Patents

Literature

8643results about How to "Reduce scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

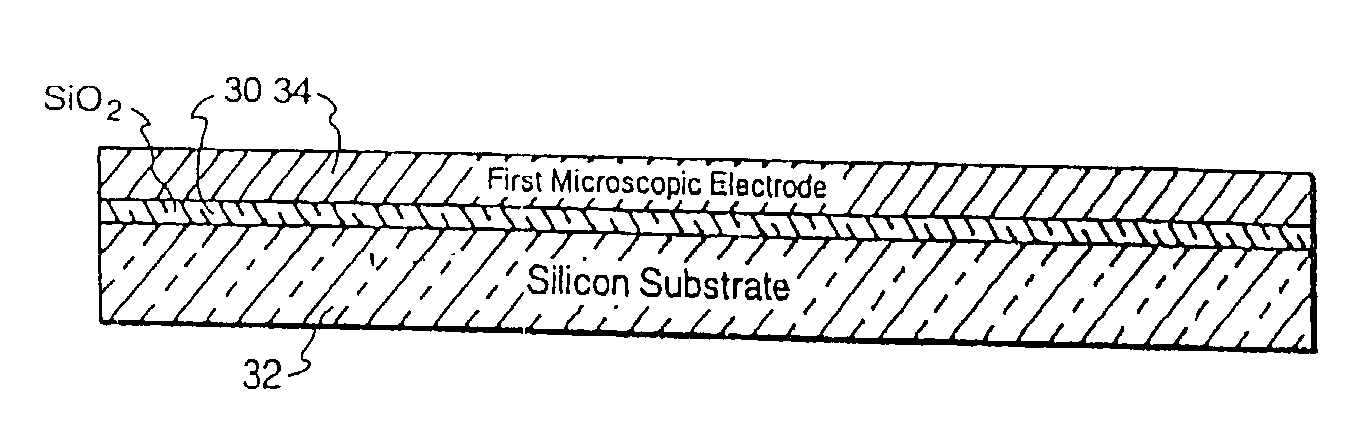

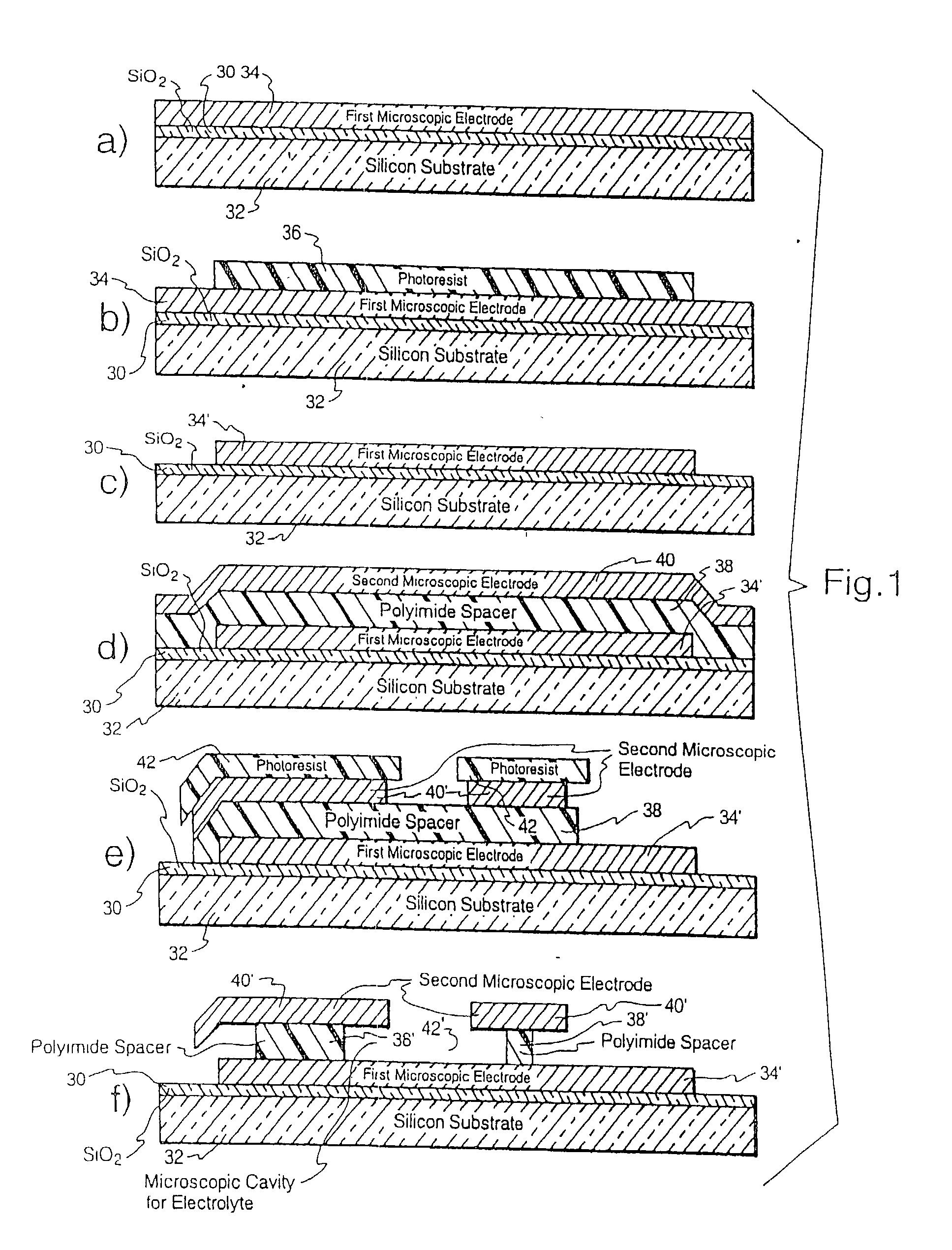

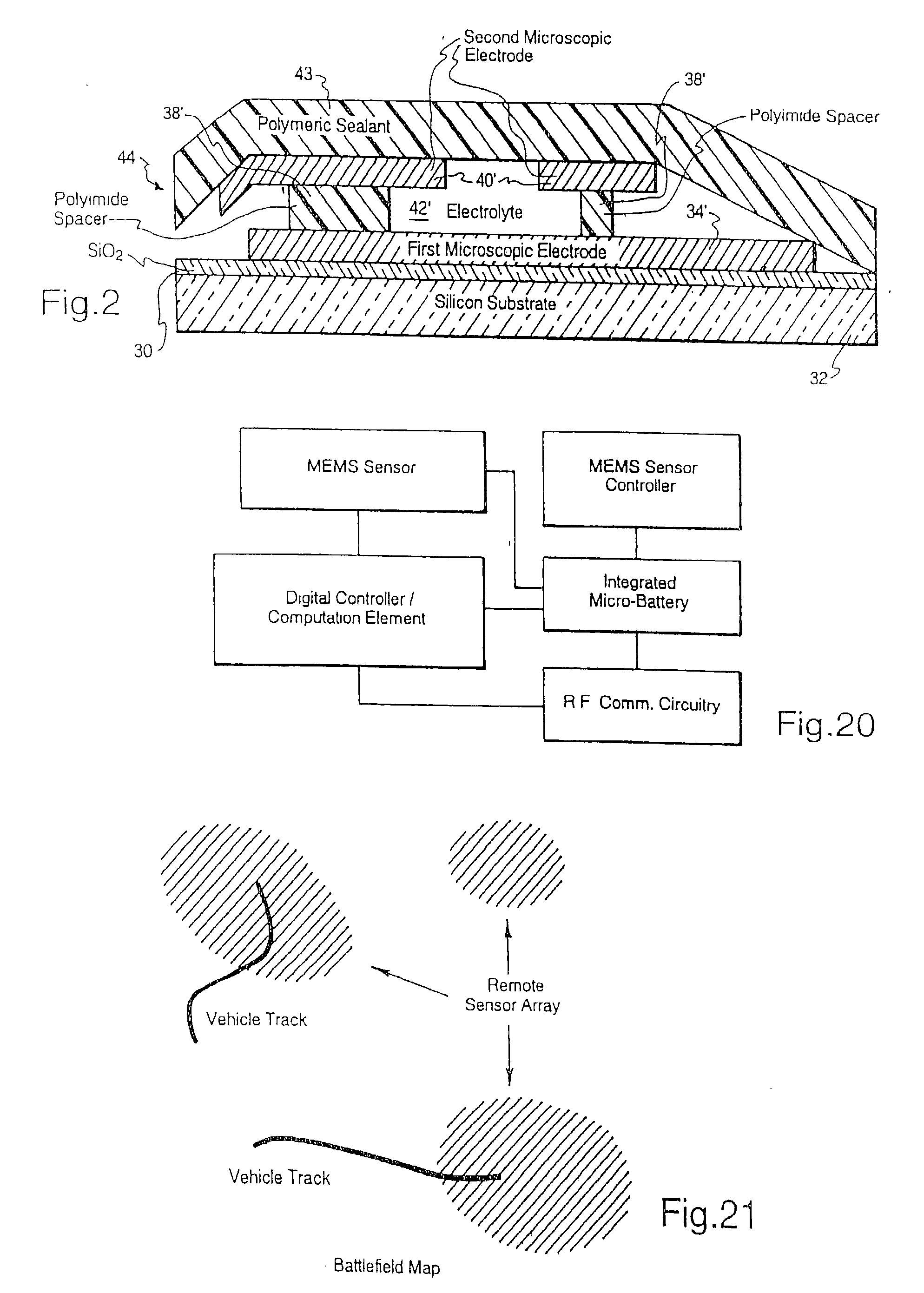

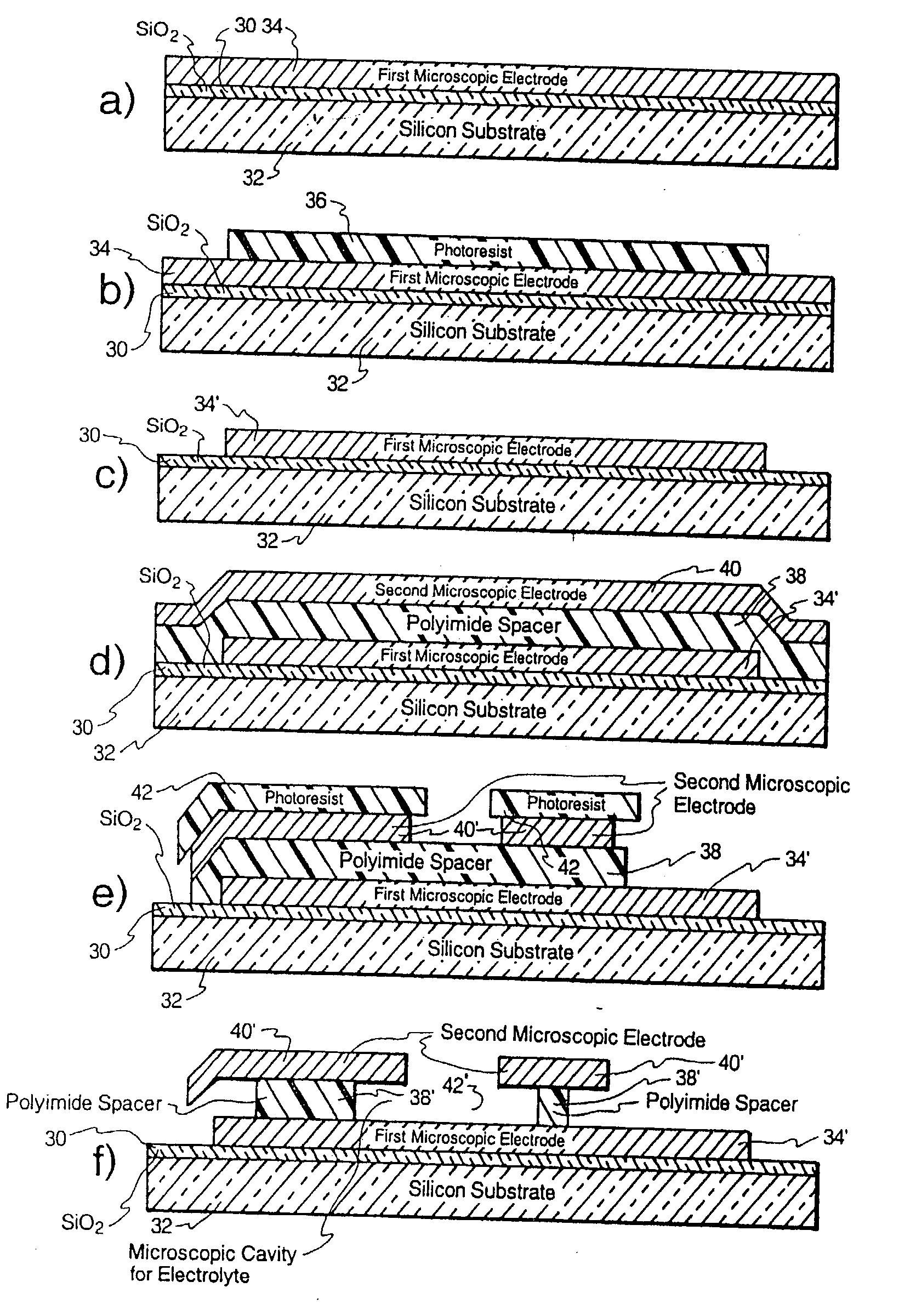

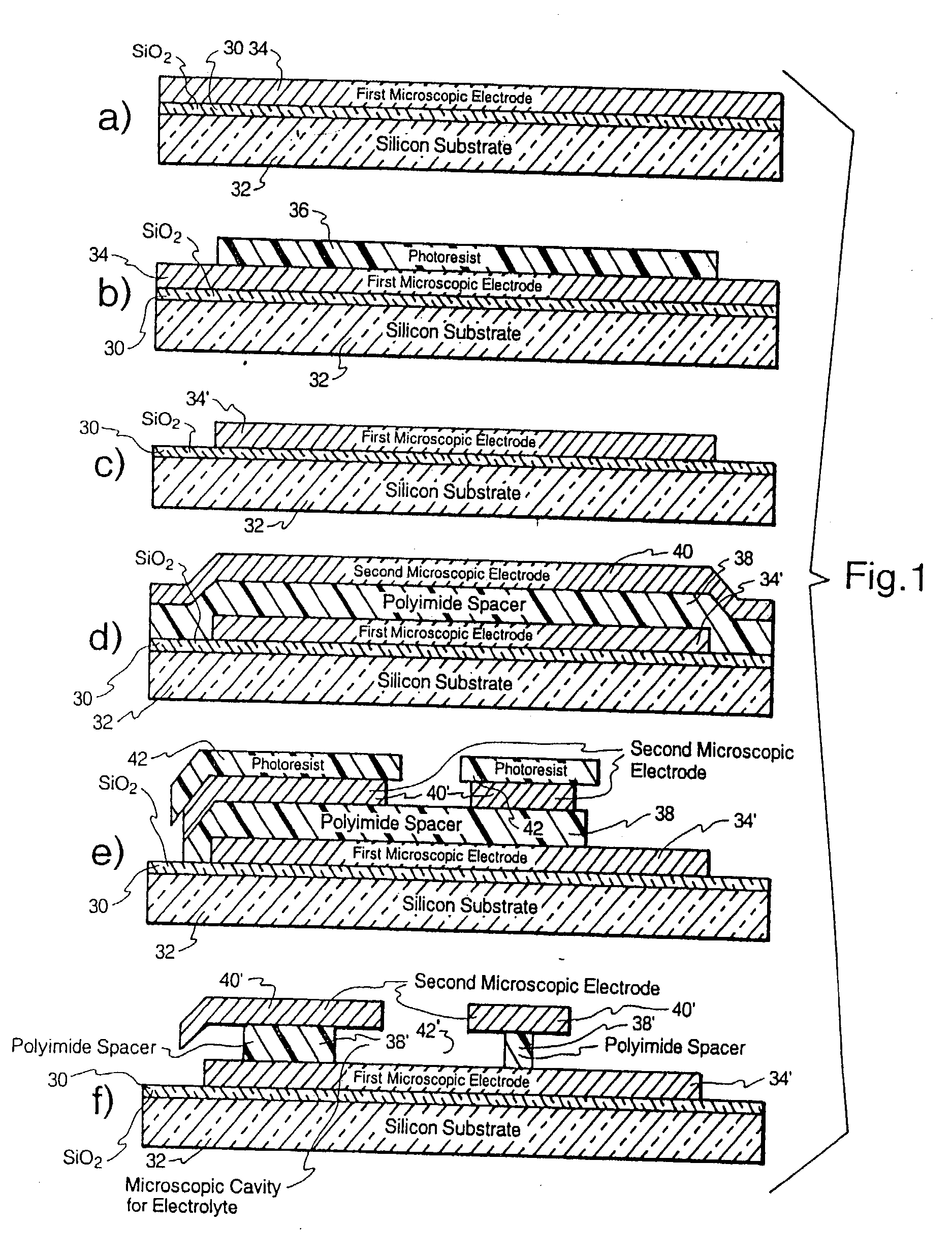

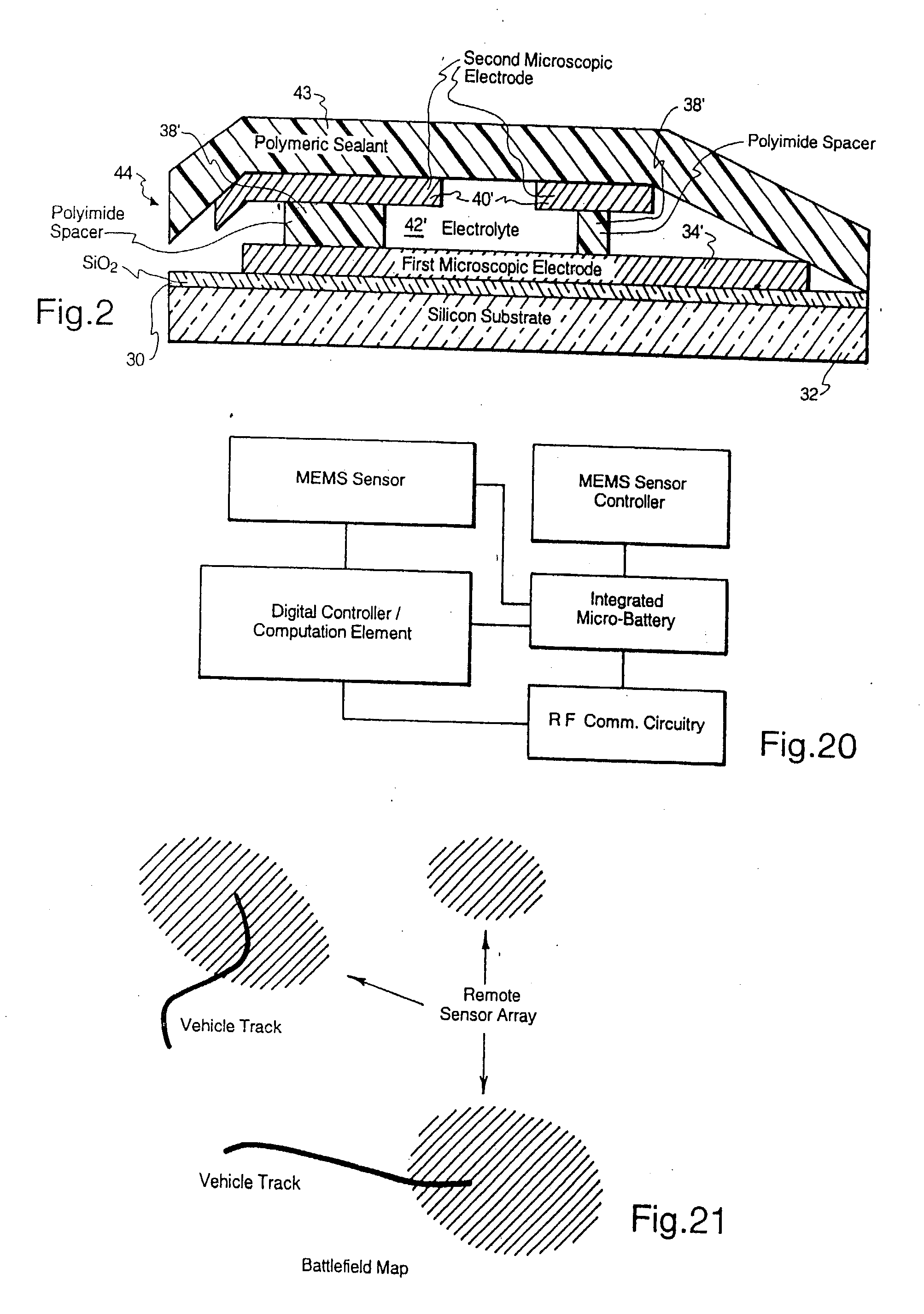

Microscopic batteries for MEMS systems

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

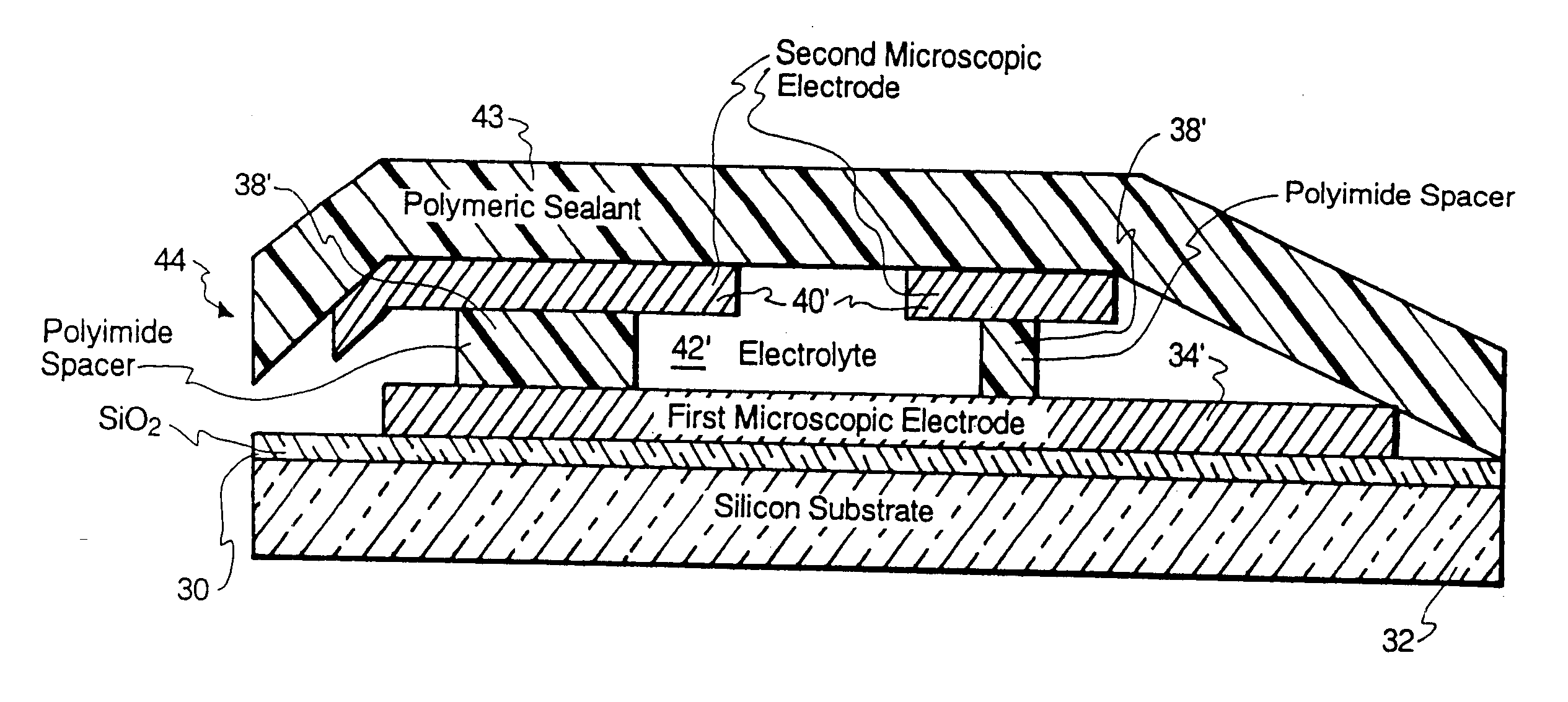

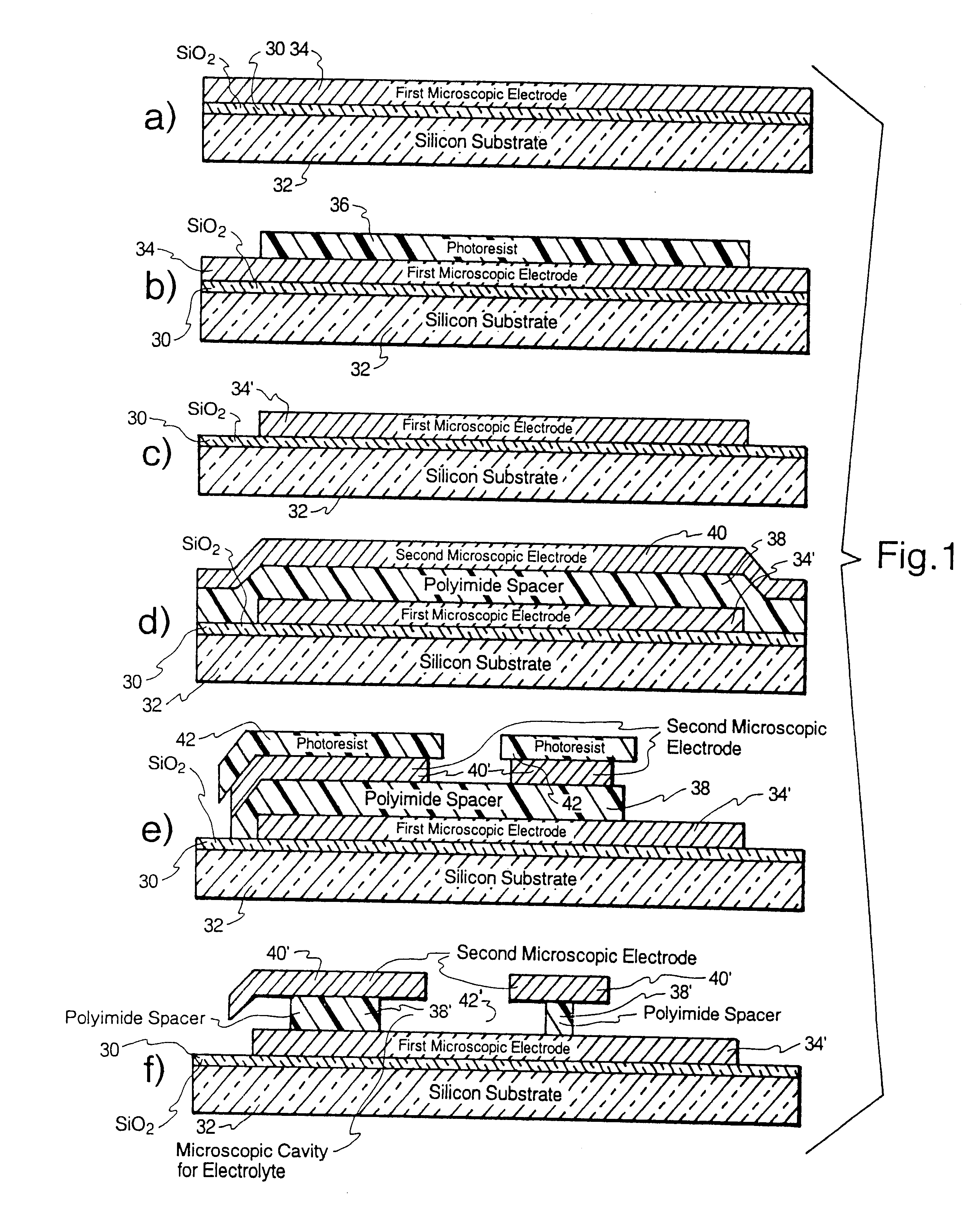

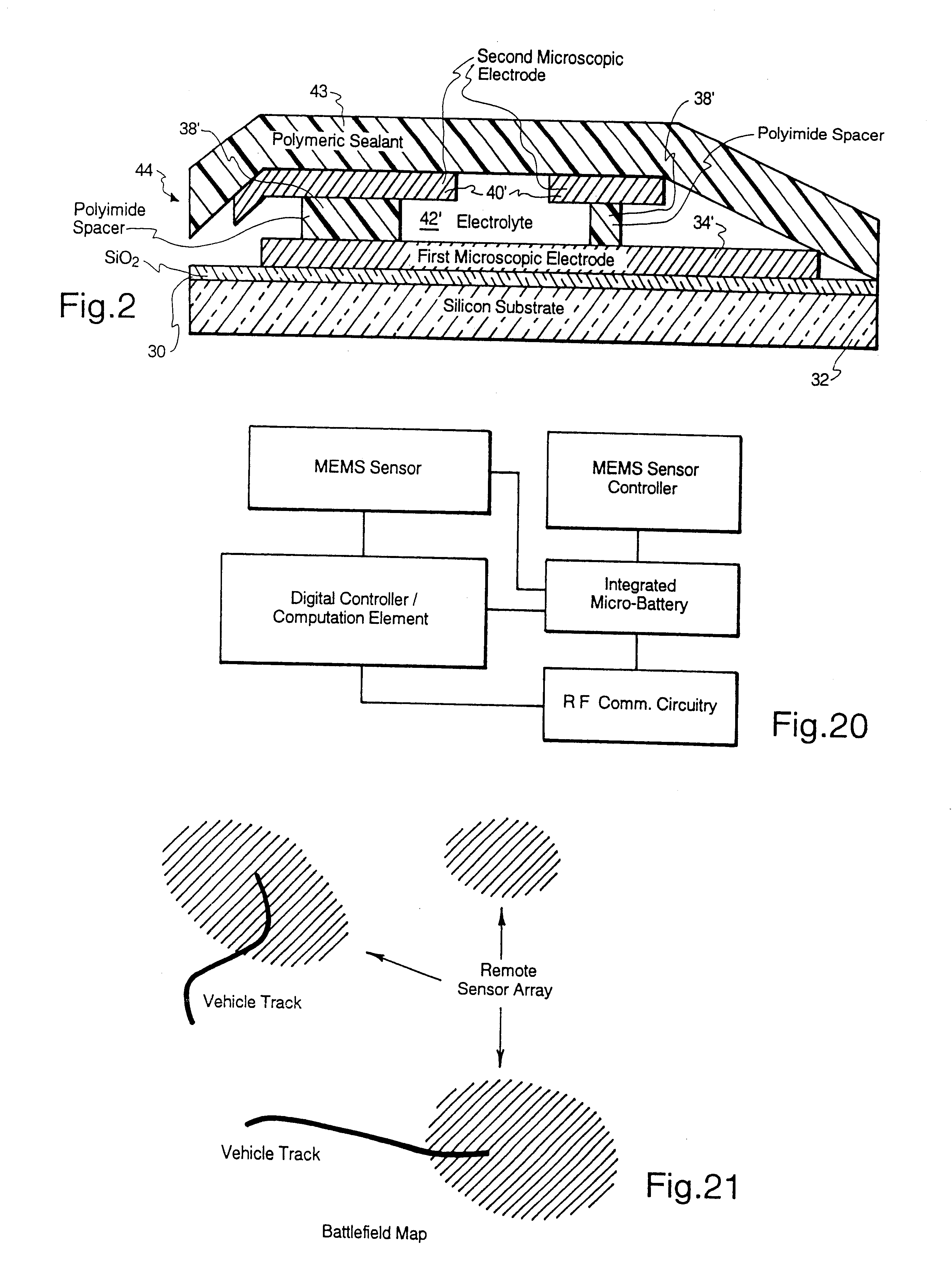

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

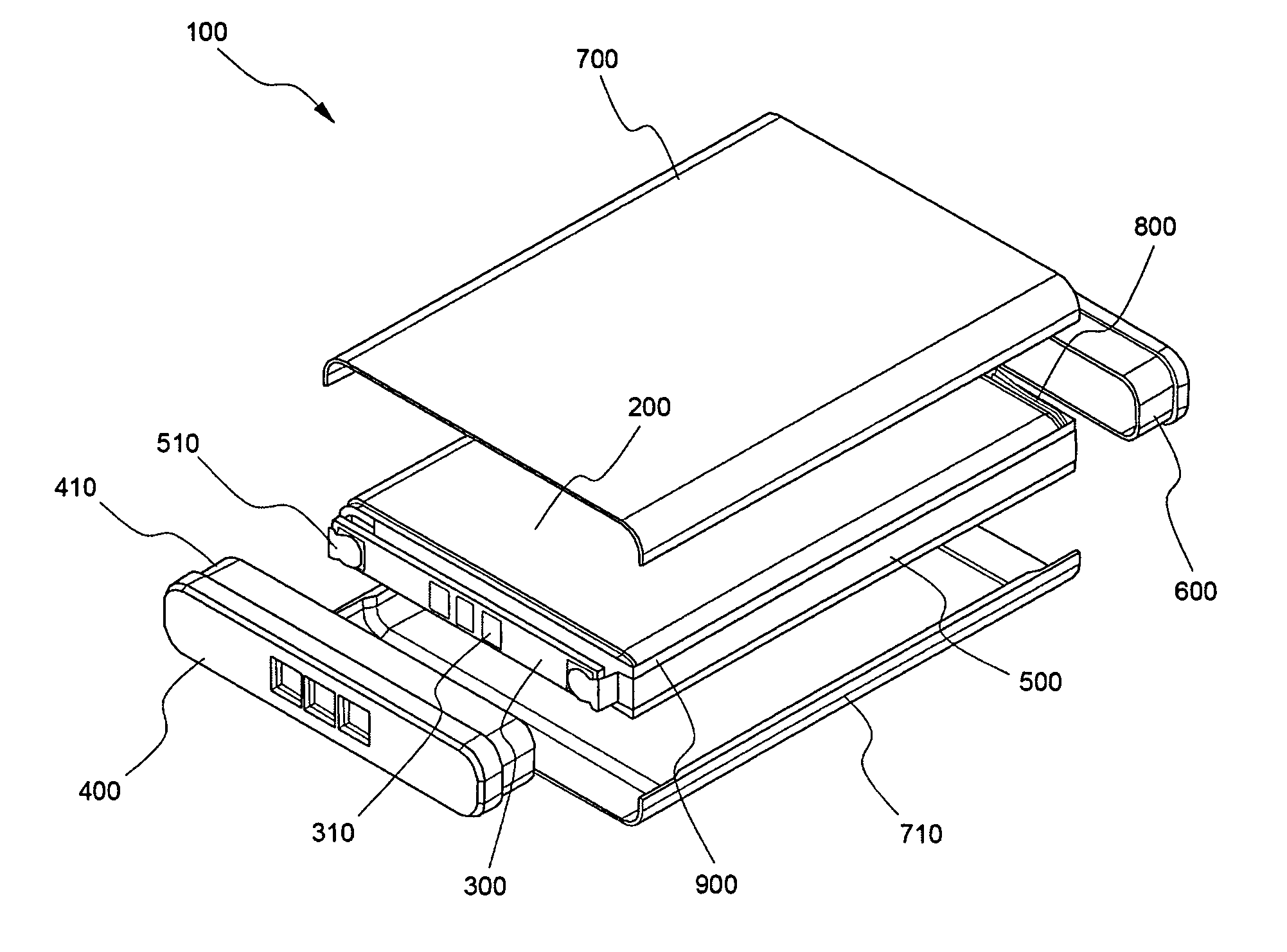

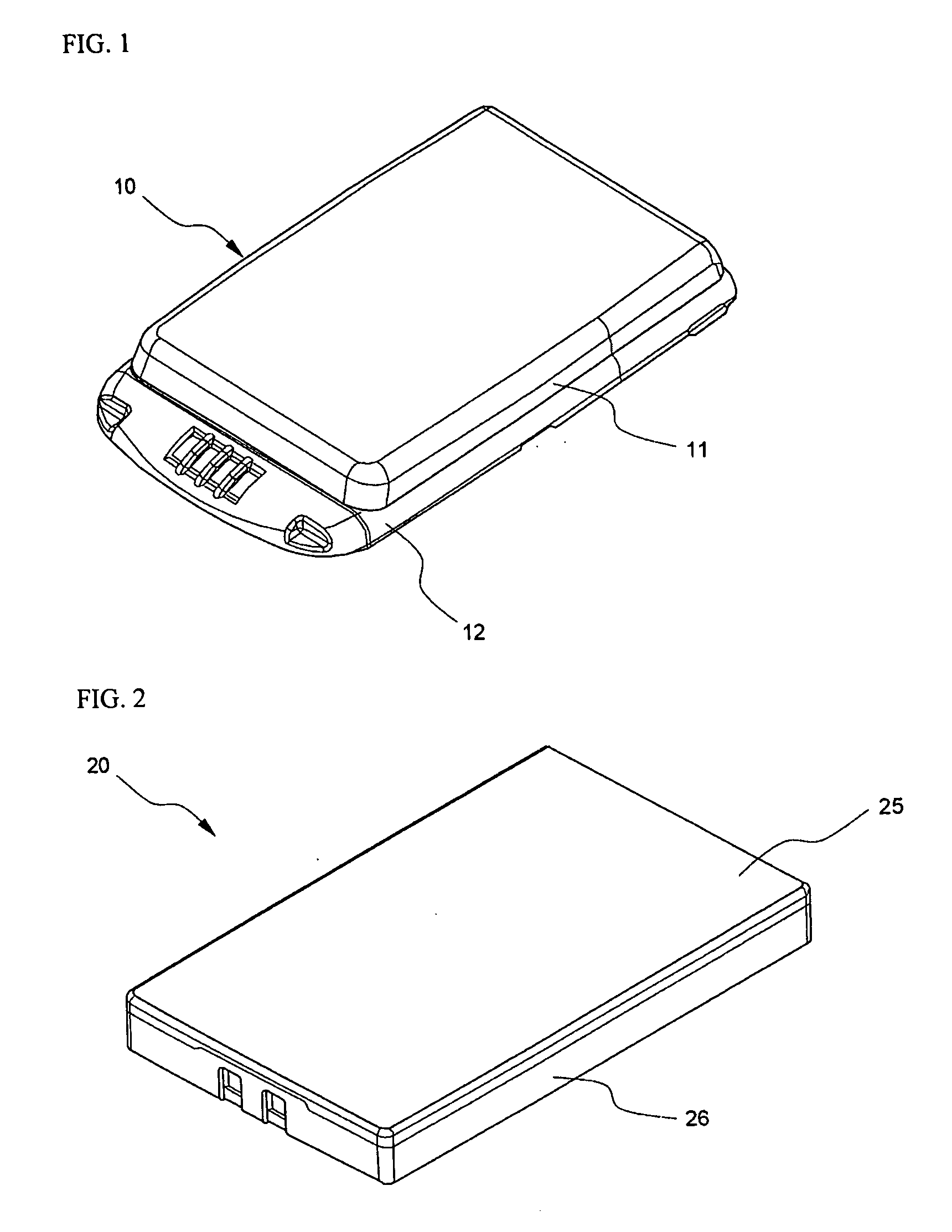

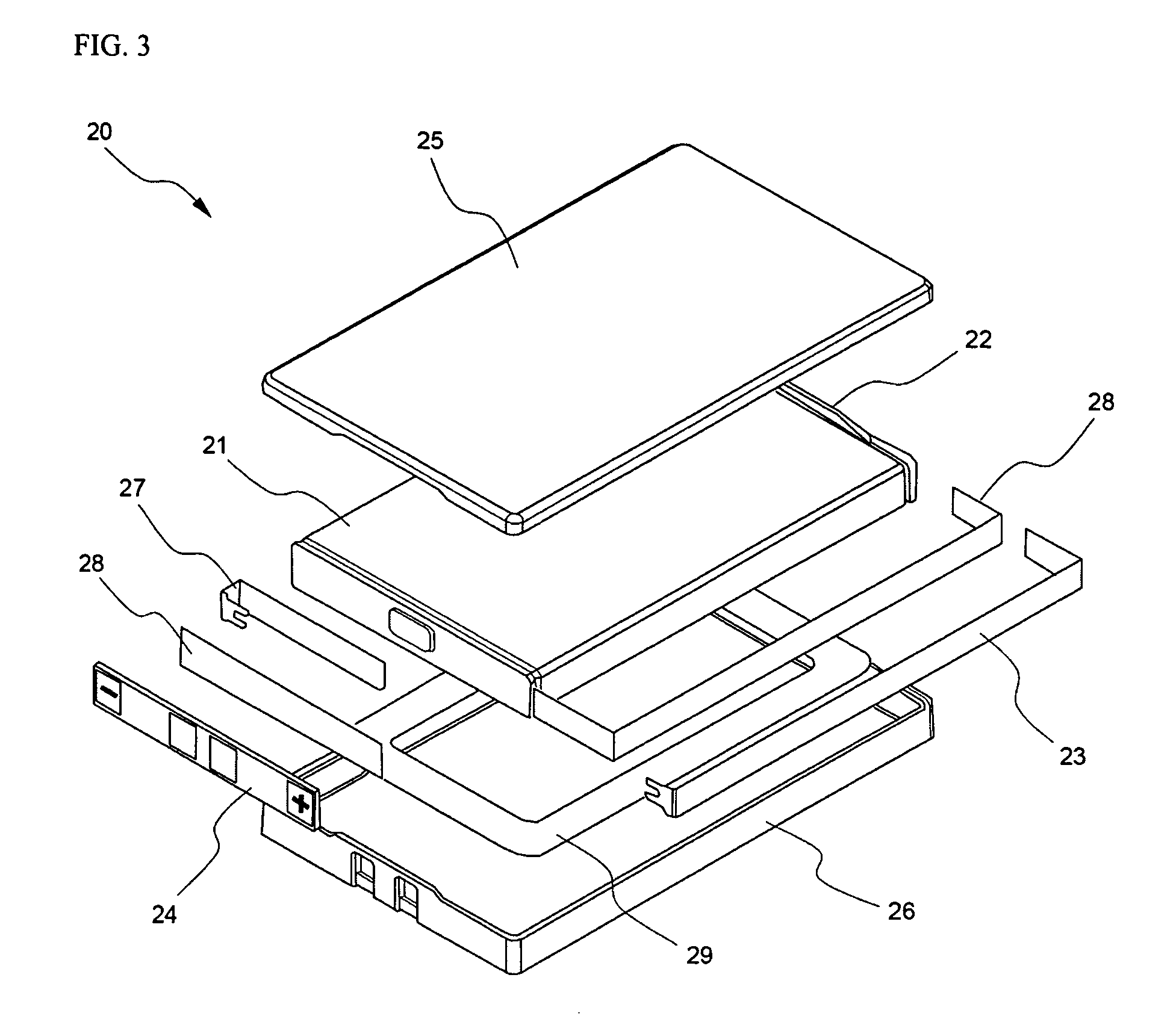

Secondary battery of assemble-type structure

ActiveUS20050208345A1Reduce scrap rateLow production costPrimary cell maintainance/servicingSecondary cell gas removalElectricityManufacturing technology

Provided is a secondary battery of an assemble-type structure, comprising: a cell body including an electrode assembly of cathode / separator / anode sealed therein; and a cap assembly including a protection circuit electrically connected to the cell body so as to control overcharge, overdischarge and overcurrent of the battery and a cap housing covering an upper part of the battery, and being detachably coupled to the cell body. In accordance with the present invention, since the cap assembly including the protection circuit, cap housing and the like is assembled detachably from the cell body and electrically connected to and also can be physically firmly fixed to one another, provided are effects capable of greatly reducing the manufacturing process steps of the battery, and solving all the problems associated with use of battery cases and insert injection molding. Therefore, the present invention can reduce battery production costs and rejection rate, facilitate greater ease of re-working upon occurrence of rejection in particular components and realize more efficient automation of the battery manufacturing process.

Owner:LG ENERGY SOLUTION LTD

Microscopic batteries for MEMS systems

InactiveUS20030152815A1Low capacityEffectively manufactureBatteries circuit arrangementsFinal product manufactureIntegrated circuitEngineering

Microscopic batteries, integratable or integrated with and integrated circuit, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed.

Owner:BIPOLAR TECH

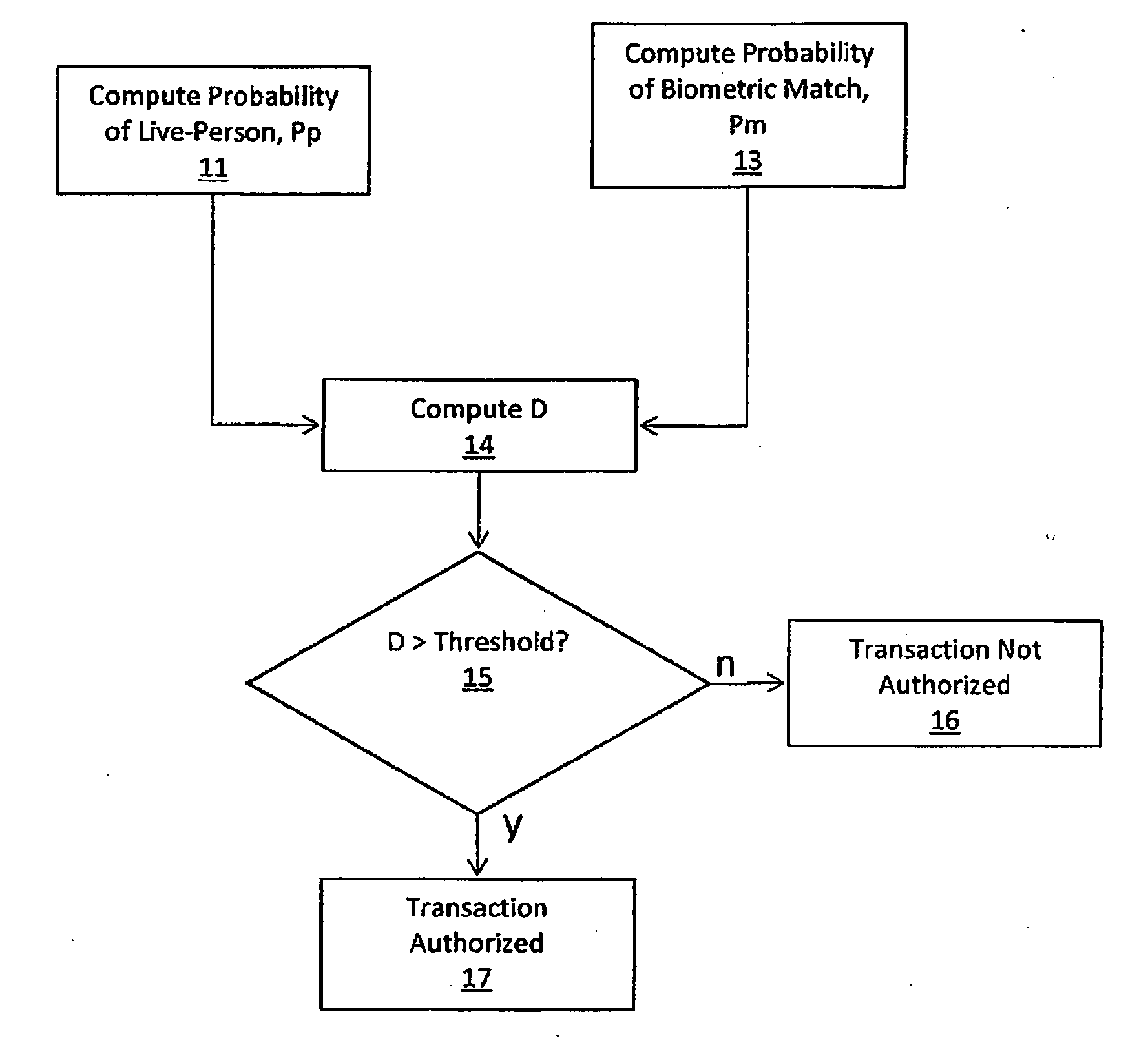

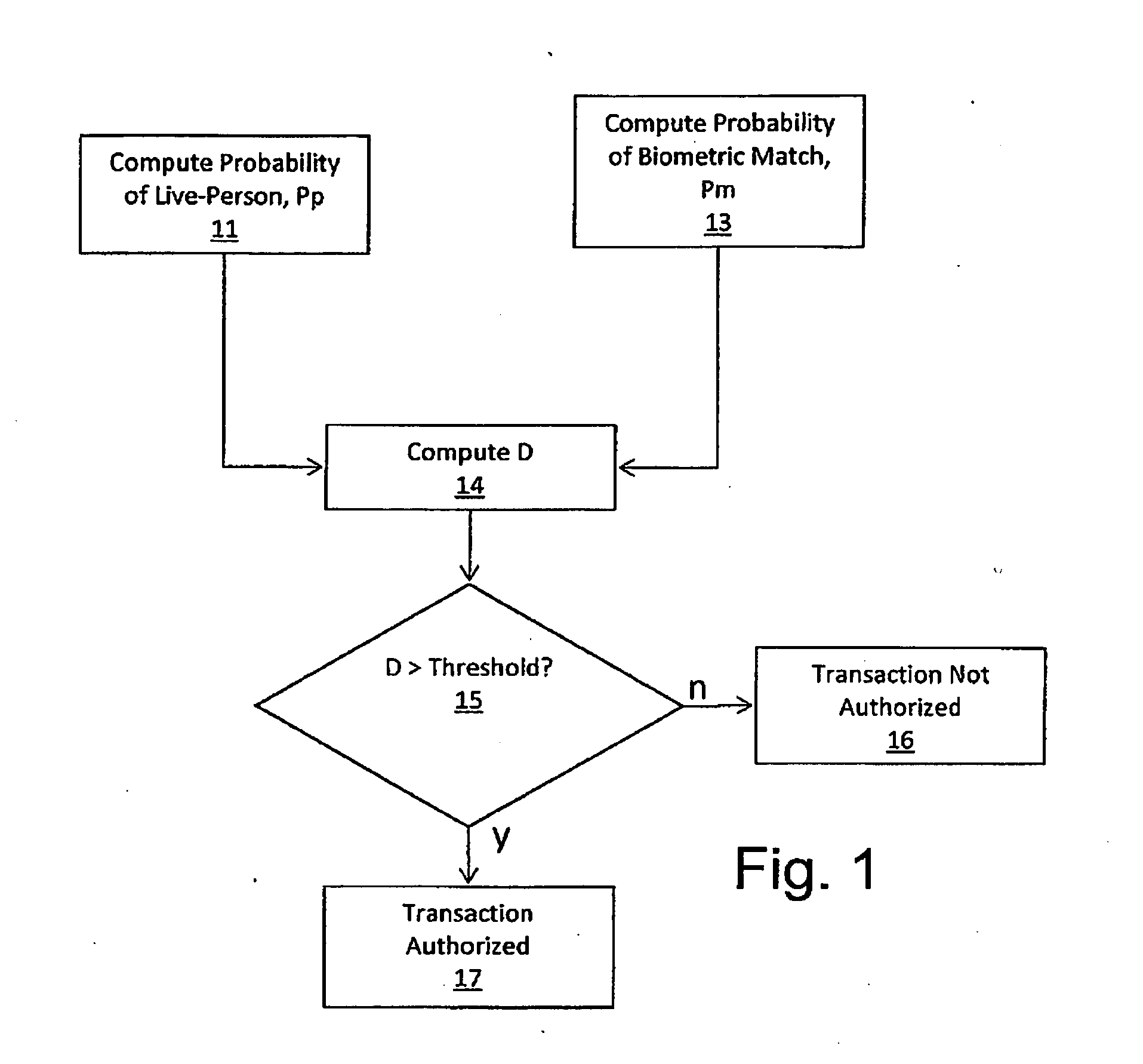

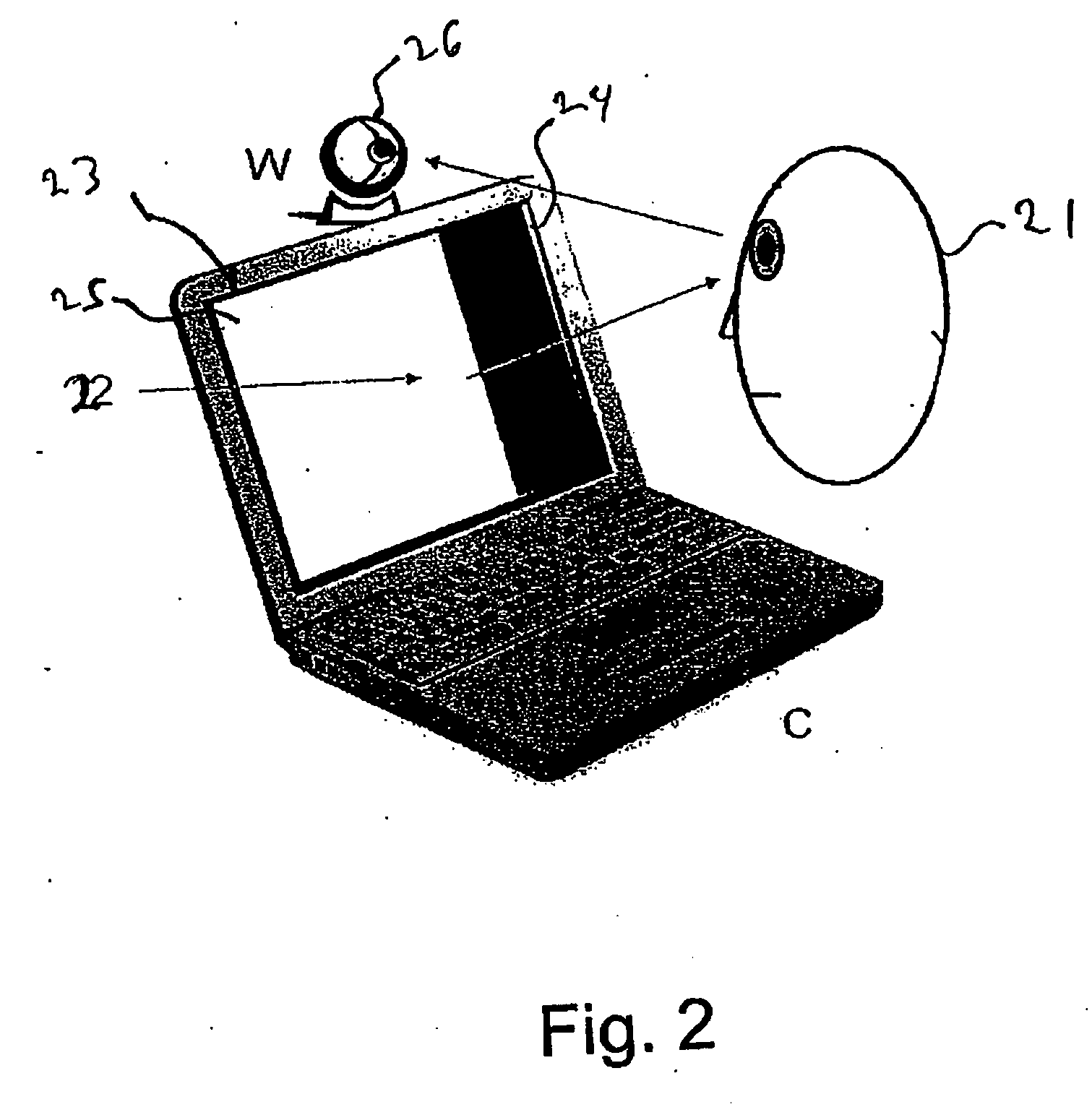

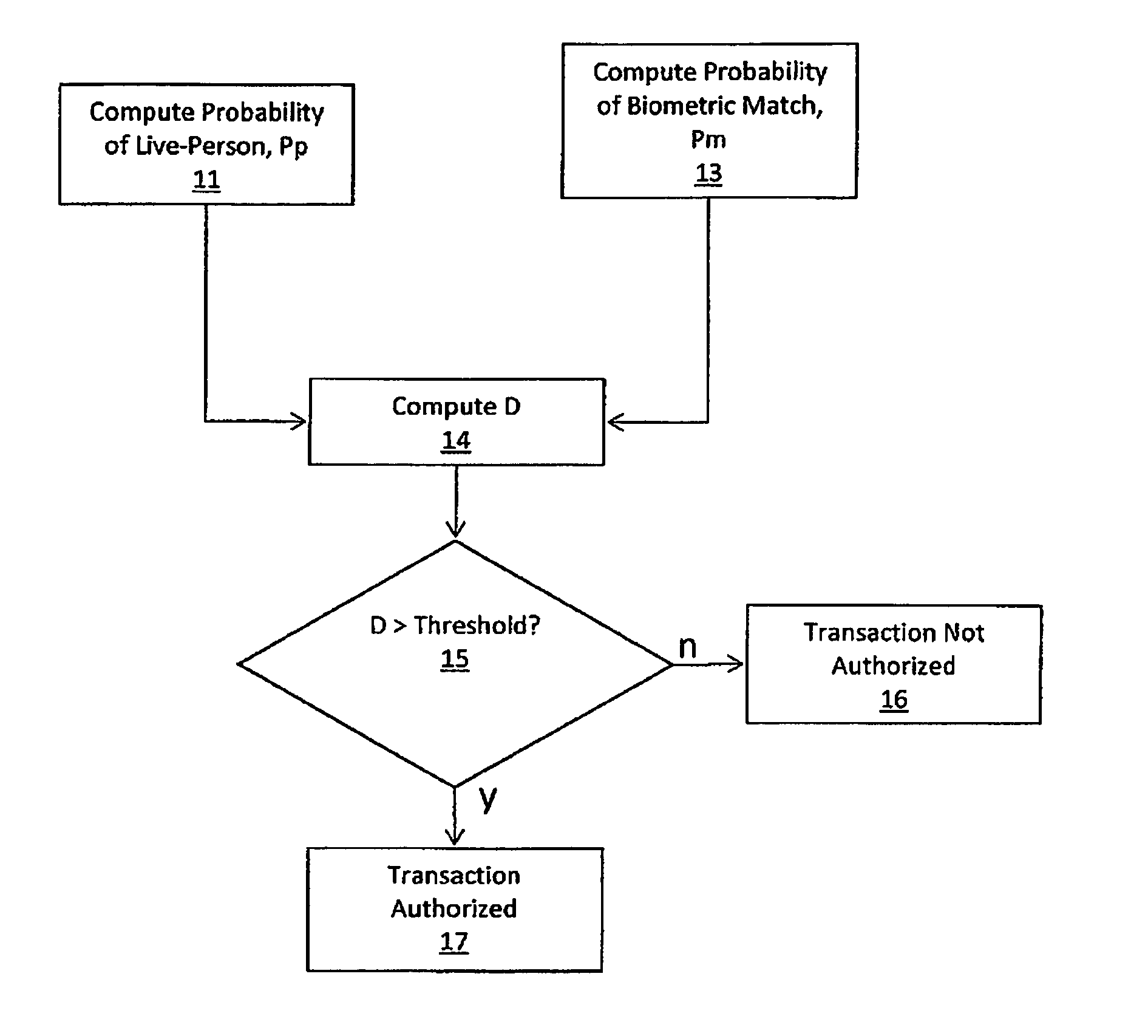

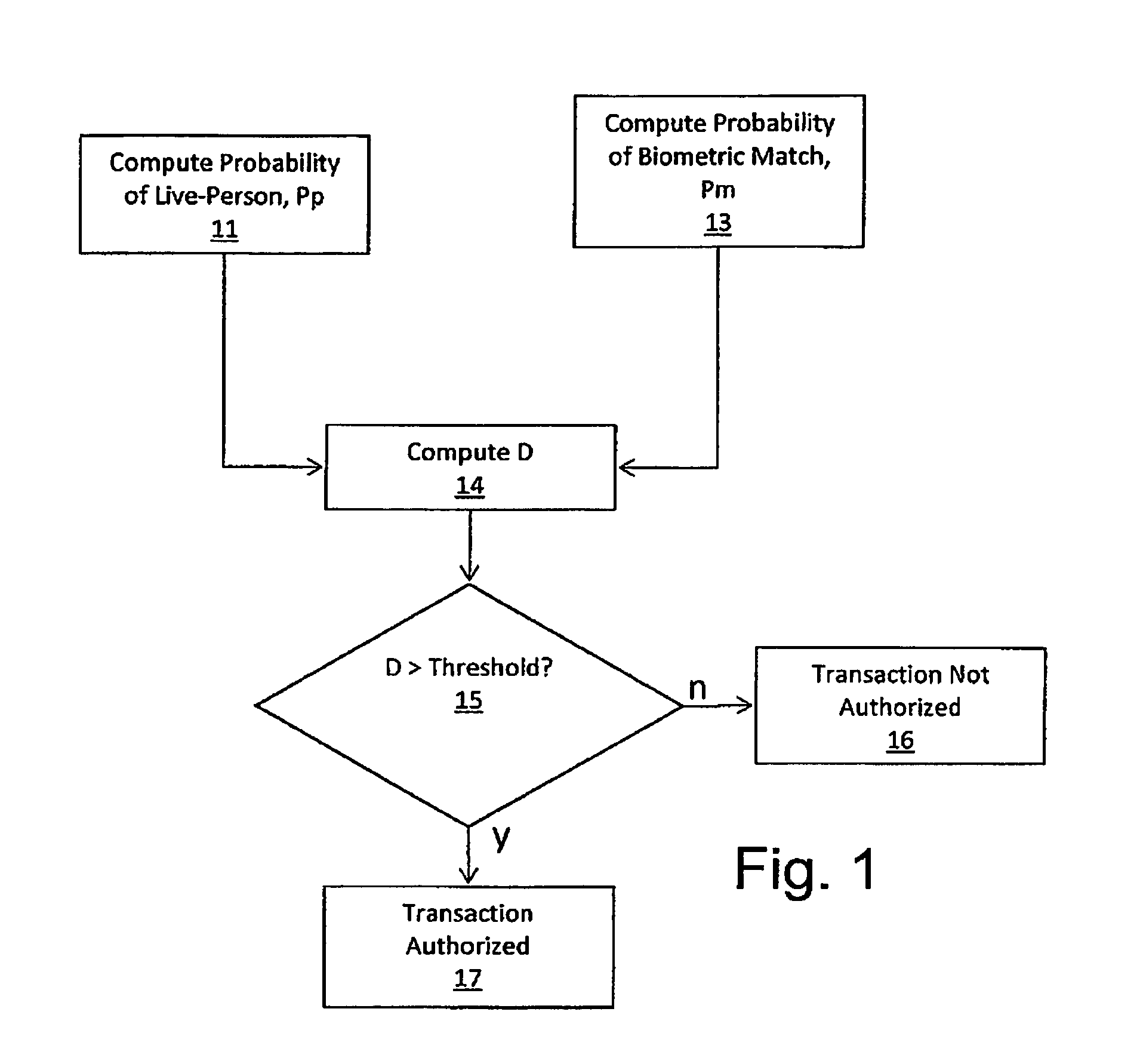

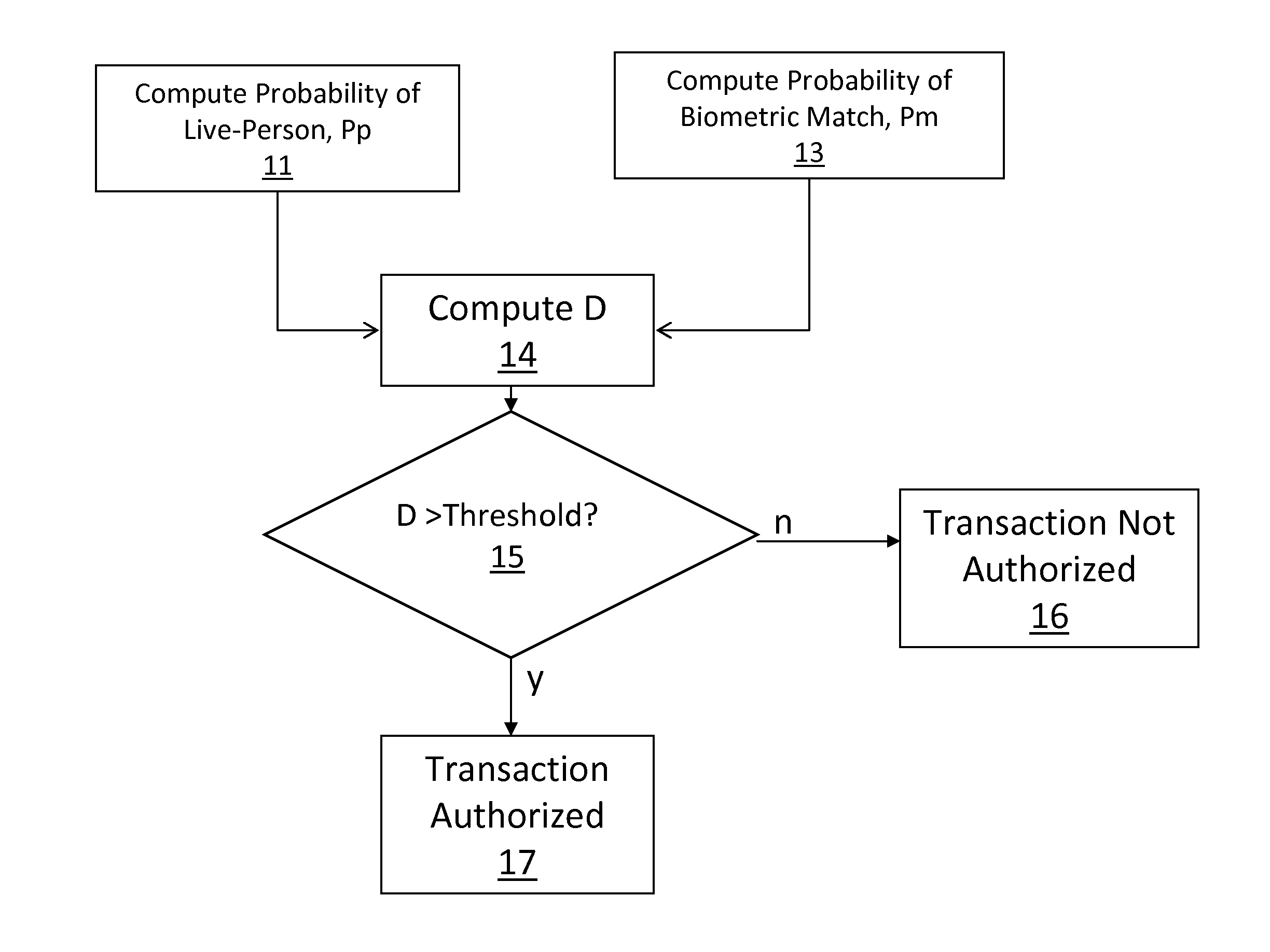

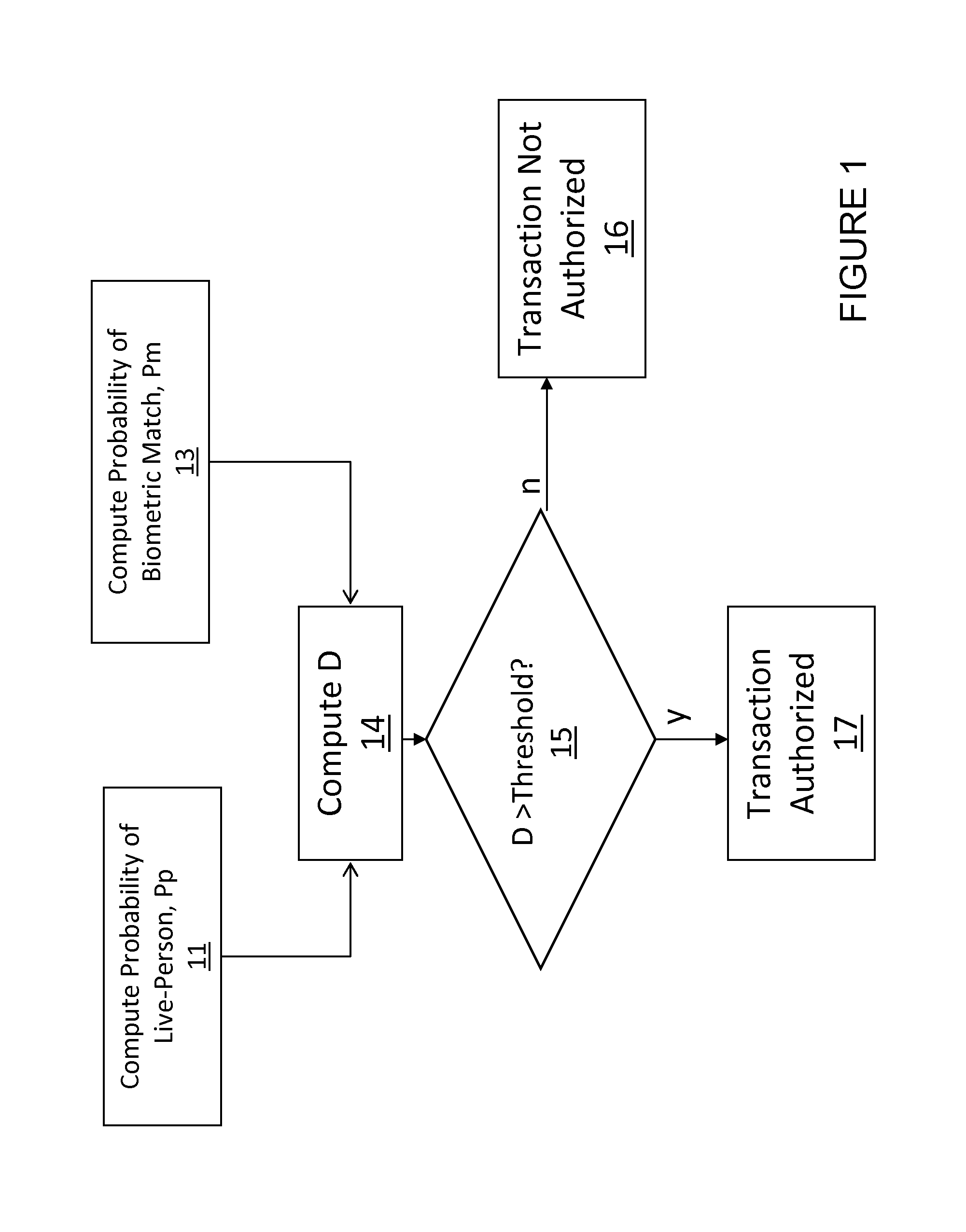

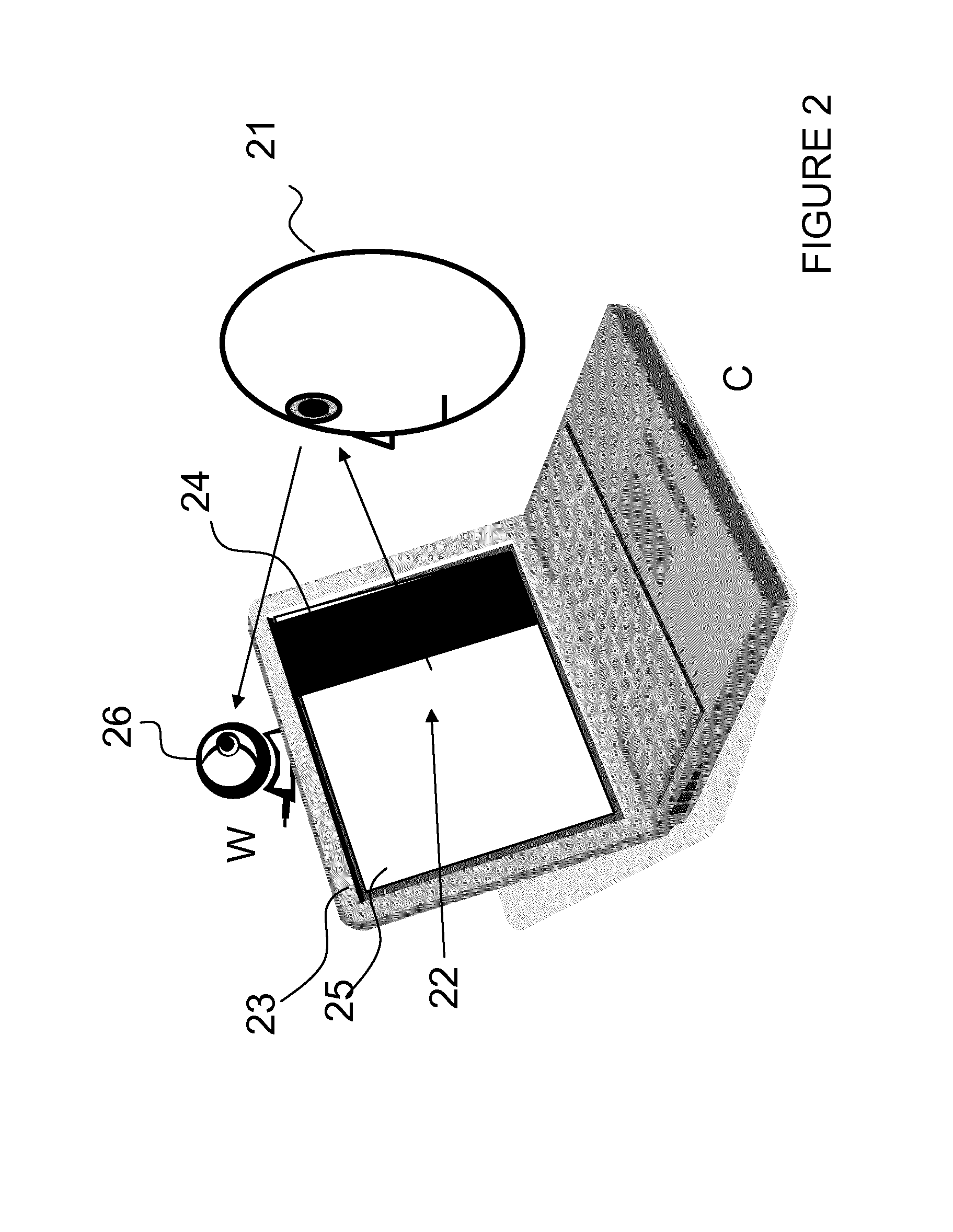

Fraud Resistant Biometric Financial Transaction System and Method

ActiveUS20100014720A1Out of controlReduce scrap rateElectric signal transmission systemsImage analysisLivenessBiometric data

A method and system for authenticating financial transactions is disclosed wherein biometric data is acquired from a person and the probability of liveness of the person and probability of a match between the person or token and known biometric or token information are calculated, preferably according to a formula D=P(p)*(K+P(m)), wherein K is a number between 0.1 and 100, and authenticating if the value of D exceeds a predetermined value.

Owner:EYELOCK

Fraud resistant biometric financial transaction system and method

ActiveUS8280120B2Out of controlReduce scrap rateElectric signal transmission systemsImage analysisLivenessBiometric data

A method and system for authenticating financial transactions is disclosed wherein biometric data is acquired from a person and the probability of liveness of the person and probability of a match between the person or token and known biometric or token information are calculated, preferably according to a formula D=P(p)*(K+P(m)), wherein K is a number between 0.1 and 100, and authenticating if the value of D exceeds a predetermined value.

Owner:EYELOCK

Micro-emulsification stainless steel cutting liquid

The invention disclose a micro-emulsification type stainless steel cutting fluid belonging to metal-cutting lubricant technical field to solve the problems that the existing cutting fluid can not be commendably used in cutting process of stainless steel and can endanger the health of the workers. The micro-emulsification type stainless steel cutting fluid comprises 20-40 wt% water, 5-20 wt% paraffin base mineral oil or naphthenic base mineral oil, 1-15 wt% non-ionic surfactant of alkyl phenol polyoxyethylene ether or fatty alcohol polyoxyethylene ether, 5-10 wt% chloroparaffin, 1-10 wt% petroleum sodium sulphonate and hardship or alkenyl succinic acid rust preventive, 5-25 wt% mixing alkyol amine of mono ethanolamine and trieanolamine, 5-15 wt% oleic acid, 2-10 wt% polyatomic alcohol lauric acid ester or polyatomic alcohol oleic acid ester, 0.1-0.5 wt%.benzotriazole, and 0.1-0.5 wt% methyl silicone oil anti-foam agent. The micro-emulsification type stainless steel cutting fluid is specially used in the cutting process of the stainless steel.

Owner:CHINA PETROCHEMICAL CORP +1

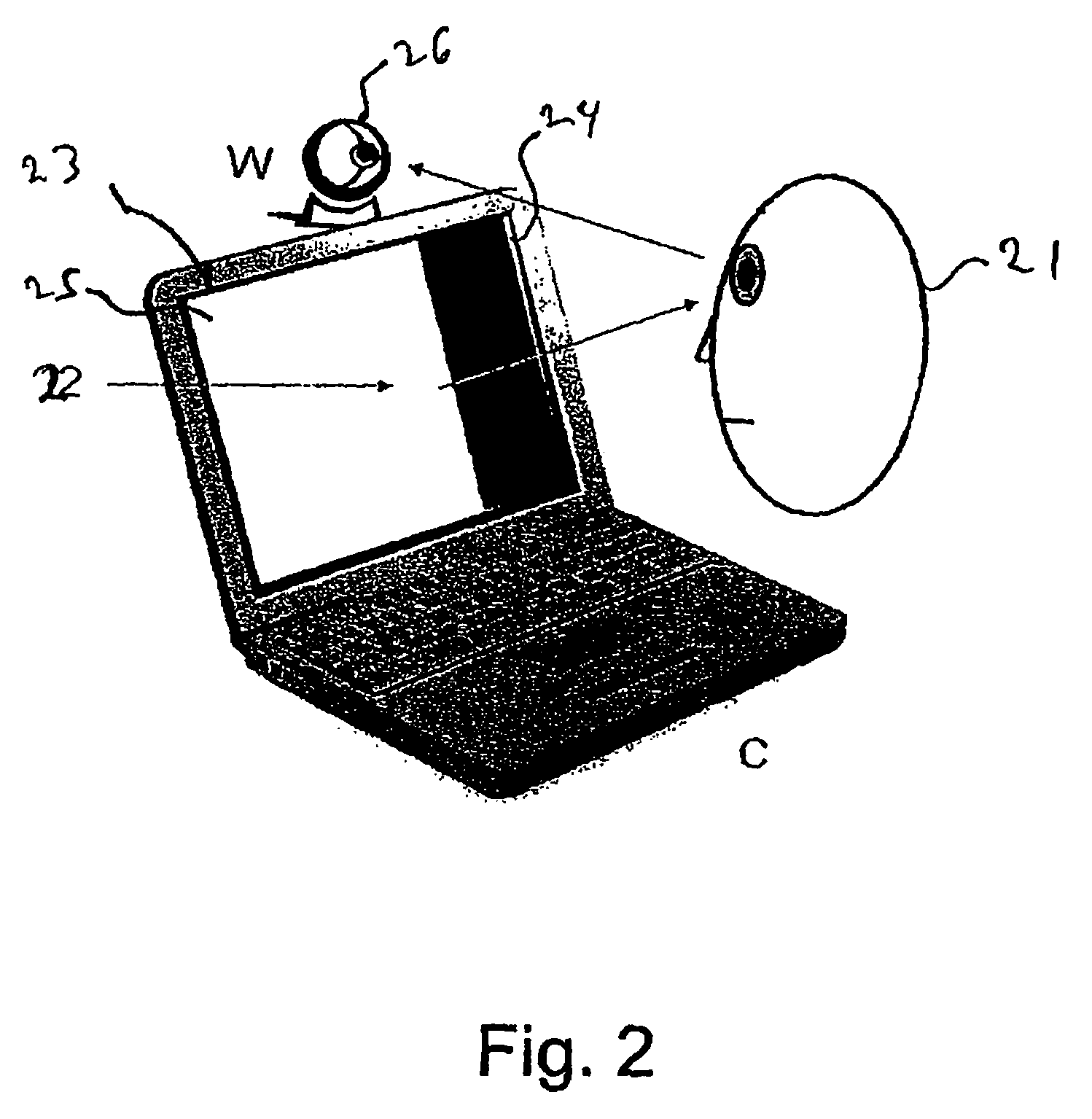

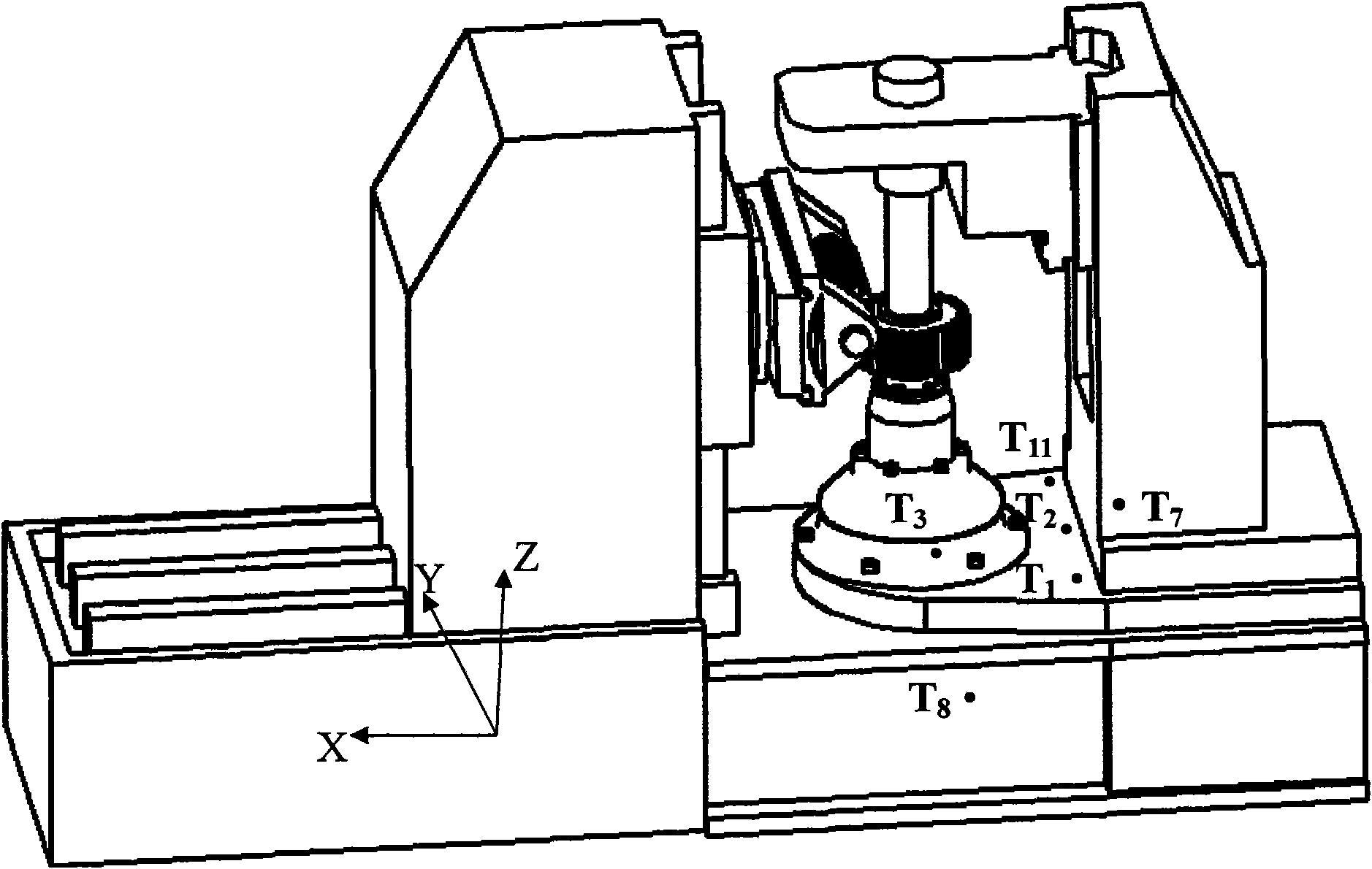

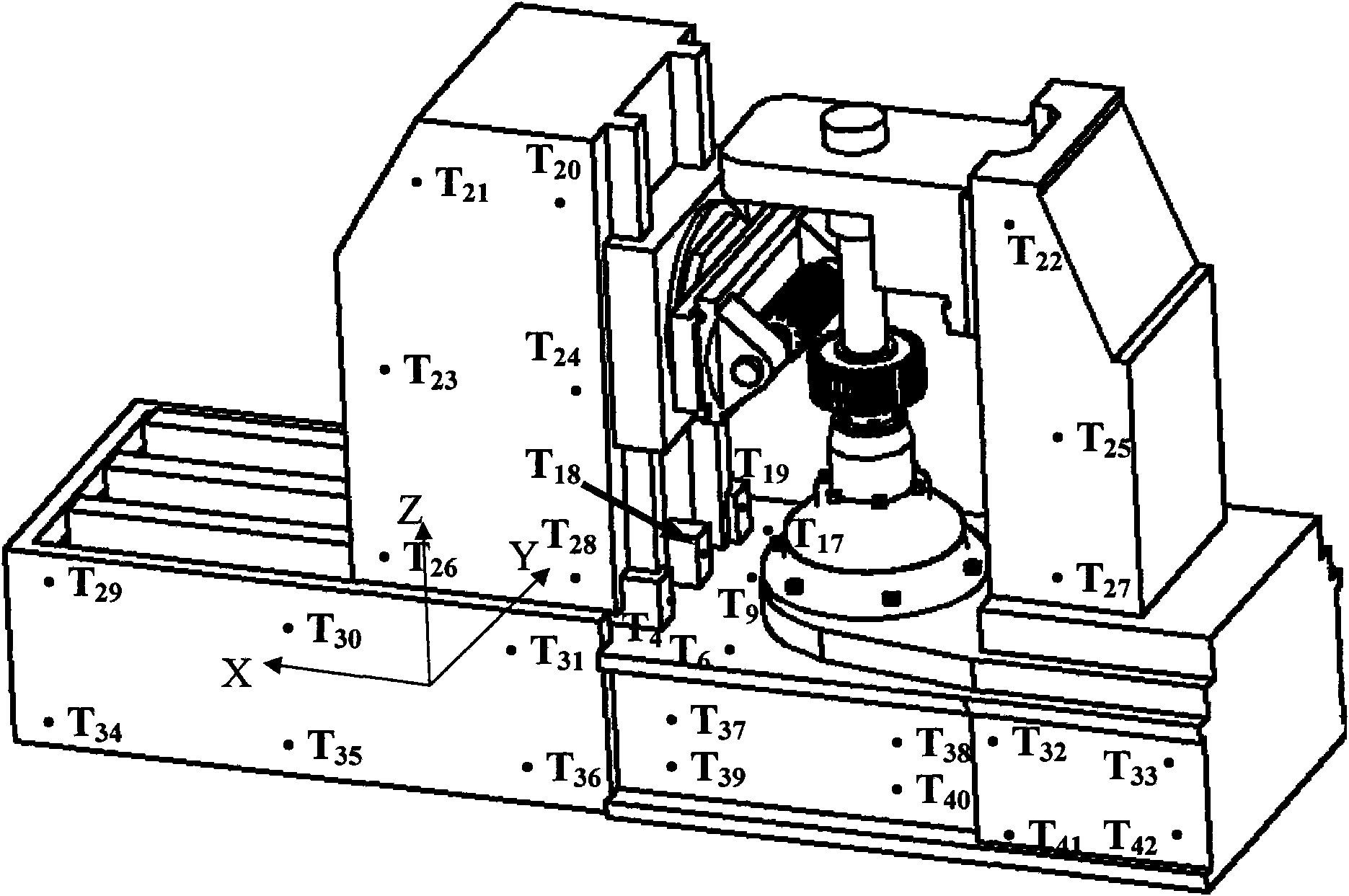

Method for thermal deformation error compensation of digital control gear hobbing machine

ActiveCN101797704APracticalImprove stabilityOther manufacturing equipments/toolsLeast squaresMachining process

The invention discloses a method for thermal deformation error compensation of a digital control gear hobbing machine, which comprises the following steps of: 1, adopting temperature and displacement sensors to detect variable values of a temperature and a thermal deformation displacement on line when the digital control gear hobbing machine is in the course of working; 2, using a fuzzy clustering analytic method to calculate linearly dependent coefficients of variables of the temperature and the displacement, performing classification and optimization on the variable of the temperature, and determining the displacement variable Xi for model building and optimized p temperature independent variables T1, T2, T3, ..., and Tp; 3, adopting a multiple linear regression-least square method to establish a mathematic model of thermal errors and temperature variables; and 4, realizing online real-time compensation of thermal deformation errors of the digital control gear hobbing machine by using a zero programming system. The method solves thermal deformation error problems of a processing gear of the digital control gear hobbing machine, and by performing the online real-time error compensation on the digital control gear hobbing machine, the method improves the gear processing quality, the accuracy and the efficiency, reduces the rejection rate, saves the cost and shortens the processing cycle.

Owner:CHONGQING MACHINE TOOL GROUP +1

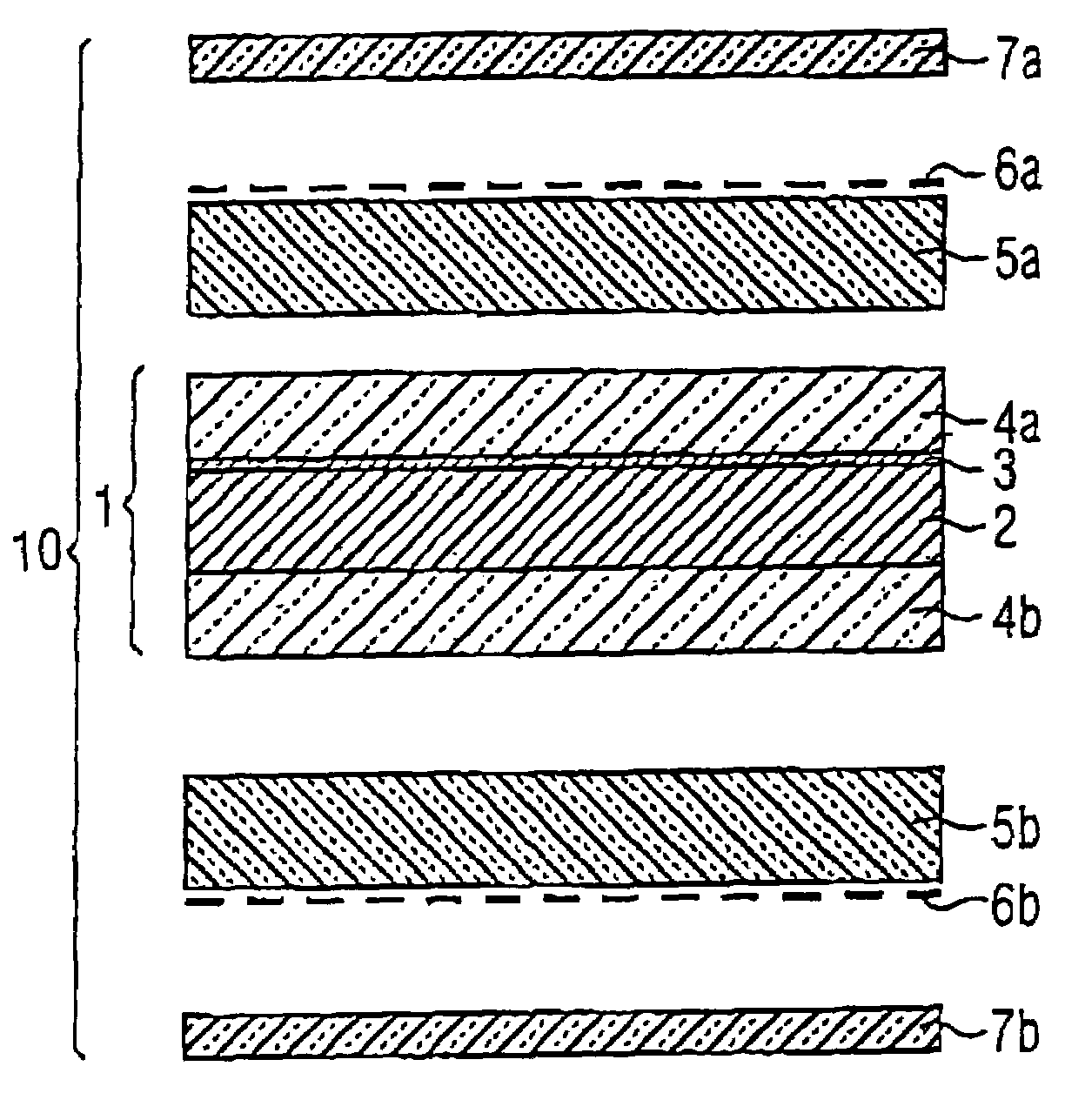

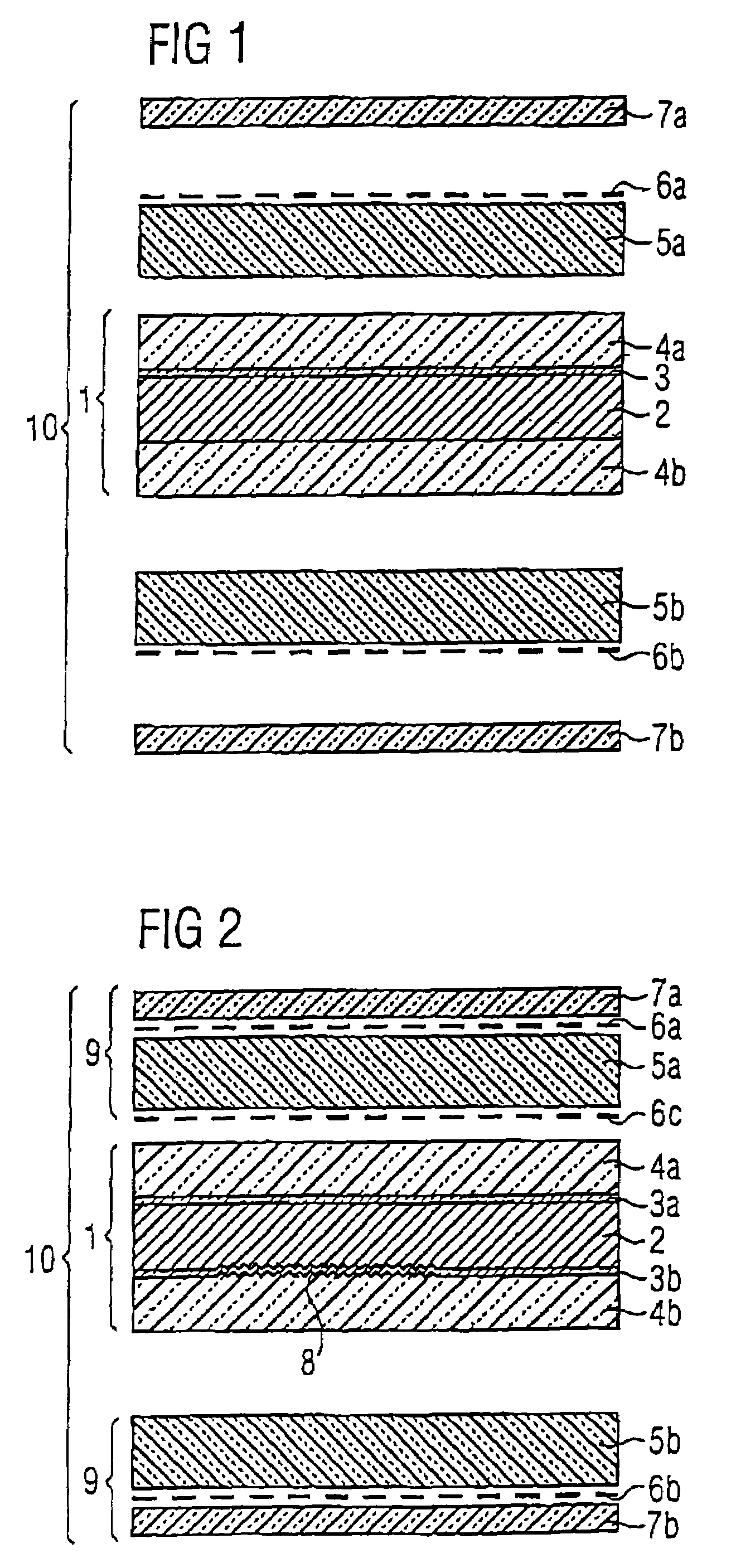

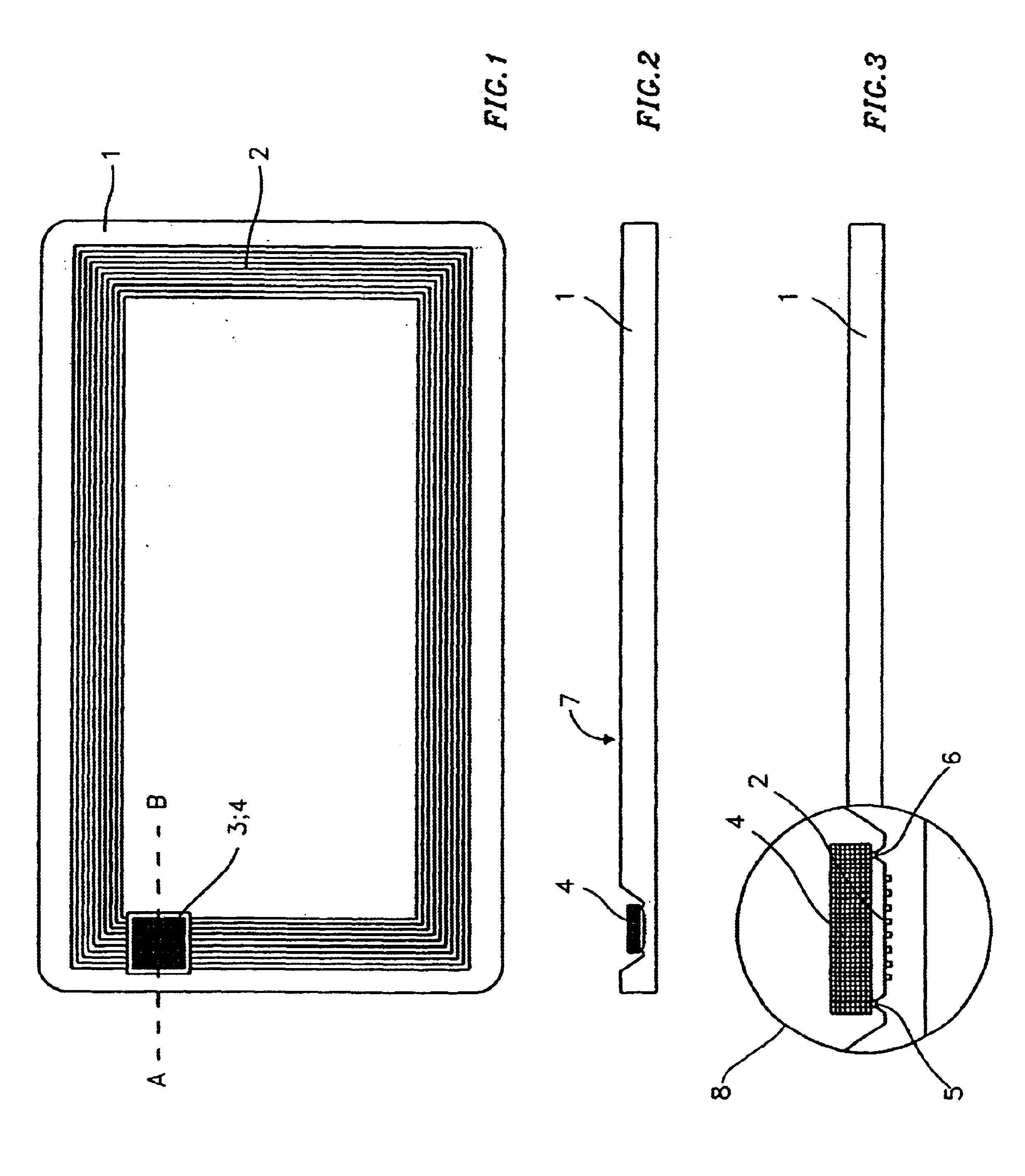

Card laminate

ActiveUS7503503B2StructuredRemarkable effectRecord carriers used with machinesProviding materialPlastic film

A card laminate is produced from a centrally disposed foil laminate (1) consisting of an interior layer (2) with a metal layer (3) and with two exterior transparent plastic layers (4a, 4b), and two exterior plastic films (5a, 5b) of which at least the plastic film (5a) overlying the metal layer (3) is transparent and carries a print (6a). If the print (6a) is on the exterior, a transparent cover layer (7a) is furthermore provided. Materials and layer thicknesses are preferably selected symmetrically to the interior, metallized layer (2, 3) in order to reduce warping effects.

Owner:GIESECKE & DEVRIENT MOBILE SECURITY GMBH

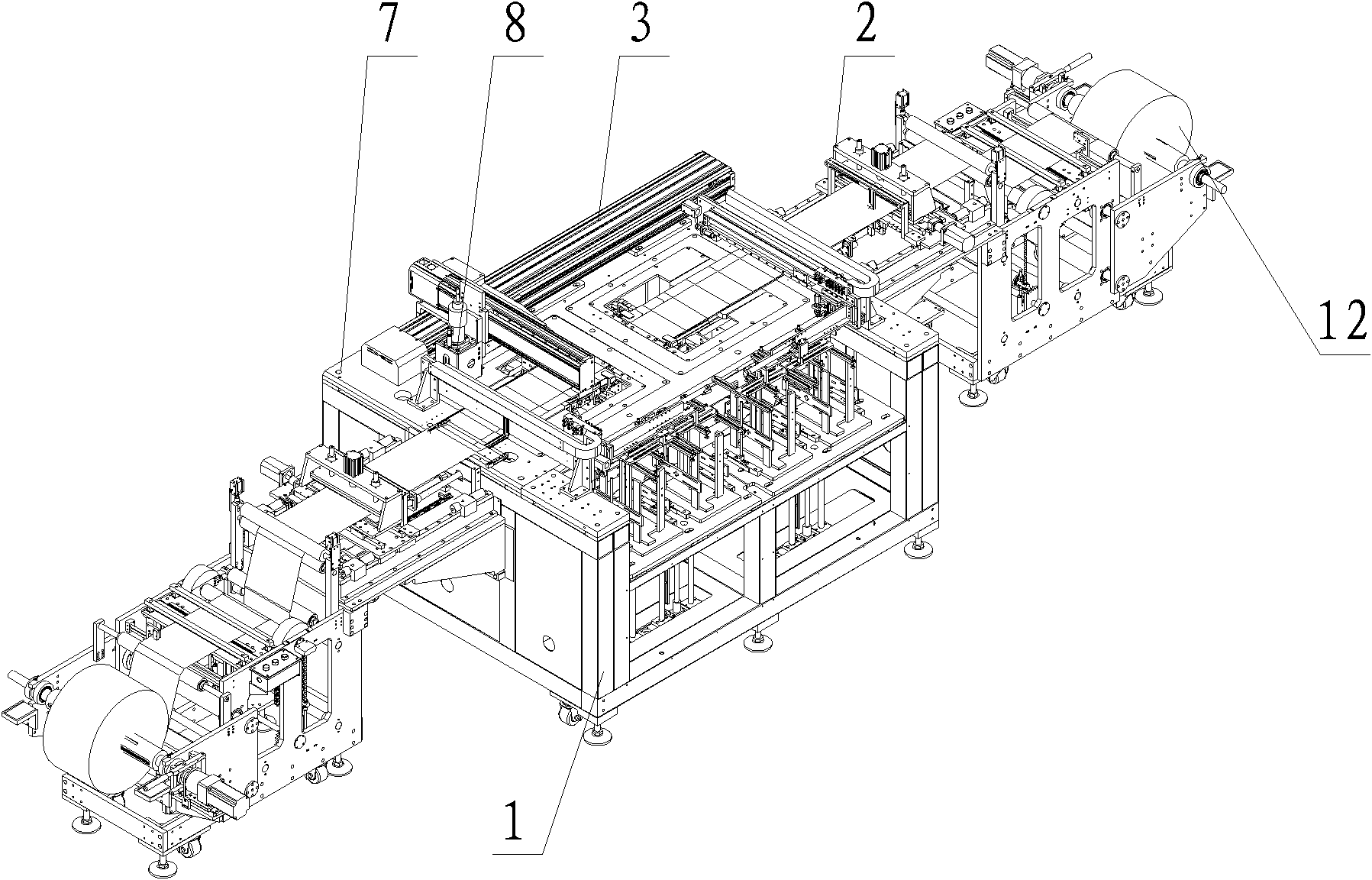

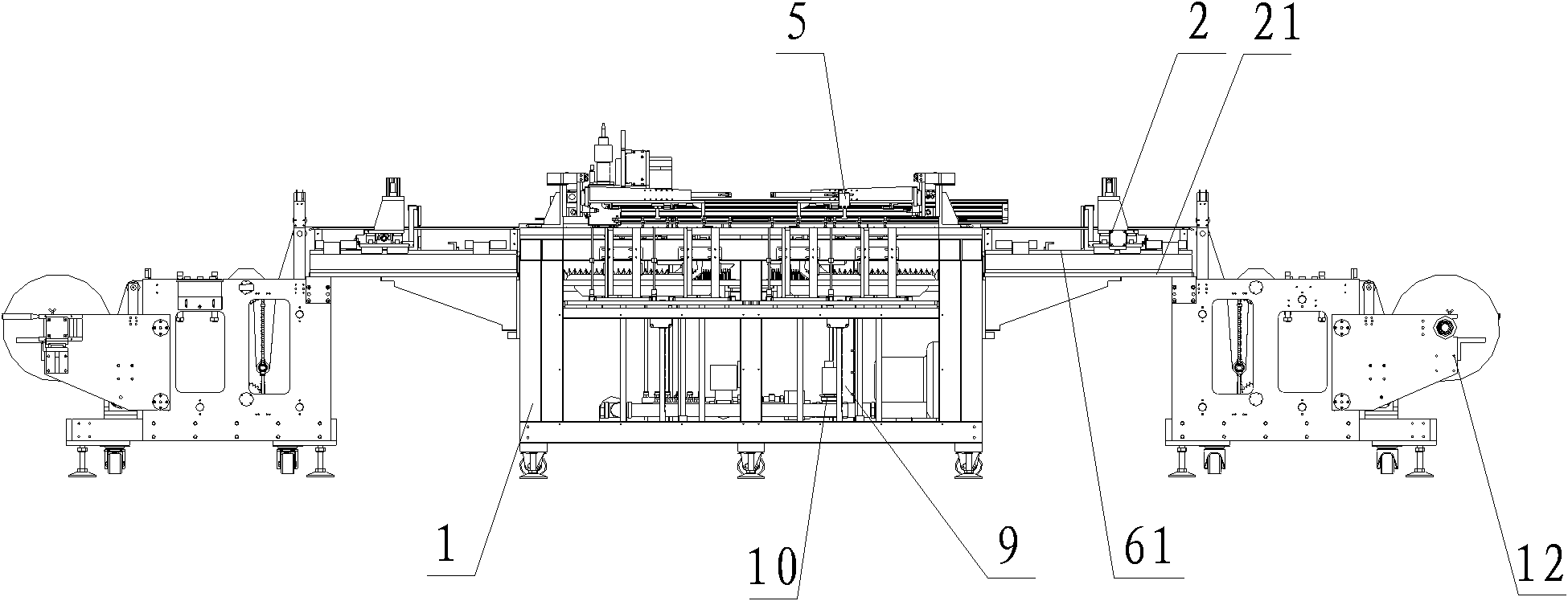

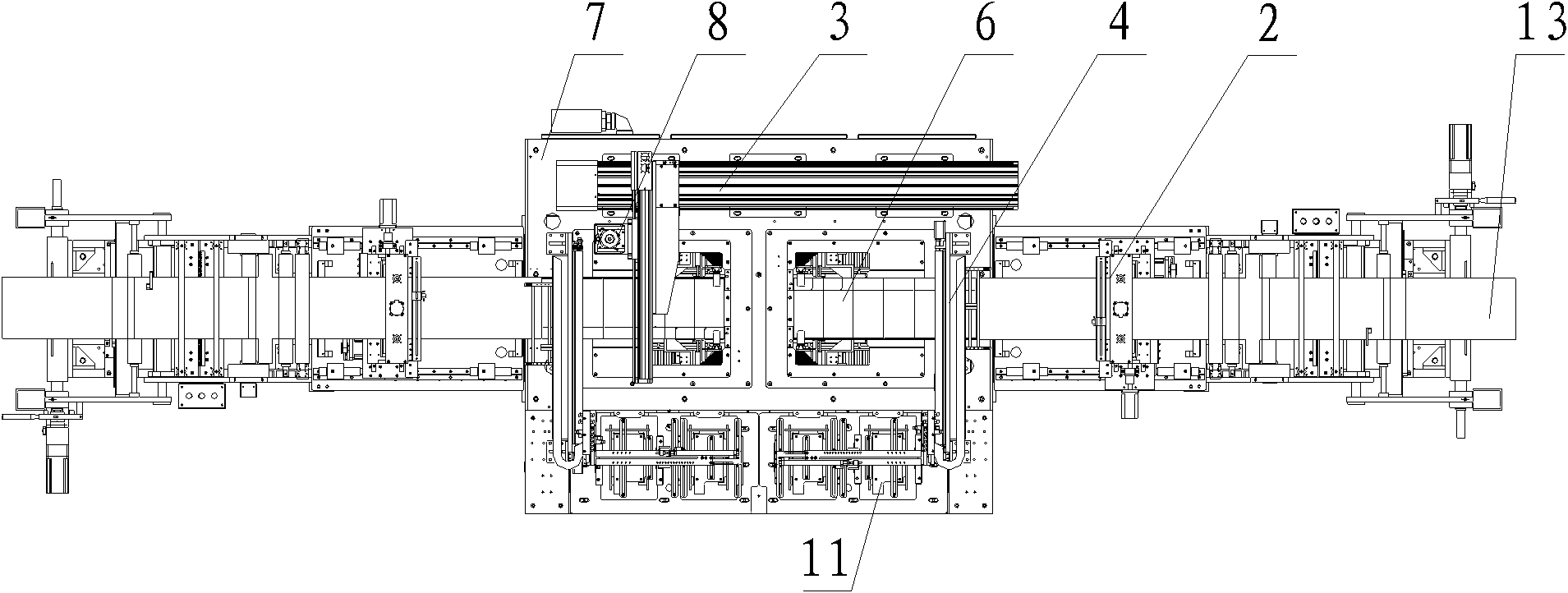

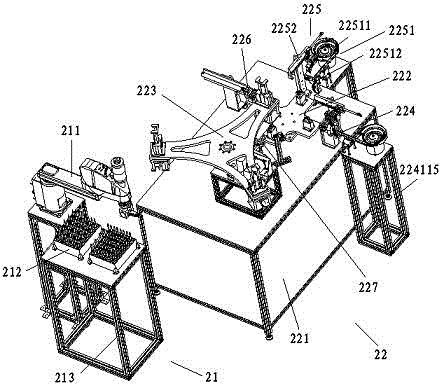

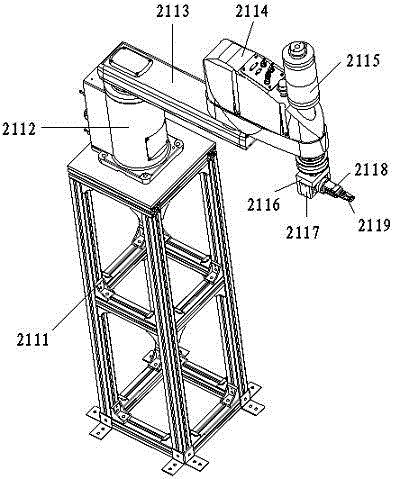

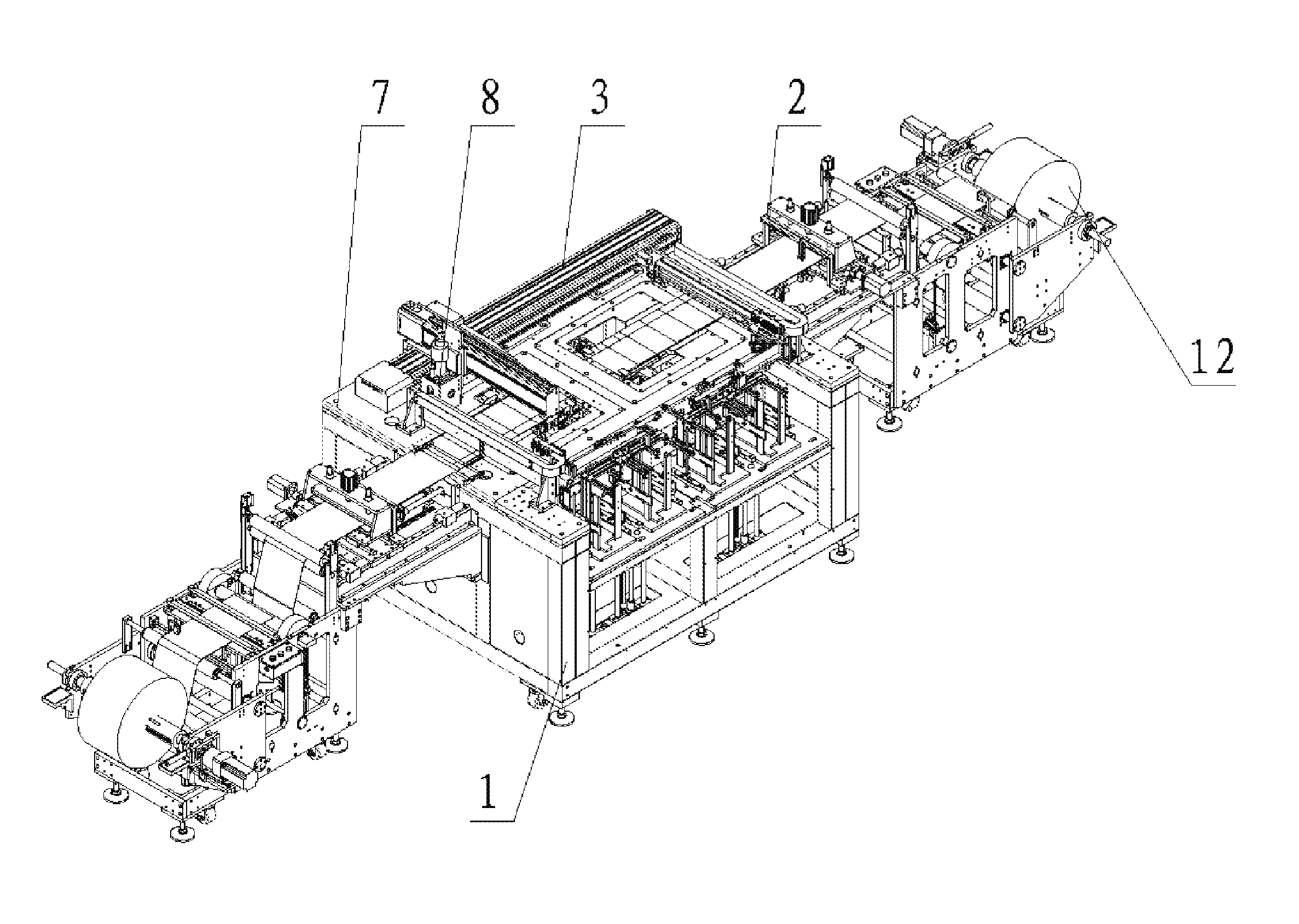

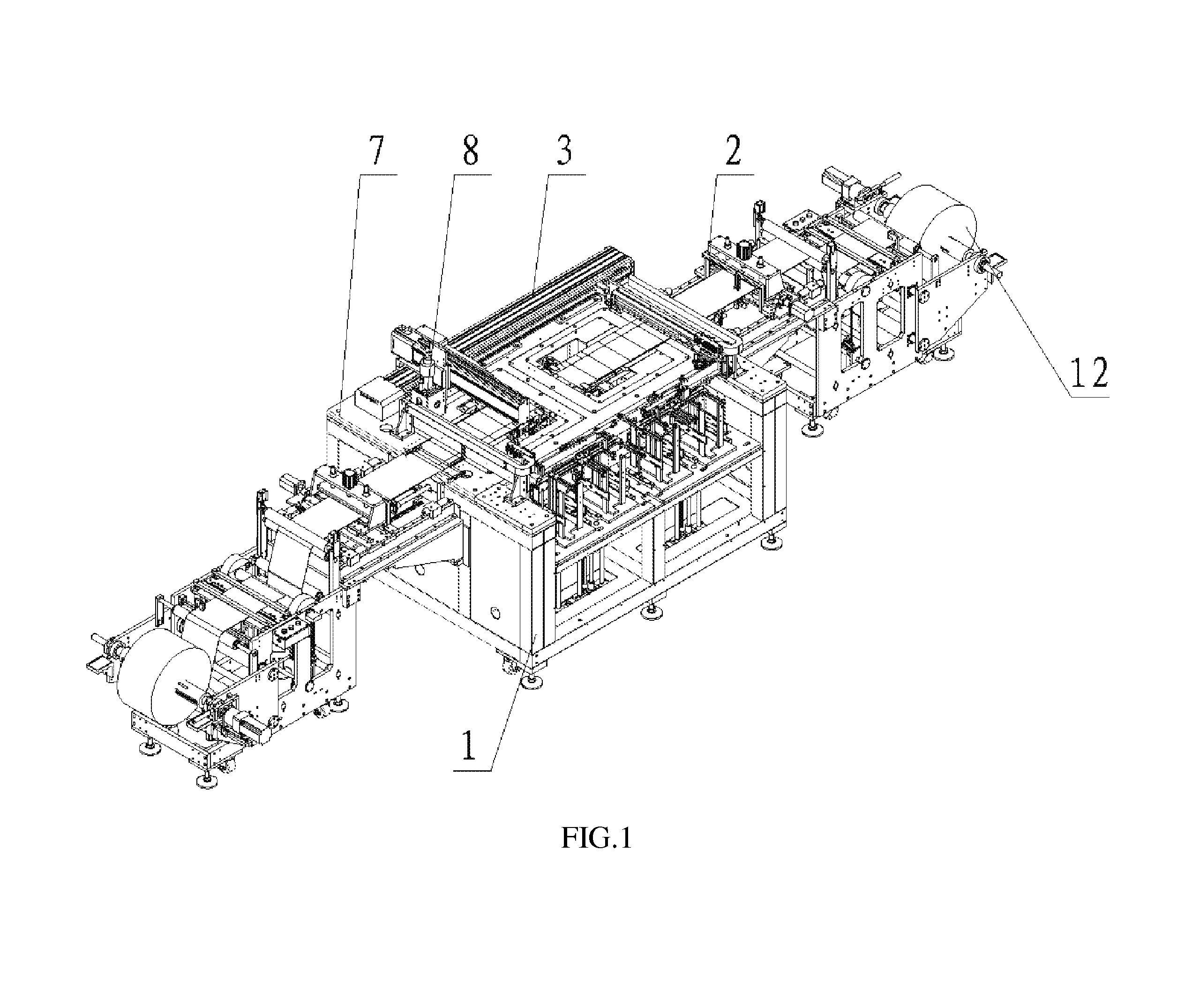

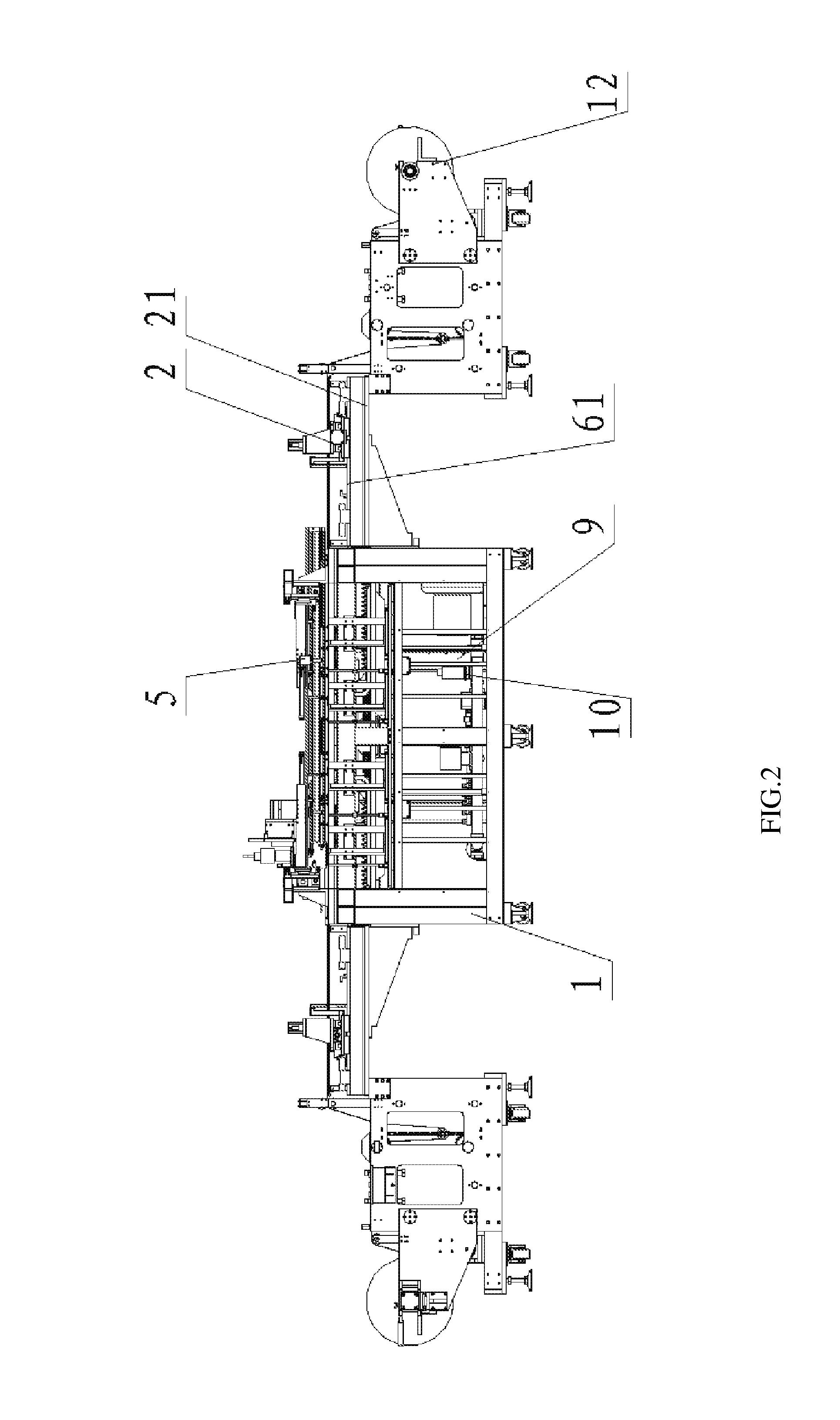

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Fraud resistant biometric financial transaction system and method

ActiveUS20120321141A1Out of controlReduce scrap rateDetecting live finger characterSpoof detectionLivenessBiometric data

A method and system for authenticating financial transactions is disclosed wherein biometric data is acquired from a person and the probability of liveness of the person and probability of a match between the person or token and known biometric or token information are calculated, preferably according to a formula D=P(p)*(K+P(m)) , wherein K is a number between 0.1 and 100, and authenticating if the value of D exceeds a predetermined value.

Owner:EYELOCK

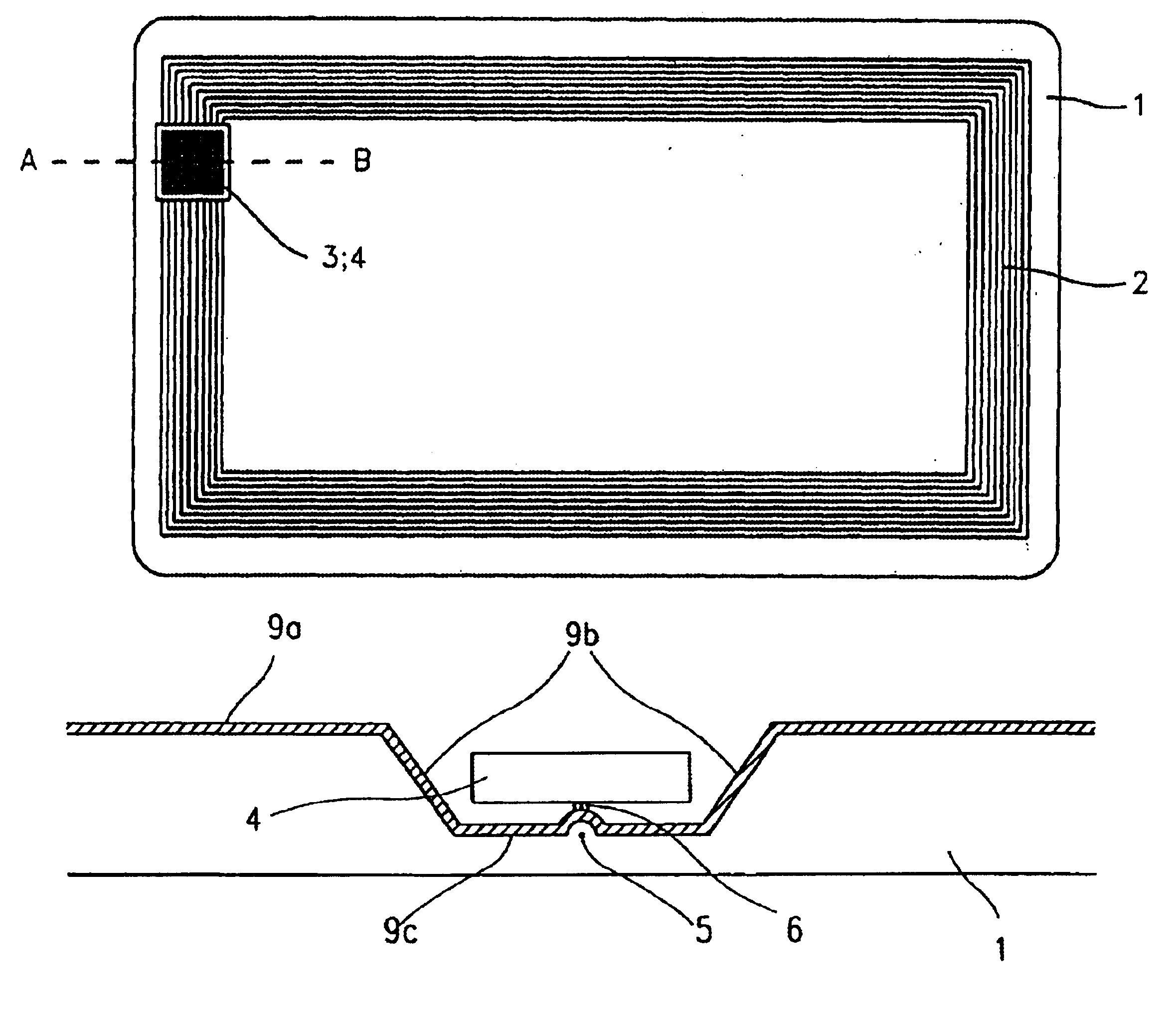

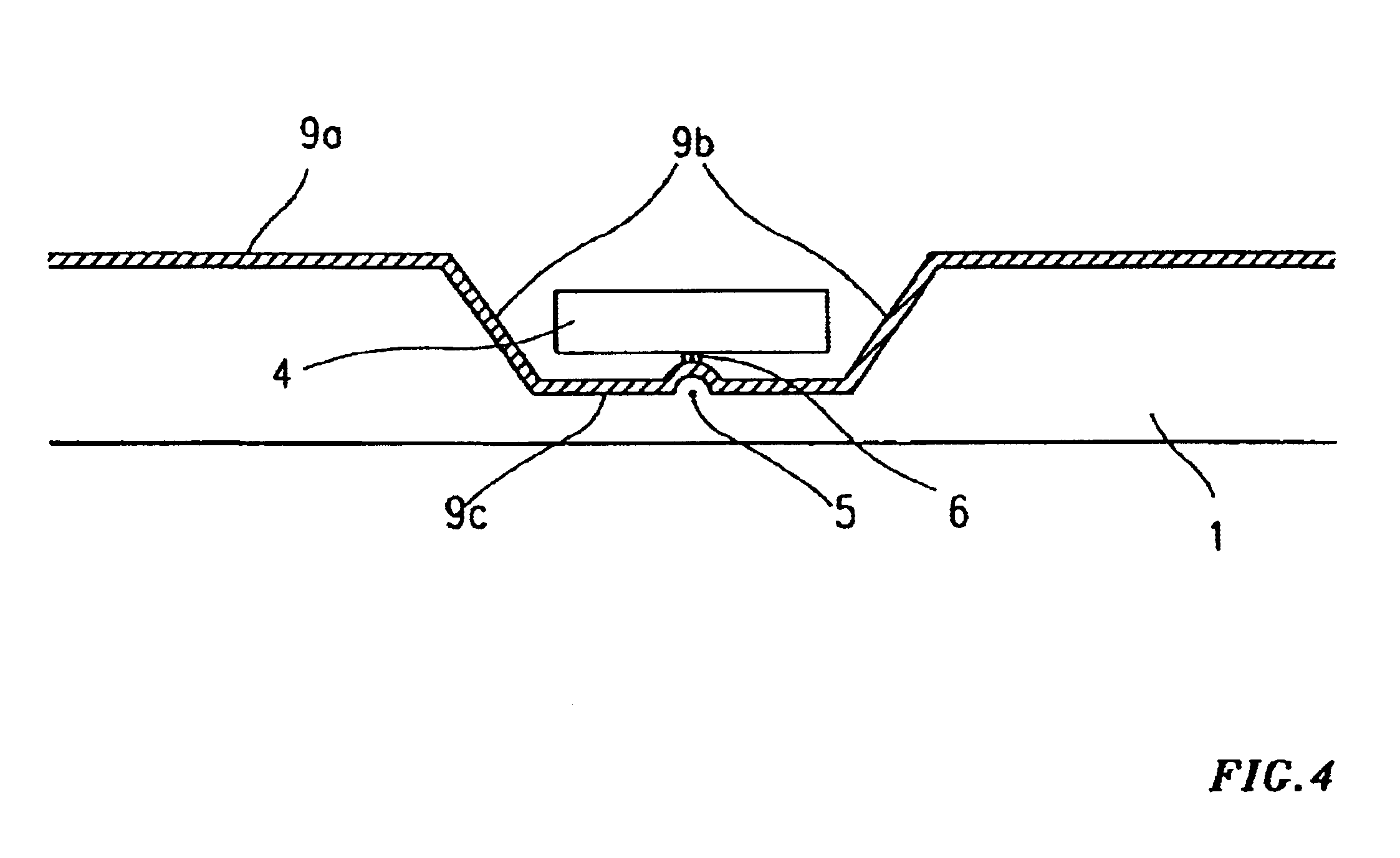

Method for producing contactless chip cards and corresponding contactless chip card

InactiveUS6651891B1Reduce riskSimple and economy-priced productionSolid-state devicesSensing record carriersElectrical conductorEngineering

The present invention relates to a method of producing a contactless chip card. In a first step of the method, a card body with one or a plurality of recesses on one card body side is produced from a theremoplastic material, preferably by injection moulding. Bumps being formed on the base surface of the recesses. Subsequently, conductor tracks corresponding to a coil as a conductor track pattern are impressed directly onto surface areas of the card body side including the recesses using a hot impressing technique. The conductor tracks are impressed especially also onto surface areas inside the recesses such that same extends across the bumps. One or a plurality of chips are then aligned in the recesses and contacted with the conductor tracks in the recesses which extend across the bumps. The method according to the present invention is advantageous insofar as it permits a simple production of a chip card, which requires only a few method steps and is therefore also economical. Furthermore, such a chip card is both mechanically stable and reliable, since it comprises very few individual layers and since the conductor tracks of the coil are applied directly to the card body.

Owner:PAC TECH PACKAGING TECH

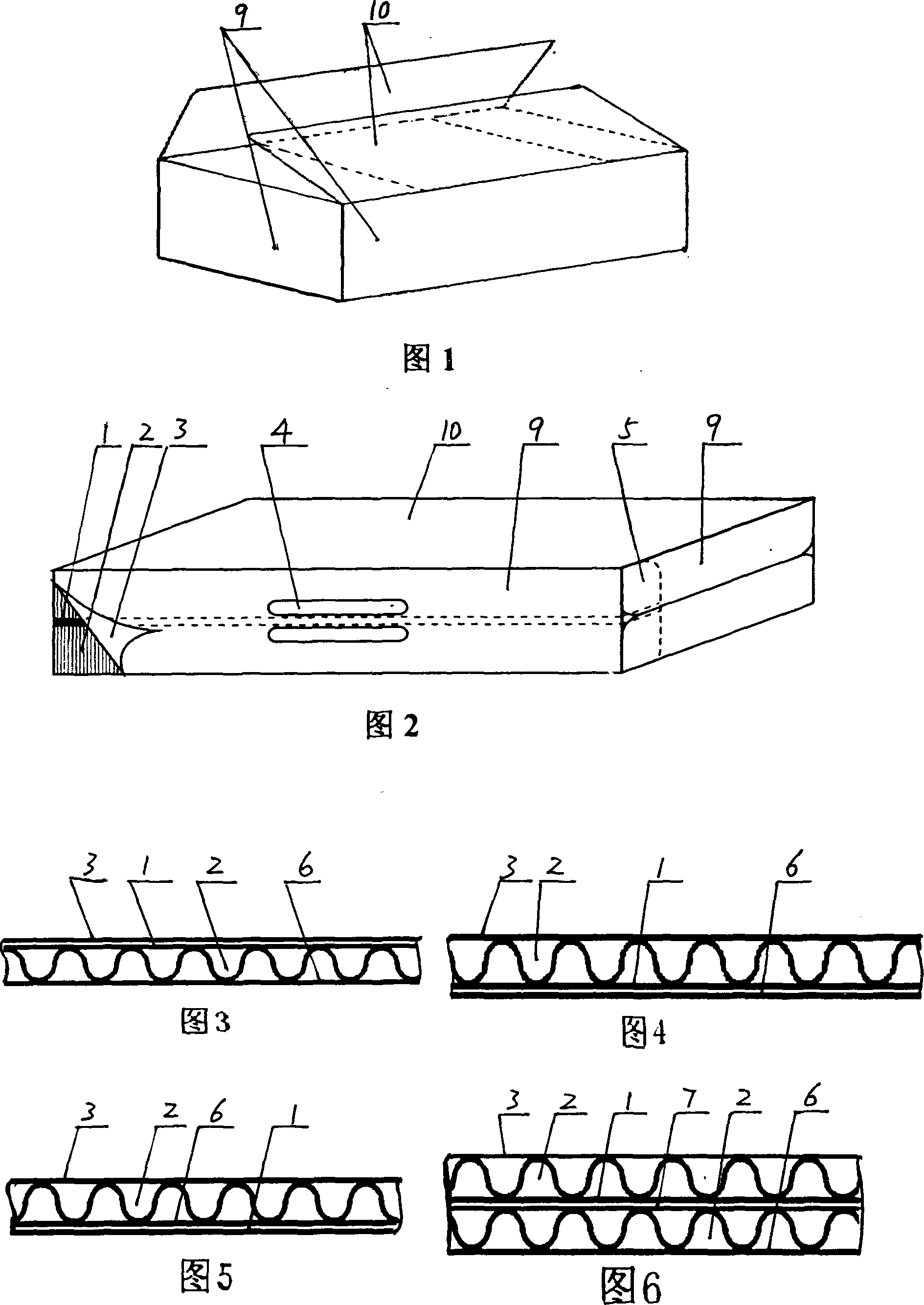

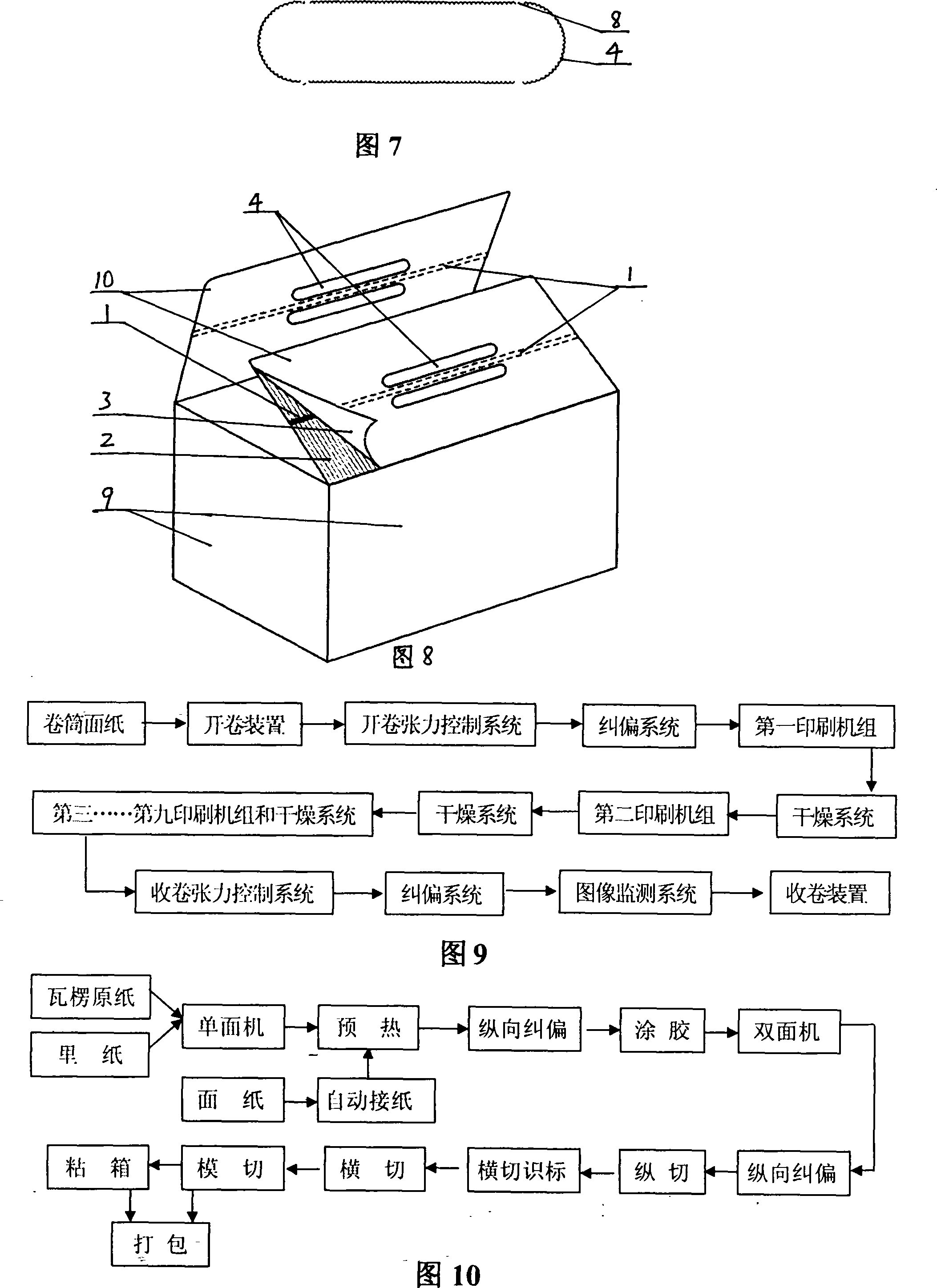

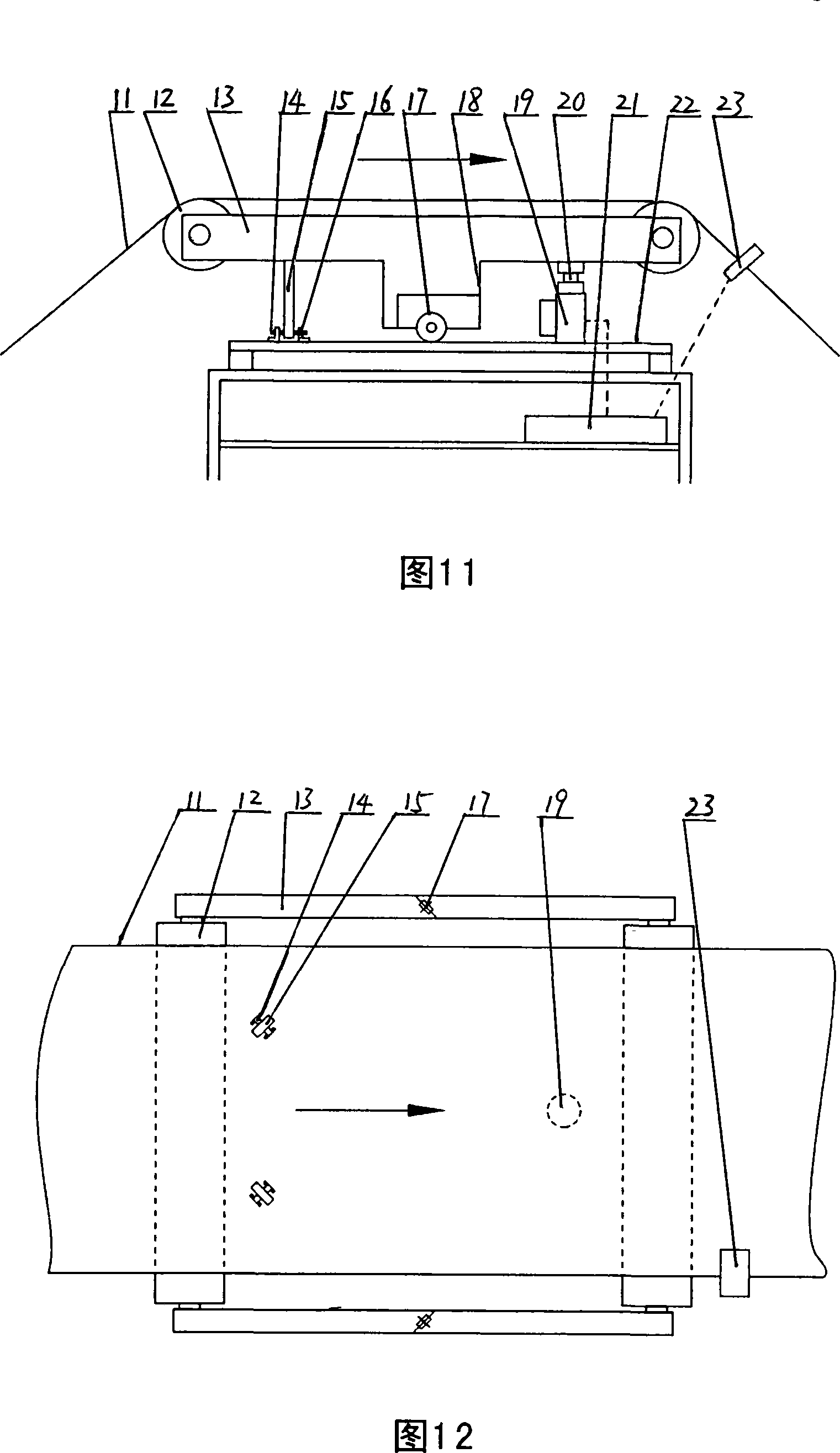

Flexible preprinting cardboard box, production method and production equipment thereof

The invention discloses a flexibly pre-printed paper box, a manufacture method and a manufacture equipment thereof; the paper box has a box body consisting of a printed sheet, corrugated paper, inner paper and in some cases core paper; color patterns on the printed sheet are flexibly printed on the printed sheet before the paper box is manufactured. The manufacture method consists of a manufacture method of flexibly printed paper sheet and a manufacture method of the paper box; firstly the color patterns are manufactured on the printed sheet with a rotary flexographic press; then bright oil is applied, and then the printed sheet, the corrugated paper and the inner paper are made into the paper box by adopting a corrugated paper manufacture device; some paper box also comprises the core paper. The manufacture device consists of the rotary flexoographic press, the corrugated paper manufacture equipment and a die-cutting machine. Adopting the method and the equipment of the invention, the manufactured paper box is green and environmental protective, nice in printed patterns, high in compressive strength, convenient in lifting and low in reject rate; compared with paper boxes which are printed with offset printing and directly with flexible plate of the same quality requirement, the paper box of the invention has lower cost.

Owner:保定中士达包装有限公司

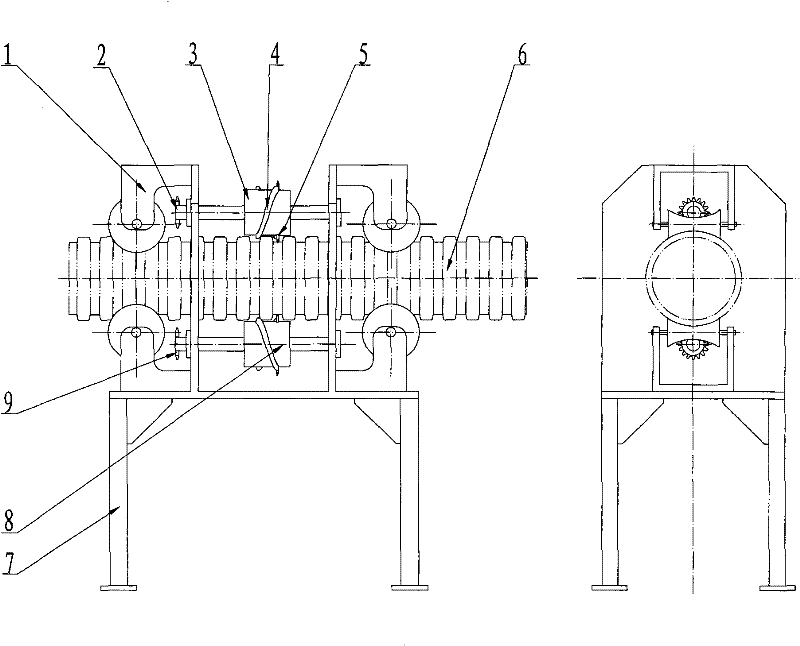

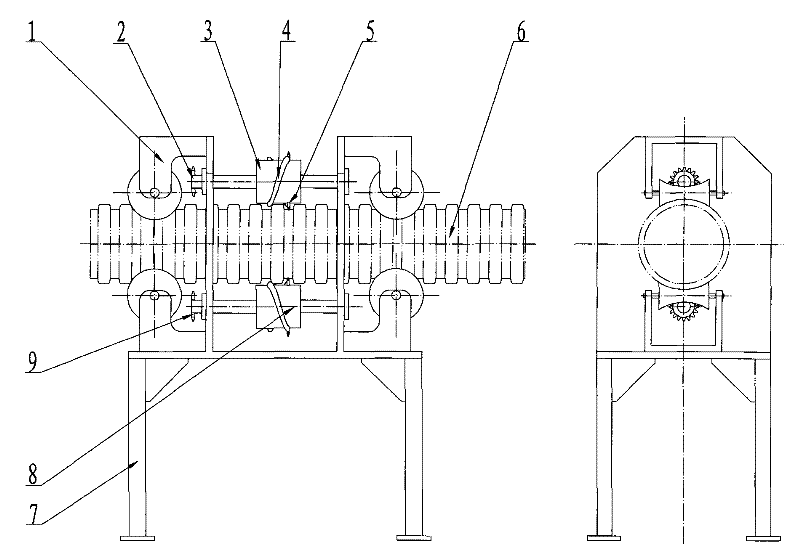

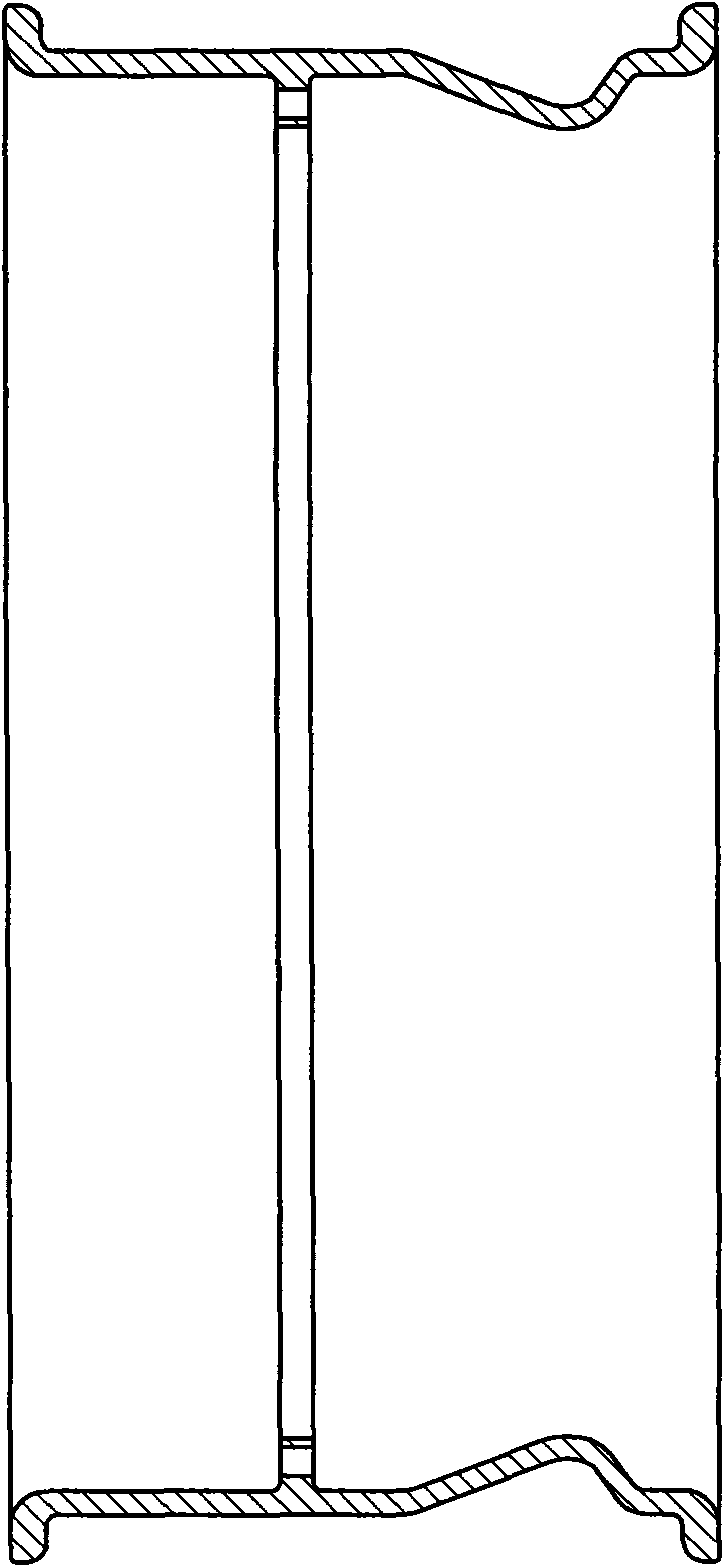

Worm-type plastic corrugated pipe grooving machine

The invention relates to a worm-type plastic corrugated pipe grooving machine. Function of conveying plastic corrugated pipes is completed by a worm curve fixed on a cutter bar of a grooving cutter; the functions of cutting and grooving are realized by one alloy cutter head arranged at the terminal of the worm curve, the worm curve is meshed with wave crests of the plastic corrugated pipes, the plastic corrugated pipes advance for one pitch when being pushed by the worm curve once the cutter bar rotates for a circle, namely the plastic corrugated pipes advance to the next wave crest from the current wave crest, the alloy cutter head arranged at the terminal of the worm curve carries out grooving on the current wave crest for once, the alloy cutter head arranged at the terminal of the worm curve is vertical to axes of the plastic corrugated pipes to ensure that a blade is in a cutting interval while the plastic corrugated pipes do not axially move, the plastic corrugated pipes continuously axially move along with rotation of the cutter bar, and the blade carries out grooving on the wave crest one by one. The grooving machine provided by the invention has simple mechanical structure, no independent pipe conveying device or electronic and electrical inductive control system is required, grooving position is accurate, grooving quality is greatly improved, and rejection rate is greatly reduced while grooving efficiency is greatly improved.

Owner:ZHANGJIAGANG BEIER MACHINERY

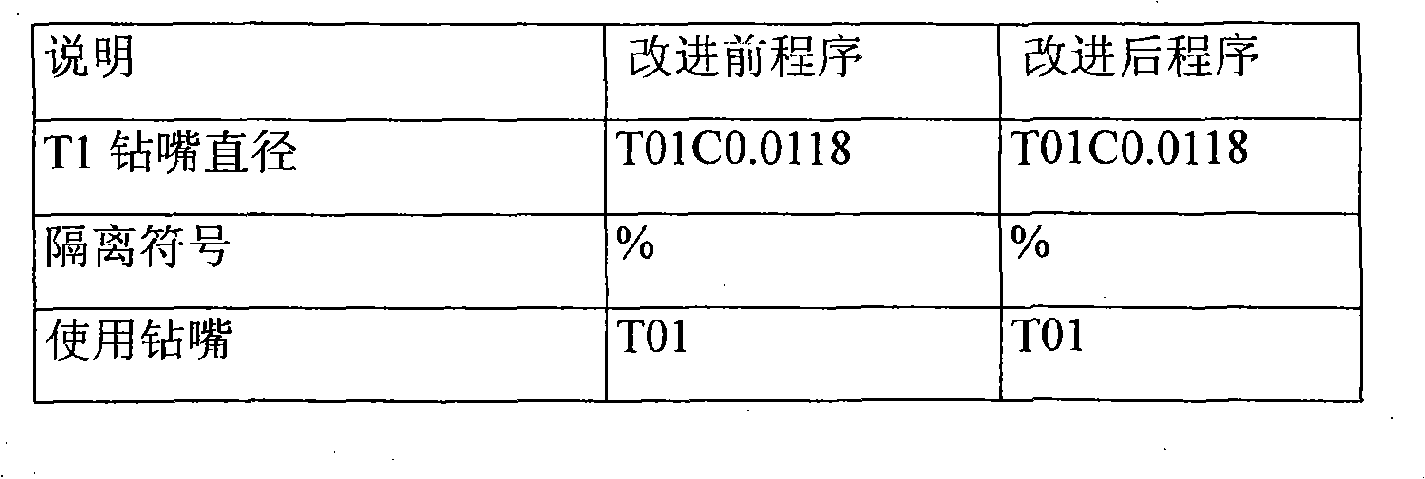

Small-aperture high-density drilling method of printed circuit board

InactiveCN101537505AIncrease working edge lengthReduce the spindle dynamic yaw valuePrinted circuit manufactureHigh densityEngineering

The invention aims at the technical state of the prior printed circuit board drilling method to provide a mechanically drilling method of a high-density and small-aperture multilayer printed circuit board, which improves the drilling machine yield and has good drilling quality by improving drilling parameters. The method mainly comprises the following steps of adjusting zero-position, setting drilling parameters, drilling positioning holes, installing bearing plate, substrate and aluminum sheet, drilling, grinding raw edges, blowing holes and inspecting, wherein the drilling order is set by a leap-frog method with coordinate hole space not smaller than 4 mm; the hole position requirements are converted into a PCB drilling program by CAM, the original hole positions are arranged in sequence, and the drilling sequence is deigned according to the standard of the coordinate hole space not smaller than 4 mm; the pressure foot gasket of a main shaft of a drilling machine is a soft plastic pressure foot gasket; and the bit is a UC-type bit with good chip removal effect, and the total thickness of the drilled substrate is up to 4.5 to 4.8 mm.

Owner:NANJING ELEC & ELTEK ELECTRON

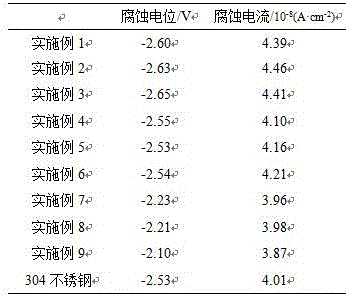

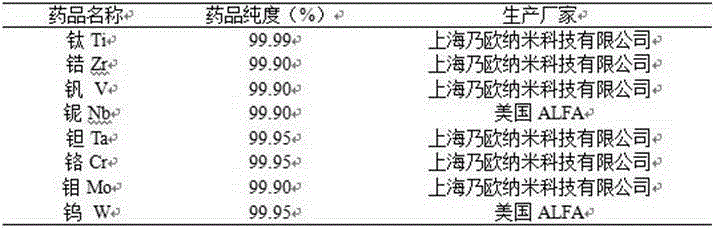

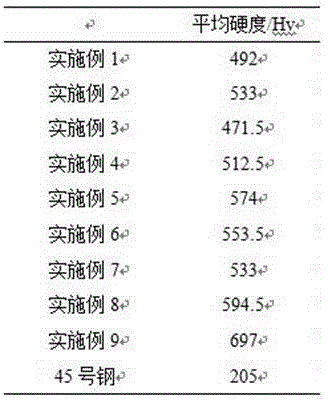

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

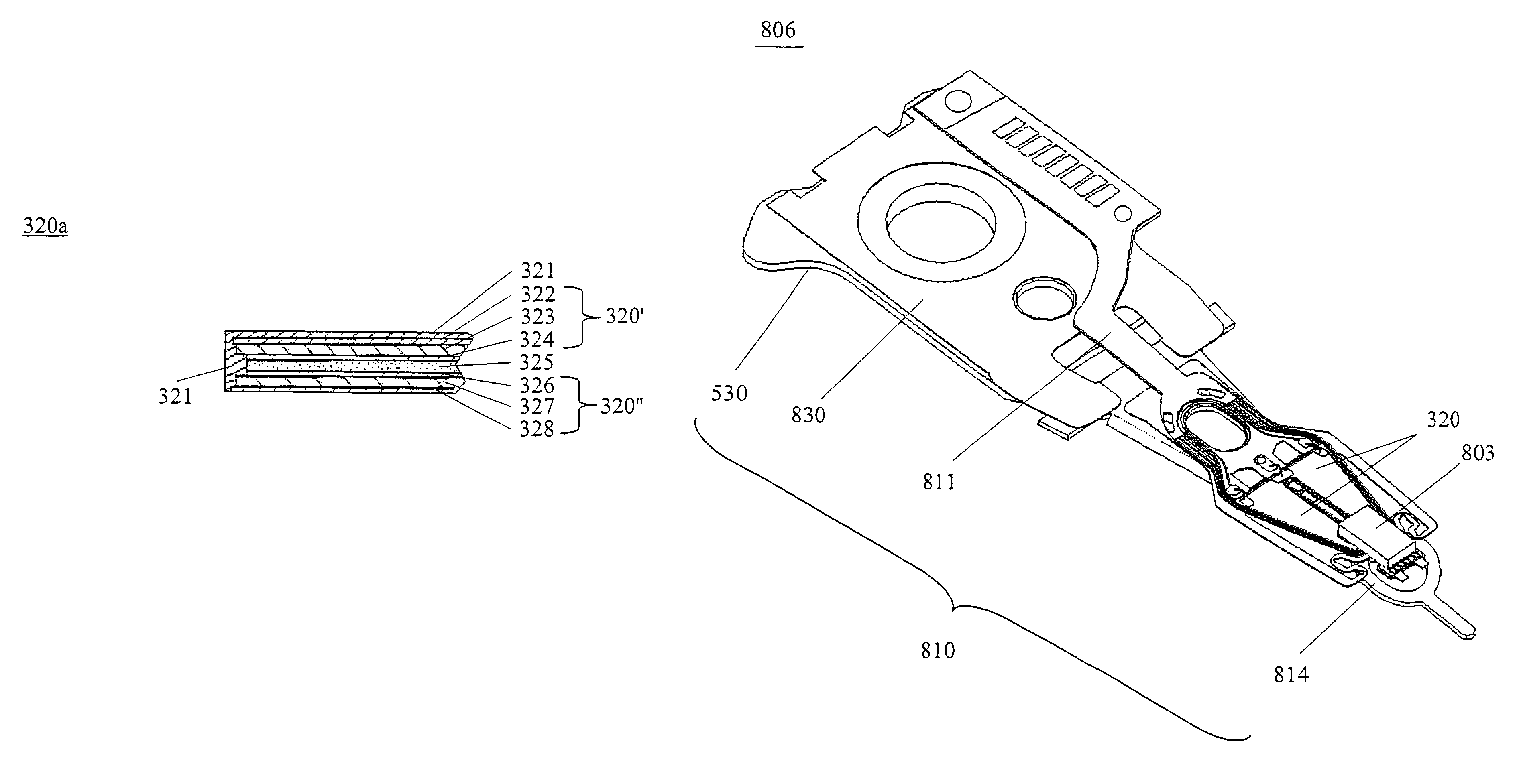

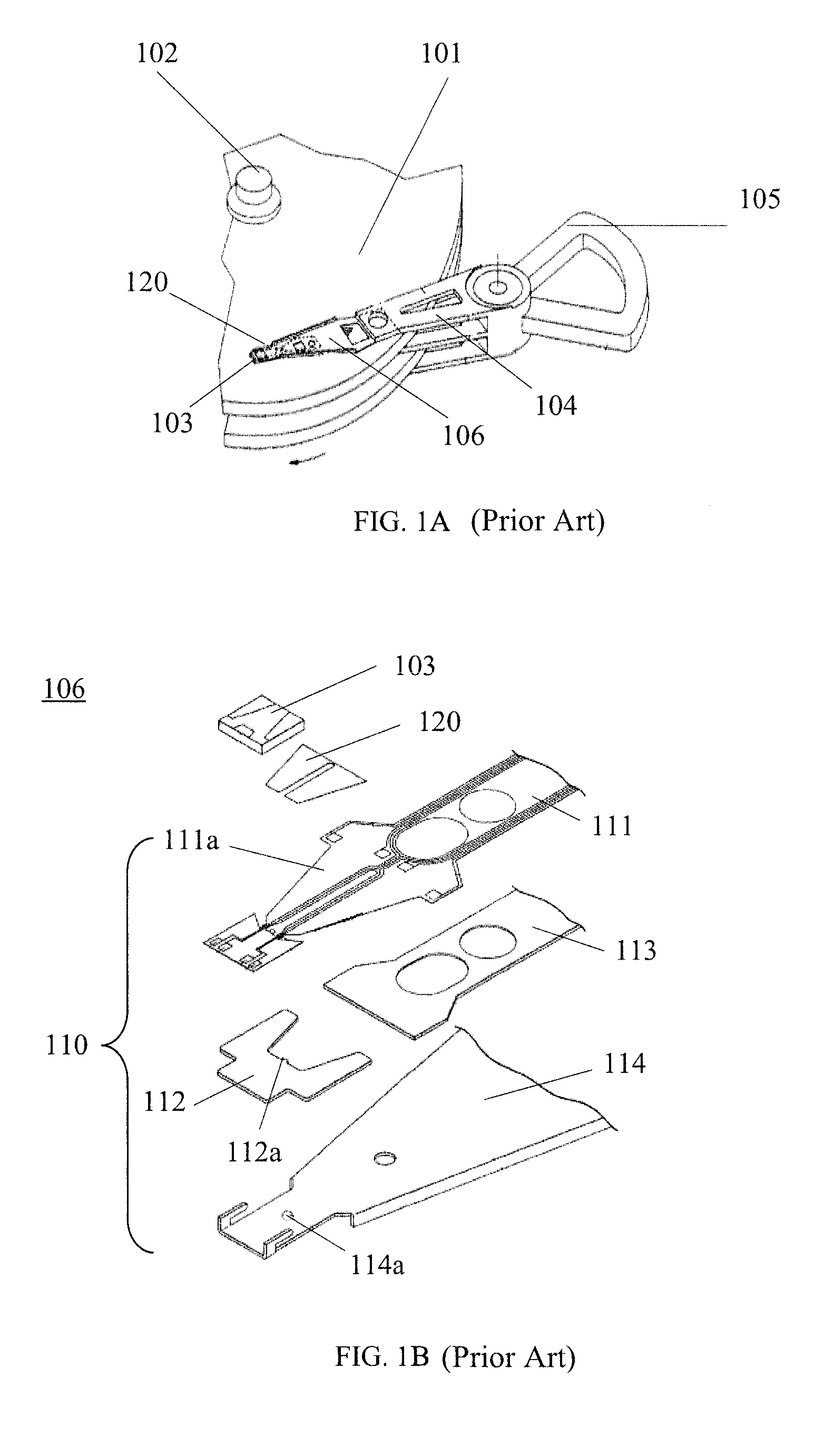

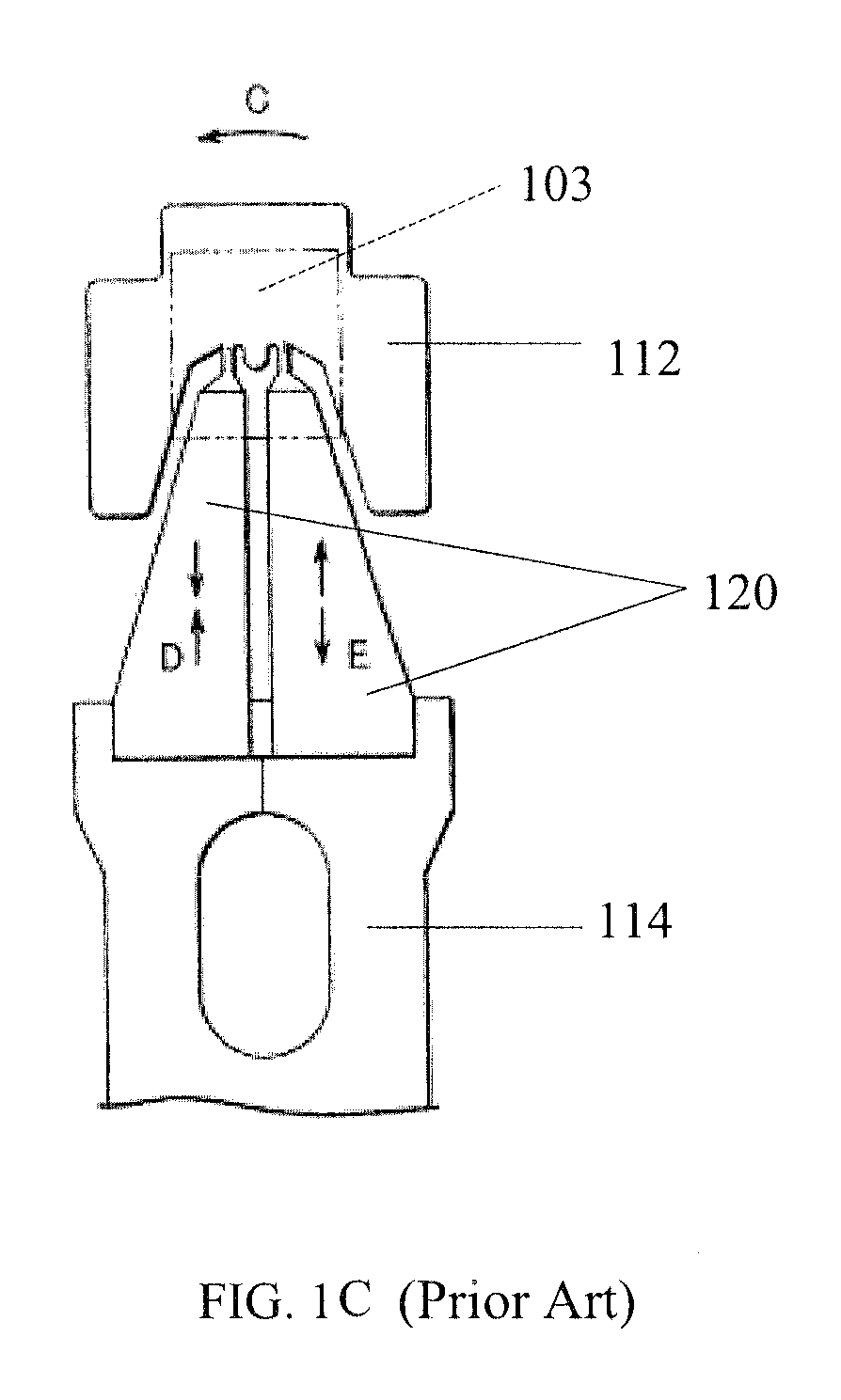

Piezoelectric element having etched portion to form stepped recesses between layers and manufacturing method thereof, head gimbal assembly, and disk drive device with the same

InactiveUS8194359B2High insulation resistanceReduce manufacturing costPiezoelectric/electrostrictive device manufacture/assemblyDisposition/mounting of recording headsElectrical resistance and conductanceStructural engineering

A piezoelectric element comprises a first laminated structure body and a second laminated structure body. Side surfaces of the first and the second laminated structure bodies that are parallel to a laminating direction both have at least a portion etched to form a recess so that a step distance is formed between sides of the two adjacent electrode layers that are parallel to the laminating direction. The design of the step distance increases insulation resistance between the two adjacent electrode layers on the opposite surfaces of the piezoelectric layer, and lowers reject rate. The first and the second laminated structure bodies are symmetrically laminated and bonded together, thus optimizing force balancing performance. The present invention also discloses a method of manufacturing a PZT element, a HGA with the PZT element and a disk drive unit having such HGA.

Owner:SAE MAGNETICS (HK) LTD

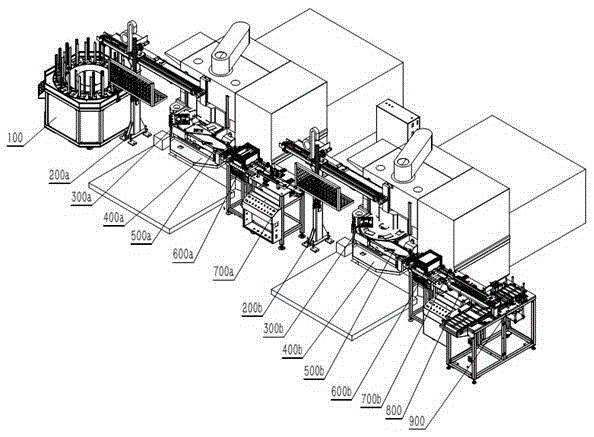

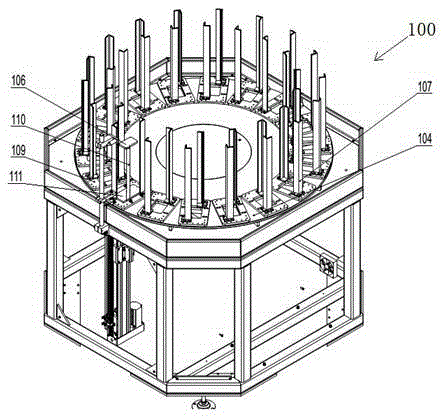

Electric heating rod assembly machine

ActiveCN105855897AImprove assembly and welding efficiencyImprove production stabilityAssembly machinesOther manufacturing equipments/toolsElectricityGrating

The invention discloses an electric heating rod assembly machine. The electric heating rod assembly machine comprises an electric control box, a rotary assembly mechanism, a chain assembly line, a coating mechanism, a drying mechanism, an indicator lamp tower and area safety gratings, wherein the indicator lamp tower is mounted on the top plate of the electric control box; the front side of the electric control box is provided with the rotary assembly mechanism; the rotary assembly mechanism is used for conveying a workpiece assembled for a first time to the chain assembly line at the rear side of the rotary assembly mechanism; the chain assembly line is used for conveying a wokpiece assembled for a second time to the coating mechanism at the front right side of the chain assembly line; the coating mechanism is used for conveying an assembled electric heating rod to the drying mechanism at the front side of the coating mechanism; and the area safety gratings are arranged around in a rectangular manner. In this way, the assembly welding efficiency is high, the production stability is good, the product scrap rate is low, and the overall production efficiency is high.

Owner:南通江海港建设工程有限公司

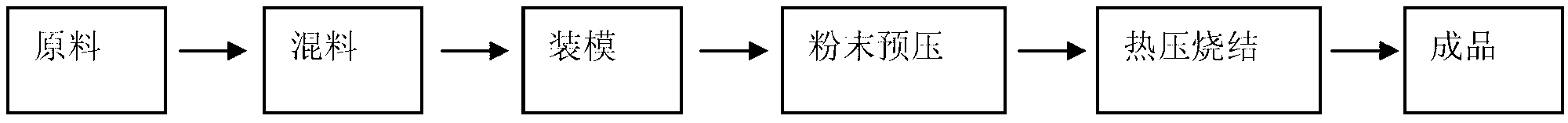

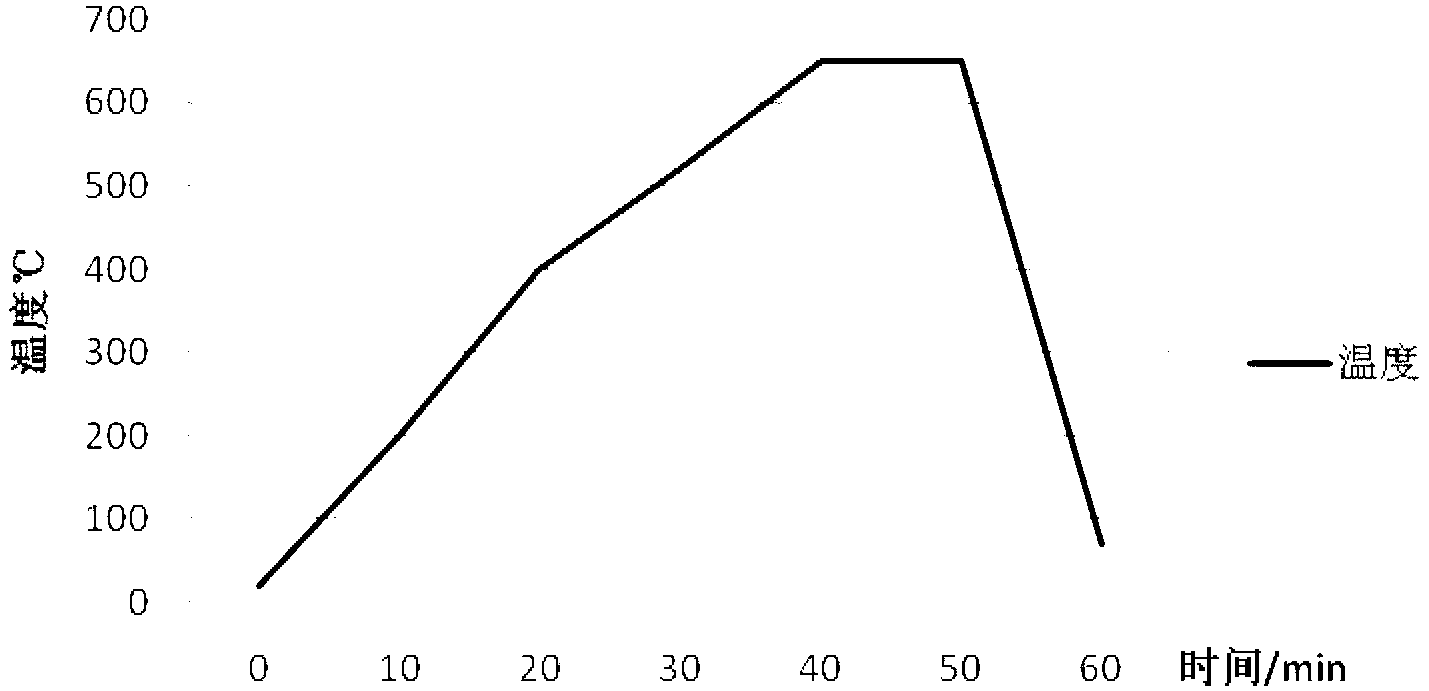

Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

InactiveCN103009270ALow shrinkageHigh strengthAbrasion apparatusGrinding devicesPolyvinyl alcoholDecomposition

The invention provides an online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and a preparation method thereof and belongs to the technical field of precision grinding pellets. Raw materials of the precision grinding pellet comprise a super-hard abrasive and a metallic bond, wherein the super-hard abrasive is diamond micro-powder; the diamond concentration falls within a range of 75-100 %; and the metallic bond uses a multicomponent alloy bond whose main components are copper powder, tin powder, aluminum powder, copper-clad ball shaped graphite powder, silicon dioxide and ferroferric oxide powder. The preparation method comprises the following steps: uniformly mixing and stirring the diamond micro-powder as well as the copper powder, the tin powder and the aluminum powder; adding polyvinyl alcohol to a mixture and mixing the polyvinyl alcohol and the mixture; adding the silicon dioxide, the copper-clad ball shaped graphite powder and the ferroferric oxide powder to an obtained mixture and mixing these materials and the obtained mixture; filling the mixture into a graphite mold; maintaining the pressure of the graphite mold for 5-10 minutes after pressurizing the graphite mold to 100-250 MPa; and carrying out hot pressing sintering on the graphite mold in a sintering furnace, wherein the sintering atmosphere is ammonia decomposition gas. Through the adoption of the online self-sharpening metallic bond and super-hard abrasive precision grinding pellet provided by the invention, online automatic sharpening can be achieved without blockage and offline repairing.

Owner:BEIJING UNIV OF TECH

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

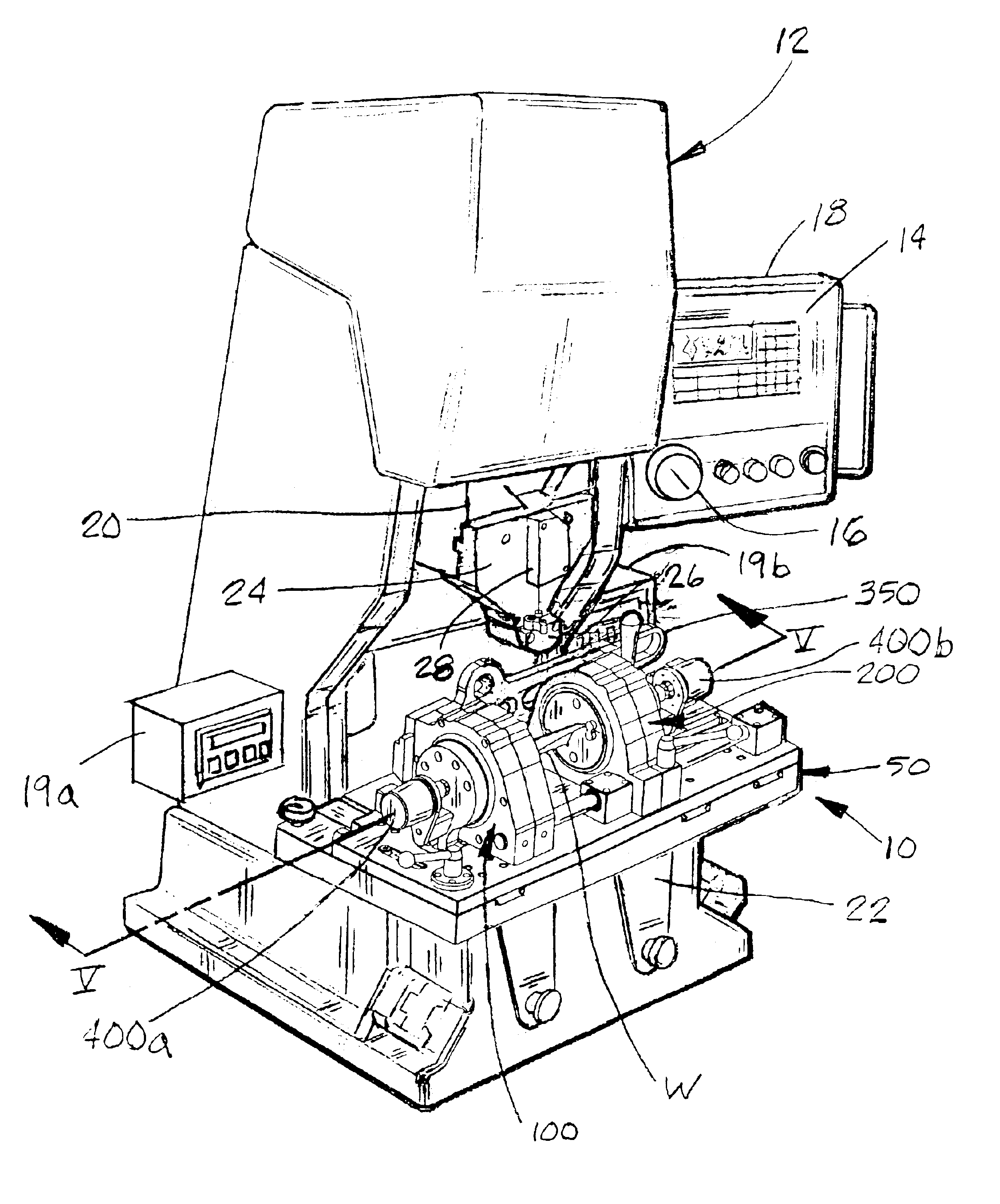

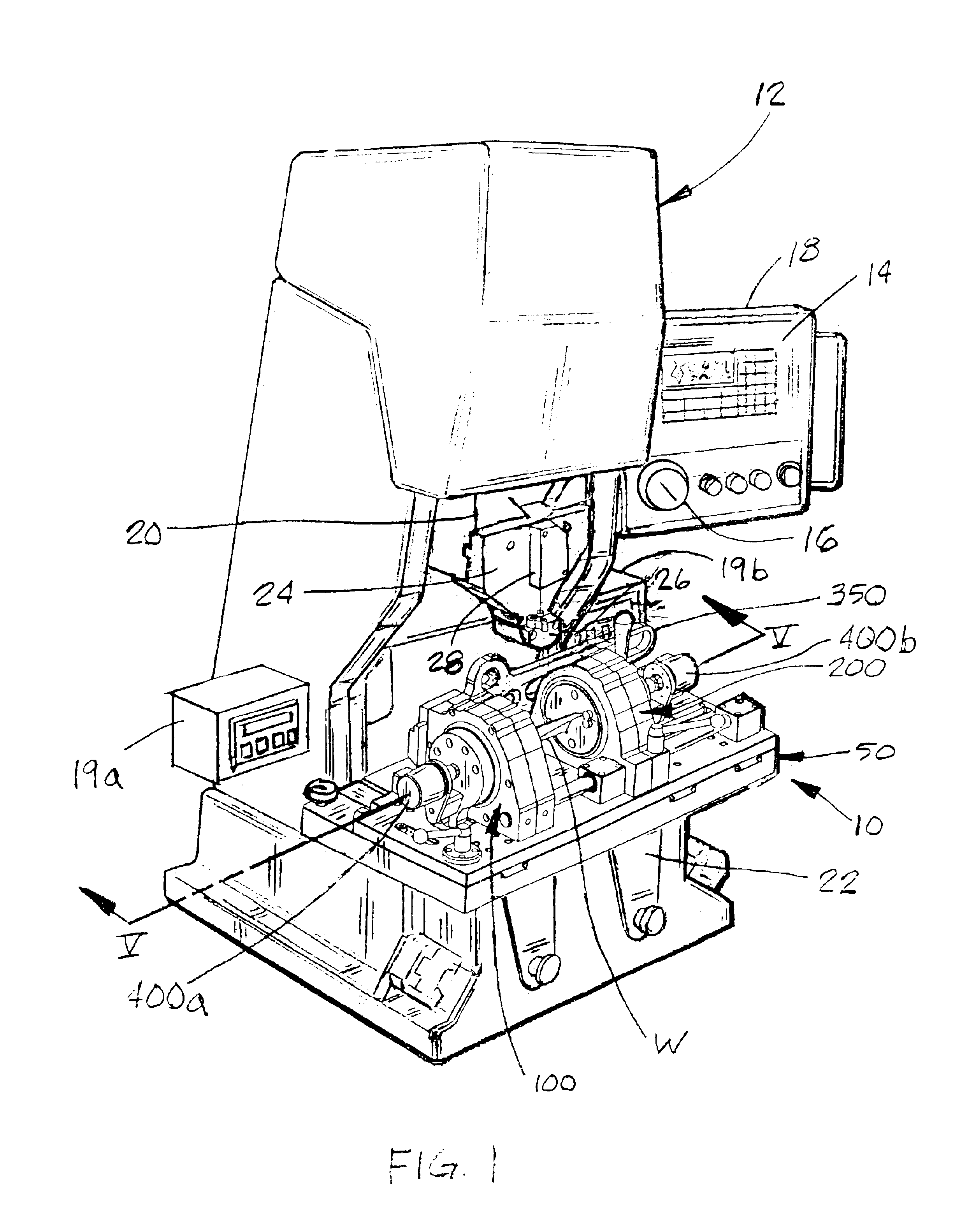

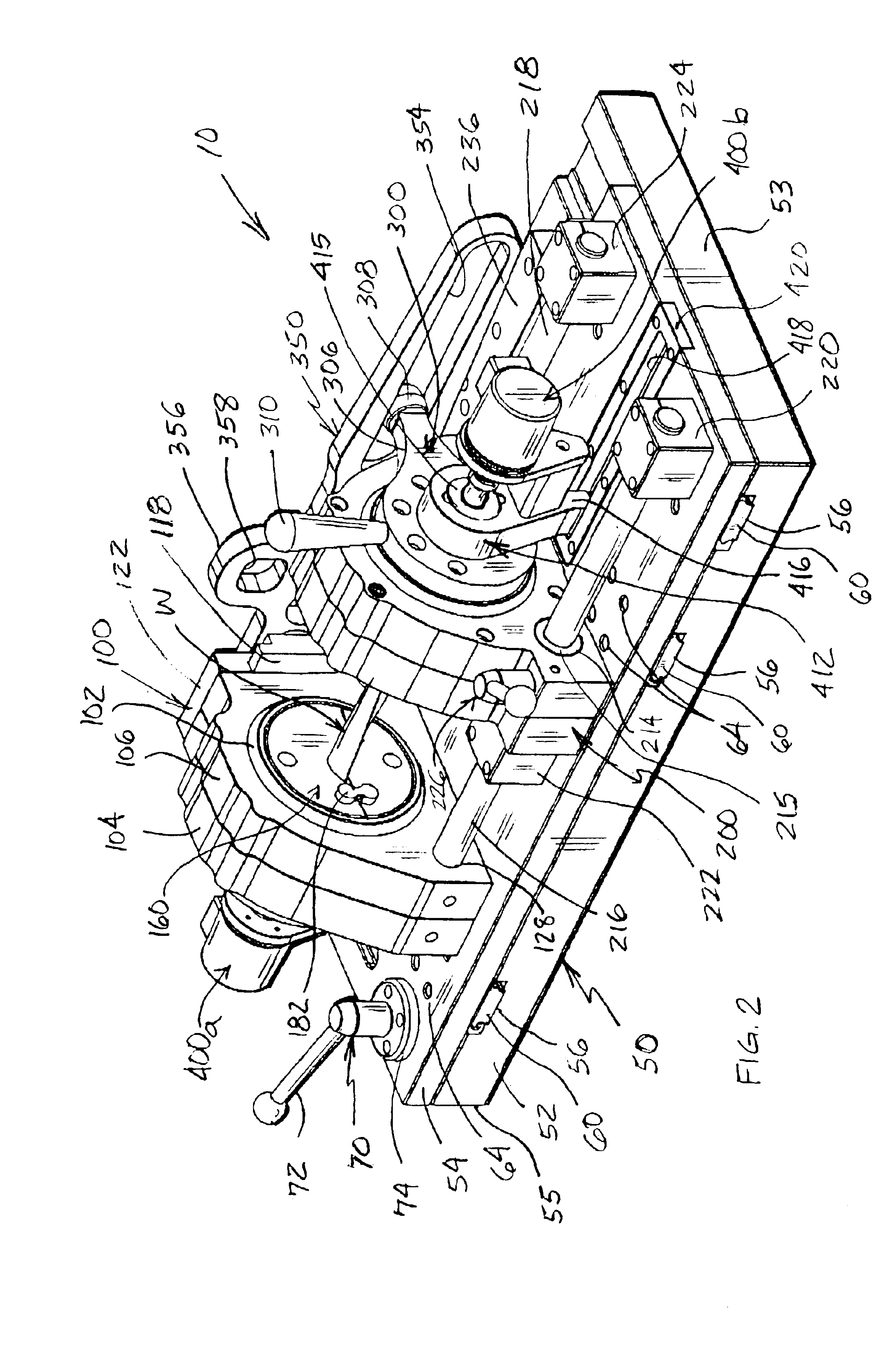

Fixture for holding metals parts for bending or twist correction

InactiveUS6959572B2Controlled and precise mannerIncrease the number ofMetal-working feeding devicesMetal working apparatusTurbine bladeEngineering

A fixture for supporting a workpiece such as a cast turbine blade allows bending and / or twist correction of the workpiece with the movable ram of a press. The fixture includes a base and a pair of workpiece supports mounted at spaced locations on the base. A bearing such as a spherical swivel bearing is included in each workpiece support. Each bearing has a mount receiving a portion of the workpiece therein. When the workpiece is supported by the bearing mounts along a support axis, and is engaged by the press ram intermediate the workpiece supports for bending correction, the bearings and workpiece can move in at least one plane including the support axis. Preferably, the bearings also allow rotational movement about the support axis, while a rotation imparting member allows twist correction by rotational movement of one bearing and the workpiece portion therein with respect to the other bearing which is restricted from rotating.

Owner:PROENTERPRIZ

Microscopic batteries for MEMS systems

InactiveUS20040018421A1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureMicro fabricationMicrofabrication

Microscopic batteries, integratable or integrated with and integrated circuit, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed.

Owner:BIPOLAR TECH

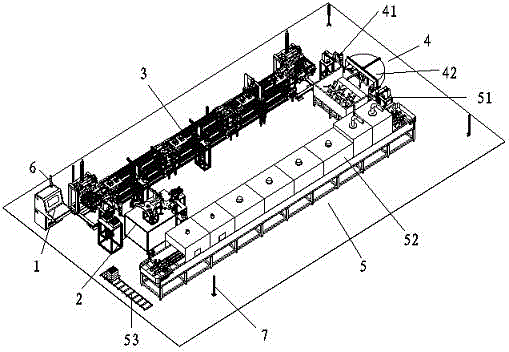

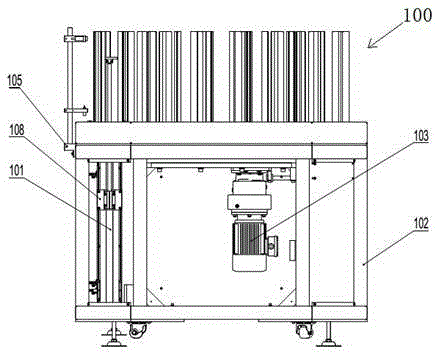

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

Preparation method of metalized film of induction cooker capacitor

ActiveCN103112169AImprove performanceGood removal effectVacuum evaporation coatingSputtering coatingMetallised filmRejection rate

The invention relates to the field of preparation of a capacitor, and in particular relates to a preparation method of a metalized film of an induction cooker capacitor. The preparation method comprises the following steps of: selection and preparation of raw materials, extruding a melt through an extruder, cooling the melt through a chilling roller and an air shower, drawing the melt in a vertical direction, drawing the melt in a transverse direction, testing the thickness of the drawn melt, performing procedures of trimming and corona treatment, rolling, time sequence treatment, slicing, and vacuum-evaporating the metalized film. Through the steps, the prepared metalized film is comparatively high in performance, comparatively low in rejection rate, low in cost and high in current carrying capability.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

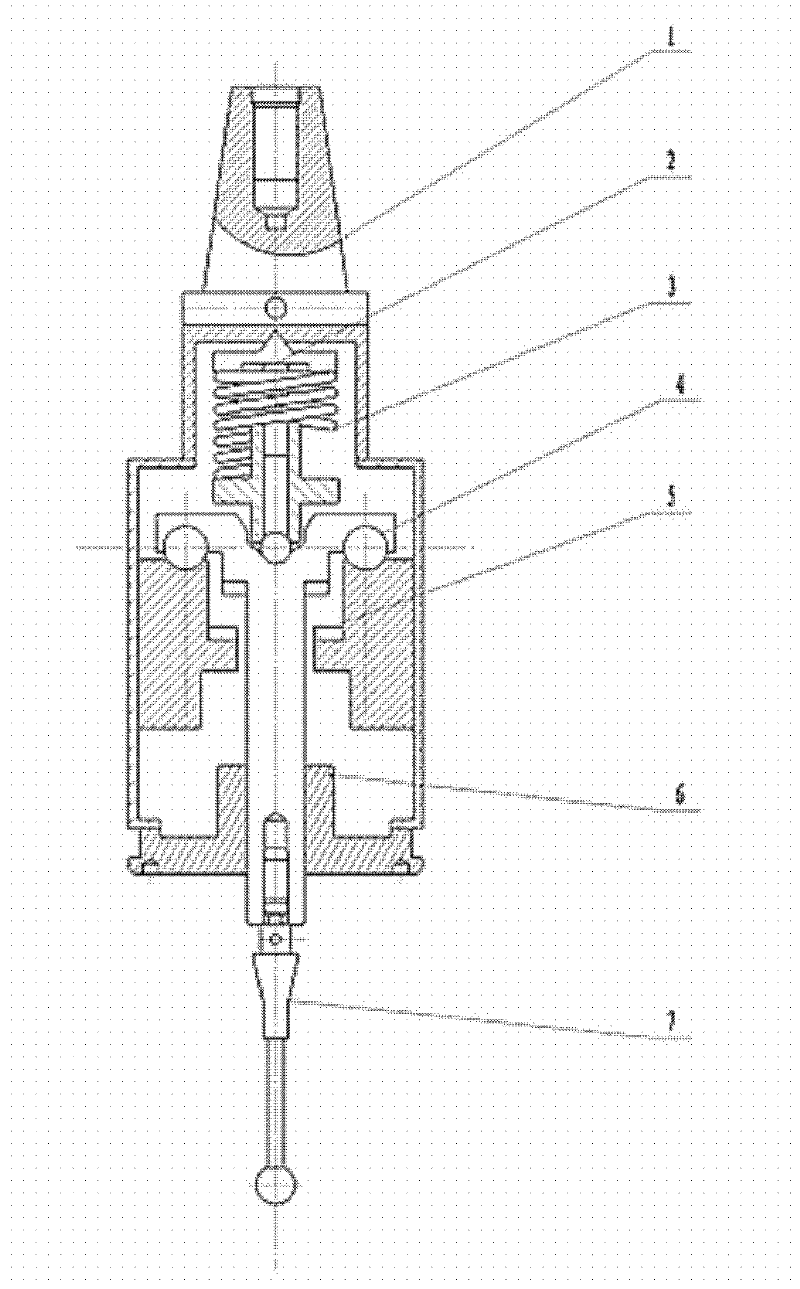

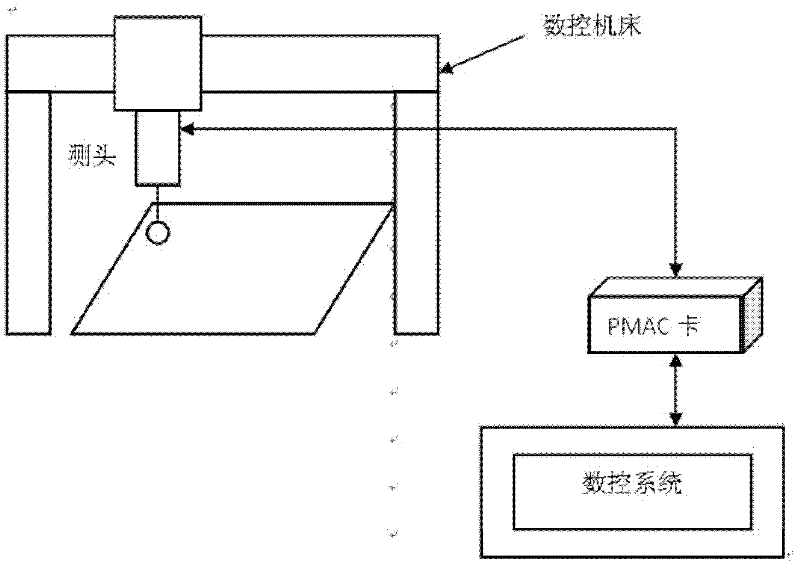

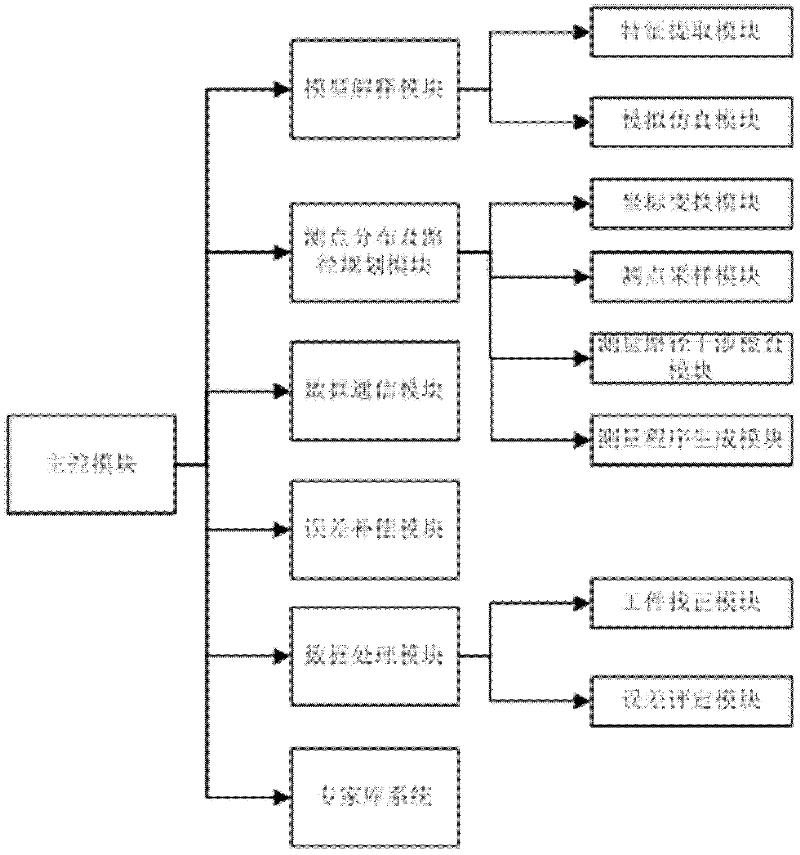

On-machine detection measuring head and detection system for numerical control machine tool

ActiveCN102501136AImprove measurement efficiencyHigh measurement accuracyProgramme controlComputer controlElectricityLinear motion

The invention discloses an on-machine detection measuring head for a numerical control machine tool. The on-machine detection measuring head comprises a measuring bar and a guide mechanism for guiding the measuring bar to make the vertical linear motion. The top of the measuring bar is provided with an elastic reset mechanism. The on-machine detection measuring head is characterized in that a linear displacement sensor is arranged at the position close to the measuring bar. The invention also discloses a detection system applying the measuring head, and the detection system comprises the measuring head, a signal acquisition circuit and a control center which are sequentially electrically connected. A numerical control system executes a measuring program to control a servo system of the machine tool to drive the measuring head to carry out measurement; coordinates of a point which is measured each time are timely transmitted back to the detection system; after the model detection is completed, the detection system carries out error compensation on measurement data; a spatial position and shape information of a measured workpiece can be calculated by carrying out corresponding operation on the corrected data; and the positioning and processing correction of the workpiece are guided by utilizing an obtained result. Auxiliary processing time can be greatly saved and the rejection rate of the workpiece is reduced.

Owner:WUHAN HENGLI HUAZHEN TECH CO LTD

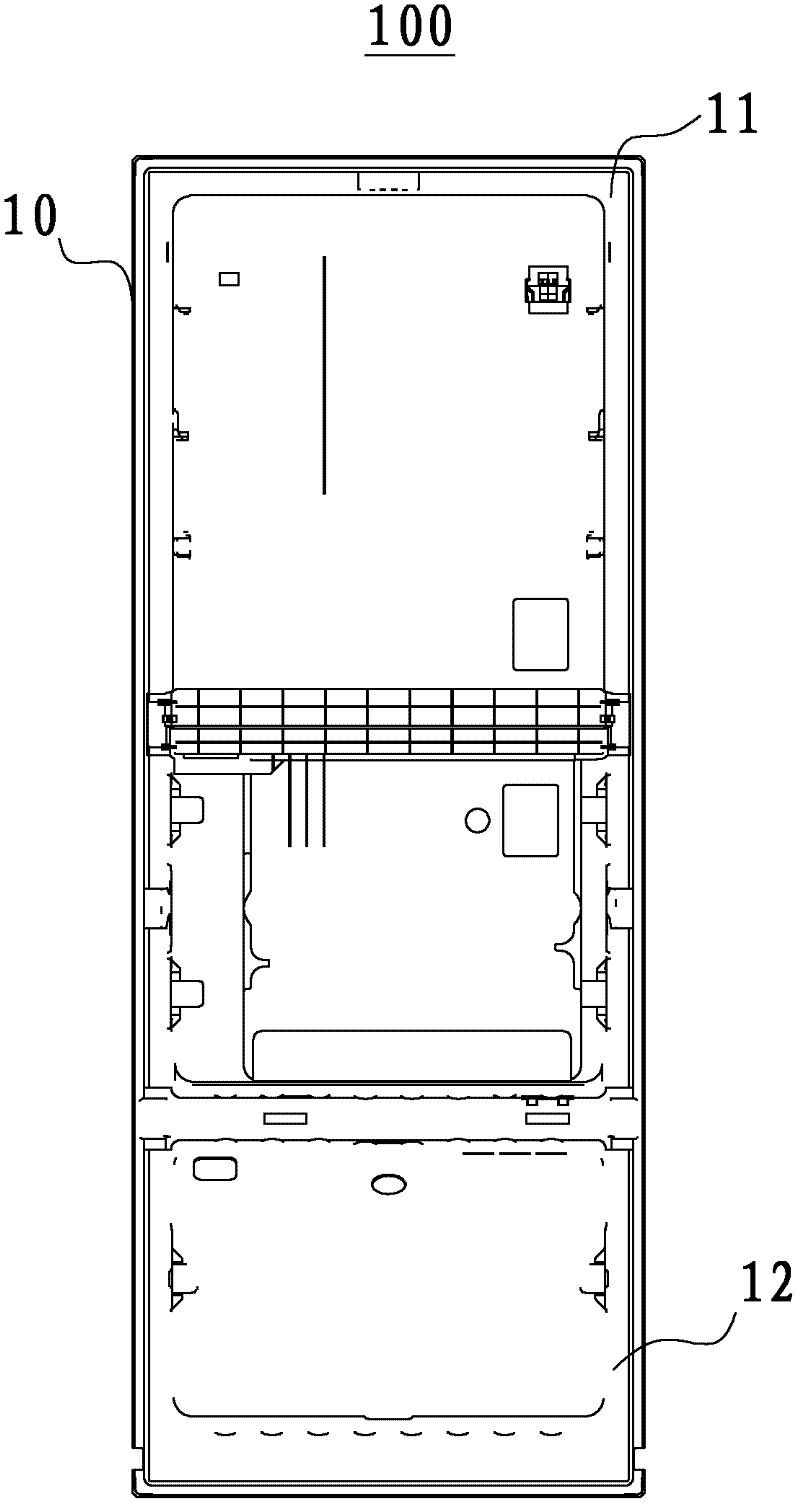

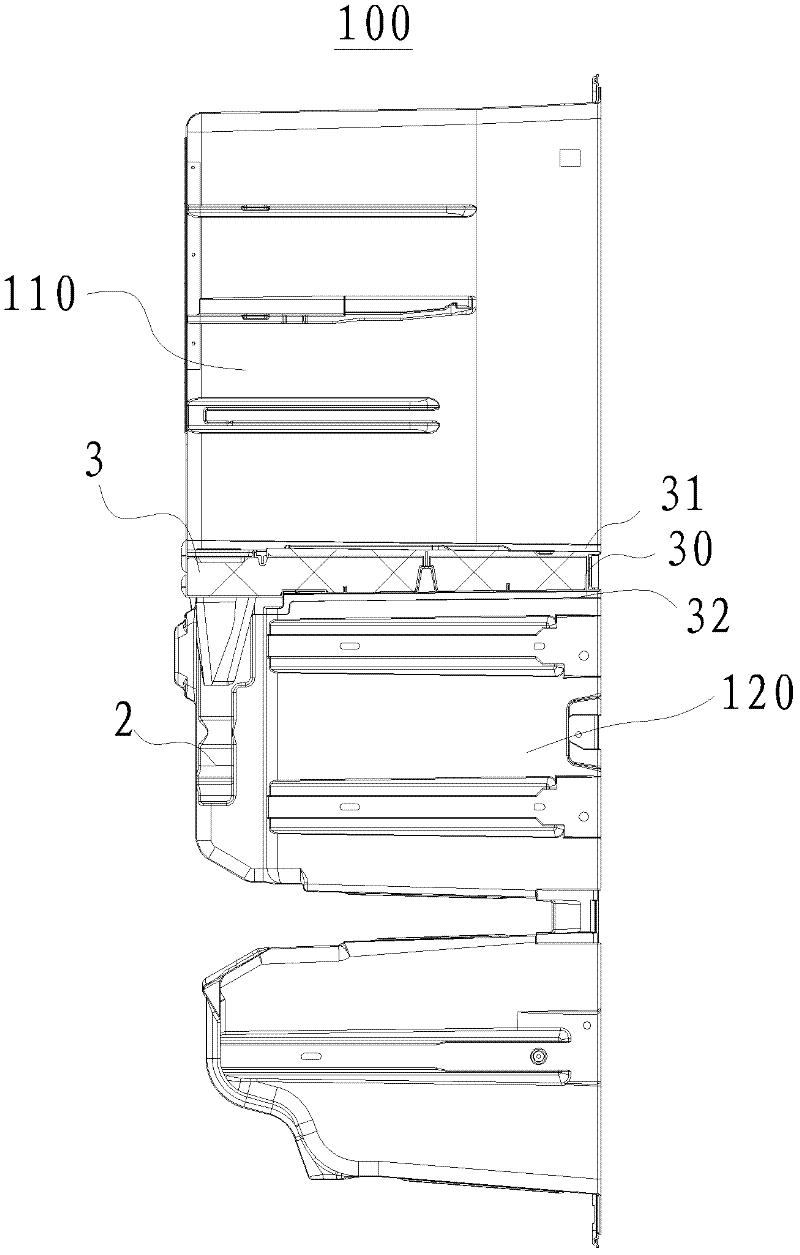

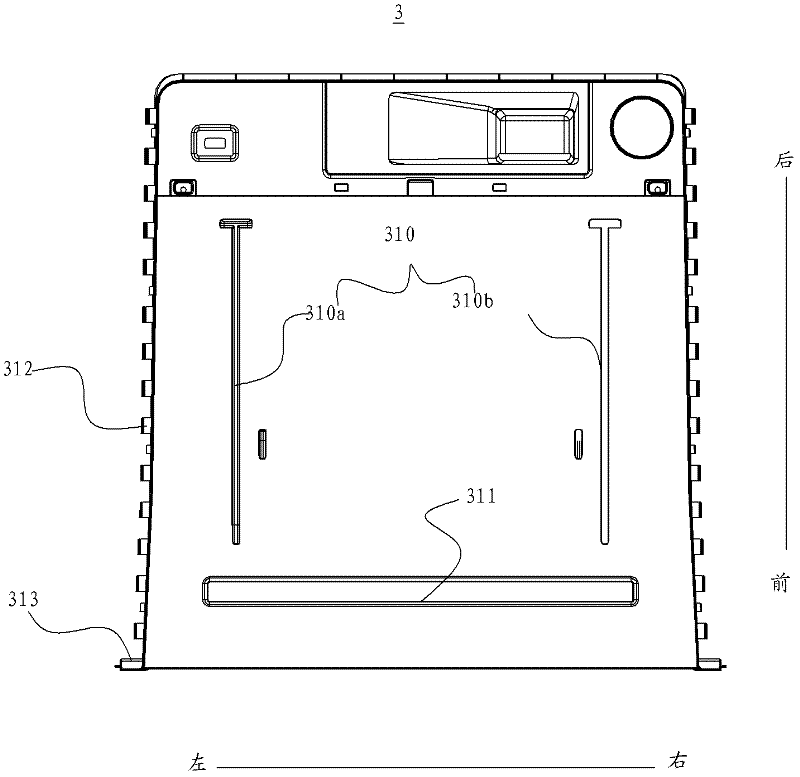

Refrigerator and assembly method thereof

ActiveCN102506537AImprove performanceLow costLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureEvaporator

The invention discloses a refrigerator and an assembly method thereof. The refrigerator comprises a refrigerator body, an evaporator, a fan and an intermediate air channel component, the intermediate air channel component comprises a main body, an upper cover plate and a lower cover plate, the upper cover plate is arranged on the upper surface of the main body, a first air outlet and a first air inlet which are spaced from each other are formed on the upper cover plate, a plurality of first fastening portions which are spaced along a front and back direction are disposed on both the left side and the right side of the upper cover plate, the lower cover plate is disposed on the lower surface of the main body, an air channel and a foam space are limited and separated among the upper cover plate, the lower cover plate and the main body, a second air inlet and a second air outlet which are spaced from each other are formed on the lower cover plate, a plurality of second fastening portions which are spaced along a front and back direction are disposed on both the left side and the right side of the lower cover plate, and the air channel is communicated with a first room via the first air outlet and the first air inlet, and is communicated with a second room via the second air inlet and the second air outlet. In the refrigerator of an embodiment of the invention, the air channel is sealed, air is not easy to leak, performances are stable, and production cost is low.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

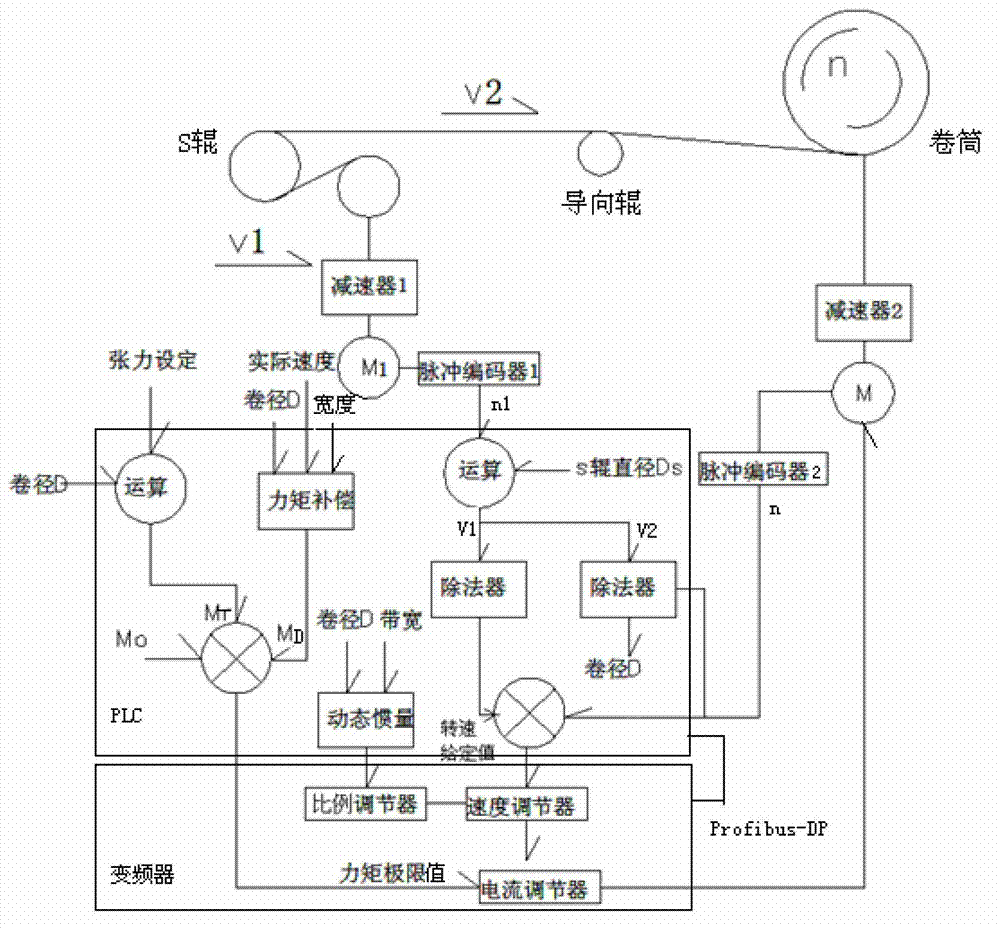

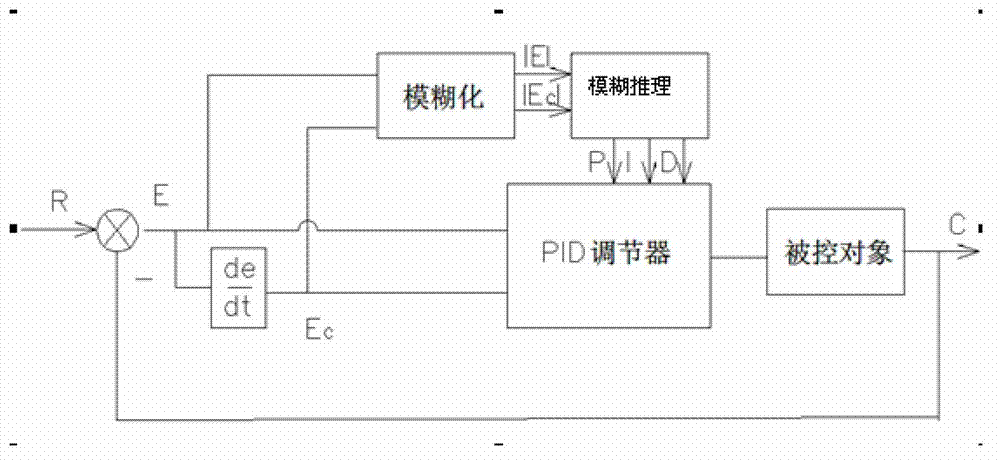

Tension fuzzy PID (Proportion Integration Differentiation) control method for recoiling machine

InactiveCN103076743AEasy to implementEasy to operateAdaptive controlAuto regulationAutomatic control

The invention discloses a tension fuzzy PID (Proportion Integration Differentiation) control method for a recoiling machine. In the method, current ring-speed ring double closed-loop control is adopted, a speed regulator and a current regulator are arranged respectively in the feedback elements of a current ring and a speed ring, six fuzzy controllers are adopted for controlling the PID parameters of the current ring and the speed ring, two inputs and one output are adopted for each fuzzy controller, input quantities are deviation values E and deviation change rates Ec of set tension, and output quantities are P, I and D parameters of a current controller and a speed controller respectively; three corresponding fuzzy controllers are connected in series respectively in front of the current regulator and the speed regulator, a subordinating degree function is regulated continuously in the running process of the recoiling machine, automatic control over the tension of the recoiling machine is realized by controlling the rotating speed of a motor and armature current, and the tension of the recoiling machine is regulated automatically and is always kept constant; and as proved by simulink simulation, the method has the advantages of quick response, high regulating capability, high robustness and effective improvement on the control effect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Swaging manufacturing method of light aluminum alloy rim

InactiveCN101653901ASimple structureEasy to manufactureShaping toolsRimsPerformance indexNational standard

The invention relates to a swaging manufacturing method of a light aluminum alloy rim. The method comprises the following processing steps: (1) baiting; (2) heating; (3) carrying out ring rolling; (4)manufacturing a spinning blank; (5) carrying out hot spinning; (6) carrying out head back hot spinning; (7) carrying out heat treatment; and (8) fine machining the blank into a rim product. The performance indexes of the rim all reach national standards. The method only needs a pair of spinning moulds, i.e. an upper spinning mould and a lower spinning mould for processing, wherein the moulds havesimple structure, easy manufacture and low manufacturing cost. High temperature and high speed hot spinning processing is adopted so as to ensure that the metallographic structure of the rim has uniformity, refined crystalline grain, light weight, thin thickness, mechanical property improvement of the rim, high precision and good quality, and compared with a rim processed by cold spinning, the rim of the invention cannot crack and generate pinholes and has long service life. The blank processed by the method is annular and has high material utilization rate, less waste and processing amount reduction. Meanwhile, the invention provides a new variety for the rims in the car accessory market. Consumers can conveniently replace and adjust the rims of different shapes and types as required atany time without dismantling a tire so as to quickly change the type of the whole tire.

Owner:丁松伟

Ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture

The invention relates to an ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture, which comprises the following process steps of 1 manufacturing digital jet printing pattern decoration picture; 2 preparing a base material; 3 coating aqueous back cover putty; 4 digitally printing a UV decoration layer in a jetting mode; 5 coating a UV primer layer; and 6 coating UV finish. The manufacturing method has the advantages of (1) directly printing on the surfaces of plate-type base materials of a density board, a multi-layer plywood, a laminated wood, a common board, a wood model and the like; (2) using electromagnetic radiation of ultraviolet light to enable UV printing ink jetted from a sprayer to be rapidly solidified on the plate-type base materials; (3) reducing scrappage of material pieces, effectively improving work efficiency and reducing cost; and (4) being free of volatile odor and environment-friendly in production processes due to the fact that the UV printing ink is solidified in a short time. In addition, during UV digital jet printing manufacture of the plate-type components of the floor boards and the furniture, production quantity can be flexibly set according to requirements, material categories, colors and pictures can be changed at random, one-piece cost and effect same regardless of the batch size.

Owner:南京雷励数码科技有限公司

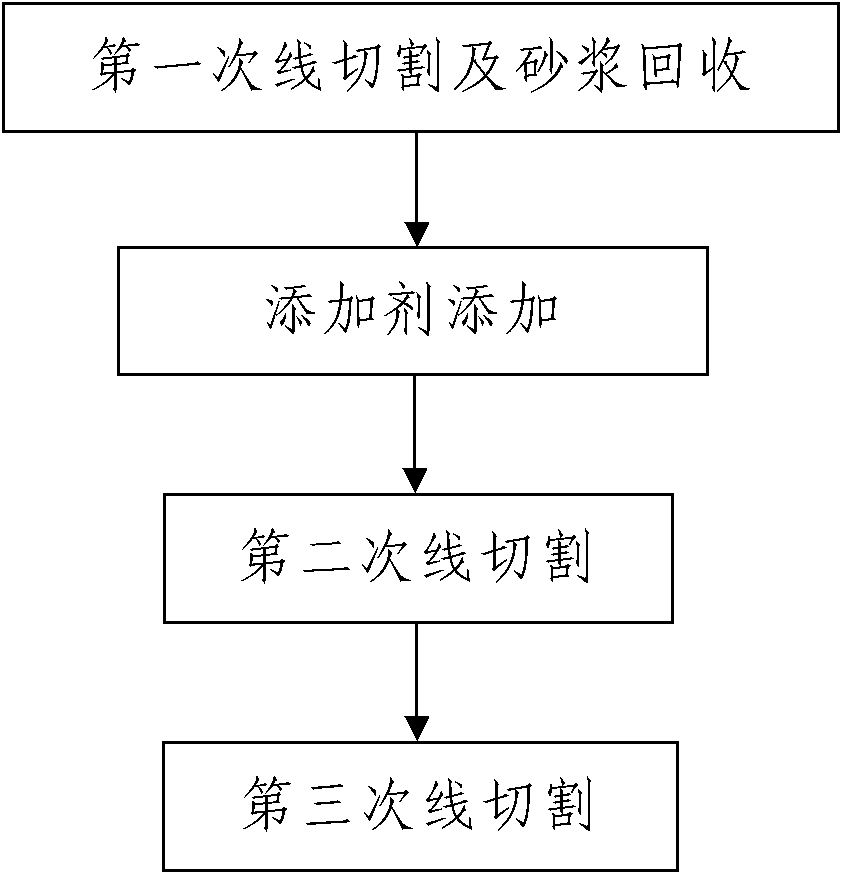

Additive for improving utilization ratio of silicon crystal line cutting mortar as well as preparation method and application method of addictive

InactiveCN102041138AIncrease profitReduce manufacturing costLubricant compositionAlcoholPolyethylene glycol

The invention discloses an additive for improving utilization ratio of silicon crystal line cutting mortar as well as a preparation method and application method of the addictive. The additive is composed of the following raw materials in percentage by weight: 50-96.5% of polyethylene glycol, 1-10% of penetrating agent, 1-20% of ether alcohol surfactant, 0.5-10% of extreme pressure resistant chelator and 1-10% of assistant detergent. The preparation method comprises the steps of weighing and mixing the raw materials. The application process comprises the following steps: 1. carrying out the first line cutting the mortar and recovering the mortar; 2. adding the additive: adding the additive to the recovered mortar after the first linear cutting based on the weight ratio of 1:100 plus / minus 10, and then evenly stirring; 3. carrying out the second line cutting; and 4. carrying out the third line cutting and recovering the mortar. The addictive is reasonable in design and has good use effect and practicable value, addictive preparation and use processes are simple, operation is convenient, and the defects of the existing silicon wafer cutting fluid such as more severe pollution, higher rejection rate, high production cost, low utilization ratio and the like can be overcome.

Owner:XIAN HUAJING ELECTRONICS TECH

Pole sheet laser cutting machine

ActiveUS20140014633A1Good monochromaticitySmall divergence angleElectrode manufacturing processesFinal product manufactureManipulatorLithium electrode

Disclosed is a pole sheet laser cutting machine. It comprises a base frame component, a laser cutting device, a cutting manipulator component for driving the laser cutting device, a control system, and at least one sheet feeding assembly; the sheet feeding assembly comprises a material grabbing manipulator component, a fixed length feeding component and a material releasing component, with both the cutting manipulator component and the material grabbing manipulator component being mounted on the base frame component, the fixed length feeding component being arranged between the material grabbing manipulator component and the material releasing component, and the control system being connected to the cutting manipulator component, the material grabbing manipulator component and the fixed length feeding component. The present invention achieves the sheet making process for lithium ion batteries or super capacitors by applying laser technology, which is able to overcome the problems that existed in the prior art through applying a traditional cutting process so that the pole sheets were easily deformed and the burrs were relatively large, etc., and at the same time, the quality of the sheet making process and hence the rate of acceptable products are improved through the control of the control system.

Owner:GEESUN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com