Patents

Literature

97results about How to "Solve the high scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

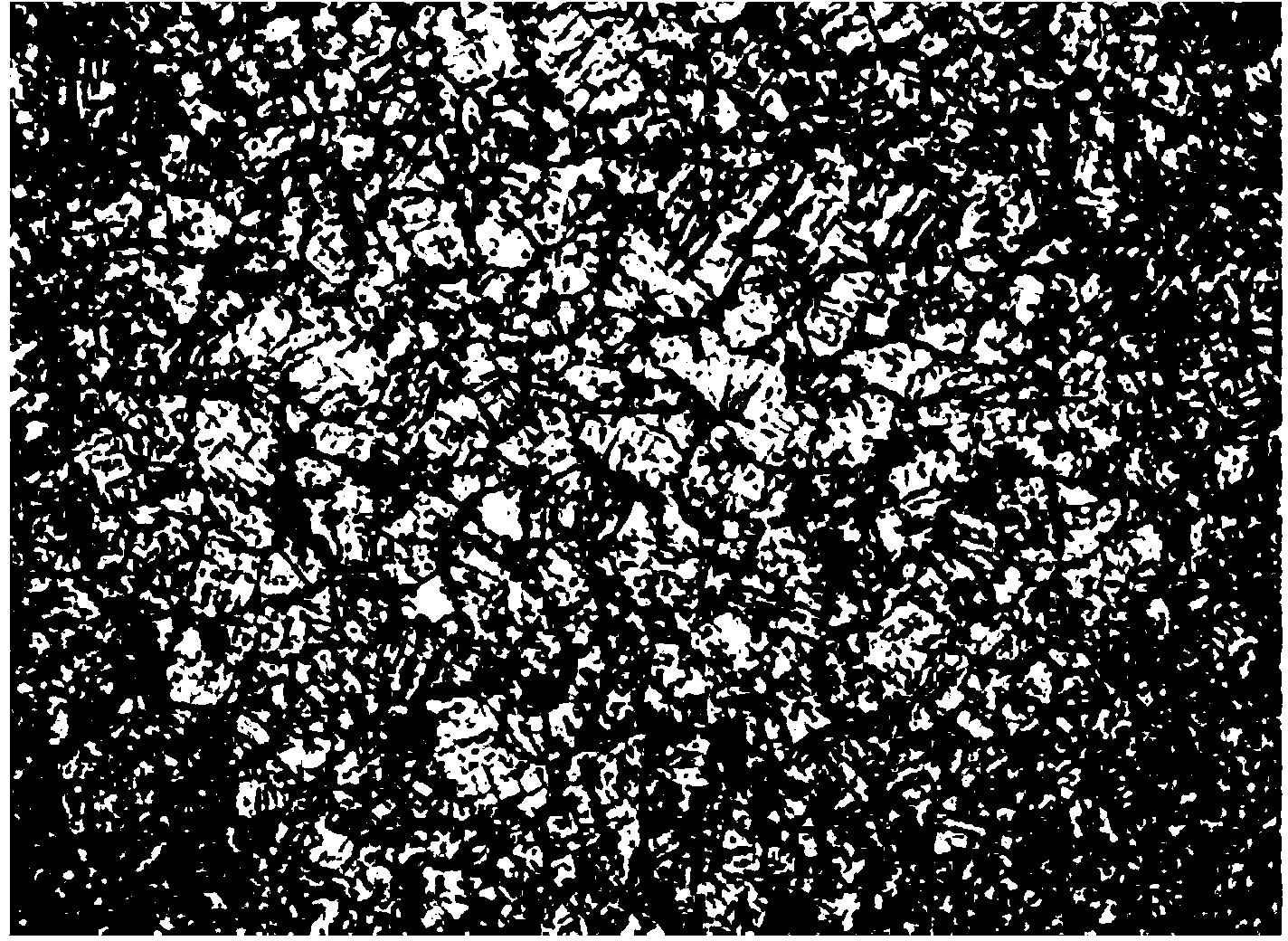

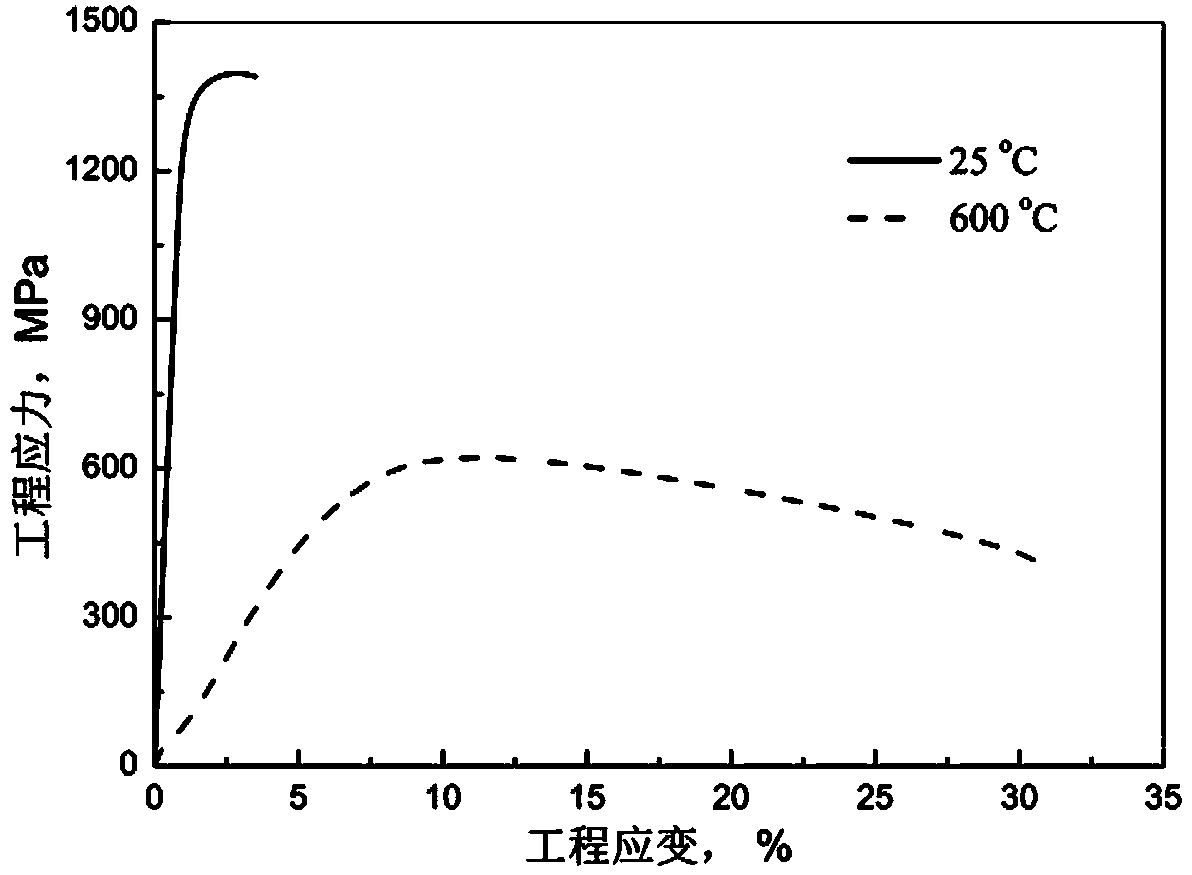

Preparation method of TiBw/Ti-6Al-4V composite bar adopting quasi-continuous reticular structure

The invention relates to a preparation method of a TiBw / Ti-6Al-4V composite bar adopting a quasi-continuous reticular structure and solves problems that existing Ti-6Al-4V composites are harsh in technological condition, high in equipment requirement, low in production efficiency, difficult to produce on a large scale and the like. The method comprises steps as follows: low-energy ball milling and mixing are performed on spherical Ti-6Al-4V powder and TiB2 powder firstly; then TiB2 / Ti-6Al-4V mixed powder is placed in a metal sheath for cold press molding, and vacuum degassing and sheath sealing welding are performed to obtain an extrusion billet; finally, short-time pre-sintering is performed on the obtained extrusion billet, and hot extrusion deformation is performed on the pre-sintered extrusion billet to obtain a required material. The method can be applied to preparation of a TiBw / Ti-6Al-4V composite adopting the quasi-continuous reticular structure.

Owner:HARBIN INST OF TECH AT WEIHAI

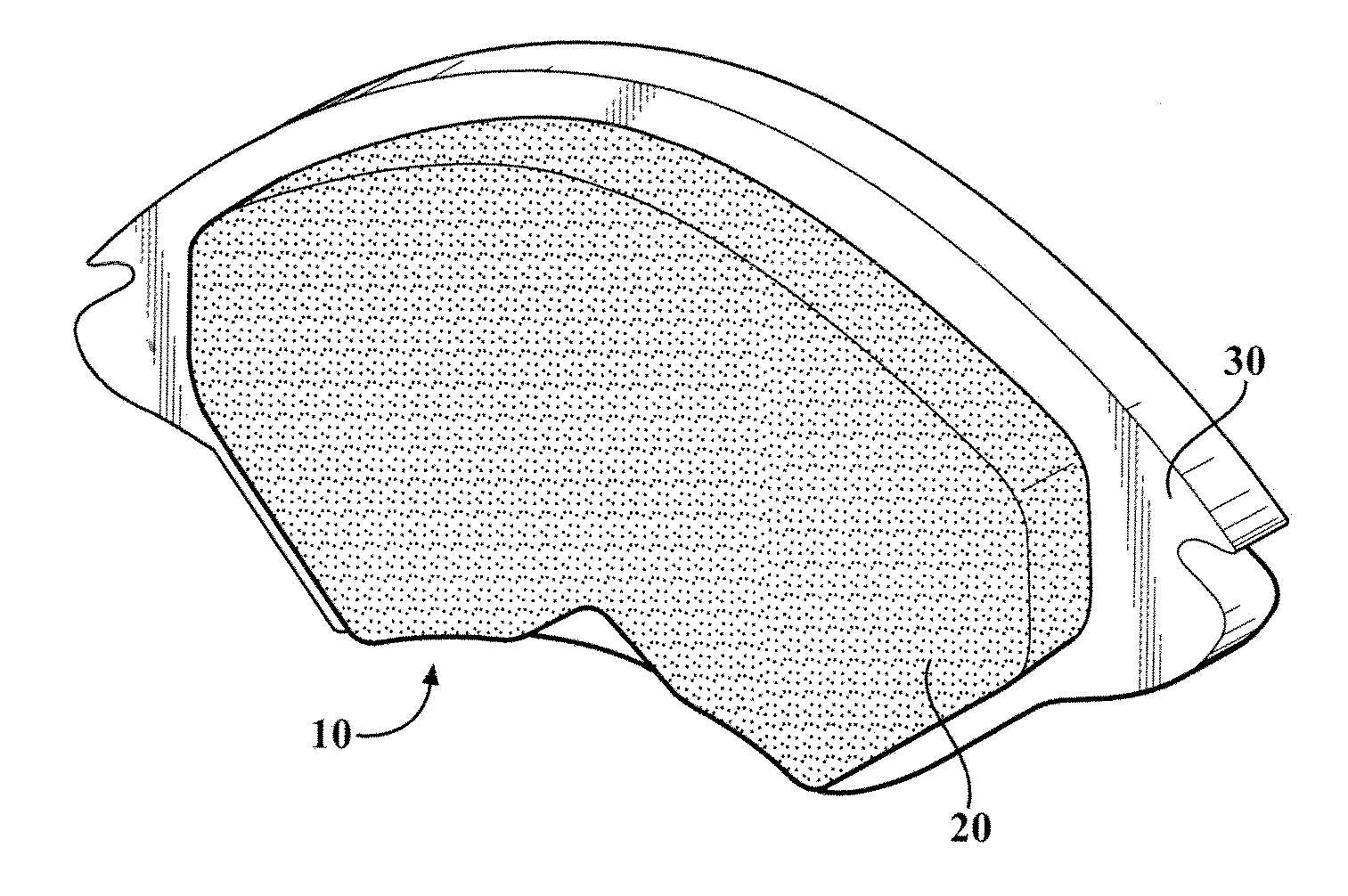

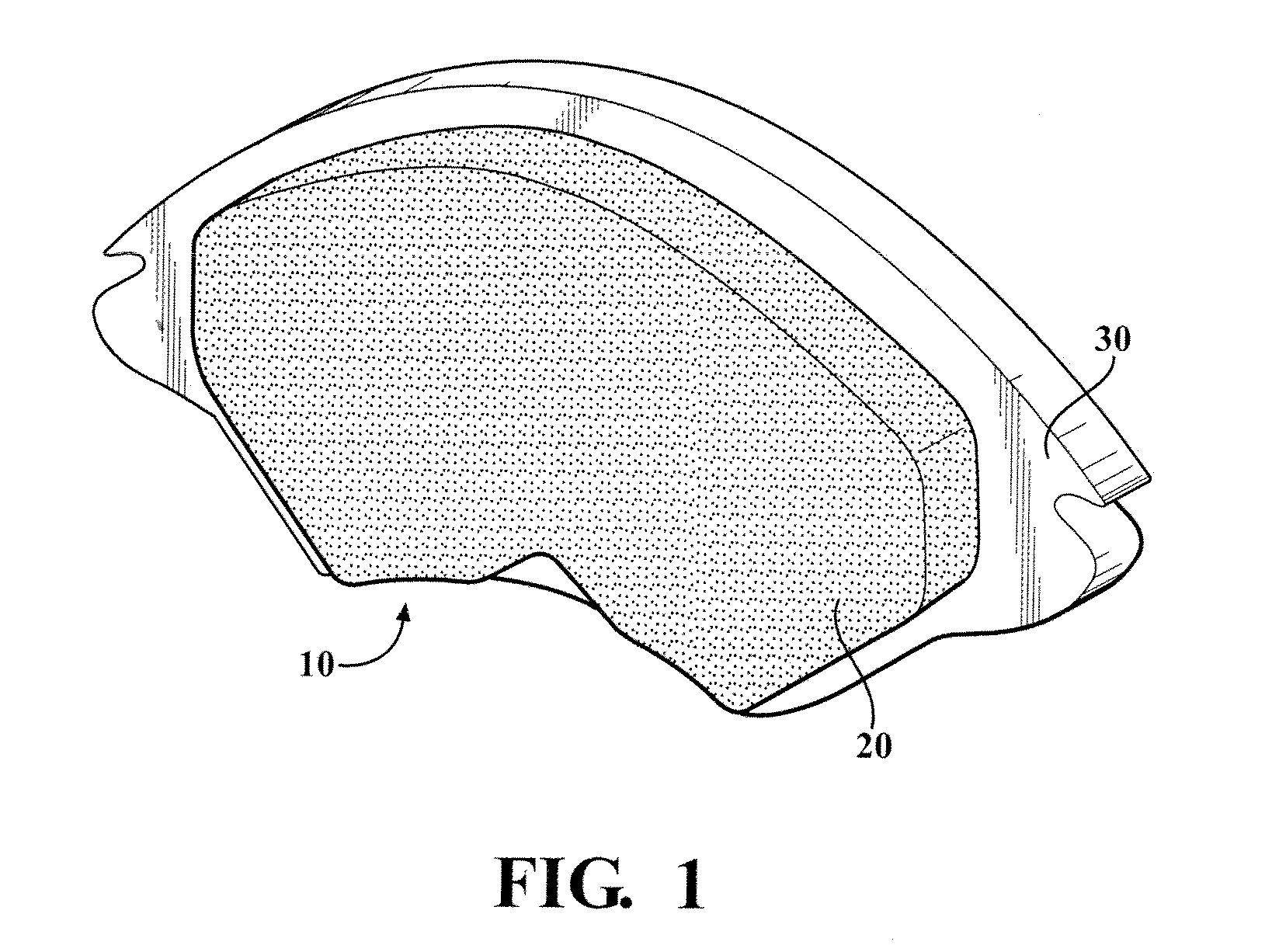

Friction material for brakes

ActiveUS20110297496A1Easy to handleImprove efficiencyWood working apparatusBraking elementsMetal fiberMetallic sulfide

A metal fiber, copper, and titanate free non-asbestos friction material for brake pads is provided. The friction material includes a binder, such as a phenolic resin, forming 16-24% by volume; a fiber, such as aramid fiber, forming 4-12% by volume; a lubricant, such as a blend of antimony tri-sulfide and another metal sulfide, forming 2-5% by volume; and at least one abrasive, such as a blend of mineral fiber, magnesium oxide, and mica, forming 10-22% by volume. The friction material further comprises rubber powder in an amount of at least 4% by volume. The brake pad can be formed by a cost effective process consisting essentially of mixing the ingredients, pressing and curing the friction material to a backing plate, and post baking the brake pad.

Owner:FEDERAL MOGUL PROD US LLC

Method for casting vermicular cast iron casting parts

The invention discloses a casting method of cast of vermicular cast iron for heavy motor cylinder lid, which is characterized by the following: combining multiple casting techniques with 'lateral casting', 'top casting', 'flanging casting', 'insulation riser' and 'shaped hollow chill' together; reducing the defect of shrinkage loose and void and synthetic waste rate; adjusting the casting technique according to the real condition; fitting to be used on other patterned products.

Owner:GUANGXI YUCHAI MASCH CO LTD

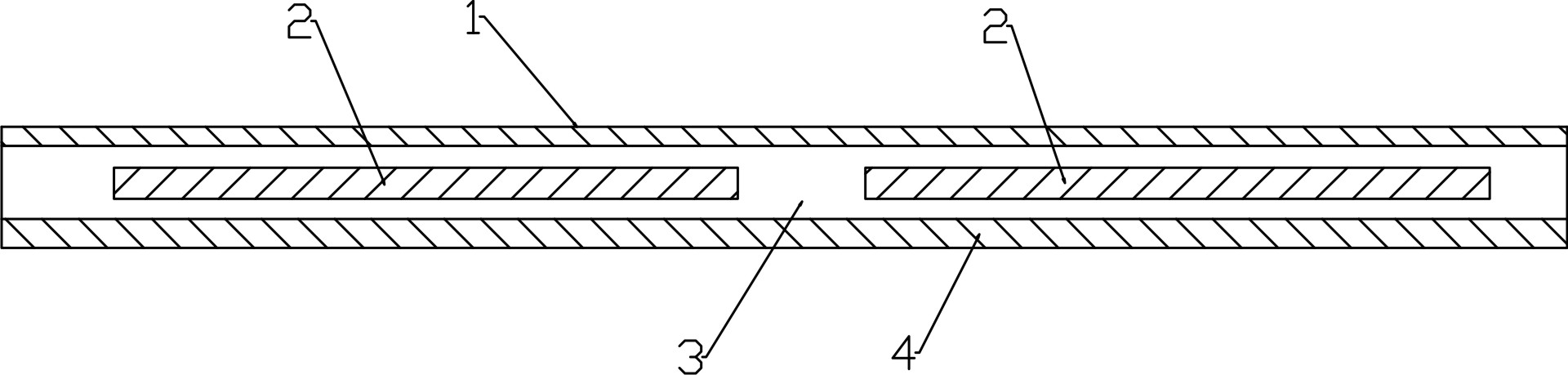

Solar panel and encapsulation process

ActiveCN101916788ASolve the flatnessSolve the bubblesFinal product manufacturePhotovoltaic energy generationWhole bodyHot melt

The invention relates to a solar panel and an encapsulation process. The solar panel comprises a silicon wafer, wherein the back of the silicon wafer is adhered to a printed circuit board (PCB) board; a polythylene terephthalate (PET) material light-transmitting layer is arranged on the upside of the silicon wafer; and the PCB board is provided with anode and cathode printed coils which are connected with the anode and cathode of the silicon wafer. The encapsulation process of the solar panel comprises the following steps of: firstly, clamping the silicon wafer and flake-like ethylene vinyl acetate (EVA) hot melt glue between the PCB board and the PET material light-transmitting layer and placing the whole body in a vacuum laminating machine; secondly, vacuumizing the vacuum laminating machine and then heating materials to be processed in the vacuum laminating machine; and finally charging air into air bags in the vacuum laminating machine for pressurization.

Owner:HANGZHOU SOLAR PHOTOELECTRICITY

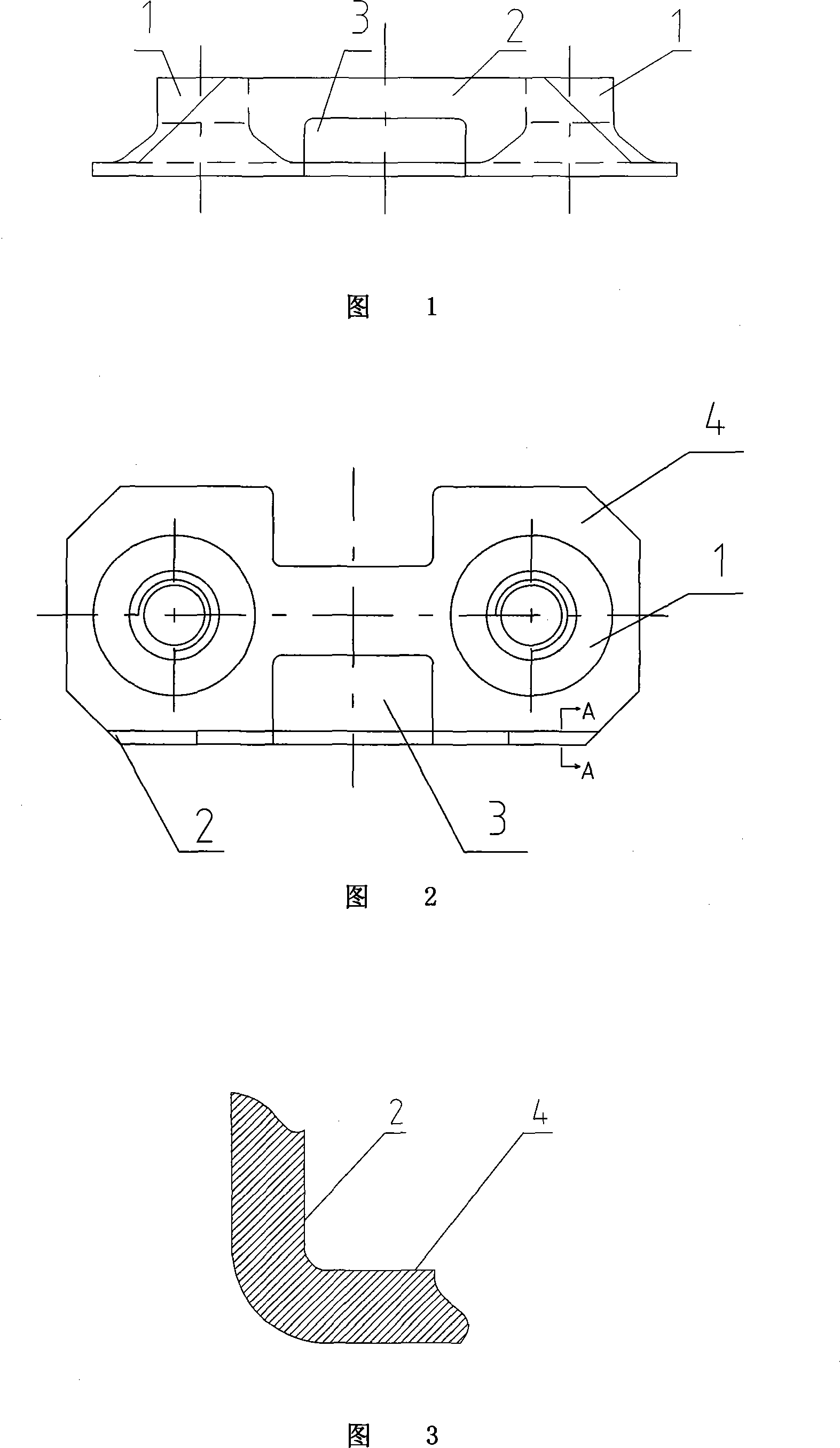

Technique for manufacturing vehicle door bonnet lock nut plate

The invention discloses a manufacturing process of a lock nut panel for a vehicle door. The lock nut panel is a baseplate provided with two lug bosses, each lug boss is provided with a screw hole, and the baseplate is provided with a hem and two square holes; and the lock catch nut panel for a front door uses Type 45 steel. The manufacturing process comprises the following steps: feeding sheet materials, stretching 1, stretching 2, stretching 3, stretching 4, stretching 5, molding, punching, shaping, ripping edges, punching the square holes, folding the hem, grinding the platform, tapping thread, quenching, tempering in low temperature and black oxide coating. By adopting the structure, the invention ensures the quality of components and the security of the whole vehicle, avoids the problem of high scrap rate of components due to instable quality, and effectively saves the cost.

Owner:SAIC MOTOR

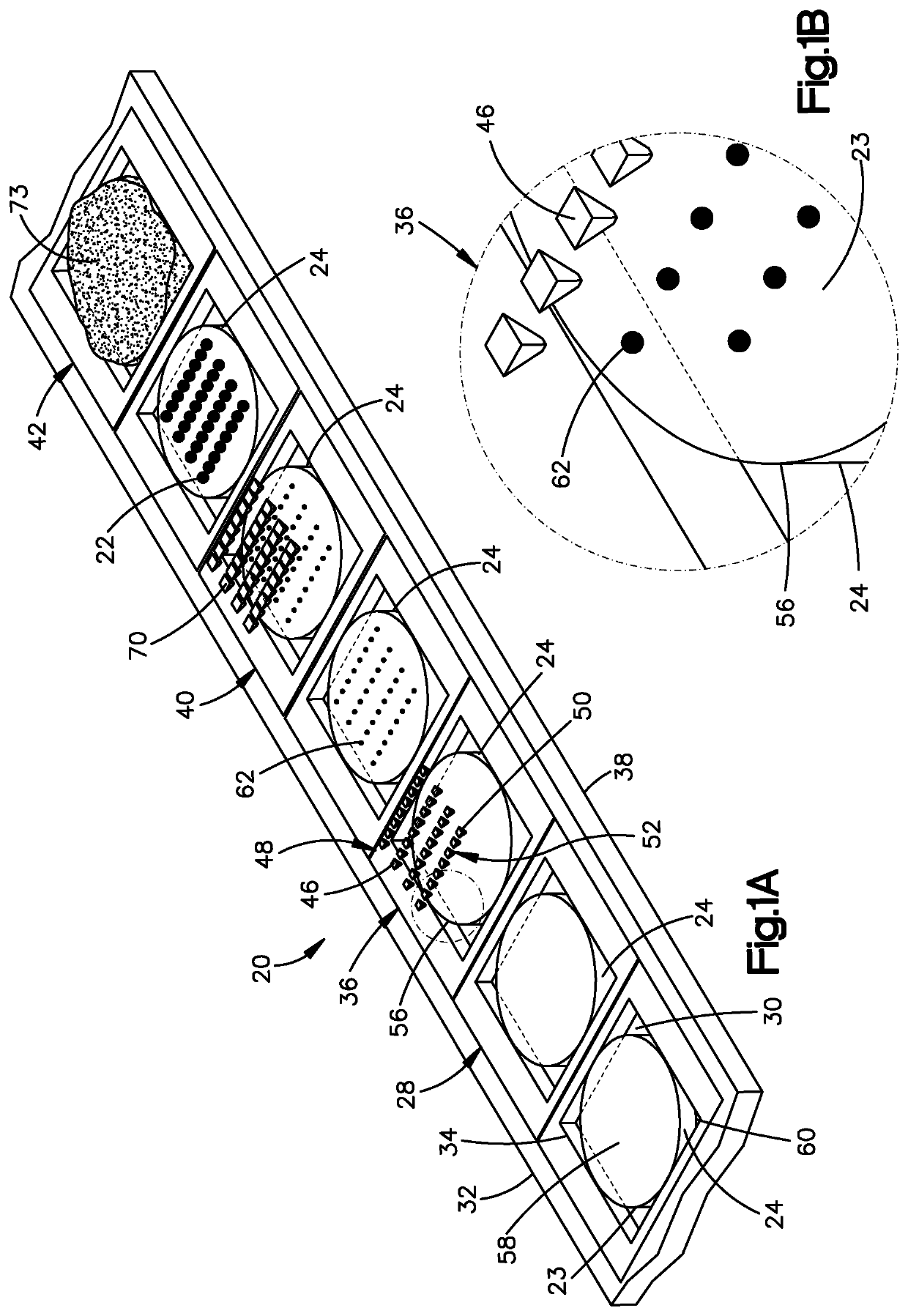

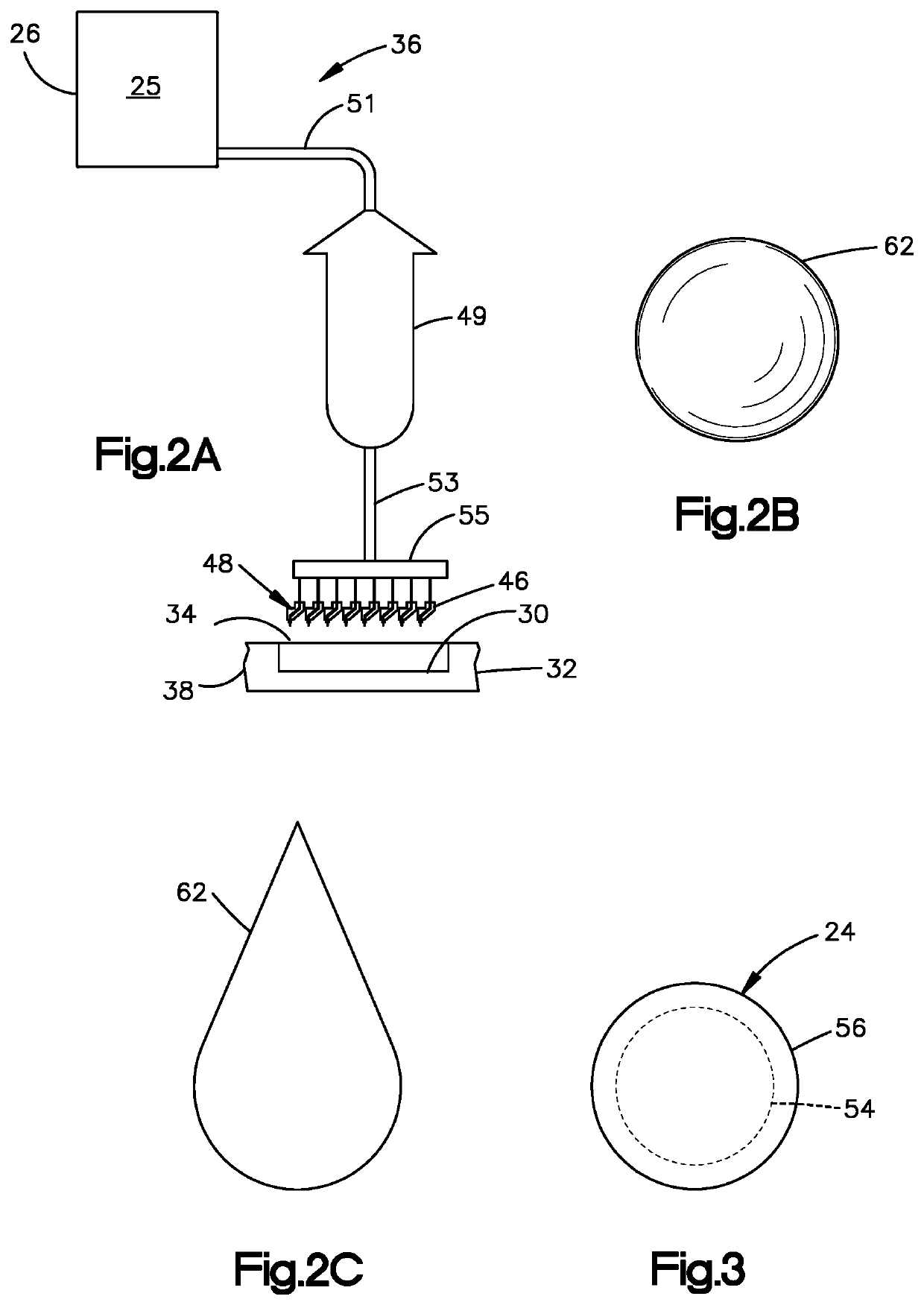

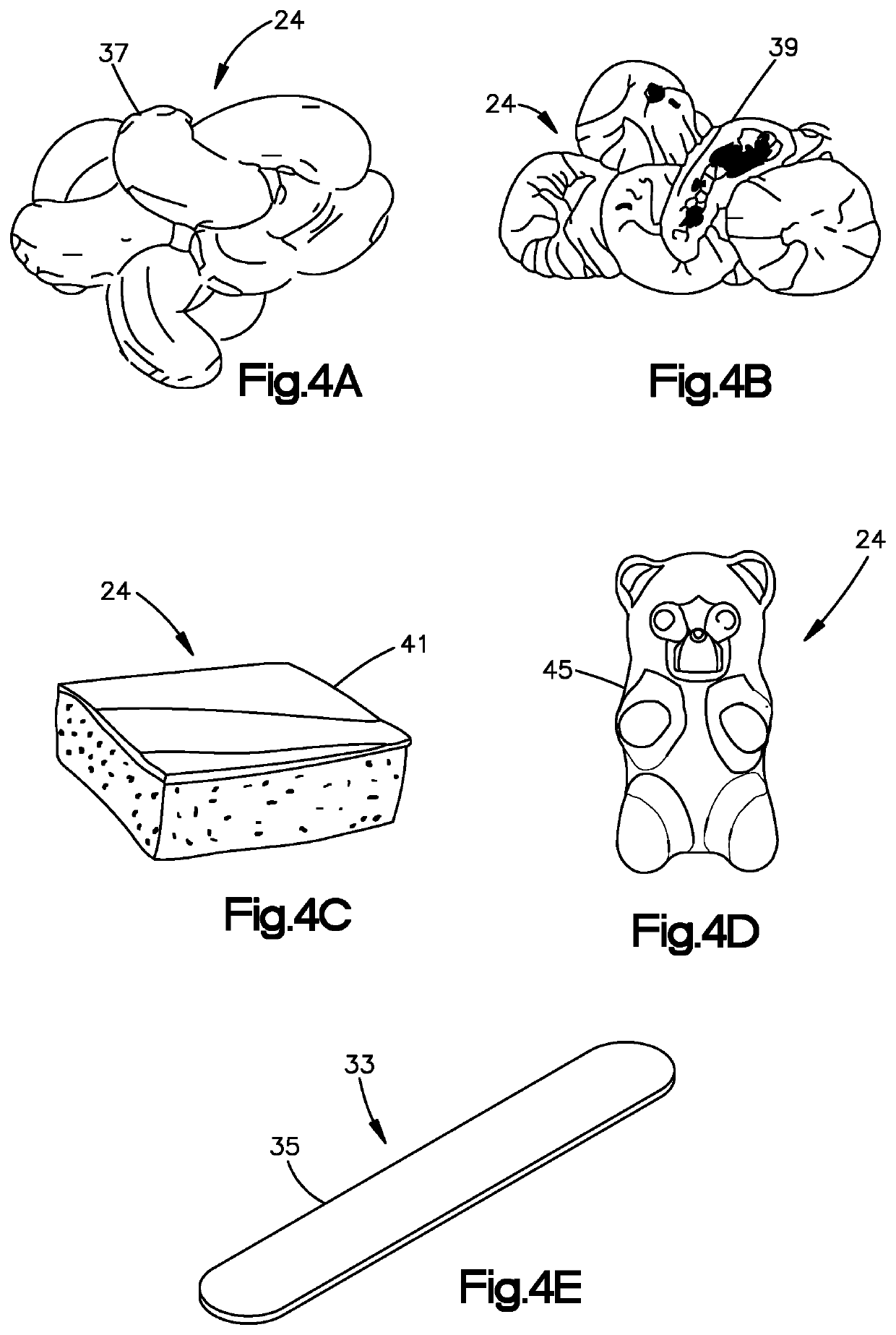

Systems And Methods For Manufacturing Cannabis Edibles, And Resulting Edible Products

PendingUS20200352826A1Quality improvementImprove consistencyConfectioneryPharmaceutical delivery mechanismBiotechnologyEngineering

This present disclosure provides reliable methods and apparatus for delivering a pharmaceutical active ingredient to a substrate. In some examples, the pharmaceutical active ingredient is applied to the substrate after the substrate has been fully prepared. The substrate can be an edible product or an inedible substrate. The edible product can be a baked or otherwise cooked good. In some examples, the edible product can be fruits and / or nuts. The method and apparatus for delivering the pharmaceutical agent can be configured to deliver microquantities of the pharmaceutical active ingredient to the substrate.

Owner:TRANSPORT AUTHORITY INC

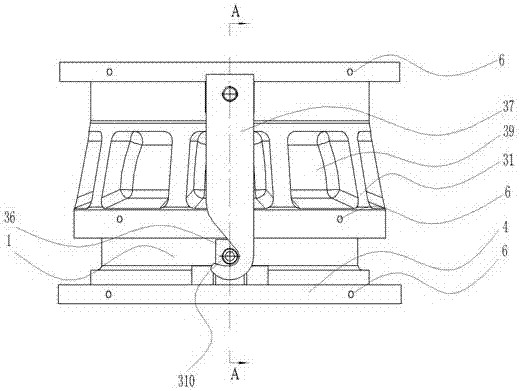

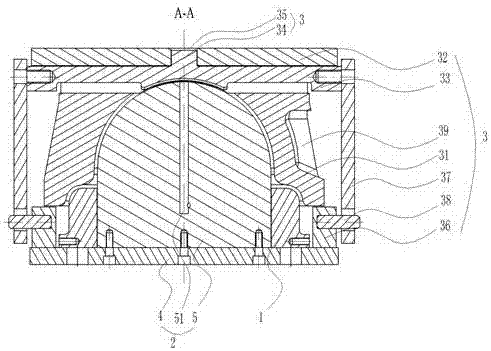

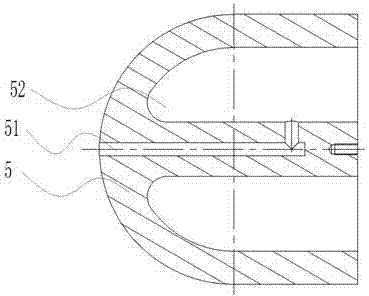

Hemisphere drawing method

PendingCN107309361AAvoid breakingAvoid wrinklesAircraft componentsMachine partsIndustrial engineering

The invention discloses a drawing method, in particular an aerospace hemisphere part drawing method, and belongs to the technical field of aerospace. The method comprises positioning of a hemisphere machined part in a drawing mold in pre-high-temperature environment for predrawing and hot drawing. The hemisphere drawing method solves the problems of high scrap rate, easiness in pulling fragmentation and high production cost in the prior art, and adopts twice drawing and setting in high-temperature environment to effectively prevent pulling fragmentation in the hemisphere drawing process; and the drawing method is lower in auxiliary condition requirements and easy to realize, reduces the production cost, further improves the production efficiency, guarantees the product quality, and is high in practicability.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

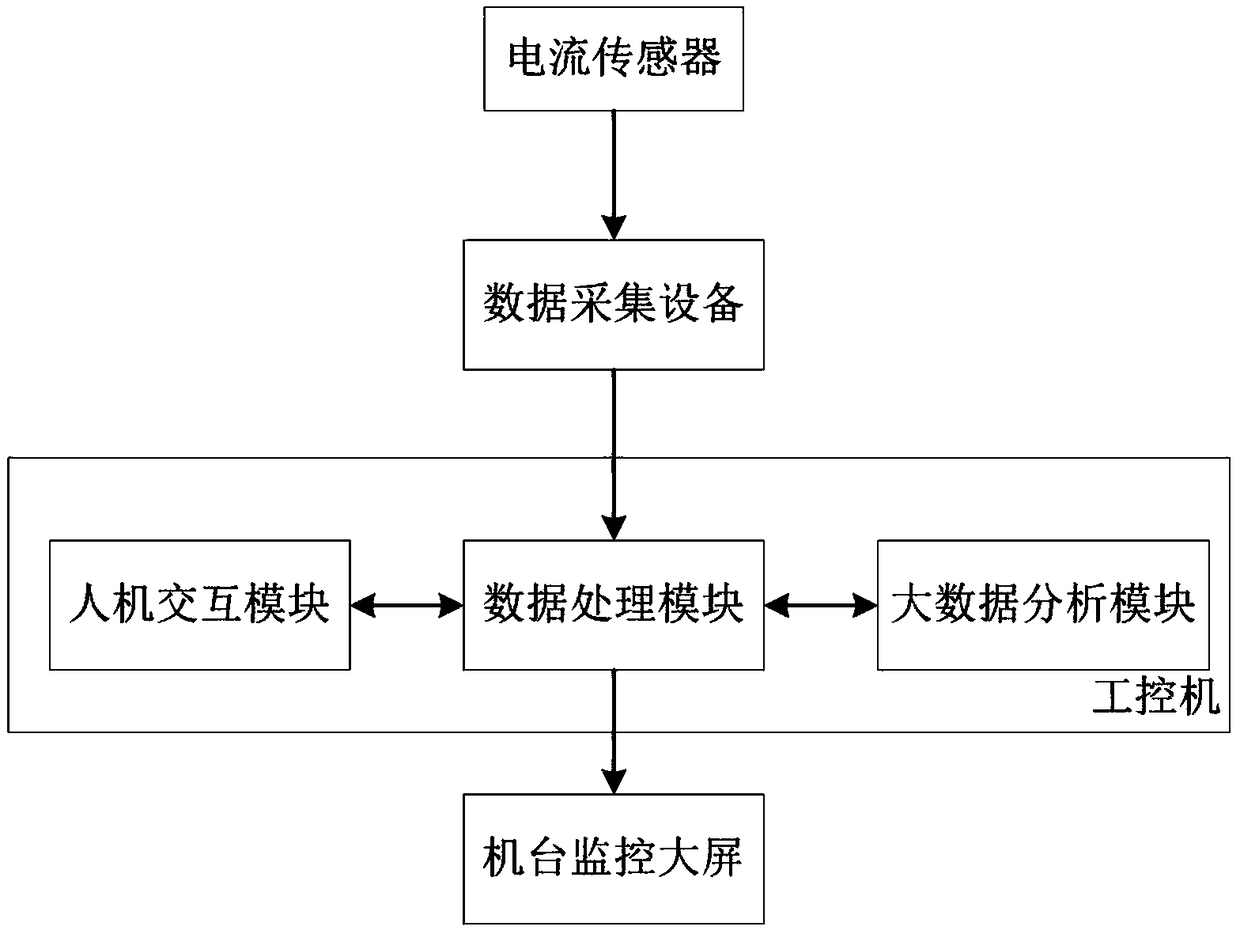

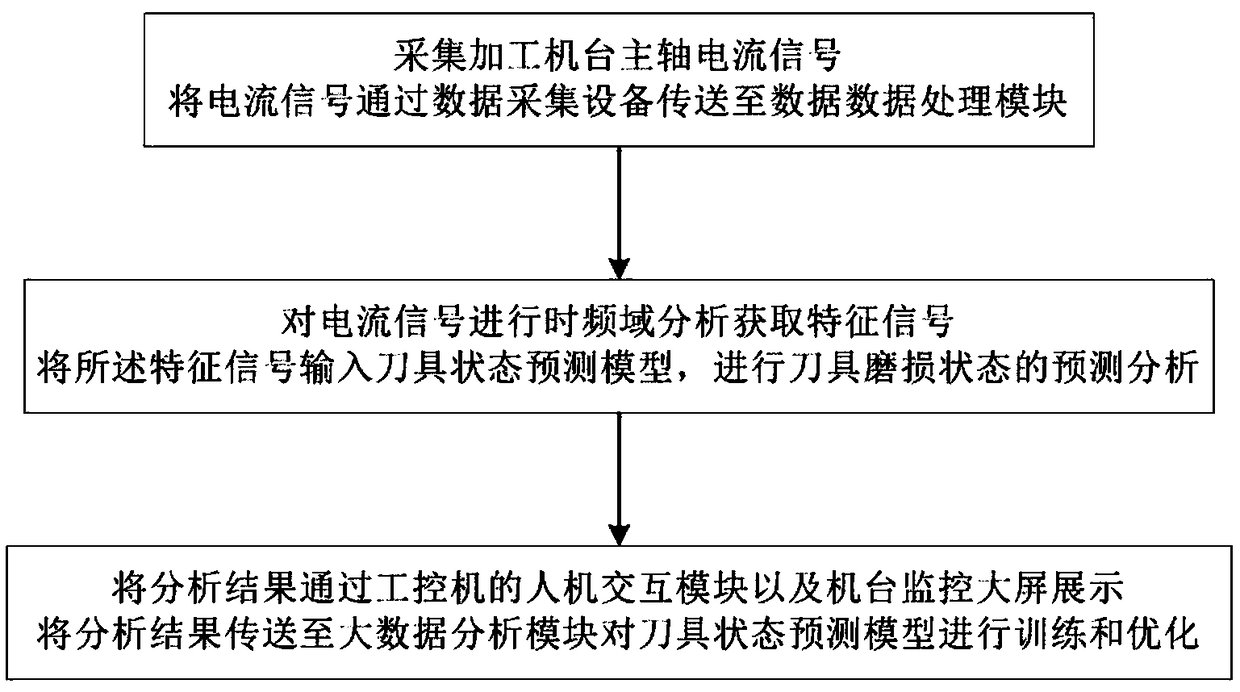

Detection system and method for cutter state

ActiveCN109262369AAvoid Increased Scrap RatesSolve the high scrap rateMeasurement/indication equipmentsFrequency domainState prediction

The invention discloses a detection system and method for a cutter state. The method comprises the steps that a current signal of a main shaft of a processing machine table is collected and transmitted to a data processing module through a data collection device; the current signal is subjected to time and frequency domain analysis to acquire a feature signal, the feature signal is input into a cutter state prediction model, and cutter wear is predicted and analyzed; the analysis result is displayed through a man-machine interaction module and a large machine table monitoring screen of an industrial personal computer; the analysis result is transmitted to a big data analysis module for training and optimizing the cutter state prediction model. According to the detection system and method for the cutter state, the cutter state can be effectively detected and predicted, early warning is conducted on cutter damage, and accordingly the situation is avoided that since a damaged cutter is not replaced in time, the rejection rate is increased.

Owner:CHENGDU UNION BIG DATA TECH CO LTD

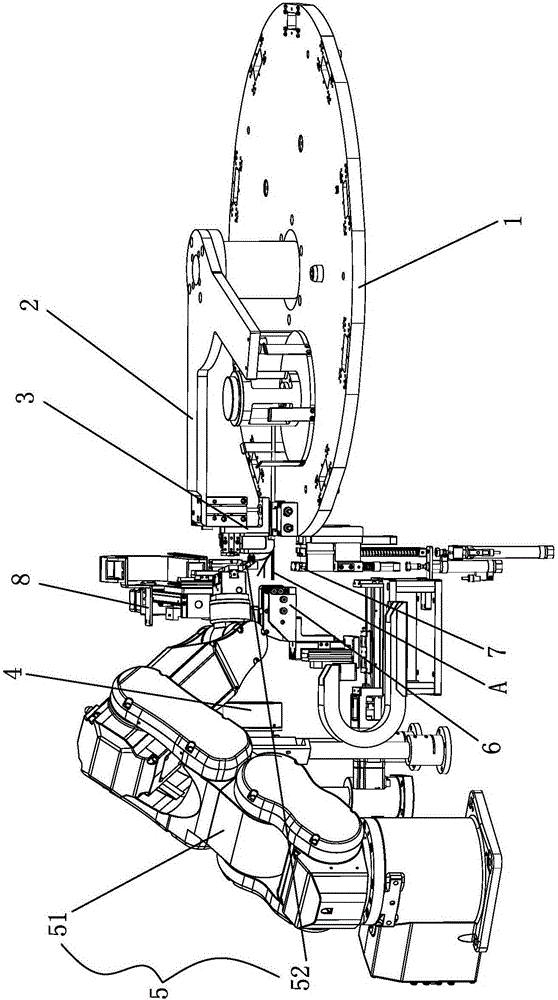

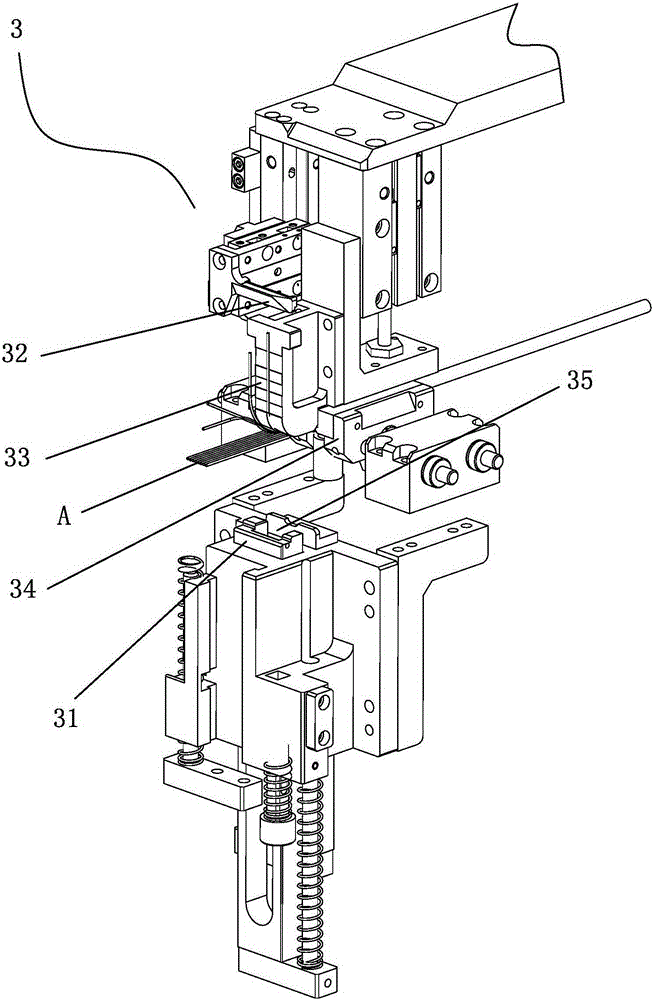

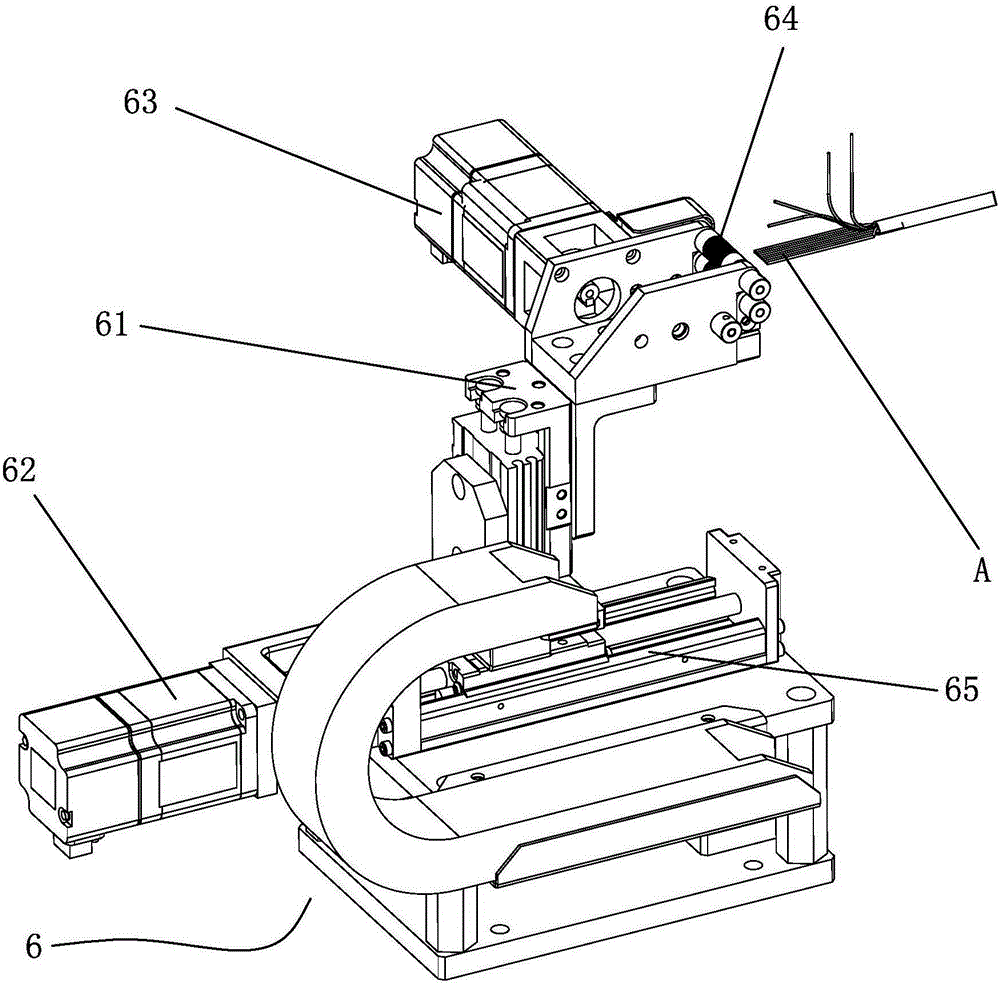

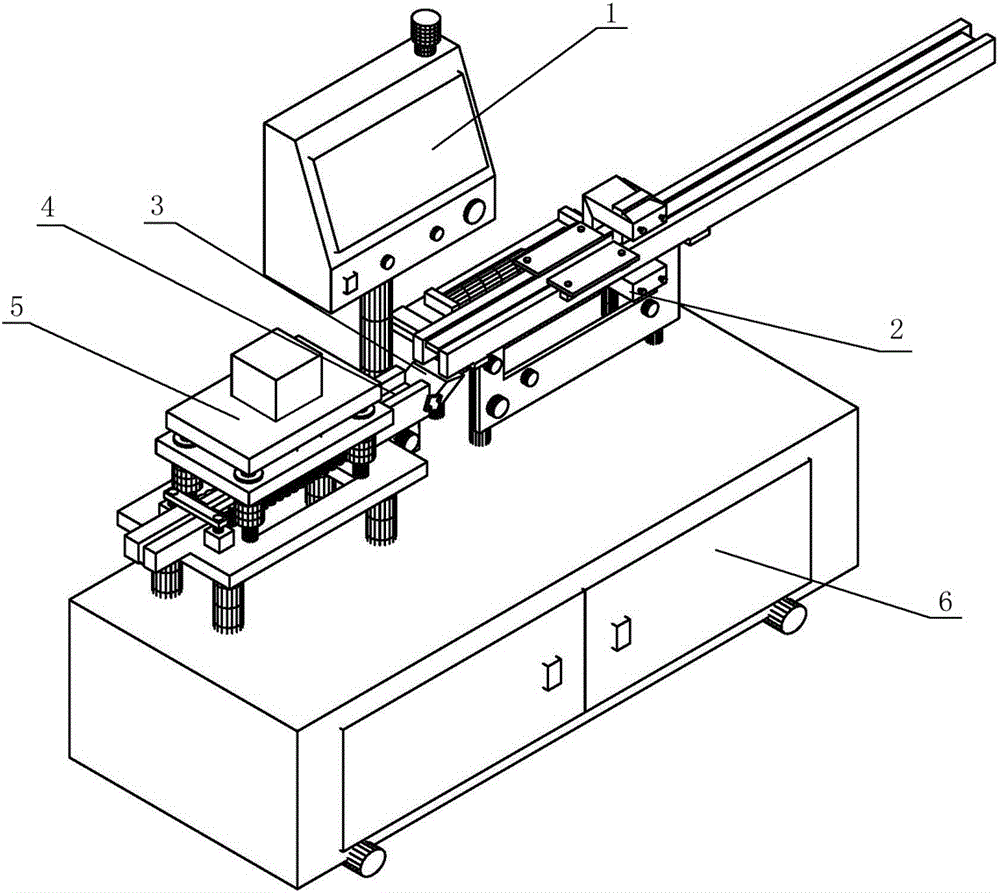

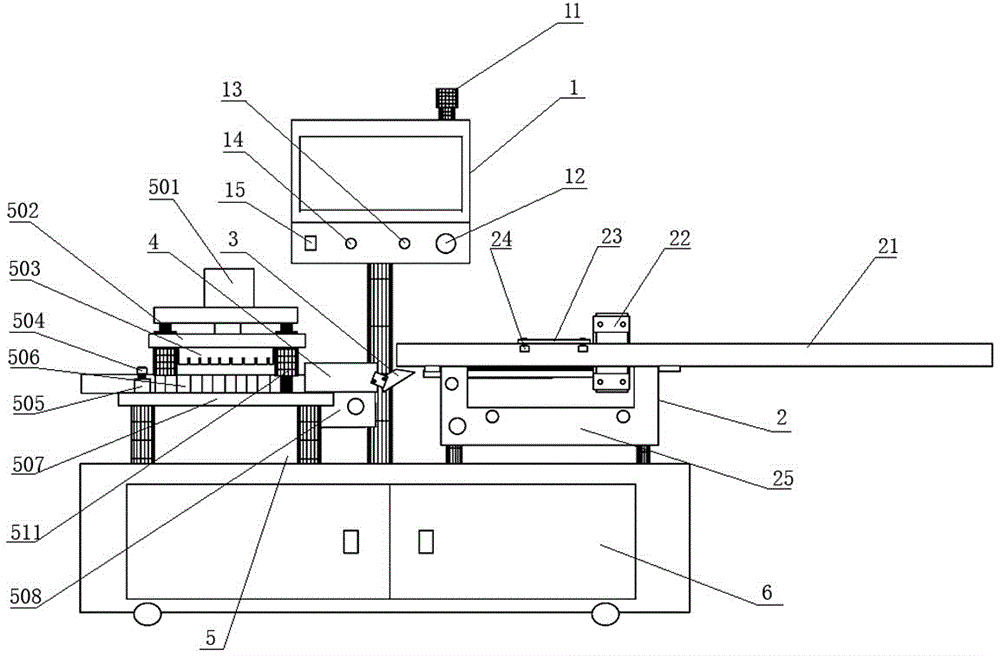

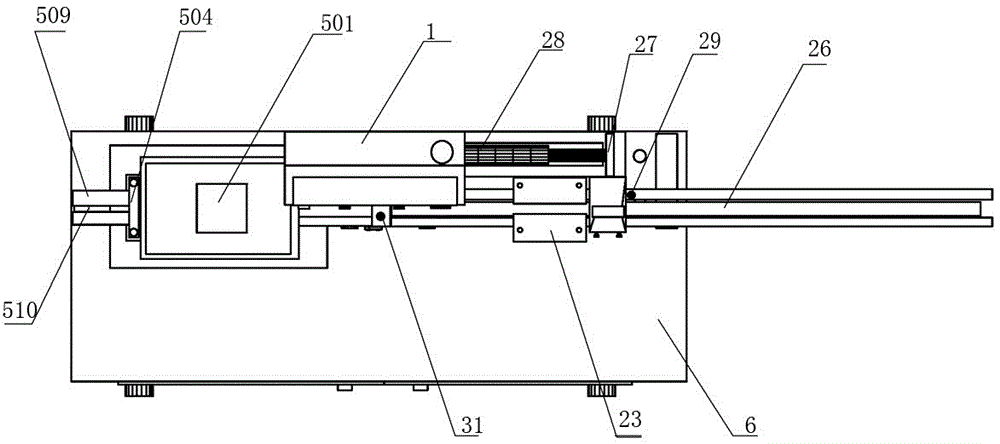

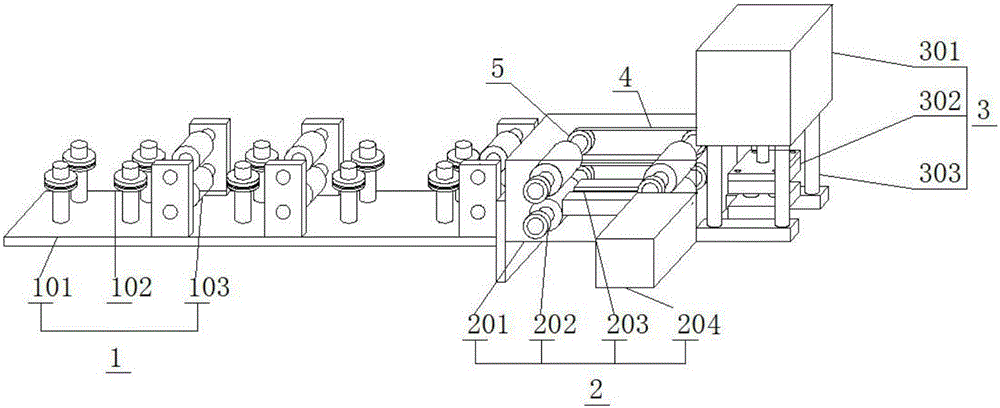

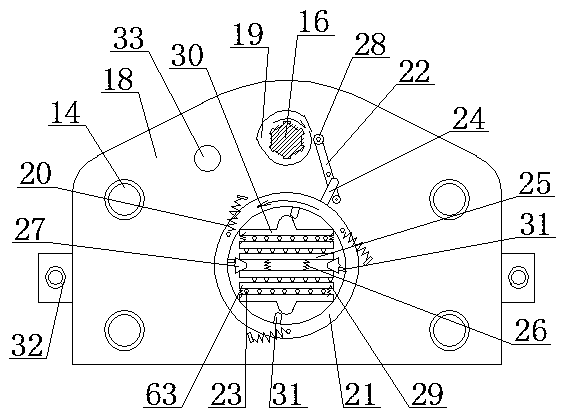

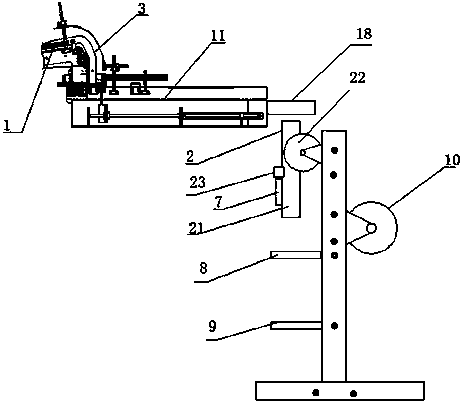

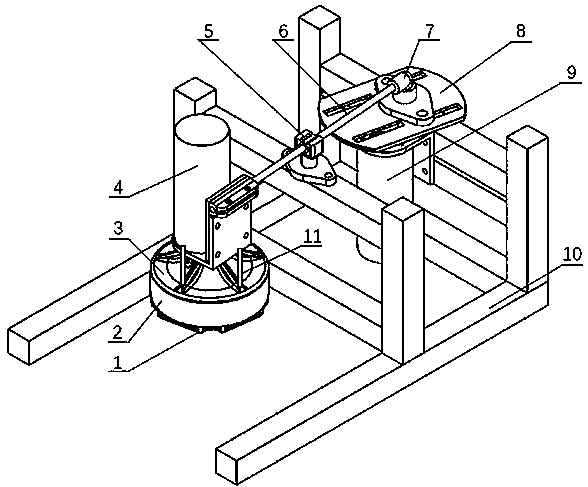

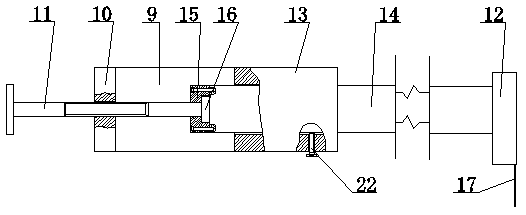

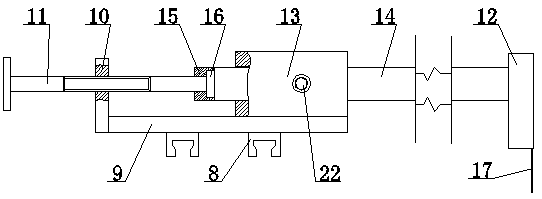

Automatic branching equipment for cables and branching method of automatic branching equipment

ActiveCN105244728AReduce labor costsSolve the high scrap rateContact member cases/bases manufacturePolygonal lineCcd camera

The invention relates to the technical field of electric wire processing, in particular to automatic branching equipment for cables and a branching method of the automatic branching equipment. The automatic branching equipment comprises a wire folding mechanism, a branching CCD camera, a branching gripping jaw mechanism, a branching roller mechanism, a branching locating mechanism and a cover board take mechanism; after the line folding mechanism vertically bends and fixes core wires, the branching CCD camera identifies the colors of the core wires in a vertical bent state and judges the positions of the core wires; the branching gripping jaw mechanism correspondingly captures each core wire and places each core wire on the corresponding position of the branching roller mechanism according to identification and judgment of the branching CCD camera; the branching roller mechanism carries out branching and line arrangement on the core wires captured by the branching gripping jaw mechanism, so that the core wires are kept in a parallel state; and finally the a branching locating mechanism is matched with the cover board take mechanism to carry out setting branching on the core wires. Compared with the traditional manual branching, a lot of labor cost is saved; the problem of high product scrap rate caused by a human error is overcome; and meanwhile, the production efficiency and the production quality are improved.

Owner:SHENZHEN AMI TECH CO LTD

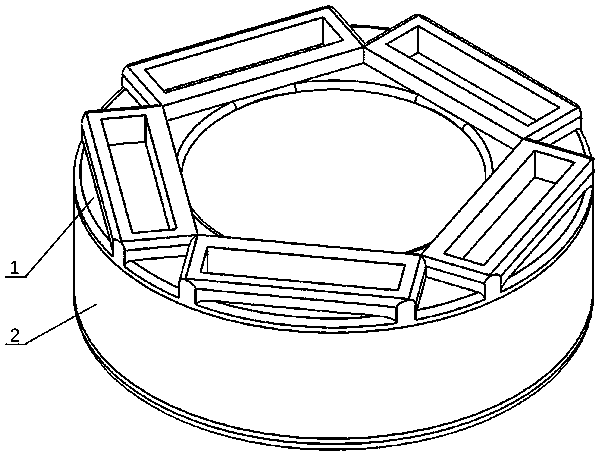

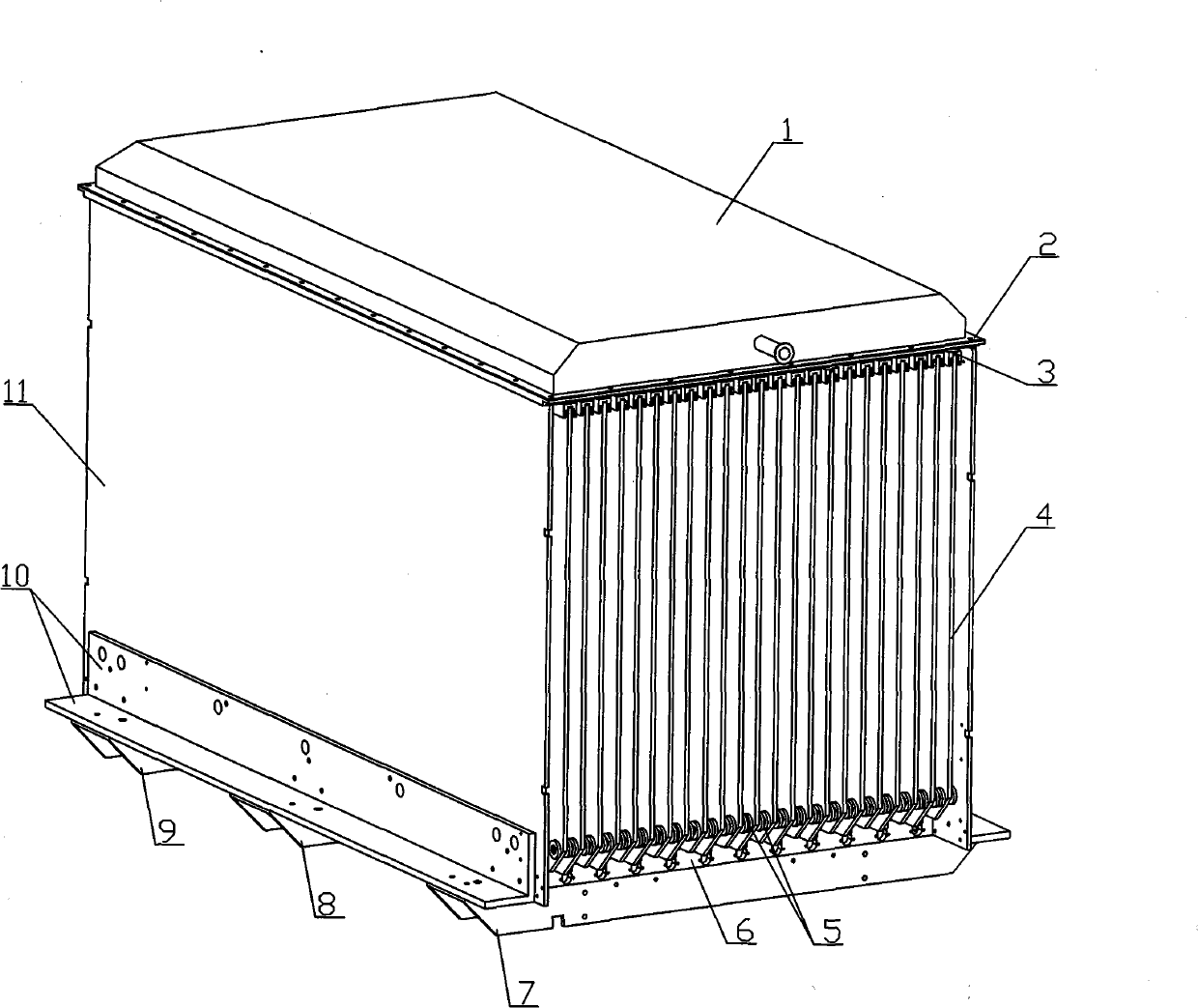

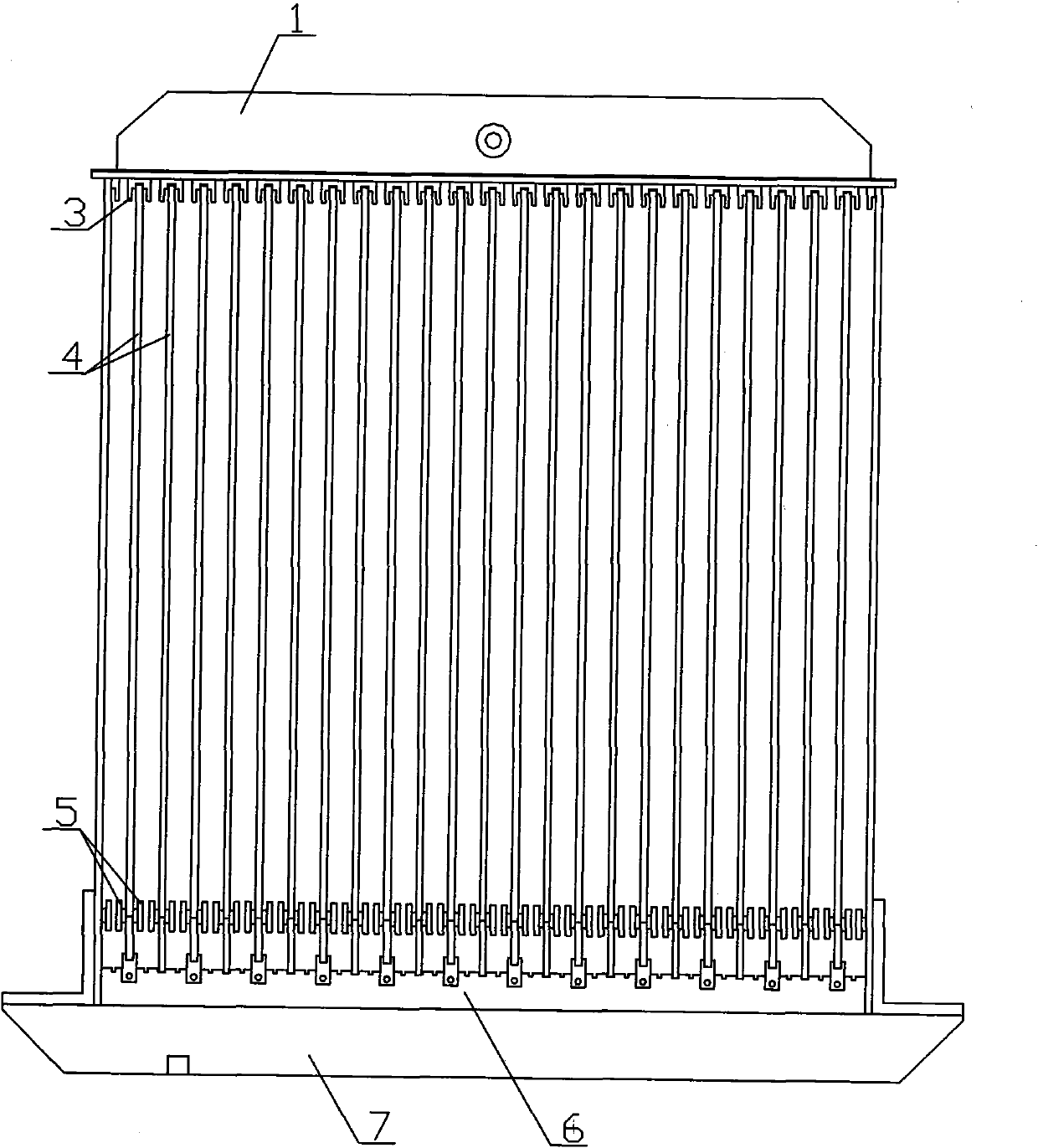

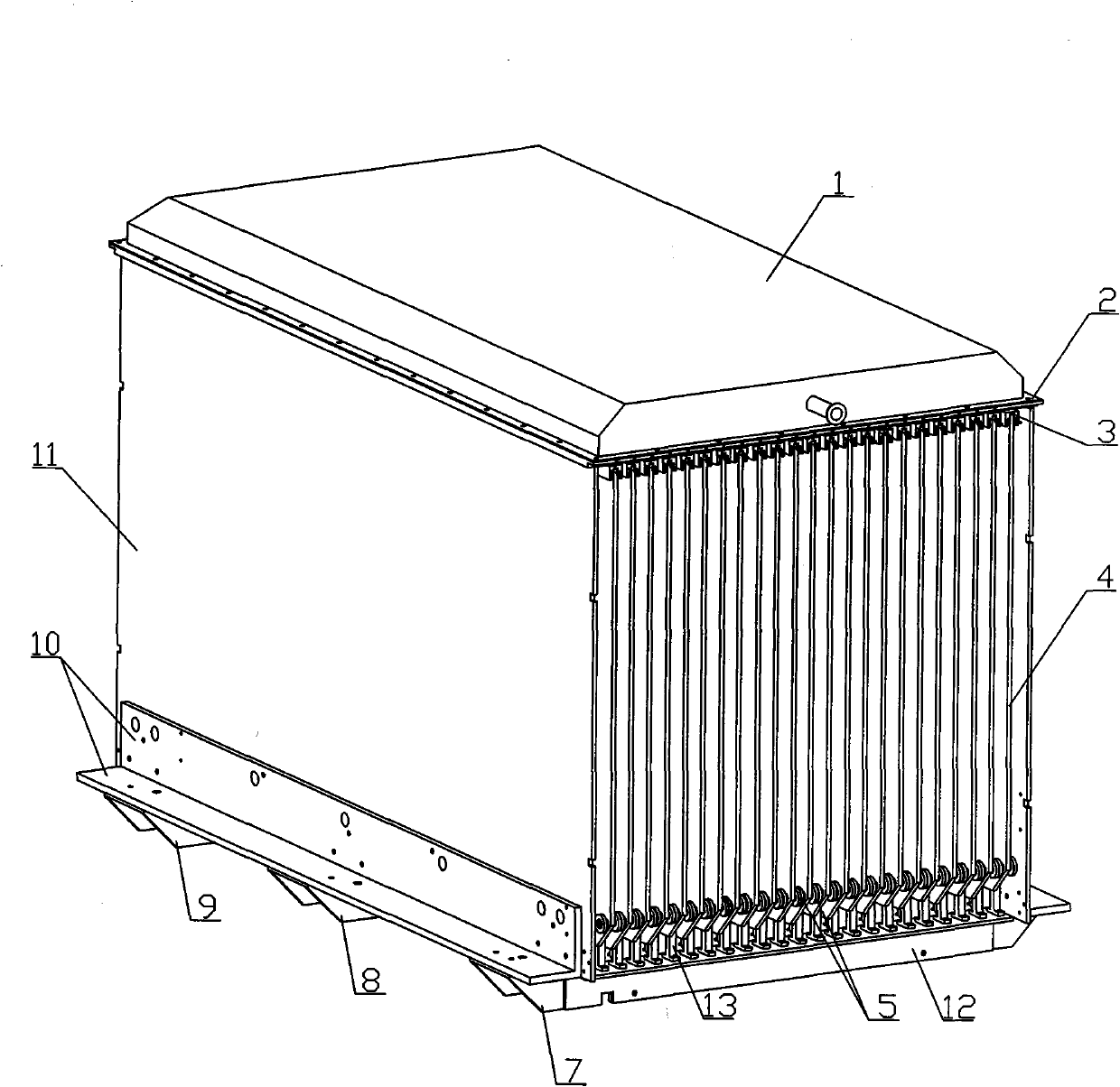

Automatic powder brushing and border cutting device of chip inductor

ActiveCN106548861AImprove cut qualitySmooth transmissionInductances/transformers/magnets manufactureCleaning using toolsInductorEngineering

The invention provides an automatic powder brushing and border cutting device of a chip inductor, and belongs to the technical field of chip inductor molding equipment. The device comprises a box body, a controller, a powder brushing mechanism and a border cutting mechanism, wherein the device is characterized in that the powder brushing mechanism is fixed at the right side of the upper end of the box body and comprises a first horizontal guide rail; a first conveyor belt is arranged in a groove of the first horizontal guide rail; two clamping plates are symmetrically arranged at two sides of the upper end of the first horizontal guide rail; a vertical air cylinder is arranged at the lower part of each clamping plate; a powder brushing rack is arranged at the right ends of the clamping plates; a first induction lamp is arranged at the right end of the powder brushing rack; a horizontal air cylinder is arranged at the rear part of the powder brushing rack; a second conveyor belt is arranged in a second horizontal guide rail of the border cutting mechanism, a third induction lamp is arranged at the right part of the second horizontal guide rail and pressure block control air cylinders are arranged at two sides of the second horizontal guide rail; and a cutter control air cylinder is arranged at the upper end of an upper support plate of the border cutting mechanism. The automatic powder brushing and border cutting device has the beneficial effects that the operation of the device is simple and automatic, the production cost is low, powder brushing and cutting are integrated, the cleaning effect is good, product positioning is accurate and the quality of a finished product is high.

Owner:JINING UNICHOKA ELECTRONICS CO LTD

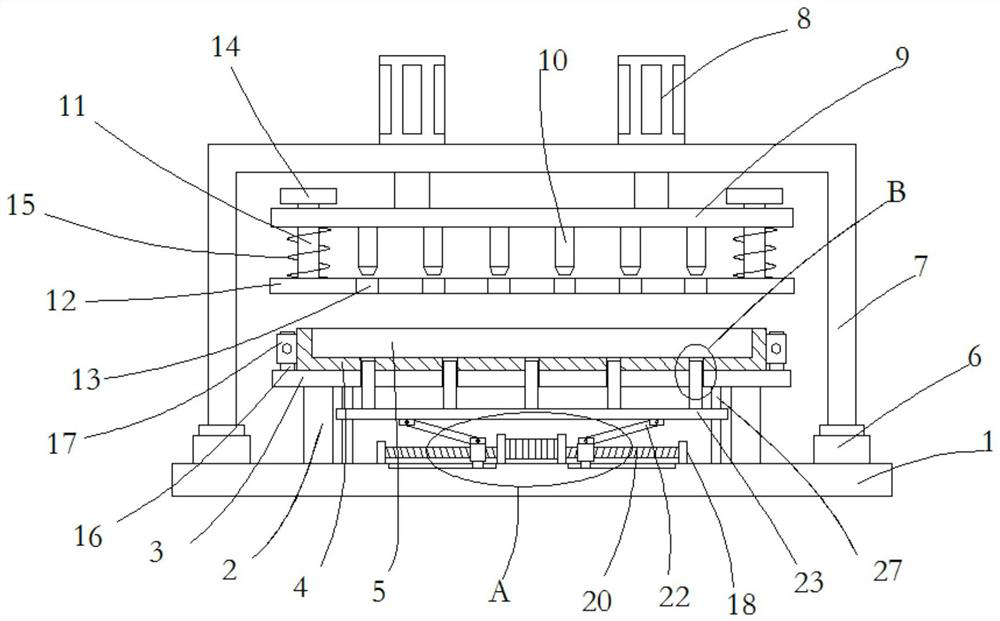

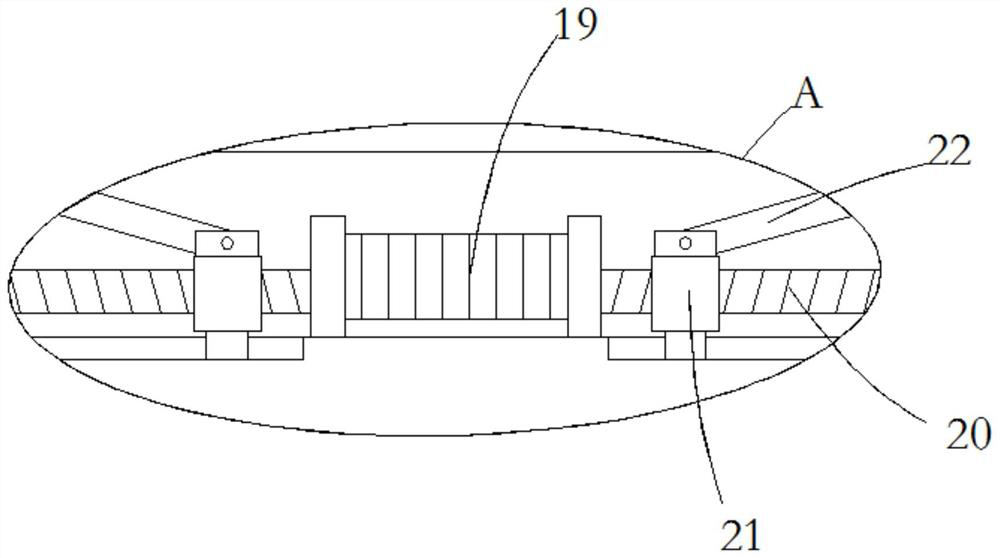

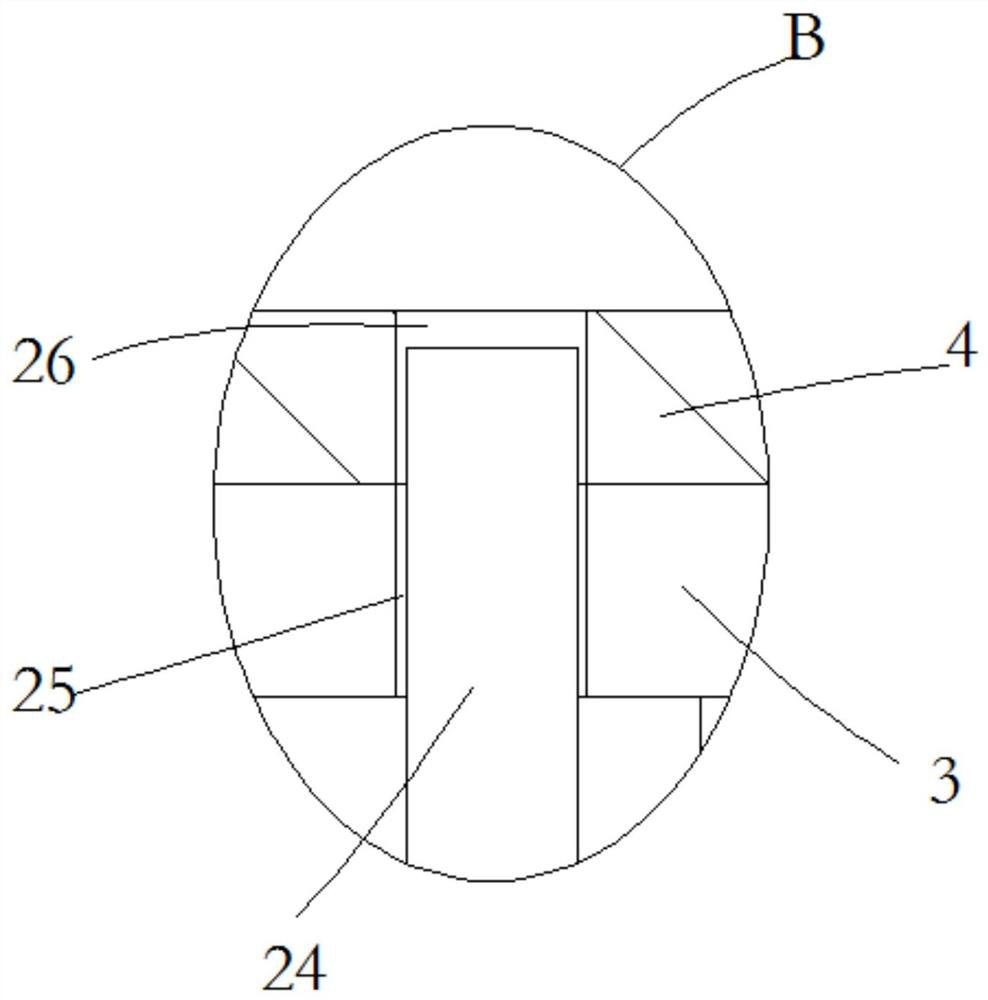

Magnesium alloy plate stamping device

PendingCN112170623AQuick placementPlace stableShaping toolsMetal-working feeding devicesStampingStructural engineering

The invention relates to the technical field of magnesium alloy plate stamping, and discloses a magnesium alloy plate stamping device. The magnesium alloy plate stamping device comprises a base, a plurality of supporting blocks are symmetrically and fixedly connected to the upper end of the base, the upper ends of the supporting blocks are fixedly connected with the same support plate, the upper end of the support plate is fixedly connected with a lower die, and two die grooves are formed in the upper end of the lower die in a front-back symmetrical mode; two electric sliding rails are fixedlyconnected to the upper end of the base in a bilateral symmetry mode, sliding blocks on the two electric sliding rails are fixedly connected with the same U-shaped supporting plate, two air cylindersare symmetrically and fixedly connected to the upper end of the horizontal portion of the U-shaped supporting plate, and output shafts at the lower ends of the two air cylinders penetrate through thelower end of the horizontal portion of the U-shaped supporting plate and are fixedly connected with the same stamping plate; and a plurality of stamping heads are uniformly and fixedly connected to the lower end of the p stamping plate. The magnesium alloy plate stamping device has the advantages that continuous stamping operation can be achieved, the production efficiency is improved, people canconduct feeding and discharging operation conveniently, and the feeding and discharging safety is guaranteed.

Owner:巢湖云海镁业有限公司

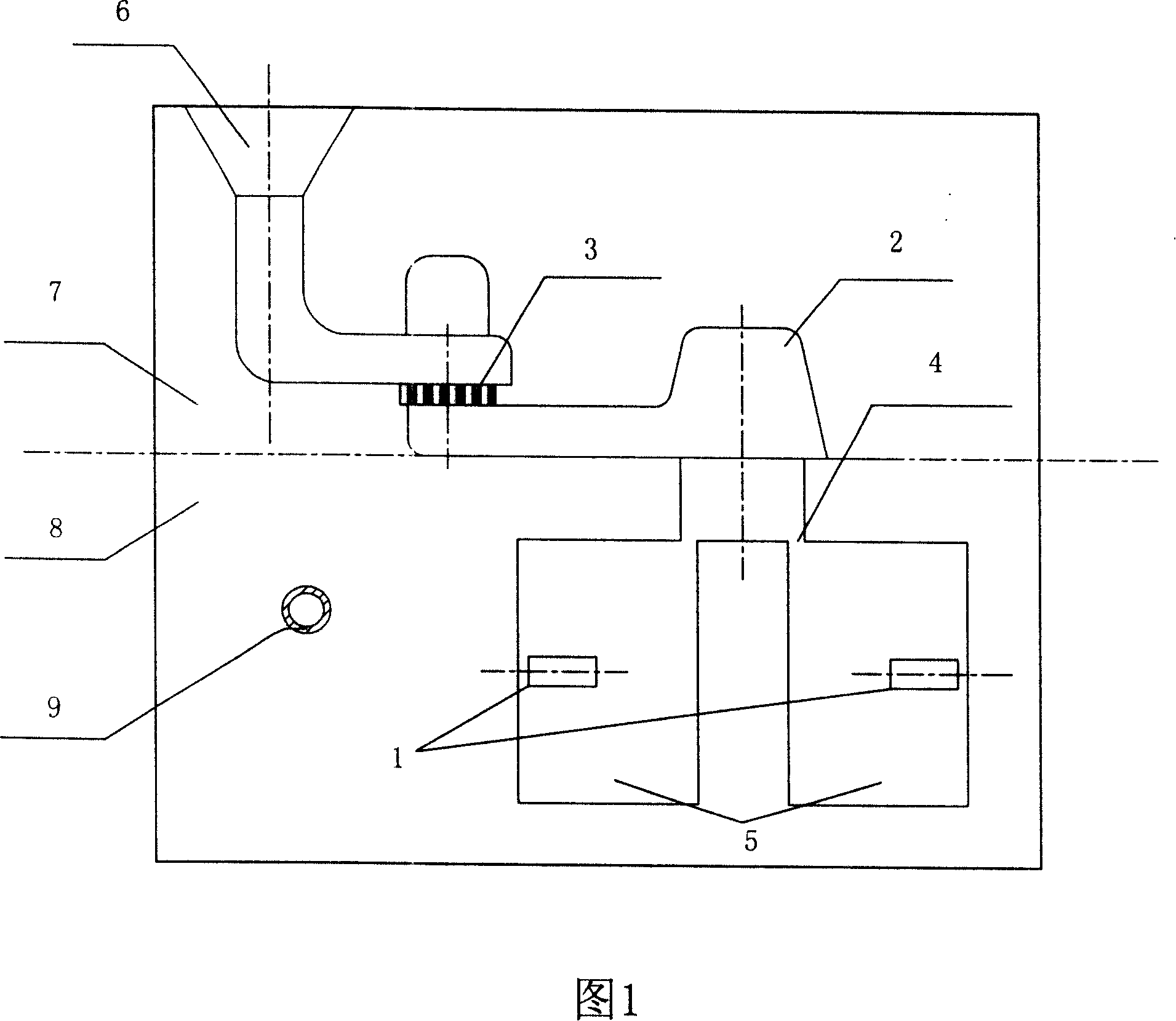

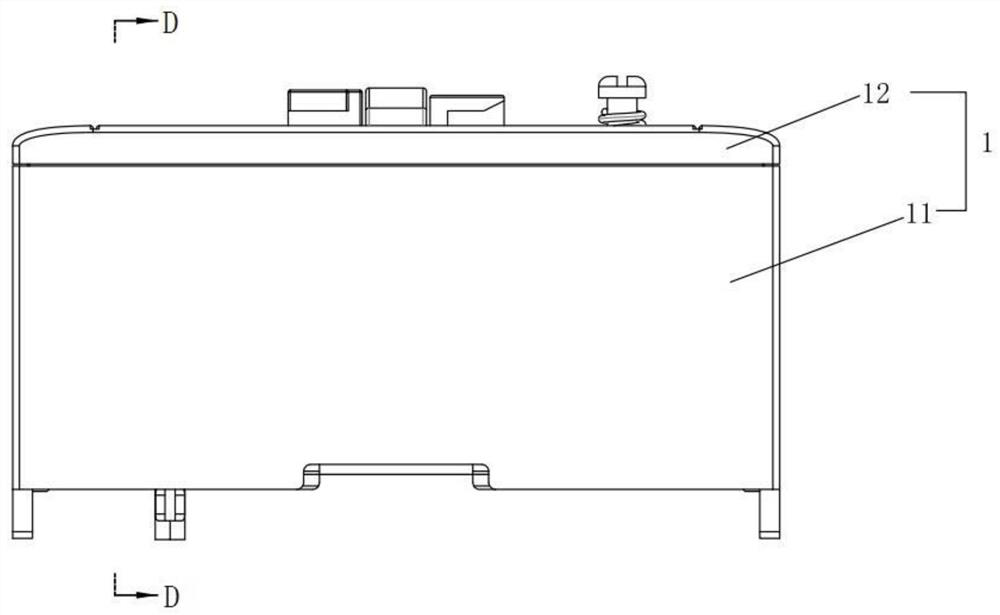

Air quantity adjusting apparatus for ageing furnace

The invention provides an air quantity adjusting apparatus for an ageing furnace. The apparatus comprises a flow deflector, an air quantity adjusting plate, an adjusting plate, an adjusting plate support an adjusting rod and an adjusting nut, the flow deflector is hinged to the air quantity adjusting plate, the air quantity adjusting plate is connected with the adjusting plate support, the adjusting plate support is hinged to the adjusting rod, the adjusting rod is provided with the adjusting nut, and the adjusting rod is arranged in a socket. The reasonable air quantity adjustment of the temperature change of circulating hot air in all positions in the furnace is carried out by the air quantity adjusting apparatus for the ageing furnace, so the temperature in the furnace tends to consistency, and no deformation or oxidation is realized. Block making does not take the influences brought by thermal expansion into account, so the temperature field of all areas in the furnace can be effectively adjusted, thereby a problem of the unimproved aluminum product quality due to the long-term non-uniform temperature of the aluminum ageing furnace is well solved, and the defects of high defective index, large energy consumption and low material performance of an aluminum product are solved.

Owner:DANYANG JIANGNAN INDAL FURNACE

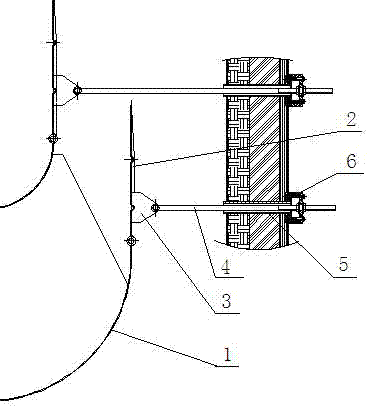

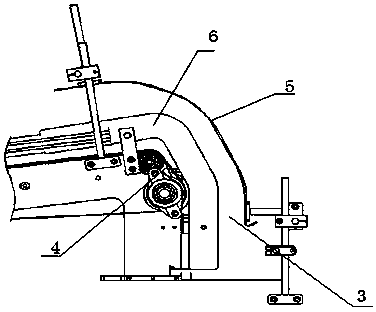

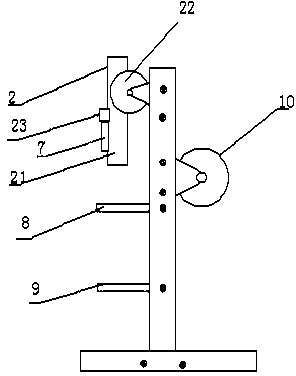

Novel length measuring and shearing device for soft magnetic stripes

InactiveCN105817698AAvoid efficiencyAvoid labor intensityShearing machine accessoriesSizingSoft mass

The invention discloses a novel soft magnetic strip length measuring and shearing device, which is characterized in that it includes a magnetic strip straightening device and a magnetic strip sizing conveying device. The magnetic strip straightening device consists of a 'T' shaped straightening table, a longitudinal straightening pulley and The horizontal correction pulley is composed of the magnetic strip sizing conveying device including a magnetic strip sizing device and a magnetic strip conveying device. The magnetic strip sizing device includes a cylinder, a shearing device and a support rod. The magnetic strip conveying device includes a protective shell, The clamping device, the magnetic strip guide groove and the servo motor, the protective shell are divided into a magnetic inlet and a magnetic outlet. A clamping device is installed at the magnetic inlet connected to the magnetic strip correction device, and another clamp is installed at the magnetic outlet. The clamping device and the magnetic strip sizing device, the magnetic strip guide groove is installed between the two clamping devices, and the servo motor is installed on the side of the protective shell. The invention can continuously cut high-precision magnetic strips, has stable structure and beautiful appearance, and is suitable for continuously providing high-precision magnetic strips in the production of door seals.

Owner:ANHUI HIGASKET PLASTICS CO LTD

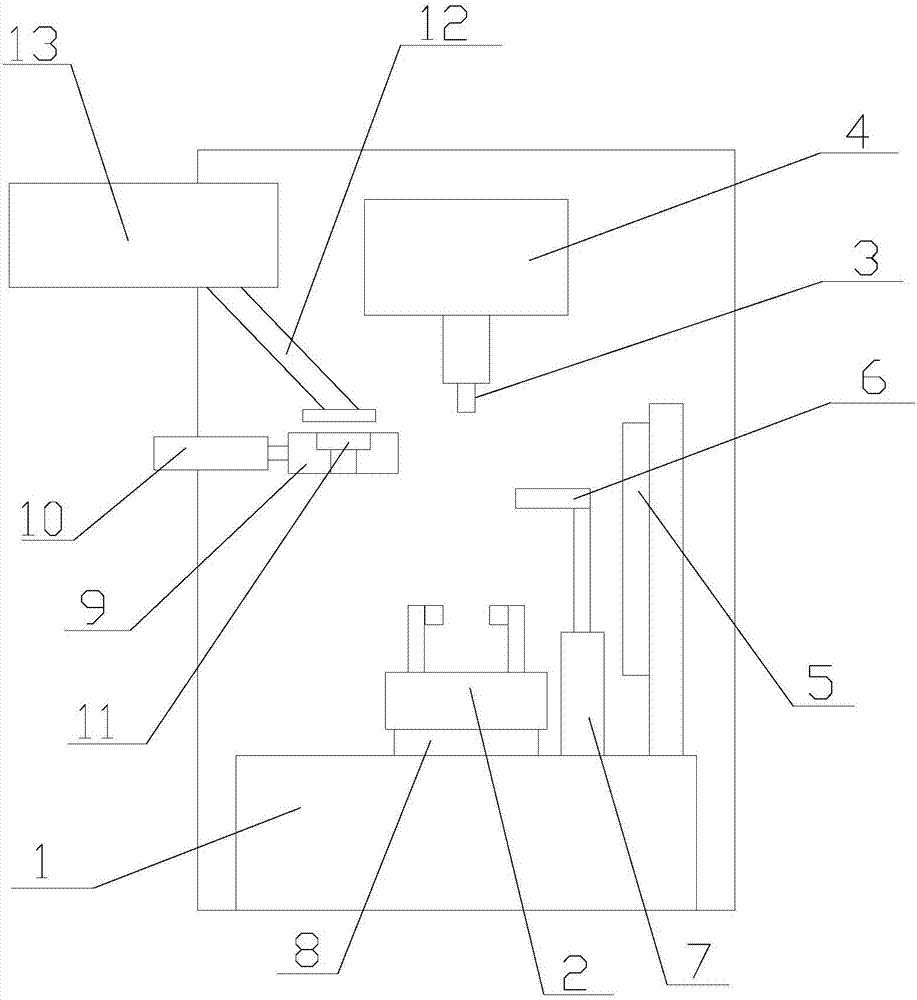

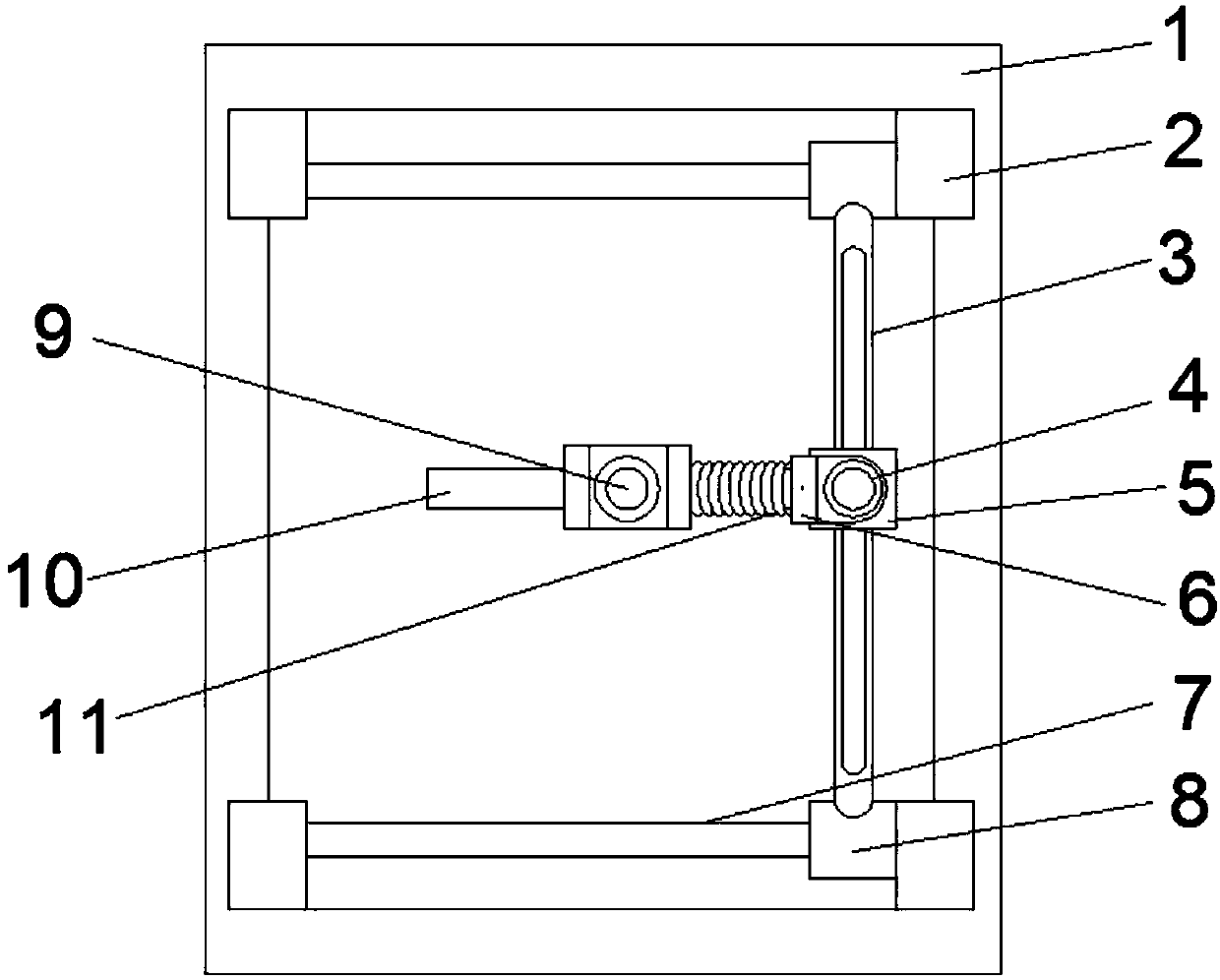

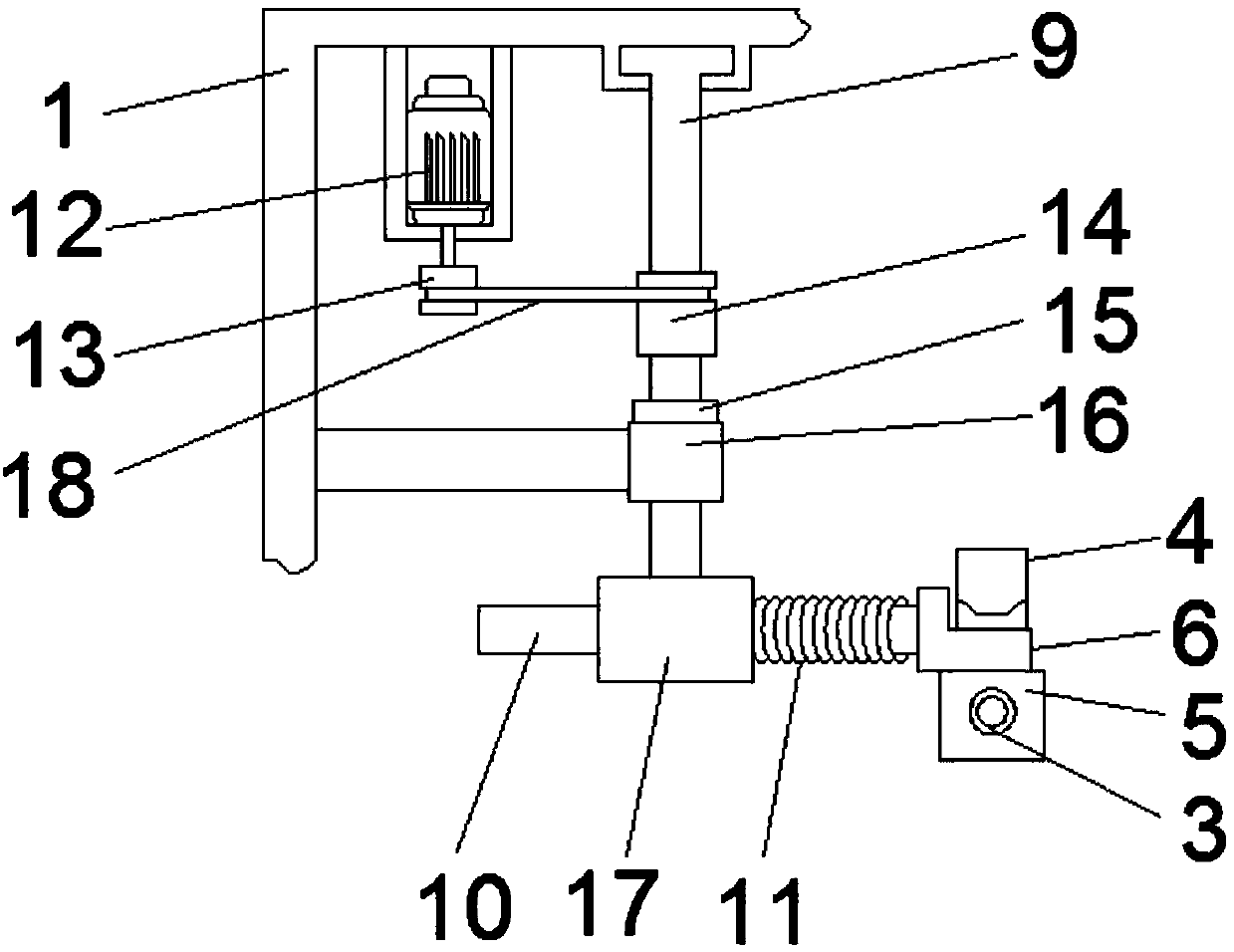

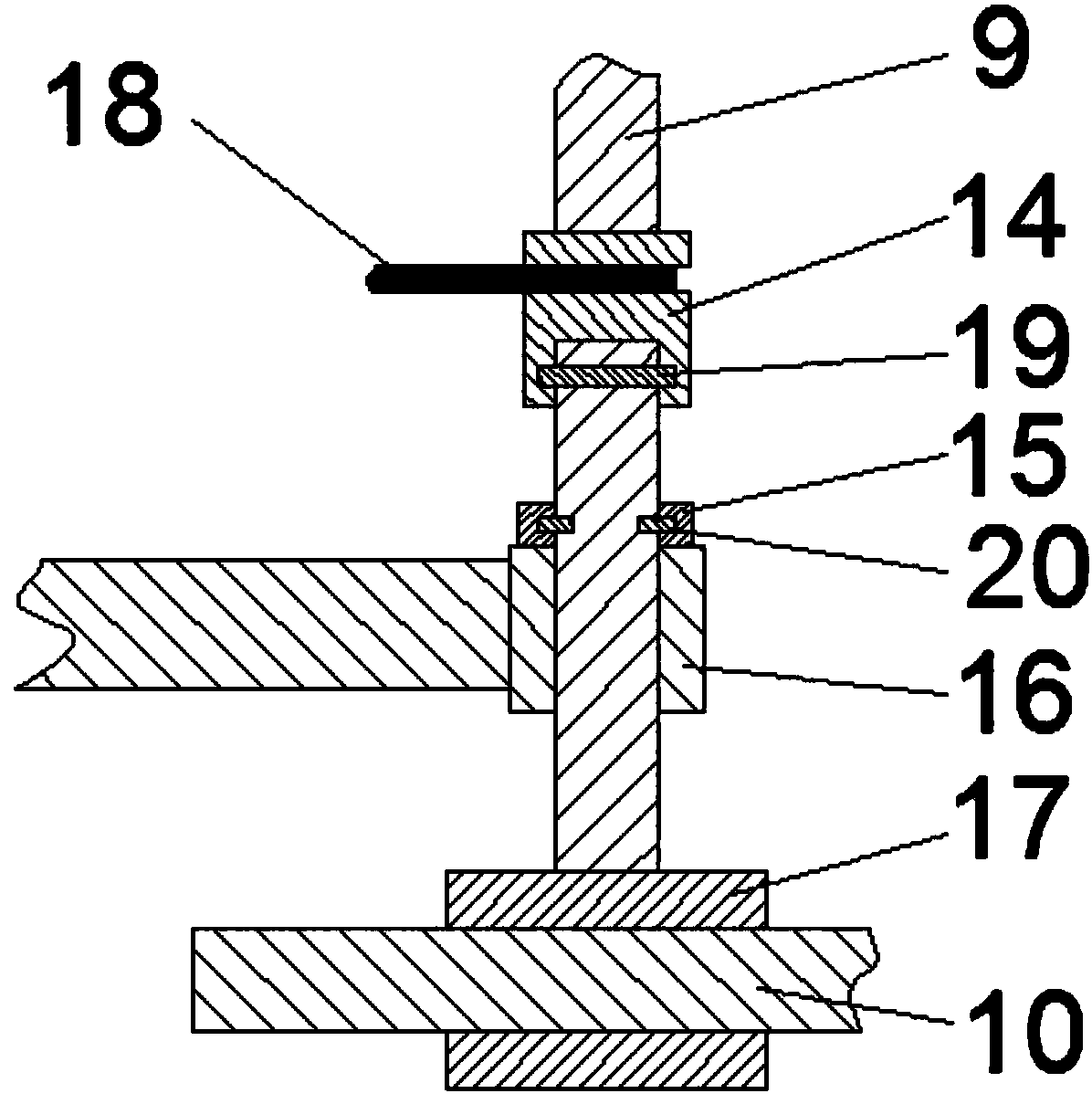

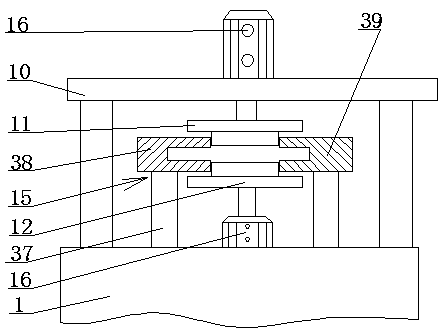

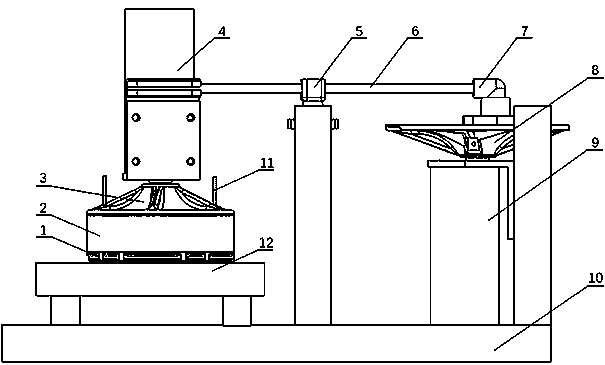

Bearing and shaft sleeve press

InactiveCN107570994ASolve the high scrap rateHigh precisionMetal working apparatusEngineeringMechanical engineering

The invention provides a bearing and shaft sleeve press. The bearing and shaft sleeve press comprises a base; a bearing fixing frame is arranged on the base; a pressing head is arranged above the bearing fixing frame; a pressing cylinder is arranged at the upper end of the pressing head; pressing position detecting devices are arranged on two sides above the bearing fixing frame, and are associated with the pressing cylinder; the pressing travel length of the pressing cylinder is controlled through the pressing position detecting devices; limiting stoppers are arranged beside the pressing position detecting devices; and the positions of the limiting stoppers are adjusted through height adjusting devices arranged at the lower ends. The position of a bearing is fixed through the bearing fixing frame; the pressing head is driven to press a shaft sleeve through the pressing cylinder; the pressing position detecting devices and the limiting stoppers are provided for limiting the pressing degree, so that the mounting position precision of the shaft sleeve is improved, and the scrap rate is prevented from increasing; and a shaft sleeve placing table and a shaft sleeve conveying rail are provided for automatically placing the shaft sleeve, so that the safety is improved.

Owner:洪泽白马湖农业科技有限公司

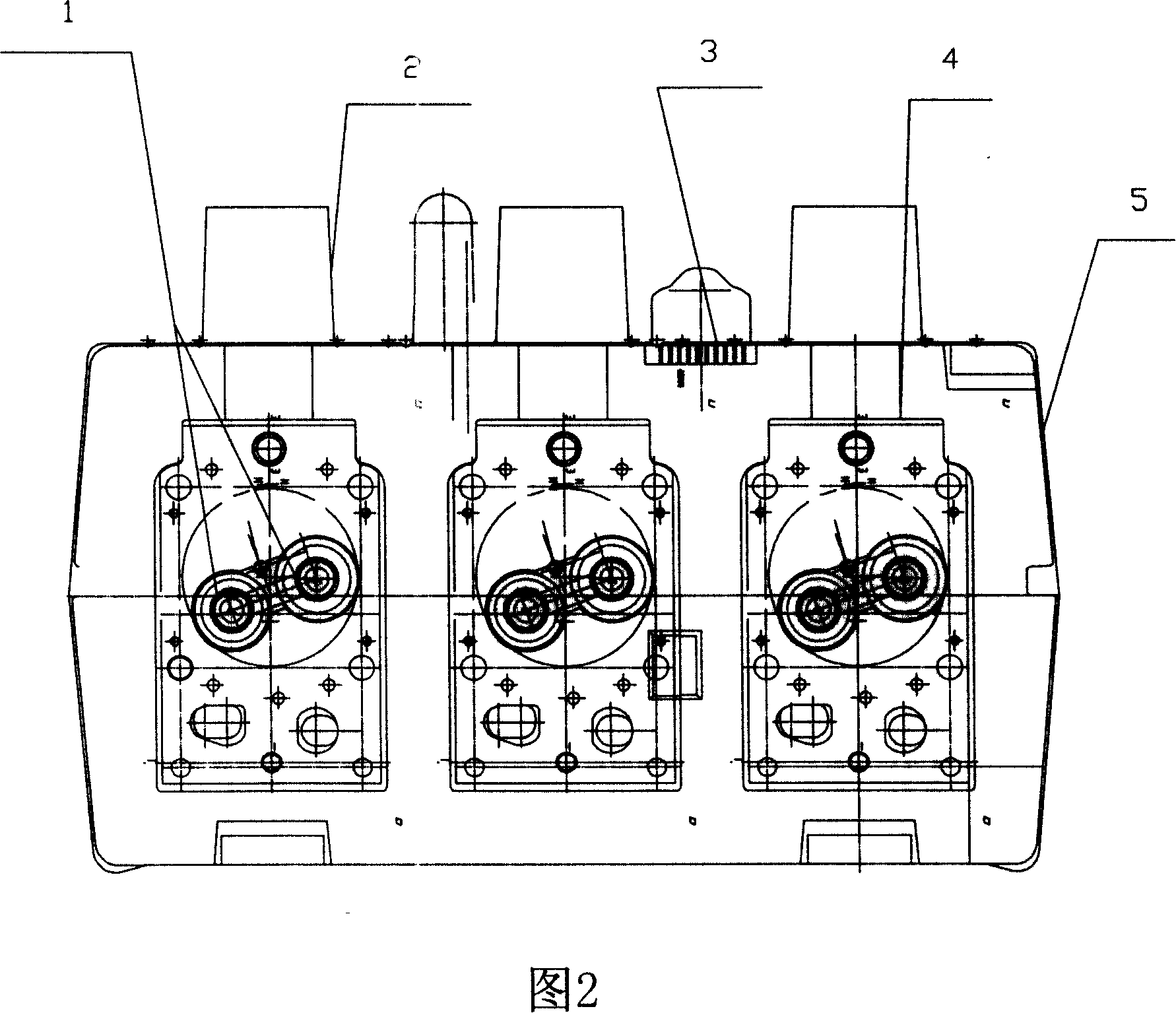

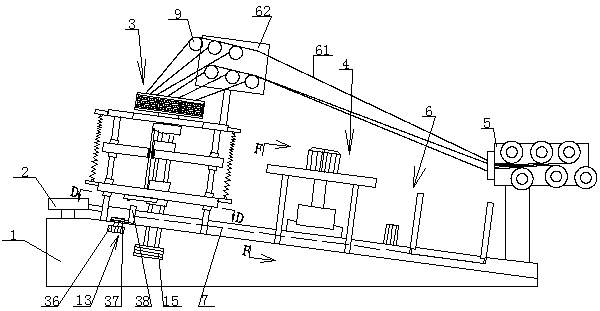

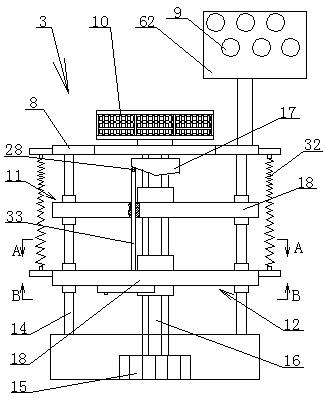

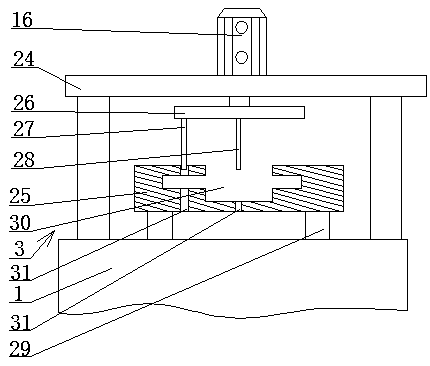

Automatic pin inserting machine of network transformer

PendingCN108616026AIngenious designSolve the high scrap rateContact member assembly/disassemblyInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to an automatic pin inserting machine of a network transformer, and belongs to the technical field of manufacturing equipment of the network transformer. The automatic pin inserting machine of the network transformer consists of a machine base, a controller, a vibration feeding plate, a pin inserting apparatus, a shaping apparatus, a material rolling frame and a packaging apparatus; the shaping apparatus is arranged on the inclined surface of the machine base; the pin inserting apparatus is arranged on the inclined surface, on one side of the shaping apparatus, of the machine base; the vibration feeding plate is arranged on one side of the pin inserting apparatus; the packaging apparatus and the material rolling frame are arranged on the other side of the shaping apparatus in sequence; a workpiece guiding groove is formed in the inclined surface of the machine base; the upper end of the workpiece guiding groove is connected with the outlet of the vibration feedingplate; and the pin inserting apparatus, the shaping apparatus and the packaging apparatus are electrically connected with the controller separately. The automatic pin inserting machine of the networktransformer is skillful in design, convenient and practical, solves the problems of high rejection rate and single function of the existing pin inserting machine and satisfies need of enterprise production and use.

Owner:湖北磁创电子科技有限公司 +1

Trajectory auxiliary device of laser cutting machine

InactiveCN108031982ANovel structureSolve the high scrap rateLaser beam welding apparatusTransmission beltLaser cutting

The invention discloses a trajectory auxiliary device of a laser cutting machine. The trajectory auxiliary device of the laser cutting machine includes a machine body, a suspension bearing is arrangedat the middle of the inner wall of the upper end of the machine body and is sleeved with a shaft sleeve, an outer ring of the upper end of the shaft sleeve is provided with gear teeth, and a motor isarranged at the side, close to the suspension bearing, of the inner wall of the upper end of the machine body; a belt wheel is fixedly connected with an output shaft at the lower side of the motor, the belt wheel is movably connected with the shaft sleeve through a transmission belt, the suspension bearing is sleeved with a support cylinder which is arranged at the lower side of the shaft sleeve,a transmission block is fixed to the lower end of the suspension bearing, a guide rod penetrates through the transmission block, a step-shaped block is fixed to one end of the guide rod, the guide rod is sleeved with a spring between the step-shaped block and the transmission block, a mounting device penetrates through the step-shaped block, the upper end of the mounting device is connected withan emitter in a clamped mode, and a sliding block is fixedly connected to the lower end of the mounting device. The trajectory auxiliary device of the laser cutting machine is novel in structure, anda cutting trajectory control device of the laser cutting machine is provided through limit transmission.

Owner:HEFEI YOUYI MEDIA TECH CO LTD

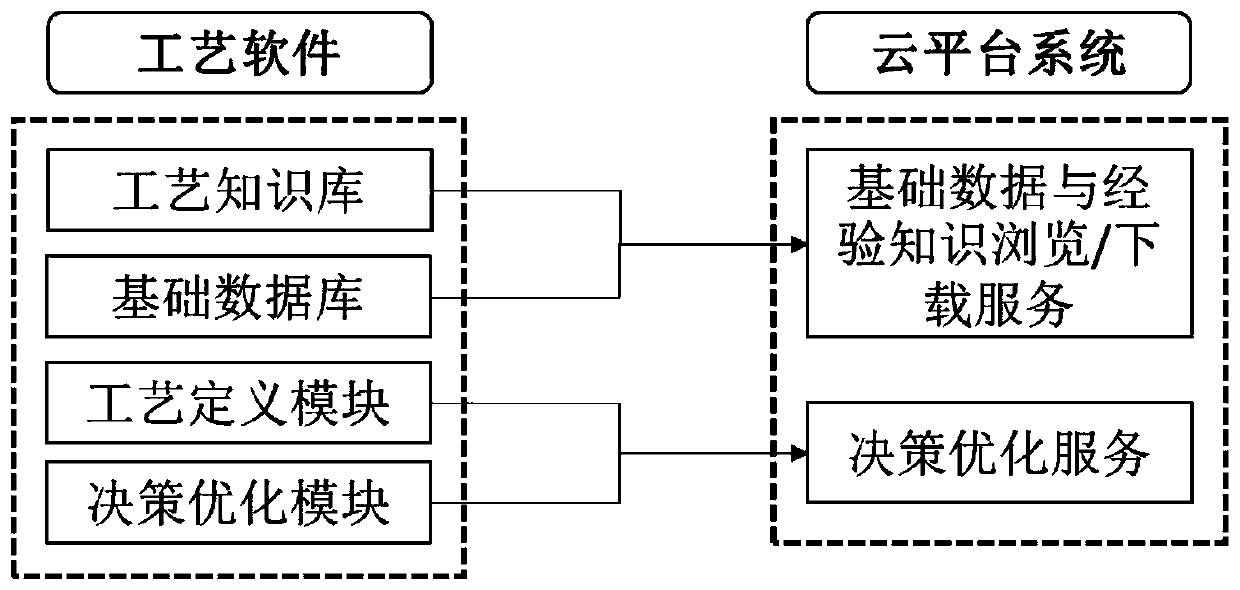

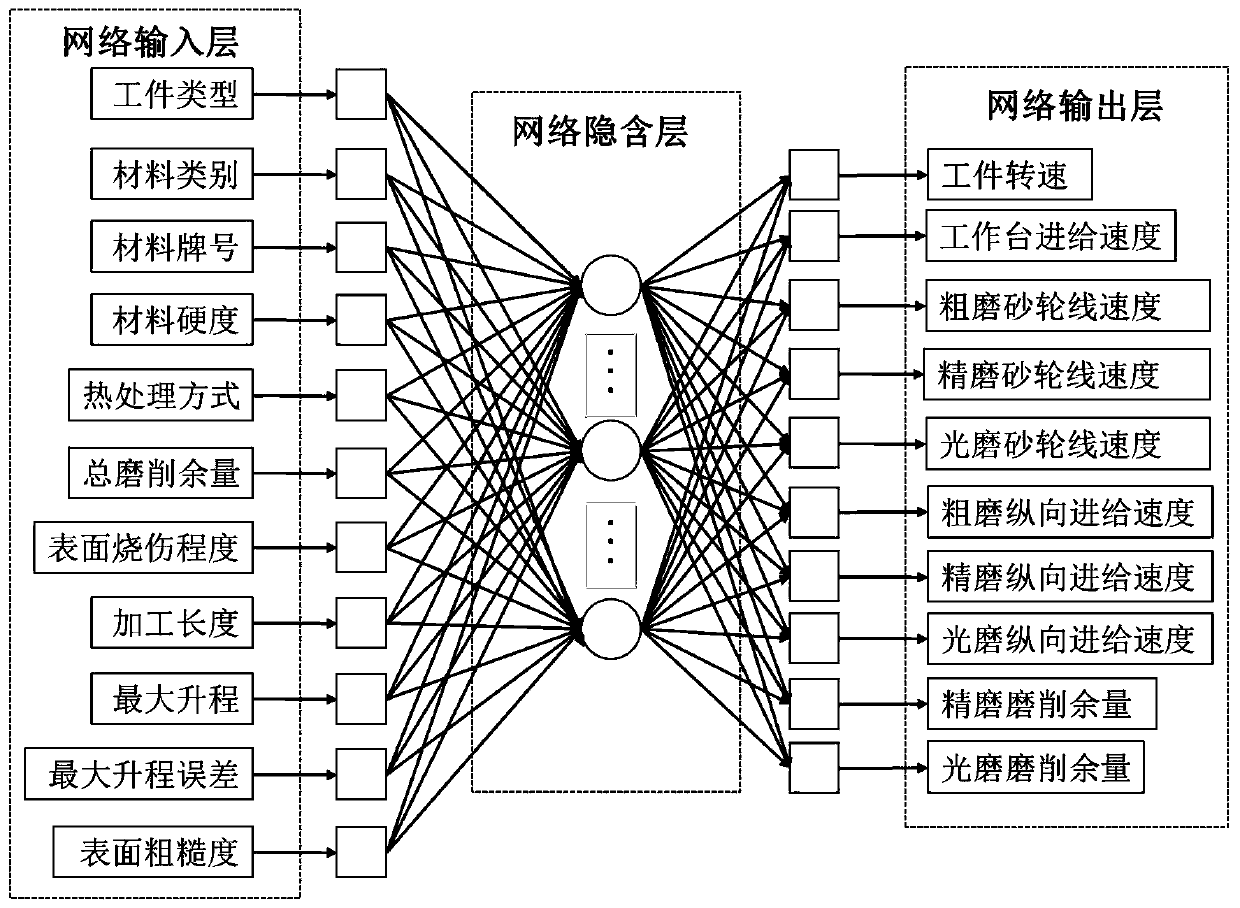

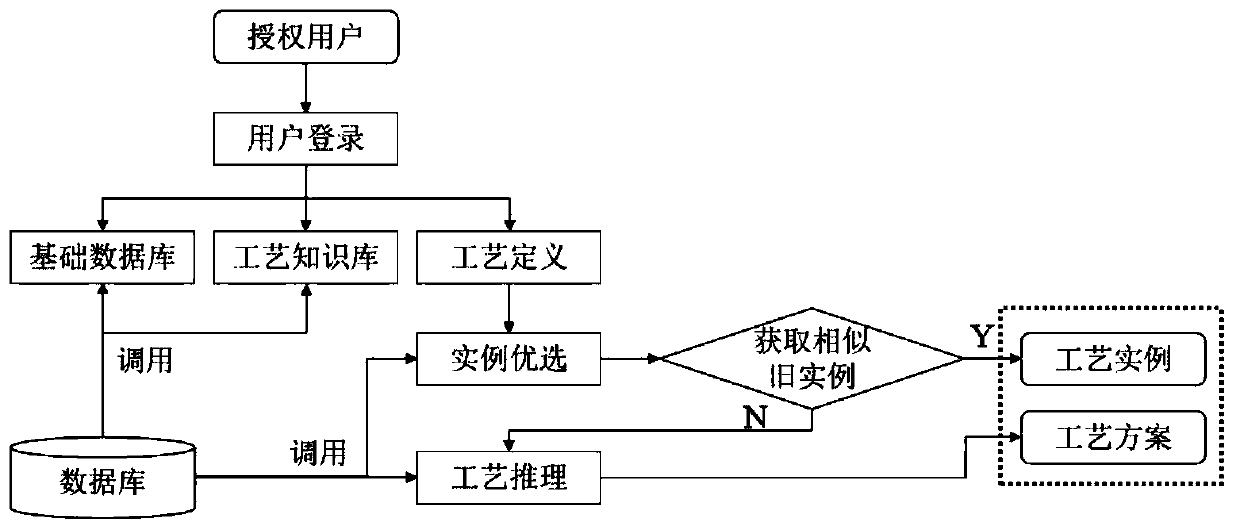

Intelligent decision-making cloud service method and system for numerical control grinding processing of camshaft

ActiveCN110216553AEfficient grindingSolve process problemsBelt grinding machinesAutomatic grinding controlNumerical controlSoftware

The invention specifically discloses an intelligent decision-making cloud service method and system for camshaft numerical control grinding processing. The method comprises the following steps that the requirements of intelligent decision-making service for the grinding process of a camshaft are analyzed, an intelligent decision-making service demand model is established, an intelligent decision-making cloud service process is designed, a front-end interactive webpage of a cloud platform system is developed, interaction with a user is realized, the process software function on the server is called through the front-end interactive page, modules of the process software are changed into services to be provided to the user, and the data and service sharing is realized. The system comprises avirtual resource layer, a data service layer and a user layer. According to the cloud service method and system, the knowledge data of the camshaft grinding process and the intelligent decision software are subjected to reclamation and systematized expression, and basic data and experience knowledge browsing / downloading service and decision-making optimization service are provided for the camshaftgrinding process in the cloud manufacturing mode, and the efficiency of the technological scheme intelligent decision-making service and the precision of camshaft grinding processing are improved.

Owner:HUNAN UNIV OF SCI & TECH

Novel packaging machine for massive food

ActiveCN104210682AImprove packaging efficiencySmooth flipWrapper twisting/gatheringSuccessive articlesFood packagingEngineering

The invention provides a novel packaging machine for massive food, and relates to the technical field of food packaging machines. A material is packaged in the film sending process, so the packaging efficiency is improved; in the packaging process, the positions of patterns on the packaging film can be well controlled, so that the patterns are packaged in the specific positions of the material, and thus the packaged tissue is more attractive, and the needs of daily life of people are met.

Owner:SUZHOU MULTITECH AUTOMATION EQUIP CO LTD

Ceramic glaze decoration method

The invention provides a ceramic glaze decoration method. The method adopting a laser decoration mode mainly comprises the following steps: 1, uniformly mixing a pigment with a glaze to prepare a color glaze slip; 2, directly or indirectly adhering the color glaze slip to a glaze to be decorated; 3, drying the color glaze slip; 4, adjusting laser parameters, and scanning the adhered dry color glaze slip by using high energy laser; and 5, flushing by using clear water. A bright-color customized character or pattern is left in the laser scanning position. The method can be used for marking the surface of a finished product white ceramic glaze and drafting the customized color pattern; and compared with traditional kiln roasting, the method provided by the invention has the advantages of energy saving and environmental protection due to small laser power.

Owner:CHONGQING UNIV

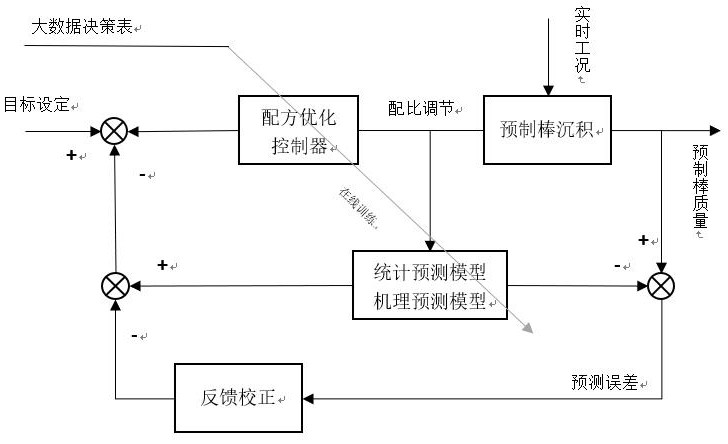

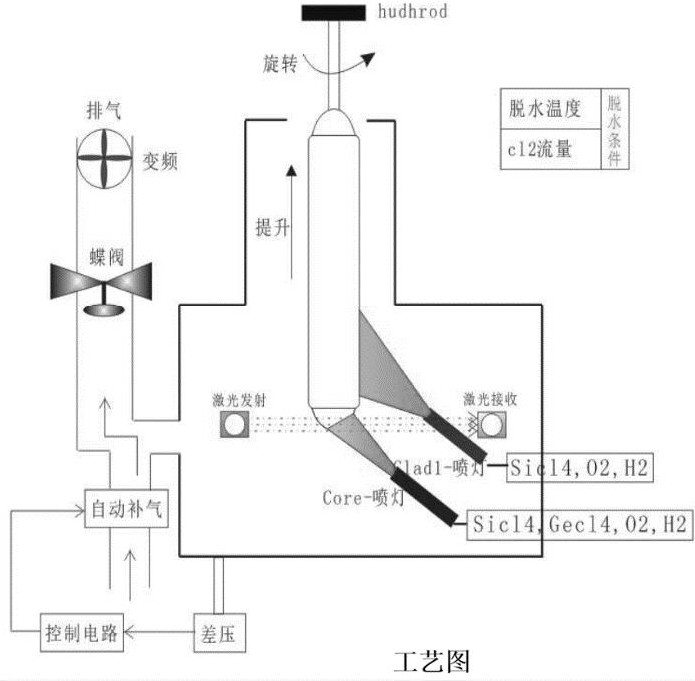

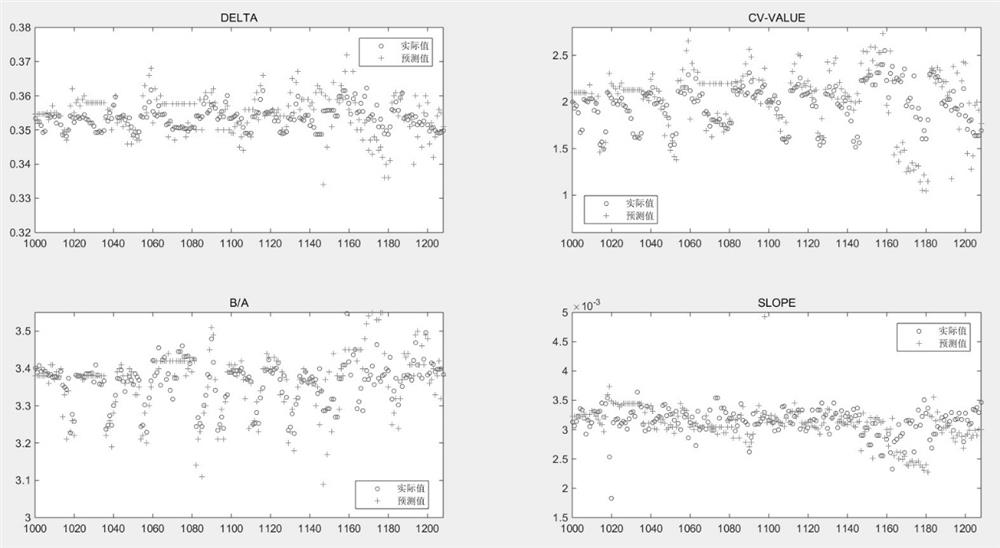

Intelligent method for optical fiber preform deposition process based on big data model prediction control framework

ActiveCN112053019AAchieve regulationQuality improvementResourcesNeural architecturesIndustrial engineeringNeural network nn

The invention discloses a method for realizing intellectualization of an optical fiber preform deposition process. Manual adjustment in the deposition process causes large fluctuation of quality key parameters of the optical fiber preform, resulting in high rejection rate of the preform, and in order to realize optimal control of the deposition process, the invention provides an intelligent methodbased on a model predictive control framework. Firstly, a decision table is formed based on historical production operation records, factors influencing the quality of the optical fiber preform are mined, a neural network online quality prediction model is established, secondly, a formula proportion is adjusted based on a prediction result to achieve rolling optimization, and then the formula proportion in the deposition process is fed back and corrected according to a PK test result to achieve the purpose of stably controlling the quality of the optical fiber preform. Finally, a field operation result proves the effectiveness of the method. The intelligent method provided by the invention is simple to operate and high in environmental change adaptability, the quality of the preform is accurately predicted, and the maximization of enterprise benefits is facilitated.

Owner:湖南纤云光电科技有限公司

Method, device and equipment for controlling FPGA board and storage medium

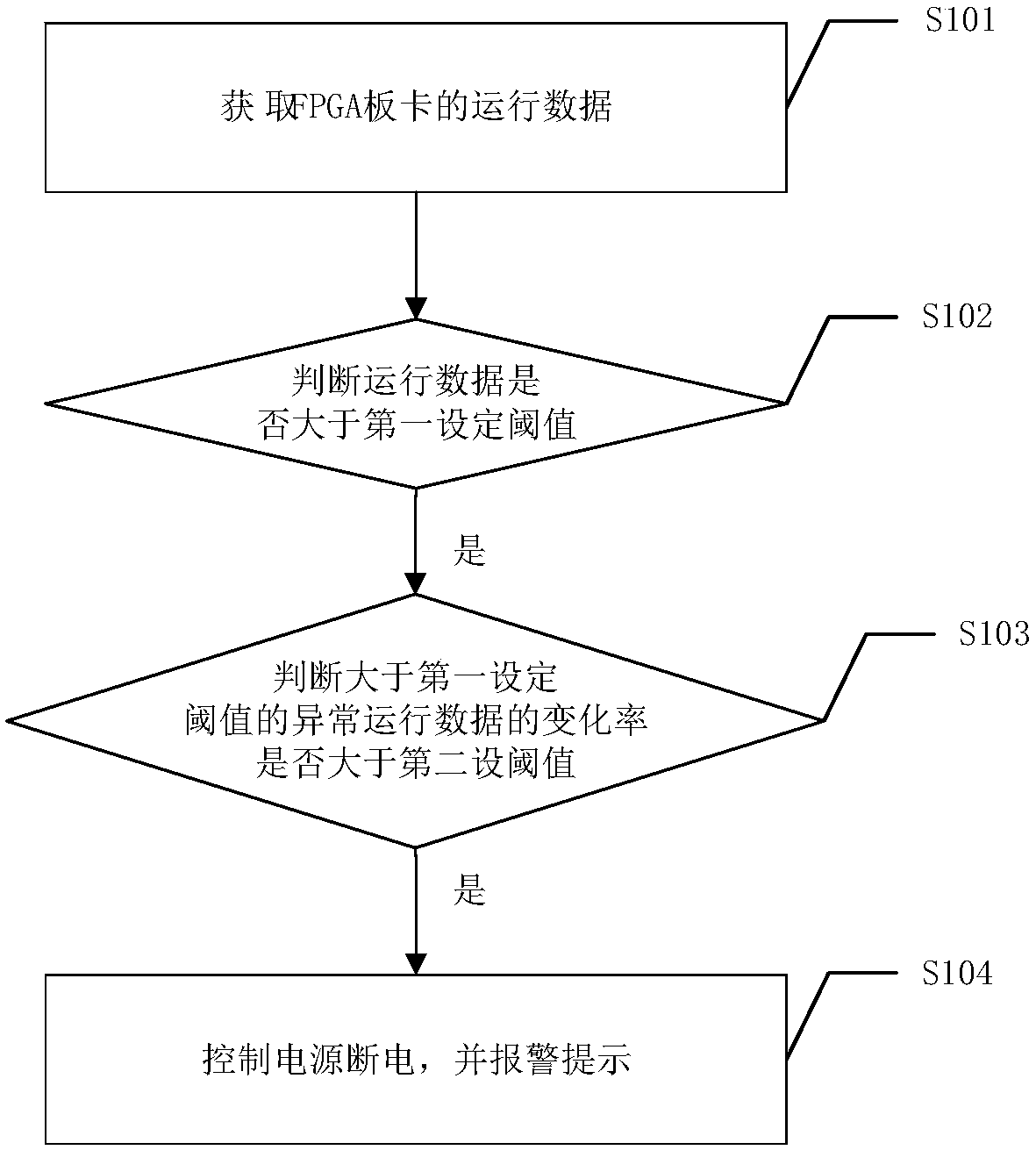

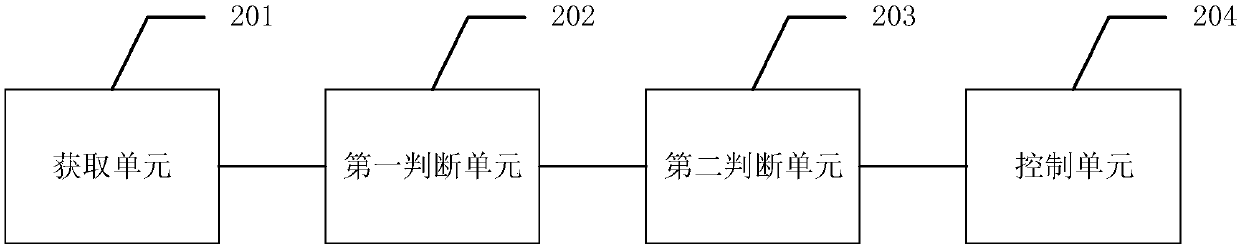

InactiveCN108052436ASolve the high scrap rateReduce scrap rateHardware monitoringNon-redundant fault processingRejection rateComputer science

The invention discloses a method for controlling an FPGA board. The method comprises the steps of obtaining running data of the FPGA board and judging whether the running data is larger than a first set threshold value or not; if yes, judging whether the change rate of abnormal running data larger than the first set threshold value is larger than a second set threshold value or not; if yes, controlling a power source to be switched off and conducting alarm prompt. By means of the method, the relevant running data of the FPGA board can be obtained in the running process of the FPGA board, whenit is judged that the obtained running data is larger than the first set threshold value and the change rate of the abnormal running data larger than the first set threshold value is larger than the second set threshold value, the power source is timely controlled to be switched off, and relevant staff are alarmed and prompted. The problem that a traditional FPGA board is high in rejection rate issolved, and the rejection rate of the FPGA board can be lowered. Besides, the invention further discloses a device and equipment for controlling the FPGA board and a storage medium. The device and equipment for controlling the FPGA board and the storage medium also have the advantages above.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

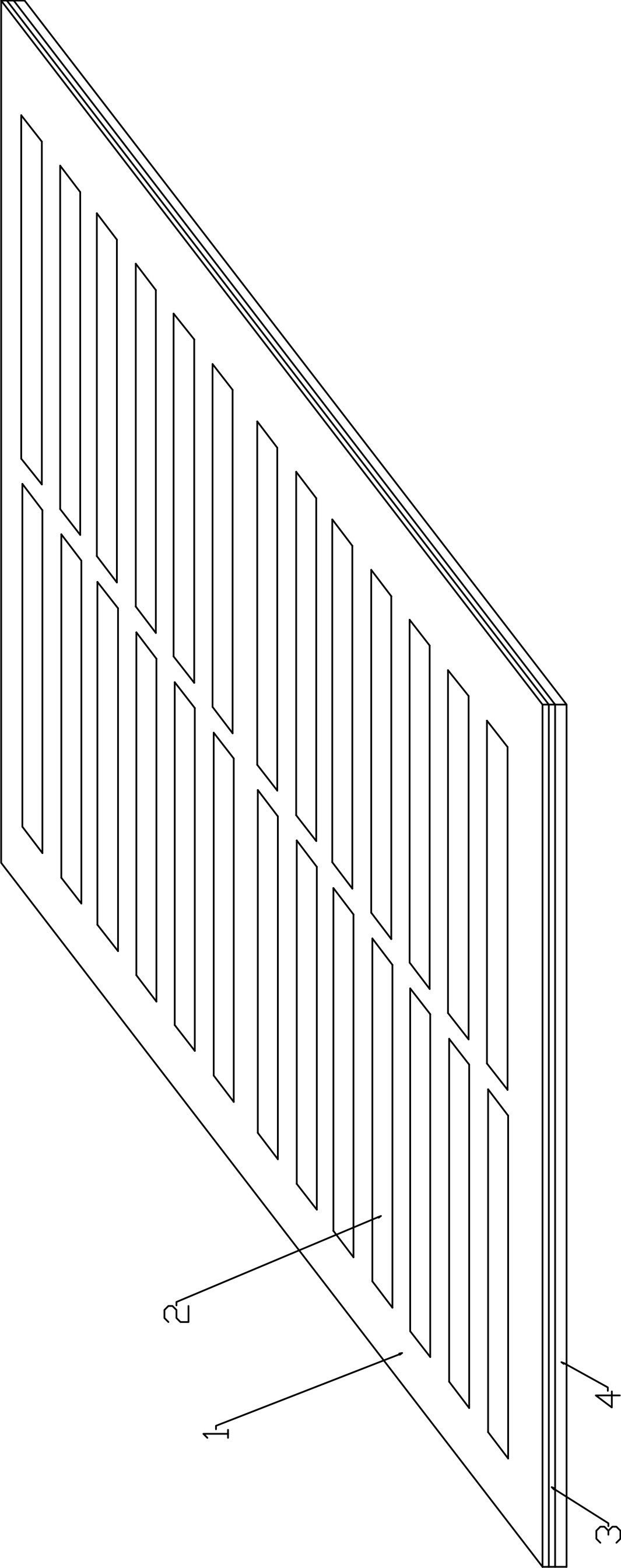

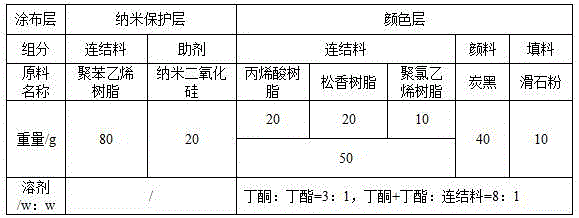

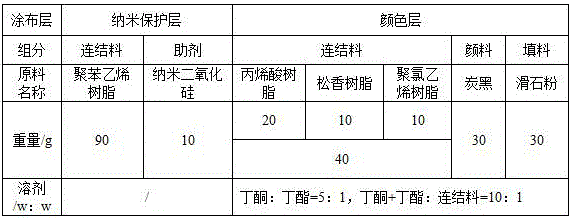

Hot stamping foil with low-temperature printing and high-temperature sterilizing properties and preparation method thereof

ActiveCN106274118ASolve temperature problemsSolve productivityDuplicating/marking methodsInksHot stampingEngineering

The invention belongs to the technical field of hot stamping materials, and particularly discloses hot stamping foil with the low-temperature printing and high-temperature sterilizing properties. The hot stamping foil is composed of a tape base and a thermal transfer printing layer applied to the surface of the other side of the tape base, and the thermal transfer printing layer is composed of a nanometer protection layer and a color layer which are sequentially applied to the surface of the tape base; the nanometer protection layer is prepared from, by weight, 80%-90% of bonding material and 10%-20% of auxiliary. According to the hot stamping foil, the nanometer protection layer is designed, content is printed through a hot stamping machine, and the surface of the color layer is covered with the protection layer after printing. The hot stamping foil has the advantages that printing can be conducted at the low temperature lower than 120 DEG C, and the printed content can resist 121-DEG C high-temperature sterilizing and is widely applied to printing of information such as character and pattern identifiers, drug safety codes, production dates and batch numbers on the surfaces of various medical infusion soft bags.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

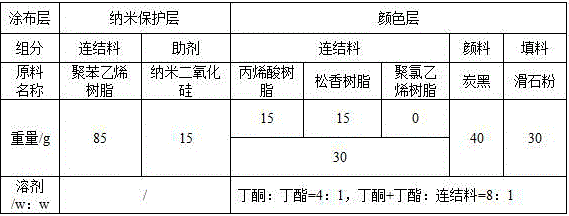

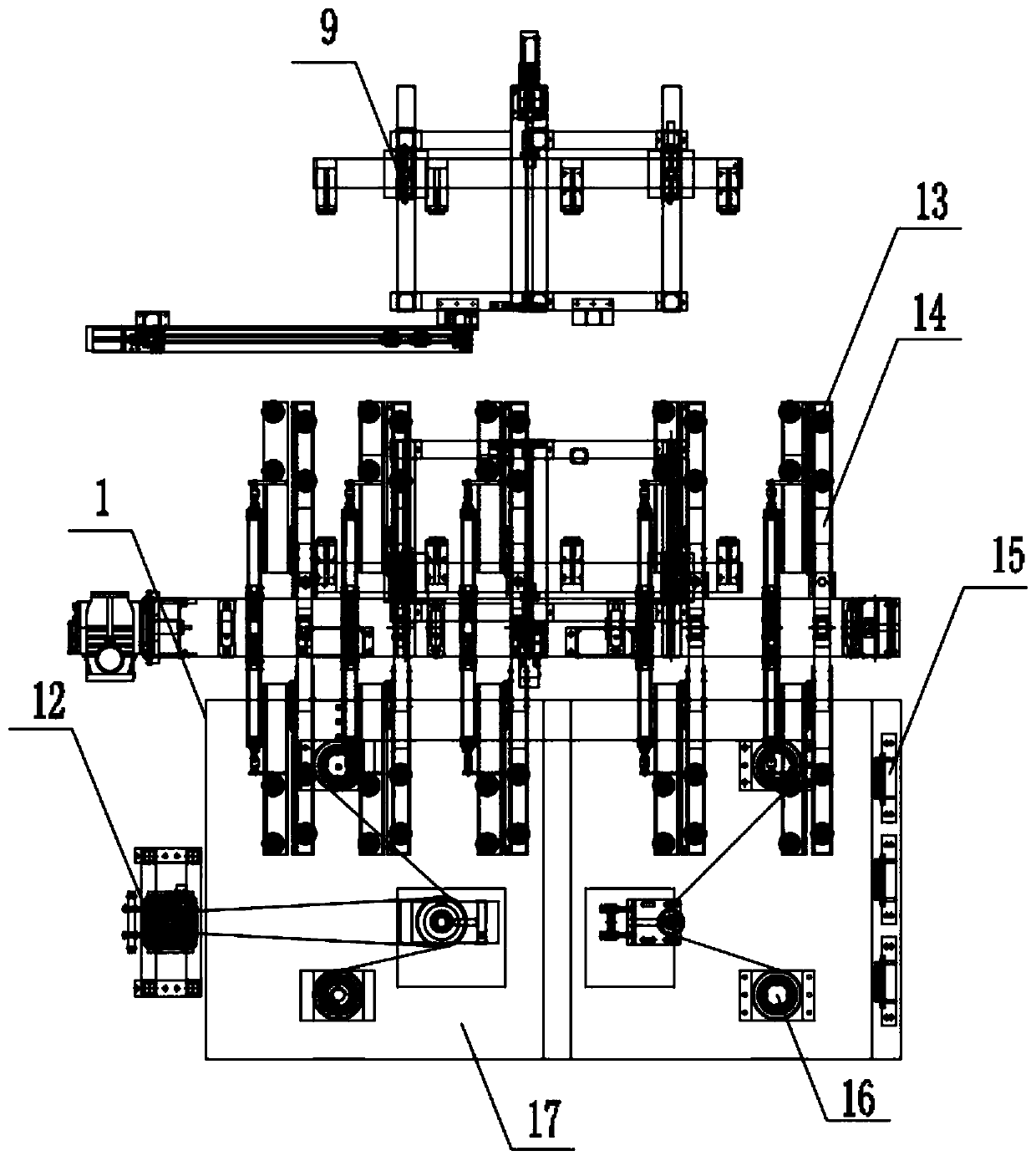

High-efficiency flexible punching and bending anti-theft door plate forming line

InactiveCN111299417ASimple structureEasy to operateMetal-working feeding devicesPositioning devicesSprocketServo

The invention discloses a high-efficiency flexible punching and bending anti-theft door plate forming line. The high-efficiency flexible punching and bending anti-theft door plate forming line comprises a feeding machine, the feeding machine comprises a base platform, one side of the upper end of the base platform is fixedly provided with a first servo motor and a chain wheel lead screw driving assembly through bolts, the output end of the first servo motor is in transmission connection with the input end of the chain wheel lead screw driving assembly through a belt, and the top end of the chain wheel lead screw driving assembly is fixedly provided with a lifting platform. According to the high-efficiency flexible punching and bending anti-theft door plate forming line, the structure is simple, the operation is convenient and rapid, by designing special bending machines and optimally arranging various combined bending machines, the automatic forming process can be effectively optimized, the probability that the bending resilience rate is too large when an anti-theft door plate is machined is reduced, and continuous automatic machining of the anti-theft door plate is realized. Compared with the prior art, the problems of high rejection rate and difficulty in mass production of anti-theft door plates machined through an existing forming line are solved through the high-efficiencyflexible punching and bending anti-theft door plate forming line, the machining cost of the anti-theft door plates is effectively reduced, and the anti-theft door plates are convenient to popularizeand use.

Owner:普瓦尼尼智能装备股份有限公司

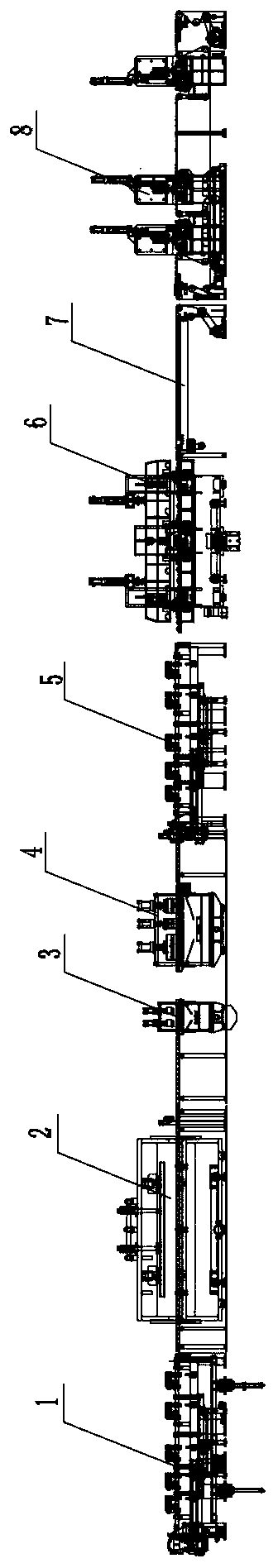

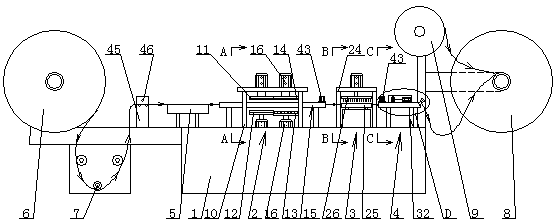

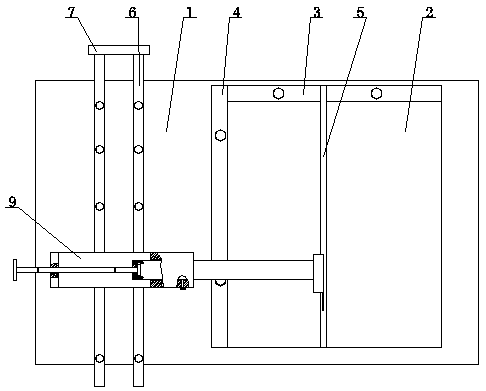

Packaging carrier tape producing device

PendingCN108058401ARealize continuous productionSolve efficiency problemsBeltsMetal working apparatusEngineeringRejection rate

The invention relates to a packaging carrier tape producing device and belongs to the technical field of packaging carrier tape producing equipment. The packaging carrier tape producing device is composed of a base, a controller, a former, a puncher and a tractor. The former is arranged on the base. A flattening table, a guider and a raw tape carrying reel are sequentially arranged on one side ofthe former. Guide rollers are arranged below the position between the raw tape carrying reel and the guider in a triangular mode. The puncher and the tractor are sequentially arranged on the other side of the former. A finished product winding reel is installed above one side of the tractor through a motor. A separation tape winding reel is arranged above the position between the finished productwinding reel and the tractor. The former, the puncher and the tractor are electrically connected with the controller. The packaging carrier tape producing device is simple in structure and ingenious in design. The problems that production efficiency is low and the rejection rate is high in the existing packaging carrier tape production process are solved, and the production and use requirements ofenterprises are met.

Owner:湖北磁创电子科技有限公司

Grinding device and method for producing semitransparent BGO scintillation crystal material

InactiveCN108972318ASolve the chippingSolve the collapseLapping machinesScintillation crystalsEngineering

The invention relates to a grinding device and method for producing semitransparent BGO scintillation crystal material. Rotation of double motors is converted into revolution and autorotation composite rotation motion, kinetic energy is transmitted to a workpiece to achieve a mechanical grinding purpose, and in this way, manual operation is replaced, and surface treatment is conducted on the workpiece.

Owner:侯琰昊

Packaging sponge cutting device

The invention relates to a packaging sponge cutting device, and belongs to the field of optical fiber packaging equipment. The packaging sponge cutting device is composed of a machine table, a cuttingplate, a transverse positioning strip, a longitudinal positioning strip and a cutting device, the cutting plate is fixedly arranged on the machine table, the transverse positioning strip and the longitudinal positioning strip are fixedly arranged on the cutting plate in a staggered mode, the cutting groove is formed in the cutting plate, the two ends of the cutting groove extend to the two ends of the cutting plate, a cutting device is arranged on the machine table on one side of the cutting plate in a sliding mode through a guide sliding rail, and a positioning block is fixedly arranged at the end of one end of the guide sliding rail. The packaging sponge cutting device is simple in structure and convenient to use, the cutting work of the packaging sponge can be completed in a mechanicalcutting mode, the problems that the labor intensity is large and the rejection rate is high in the existing cutting mode are solved, and the requirements of enterprise production and use are met.

Owner:湖北辰朗科技有限公司 +1

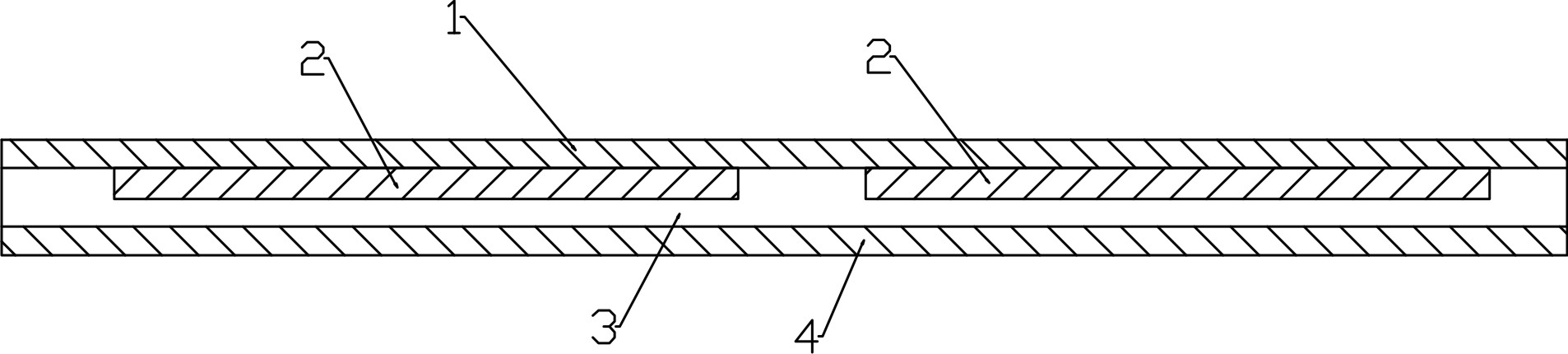

Method for loading plasma enhanced chemical vapor deposition equipment and glass panel

InactiveCN101770923AReduce frictionSolve the high scrap rateElectric discharge tubesFinal product manufactureWaste productEconomic benefits

The invention discloses a method for loading plasma enhanced chemical vapor deposition equipment and a glass panel, comprising the following steps of: improving the sizes of the slot and the supporting plate wheel in the equipment, wherein the pitch between the inner wall of the slot and the polar plate is greater than the thickness of the glass panel, and the width of the supporting plate wheel is greater than the thickness of the glass panel; further fixedly connecting a clamp mechanism supporting plate outside the U-shaped aluminum grooves on both ends, wherein the clamp mechanism supporting plate is fixed with clamp mechanism brackets, and a clamp mechanism is connected between the clamp mechanism brackets corresponding on both ends; when loading, firstly, loading the lower locking strip clinging to both sides of the lower part of the polar plate, then, loading the glass panel and the upper locking strip on both sides of the polar plate; taking out all the upper and lower locking strips out after loading the glass panel, and finally rotating the clamp mechanisms from the lower part to the upper part with 90 degrees, so that the glass panel leans against both sides of the polar plate to be loaded. The invention can reduce the friction between the glass panel and the polar plate to a maximum extent and ensure the quality of the coating film, thereby reducing the defective index and improving the economic benefit.

Owner:TIANJIN UNIV

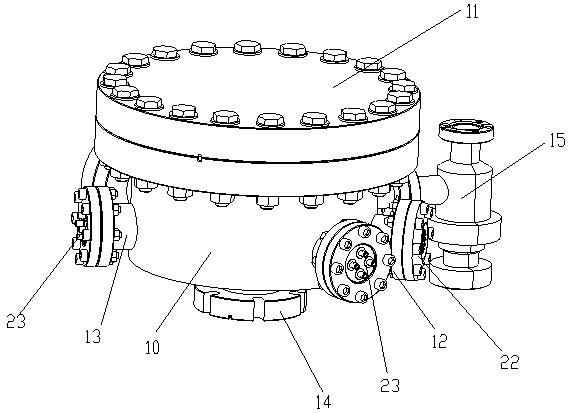

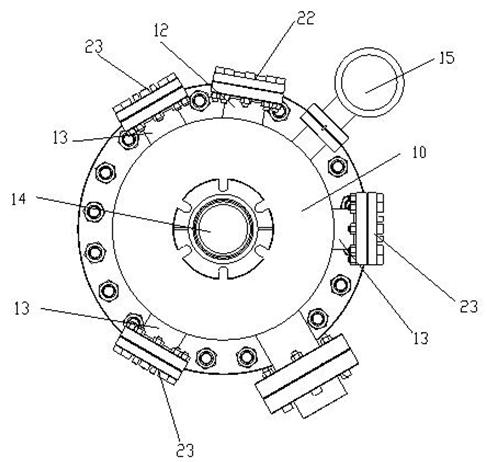

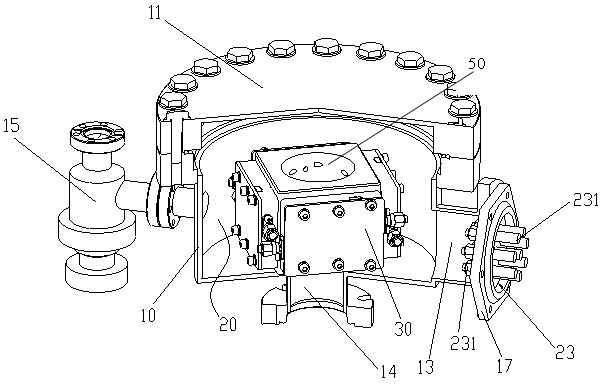

Ultralow-temperature vacuum multi-channel combined type dewar

ActiveCN102109087AFew partsSolve the contradiction of high leakage rateContainer filling methodsPressure vesselsWorking environmentWaste product

The invention discloses an ultralow-temperature vacuum multi-channel combined type dewar which comprises a dewar flask, wherein the dewar flask is internally provided with an air tightness chamber; the side wall of the dewar flask is provided with a multi-channel radio frequency coaxial air-tight seal adapter and a multi-core low frequency air-tight seal connector which are connected to the inner circuits and outer circuits of the dewar, thus the external ports of the dewar flask are reduced, and the integral leakage rate of the dewar is lowered greatly. According to the business necessities, the multi-channel radio frequency coaxial air-tight seal adapter can be distributed on the side wall of the dewar flask by multiple combination methods, the wire cable layout in the dewar flask can be optimized, and the insertion loss and heat dissipation of the wire cable in the dewar can be lowered; and the difficulty of providing an ultralow temperature and long-term high-vacuum degree pressure maintaining working environment is solved effectively, the operation risk occurred during the welding of the multi-channel radio frequency coaxial air-tight seal adapter, the multi-core low frequency air-tight seal connector and the dewar flask is avoided by adopting a flange air-tight connection, the generality and standardization degree of components are improved, the waste product rate is reduced, and the manufacturing, using and maintaining costs of equipment are lowered.

Owner:广东特信超导技术有限公司

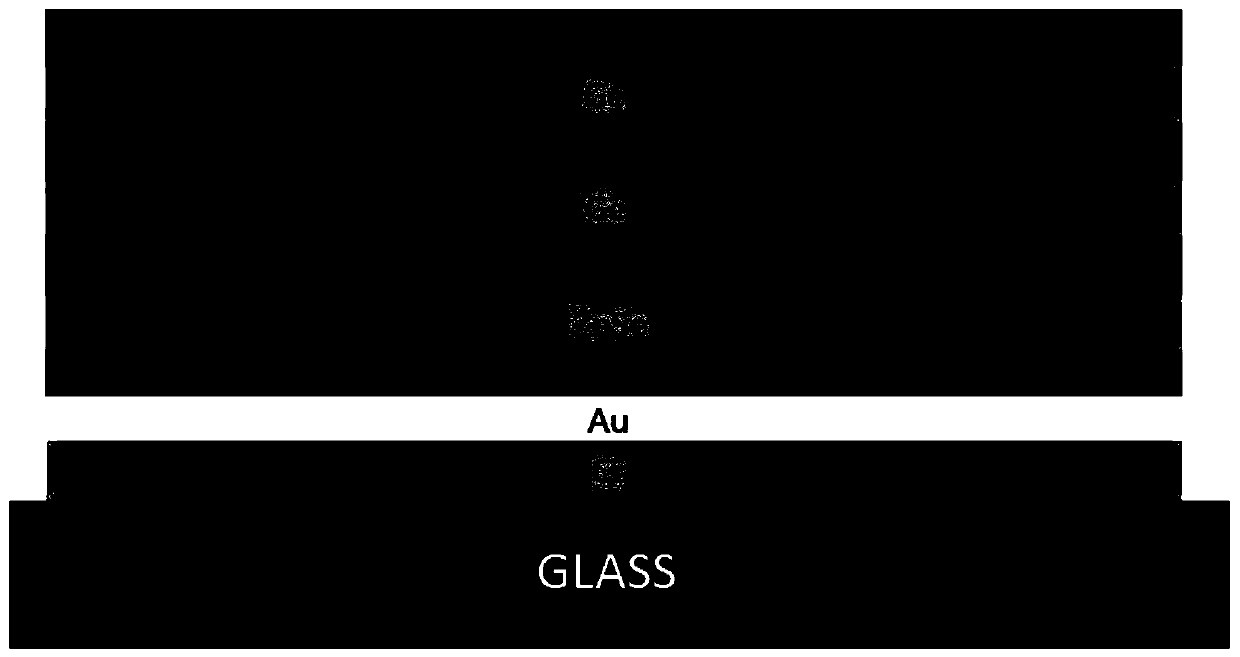

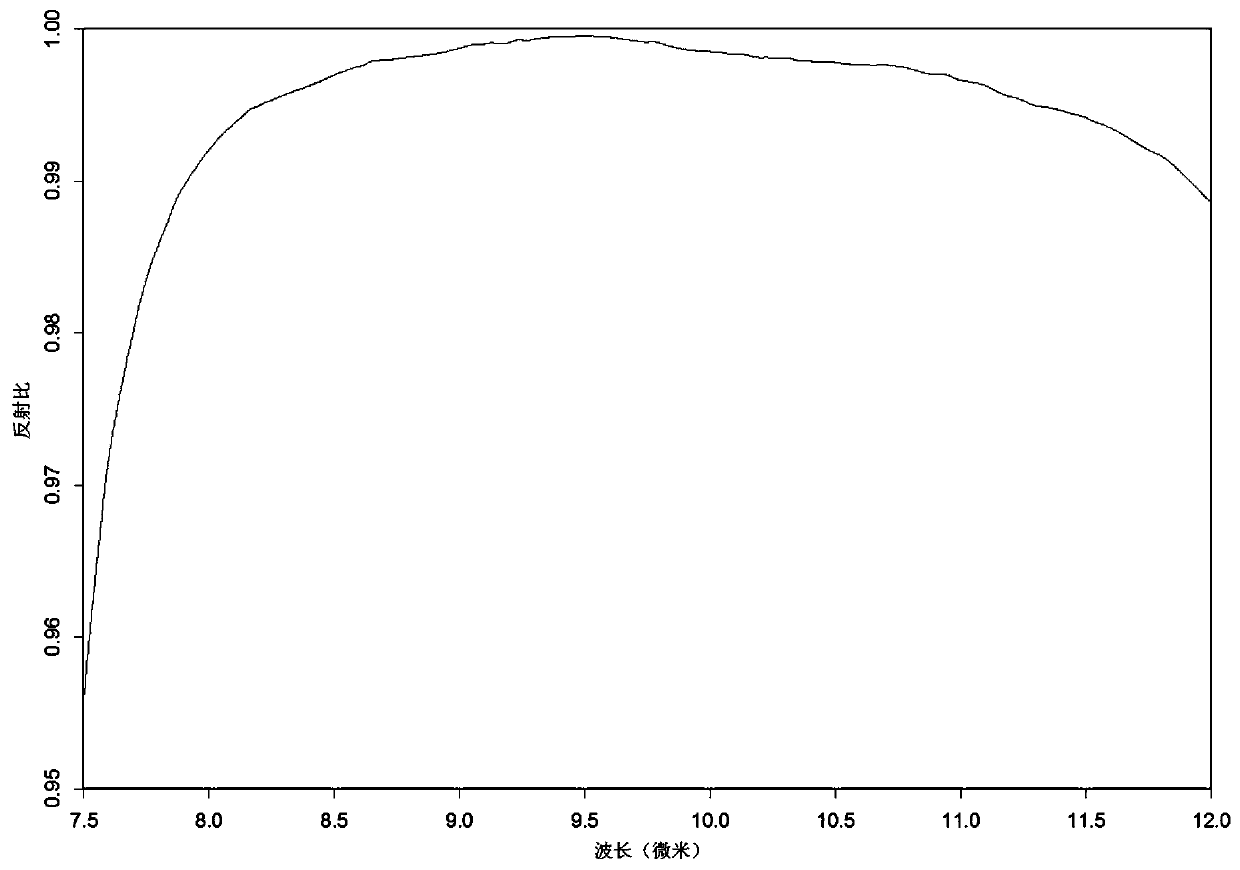

Efficient gold reflective film suitable for 7.5-12-micrometer waveband and preparation method of efficient gold reflective film

ActiveCN110850519AImprove reflectivityGuaranteed firmnessMirrorsOptical instrumentationPhysical chemistry

The invention discloses an efficient gold reflective film suitable for a 7.5-12-micrometer waveband and a preparation method of the efficient gold reflective film and relates to the technical field ofinfrared film coating. In order to solve the technical problem that in the prior art, the average reflectivity of a gold reflective film in the 7.5-12-micrometer waveband is 98.5%, and consequently the application requirement on a novel optical instrument cannot be well met, the following technical scheme is proposed: the efficient gold reflective film comprises a microcrystalline glass substratelayer and an air layer from bottom to top and further comprises a film layer structure arranged between the microcrystalline glass substrate layer and the air layer, and the film layer structure comprises a Cr layer, an Au layer, a Y<2>O<3> layer, a first ZnSe layer, a YbF<3> layer, a first Ge layer, a second ZnSe layer, a second Ge layer and a third ZnSe layer which are sequentially connected from bottom to top.

Owner:YUNNAN KIRO CH PHOTONICS

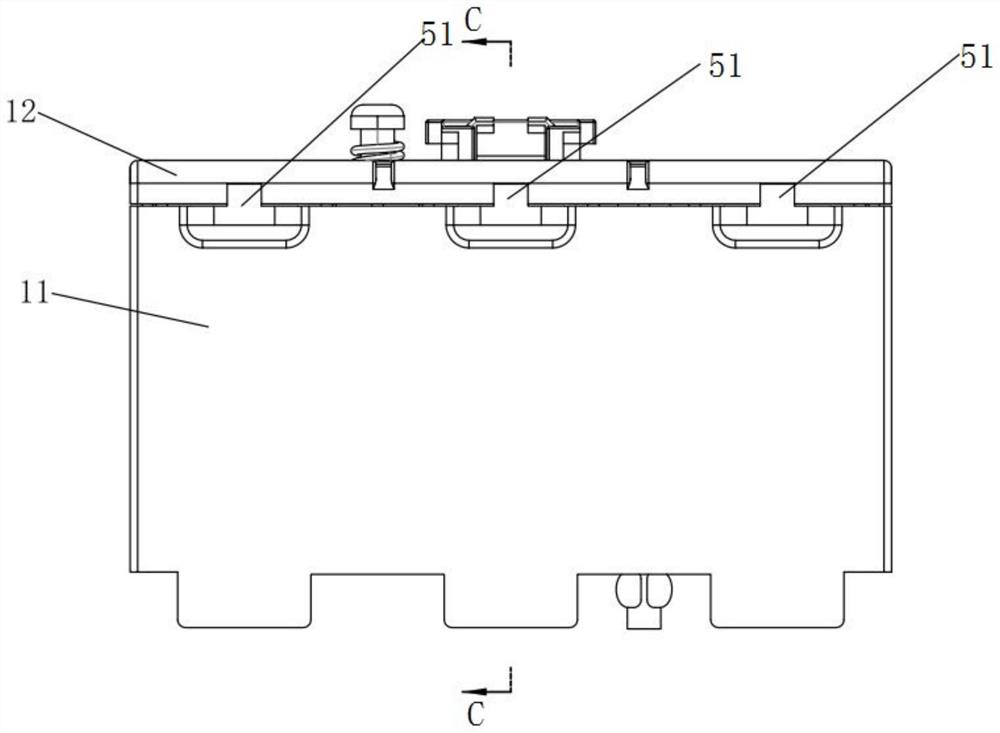

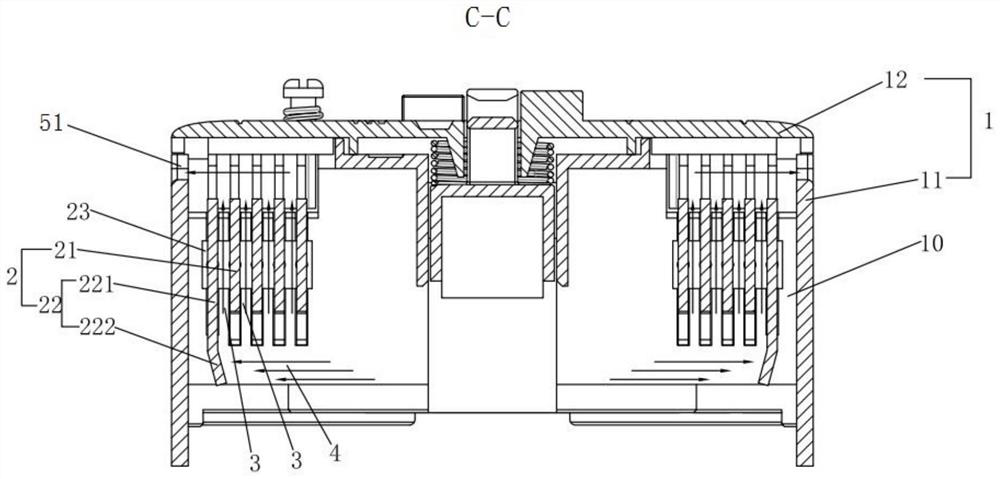

Arc extinguishing system and contactor

PendingCN112599373ASolve the high scrap ratePrevent outside escapeElectric switchesElectromagnetic relay detailsEngineeringArc extinction

The invention relates to the technical field of contactors and particularly relates to an arc extinguishing system and a contactor. The arc extinguishing system comprises an arc extinguishing cover assembly, wherein at least one arc extinguishing cavity is arranged in the arc extinguishing cover assembly, and at least two mounting parts arranged at intervals are arranged in the arc extinguishing cavity; the arc extinguishing sheet assembly comprises at least one first arc extinguishing sheet and one second arc extinguishing sheet which are suitable for being installed in the installation partrespectively, and a first arc supply channel is formed by the interval between any two adjacent first arc extinguishing sheets and the interval between the second arc extinguishing sheet and the firstarc extinguishing sheet adjacent to the second arc extinguishing sheet; the second arc extinguishing sheet comprises an arc extinguishing sheet body with the same height as the first arc extinguishing sheet and a bending part formed by bending and extending the lower end of the arc extinguishing sheet body towards the direction of the first arc extinguishing sheet or the moving contact, and the bending part, the bottom end of the first arc extinguishing sheet and an area among the contacts form an arc striking channel for introducing an arc into the first arc channel. The arc extinguishing system is advantaged in that a problem that an existing arc extinguishing sheet assembly needs to be riveted during installation, and consequently the rejection rate is high is solved.

Owner:ZHEJIANG TENGEN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com