Patents

Literature

362results about How to "High softening temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

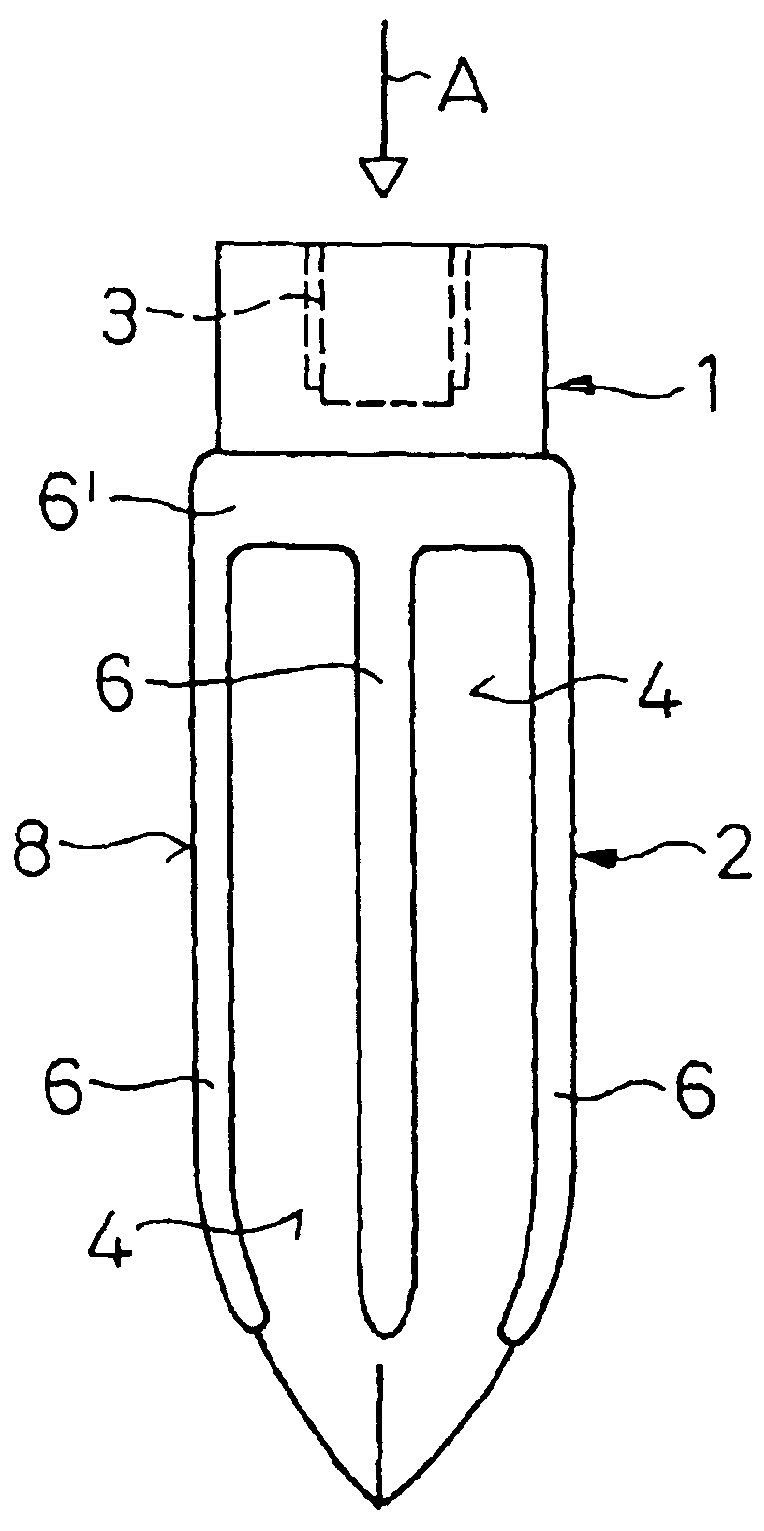

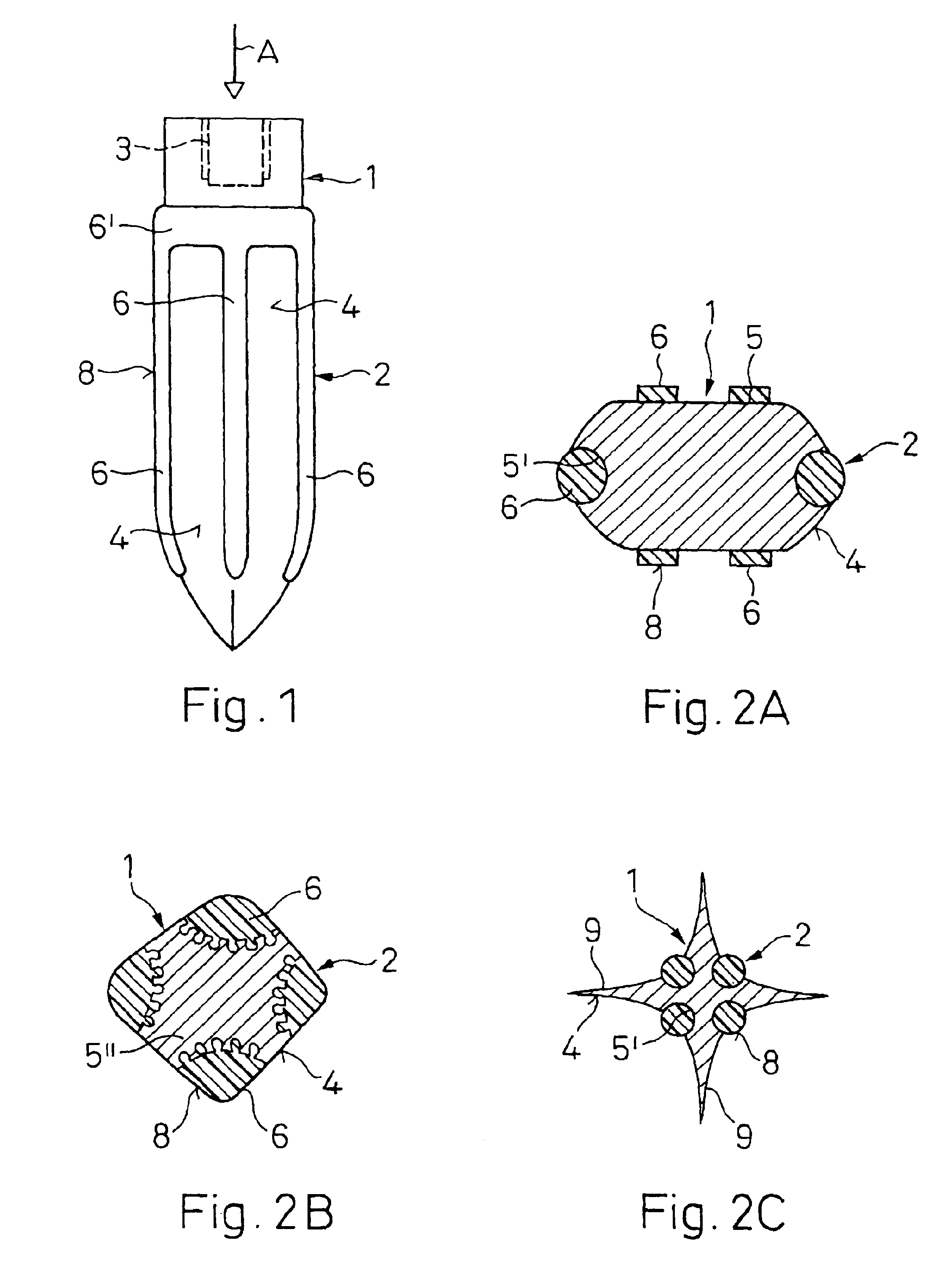

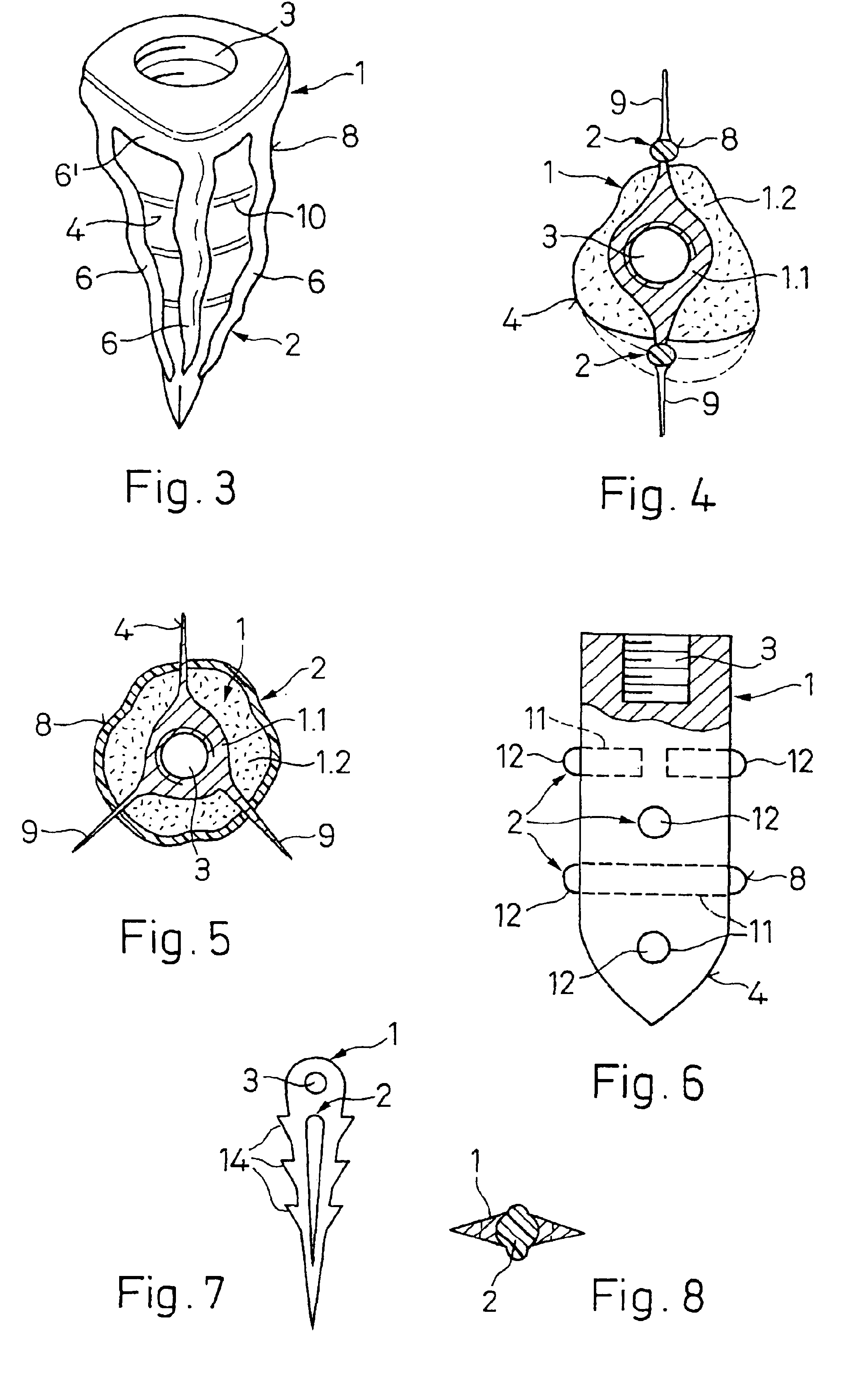

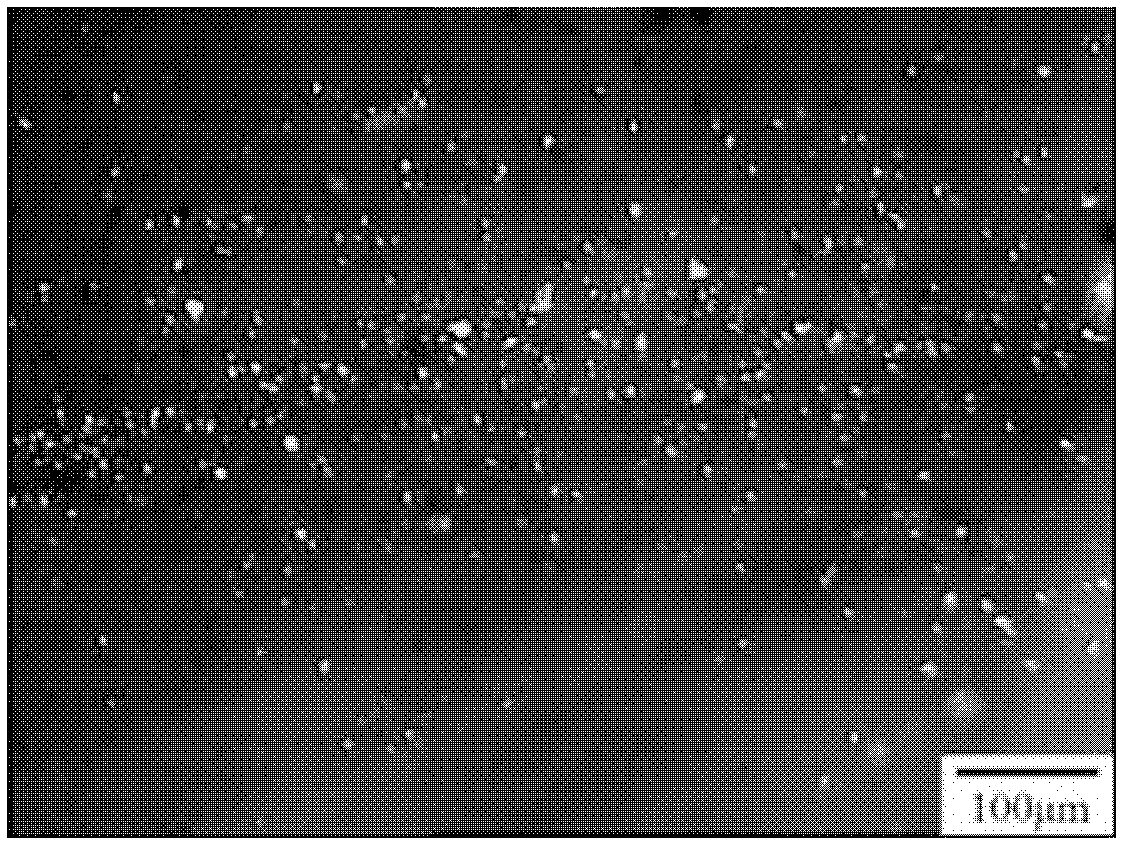

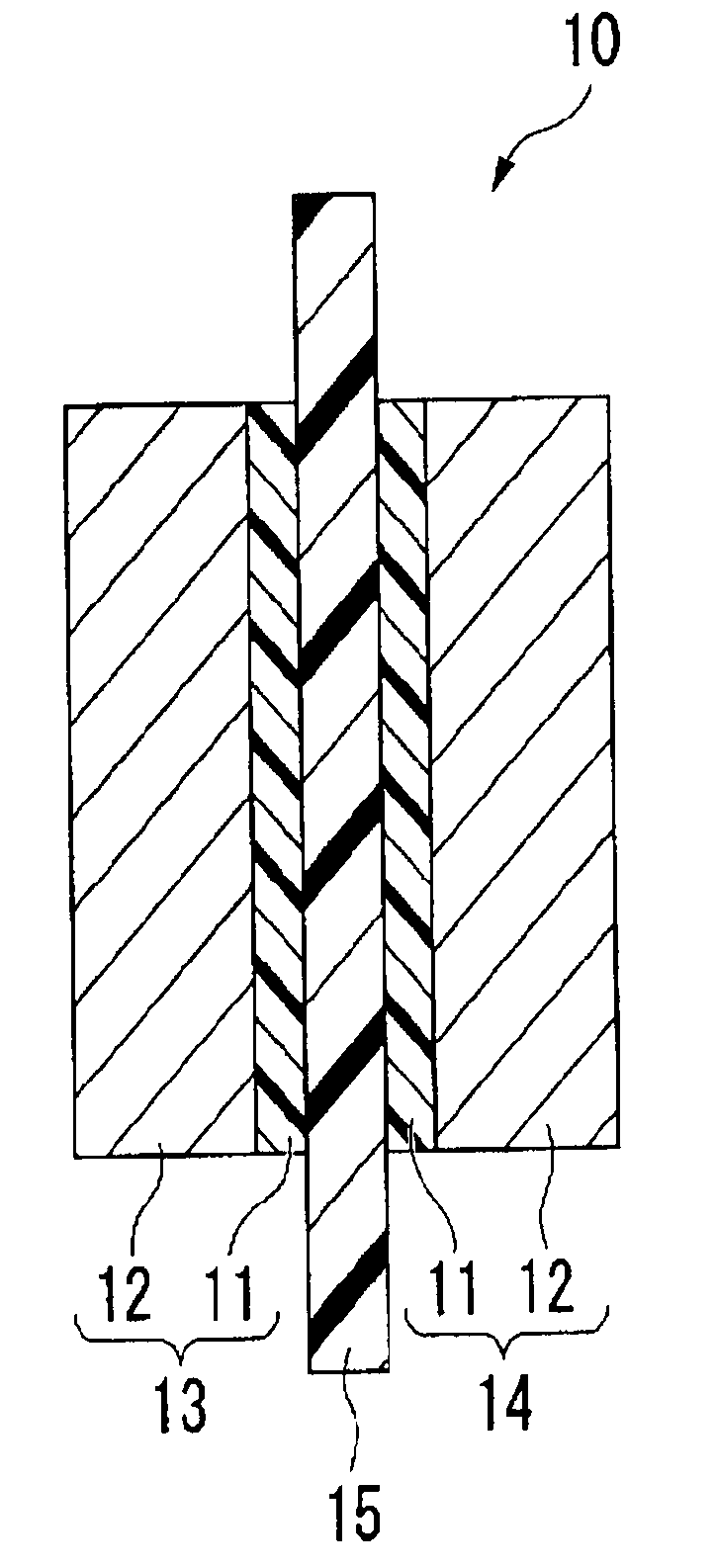

Implant to be implanted in bone tissue or in bone tissue supplemented with bone substitute material

InactiveUS6921264B2High softening temperatureLow softening temperatureDental implantsInternal osteosythesisBone tissueGrowth promoting

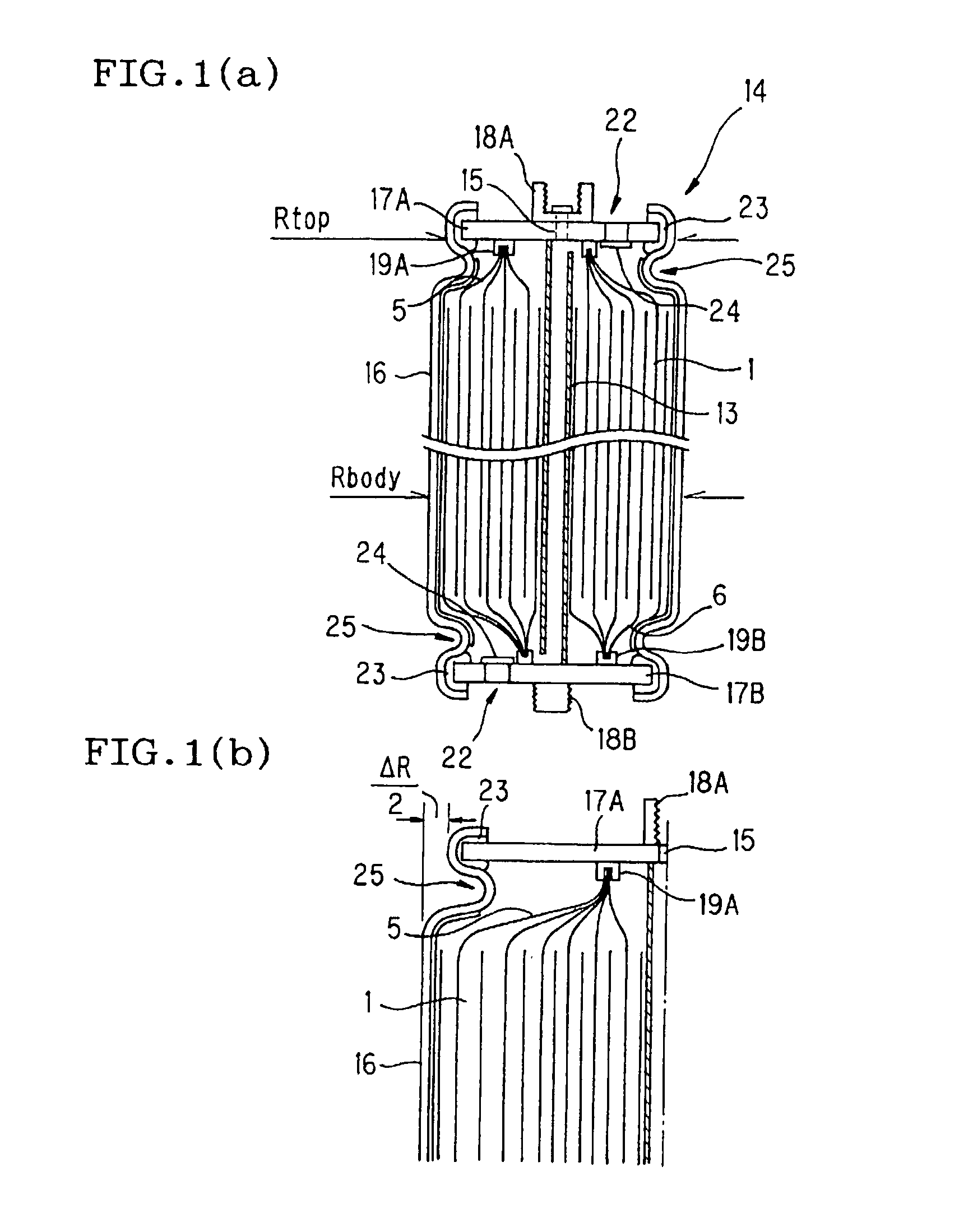

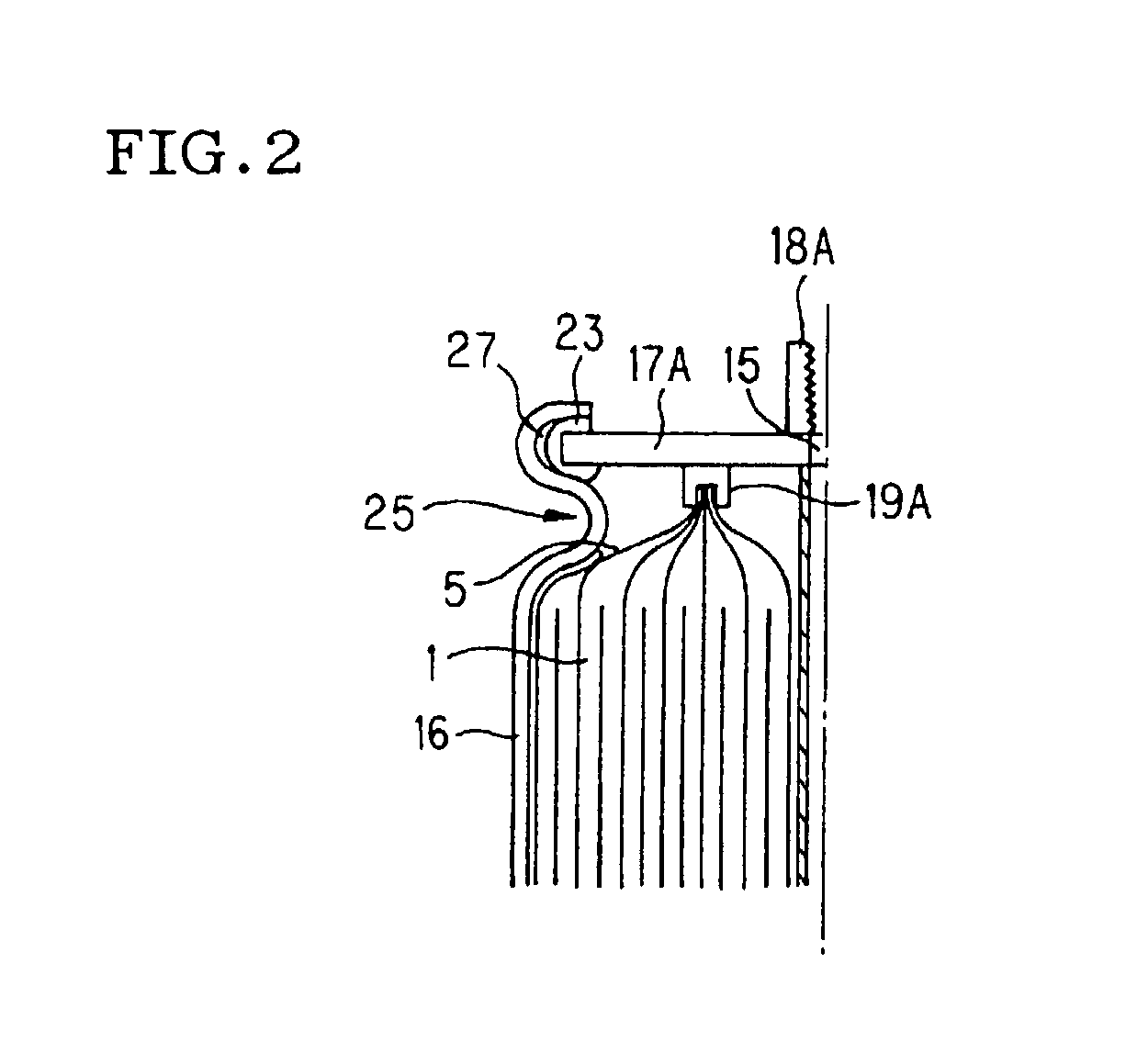

An implant (1) to be implanted in bone tissue, e.g. a dental implant or an implant for an orthopedic application, comprises surface regions (4) of a first type which have e.g. osseo-integrative, inflammation-inhibiting, infection-combating and / or growth-promoting properties, and surface regions (8) of a second type which consist of a material being liquefiable by mechanical oscillation. The implant is positioned in an opening of e.g. a jawbone and then mechanical oscillations, e.g. ultrasound is applied to it while it is pressed against the bone. The liquefiable material is such liquefied at least partly and is pressed into unevennesses and pores of the surrounding bone tissue where after resolidification it forms a positive-fit connection between the implant and the bone tissue. The surface regions of the two types are arranged and dimensioned such that, during implantation, the liquefied material does not flow or flows only to a clinically irrelevant degree over the surface regions of the first type such enabling the biologically integrative properties of these surface regions to start acting directly after implantation. The implant achieves with the help of the named positive fit a very good (primary) stability, i.e. it can be loaded immediately after implantation. By this, negative effects of non-loading are prevented and relative movements between implant and bone tissue are reduced to physiological measures and therefore have an osseo-integration promoting effect.

Owner:WOODWELDING

TPE composition that exhibits excellent adhesion to textile fibers

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

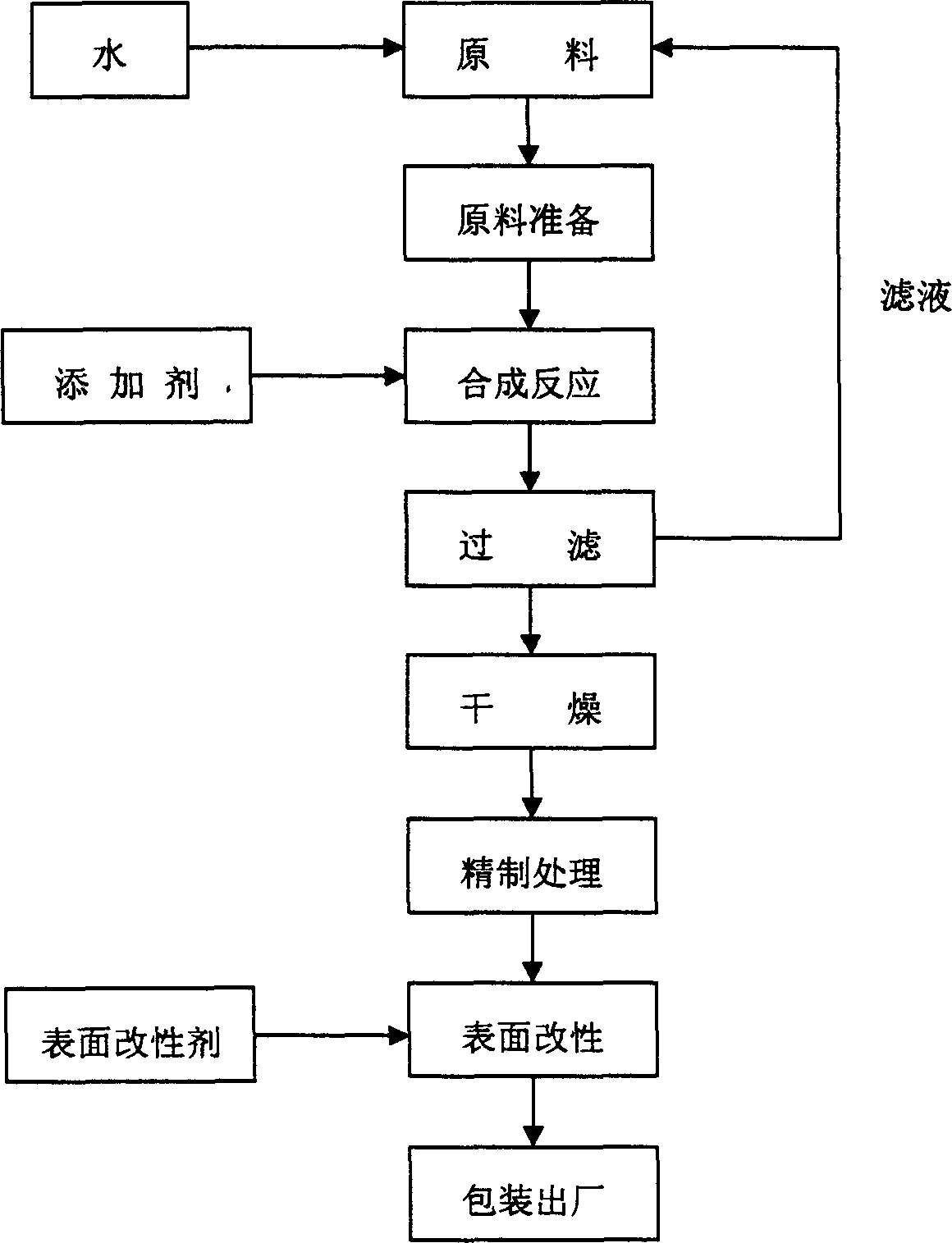

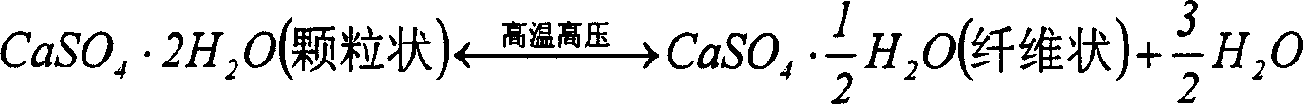

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

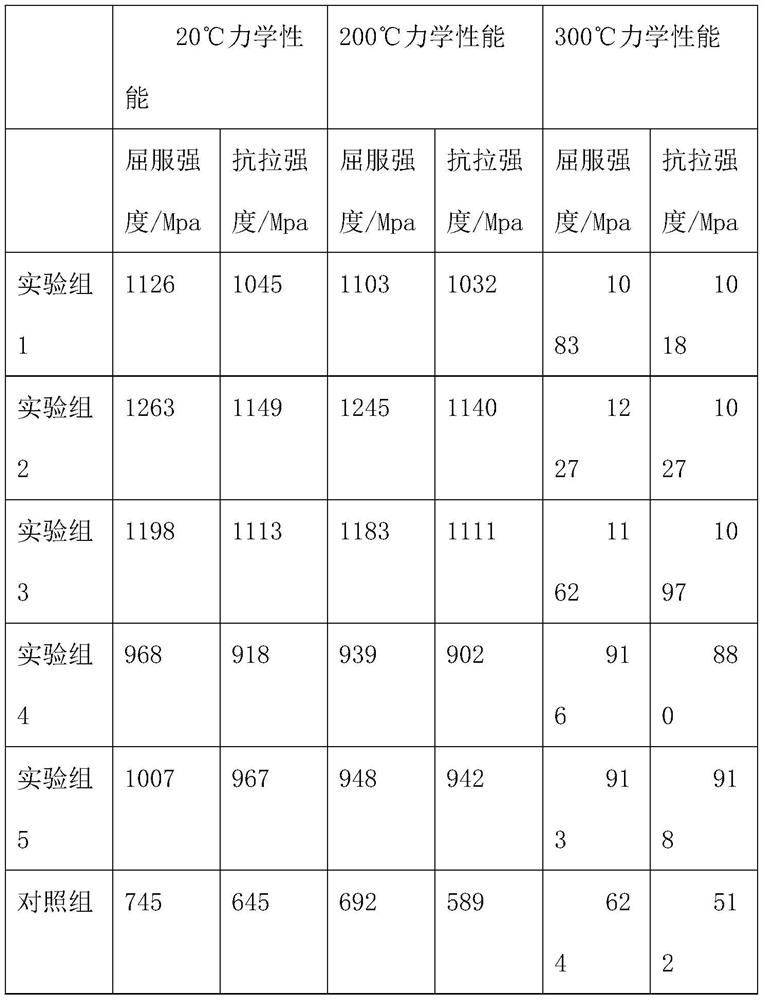

Aluminum bronze and preparation method thereof

The invention discloses an aluminum bronze. The aluminum bronze comprises the following components in percentage by weight: 9.0-18.0% of aluminum, 2.0-7.0% of iron, 1-5% of manganese, 0.01-1% of zinc and the balance of copper and inevitable impurities. The aluminum bronze has the following advantages that through utilizing specific element ratio, specific processing mode and composition, the tensile strength of the aluminum bronze can reach above 700 MPa, the Brinell hardness (HB) of the aluminum bronze is 300-400, and the compressive strength of the aluminum bronze is above 1000MPa; the aluminum bronze has high wear resistance; the friction coefficient of the aluminum bronze is less than 0.15, so that scratched products and adhered products cannot be caused; the alloy has good hot working character; the alloy has high anti-softening temperature; and the aluminum bronze is not added with noble elements such as Ag and Ni, does not need to be thermally treated, and the raw material and production costs are lowered.

Owner:NINGBO POWERWAY ALLOY MATERIAL

A tpe composition that exhibits excellent adhesion to textile fibers-

InactiveUS20020010265A1Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

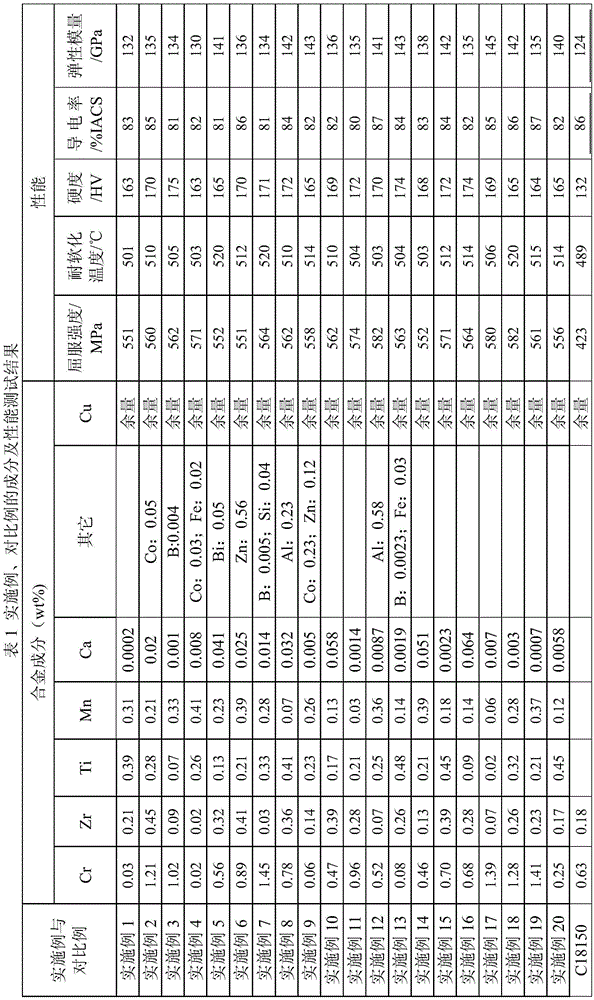

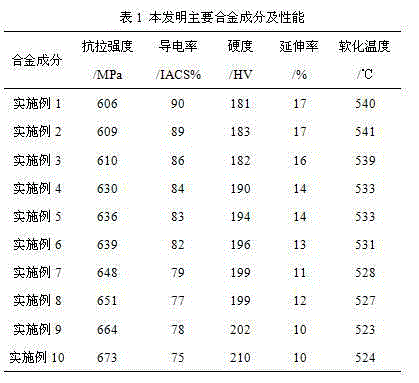

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

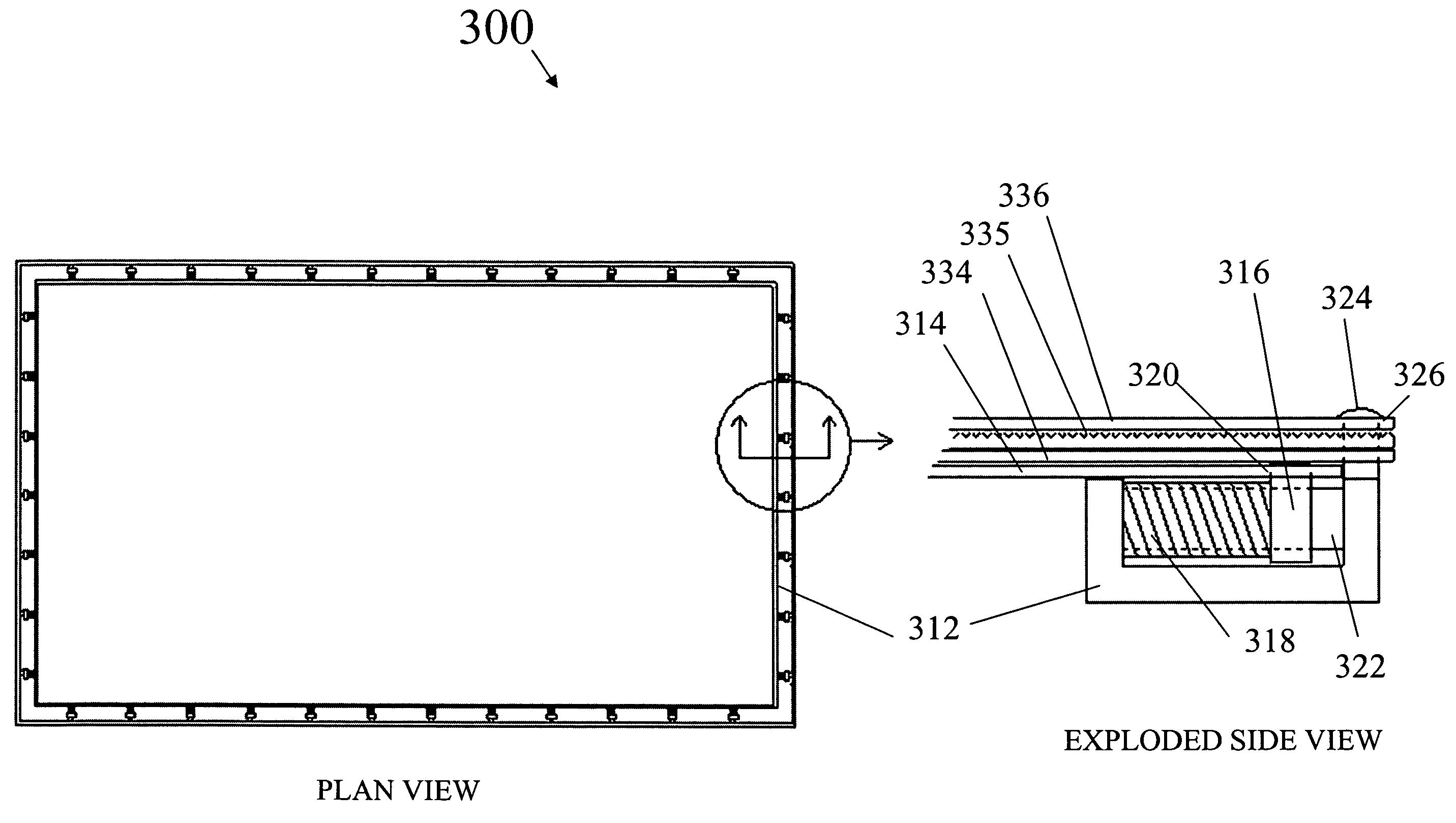

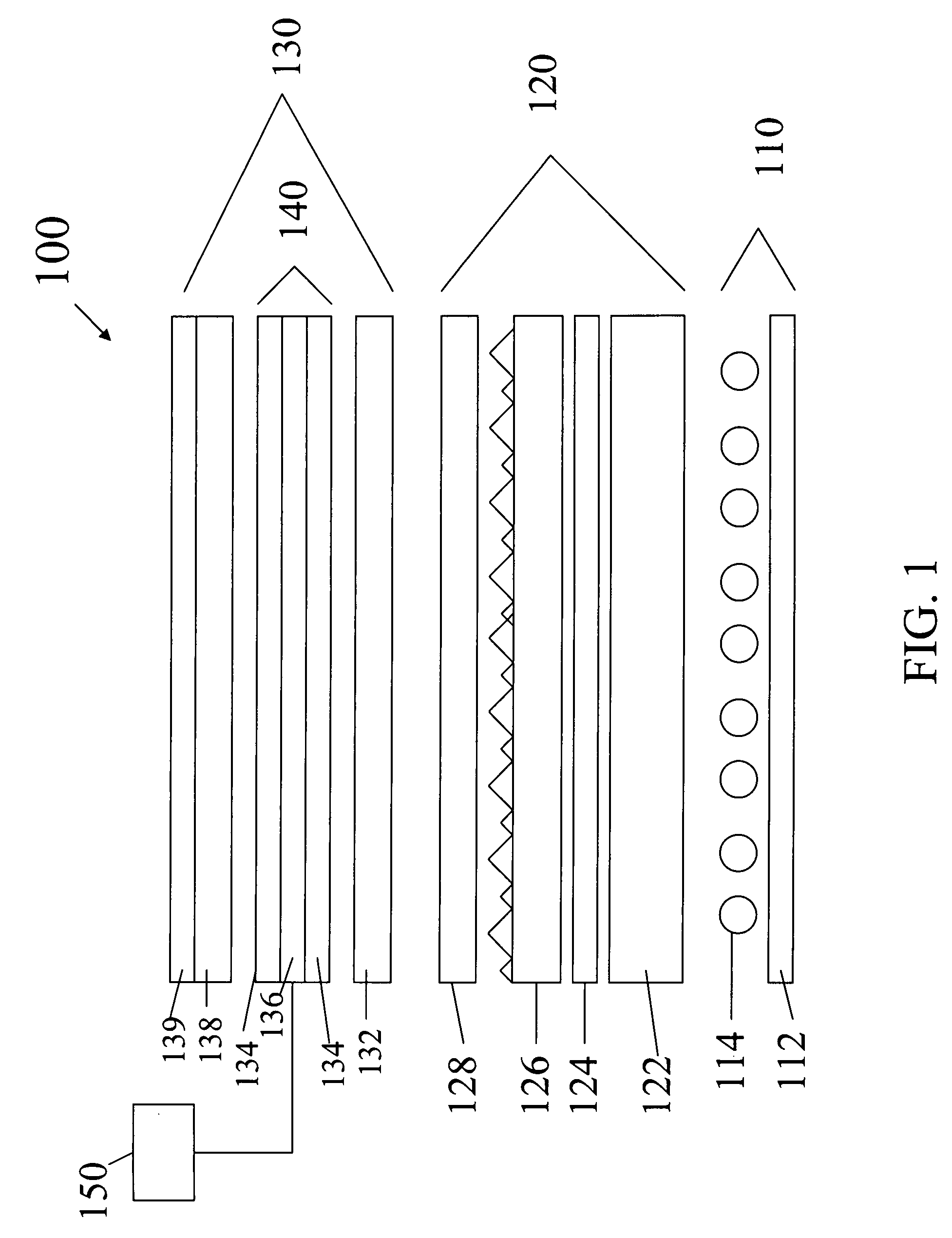

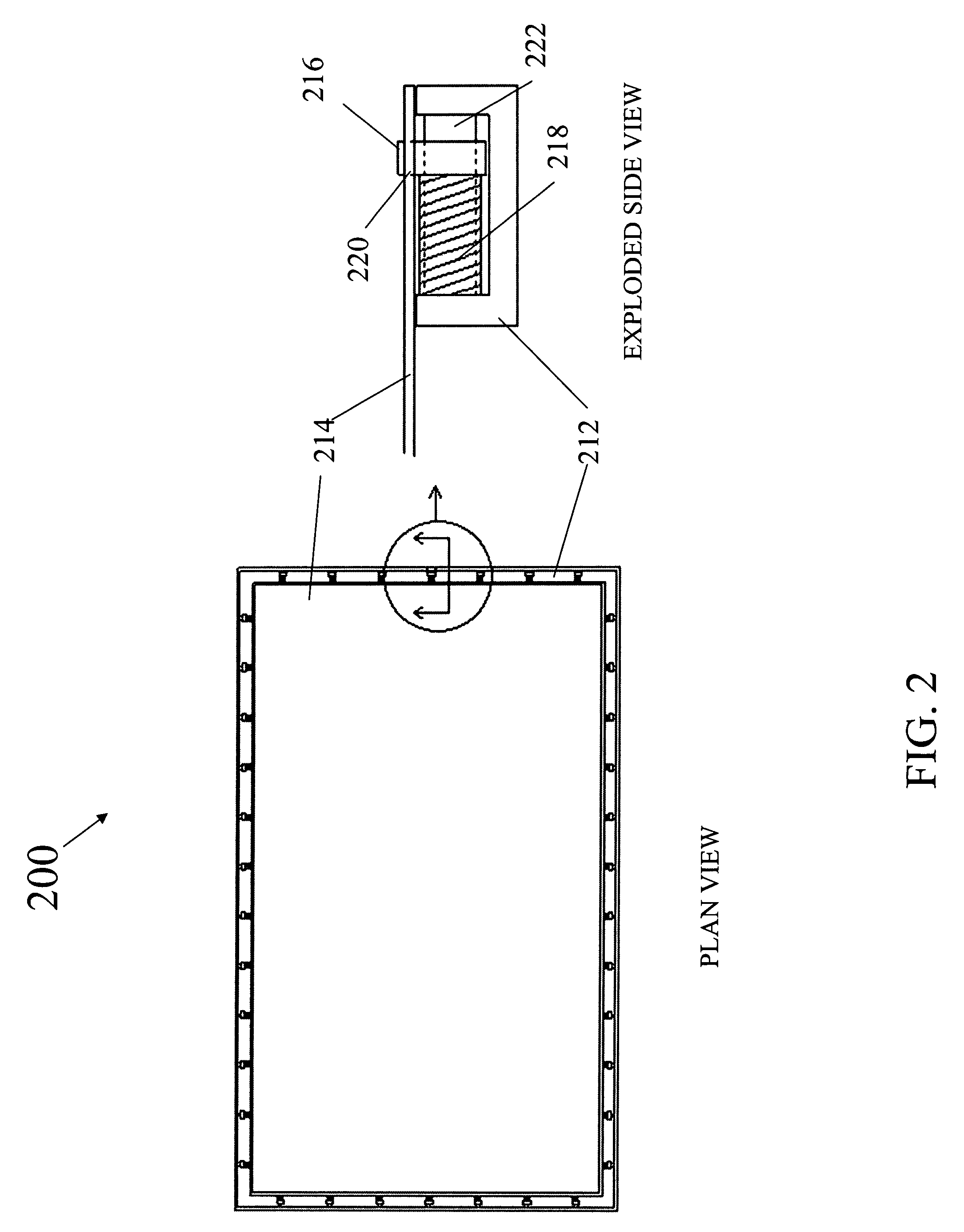

Optical element comprising restrained asymmetrical diffuser

InactiveUS20090040772A1Improve throughputIncreased/decreased diffusionDiffusing elementsOptical light guidesEngineeringOptical film

The present invention provides an optical element having an optical film, the optical element comprising a support frame having a shaft therein, the support frame being provided around a perimeter of the optical element and the optical film having slots on a periphery thereon, the periphery of the optical film being provided on the support frame. The invention further provides a pin provided in each of the slots and protruding into the support frame and slidable on the shaft by a controlled tensile force and a spring mechanism that is slidable on the shaft for providing the controlled tensile force to the optical film, wherein the optical film is an asymmetric diffuser.

Owner:SKC HAAS DISPLAY FILMS CO LTD

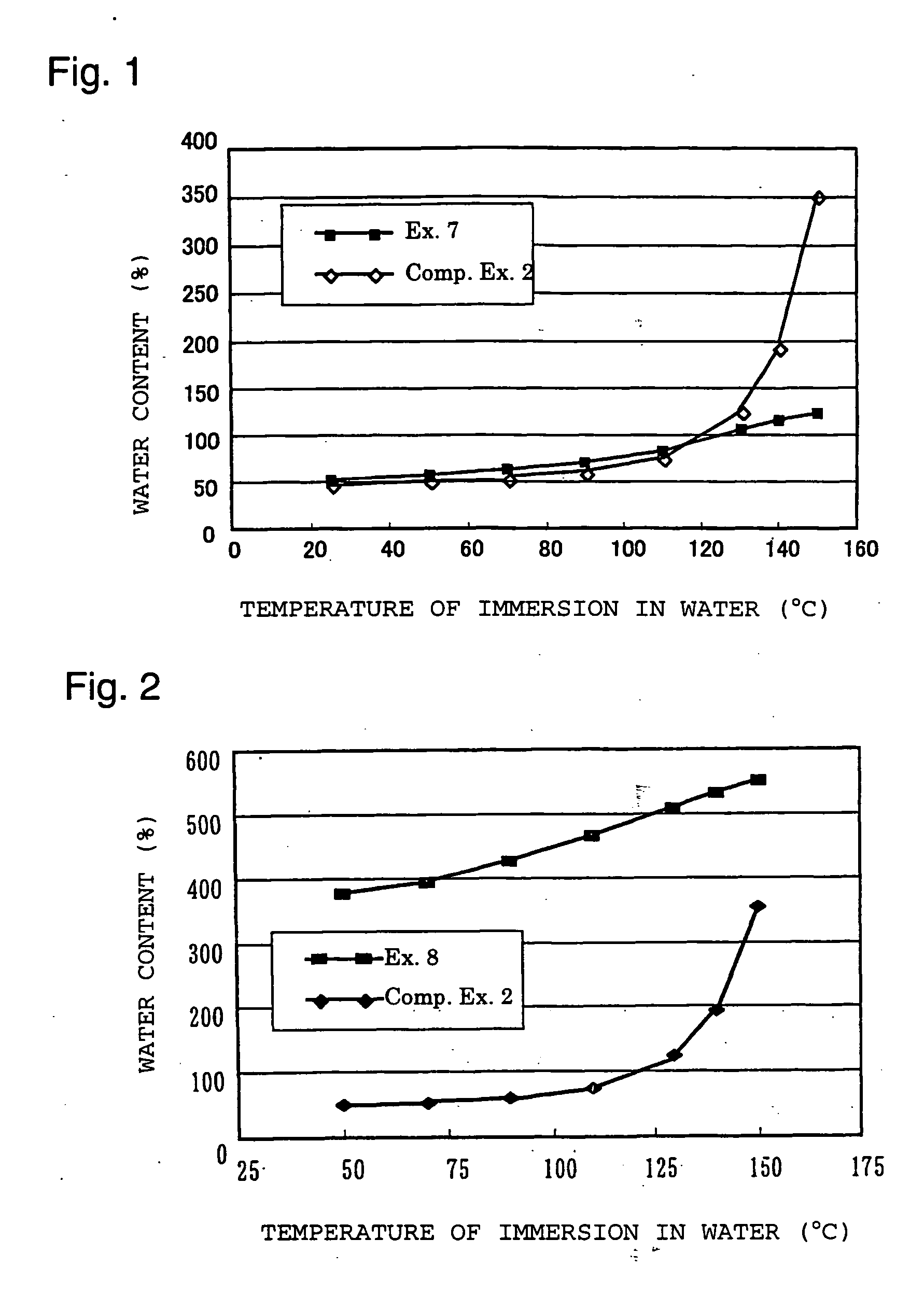

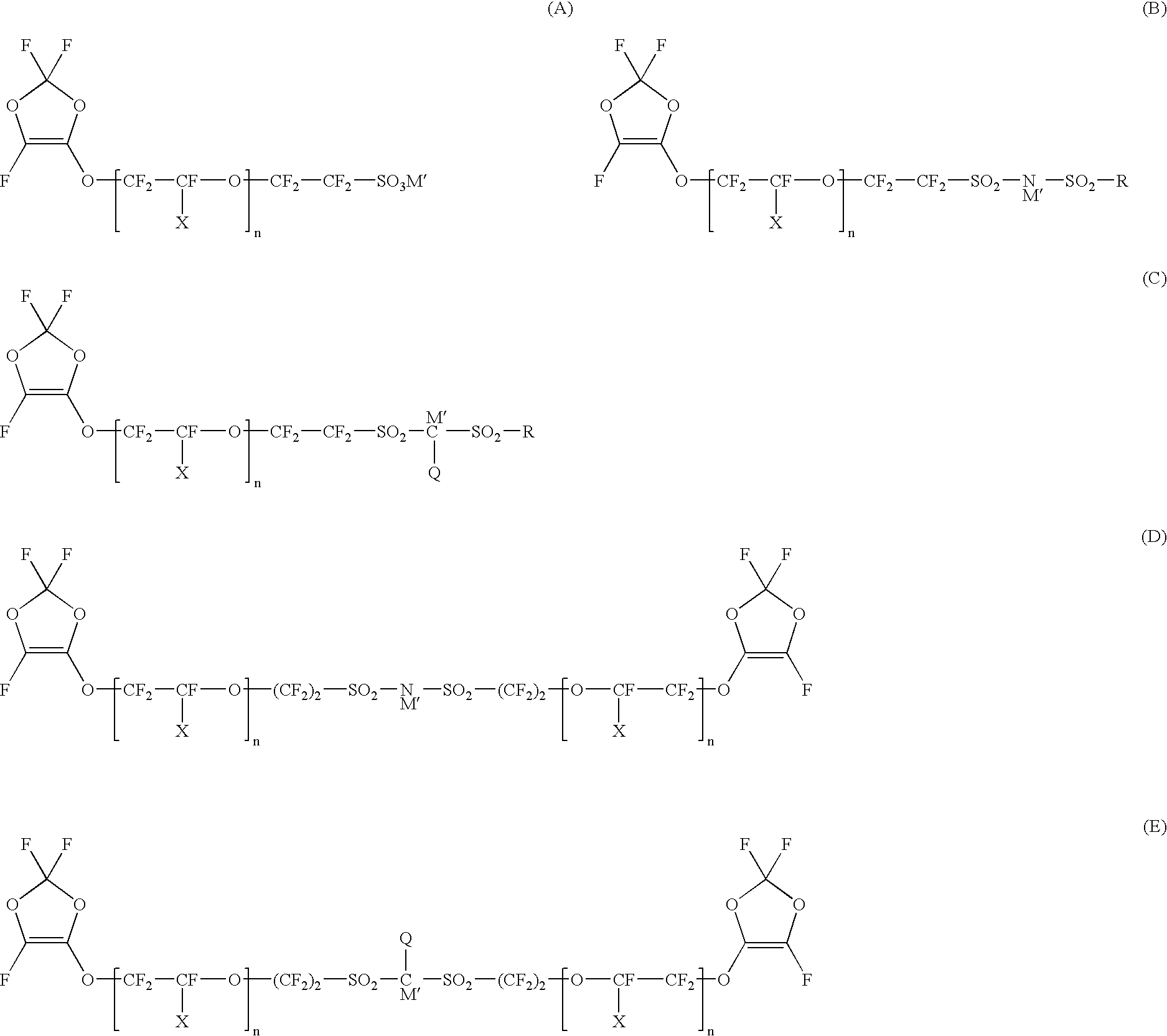

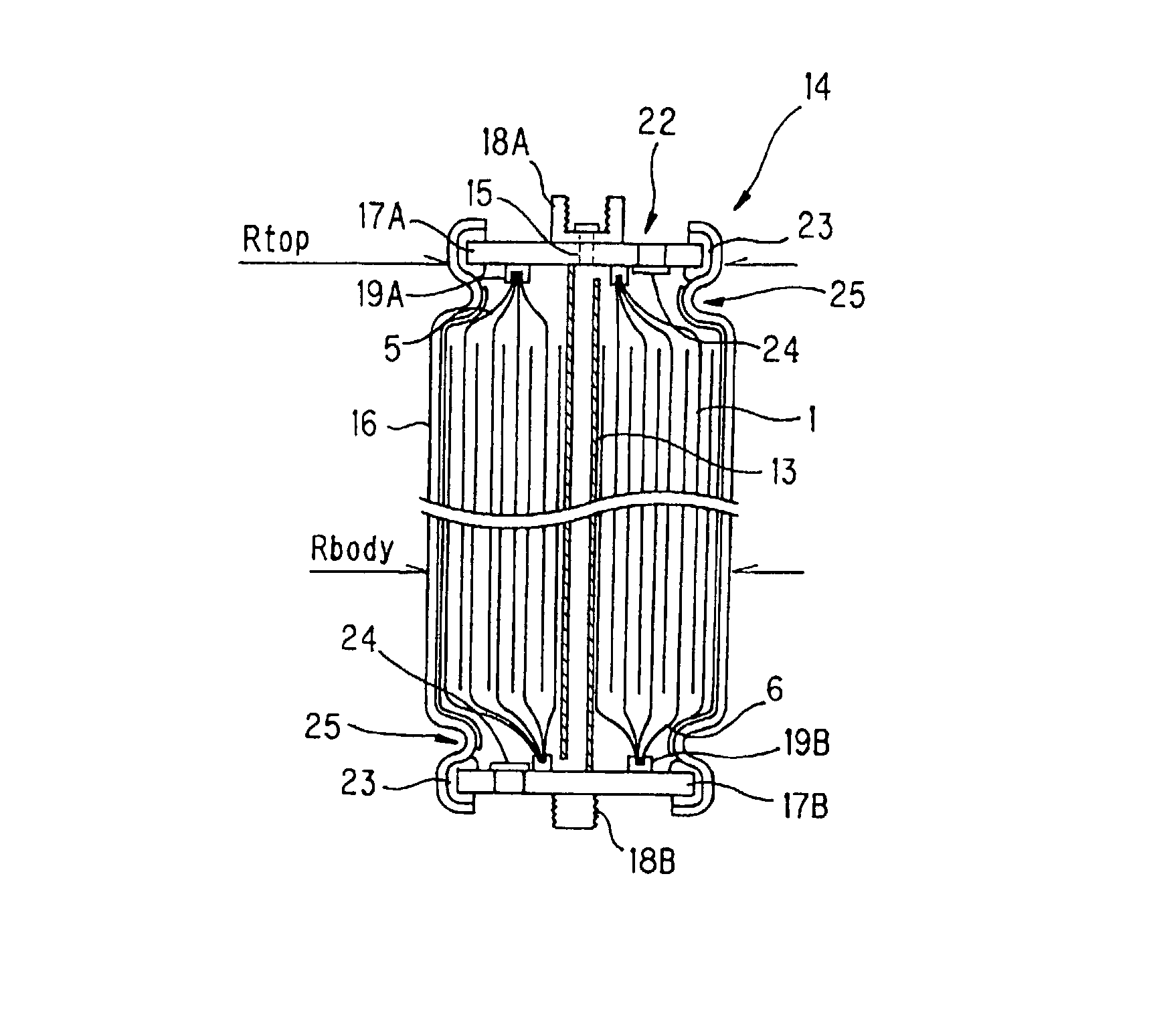

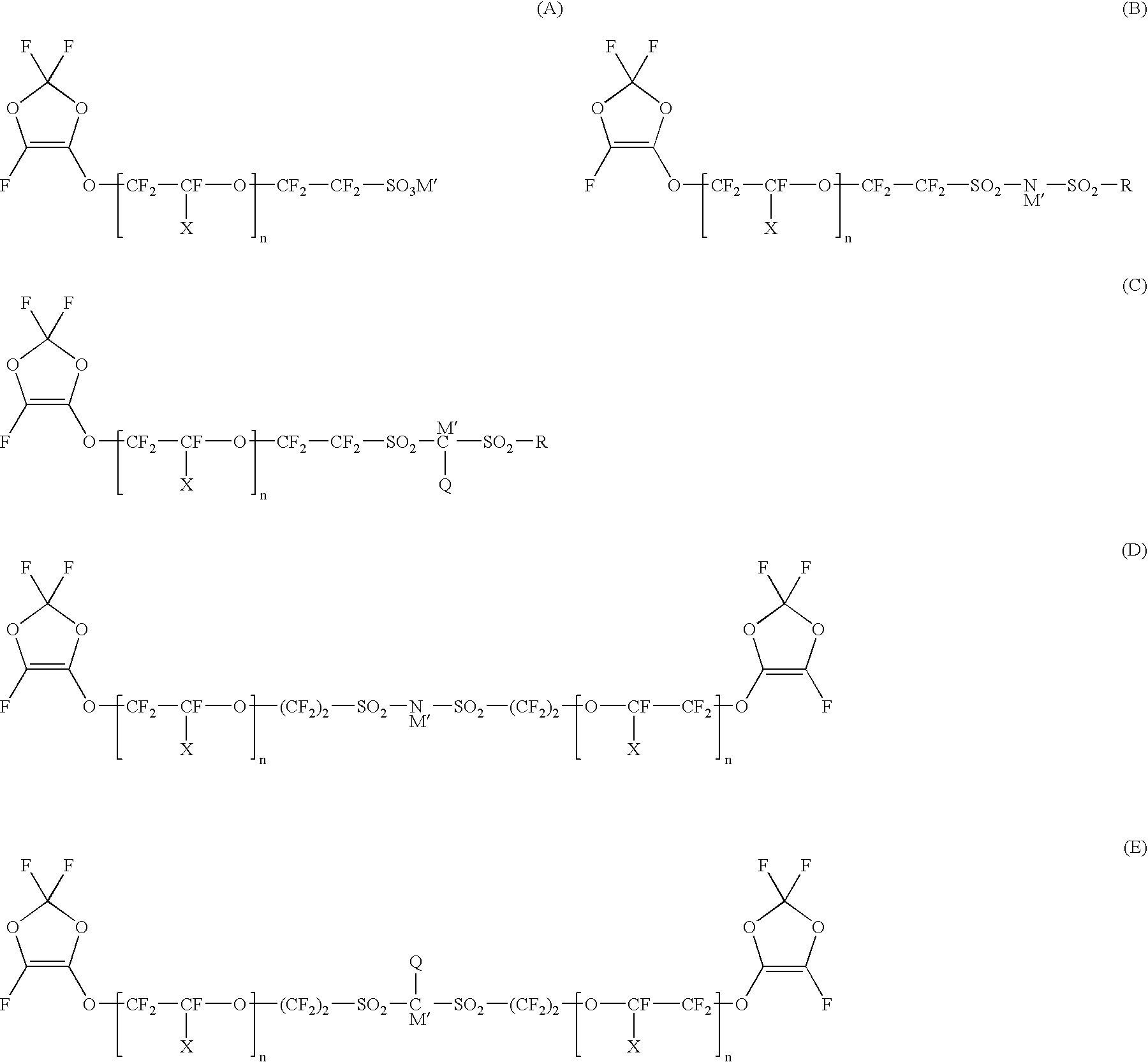

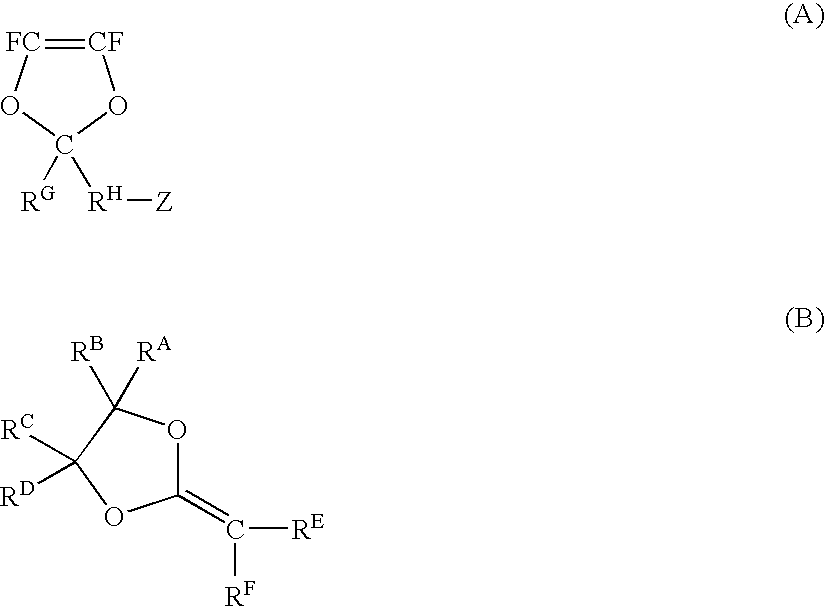

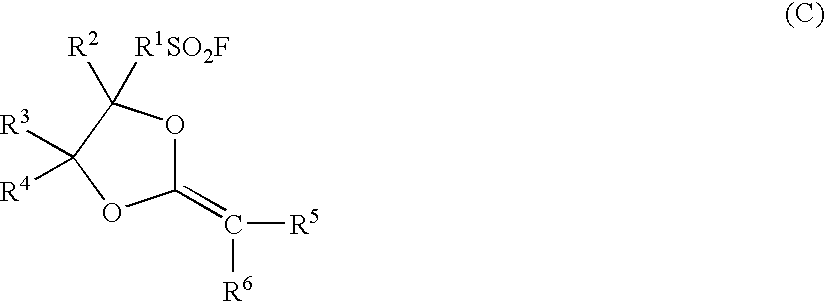

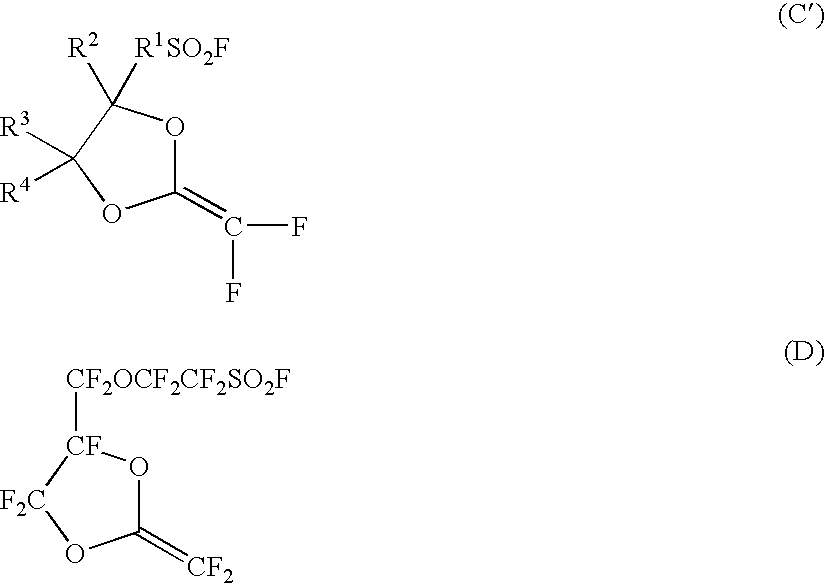

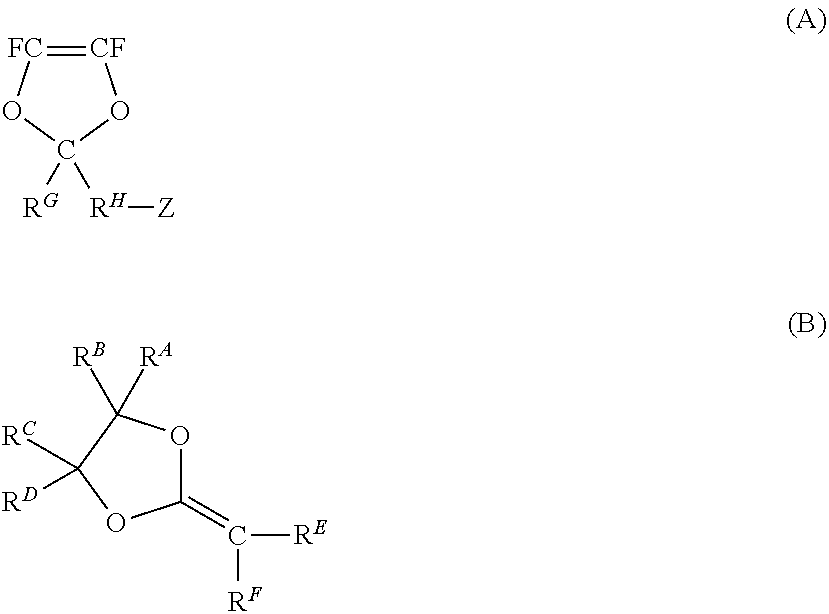

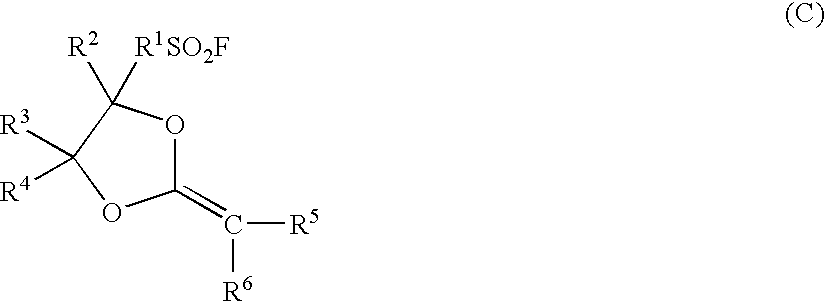

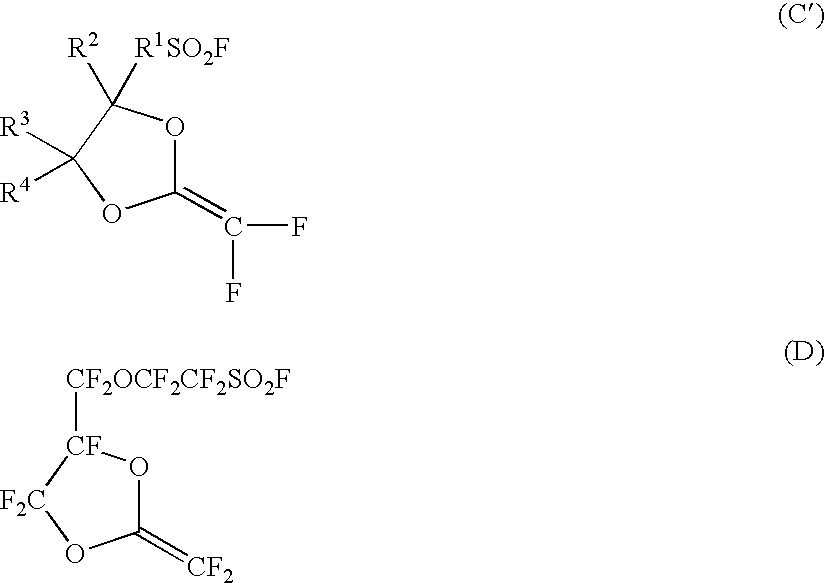

Polymer electrolyte material, production method thereof and membrane electrode assembly for polymer electrolyte fuel cell

ActiveUS20050266291A1Increase productionIncrease temperatureSolid electrolytesIon-exchanger regenerationPolymer electrolytesFuel cells

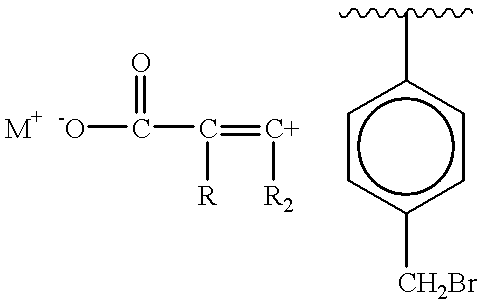

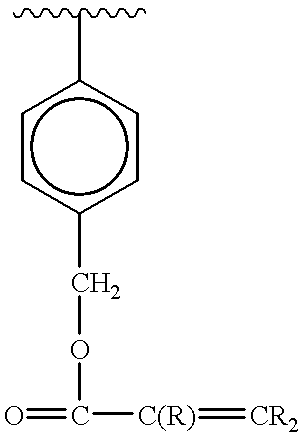

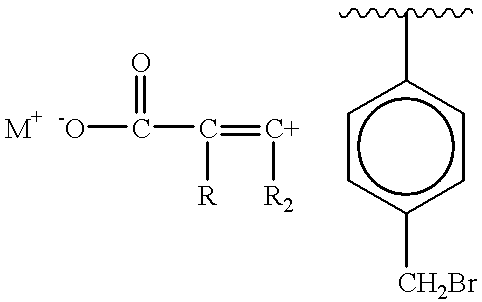

The present invention provides a polymer electrolyte material comprising a polymer having a repeating unit based on an alicyclic fluoromonomer having a carbon-carbon double bond with radical polymerization reactivity, wherein either of carbon atoms at both ends of the double bond constitutes a ring structure; the repeating unit contains a strongly acidic group such as a sulfonic acid group; the polymer is preferably perfluorinated. This electrolyte material has a high softening temperature and a polymer electrolyte fuel cell using this electrolyte material can be operated at higher temperatures than before. Furthermore, when this electrolyte material is used for a catalyst layer of a cathode in a polymer electrolyte fuel cell, an output voltage of the cell can be increased.

Owner:ASAHI GLASS CO LTD

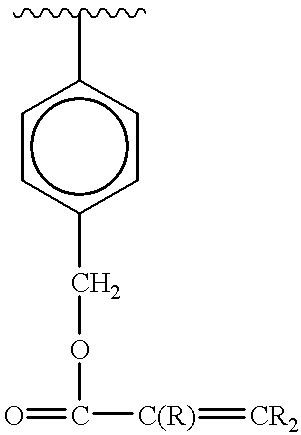

Segmented copolymer with fully-saturated soft segment and crystallizable hard segment and preparation method of segmented copolymer

ActiveCN103122052AEliminate the purification processSave drynessPolymer scienceCationic polymerization

The invention relates to a segmented copolymer with a fully-saturated soft segment and a crystallizable hard segment and a preparation method of the segmented copolymer. A segmented copolymer with a fully-saturated polyisobutene segment as the soft segment and a crystallizable polystyrene or polyalkyl substituted styrene segment as the hard segment is synthesized by combining cationic polymerization of isobutene with cationic steric polymerization of styrene or alkyl substituted styrene cations, wherein as the hard segment has the crystallizability, physical crosslinking points are more stable, not only is a self-enhancement role achieved, but also the softening temperature of the segmented copolymer is effectively improved, and the melting point ranges from 150 DEG C to 210 DEG C; and according to the segmented copolymer, the use temperature is improved by 50-110 DEG C, and the heat resistance, the material size stability and the physical and mechanical properties are also improved.

Owner:BEIJING UNIV OF CHEM TECH

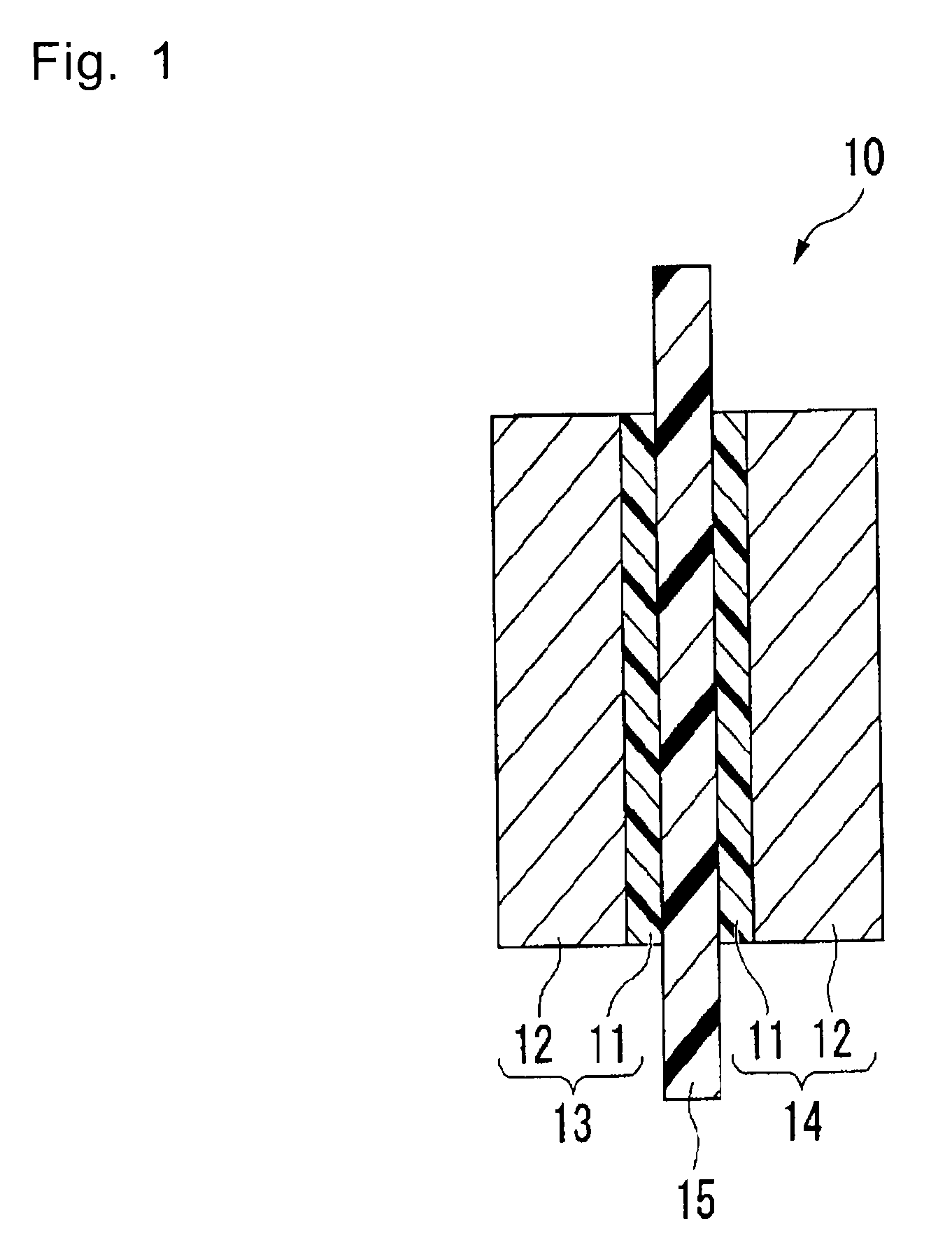

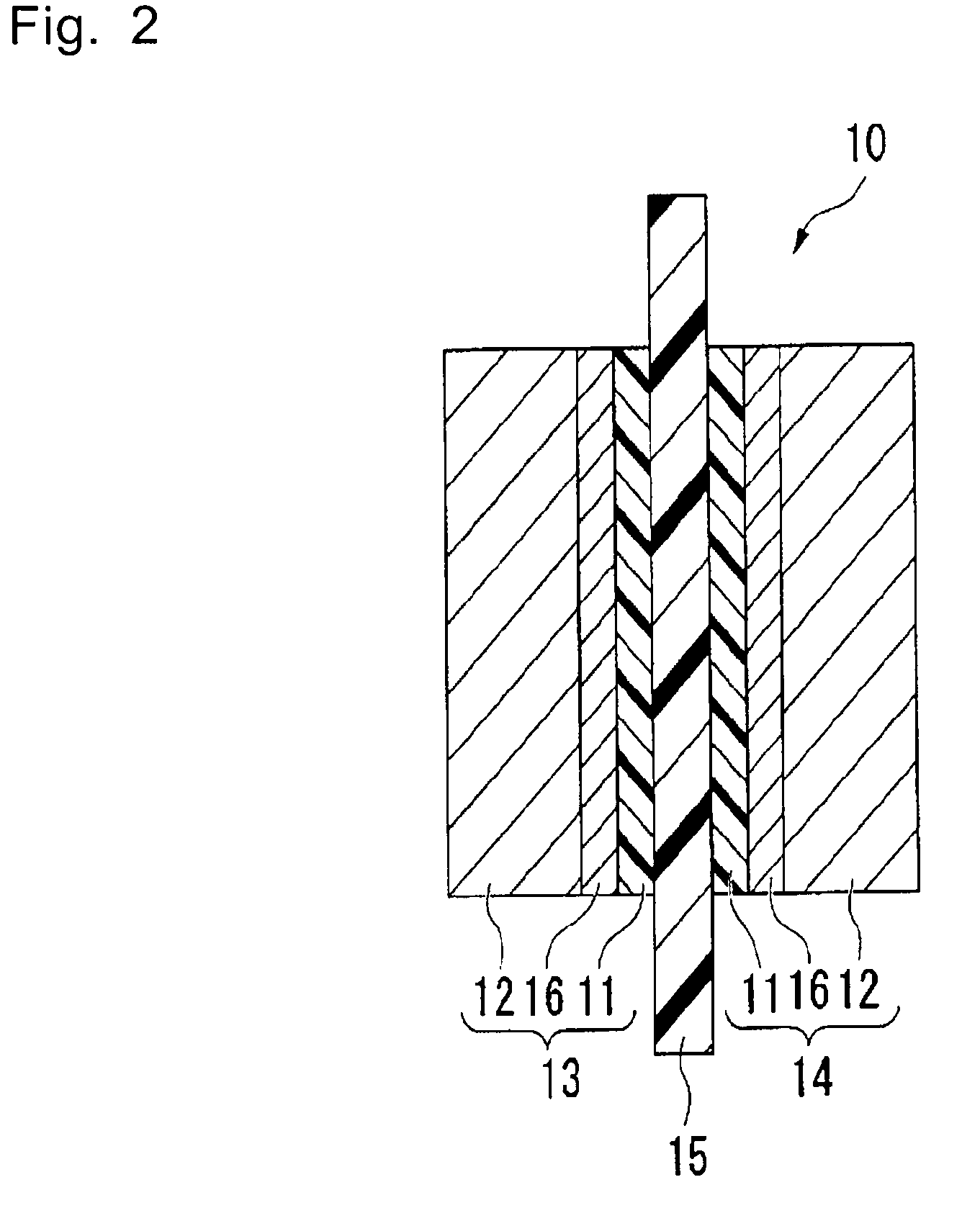

Lithium secondary cell and method for producing the same

InactiveUS20030035993A1Control battery temperature increaseIncrease energy densityPrimary cellsElectrode carriers/collectorsLithiumEngineering

Owner:NGK INSULATORS LTD

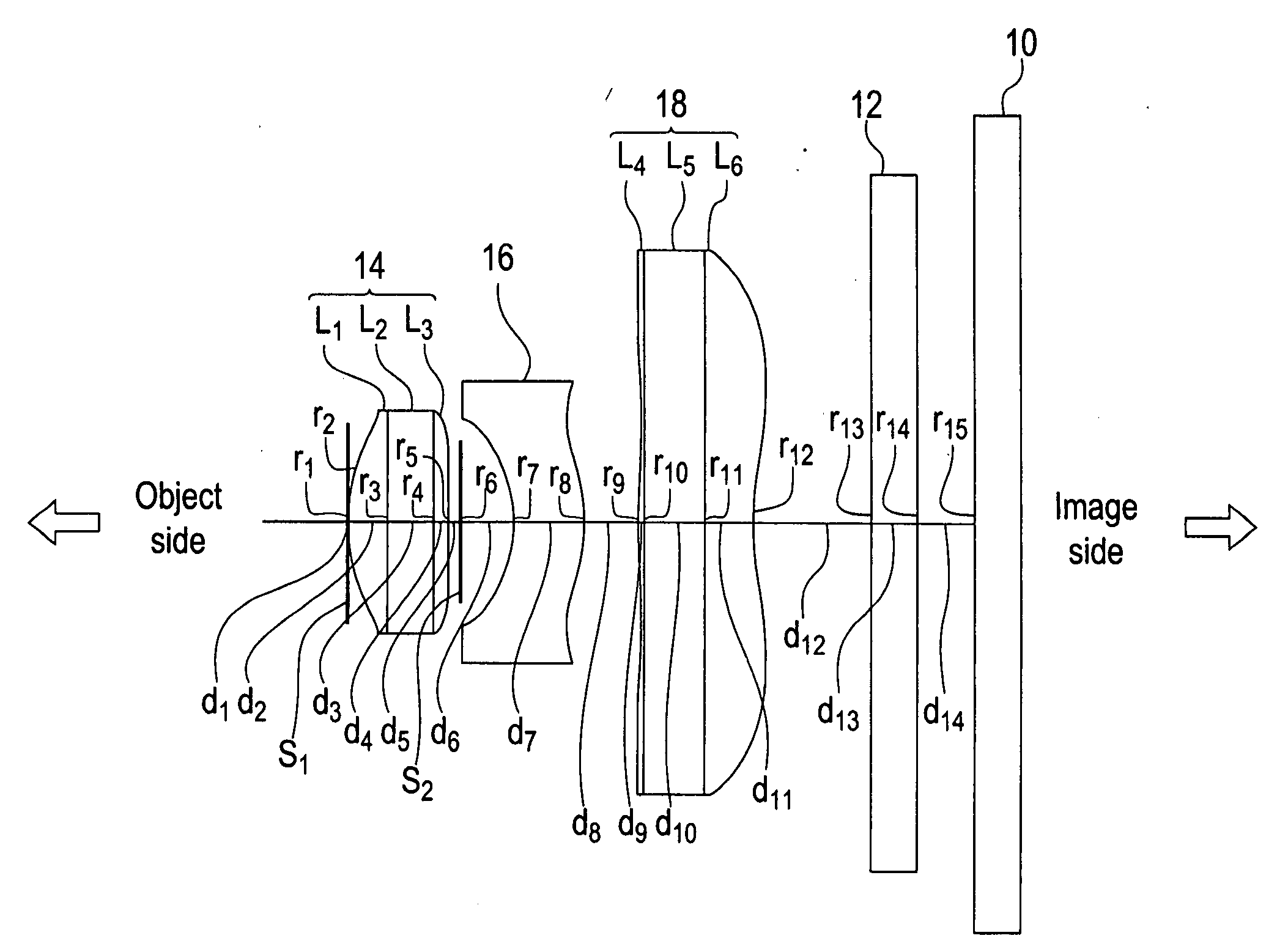

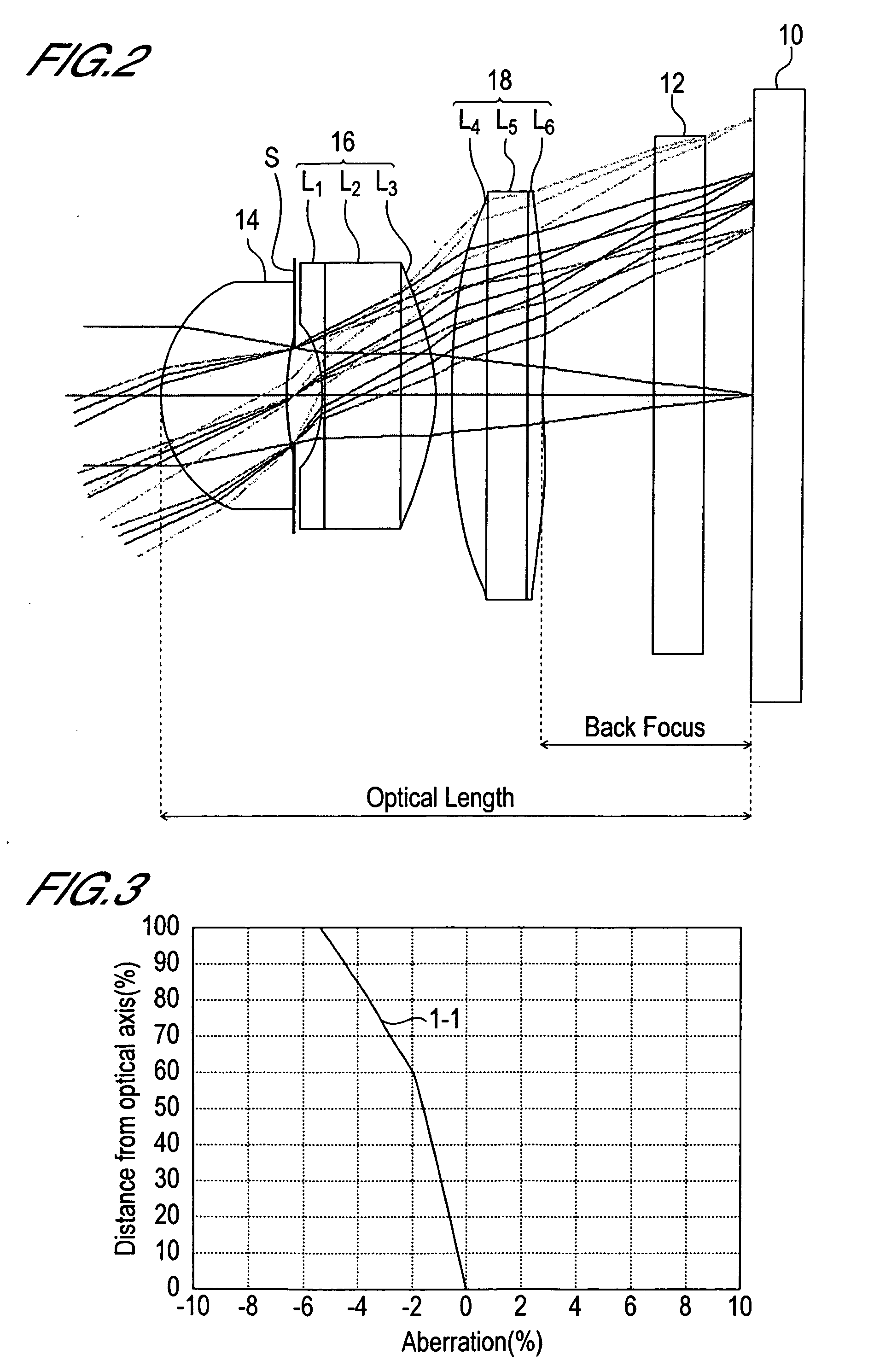

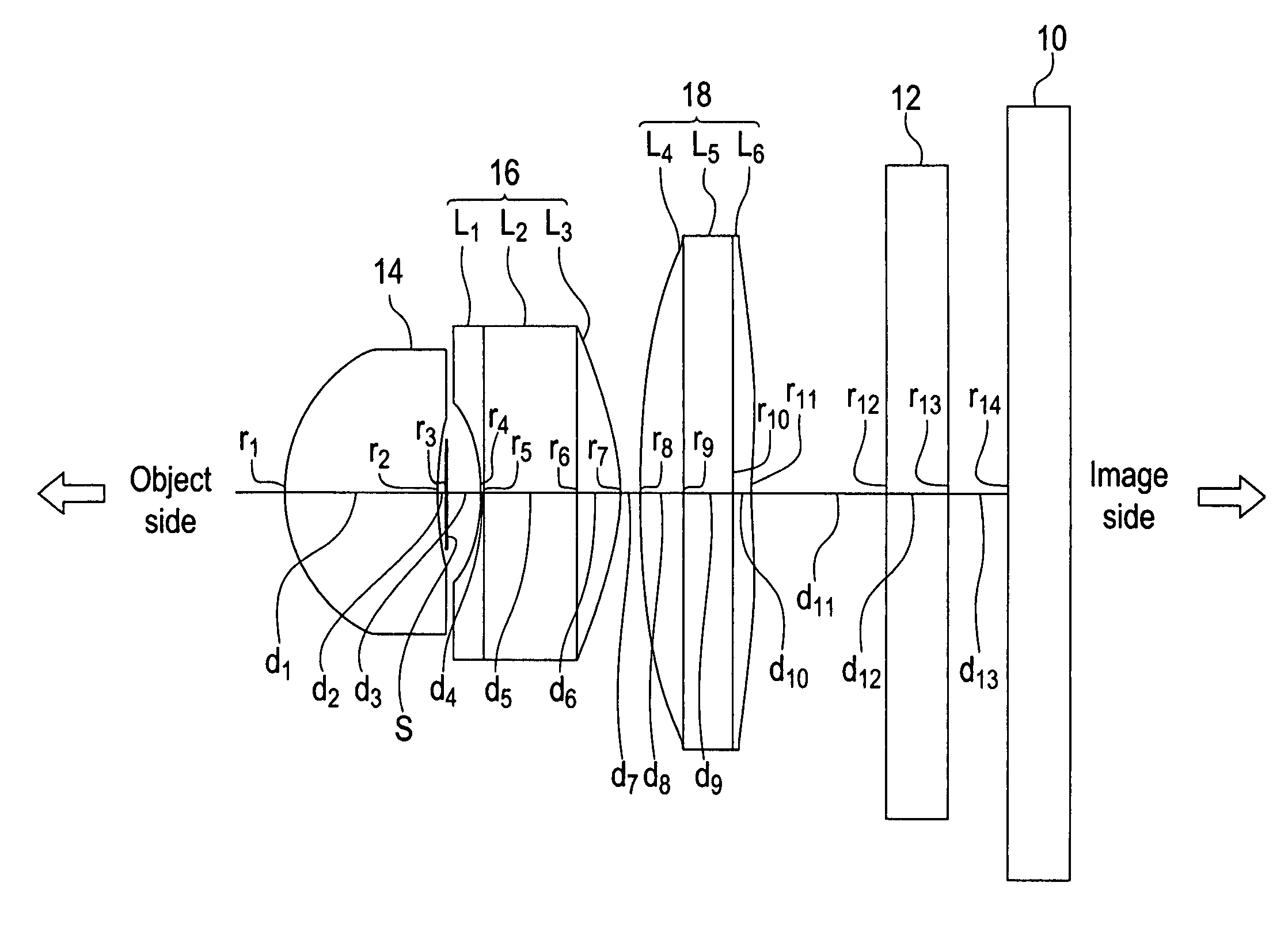

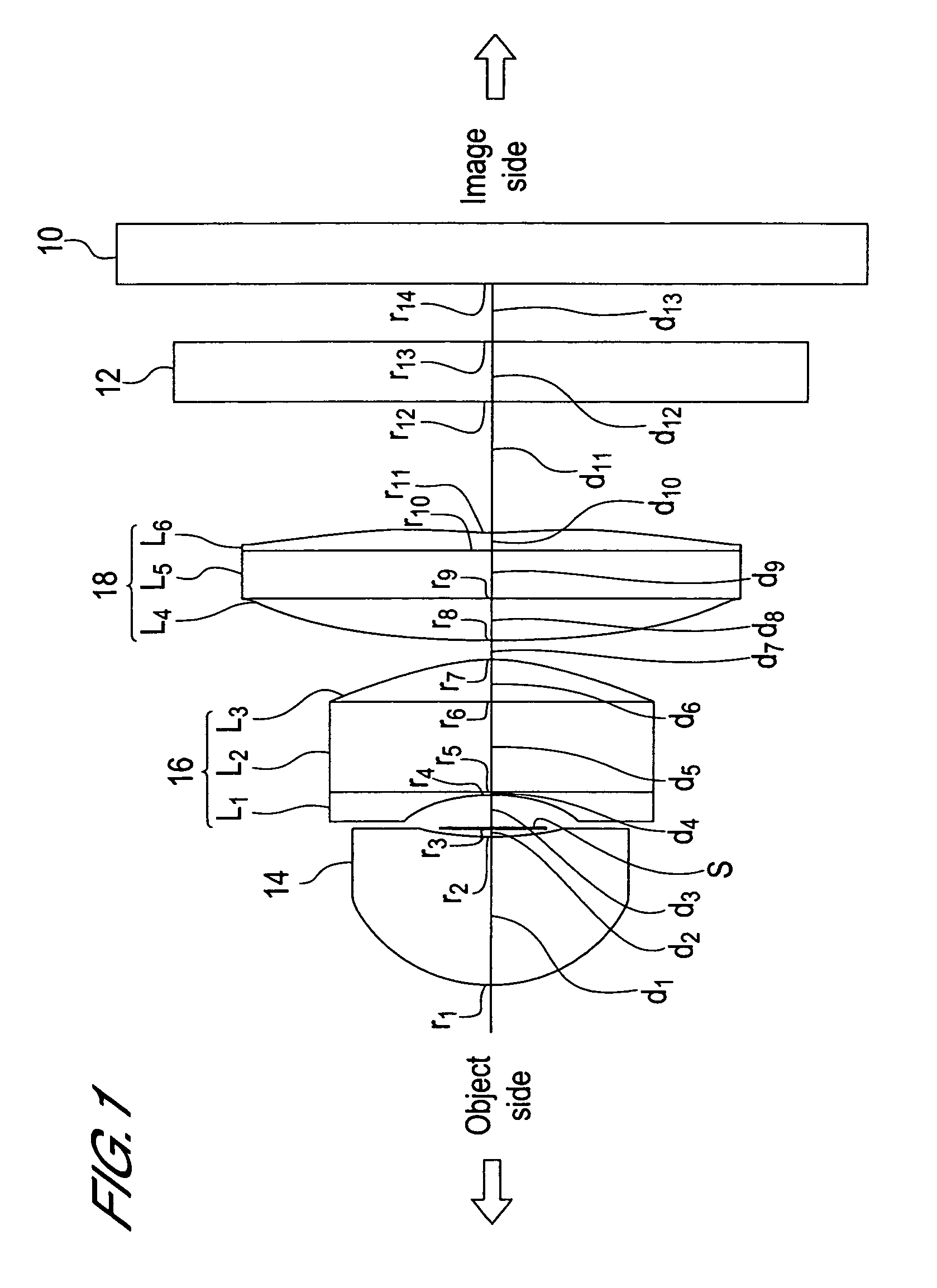

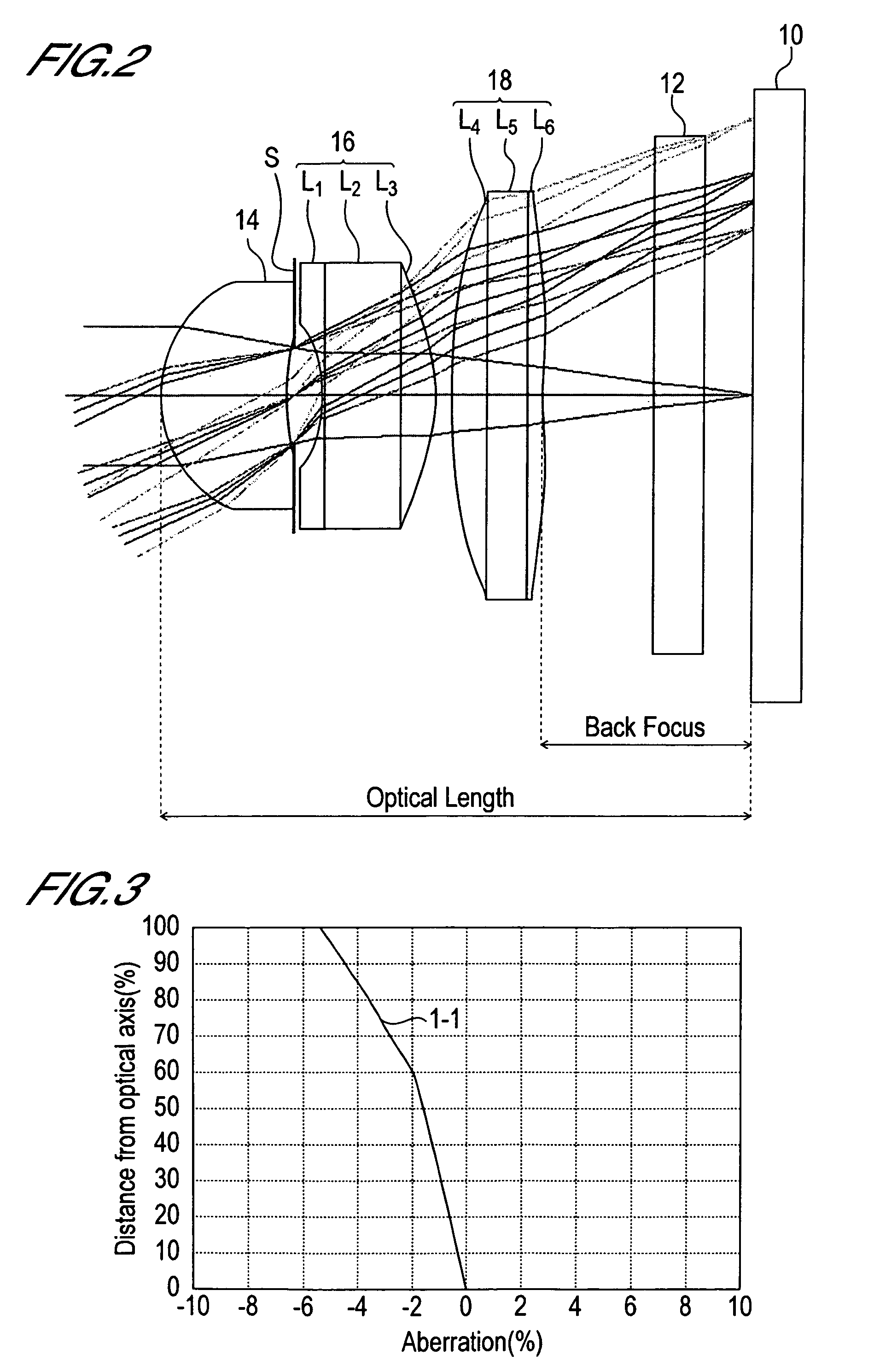

Imaging lens

The present invention is an imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, the imaging lens comprising a first lens 14, an aperture stop S, a second lens 16, and a third lens 18, which are arranged in this sequence from an object side to an image side. For the first lens, a single lens is used. The second lens comprises a first sub-lens L1, a second sub-lens L2 and a third sub-lens L3, arranged in this sequence from the object side to the image side. The third lens comprises a fourth sub-lens L4, a fifth sub-lens L5 and a sixth sub-lens L6, arranged in this sequence from the object side to the image side. The first lens is formed of a transparent curable silicone resin, and the first, third, fourth and sixth sub-lenses are also formed of the transparent curable silicone resin. The second sub-lens and the fifth sub-lens are formed of a high softening temperature glass material.

Owner:SEIKOH GIKEN

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

Polymer electrolyte material, production method thereof and membrane electrode assembly for polymer electrolyte fuel cell

InactiveUS7429428B2Increase productionIncrease temperatureSolid electrolytesIon-exchanger regenerationDouble bondMembrane electrode assembly

Owner:ASAHI GLASS CO LTD

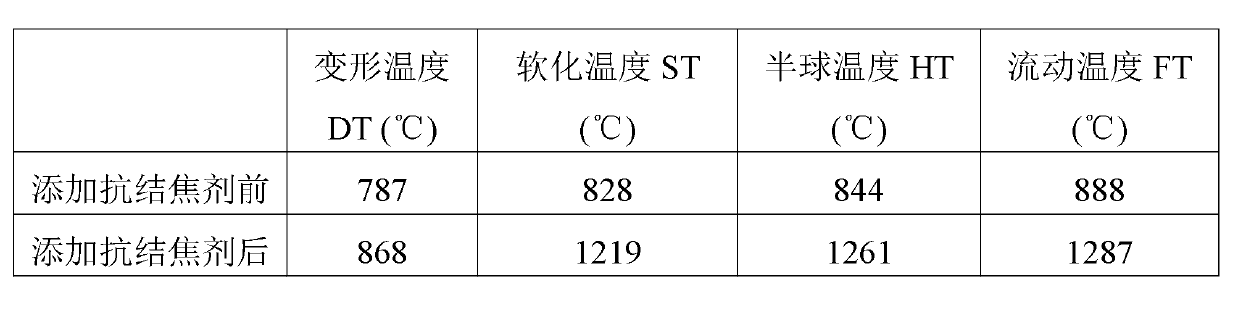

High-strength and high-conductivity rare earth copper alloy for contact lines and preparation method thereof

The invention relates to a high-strength and high-conductivity rare earth copper alloy for contact lines and a preparation method thereof. The rare earth copper alloy is composed of chromium, zirconium, zinc, titanium, silver, copper, rare earth elements and inevitable impurity elements, wherein during preparation, a Cu-Zr intermediate alloy and a Cu-rare earth intermediate alloy are prepared at first, and then the Cu-Zr intermediate alloy and the Cu-rare earth intermediate alloy are smelted and subjected to mould casting with copper, zinc, silver and titanium to form a cast ingot, the cast ingot is subjected to hot extrusion to obtain a bar billet, the bar billet is subjected to solution treatment, the treated alloy is subjected to drawing deformation, and then subjected to aging treatment to prepare the high-strength and high-conductivity rare earth copper alloy. The conductivity, elongation, strength and softening temperature of the alloy disclosed by the invention can be greatly improved; the machining performances of the alloy are remarkably improved; the manufacturability of the alloy can be changed, thus benefiting refining, degassing and microalloying; and the requirements of a material for the industrial field of contact lines on the performances of copper alloys can be met well. The alloy disclosed by the invention is simple in preparation process, short in process flow, high in strength, good in conductivity and excellent in hot-working property.

Owner:HENAN UNIV OF SCI & TECH

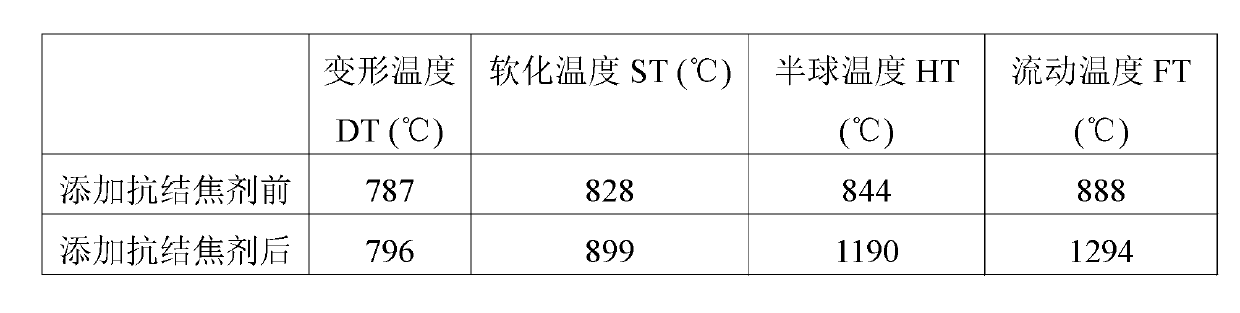

Industrial residue boiler anti-coking agent and application method thereof

InactiveCN103013617ARaise the ash melting temperatureAlleviate coking and slagging in the furnaceSolid fuelsFuel additivesPulverised fuel ashEngineering

The invention discloses an industrial residue boiler anti-coking agent and an application method thereof, belonging to the technical field of anti-coking additives. The industrial residue boiler anti-coking agent comprises the following components in percentage by mass: 30-60% of kaolin, 30-60% of CaO and 10-20% of fly ash. When in use, the industrial residue boiler anti-coking agent, accounting for 1-2% of the total mass of the industrial residue fuel, is added to the industrial residue fuel and evenly mixed. The industrial residue boiler anti-coking agent disclosed by the invention has high porosity, and the surface micropores have adsorbability; the industrial residue boiler anti-coking agent is simple to use, and the addition amount is only 1-2% of the total weight of the fuel, so that the invention does not influence the combustion characteristics of the fuel and the normal operation of the boiler, and does not need to modify the existing combustion equipment, thereby greatly lowering the investment cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-strength Cu-Ni-Si alloy and preparation method thereof

The invention relates to a high-strength Cu-Ni-Si alloy and preparation method thereof. The alloy comprises 2.0-6.0% of Ni, 0.5-1.5% Si, 0.5-1.0% of Ti, 0.5-1.0% of Mn, 0.5-1.0% of Ag and the balance of copper and unavoidable impurity elements. The preparation method sequentially comprises the following steps of smelting; casting; homogenization treatment; hot rolling and solution treatment; pre-cold rolling and aging treatment; and cold-rolling deformation. A Ni2Si non-oxide reinforcing phase is generated in the alloy disclosed by the invention; after the rolling is carried out repeatedly, the nucleation positions of precipitated phases can be increased, the more the broken grains, the more grain boundaries, the more nucleation positions of the precipitated phases and the more the precipitated phases; and under the condition that aging treatment is carried out repeatedly, the more precipitated phases are precipitated and thus the comprehensive performance of the alloy is dramatically increased, the strength, the elongation property at a high temperature and the electric conductivity are improved and the bending workability of the alloy is also improved.

Owner:HENAN UNIV OF SCI & TECH

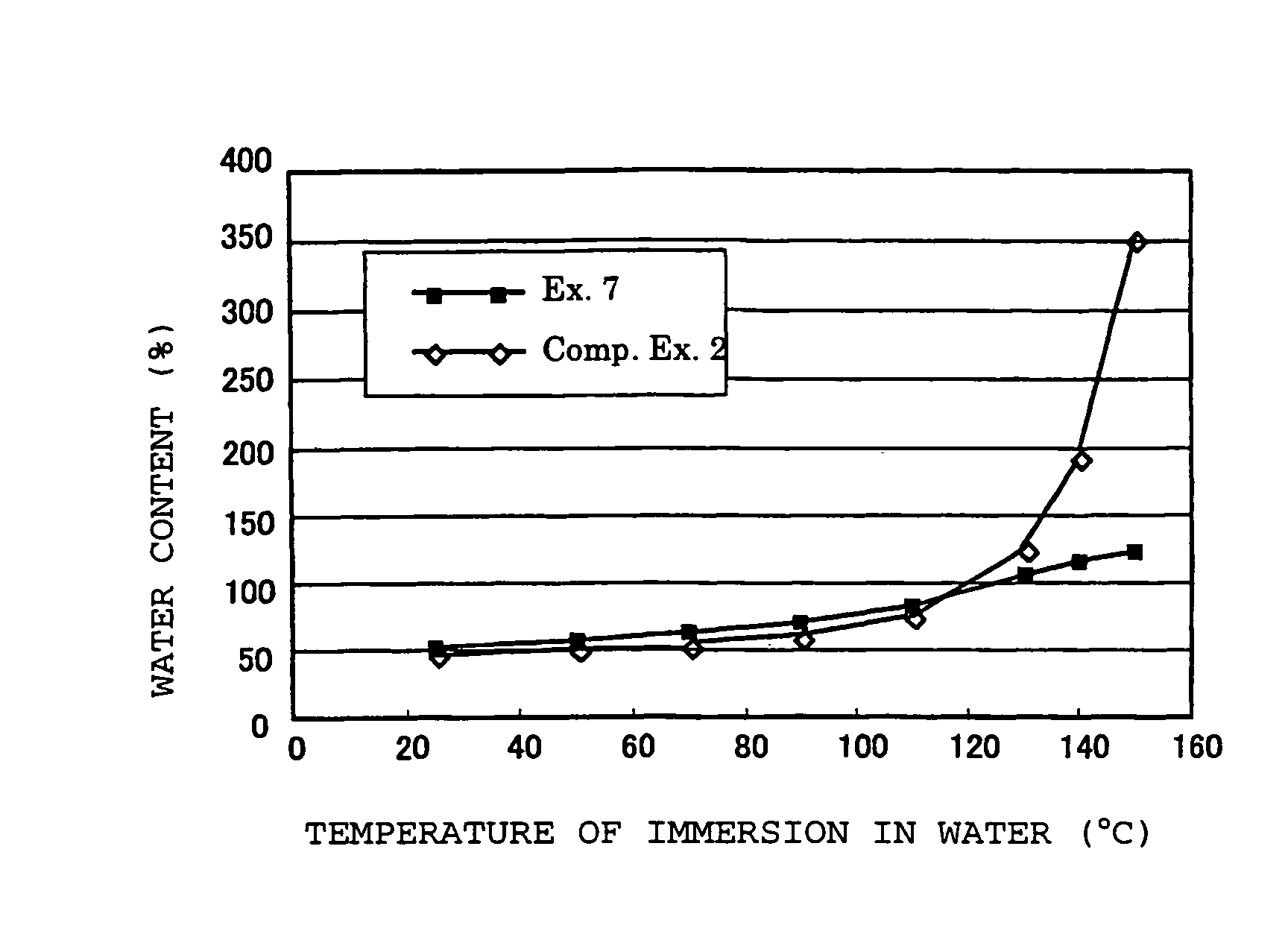

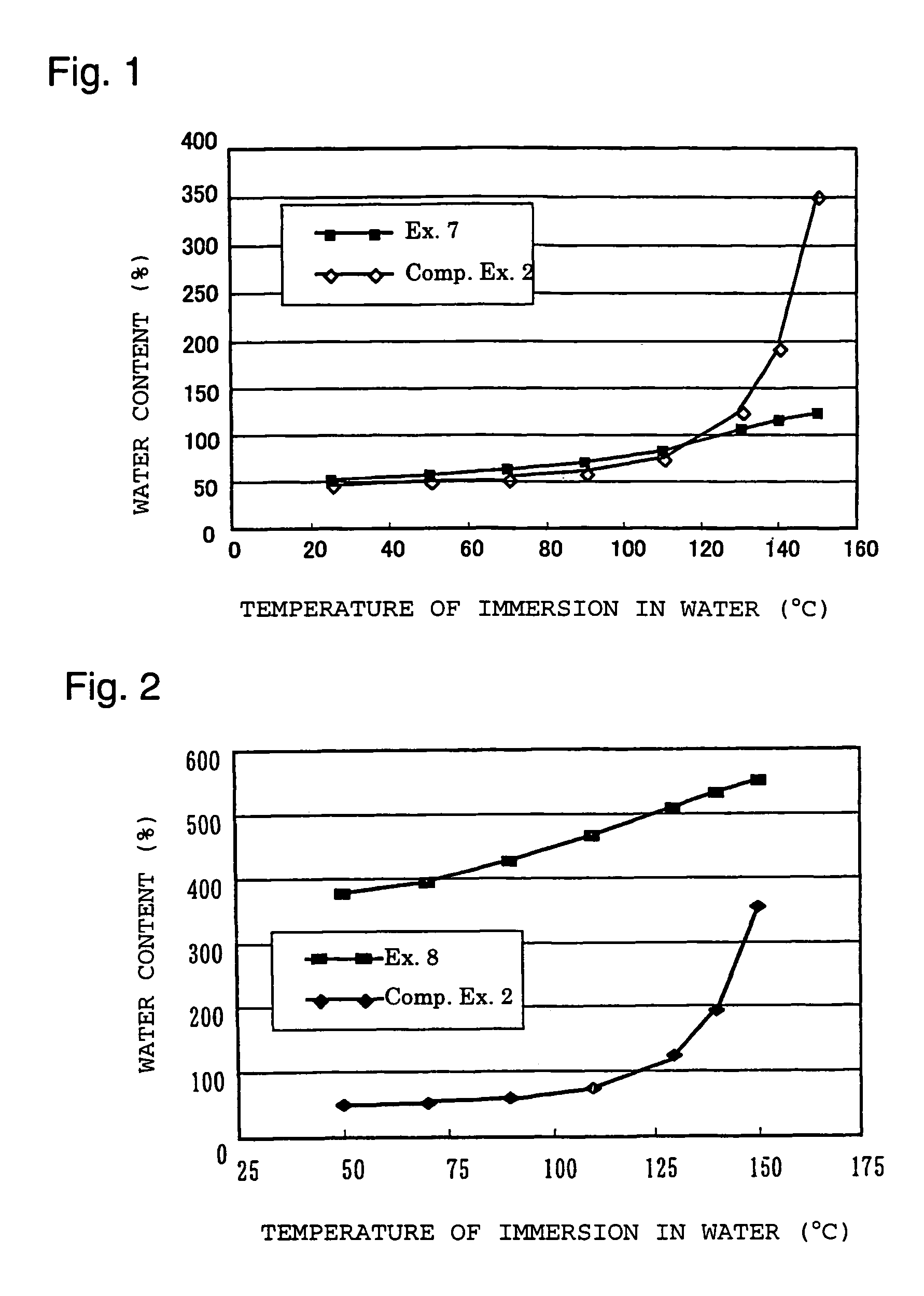

Electrolyte material, electrolyte membrane and membrane-electrolyte assembly for polymer electrolyte fuel cells

ActiveUS20070202377A1Excellent chemical durabilityHigh softening temperatureIon-exchange process apparatusSemi-permeable membranesFuel cellsIon exchange

To provide an electrolyte material for polymer electrolyte fuel cells having a high softening temperature and being excellent in durability, and an electrolyte membrane and a process for producing a membrane-electrode assembly using it. An electrolyte material made of a polymer containing a segment A of a polymer containing repeating units based on a perfluoromonomer having an ion exchange group and having a polymerizable double bond, at least one of carbon atoms in the polymerizable double bond being a carbon atom contained in an alicyclic structure, and a segment B of a fluoropolymer containing substantially no ion exchange group, and an electrolyte membrane and a membrane-electrode assembly using it.

Owner:ASAHI GLASS CO LTD

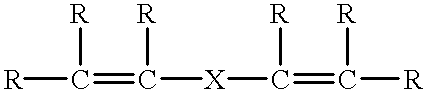

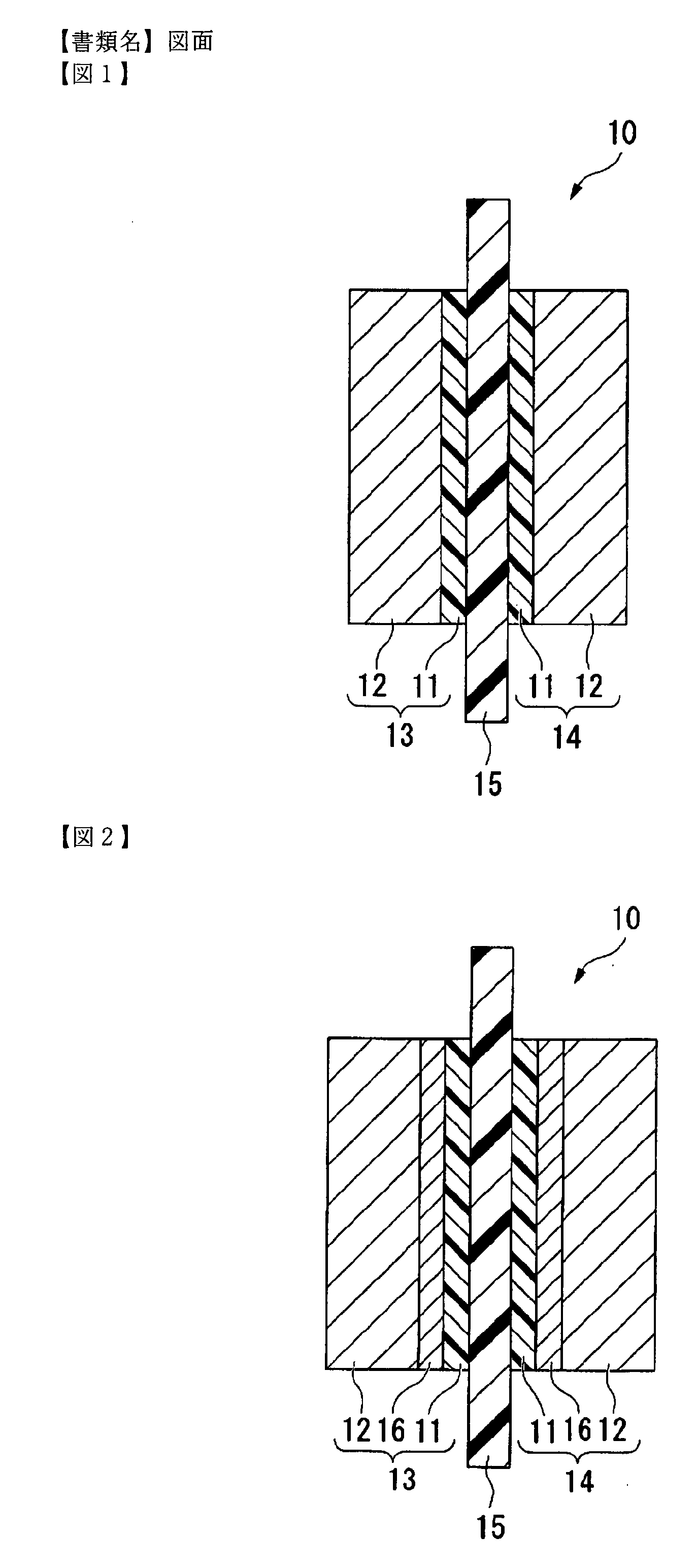

Polymer, polymer electrolyte membrane for polymer electrolyte fuel cell, and membrane/electrode assembly

ActiveUS20080193821A1Lower resistanceIncrease flexibilitySolid electrolytesSolid electrolyte fuel cellsPolymer electrolytesPolymer science

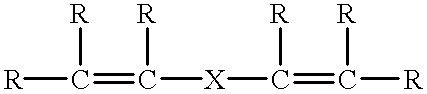

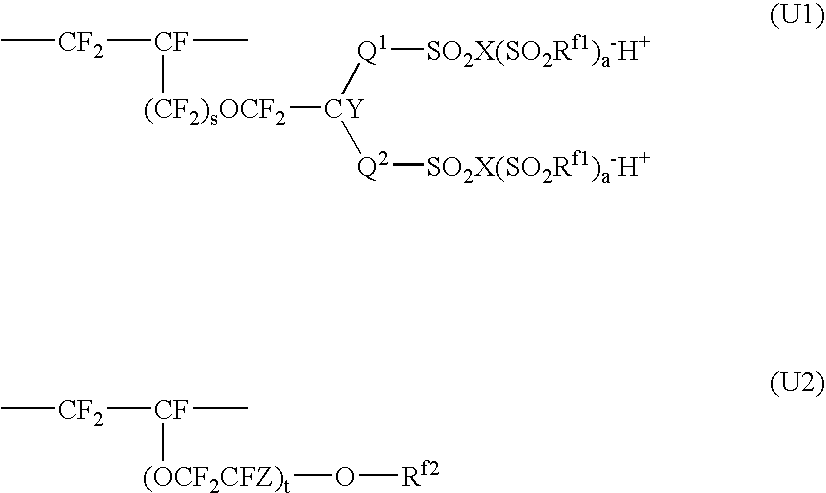

A polymer electrolyte membrane made of a polymer has a low electrical resistance, high heat resistance and is strong against repeats of swelling and shrinkage. Thus, a membrane / electrode assembly for polymer electrolyte fuel cells having high power generation performance and excellent in durability can be provided.For a polymer electrolyte membrane 15 or for a catalyst layer 11 constituting electrodes 13 and 14, a polymer comprising units (U1) and units (U2) is used:Q1, Q2: a perfluoroalkylene group which may have —O— or the like; Rf1, Rf2: a perfluoroalkyl group which may have —O—; X: an oxygen atom or the like; a: 0 or the like; Y, Z: a fluorine atom, or a monovalent perfluoroorganic group such as —CF3; S: 0 to 1; and t: 0 to 3.

Owner:ASAHI GLASS CO LTD

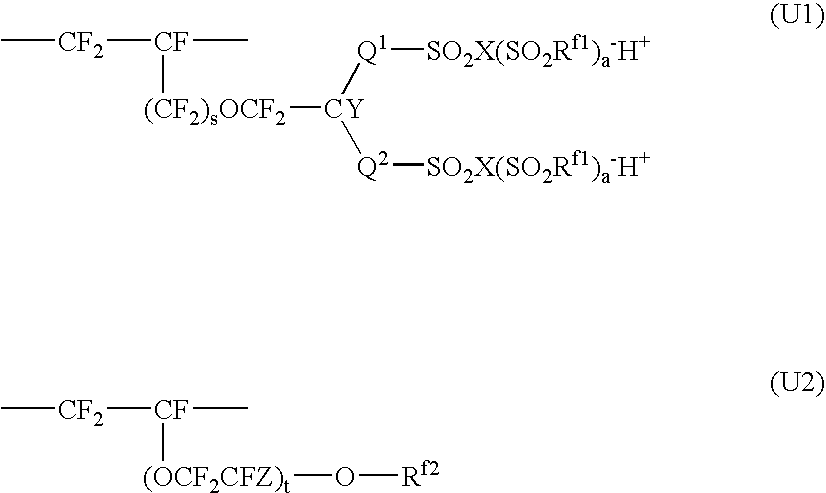

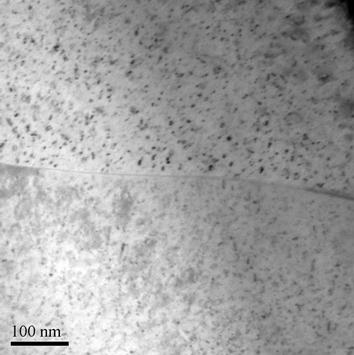

Dispersion strengthening copper-based composite material and preparation method thereof

The invention relates to a dispersion strengthening copper-based composite material and a preparation method thereof. The dispersion strengthening copper-based composite material and the preparation method thereof are characterized in that A dispersion strengthening phase is yttrium oxide, and the content of yttrium oxide in copper is 1-2.5 percent by weight, and the preparation method comprises the processes of alloy smelting, rolling, internal oxidation, reduction and the like. The preparation method has the advantages of short process and low production cost. The tensile strength of the product is greater than 550 MPa, the conductivity exceeds 90 percent IACS (international annealed copper standard), and the softening temperature is higher than 900 DEG C. The dispersion strengthening copper-based composite material has higher mechanical property, excellent electrical conductivity and high-temperature softening resistance. The Y2O3 granulate dispersion strengthening copper-based composite material prepared in the invention can be applied to computer integrated circuit lead frames, resistance welding electrodes for automobile industry, linings of crystallizers of continuous casting machines for metallurgical industry, equipment and carrier rockets, electric car and electric power train aerial conductor and the like, and the character of service and the service life can be obviously improved.

Owner:NANCHANG UNIV

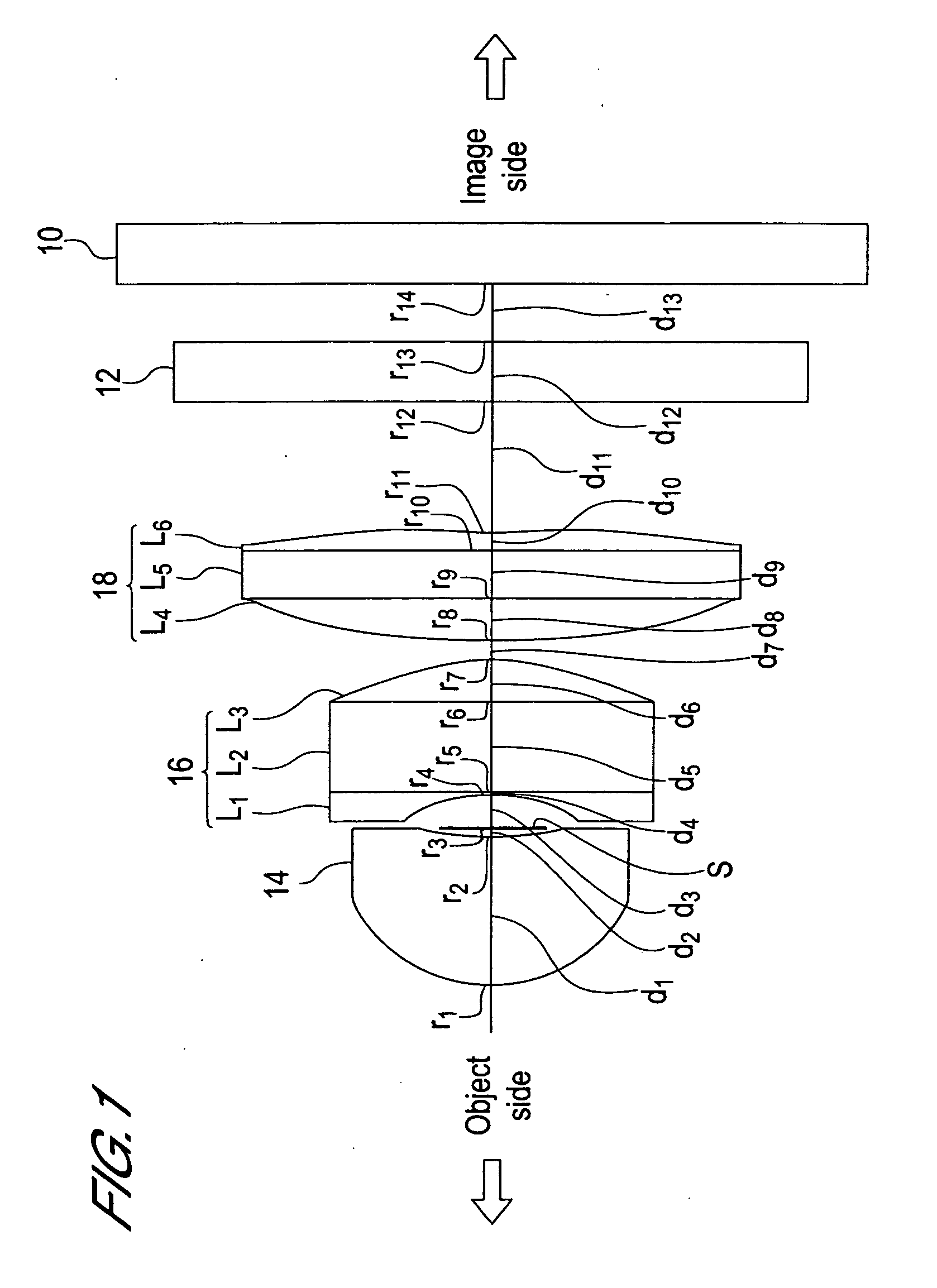

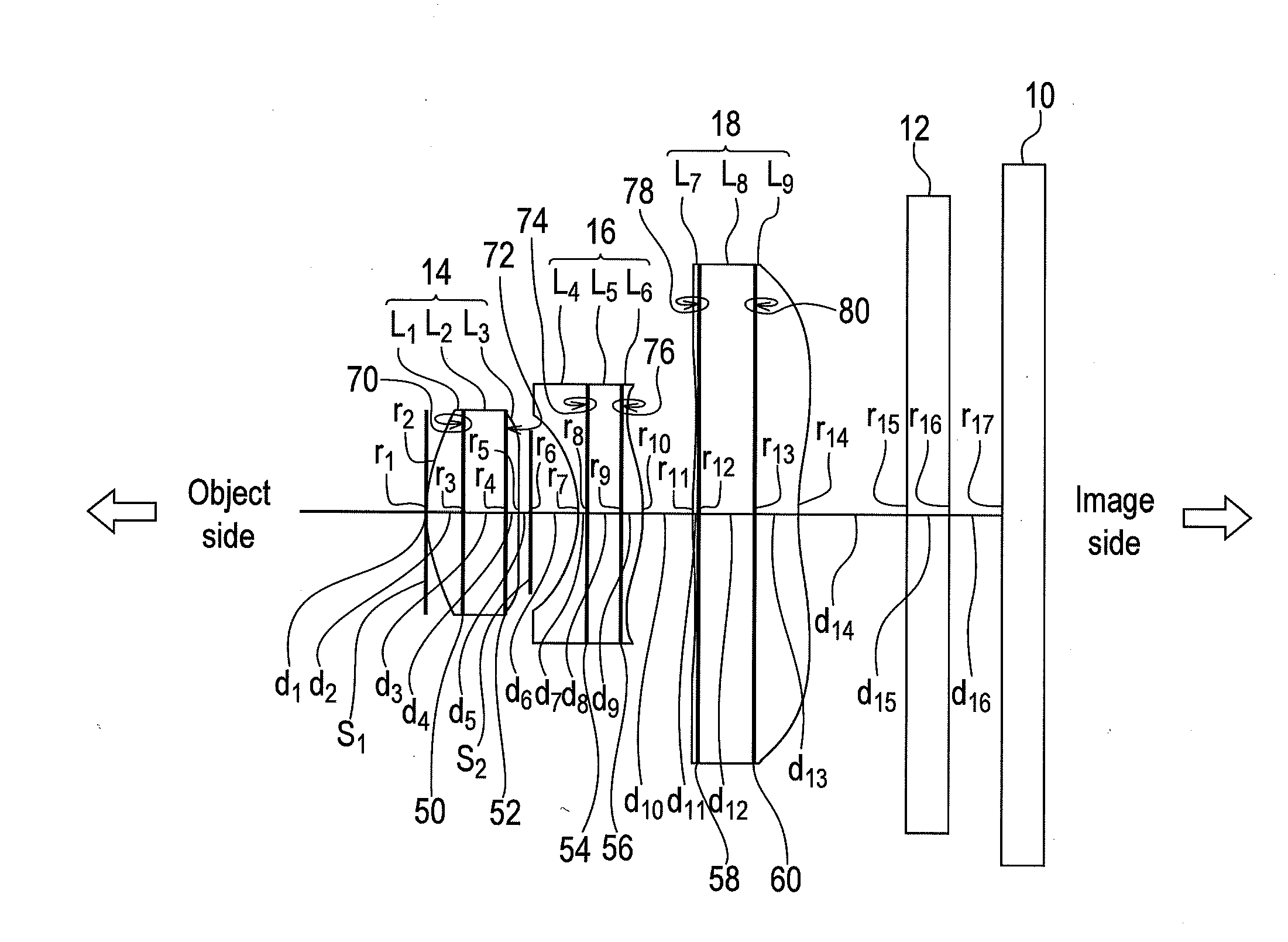

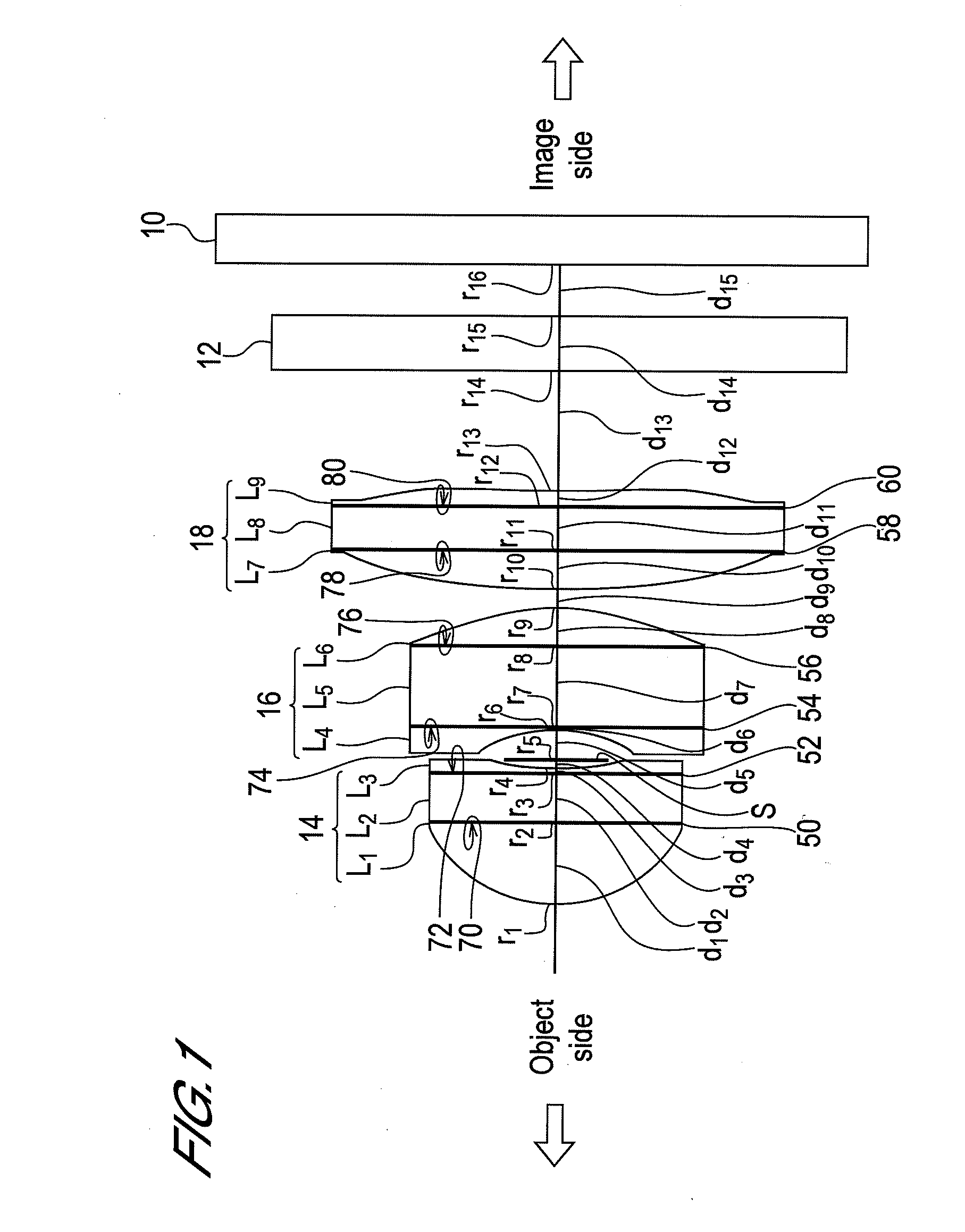

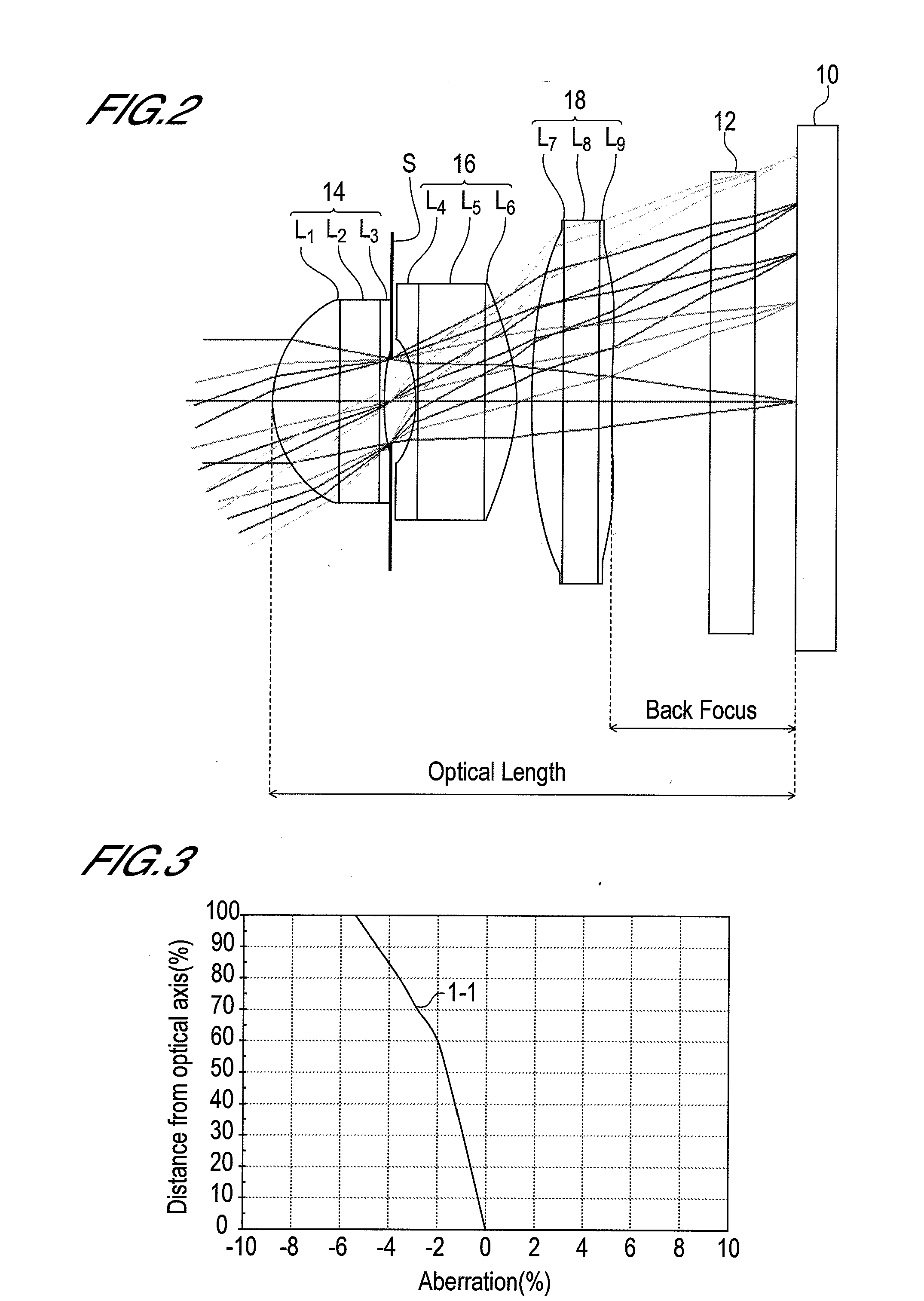

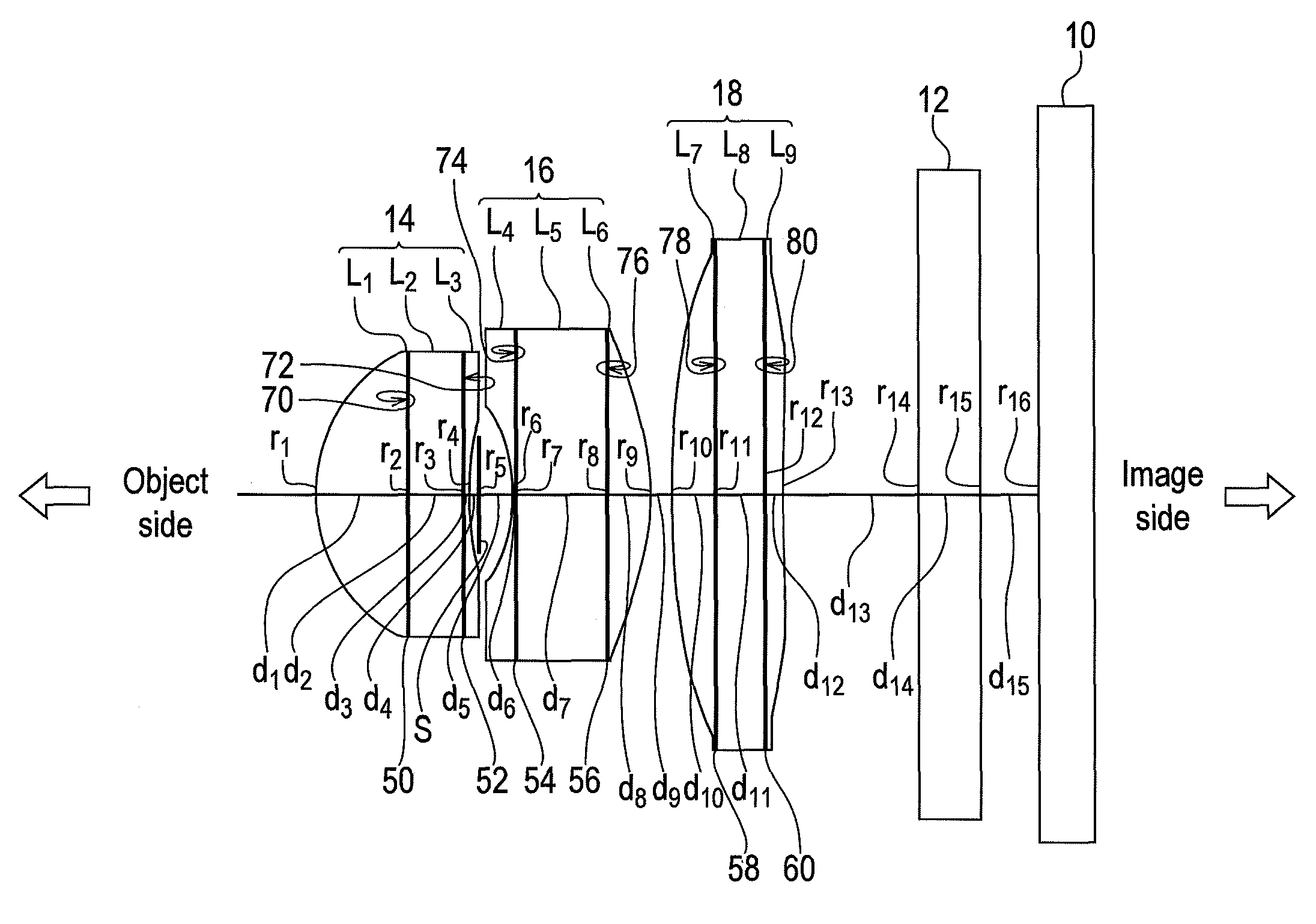

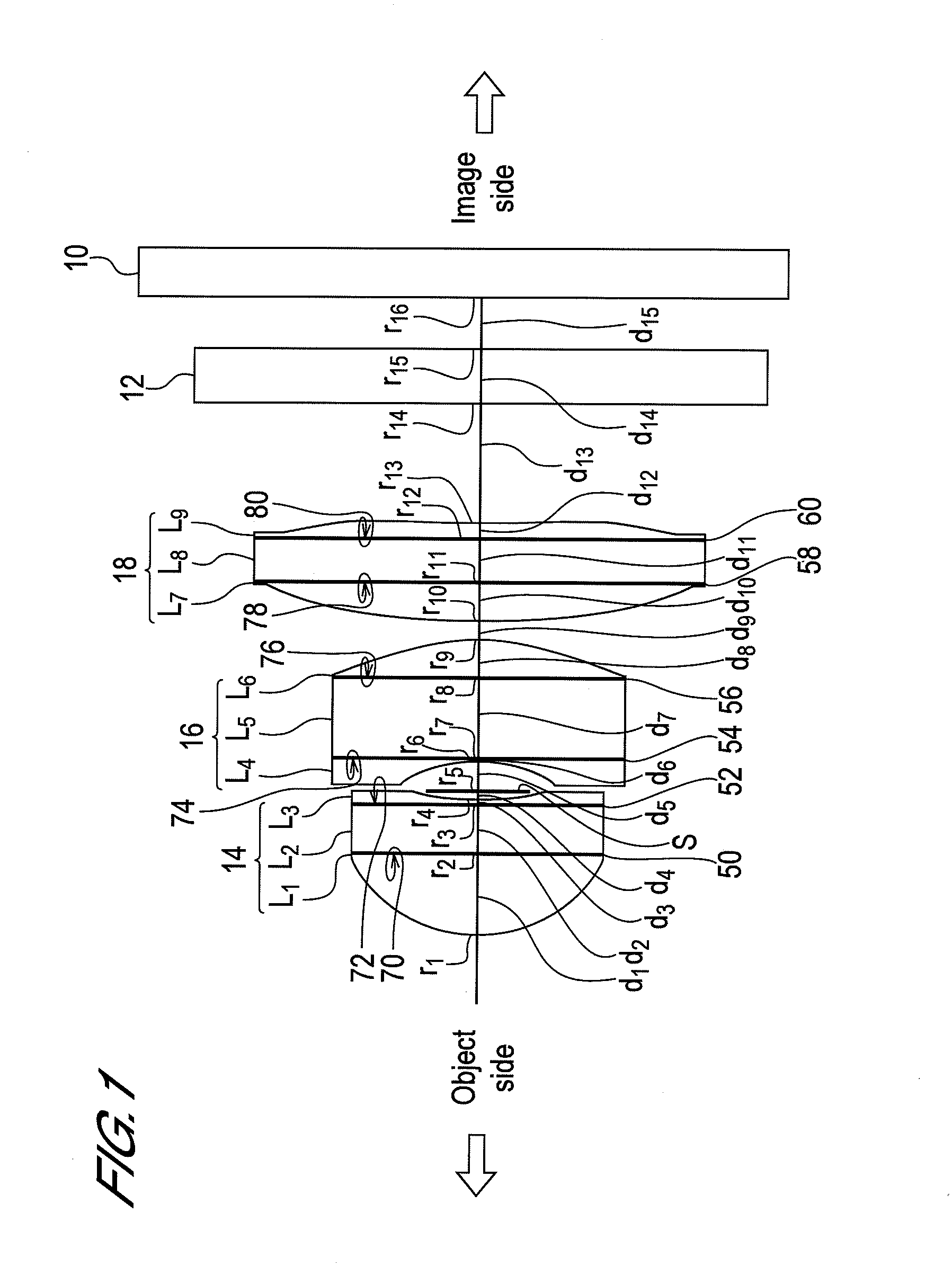

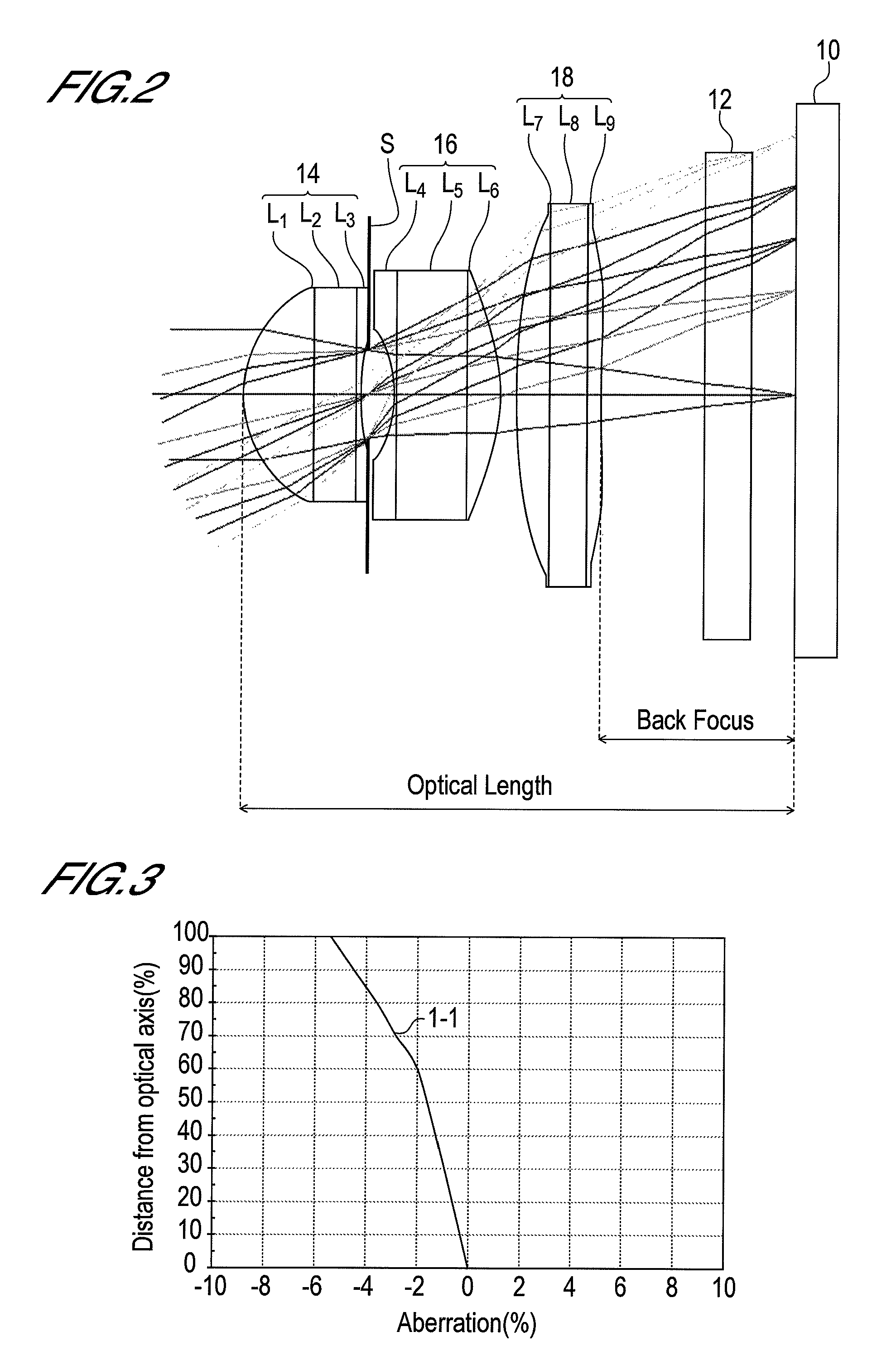

Imaging lens

InactiveUS20100118416A1High softening temperatureHigh materialMountingsLensOphthalmologyImaging lens

The present invention is an imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, the imaging lens comprising a first junction type compound lens, an aperture stop S, a second junction type compound lens, and a third junction type compound lens, which are arranged in this sequence from an object side to an image side. The first junction type compound lens comprises a first lens L1, a second lens L2 and a third lens L3 arranged in this sequence from the object side to the image side, the second junction type compound lens comprises a fourth lens L4, a fifth lens L5 and a sixth lens L6 arranged in this sequence from the object side to the image side, and the third junction type compound lens comprises a seventh lens L7, an eighth lens L8 and a ninth lens L9 arranged in this sequence from the object side to the image side. The first lens, the third lens, the fourth lens, the sixth lens, the seventh lens and the ninth lens are formed of a curable resin material, and the second lens, the fifth lens and the eighth lens are formed of a high softening temperature optical glass material.

Owner:SEIKOH GIKEN

High temperature copper alloy for lead frame and its making process

ActiveCN1932056AHighlight substantive featuresSignificant progressSemiconductor/solid-state device detailsSolid-state devicesLead frameContinuous annealing

The present invention provides one kind of copper alloy for high temperature softening resistant lead frame and its making process. The copper alloy contains Fe 2.0-2.6wt %, Zn 0.05-0.1wt %, P 0.01-0.03wt %, Cr 0.01- 0.1wt %, and Re 0.01-1.5wt % except Cu. The making process includes the following steps: smelting in protecting atmosphere, casting and cooling at the speed of 80 deg.c / min between the liquid phase temperature and 400 deg.c; hot rolling the cast blank at 1000 deg.c, repeated cold rolling and double continuous annealing at 400-600 deg.c; cold rolling to reach thickness change over 50 % and final low temperature annealing at temperature below 450 deg.c. The copper alloy has excellent high temperature softening tolerance, high tensile strength, high elongation, high electric conductivity and other features and is excellent material for producing lead frame.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Imaging lens

The present invention is an imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, the imaging lens comprising a first lens 14, an aperture stop S, a second lens 16, and a third lens 18, which are arranged in this sequence from an object side to an image side. For the first lens, a single lens is used. The second lens comprises a first sub-lens L1, a second sub-lens L2 and a third sub-lens L3, arranged in this sequence from the object side to the image side. The third lens comprises a fourth sub-lens L4, a fifth sub-lens L5 and a sixth sub-lens L6, arranged in this sequence from the object side to the image side. The first lens is formed of a transparent curable silicone resin, and the first, third, fourth and sixth sub-lenses are also formed of the transparent curable silicone resin. The second sub-lens and the fifth sub-lens are formed of a high softening temperature glass material.

Owner:SEIKOH GIKEN

Table tennis ball and production method thereof

ActiveCN105111671AHigh impact strengthHigh elastic modulusSport apparatusElastic modulusInternal stress

The invention relates to a table tennis ball, 40.00-40.60mm in diameter, 0.4-0.8mm in ball wall thickness and 2.1-3.5g in weight. A body of the table tennis ball comprises, by weight, 70-90wt% of body material and 10-30wt% of toughening material; the body material is engineering plastic; the toughening material is chosen from any one of, or a combination of at least two of MBS (methylmethacrylate-butadiene-styrene copolymer), ACR (methylmethacrylate-acrylate copolymer), NBR (butadiene-acrylonitrile rubber) and TPU (thermoplastic polyurethane). The engineering plastic is used as the body material of the table tennis ball, is AS and / or ABS, is not a flammable and combustible hazardous article, and accordingly is free of flaming and combusting danger; by selecting formula components, the body material high in impact strength, high in elastic modulus, rarity of internal stress cracking and high in softening temperature is obtained, and the produced table tennis ball meets the requirements of International Table Tennis Federation.

Owner:苏州聚慧体育用品有限公司

Polymer, polymer electrolyte membrane for polymer electrolyte fuel cell, and membrane/electrode assembly

ActiveUS20090004527A1Low electric resistanceHighly flexibleSolid electrolytesCell electrodesOxygen atomPolymer electrolytes

A polymer electrolyte membrane made of a polymer has a low electrical resistance, high heat resistance and is strong against repeats of swelling and shrinkage. Thus, a membrane / electrode assembly for polymer electrolyte fuel cells having high power generation performance and excellent in durability can be provided.For a polymer electrolyte membrane 15 or for a catalyst layer 11 constituting electrodes 13 and 14, a polymer comprising units (U1) and units (U2) is used:Q1, Q2, Q3: a perfluoroalkylene group which may have —O— or the like; Rf1, Rf2: a perfluoroalkyl group which may have —O—; X1, X2: an oxygen atom or the like; a, b: 0 or the like; Y1, Y2: a fluorine atom or a monovalent perfluoroorganic group; and s, t: 0 to 1.

Owner:ASAHI GLASS CO LTD

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

Electrolyte material, electrolyte membrane and membrane-electrolyte assembly for polymer electrolyte fuel cells

ActiveUS7910236B2Excellent chemical durabilityHigh softening temperatureIon-exchange process apparatusSemi-permeable membranesFuel cellsIon exchange

To provide an electrolyte material for polymer electrolyte fuel cells having a high softening temperature and being excellent in durability, and an electrolyte membrane and a process for producing a membrane-electrode assembly using it.An electrolyte material made of a polymer containing a segment A of a polymer containing repeating units based on a perfluoromonomer having an ion exchange group and having a polymerizable double bond, at least one of carbon atoms in the polymerizable double bond being a carbon atom contained in an alicyclic structure, and a segment B of a fluoropolymer containing substantially no ion exchange group, and an electrolyte membrane and a membrane-electrode assembly using it.

Owner:ASAHI GLASS CO LTD

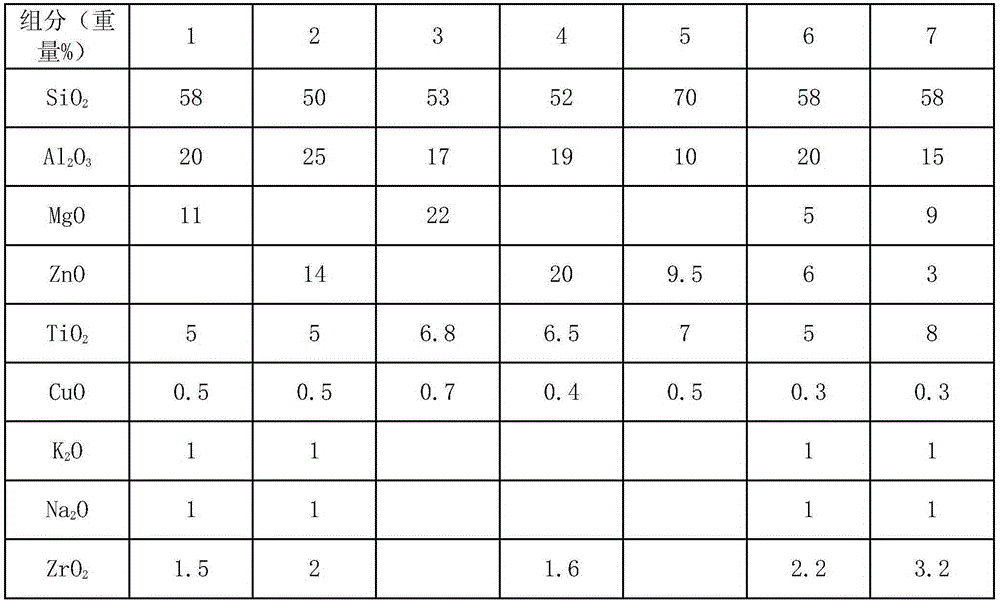

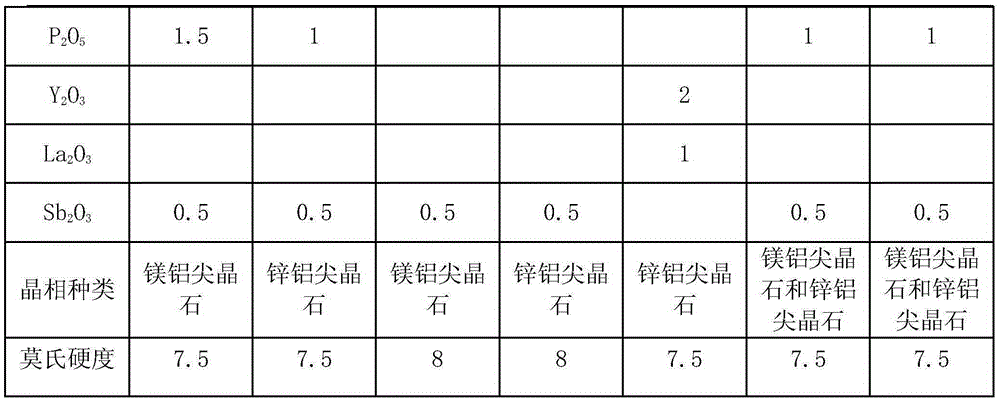

Glass ceramic and preparation method thereof

The invention provides an amber glass ceramic which is relatively high in hardness and resistant to high temperature. The amber glass ceramic comprises the following ingredients by weight percent: 50-70 percent of SiO2, 10.0-25 percent of Al2O3, 3-10 percent of TiO2, 0.2-0.7 percent of CuO, 0-22 percent of MgO and 0-20 percent of ZnO, and comprises at least one of MgO and ZnO. The glass ceramic has the Moh's hardness of 7.5-8 H, can be applied to decorative materials and ornaments, can solve the problem of scratching of ordinary amber glass, is not softened at the high temperature of 1150 DEG C, therefore, is high-temperature resistant and can be further processed under the high-temperature condition. The glass ceramic is high in mechanical strength, hardness and thermal stability, and excellent in chemical stability, wearing resistance and electric insulativity, and can be used for decorative materials, building inner and outer walls, grounds, gallery-column and other high-grade decoration projects.

Owner:CDGM GLASS LLC

Imaging lens

The present invention is an imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, the imaging lens comprising a first junction type compound lens, an aperture stop S, a second junction type compound lens, and a third junction type compound lens, which are arranged in this sequence from an object side to an image side. The first junction type compound lens comprises a first lens L1, a second lens L2 and a third lens L3 arranged in this sequence from the object side to the image side, the second junction type compound lens comprises a fourth lens L4, a fifth lens L5 and a sixth lens L6 arranged in this sequence from the object side to the image side, and the third junction type compound lens comprises a seventh lens L7, an eighth lens L8 and a ninth lens L9 arranged in this sequence from the object side to the image side. The first lens, the third lens, the fourth lens, the sixth lens, the seventh lens and the ninth lens are formed of a curable resin material, and the second lens, the fifth lens and the eighth lens are formed of a high softening temperature optical glass material.

Owner:SEIKOH GIKEN

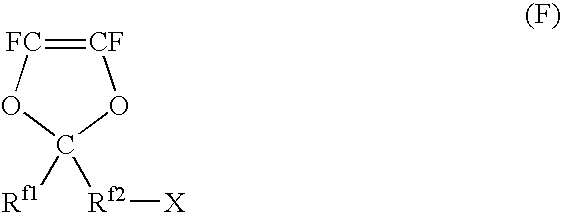

Method of manufacturing aqueous dispersion of resin fine particles, aqueous dispersion of resin fine particles, method of manufacturing toner, and toner

InactiveUS20080299482A1High softening temperatureDesired rangeOrganic dyesDevelopersVitrificationAqueous medium

A method of manufacturing an aqueous dispersion of resin fine particles, including: a mixing step of mixing an aqueous medium, a resin having an acid group, a basic substance, and a surfactant to obtain a mixture; an emulsification step of applying a shearing force to the mixture while heating at temperature 10.0° C. or more higher than a softening temperature (Tm) of the resin having the acid group to obtain an emulsified product; and a cooling step of obtaining an aqueous dispersion of resin fine particles by cooling the emulsified product, in which, in the cooling step, cooling is carried out at a cooling rate of 0.5° C. / min or more to 10.0° C. / min or less to a glass transition temperature (Tg) of the resin having the acid group or lower while a shearing force is applied.

Owner:CANON KK

High-strength beryllium-copper alloy bar and preparation process thereof

ActiveCN113174509AHigh strengthGrain refinementFurnace typesHeat treatment furnacesRare-earth elementVanadium atom

The invention discloses a high-strength beryllium-copper alloy bar, and particularly relates to the technical field of beryllium-copper alloys. The high-strength beryllium-copper alloy bar comprises the following elements: Be, Si, Ni, Co, Zr, Ti, V, rare earth elements, and the balance of Cu and inevitable impurities. According to the produced high-strength beryllium-copper alloy bar, nickel, cobalt, zirconium, titanium, vanadium and rare earth elements are added, the addition of nickel and cobalt can refine crystal grains in an alloy material and improve the uniformity of an internal structure, so that the beryllium-copper alloy material has good mechanical properties, zirconium can improve the softening temperature of the beryllium-copper alloy and refine recrystallized crystal grains, and titanium can effectively enhance the strength of the beryllium-copper alloy, the vanadium can purify, deteriorate and refine crystal grains and can improve the wear resistance of the beryllium-copper alloy bar, and the rare earth elements can refine the crystal grains to make the crystal grains uniform and can effectively improve the strength and corrosion resistance of the beryllium-copper alloy bar. The practicability of the beryllium-copper alloy bar can be improved, and the beryllium-copper alloy bar can meet the use requirements of people.

Owner:江阴金湾合金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com