Patents

Literature

838 results about "Chemical vapors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

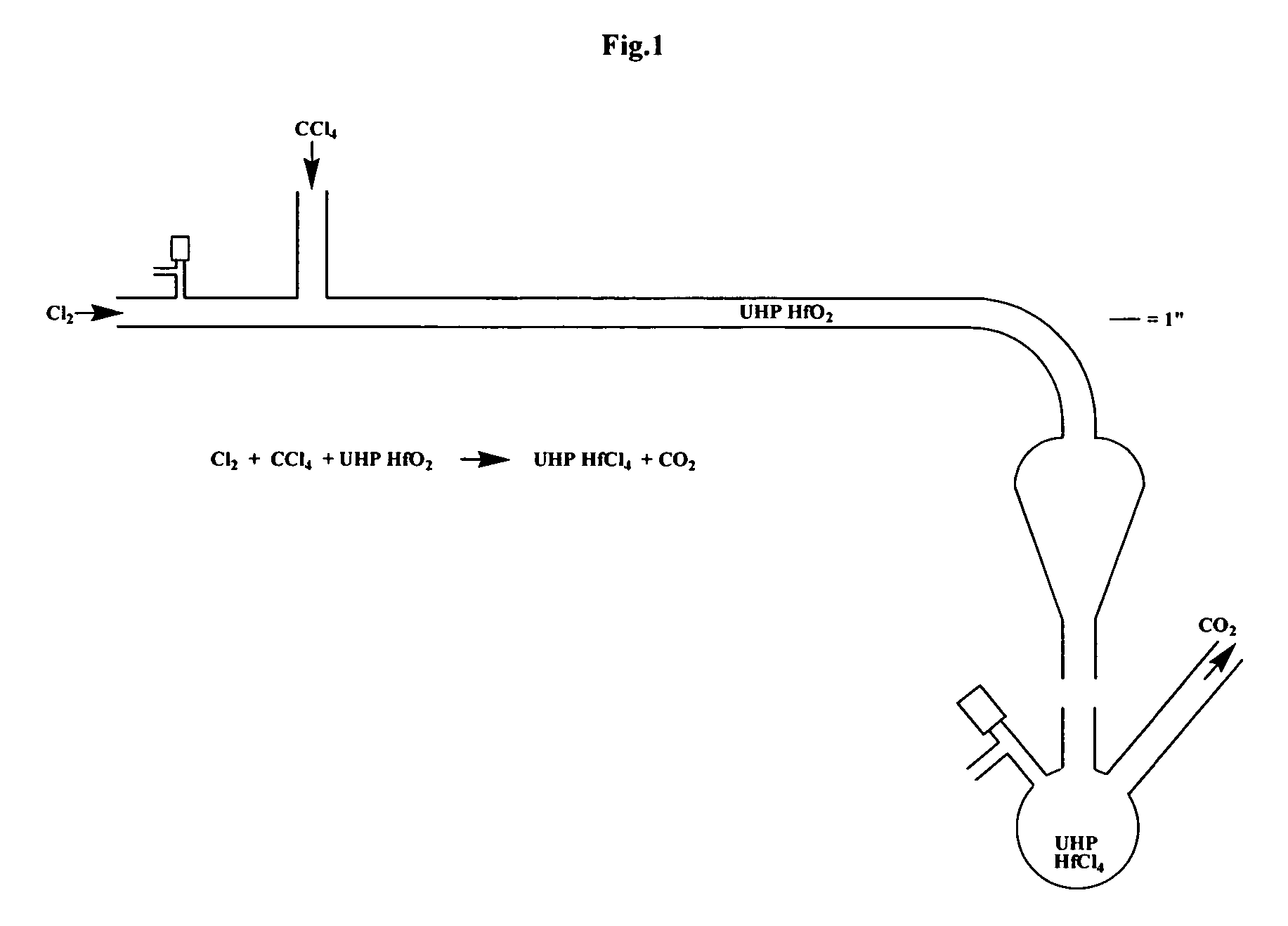

Low zirconium hafnium halide compositions

InactiveUS20050214458A1Improve smoothnessShort incubation timeSemiconductor/solid-state device manufacturingTitanium organic compoundsGas phaseHafnium

This invention relates to hafnium halide compositions having a zirconium concentration of less than about 1000 parts per million, a process for producing the hafnium halide compositions having a zirconium concentration of less than about 1000 parts per million, organometallic compound precursors, a process for producing the organometallic compound precursors, and a method for producing a film or coating from the organometallic compound precursors. The organometallic compounds are useful in semiconductor applications as chemical vapor or atomic layer deposition precursors for film depositions.

Owner:PRAXAIR INC

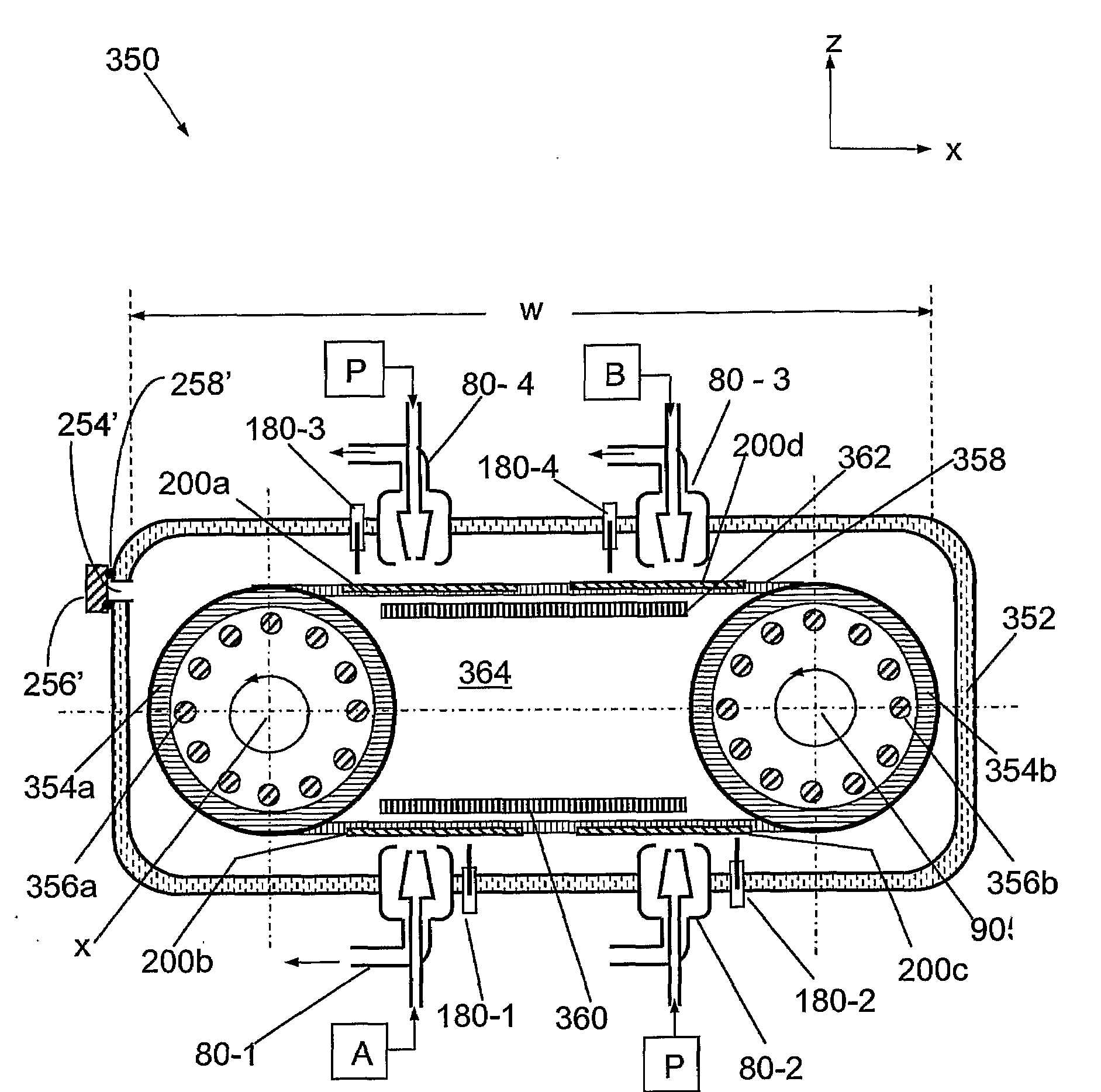

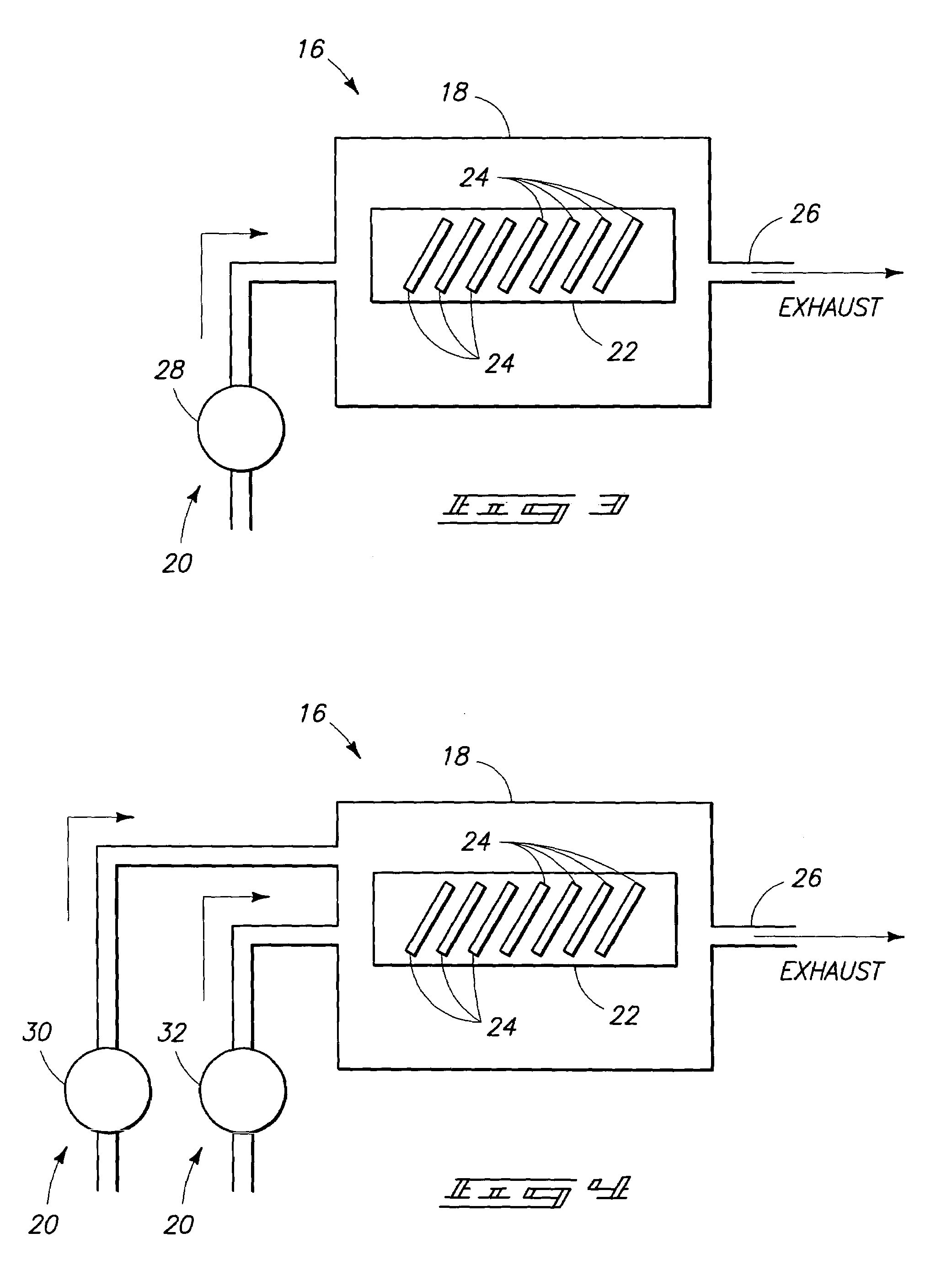

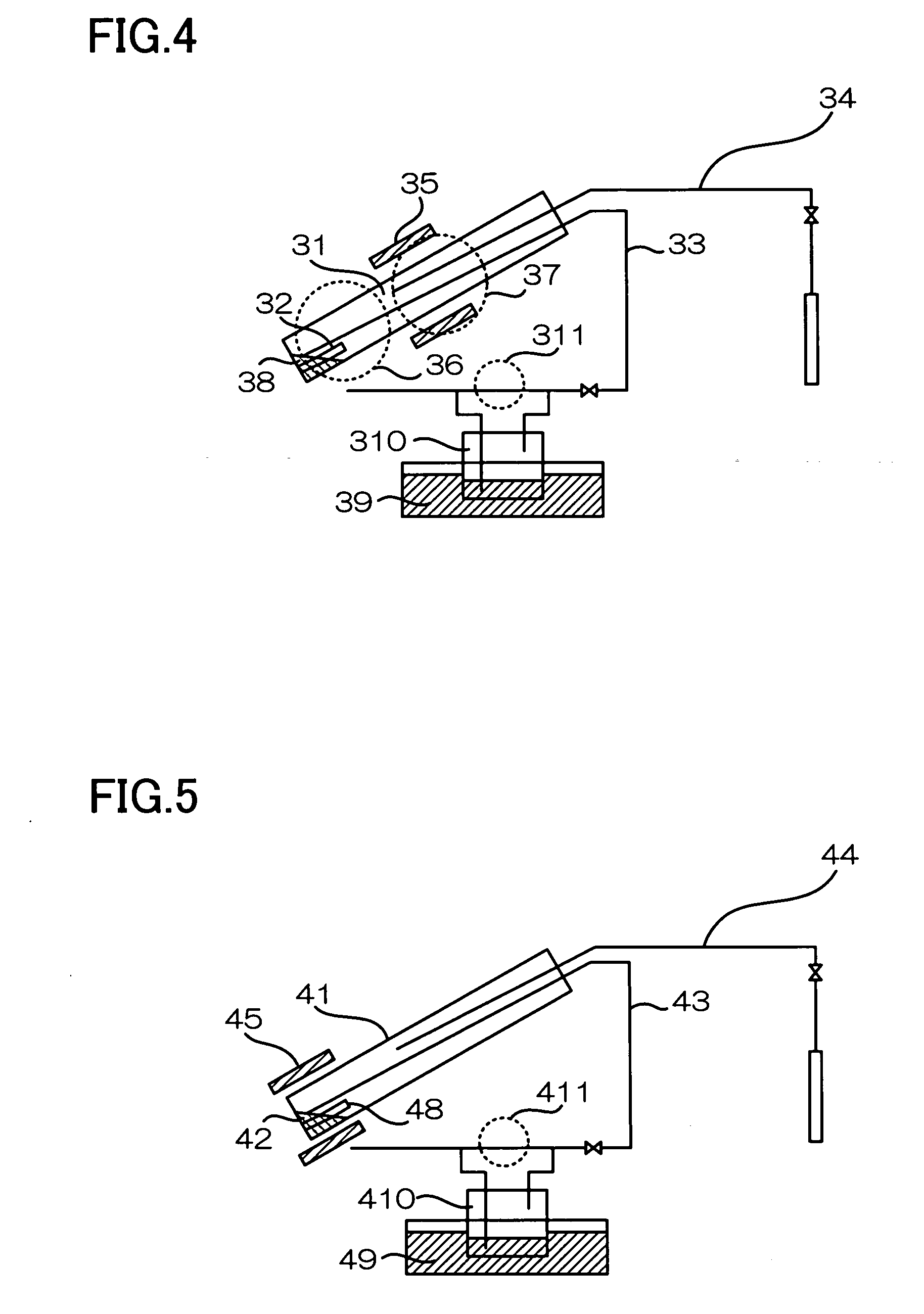

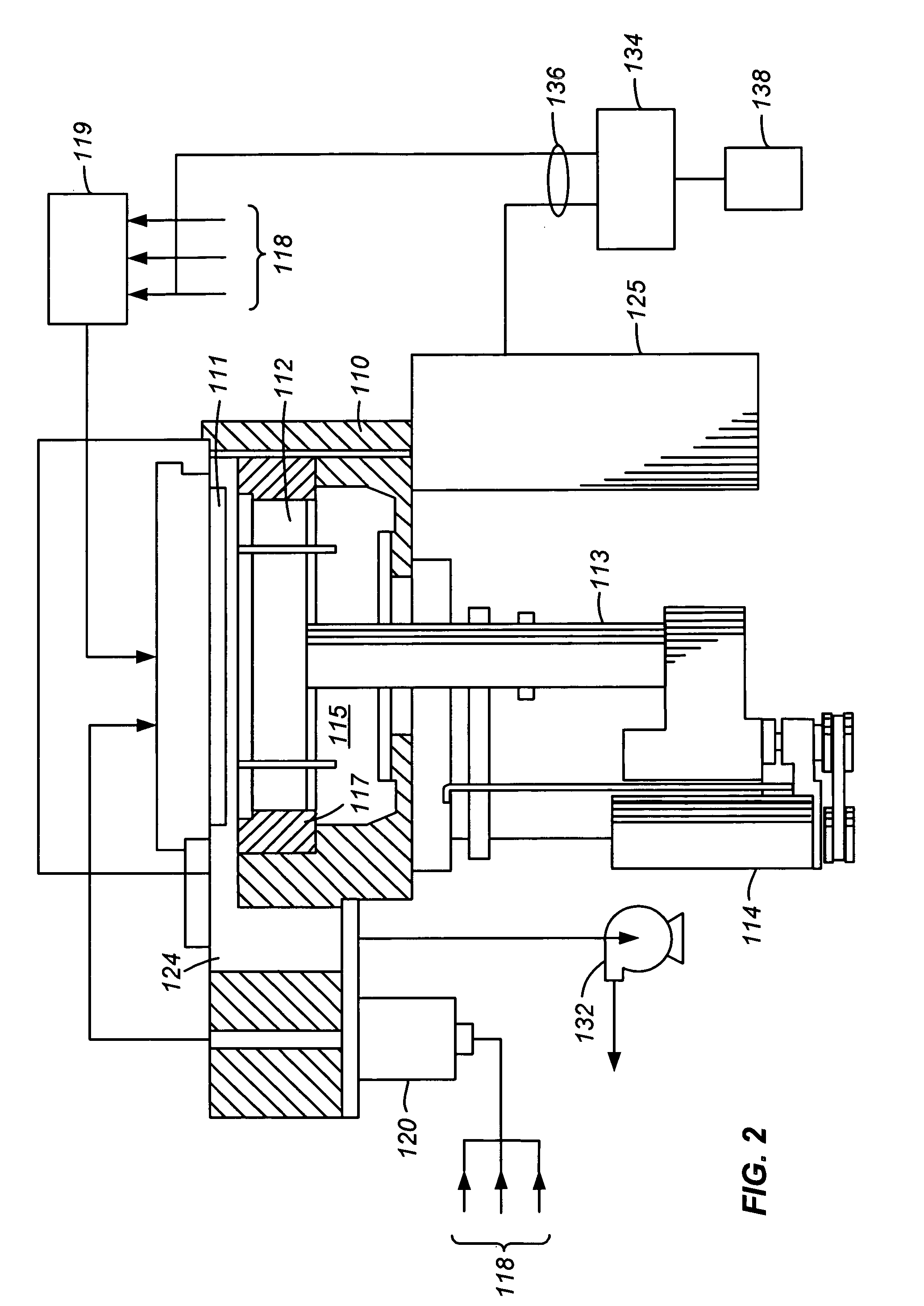

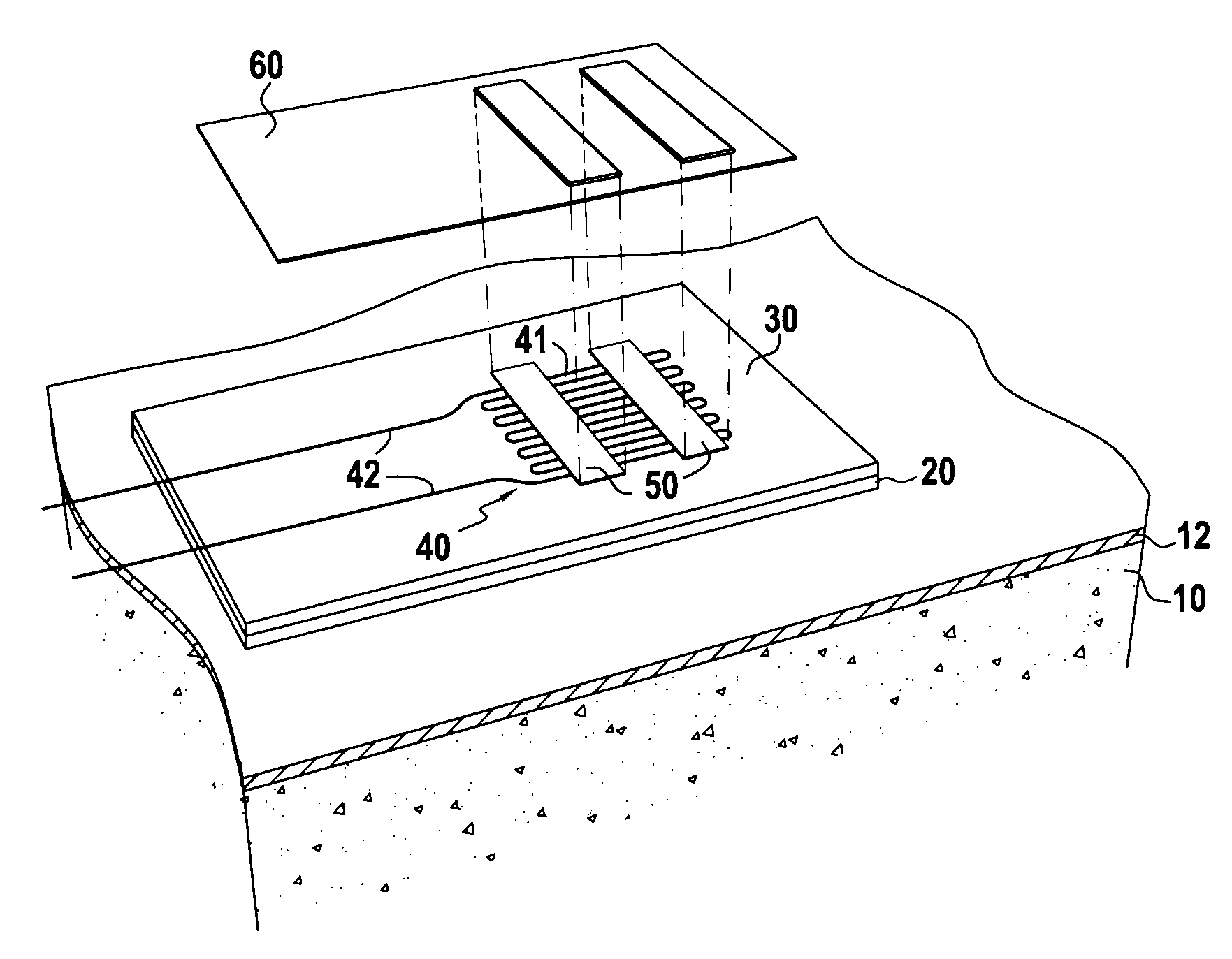

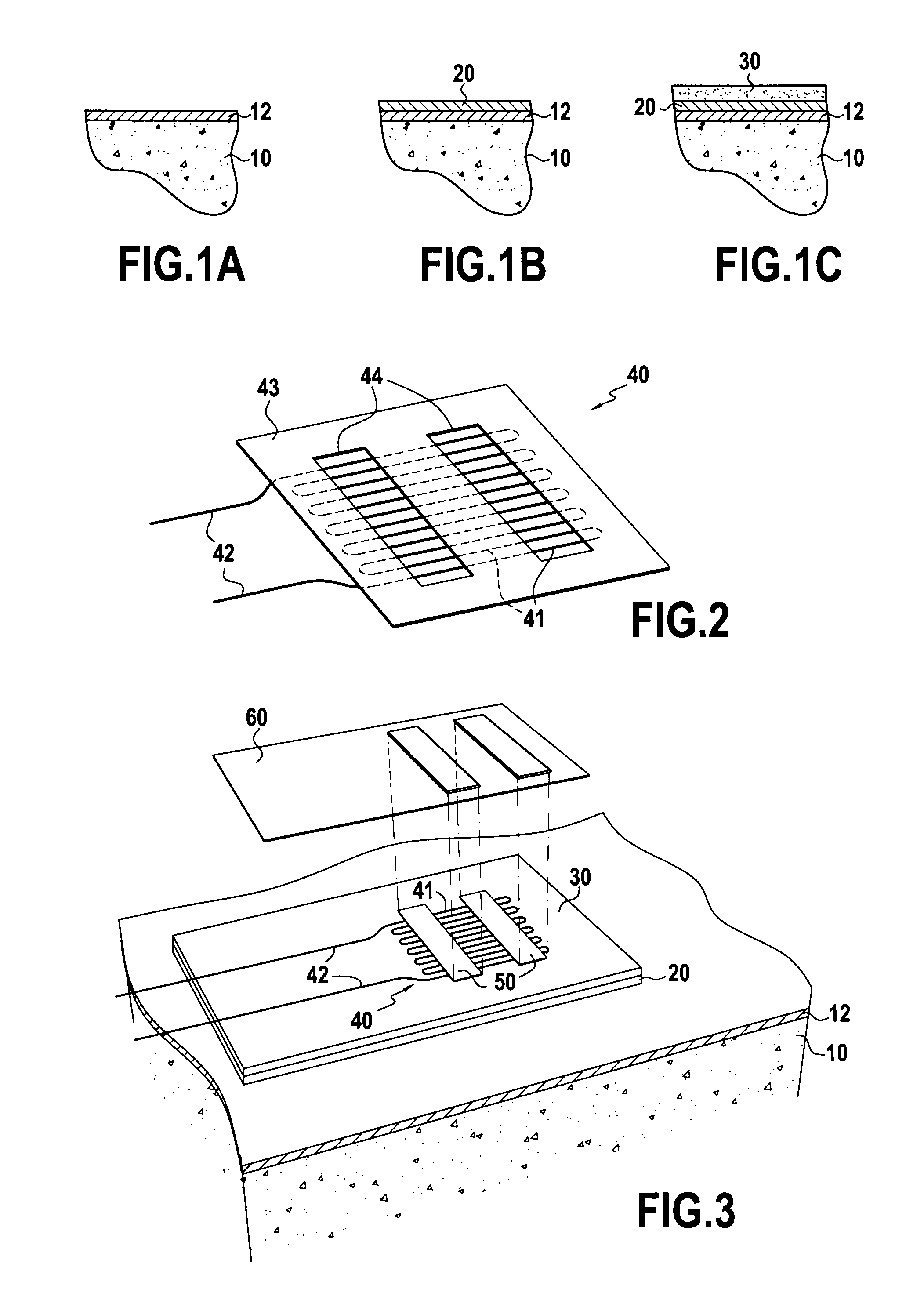

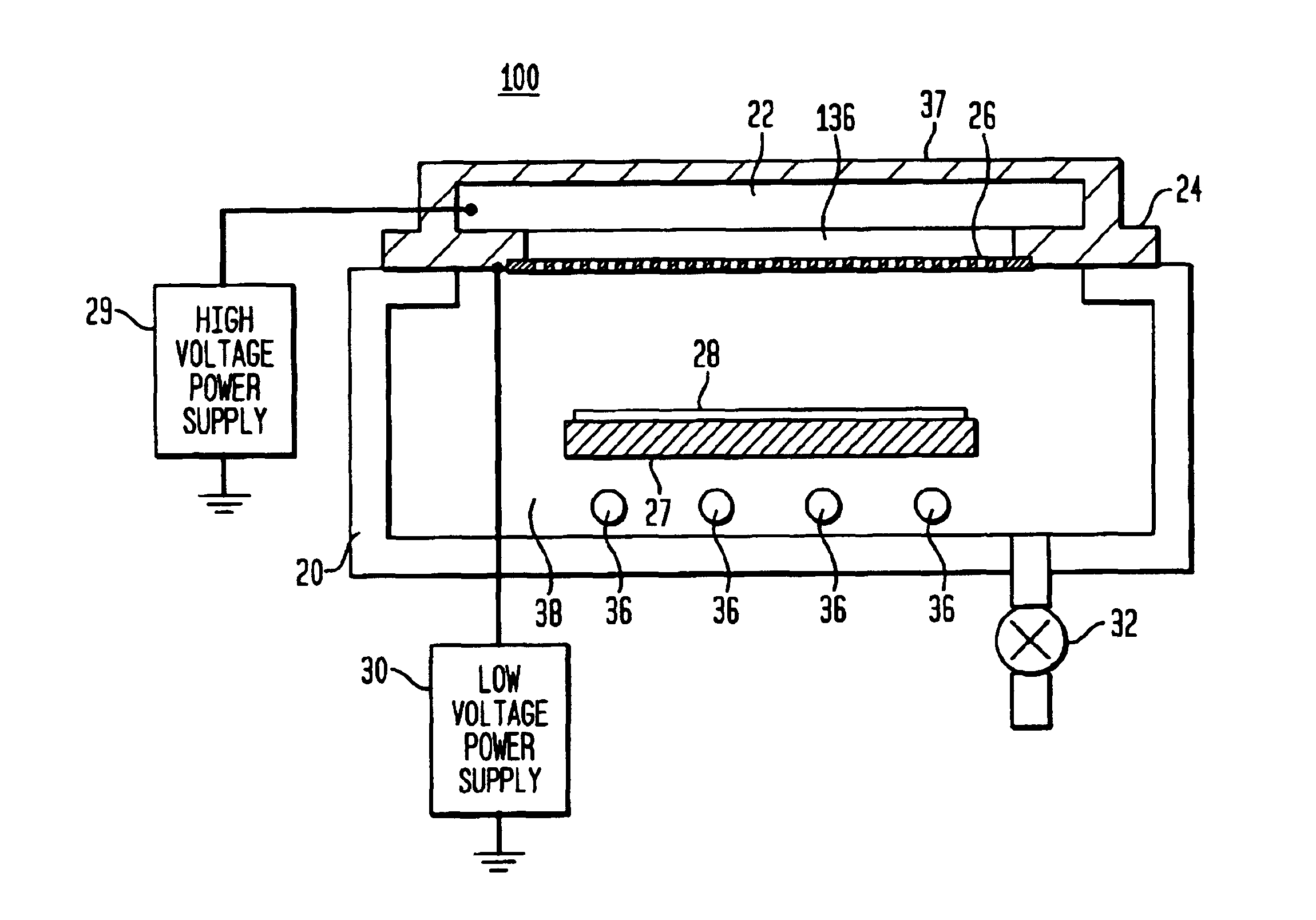

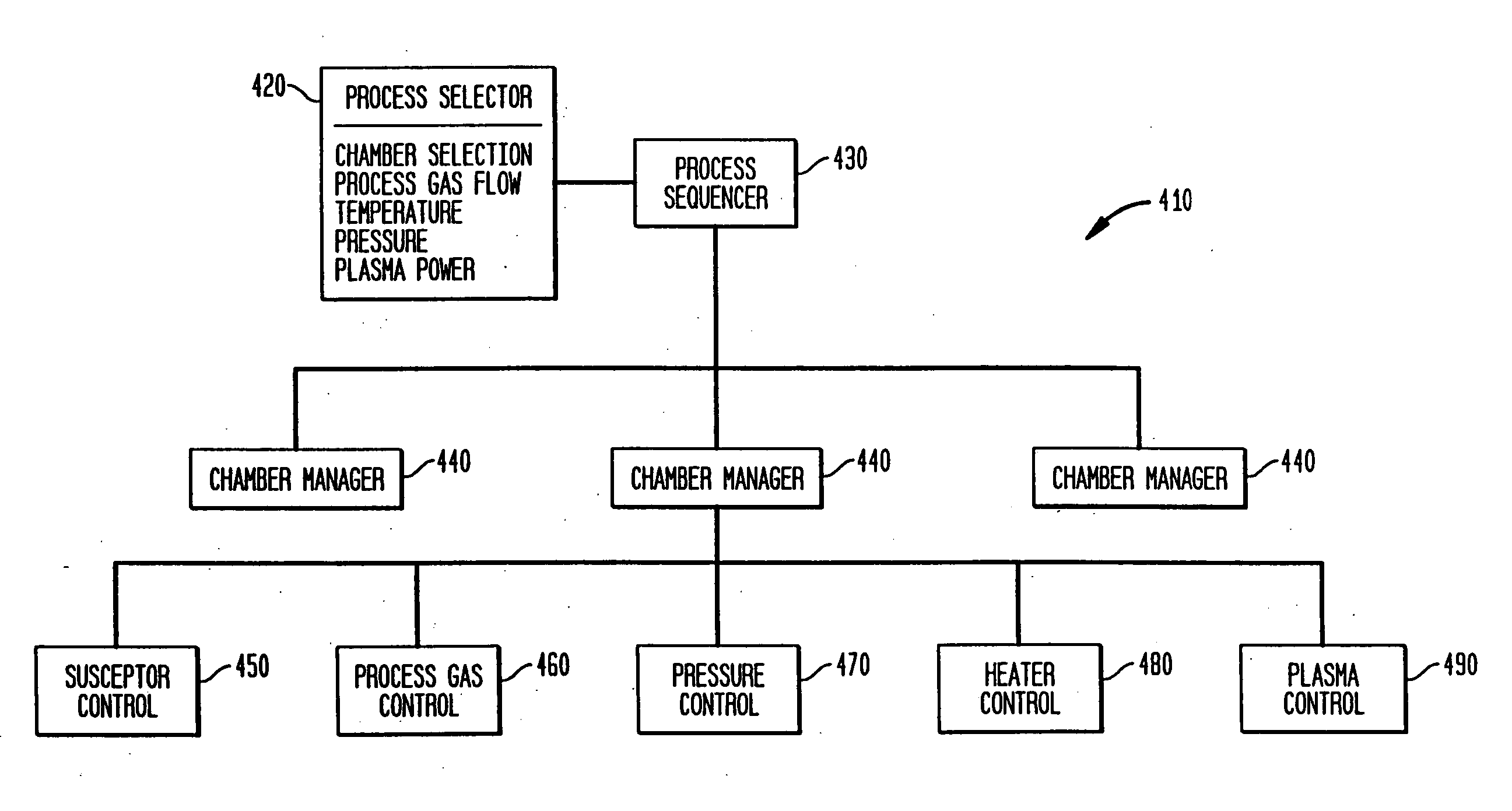

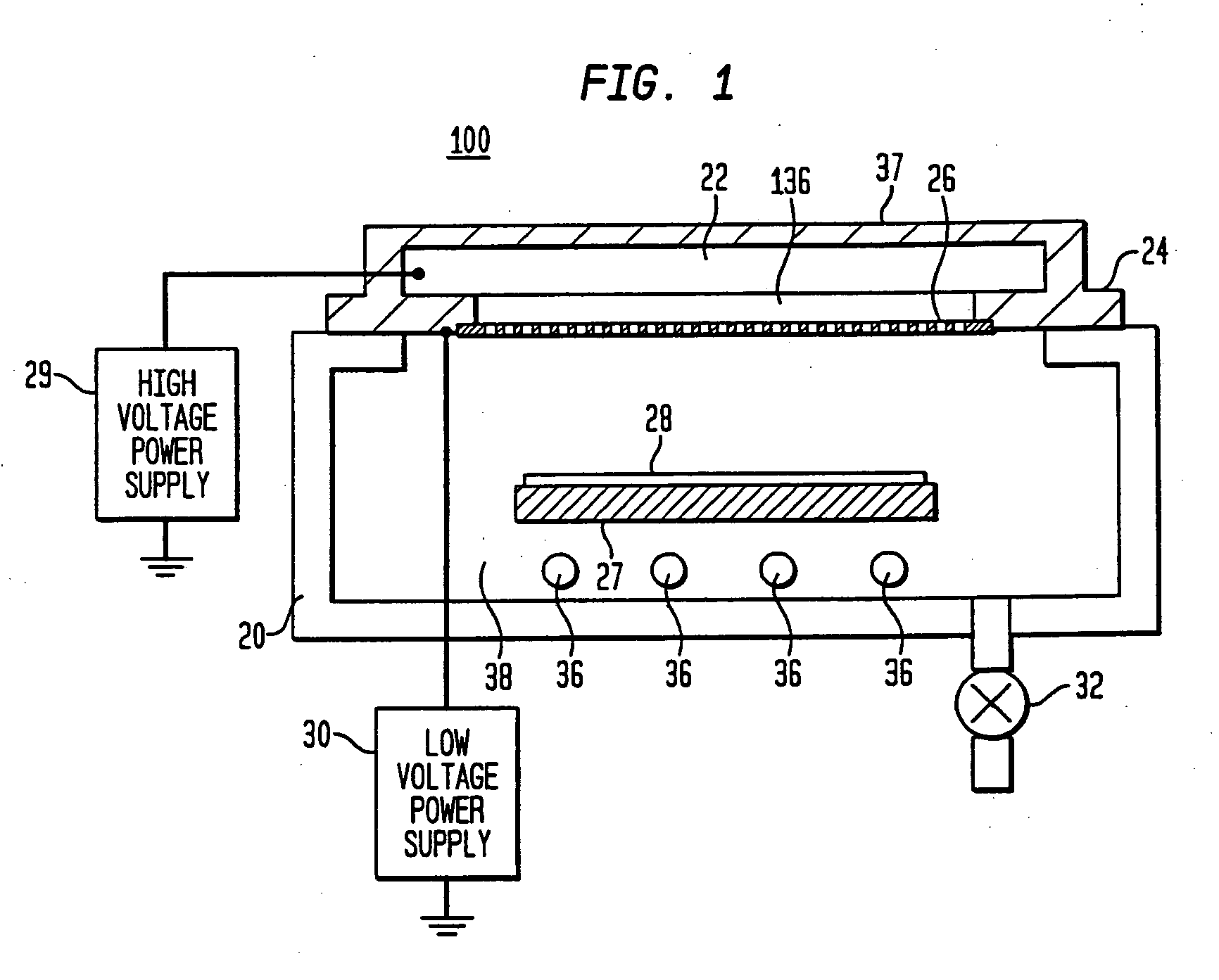

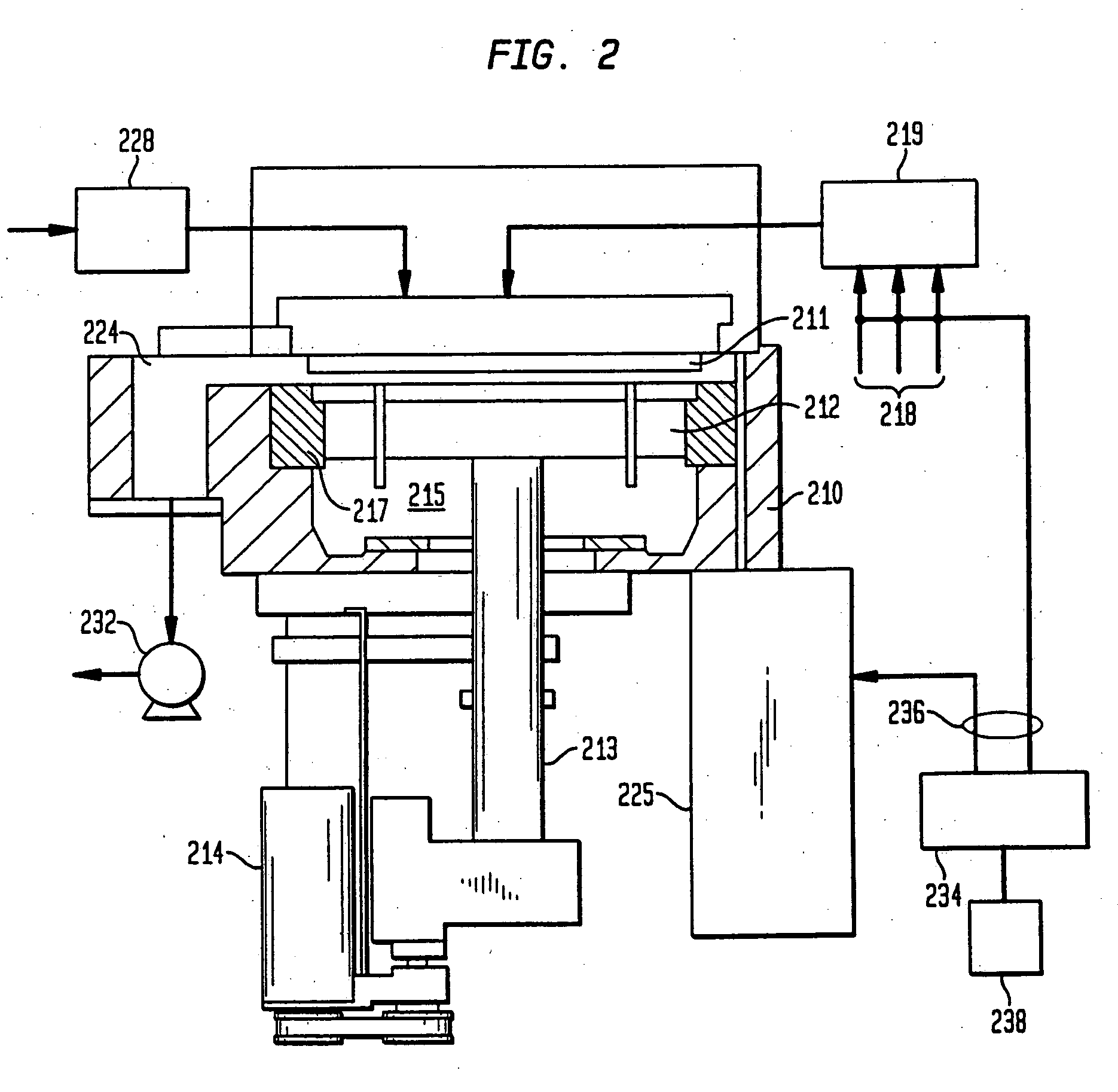

Apparatus and method for large area multi-layer atomic layer chemical vapor processing of thin films

An apparatus and method for large area high speed atomic layer chemical vapor processing wherein continuous and alternating streams of reactive and inert gases are directed towards a co-axially mounted rotating cylindrical susceptor from a plurality of composite nozzles placed around the perimeter of the processing chamber. A flexible substrate is mounted on the cylindrical susceptor. In one embodiment, the process reactor has four composite injectors arranged substantially parallel to the axis of rotation of the cylindrical susceptor. In the other embodiment, the susceptor cross section is a polygon with a plurality of substrates mounted on its facets. The reactor can be operated to process multiple flexible or flat substrates with a single atomic layer precision as well as high-speed chemical vapor processing mode. The atomic layer chemical vapor processing system of the invention also has provisions to capture unused portion of injected reactive chemical precursors downstream.

Owner:GADGIL PRASAD

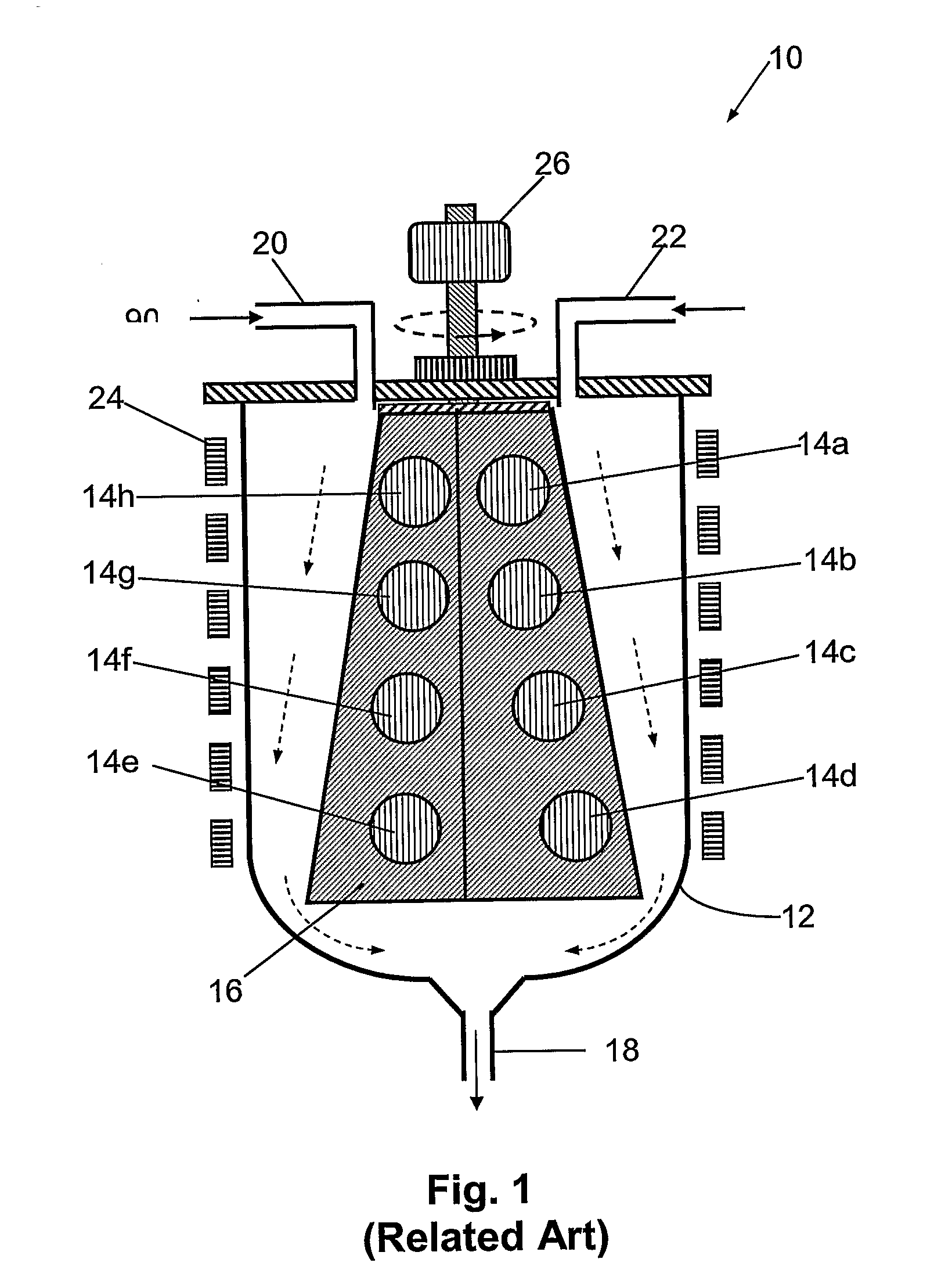

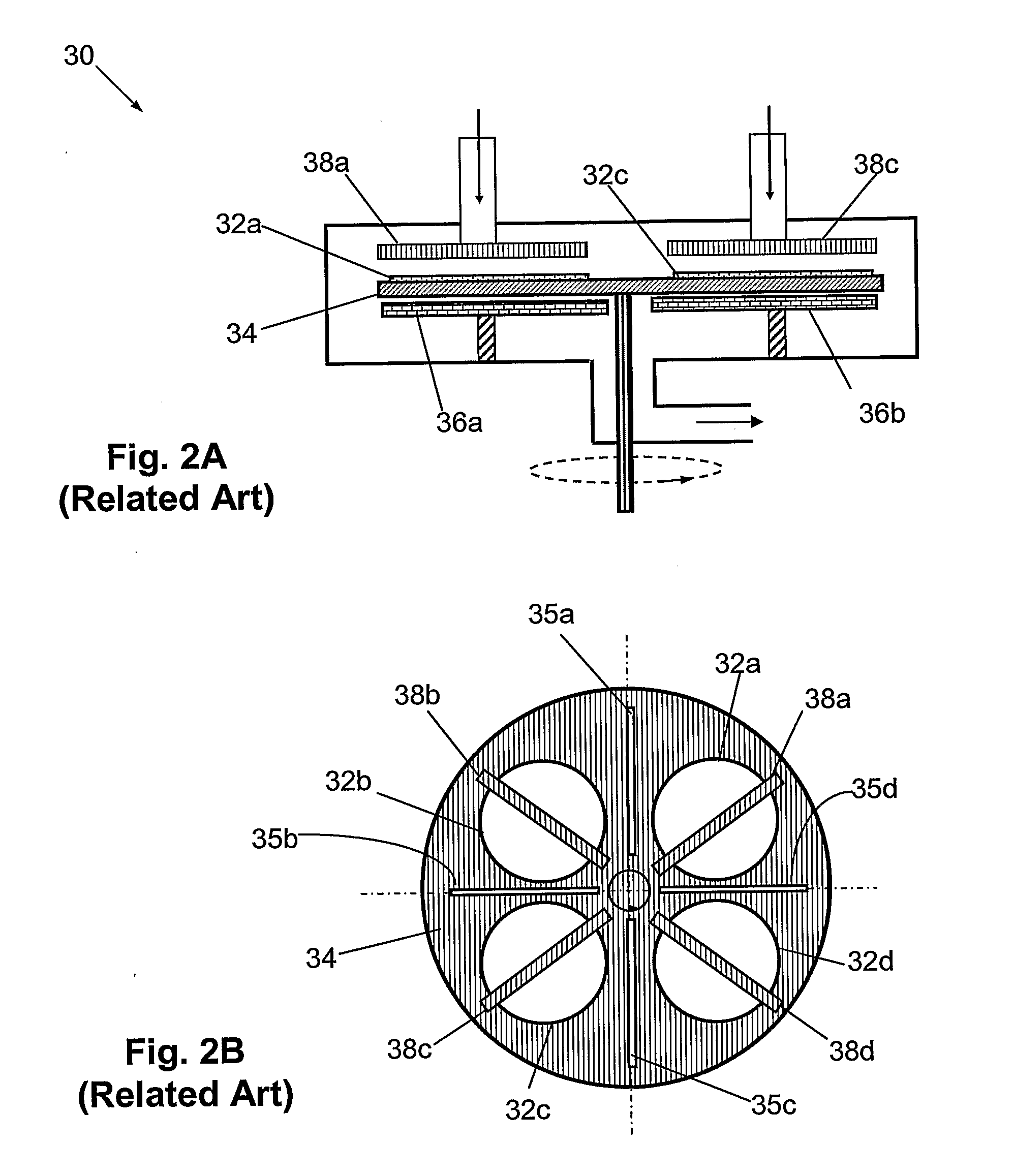

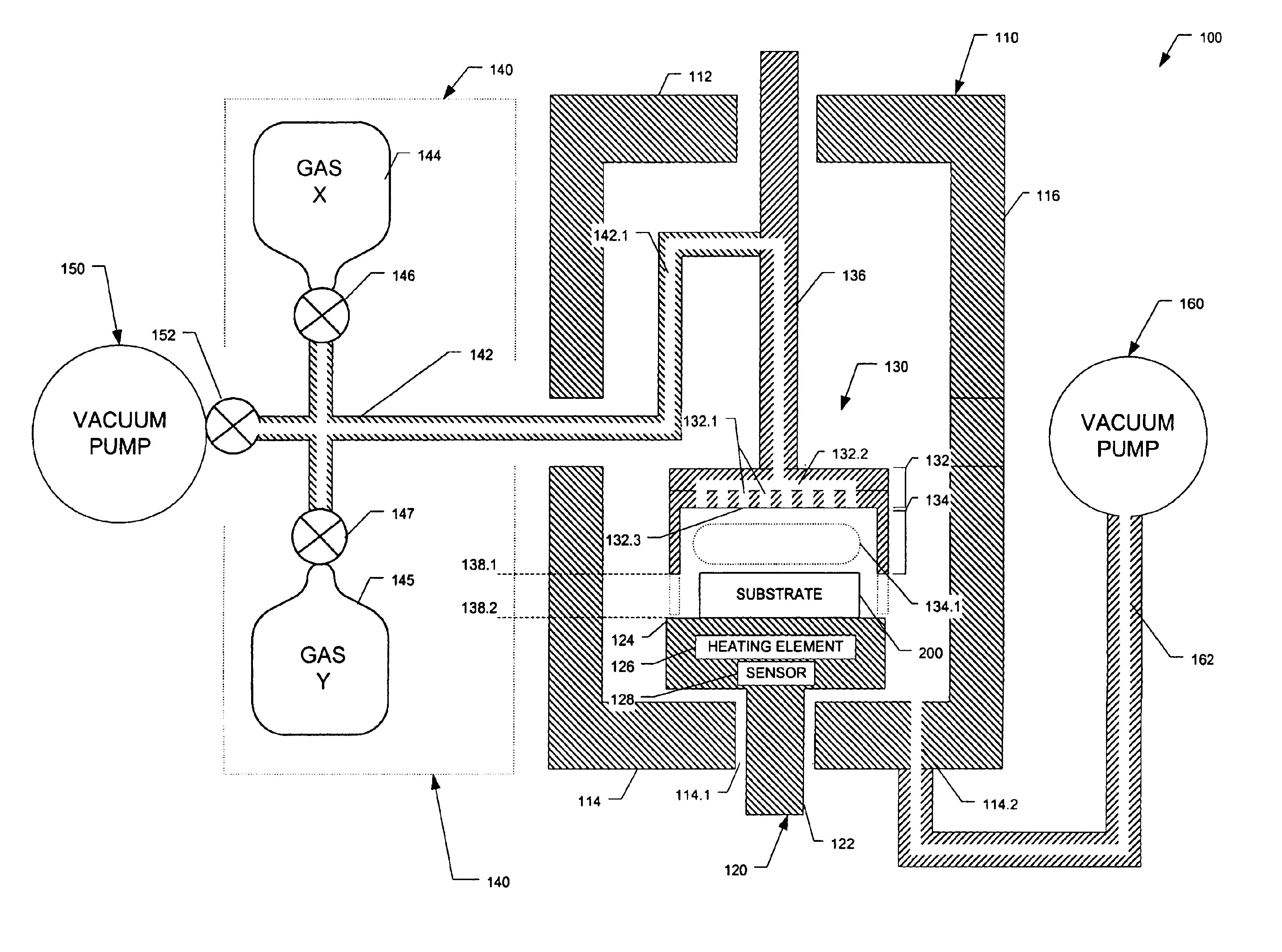

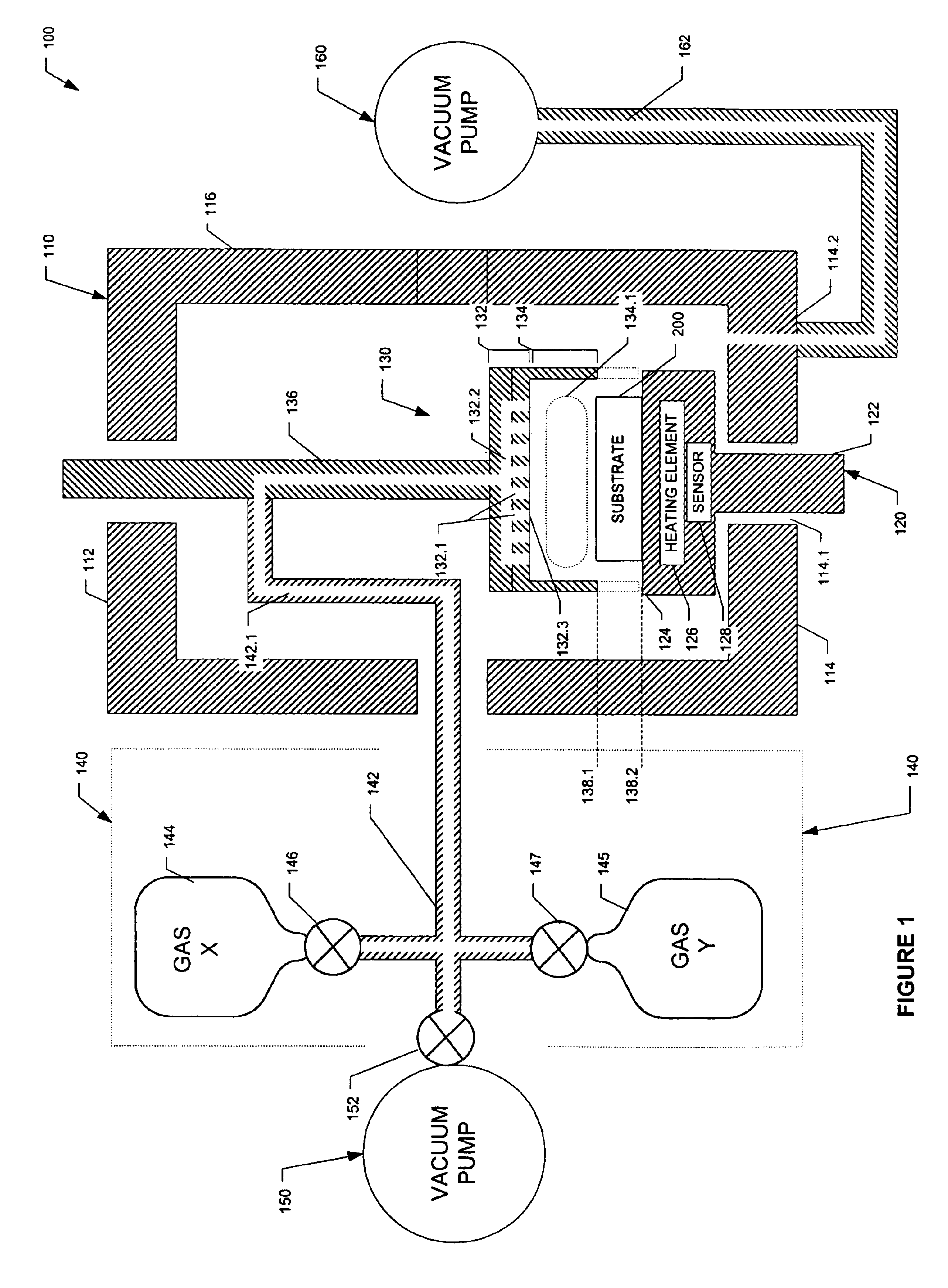

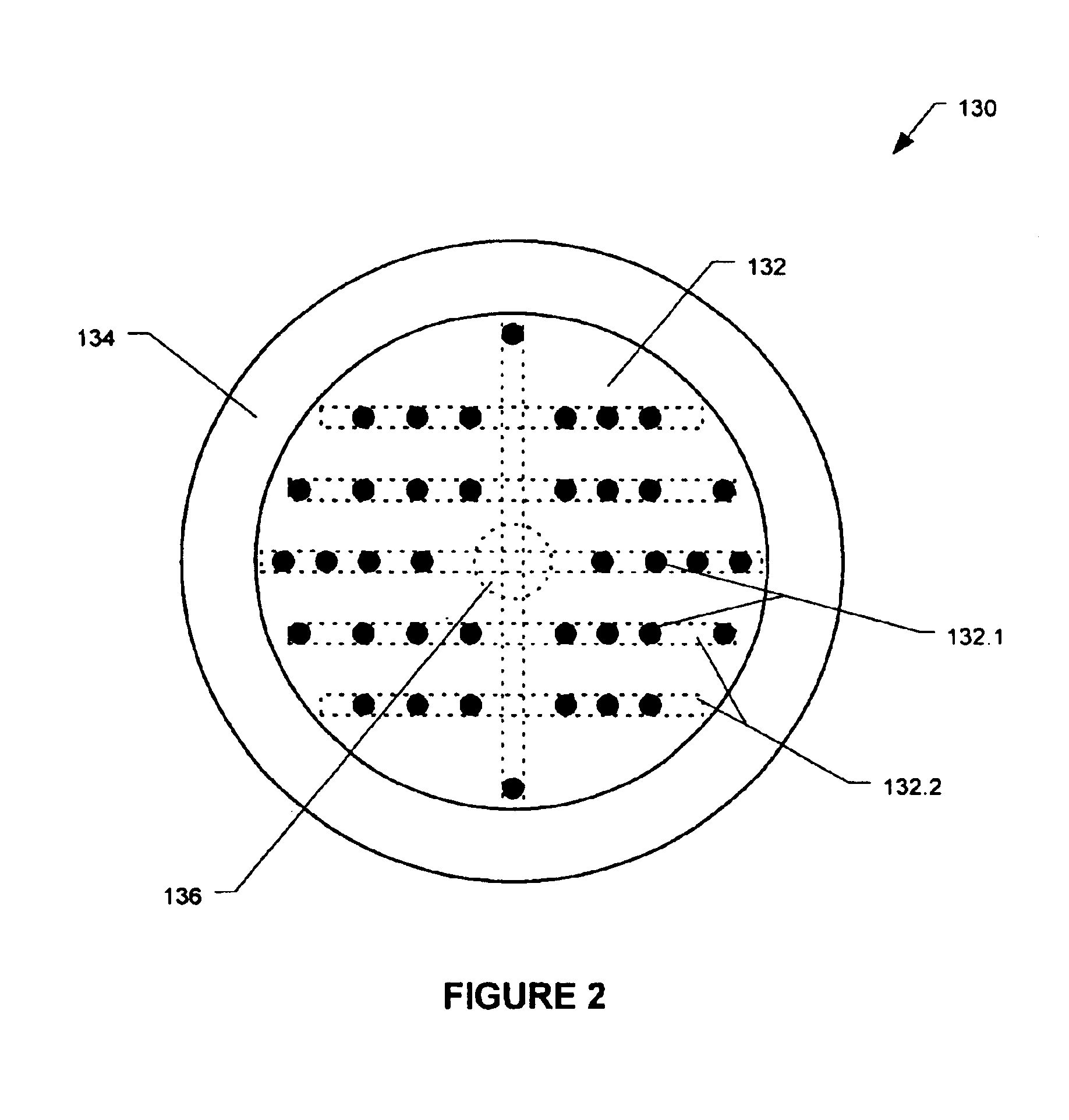

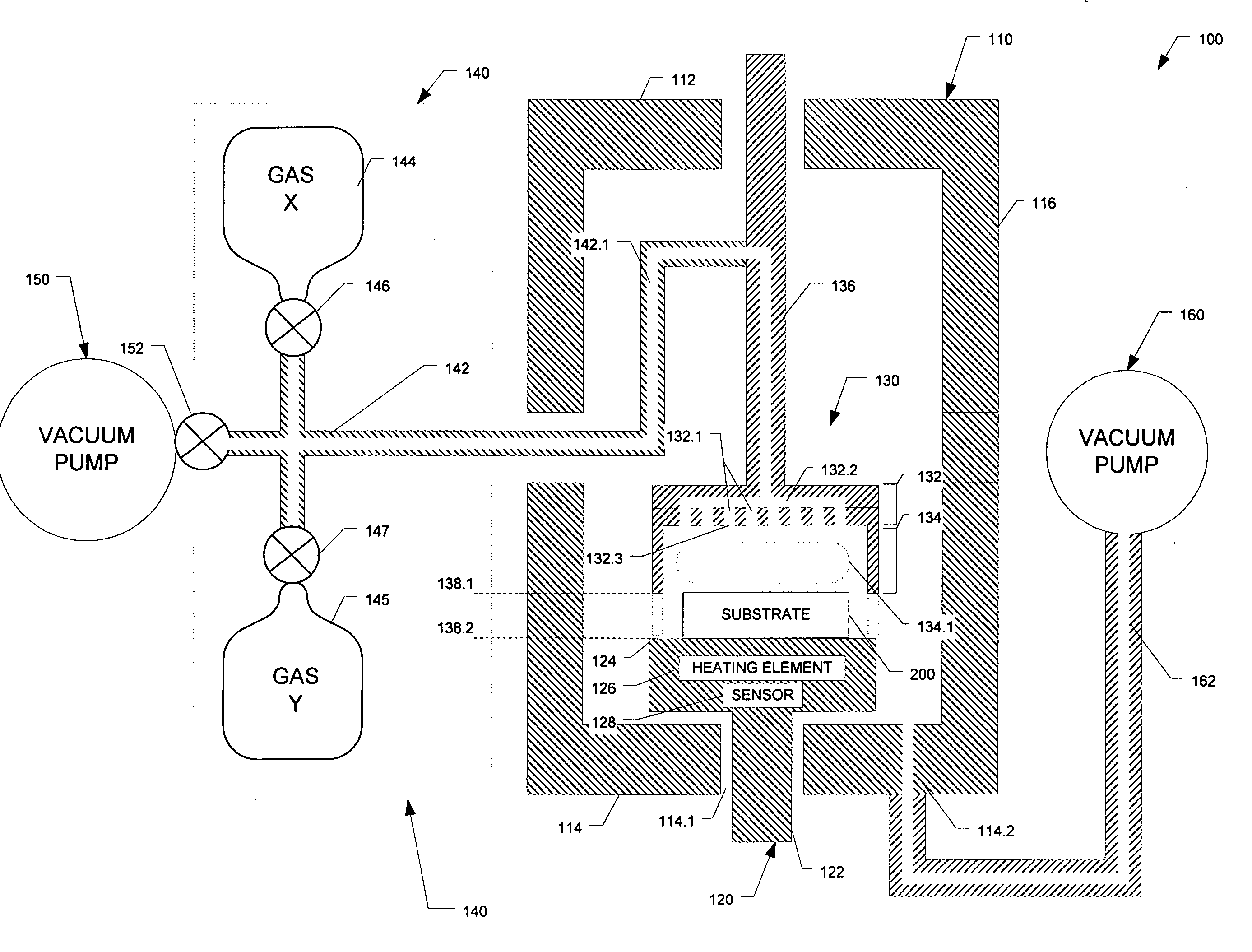

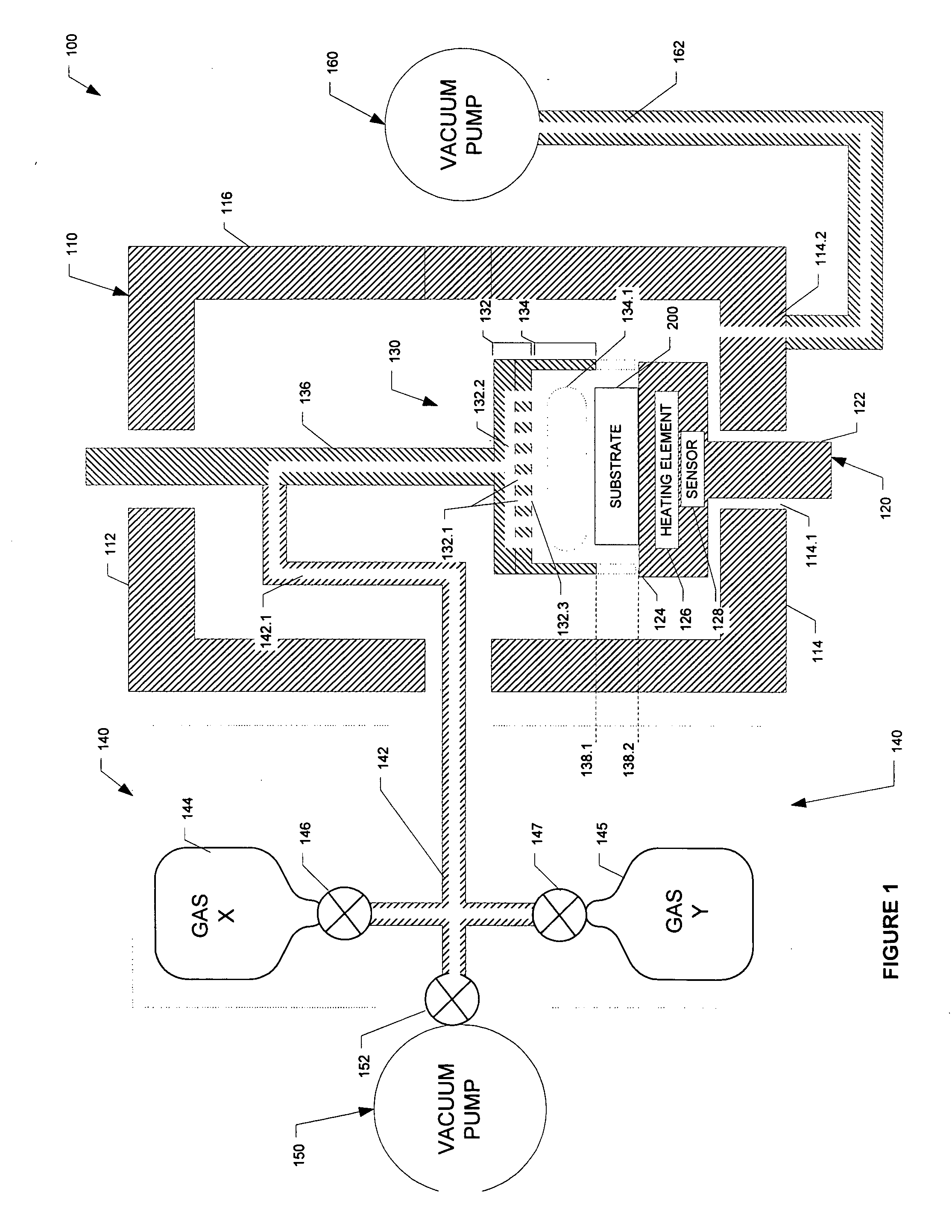

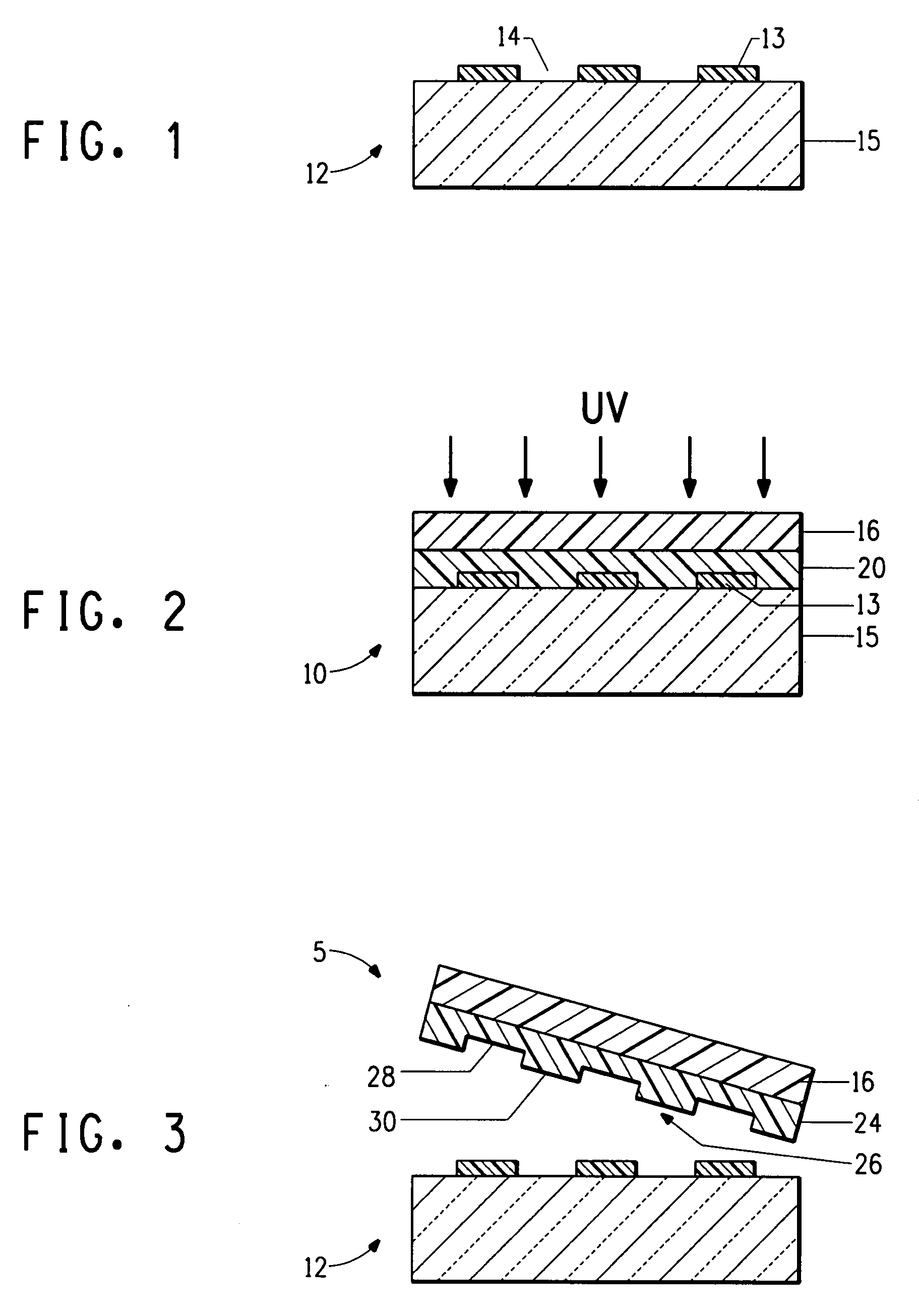

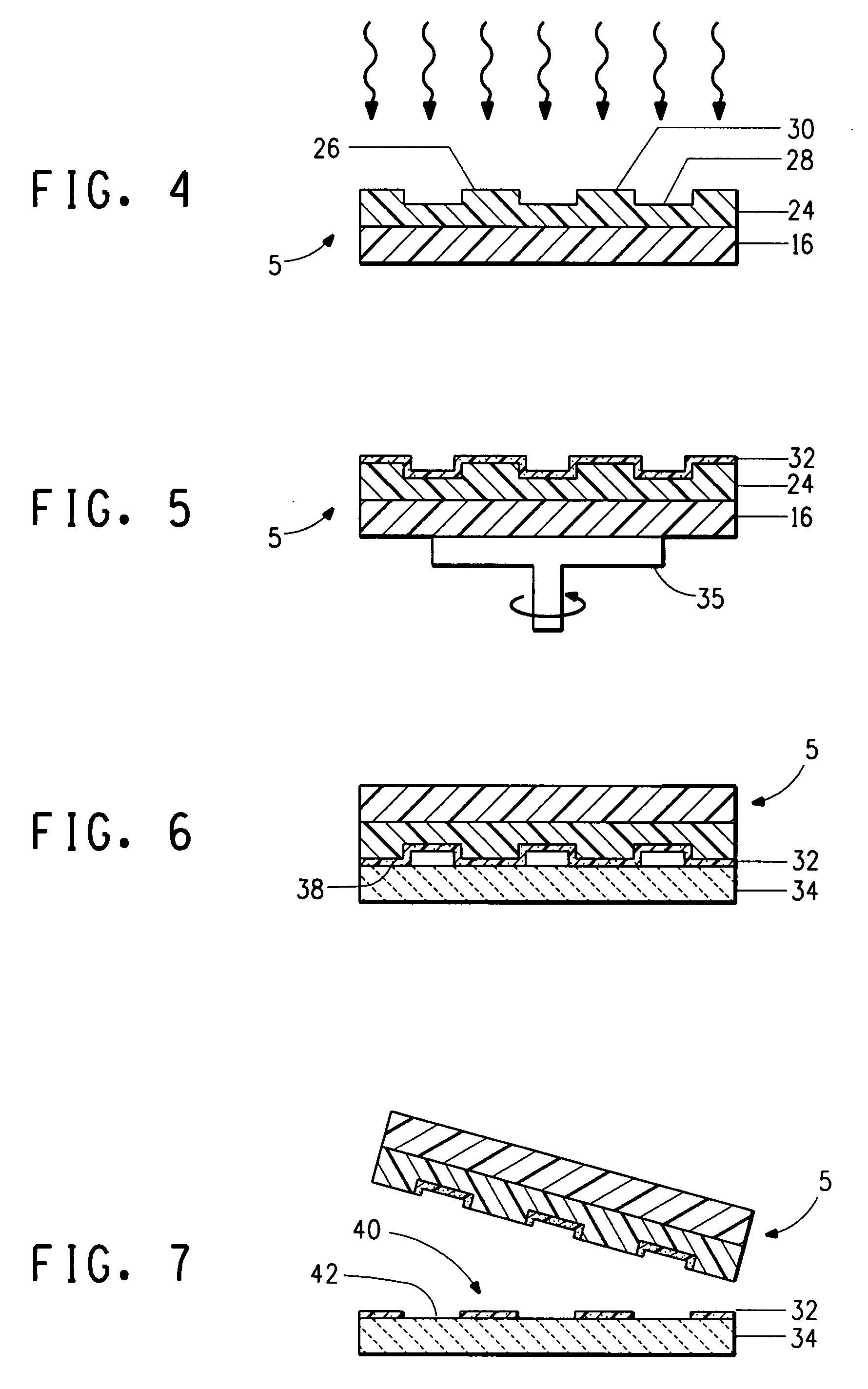

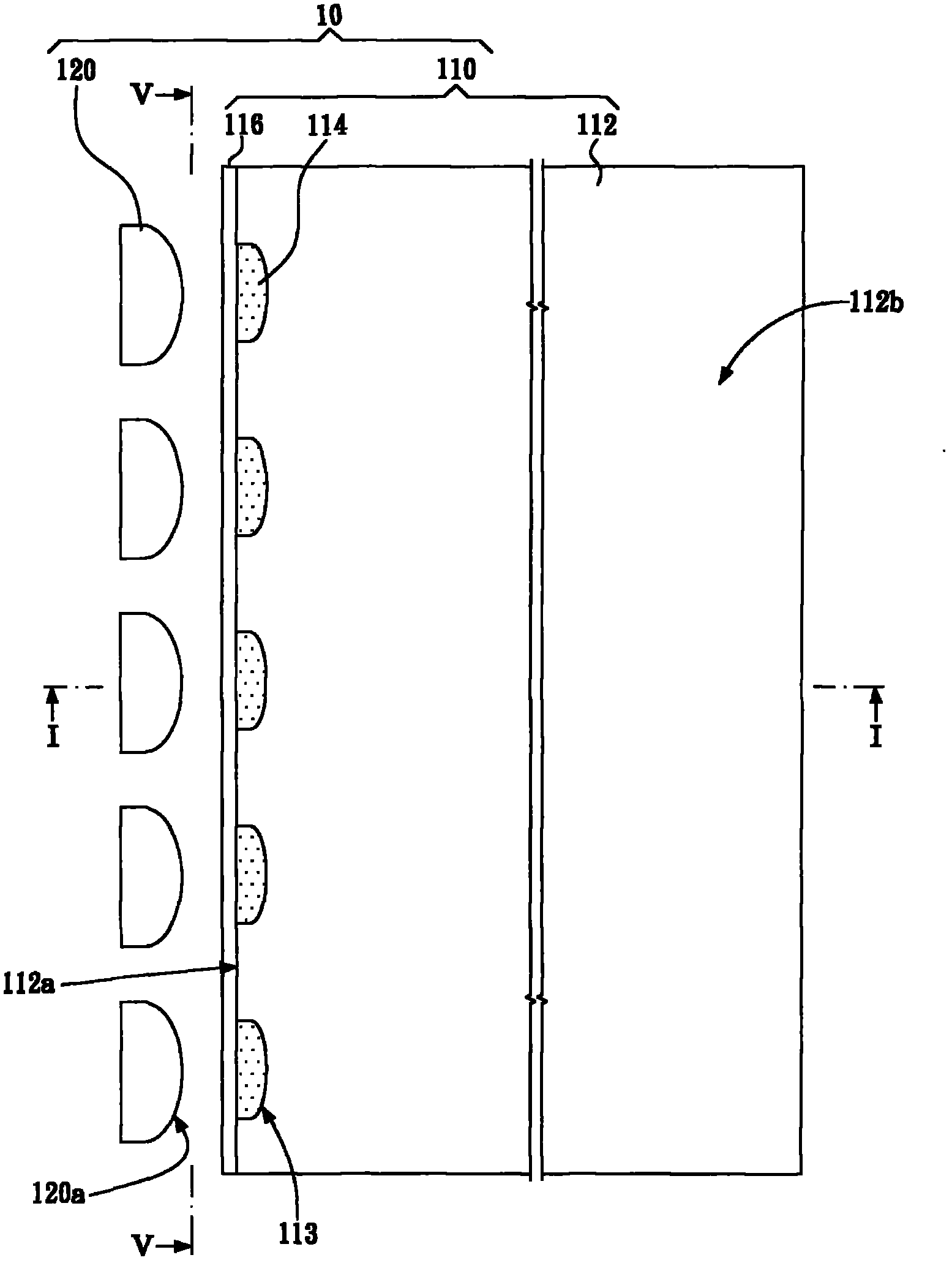

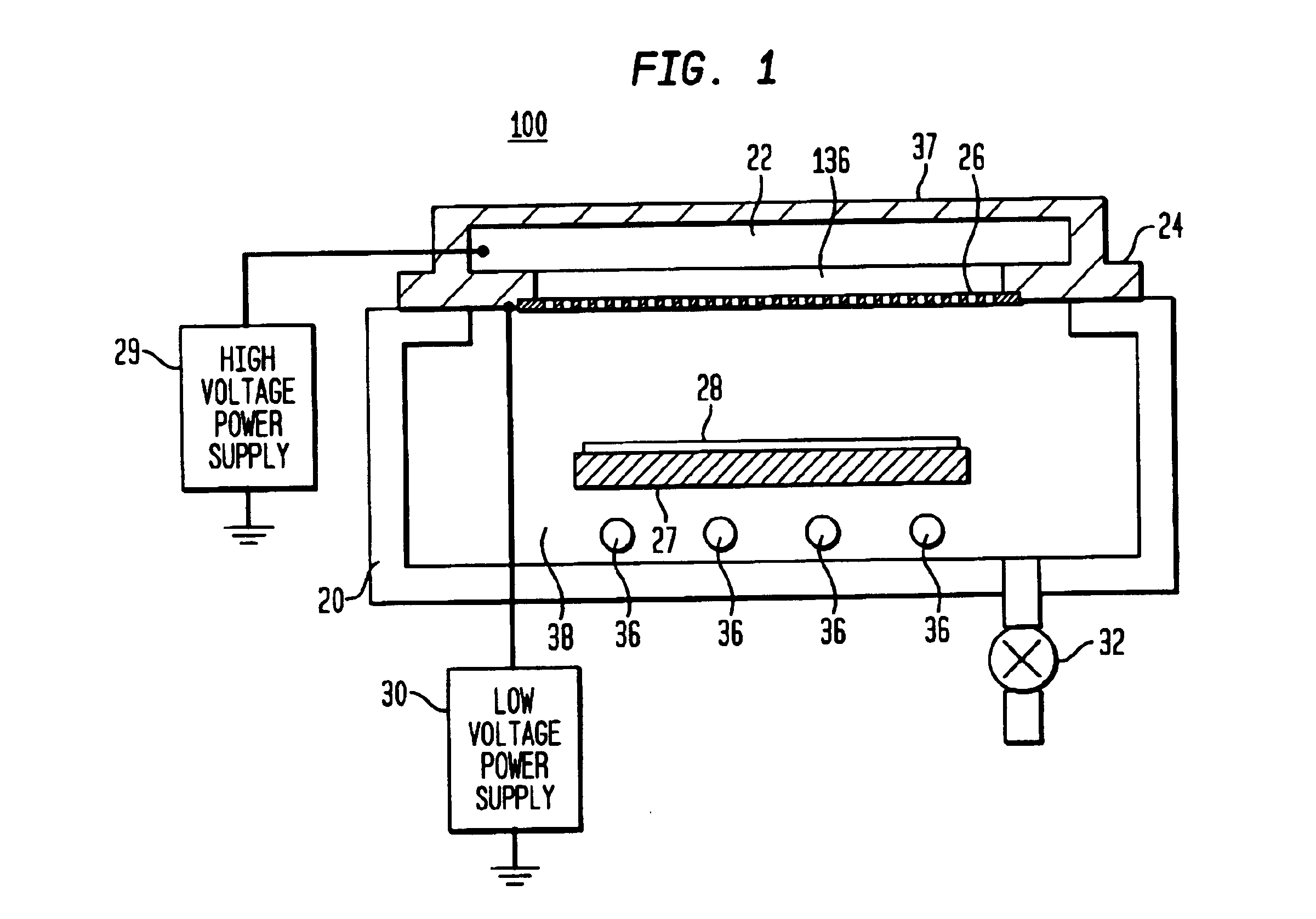

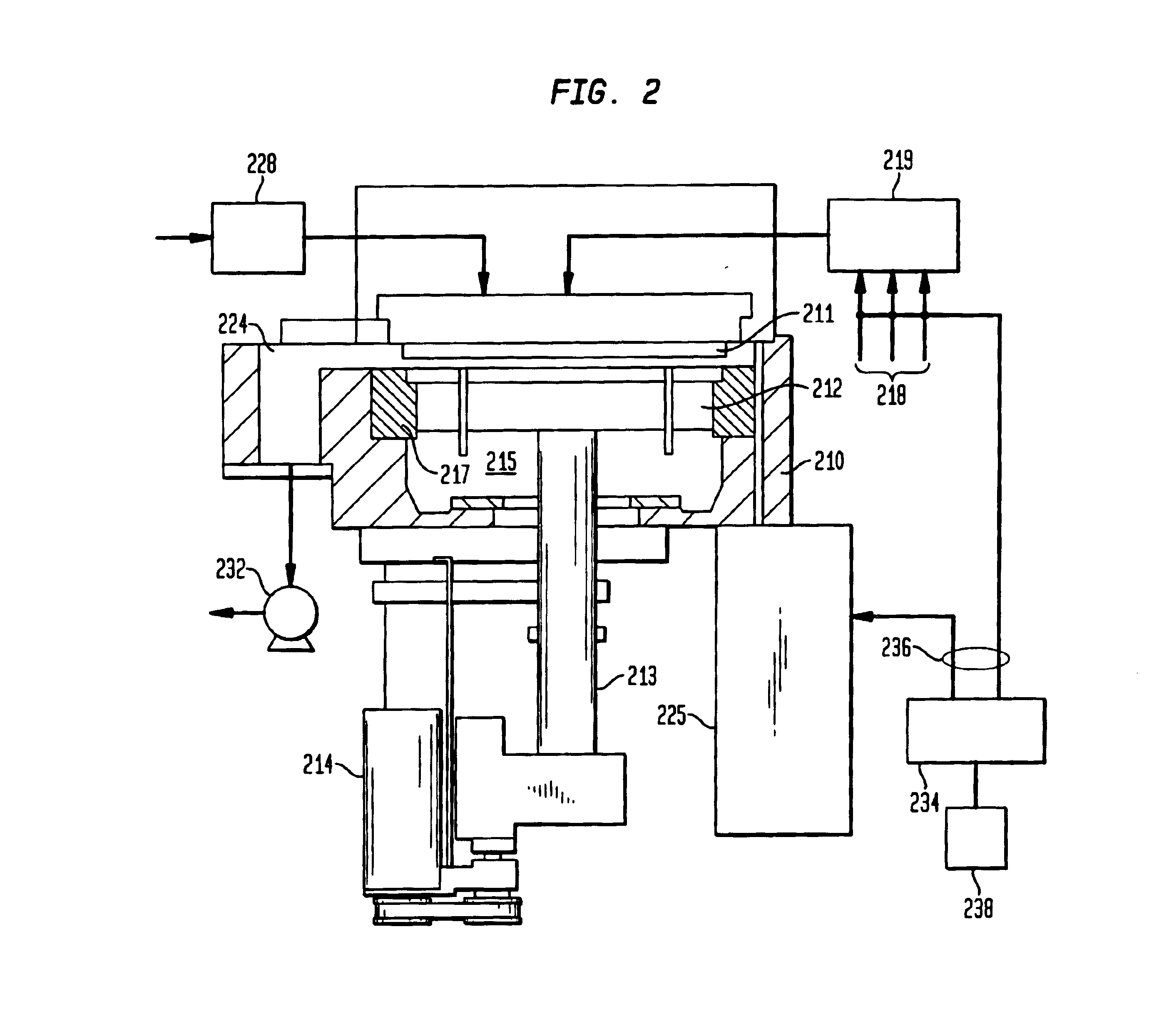

Methods, systems, and apparatus for uniform chemical-vapor depositions

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common technique for forming layers is called chemical-vapor deposition (CVD.) Conventional CVD systems not only form layers that have non-uniform thickness, but also have large chambers that make the CVD process wasteful and slow. Accordingly, the inventor devised new CVD systems, methods, and apparatuses. One exemplary CVD system includes an outer chamber, a substrate holder, and a unique gas-distribution fixture. The fixture includes a gas-distribution surface having holes for dispensing a gas and a gas-confinement member that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which not only facilitates depositions of more uniform thickness, but also saves gas and speeds up the deposition process.

Owner:MICRON TECH INC

Semiconductor processing methods of chemical vapor depositing SiO2 on a substrate

InactiveUS6974780B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction intermediateChemical vapor deposition

Owner:MICRON TECH INC

Methods, systems, and apparatus for uniform chemical-vapor depositions

InactiveUS20050034662A1Consumes less gasIncrease ratingsChemical vapor deposition coatingGas phaseDeposition process

Owner:MICRON TECH INC

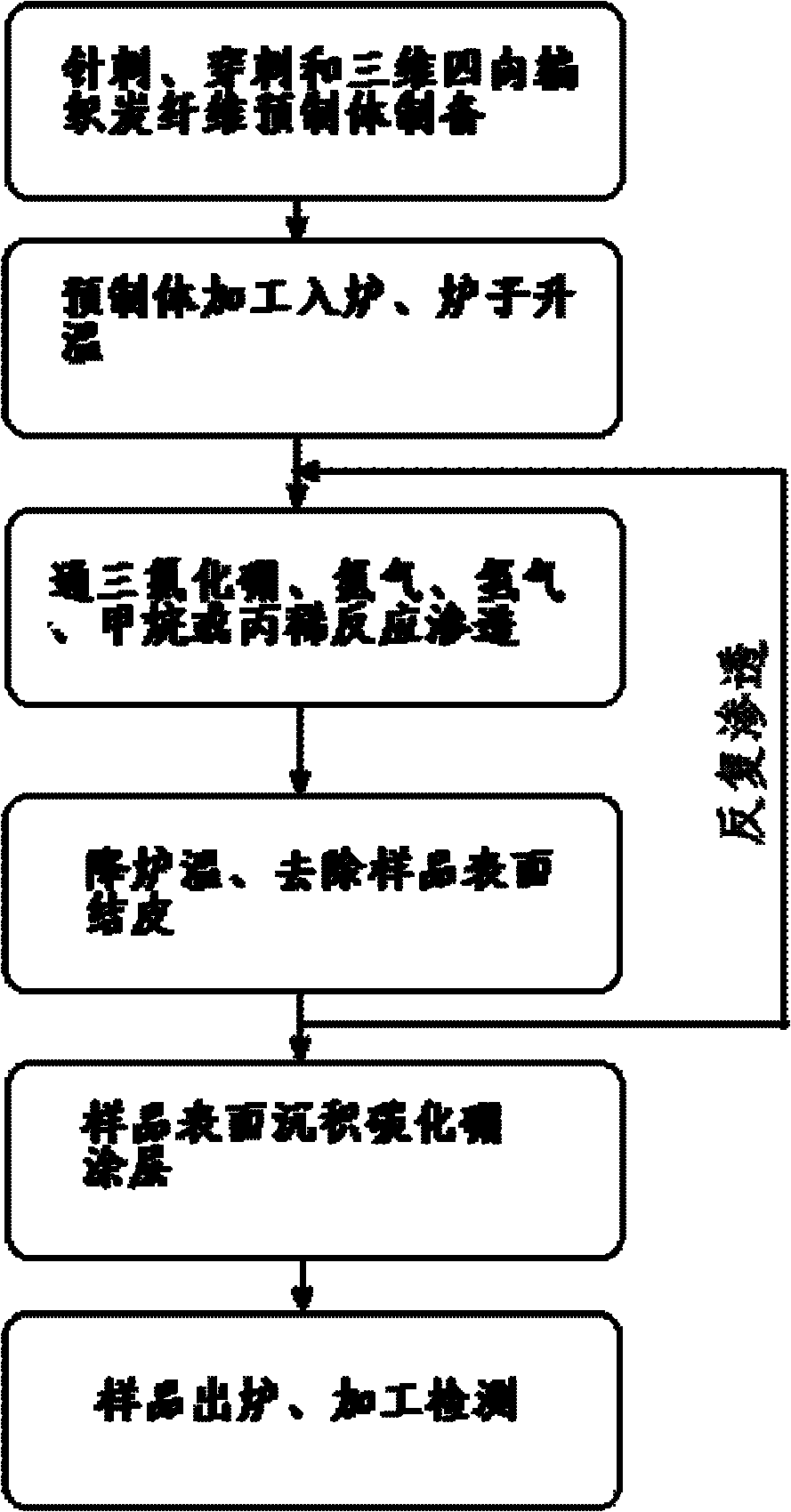

Carbon fiber reinforced boron carbide composite material and preparation method thereof

The invention relates to a carbon fiber reinforced boron carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: preparing a carbon fiber preform by adopting a needling, puncturing or three-dimensional weaving process; and depositing boron carbide matrix in the porous carbon fiber preform by osmosis to form the compact carbon fiber reinforced boron carbide composite material. Aiming at a certain specific application environment, a boron carbide coat can be deposited on the surface of a sample by adopting the same chemical vapor osmosis process. The carbon fiber reinforced boron carbide-based composite material manufactured by the method has the characteristics of good mechanical property, toughness superior to that of the traditional sintered boron carbide, compact structure, light weight, abrasion resistance and high hardness, and is suitable to be applied to a high-temperature light structural component.

Owner:CENT SOUTH UNIV

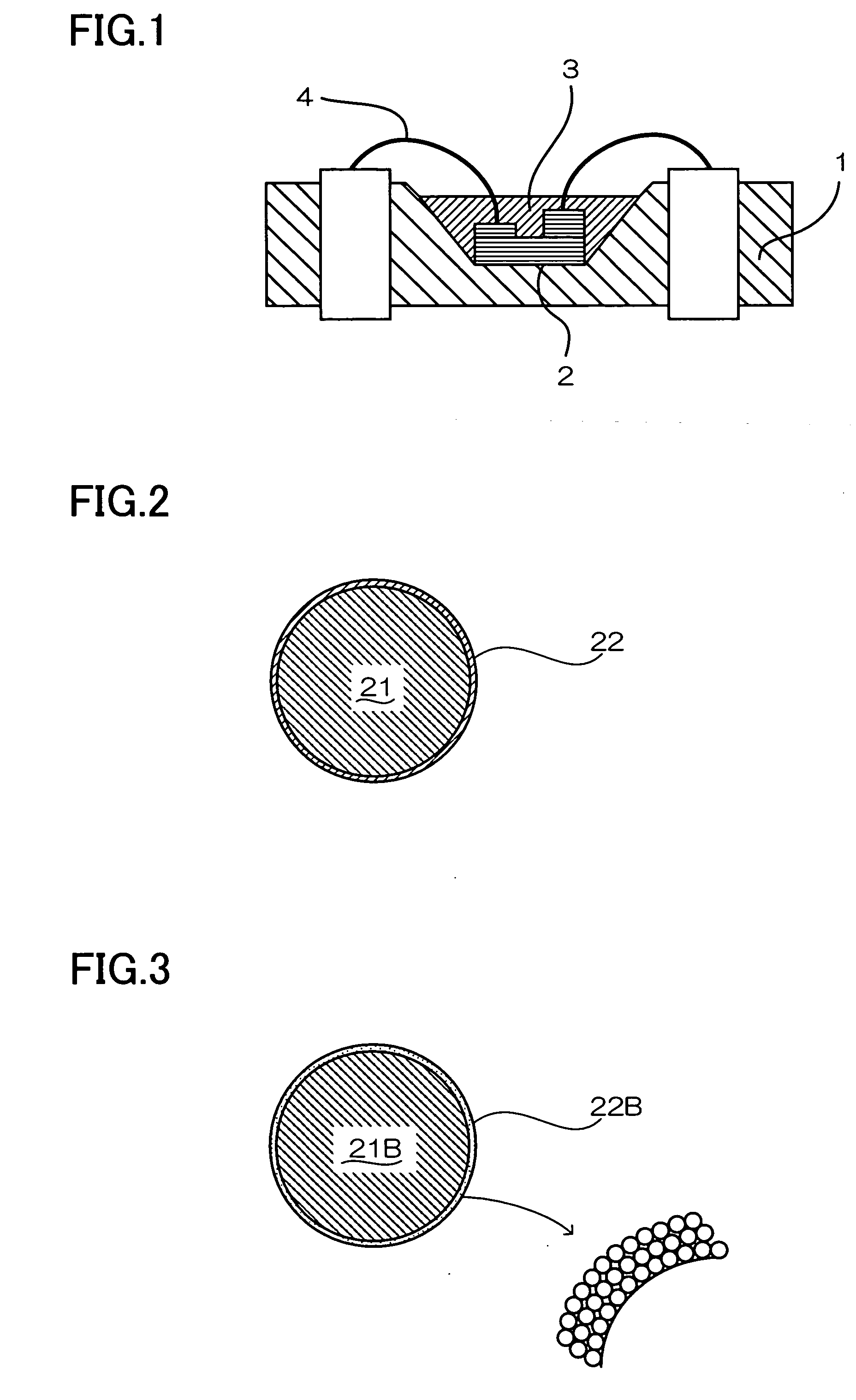

Light emitting device, phosphor, and method for preparing phosphor

ActiveUS20060001352A1Solve the lack of lifeIncrease thermal resistanceGas-filled discharge tubesDischarge tube luminescnet screensRare-earth elementOxygen

The surface of a phosphor is coated with a coating member made of a material different from the phosphor in chemical vapor-phase reaction. The coating member is made of any of metal oxide, metal nitride and metal oxynitride. The coating member coats the surface of the phosphor whereby having a substantially smooth film, or is formed such that a large number of fine particles relatively smaller than the phosphor aggregate to coat the whole surface of the phosphor. The coating member contains at least one metallic element selected from the group consisting of Al, Si, and rare earth elements. In addition, the phosphor is a transparent water-soluble phosphor and is an alkaline-earth silicon-nitride phosphor, an alkaline-earth silicon oxynitride phosphor, or the like. The BET value of the coated phosphor is 1.0 to 10 times the BET value before coating. The average thickness of the coating is 10 nm to 500 nm.

Owner:NICHIA CORP

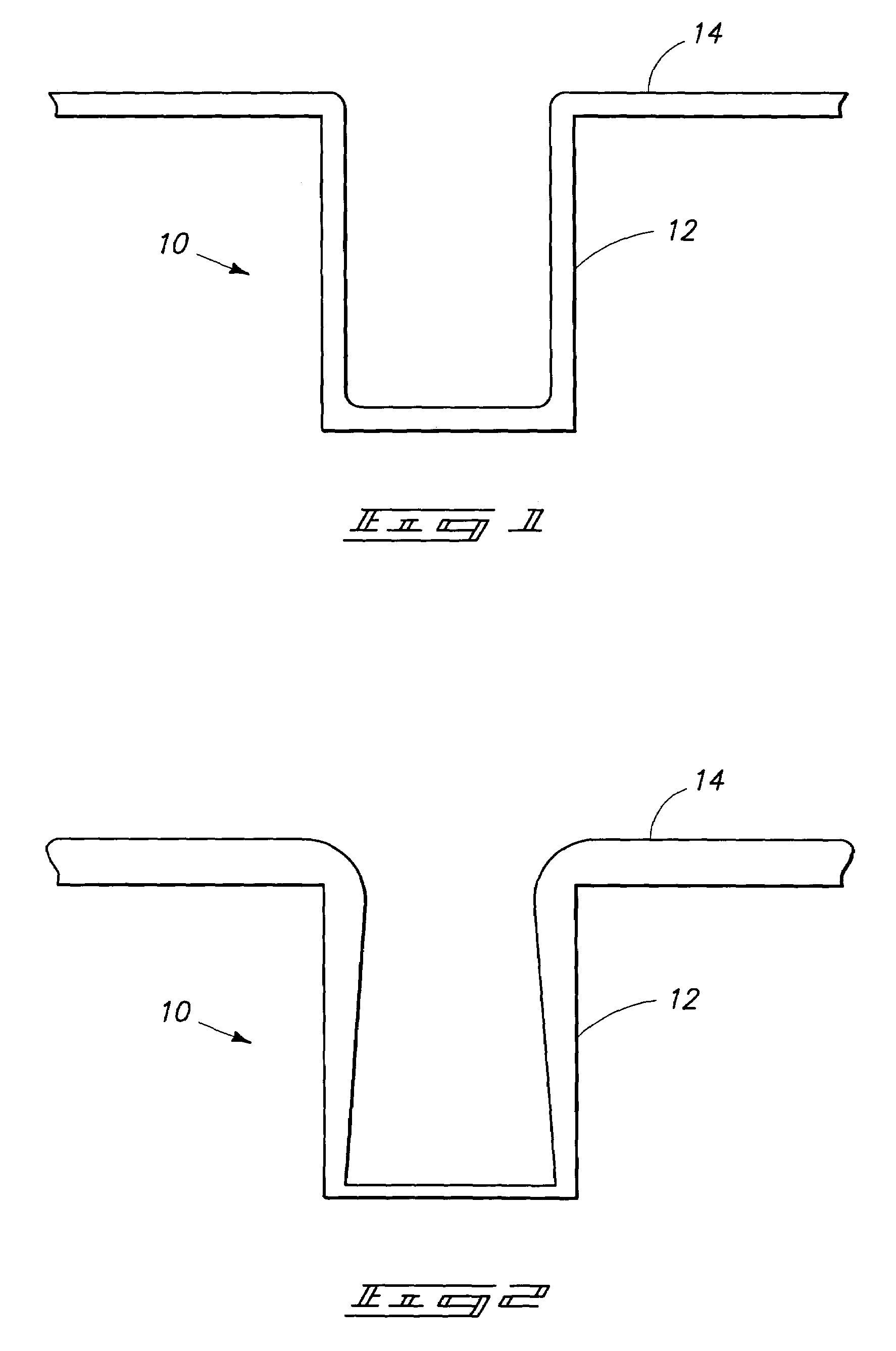

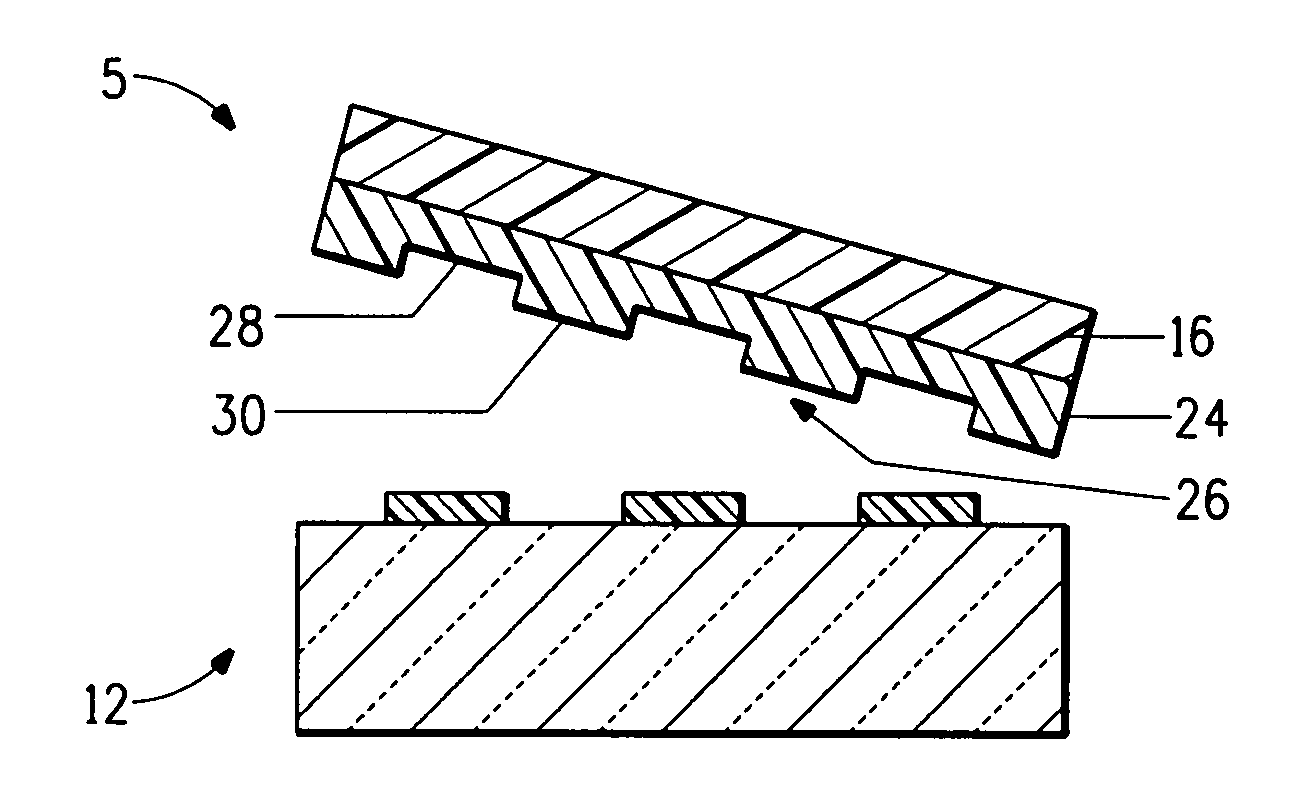

Method to form a pattern of functional material on a substrate by treating a surface of a stamp

InactiveUS20080233280A1Fully removedNanostructure manufactureLayered productsCompound (substance)Electron

The invention provides a method to form a pattern of functional material on a substrate. The method uses an elastomeric stamp having a relief structure with a raised surface and having a modulus of elasticity of at least 10 MegaPascal. At least the raised surface of the stamp is treated by exposing the stamp to heat, radiation, electrons, a stream of charged gas, chemical fluids, chemical vapors, and combinations thereof, to enhance wettability of the surface. A composition of the functional material and a liquid is applied to the relief structure and the liquid is removed to form a film on the raised surface. The elastomeric stamp transfers the functional material from the raised surface to the substrate to form a pattern of the functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

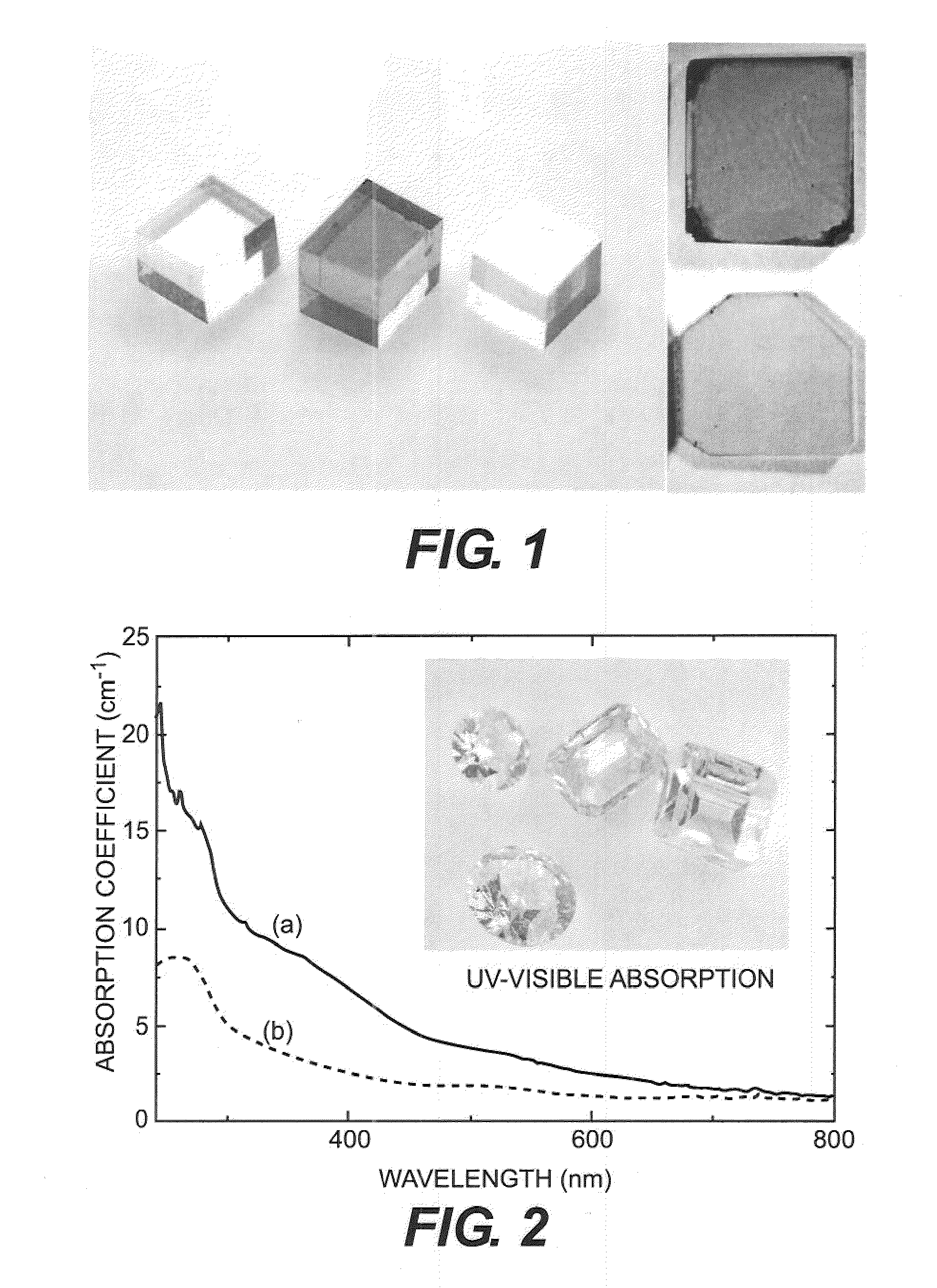

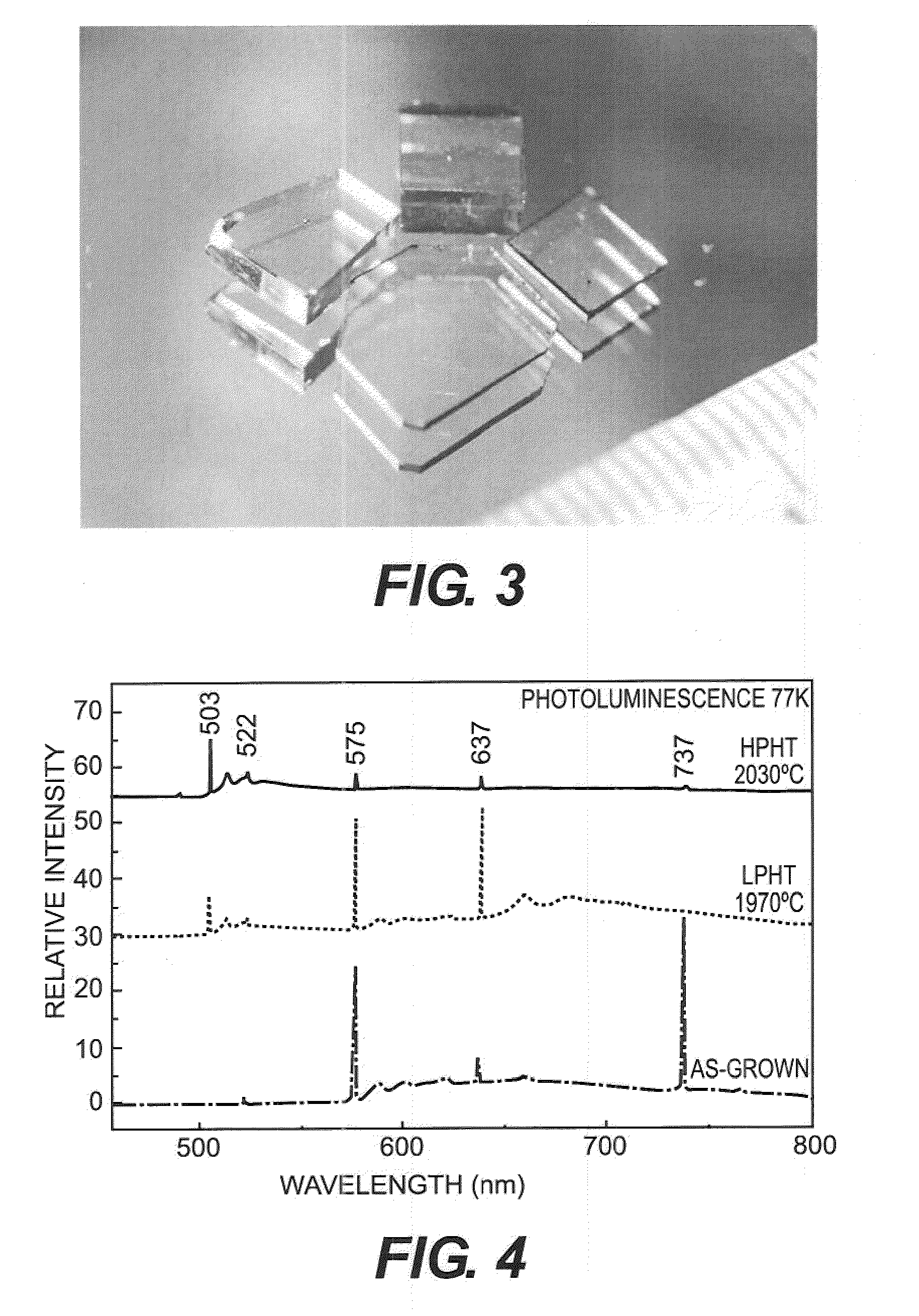

Enhanced Optical Properties of Chemical Vapor Deposited Single Crystal Diamond by Low-Pressure/High-Temperature Annealing

InactiveUS20100104494A1Good optical performanceIncrease probabilityPolycrystalline material growthCyanogen compoundsOptical propertyGas phase

The method of improving the optical properties of single crystal CVD diamond which comprises annealing the crystals at a temperature of up to 2200° C. and a pressure below 300 torr.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

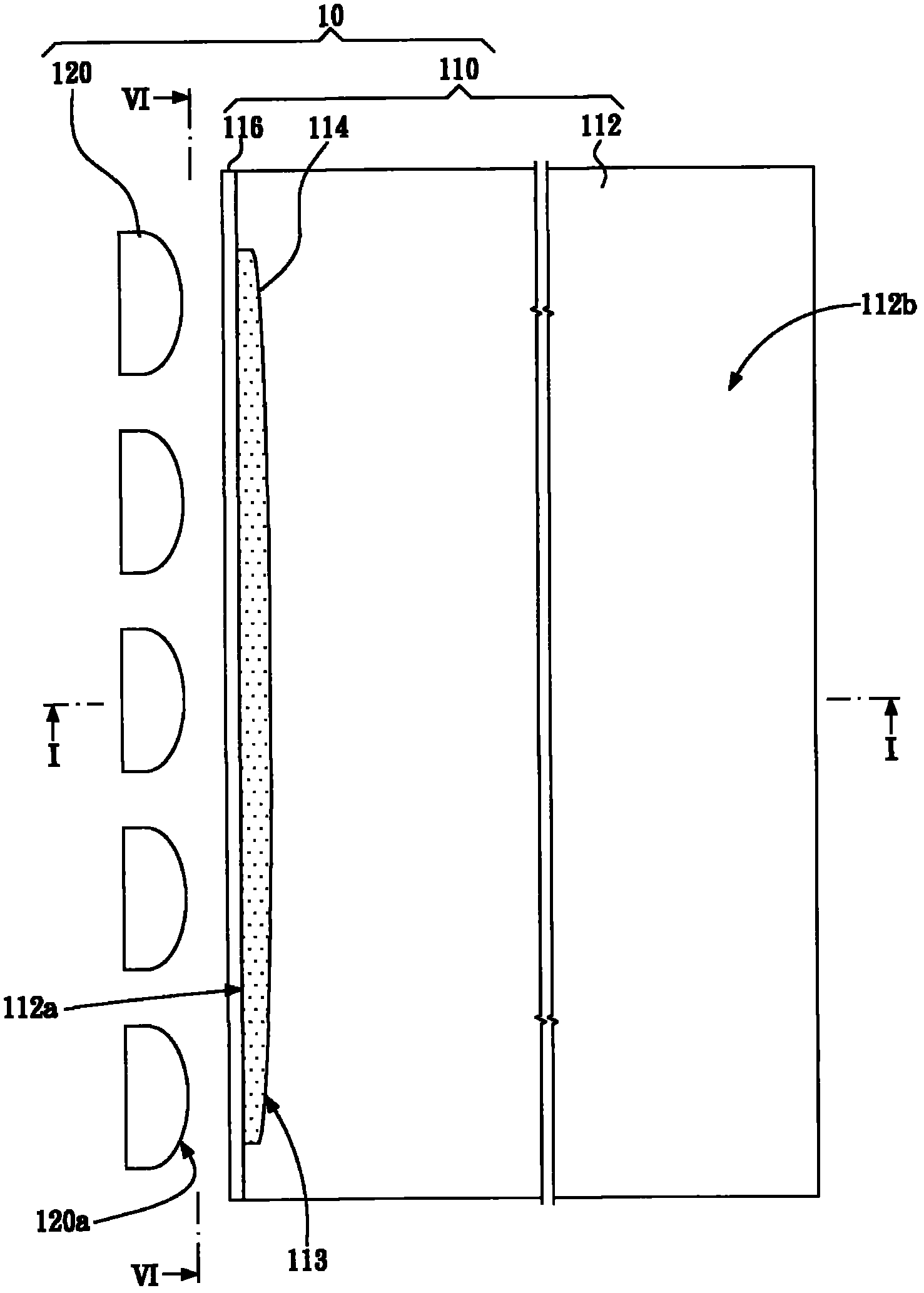

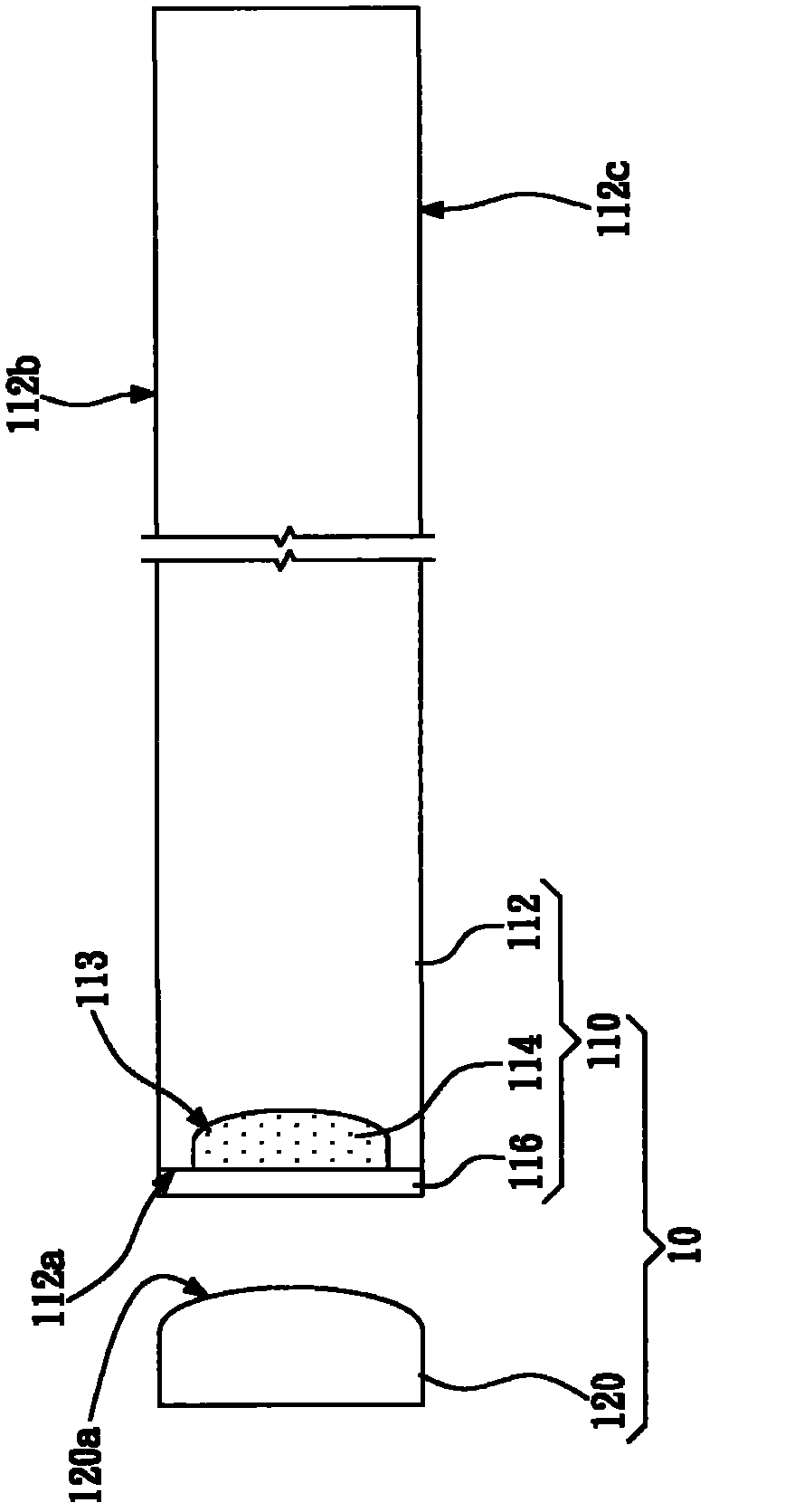

Light guide structure, backlight module and manufacturing method thereof

InactiveCN102628580ALight conversion efficiency attenuationMechanical apparatusPoint-like light sourceVapor barrierLight guide

The invention provides a light guide structure, a backlight module and a manufacturing method thereof. The light guide structure includes a light guide plate, an optical converting element and an optical vapor barrier. The light guide plate is provided with a light receiving face. The chemical vapor barrier covers the light receiving face. The optical converting element is arranged on the light receiving face and between the light guide plate and the optical vapor barrier. The invention utilizes the optical vapor barrier to separate optical converting element and the external world, thereby preventing the optical converting element from being affected with damp. Thus, the reduction of the optical converting efficiency is decelerated.

Owner:AU OPTRONICS CORP

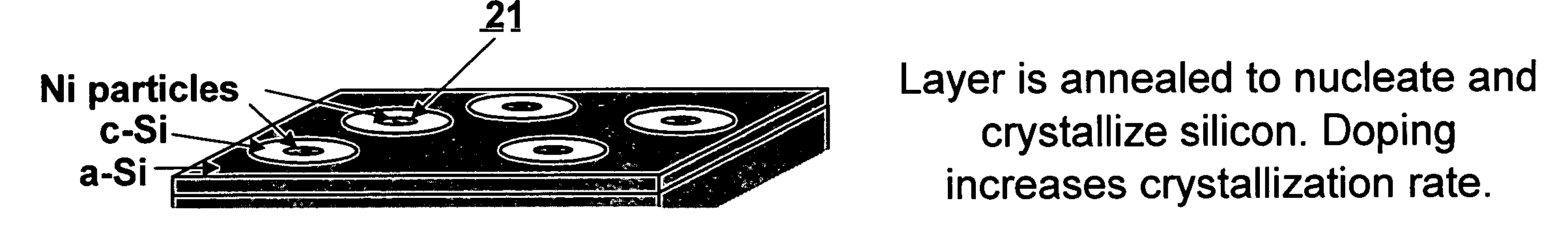

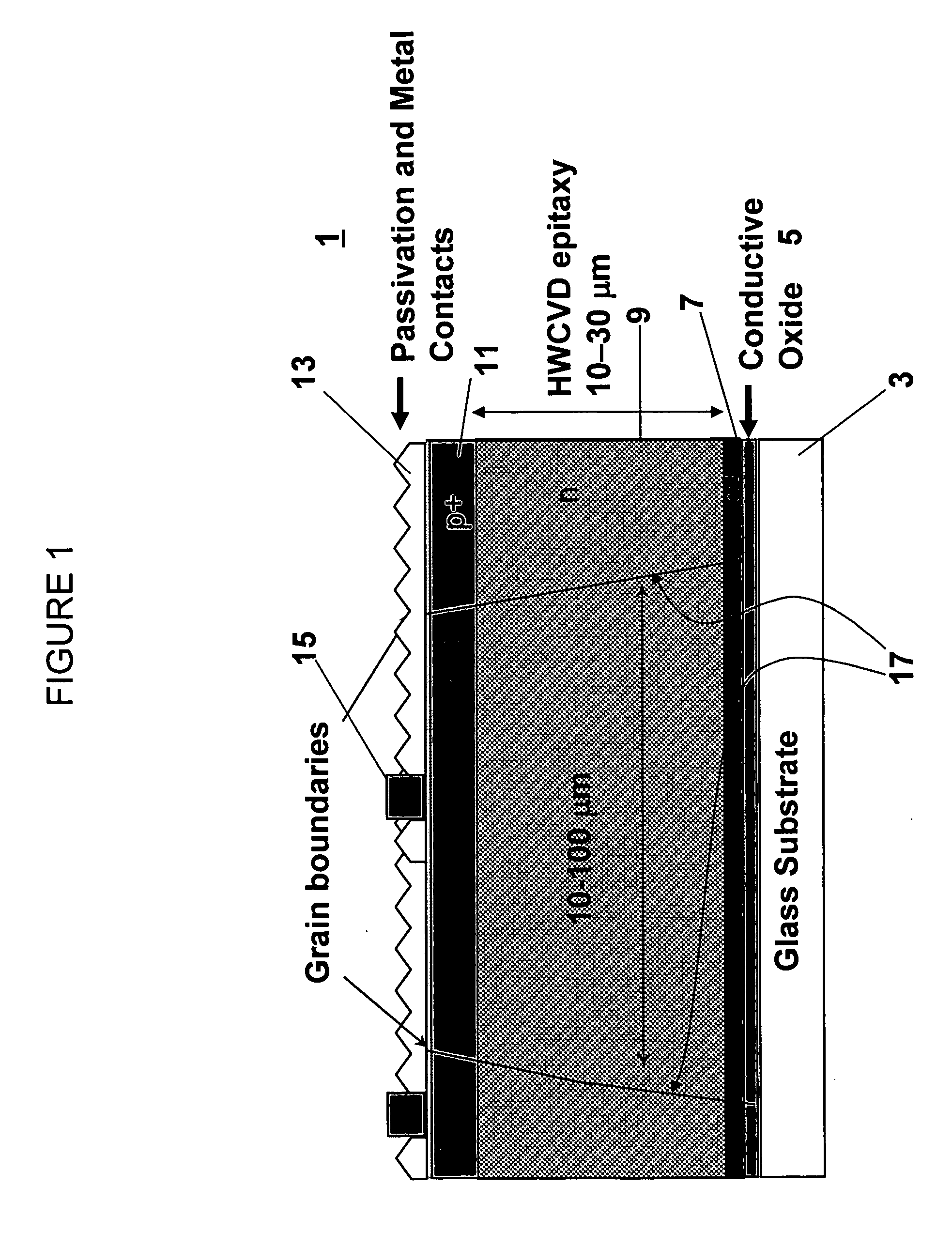

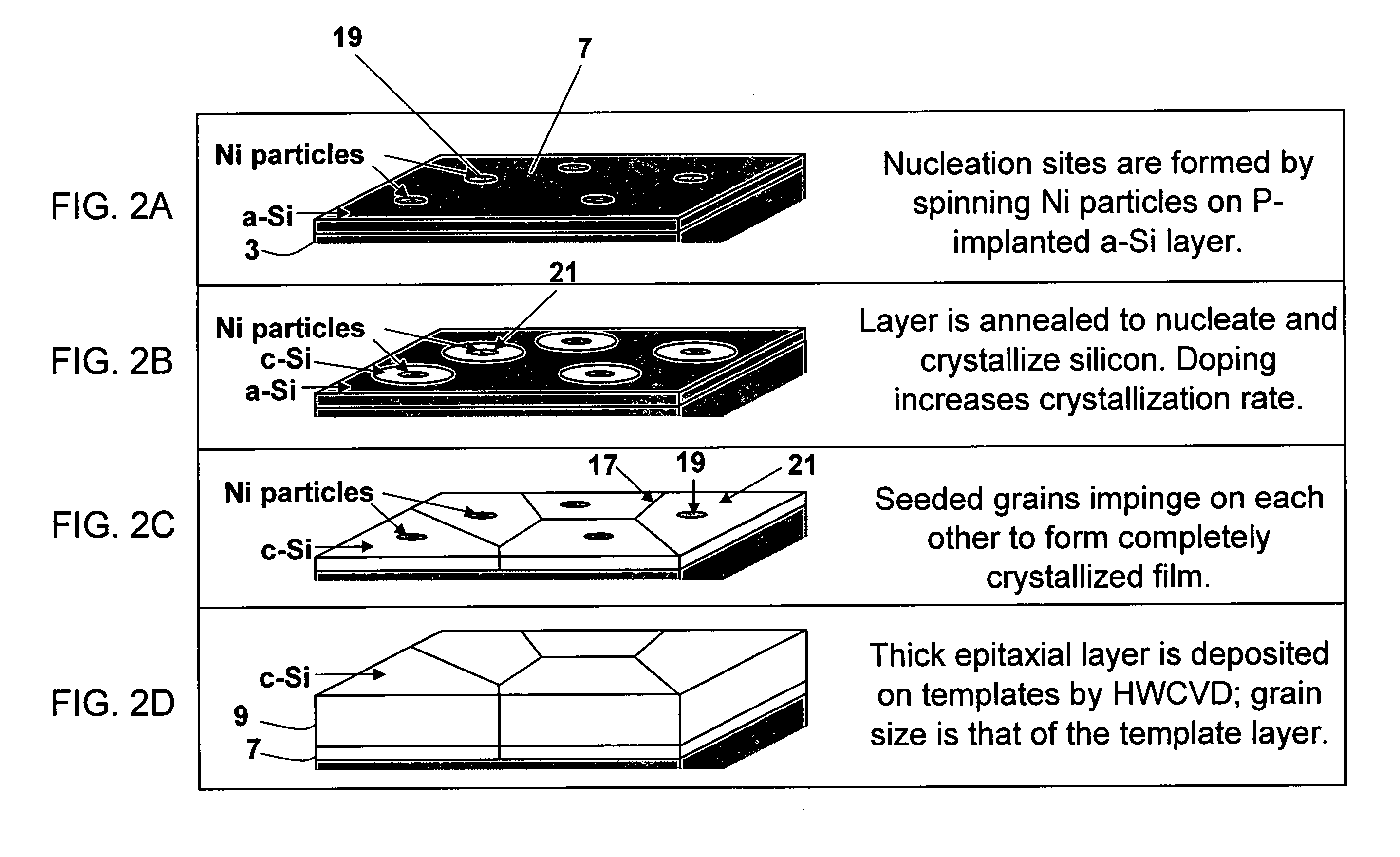

Large grained polycrystalline silicon and method of making same

InactiveUS20060108688A1Final product manufactureSemiconductor/solid-state device detailsPtru catalystSolar cell

A silicon structure includes a selective nucleating single phase epitaxial (SNSPE) template polysilicon layer containing crystallization catalyst residue, and a hot wire chemical vapor deposited (HWCVD) epitaxial polysilicon layer epitaxially grown on said template layer. The silicon structure may satisfy at least one of the following: 1) a thickness of the SNSPE template layer is less that about 60 nm; 2) a thickness of the HPCVD layer is greater than about 60 nm. The silicon structure may be used in a polysilicon solar cell or other solid state devices. A method of making a polysilicon layer includes providing a first layer comprising an amorphous silicon or a polysilicon layer containing a crystallization catalyst or in contact with a crystallization catalyst, and annealing the first layer in a silicon containing atmosphere to at least partially crystallize the first layer.

Owner:CALIFORNIA INST OF TECH

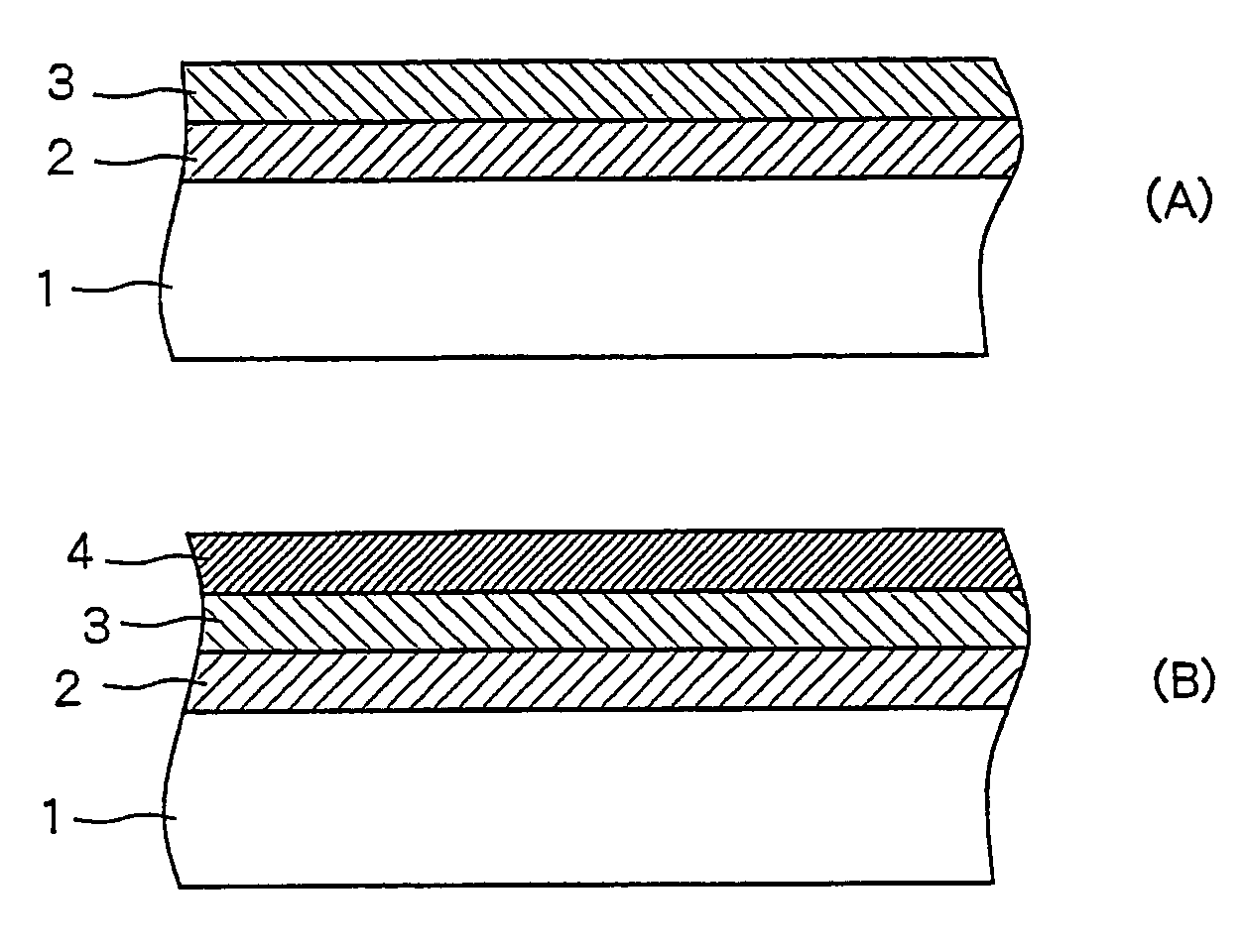

Plasma-enhanced chemical vapor deposited SIO2/SI3N4 multilayer passivation layer for semiconductor applications

InactiveUS6017614ASemiconductor/solid-state device detailsSolid-state devicesResistCorrosive chemical

A method was achieved for forming a multilayer passivation layer comprised of a silicon oxide / silicon nitride / silicon oxide / silicon nitride by depositing the layers consecutively in a single PECVD system. The method consists of depositing a first SiO2 layer that serves as a stress-release layer, a thin Si3N4 layer that serves as a buffer layer that minimizes cracking and as a passivation layer that prevents mobile alkaline ion penetration, a thin second SiO2 layer to fill and seal any remaining cracks and pinholes in the first Si3N4 layer, and a main Si3N4 passivation layer that prevents water and / or other corrosive chemicals from attacking the metal. Since this multilayer passivation layer can be deposited essentially pinhole-free to a thickness that is less than the prior art's passivation layer of 8000 Angstroms needed to prevent pinholes, it can be used on 0.38 to 0.25 um DRAM technology, which eliminates voids that could otherwise trap photoresist which can later cause corrosion of the metal lines.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

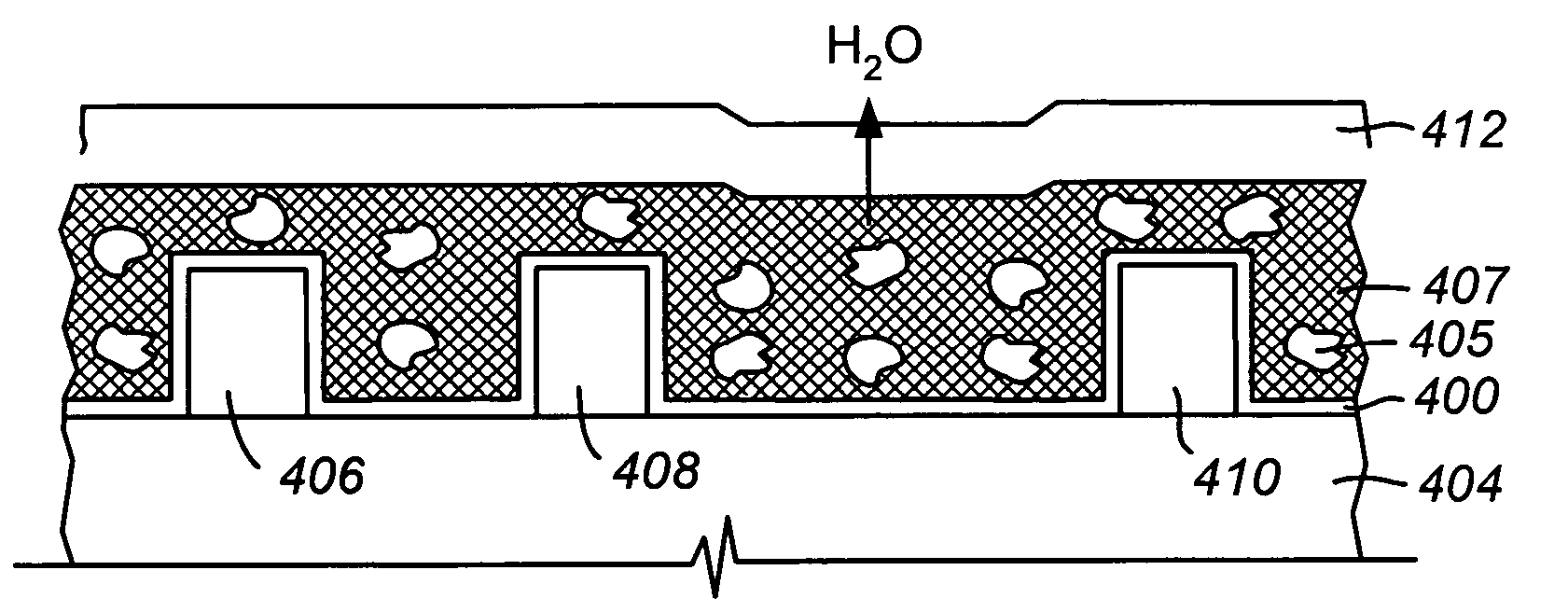

Multi-stage curing of low K nano-porous films

InactiveUS20050230834A1Semiconductor/solid-state device detailsSolid-state devicesThermal energyGas phase

Embodiments in accordance with the present invention relate to multi-stage curing processes for chemical vapor deposited low K materials. In certain embodiments, a combination of electron beam irradiation and thermal exposure steps may be employed to control selective outgassing of porogens incorporated into the film, resulting in the formation of nanopores. In accordance with one specific embodiment, a low K layer resulting from reaction between a silicon-containing component and a non-silicon containing component featuring labile groups, may be cured by the initial application of thermal energy, followed by the application of radiation in the form of an electron beam.

Owner:APPLIED MATERIALS INC

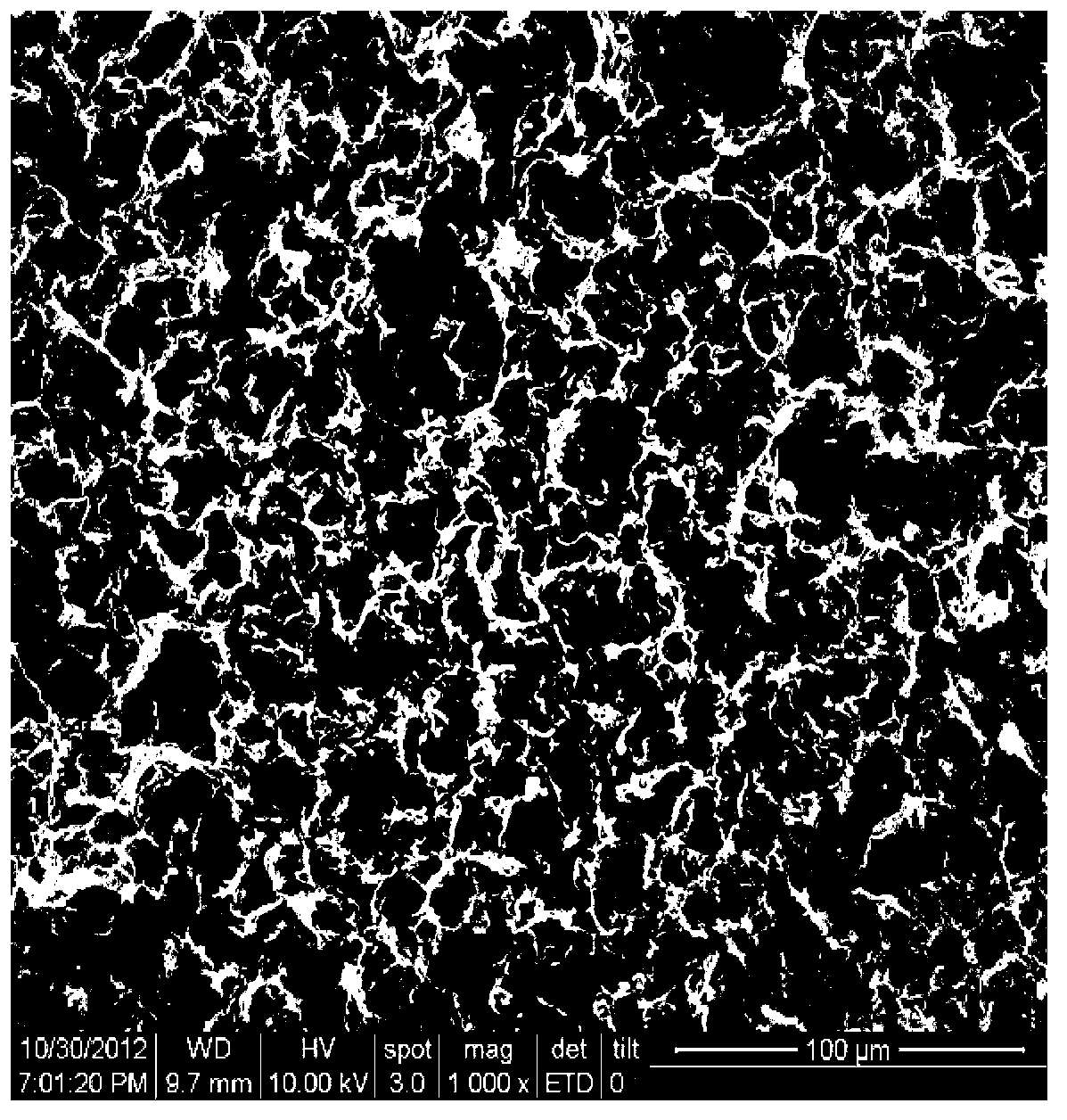

Preparation method of three-dimensional graphene or composite system thereof

The invention discloses a preparation method of three-dimensional graphene or a composite system thereof. The preparation method comprises the steps of: by taking a transition metal elementary substance and / or a compound containing a transition metal element as raw materials, preparing a three-dimensional porous metal catalyst template through high-temperature reduction; growing the three-dimensional graphene by utilizing a chemical vapor phase deposition method to obtain the three-dimensional graphene with a catalyst framework; furthermore, etching the three-dimensional graphene with the catalyst framework to obtain three-dimensional graphene powder; and furthermore, compositing the three-dimensional graphene powder with metal, a macromolecular material, a biomolecular material and the like to form a composite material system. The preparation method is simple in technique, capable of fast and massively preparing high-quality and high-density three-dimensional graphene or composite material thereof, and has wide application prospects on the aspects of water treatment, biomedicines, energy generation and conversion and energy accumulation devices, static resistance, thermal management, heat conduction and dissipation, sensors, electromagnetic shielding, wave absorption, catalysis and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method of making an alumina deposit on a substrate covered in sic

ActiveUS20080264176A1Improve toughnessEnhancing mechanical anchoringMolten spray coatingWave amplification devicesThermal sprayingStrain gauge

The invention relates to a method of depositing an alumina coating on a part having a silicon carbide surface. The method comprises the following steps:a) depositing a silicon adhesion underlayer on the SiC surface by chemical vapor spraying; andb) depositing a coating on the silicon adhesion underlayer by atmospheric thermal spraying.The invention also provides a device for measuring deformation, which device comprises a first alumina coating obtained by atmospheric thermal spraying onto the silicon adhesion underlayer deposited on the silicon carbide layer covering the substrate of the part, a free filament strain gauge placed on the coating, and an additional alumina coating obtained by atmospheric thermal spraying onto the strain gauge.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

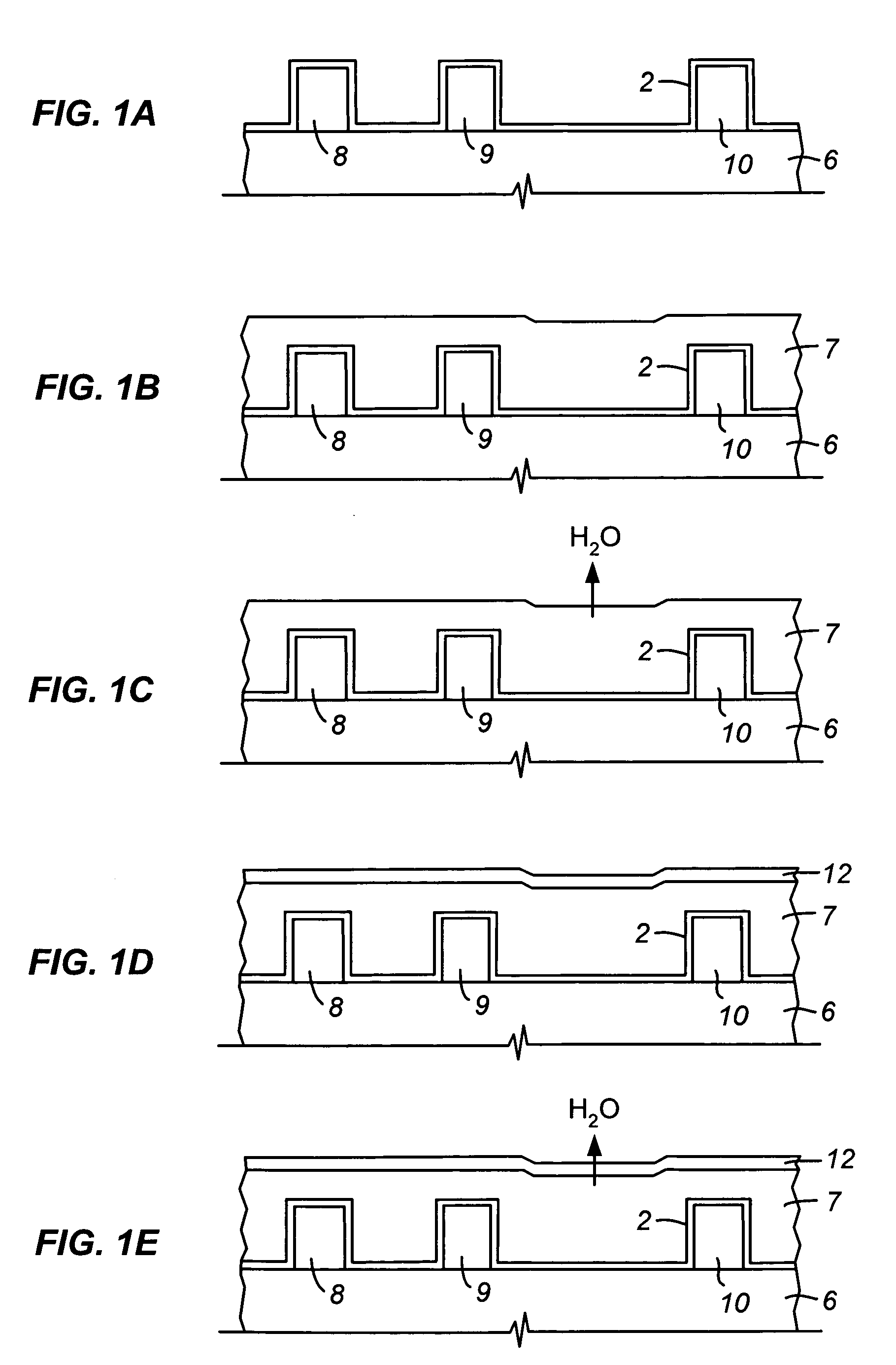

Methods and apparatus for E-beam treatment used to fabricate integrated circuit devices

InactiveUS6936551B2Improves property and performance of filmImprove mechanical propertiesPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that includes steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

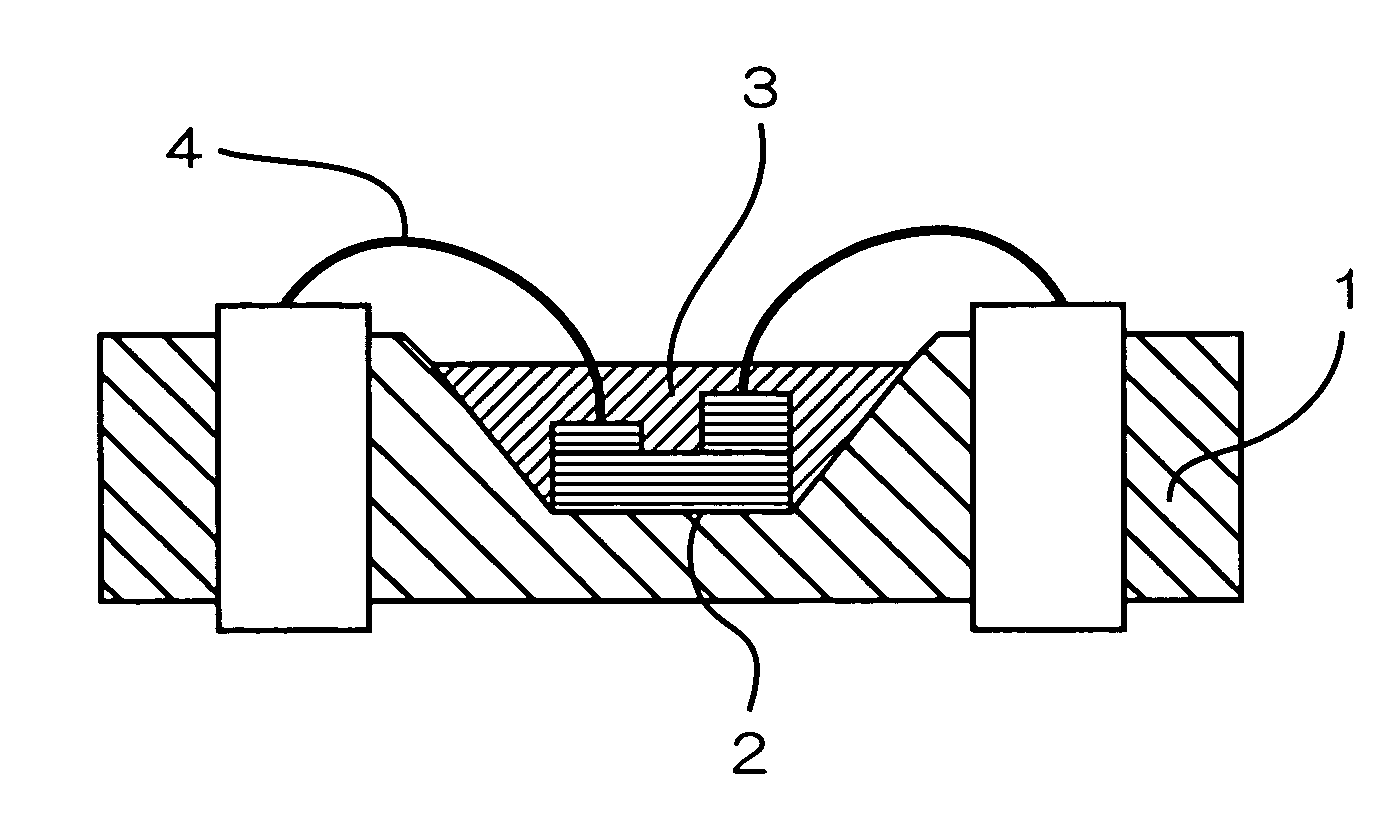

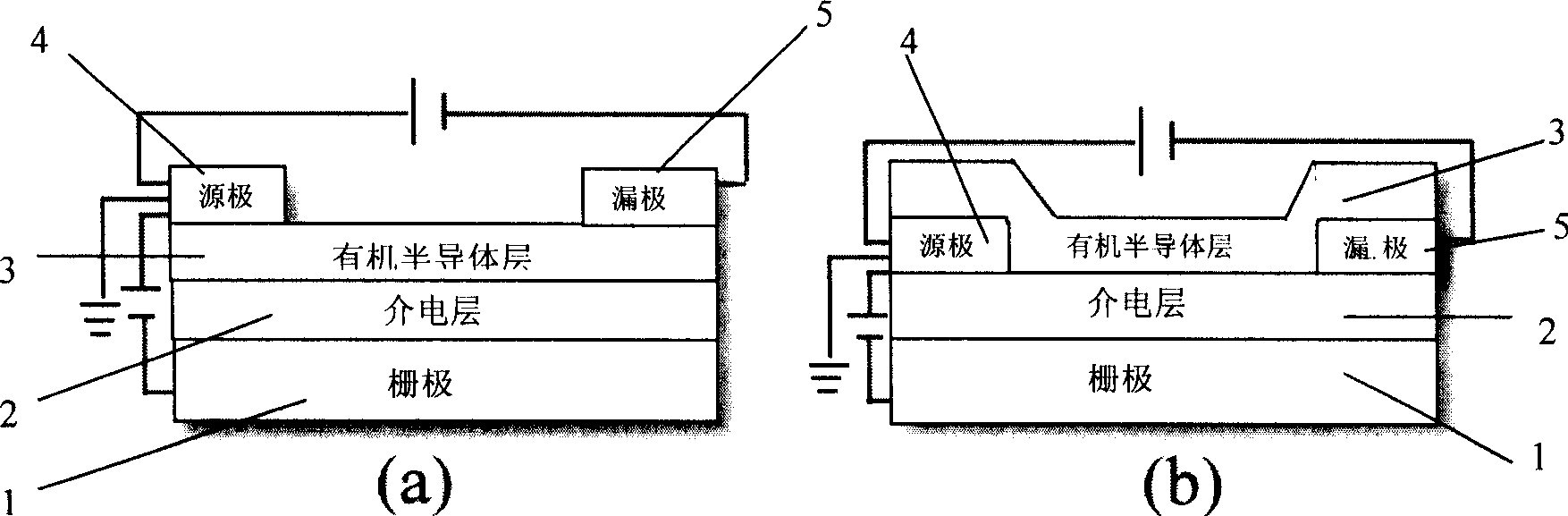

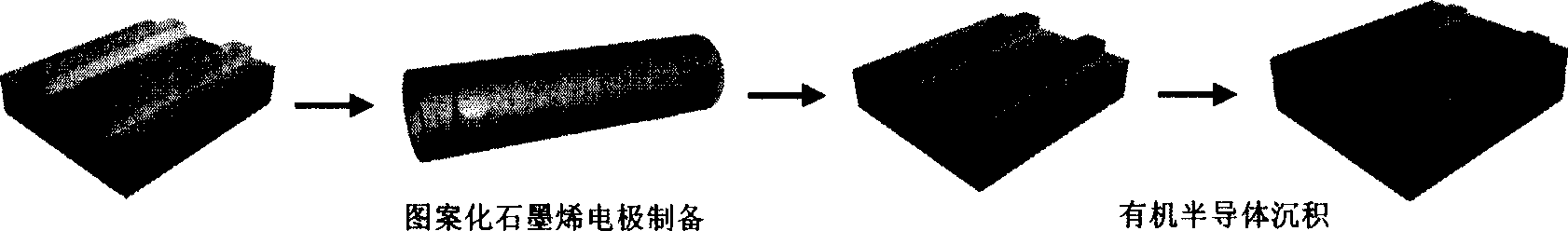

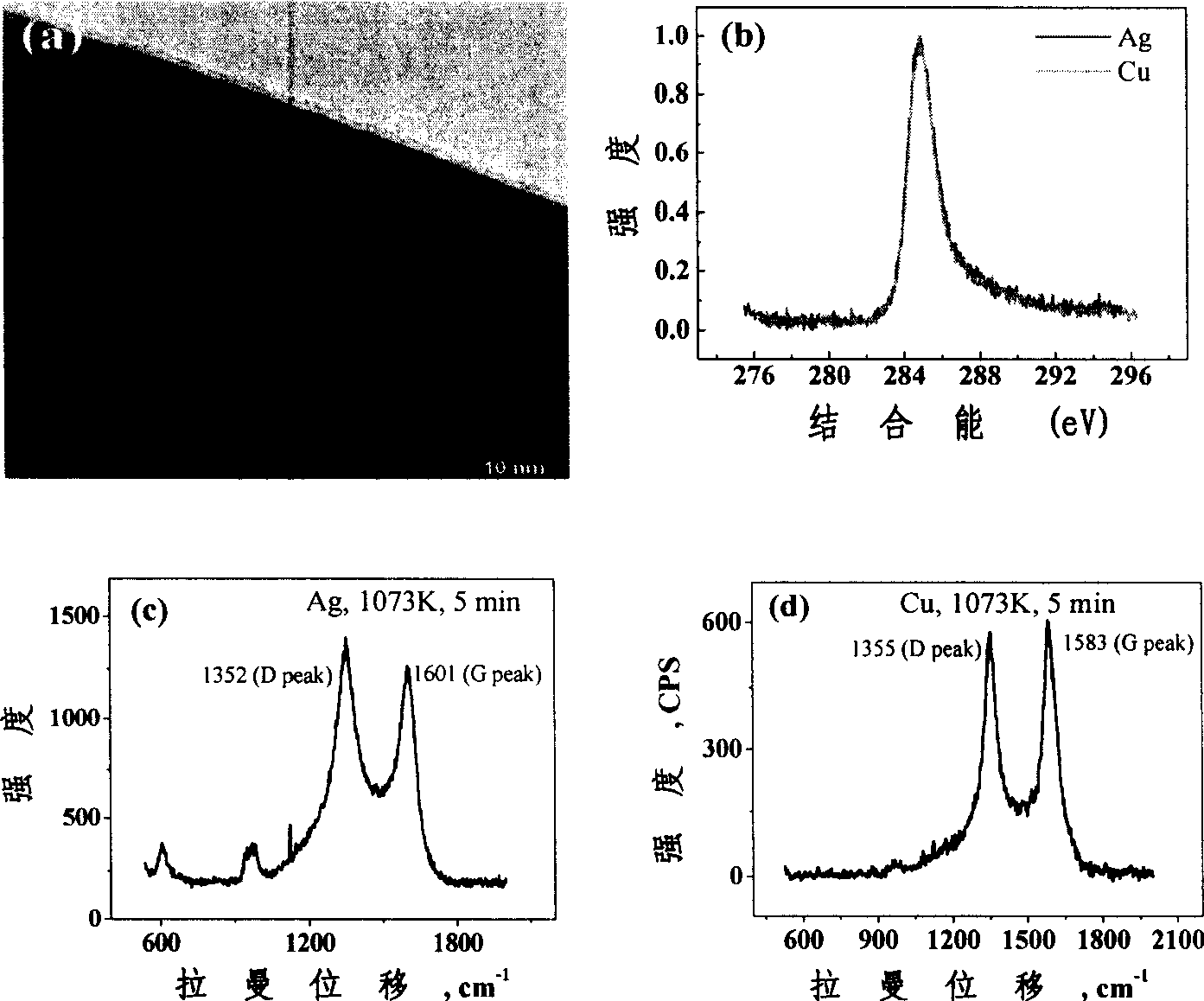

Organic field effect transistor and special source/drain electrode and preparation method thereof

InactiveCN101442105ALow costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorGas phase

The invention discloses an organic field effect transistor (FET), as well as a special source-drain electrode and a preparation method thereof. The organic FET with an electrode structure comprises a gate electrode, a dielectric layer, an organic semiconductor layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are patterned Graphene electrodes. The method for preparing the patterned Graphene electrodes comprises the following steps: 1) a metal film is deposited on a substrate and is patterned; and 2) the substrate on which the patterned metal film is deposited is placed in a chemical vapor deposition system, and chemical vapor Graphene deposition is performed on the surface of a patterned metal electrode material, so as to obtain the patterned Graphene electrodes, wherein a carbon source used in chemical vapor deposition is methanol, ethanol, propanol, pentanol, benzene, toluene, xylene, methane and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Methods and apparatus for e-beam treatment used to fabricate integrated circuit devices

InactiveUS20050130404A1Improves property and performance of filmImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that included steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

Handheld FT-IR spectrometer

InactiveUS20080204757A1Improves state-of-the-artRadiation pyrometryInterferometric spectrometryMetrologyFtir spectra

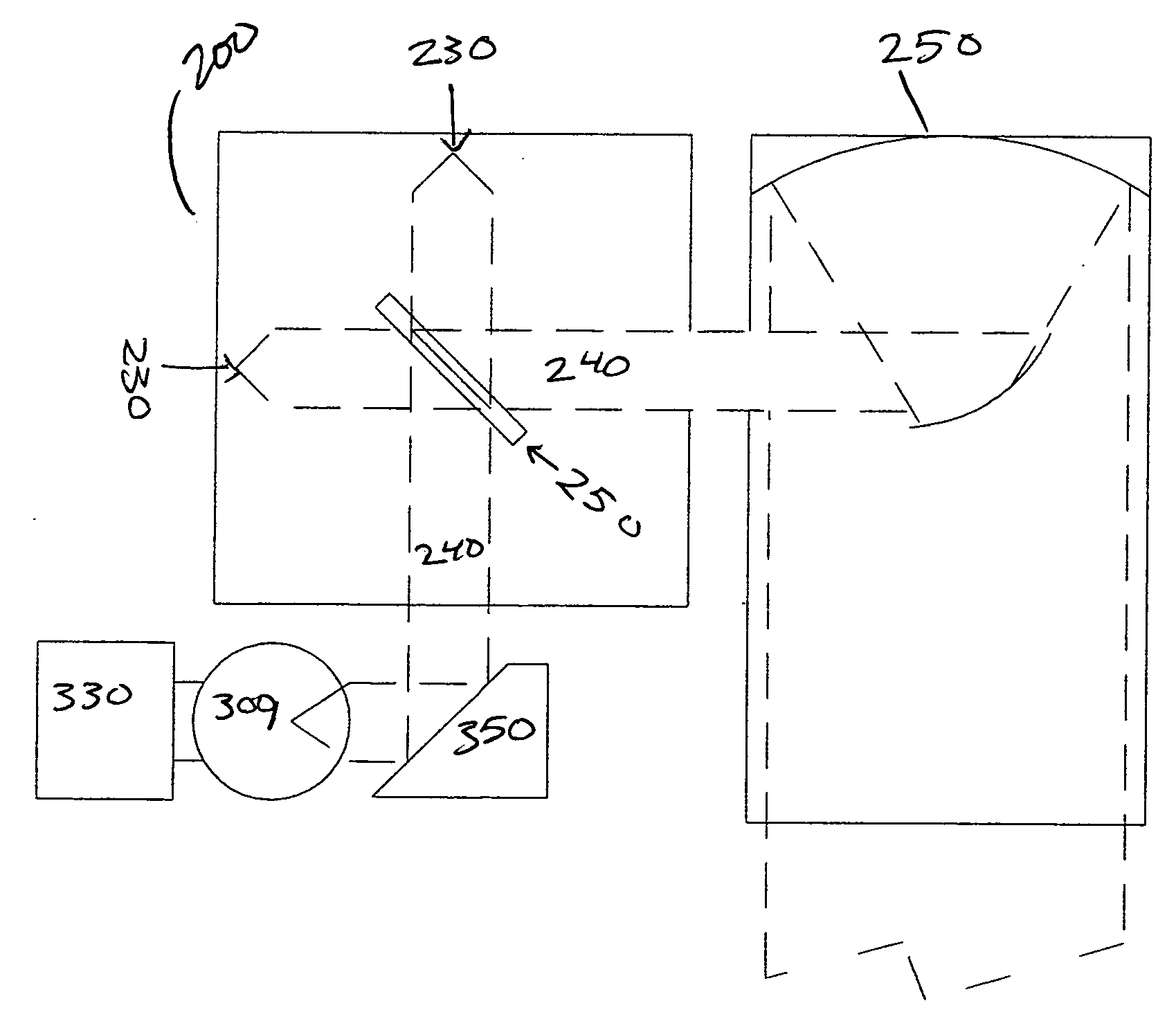

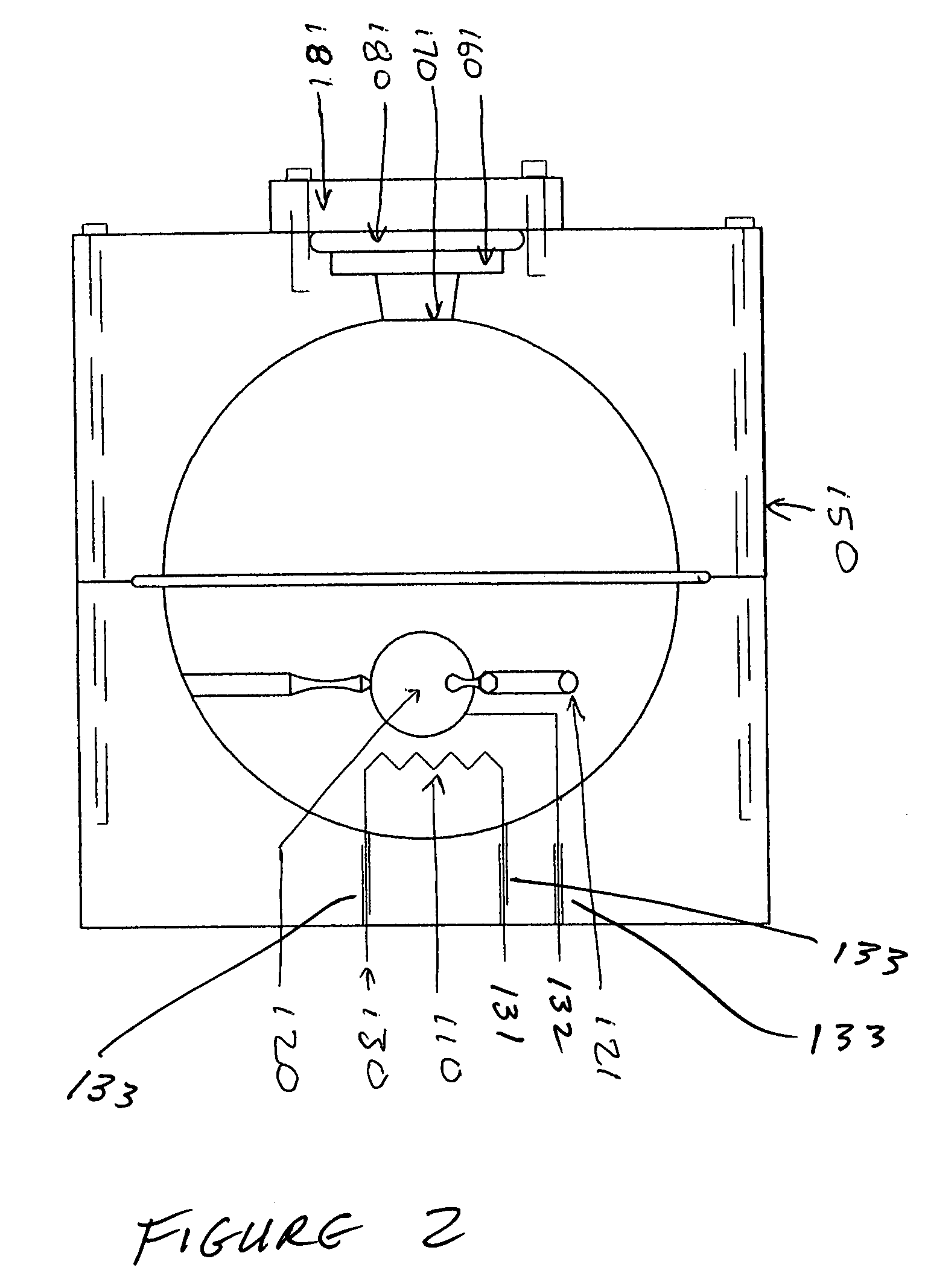

Novel spectrometer arrangements are described. They may employ a resin-based preconcentration system to sample chemical vapors. A field-widened interferometer modulates radiant energy. The signal generated by the interaction of the radiant energy with the sample is detected and processed by a computer. A variety of enhancements to the basic design are described, providing a family of related spectrometer designs. These spectrometers have applications in spectrometry, spectral imaging and metrology.

Owner:MANNING CHRISTOPHER

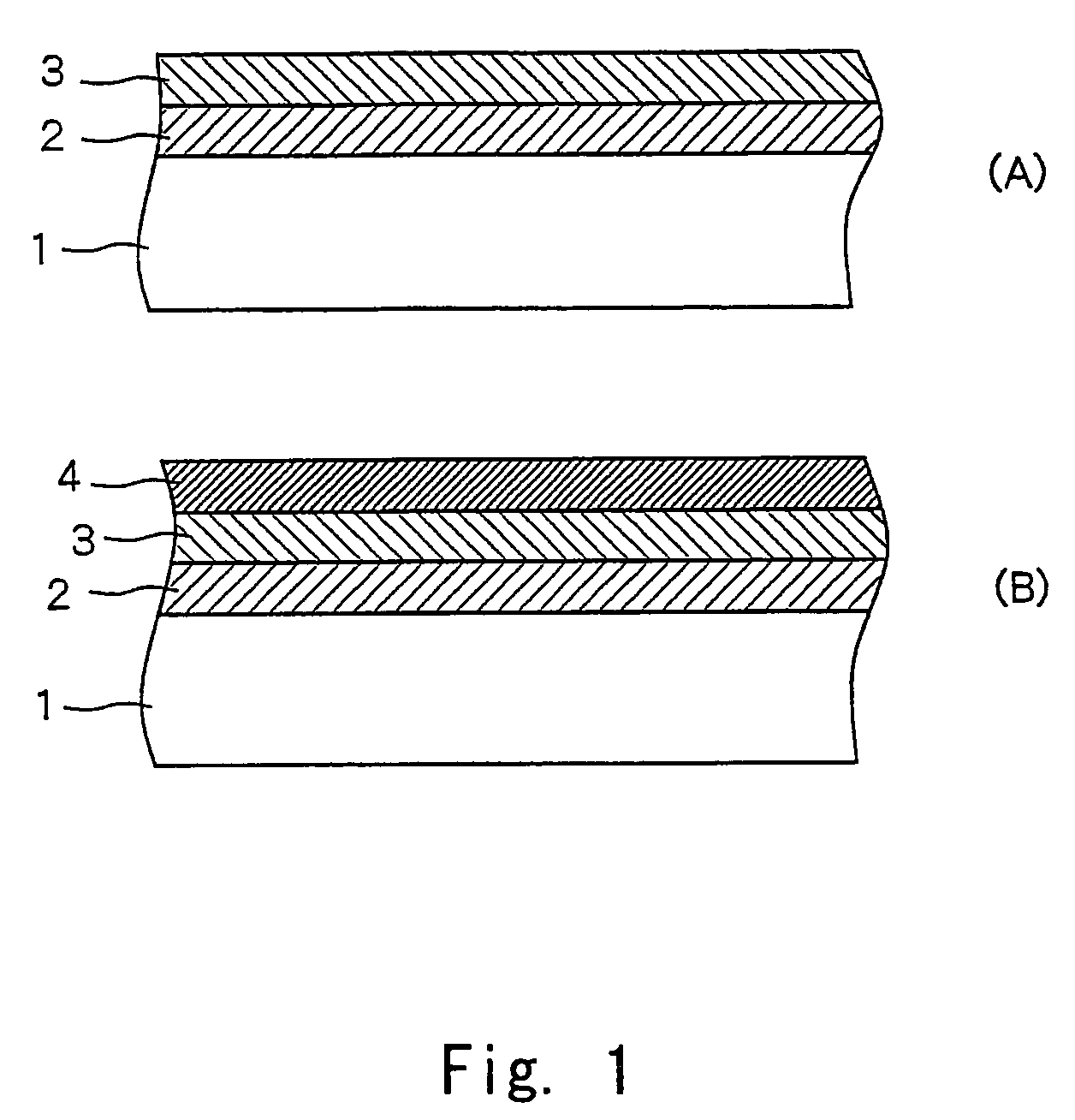

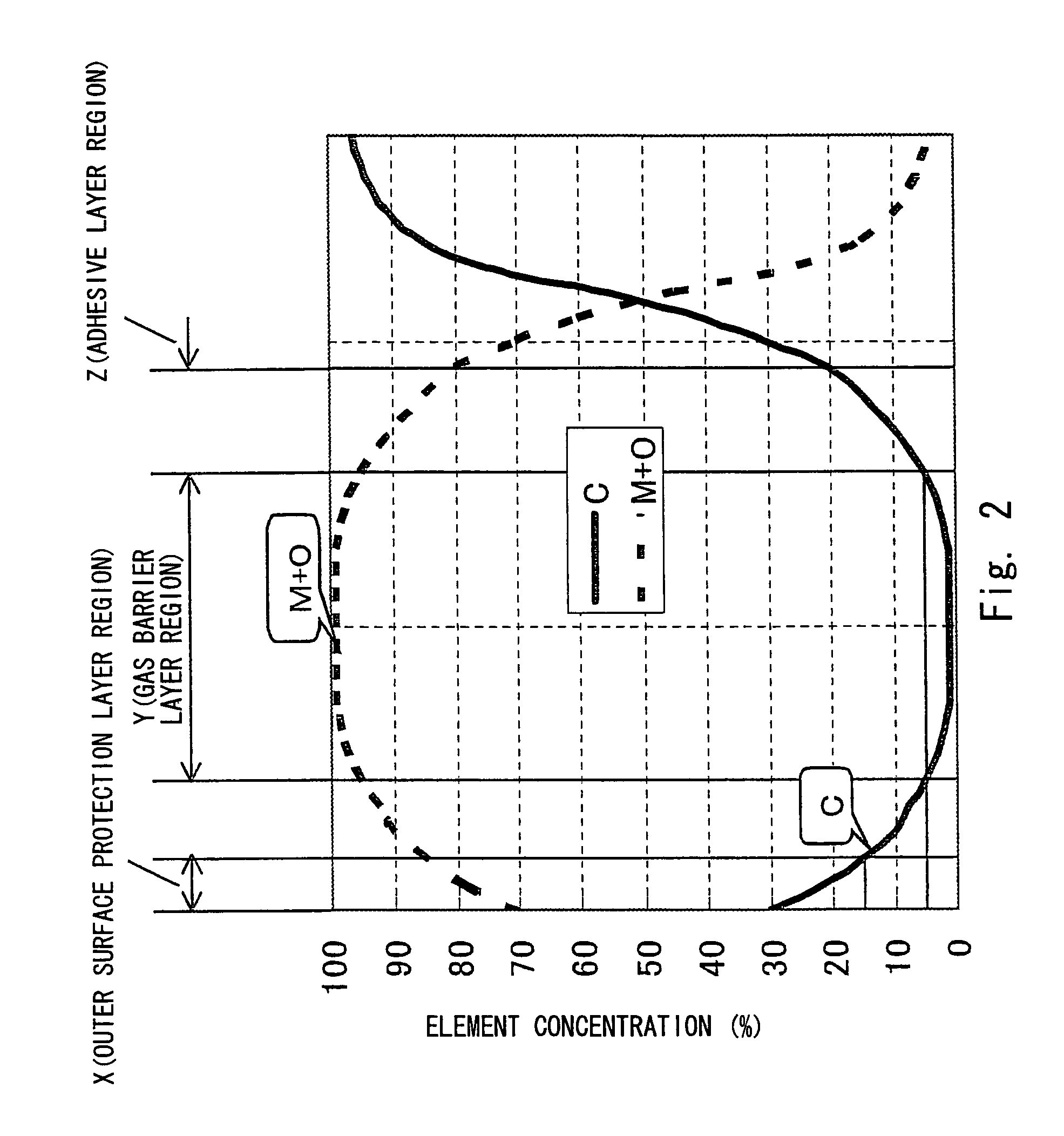

Chemical vapor deposited film based on a plasma CVD method and method of forming the film

InactiveUS7488683B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingFilm baseSilicon oxide

A method of forming a vapor deposited film of a silicon oxide on the surface of a substrate by holding the substrate to be treated in a plasma-treating chamber, and effecting the treatment with a chemical plasma by feeding an organosilicon compound and an oxidizing gas into the treating chamber, wherein the rate of feeding the oxidizing gas is varied while maintaining constant the rate of feeding the organosilicon compound gas into the plasma-treating chamber during the formation of the vapor deposited film. A chemical vapor deposited film is formed featuring excellent adhesiveness, softness, flexibility, oxygen-barrier property and water-barrier property.

Owner:TOYO SEIKAN KAISHA LTD

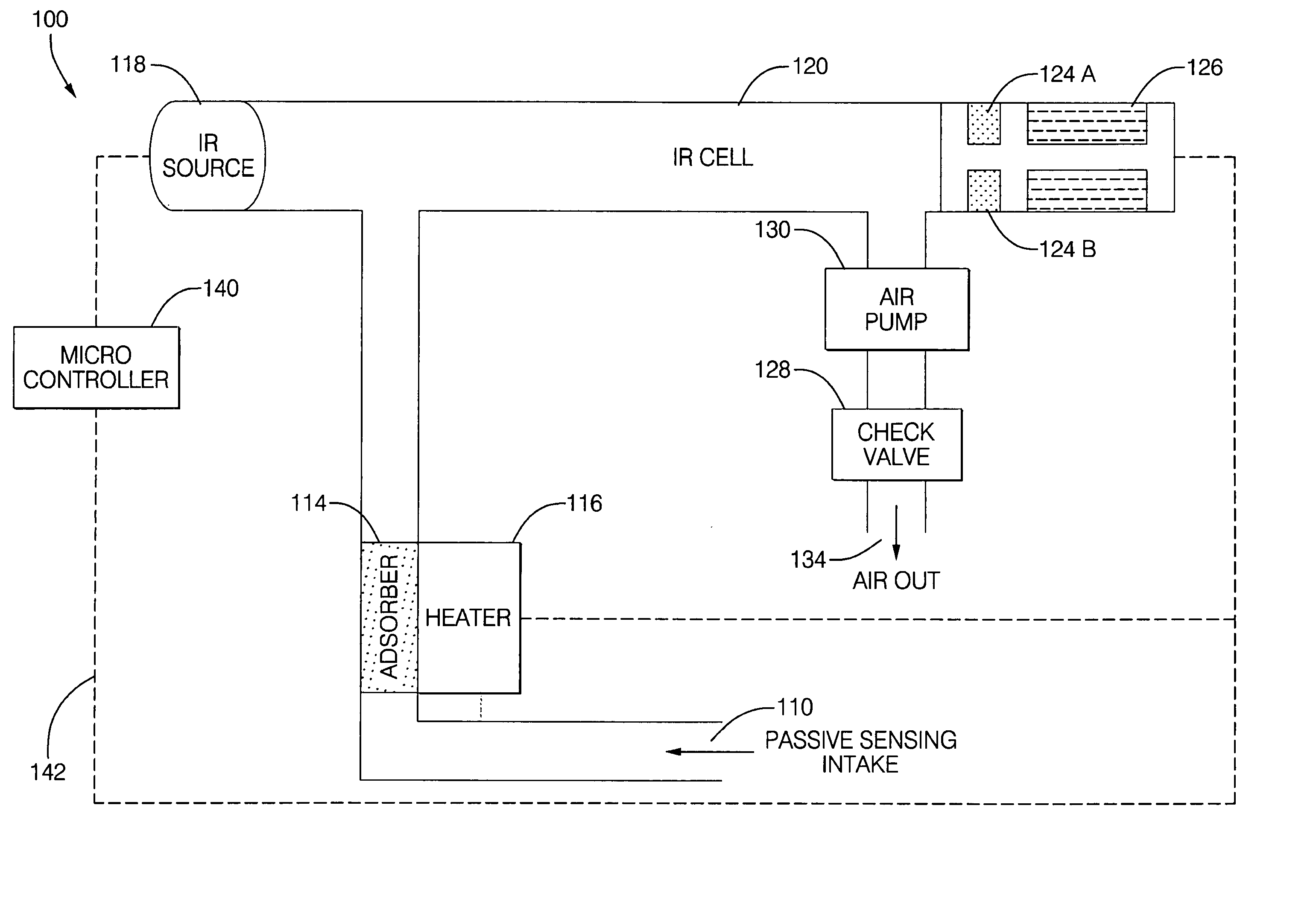

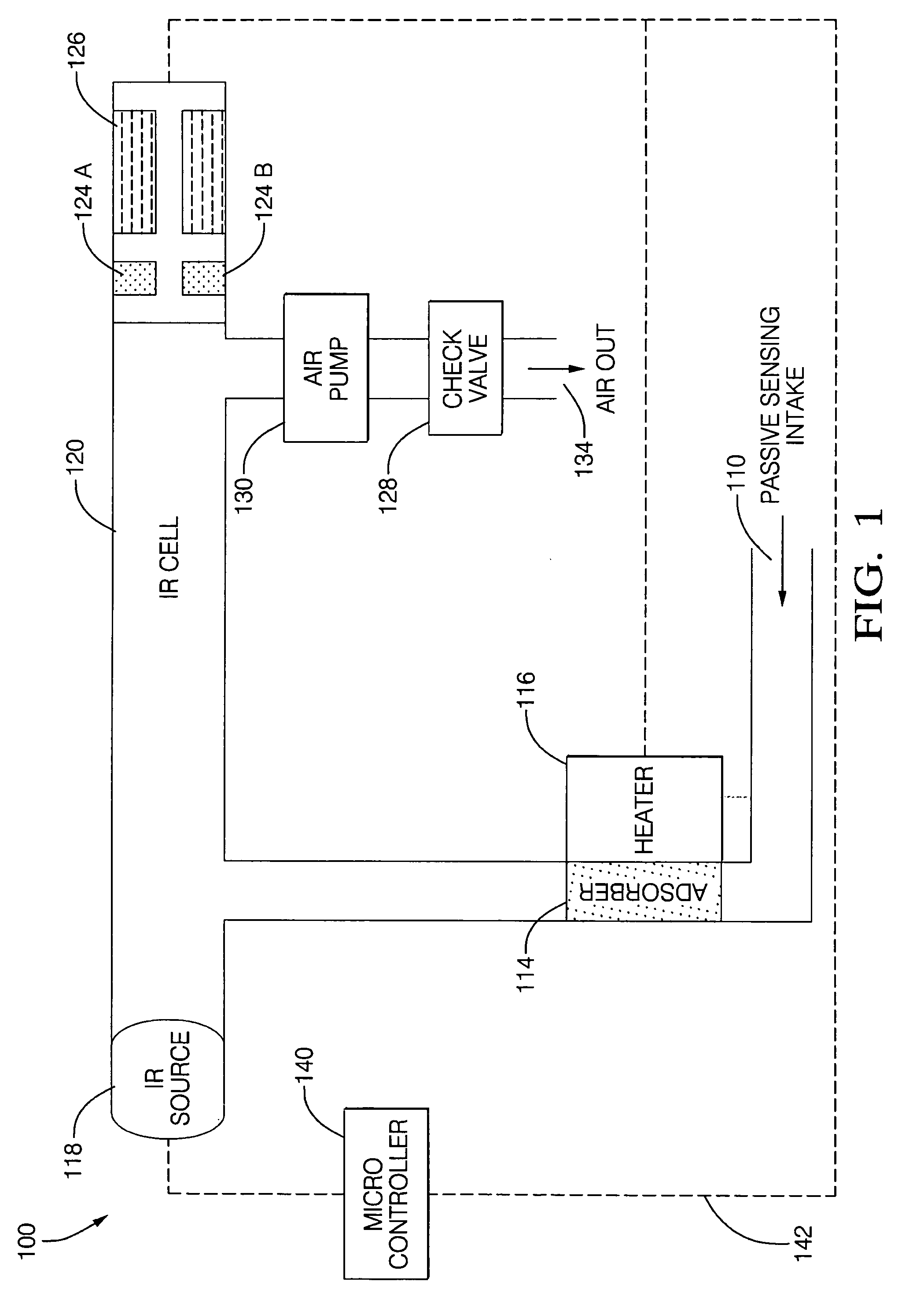

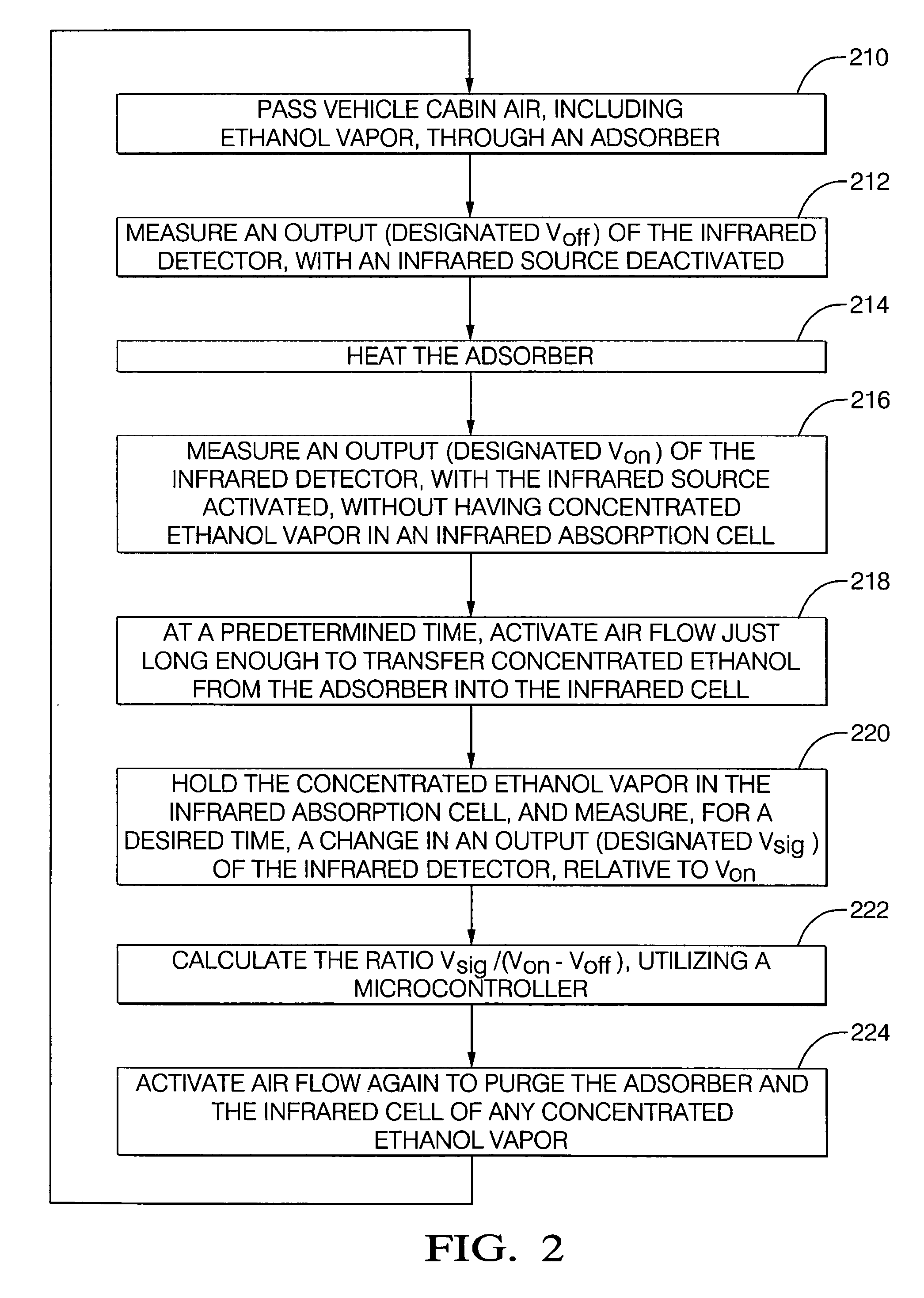

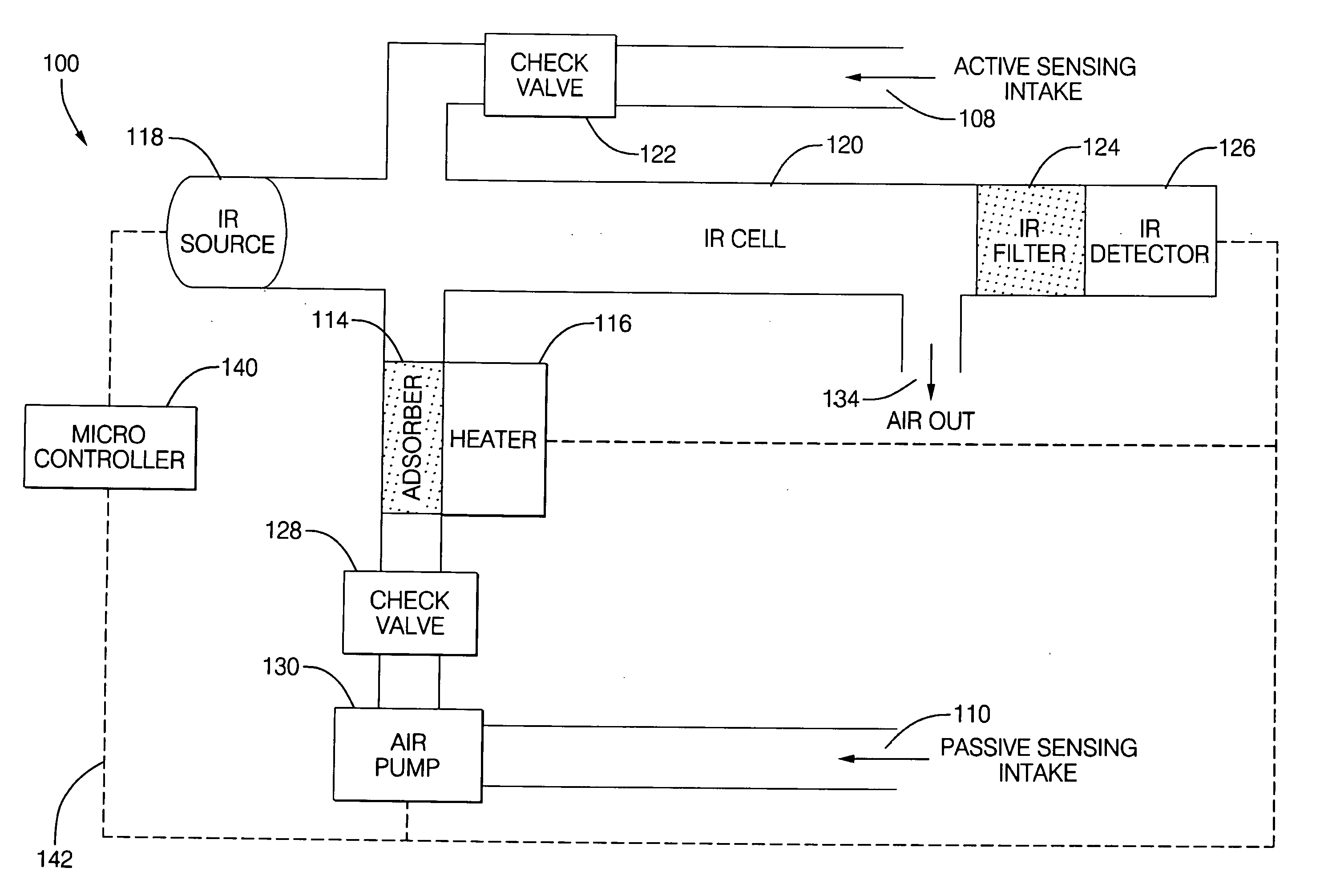

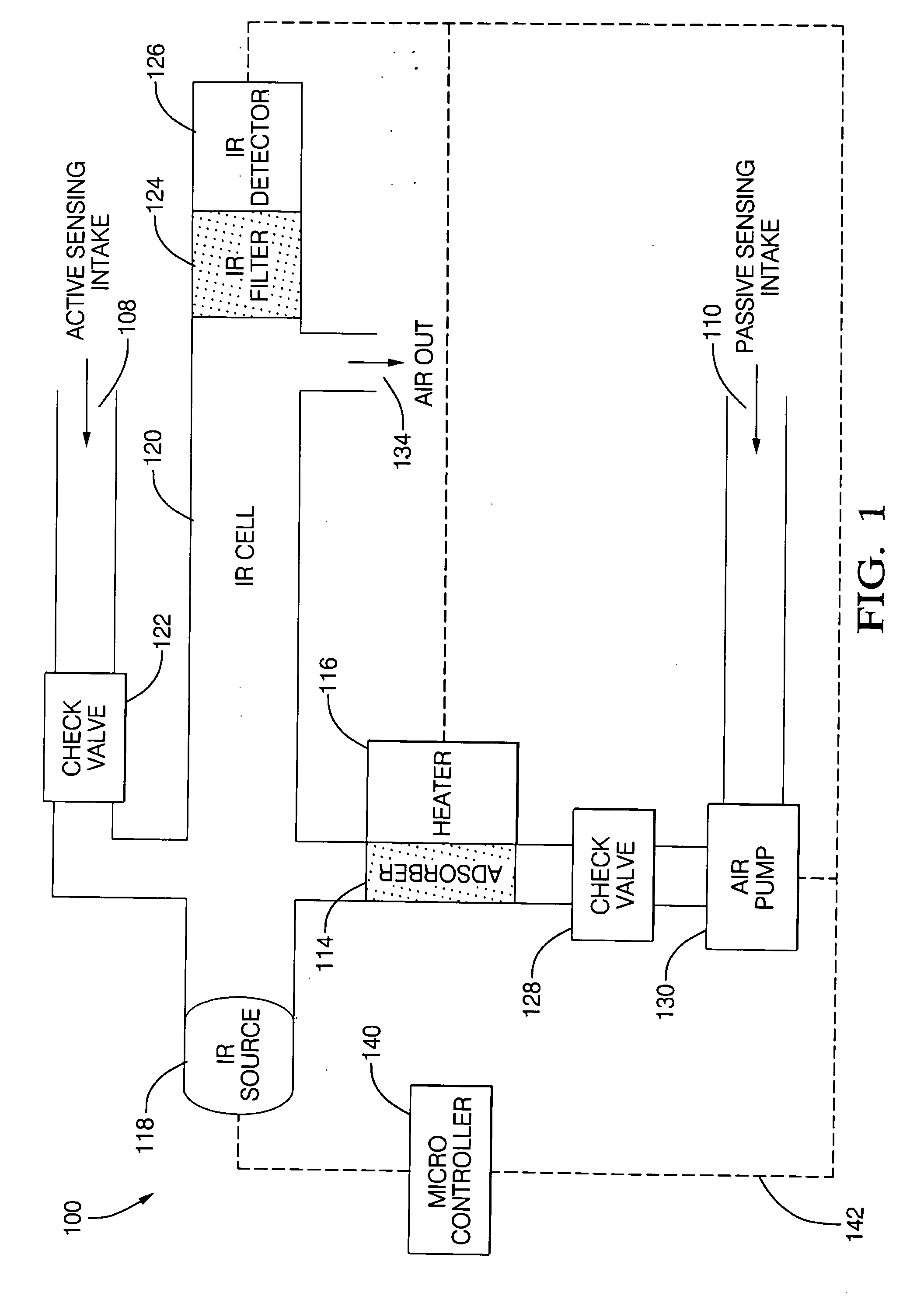

Tracer to compensate for environmental variations that influence a chemical vapor sensor measurement

ActiveUS20070077176A1High sensitivityHigh detection sensitivityRadiation pyrometryWithdrawing sample devicesSoil scienceChemical species

A chemical vapor sensor is provided that passively measures a suspect chemical species of interest with high sensitivity and chemical specificity, for use with safety systems. A vapor concentrator amplifies a suspect chemical vapor concentration to a detectible level, for use with an infrared detector. Compensation is provided for environmental variations that may influence the passive measurement of the chemical vapor sensor. Environmental variations may include extrinsic vapors in the surrounding air, or air currents that divert the sample vapor as it drifts from the suspect vapor source to a sampling intake. In an example, ethanol vapor is measured and carbon dioxide tracer measurements are used to calculate an ethanol vapor measurement that is adjusted for environmental variations. In an aspect, a time artifact filter sets the output of the carbon dioxide sensor to match the time dependence of the ethanol sensor, to calculate blood alcohol concentration.

Owner:APTIV TECH LTD

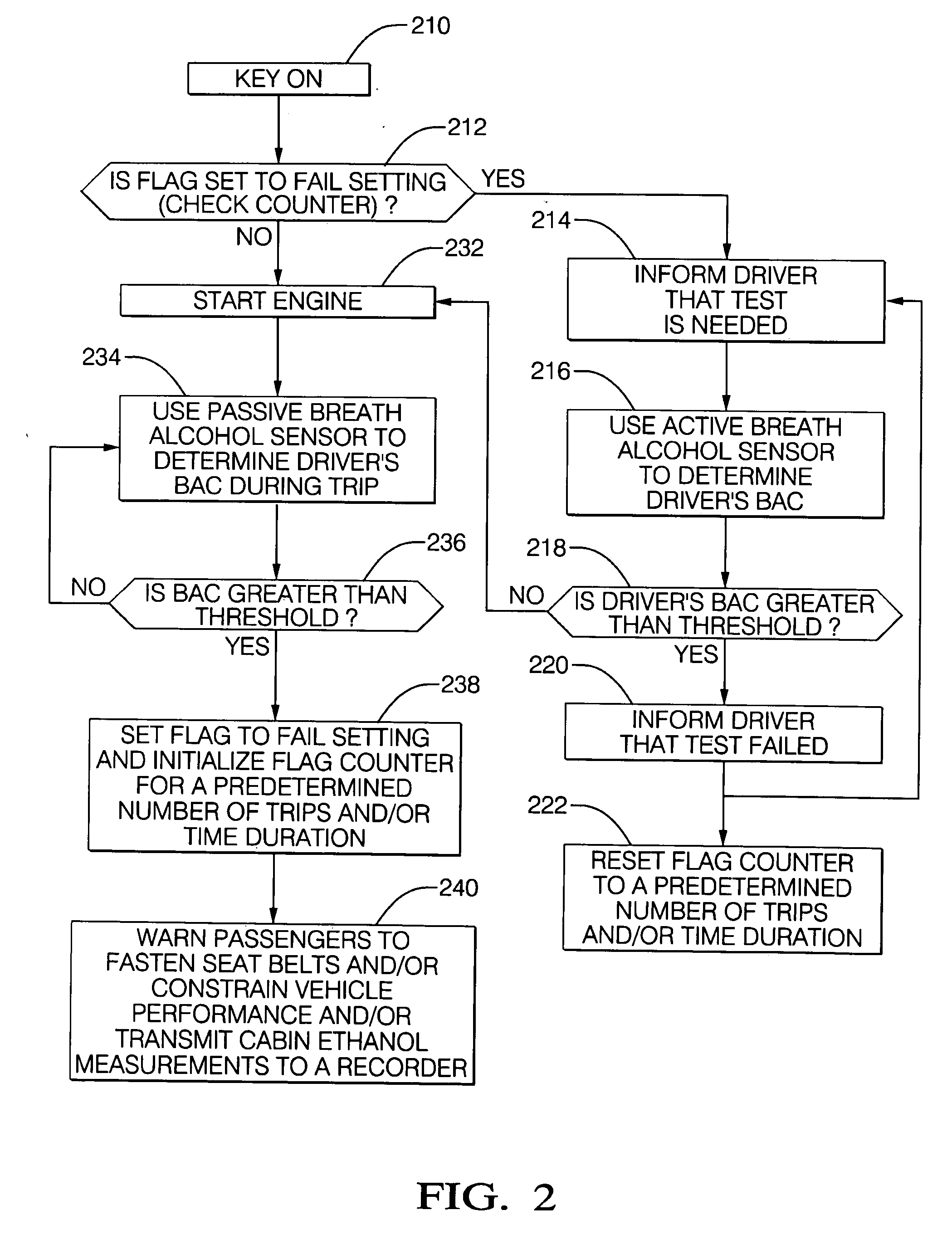

Chemical vapor sensor having an active and a passive measurement mode

ActiveUS20060153740A1High detection sensitivityMinimize time inconvenienceAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationDriver/operatorOn board

A chemical vapor sensor is provided that measures a chemical species of interest with high sensitivity and chemical specificity. In an aspect, an ethanol vapor sensor is provided, sized for being inconspicuous and on-board a vehicle, having a passive measurement mode and an active breathalyzer mode, for detecting a motor vehicle driver that exceeds a legal limit of blood alcohol concentration (BAC), for use with vehicle safety systems. For the passive mode, a vapor concentrator is utilized to amplify a sampled vapor concentration to a detectible level for use with an infrared (IR) detector. In an aspect, ethanol vapor in a vehicle cabin is passively measured and if a predetermined ethanol level is measured, a countermeasure is invoked to improve safety. In an aspect, an active breathalyzer is used as a countermeasure. The active breathalyzer can be imposed for a number of vehicle trips or for a predetermined time period.

Owner:APTIV TECH LTD

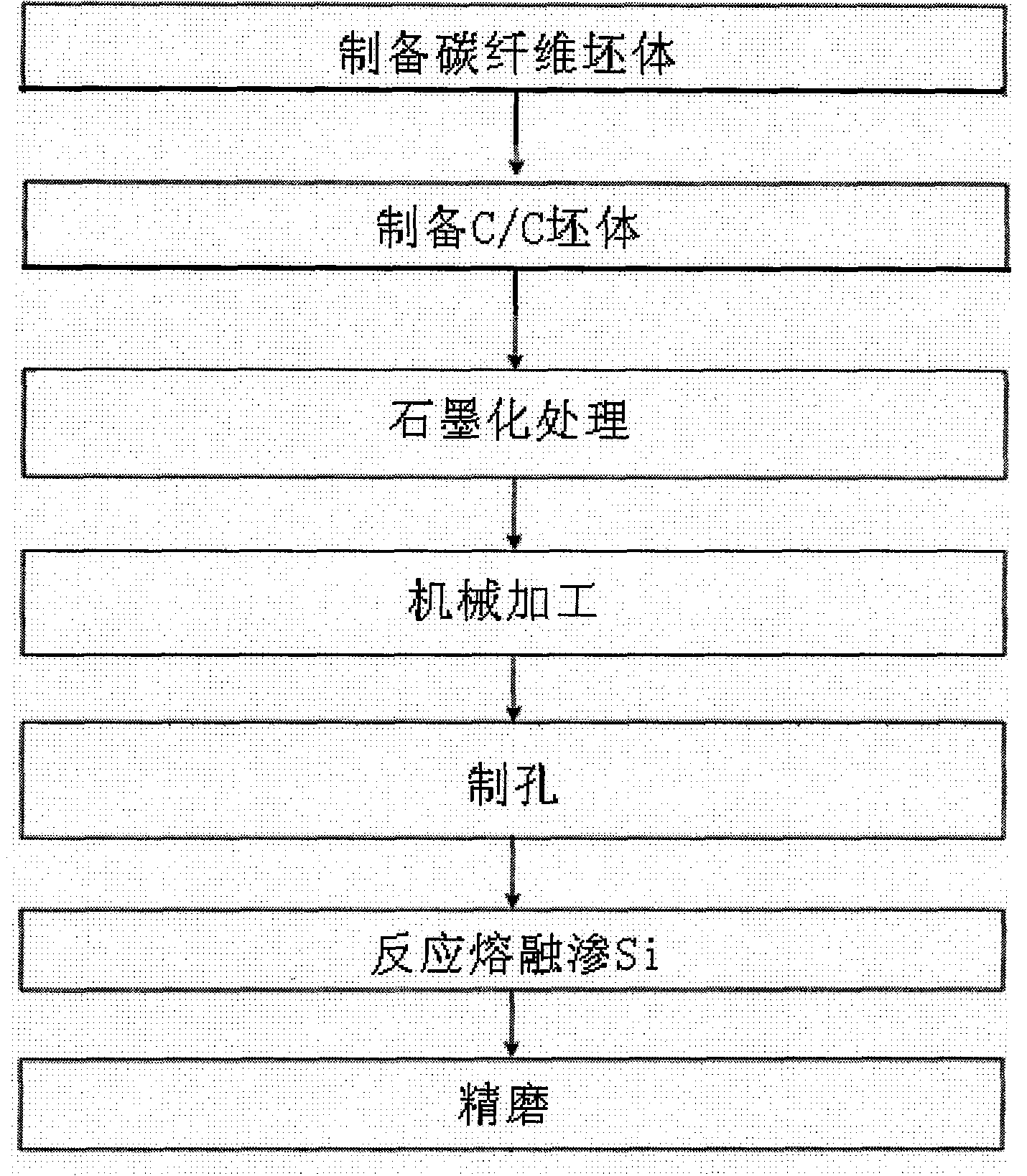

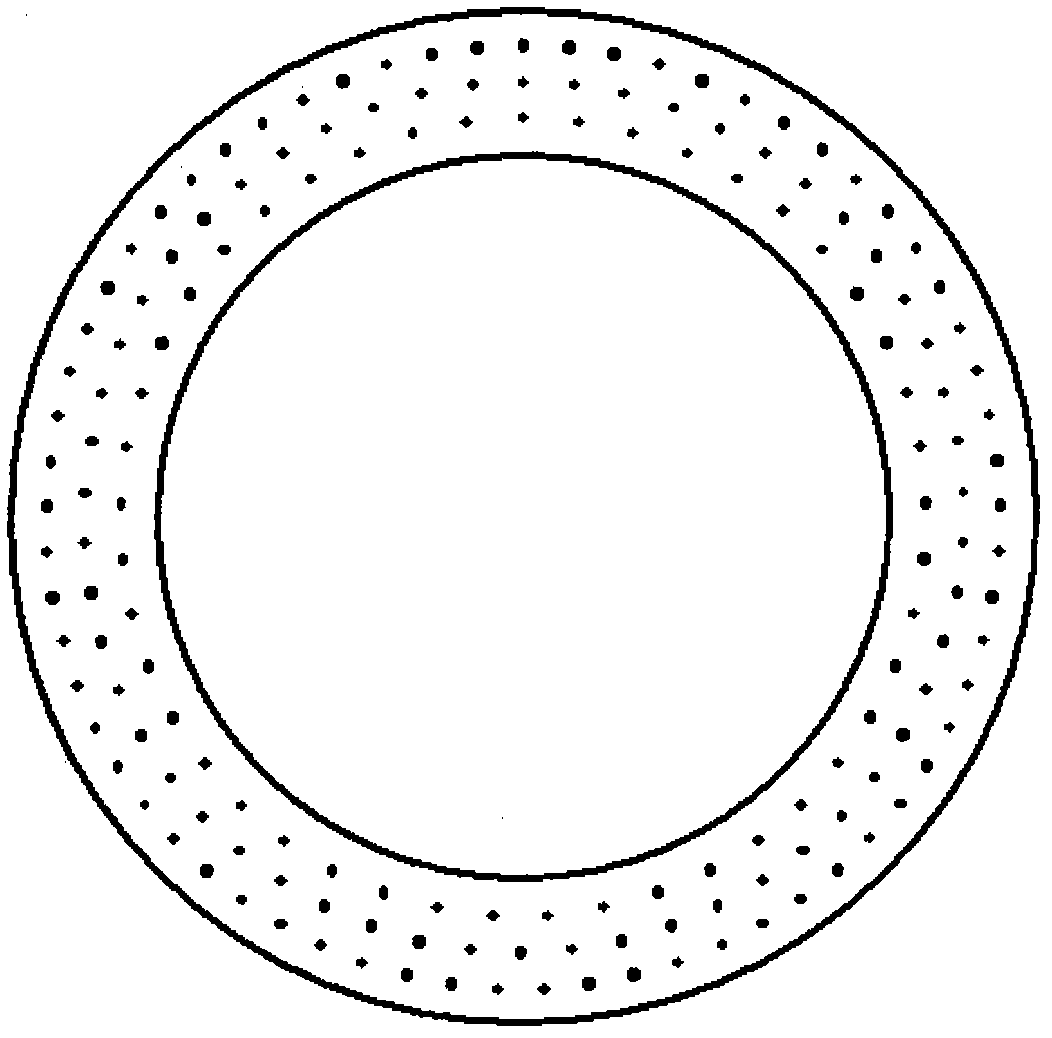

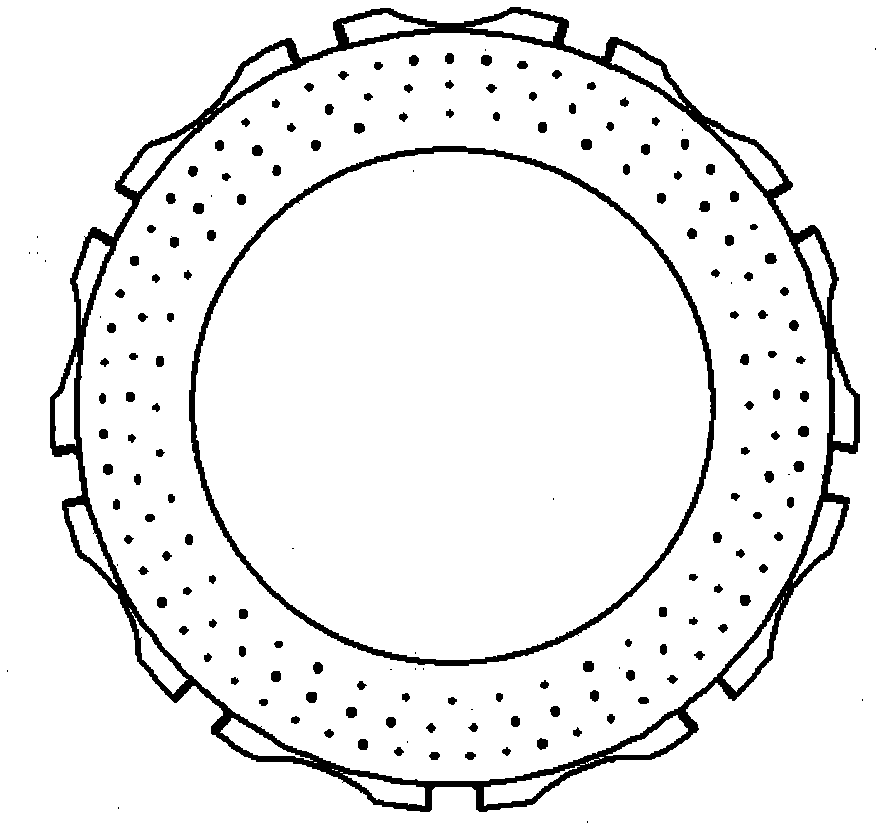

Method for manufacturing carbon ceramic brake disc

The invention relates to a method for manufacturing a carbon ceramic brake disc, which comprises the following steps of: preparing a carbon fiber blank body, performing natural gas chemical vapor immersion (CVI), graphitizing, machining, making holes, performing a melting reaction and grinding accurately to prepare a carbon ceramic composite brake disc, wherein in the hole making step, a plurality of through holes are distributed on a disc surface of the brake disc fully, and the center line of each through hole is perpendicular to the disc surface of the brake disc. In the method, the through holes distributed on the disc surface of the brake disc fully allows liquid state Si to permeate in the thickness direction of the brake disc uniformly and permeate on the whole friction surface uniformly in a melting Si permeating reaction and ensure the melting Si permeating reaction occurs at an area in the thickness direction intensively and influences the size of the thickness direction only without influencing the size at an area in the radial circumferencial direction basically, so that in the subsequent carbon ceramic machining, the thickness area is machined only. Therefore, the method has the characteristics that the Si permeating depth is desirable; the Si permeation is uniform; and products are easy to machine.

Owner:XIAN AVIATION BRAKE TECH

Composite coating carbon/carbon composite material crucible and preparation method thereof

The invention discloses a composite coating carbon / carbon composite material crucible comprising a carbon / carbon composite material crucible, a silicon carbide coating adhered on the inner surface of the carbon / carbon composite material crucible, a silicon coating adhered on the silicon carbide coating, and a silicon nitride coating adhered on the silicon coating. Also, the invention discloses a preparation method of the composite coating carbon / carbon composite material crucible. According to the invention, silicon nitride is combined with the silicon carbide composite coating, such that corrosion of silicon-containing steam upon the inner profile of the carbon / carbon composite material crucible can be effectively inhibited, and crucible service life is greatly improved. With a chemical vapor reaction method, SiC coating in-situ production is achieved. Compared with a traditional SiC coating prepared with a CVD method, the bonding strength with the carbon / carbon substrate is higher. Also, excessive Si coating is produced on site, such that Si source is provided for the production of the silicon nitride coating. The silicon nitride coating produced with high-purity nitrogen has improved bonding strength, such that corrosion resistance of the crucible is further improved.

Owner:XIAN CHAOMA SCI TECH

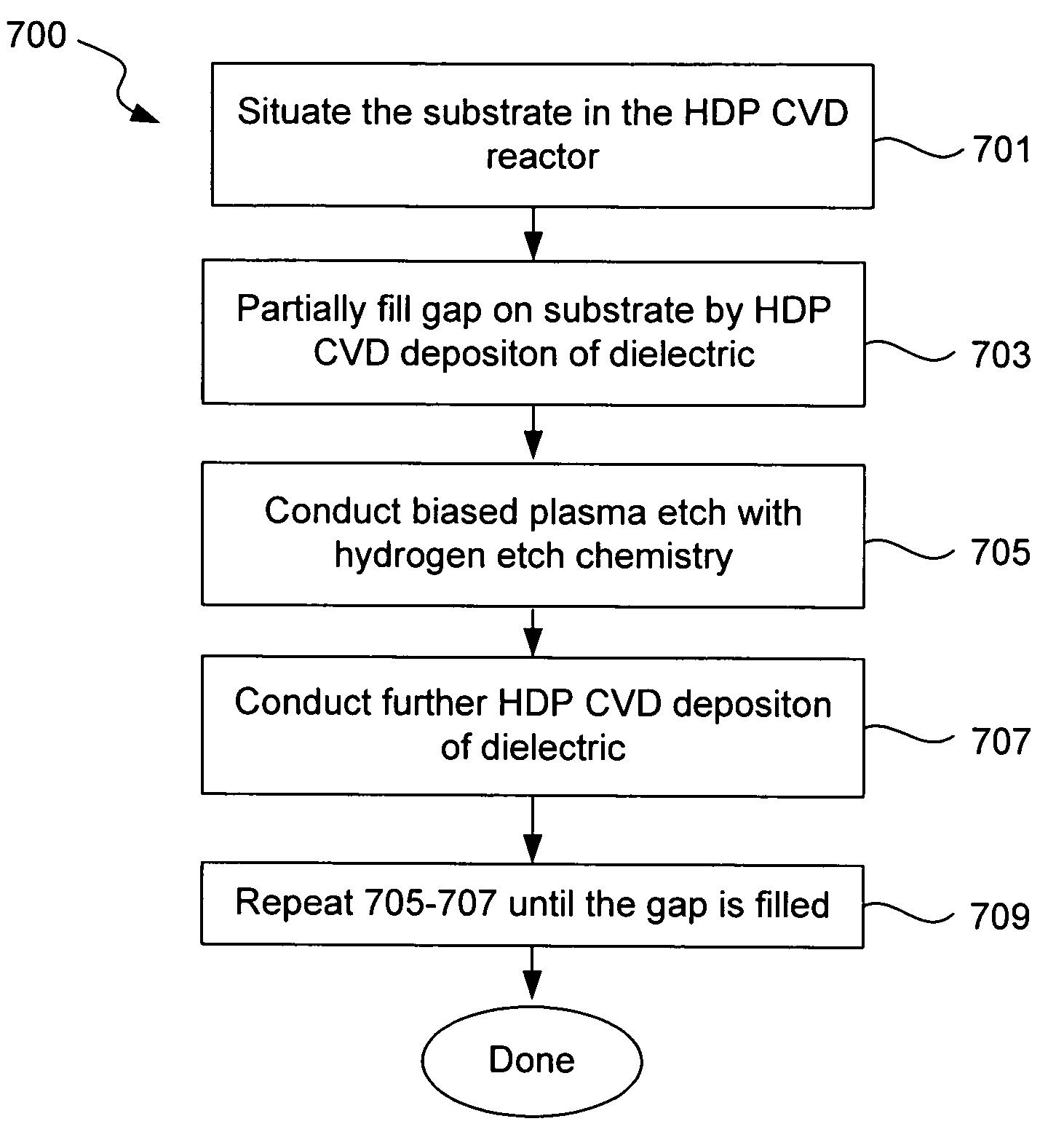

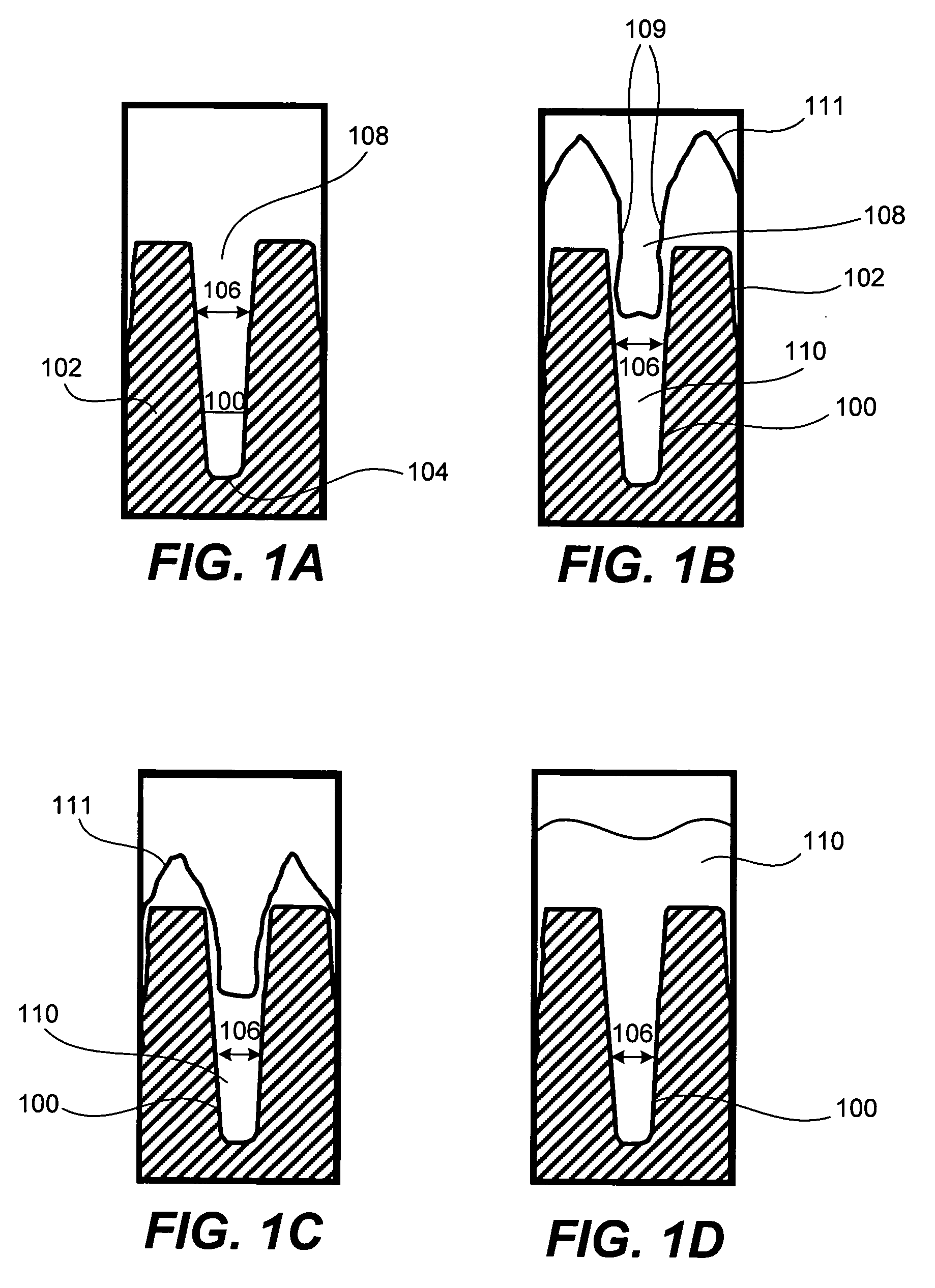

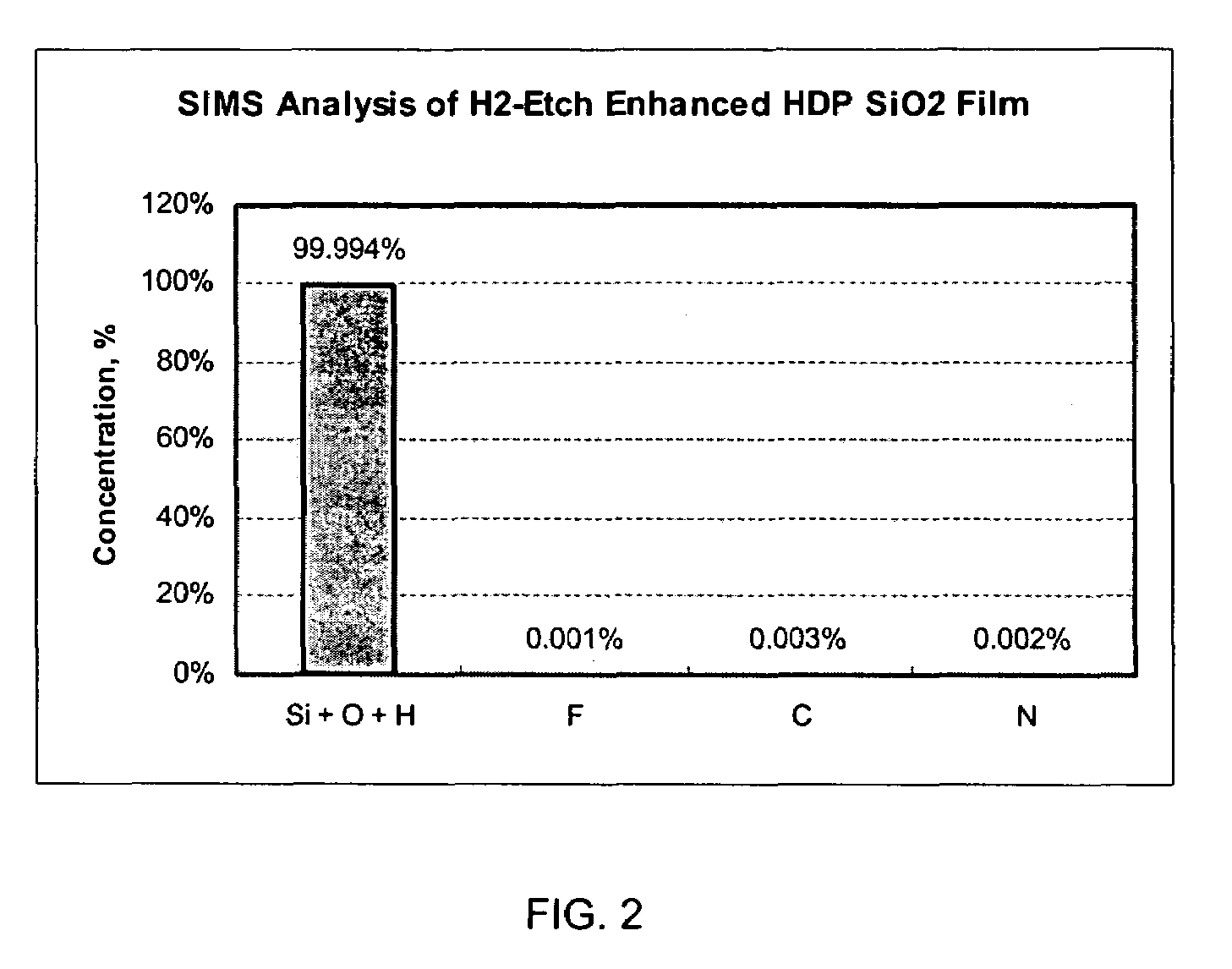

Biased H2 etch process in deposition-etch-deposition gap fill

ActiveUS7163896B1Reducing and eliminating dielectric contaminationEfficient fillingSemiconductor/solid-state device manufacturingChemical speciesHigh density

Owner:NOVELLUS SYSTEMS

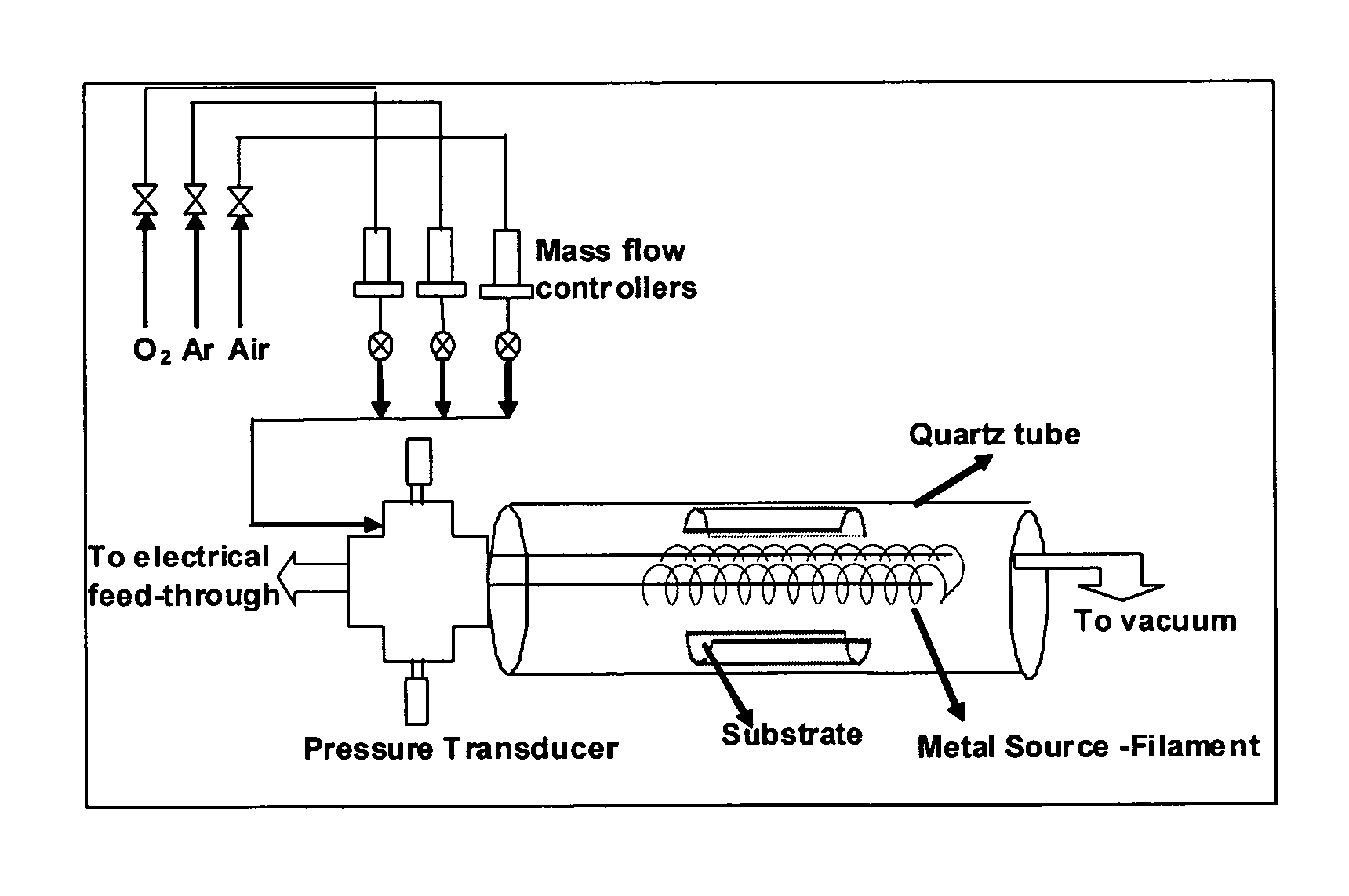

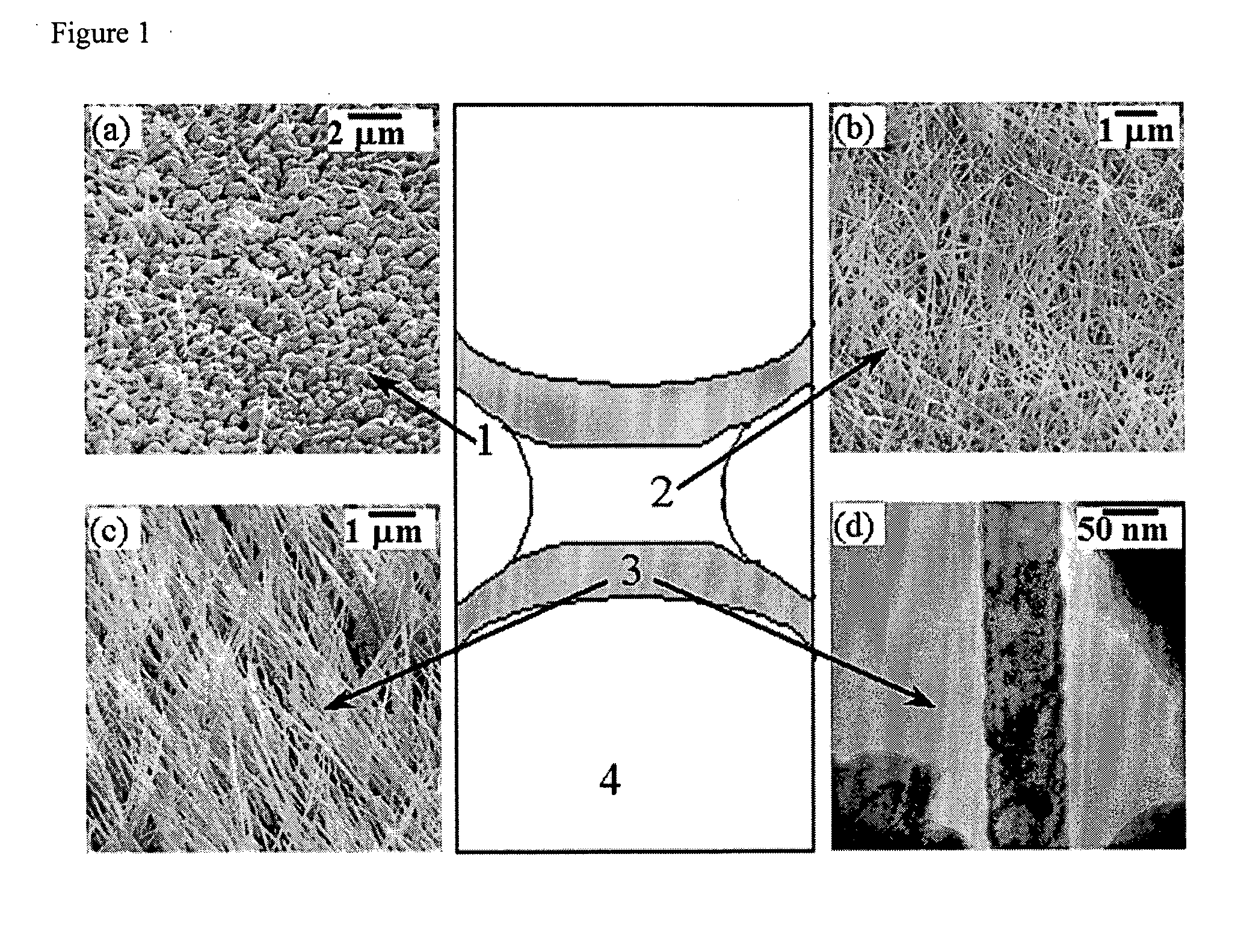

Vapor phase synthesis of metal and metal oxide nanowires

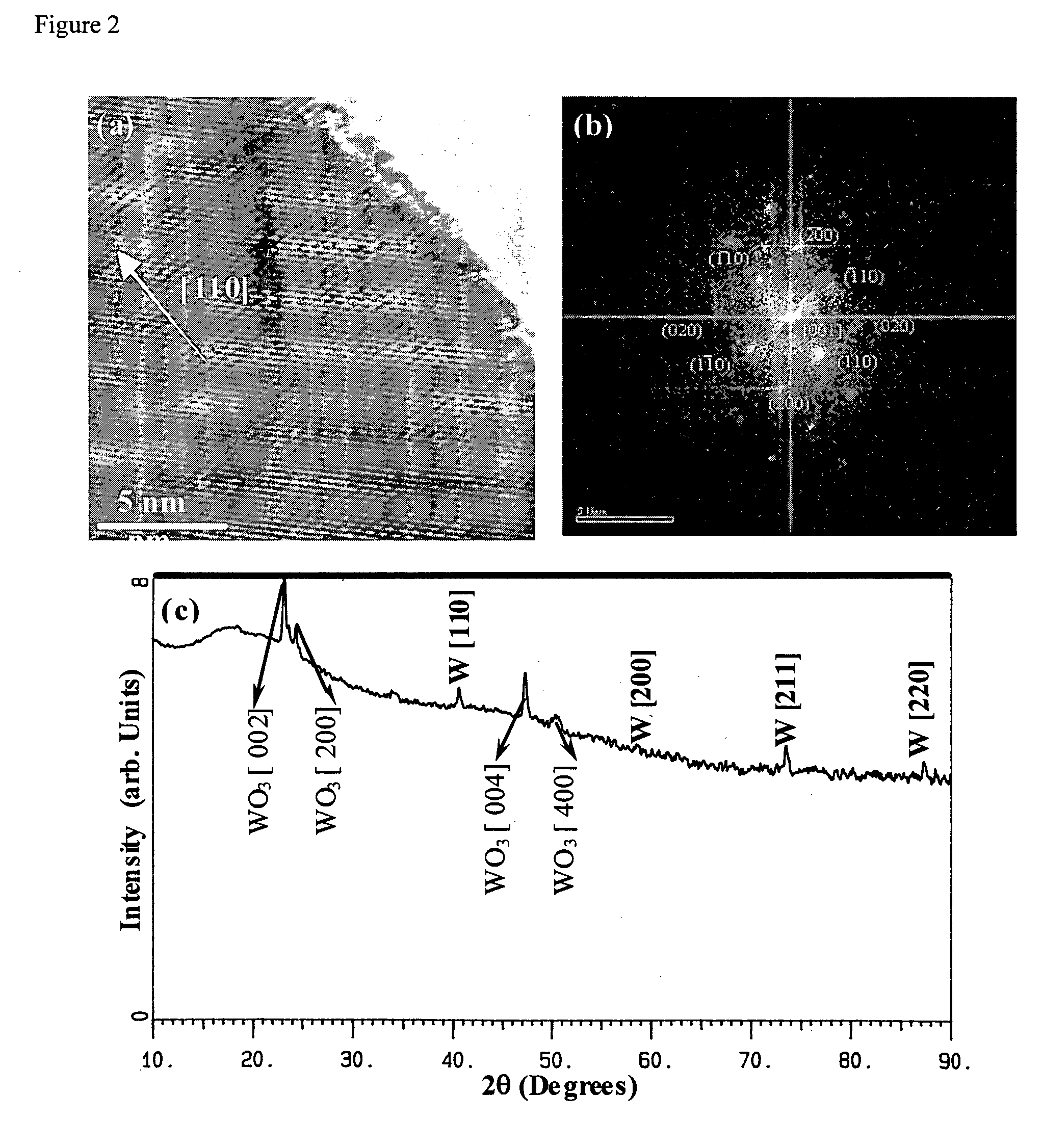

InactiveUS20070087470A1Reduce the temperaturePolycrystalline material growthSolid-state devicesDecompositionGas phase

Vapor phase methods for synthesizing metal nanowires directly without the help of templates. A vapor phase method in which nucleation and growth of metal oxides at temperatures higher than the oxide decomposition temperatures lead to the respective metal nanowires. The chemical vapor transport of tungsten in the presence of oxygen onto substrates kept at temperatures higher than the tungsten oxide decomposition temperature (˜1450° C.) led to nucleation and growth of pure metallic tungsten nanowires. In a similar procedure, tungsten oxide nanowires were synthesized by maintaining the substrates at a temperature lower than the decomposition temperature of tungsten oxide. The vapor transport of low-melting metal oxides provides a procedure for synthesizing metal and metal oxide nanowires.

Owner:UNIV OF LOUISVILLE RES FOUND INC

Deposition precursors for semiconductor applications

InactiveUS20080248648A1Improve responseHigh crystallinityCobalt organic compoundsSemiconductor/solid-state device manufacturingElectron donorGas phase

This invention relates to organometallic compounds comprising at least one metal or metalloid and at least one substituted anionic 6 electron donor ligand having sufficient substitution (i) to impart decreased carbon concentration in a film or coating produced by decomposing said compound, (ii) to impart decreased resistivity in a film or coating produced by decomposing said compound, or (iii) to impart increased crystallinity in a film or coating produced by decomposing said compound. The organometallic compounds are useful in semiconductor applications as chemical vapor or atomic layer deposition precursors for film depositions.

Owner:PRAXAIR TECH INC

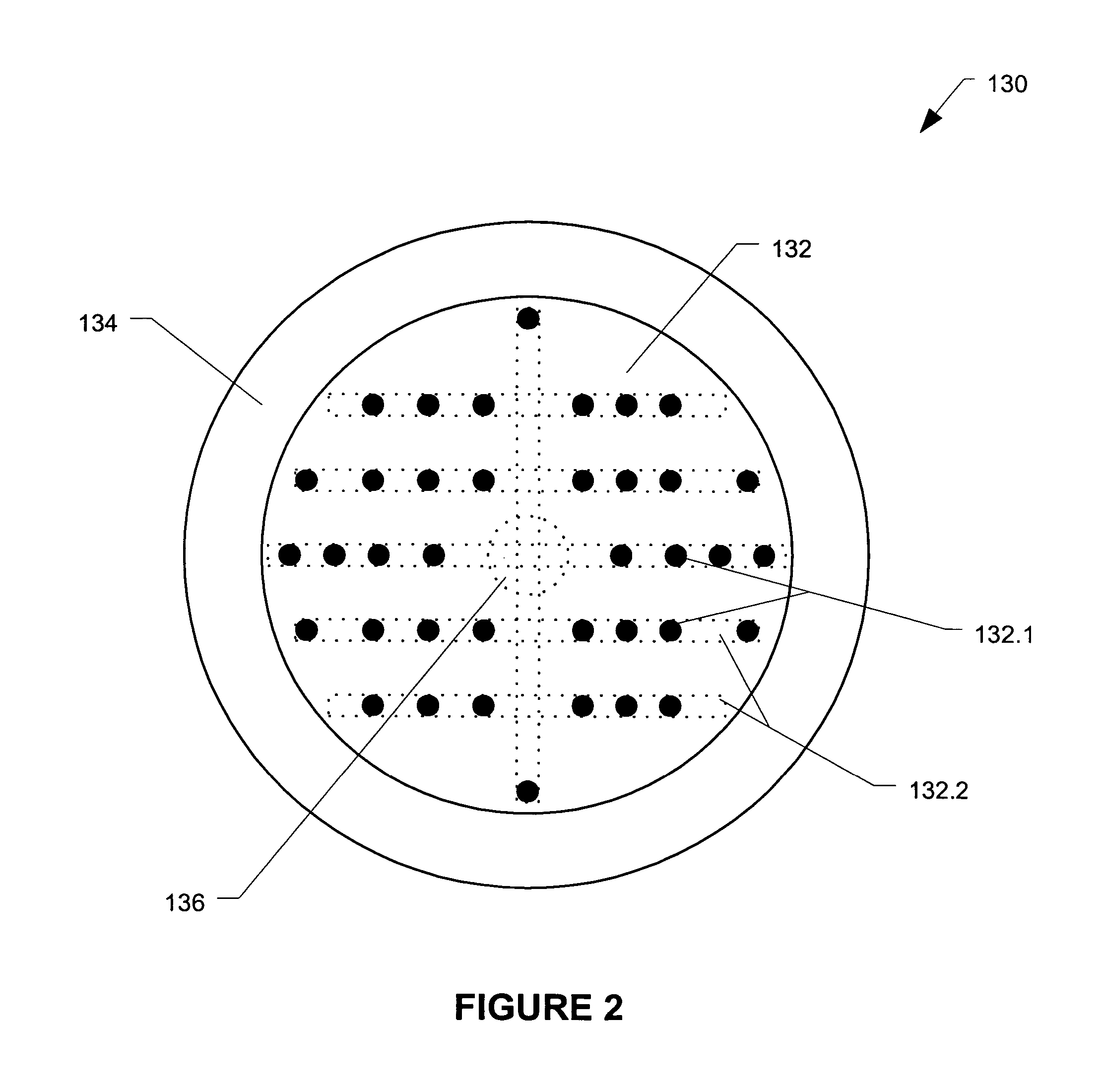

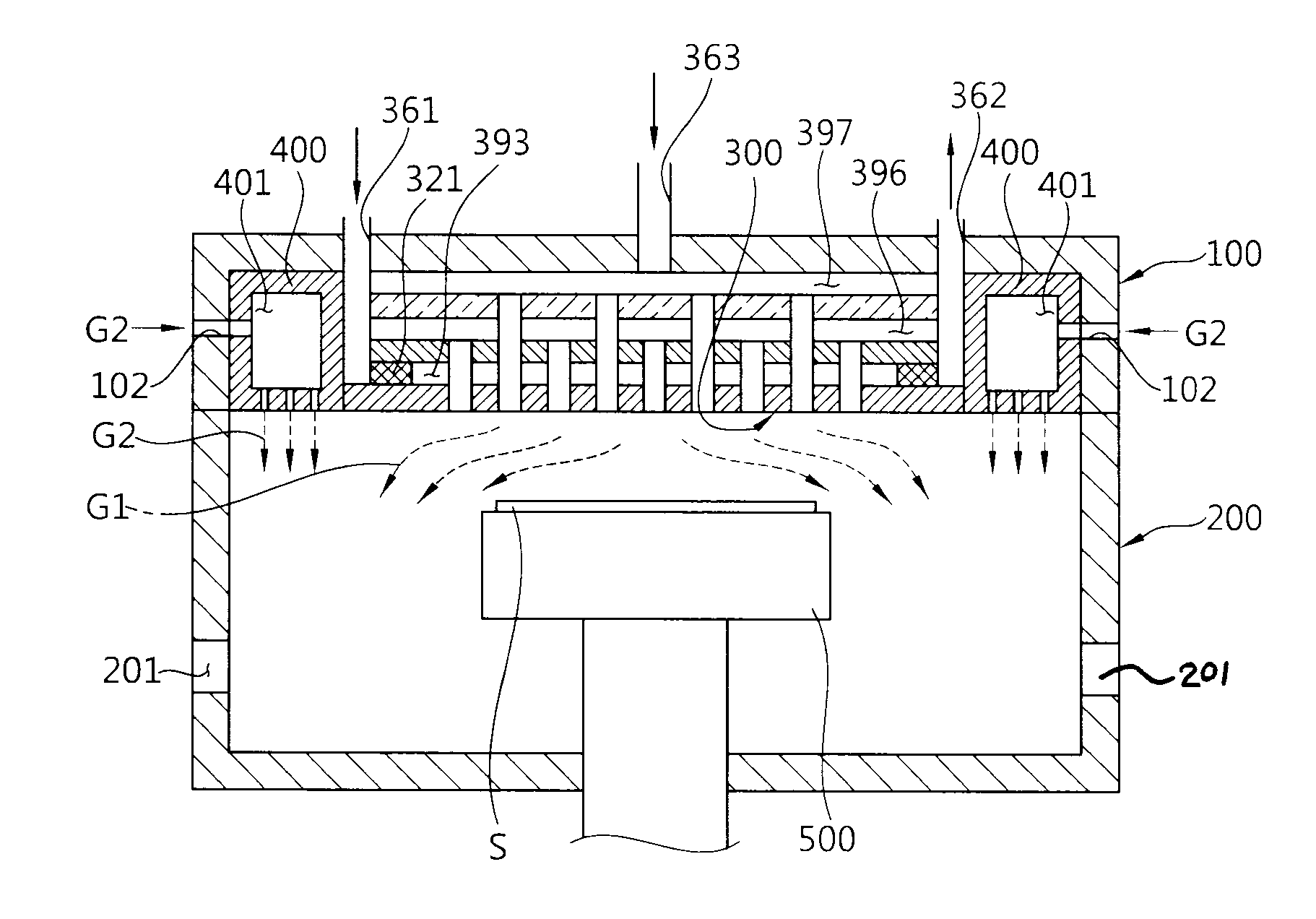

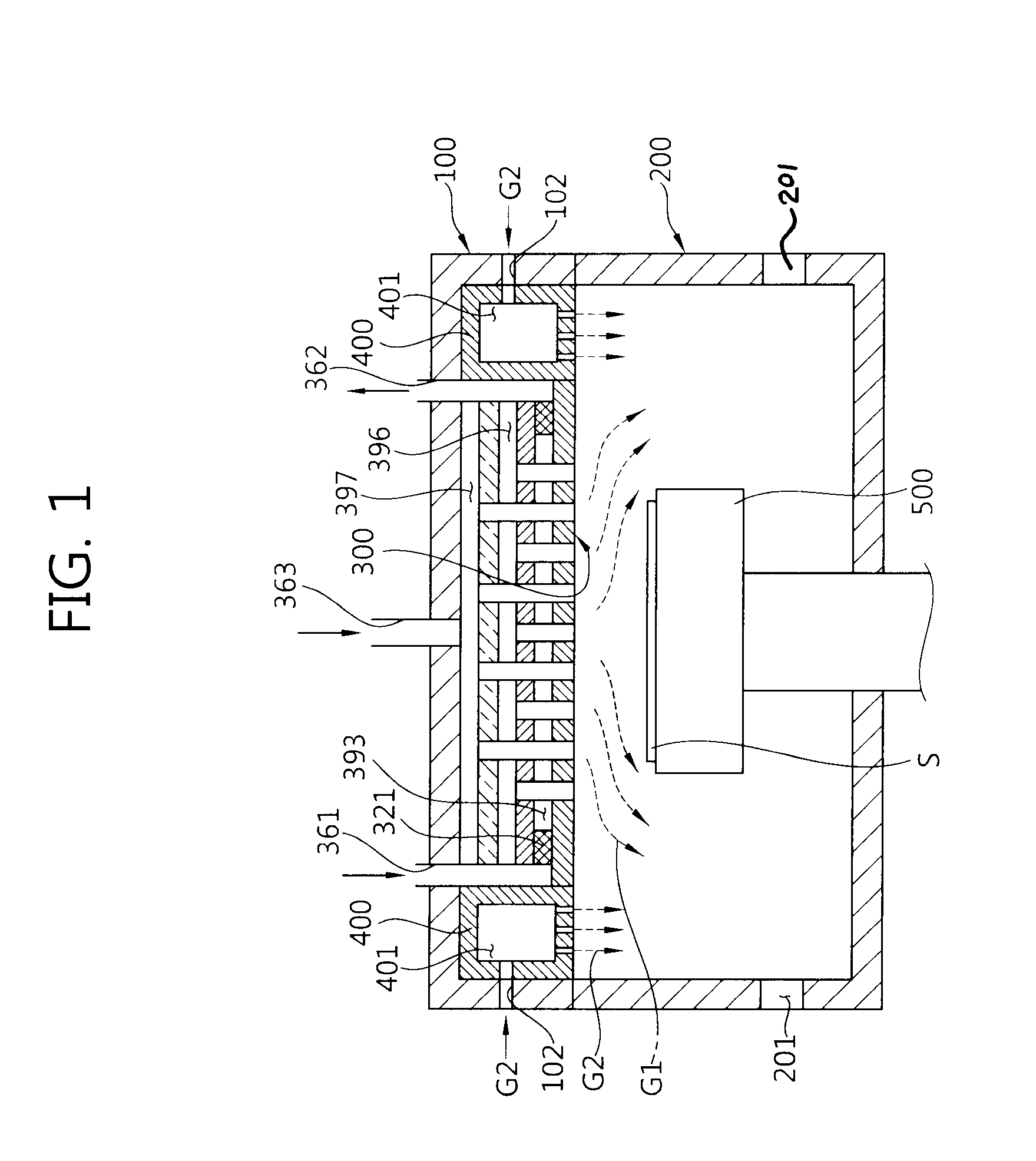

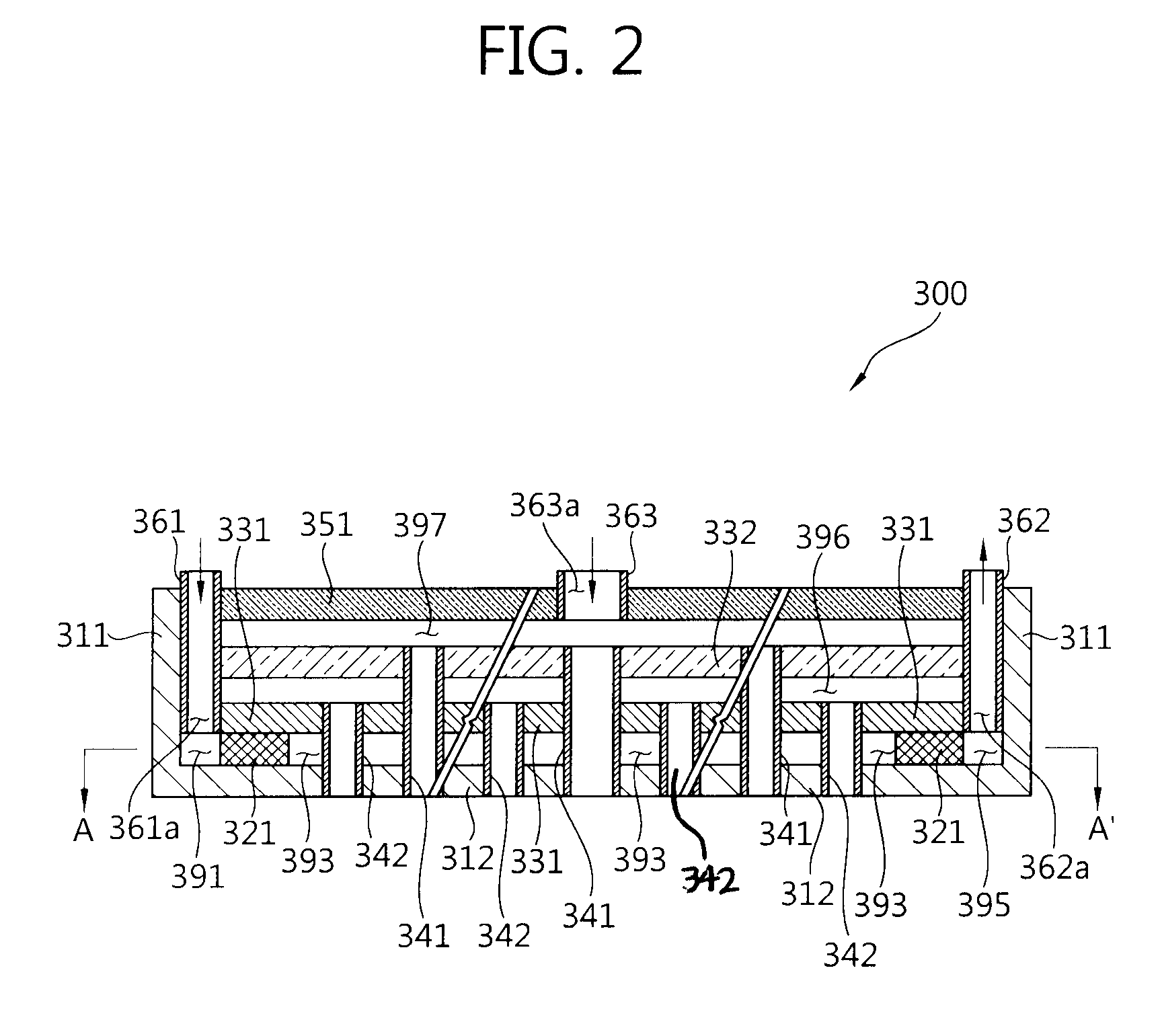

Gas injection unit for chemical vapor desposition apparatus

InactiveUS20110023782A1Easy to manufactureCool evenlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

A gas injection unit allows uniform cooling thereof via smooth flow of coolant and can be easily manufactured. The gas injection unit for a chemical vapor deposition apparatus includes, inter alia: a gas distribution housing; a cooling housing positioned between the gas distribution housing and a processing chamber where a deposition process is performed, and formed with a coolant inlet through which coolant is introduced, and a coolant outlet through which the coolant is discharged; a processing gas pipe of which one end is opened to the gas distribution housing and the other end is opened to the processing chamber, the processing gas pipe penetrating the cooling housing; and a first wall part positioned inside the cooling housing such that an inside of the cooling housing is partitioned into a central path and a peripheral path, and formed with a penetration hole such that the central path communicates with the peripheral path.

Owner:LIGADP

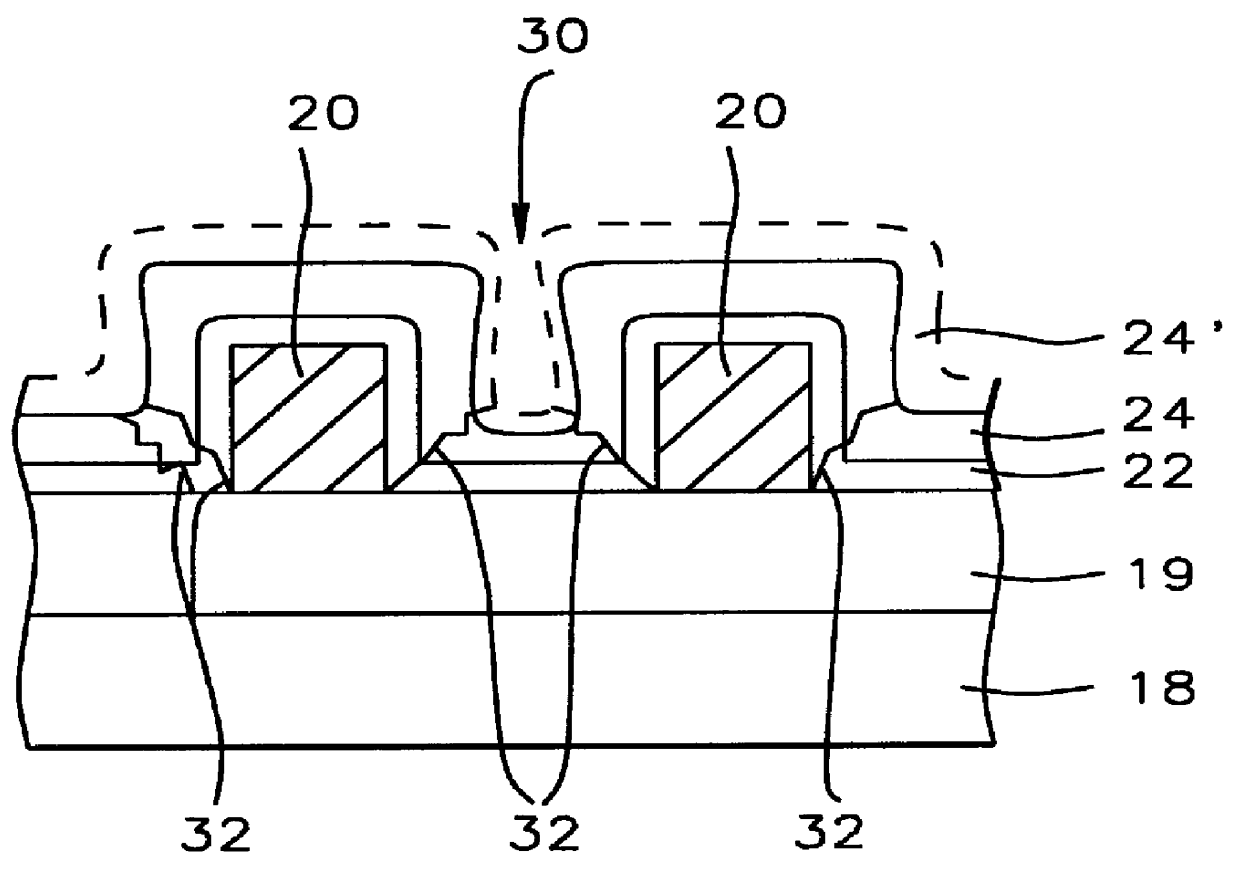

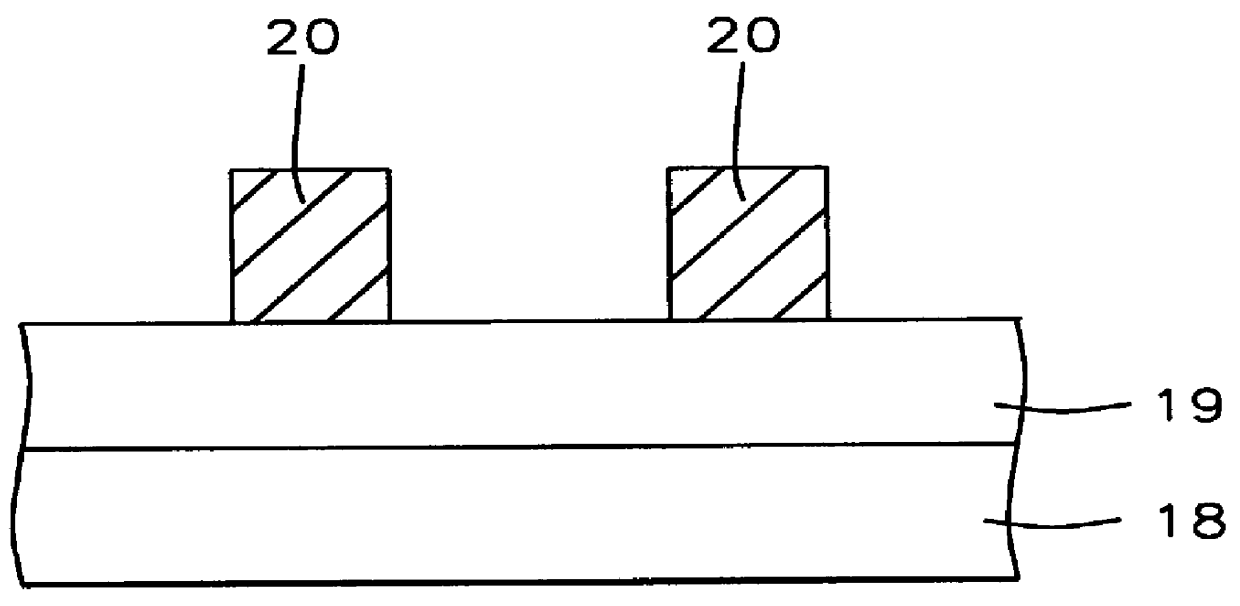

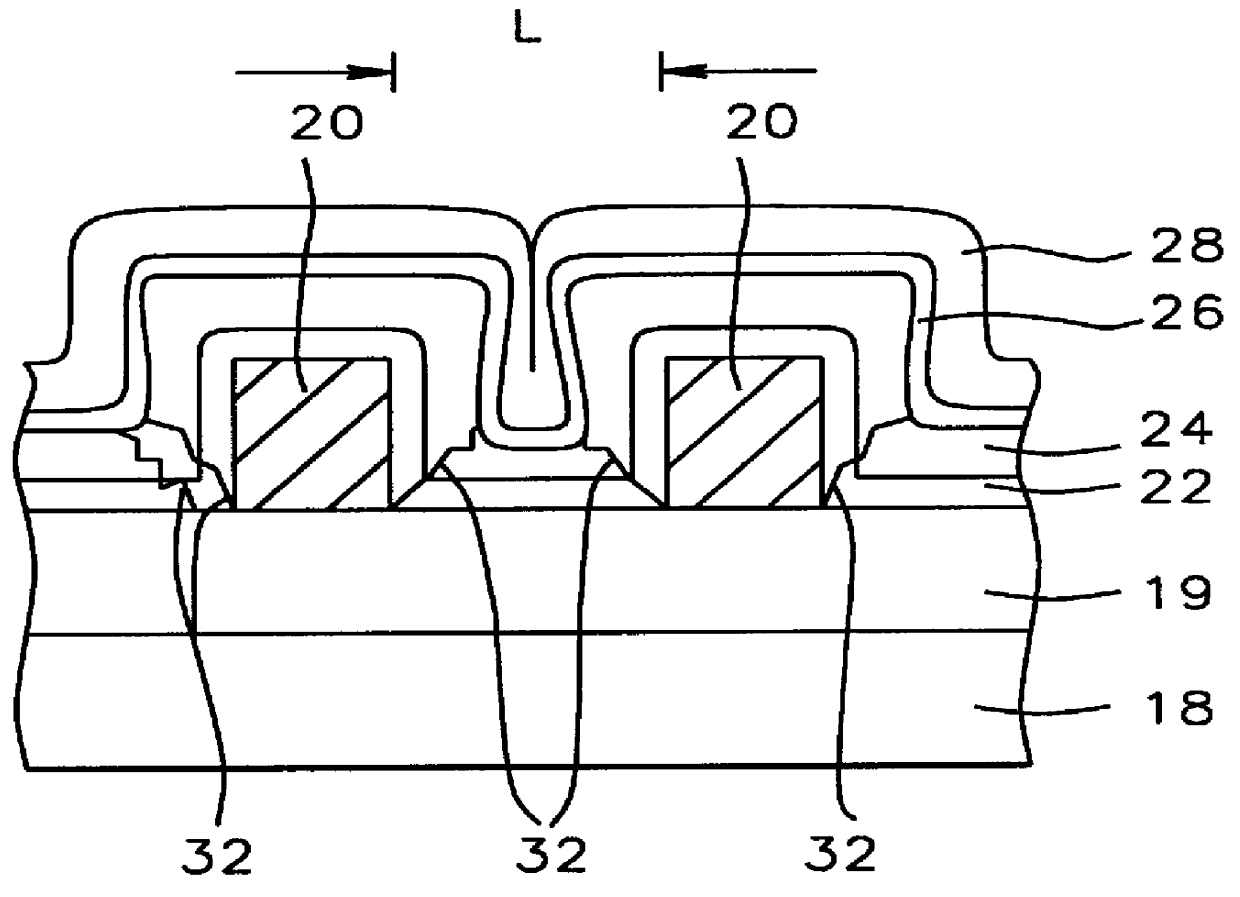

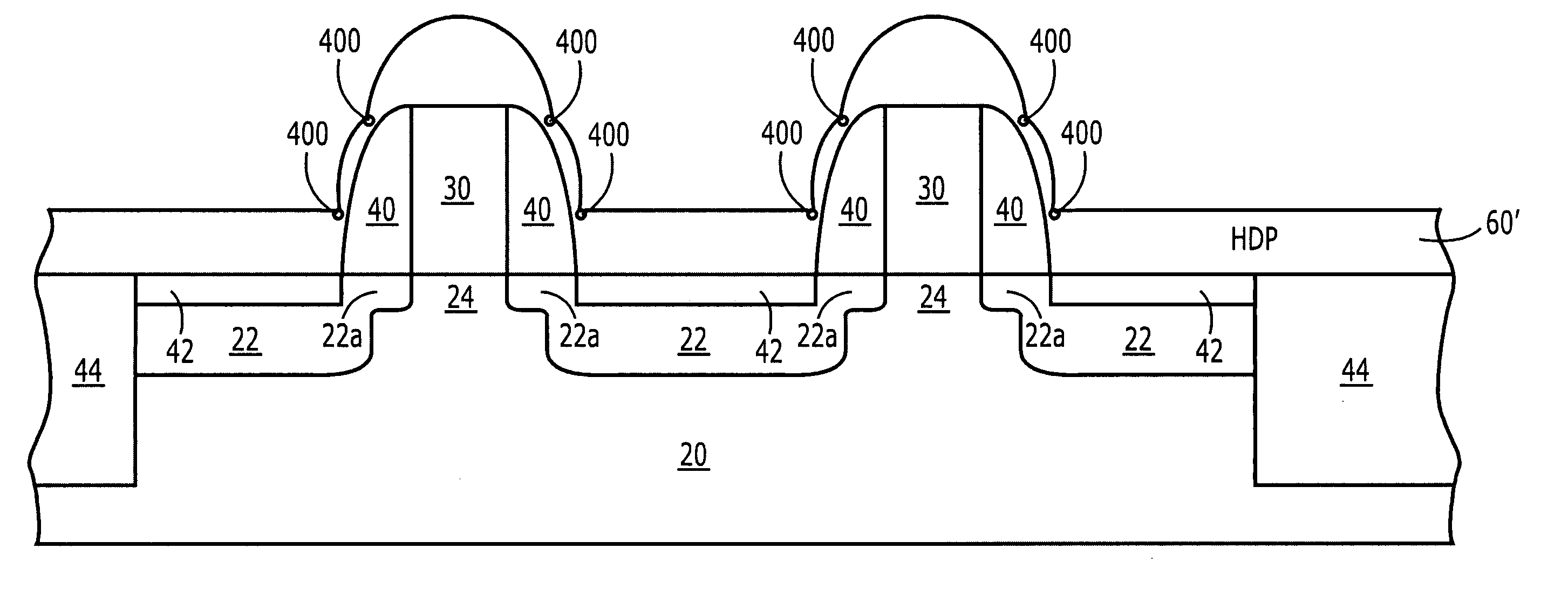

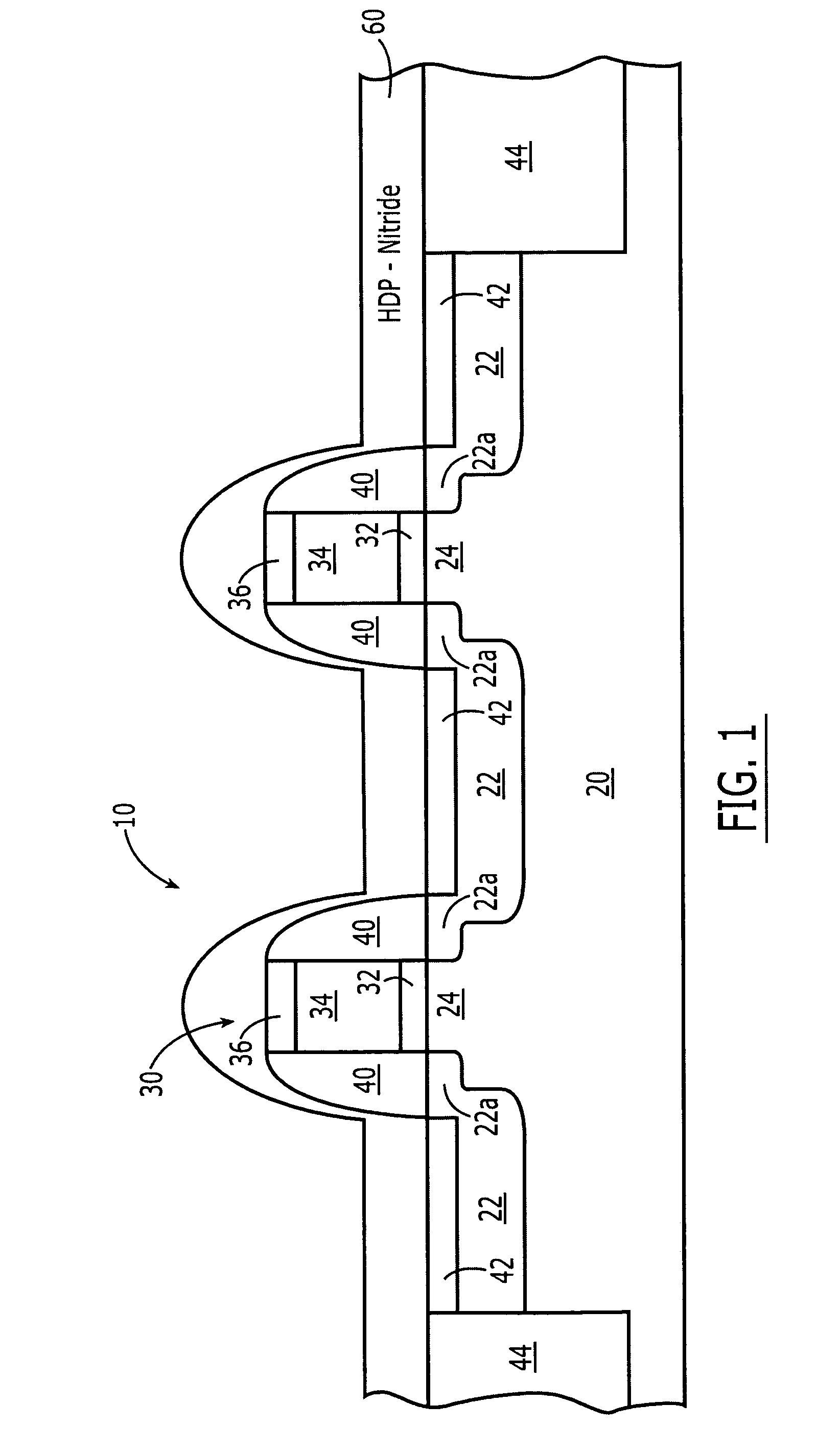

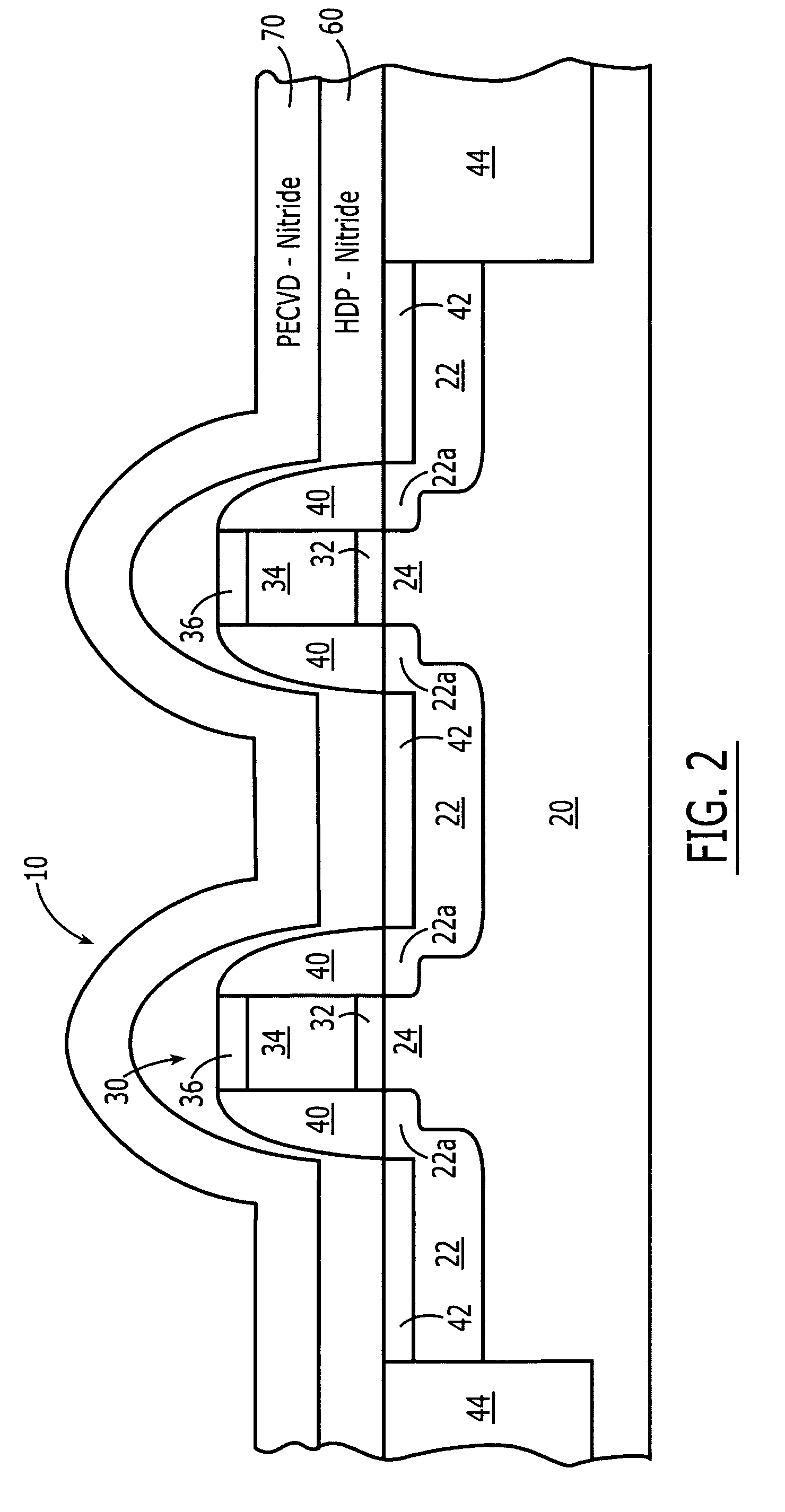

HDP/PECVD methods of fabricating stress nitride structures for field effect transistors, and field effect transistors so fabricated

ActiveUS20070096220A1Uniform thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesHigh densityComputational physics

A stress nitride structure is formed on an integrated circuit field effect transistor by high density plasma (HDP) depositing a first stress nitride layer on the integrated circuit field effect transistor and then plasma enhanced chemical vapor depositing (PECVD) a second stress nitride layer on the first stress nitride layer. The first stress nitride layer is non-conformial and the second stress nitride layer is conformal. Related structures also are described.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com