Method for casting vermicular cast iron casting parts

A technology of vermicular graphite cast iron and castings, which is applied in the field of vermicular graphite cast iron casting of heavy-duty engine cylinder heads, can solve problems such as leakage, shrinkage cavity, shrinkage porosity, etc., achieve simple process operation, reduce the influence of thermal knots, and prevent water leakage The effect of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

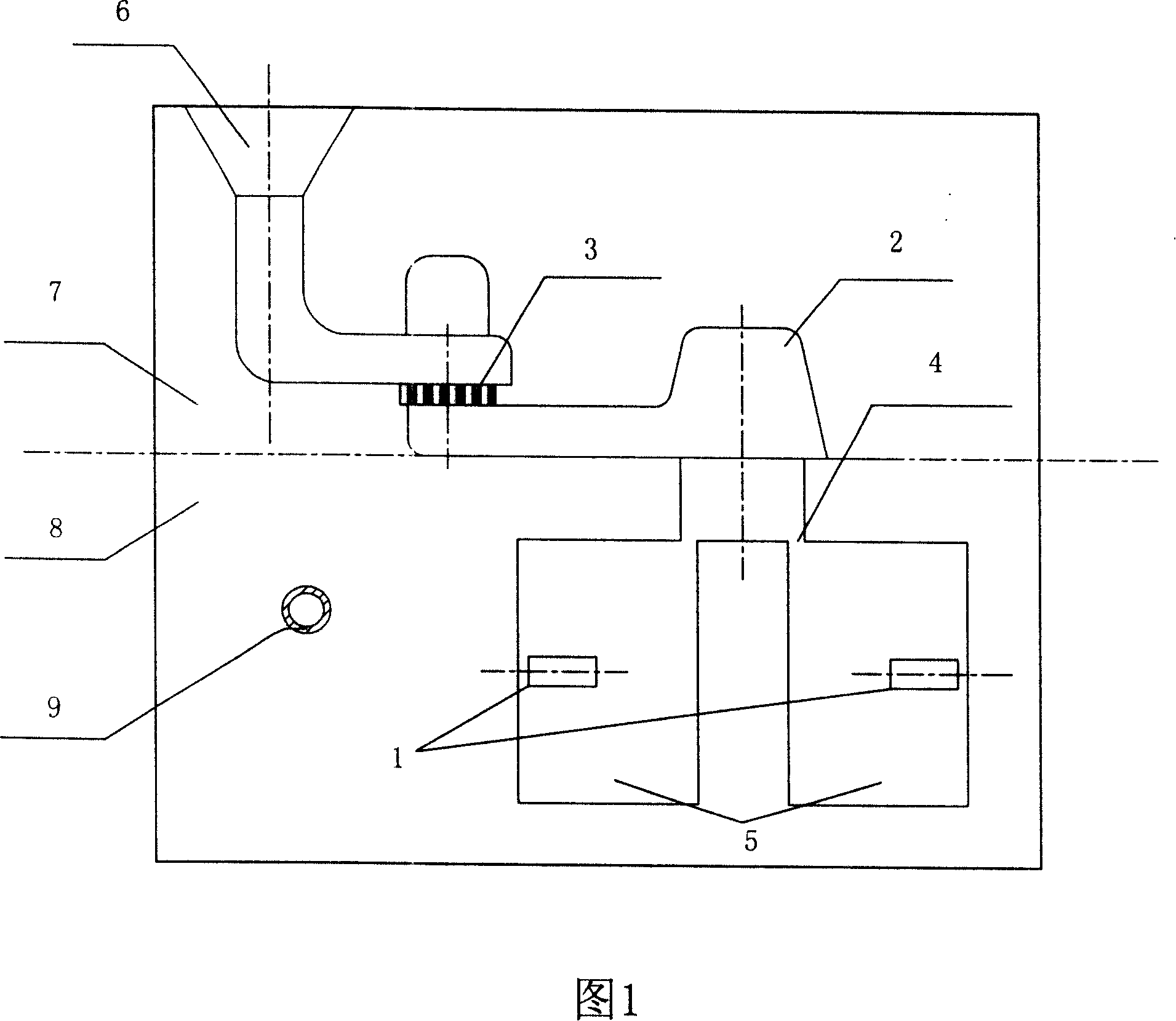

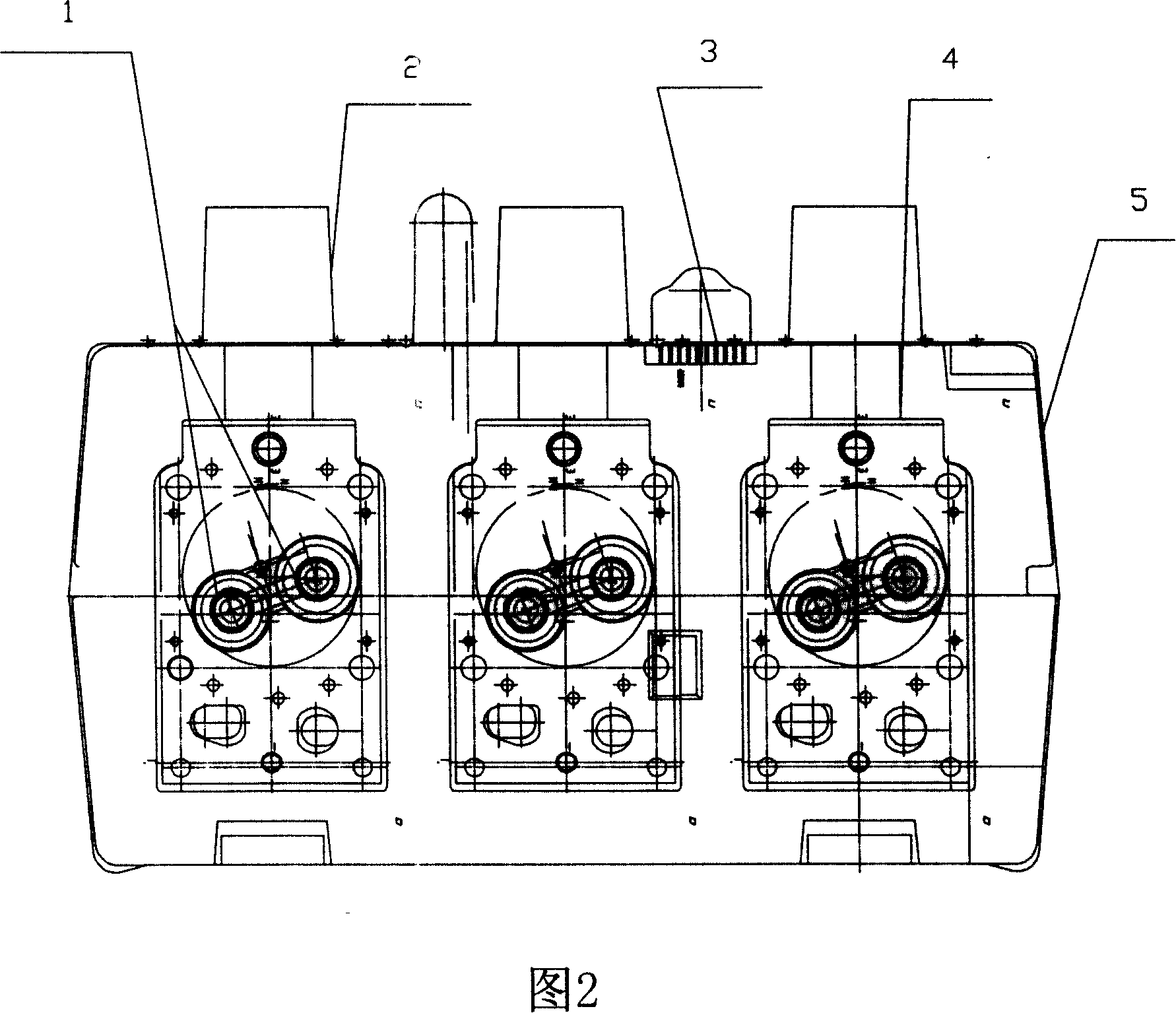

[0025] The process of the present invention modifies the mold according to processes such as side casting and edge casting when designing the pouring system. The engine cylinder head casting process adopts the side pouring process, that is, the castings are placed sideways for pouring. The side pouring can facilitate the arrangement of the pouring system. One box can hold six molds, which improves the productivity.

[0026] The edge gate 4 is made on the sand core by adopting the casting side casting process 5 and the top casting process. The top pouring process can improve the feeding effect very well, and not only will it not hinder the exhaust, it will not be involved in the gas, because it can increase the temperature of the top surface of the casting, but it can prevent the temperature of the top surface of the casting from being low and prematurely solidified. Problems such as top air holes.

[0027] Place the insulation riser 2 (also called heating riser) at a suitable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com