Patents

Literature

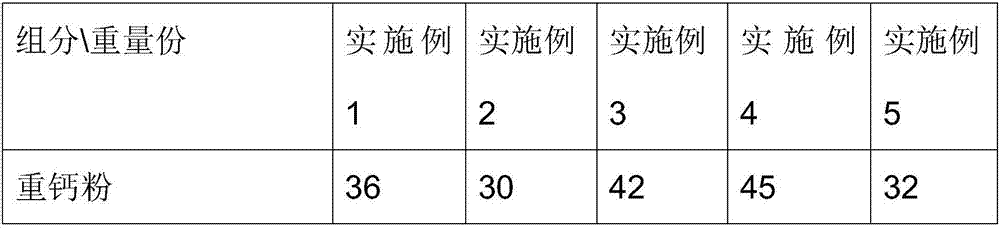

73results about How to "Guaranteed surface smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

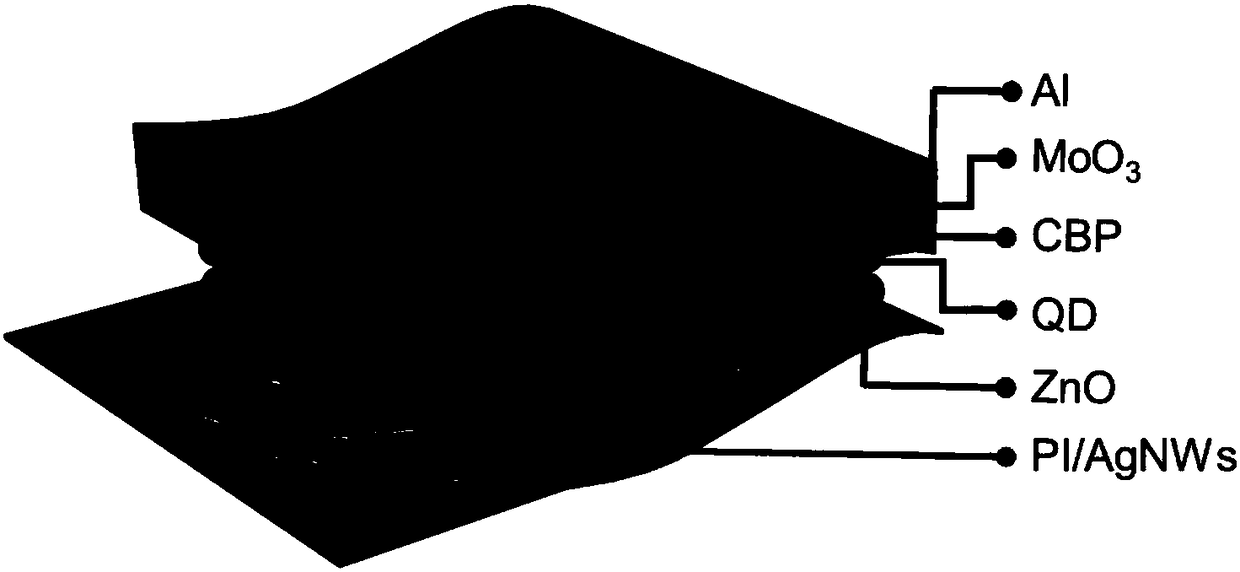

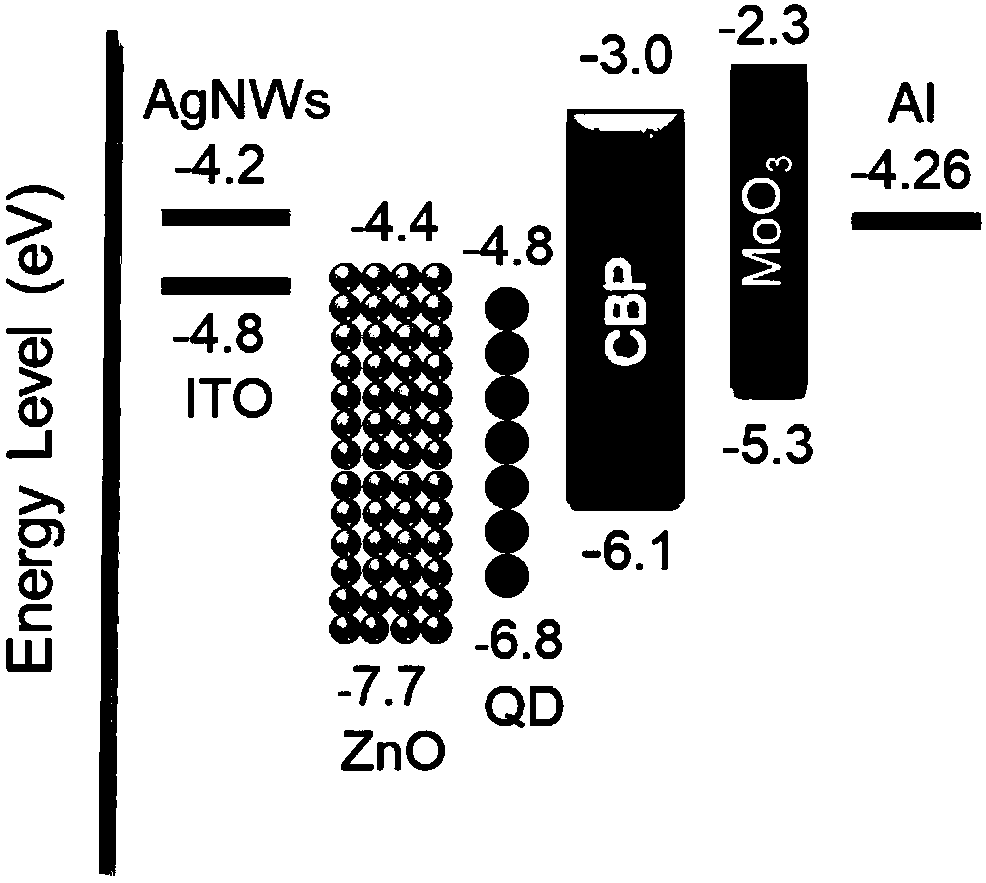

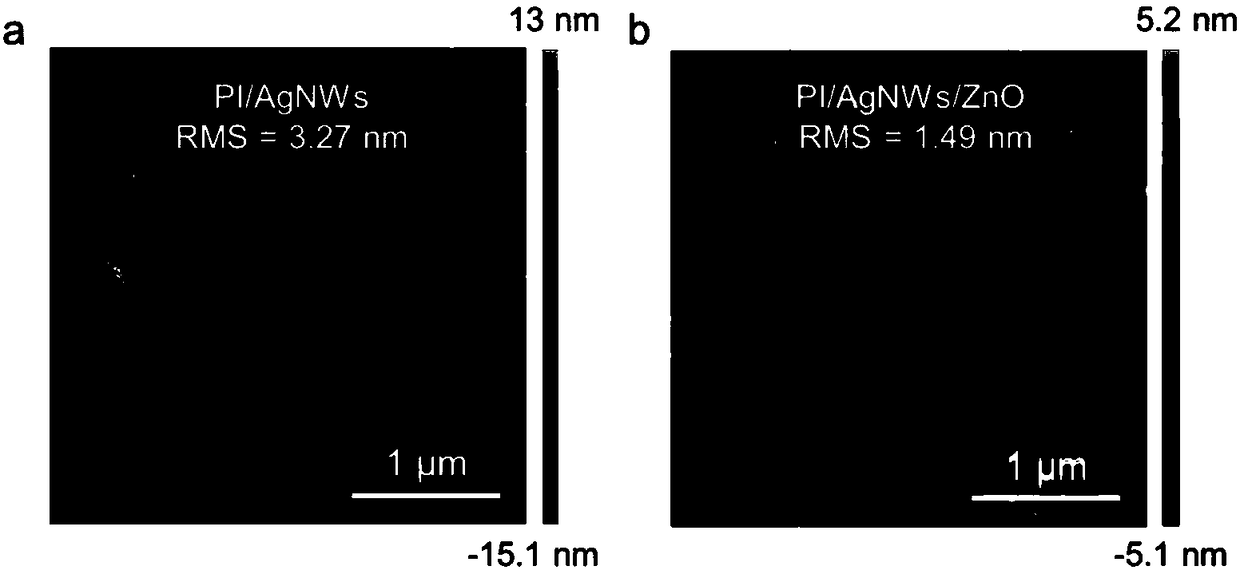

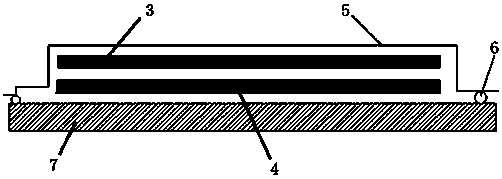

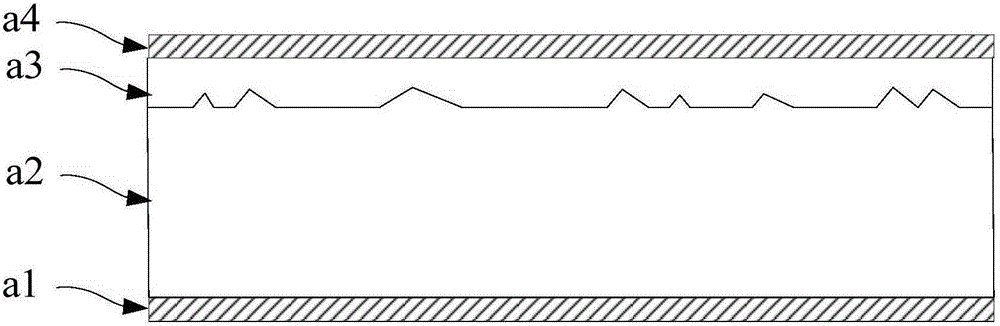

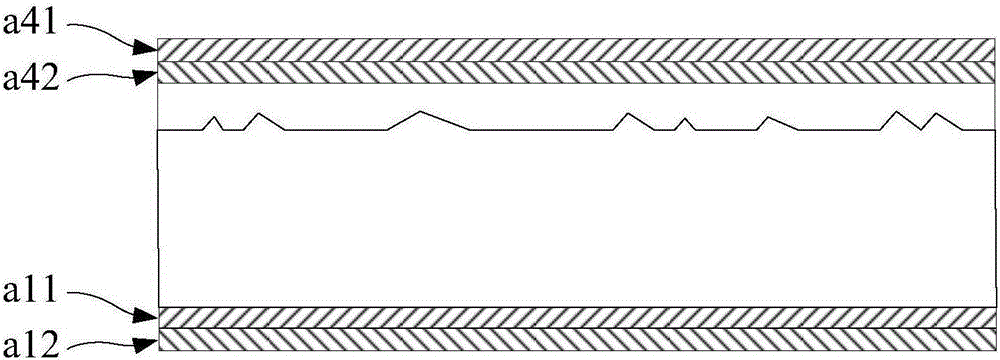

Silver nanowire electrode-based efficient flexible quantum dot light-emitting diode and preparation thereof

InactiveCN108598273ASimple preparation processLow costSolid-state devicesSemiconductor/solid-state device manufacturingZno nanoparticlesHole transport layer

The invention discloses a silver nanowire electrode-based efficient flexible quantum dot light-emitting diode and preparation thereof. The silver nanowire transparent electrode-based flexible quantumdot light-emitting diode is characterized by comprising a flexible transparent cathode, an electron transport layer, a quantum dot light-emitting layer, a hole transport layer, a hole injection layerand a metal anode from bottom to top, wherein the flexible transparent cathode is a composite electrode formed by embedding silver nanowires into a flexible substrate. According to the silver nanowireelectrode-based efficient flexible quantum dot light-emitting diode, the smooth surface of a nano zinc oxide layer is obtained through improving the key parameters and conditions of a corresponding device preparation process and modifying the surface of the electrode by using nano zinc oxide, so that the electron transport property of the nano zinc oxide is ensured, the effect, of enhancing the light extraction efficiency of the flexible quantum dot light-emitting diode, of the silver nanowire flexible transparent electrode is brought into fully play, and the light-emitting efficiency of theflexible quantum dot light-emitting diode is effectively improved to the world leading level.

Owner:HUAZHONG UNIV OF SCI & TECH

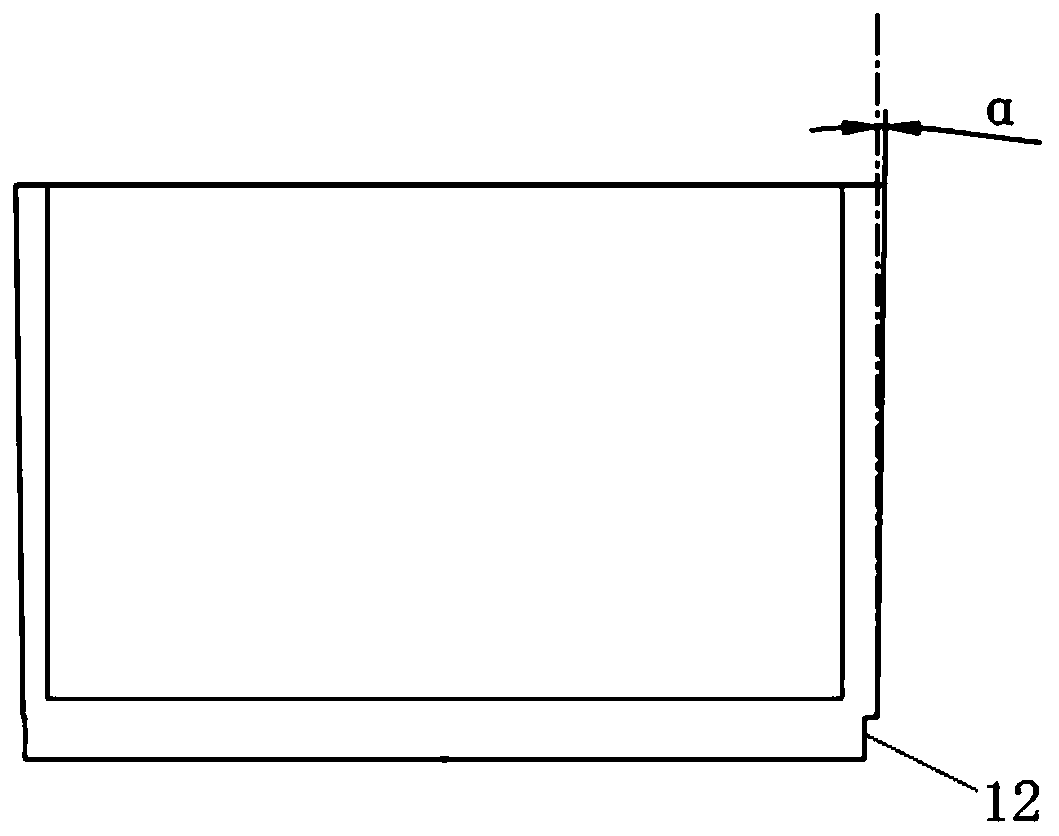

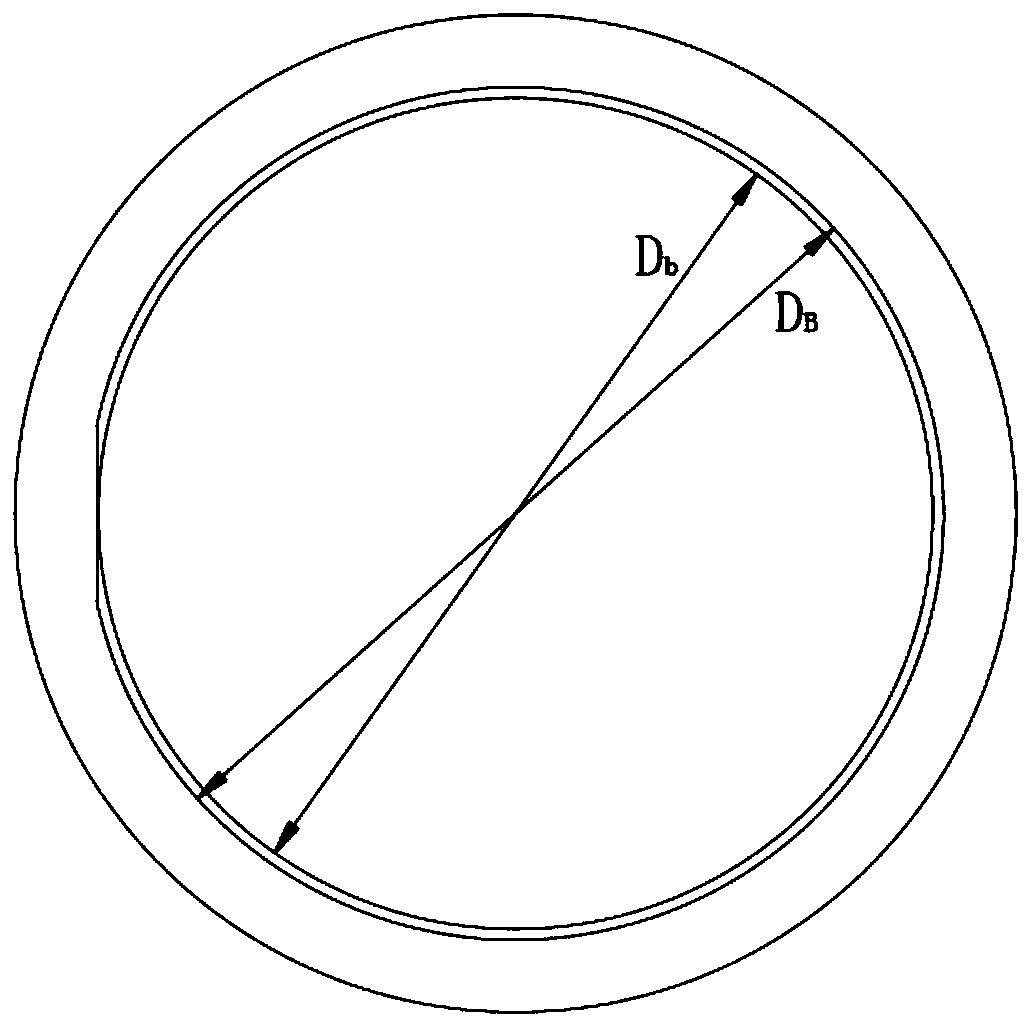

Cable insulating layer specimen cutting device and cutting method

ActiveCN104359708AImprove thickness uniformityGood experimental basisWithdrawing sample devicesElectrical and Electronics engineering

The invention discloses a cable insulating layer specimen cutting device and cutting method. The device comprises a blade, a fixed shaft and a fixed base, wherein the fixed shaft comprises a first assembly section and a second assembly section which are connected with each other; the first assembly section is connected with a rotating shaft of a lathe, and the second assembly section is sleeved with a cable insulating layer specimen; the fixed base is arranged on the lathe, a blade groove matched with the blade is formed in the fixed base, the blade is fixedly arranged in the blade groove, and the edge of the blade is parallel to the axial direction of the fixed shaft. Along with rotation of the cable insulating layer specimen, the blade approaches the surface of the cable insulating layer specimen and cuts along the perimeter direction of the specimen to obtain a specimen slice, so that the inner, middle and outer layers of the cable insulating layer specimen can be definitely separated, and the thicknesses of the specimen slices are good in uniformity, so that an excellent experimental basis is provided to researches on the aging mechanism of insulating layer materials with different distances from cable cores.

Owner:ZHUHAI POWER SUPPLY BUREAU GUANGDONG POWER GIRD CO +1

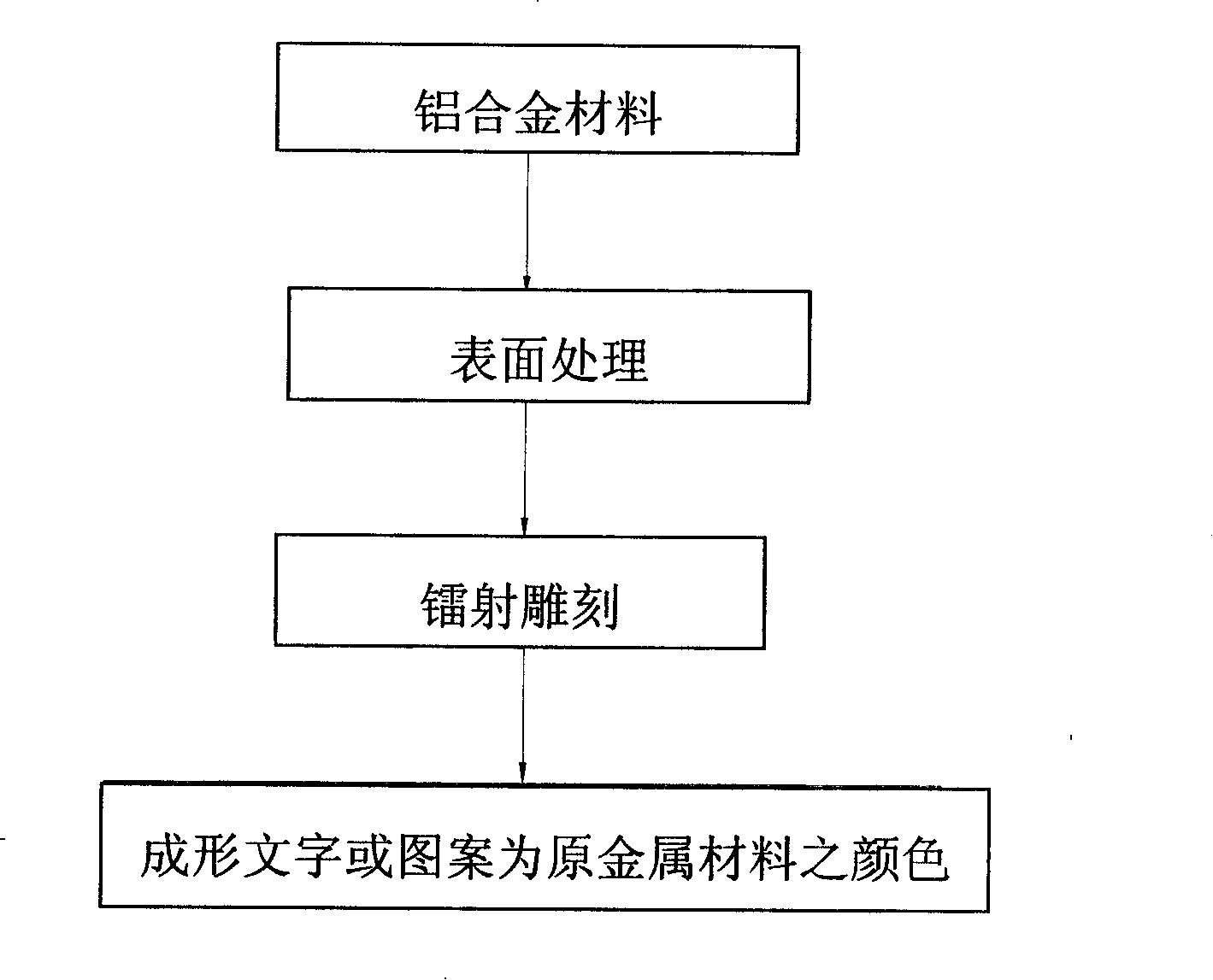

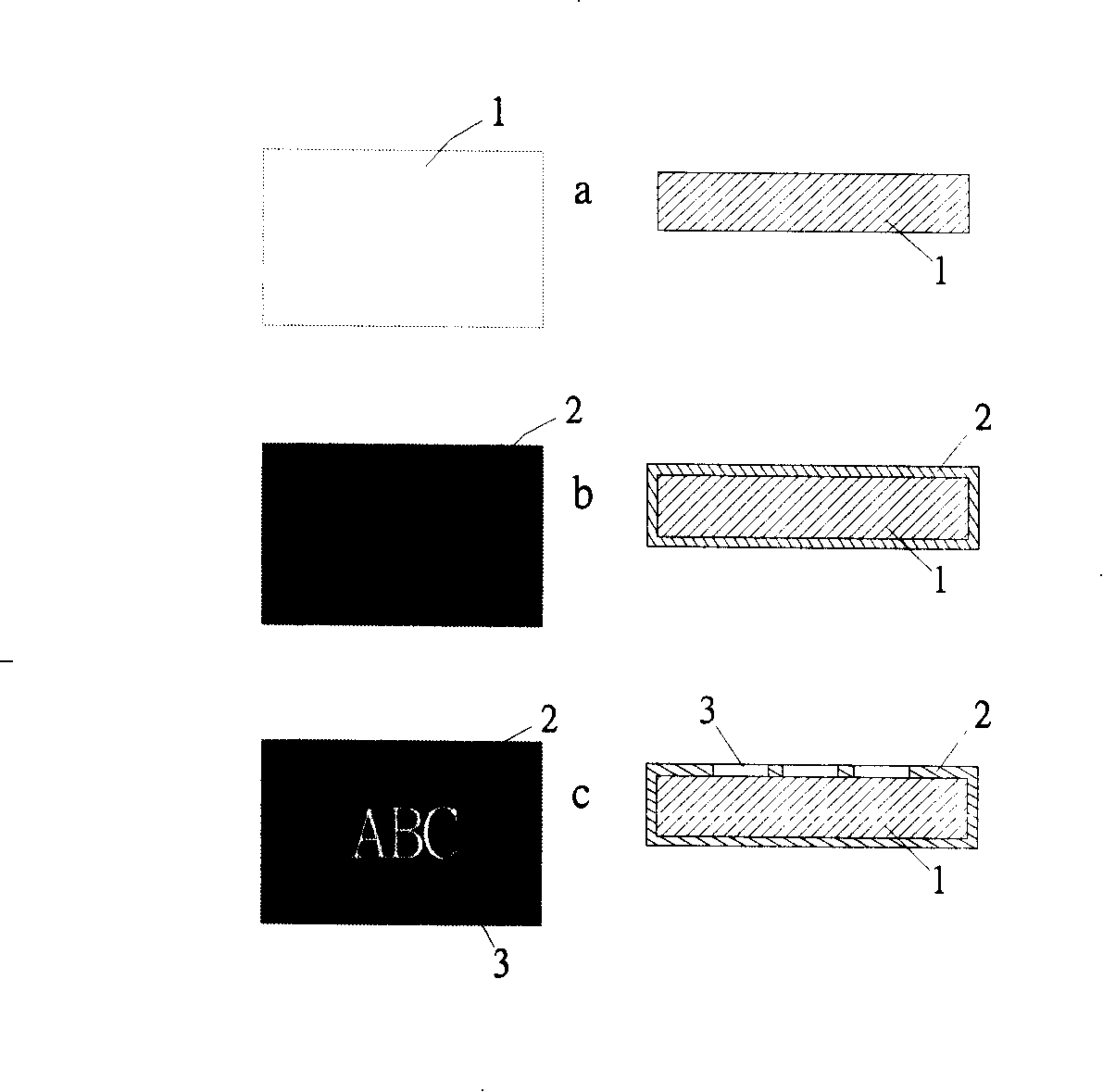

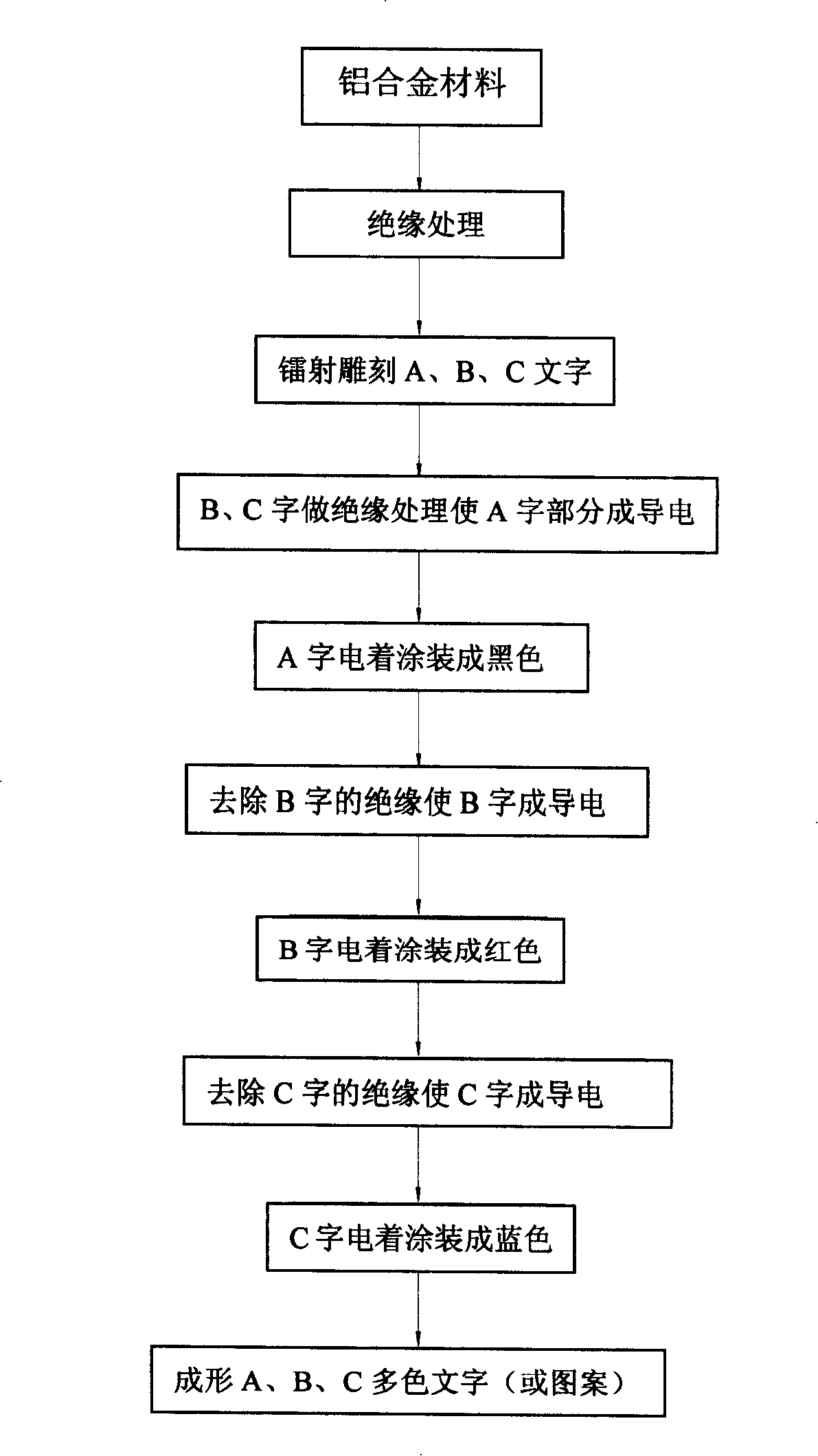

Method for coloring pattern or character on surface of aluminum alloy material and product thereof

InactiveCN101229742ARich color variationMaintain surface flatnessLiquid surface applicatorsDecorative surface effectsAluminium alloyCoating

The invention relates to a method for coloring surface pattern or character of aluminum alloy material and products thereof. The method comprises the following steps: a surface of the aluminum alloy material is provided with an insulating layer and the pattern or character is carved by laser to become a status of local insulation and local conduction ; then by using a way of electrical coating, the conductive part of the pattern or character is sequentially processed by electrical draping to enable the pattern or character to have a draping layer different with the color of the aluminum alloy material and represent different colors as well as keeping a flat surface.

Owner:张世杰

Degradable rice sucker and preparation method thereof

The invention discloses a degradable rice sucker. The sucker is prepared from, by weight, 40-65 parts of rice flour, 30-45 parts of cassava flour, 10-20 parts of water, 0.5-2 parts of edible pigments,0.2-0.5 part of sugar, 0.1-0.2 part of salt and 0.3-0.4 part of a curing agent, 0.4-0.5 part of a waterproof agent and 0.5-1 part of an antioxidant. Accordingly, grain rice and cassava serve as raw materials to make a disposable edible thermoplastic starch fully degradable sucker, the durability is high, recovery is easy, the decomposition speed is high, environmental friendliness is achieved, and the sucker is beneficial to human health.

Owner:陈星岫

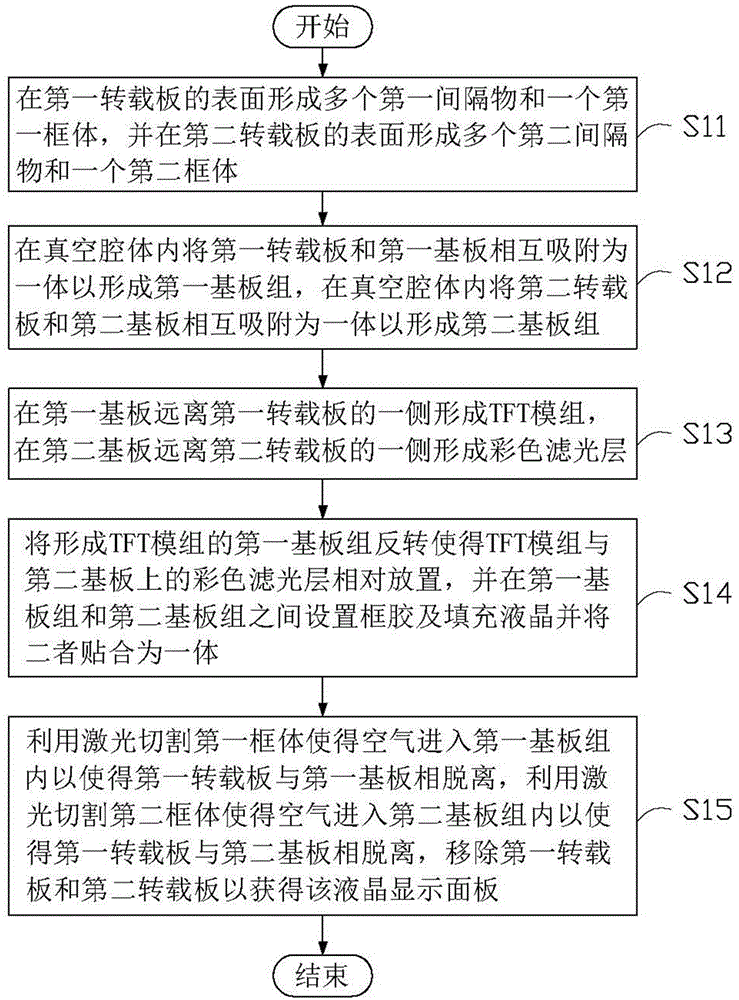

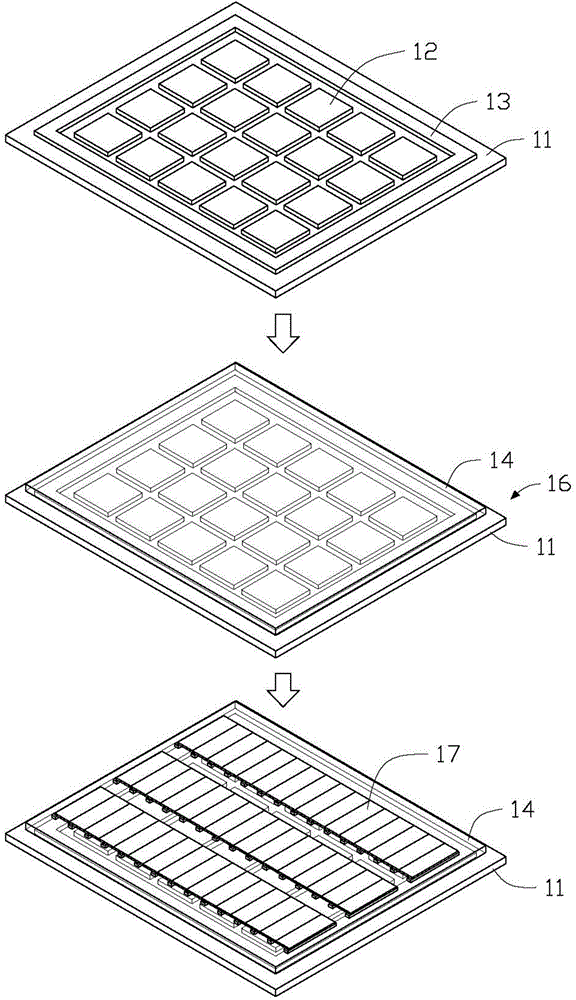

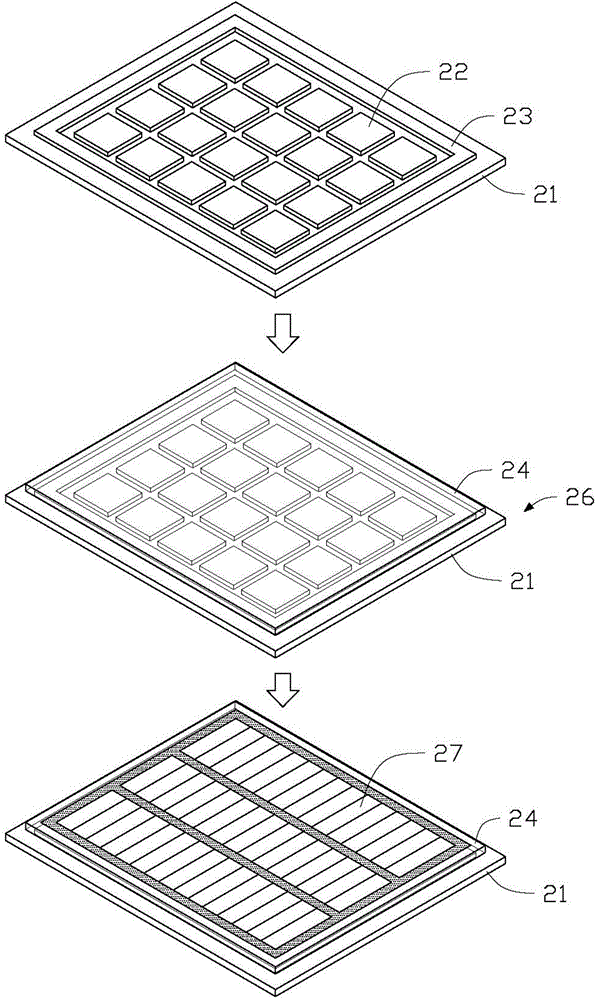

Method of manufacturing liquid crystal display panel

InactiveCN106154609AHigh strengthAvoid breakingNon-linear opticsTransistor arrayLiquid-crystal display

A method of manufacturing a liquid crystal display panel comprises: forming multiple spacers and a frame respectively on the surfaces of a first transfer board and a second transfer board; in a vacuum chamber, adsorbing the first transfer board and a first substrate to integrally form a first substrate assembly, and adsorbing the second transfer board and a second substrate to integrally form a second substrate assembly; forming a thin-film transistor array on the first substrate and a color filter layer on the second substrate; reversing the first substrate assembly so that the TFT array and the color filter layer are arranged oppositely, and providing frame glue and filling liquid crystal between the first substrate and the second substrate, and attaching them into a whole; laser-cutting a first frame to separate the first transfer board and the first substrate, cutting a second frame to separate the first transfer board and the second substrate, and removing the first transfer board and the second transfer board.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

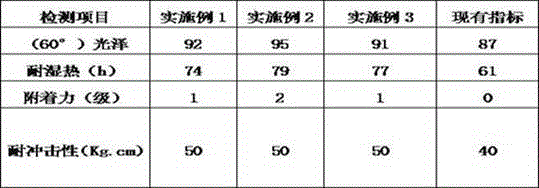

Preparation of baking finish for paint-drying bucket and spraying method

InactiveCN105907272AGood surface effectHigh temperature resistanceFireproof paintsPretreated surfacesEpoxyLacquer

The invention discloses preparation of a baking finish for a paint-drying bucket and a spraying method. According to the components and the ratio of ingredients of a primer and a pearlescent lacquer, the baking finish has an excellent surface effect and high temperature resistance. A fire retardant and epoxy resin can also be added to the ingredients, so that flame retardant and corrosion prevention effects can be achieved while the high temperature resistance is achieved; and the performance of the baking finish is improved. After the addition of pearl powder, a waterborne silver directional promoter is added, thereby promoting the parallel arrangement of the pearl powder on the paint surface and ensuring the surface smoothness of the baking finish. The waterborne resin is acrylic acid-modified polyester resin, so that the prepared baking finish is high in fullness and glossiness. The baking finish prepared by the preparation method and the spraying method has excellent performance; the sprayed product has high-temperature resistance, flame retardant and corrosion prevention effects, and is great in market potential and wide in prospect.

Owner:SUQIAN SANSHI PACKING CONTAINER

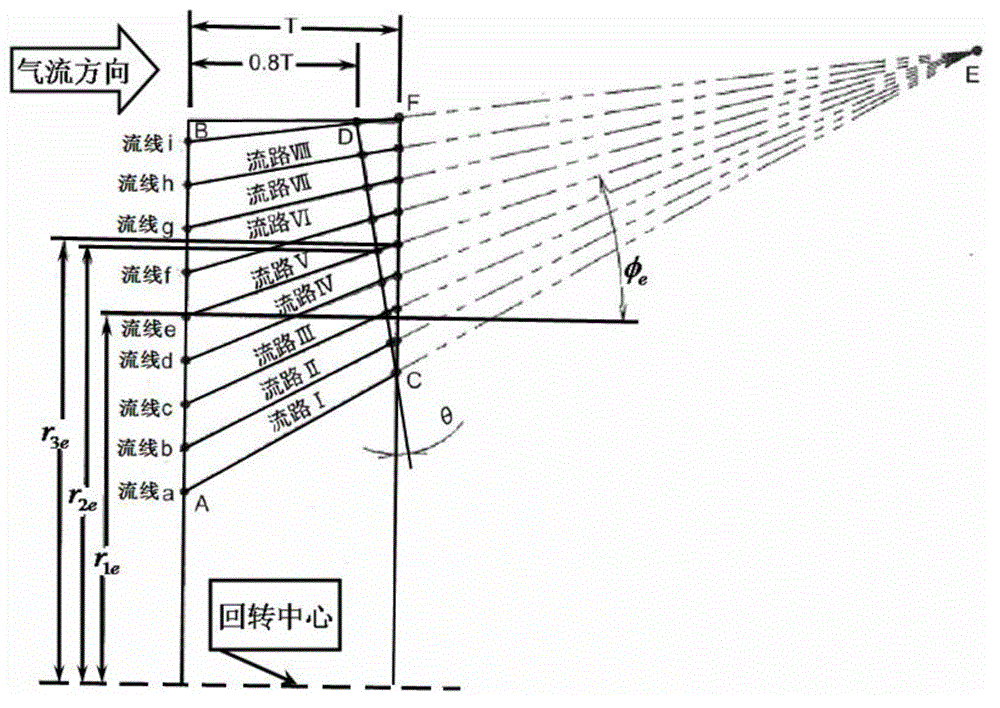

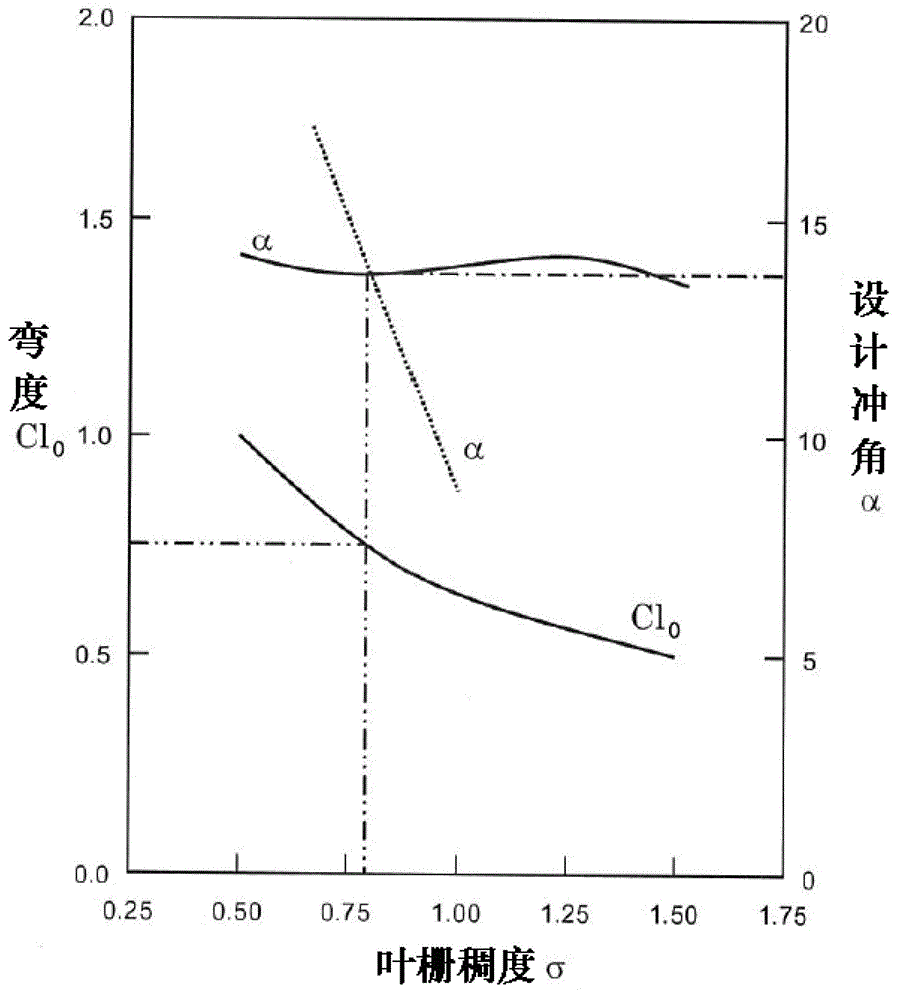

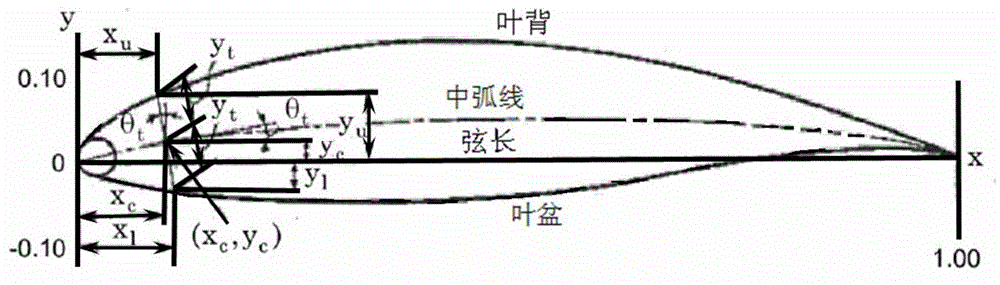

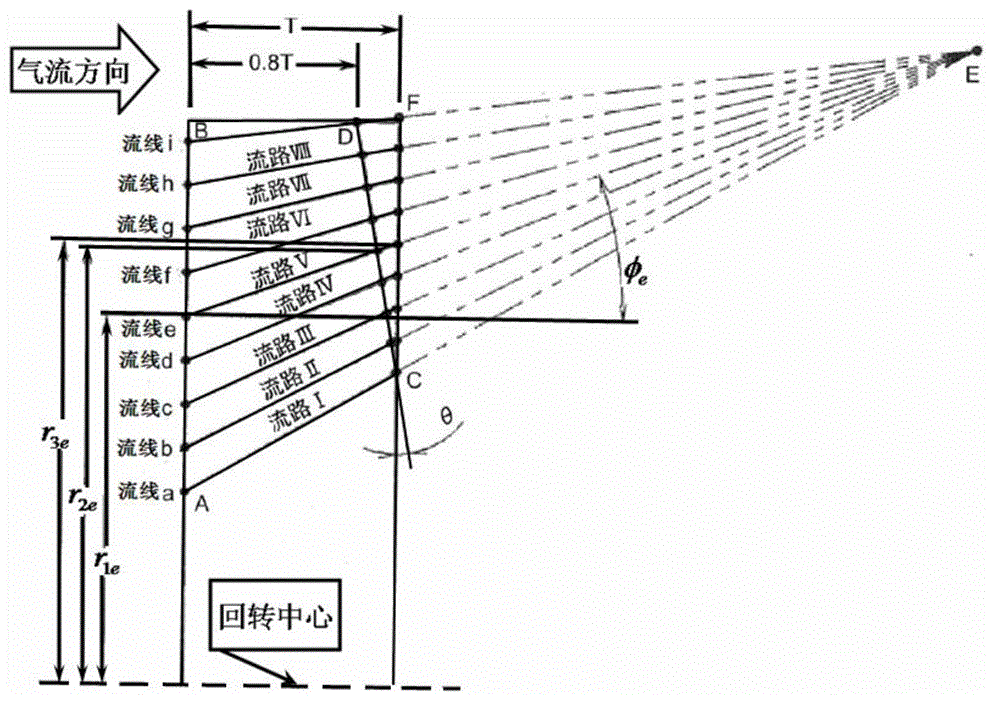

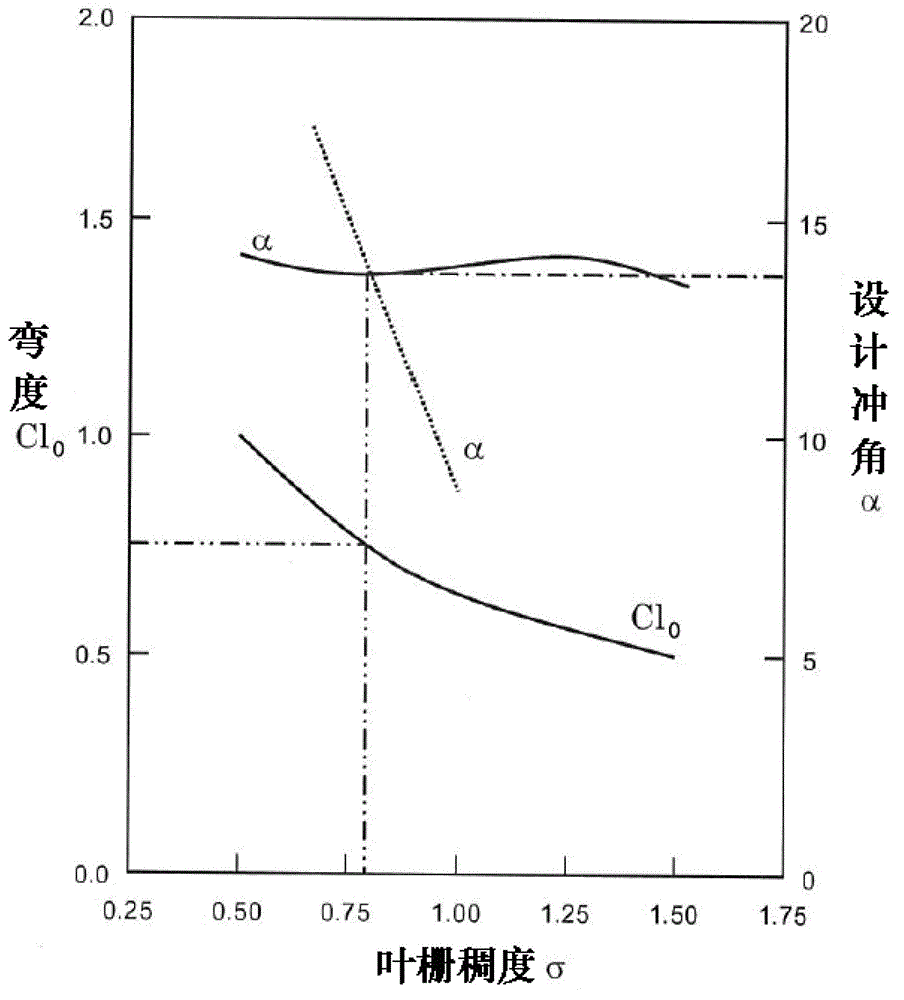

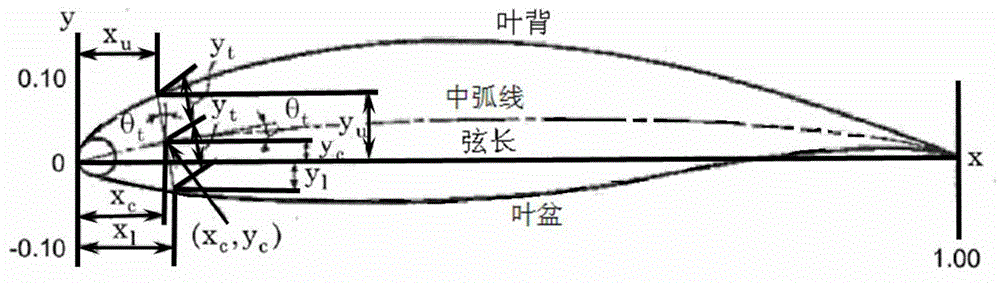

Method for determining wing-shaped oblique-flow cooling fan of automobile engine

InactiveCN102945292AReasonable structureReduce power consumptionSpecial data processing applicationsDesign cycleEngineering

The invention discloses a method for determining a wing-shaped oblique-flow cooling fan of an automobile engine. The method is implemented by the following steps: obtaining essential parameters of a plane blade lattice, obtaining the definite shape of a meridian plane, calculating a theoretical total pressure rise value, calculating flow velocity distribution, mapping and obtaining an equivalent velocity triangle, selecting blade profile parameters, performing correction compensation on the wing-shaped blade profile, calculating blade profile parameters, calculating blade coordinate values, fitting to obtain a blade cross-sectional line by using the obtained blade coordinate values, superposing individual cross-sectional planes in the radial direction to form a blade profile, and finally determining the wing-shaped oblique-flow cooling fan. The method can not only ensure the smoothness of curved surface of the fan but also meet the requirements for pneumatic property and process, greatly reduces the design cycle, facilitates the modification of the following design, and greatly reduces the development cost.

Owner:XIAN UNIV OF TECH

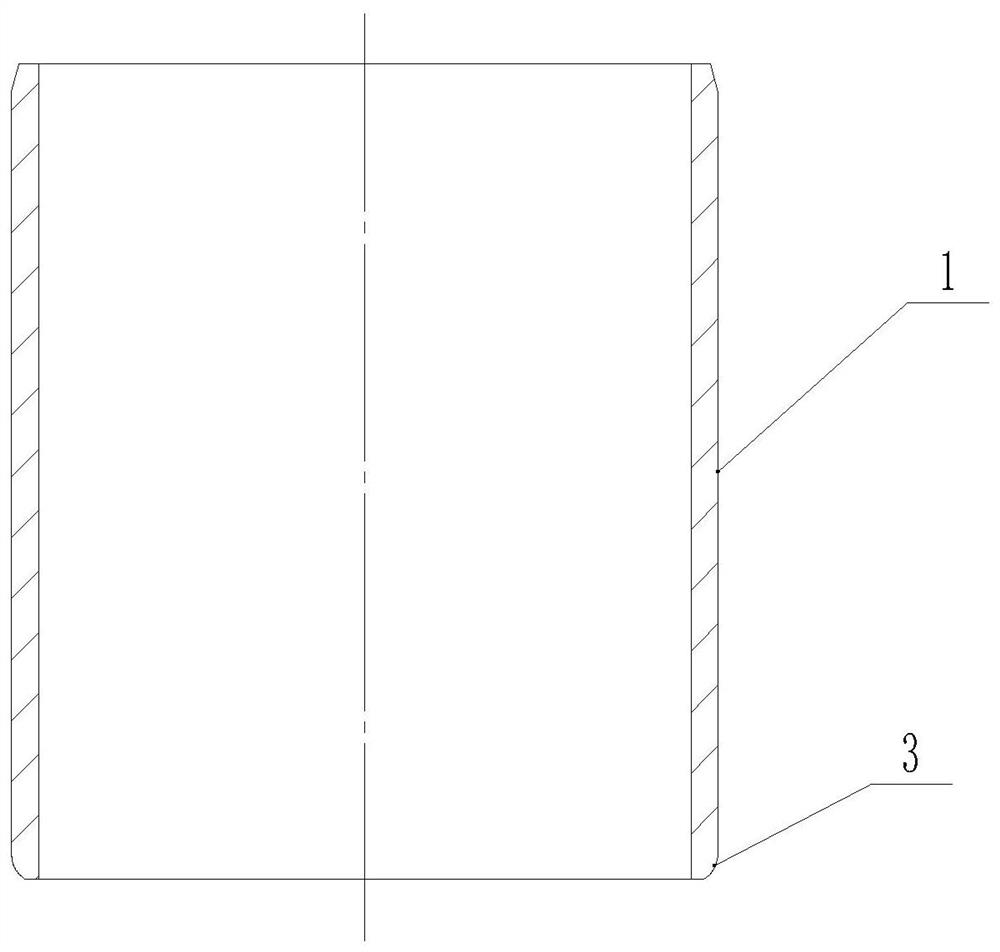

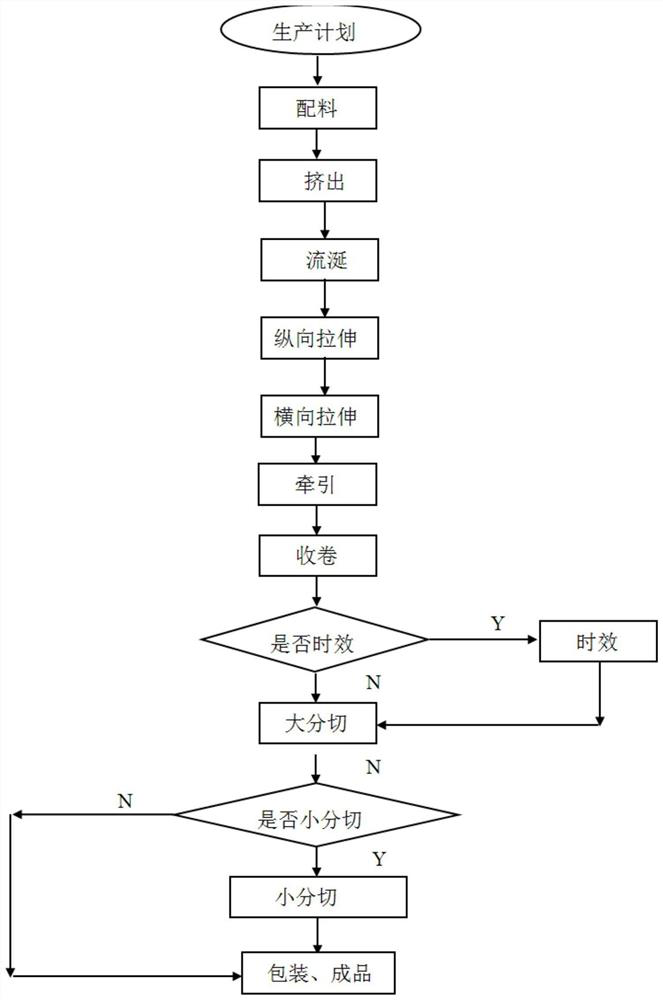

Technology for manufacturing flat enamel-cover copper wire with large width-to-thickness ratio

ActiveCN107240464AHigh aspect ratioLarge aspect ratioFlat/ribbon cablesManufacturing wire harnessesManufacturing technologyCopper wire

The invention belongs to the conductive wire manufacturing field and more particularly, to a technology for manufacturing flat enamel-cover copper wire with a large width-to-thickness ratio. The invention aims to solve the technical problems that the flat enamel-cover copper with a large width-to-thickness ratio manufactured by the existing technology has a low uniformity and poor consistency, which compromises the overall conductivity and cannot meet the manufacturing requirement for the flat enamel-cover copper wire with a large width-to-thickness ratio. The manufacturing technology comprises the following steps: A) releasing and correcting straight the wire; B) squeezing to make a round wire; C) squeezing to make a flat wire I; D) squeezing to make a flat wire II; E) squeezing to make a flat wire III; F) cooling; G) performing ultrasonic cleaning; H) annealing; I) cleaning and baking; J) painting and baking; and K) cooling, attracting and collecting the wires. With the technology proposed by the invention, the manufacturing for a flat enamel-cover copper wire with a large width-to-thickness ratio can be realized easily so that the manufactured flat enamel-cover copper wire has better conductivity and consistency.

Owner:WELL ASCENT ELECTRONIC (GANZHOU) CO LTD

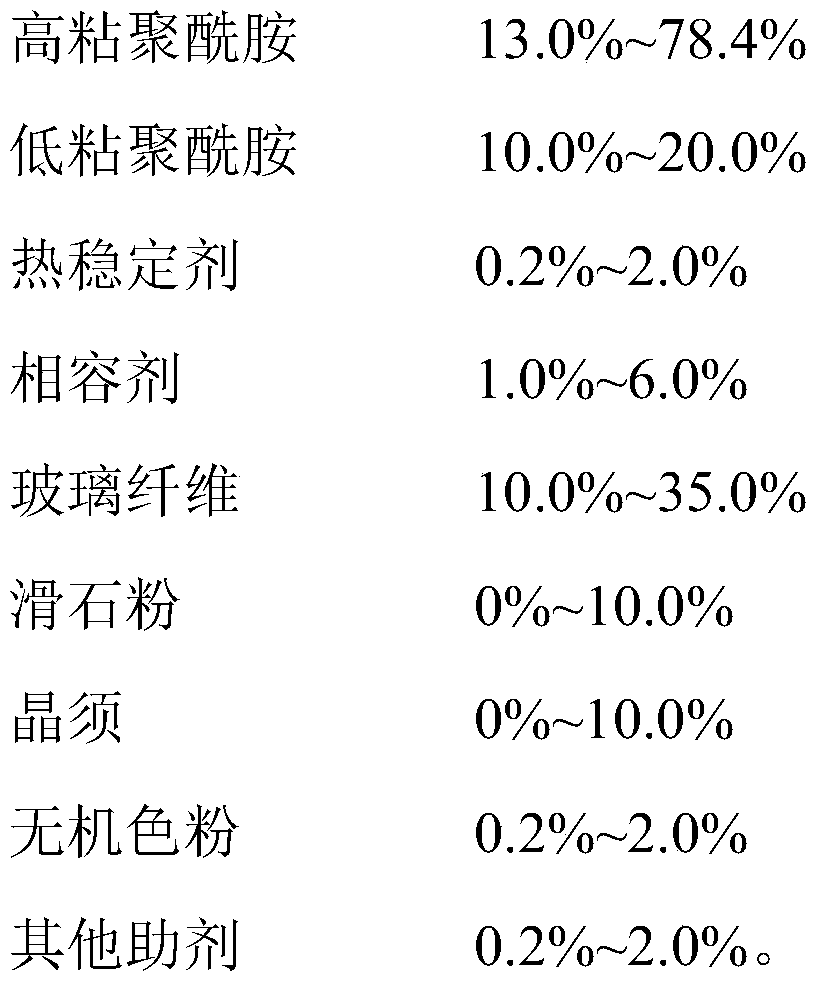

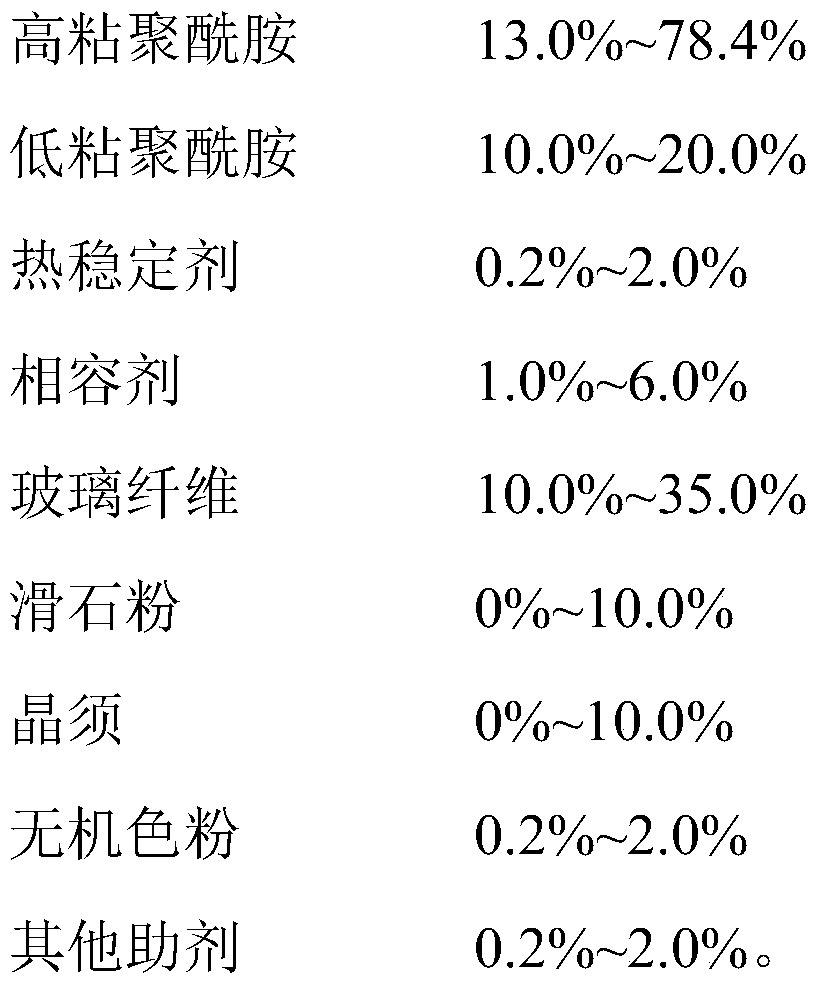

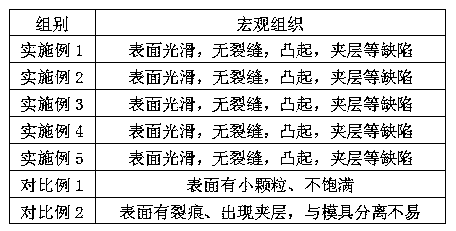

Polyamide compound material and production method thereof

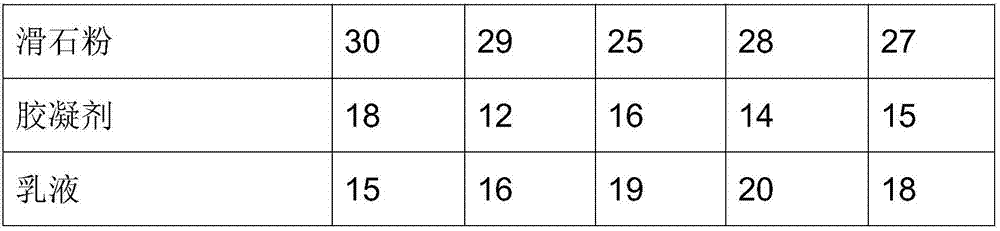

The invention provides a polyamide compound material and a production technology thereof. The polyamide compound material comprises the following components of, in parts by weight, 78.4-13% of high-viscosity polyamide, 10-20% of low-viscosity polyamide, 0.2-2% of a thermal stabilizer, 1-6% of a compatilizer, 10-35% of glass fibers, 0-10% of talcum powder, 0-10% of whiskers, 0.2-2% of inorganic toner and 0.2-2% of another assistant. According to the polyamide compound material and the production technology thereof, the high-viscosity polyamide and the low-viscosity polyamide are adopted for compounding, the proper glass fibers, talcum powder, whiskers, compatilizer, assistant and inorganic toner are added to make the produced polyamide compound material capable of resisting high and low temperature, good mechanical performance is maintained, meanwhile, good surface appearance is obtained, and the rigidity and the tenacity of the material are improved so that the mechanical performance of the material can be maintained for a long term, change of material color is reduced, and the polyamide compound material can be applied more widely.

Owner:江苏沃特新材料科技有限公司

Hot forging and molding process for oxygen free copper material

ActiveCN103706741AAvoid unstable performanceAvoid damageMetal-working apparatusCombustionLubrication

The invention discloses a hot forging and molding process for oxygen free copper materials. The hot forging and molding process is different from the traditional cold extrusion process in prior art. According to this process, a hot forging method is adopted to process the oxygen free copper materials and process parameters including a preheating temperature of moulds, a heating temperature of materials, and a lubrication oil component are ensured. The hot forging and molding process can be used to prepare precise oxygen free copper components which are smooth on surface, good in performance, and qualified in combustion. The process steps are simple to operate and applicable to industrialization promotion, the finished product rate is high, and all the parameters of products are excellent.

Owner:JIANGXI AUDY BRASSWORK

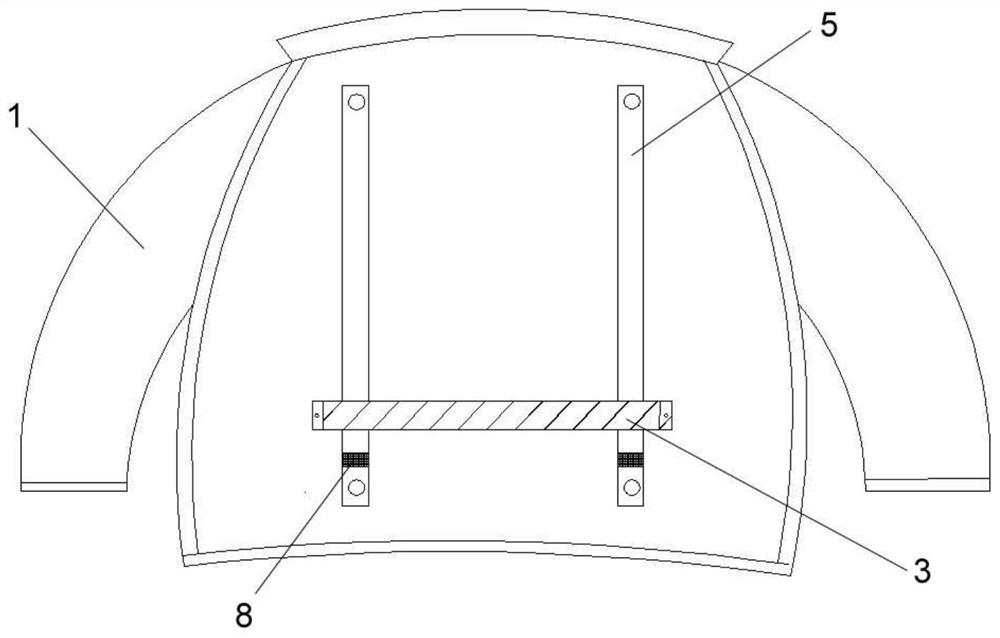

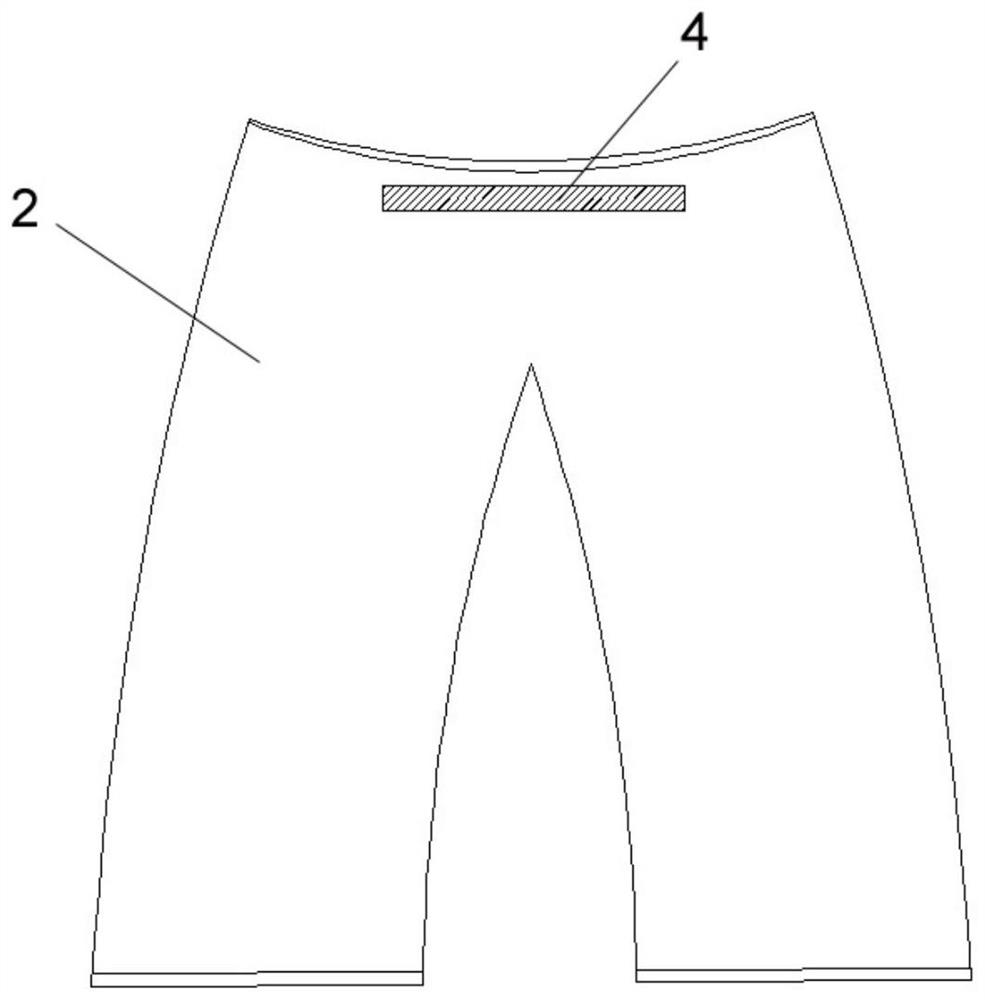

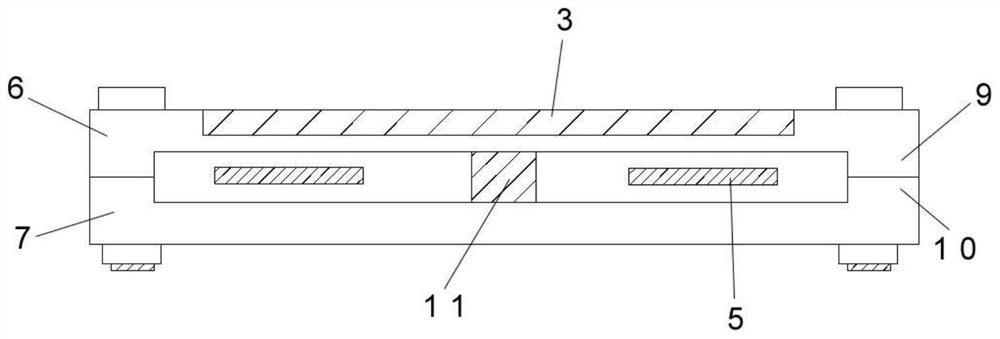

a school uniform

The invention discloses a novel school uniform. The uniform comprises an upper outer garment and trousers; a first magnet is fixed to the inner side of the lower hem of the back of the upper outer garment, a second magnet is fixed to the outer side of the back waist part of the trousers, and the first magnet attracts the second magnet mutually; the first magnet can freely slide on a sliding guiding strip on the inner side of the upper outer garment through a slide device. According to the novel school uniform, the lower hem of the upper outer garment is connected with the back waist part of the trousers, so that the waist and back of a student cannot be exposed in the strenuous exercise process such as back bending and the like, and embarrassment is avoided; the school uniform can be conveniently washed, and the attractive appearance of the school uniform, the comfort of wearing and the effectiveness of subsequent using are ensured.

Owner:巴彦淖尔市安利特制衣有限公司

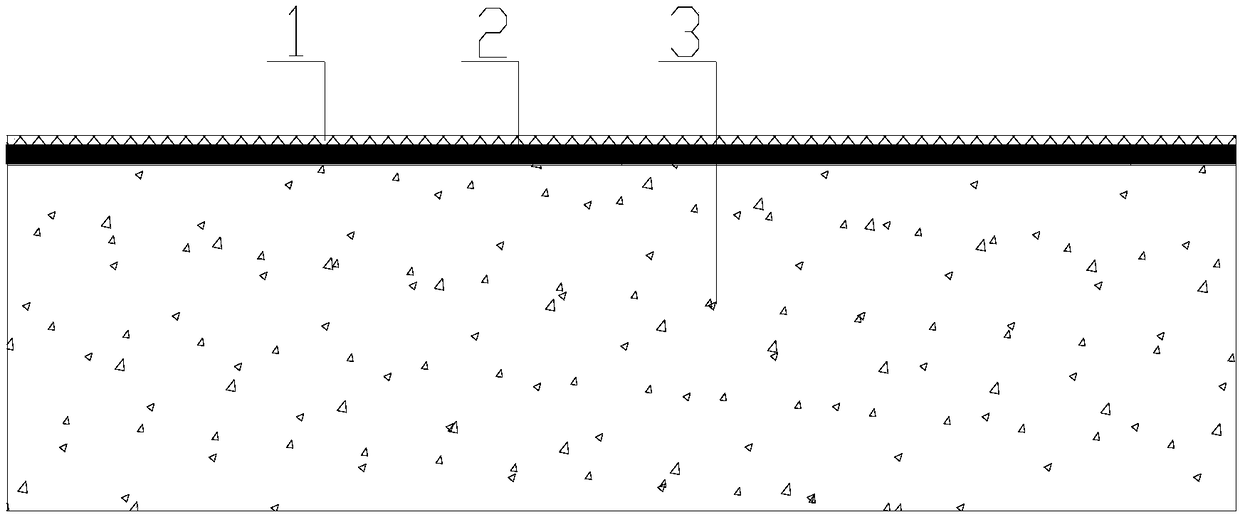

Sand-exposing concrete and preparation method thereof

ActiveCN109372224AGuaranteed surface smoothnessDisplay quality is easy to controlFlooringCrack resistanceCase hardening

The invention provides sand-exposing concrete and a preparation method thereof. The sand-exposing concrete adopts a sand-exposing concrete surface hardening material, is subjected to erosion process treatment and comprises a sand-exposing face layer, a sand-exposing concrete surface hardening layer and a concrete base layer. The preparation method comprises the steps that the concrete base layer is cast in place; when the cast-in-place concrete base layer is going to initial setting, the sand-exposing concrete surface hardening material is spread, and after the sand-exposing concrete surface hardening material fully absorbs water to be wetted, trowelling and finishing are conducted; the concrete is subjected to moisture insulating and curing for 3 days, and thus the sand-exposing concretesurface hardening layer is formed; an aggressive agent is splashed on the sand-exposing concrete surface hardening layer, then washing treatment is conducted through a brush, and the sand-exposing face layer is formed; and the concrete is continued to be subjected to moisture insulating and curing for at least 7 days. According to the sand-exposing concrete and the preparation method thereof, sandgravels are exposed, thus the veneer effect is achieved, the sand-exposing face is even and flat, the problems that as for a traditional delayed-setting flushing process, the surface flatness is difficult to control, the exposed depths are not consistent, and sand exposing is uneven are avoided, and the sand-exposing concrete has the excellent mechanical properties, anti-skid performance, crack resistance and the like.

Owner:HUAXIN CEMENT

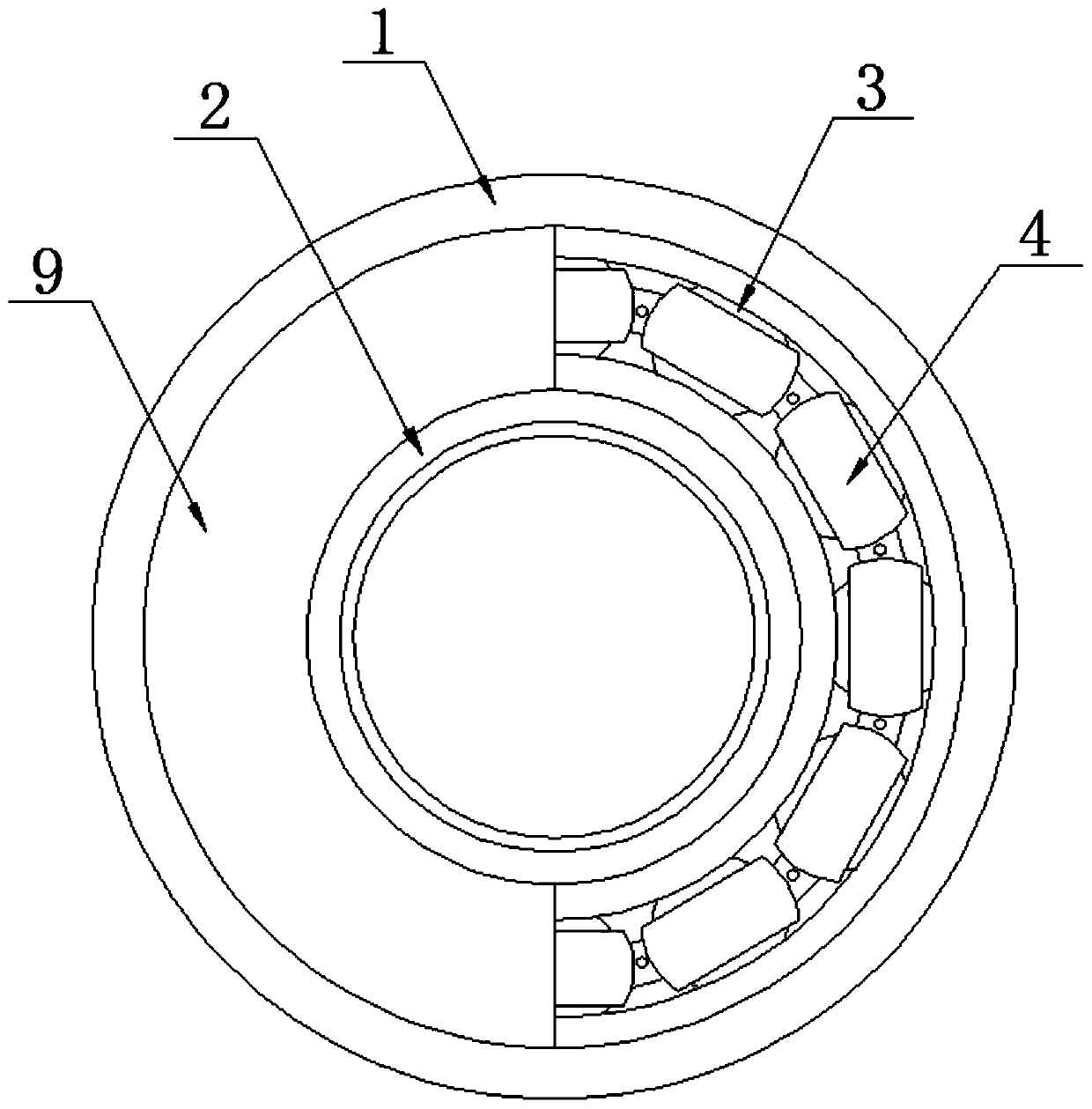

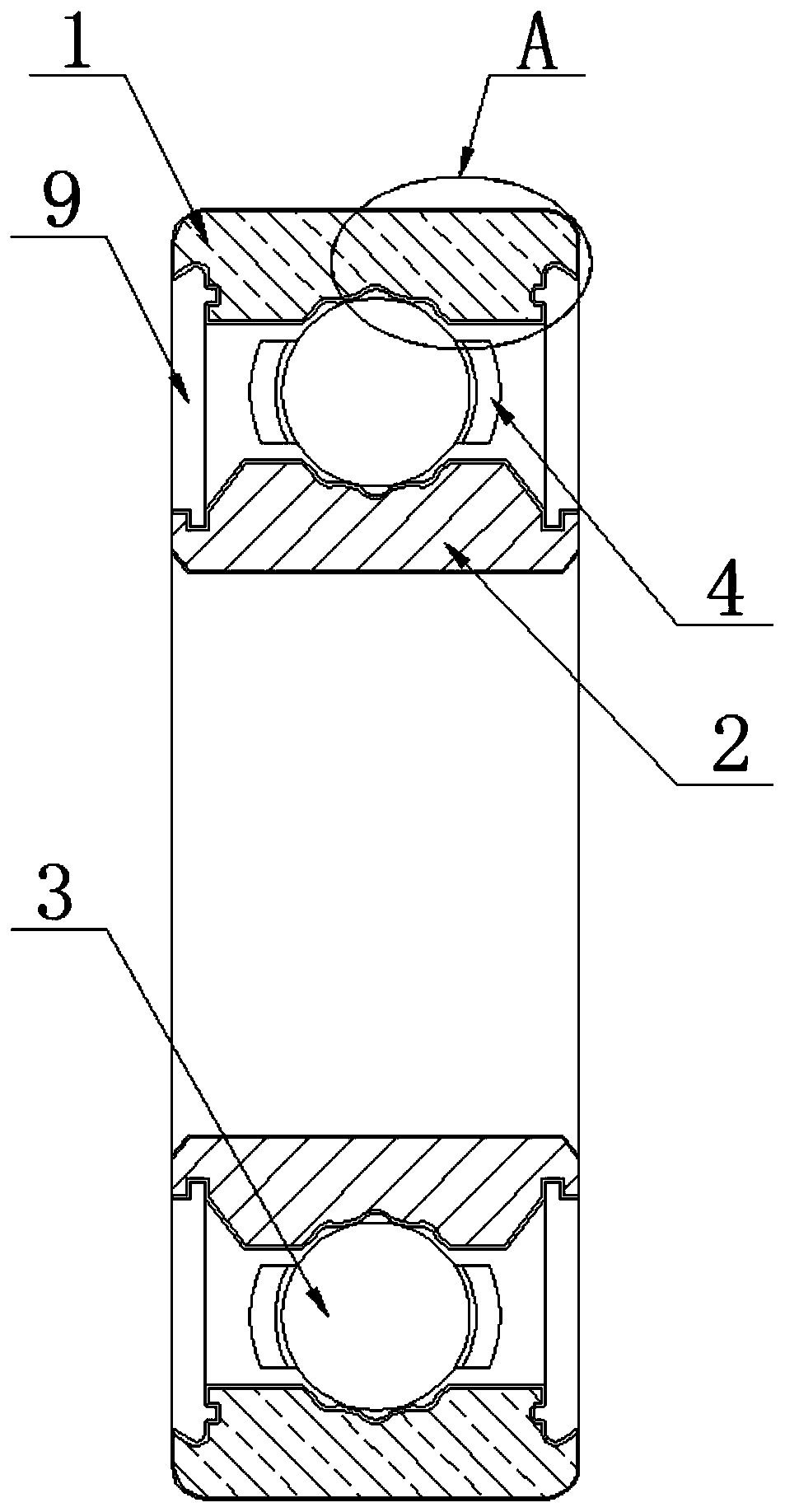

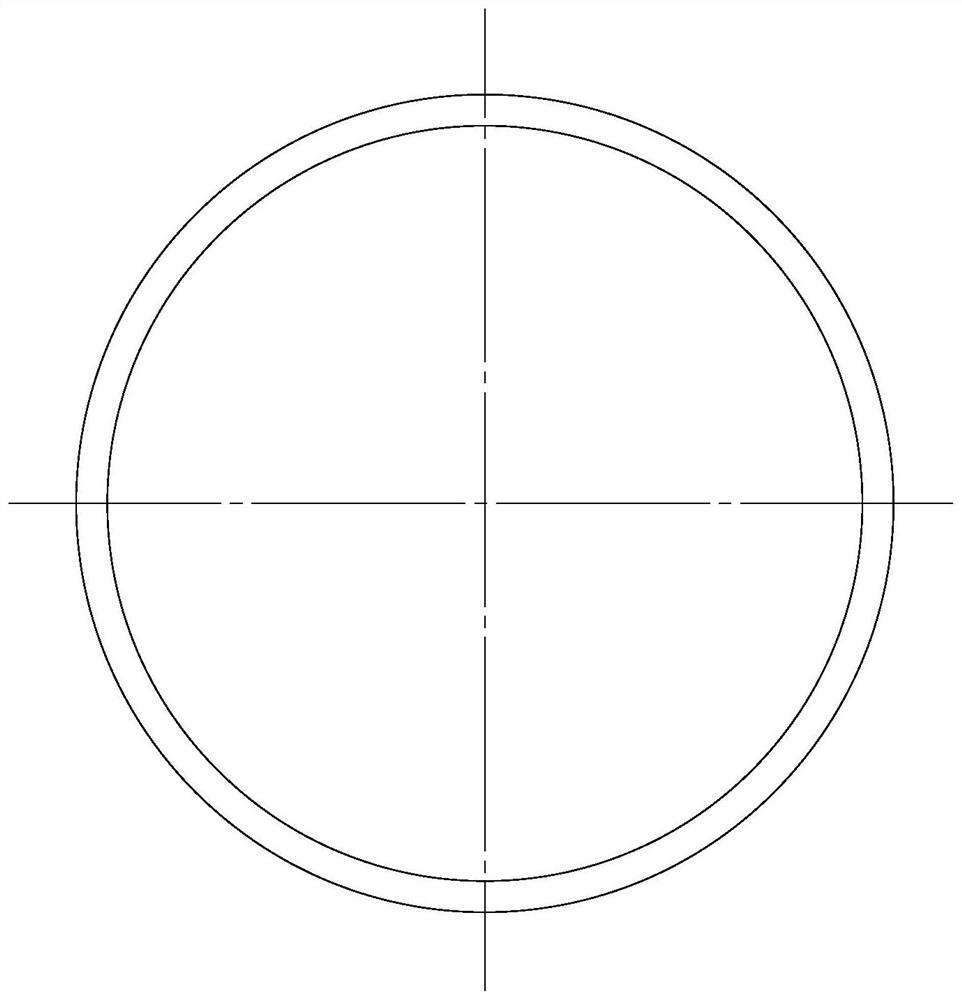

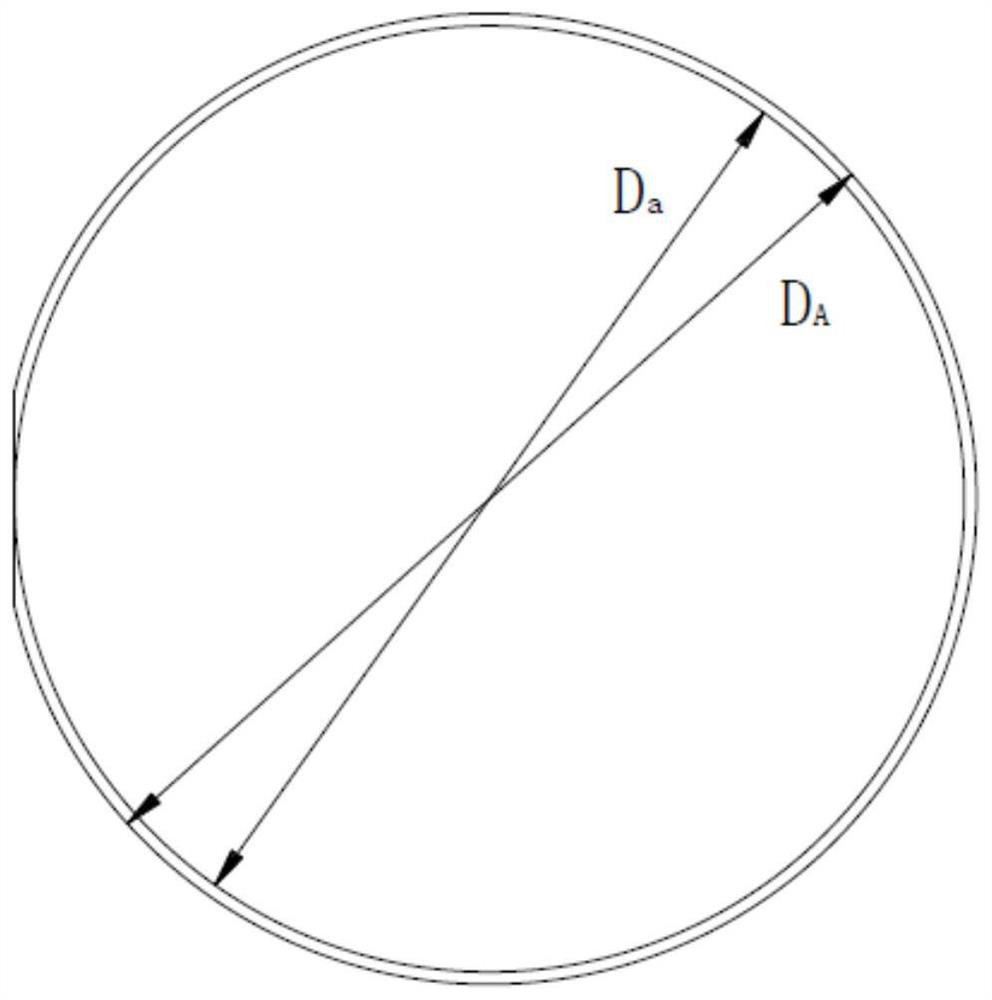

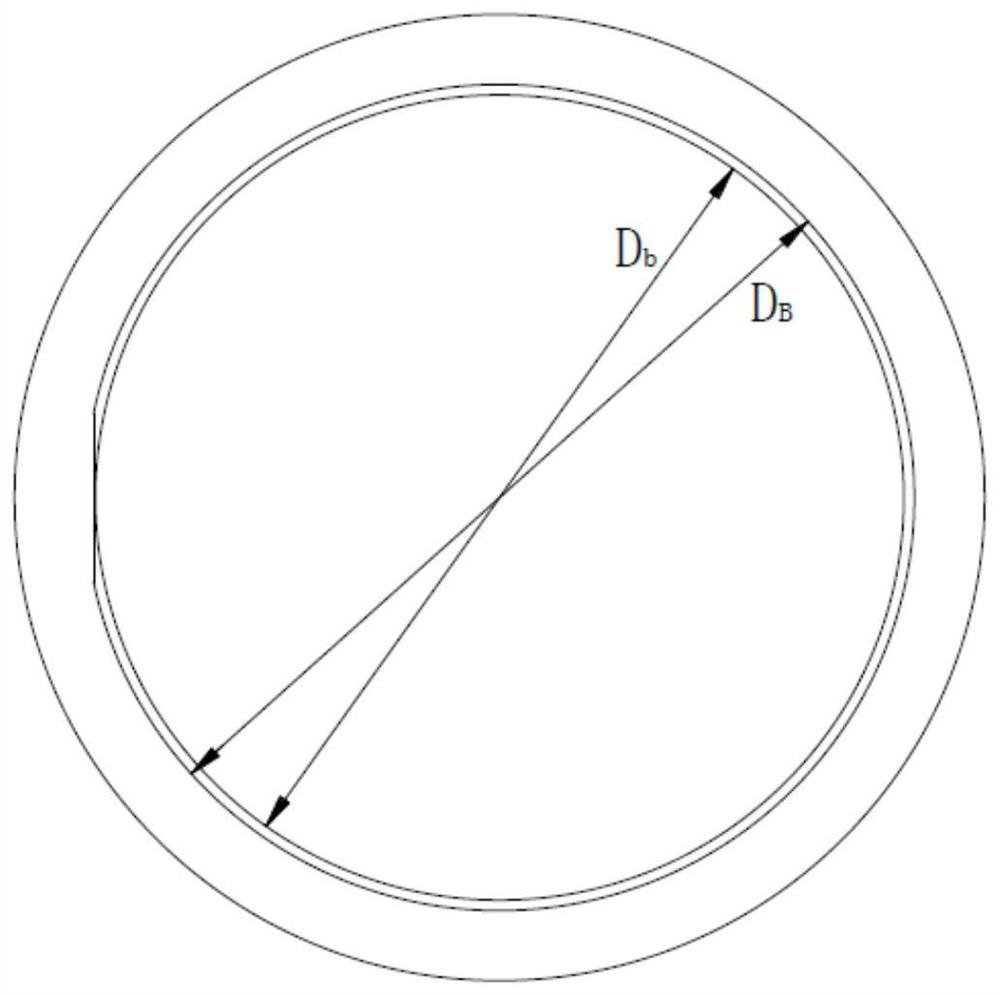

Deep groove ball bearing subjected to nickel coating treatment and machining method thereof

InactiveCN109707743AImprove connection strengthNot easy to rustMolten spray coatingBearing componentsBall bearingSalt spray test

The invention discloses a deep groove ball bearing subjected to nickel coating treatment, and relates to the technical field of bearings. The deep groove ball bearing comprises an outer bearing ring,an inner bearing ring and steel balls; the inner surface of the outer bearing ring and the outer surface of the inner bearing ring are in rolling connection with the surfaces of the steel balls correspondingly; steel ball retainers are arranged on the positions, between the outer bearing ring and the inner bearing ring, on the left sides and the right sides of the steel balls in a sleeving mode; and wavy circular grooves matched with the steel balls are formed in the inner surface of the outer bearing ring and the outer surface of the inner bearing ring correspondingly. According to the deep groove ball bearing subjected to nickel coating treatment and a machining method thereof, a thick nickel-chromium coating and a thin nickel-chromium coating are arranged to wrap the outer bearing ringand the inner bearing ring, thus the outer bearing ring and the inner bearing ring are not prone to being corroded, rusting is avoided during 72 hours of a salt spray test, and the abrasion-resistantstrength is improved; and frosted surfaces are arranged, thus the connecting strength of the coatings is enhanced, the coatings can be prevented from falling off easily, and meanwhile through specialstructures of the wavy circular grooves, the deep groove ball bearing cannot be abraded completely by the steel balls after being used for a long time.

Owner:宁波市镇海甬明轴承有限公司

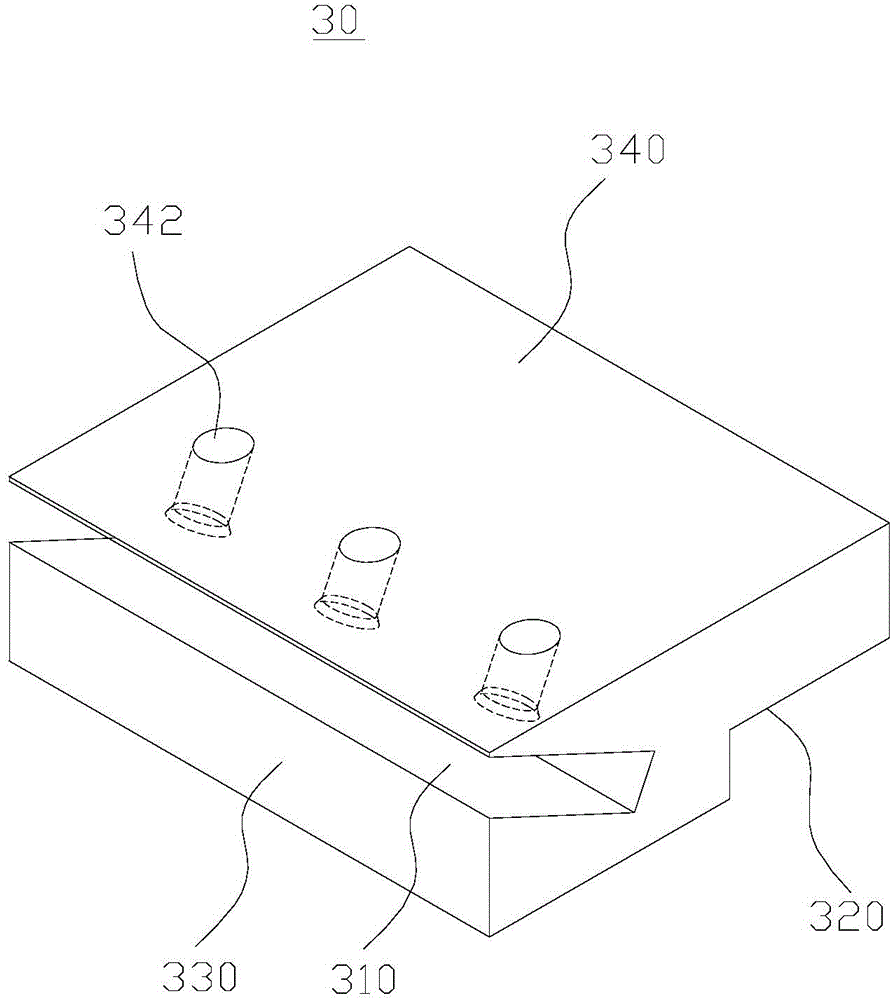

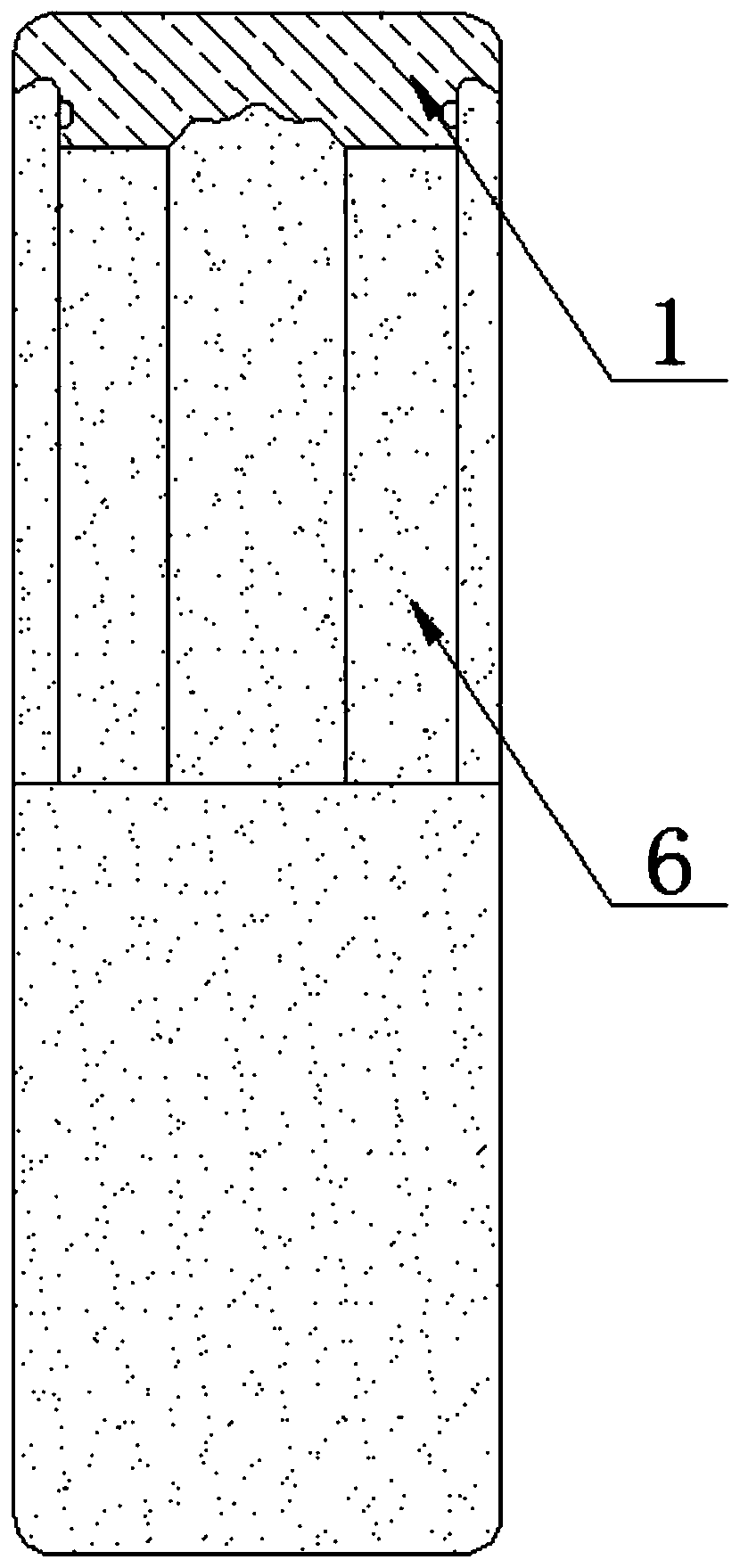

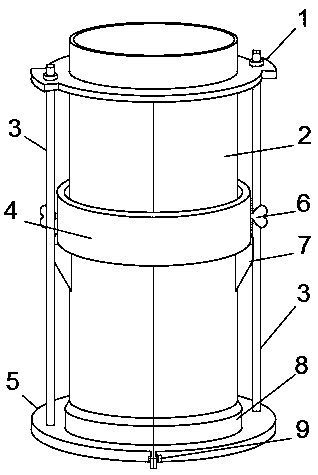

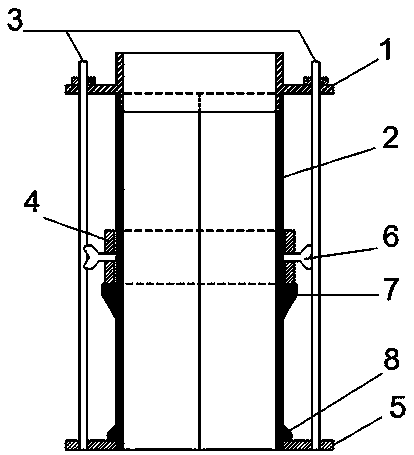

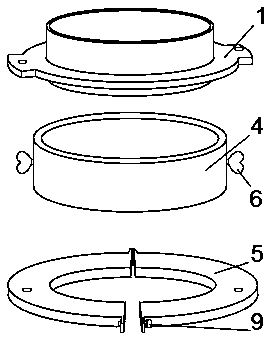

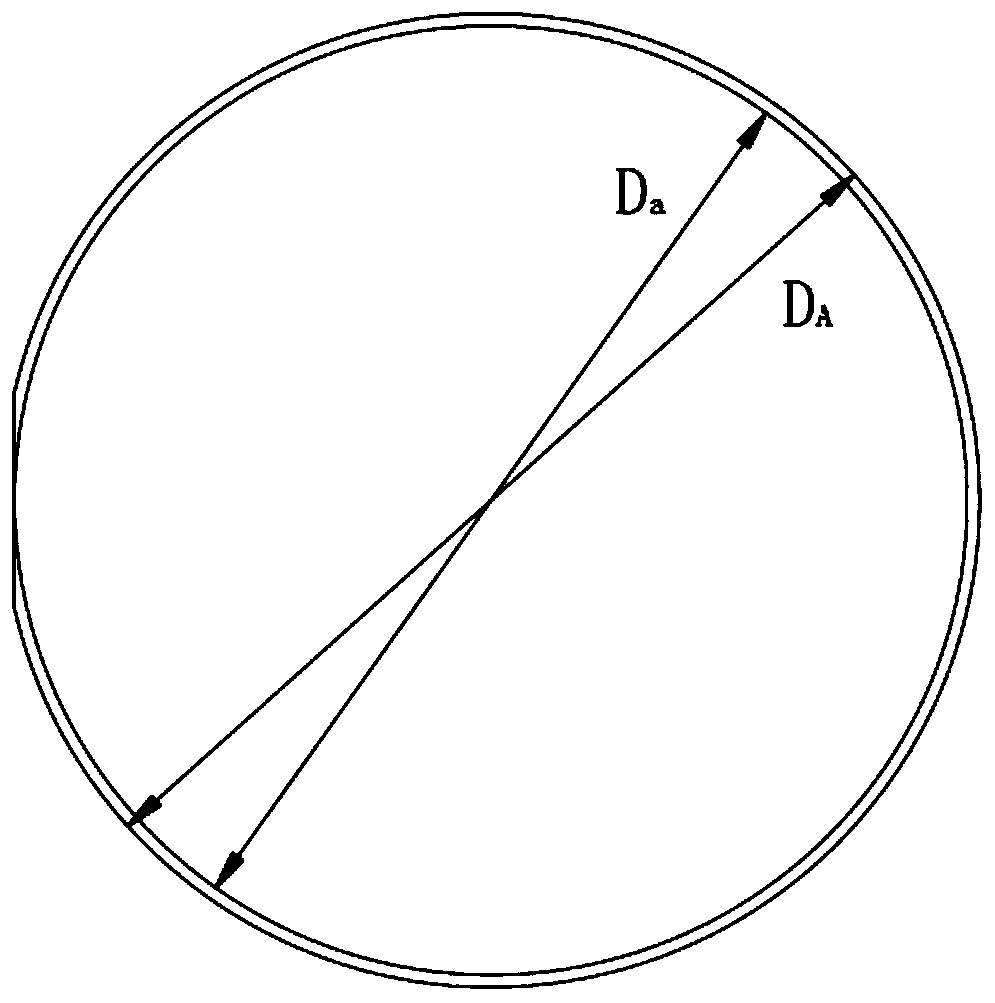

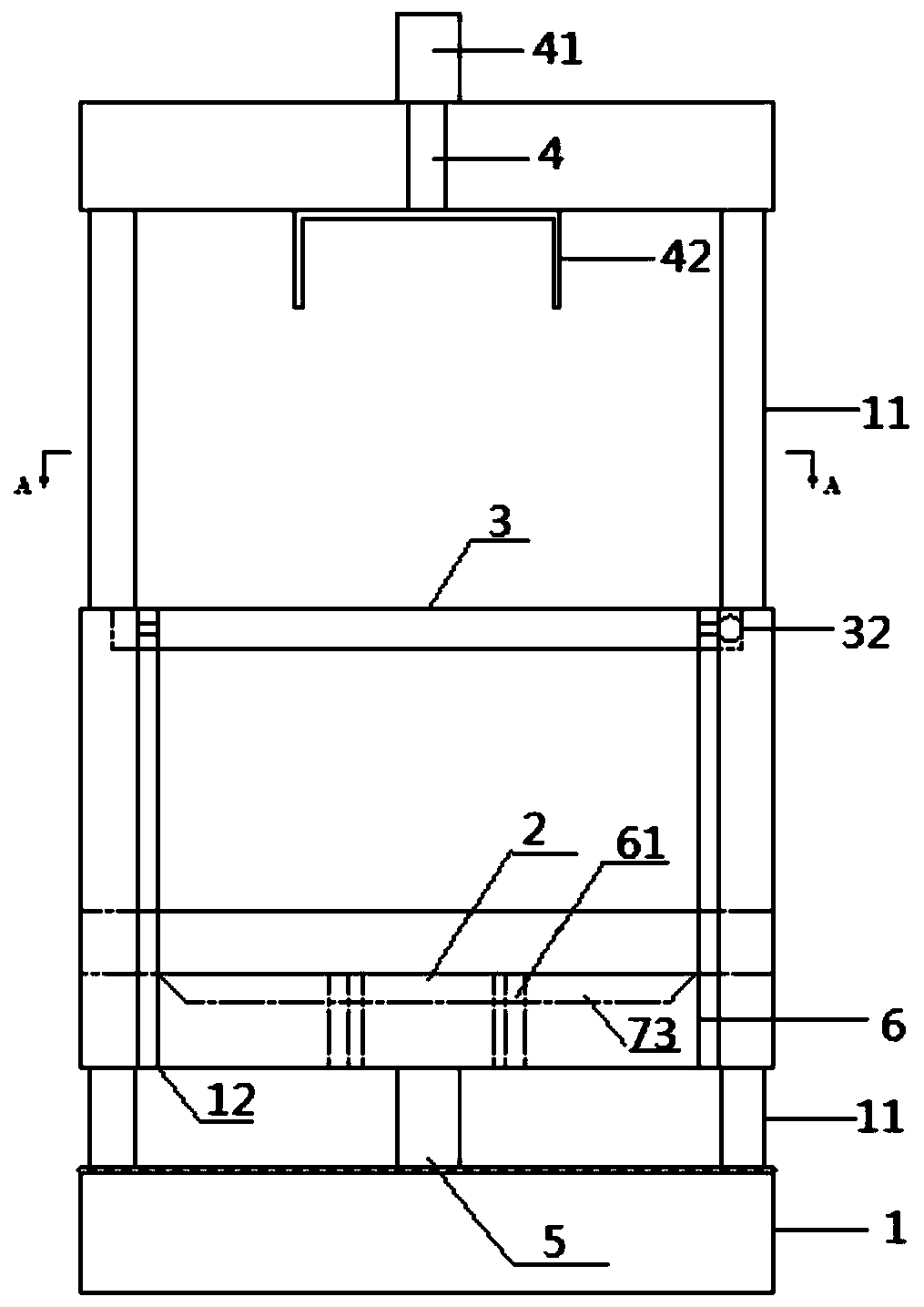

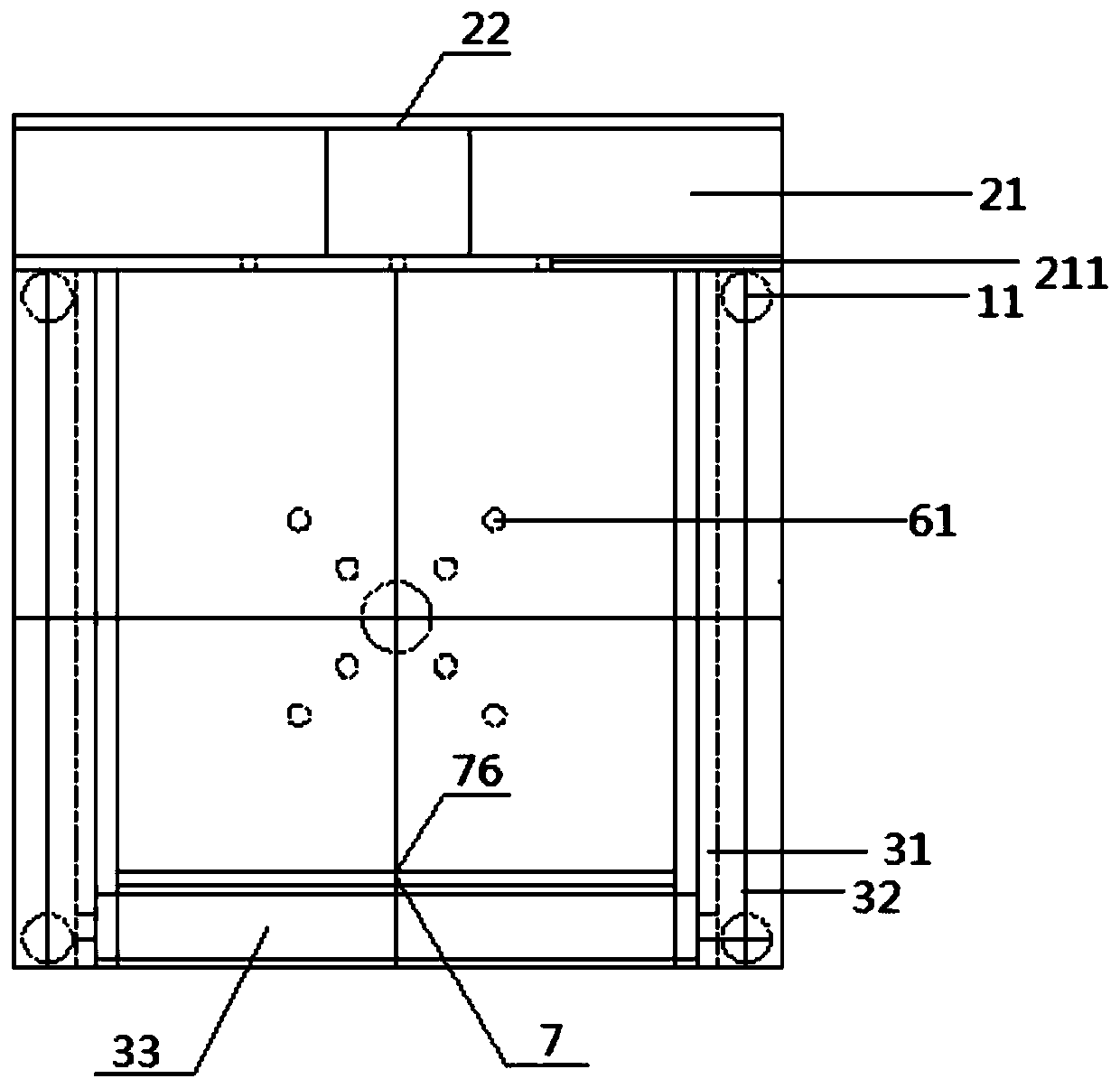

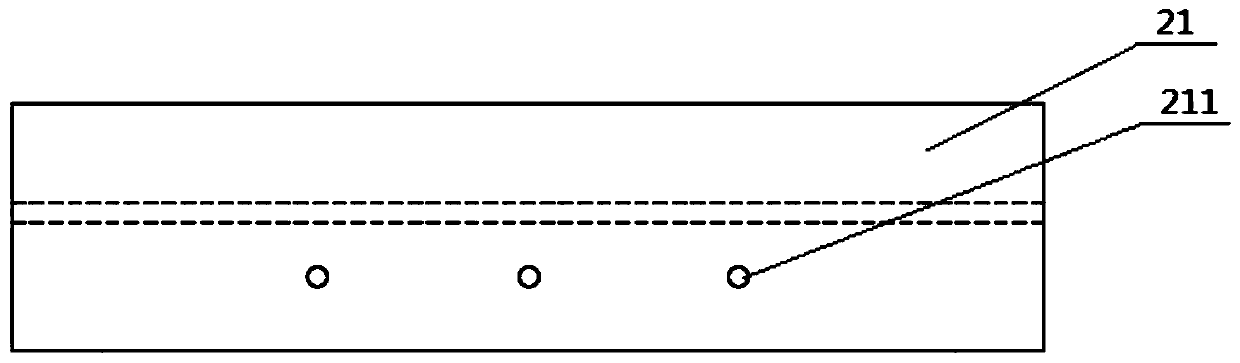

Sample preparation die for large coarse-grained soil triaxial test

PendingCN111141579AAvoid deformation and fractureSimplify the sample preparation processPreparing sample for investigationTriaxial shear testClassical mechanics

The invention relates to a sample preparation die for a large coarse-grained soil triaxial test. The die comprises a die annular bottom plate, a die top limiting lantern ring, a middle lantern ring, two semi-cylindrical steel plates with clamping tables, and two fixed limiting screw rods, and is characterized in that two semi-cylindrical steel plates with clamping tables are folded to form a sample cylinder; the sample cylinder is mounted above the die annular bottom plate; the die top limiting lantern ring is mounted at the top of the sample cylinder; the fixed limiting screw rod is used fortensioning the die annular bottom plate and the die top limiting lantern ring; and the middle lantern ring is installed outside the semi-cylindrical steel plate and clamped on the semi-cylindrical steel plate clamping table; and the middle lantern ring is provided with two screw rods used for clamping the two semi-cylindrical steel plates. Thus, the die disclosed in the invention is used for preparing a sample for triaxial test of large coarse granular materials.

Owner:SHIHEZI UNIVERSITY

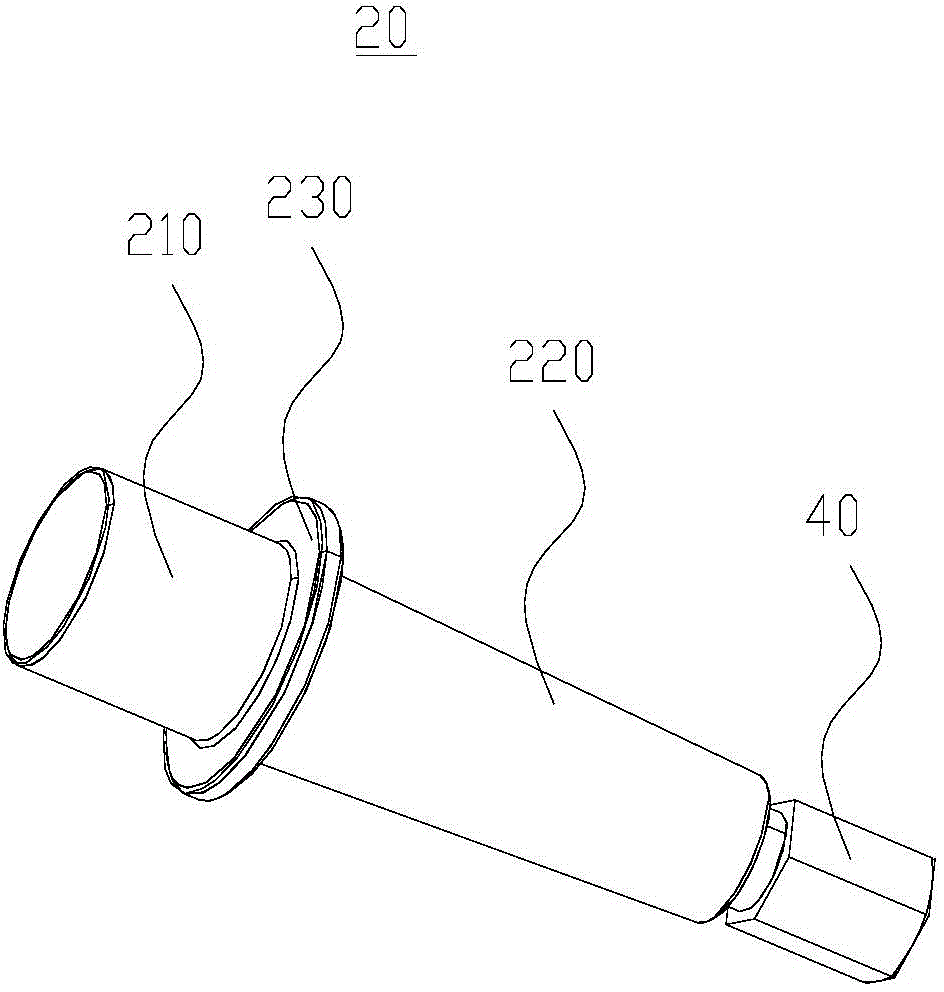

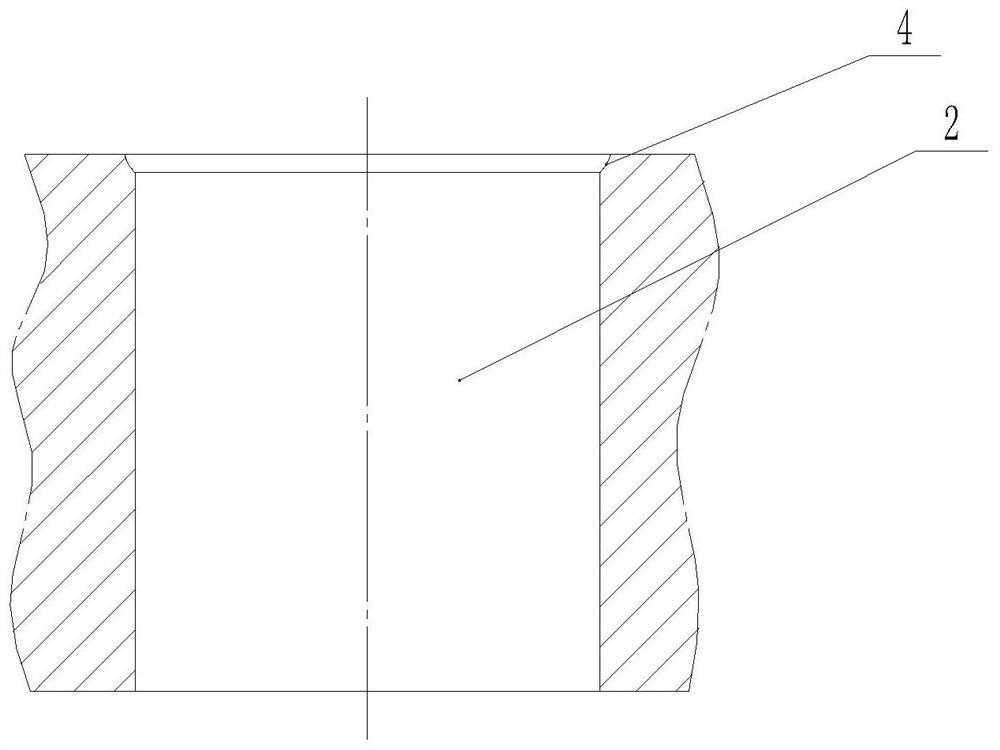

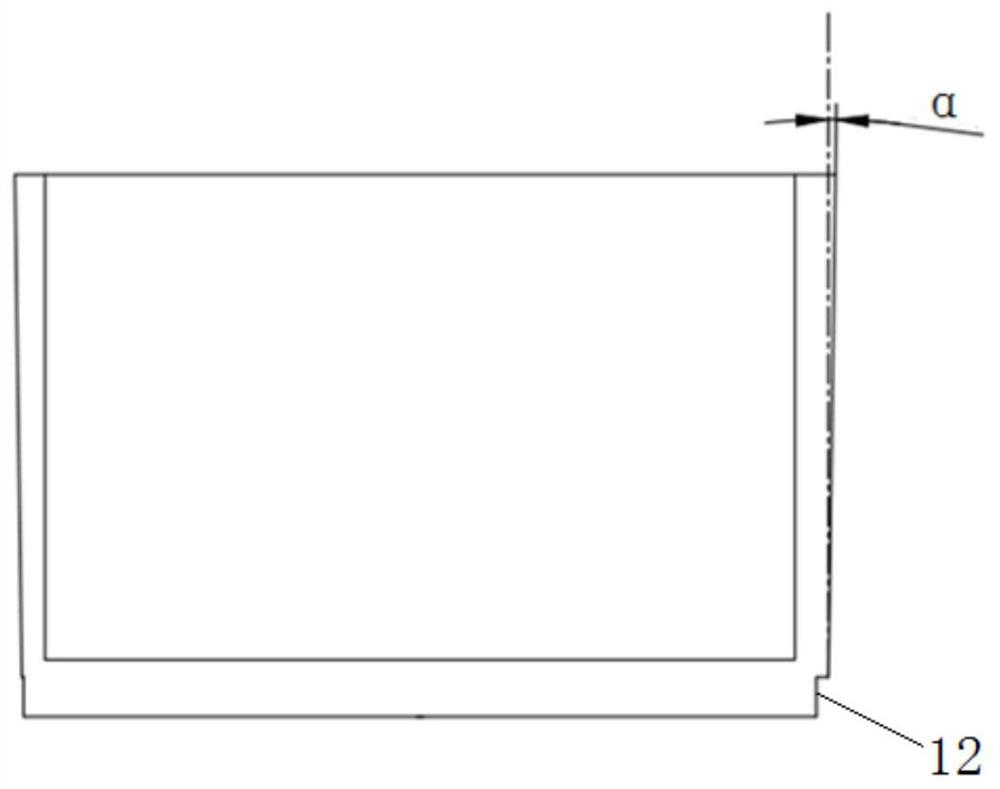

Cold-hot combined interference fit assembly method and LED lamp

ActiveCN110116292AImprove heat transfer performanceReduce contact areaVehicle headlampsLighting heating/cooling arrangementsInterference fitDie casting

The invention relates to a cold-hot combined assembly method of two metal castings, and an LED lamp for assembling a main body radiator as an A die casting piece and a heat dissipating module as a B die casting piece by adopting the method. The method comprises the following steps: the cylindrical A die casting piece with a draft angle of 0.8-5 degrees and a thermal expansion coefficient of 1 E-6 / DEG C is produced and cooled to the normal temperature; the B die casting piece with a circular hole is produced, and the mold stripping temperature is 150-400 DEG C; the thermal expansion coefficientgamma B of the B die casting piece is 1E-6 / DEG C; and within half a minute of mold stripping of the B die casting piece, an outer limiting piece of the A die casting piece is aligned to an inner limiting surface of the B die casting piece to place in the circular hole of the B die casting piece for cooling to the normal temperature. The method can save the energy and guarantee the precision and the surface smooth of produced devices.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

A production process of flat enamelled copper wire with large aspect ratio

ActiveCN107240464BHigh aspect ratioLarge aspect ratioFlat/ribbon cablesManufacturing wire harnessesCooking & bakingManufacturing technology

The invention belongs to the conductive wire manufacturing field and more particularly, to a technology for manufacturing flat enamel-cover copper wire with a large width-to-thickness ratio. The invention aims to solve the technical problems that the flat enamel-cover copper with a large width-to-thickness ratio manufactured by the existing technology has a low uniformity and poor consistency, which compromises the overall conductivity and cannot meet the manufacturing requirement for the flat enamel-cover copper wire with a large width-to-thickness ratio. The manufacturing technology comprises the following steps: A) releasing and correcting straight the wire; B) squeezing to make a round wire; C) squeezing to make a flat wire I; D) squeezing to make a flat wire II; E) squeezing to make a flat wire III; F) cooling; G) performing ultrasonic cleaning; H) annealing; I) cleaning and baking; J) painting and baking; and K) cooling, attracting and collecting the wires. With the technology proposed by the invention, the manufacturing for a flat enamel-cover copper wire with a large width-to-thickness ratio can be realized easily so that the manufactured flat enamel-cover copper wire has better conductivity and consistency.

Owner:WELL ASCENT ELECTRONIC (GANZHOU) CO LTD

Steering knuckle and bushing push-free process

ActiveCN111922631AReduce resistanceImprove integrityMetal working apparatusStructural engineeringMachine

The invention provides a steering knuckle and bushing push-free process. The process comprises the following steps that S1, a bushing is placed in a numerically controlled lathe, and an excircle guideangle at the bottom of the bushing is turned and formed; S2, a steering knuckle is fixed in a vertical machining center, and main pin holes of an upper lug and a lower lug of the steering knuckle arebored and formed through rough boring, chamfering and fine boring by adopting a fine machining process; S3, pretreatment before press-in is carried out, specifically, the bushing is placed in a liquid nitrogen environment to be treated for 2-3 hours; and S4, press fitting of the bushing is carried out, the bushing is pressed into the main pin holes in the two sides by adopting a press fitting machine. According to the process, the improvements in three aspects of processing technology, structure and mounting operation of the bushing and the steering knuckle are adopted, which are different from the prior art that an ironing rod needs to be used for ironing and pushing the interior of the bushing, so that the steering knuckle and bushing push-free process is realized, the bushing is smallin deformation, free of bulges, good in coaxiality and complete and attractive in inner hole surface of the bushing after pressing, and finally, the purpose of prolonging the service life of the steering knuckle, the bushing, a main pin and even the whole front axle is achieved.

Owner:HUBEI TRI RING FORGING

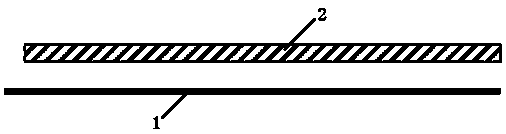

Simple flexible pressure equalizing pad for hot press molding of composite material and application thereof

PendingCN110815867ASimple structureReduce manufacturing costSynthetic resin layered productsFiberMechanical engineering

The invention discloses a simple flexible pressure equalizing pad for hot press molding of a composite material and application thereof. The simple flexible pressure equalizing pad comprises a demolding cloth layer and a fiber cloth layer, wherein the demolding cloth layer is laid and attached to the fiber cloth layer. The simple flexible pressure equalizing pad is mainly used for assisting the molding process of a composite material part autoclave. Compared with a traditional pressure pad, the simple flexible pressure equalizing pad is simple in structure, low in manufacturing cost and shortin preparation period; and the flexibility of the simple flexible pressure equalizing pad is better than that of the pressure pad, the matching degree of the simple flexible pressure equalizing pad and a composite material part in the auxiliary molding process is good, and the surface smoothness of the composite material part after molding is better guaranteed.

Owner:航天海鹰(镇江)特种材料有限公司

A cold and hot combination interference fit assembly method and LED lamps

ActiveCN110116292BImprove heat transfer performanceReduce contact areaVehicle headlampsLighting heating/cooling arrangementsThermal dilatationInterference fit

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

Dendritic polyamide-amine modified raw lacquer coating and preparation method thereof

ActiveCN110776828AHigh hardnessIncrease elasticityNatural resin coatingsAnti-corrosive paintsPolymer sciencePOLYMER SUBSTANCE

The invention discloses a dendritic polyamide-amine modified raw lacquer coating and a preparation method thereof. The preparation method comprises the following steps: taking a natural polymer raw lacquer as a main body, adding dendritic polyamide-amine accounting for 0.2-5% of the mass of the raw lacquer into a raw lacquer solution, fully and uniformly mixing the dendritic polyamide-amine and the raw lacquer solution at room temperature in a magnetic stirring mode, and then coating various common carriers with the obtained mixture to form a film with the thickness of 75-100 [mu]m; and dryingthe film at 120 DEG C for 6 h to form the dendritic molecular modified raw lacquer coating. The dendritic molecular modified raw lacquer coating has the good corrosion resistance of the pure raw lacquer, improves the adhesion of the raw lacquer to plastics, metals, glass and the like through crosslinking of urushiol serving as the main component of the raw lacquer and dendritic polyamide-amine, improves the hardness and the elasticity of the raw lacquer, improves the glossiness of the raw lacquer, obviously improves the impact resistance of the raw lacquer, and improves the alkali resistanceof the raw lacquer.

Owner:FUZHOU UNIV

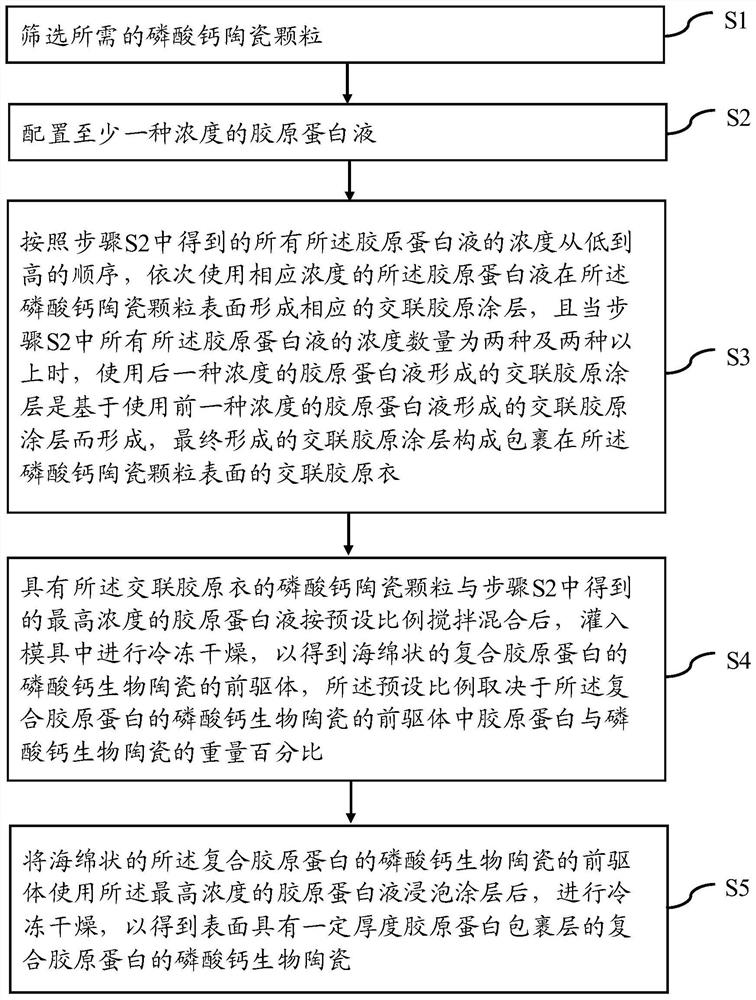

Collagen-composite calcium phosphate bioceramics and methods of making and using the same

ActiveCN110180030BClosely connectedAvoid side effectsTissue regenerationCoatingsFreeze-dryingCalcium phosphate ceramics

The invention provides a calcium phosphate bioceramic compounded with collagen and its preparation and use method. The preparation method of the calcium phosphate bioceramic compounded with collagen comprises: using collagen solution from low to high concentration on the surface of calcium phosphate ceramic particles Form a cross-linked collagen coating to obtain a cross-linked collagen coating wrapped on the surface of calcium phosphate ceramic particles, then mix with collagen solution and freeze-dry to obtain the precursor of calcium phosphate bioceramic composite collagen, and then use collagen solution to soak Freeze-dry after coating to obtain calcium phosphate bioceramics with collagen coating. The technical solution of the present invention improves the repair ability and degradation performance of the calcium phosphate bioceramics compounded with collagen, avoids aseptic inflammation caused by the shedding of calcium phosphate ceramic particles during clinical use, and utilizes the plasticity of shape and size and The convenience of use solves many problems encountered in the clinical application of bioceramics.

Owner:SHANGHAI BIO LU BIOMATERIALS

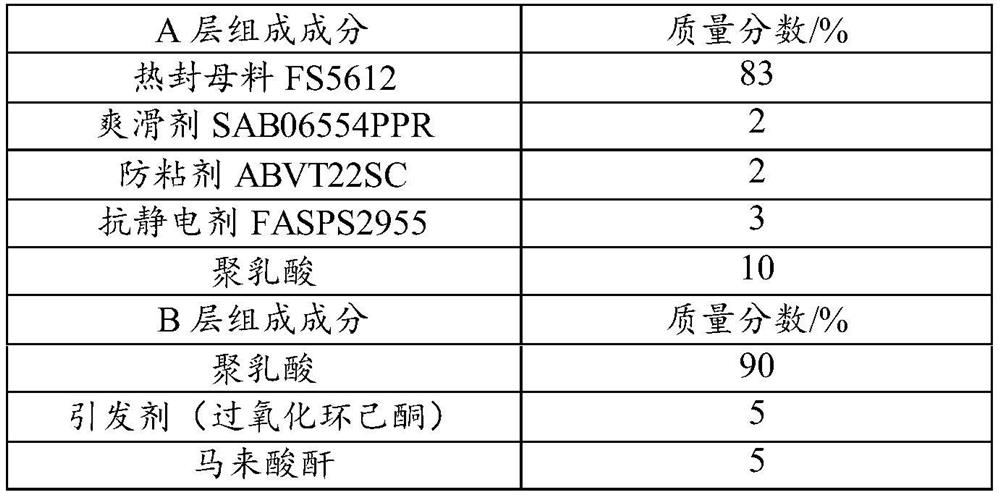

Two-way stretching degradable film and preparation method thereof

InactiveCN113172974AGuaranteed elongation at breakGuaranteed heat seal strengthBio-packagingSynthetic resin layered productsMasterbatchPolymer science

The invention provides a two-way stretching degradable film, which comprises a layer A, a layer B and a layer C; wherein the layer A is prepared from, by mass, 83%-85% of heat sealing master batch A, 2%-3% of slipping agent, 2%-3% of anti-sticking agent A, 3%-5% of antistatic agent A and 4%-10% of polylactic acid; the layer B comprises the following raw materials in percentage by mass: 80-90% of polylactic acid, 1-5% of an initiator and 5-15% of maleic anhydride; and the layer C is prepared from the following raw materials in percentage by mass: 85 to 88 percent of heat-sealing master batch C, 2 to 5 percent of anti-sticking agent C and 3 to 5 percent of an antistatic agent C; and 2-10% of polylactic acid. The modified polylactic acid and the modified polypropylene are compounded, so that other properties of the film greatly meet the requirements of the existing cigarette packaging film while the degradable requirement is met. The invention also provides a preparation method of the two-way stretching degradable film.

Owner:HAINAN SHINER IND

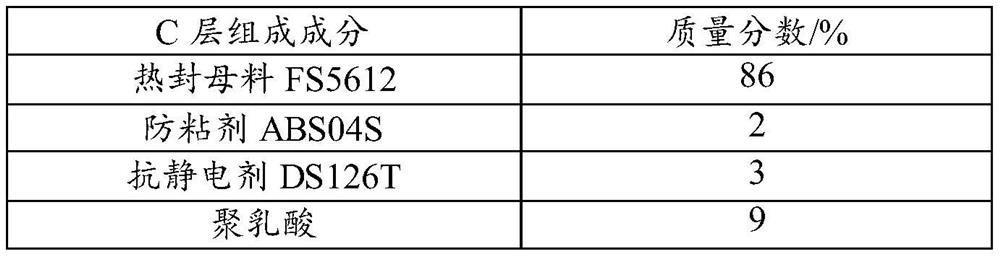

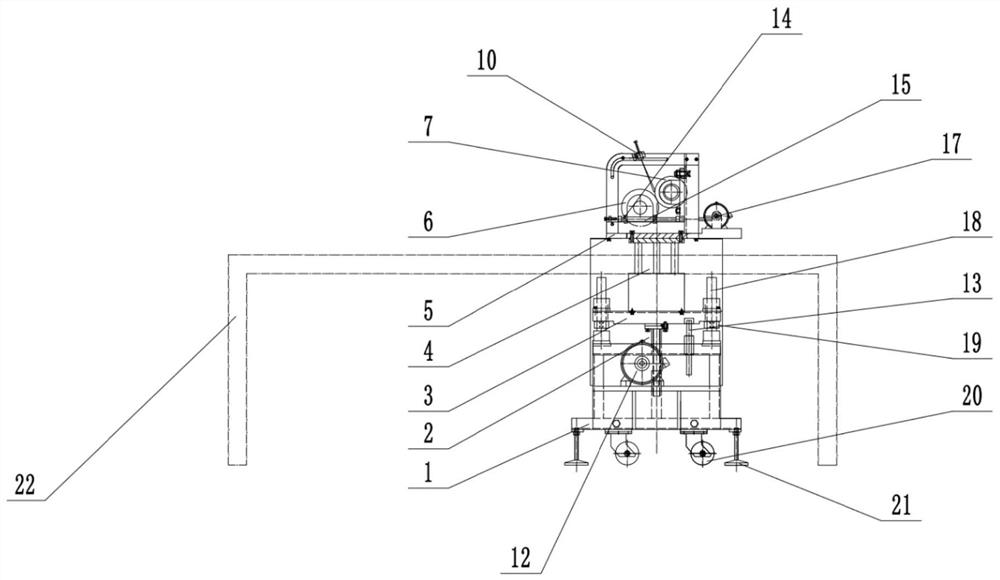

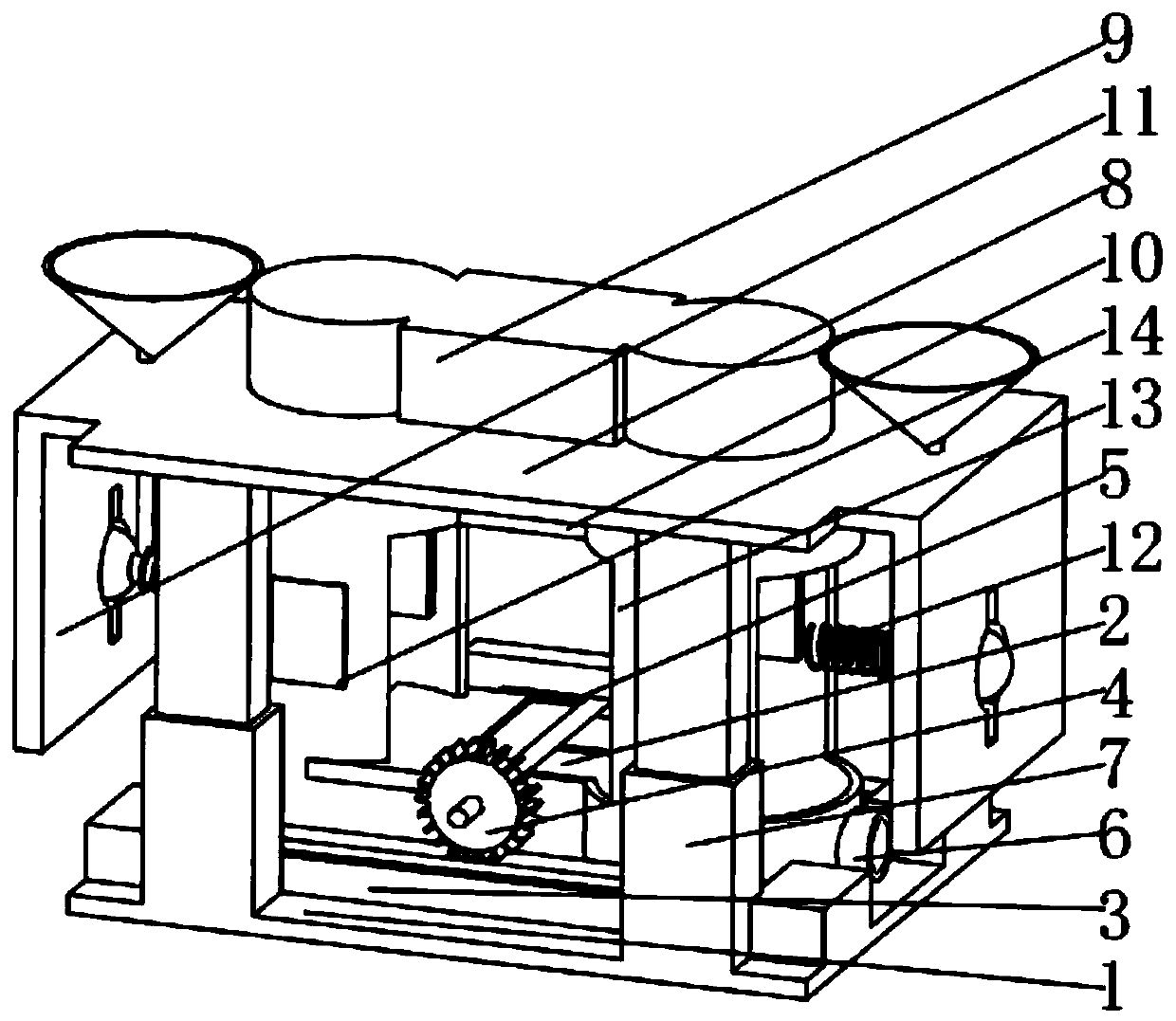

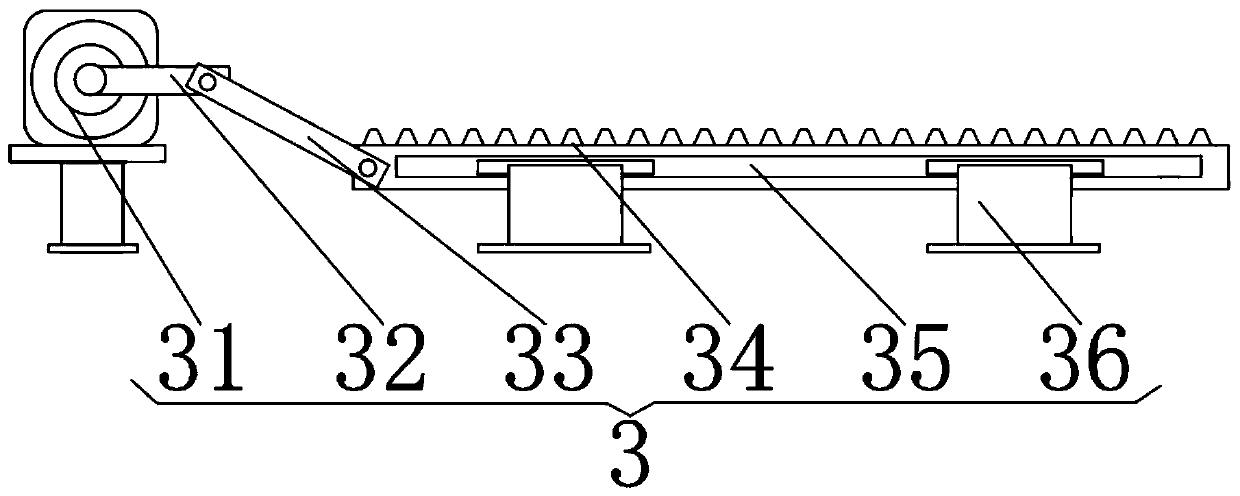

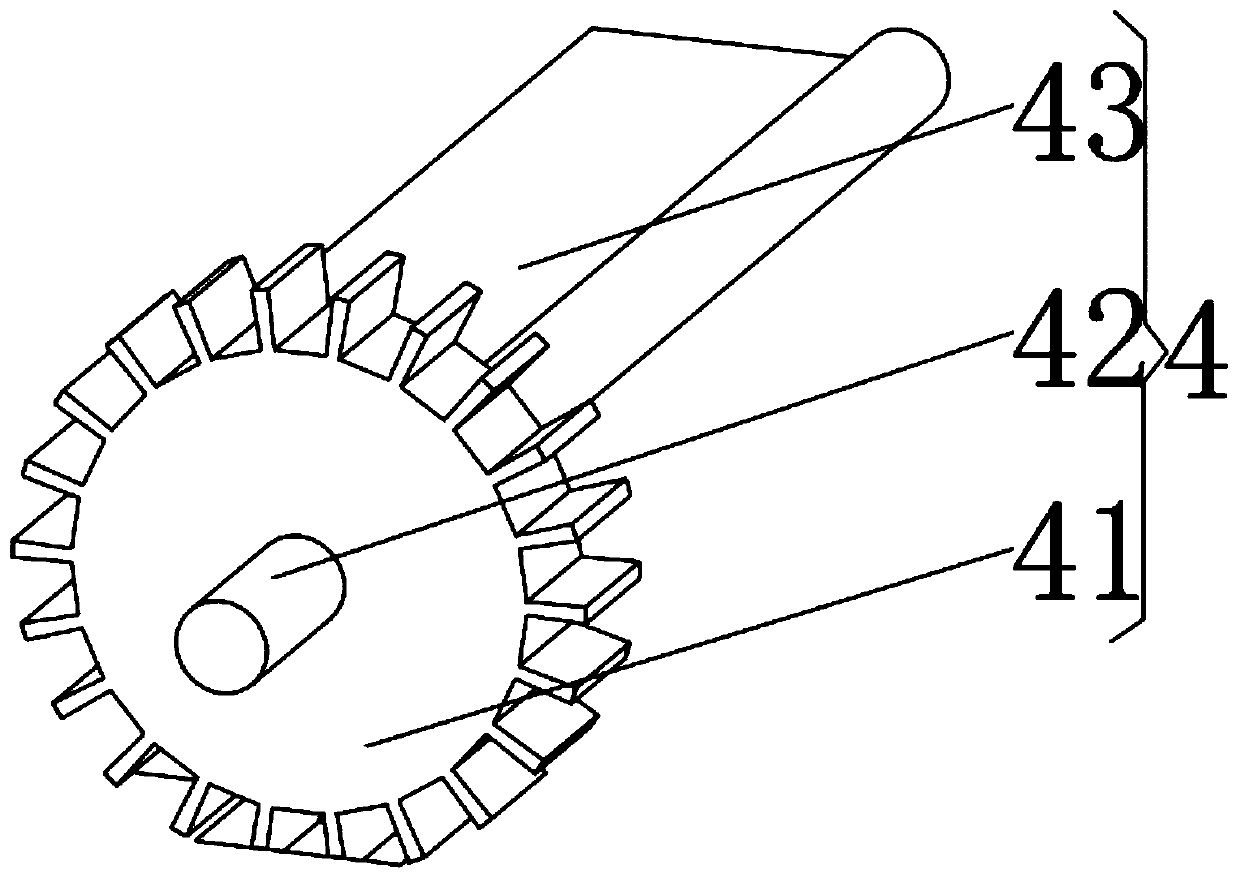

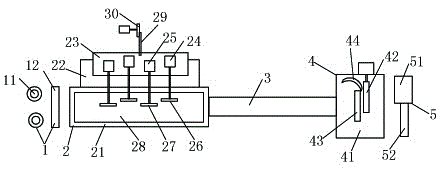

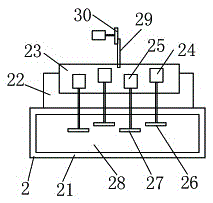

Viscous slurry grinding machine and using method thereof

PendingCN112692965AGuaranteed surface smoothnessGuaranteed to be smoothPress rollersAuxillary shaping apparatusEngineeringSlurry

The invention discloses a viscous slurry grinding machine and a using method thereof. The viscous slurry grinding machine comprises a rack, the two ends of the rack are each provided with a first height adjusting device, the upper end of each first height adjusting device is connected with a supporting plate, and the first height adjusting devices are used for finely adjusting the height of the supporting plates. The upper end face of each supporting plate is provided with a second height adjusting device, the upper end of each second height adjusting device is connected with a support, and the second height adjusting devices are used for roughly adjusting the height of the supports. A grinding roller and a cleaning roller are mounted between the two supports, one end of the grinding roller and one end of the cleaning roller are connected with a first driving device and a second driving device correspondingly, the grinding roller and the cleaning roller are arranged in parallel, and a gap is formed between the grinding roller and the cleaning roller. A spraying pipe is further mounted between the two supports and is aligned to the gap between the grinding roller and the cleaning roller. According to the viscous slurry grinding machine, the height of the grinding roller can be adjusted, the surface smoothness of a gypsum board is guaranteed, operation is easy, and the production efficiency can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for determining wing-shaped oblique-flow cooling fan of automobile engine

InactiveCN102945292BReasonable structureReduce power consumptionSpecial data processing applicationsDesign cycleEngineering

The invention discloses a method for determining a wing-shaped oblique-flow cooling fan of an automobile engine. The method is implemented by the following steps: obtaining essential parameters of a plane blade lattice, obtaining the definite shape of a meridian plane, calculating a theoretical total pressure rise value, calculating flow velocity distribution, mapping and obtaining an equivalent velocity triangle, selecting blade profile parameters, performing correction compensation on the wing-shaped blade profile, calculating blade profile parameters, calculating blade coordinate values, fitting to obtain a blade cross-sectional line by using the obtained blade coordinate values, superposing individual cross-sectional planes in the radial direction to form a blade profile, and finally determining the wing-shaped oblique-flow cooling fan. The method can not only ensure the smoothness of curved surface of the fan but also meet the requirements for pneumatic property and process, greatly reduces the design cycle, facilitates the modification of the following design, and greatly reduces the development cost.

Owner:XIAN UNIV OF TECH

Cutting and polishing integrated device for standard test block of stratified soft rock and use method

PendingCN111482852AImprove accuracyImprove production efficiencyGrinding carriagesRevolution surface grinding machinesPolishingClassical mechanics

The invention discloses a cutting and polishing integrated device for a standard test block of stratified soft rock and a use method, and relates to the technical field of mechanical test devices forstratified soft rock. The cutting and polishing integrated device comprises a base, a mobile cutting mechanism, a horizontal polishing mechanism and a rotating disc mechanism, wherein the base is arranged on the first layer, the mobile cutting mechanism and the horizontal polishing mechanism are arranged on the second layer, and the rotating disc mechanism is arranged on the third layer; the baseis provided with an oil pressure device and supporting columns for supporting a mobile platform on the second layer; and the mobile platform is provided with a baffle and a baffle insertion groove forclamping and fixing the rock test block on the mobile platform, and the mobile platform is provided with preformed holes for installing polishing rods to polish and cut the rock test block into a rock test block of a cylindrical structure in cooperation with the rotating disc mechanism. By means of the technical scheme, the technical problem that it is very difficult to make an existing mechanical test standard test block of stratified soft rock can be effectively solved, the standard rock test block of the stratified soft rock can be efficiently made, the surface smoothness is guaranteed while the cutting speed is increased, and meanwhile, the making accuracy and the making efficiency are improved.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD +2

Putty construction method capable of improving strength and durability

InactiveCN107401256ASimple processThe craftsmanship is distinctCovering/liningsFilling pastesLacquerCellulose

The invention discloses a putty construction method capable of improving strength and durability. The putty construction method comprises the following steps: removing stuck mortar, burrs and splashes from pits and raised parts of a wall; adding water into a putty powder, and filling and leveling up the pits and cracks; adding water into the putty powder, stirring, mixing, scraping a layer of putty, polishing by different layers, coating with a cellulose solution, brushing with caustic soda, air-drying, and repeating the steps for several times; wiping stains and floating powder on the putty surface by using water, continuing air-drying, and painting with finish paint. The putty construction method is distinct in level, and is efficient; compared with the conventional brush coating method, the putty construction method has the advantage of higher interface bonding force; through layered brushing of effective components, the overall flexibility and compactness are improved, so that an obtained putty layer is high in strength and durable.

Owner:苏州振振好新型建材科技有限公司

Metal magnetic-acceleration sand-blasting plating equipment adopting metal plating electro-thermal process

InactiveCN111593385AExtended service lifeIntegrity guaranteedAbrasive machine appurtenancesAbrasive blasting machinesSand blastingElectron flow

The invention discloses metal magnetic-acceleration sand-blasting plating equipment adopting a metal plating electro-thermal process. The metal magnetic-acceleration sand-blasting plating equipment comprises a base, wherein the middle position of the top of a protective top plate is fixedly connected to a plating liquor raining mechanism; the middle positions of outer walls of two sides of the protective top plate are fixedly connected to sand-blasting mechanisms; and sides, close to a limiting circular slot, of the sand-blasting mechanisms are provided with magnetic acceleration mechanisms. The invention relates to the technical field of metal plating. Magnetic fields are knitted through a permanent magnet, and spraying and accelerating of sand-blasting gravels are performed through magnetic force, so that electron flow is formed by internally charging; electron flow hits against a plated part, so that a surface phase of the plated part generates changes, and therefore, plating effectis better, is more uniform and is deeper, a clad layer is prevented from being shallow to wear easily, and the service life of the plated part is prolonged; and moreover, the sand-blasting gravels hit against the clad layer to form vibration, so that residual impurities and plating liquor on the surface are removed to form resonance, and therefore, plating liquor is more uniform, surface smoothness is improved, and integrity and aesthetics of the plated part are guaranteed.

Owner:徐敬

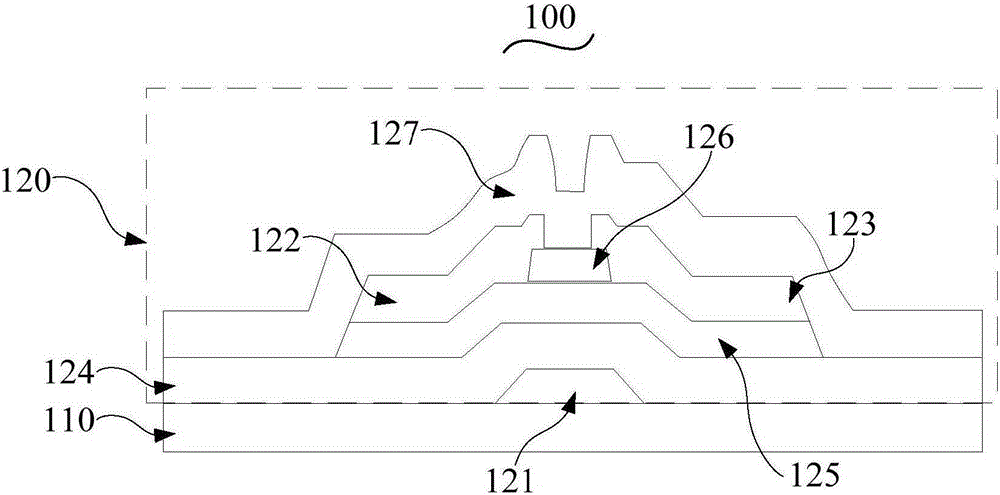

Thin-film transistor, array substrate and production method thereof

InactiveCN105185840AGuaranteed production efficiencyImprove production efficiencyTransistorSolid-state devicesEtchingTransistor

The invention discloses a thin-film transistor, an array substrate and a production method of the thin-film transistor and the array substrate, wherein the thin-film transistor comprises a grid electrode, a source electrode and a drain electrode, and both the source electrode and the drain electrode are arranged on the same side of the grid electrode, wherein the grid electrode comprises a first buffer layer, a first copper layer, a second copper layer and a second buffer layer which are sequentially superimposed, and the second buffer layer is arranged on one side close to the source electrode and the drain electrode; and / or the source electrode and the drain electrode respectively comprise a first buffer layer, a first copper layer, a second copper layer and a second buffer layer which are sequentially superimposed, and the first buffer layer is arranged on one side close to the grid electrode; and the first copper layer is obtained by deposition at first power, the second copper layer is obtained by deposition at second power, and the first power is higher than the second power. Through the way, the light resistance loss in etching can be prevented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Production process of disposable pipette

ActiveCN104290212BGuaranteed StrengthGuaranteed toughnessLaboratory glasswaresTubular articlesPipetteForming processes

The invention discloses a process for preparing a disposable pipette, one-body drawing forming process is used, the deficiency existed in the welding process is avoided, and through grasp of the process parameters, a qualified pipette is obtained, and especially the pipette nozzle is not fragile; the process comprises the following steps: (1) adding raw material resin into a granulator to obtain a first particle; (2) mixedly adding the first particle and an additive into the granulator to obtain a second particle; (3) adding the second particle into an extruder for extrusion molding to obtain a precursor, wherein the extrusion speed is 20-25m / min, and the extrusion temperature is 150 to 180 DEG C; (4) cutting the precursor to obtain a cutting body, wherein the cutting temperature is 120 to 180 DEG C; (5) stretching the cutting body, cooling to obtain an initial product; wherein the stretching temperature is 200 to 400 DEG C, and the stretching speed is 10-15m / min; and (6) printing the initial product, and installing an filter element to obtain a finished product.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

A kind of flat wire material processing equipment for chain

ActiveCN104070358BQuick rust removalQuick Decontamination TreatmentOther manufacturing equipments/toolsMetal chainsEngineeringMaterials processing

The invention belongs to the technical field of chain tools, and particularly relates to a flat wire material processing device for a chain. The flat wire material processing device for the chain comprises a material pressing device, a surface treatment device, a rinse tank, a reshaping device and a material receiving device, wherein the material pressing device comprises a group of lateral concave wheels and a group of upper and lower idler wheels, the surface treatment device comprises a machine frame, a water tank is arranged on the machine frame, an upper abrasive wheel and a lower abrasive wheel can be driven by a rotation disk to polish the upper face and the lower face of a flat wire material, the reshaping device comprises a reshaping machine frame, an upper rolling wheel and a lower rolling wheel are arranged on the reshaping machine frame, the material receiving device comprises a coiling motor, and a coiling rod is arranged at the output end of the coiling motor. According to the flat wire material processing device for the chain, fast polishing is performed back and forth by driving the upper abrasive wheel and the lower abrasive wheel through the rotation disk, and the mechanical surface treatment mode protects environment, and can guarantee smoothness of the surface of the flat wire material.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com