Patents

Literature

510 results about "Insulated glazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insulating glass (IG), more commonly known as double glazing (or double-pane, and increasingly triple and quadruple glazing/pane), consists of two or more glass window panes separated by a vacuum or gas filled space to reduce heat transfer across a part of the building envelope.

Electrochromic window fabrication methods

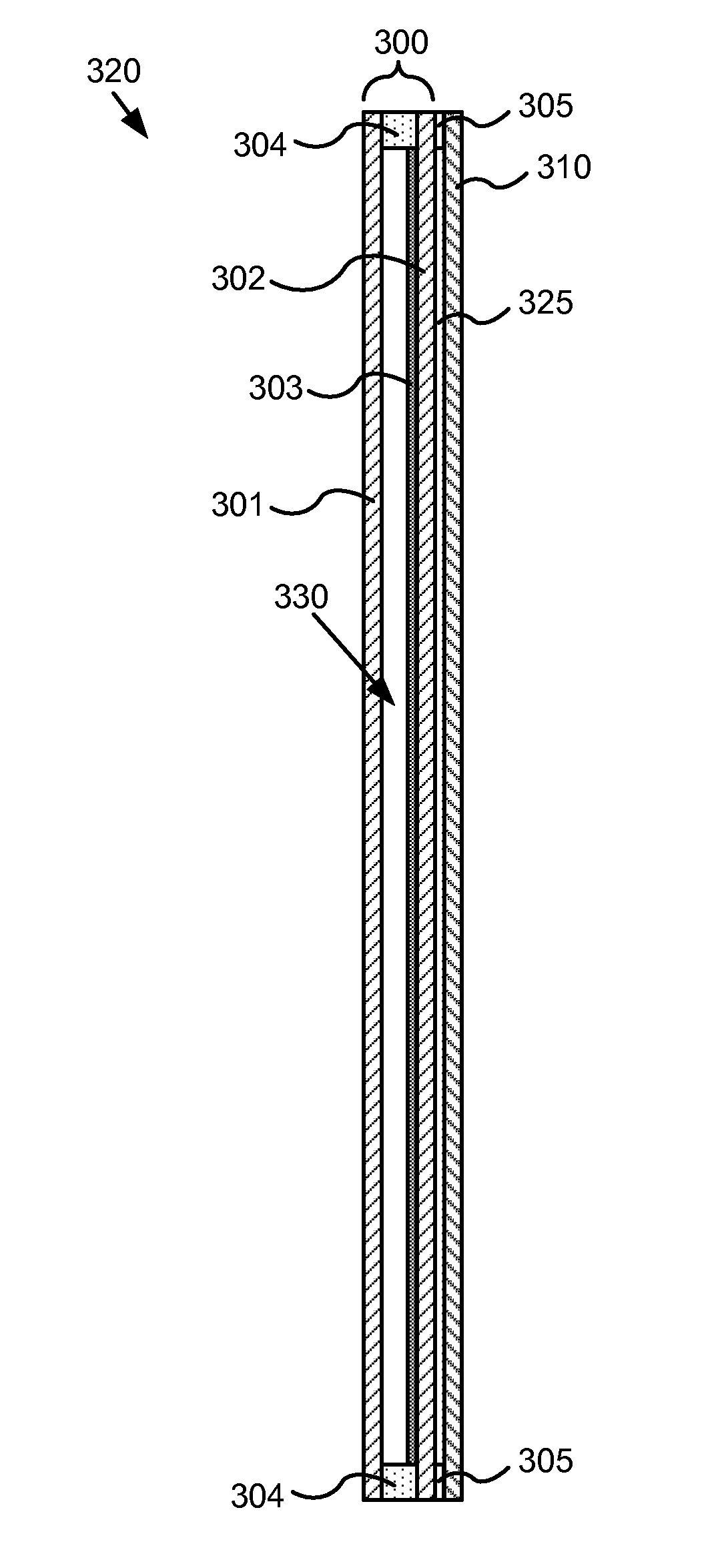

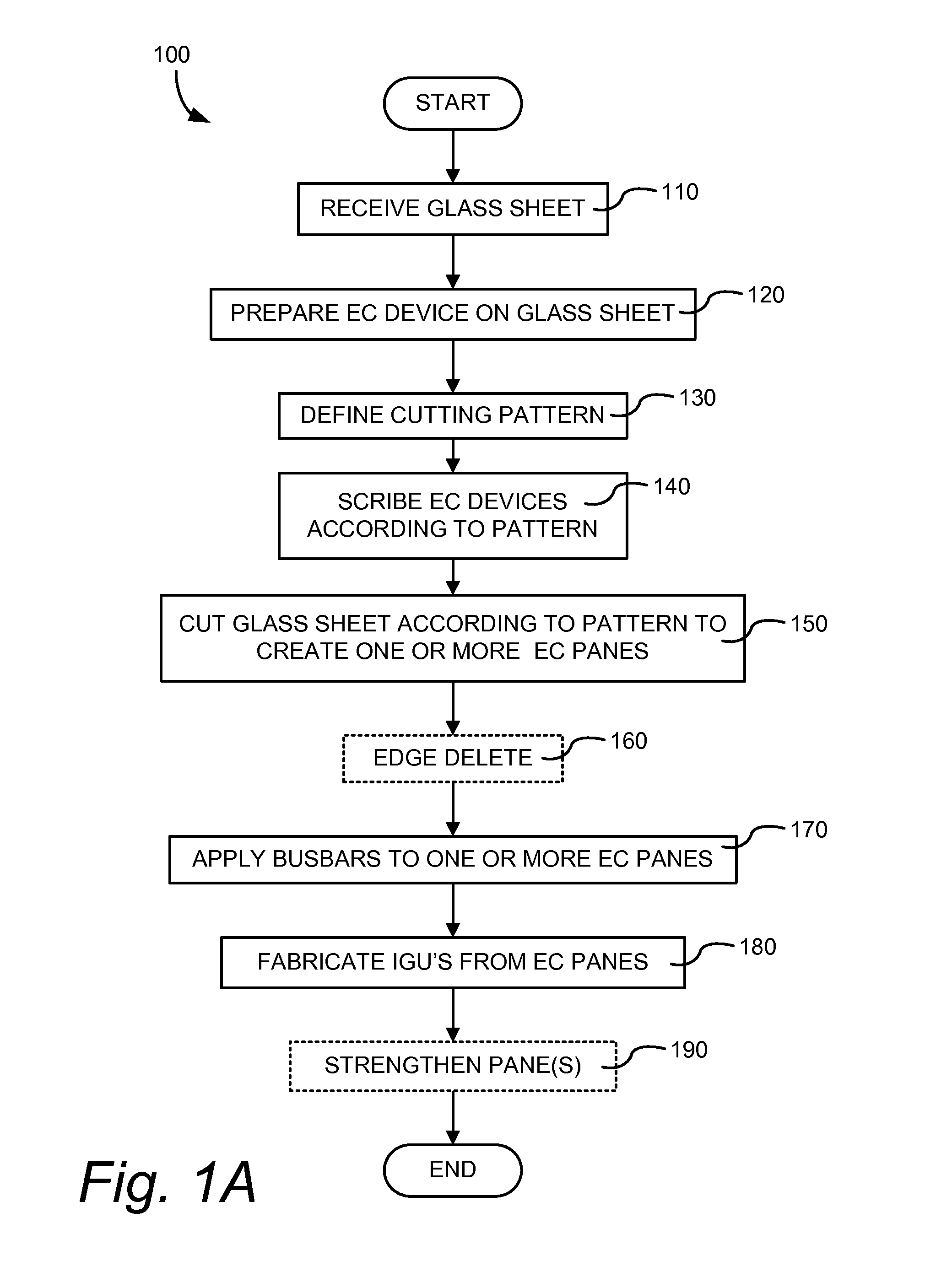

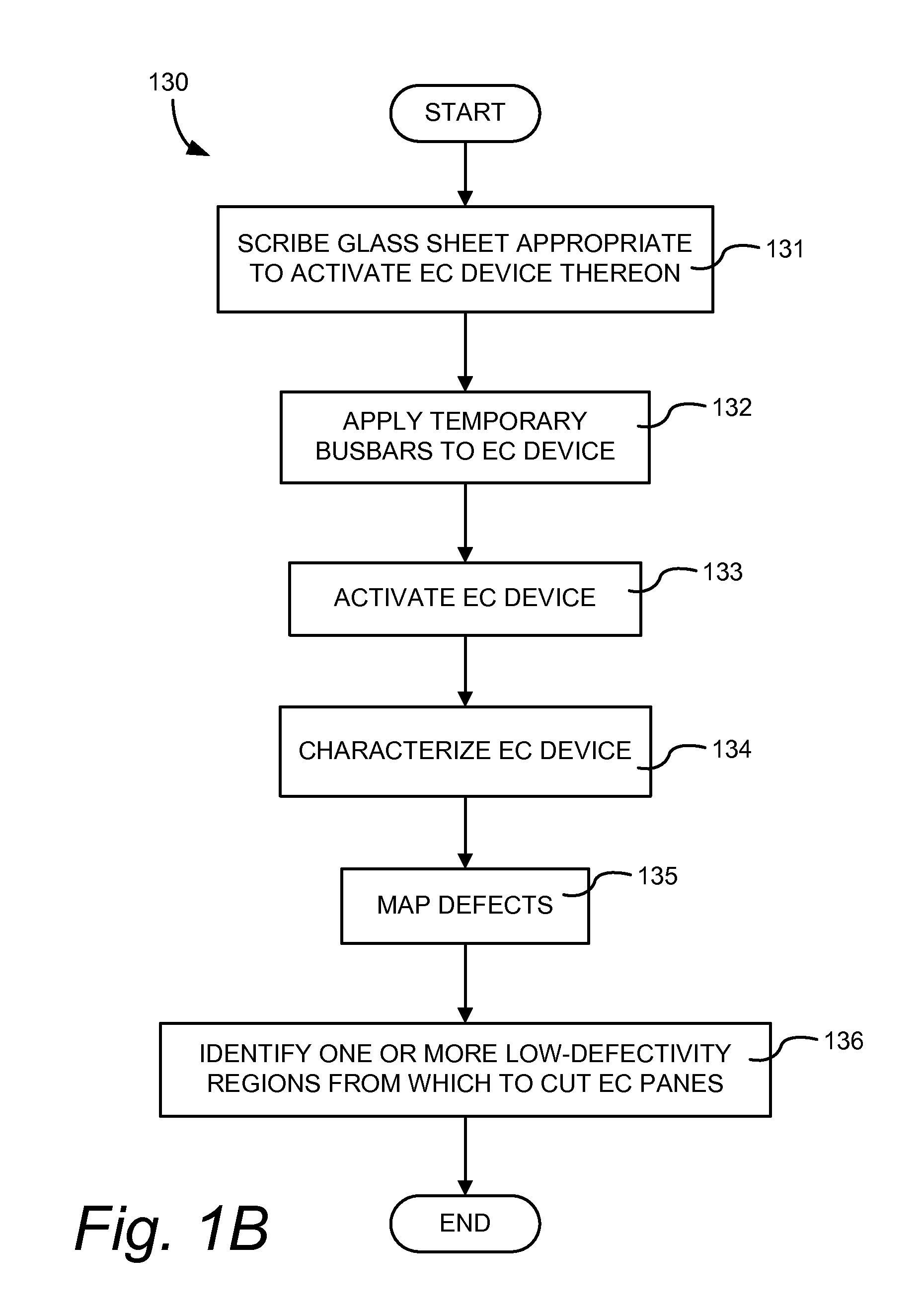

ActiveUS20120026573A1Maximize effective useLamination ancillary operationsLaminationEngineeringElectrochromism

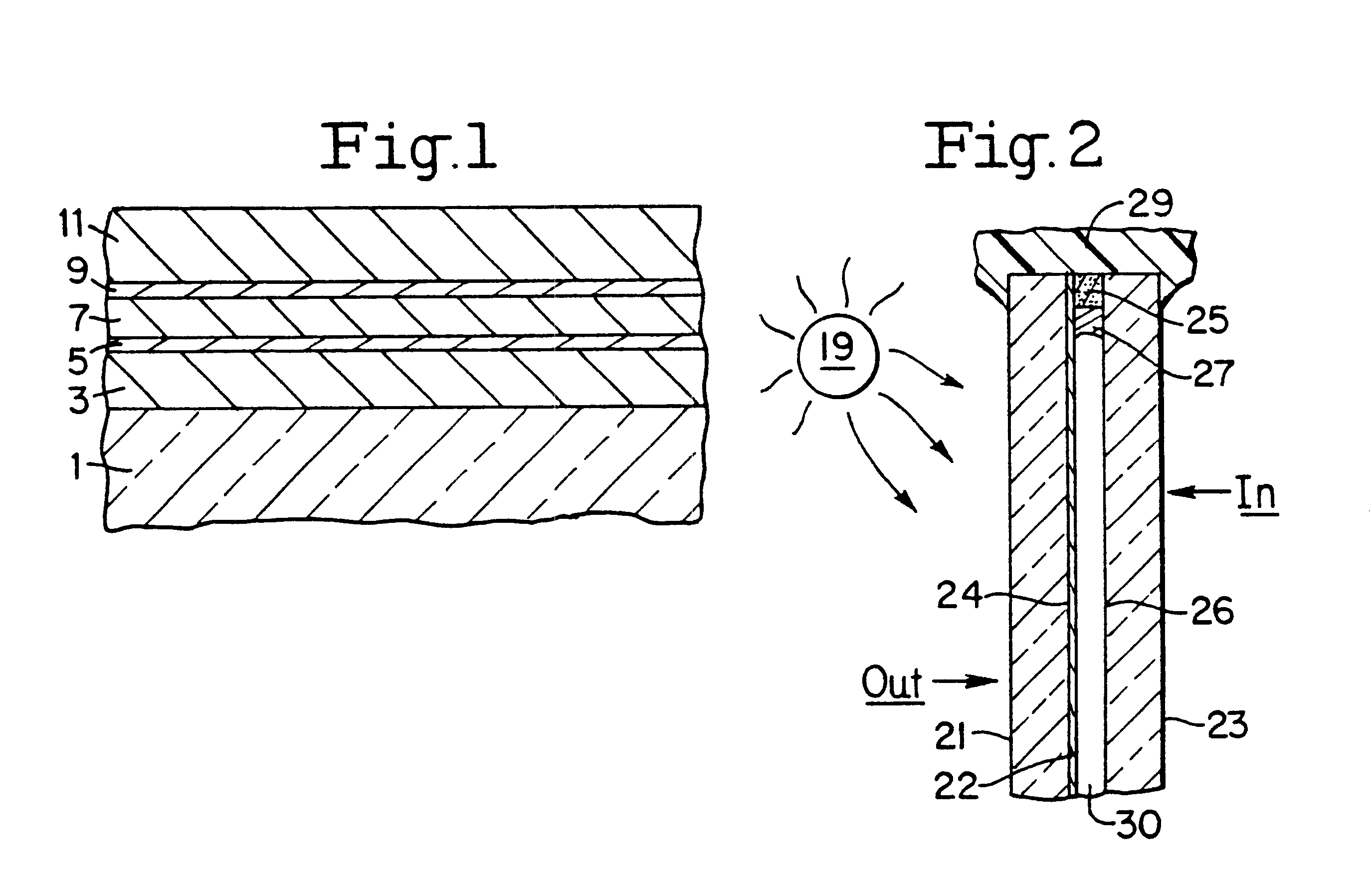

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

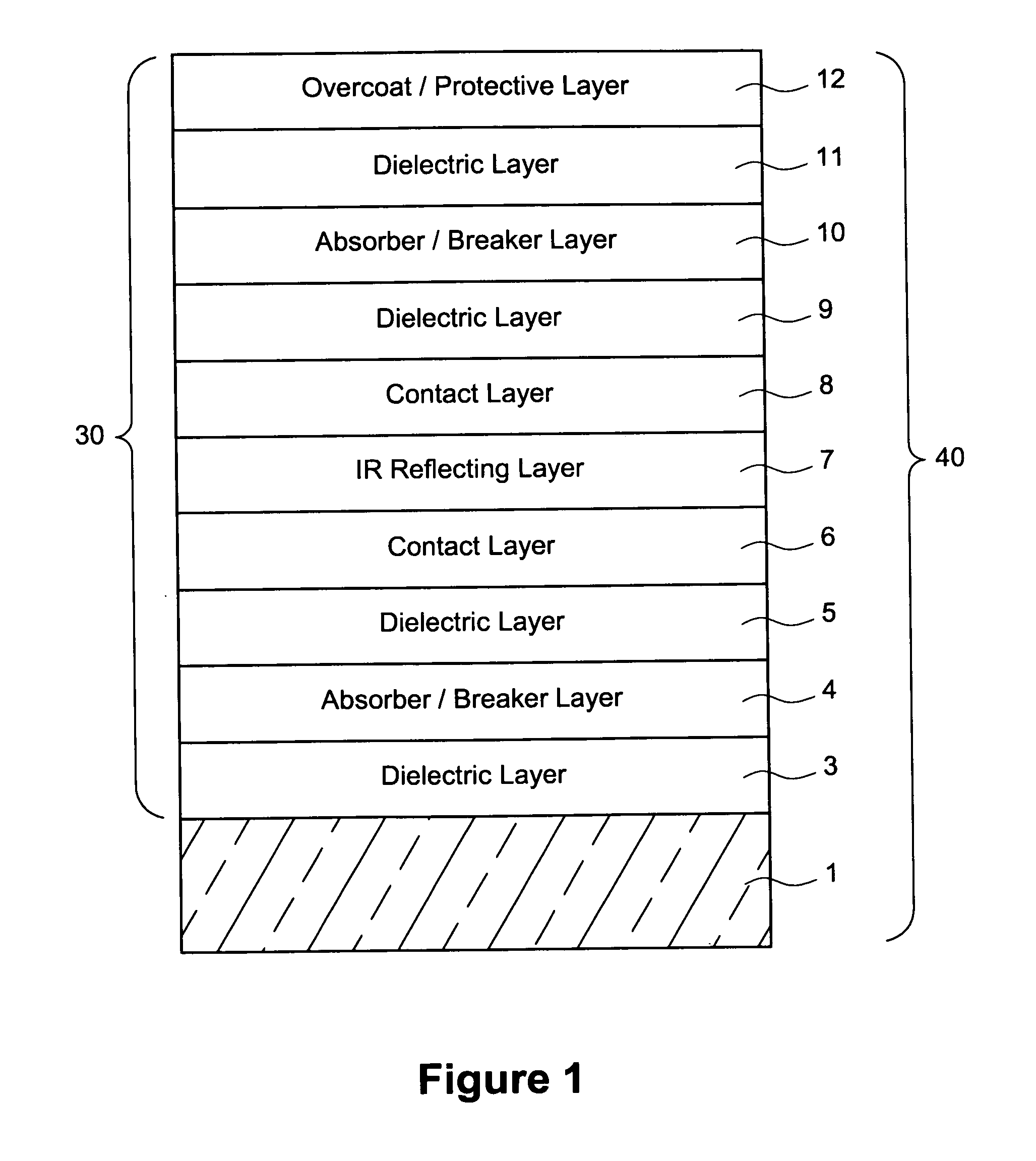

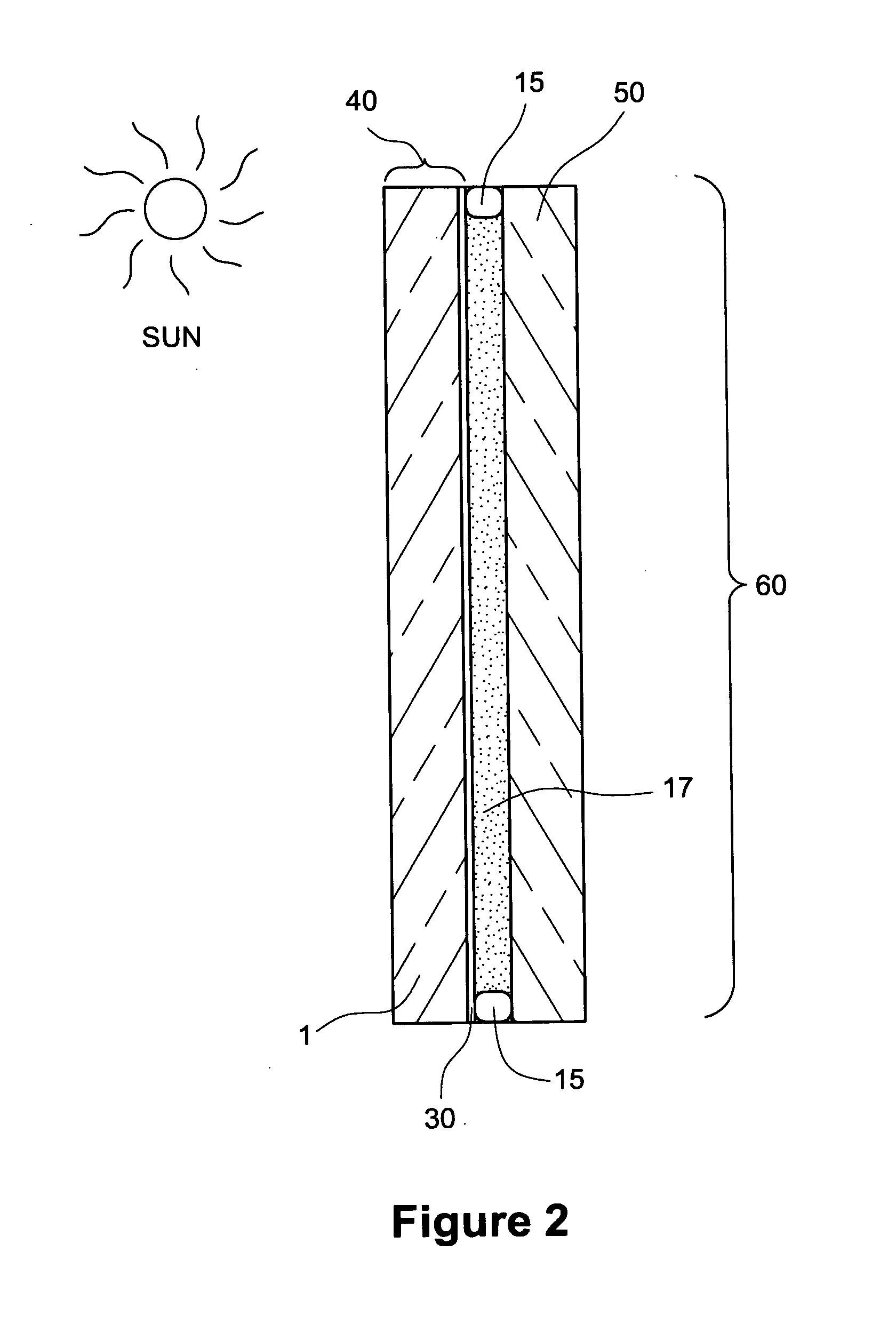

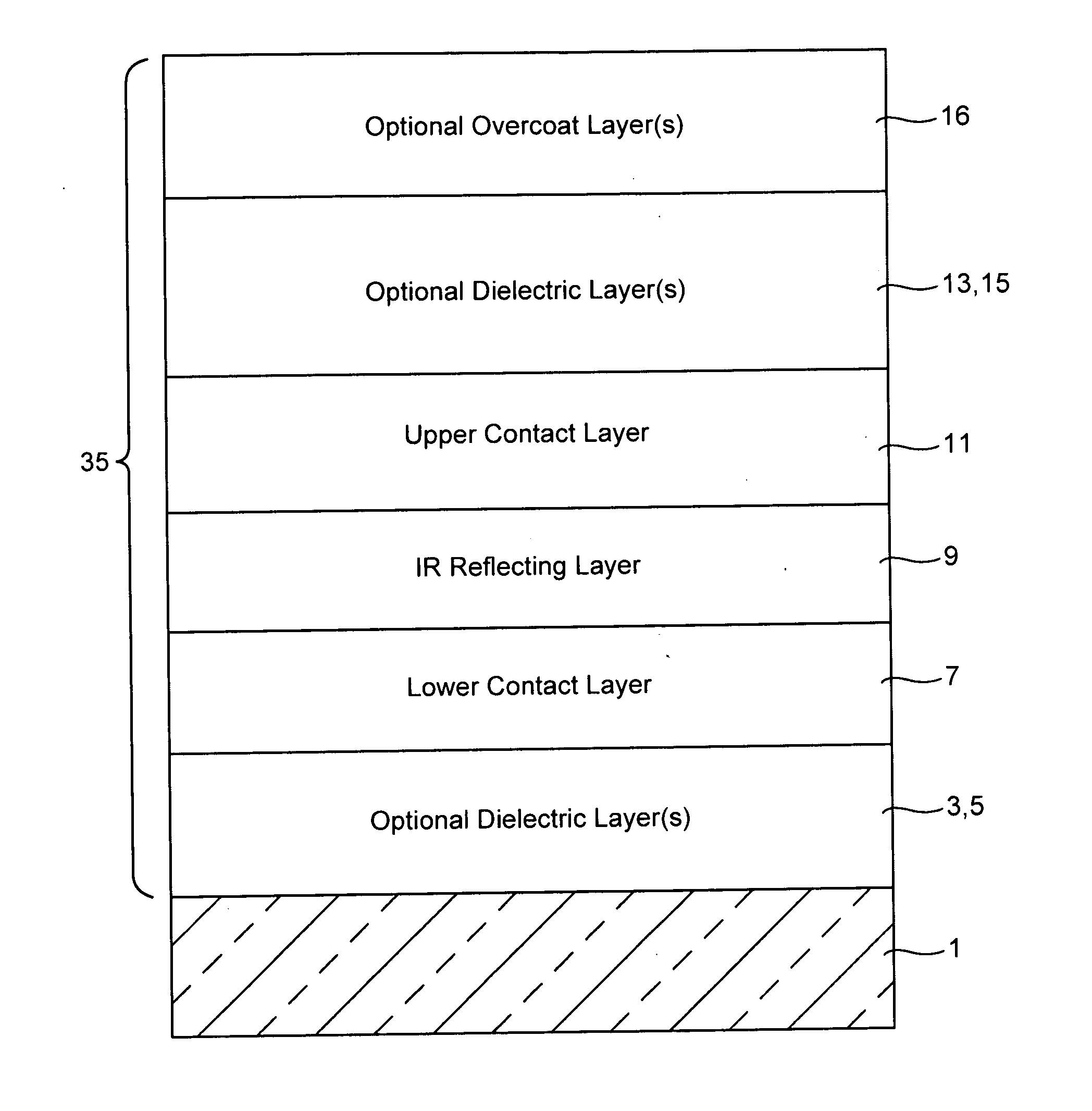

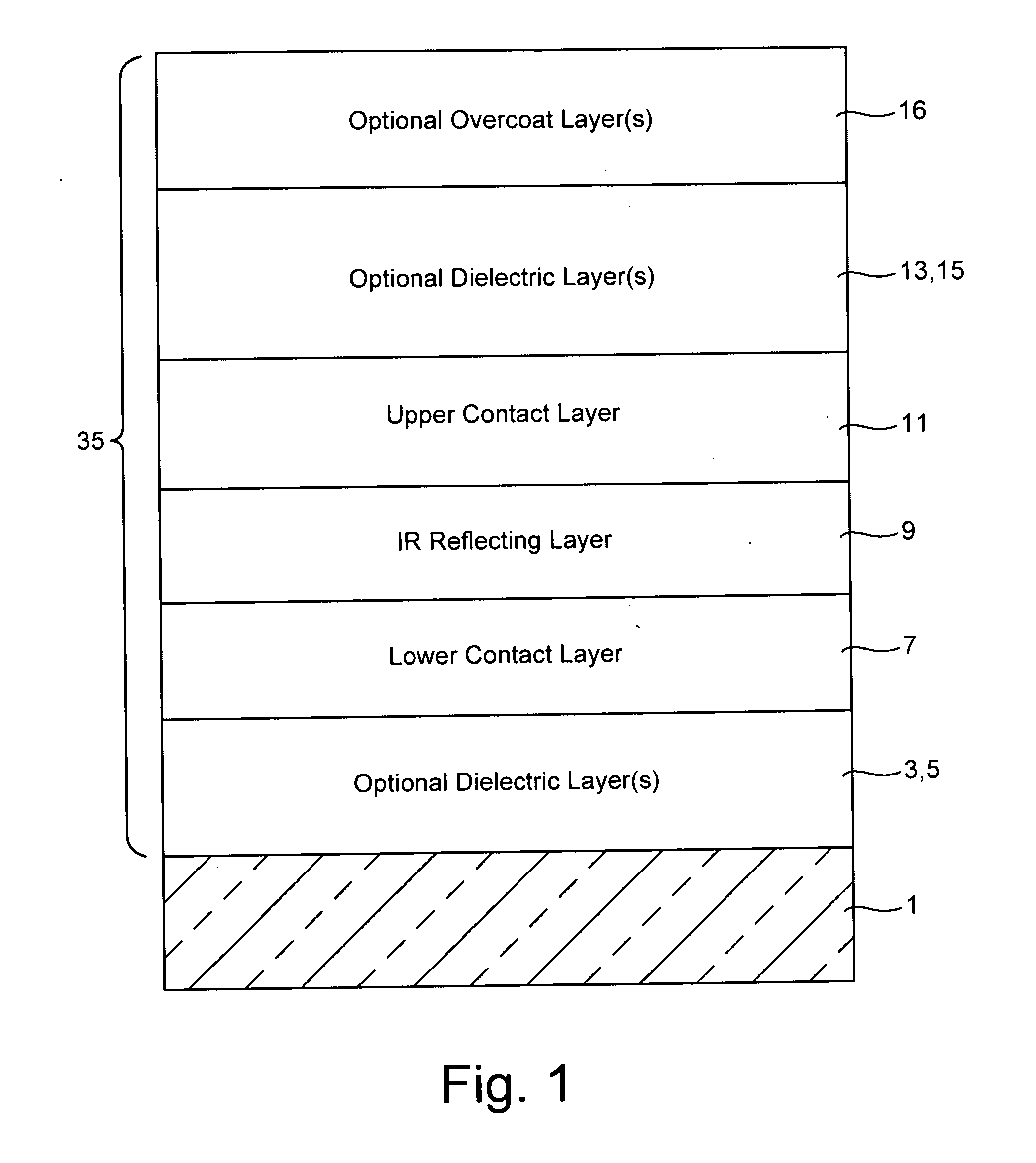

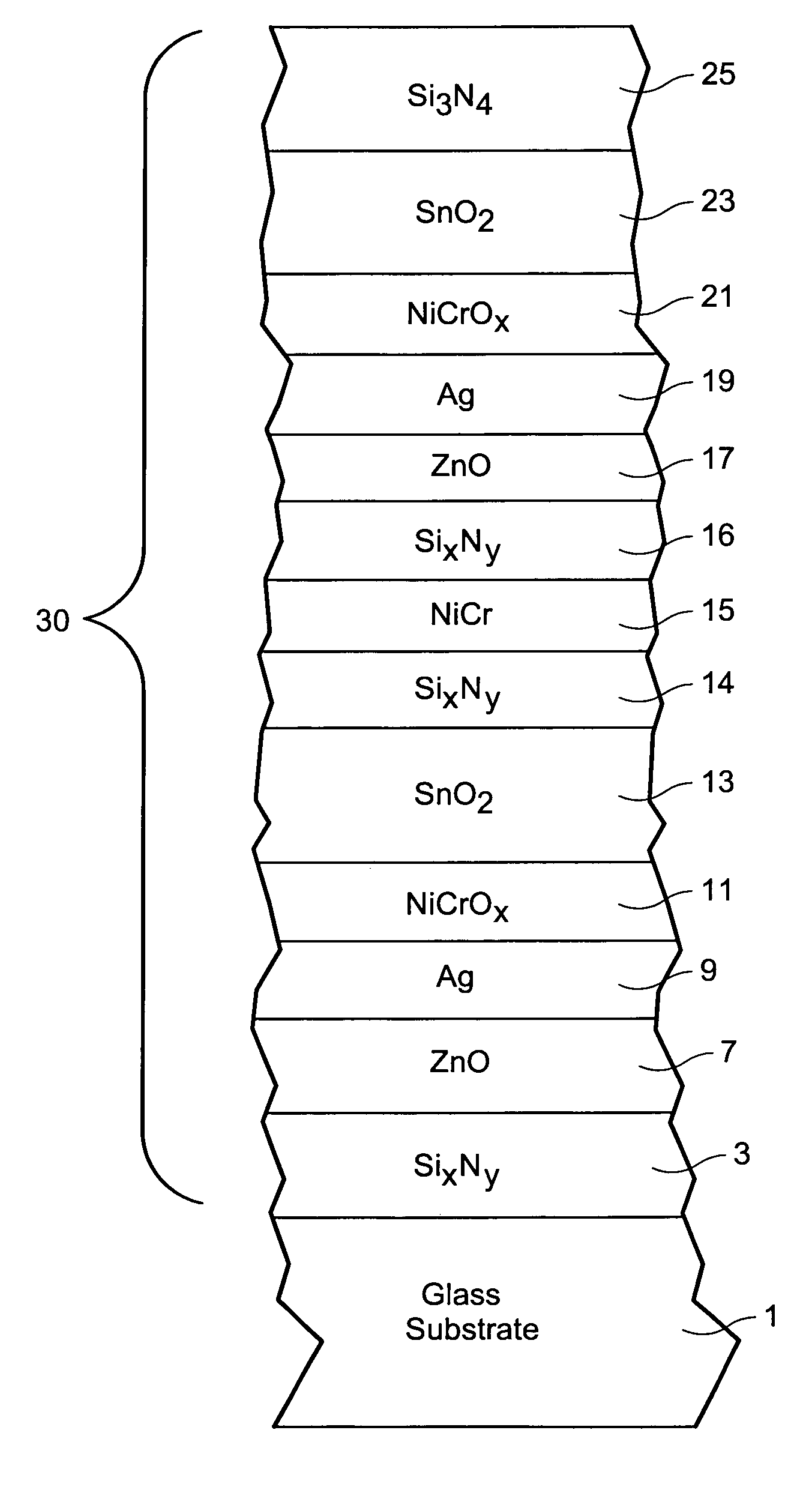

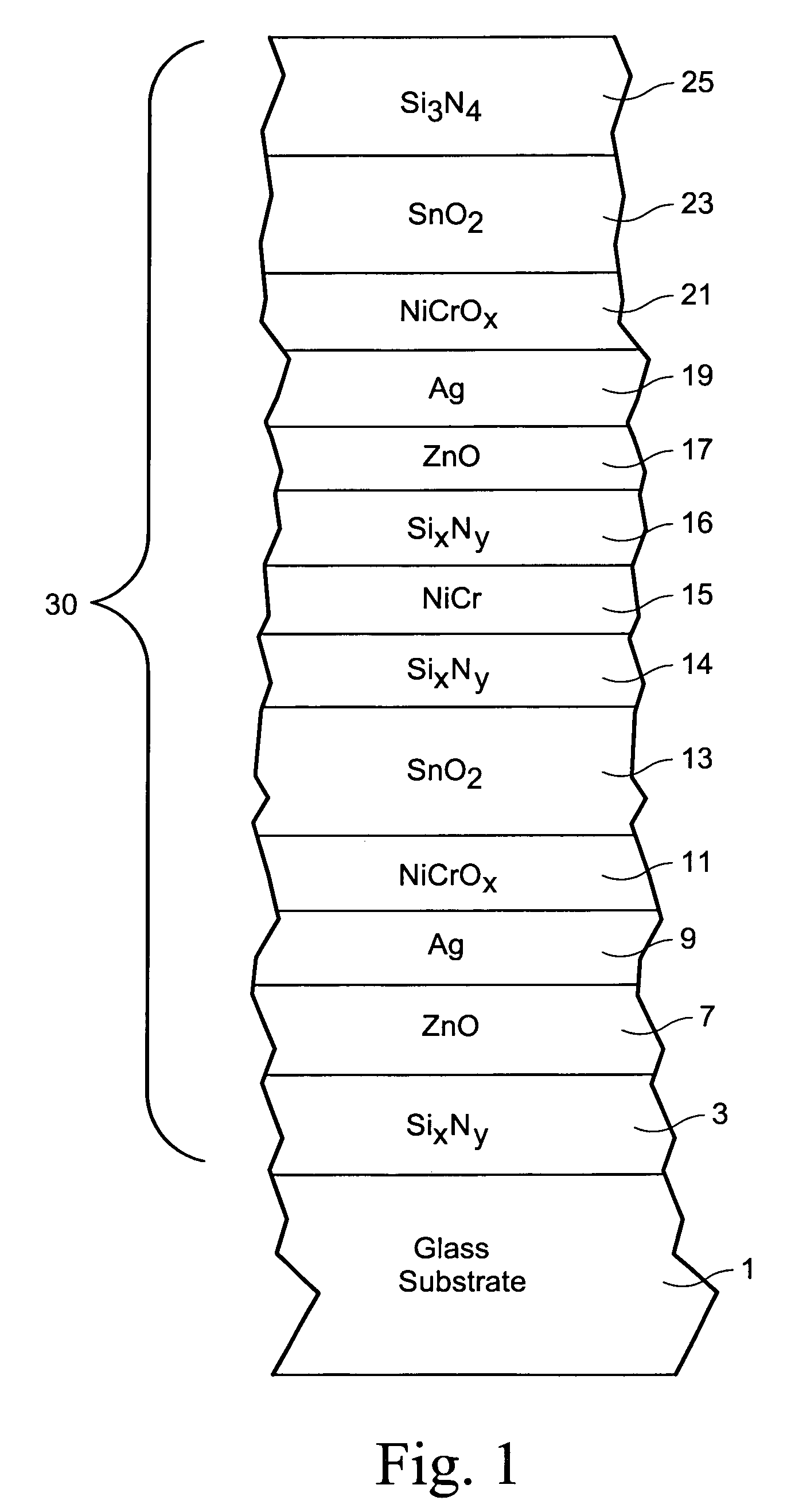

Coated article having low-E coating with absorber layer(s)

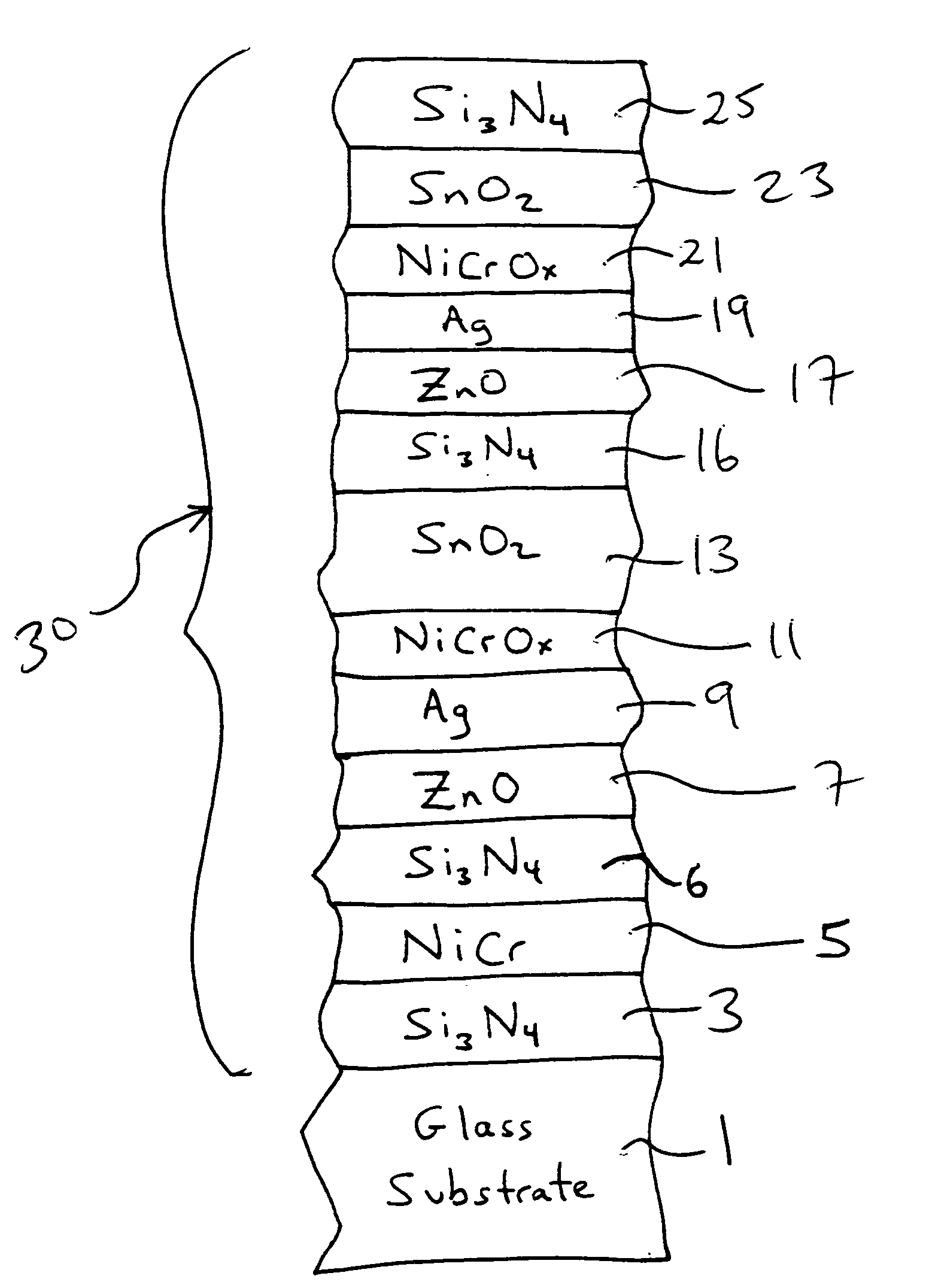

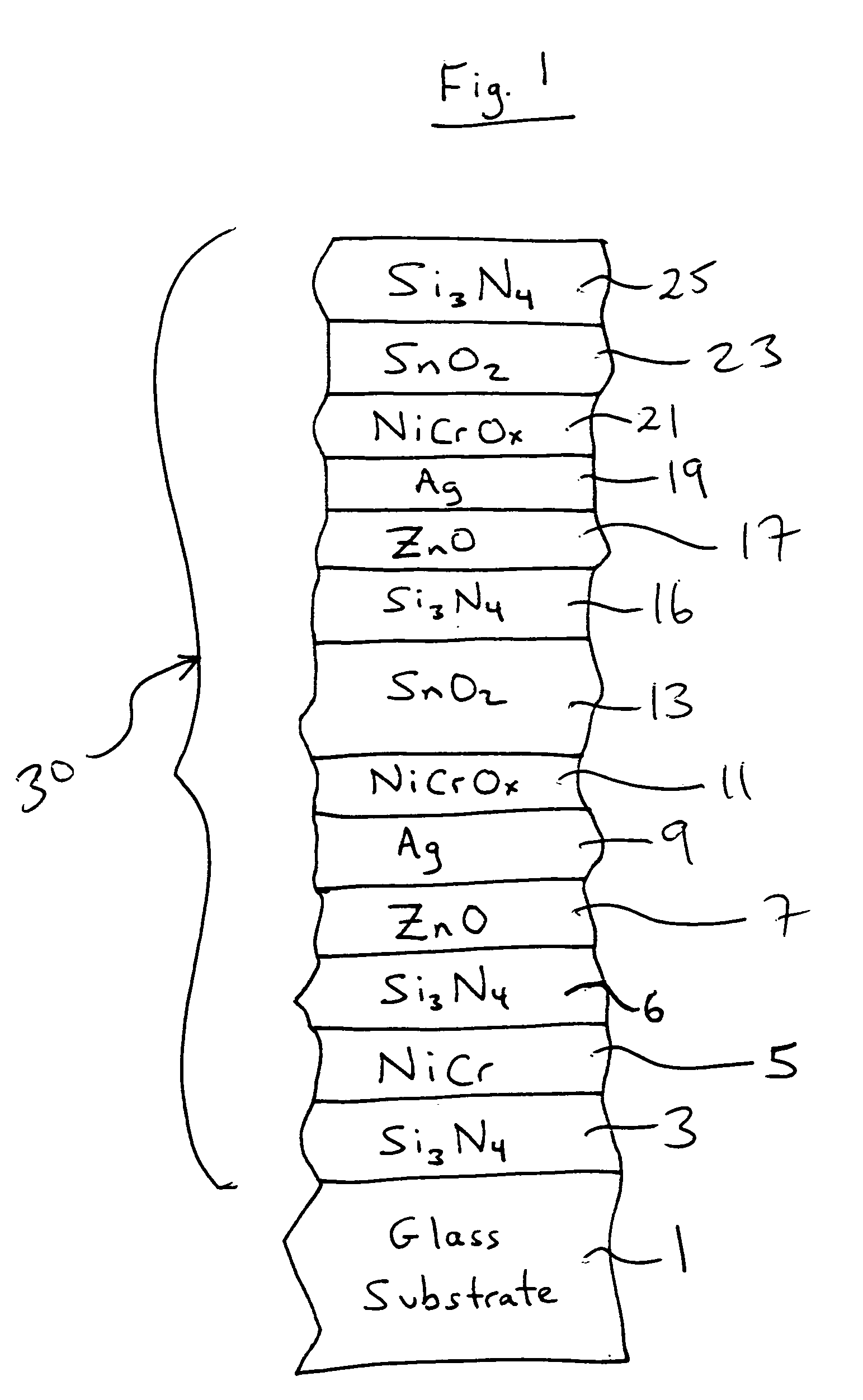

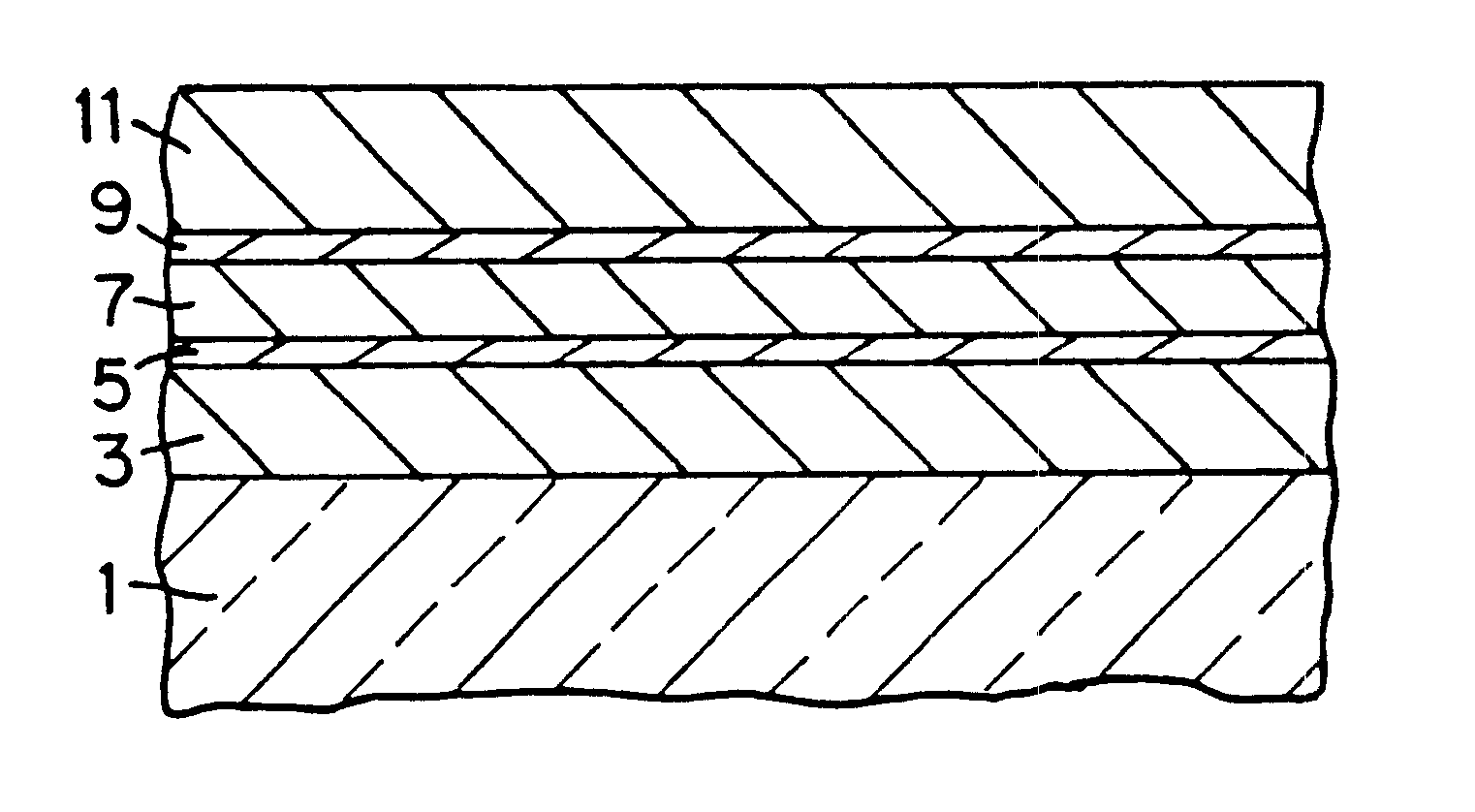

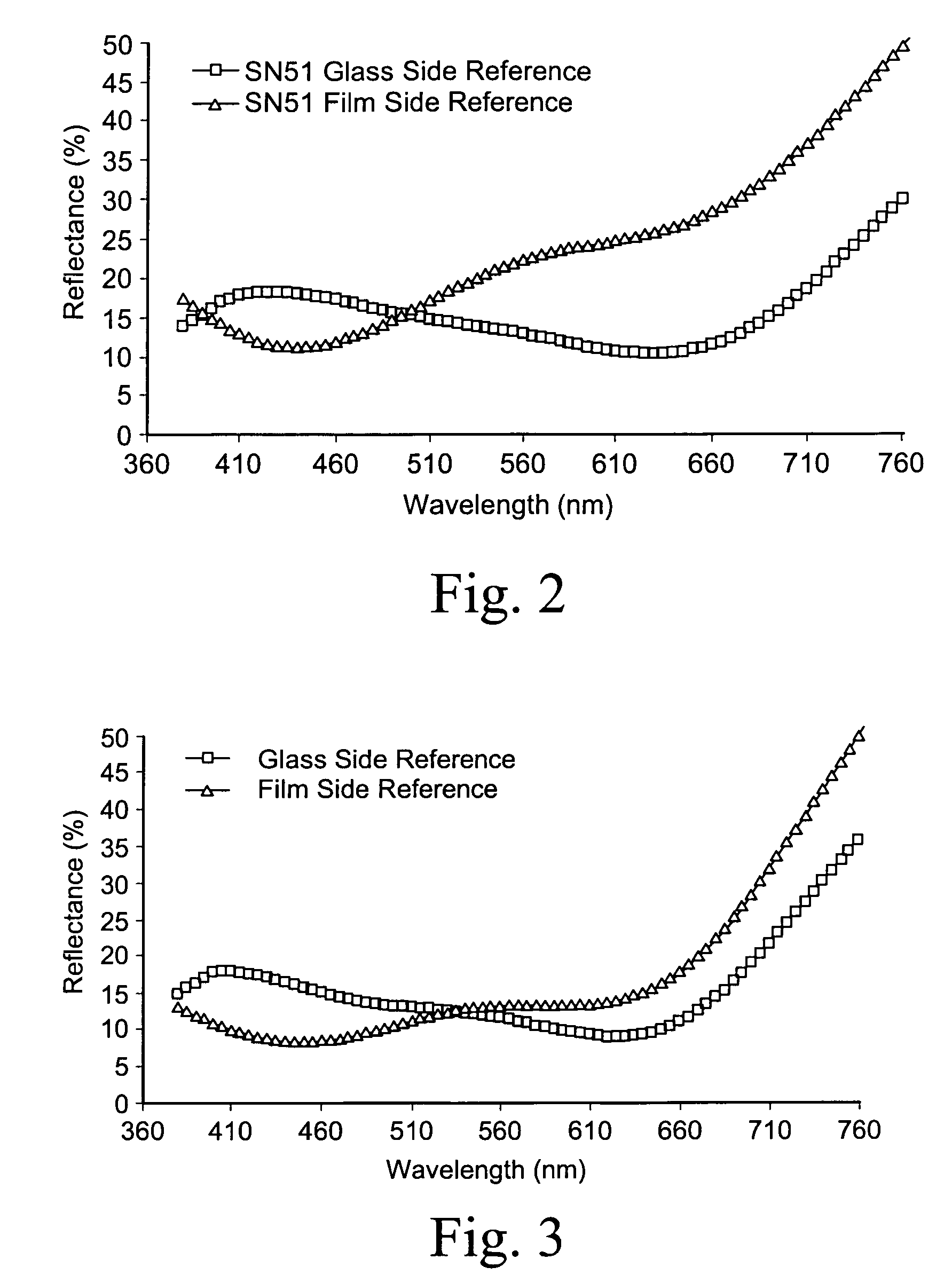

ActiveUS20110262726A1Low emissivityReduce sheet resistanceGlass/slag layered productsThin material handlingElectrical resistance and conductanceInsulated glazing

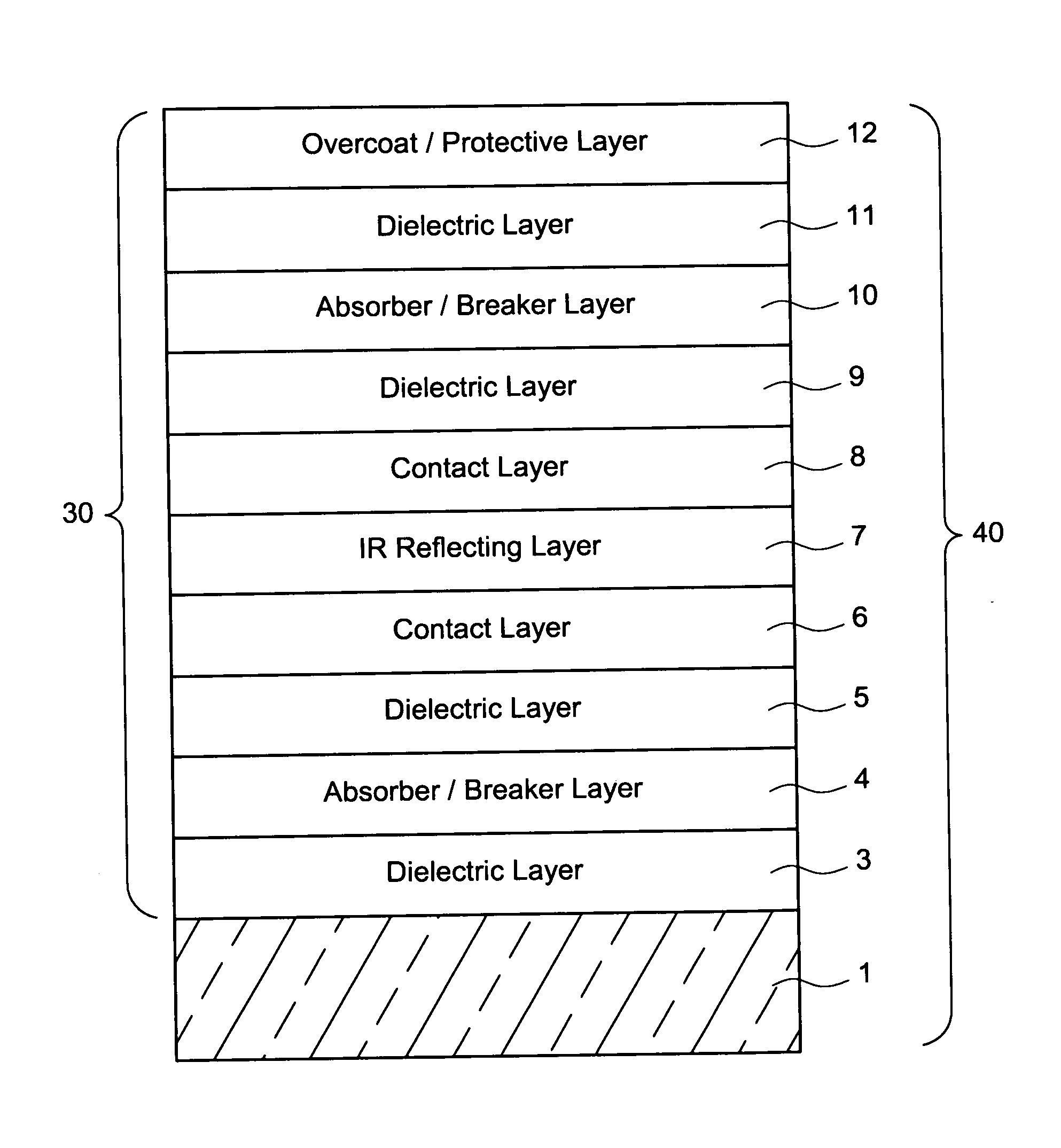

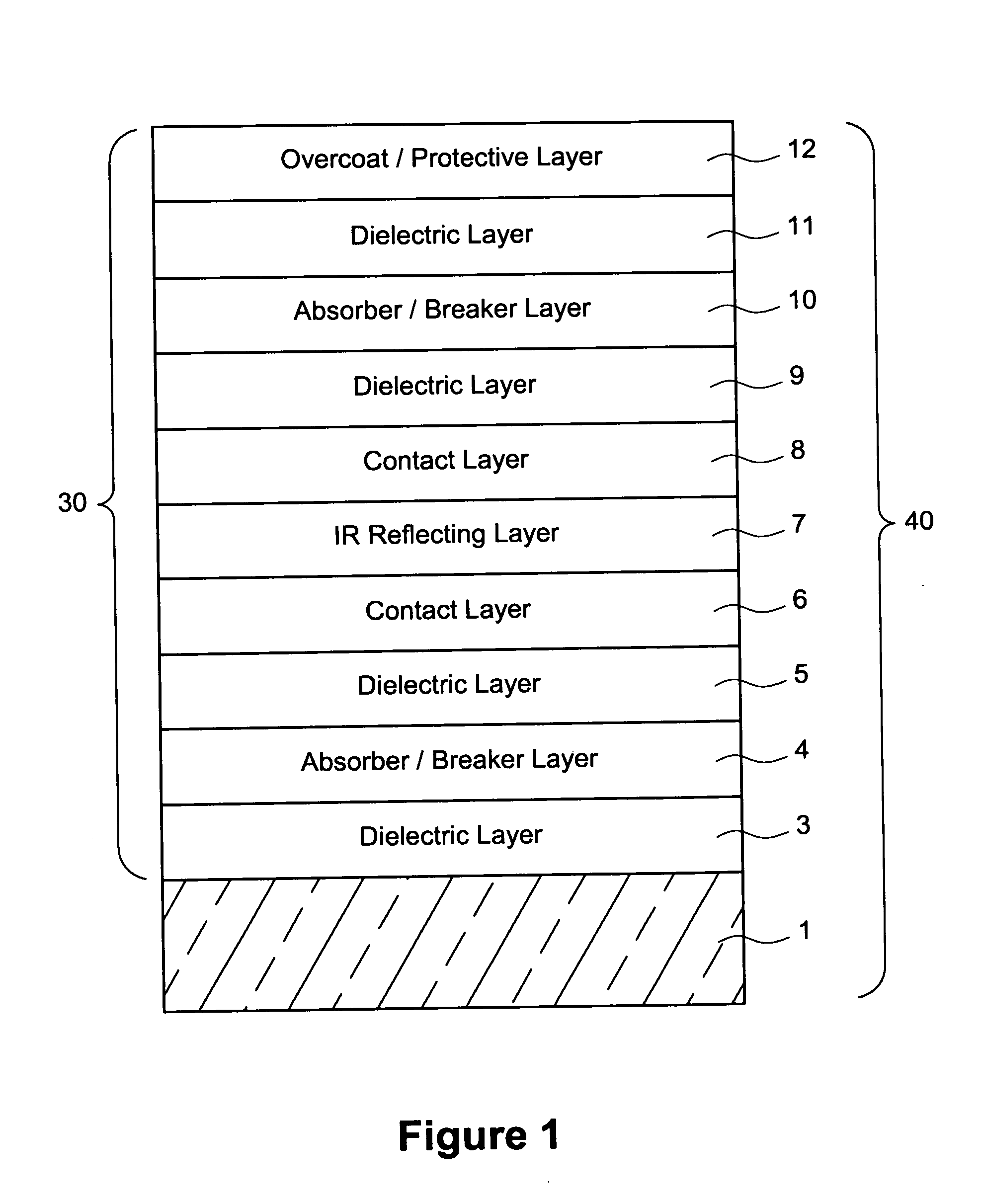

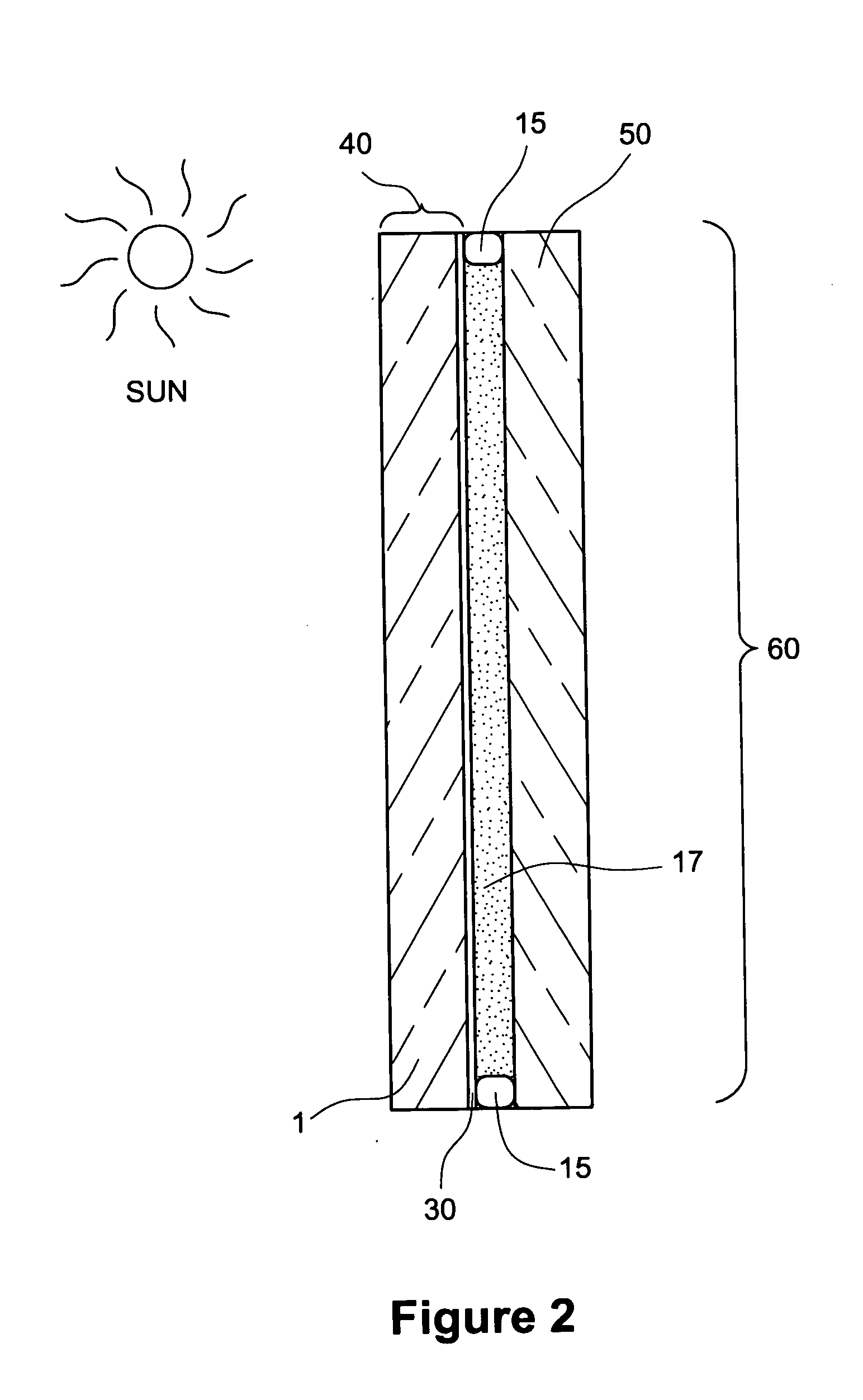

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN GLASS LLC +1

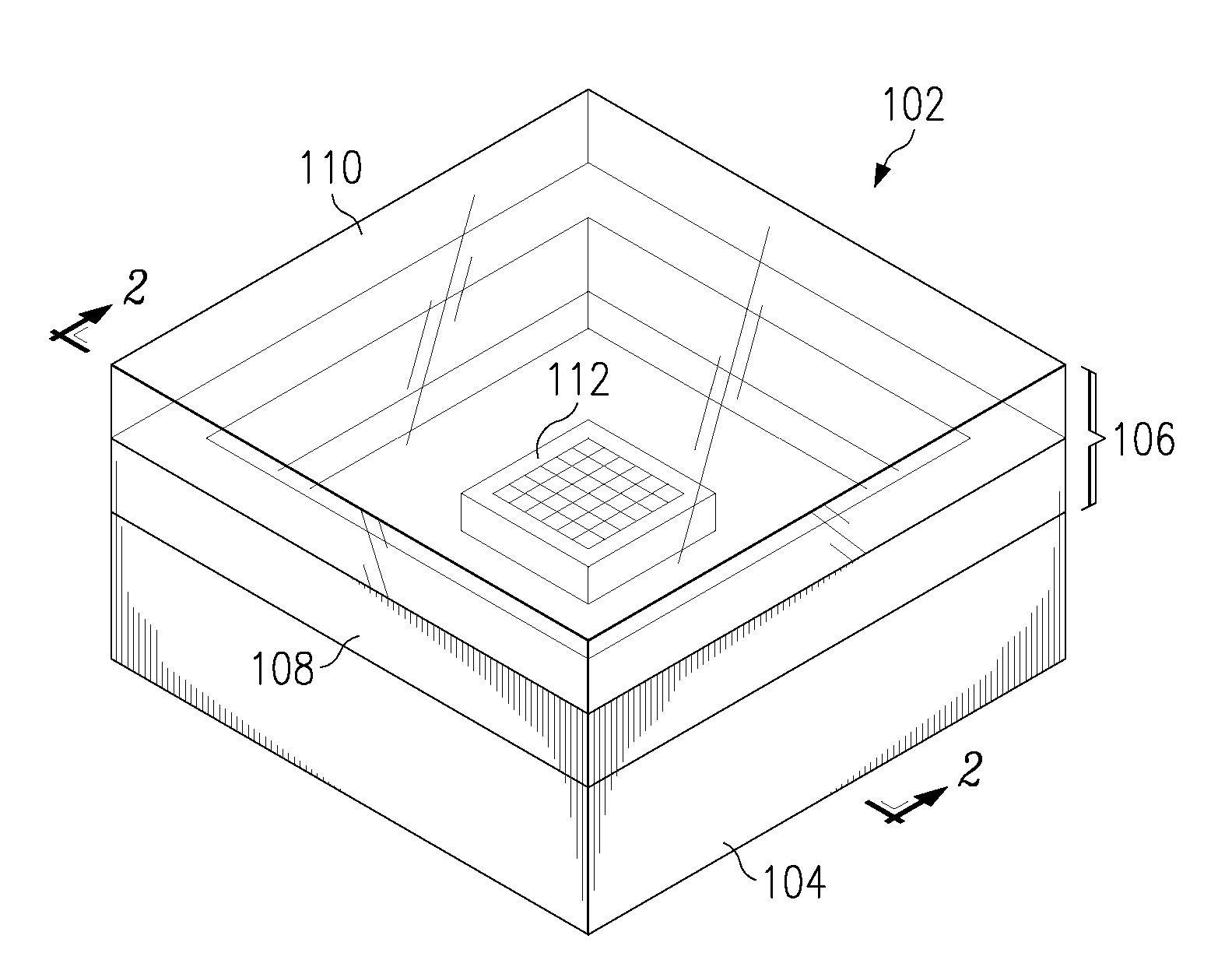

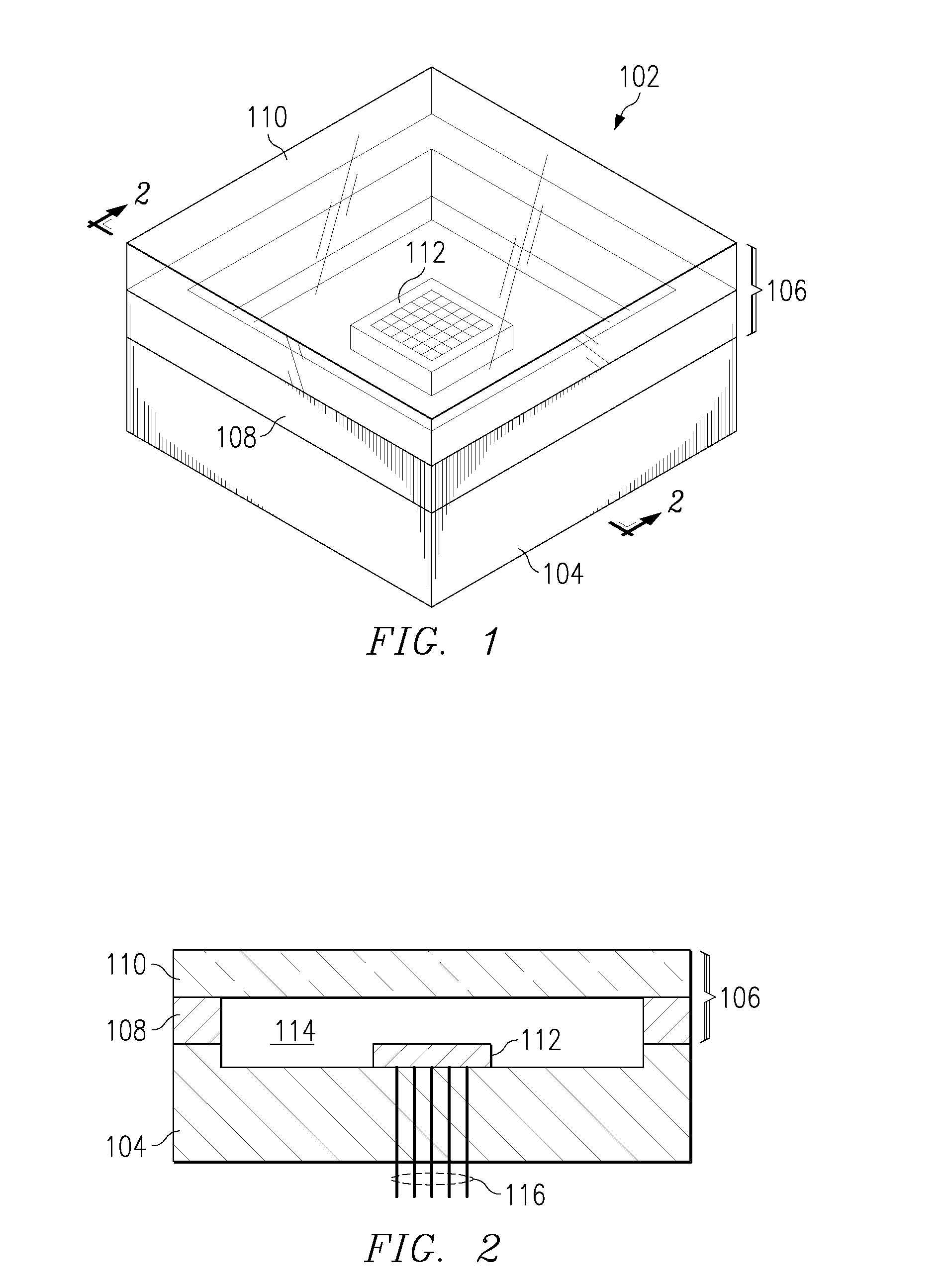

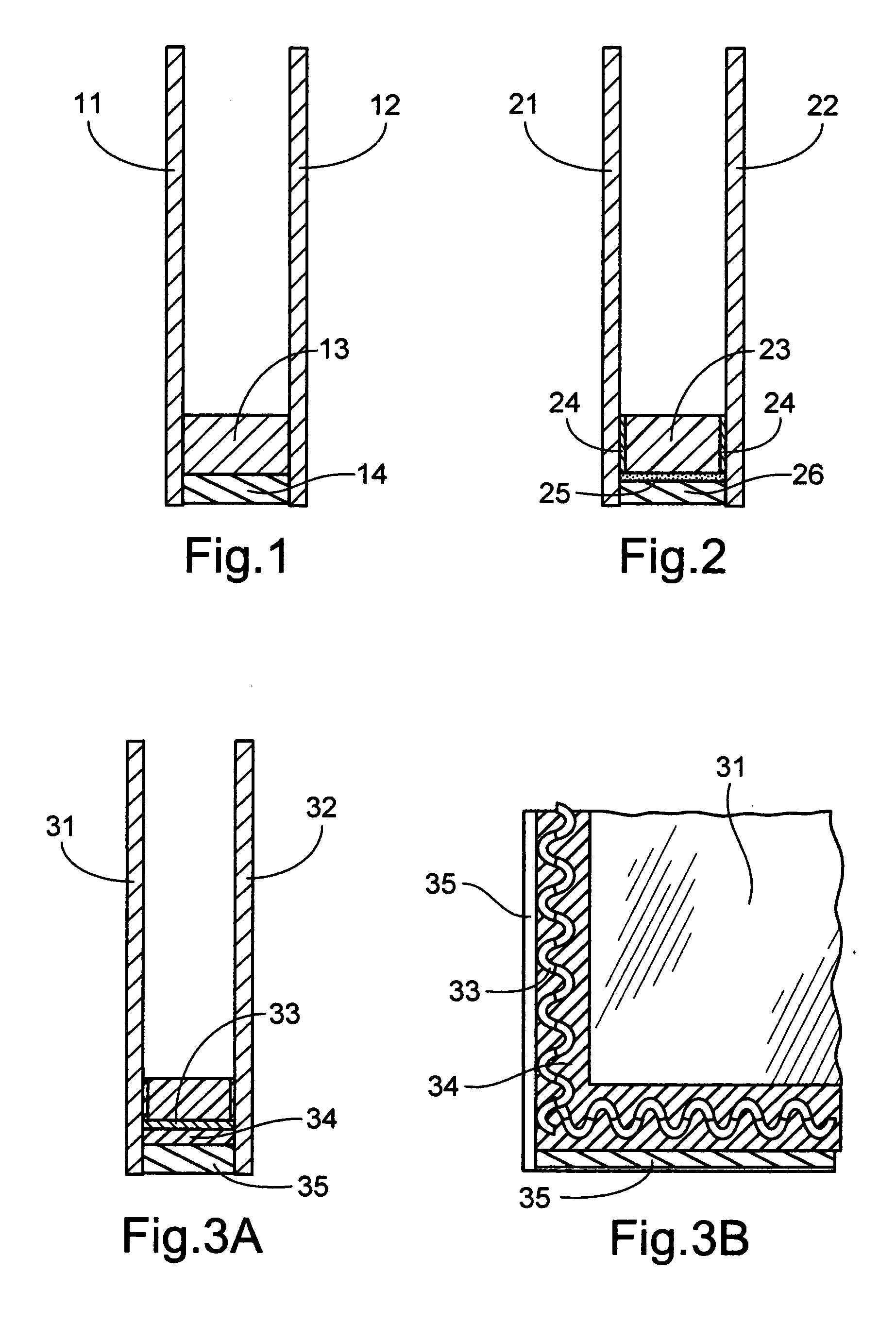

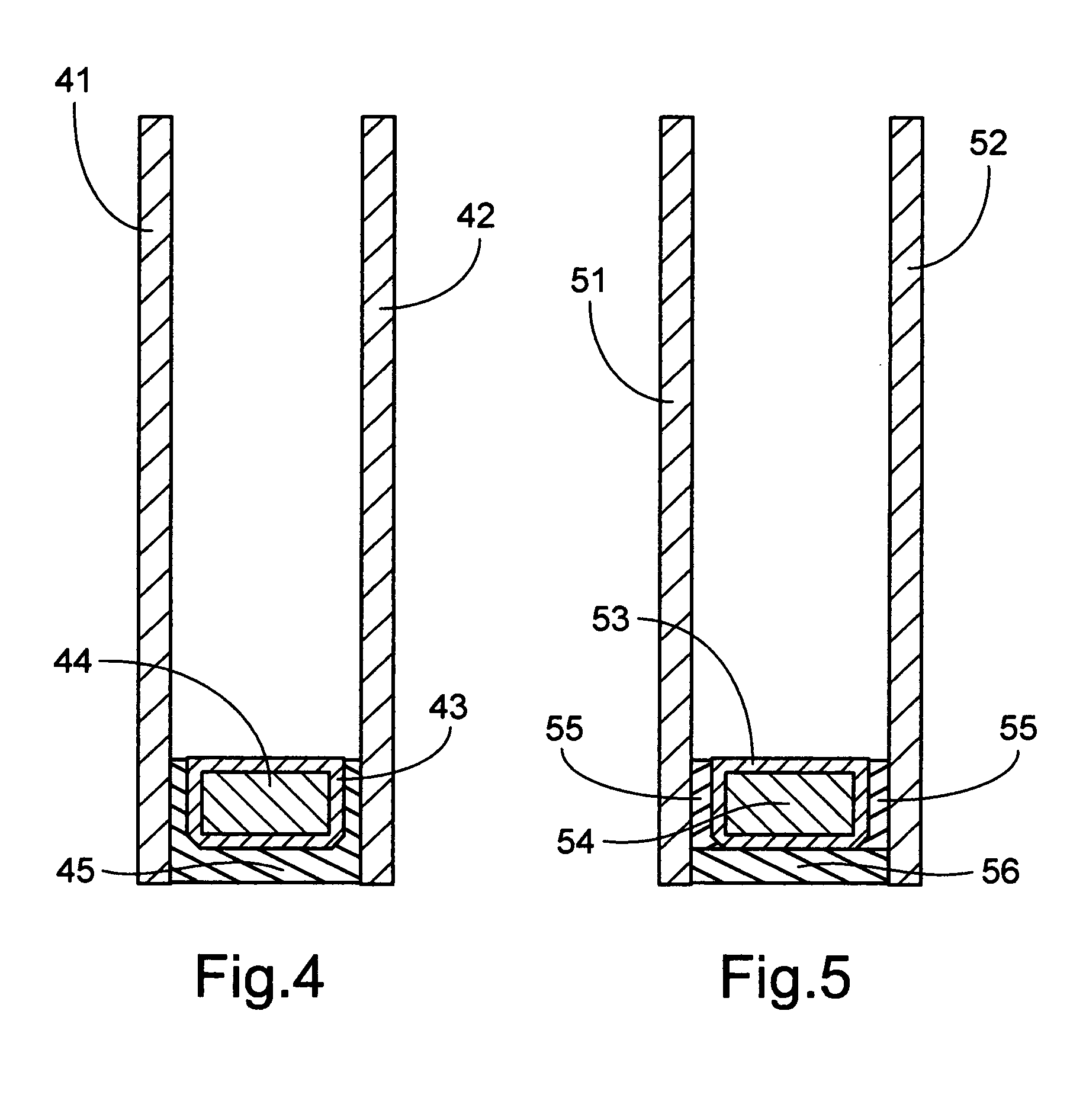

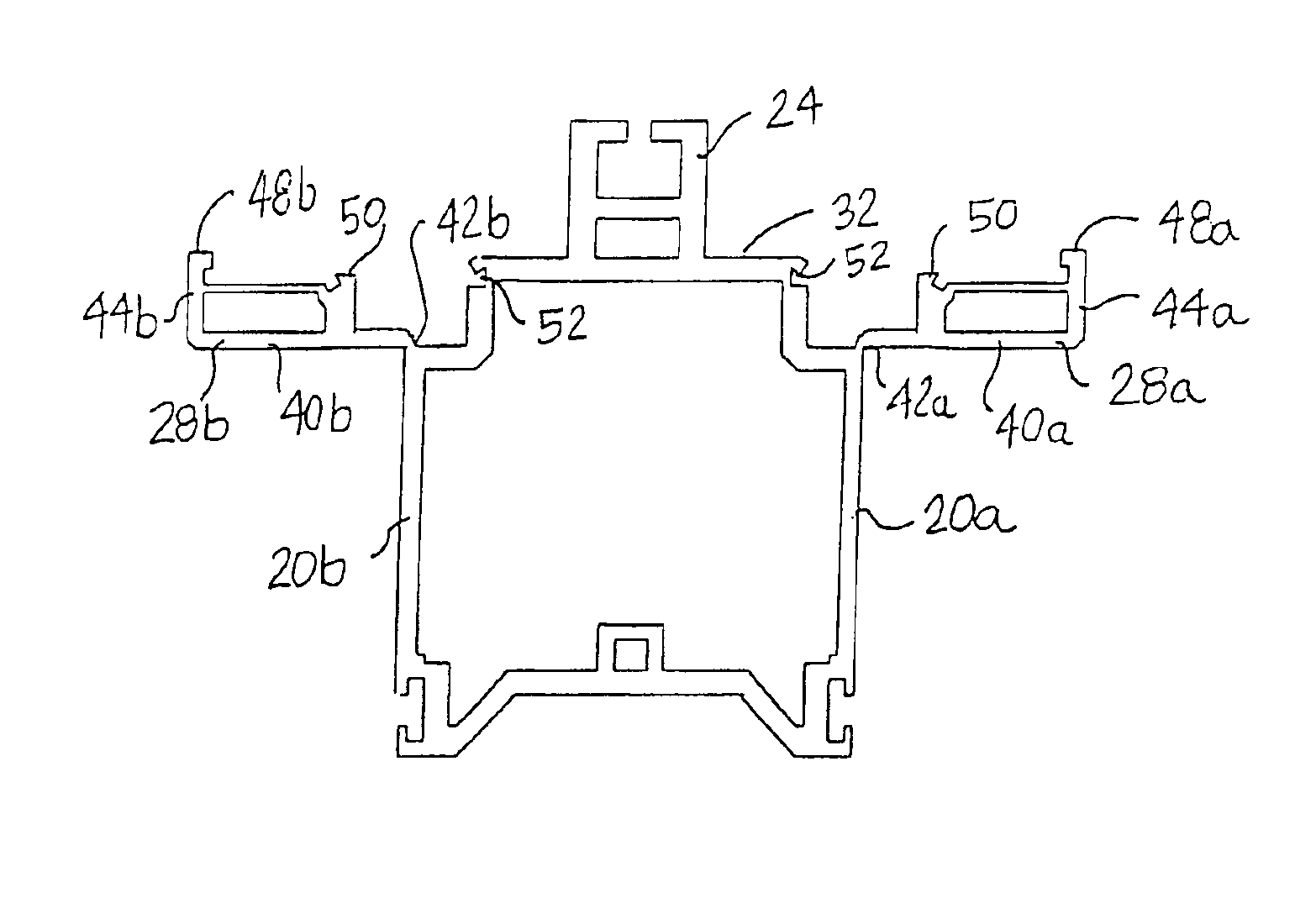

Insulated glazing units

InactiveUS20060187608A1Improve heat resistanceReduce weight and depthDoors/windowsSemiconductor/solid-state device detailsInsulated glazingEngineering

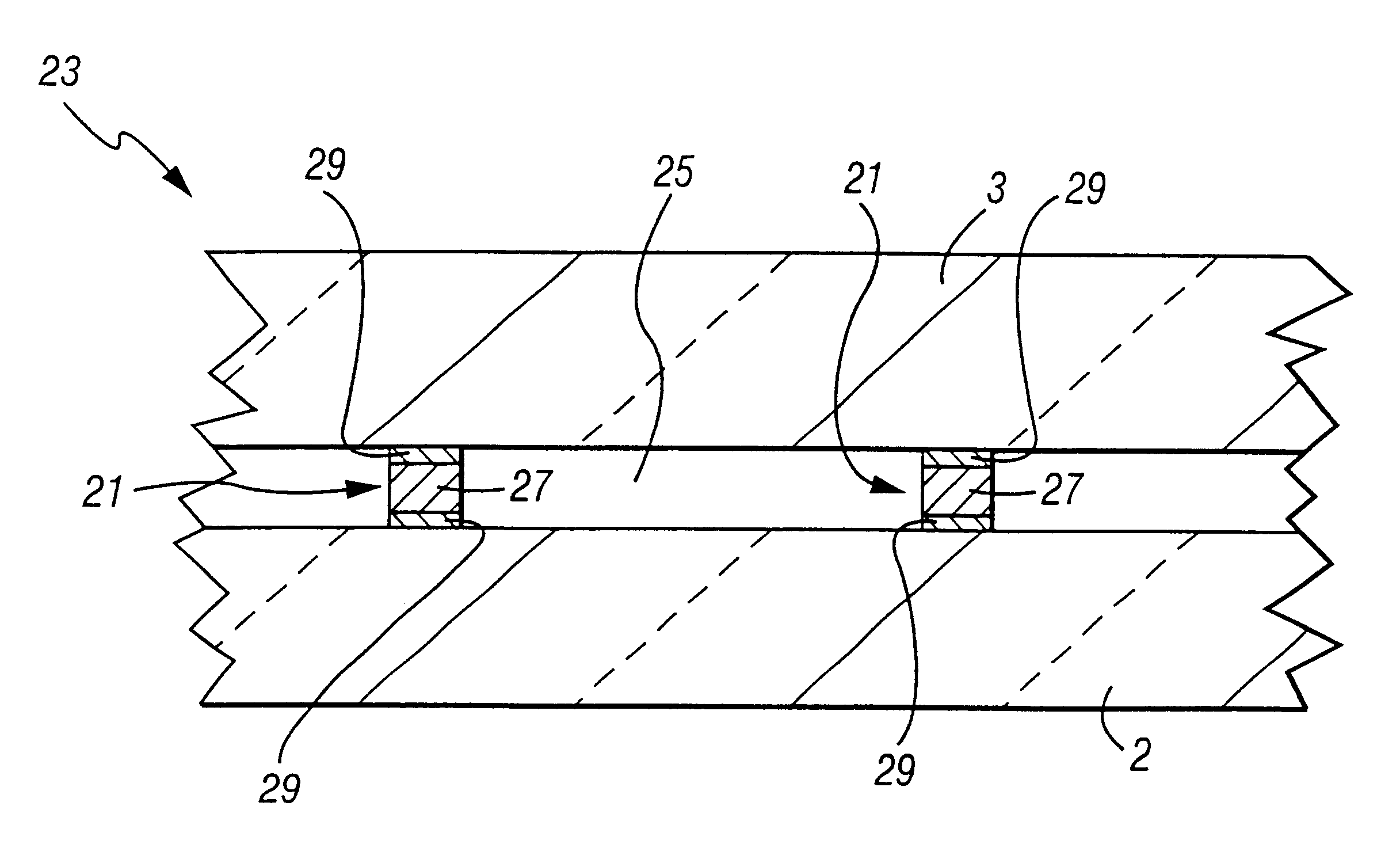

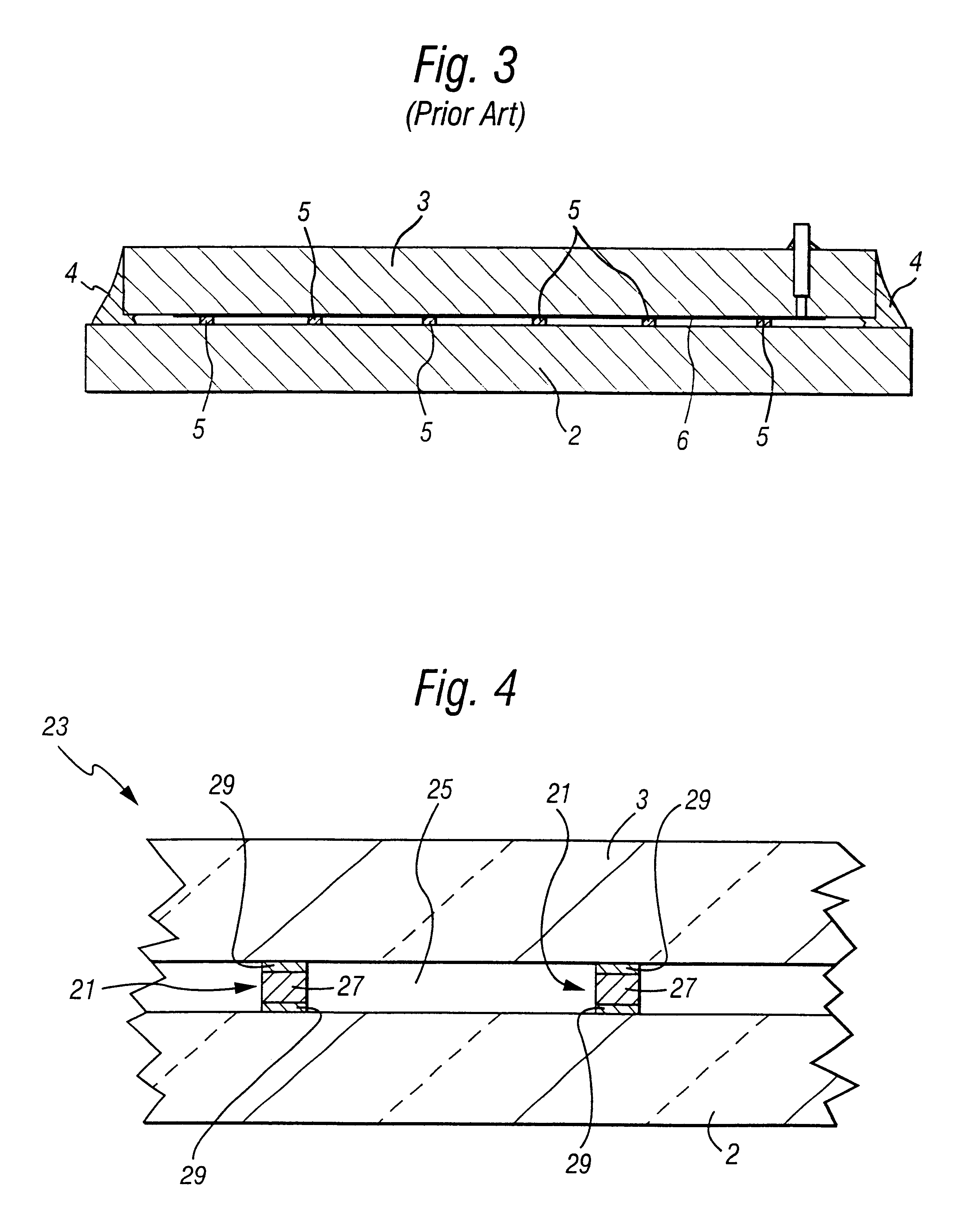

A hermetically sealed multi-pane window assembly comprises first and second windowpane sheets formed of transparent materials. A first sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the first windowpane sheet by diffusion bonding. A second sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the second windowpane sheet by diffusion bonding and the outer edge being hermetically attached to the outer edge of the first sealing member. A spacer assembly is disposed between the first and the second windowpane sheets for maintaining a gap therebetween, whereby a hermetically sealed cavity is defined between the first and the second windowpanes.

Owner:ASTRAVAC GLASS INC

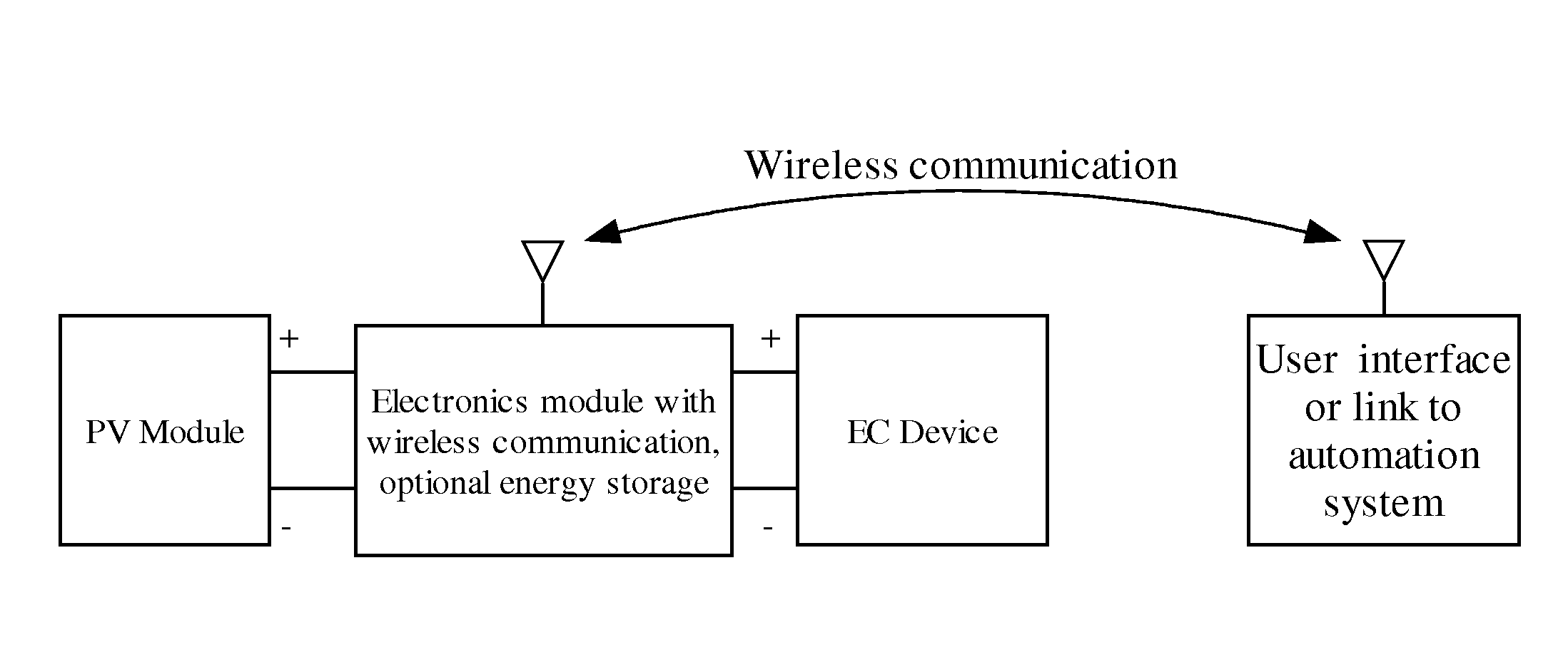

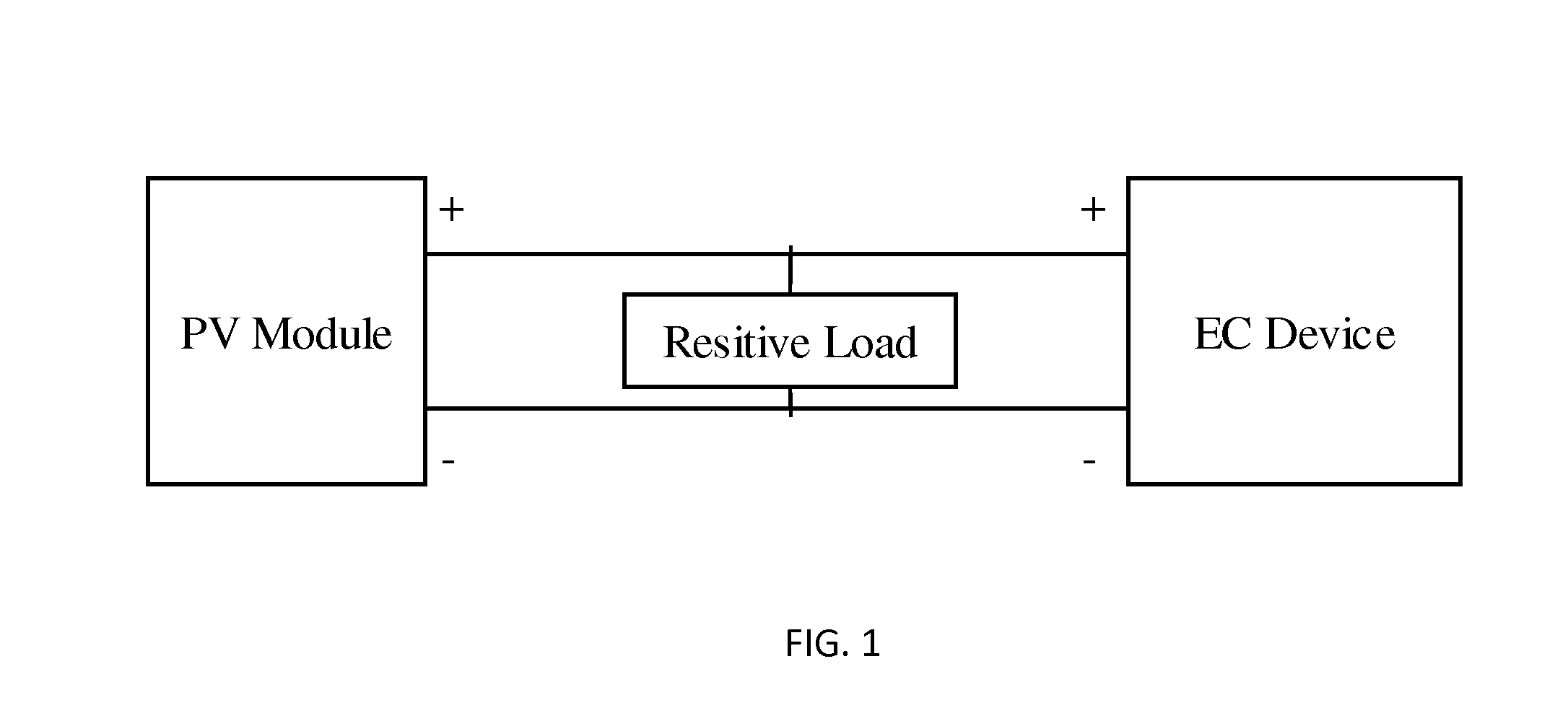

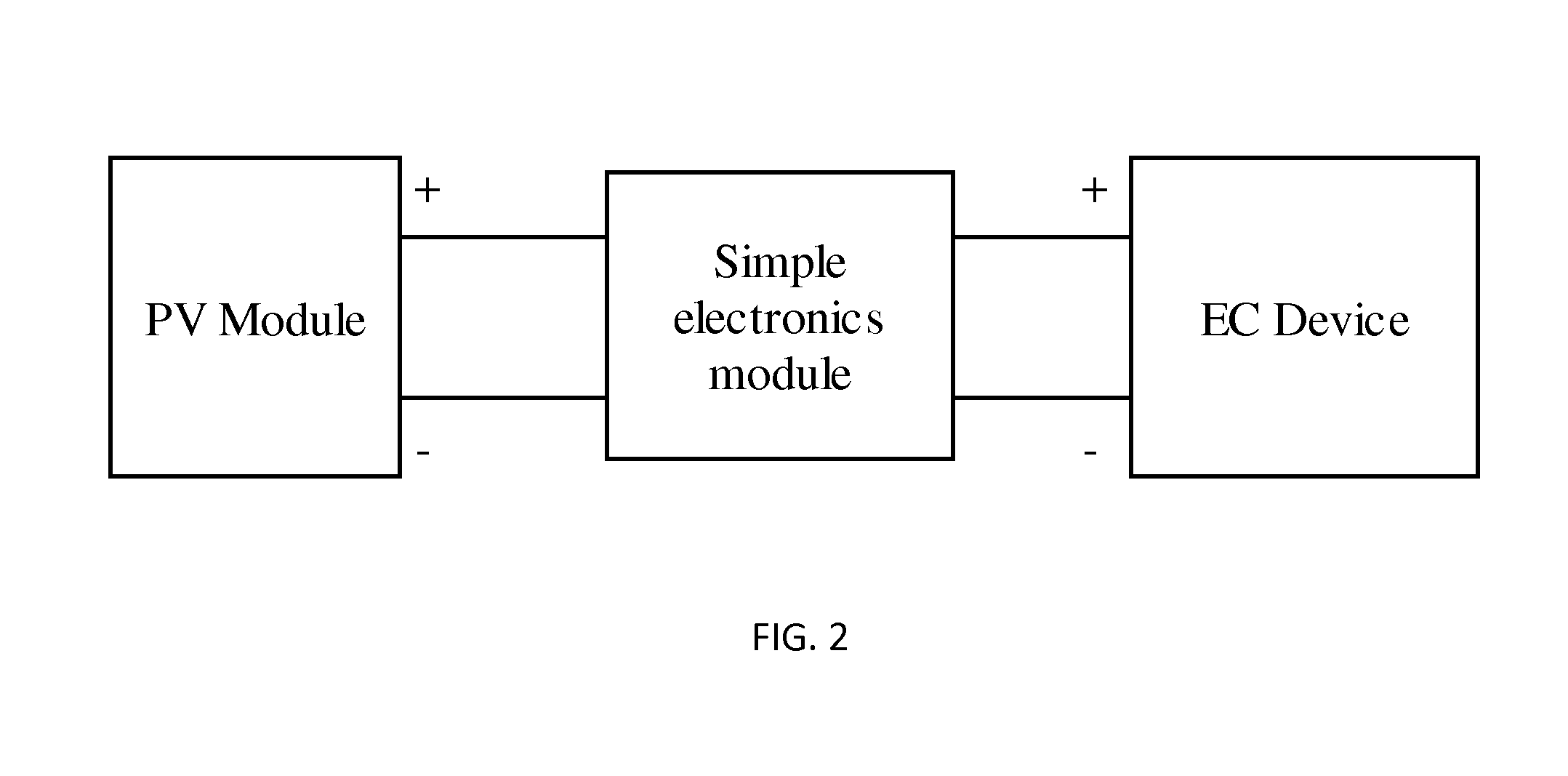

Control system for electrochromic device

The present invention is directed to electrochromic systems comprising an electrochromic glazing or insulated glazing unit, a photovoltaic module for supplying power to the electrochromic glazing or IGU, and an electronics module in communication either the electrochromic glazing and / or photovoltaic module.

Owner:SAGE ELECTROCHROMICS

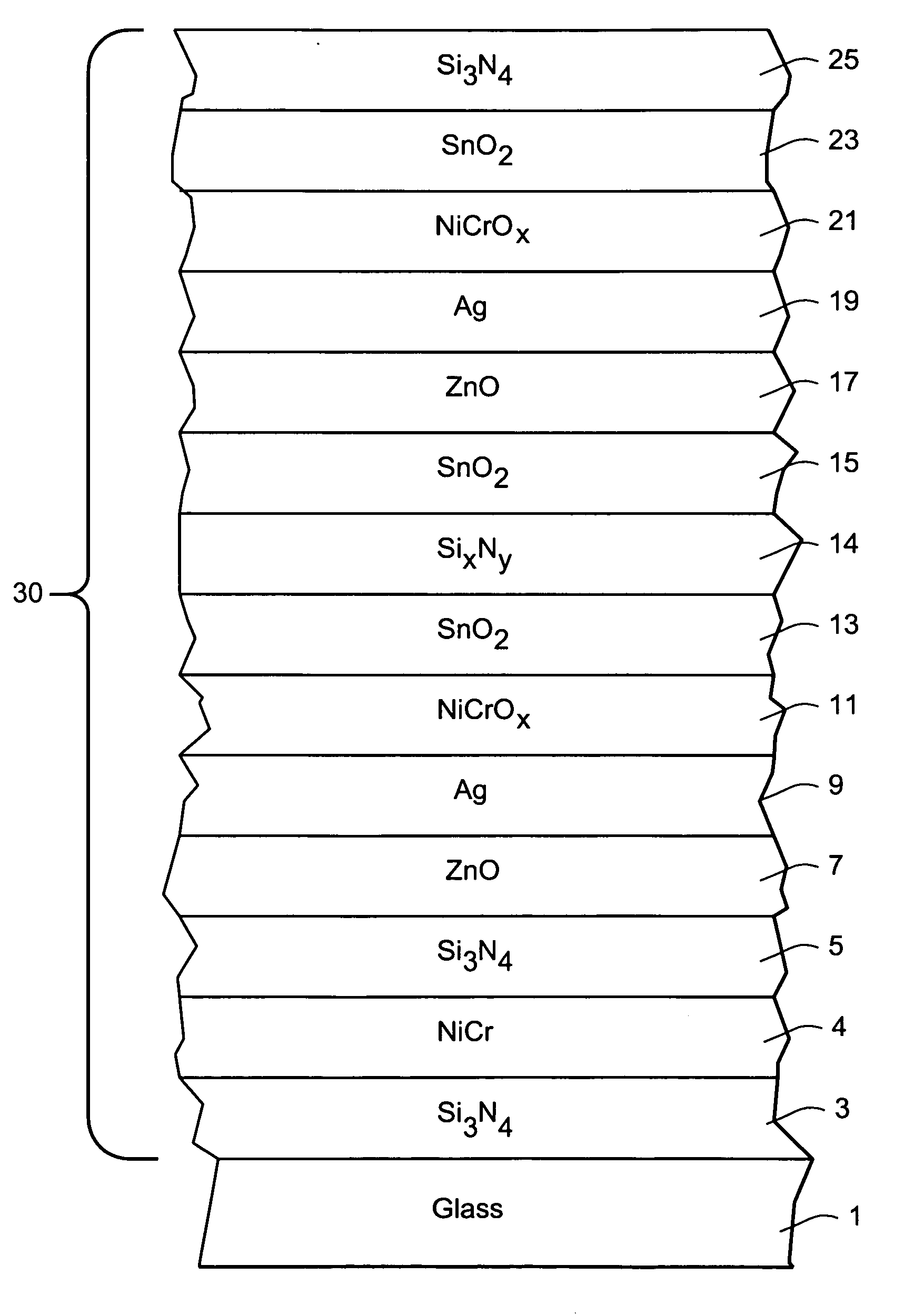

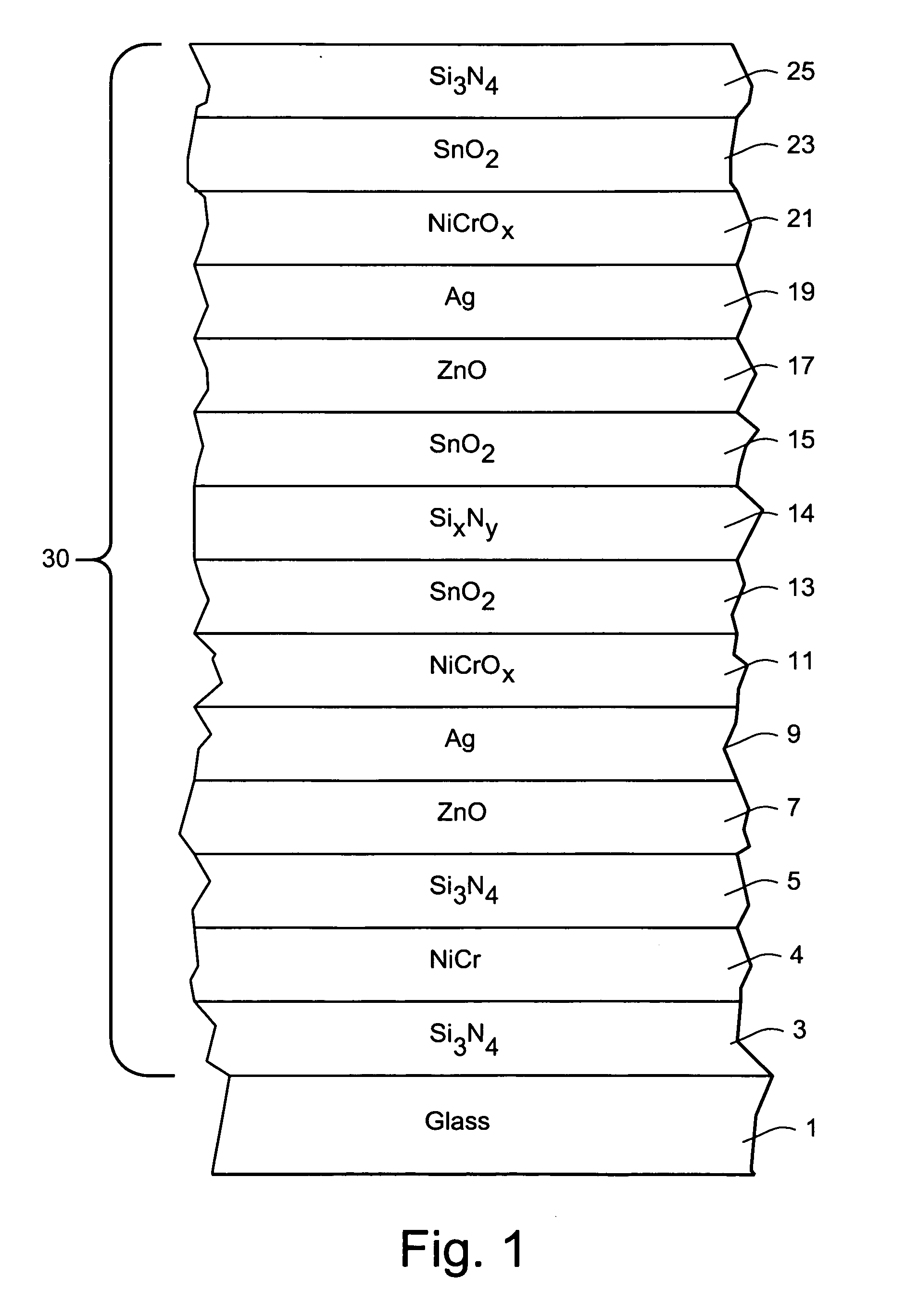

Coated article having low-E coating with absorber layer(s)

ActiveUS20110261442A1Low emissivityReduce sheet resistanceMirrorsOptical filtersElectrical resistance and conductanceInsulated glazing

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN EURO S A R L +1

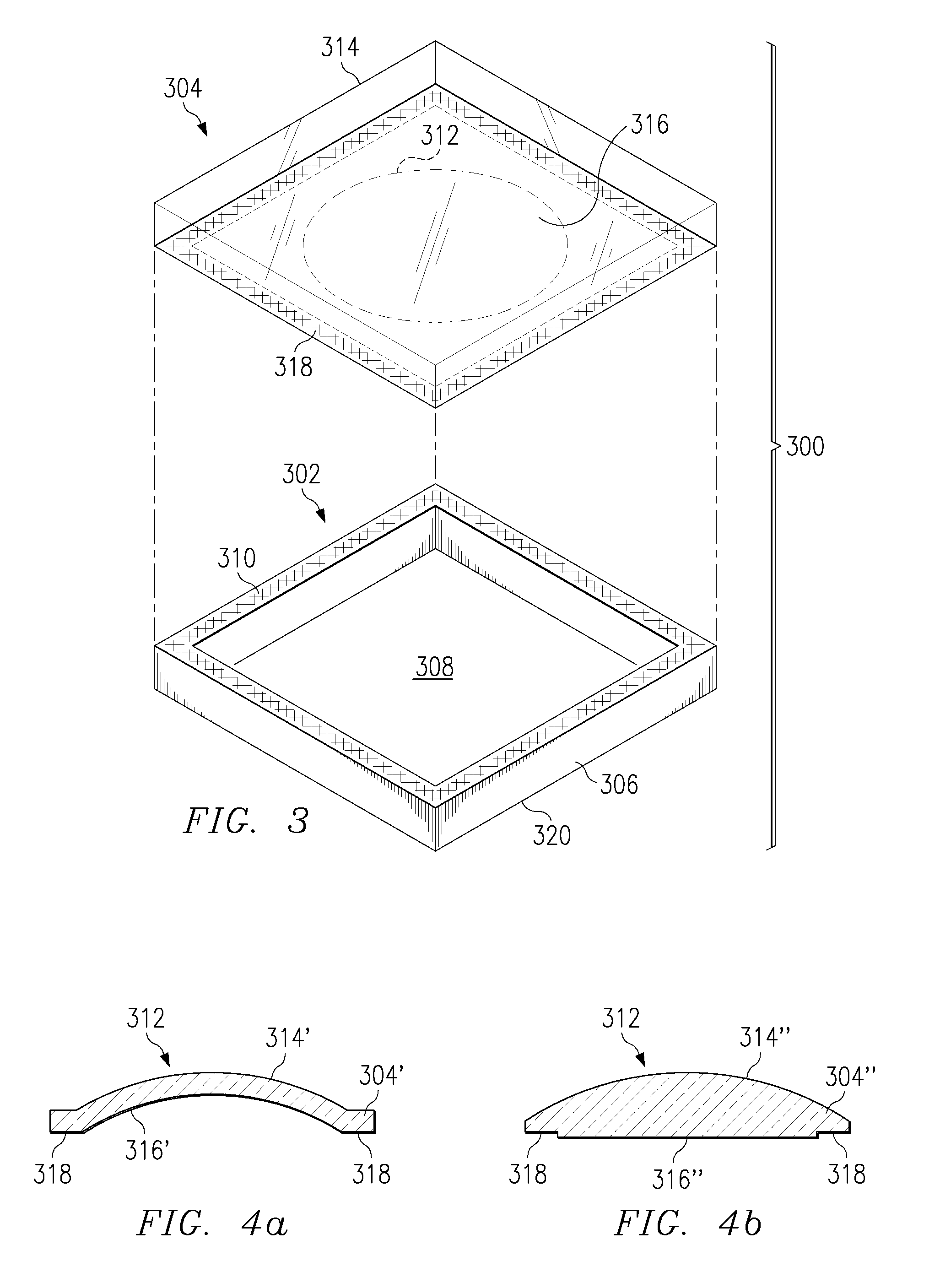

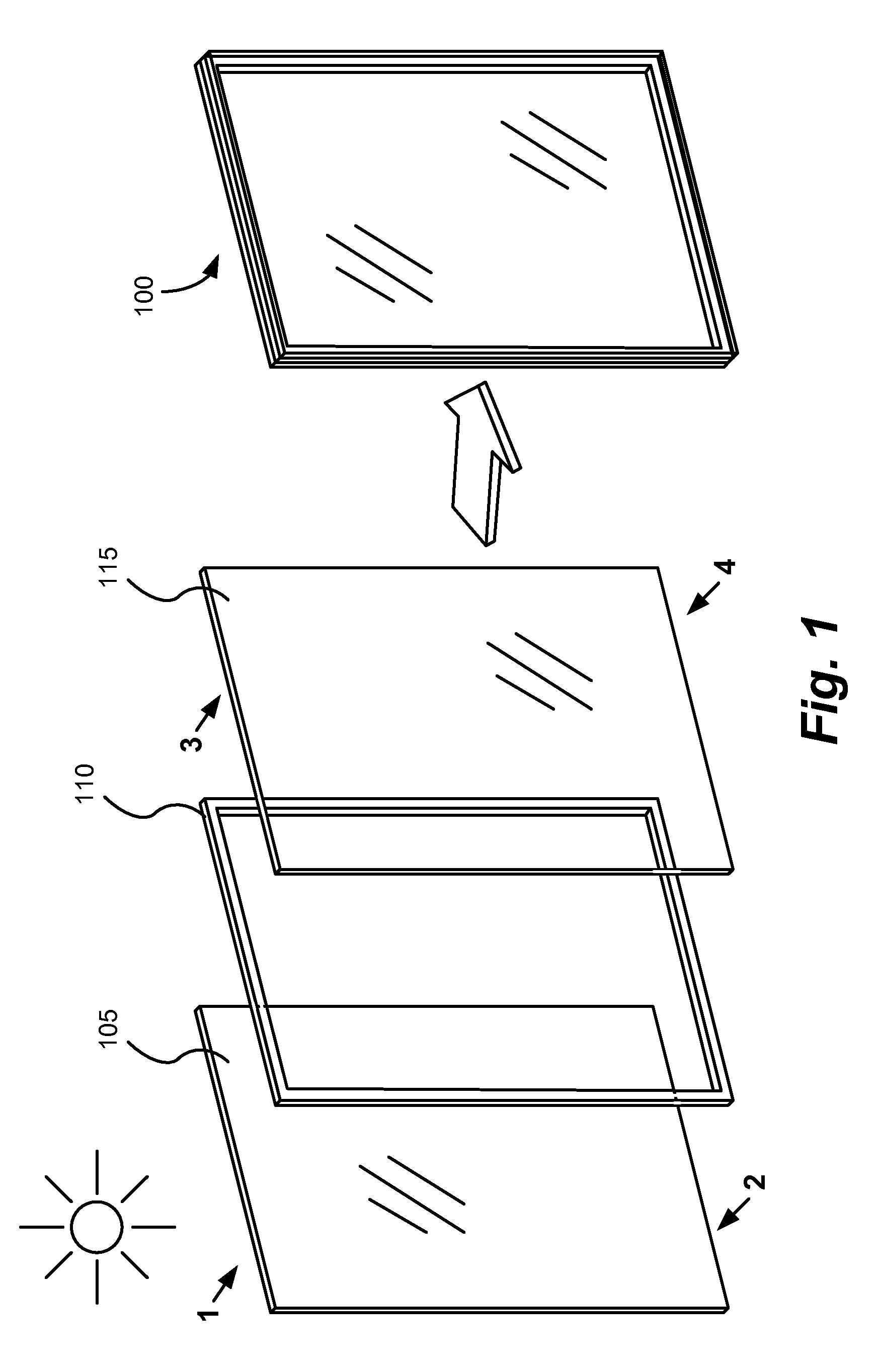

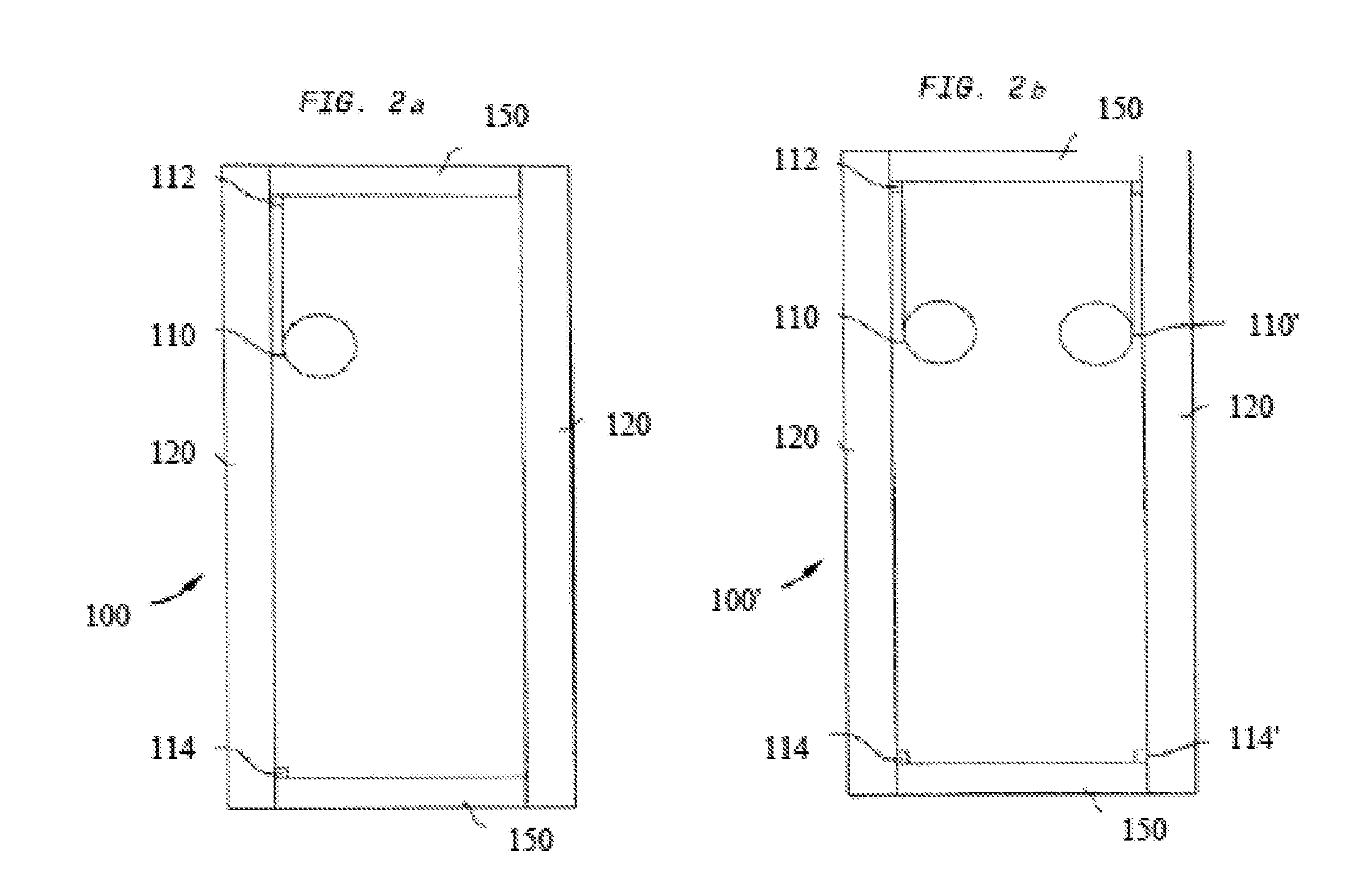

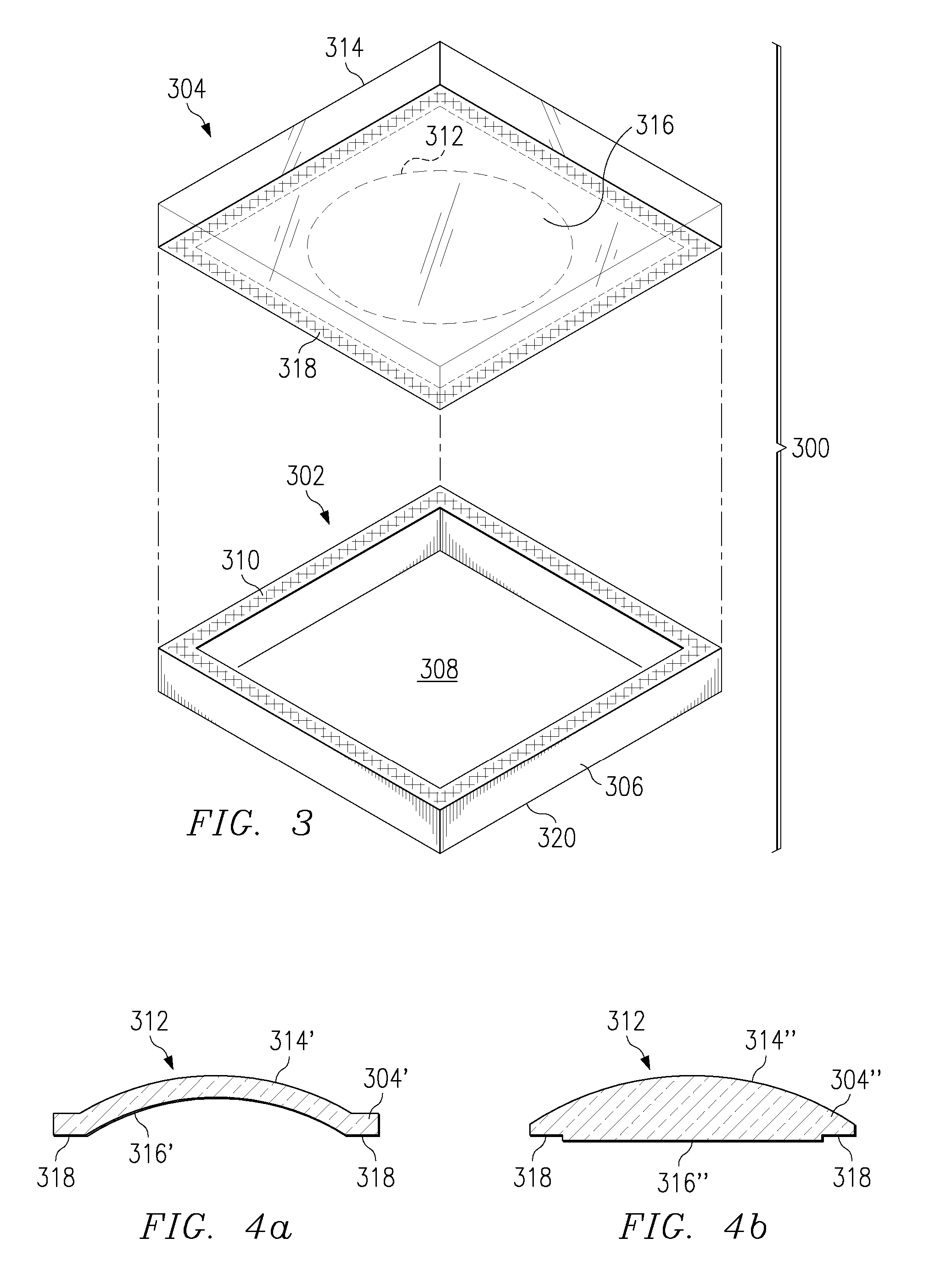

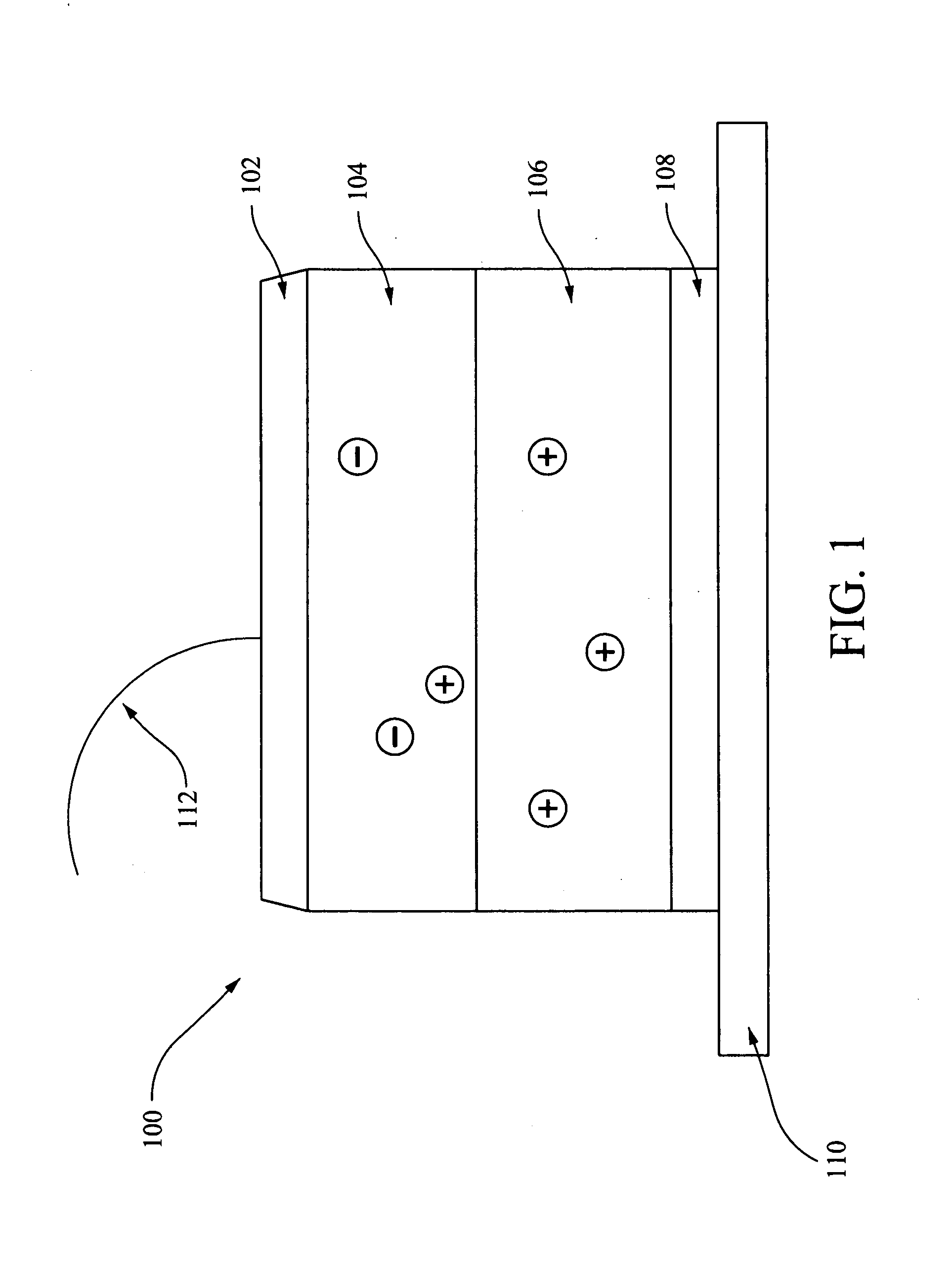

Multi-pane electrochromic windows

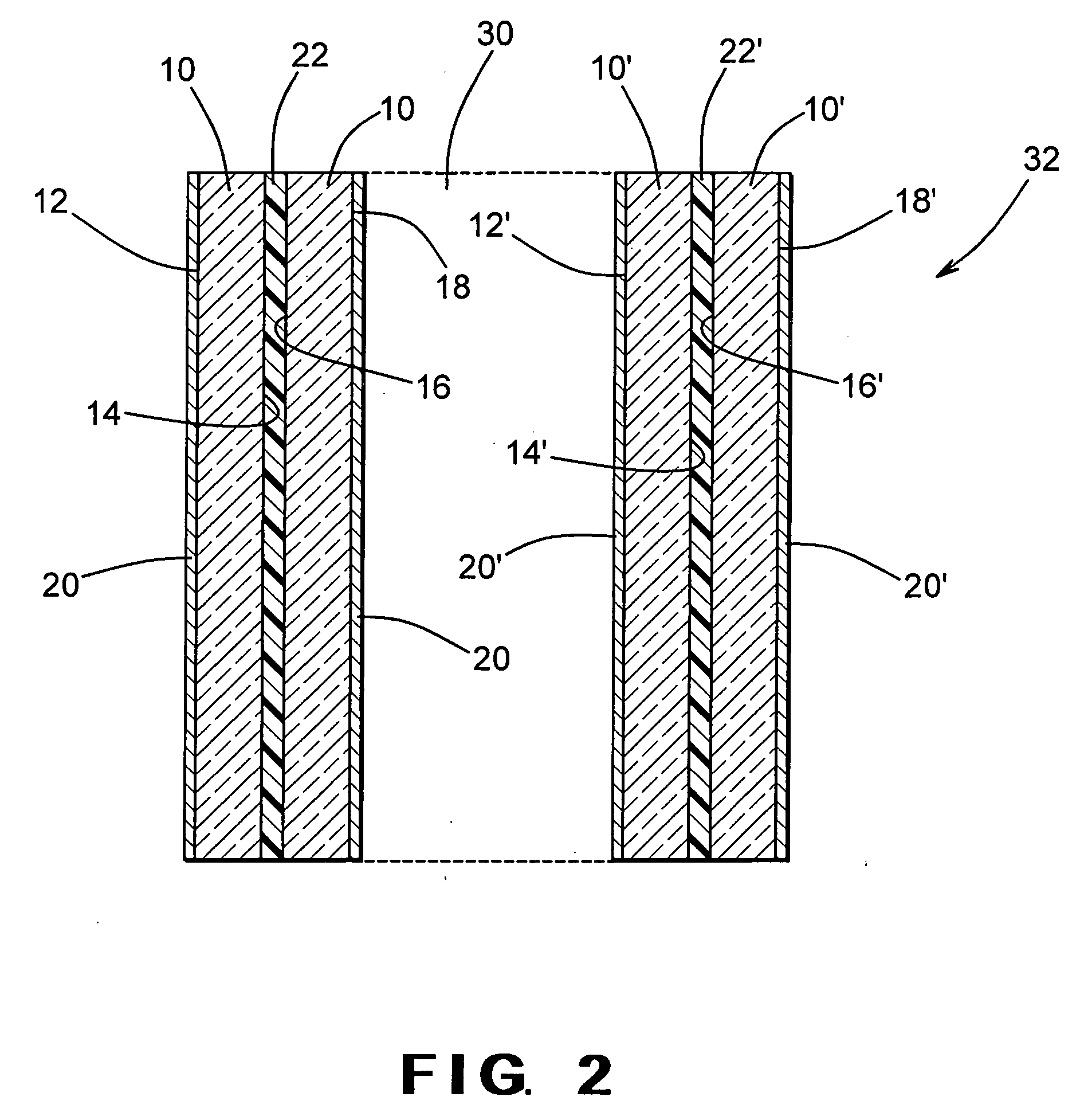

ActiveUS8270059B2Increased defectivityGood choiceTransparent/reflecting heating arrangementsLight protection screensElectricityElectrochromism

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

Coated article including low-emissivity coating, insulating glass unit including coated article, and/or methods of making the same

InactiveUS20120219821A1Reduce sheet resistanceImprove transmittancePretreated surfacesLaminationInsulated glazingLow emissivity

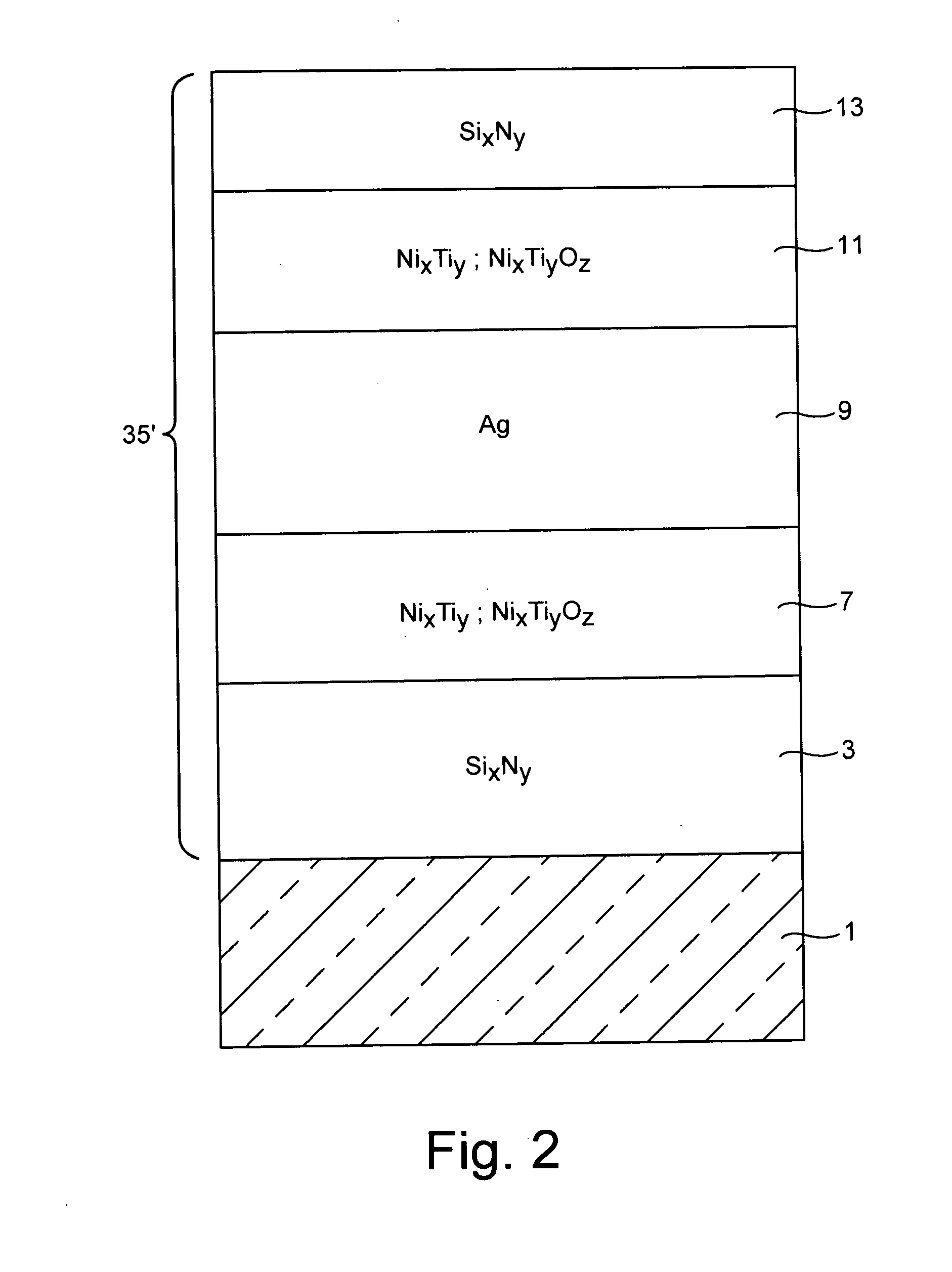

Certain example embodiments relate to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating, and methods of making the same. In certain cases, at least one layer of the coating is of or includes nickel and / or titanium (e.g., NixTiyOz). The provision of a layer including nickel titanium and / or an oxide thereof may permit a layer to be used that has good adhesion to the IR reflecting layer, and reduced absorption of visible light (resulting in a coated article with a higher visible transmission). When a layer including nickel titanium oxide is provided directly over and / or under the IR reflecting layer (e.g., as a barrier layer), this may result in improved chemical and mechanical durability. Thus, visible transmission may be improved if desired, without compromising durability; or, durability may simply be increased.

Owner:GUARDIAN EURO S A R L +1

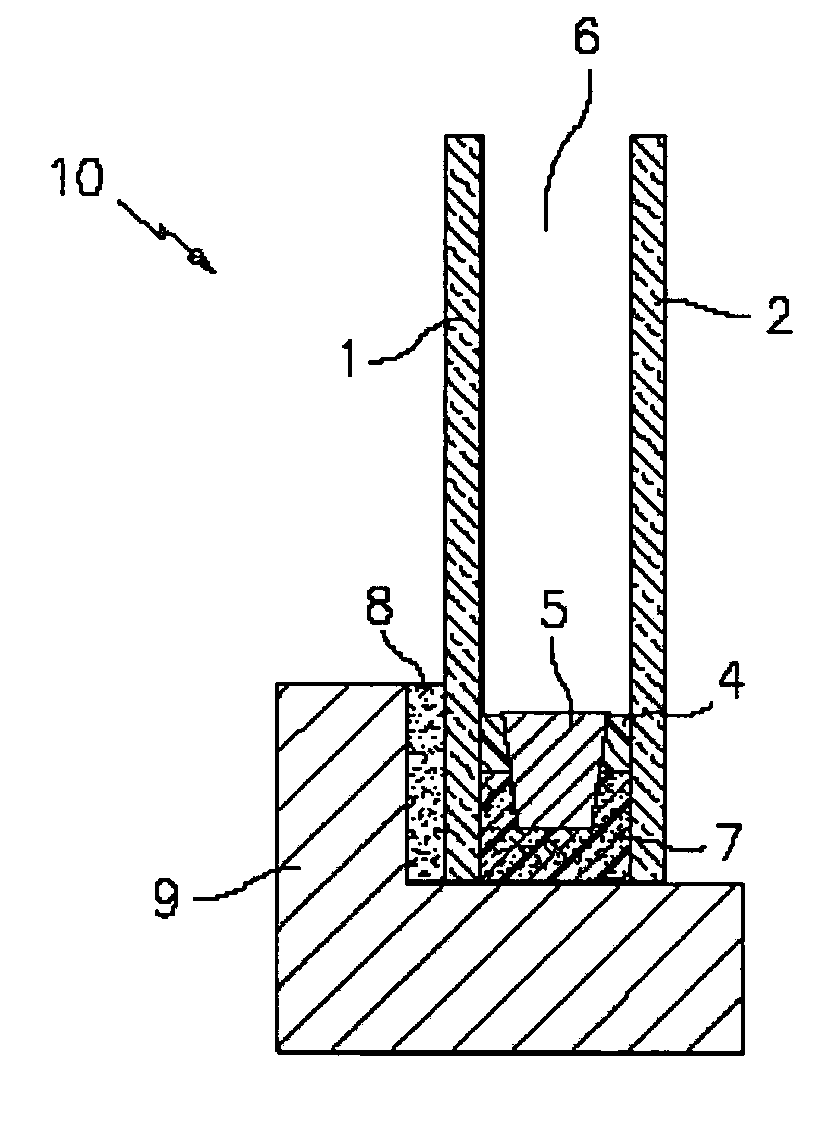

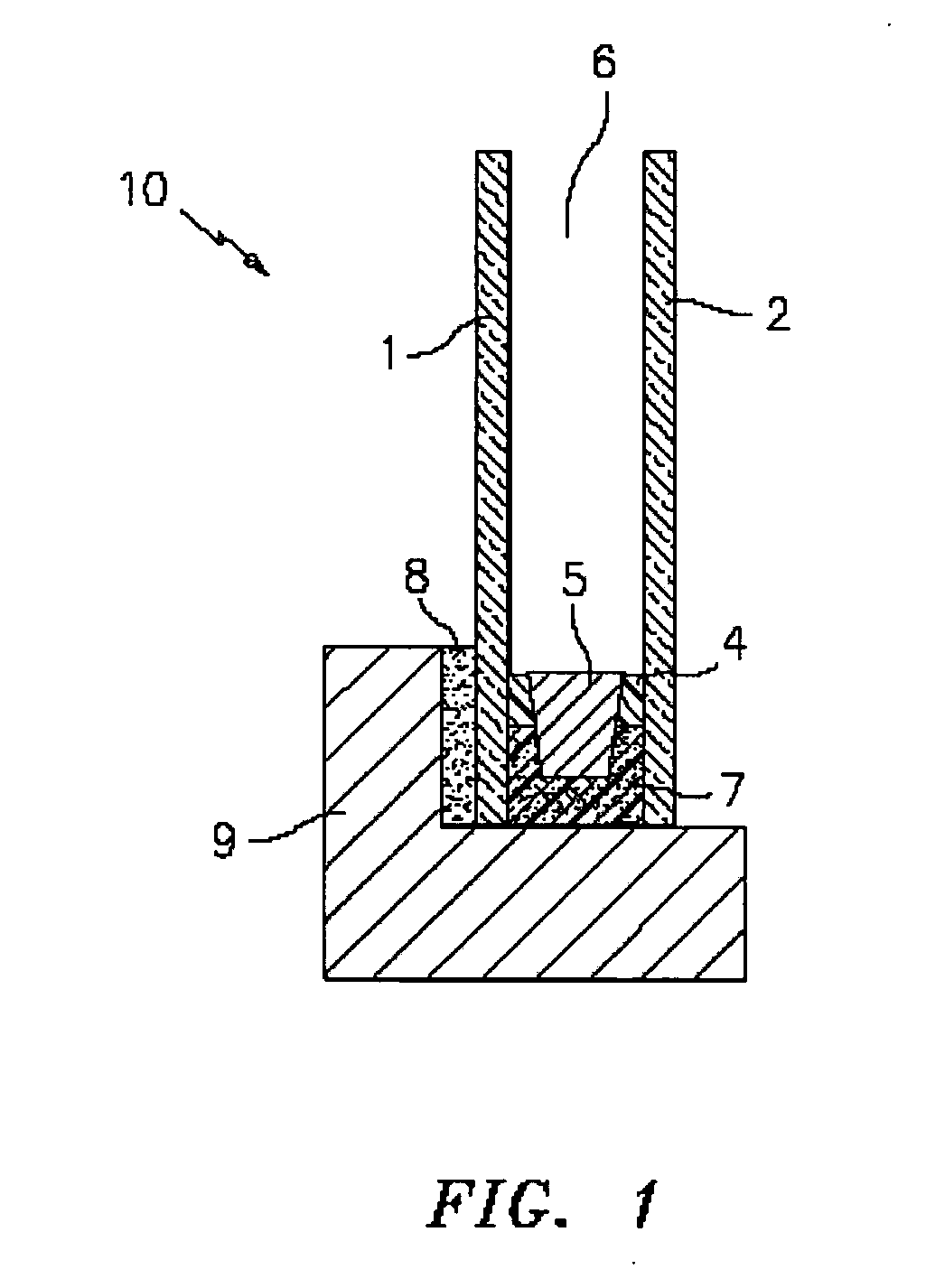

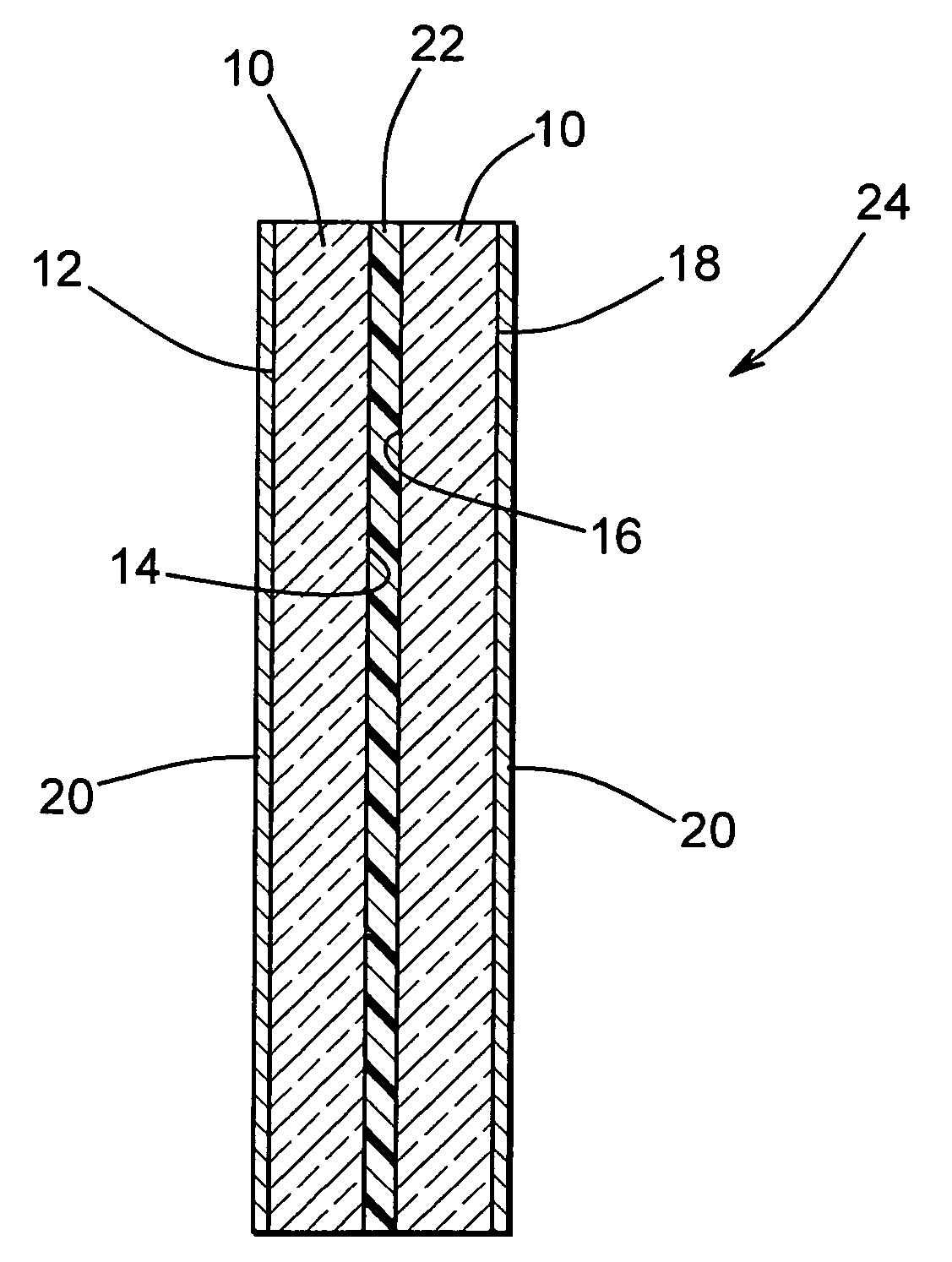

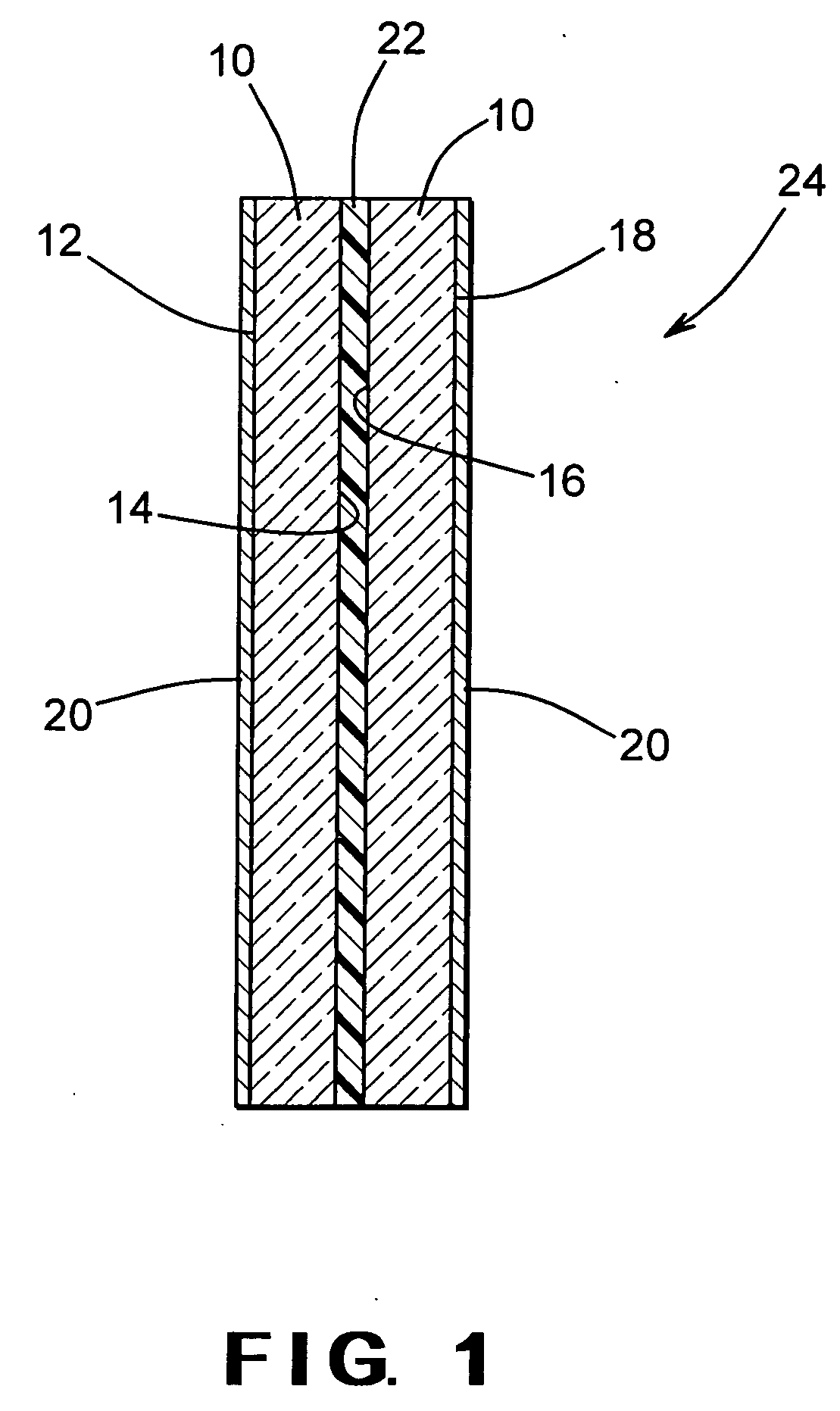

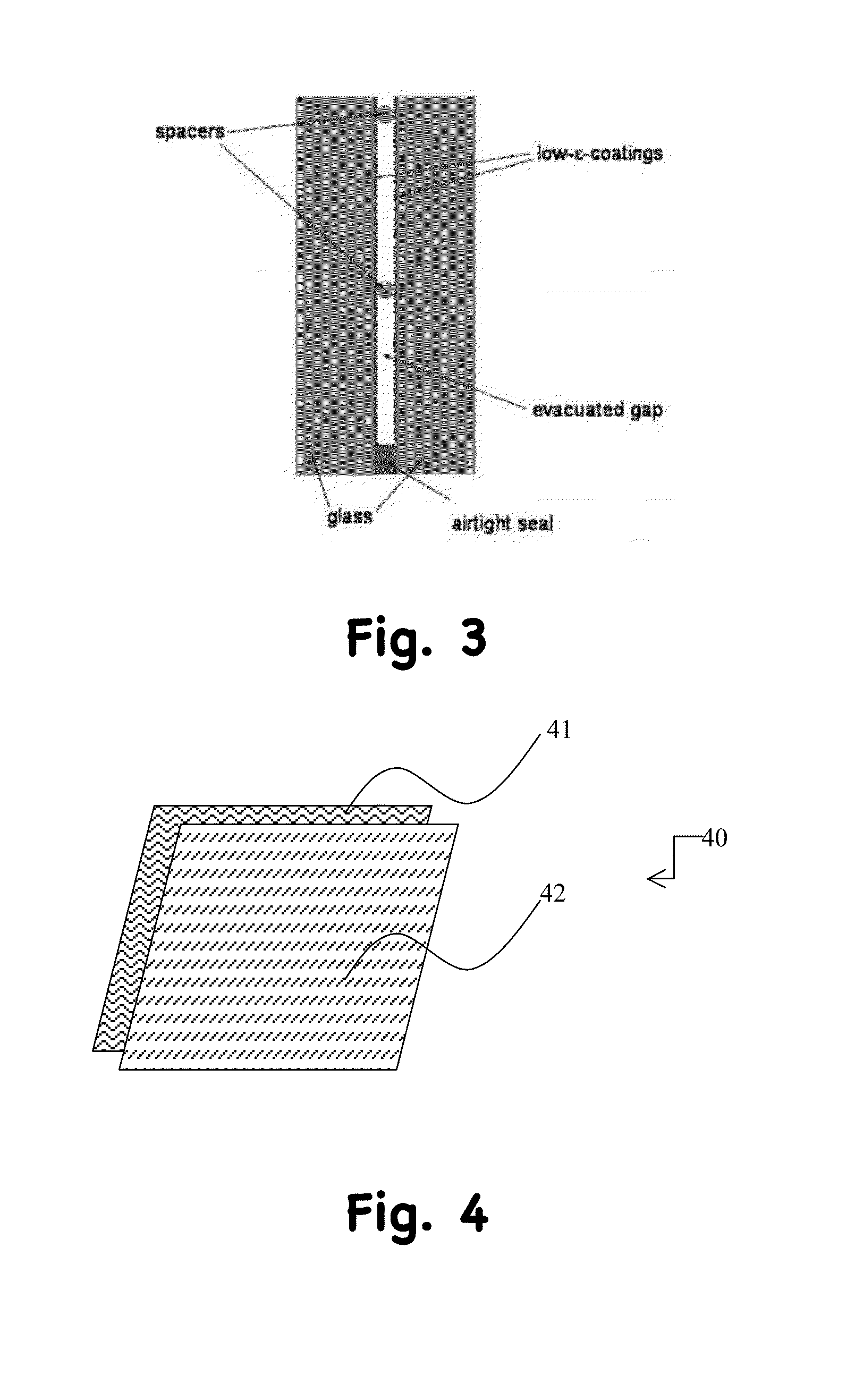

Vacuum IG pillar with lubricating and/or reflective coating

InactiveUS6946171B1Less visibly obtrusiveMinimize cracksClimate change adaptationWindows/door improvementChemical reactionThermal expansion

A vacuum insulating glass (IG) unit is provided with an array of spacers / pillars between opposing glass sheets. At least some of the spacers / pillars are coated on at least one surface thereof with a dry lubricant and / or reflective material such as silver. This coating permits the glass sheet(s) to move relative to one another during thermal expansion while minimizing the degree to which the spacers / pillars scratch or crack the glass during such relative movement. A method of making an exemplary spacer / pillar includes transforming by chemical reaction silver ions on a core into a metallic silver coating thereby resulting in a coated spacer / pillar.

Owner:GUARDIAN GLASS LLC

Low-emissivity coating having low solar reflectance

InactiveUS7063893B2Low-emissivity coatingPromote absorptionRecord information storageDoor/window applicationsInsulated glazingLow emissivity

The invention provides low solar reflectance, low-emissivity coatings. The invention also provides a pane bearing a low solar reflectance, low-emissivity coating. Further, the invention provides an insulating glass unit comprising first and second panes held in a spaced-apart configuration, wherein the panes have confronting inner surfaces oriented toward a between-pane space and opposed outer surfaces oriented away from the between-pane space, and wherein one of these inner surfaces bears a low solar reflectance, low-emissivity coating. Also provided are methods of producing coated substrates.

Owner:CARDINAL CG

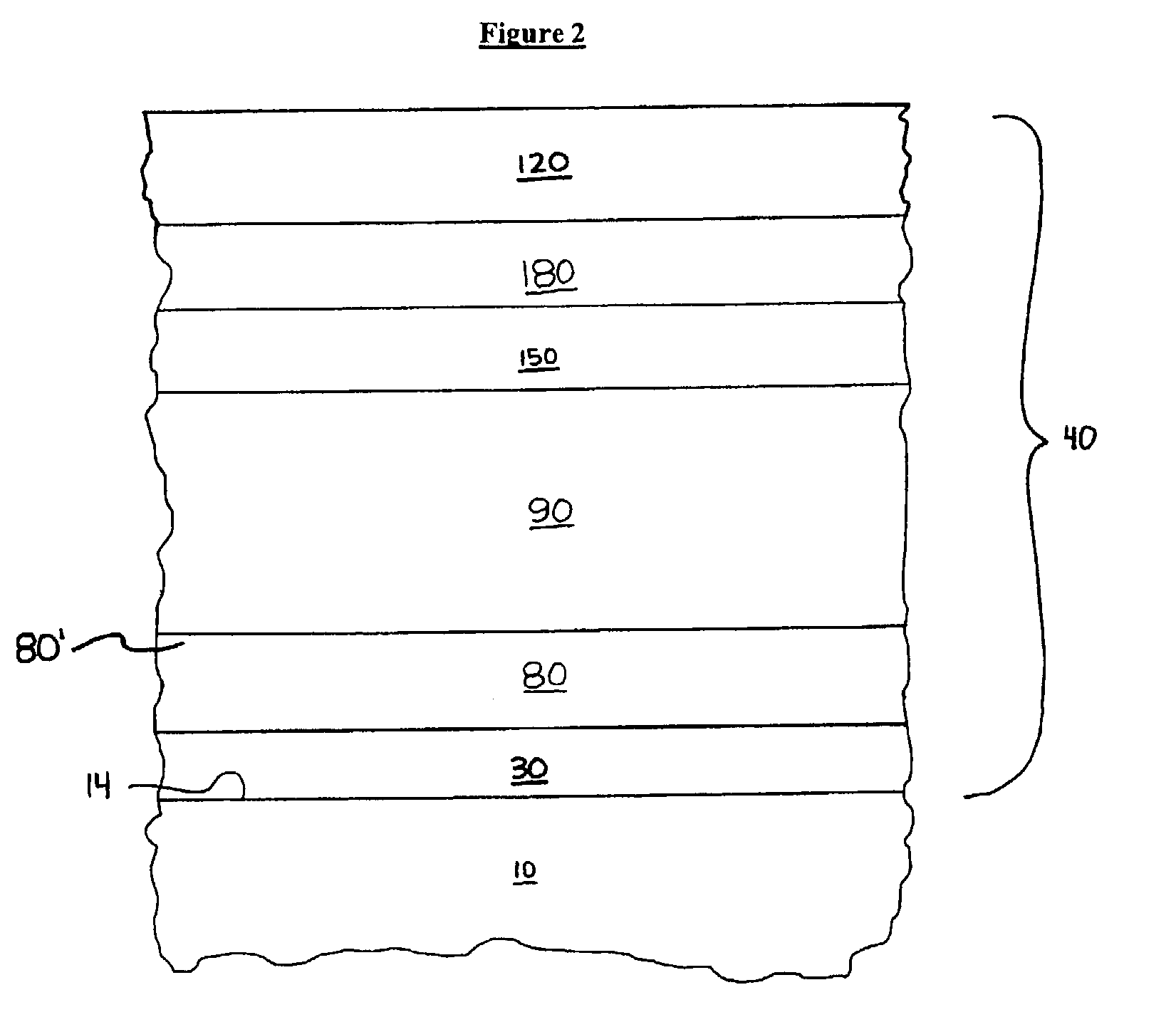

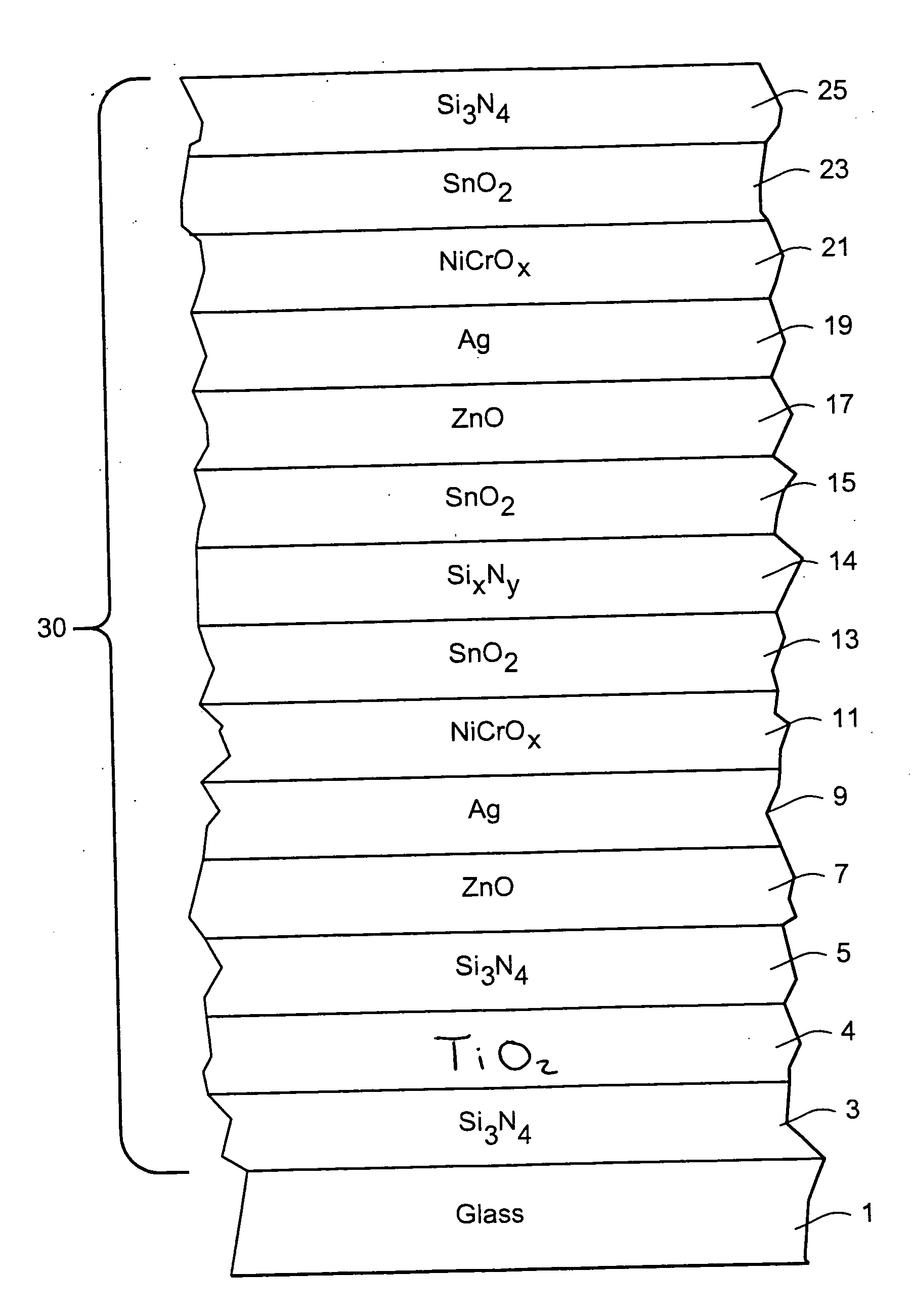

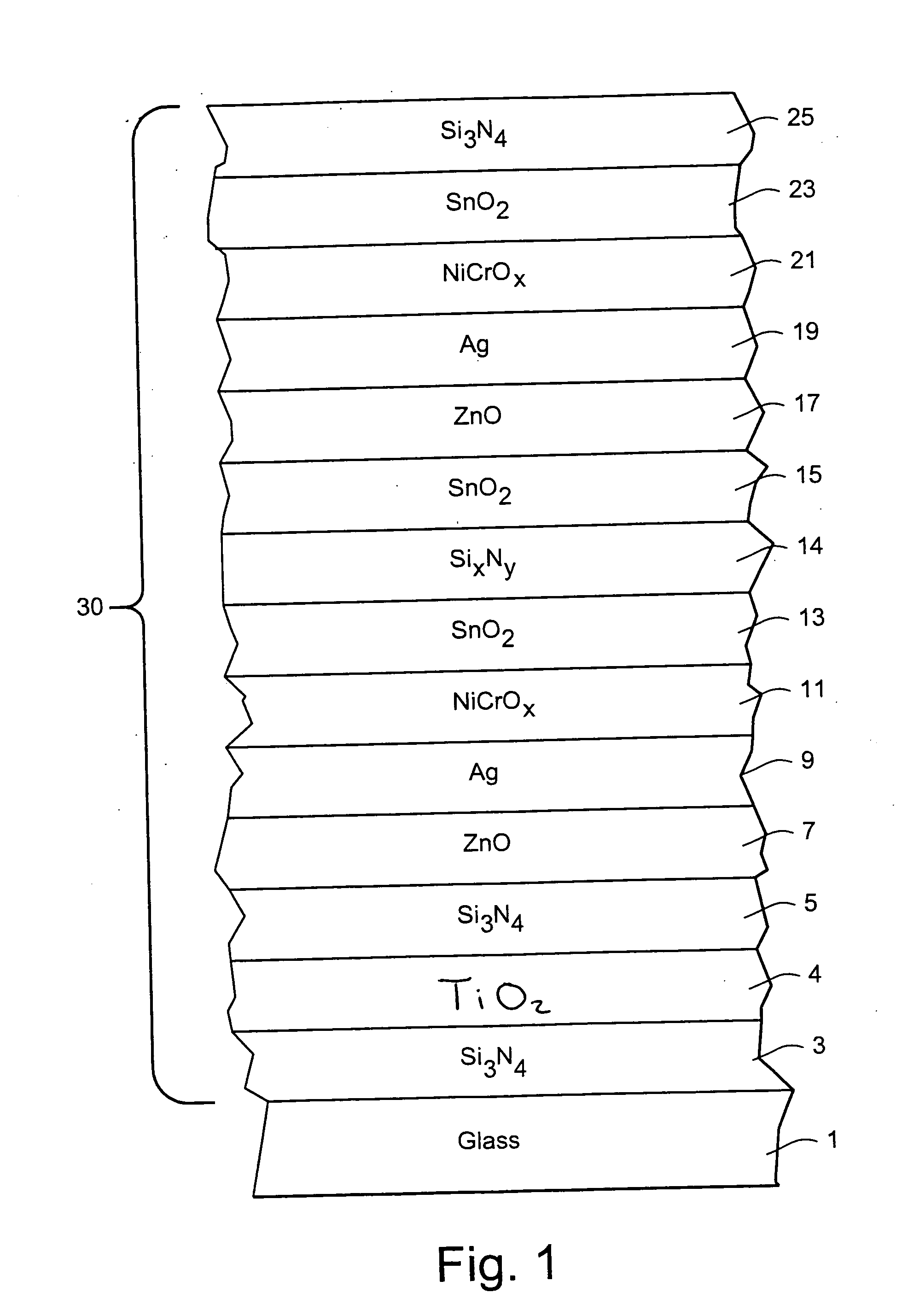

Coated article with low-E coating having titanium oxide layer and/or nicr based layer(s) to improve color values and/or transmission, and method of making same

InactiveUS20100279144A1Lower transmissive b * valueHigher visible transmissionVacuum evaporation coatingSputtering coatingInsulated glazingTransmittance

Certain example embodiments of this invention relate to a coated article including a low-E coating. In certain example embodiments, a titanium oxide inclusive bottom layer stack and / or a NiCr-based layer(s) are designed to improve b* coloration values and / or transmission of the coated article. These layer stack portions also are advantageous in that they permit a double-silver coated article to achieve (i) an LSG value (Tvis / SHGC) of at least 2.0, (ii) an SHGC value of no greater than 35%, more preferably no greater than 33, 32 or 30%, and (iii) a U-value (BTU h−1 ft−2° F.−1) (e.g., x=12 mm) of no greater than 0.30, more preferably no greater than 0.28 or 0.25. In certain example embodiments, the titanium oxide based layer may be an interlayer provided in a bottom portion of the layer stack between first and second layers comprising silicon nitride. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, other types of windows, or in any other suitable application.

Owner:GUARDIAN GLASS LLC

Insulating Glass Unit With An Electronic Device and Process For Its Production

A sealed insulating glass unit comprises two glass sheets held apart by a spacer, optionally with a sealant between the edges of the glass sheets outside the spacer. The insulating glass unit contains an electronic device, having information relating to the origin, manufacture and / or properties of the insulating glass unit capable of being read from the device by means actuated from outside the insulating glass unit. The device is embedded within the spacer or sealant so that it is concealed within the insulating glass unit.

Owner:DOW SILICONES CORP +1

Coated article with absorbing layer

ActiveUS20050196622A1Easy and efficient adjustmentIncrease and reduce visible transmissionGlass/slag layered productsNatural mineral layered productsInsulated glazingMedicine

A coated article is provided with an absorbing layer(s). The coating is, in certain example embodiments, designed so that significant changes in visible transmission can be made by adjusting thickness of the absorbing layer without significantly affecting certain other characteristics such as certain color values. Such coated articles may be used monolithically or in the context of insulating glass (IG) units in different embodiments of this invention, and may or may not be heat treated.

Owner:GUARDIAN GLASS LLC

Low-E matchable coated articles and methods of making same

InactiveUS6475626B1Improved color stabilityEasy to controlMirrorsDoors/windowsInsulated glazingRadiance

A heat treatable coated article including an infrared (IR) reflecting layer (e.g., of or including Ag), the coated article being able to attain a .DELTA.E* (glass side) no greater than about 3.0, more preferably no greater than 2.5, and even more preferably no greater than 2.0, following or due to heat treatment (e.g., thermal tempering). Accordingly, low-E (i.e., low emissivity) coated articles of certain embodiments of this invention appear from the glass side thereof visually similar to the naked eye both before and after heat treatment. Coated articles herein may be used in the context of insulating glass (IG) window units, vehicle windshields, or any other suitable applications. In certain embodiments of this invention, an exemplary layer stack includes: glass / Si.sub.3 N.sub.4 / NiCr / Ag / NiCr / Si.sub.3 N.sub.4. Other materials may instead be used without departing from the scope and / or spirit of the instant invention which is a low-E matchable product.

Owner:GUARDIAN GLASS LLC

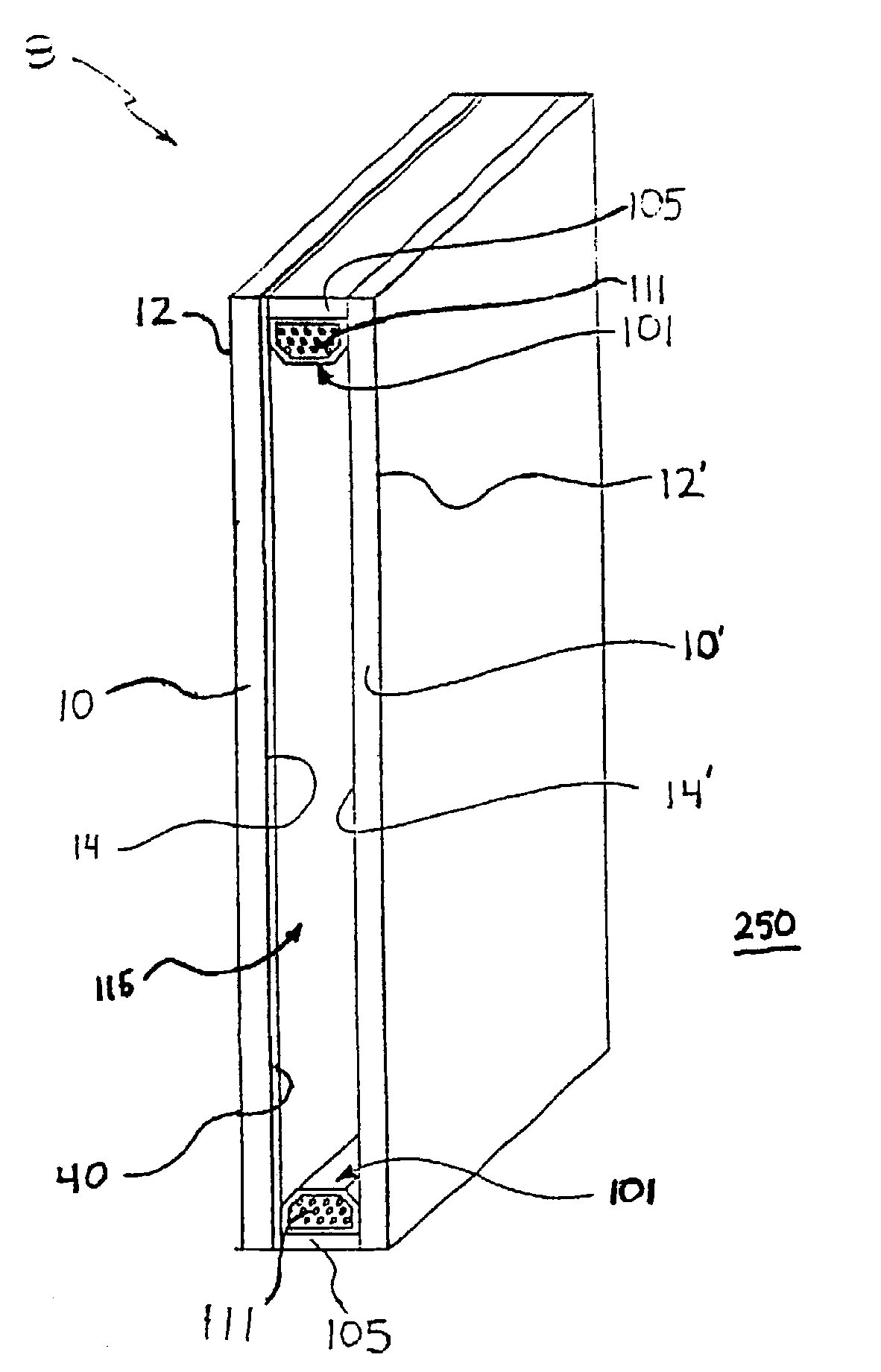

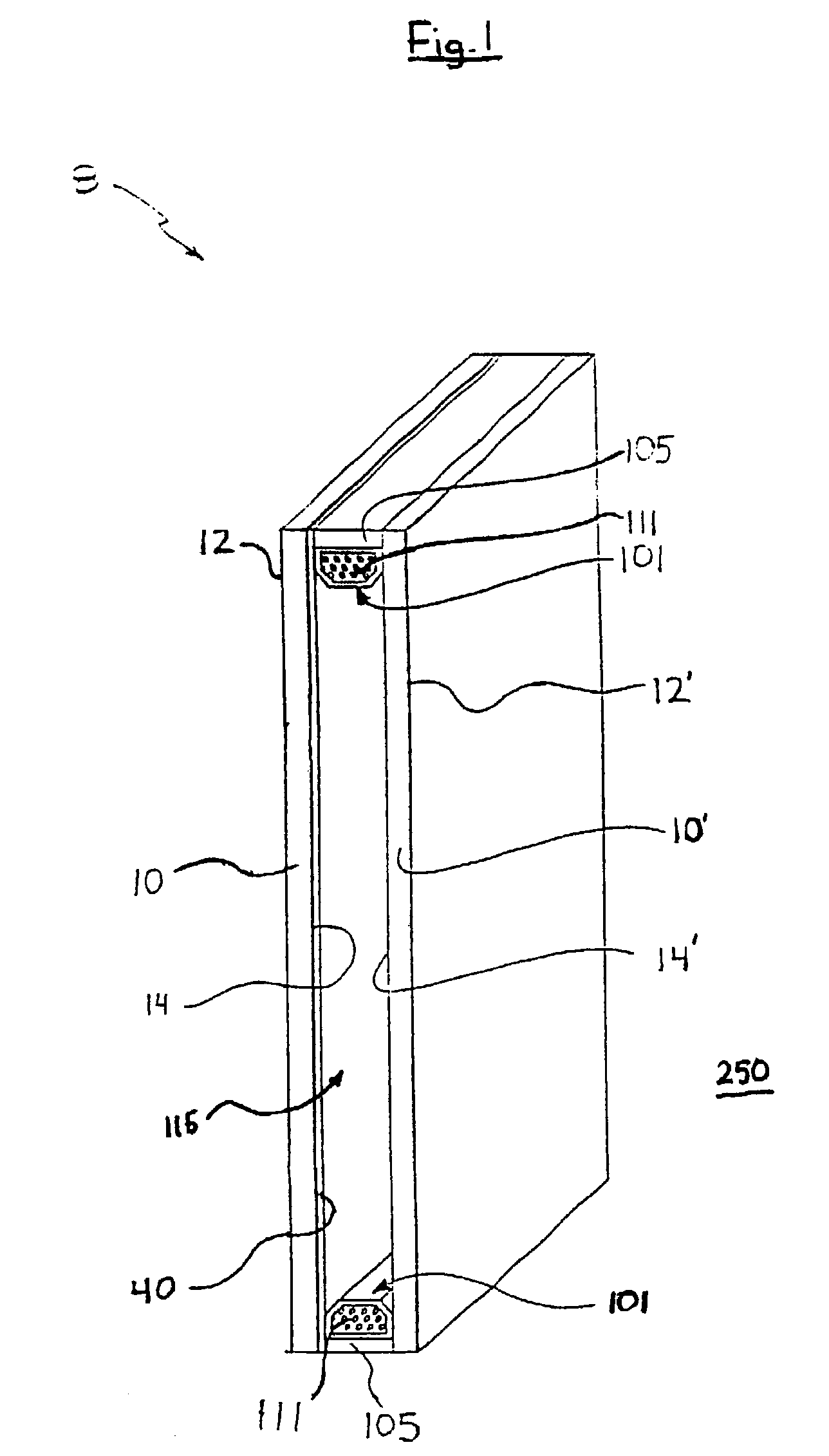

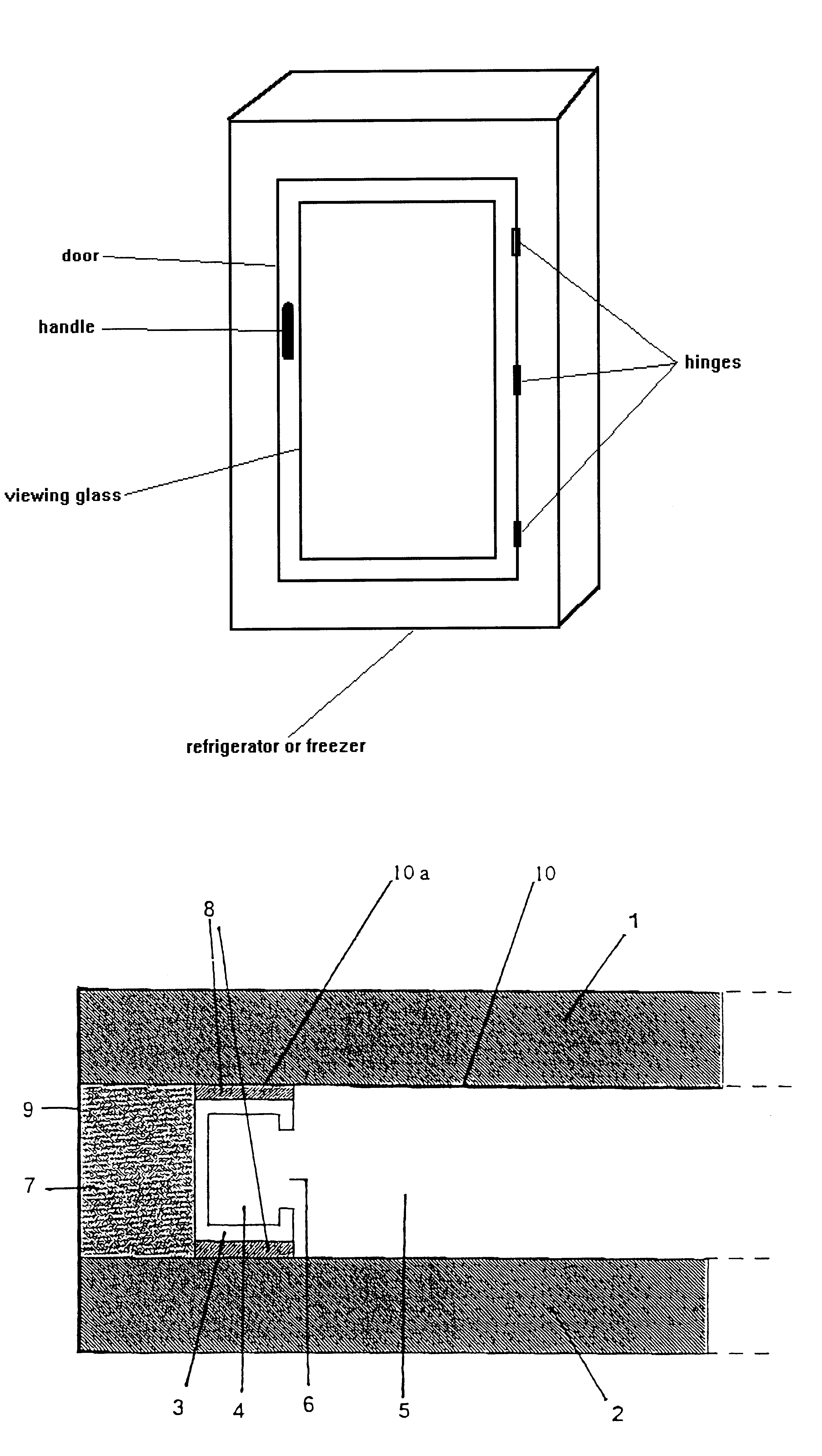

Appliance such as a refrigerator or freezer with a transparent viewing door and a method of manufacture of a refrigerator or freezer with a transparent viewing door

InactiveUS6268594B1Reduce formationLittle process outlayShow cabinetsConductive layers on insulating-supportsFlat glassInsulated glazing

A multipane insulating glass for appliances having an inner-chamber temperature which is lower than the ambient temperature, in particular for viewing doors of refrigerators and freezers comprises at least two panes which are of approximately equal size and are arranged at a distance from one another. The distance is maintained by a spacer which runs continuously around the vicinity of the edge. One of the two outer panes is provided with an electrically conductive, transparent coating on its side which faces towards the space between the panes. In this glass, the coating, which is applied to the entire surface, is deactivated in the peripheral area of the pane, containing the contact surface for the spacer. Also, a process for producing coated flat glass materials for such insulating glass materials, as described above.

Owner:GLAS SCHOTT +1

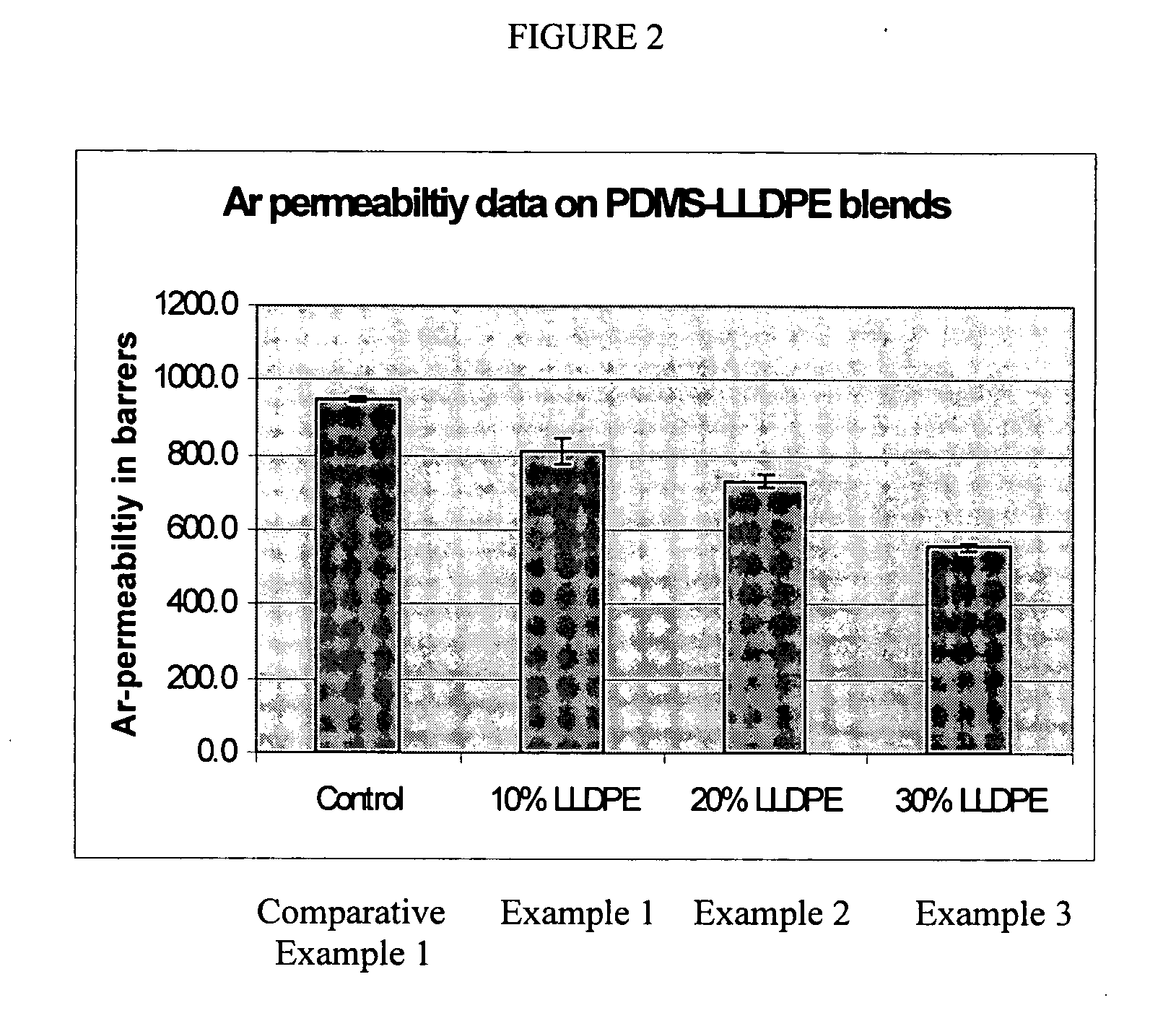

Insulated glass unit possessing room temperature-cured siloxane sealant composition of reduced gas permeability

InactiveUS20070116907A1Easy to useReduce air permeabilityAdhesivesUnits with parallel planesPolymer scienceInsulated glazing

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

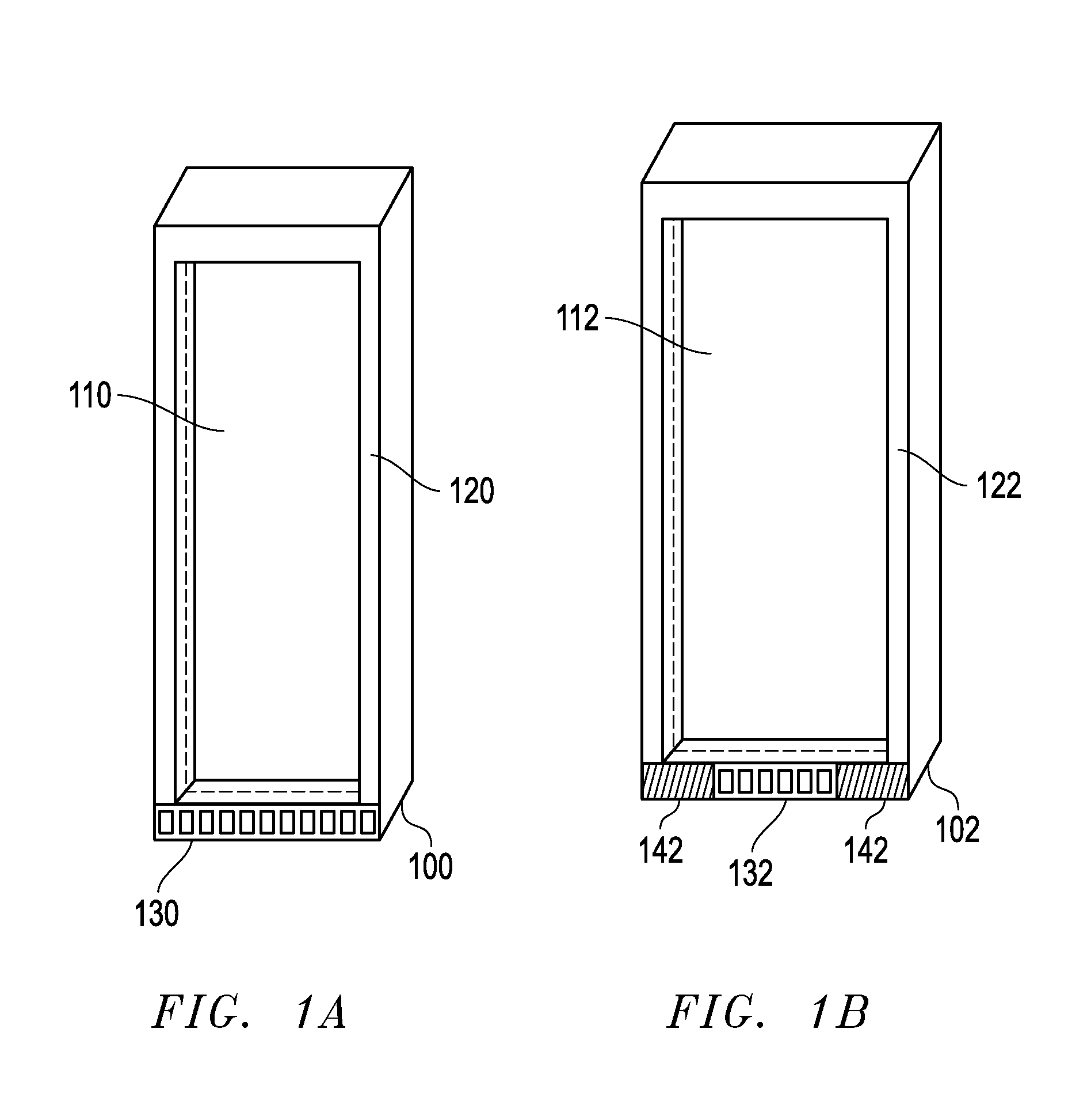

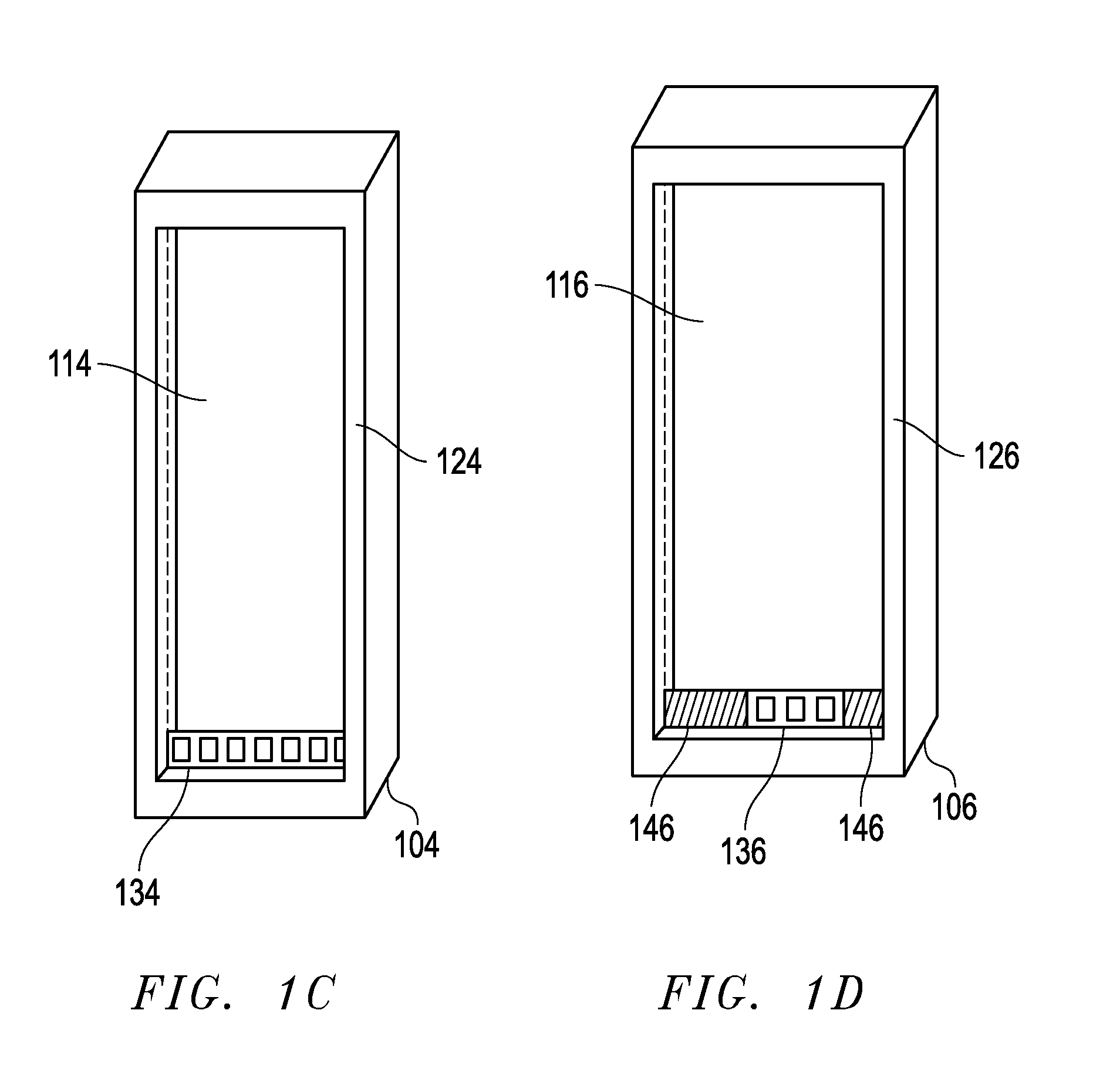

Electronically controlled insulated glazing unit providing energy savings and privacy

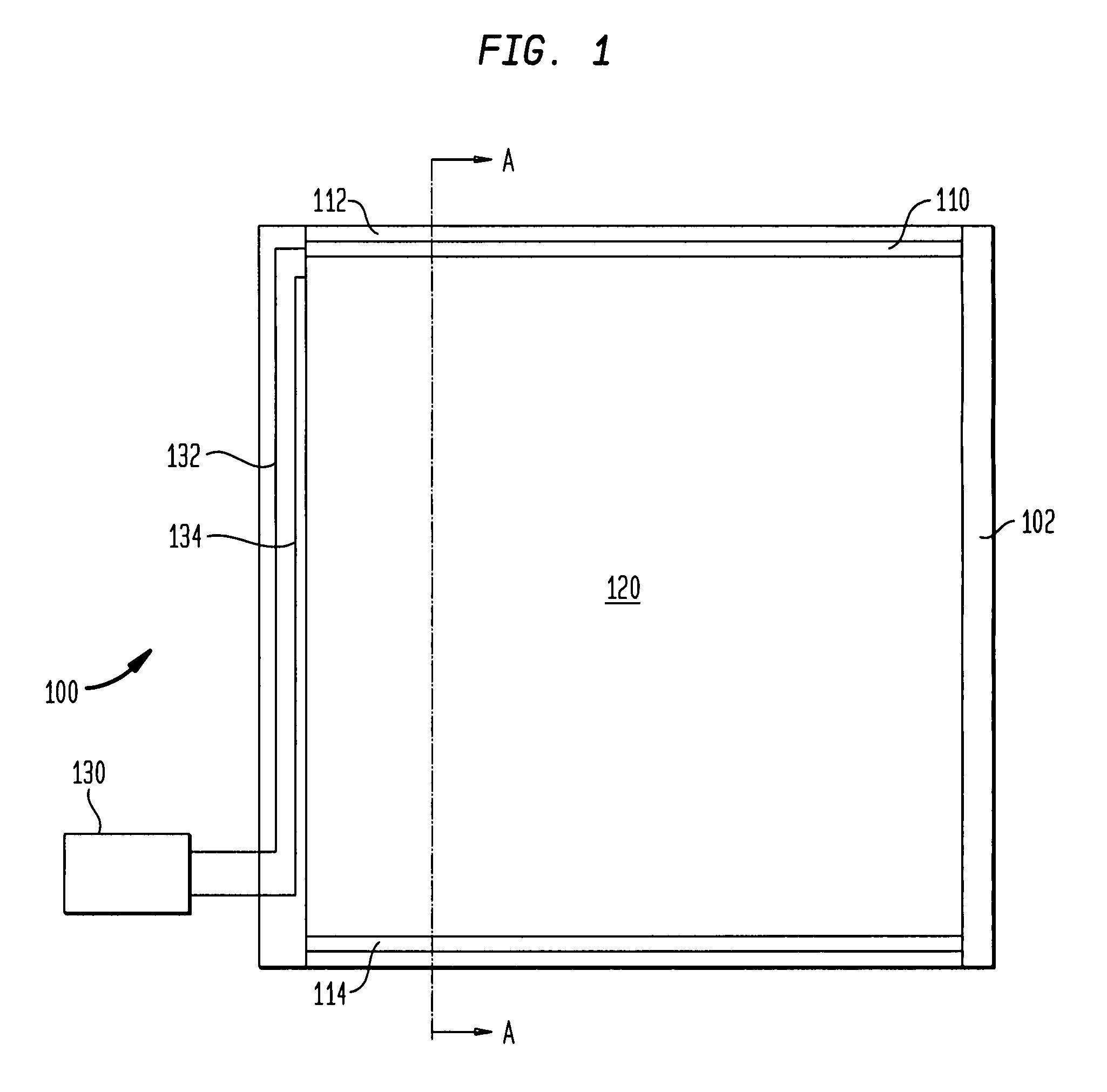

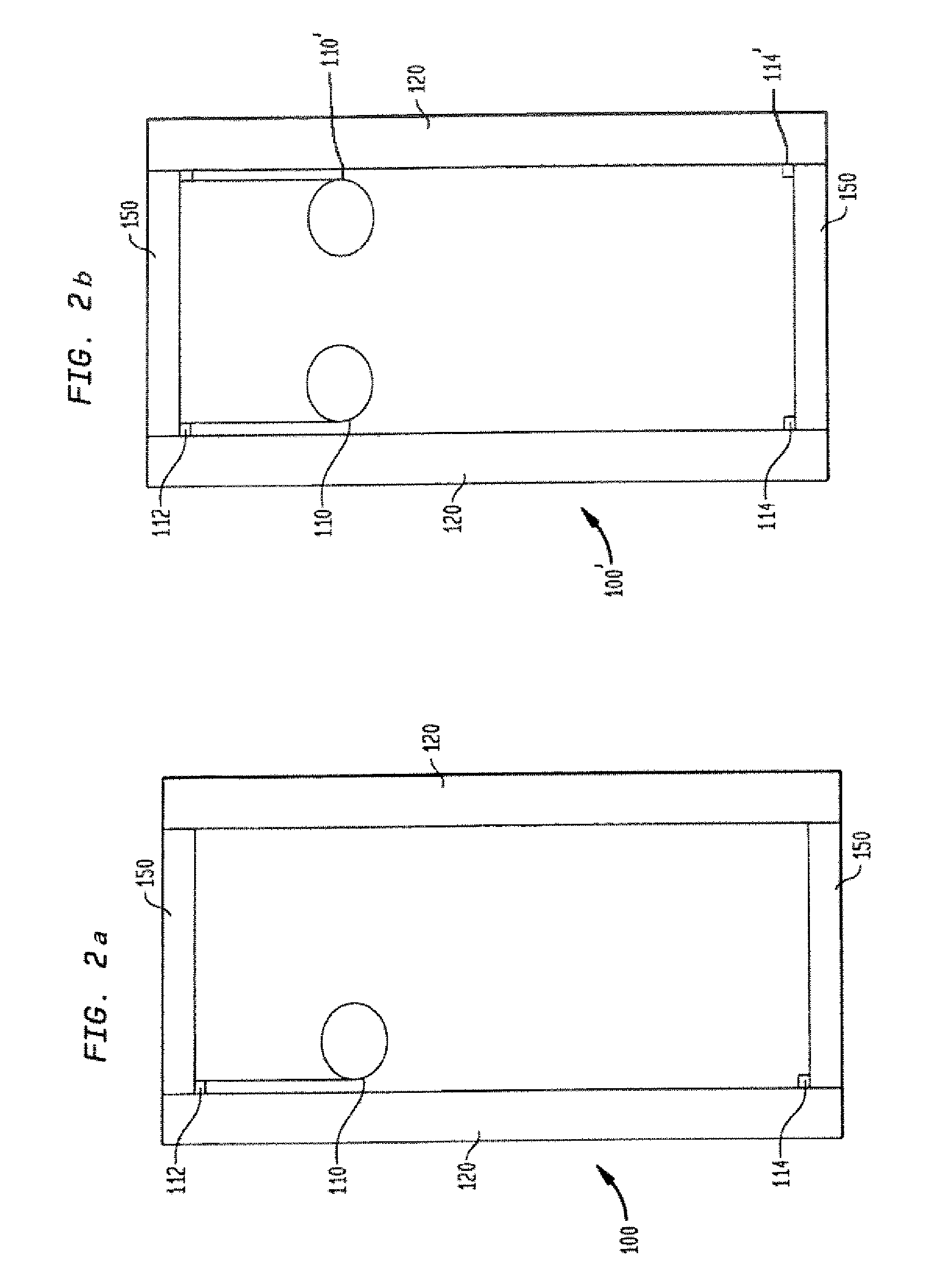

ActiveUS8736938B1Solution to short lifeEffective controlDoor/window protective devicesOptical elementsElectricityInfrared

An insulated glazing unit includes a spacer defining a framed area, first and second glazing panes attached to the spacer, a pane conductive layer on an inner surface of the first glazing pane, and a dielectric layer disposed on the pane conductive layer. A shade for use with the insulated glazing unit is affixed to the first glazing pane. The shade includes one or more layers selected from a resilient layer, a substantially transparent shade conductive layer, and an opaque shade conductive layer. When an electric drive is applied between the pane conductive layer and the shade conductive layer, a potential difference between the pane conductive layer and the shade conductive layer causes the shade to extend from a retracted configuration to an extended configuration. The shade can further include at least one ink coating layer including pigments that selectively reflect or absorb certain visible colors and infrared.

Owner:GUARDIAN GLASS LLC

Anti-reflective, thermally insulated glazing articles

A laminated glass unit having at least two sheets of glass separated and bonded by a polymeric interlayer material, and further having multi-layer thin film coatings on each of the unbonded surfaces of the at least two glass sheets, is disclosed. Two or more of such laminated glass units can be utilized in various configurations to form an insulated glass unit. The thin films deposited on the unbonded glass surfaces have anti-reflective, iridescence-suppressing and solar control properties when suitable configurations, materials and layer thicknesses are chosen. The laminated glass unit and insulated glass units of the invention exhibit an excellent combination of low visible light reflectance and thermal insulating properties.

Owner:PILKINGTON NORTH AMERICA INC

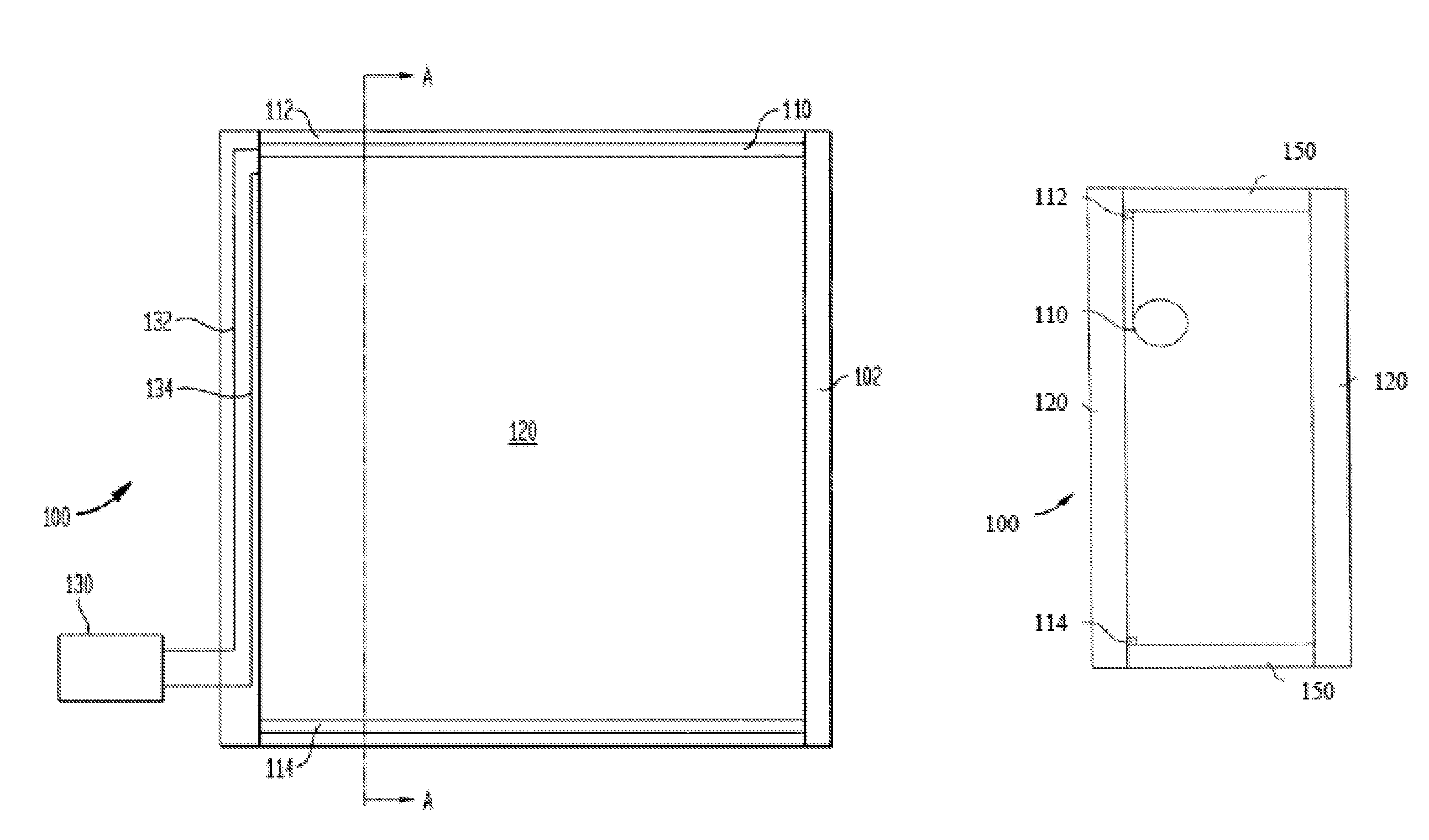

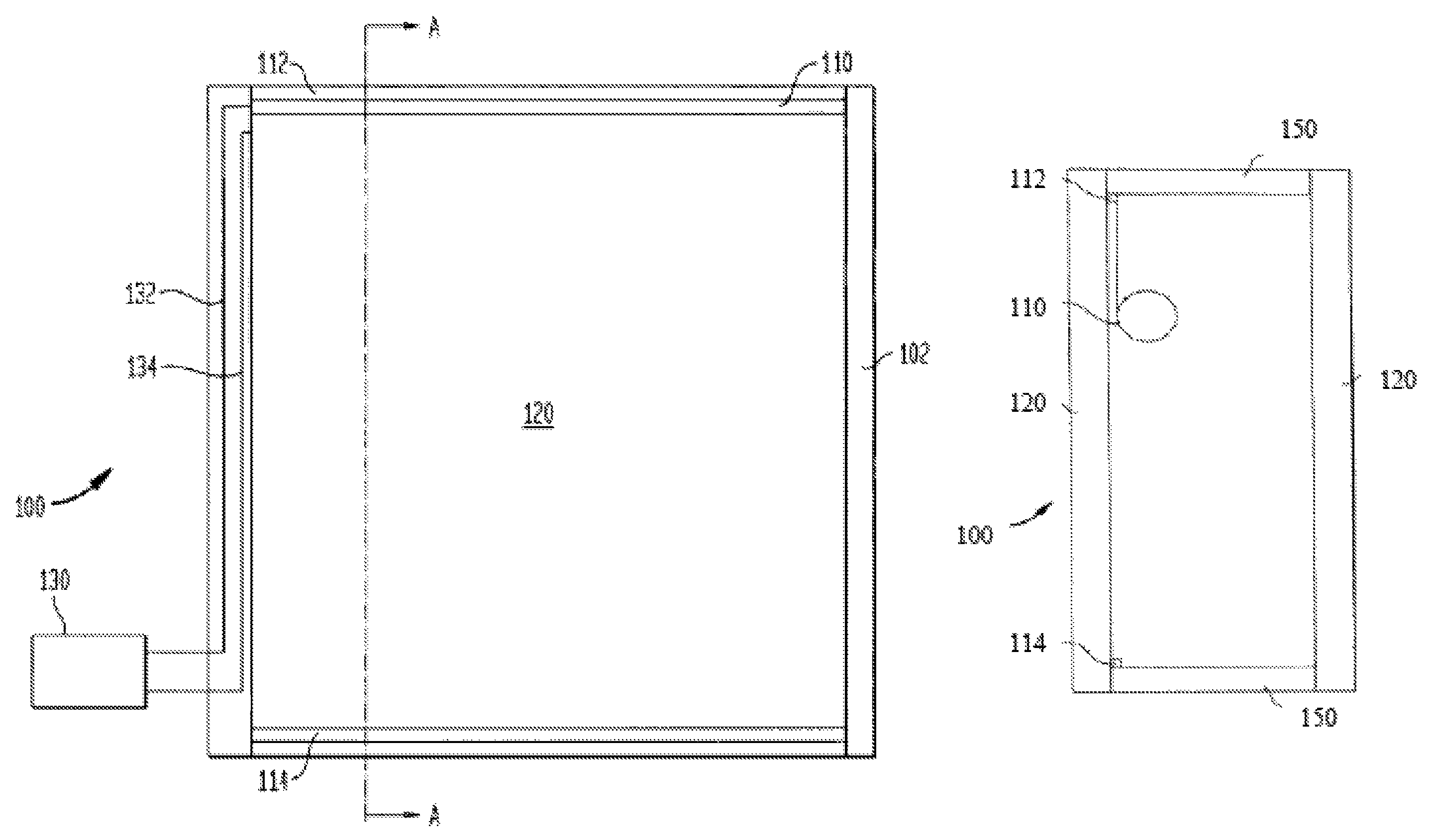

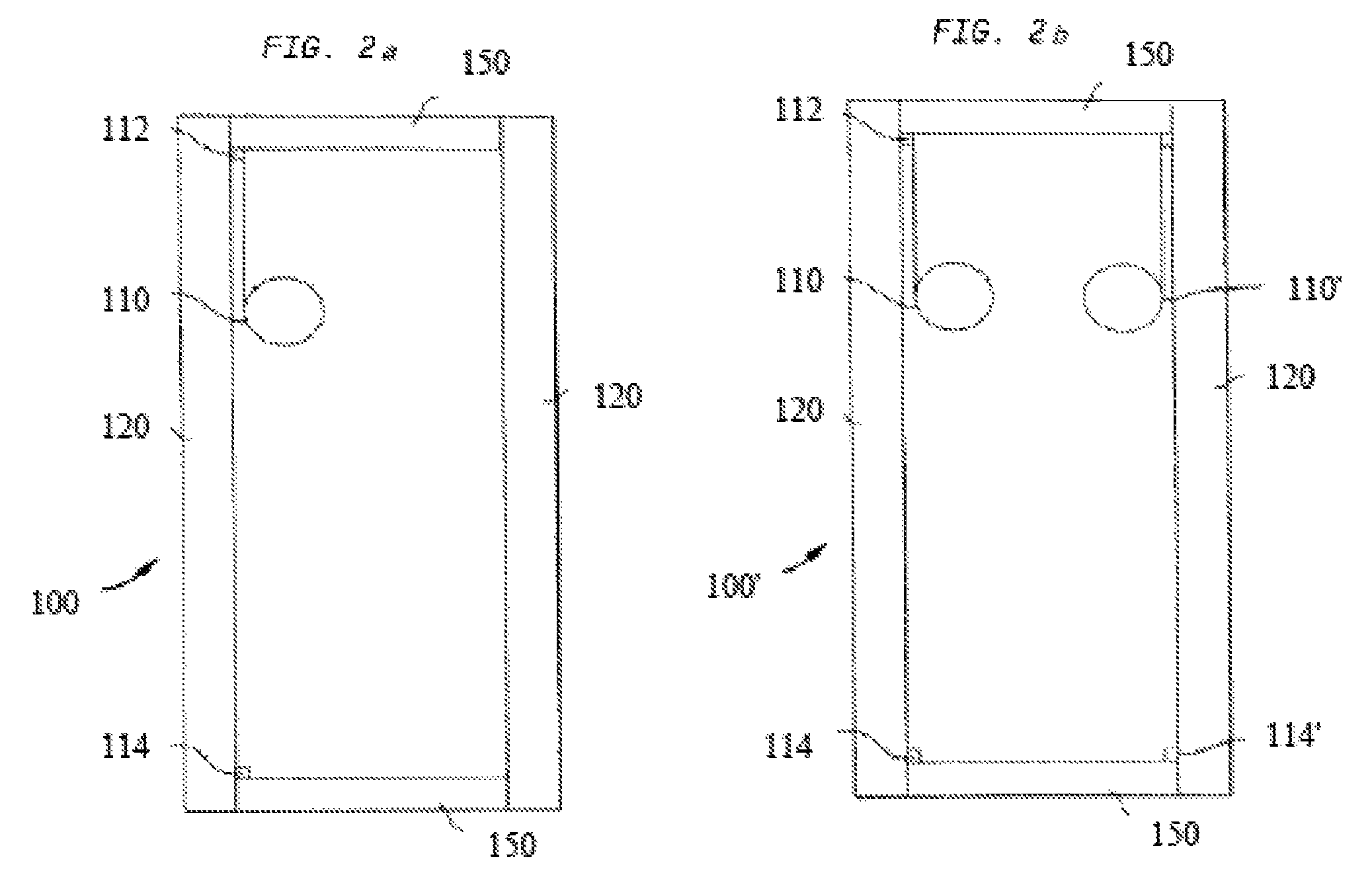

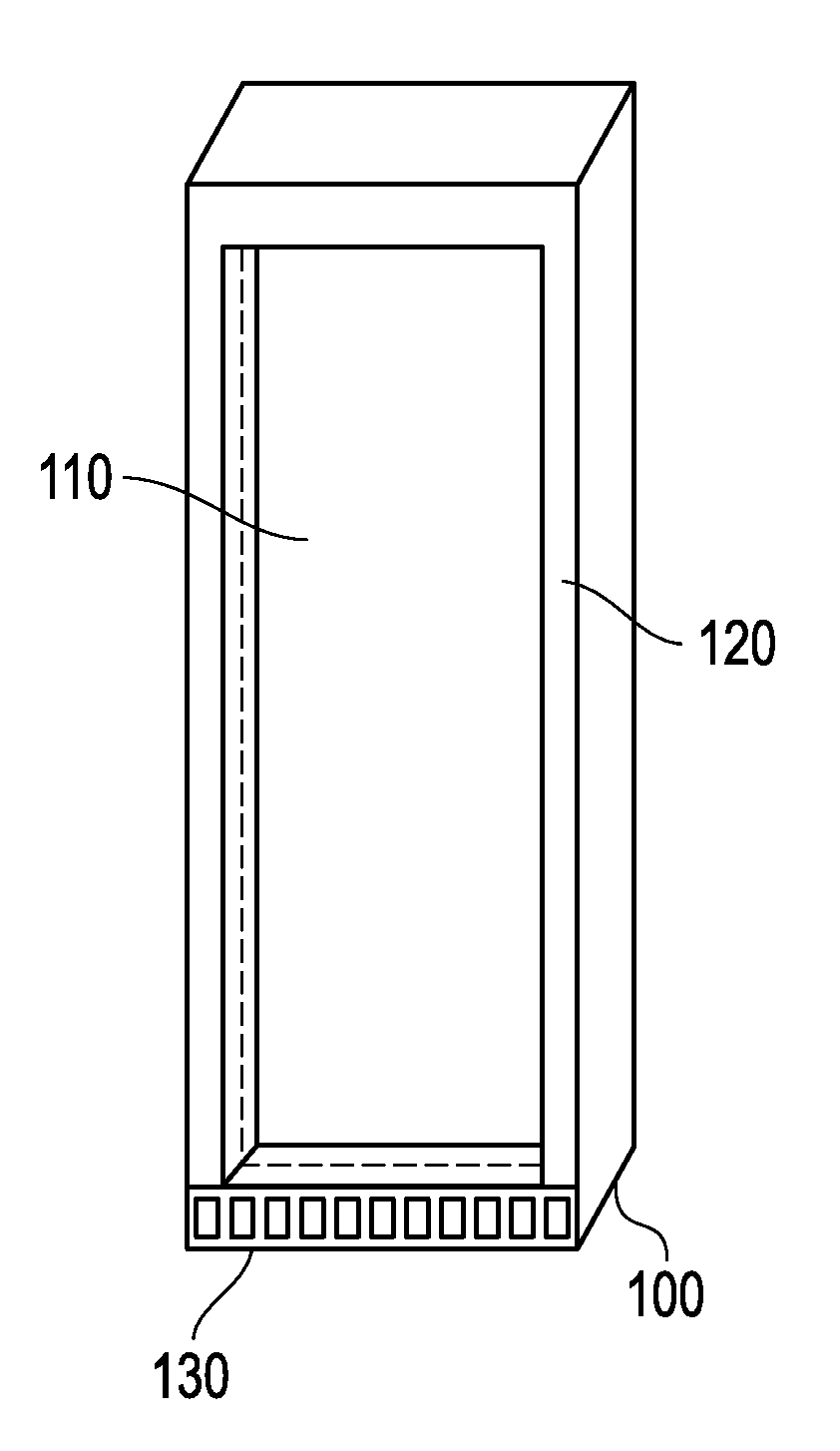

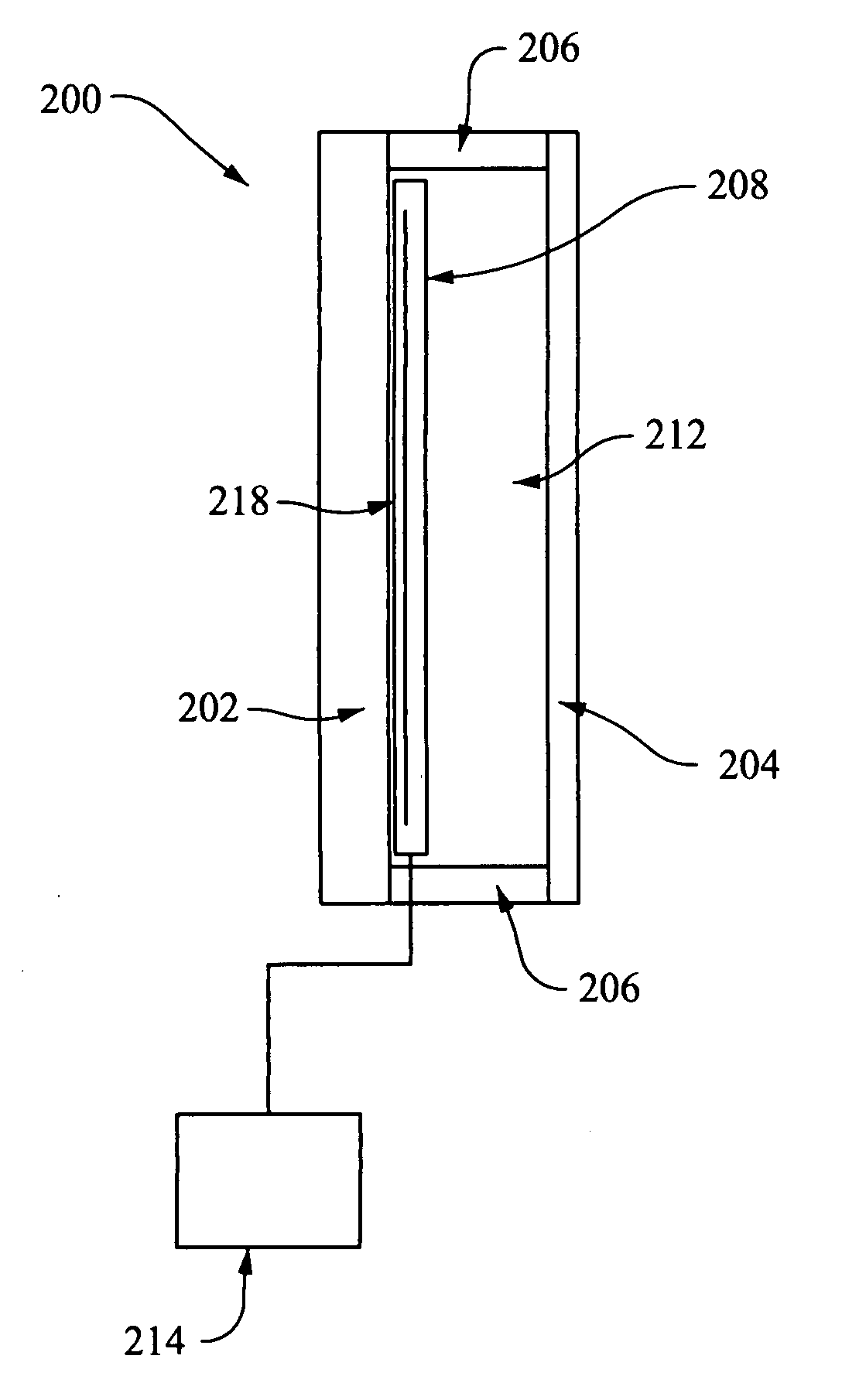

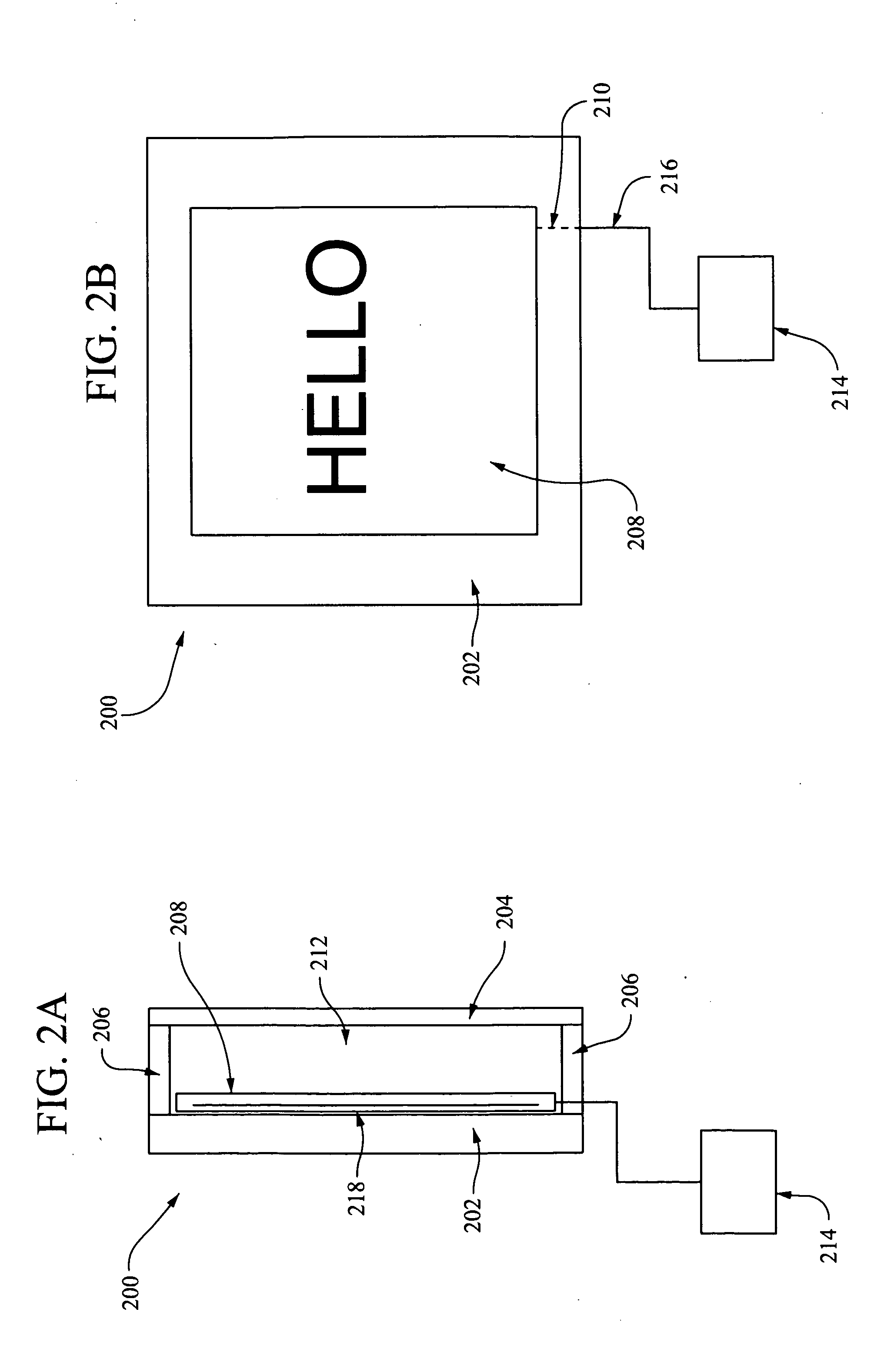

Low cost dynamic insulated glazing unit

ActiveUS7645977B2Reduce radiation intensityRoof covering using slabs/sheetsRoof covering using tiles/slatesDielectricElectricity

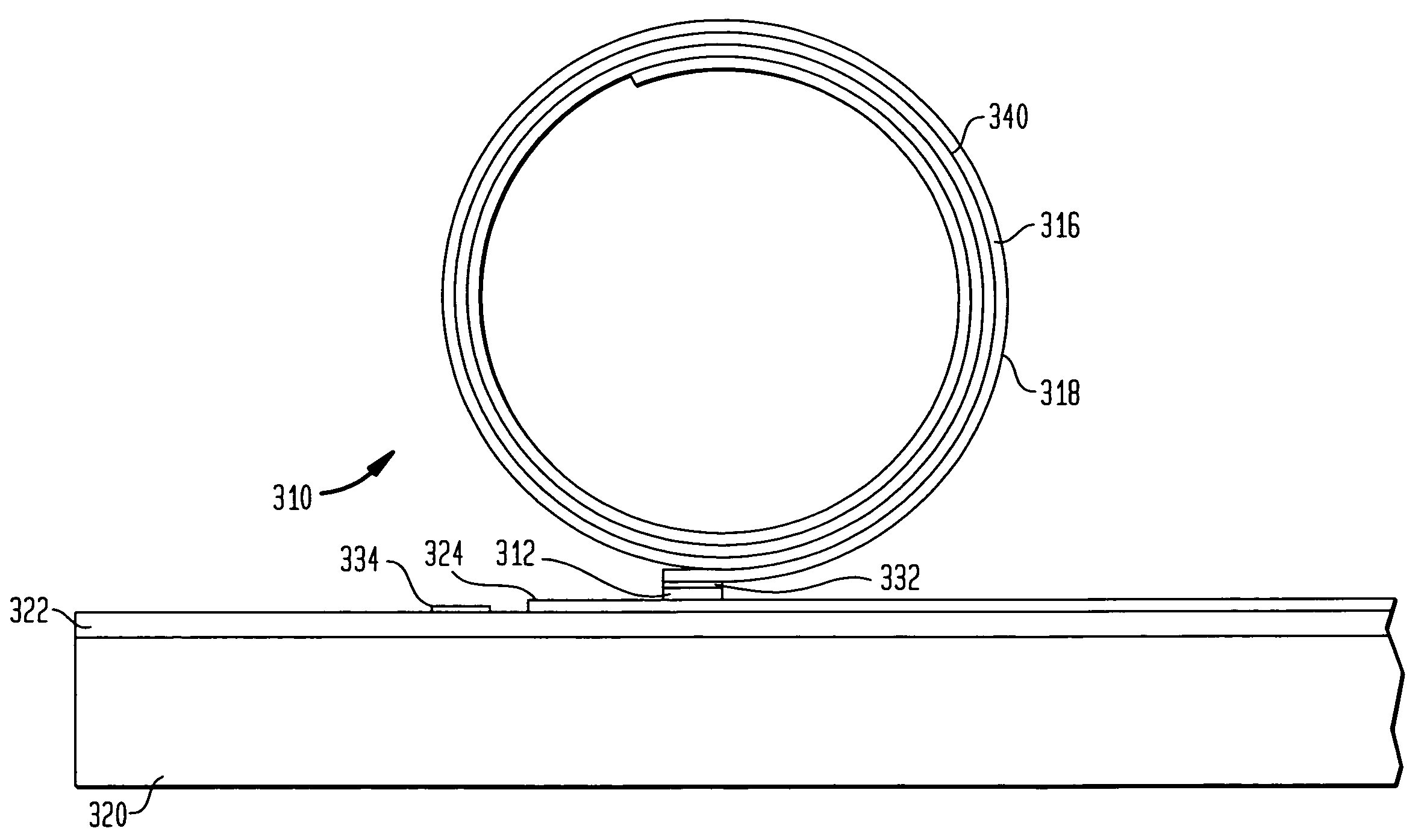

An insulated glazing unit has controllable radiation transmittance. Peripheries of first and second glazing panes are attached and spaced apart facing each other and then attached to a supporting structure. A conductive layer is atop the first glazing pane inner surface as a fixed position electrode. A dielectric is atop the conductive layer. A coiled spiral roll, variable position electrode is between the first and second glazing panes, a width of its outer edge attached to the dielectric. A first electrical lead is connected to the variable position electrode's conductive layer. A second electrical lead is connected to the conductive layer atop the first glazing pane. Applied voltage between the first and second electrical leads creates a predetermined potential difference between the electrodes, and the variable position electrode unwinds and rolls out to at least partially cover the first glazing pane, at least reducing the intensity of passing radiation.

Owner:GUARDIAN GLASS LLC

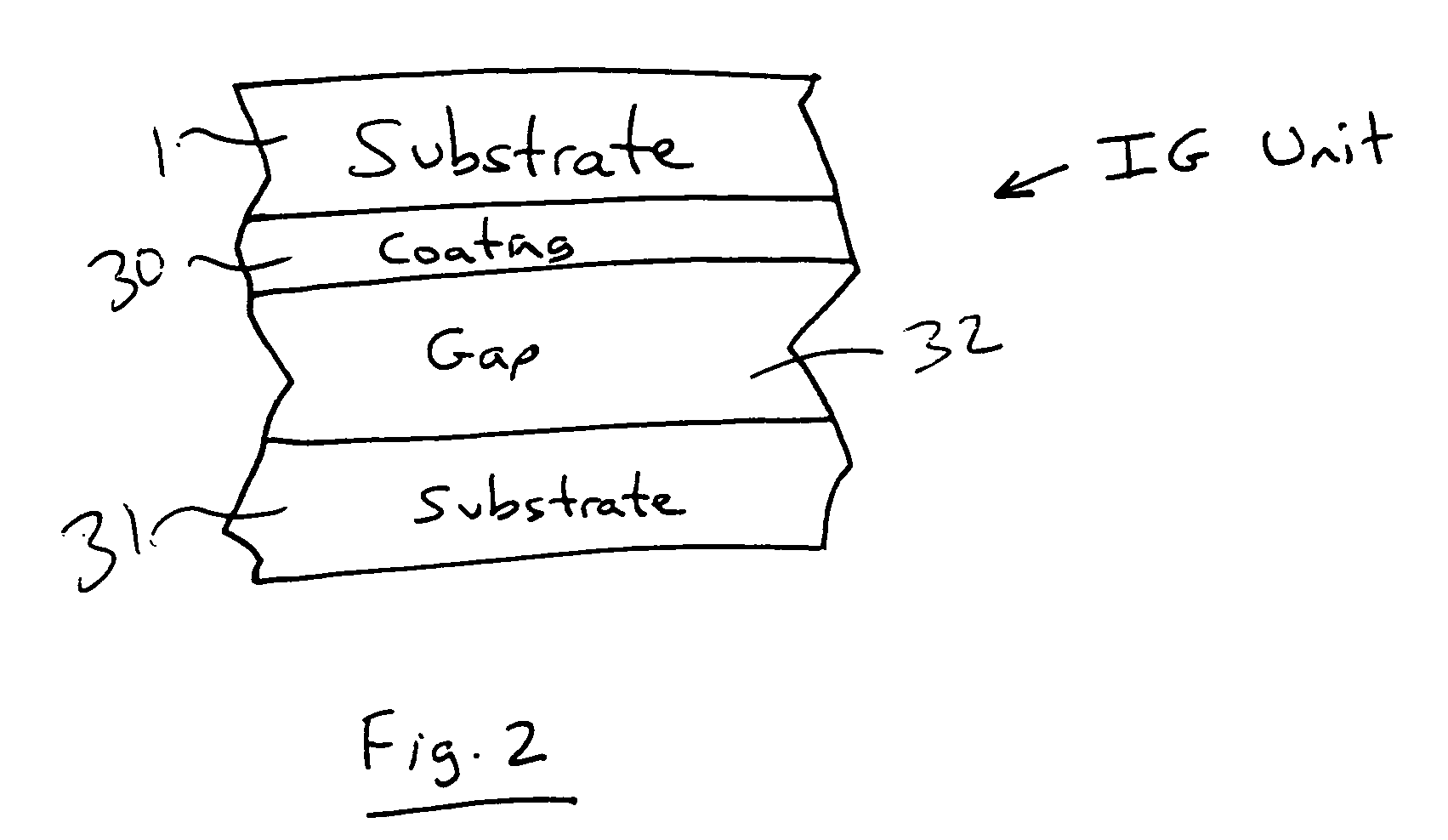

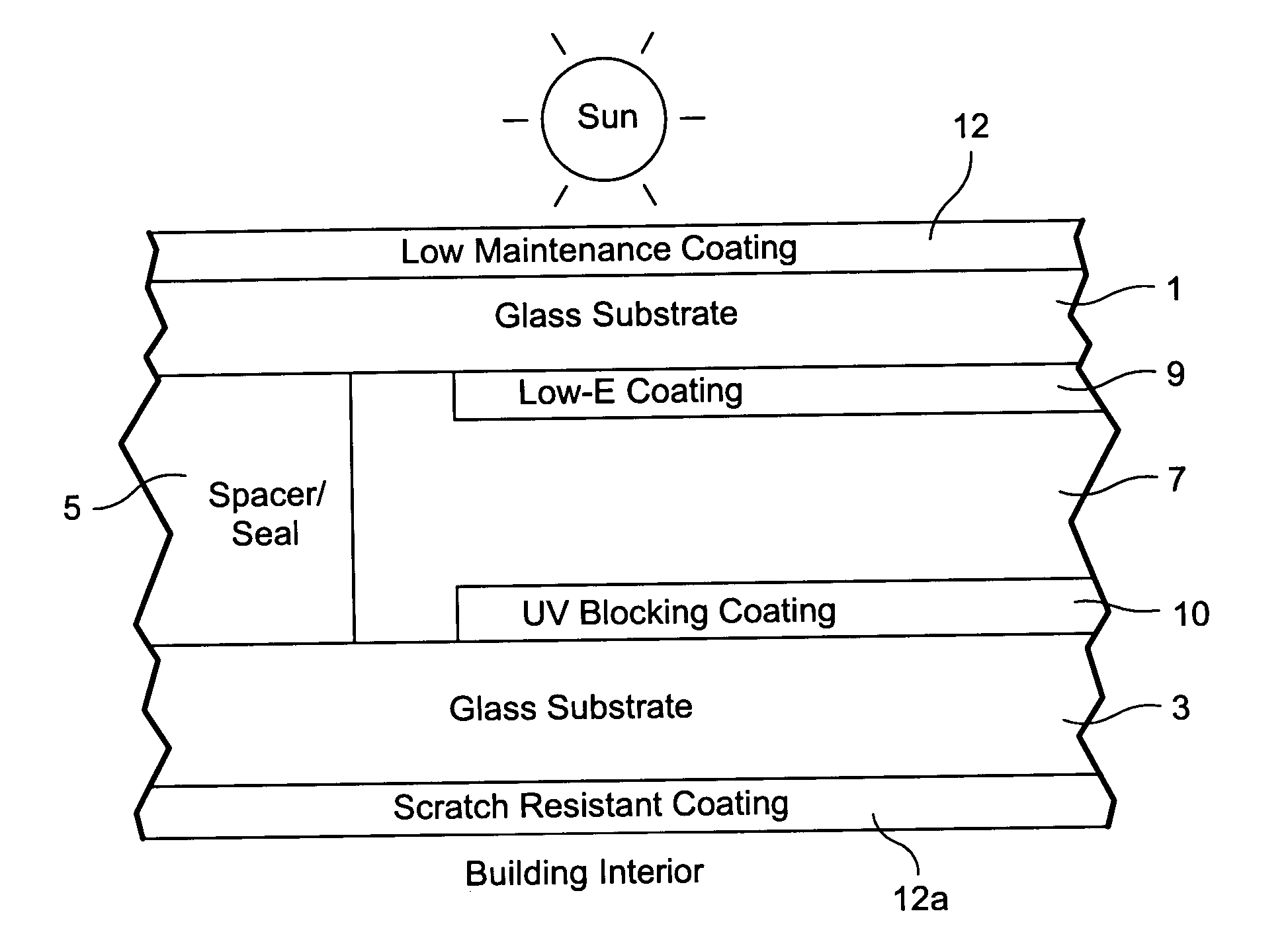

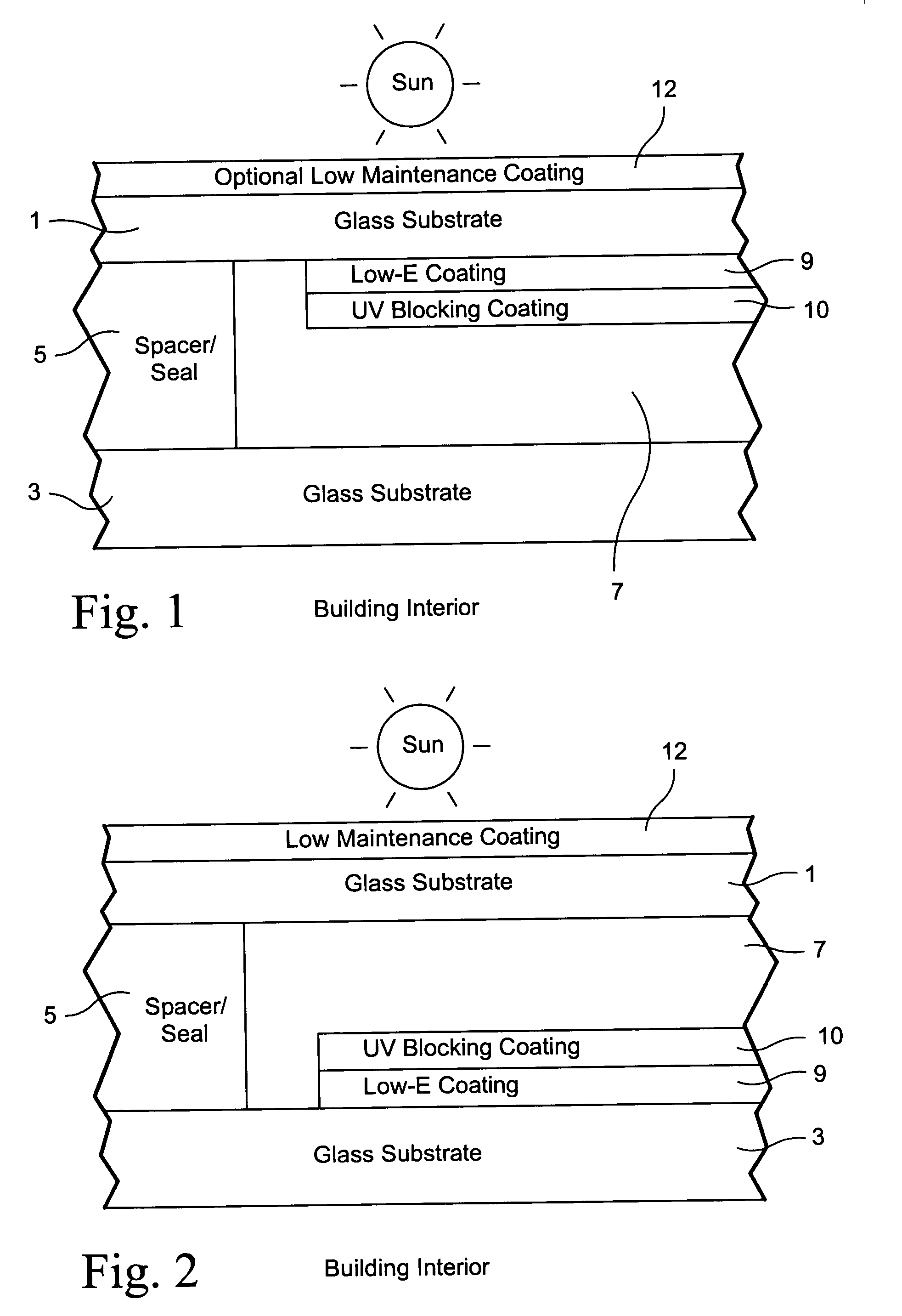

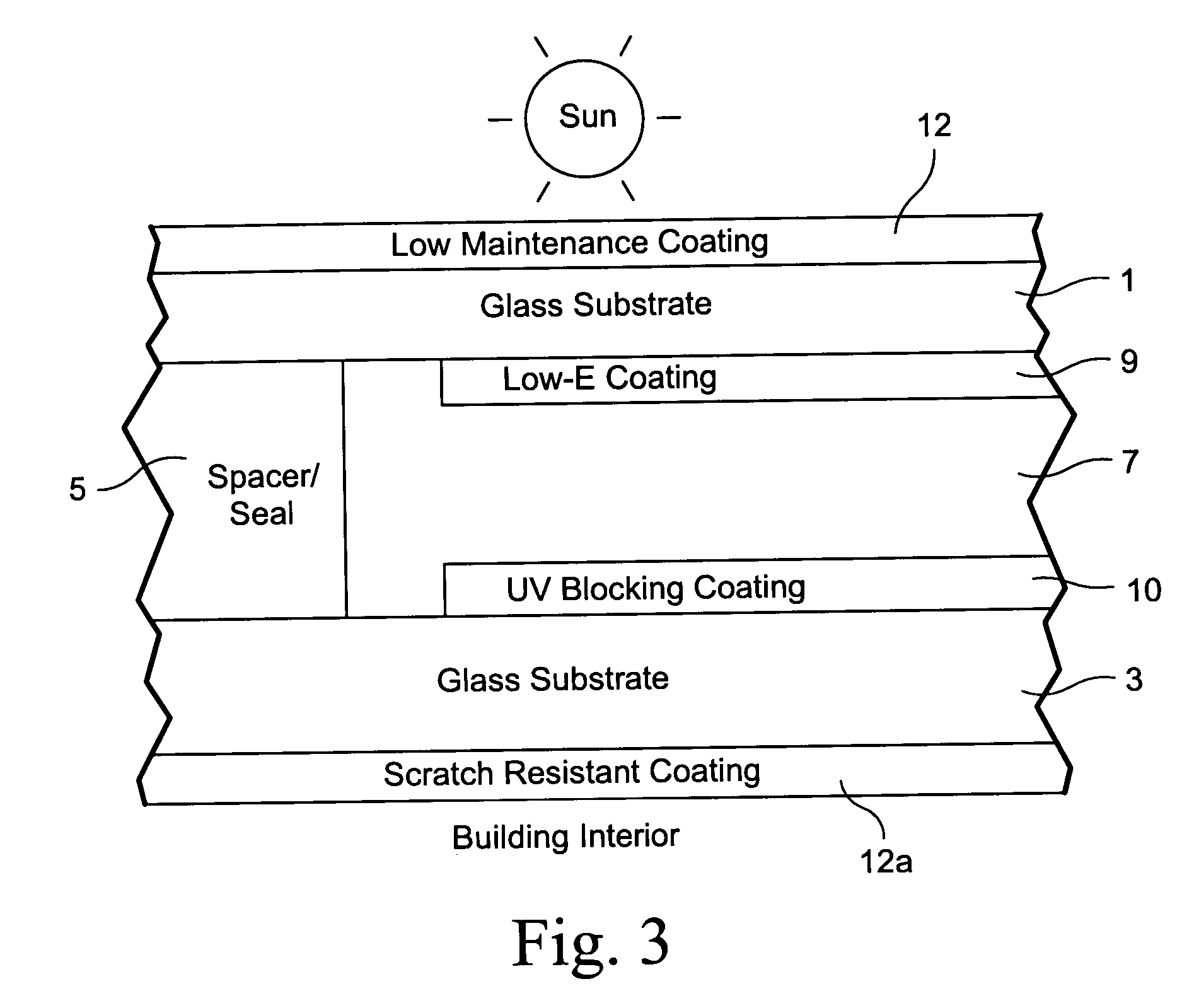

IG window unit and method of making the same

InactiveUS20070128449A1Reduce risk of damageDoors/windowsGlass/slag layered productsInsulated glazingUltraviolet

An insulating glass (IG) window unit, and / or a method of making the same is / are provided. The IG window unit includes two spaced apart substrates that are separated from one another by at least one seal and / or spacer. One of the substrates supports both a solar management coating for blocking significant amounts of infrared (IR) radiation and a coating for blocking amounts of ultraviolet (UV) radiation.

Owner:GUARDIAN GLASS LLC

Insulated glazing unit and controller providing energy savings and privacy

ActiveUS8982441B2Solution to short lifeEffective controlDoor/window protective devicesOptical elementsInfraredElectricity

Owner:GUARDIAN GLASS LLC

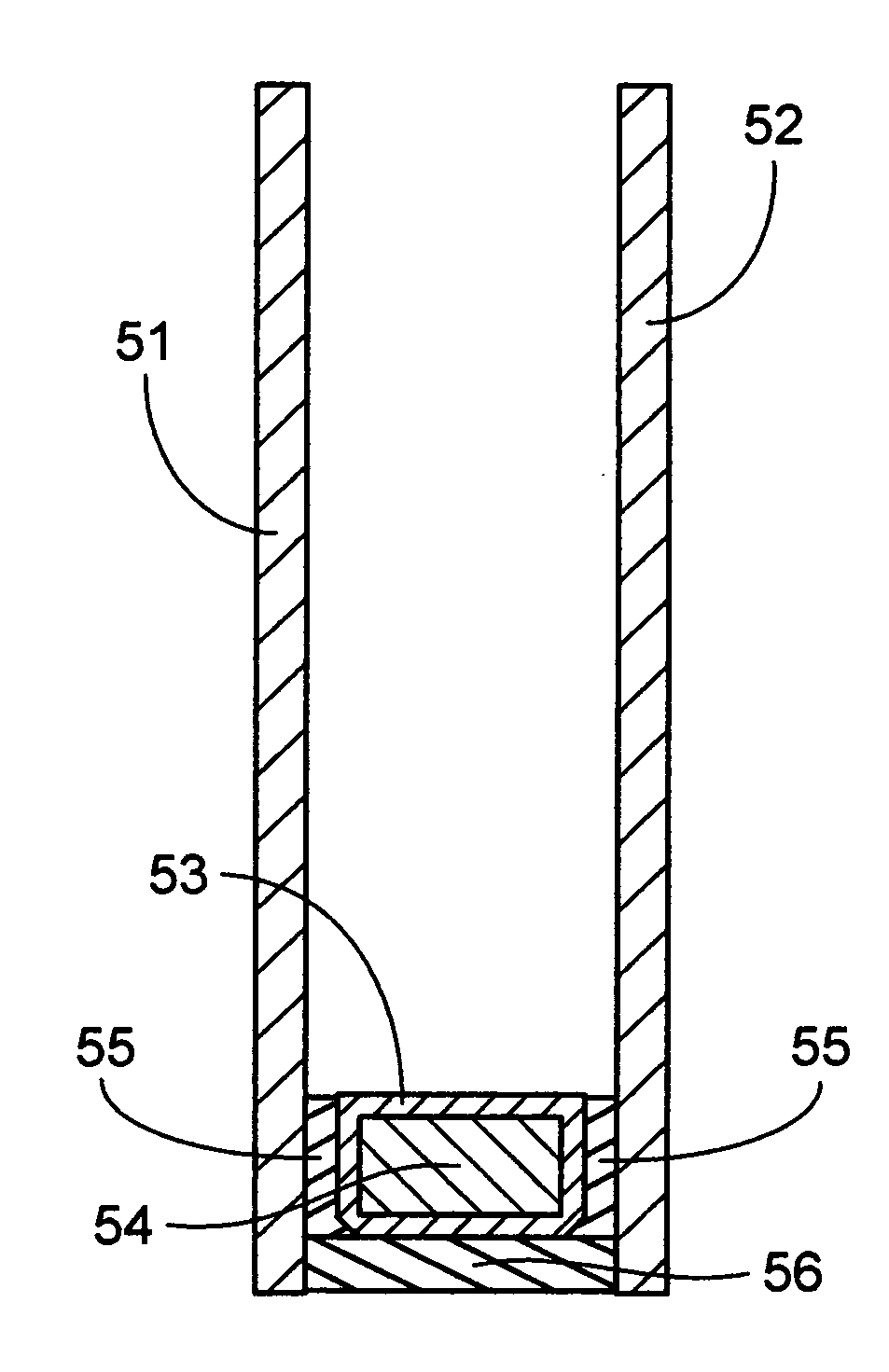

Insulated glazing units and methods

InactiveUS20060191215A1Improve heat resistanceReduce weight and depthFixed grillesSemiconductor/solid-state device detailsContact pressureInsulated glazing

A method for manufacturing a hermetically sealed window assembly. A first windowpane is provided, as is a first sealing member having inner and outer edges. The inner edge is positioned against the windowpane and pressed against it with sufficient force to produce a first contact pressure along a first junction. The junction is heated to produce a first temperature. The contact pressure and temperature are maintained until a diffusion bond is formed between the member and the windowpane. A second windowpane is provided, as is a second sealing member having inner and outer edges. The inner edge is positioned against the windowpane and pressed against it with sufficient force to produce a second contact pressure along a second junction. The junction is heated to produce a second temperature. The contact pressure and temperature are maintained until a diffusion bond is formed between the member and the windowpane. A spacer assembly is positioned between the first and second windowpanes for maintaining a gap therebetween. The outer ends of the sealing members are hermetically connected to one another, whereby a hermetically sealed cavity is defined between the windowpanes.

Owner:ASTRAVAC GLASS INC

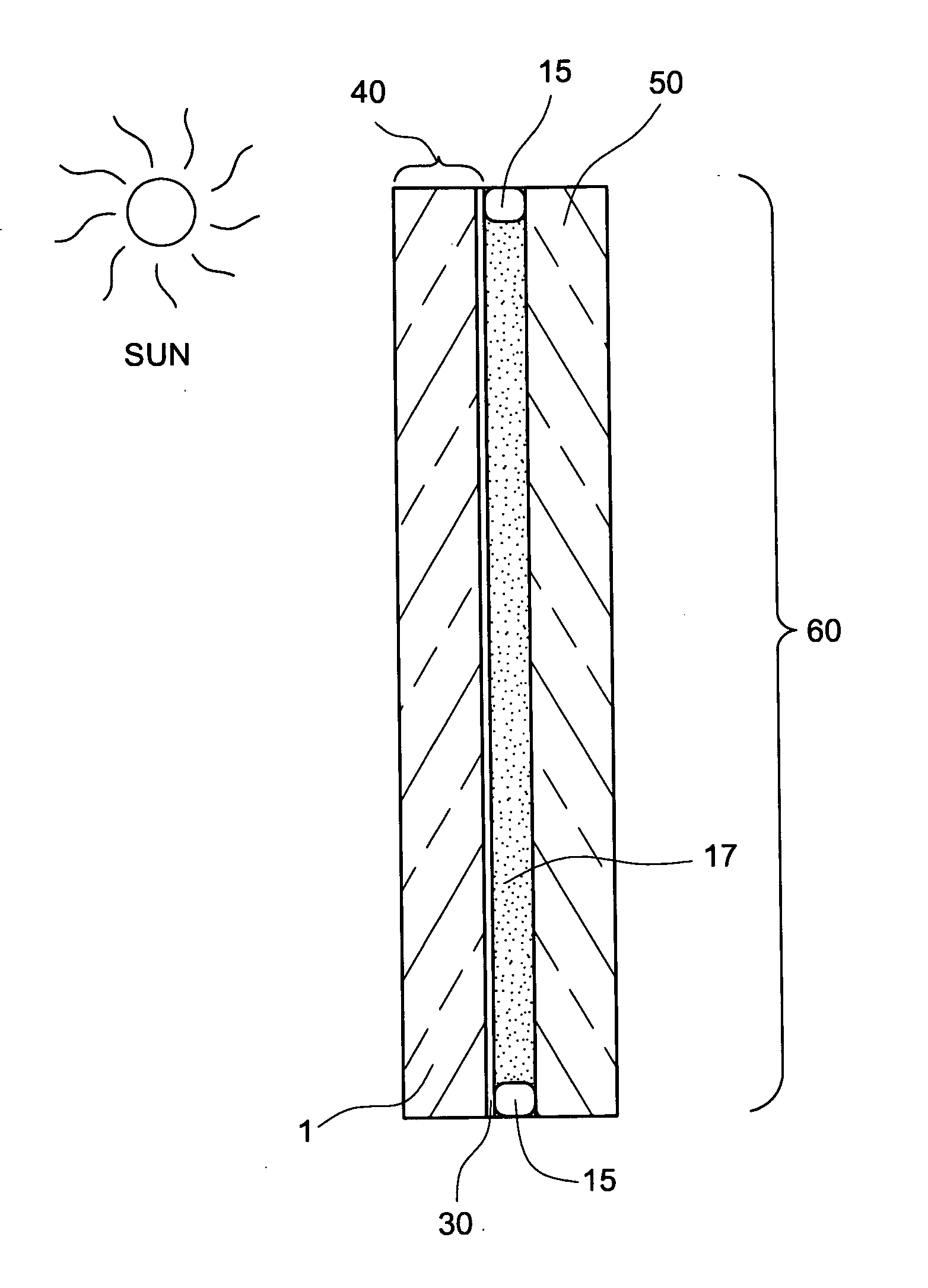

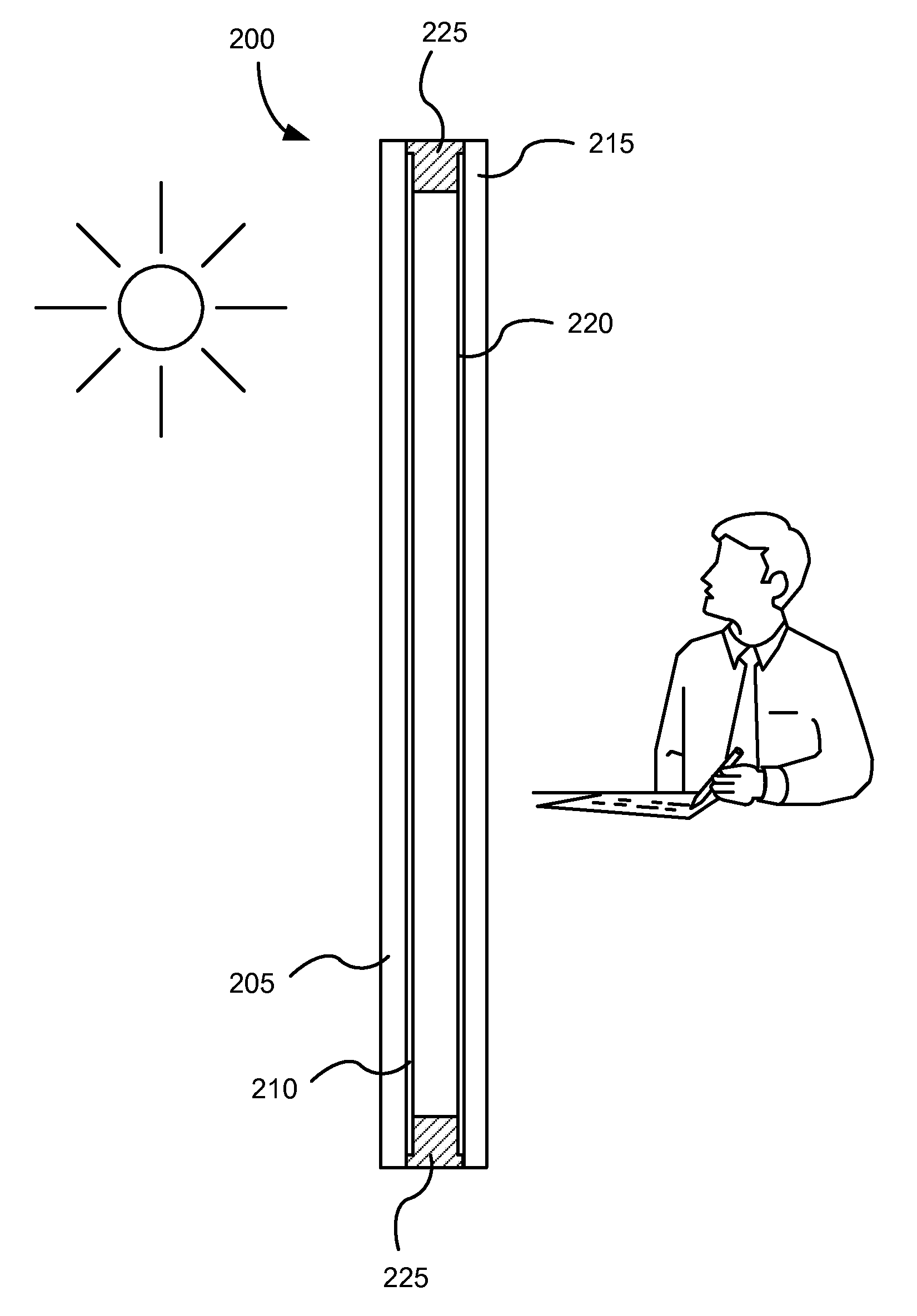

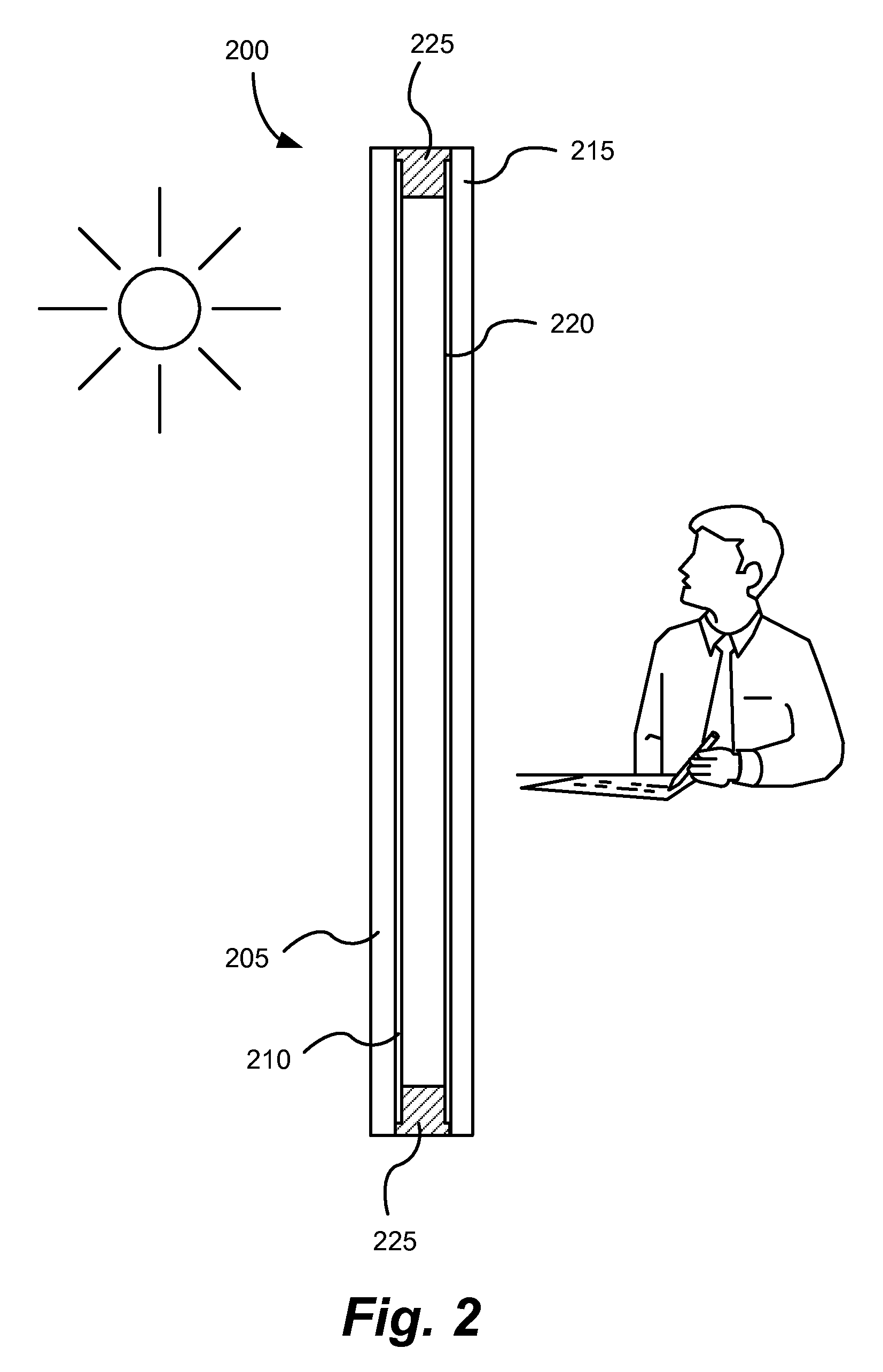

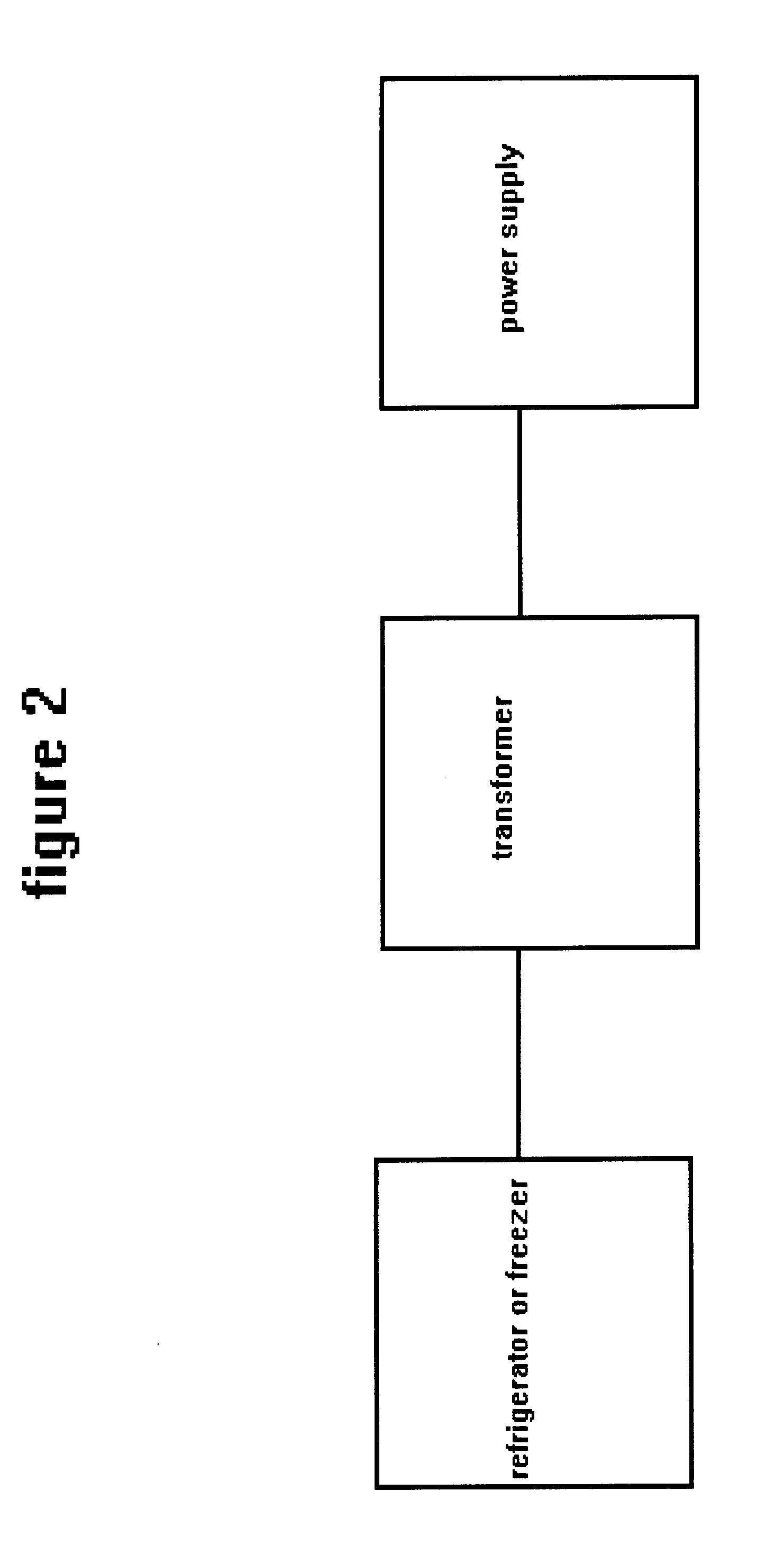

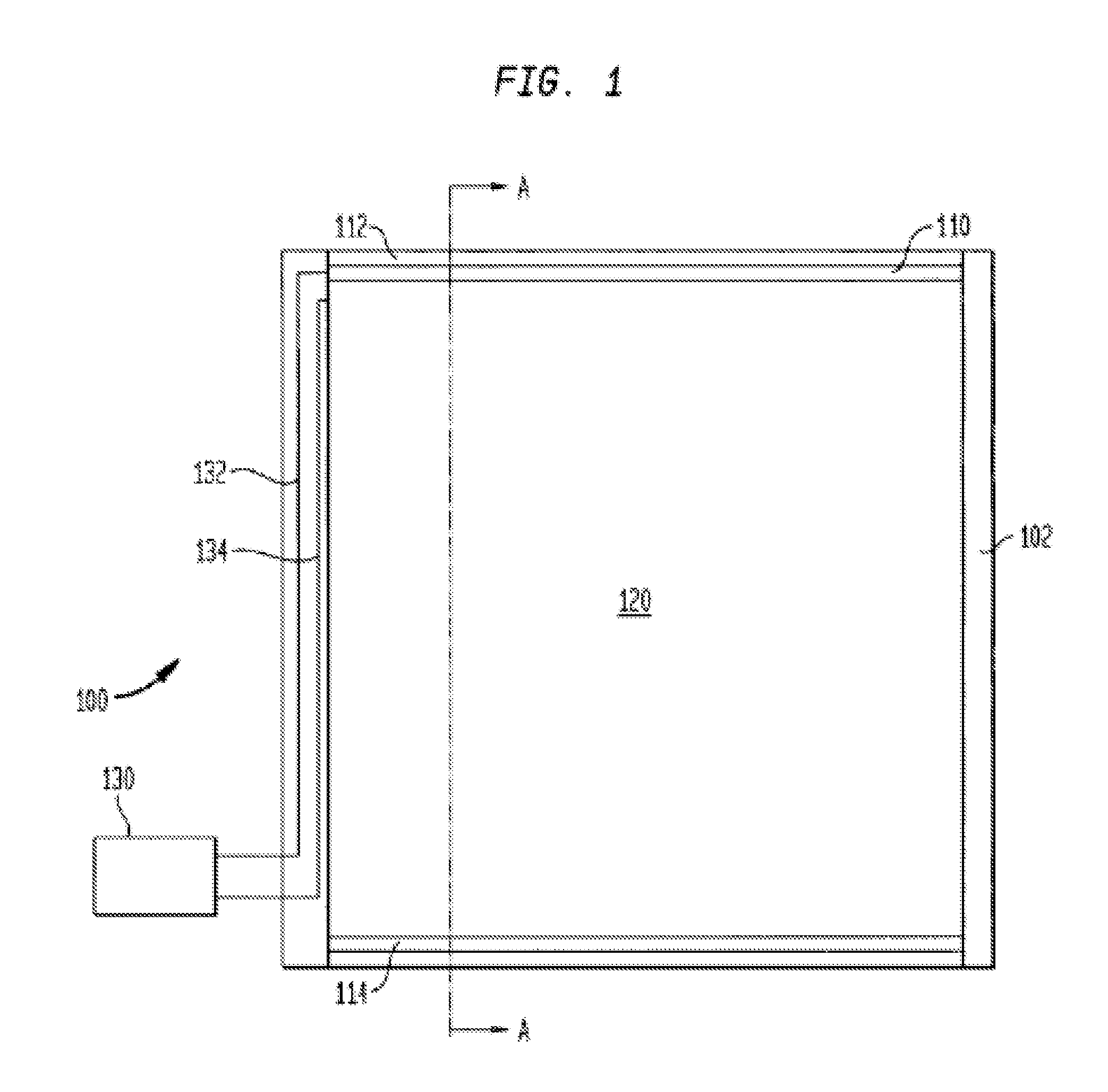

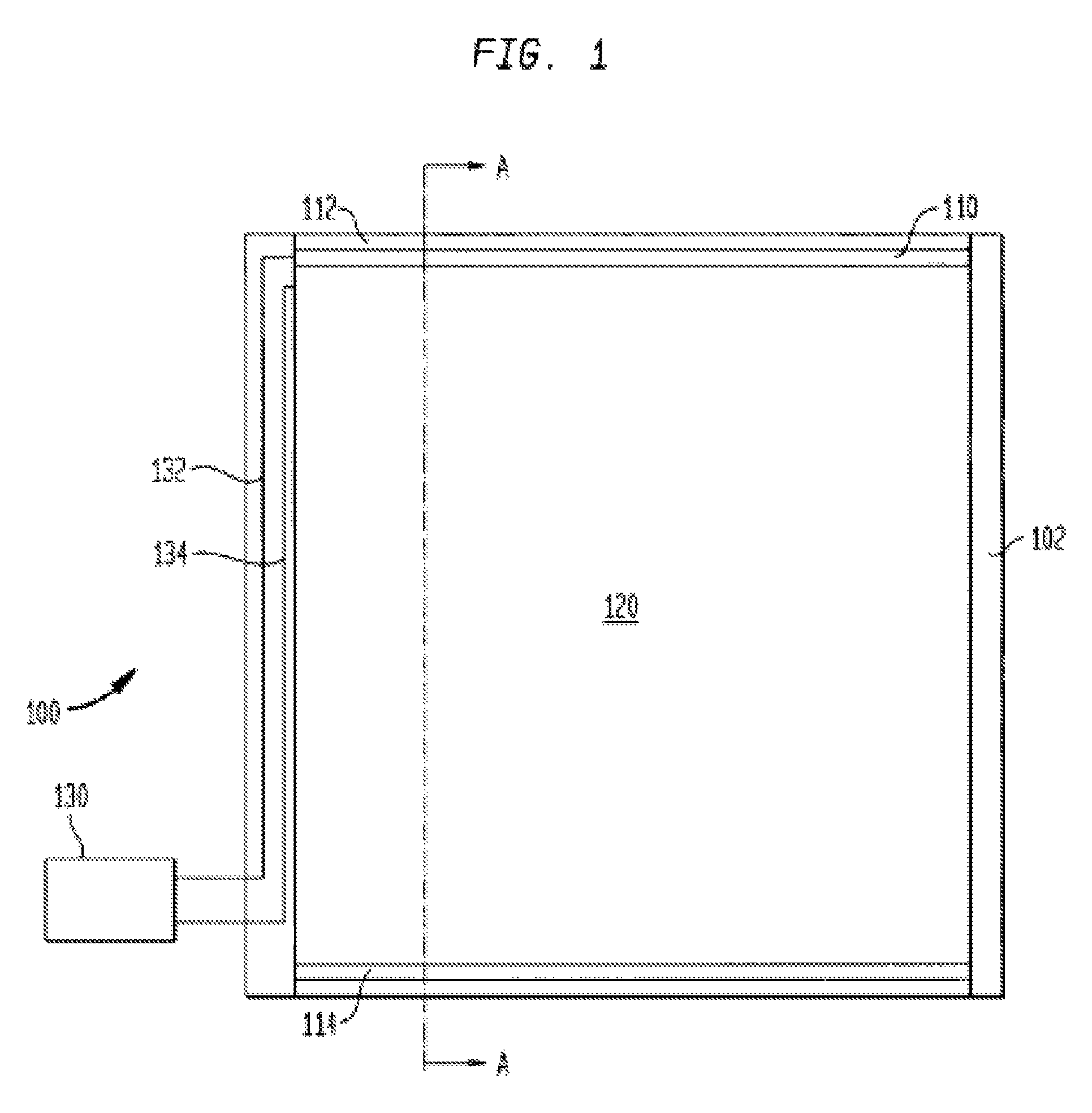

Solar Powered Device With Scalable Size And Power Capacity

A window transmissivity control assembly having a power source with scalable size and power capacity is provided. The assembly includes an insulated glazing unit including a variably transmissive glazing, a photovoltaic module attached to the insulated glazing unit and electrically coupled to the variably transmissive glazing, and a control module having a control circuit for controlling transmissivity of the glazing and a battery for providing power to the glazing. The photovoltaic assembly is attached to an exterior face portion of the insulated glazing unit, and a control module is attached to an interior face portion of the insulated glazing unit. Each module may extend from a first end of the insulated glazing unit to an opposing second end of the insulated glazing unit, wherein the length of the module being substantially the same as the distance between the first and second ends of the insulated glazing unit.

Owner:SAGE ELECTROCHROMICS

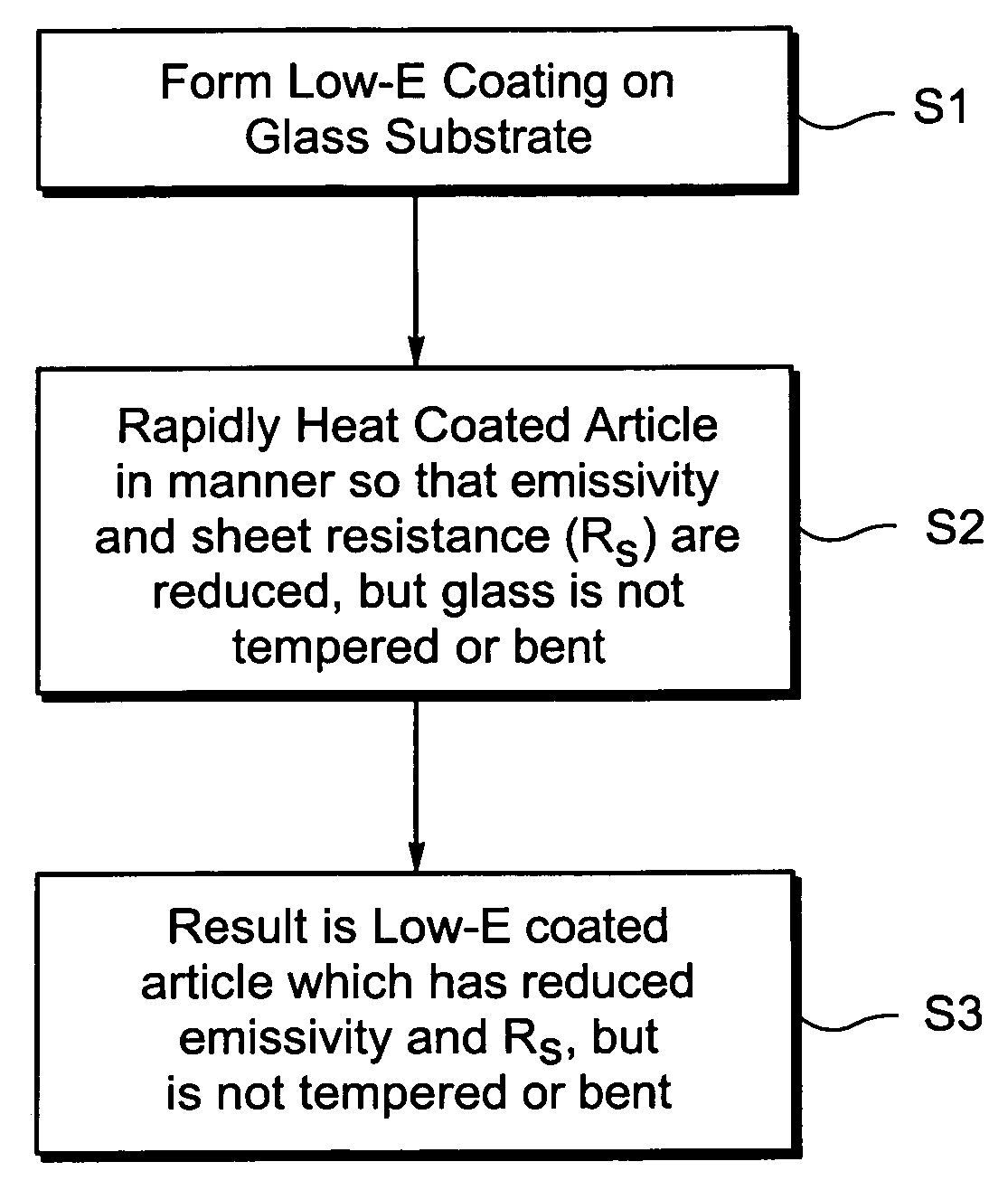

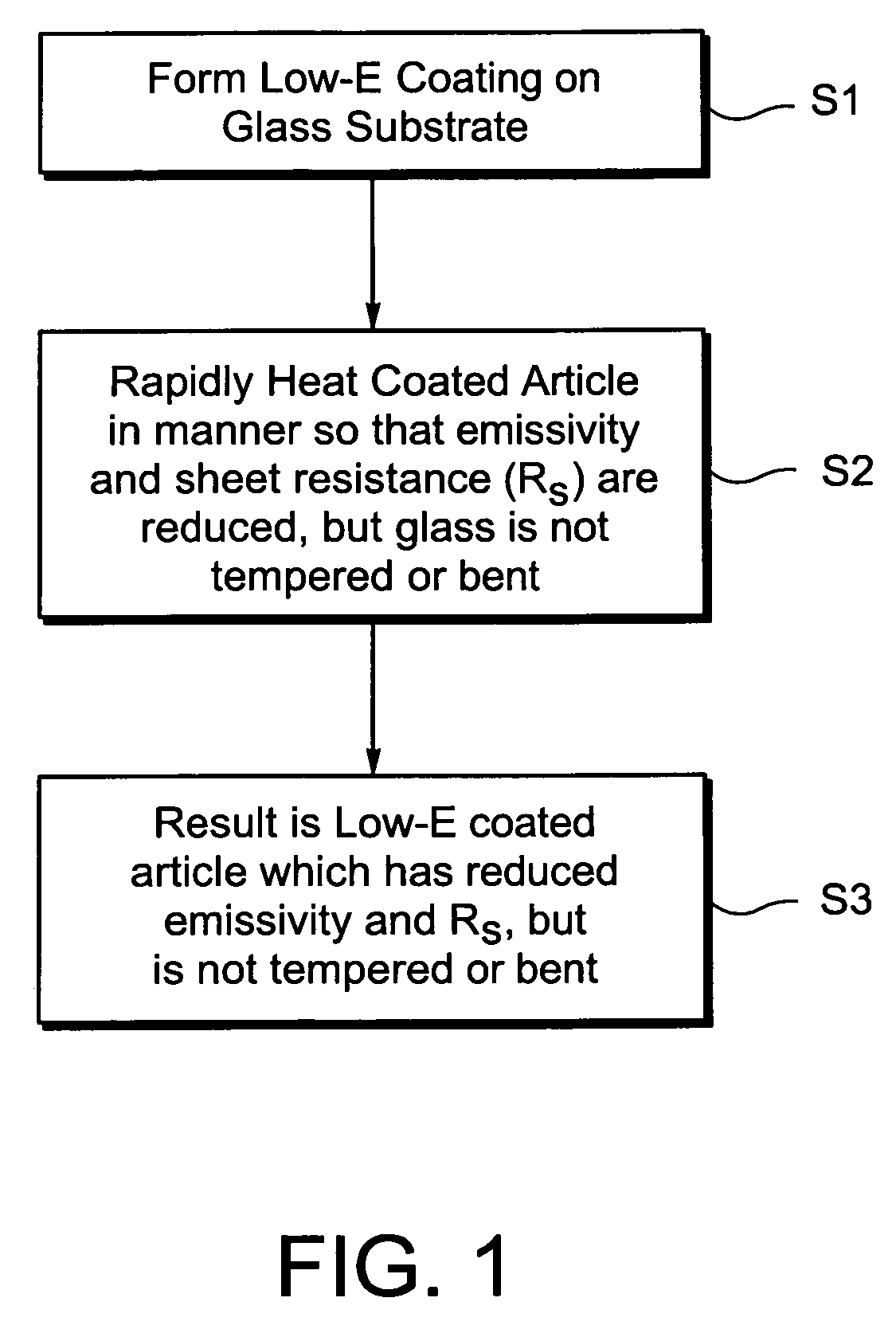

Method of making coated article using rapid heating for reducing emissivity and/or sheet resistance, and corresponding product

ActiveUS20080008829A1Decreased emissivityHigh carrier mobilityPretreated surfacesSpecial surfacesInsulated glazingLow emissivity

This invention relates to a method of making a coated article for use in insulating glass (IG) window units, vehicle windows, or the like. The coated article typically includes a low-E coated article, including a low-E (low emissivity) coating supported by a glass substrate. In certain example embodiments, rapid heating (not sufficient for tempering or heat bending) of the coated article is utilized in order to reduce the emissivity and / or sheet resistance of the coated article without significantly damaging the infrared (IR) reflecting layer(s) of the coating, thereby activating the coated article. The glass of the coated article does not become too hot during such rapid heating.

Owner:GUARDIAN EURO S A R L +1

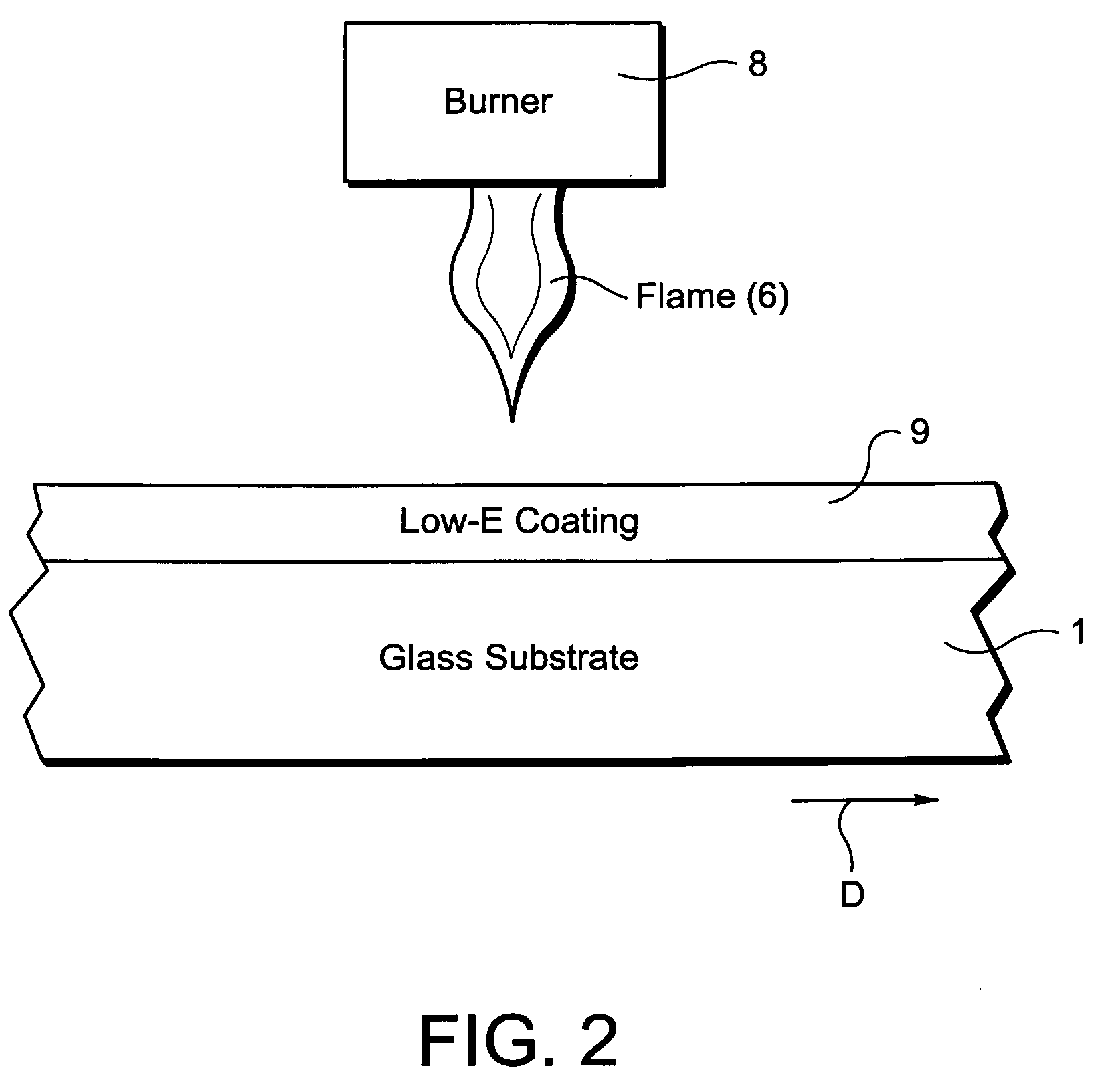

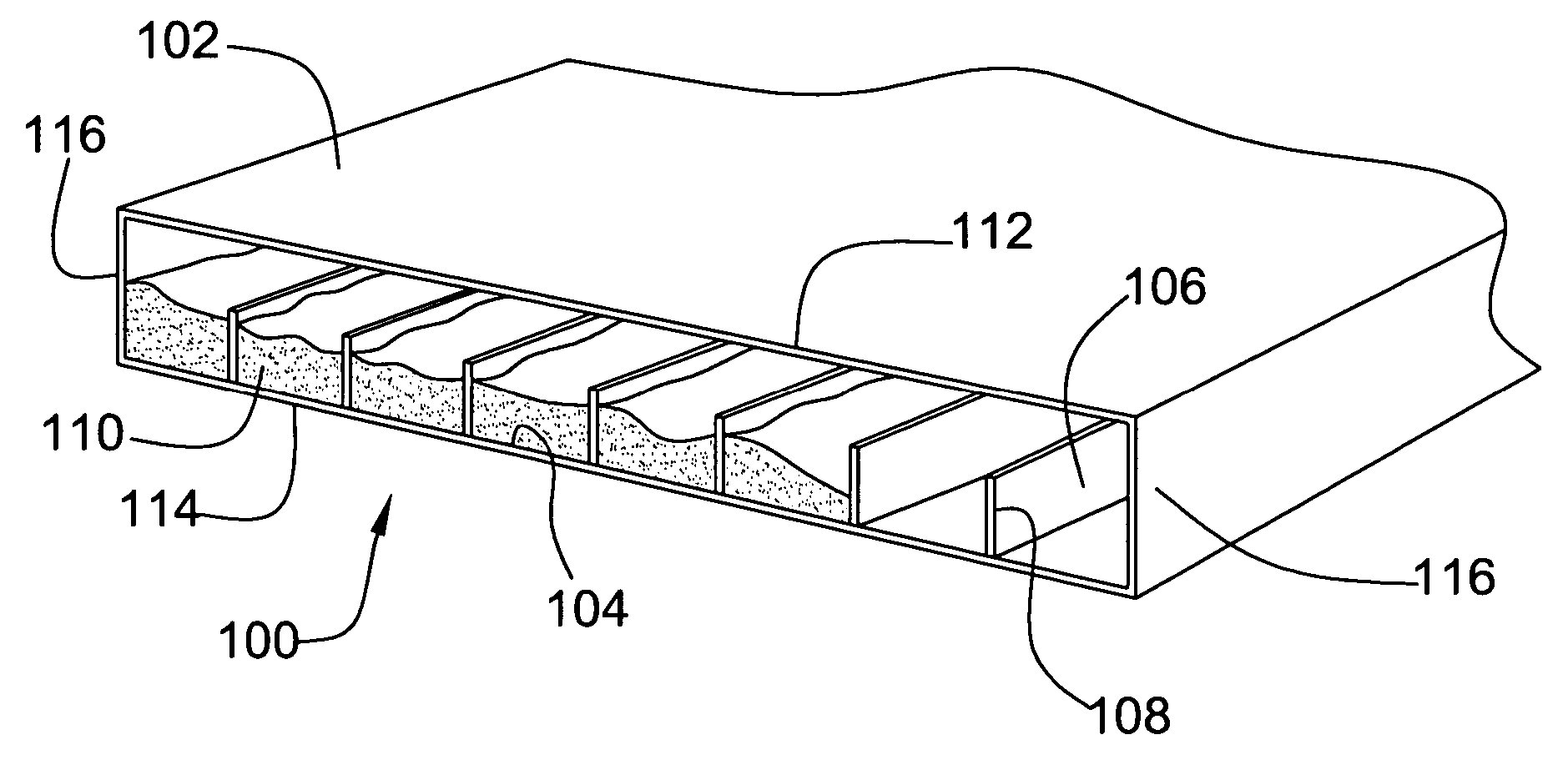

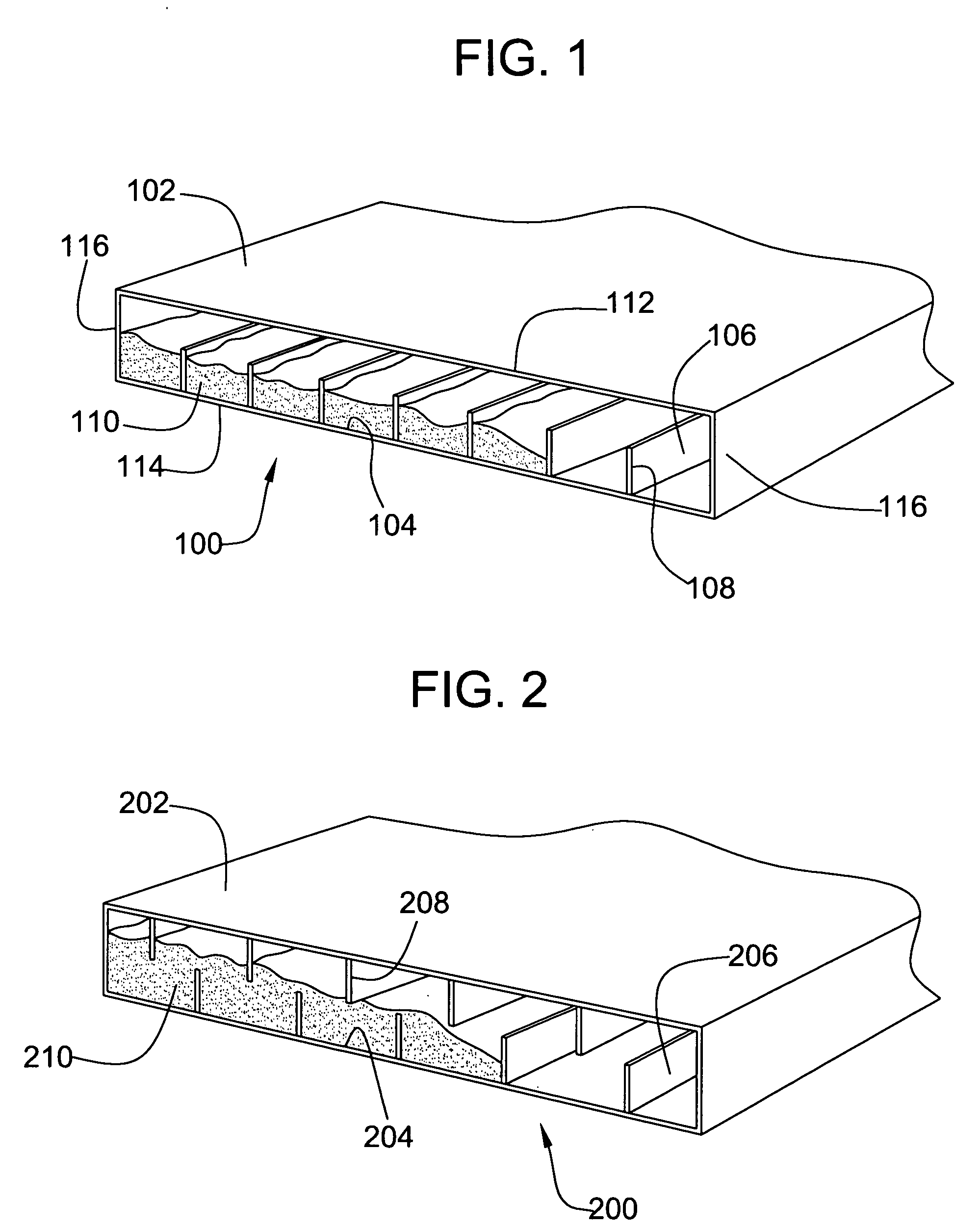

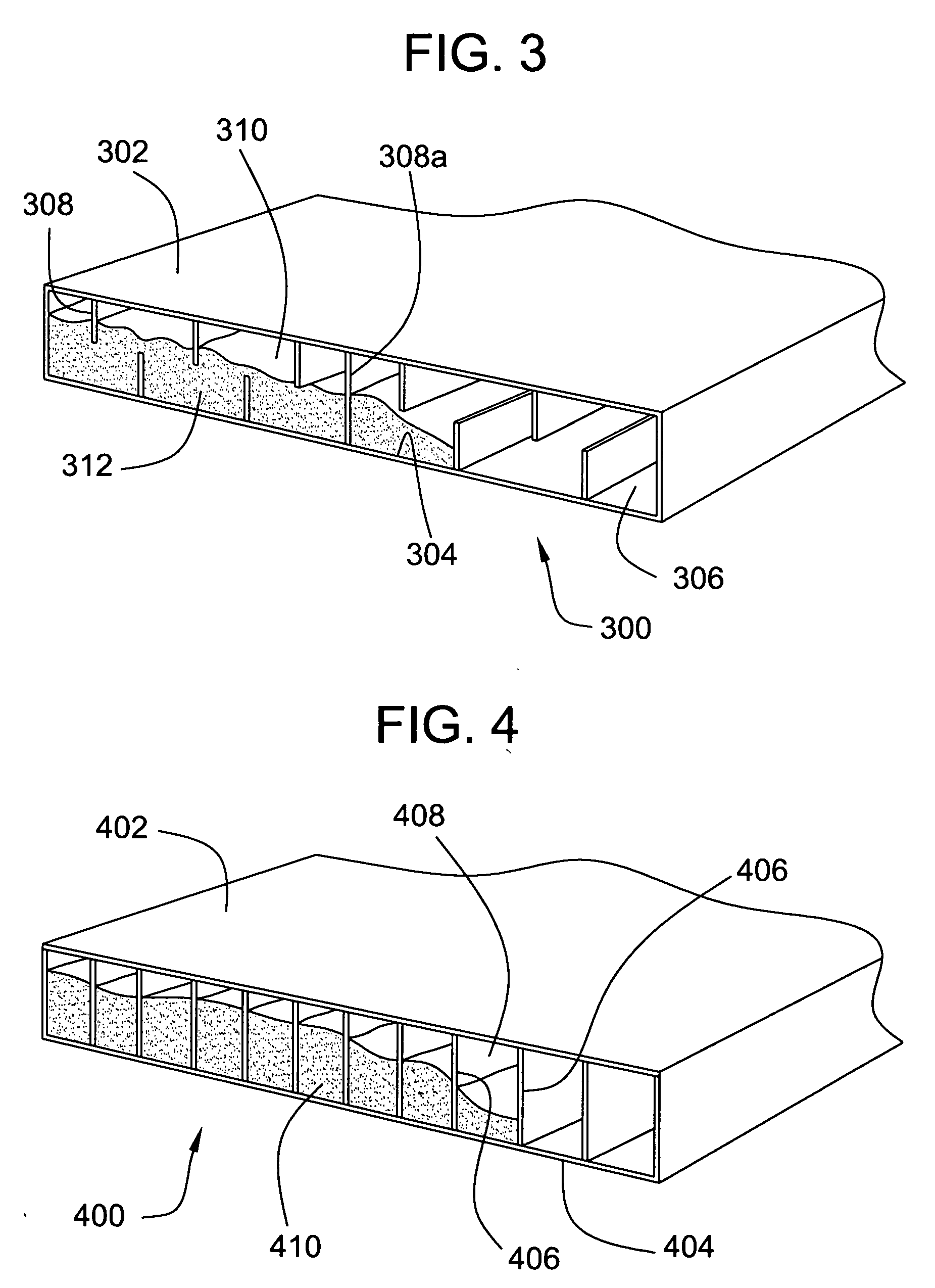

Insulated panel and glazing system comprising the same

The invention provides a translucent glazing panel comprising: (a) a thermoplastic panel comprising (i) an outer wall having an inner surface defining an internal channel, the internal channel having an internal volume, and (ii) at least one inner wall protruding from the inner surface into the internal channel, and (b) hydrophobic aerogel particles, the hydrophobic aerogel particles being disposed within the channel. The invention also provides an insulated glazing system comprising: (a) a first U-shaped element, (b) a second U-shaped element, the first and second elements being disposed to define a cavity therebetween, and (c) an insulating panel disposed within the cavity. The insulated glazing system can further comprise hydrophobic aerogel particles disposed within the internal channel of the insulating panel. The insulating panel of the glazing system also can be the same as the translucent glazing panel described herein.

Owner:CABOT CORP

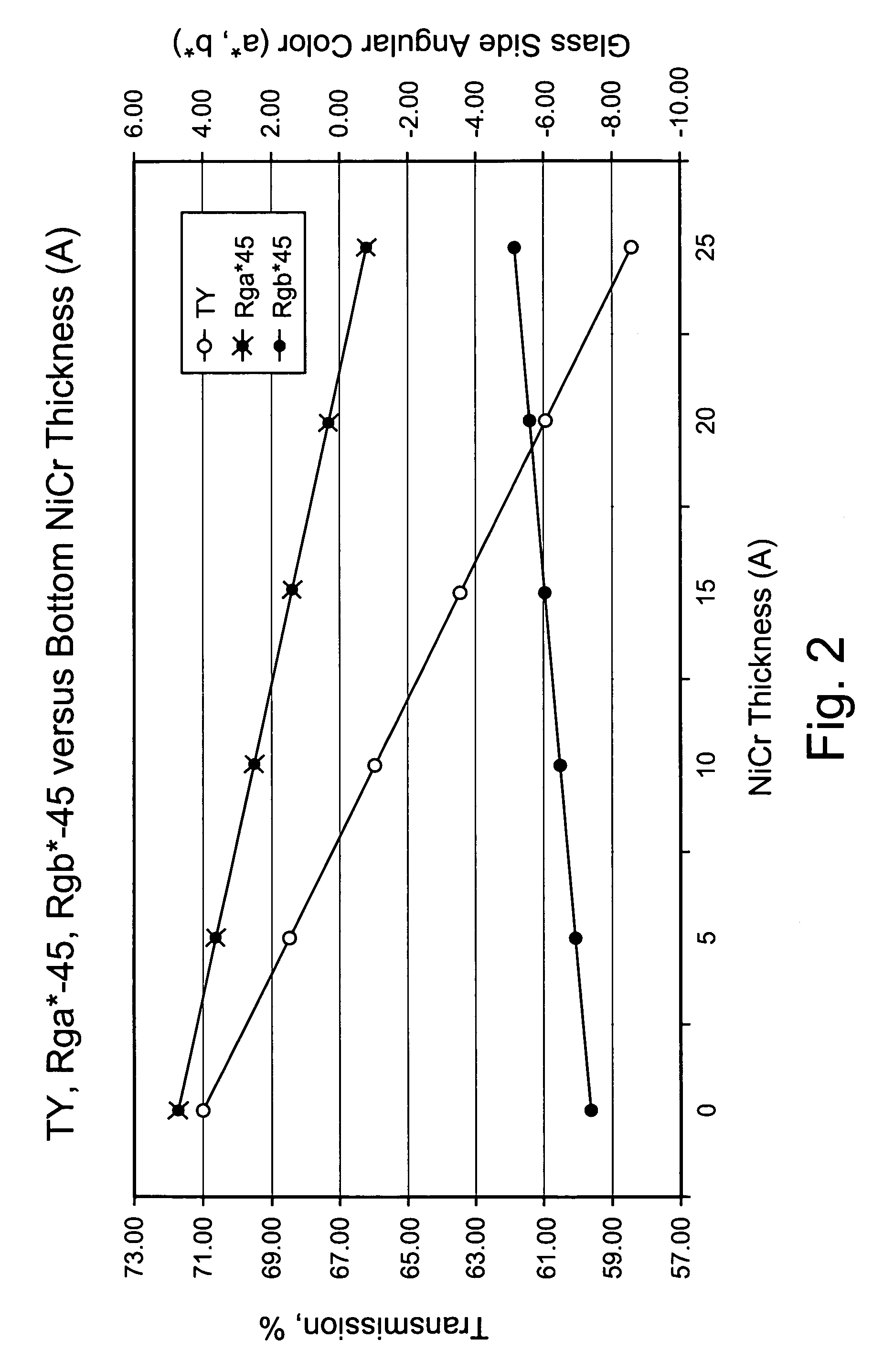

Coated article with low-E coating having absorbing layer designed for desirable bluish color at off-axis viewing angles

An absorbing layer of a low-E coating is designed to cause the coating to have a more bluish color at normal and / or certain off-axis viewing angles. In certain example embodiments, the metallic or substantially metallic absorbing layer (e.g., NiCr) is located in the middle section of the layer stack and has been found to unexpectedly provide desirable bluish glass side reflective color for the coated article at certain off-axis viewing angles (e.g., at a 45 degree off-axis viewing angle). In certain example embodiments, the absorbing layer is provided between first and second nitride inclusive or based layers in order to reduce or prevent oxidation thereof during heat treatment thereby permitting predictable coloration to be achieved following the heat treatment. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, vehicle windows, other types of windows, or in any other suitable application.

Owner:GUARDIAN EURO S A R L +1

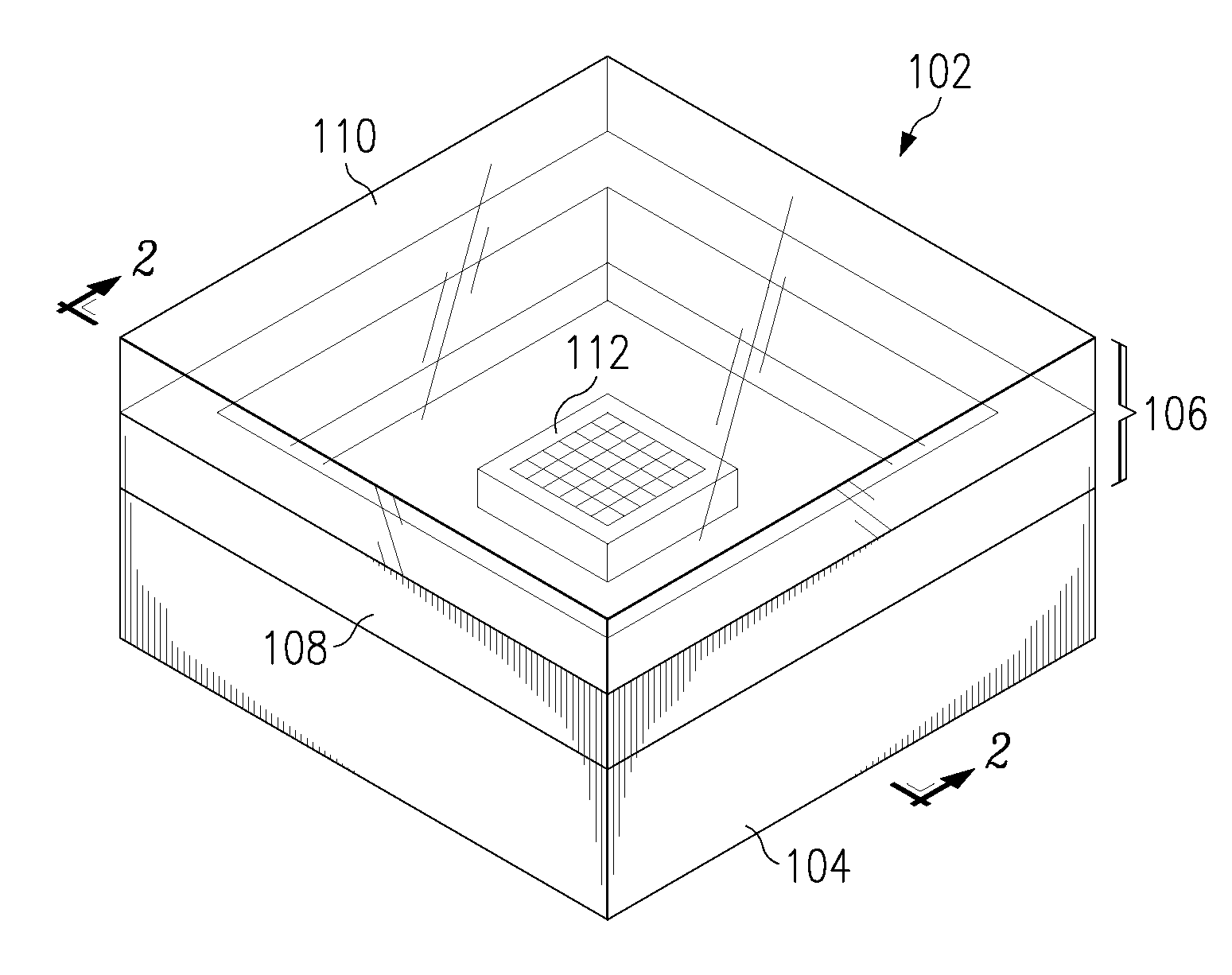

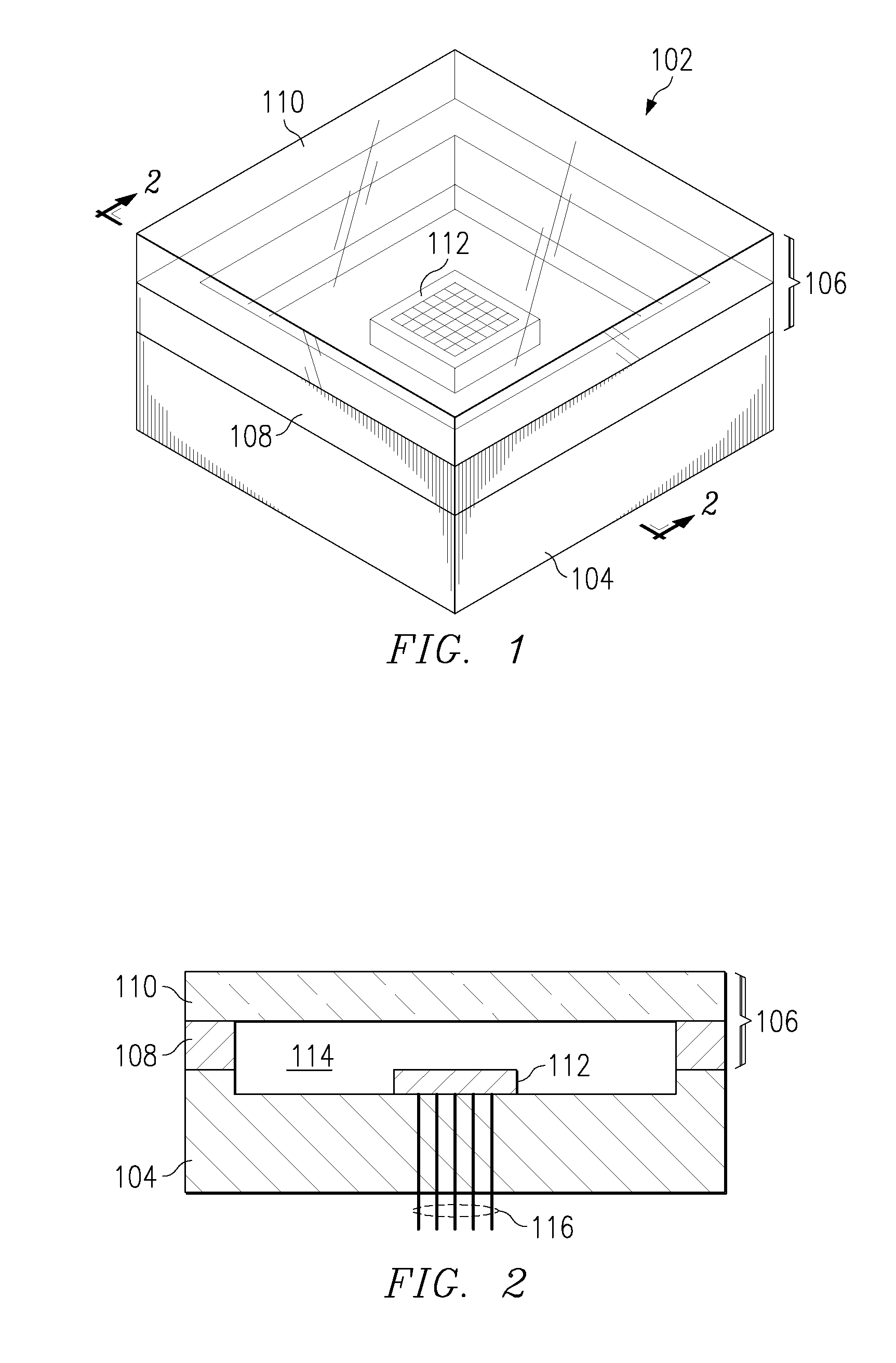

Insulated glass units incorporating emitters, and/or methods of making the same

ActiveUS20120140492A1Increased lighting and versatilityPlanar light sourcesPoint-like light sourceInsulated glazingHermetic seal

Certain example embodiments relate to an improved IGU with first and second glass substrates, spaced apart and defining a gap therebetween. An edge seal is provided around a periphery of the first and second substrates, the edge seal forming an hermetic seal in certain example instances. An emitter is disposed in the gap defined by the first and second glass substrates. A conductive interface is provided through the edge seal, and is arranged to interface with the emitter and to provide electrical current to the emitter. The conductive interface in certain example embodiments may include one or more bus bars, one or more pattered thin film lines, etc.

Owner:GUARDIAN GLASS LLC

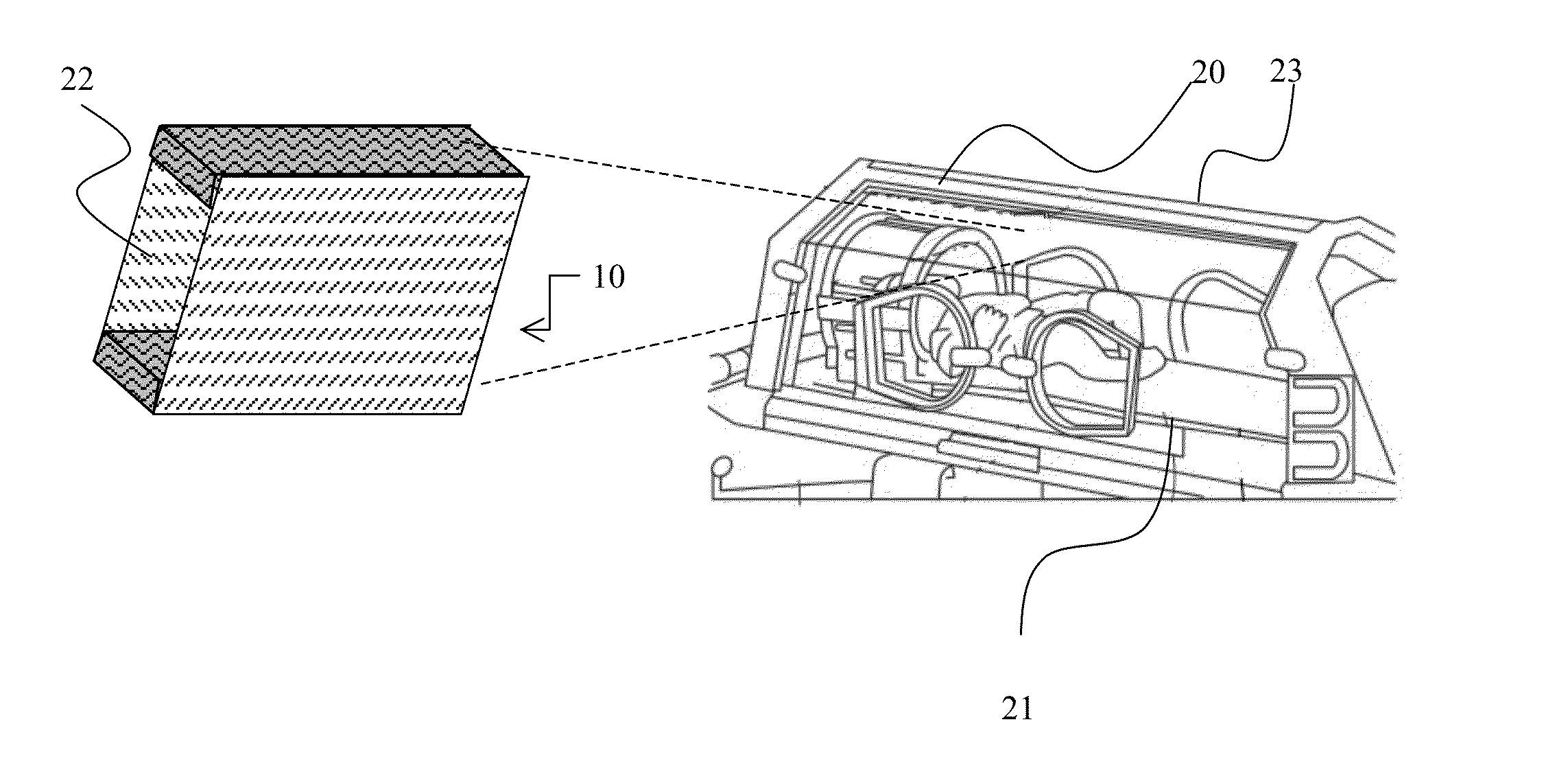

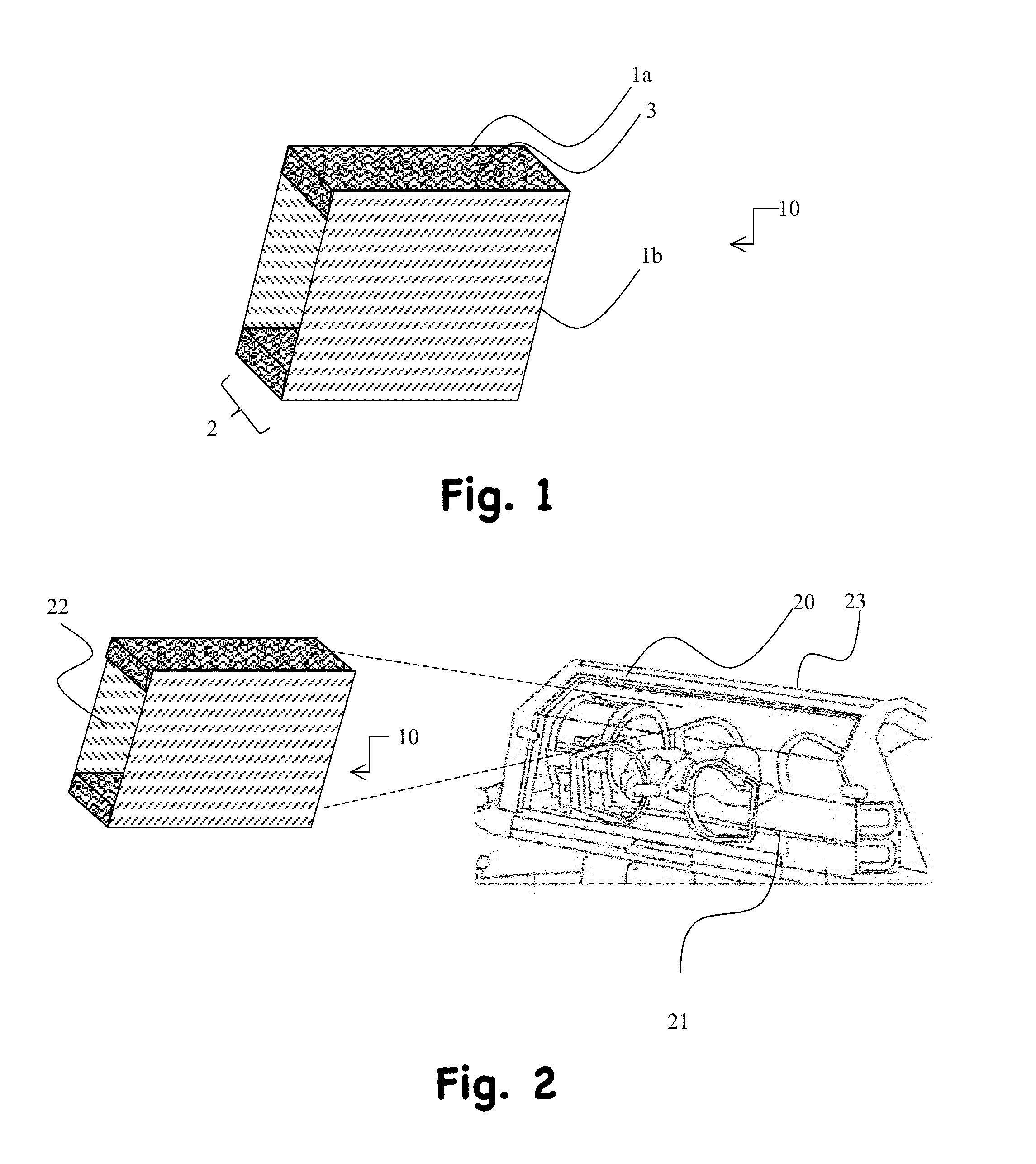

Incubator with double glazed wall and methods thereof

InactiveUS20150065788A1Easy temperature adjustmentLevel avoidBaby-incubatorsDiagnosticsInsulated glazingEngineering

An incubator with a double glazed wall that promotes regulation of sound pressure levels and temperature levels the incubator, using an insulated glass unit. The canopy of the incubator has at least one insulated glass unit. This unit includes at least one first inner glass and at least one second external glass. The inner and external glasses are spaced by a spacer, and are characterized by an inner atmosphere confined within the canopy and an external atmosphere.

Owner:ASPECT IMAGING

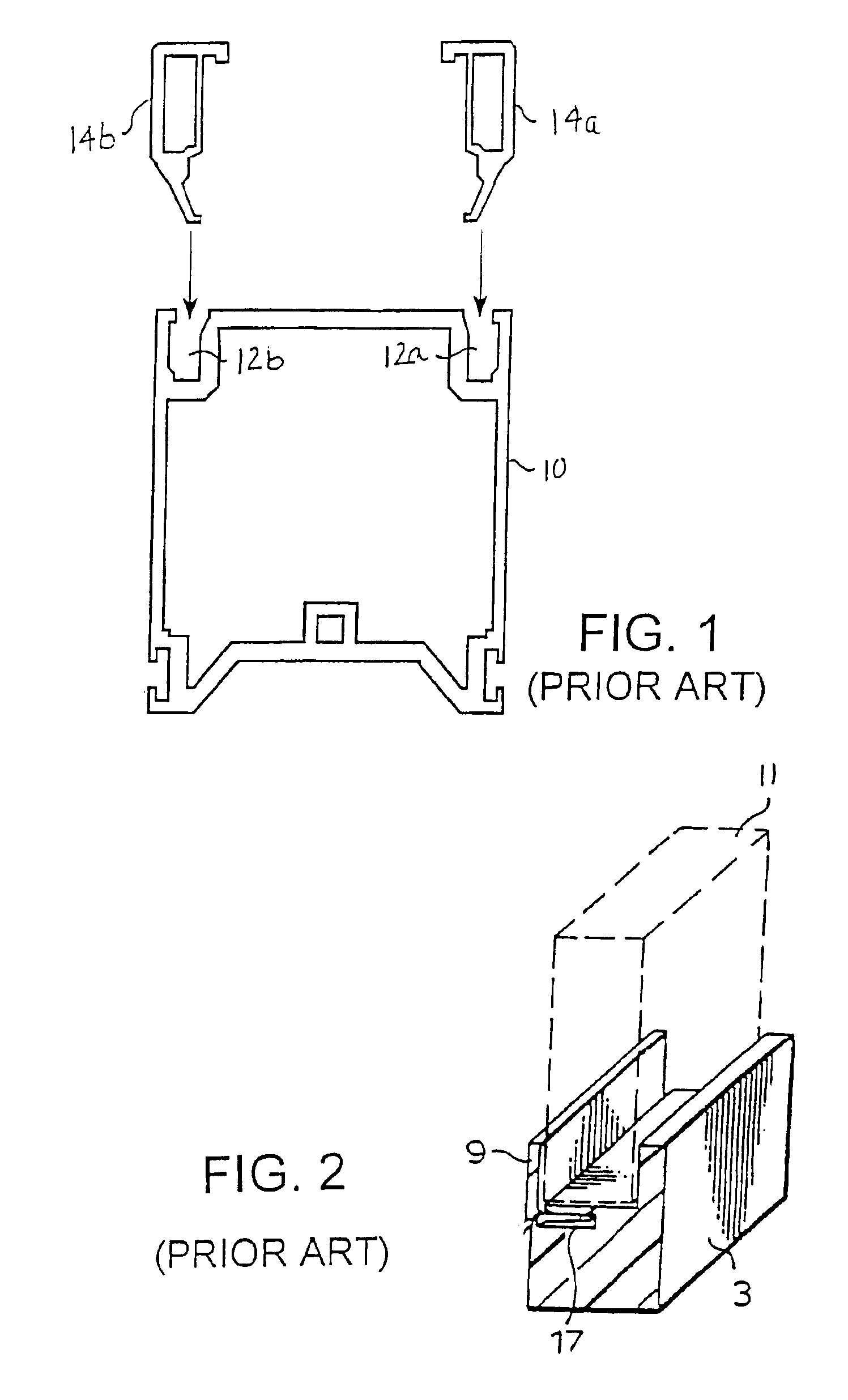

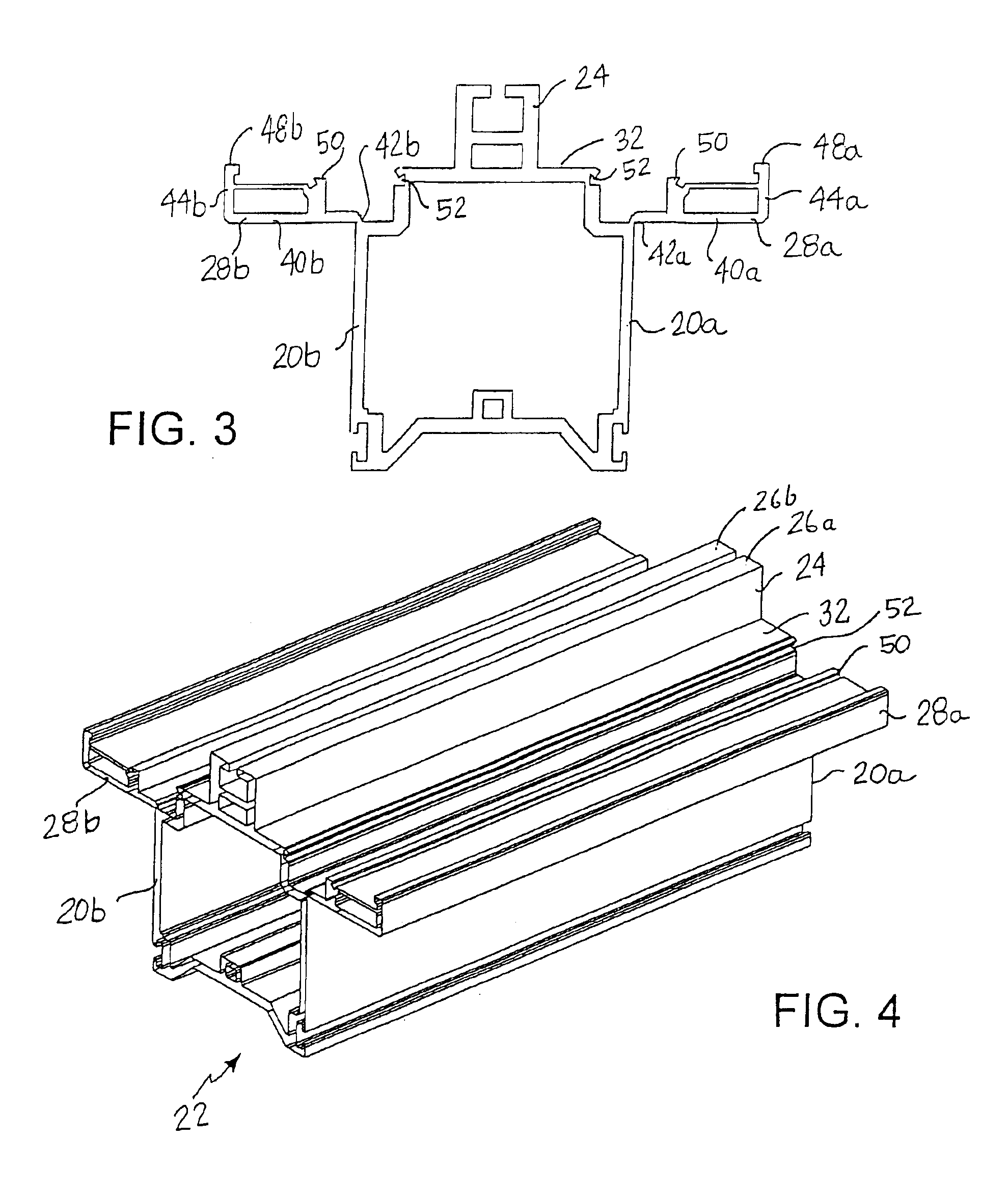

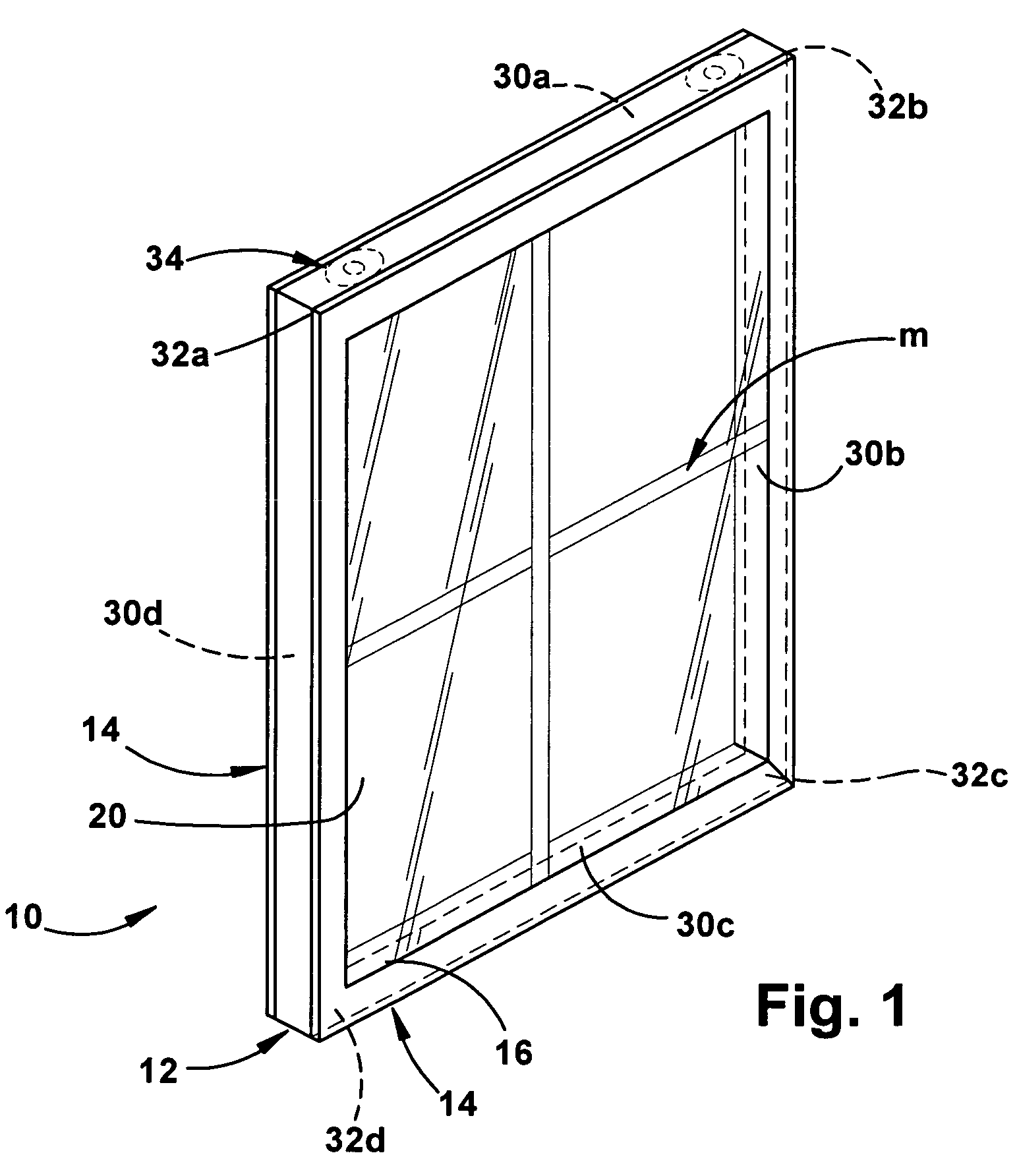

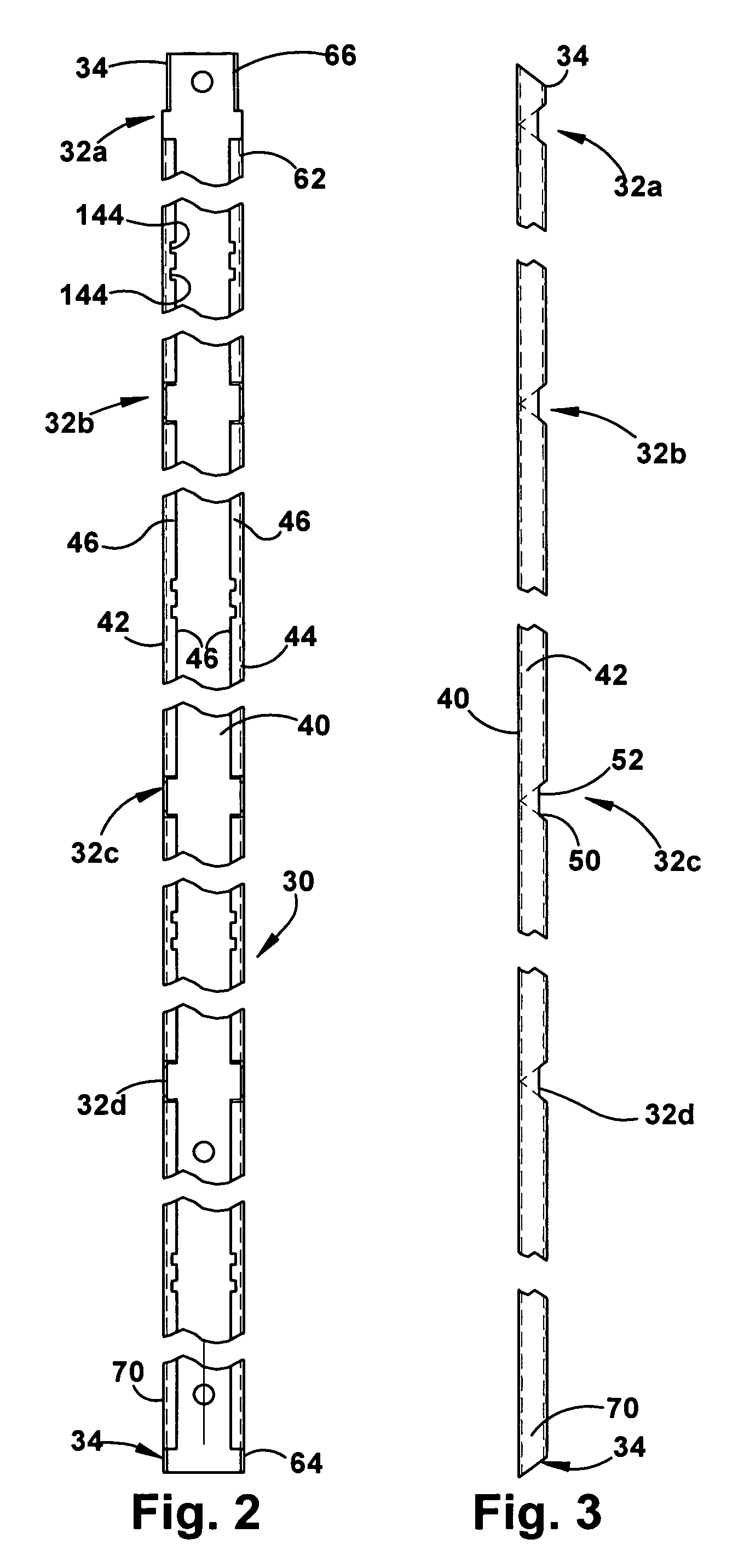

Window sash frame with hinged components

InactiveUS6928776B2Less capital intensiveLess equipmentInsect protectionGlass/slag layered productsEngineeringMechanical engineering

Methods and apparatus are provided for mounting one or more glazing panes or insulating glass units into a window sash frame member having spaced side walls joined by an inner facing frame surface with a spacing structure disposed on the frame surface. Glazing panes are placed against strips of adhesive sealant within the window sash frame. Folding glazing beads hingedly attached to the side or inner walls of the frame member are folded against the glazing panes to secure them to the window sash frame member and / or to cover the glazing pane edges.

Owner:SASHLITE

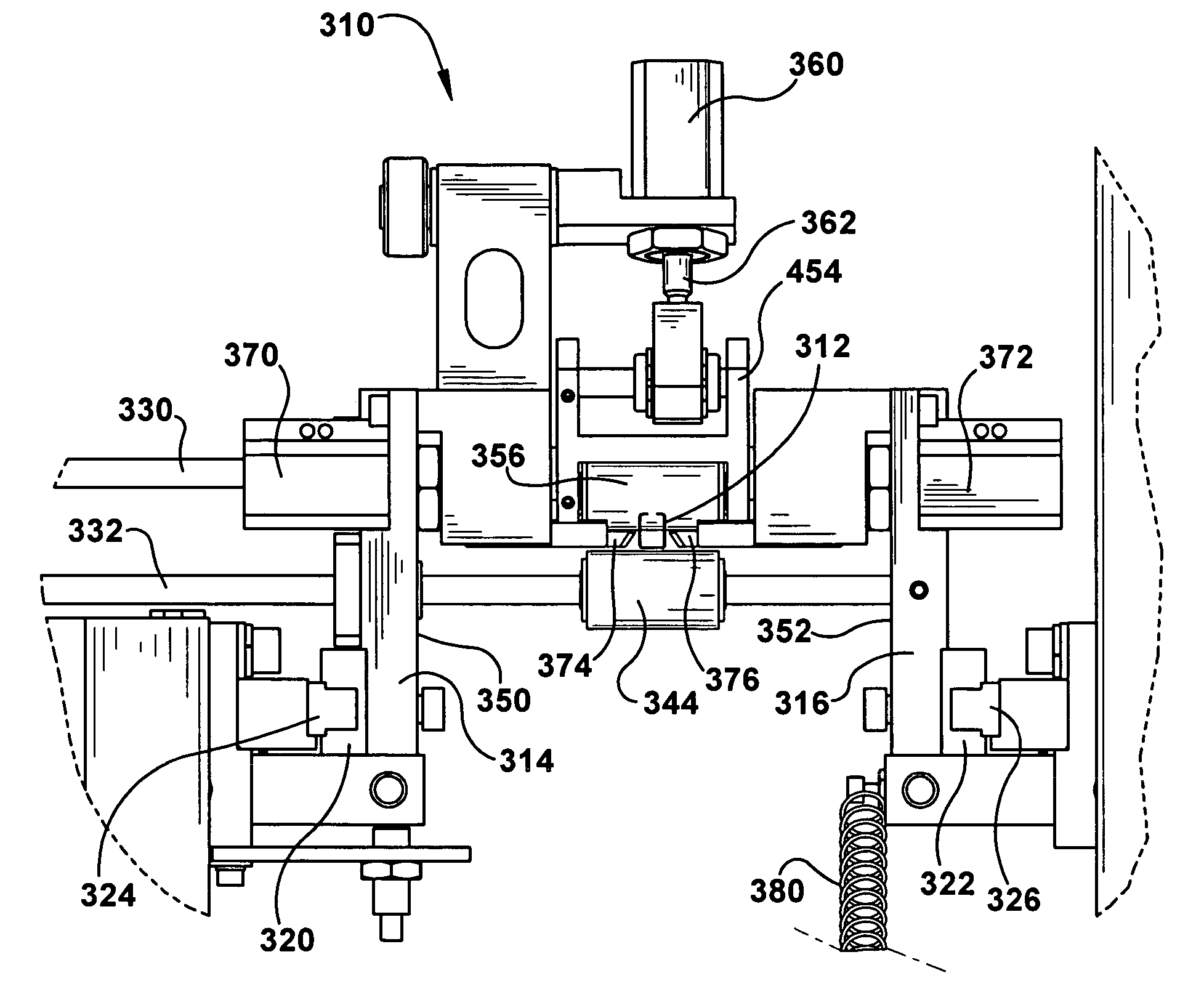

Window frame corner fabrication

Owner:GED INTEGRATED SOLUTIONS

Coated article with low-E coating having absorbing layer designed to neutralize color at off-axis viewing angles

ActiveUS20080070044A1Improve mechanical durabilityImprove thermal stabilityGlass/slag layered productsNatural mineral layered productsInsulated glazingNitride

An absorbing layer of a low-E coating is designed to cause the coating to have a more neutral and / or green color at normal and / or certain off-axis viewing angles. In certain example embodiments, the metallic or substantially metallic absorbing layer (e.g., NiCr) is from about 20-30 angstroms (Å) thick; this thickness has been found to unexpectedly provide less red and more neutral coloration for the coated article at certain off-axis viewing angles (e.g., at a 45 degree off-axis viewing angle). In certain example embodiments, the absorbing layer is provided between first and second nitride layers in order to reduce or prevent oxidation thereof during heat treatment thereby permitting predictable coloration to be achieved following the heat treatment. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, vehicle windows, other types of windows, or in any other suitable application.

Owner:GUARDIAN GLASS LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com