Full-automatic double-end-face grinding production line

A technology of automatic production line and double-end grinding machine, which is applied in the direction of grinding feed motion, grinding machine parts, grinding/polishing equipment, etc. Labor intensity, the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

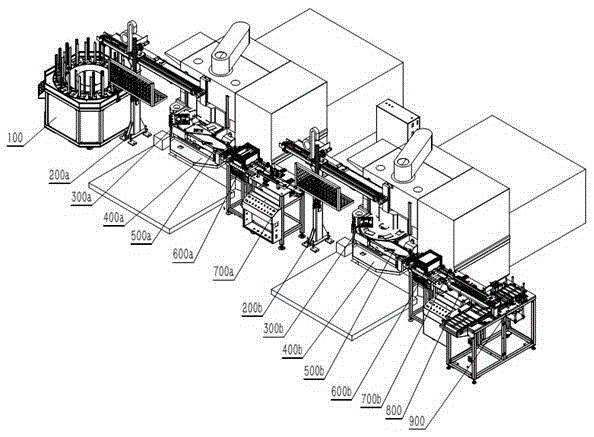

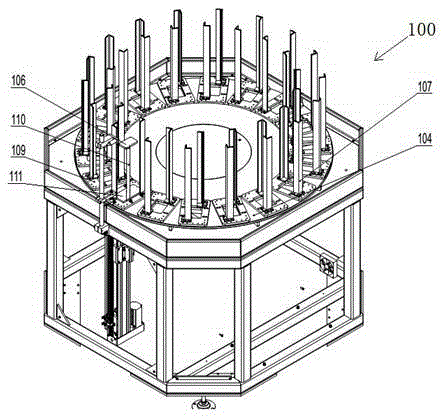

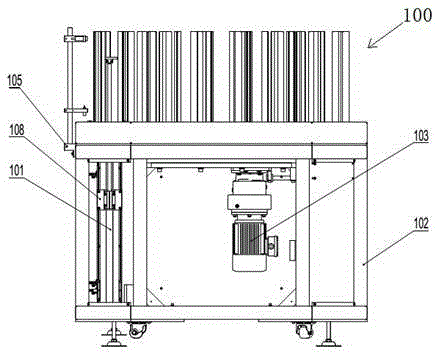

[0026] Figure 1 shows an embodiment of the fully automatic double-end grinding production line of the present invention. The production line is arranged in a straight line, and is sequentially provided with a feeding mechanism 100, a feeding manipulator 200a, a double-end grinding machine 400a, a transfer conveyor belt 500a, and a cleaning mechanism. 600a, detection device 700a, transfer manipulator 200b, double-end grinder 400b, transfer conveyor belt 500b, cleaning mechanism 600b, detection device 700b, blanking manipulator 800, blanking mechanism 900, double-end grinder 400a is provided with grinder blanking plate 300a and The feeding manipulator 200a is connected, and the double-end grinder 400b is provided with a grinder blanking plate 300b connected with the transfer manipulator 200b. The technological process is that the loading mechanism 100 loads the pre-placed workpieces to be processed, and the loading robot 200a takes out the workpieces to be processed from the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com