Patents

Literature

1986 results about "Boron carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron carbide (chemical formula approximately B₄C) is an extremely hard boron–carbon ceramic and covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications. With a Vickers Hardness of >30 GPa, it is one of the hardest known materials, behind cubic boron nitride and diamond.

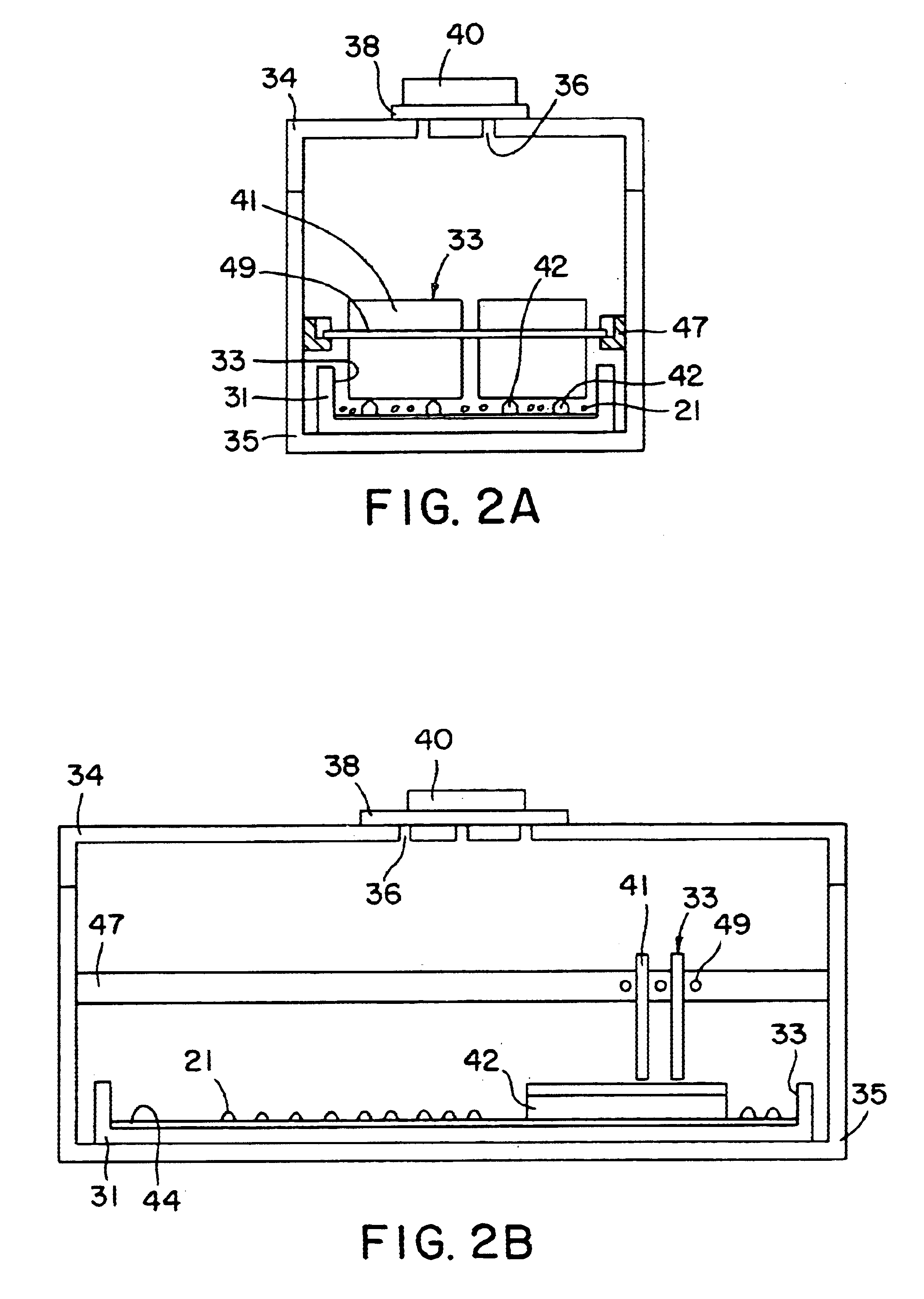

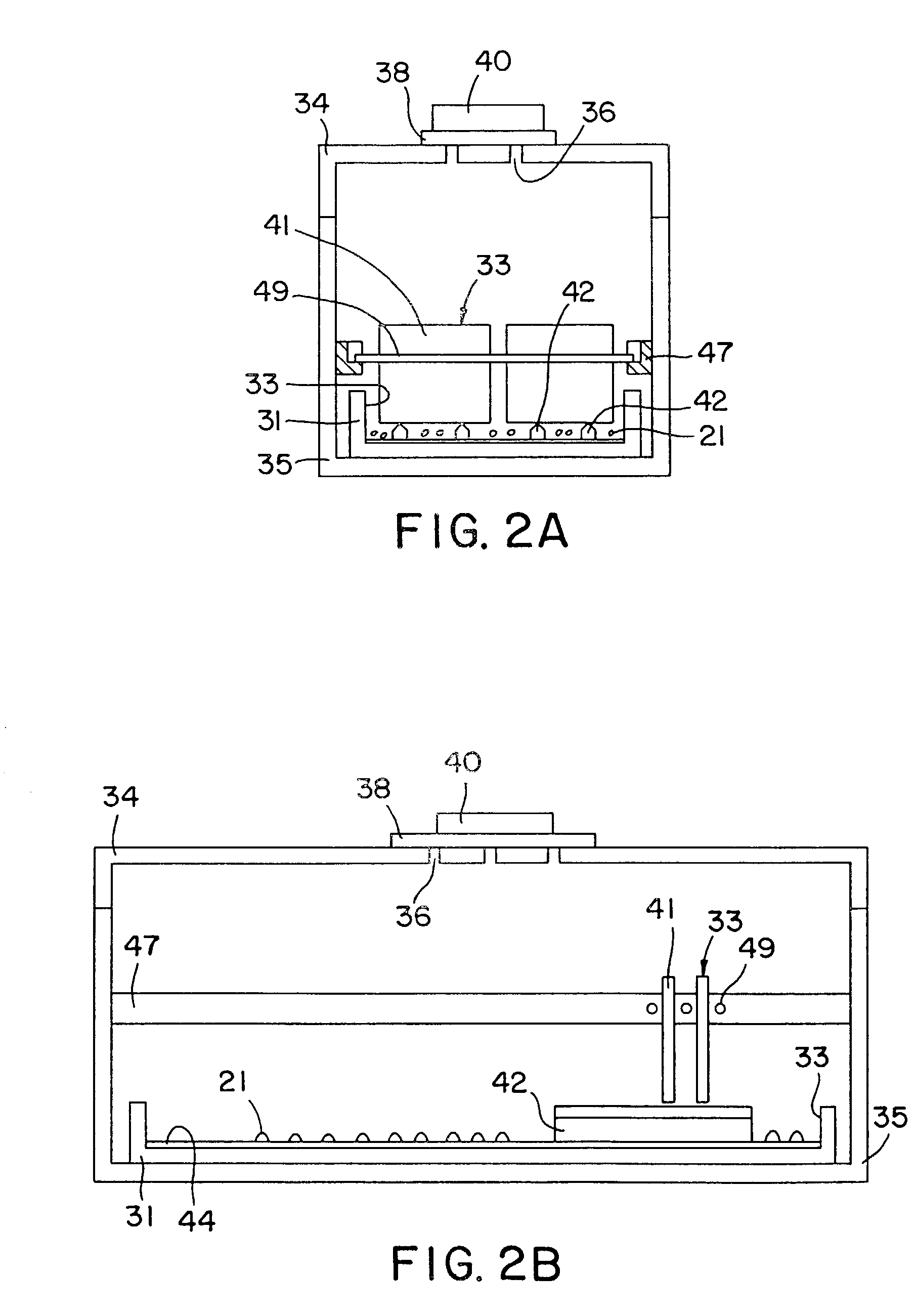

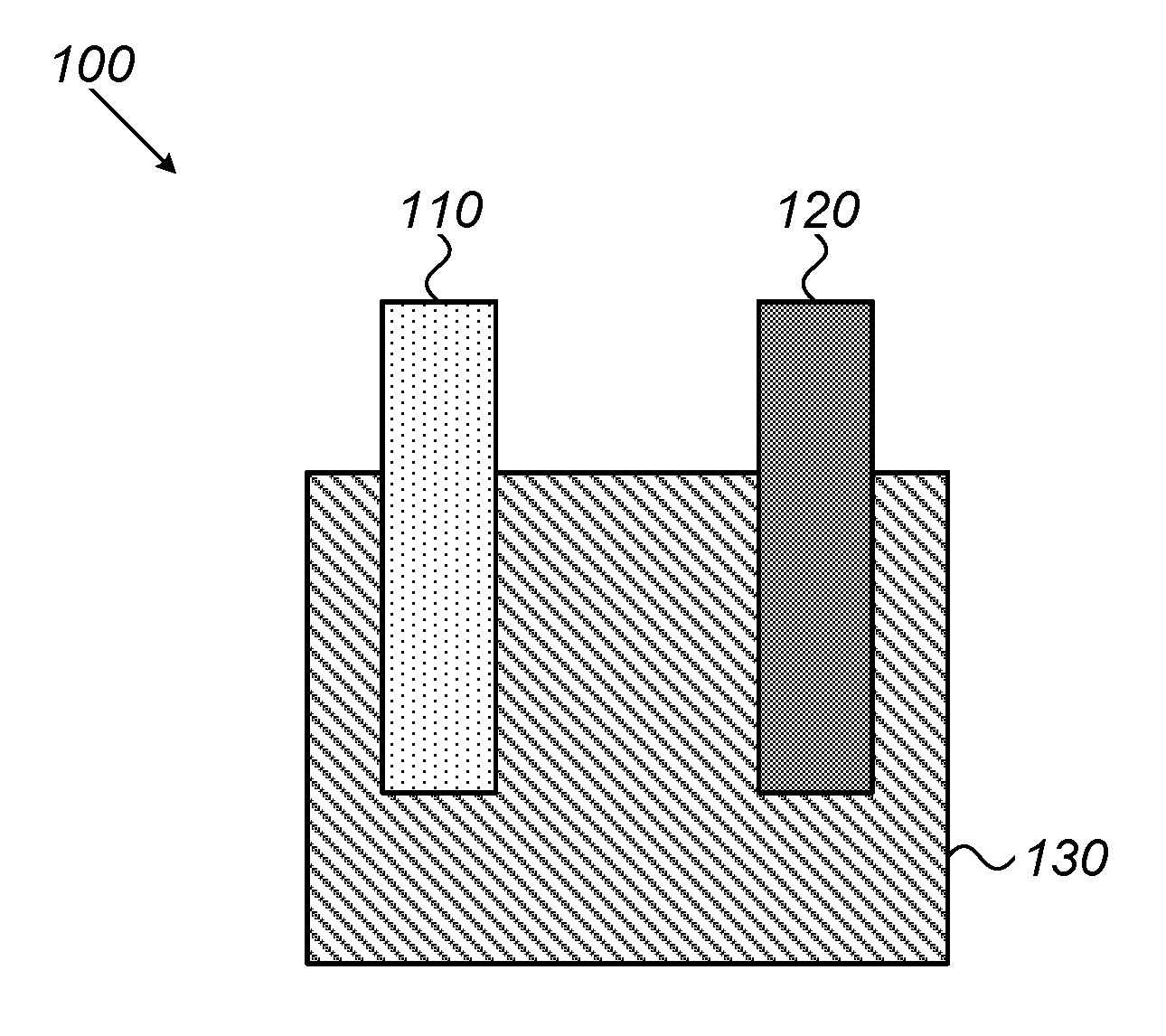

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

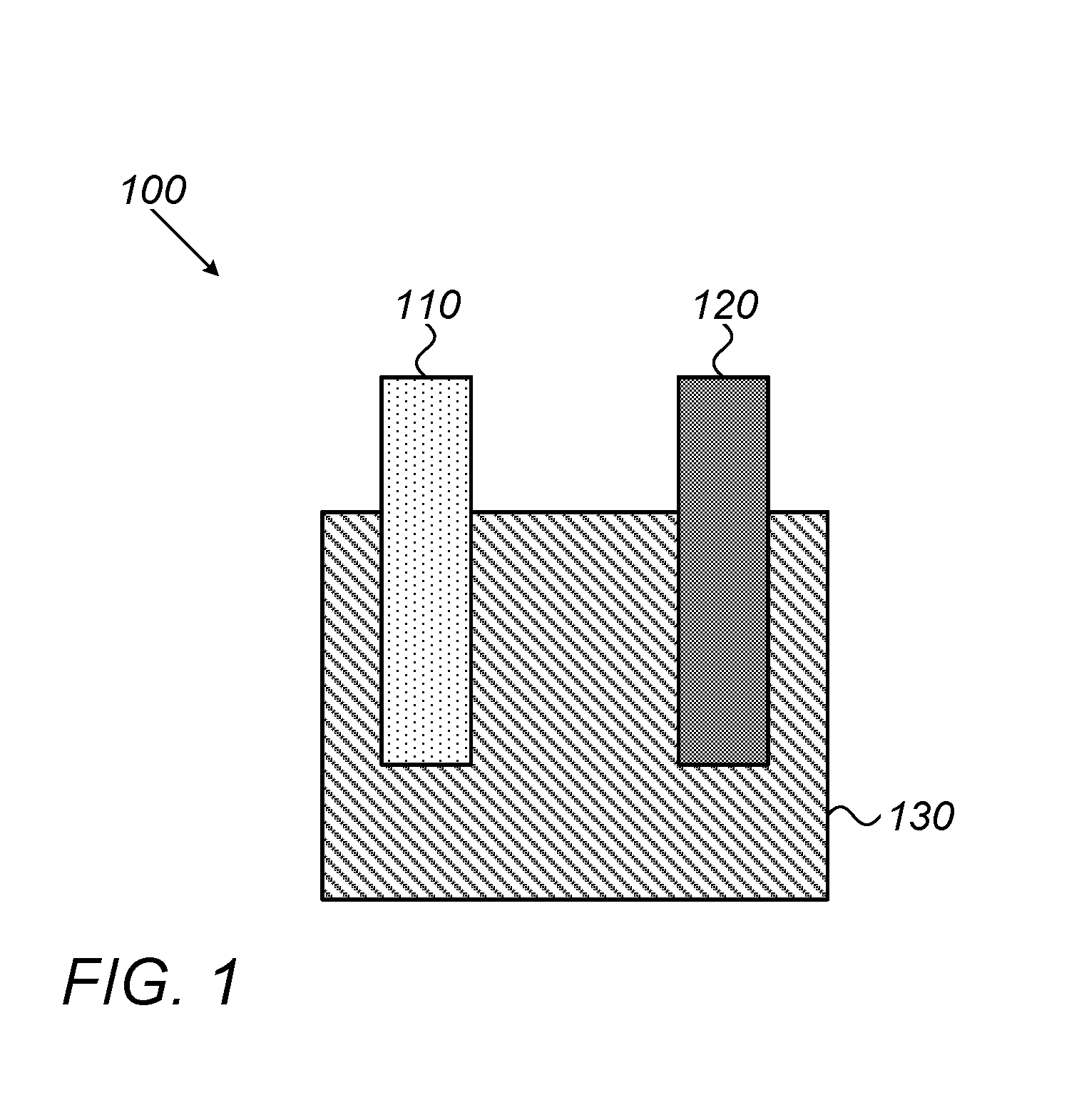

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

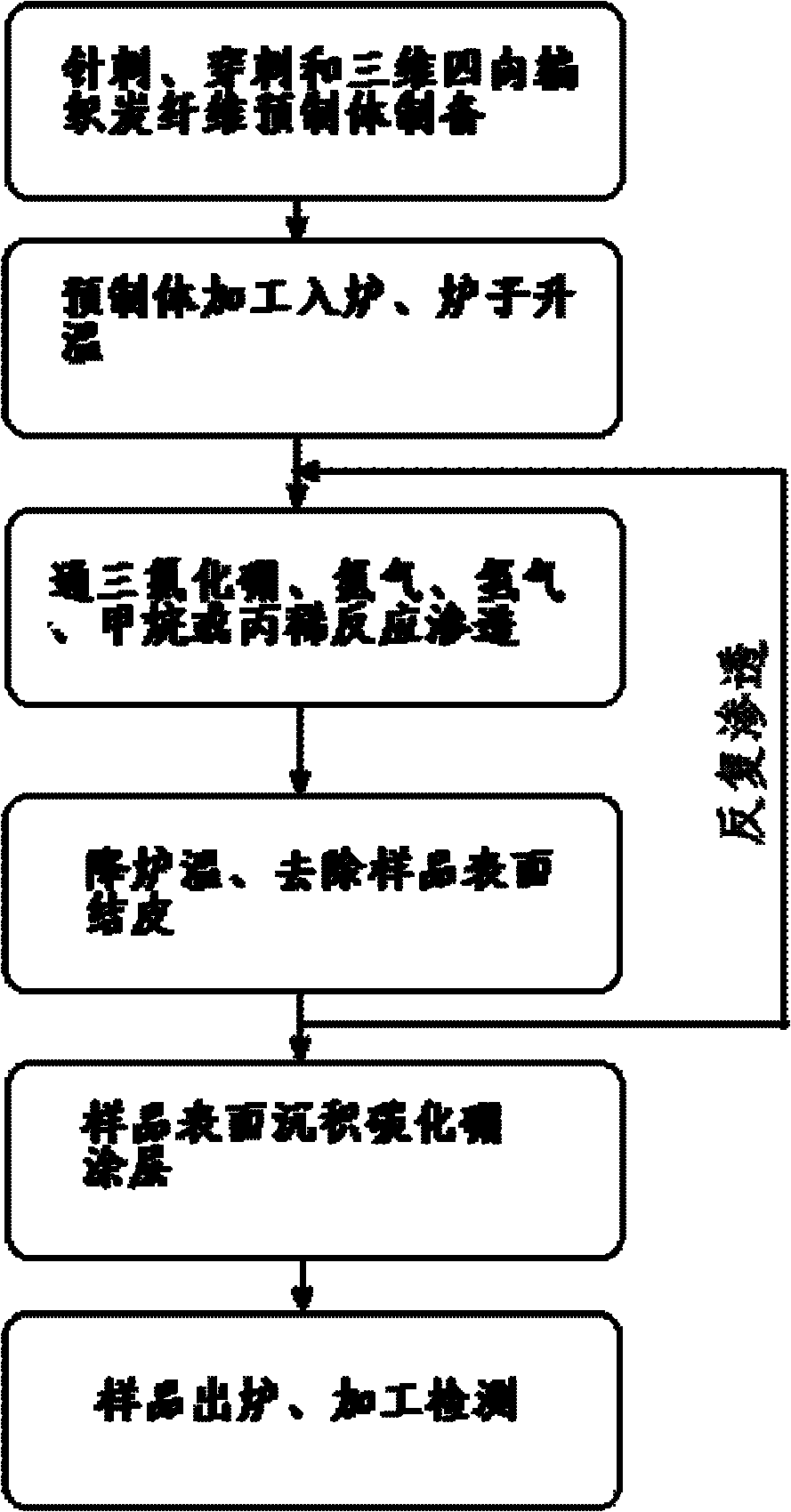

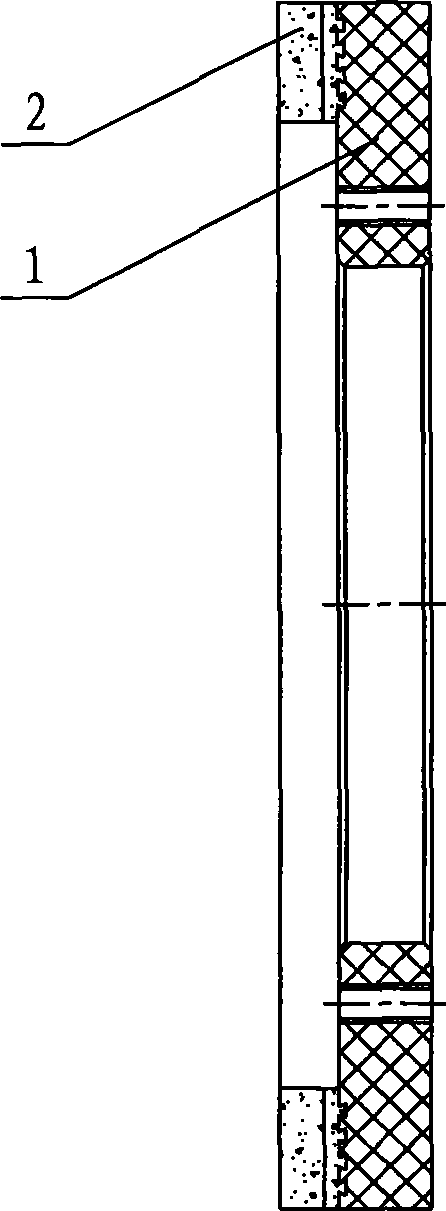

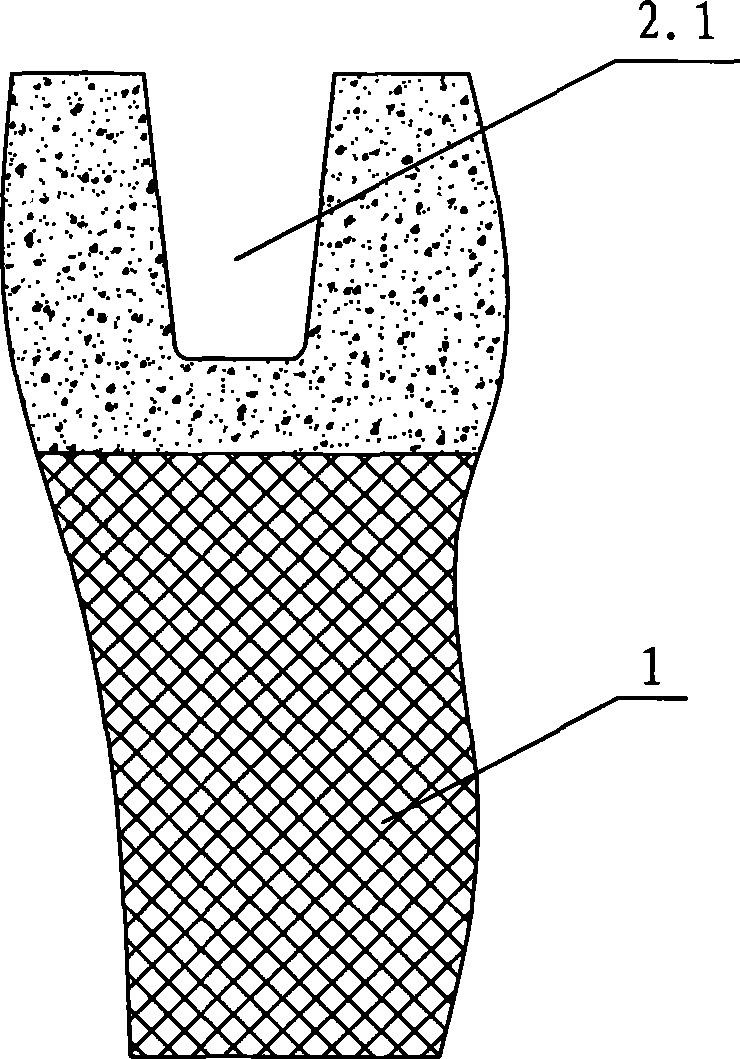

Carbon fiber reinforced boron carbide composite material and preparation method thereof

The invention relates to a carbon fiber reinforced boron carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: preparing a carbon fiber preform by adopting a needling, puncturing or three-dimensional weaving process; and depositing boron carbide matrix in the porous carbon fiber preform by osmosis to form the compact carbon fiber reinforced boron carbide composite material. Aiming at a certain specific application environment, a boron carbide coat can be deposited on the surface of a sample by adopting the same chemical vapor osmosis process. The carbon fiber reinforced boron carbide-based composite material manufactured by the method has the characteristics of good mechanical property, toughness superior to that of the traditional sintered boron carbide, compact structure, light weight, abrasion resistance and high hardness, and is suitable to be applied to a high-temperature light structural component.

Owner:CENT SOUTH UNIV

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

Boron carbide composite bodies, and methods for making same

InactiveUS6862970B2Less expensivelyLow production costDoor/window protective devicesLayered productsReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC +1

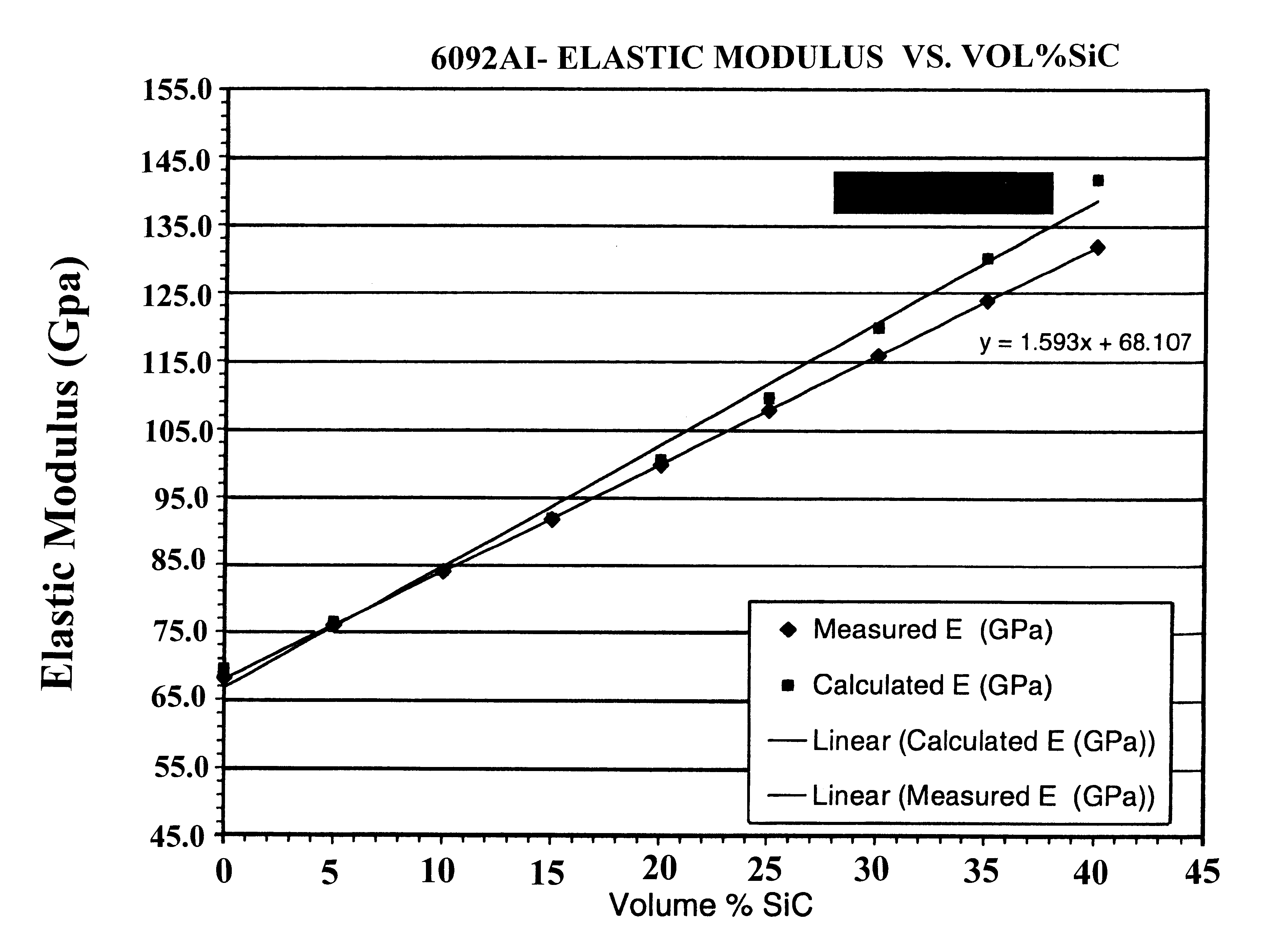

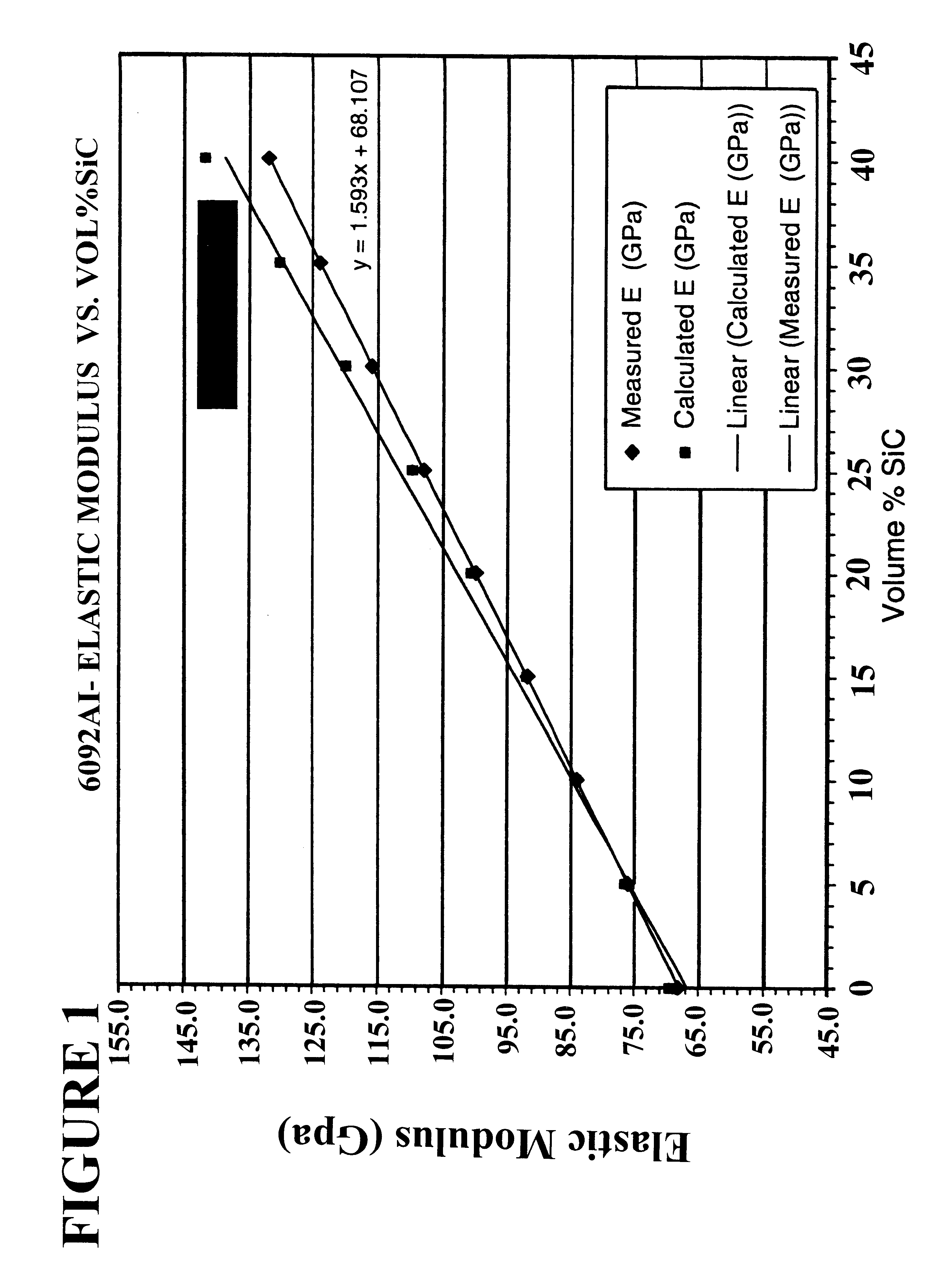

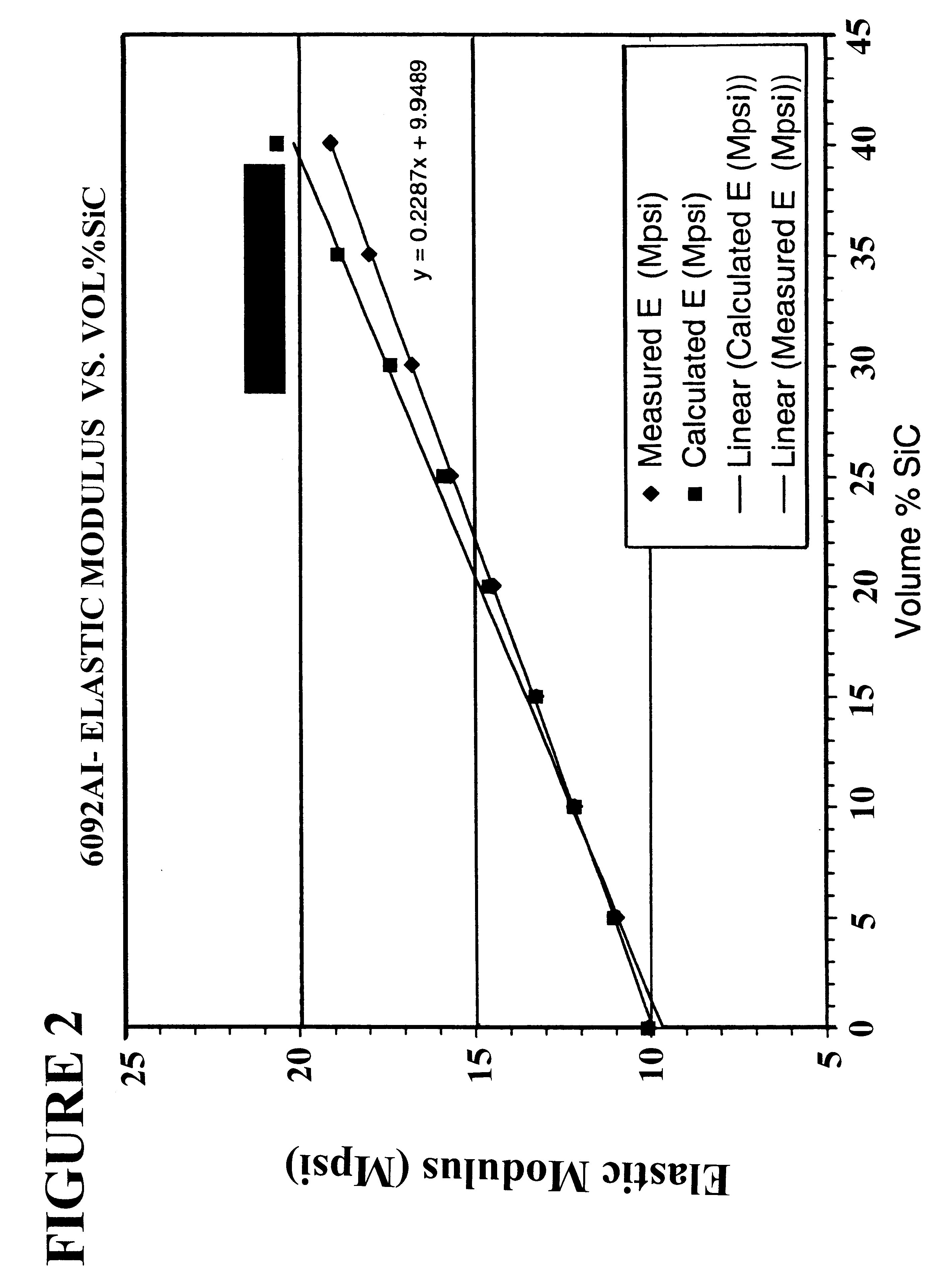

Metal matrix composite

InactiveUS6284014B1Reduce weightHigh strengthCell electrodesSemiconductor/solid-state device detailsBoron carbideAlloy composite

An extrudable and weldable matrix alloy composite comprising: a) a base material metal of about 50 to 99.9% by weight, b) boron carbide or silicon carbide of about 0.1 to 50% by weight, c) less than about 3.0% by weight of at least one metal having an intermetallic phase temperature lower than the melting point of the base material metal, and d) a reinforcement agent of up to about 5% by weight.

Owner:TN INT (FR)

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Reinforced carbon nanotubes

InactiveUS6911260B2Improve mechanical propertiesHigh strengthMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeBoron carbide

The present invention relates generally to reinforced carbon nanotubes, and more particularly to reinforced carbon nanotubes having a plurality of microparticulate carbide or oxide materials formed substantially on the surface of such reinforced carbon nanotubes composite materials. In particular, the present invention provides reinforced carbon nanotubes (CNTs) having a plurality of boron carbide nanolumps formed substantially on a surface of the reinforced CNTs that provide a reinforcing effect on CNTs, enabling their use as effective reinforcing fillers for matrix materials to give high-strength composites. The present invention also provides methods for producing such carbide reinforced CNTs.

Owner:BOSTON COLLEGE

Method for preparing dense boron carbide matrix ceramic material by sintering

The invention relates to a method for preparing a dense boron carbide matrix ceramic material by sintering. The method includes fully mixing boron carbide powders and a sintering aid and subjecting the mixture to forming, drying, binder-removing and sintering to obtain the dense boron carbide matrix ceramic material, wherein the sintering aid at least comprises a first sintering aid which is chromium carbide powders.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

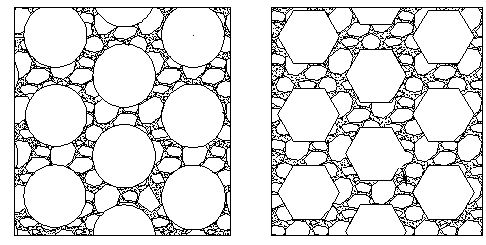

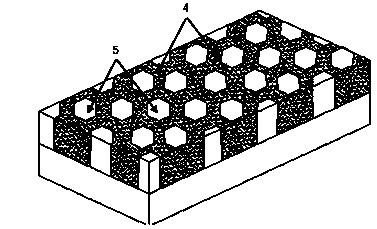

Preparation method and application of ceramic preform

The invention discloses a preparation method and application of a ceramic preform, belonging to the field of metal matrix composite. The preparation method comprises steps of mixing adhesive with ceramic particles, fully mixing powder of carbide such as silicon carbide and boron carbide with powder of oxide, then adding into adhesive coated ceramic particles to be mixed, filling the mixed material into a die so as to prepare the cellular porous ceramic preform, wherein a coating layer well wetted by molten metal is formed on the surface of the ceramic particle. The ceramic particles prepared by the method allow the ceramic particles of the metal matrix composite to be distributed more uniformly in the metal matrix, the composite layer is thick, the coated surface of the ceramic particle is easy to be wetted by molten metal, the bonding strength of the metal and the ceramic is greatly improved, and the service life of the composite is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

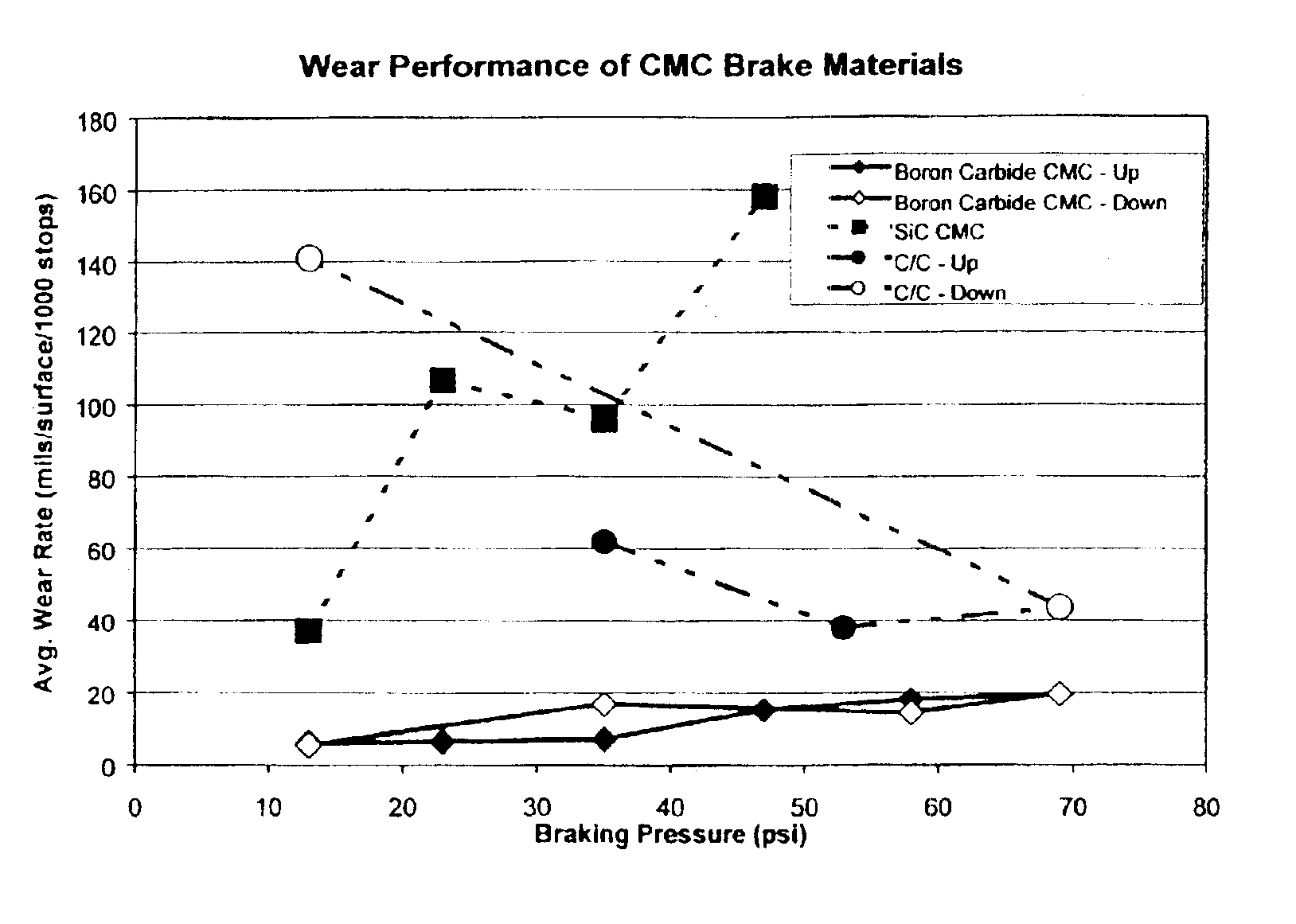

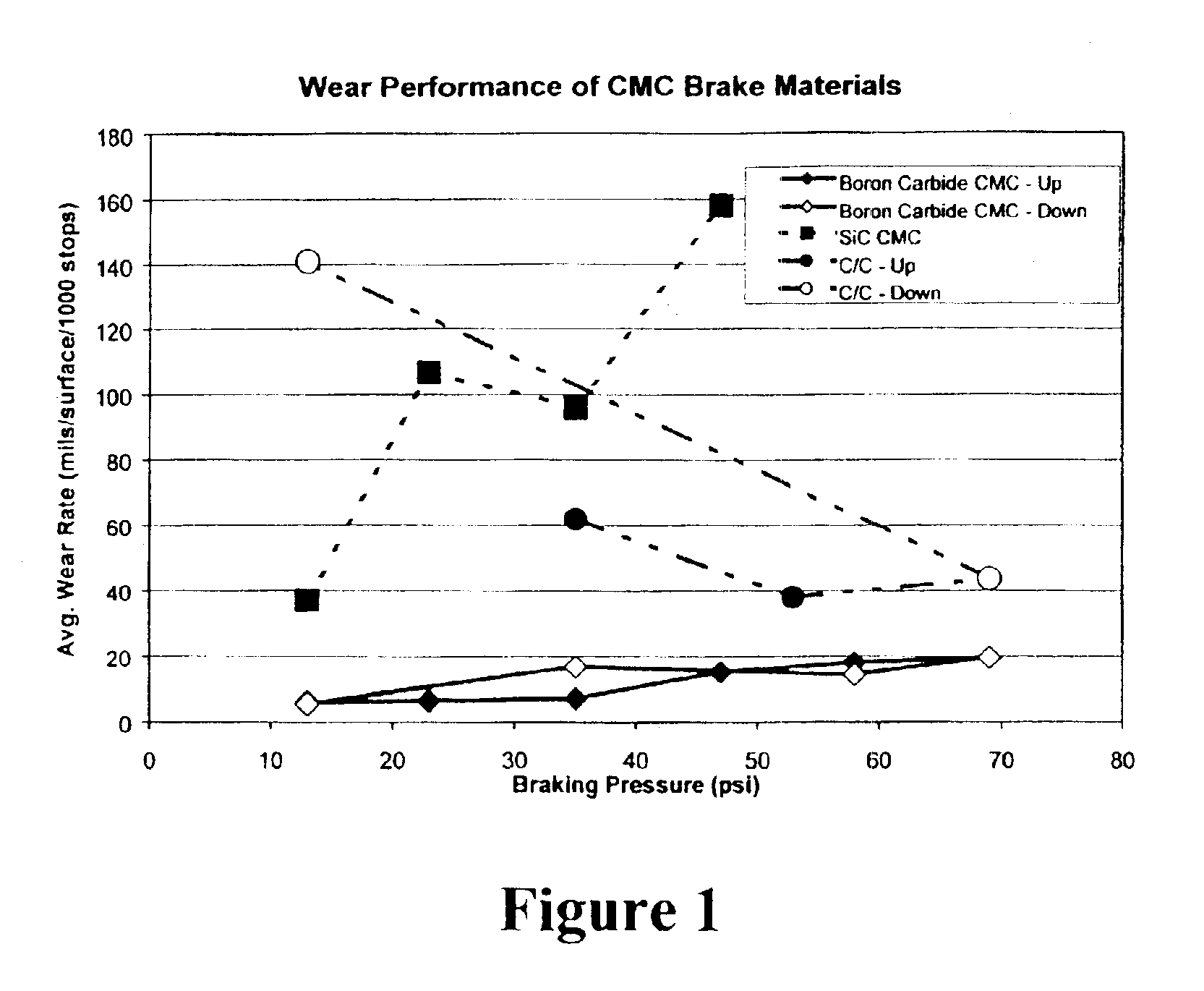

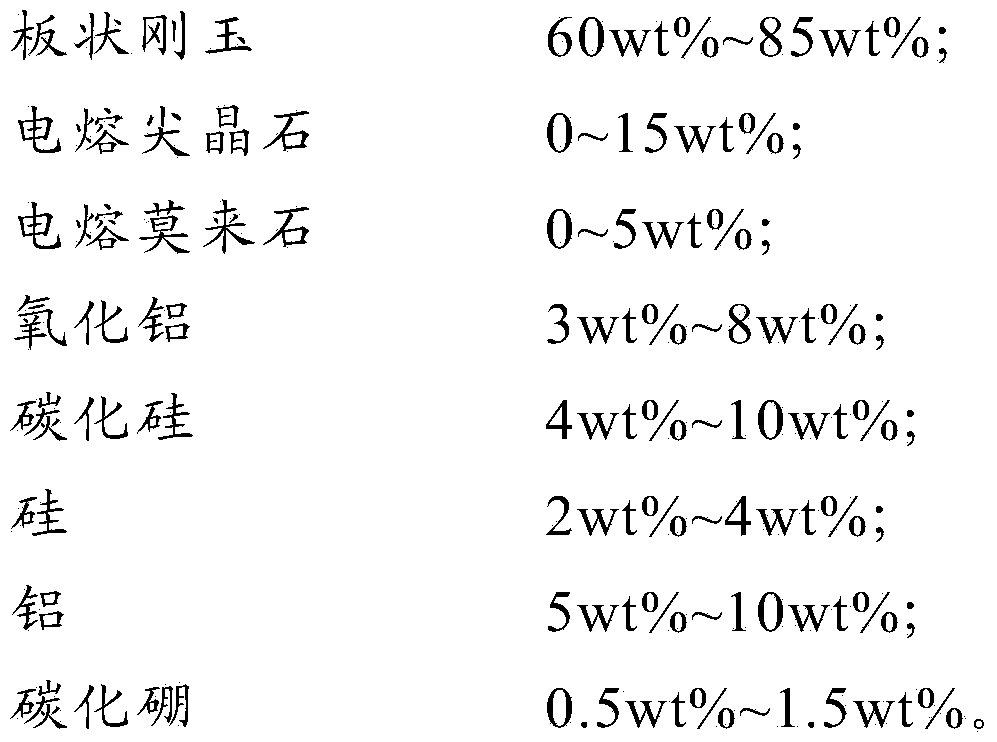

Boron carbide based ceramic matrix composites

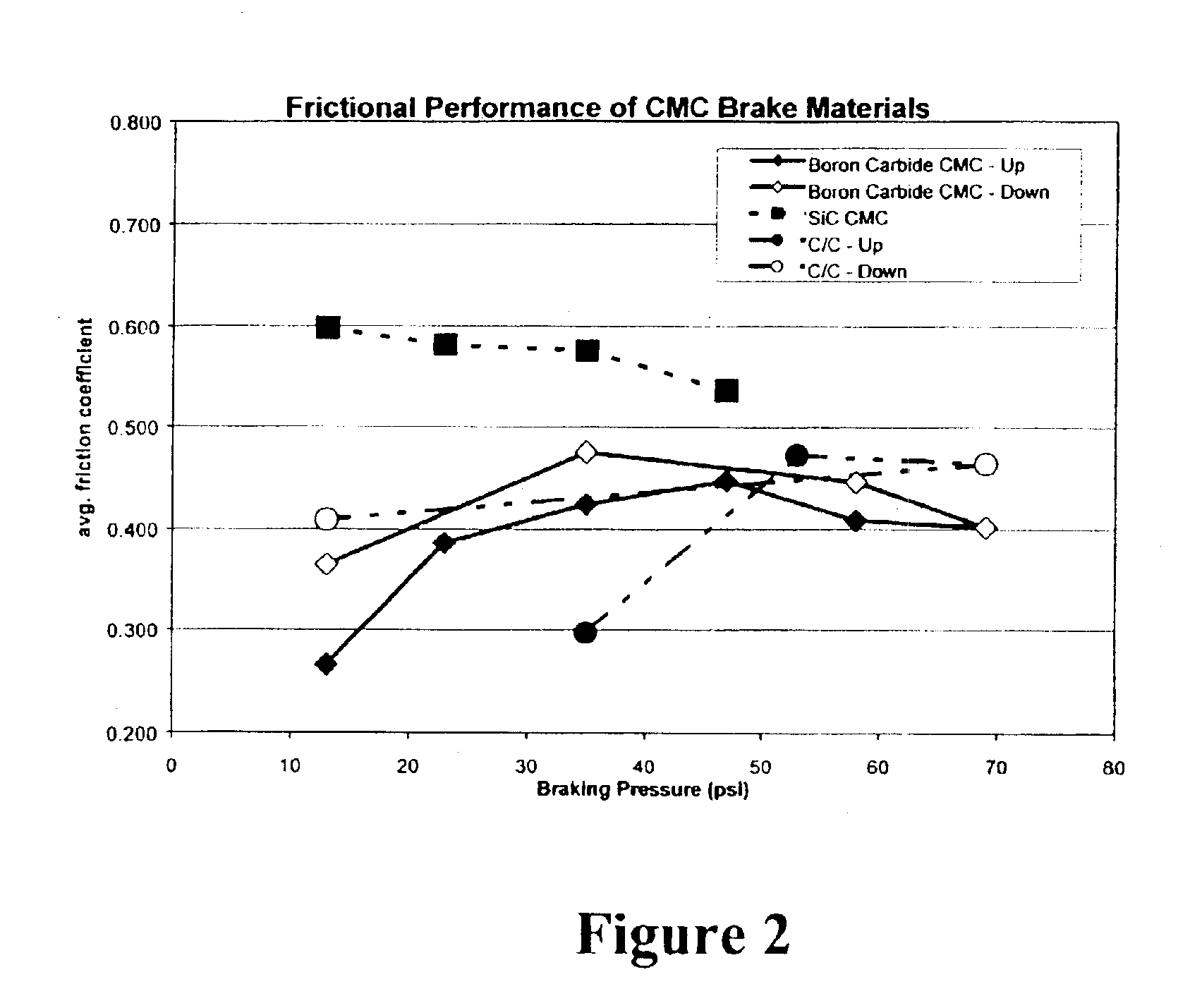

InactiveUS6855428B2Big advantageReduce wear rateBraking discsPretreated surfacesSilicon matrixBoron carbide

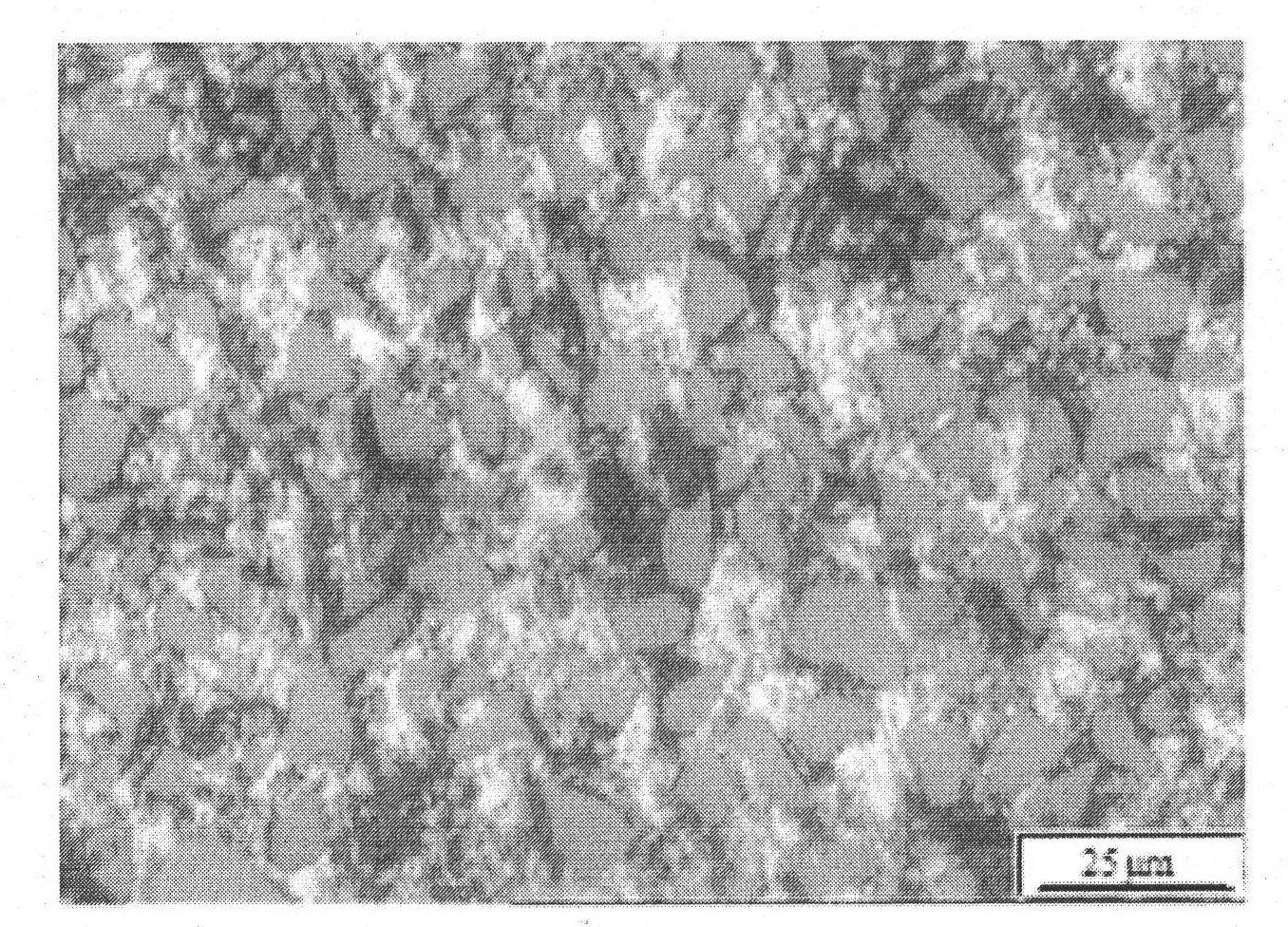

The present invention is a composite material and process to produce same. That material comprises a fibrous structure which is initially predominantly coated with elemental carbon; that fibrous structure is then subsequently predominantly coated with at least one ceramic material, e.g., boron carbide, which is non-reactive with silicon. The composite material also comprises a silicon matrix which is continuous and predominantly surrounds the fibrous structure, which has been initially predominantly coated with elemental carbon and subsequently predominantly coated with at least one ceramic material. The matrix which has a fine grain crystalline structure of predominantly 20 microns or less in size. The at least one ceramic material is discontinuous within that matrix. The fibrous material pulls out of the elemental carbon, which initially predominantly coats that fibrous structure, when the composite is subjected to fracture.

Owner:THE BF GOODRICH CO

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

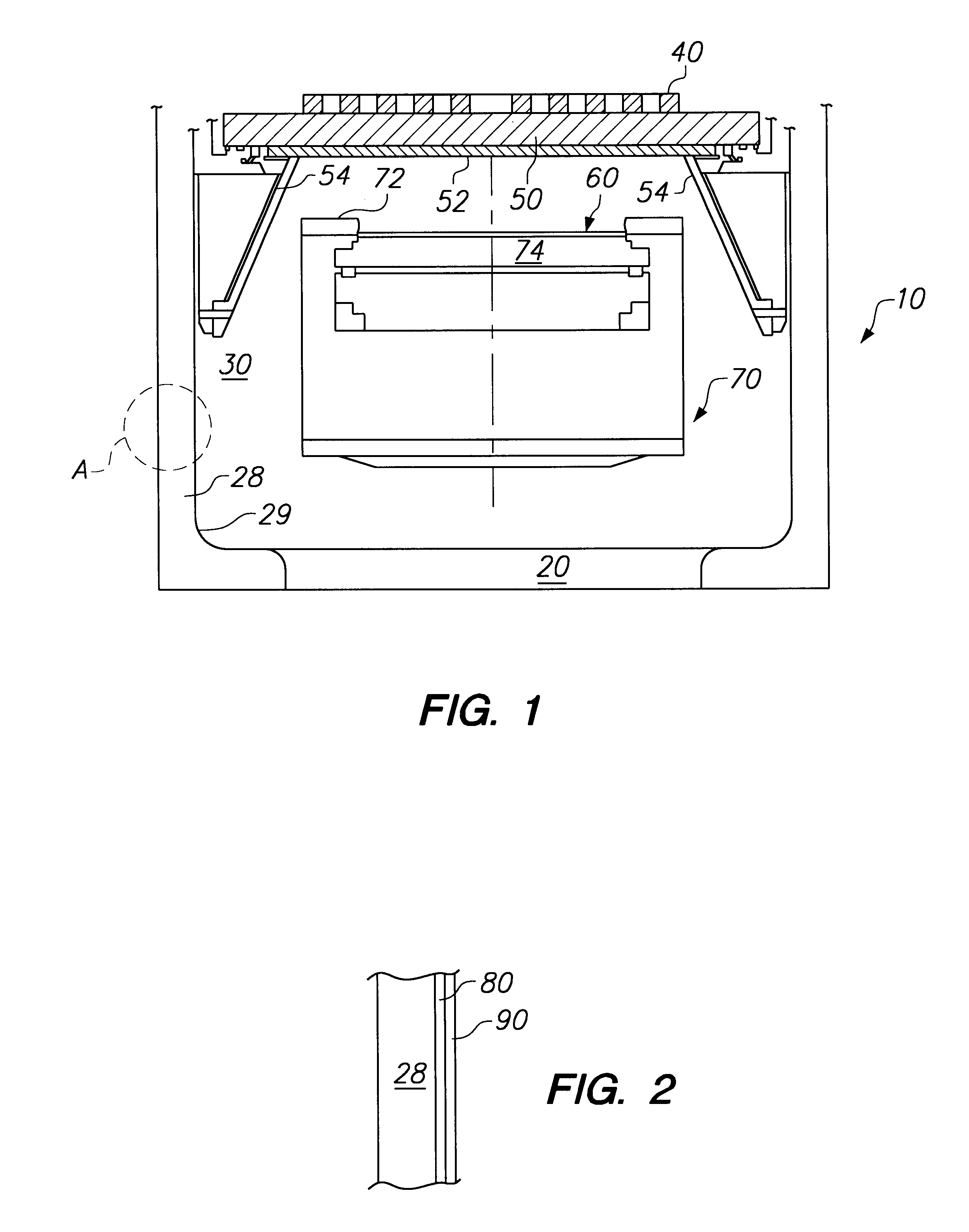

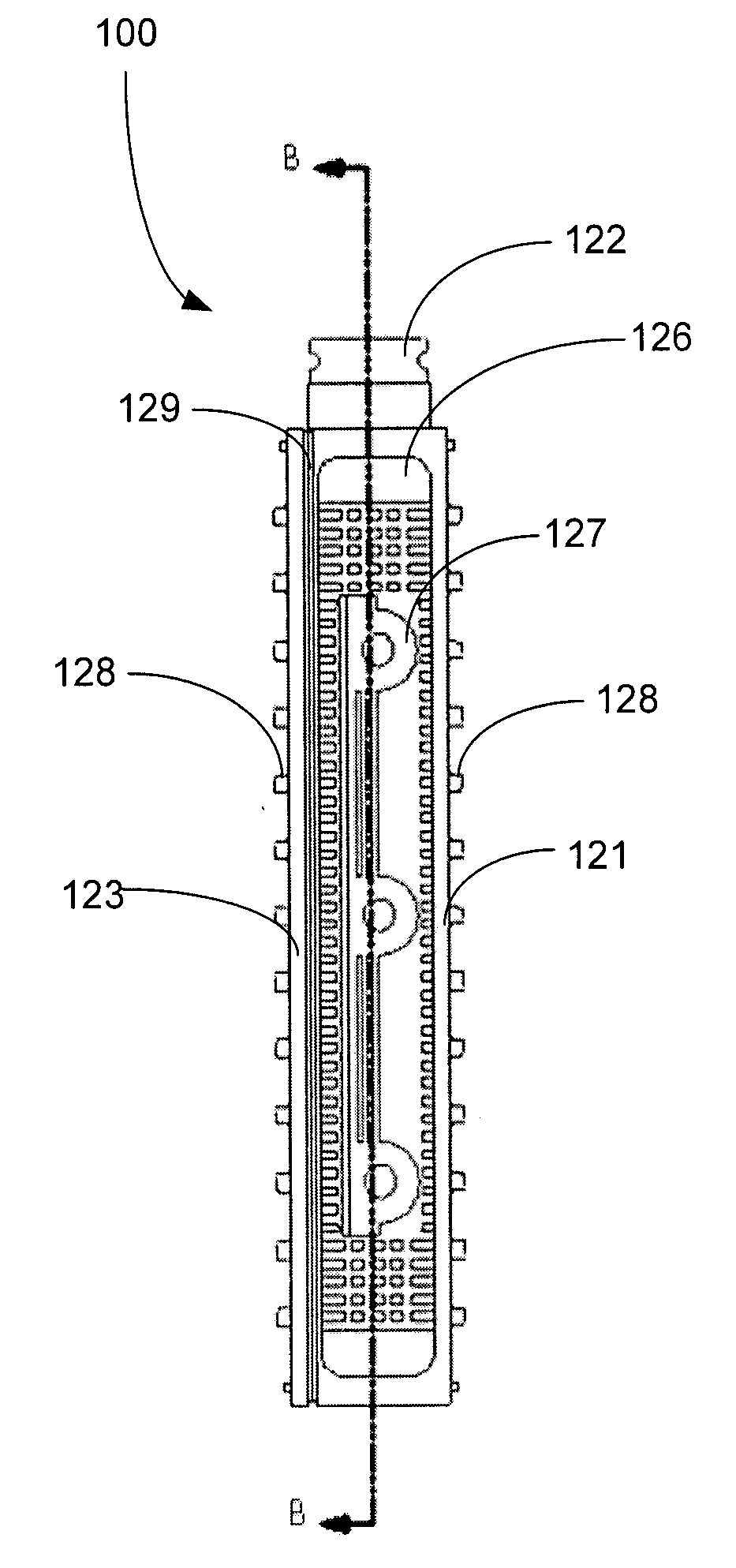

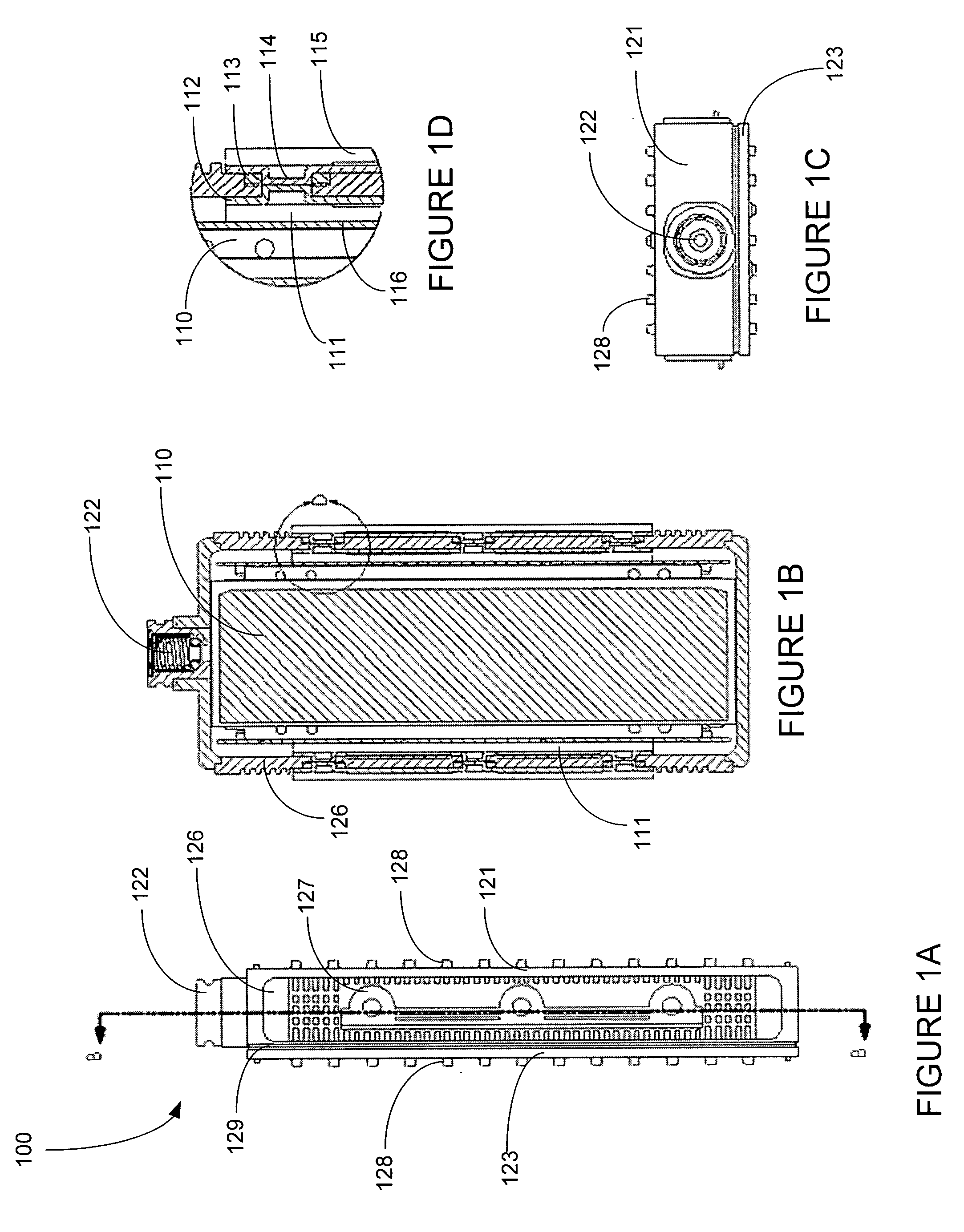

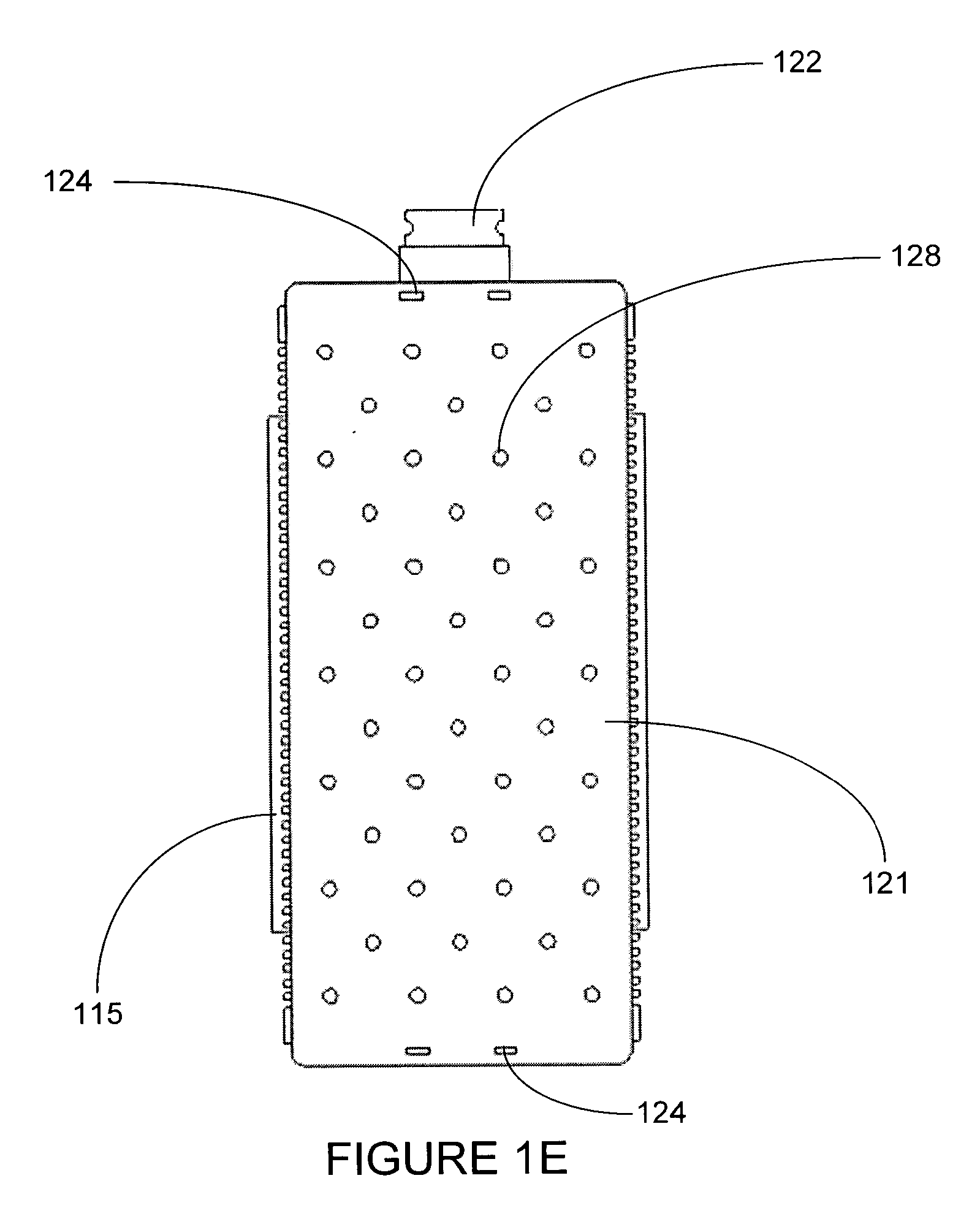

Battery case having improved thermal conductivity

InactiveUS20070037053A1Improve cooling effectProviding mechanical stabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsFiberBoron carbide

The present invention discloses is a battery case, comprising a base case and an insert as two parts of the exterior case. The base case is formed of a first polymeric material and the insert is formed of a second polymeric material, wherein the second polymeric material has a higher thermal conductivity than the first polymeric material. The second polymeric material may comprise a base polymer and at least one thermally conductive filler, such as ceramic, glass or carbon fiber. The base polymer of the second polymeric material may be selected from the group consisting of polyphenylene ether, polystyrene, polypropylene, polyphenylene sulfide and the ceramic filler may be selected from the group consisting of alumina, fused silica, a glass ceramic sold under the trademark MACOR®, boron nitride, silicon nitride, boron carbide, aluminum nitride, silicon carbide, zirconia and combinations thereof. The first polymeric material may be selected from the group consisting of polyphenylene ether, polystyrene, polypropylene, polyphenylene sulfide. The base case and insert may be integrally molded by one of two-color molding and insert molding with the first polymeric material and the second polymeric material. The battery case of the present invention may comprise a monoblock alkaline storage battery case.

Owner:BATTERY PATENT TRUST

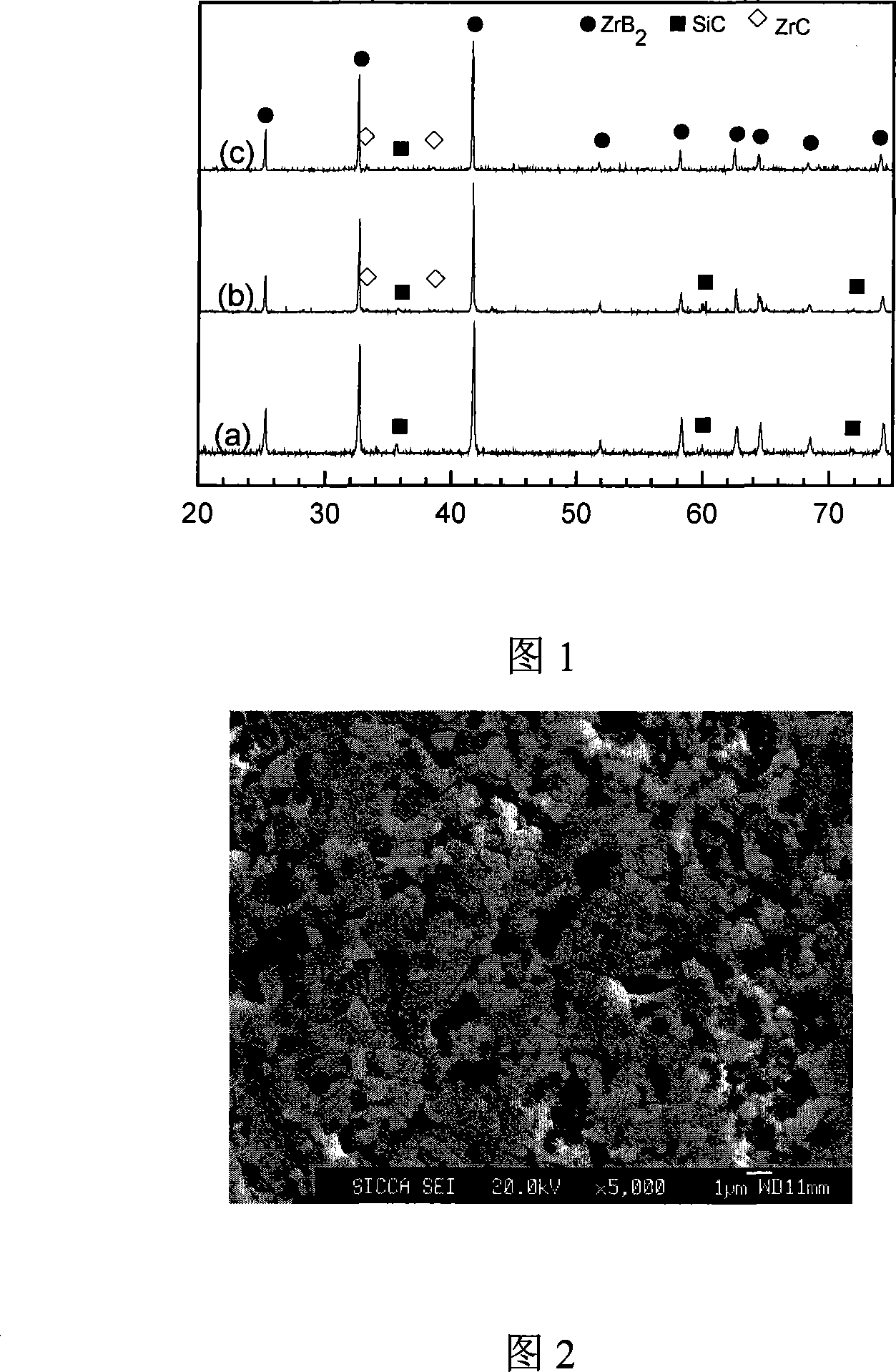

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

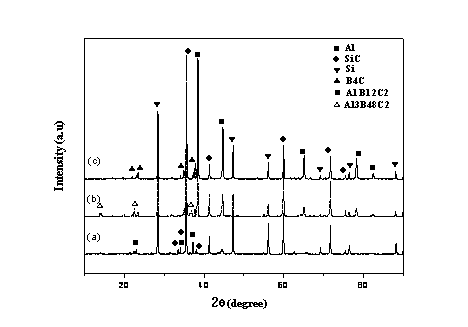

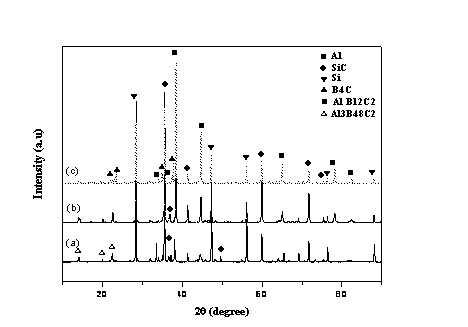

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

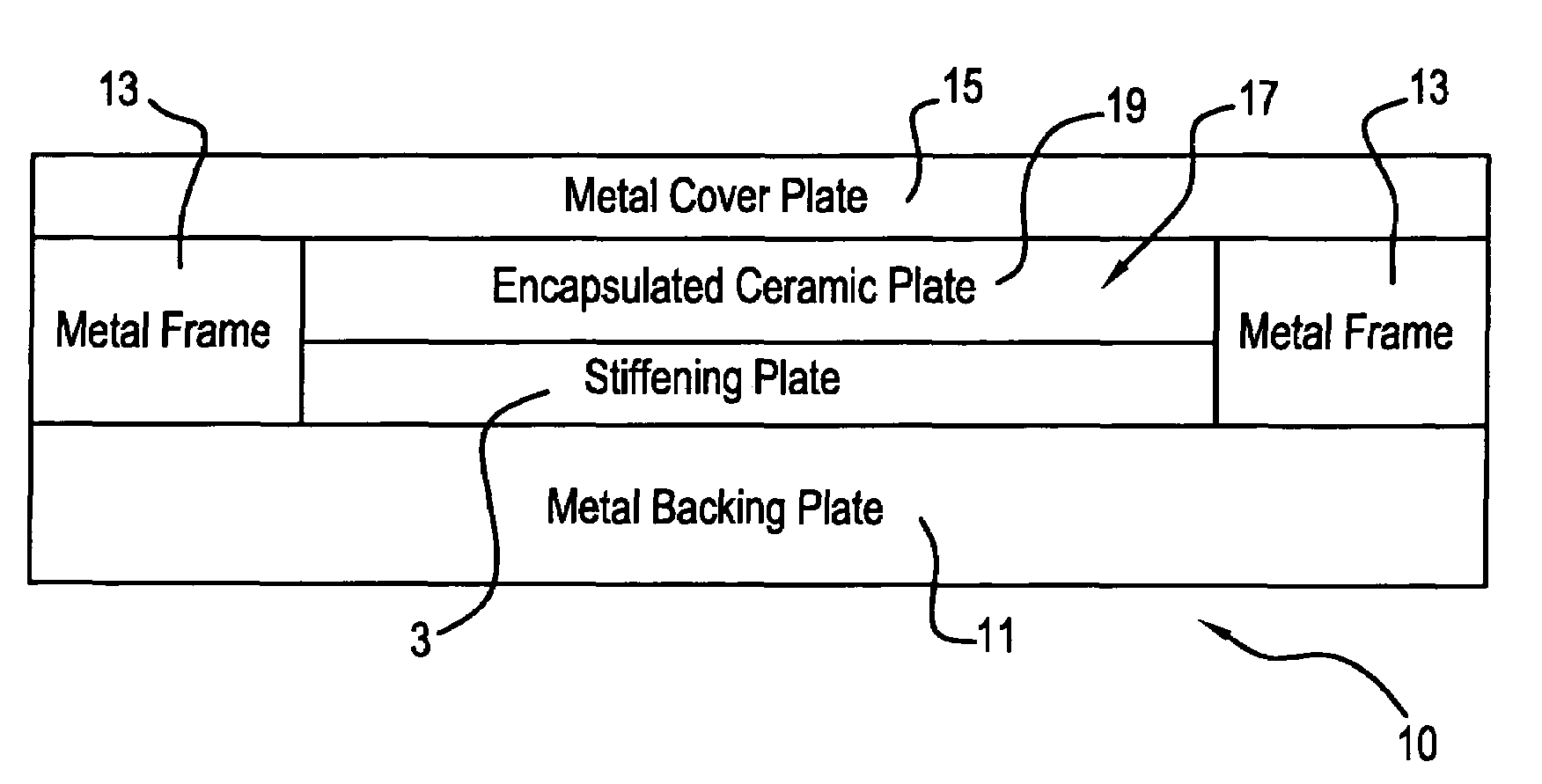

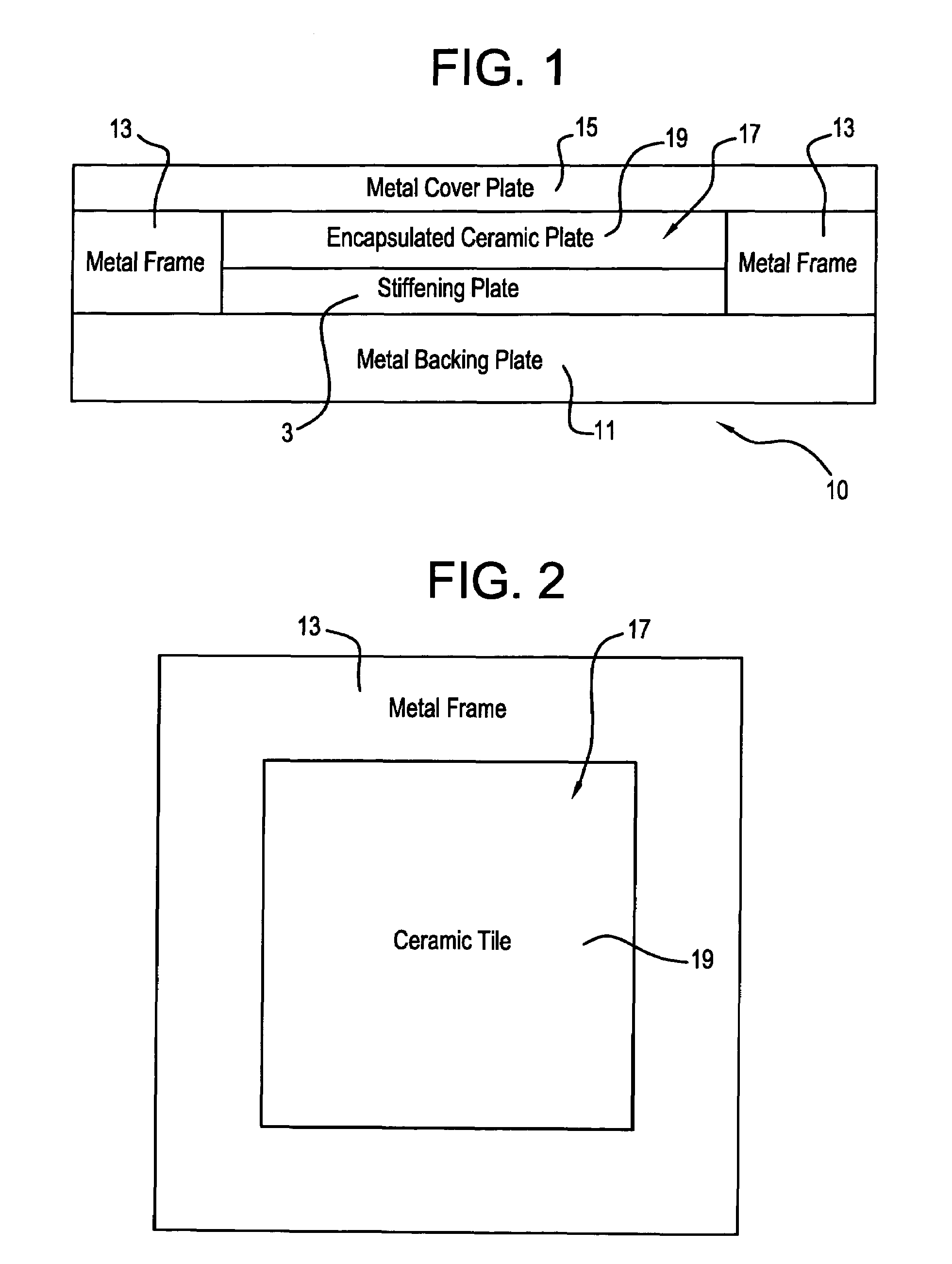

Ceramic armor and method of making by encapsulation including use of a stiffening plate

InactiveUS7069836B1Improve simplicityDoor/window protective devicesArmoured vehiclesCeramic compositeBoron carbide

A ceramic armor is disclosed in several embodiments. In a first embodiment, a metal base plate has a metal frame assembled on it having a central opening into which the ceramic material and stiffening plate are placed. A cover plate is placed over the frame to enclose the ceramic material on all sides. In a second embodiment, the frame has an open central area that has two crossing walls that define four sub-chambers. Four sets of ceramic material and stiffening plate are placed in the respective sub-chambers and a covering plate is placed over them. In a further embodiment, the frame has a plurality of cavities mechanically formed in it. A stiffening plate and a ceramic tile or plate are placed in each cavity and a cover plate is placed over the frame. The metal used to encapsulate the ceramic material may, if desired, comprise a Titanium alloy such as Ti-6Al-4V, and the ceramic material may comprise Silicon Carbide, Boron Carbide, Tungsten Carbide, Titanium Diboride, Aluminum Oxide or Aluminum Nitride. The stiffening plate is preferably made of a Ti—TiB cermet composite but may also be comprised of an armor ceramic such as WC, TiB2, Al2O3 or B4C. A hot pressing procedure is carried out on the armor to cause the metal to plastically deform about the encapsulated ceramic material.

Owner:BAE SYST ADVANCED CERAMICS

Additive for lubricant for improving the tribologic properties, a method for its production and application

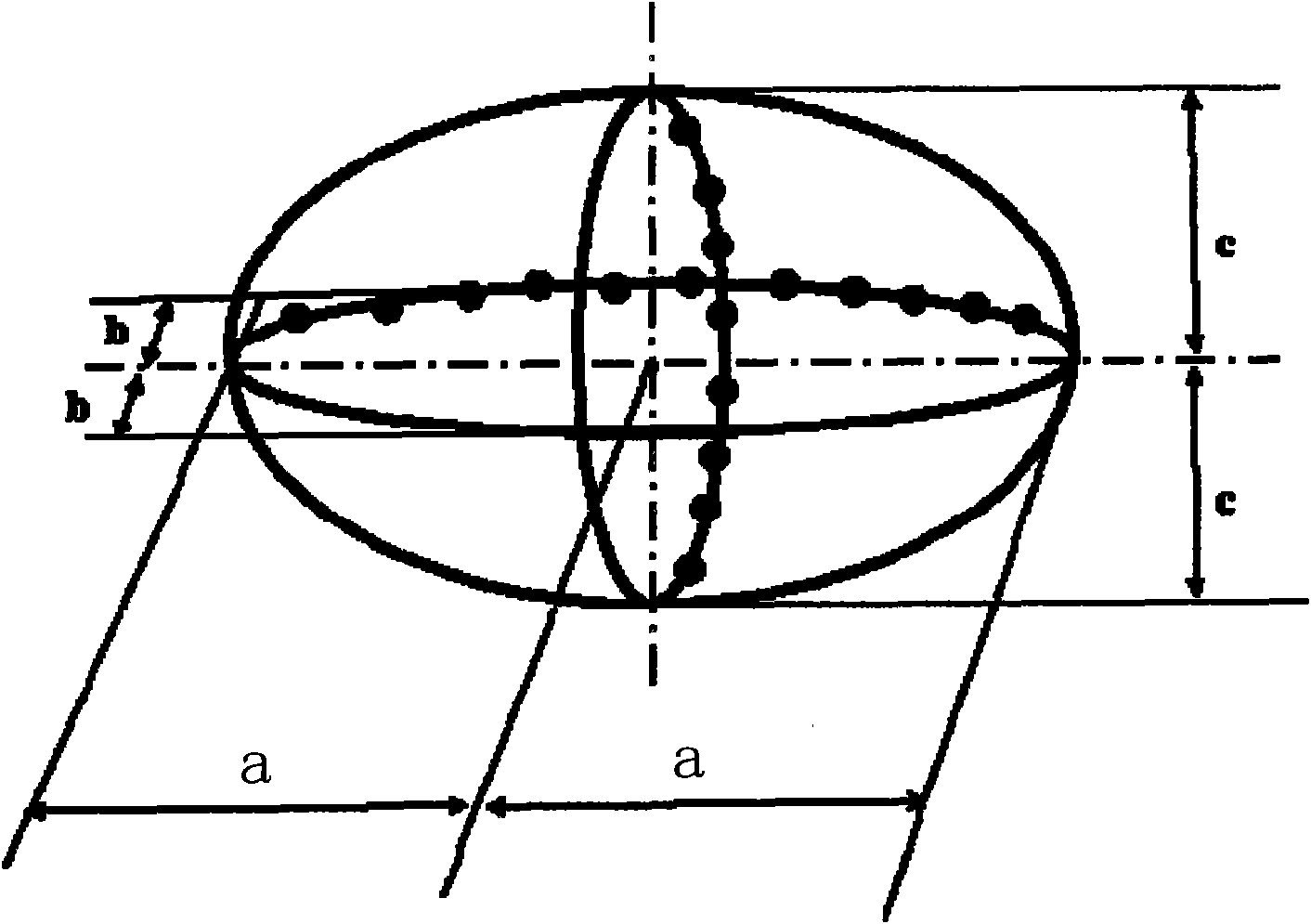

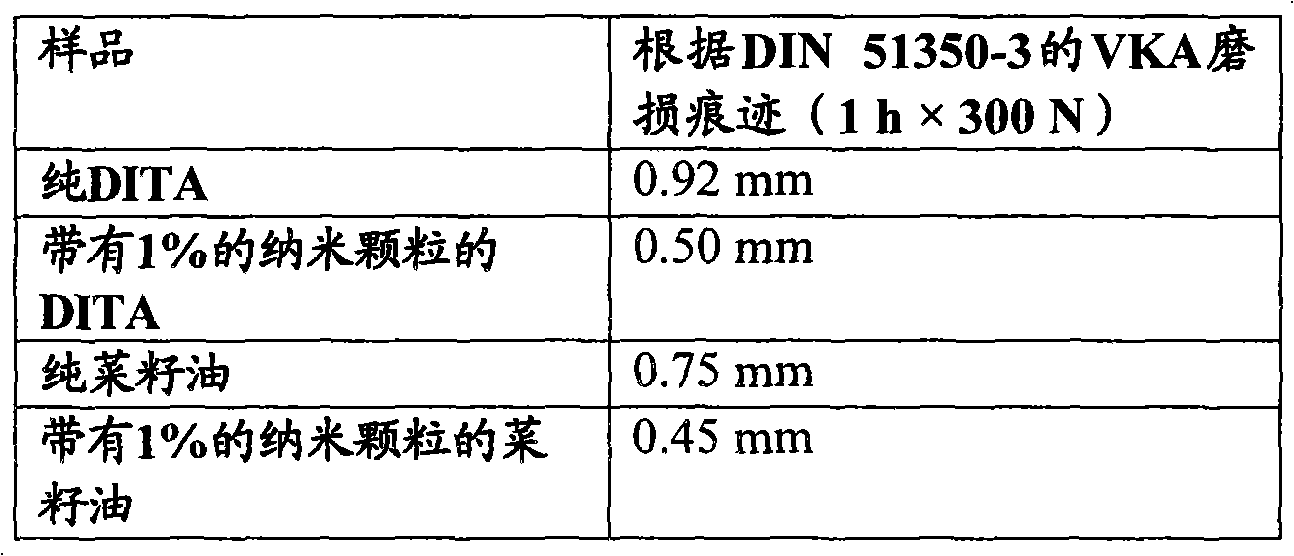

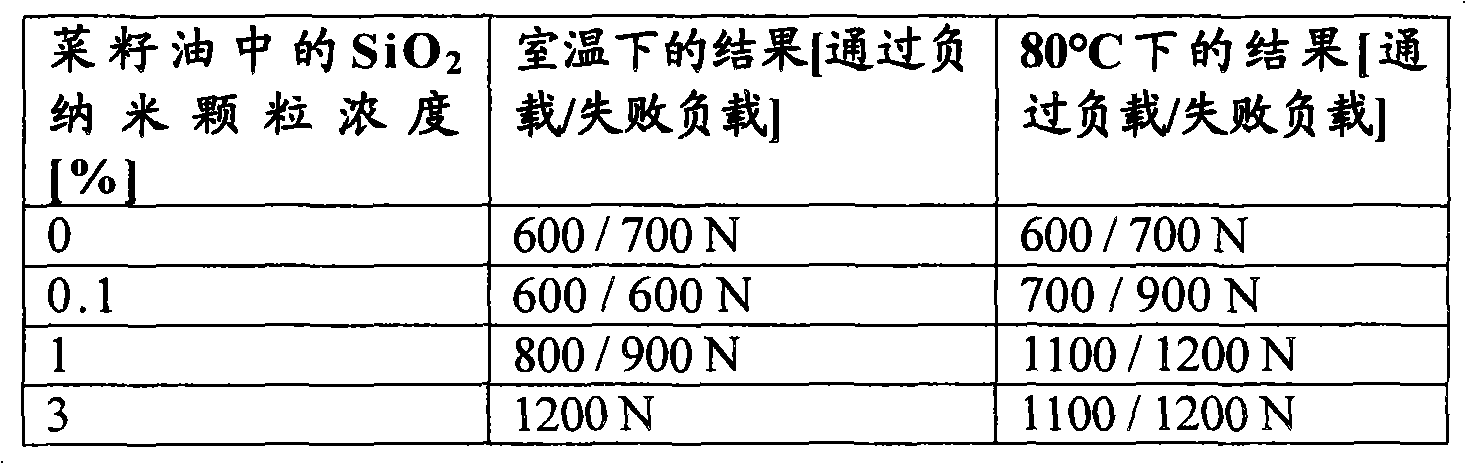

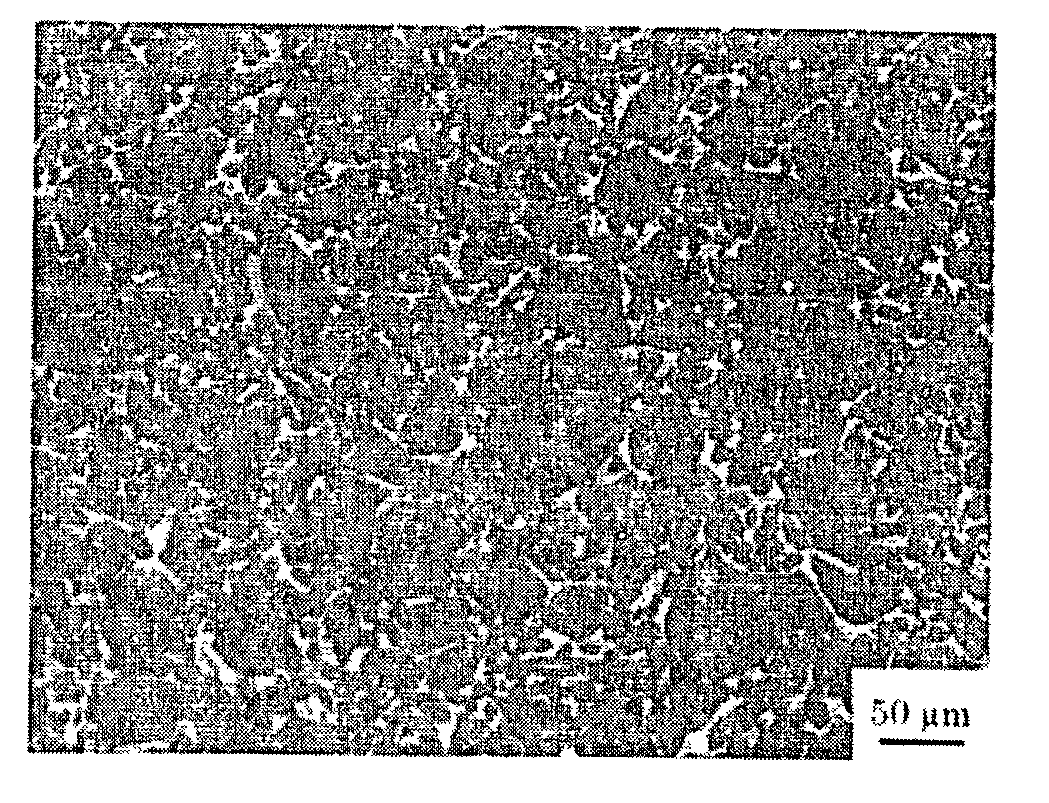

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

Composite metal carbide wear-resistant coating and preparation process thereof

The invention relates to a composite metal carbide wear-resistant coating and a preparation process thereof, and belongs to a wear-resistant coating and a preparation process thereof. The composite metal carbide wear-resistant coating consists of adhesive coated tungsten carbide and other carbides, wherein the adhesive coated tungsten carbide has the grain size of WC-Co or WC-Ni; and the other carbides comprise chromium carbide, vanadium carbide, iron carbide, titanium carbide and the like. The preparation process comprises the following steps of: mixing the adhesive coated tungsten carbide and one or more kinds of the carbide powder; and performing spray coating (welding) or plasma spray coating (welding) on the surface of a medium-carbon steel part through supersonic flame to form the wear-resistant coating, wherein the carbon content of the medium-carbon steel is 0.35 to 0.55 weight percent (wt); the medium-carbon steel is subjected to the thermal refining state of quenching and high-temperature tempering; and the supersonic flame spray coating (welding) or plasma spray coating (welding) process sequentially comprises steps of performing sand blasting and rust removal on the surface of the medium-carbon steel, spraying a Ni-5 percent Al alloy adhesive coating and spraying a composite carbide wear-resistant coating. The composite carbide wear-resistant coating has Vickers hardness (HV) of 1,200 to 1,800, bonding force of more than 60 Mpa, and high mechanical property, wear resistance and corrosion resistance.

Owner:CHINA UNIV OF MINING & TECH +1

Toughness enhanced silicon-containing composite bodies, and methods for making same

InactiveUS6995103B2Improve toughnessDoor/window protective devicesLayered productsCeramic compositeBoron carbide

A silicon-containing composite body that would otherwise be brittle can be engineered to exhibit enhanced fracture toughness. Specifically, a silicon-ceramic composite body is produced, preferably by a reactive infiltration technique. The ceramic is selected such that it has a higher coefficient of thermal expansion (CTE) than does the silicon phase. At least at some point during processing, the silicon phase is at a temperature above its normal ductile / brittle transition temperature of about 500° C., and preferably above its melting point. The formed composite body containing the silicon phase is then cooled below its ductile / brittle transition. During cooling, the ceramic phase shrinks more than does the silicon phase, thereby placing the latter in a state of compressive stress. By the time the composite body has cooled to substantially ambient temperature, the induced compressive stress in the silicon phase is sufficient as to impart a measurable degree of semi-ductile character to the silicon phase. This pseudo-ductility manifests itself in the composite body as a significant increase in the fracture toughness of the body. For example, when the ceramic reinforcement was boron carbide particulate instead of silicon carbide (which has a CTE similar to that of silicon), fracture toughness increased by almost 30 percent.

Owner:BUSINESS ALLIANCE CAPITAL +1

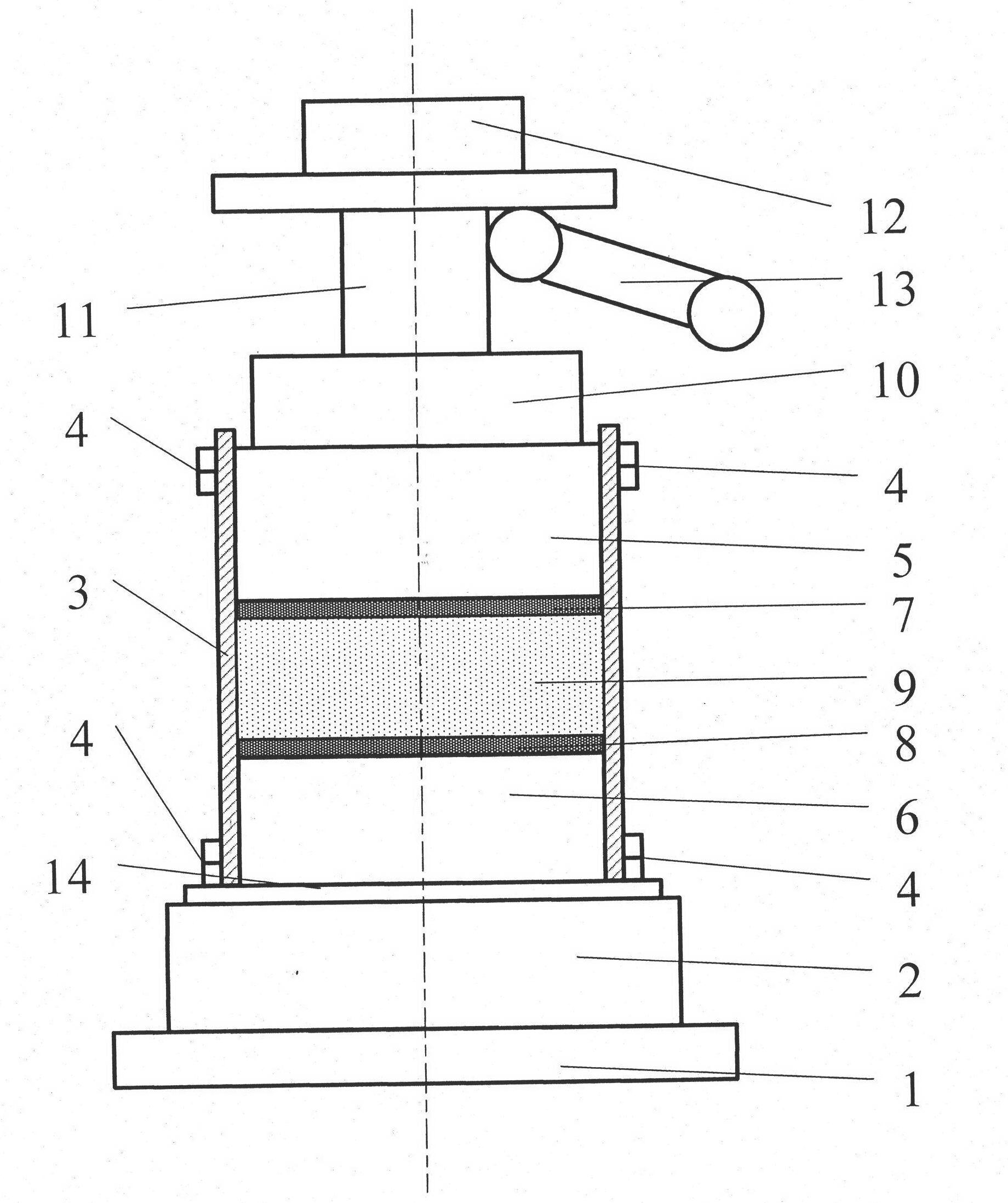

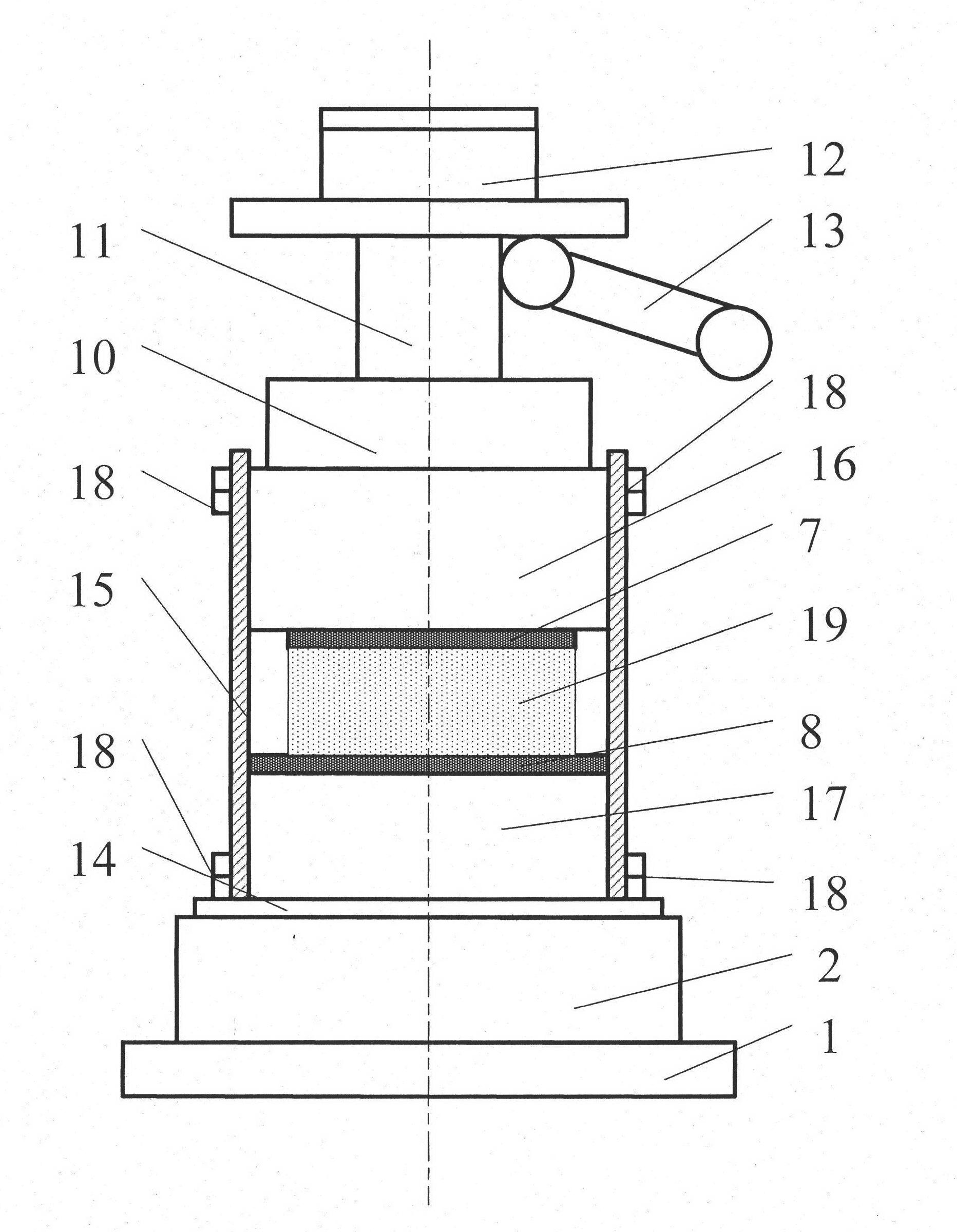

Boron carbide based bulletproof composite ceramic and preparation method thereof

The preparation method for boron carbide composite bulletproof ceramics comprises: selecting the material by weight ratio as 85~95 boron carbide, 1~15 carborundum whisker, 2~15 silicon powder, and 1~5 boride; with anhydrous alcohol as medium, grinding and mixing the material; then drying in vacuum to prepare the mixed powder and add into the graphite mould with layers separated by graphite spacer and graphite paper; hot pressing and sintering with pressure as 30~40MPa at 1700~2000Deg. This product has low density, high strength and elastic modulus.

Owner:SHANDONG UNIV

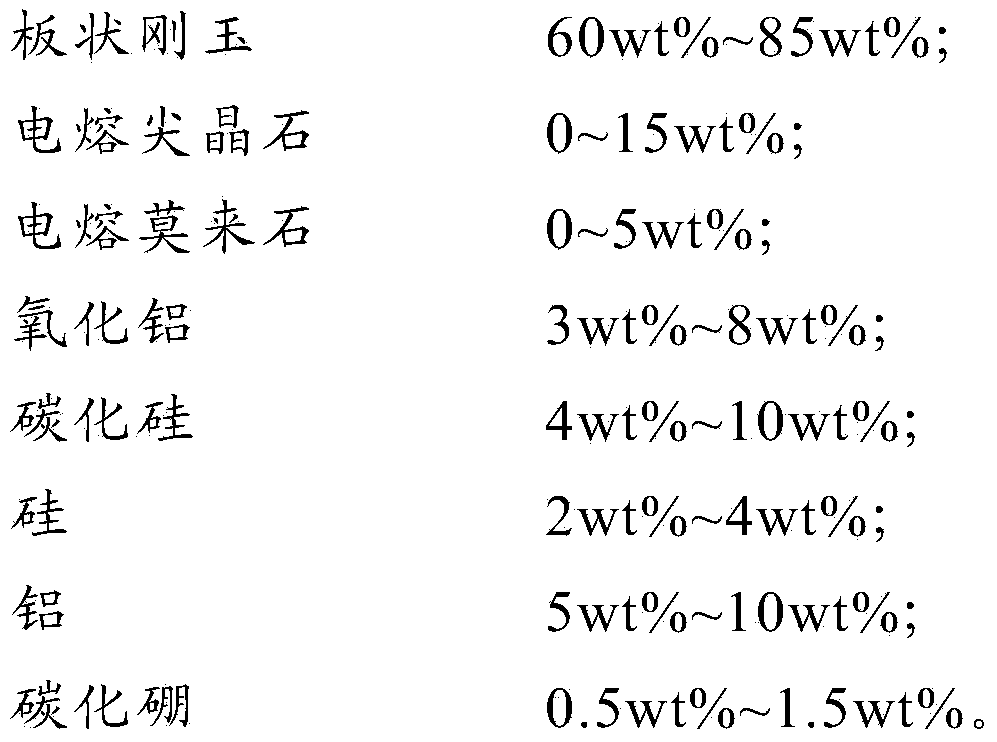

Sliding brick and preparation method thereof

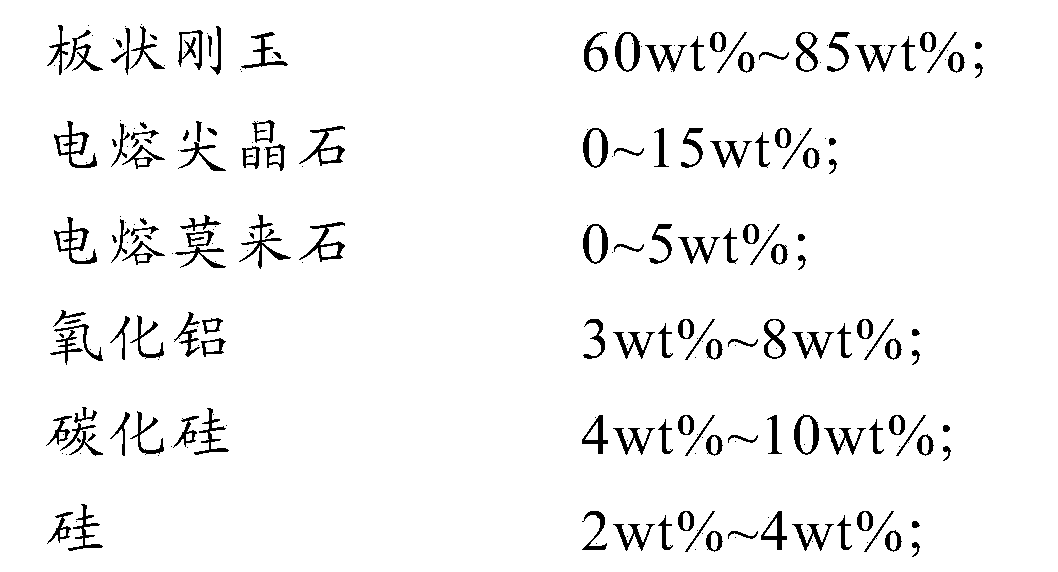

The invention provides a sliding brick and a preparation method thereof. The sliding brick is prepared from a mixture through molding and sintering, wherein the mixture comprises plate-shaped corundum, fused spinel, fused mullite, alumina, silicon carbide, silicon, aluminum and boron carbide. According to the invention, plasticity of both aluminum and silicon is combined together, which is favorable for improvement of density and strength of the sliding brick; meanwhile main materials like plate-shaped corundum are used, so the sliding brick has good high temperature performance, erosion resistance and thermal shock resistance. In the process of preparation of the sliding brick, light roasting or high temperature sintering is employed, so the prepared sliding brick has high hot strength and erosion resistance and good cold strength, anti-scouring performance and oxidation resistance.

Owner:HUNAN XIANGGANG RUITAI TECH

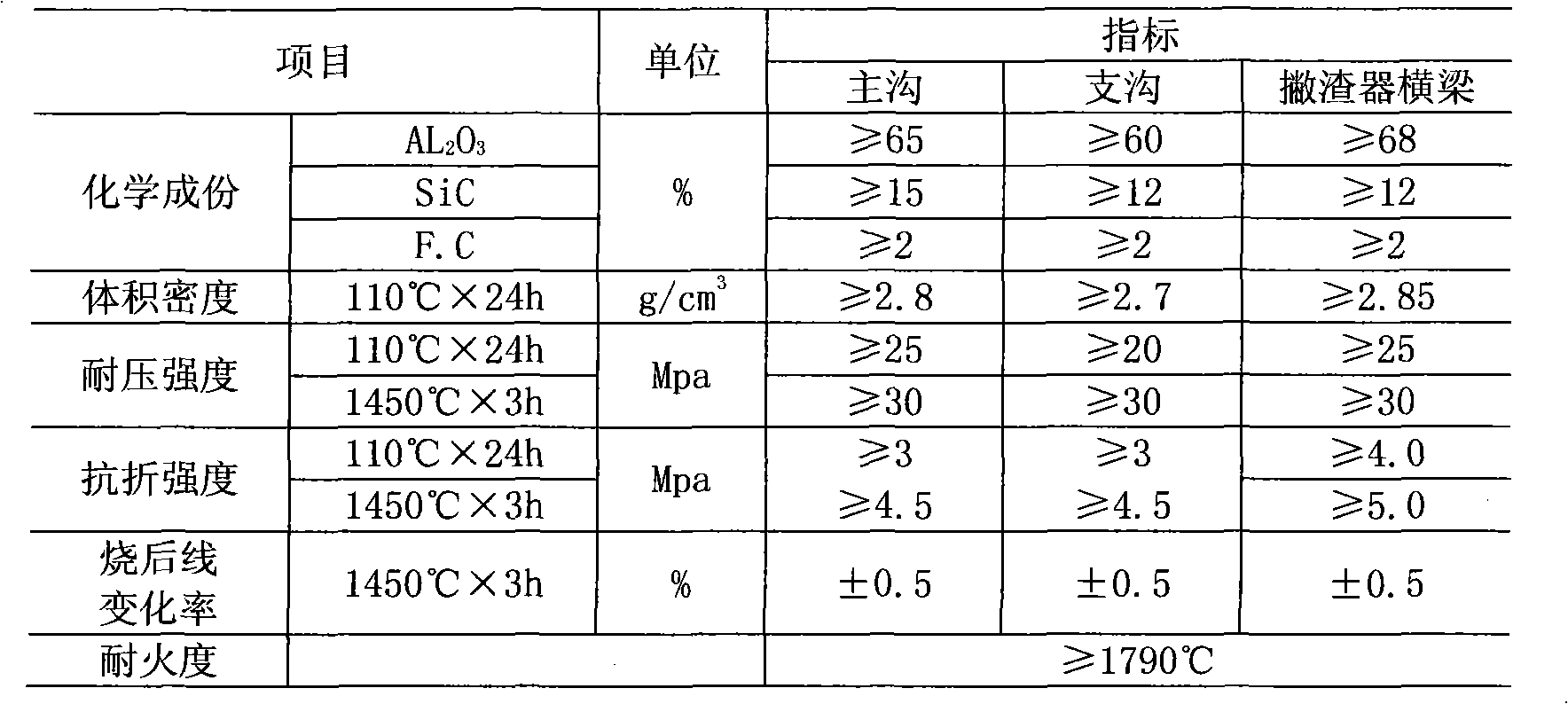

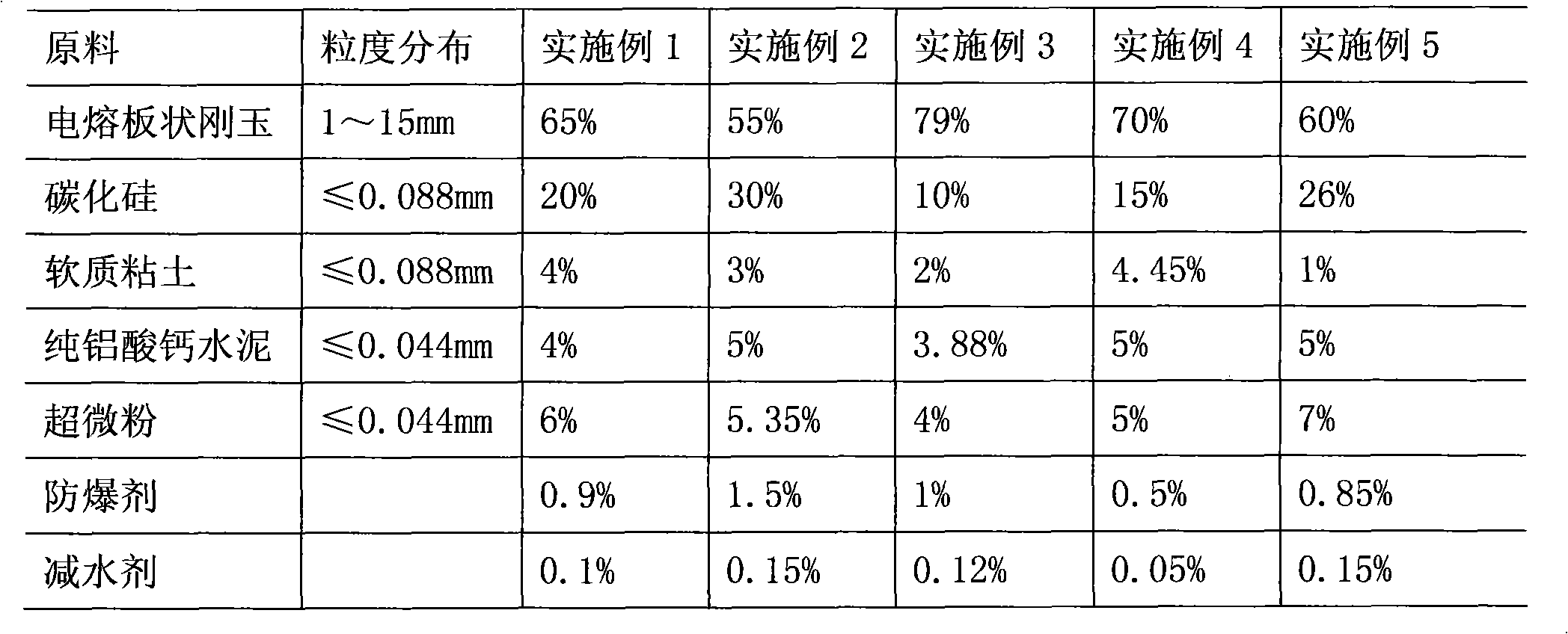

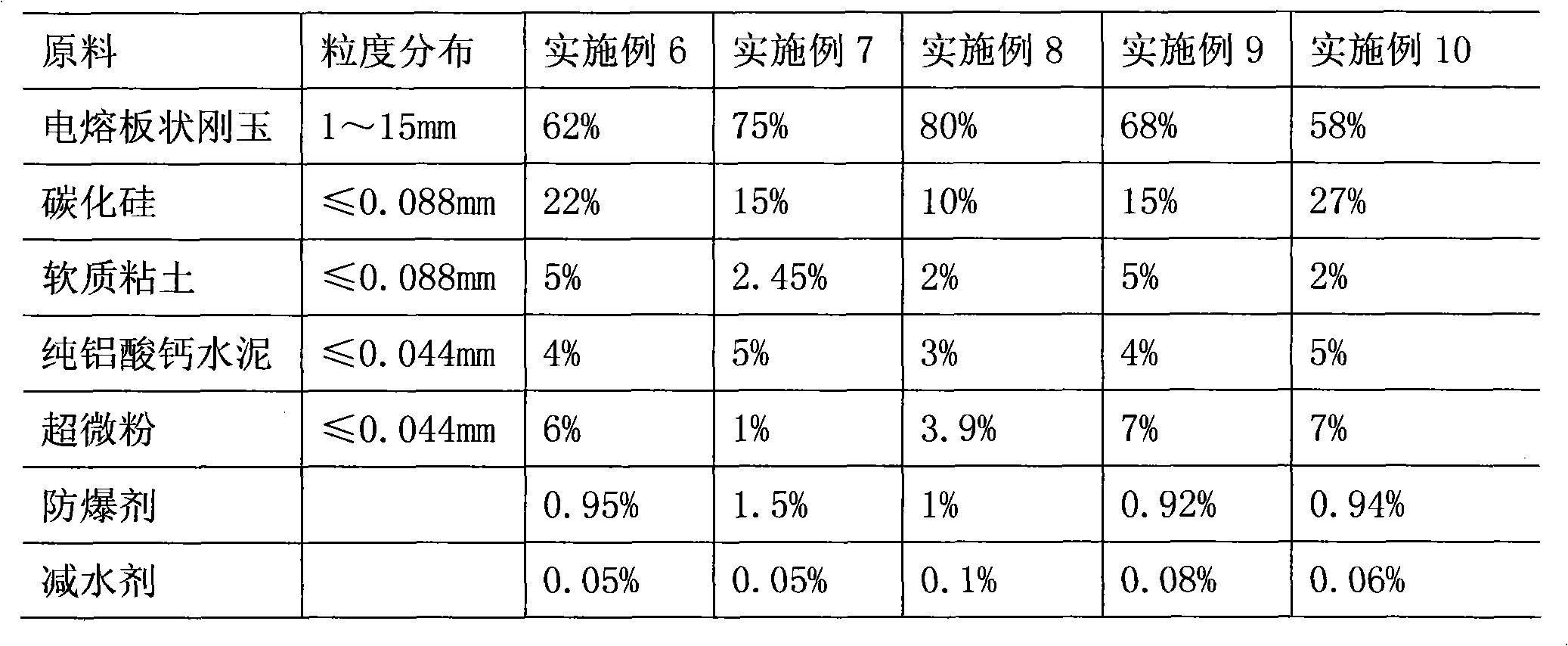

Explosion-proof iron runner castable

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

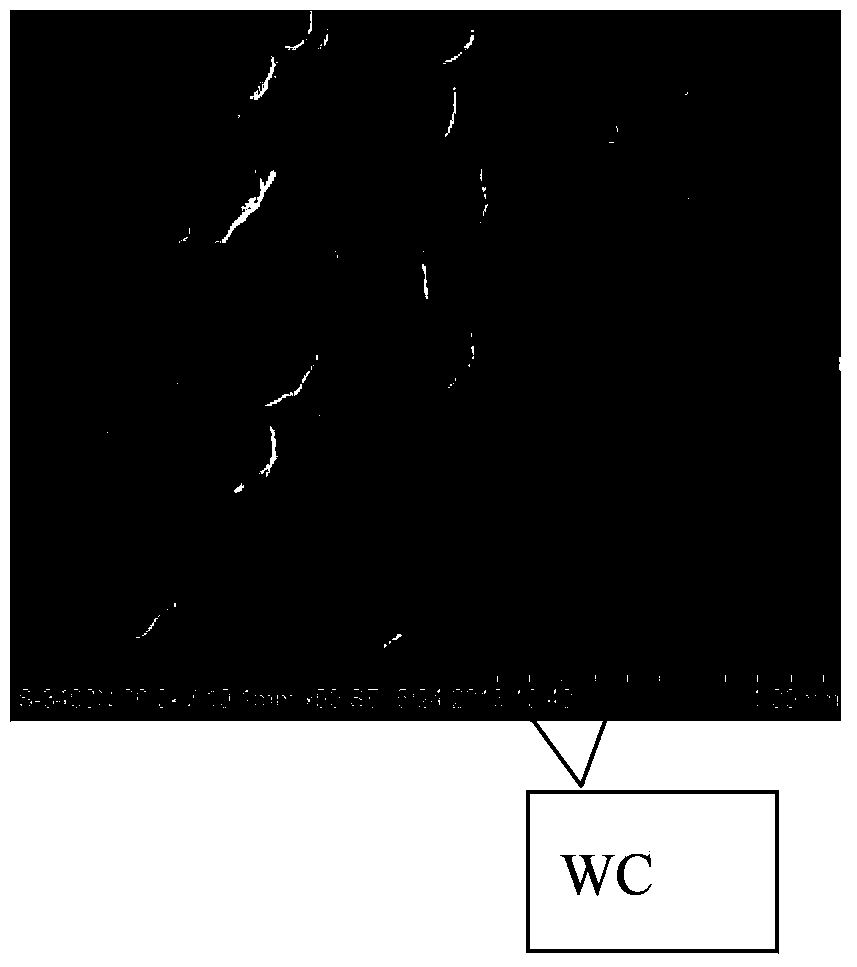

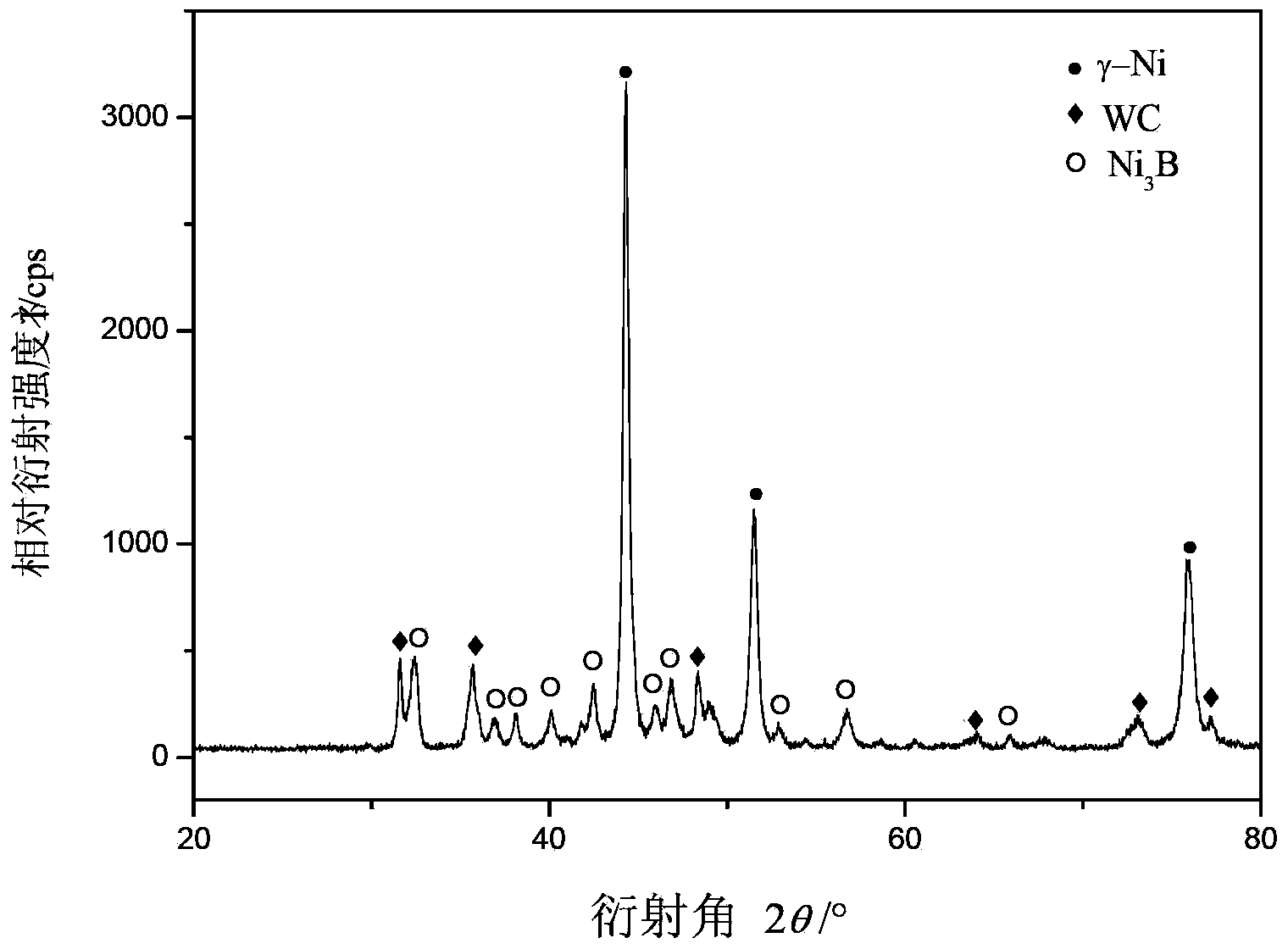

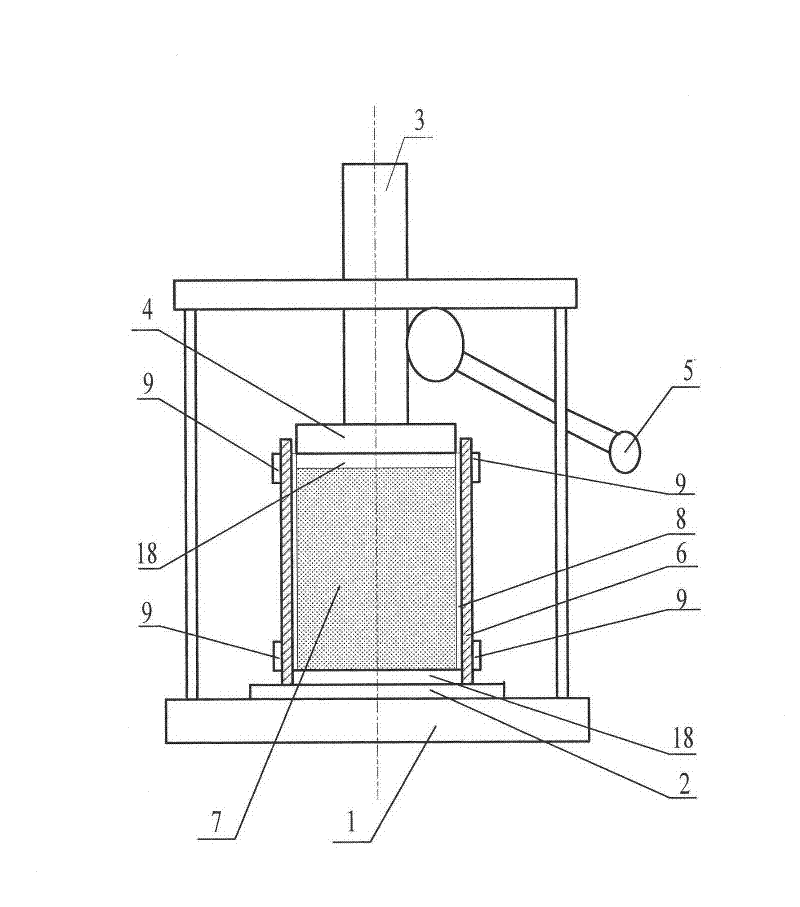

WC particle-reinforced Ni-based MIG hardfacing flux-cored wire

InactiveCN103406689AImprove toughnessGood "supportArc welding apparatusWelding/cutting media/materialsManganeseBoron carbide

The invention discloses a WC particle-reinforced Ni-based MIG hardfacing flux-cored wire and belongs to surface-modified cored wires used in the technical field of engineering application. The flux-cored wire is composed of a nickel strap wrapper and core portion powder. Core ingredients comprise, by mass, 30%-75% of tungsten carbide, 4%-17% of silicon carbide, 3%-15% of boron carbide, 1%-5% of electrolytic manganese powder, 1%-12% of sodium fluoride and the balance of nickel powder. Ingredients of obtained deposited metal comprise 11.1%-30% of tungsten carbide, 1.3%-5.6% of silicon, 1%-5% of boron, 0.3%-1.48% of manganese and the balance of nickel. A surfacing layer prepared by flux-cored wires is high in hardness (>45HRC), and the hardness of WC hard phases in the surfacing layer reaches 1800HV0.3. According to the WC particle-reinforced Ni-based MIG hardfacing flux-cored wire, the 'shadow protection' effect is achieved mainly through matching of added WC particles and a Ni-based substrate, and therefore wear resistance can be achieved; besides, welding performance of surfacing alloy is improved by adding the deoxidizing agents including silicon and manganese, alterative Na / F and the like.

Owner:BEIJING UNIV OF TECH

Preparation method of aluminum-based boron carbide neutron absorption composite material

The invention relates to a preparation method of an aluminum-based boron carbide neutron absorption composite material. The preparation method comprises the following steps of: according to the characteristics of a neutron absorption composite material, grinding, blanking, cold-pressing, baking, hot-pressing raw materials of aluminum powder, silica powder, titanium powder and boron carbide powderby using a powder metallurgic method to prepare the aluminum-based boron carbide neutron absorption composite material in a vacuum state. The tempering quantitative treatment is carried out on the aluminum-based boron carbide neutron absorption composite material so that chemical and physical properties of the aluminum-based boron carbide neutron absorption composite material are more stable. Thepreparation method has the advantages of advanced and reasonable process, continuity and compact, detailed and accurate data, reasonable material proportioning, stable chemical and physical properties and mechanical property and favorable product purity as high as 99.5% and is ideal. Various neutron absorption parts can be prepared by using the aluminum-based boron carbide neutron absorption composite material.

Owner:TAIYUAN UNIV OF TECH +1

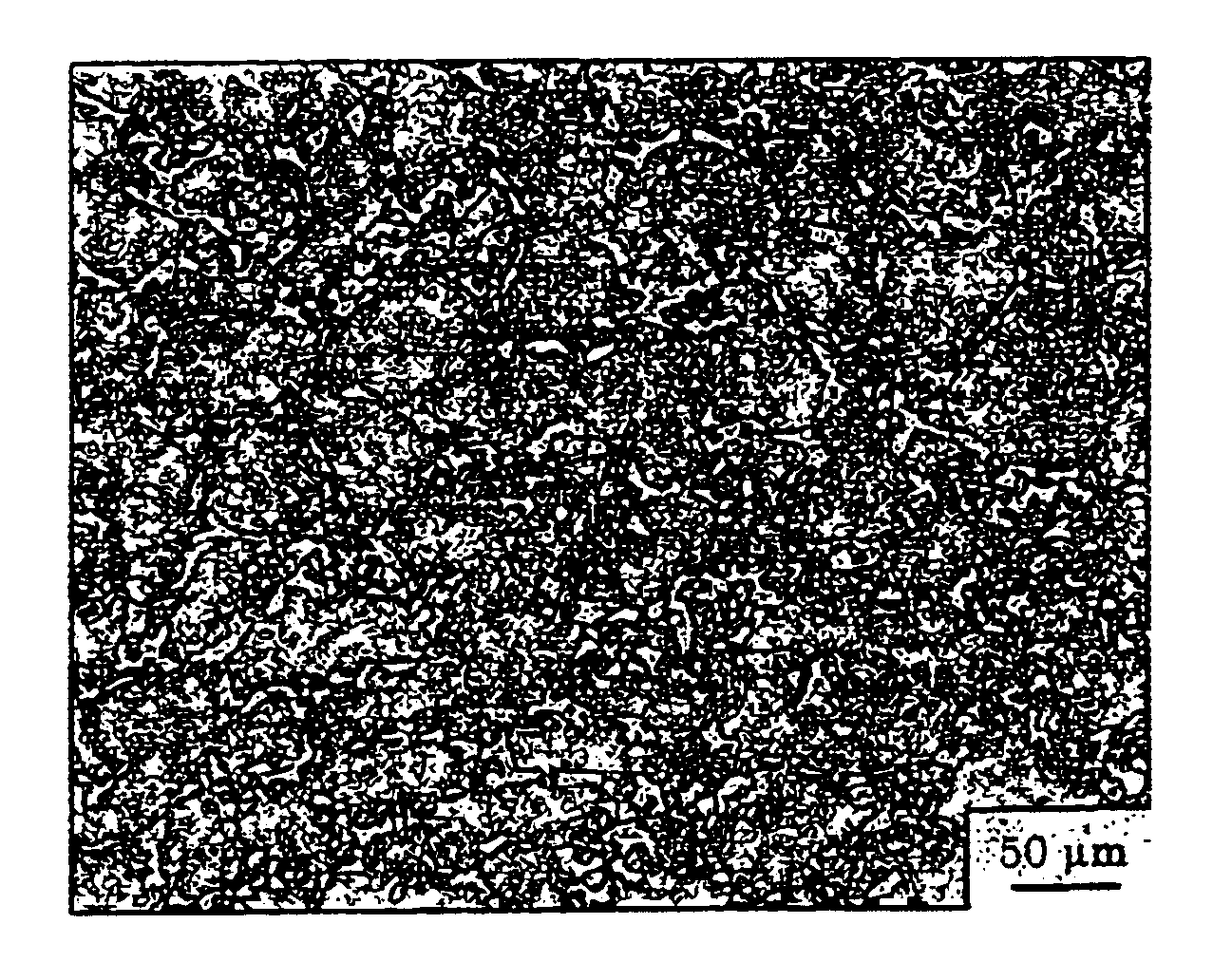

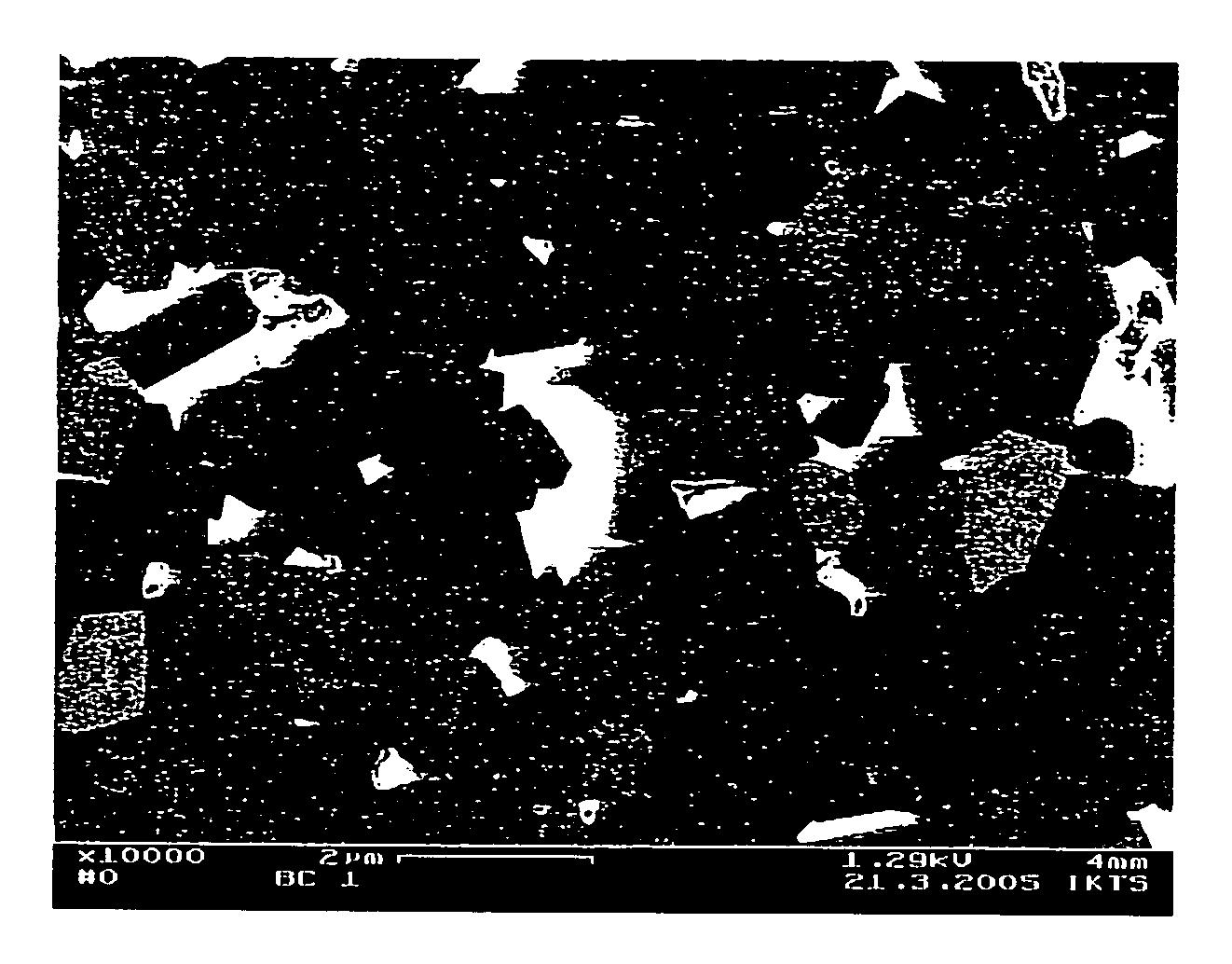

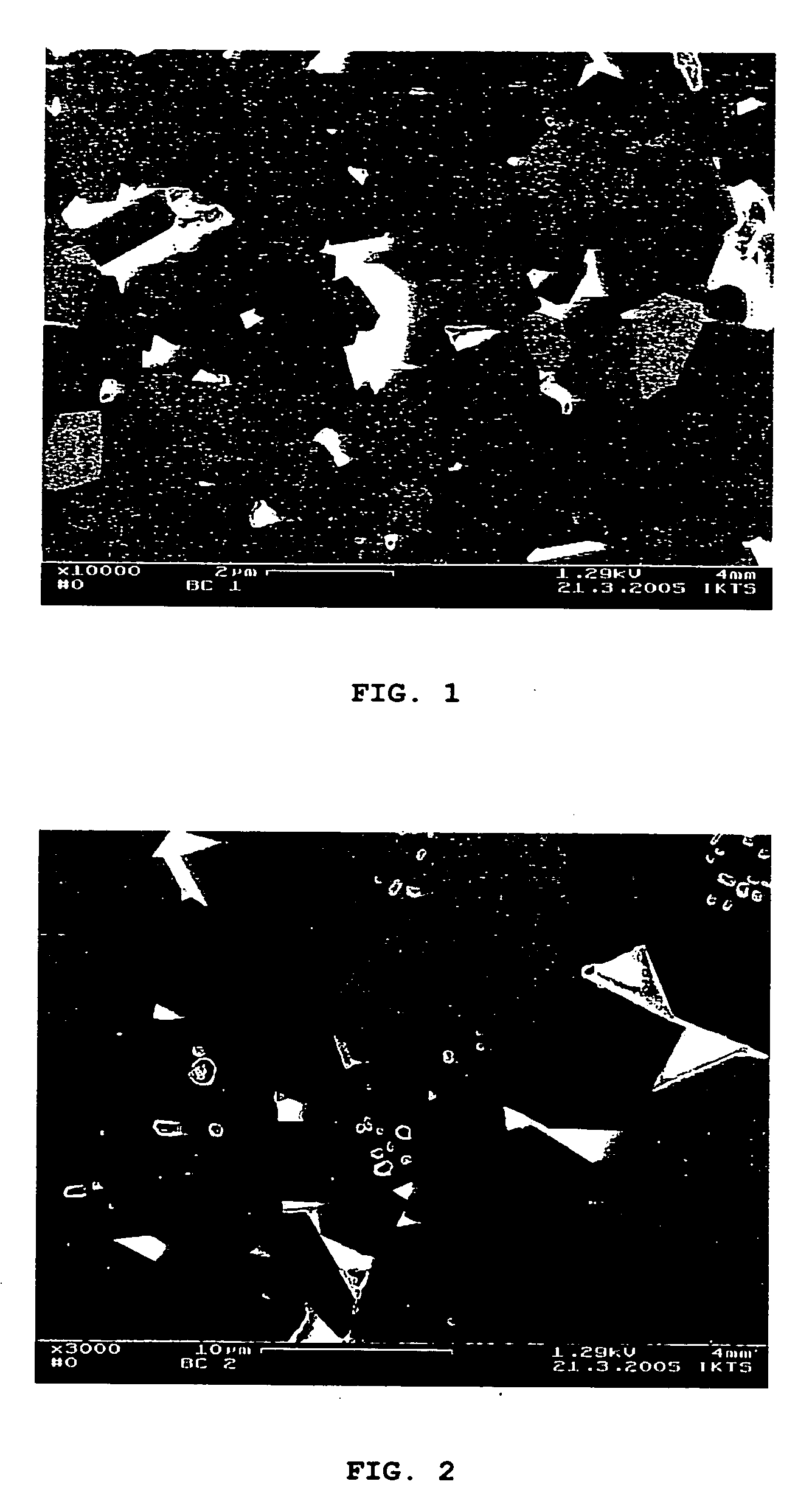

Lightweight boron carbide materials with improved mechanical properties and process for their manufacture

This disclosure describes sintered bodies comprising about 90 wt % to about 99 wt % of boron carbide, wherein the B:C atomic ratio ranges from 3.8 to 4.5:1; 0 to 1 wt % free carbon; 0 to 1 wt % BN or AlN, remainder an oxide binder phase; said sintered body having a uniform microstructure composed of substantially equiaxed grains of said boron carbide; the oxide binder phase comprising a least a rare earth aluminate and optionally other ternary or binary phases of rare earth oxide—alumina systems; the binder phase being present in form of pockets at the multiple grain junctions and the density of no more than 2.6 g / cm3. Also described is a manufacturing process for the above described substantially pore-free, sintered boron carbide materials with high strength and fracture toughness, which can be used for production of large-area parts. It is achieved by liquid phase low temperature—low pressure hot pressing of boron carbide in an argon atmosphere.

Owner:CERADYNE

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

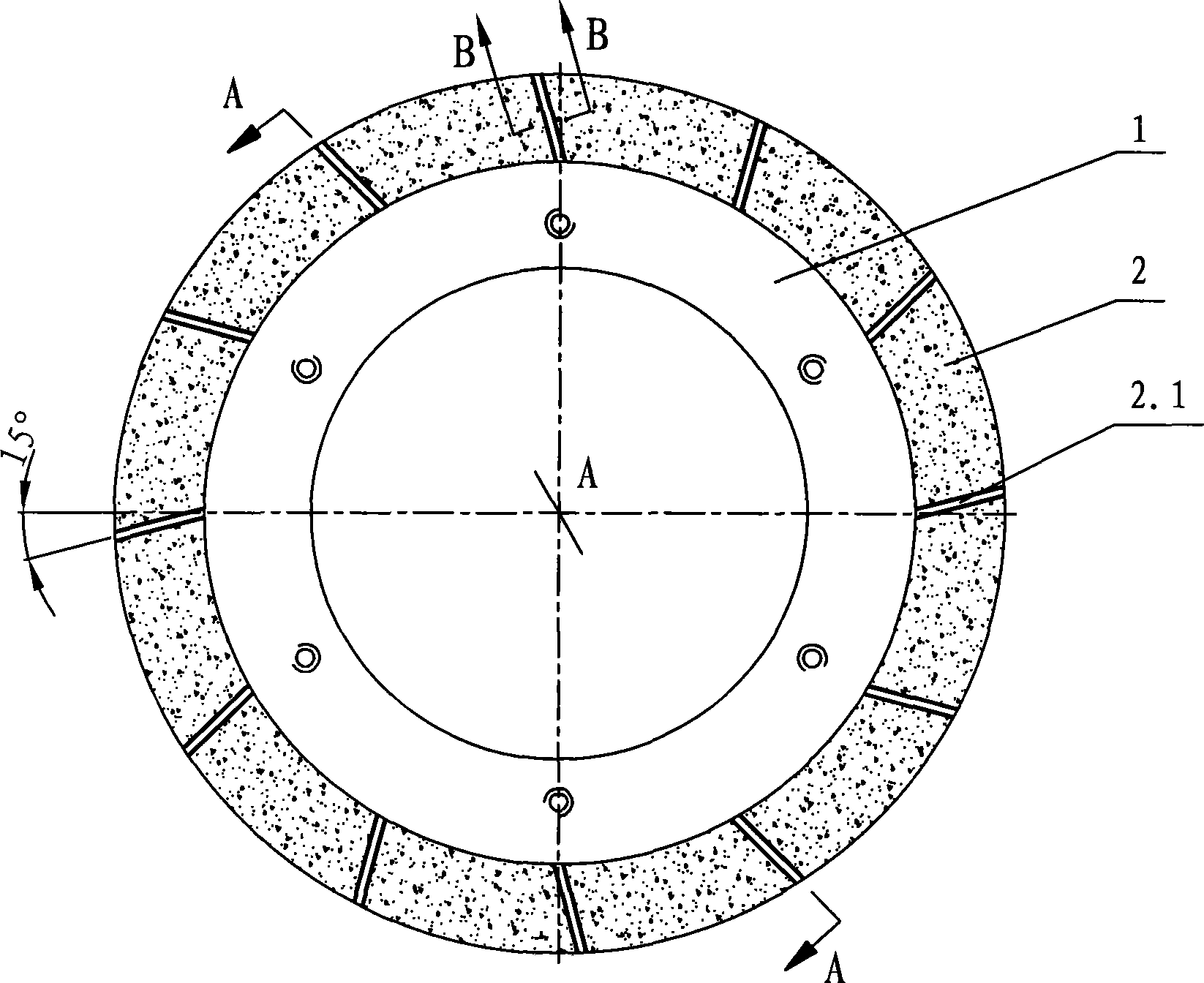

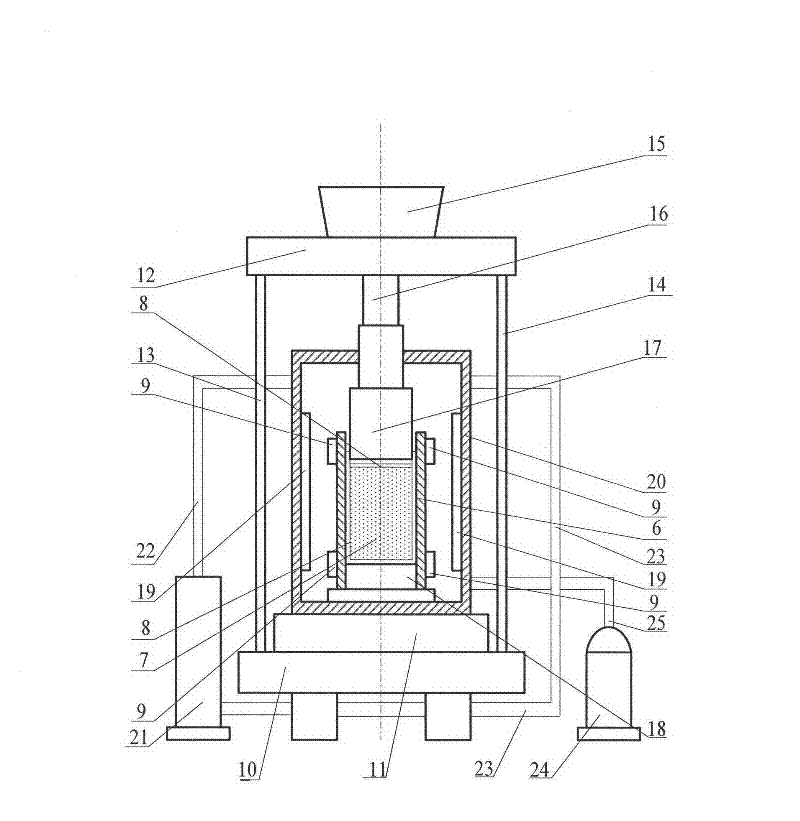

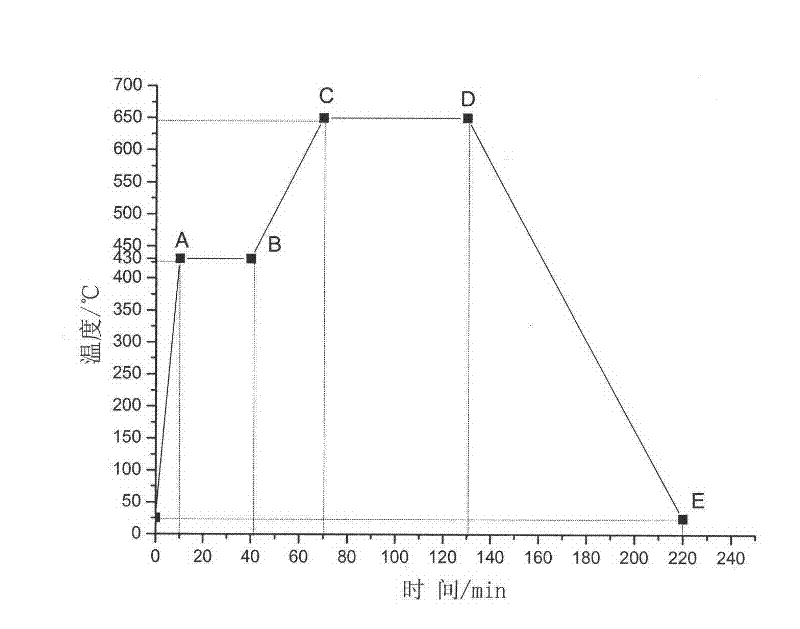

A kind of preparation method of aluminum-based boron carbide neutron absorbing plate

The invention relates to a method for preparing an aluminum-based boron carbide neutron absorption board. According to a requirement on nuclear device protection, the compact aluminum-based boron carbide neutron absorption board is formed by mixing aluminum powder, boron carbide powder, silicon powder, titanium powder and boracic acid crystal, performing powder metallurgy to make a rectangular board, and performing hot extrusion molding on the rectangular board on a pressing machine in a die in a heating state; the compound neutron absorption board is grey white; the neutron absorption rate is more than or equal to 90 percent, the boron carbide is distributed uniformly, and particles and a base body are tightly combined together; the micro hardness of the base body is up to 185.8HV and the micro hardness of the particles is up to 2,022.2HV; a corrosion resistance level on the surface of the board is -0.45 voltage, the anti-bending angle is more than or equal to 10 degrees, the tensilestrength is more than or equal to 200 MPa, the fracture elongation rate is 1.8 percent and the fracture contractibility rate is more than or equal to 1.0 percent. The preparation method is advanced and rational in process, and is full and accurate in parameter; and the preparation method is an ideal method for preparing the aluminum-based boron carbide neutron absorption board.

Owner:DALIAN BAOYUAN NUCLEAR EQUIP +2

Boron carbide-silicon carbide complex ceramic and preparation method thereof

The invention relates to the field of ceramic materials and in particular relates to a boron carbide-silicon carbide complex ceramic and a preparation method thereof. The boron carbide-silicon carbide complex ceramic is prepared through the following steps: degreasing a boron carbide and carbon mixed powder preform and then carrying out alloy infiltration reactive sintering on the degreased preform, wherein the boron carbide and carbon mixed powder preform comprises 85wt%-98wt% of boron carbide, 1.0wt%-14.0wt% of carbon and an organic bonding agent with a use amount for prefabrication and formation; and alloy is composed of 12.5wt% of silicon and 5wt%-87.5wt% of aluminum. According to the invention, a technology combining infiltration with reactive sintering is adopted, and a bidirectional interconnection microstructure is formed, so that the product has high mechanical property and can resist shooting of bullets; and the complex ceramic is low in density, is an optimal bulletproof and armour material, and is mainly applied to low-density high-property materials in the bulletproof and armour fields.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

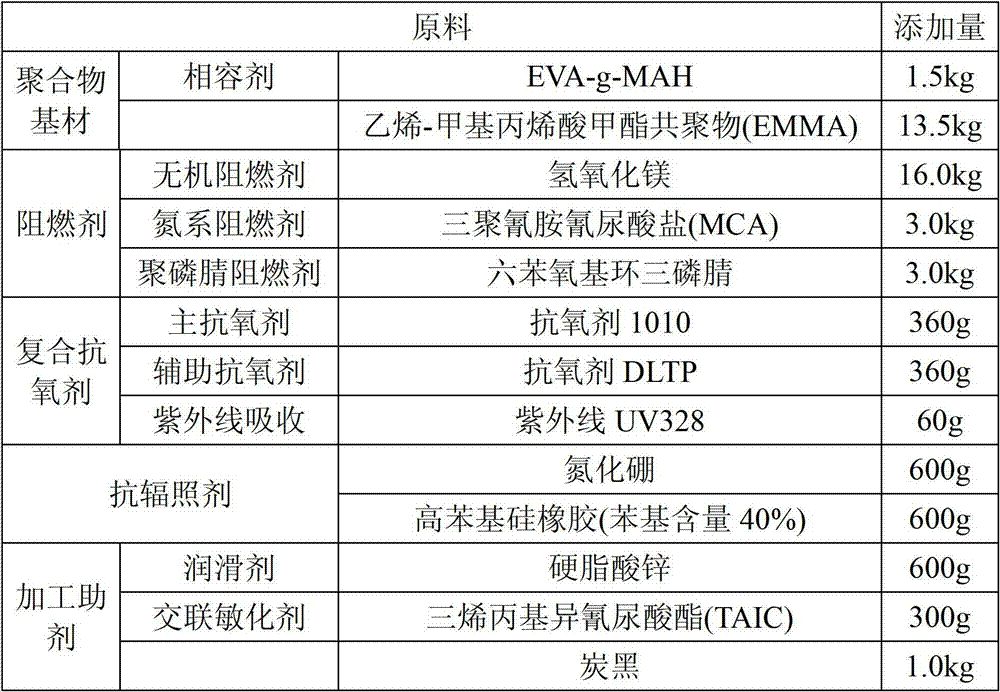

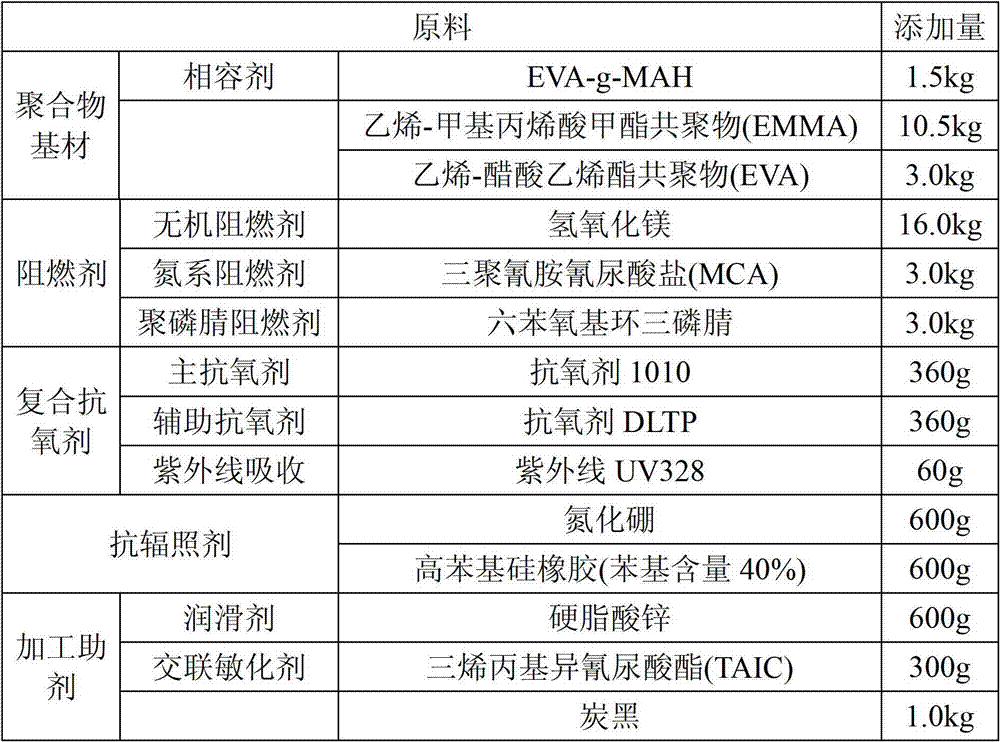

Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

ActiveCN102875947AImprove performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention discloses a halogen-free flame retardant sheath material for a nuclear cable, a cable sheath, and a preparation method and an application of the cable sheath. The halogen-free flame retardant sheath material for the nuclear cable comprises the following raw materials: 100 parts of a polymer base material comprising ethylene vinyl acetate copolymer and ethylene methyl methacrylate copolymer, 100-140 parts of an inorganic fire retardant comprising magnesium oxide, 15-25 parts of phenoxycycloposphazene; 15-30 parts of nitrogen fire retardant comprising melamine cyanurate, 4-8 parts of a compound antioxidant comprising a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of an anti-radiation agent comprising high phenyl siloxane rubber and an anti-radiation agent A, and 6-12 parts of a processing aid comprising a cross-linking sensitizing agent and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The halogen-free sheath material for the nuclear cable disclosed by the invention is good in superior performance, good fire retardant performance, and stable anti-radiation performance, electrical performance and mechanical performance.

Owner:青岛中科汉缆高分子材料有限公司

Ceramic-fiber-paper-based friction plate and production method thereof

ActiveCN102878232AGuaranteed stabilityGuaranteed oil conductivityNon-macromolecular organic additionPaper/cardboardAdhesiveBoron carbide

The invention relates to a ceramic-fiber-paper-based friction plate and a production method thereof and aims to provide the friction plate which is high in friction coefficient and fine in wear resistance and the production method which is simple in procedure and easy and convenient for production. According to the technical scheme, the ceramic-fiber-paper-based friction plate comprises ceramic fiber, carbon fiber, aramid pulp fiber, long staple cotton paper, diatomite, cashew shell oil friction powder, calcium carbonate whisker, boron carbide, potassium feldspar powder, rubber granule, iron sulfide, mica, alum, magnesia, cashew shell oil modified phenolic resin, powdered fluorine rubber, butyronitrile rubber latex, boron-tung oil modified phenolic resin and moderate additives. The production method includes the steps of firstly, producing pretreatment material, mixing material and size and performing papermaking to produce raw paper of ceramic-fiber-paper-base friction material; and secondly, soaking the raw paper in adhesive, cutting into strips after hot-pressing solidification, and adhering to a friction plate core plate to obtain the ceramic-fiber-paper-based friction plate.

Owner:杭州克尔菲利科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com