Sand-exposing concrete and preparation method thereof

A technology for concrete and concrete surface, applied in the direction of building, building structure, floor, etc., can solve the problems of inconsistent exposure depth, uneven sand exposure, difficult to control surface flatness, etc., to achieve convenient exposure quality and ensure surface flatness. , excellent mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

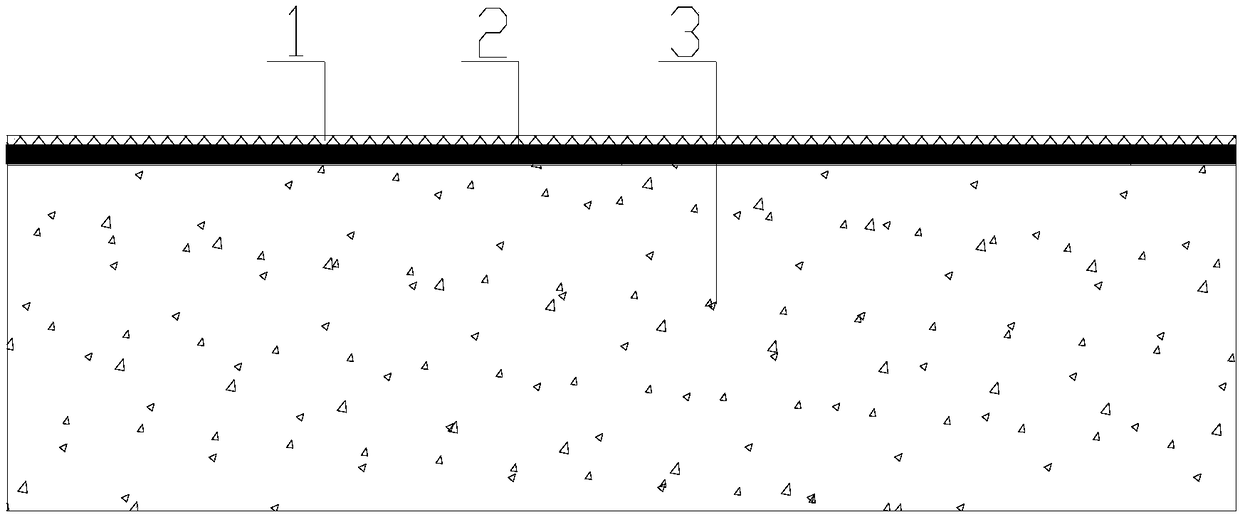

[0023] Example 1, see figure 1 :

[0024] The present invention provides an exposed sand concrete and a preparation method thereof, including the following steps:

[0025] 1) Cast-in-place concrete base 3 with strength grade C20, pave and vibrate to compact until the concrete surface has a 3mm thick mortar layer, and smooth it;

[0026] 2) Press 5kg / m 2 Dosage: Weigh the exposed sand concrete surface hardening material. When the cast-in-place concrete base 3 is close to the initial setting, spread the exposed sand concrete surface hardening material on the surface of the concrete base layer 3 twice, each time the exposed sand concrete surface hardening material is fully absorbed and wetted After finishing, smoothing and finishing, the surface hardening material is sprayed with 2 / 3 of the total amount for the first time, and 1 / 3 of the total amount for the second time;

[0027] 3) Moisturizing and curing the concrete for 3 days to form a hardened layer of exposed sand concrete surface...

Embodiment 2

[0032] The present invention provides an exposed sand concrete and a preparation method thereof, including the following steps:

[0033] 1) The cast-in-place concrete base of C30 strength grade, pave and vibrate to compact until the concrete surface has a 5mm thick mortar layer, and smooth it;

[0034] 2) Press 6kg / m 2 Dosage Weigh the exposed sand concrete surface hardening material. When the cast-in-place concrete base is close to the initial setting, spread the exposed sand concrete surface hardening material on the surface of the concrete base twice, each time after the exposed sand concrete surface hardening material is fully absorbed and wetted, Carry out smoothing and finishing, the surface hardening material's first application amount is 2 / 3 of the total amount, and the second application amount is 1 / 3 of the total amount;

[0035] 3) Moisturizing and curing the concrete for 3 days to form a hardened surface of exposed sand concrete;

[0036] 4) Sprinkle an etchant mixed with ...

Embodiment 3

[0040] The present invention provides an exposed sand concrete and a preparation method thereof, including the following steps:

[0041] 1) The cast-in-place concrete base of C30 strength grade, pave and vibrate to compact until the concrete surface has a 5mm thick mortar layer, and smooth it;

[0042] 2) Press 4kg / m 2 Dosage Weigh the exposed sand concrete surface hardening material. When the cast-in-place concrete base is close to the initial setting, spread the exposed sand concrete surface hardening material on the surface of the concrete base twice, each time after the exposed sand concrete surface hardening material is fully absorbed and wetted, Carry out smoothing and finishing, the surface hardening material's first application amount is 2 / 3 of the total amount, and the second application amount is 1 / 3 of the total amount;

[0043] 3) Moisturizing and curing the concrete for 3 days to form a hardened surface of exposed sand concrete;

[0044] 4) Sprinkle an etchant mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com