Tension fuzzy PID (Proportion Integration Differentiation) control method for recoiling machine

A control method, a technology of a fuzzy controller, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve problems such as inappropriate use of precise mathematical method control, cumbersome training process, unsuitable for coilers, etc. Achieve ease of implementation and operation, reduced cost, precise tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

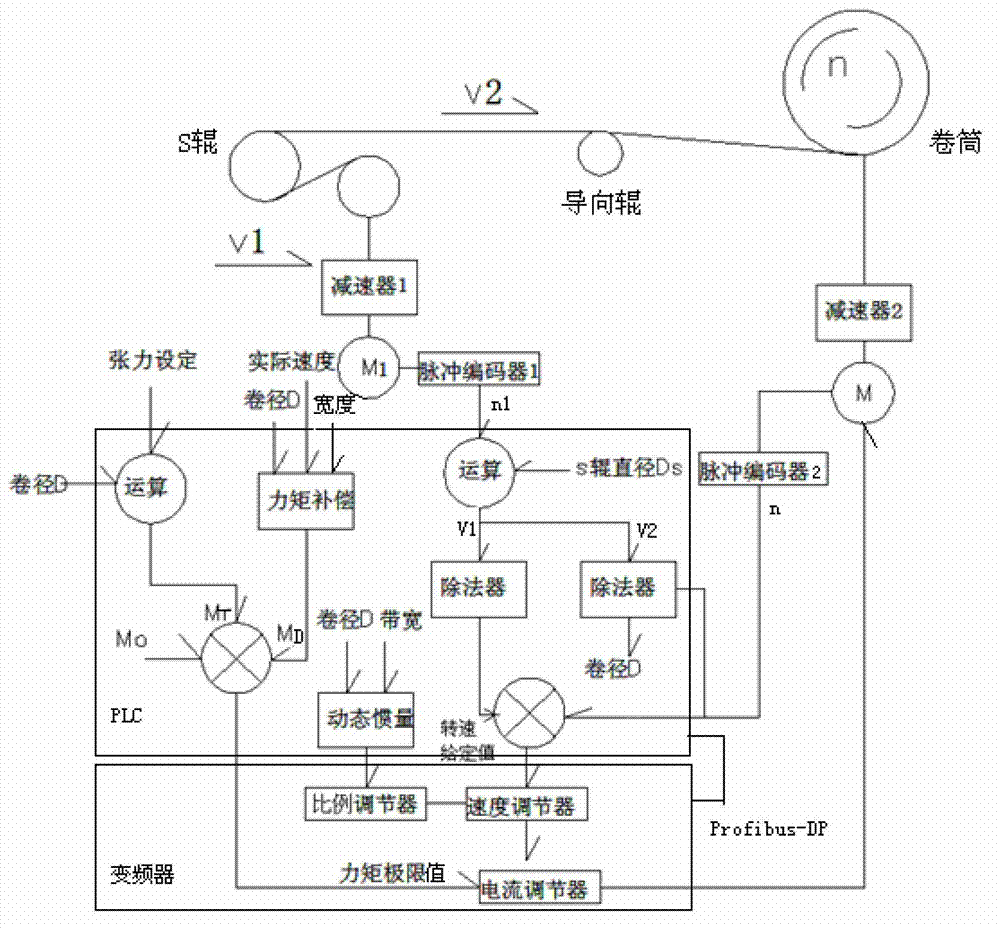

[0050] 1 The establishment of the coiler

[0051] 1.1 Realization principle of indirect tension control of coiler

[0052] When the coiler coils the strip steel, the linear speed of the S roller is set to v1, and the linear speed on the reel is set to v2. When the coiling starts, v2 is obviously greater than that of v1. Only in this way can the strip The steel is wound tightly on the reel. Otherwise it will make the strip loose. According to Hooke's law F=-kx, the calculation formula of the tension T of the strip is obtained:

[0053] T = Kx = K · A l ∫ 0 1 ( v 2 - v 1 ) dt = K 0 ∫ 0 1 ( v 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com