Aluminum silicate fiber reinforced oxide ceramic containing interface phase and preparation method thereof

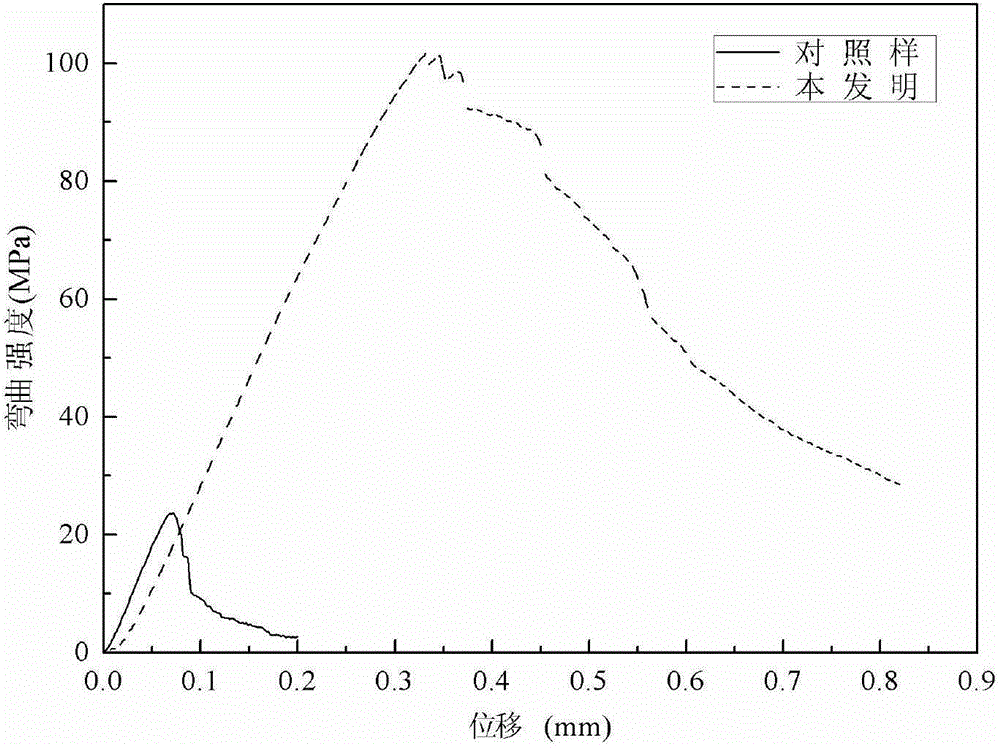

A technology of aluminum silicate fiber and oxide ceramics, which is applied in the field of aluminum silicate fiber reinforced oxide ceramics and its preparation, can solve the impact of unreported fiber surface composite material properties, poor high-temperature structural stability of composite materials, and limited composite materials. High temperature applications and other issues, to achieve the effect of improving room temperature and high temperature mechanical properties, high service temperature, and weakening interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

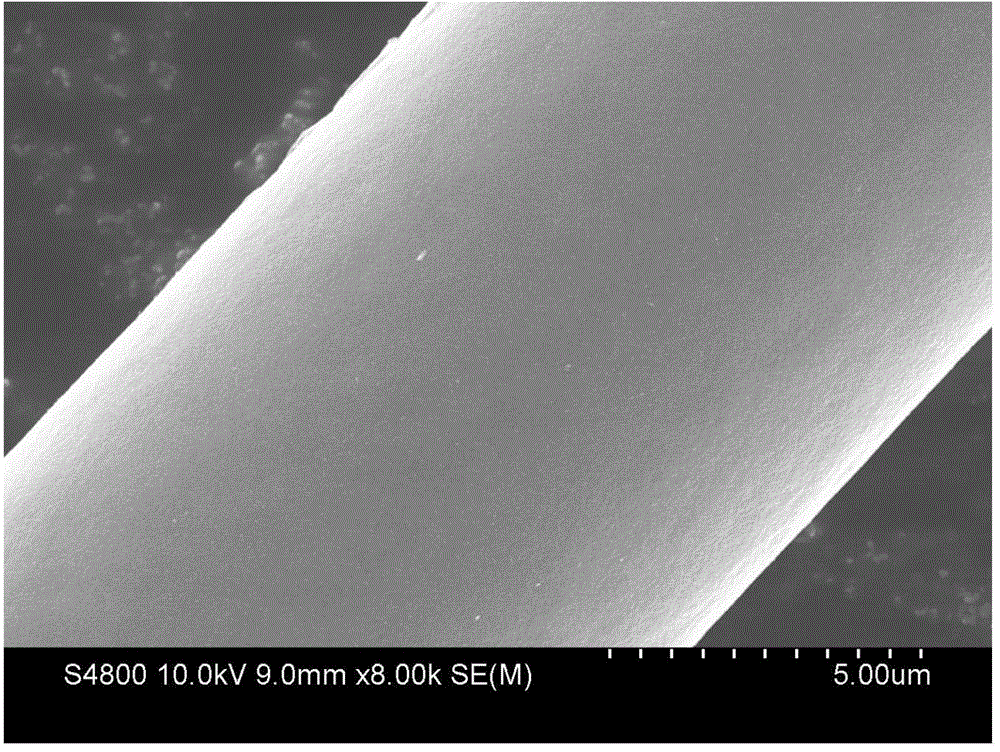

[0038] An aluminum silicate fiber-reinforced alumina ceramic containing interfacial phases of the present invention. The aluminum silicate fiber-reinforced alumina ceramic uses alumina as a matrix and three-dimensional aluminum silicate fibers as a reinforcing phase. A sacrificial carbon interface phase is formed, and the sacrificial carbon interface phase is formed by first preparing a cracked carbon coating on the surface of the three-dimensional aluminum silicate fiber fabric through a chemical vapor deposition process (CVD), and then forming after high temperature oxidation.

[0039] The method for preparing aluminum silicate fiber-reinforced alumina ceramics containing interfacial phases in this embodiment specifically includes the following steps:

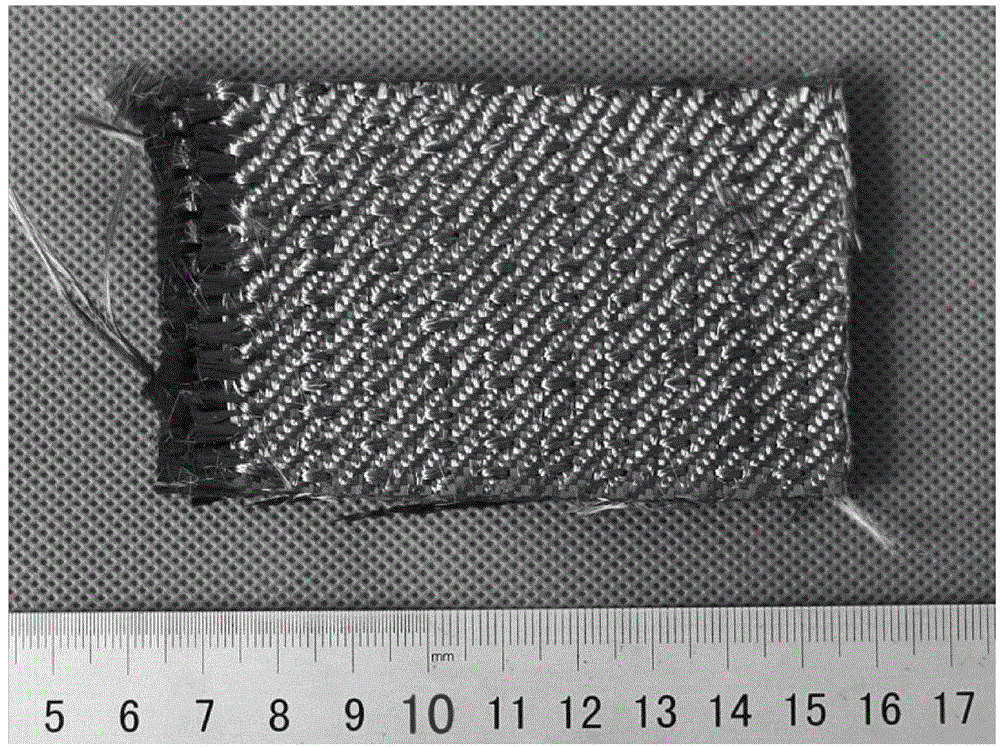

[0040] (1) Preparation of cracked carbon coating: A three-dimensional orthogonal weaving process is used to prepare aluminum silicate fiber fabric with a fiber volume fraction of 40%, and a cracked carbon coating is prepared on the...

Embodiment 2

[0049] An aluminum silicate fiber-reinforced aluminum silicate ceramic containing interfacial phases of the present invention. The aluminum silicate fiber-reinforced aluminum silicate ceramic is based on aluminum silicate, and three-dimensional aluminum silicate fibers are used as the reinforcing phase. A sacrificial carbon interface phase is formed between the phases. The sacrificial carbon interface phase is formed by first preparing a cracked carbon coating on the surface of the three-dimensional aluminum silicate fiber fabric through a chemical vapor deposition process (CVD), and then forming after high temperature oxidation.

[0050] The method for preparing aluminum silicate fiber-reinforced aluminum silicate ceramics containing interfacial phases in this embodiment specifically includes the following steps:

[0051] (1) Preparation of pyrolysis carbon coating: A three-dimensional orthogonal weaving process is used to prepare aluminum silicate fiber fabric with a fiber volume ...

Embodiment 3

[0059] An aluminum silicate fiber-reinforced mullite ceramic containing interfacial phases of the present invention. The aluminum silicate fiber-reinforced mullite ceramic uses mullite as a matrix and three-dimensional aluminum silicate fibers as a reinforcing phase. A sacrificial carbon interface phase is formed between the phases. The sacrificial carbon interface phase is formed by first preparing a cracked carbon coating on the surface of the three-dimensional aluminum silicate fiber fabric through a chemical vapor deposition process (CVD), and then forming after high temperature oxidation.

[0060] The method for preparing the aluminum silicate fiber-reinforced mullite ceramics containing interfacial phases in this embodiment specifically includes the following steps:

[0061] (1) Preparation of cracked carbon coating: A three-dimensional orthogonal weaving process is used to prepare aluminum silicate fiber fabric with a fiber volume fraction of 38%, and a cracked carbon coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com