Patents

Literature

175results about How to "Inhibit interface reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

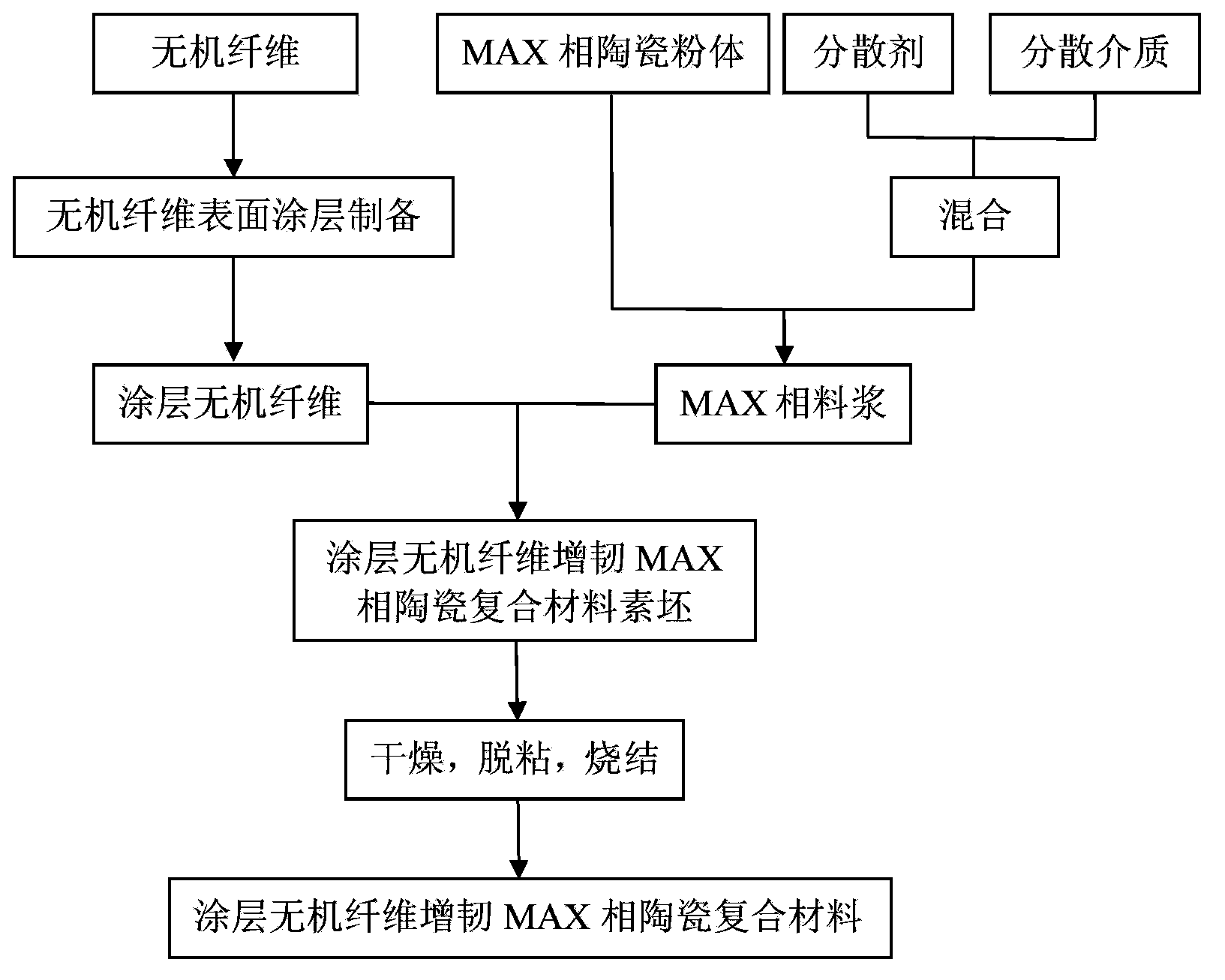

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

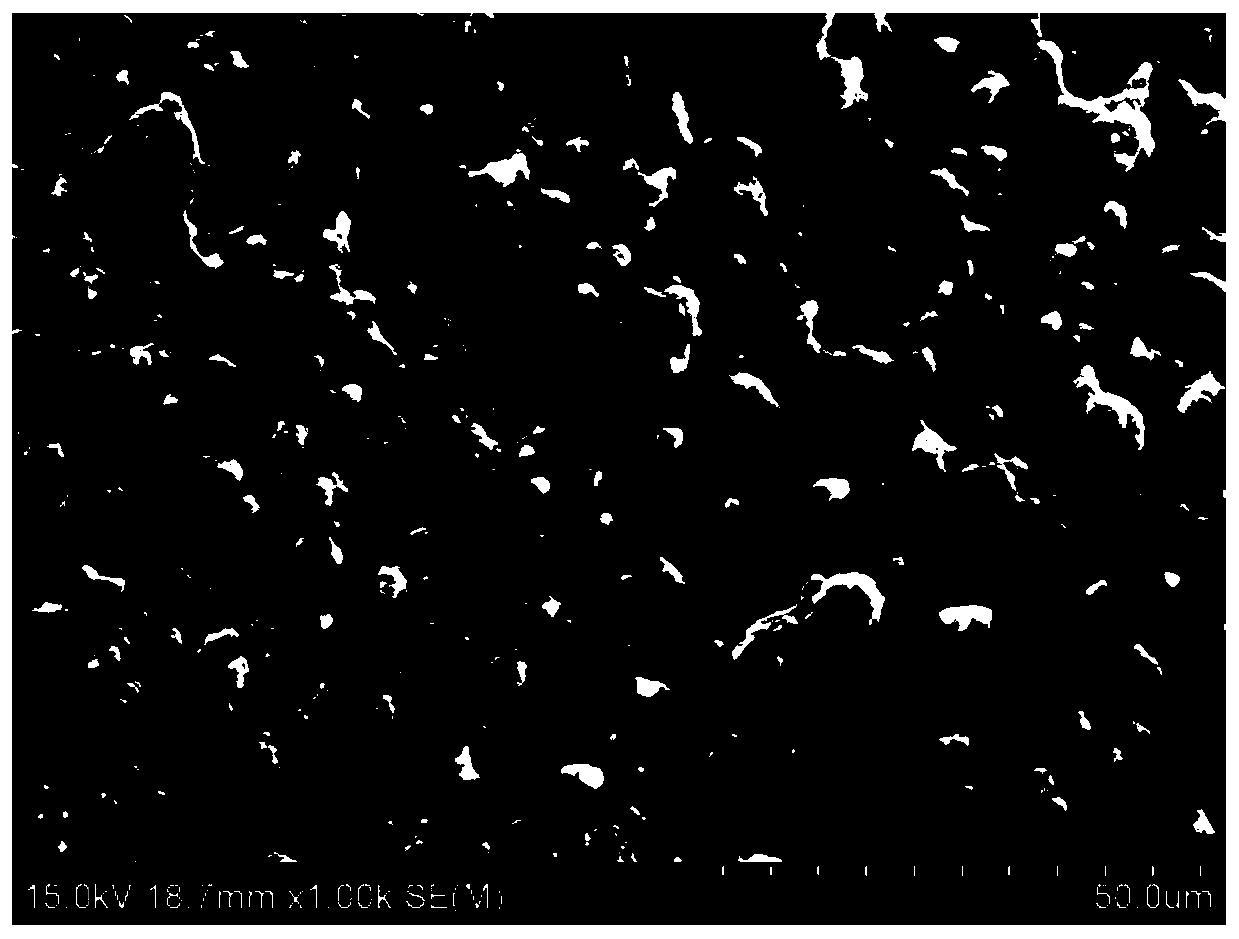

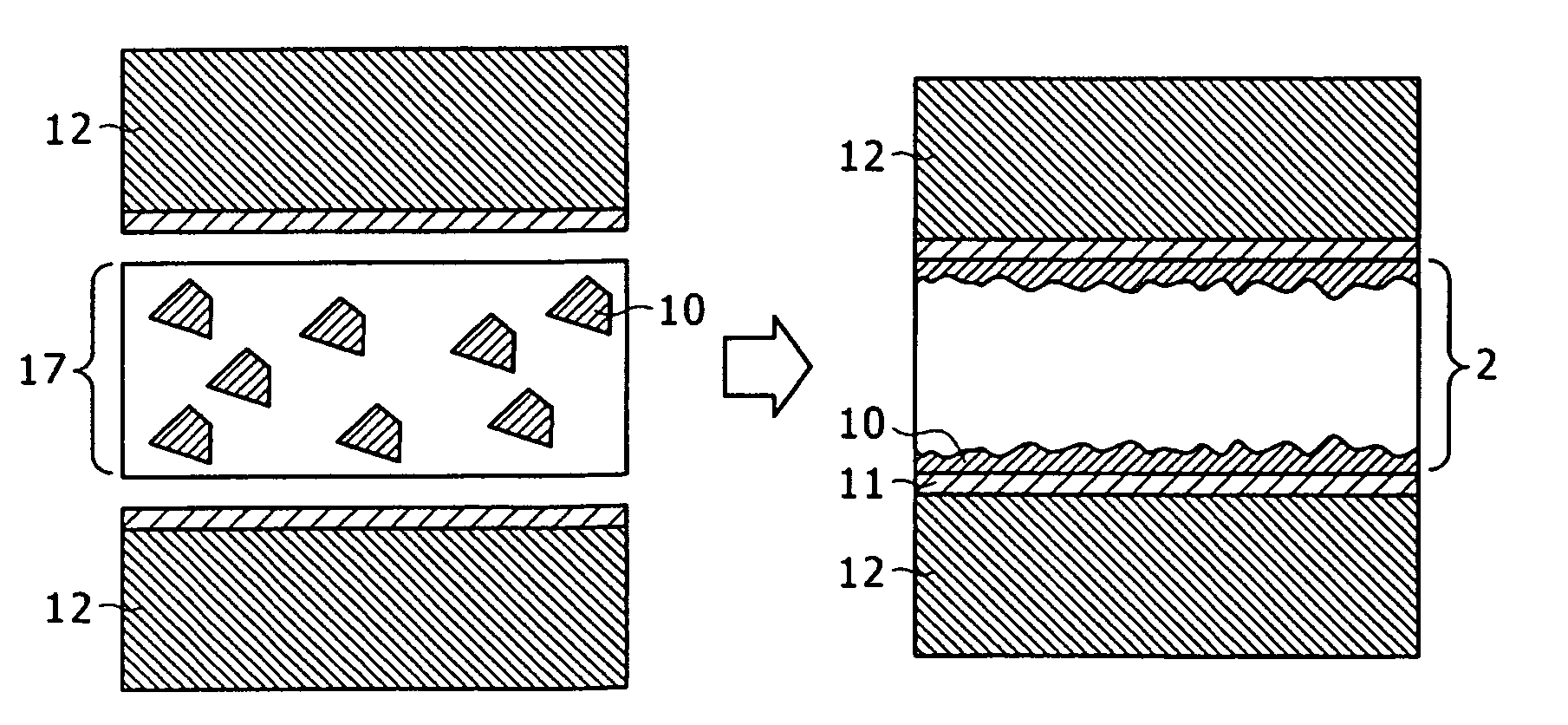

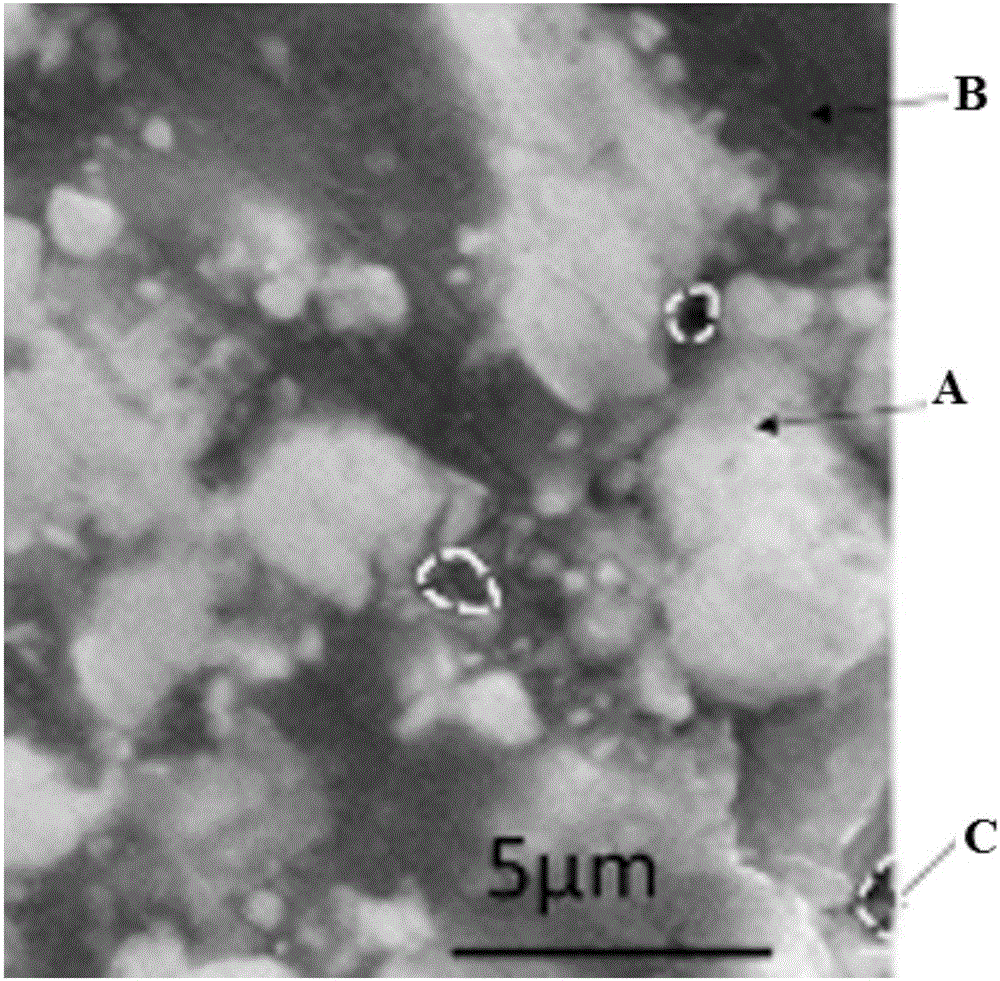

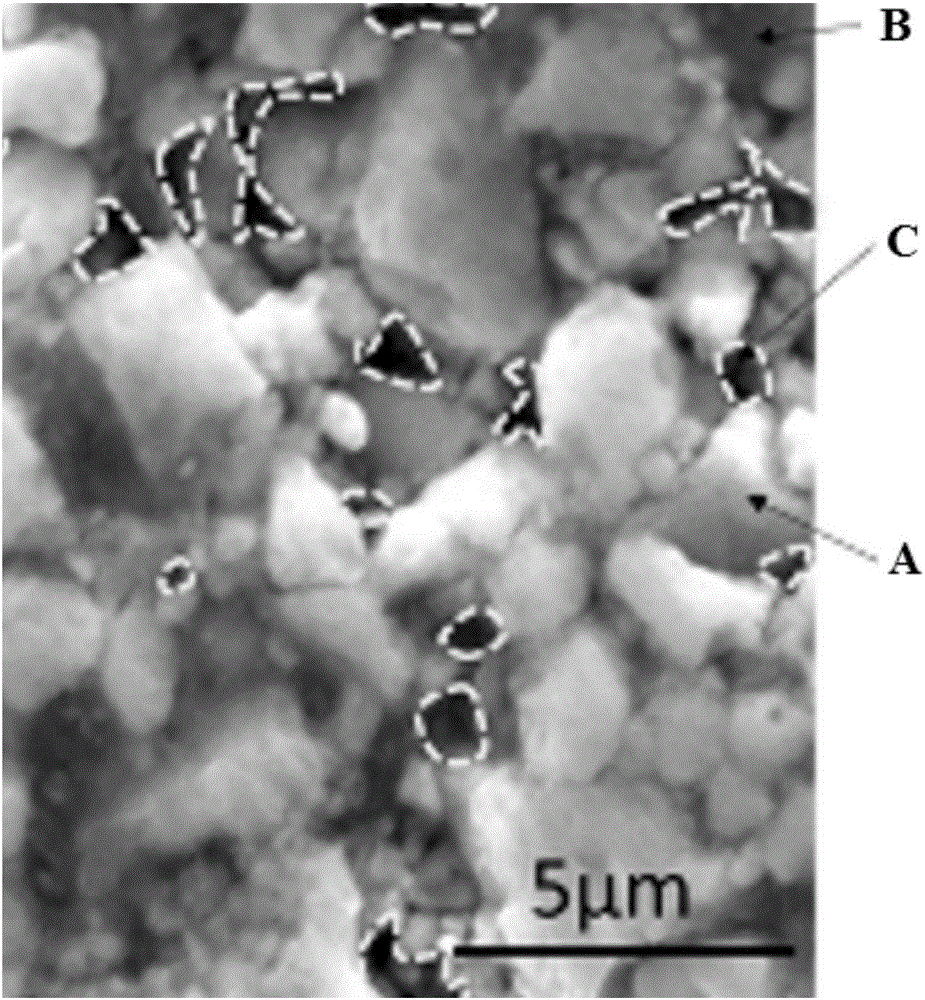

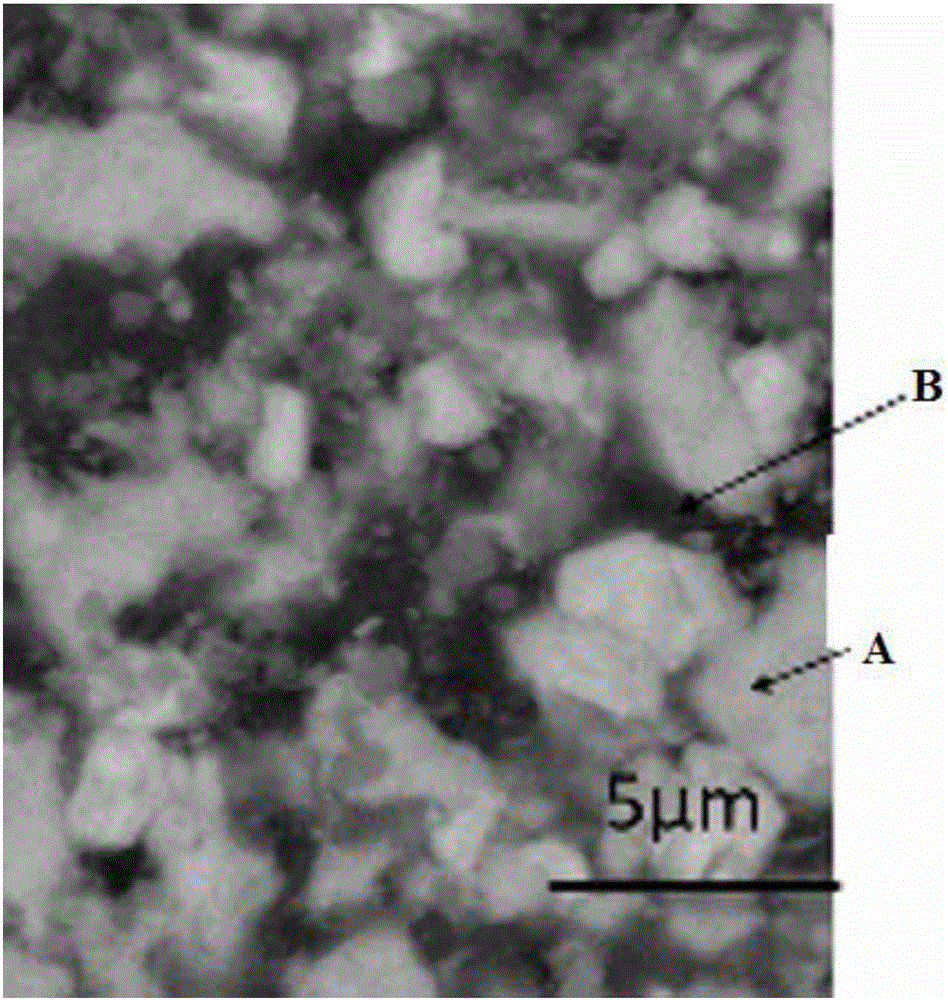

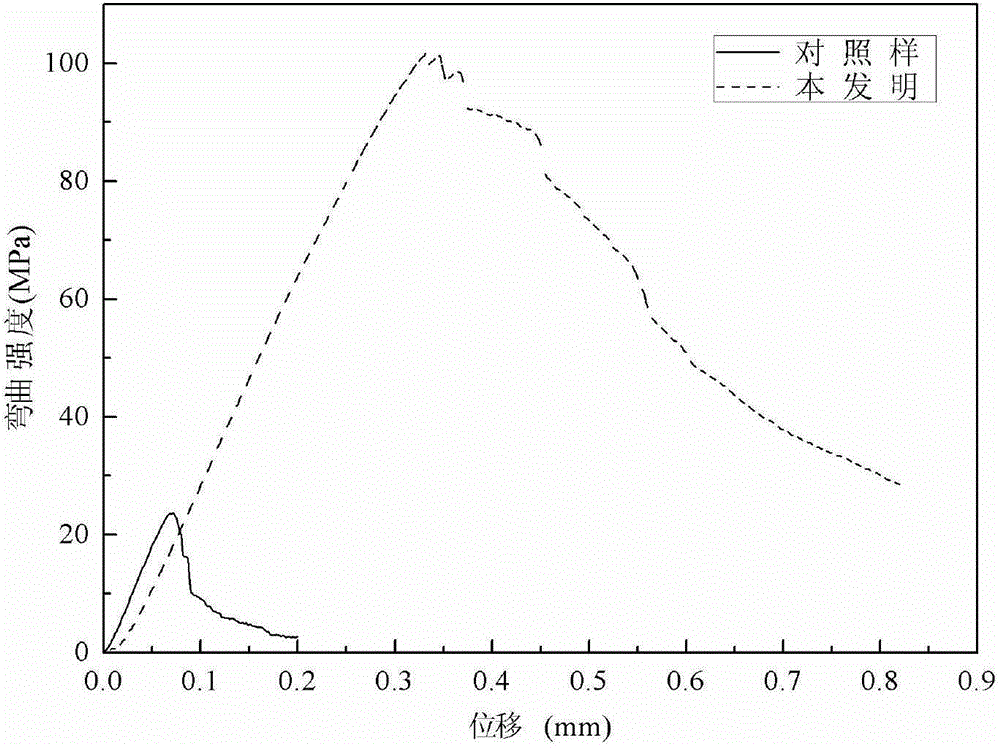

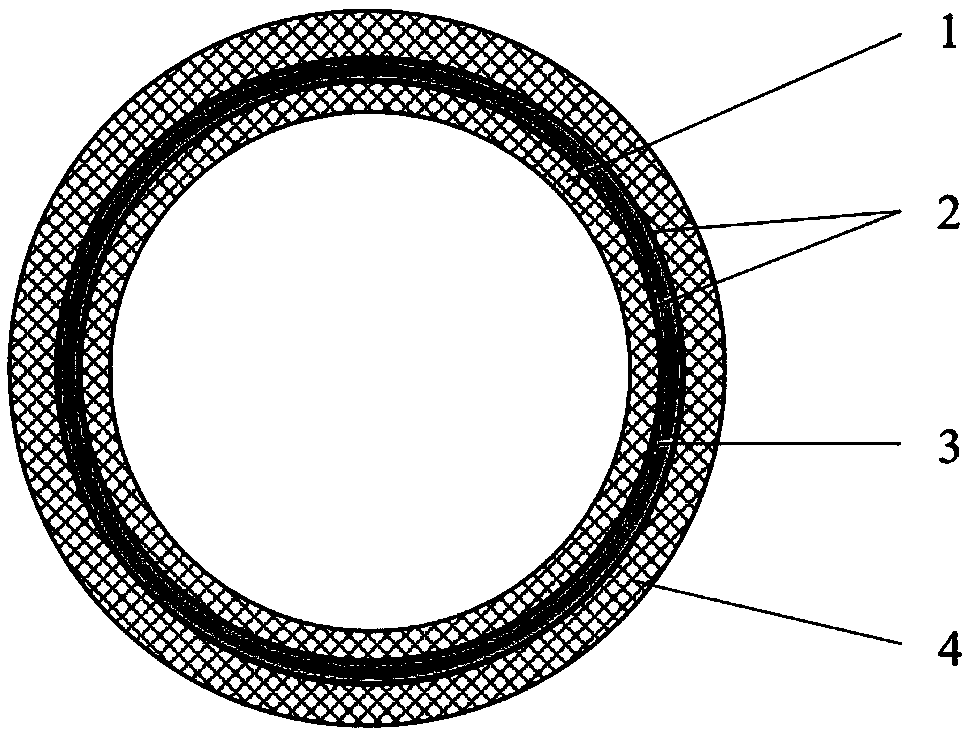

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

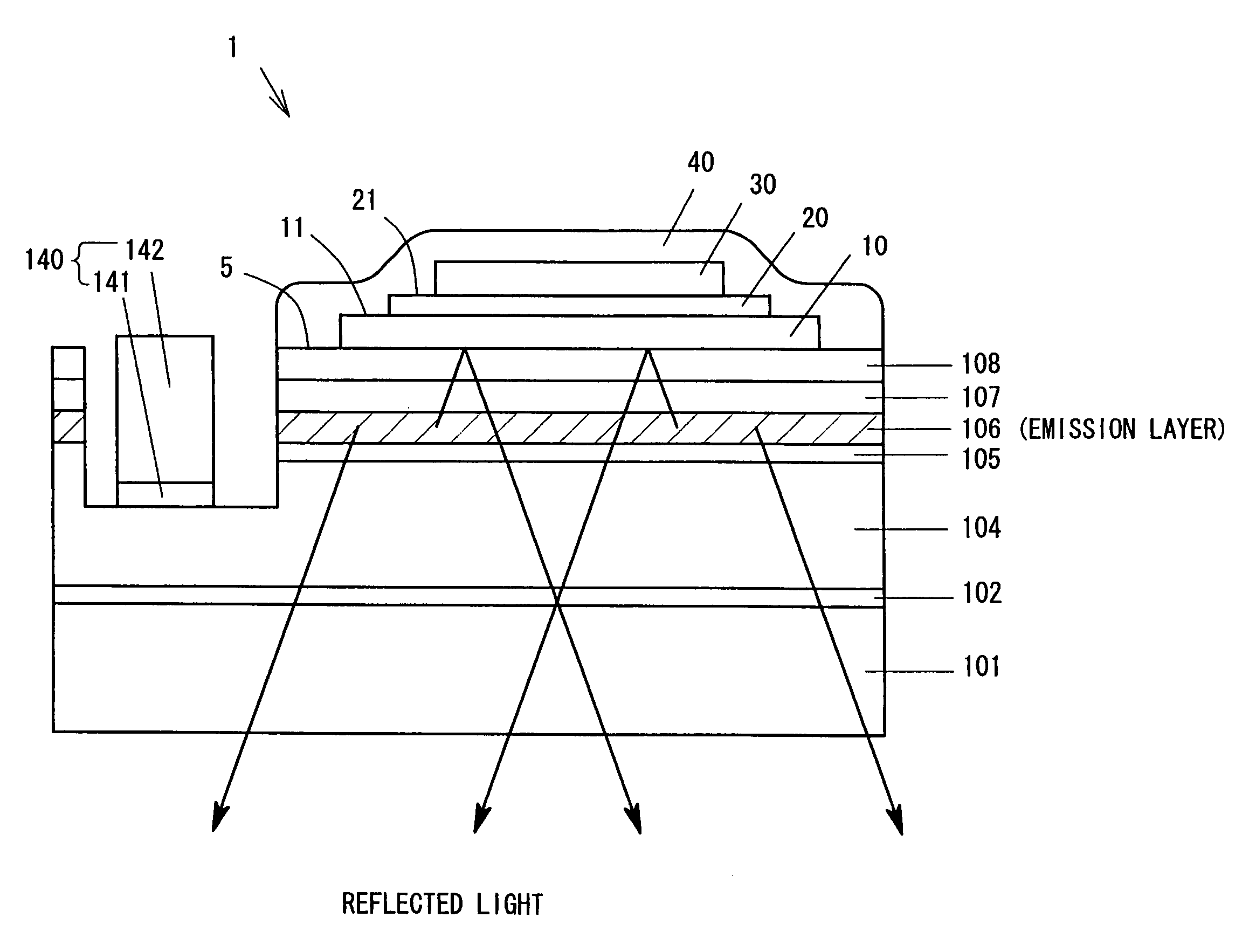

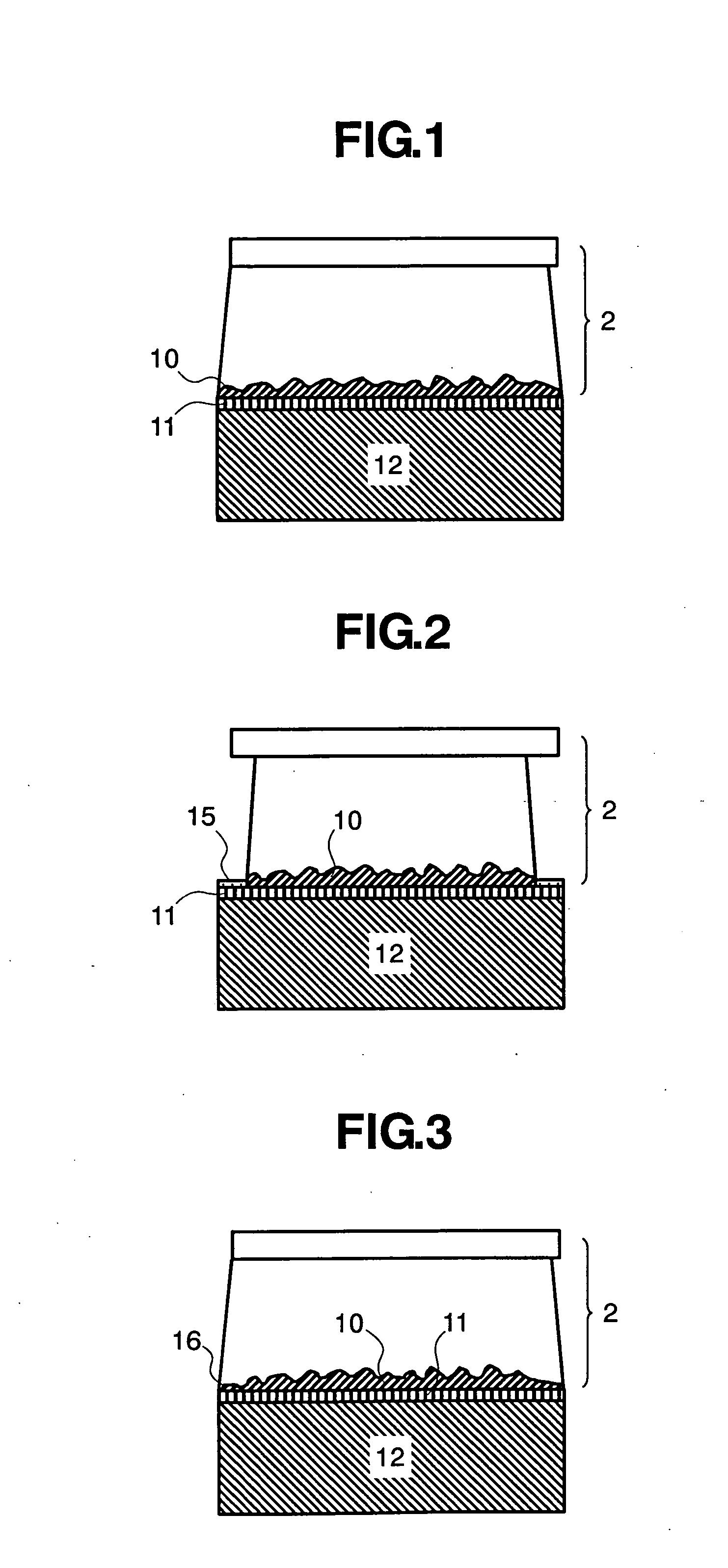

Light-emitting semiconductor device

ActiveUS7291865B2Inhibit interface reactionReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingContact layerLight emitting device

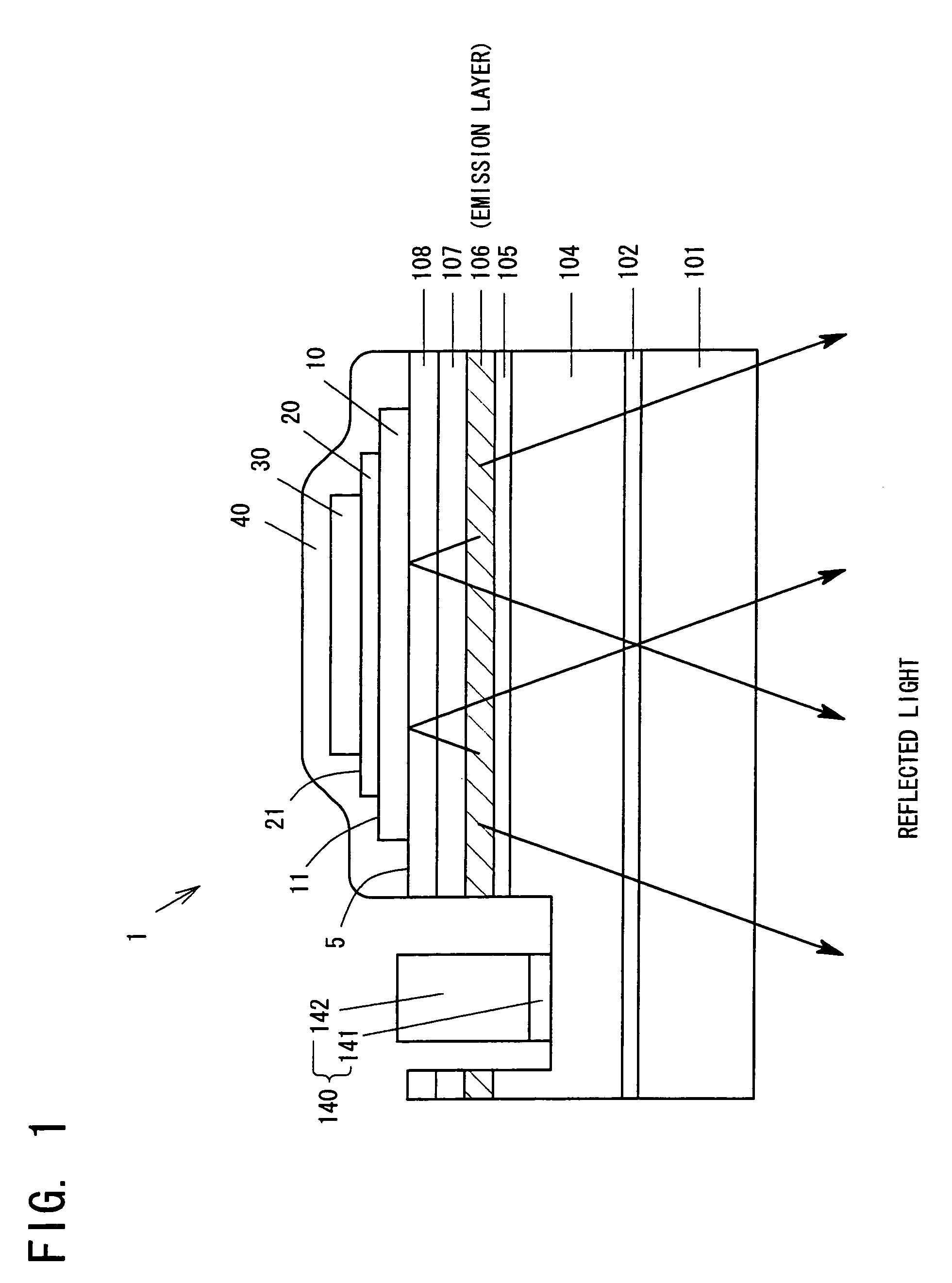

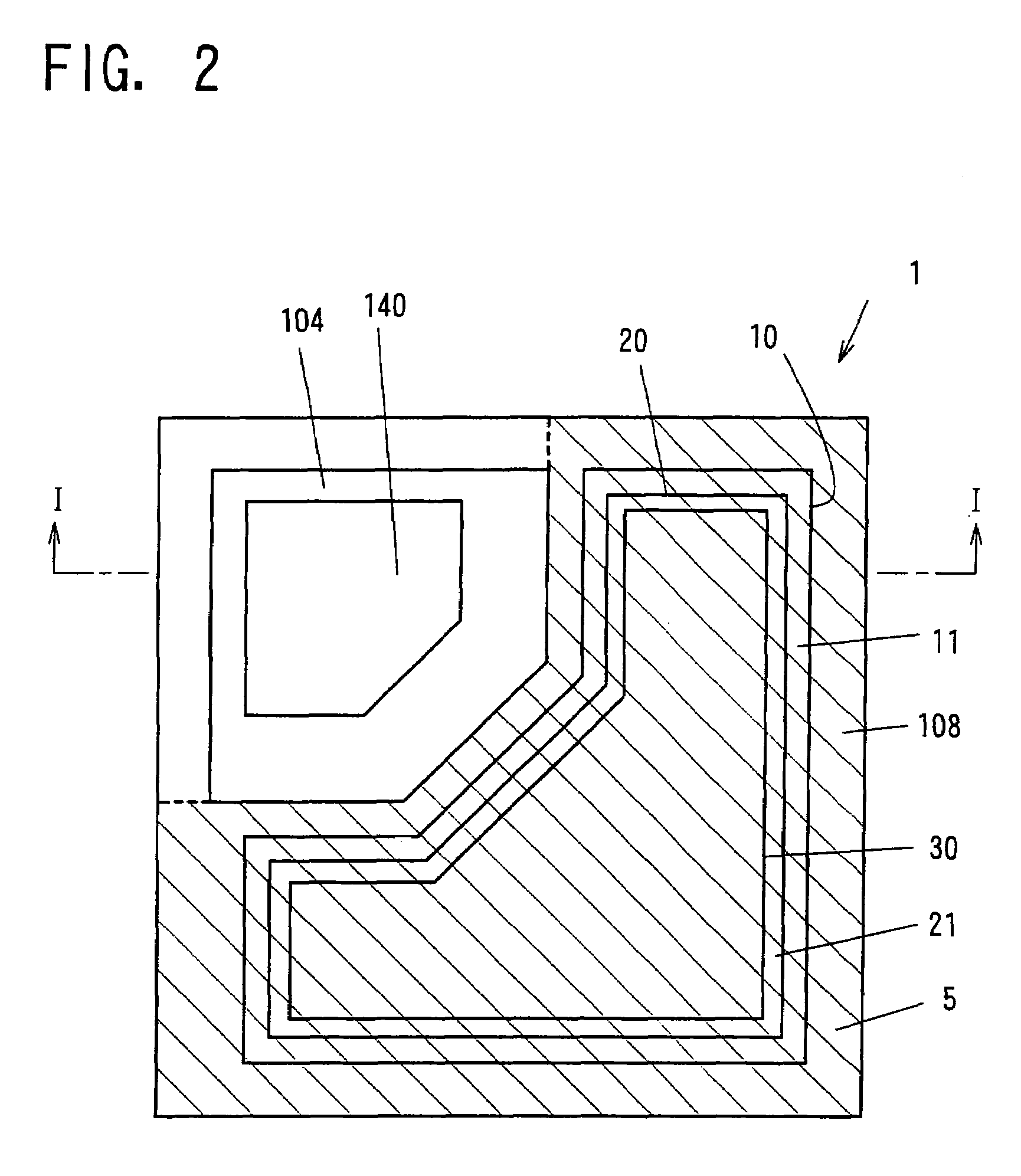

A flip-chip type of Group III nitride based compound semiconductor light-emitting device comprises a transparent conductive film 10 made of ITO on a p-type contact layer. On the transparent conductive film, an insulation protection film 20, a reflection film 30 which is made of silver (Ag) and aluminum (Al) and reflects light to a sapphire substrate side, and a metal layer 40 made of gold (Au) are deposited in sequence. Because the insulation protection film 20 exists between the transparent conductive film 10 and the reflection film 30, metal atoms comprised in the reflection film 30 can be prevented from diffusing in the transparent conductive film 10. That enables the transparent conductive film 10 to maintain high transmissivity. As a result, a light-emitting device having high external quantum efficienty can be provided.

Owner:TOYODA GOSEI CO LTD

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

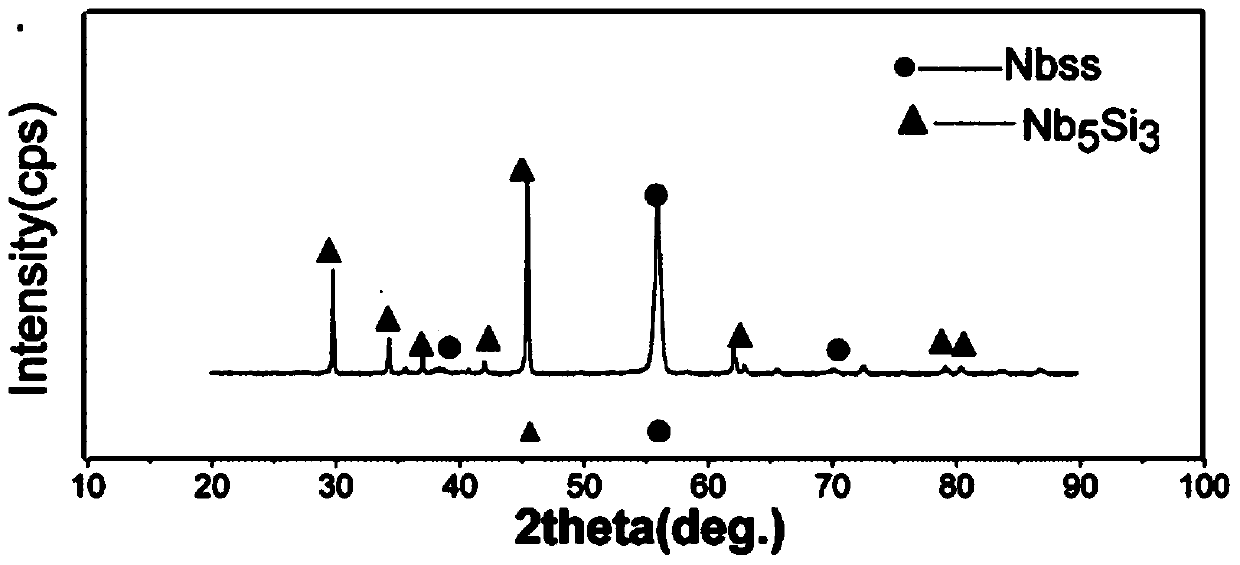

Method for preparing NbSi-base ultrahigh-temperature alloy through EBM (Electron Beam Melting)

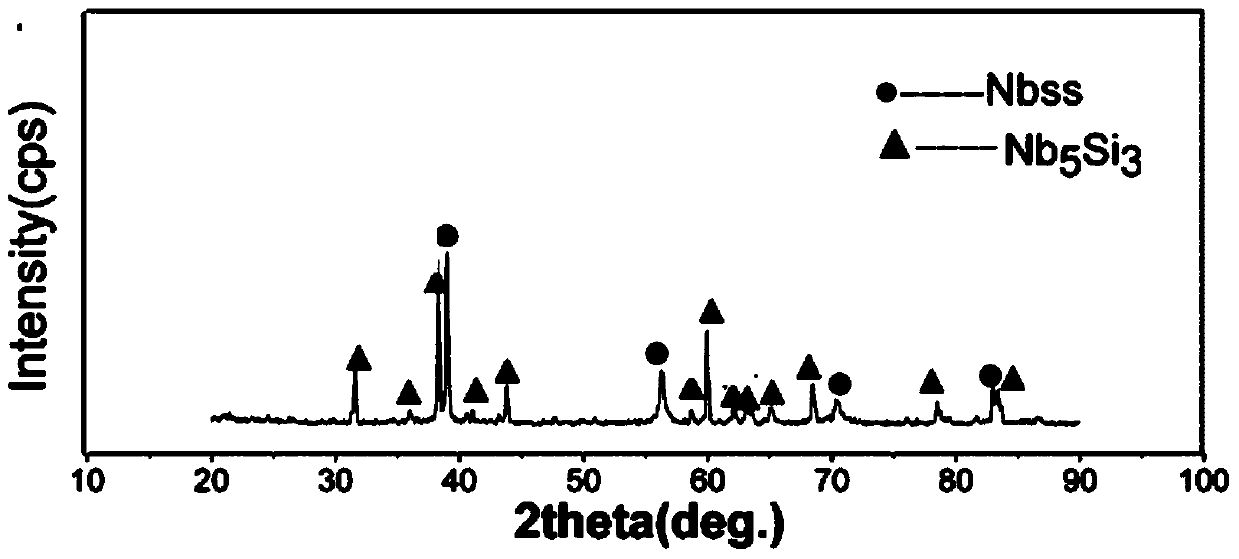

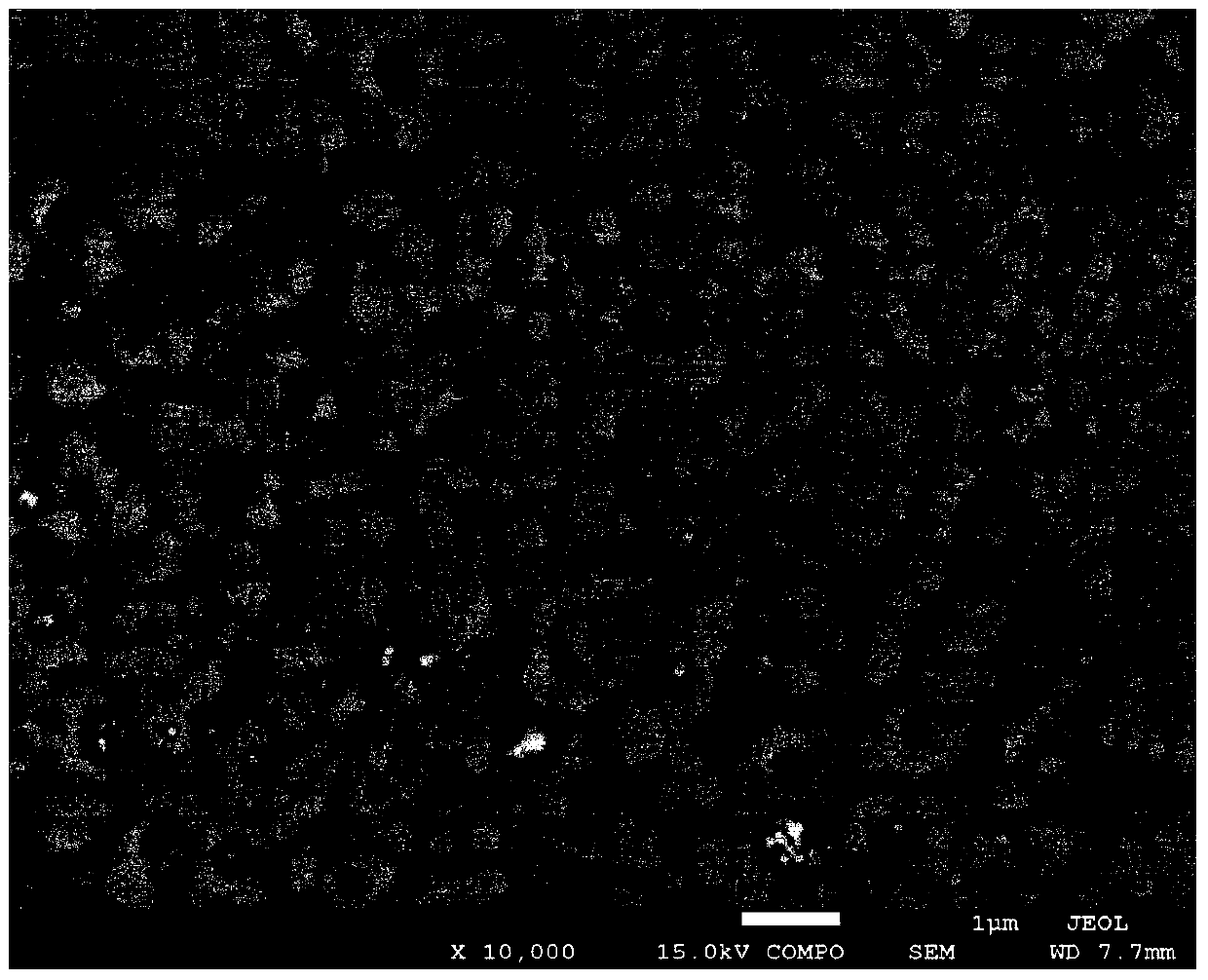

InactiveCN103949640AReduce pollutionInhibit interface reactionIncreasing energy efficiencyComputer Aided DesignVolumetric Mass Density

The invention belongs to the technical field of high-temperature alloy preparation and particularly relates to a method for preparing NbSi-base ultrahigh-temperature alloy through EBM (Electron Beam Melting). By using electron beam selective melting equipment and arranging reasonable process parameters, the preparation of an NbSi-base alloy three-dimensional formed part can be completed in one step directly through a CAD (Computer-Aided Design) model. The density of the obtained NbSi-base alloy is high, the NbSi-base alloy mainly comprises NbSS (Nb Solid Solution) and an Nb5Si3 strengthening phase, the phase size is very fine (smaller than 1[mu]m) and the distribution is uniform. The method has the advantages that a mold is not needed during the preparation of the NbSi-base alloy, the alloy pollution is reduced, the impurity content is decreased, the material utilization ratio is high, and the mechanical property and the production efficiency of the NbSi-base ultrahigh-temperature alloy can be improved.

Owner:BEIHANG UNIV

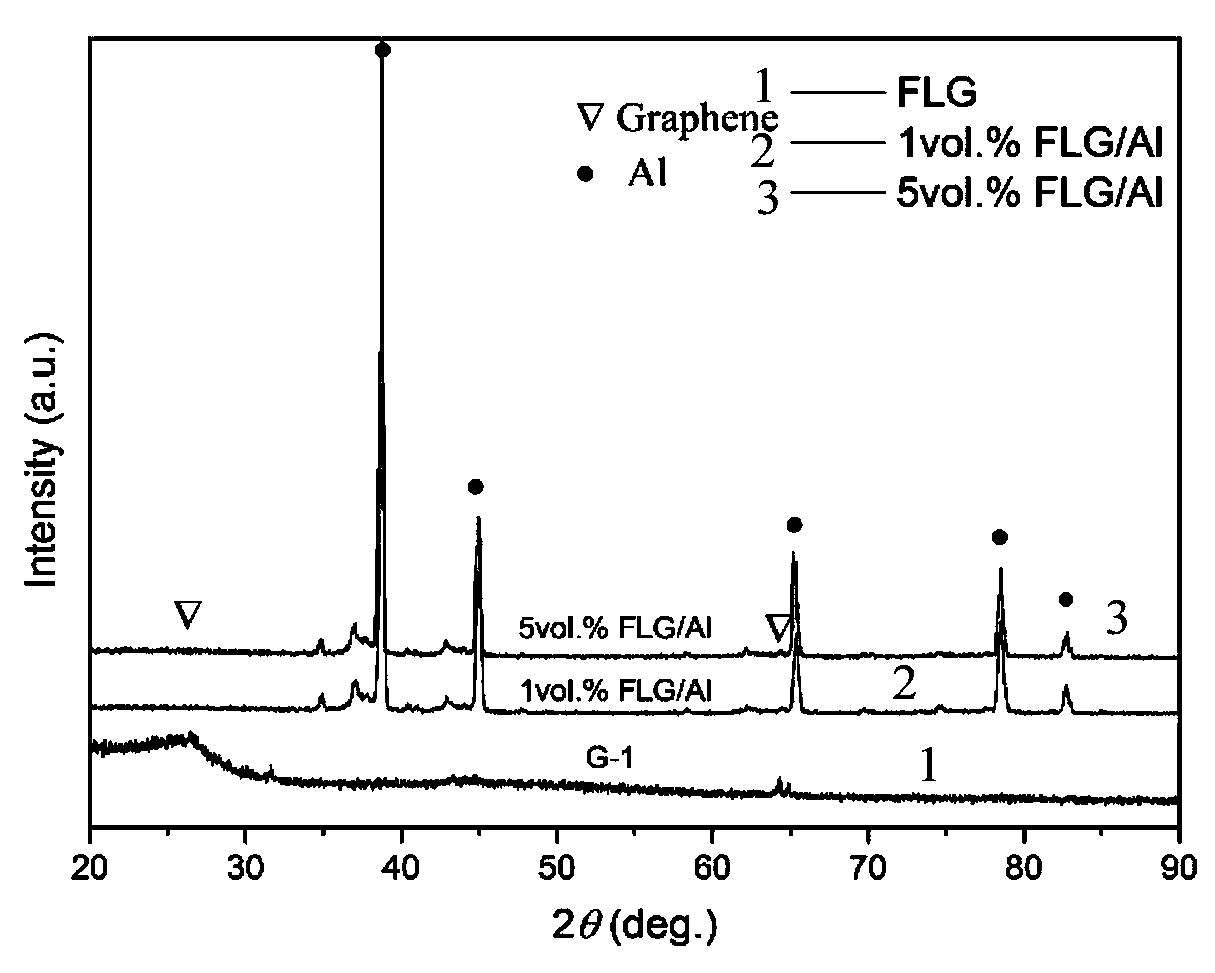

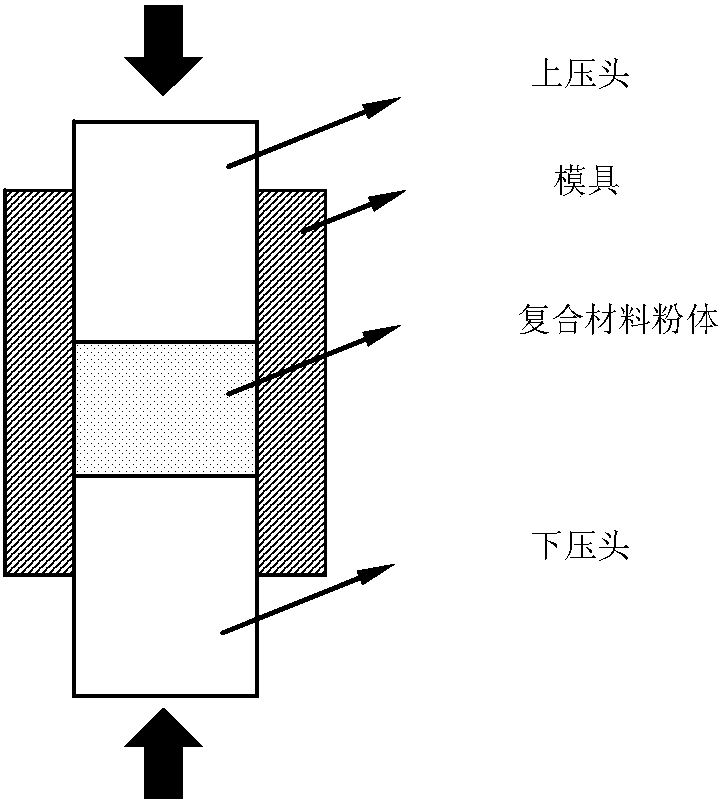

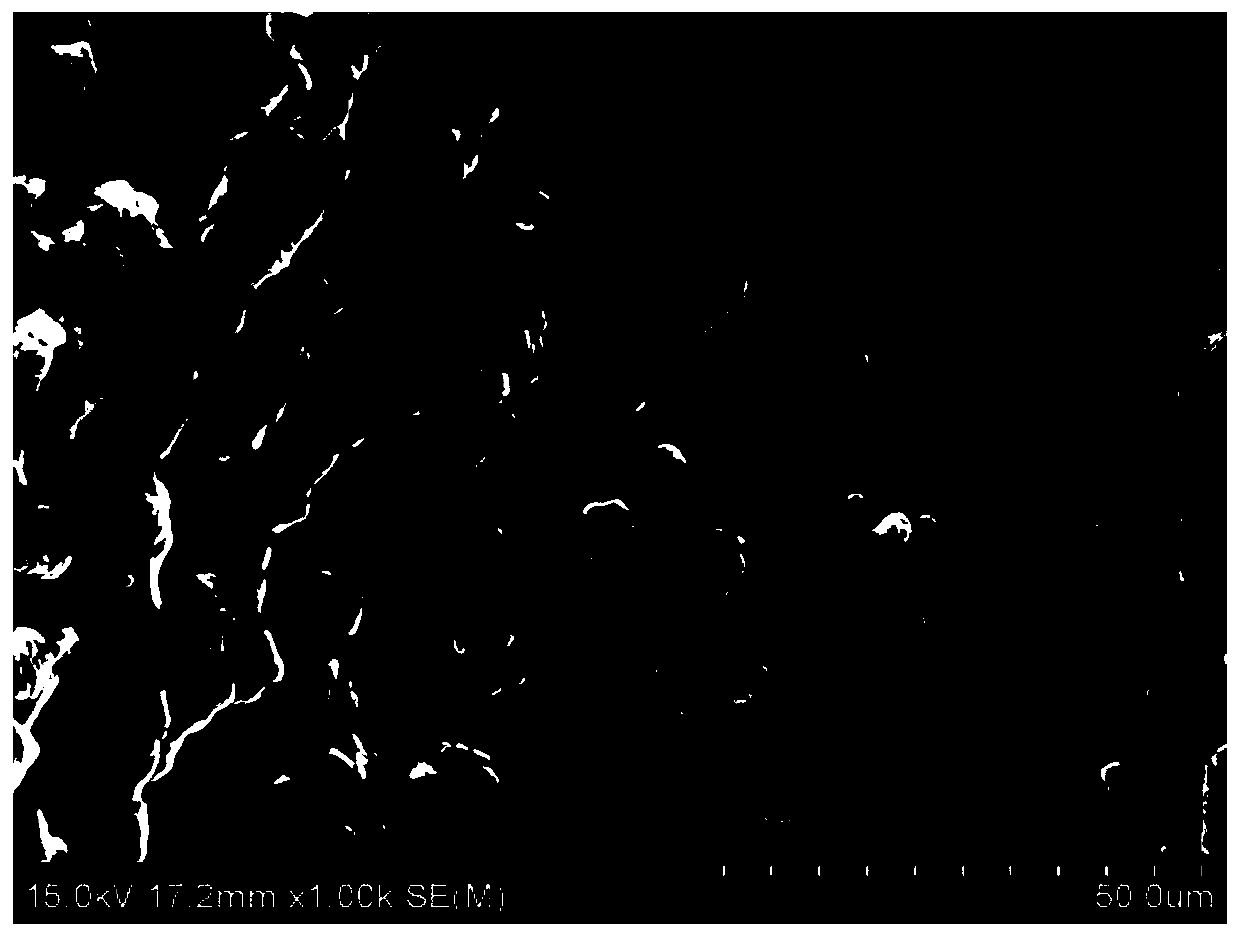

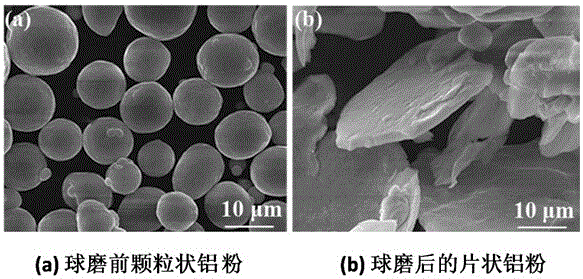

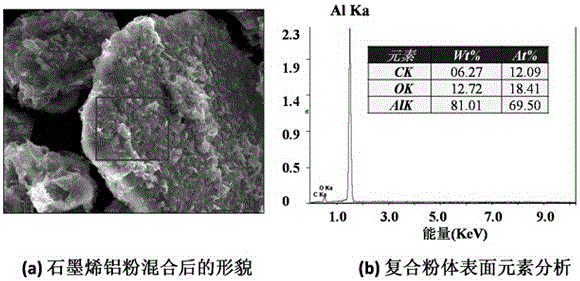

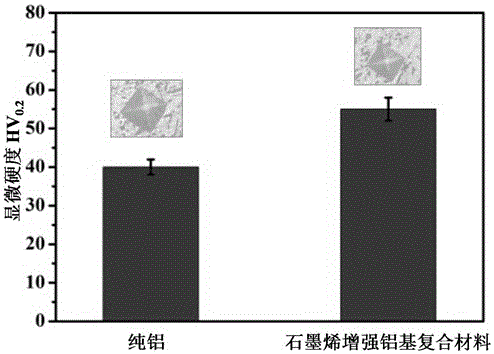

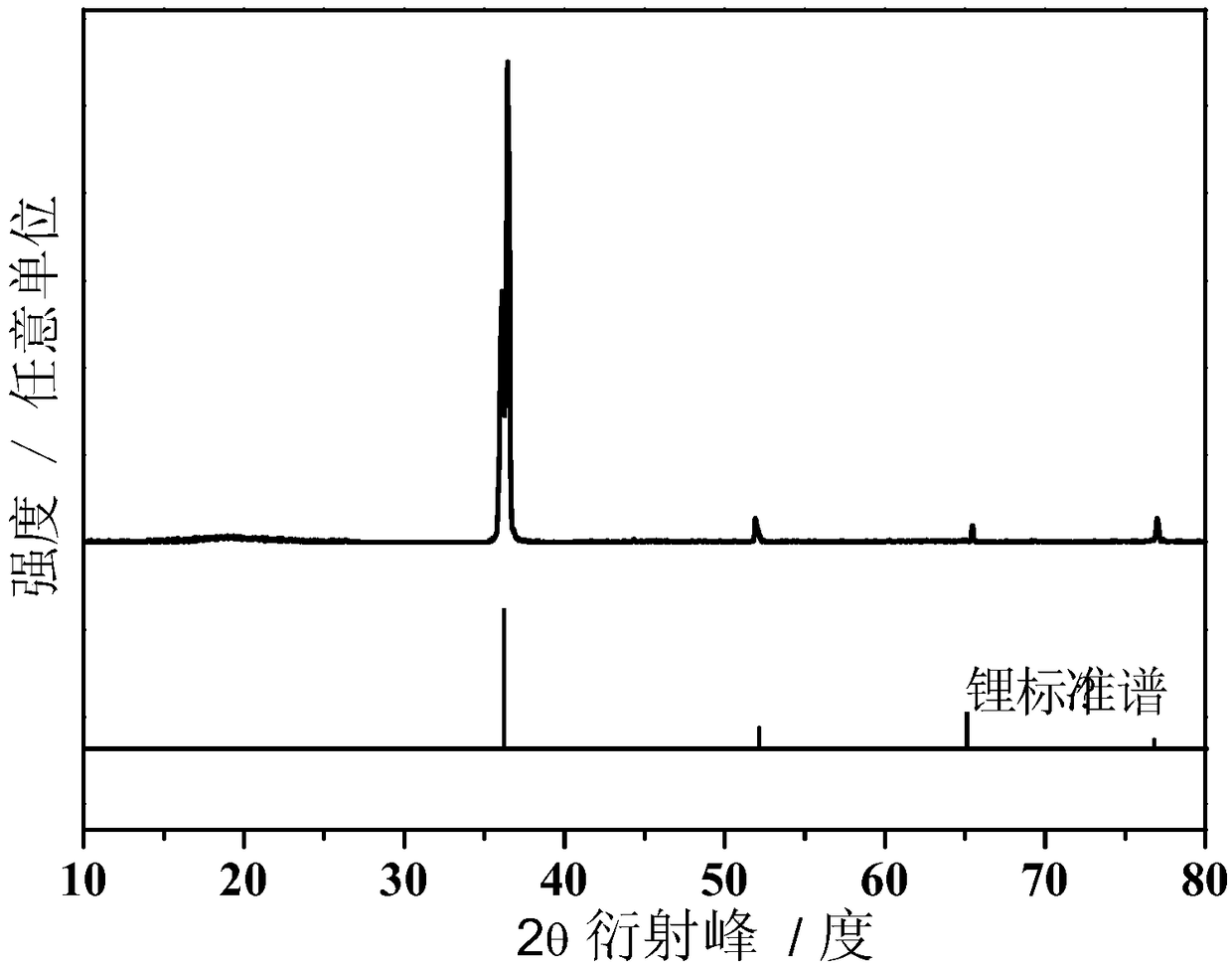

Preparation method of graphene-reinforced aluminum-based composite material

The invention provides a preparation method of a graphene-reinforced aluminum-based composite material. The graphene / aluminum composite material is prepared through the steps of preparing of graphene / aluminum mixed powder through a two-step ball milling method, cold pressing forming of a graphene / aluminum composite material blank, hot squeezing forming and the like. Through a special technologicalmode, graphene is evenly dispersed in aluminum bases, generation of a brittle phase Al4C3 is reduced, and the graphene / aluminum composite material with the high compactness and high volume fraction is obtained finally.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

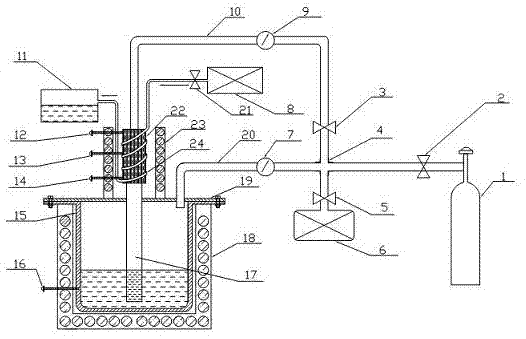

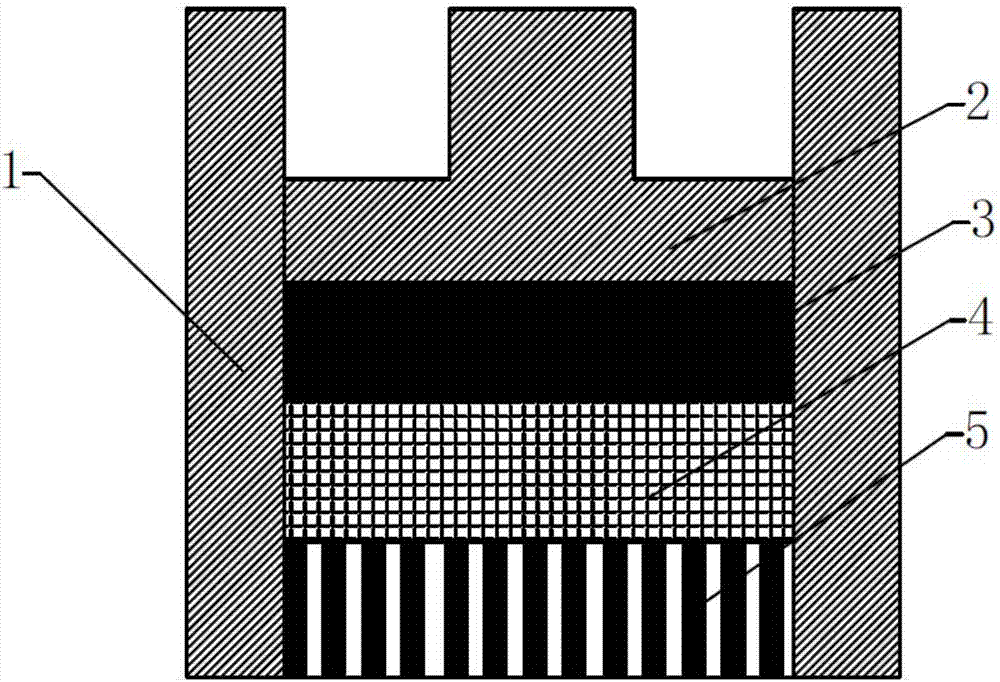

Liquid-state near-net forming method and device for continuous carbon fiber enhanced aluminum-based composite material

InactiveCN103540873ARealize hypoxic temperature control preheatingAchieve cooling rate controlFiberCarbon fibers

The invention discloses a liquid-state near-net forming method and device for a continuous carbon fiber enhanced aluminum-based composite material, namely a vacuum-assisted pressure-adjusting and infiltration casting method and device. The method comprises four procedures of smelting an alloy and pre-heating fibers, carrying out vacuum-assisted pressure-adjusting and infiltration, condensing at a high pressure and cooling rapidly. The device is composed of an alloy smelting device, a vacuum-assisted pressure-adjusting and infiltration device and a casting rapid cooling device. The liquid-state near-net forming method and device have the characteristics that (1) low-oxygen and temperature-controllable pre-heating of nickel-plated carbon fibers is realized; (2) low-pressure infiltration and high-pressure condensation of the aluminum-based composite material are realized; (3) the control of a cooling speed in the condensation of a composite material casting is realized. According to the liquid-state near-net forming method and device for the continuous carbon fiber enhanced aluminum-based composite material, oxidization and burning loss caused by pre-heating the carbon fibers, prefabricated body deformation in the infiltration process and interface reaction problems in the condensation process of the composite material are solved. The liquid-state near-net forming of the continuous carbon fiber enhanced aluminum-based composite material can be realized and the prepared composite material has the advantages of dense tissues, few interface reactions, high mechanical properties and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

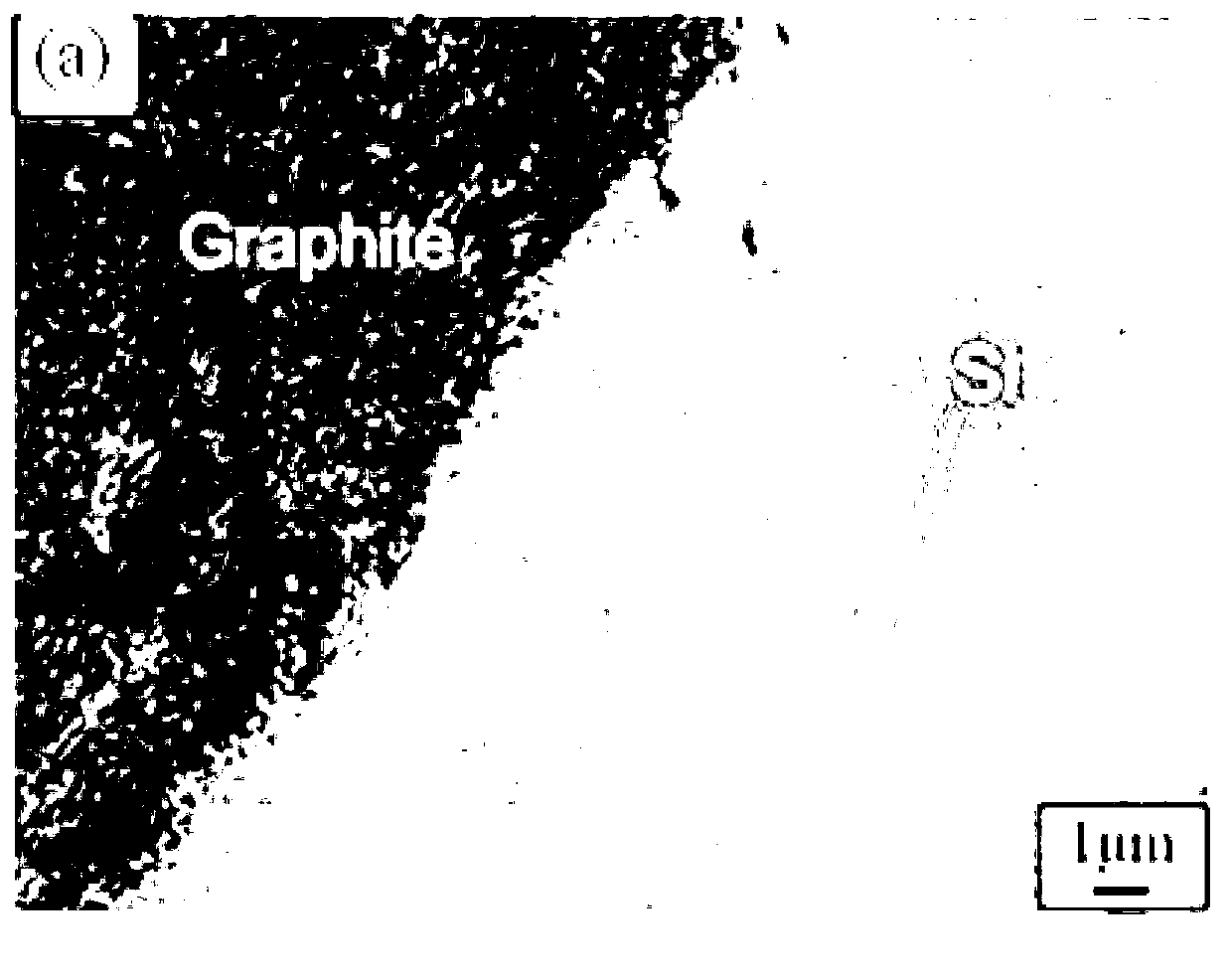

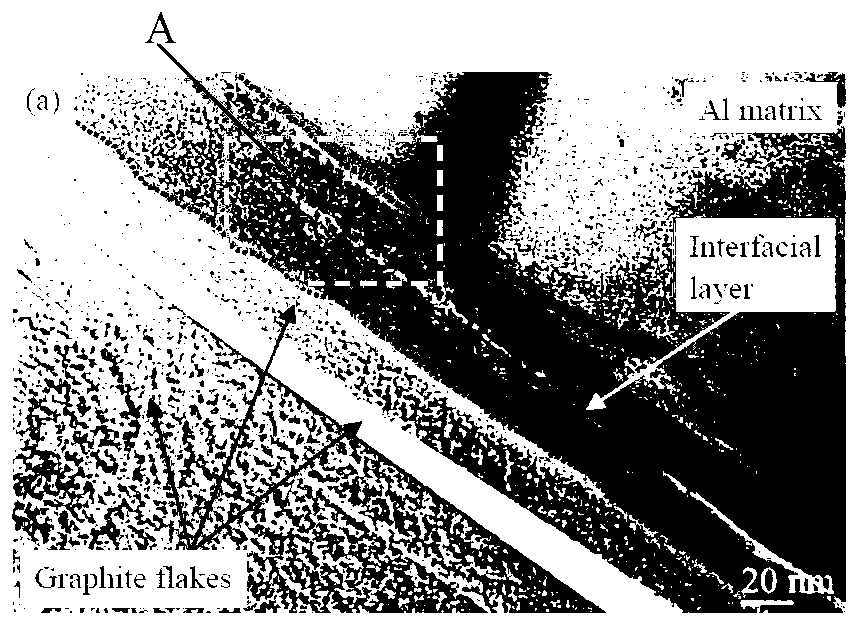

Aluminum matrix composite with low expansion and high thermal conductivity reinforced by mixing graphite and silicon

The invention relates to an aluminum matrix composite with low expansion and high thermal conductivity reinforced by mixing graphite and silicon. The aluminum matrix composite comprises an aluminum matrix or an aluminum alloy and graphite and silicon, the volume fraction of the graphite is 20%-65%, the volume fraction of the silicon is 3%-40%, the rest is aluminum or aluminum alloy, and the composite also comprises an interfacial modification additive for inhibiting the generation of graphite aluminum harmful interface reactant Al4C3. Compared with the prior art, the additive is introduced into the graphite or silicon or aluminum composite, additive elements are used for aluminum carbon interfacial modification, so as to inhibit the harmful Al4C3 phase from generating, and the thermal conductivity is improved by reducing the interface thermal resistance. The prepared composite has a compact structure and excellent mechanical property, the thermal conductivity of the composite is 210-780W / mK, the coefficient of thermal expansion is 2.3-10*10<-6>m / K. The aluminum matrix composite is mainly used as the electronic packaging material and the heat conduction material in high power density and high heating flux density electronic or micro-electronic equipment.

Owner:SHANGHAI JIAO TONG UNIV

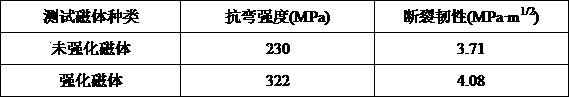

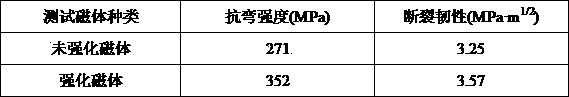

Method for preparing crystal boundary nano-composite intensified neodymium iron boron magnet

InactiveCN103646777AImprove magnetismImprove toughnessInductances/transformers/magnets manufactureMagnetic materialsAlloyQuenching

The invention discloses a method for preparing a crystal boundary nano-composite intensified neodymium iron boron magnet, and relates to the technology of preparing permanent magnet materials. The method comprises the steps that firstly, principal phase alloy is manufactured into an ingot casting or rapid hardening ribbon through a casting method or a rapid hardening melt-spinning method, and the crystal boundary phase alloy is manufactured into a rapid quenching belt through a rapid quenching method; secondly, the principal phase alloy and the crystal boundary phase alloy are respectively manufactured into powder; thirdly, the graphene nanosheet powder and the crystal boundary phase alloy powder are mixed, then ball-milling is carried out, and the graphene nanosheet powder is evenly scattered into the crystal boundary phase alloy powder; fourthly, the crystal boundary phase alloy powder intensified through the graphene nanosheet powder is evenly mixed with the principal phase alloy powder to be directionally pressed in a magnetic field into a green body; fifthly, the spark plasma sintering and tempering are carried out on the green body, and then the high-tenacity crystal boundary nano-composite intensified neodymium iron boron magnet is manufactured. The tenacity of the crystal boundary phase is improved through the crystal boundary nanometer composite intensifying, and on the premise of guaranteeing the magnetic performance of the magnet, the tenacity of the magnet is improved. The method is simple in technology, easy to operate and suitable for being produced in batches on a large scale.

Owner:JIANGSU UNIV

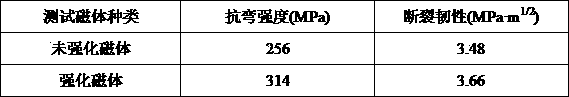

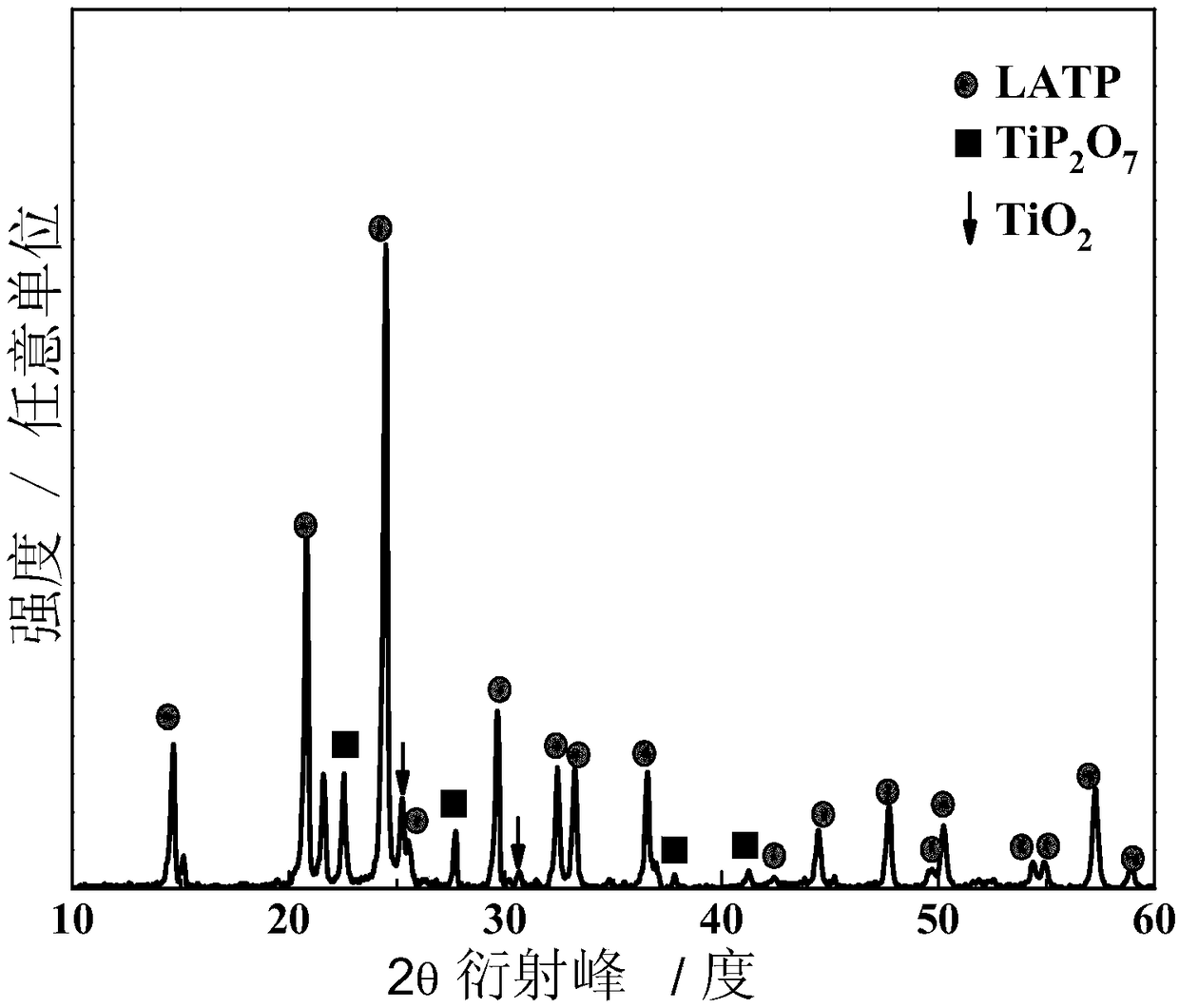

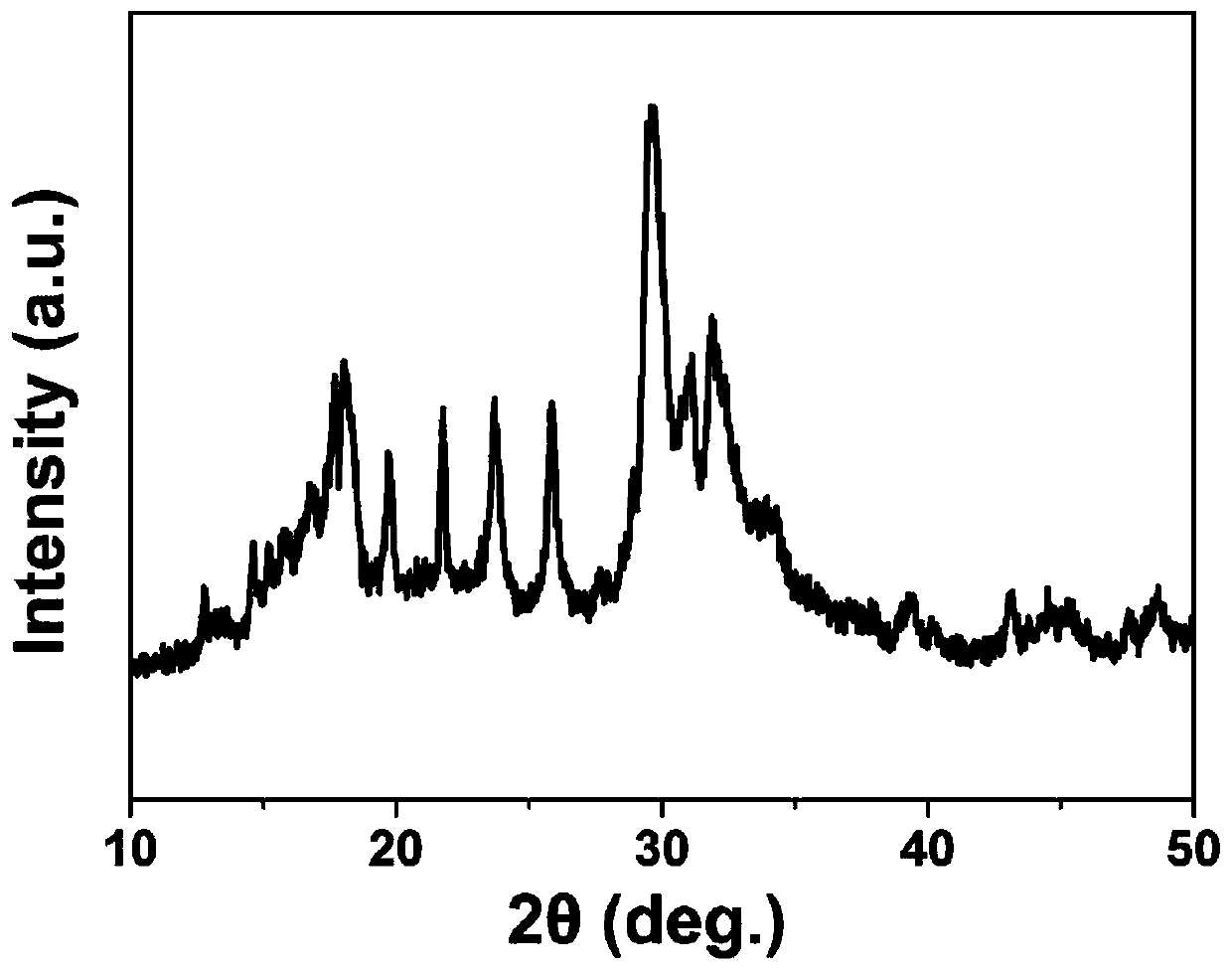

Quasi-solid electrolyte as well as preparation method and application thereof

ActiveCN108365260AImprove mechanical propertiesGood chemistrySolid electrolytesSecondary cellsSolid state electrolyteHexafluoropropylene

The invention discloses a quasi-solid electrolyte which is prepared from the following raw materials including a polymer, a ceramic electrolyte, lithium salt and ionic liquid; the polymer is preparedfrom polyvinylidene fluoride-hexafluoropropylene and polypropylene carbonate; the ceramic electrolyte is prepared from a principal-phase lithium titanium aluminum phosphate and impurity-phase TiP2O7 / TiO2; and the ionic liquid is fluorine-containing imidazolium ionic liquid. The invention also discloses the quasi-solid electrolyte which has high mechanical strength and toughness, high room-temperature lithium ion conductivity and high chemical / electrochemical stability with a metal lithium negative electrode and an oxide positive electrode, is used for a metal lithium cell, a lithium air cell and a lithium-sulfur battery and can realize good electrochemical performance.

Owner:ZHEJIANG UNIV

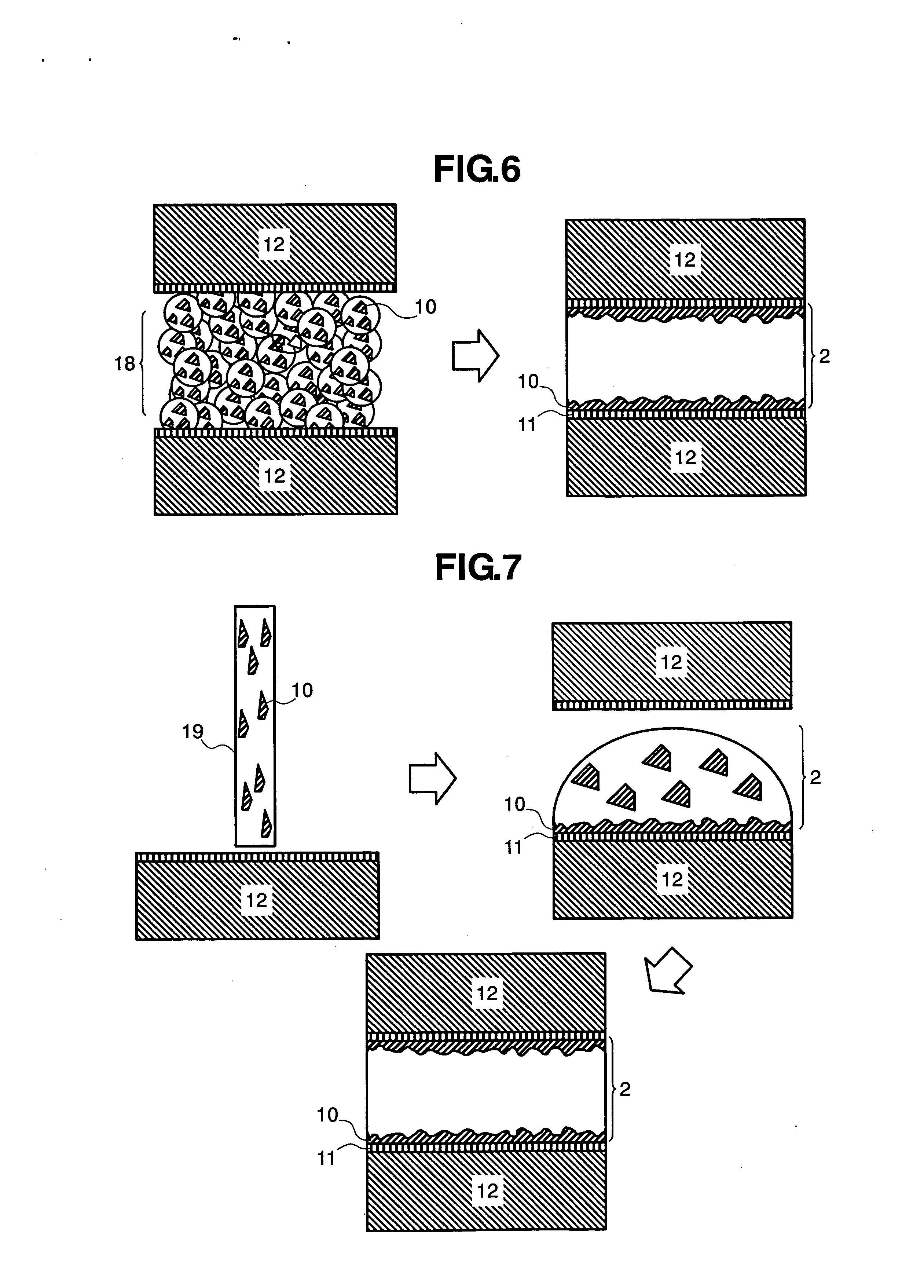

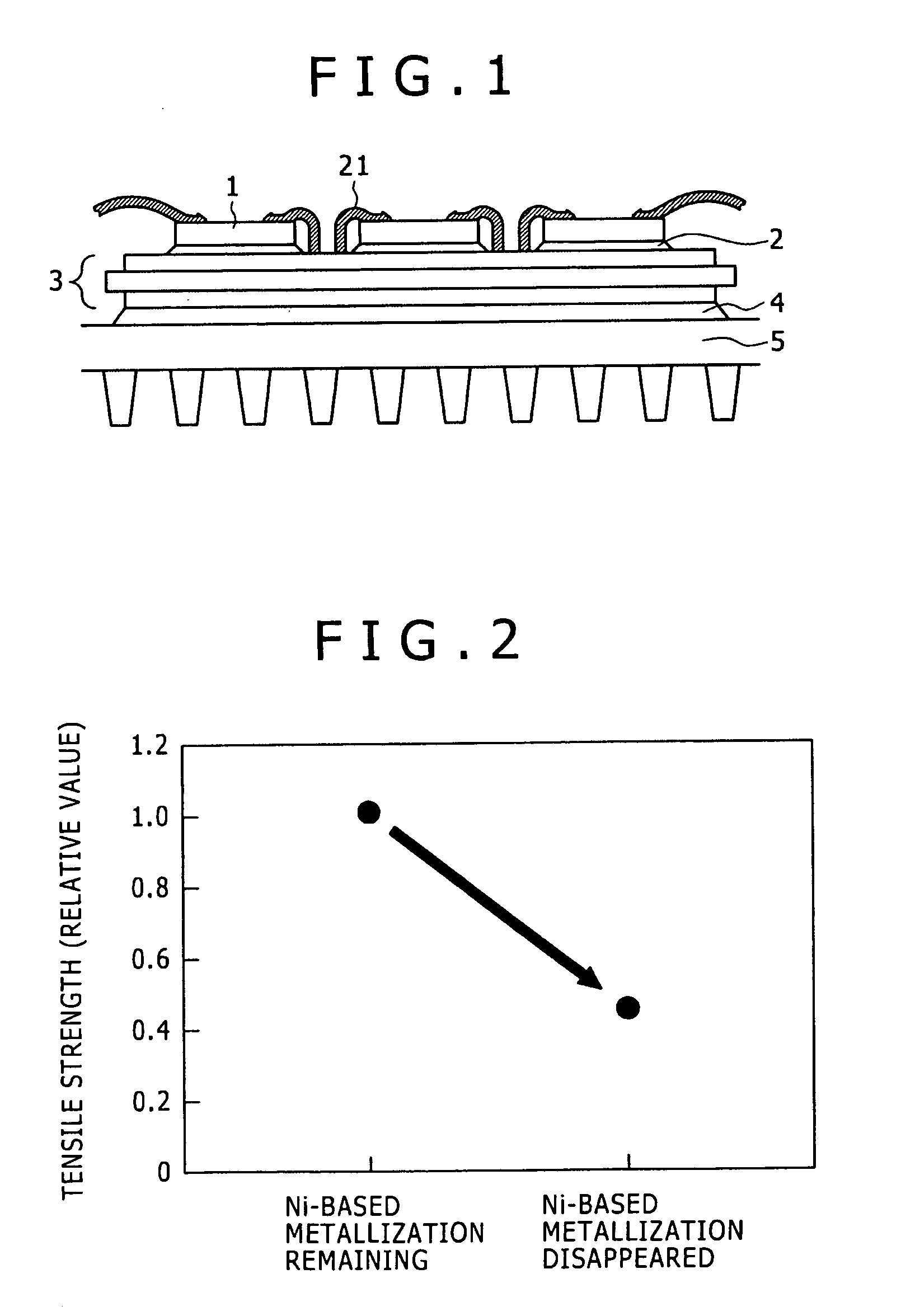

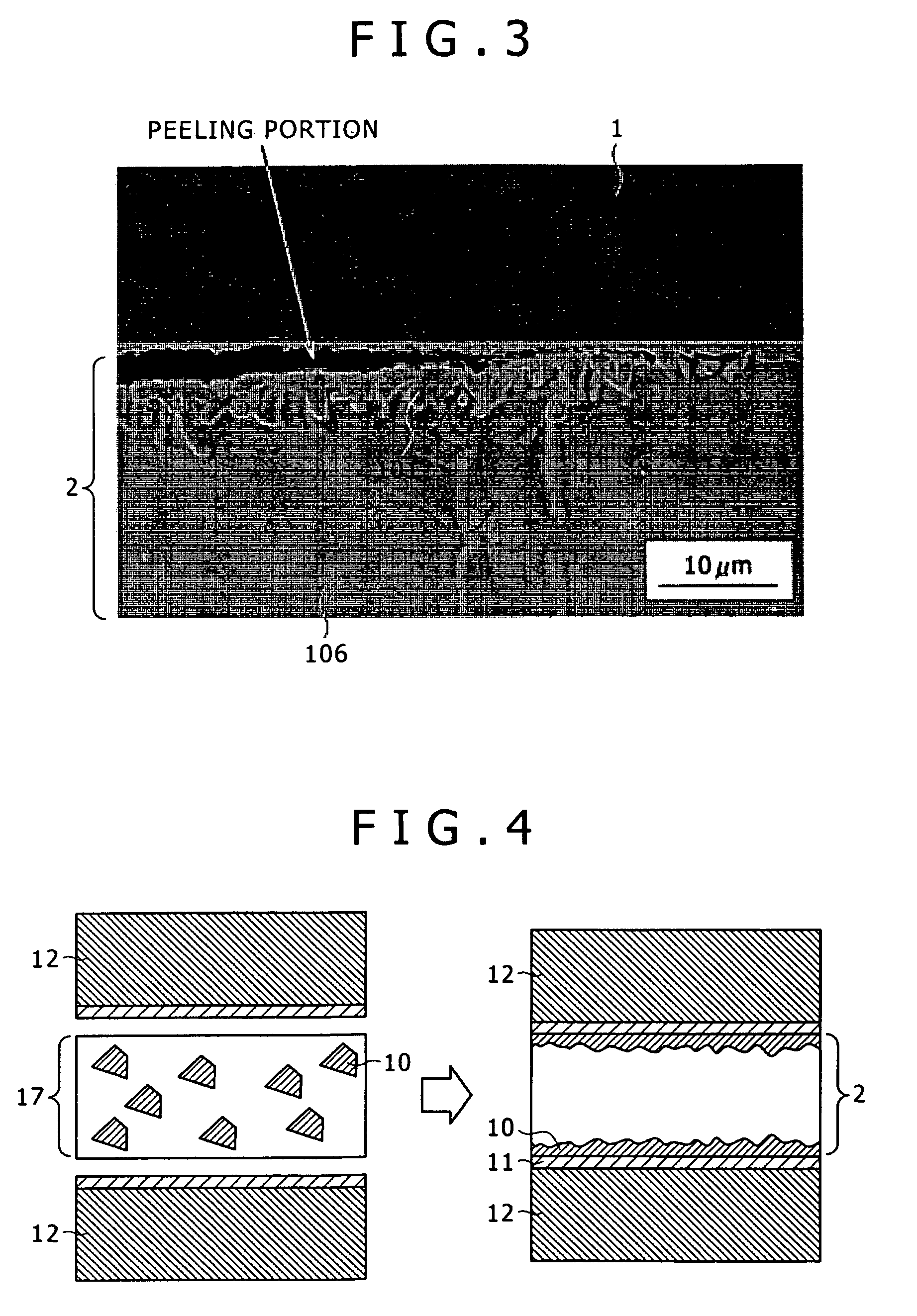

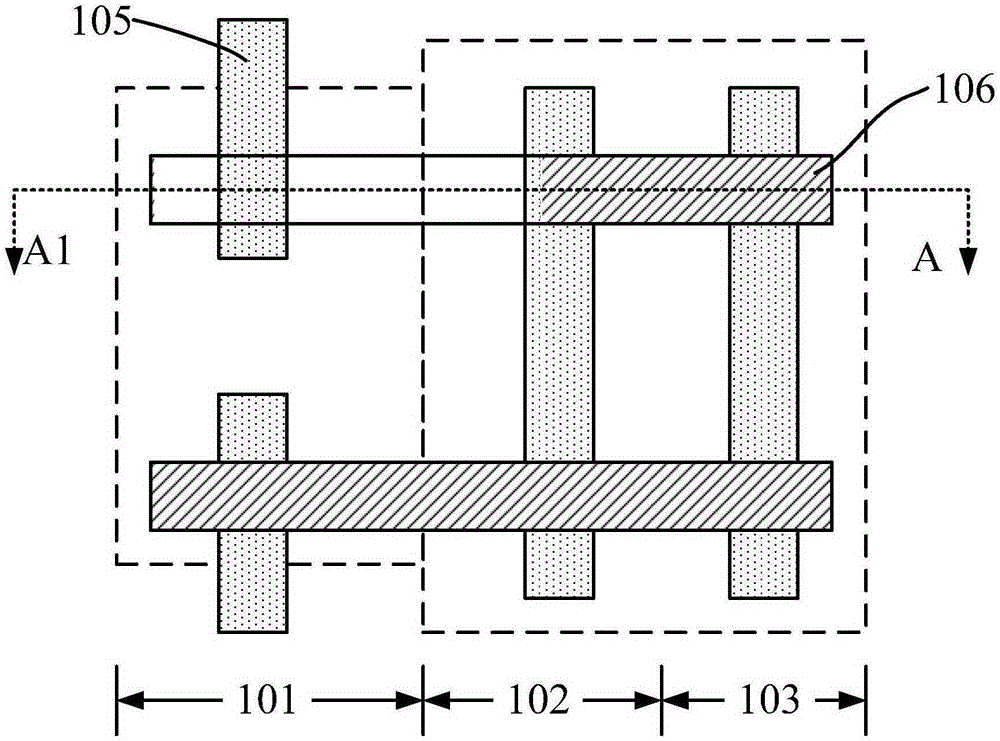

Semiconductor device and automotive AC generator

InactiveUS20070057021A1Inhibit interface reactionLower Reliability RequirementsCooking-vessel materialsSolid-state devicesDevice materialEngineering

A semiconductor device includes a semiconductor element, a support member bonded to a first surface of the semiconductor element with a first bonding material, and a lead electrode bonded to a second surface of the semiconductor element supported on the support member with a second bonding material. Respective connecting parts of the support member and the lead electrode are Ni-plated and each of the first and the second bonding material is a Sn solder having a Cu6Sn5 content greater than a eutectic content.

Owner:HITACHI LTD

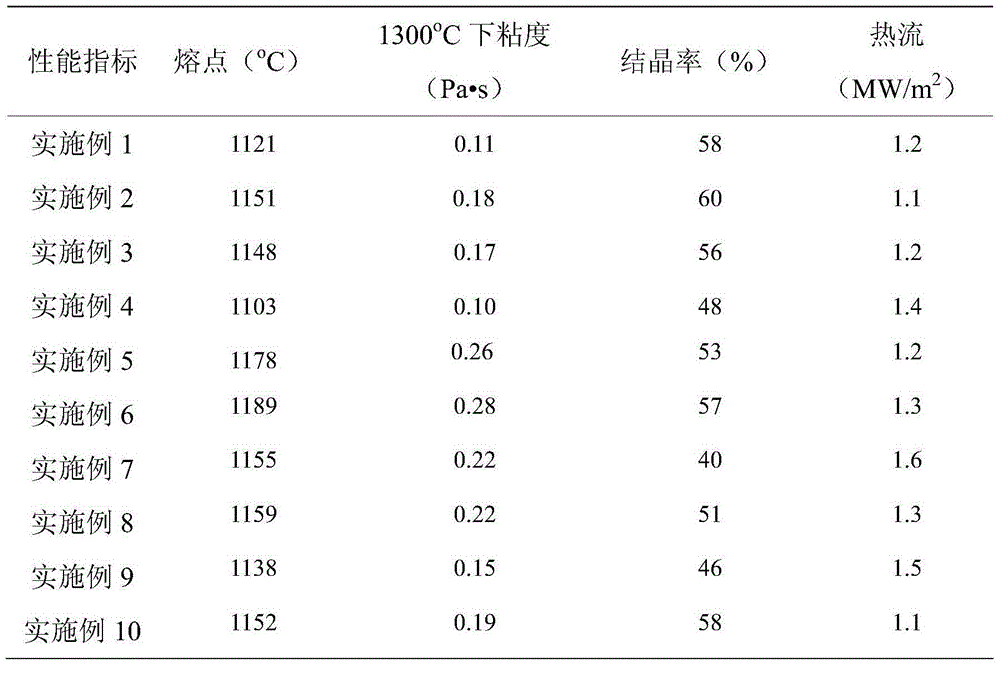

Novel medium manganese steel casting powder for automobile and application thereof

The invention relates to a novel medium manganese steel casting powder for an automobile and application of the novel medium manganese steel casting powder and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises, by mass, CaO 29%-37%, Al2O3 16%-25%, SiO2 11%-15%, MgO 2%-7%, Na2O 10%-14%, Li2O 1%-5%, MnO 1%-7% and F- 9%-13%. The melting point of the casting powder is 1,100-1,200 DEG C; at 1,300 DEG C, the viscosity of the casting powder is 0.10-0.30 Pa*s, and the crystallizing rate is 40%-70%; the heat flow is 1.1-1.6 MW / m<2> in the continuous casting process. The designed casting powder can be well used in the medium manganese steel continuous casting process for the automobile with the mass percentage of Mn being 3.0%-15.0%.

Owner:CENT SOUTH UNIV

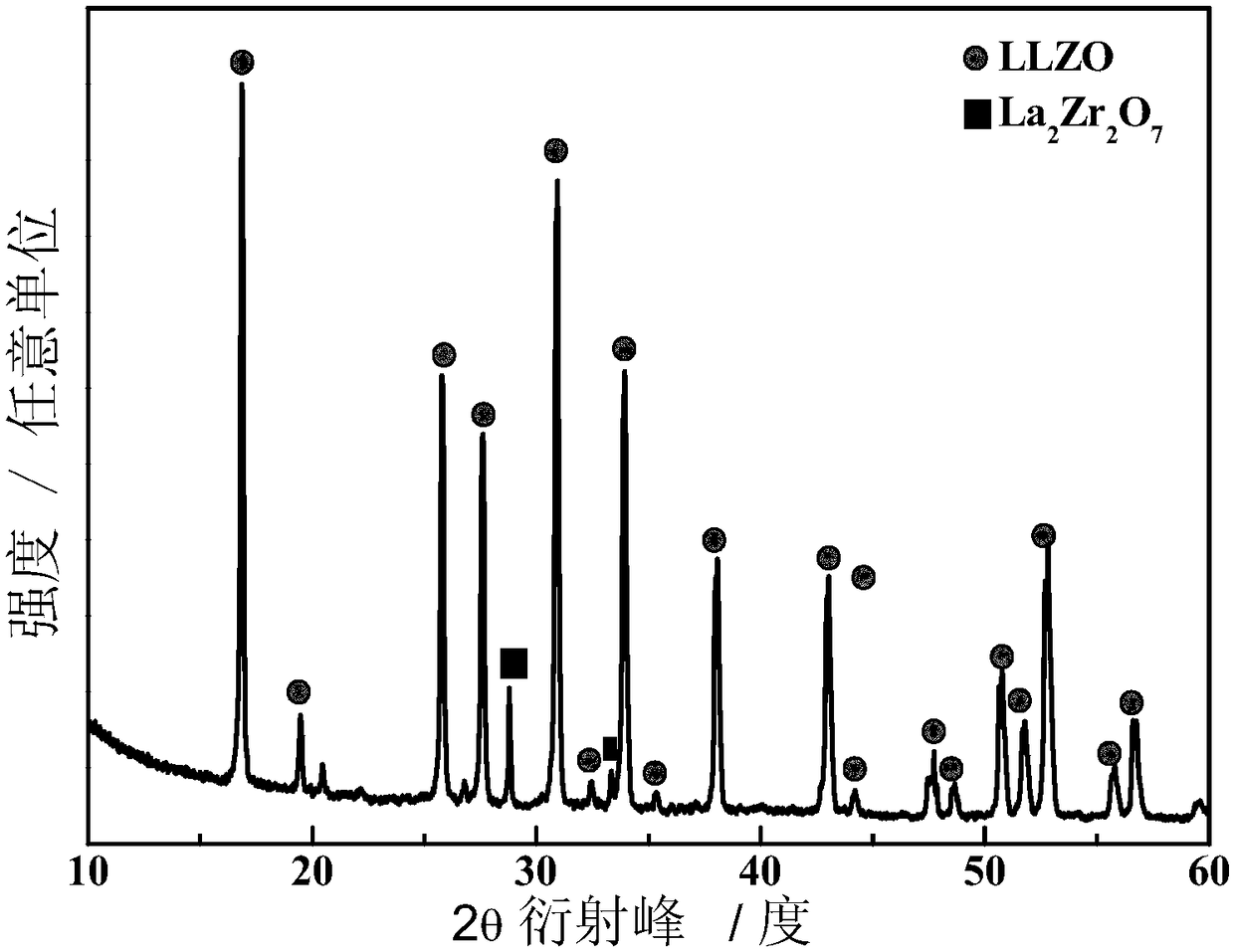

Quasi-solid state lithium ion conductive electrolyte and preparation method and application thereof

ActiveCN108598561AImprove mechanical propertiesGood chemistrySecondary cellsElectrolytesHexafluoropropyleneLanthanum

The invention discloses a quasi-solid state lithium ion conductive electrolyte. The raw material comprises a polymer, a ceramic electrolyte, a lithium salt and an ionic liquid, wherein the polymer comprises polyvinylidene fluoride-hexafluoropropylene and polypropylene carbonate, the ceramic electrolyte comprises a main phase lanthanum-lithium-zirconium-oxygen and an impurity phase La2Zr2O7, and the ionic liquid is a fluorine-containing imidazolium ionic liquid. The invention discloses the quasi-solid state lithium ion conductive electrolyte. The quasi-solid state lithium ion conductive electrolyte has high mechanical strength, is compatible with flexibility, has high room-temperature lithium ion conductivity and high chemical / electrochemical stability with a metal lithium negative electrode and an oxide positive electrode, and favorable electrochemical performance can be achieved when the quasi-solid state lithium ion conductive electrolyte is used for a metal lithium battery, a lithium-air battery and a lithium-sulfur battery.

Owner:ZHEJIANG UNIV

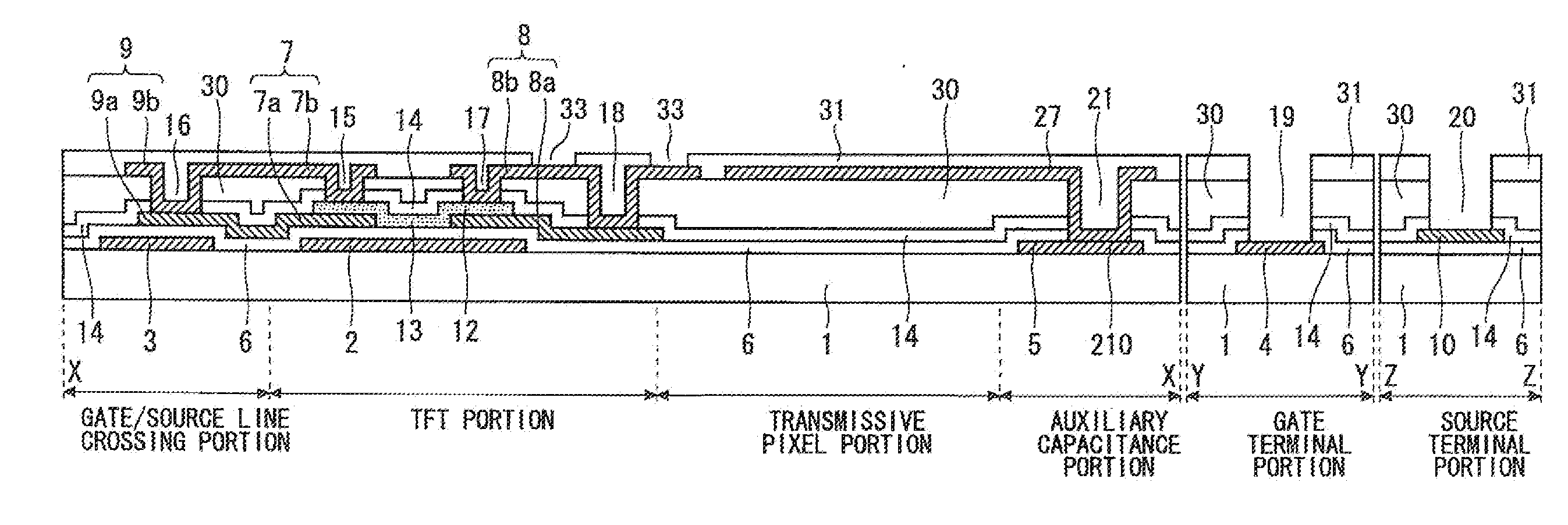

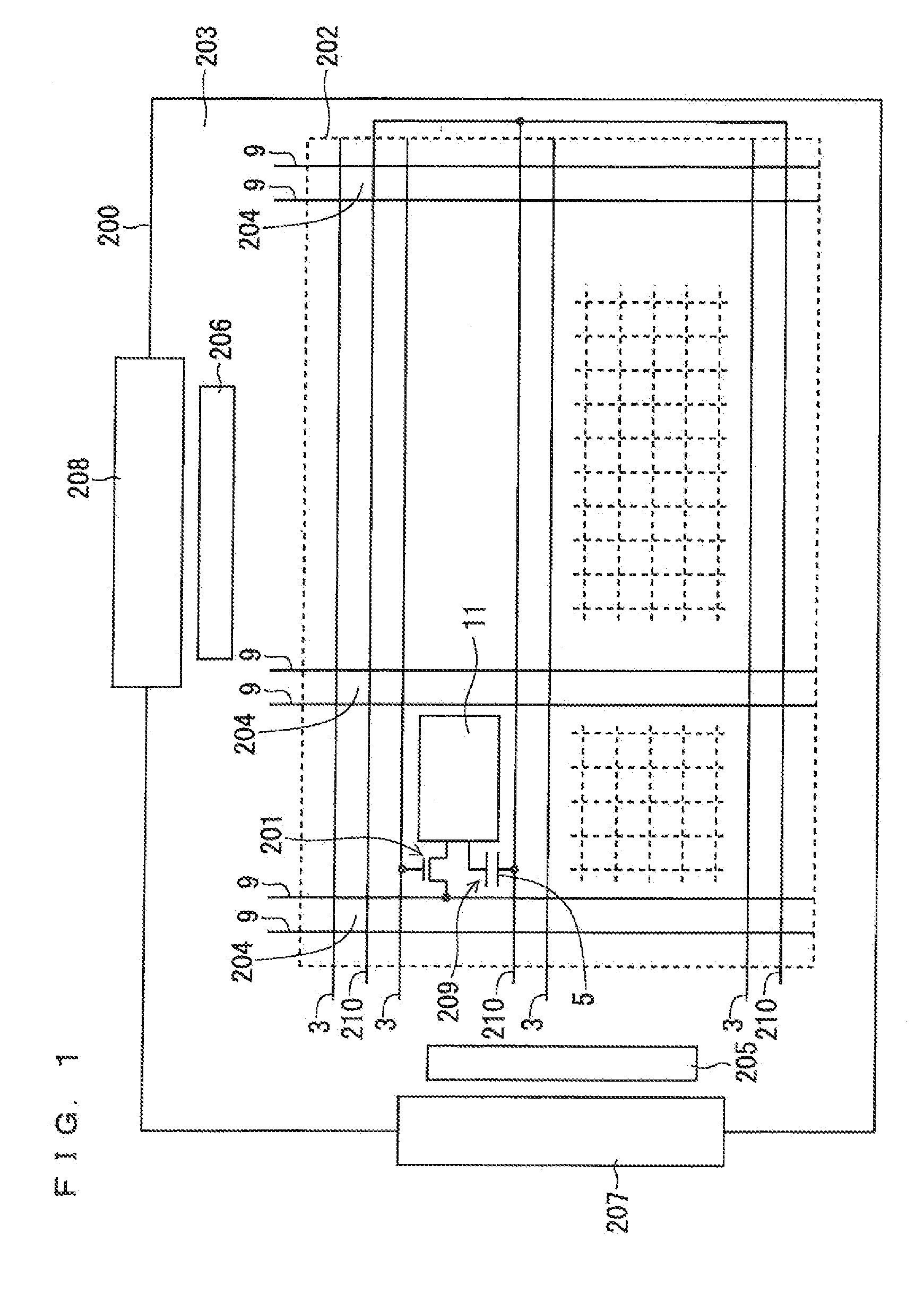

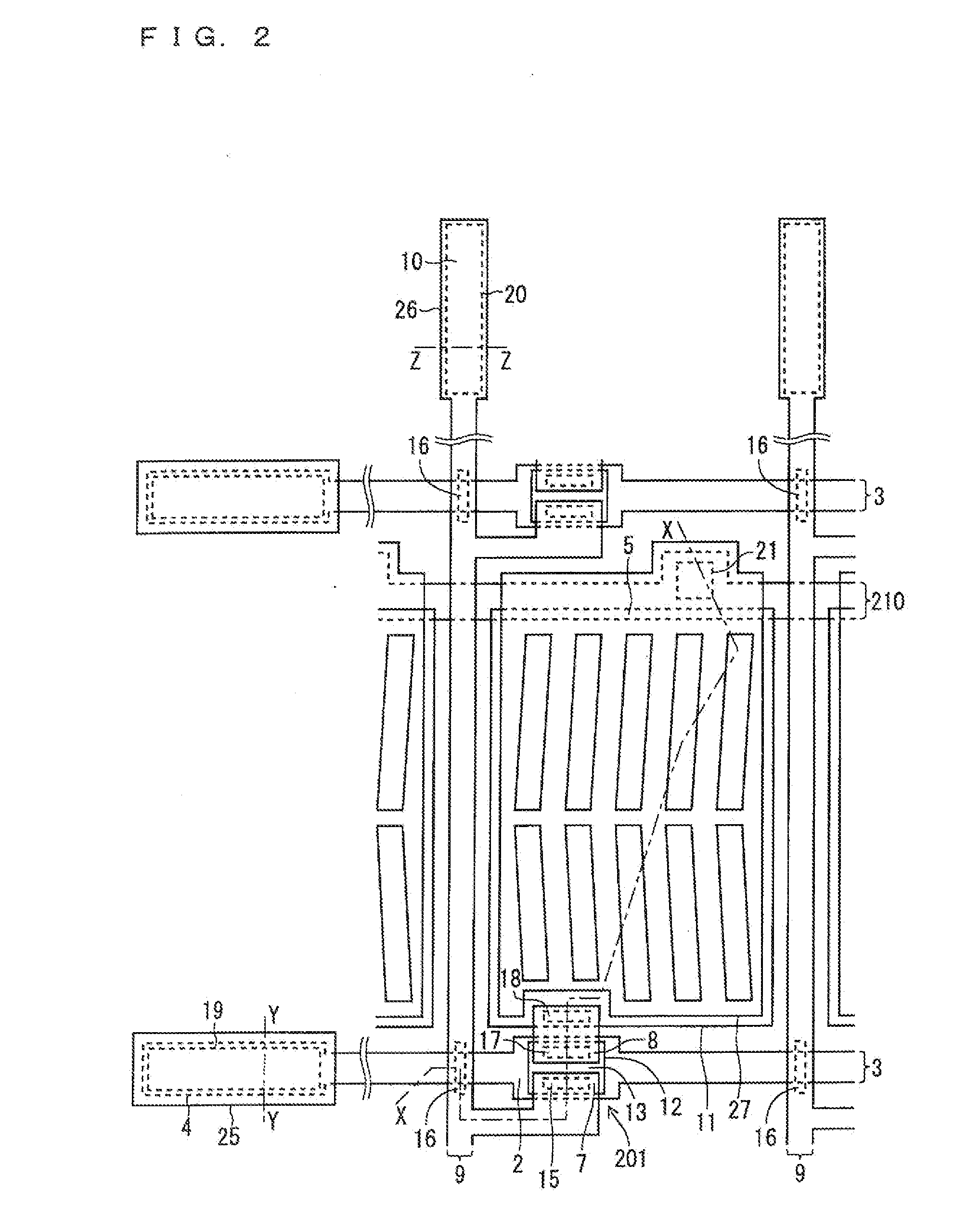

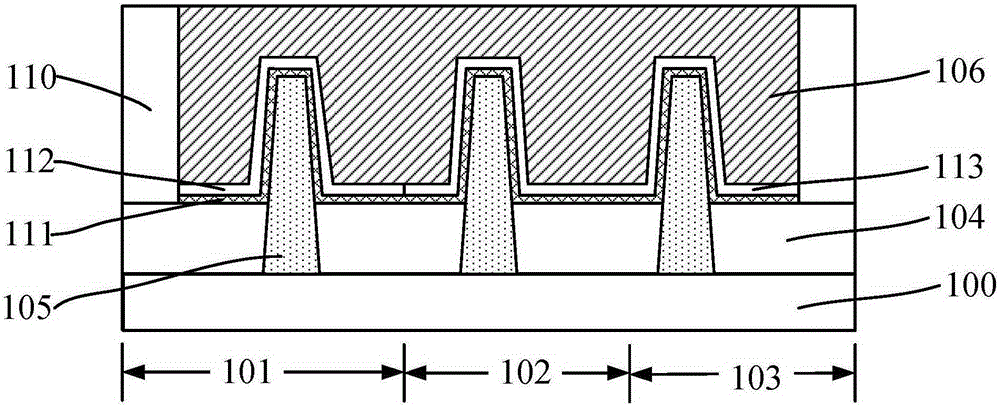

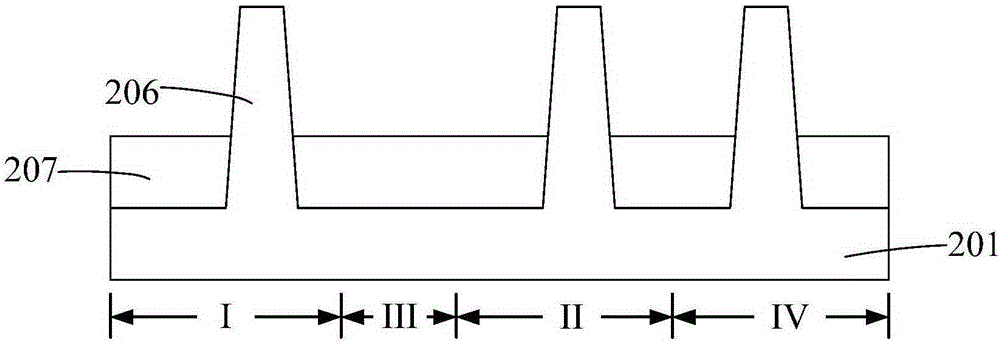

Thin film transistor substrate and manufacturing method thereof

ActiveUS20140319515A1Satisfactory connection propertyInhibit interface reactionTransistorSolid-state devicesEngineeringSemiconductor

A TFT substrate includes a TFT including a source electrode having a lower source electrode and an upper source electrode, which are electrically connected to each other, and a drain electrode having a lower drain electrode and an upper drain electrode, which are electrically connected to each other. The lower source electrode and the lower drain electrode are in contact with a lower surface of the semiconductor film, and the upper source electrode and the upper drain electrode are in contact with an upper surface of the semiconductor film.

Owner:TRIVALE TECH

Organic/inorganic composite solid electrolyte and preparation method thereof

ActiveCN109888373AImprove ionic conductivityReduce interface resistanceSecondary cellsSolid state electrolyteComposite electrolyte

The invention relates to an organic / inorganic composite solid electrolyte and a preparation method thereof. The sulfide is pretreated, the sulfide obtained by the pretreatment is subjected to high-temperature heat treatment to obtain a sulfur-based solid electrolyte, and the sulfur-based solid electrolyte is mixed with an organic polymer and a lithium salt in an organic solvent. The organic solvent is removed and the organic / inorganic composite solid electrolyte is obtained by drying. The inner layer of the organic / inorganic composite solid electrolyte material is a sulfur-based solid electrolyte, the organic polymer is coated on the outside of the sulfur-based solid electrolyte, the sulfur-based solid electrolyte has a structure of three phases or more, or an organic / inorganic composite electrolyte is composed of a two-phase sulfide solid electrolyte and a low-decomposition-temperature polymer organic matter, so that the activity of the obtained organic / inorganic composite solid electrolyte is improved, the conductivity is improved, and the cycle performance of the lithium-sulfur battery is improved.

Owner:深圳索理德新材料科技有限公司

Semiconductor device and on-vehicle ac generator

InactiveUS20110042815A1Reliability be lowerSuppress interface reactionSemiconductor/solid-state device detailsSolid-state devicesLead electrodeDynamo

Owner:HITACHI LTD

Semiconductor structure and formation method thereof

ActiveCN106558584ASimple forming processReduce process stepsSolid-state devicesSemiconductor devicesSemiconductor structureWork function

The invention provides a semiconductor structure and a formation method thereof. The semiconductor structure comprises a substrate; a first gate structure which is arranged on the surface of the substrate of the first regional part, wherein the first gate structure comprises a first work function layer; a second gate structure which is arranged on the surface of the substrate of the second regional part, wherein the second gate structure comprises a second work function layer, and the work function type of the second work function layer is different from the work function type of the first work function layer; an insulating layer which is arranged on the surface of the substrate of the third regional part, wherein the insulating layer covers the surface of the side wall of the first gate structure and the surface of the side wall of the second gate structure; an upper dielectric layer which is arranged on the top surface of the first gate structure, the top surface of the second gate structure and the top surface of the insulating layer; an opening which is arranged in the upper dielectric layer, wherein the top part of a first metal gate, the top part of a second metal gate and the top part of the insulating layer are exposed out of the bottom part of the opening; and a conductive layer which fully fills the opening, wherein the conductive layer is electrically connected with the first metal gate and the second metal gate. The electrical performance of the semiconductor structure can be improved by the semiconductor structure and the formation method thereof.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

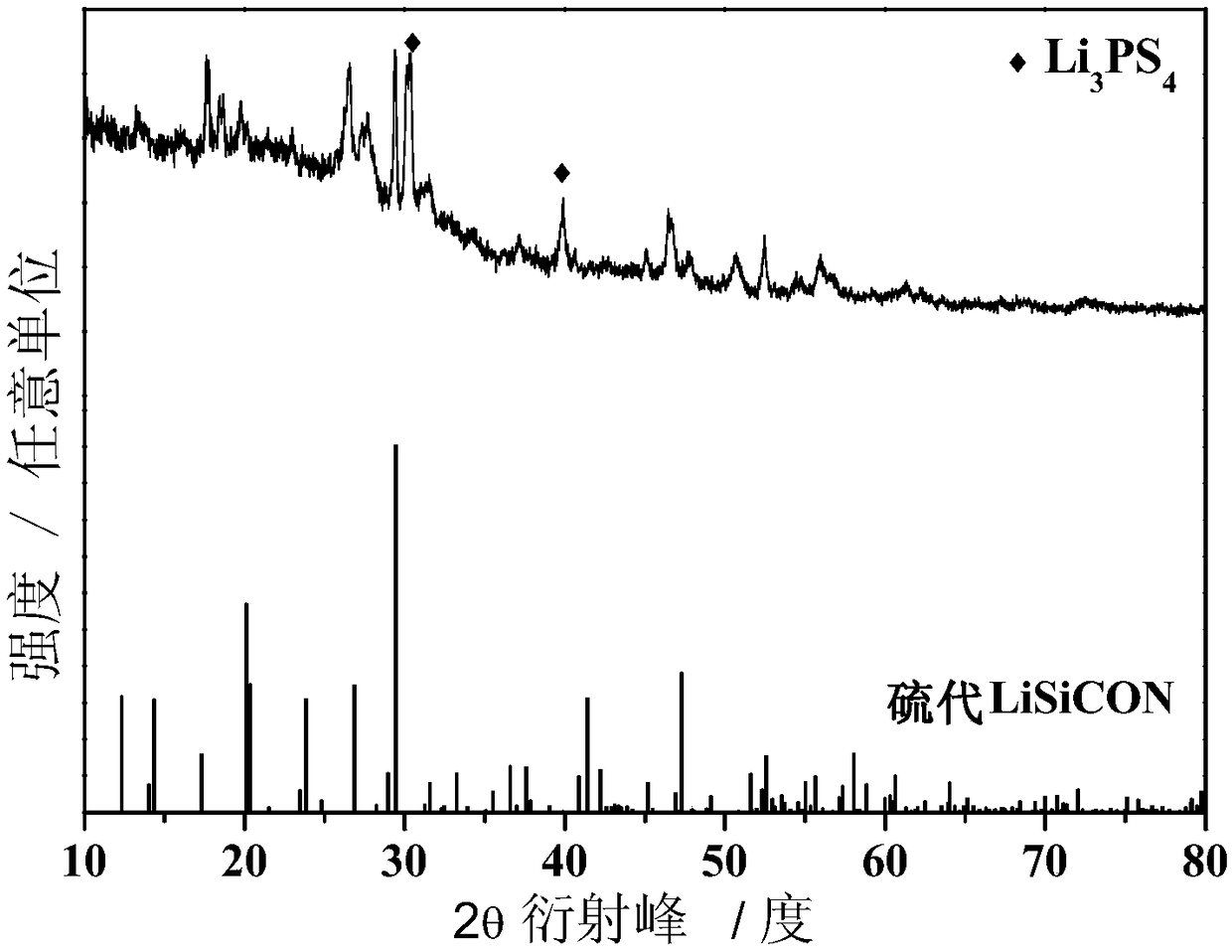

Quasi-solid-state electrolyte film as well as preparation method and application thereof

ActiveCN108511791AImprove mechanical propertiesGood chemistrySolid electrolytesFinal product manufacturePolyvinylidene fluorideOxide

The invention discloses a quasi-solid-state electrolyte film which is prepared from the following raw materials including polymer, ceramic electrolyte, lithium salt and ionic liquid; the polymer comprises polyvinylidene fluoride-hexafluoropropylene and poly(propylene oxide carbonate); the ceramic electrolyte comprises a main-phase thio LISICON type compound and impurity phase Li3PS4; and the ionicliquid is fluorine-containing imidazole ionic liquid. The invention discloses the quasi-solid-state electrolyte film which has high mechanical strength, toughness, high room-temperature lithium ion conductivity and high chemical / electrochemical stability with a metal lithium negative electrode and an oxide positive electrode, is used for a metal lithium battery, a lithium air battery and a lithium-sulfur battery and can realize good electrochemical performance.

Owner:ZHEJIANG UNIV

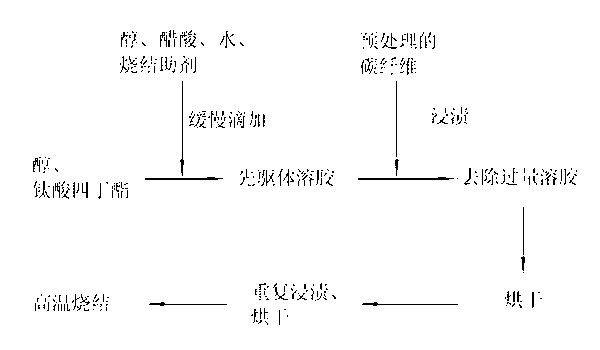

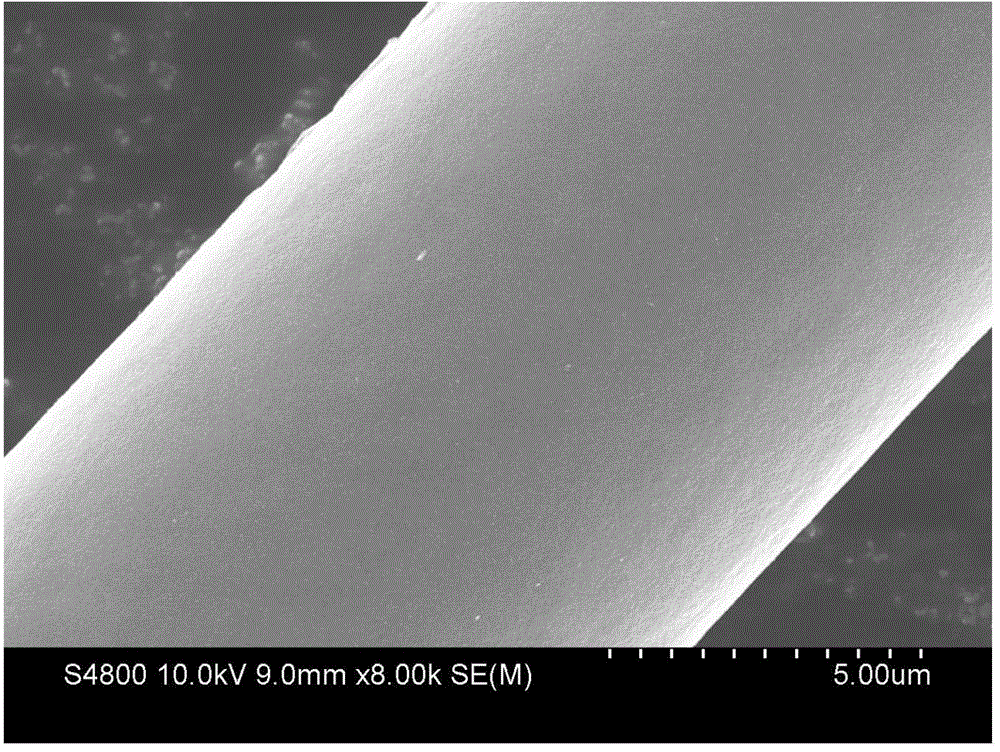

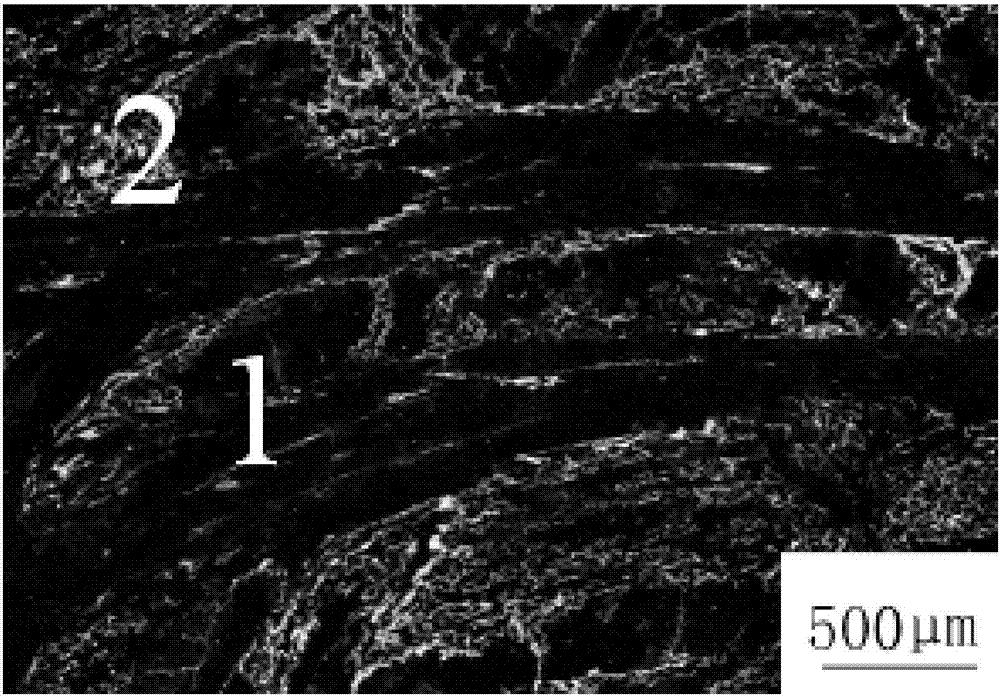

Method for preparing carbon fiber surface densified sintering TiO2 coating

InactiveCN103184687AStay flexibleImprove high temperature oxidation resistanceCarbon fibresFiberCarbon fibers

The invention discloses a method for preparing carbon fiber surface densified sintering TiO2 coating. The method takes titanate as a titanium source, an alcohol solution as a solvent, low melting point salt as an sintering aid, and organic acid as an chelating agent and a pH value regulator, and comprises the following steps: firstly, a precursor solution containing the sintering aid is obtained through hydrolysis, and then carbon fibers are dipped, dried, and sintered to obtain densified carbon fiber surface TiO2 coating. The method uses the low melting point salt as a fluxing agent which is converted into a liquid phase wet solid, penetrates between solid particles, dissolves sintering keys, and induces titanium dioxide particles to be rearranged, thereby achieving the effect of densifying the coating. The densified sintering TiO2 coating carbon fiber prepared by the method has the flexibility and stitchability of carbon fibers, simultaneously improves the high-temperature oxidation resistance performance of the carbon fibers, and avoids the interface reaction between the carbon fibers and a composite material matrix.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Graphene reinforced aluminum matrix composite material and preparation method

The invention provides a graphene reinforced aluminum matrix composite material and a preparation method. The preparation method comprises the following steps that S1, graphene is subjected to metal plating treatment; S2, the graphene after metal plating treatment and metal powder are subjected to ball-milling treatment, and a surfactant is added during the ball-milling process to obtain a uniformly-mixed mixture; and S3, the mixture is added into aluminum or aluminum alloy melt under the action of air flow and ultrasonic, the flow rate of the mixture and the temperature of the melt are controlled, and the graphene reinforced aluminum matrix composite material is obtained after cooling and solidifying. The graphene reinforced aluminum matrix composite material prepared by the preparation method has semi-solid structure characteristics, the graphene is relatively complete in structure, and the material performance is excellent. The tensile strength of the aluminum matrix composite material prepared by the preparation method is improved by 30%-70% compared with that of a matrix, and is improved by 10%-30% compared with a graphene reinforced aluminum matrix composite material with non-semi-solid structure characteristics.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing porous zirconium/aluminum tungstate composite material by spark plasma sintering

The invention discloses a method for preparing a porous zirconium / aluminum tungstate composite material by spark plasma sintering, relates to a preparation method for a porous zirconium / aluminum tungstate composite material, and aims to solve the problems of large fluctuation of a thermal expansion curve of a conventional aluminum-base zirconium tungstate particle composite material and high thermal expansion value. The method comprises the following steps: 1, weighing 50 to 60 percent of zirconium tungstate powder and 40 to 50 percent of aluminum powder in volume fraction; 2, performing ball-milling mixing to obtain a ball-milled mixed material; 3, performing drying and sieving to obtain mixed powder; 4, performing spark plasma sintering to obtain the porous zirconium / aluminum tungstate composite material. The method has the advantages that 1, the crystal completeness of zirconium tungstate is guaranteed, and direct interface reaction between the zirconium tungstate and aluminum is effectively inhibited; 2, a sintering aid is not added; 3, generation of a gamma phase is greatly reduced; 4, the porosity is higher while the axial pressure is lower, and the thermal expansion value is smaller while the content of the gamma phase is lower. The method is mainly used for preparing the porous zirconium / aluminum tungstate composite material.

Owner:HARBIN INST OF TECH

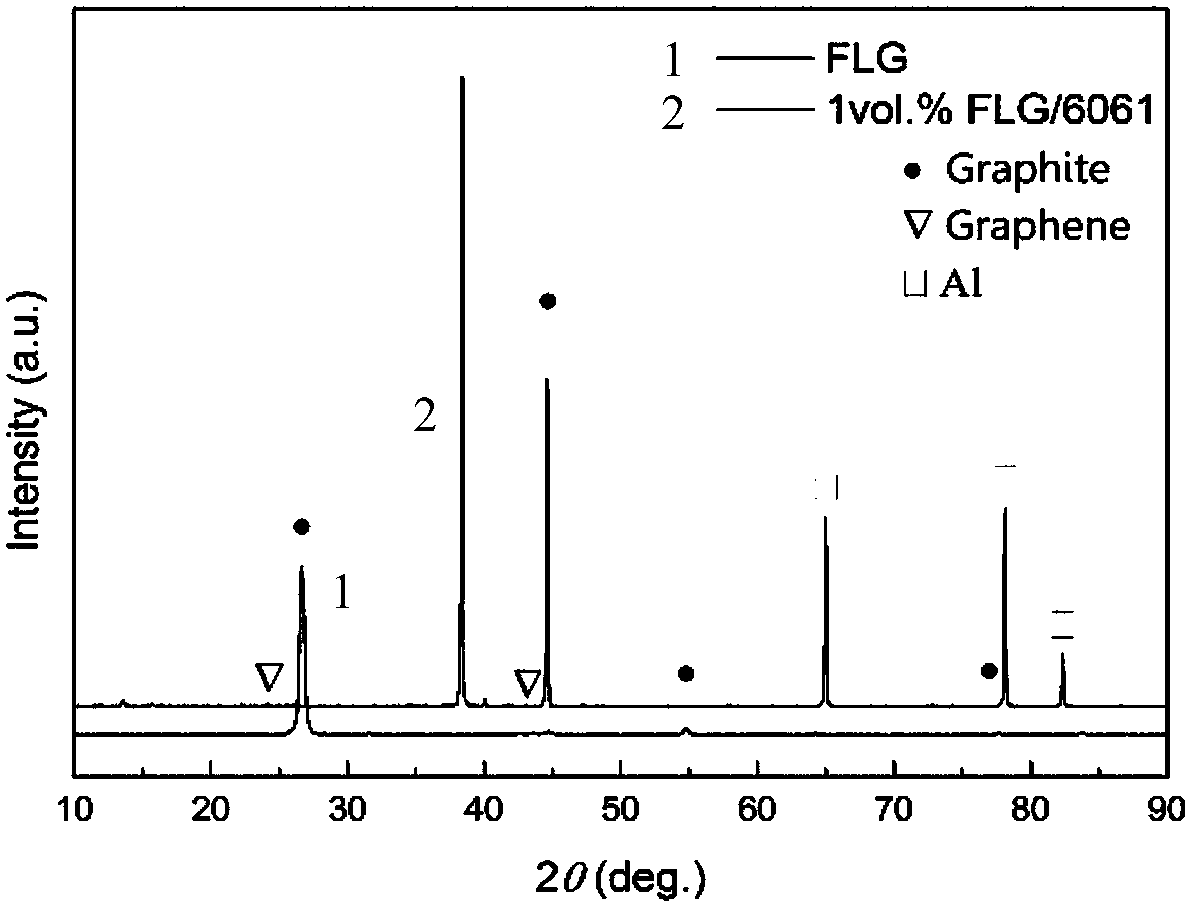

A method of preparing a high-performance graphene reinforced aluminium-based composite material

A method of preparing a graphene reinforced aluminium-based composite material is provided. The method includes a step of preparing graphene oxide; a step of performing surface modification on aluminum powder to prepare flake-like aluminum powder; a step of preparing graphene / aluminium hydroxide / aluminum multilayer clad structured powder, namely a step of mixing graphene and the aluminum powder, then adding the mixture into an alcohol solution, and performing ultrasonic treatment for 0.1-1 h at 30-50 DEG C to obtain the graphene / aluminium hydroxide / aluminum multilayer clad structured powder; and a step of adding the prepared graphene / aluminium hydroxide / aluminum multilayer clad structured powder into a hot pressing sintering mold, applying a pressure of 100-200 MPa, protecting the powder with argon or nitrogen and performing hot pressing sintering to obtain the high-performance graphene reinforced aluminium-based composite material. The method effectively avoids graphene agglomeration and interface reactions between the graphene and aluminum. The microhardness of the composite material prepared by the method is increased by 30% or above.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Process for preparing carbon-carbon precast member for carbon-carbon/aluminium composite material

The invention designs a kind of carbon - carbon / aluminum compound material with the carbon - carbon pre- workpiece preparation method, specially involves a kind the carbon - carbon pre- workpiece preparation method which prepares the high heat conduction, the low inflation carbon - carbon / aluminum compound material uses, is the inorganic compound material manufacture craft area of technology. The invention a kind of carbon - carbon / aluminum compound material uses the carbon - carbon pre- workpiece the preparation method, including following craft step: Pre- workpiece skeleton material preparation: May use in the following three kind of structures the person a kind, namely carbon fiber overall felt, or polypropylene nitrile pre- oxycellulose (PANOF) overall felt, or carbon fiber and textile fiber net in turn lamellar structure; Carries on the heat treatment to the pre- workpiece skeleton material; The heat treatment temperature is 970~1000deg.C, keeps warm for 2 hours; Take six hydrogenation three carbon as the forerunner body. Carries on chemistry gas phase seepage to the pre- workpiece skeleton, causes under the hot conditions the thermal decomposition, forms the thermal decomposition carbon to permeate in the pre- workpiece skeleton material and the deposition to the carbon fiber surface; Carries on the high temperature heat treatment to the above pre- workpiece under the 2200~~2300deg.C temperature, like this may prepare the carbon - carbon pre- workpiece. It may supply the high heat conduction, the inflation performance requirement carbon - carbon / aluminum compound material use. The invention craft is simple, the ease of operation, may reduce the cost.

Owner:SHANGHAI UNIV

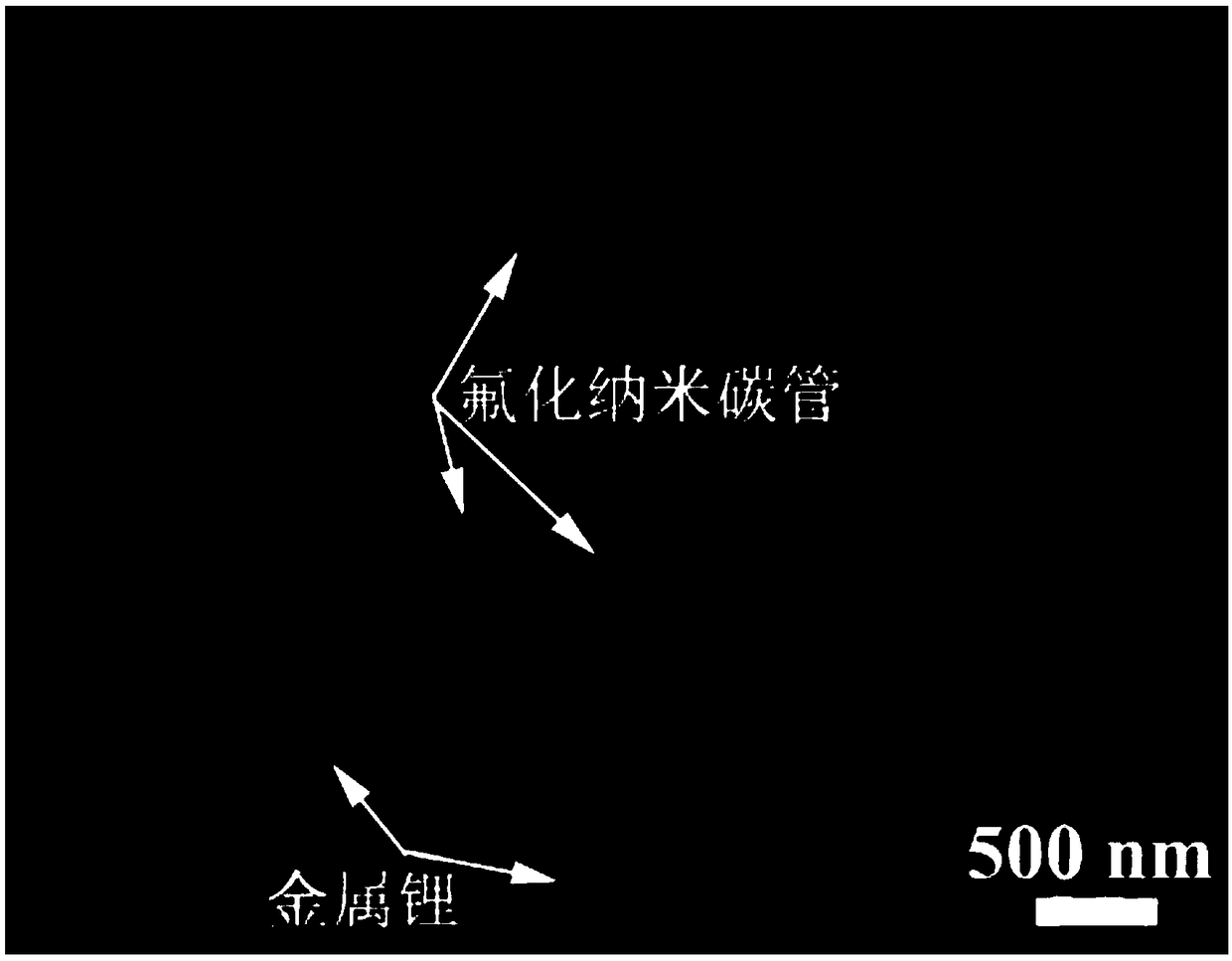

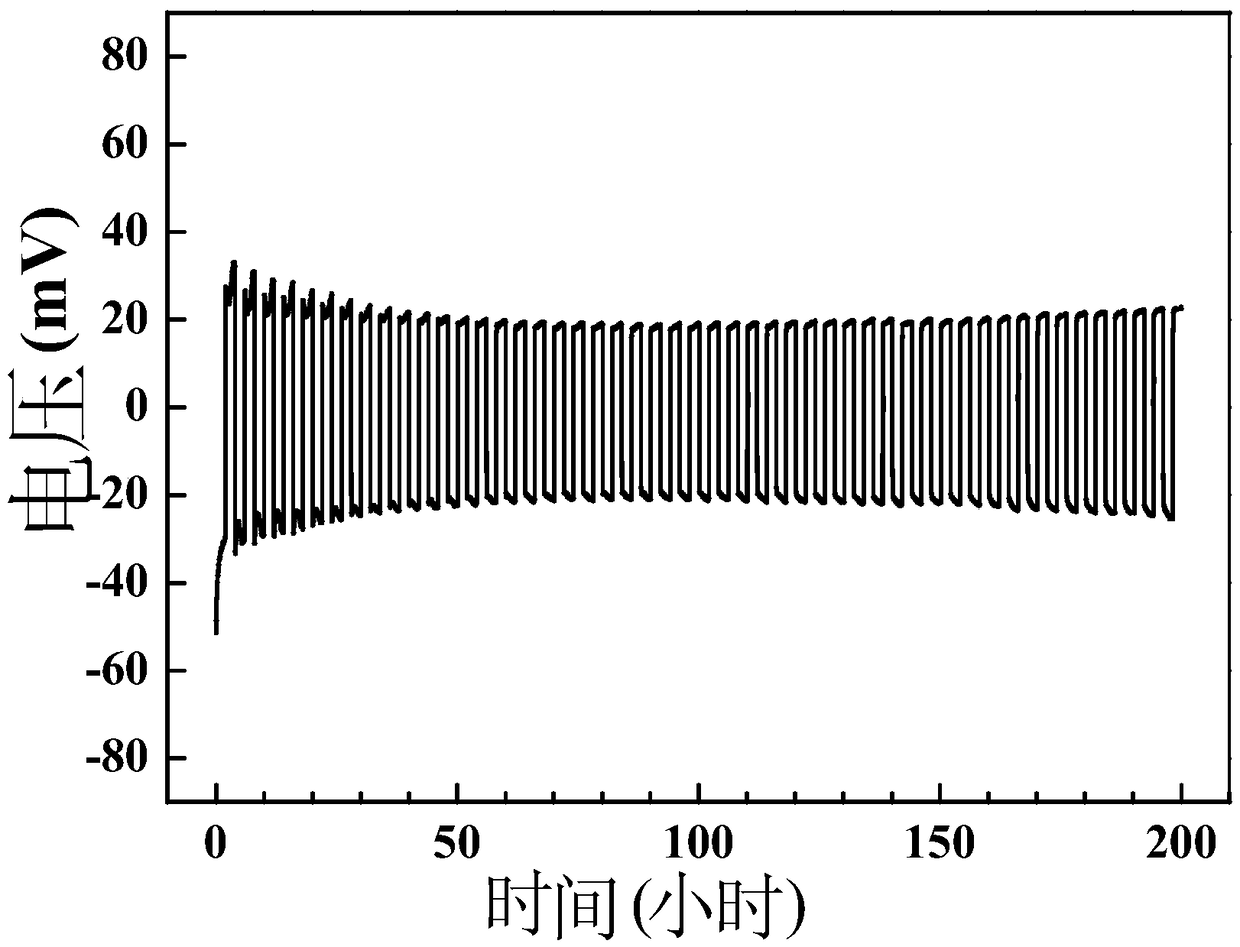

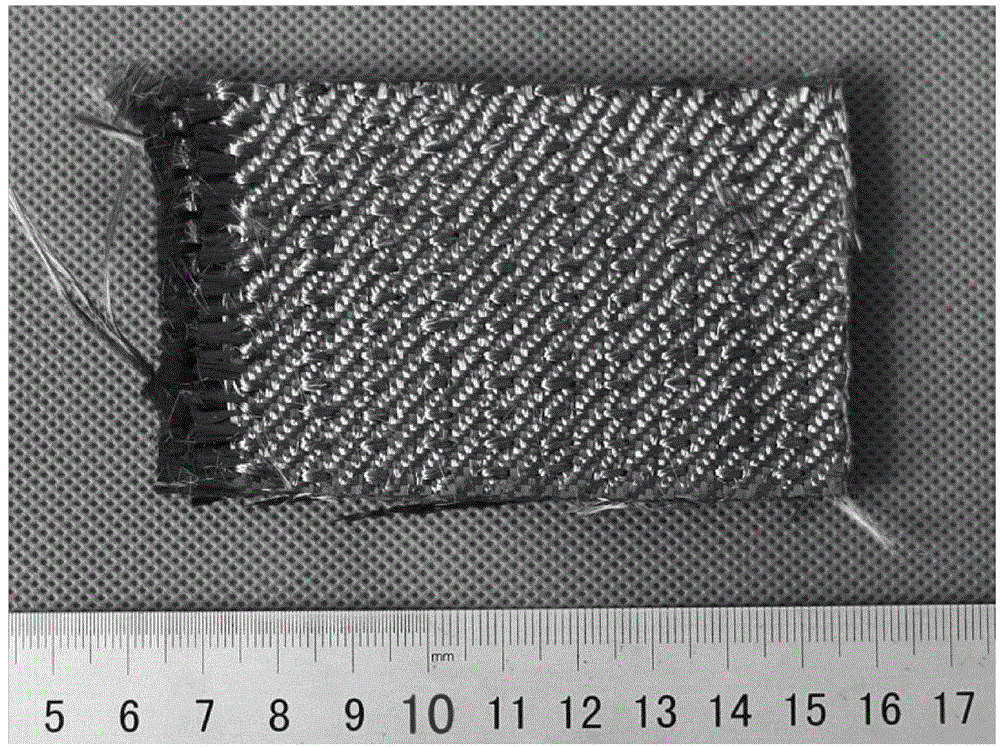

An alkali metal-based negative electrode and a preparation method and application thereof

ActiveCN109037626AInhibition formationInhibit interface reactionFuel and secondary cellsCell electrodesPhysical chemistryFluorocarbon

The invention discloses an alkali metal-based negative electrode and a preparation method and application thereof. The alkali metal-based negative electrode comprises an alkali metal and a fluorocarbon material uniformly distributed in the alkali metal. The present invention introduces a fluorocarbon material into an alkali metal, alkali metal fluoride can be formed in situ during the charge and discharge process, a synergistic effect is formed between the fluoride and the carbon material, and a uniform electric field is formed during the charging and discharging process, thereby promoting theuniform deposition of the alkali metal, effectively inhibiting the formation of the alkali metal dendrite and the interface reaction between the alkali metal and the electrolyte, and improving the safety performance and cycle stability of the alkali metal battery.

Owner:ZHEJIANG UNIV

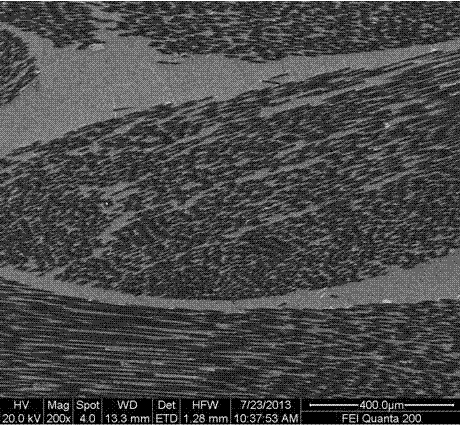

Aluminum silicate fiber reinforced oxide ceramic containing interface phase and preparation method thereof

The invention relates to aluminum silicate fiber reinforced oxide ceramic containing an interface phase. The aluminum silicate fiber reinforced oxide ceramic adopts one or a mixture of more of mullite, aluminum silicate and aluminum oxide as a ceramic substrate and adopts aluminum silicate fiber as a reinforcing phase, and a sacrifice carbon interface phase is formed between the substrate and the reinforced phase. The preparation method of the aluminum silicate fiber reinforced oxide ceramic comprises the following steps: preparing a three-dimensional aluminum silicate fiber fabric, and preparing a pyrolytic carbon coating on the surface of the fiber fabric by utilizing a chemical vapor phase deposition process; taking oxide sol as a precursor, vacuum impregnating the fiber fabric, carrying out the gelatization, then carrying out the high-temperature ceramization, and completing the primary compacting process; repeating compacting for at least 10 times; finally carrying out oxidative cracking on carbon interface phase coating, forming a gap between the aluminum silicate fiber and the substrate, and preparing the product. The product is excellent in mechanical property both at the room temperature and high temperature and has the advantages of short preparation period, low cost, wide applicability and the like.

Owner:NAT UNIV OF DEFENSE TECH

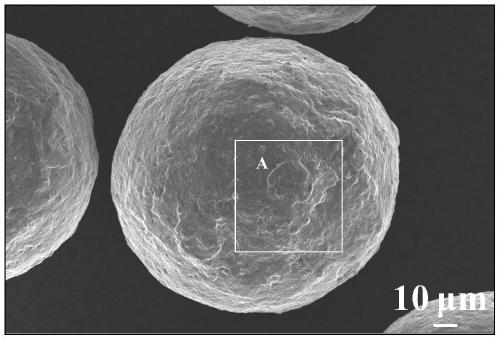

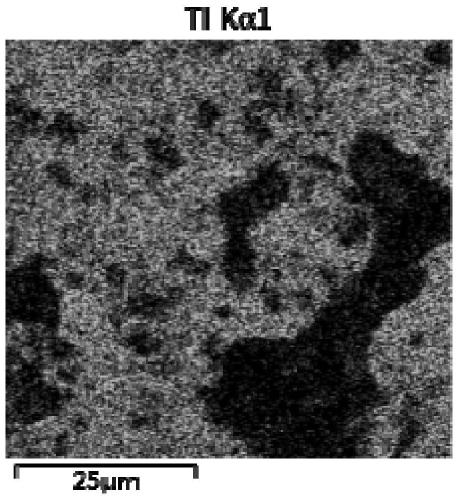

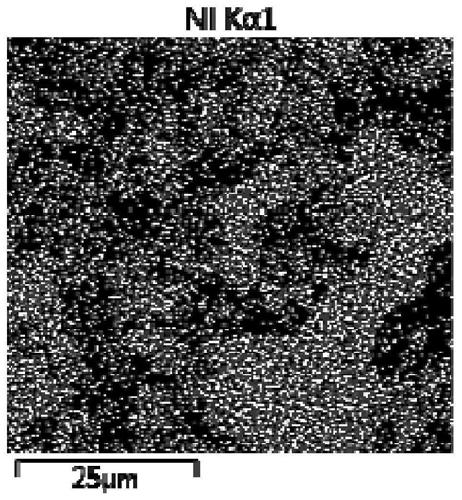

Microalloying synergistically strengthened graphene titanium-based composite material and preparation method thereof

ActiveCN111270101AAvoid contactImprove distribution uniformityTransportation and packagingMetal-working apparatusMetal coatingNanoparticle

The invention discloses a microalloying synergistically strengthened graphene titanium-based composite material. The microalloying synergistically strengthened graphene titanium-based composite material takes titanium or titanium alloy as a matrix, metal for microalloying is uniformly coated on the surface of the titanium or titanium alloy matrix in a quasi-continuous manner through a physical bonding manner, graphene is dispersed on the outer surface of the metal-coated titanium or titanium alloy matrix for microalloying, the graphene is dispersed on the outer surface of the metal-coated titanium or titanium alloy matrix, the graphene, in-situ synthesized TiC nanoparticles and intermetallic compound particles jointly form a quasi-continuous net structure; and the invention further discloses a preparation method of the microalloying synergistically reinforced graphene titanium-based composite material, and the preparation method comprises the following steps of ball milling the raw material powder, uniformly stirring with the graphene nanosheet suspension solution, drying, and carrying out hot pressed sintering. According to the microalloying synergistically strengthened graphene titanium-based composite material and the preparation method thereof, microalloying metal coating is adopted, so that direct contact between graphene and the matrix is avoided, the distribution uniformity and structural integrity of the graphene are improved, the graphene, TiC nanoparticles and intermetallic compound particles have a synergistic reinforcing effect; and the method is high in operability, and the microalloying synergistically strengthened graphene titanium-based composite material is suitable for industrial production.

Owner:西安稀有金属材料研究院有限公司

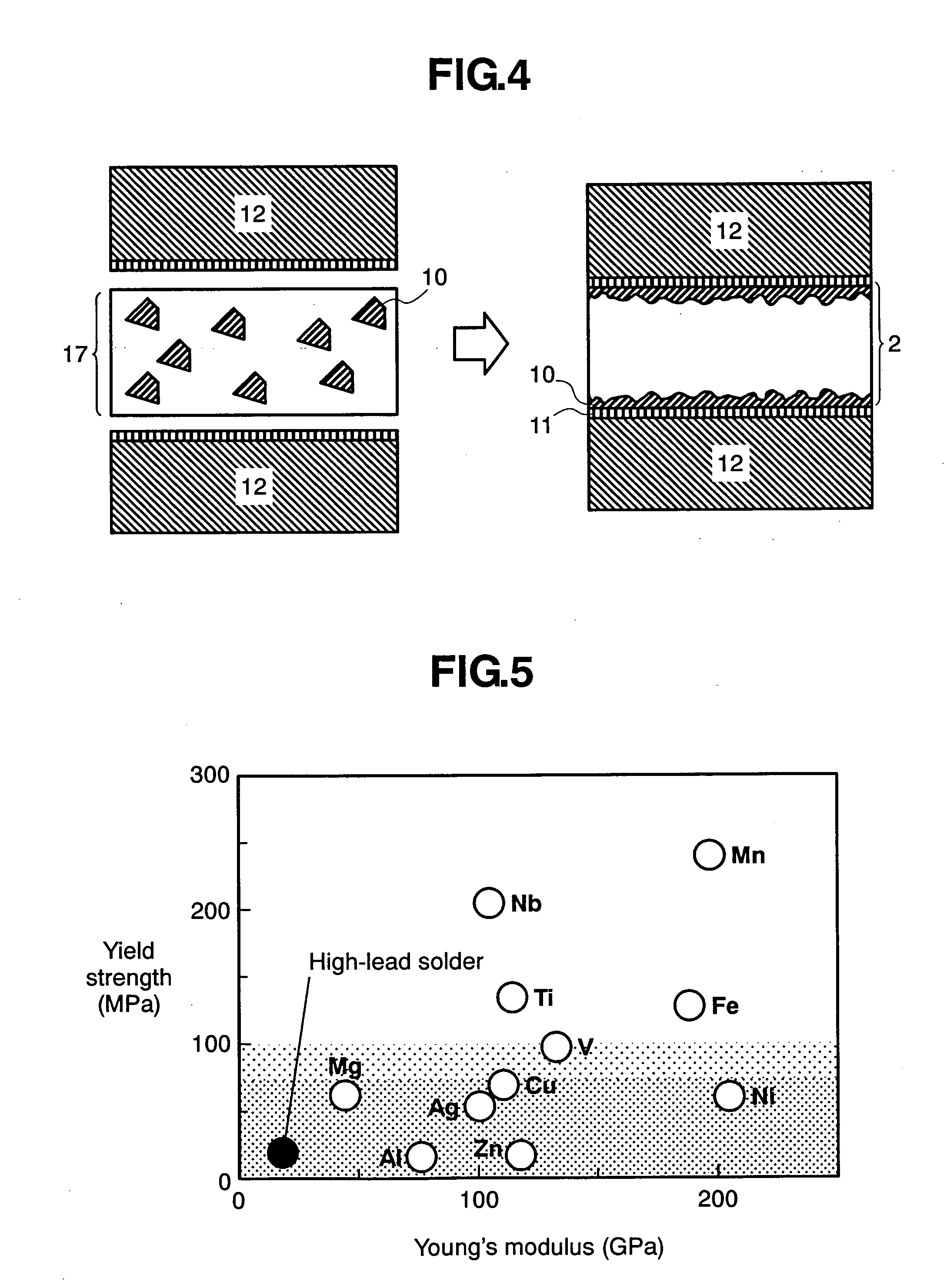

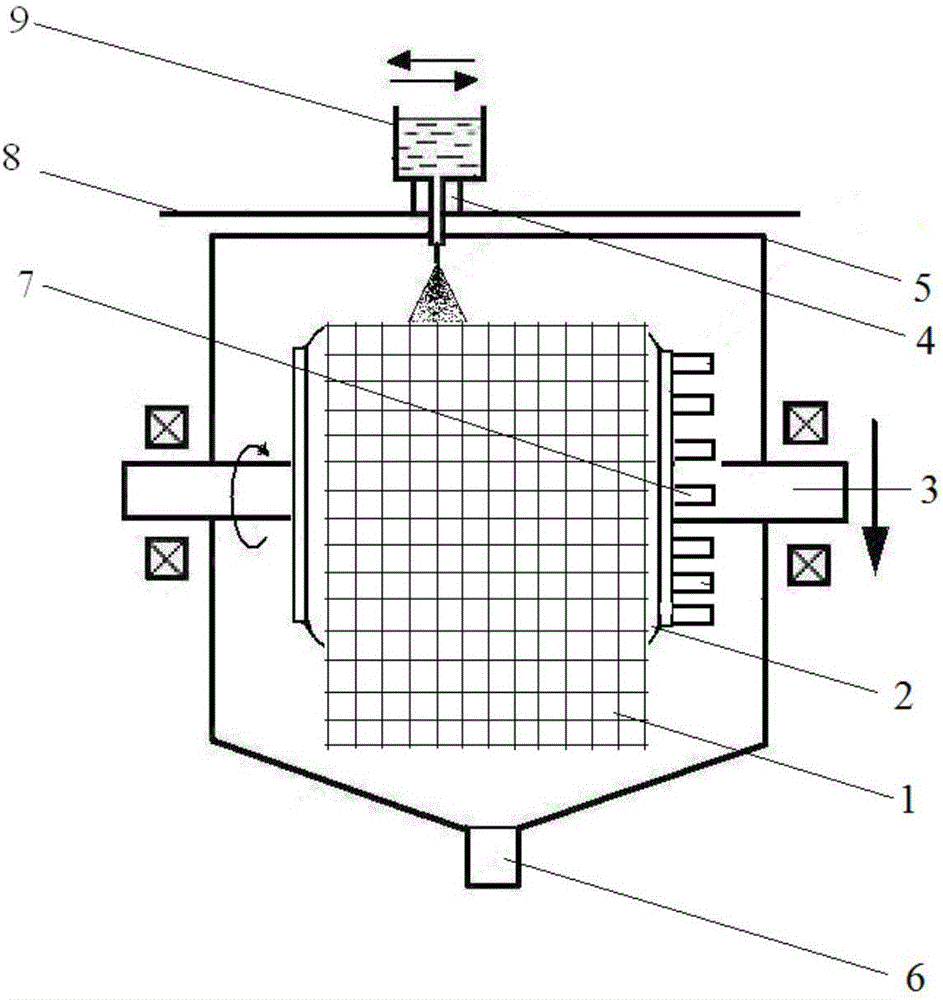

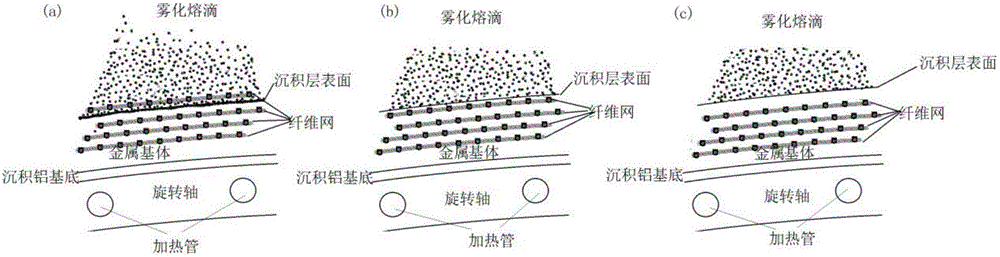

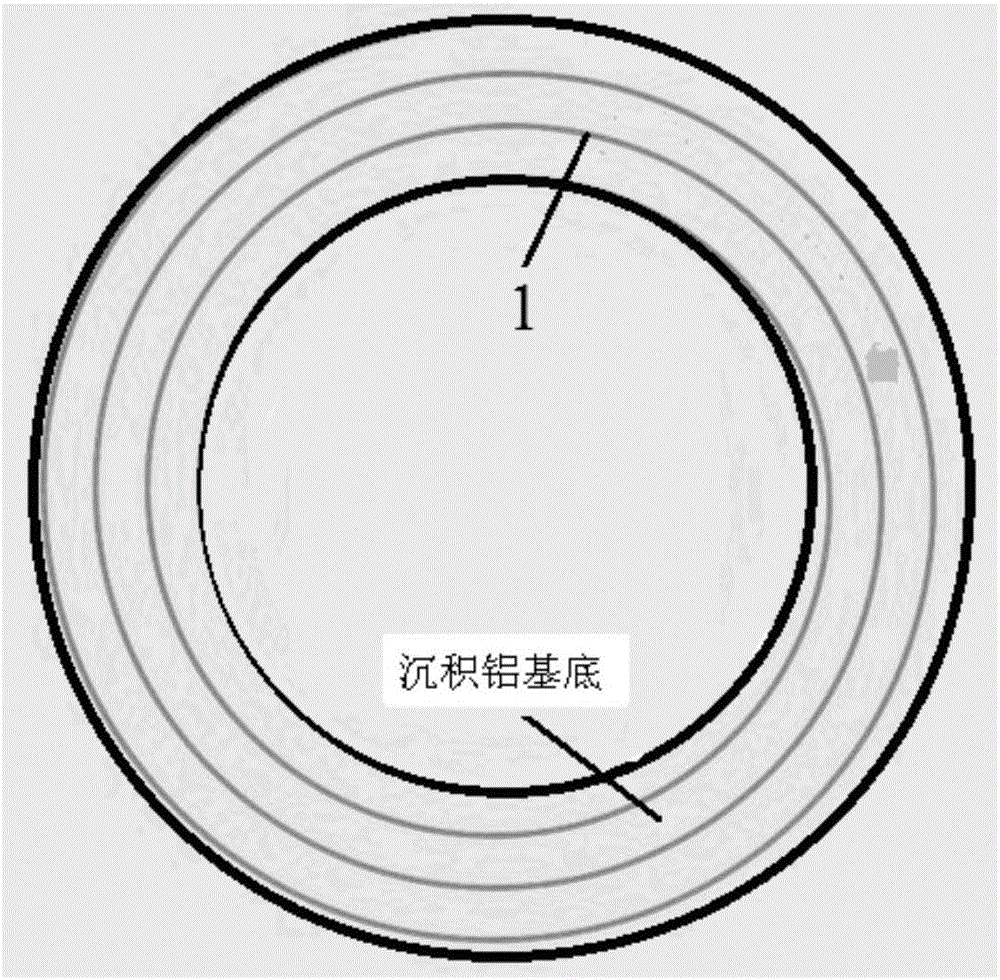

Preparation method and device for fiber reinforced metal matrix composite

The invention provides a preparation method for a fiber reinforced metal matrix composite. Good bonding between a matrix alloy and a fiber mesh and between the matrix alloy and a settled layer is realized by adopting the preparation method. The invention further provides a preparation device for realizing the preparation method and application of the preparation device. The preparation device can realize thickness control over a metal matrix layer between fiber layers and uniform distribution of fibers or enhancement of graded fibers. The preparation device can be used for preparing molten-state metal alloys of an aluminium alloy, a tin alloy, a lead alloy, a copper alloy, an iron alloy and a titanium alloy, and tubular bases made of an aluminium-base alloy, a copper-base alloy, an iron-base alloy, a tin-base alloy and a lead-base alloy. The preparation method and device can realize regulation of the thickness of the metal matrix layer between the fiber layers; the shorter the rotation interval time of a matrix rotating shaft is, the smaller the thickness of the metal matrix layer is, and otherwise, the larger the thickness of the metal matrix layer is; and progressive regulation of the rotation interval time can be realized by a controller, and enhancement of the graded fibers is conveniently realized.

Owner:HUAIHAI INST OF TECH

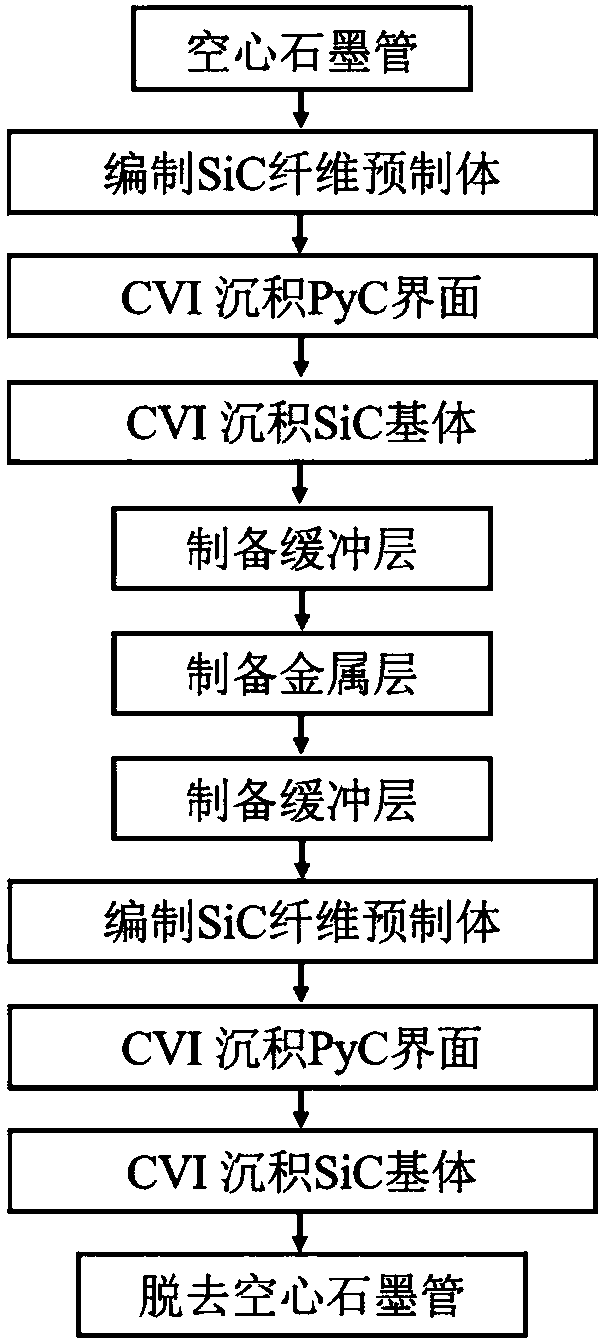

Accident-resistant fuel core cladding tube and preparation method thereof

InactiveCN109020589AOvercome catastrophic accidentsPrevent interface reactionFuel elementsNuclear energy generationSic fiberCeramic matrix composite

The invention relates to an accident-resistant fuel core cladding tube and a preparation method thereof. The accident-resistant fuel core cladding tube is a sandwich multilayered structure formed by alternately superimposing a continuous SiC fiber toughened SiC ceramic matrix composite material and a refractory metal layer according to design requirements. According to the multilayered structure,the continuous SiC fiber toughened SiC ceramic matrix composite material is used as an inner tube layer, the refractory metal layer is used as an intermediate tube layer, and the continuous SiC fibertoughened SiC ceramic matrix composite material is used as an outer tube layer. In the multilayered structure, the continuous SiC fiber toughened SiC ceramic matrix composite material layer mainly plays a support and bearing role, and the refractory metal layer mainly plays a sealing antiseep role. The accident-resistant fuel core cladding tube of the invention can maintain the airtightness of thecore cladding tube when the stress exceeds the elastic deformation range of the ceramic matrix composite material and the crack has been expanded in the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of C/Al-Si-X ablation-resisting composite material

ActiveCN106966753AImprove thermal shock resistanceLower the joining temperatureMatrix damageMelting temperature

The invention discloses a preparation method of a C / Al-Si-X ablation-resisting composite material. The invention relates to the technical field of preparation of high-temperature ablation-resisting composite material. The invention solves the technical difficulty of too high melting temperature when a heatproof material is modified by a refractory metal during the preparation process, and overcomes the technical problem of interface reaction and C / C matrix damage. The method includes steps of firstly, weighing a raw material; secondly, preparing a carbon material-X precursor composite body; thirdly, splitting; fourthly, reducing; fifthly, preparing a prefabricating body; sixthly, processing impregnant; seventhly, applying pressure, and filling the impregnant in a prefabricating body hole. The preparation method is short in technical cycle and low in matrix price; the preparation method overcomes the shortcomings of interface reaction and C / C matrix damage caused by too high melting temperature of the refractory metal. The invention is used for preparing the ablation-resisting composite material.

Owner:HARBIN INST OF TECH

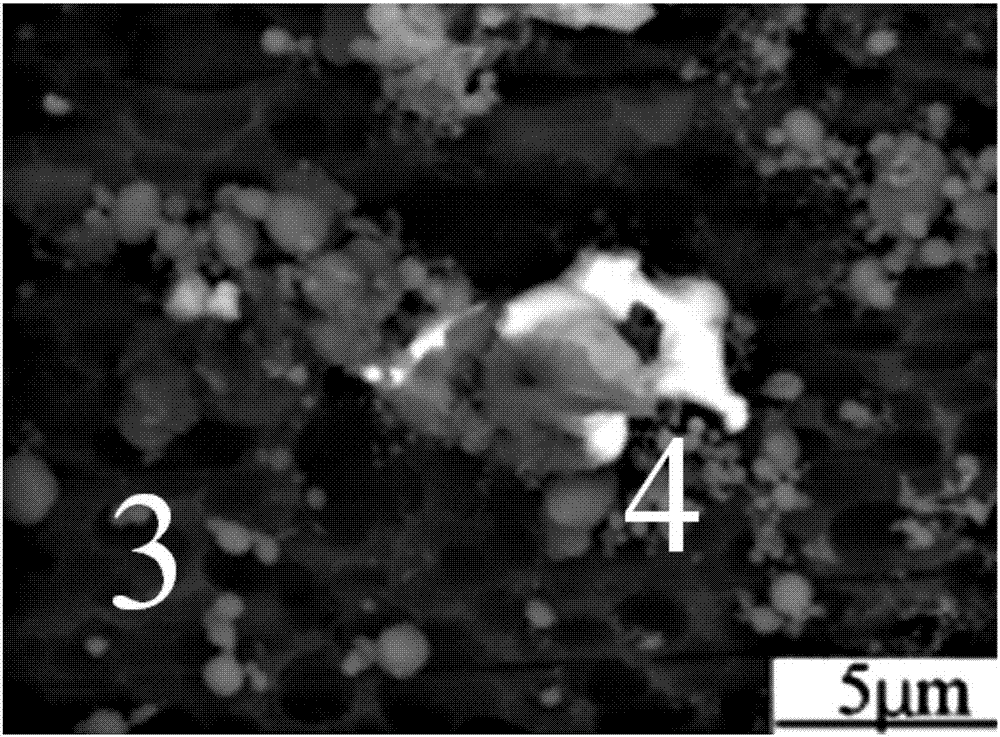

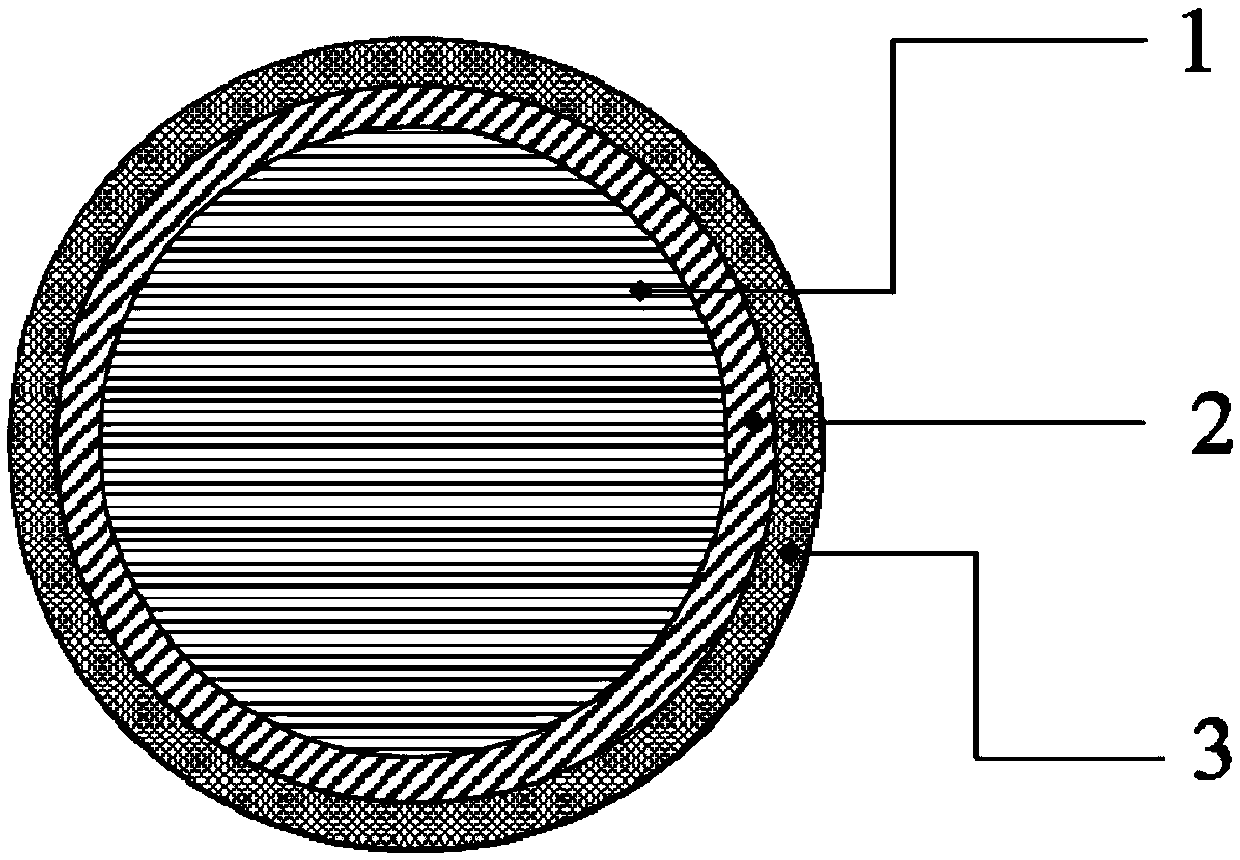

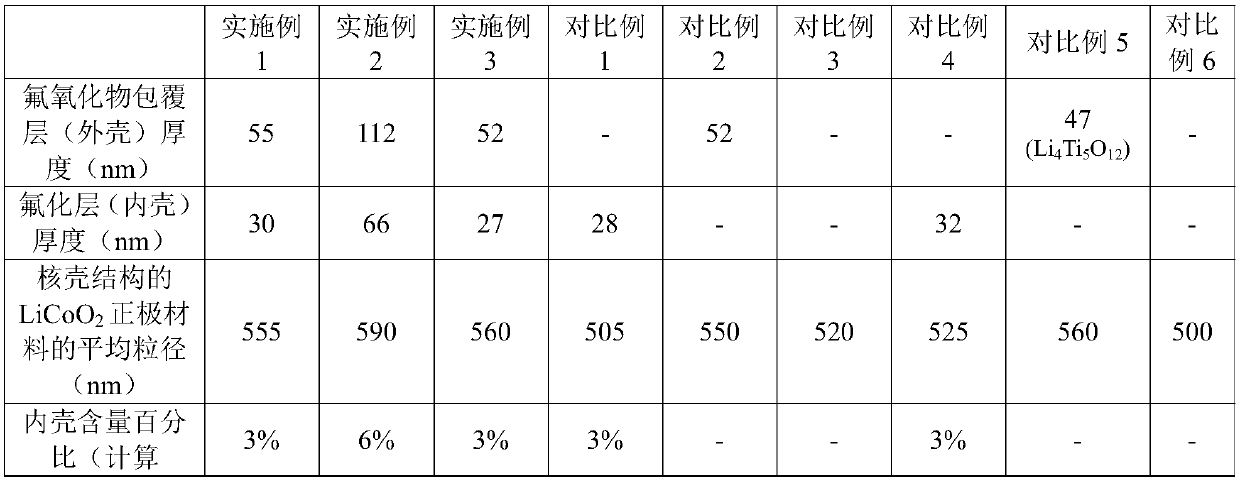

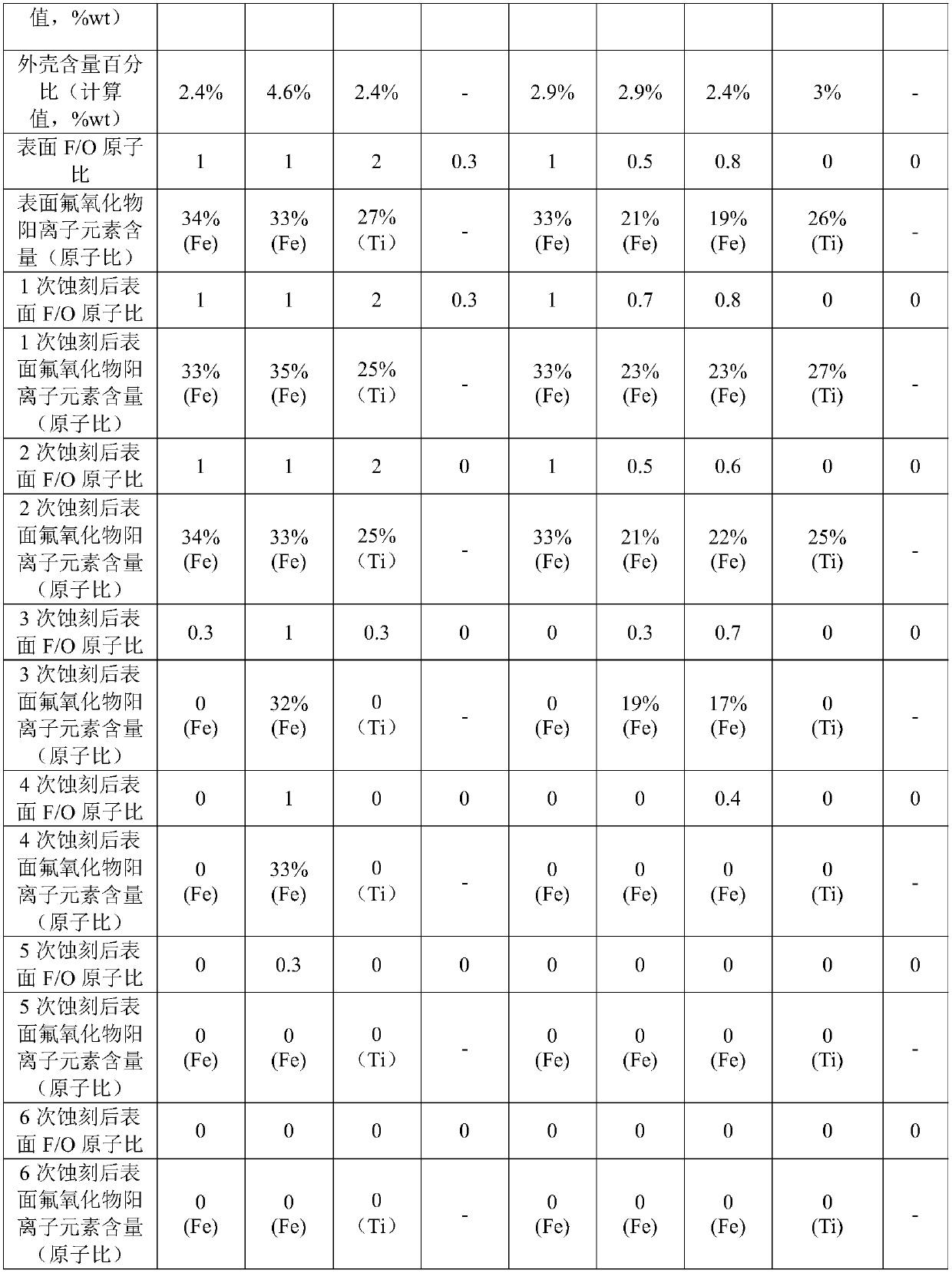

Lithium ion battery positive pole material, preparation method thereof, lithium ion battery positive pole and all-solid-state lithium battery

InactiveCN110660976AInhibit interface reactionSimple interfaceCell electrodesSecondary cellsComposite materialAll solid state

The invention relates to a lithium ion battery positive pole material, a preparation method thereof, a lithium ion battery positive pole and an all-solid-state lithium battery. The positive pole material comprises a core-shell structure composite material; the core-shell structure composite material comprises a core material, an inner shell material and an outer shell material; the core material comprises a positive pole active substance; the inner shell material is a positive pole active substance containing fluorine; and the outer shell material contains oxyfluoride. According to the lithiumion battery positive pole material disclosed by the invention, a fluorinated layer is adopted as an inner shell, the oxyfluoride is adopted as an outer shell; and since the formed core-shell structure is coated with the two shells, a coating structure is stable, and therefore, interface reaction or element diffusion between the positive pole material and a solid electrolyte can be avoided, and atthe same time, element diffusion between the positive pole material and the coating is reduced, and therefore, the interface of the positive pole material can be greatly optimized. With the method for preparing the positive pole material disclosed by the invention adopted, coating and fluorination can be completed in one step; coating temperature is low; operation is simple and feasible; elementinterpenetration is reduced; and the interface of the positive pole material is optimized.

Owner:BYD CO LTD

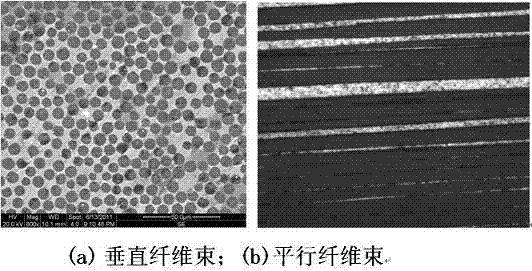

Preparation method of SiC continuous fiber reinforced titanium-based composite, and product

The invention discloses a preparation method of a SiC continuous fiber reinforced titanium-based composite, and a product. The preparation method comprises the following steps that a SiC continuous fiber with the diameter being 10-15 [mu]m is placed in the air environment to be subjected to heat treatment, then, with the SiC continuous fiber as a base material, Al2O3 is sputtered on the surface ofthe SiC continuous fiber through magnetron sputtering, and thus the SiC continuous fiber covered with an Al2O3 coating is obtained; a titanium or titanium alloy base body is heated to be melted, andthus a melted titanium or titanium alloy solution is obtained; the SiC continuous fiber covered with the Al2O3 coating is placed in a mould, preheating is conducted, and the mould is vacuumized; and the melted titanium or titanium alloy solution is pressed into the mould, heat preservation and cooling are conducted, and thus the SiC continuous fiber reinforced titanium-based composite is obtained.The filament SiC continuous fiber is adopted as the reinforcing base material, and the magnetron sputtering technology and a vacuum pressure impregnation method are combined, so that the prepared SiCcontinuous fiber reinforced titanium-based composite has the advantages that the structure is compact, the mechanical property is high, the interface stable property is good, and the service life islong.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com