Putty construction method capable of improving strength and durability

A construction method and putty technology, applied in the direction of filling slurry, etc., can solve the problems of easy hollowing, poor adhesion between putty and wall, consumption process, low efficiency, etc., to achieve enhanced elasticity and tightness, and distinct process levels , the effect of high interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

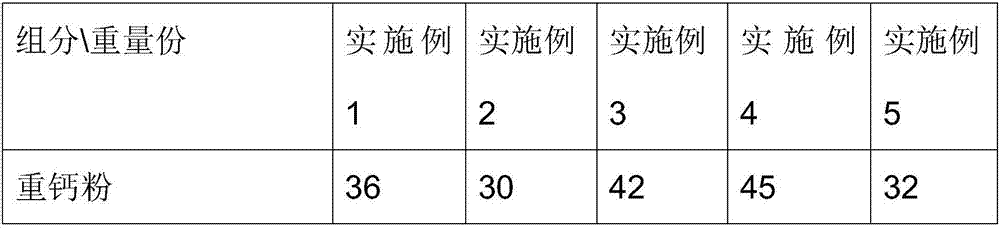

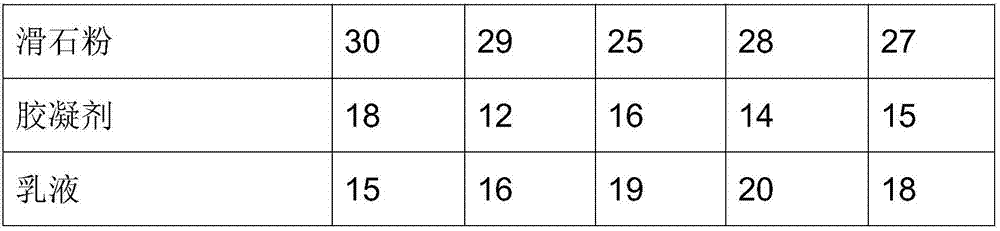

Examples

Embodiment Construction

[0019] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below. A method for strengthening and durable putty construction, comprising the following steps:

[0020] (1) For the concave and convex parts of the wall, first use a metal shovel and then use a brush to remove the slurry, dust and splash, and level the convex parts;

[0021] (2) Take putty powder and add water, stir evenly, fill up the depressions and cracks, and the precision is within 20 μm; the weight mixing ratio of putty powder and water is putty powder: water = (3.2~6.5): 1;

[0022] (3) Take the putty powder and add water and put it in a container, slightly heat the container, use a mixer, stir at 350-500rpm for 5-8 minutes, take a scraper, scrape a layer of putty, scrape back from top to bottom, from left to right, The joint is smooth; the weight mixing ratio of putty powder and water is putty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com