Patents

Literature

791 results about "Thermal aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal aging refers to the characteristic of iron powder cores where the core loss increases dramatically when the core is exposed to high temperatures over some period of time.

Exhaust gas aftertreatment systems

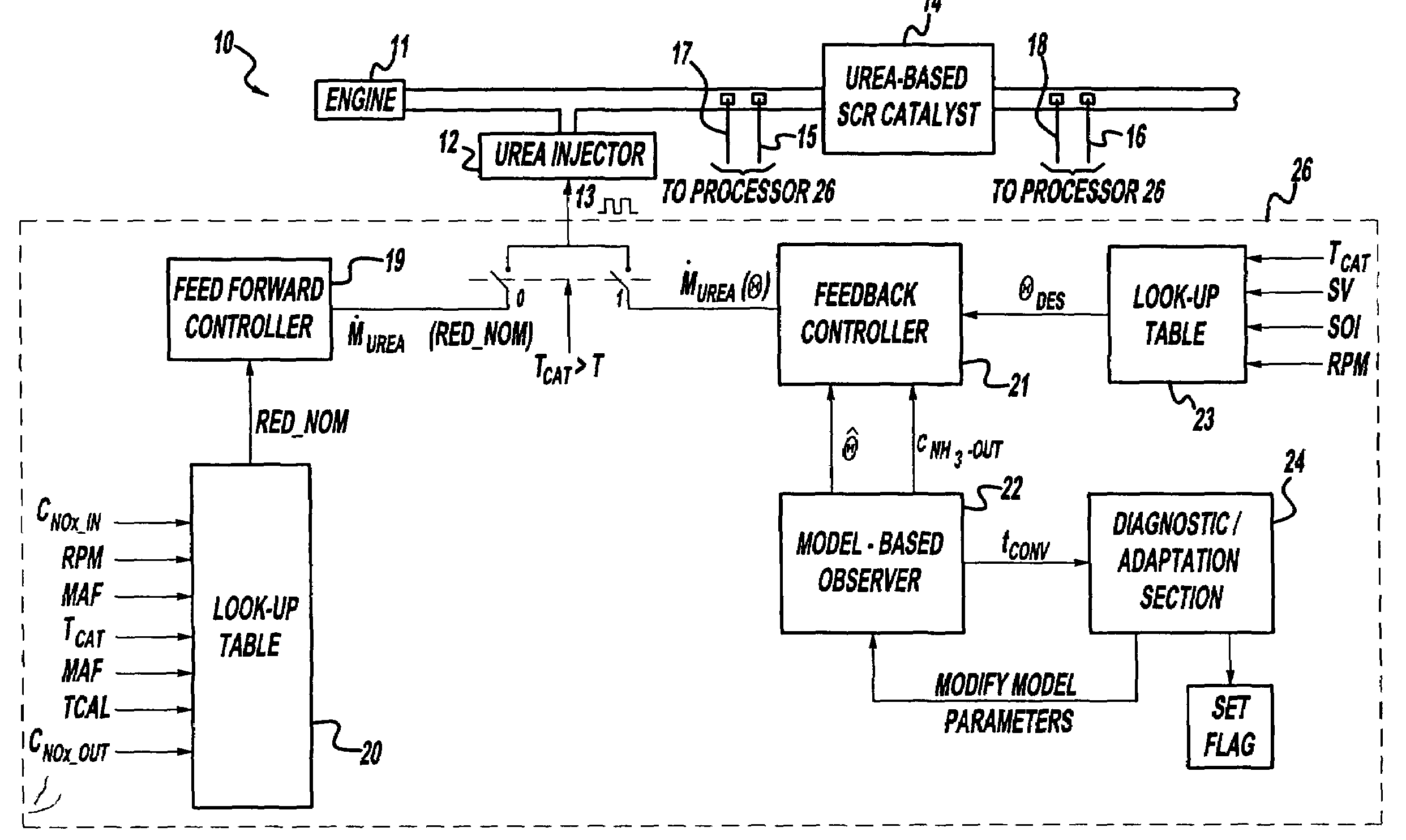

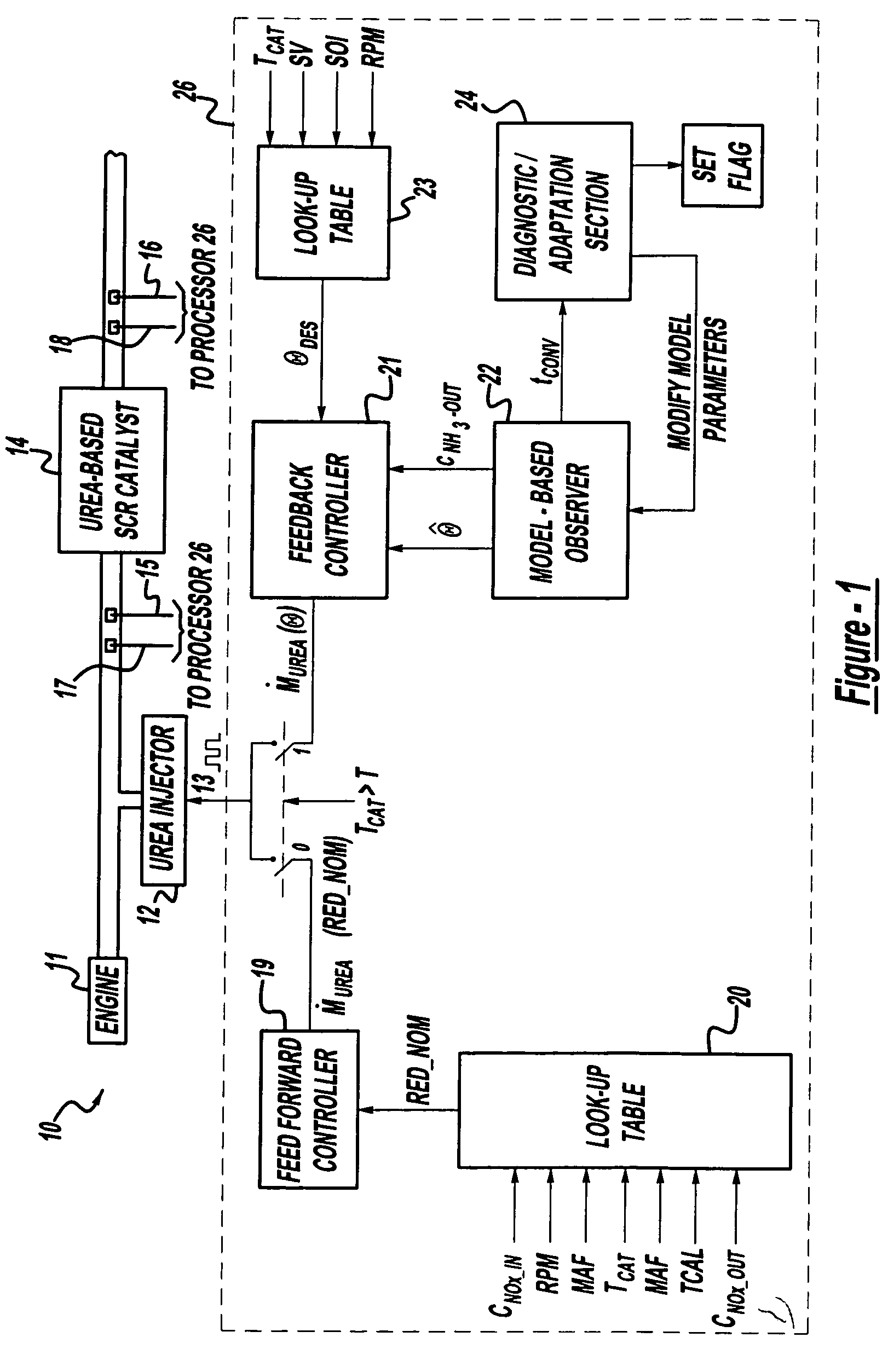

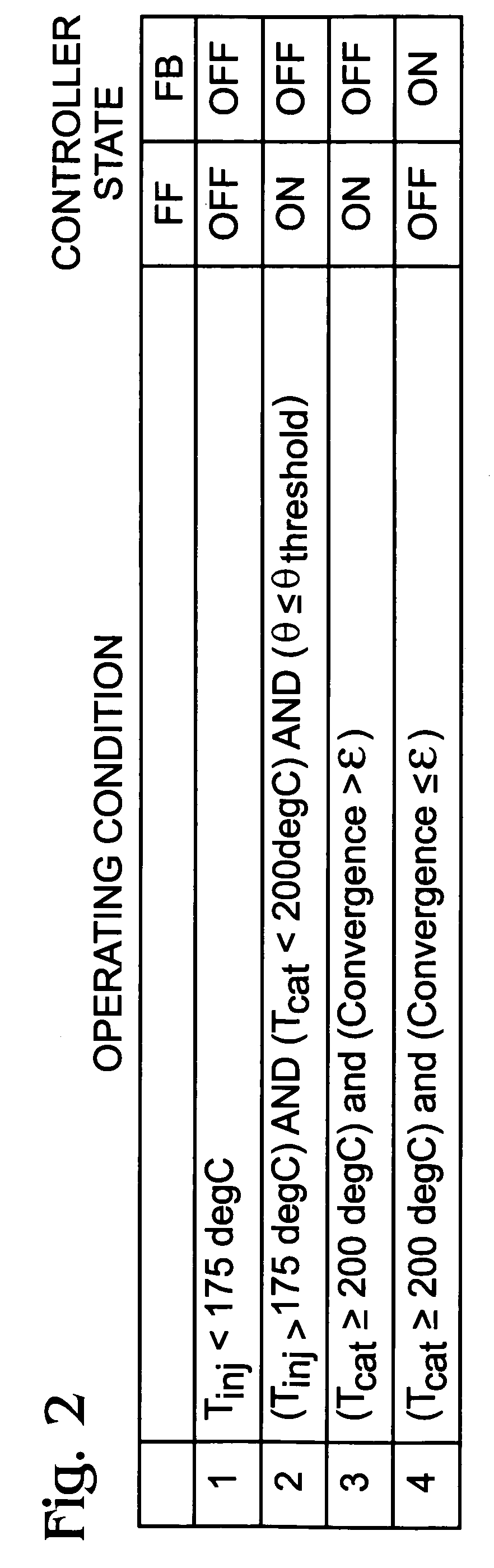

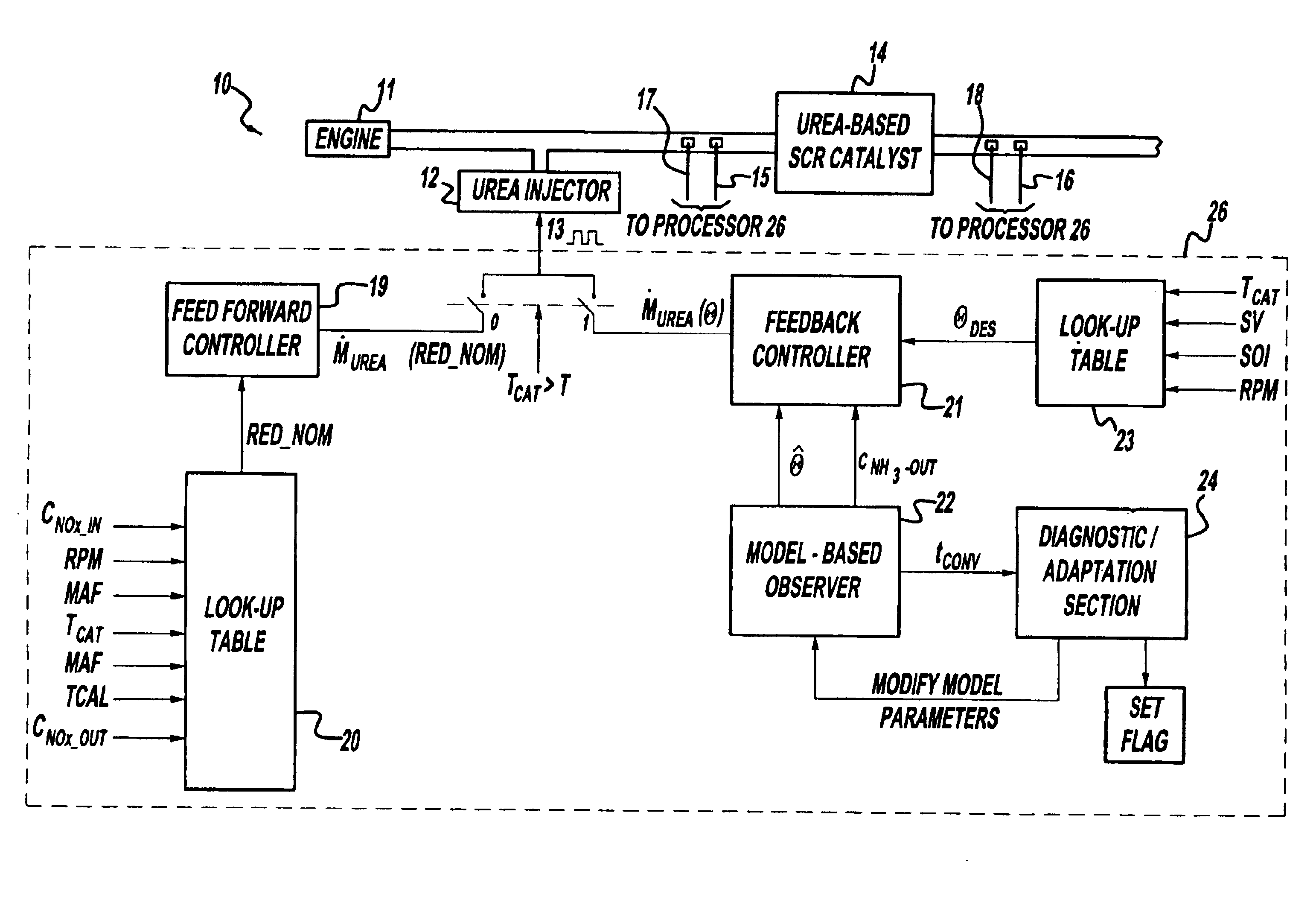

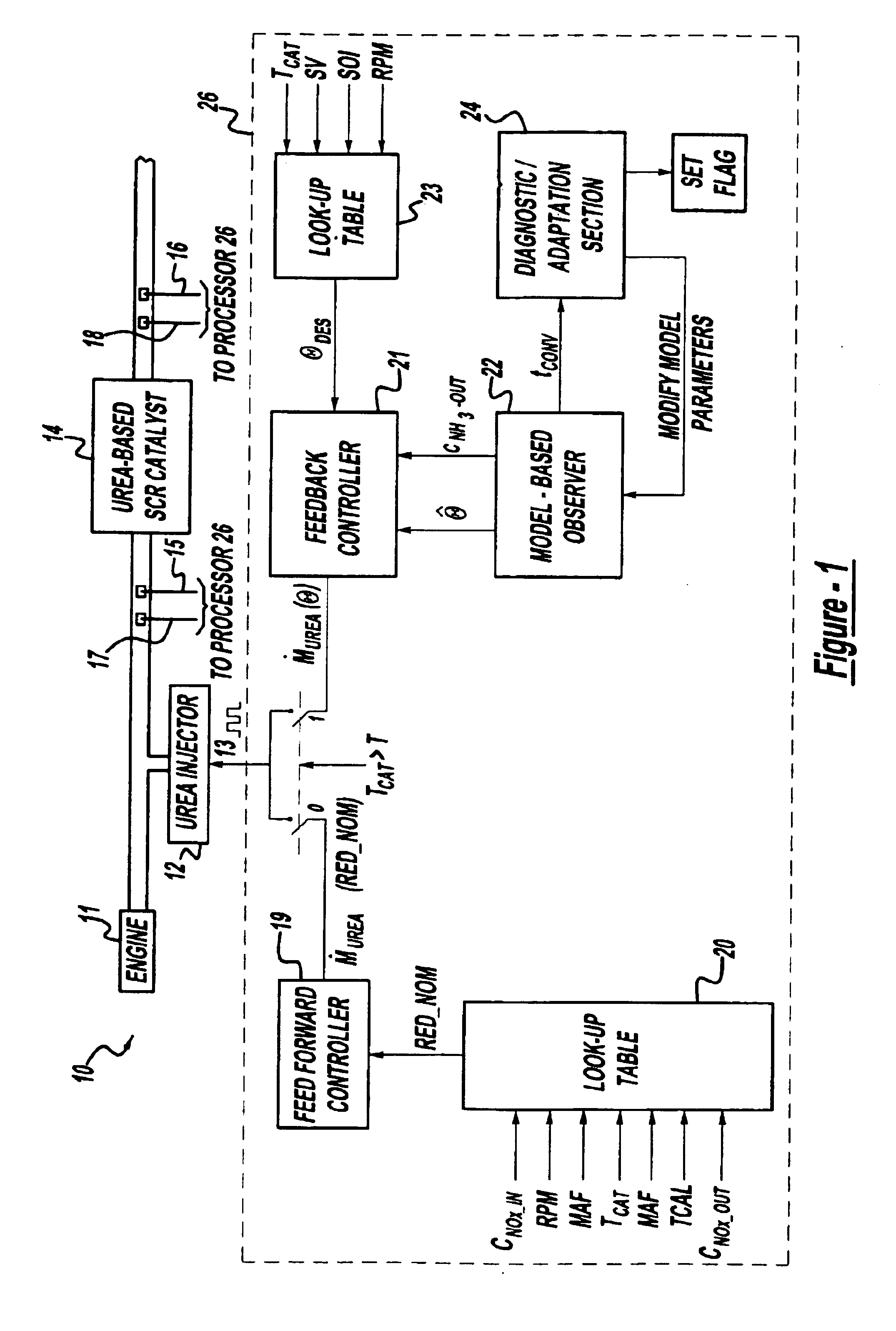

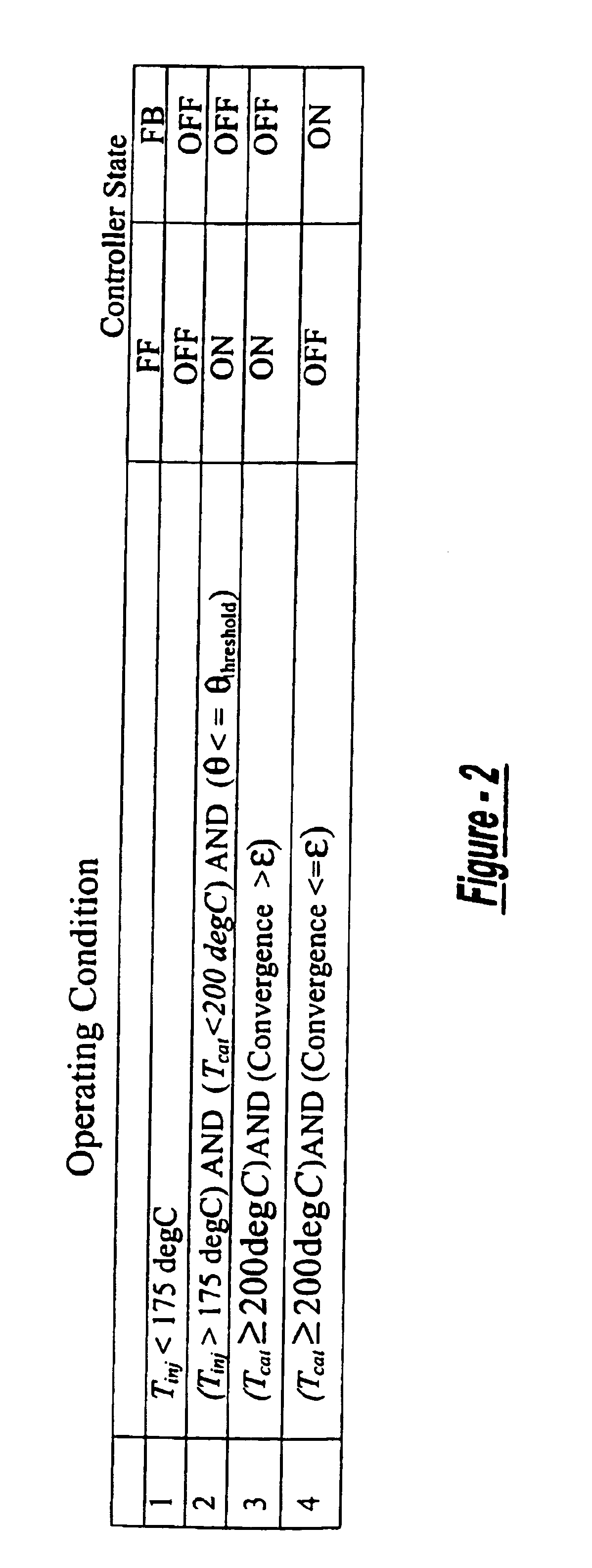

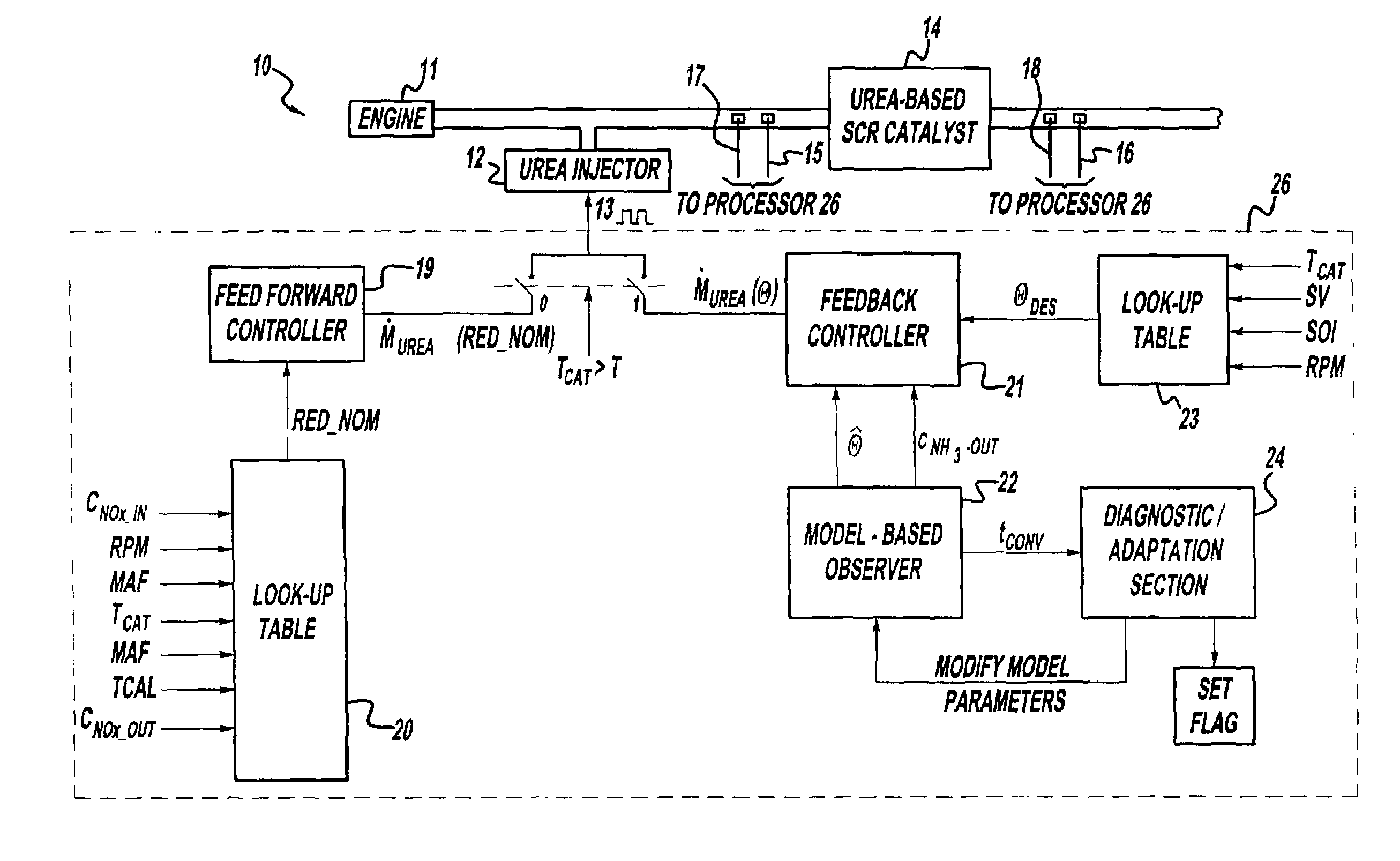

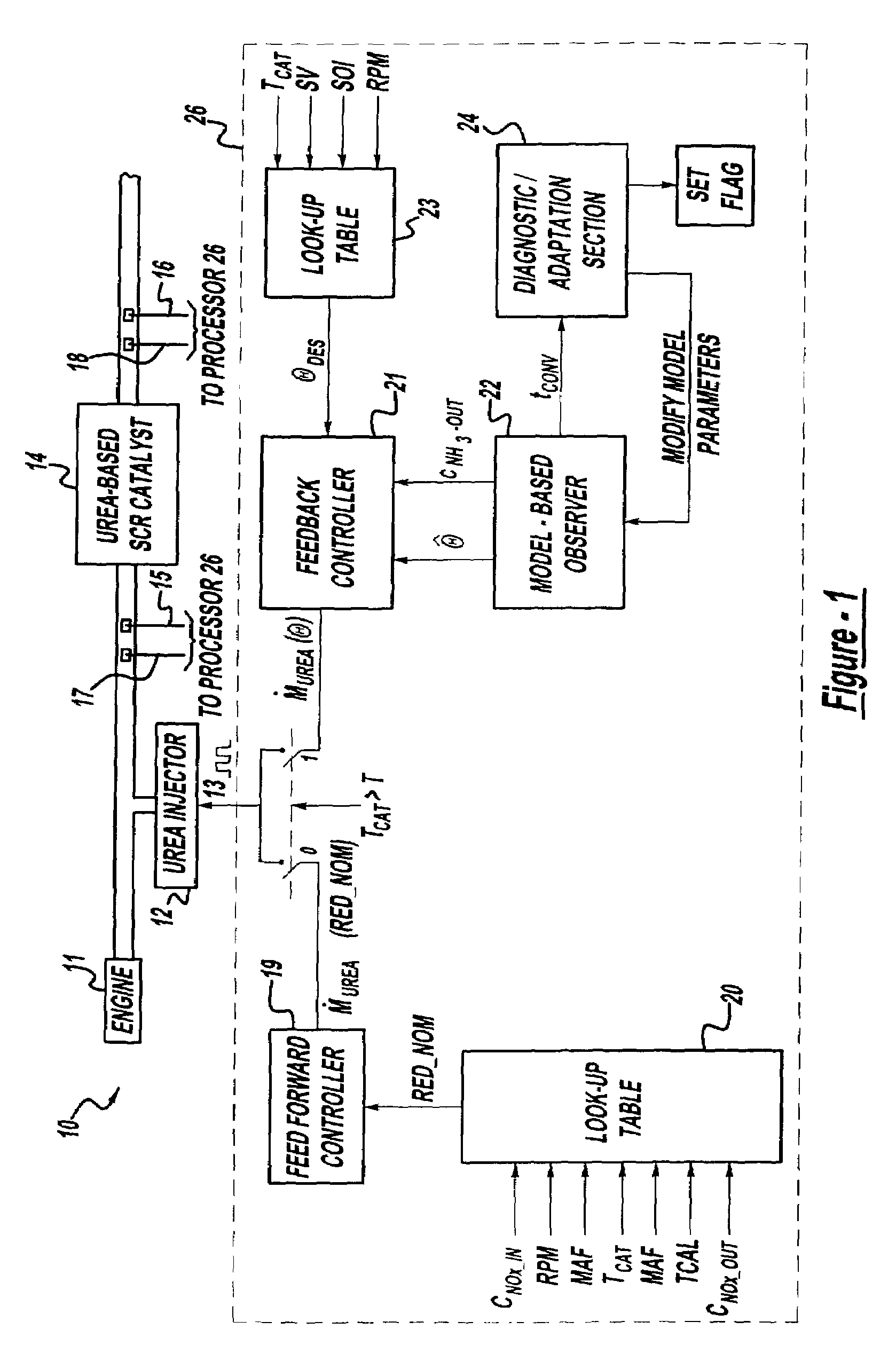

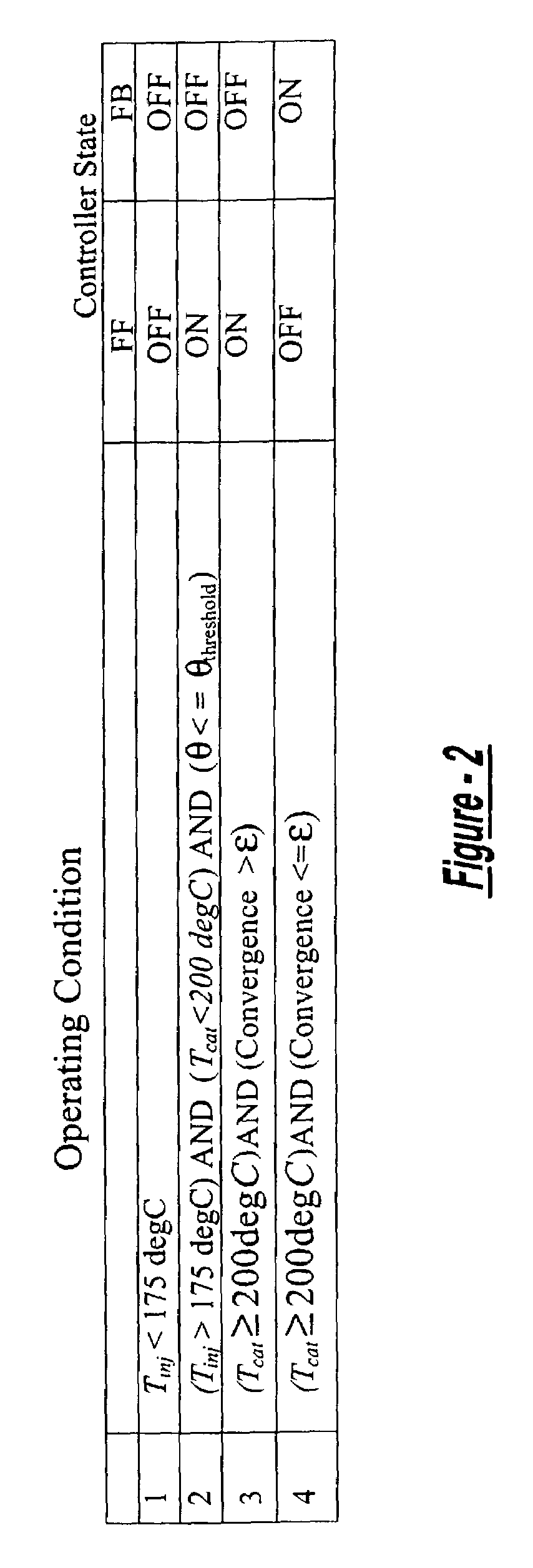

InactiveUS7093427B2Accurate estimateImprove NOx conversion efficiencyInternal combustion piston enginesAuxillariesDynamic modelsAmmonia storage

A method is presented for estimating an amount of ammonia stored in a urea-based SCR catalyst based on a dynamic model of the catalyst. The model takes into account chemical and physical properties of the catalyst, such as catalyst volume, the number of available ammonia storage cites, adsorption and desorption dynamics, as well as sulfur poisoning, thermal aging, and different catalyst operating temperatures, and generates the estimate based on a measured or estimated amount of NOx in an exhaust gas mixture upstream of the catalyst, an amount of reductant injected into the catalyst to facilitate NOx reduction, and on a measured value of NOx in an exhaust gas mixture downstream of the catalyst. The estimated ammonia storage amount is then used to control the amount of reductant injected into the catalyst to maintain desired ammonia storage amount such that maximum NOx conversion efficiency coupled with minimum ammonia slip are achieved.

Owner:FORD GLOBAL TECH LLC

Exhaust gas aftertreatment systems

InactiveUS6993900B2Accurate estimateImprove NOx conversion efficiencyInternal combustion piston enginesExhaust apparatusAmmonia storageDynamic models

A method is presented for estimating an amount of ammonia stored in a urea-based SCR catalyst based on a dynamic model of the catalyst. The model takes into account chemical and physical properties of the catalyst, such as catalyst volume, the number of available ammonia storage cites, adsorption and desorption dynamics, as well as poisoning, thermal aging, and different catalyst operating temperatures, and generates the estimate based on a measured or estimated amount of NOx in an exhaust gas mixture upstream of the catalyst, an amount of reductant injected into the catalyst to facilitate NOx reduction, and on a measured value of NOx in an exhaust gas mixture downstream of the catalyst. The estimated ammonia storage amount is then used to control the amount of reductant injected into the catalyst to maintain desired ammonia storage amount such that maximum NOx conversion efficiency coupled with minimum ammonia slip are achieved.

Owner:FORD GLOBAL TECH LLC

Exhaust gas aftertreatment systems

InactiveUS6981368B2Accurate estimateImprove NOx conversion efficiencyGas treatmentInternal combustion piston enginesDynamic modelsAmmonia storage

A method is presented for estimating an amount of ammonia stored in a urea-based SCR catalyst based on a dynamic model of the catalyst. The model takes into account chemical and physical properties of the catalyst, such as catalyst volume, the number of available ammonia storage cites, adsorption and desorption dynamics, as well as poisoning, thermal aging, and different catalyst operating temperatures, and generates the estimate based on a measured or estimated amount of NOx in an exhaust gas mixture upstream of the catalyst, an amount of reductant injected into the catalyst to facilitate NOx reduction, and on a measured value of NOx in an exhaust gas mixture downstream of the catalyst. The estimated ammonia storage amount is then used to control the amount of reductant injected into the catalyst to maintain desired ammonia storage amount such that maximum NOx conversion efficiency coupled with minimum ammonia slip are achieved.

Owner:FORD GLOBAL TECH LLC

Low temperature curing high temperature resistant inorganic / organic hybridization epoxy adhesive and preparation thereof

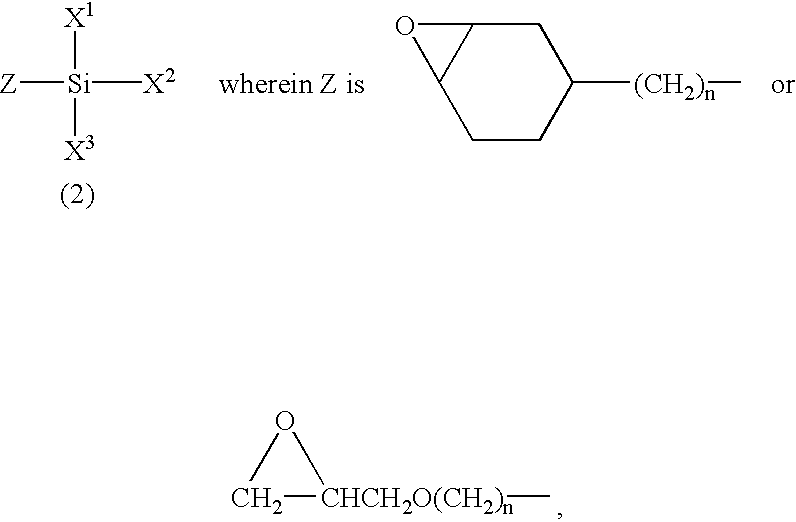

InactiveCN101440268AImprove brittlenessImprove high temperature heat aging resistanceInorganic adhesivesEpoxy resin adhesivesCouplingLow temperature curing

The invention discloses a low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive and a preparation method thereof, which relate to an inorganic / organic hybrid epoxy adhesive and a preparation method thereof. The invention solves the problems that inorganic / organic hybrid epoxy adhesive prepared by the prior art has poor high-temperature thermal aging resistance and needs high curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive is prepared by an epoxy resin, an epoxy resin low-temperature curing agent, a coupling agent, an inorganic active hybrid material and a dispersant. The preparation method comprises the following steps: the epoxy resin, the epoxy resin low-temperature curing agent and the coupling agent are mixed and stirred evenly, and then the inorganic active hybrid material and the dispersant are added into the mixture to be stirred evenly to obtain the low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has high high-temperature bonding strength, good high-temperature thermal aging performance and low curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has the advantages of simple production technology, convenient operation and broad application.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

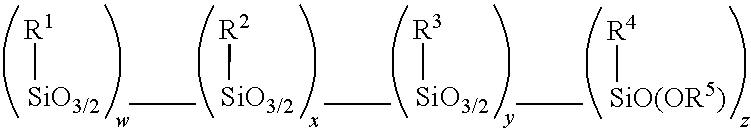

Amino alkoxy-modified silsesquioxane adhesives for improved metal adhesion and metal adhesion retention to cured rubber

InactiveUS20090165913A1Improve adhesion performanceImproved metal adhesion metal retention propertySpecial tyresTyresEndcappingPolymer science

Amino alkoxy-modified silsesquioxanes (amino AMS), and / or amino co-AMS compounds that also comprise a mercaptosilane or a blocked mercaptosilane, are excellent adhesives for coating plated or unplated metal wire for adherence of the wire to a rubber stock. The amino AMS and / or the amino / mercaptan co-AMS adhesives can be used with all types of rubber and there is no requirement for the use of special adhesive additives to the rubber vulcanizates, such as, but not limited to, cobalt, resins and high sulfur levels. In particular, the use of amino AMS and / or amino / mercaptan co-AMS compounds as adhesives for bonding wire to rubber also improves the adherence performance of the reinforcements to obtain sufficient bonding that is resistant to degradation over the course of time, especially resistance to thermal aging and / or thermo-oxidizing aging, in particular corrosion in the presence of water.

Owner:BRIDGESTONE CORP

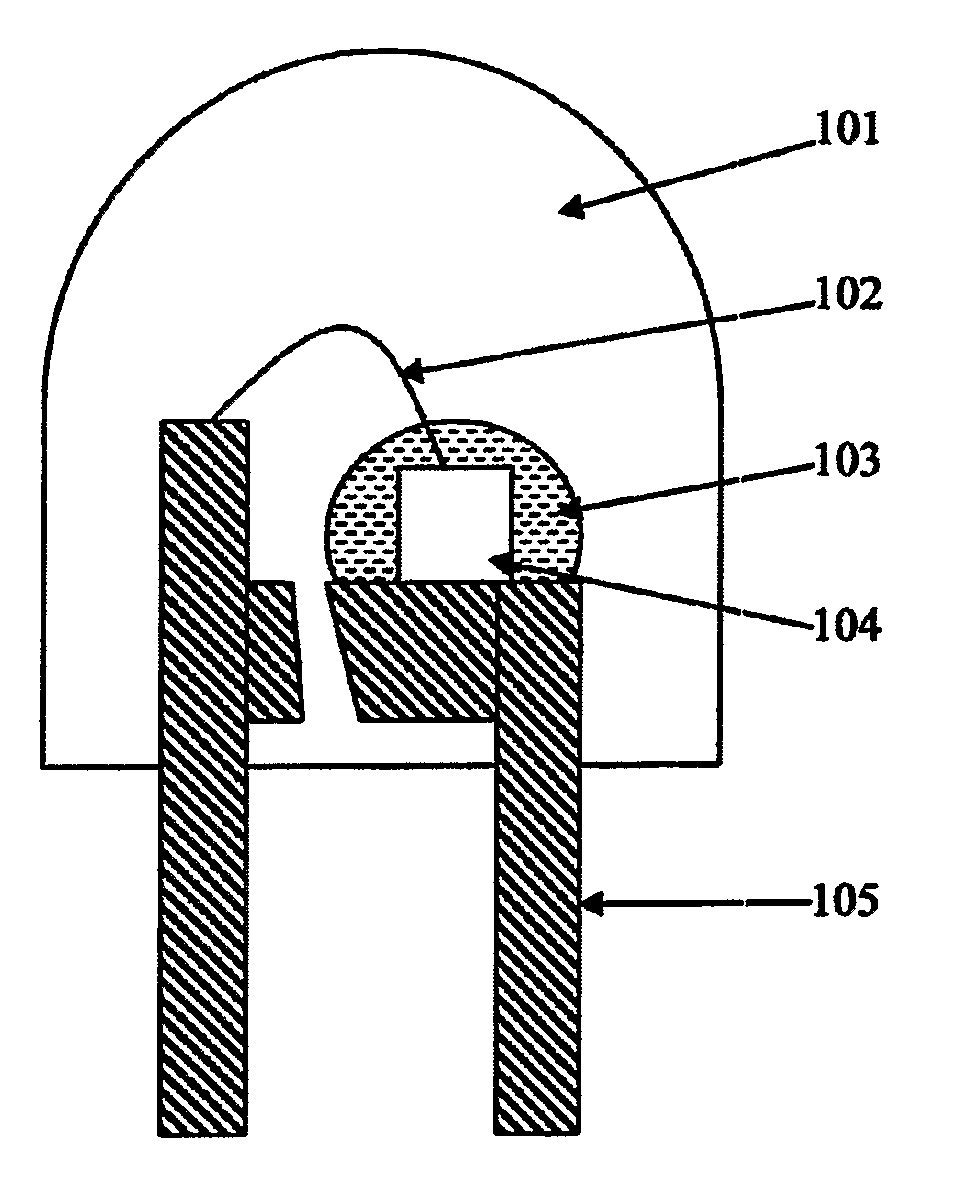

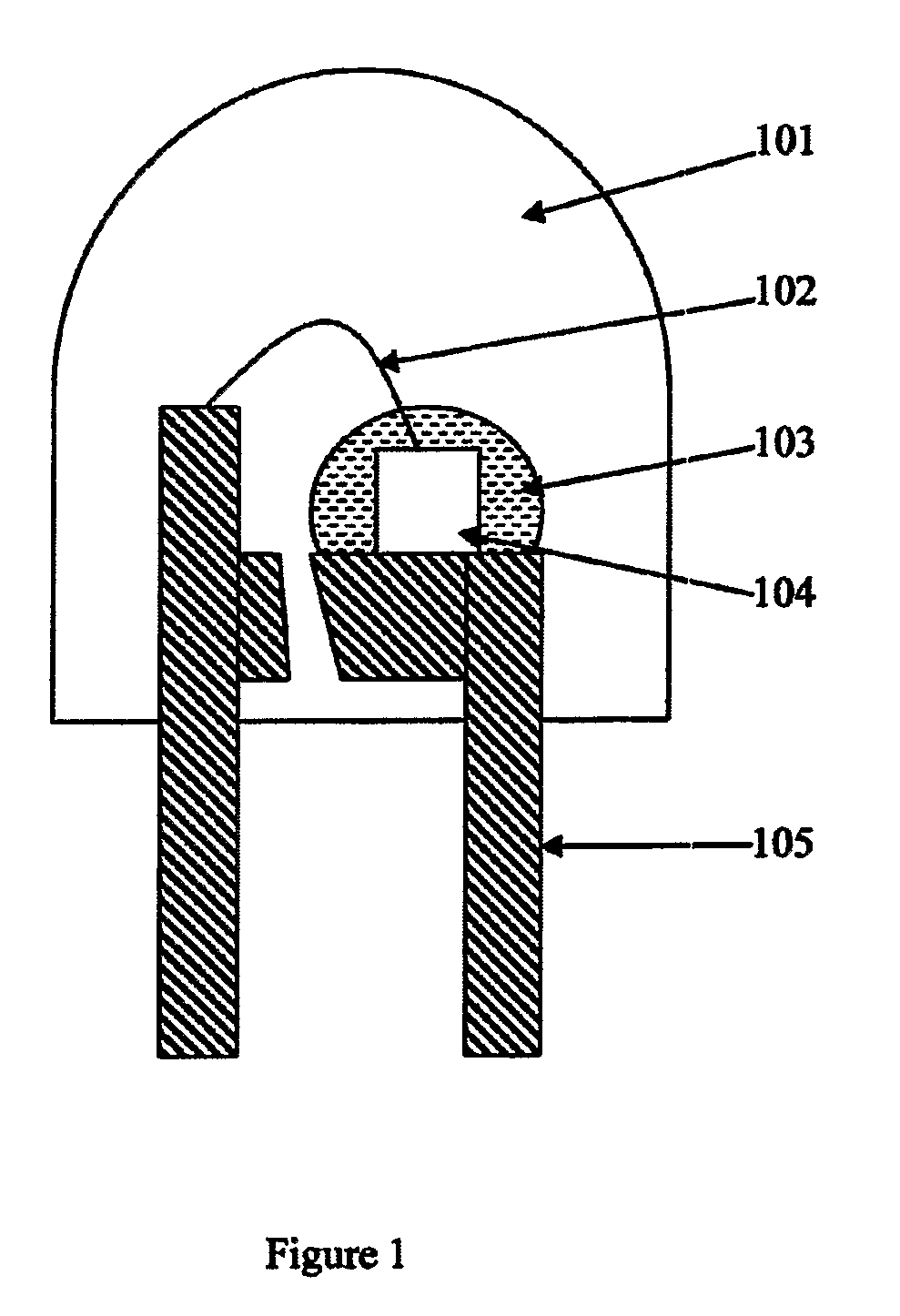

Electrical-thermal aging device of cable accessories under high voltage and high current and test method thereof

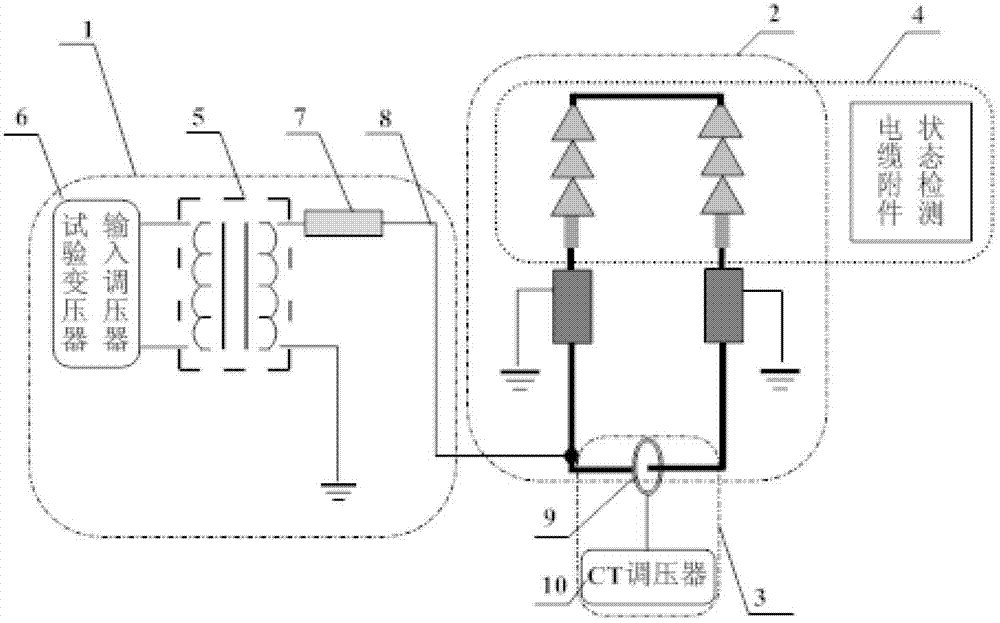

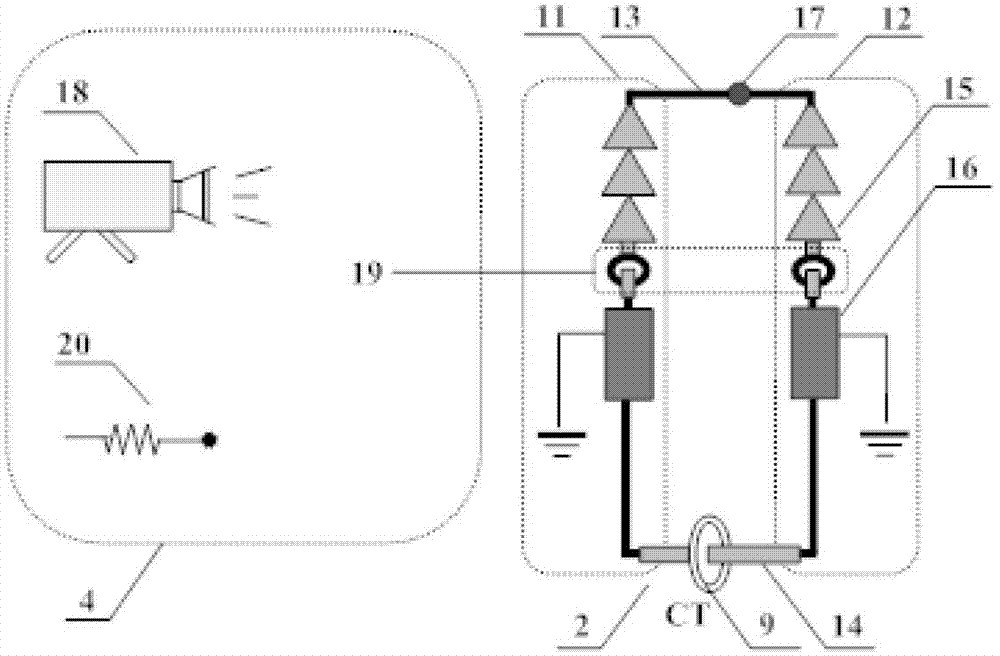

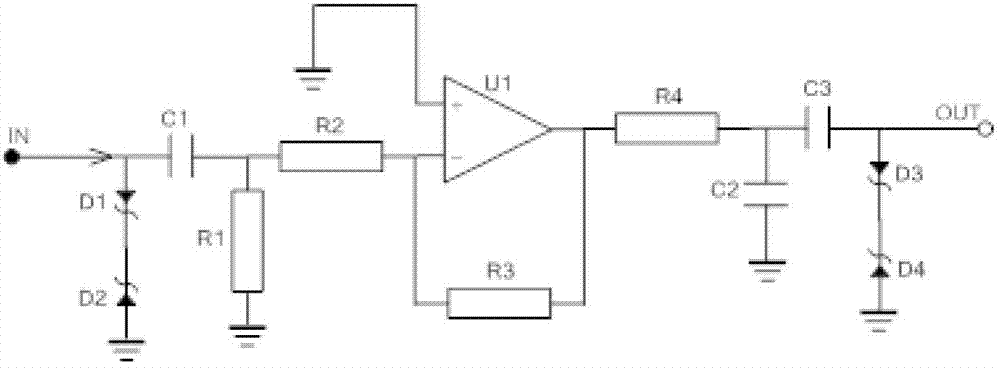

InactiveCN102735977AEasy to makeEasy to operateTesting dielectric strengthPower flowMagnetic field coupling

The invention discloses an electrical-thermal aging test device of cable accessories under high voltage and high current. The electrical-thermal aging test device is characterized by comprising the following four functional parts: a high-voltage generation unit (1), a test loop unit (2), a high-current generation unit (3) and a signal measurement unit (4). The high-voltage generation unit (1) is connected with the test loop unit (2) so as to introduce the high voltage to a test loop; the test loop unit (2) passes through the high-current generation unit (3) to form a magnetic field couple and generate the high current, and when the aging test is performed, the high-voltage generation unit and the high-current generation unit work at the same time to realize the purpose of applying the high voltage and the high current in the test loop unit; and the signal measurement unit (4) is installed in the test loop unit (2), so that the isolation aging state detection of the cable accessories can be realized through collecting the electrical characteristic parameters which are used for detecting the partial discharge of the sample cable accessories.

Owner:SICHUAN UNIV

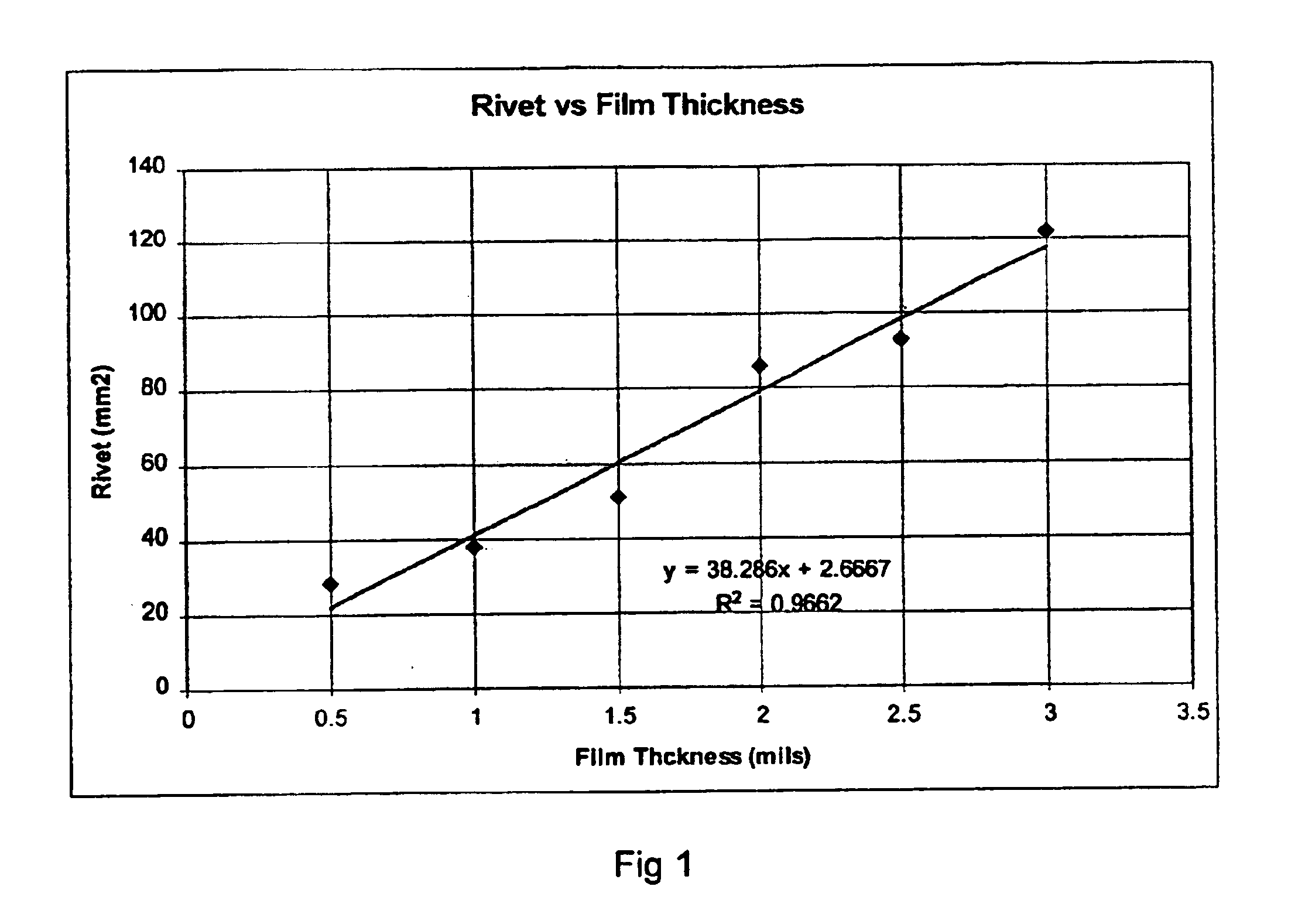

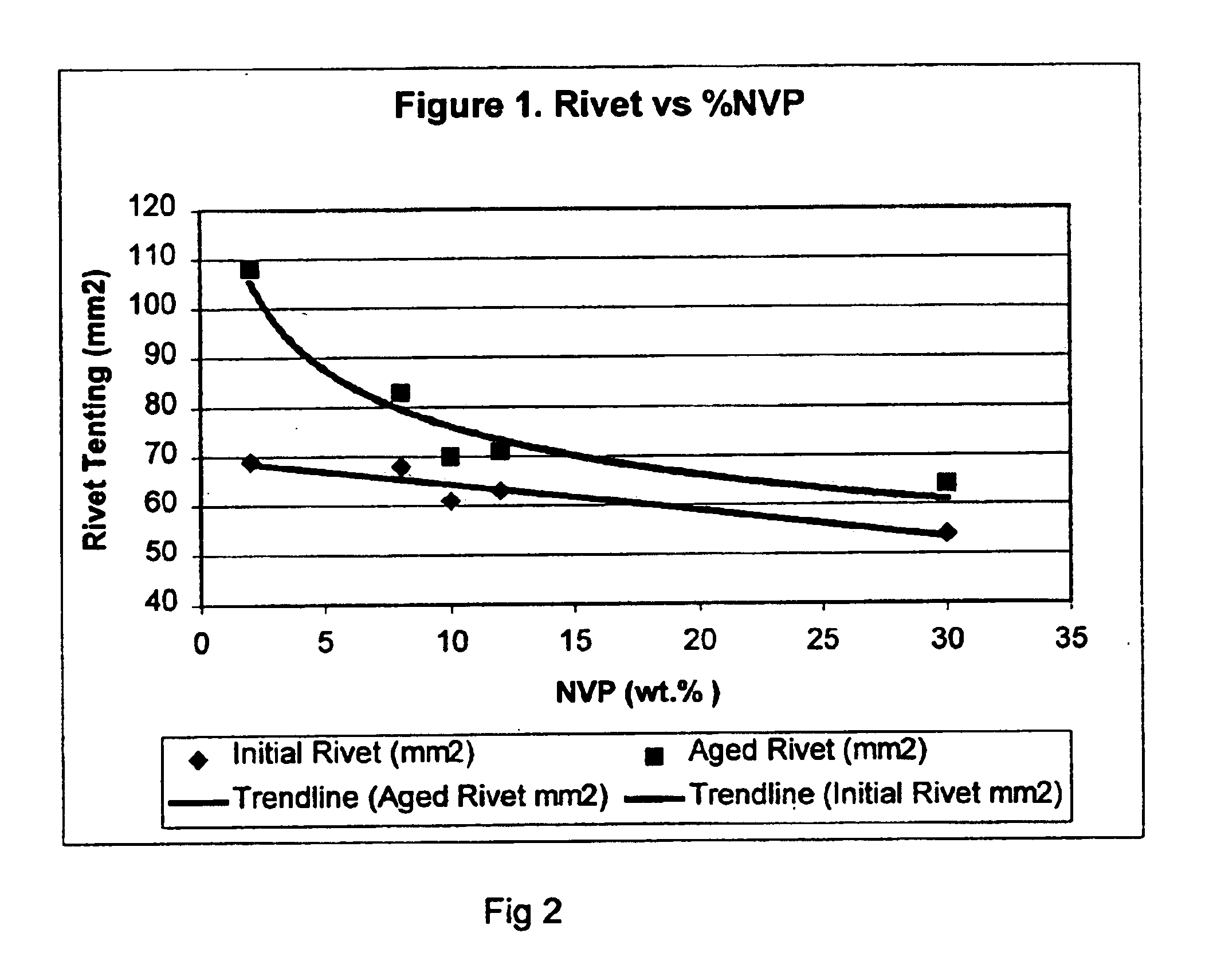

Adhesives with improved rivet properties and laminates using the same

InactiveUS6844391B1Improve performanceOutstanding removal characteristicLiquid surface applicatorsChemical liquid solidificationMethacrylateCohesive strength

Acrylate copolymer pressure-sensitive adhesive constructions are described which provide excellent retention of rivet properties. Tenting around rivets is minimized even after undergoing thermal aging while in contact with additive rich films like PVC. This is achieved by the inclusion of a synergistic amount of an N-vinyl lactam monomer and acid monomer with the bulk of the monomers being an alkyl acrylate save and / or methacrylate esters. A concomitant increase in cohesive strength is also achieved which affords good removal characteristics. The use of appropriate adhesive blends is further disclosed which allows retention of these features while also improving cold temperature properties.

Owner:AVERY DENNISON CORP

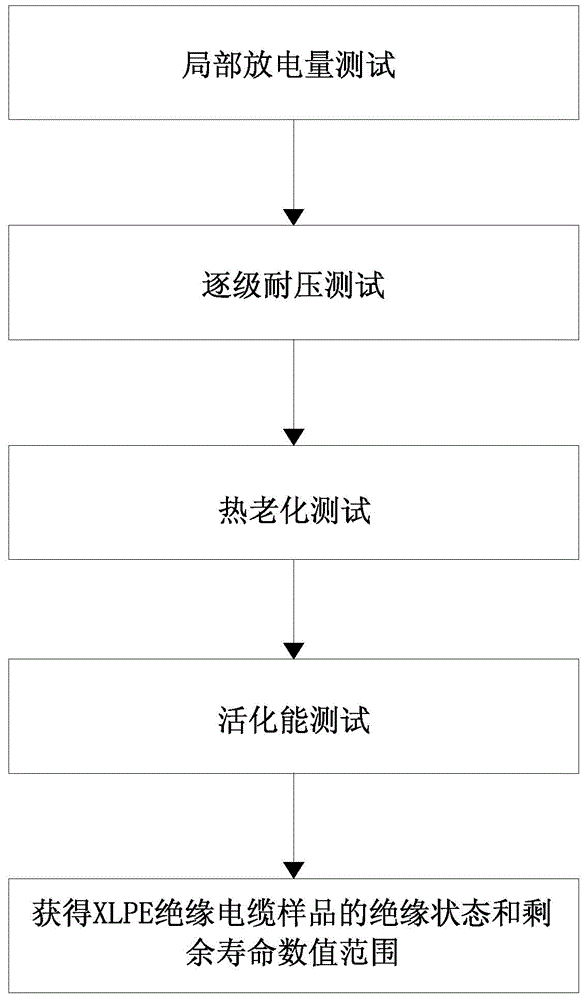

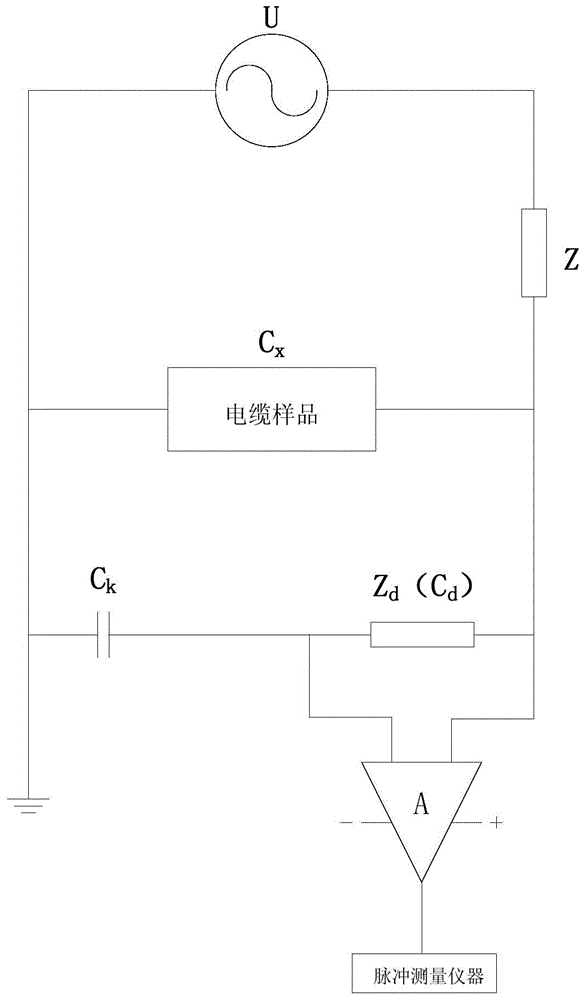

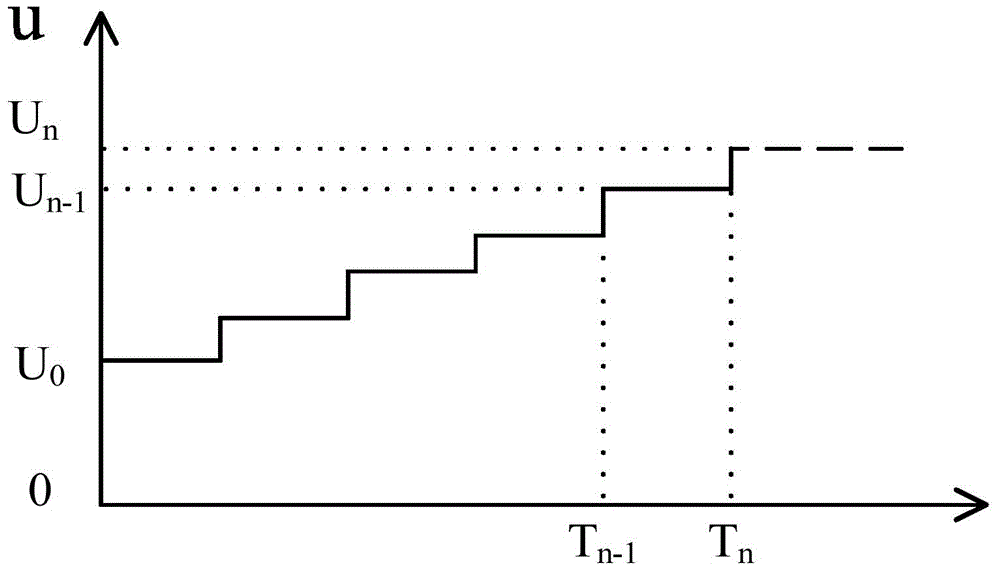

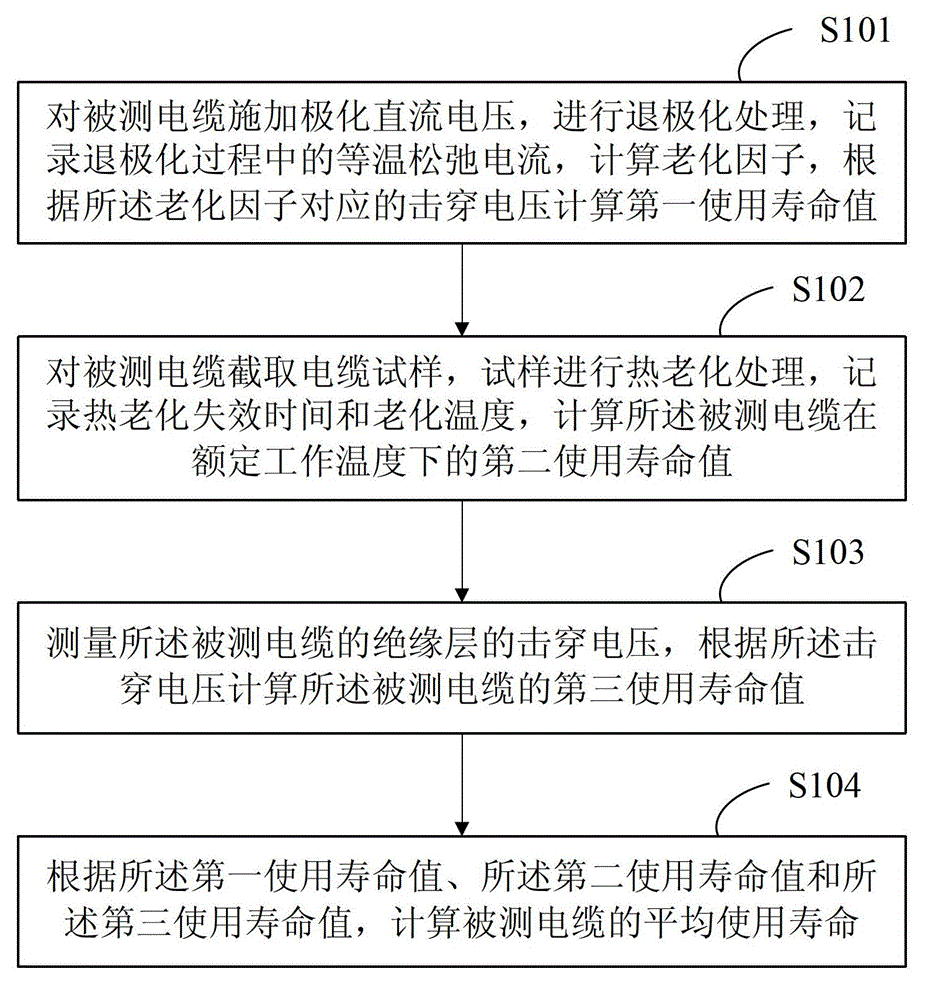

Insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties

The invention discloses an insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties. An insulating cable is an XLPE (Cross Linked Polyethylene) insulating cable. The method comprises a partial discharging amount test, a gradual layer voltage-resisting test, a thermal aging test and an activating energy test; an insulating state of an XLPE insulating cable sample is obtained according to a partial discharging amount calculated by he partial discharging amount test; a residual service life numerical value range of the XLPE insulating cable sample is obtained according to testing results of the gradual layer voltage-resisting test, the thermal aging test and the activating energy test. The method can integrate a plurality of indexes of cable aging evaluation, and combines macroscopic and microscopic change conditions, so that the residual service life data of the cable is completely analyzed in the three aspects of physical performances, chemical performances and electric performances, and the method has important guiding meanings on line modification and power grid planning.

Owner:SOUTH CHINA UNIV OF TECH

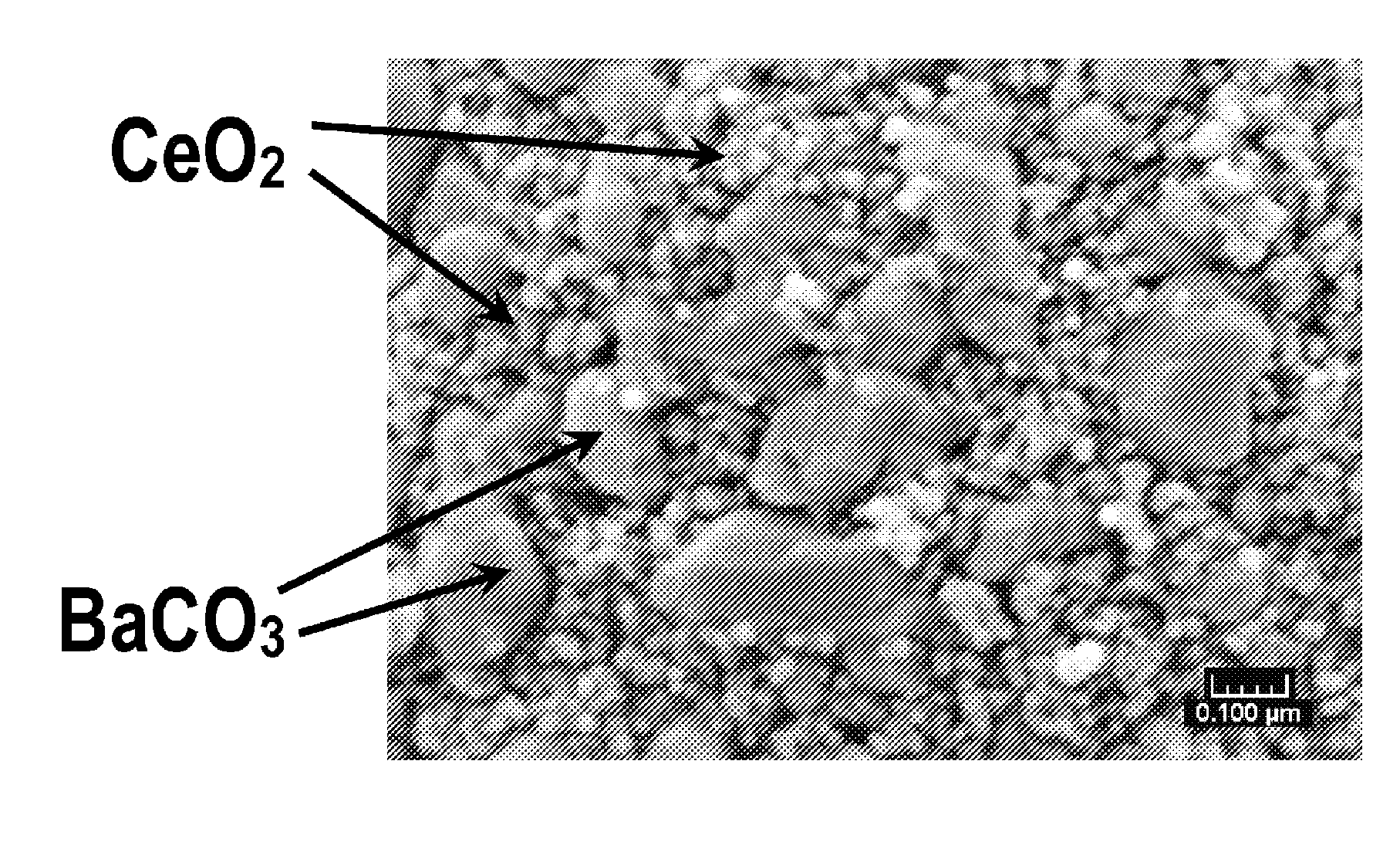

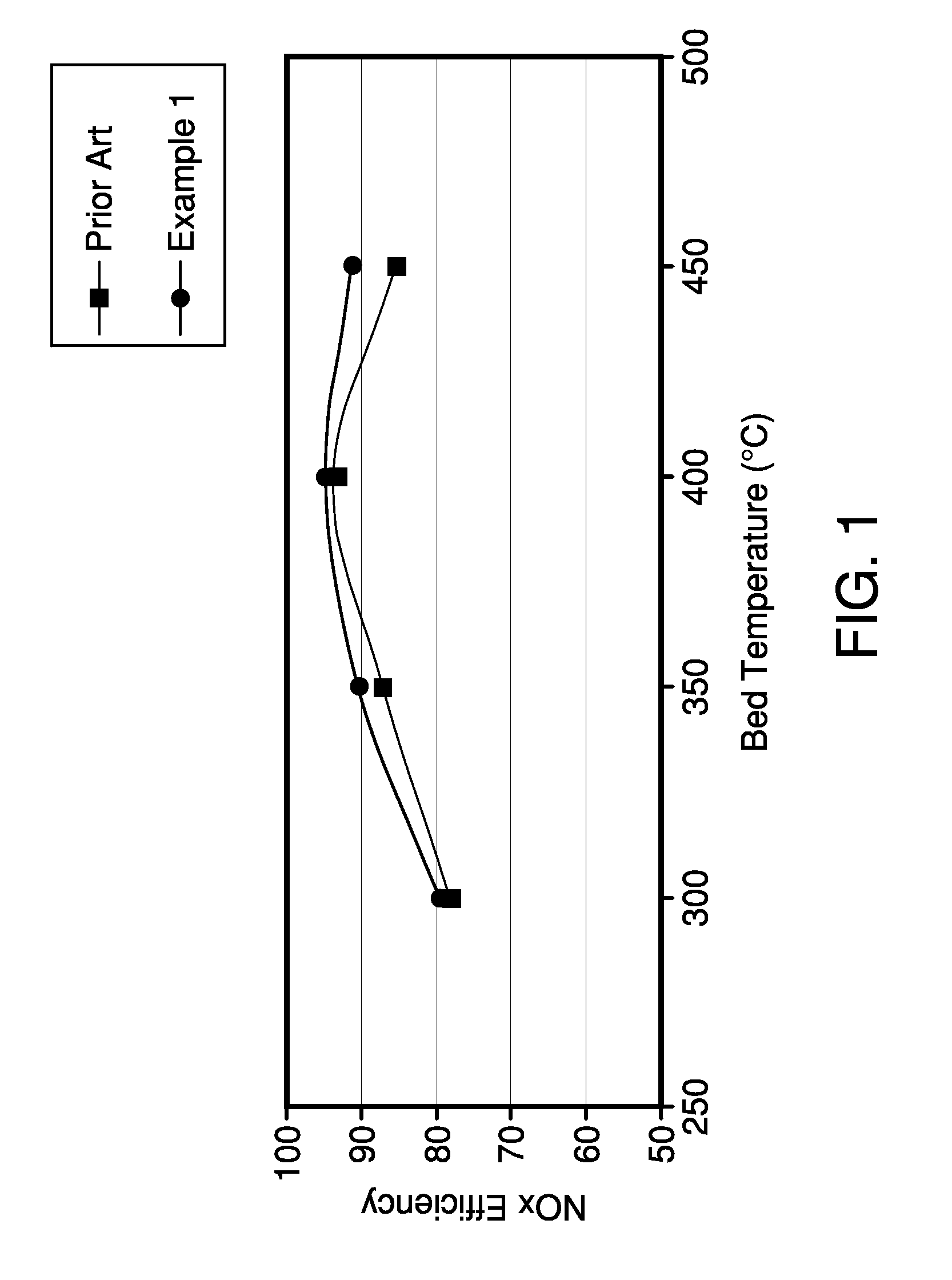

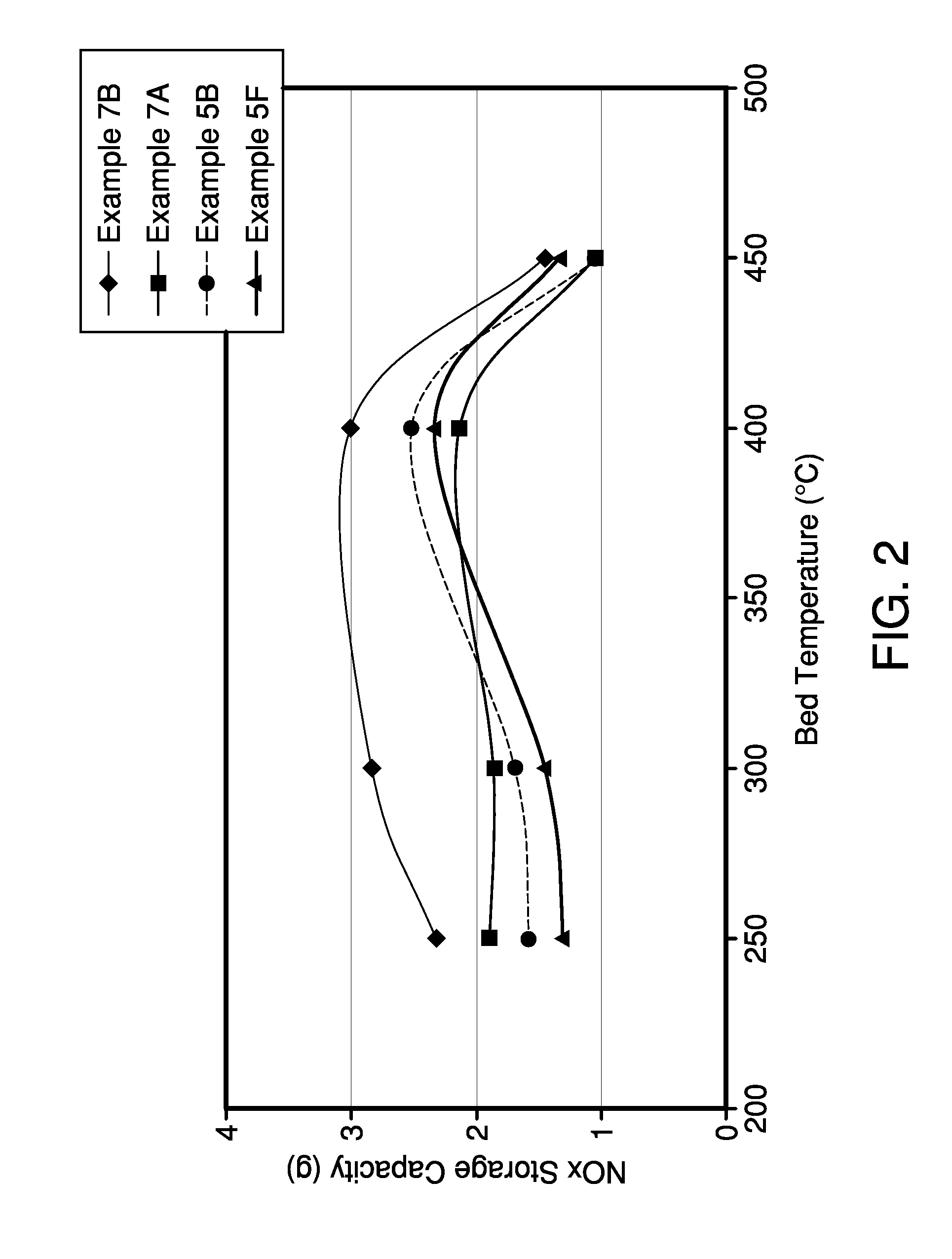

NOx Storage Materials and Traps Resistant to Thermal Aging

InactiveUS20080120970A1Promote lowerExhaust apparatusDispersed particle separationChemical conditionEarth materials

Nitrogen oxide storage materials and methods of manufacturing nitrogen oxide storage materials are disclosed. The nitrogen oxide storage materials can be used to manufacture catalytic trap disposed in an exhaust passage of an internal combustion engine which is operated periodically between lean and stoichiometric or rich conditions, for abatement of NOx in an exhaust gas stream which is generated by the engine. In one embodiment, the nitrogen oxide storage material comprises alkaline earth material supported on ceria particles having a crystallite size of between about 10 and 20 nm and the alkaline earth oxide having a crystallite size of between about 20-40 nm.

Owner:BASF CATALYSTS LLC

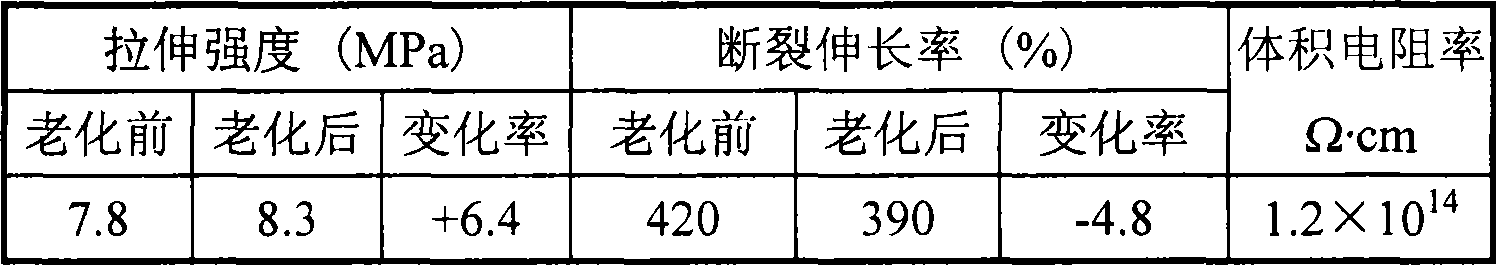

Ultraviolet light crosslinked EPT rubber cable insulation material and preparation thereof

ActiveCN101434728AHigh volume resistivityIncrease productivityRubber insulatorsInsulated cablesCross-linkPolymer science

The invention discloses an ultraviolet cross-linking EPDM (ethylene propylene diene monomer) rubber cable insulation material and a preparation method thereof. The method is characterized in that: by weight, 100 portions of EPDM rubber, 100 portions to 120 portions of inorganic filling, 0.5 portion to 5.0 portions of ultrasonic initiator, 0.5 portion to 5.0 portions of polyfunctional cross-linking agent, 5.0 portions to 10.0 portions of softener, 0.8 portion to 1.2 portions of silane coupling agent and 0.01 portion to 1.0 portion of complex antioxidant are evenly mixed and extruded at the temperature of 100 DEG C to 150 DEG C, thereby obtaining the ultraviolet cross-linking EPDM rubber cable insulation material; then the wire core is fused and extruded coating to form an insulation layer or a protective coating; and ultraviolet cross linking is carried out under 200nm to 400nm of wave length and 400mW / cm<2> to 2000mW / cm<2> of light intensity. The cable insulation material has tensile strength of larger than 6.5MPa, elongation at break of higher than 300 percent and volume resistivity of higher 10<12>Omega question mark cm, and can pass a thermal aging test under the temperature of 135 DEG C for 168h.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

Method of producing fuel hose and fuel hose obtained thereby

InactiveUS6602565B1Improve bond reliabilityAdhesive strengthLayered product treatmentSynthetic resin layered productsEngineeringThermal aging

A method of producing a fuel hose having superior adhesive reliability with superior initial adhesive strength between a tubular fluororesin inner layer and a thermoplastic resin outer layer and with restrained deterioration in adhesive strength after heat aging and immersion into fuel under severe conditions such as an inside of an engine compartment. The method includes plasma treatment on a peripheral surface of the tubular fluororesin inner layer, at least one treatment of water treatment and silane coupling agent treatment on the plasma treated surface and formation of the thermoplastic resin outer layer on the treated peripheral surface.

Owner:SUMITOMO RIKO CO LTD

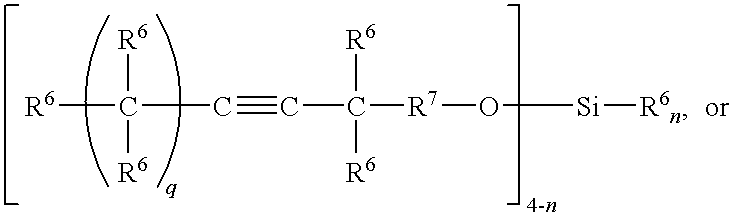

Thermal stable transparent silicone resin compositions and methods for their preparation and use

A curable silicone composition includes (A) a polydiorganosiloxane having an average, per molecule, of at least two aliphatically unsaturated organic groups and at least one aromatic group; (B) a branched polyorganosiloxane having an average, per molecule, of at least one aliphatically unsaturated organic group and at least one aromatic group; (C) a polyorganohydrogensiloxane having an average per molecule of at least two silicon-bonded hydrogen atoms and at least one aromatic group, (D) a hydrosilylation catalyst, and (E) a silylated acetylenic inhibitor. The curable silicone composition cures to form a cured silicone resin having a refractive index >1.40. The curable silicone composition cures by heating to form a cured silicone resin with an optical transparency >95% at a thickness of 2.0 mm or less at 400 nm wavelength after thermal aging by heating at 200° C. for 14 days.

Owner:DOW CORNING CORP

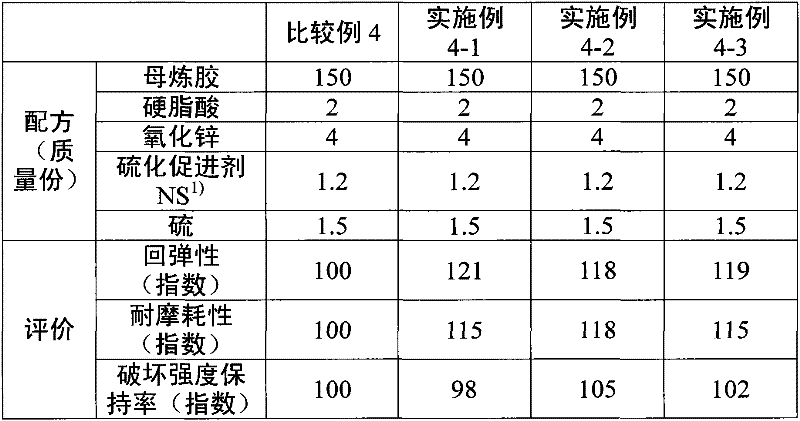

Dispersion liquid of chemical for rubbers, method for producing same, rubber wet master batch containing chemical for rubbers, rubber composition, and tire

Owner:BRIDGESTONE CORP

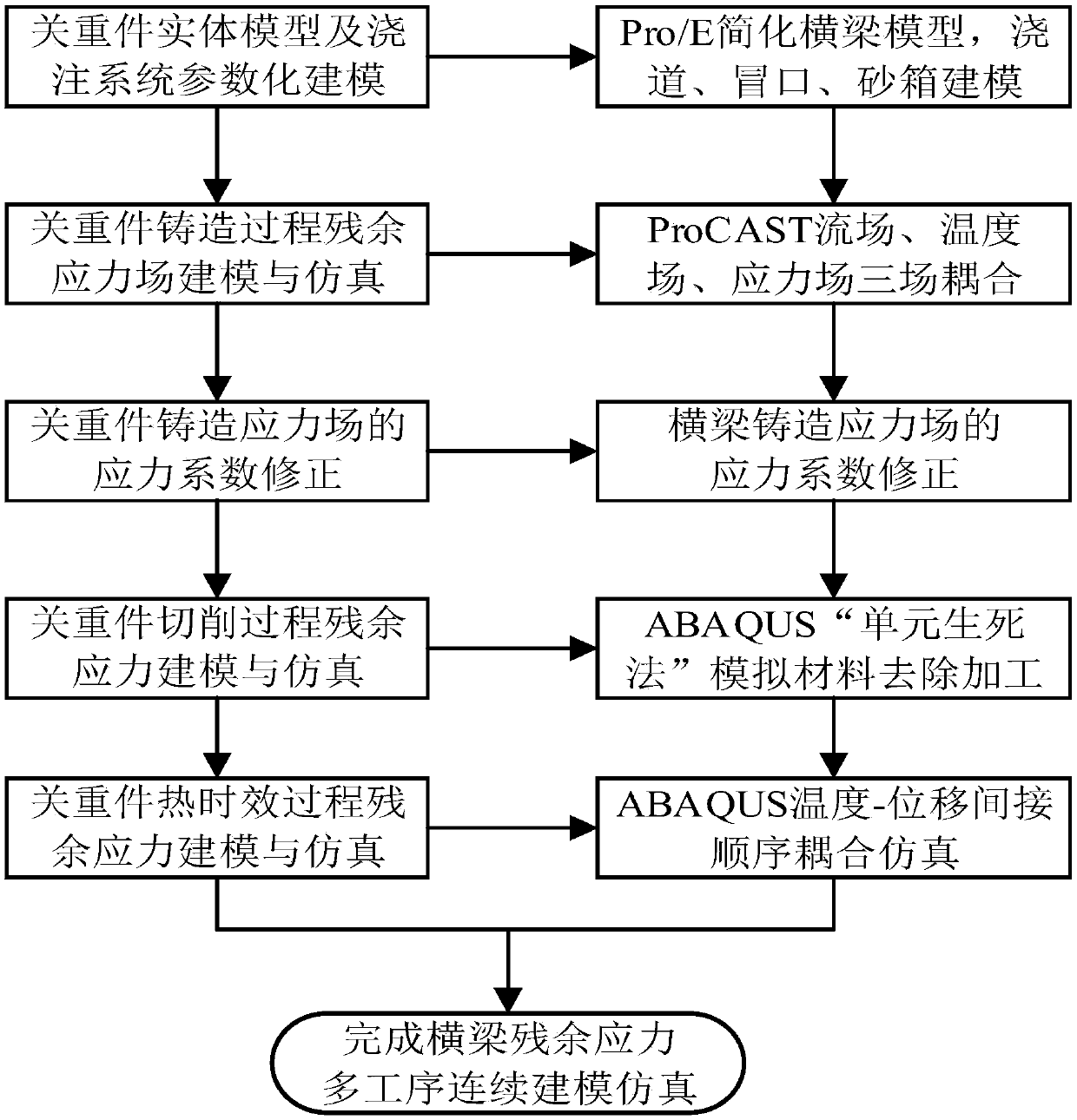

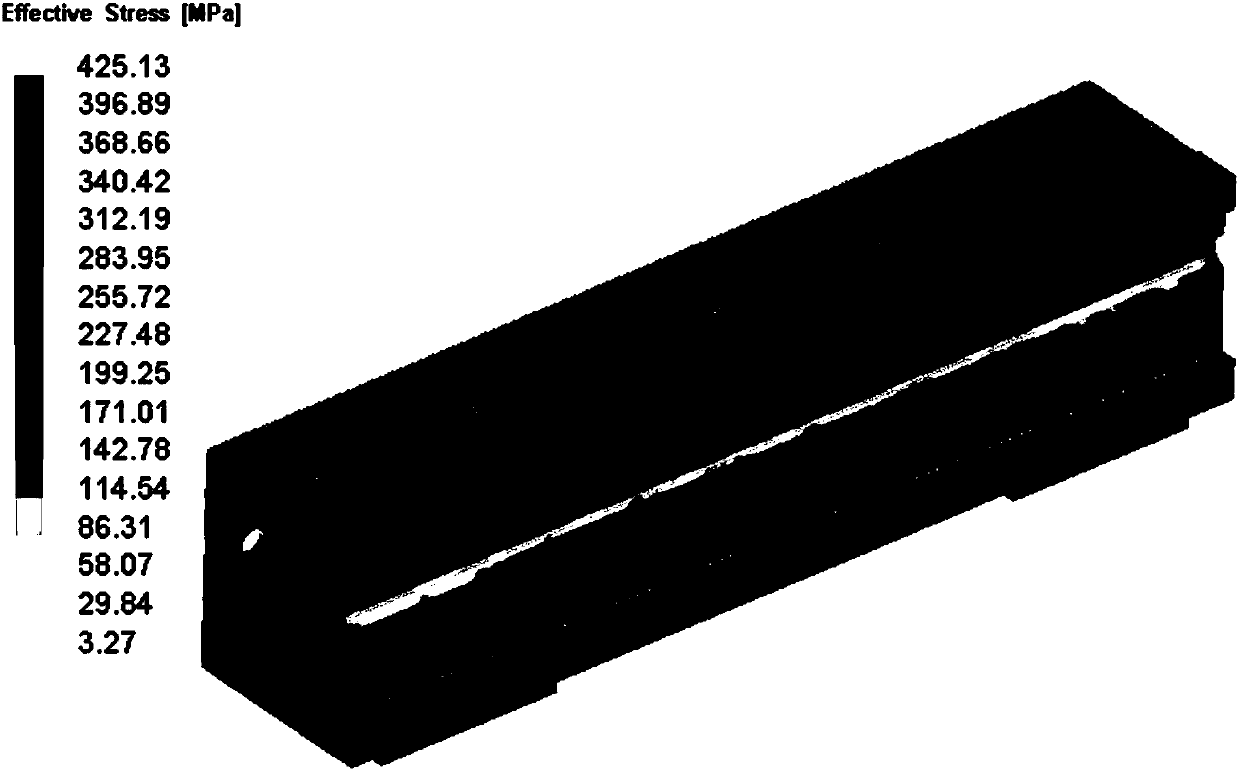

Finite-element-based machine tool important part residual stress multi-process continuous modeling simulation method

ActiveCN108304657AEnable continuous simulationImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsMethod testMATLAB

The invention discloses a finite-element-based machine tool important part residual stress multi-process continuous modeling simulation method. The method comprises the steps of important part model simplification and casting system three-dimensional modeling, important part casting process finite element simulation, important part casting stress field coefficient correction, important part machining residual stress simulation, and important part thermal aging process residual stress finite element simulation. Accordingly, multi-process continuous simulation of casting, cutting and thermal aging processes are implemented; a blind hole method test measurement value serves as a reference, a stress value of an important part casting simulation corresponding point is extracted, a test value ofthe corresponding point and a correction coefficient with the minimum simulation value error are fitted by applying a least square method through MATLAB, and then the whole casting stress field datais corrected; the calculation accuracy of finite element simulation is improved, and the technical purpose that the casting stress field obtained after a beam is corrected is guided into an ABAQUS accurately is achieved.

Owner:CHONGQING UNIV

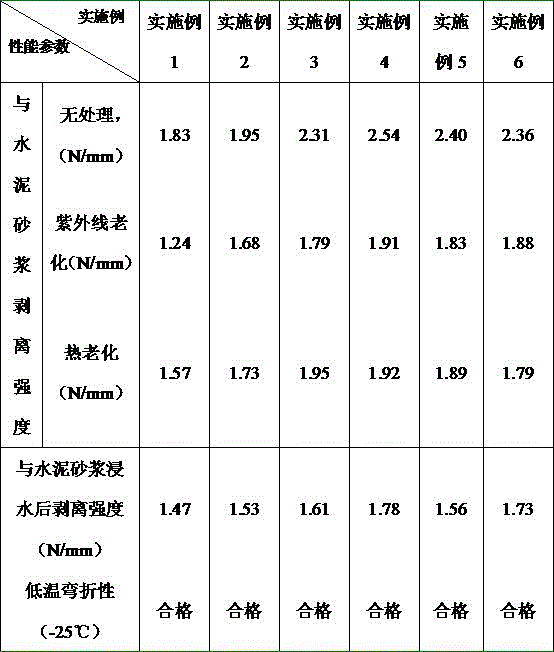

High-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN105694776AImprove heat aging resistanceAccelerated agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerButadiene-styrene rubber

The invention discloses a high-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by mass: 30-200 parts of elastomer composition, 40-100 parts of tackifying resin, 20-70 parts of plasticizer, 0.3-5 parts of stabilizer and 0.1-3 parts of additive. The elastomer composition is selected from SIS (styrene-isoprene-styrene) / SEPS (styrene-ethylene / propylene-styrene), SIS / SBS (styrene-butadiene-styrene), and / or SBS / SEBS (styrene-ethylene-butadiene-styrene). The mass ratio of the two components in the elastic composition is 1-20; the styrene in the SIS in the elastic composition accounts for 15-30 wt%, the styrene in the SEPS accounts for 10-30 wt%, the styrene in the SBS accounts for 20-50 wt%, and the styrene in the SEBS accounts for 10-40 wt%. The hot-melt pressure-sensitive adhesive has the characteristics of excellent ultraviolet aging resistance, favorable thermal aging resistance, high peel strength, simple technique and low cost.

Owner:HUIZHOU NENGHUI CHEM CO LTD

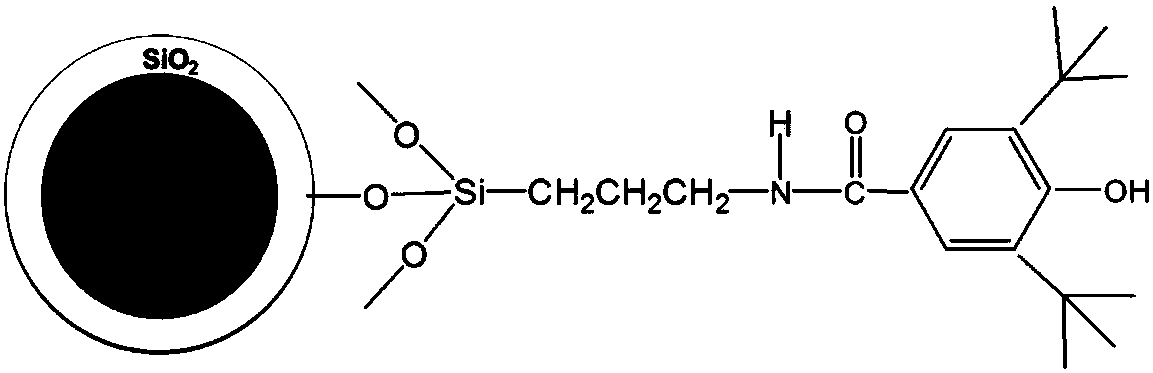

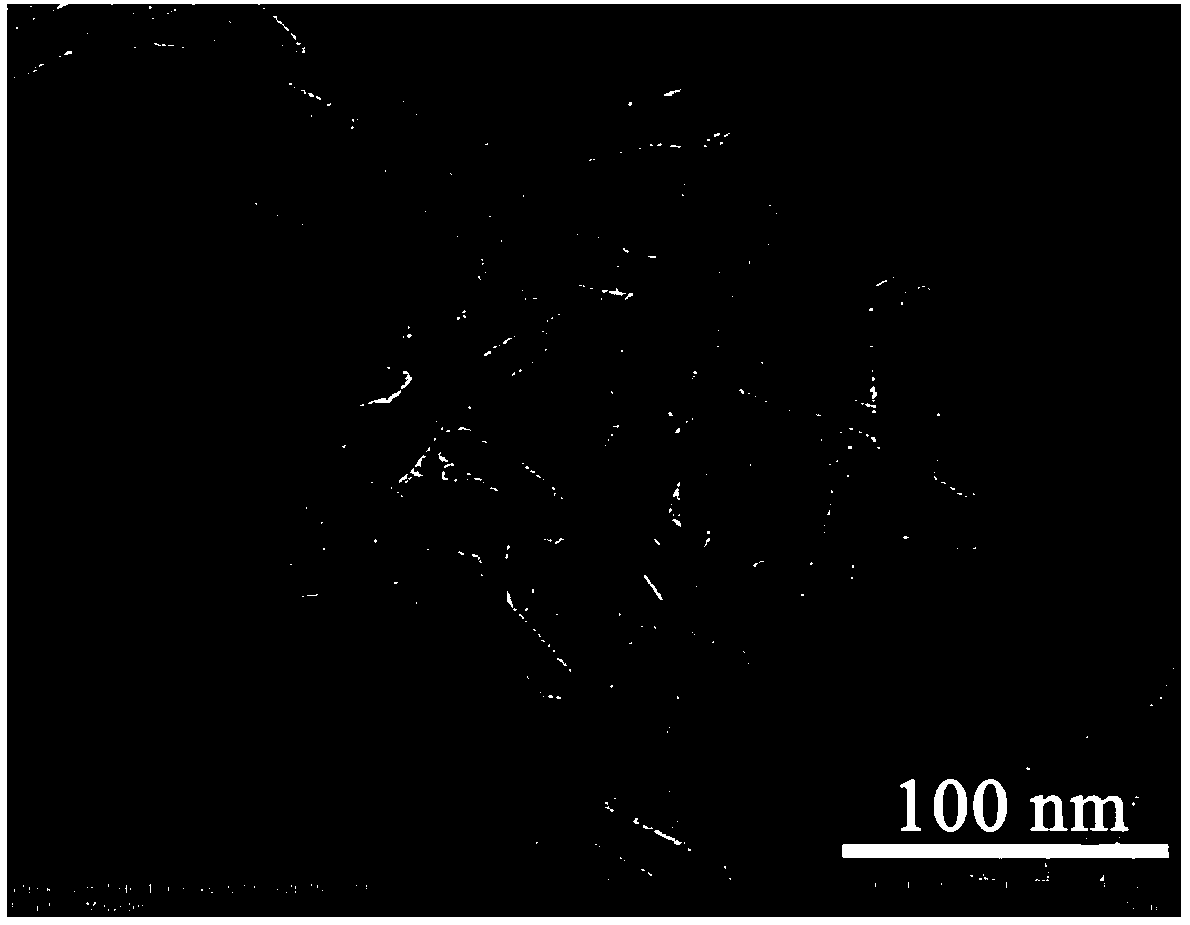

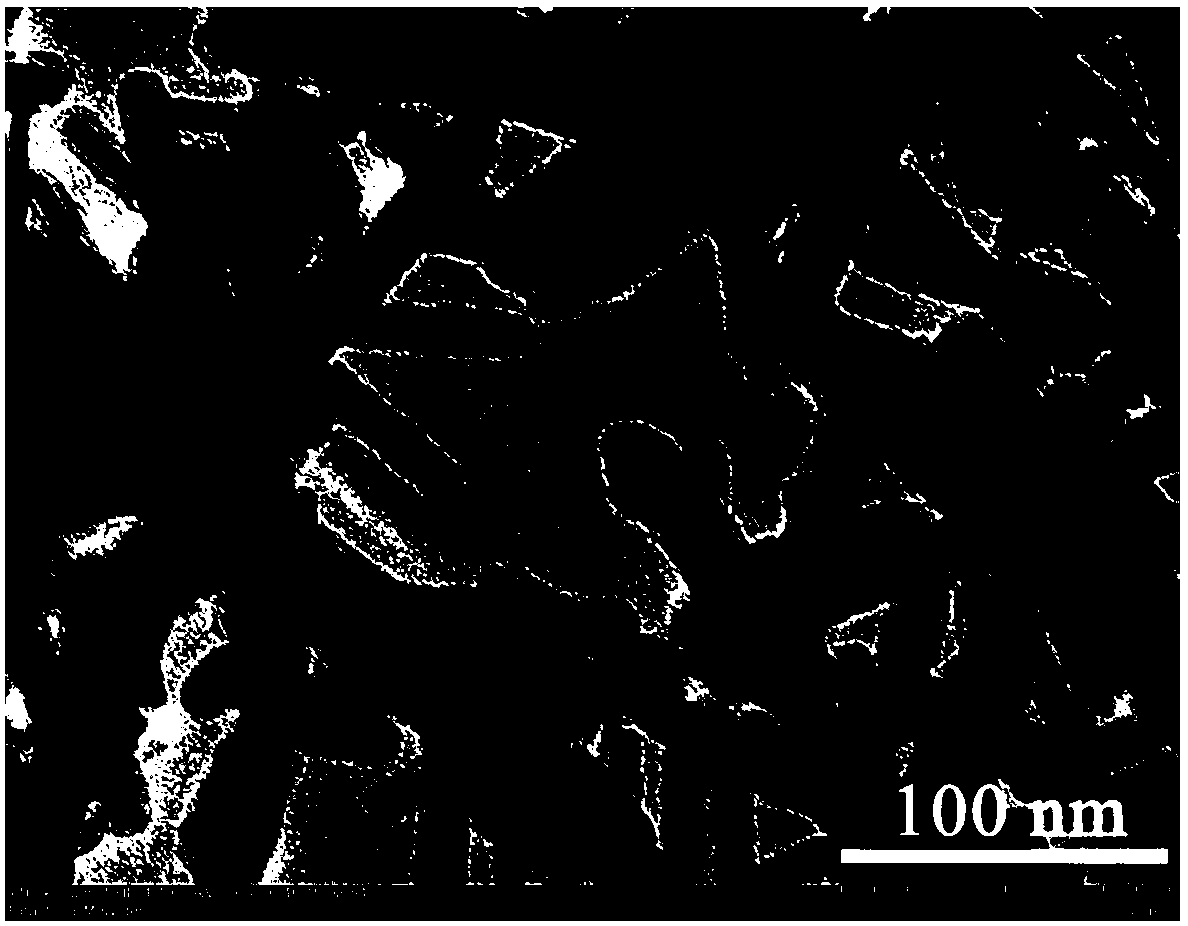

Functional nano-titanium dioxide grafted with antioxidant molecules on surface and preparation method of functional nano-titanium dioxide

InactiveCN108084494AImproves anti-photoagingImprove heat aging resistanceAging resistanceSilicon dioxide

The invention relates to a functional nano titanium dioxide grafted with antioxidant molecules on the surface. The surface of the nano-titanium dioxide is coated with silica; an aminosilane coupling agent reacts with the silica and is grafted with an antioxidant. Meanwhile, the invention also relates to a preparation method of the functional nano-titanium dioxide grafted with the antioxidant molecules on the surface. According to the preparation method disclosed by the invention, the surface of the nano-titanium dioxide is coated with a layer of the silica and then the aminosilane coupling agent is used for bridging, and a hindered phenol antioxidant is chemically grafted onto functional nano-titanium dioxide particles. According to the functional nano-titanium dioxide grafted with the antioxidant on the surface, disclosed by the invention, light weathering property and thermal aging resistance of a polymer can be simultaneously improved; in addition, an additive has the advantages ofno toxicity, low possibility of seeping and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for detecting service life of cable

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

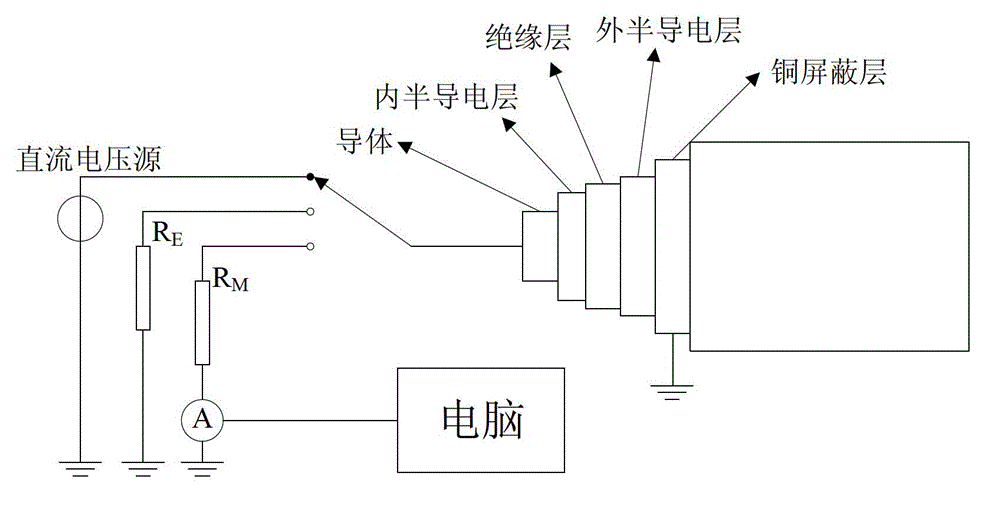

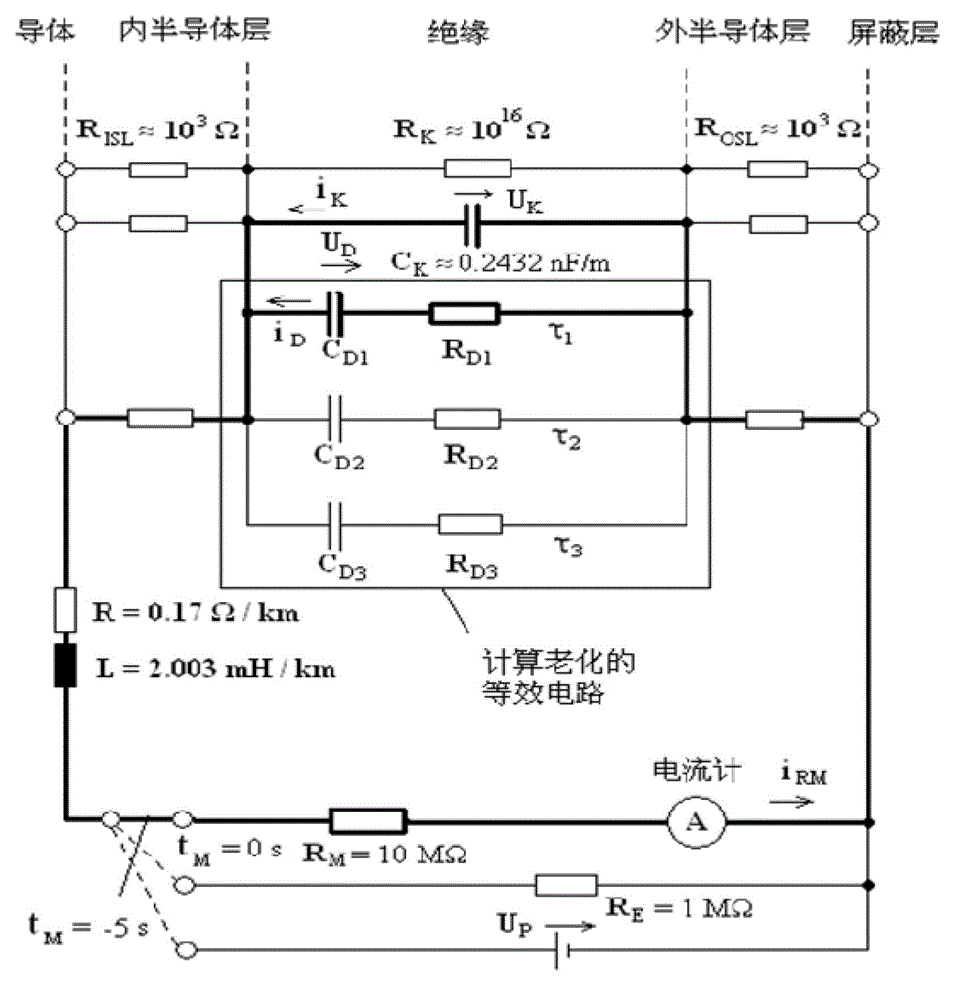

Evaluation method for paper oil insulation aging state through characteristic parameters based on time domain dielectric response

ActiveCN103197171AEasy to operateHigh sensitivityMaterial analysis by electric/magnetic meansElectrical testingTime domainEngineering

The invention discloses an evaluation method for a paper oil insulation aging state through characteristic parameters based on time domain dielectric response. The evaluation method for the paper oil insulation aging state through the characteristic parameters based on the time domain dielectric response comprises the steps of measuring a polarization and depolarization current of a system, simulating an equivalent circuit of the polarization and depolarization current, calculating circuit parameters of an equivalent circuit model to obtain a depolarization current, smoothing the depolarization current and fitting the depolarization current to obtain depolarization power quantity, building a function relationship of aging time and characteristic parameters of the depolarization power quantity, integrating the relationship between the polymerization degree changing rule and the characteristic parameters of the depolarization power quantity through combining a first order dynamical model of a polymerization degree changing rule of mineral paper oil insulation acceleration thermal aging. By the utilization of the evaluation method for the paper oil insulation aging state through the characteristic parameters based on the time domain dielectric response, the operation is simple, sensitivity is high, and the evaluation method for the paper oil insulation aging state through the characteristic parameters based on the time domain dielectric response is suitable for the use of engineering.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO

Thermal aging-resistant polyurethane elastomer and preparation method thereof

InactiveCN103396527ASignificant improvement in heat aging resistanceSimple preparation processPolyurethane elastomerCross-link

The invention provides a thermal aging-resistant polyurethane elastomer. The polyurethane elastomer is formed by mixing a polyurethane prepolymer, a chain extension cross-linking agent and auxiliaries, pouring, demolding and vulcanizing, wherein the polyurethane prepolymer is formed by stirring polymer diol, diisocyanate and a catalyst at the temperature of 50-100 DEG C, and the raw materials respectively comprise the following components in percentage by weight: 47-60wt% of polymer diol, 15-30wt% of diisocyanate, 0-4wt% of catalyst, 8-17wt% of chain extension cross-linking agent and 1-6wt% of auxiliaries. The invention simultaneously provides a preparation method of the thermal aging-resistant polyurethane elastomer. The method has the advantages of simple process and low equipment cost, and the produced polyurethane elastomer has excellent thermal aging resistance.

Owner:HUBEI CHENGYU XINNUO TECH

Reinforced toughening anti-aging polypropylene/nano calcium carbonate composite material and its preparation method

The invention discloses a reinforced toughened anti-aging PP / nano-calcium carbonate composite material, consisting of (weight parts) PP resin 100, composite coupling agent 2-30, long glass fibers 2-30, composite toughener 5-40, nano-fillers 5-40, composite antioxidants 0.2-2, and processing aids 0.5-5. This composite material not only retains the original fine performances of polypropylene resin, but also improves markedly the physical and mechanical properties, thermal aging properties by using nanomaterial / new antioxidant synthetic modification technology. This invention also discloses the preparation method for reinforced toughened anti-aging PP / nano-calcium carbonate composite material.

Owner:哈尔滨鑫达高分子材料股份有限公司

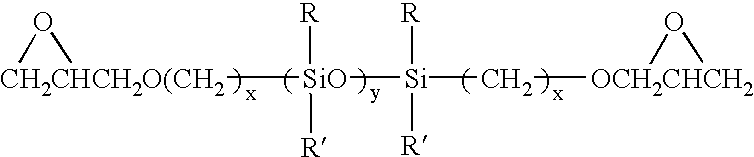

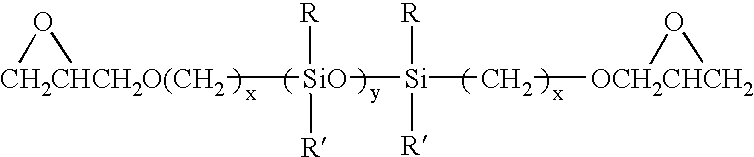

Epoxy-siloxanes based electrically conductive adhesives for semiconductor assembly and process for use thereof

InactiveUS20020127406A1Keep performance stableLow resistivitySolid-state devicesPretreated surfacesEpoxyElectrically conductive adhesive

The invention is directed to improved conductive adhesives for solder-free interconnections in microelectronic assembly processes such as for chip carrier-to-substrate attachment. These adhesives are characterized by low tensile modulus, low resistivity, high adhesion strength, and durability of these properties during reliability stress conditions of thermal shock, thermal aging, and temperature / humidity (85.degree. C. / 85%) exposure of the assembled devices. The adhesives contain a homogeneous solution of a siloxane containing epoxide, a curing agent, a curing catalyst and an organic polymeric or oligomeric additive. A conductive filler is added to the solution forming the filler. Preferred fillers are Ag coated with Pd and Ag coated with Au.

Owner:IBM CORP

Compositions of polyhydric alcohols and polyamides

ActiveUS20130228728A1Improve aging stability performanceRetention strengthFireproof paintsSpecial tyresPolyolAlcohol

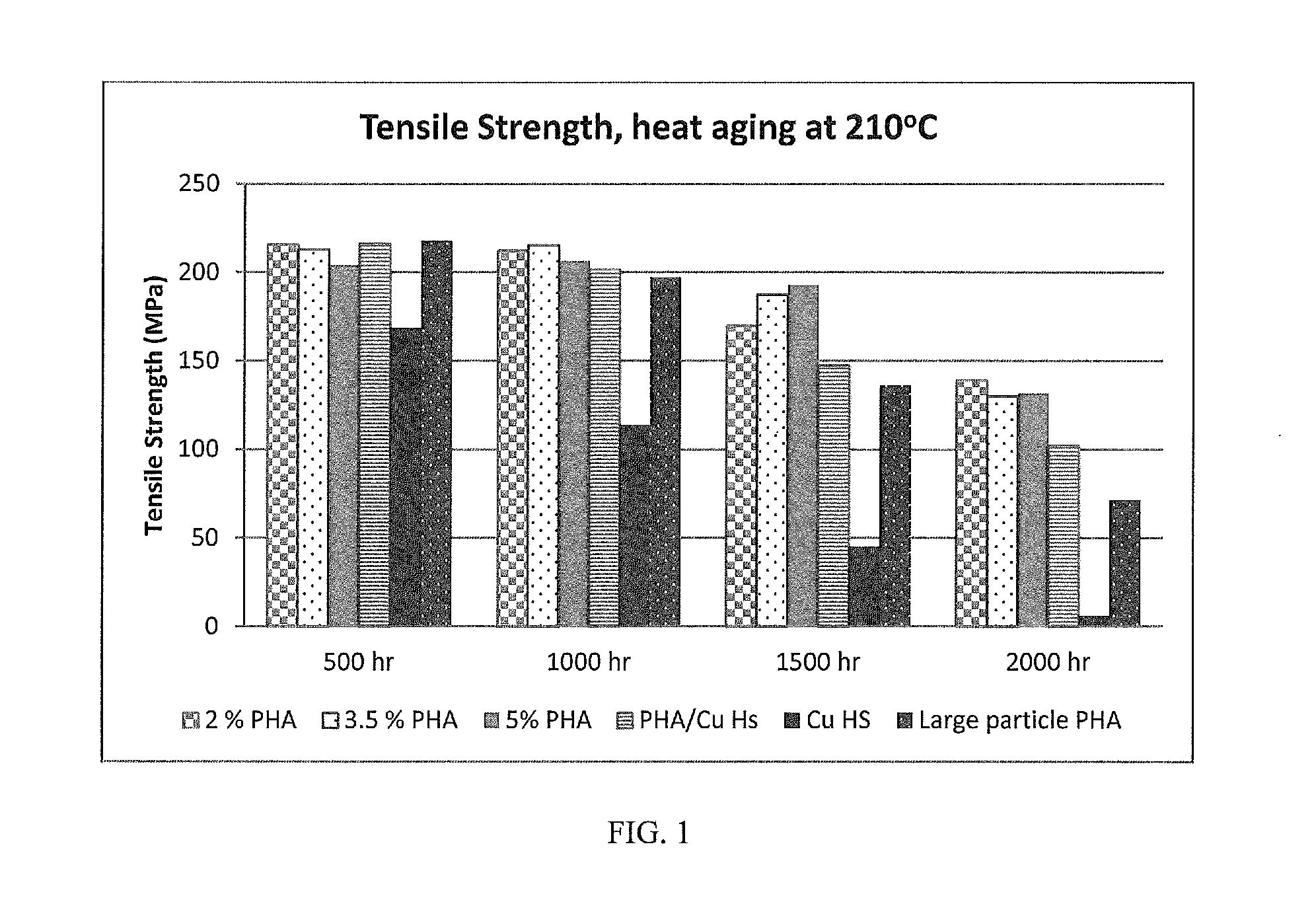

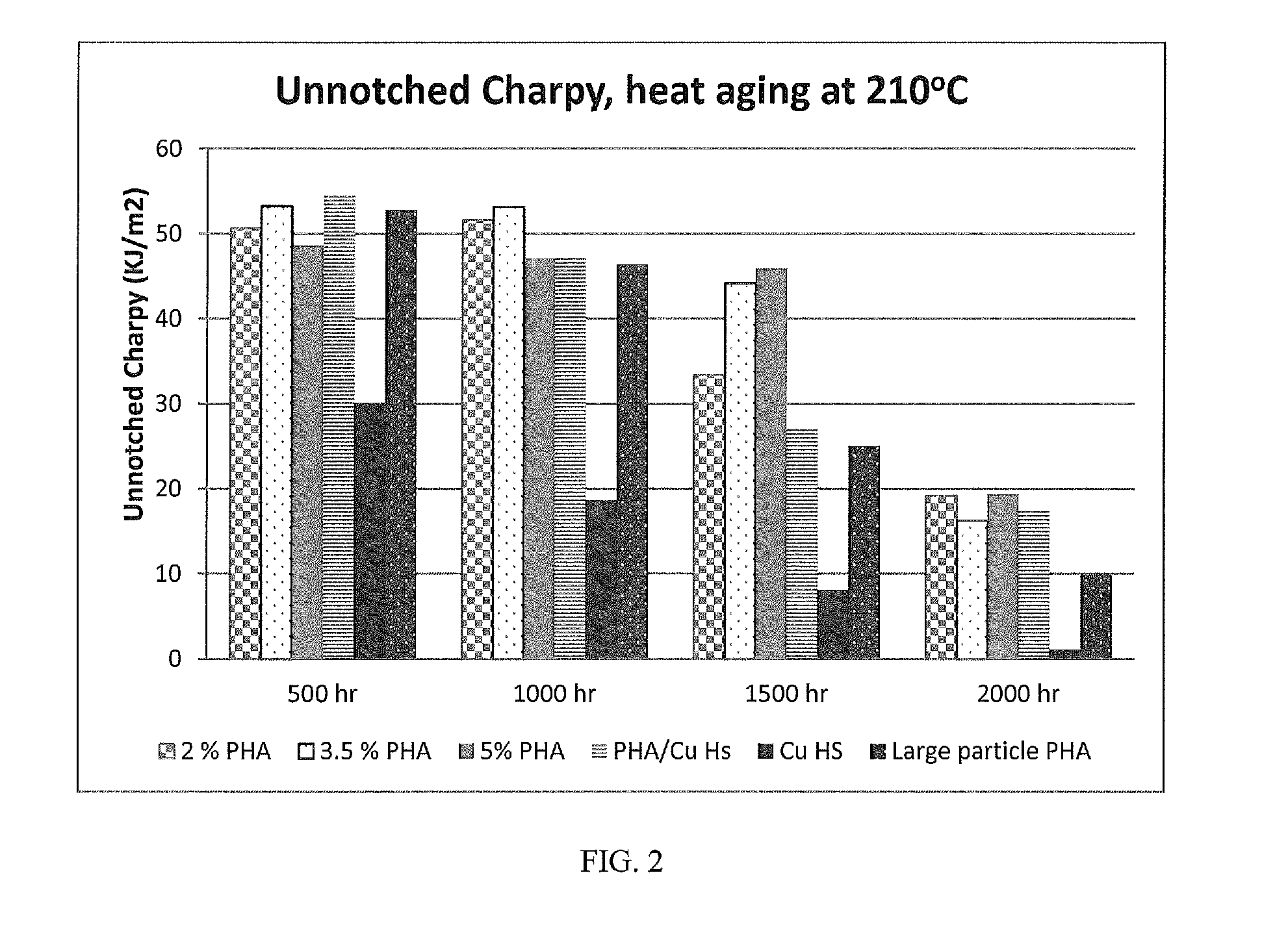

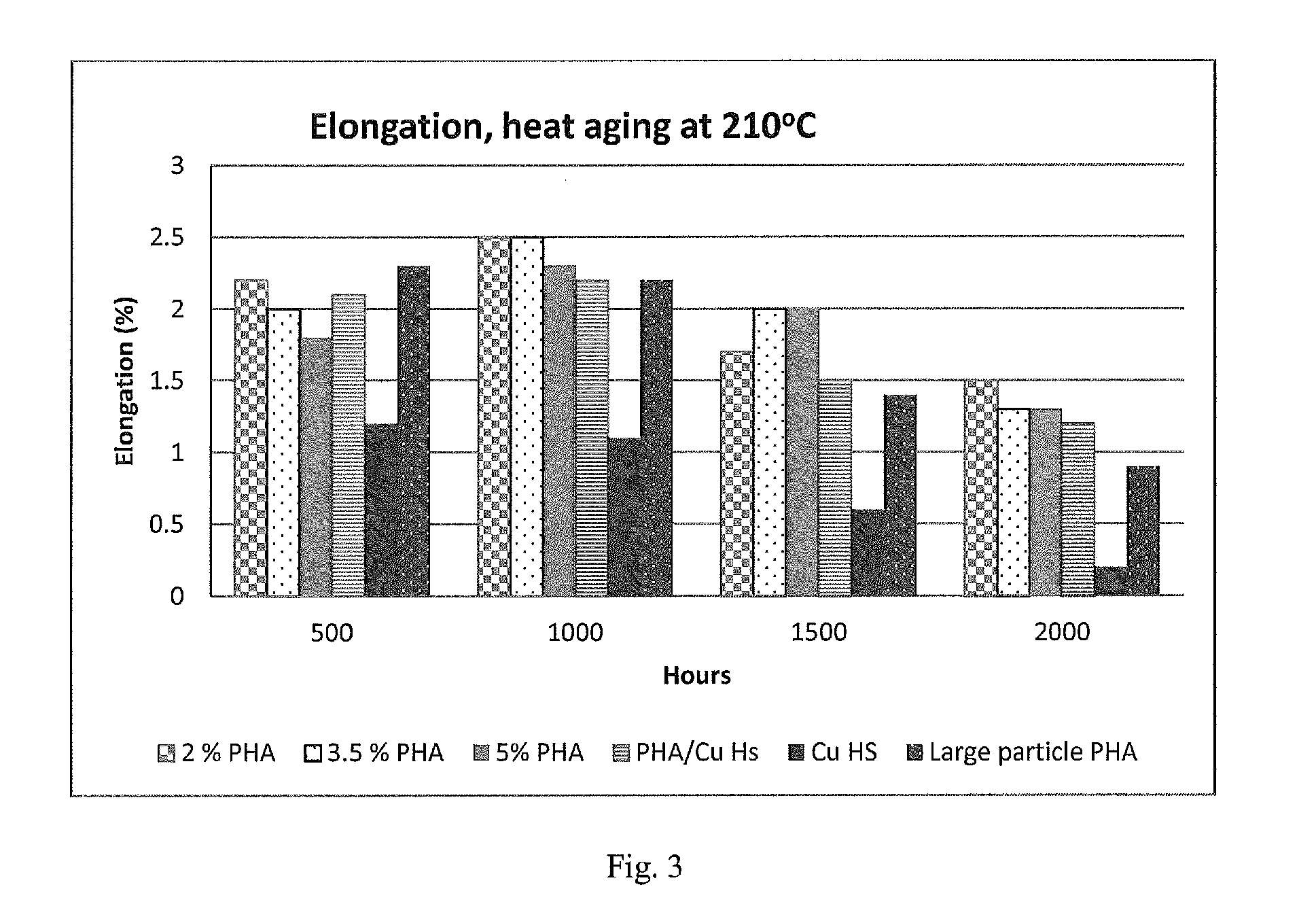

The present invention relates to a thermoplastic composition that provides improved thermal aging stability along with durability. The thermoplastic composition comprises a polyamide resin, and a polyhydric alcohol, wherein a majority of the polyhydric alcohol particles have a particle size that is less than about 70 microns. It has been found that a combination of a polyamide resin and a polyhydric alcohol with this particle size produces a superior product demonstrating greater thermal stability and durability than the polyamide resin alone.

Owner:RADICI PLASTICS USA INC

Rubber compositions for oil seal of rubber framework and method for manufacturing same

Owner:青岛茂林橡胶制品有限公司

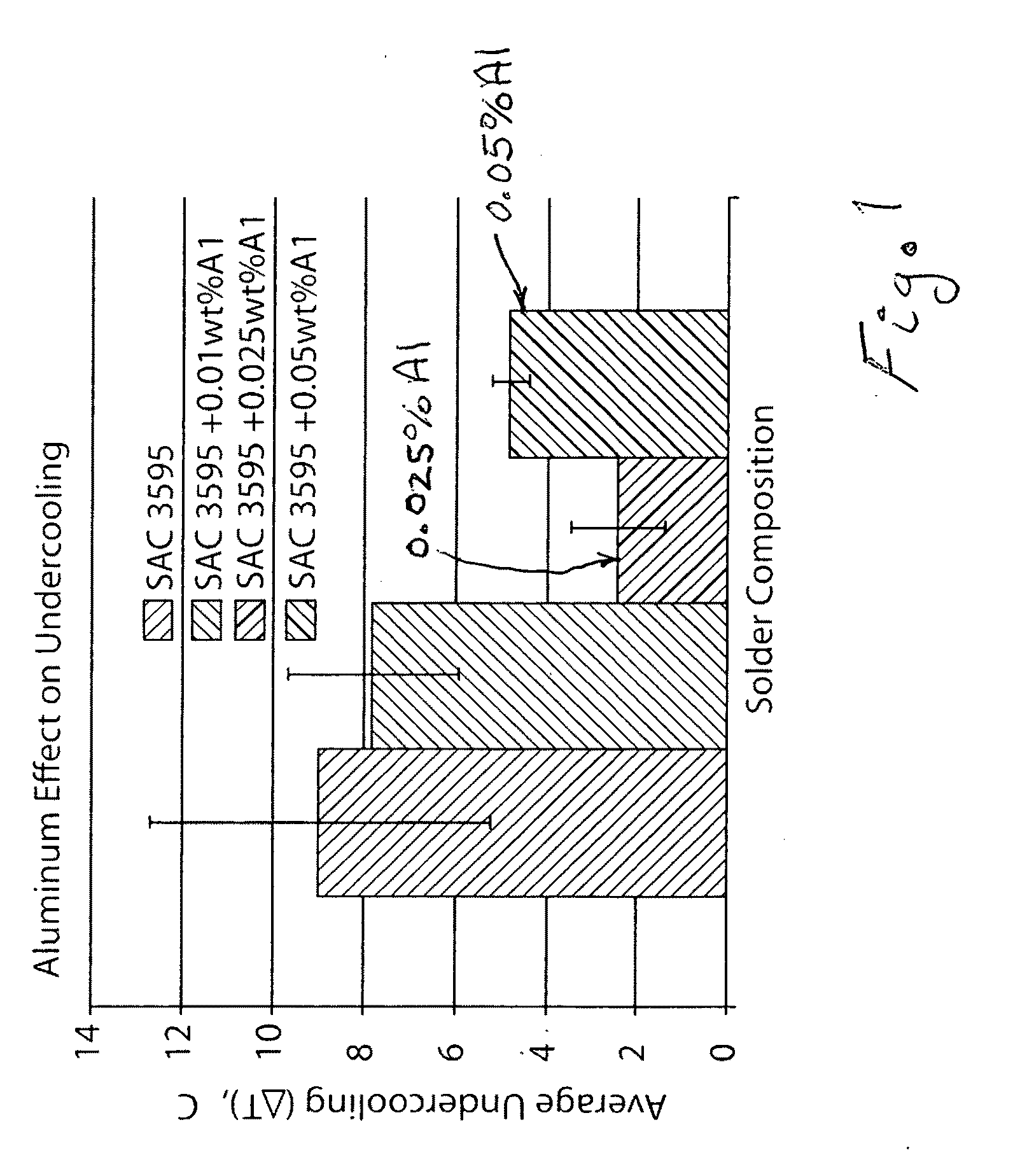

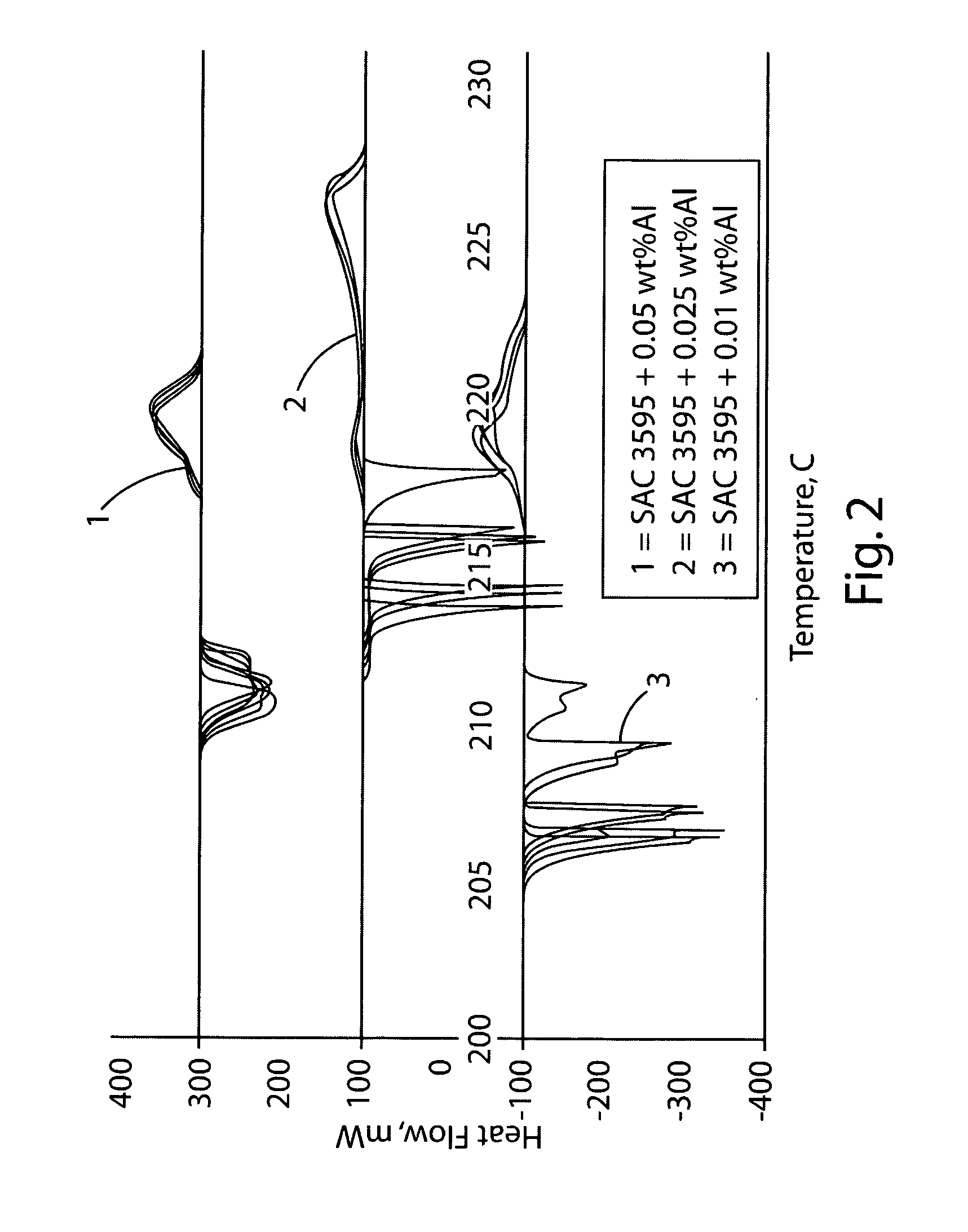

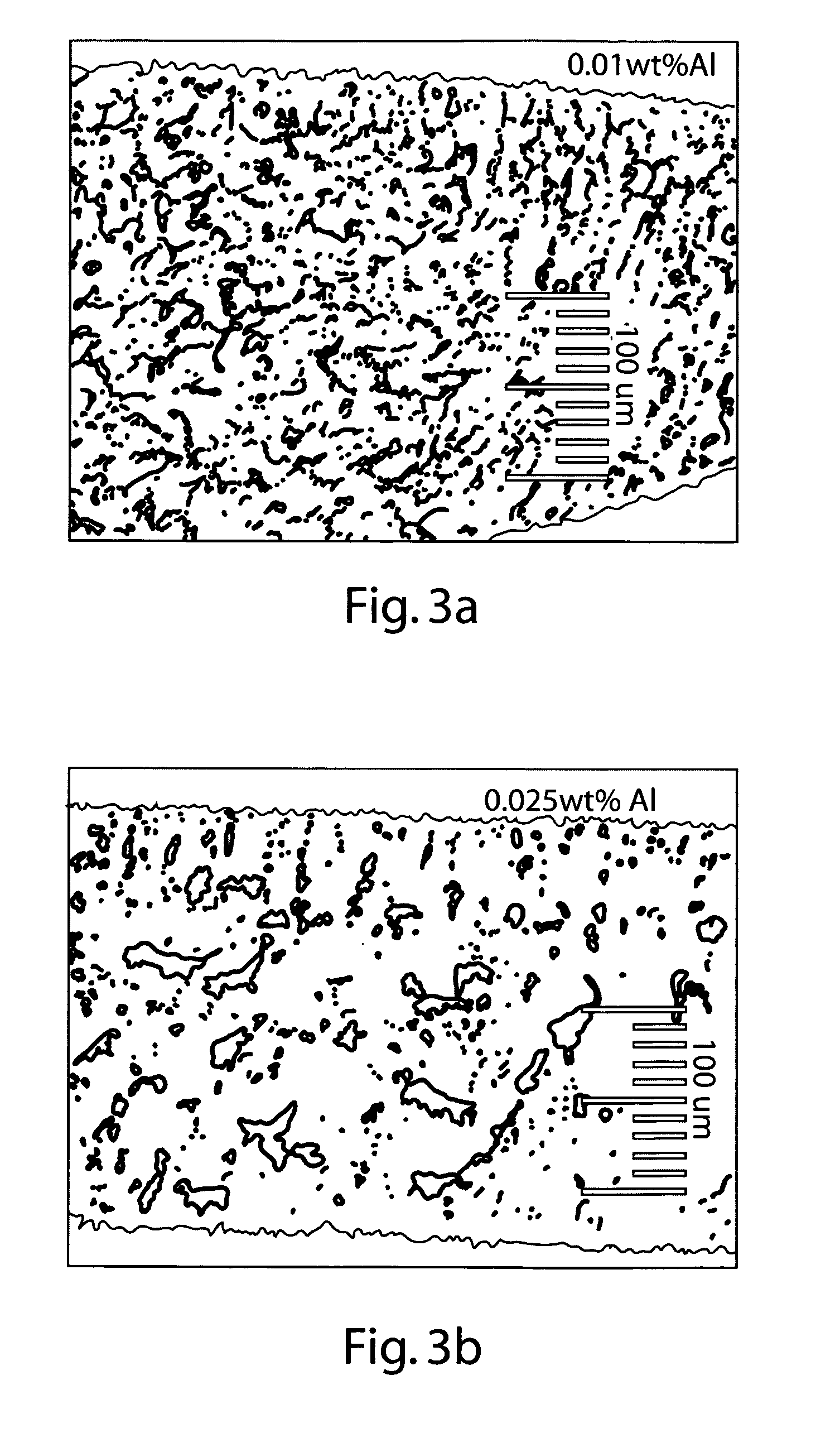

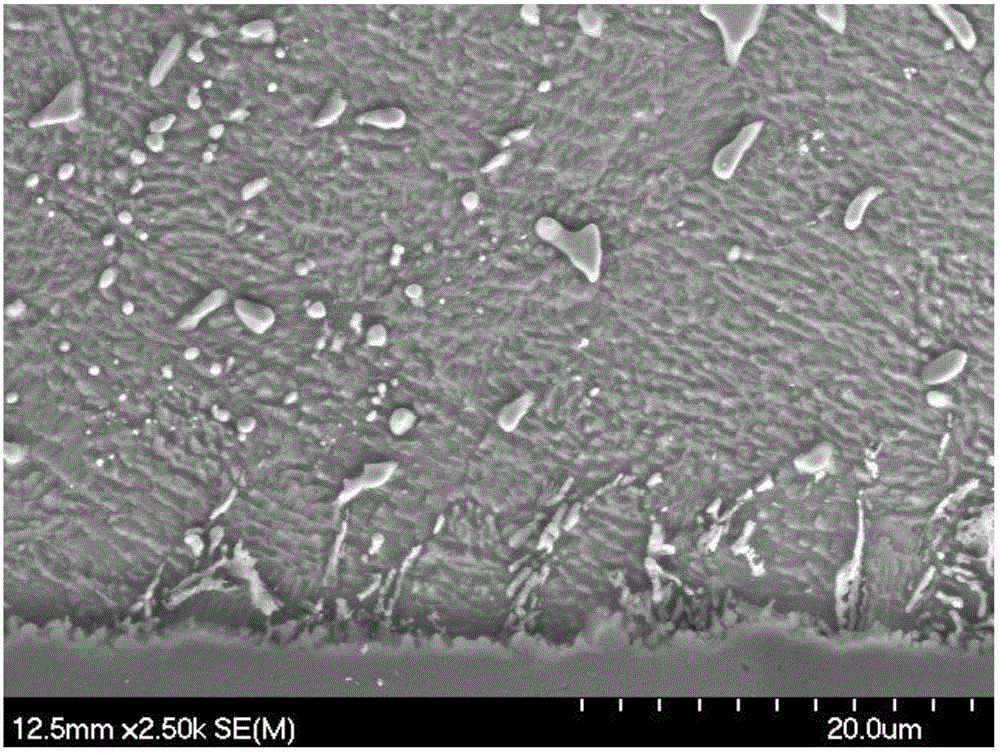

Pb-Free Sn-Ag-Cu-Al or Sn-Cu-Al Solder

InactiveUS20110303448A1Improve wettabilityLow melting pointCooking-vessel materialsPrinted circuit detailsThermal agingMicrostructure

A solder alloy includes Sn, optional Ag, Cu, and Al wherein the alloy composition is controlled to provide a strong, impact-and thermal aging-resistant solder joint that has beneficial microstructural features and is substantially devoid of Ag3Sn blades.

Owner:IOWA STATE UNIV RES FOUND

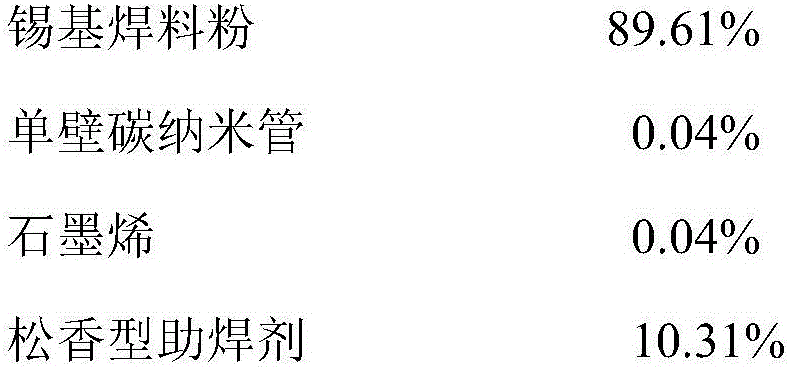

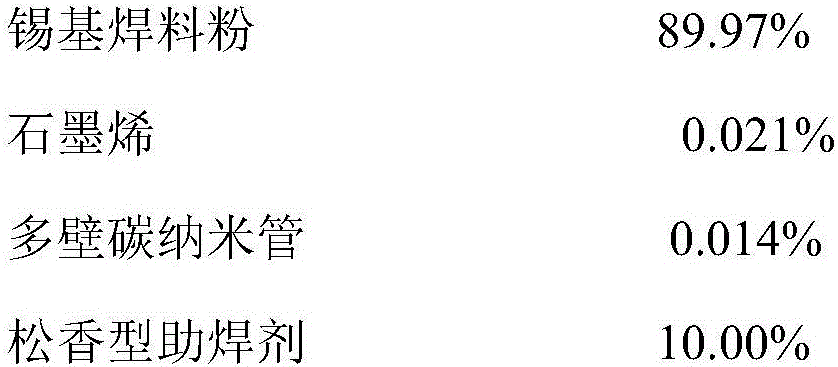

Tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof

ActiveCN106363315AImprove creep resistanceImproved electromigration performanceWelding/cutting media/materialsSoldering mediaTinningAging resistance

The invention provides tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof. The tinned carbon nanomaterial reinforced compound solder alloy comprises, by weight, 84-95 parts of tin-based solder, 0.01-0.2 part of carbon nanomaterials and 5-15 parts of soldering flux. By the adoption of the technical scheme, the creep resistance, electrical conductivity and thermal aging resistance of soldered dots generated by the tinned carbon nanomaterial reinforced compound solder alloy and the solder paste thereof are improved. The carbon nanomaterials in the prepared solder paste are uniform in distribution, the process is simple and reliable, adaptability is high, and cost is low.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN +2

Composite nano silicon dioxide/quartz stone plate product and preparation method thereof

InactiveCN102531468ALarge specific surface areaA high proportion of surface atomsPolyester resinAccelerant

The invention discloses a composite nano silicon dioxide / quartz stone plate product and a preparation method thereof. The composite nano silicon dioxide / quartz stone plate product is prepared from the following components and raw materials in parts by weight: quartz stone sand, pigment, a silane coupling agent, nano silicon dioxide, unsaturated polyester resin, a curing agent and a certain amountof accelerant by the steps of mixing, adding to a mold, carrying out vibration compaction, curing, determining thickness, grinding and polishing and carrying out other working procedures. The invention also discloses a preparation process of the composite nano silicon dioxide / quartz stone plate product. According to the invention, the prepared composite nano silicon dioxide / quartz stone plate is a composite quartz stone plate product which is a large network structure formed by tight embedding and chemical bond cross-linking of all the components; and the prepared composite quartz stone plateproduct has the advantages of high silicon dioxide content, high strength and hardness, ultraviolet aging and thermal aging resistance, high fire retardancy and high heat insulating property, compactand glabrous surface and durability. The use range of the quartz stone plate is enlarged.

Owner:吉林吉瑞莱板材科技有限公司

Optical crosslinking halogen-free flame-retardant EPT rubber cable material and preparation thereof

ActiveCN101486819AIncrease productivityImprove flame retardant performanceRubber insulatorsEthylene-propylene-diene-monomerCross linker

The invention discloses a uv photocrosslinking halogen free flame retarding ethylene propylene diene monomer (EPDM) cable material and a preparation method thereof. The method is characterized by uniformly mixing 100 parts of EPDM, 100-150 parts of metal hydroxid, 0.5-5.0 parts of uv-light initiator, 0.5-5.0 parts of polyfunctional group cross linker, 5.0-10.0 parts of softener and 0.01-1.0 part of compound antioxidant and consequently extruding the mixture into platy material, namely, the photocrosslinking EPDM cable material; then the EPDM cable material is covered on a cable electric lead core by melt extrusion to form an insulating layer or a sheathing layer and subsequently is radiated by uv light with the dominant wavelength of 200-400nm and the light intensity of 400-4000mW / cm for crosslinking; and the tensile strength of the obtained cable insulating layer or the sheathing layer is more than 7.0MPa, the elongation at break is more than 350 percent and the electric volume resistivity is more tan 10Omega.cm. The cable material can pass the thermal aging test at the temperature of 135 DEG C for 168h.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Expanding damping adhesive with good damp heat resistance ageing performance

ActiveCN102516899AGood moisture and heat aging resistancePlay the role of cushioning and dampingNatural rubber adhesivesNon-macromolecular adhesive additivesFoaming agentAdhesive

The invention relates to an expanding damping adhesive with good damp heat resistance ageing performance, which belongs to the technical field of the expanding damping adhesive and mainly solves the problems that the damp heat resistance aging performance of the existing expanding damping adhesive is not good enough so as to affect service life of the expanding ageing performance. The expanding damping adhesive is mainly characterized by comprising the following components, by weight, 10-40 parts of liquid polybutadiene, 0-10 parts of solid rubber, 0-20 parts of softener, 0-10 parts of tackifier, 0-10 parts of sulphur, 0-10 parts of accelerating agent, 0.1-3 parts of antioxygen, 0.1-10 parts of active agent, 0-3 parts of foaming agent and 10-50 parts of filler. The expanding damping adhesive has good strength keeping rate after damp heat ageing and long service life, is widely used for adhesion and filling between an outer plate and a strengthening beam of an auto-body panel of a welding line, and has buffering and damping effects.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

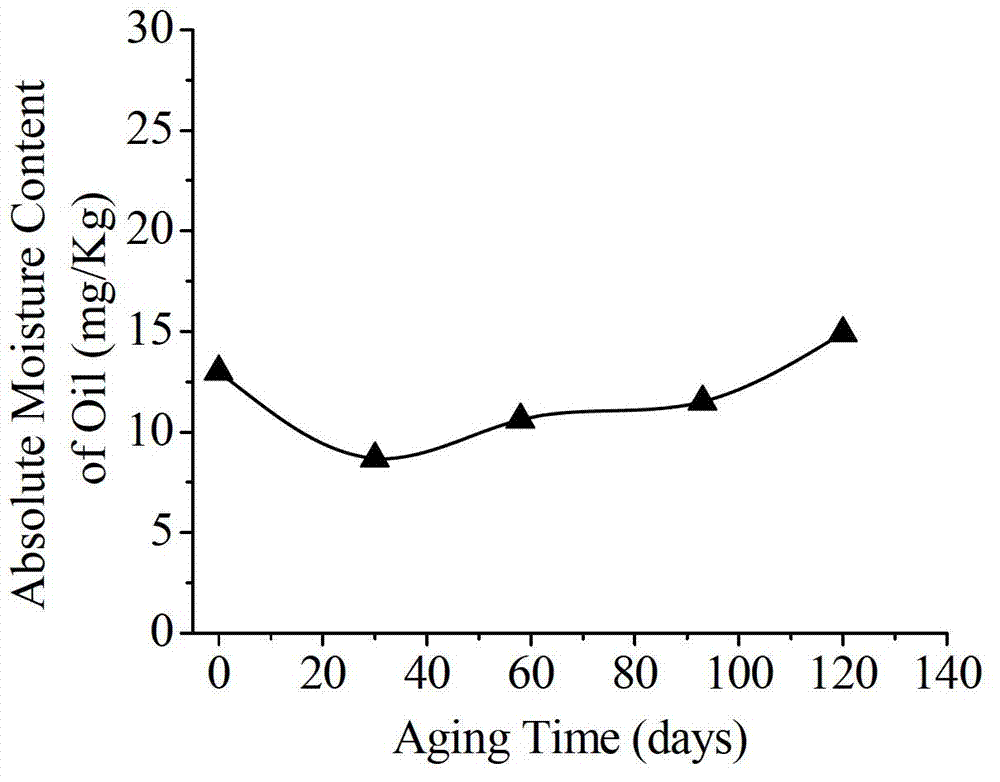

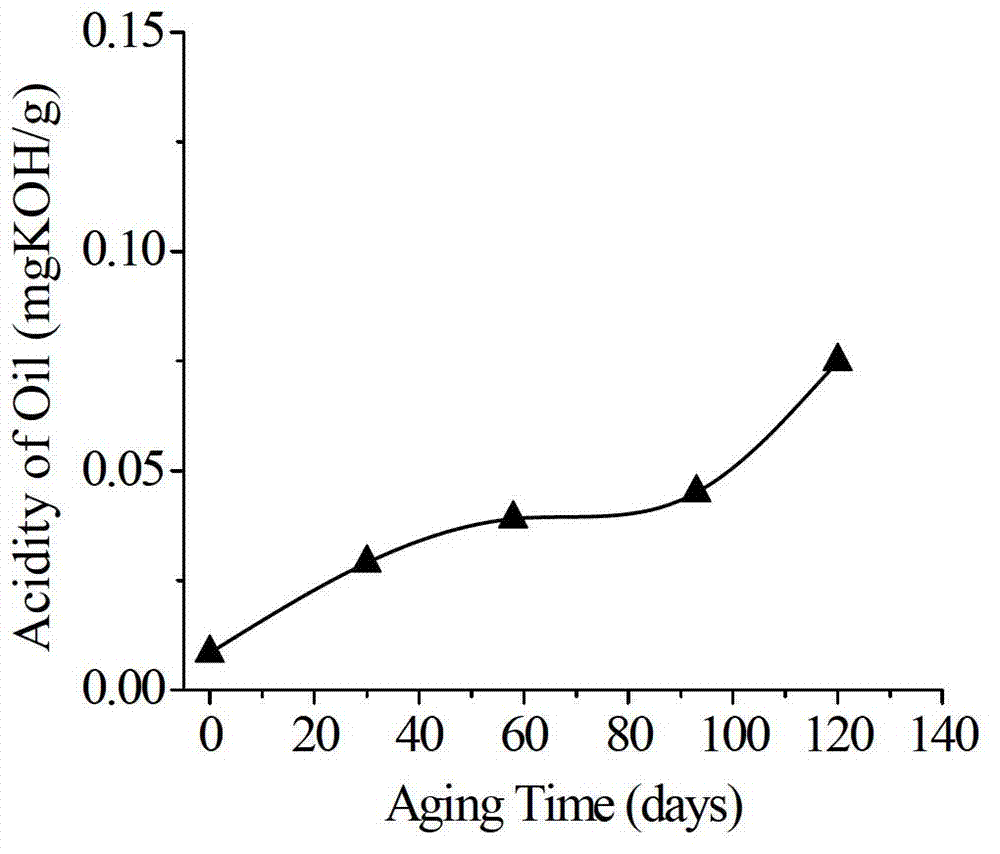

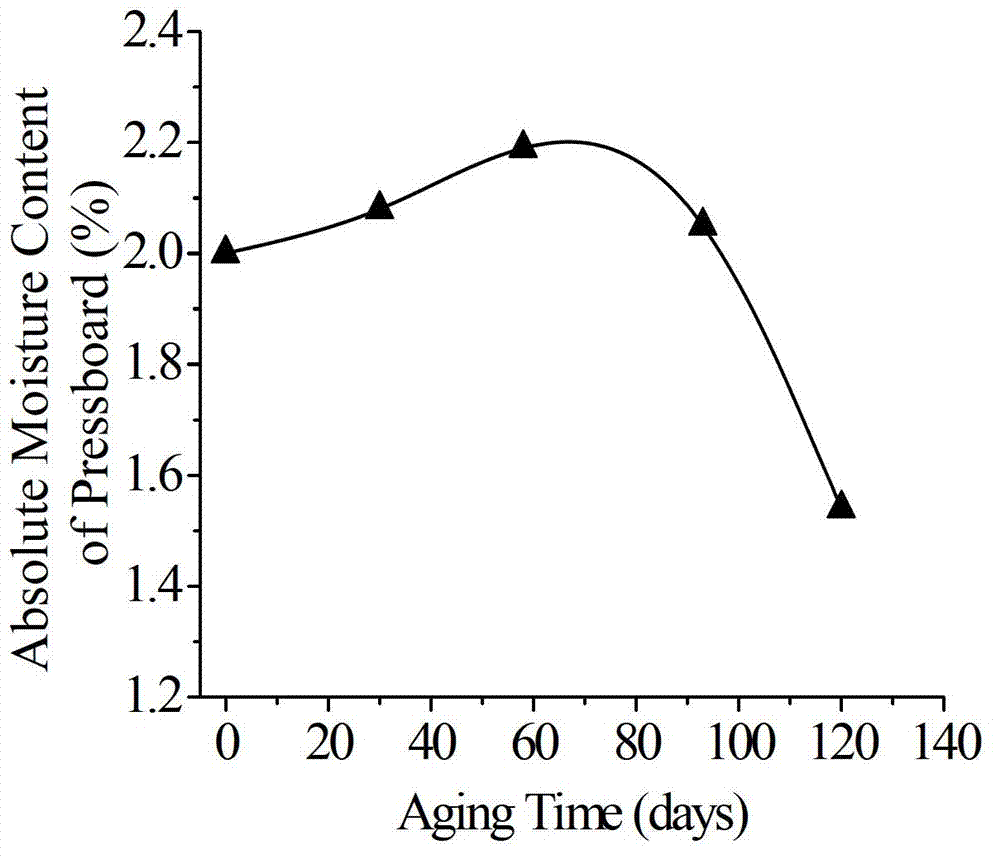

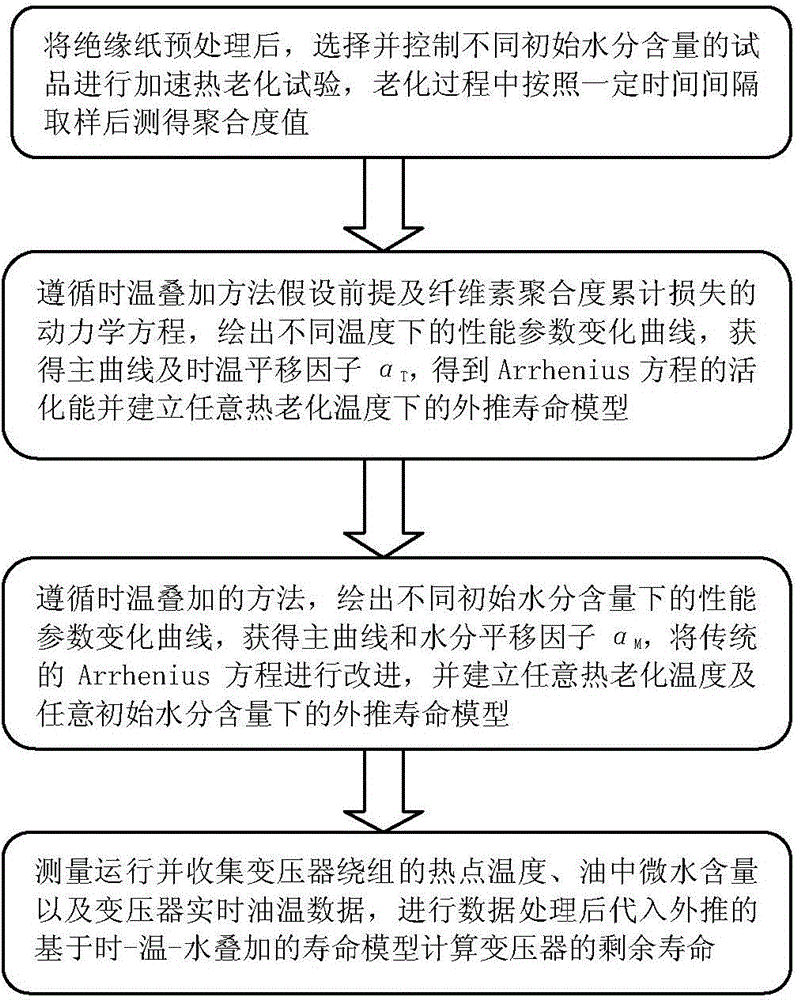

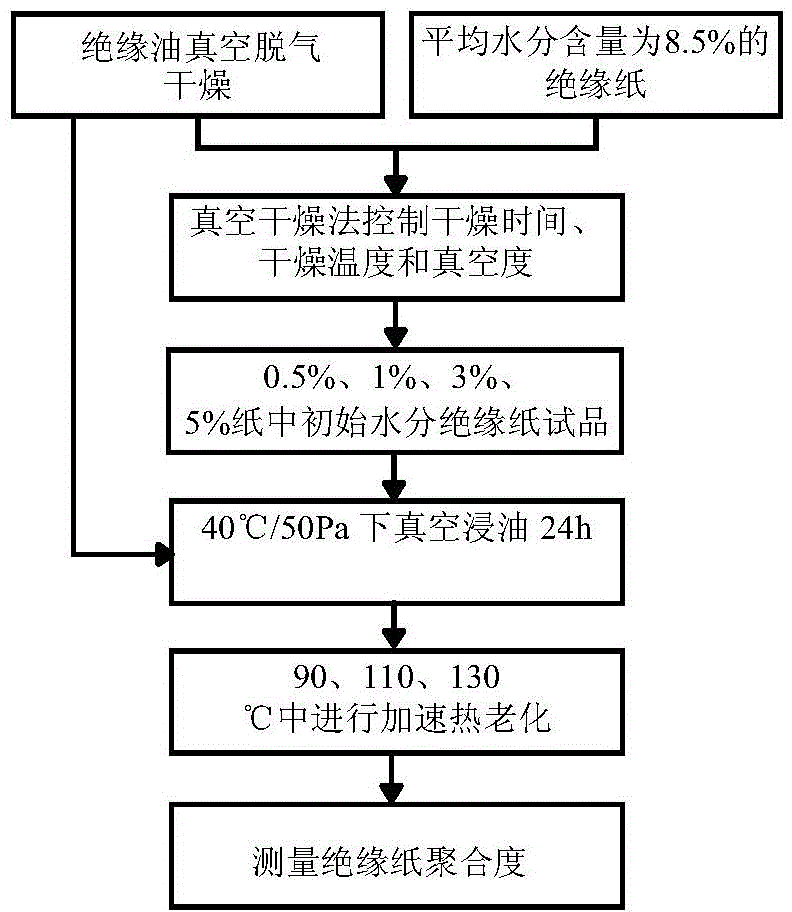

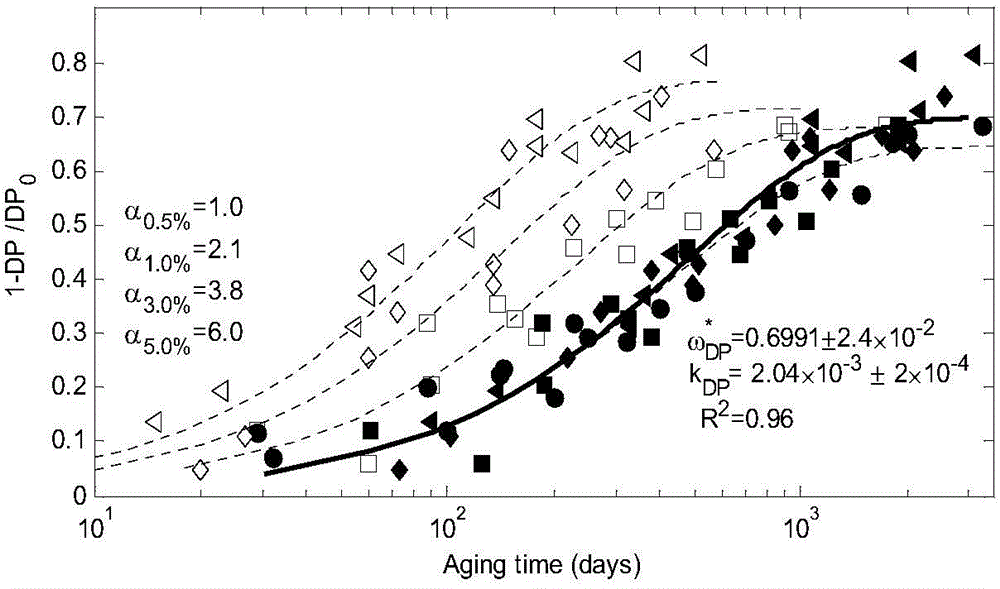

Oil paper insulation thermal aging life assessment method based on time temperature water superposition method

InactiveCN104407238AAccurate life assessmentComprehensive life assessmentElectrical testingAccelerated agingEngineering

The invention discloses an oil paper insulation thermal aging life assessment method based on a time temperature water superposition method, and belongs to the technical field of transformer oil paper insulation thermal aging life assessment. When extrapolation is performed on high temperature accelerated aging data by the method, influence of water content and the collaborative acceleration effect of water and temperature are fully considered, and the accelerated aging data under high temperature high initial water content are extrapolated to data under the operation condition of low temperature low water content so that defects in a conventional time temperature superposition model are overcome, and thus the more accuracy and comprehensive life assessment method aiming at transformer oil paper insulation thermal aging is provided.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com