Light-emitting semiconductor device

a technology of semiconductor devices and light-emitting semiconductors, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical equipment, etc., can solve the problem that the gallium nitride-based compound semiconductor layer can barely obtain ohmic characteristics, and achieve the effect of preventing driving voltage from increasing, preventing the transparency of transparent conductive films and preventing the reflection of films from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

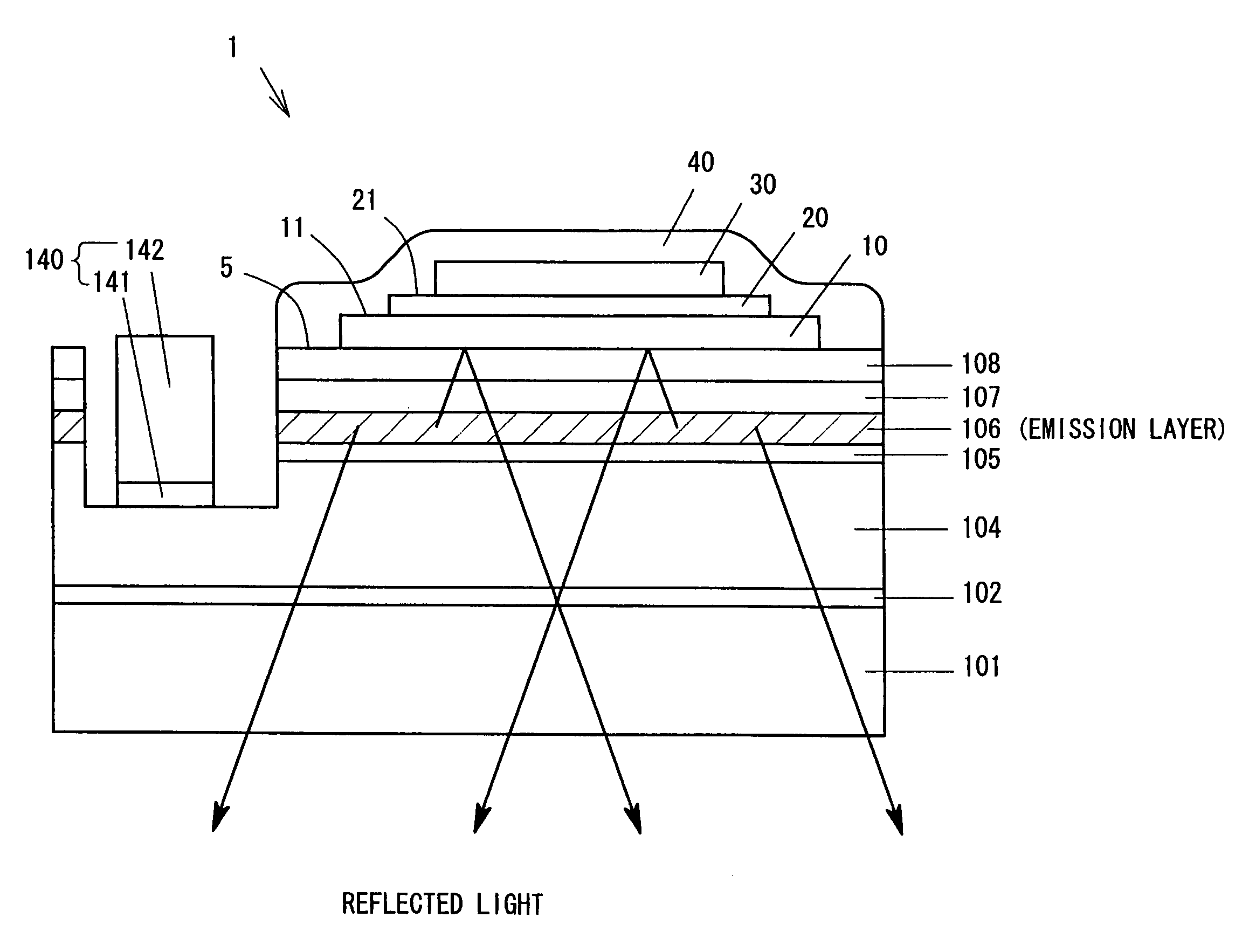

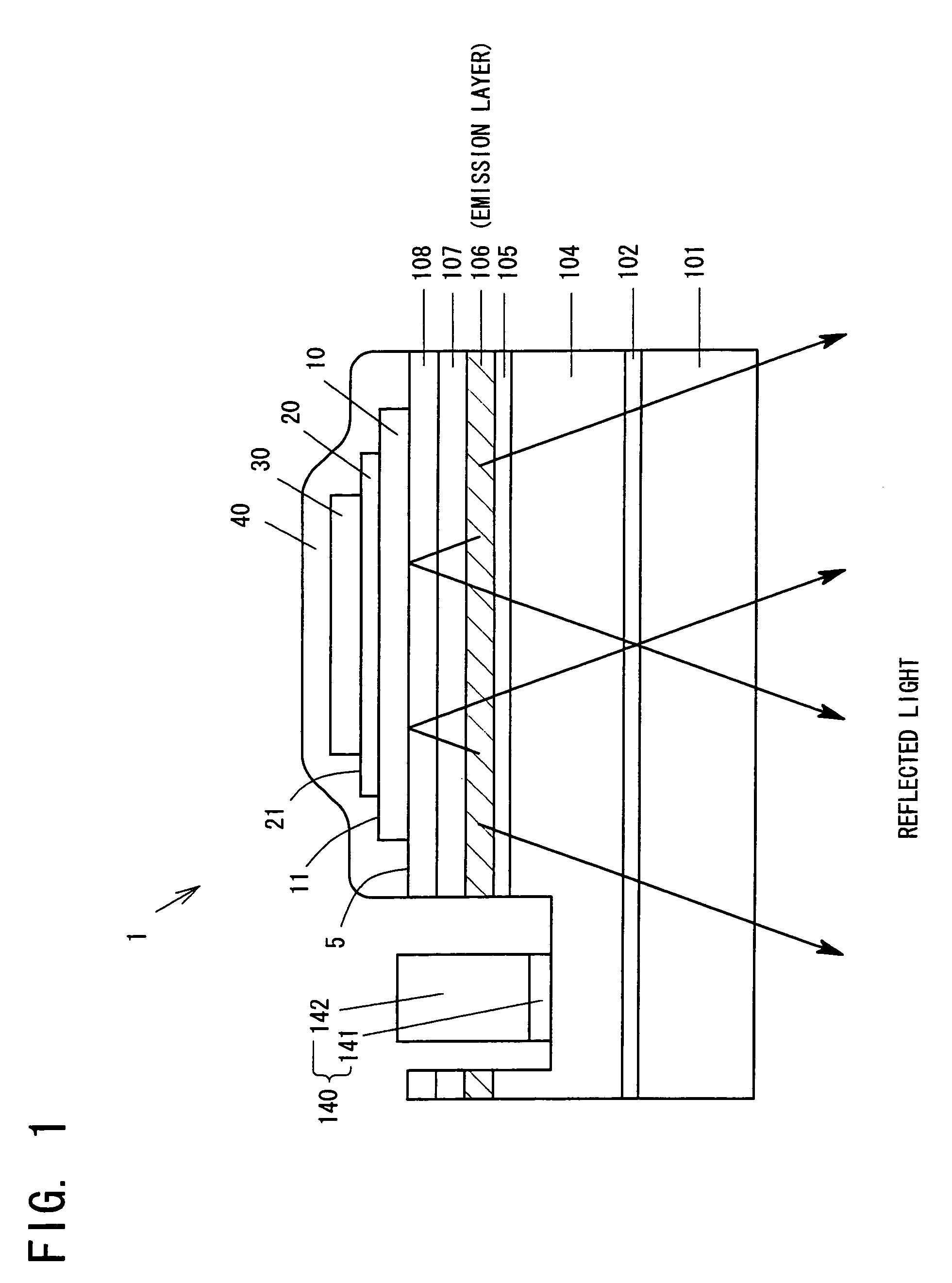

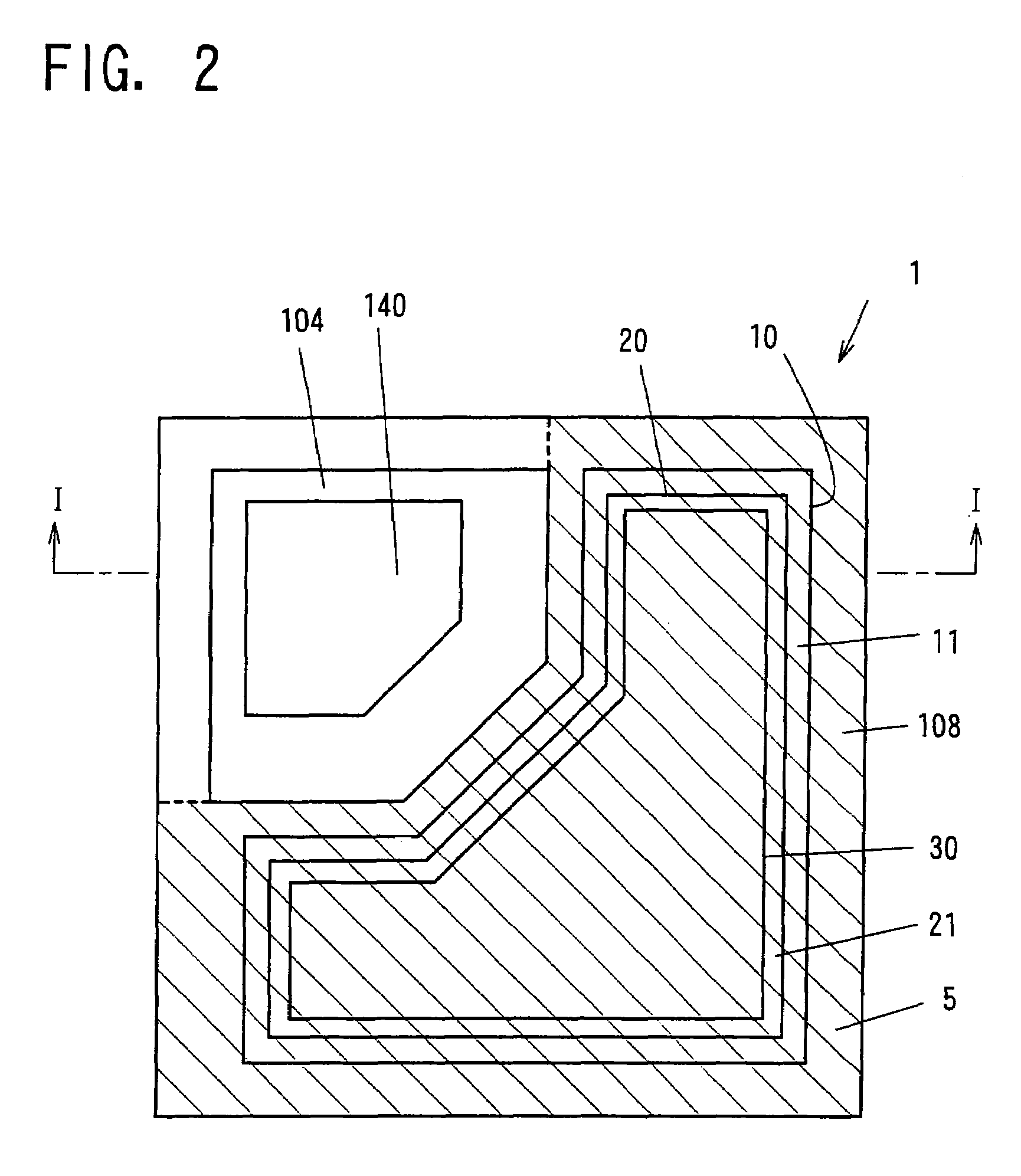

[0089]FIG. 1 is a sectional view and FIG. 2 is a plane view of a light-emitting semiconductor device 1 in the present embodiment 1. About 20 nm in thickness of aluminum nitride (AlN) buffer layer 102 is formed on 100 μm in thickness of light-transmitting sapphire substrate 101. About 8.0 μm in thickness of silicon (Si) doped GaN high-carrier concentration n+-layer is formed thereon as an n-type contact layer 104. The n-type contact layer 104 has electron concentration of 5×1018 / cm3. The higher the electric concentration of the n-type contact layer 104 is, the more preferable, and it is possible to increase the electric concentration to 2×1019 / cm3. And 200 nm in thickness of In0.03Ga0.97N strain relaxation layer 105 is formed on the n-type contact layer 104. An emission layer 106 having multiple quantum-well (MQW) structure which comprises 3 periods in total of about 20 nm in thickness of undoped GaN and about 3 nm in thickness of undoped Ga0.8In0.2N is formed on the strain relaxatio...

embodiment 2

[0096]A light-emitting semiconductor device shown in FIGS. 3, 4, and 5 is manufactured as explained in the best mode for carrying out the present invention, respectively. The light-emitting semiconductor device has effect similar to the device manufactured in the first embodiment. Each member which is shown in FIGS. 3, 4, and 5 and has same number as members in FIGS. 1 and 2 corresponds to each component in the first embodiment and in the best mode for carrying out the present invention.

[0097]FIG. 3 illustrates a device which does not comprise the first exposed portion and the third exposed portion but comprises only the second exposed portion 11 in L-shape at the right side A and the bottom side B. The transparent conductive film 10 made of ITO is formed in the same plane form as the p-type contact layer 108, and the insulation protection film 20 made of SiO2 is formed in the same plane form as the reflection film 30 made of Ag. And the electrode layer 40 made of Au is formed to co...

embodiment 3

[0099]Next, Embodiment 3 of the present invention is explained as follows.

[0100](Crystal Growth of a Gallium Nitride Compound semiconductor)

[0101]As a substrate to grow a gallium nitride based compound semiconductor thereon, a sapphire substrate 310 is used. After carrying out washing and vapor phase etching treatment, about 20 nm in thickness of AlN low temperature deposition buffer layer 311, about 4 μm in thickness of Si-doped GaN n-type layer 312, an active layer 313 which has multiple quantum-well (MQW) structure and is made of GaN and GaInN, 60 nm in thickness of Mg-doped AlGaN p-type layer 314, and 150 nm in thickness of Mg-doped GaN p-type layer 315 are deposited on the sapphire substrate 310 in sequence through metal organic vapor phase epitaxy (MOVPE) (FIG. 6). Alternatively, in order to obtain 280 nm of luminous wavelength, a Si-doped AlGaN layer is used as the n-type layer 312 and the active layer 313 having multiple quantum-well (MQW) structure is formed by using AlGaIn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com