Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

A technology of flame retardant sheath and inorganic flame retardant, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of thermal aging of cable sheath materials, unsatisfactory halogen-free flame retardant properties, and poor mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Synthesis of polyphosphazene flame retardant hexaphenoxycyclotriphosphazene:

[0074] The specific operation process is:

[0075] 1), the preparation of phenol sodium salt: in the stainless steel reactor of 100L, add the sodium hydroxide solution of 10Kg phenol, 50L chlorobenzene, 1Kg Polyethylene Glycol, 45% under nitrogen protection, wherein contain the sodium hydroxide of 10mol, The reaction temperature is 120-130° C., and the reaction time is 8-12 hours. After the reaction is completed, azeotropic distillation is carried out to separate water, and the reactant is cooled to room temperature for use.

[0076] 2), the preparation of hexaphenoxycyclotriphosphazene: in step 1) in the phenol sodium salt of preparation, add the 30% chlorobenzene solution that contains the hexachlorocyclotriphosphazene of commercially available 5.8Kg under nitrogen protection, in React at 130-132°C for 6-12 hours, cool, filter, distill the filtrate under reduced pressure, recover the solve...

Embodiment 2

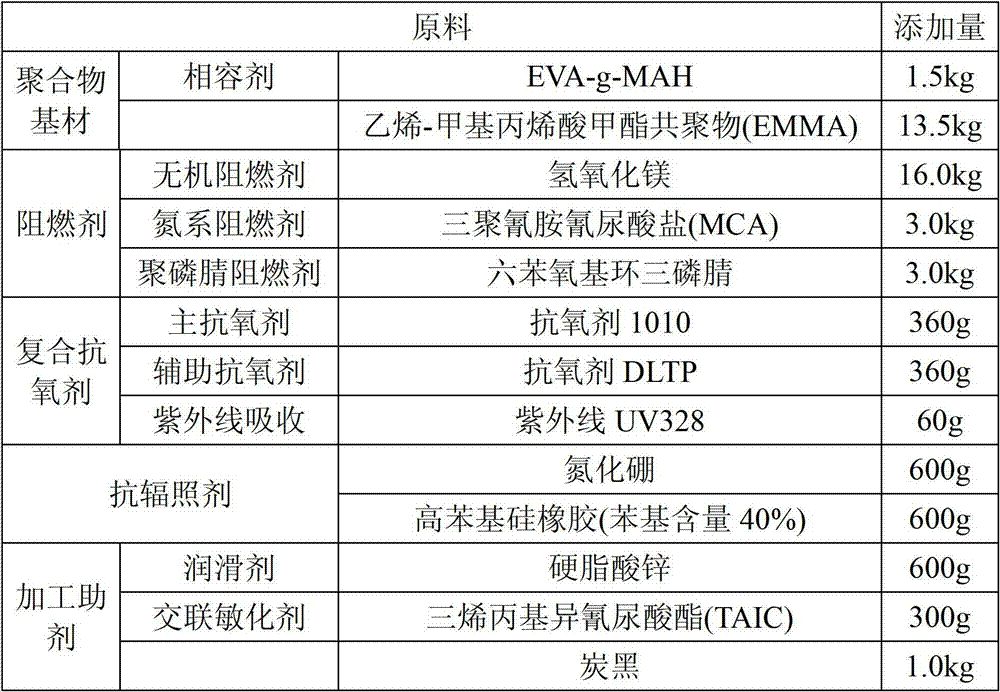

[0078] raw material:

[0079]

[0080] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0081] Steps:

[0082] The compatibilizer EVA-g-MAH, ethylene-methyl methacrylate copolymer (EMMA, antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, magnesium hydroxide, melamine cyanurate (MCA ), hexaphenoxycyclotriphosphazene and carbon black were put into a 35-liter internal mixer, and when banburying to 130°C, high-phenyl silicone rubber (40% phenyl content, zinc stearate, triallyl Based on isocyanurate (TAIC), after mixing for 10 minutes (mixing temperature 120-140°C), turn over the internal mixer, pour the material into the elevator and raise it to A twin-screw extruder is used to extrude and granulate at 110-150°C, and air-cooled to obtain nuclear power K1 halogen-free flame-retardant sheathing material.

Embodiment 3

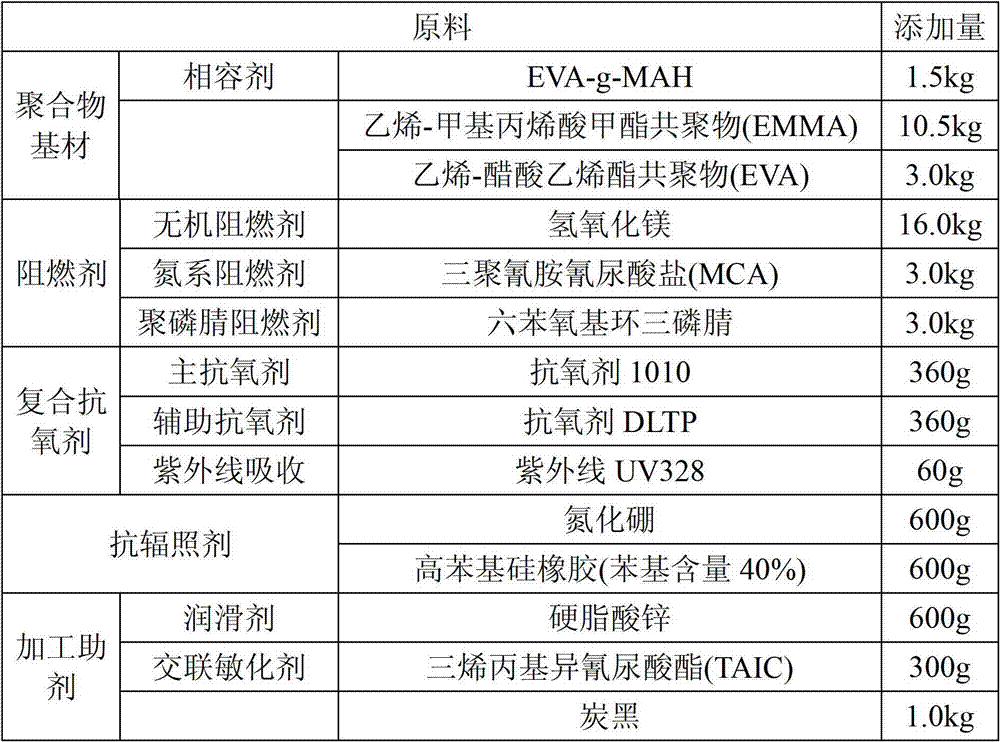

[0084] raw material:

[0085]

[0086] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0087] Steps:

[0088] The compatibilizer EVA-g-MAH, ethylene-methyl methacrylate copolymer (EMMA), ethylene-vinyl acetate copolymer (EVA), antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride , magnesium hydroxide, melamine cyanurate (MCA), hexaphenoxycyclotriphosphazene and carbon black were put into a 35-liter internal mixer, and when it was mixed to 130°C, high-phenyl silicone rubber (phenyl Content 40%, zinc stearate, triallyl isocyanurate (TAIC), after mixing for 10 minutes (mixing temperature 120-140 ℃), turn over the internal mixer, pour the material into the elevator and raise it to A twin-screw extruder is used to extrude and granulate at 110-150°C, and air-cooled to obtain nuclear power K1 halogen-free flame-retardant sheathing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com