Patents

Literature

7412 results about "Powder coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods. The powder coating process was invented around 1945 by Daniel Gustin US Patent 2538562.

Semiconductor processing apparatus with improved thermal characteristics and method for providing the same

InactiveUS20090308315A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGaseous atmosphereEngineering

A semiconductor processing apparatus is disclosed, comprising a process chamber configured to contain a heated, gaseous atmosphere, the apparatus further comprising a number of mechanical parts, at least one of which parts is provided at least partly with a heat reflective, amorphous SiO2 powder coating. Also disclosed is a method for treating a component of a semiconductor processing apparatus, comprising at least partly providing a surface of the component with an amorphous SiO2 powder coating, and optionally sealing a surface of the applied coating.

Owner:ASM INTERNATIONAL

Aqueous dispersions of polymer-enclosed particles, related coating compositions and coated substrates

ActiveUS20060251896A1Nanostructure manufactureSynthetic resin layered productsNanoparticleMaterials science

Disclosed are aqueous dispersions of polymer-enclosed particles, such as nanoparticles. Also disclosed are methods for making an aqueous dispersion of polymer-enclosed particles, polymerizable polymers useful in such a method, powder coating compositions formed from such an aqueous dispersion, substrates at least partially coated with such a composition, and reflective surfaces comprising a non-hiding coating layer deposited from such a composition.

Owner:PPG IND OHIO INC

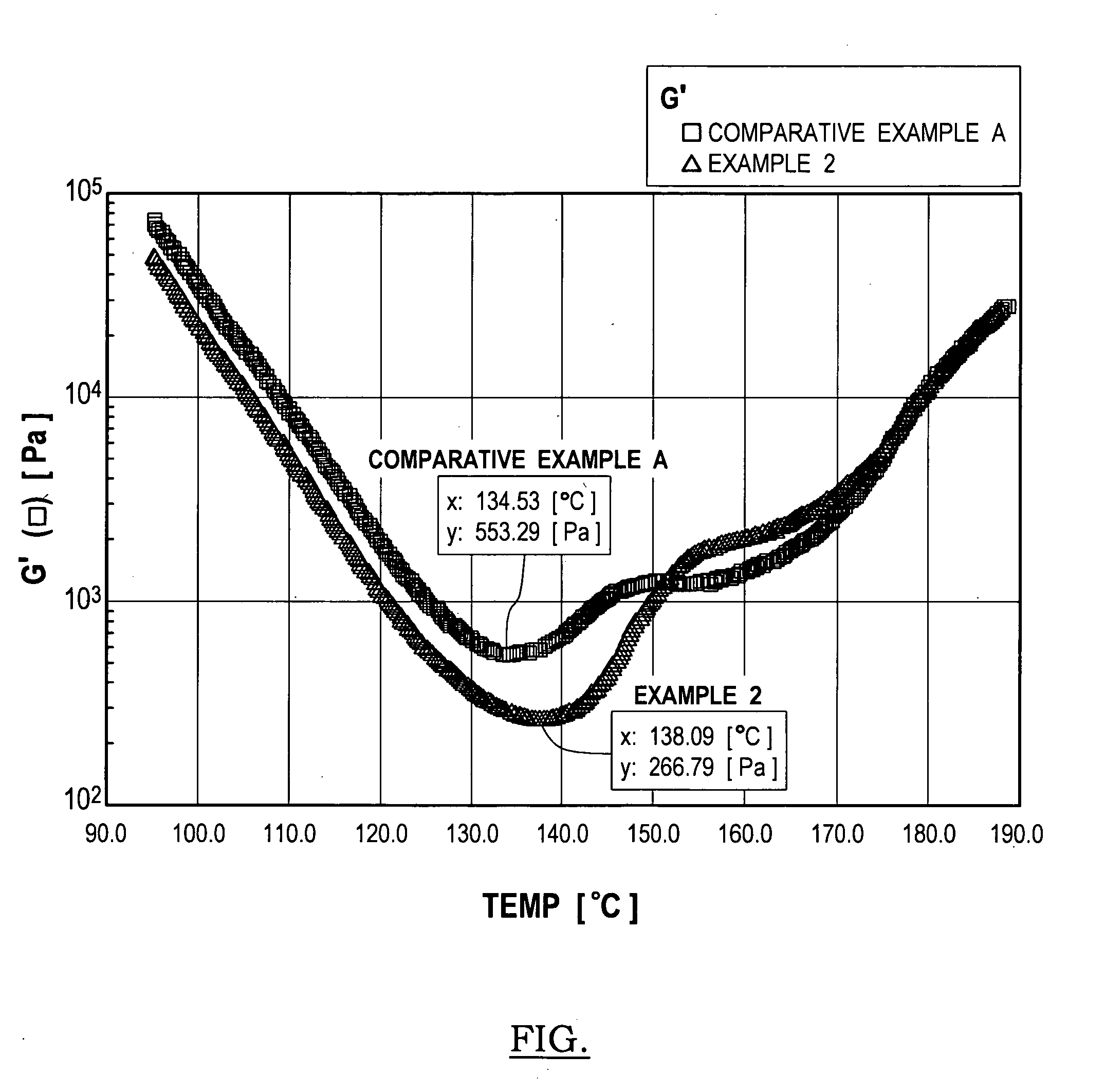

Smooth, flexible powder coatings

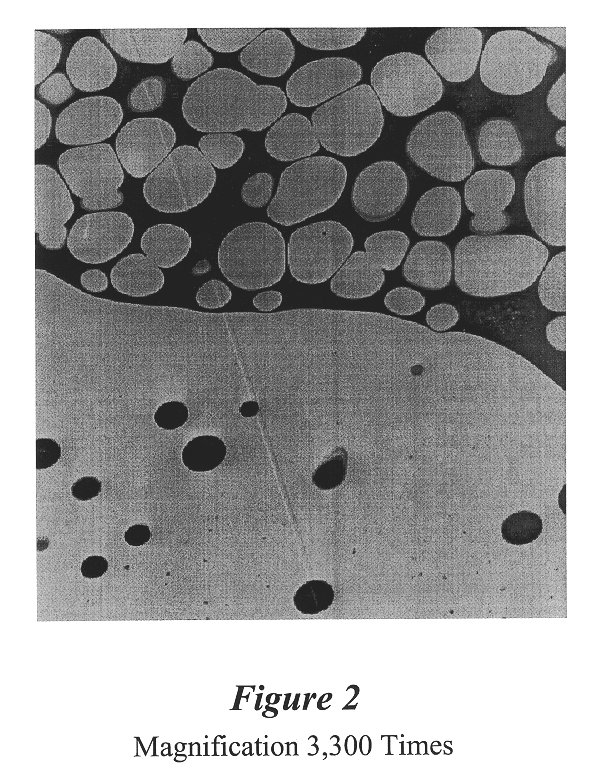

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

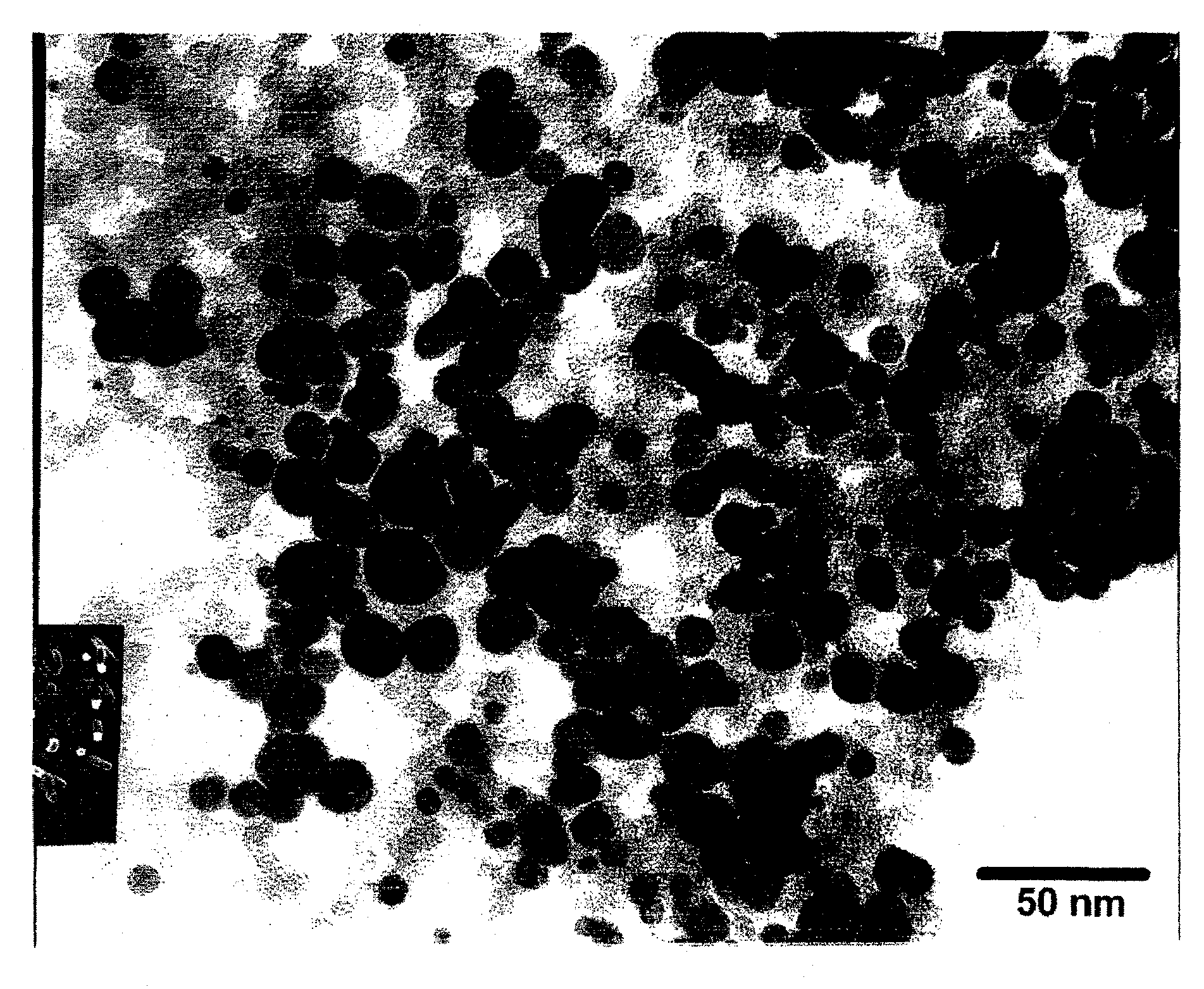

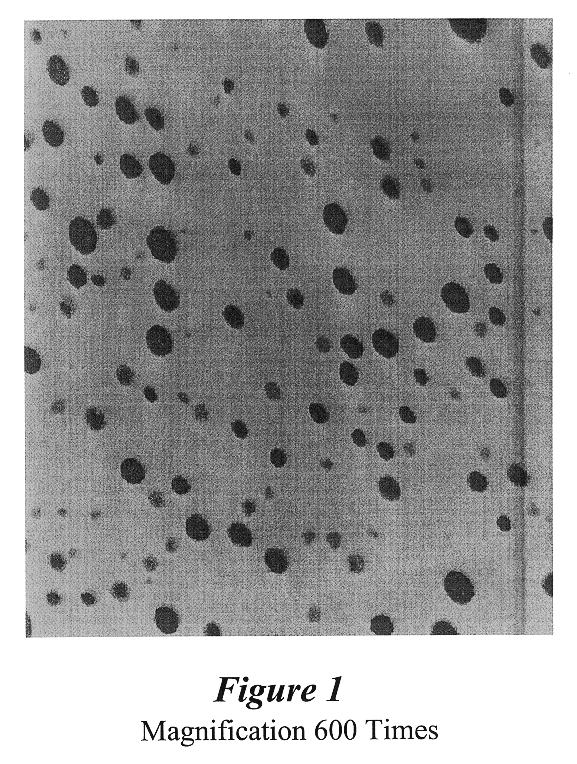

Nanoparticle-based power coatings and corresponding structures

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

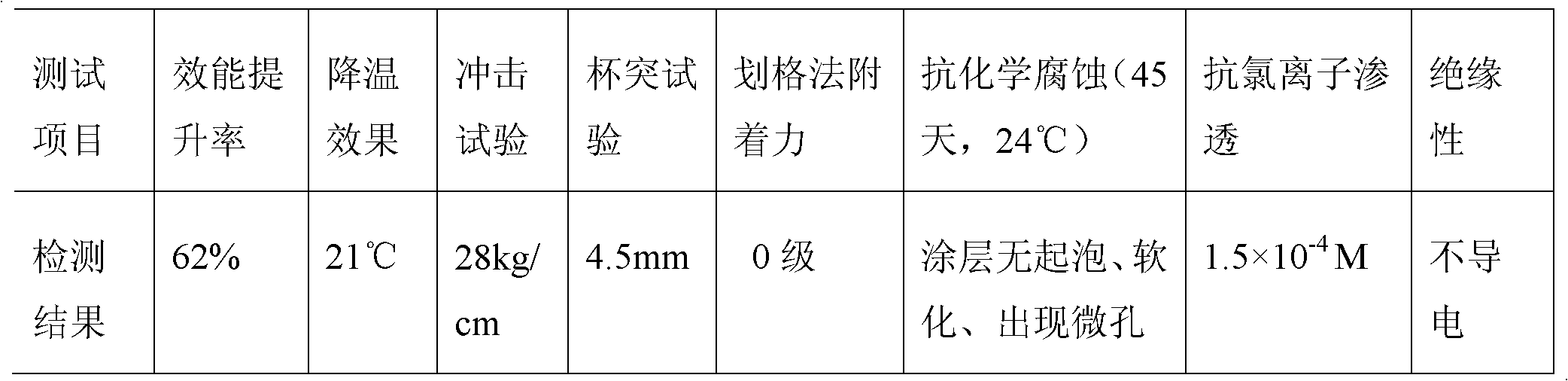

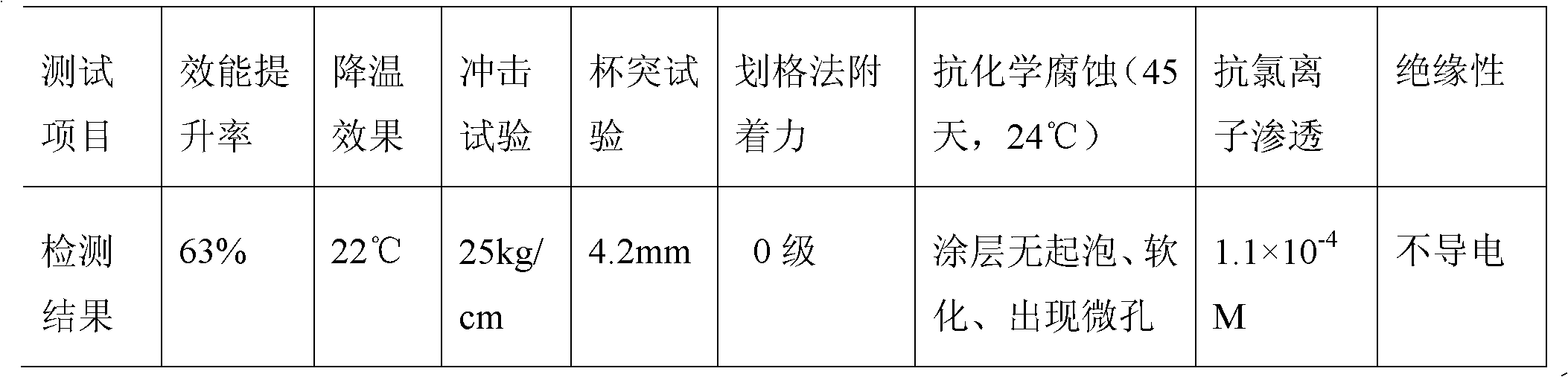

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

Compositions and processes for producing durable hydrophobic and/or olephobic surfaces

InactiveUS20100004373A1Reduce contact areaProtection is in progressGroup 4/14 element organic compoundsSpecial tyresPowder coatingMaterials science

Coating compositions for producing hydrophobic or super-hydrophobic surfaces and olephobic or super-olephobic surfaces, and to processes for producing such surfaces. In particular, the present invention relates to hydrophobic or olephobic powder coatings and their use for transforming surfaces of articles into hard-to-wet and self-cleaning surfaces.

Owner:UNIV OF WESTERN ONTARIO

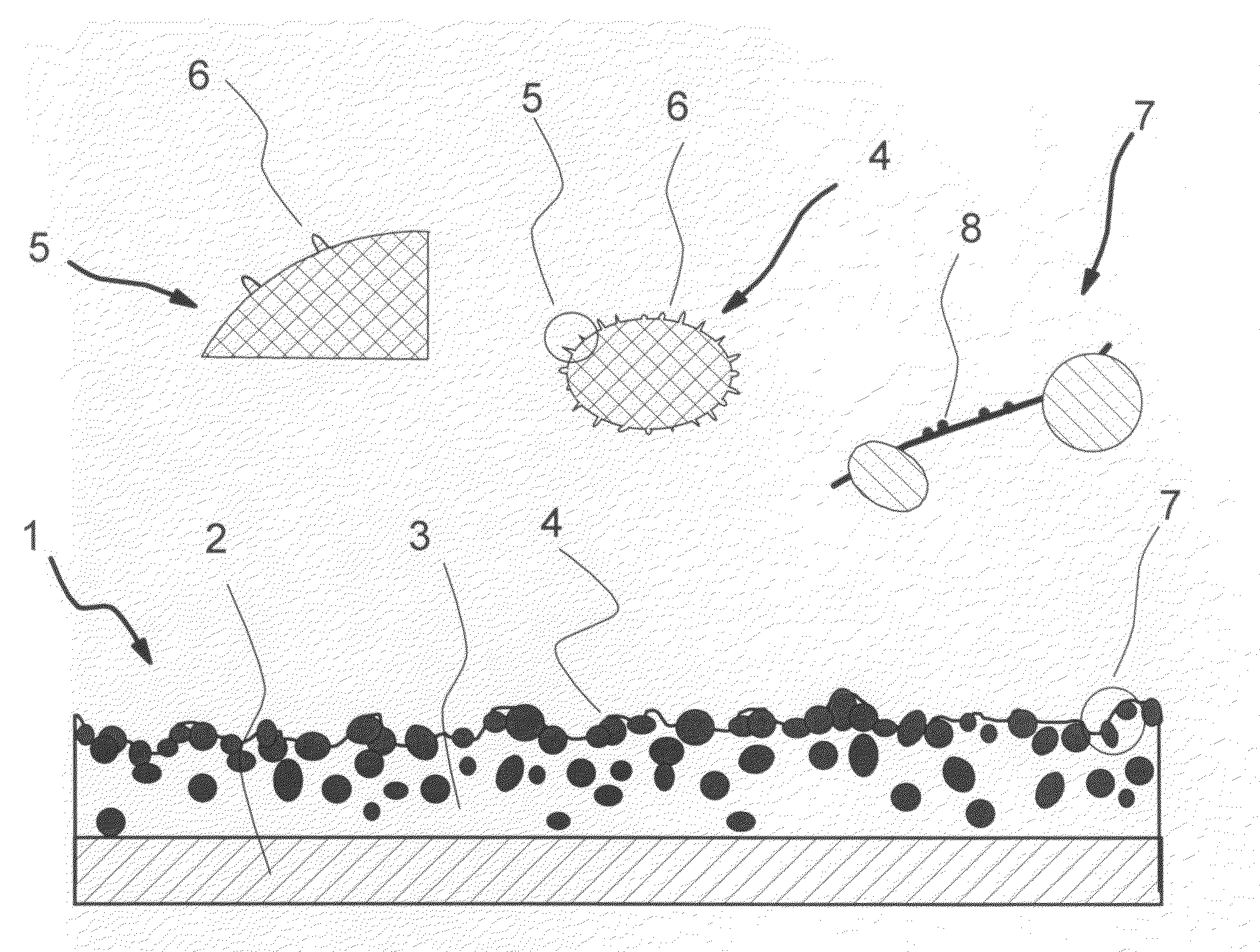

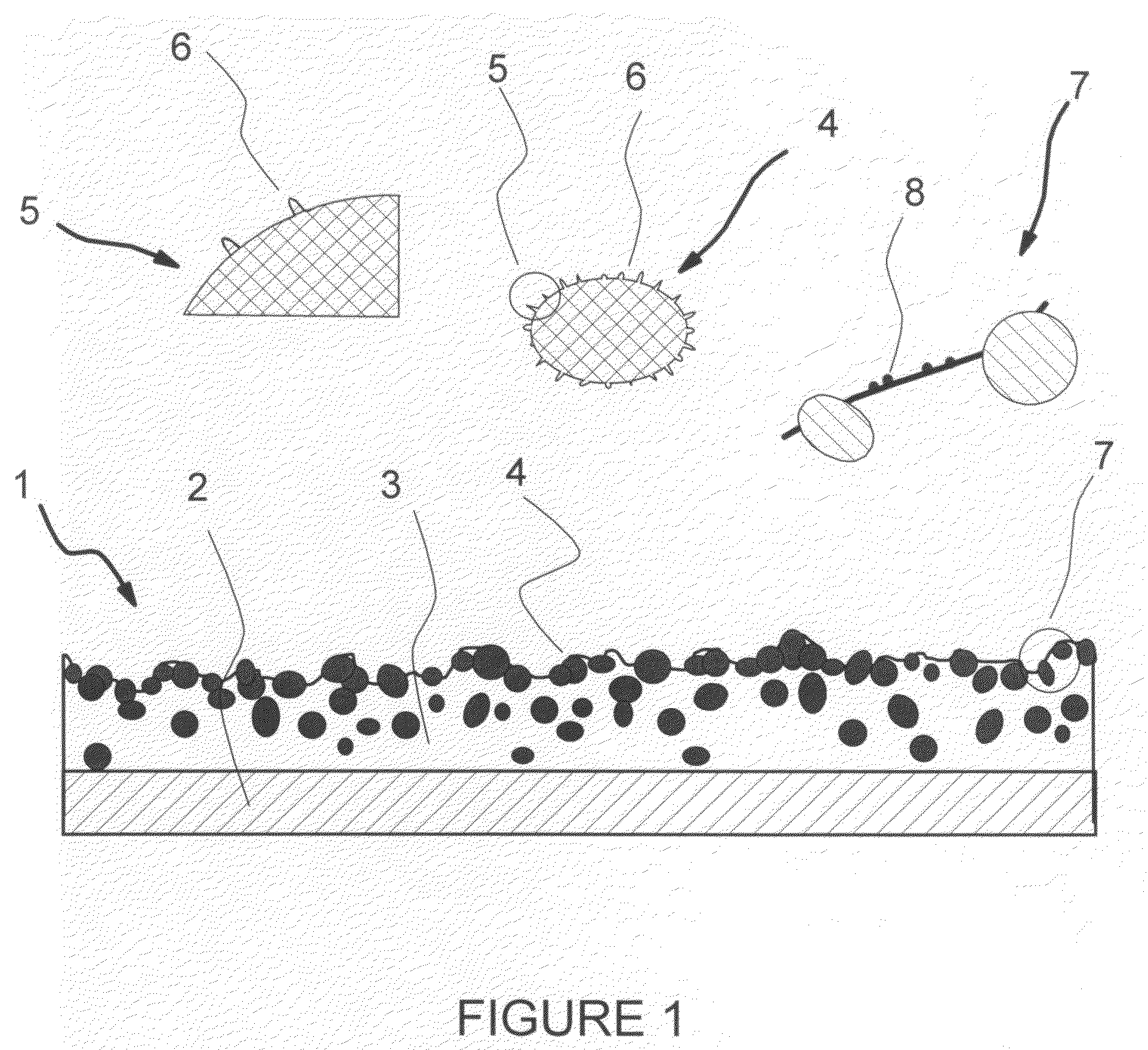

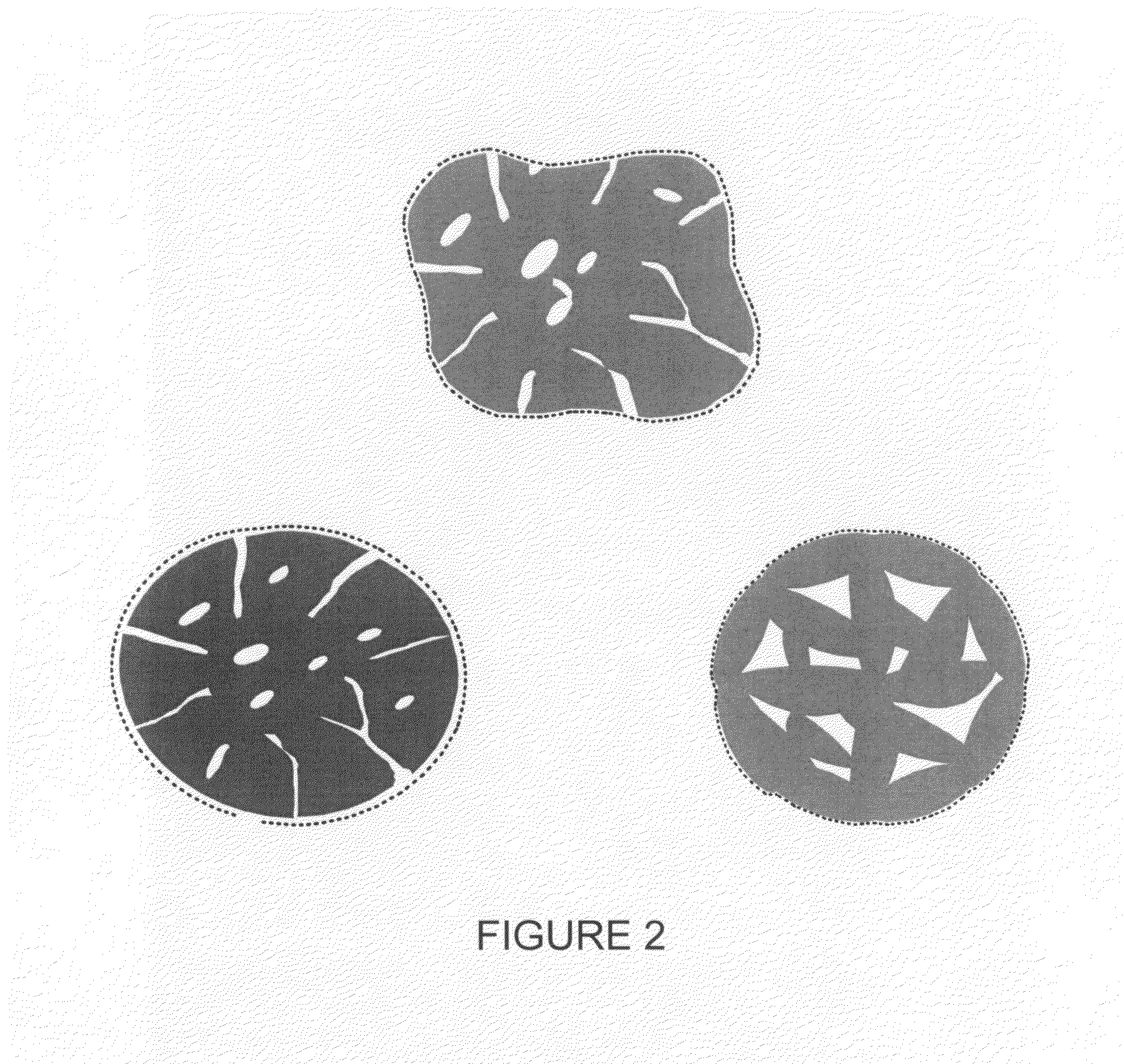

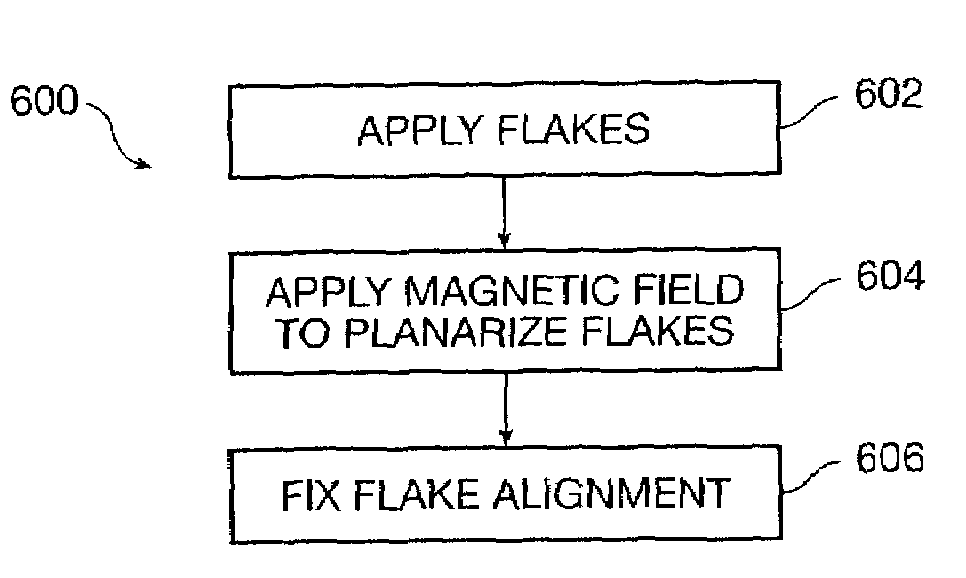

Magnetic planarization of pigment flakes

InactiveUS7258900B2Improve visual appearanceGood lookingPretreated surfacesPattern printingOut of planePigment

A magnetic field is applied to planarize magnetic pigment flakes relative to a surface. Pigment flakes, such as optically variable pigment flakes, are used in a variety of paints, inks, extrusions, powder coatings, and other forms for decorative and security applications. In many applications pigment flakes tend to align parallel to each other and to the surface to which they are applied. If the pigment flakes include a suitable magnetic structure, a magnetic field can be applied to subsequently align the flakes or enhance the alignment of the flakes in the plane of the substrate if the carrier that the flakes are dispersed in is still fluid. In some printing operations, pigment flakes that are applied parallel to the substrate are pulled out of plane when the print screen or printing die is lifted off the substrate. Application of a magnetic field can re-align pigment flakes to the plane of the substrate, enhancing the visual quality of the printed image, especially with optically variable pigments.

Owner:VIAVI SOLUTIONS INC

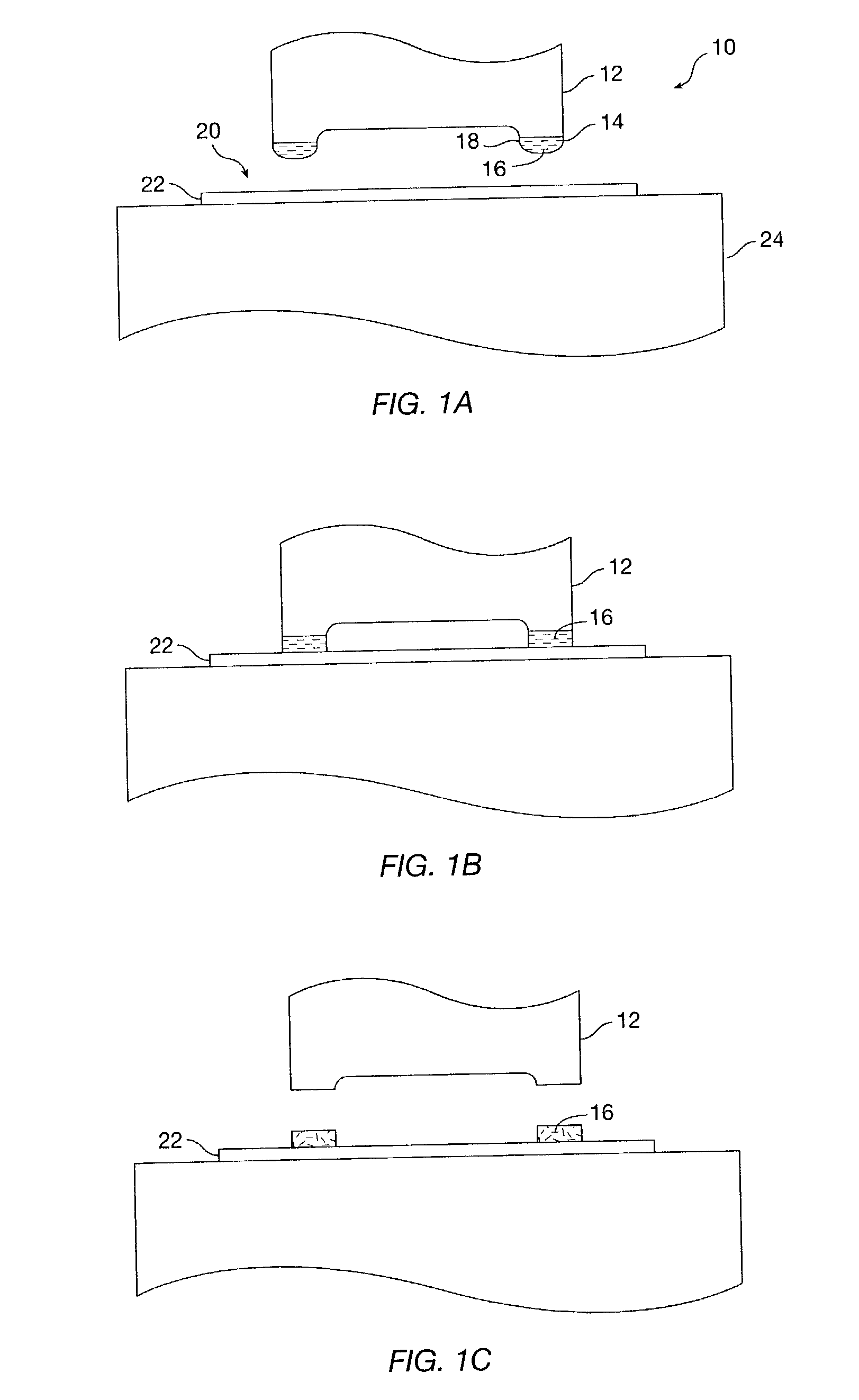

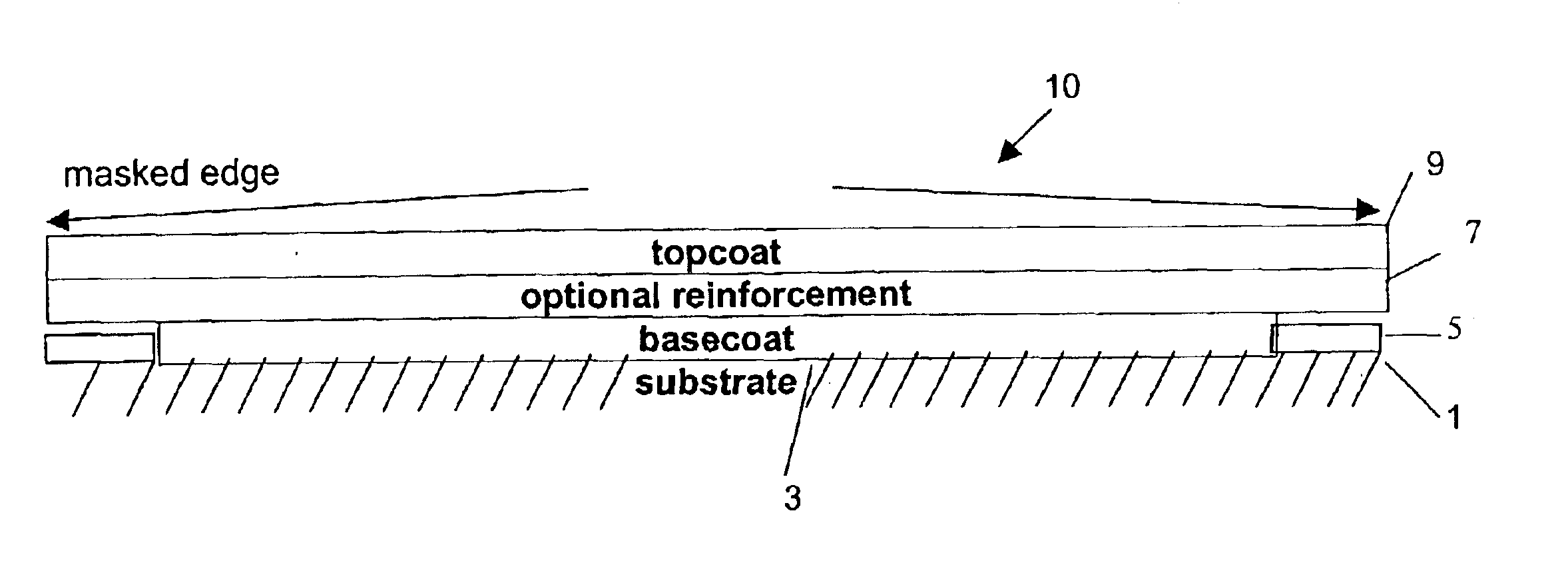

Coating system for a porous substrate using an asphalt-containing thermosetting basecoat composition and a thermoplastic top coat composition

InactiveUS6849338B2Reduce viscosity of compositionIncreasing imperfectionSynthetic resin layered productsPretreated surfacesPorous substrateCross-link

A coating system comprises a basecoat of an thermosetting asphalt extended, chemically cross linked-urethane / epoxy hybrid basecoat resting on a substrate, preferably a porous substrate such as concrete or wood that off-gas when coated with a thermoplastic material; and a thermoplastic powder coating topcoat overlying at least the base coat. The thermosetting basecoat composition consisting essentially of, in weight percent based on final formulation, and between 10 and 90% of a petroleum asphalt; between 10 and 90%, of a hydroxy-terminated homopolymer; and between 0.1 and 30% of a functional epoxy reactive diluent for reducing the viscosity of the composition; and further up to 5% of a surfactant for improving surface imperfections, up to 5% of an anti-oxidant; and up to 25% of a thickening agent.

Owner:PACIFIC NORTHWEST COATINGS

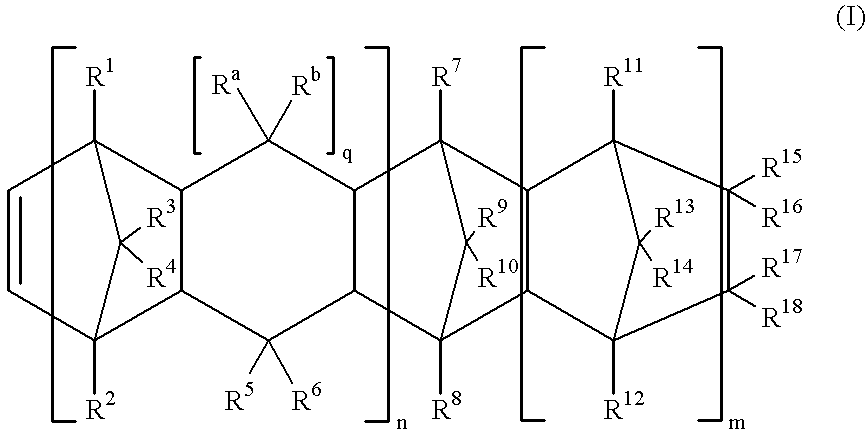

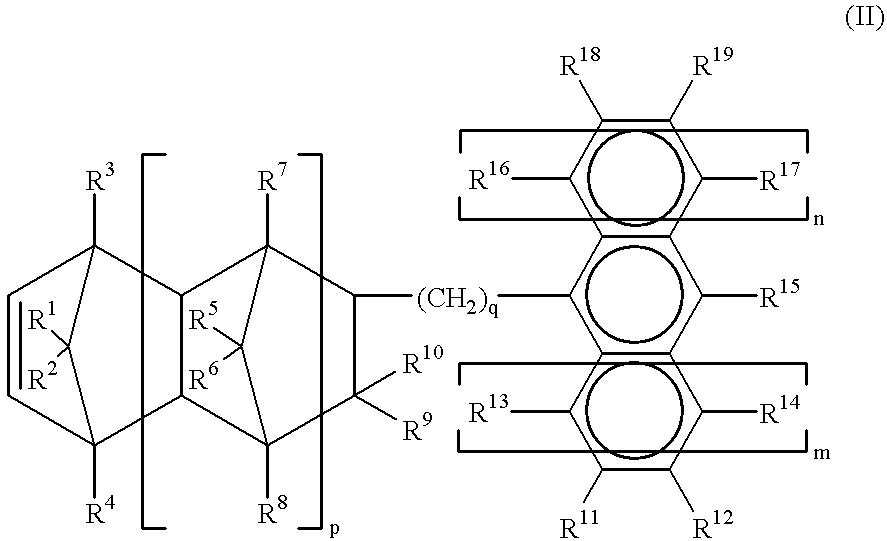

Cycloolefin resin pellets and a process for producing a molded product thereof

InactiveUS6342549B1High transparencyReduce the amount requiredAluminium compoundsSolesVitrificationShell molding

Cycloolefin resin pellets of the present invention comprises a cycloolefin resin pellet and a powdery coating material and / or a liquid coating material, the melting point or the glass transition point of the coating material being 200° C. or lower, and the coating material being adhered onto the surface of the cycloolefin resin pellets, so that the molded product thereof is excellent in transparency.

Owner:TICONA GMBH +1

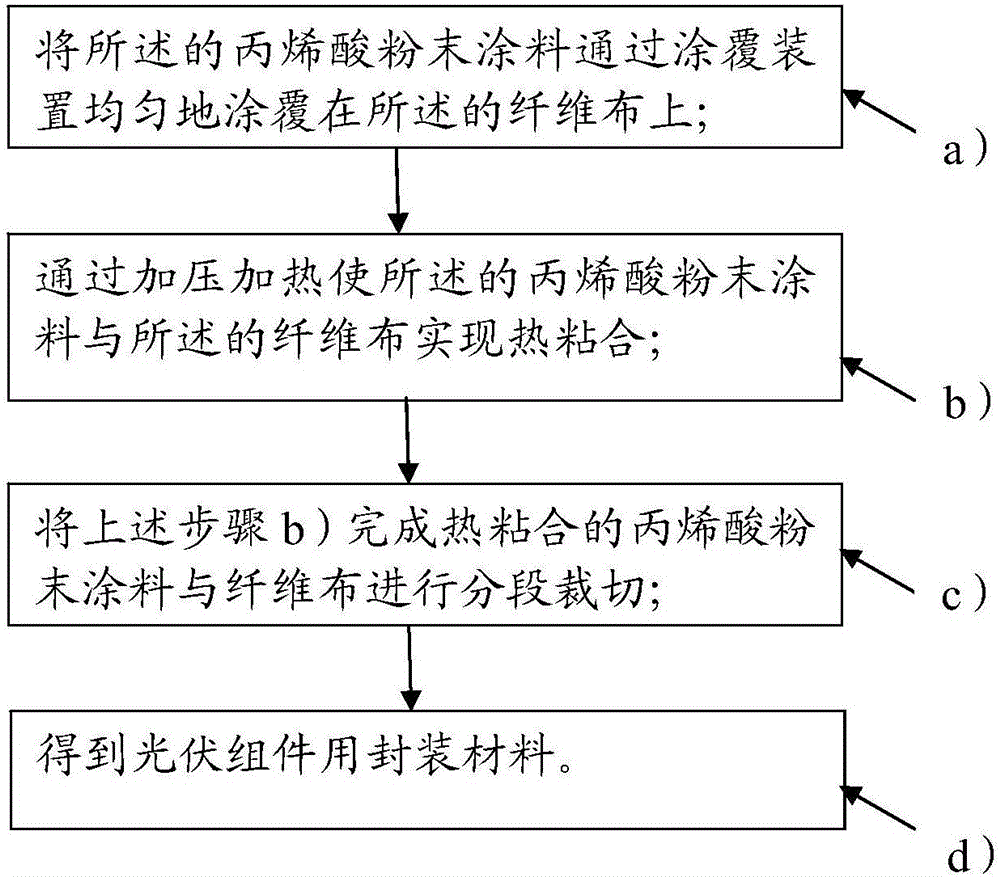

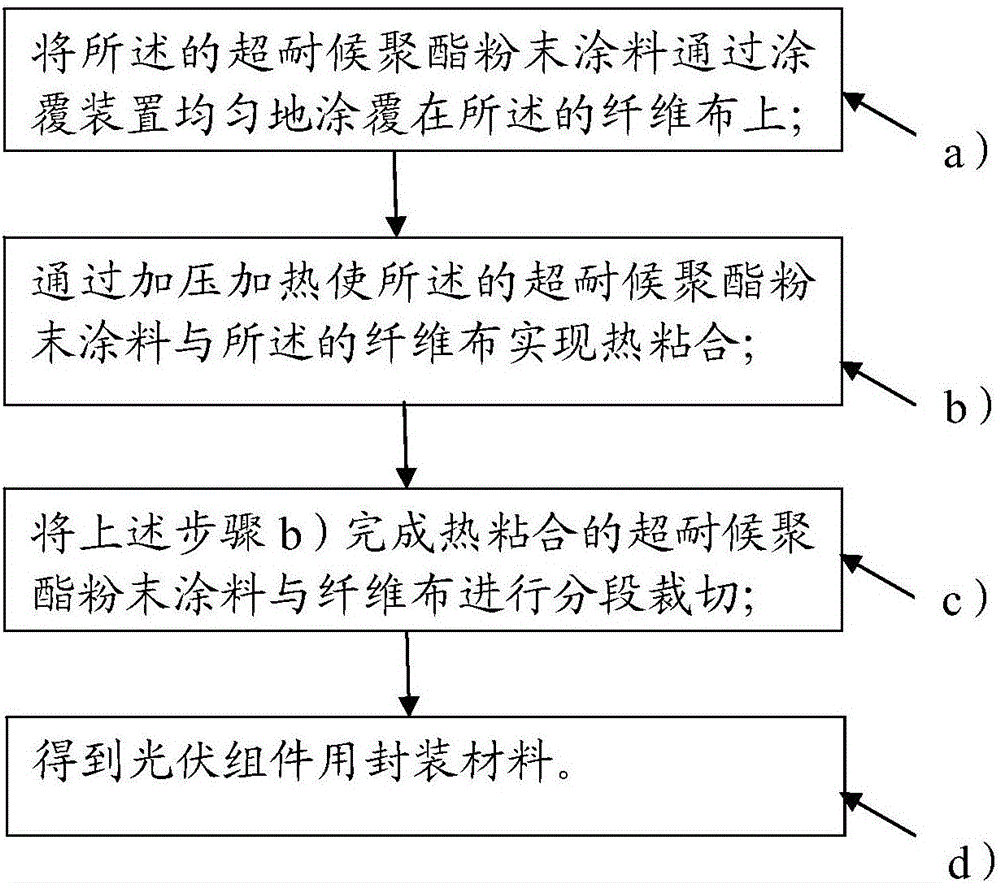

Packaging material for photovoltaic module and preparation method of the packaging material

ActiveCN106299000AReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for a photovoltaic module. The packaging material comprises the following raw materials in parts by weight: 30-50 parts of fiber cloth produced from fiber material through weaving; and 50-70 parts of acrylic powder coating including acrylic resins and a curing agent. The acrylic powder coating is evenly spread on the fiber cloth. The packaging material is low in manufacturing cost. While meeting the prerequisites of resistance to ultraviolet, aging, impact and fire which are standard requirements of the photovoltaic industry, the packaging material solves the problem of lightweight photovoltaic module packaging material, makes installation more convenient, reduces the installation cost, and thus is very suitable for large-scale promotion and application in the photovoltaic field. The invention also discloses a preparation method of the packaging material for a photovoltaic module. The method meets installation requirement for changing the packaging size of a photovoltaic module at will to adapt to different buildings and thus further facilitates installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

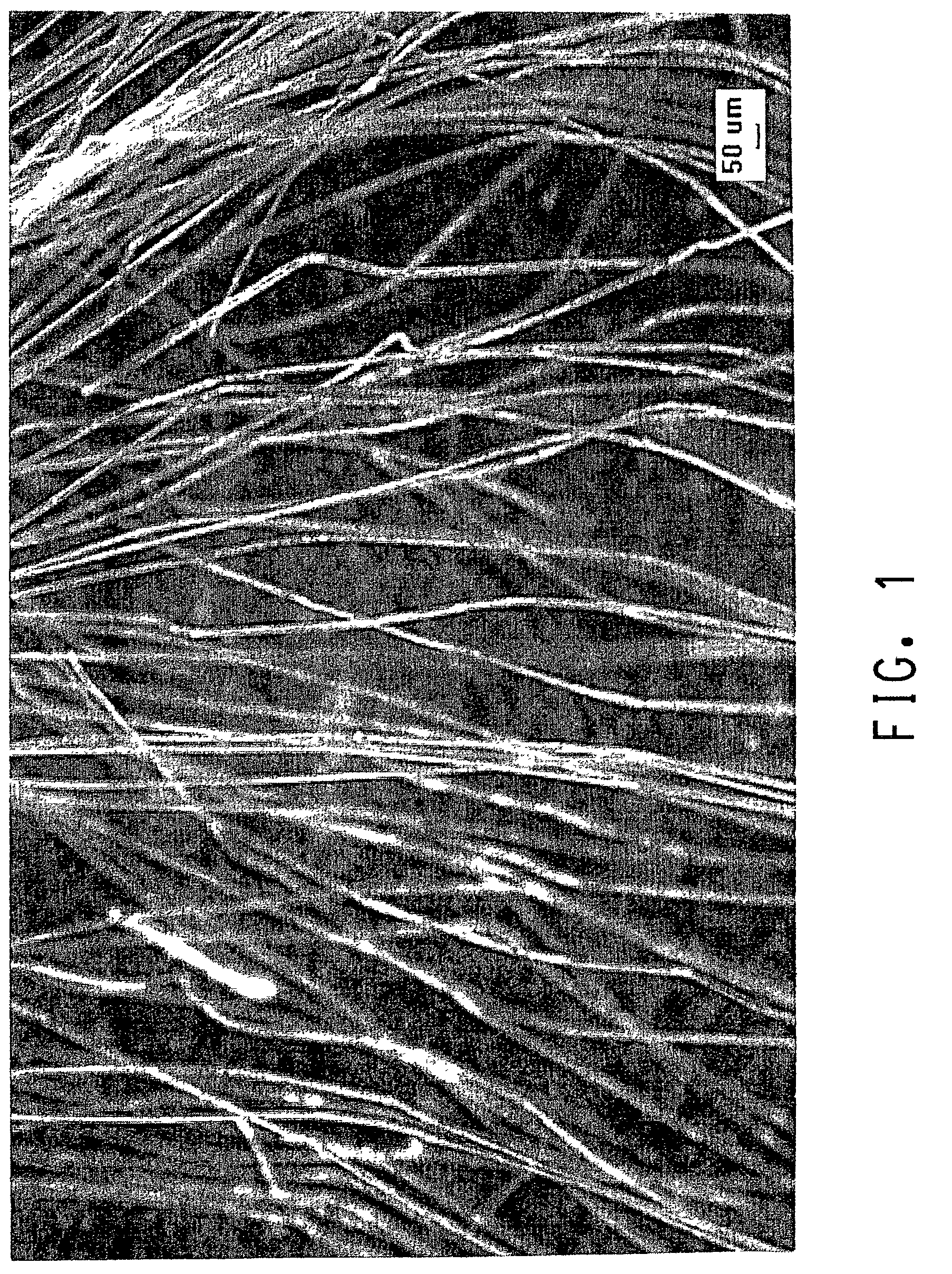

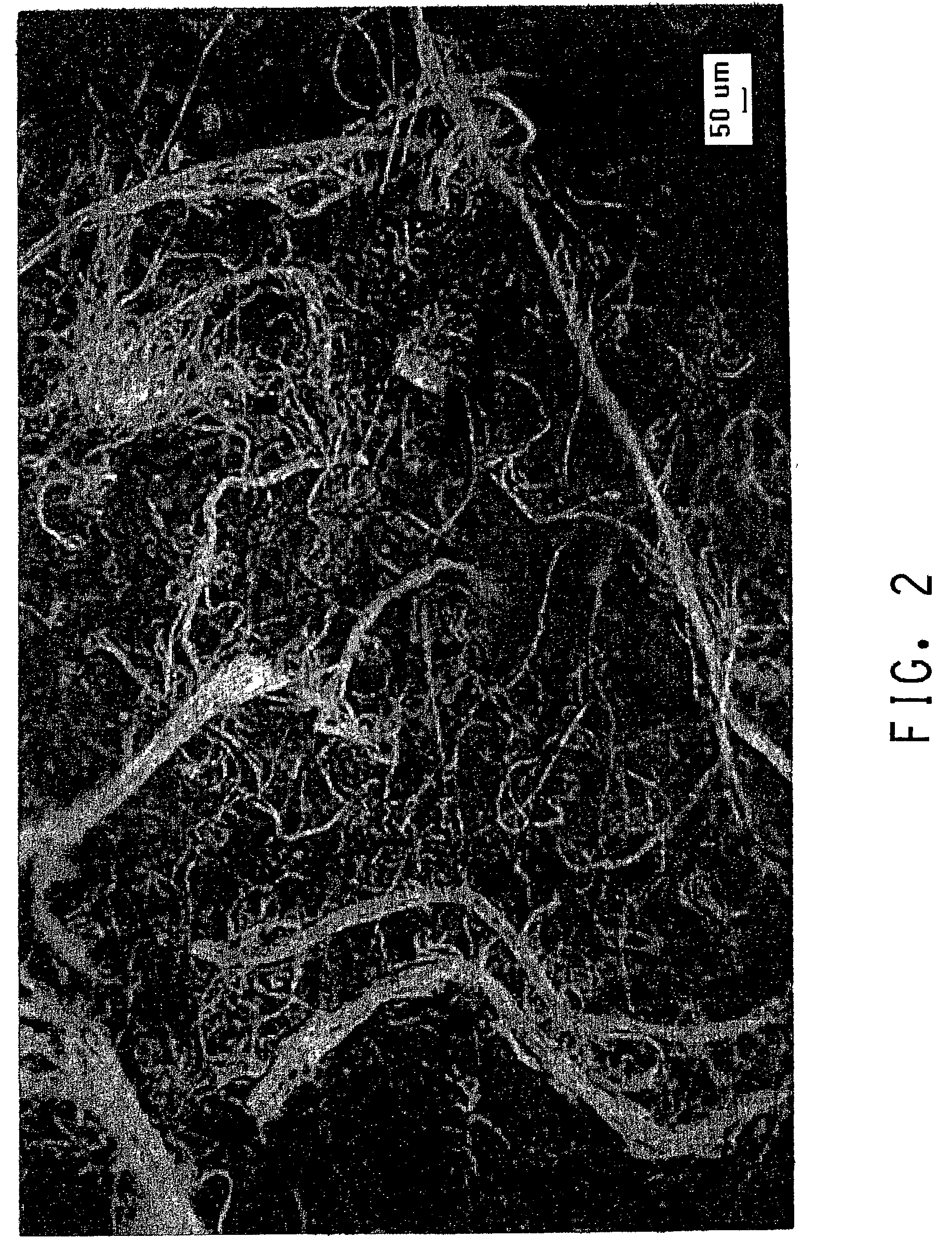

Method of producing micropulp and micropulp made therefrom

InactiveUS20030114641A1More cost-effectivelySmall sizeCellulose coatingsPaper/cardboardFiberSolid component

The present invention is directed to a process for producing micropulp. The process includes contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to transform the organic fibers into the micropulp dispersed in the medium. If desired, the slurry of the micropulp in the liquid component can be used or the micropulp can be separated from the medium. The micropulp can be readily incorporated into coating compositions such as those used in automotive OEM or refinish applications. The micropulp can also be incorporated into powder coating applications or as a thixotrope or reinforcement in polymer formulations.

Owner:EI DU PONT DE NEMOURS & CO

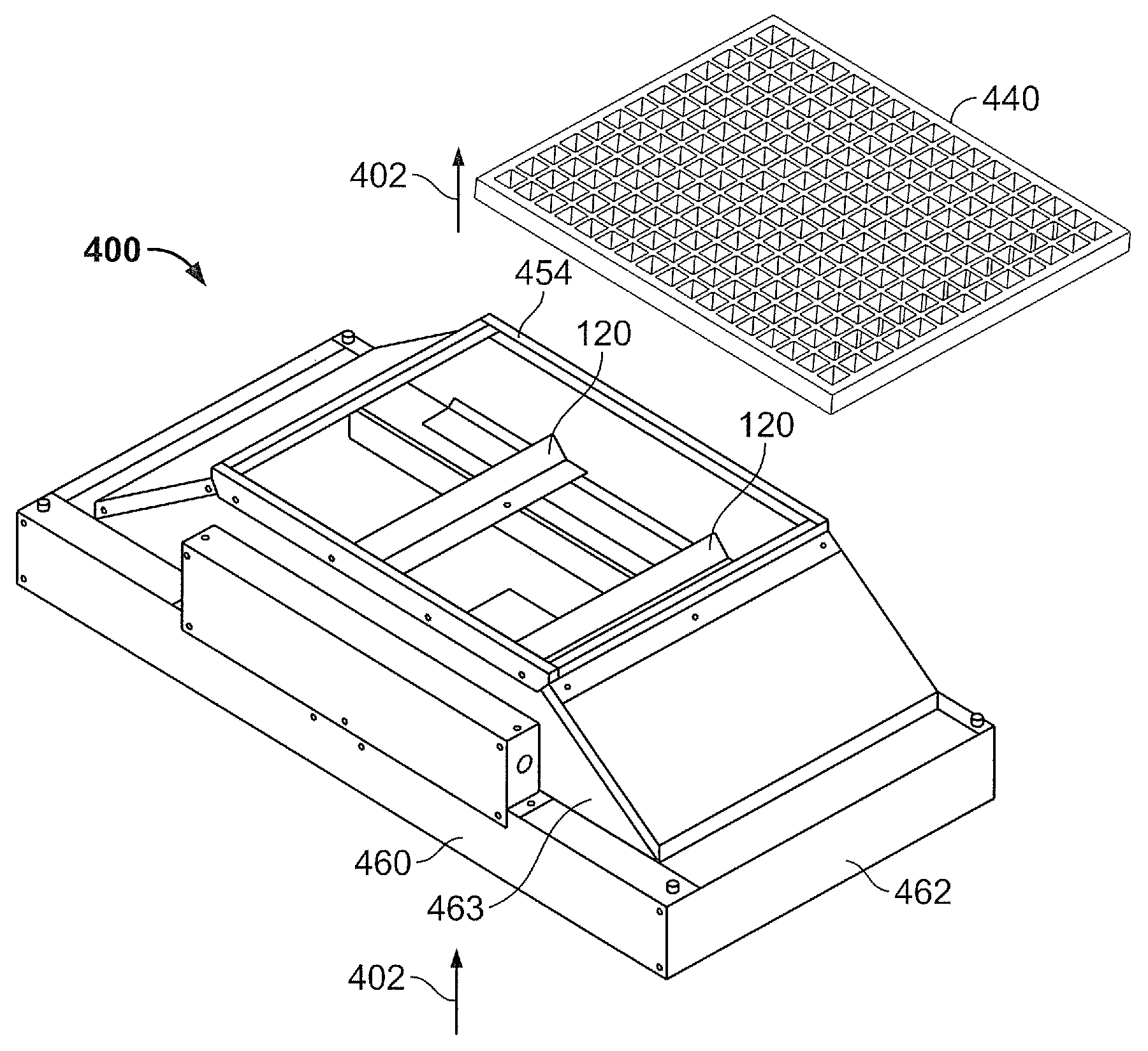

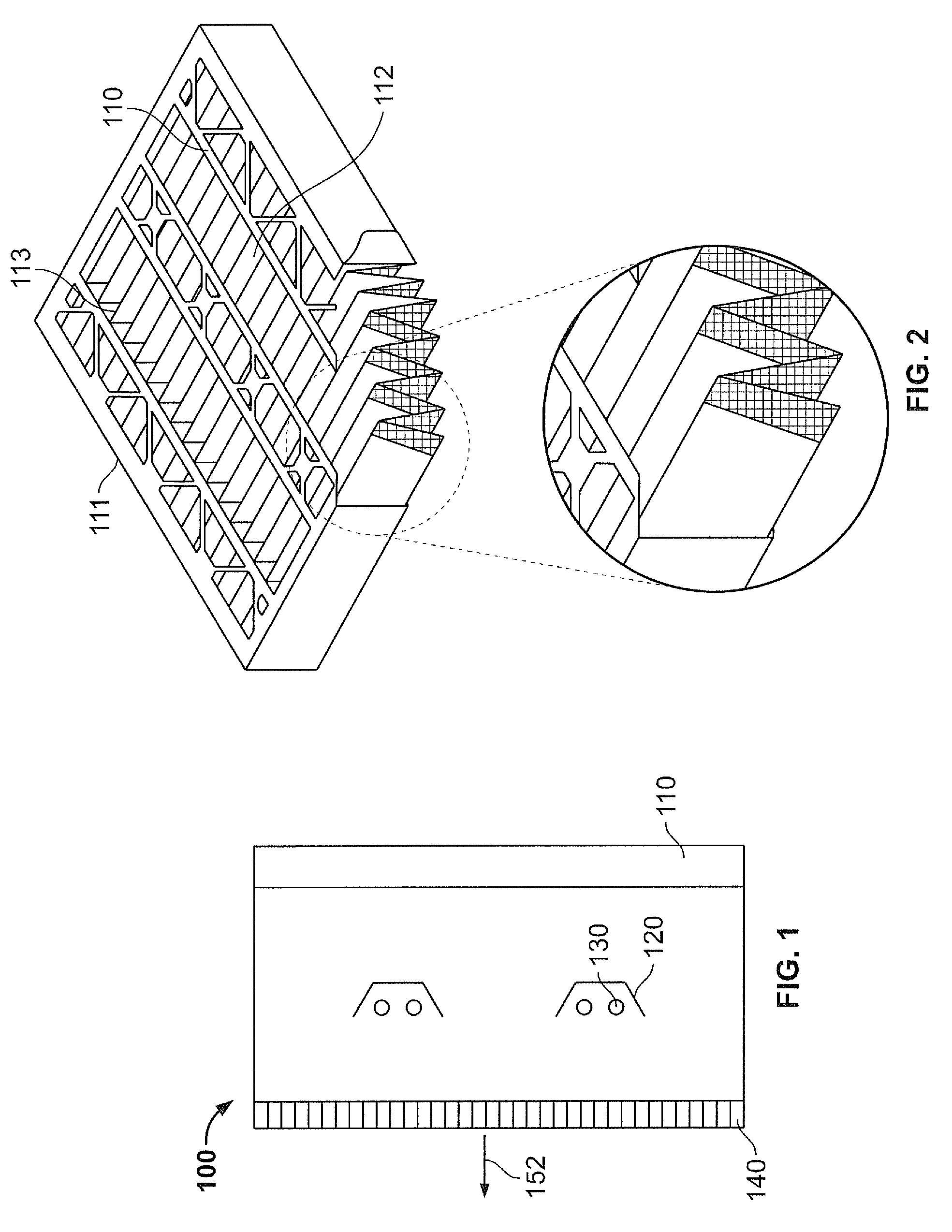

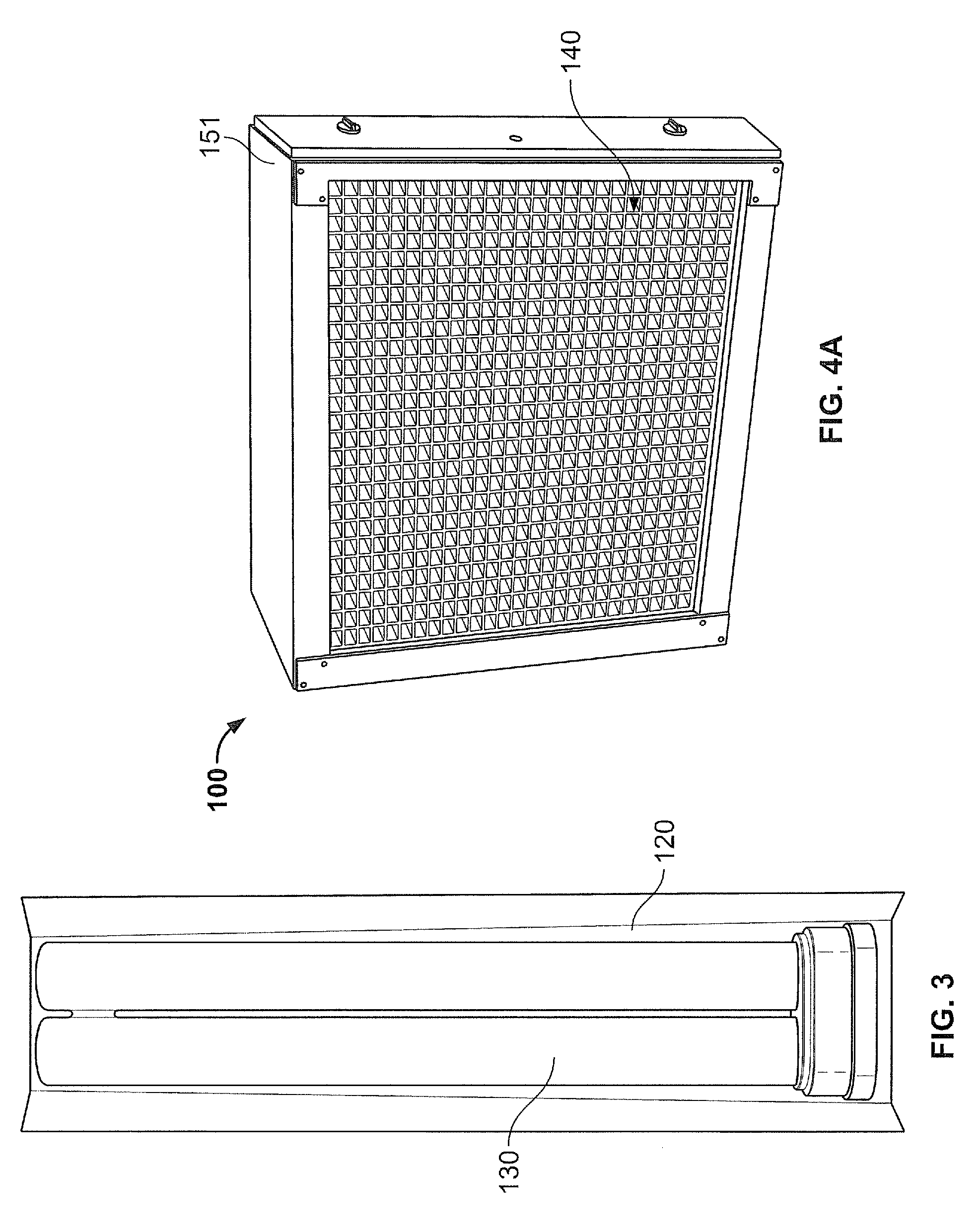

System and method for photocatalytic oxidation air filtration using a substrate with photocatalyst particles power coated thereon

ActiveUS20080286163A1Control thicknessControl UniformityPump componentsLighting and heating apparatusAir filtrationPhysical chemistry

The present invention relates to an air filtration system and a method for making a photocatalytic oxidation substrate by powder coating a photocatalyst onto a metal substrate.

Owner:SCI HEALTH DEV LTD

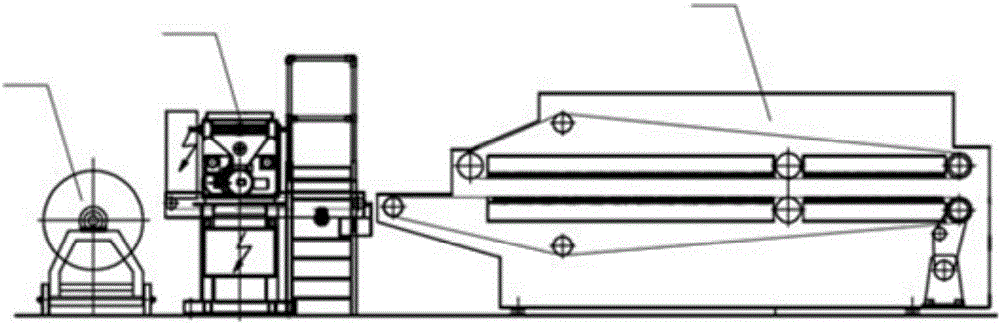

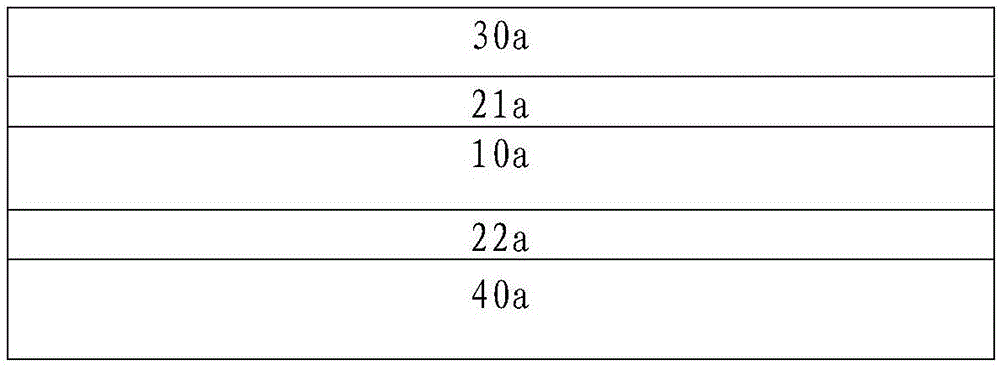

Packaging material for photovoltaic module and method for preparing packaging material

ActiveCN106283677AReduce weightReduce installation costsTextiles and paperPhotovoltaic energy generationFiberWeather resistance

The invention discloses a packaging material for a photovoltaic module. The packaging material is prepared from the following raw materials in parts by weight: 30-50 parts of fiber cloth woven by adopting a fiber material, and 50-70 parts of extra-weather-resistance polyester powder coating which is prepared from extra-weather-resistance polyester resin and a curing agent, wherein the fiber cloth is uniformly coated with the extra-weather-resistance polyester powder coating. The packaging material has low manufacture cost, can be used for effectively realizing light weight of the packaging material of a photovoltaic module, improving the assembly convenience and reducing assembly cost, and is suitable for large-scale popularization and application in the photovoltaic field. The invention further discloses a method for preparing the packaging material for the photovoltaic module, which realizes arbitrary size change of the photovoltaic module to adapt to the assembly requirement of different constructions, and the assembly application of the photovoltaic module can be further facilitated.

Owner:TIGER DRYLAC TAICANG +1

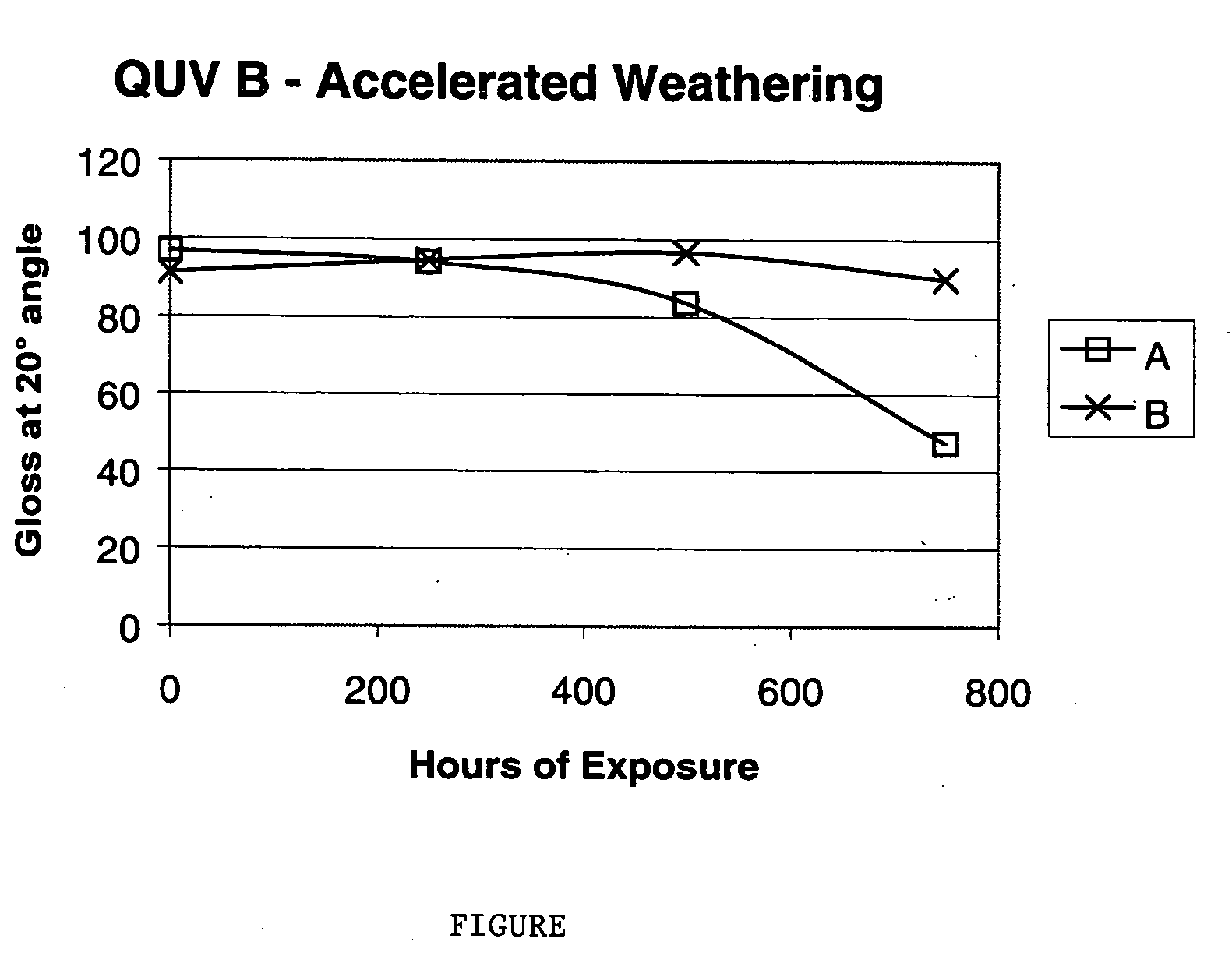

Flexible, super durable powder coating composition

InactiveUS20060079650A1Good weather resistanceImprove mechanical propertiesPolyurea/polyurethane coatingsPowdery paintsPolyesterPolymer science

Powder coatings having good impact resistance and weatherability characteristics are produced with an isophthalic acid-based polyester and an isocyanate-based curing agent.

Owner:BAYER MATERIALSCIENCE AG

Powder coated proppant and method of making the same

A process for producing a proppant particulate substrate having a coating layer thereon including the step of blending a proppant particulate substrate with a powder coating composition at a temperature sufficient to cause the powder coating composition to coat the proppant particulate substrate with a powder coating; and a proppant particulate substrate coated by such a process.

Owner:DOW GLOBAL TECH LLC

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Powder coating with super-weathering resistance, preparation method and application thereof

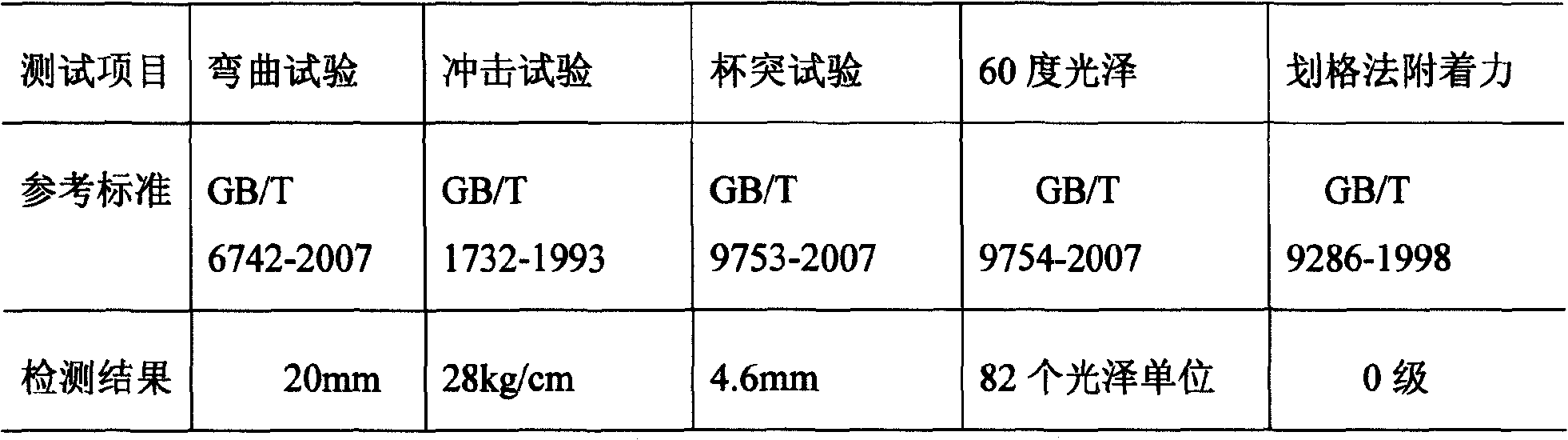

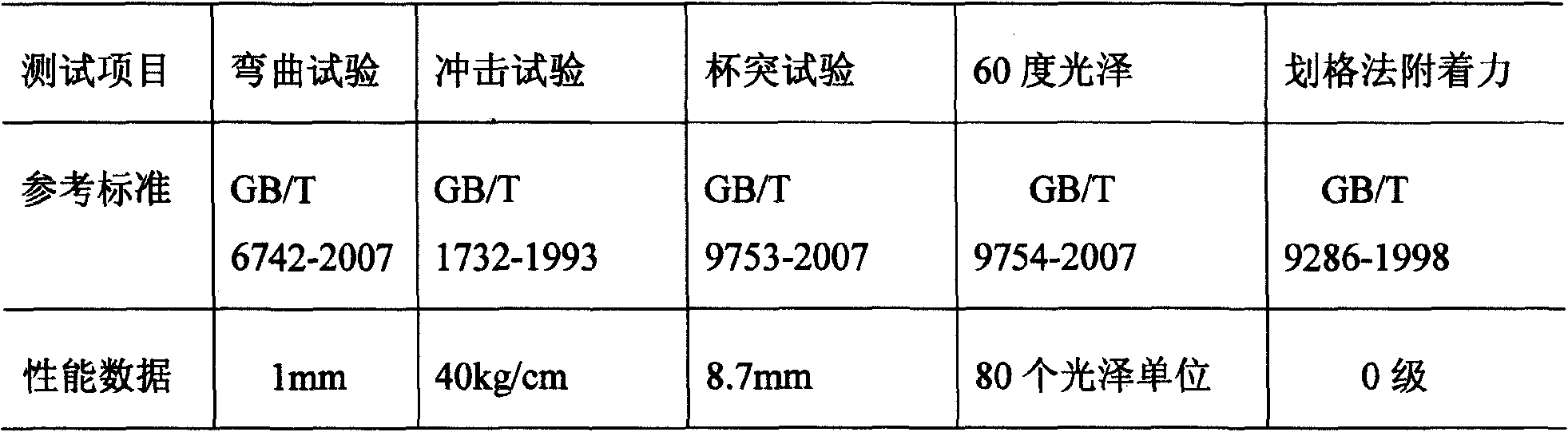

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

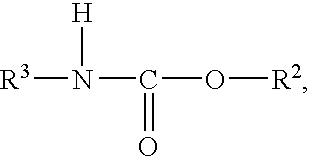

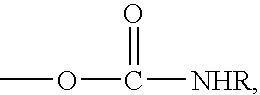

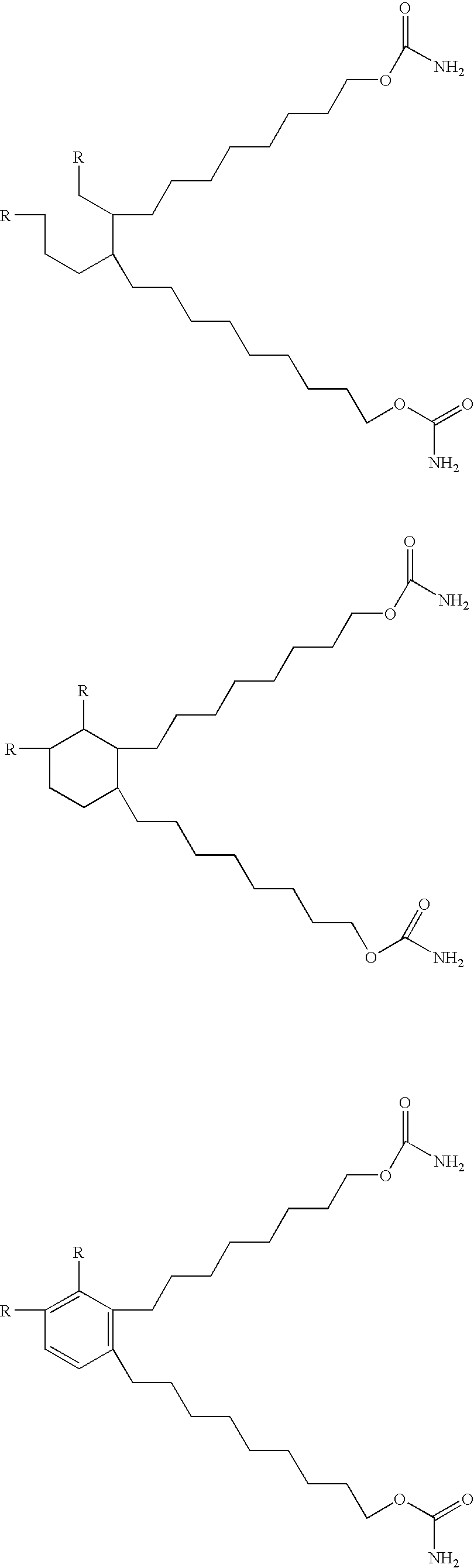

Use of carbamate-modified aminoplast resins to improve the appearance and performance of powder coatings

InactiveUS20050182189A1Low viscosityPowdery paintsPaints for electrolytic applicationsCarbamatePowder coating

A powder coating composition comprising at least about 0.1% by weight of a reaction product of an aminoplast and a compound having one carbamate group has improved smoothness.

Owner:BASF CORP

Surface conditioner for powder coating systems

The present invention relates to methods for conditioning a surface before application of powder coating, methods for improving powder coating transfer to a surface, methods for reducing defects on powder painted surfaces, methods for providing homogenous surface charge on a surface, methods for increasing adhesion of powder paint to a surface, and surface conditioners for use in such methods.

Owner:HENKEL KGAA

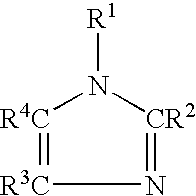

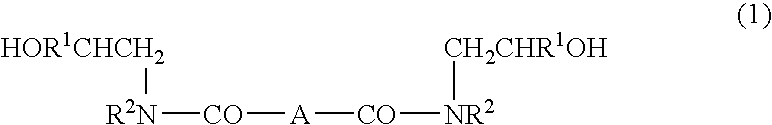

Powder coating composition and coating method of aluminum wheel

InactiveUS20060173113A1Sufficient hiding powerGood lookingPretreated surfacesCoatingsEthyl groupMaterials science

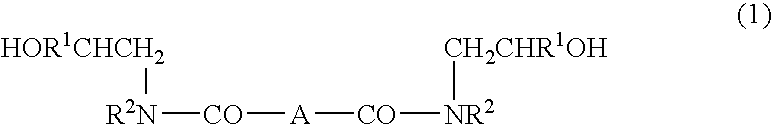

It is an object of the present invention to provide a powder coating composition, which can exhibit a sufficient hiding power, a corrosion resistance and an excellent appearance and can reduce a coating process and is particularly suitable for coating of an aluminum wheel because of its high low temperature curability and has excellent storage stability, and a coating method of an aluminum wheel using the same. A powder coating composition consisting of a powder coating composition particle, wherein said powder coating composition particle comprises at least a thermosetting resin powder formed by binding a metallic pigment with a binder and said thermosetting resin powder comprises a β-hydroxyalkylamide curing agent expressed by the following general formula (1): wherein R1 represents a hydrogen atom, a methyl group or an ethyl group, R2 represents a hydrogen atom, an alkyl group having 1 to 5 carbon atoms or HOCH(R1)CH2—, and A represents a bivalent hydrocarbon group.

Owner:NIPPON PAINT CO LTD

Nanoparticle production and corresponding structures

InactiveUS20060147369A1Material nanotechnologyCarbon compoundsProduction rateNanoparticle Production

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NEOPHOTONICS CORP

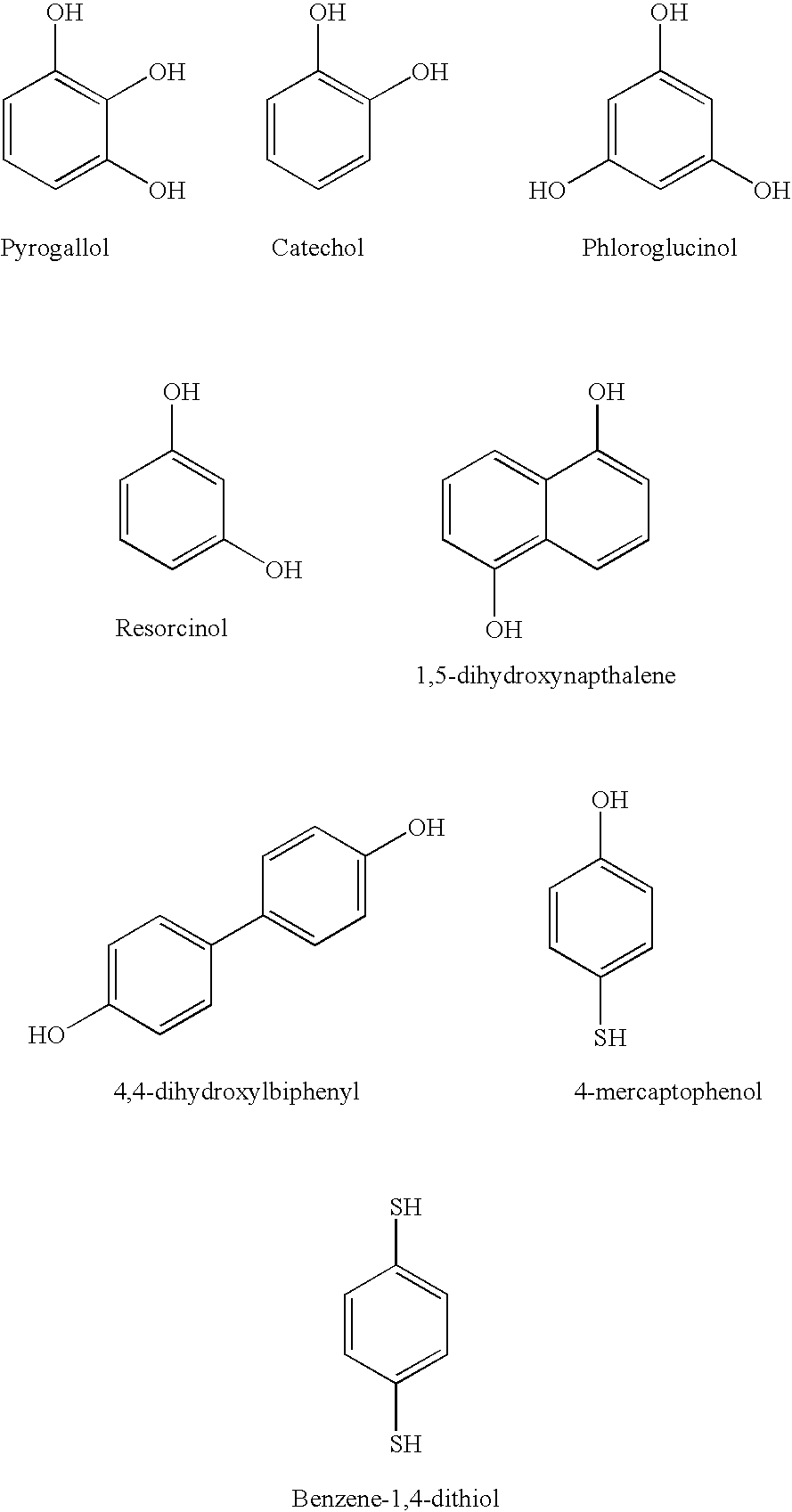

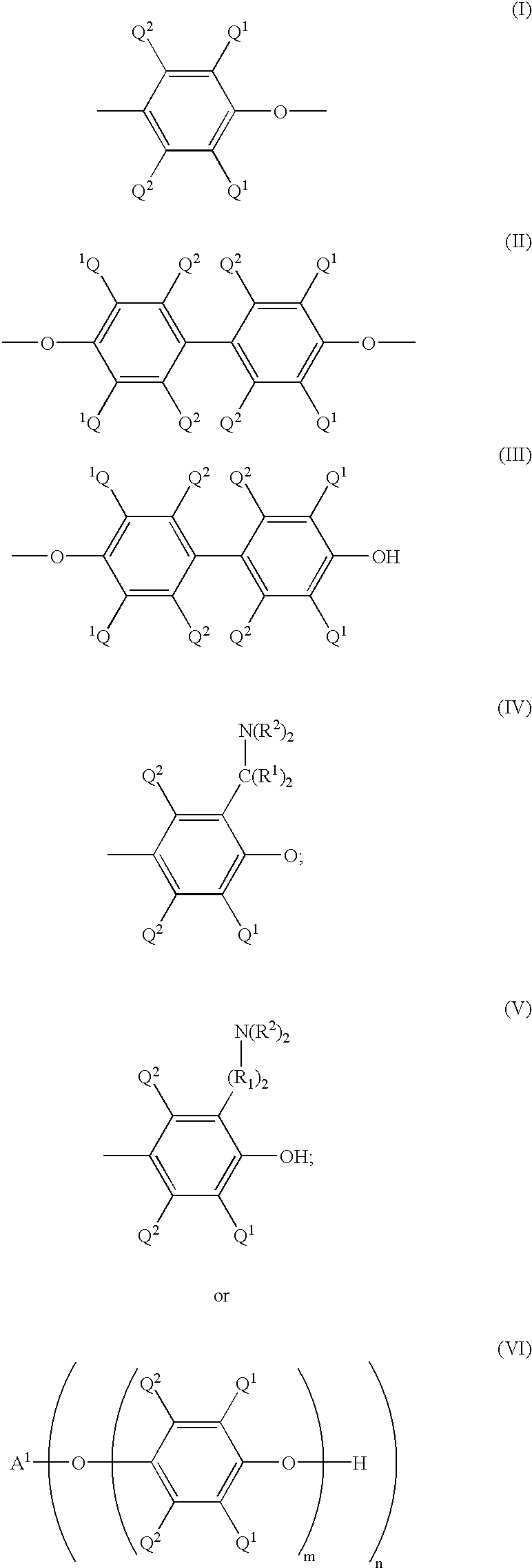

Powder coating fluoropolymer compositions with aromatic materials

Provided is a composition comprising an aromatic material selected from a polythiol aromatic compound or resin, a hydroxythiophenol compound or resin, a catechol novolak resin, a catechol cresol novolak resin, a polyhydroxy aromatic resin or compound comprising at least one aromatic ring having at least one hydroxyl group attached directly to the aromatic ring wherein at least one hydroxyl group is a phenolate salt, or a combination thereof, and a salt former compound capable of forming a salt with the aromatic material, a fluoropolymer, and optionally a phase transfer catalyst. Also provided are articles comprising powder-coated fluoropolymers with aromatic compounds, and methods for making the compositions and articles.

Owner:3M INNOVATIVE PROPERTIES CO

Powder coating of thermosetting resin(s) and poly(phenylene ethers(s))

InactiveUS6576718B1High softening temperatureSignificant positive effectSynthetic resin layered productsPolyether coatingsEtherPowder coating

Owner:SABIC INNOVATIVE PLASTICS IP BV

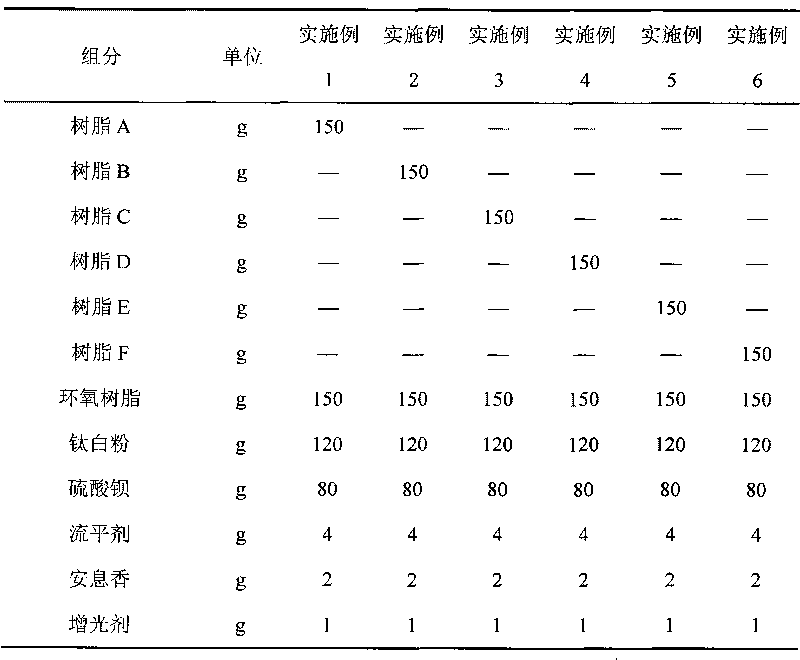

Graphene anticorrosive powder paint and preparation method thereof

ActiveCN104109450AImprove corrosion resistanceIncrease resistanceAnti-corrosive paintsPowdery paintsEpoxyArray data structure

The invention relates to a graphene anticorrosive powder paint which is composed of the following components in parts by weight: 25-70 parts of epoxy resin, 25-70 parts of polyester resin, 5-40 parts of titanium white, 5-40 parts of barium sulfate, 3-10 parts of assistant, 0.5-10 parts of graphene and the balance of other pigments. The powder paint has excellent anticorrosive property and favorable powdering penetrating power, and the surface scratch resistance is up to 2H above. The preparation technique is simple; the application technique is convenient; and the paint has excellent comprehensive properties.

Owner:宁波派特勒新材料股份有限公司

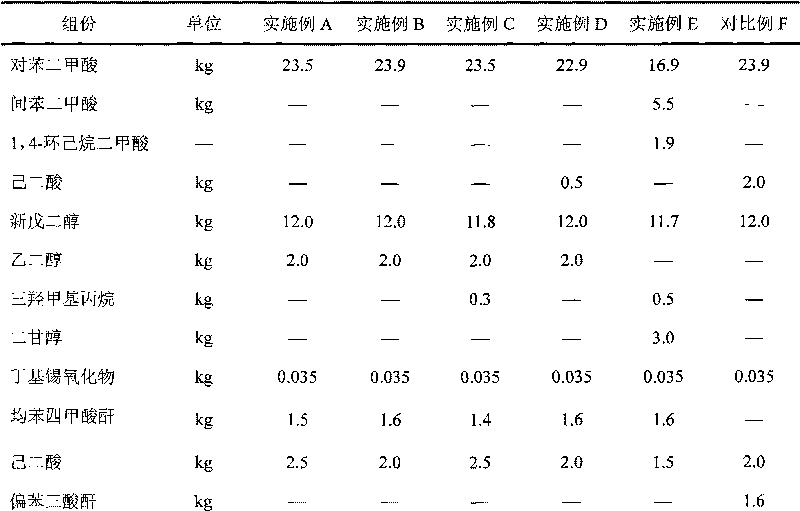

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

Process for applying fluoropolymer powder coating as a primer layer and an overcoat

InactiveUS20060110601A1Superior and durable adhesionIncrease temperatureSynthetic resin layered productsPackagingTetrafluoroethylenePolymer science

The invention relates to use of a tetrafluoroethylene / perfluoroolefin copolymer applied as a primer powder in conjunction with a powder overcoat of tetrafluoroethylene / perfluoro (vinyl alkyl ether) copolymer, also known as perfluoroalkoxy polymer (PFA), which when baked onto a substrate gives superior and more durable adhesion of the coating system to the substrate. The quality of the adhesion is measured by a boiling water peel test.

Owner:THE CHEMOURS CO FC LLC

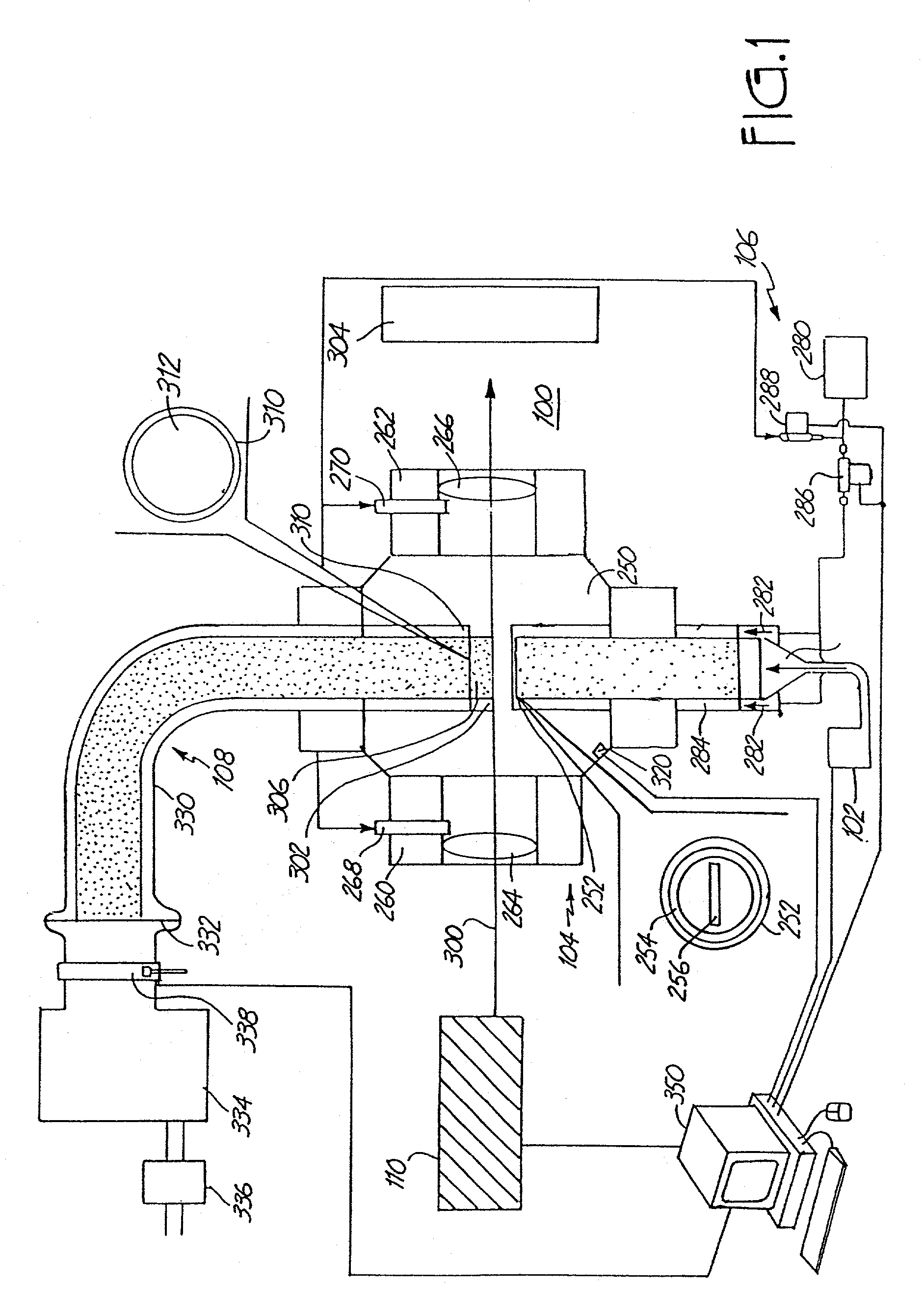

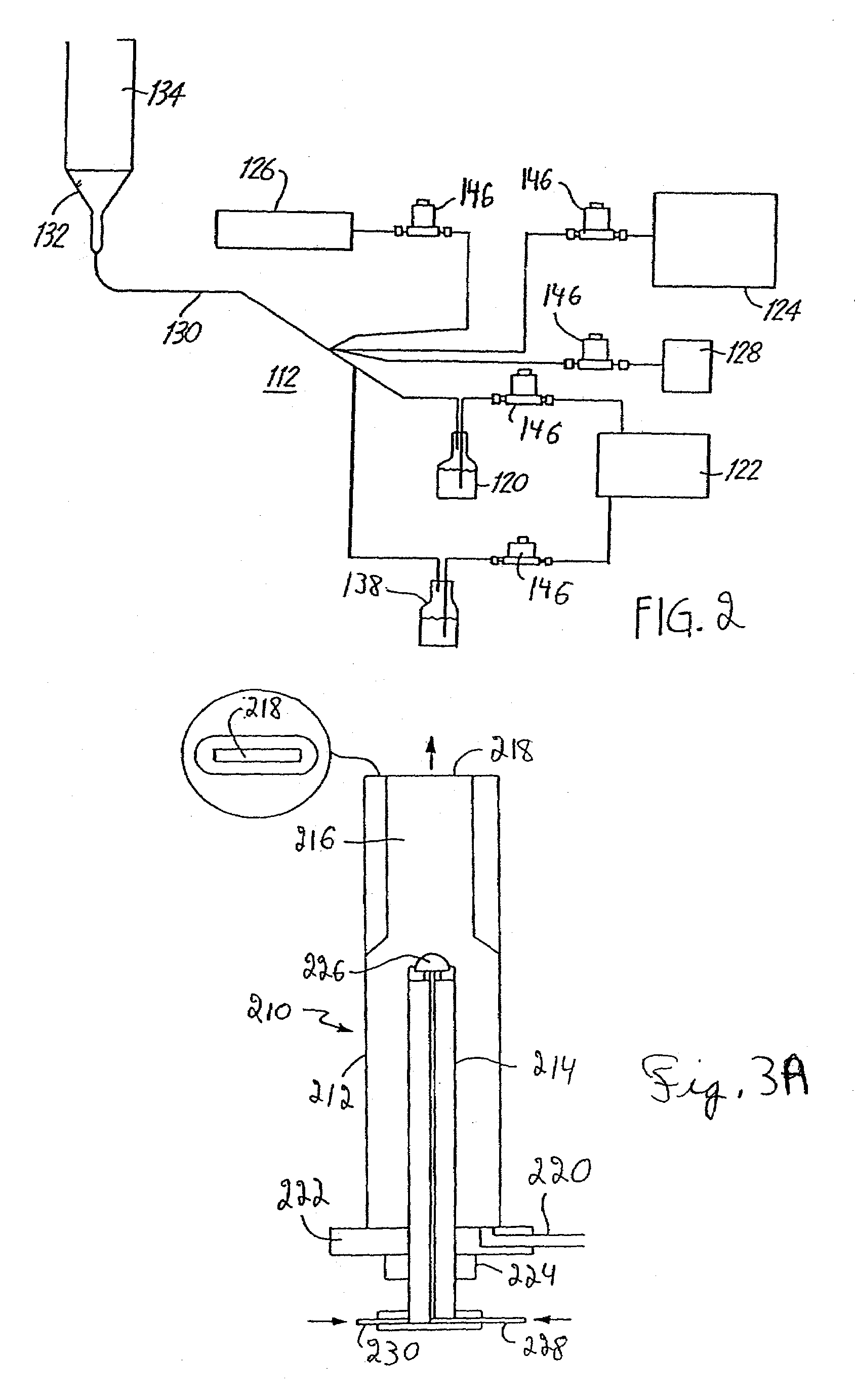

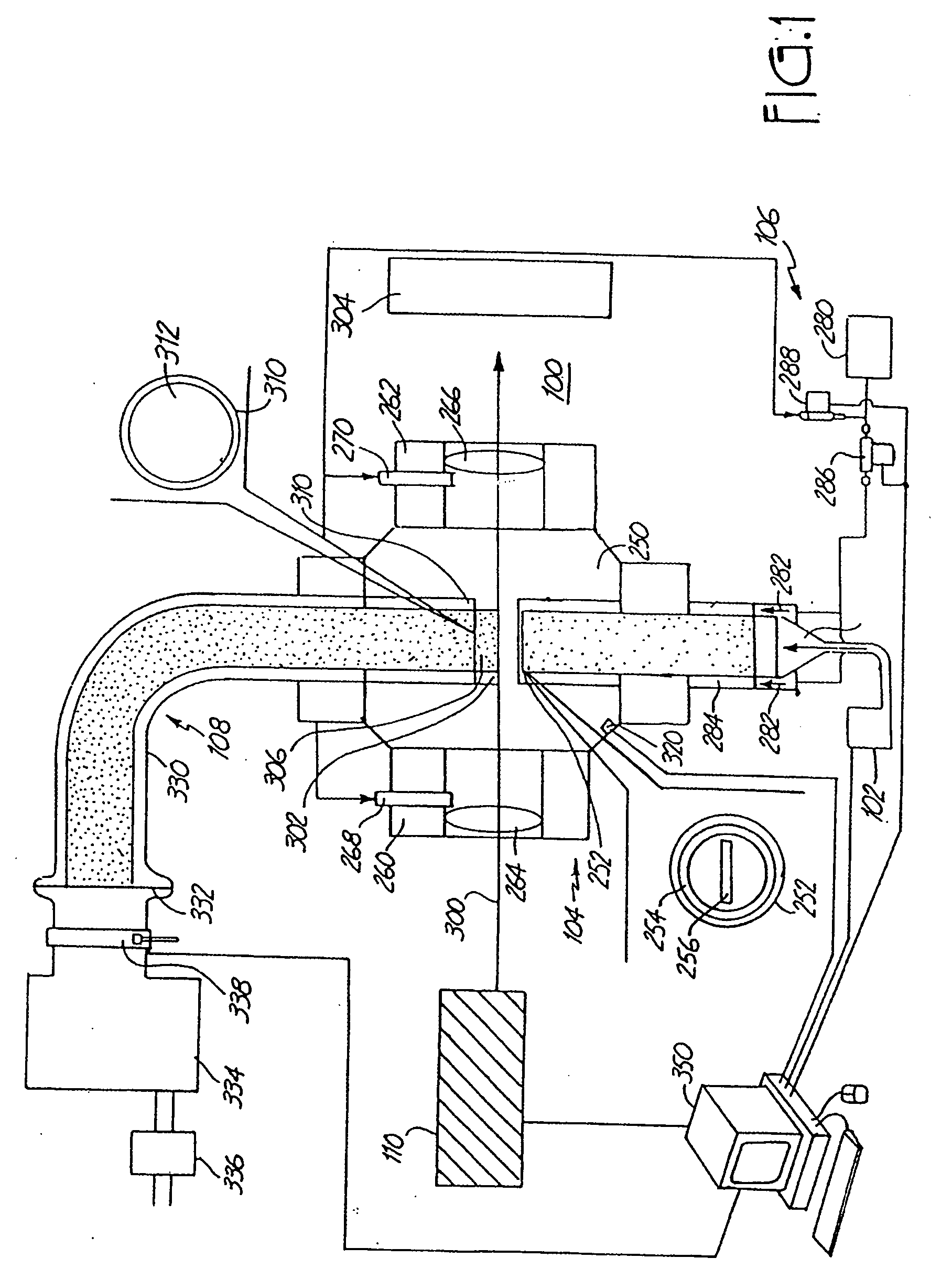

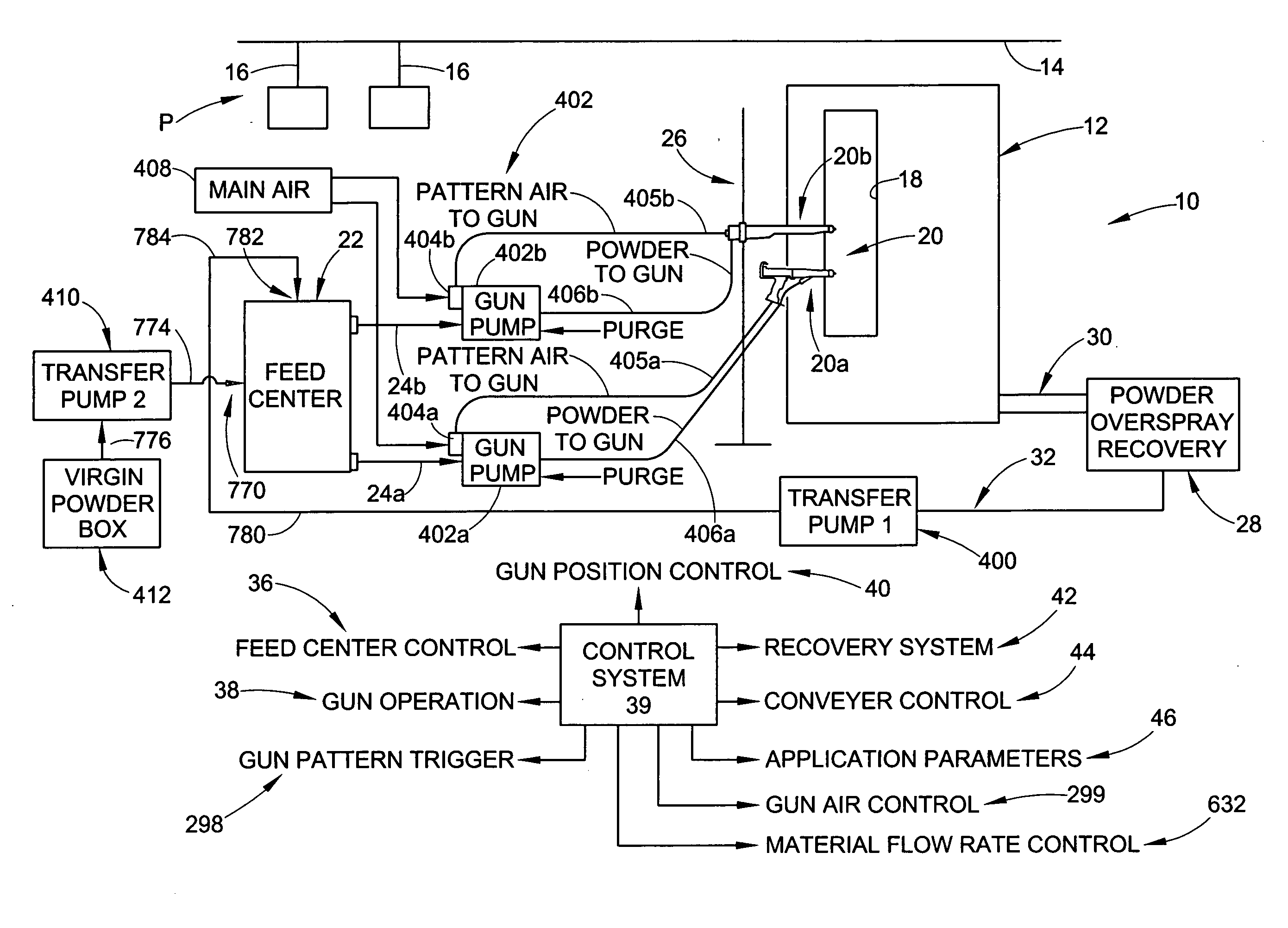

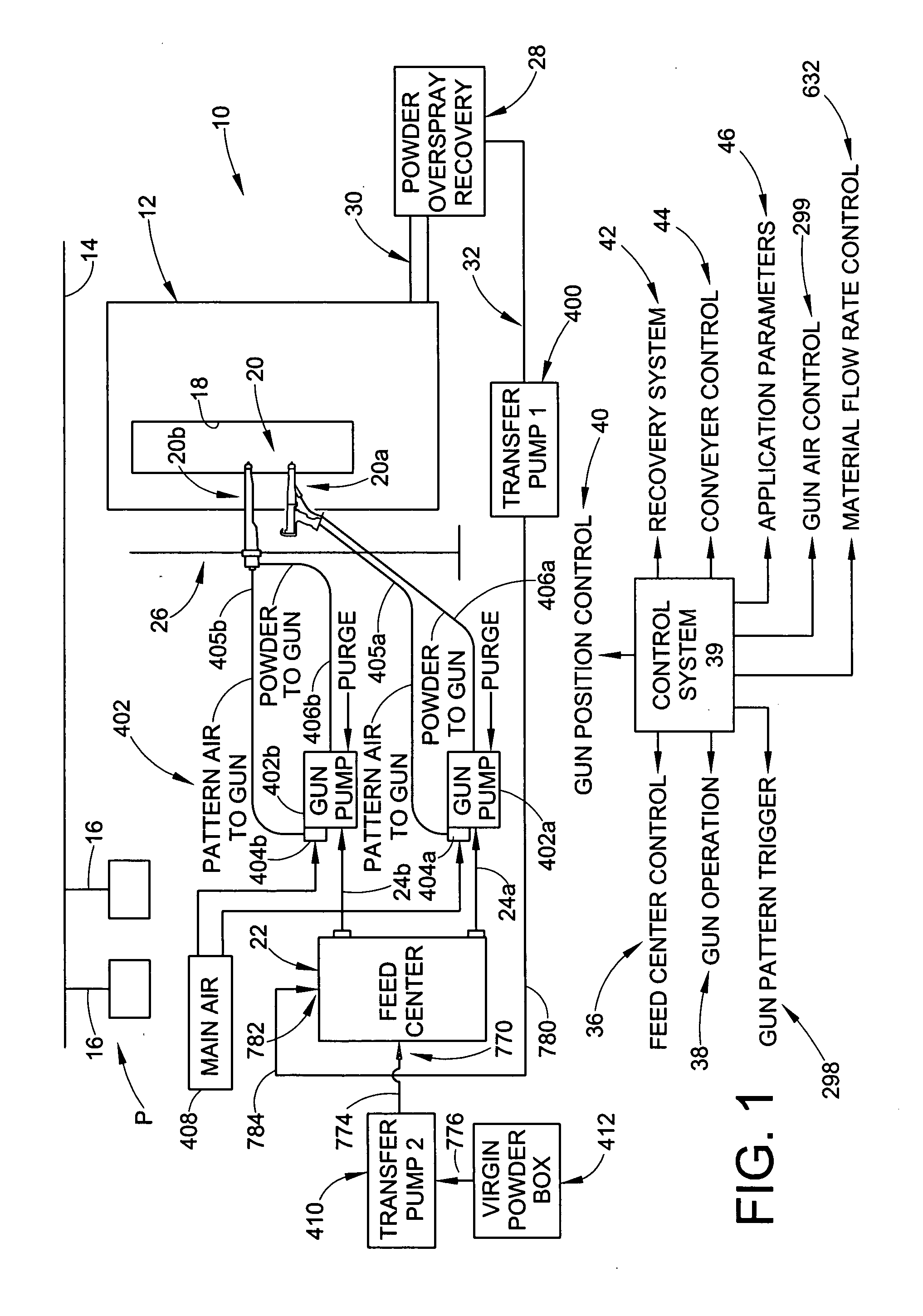

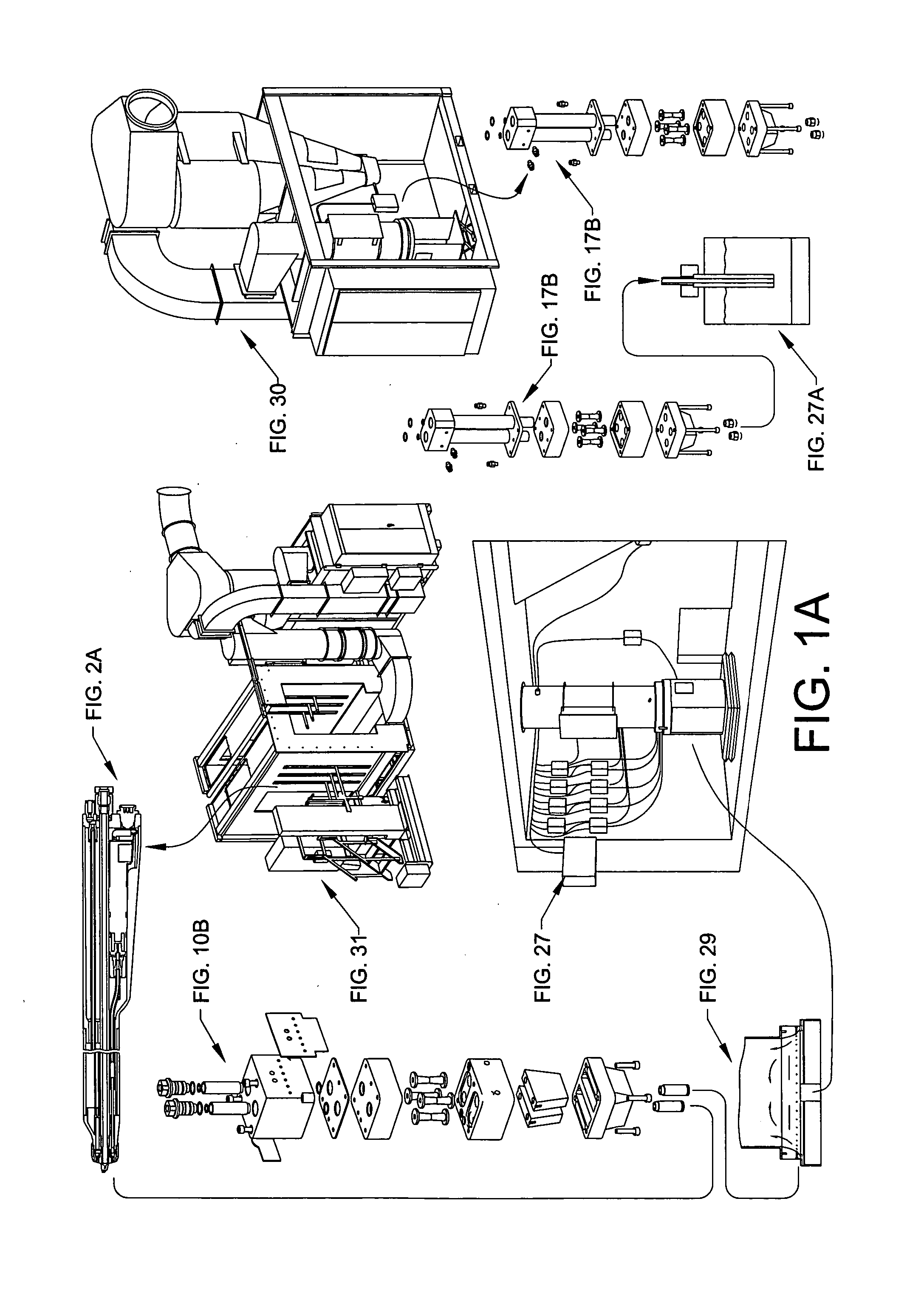

Improved particulate material application system

InactiveUS20050126476A1Good cleanabilityShorten color change timeLiquid surface applicatorsLiquid spraying apparatusSiphonAmbient pressure

A material supply for a material application system such as a powder coating application system includes a feed hopper in the form of a duct. The duct is connectable to negative pressure during a color change process and is disconnected from the negative pressure during a spray application process. The negative pressure can be provided from a powder overspray recovery system such as an after filter blower. Dampers are provided to control air flow through the hopper duct and to allow the duct to be at ambient pressure during a supply mode of operation. The hopper duct also includes a suction interface for pumps, in the form of a siphon ring, as well as a fluidizing function. A removable sieve is provided with an optional vibration feature. Powder may be added to the duct via an access door or transfer pumps for new powder and / or reclaimed powder overspray.

Owner:NORDSON CORP

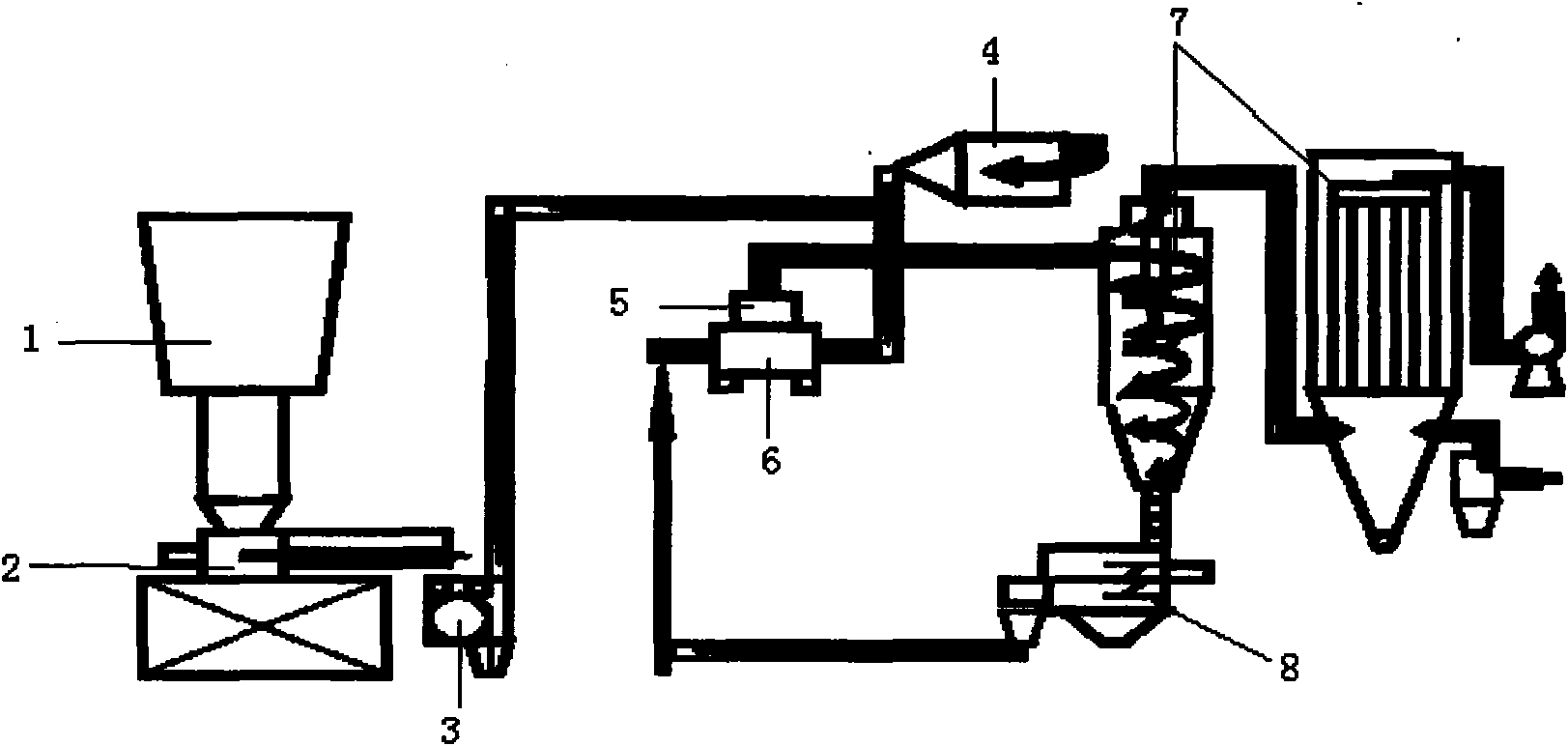

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

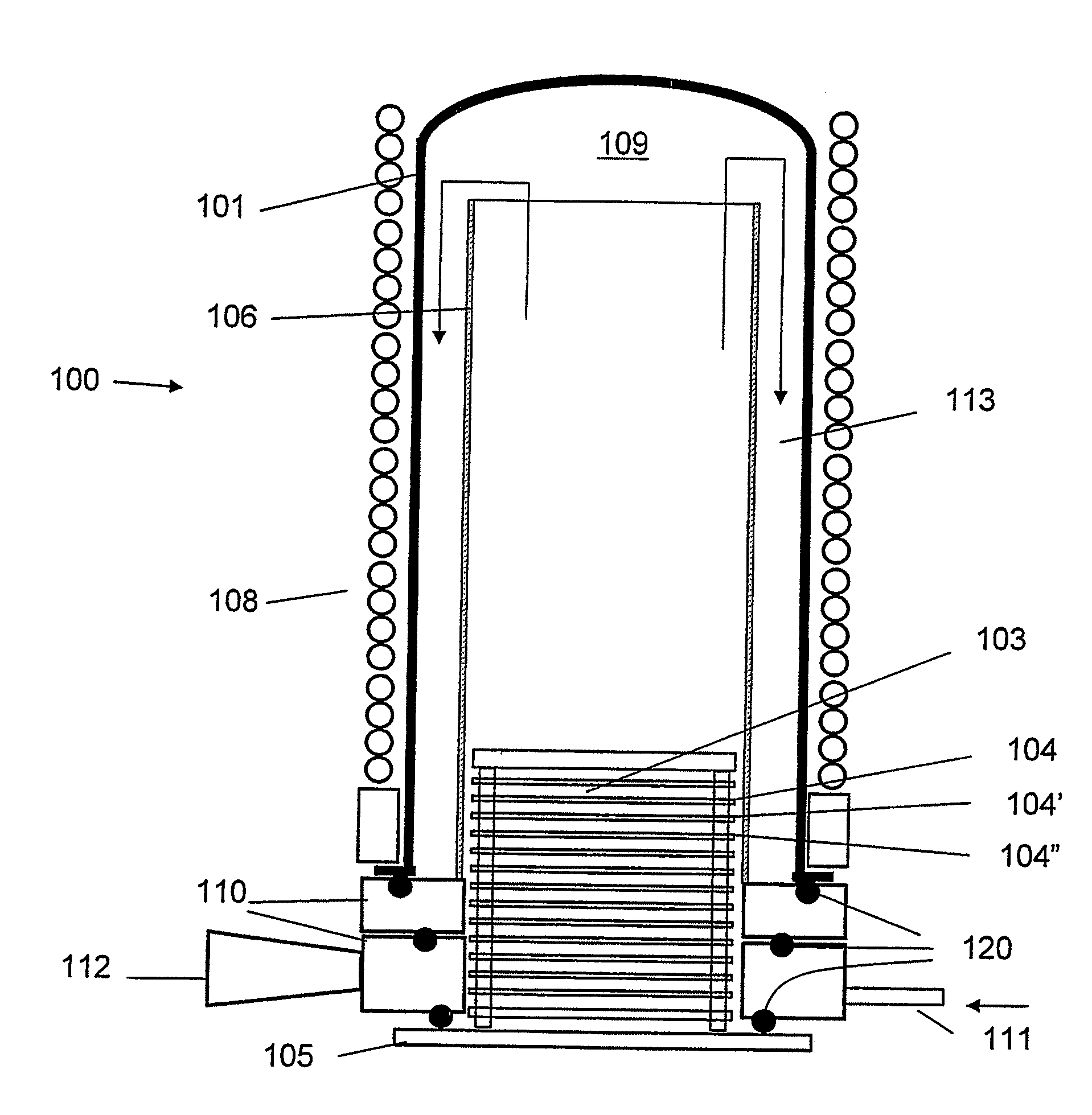

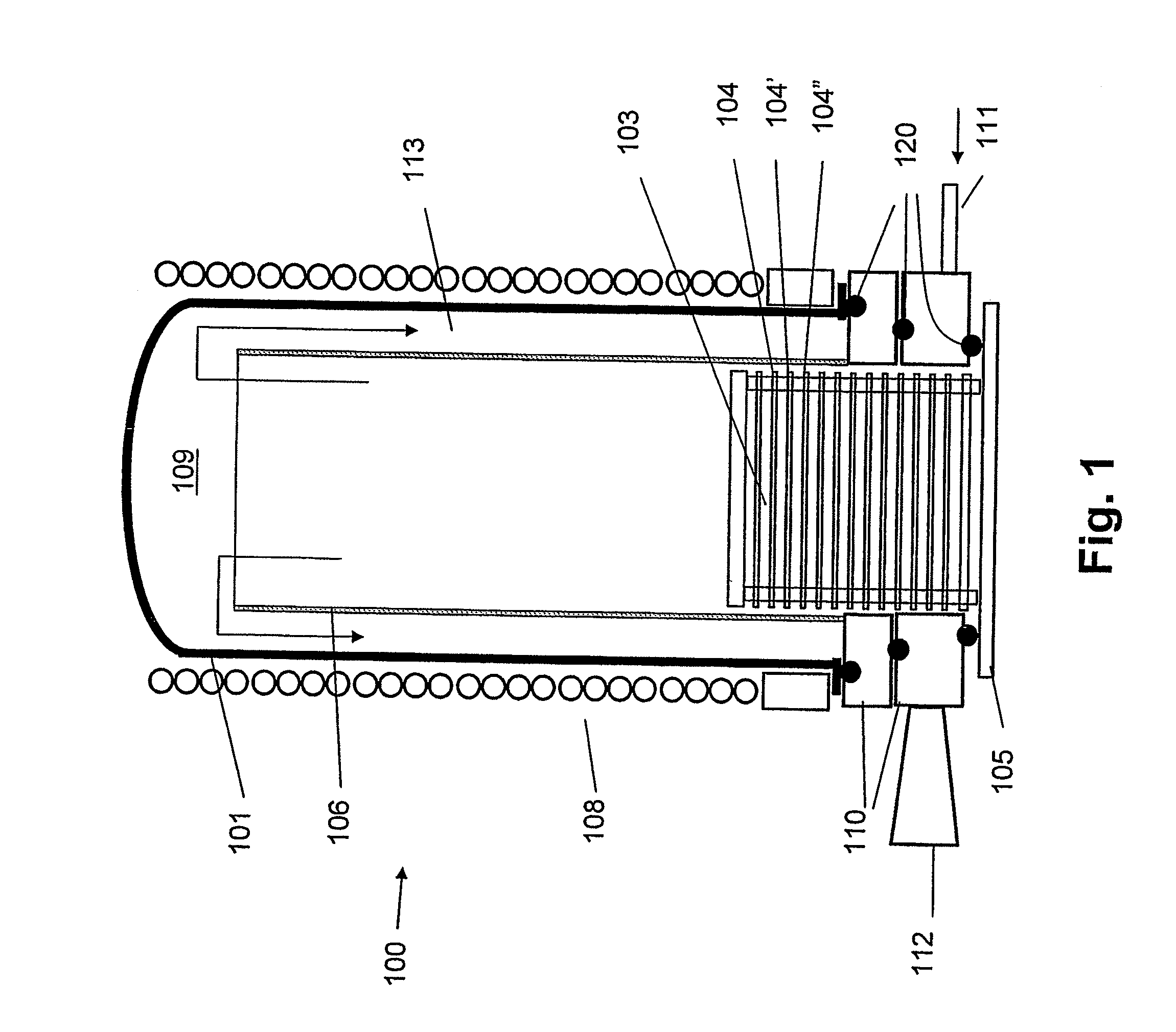

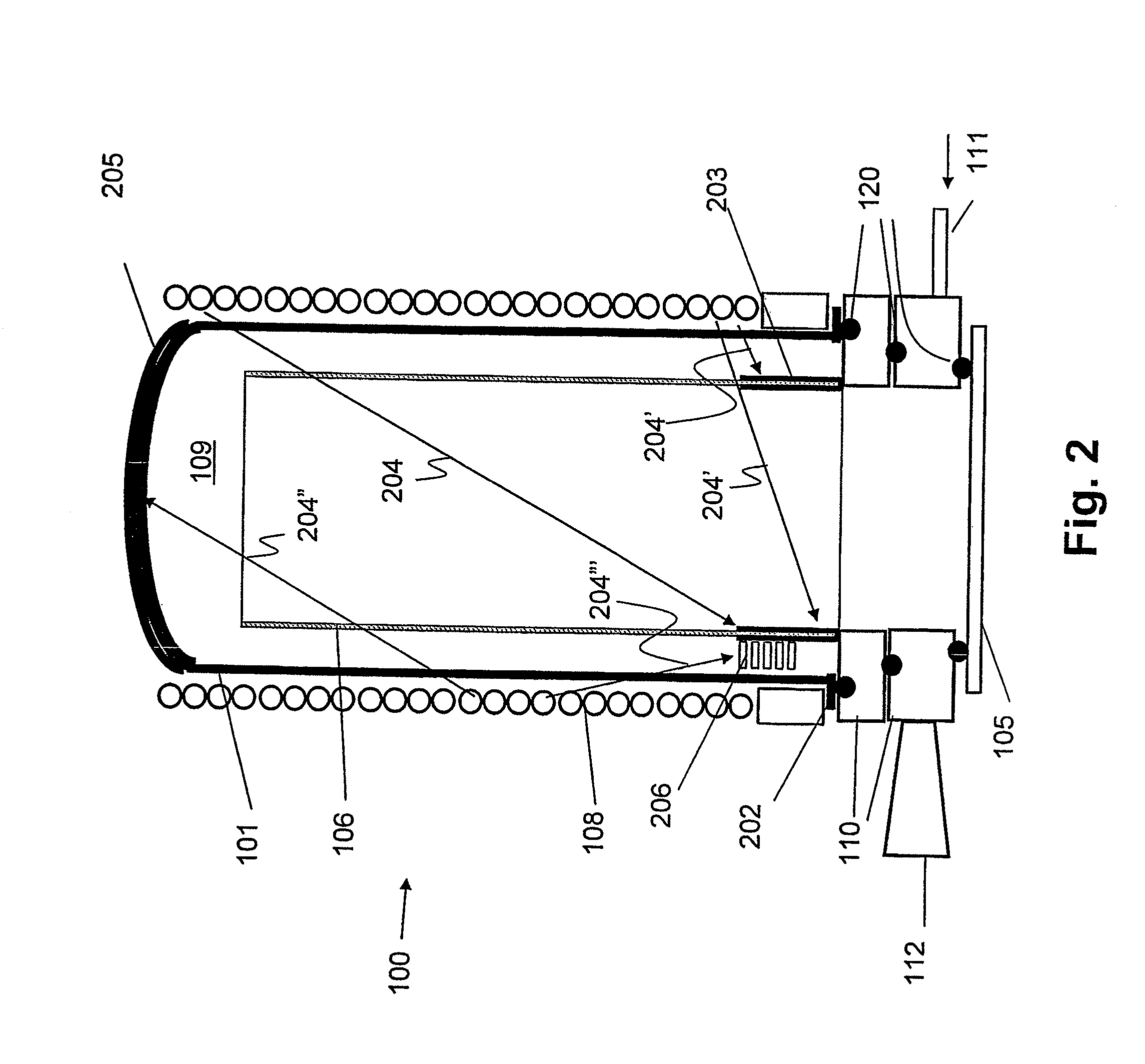

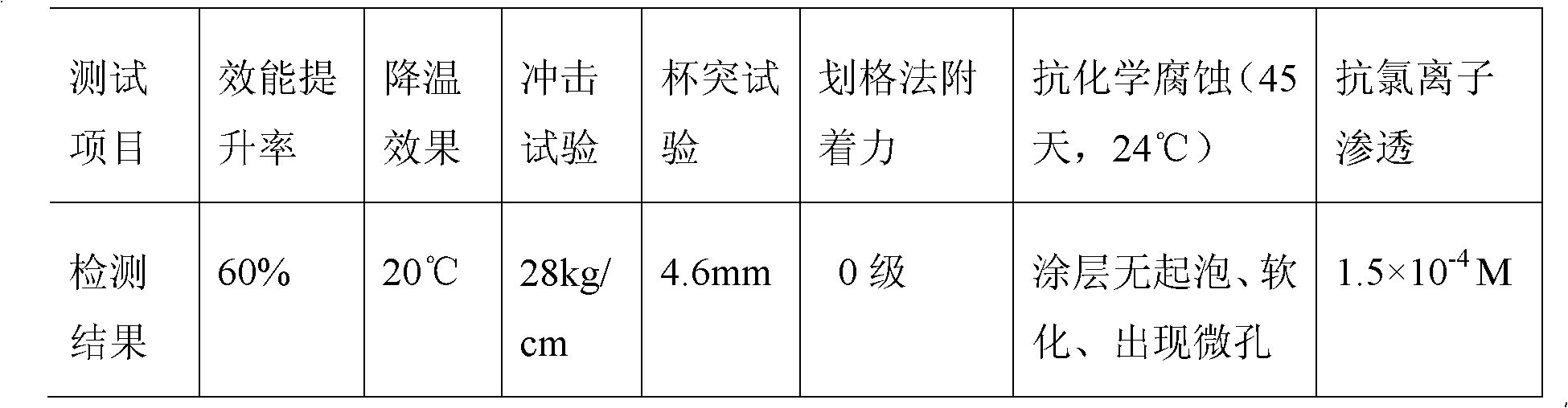

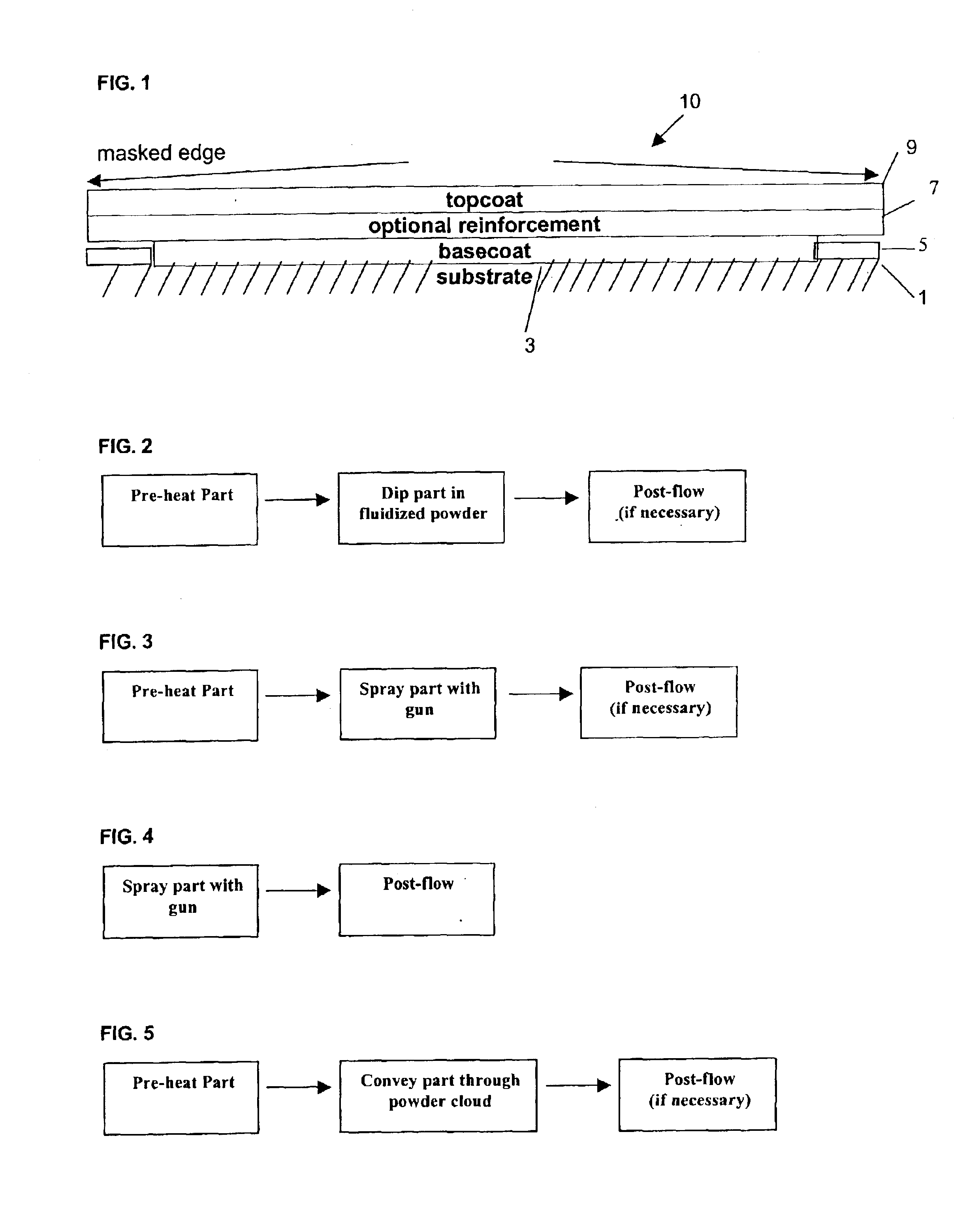

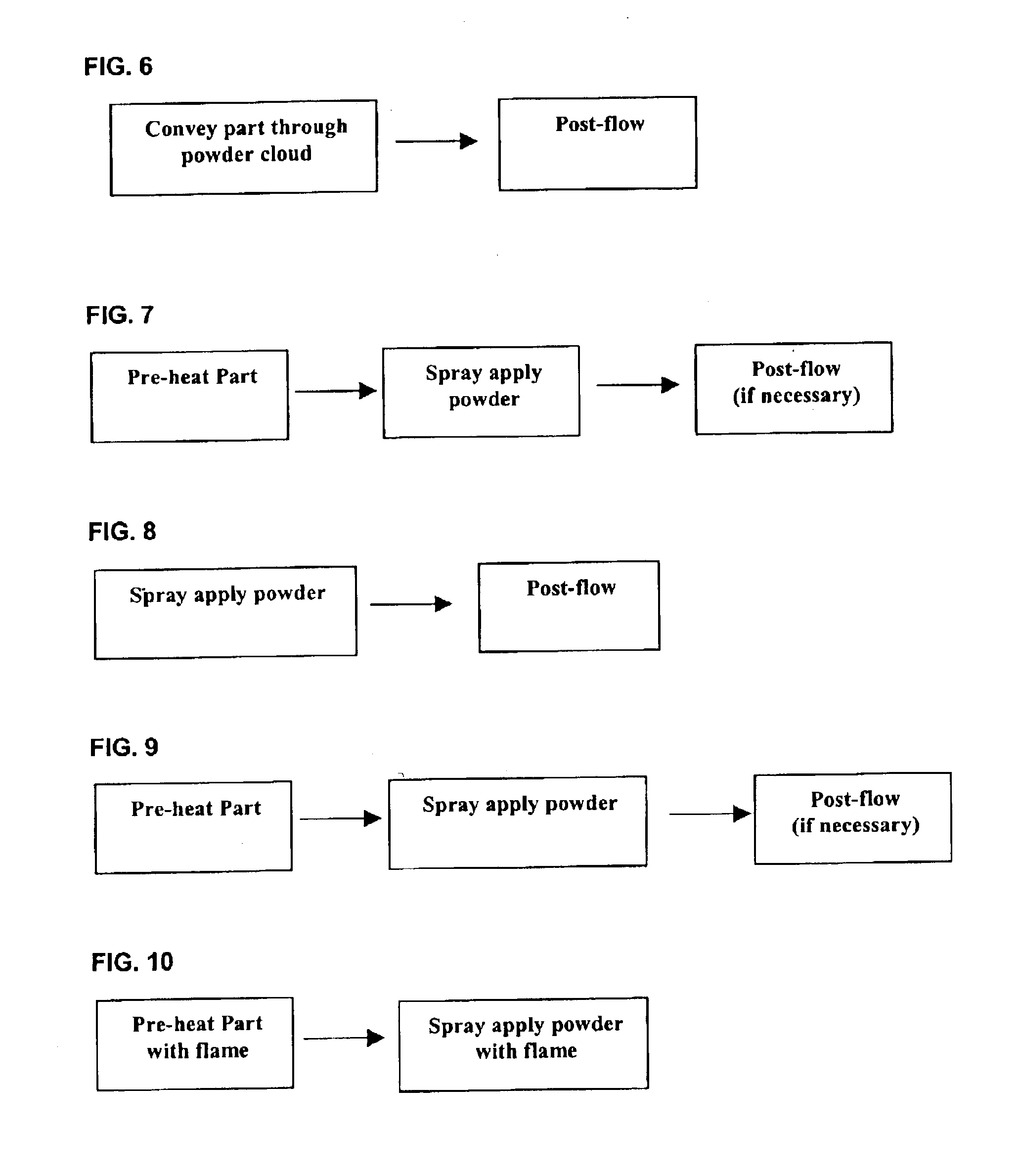

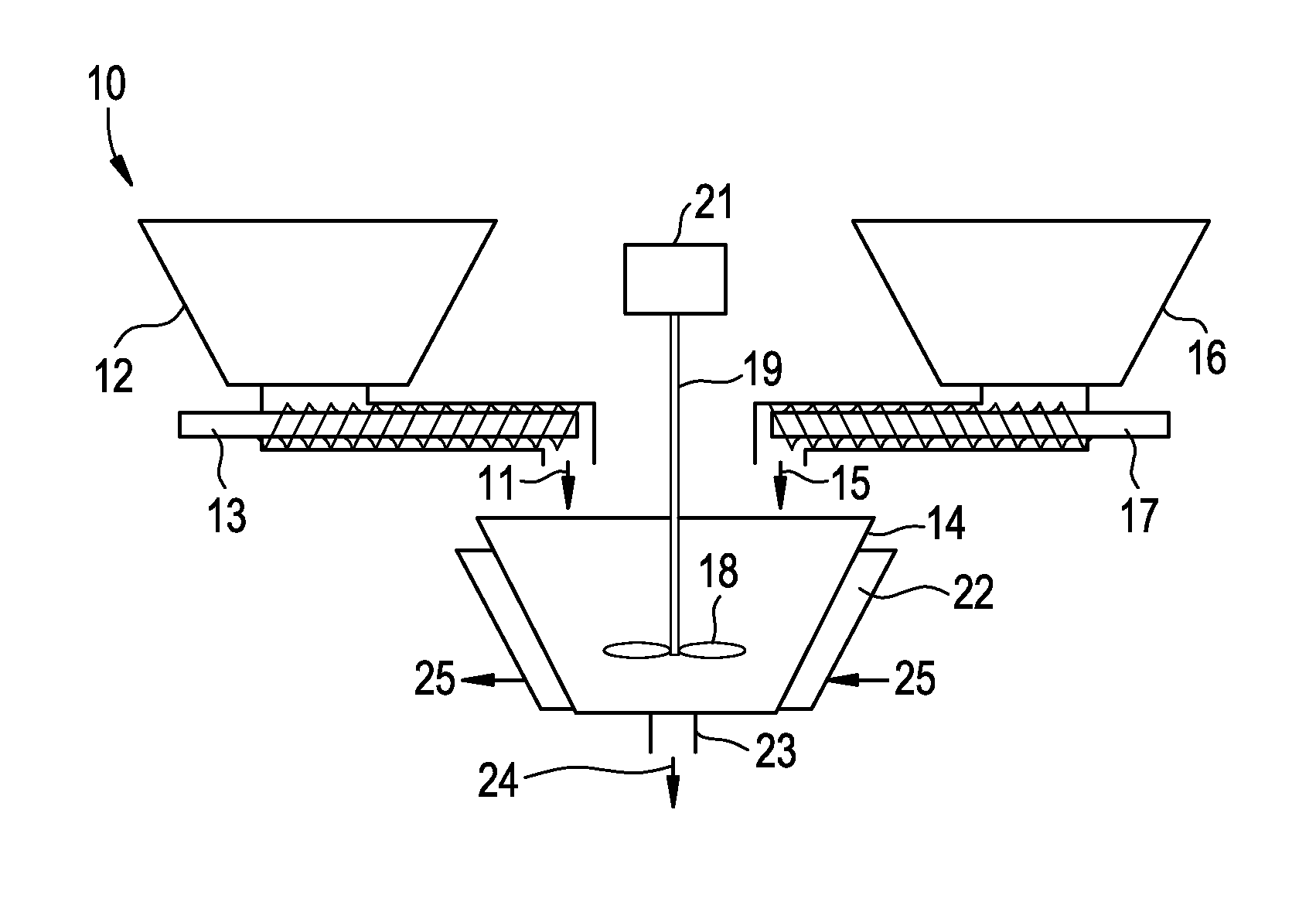

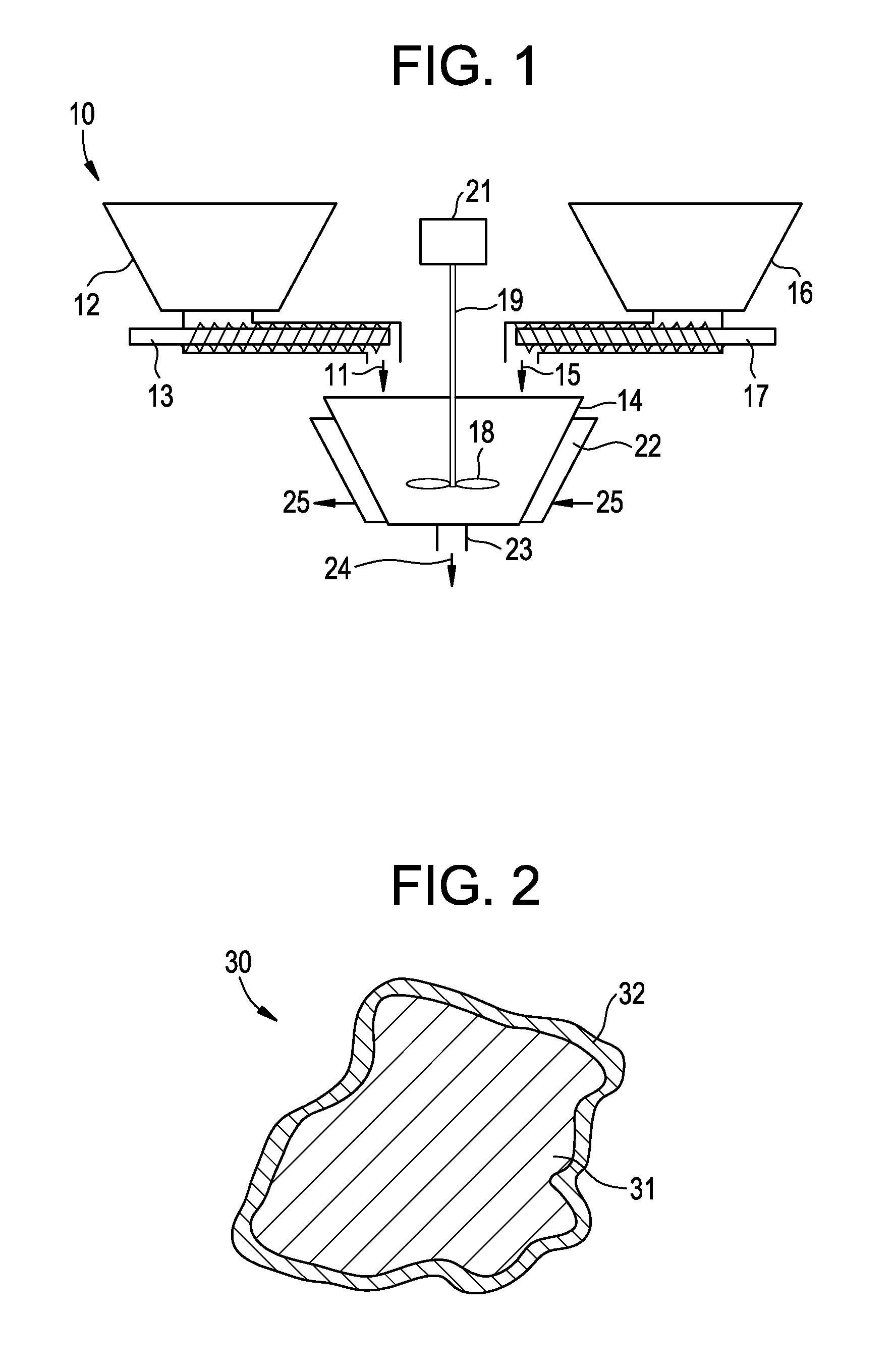

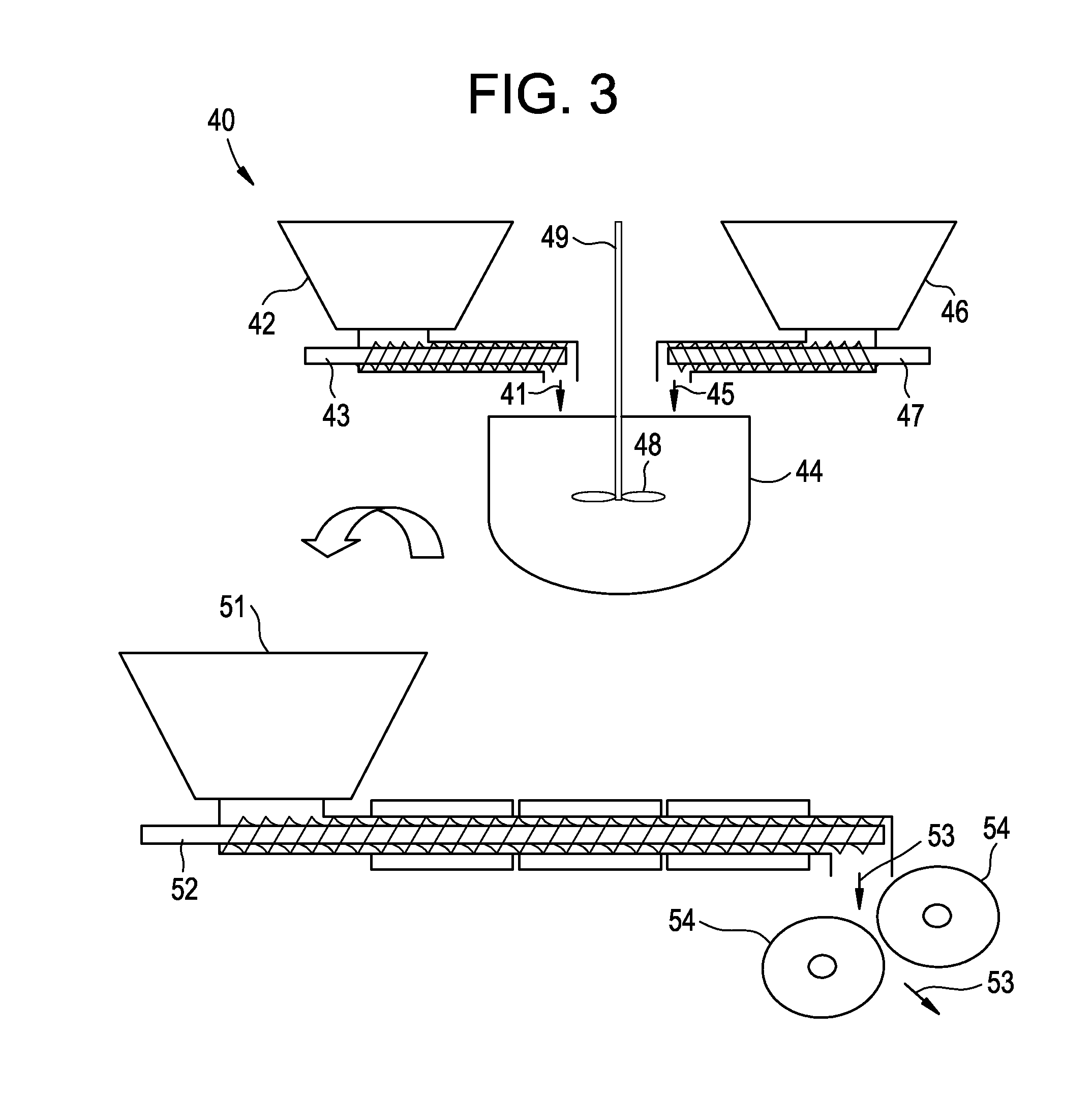

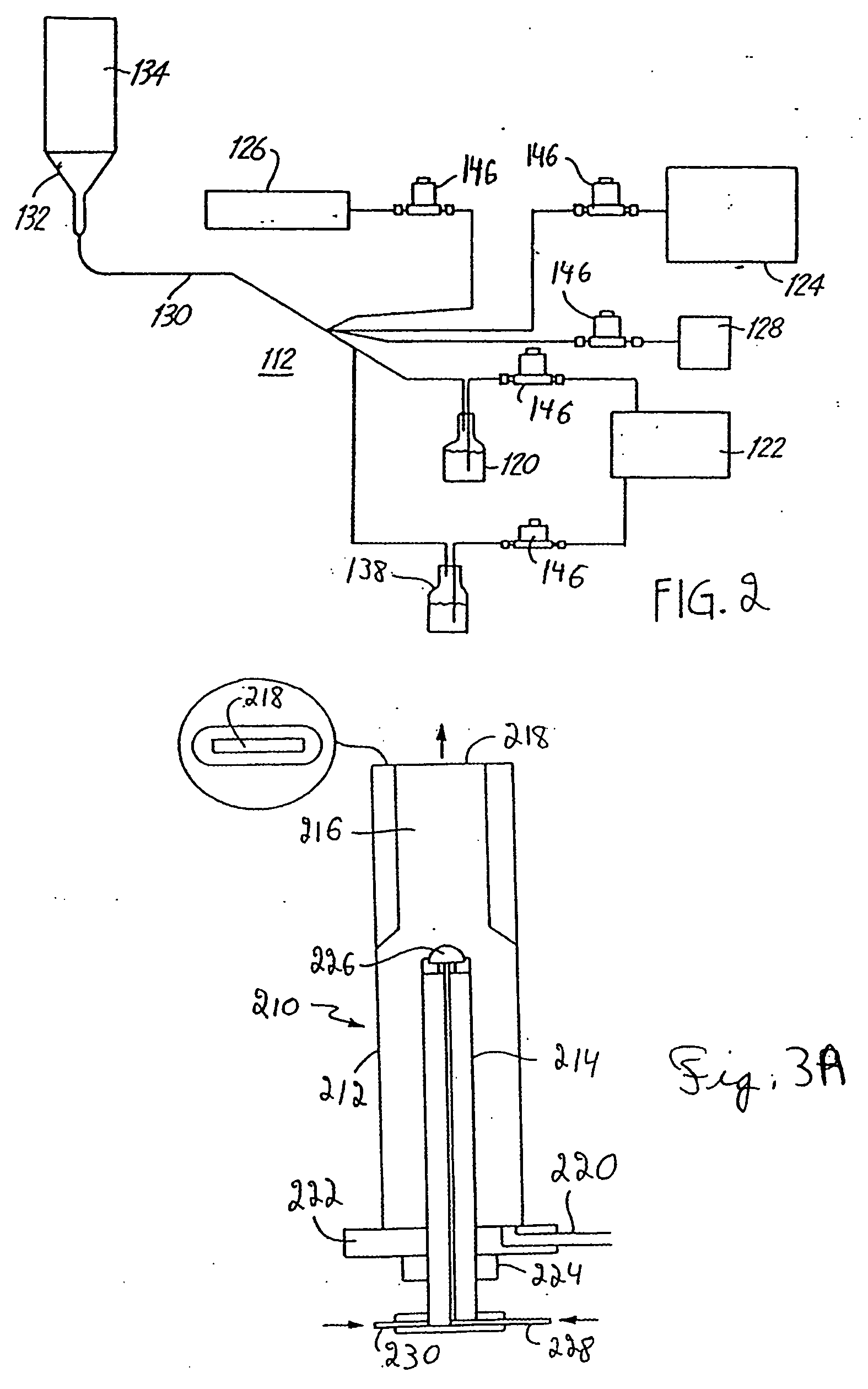

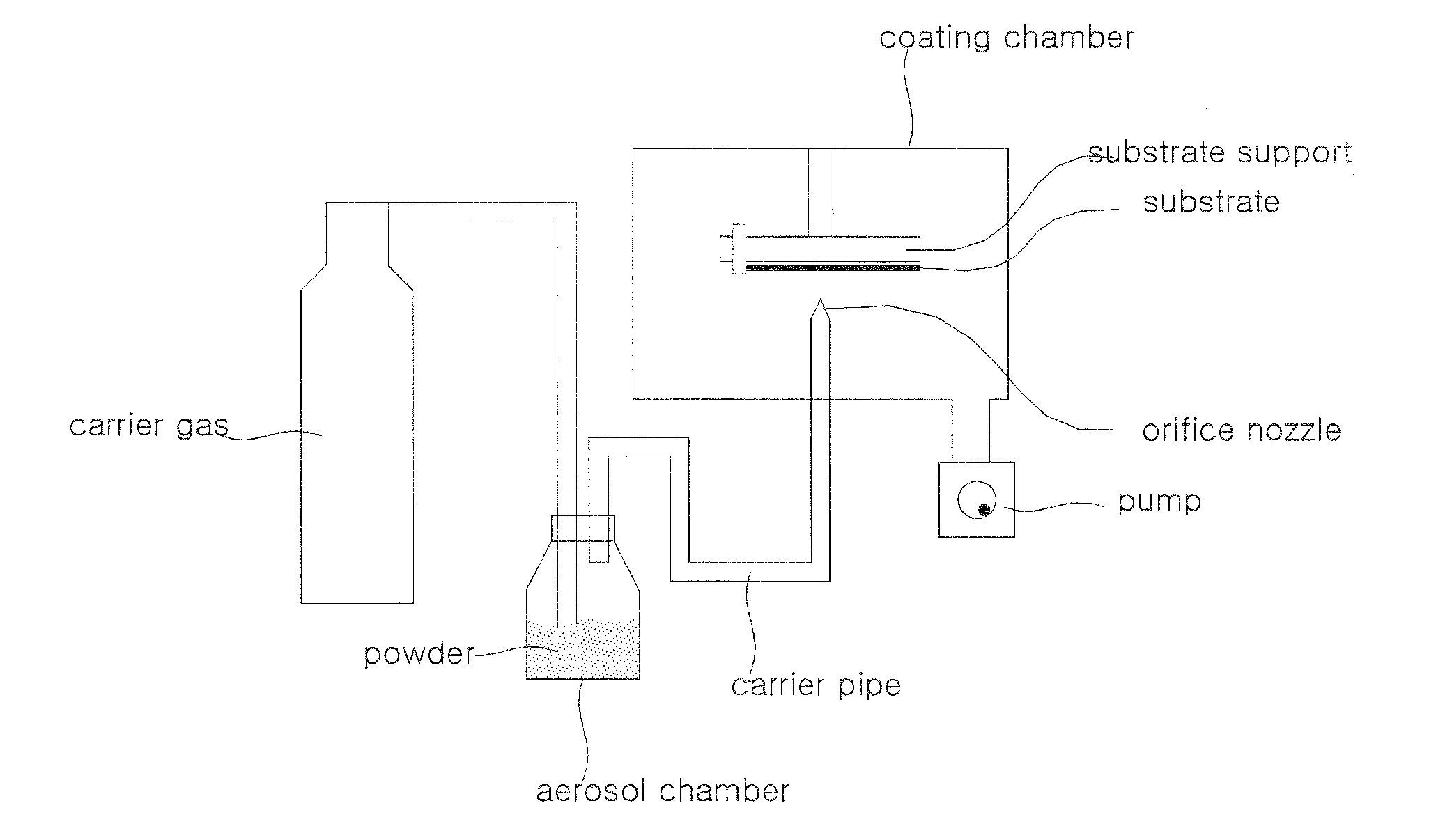

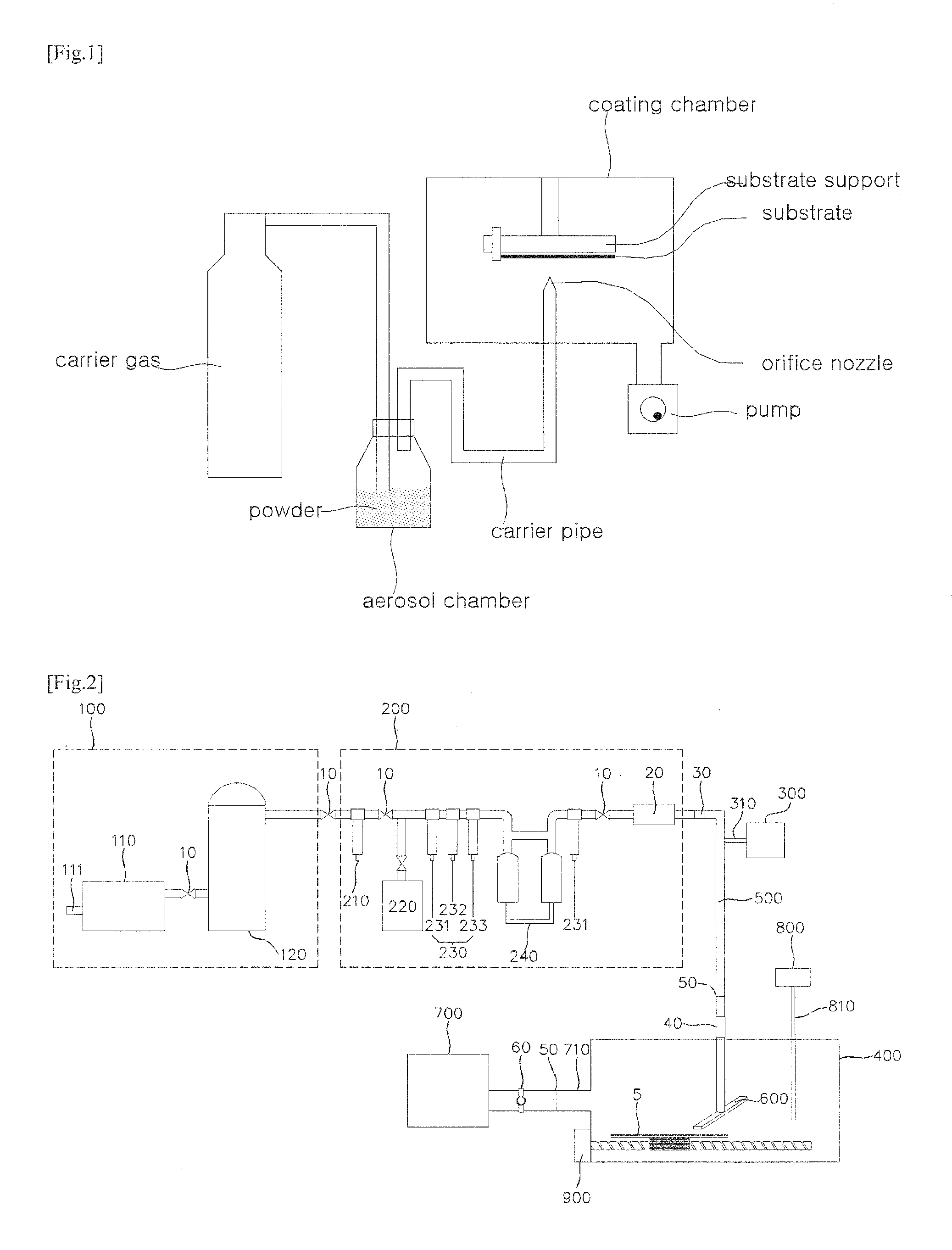

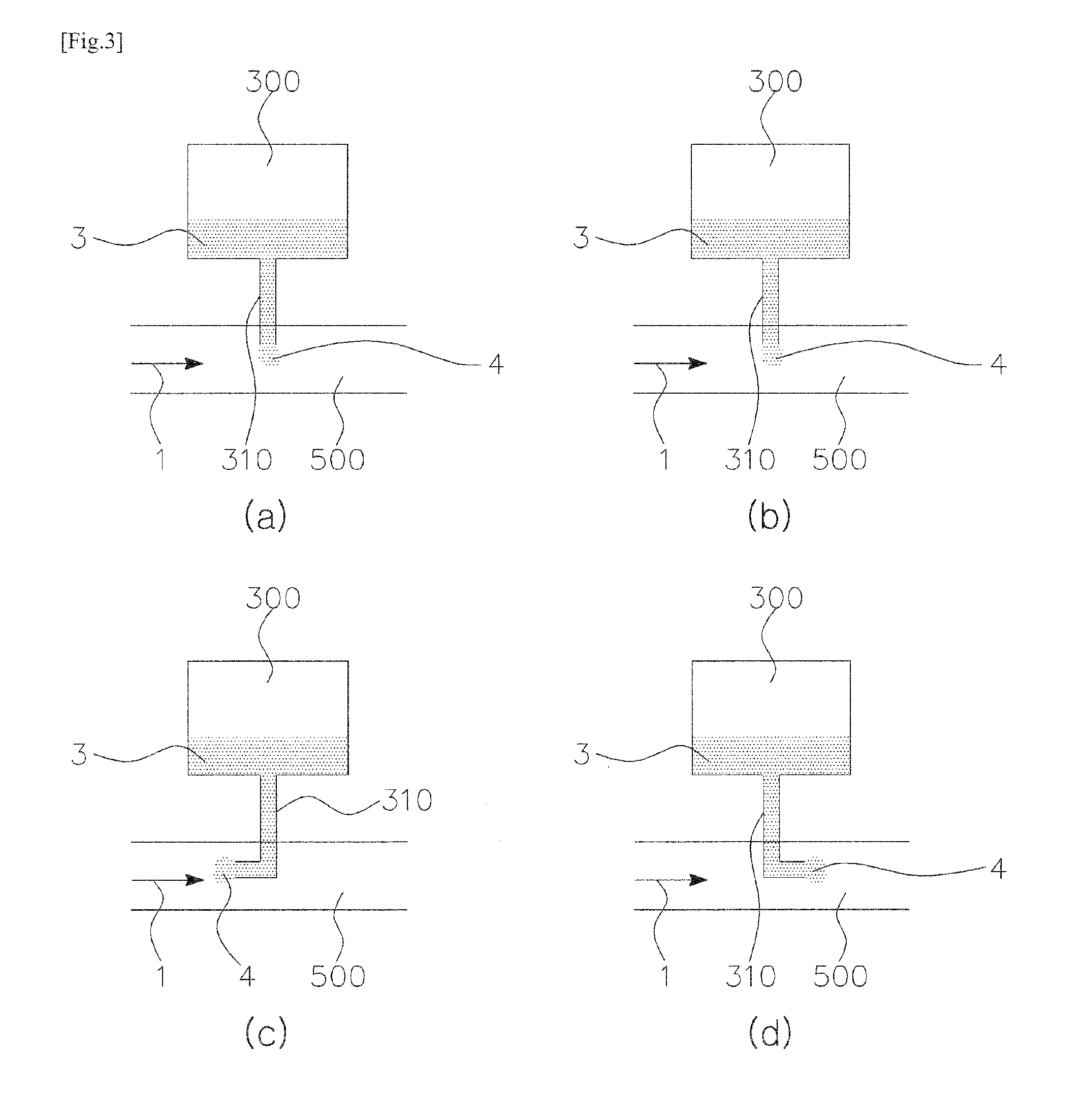

Apparatus and method for continuous powder coating

ActiveUS20110104369A1Effectively andUniform concentrationLiquid surface applicatorsLiquid spraying apparatusMetallurgyPowder coating

The present invention relates to a method and an apparatus by which powder is evenly dispersed and is coated on a substrate uniformly and continuously so that a uniform layer may be formed. More specifically the present invention provides a method and an apparatus for forming a coating layer that powder is coated on an entire surface of a substrate uniformly and continuously, regardless of the material or the size of the substrate, as a uniform amount of powder entrained on the carrier air which is generated by carrier air and powder transported to a carrier pipe at a certain rate is consistently fed in to a nozzle, regardless of the size, morphology, and specific weight of the powder particles.

Owner:FEMVIX +2

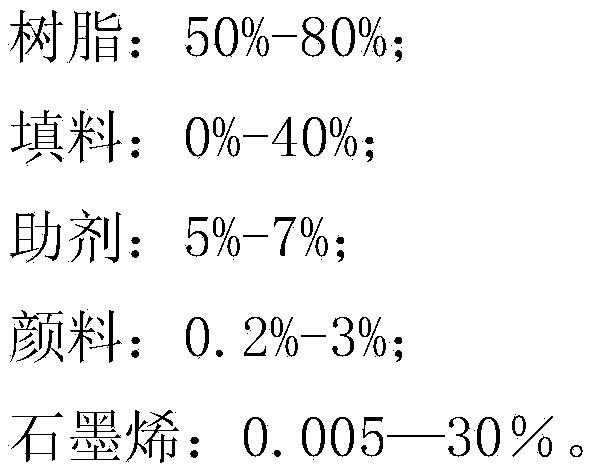

Graphene-modified resin powder coating and production process thereof

InactiveCN104194585AIncrease profitReduce pollutionFireproof paintsPolyurea/polyurethane coatingsWeather resistanceGraphene

The invention relates to graphene-modified resin powder coating and a production process thereof. The graphene-modified resin powder coating comprises the following components in percentage by weight: 50-80 percent of resin, 0-40 percent of filler, 5-7 percent of an auxiliary agent, 0.2-3 percent of pigment and 0.005-30 percent of graphene. According to the graphene-modified resin powder coating provided by the invention, a proper amount of graphene is added in the traditional resin powder coating, so that the mechanical property, the conductivity, thermal conductivity, flame resistance, corrosion resistance and weather resistance of the resin powder coating are greatly improved; the graphene-modified resin powder coating has a broad market prospect.

Owner:周诚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com