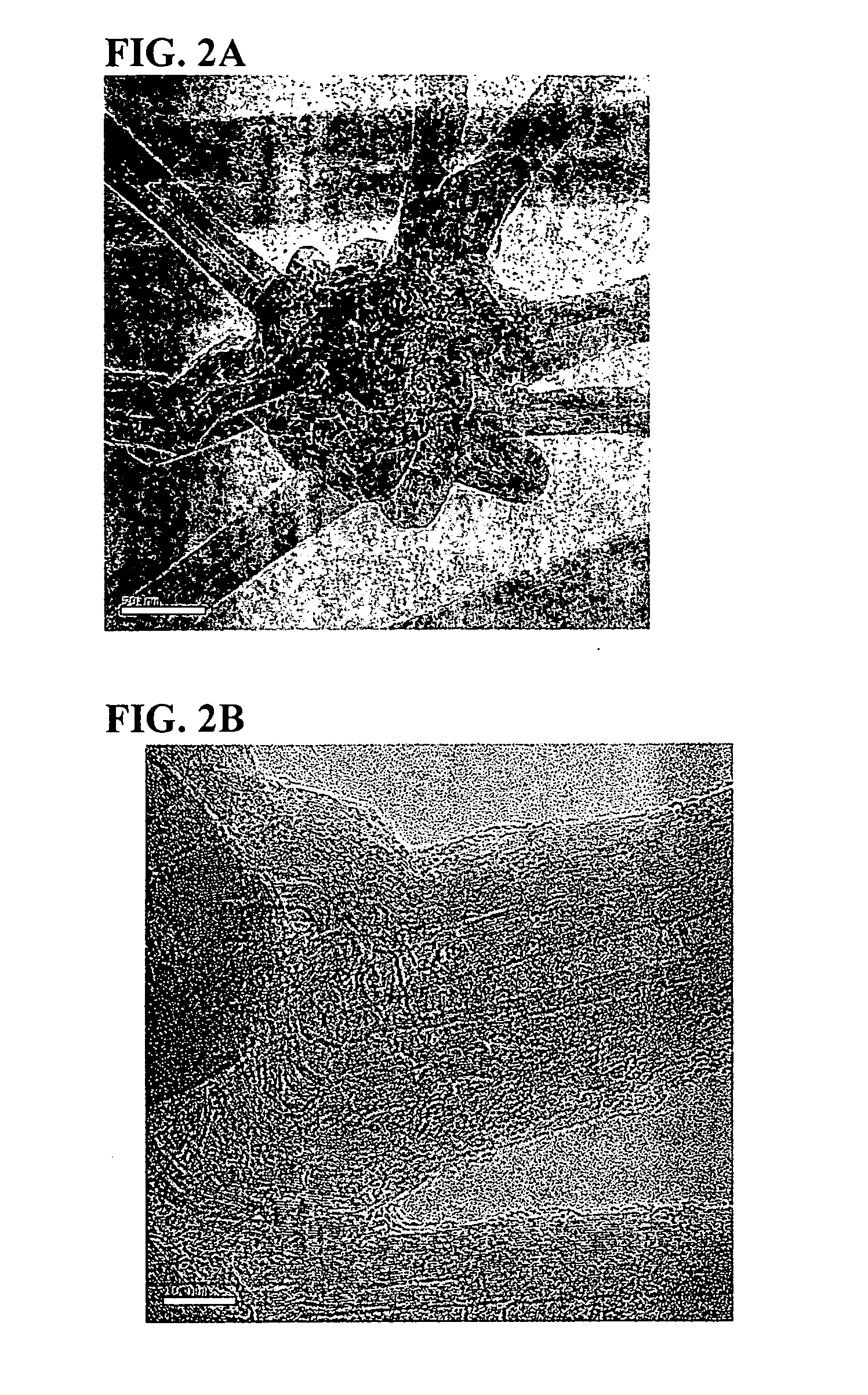

Graphene film as transparent and electrically conducting material

ActiveUS20070284557A1Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

A transparent and conductive film comprising at least one network of graphene flakes is described herein. This film may further comprise an interpenetrating network of other nanostructures, a polymer and / or a functionalization agent(s). A method of fabricating the above device is also described, and may comprise depositing graphene flakes in solution and evaporating solvent therefrom.

Owner:SAMSUNG ELECTRONICS CO LTD

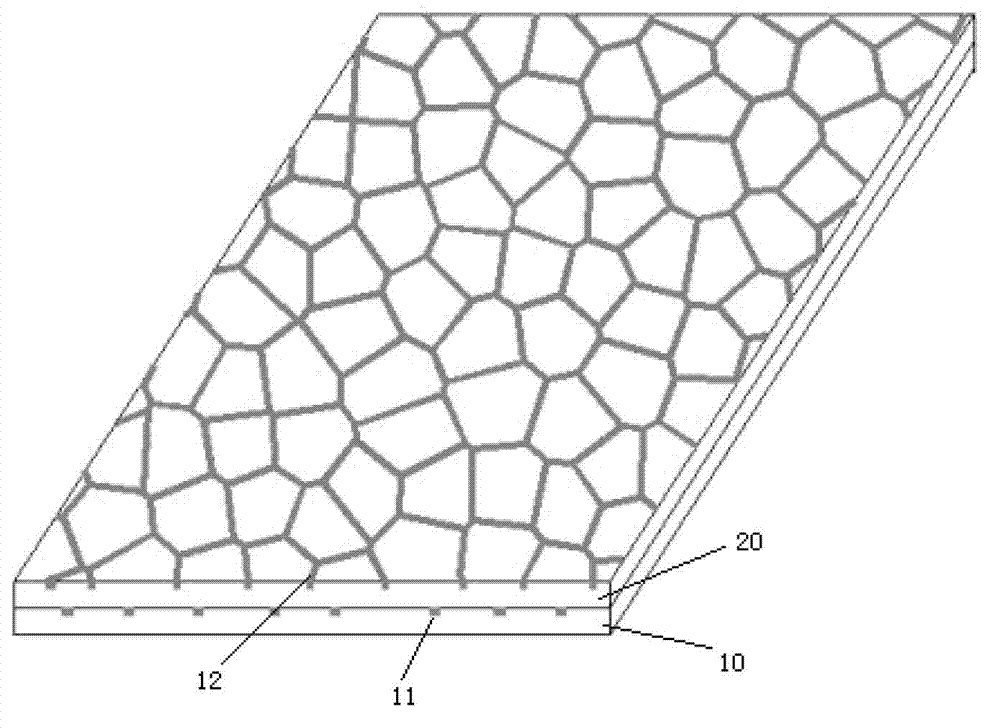

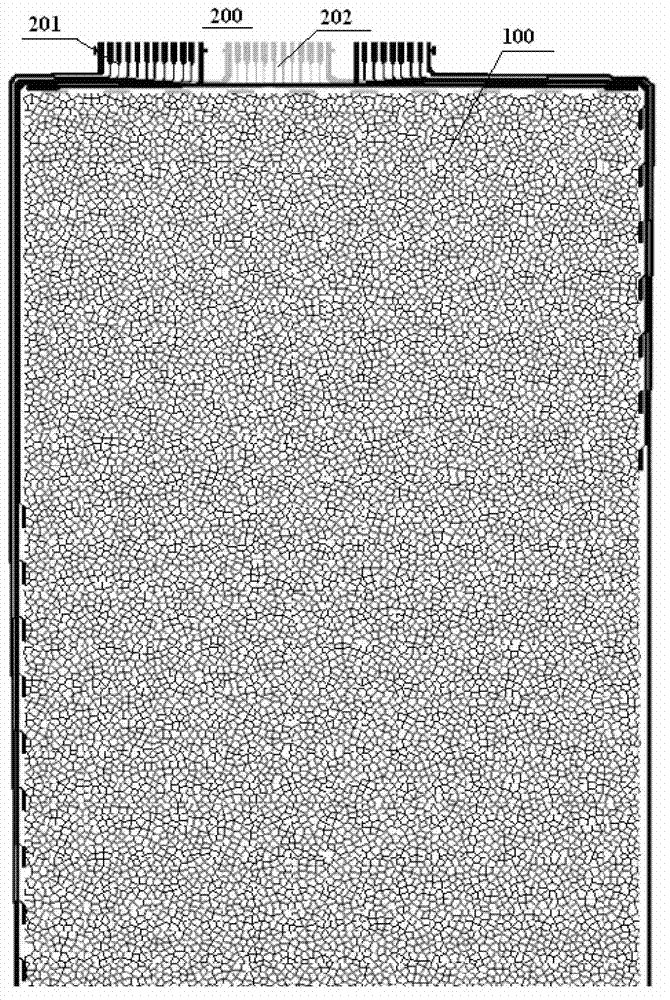

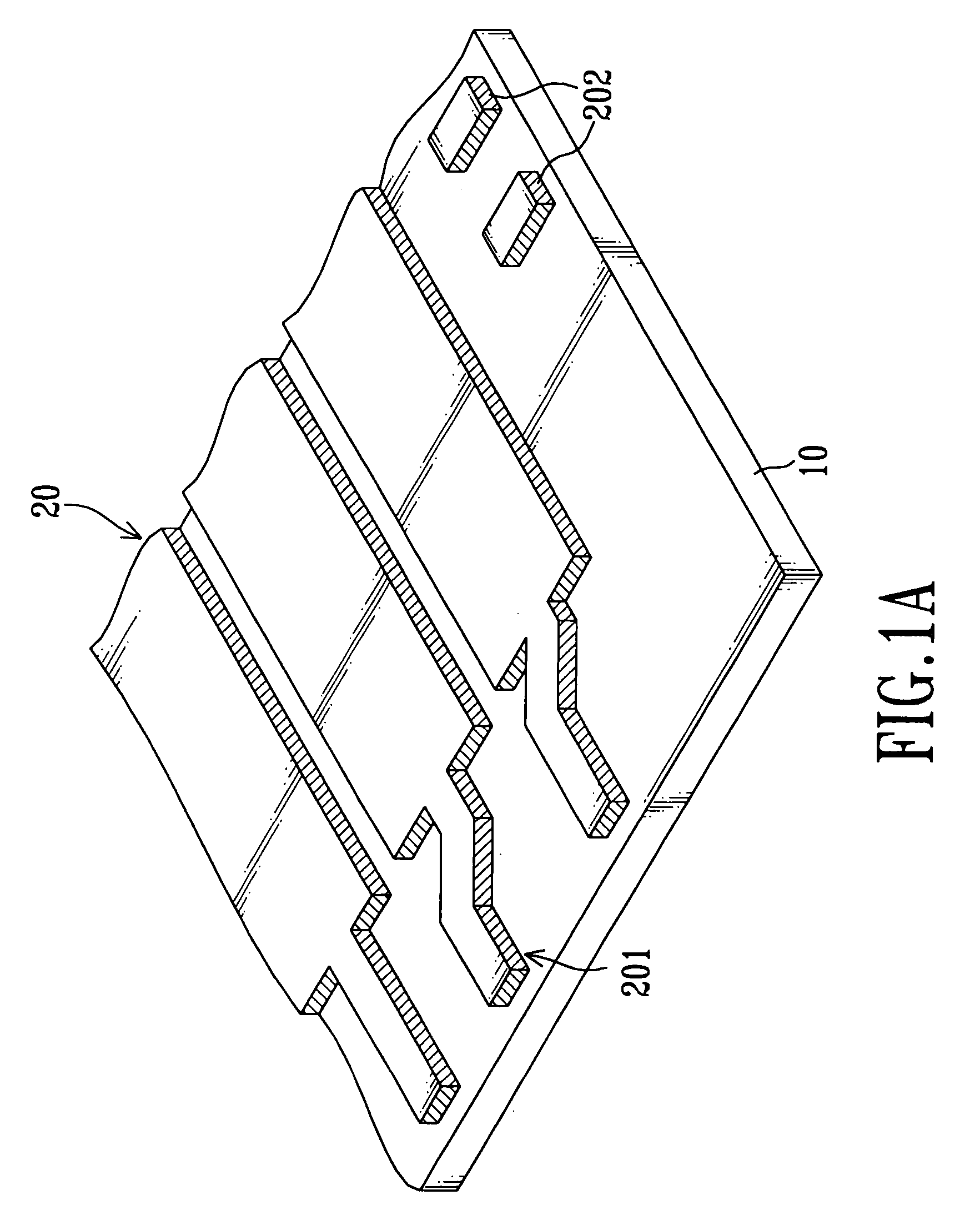

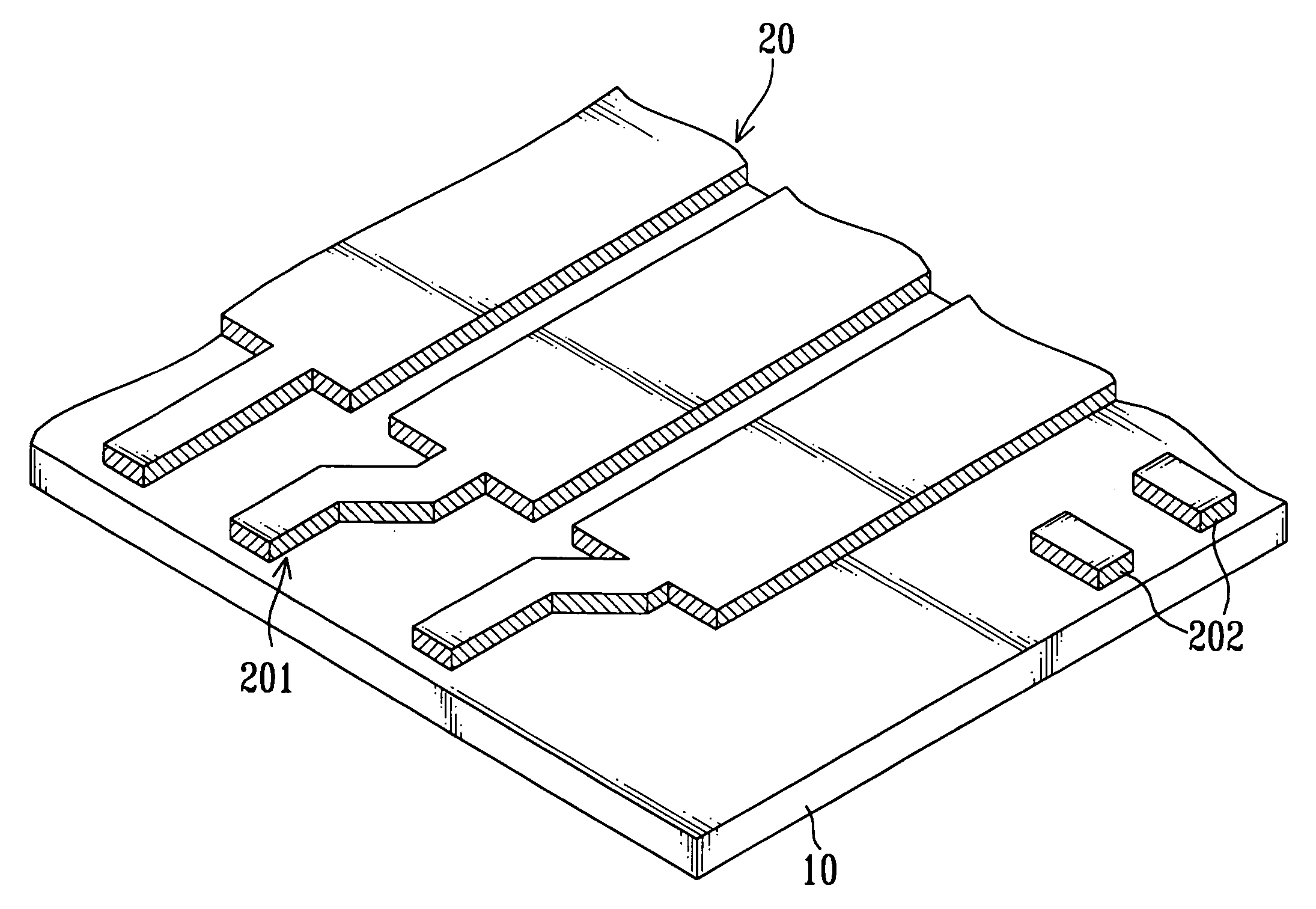

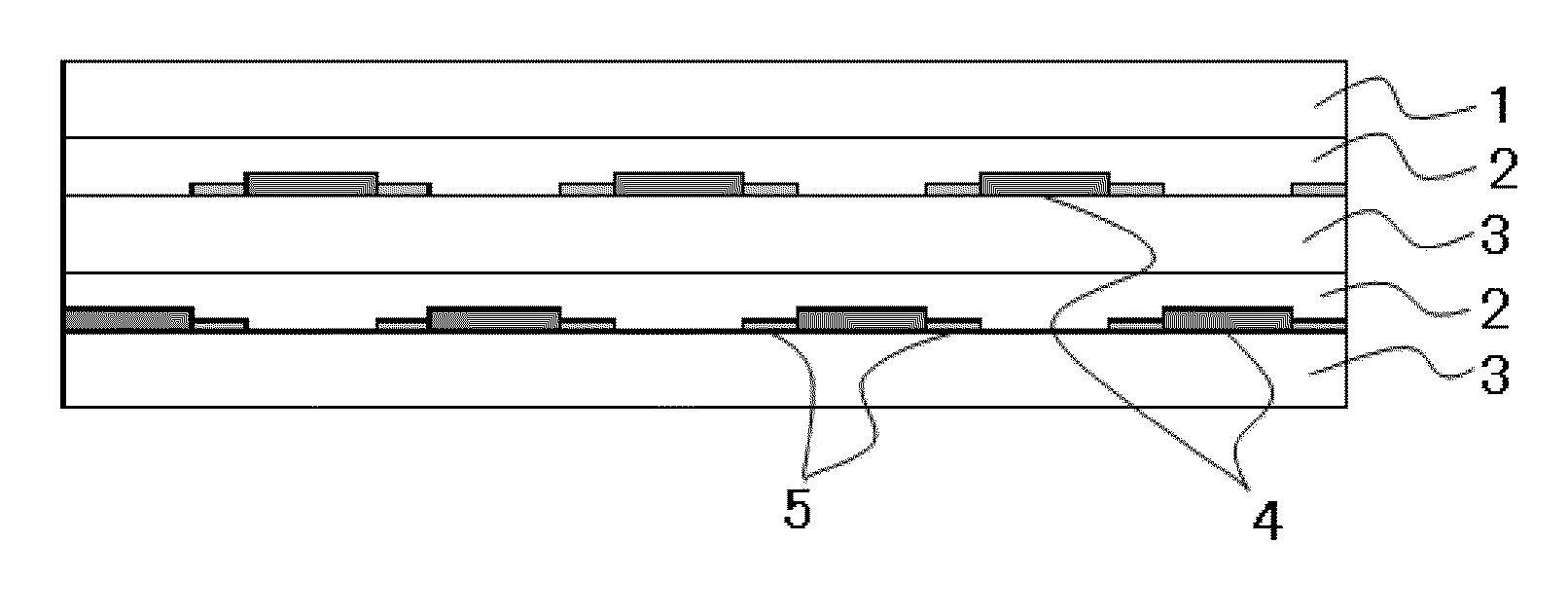

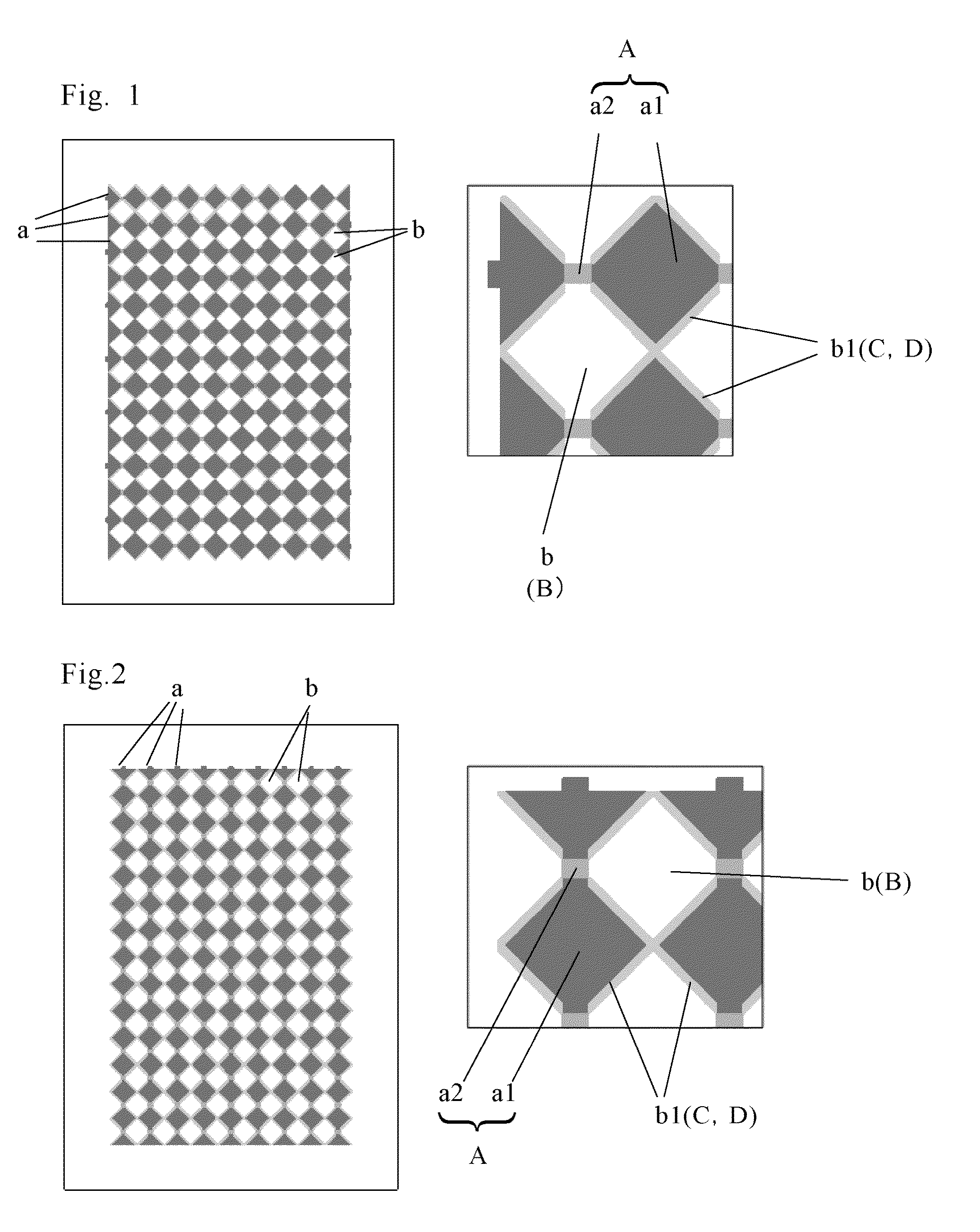

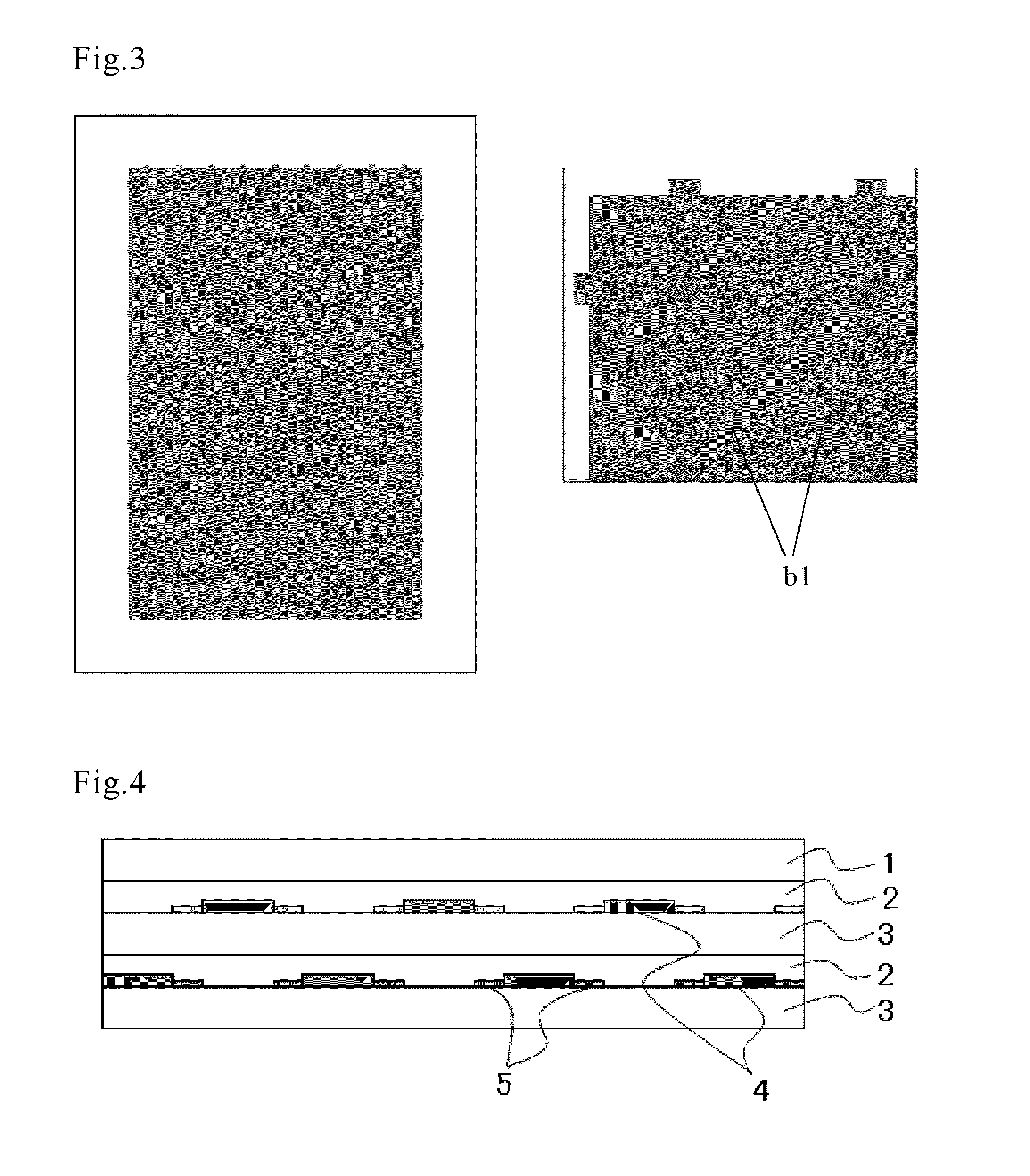

Conduction structure in transparent conduction film, transparent conduction film and manufacture method thereof

ActiveCN102903423AConductive layers on insulating-supportsTransparent dielectricsTransmittanceConductive materials

The invention discloses a transparent conduction film, a conduction structure thereof and a preparation method of the transparent conduction film. The transparent conduction film is of a single-sided dual-layer conduction structure. The conduction structure comprises a first metal embedding layer and a second metal embedding layer, wherein the first metal embedding layer is formed by impressing on a substrate or impressing on a polymer layer on the surface of the substrate; and the second metal embedding layer is formed by coating the polymer layer on the surface of the first metal embedding layer through impressing, the first layer of conduction structure and the second layer of conduction structure have a grid groove structure, and conductive materials are filled in grooves. The single-sided graphical transparent conduction film provided by the invention has the advantages of high resolution and transmittance, independent and adjustable sheet resistance, and the like. According to the transparent conduction film, the cost can be reduced, and the weight and the thickness of a manufactured touch panel can be reduced.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Transparent Planar Body and Transparent Touch Switch

ActiveUS20080138589A1Increase awarenessConductive layers on insulating-supportsDecorative surface effectsVisibilityTransmittance

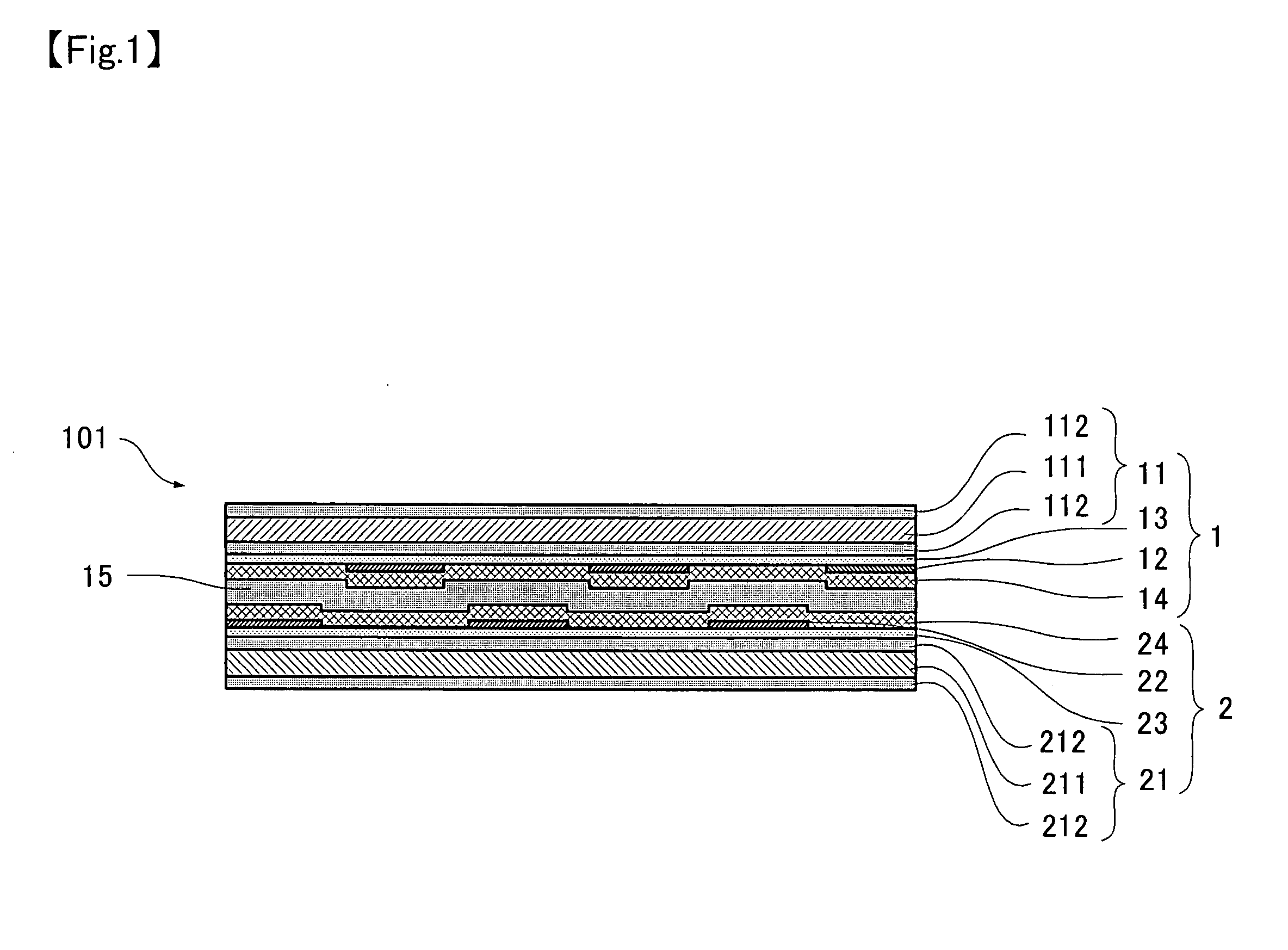

The present invention provides a transparent planar body and a transparent touch switch that can improve visibility. Specifically, the transparent planar body (1) has a patterned transparent conductive film (12) on at least one surface of a transparent substrate (11). This transparent planar body (1) comprises a transmittance-adjusting layer for equalizing the transmission spectrum of light transmitted through a patterned region wherein the transparent conductive film (12) is provided via the transparent substrate (11) with that transmitted through a non-patterned region wherein the transparent conductive film (12) is not provided via the transparent substrate (11).

Owner:GUNZE LTD

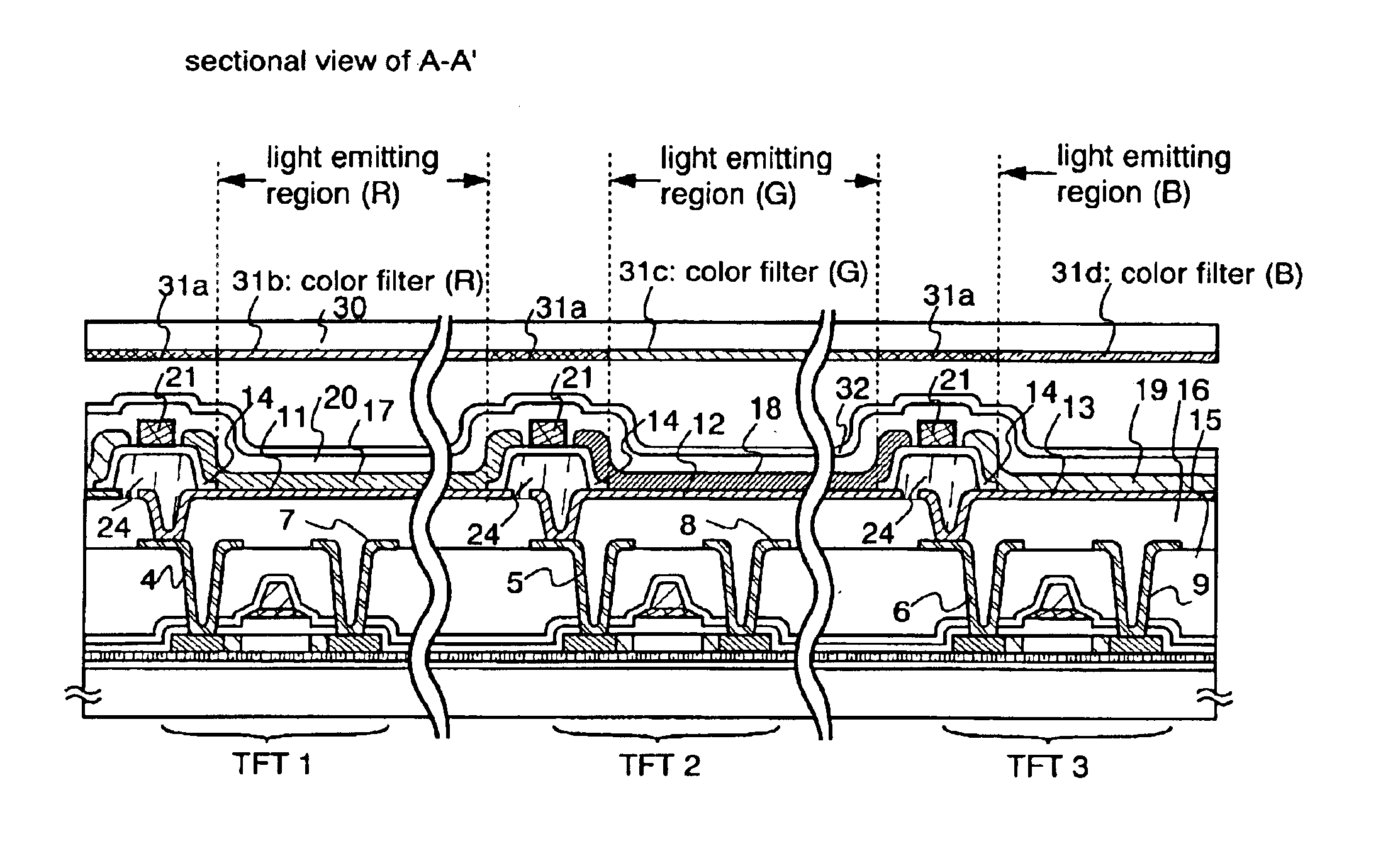

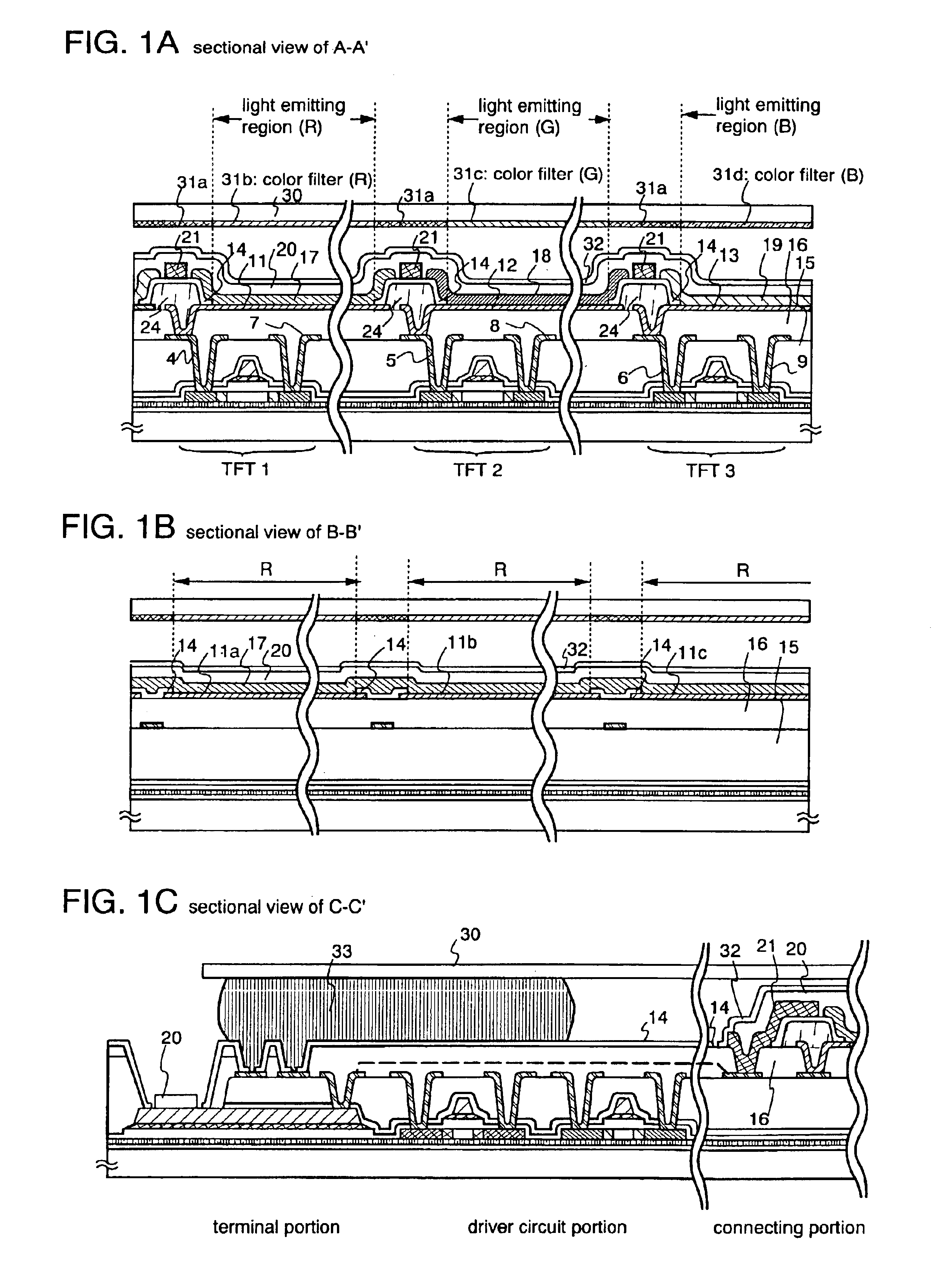

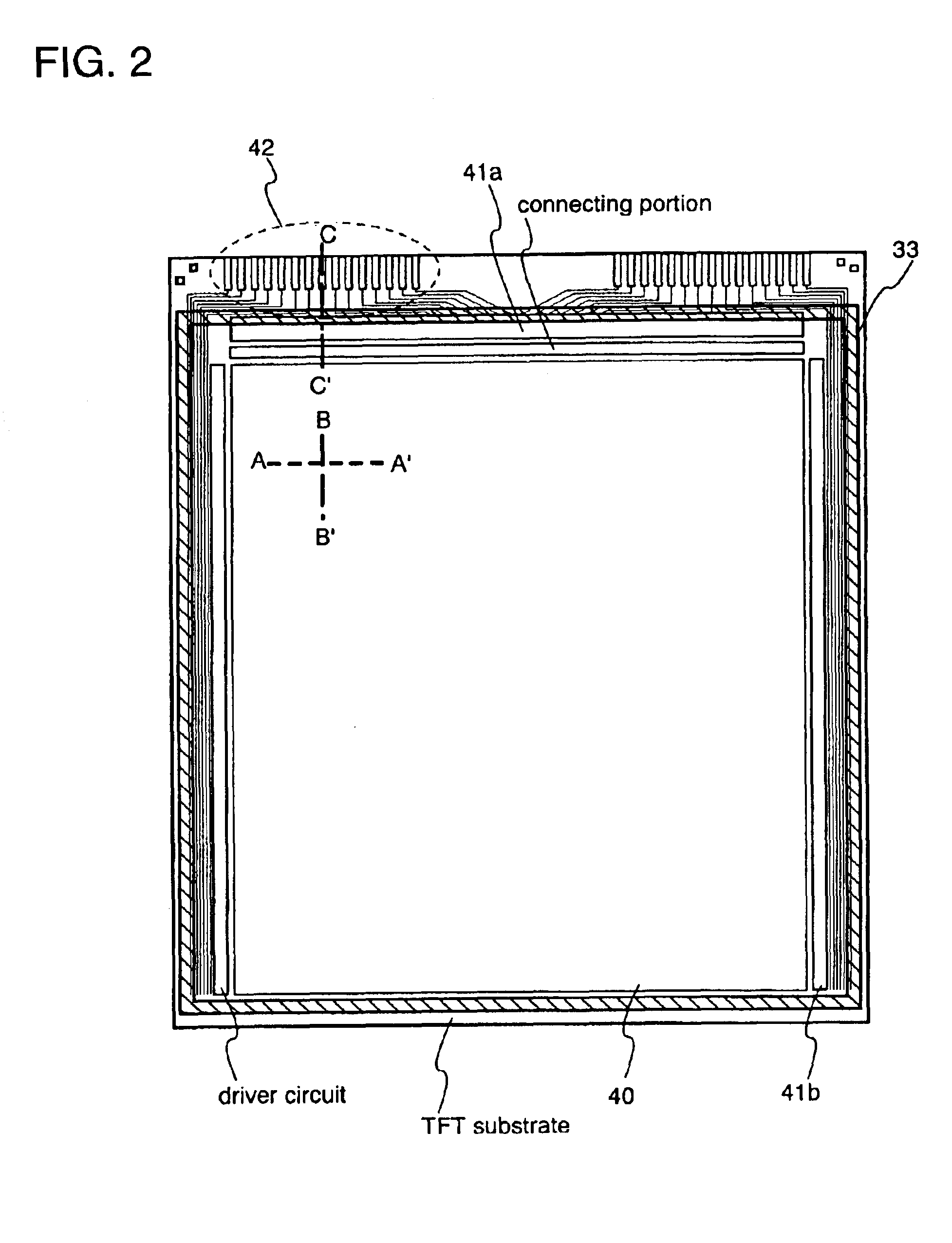

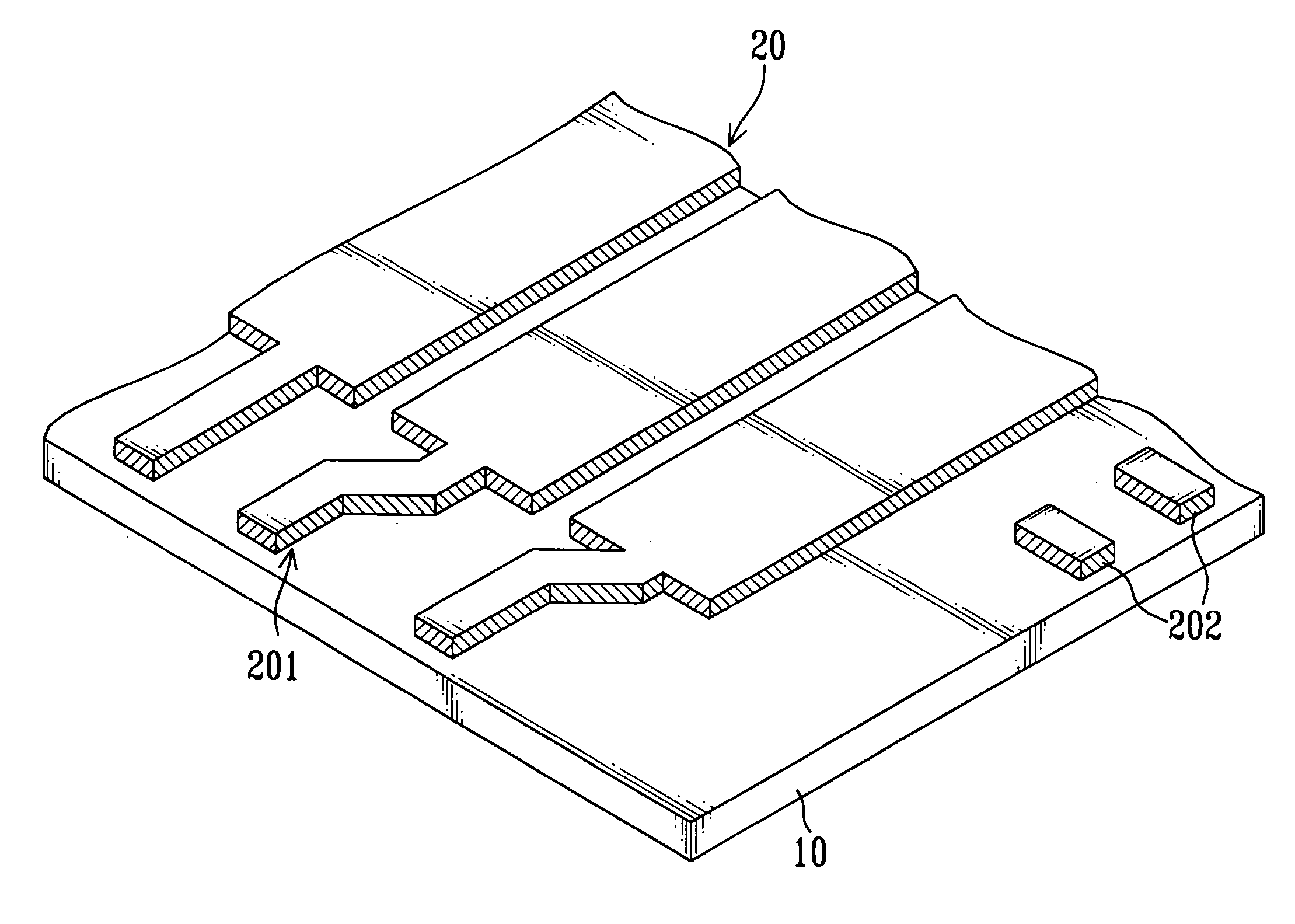

Light emitting device and method of manufacturing the same

InactiveUS6781162B2Effective diffusionImproved light emissionElectroluminescent light sourcesSolid-state devicesHydrogenTransparent conducting film

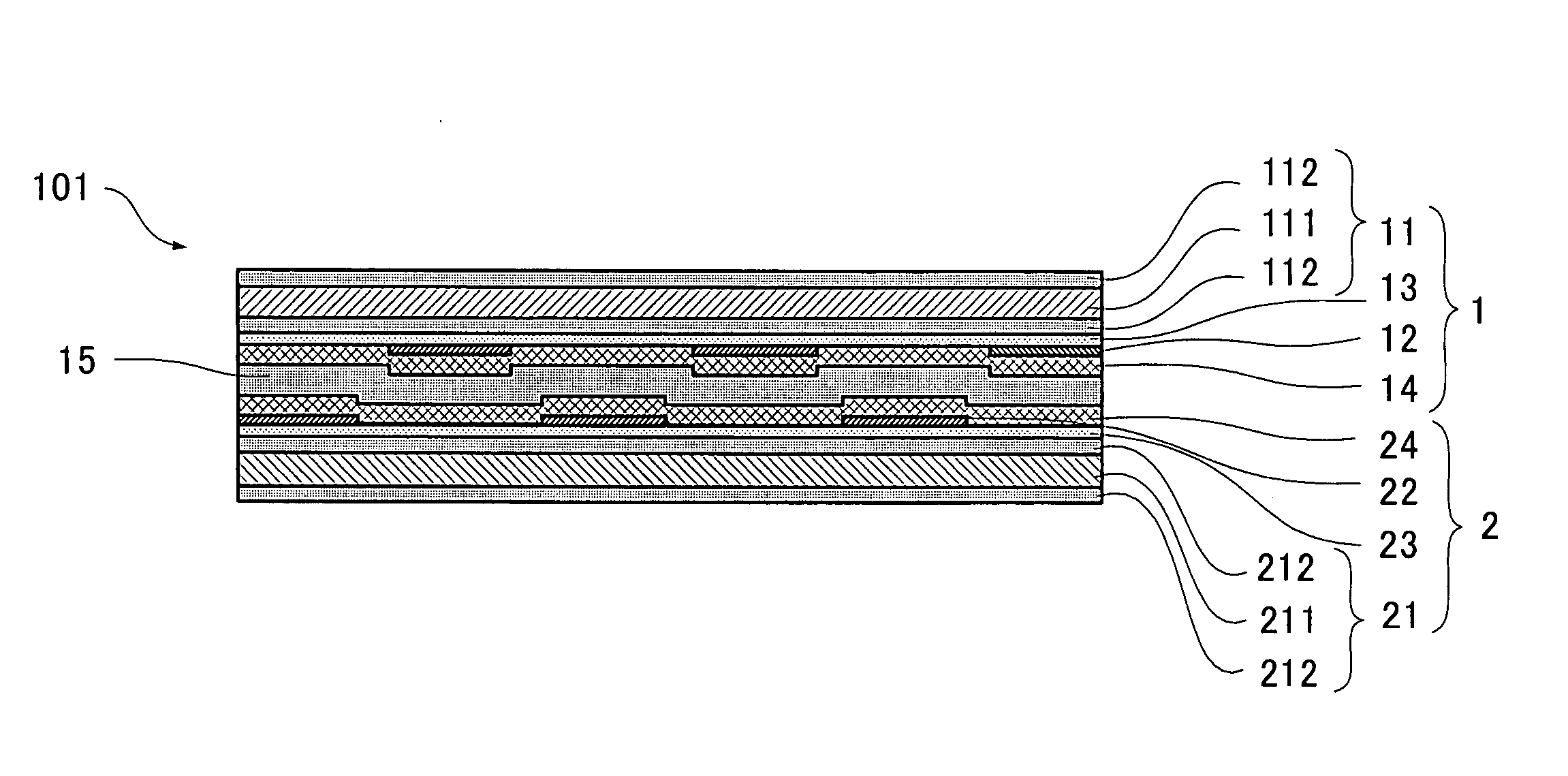

To provide a light emitting device high in reliability with a pixel portion having high definition with a large screen. According to a light emitting device of the present invention, on an insulator (24) provided between pixel electrodes, an auxiliary electrode (21) made of a metal film is formed, whereby a conductive layer (20) made of a transparent conductive film in contact with the auxiliary electrode can be made low in resistance and thin. Also, the auxiliary electrode (21) is used to achieve connection with an electrode on a lower layer, whereby the electrode can be led out with the transparent conductive film formed on an EL layer. Further, a protective film (32) made of a film containing hydrogen and a silicon nitride film which are laminated is formed, whereby high reliability can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

Optical-interference type display panel and method for making the same

InactiveUS20040147198A1Semiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

An optical-interference type display panel and a method for making the same are disclosed, wherein the display panel has a substrate on which multiple first conductive optical film stacks, supporting layers and multiple second conductive optical film stacks are formed. The substrate further has a plurality of connecting pads consisting of a transparent conductive film of the first conductive optical film stacks. Since the transparent conductive film is made of indium tin oxide, these connecting pads have the excellent anti-oxidation ability at their surface.

Owner:SNAPTRACK

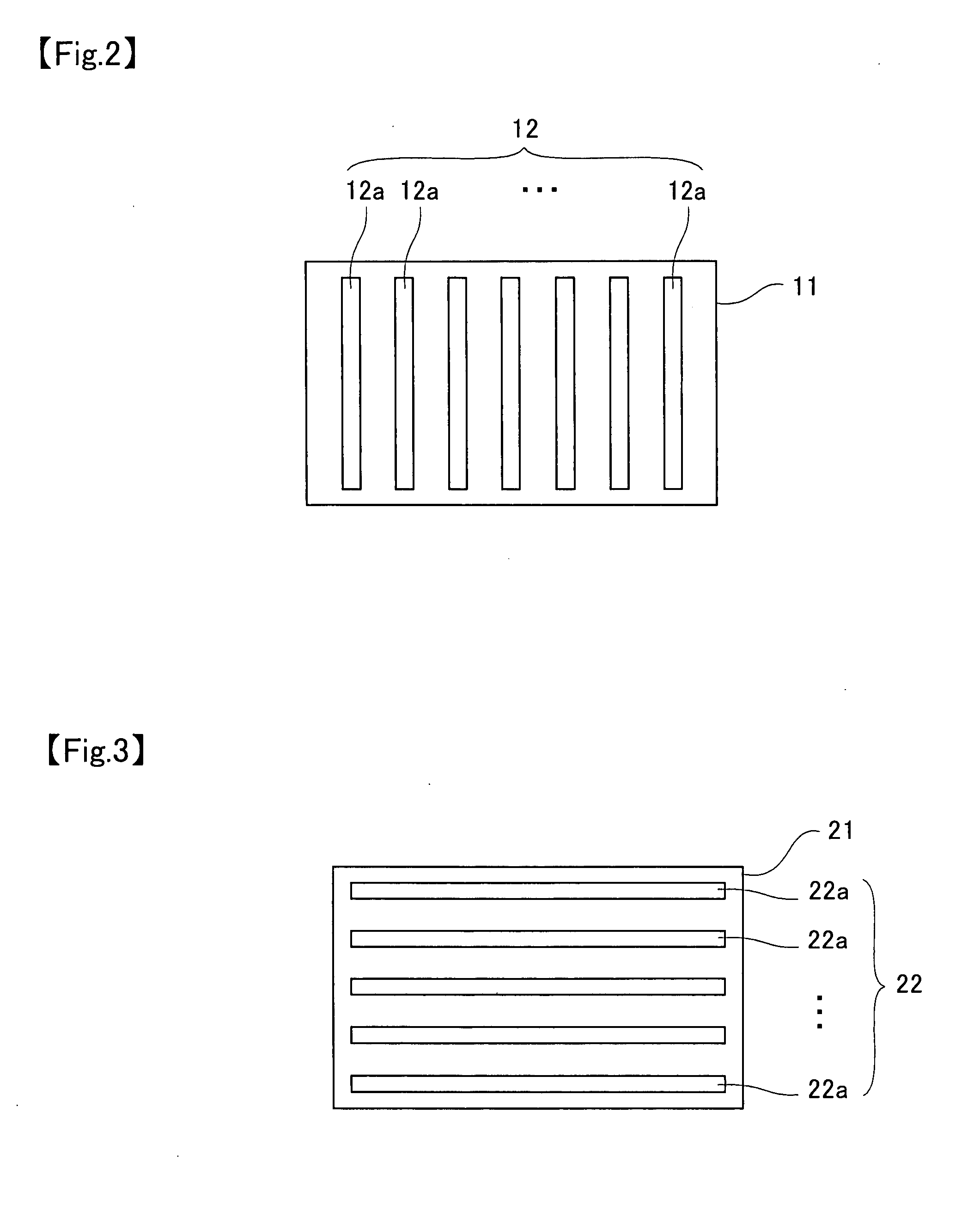

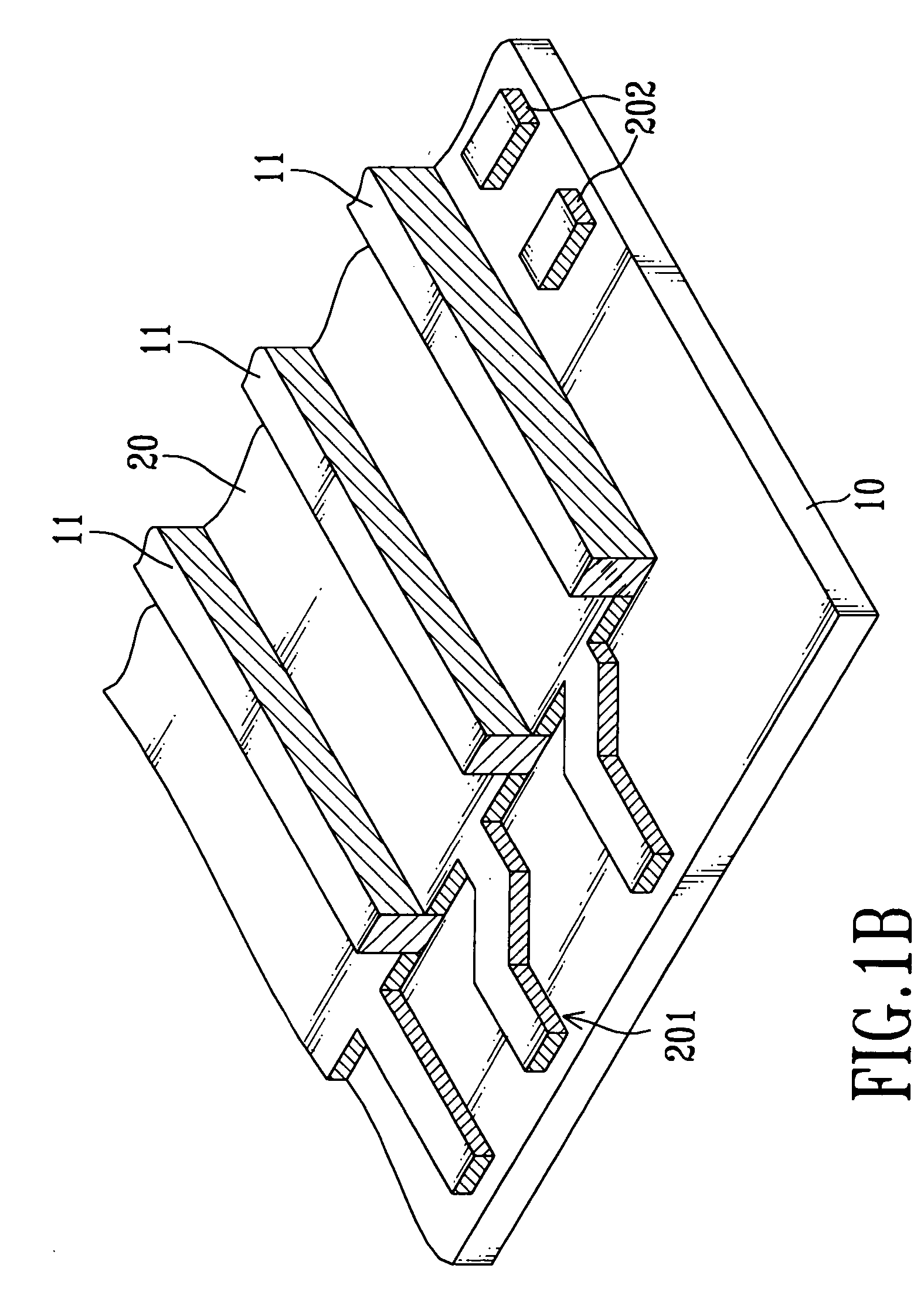

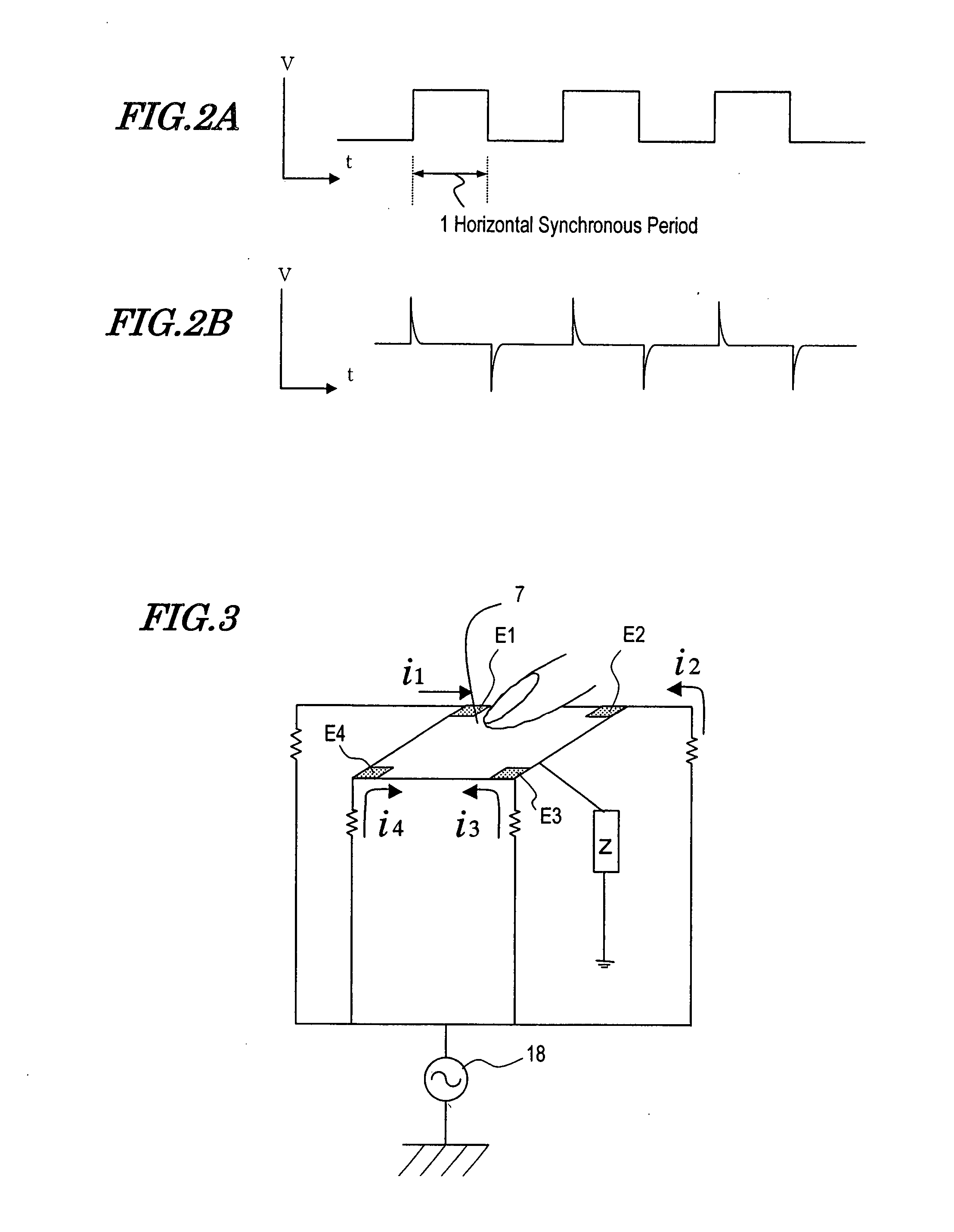

Display Device with Touch Sensor, and Drive Method for the Device

InactiveUS20070262966A1Raise the ratioImprove position detection accuracyInput/output processes for data processingActive matrixDisplay device

A touch-sensored display device 20 according to the present invention includes: a counter substrate 6 disposed on a viewer side of an active matrix substrate 8 via a display medium layer 4, the counter substrate 6 having a counter electrode 5 which opposes pixel electrodes; a display panel driving circuit 14 for supplying to the counter electrode 5 a common voltage which undergoes periodic inversion in polarity; a transparent conductive film 7 for position detection placed so as to oppose the counter electrode 5 via the counter substrate 6; a strobe signal generation circuit 32 for generating a strobe signal which is in synchronization with a polarity inversion period of the common voltage, and a noise-cut current signal generation circuit 30 for generating a noise-cut current signal which is obtained by eliminating based on the strobe signal a predetermined portion from a current flowing from a terminal connected to the transparent conductive film 7 for position detection.

Owner:SHARP KK

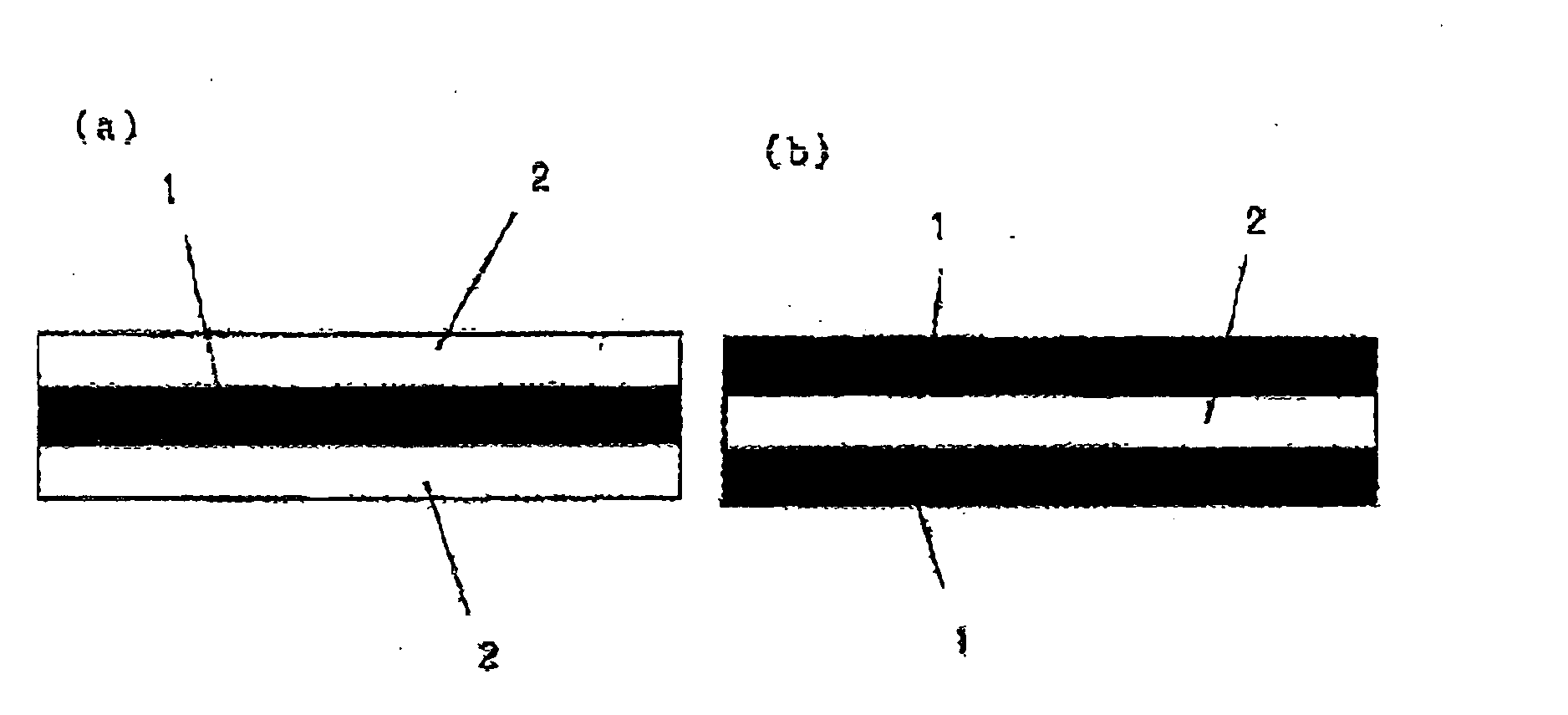

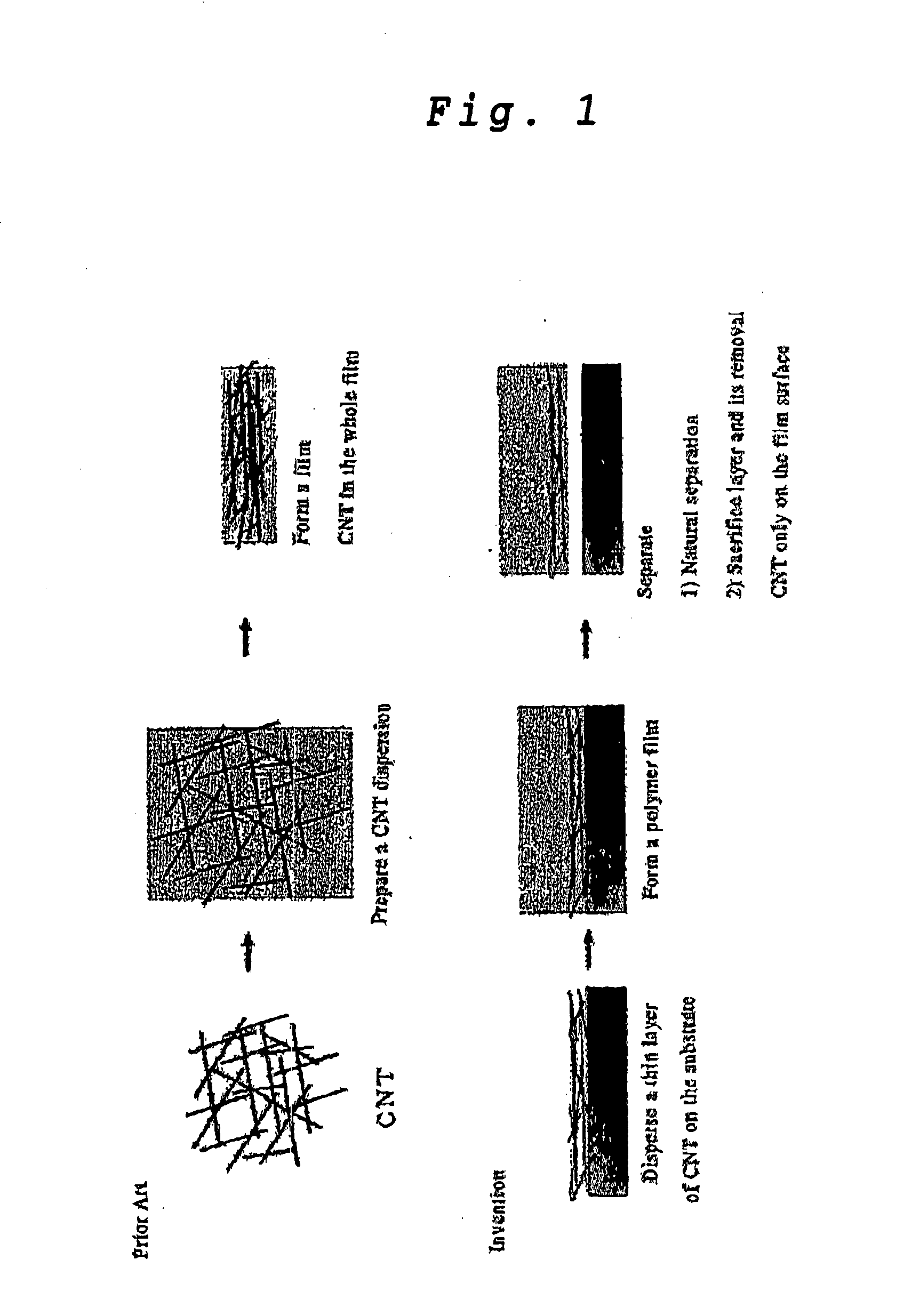

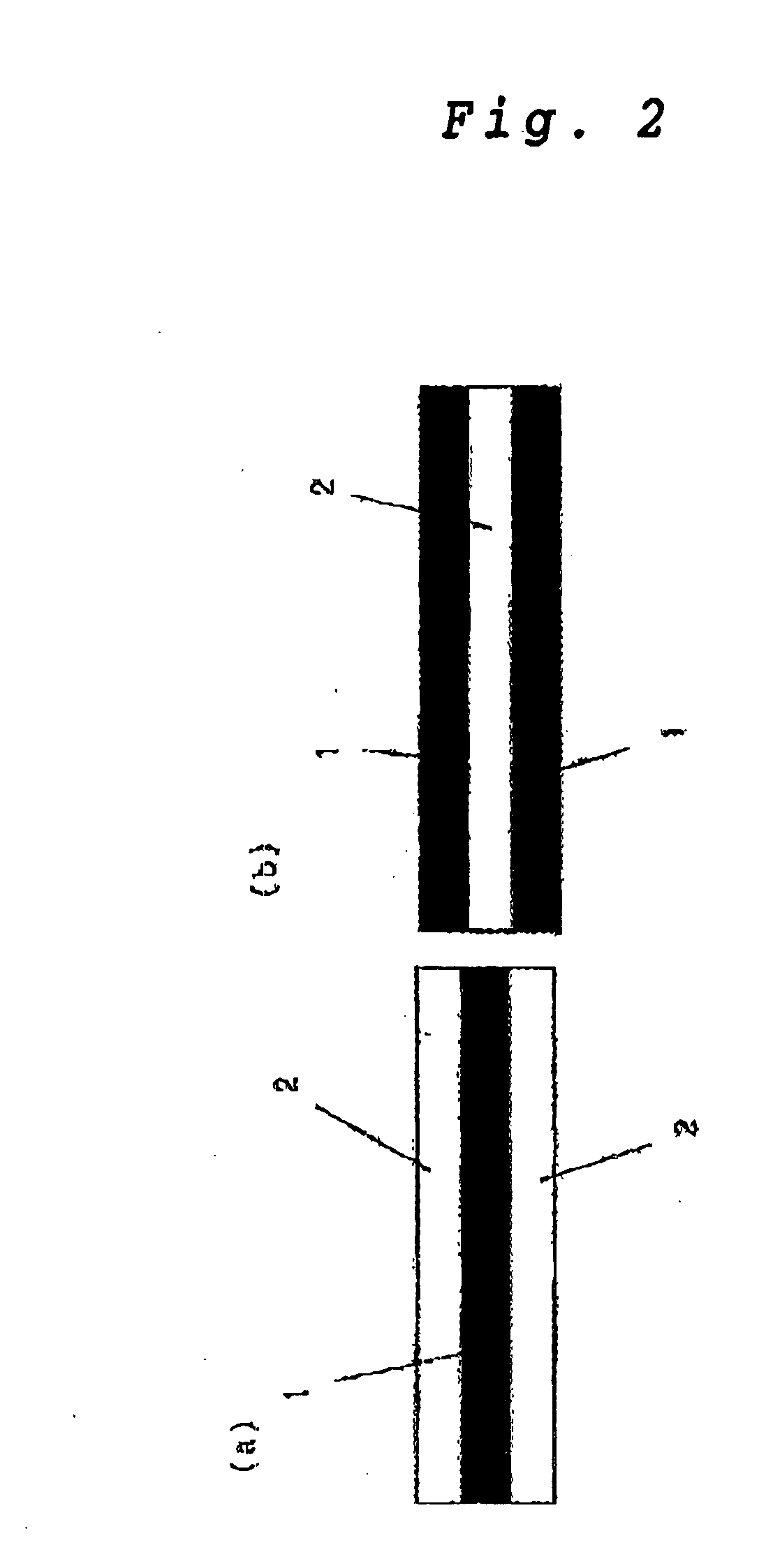

Transparent Conductive Carbon Nanotube Film and a Method for Producing the Same

InactiveUS20070298253A1Conductive and soft and flexibleImprove conductivityMaterial nanotechnologyConductive layers on insulating-supportsCarbon nanotubeTransparent conducting film

A transparent conductive film wherein carbon nanotubes are discursively embedded in the surface portion of a resin film is produced by (A) dispersing carbon nanotubes on a substrate surface, (B) forming a transparent resin film over the substrate on which the carbon nanotubes are dispersed, and then (C) separating the thus-formed resin film. This is a novel technique for realizing a highly transparent conductive film which is flexible and highly conductive even when amount of carbon nanotubes used therefor is small.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Organic electroluminescent display element, finder screen display device, finder and optical device

InactiveUS6468676B1Discharge tube luminescnet screensElectroluminescent light sourcesNitrosoAlkaline earth metal

An organic electroluminescent display element has at least a positive electrode, an organic luminescent film, an electron injection layer and a negative electrode. Each of the positive and negative electrodes is formed of a transparent conductive film, the electron injection layer is formed of a thin transparent film made of a halogenide of an alkali metal or an alkaline earth metal, or an organic metal complex containing an alkali metal or an alkaline earth metal as a metal, and the organic metal complex is at least one complex selected from the group consisting of acetylacetonate complexes, alpha-nitroso-beta-naphthol complexes, salicylaldoxime complexes, cupferron complexes, benzoinoxime complexes, bipyridine complexes, phenanthroline complexes, crown complexes, proline complexes and benzoylacetone complexes.

Owner:KONICA MINOLTA INC

Optical-interference type display panel and method for making the same

InactiveUS7172915B2Improve antioxidant capacityConnecting qualitySemiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

Owner:SNAPTRACK

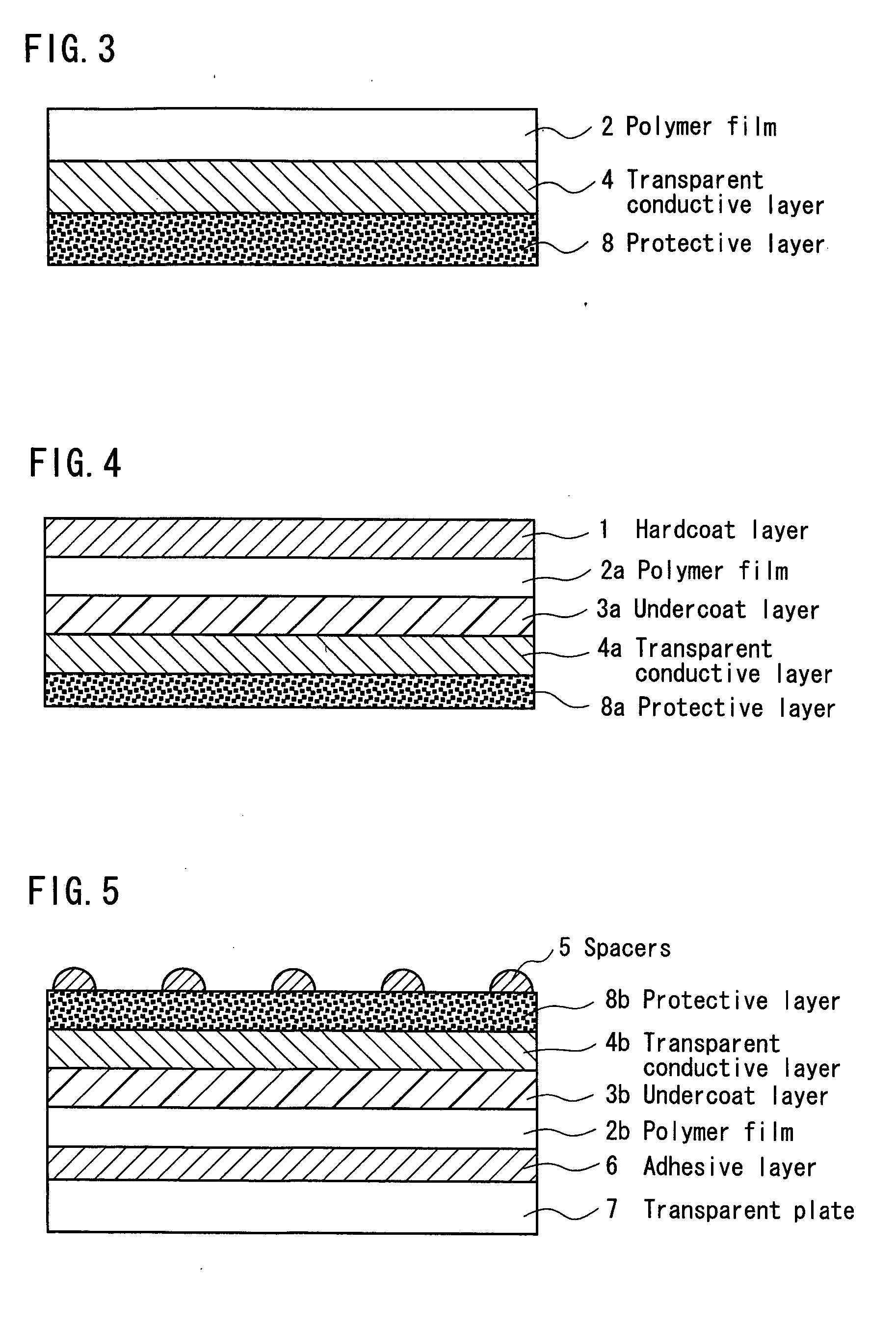

Transparent electroconductive film, method for manufacture thereof, and touch panel

InactiveUS20040265602A1Easy to prepareIncreased durabilityConductive layers on insulating-supportsContact surface shape/structurePhosphoric acidTransparent conducting film

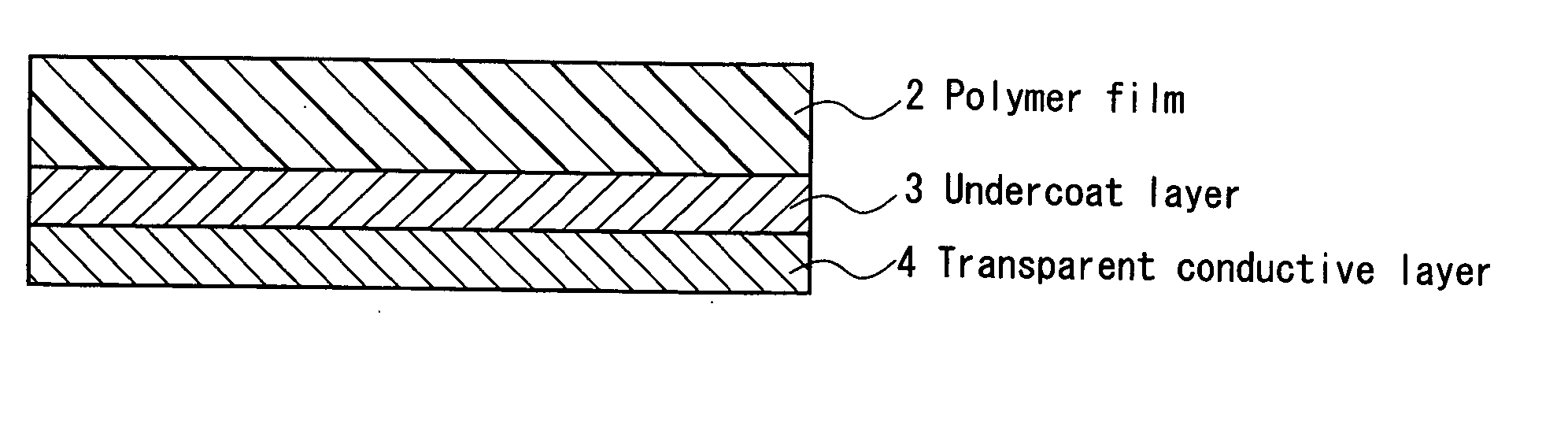

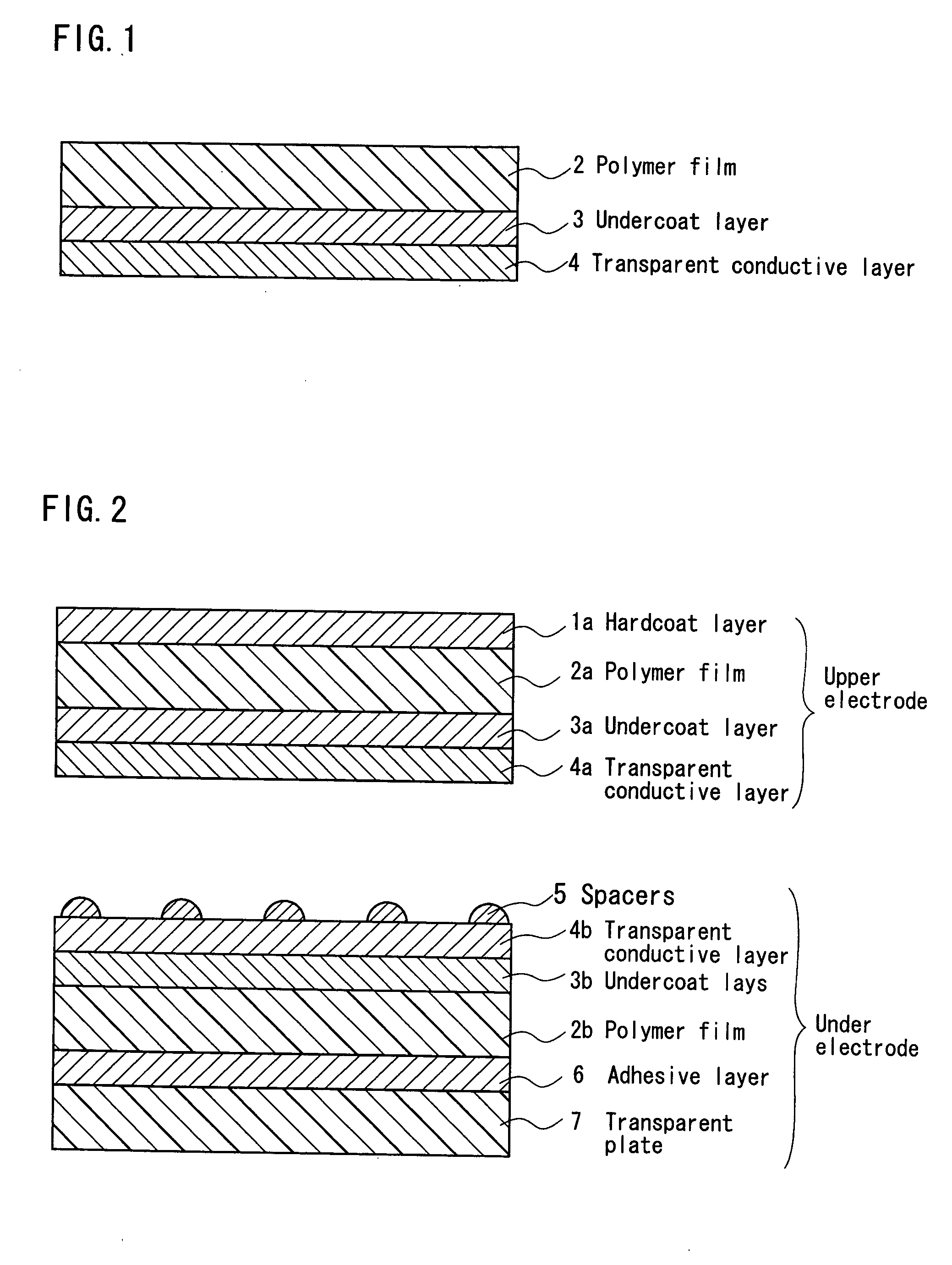

A transparent conductive film comprising a polymer film and a transparent conductive layer provided thereon, especially a transparent conductive film improved in durability and mechanical and electrical properties, a process for the preparation thereof, and a touch panel provided with the transparent conductive film, as well as transparent conductive plate and the process for the preparation thereof. The transparent conductive film comprising a polymer film, an undercoat layer and a transparent conductive layer which are superposed in this order, and the undercoat layer contains a compound having at least one selected from an amino group and a phosphoric acid group.

Owner:BRIDGESTONE CORP

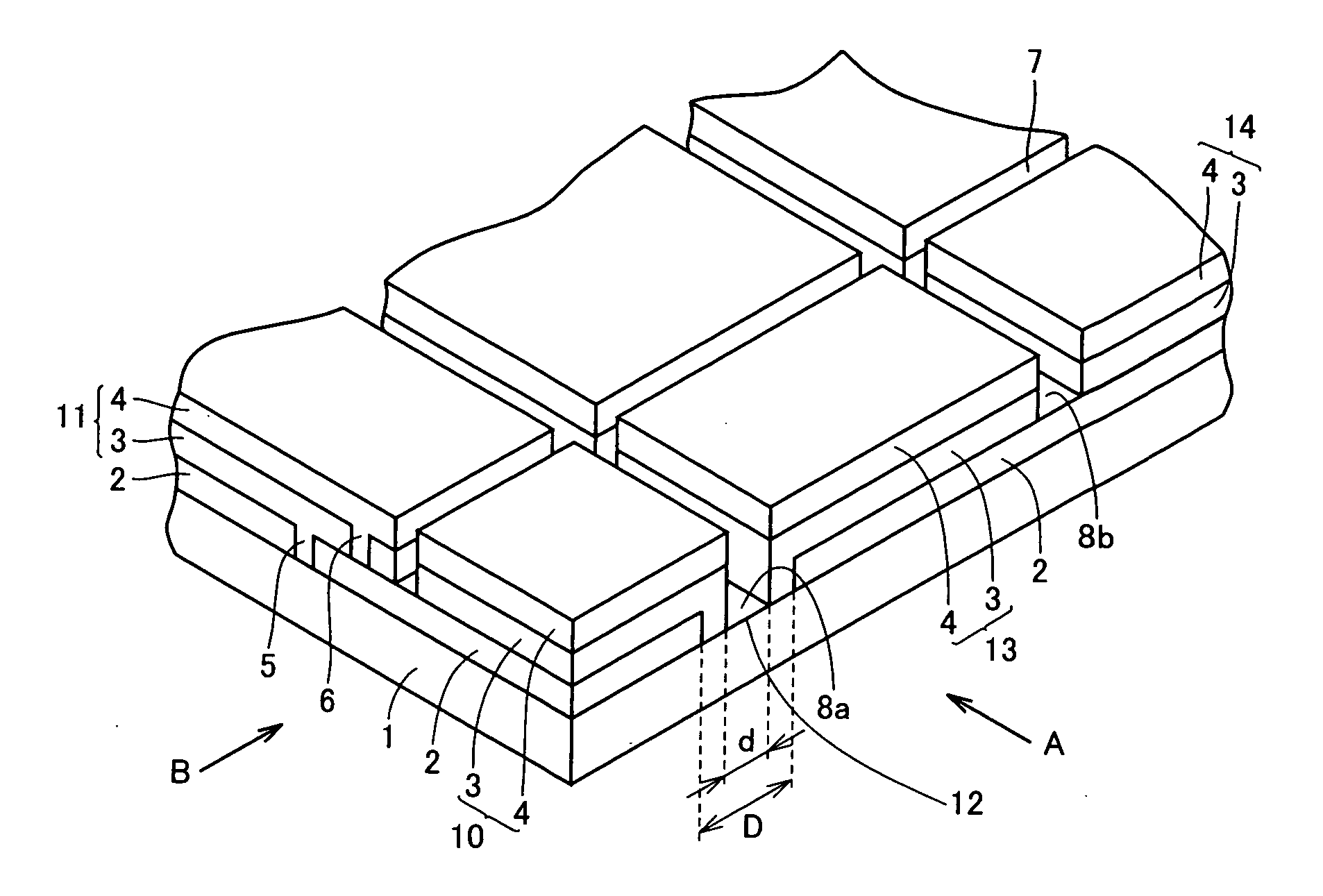

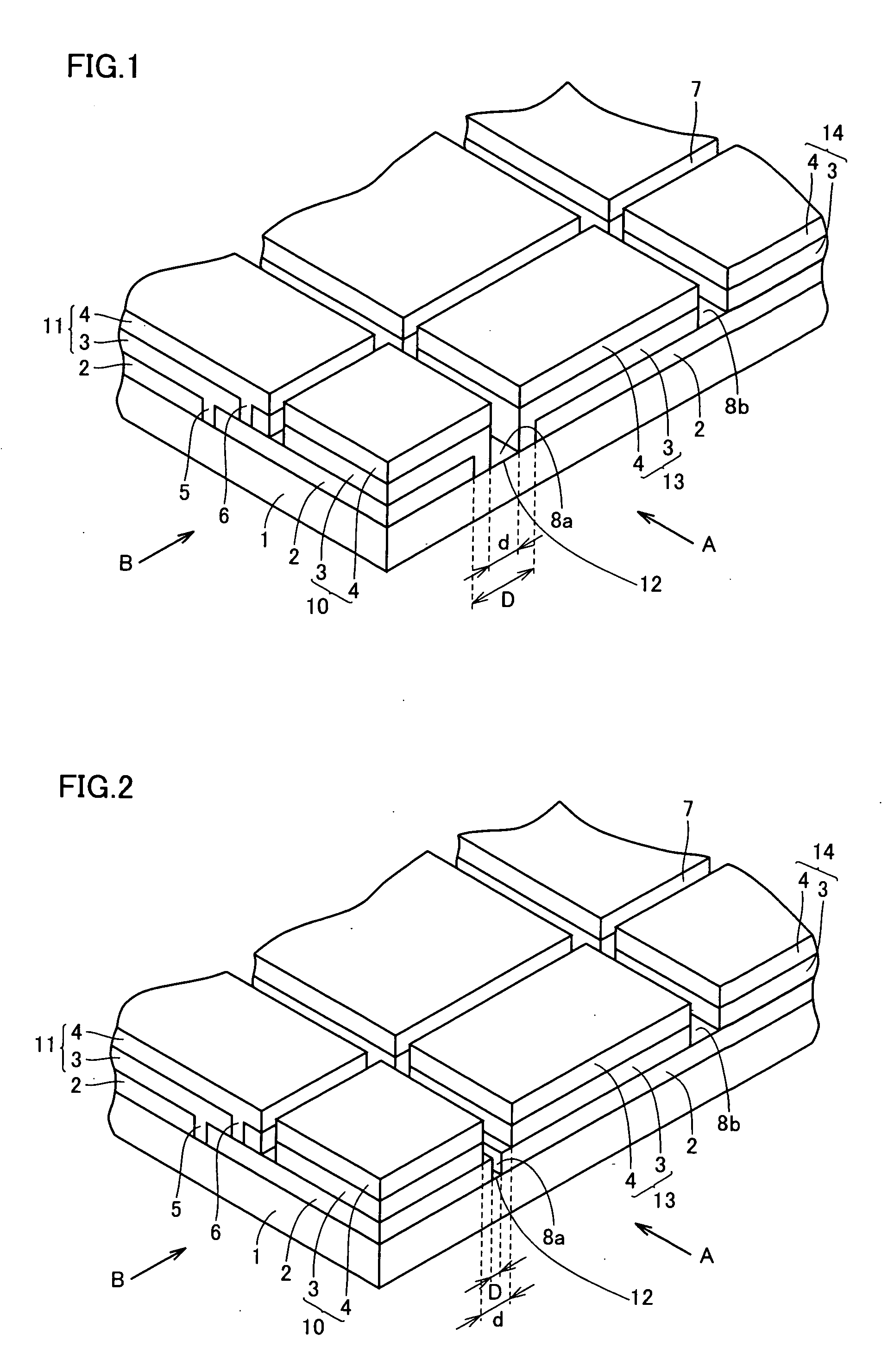

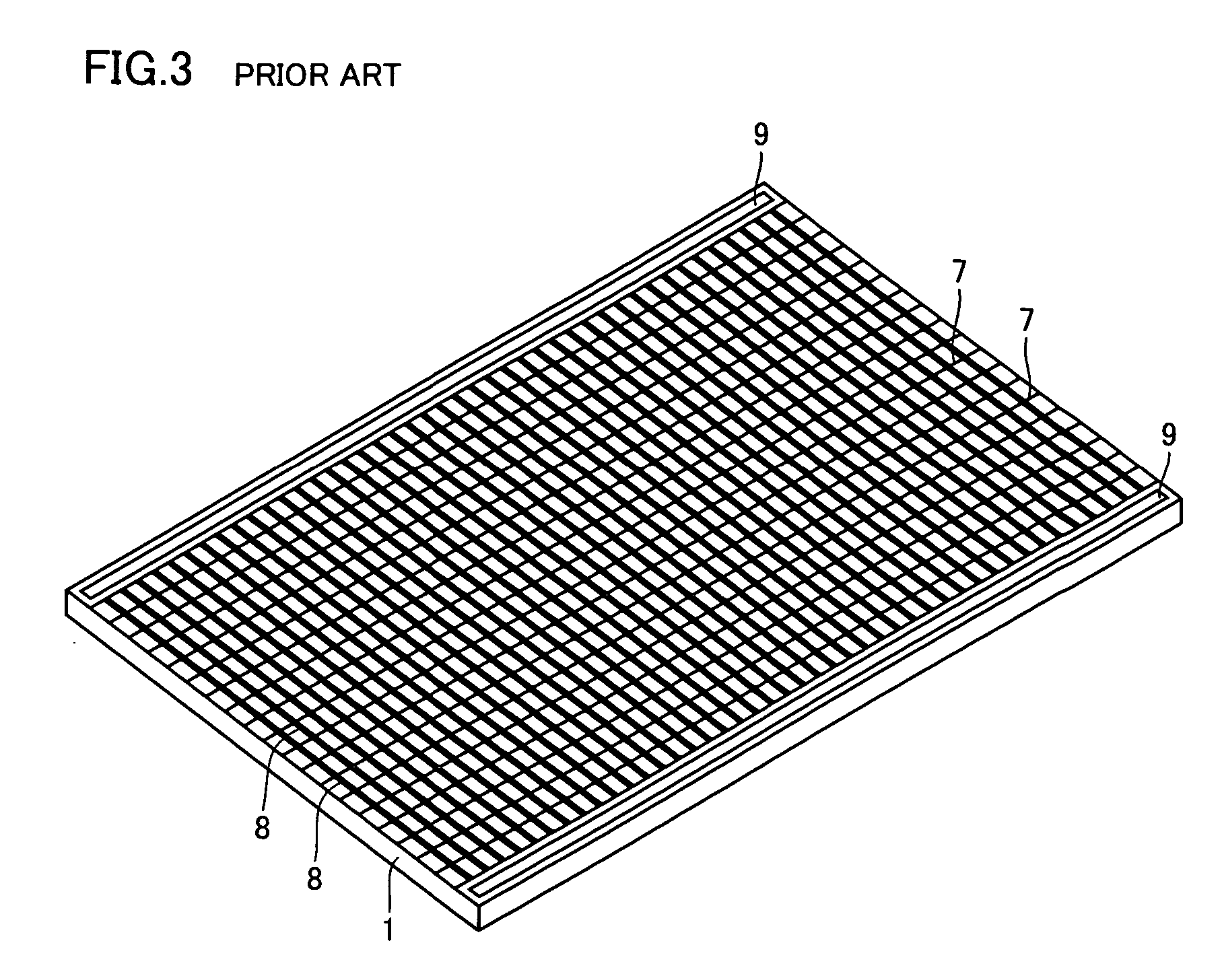

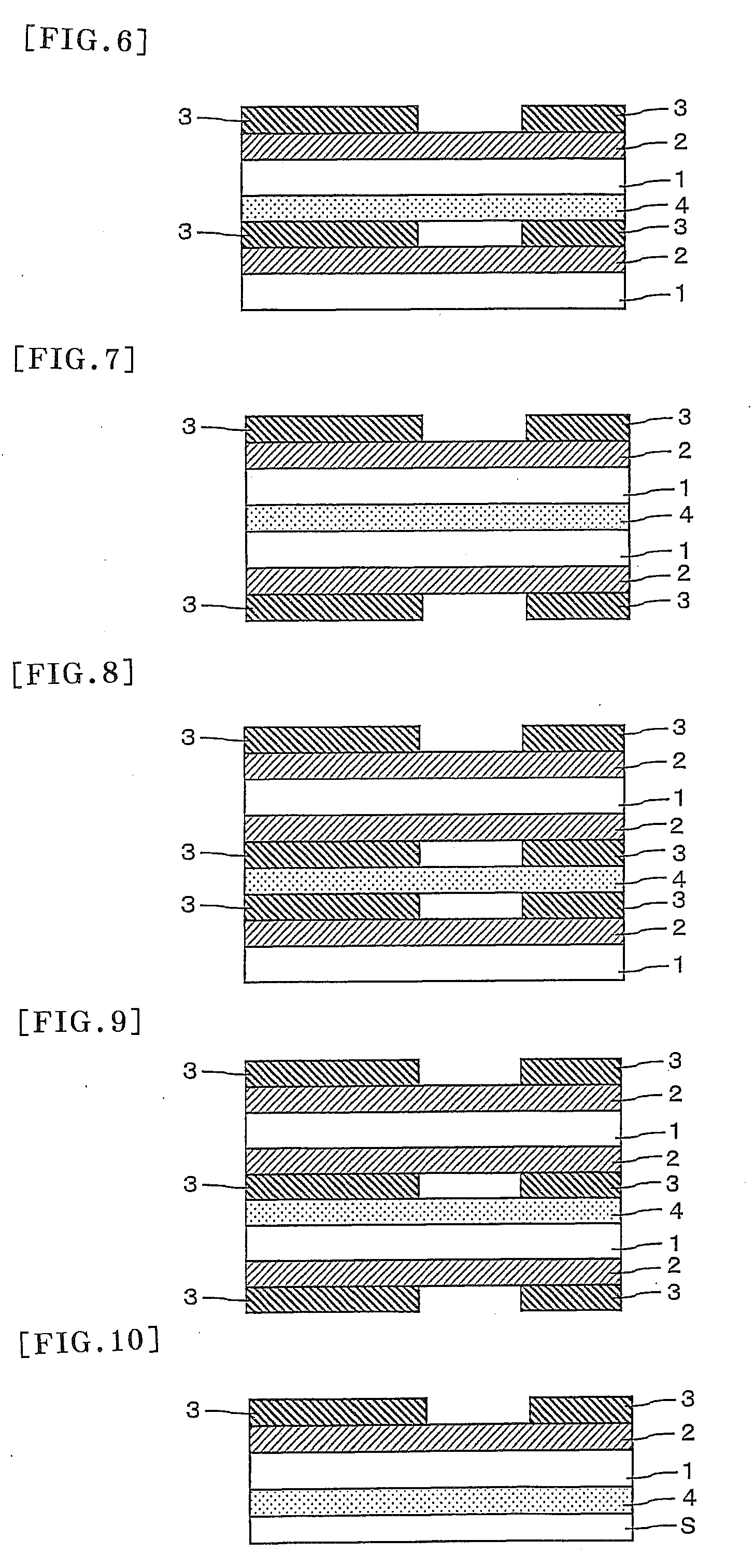

Thin film solar cell and manufacturing method thereof

InactiveUS20060196536A1Improve production yieldPrevent degradationPV power plantsSolid-state devicesTransparent conducting filmEngineering

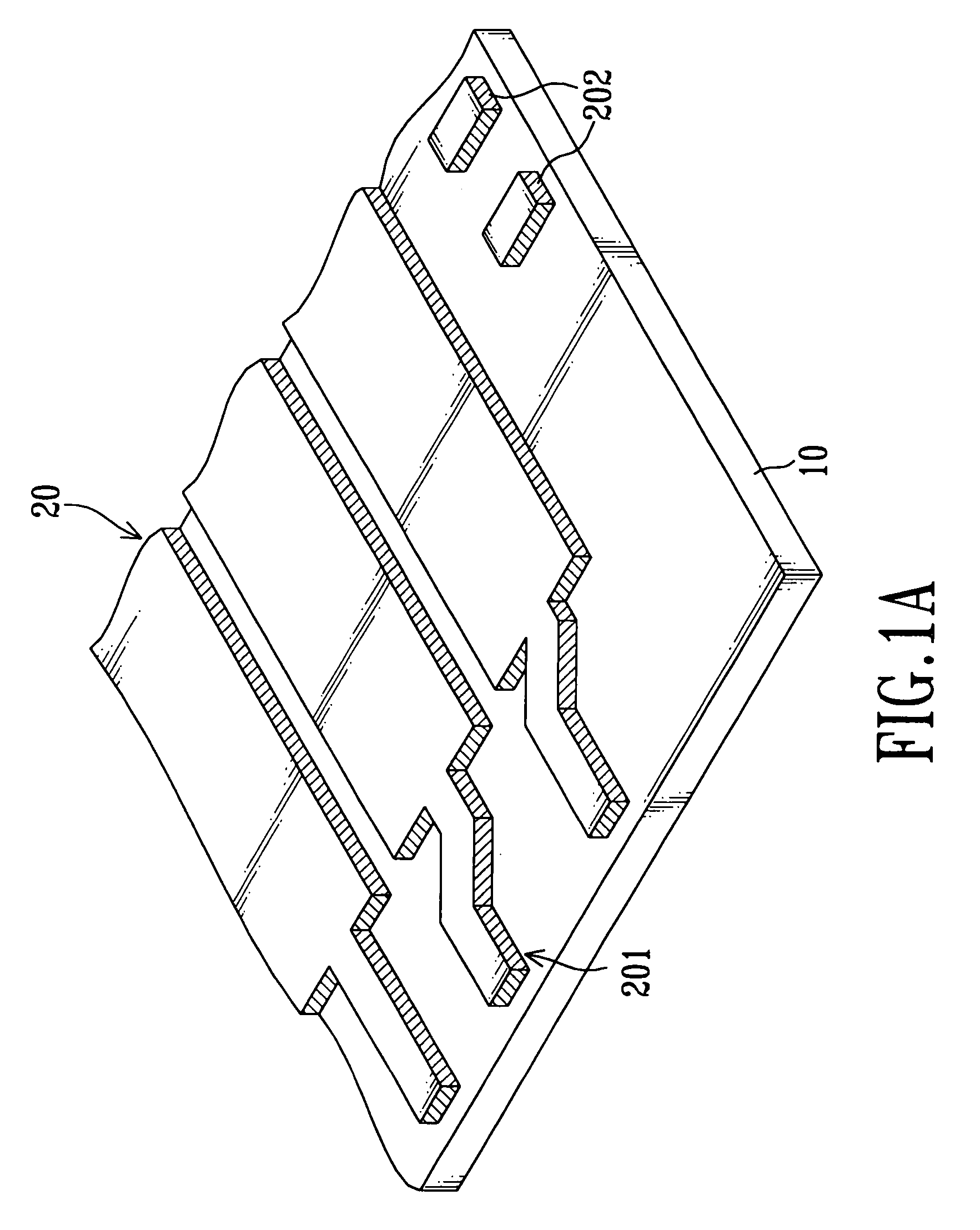

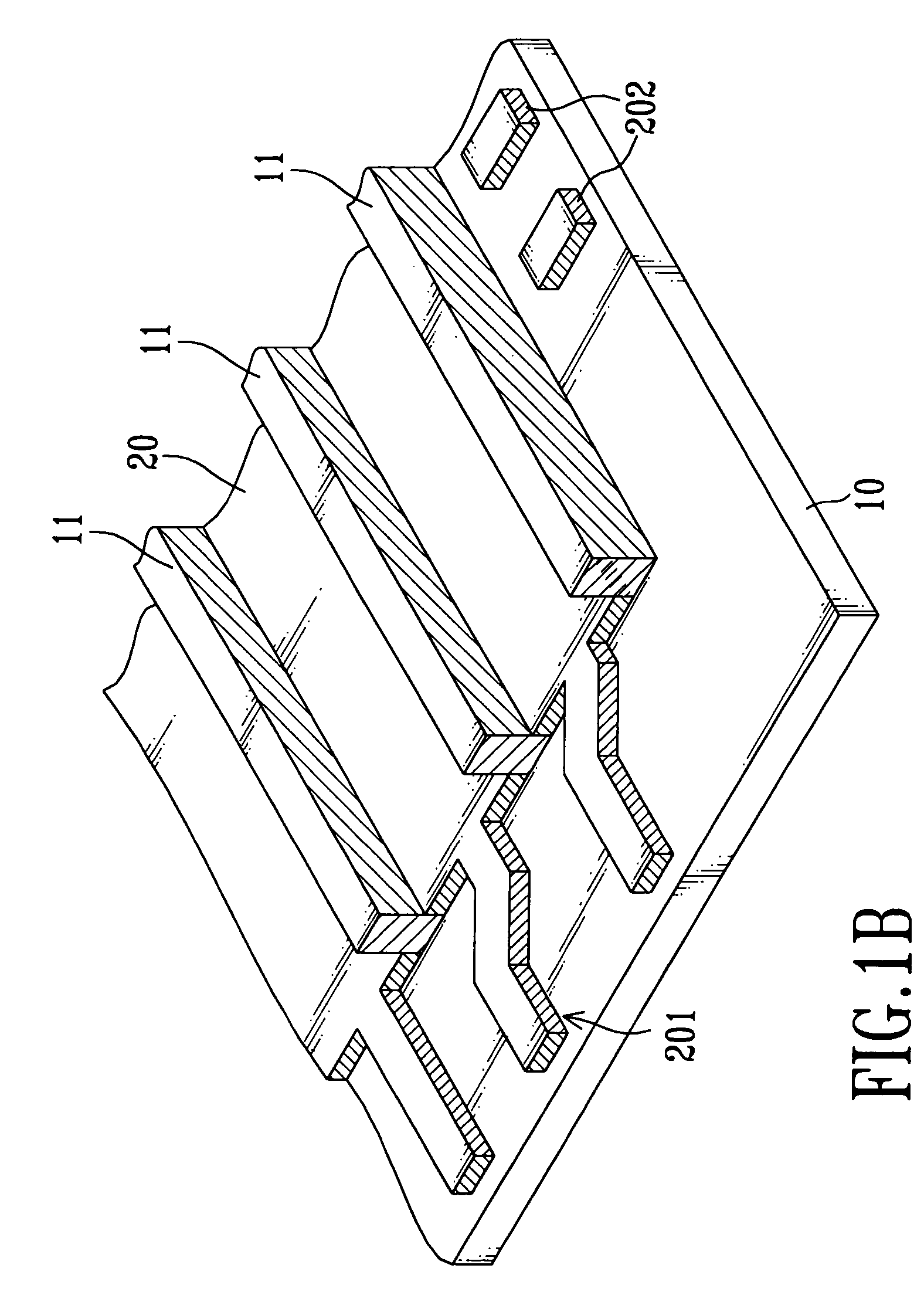

A thin film solar cell includes: a transparent conductive film arranged on a translucent insulating substrate; first and second separation trenches orthogonal to each other on the translucent insulating substrate and separating the transparent conductive film; and a first opening trench parallel to the first separation trench and second opening trenches parallel to said second separation trench, orthogonal to each other on the translucent insulating substrate; wherein solar cells formed on the translucent insulating substrate are arranged at adjacent positions with said first opening trench positioned therebetween and at adjacent positions with said second opening trench positioned therebetween; pairs of said solar cells adjacent to each other with said first opening trench positioned therebetween are electrically connected, and among pairs of solar cells positioned adjacent to each other with the second opening trench in between, some are electrically connected to each other, and others are electrically insulated from each other. Method of manufacturing the thin film solar cell is also provided.

Owner:SHARP KK

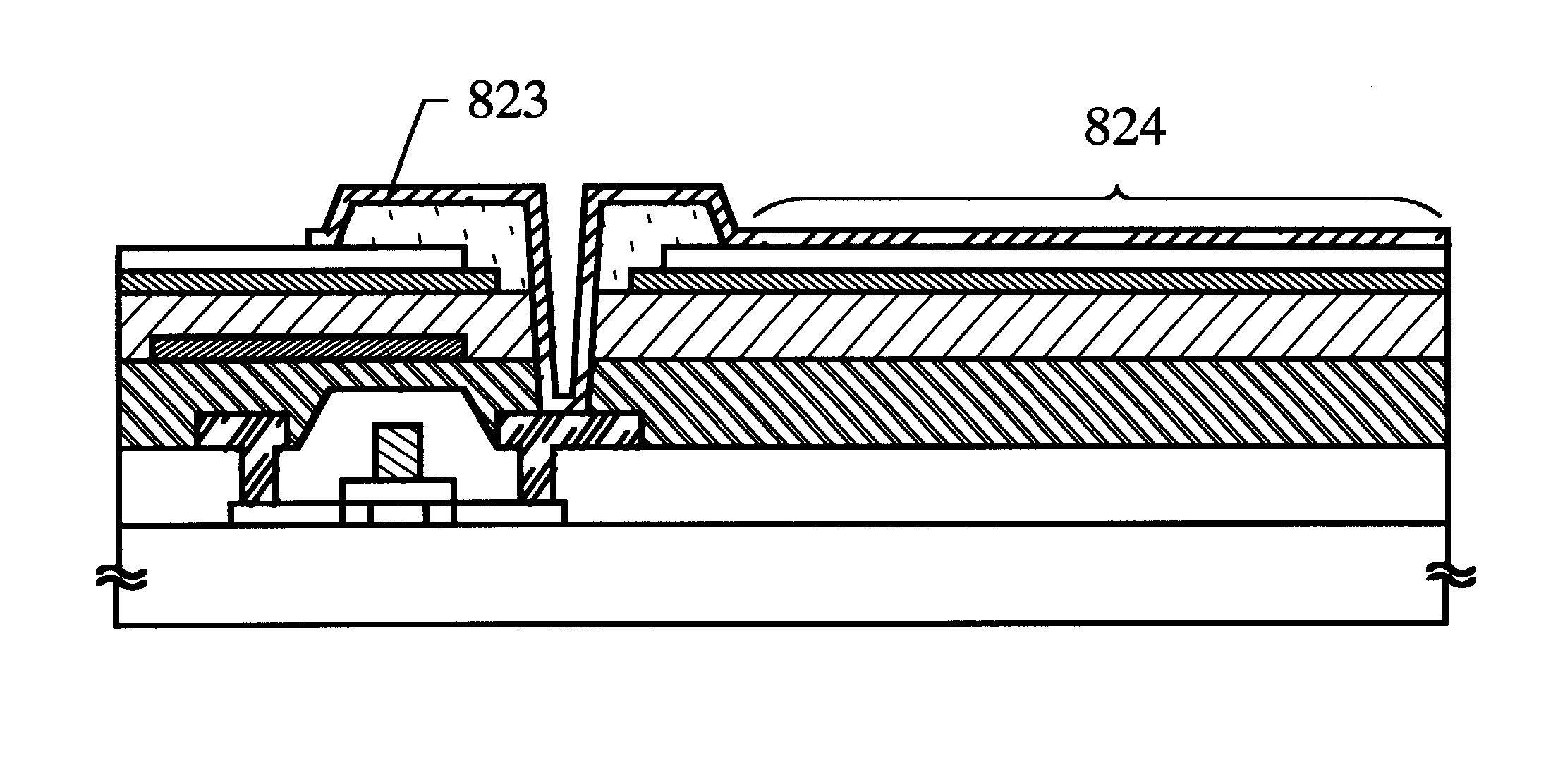

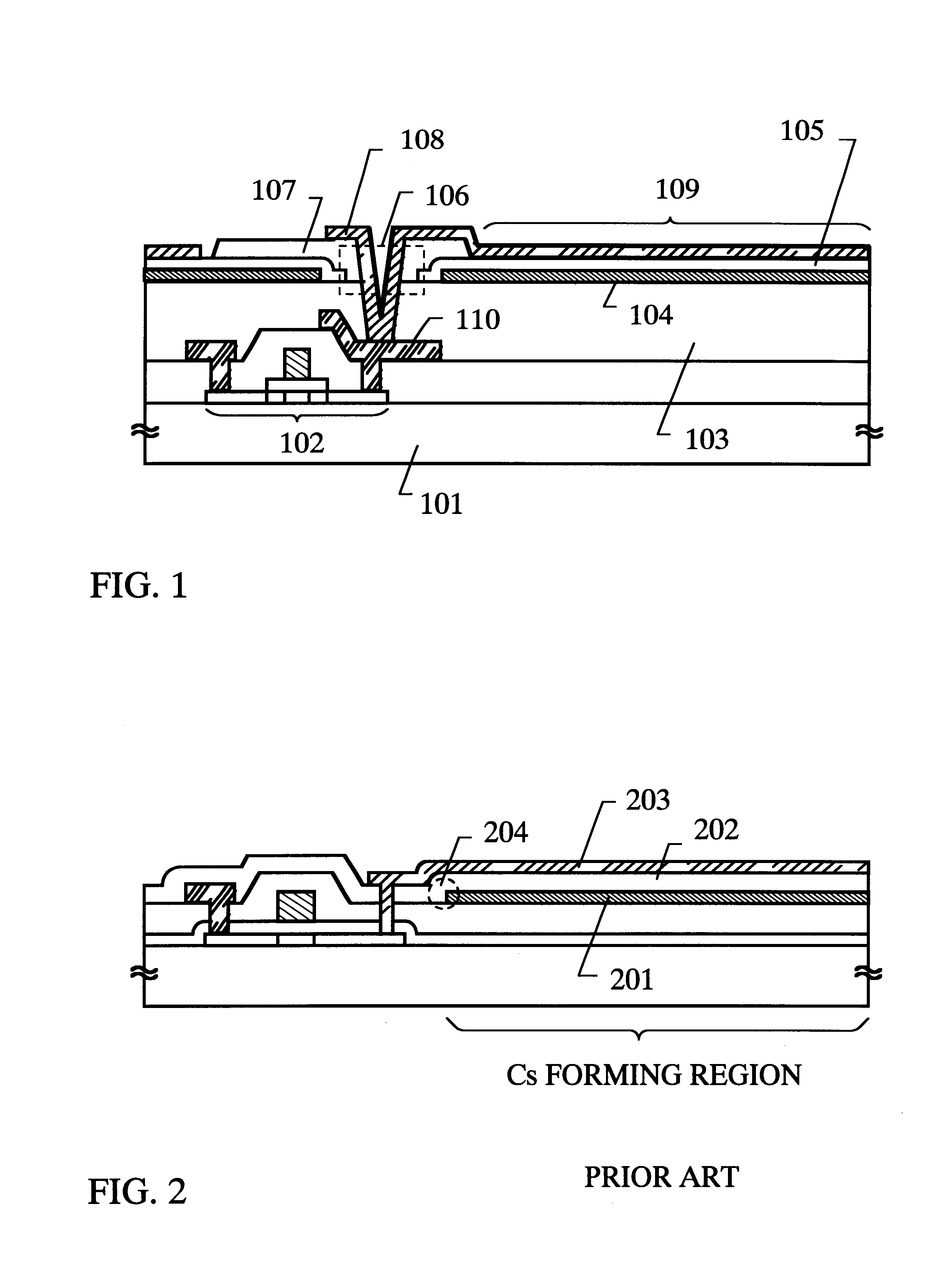

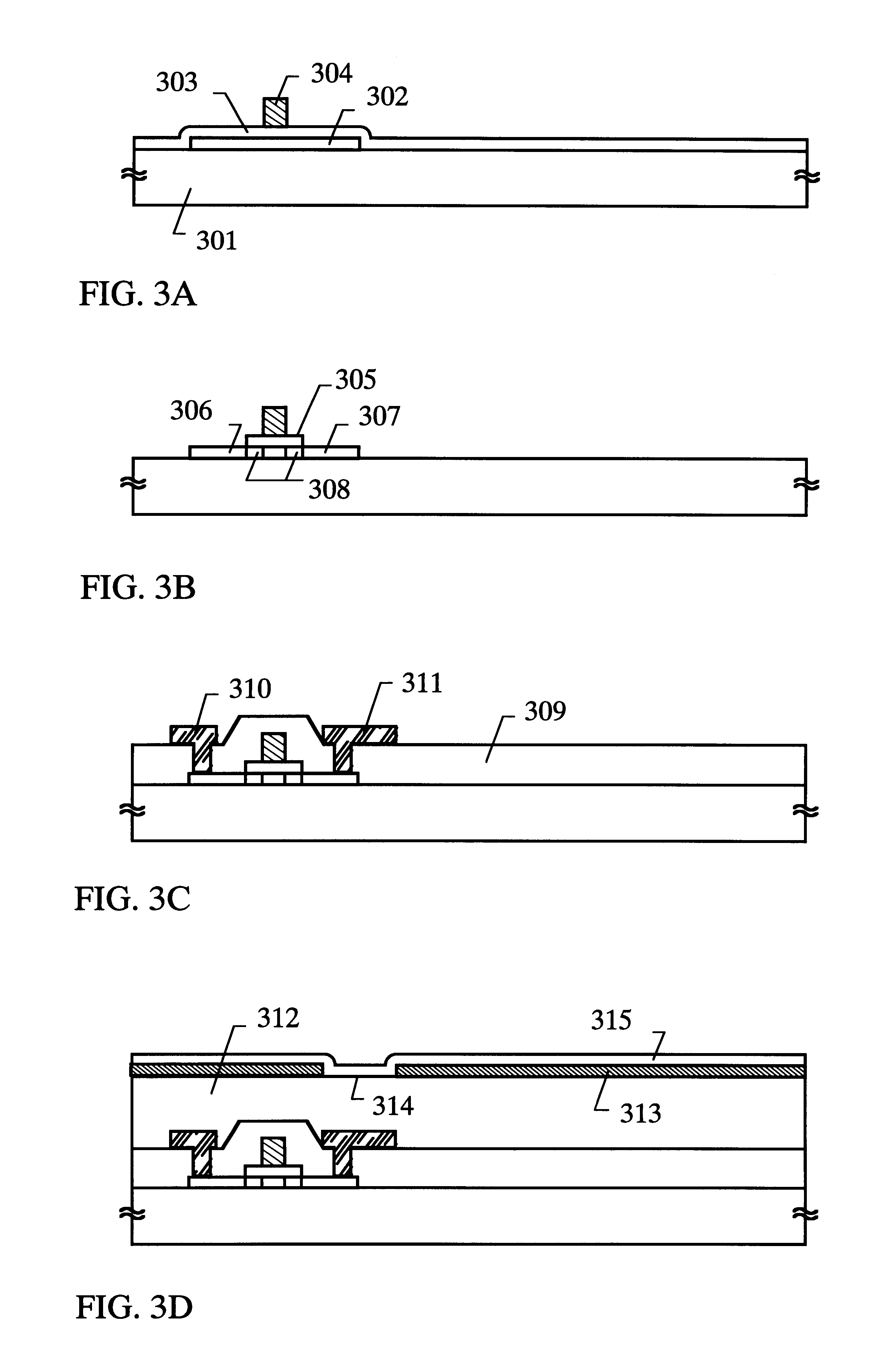

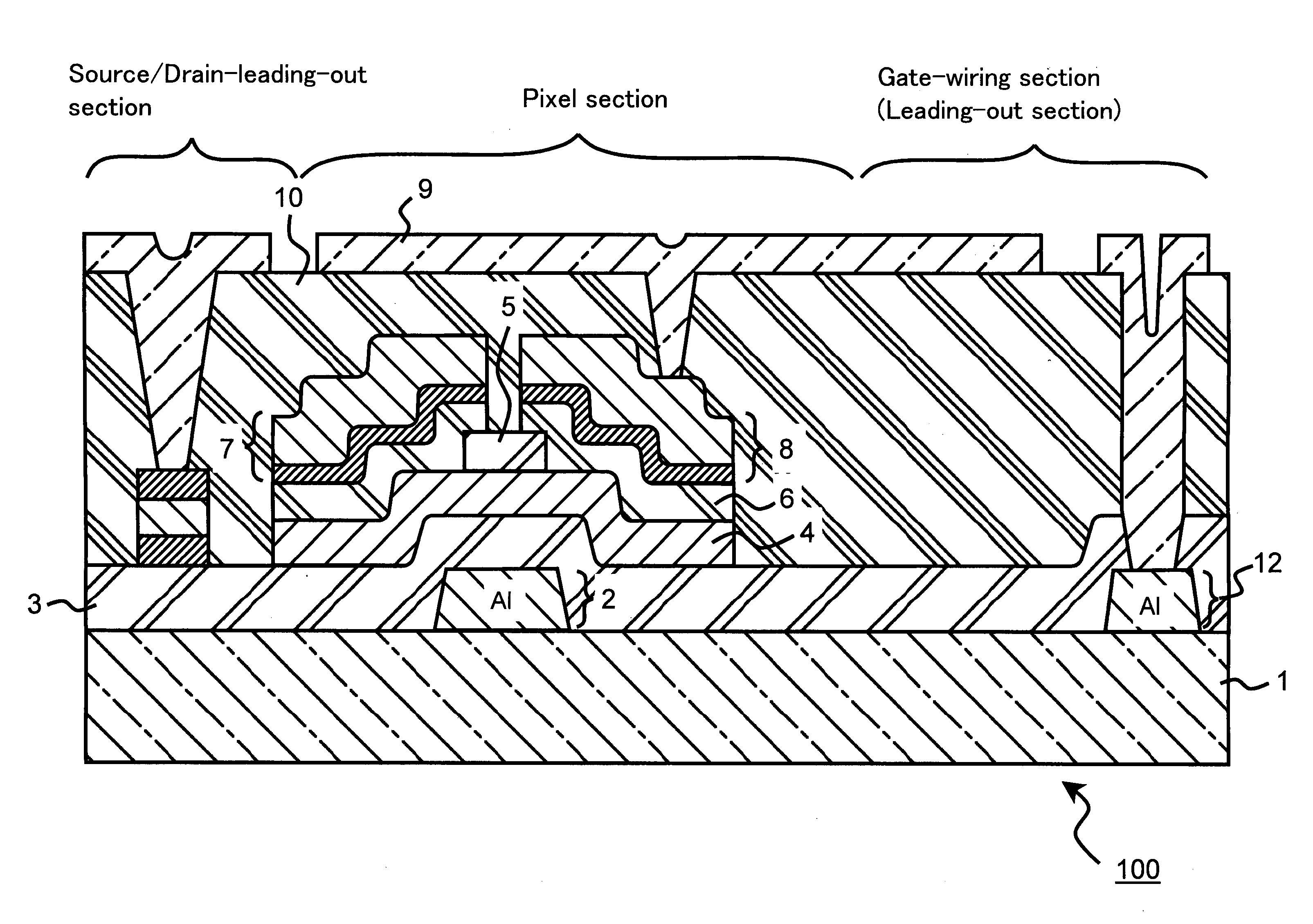

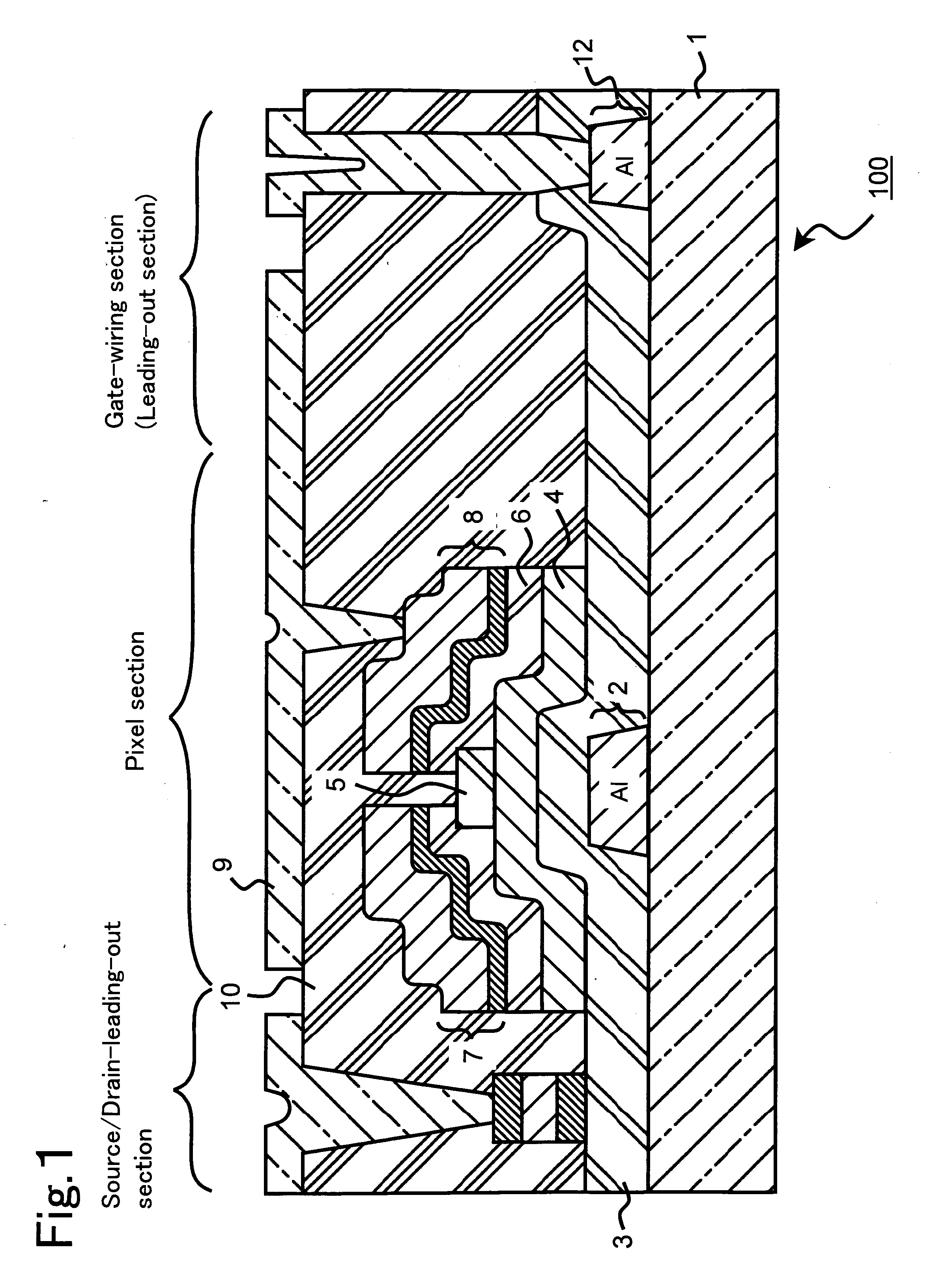

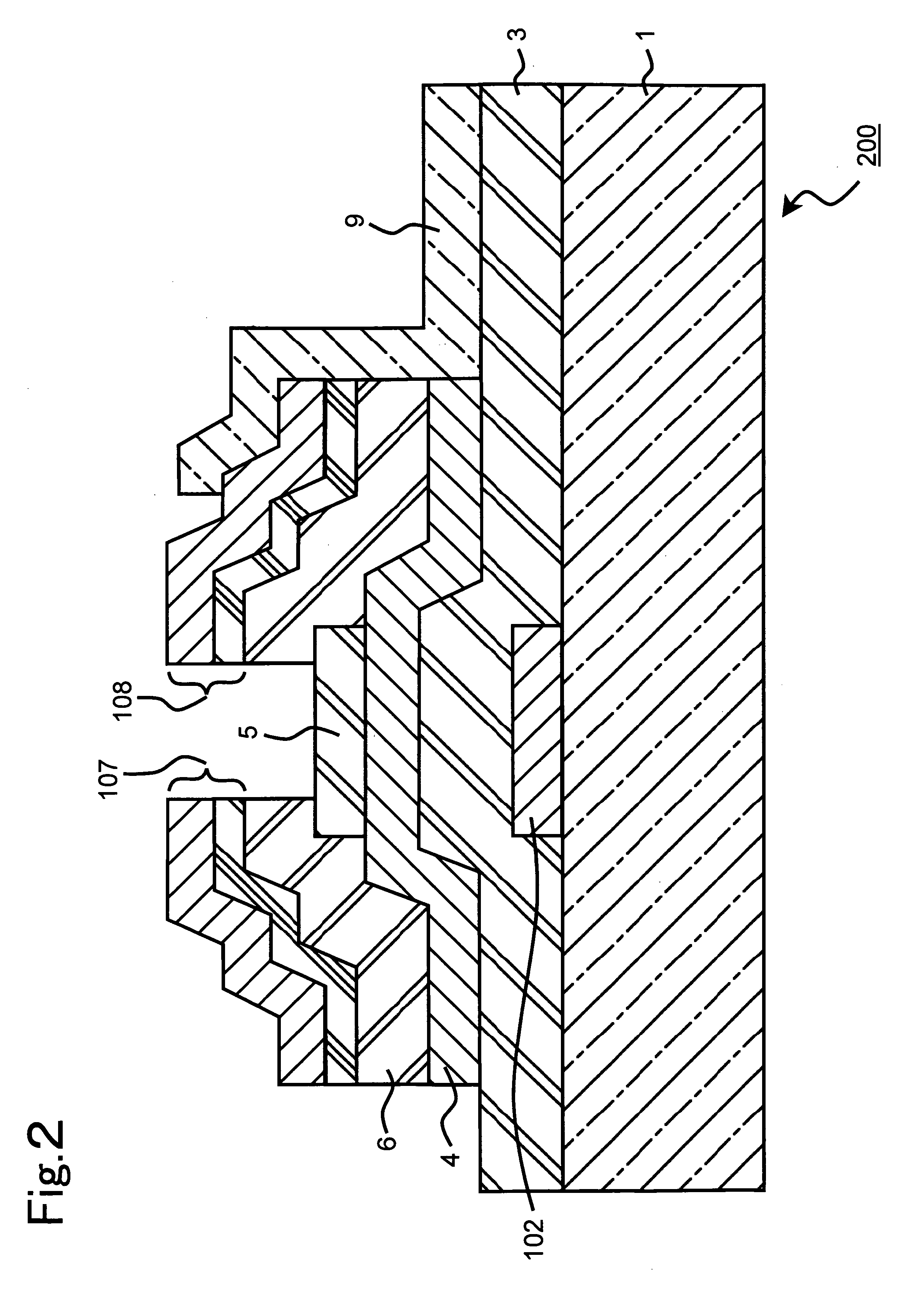

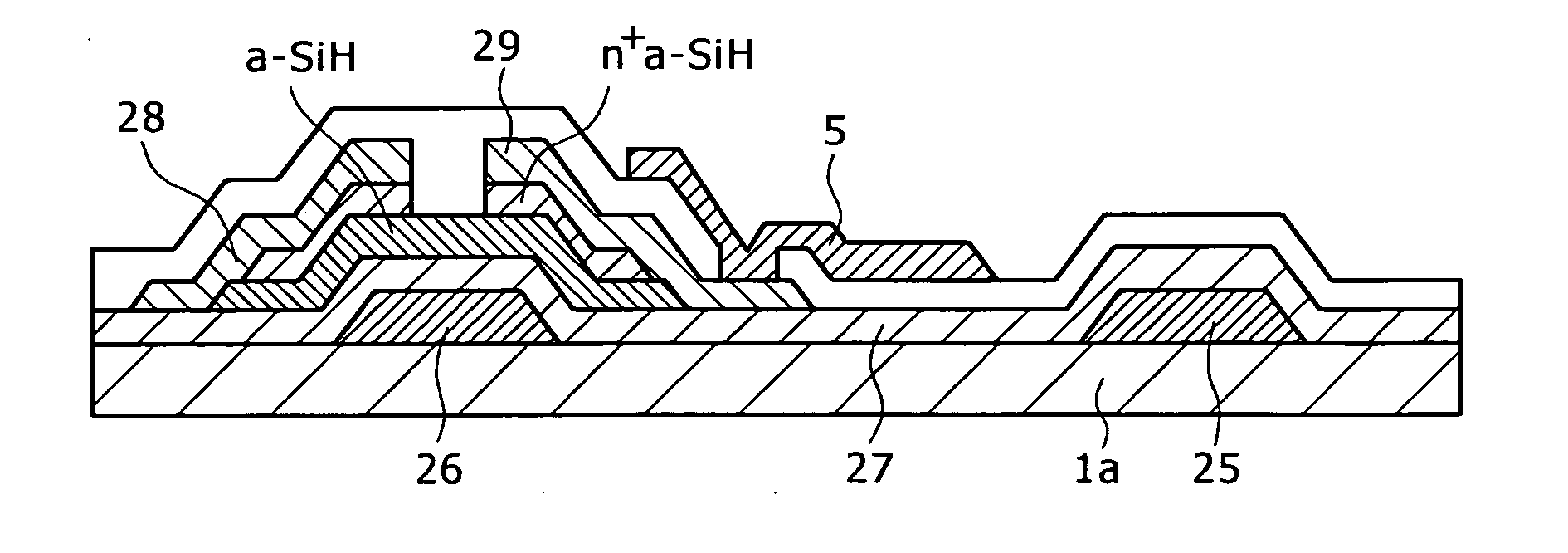

Semiconductor device and a method of manufacturing the same

InactiveUS6313481B1Solid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLiquid-crystal display

In a liquid crystal display device, an improved storage capacitance that uses a pair of transparent conductive films for electrodes is provided. On a flattening film made of a resin, a first transparent conductive film and an insulating film for capacitance are formed into a lamination to form in this laminated film an opening portion. An insulating film covering near the opening portion is formed. A transparent conductive film is formed and patterned to form a pixel electrode. Thus is formed a storage capacitance having the structure where the insulating film for capacitance is sandwiched between the first transparent conductive film and the pixel electrode.

Owner:SEMICON ENERGY LAB CO LTD +1

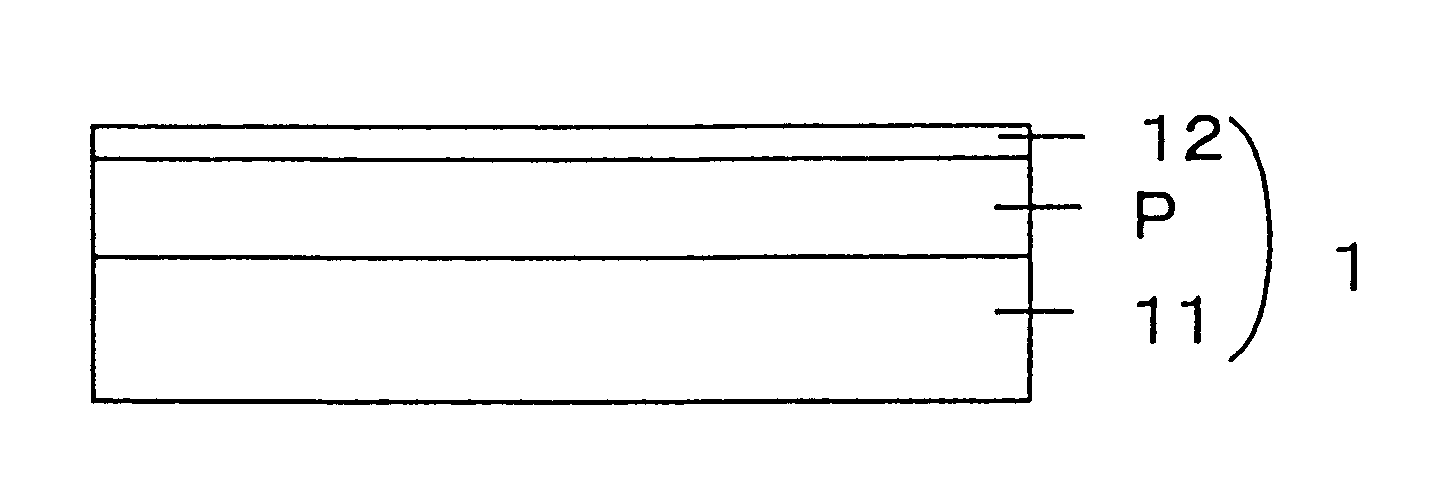

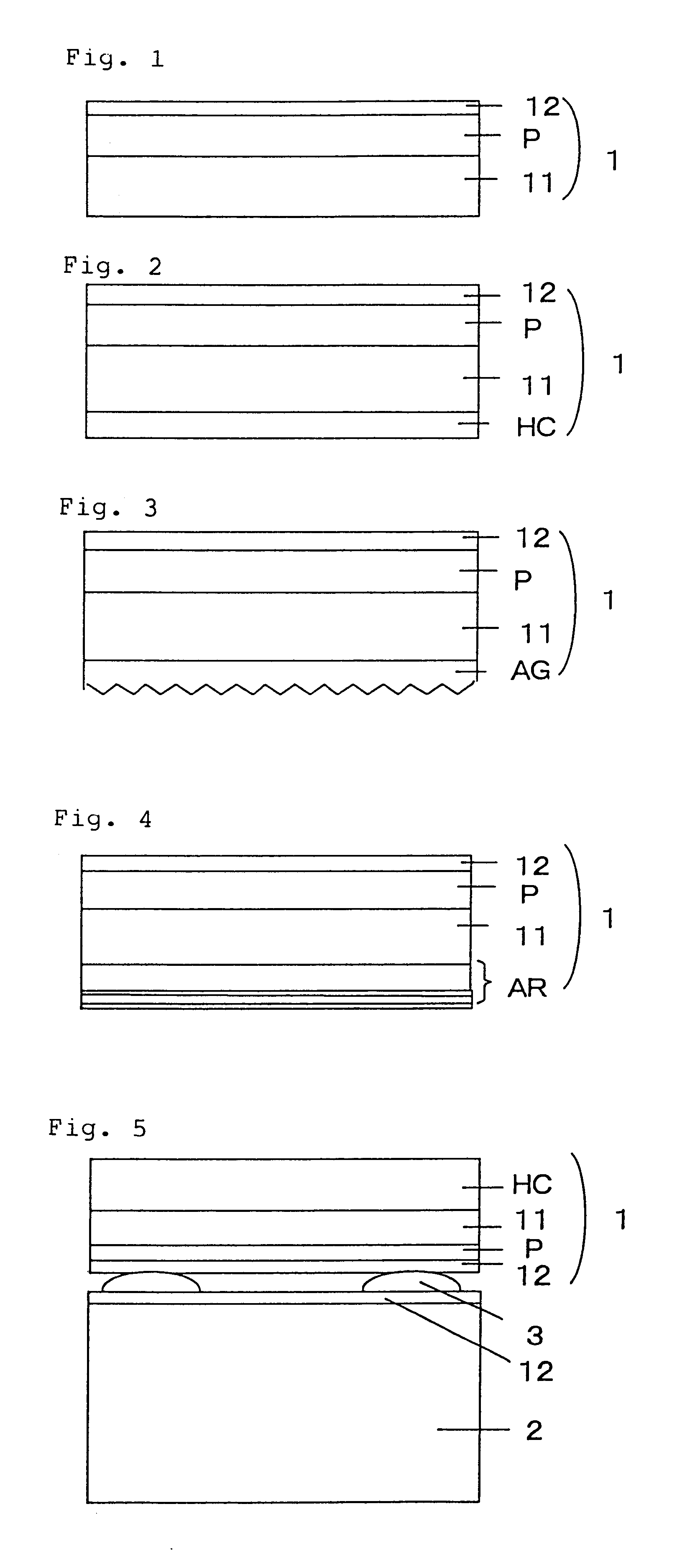

Transparent conductive film and touch panel

InactiveUS6629833B1Increased durabilityImprove adhesionLiquid surface applicatorsConductive layers on insulating-supportsCross-linkTouchpad

A transparent conductive film (1) having a transparent plastic film (11) and a transparent conductive thin film (12) formed on at least one side thereof, characterized in that a resin layer (P) containing an ionic group in the range of 20 to 1000 eq / ton is provided between the transparent plastic film and the transparent conductive thin film and the ionic group containing resin has a cross-linked structure. The transparent conductive film has excellent adhesion to other conductive thin films and therefore exhibits excellent durability to input with a pen when used in touch panels.

Owner:TOYO TOYOBO CO LTD

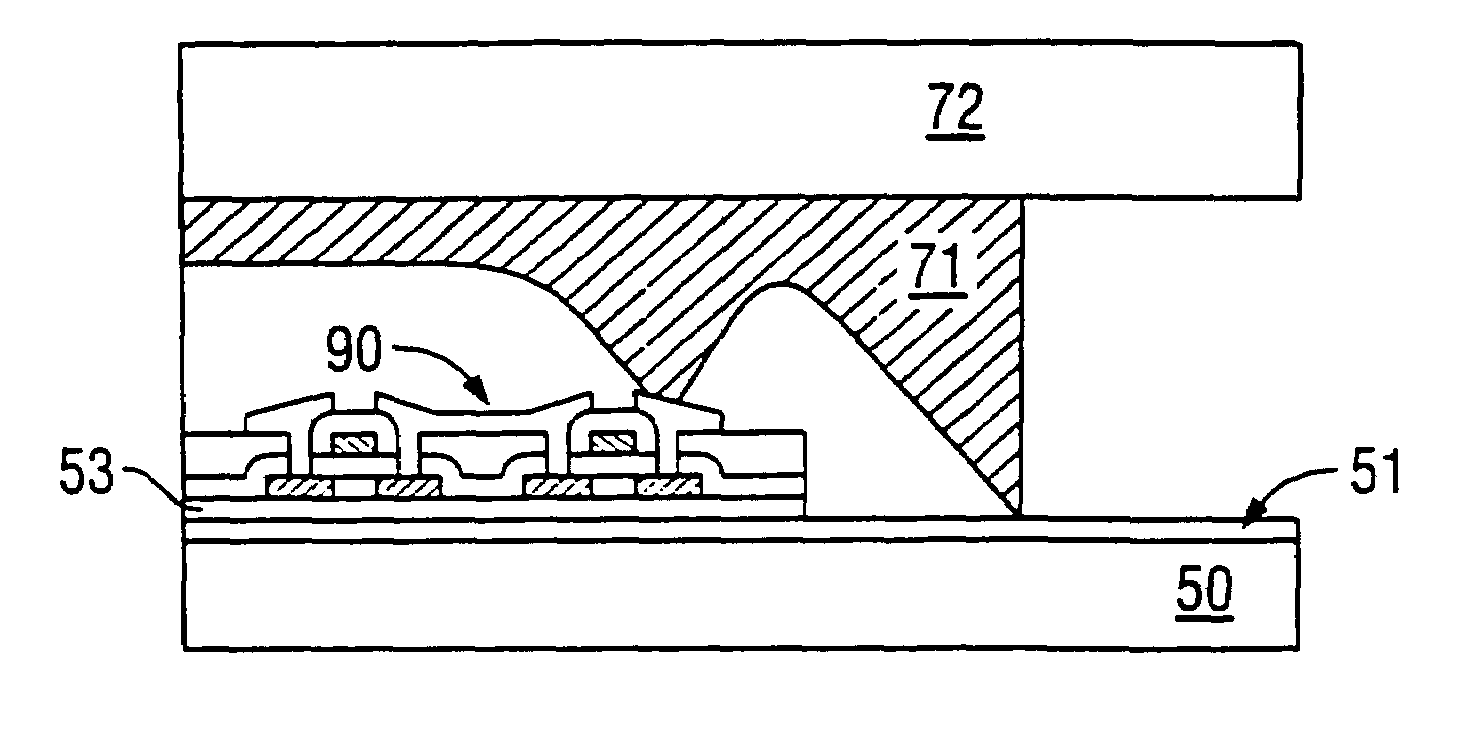

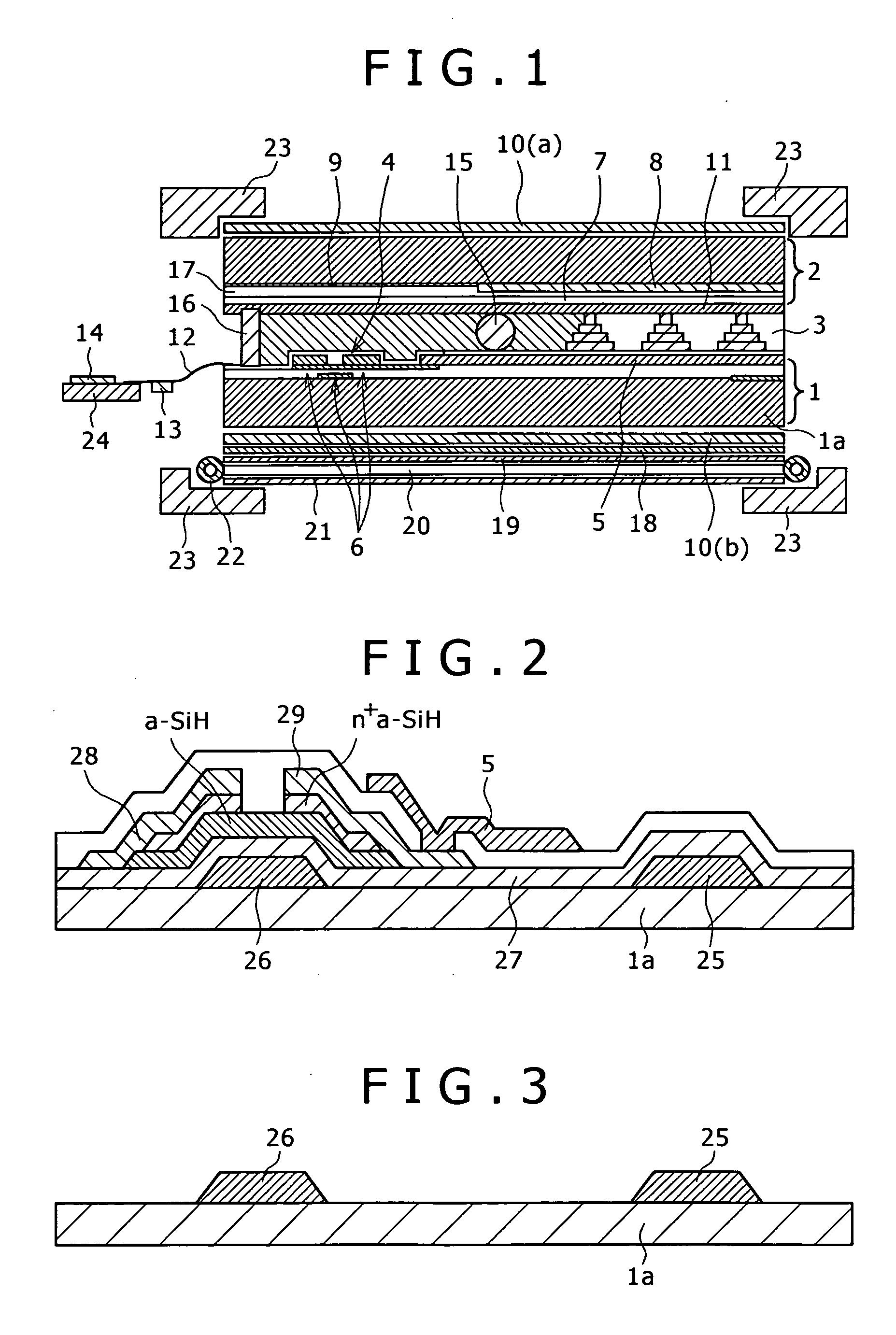

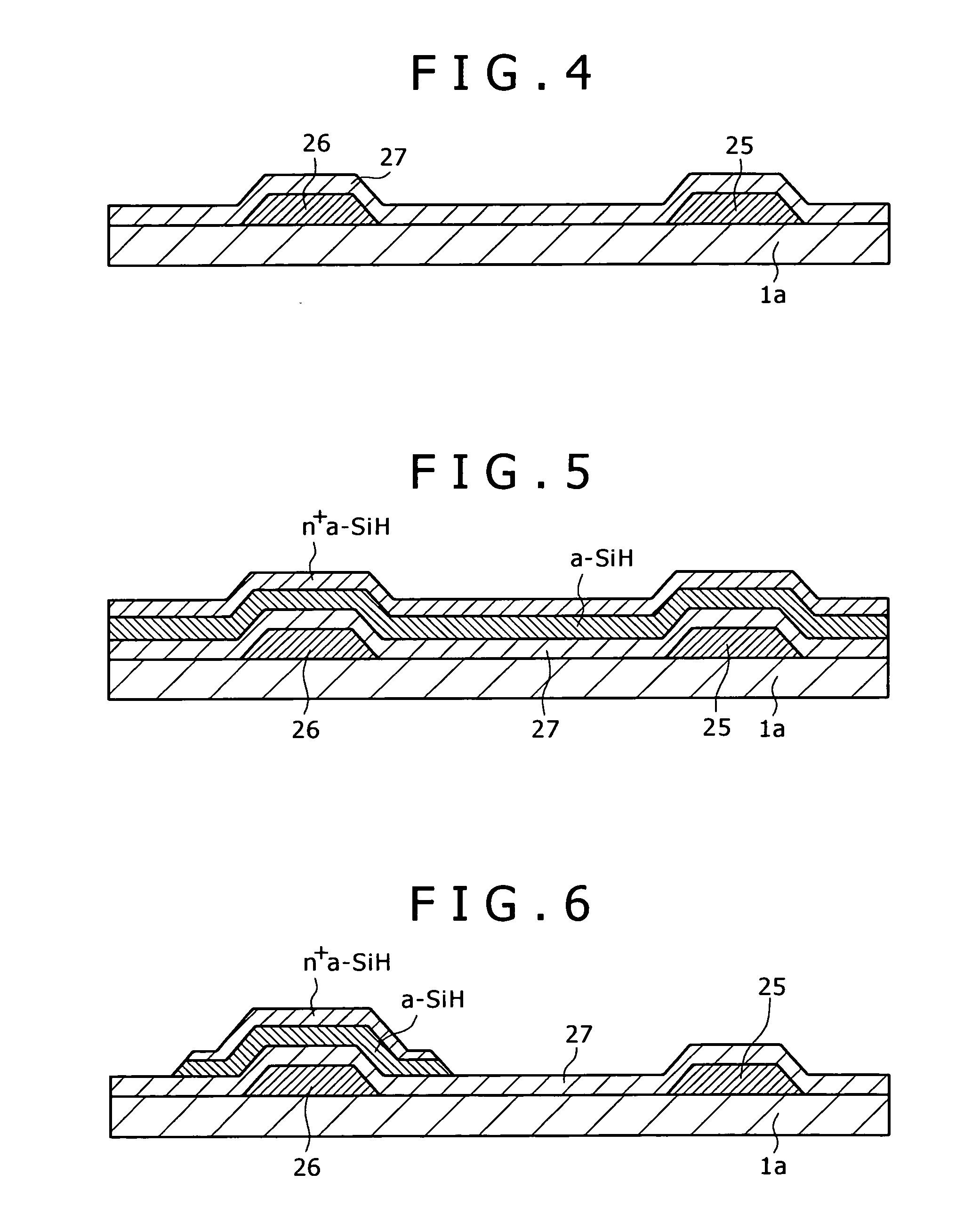

Method for producing display device

InactiveUS7214555B2Small displayImprove reliability and durabilitySolid-state devicesSemiconductor/solid-state device manufacturingDriver circuitLiquid-crystal display

In a liquid crystal display device, a first substrate includes electrical wirings and a semiconductor integrated circuit which has TFTs and is connected electrically to the electrical wirings, and a second substrate includes a transparent conductive film on a surface thereof. A surface of the first substrate on which the electrical wirings are formed is opposite to the transparent conductive film on the second substrate. The semiconductor integrated circuit has substantially the same length as one side of a display screen (i.e., a matrix circuit) of the display device and is obtained by peeling it from another substrate and then forming it on the first substrate. Also, in a liquid crystal display device, a first substrate includes a matrix circuit and a peripheral driver circuit, and a second substrate is opposite to the first substrate, includes a matrix circuit and a peripheral driver circuit and has at least a size corresponding to the matrix circuit and the peripheral driver circuit. Spacers are provided between the first and second substrates. A seal material is formed outside the matrix circuits and the peripheral driver circuits in the first and second substrates. A liquid crystal material is filled inside a region enclosed by the seal material. A protective film is formed on the peripheral driver circuit that has a thickness substantially equivalent to an interval between the substrates which is formed by the spacers.

Owner:SEMICON ENERGY LAB CO LTD

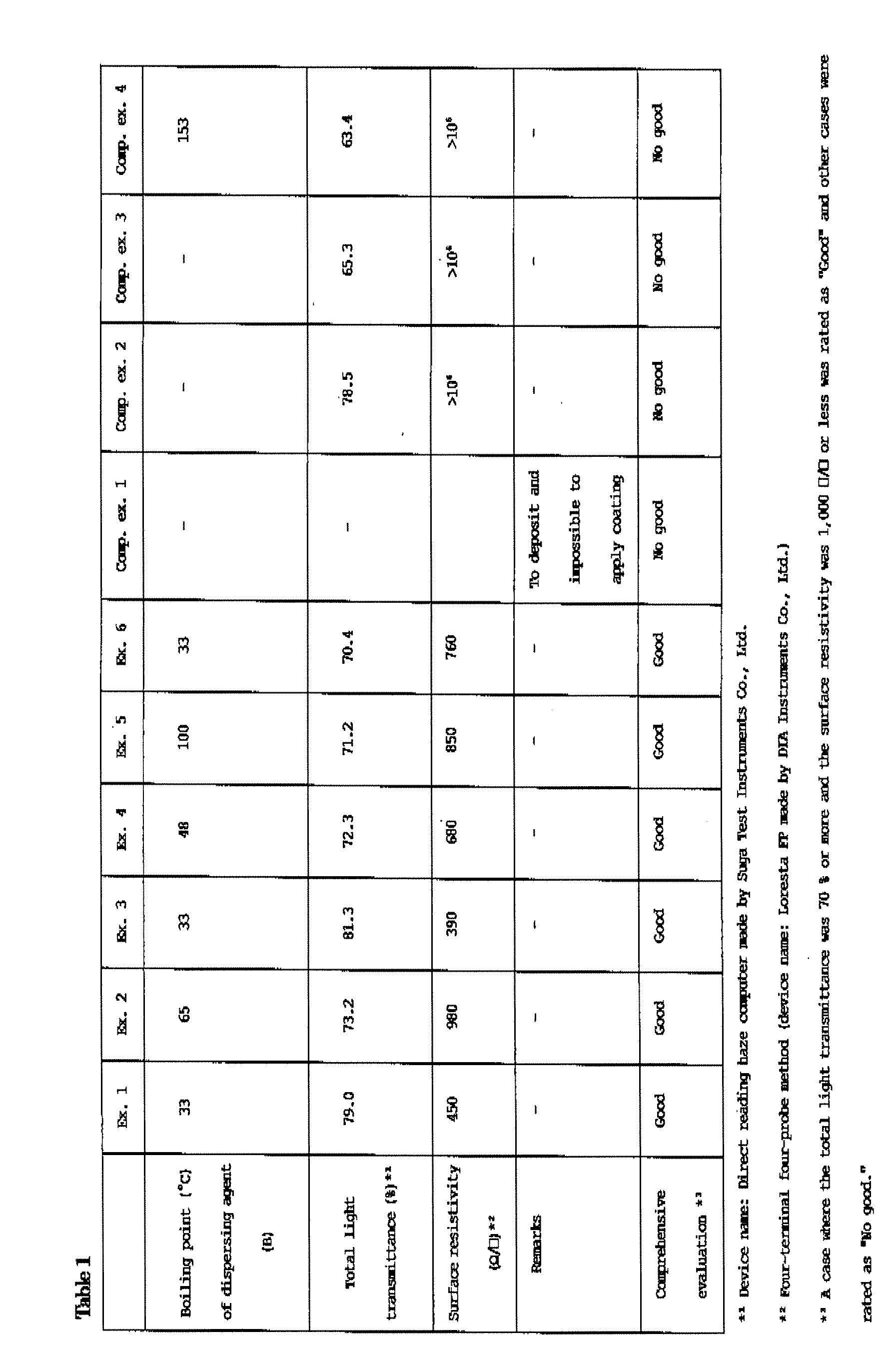

Carbon nanotube dispersion liquid and transparent conductive film using same

Disclosed is a carbon nanotube dispersion liquid which enables to easily form a transparent conductive film. Also disclosed is a transparent conductive film obtained by using such a carbon nanotube dispersion liquid. Specifically disclosed is a carbon nanotube dispersion liquid containing a carbon nanotube (A), a dispersing agent (B) composed of an organic compound containing one of a carboxyl group, epoxy group, amino group and sulfonyl group and having a boiling point of not less than 30˚C and not more than 150˚C, and a solvent (C). Also disclosed are a transparent conductive film containing a layer composed of a solid component of such a dispersion liquid, and a method for producing such a transparent conductive film.

Owner:KURARAY CO LTD

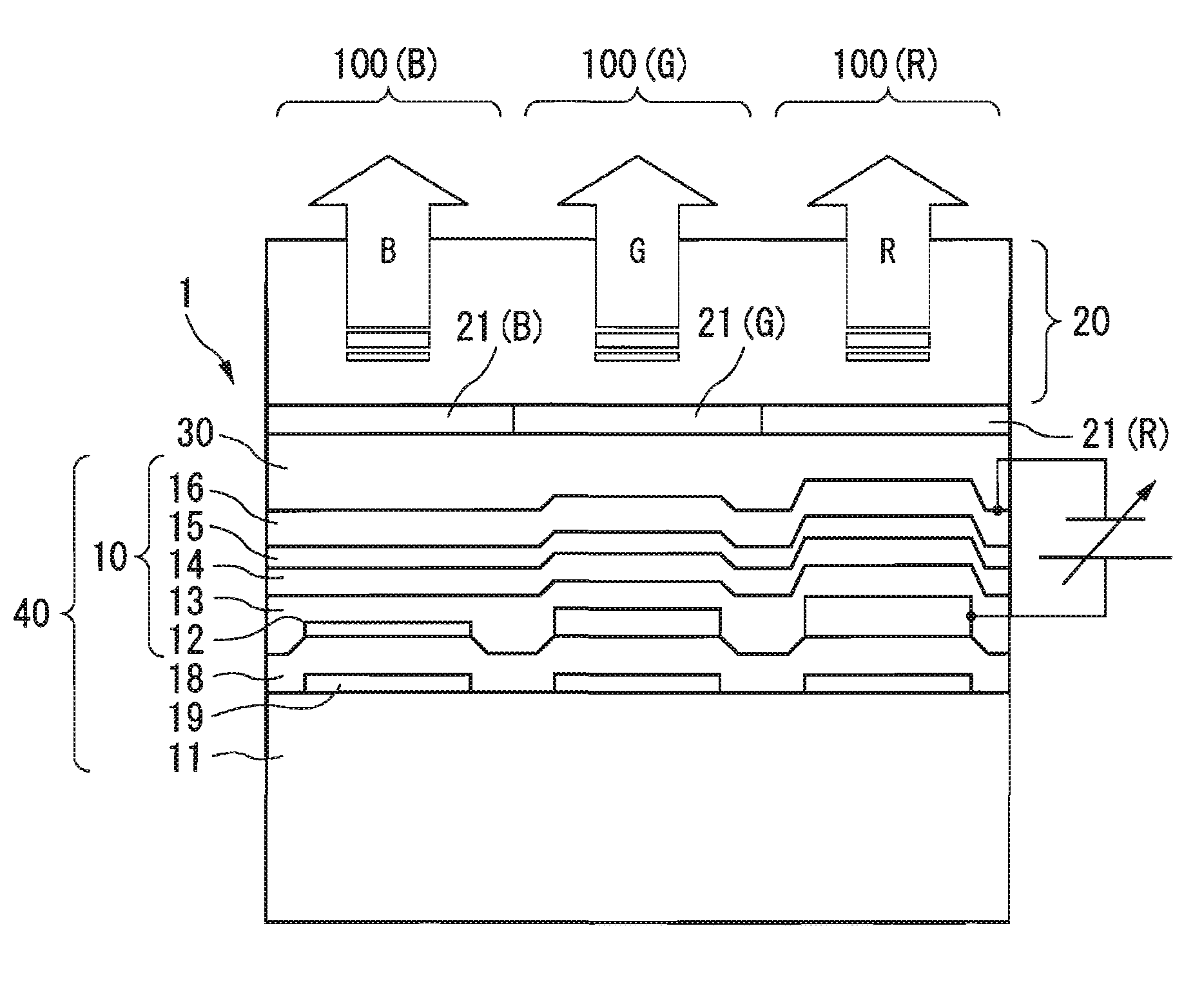

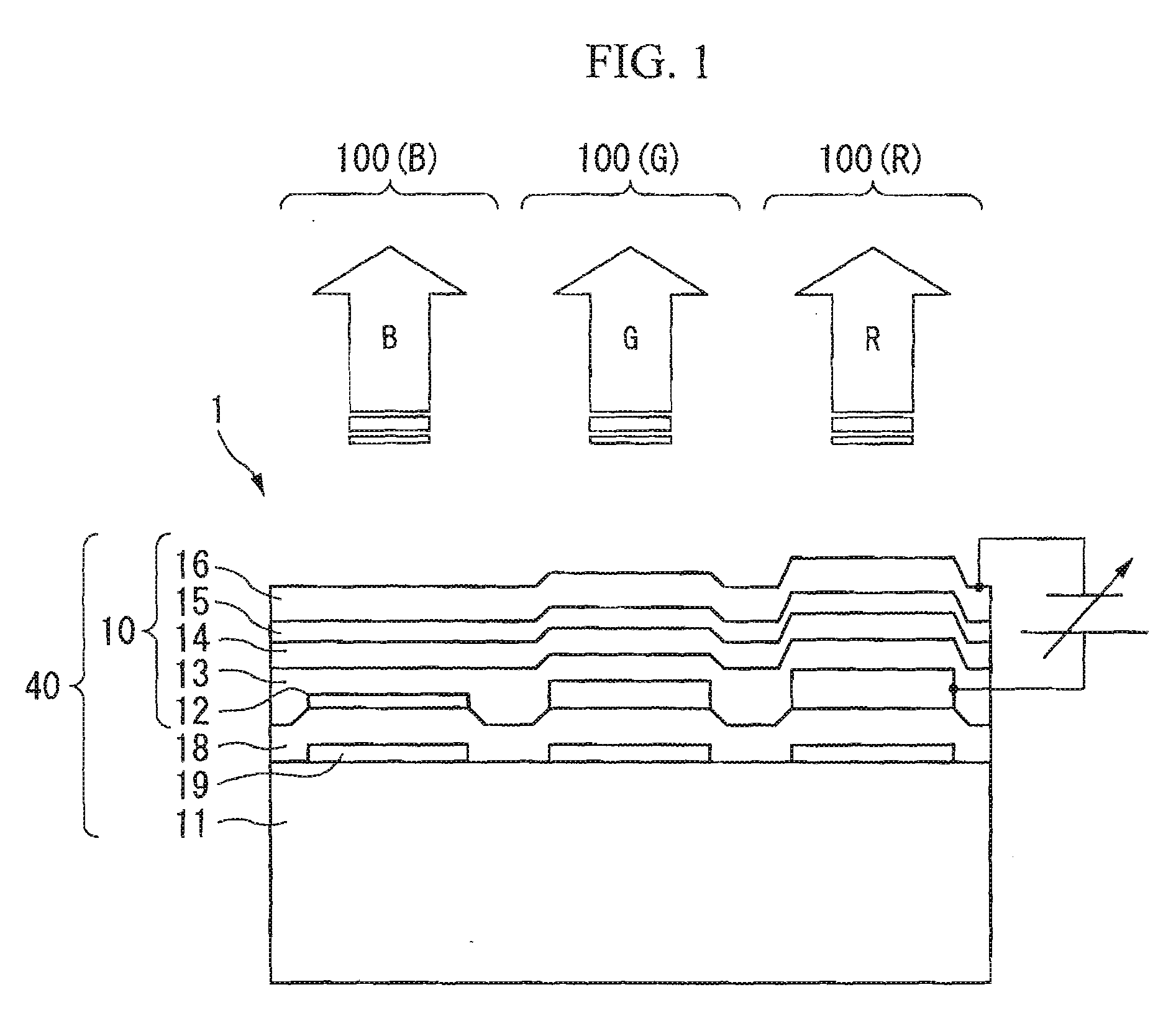

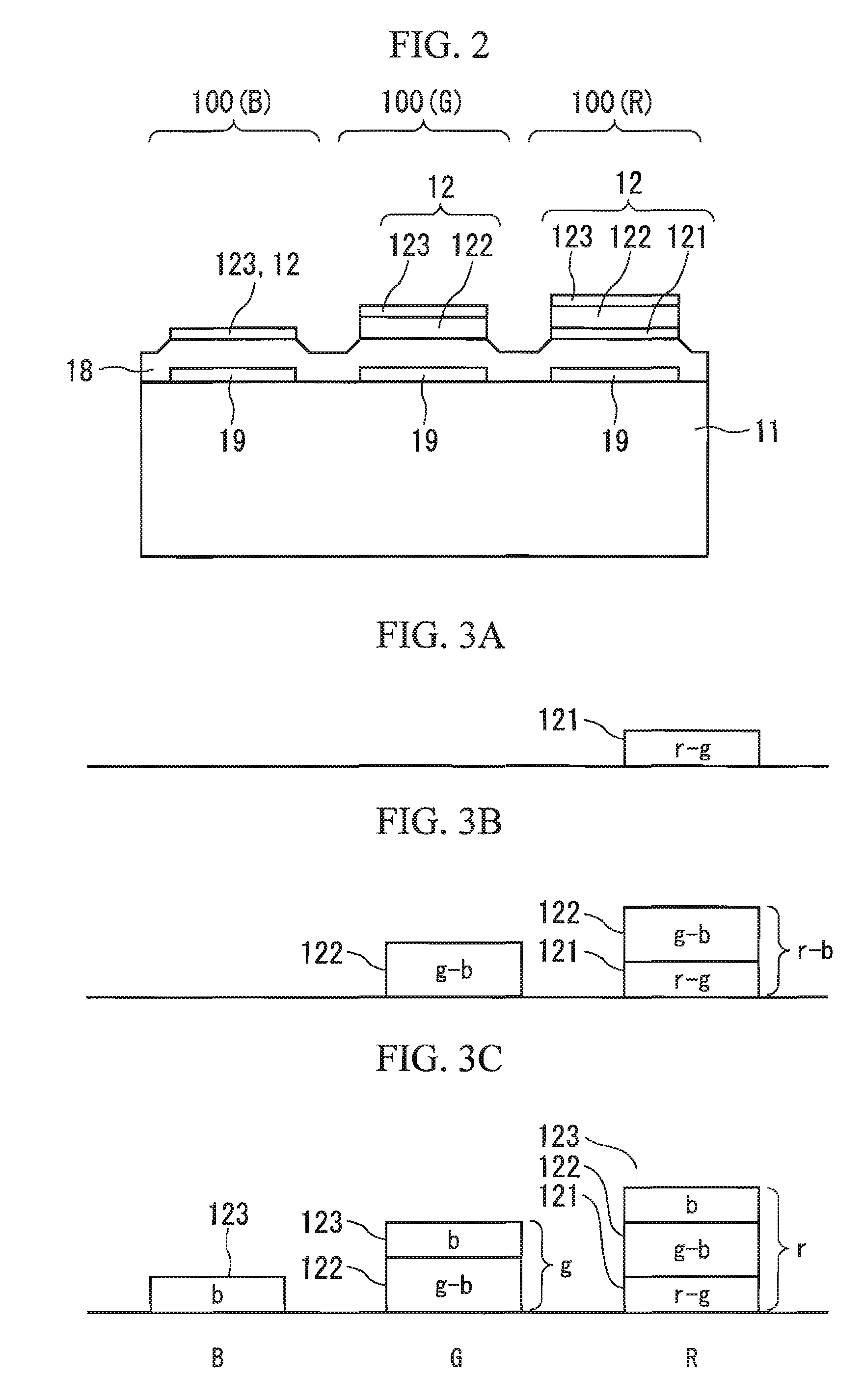

Electroluminescence device, method of manufacturing electroluminescence device, and electronic apparatus

ActiveUS20070015429A1Well formedImprove accuracyDischarge tube luminescnet screensElectroluminescent light sourcesTransparent conducting filmLight emission

Provided is a method of manufacturing an electroluminescence device, in which a plurality of pixel forming regions is formed on a substrate, a light emitting element, in which an anode having a light transmission property, a light emission function layer including at least a light emitting layer and a cathode are laminated, is provided in each of the plurality of pixel forming regions, the pixel forming regions include a pixel forming region of first color and a pixel forming region of second color different from the first color, and the anode includes a first anode formed in the pixel forming region of the first color with a first thickness and a second anode formed in the pixel forming region of the second color with a second thickness, including: forming a first transparent conductive film in the pixel forming region of the first color with a thickness obtained by subtracting the second thickness from the first thickness; and forming a second transparent conductive film in the pixel forming region of the second color with the second thickness.

Owner:SEIKO EPSON CORP

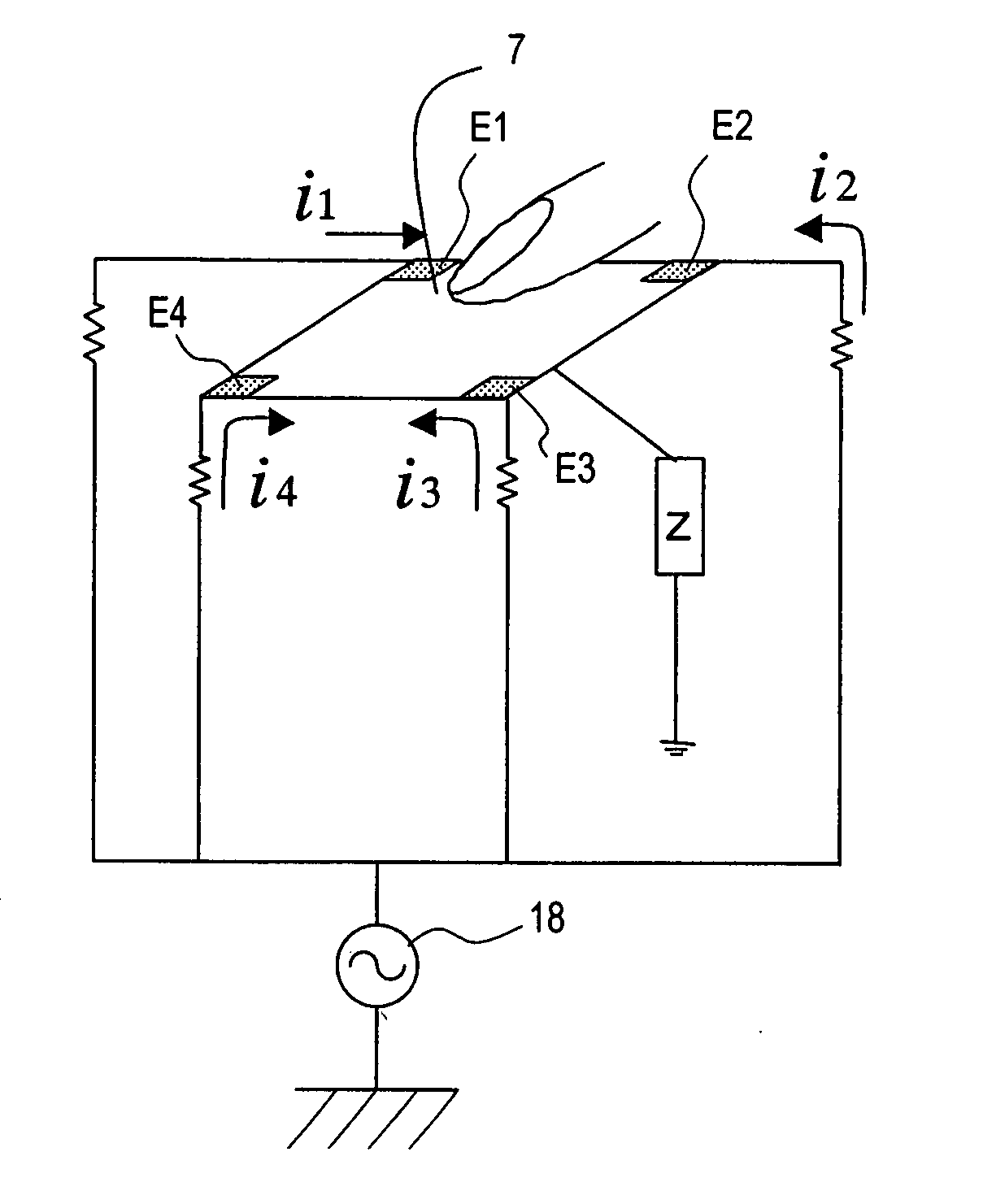

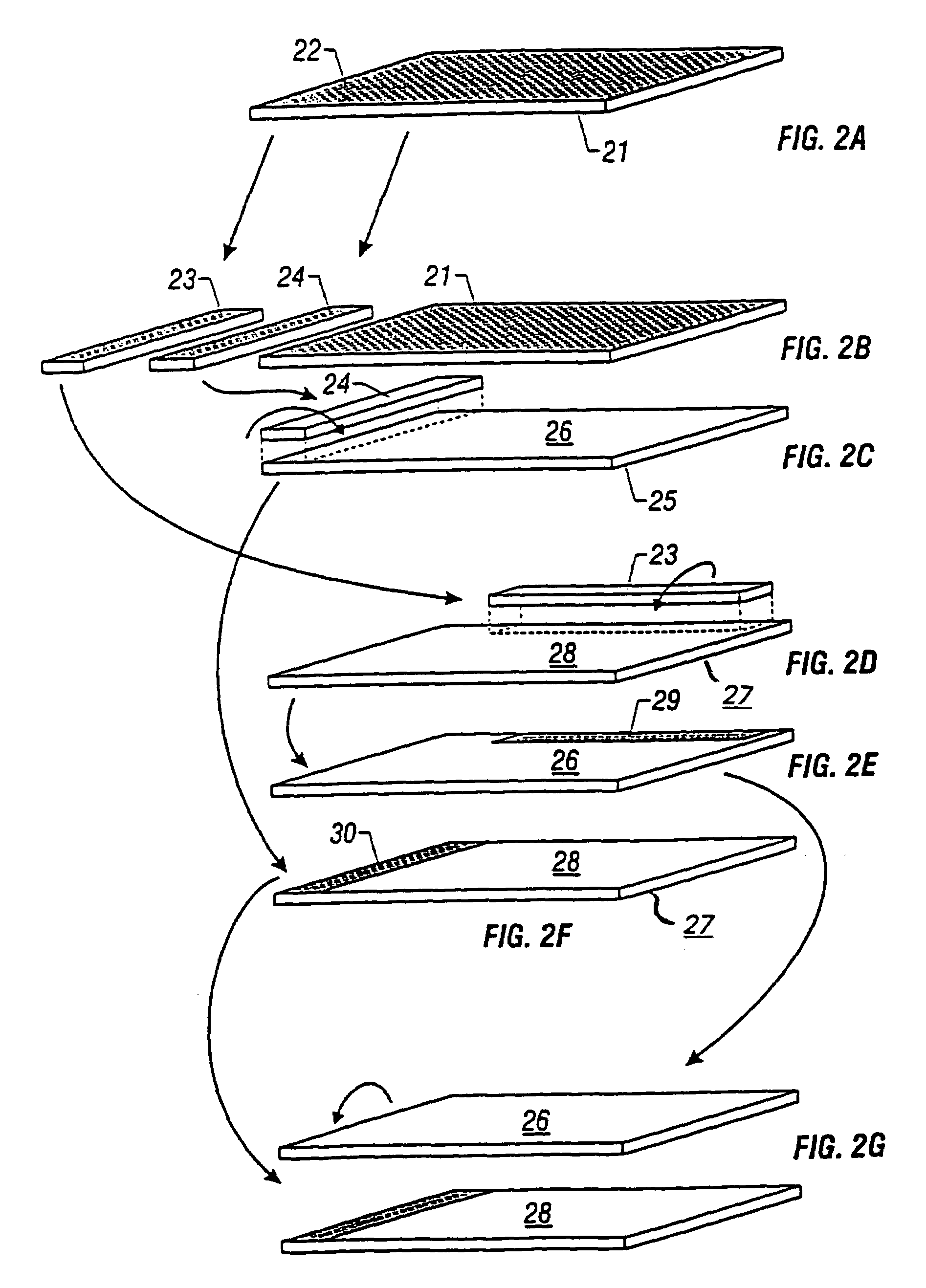

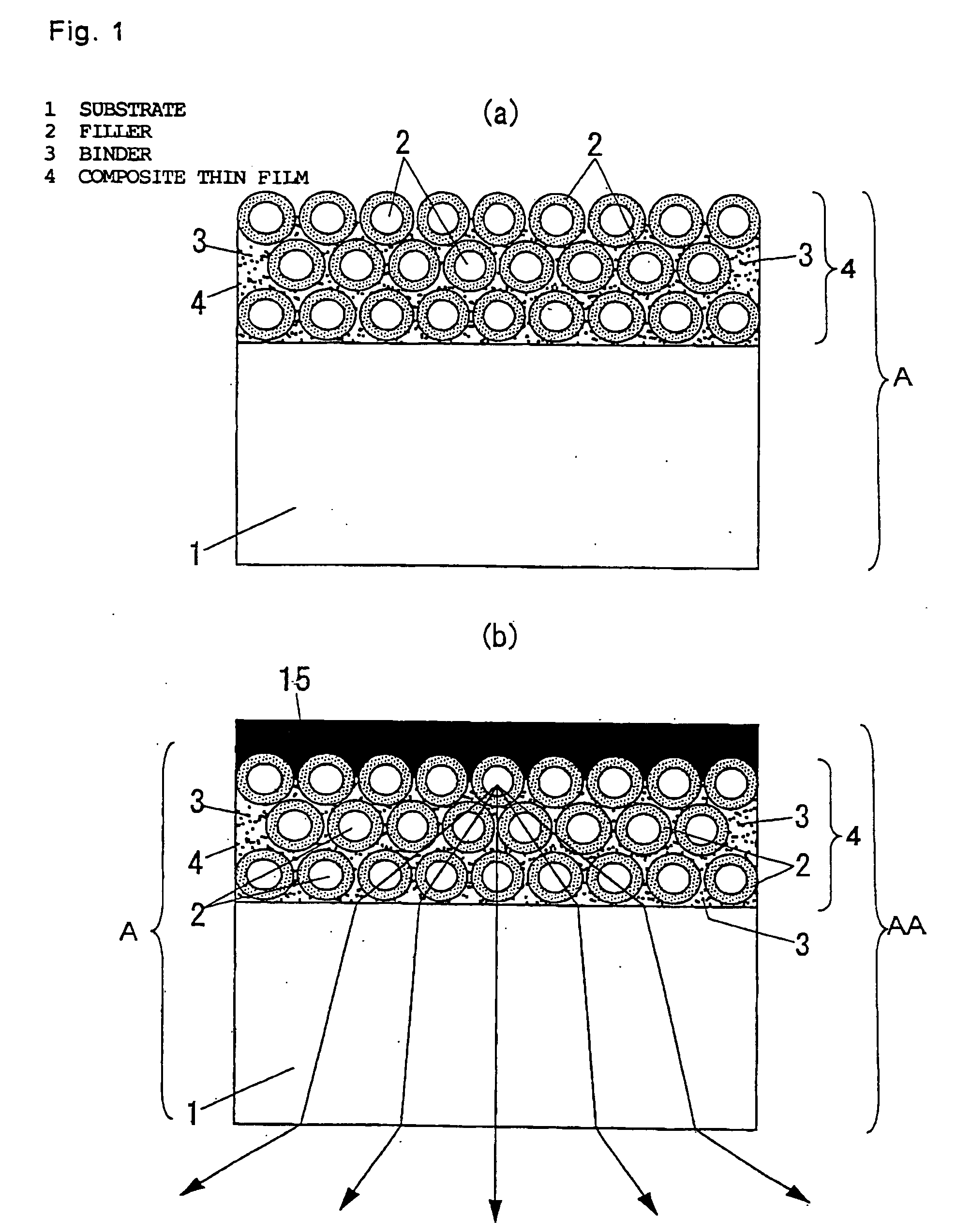

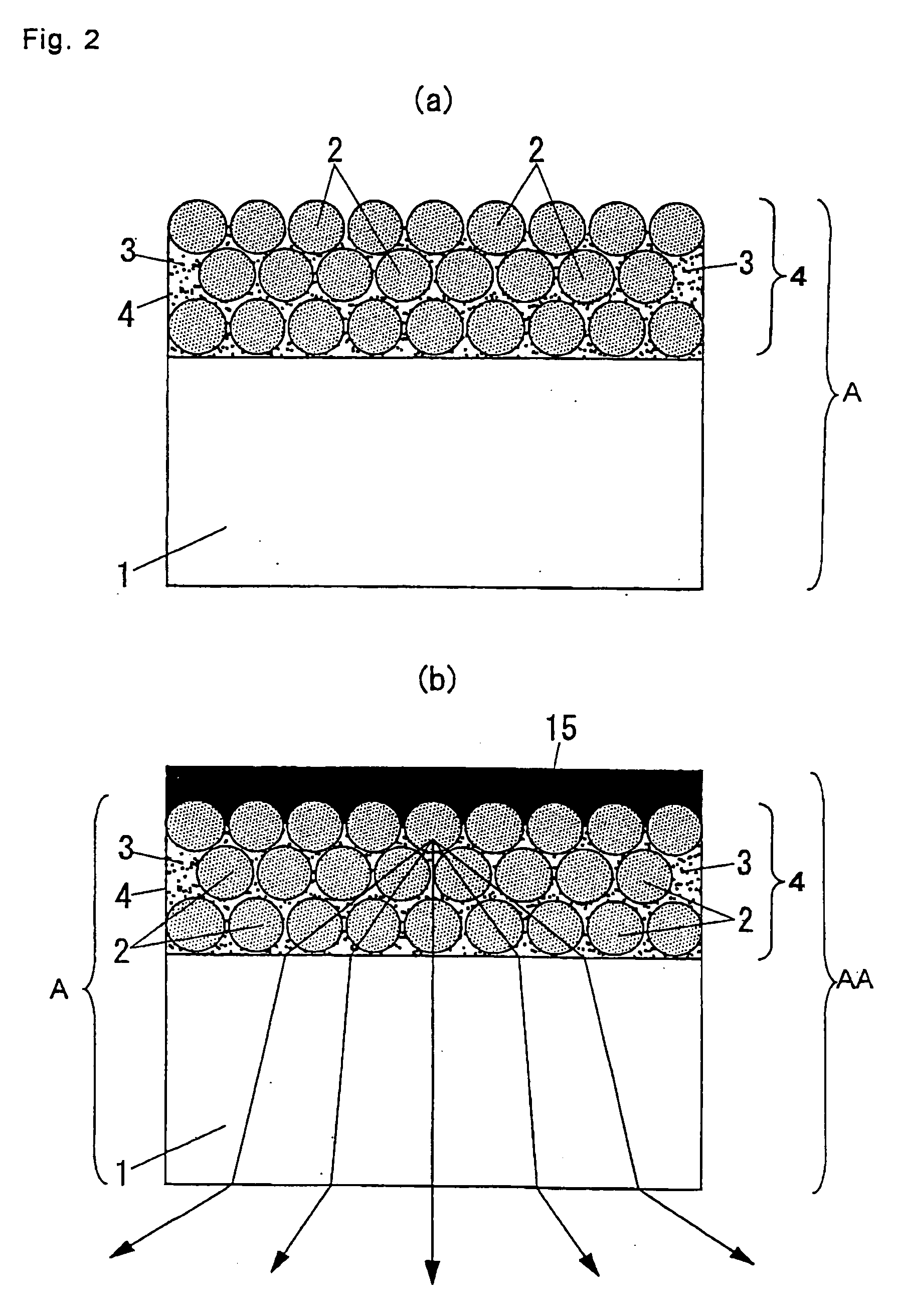

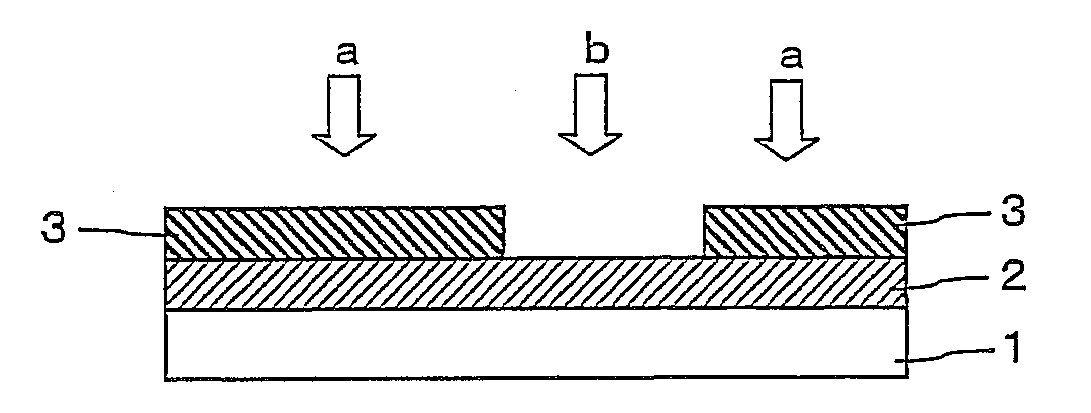

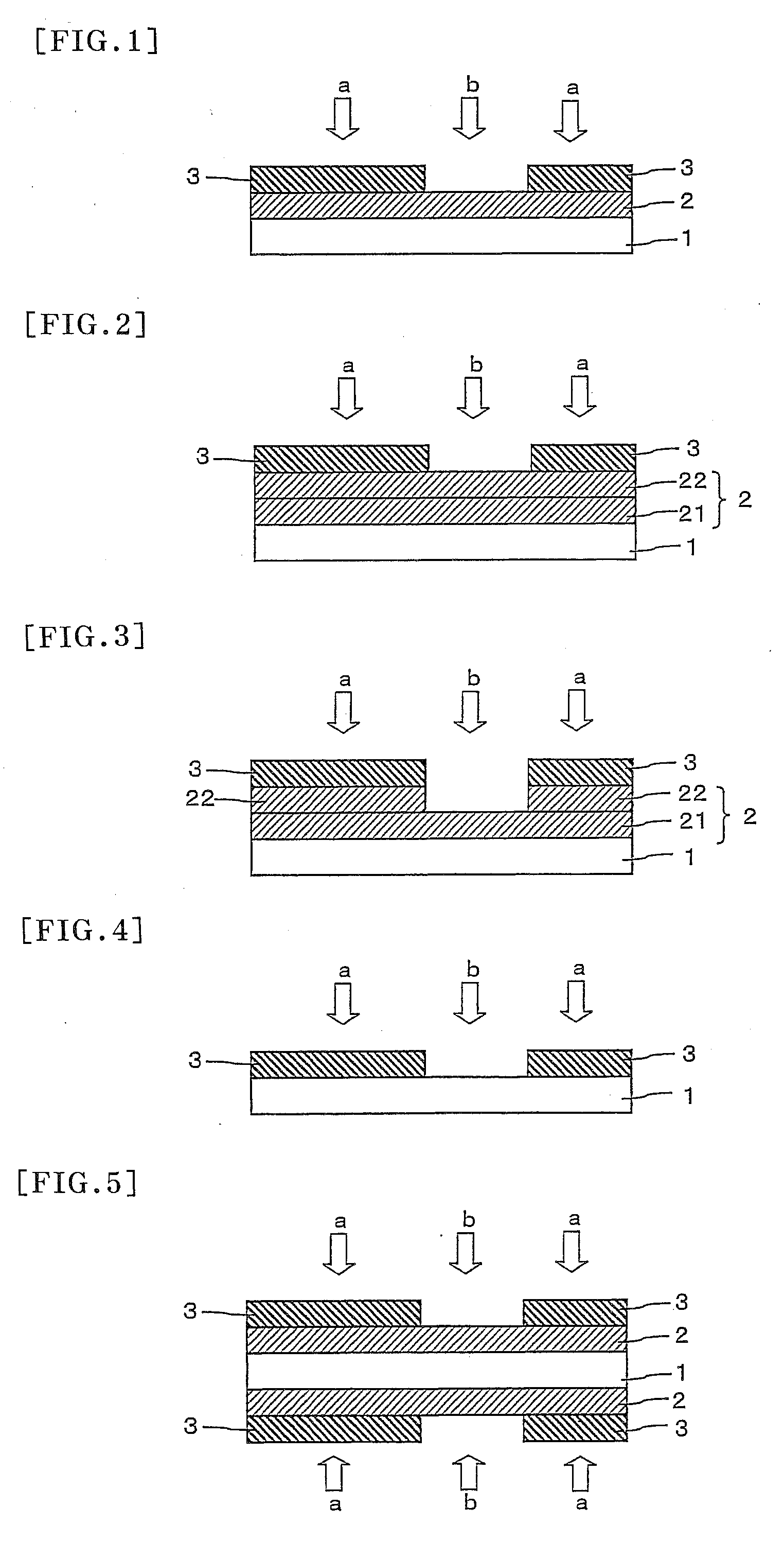

Composite thin film holding substrate, transparent conductive film holding substrate, and panel light emitting body

ActiveUS20040253427A1Improve efficiencyReduced strengthDiffusing elementsSolid-state devicesDischarge efficiencyComposite film

There is provided a composite thin film-holding substrate in which a composite thin film (4) comprising a filler (2) having a refractive index lower than that of a substrate (1) and a binder (3) having a refractive index higher than that of the filler (2) is formed on a surface of the substrate (1). Light is efficiently scattered when passing through the composite thin film (3) which comprises the filler (2) and the binder (3) having different refractive indexes from each other. In addition, the refractive index of a composite thin film (4) comprising a filler (2) having a low refractive index is low. As a result, the discharge efficiency of light which passes through the composite thin film (4) from the substrate (1) to the external is improved.

Owner:SAMSUNG DISPLAY CO LTD

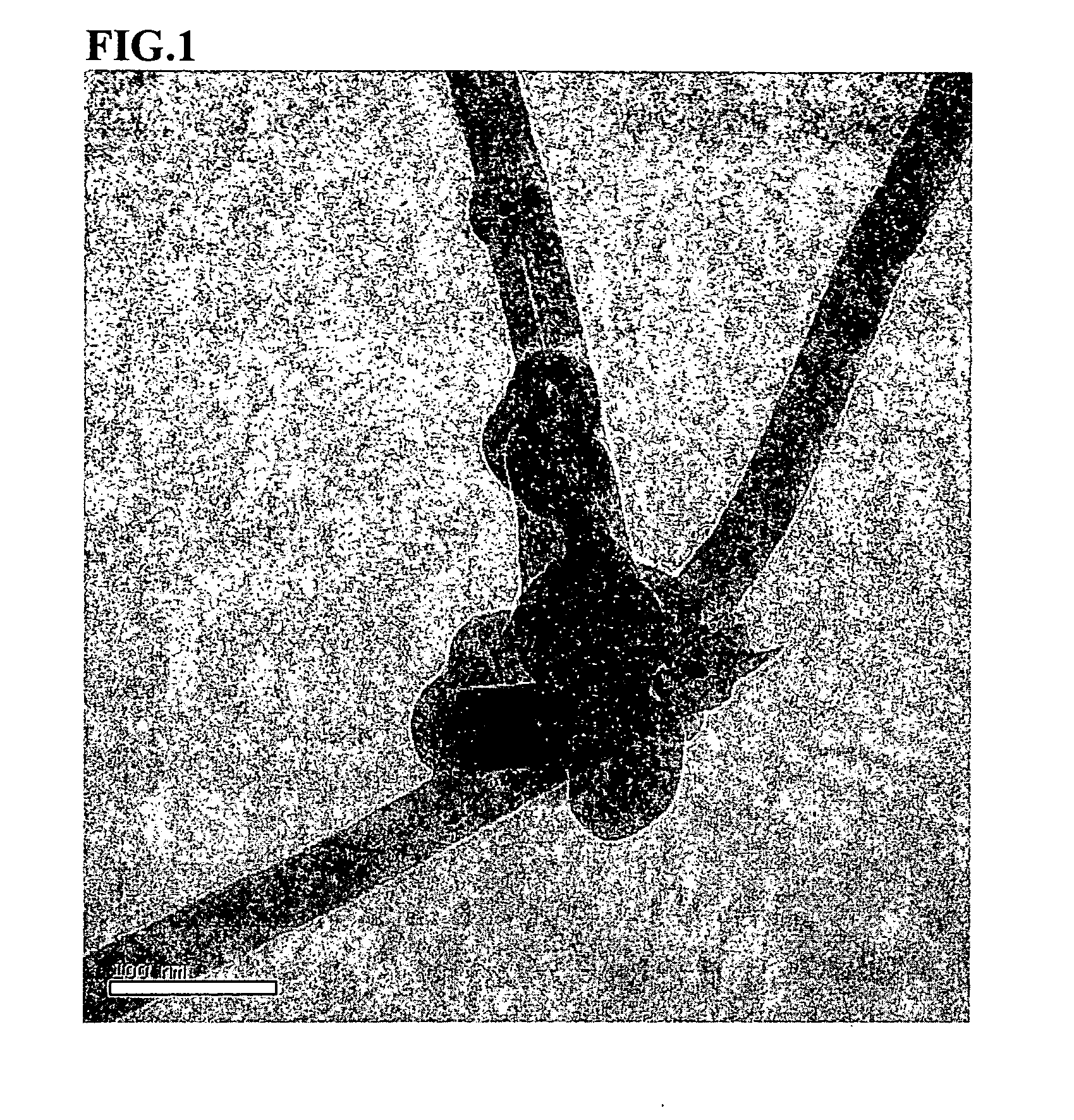

Transparent conductive film and coating composition therefor

InactiveUS20060263588A1High transparencyImproved and well controllable electrical propertiesMaterial nanotechnologyConductive layers on insulating-supportsPolymer scienceCarbon fibers

The disclosed is a transparent conductive film that includes a matrix and carbon fibrous structures added to the matrix, wherein the carbon fibrous structures comprise carbon fibers, each having an outside diameter of 15-100 nm, and wherein the carbon fibrous structures each comprise a granular part at which two or more carbon fibers are bound to each other, and wherein the granular part is concurrently produced in a growth process for the carbon fibers. When the transparent conductive film is formed at a thickness of 0.1-5 μm on a glass substrate, it shows a surface resistivity of not more than 1.0×1012Ω / □, and a total light transmittance of not less than 30%. A coating composition for the conductive transparent film is prepared by using a media mill equipped with beads having an average diameter of 0.05-1.5 mm to disperse the carbon fibrous structures into the liquid resinous composition.

Owner:MITSUI & CO LTD +1

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

Image reading apparatus and image reading system equipped with the image reading apparatus

ActiveUS7321672B2Easy to readIncrease in sizeStatic indicating devicesFibre treatmentDriver circuitTransparent conducting film

An image reading system comprising a display panel with an image display area formed by a plurality of display pixels which emits display light and displays an image in a viewing field side corresponding to a display signal from the image display area; a transparent substrate which has a read area provided in a viewing field side of the display panel; a plurality of photosensors formed in the read area above the transparent substrate; a driver circuit section formed in an outer side of the read area as one unit with the photosensors; a transparent conductive film for electrostatic protection is provided in an upper part of a plurality of photosensors and the driver circuit section; and comprises a photosensor panel which reads an image of a detectable object placed on the read area that penetrated at least some of the display light emitted from the image display area.

Owner:ORTUS TECH

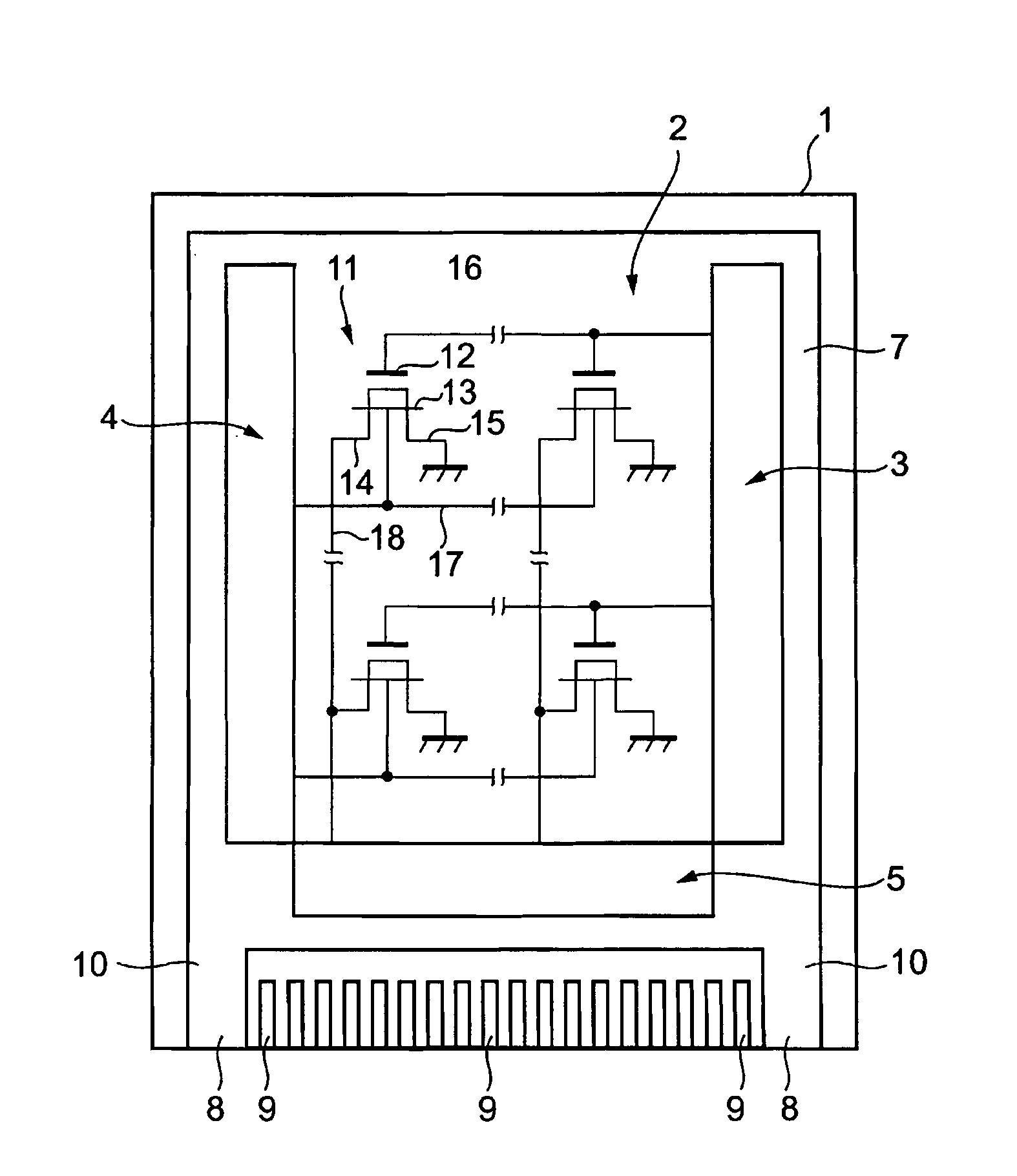

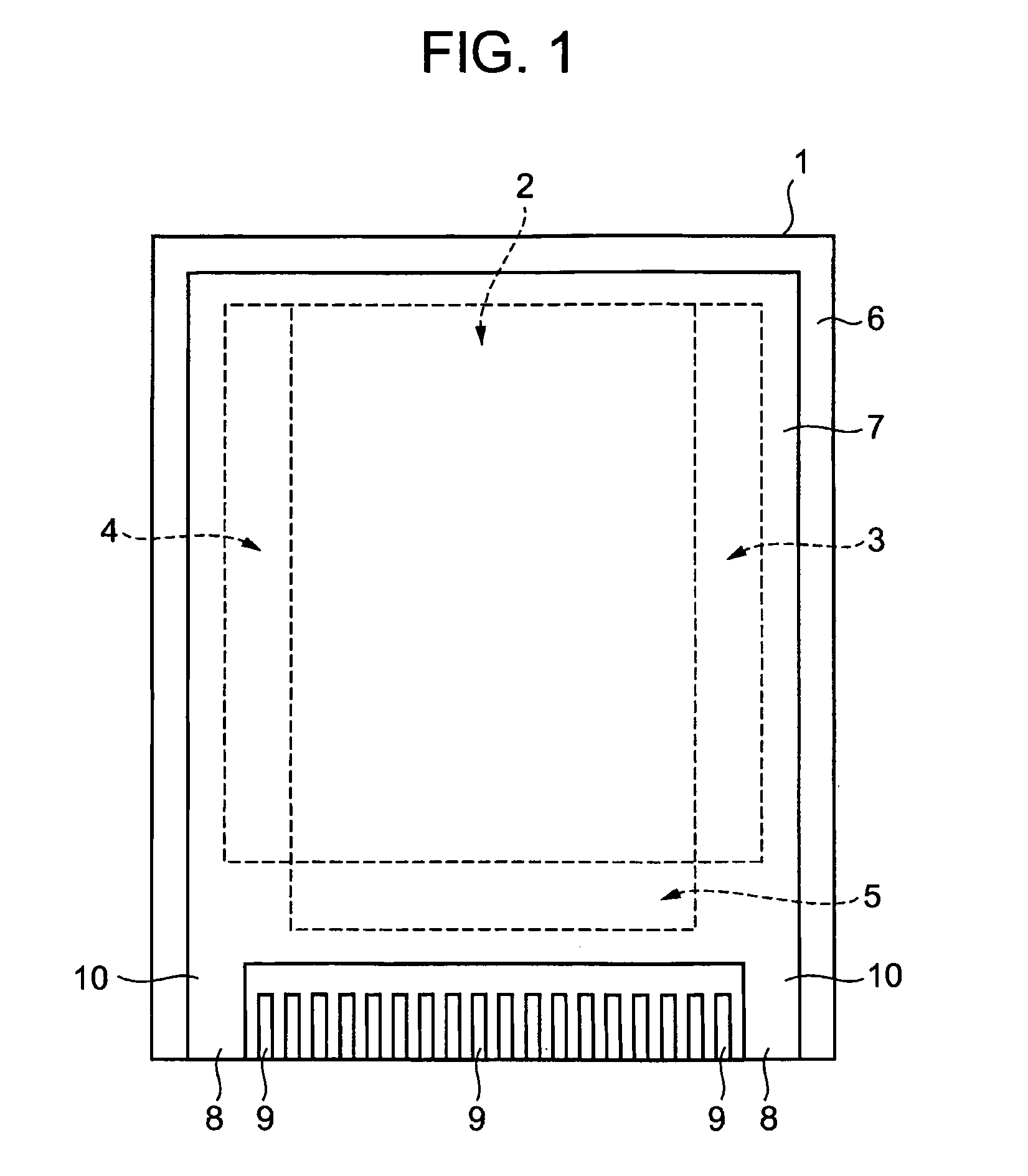

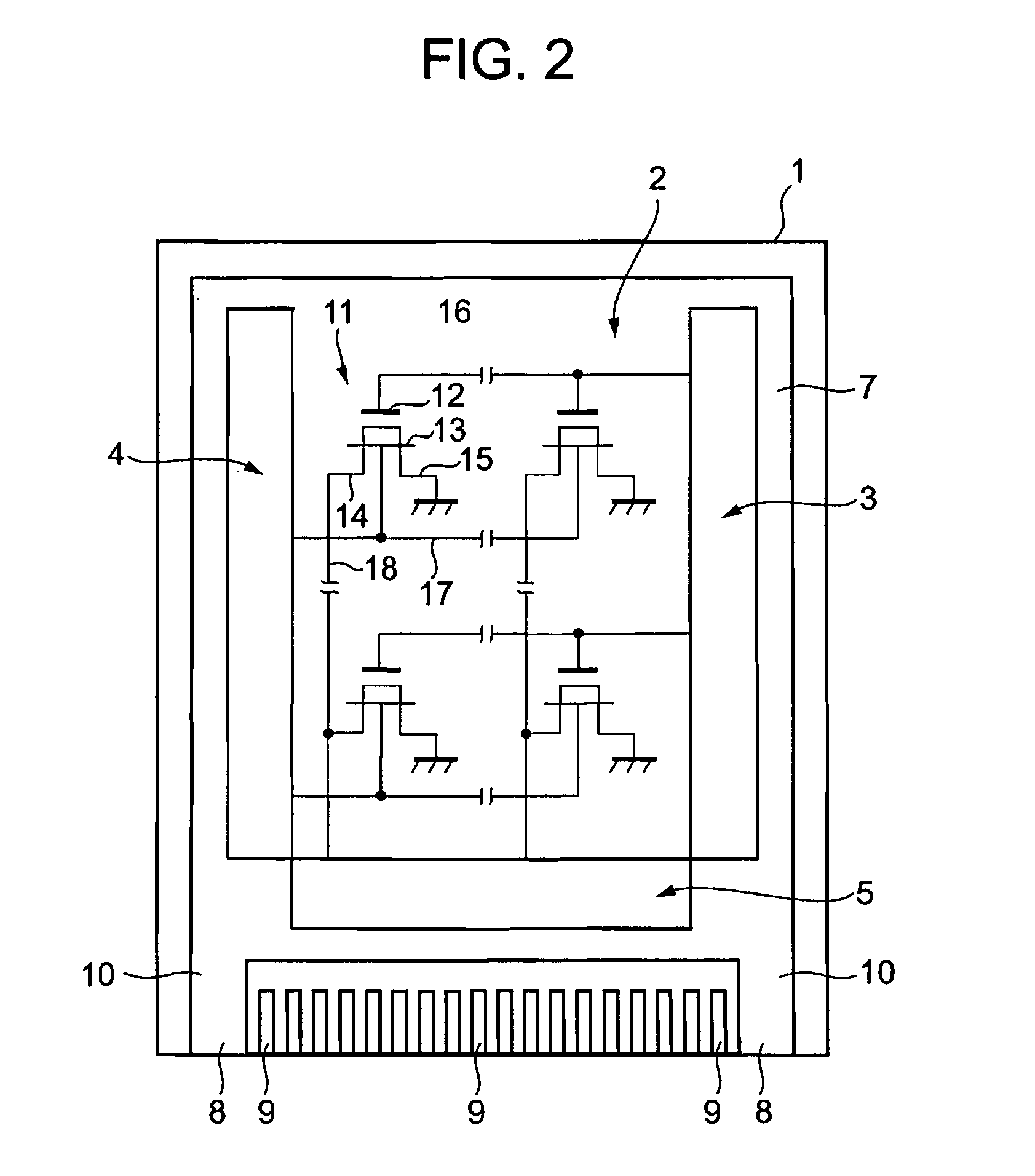

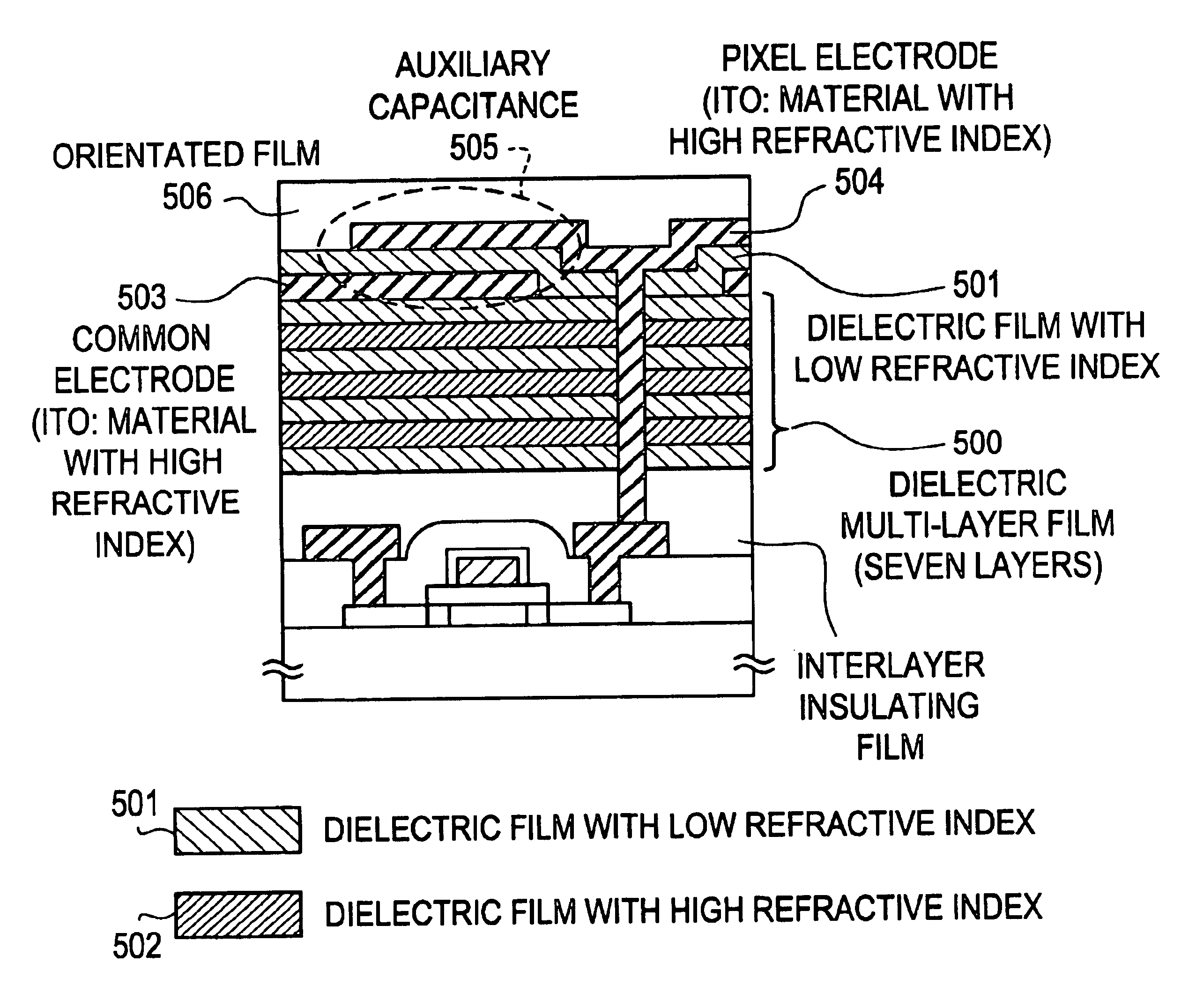

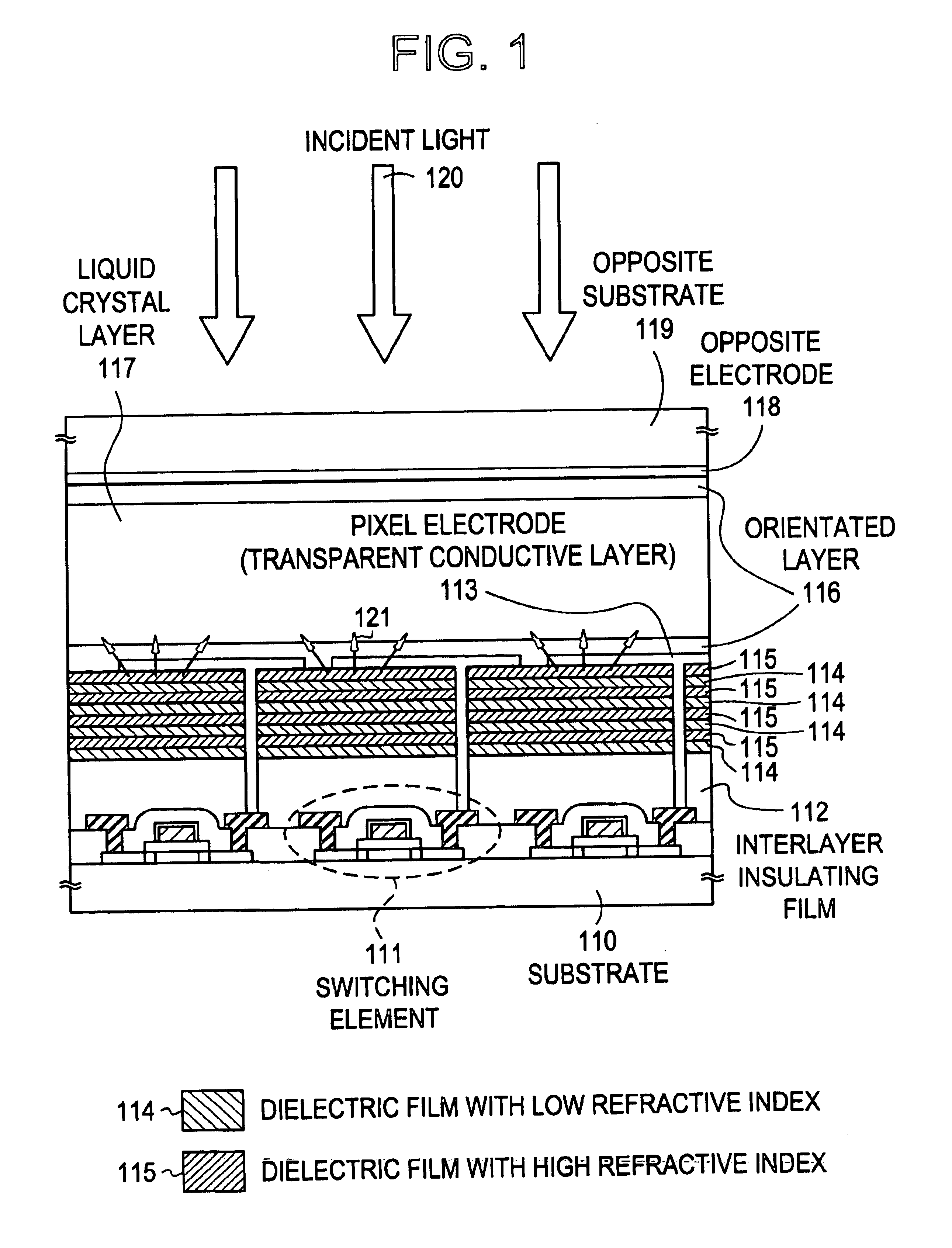

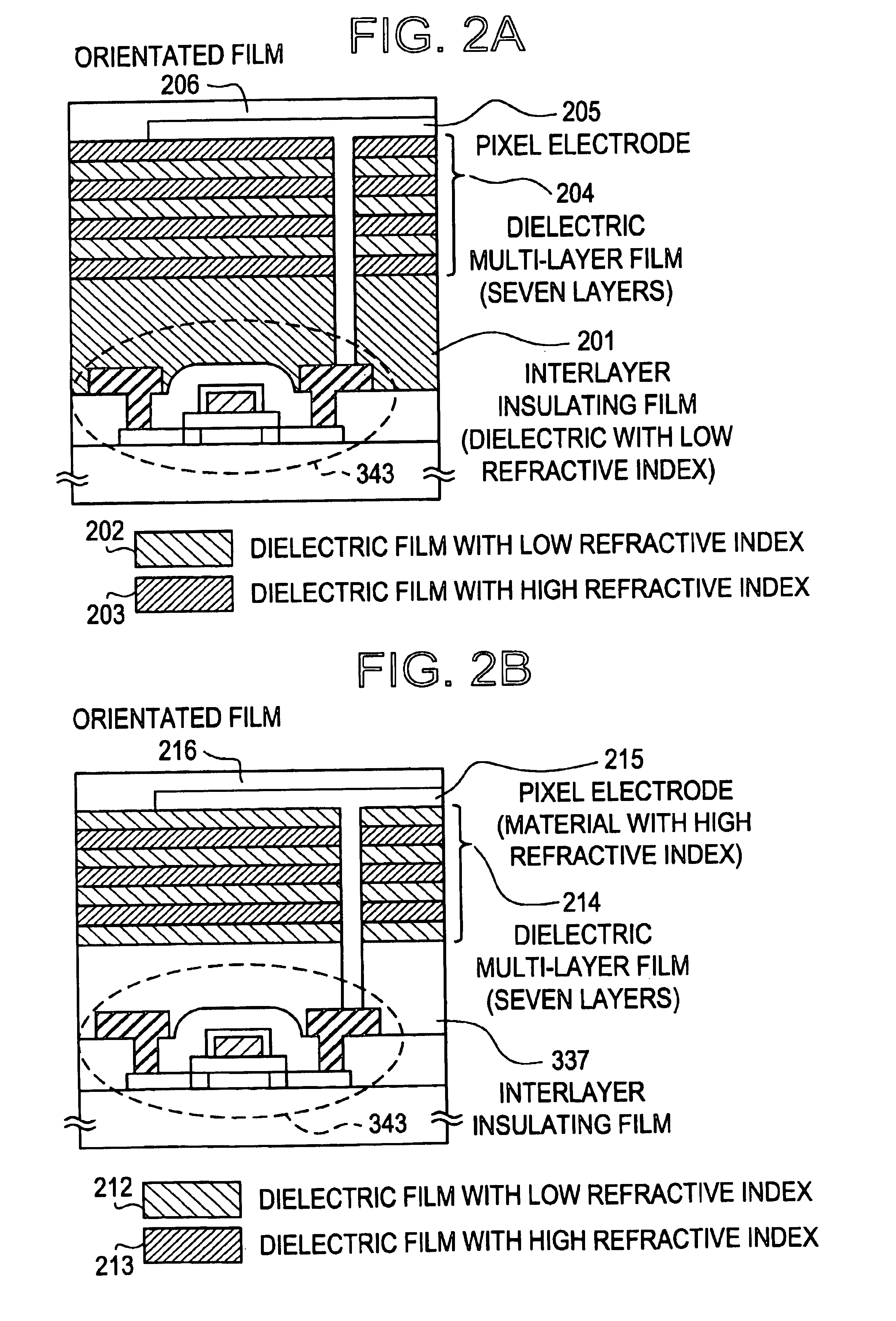

Liquid crystal display device and method of manufacturing the same

InactiveUS6839108B1Effective reflectionSimple matrix type driving systemStatic indicating devicesNon-linear opticsElectricityLiquid-crystal display

To provide a novel liquid crystal display device comprising a light reflection layer where light is likely to more effectively reflect, and a method of manufacturing the same. The present invention can realize high resolution and high opening rate by using a dielectric multi-layer film as the light reflection layer to form thereon a pixel electrode consisting of a transparent conductive films.

Owner:SEMICON ENERGY LAB CO LTD

Transparent conductive film, method for production thereof and touch panel therewith

ActiveUS20080176042A1Good lookingIncrease the scope of applicationConductive layers on insulating-supportsLegendsTransparent conducting filmTouch panel

Owner:NITTO DENKO CORP

Display device

InactiveUS20060275618A1Low electrical connection resistivityImprove display qualitySolid-state devicesNatural mineral layered productsLiquid-crystal displayDisplay device

A display device in which interconnection—electrode comprising a Cu alloy film having a lower electrical resistivity than Al alloy and a transparent conductive film are directly connected not by way of a refractory metal thin film, wherein the Cu alloy film contains Zn and / or Mg in a total amount from 0.1 to 3.0 at %, or Ni and / or Mn in a total amount from 0.1 to 5 at %, thereby enabling the direct connection at low resistivity between the Cu alloy film and the transparent electrode without using a barrier metal, and giving high display quality in a case of application, for example, to a liquid crystal display.

Owner:KOBE STEEL LTD

Process For Producing Zno Transparent Conductive Film By Mocvd (Metal-Organic Chemical Vapor Deposition) Method

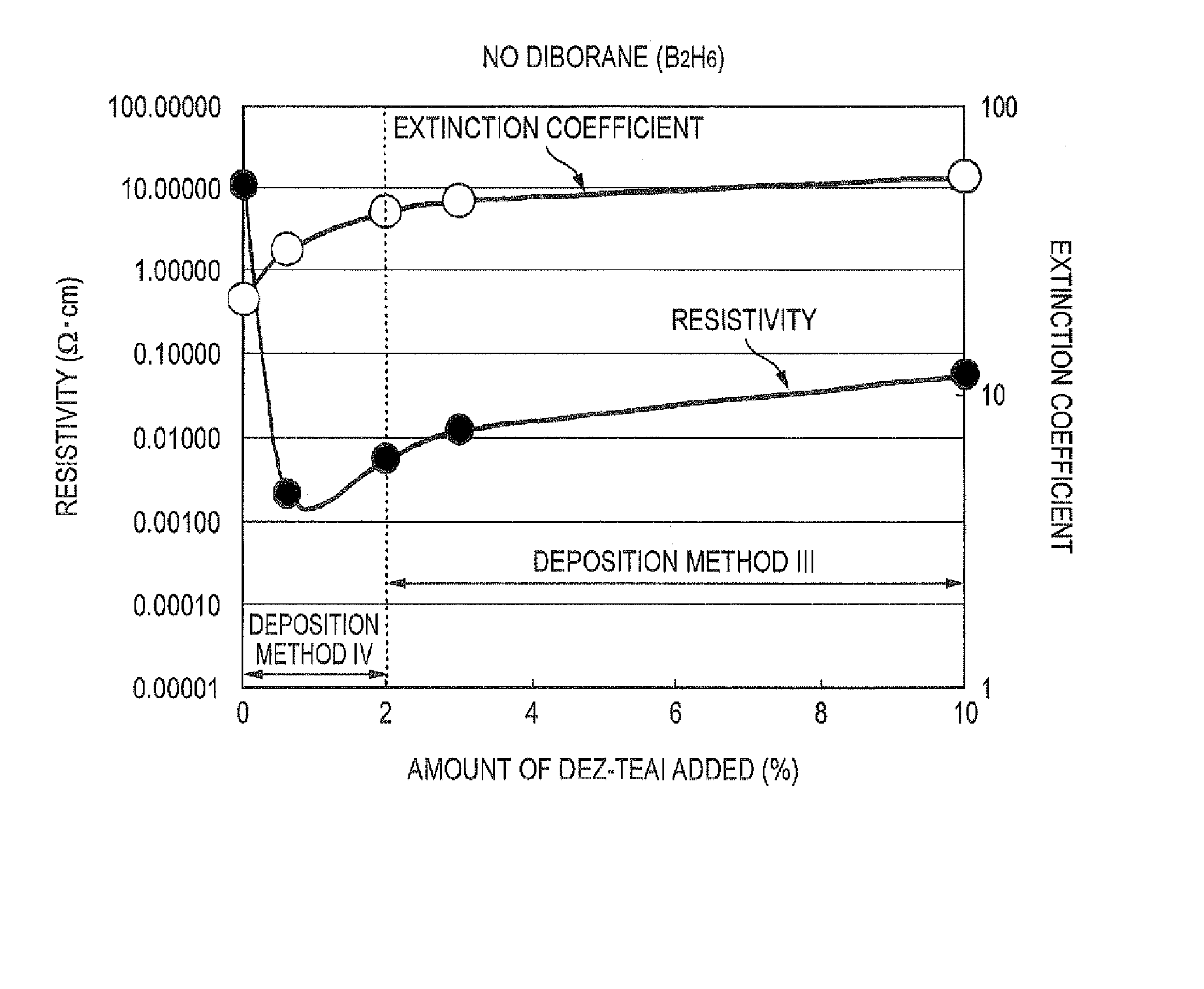

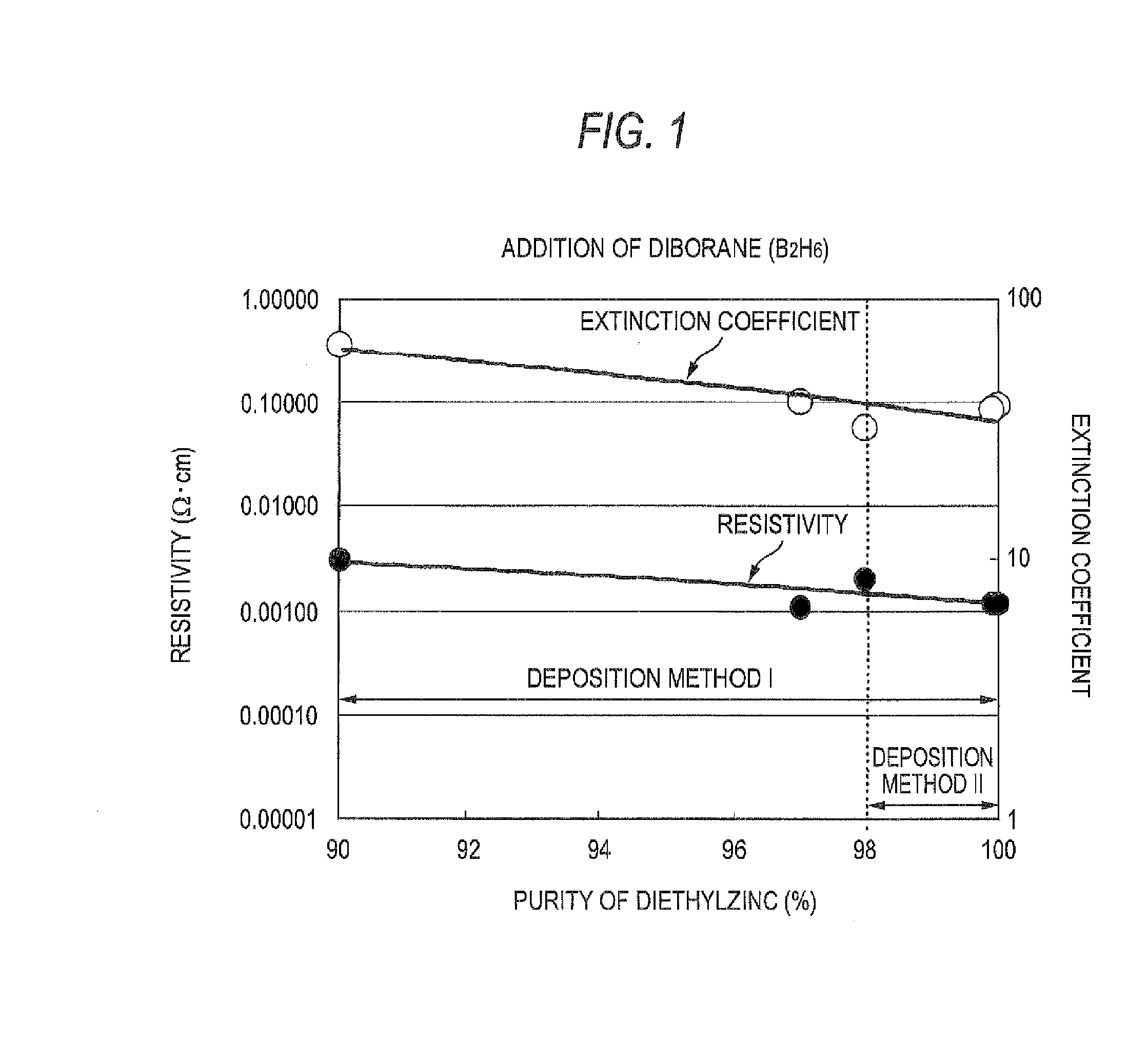

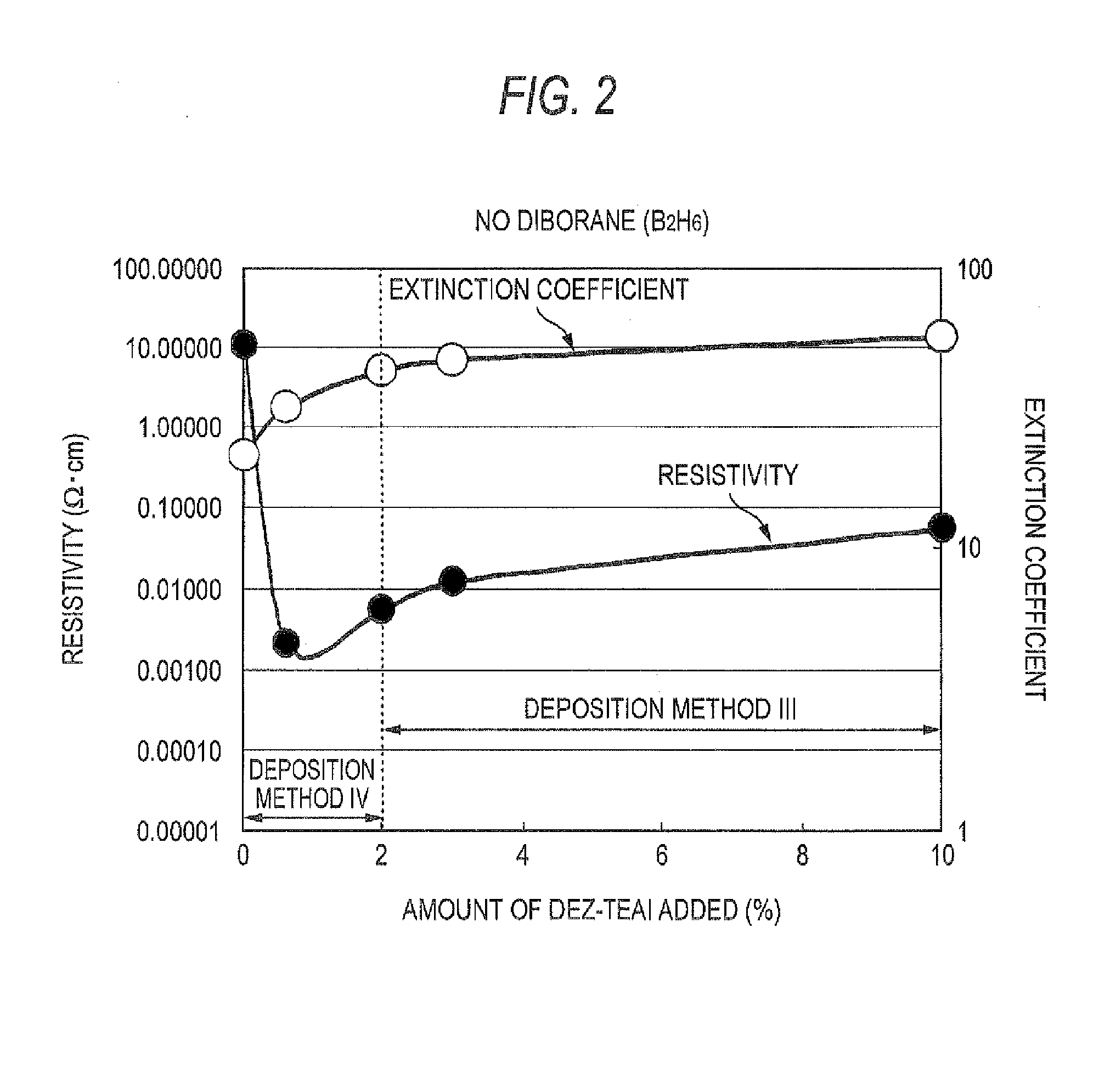

InactiveUS20080032044A1Low costEliminate useChemical vapor deposition coatingPhotovoltaic energy generationWater vaporGas phase

The triethylaluminum contained as an impurity in low-purity raw-material diethylzinc, which is inexpensive, is utilized as an additive to reduce the cost of film formation. Diethylzinc having a low purity (99.99-98% or 99.99-90%) is used as a raw material to produce a ZnO transparent conductive film by the MOCVD (metal-organic chemical vapor deposition) method. Water vapor (H2O) is used as an oxidizing agent and the triethylaluminum contained as an impurity in the raw material is utilized as an additive (diborane is further added as an additive) to cause the diethylzinc, the water vapor (H2O), and the triethylaluminum (and the diborane) to undergo a vapor-phase reaction to produce a ZnO transparent conductive film.

Owner:SHOWA SHELL SEKIYU KK

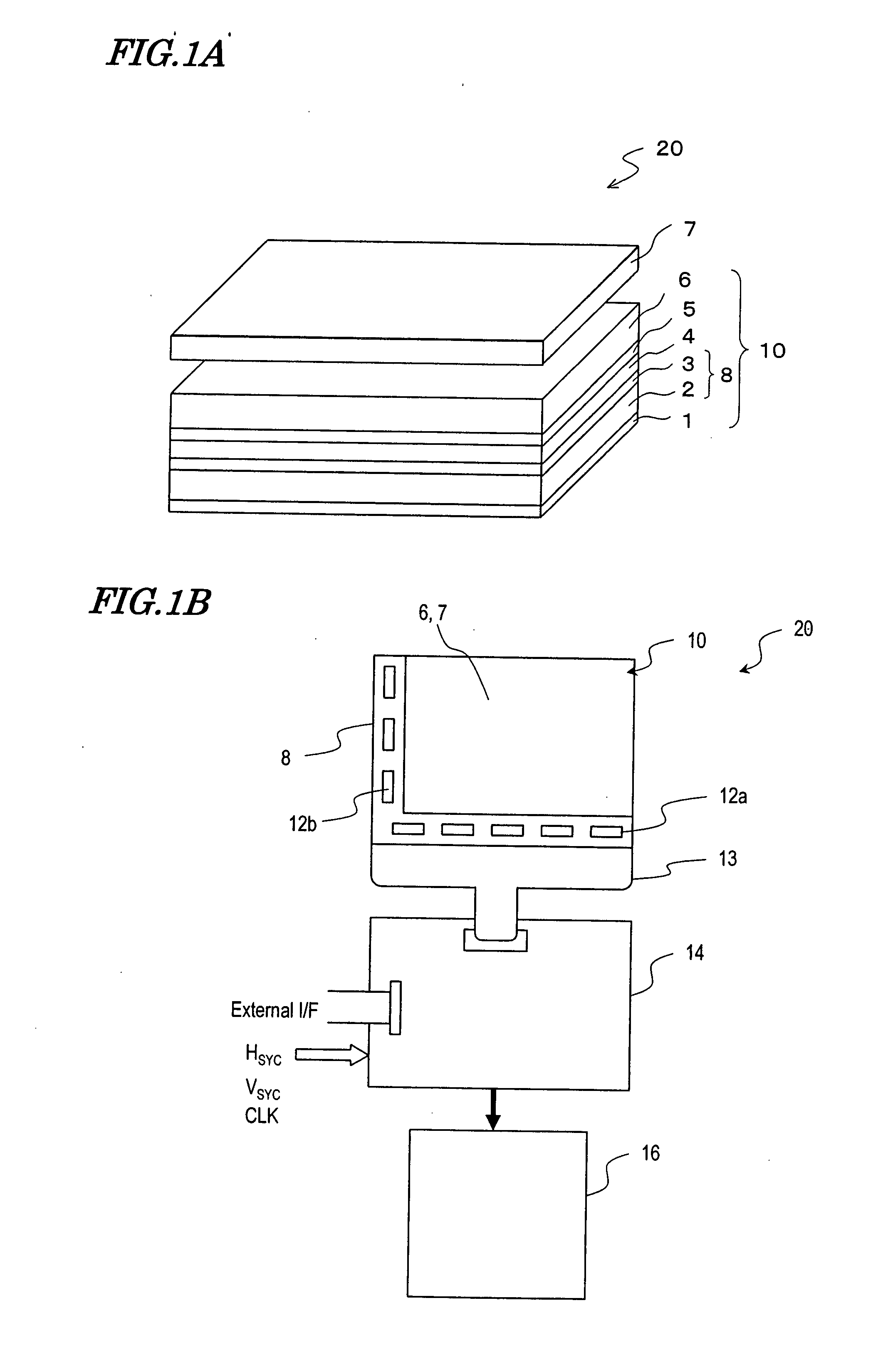

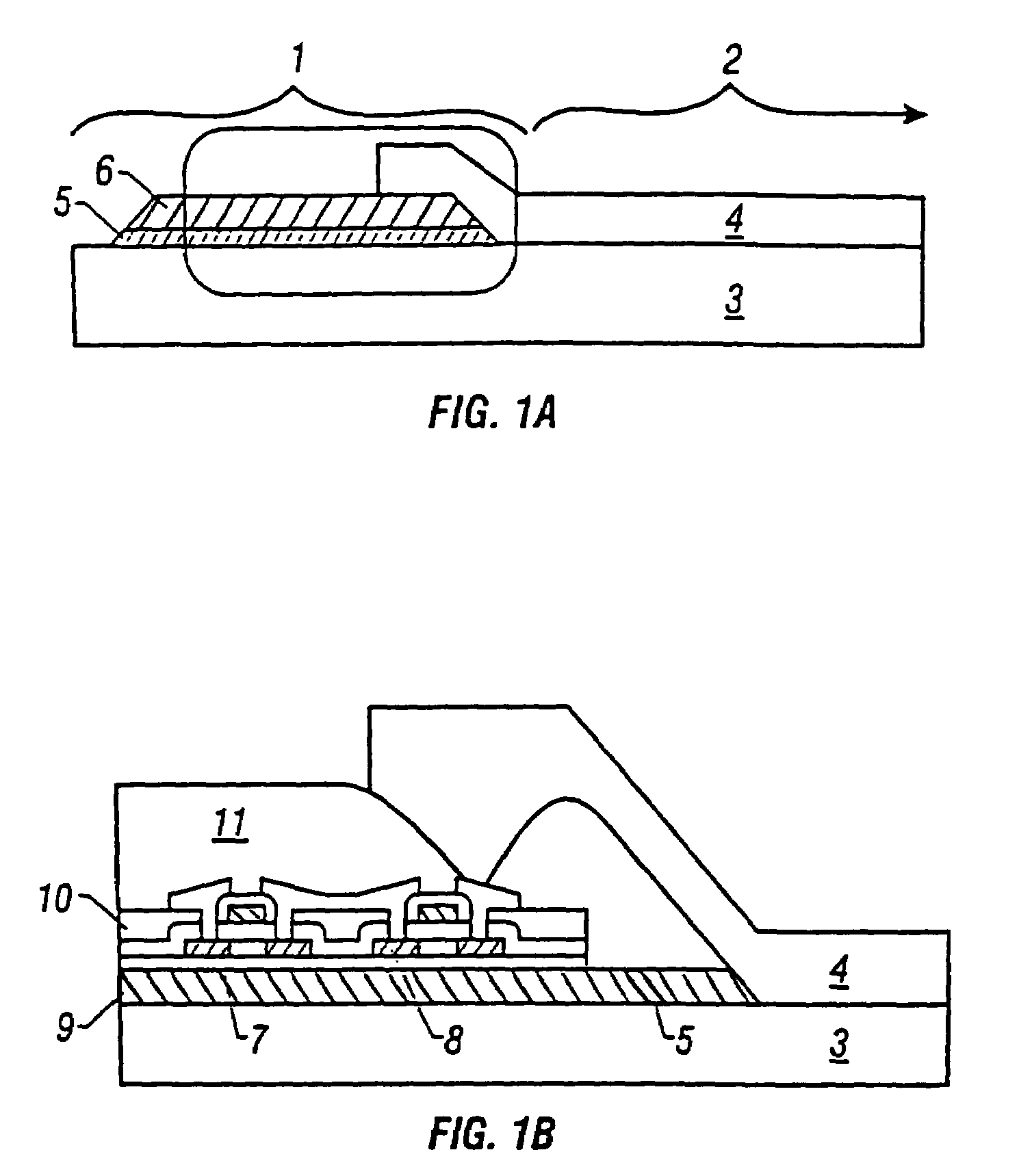

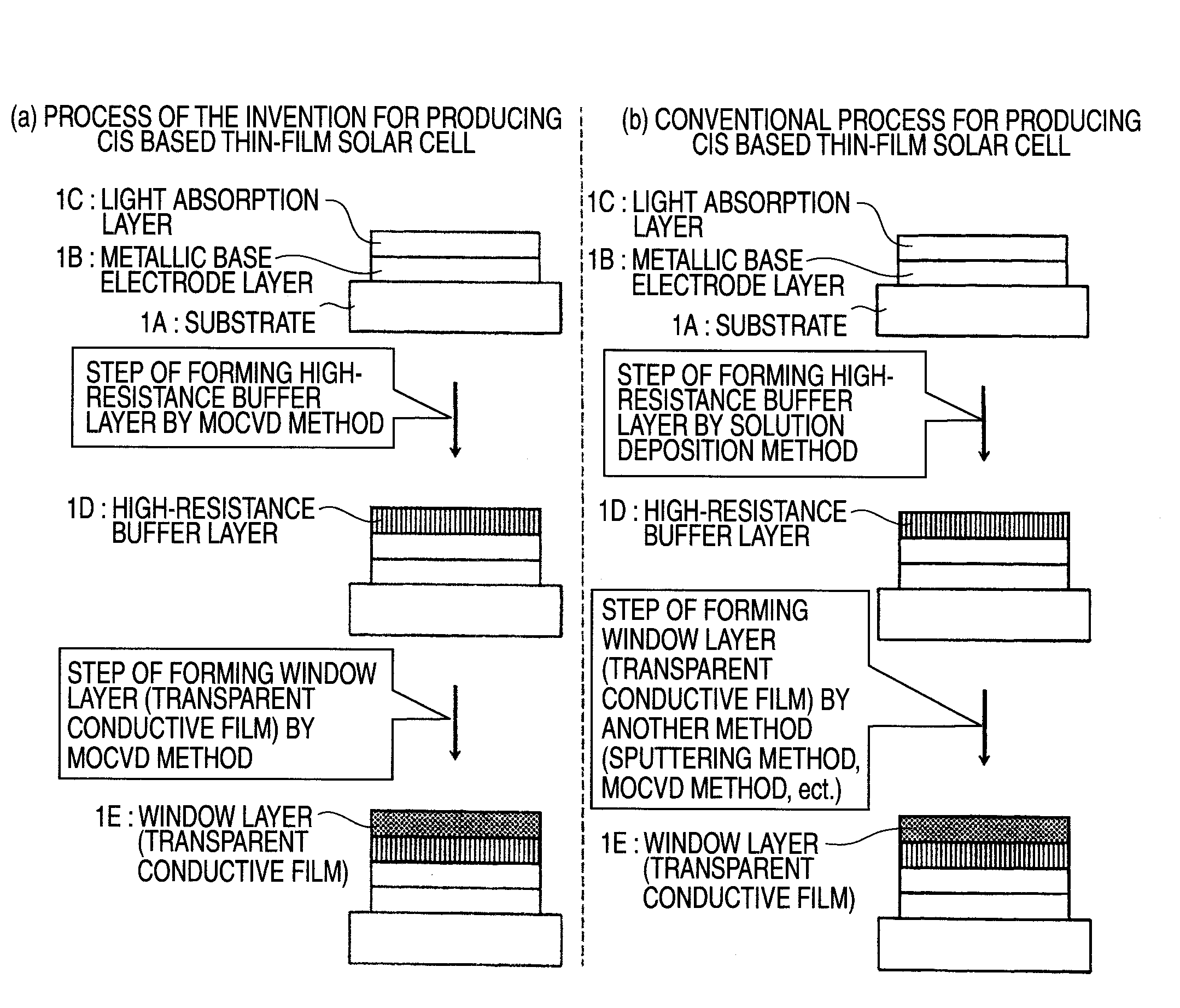

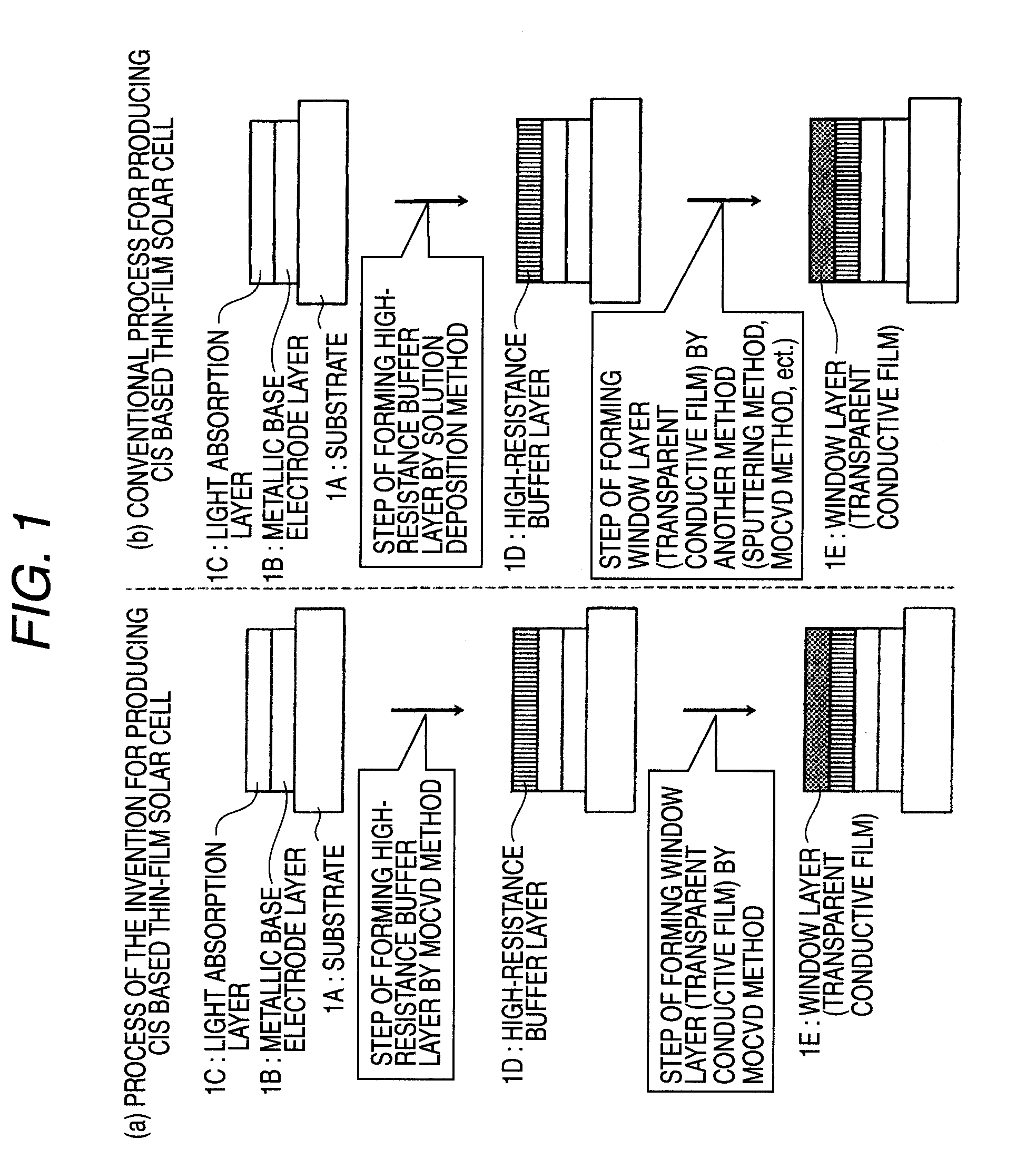

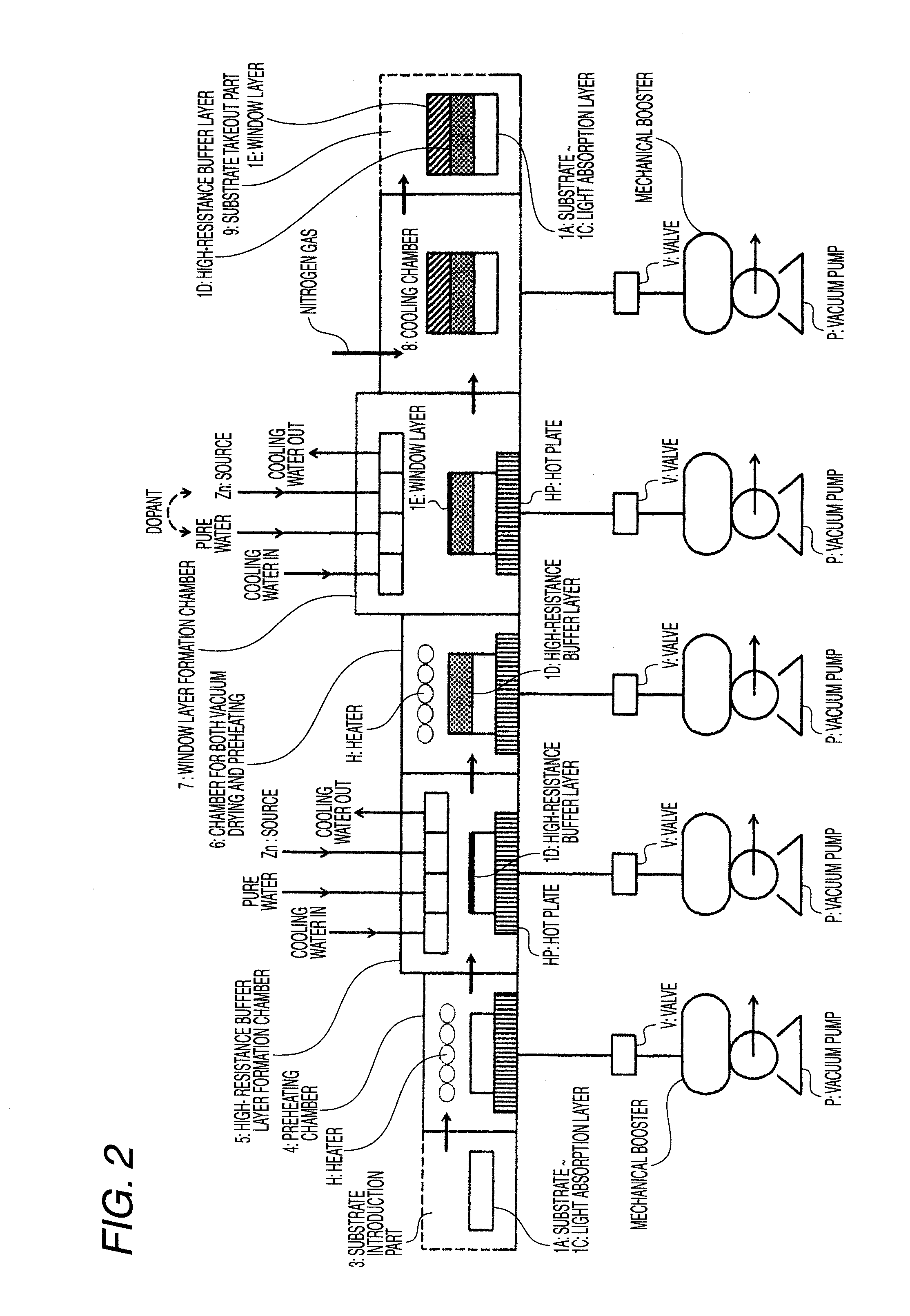

Method of Successive High-Resistance Buffer Layer/Window Layer (Transparent Conductive Film) Formation for CIS Based Thin-Film Solar Cell and Apparatus for Successive Film Formation for Practicing the Method of Successive Film Formation

ActiveUS20090087940A1Reduction in raw-material costLow cost of treatmentFinal product manufactureSemiconductor/solid-state device manufacturingHigh resistanceWork in process

A high-resistance buffer layer and a window layer (transparent conductive film) are successively formed by the MOCVD method to obtain the same output characteristics as in conventional film deposition by the solution deposition method and to simplify a film deposition method and apparatus. Thus, the cost of raw materials and the cost of waste treatments are reduced to attain a considerable reduction in production cost.After a metallic base electrode layer 1B and a light absorption layer 1C are formed in this order on a glass substrate 1A, a high-resistance buffer layer 1D and a window layer 1E are successively formed in this order in a multi layer arrangement on the light absorption layer 1C of the resultant semifinished solar cell substrate by the MOCVD method. Consequently, a film deposition method and apparatus are simplified and the cost of raw materials and the cost of waste treatments can be reduced.

Owner:SOLAR FRONTIER

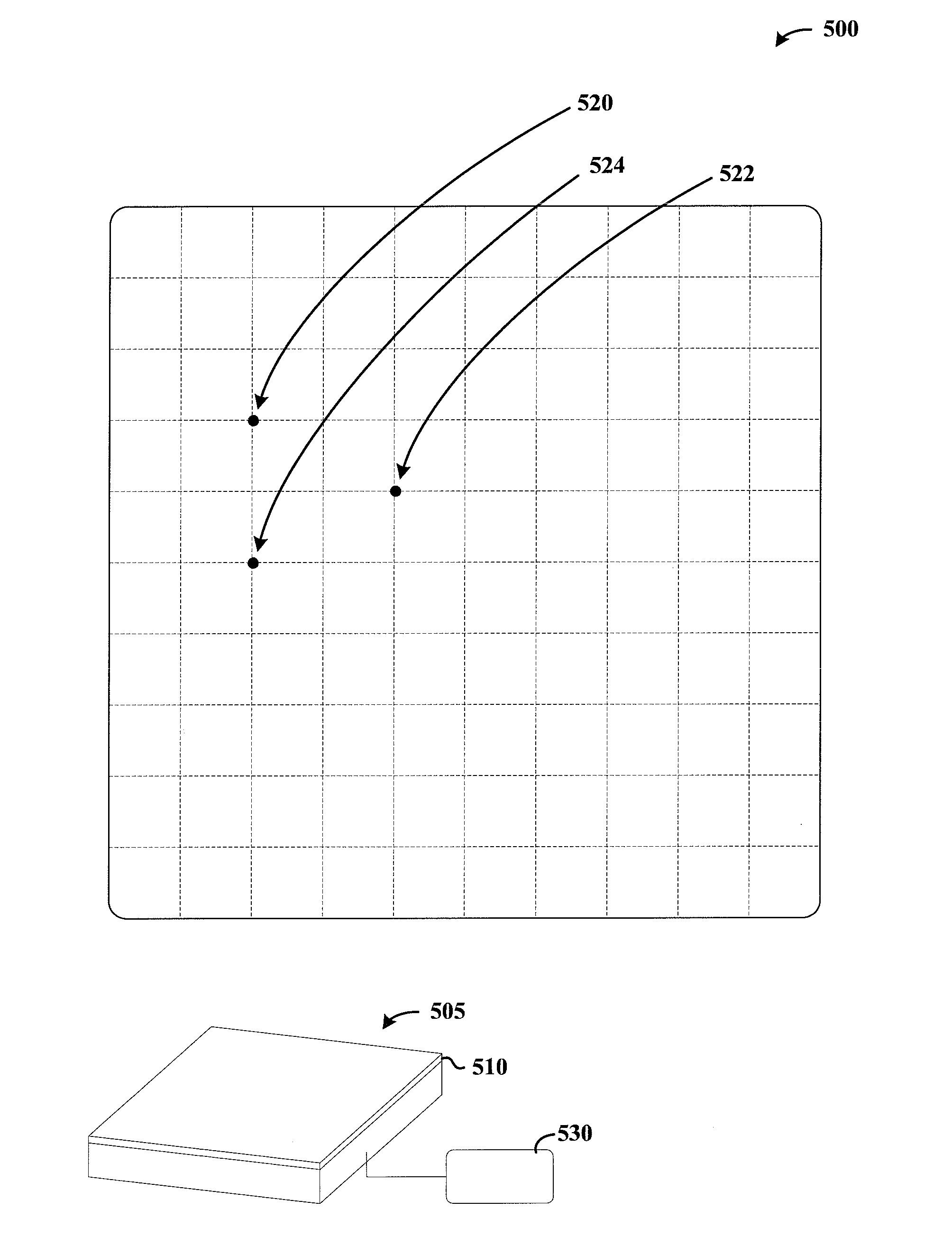

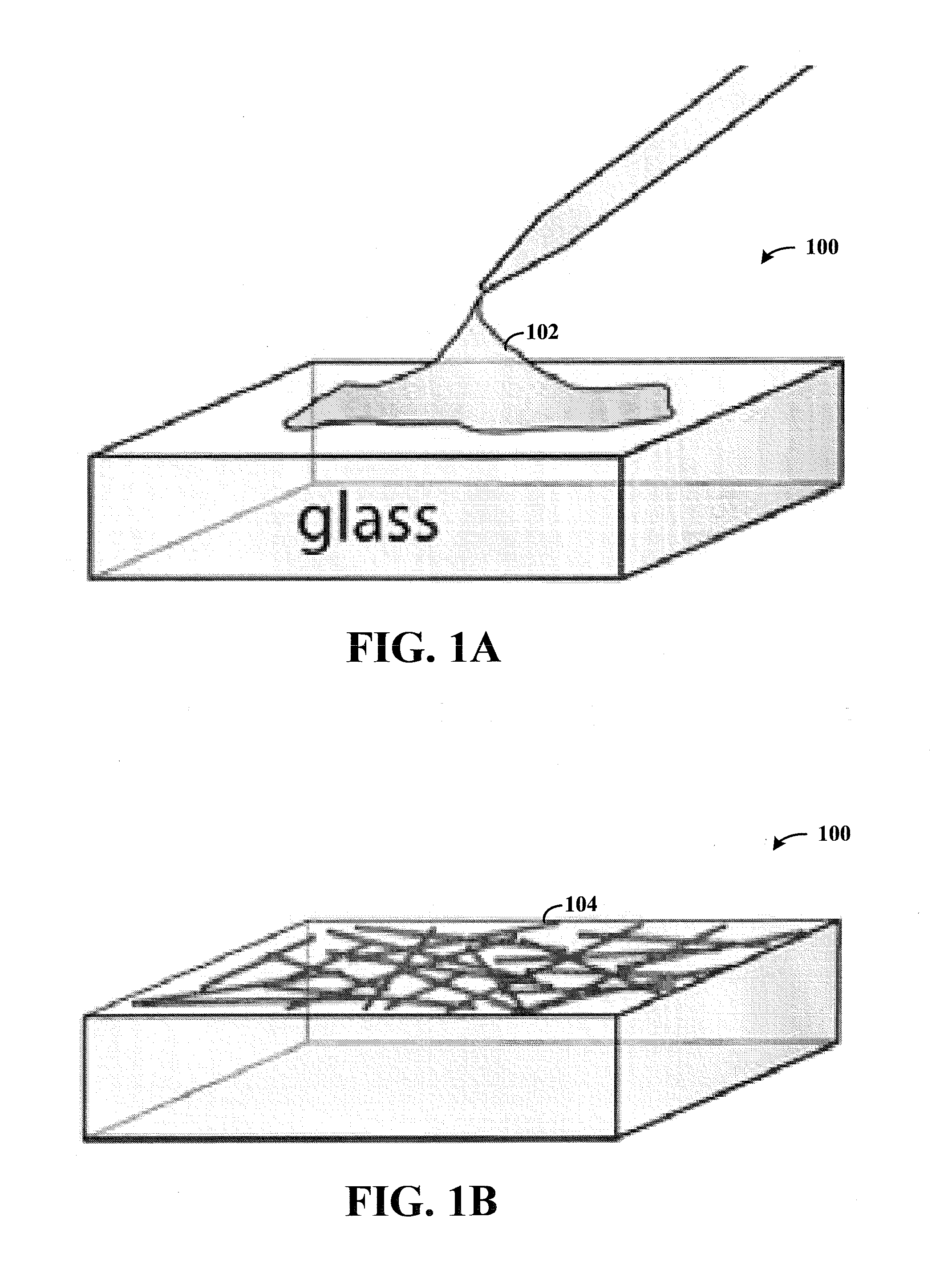

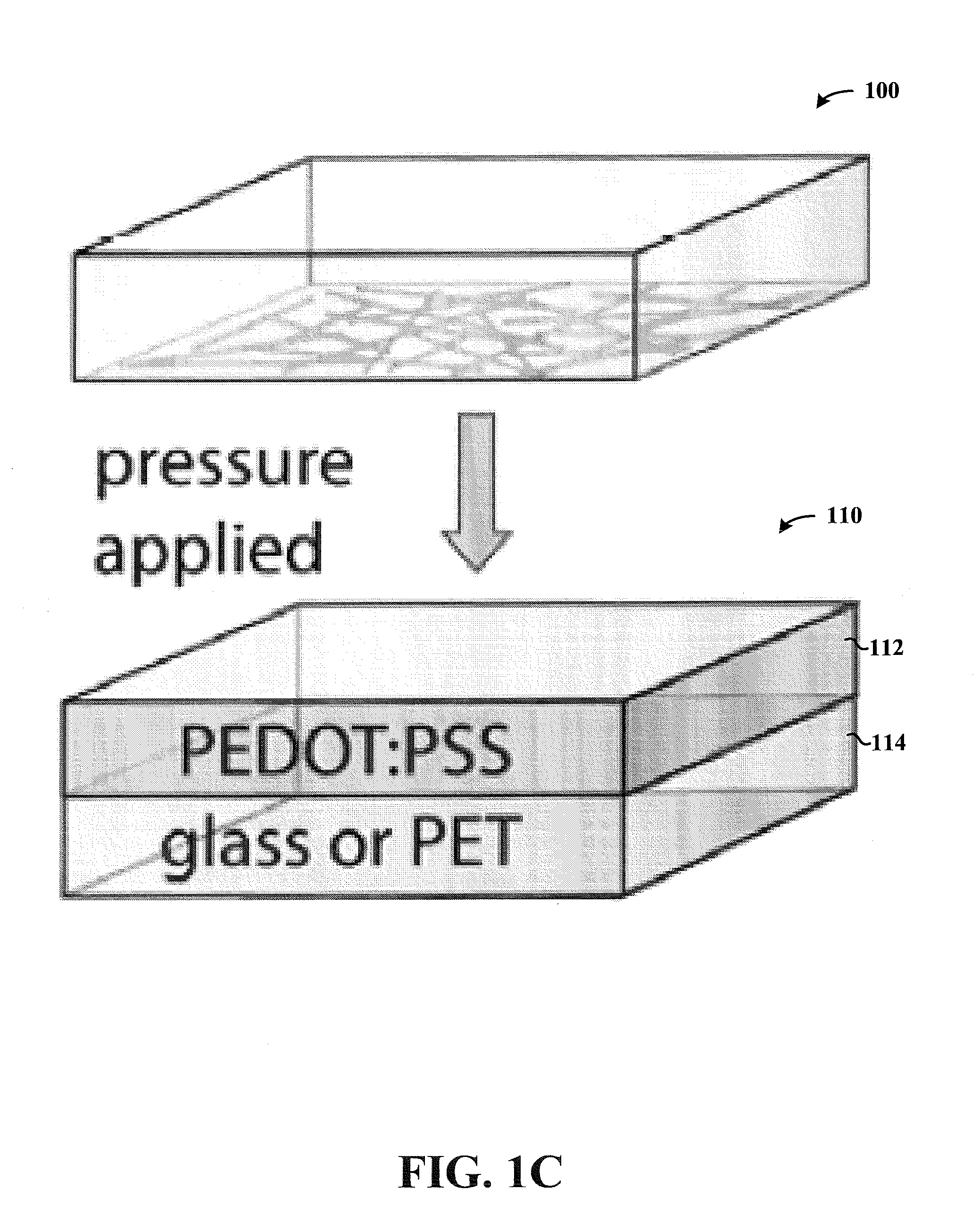

Conductive films

Conductive films with transparency characteristics are provided. In accordance with various example embodiments, a transparent conductive film includes an inorganic nanowire mesh embedded in an organic substrate layer. The embedding may involve, for example, embedding a majority of, or substantially all of the nanowire mesh in the organic substrate layer to facilitate a resulting surface roughness of the combined nanowire mesh-polymer that is less than a surface roughness of the mesh alone (e.g., or otherwise embedded), and in turn facilitates desirable conductivity characteristics.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

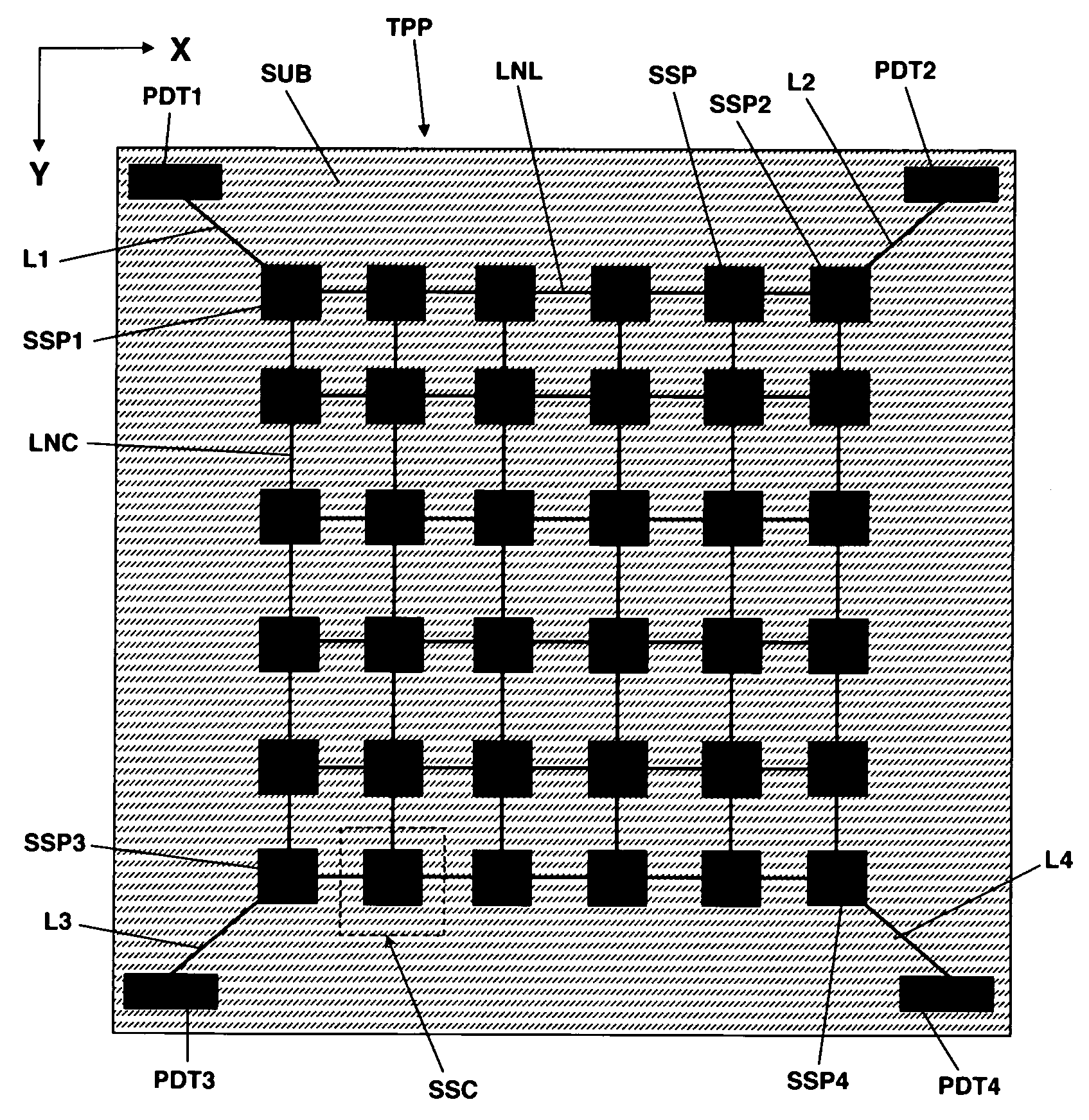

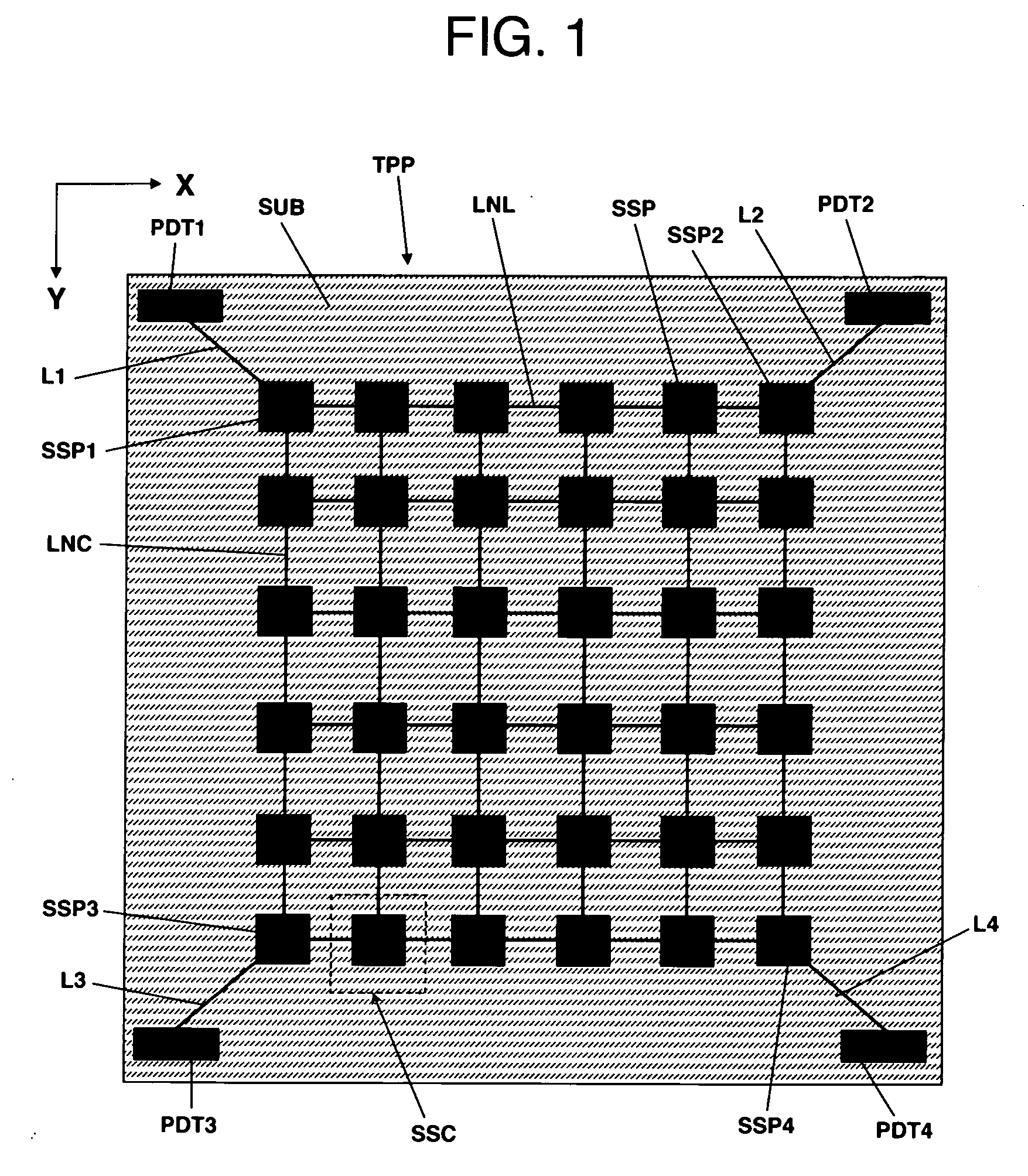

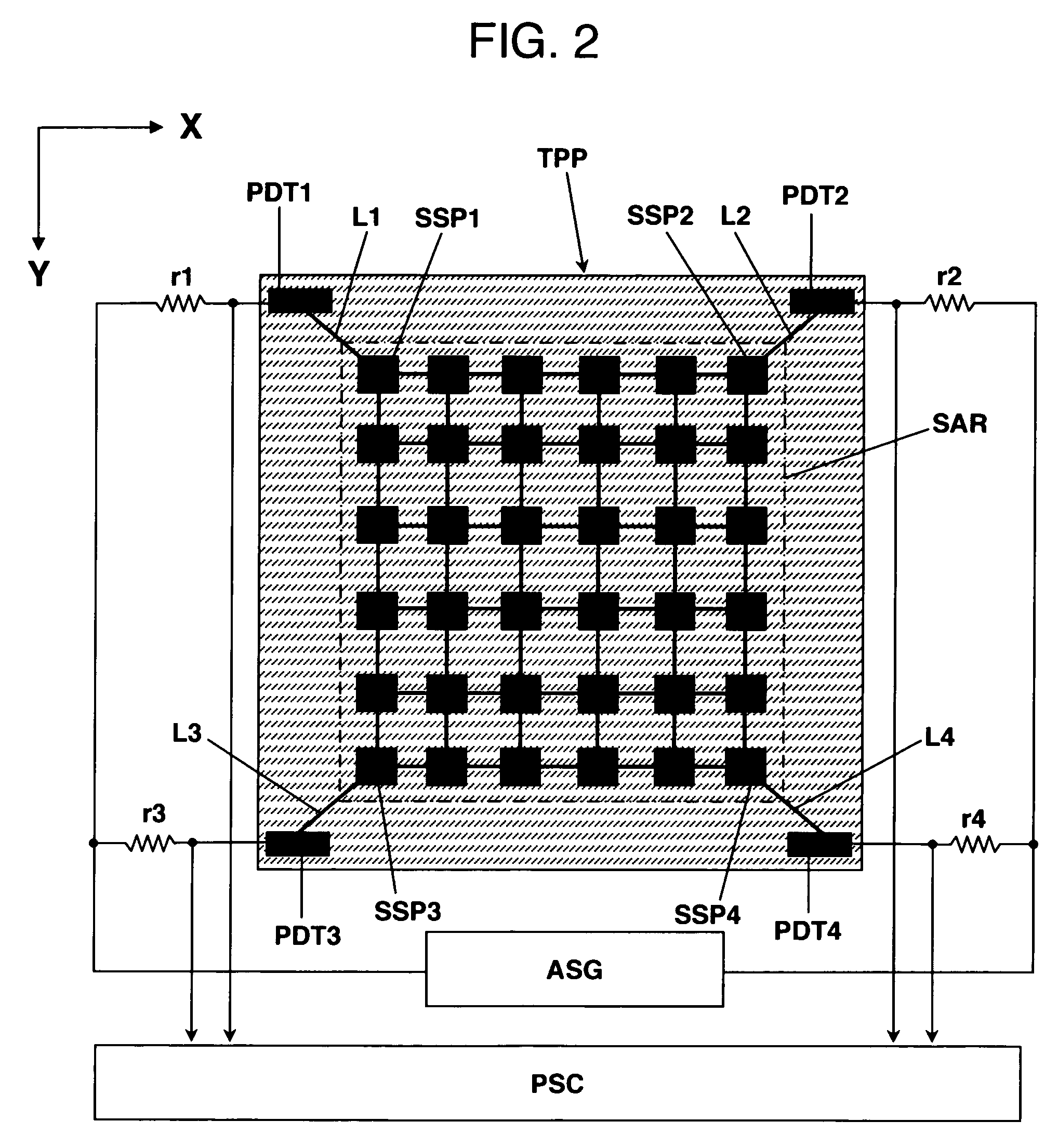

Screen input type image display

InactiveUS20090002338A1Simple structureImprove accuracyInput/output processes for data processingTransparent conducting filmComputer science

In an image display device incorporating a touch sensor capable of detecting coordinates with simple structure and high precision, a transparent conductive film on a substrate SUB forming a display screen of the image display device is patterned to form detection electrodes taking the shape of a plurality of pad electrodes SSP arranged in a two-dimensional matrix form of rows (X direction) and columns (Y direction). Row connection electrodes LNL and column connection electrodes LNC connecting the detection electrodes in rows and columns of the two-dimensional matrix to each other are formed of the same transparent conductive film as the pad electrodes. By arranging the pad electrodes in the matrix form, the contact area of a finger or the like touching the screen can be made large, resulting in improved detection precision (resolution). The pad electrodes are connected at four corners to coordinate detection terminals PDT1 to PDT4.

Owner:JAPAN DISPLAY INC

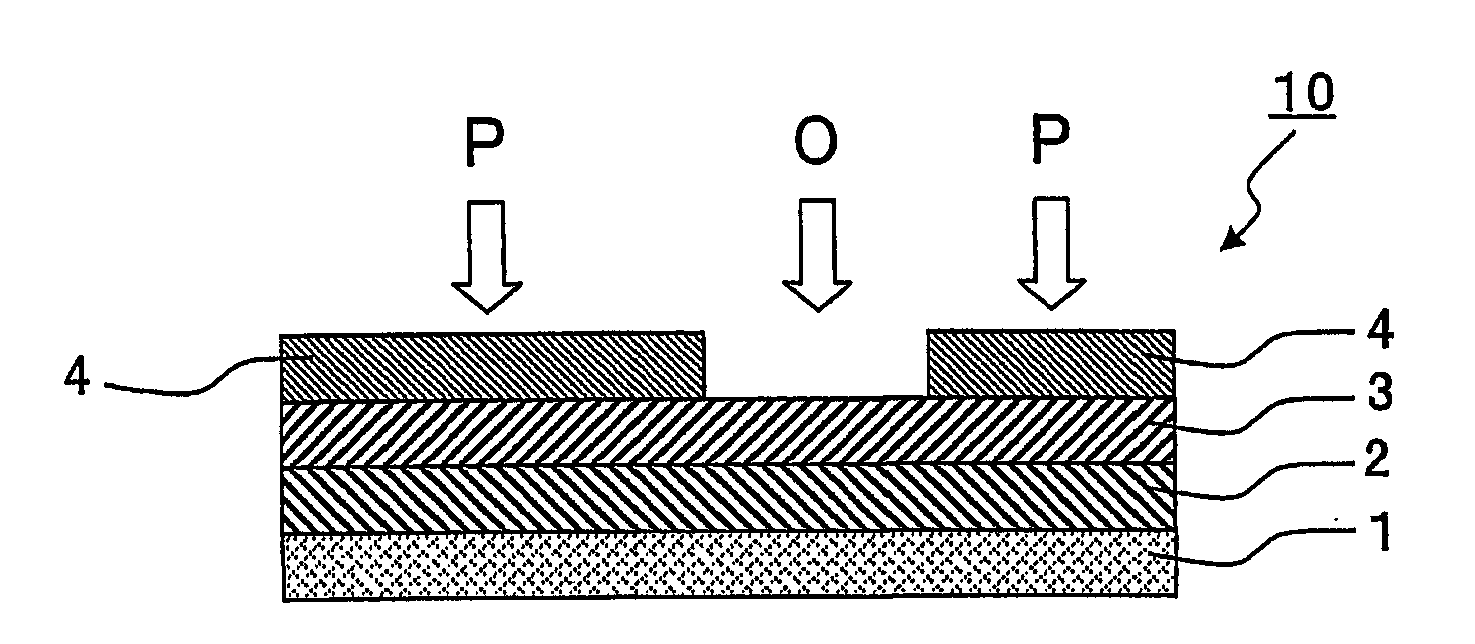

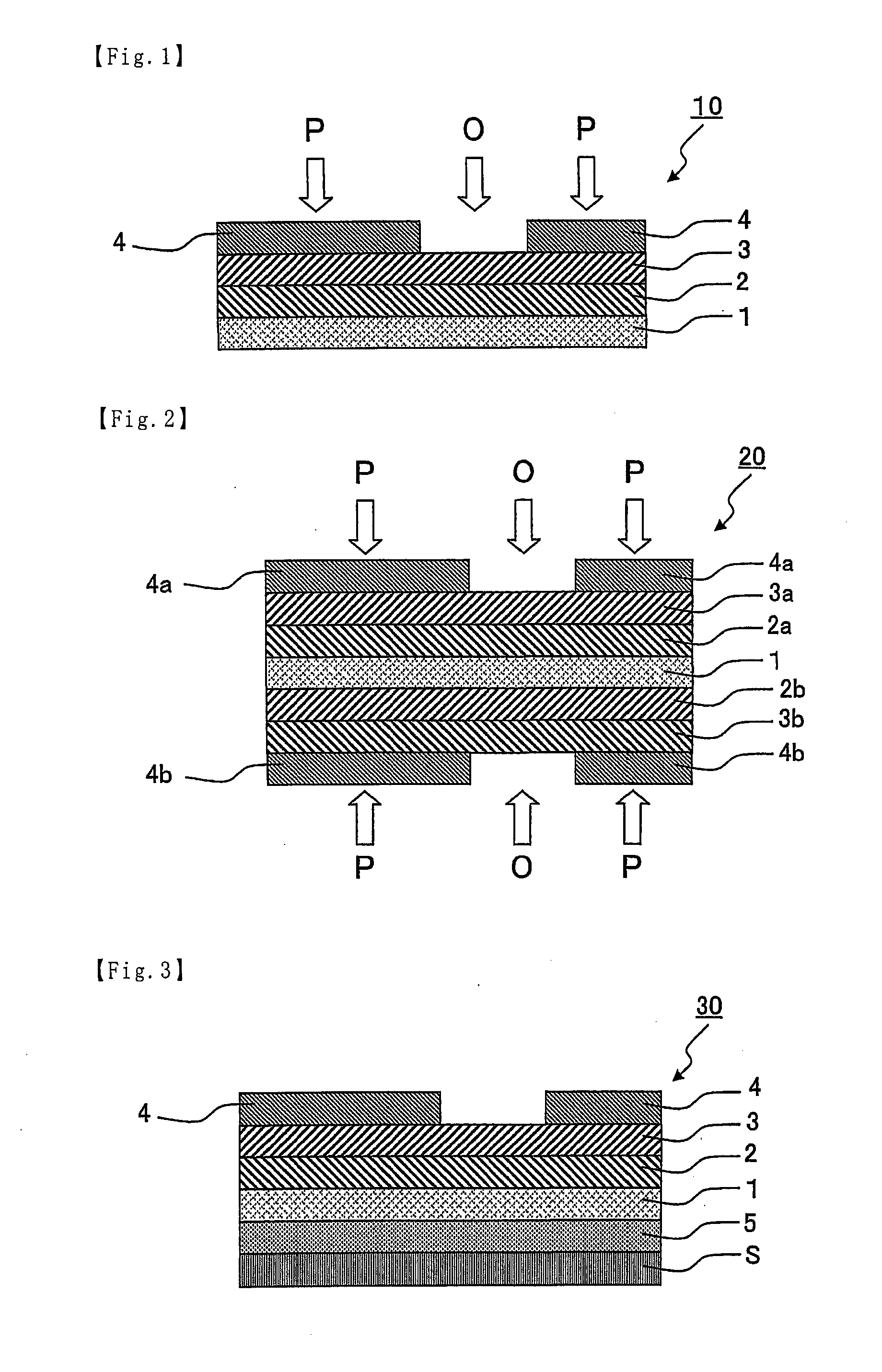

Transparent conductive film, transparent conductive laminate, touch panel, and method for producing transparent conductive film

ActiveUS20100013784A1High film strengthHigh mechanical strengthConductive layers on insulating-supportsDecorative surface effectsRefractive indexTransparent conducting film

The transparent conductive film of the present invention is a transparent conductive film, comprising a transparent film substrate, and a first transparent dielectric layer, a second transparent dielectric layer and a transparent conductive layer that are formed on one or both sides of the transparent film substrate in this order from the transparent film substrate side, wherein the transparent conductive layer is patterned, the relation n2<n3<n1 is satisfied, wherein n1 is the refractive index of the first transparent dielectric layer, n2 is the refractive index of the second transparent dielectric layer, and n3 is the refractive index of the transparent conductive layer, the first transparent dielectric layer has a thickness of from 2 nm to less than 10 nm, the second transparent dielectric layer has a thickness of from 20 nm to 55 nm, and the transparent conductive layer has a thickness of from 15 nm to 30 nm.

Owner:NITTO DENKO CORP

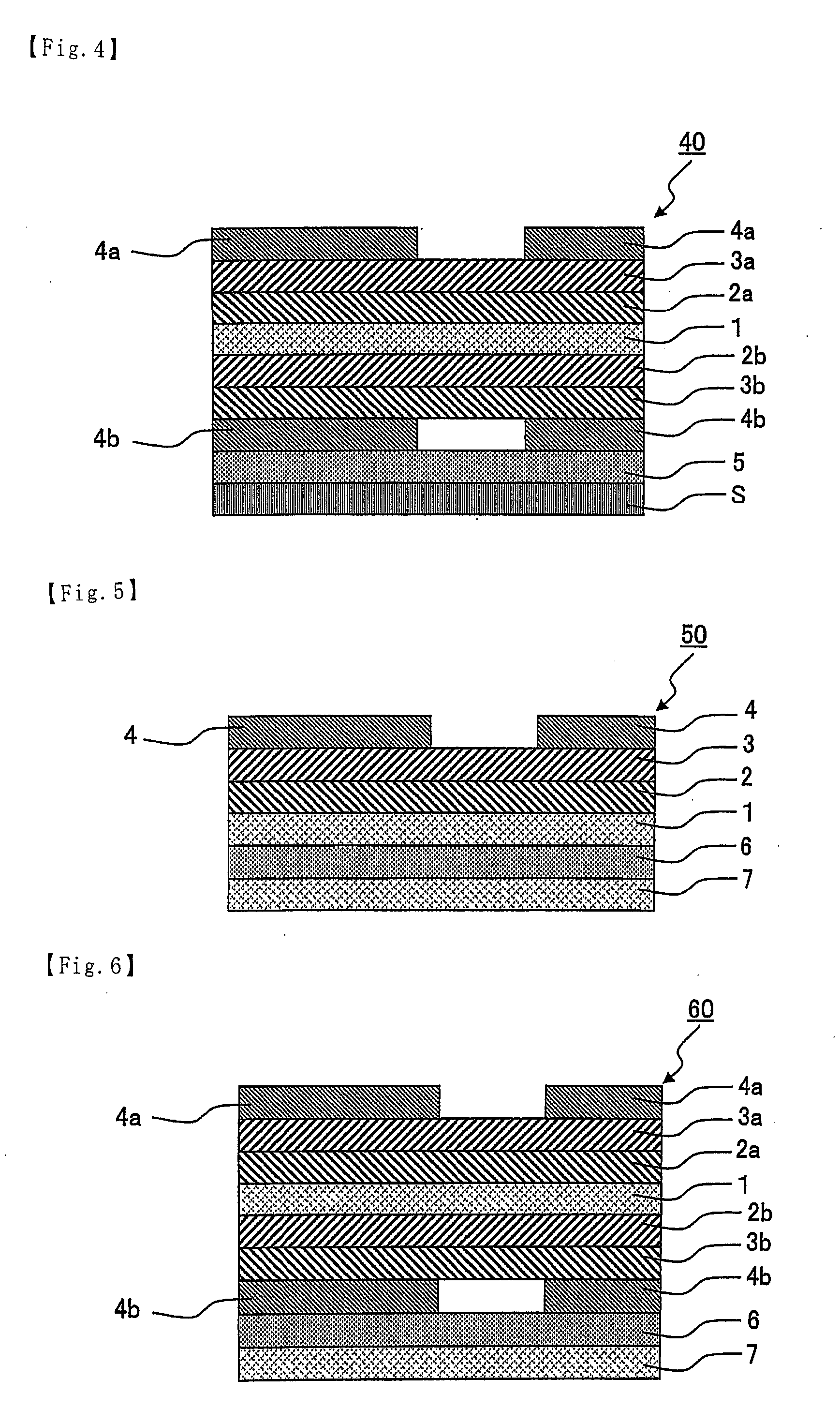

Substrate having transparent conductive layer, method for producing same, transparent conductive film laminate for touch panel, and touch panel

InactiveUS20130168138A1Difference in optical propertyEasy to identifyConductive layers on insulating-supportsSpecial surfacesHigh resistanceTransparent conducting film

A substrate having a transparent conductive layer has a transparent conductive pattern that is not easily visually recognizable by a naked human eye on a transparent substrate and can be formed by a simple and efficient method. In the case where a transparent conductive pattern is formed on a transparent substrate, the pattern region does not include conductive regions covered with uniform transparent conductive films or a high-resistance region that is not covered with the transparent conductive film, the high-resistance region electrically insulating the conductive regions. Instead of the conductive regions or the high-resistance region, the inventors use a region having a structure including a mixture of a portion covered with the transparent conductive film and a portion not covered with the transparent conductive film, thereby solving the foregoing visual recognition issue.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com