Patents

Literature

174results about How to "Excellent chemical durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

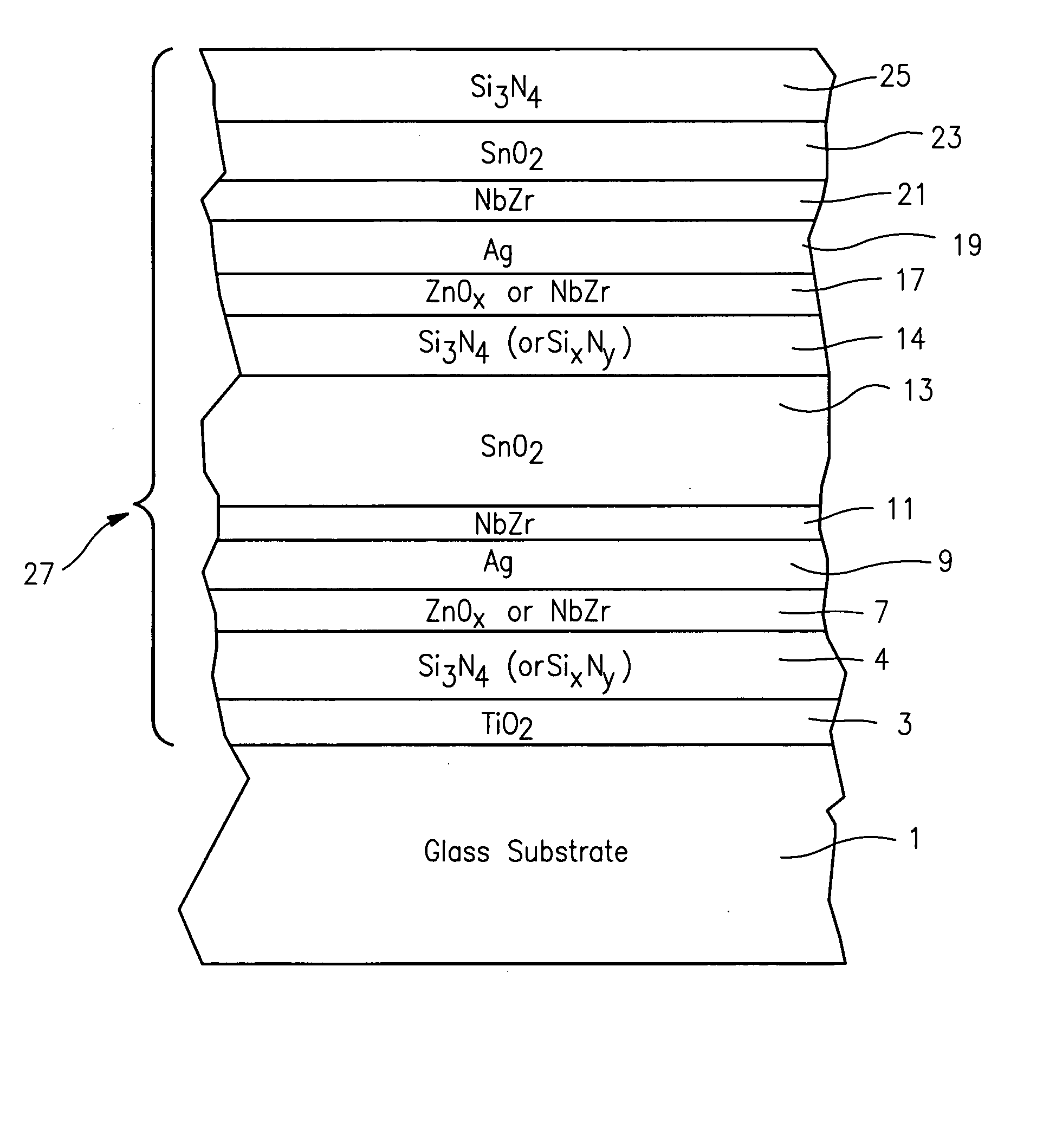

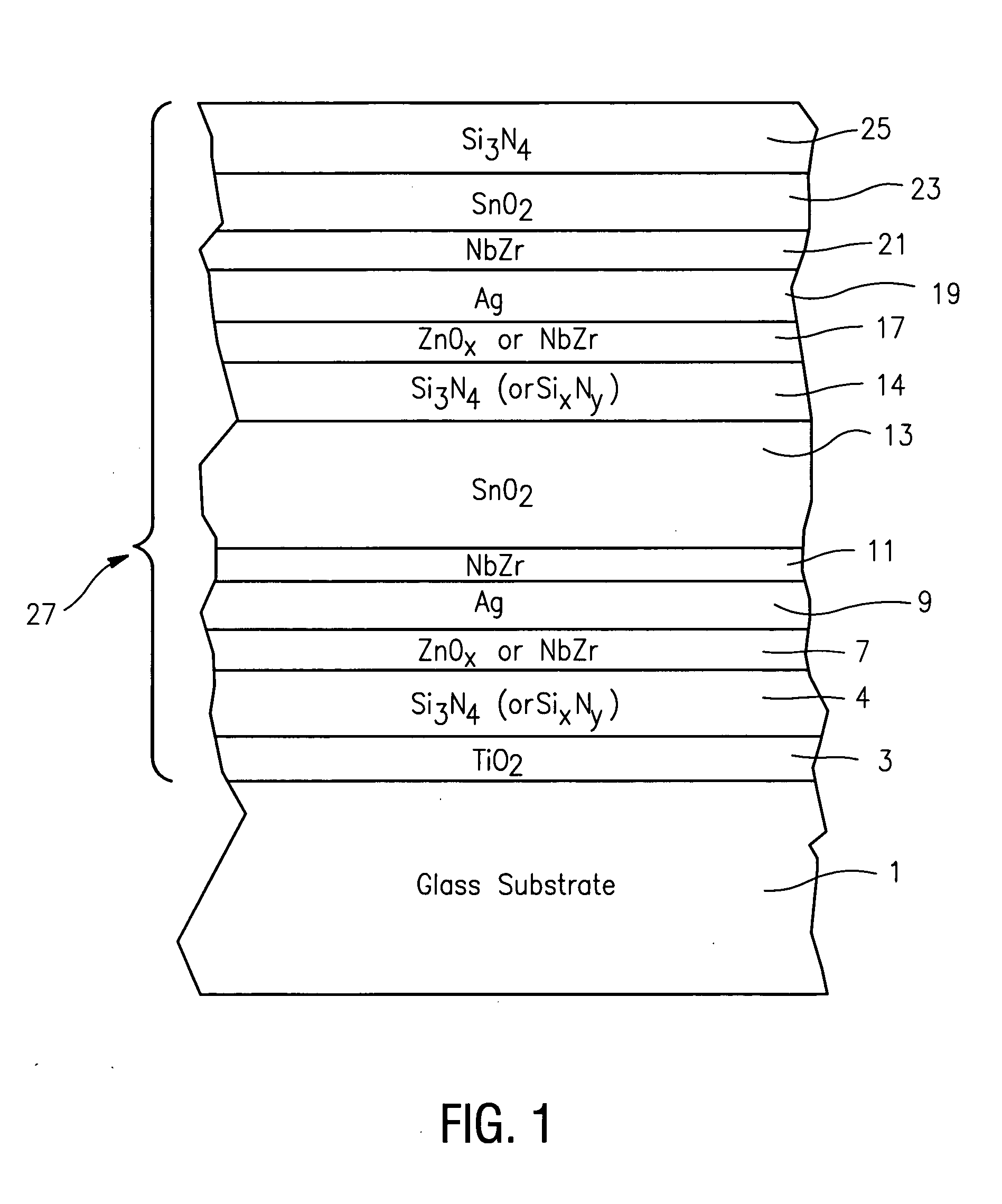

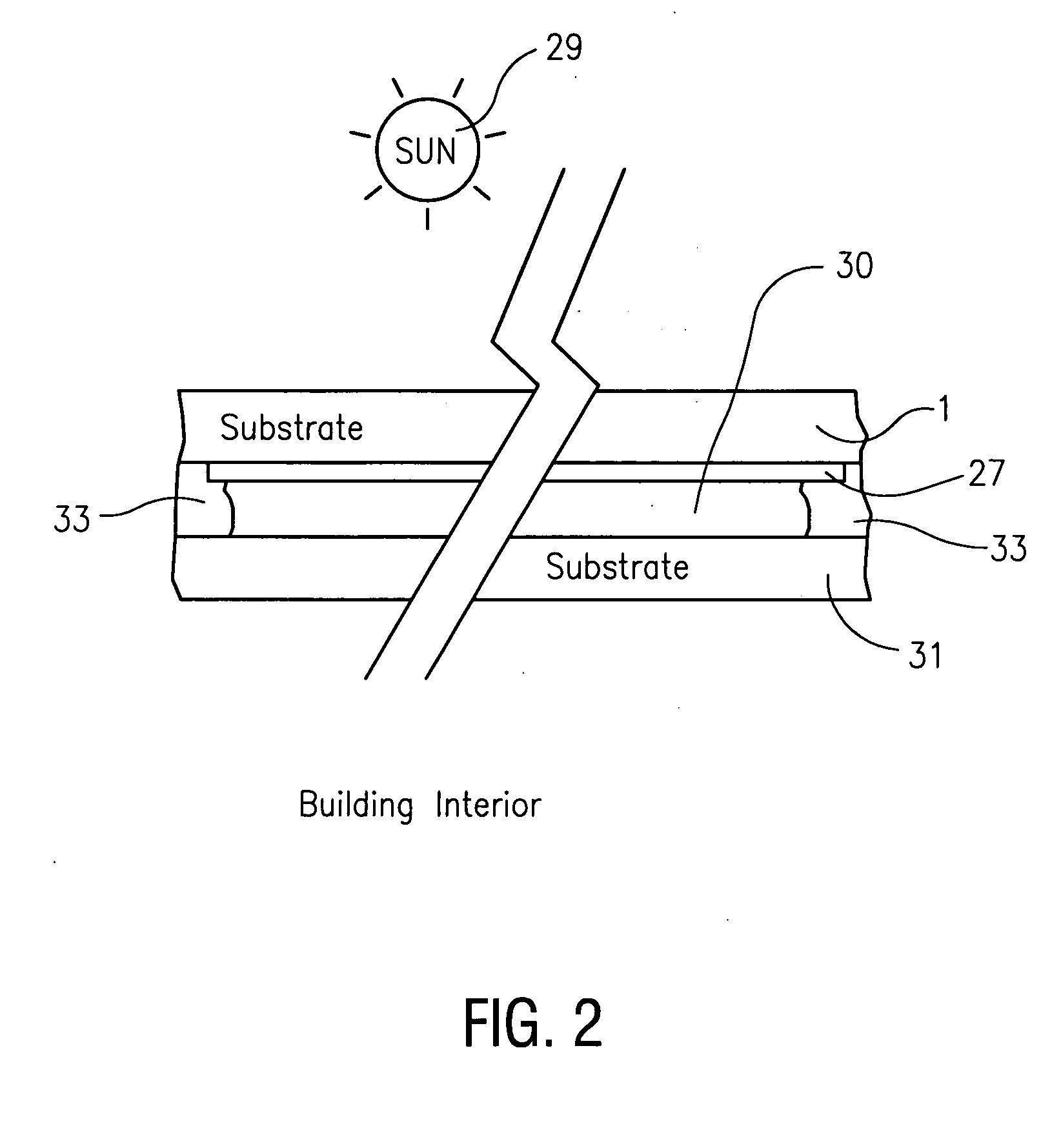

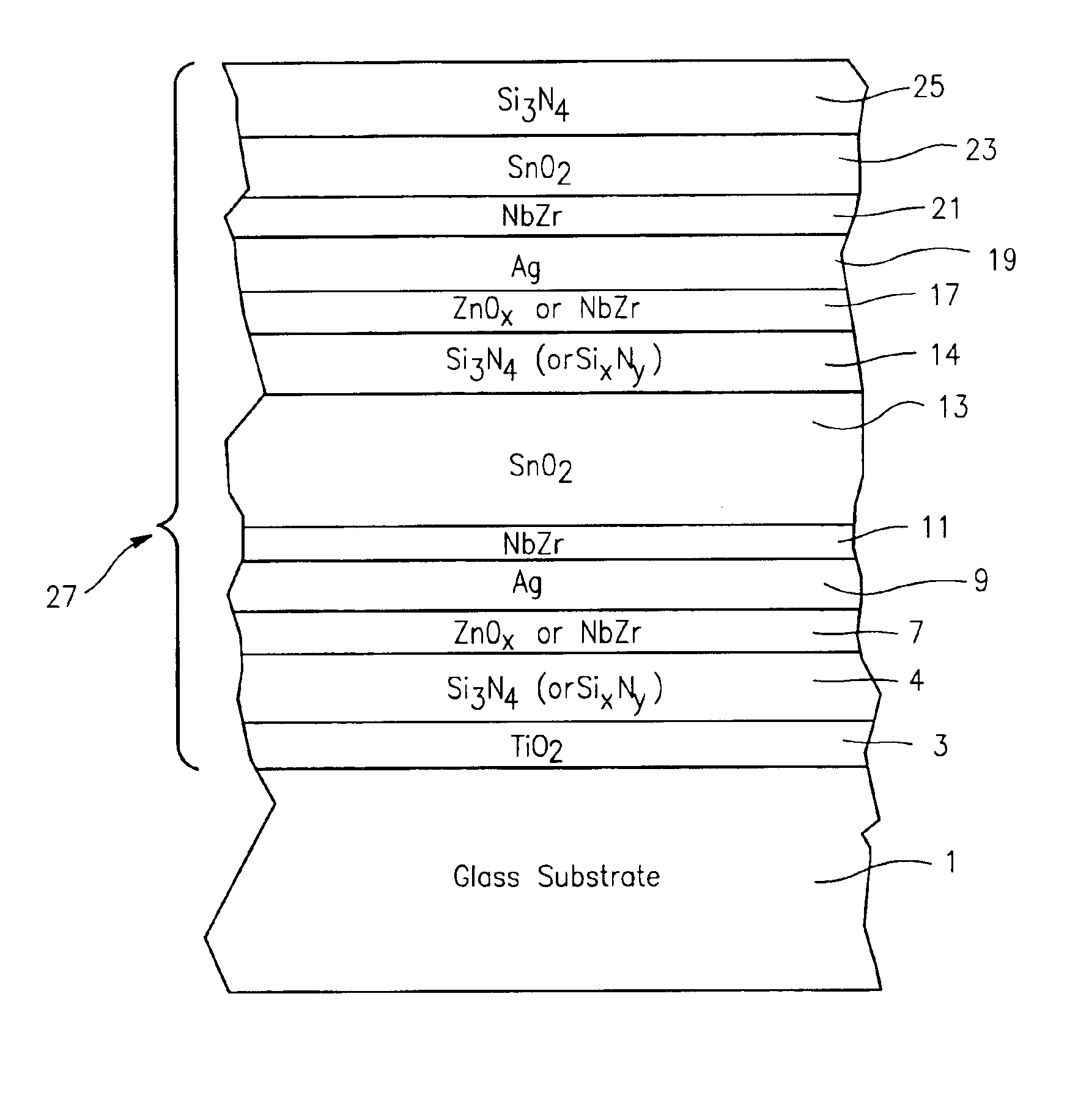

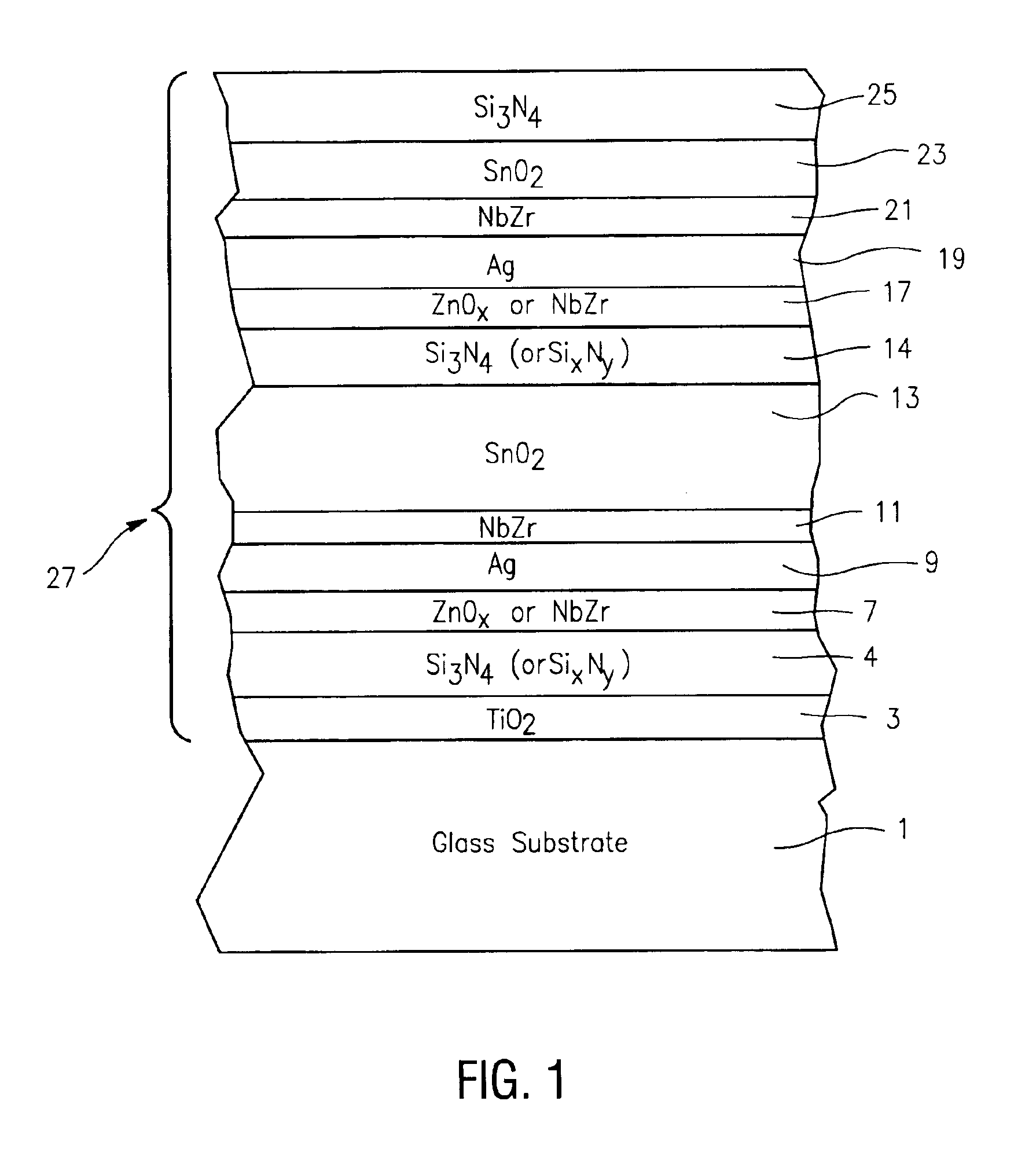

Coated article with niobium zirconium inclusive layer(s) and method of making same

ActiveUS20040224167A1Excellent chemical and mechanical durabilityImproved chemical durabilityVacuum evaporation coatingSputtering coatingOxideNiobium

A coated article is provided so as to include a coating (e.g., low-E coating, or the like) having at least one layer of or including niobium zirconium (NbZr). The NbZr layer may be metallic in certain example embodiments. Alternatively, an oxide and / or nitride of NbZr may be provided in other example embodiments. The NbZr inclusive layer may be provided as any suitable layer of the multi-layer coating, but in certain example instances may be used as a contact layer adjacent to an infrared (IR) reflecting layer. Coated articles herein may be used in the context of insulating glass (IG) window units, laminated windows, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

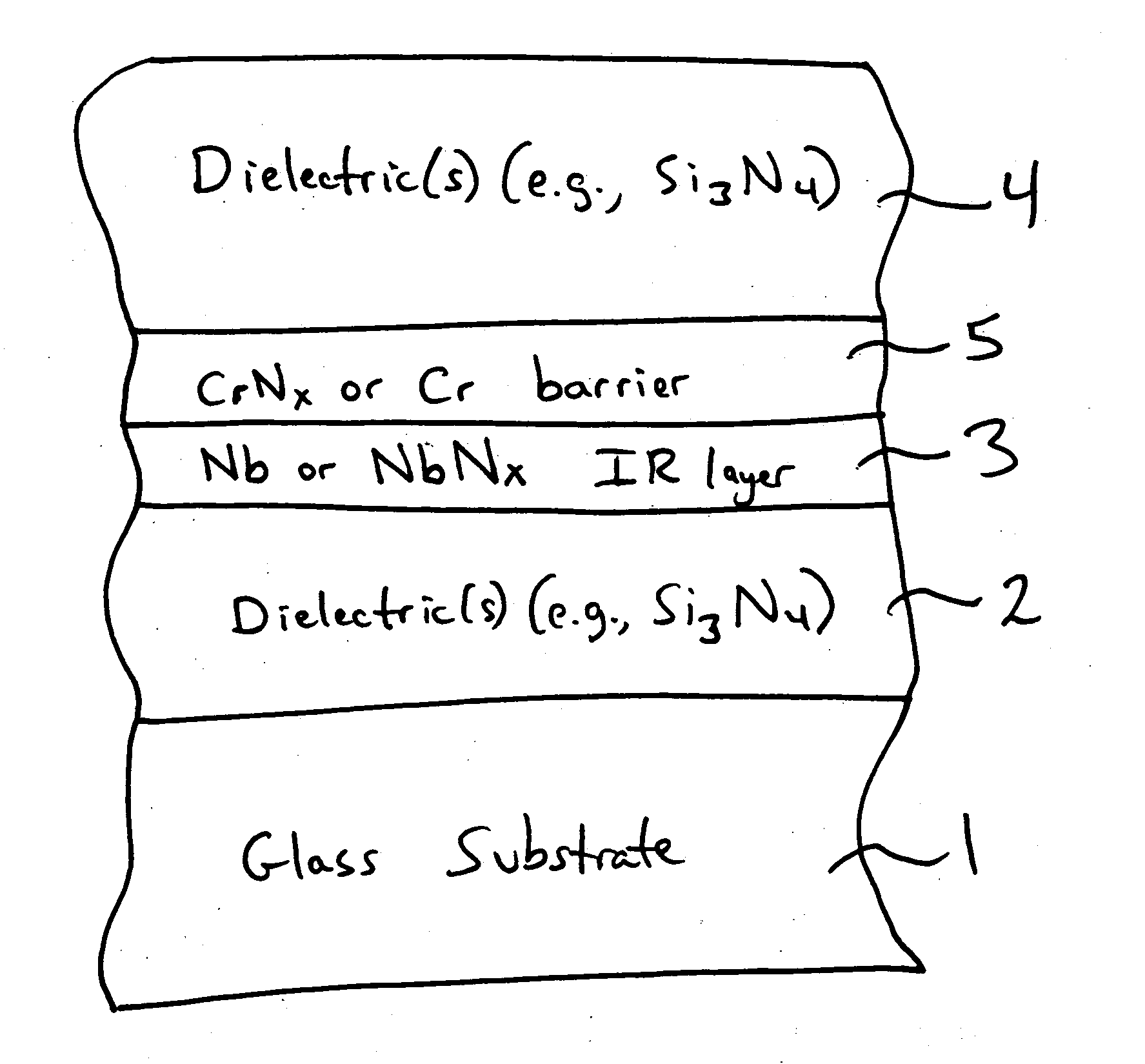

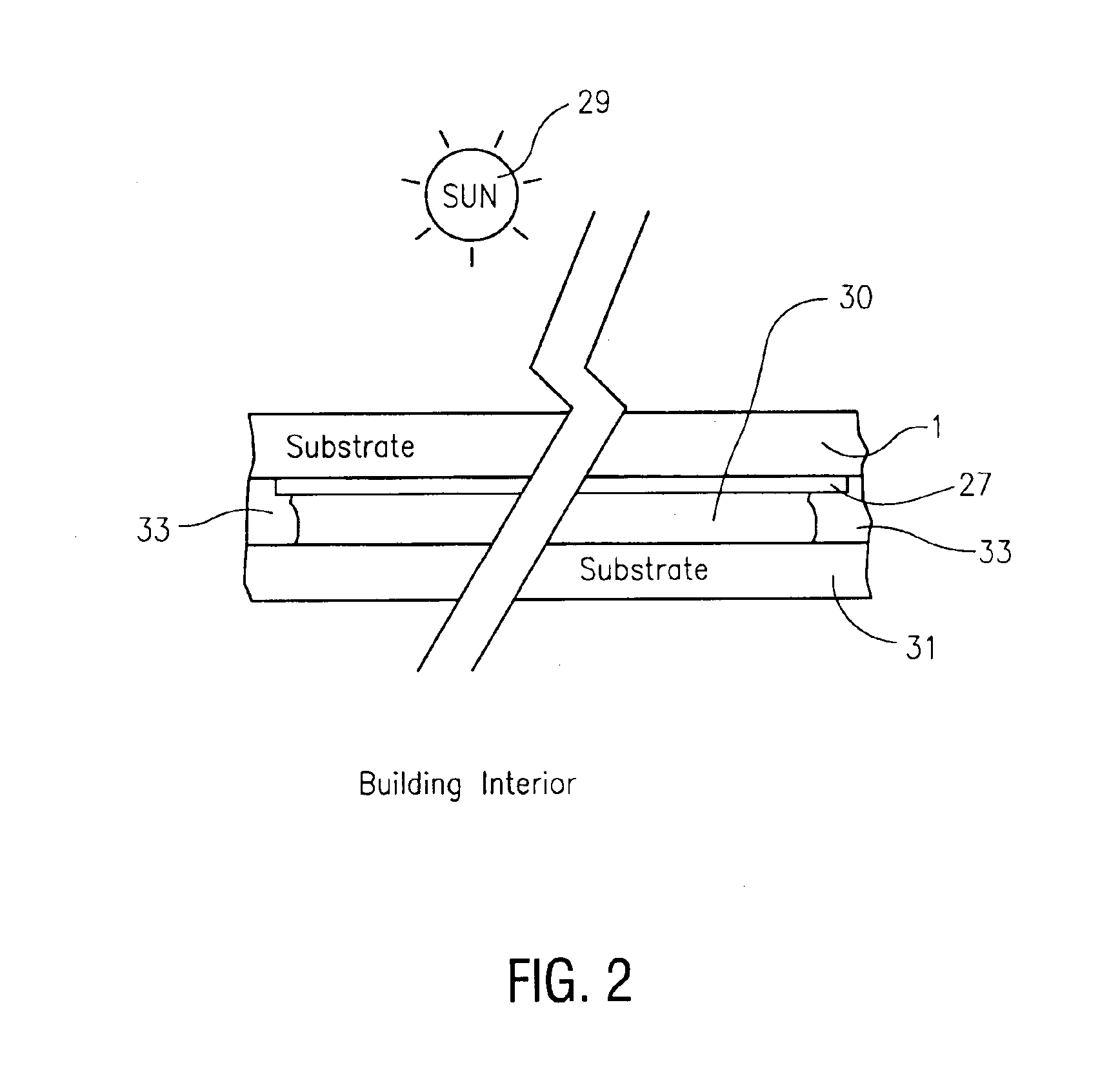

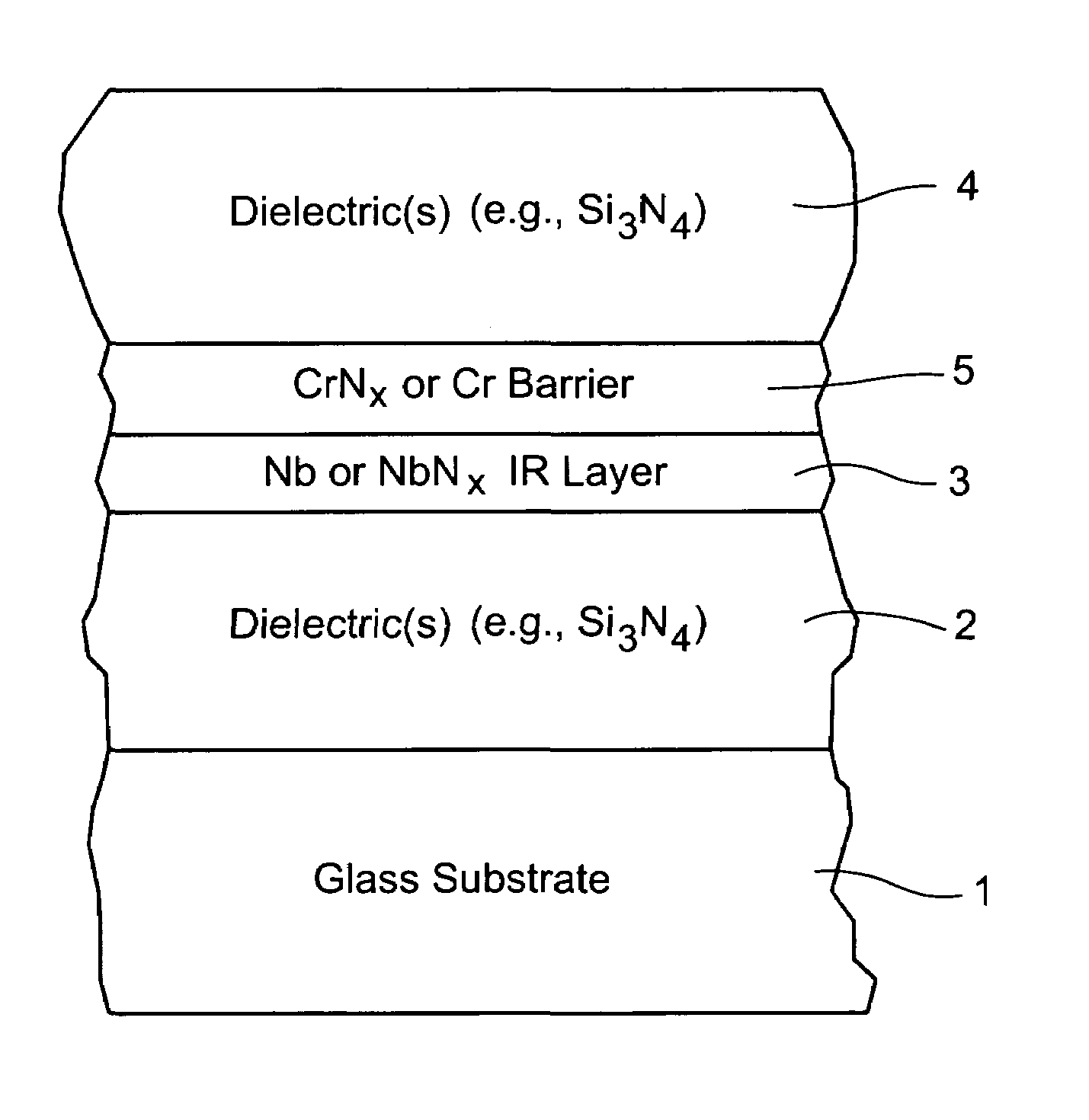

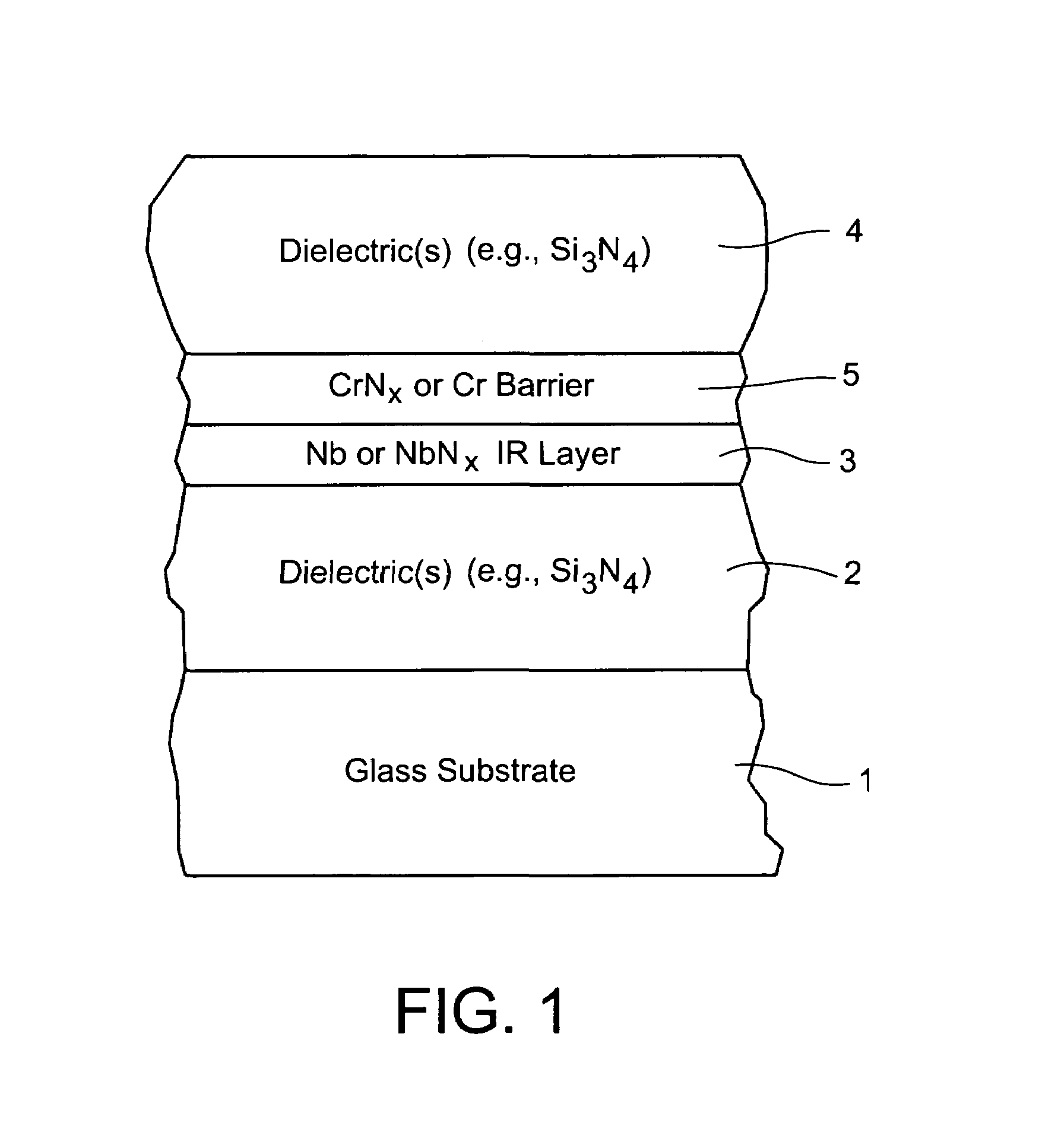

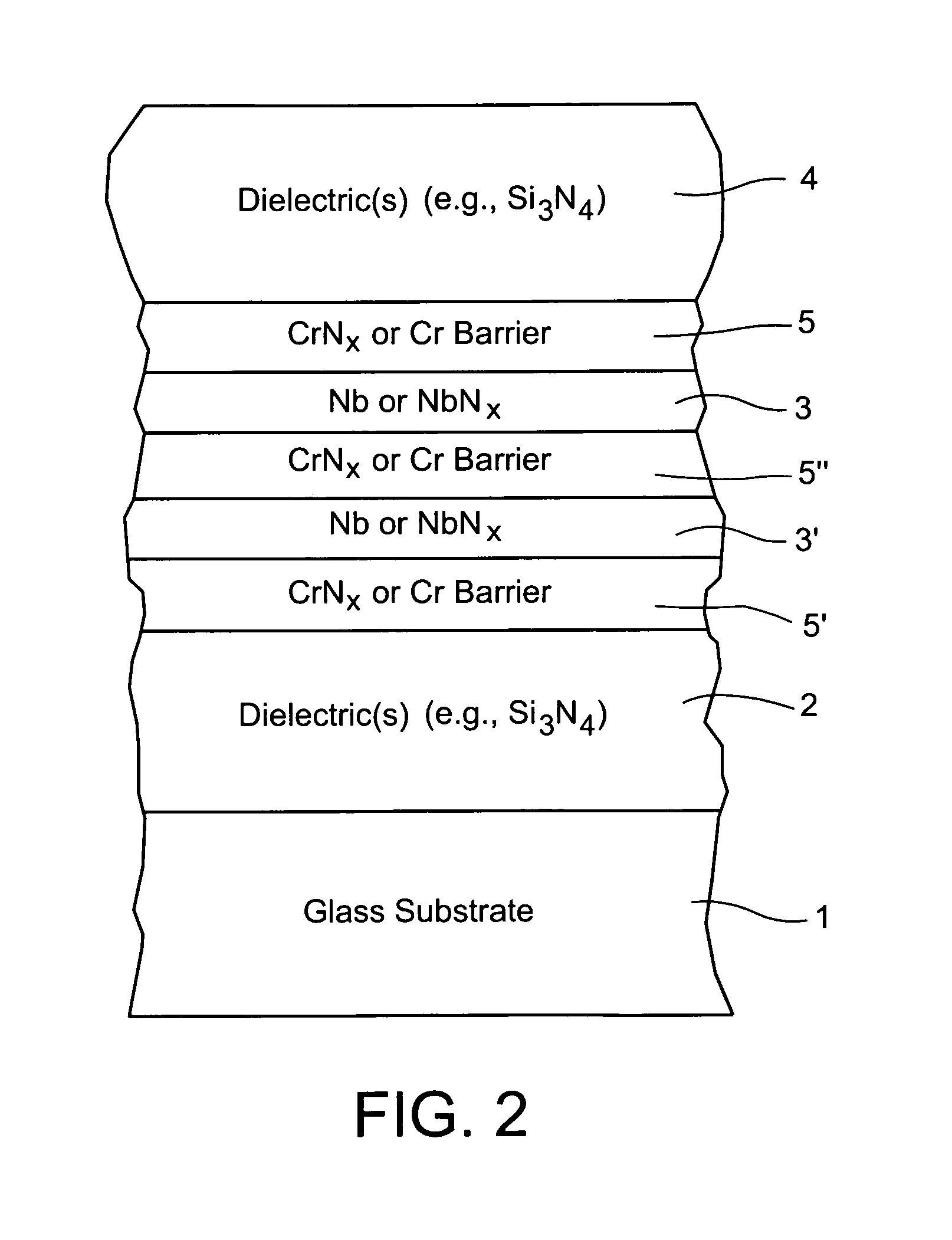

Heat treatable coated article and method of making same

ActiveUS20050079369A1More durableImproved color stabilityGlass/slag layered productsCoatingsNiobiumReflective layer

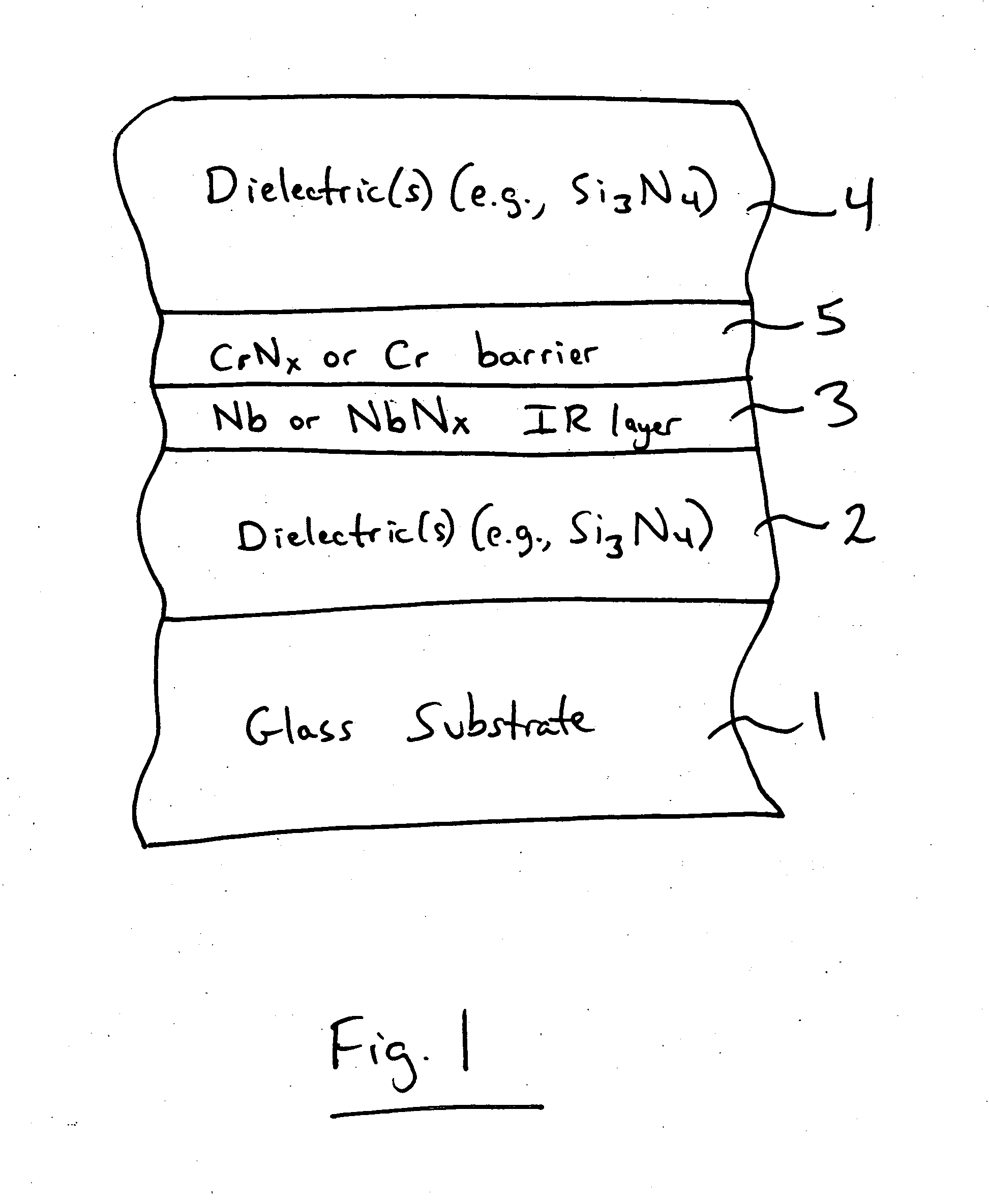

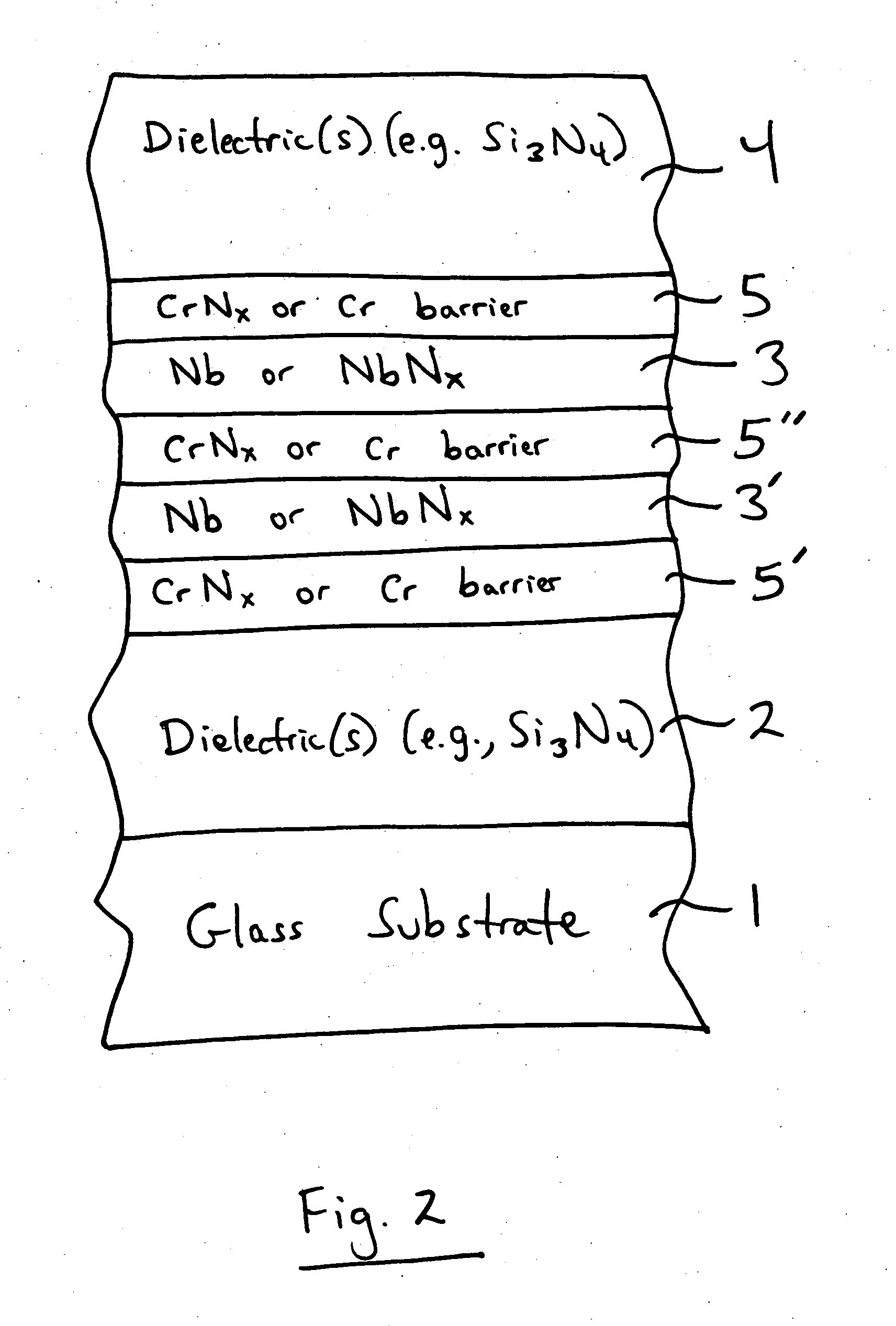

A coated article or layer system is provided which includes at least one infrared (IR) reflecting layer including niobium (Nb) sandwiched between at least a pair of dielectric layers. In certain embodiments, a Cr inclusive barrier layer is provided to protect the Nb inclusive IR reflecting layer, for chemical durability purposes. In other example embodiments, a protective overcoat including a zirconium oxide inclusive layer may be provided to protect the Nb inclusive IR reflecting layer for durability purposes.

Owner:GUARDIAN GLASS LLC

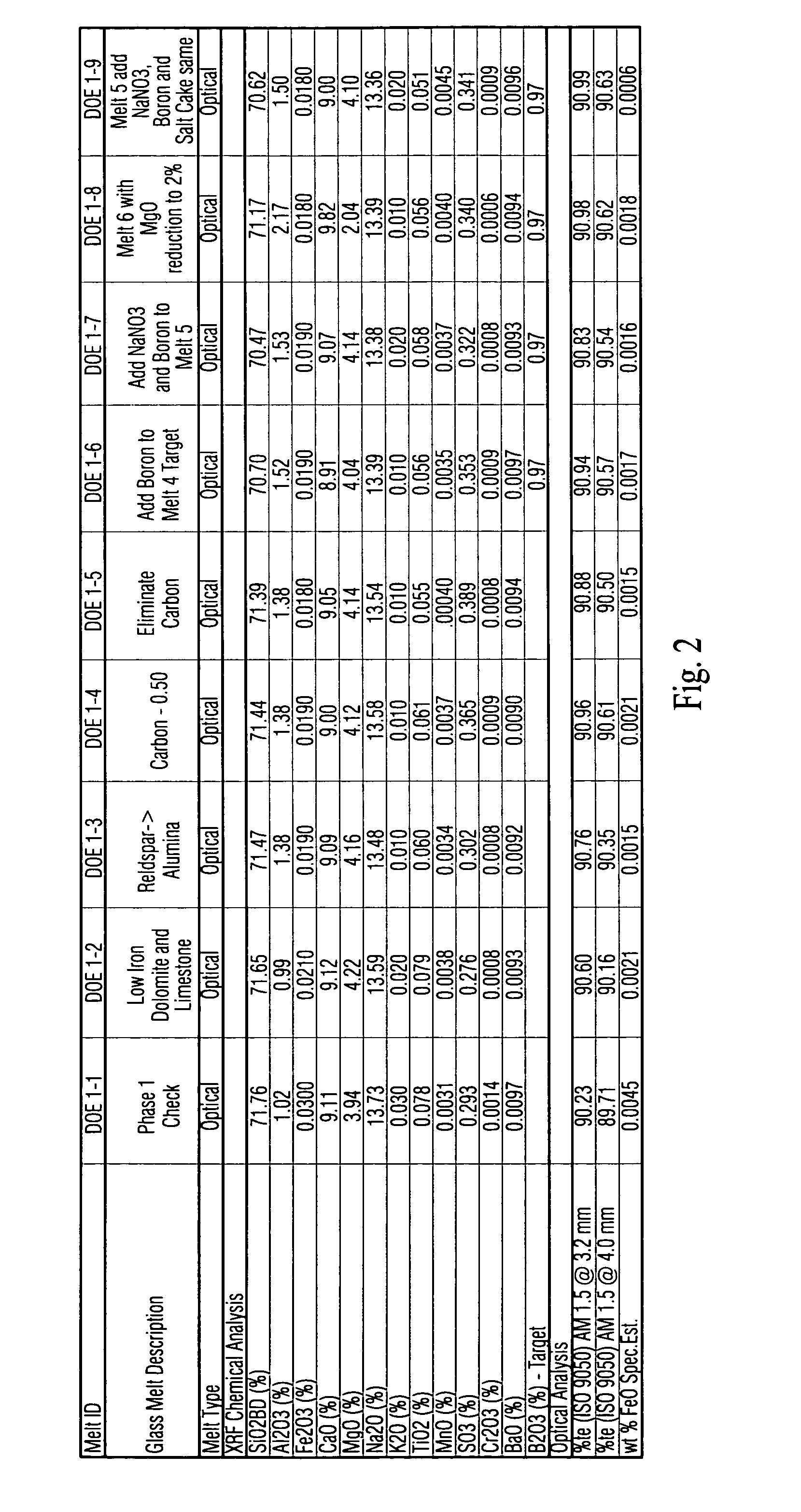

Low iron high transmission glass with boron oxide for improved optics, durability and refining, and corresponding method

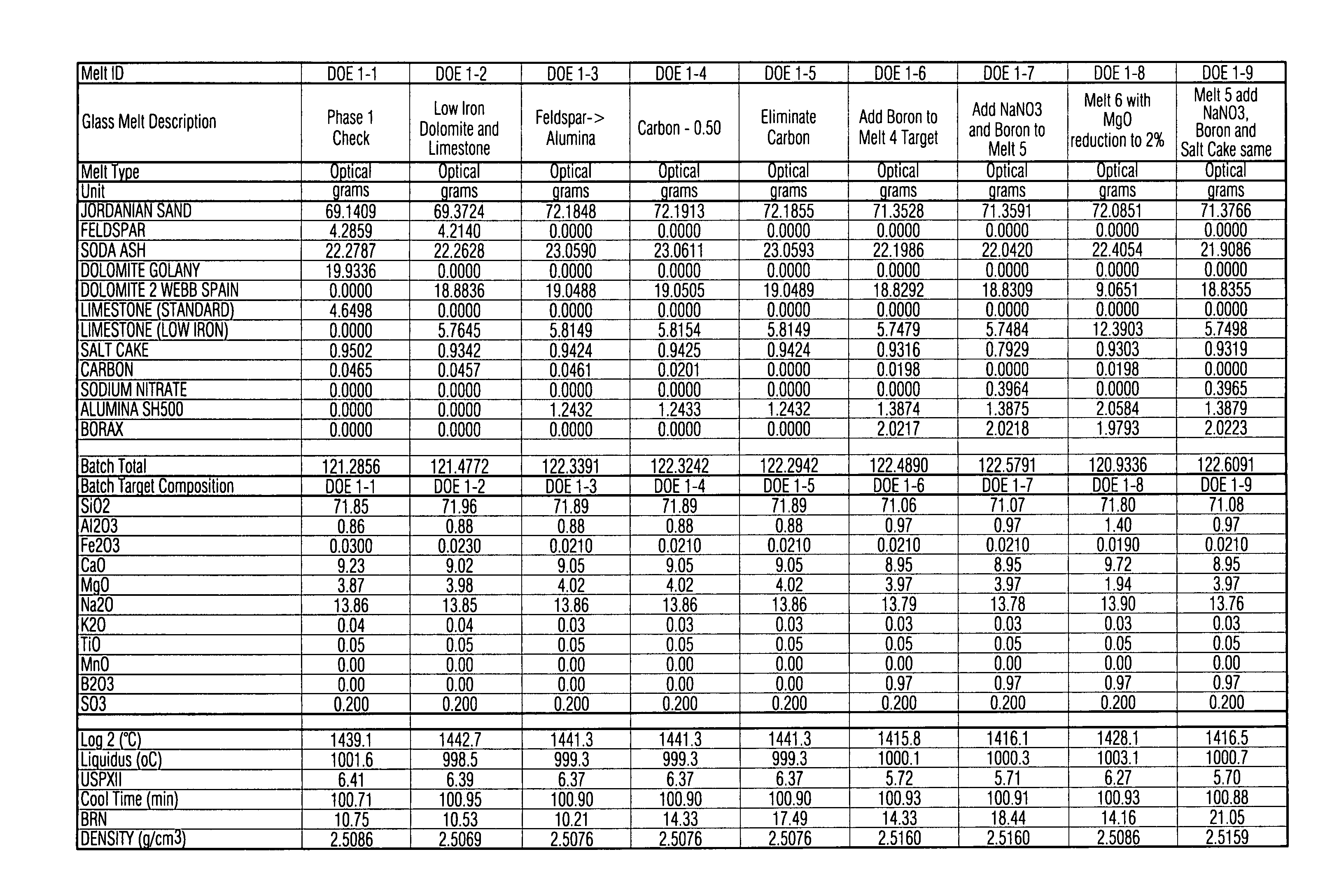

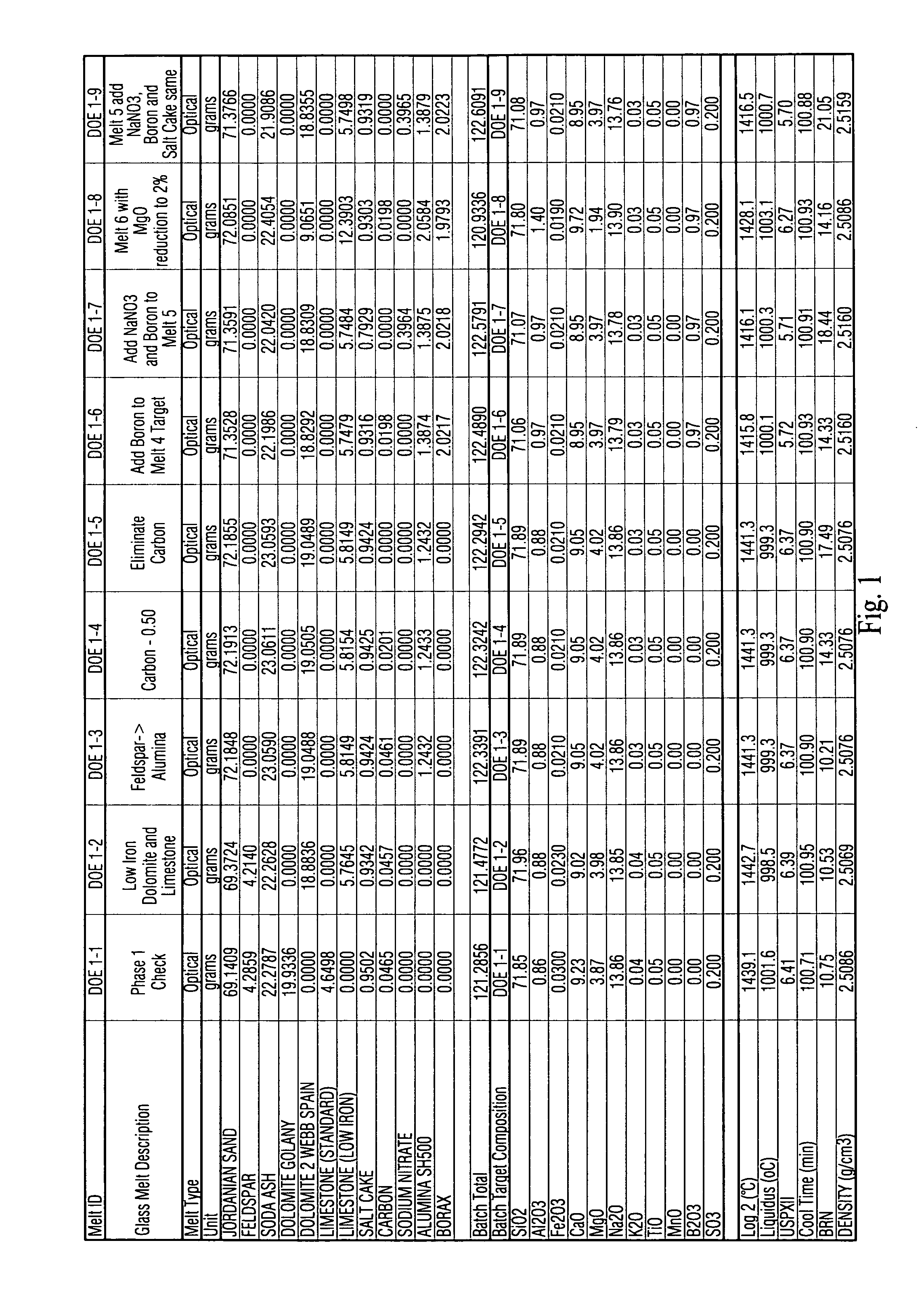

This invention relates to a high transmission low iron glass that includes boron oxide. The boron oxide, added to this low iron glass, has the effect of improving glass refining, homogeneity and quality (lower seed count) through its flux action and improves glass optical parameters of green and clear glass through the change in refractive index and surface tension. Boron oxide lends to broader and weaker absorption band of such transition element(s) as iron which additionally improves the transmittance of low iron clear glass in certain example embodiments of this invention. In certain example embodiments, the addition of boron oxide in certain quantities in advantageous in that it improves the chemical durability of the glass by decreasing the USPX (or USPXIII) value of the glass via suppression of the silica, sodium ions in the glass structure.

Owner:PHOENICIA AMERICA ISRAEL FLAT GLASS +1

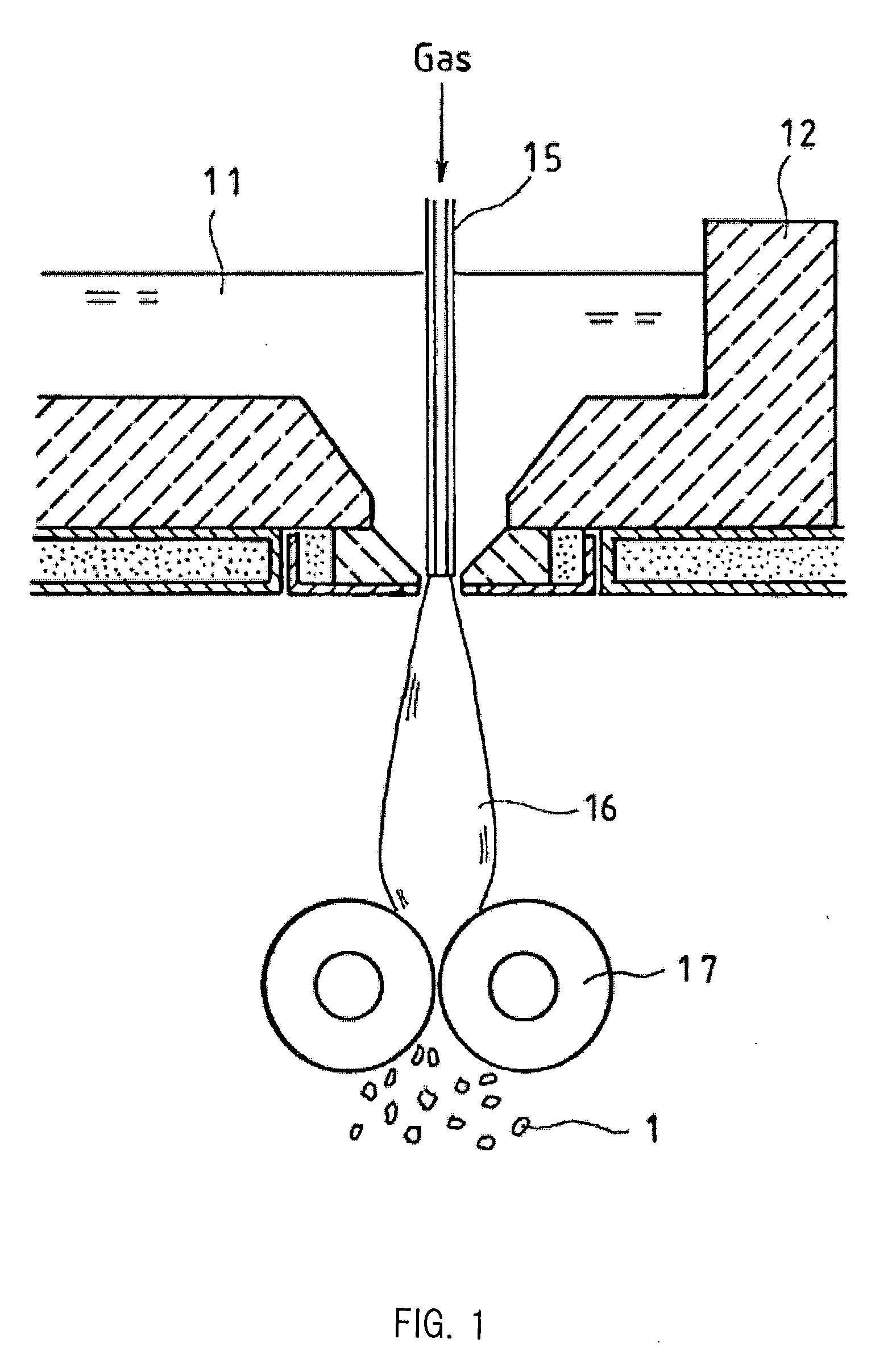

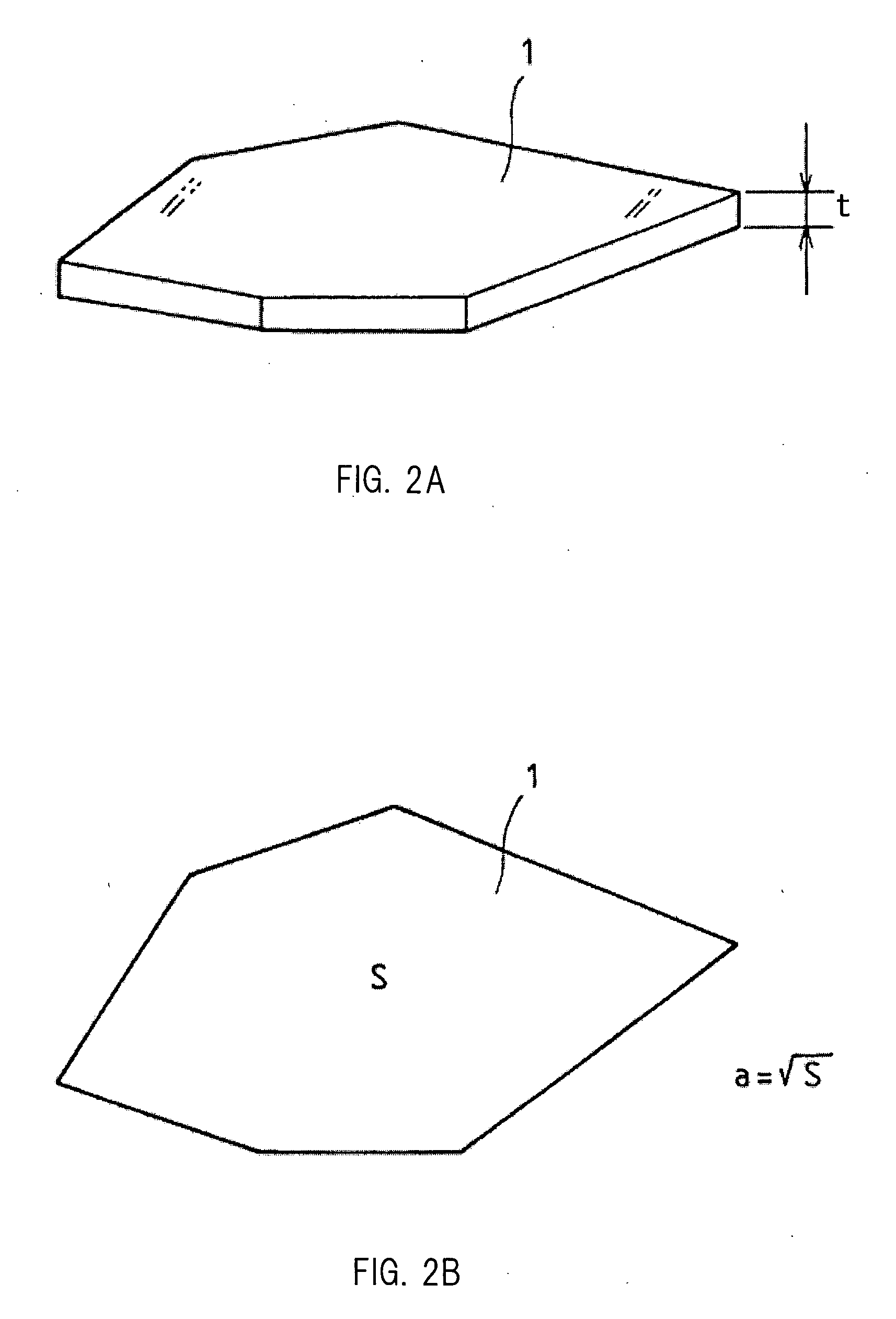

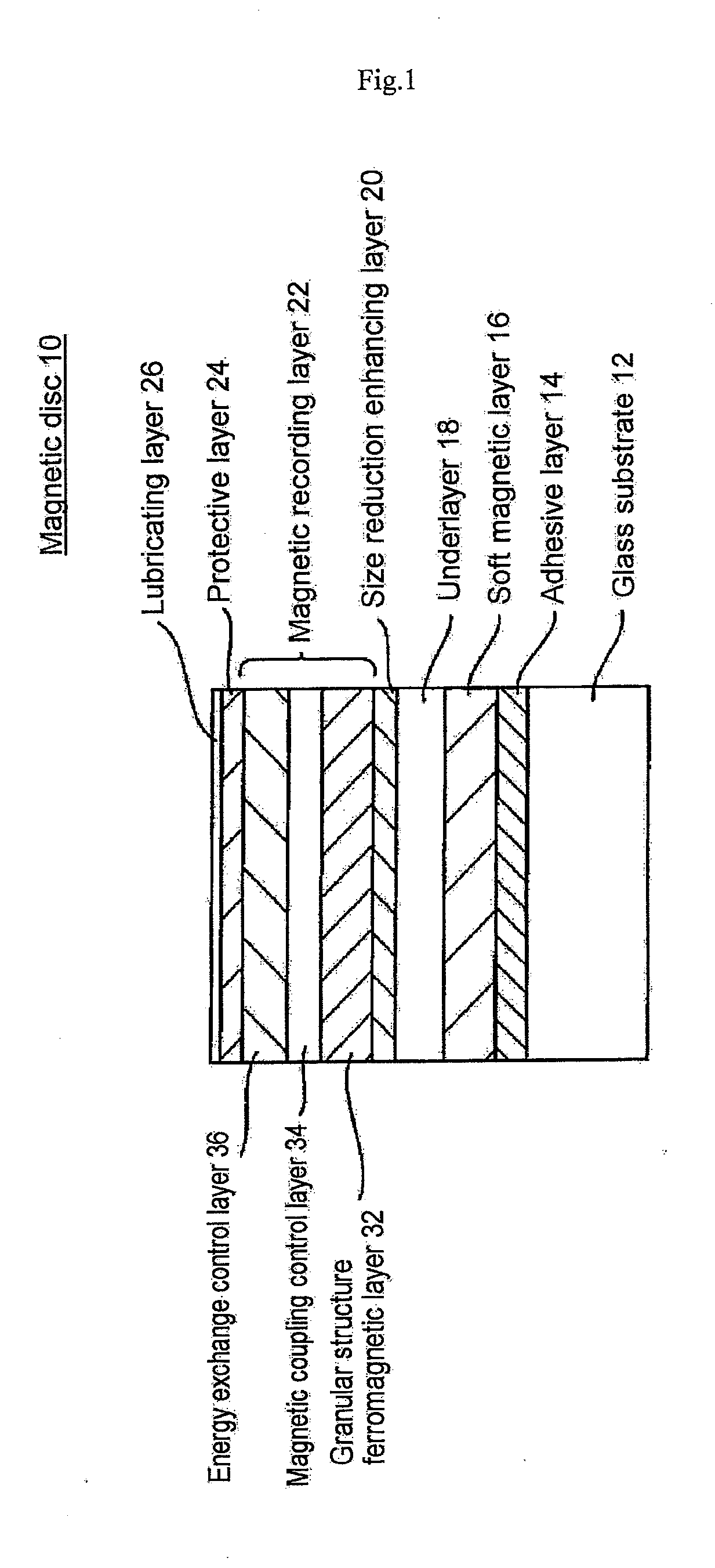

Glass-ceramic composition for recording disk substrate

InactiveUS6593257B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicOxide

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 15 wt % of ZrO2, wherein a value of ZrO2 / P2O5 is within a range from 1.1 to 8.5, expressed in terms of weight percent on the oxide basis.

Owner:HOYA CORP

Protective layers for sputter coated article

InactiveUS6833194B1Improve throughputTendency increaseVacuum evaporation coatingSputtering coatingLow emissivityMetal Primer

Owner:VITRO FLAT GLASS LLC

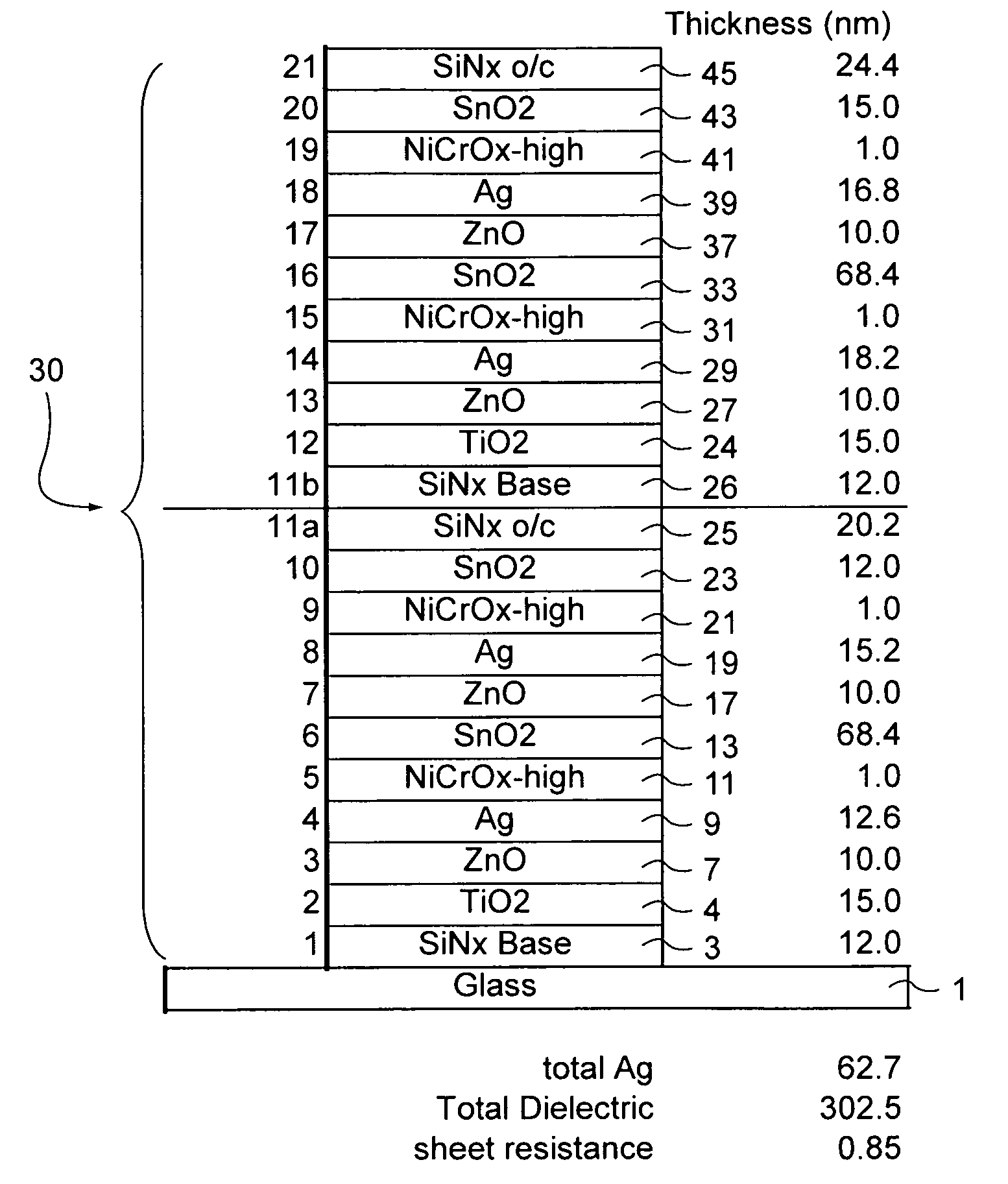

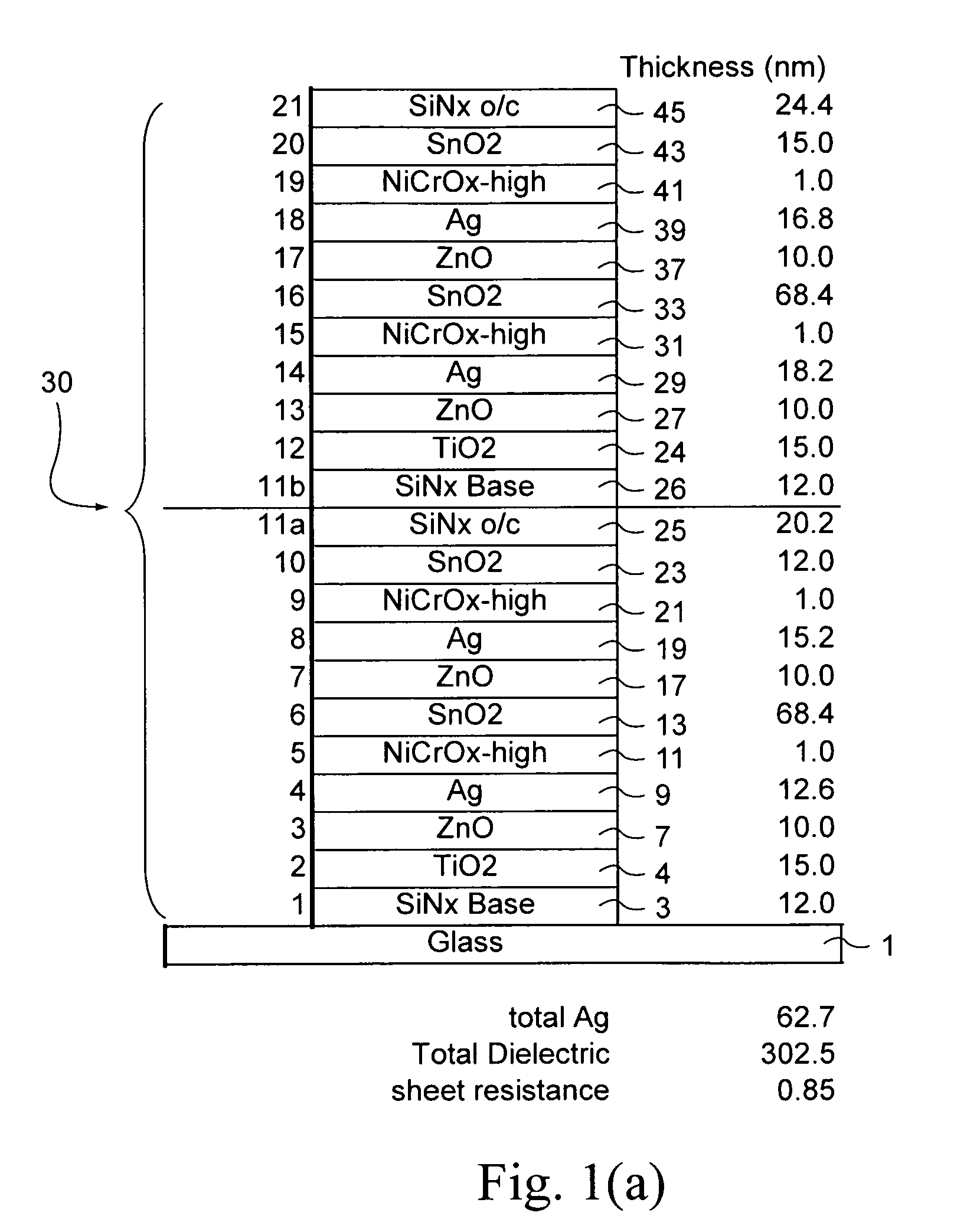

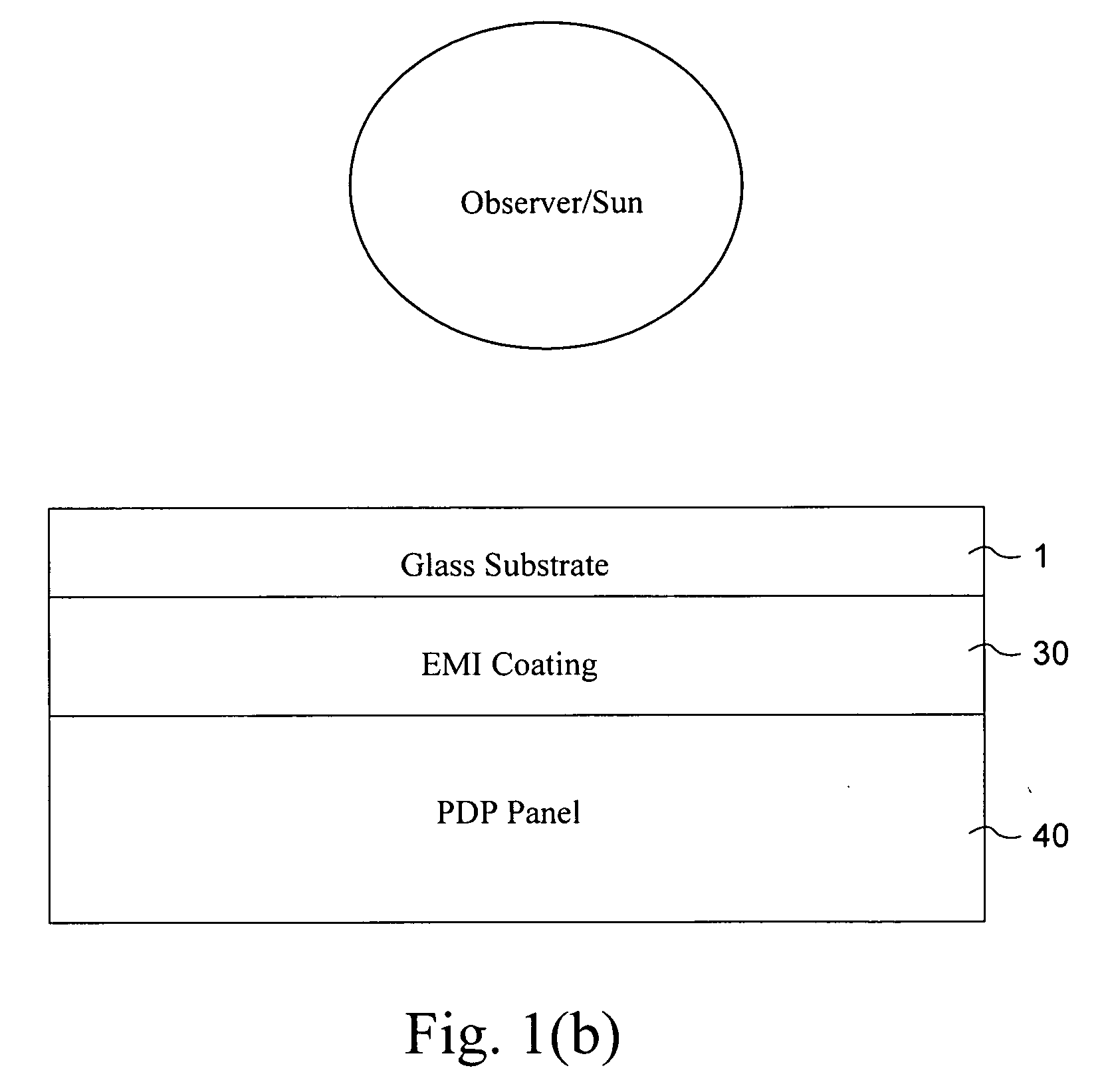

Plasma display panel including frameless EMI filter, and/or method of making the same

ActiveUS20100046191A1Easy to makeImprove display effectMagnetic/electric field screeningAlternating current plasma display panelsInfraredConductive coating

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

Shippable heat-treatable sputter coated article and zinc cathode sputtering target containing low amounts of tin

InactiveUS6899953B1Improve chemical durabilityReduced hazeVacuum evaporation coatingSputtering coatingMetal PrimerLow emissivity

Tin is added to a zinc cathode target to enhance the sputter efficiency of the target. Films deposited using the cathode, e.g., greater than zero but less than 10 weight percent tin and greater than 90 but less than 100 weight percent zinc improve the chemical durability of a high transmittance, low emissivity coating stack over coating stacks having zinc oxides without tin oxide. High transmittance, low emissivity coating stacks are heated with the heated coating having reduced haze by selecting the thickness of metal primer layer between an infrared reflective film, e.g. a silver film and a dielectric film, e.g., a 52-48 zinc stannate, zinc oxide, tin oxide film or a zinc oxide film. Also disclosed are enhancing films that lower the resistivity of silver films deposited thereon and improve chemical durability of the coating stack.

Owner:VITRO FLAT GLASS LLC

Lithium silicate glass ceramic

ActiveUS7867930B2Easy to shapeExcellent chemical durabilityDental implantsGlass drawing apparatusSilicate glassPhysical chemistry

Owner:IVOCLAR VIVADENT AG

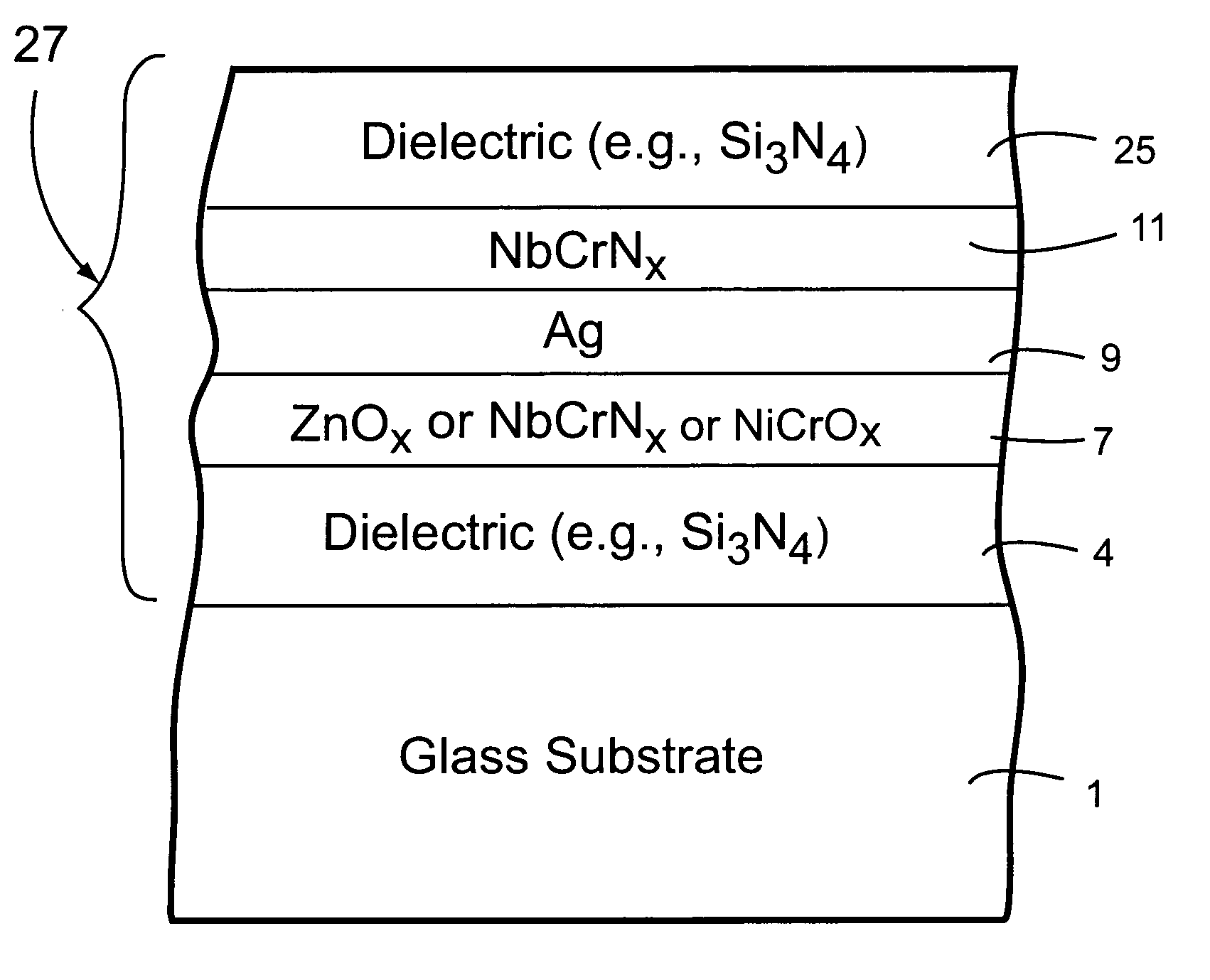

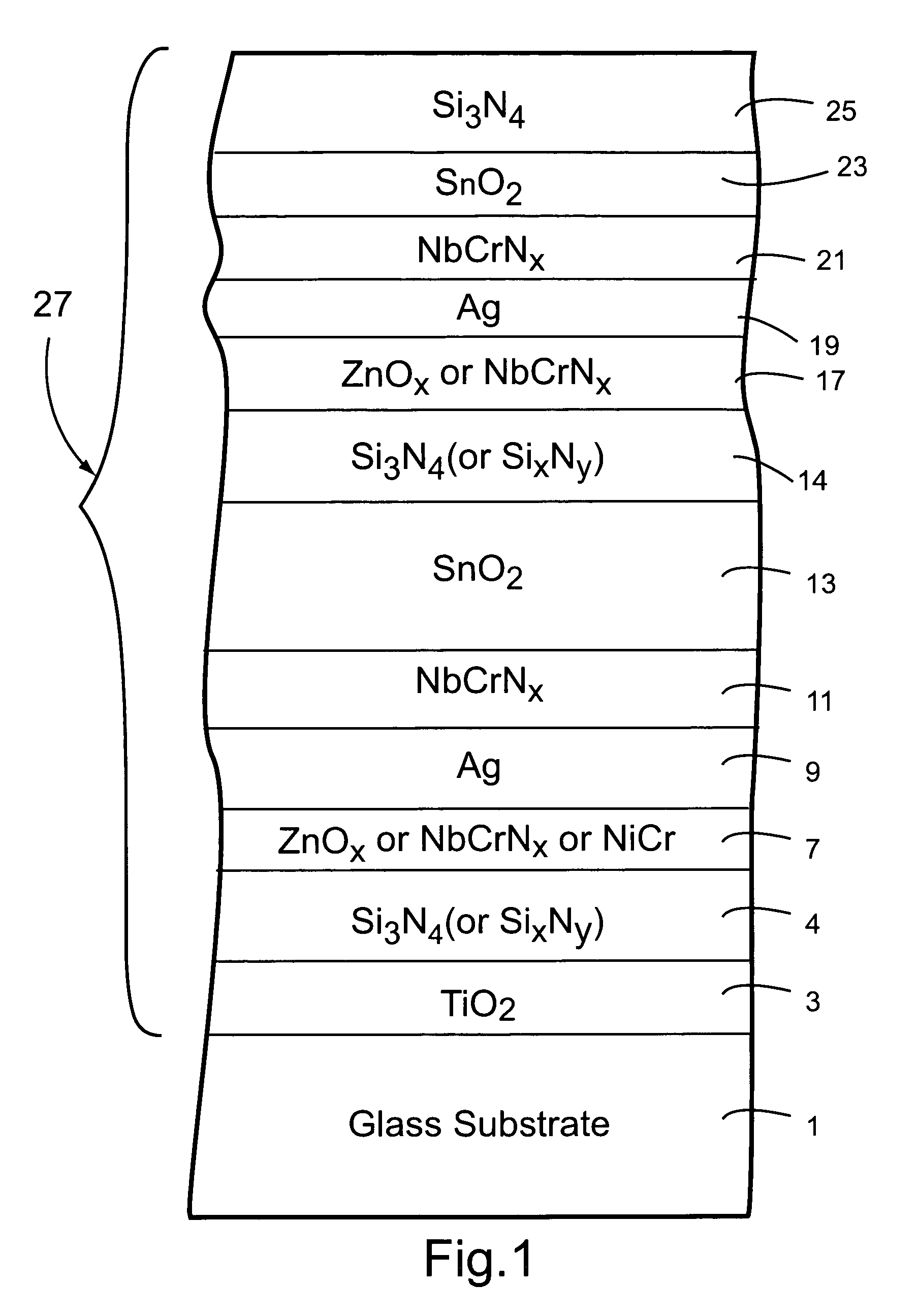

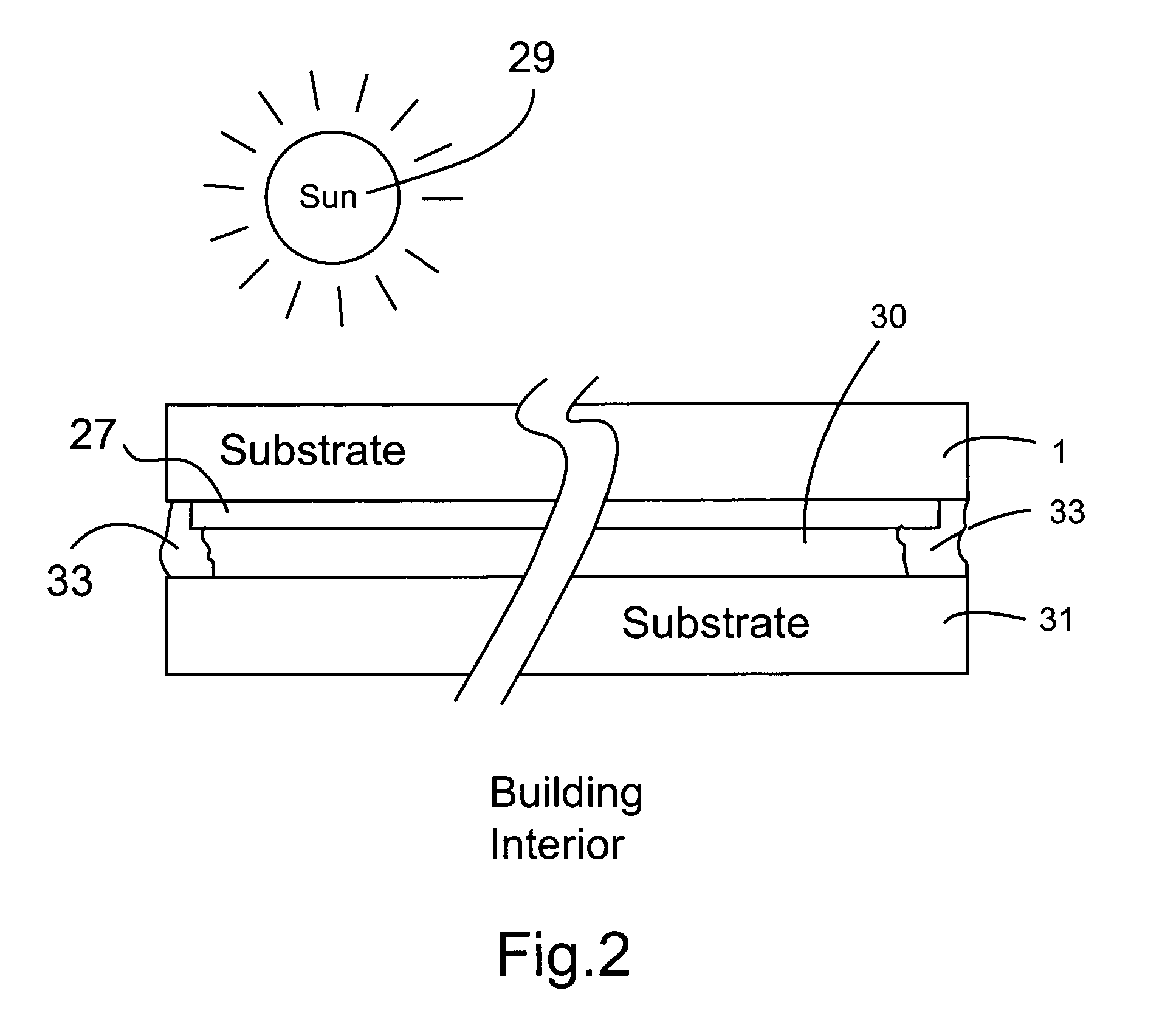

Coated article with niobium chromium inclusive barrier layer(s) and method of making same

ActiveUS6974630B1Improve thermal performanceExcellent chemical durabilityGlass/slag layered productsWing framesNiobiumContact layer

A coated article is provided so as to include a coating (e.g., low-E coating, or the like) having at least one layer of or including niobium chromium (NbCr). The NbCr layer may be nitrided. The NbCr inclusive layer (e.g., NbCrNx) may be provided as any suitable layer of the multi-layer coating, but in certain example instances may be used as a contact layer adjacent to an infrared (IR) reflecting layer. Coated articles herein may be used in the context of insulating glass (IG) window units, laminated windows, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

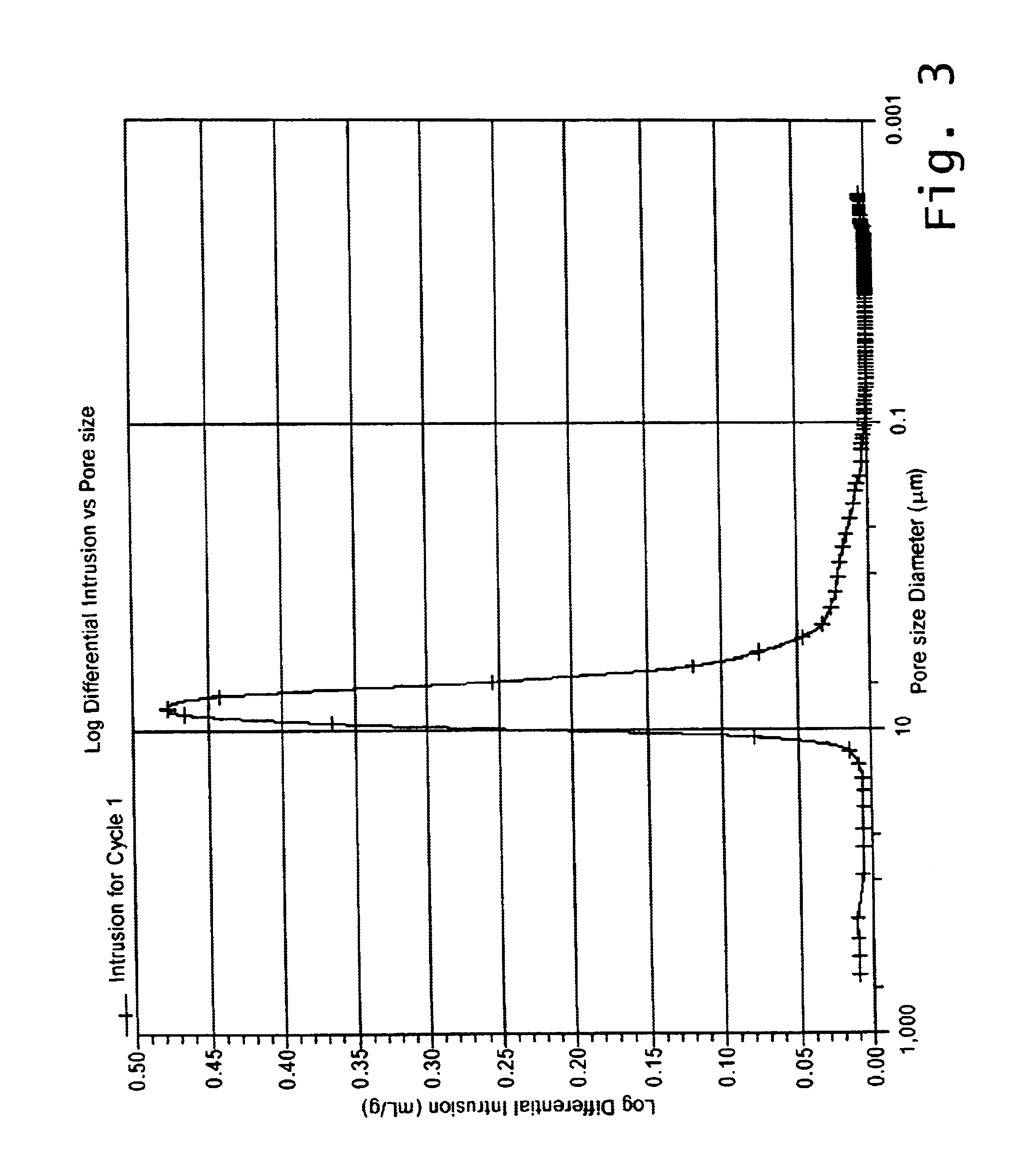

Reaction bonded alumina filter and membrane support

InactiveUS6695967B2Minimize changesIncrease the volume ratioSemi-permeable membranesDispersed particle filtrationAluminum metalMaterials science

A reaction-bonded alpha-alumina filter element is provided. The filter element includes a monolith of porous material having multiple passageways extending from one end face to an opposing end face. The monolith is extruded from a mixture containing at least aluminum metal and alumina powders in a proportion such that on sintering the volume change of the monolith is minimized. The filter body can be used as a filter or as a membrane support for crossflow or dead end flow filter elements. A method for making the filter element is also provided.

Owner:HPD

Lithium silicate glass ceramic

ActiveUS20090038344A1High chemical durabilityReduce shrinkageDental implantsOther chemical processesHigh intensityLithium

Owner:IVOCLAR VIVADENT AG

Coated article with niobium zirconium inclusive layer(s) and method of making same

InactiveUS6967060B2Good affinity (attraction)Increased durabilityVacuum evaporation coatingSputtering coatingIr reflectionInsulated glazing

A coated article is provided so as to include a coating (e.g., low-E coating, or the like) having at least one layer of or including niobium zirconium (NbZr). The NbZr layer may be metallic in certain example embodiments. Alternatively, an oxide and / or nitride of NbZr may be provided in other example embodiments. The NbZr inclusive layer may be provided as any suitable layer of the multi-layer coating, but in certain example instances may be used as a contact layer adjacent to an infrared (IR) reflecting layer. Coated articles herein may be used in the context of insulating glass (IG) window units, laminated windows, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

Lithium silicate glass ceramic

ActiveUS20090038508A1High chemical durabilityReduce shrinkageDental implantsImpression capsHigh intensityLithium

Owner:IVOCLAR VIVADENT AG

Lithium silicate glass ceramic

ActiveUS7867933B2Easy to shapeExcellent chemical durabilityDental implantsAlkali metal silicatesLithiumSilicate glass

Owner:IVOCLAR VIVADENT AG

Glass-ceramic composition for recording disk substrate

InactiveUS6514890B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicMaterials science

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 0.8 wt % of ZrO2.

Owner:HOYA CORP

Coated article with and oxide of silicon zirconium or zirconium yttrium oxide in overcoat, and/or niobium nitrude in ir reflecting layer

ActiveUS7081301B2More durableImproved color stabilityGlass/slag layered productsCoatingsNiobiumReflective layer

A coated article or layer system is provided which includes at least one infrared (IR) reflecting layer including niobium (Nb) sandwiched between at least a pair of dielectric layers. In certain embodiments, a Cr inclusive barrier layer is provided to protect the Nb inclusive IR reflecting layer, for chemical durability purposes. In other example embodiments, a protective overcoat including a zirconium oxide inclusive layer may be provided to protect the Nb inclusive IR reflecting layer for durability purposes.

Owner:GUARDIAN GLASS LLC

Shippable heat-treatable sputter coated article and method of making same

InactiveUS7329433B2Reduce smogReduce heatVacuum evaporation coatingSputtering coatingAlloySilicon oxide

The present invention provides a method of making a coated article, including the steps of: (A) providing a substrate; (B) depositing one or more dielectric layers over the substrate, the dielectric layers comprising: (i) a first dielectric film having at least one film of zinc oxide, silicon oxide, tin oxide, silicon nitride, silicon oxynitrate, or an oxide of an alloy of zinc and tin having zinc in a weight percent range of 10 to 90 and tin in a weight percent range of 90 to 10, and (ii) a second dielectric film deposited over the first dielectric film, the second dielectric film having at least: a zinc oxide, tin oxide film, wherein the zinc oxide, tin oxide film has tin in a weight percent range of greater than 0 to less than 10 and the majority of the balance being zinc; and (C) depositing one or more infrared reflective layers on at least one of the dielectric layers.

Owner:VITRO FLAT GLASS LLC

Alkali-free glass substrate

ActiveUS20050065014A1Increase percentageSuitable for useGlass furnace apparatusNon-linear opticsAlkali freeMaterials science

An alkali-free glass substrate containing, by mass percent, 50-70% of SiO2, 10-25% of Al2O3, 5-20% of B2O3, 0-10% of MgO, 0-15% of CaO, 0-10% of BaO, 0-10% of SrO and 0-5% of ZnO, also containing SnO2 and / or Sb2O3 and having a B-OH value of at least 0.485 / mm.

Owner:NIPPON ELECTRIC GLASS CO LTD

Glass Flake

ActiveUS20080124559A1Excellent heat resistance , chemical durability , and formabilityImproved chemical durabilityCosmetic preparationsToilet preparationsChemistry

A glass flake of the present invention has a composition that includes, in terms of mass %, 59≦SiO2<65, 8≦Al2O3≦15, 47<(SiO2—Al2O3)≦57, 1≦MgO≦5, 20≦CaO≦30, 0<(Li2O+Na2O+K2O)<2, and 0≦TiO2≦5 and that is substantially free from B2O3, F, ZnO, BaO, SrO, and ZrO2.

Owner:NIPPON SHEET GLASS CO LTD

Easy-to-clean matte acid resistant ground coat

InactiveUS6511931B1Good spot acid resistanceEasy to cleanGlass/slag layered productsSuperimposed coating processSheet steelAcid resistance

The present invention provides a ground coat composition for use in forming an enamel layer on sheet steel that exhibits good spot acid resistance, a satin finish, good bond, and is easy-to-clean. The composition according to the invention includes a glass component that includes a blend of from about 40% to about 70% by weight of a first glass portion including one or more alkali aluminophosphate frits, up to about 30% by weight of a second glass portion including one or more zirconia-phosphate frits, and up to about 30% by weight of a third glass portion including one or more alkali borosilicate frits.

Owner:FERRO CORP

Glass-ceramic composition for recording disk substrate

InactiveUS6458728B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicOxide

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 0.8 wt % of TiO2.

Owner:HOYA CORP

Optical glass suitable for mold forming

The present invention provides a low softening point glass, capable of being molded at a low temperature of about 270 to 400° C. and excellent chemical durability. That is to say, the feature consists in an optical glass for molding, being excellent in chemical durability and having a transformaion temperature (Tg) of at most 350° C. and a specific gravity (Sg) of at most 3.1, which is represented, in term of elements for making up the glass, by the following chemical composition (wt % on oxide basis, calculated from the component composition):

Owner:SUMITA OPTICAL GLASS

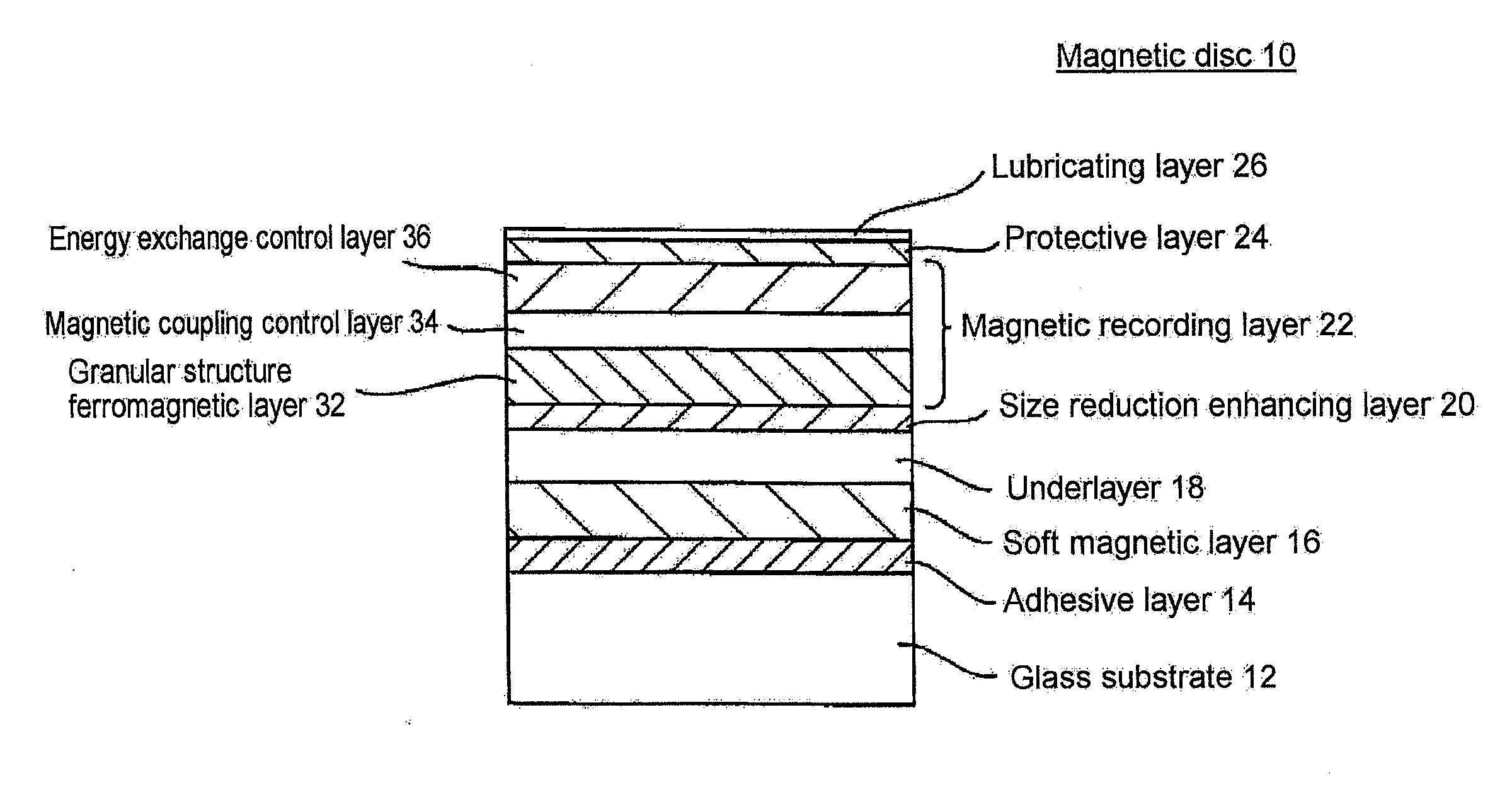

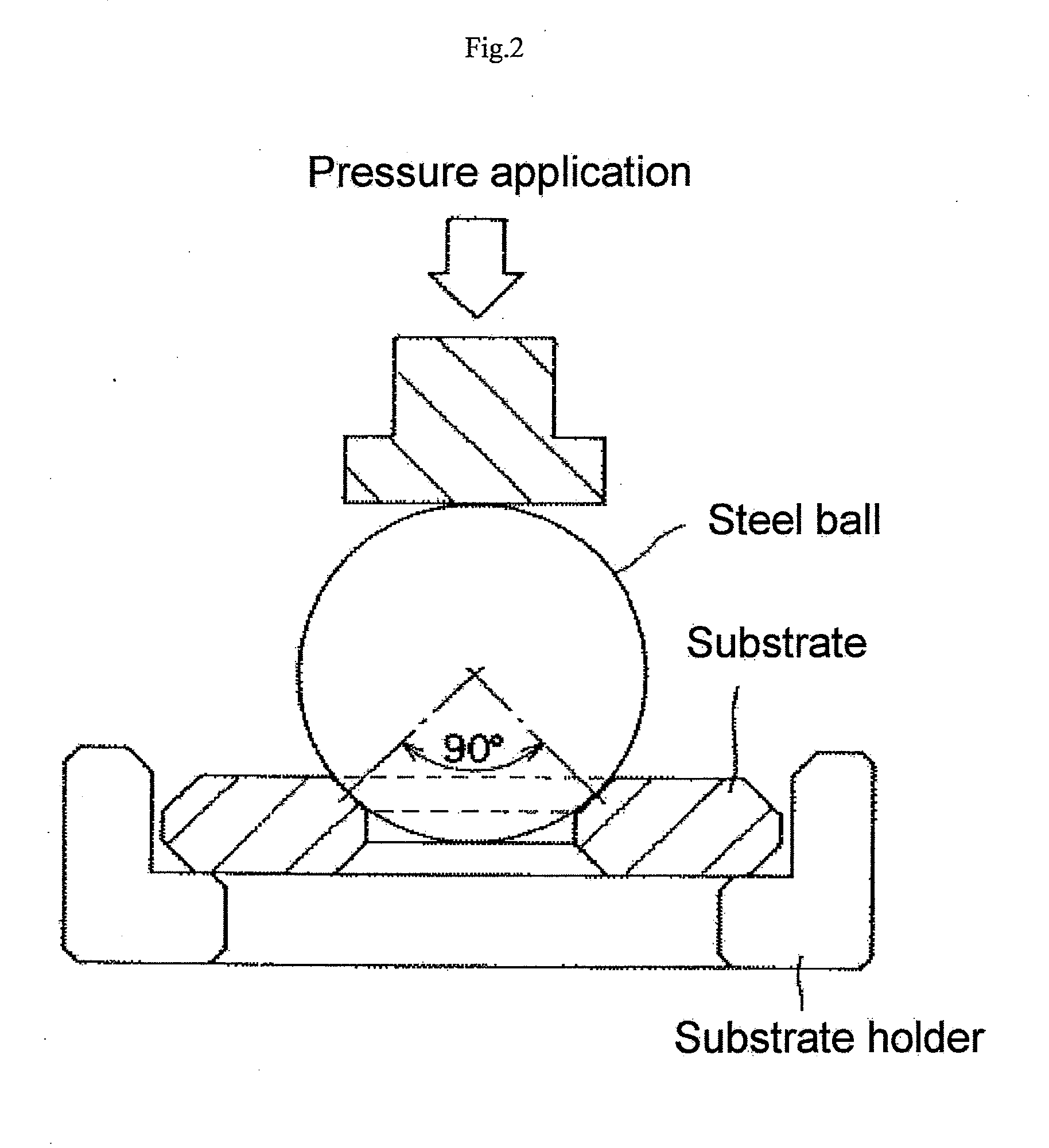

Glass for magnetic recording media substrates, magnetic recording media substrates, magnetic recording media and method for preparation thereof

ActiveUS20110086241A1Excellent chemical durabilityFlat surfaceMagnetic materials for record carriersGlass drawing apparatusRecording mediaChemistry

The provided are a glass for a magnetic recording medium substrate permitting the realization of a magnetic recording medium substrate affording good chemical durability and having an extremely flat surface, a magnetic recording medium substrate comprised of this glass, a magnetic recording medium equipped with this substrate, and methods of manufacturing the same. Glasses for a magnetic recording medium substrate are, glass I comprised of an oxide glass, comprising, denoted as mass percentages:Si 20 to 40 percent,Al 0.1 to 10 percent,Li 0.1 to 5 percent,Na 0.1 to 10 percent,K 0 to 5 percent(where the total content of Li, Na, and K is 15 percent or less),Sn 0.005 to 0.6 percent, andCe 0 to 1.2 percent;the Sb content is 0 to 0.1 percent; andnot comprising As or F;glass II comprised of oxide glass, comprising, as converted based on the oxide, denoted as molar percentages:SiO2 60 to 75 percent,Al2O3 1 to 15 percent,Li2O 0.1 to 20 percent,Na2O 0.1 to 15 percent, andK2O 0 to 5 percent(where the total content of Li2O, Na2O, and K2O is 25 percent or lower);based on the total amount of the glass components, 0.01 to 0.7 mass percent of Sn oxide and 0 to 1.4 mass percent of Ce oxide are added;the content of Sb oxide is 0 to 0.1 mass percent; andnot comprising As or F; andglass III comprised of oxide glass, comprising, converted based on the oxide, denoted as molar percentages:SiO2 60 to 75 percent,Al2O3 1 to 15 percent,Li2O 0.1 to 20 percent,Na2O 0.1 to 15 percent,K2O 0 to 5 percent(where the total content of Li2O, Na2O, and K2O is 25 percent or less);by comprising a 0.1 to 3.5 mass percent of total content of Sn oxide and Ce oxide, based on the total amount of the glass components;the ratio of the Sn oxide content to the total content of Sn oxide and Ce oxide (Sn oxide content / (Sn oxide content+Ce oxide content)) is 0.01 to 0.99;the Sb oxide content is 0 to 0.1 percent; andcomprising no As or F.

Owner:HOYA CORP

Crystallized glass for optical filter substrate, and optical filter

InactiveUS20040116268A1Easy to adjustExcellent chemical durabilityGlass/slag layered productsOptical elementsLinear expansion coefficientMaterials science

A crystallized glass for an optical filter substrate, which has an average linear expansion coefficient alphaL of from 95x10<-7> / ° C. to 130x10<-7> / ° C. at from -30° C. to 70° C. and which has a crystal or the like of Na4-xKxAl4Si4O16 (1<x<=4) precipitated therein. Further, a crystallized glass for an optical filter substrate, which comprises from 35 to 60% of SiO2, from 10 to 30% of Al2O3, from 1 to 15% of TiO2+ZrO2, from 4 to 20% of Na2O, from 4 to 20% of K20, from 0.1 to 10% of CaO+SrO+Bao, from 0 to 10% of MgO, etc., and which has alphaL of from 95x10<-7> / ° C. to 130x10<-7> / ° C. and which has a crystal or solid solution precipitated therein.

Owner:ASAHI GLASS CO LTD

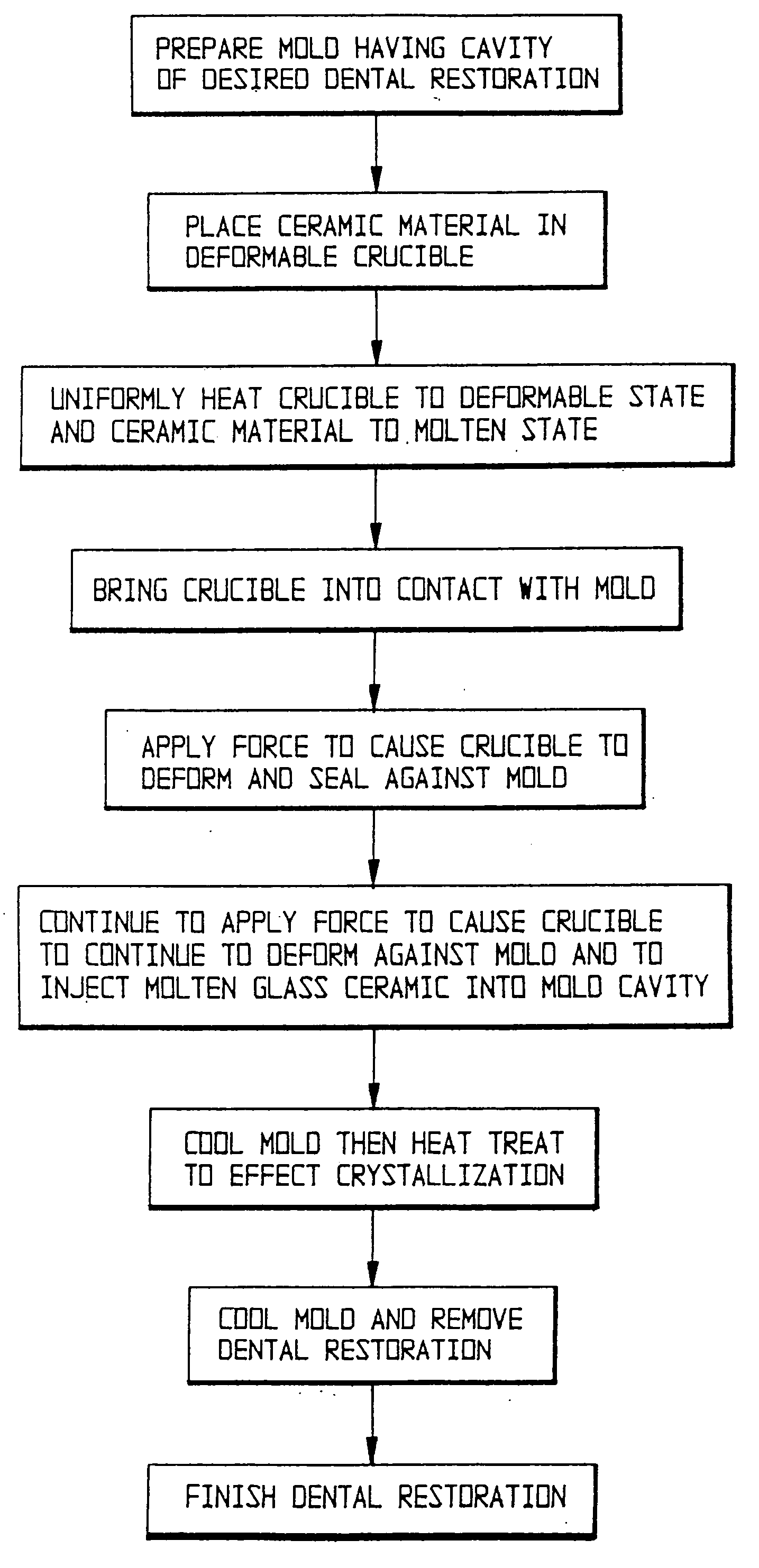

Method for molding dental restorations and related apparatus

InactiveUS20050115460A1Readily molded into dental restorationEasy to useImpression capsOther chemical processesWorking temperatureDental restoration

The present invention is concerned with a process for the formation of dental restorations from glass-ceramic materials, and the resulting dental restorations. In this invention, a dental restoration is prepared by placing a glass-ceramic material in a heat-pressure deformable crucible. Heat is then applied to the crucible in order to bring the glass-ceramic material to working range at temperatures above its liquidus temperature. The crucible in which the glass-ceramic material is placed has heat-pressure deformation properties which are matched to the working temperature of the glass-ceramic material being heated. The heat deformation properties of the crucible must be such that when the glass-ceramic material in the crucible is in the working range, the crucible is heat-pressure deformable without rupturing. Once the glass-ceramic material is heated to its working temperature, the crucible is brought into contact with a mold having a preformed cavity therein, the cavity being in the shape of the desired dental restoration. As the distance between the heated glass-ceramic material and the mold is decreased, the crucible is deformed to form a seal with the mold, thereby facilitating the injection of the molten glass-ceramic material into the mold cavity. An interactive seal between the crucible and the mold may be provided for. The composite process may be carried out in a vacuum. The resulting dental restoration has superior optical esthetic and strength properties. The invention further includes the heat-pressure deformable crucible. The invention includes dental restorations which are formed from particular lithium-disilicate glass-ceramics. In addition to forming dental restorations by the process of this invention, the dental restorations may be milled.

Owner:PETTICREW RICHARD W

Shippable heat-treatable sputter coated article and method of making same

InactiveUS20050155695A1Reduce smogReduce heatVacuum evaporation coatingSputtering coatingSilicon oxideReflective layer

The present invention provides a method of making a coated article, including the steps of: (A) providing a substrate; (B) depositing one or more dielectric layers over the substrate, the dielectric layers comprising: (i) a first dielectric film having at least one film of zinc oxide, silicon oxide, tin oxide, silicon nitride, silicon oxynitrate, or an oxide of an alloy of zinc and tin having zinc in a weight percent range of 10 to 90 and tin in a weight percent range of 90 to 10, and (ii) a second dielectric film deposited over the first dielectric film, the second dielectric film having at least: a zinc oxide, tin oxide film, wherein the zinc oxide, tin oxide film has tin in a weight percent range of greater than 0 to less than 10 and the majority of the balance being zinc; and (C) depositing one or more infrared reflective layers on at least one of the dielectric layers.

Owner:VITRO FLAT GLASS LLC

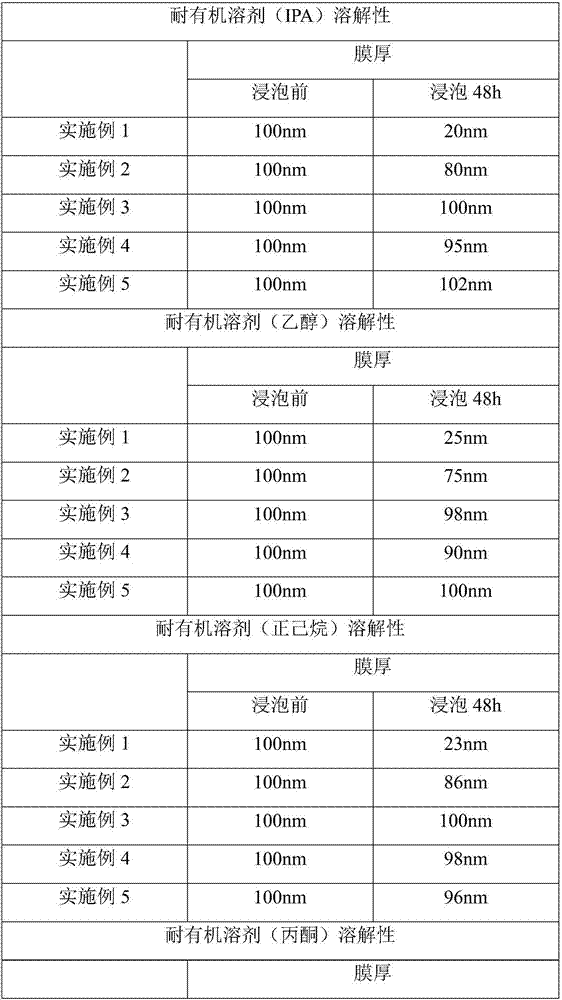

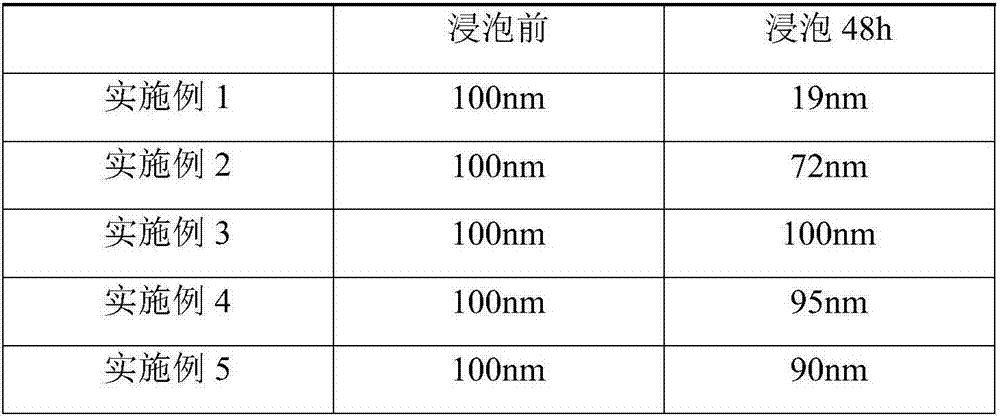

Preparing method for coating with controllable crosslinking degree

ActiveCN106906456AImprove compactnessImprove the protective effectChemical vapor deposition coatingNitrogen gasActive point

The invention discloses a preparing method for a coating with the controllable crosslinking degree, and belongs to the technical field of plasma chemical vapor deposition. The method mainly comprises the following steps that firstly, a base material is placed in a reaction cavity of a plasma chamber, the reaction cavity is continuously subjected to vacuum pumping, the vacuum degree in the reaction cavity reaches 10-200 millitorrs through pumping, the reaction cavity is inflated with inert gases or nitrogen, and a stable plasma environment is provided; then, the reaction cavity is inflated with monomer steam, plasma discharge is started, and chemical vapor deposition is conducted; and discharge is ended, a plasma power source is turned off, inflation of the monomer steam is stopped, vacuum pumping is continuously conducted, and after the vacuum degree of the reaction cavity is kept to range from 10 millitorrs to 200 millitorrs for 1-5 min, inflation of the atmosphere is conducted to one atmospheric pressure, and then the base material is taken out. According to the preparing method, through introduction of polyfunctionality monomer, a dense net-shaped structure is formed by the coating, the material is endowed with good physical and chemical durability, and meanwhile the material can be endowed with excellent waterproof and oil preventing functions; and the binding force and the mechanical strength are improved through combination of the base material and monomer active points.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

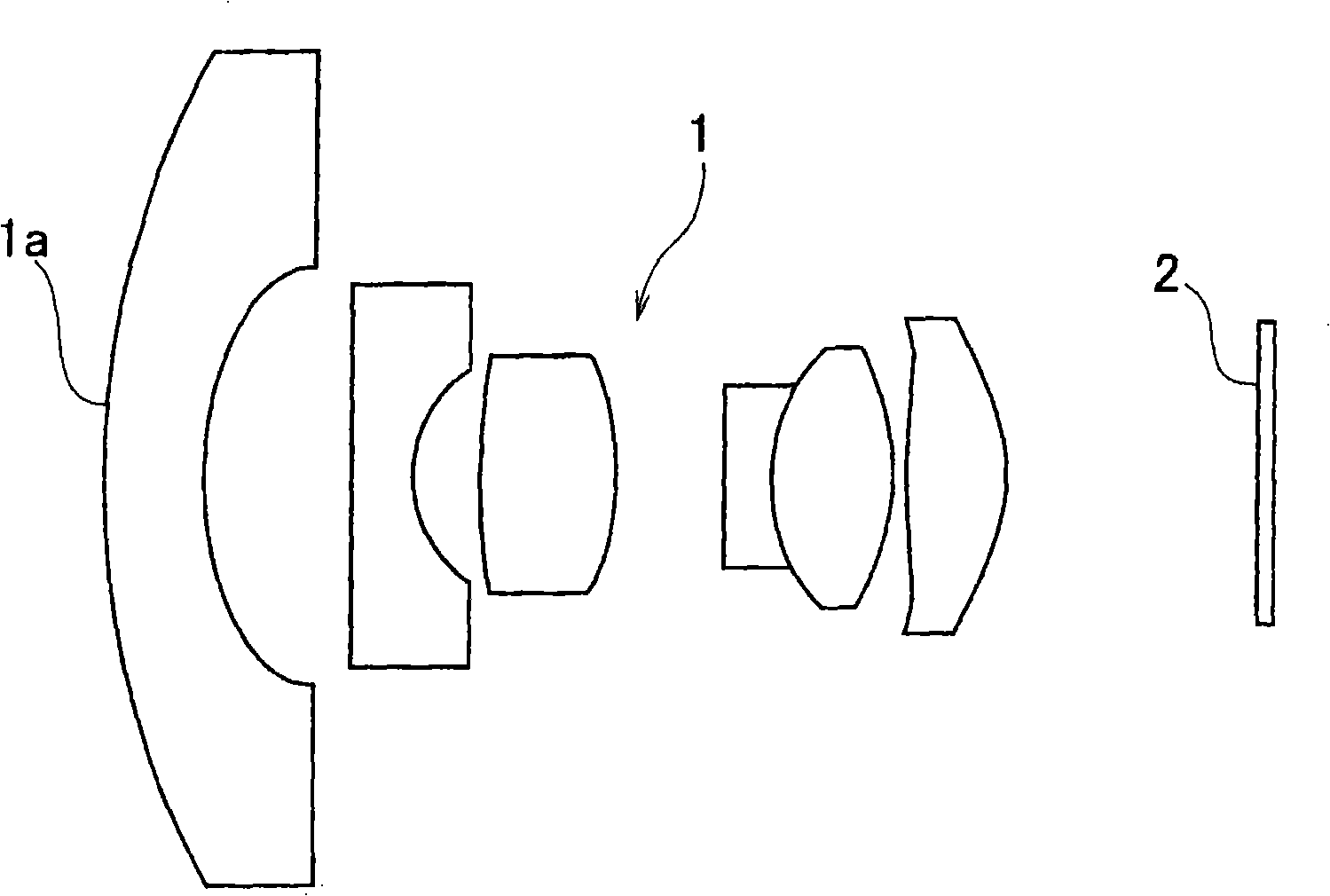

On-vehicle camera lens glass material and on-vehicle camera lens

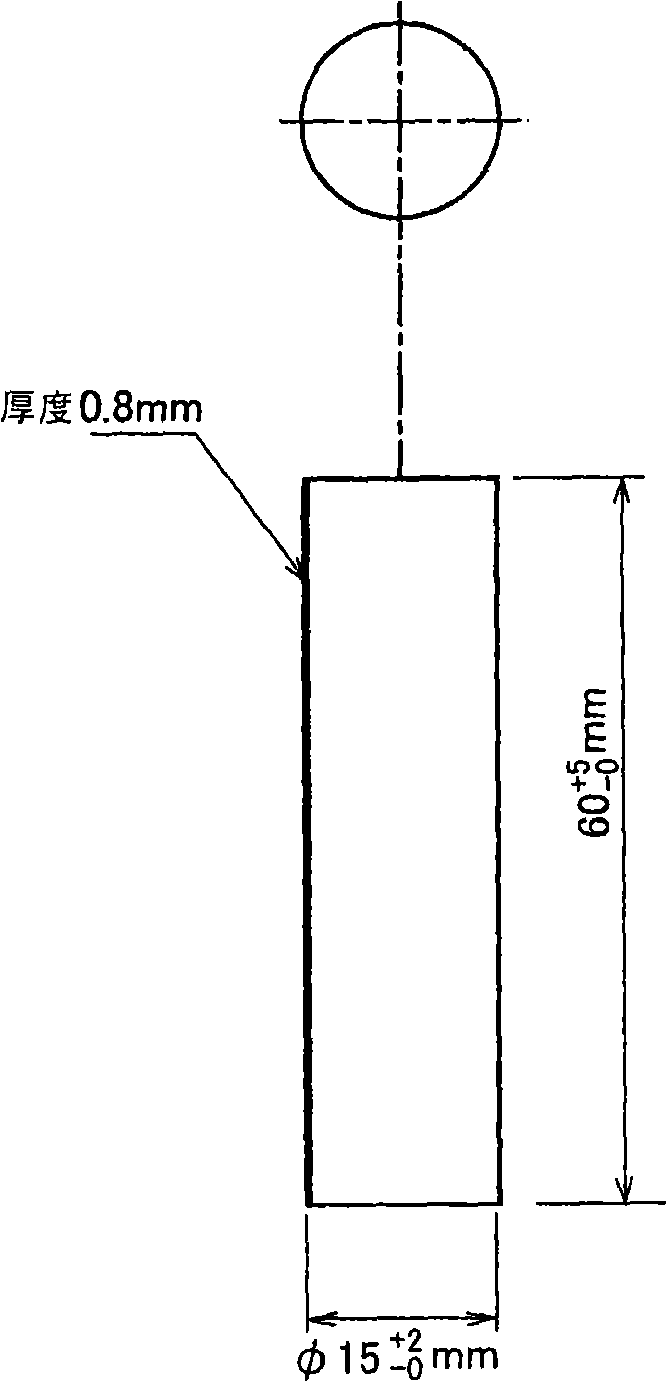

InactiveCN101271165AExcellent chemical durabilityImprove resistance to damageOptical viewingOptical elementsCamera lensRefractive index

This invention provides an on-vehicle camera lens glass material with excellent resistance to acid rain or medicine and full hardness, which comprises high reflection ratio through reducing the characteristic deterioration caused by ultraviolet ray, and is suitable for composing optical components such as on-vehicle camera lens on the on-vehicle camera which can be exposed under cruel environment, additionally, this invention provides an on-vehicle camera lens made of this on-vehicle camera lens glass material. The on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is the first class; a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is sixth class or higher; a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less; and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is less than 100*10(-7) DEG C (-1).

Owner:HOYA CORP

Electrolyte material, electrolyte membrane and membrane-electrolyte assembly for polymer electrolyte fuel cells

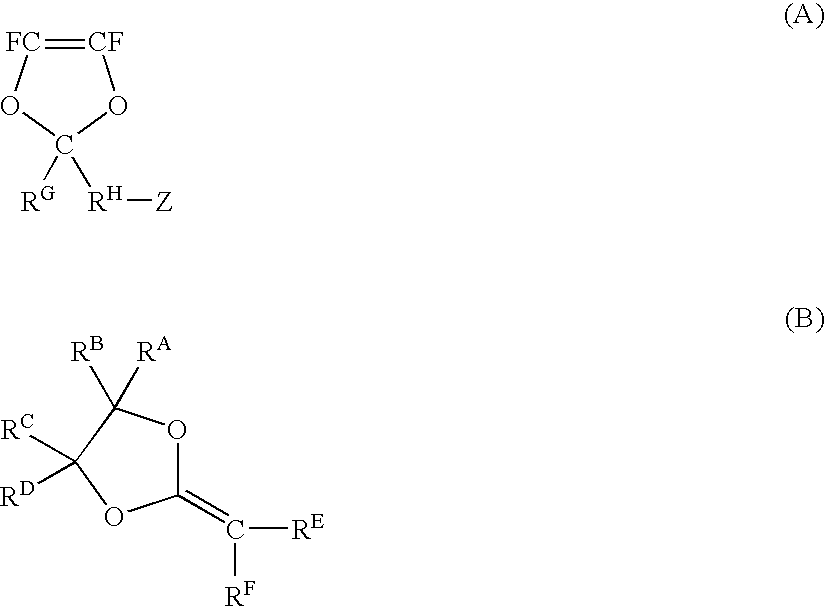

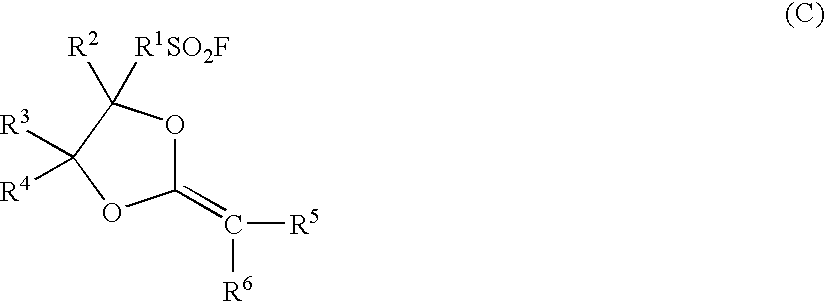

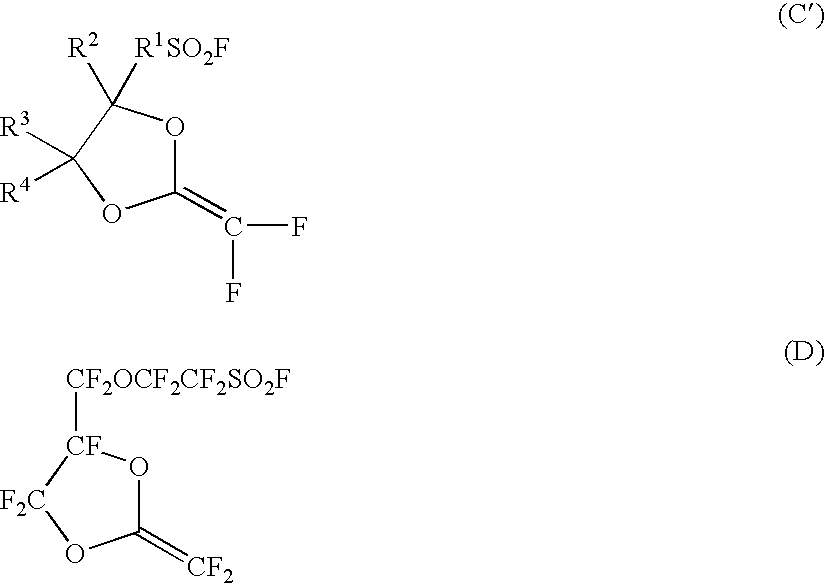

ActiveUS20070202377A1Excellent chemical durabilityHigh softening temperatureIon-exchange process apparatusSemi-permeable membranesFuel cellsIon exchange

To provide an electrolyte material for polymer electrolyte fuel cells having a high softening temperature and being excellent in durability, and an electrolyte membrane and a process for producing a membrane-electrode assembly using it. An electrolyte material made of a polymer containing a segment A of a polymer containing repeating units based on a perfluoromonomer having an ion exchange group and having a polymerizable double bond, at least one of carbon atoms in the polymerizable double bond being a carbon atom contained in an alicyclic structure, and a segment B of a fluoropolymer containing substantially no ion exchange group, and an electrolyte membrane and a membrane-electrode assembly using it.

Owner:ASAHI GLASS CO LTD

Optical glass suitable for mold forming at low temperature

InactiveUS20080032879A1High stability against devitrificationImprove mass productionDevitrificationMetallurgy

An optical glass suitable for mold forming at a low temperature including, in percent by weight, 9-25 percent of P2O5, 1-20 percent of GeO2, 12-28 percent of Nb2O5, 1-7 percent of TiO2, 0-55 percent of Bi2O3, 0-38 percent of WO3, 0-3 percent of SiO2, 0-5 percent of B2O3, 0-2 percent of Al2O3, 0-5 percent of Li2O, 0-11 percent of Na2O, 0-5 percent of K2O, 0-3 percent of Ta2O5, 0-1 percent of Sb2O3, at most 13 percent of at least one R2O selected from the group consisting of Li2O, Na2O and K2O, and at most 15 percent of at least one XO selected from the group consisting of CaO, SrO, BaO and ZnO. The optical glass essentially contains no environmental and human harmful components, facilitates mass production and is stable against devitrification near its softening temperature.

Owner:ASIA OPTICAL INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com