Patents

Literature

965results about How to "Effective reflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

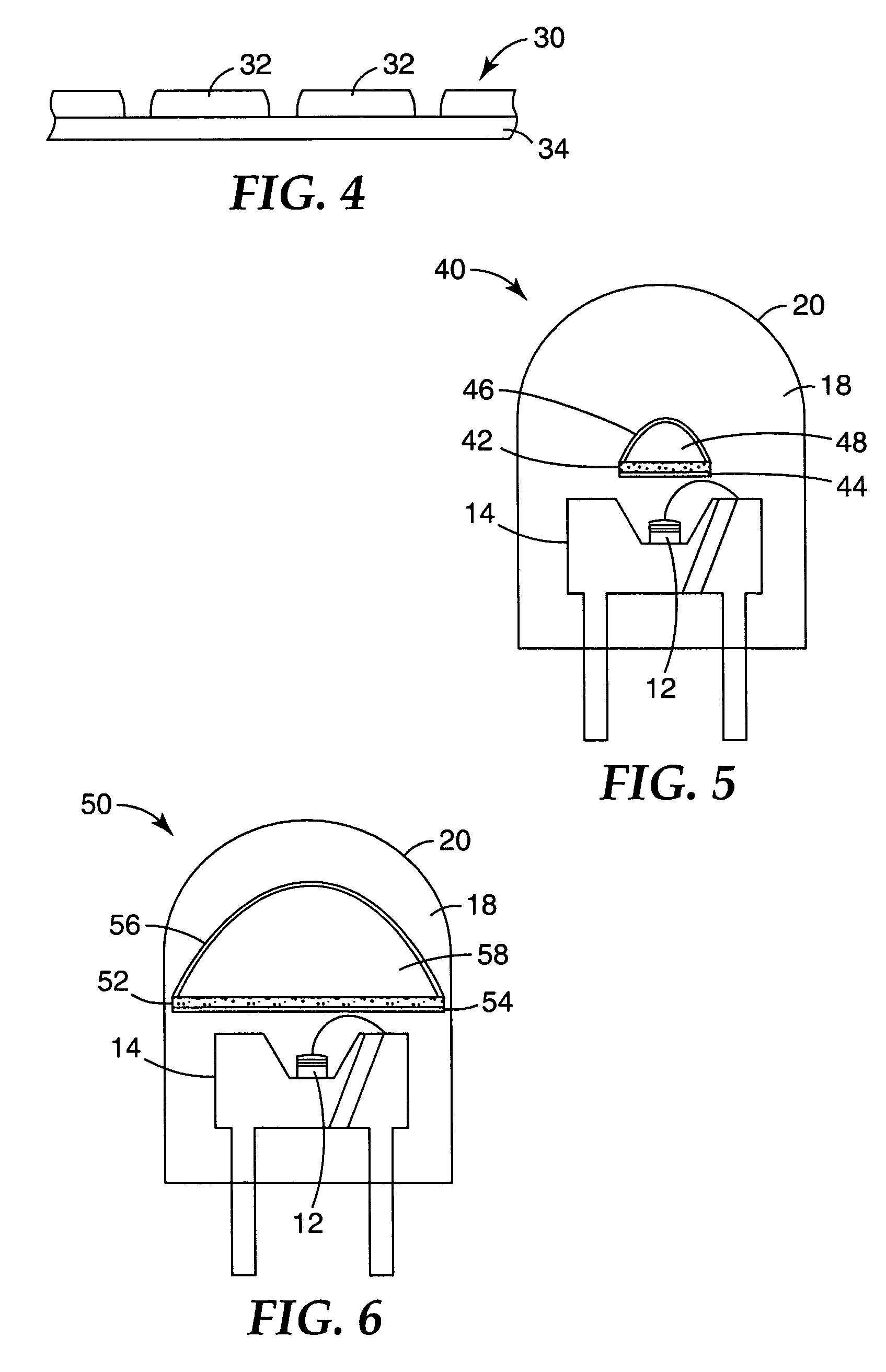

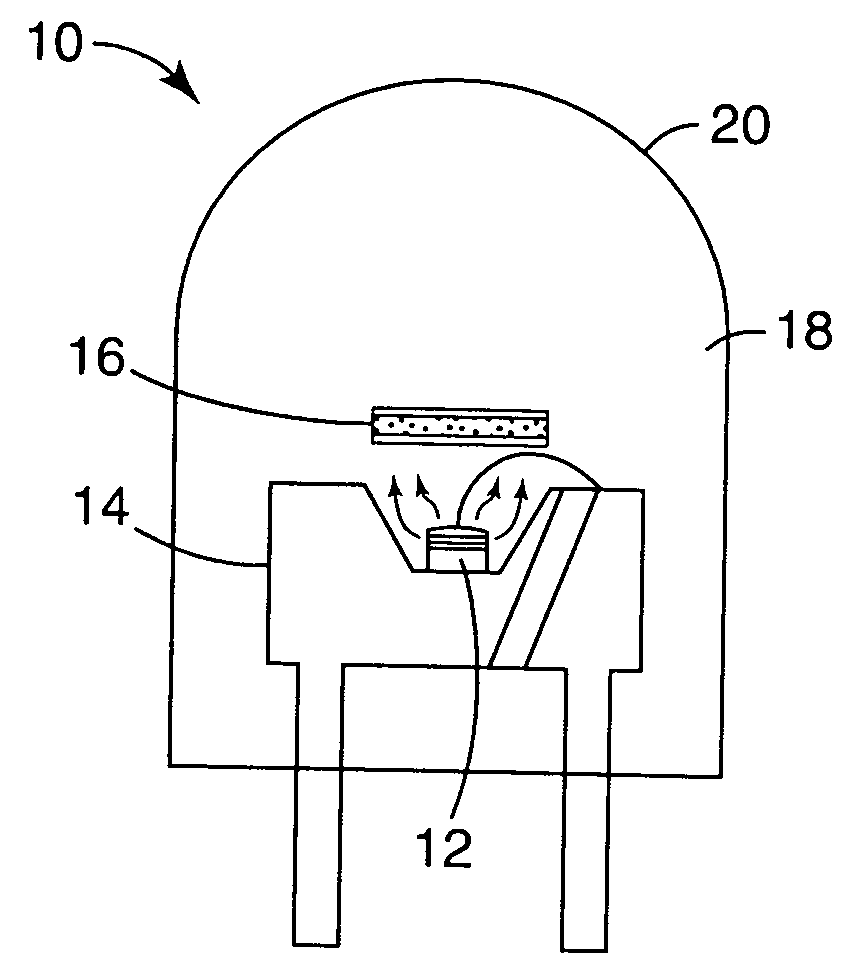

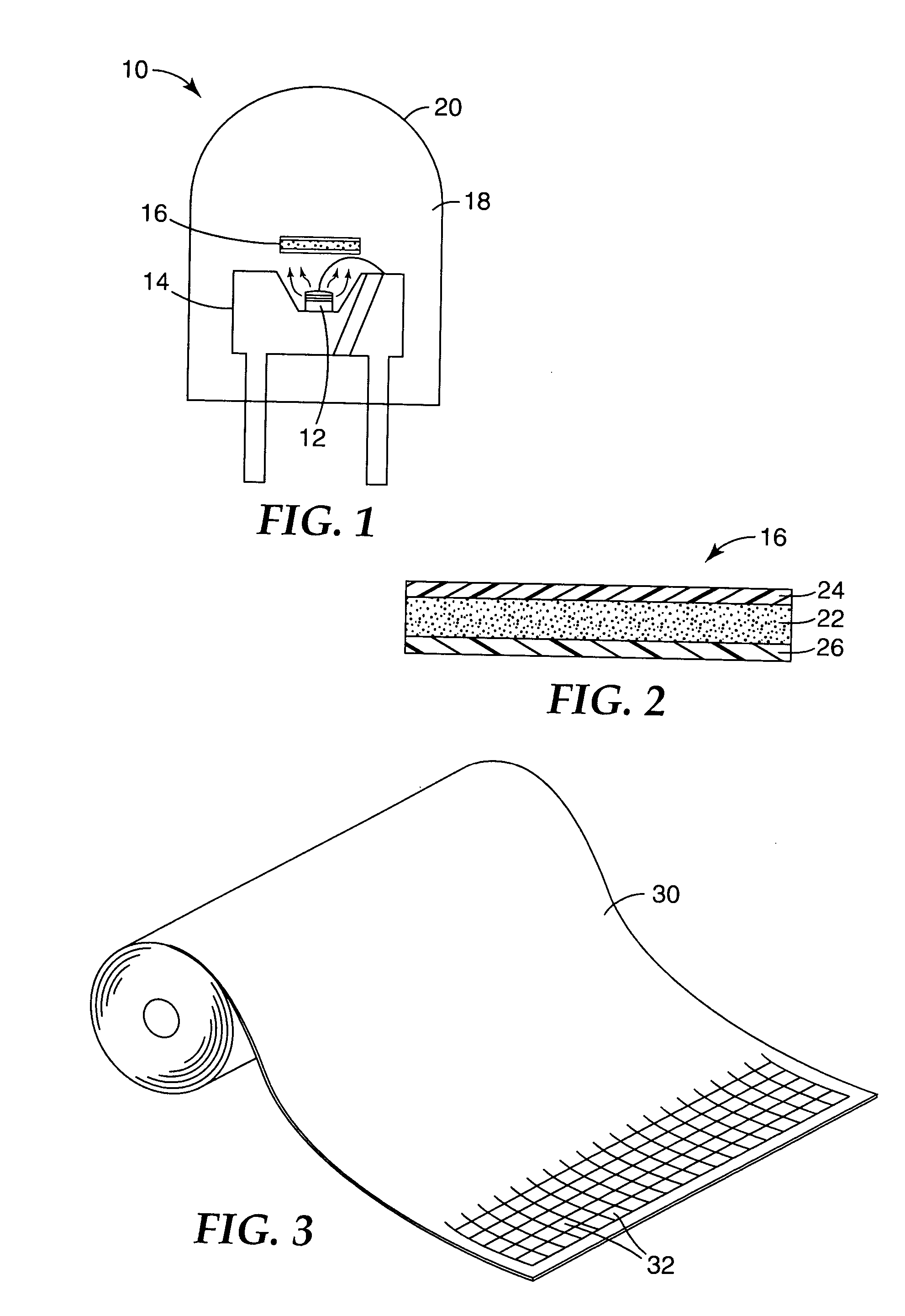

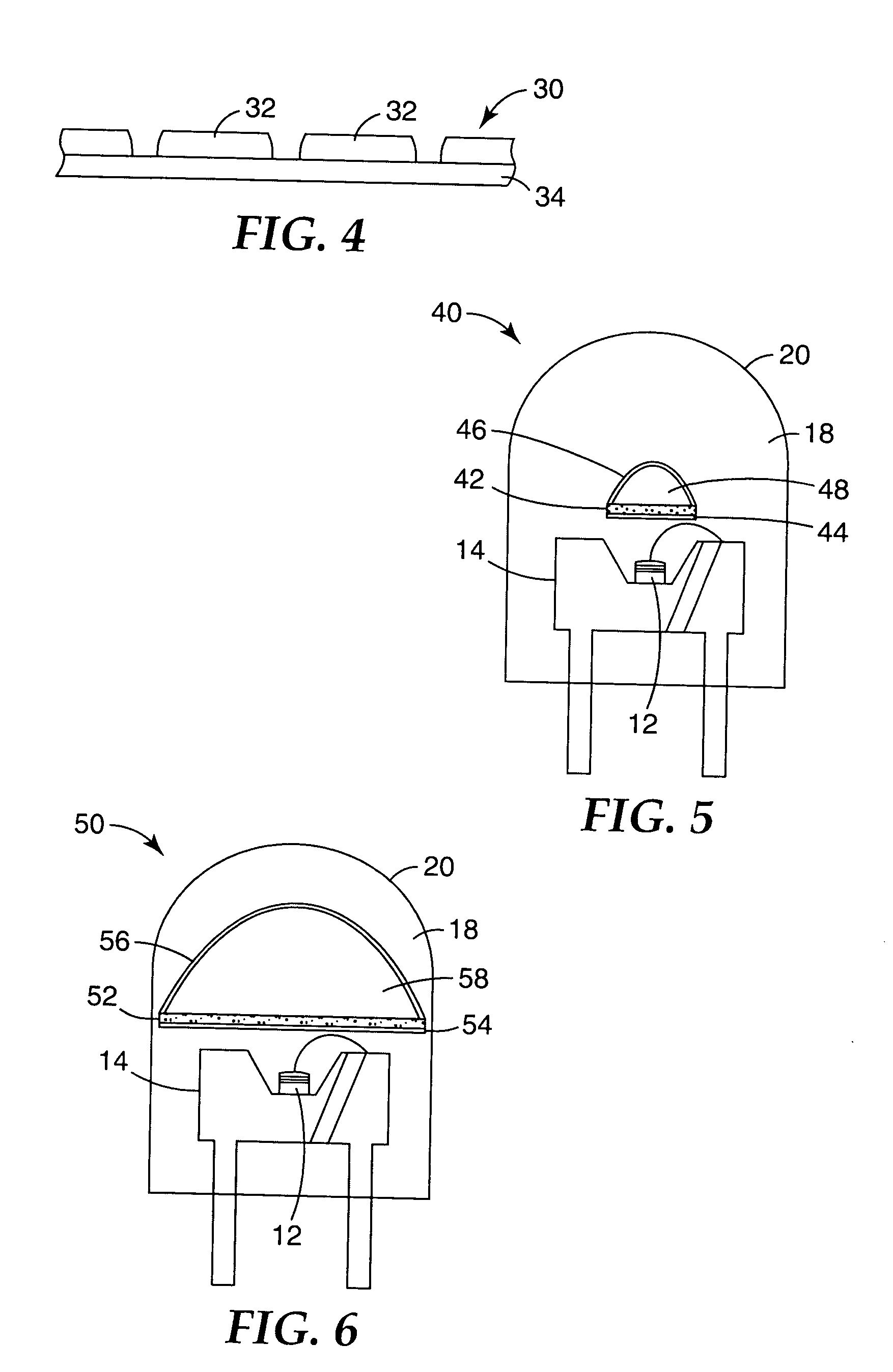

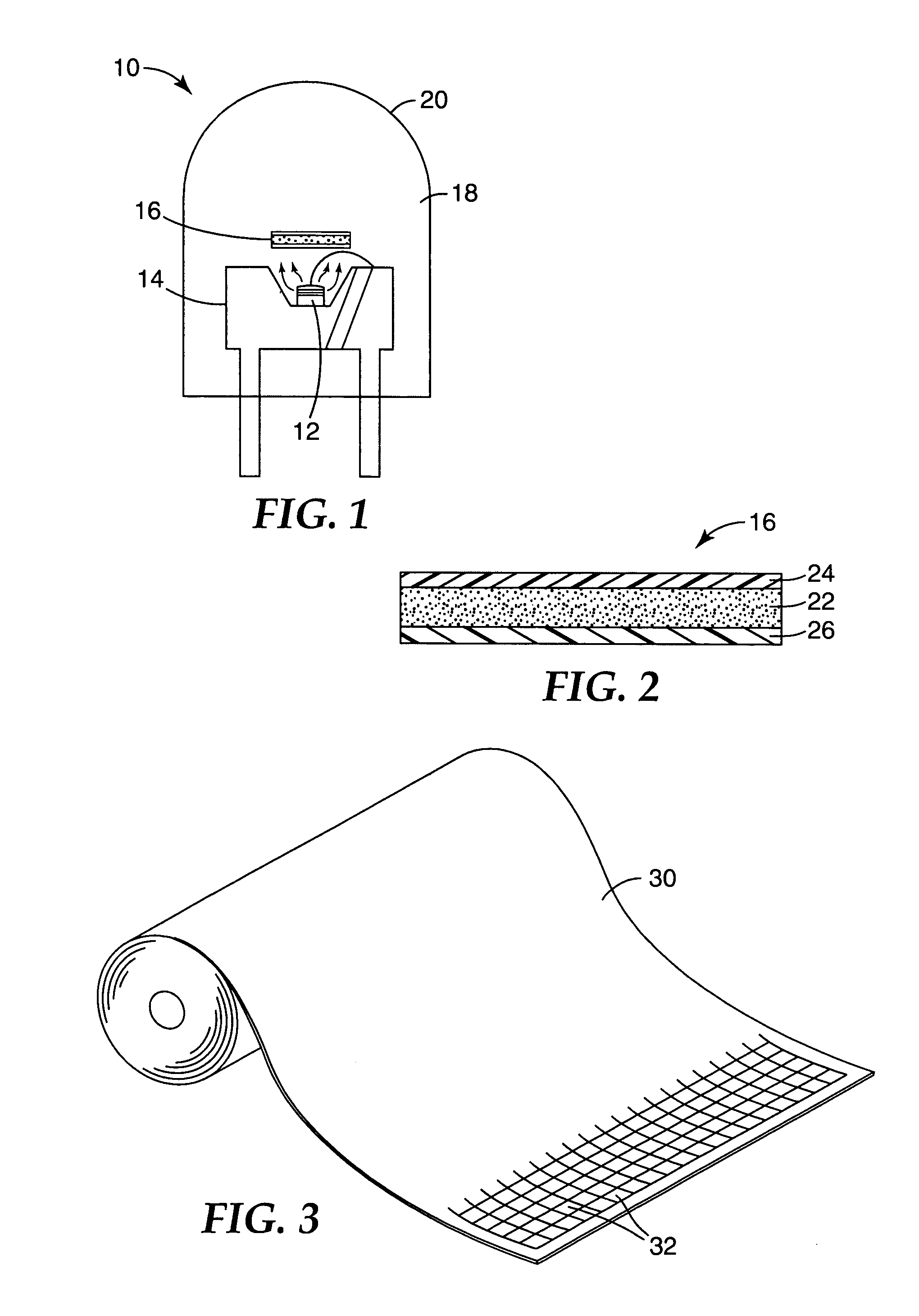

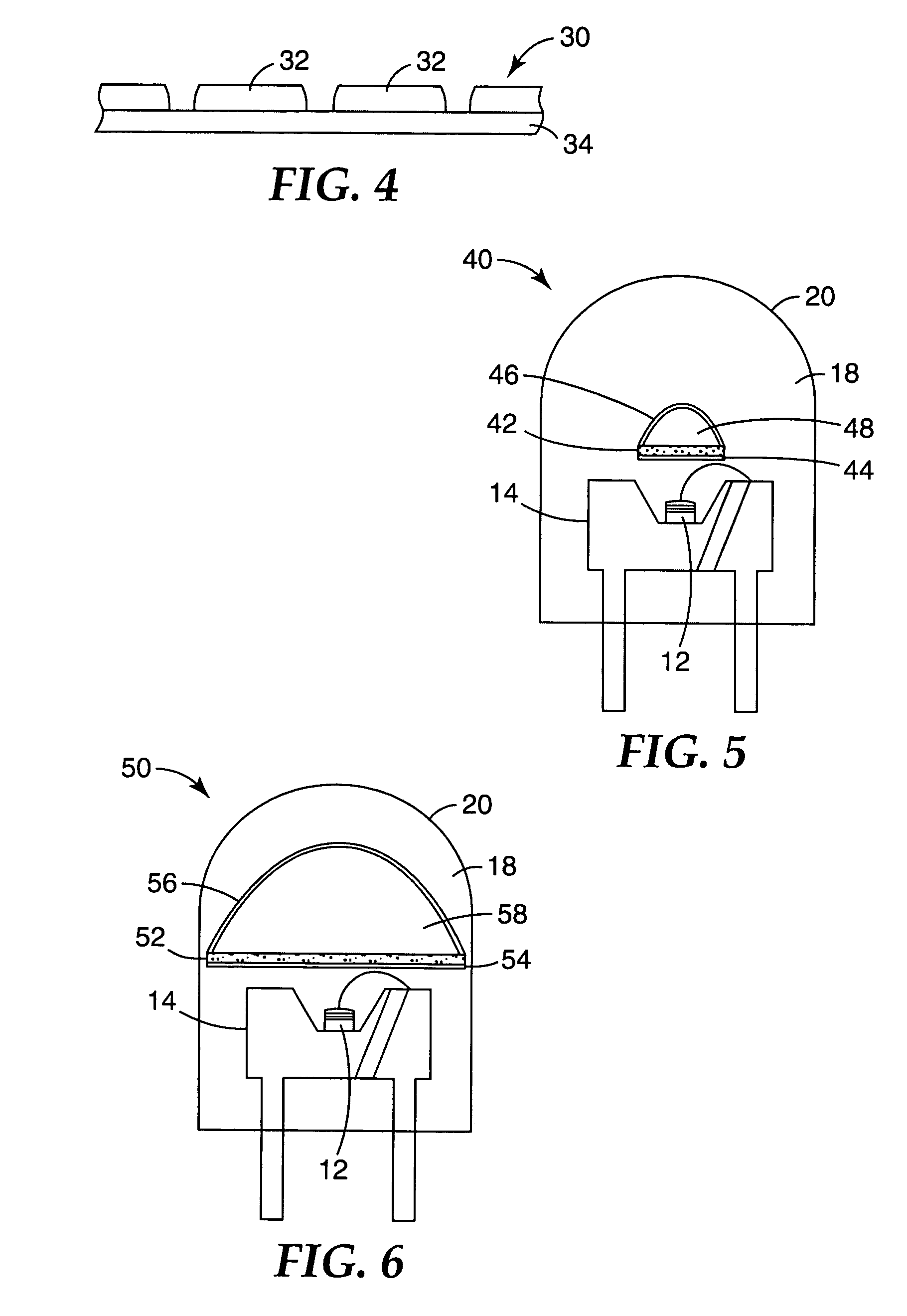

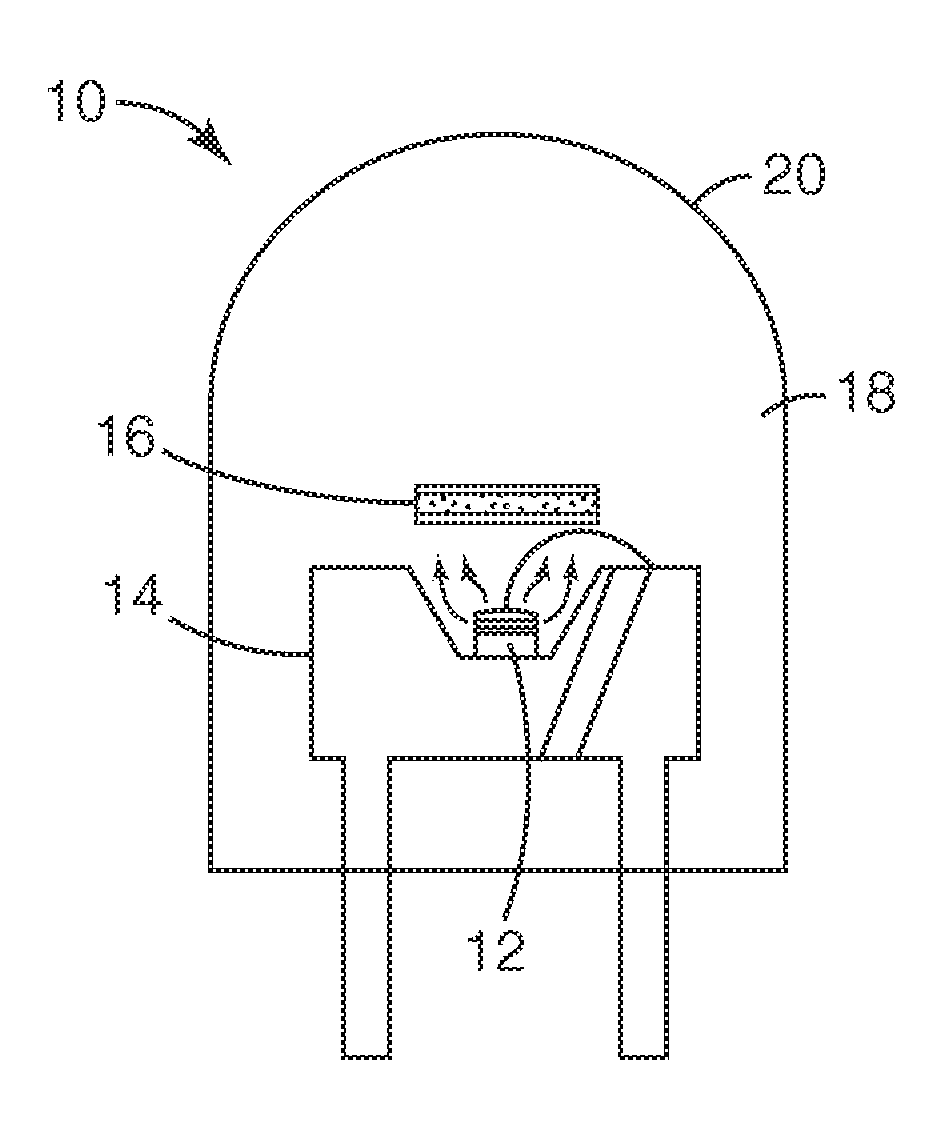

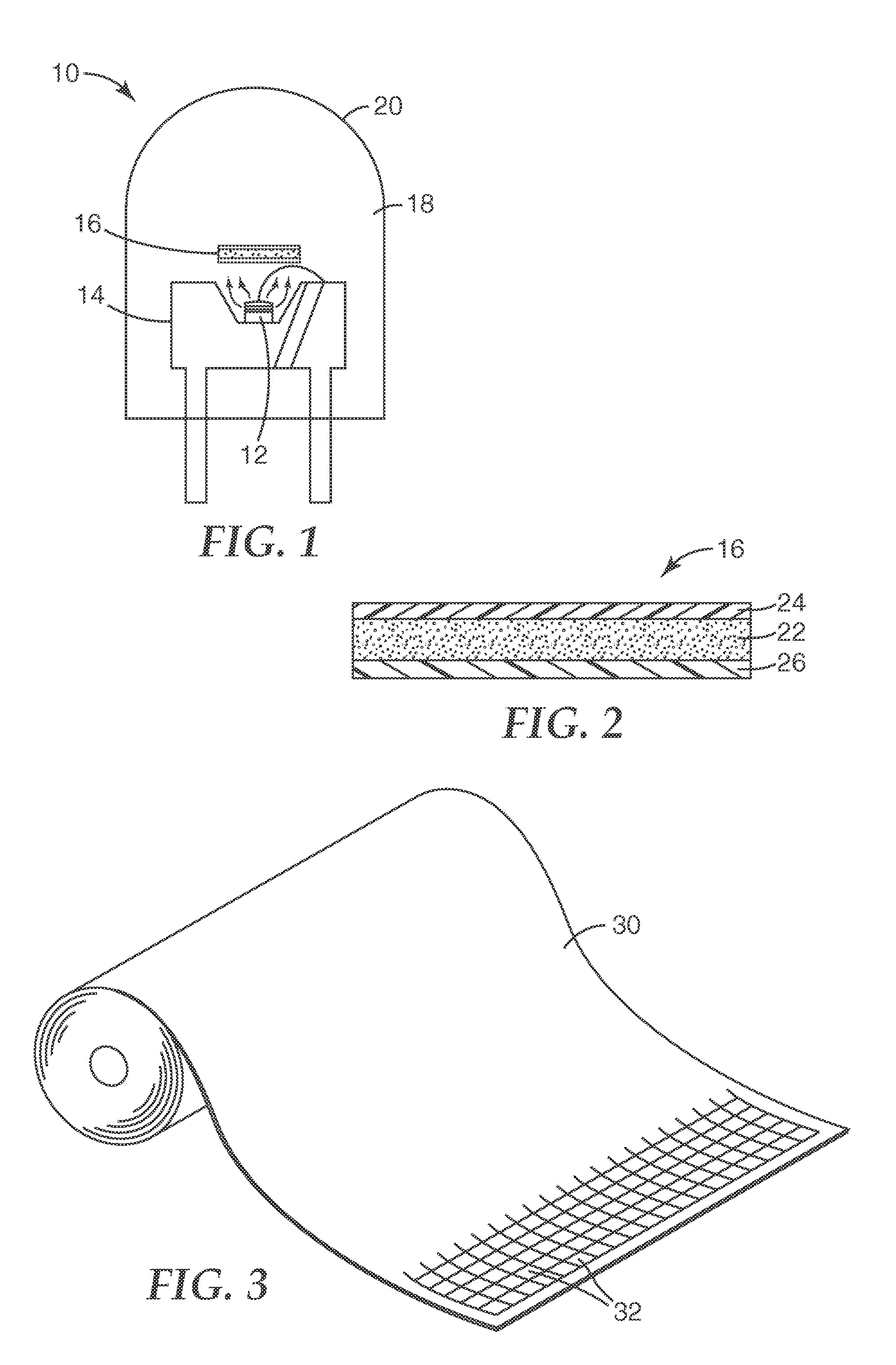

Phosphor based light sources having a non-planar long pass reflector

ActiveUS7091653B2Maintain reflectivityPrevent leakageIncadescent screens/filtersDischarge tube luminescnet screensPhosphorPhysics

A light source includes an LED that emits excitation light, an optically transparent body, a phosphor material positioned to receive the excitation light and disposed on or in the optically transparent body, the phosphor material emitting visible light when illuminated with the excitation light, and a non-planar flexible multilayer reflector that reflects the excitation light and transmits visible light. The non-planar polymeric multilayer reflector is positioned to reflect LED light onto the phosphor material.

Owner:3M INNOVATIVE PROPERTIES CO

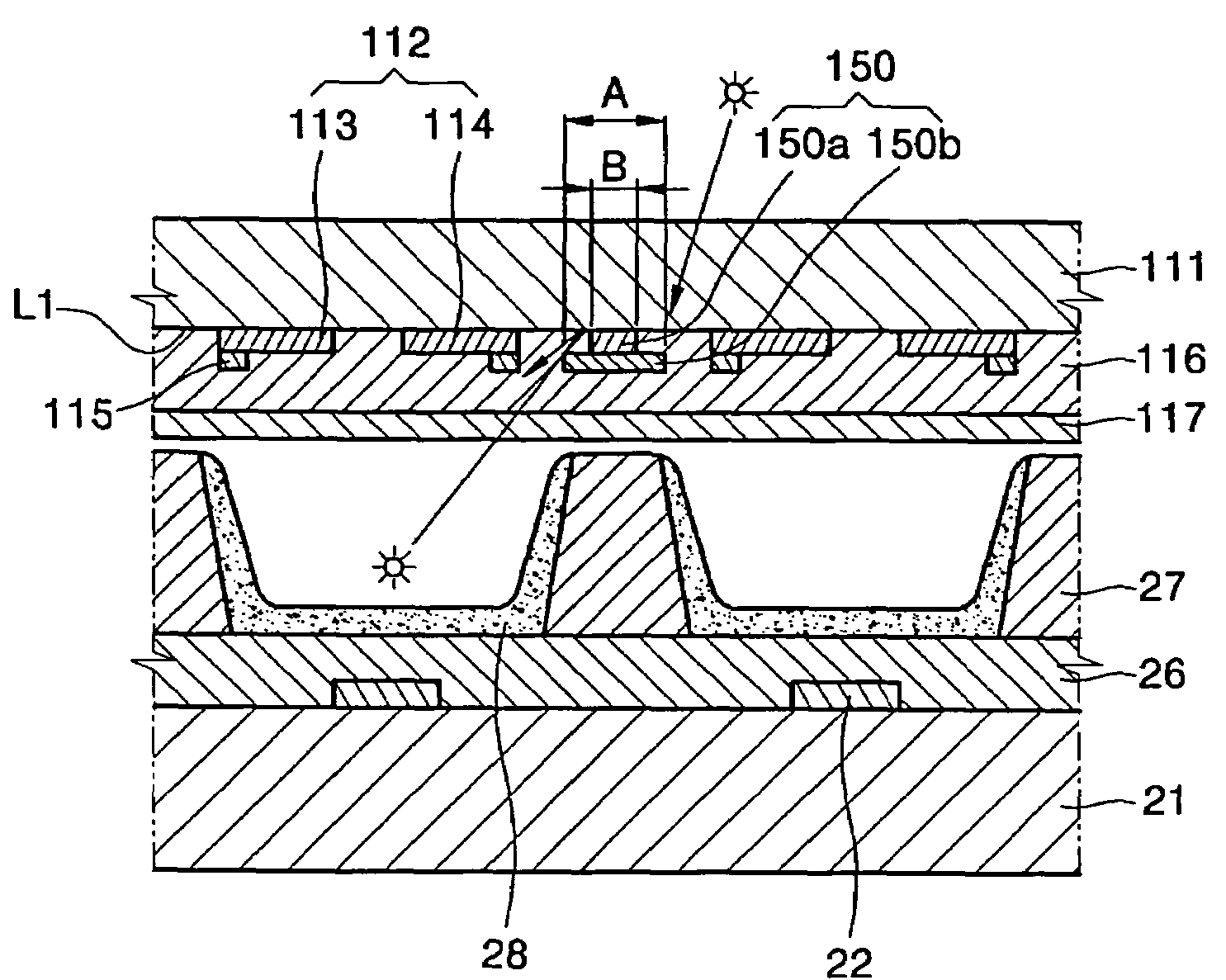

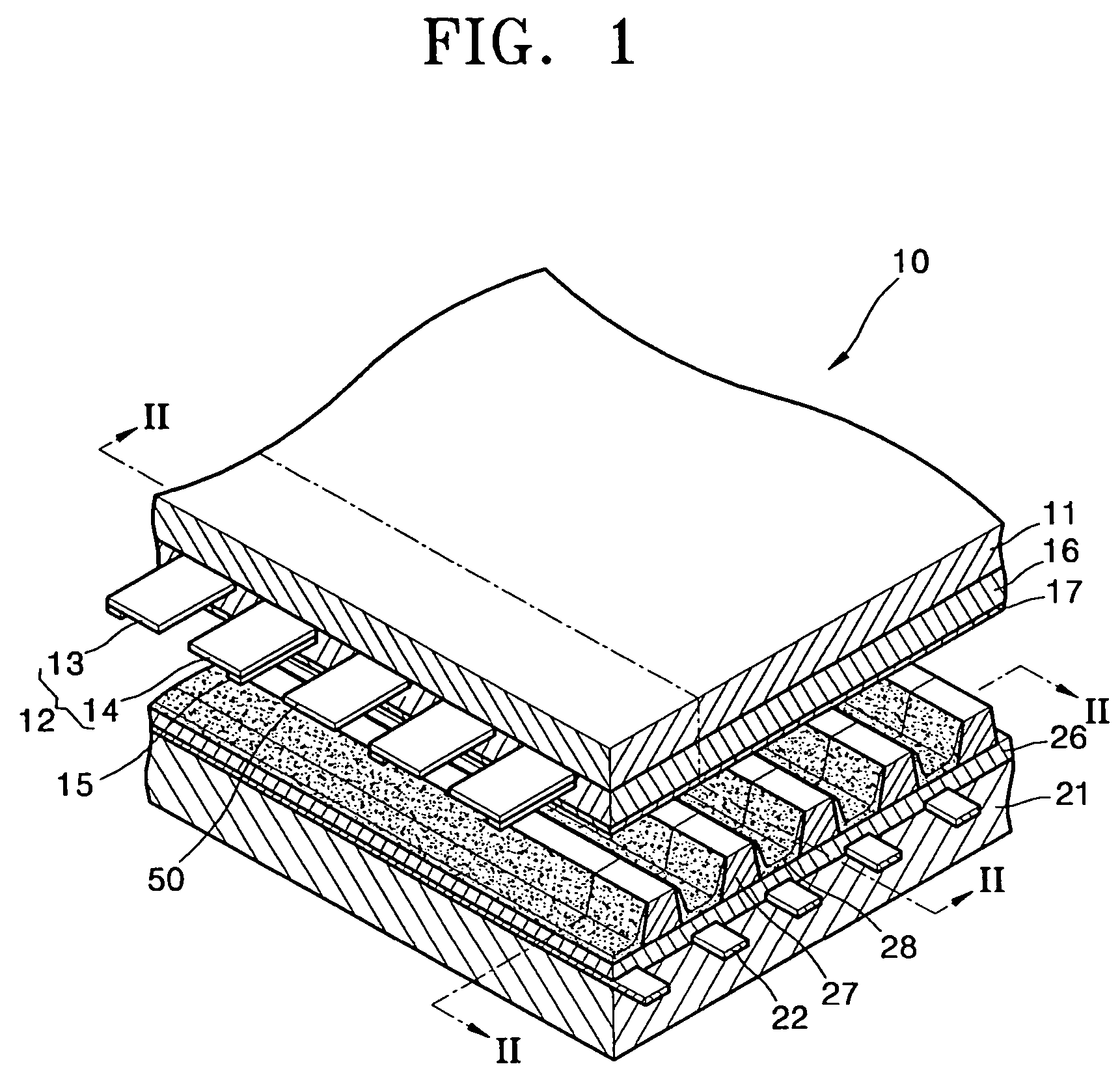

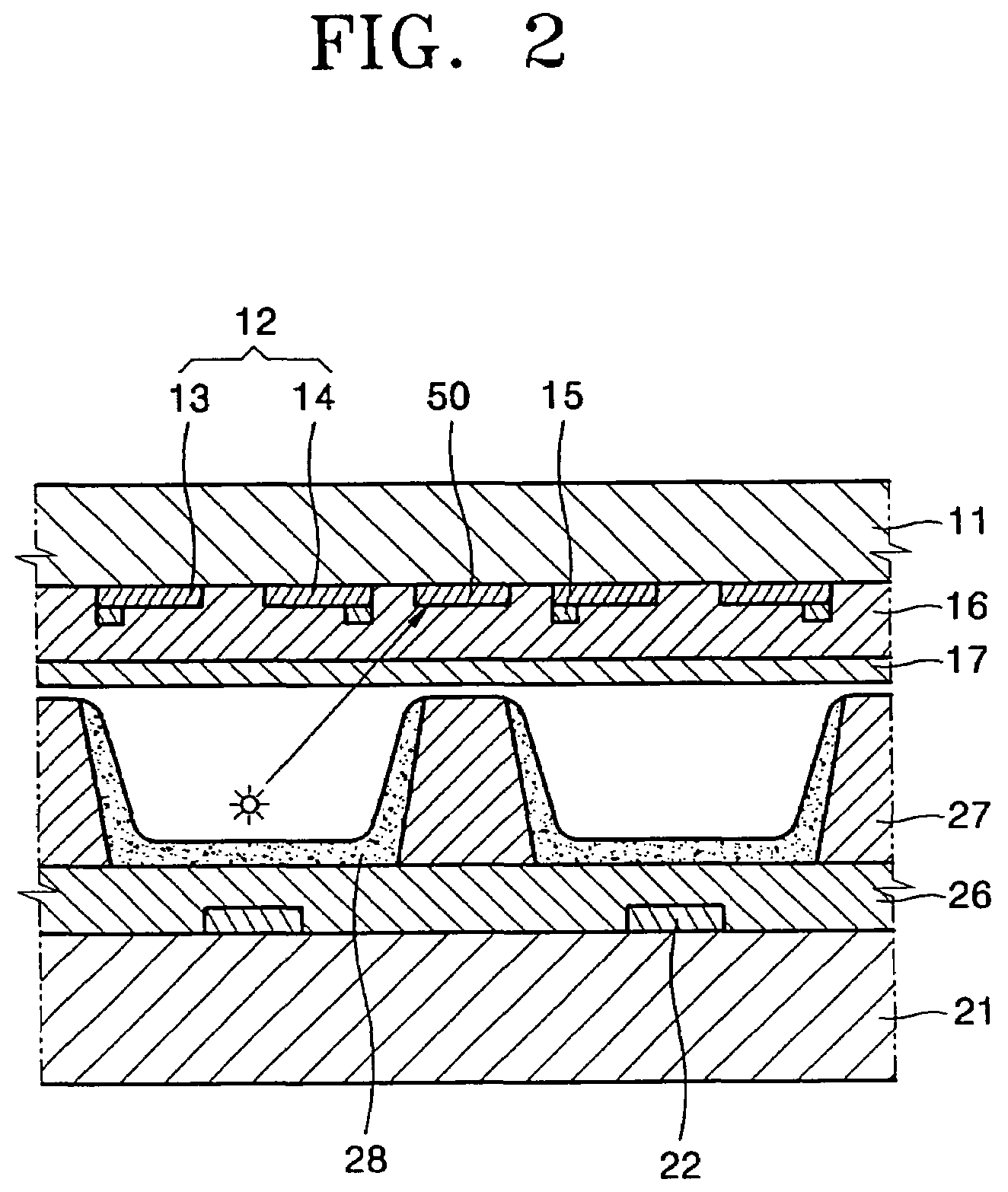

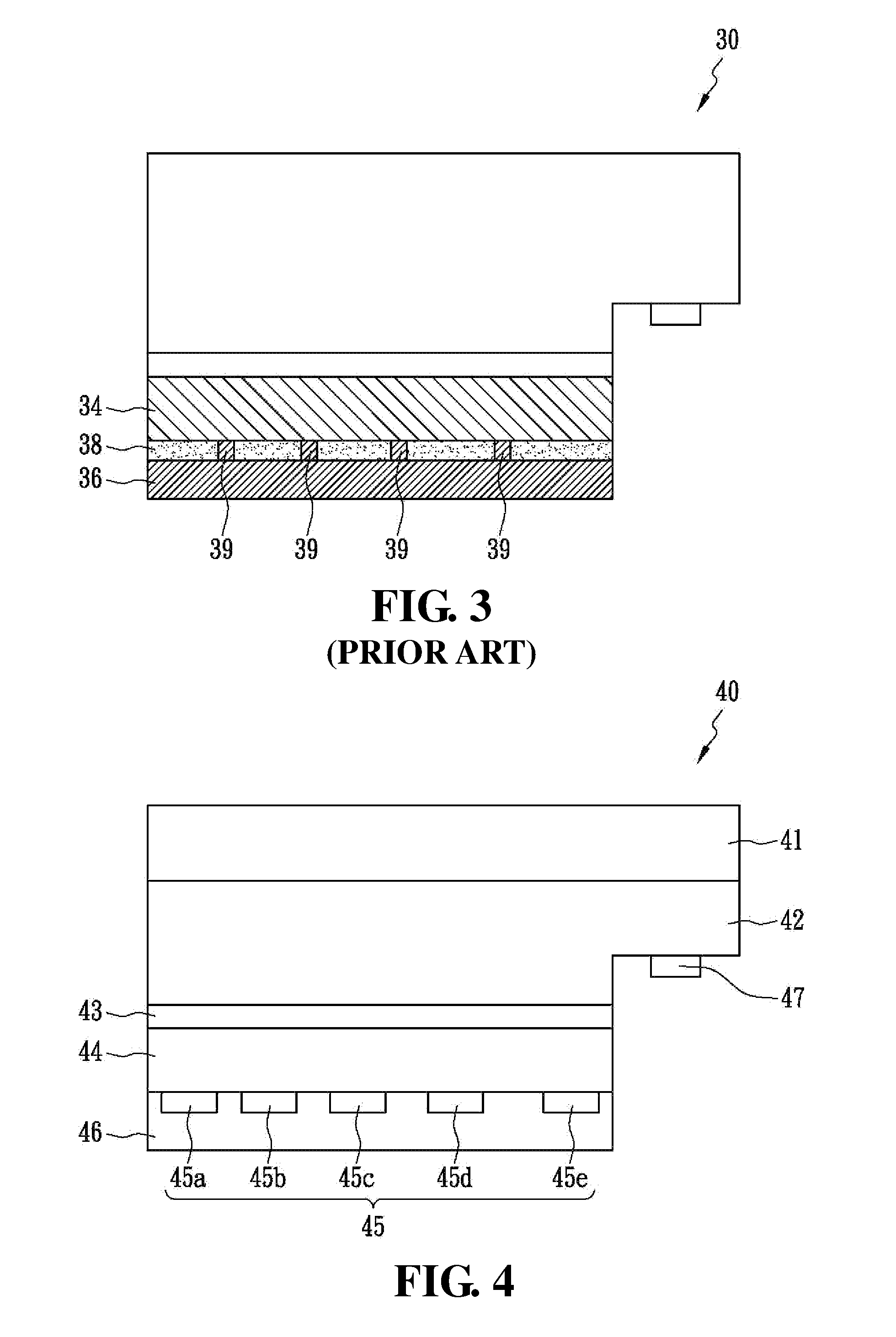

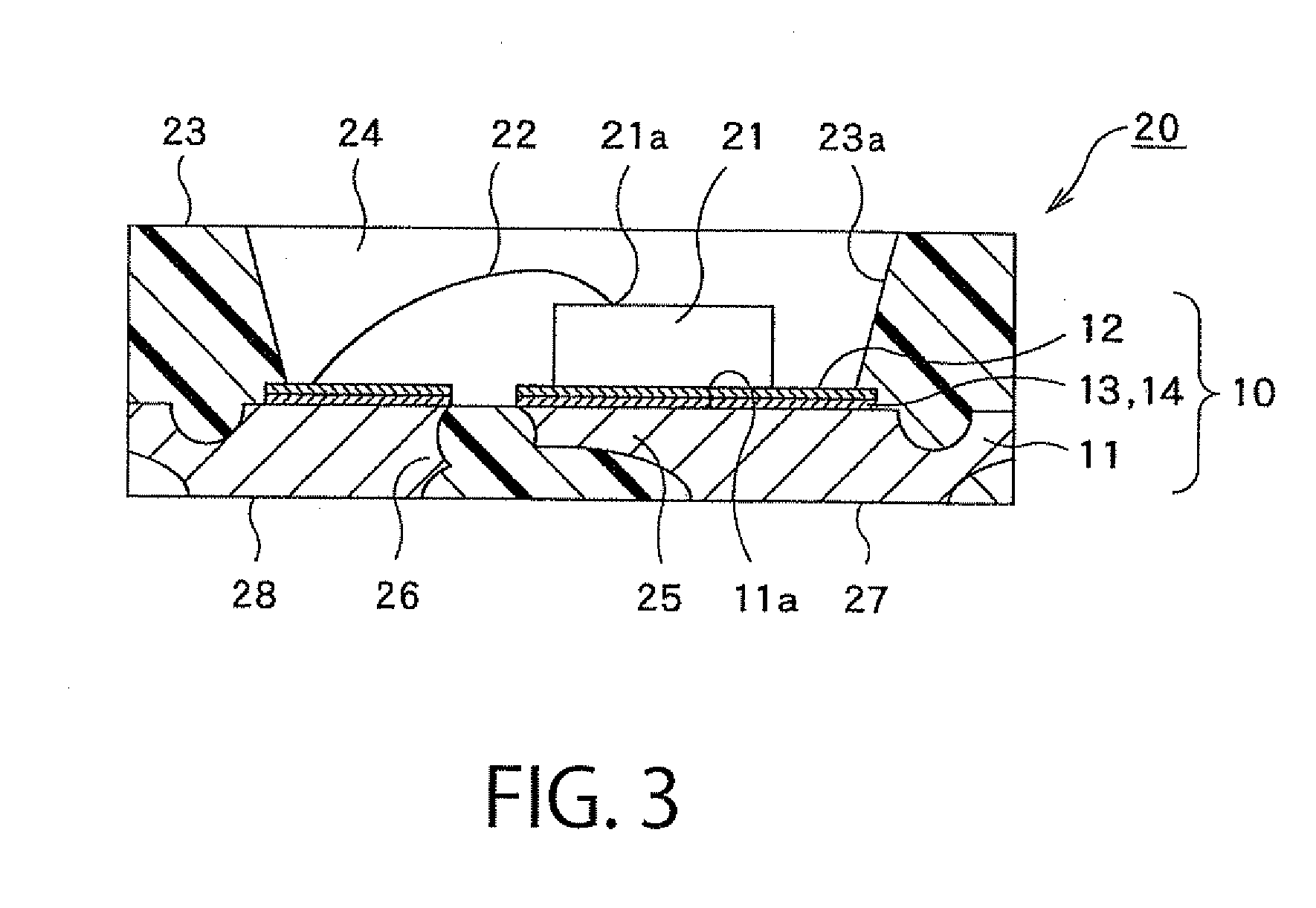

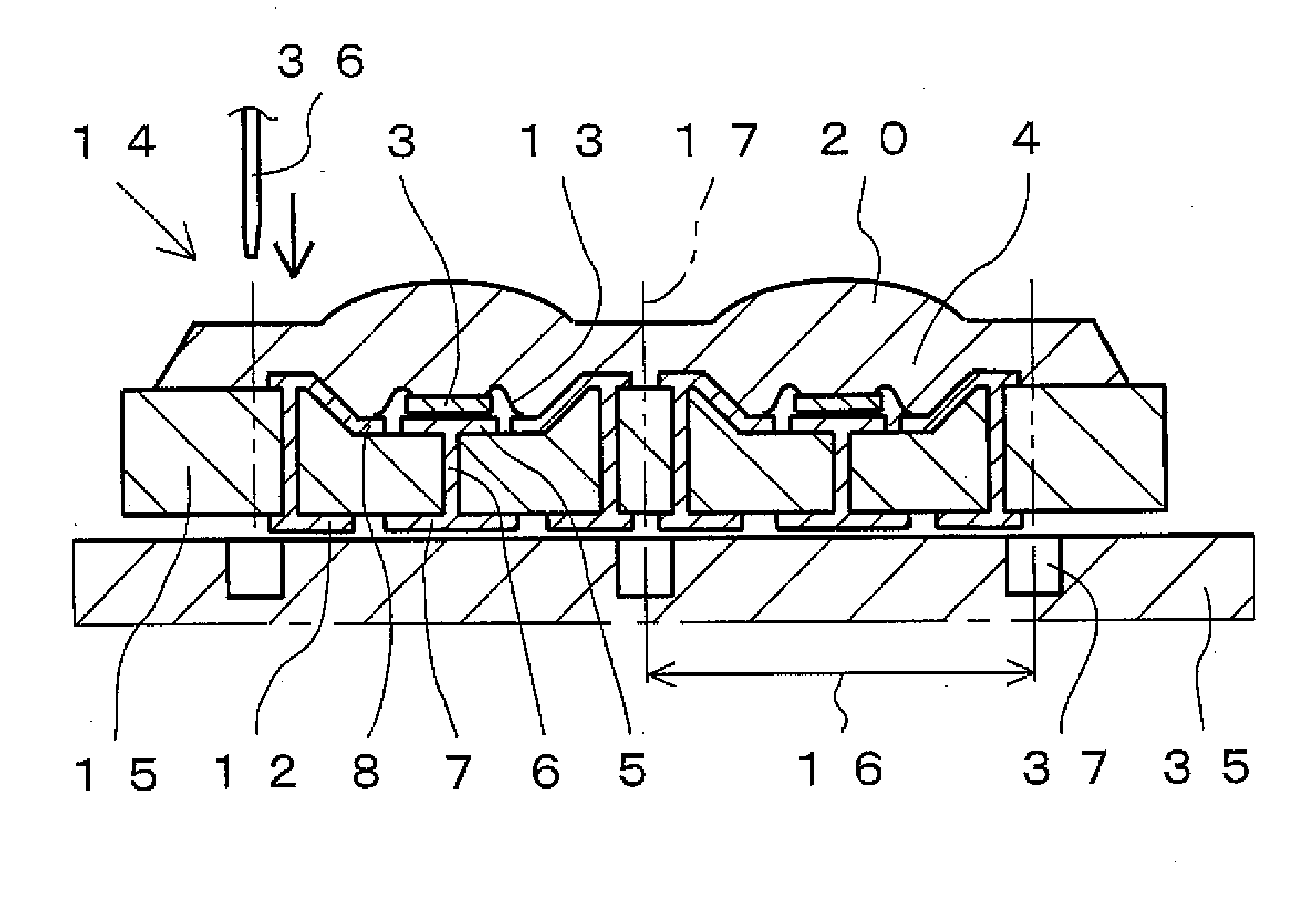

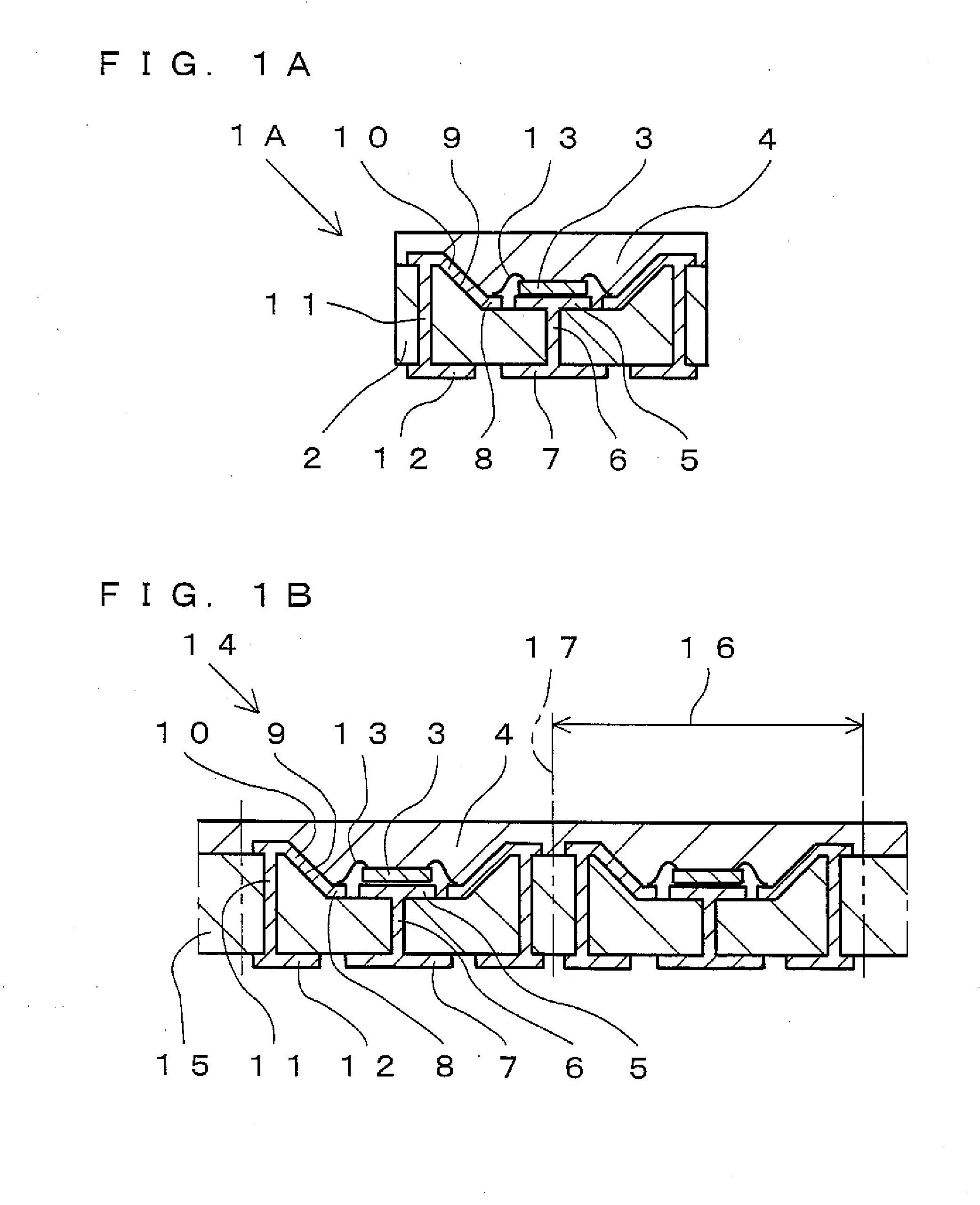

Plasma display panel having high brightness and high contrast using light absorption reflection film

InactiveUS7323819B2Effective reflectionAlternating current plasma display panelsCold-cathode tubesElectrode pairDielectric layer

A plasma display panel having a light absorption reflection film that does not reflect light emitted from a discharge space in a non-discharge region includes: a rear substrate; a plurality of address electrodes arranged on a surface of the rear substrate; a rear dielectric layer arranged on the rear substrate to cover the address electrodes; a plurality of barrier ribs arranged on the rear dielectric layer to define discharge cells; a front substrate facing the rear substrate; a plurality of sustaining electrode pairs composed of X and Y electrodes; a light absorption reflection film including a first light absorption reflection film arranged between the adjacent sustaining electrode pairs and a second light absorption reflection film having a different width than that of the first light absorption reflection film, the second light absorption reflection film arranged on a lower surface of the first light absorption reflection film; and a front dielectric layer arranged on a lower surface of the front substrate to cover the X and Y electrodes and the light absorption reflection film.

Owner:SAMSUNG SDI CO LTD

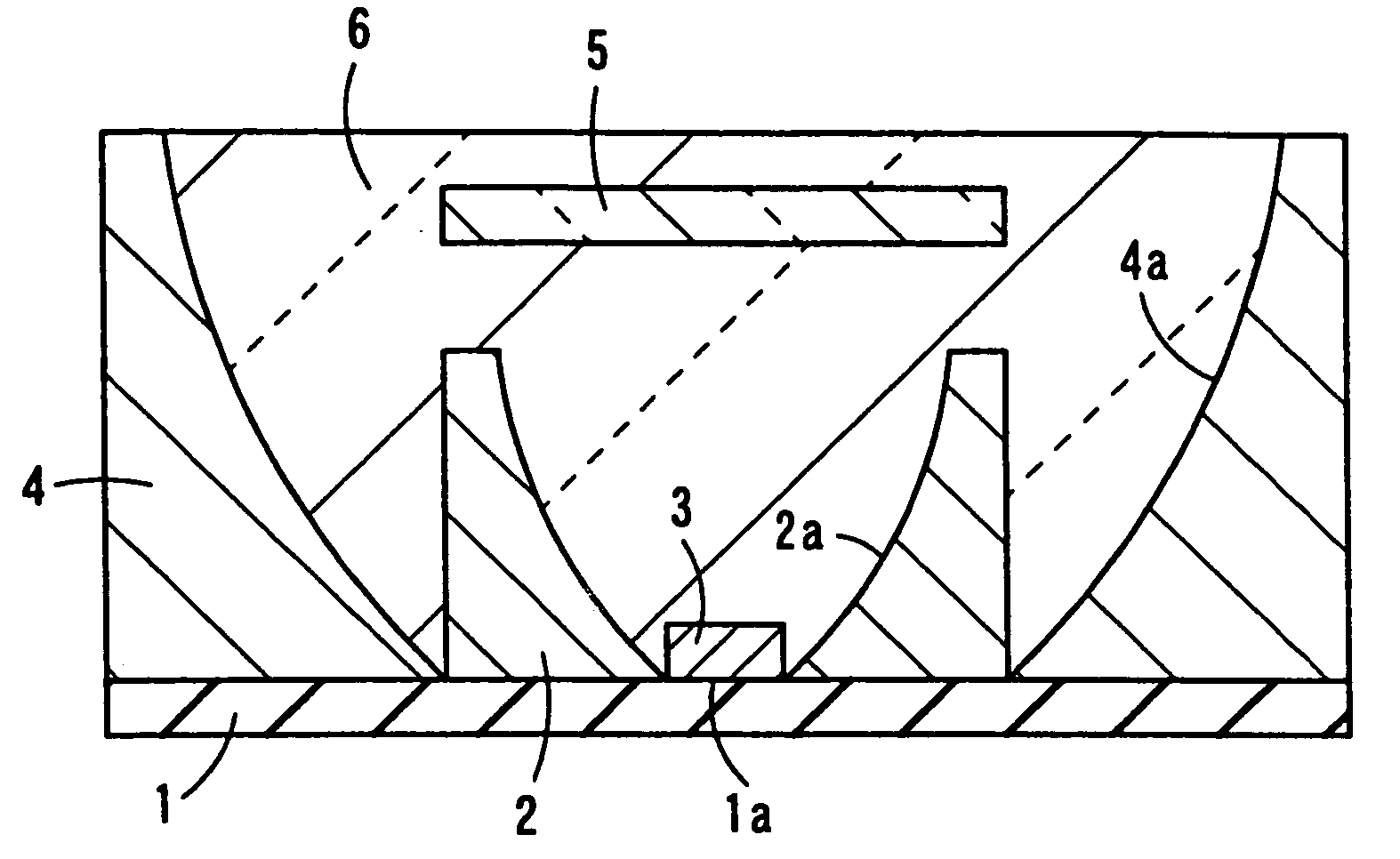

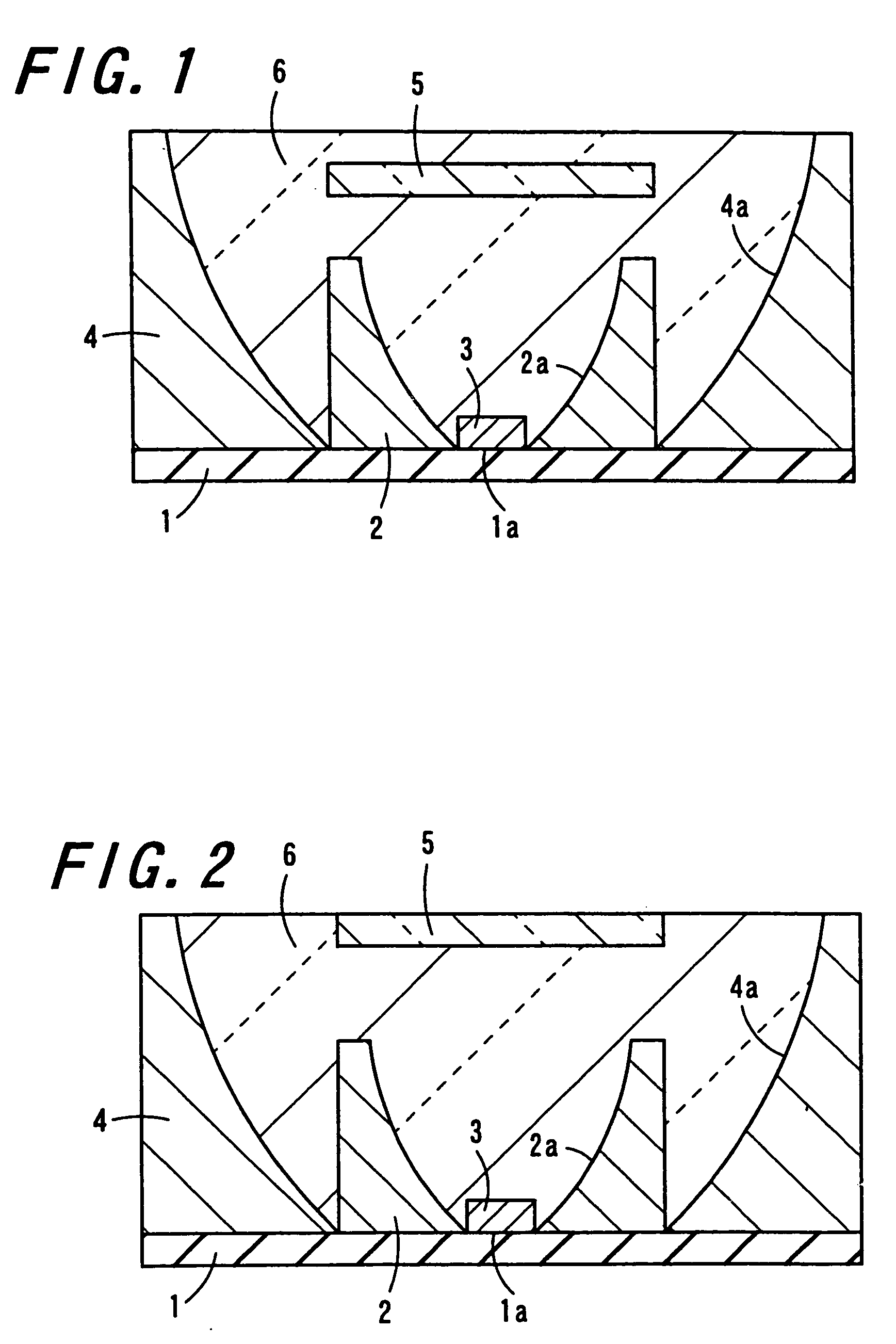

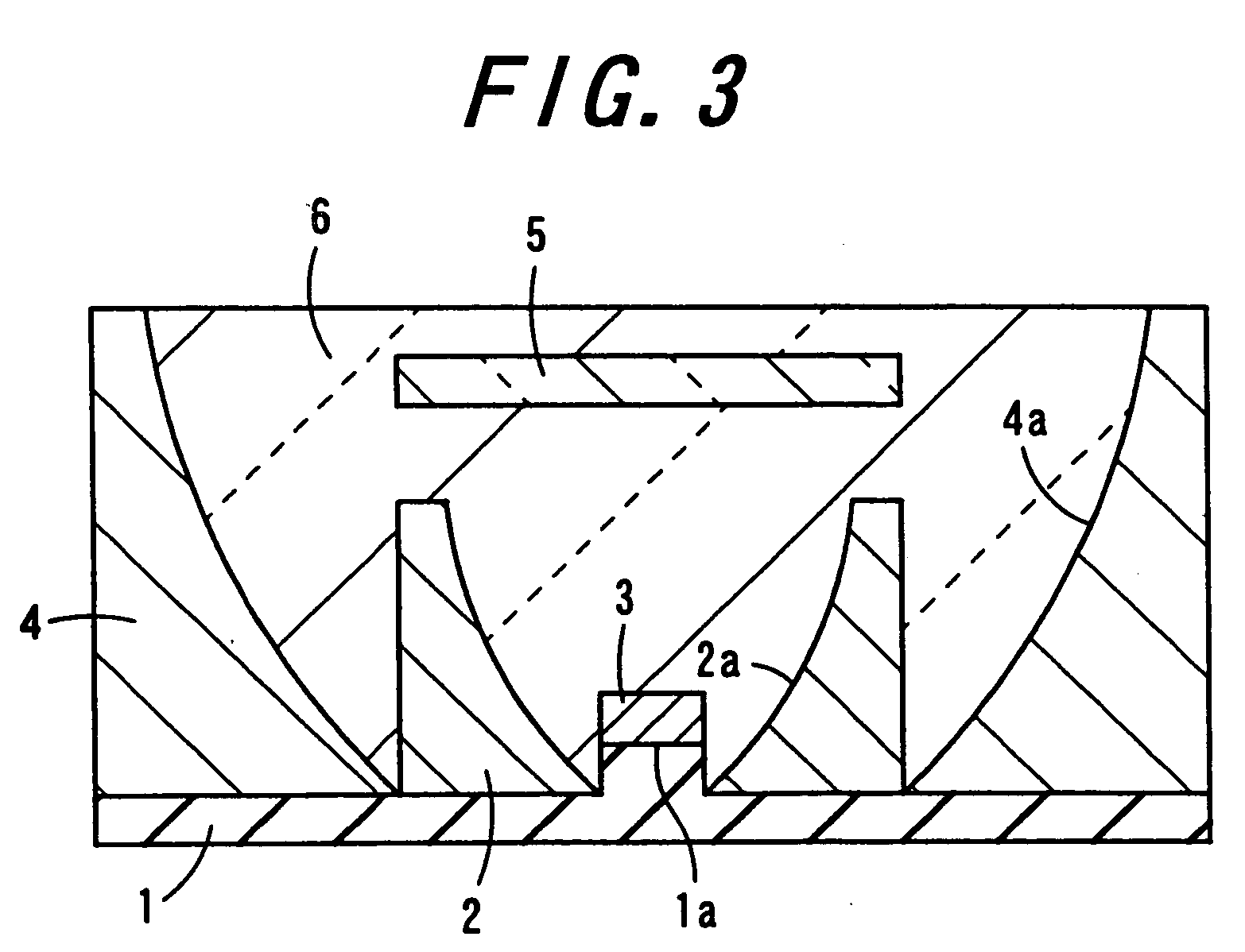

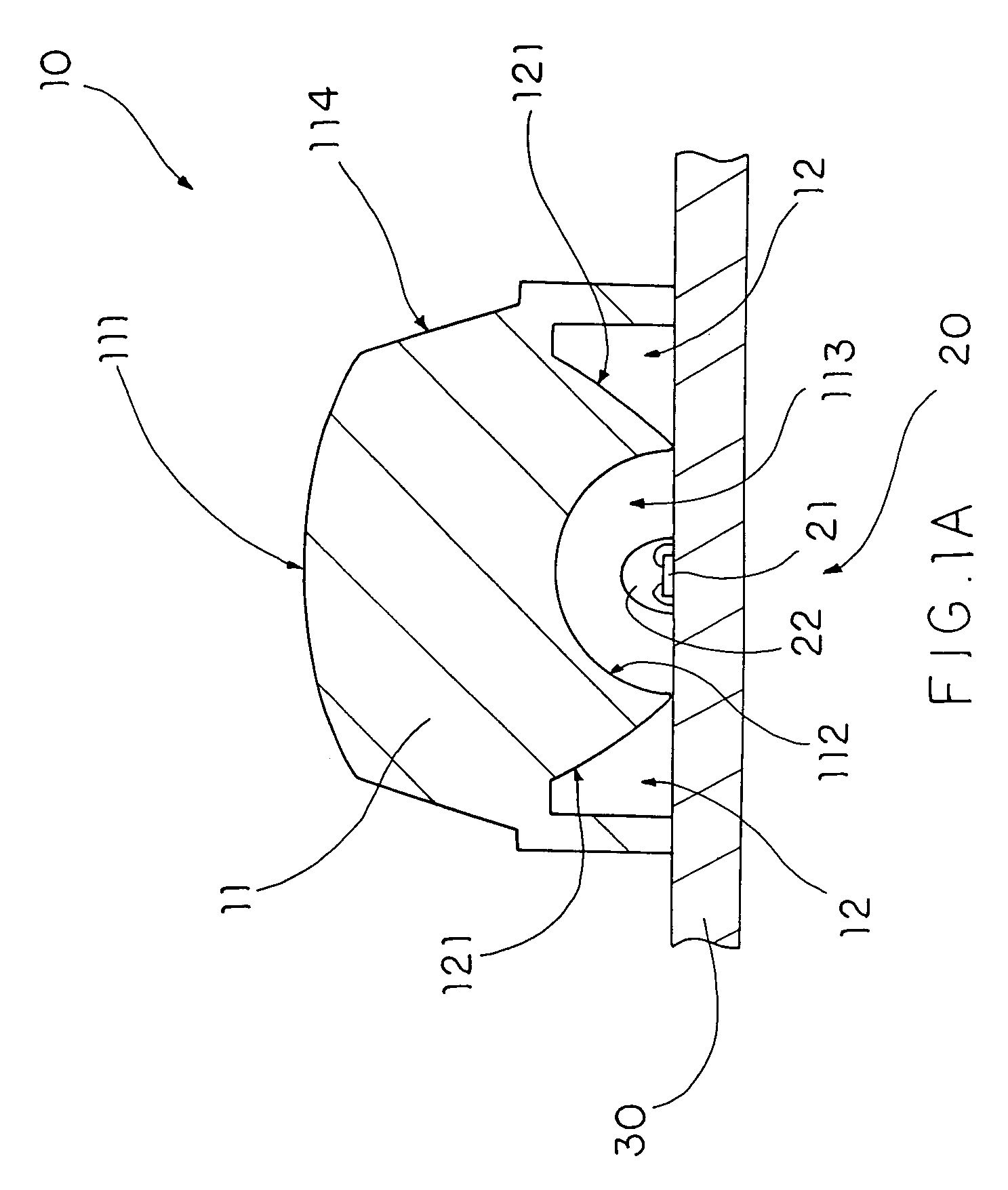

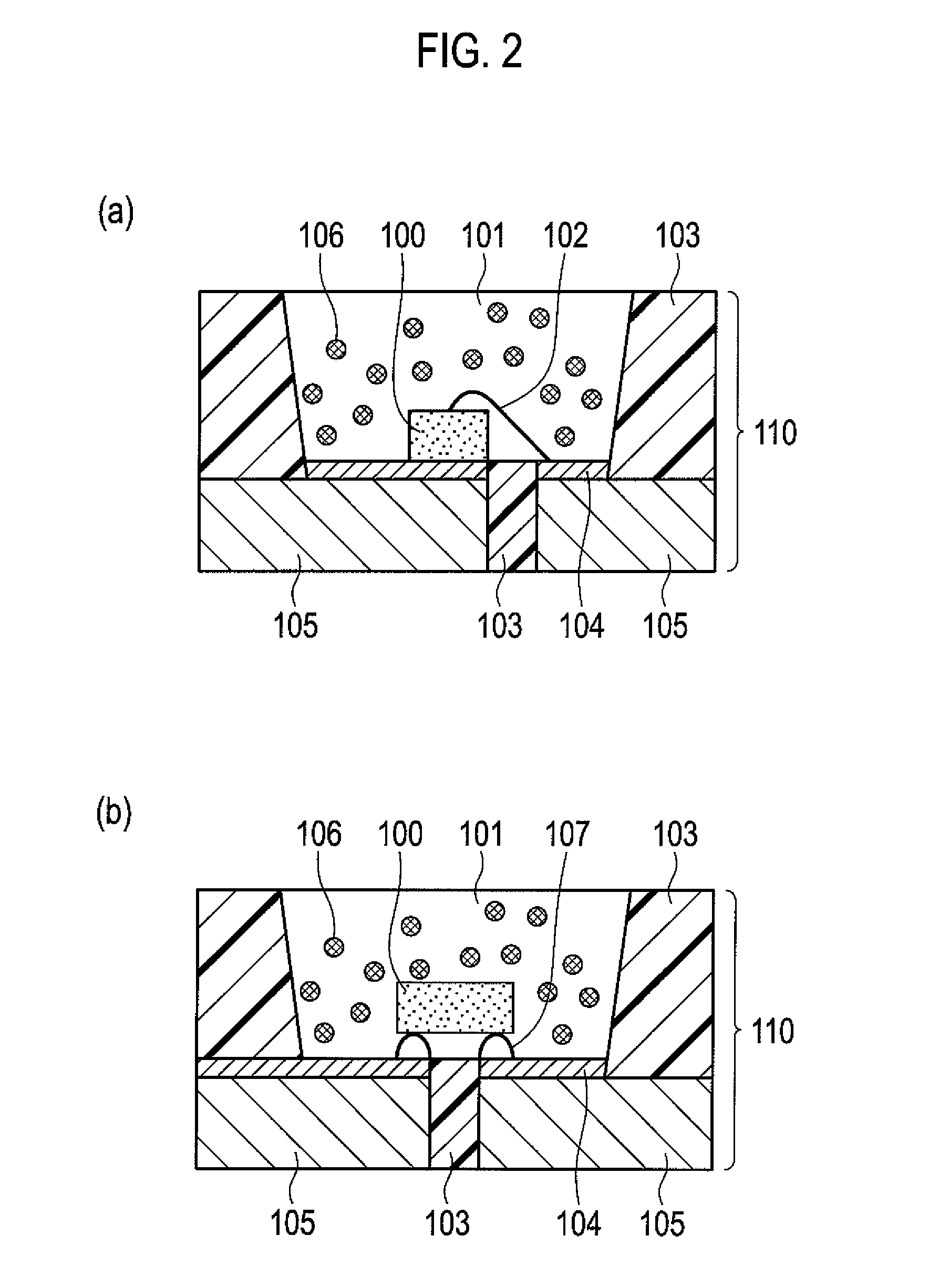

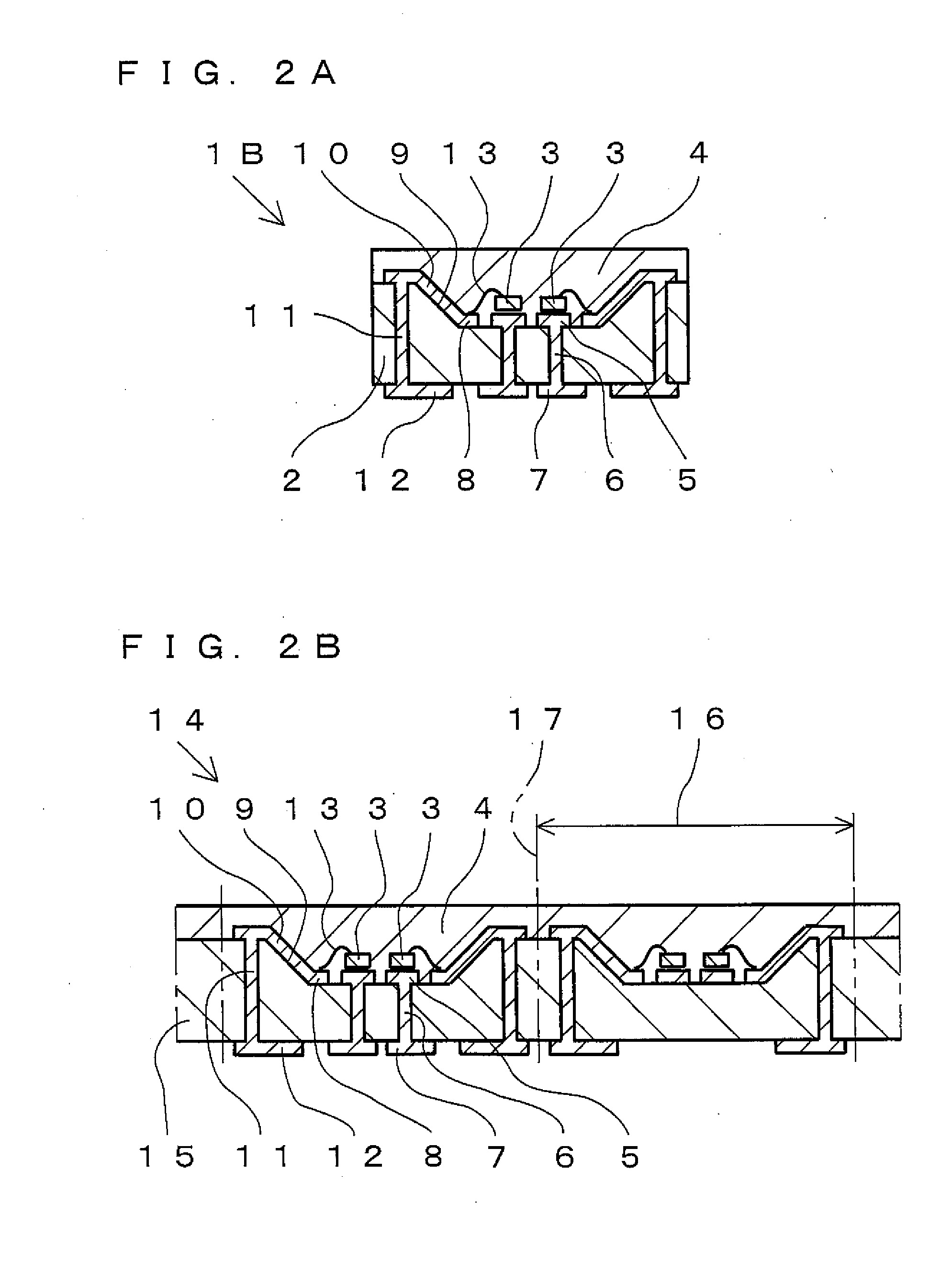

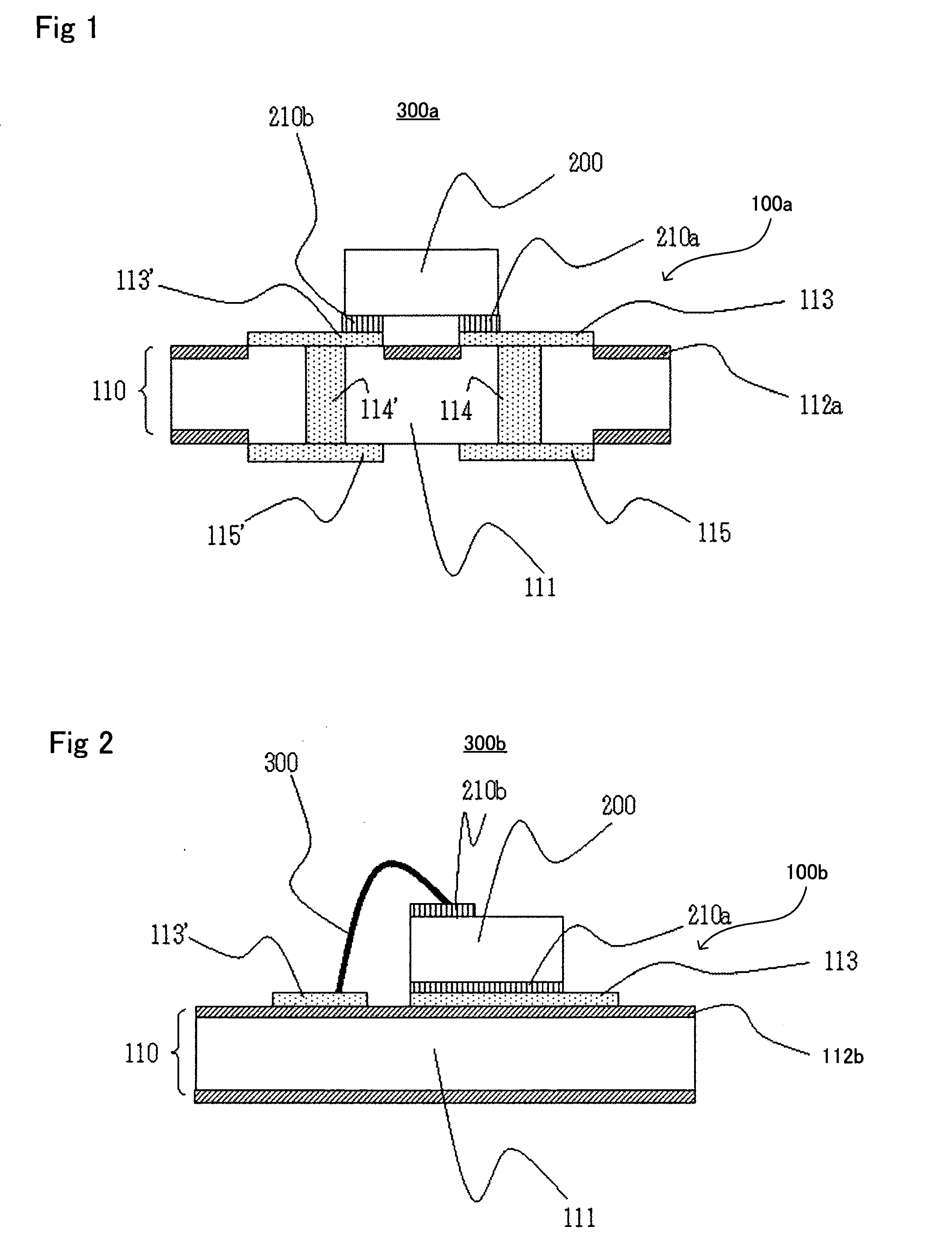

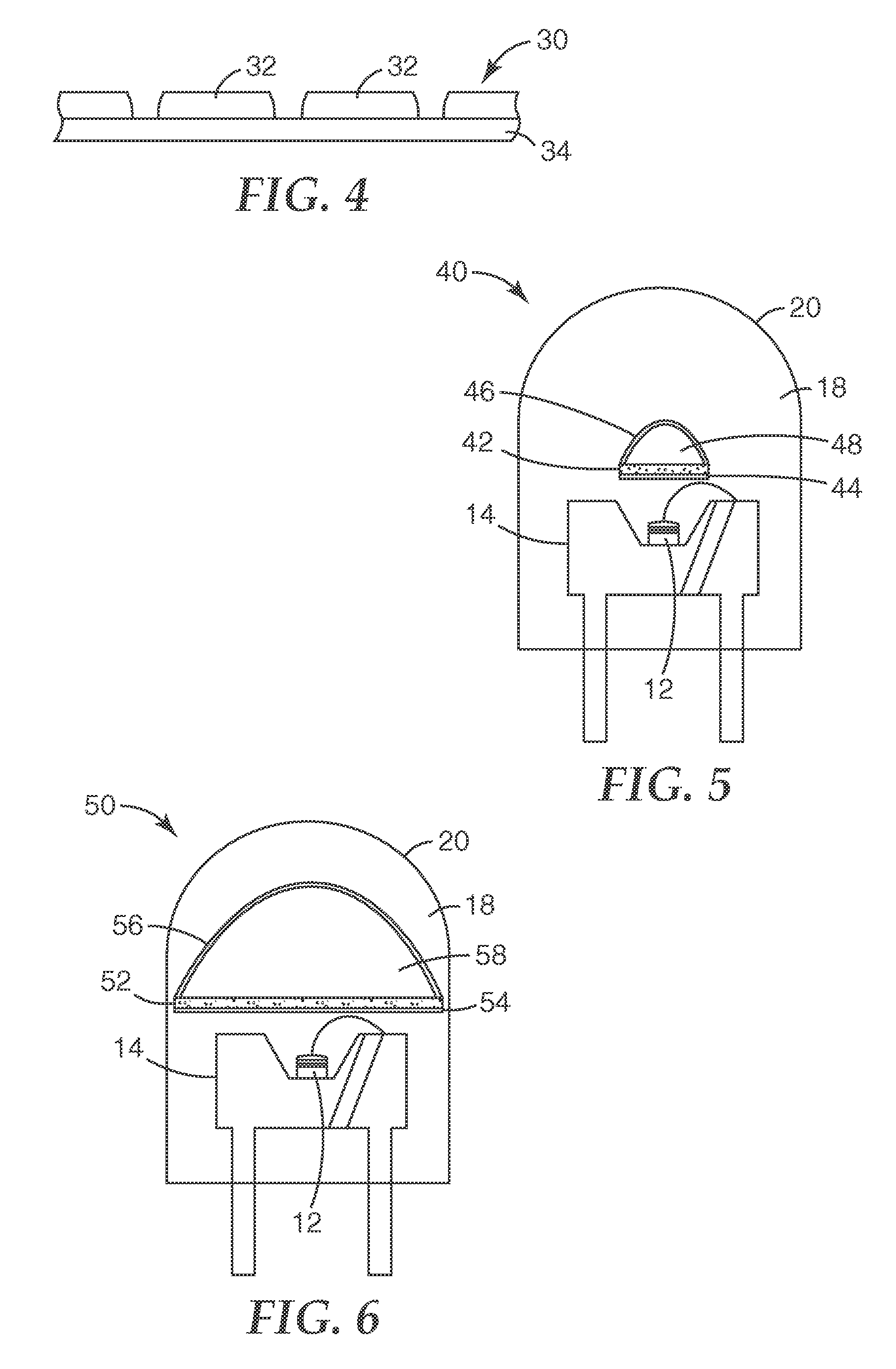

Light-emitting apparatus and illuminating apparatus

InactiveUS20060034084A1High strengthReduce light intensityPlanar light sourcesSolid-state devicesEngineeringLength wave

The light-emitting apparatus includes a light-emitting element, a base body having, on its upper principal surface, a placement portion for emplacing thereon the light-emitting element; a first reflecting member formed in a frame-like shape and attached to the upper principal surface of the base body so as to surround the placement portion; a second reflecting member formed in a frame-like shape and attached to the upper principal surface of the base body so as to surround the first reflecting member; a light transmitting member provided inside the second reflecting member so as to cover the light-emitting element and the first reflecting member; and a first wavelength-conversion layer for converting a wavelength of light from the light-emitting element, the first wavelength-conversion layer being provided inside the light transmitting member disposed above the light-emitting element, spaced from the first and second reflecting members.

Owner:KYOCERA CORP

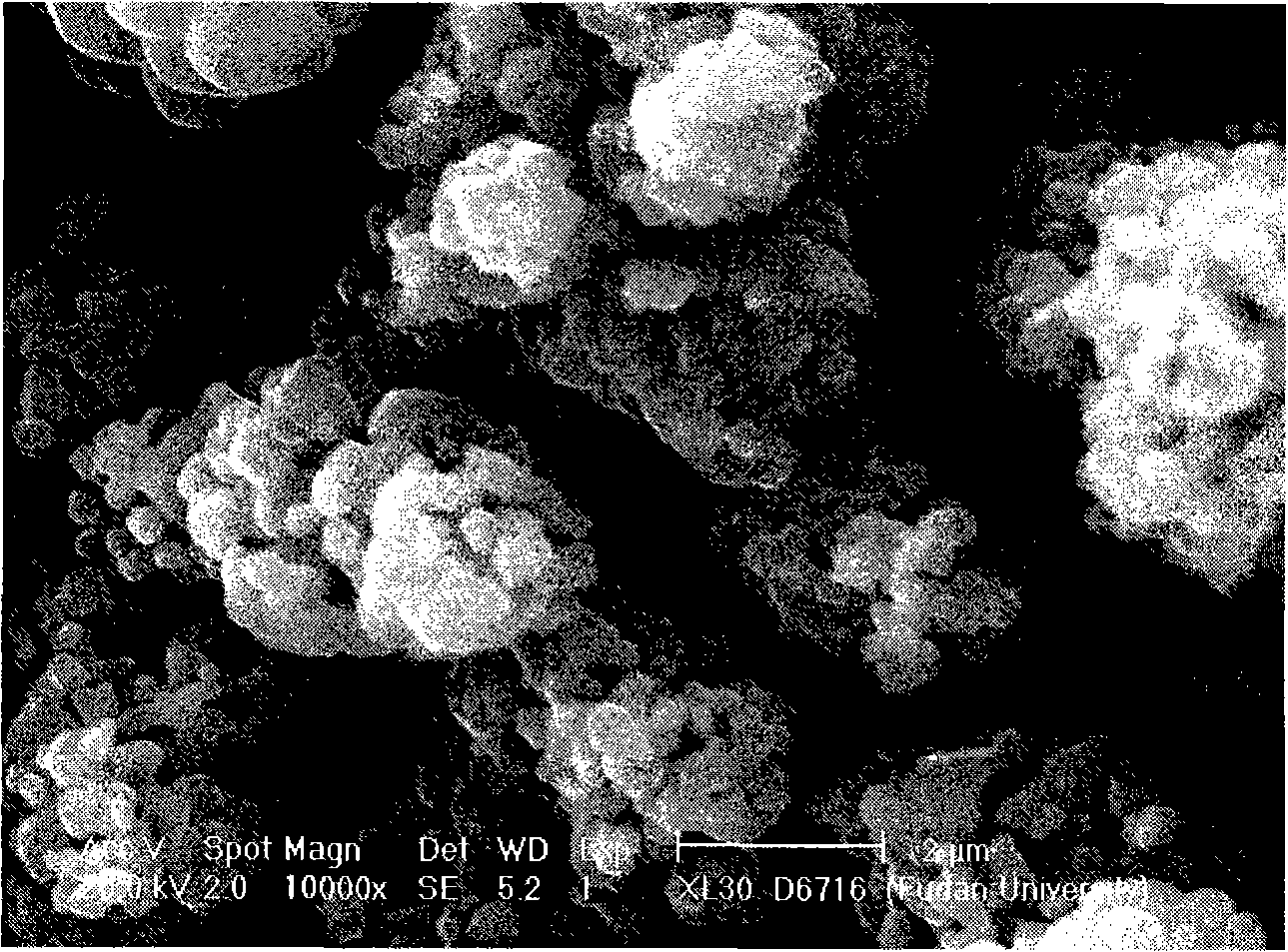

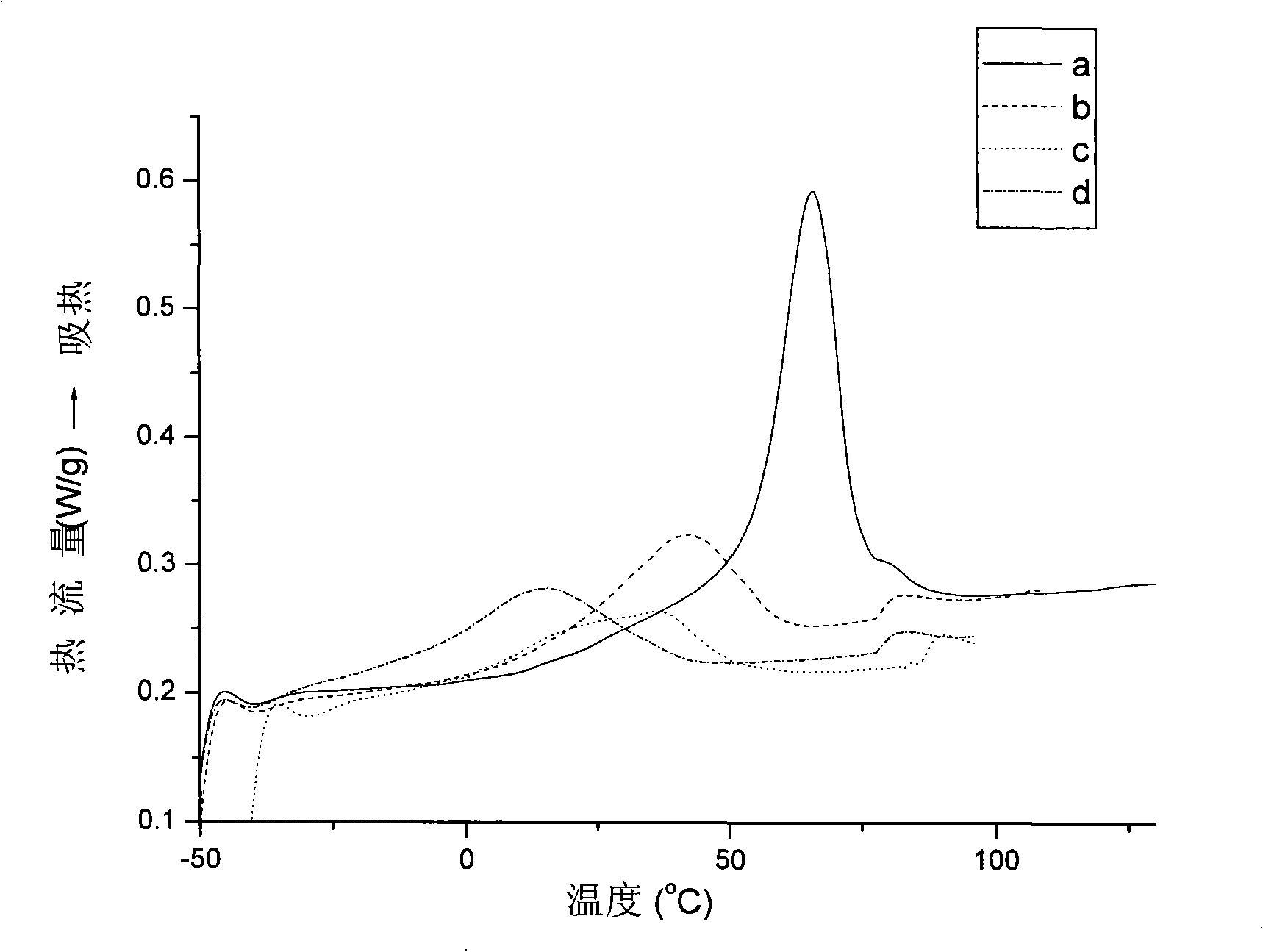

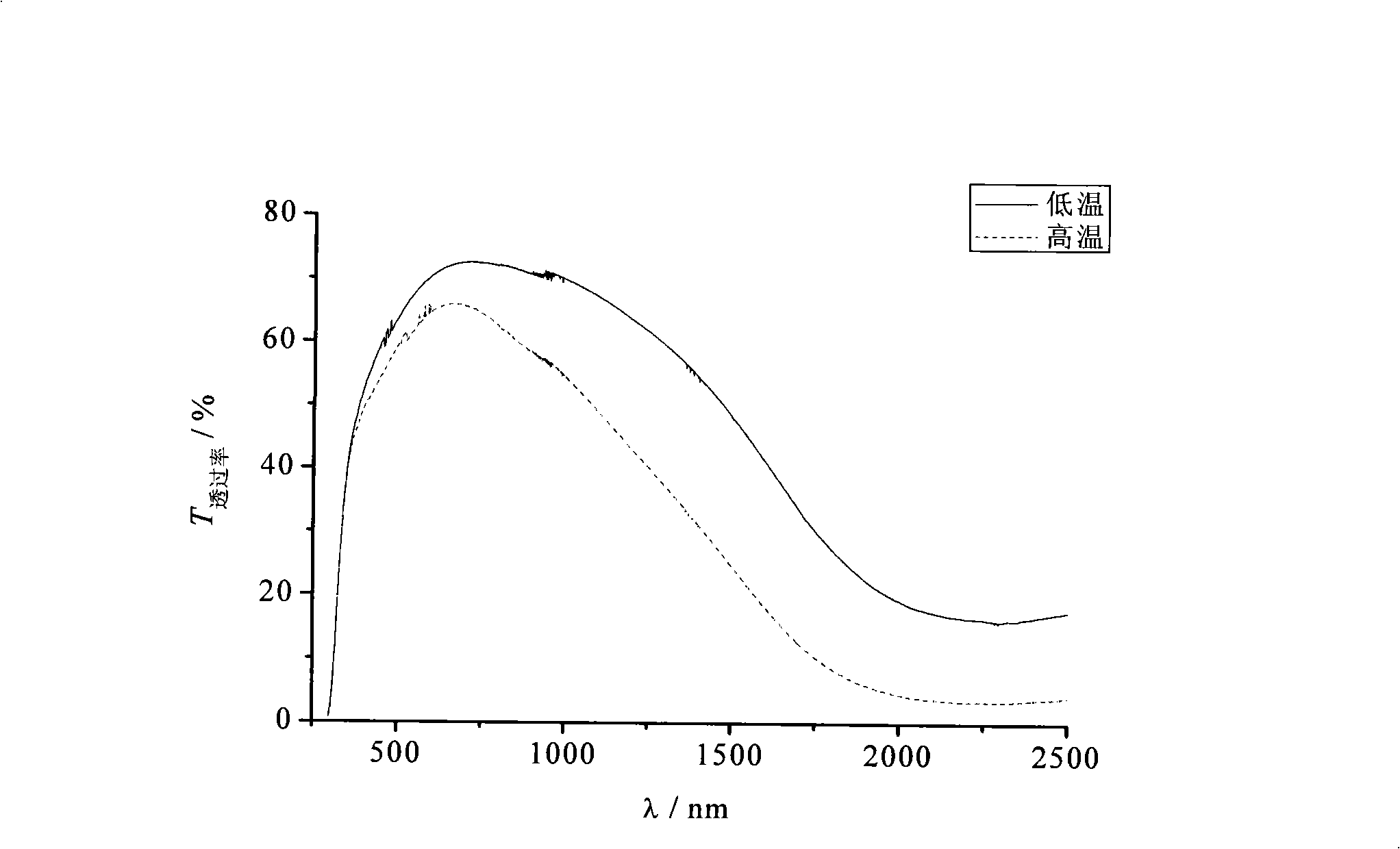

Intelligent heat-insulating film and its preparing process

InactiveCN101265374AGood transparencyEasy constructionFireproof paintsPolyurea/polyurethane coatingsTransmittanceHigh reflectivity

The invention relates to an intelligent heat-insulating film and a preparation method thereof. The invention adopts the mixture of phase transition intelligent nanometer powder in the rutile crystal structure and vanadium dioxide V1-XO2(X is more than 0 and less than 0.06) to uniformly disperse on a material which can be formed into films, thus preparing the intelligent heat-insulating film with the phase transition function. The intelligent heat-insulating film is a novel energy-saving material with the phase transition temperature adjustable within -10 DEG C to 70 DEG C. The film has high infrared transmittance and low reflectivity as well as excellent heat-insulating property at low temperatures. At high temperatures, the film has low infrared transmittance and high reflectivity as well as excellent heat insulating effect. The intelligent heat-insulating film can be used for heat-insulation and decorative-protection of the surfaces such as glass, plastic, metal, wood, concrete and so on.

Owner:FUDAN UNIV

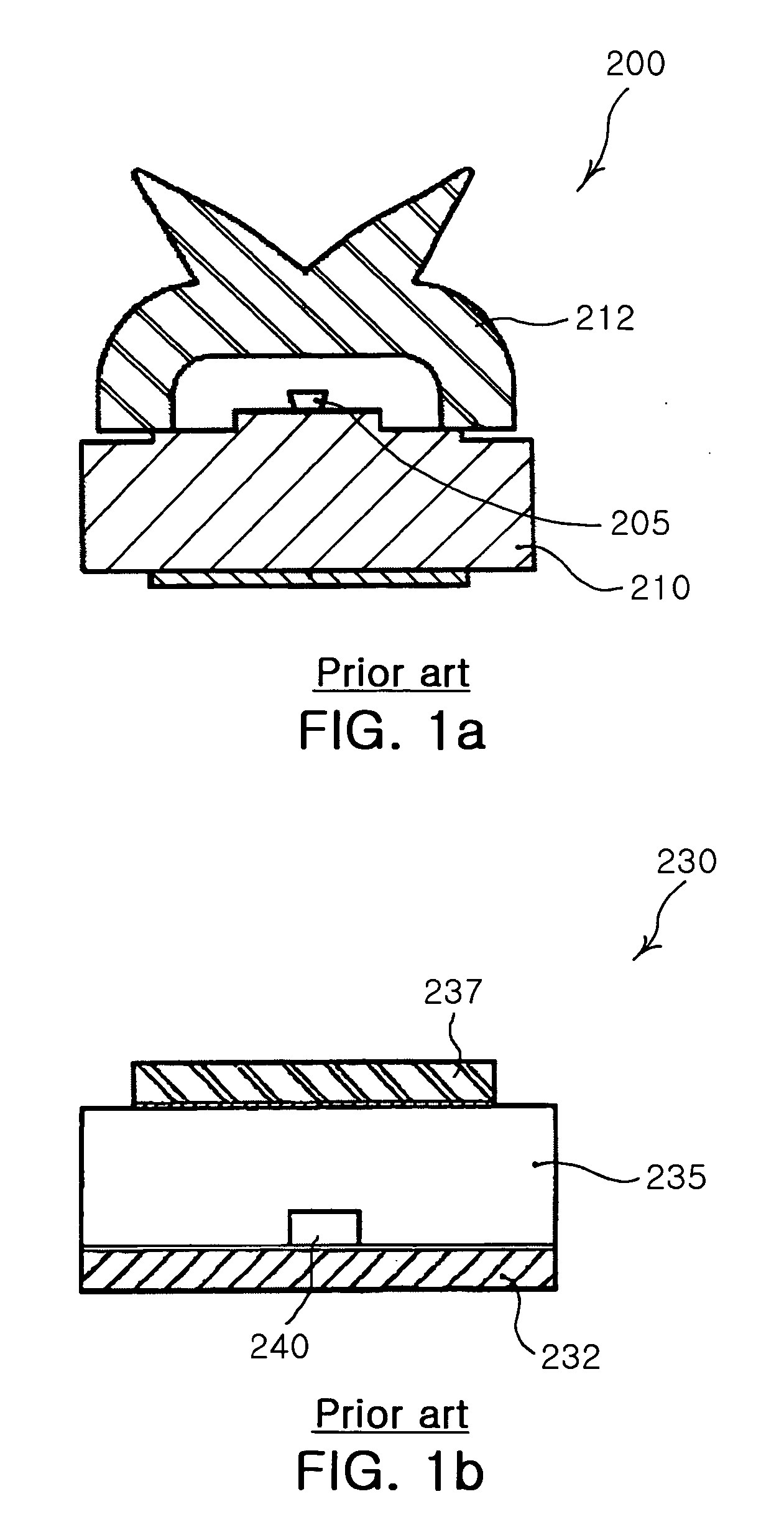

Semiconductor light-emitting device

InactiveUS20080246047A1Improve reflectivityGood ohmic contactSolid-state devicesSemiconductor devicesOhmic contactHigh reflectivity

A semiconductor light-emitting device comprises an N-type semiconductor layer, an active layer formed on the surface of the N-type semiconductor layer, a P-type semiconductor layer formed on the surface of the active layer, and a reflective layer formed on the surface of the P-type semiconductor layer. A plurality of ohmic contact blocks with electrical properties of ohmic contact are on the surface of the reflective layer adjacent to the P-type semiconductor layer, and the remaining part of the surface acts as the reflective regions with higher reflectivity, and the reflective regions can effectively reflect the light generated from the active layer.

Owner:ADVANCED OPTOELECTRONICS TECH

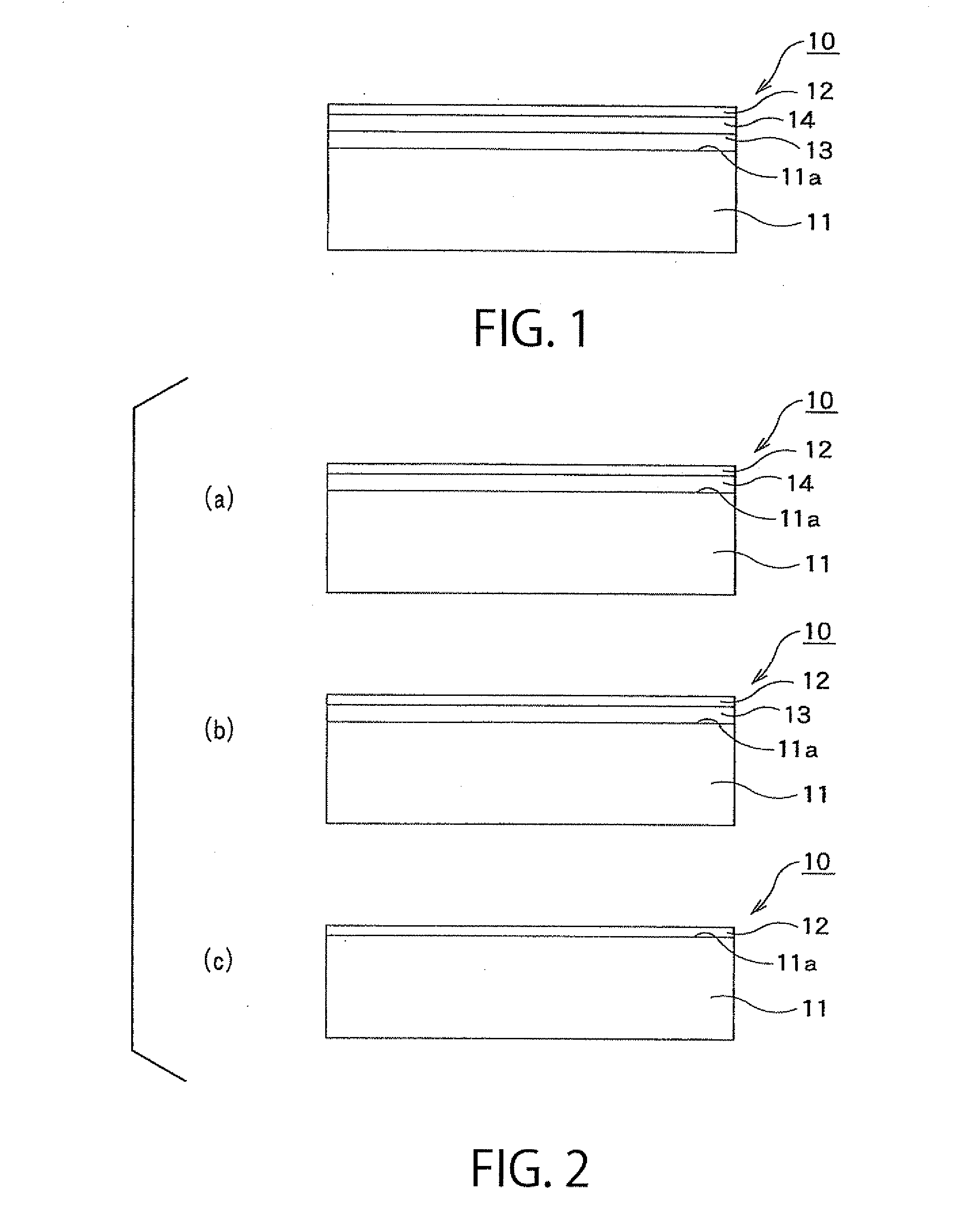

LED leadframe or LED substrate, semiconductor device, and method for manufacturing LED leadframe or LED substrate

ActiveUS20120313131A1Less discolorationImprove featuresSemiconductor/solid-state device detailsSolid-state devicesAlloySemiconductor

An LED leadframe or LED substrate includes a main body portion having a mounting surface for mounting an LED element thereover. A reflection metal layer serving as a reflection layer for reflecting light from the LED element is disposed over the mounting surface of the main body portion. The reflection metal layer comprises an alloy of platinum and silver or an alloy of gold and silver. The reflection metal layer efficiently reflects light emitted from the LED element and suppresses corrosion due to the presence of a gas, thereby capable of maintaining reflection characteristics of light from the LED element.

Owner:DAI NIPPON PRINTING CO LTD

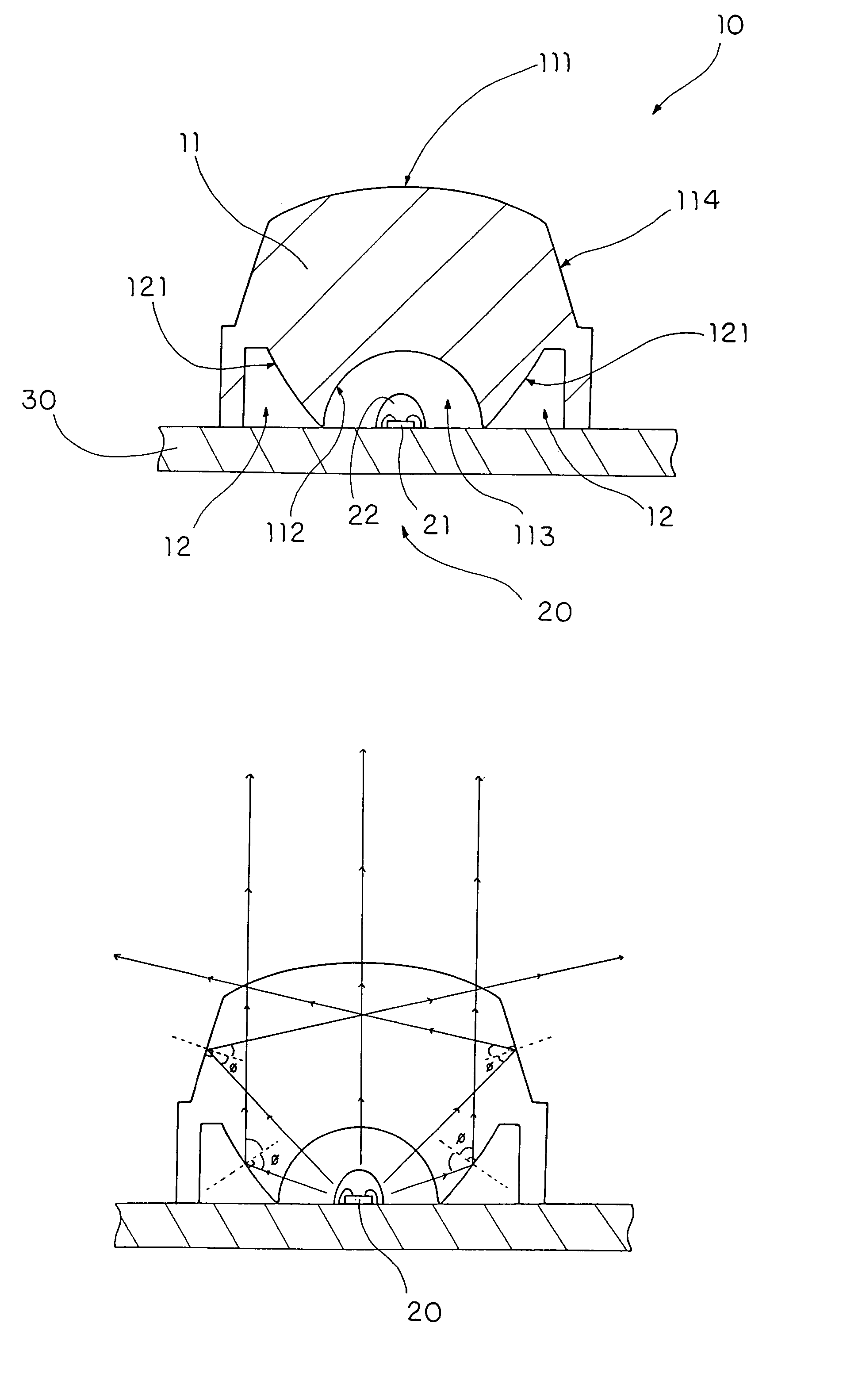

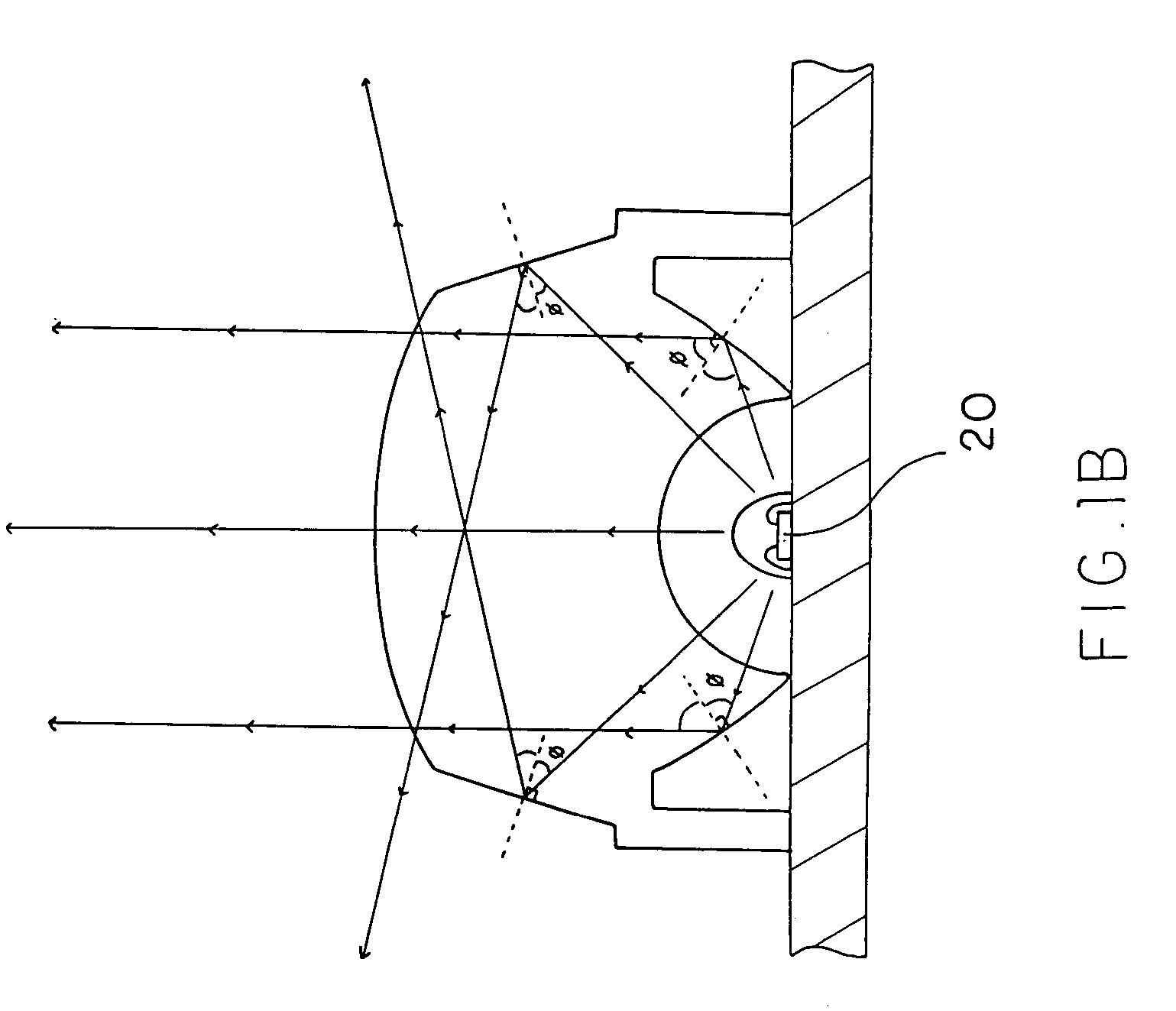

Projection lens for light source arrangement

InactiveUS7104672B2Increase light intensityEffective convergenceVehicle lighting systemsRoad vehiclesCamera lensEffect light

A light source arrangement for substantially enhaning the lighting intensity of the light beams emitted from the light source therefore includes a lens body and an illumination unit. The lens body has an illumination portion defining a light projecting surface and at least a diffraction portion defining a light diffraction surface inclinedly extended at a diffraction angle, wherein a diffraction density of the illumination portion is different from that of the diffraction portion. The illumination unit is covered by the lens body for radially generating light towards the illumination portion. When the light reaches the light diffraction surface of a diffraction portion at an angle larger than the diffraction angle, the light is substantially reflected at the light diffraction surface back towards the light projecting surface, such that the light from the illumination unit is converged to project at the light projecting surface of the lens body.

Owner:CHEN AMY YUN

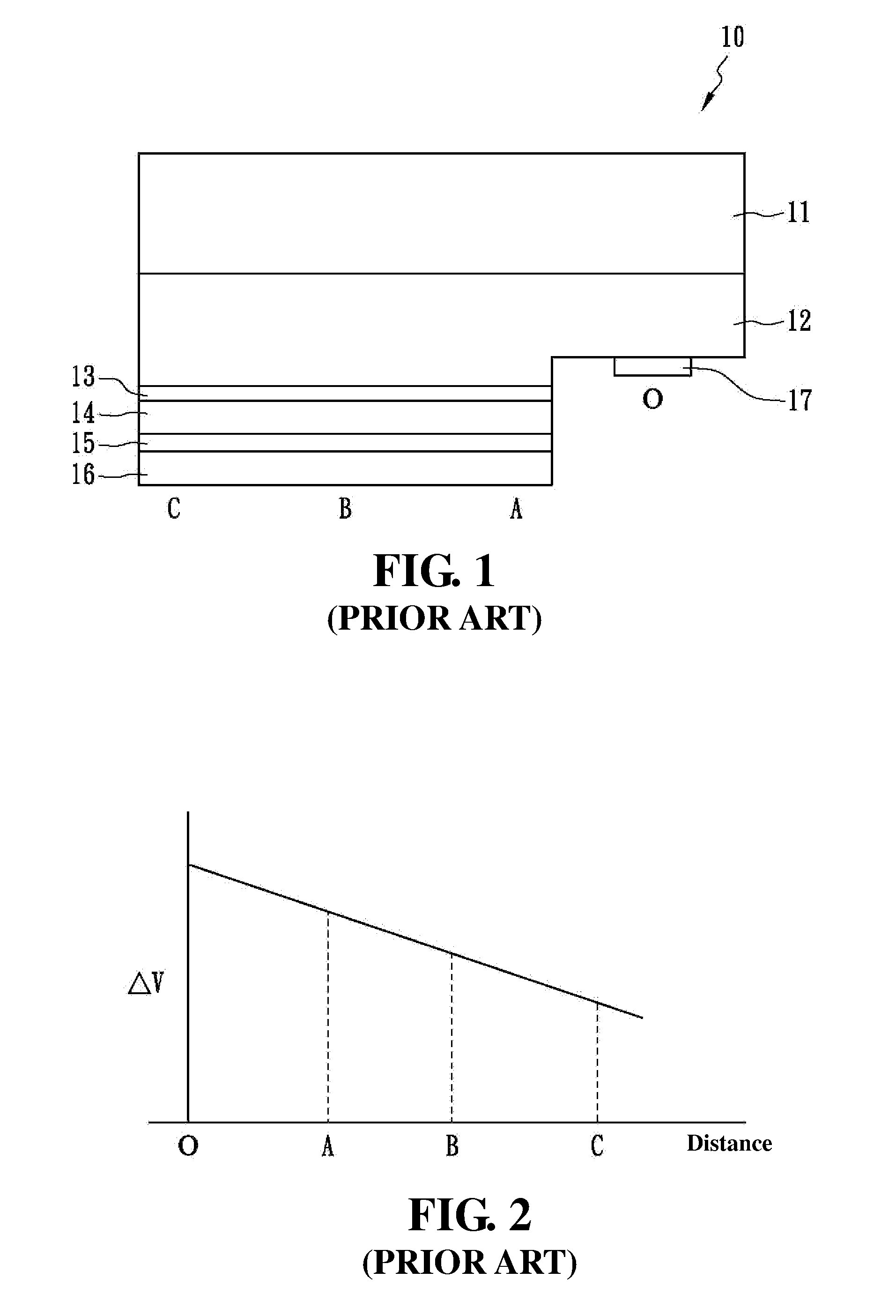

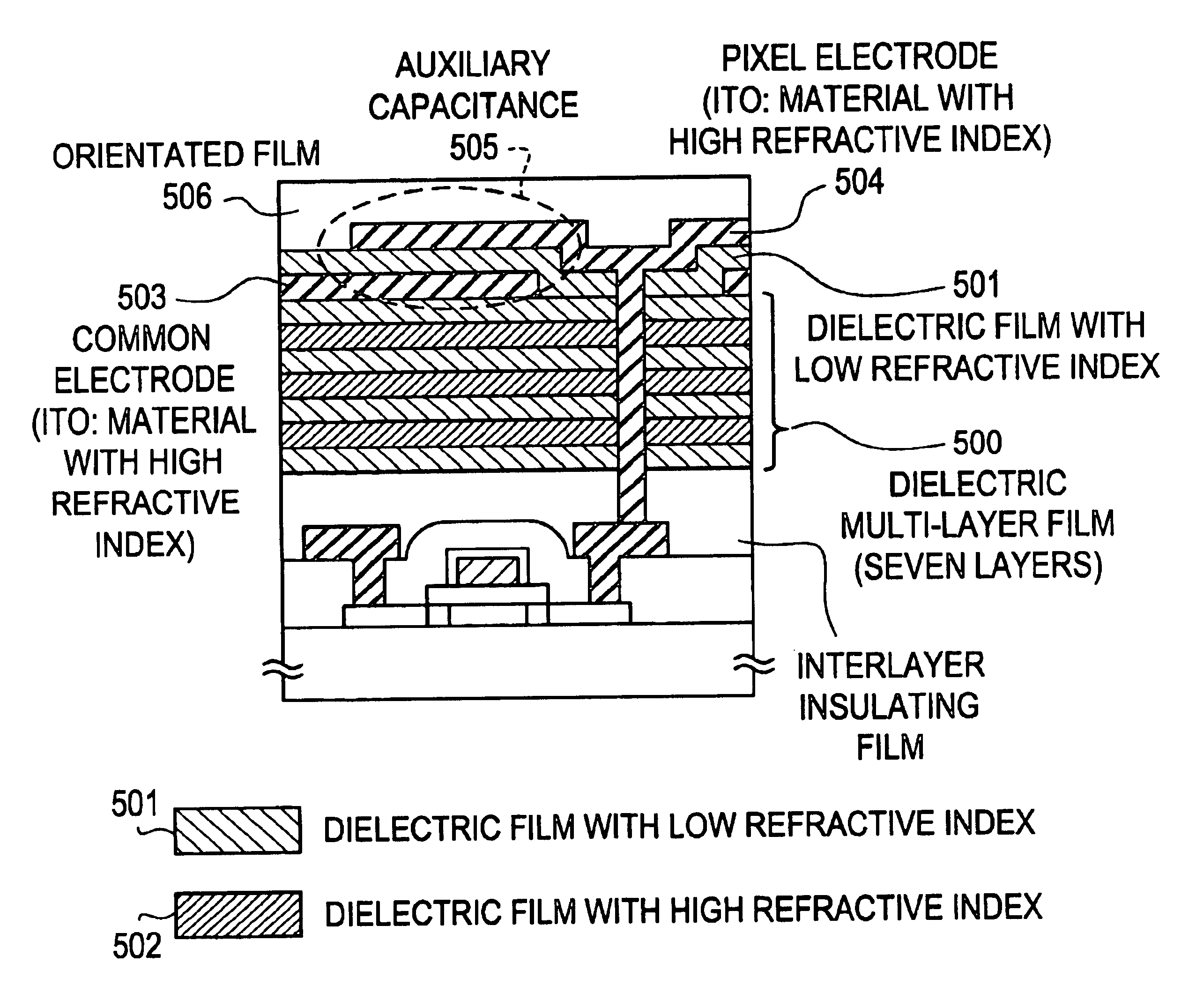

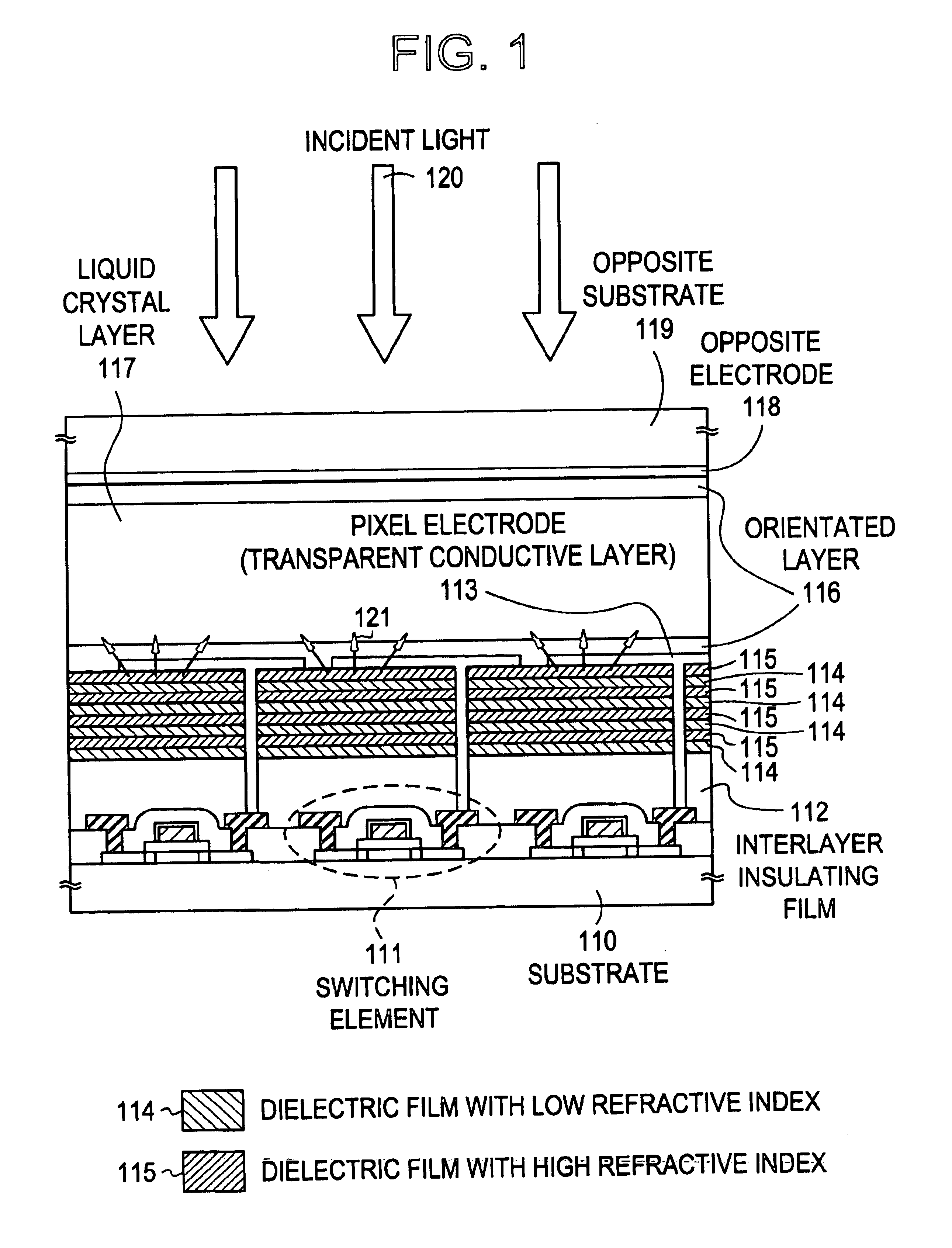

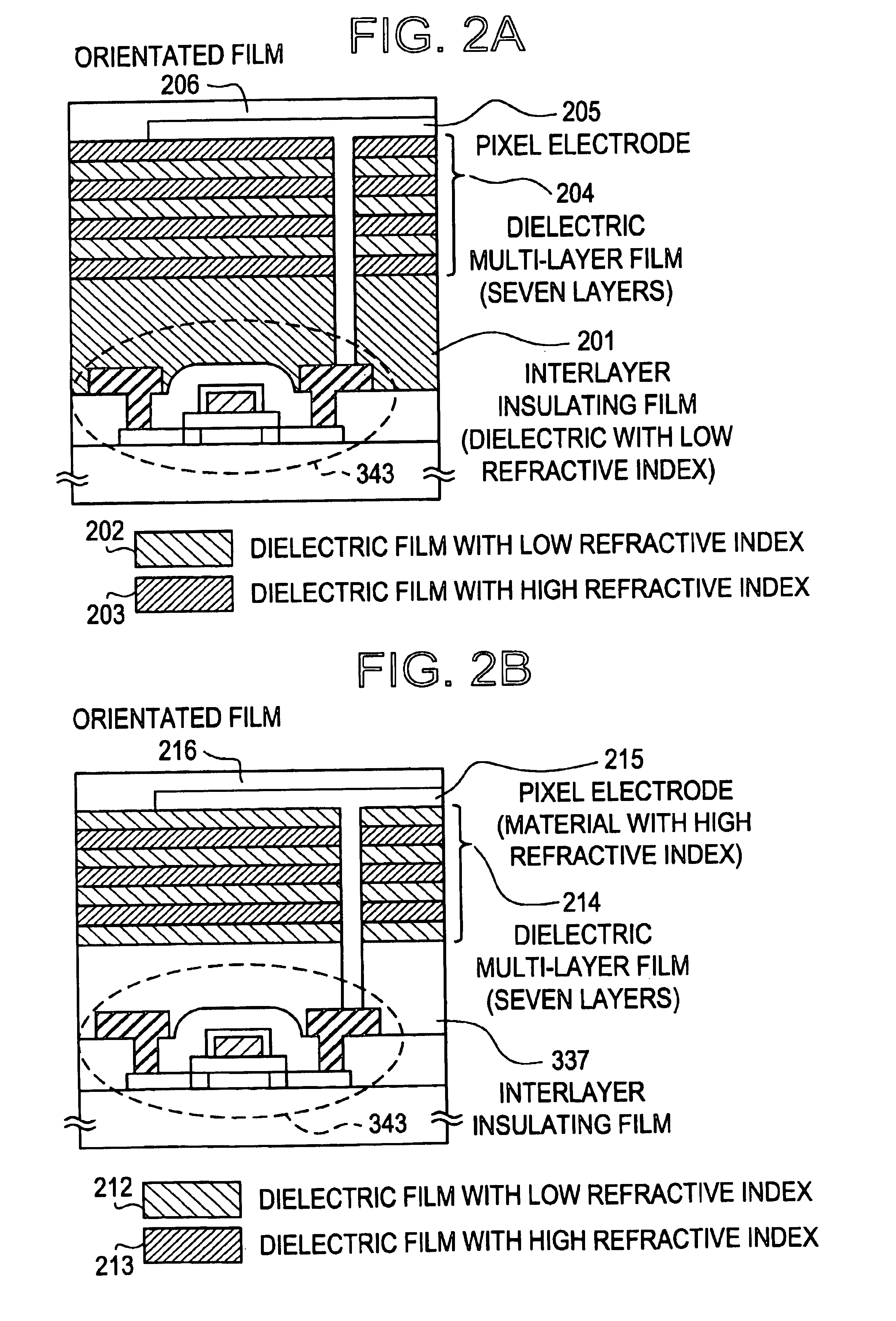

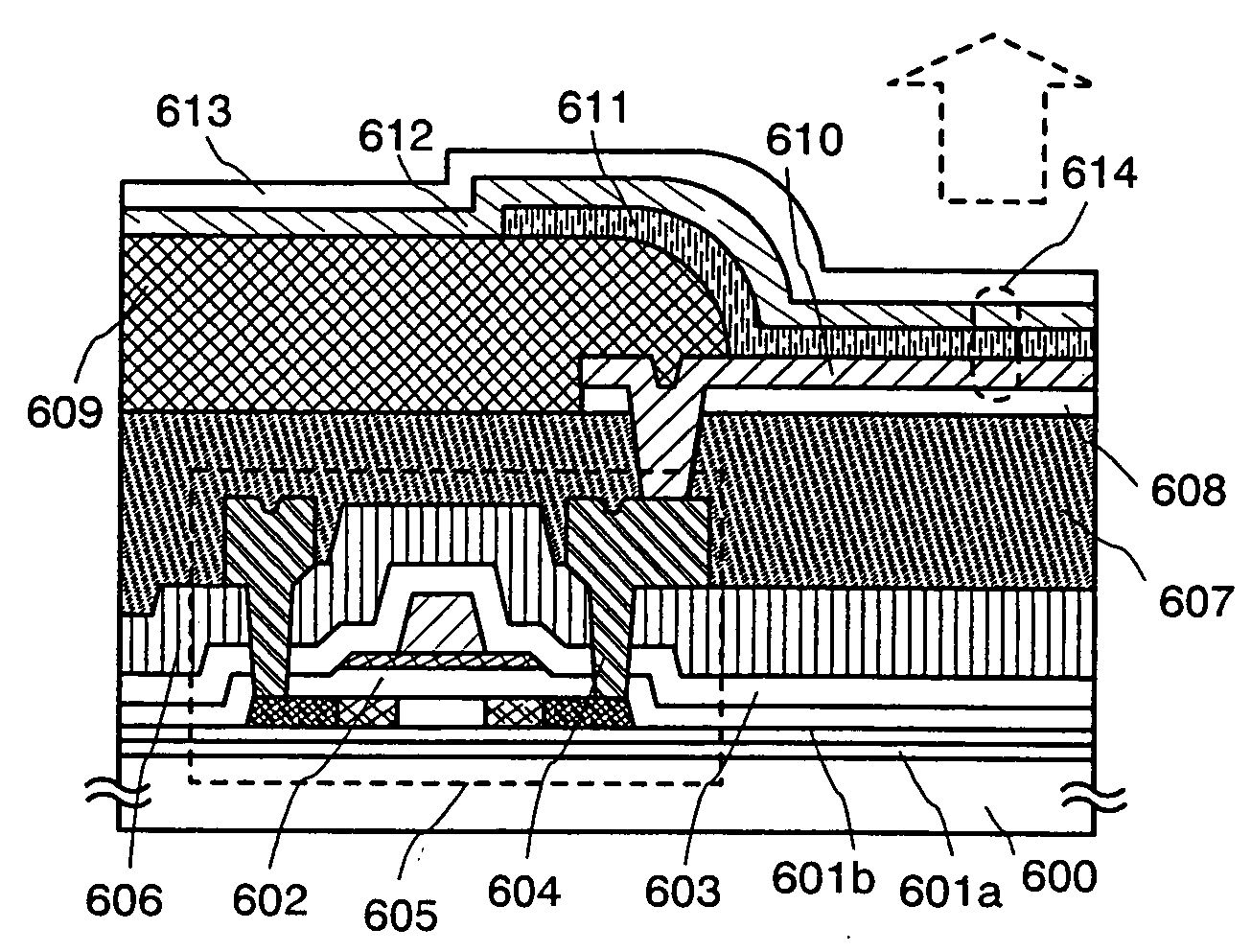

Liquid crystal display device and method of manufacturing the same

InactiveUS6839108B1Effective reflectionSimple matrix type driving systemStatic indicating devicesNon-linear opticsElectricityLiquid-crystal display

To provide a novel liquid crystal display device comprising a light reflection layer where light is likely to more effectively reflect, and a method of manufacturing the same. The present invention can realize high resolution and high opening rate by using a dielectric multi-layer film as the light reflection layer to form thereon a pixel electrode consisting of a transparent conductive films.

Owner:SEMICON ENERGY LAB CO LTD

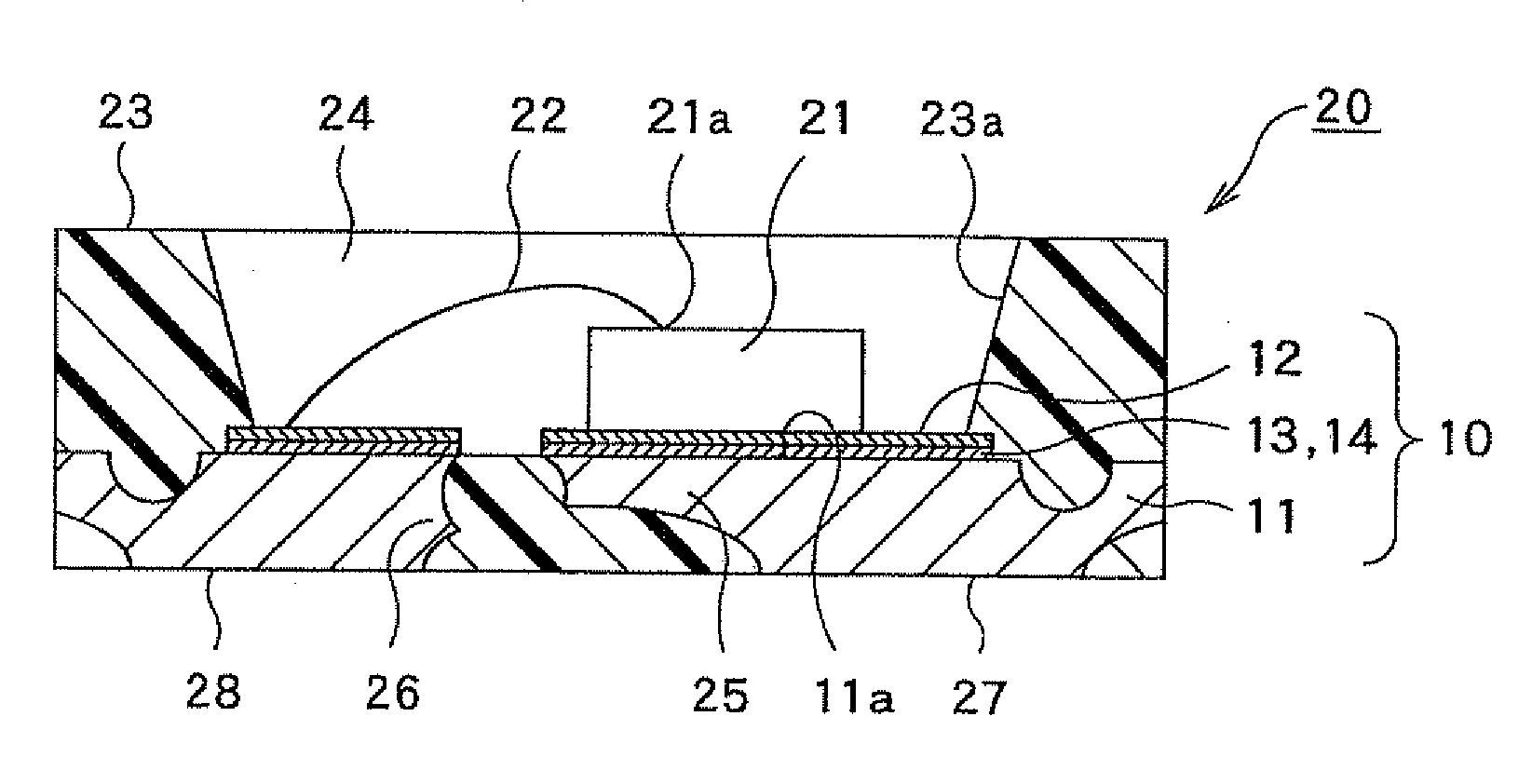

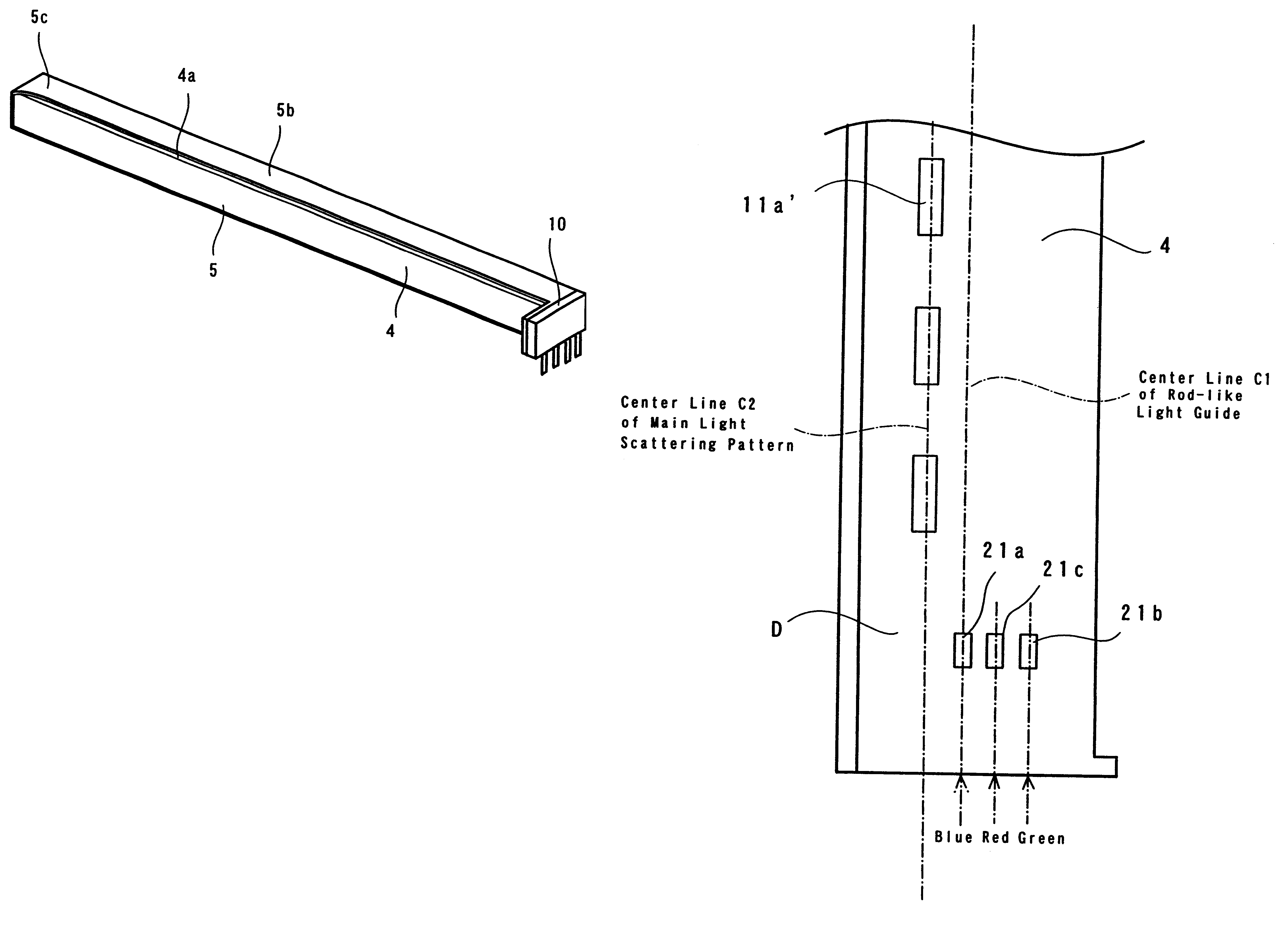

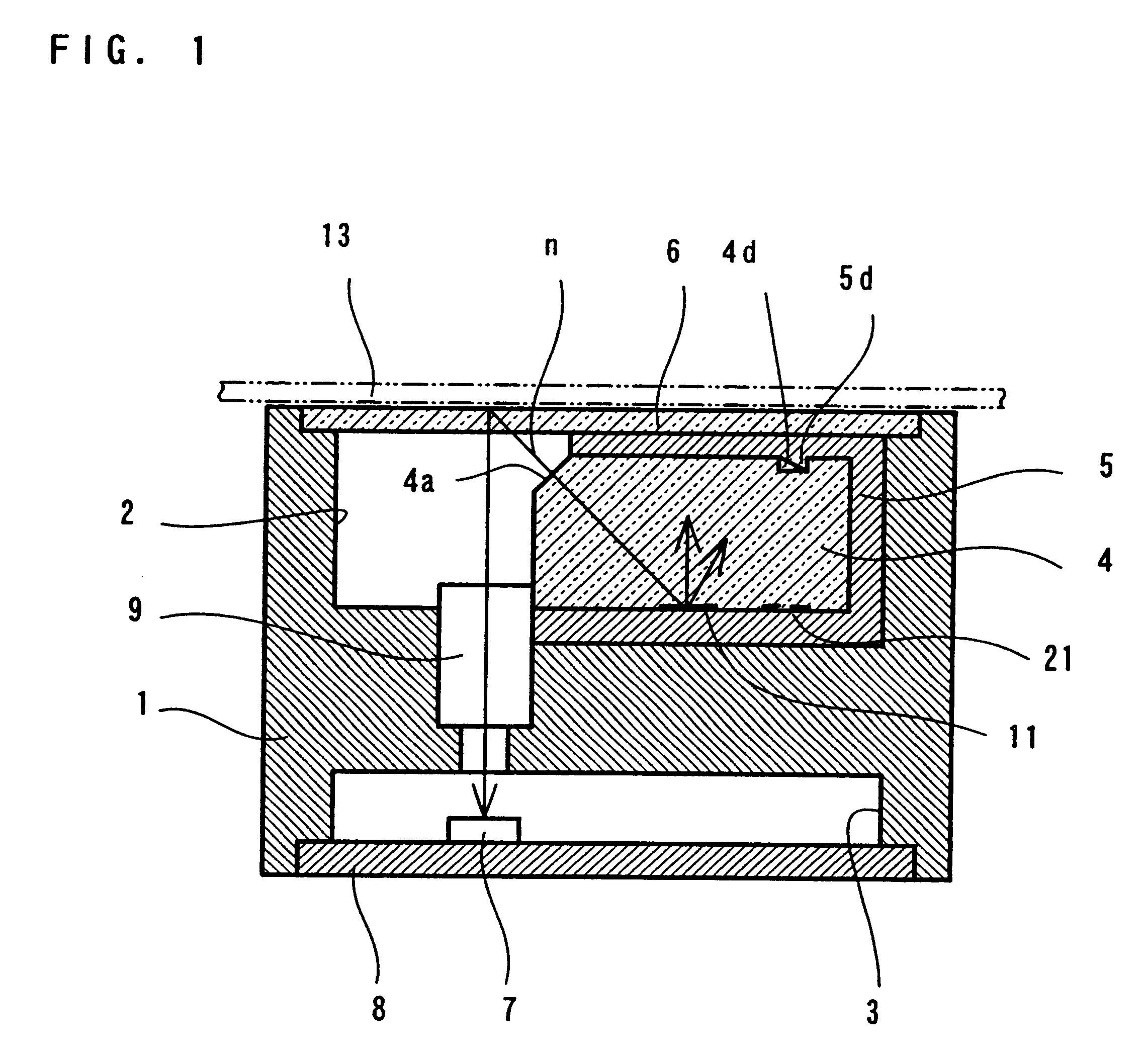

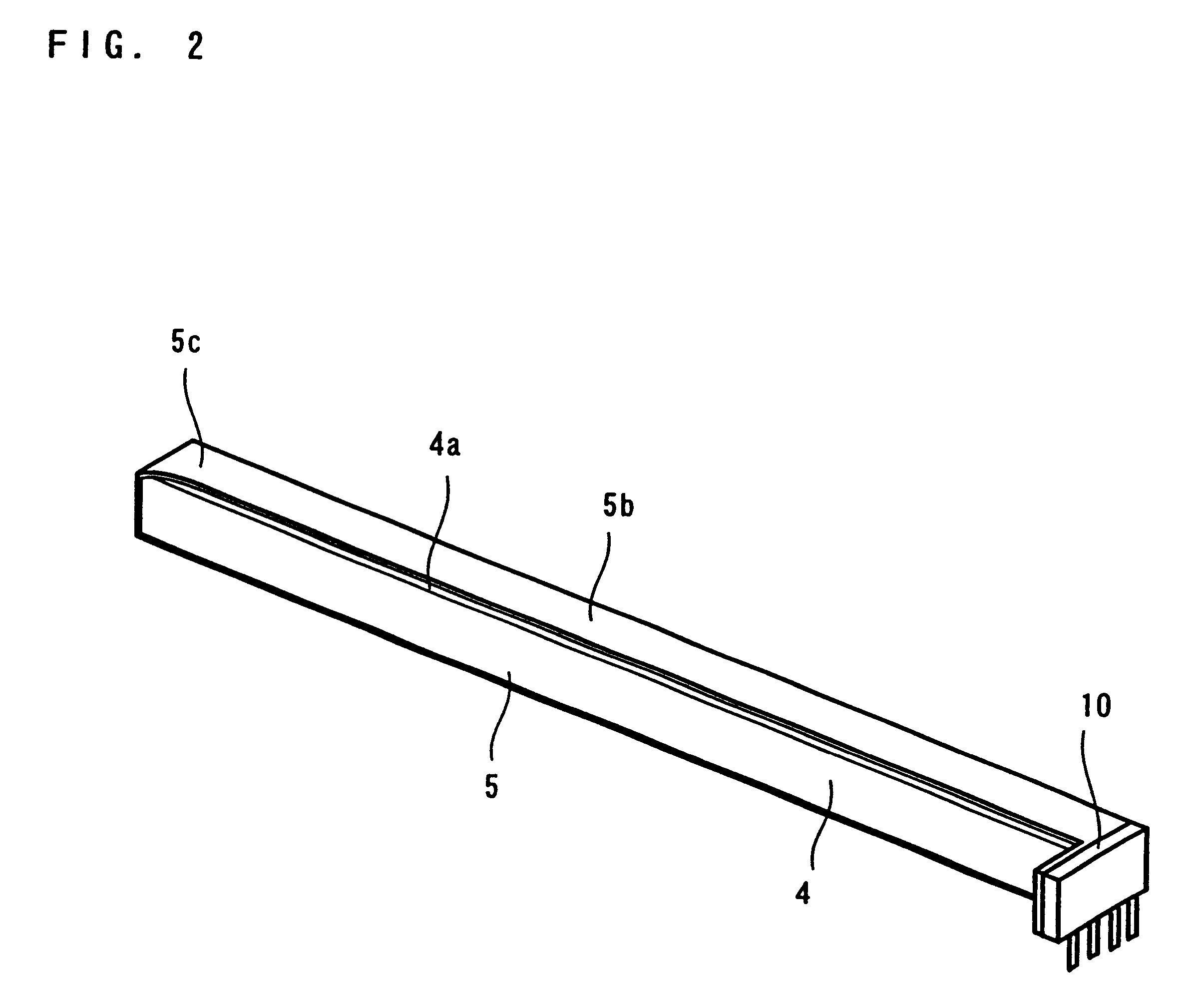

Line type illuminator

InactiveUS6357903B1Easy to manufactureReflect light moreMechanical apparatusDisplay meansLight guideOptoelectronics

A line type illuminator comprising a plurality of light sources at a side of one end of a rod-like transparent light guide, wherein an auxiliary light scattering pattern is formed with two (2) spot-like patterns, which are provided at positions being shifted from a center line of a main light scattering pattern in the longitudinal direction and are separate in a width direction, for maintaining evenness or uniformity of illumination intensity in a longitudinal direction. Normal lines of those two (2) spot-like patterns and the center line of any one of the plurality of light sources, extending in the longitudinal direction, intersect each other. Specifically, the longitudinal center lines of the red-color light sources and the green-color light source intersect the respective normal lines of the spot-like patterns 21a and 21a.

Owner:NIPPON SHEET GLASS CO LTD

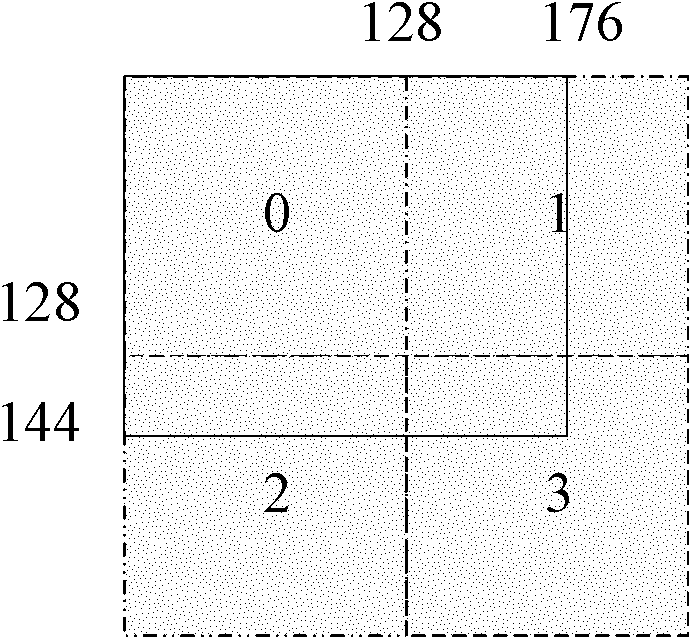

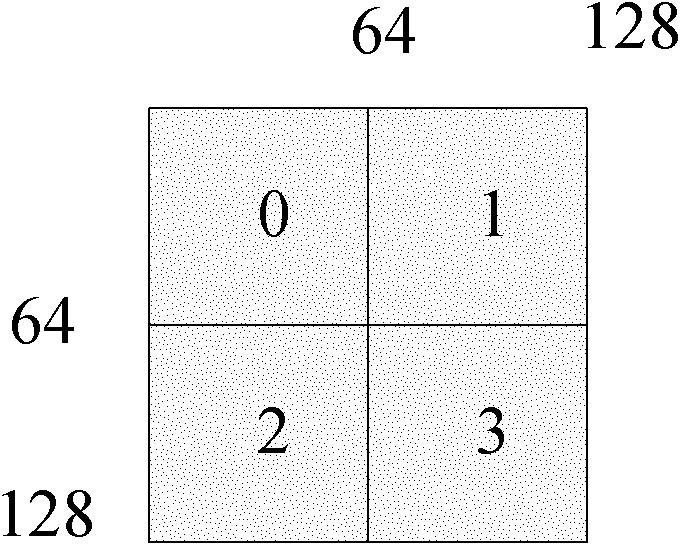

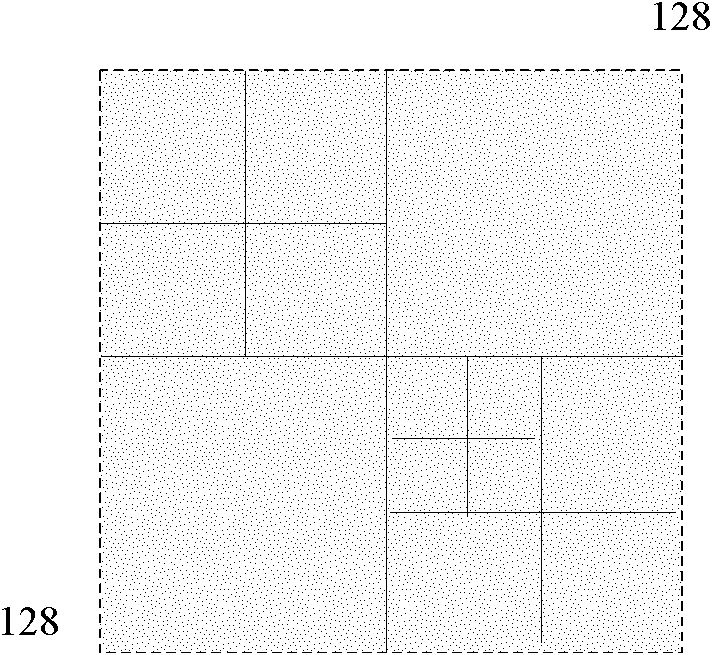

Self-adaptively dividing method for code units in high-efficiency video coding

InactiveCN101938657AImprove compression efficiencyEffective reflectionTelevision systemsDigital video signal modificationComputer architectureRate distortion

The invention discloses a self-adaption dividing method for code units in high-efficiency video coding, which mainly solves the problems that a largest code unit and a smallest code unit in the division of the code units in the prior art can not be regulated according to the characteristics of video content, and the dividing mode quantity of blocks on the boundary of a video frame is few. The method comprises the steps of: firstly, adopting the rate distortion rule or the relativity among video frames to self-adaptively determine the largest code unit and the smallest code unit in each video frame; secondly, expanding a rectangular block within the video frame in the largest code unit on the boundary of a video frame into a square block, and dividing the square block; then, marking the rectangular blocks after dividing, and carrying out frame prediction to the rectangular blocks after dividing; and finally, transforming, quantizing and entropy coding to prediction residuals. The invention has the advantage of high video compression efficiency, and can be applied to high-performance video coding standards.

Owner:XIDIAN UNIV

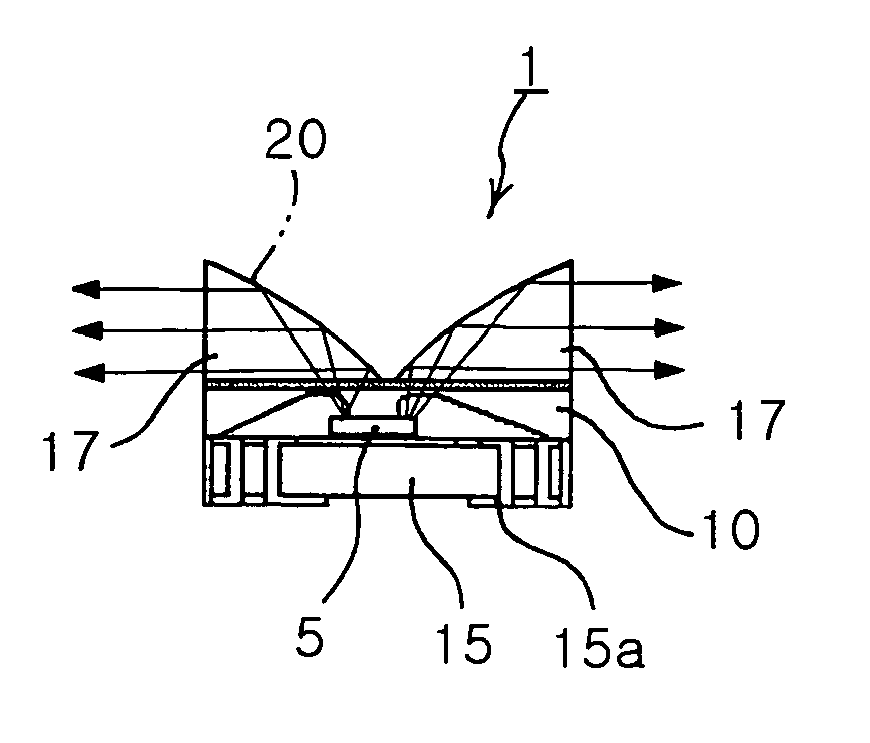

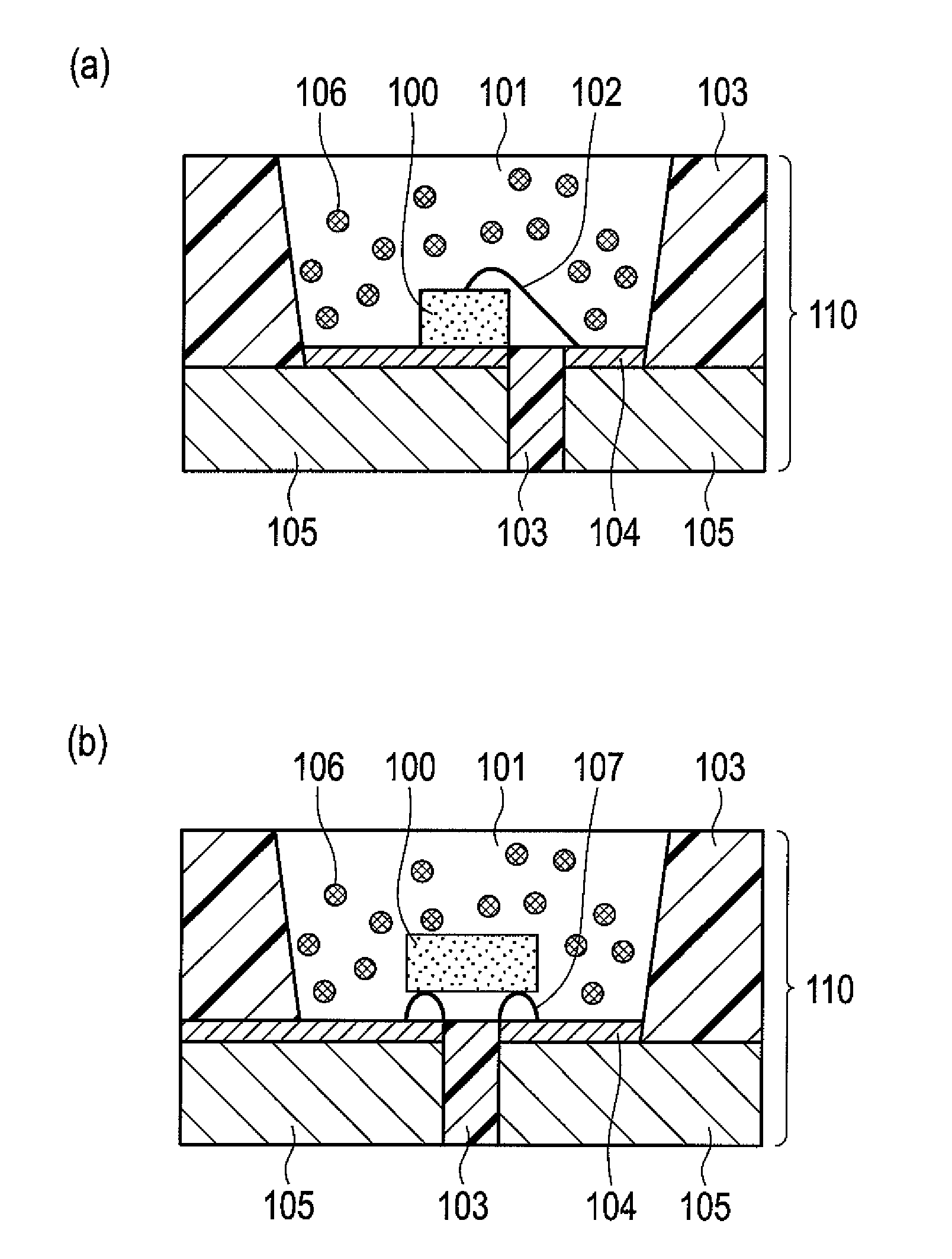

Side-emitting LED package and method of manufacturing the same

InactiveUS20060273337A1Effective reflectionEasy to manufactureSolid-state devicesSemiconductor devicesChip sizeEngineering

The invention relates to a side-emitting LED package and a manufacturing method thereof. The side-emitting LED package includes a substrate with an electrode formed thereon, and a light source disposed on the substrate and electrically connected to the electrode. The side-emitting LED package also includes a molded part having an upper surface with a center thereof depressed concavely, covering and protecting the substrate and the light source, and a reflection layer covering an entire upper surface of the molded part to reflect light sideward from the molded part which forms a light transmitting surface. The package is not restricted in the shape of the molded part and is not affected by the LED chip size, enabling a compact structure. The invention can also process a substrate by a PCB process, enabling mass-production.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

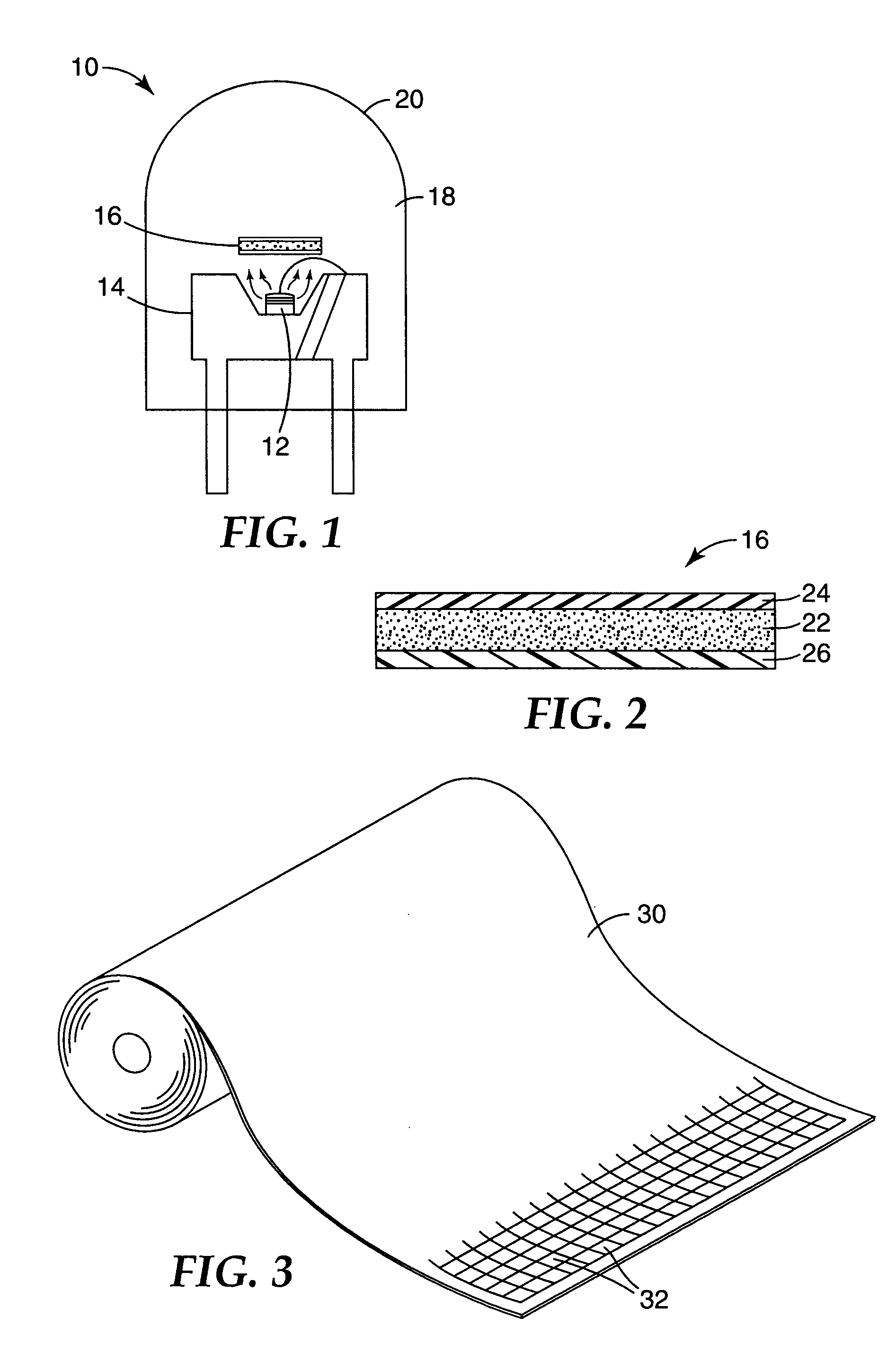

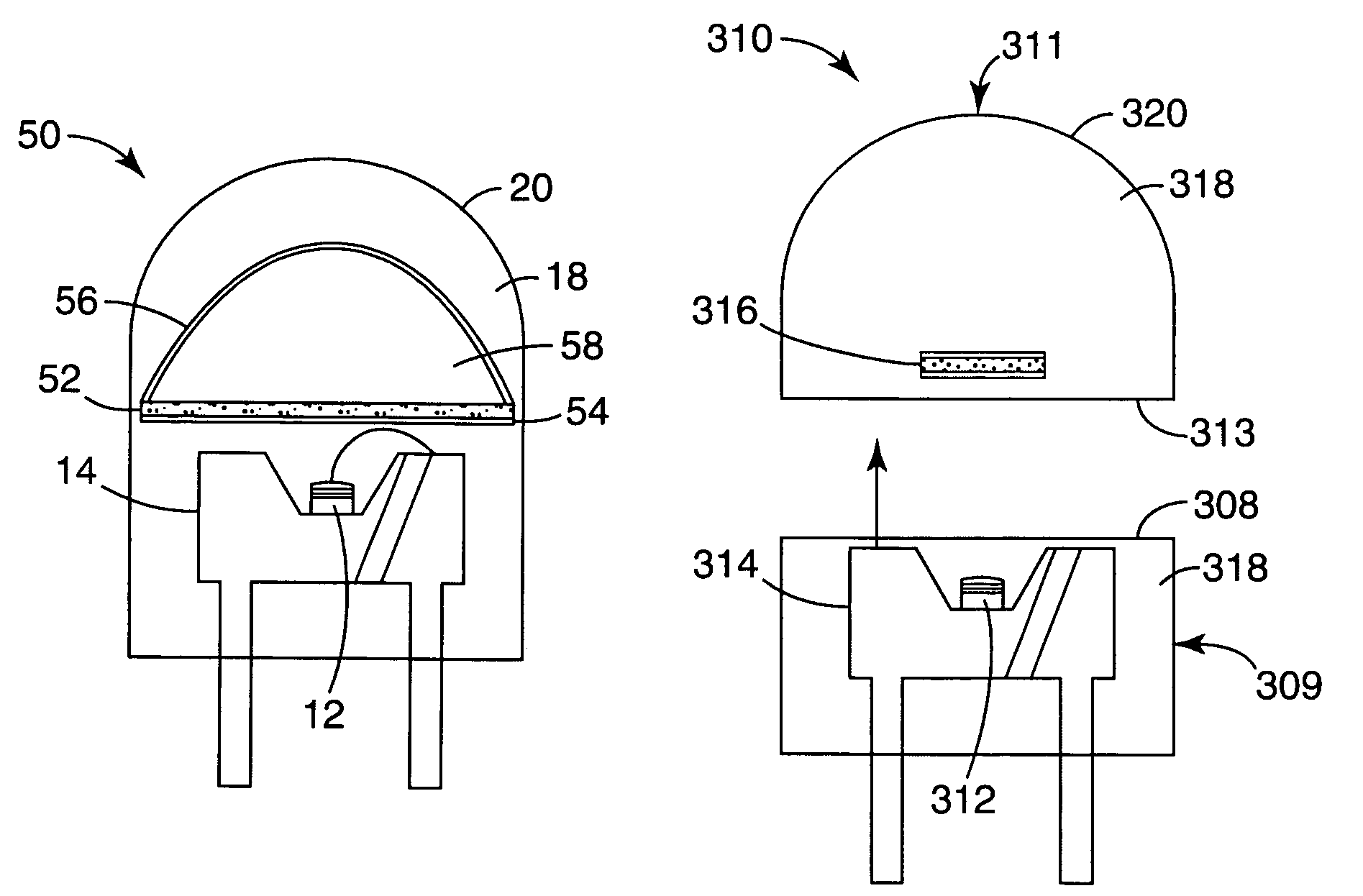

Phosphor based light sources having a reflective polarizer

ActiveUS7091661B2Maintain reflectivityPrevent leakageIncadescent screens/filtersDischarge tube luminescnet screensPhosphorPolarizer

A LED package includes an LED that emits excitation light and an optically transparent body. A layer of phosphor material is positioned to receive the excitation light and is disposed on or in the optically transparent body. The phosphor material emits visible light when illuminated with the excitation light. A reflective polarizer layer is disposed on or in the optically transparent body and is positioned to receive the emitted visible light.

Owner:3M INNOVATIVE PROPERTIES CO

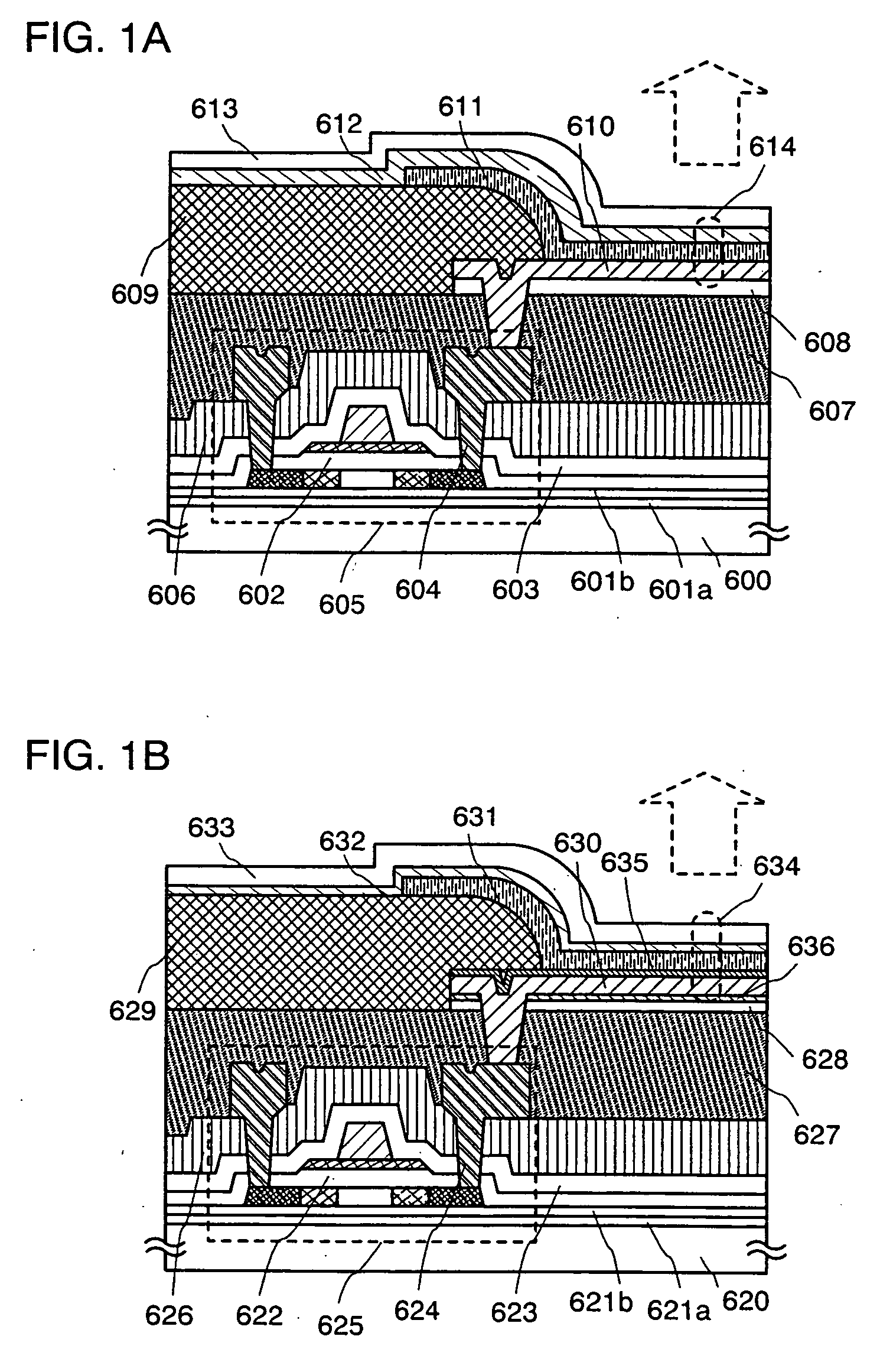

Display device and method for manufacturing the same

InactiveUS20060091397A1Improve reliabilityHigh definitionElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsDisplay device

It is an object of the invention to manufacture a highly reliable display device at a low cost with high yield. A display device of the invention includes: a first reflective electrode layer; and a second transparent electrode layer with an electroluminescent layer interposed therebetween, wherein the electroluminescent layer has a layer containing an organic compound and an inorganic compound, and the first electrode layer contains an aluminum alloy containing at least one or more selected from the group consisting of molybdenum, titanium, and carbon.

Owner:SEMICON ENERGY LAB CO LTD

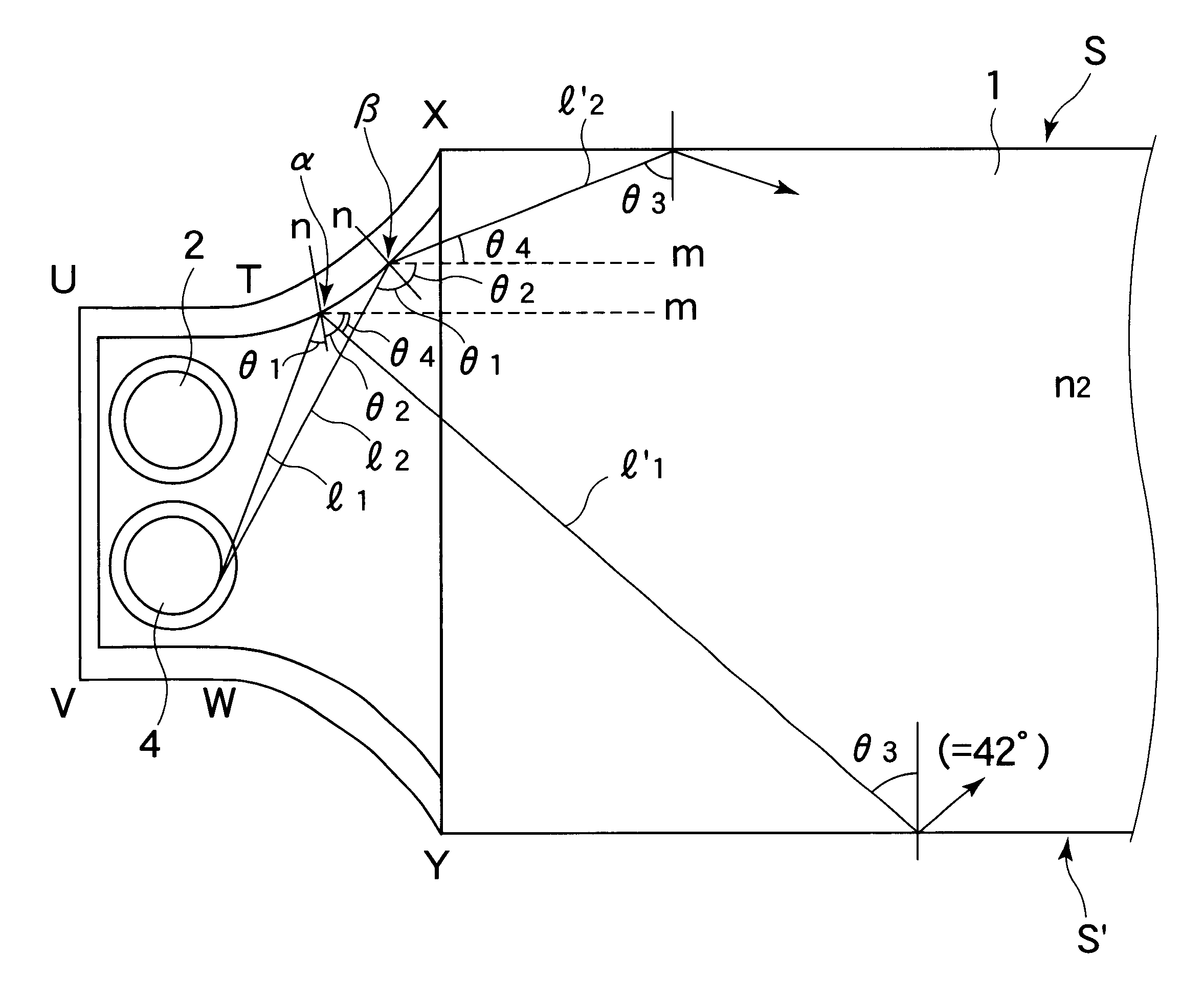

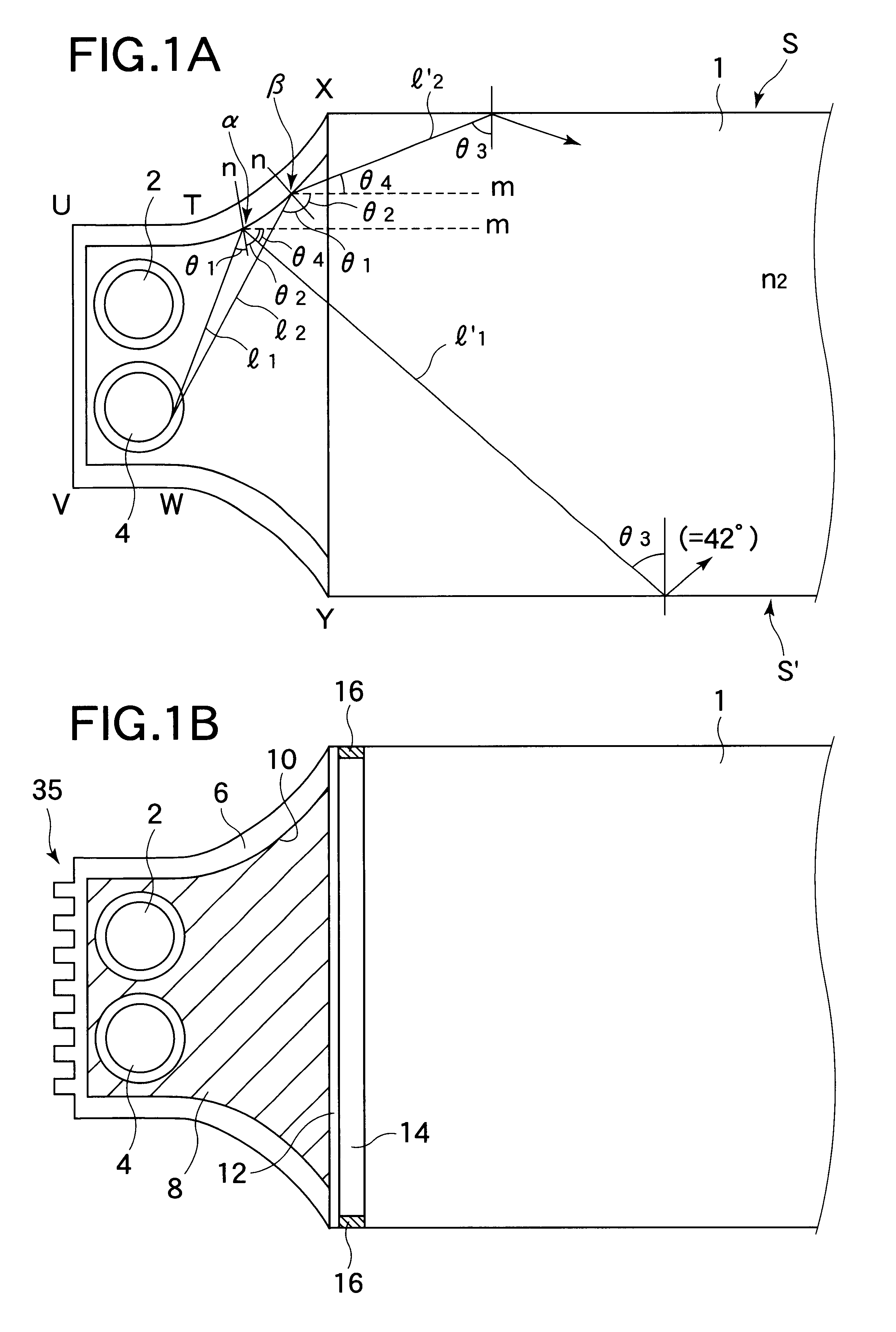

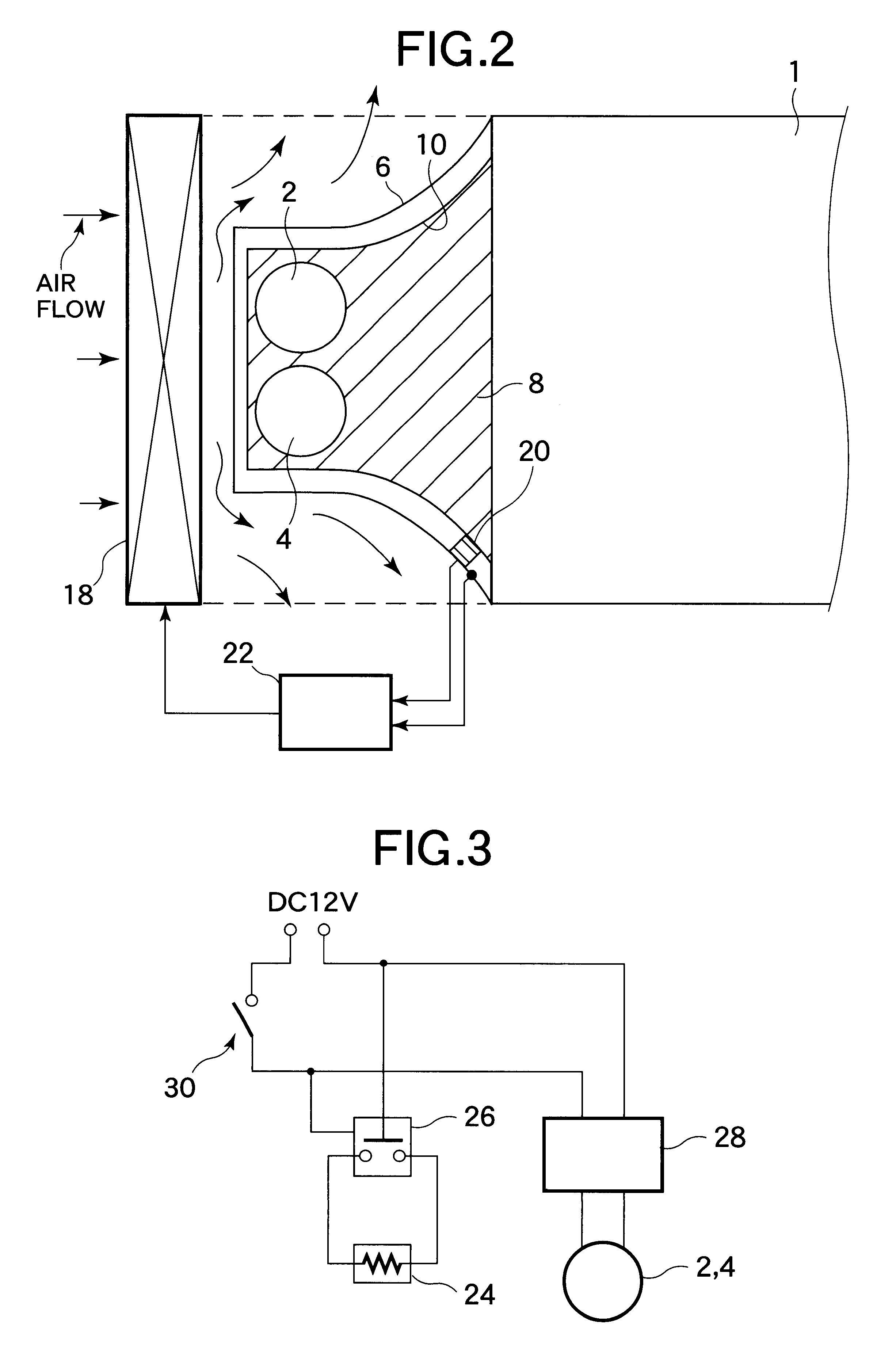

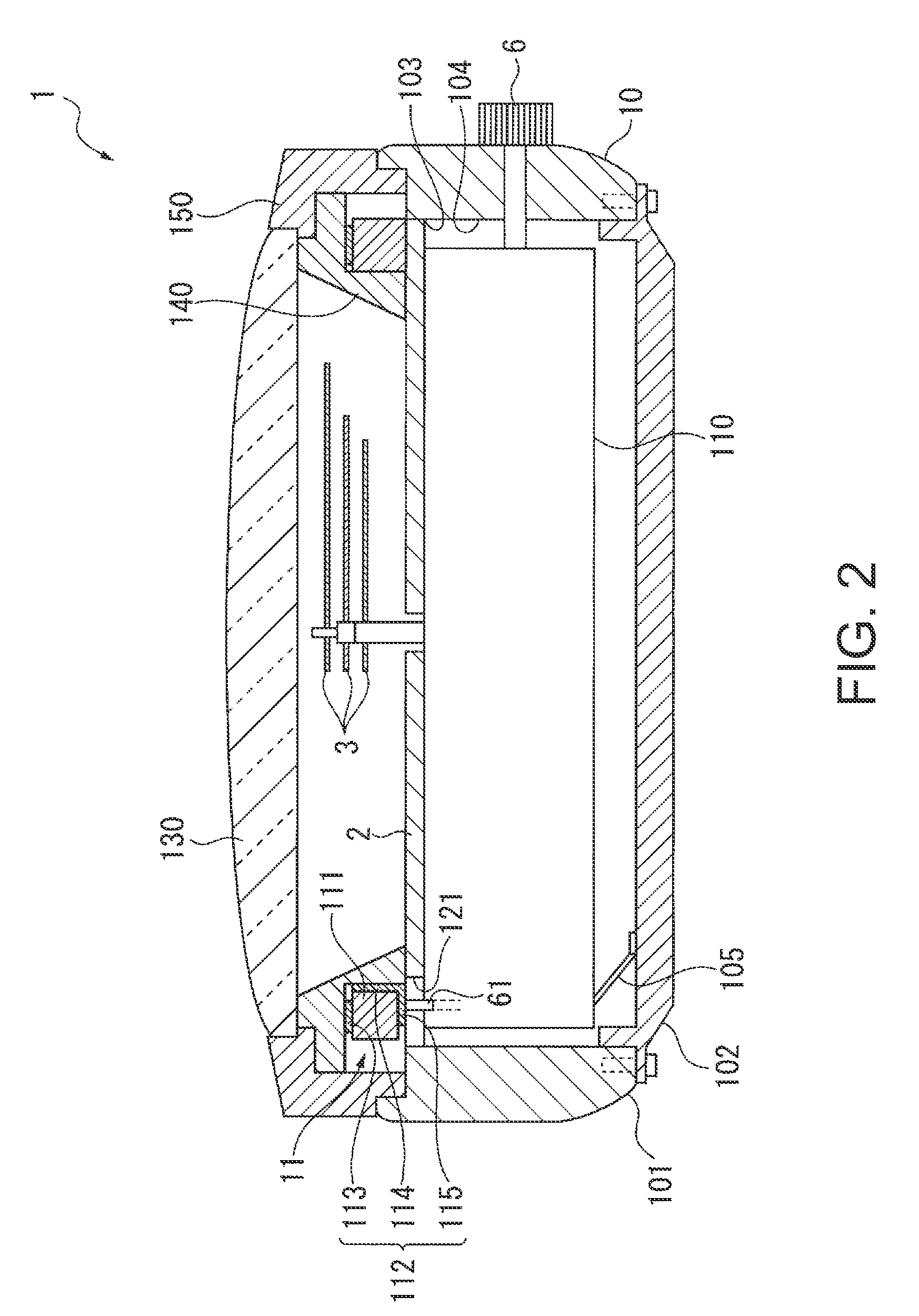

Lighting unit

InactiveUS6655810B2Effective reflectionIncrease brightnessMeasurement apparatus componentsLighting elementsLiquid-crystal displayRefractive index

The invention relates to a backlight unit for liquid crystal displays, etc.; and its object is to provide a backlight unit not involving the problem that the emitted light leaks out of the optical waveguide, even when the space around the cold-cathode tubes in the light source unit for it is filled with a liquid of which the refractive index is nearly the same as that of the glass material that forms the outer wall of the cold-cathode tubes. The backlight unit comprises a housing 6 which houses cold-cathode tubes 2, 4 therein and of which the inner surface is coated with a light reflector 10; a transparent liquid filled in the housing 6; and an optical waveguide 1 made of a transparent substance and having a light-emitting surface S. The reflective surface of the light reflector 10 has a cross-section profile of X-T-U-V-W-Y, on which the light emitted by the cold-cathode tubes 2, 4 is reflected, and the thus-reflected light is led to the light-emitting surface S of the optical waveguide 1 at an incident angle not smaller than the critical angle to the surface S.

Owner:SHARP KK

Thermosetting light-reflecting resin composition, optical semiconductor element mounting board produced therewith, method for manufacture thereof, and optical semiconductor device

ActiveUS20100200882A1High levelHigh releasabilityLiquid crystal compositionsDiffusing elementsReflectivityLight wave

There is provided a thermosetting light-reflecting resin composition that has a high level of various characteristics required of optical semiconductor element mounting boards, such as optical properties and thermal discoloration resistance, provides high releasability during molding such as transfer molding, and allows molding processes to be performed continuously. There are also provided a highly-reliable optical semiconductor element mounting board and an optical semiconductor device each produced with the resin composition, and methods for efficient production thereof. A thermosetting light-reflecting resin composition is prepared and used, which includes (A) an epoxy resin, (B) a curing agent, (C) a curing catalyst, (D) an inorganic filler, (E) a white pigment, (F) an additive, and (G) a release agent as major components, wherein the resin composition, after curing, has a diffuse reflectance of 80% or more at a light wavelength of 400 nm; and the resin composition is possible to perform transfer molding 100 times or more continuously.

Owner:RESONAC CORP

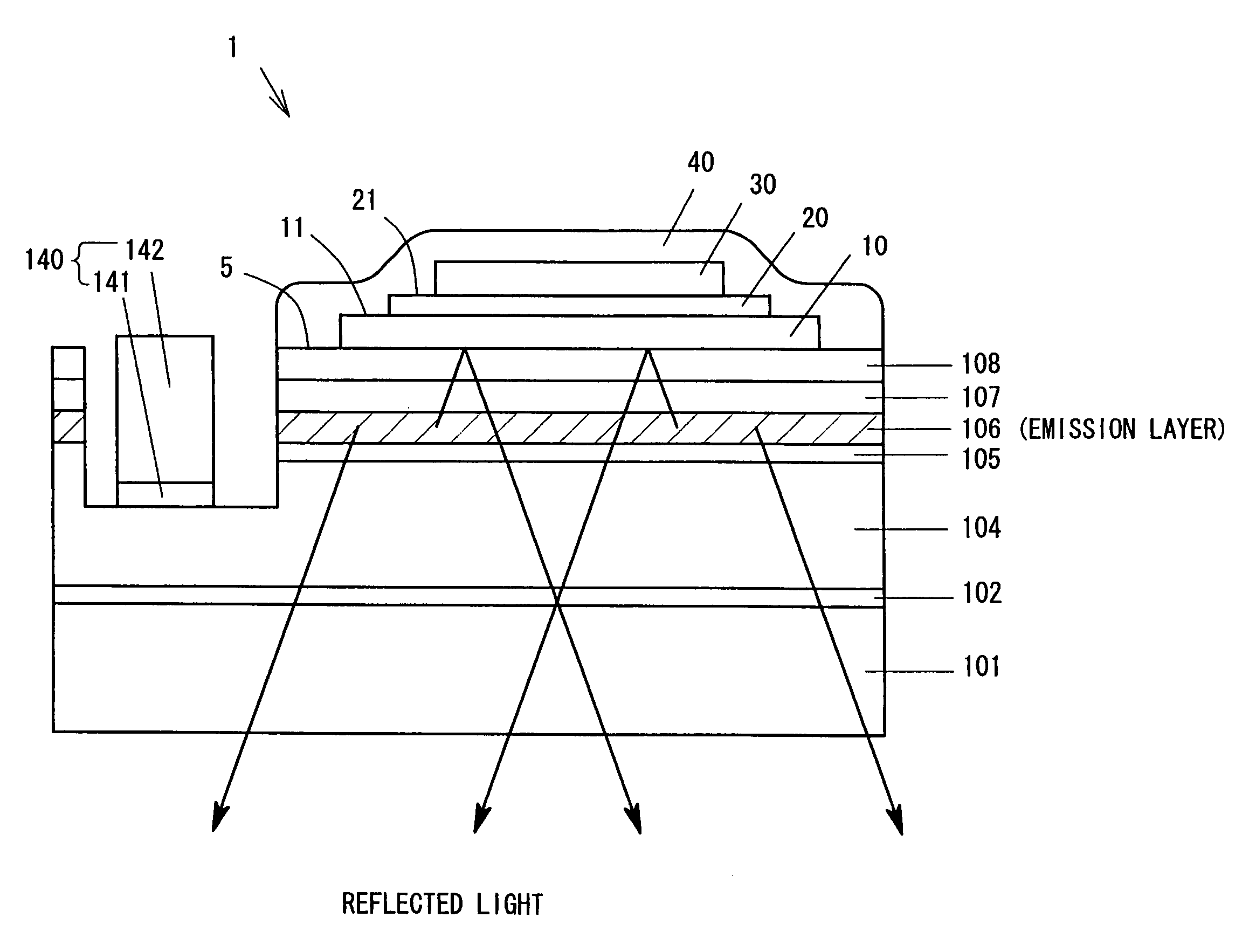

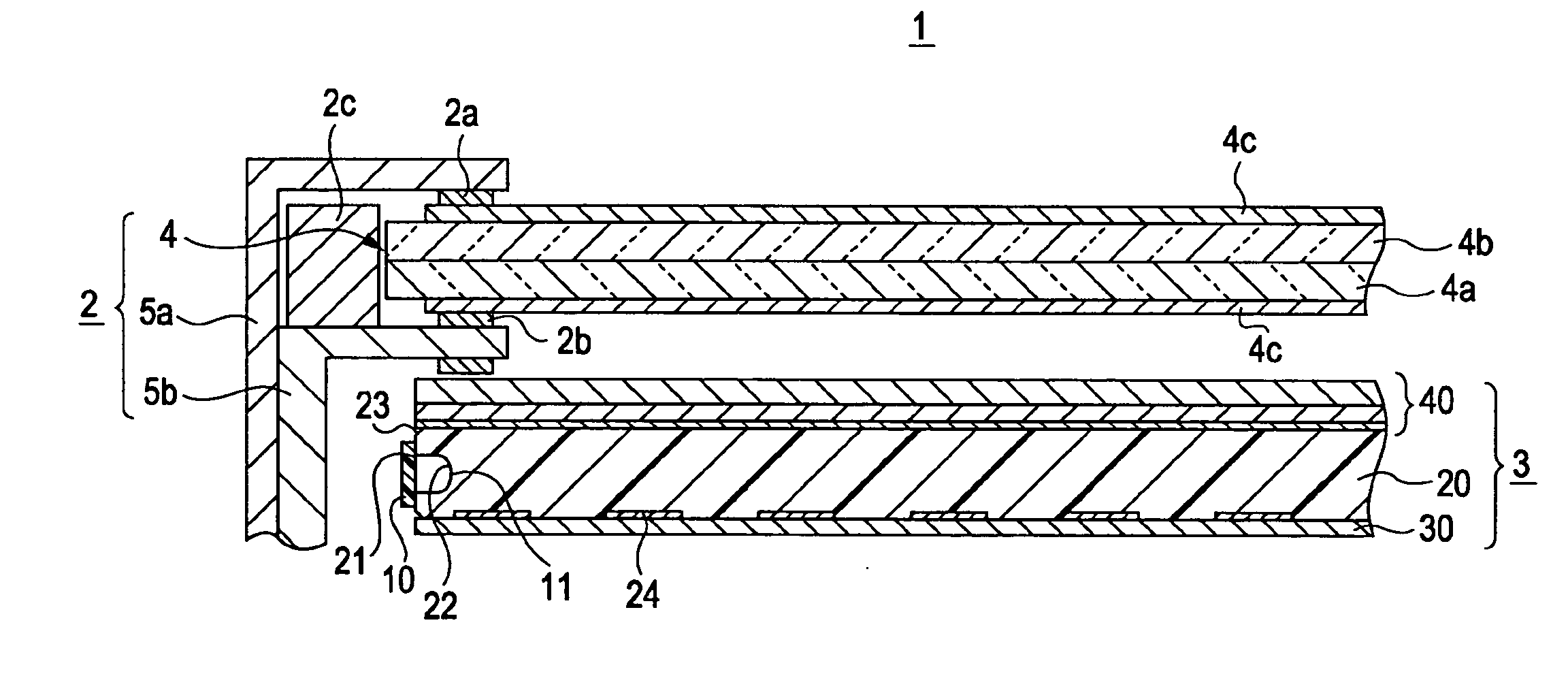

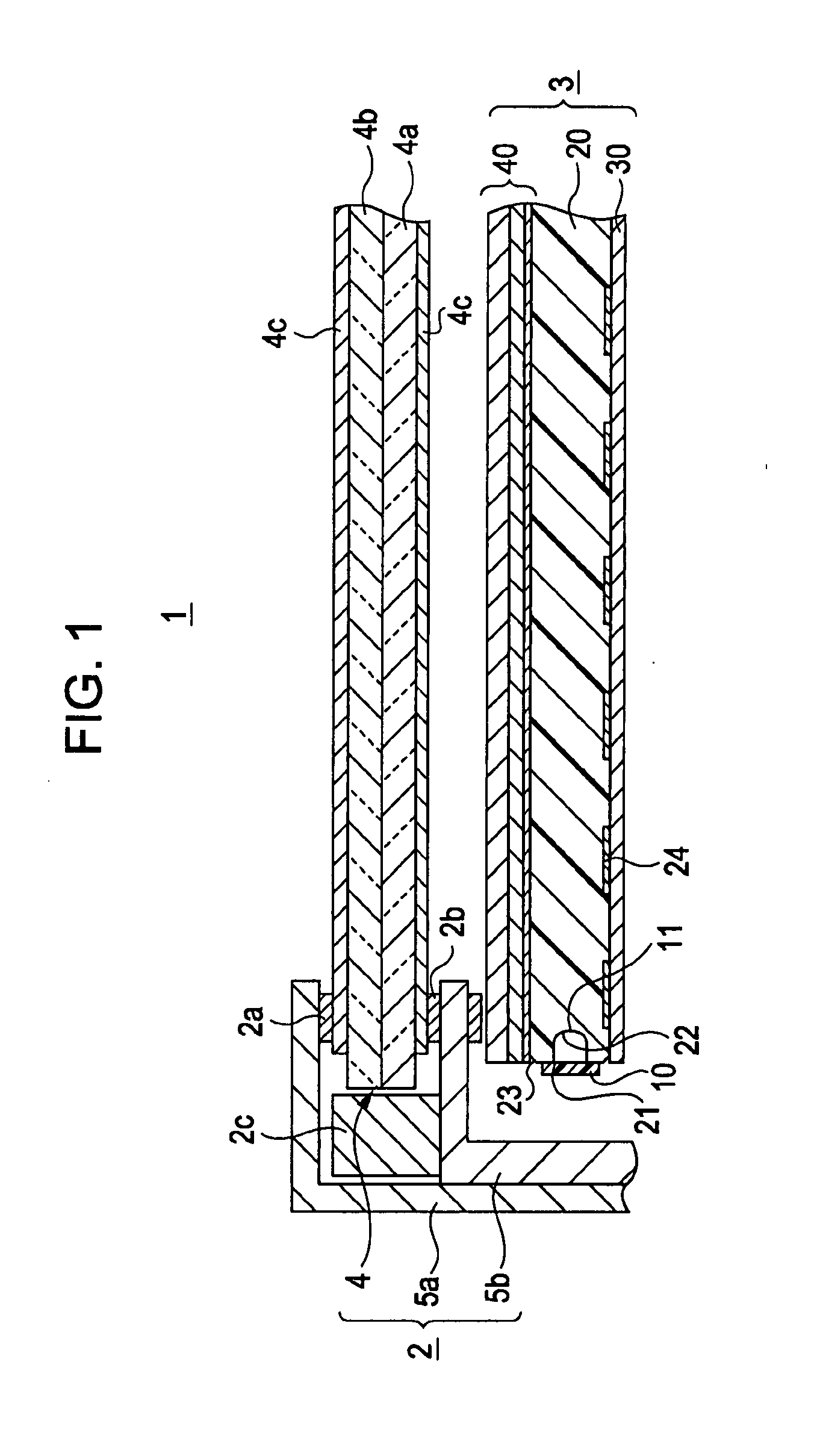

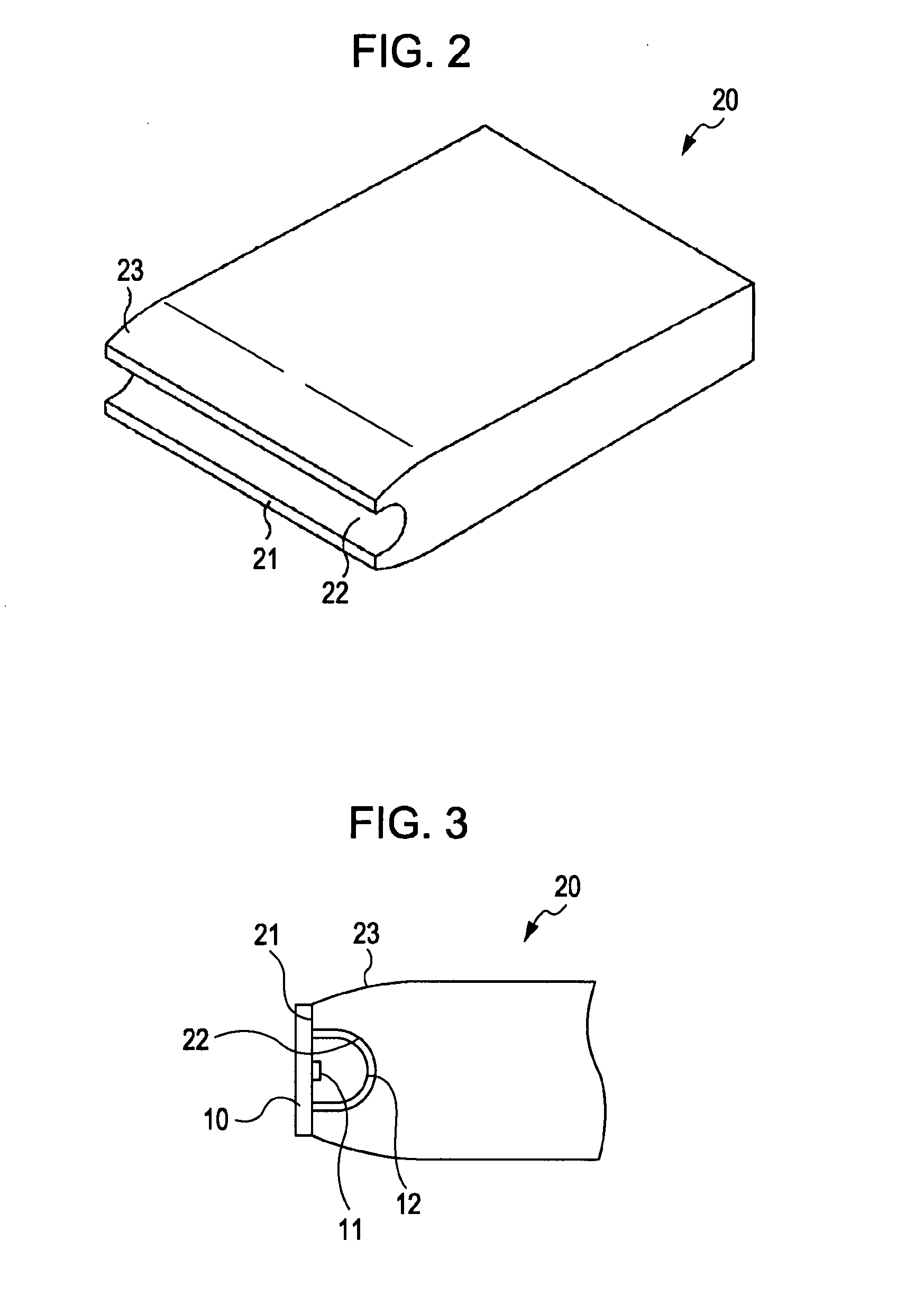

Light-emitting semiconductor device

ActiveUS7291865B2Inhibit interface reactionReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingContact layerLight emitting device

A flip-chip type of Group III nitride based compound semiconductor light-emitting device comprises a transparent conductive film 10 made of ITO on a p-type contact layer. On the transparent conductive film, an insulation protection film 20, a reflection film 30 which is made of silver (Ag) and aluminum (Al) and reflects light to a sapphire substrate side, and a metal layer 40 made of gold (Au) are deposited in sequence. Because the insulation protection film 20 exists between the transparent conductive film 10 and the reflection film 30, metal atoms comprised in the reflection film 30 can be prevented from diffusing in the transparent conductive film 10. That enables the transparent conductive film 10 to maintain high transmissivity. As a result, a light-emitting device having high external quantum efficienty can be provided.

Owner:TOYODA GOSEI CO LTD

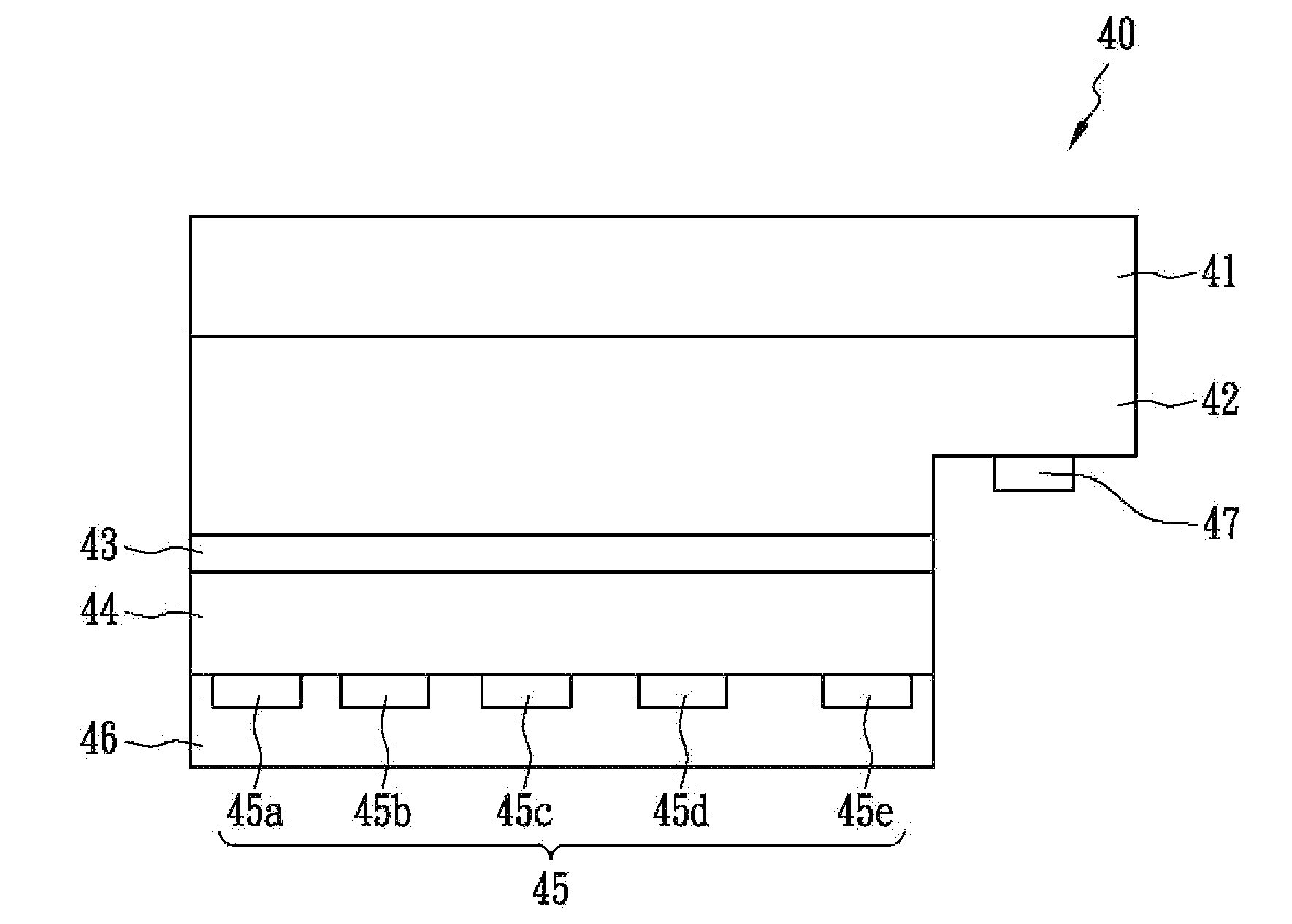

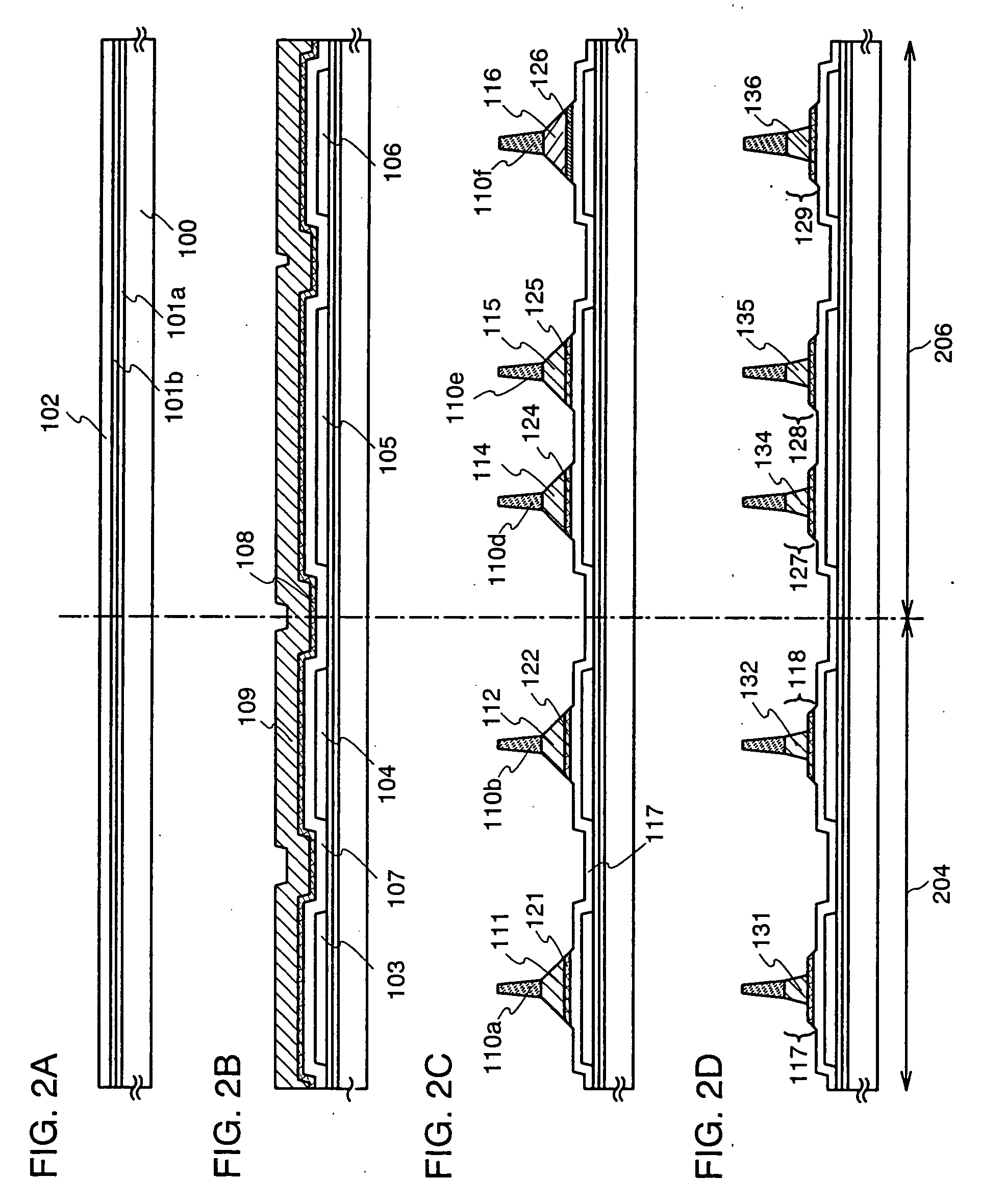

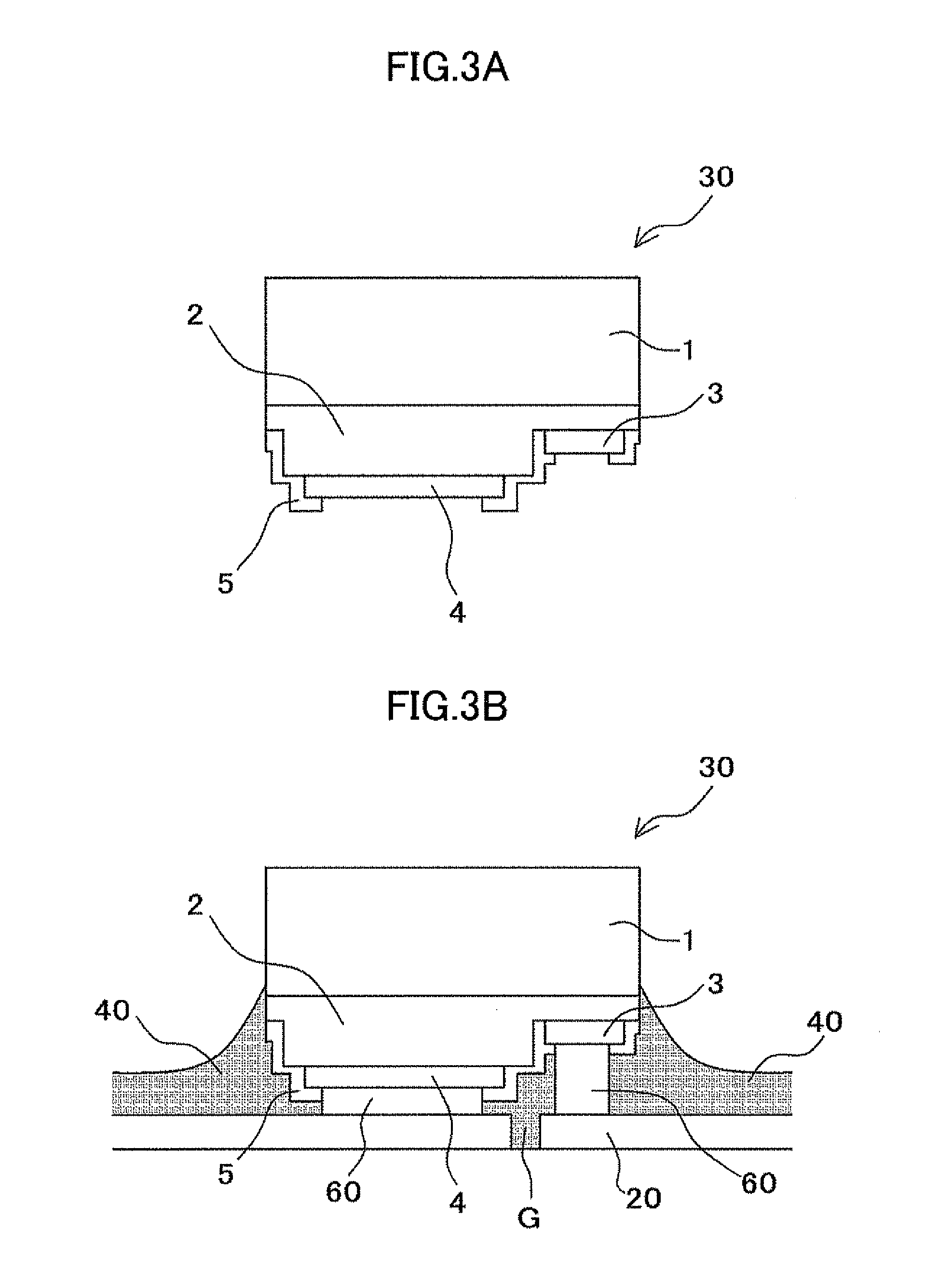

Backlight unit and liquid crystal display device

InactiveUS20080049168A1Avoid it happening againWidely distributedMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A backlight unit includes a light-source substrate having mounted thereon a plurality of light-emitting elements emitting illumination light; a light guide plate having a side surface with the light-source substrate attached thereto so as to receive the illumination light from the light-emitting elements, the light guide plate also having a first surface extending substantially perpendicular to the side surface, and a second surface; a reflective sheet attached to the first surface and reflecting the illumination light towards the second surface; and an optical sheet layer attached to the second surface and including a plurality of stacked optical sheets. The side surface has a reflective portion that reflects at least a part of the illumination light. The at least a part of the illumination light to be reflected at the reflective portion is incident on the reflective portion at an incidence angle equal to or above a critical angle.

Owner:SATURN LICENSING LLC

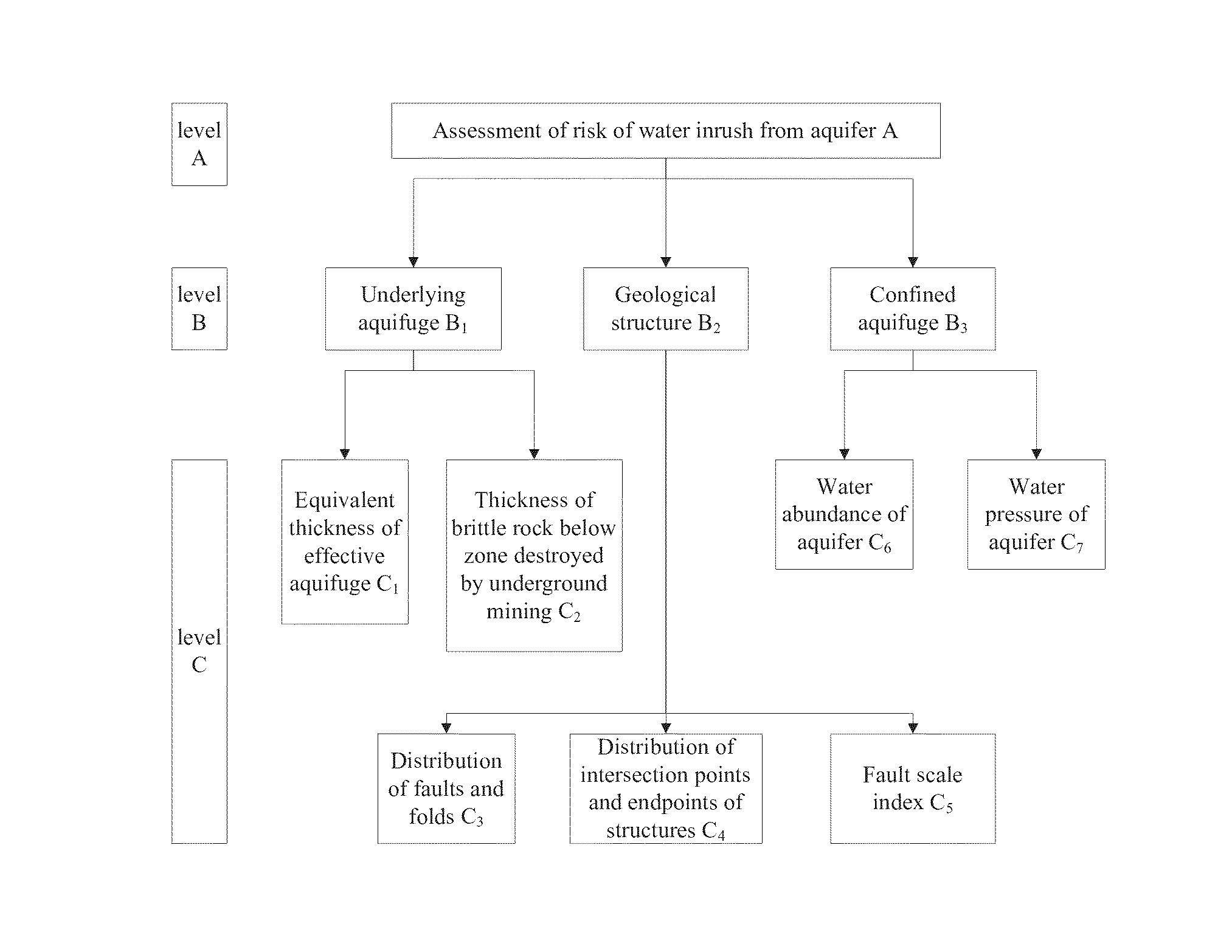

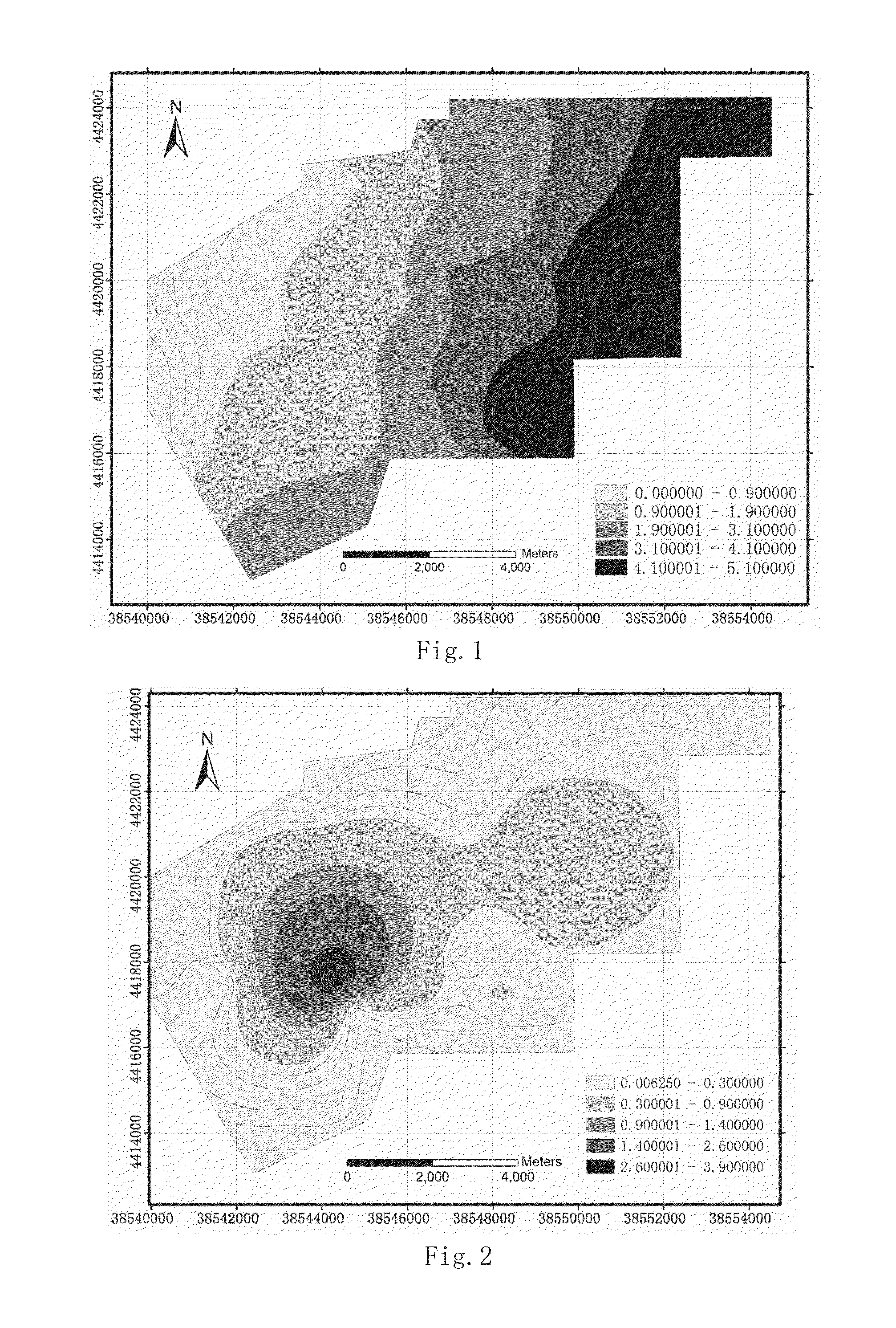

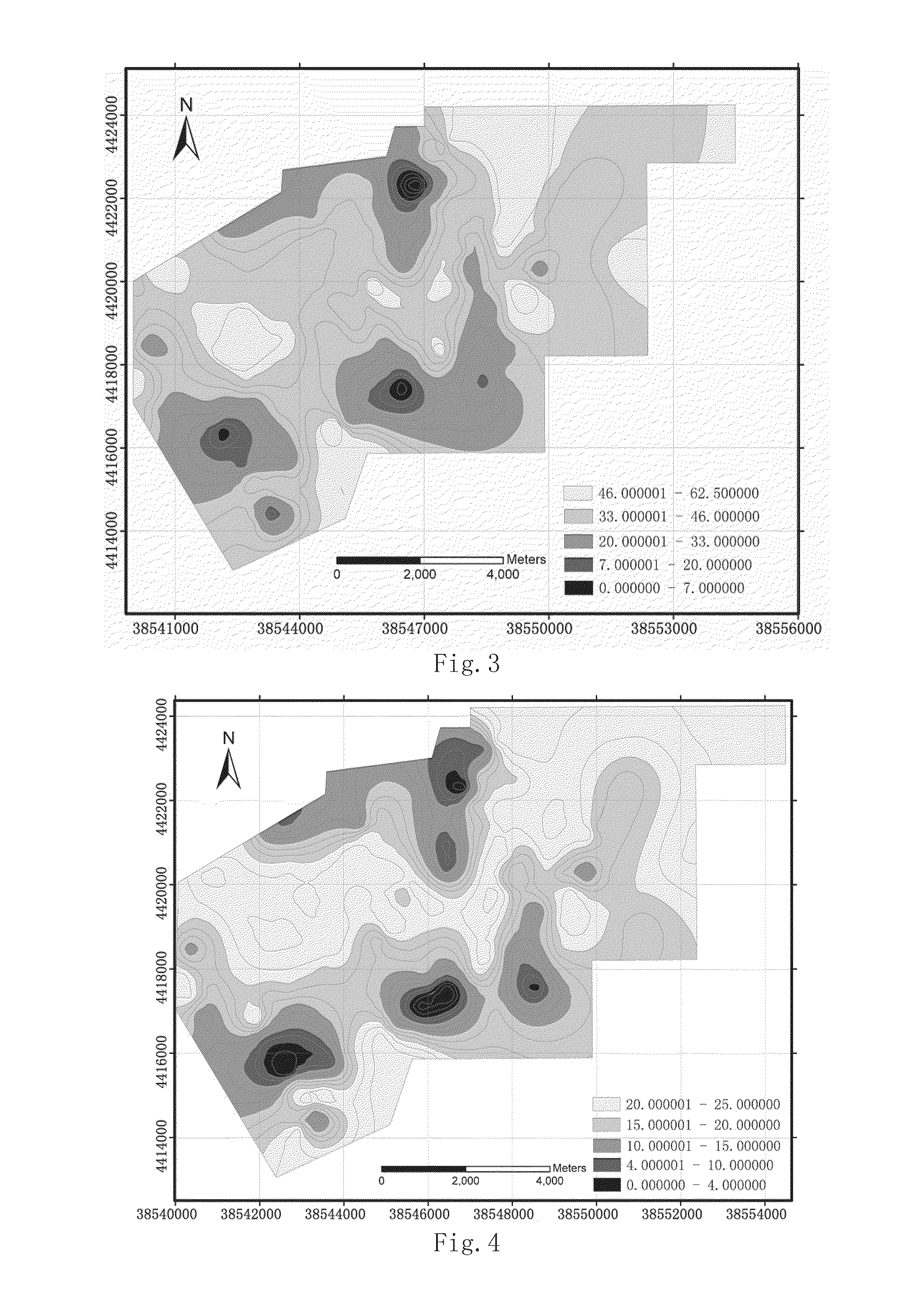

Vulnerability Assessment Method of Water Inrush from Aquifer Underlying Coal Seam

InactiveUS20160070828A1Improve vulnerabilitySolve the real problemMining devicesSeismologySuperimpositionThematic map

A vulnerability assessment method of water inrush from an aquifer underlying coal seam includes steps of: collecting main control factors determined by geological data of a target area to be assessed; quantifying relevant data against the main control factors to form thematic maps; performing normalization processing against attribute data corresponding to the respective thematic maps; establishing databases of normalized attribute data corresponding to the normalized thematic maps by utilizing GIS; determining a weight of each main control factor based on a constant weight model; determining a variable weight of each main control factor based on a zonation variable weight model; performing composite superimposition on the normalized thematic maps of the respective single main control factors, and newly building a topological relation of the relevant data among the attribute databases for performing multi-factor fitting analysis; and establishing a vulnerability assessment model based on the zonation variable weight model.

Owner:CHINA UNIV OF MINING & TECH BEIJNG

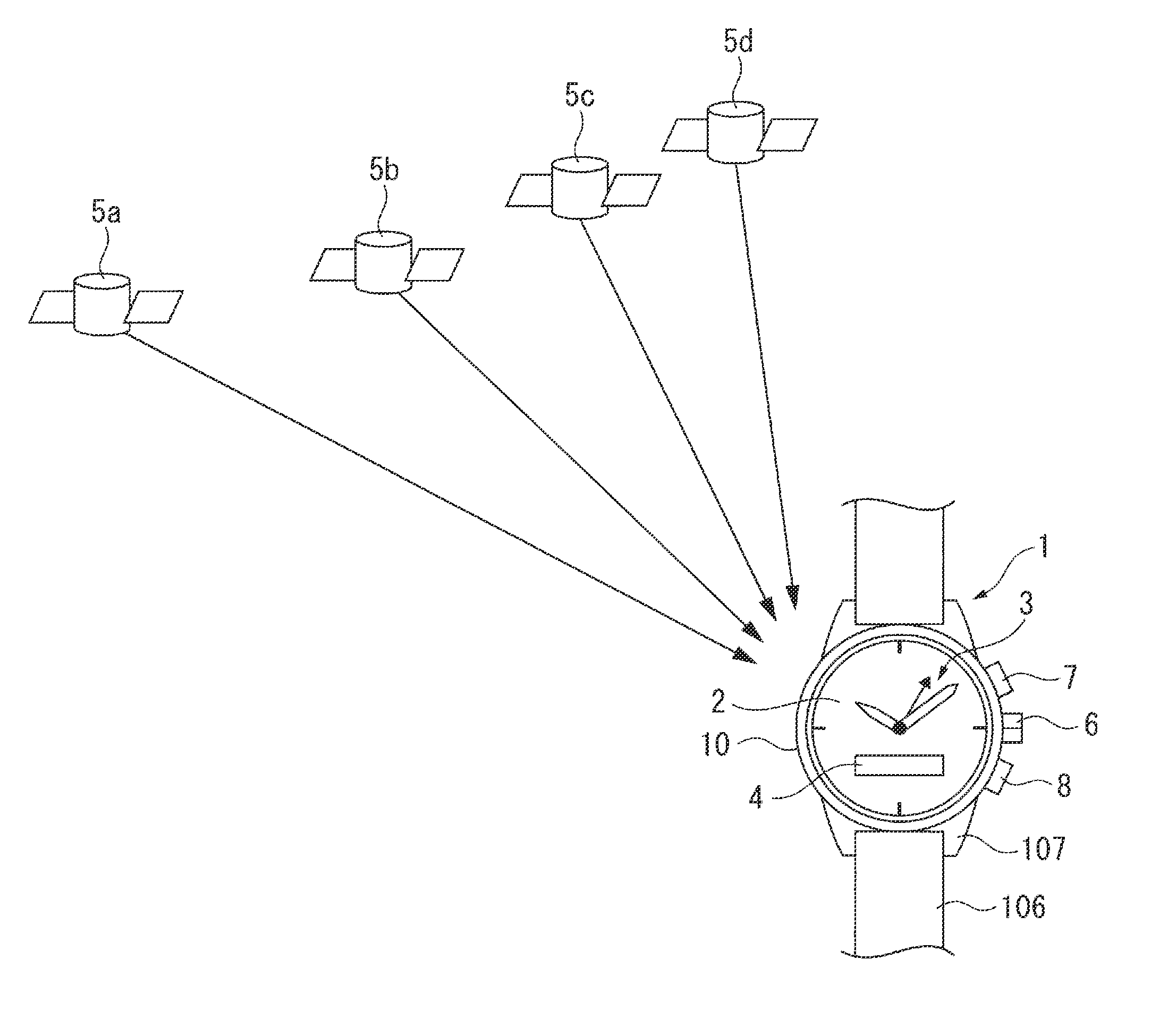

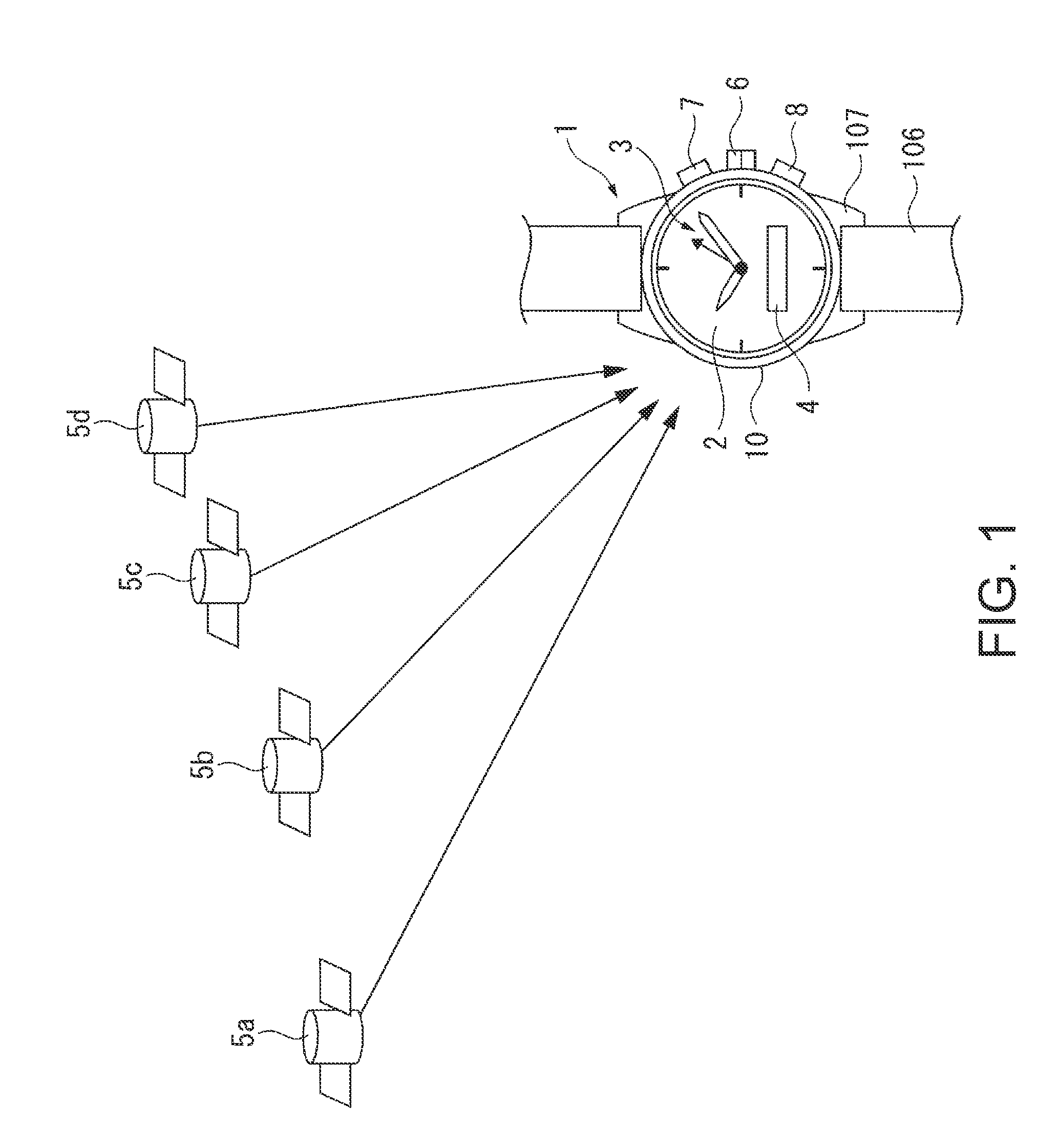

Electronic Device That is Worn on the Wrist

ActiveUS20110102274A1Improve reception performanceImprove performanceAntenna supports/mountingsProtective material radiating elementsEngineeringConductive materials

A wrist-worn electronic device includes an antenna that receives externally transmitted radio signals; a case of which at least part is made of a non-conductive material; an information display unit that is housed inside the case, is flat, and is made of a non-conductive material; a back cover that is attached to the case and is made of a conductive material; and a reception unit that is positioned and housed inside the case between the information display unit and the back cover, and processes a reception signal based on radio signals received by the antenna. The antenna has an antenna electrode that is disposed and formed as a line around the outside of the information display unit. The back cover is connected to the ground potential of the reception unit and reflects the radio signals.

Owner:SEIKO EPSON CORP

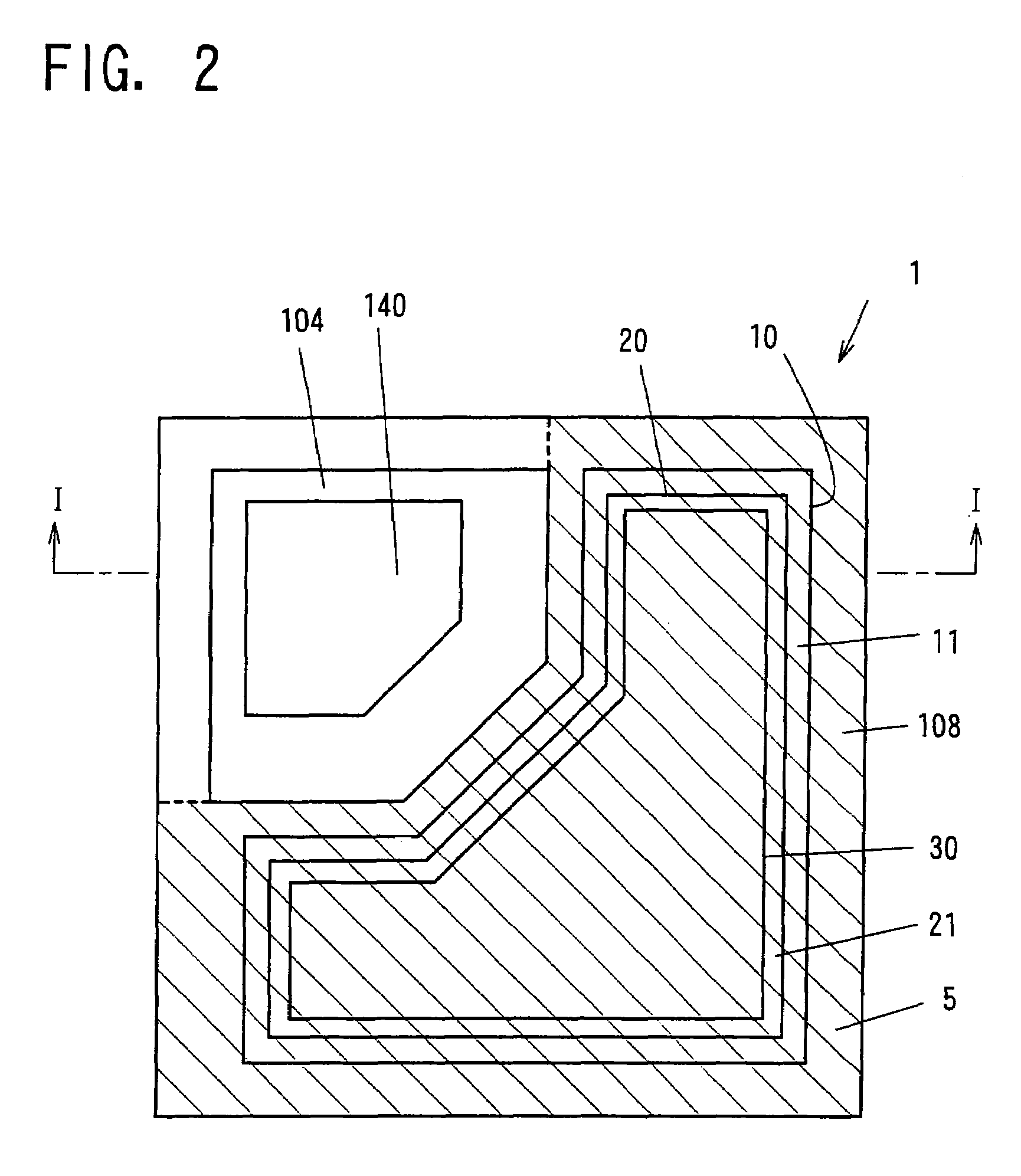

Resin-sealed light emitting device and its manufacturing method

InactiveUS20090114937A1Prolong lifeImprove reliabilitySolid-state devicesOptical articlesLight reflectionThermal radiation

An LED package is formed by separating a sealed body containing a substrate having a plurality of regions into individual bodies. The LED package includes an LED chip mounted on a recessed part in an upper surface of a substrate, a sealing resin to cover an entire surface of the region, a setting pattern provided on a bottom surface of the recessed part to set the LED chip, a wiring pad provided on the bottom surface of the recessed part, a wiring pattern provided on a slanted surface of the recessed part and serving as a light reflection part also, a wire to connect an electrode of the LED chip to the wiring pad, an external terminal provided on a lower surface of the substrate, a connection part to connect the wiring pattern connected to the wiring pad to the external terminal, and a heat radiating pattern provided on a lower surface to radiate a heat generated in the LED chip outside the LED package. The setting pattern is connected to the heat radiating pattern through the connection part.

Owner:TOWA

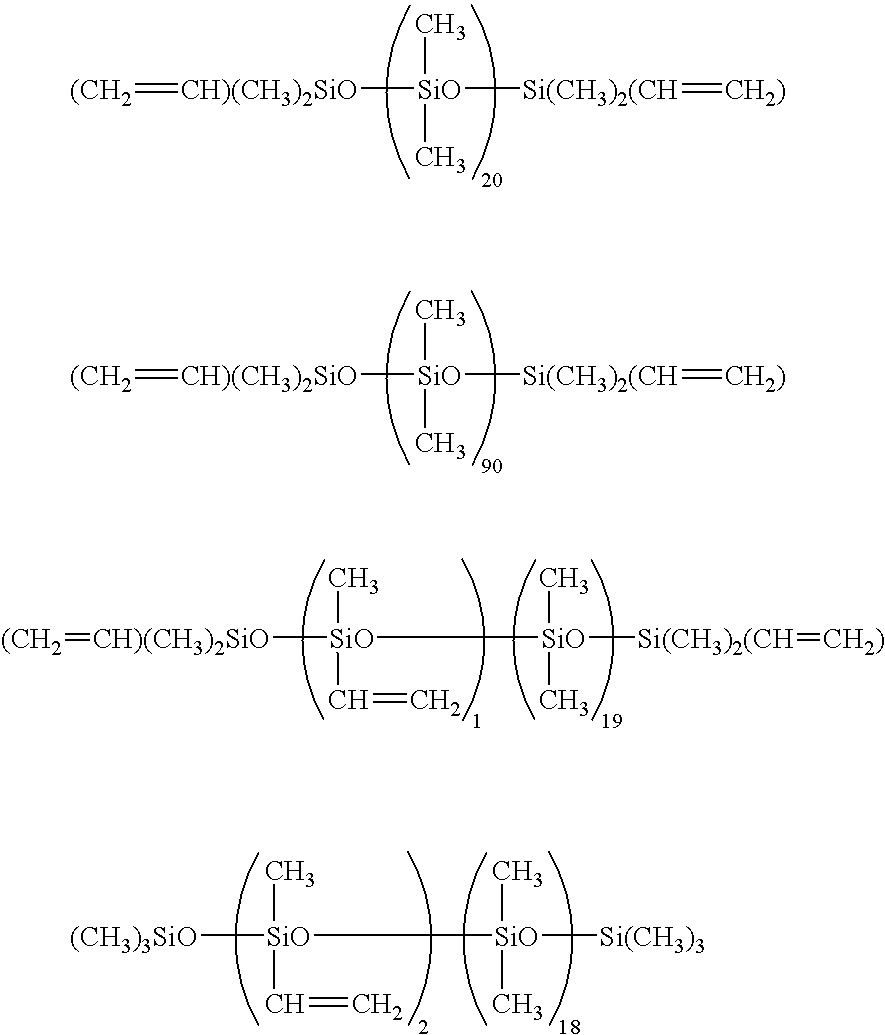

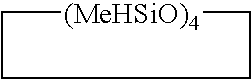

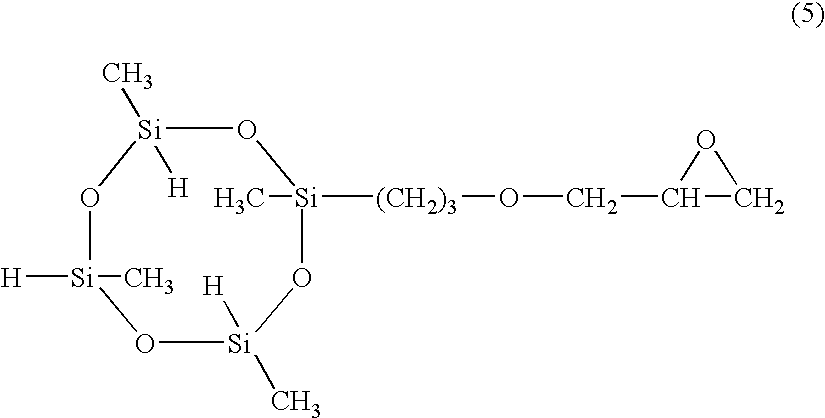

Silicone adhesive for semiconductor element

InactiveUS20090258216A1Improve concealmentEffective reflectionNon-macromolecular adhesive additivesLayered productsPolymer scienceColored white

A silicone adhesive for a semiconductor element that is suitable as a die bonding material for fixing a light emitting diode chip to a substrate. The adhesive includes (a) an addition reaction-curable silicone resin composition having a viscosity at 25° C. of not more than 100 Pa·s, and yielding a cured product upon heating at 150° C. for 3 hours that has a type D hardness prescribed in JIS K6253 of at least 30, (b) a white pigment powder having an average particle size of less than 1 μm, and (c) a white or colorless and transparent powder having an average particle size of at least 1 μm but less than 10 μm. The adhesive exhibits high levels of concealment, effectively reflects light emitted from the LED chip, and also exhibits favorable chip positioning properties, superior adhesive strength, and excellent durability.

Owner:SHIN ETSU CHEM IND CO LTD

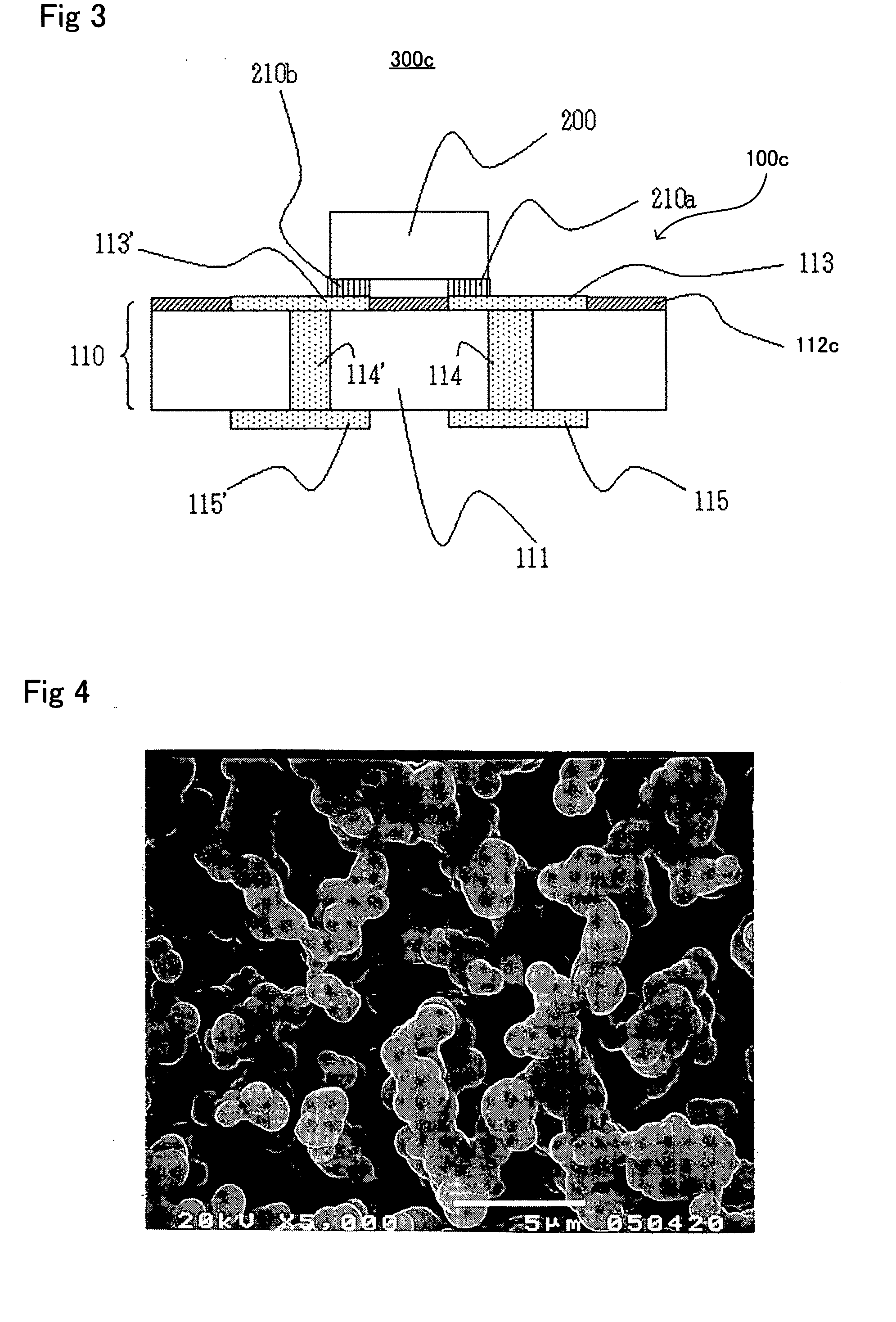

Ceramic Substrate for Mounting a Light Emitting Element and Method for Manufacturing the Same

InactiveUS20070252523A1Damage suppressionIncrease brightnessDischarge tube luminescnet screensCircuit optical detailsLength waveNitride

A ceramic substrate for mounting a light emitting element. The ceramic substrate has a placement surface for placing a light emitting element having an electrode; and an electrode electrically-connected with the electrode of the light emitting element, wherein the ceramic substrate comprises a substrate body consisting of a nitride ceramics; and a coat layer coating at least a part of a surface of the substrate body and consisting of a ceramics different from the nitride ceramics forming the substrate body; and the coat layer has an optical reflectance of 50% or more for any light having a wavelength of from 300 to 800 nm, which can increase a luminance of the light emitting element by reflecting the light emitted from the element efficiently with certainty, and which has a high heat radiation property; and a manufacturing method therefor.

Owner:TOKUYAMA CORP

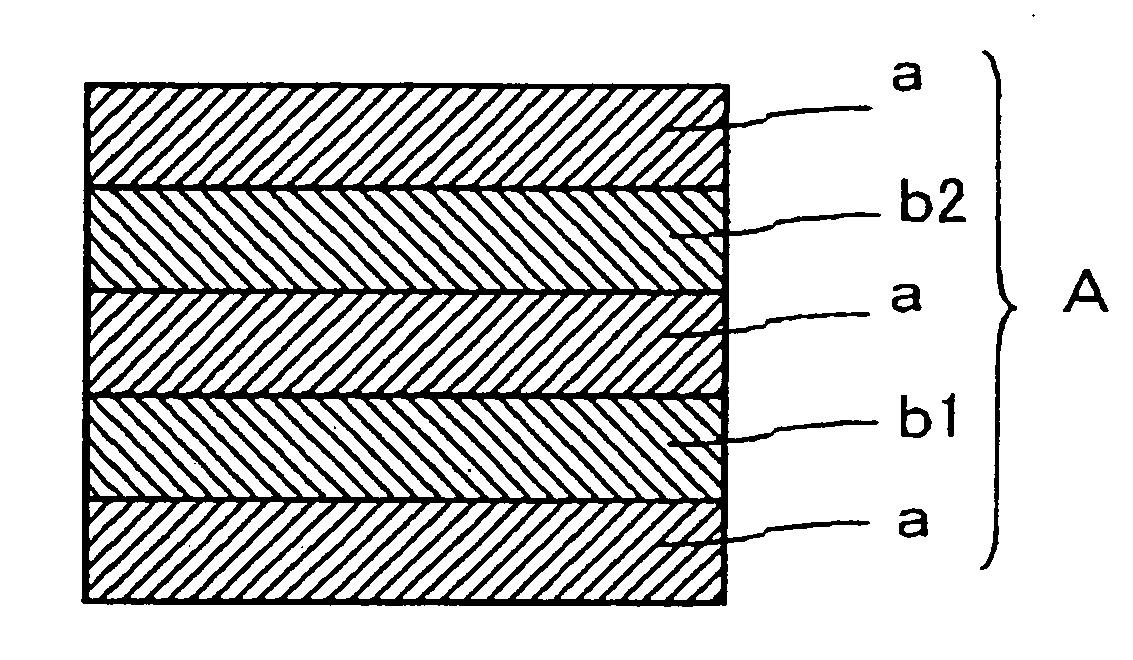

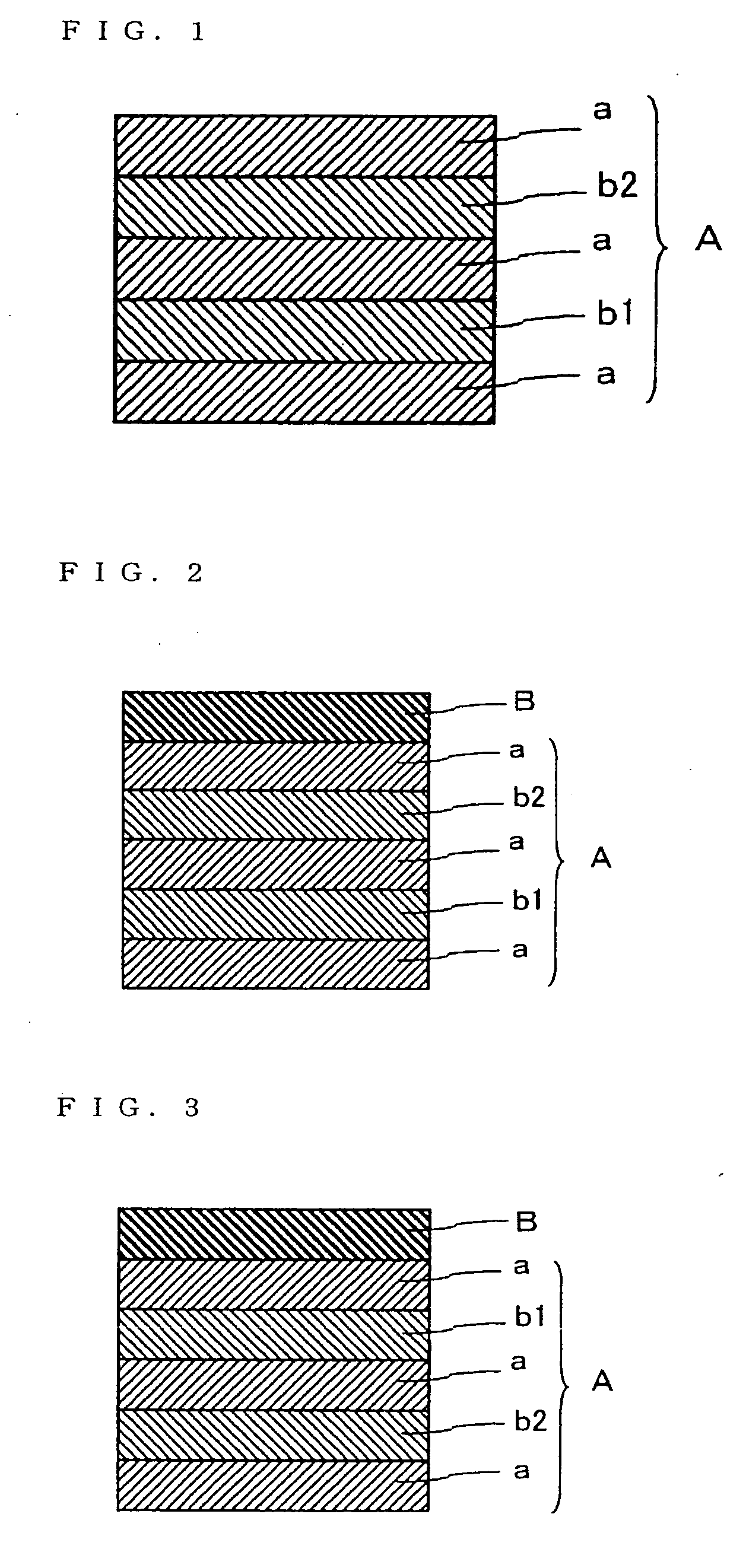

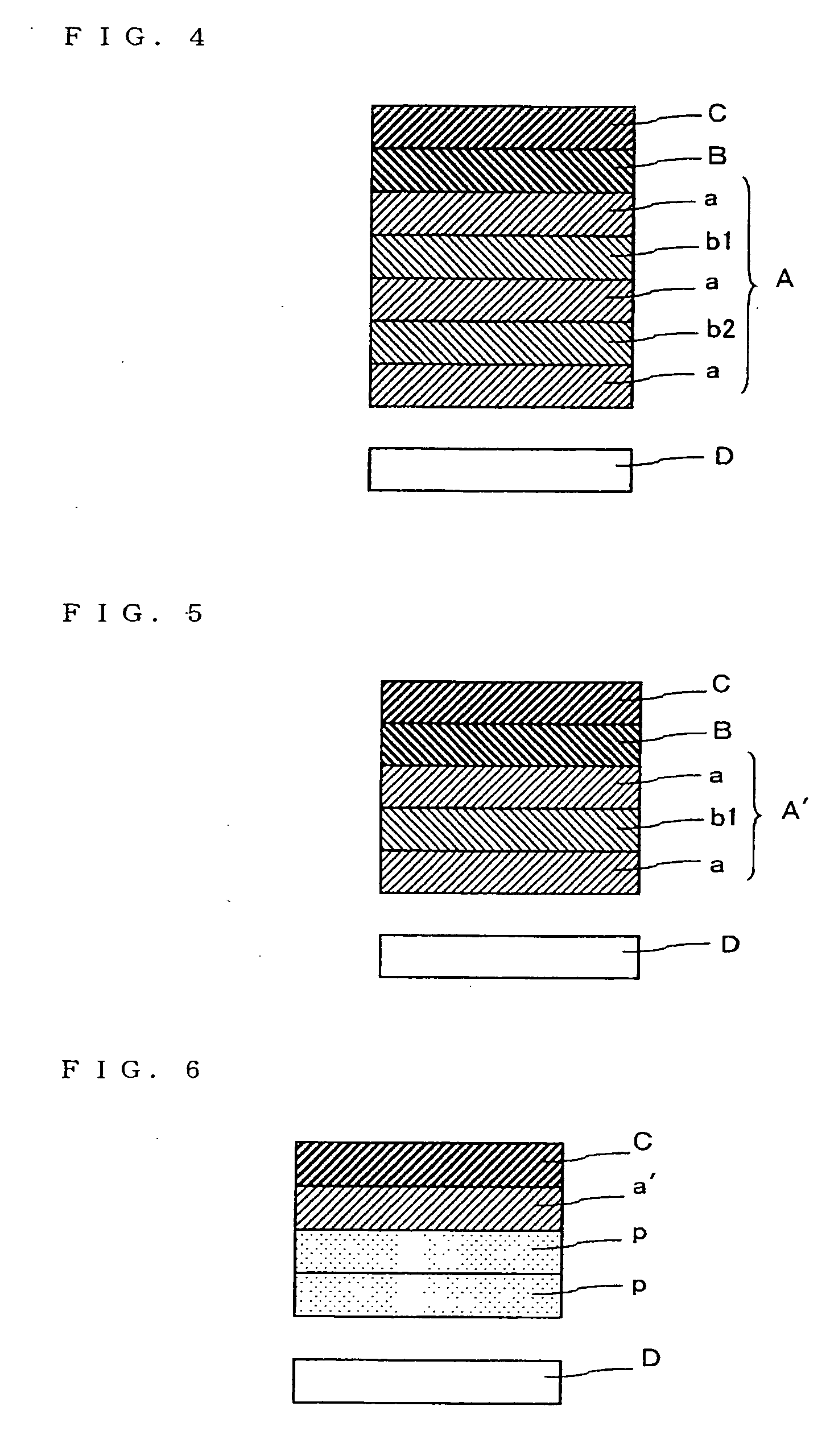

Optical device, light-condensing backlight system, and liquid crystal display

InactiveUS20060238867A1Effective reflectionIncrease brightnessLiquid crystal compositionsPolarising elementsLiquid-crystal displayAngle of incidence

An optical element of the invention comprises at least three laminated circular-polarization-type-reflection polarizers (a) whose wavelength bands for selective reflection of polarized light overlap one another; a layer (b1) which is placed between at least a pair of the circular-polarization-type-reflection polarizers (a) and has a front retardation of substantially zero (in the normal direction) and a retardation of at least λ / 8 with respect to incident light inclined by at least 30° relative to the normal direction; and a layer (b2) which is placed between at least another pair of the circular-polarization-type-reflection polarizers (a) and has a front retardation of substantially zero (in the normal direction) and a retardation of at most μ / 2 with respect to incident light inclined by 60° relative to the normal direction. The optical element condenses or collimates incident light from a light source and can control transmission of light at large incident angles relative to the normal direction, increase front brightness and reduce coloration.

Owner:NITTO DENKO CORP

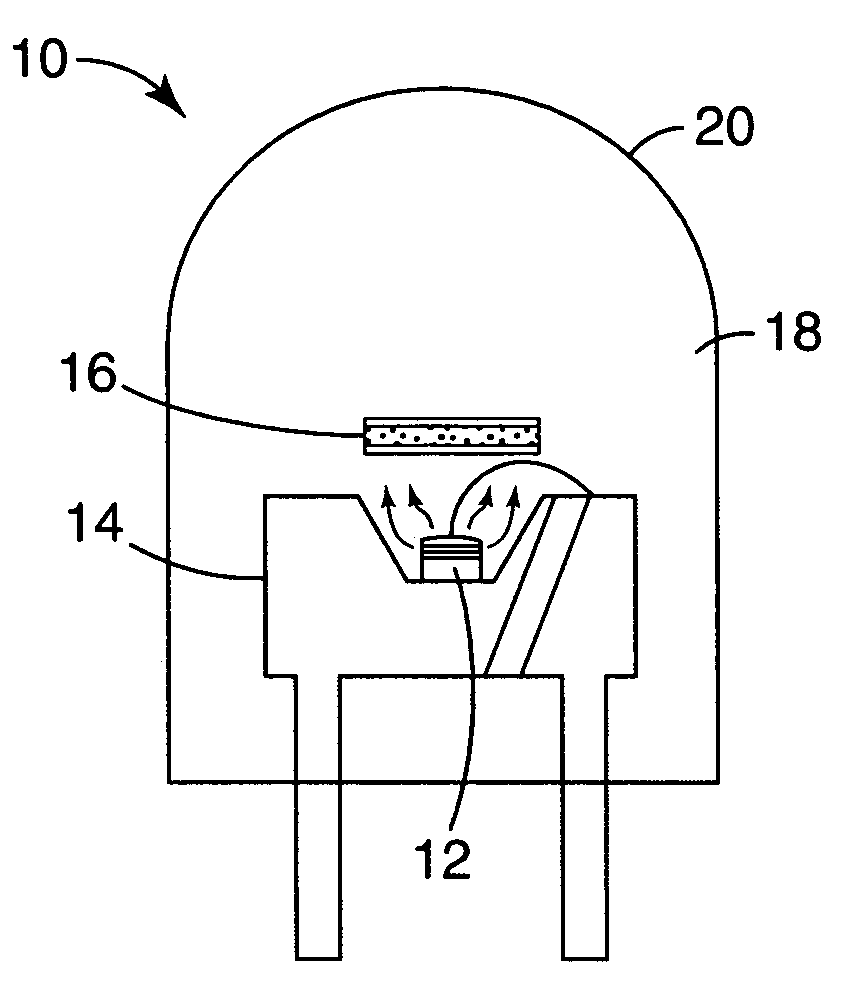

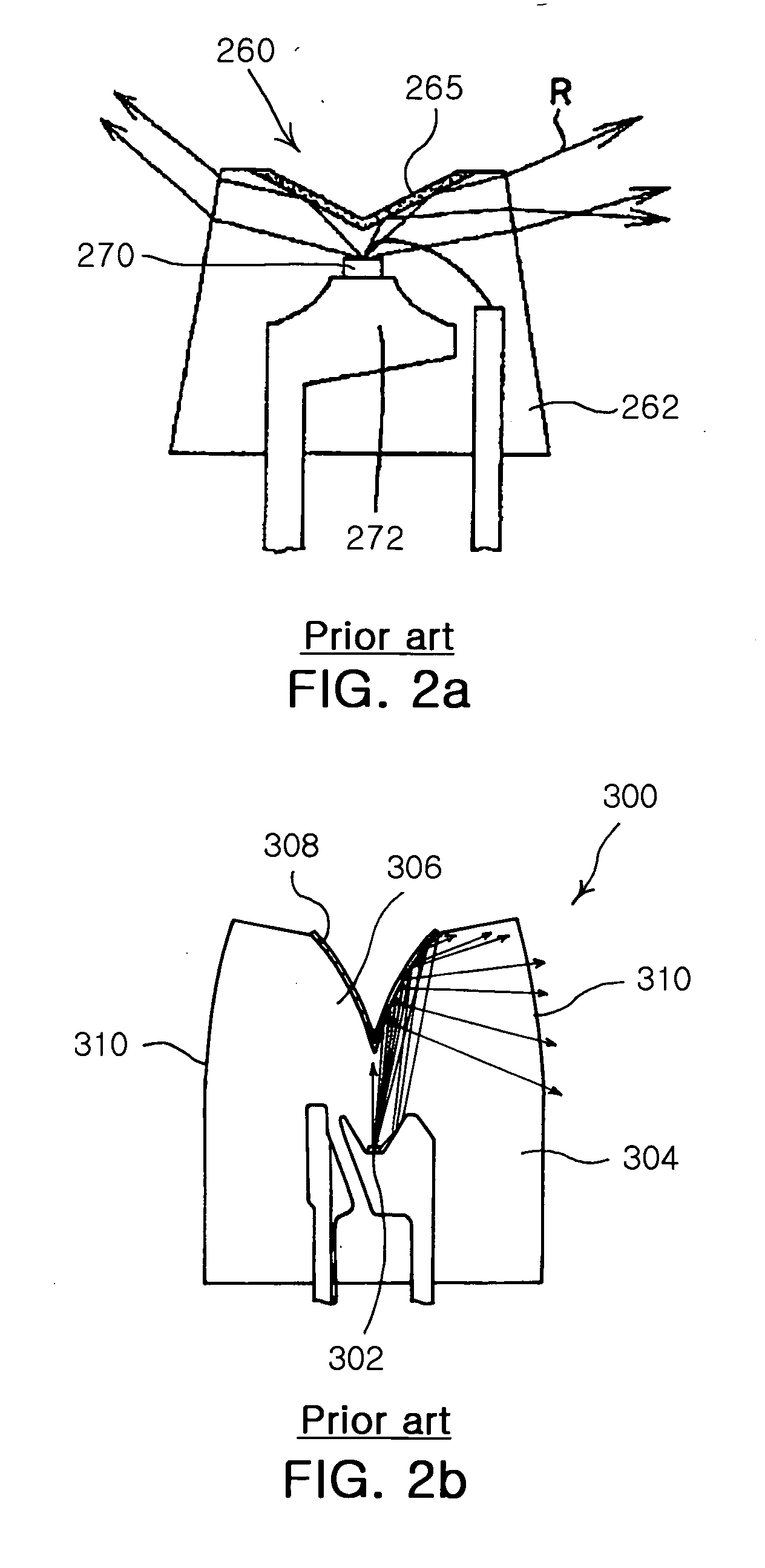

Phosphor based light sources having a polymeric long pass reflector

InactiveUS7245072B2Maintain reflectivityPrevent leakageDischarge tube luminescnet screensLamp detailsPhosphorPolymer

A light source includes an LED that emits excitation light, a polymeric multilayer reflector that reflects the excitation light and transmits visible light, and a layer of phosphor material spaced apart from the LED. The phosphor material emits visible light when illuminated with the excitation light. The polymeric multilayer reflector reflects excitation light onto the phosphor material. The layer of phosphor material is disposed between the LED and the polymeric multilayer reflector.

Owner:3M INNOVATIVE PROPERTIES CO

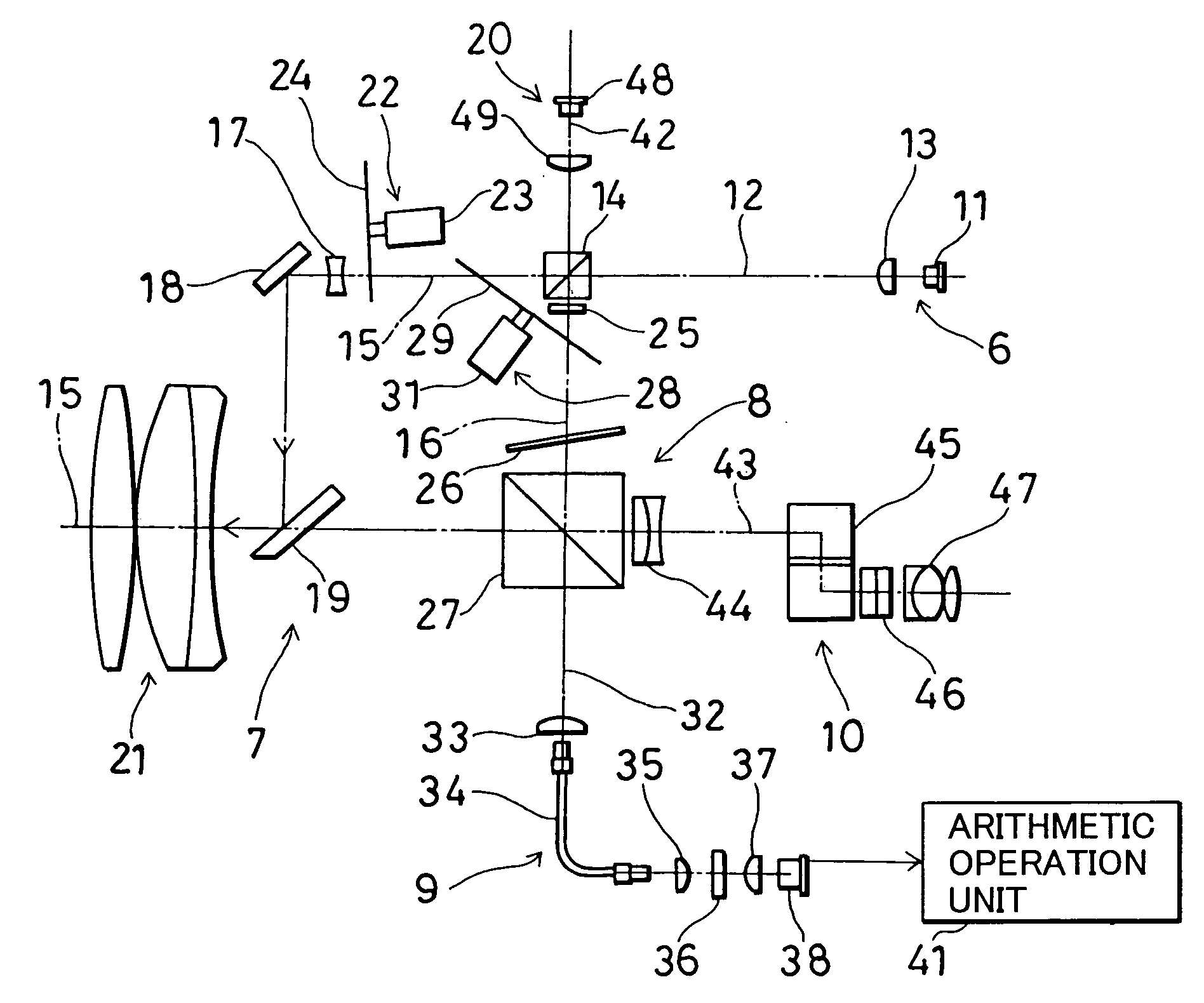

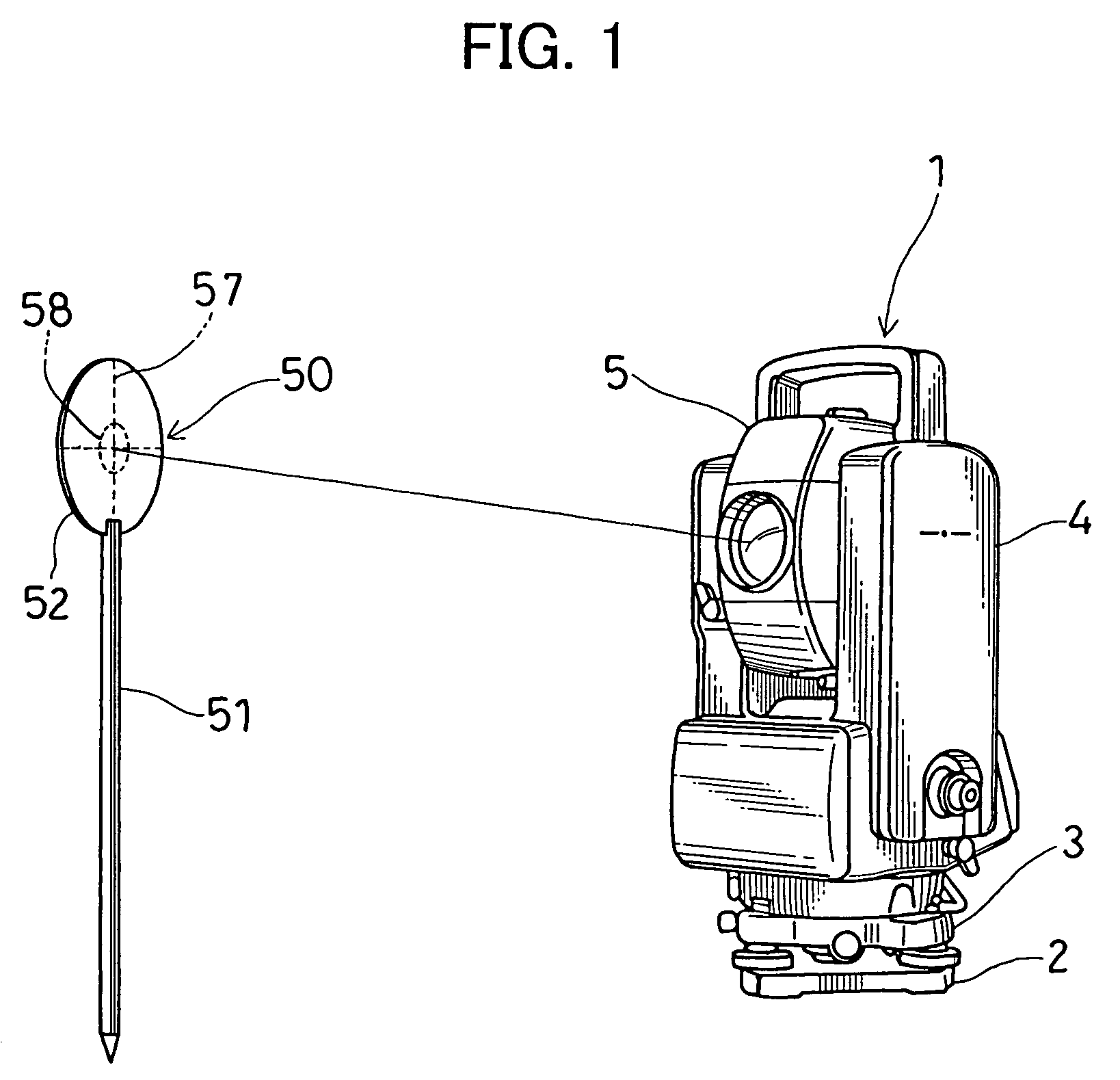

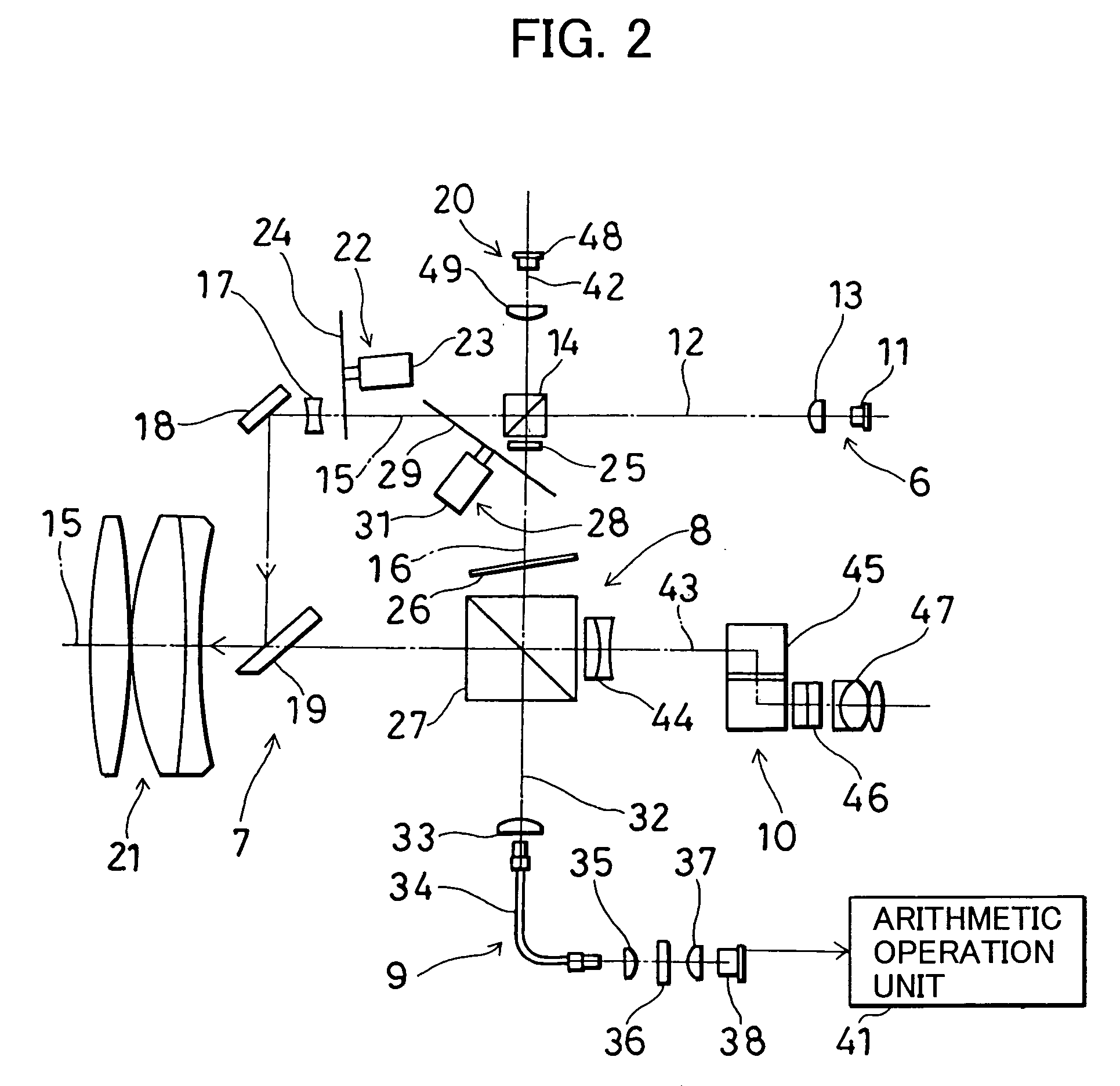

Target for surveying instrument

ActiveUS7130035B2Efficiently confirmed visuallyLong distanceAngle measurementOptical rangefindersPoint lightWavelength filter

A target for a surveying instrument, which receives from the surveying instrument a laser point light indicating a position and a distance measuring light to measure a distance, comprising a reflection diffusion layer for reflecting and diffusing the distance measuring light, a wavelength filter layer for selectively transmitting the laser point light passing through the reflection diffusion layer, and a transmission diffusion layer for spreading in a given direction and for transmitting the laser point light passing through the wavelength filter layer, wherein a projecting position of the laser point light can be confirmed.

Owner:KK TOPCON

Phosphor based light source component

InactiveUS20070182299A1Maintain reflectivityPrevent leakageIncadescent screens/filtersDischarge tube luminescnet screensPhosphorLight source

A method of making a light source includes the steps of forming a first optical component having a phosphor material in fixed relation to a first multilayer interference reflector, providing a second optical component having an LED capable of emitting light that excites the phosphor material, and positioning the first optical component to receive emitted light from the second optical component. Corresponding articles are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

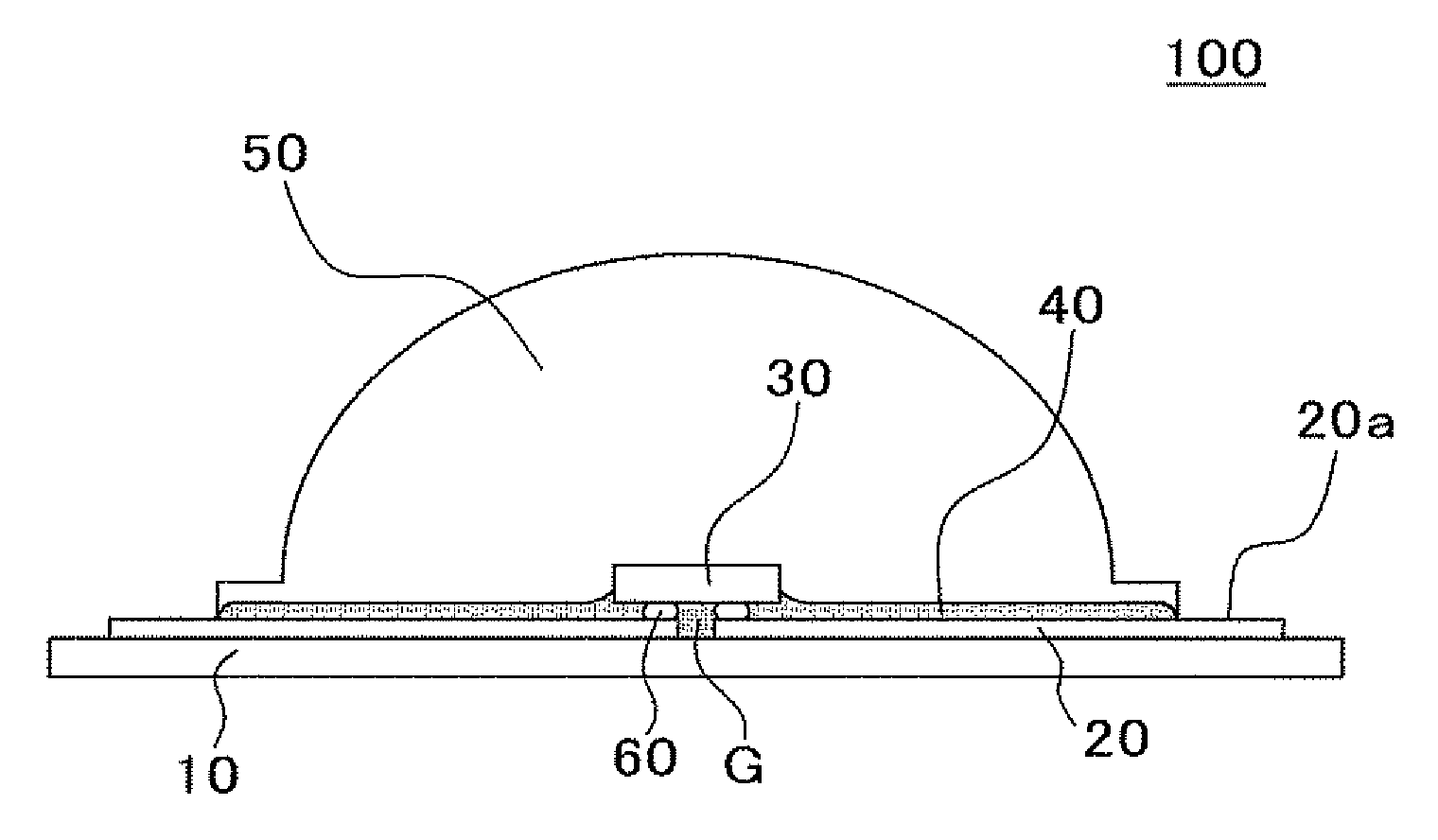

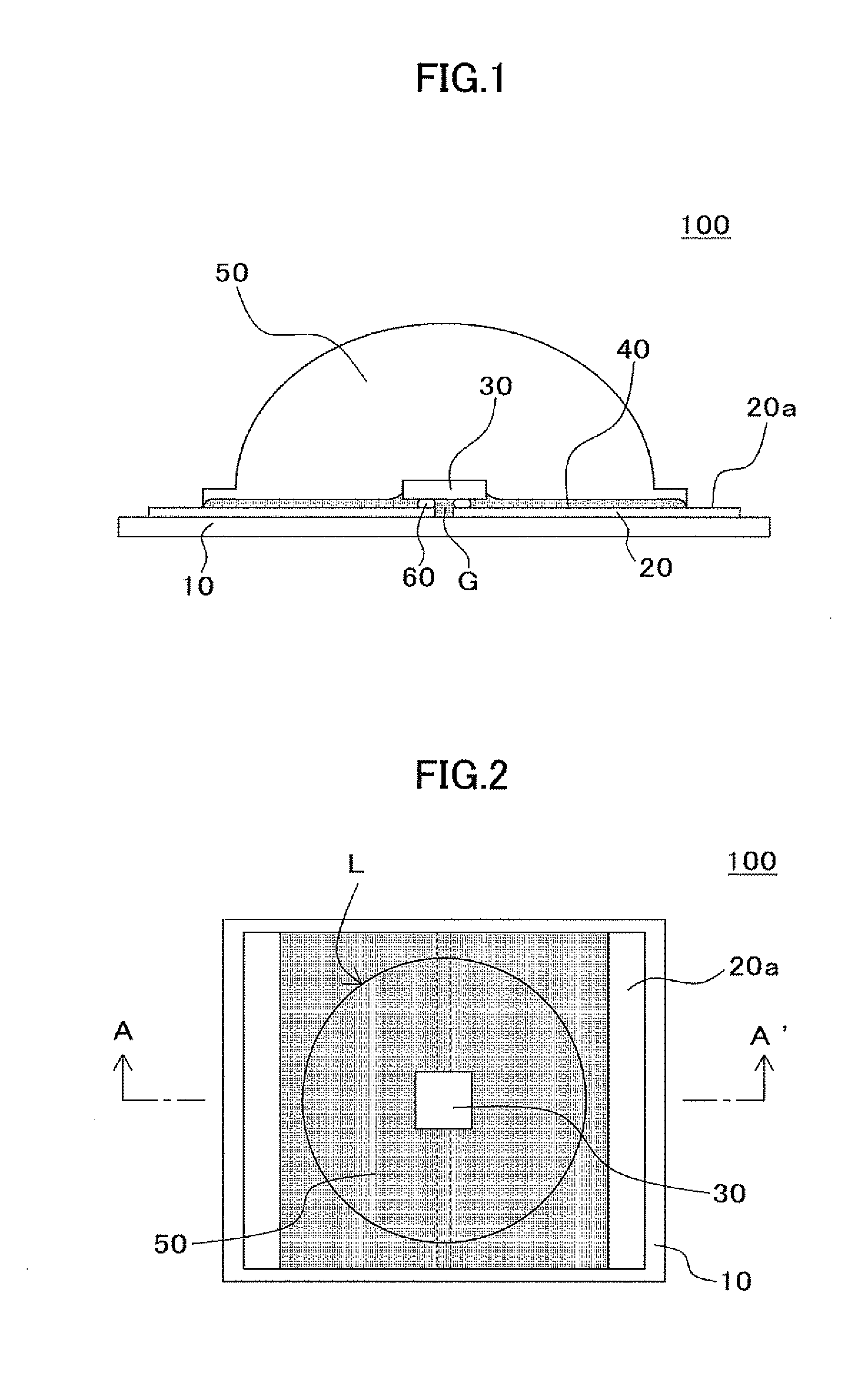

Light emitting device

ActiveUS20120193665A1Effective reflectionImprove light extraction efficiencySolid-state devicesSemiconductor devicesLight reflectionLight emitting device

A light emitting device which includes: a base body; a conductive member disposed on the base body; a light emitting element placed on the conductive member; and a translucent member disposed above the light emitting element. A surface of the translucent member is formed in a lens shape, and when a portion formed in the lens shape of the translucent member on a surface of the conductive member is perspectively seen from above, an area other than a portion where the light emitting element is placed is coated with an insulating filler to form a light reflection layer.

Owner:NICHIA CORP

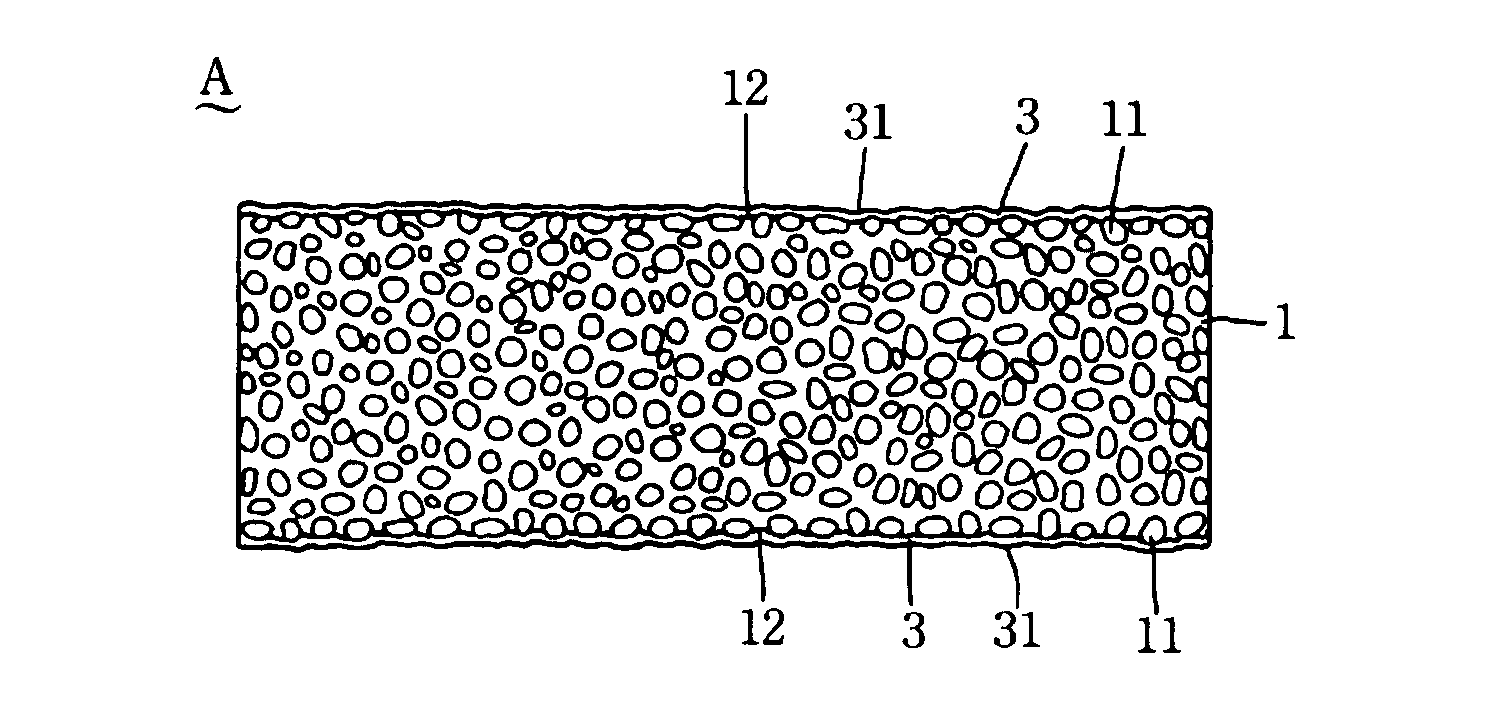

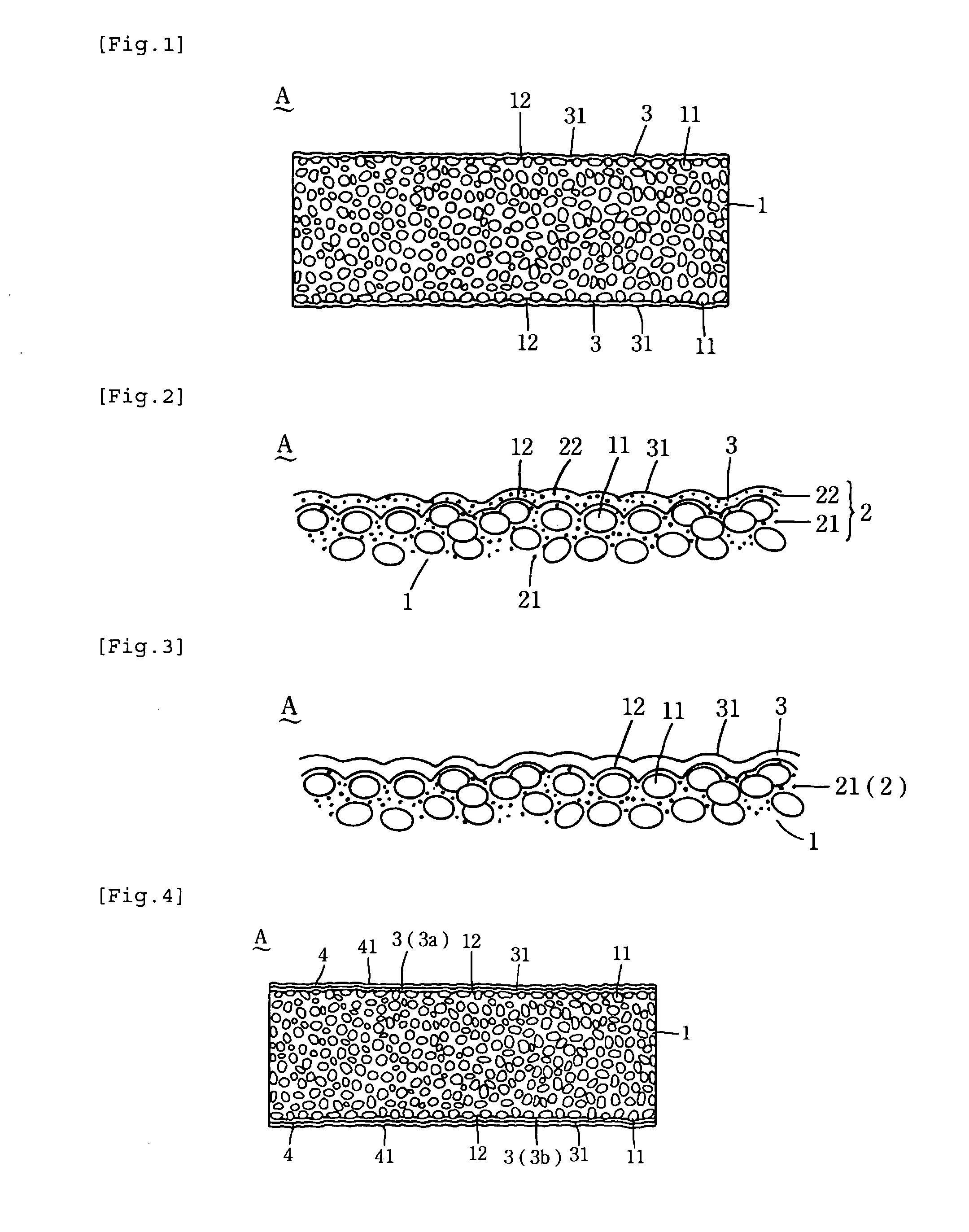

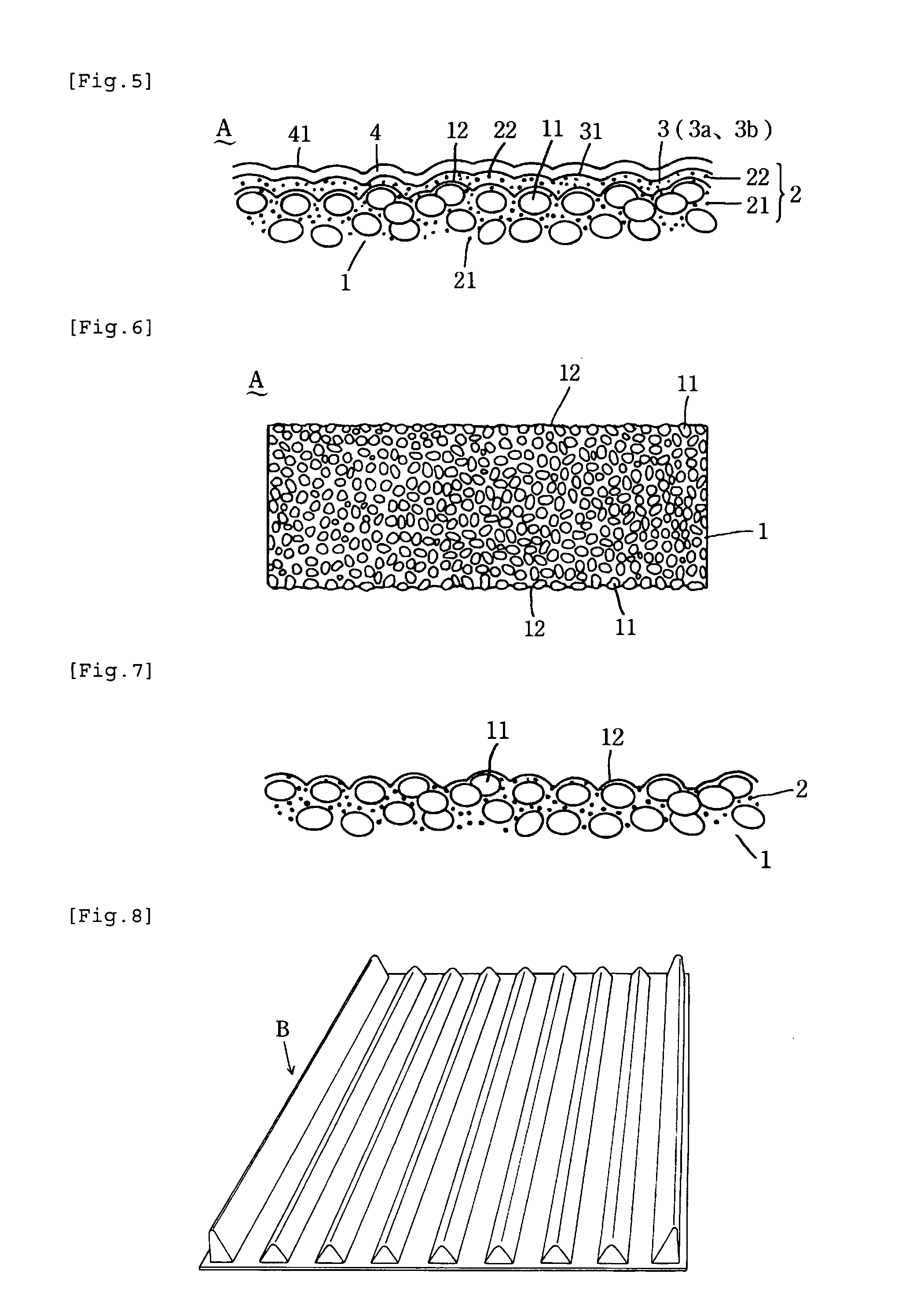

Foamed Sheet for Reflector, Reflector, and Method for Producing Foamed Sheet for Reflector

InactiveUS20090068402A1Easy to adjustEffective reflectionMirrorsDiffusing elementsRefractive indexPolypropylene

The present invention provides a foamed sheet for a reflector which can be transformed to a reflector having a desired shape by thermoforming.A foamed sheet A for a reflector of the present invention is characterized by being a foamed sheet for a reflector including a polypropylene-based resin foamed sheet 1 which has an average cell diameter of from 50 to 650 μm and at least one surface which is an uneven surface 12 formed by cells 11 located in the vicinity of the surface, and a polypropylene-based resin non-foamed sheet 3 integrally laminated on the polypropylene-based resin foamed sheet 1 in conformity with the uneven surface 12 and having an uneven surface 31, wherein the foamed sheet A for a reflector contains an inorganic filler in an amount of from 50 to 200 g / m2, the whole or part of the inorganic filler is contained in the polypropylene-based resin foamed sheet 1, a refractive index of an inorganic filler 2 differs by 1.0 or more from a refractive index of the polypropylene-based resin, and the foamed sheet A for a reflector has an overall thickness of from 0.2 to 2.0 mm and a light reflectance of 97% or more.

Owner:SEKISUI PLASTICS CO LTD

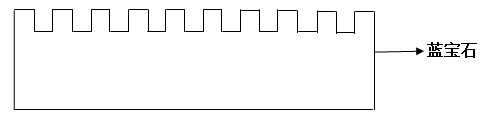

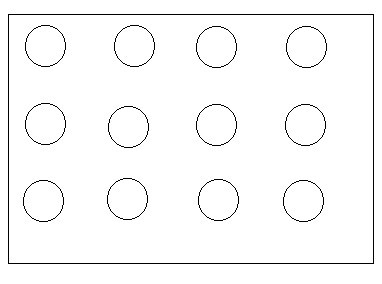

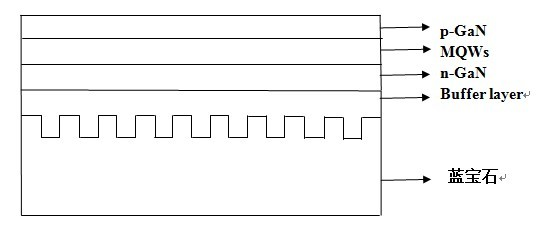

Flip-chip LED chip structure and manufacturing method thereof

InactiveCN102044608AGuaranteed compositeGuaranteed to workSemiconductor devicesContact layerMaterials science

The invention discloses a flip-chip LED chip structure and a manufacturing method thereof. The LED chip comprises an epitaxial layer taking sapphire as substrate and an electrode layer taking SiO2 / Si as substrate; holes of periodical structure are etched on the front surface of the sapphire substrate, and random patterns are etched on the back surface; a growth buffer layer, an n type GaN layer (n-GaN), an MQWs (multi quantum wells) layer and a p type GaN layer (p-GaN) are successively grown on the sapphire substrate etched with holes as the epitaxial layer; one or more negative electrode grooves are etched on the p type GaN layer (p-GaN); a p type contact layer is sputtered on the p type GaN layer (p-GaN); an n type ohmic contact layer is electroplated on the n type GaN layer (n-GaN) exposed after etching; titanium (Ti), platinum (Pt) and aurum (Au) are successively deposited on the SiO2 / Si substrate as an electrode layer; the electrode distribution on the electrode layer is coincident with that on the etched epitaxial layer; and the LED chip is formed by bonding the epitaxial layer on the front surface of the sapphire substrate and the electrode layer on the SiO2 / Si substrate with Au solder. The structure has the advantages of stable performance, high utilization rate of electric energy and long service life.

Owner:CHONGQING UNIV

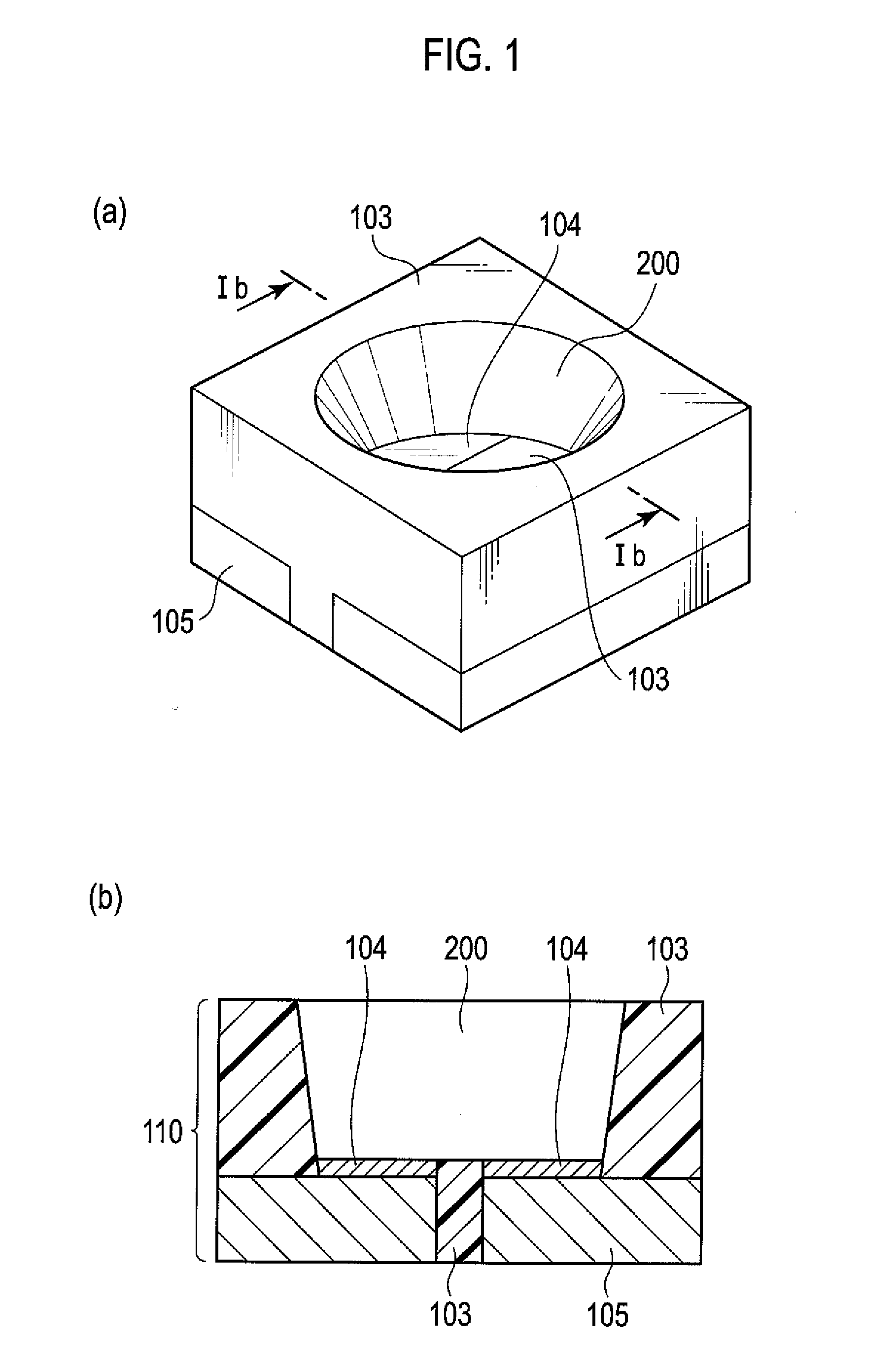

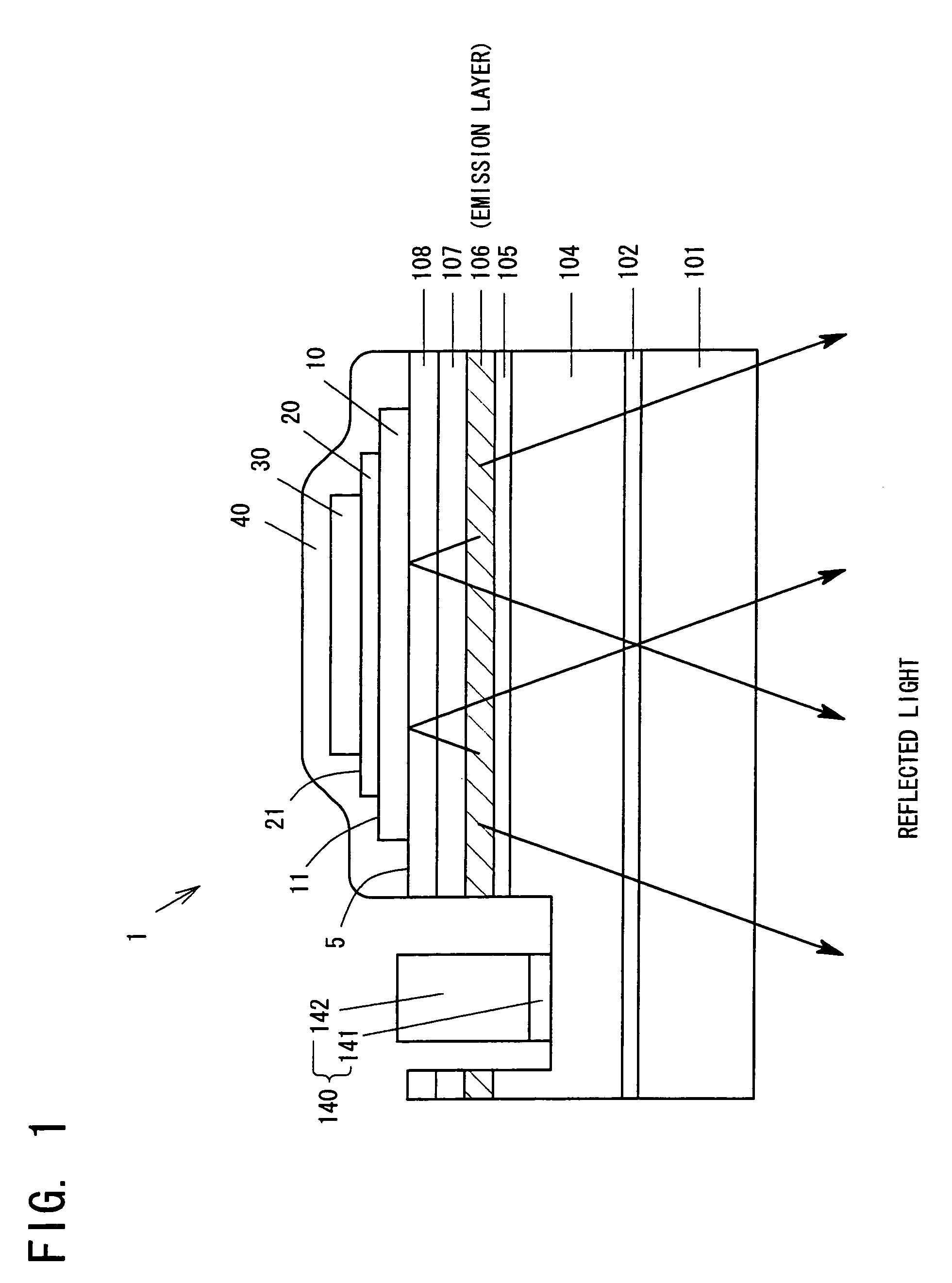

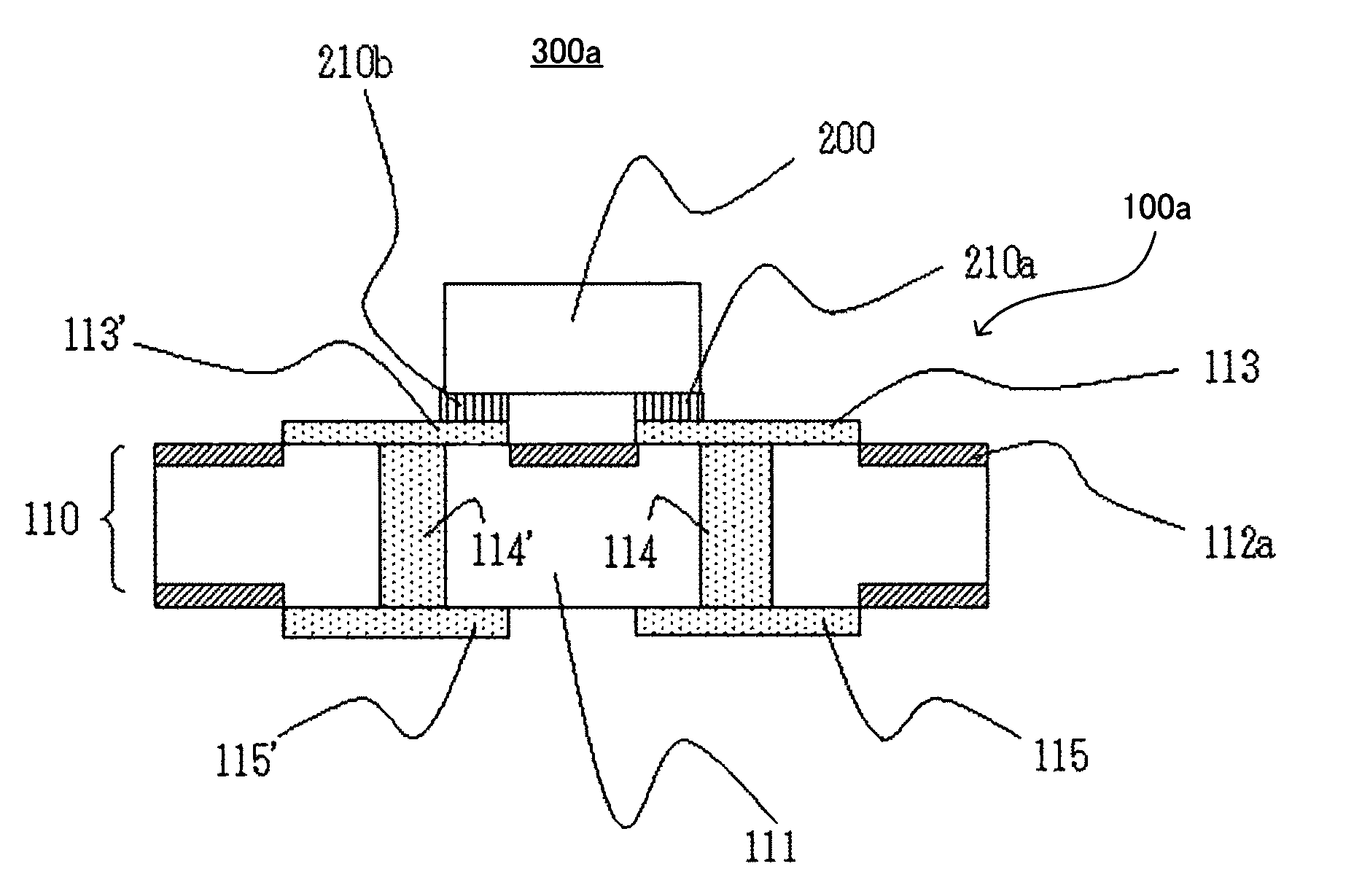

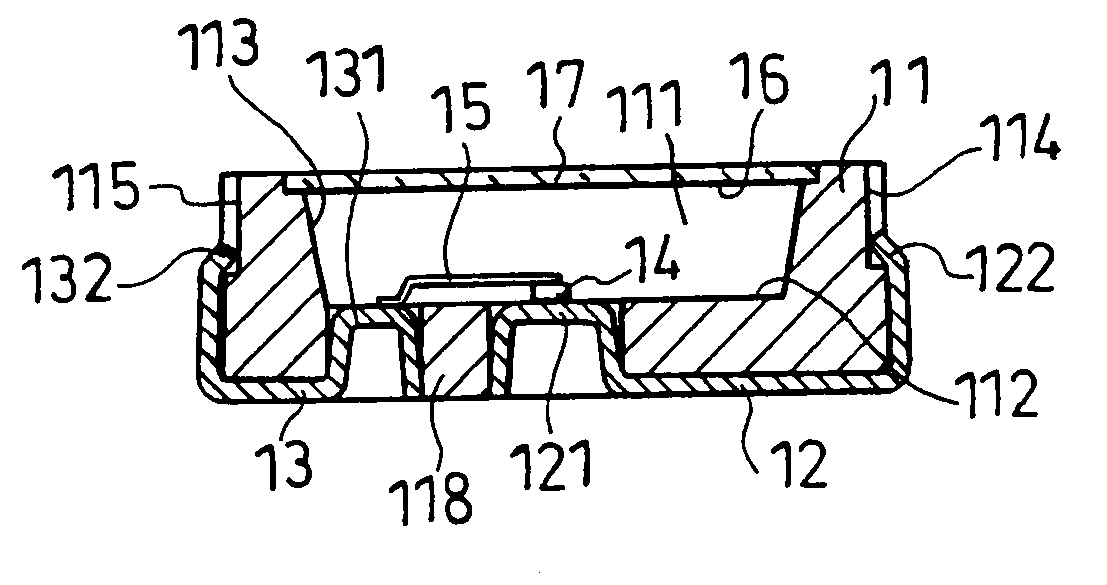

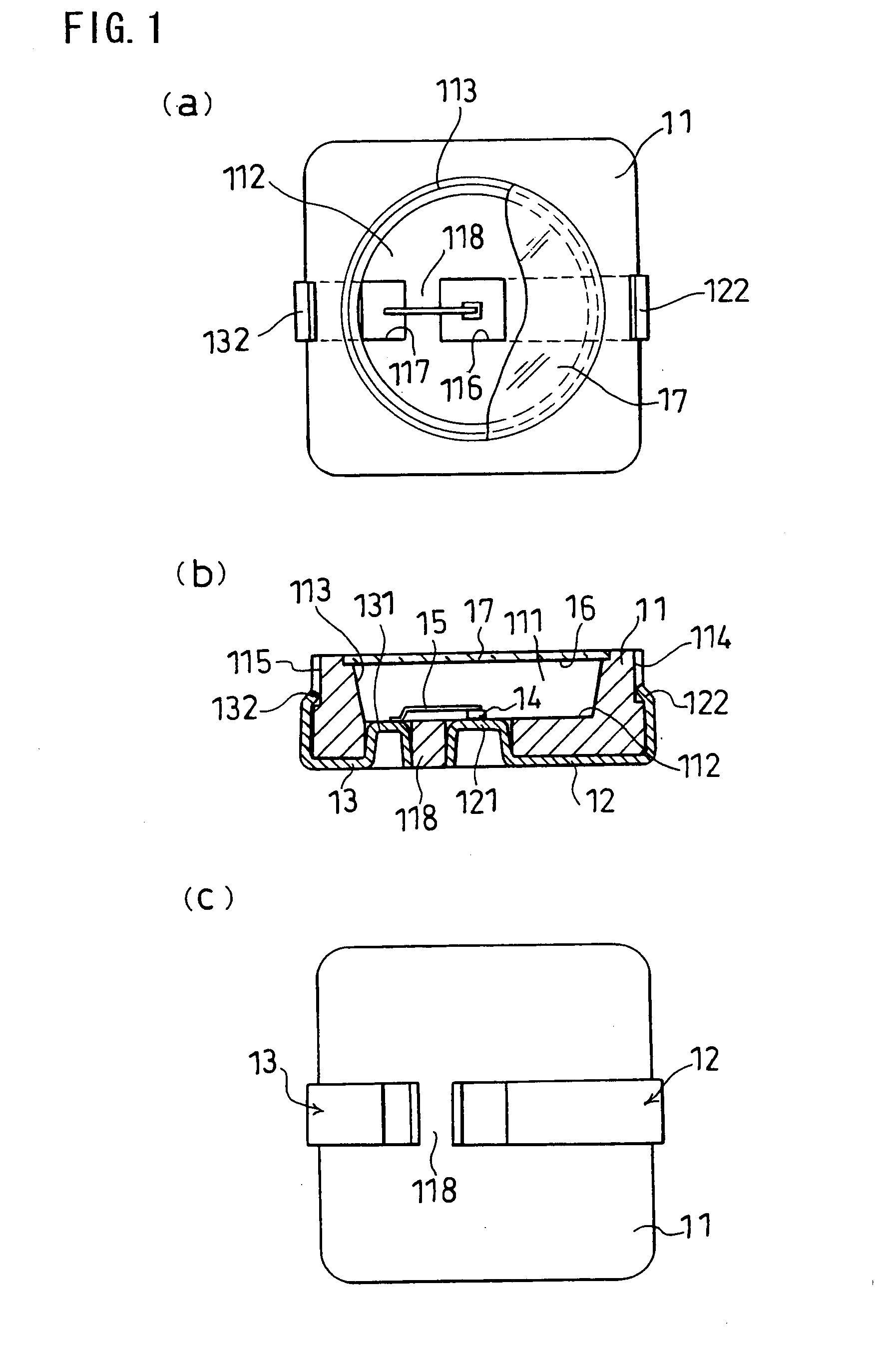

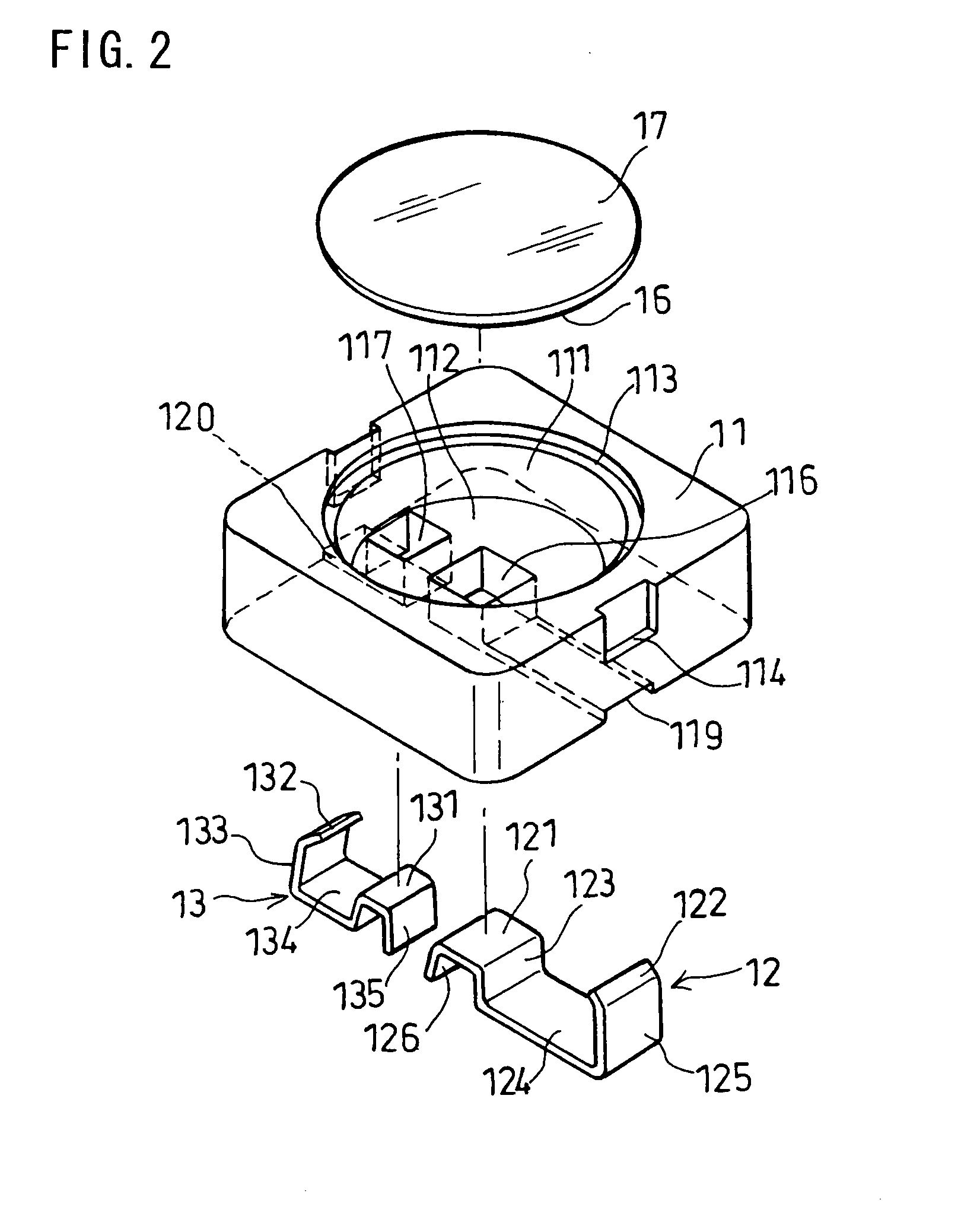

Package for light emitting diode, light emitting device, and light emitting device manufacturing method

InactiveUS20110037091A1Few defectEffective reflectionSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceLight emitting device

The present invention relates to a light emitting diode package for mounting a light emitting diode, a light emitting diode device with the light emitting diode package mounting a vertical electrode type light emitting diode thereon and a manufacturing method for manufacturing the light emitting device.The light emitting diode package of the invention comprises at least a molding, and a first clip 122 and a second clip 123 fitted on the molding. The molding has at least a first opening 1212 and a second opening 1213 formed in a bottom portion thereof. The molding also has a reflecting portion 1214 formed around the first opening 1212 and the second opening 1213 for reflecting light. The molding further has a fluorescent film member mounting portion 1113 formed integrally for mounting a fluorescent film member 116 in the opening of the reflecting portion 1214. The first clip 122 has a light emitting diode mounting projection formed substantially at the center portion thereof for mounting the light emitting diode and is made to engage resiliently with the molding at both ends thereof. The first clip 122 engages with the molding at both ends thereof. The second clip 123 has a bonding projection formed to engage resiliently with the molding at both ends thereof.

Owner:CI KASEI COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com