Patents

Literature

354results about How to "Easy temperature adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

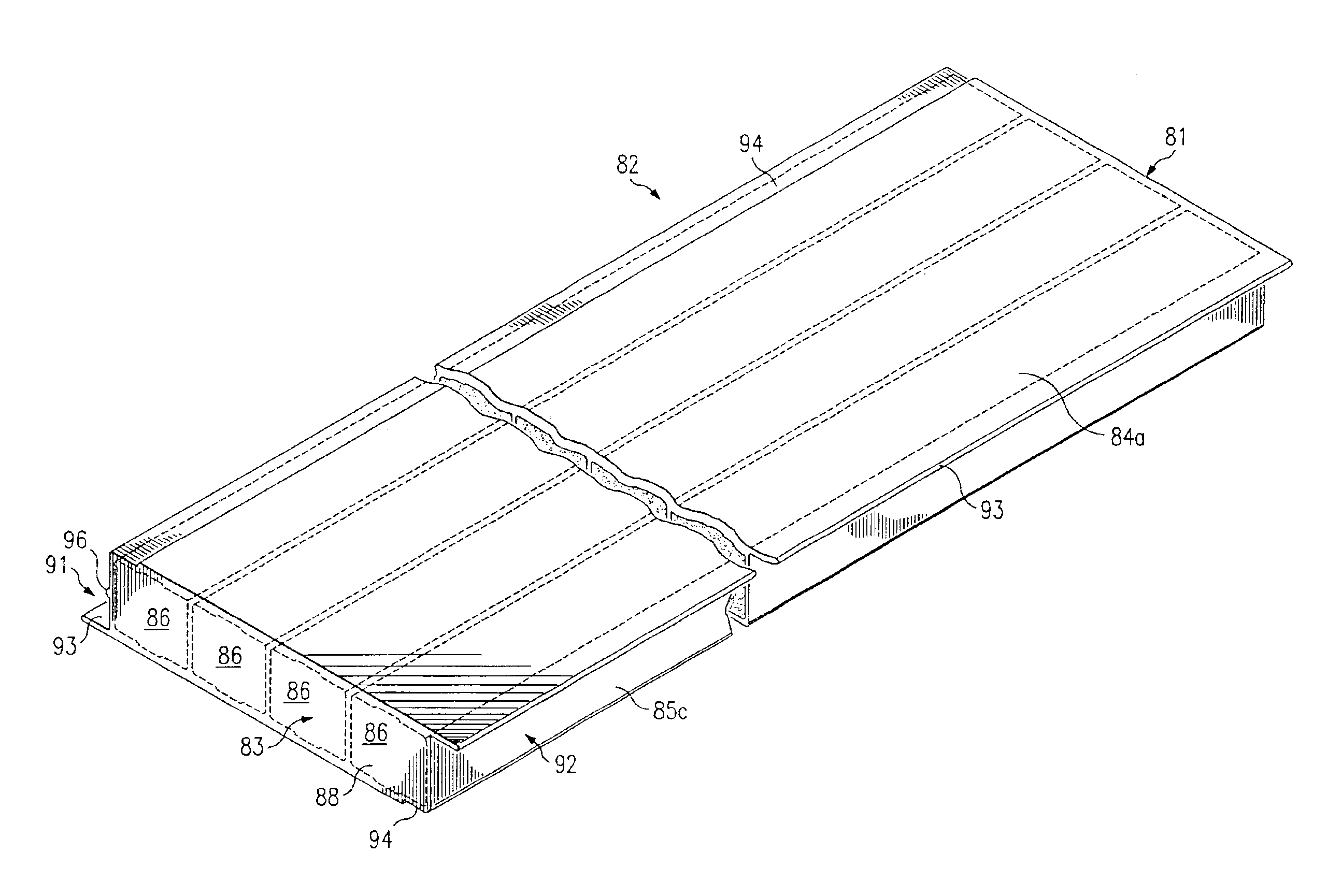

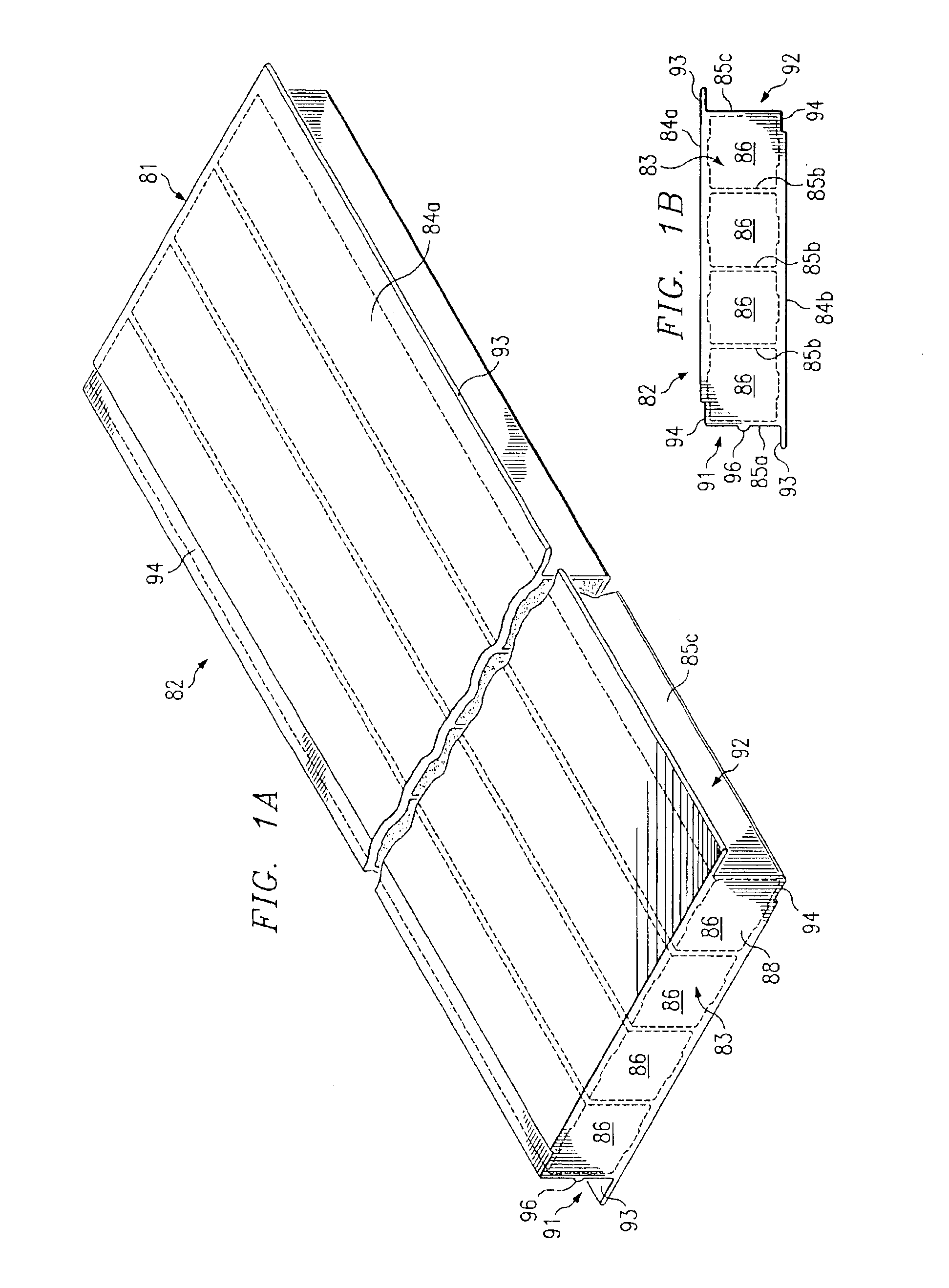

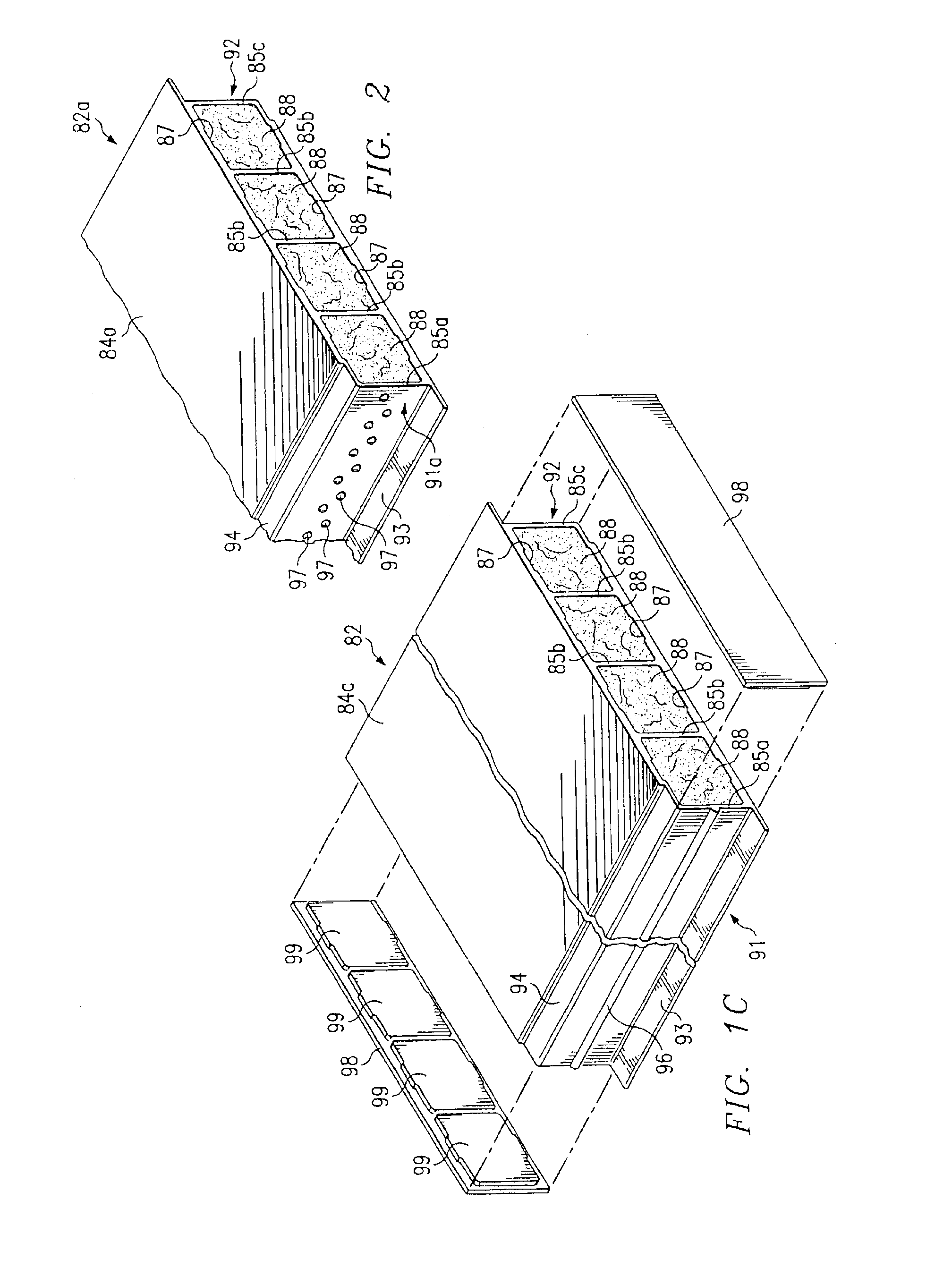

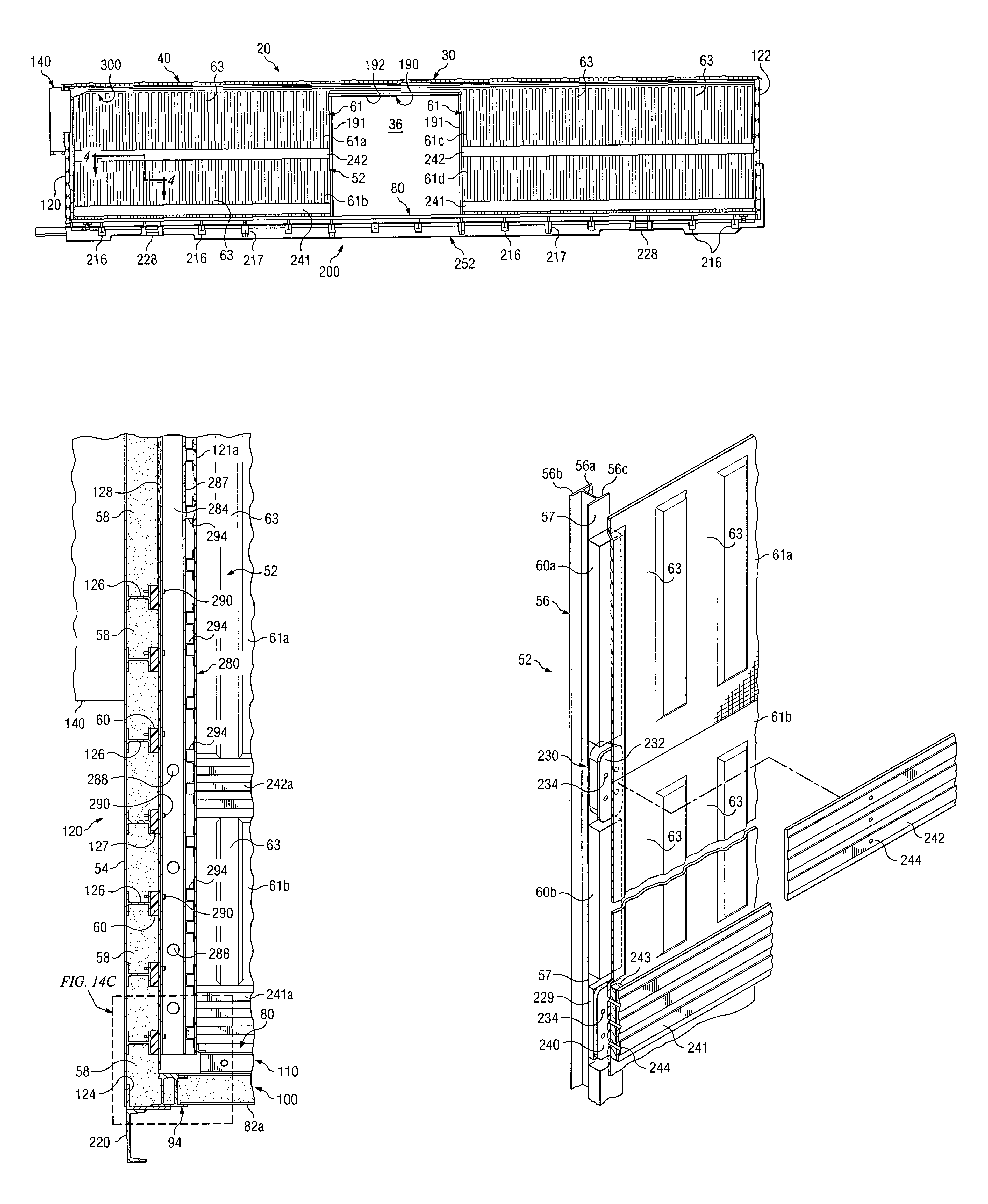

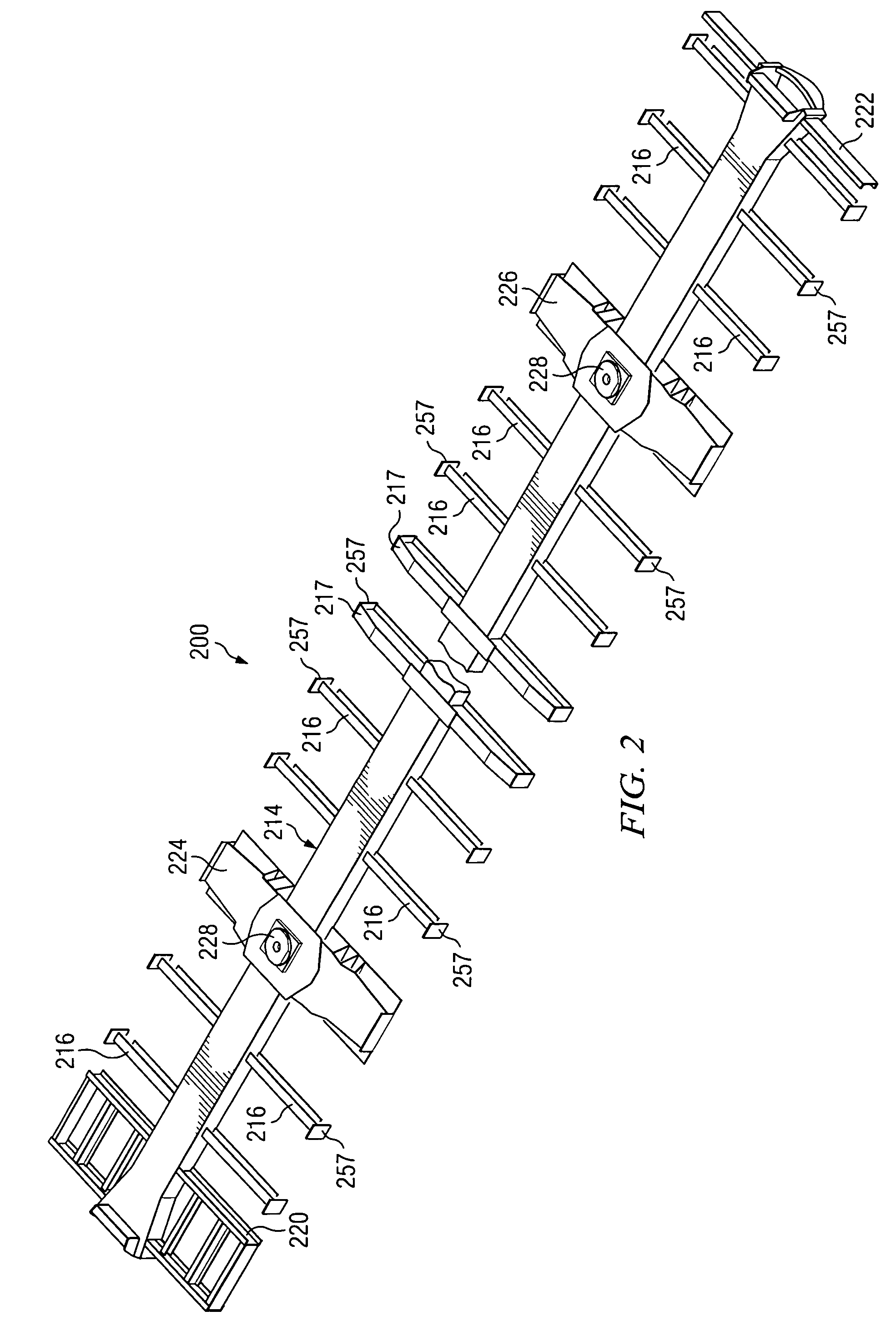

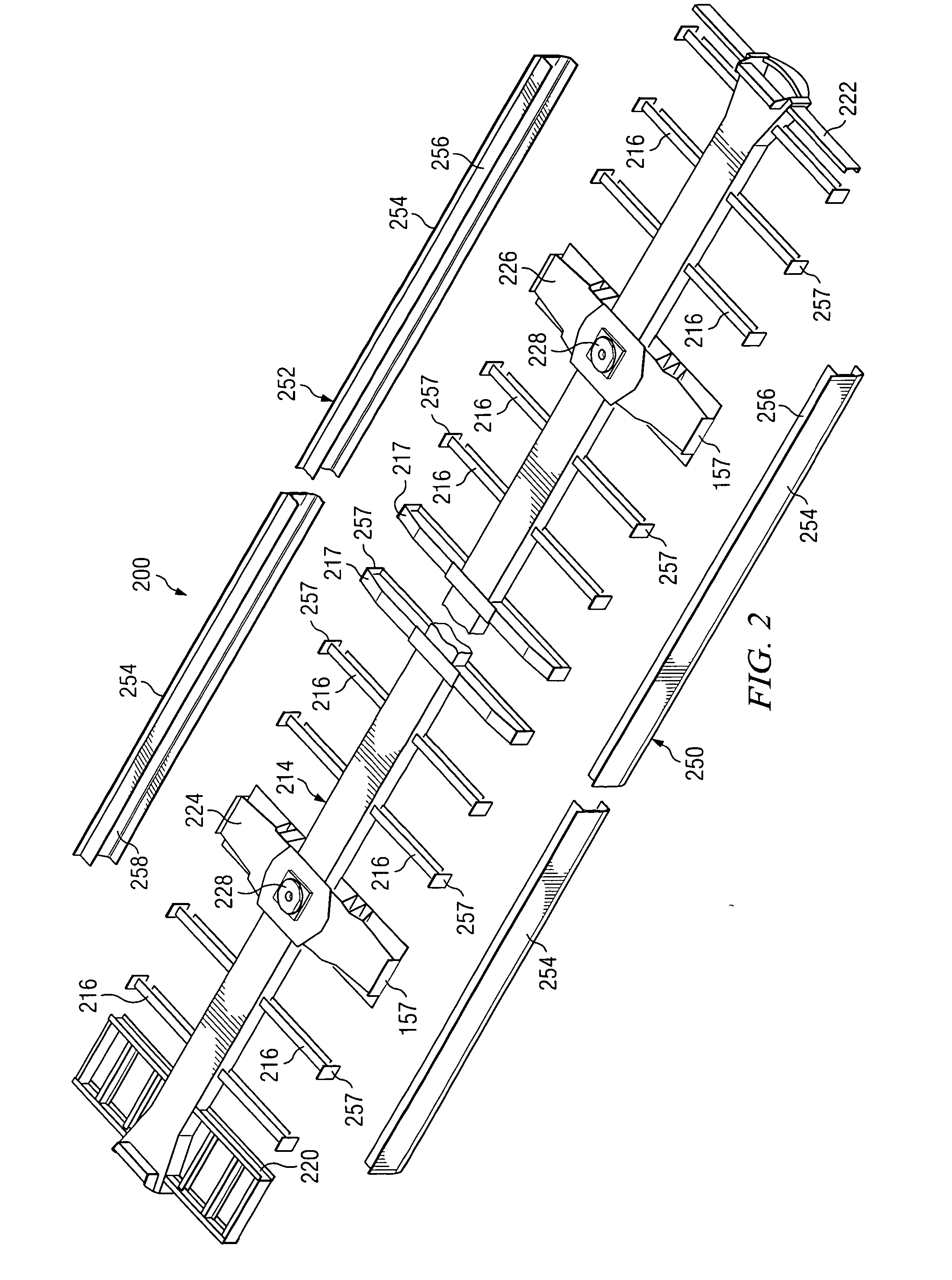

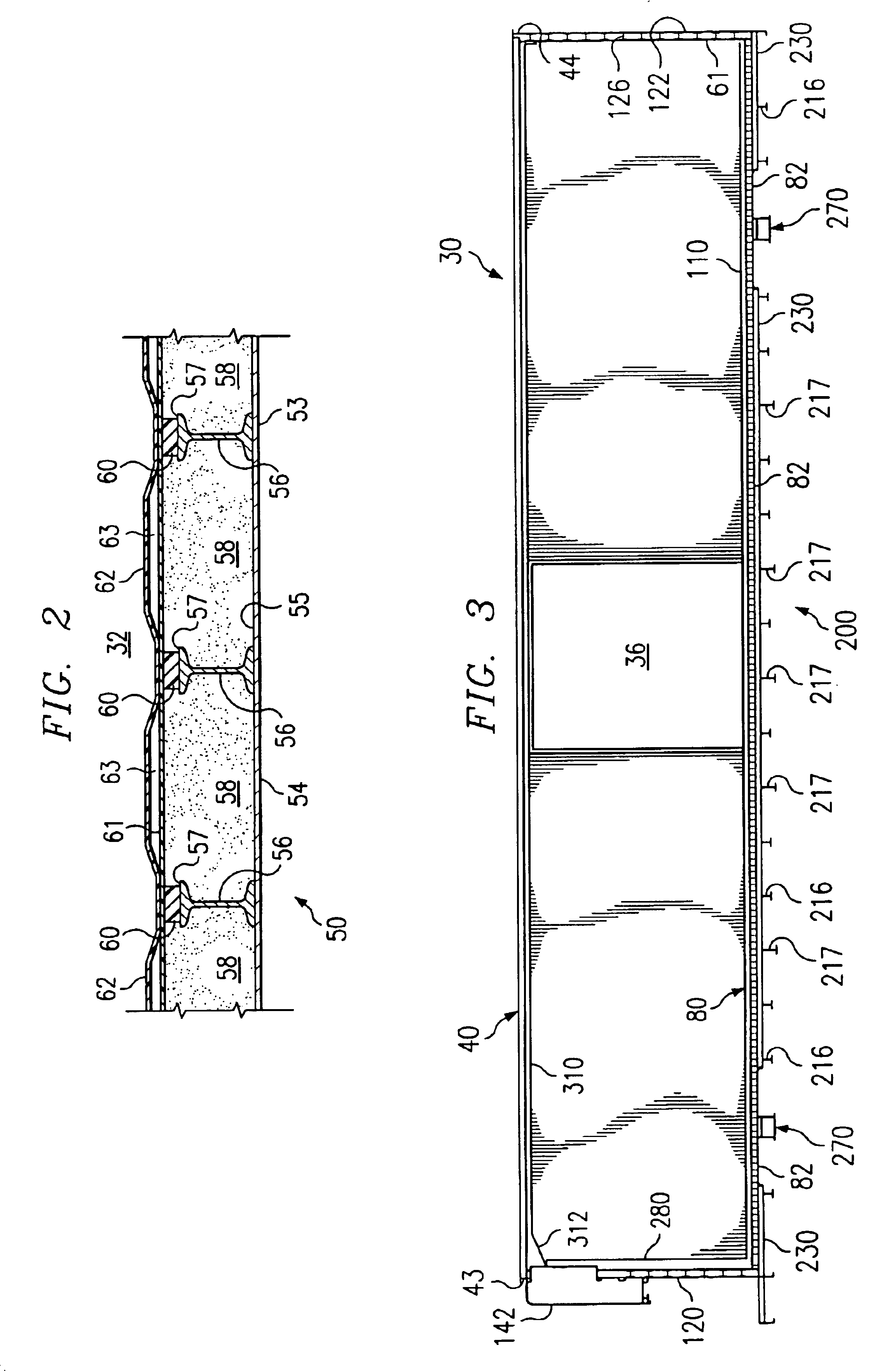

Pultruded panel

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

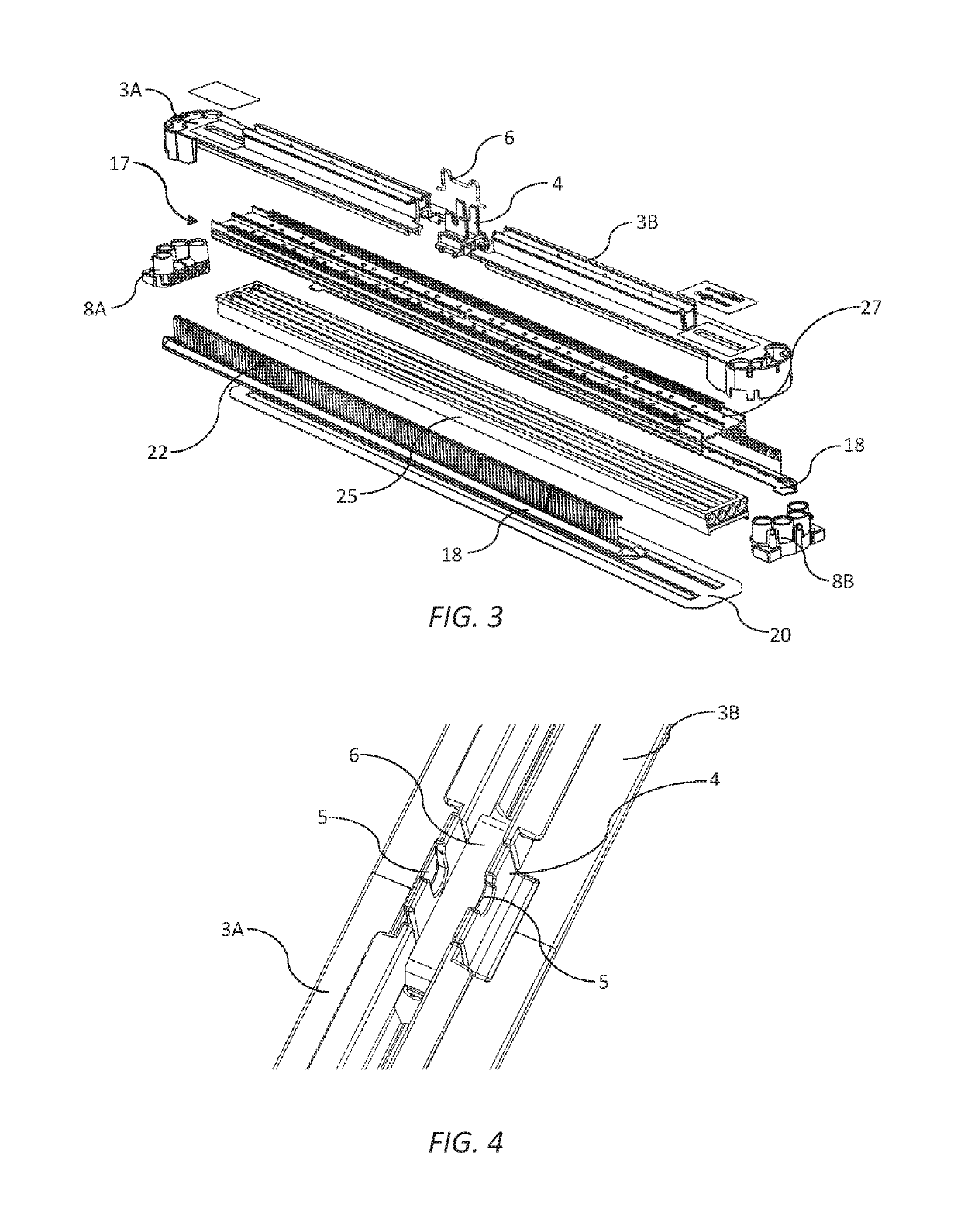

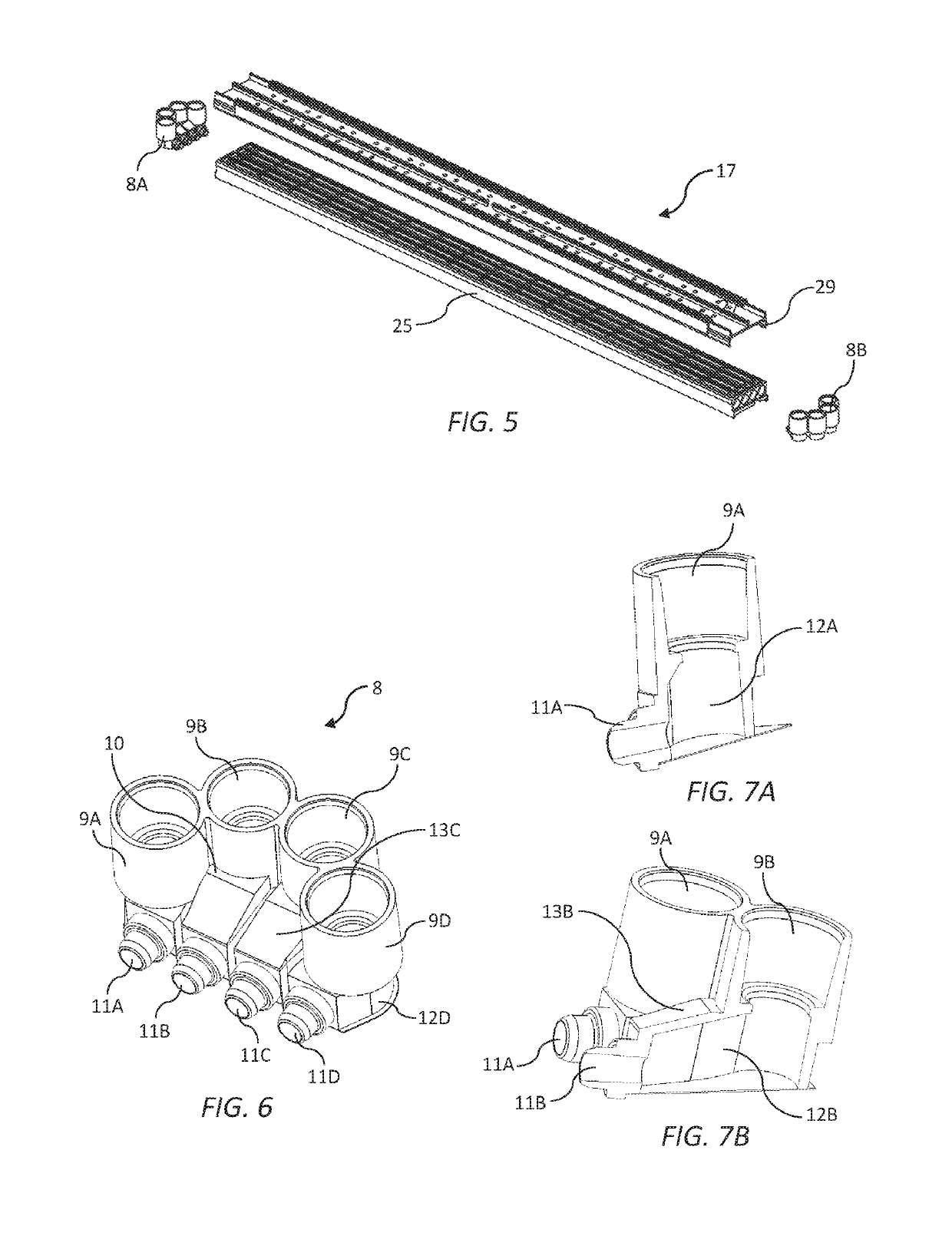

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

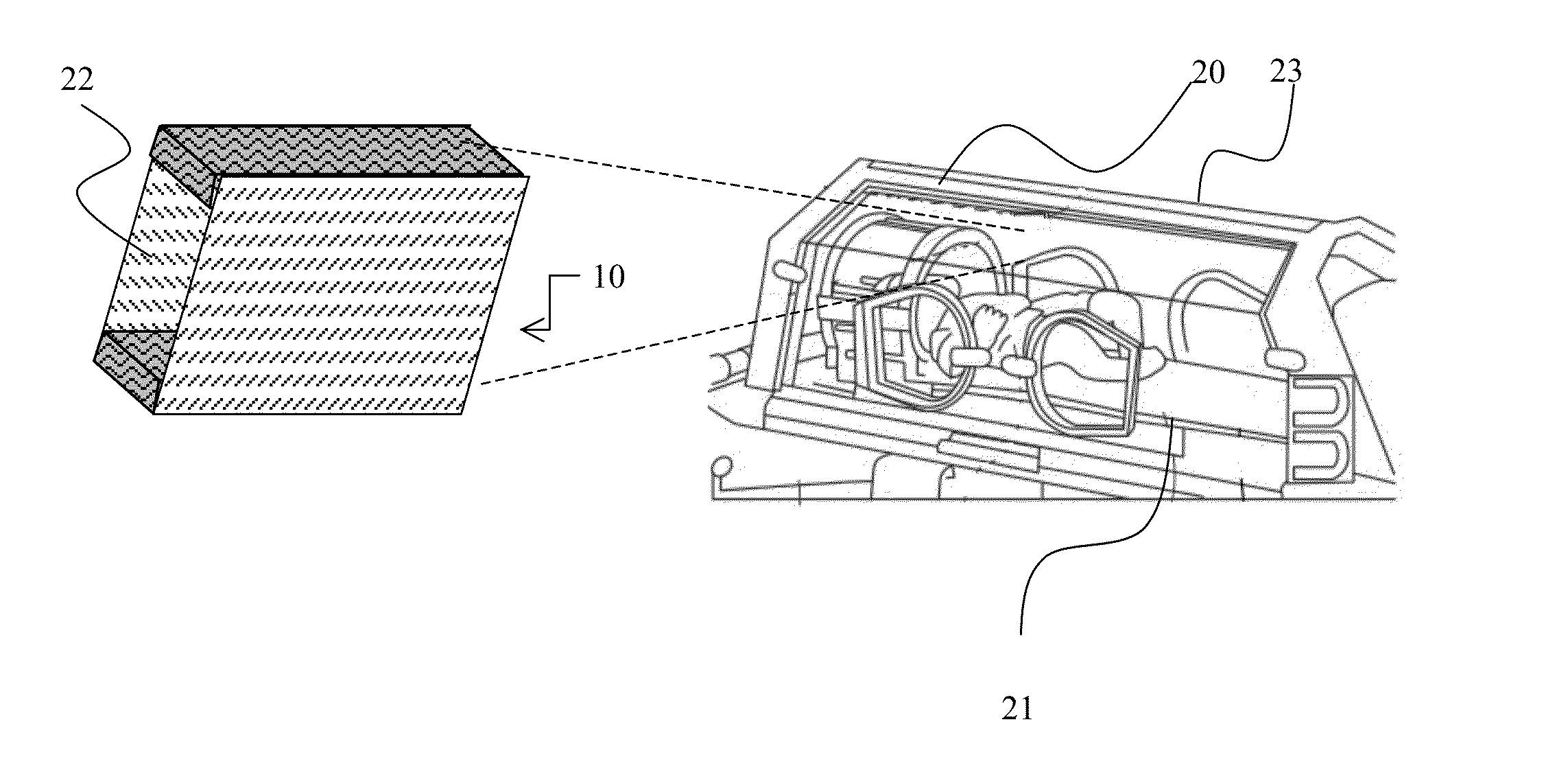

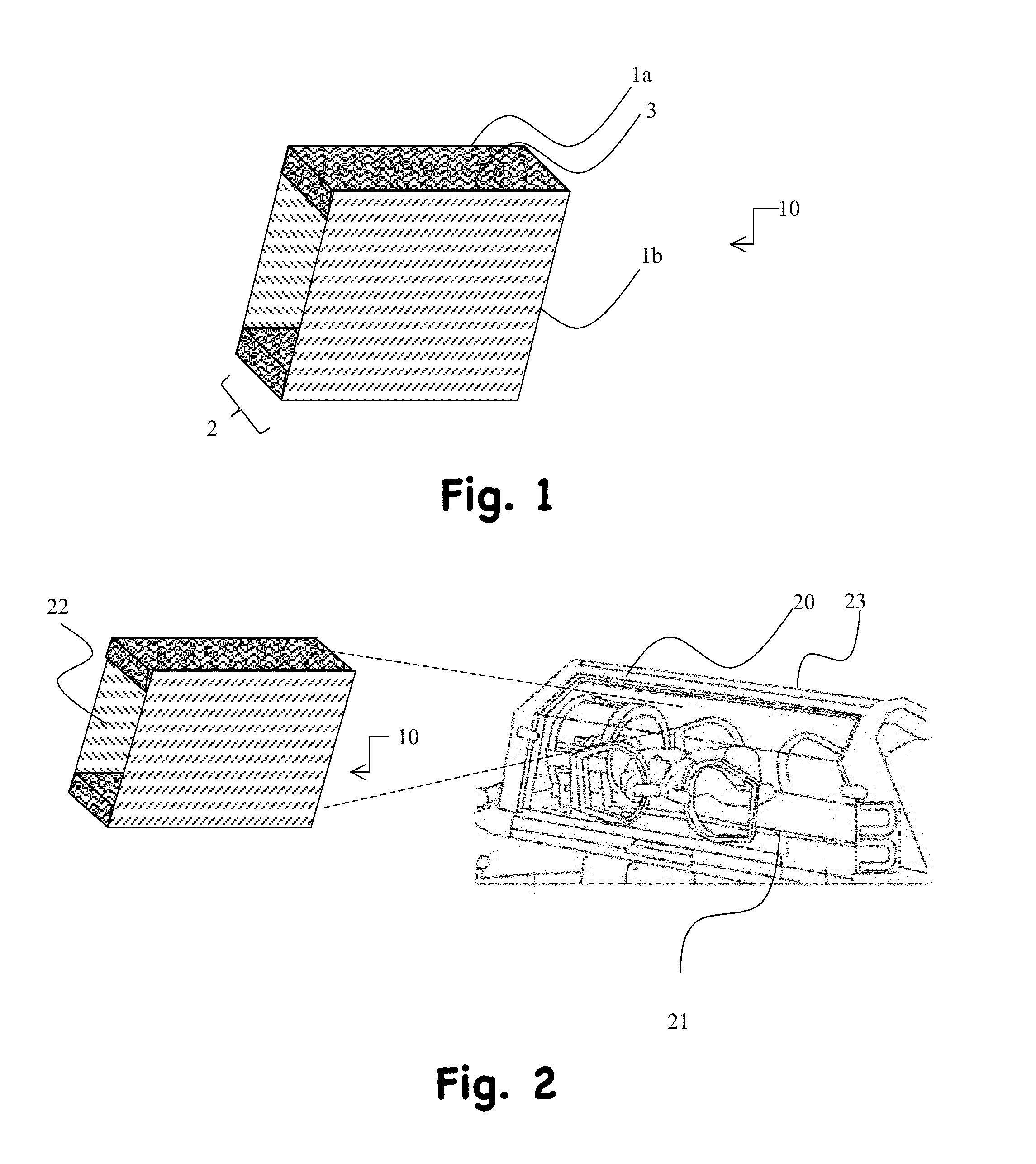

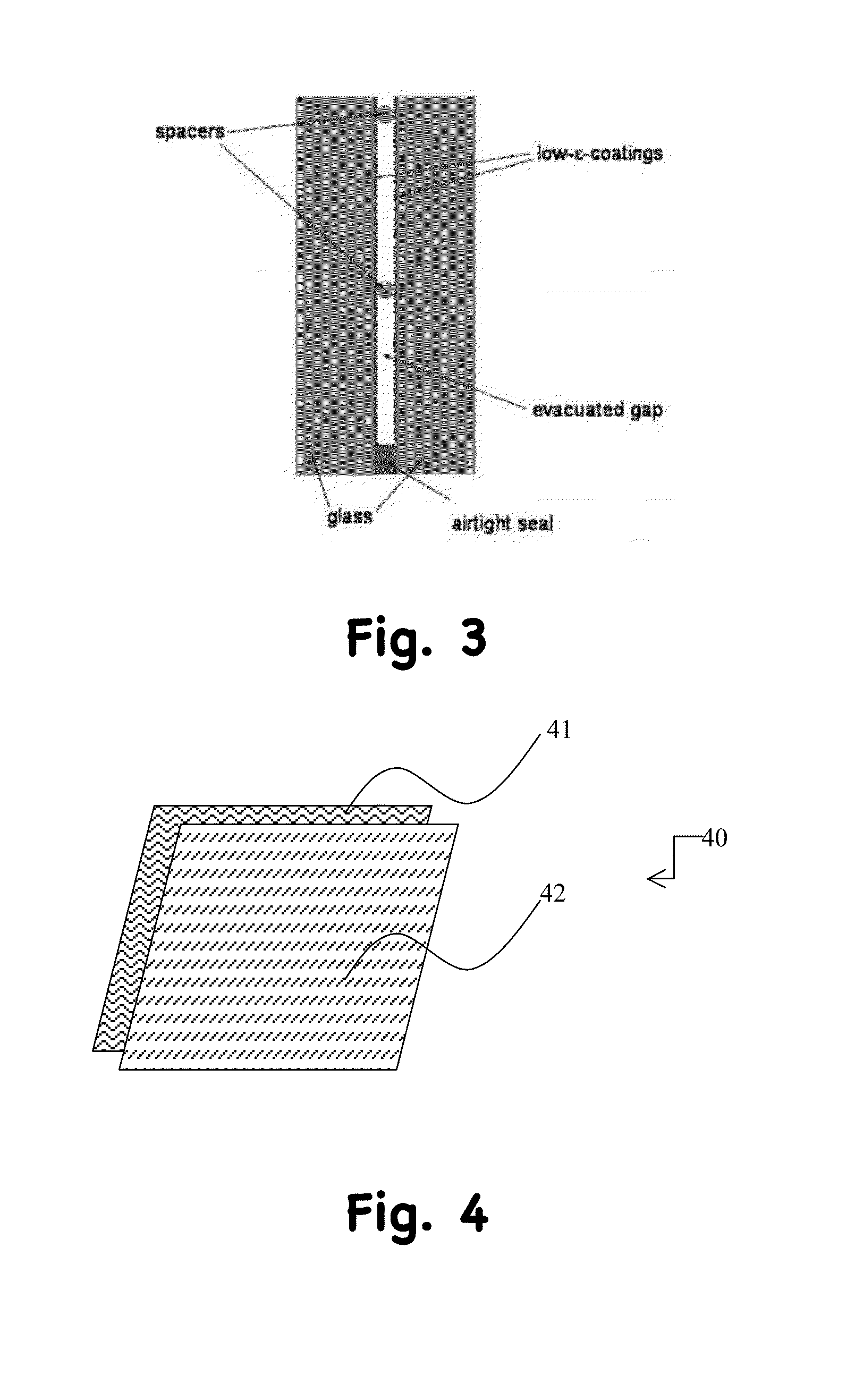

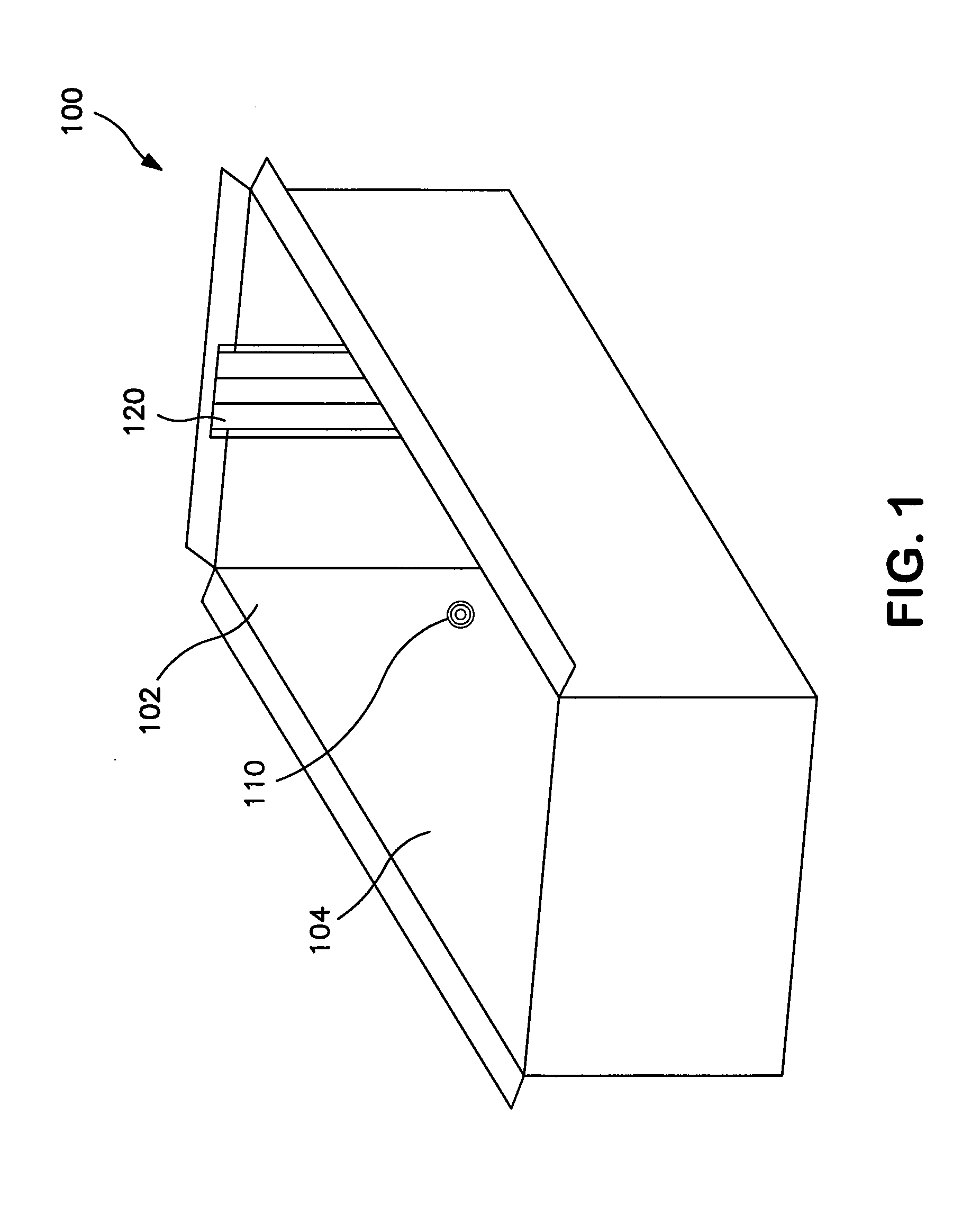

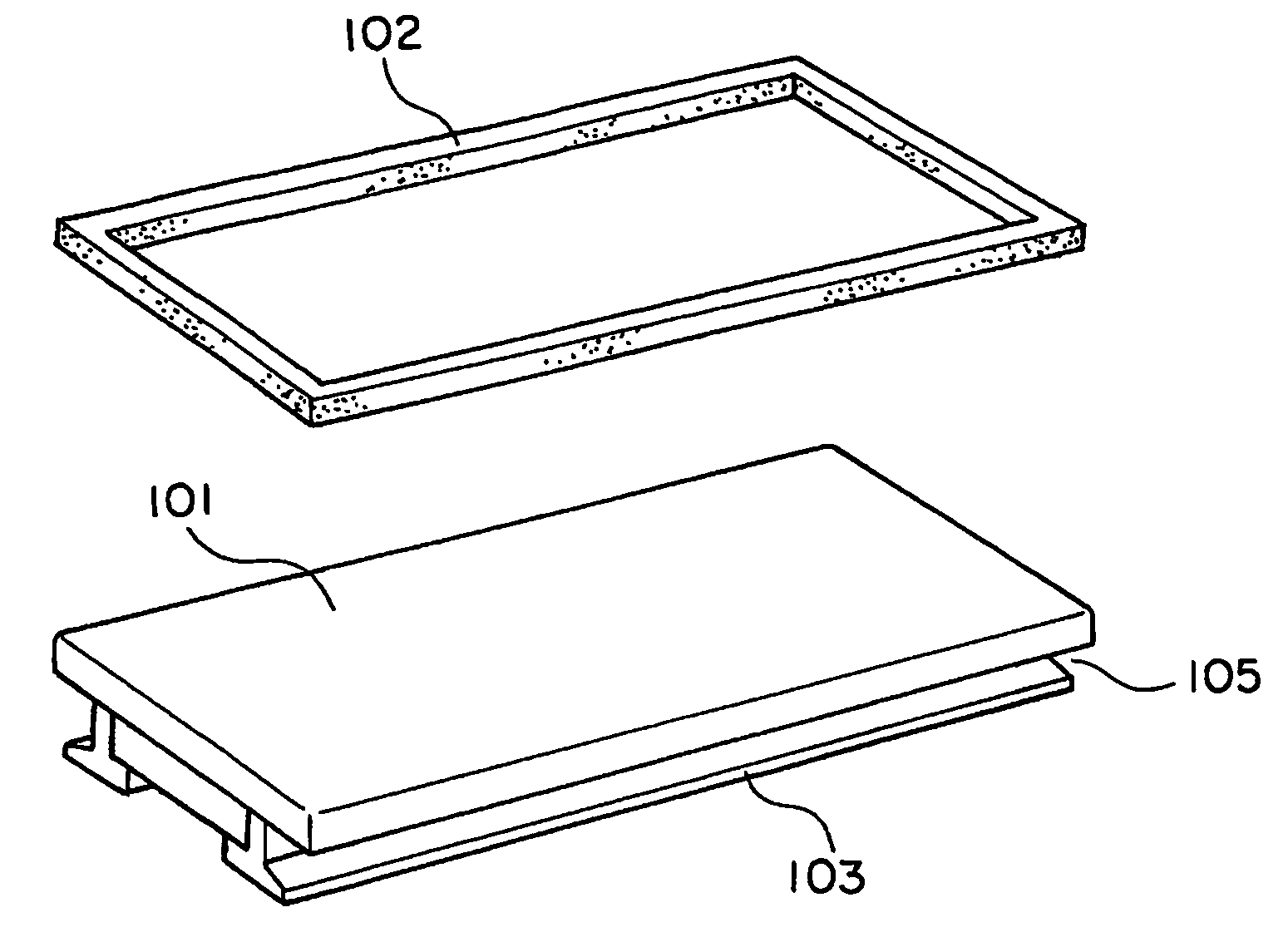

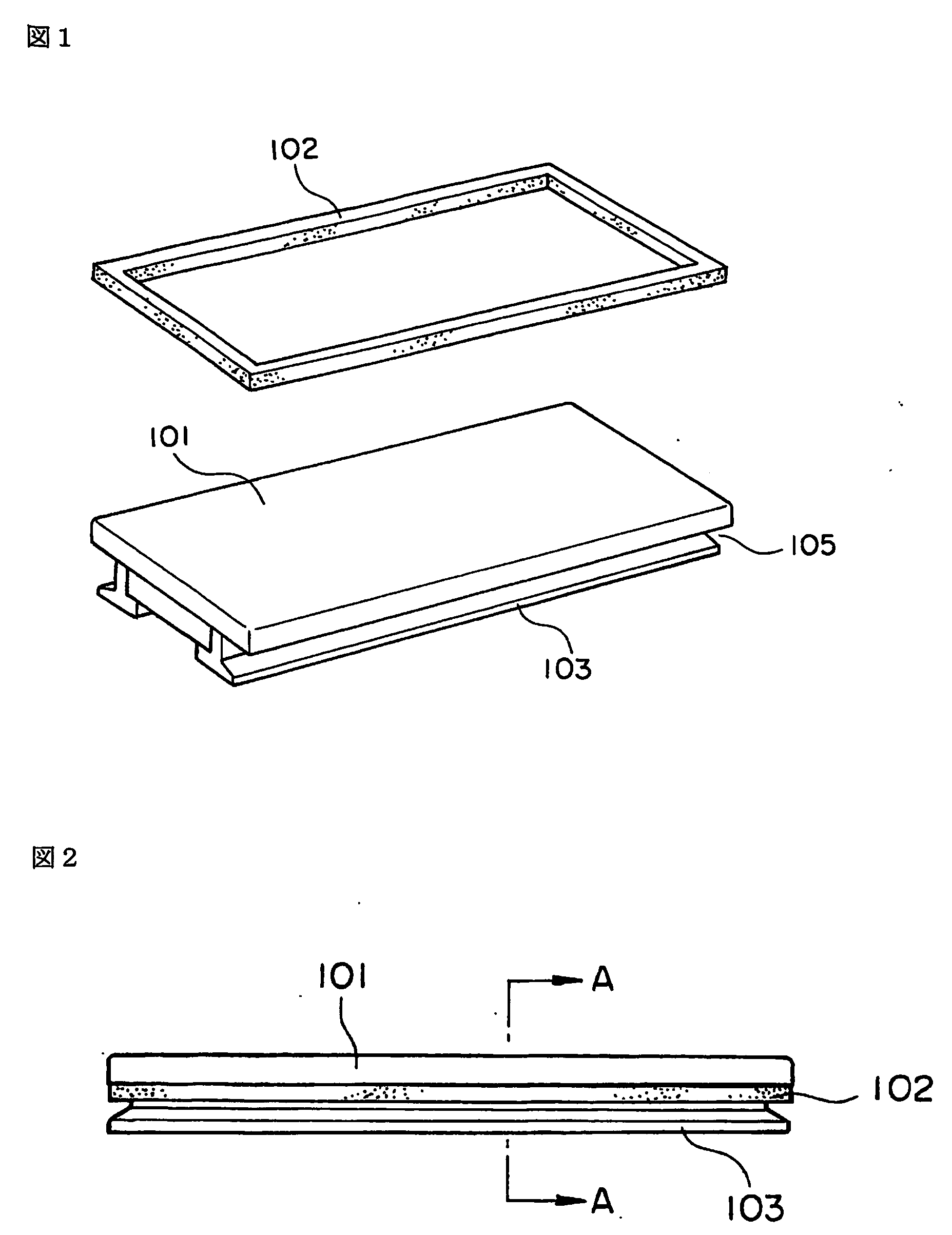

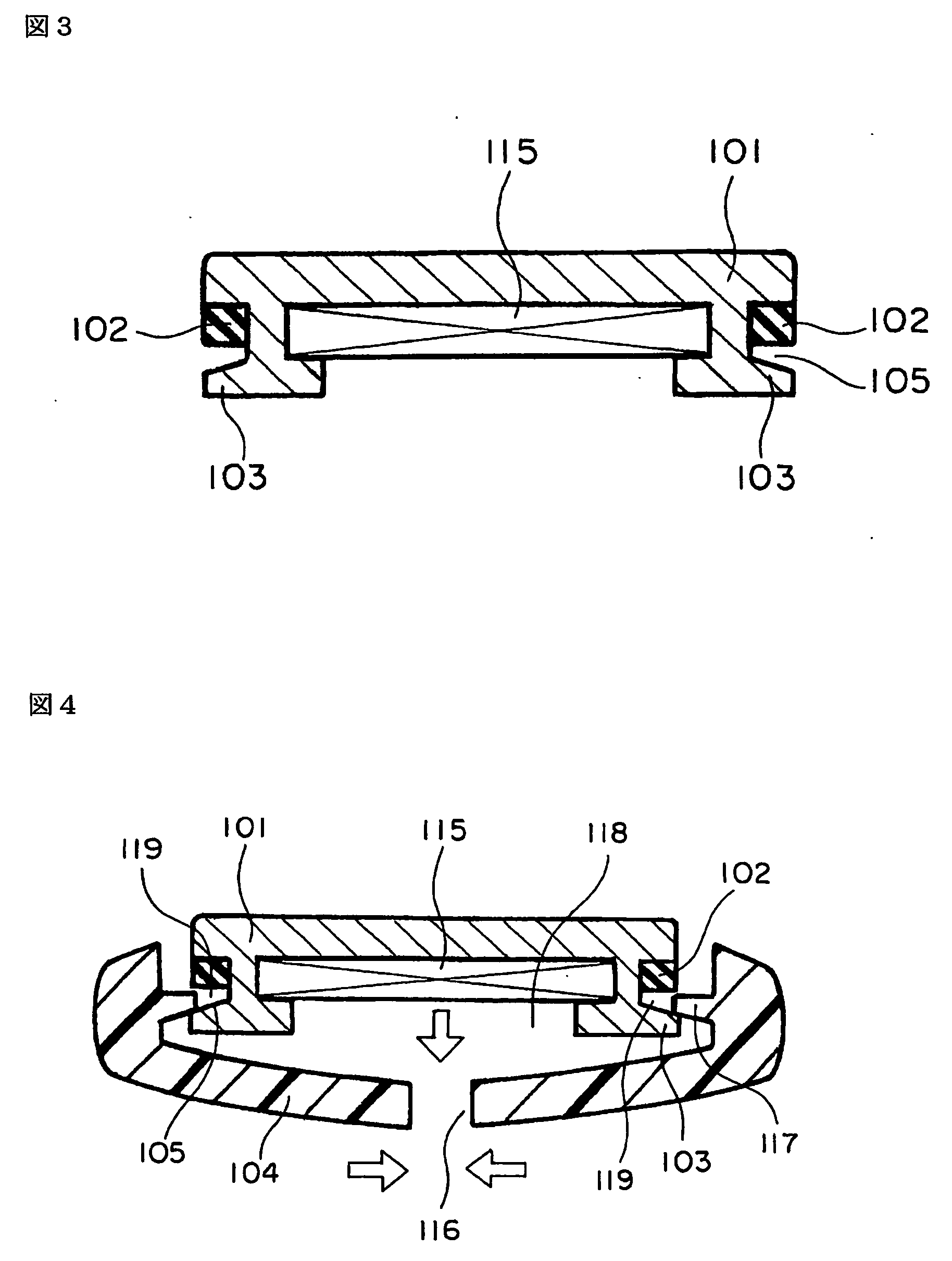

Incubator with double glazed wall and methods thereof

InactiveUS20150065788A1Easy temperature adjustmentLevel avoidBaby-incubatorsDiagnosticsInsulated glazingEngineering

An incubator with a double glazed wall that promotes regulation of sound pressure levels and temperature levels the incubator, using an insulated glass unit. The canopy of the incubator has at least one insulated glass unit. This unit includes at least one first inner glass and at least one second external glass. The inner and external glasses are spaced by a spacer, and are characterized by an inner atmosphere confined within the canopy and an external atmosphere.

Owner:ASPECT IMAGING

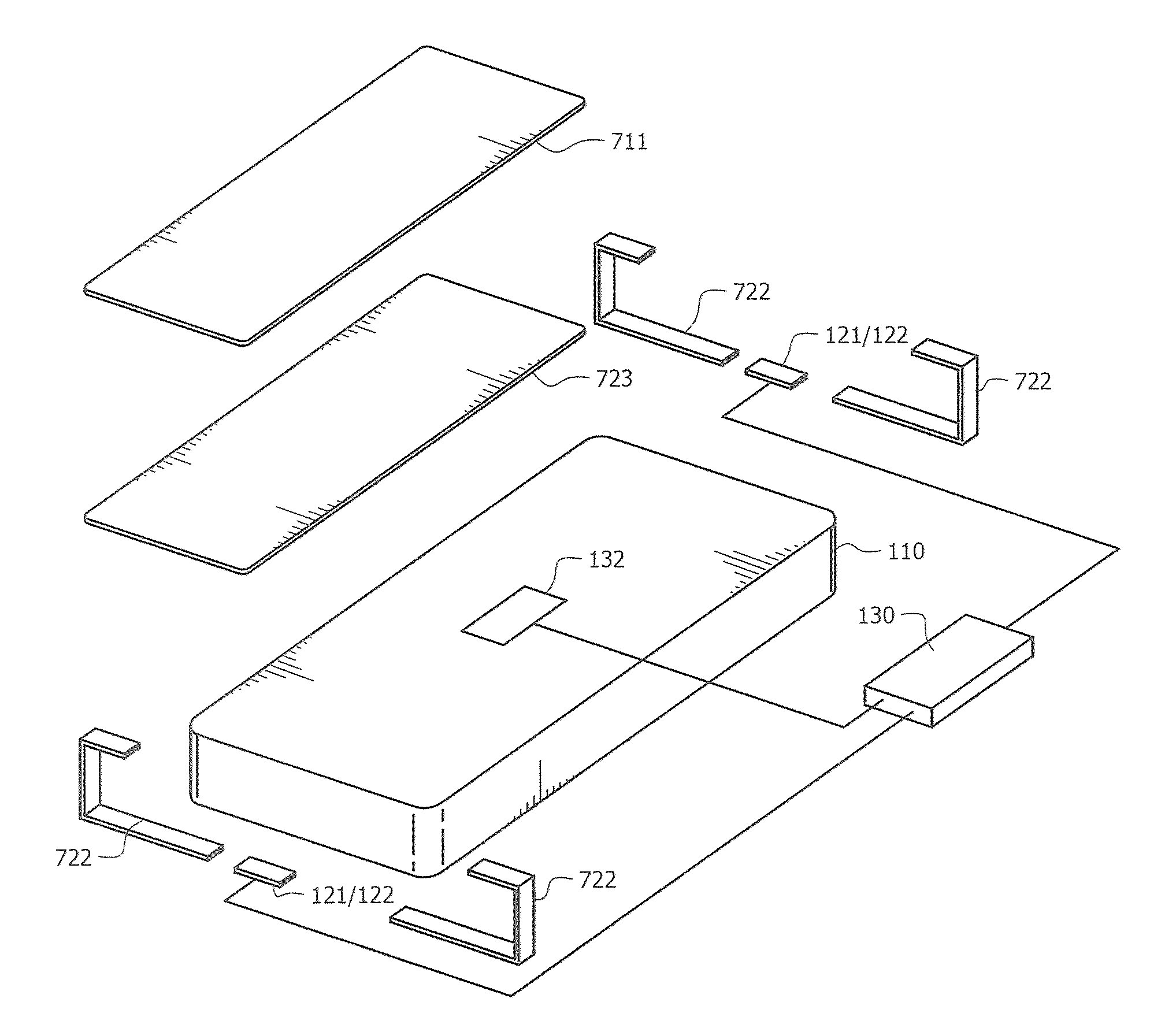

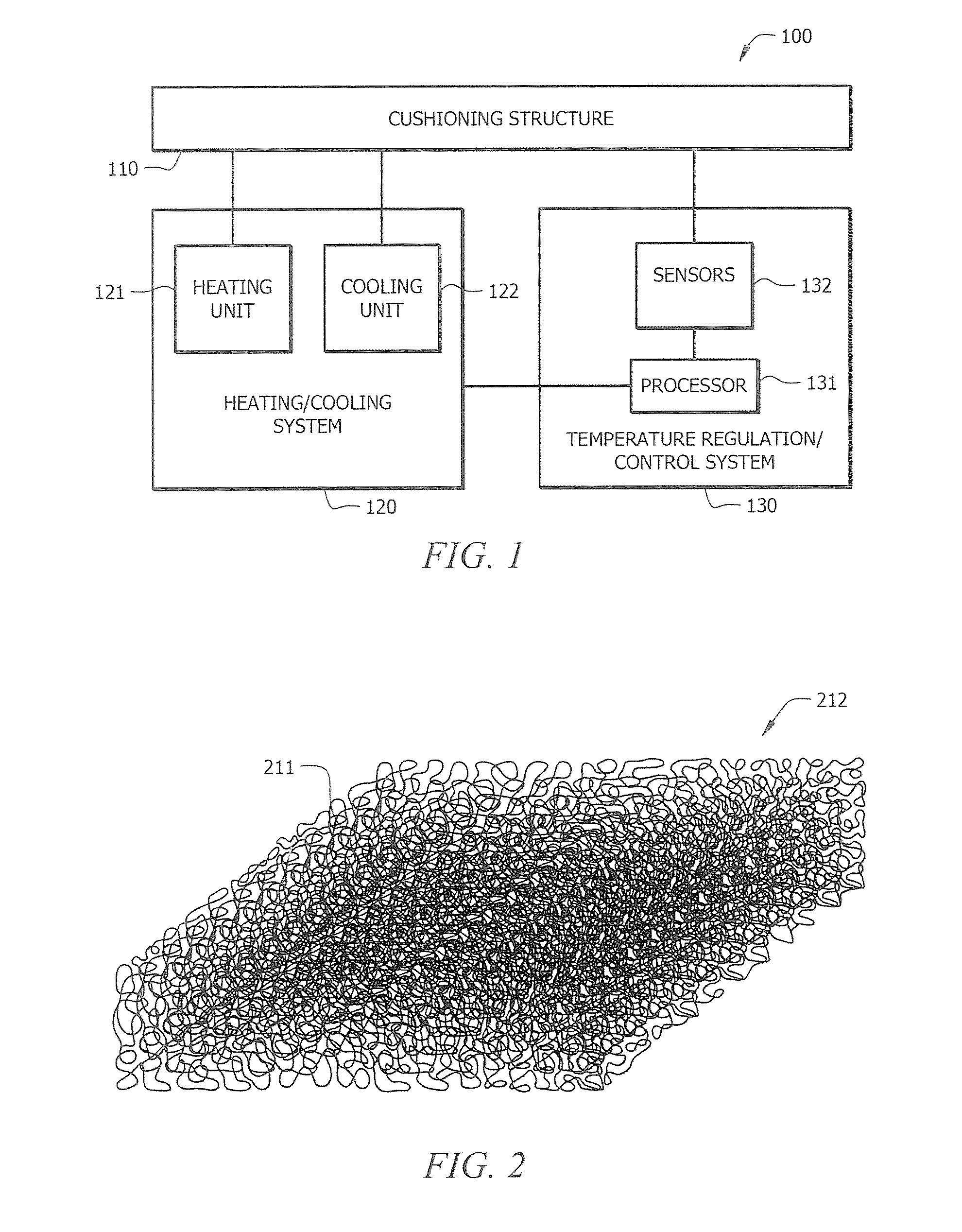

Systems and methods providing temperature regulated cushion structure

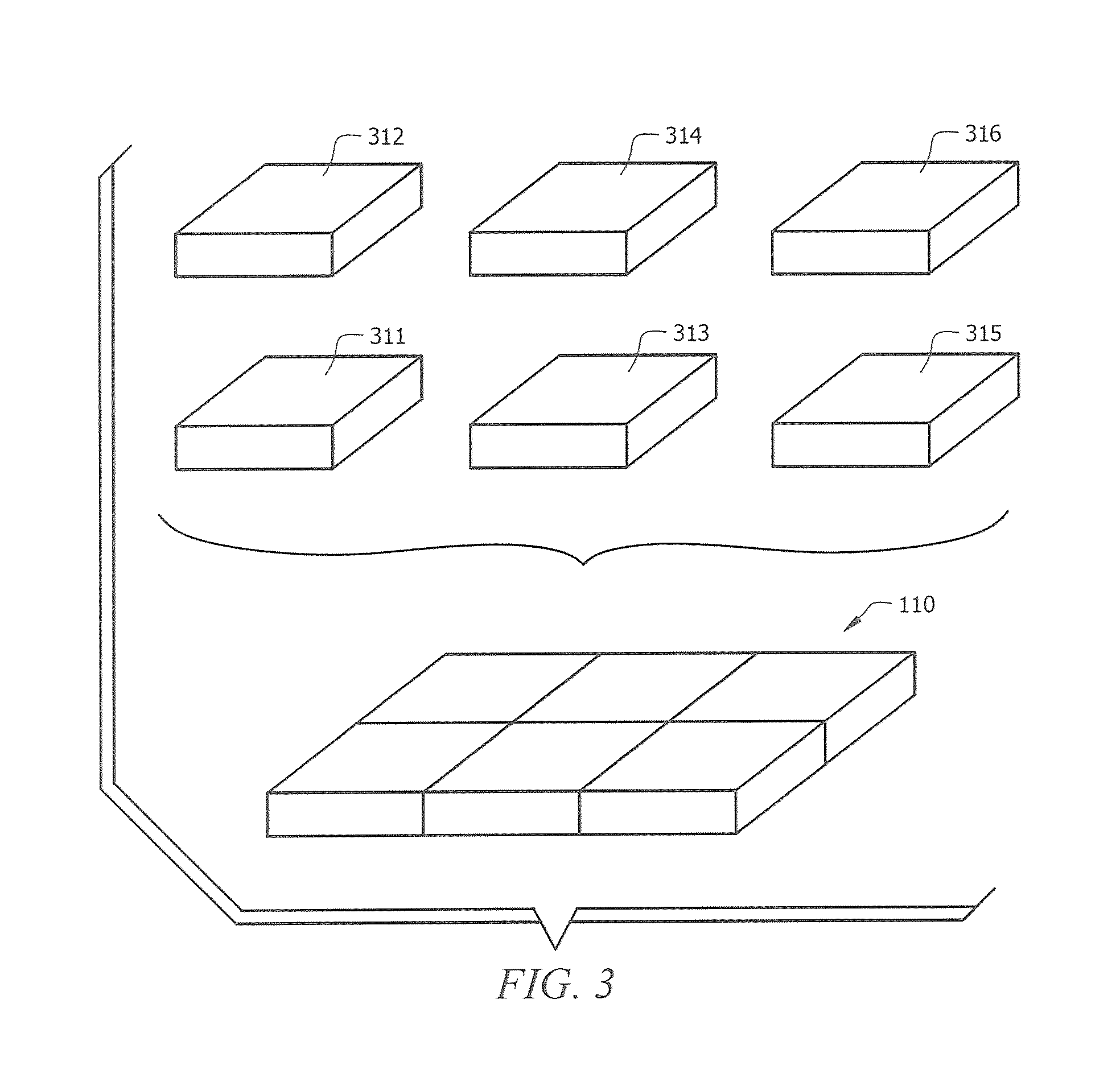

InactiveUS20110041246A1Reduce weightUniform densityStuffed mattressesElectric heatingCushioningModularity

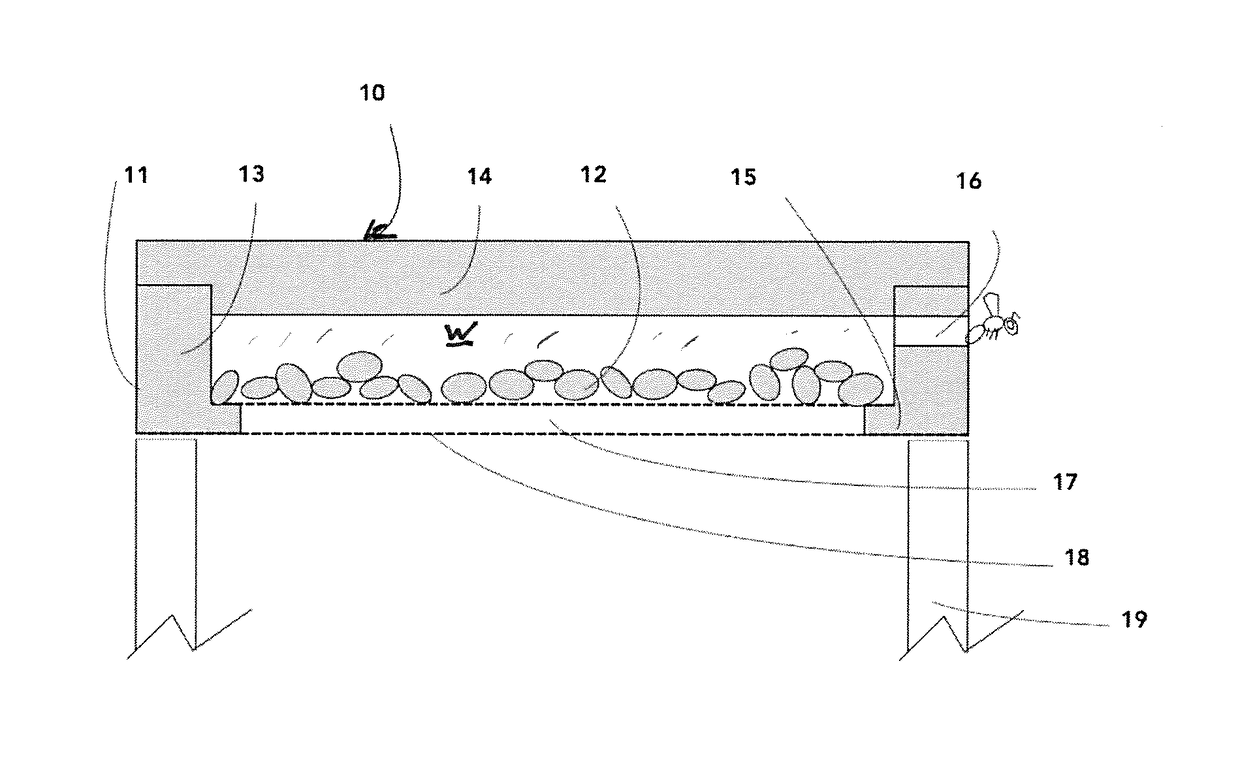

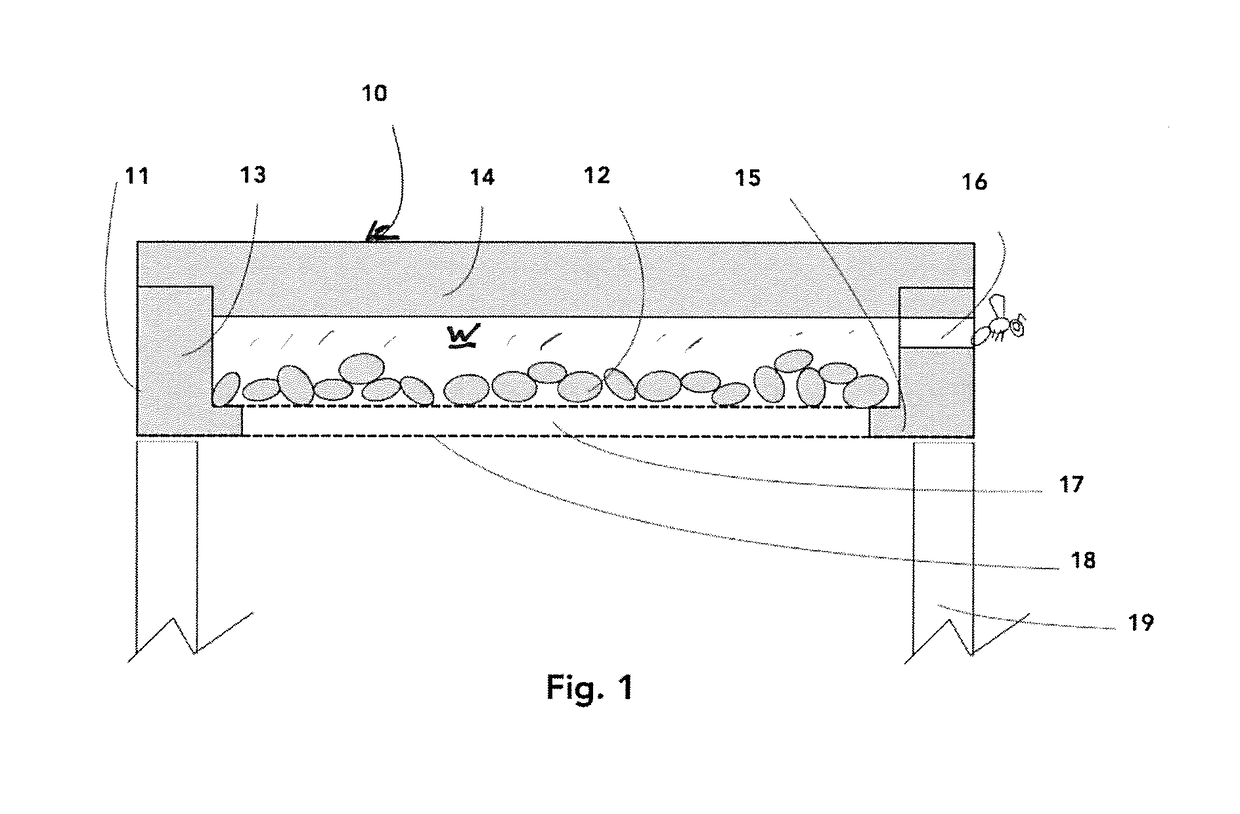

Systems and methods in which temperature regulated cushioning systems are provided in hygienic, convenient configurations are shown. Embodiments provide heating and cooling to provide temperature regulation adapted for human comfort and / or therapeutic effects. Heating and cooling systems implemented with respect to cushioning systems are configured to provided desired temperature regulation for the cushioning system when in use while facilitating hygienic cleaning of the cushioning system. Cushioning structure is preferably adapted to be low weight and to facilitate desired temperature regulation while providing a structure which passively supports and cushions expected loads. Cushion media utilized according to embodiments is modular, such as may comprise a plurality of smaller blocks adapted to cooperate to form a larger cushioning structure. A frame system is utilized according to embodiments to facilitate a desired cooperative arrangement of individual cushion media components and / or to provide various cushioning structure configurations using the cushion media.

Owner:HONG KONG APPLIED SCI & TECH RES INST

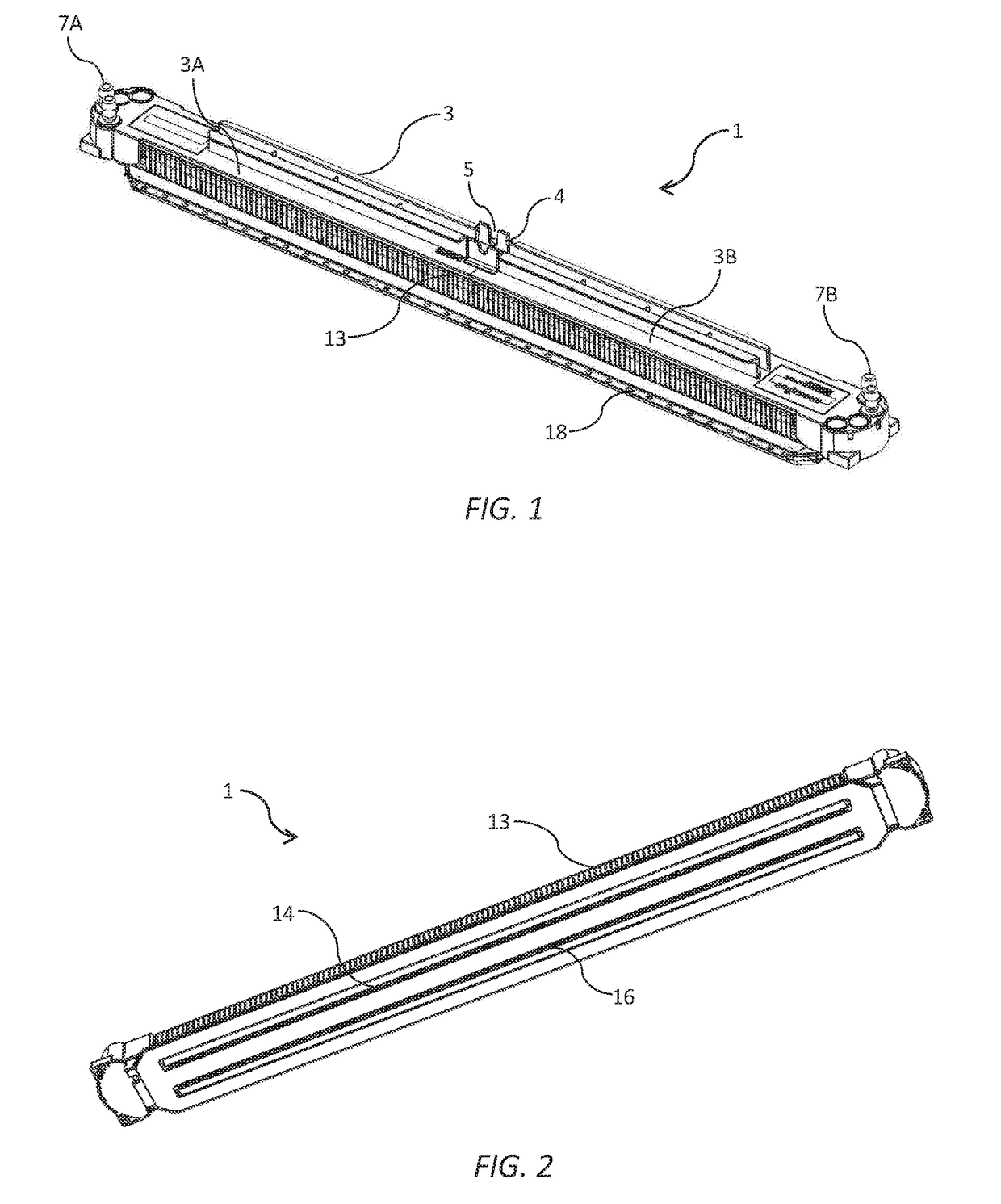

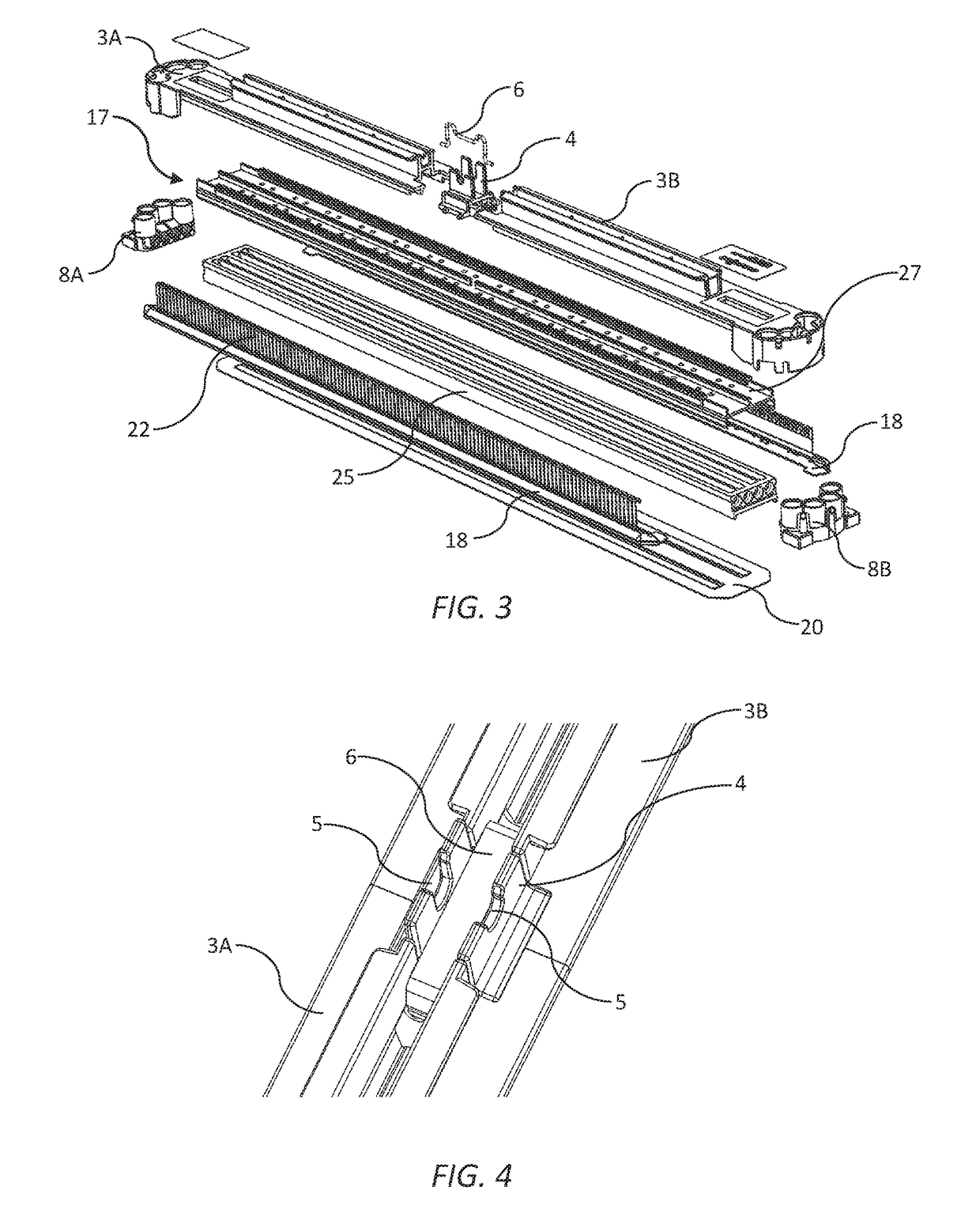

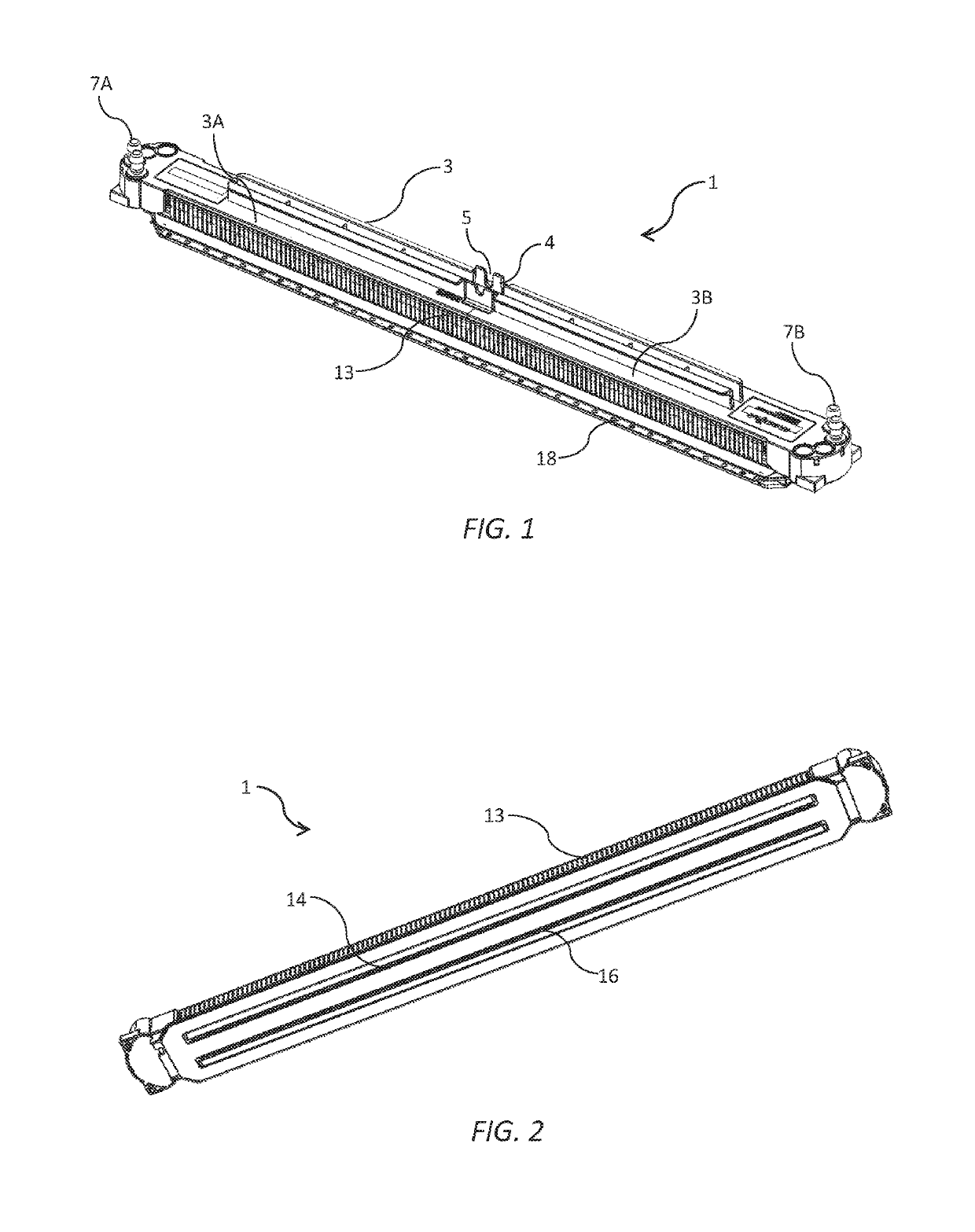

Inkjet printhead for full color pagewide printing

ActiveUS20180222198A1Increase distanceMinimize color mixingInking apparatusPower drive mechanismsEngineeringMechanical engineering

Owner:MEMJET TECH LTD

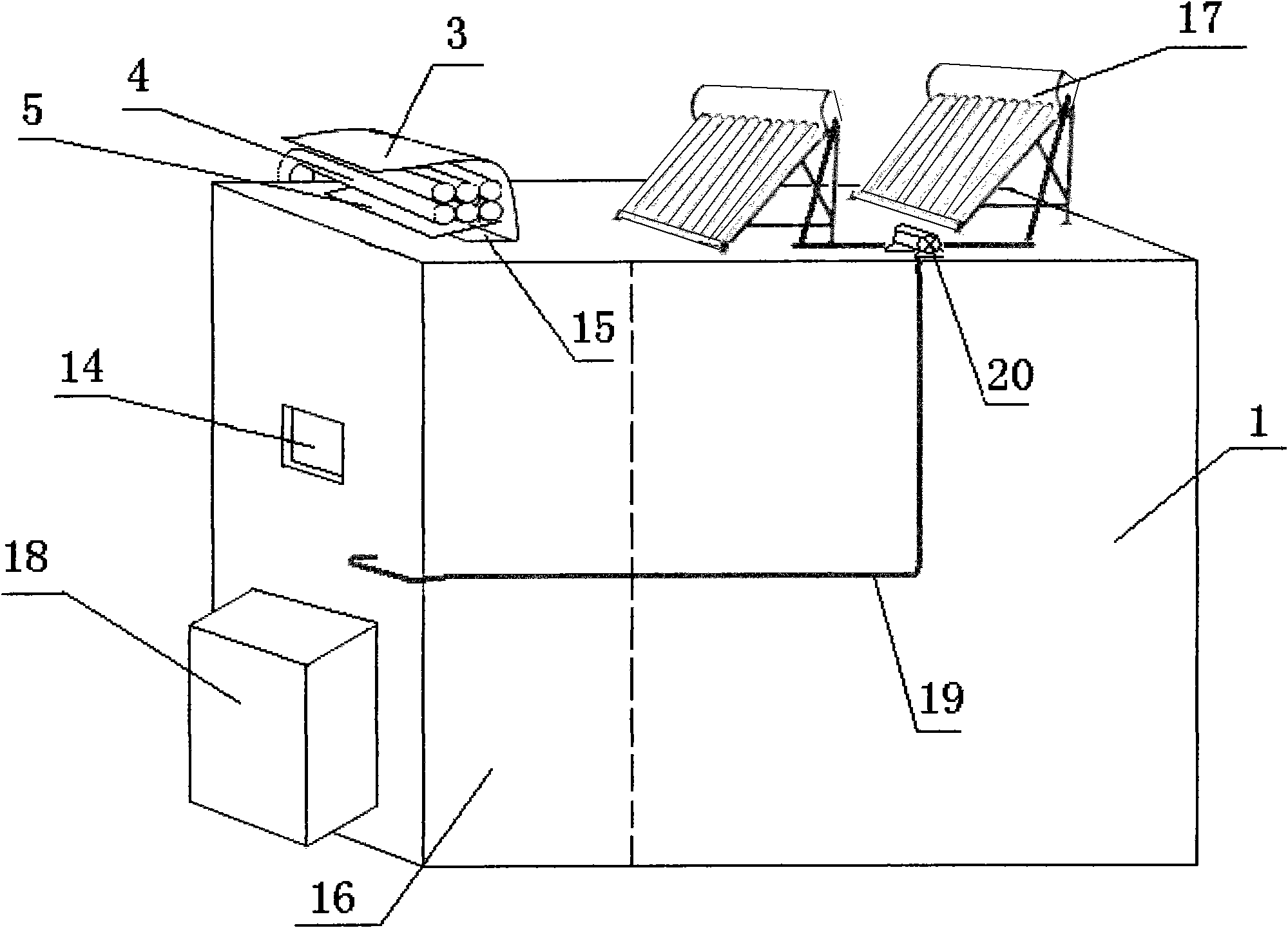

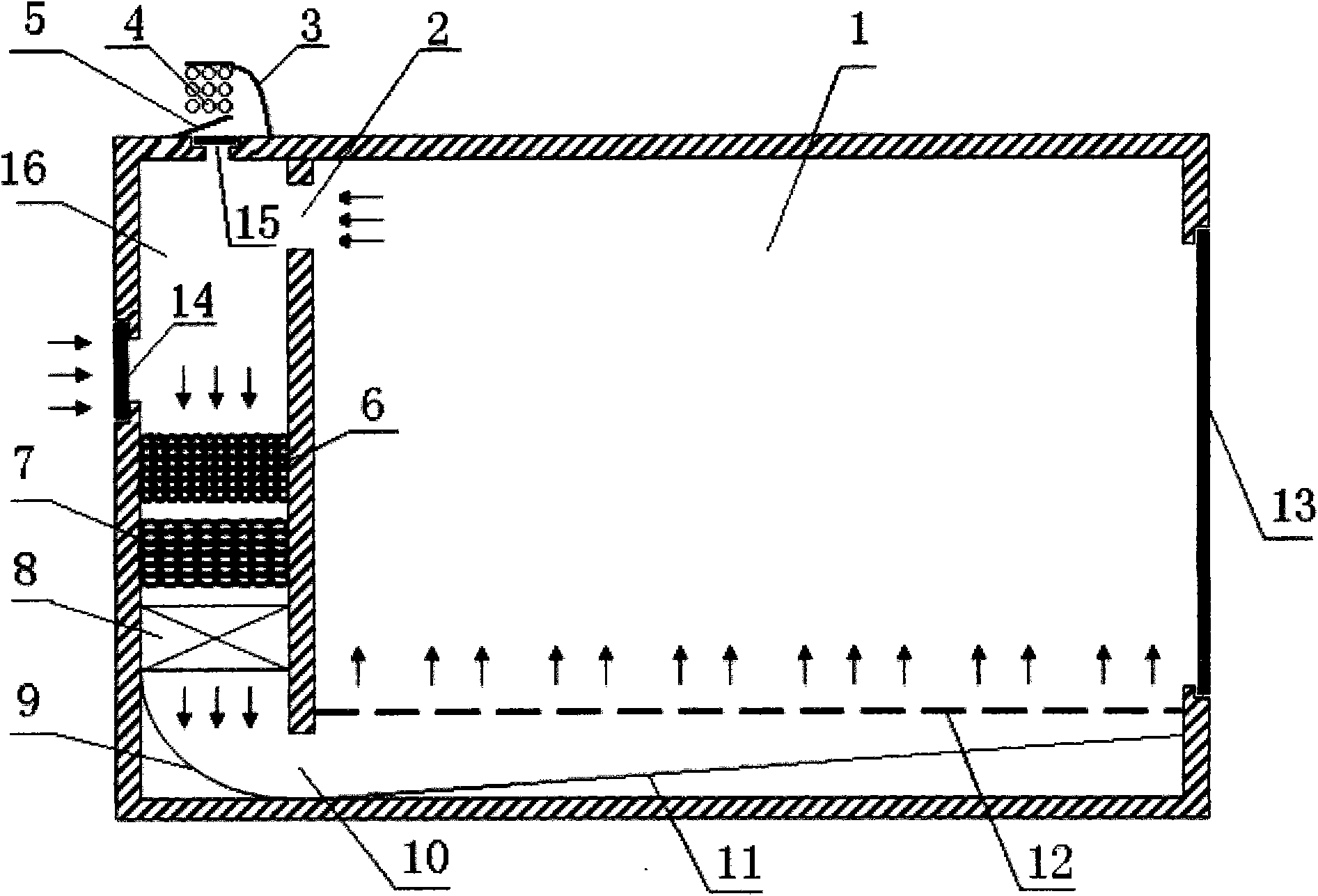

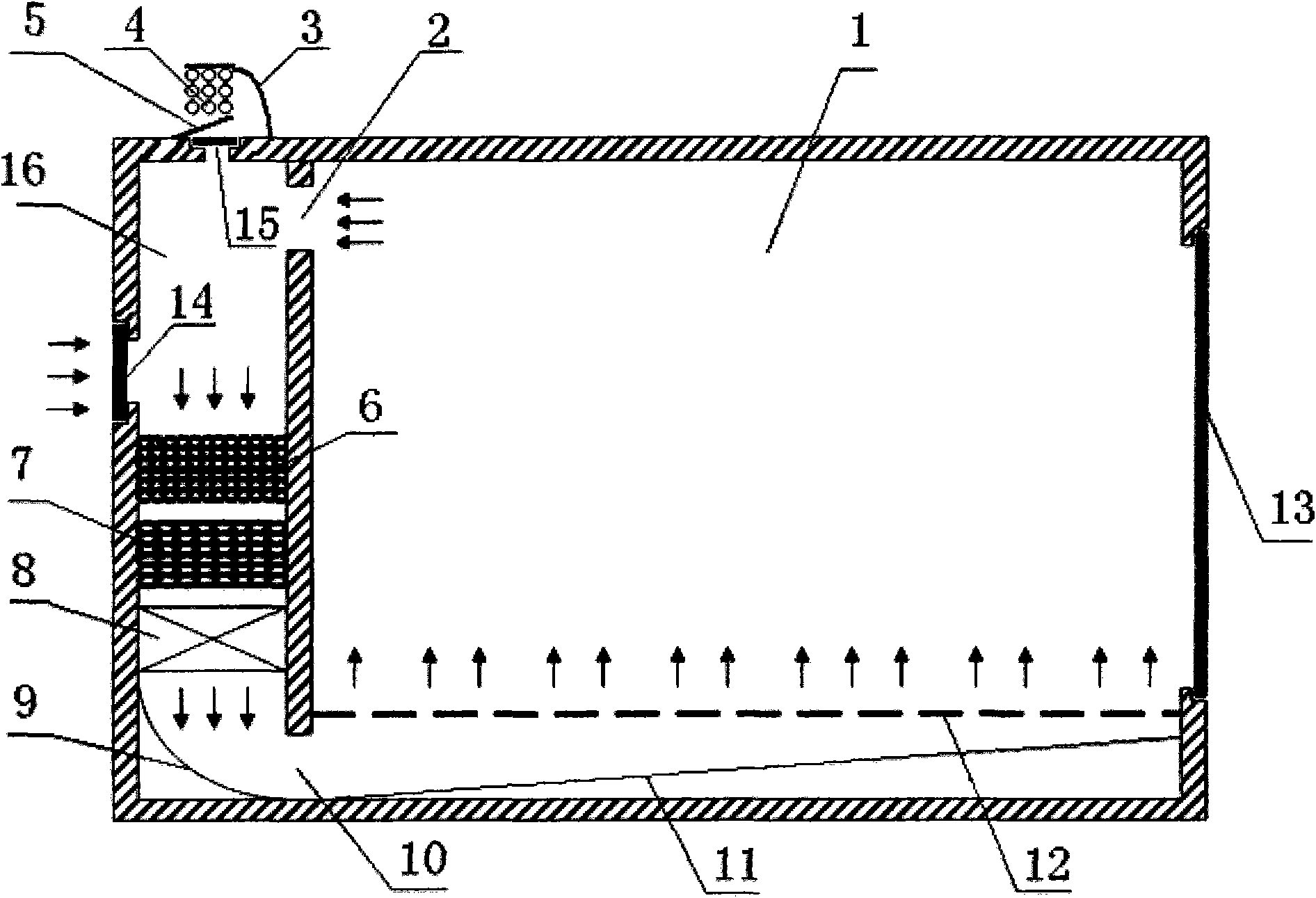

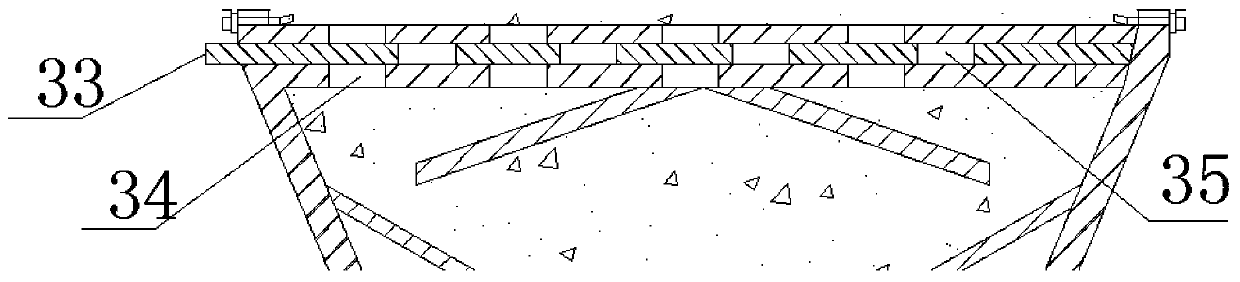

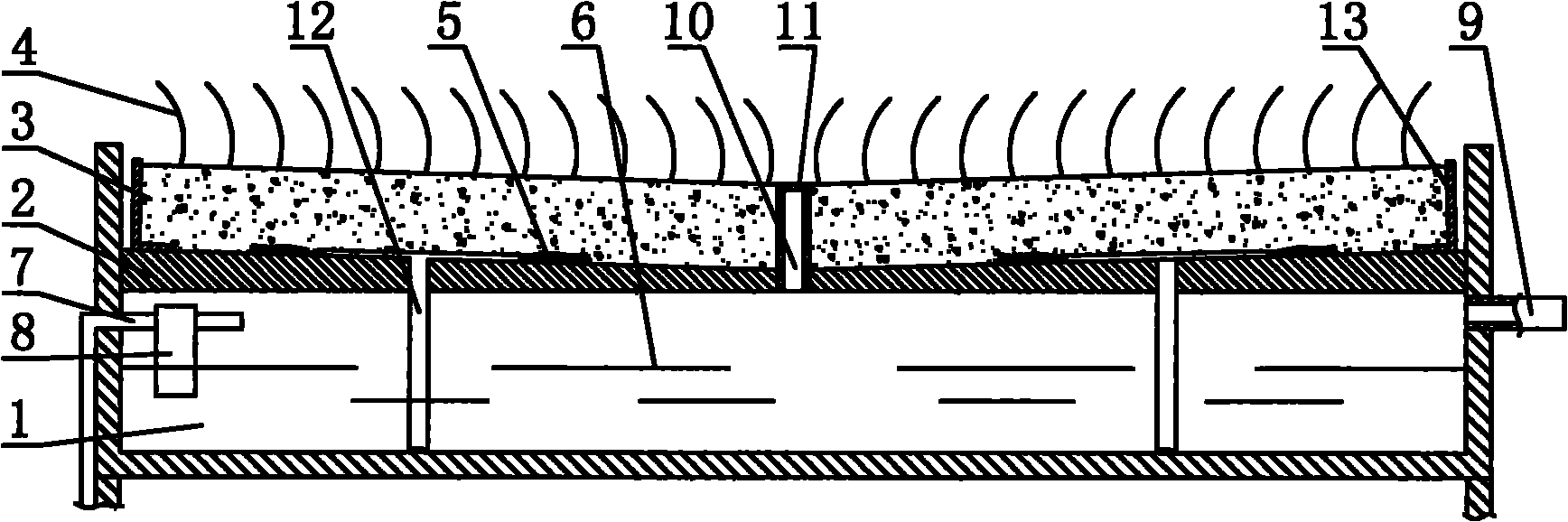

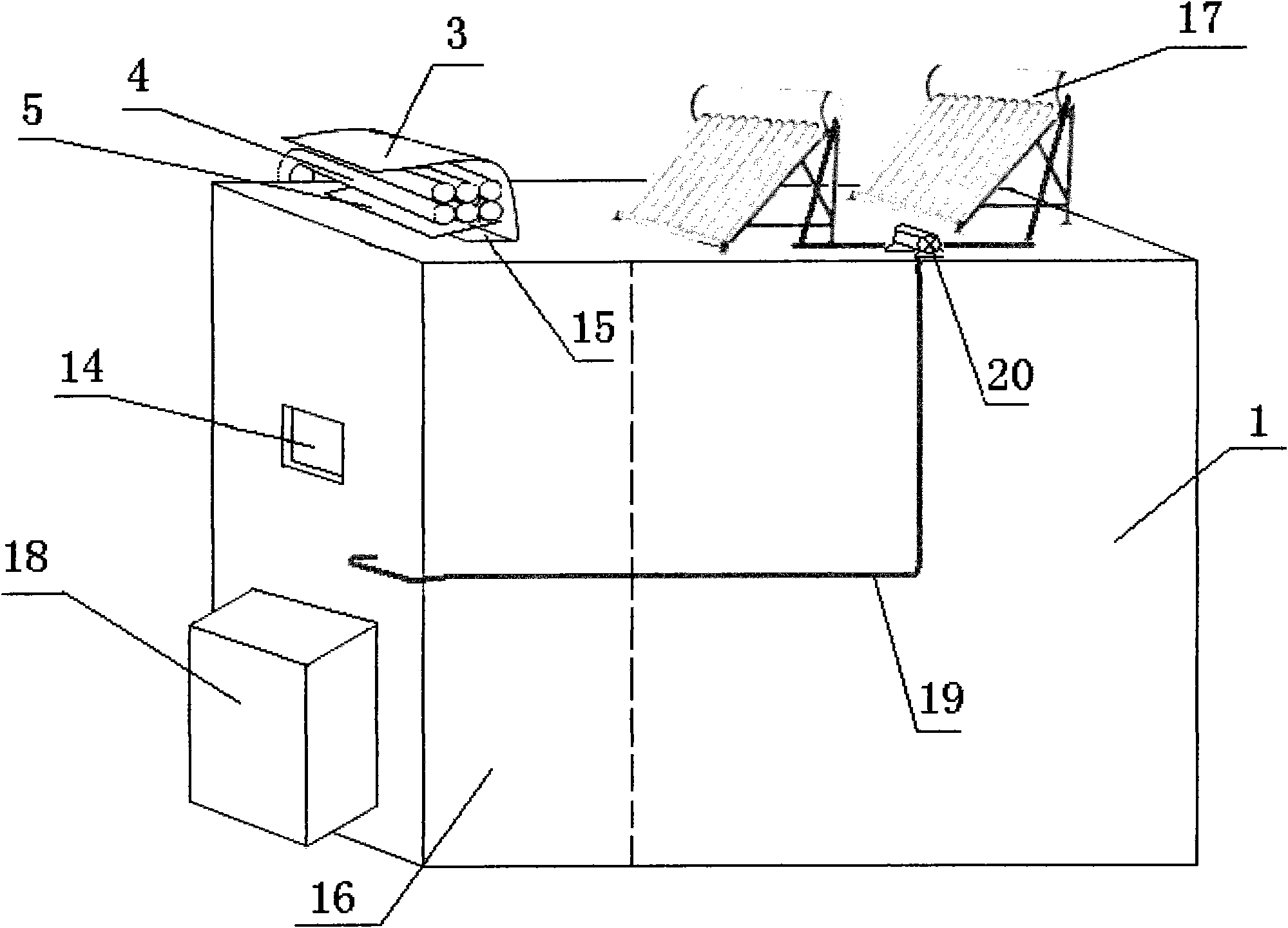

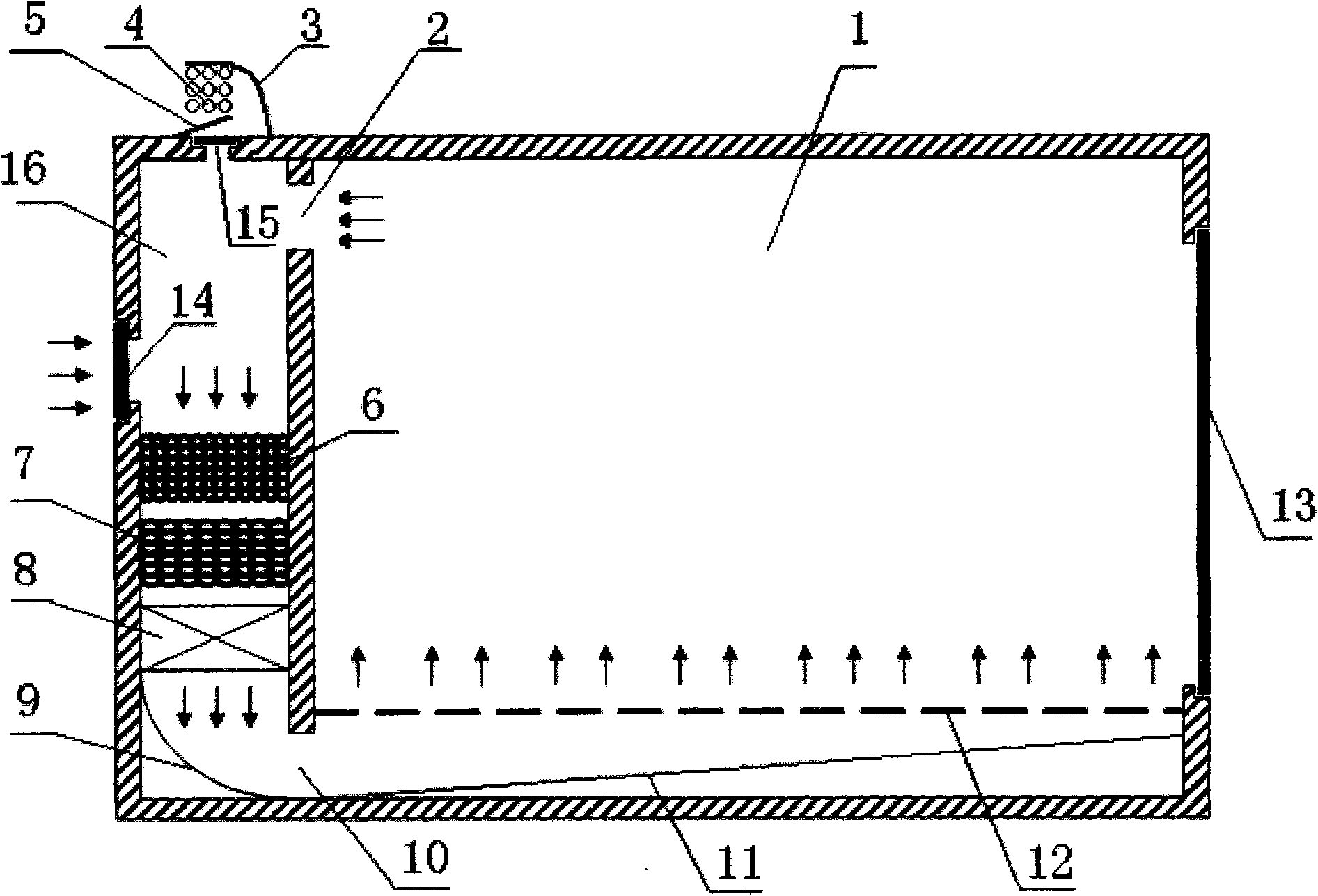

Tobacco curing barn taking air source heat pump as heat source

InactiveCN101940358AReduce labor intensityEasy temperature adjustmentTobacco preparationBusiness efficiencyHigh energy

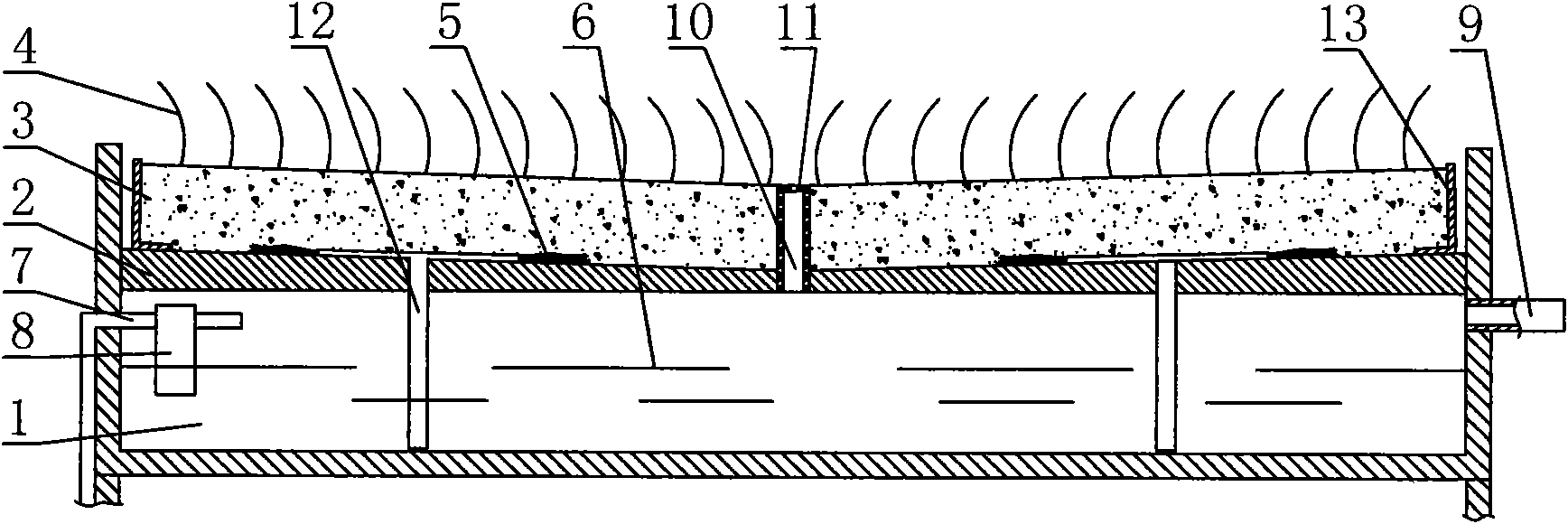

The invention discloses a tobacco curing barn taking an air source heat pump as a heat source, which comprises a heating chamber with a fresh air opening, and a drying chamber with temperature and humidity probes. A dehumidifying opening is reserved above the curing barn. The tobacco curing barn further comprises the air source heat pump and a condenser fan. The ratio of the heat exchange area ofa condenser to the input power of a compressor is numerically 7 to 12 m<2> / kw. The condenser and the suction type air supply fan thereof are arranged in the heating chamber. The drying chamber and / orthe heating chamber are / is provided with a heat preservation layer. By taking the air source heat pump and solar energy as the novel heat sources, the tobacco curing barn of the invention has the characteristics of energy saving, normal and stable running of a system, high energy efficiency ratio, convenient operation, capability of providing hot air at relatively higher temperature and greatly expanding the application range of the air source heat pump and the solar energy, and positive role in saving energy sources and protecting the environment. Due to the large-scale popularization and utilization of the technology in tobacco production areas, the sulfur content of the air, soil and tobacco can be reduced and the quality of the tobacco can be improved.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO +1

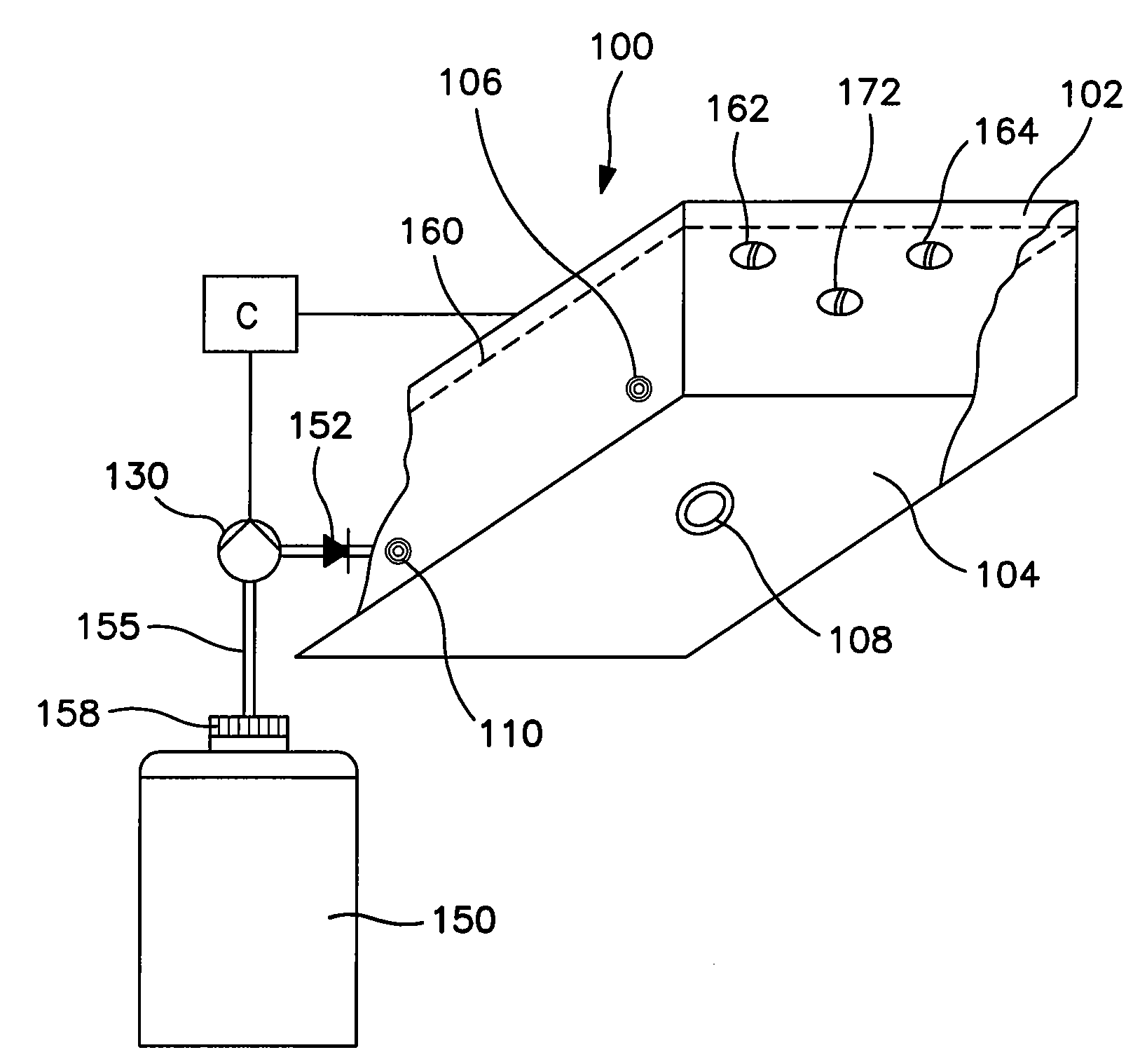

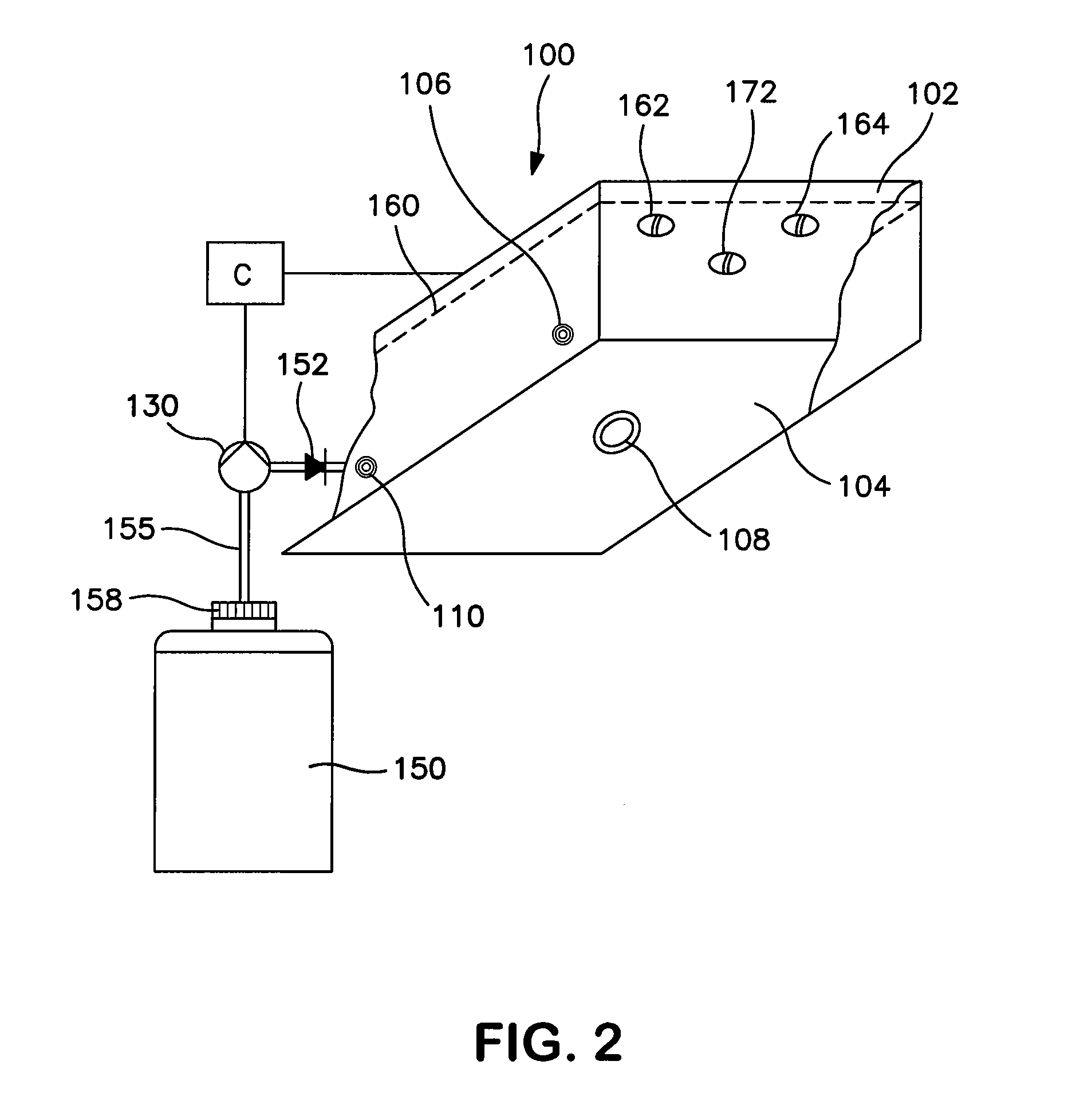

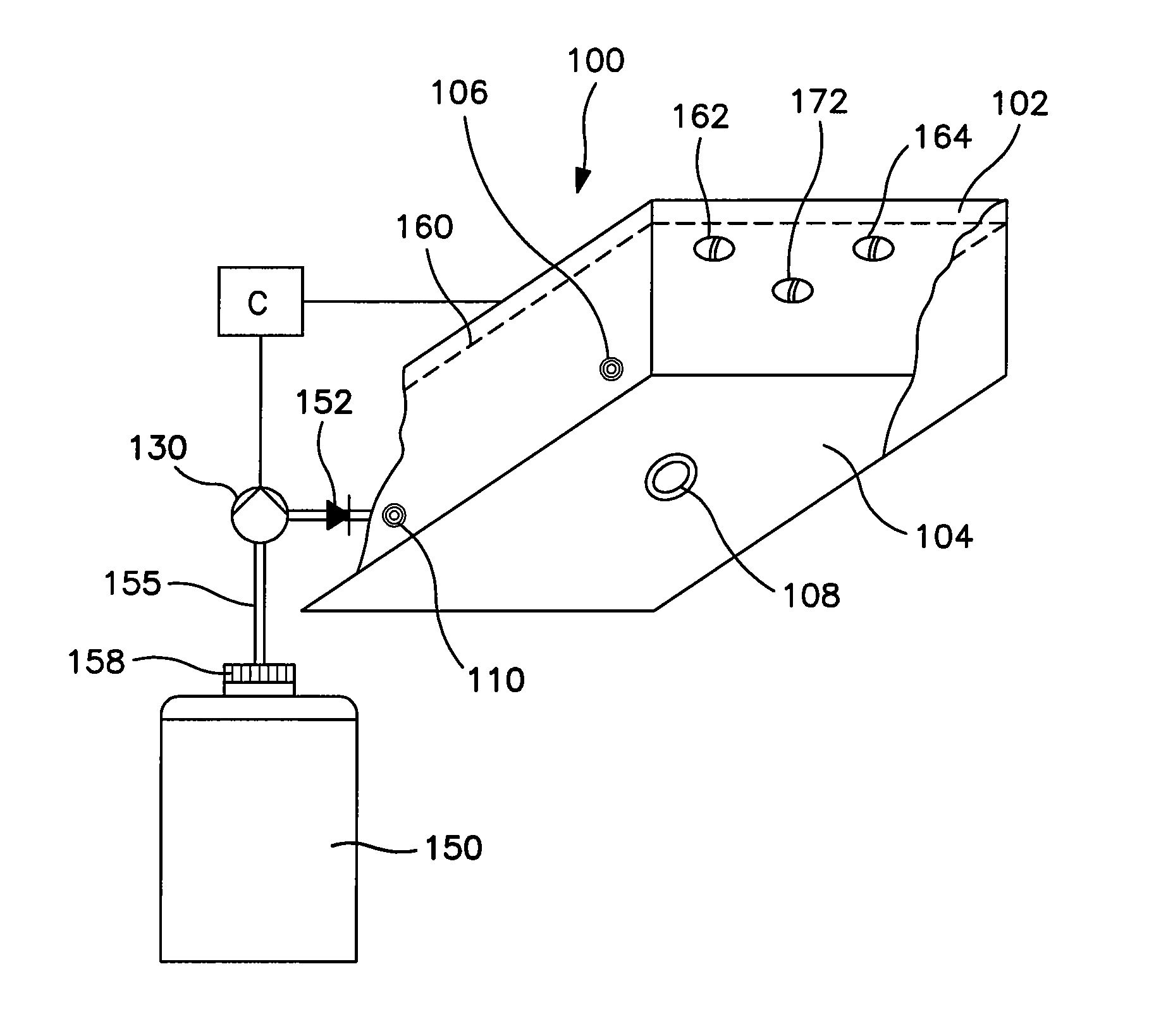

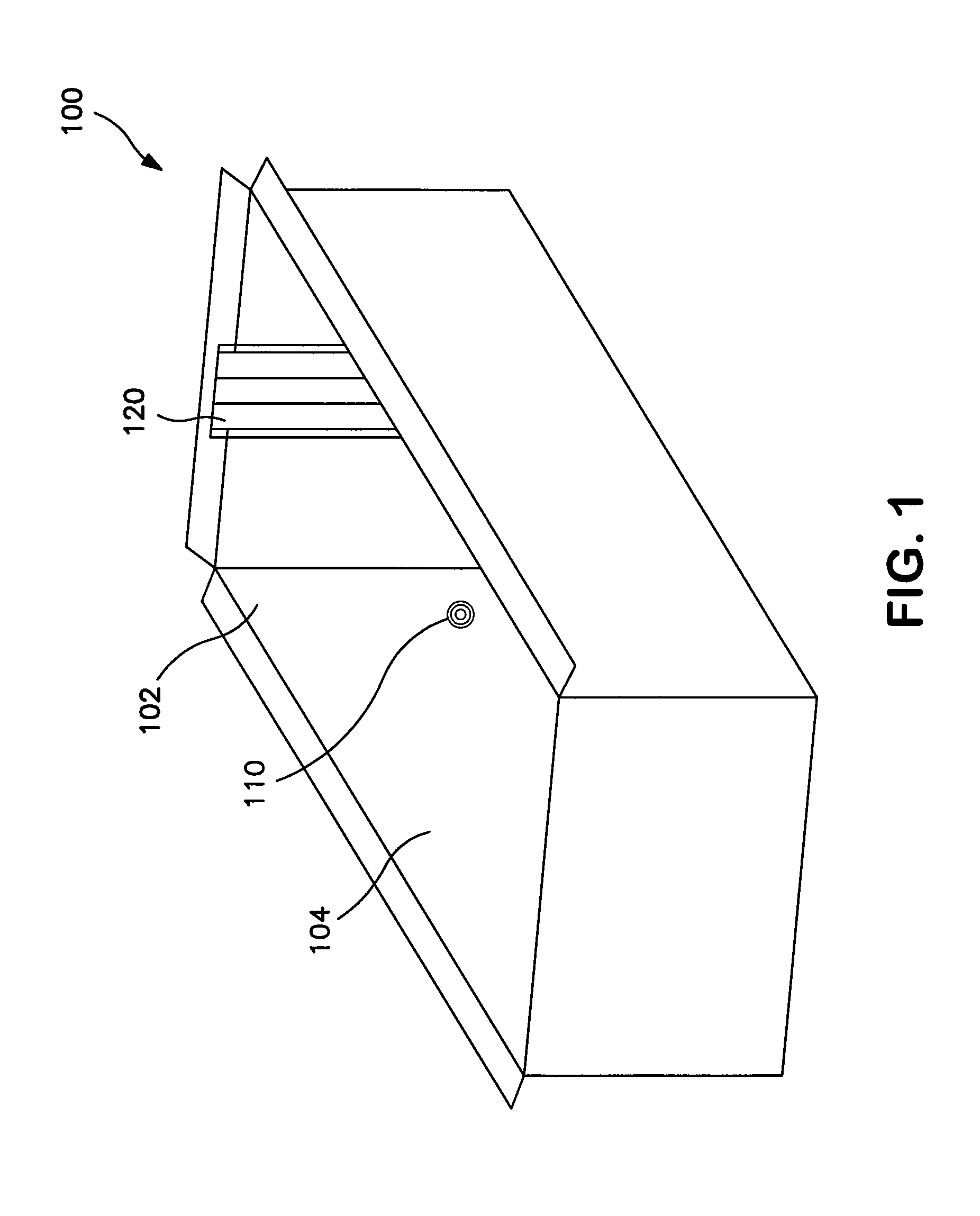

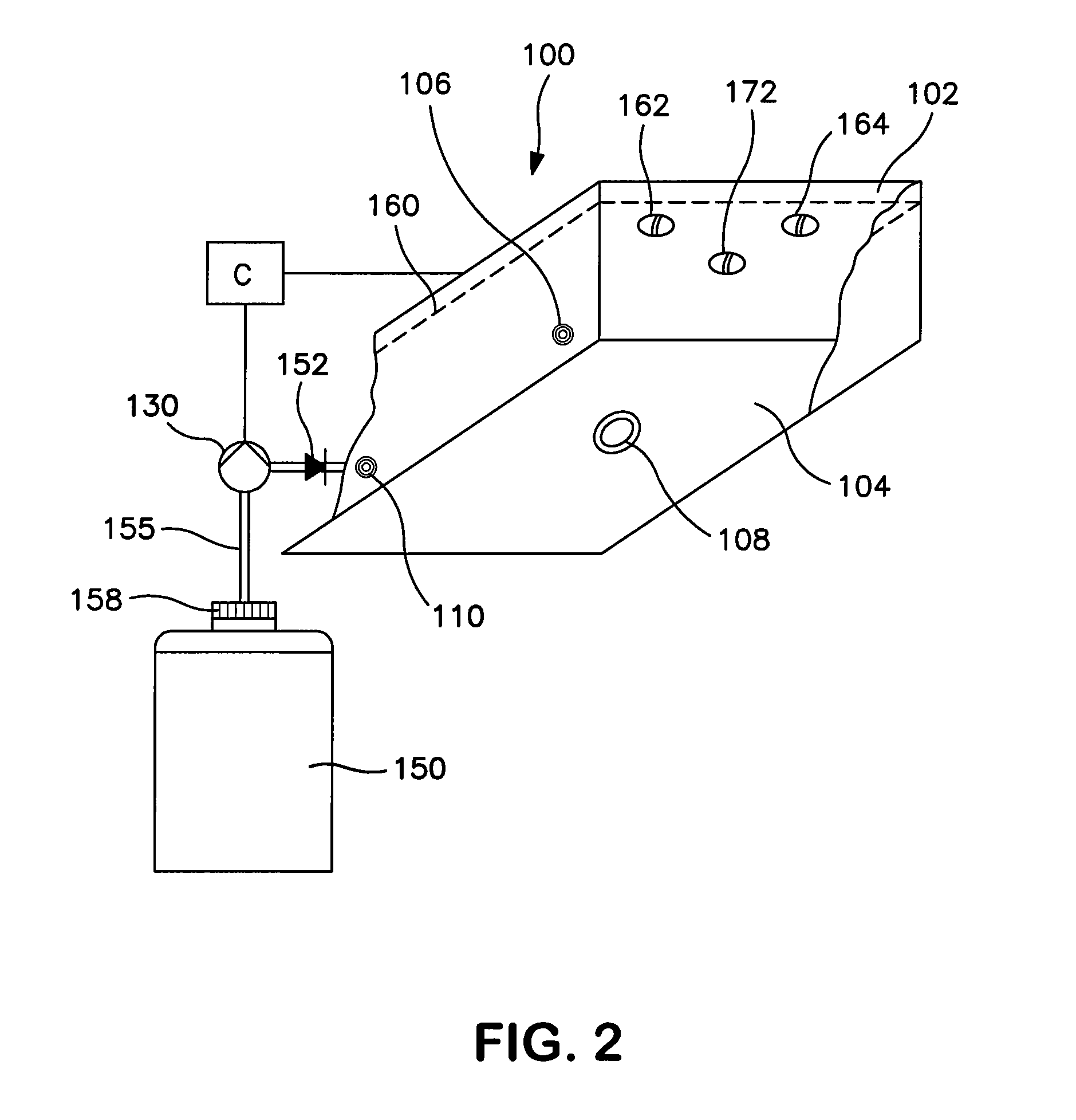

Automatic cooking medium level control systems and methods

ActiveUS20080121115A1Insufficient levelPrevents overcyclingBread-toastersDeep fat fryersControl systemProcess engineering

An automatic cooking medium level control system for a cooking apparatus, e.g., a fryer, may include a cooking vessel having a first temperature sensor at a first level of the cooking vessel and a second temperature sensor at a second level of the cooking vessel. A reservoir holding a cooking medium, such as cooking oil, may be in fluid communication with the cooking vessel. A controller may monitor temperature data from the first and second temperature sensors to determine whether the level of cooking oil in the cooking vessel has lowered. Upon determining that the cooking oil level has lowered, the controller may actuate a supply mechanism, such as a pump, which may be disposed on a fluid communication path between the reservoir and cooking vessel, which may enable the introduction of cooking medium from the reservoir to the to the cooking vessel.

Owner:HENNY PENNY

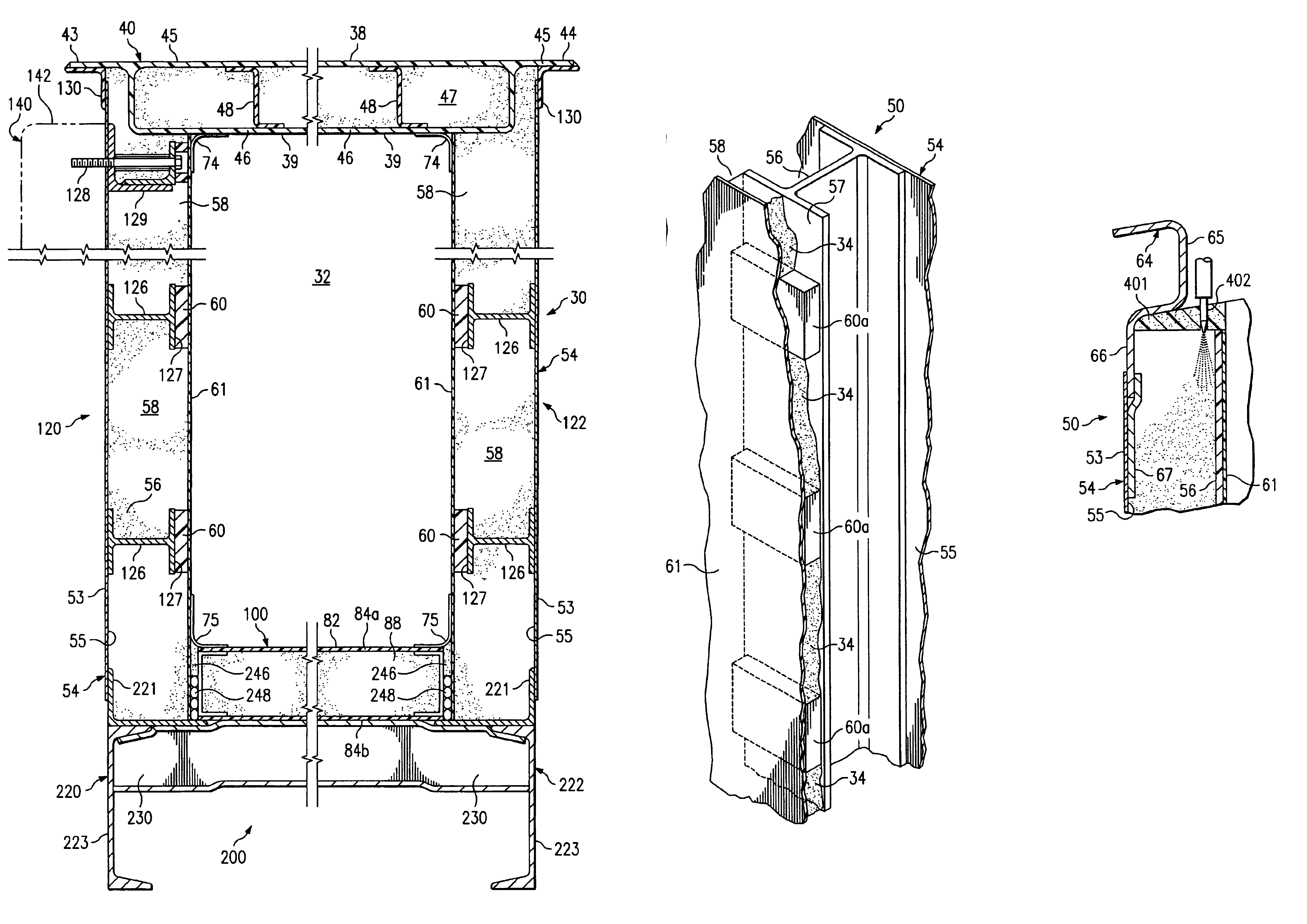

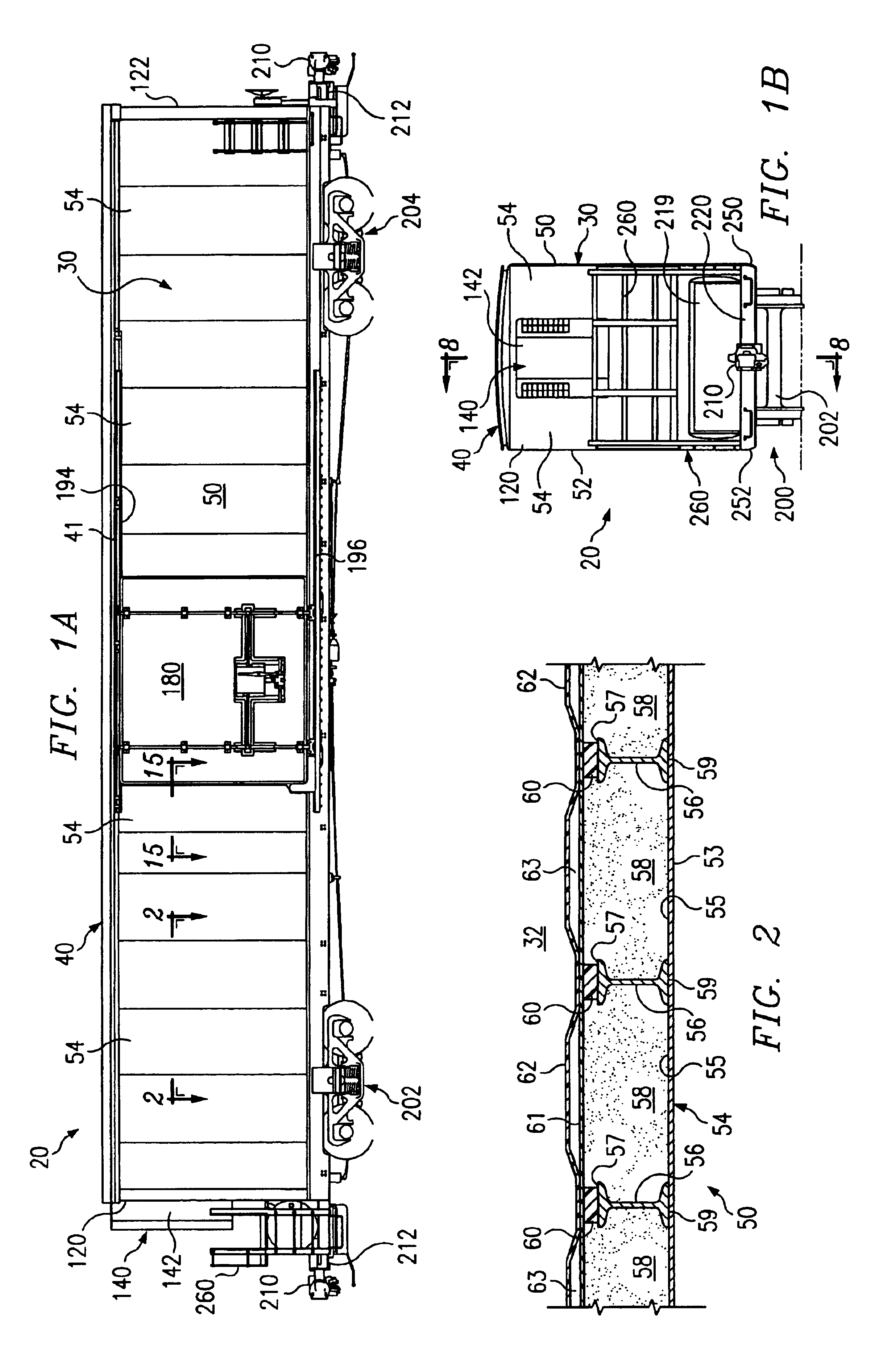

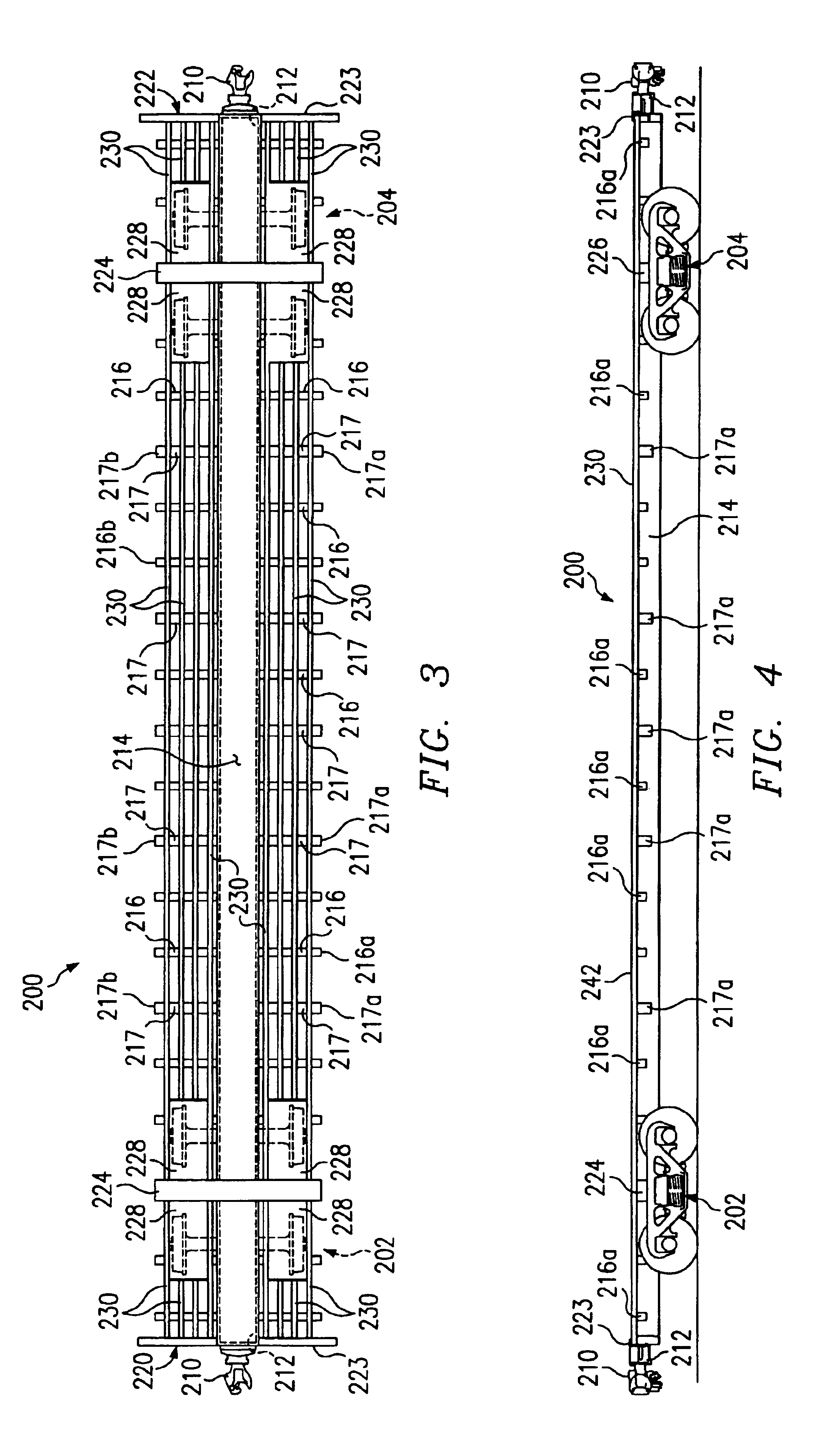

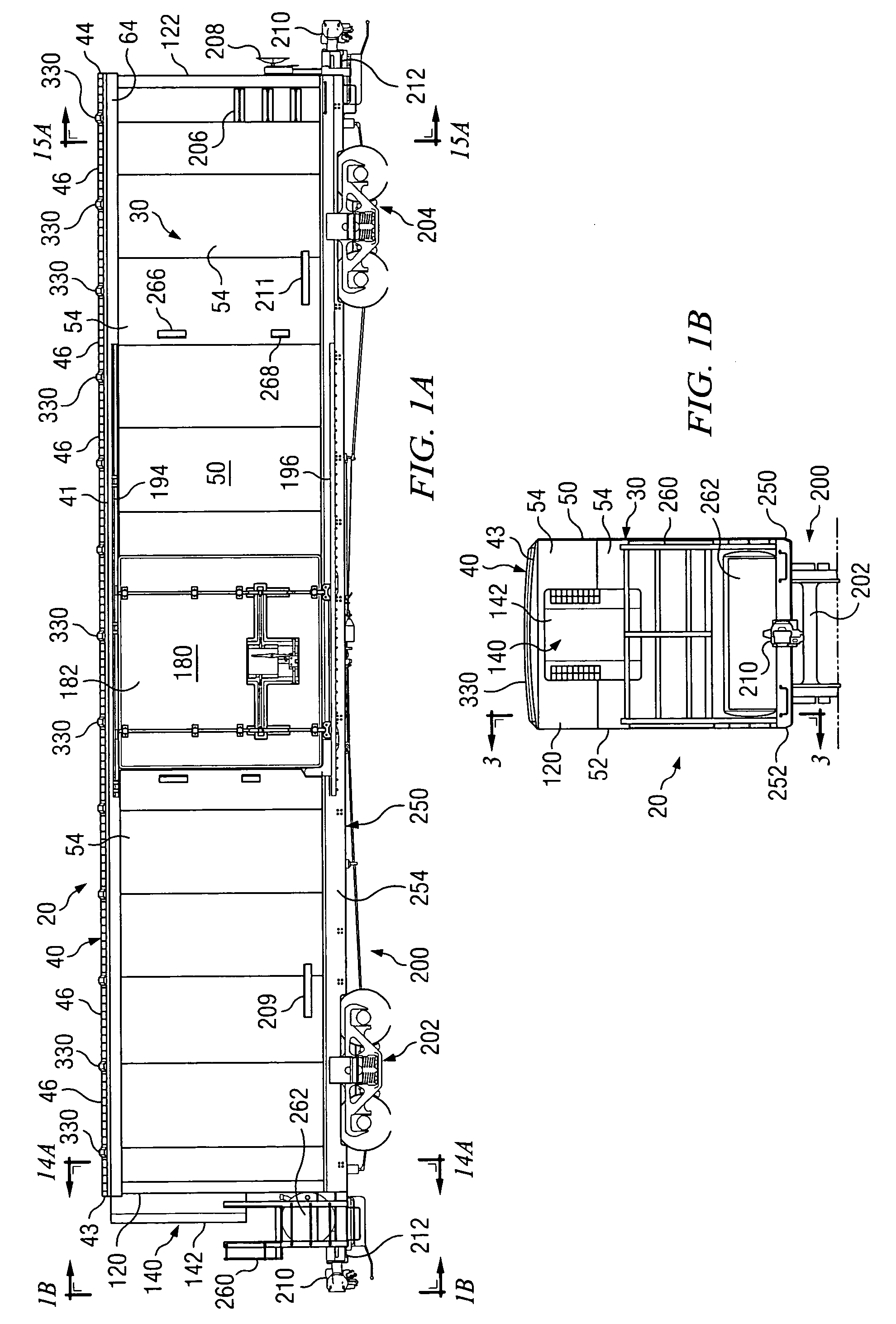

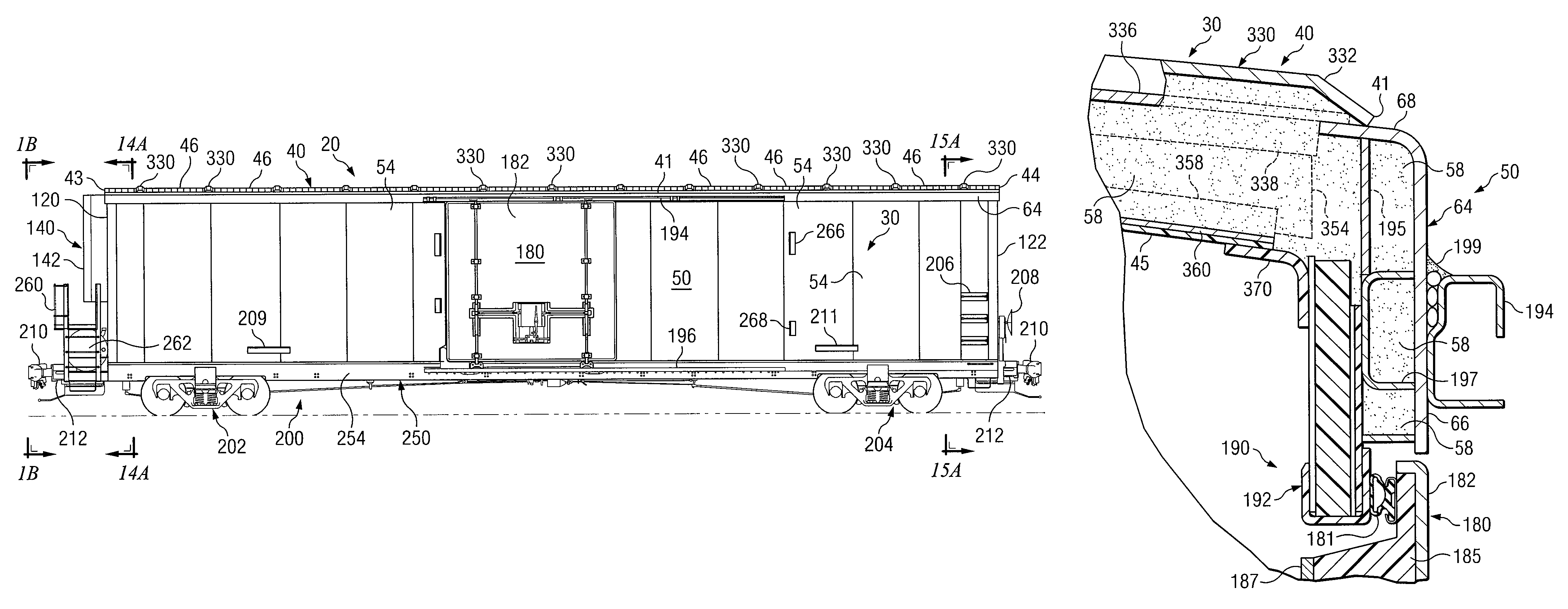

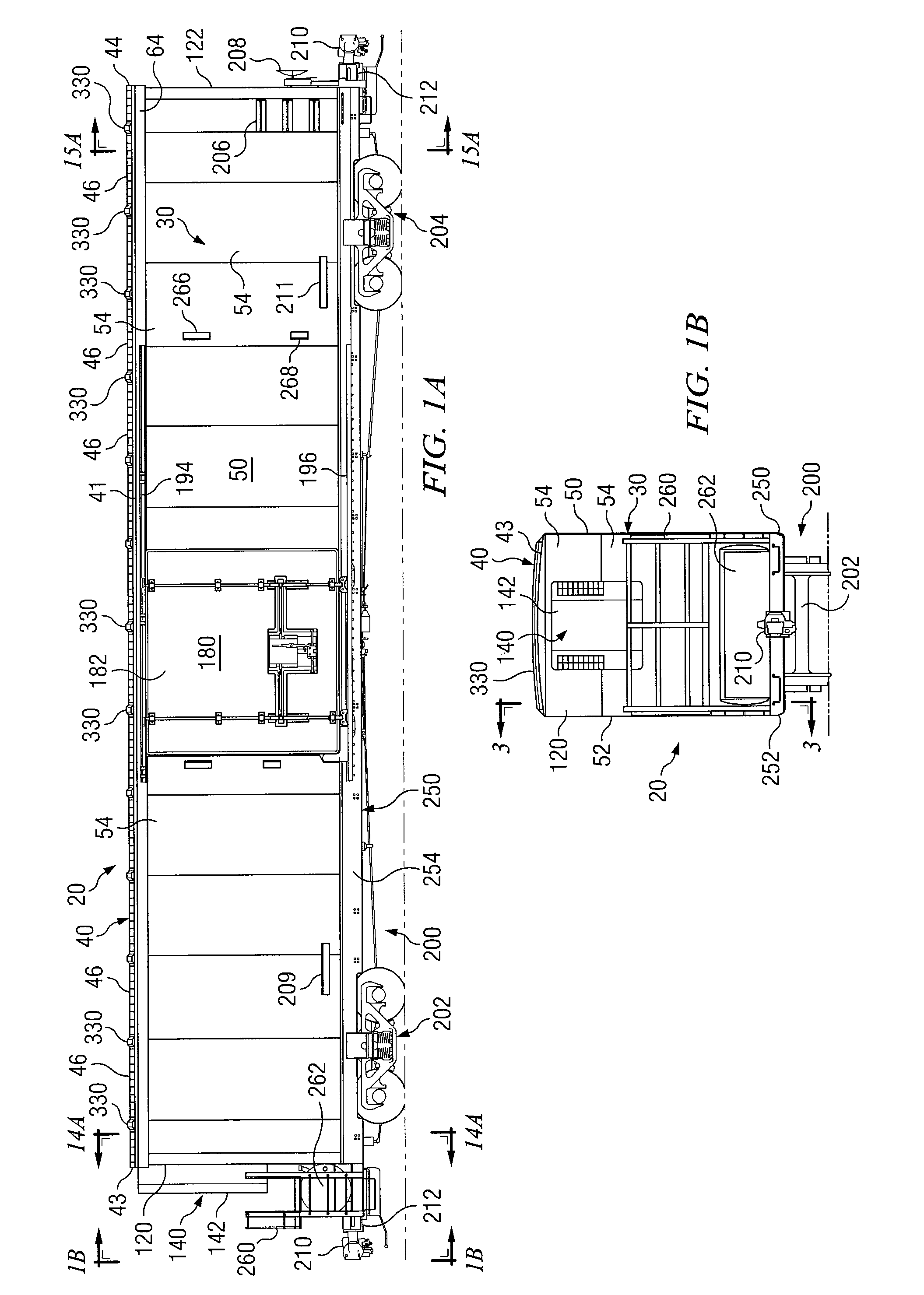

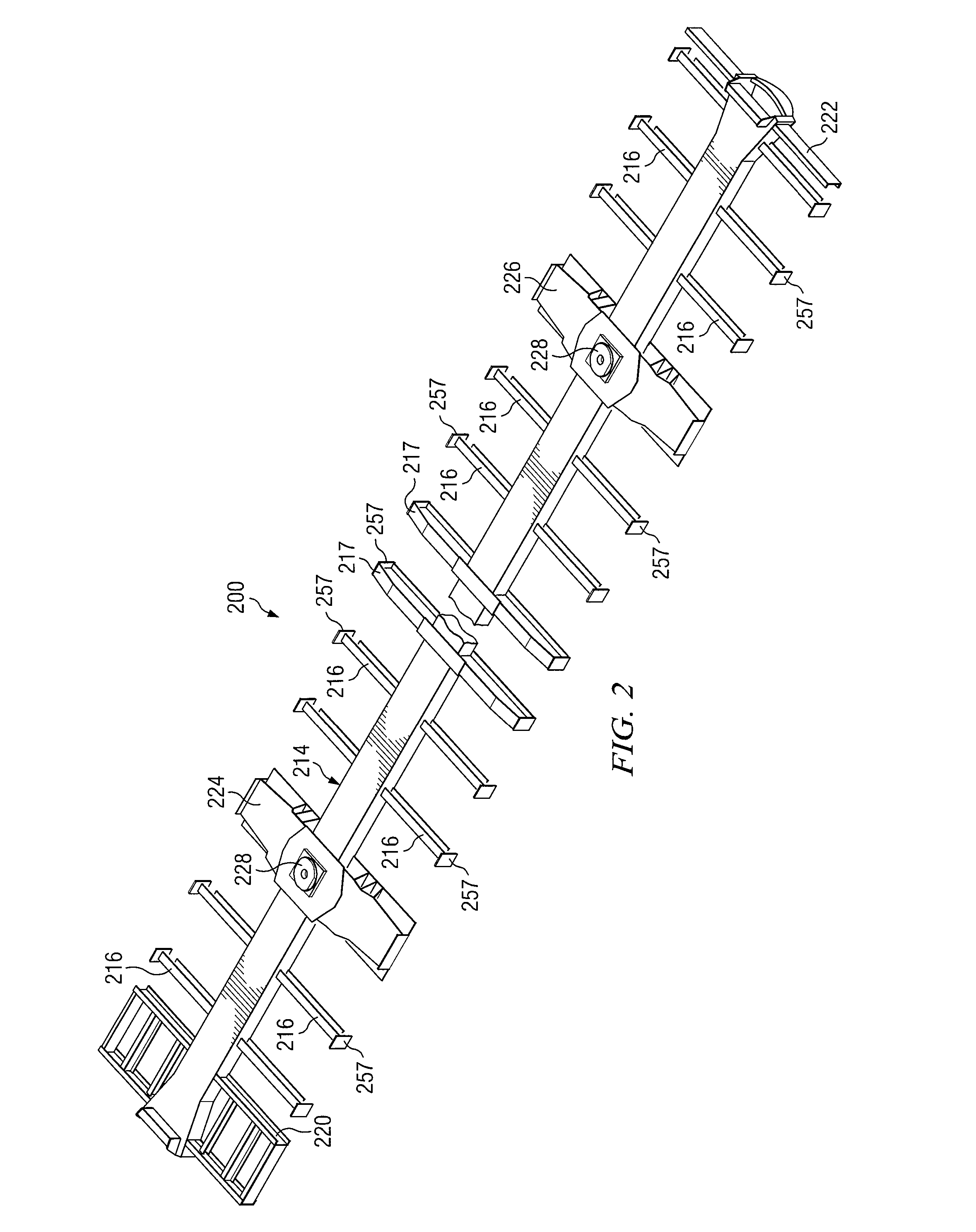

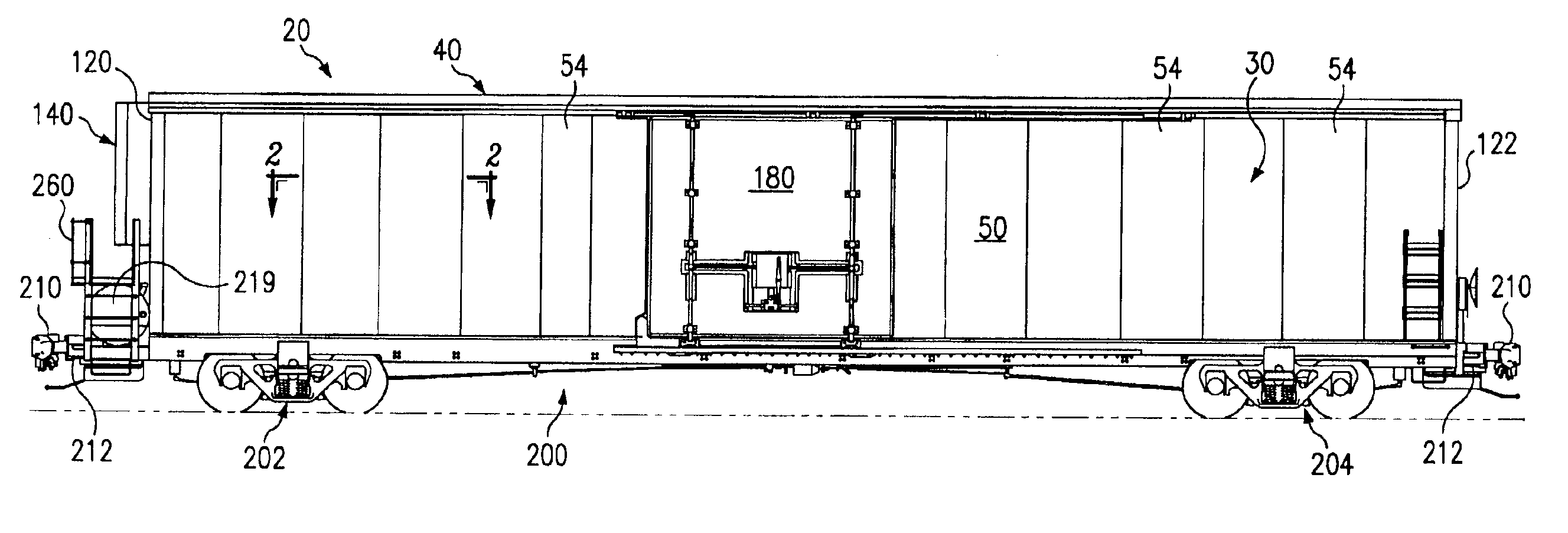

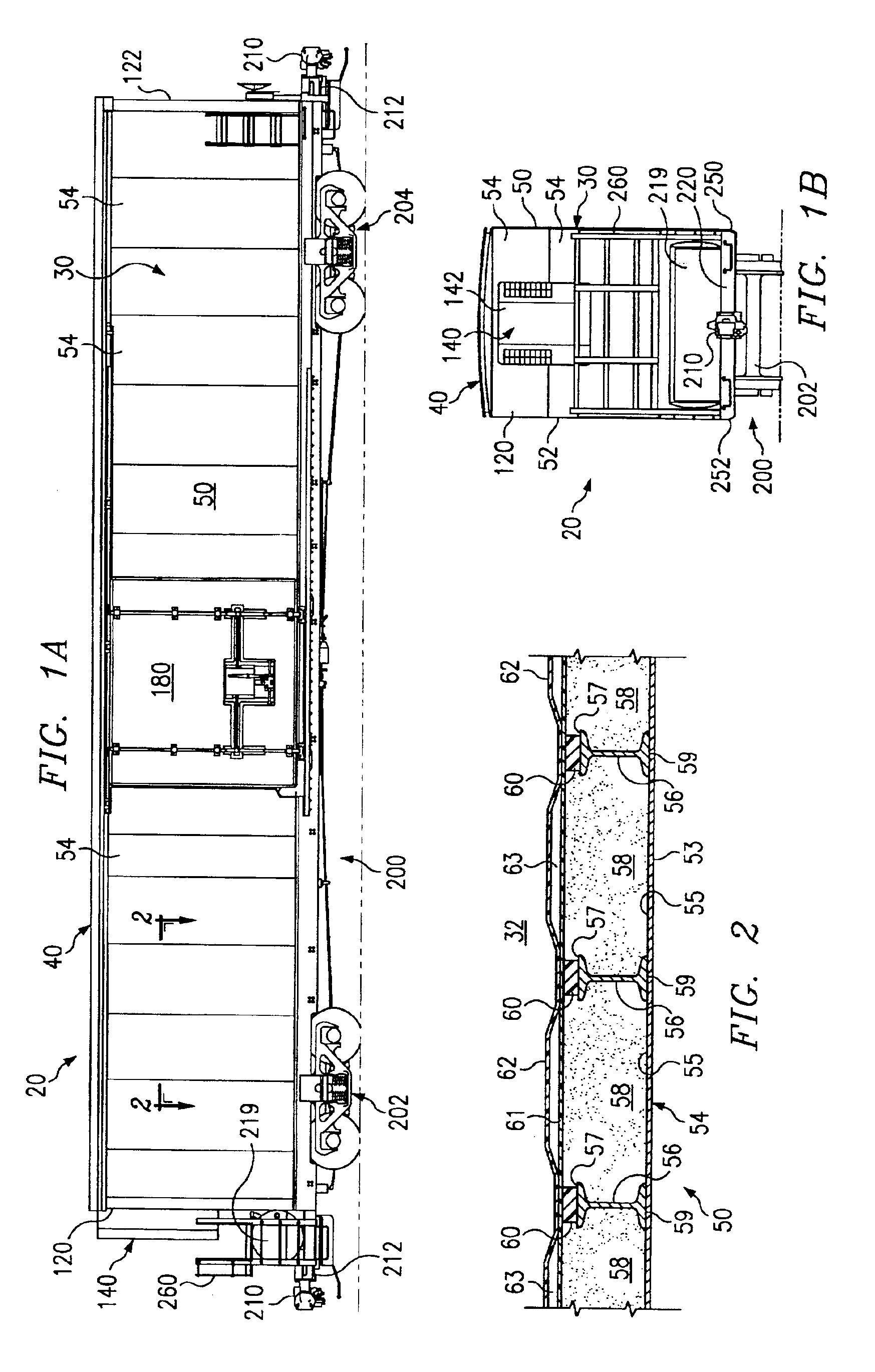

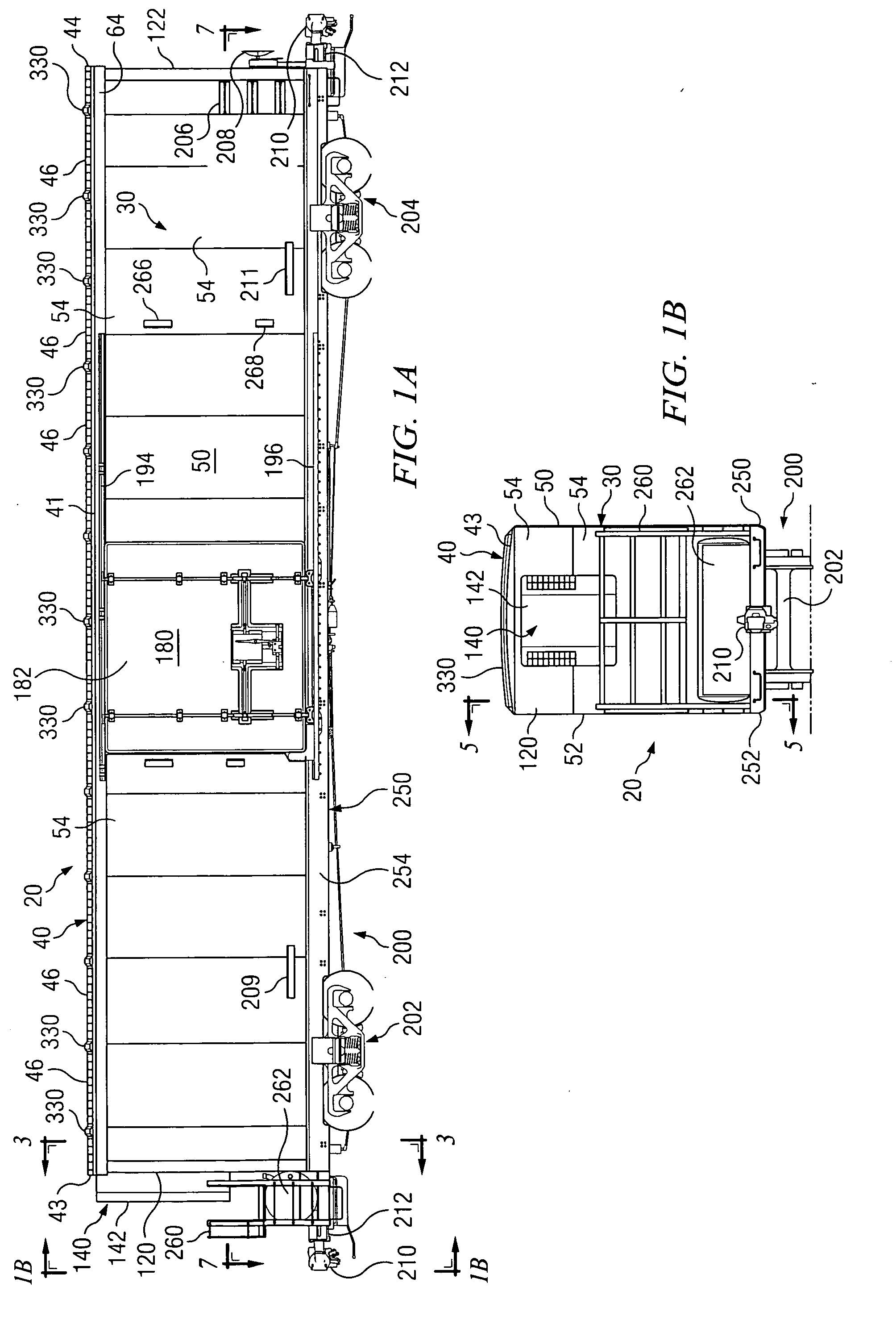

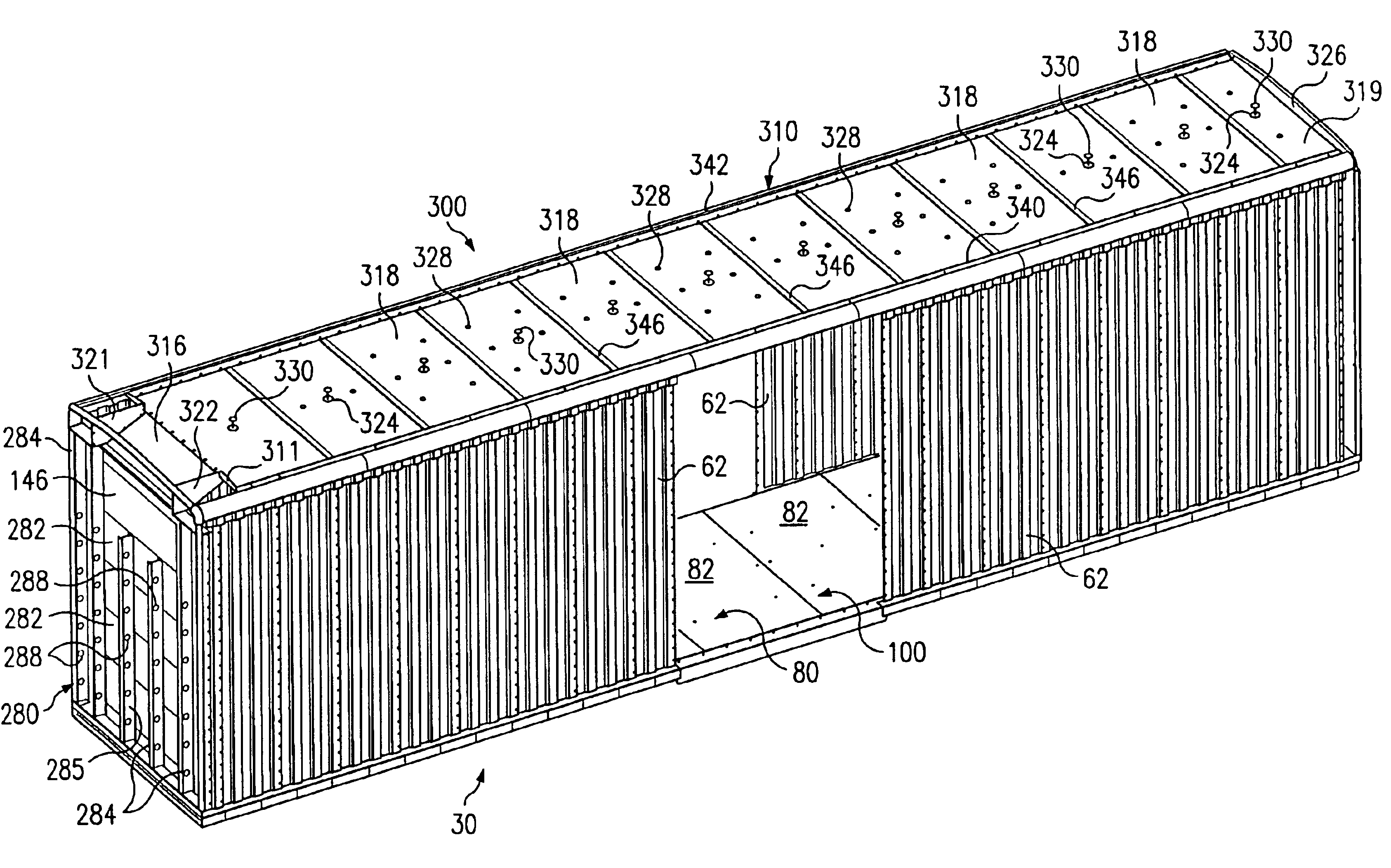

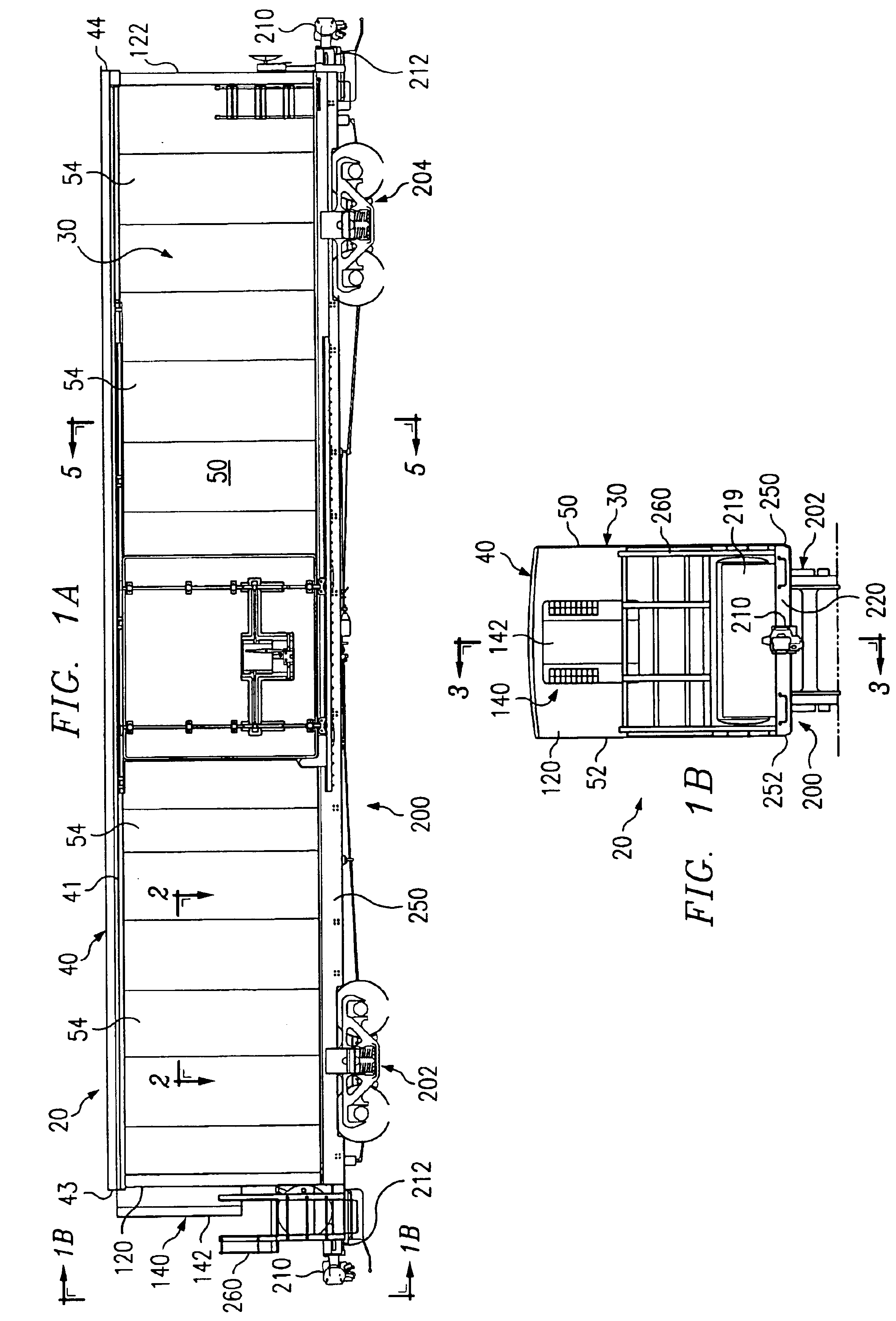

Temperature controlled railway car

A composite box structure assembled on and securely attached to a railway car underframe to form a temperature controlled railway car or on insulated boxcar. The composite box structure defined in part by an exterior metal surface, interior side stakes and at least one layer of fiber reinforced plastic attached to the side stakes. Foam insulation may be disposed between the side stakes, the exterior metal surface and the at least one layer of fiber reinforced plastic. The foam insulation provides improved resistance to heat transfer between the interior and the exterior of the composite box structure. An airflow management system may be incorporated into the composite box structure.

Owner:TRINITY IND INC

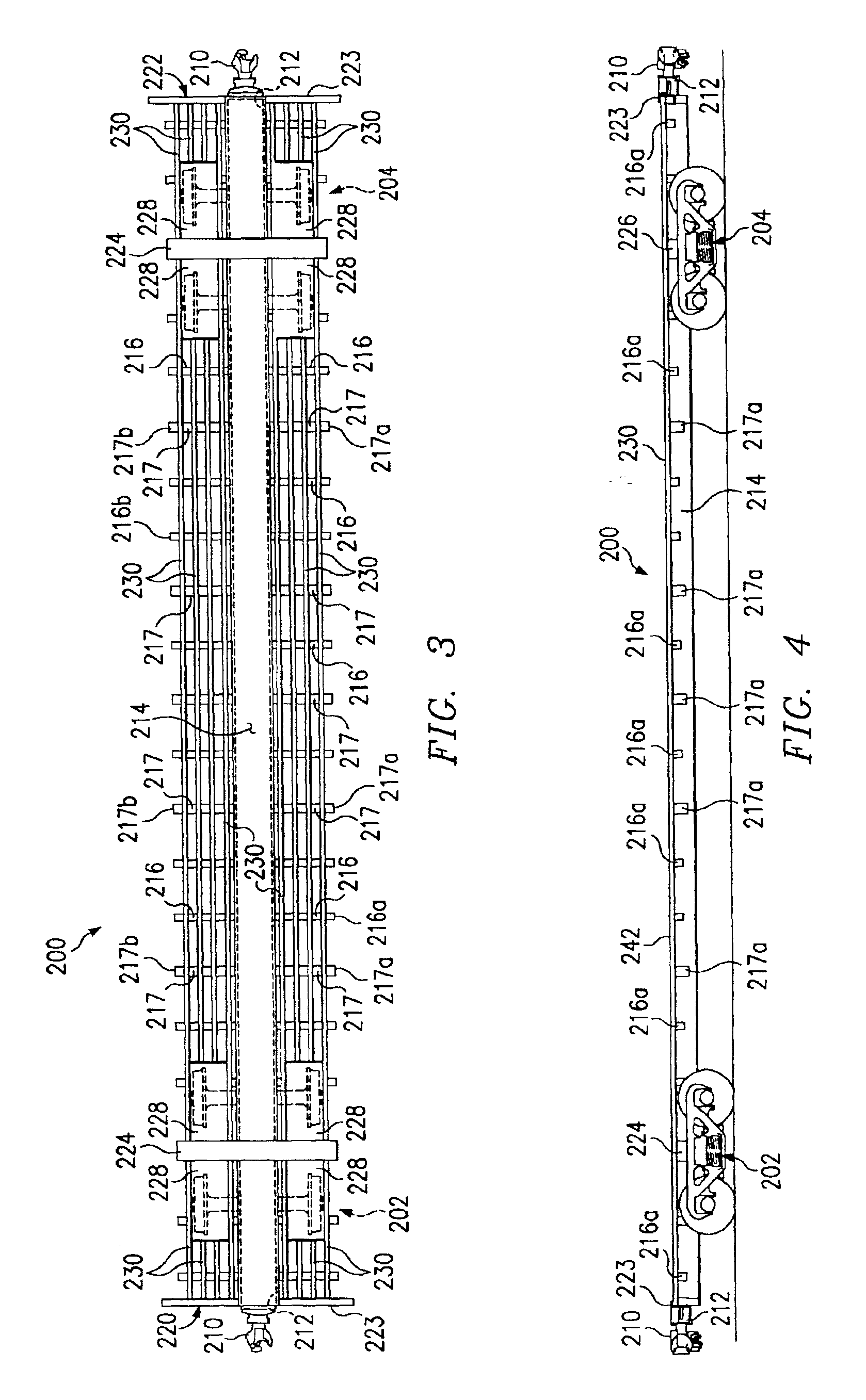

Temperature controlled railway car

InactiveUS7228805B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingFiberTemperature control

A composite box structure mounted on and attached to a railway car underframe to form a temperature controlled railway car. The composite box structure defined in part by an exterior metal surface, interior side stakes and at least one layer of fiber reinforced material attached to the side stakes. Insulating material may be disposed between the side stakes, the exterior metal surface and the at least one fiber reinforced layer of fiber reinforced material. The insulating materials provide resistance to heat transfer between the interior and the exterior of the composite box structure. A primary floor assembly and a secondary floor assembly may be mounted on the railway car underframe.

Owner:TRINITY IND INC

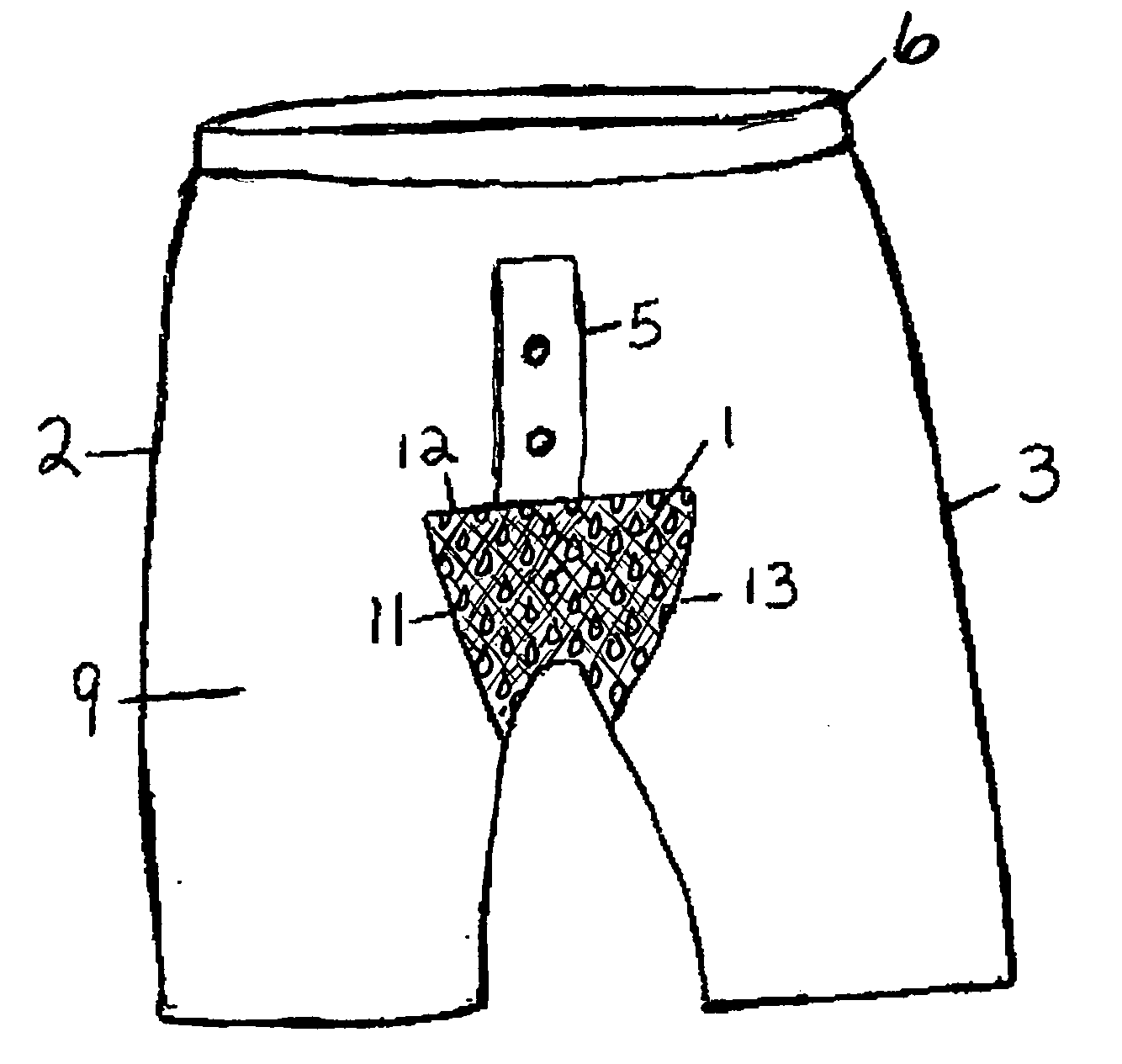

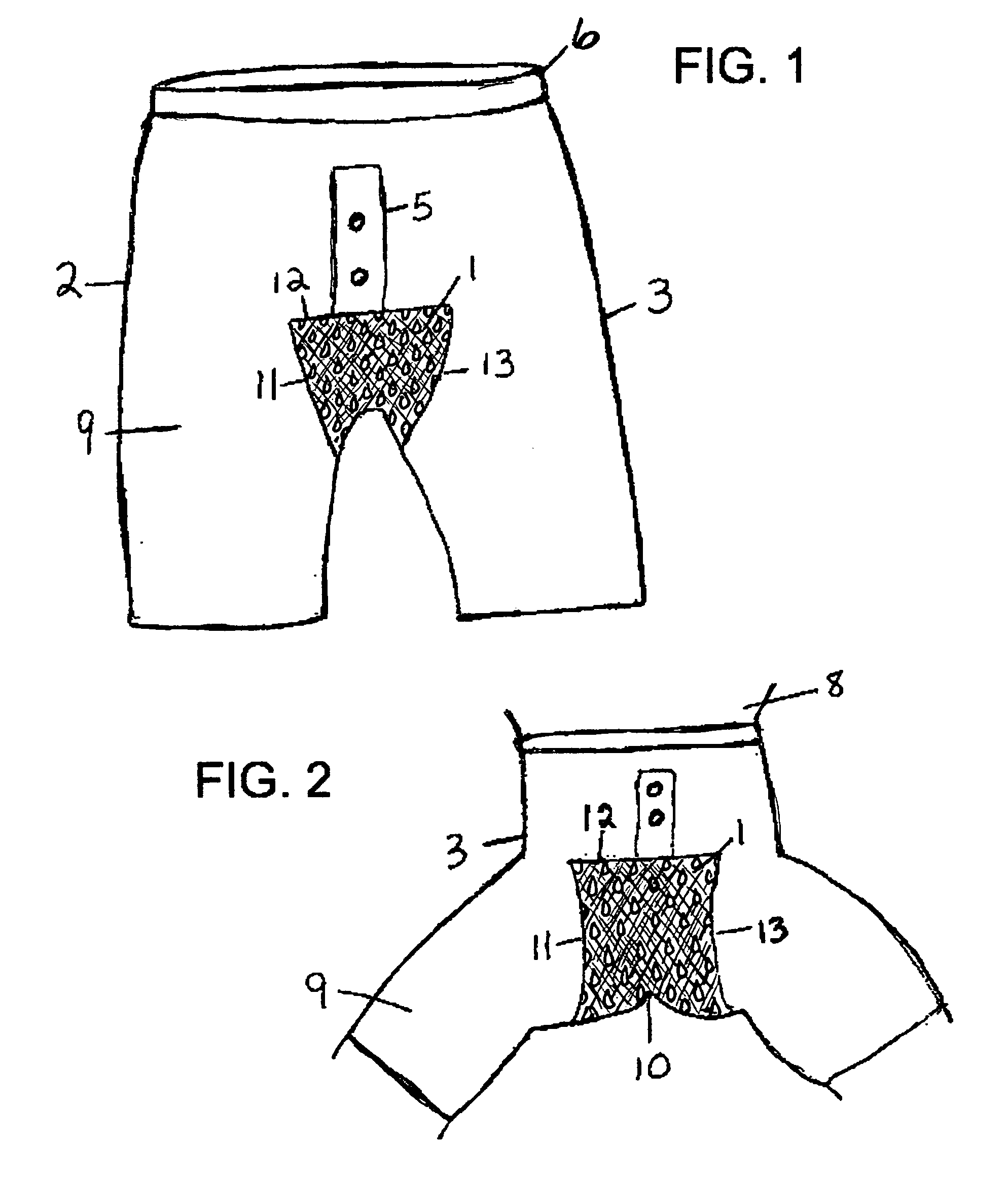

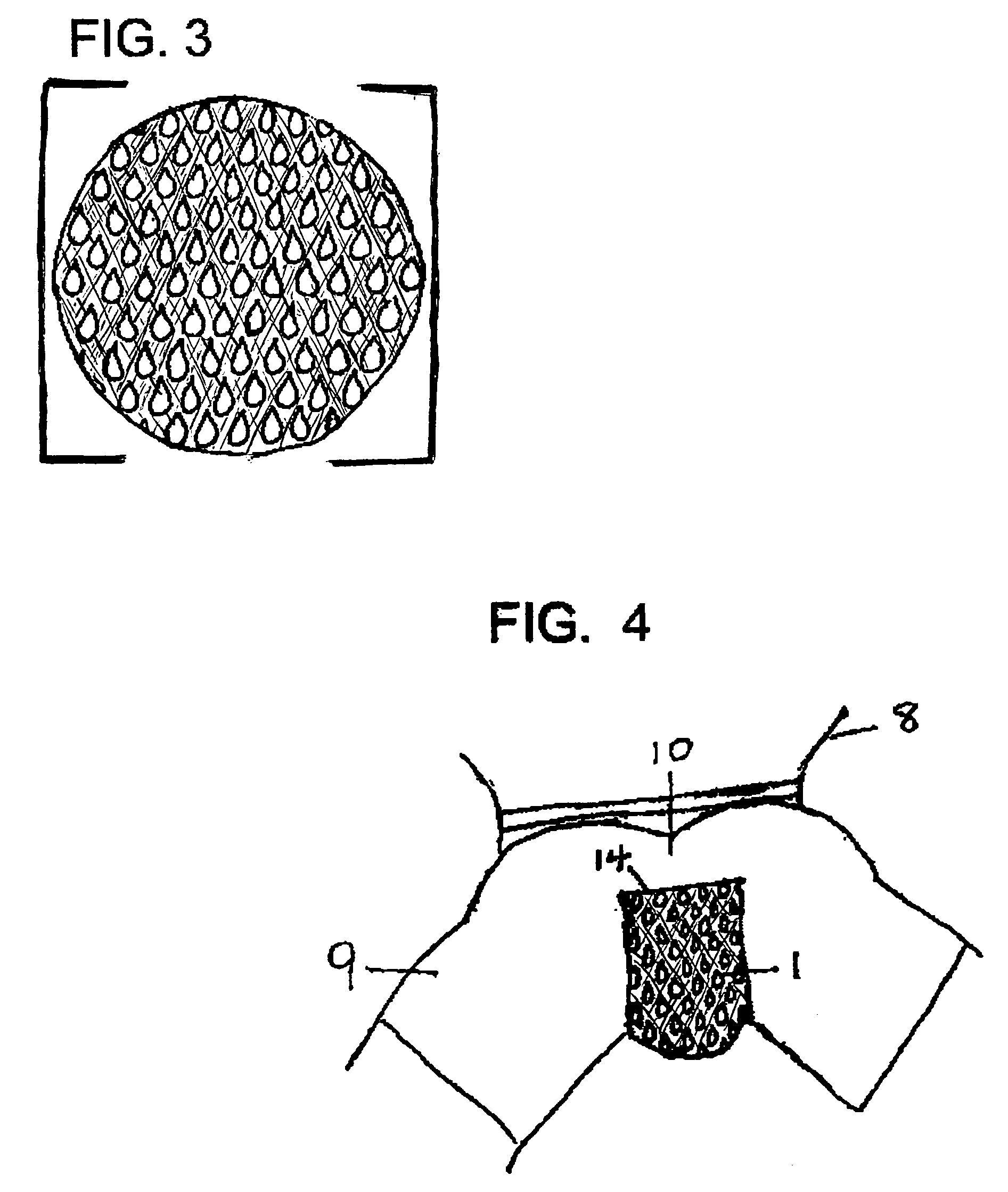

Breathable underwear

InactiveUS20060005301A1Increase air circulationReduce the temperatureHandkerchiefsBaby linensPerspirationEngineering

Breathable underwear for men that has an open weave netting, similar to that found in men's bathing trunks, as the sole crotch material. The small holes in this open weave netting encourages air circulation, lowers the temperature to which the testes, groin and pubic area are subjected, thereby facilitating heat dissipation, reducing perspiration and wetness, and increasing the comfort of the wearer.

Owner:TAYLOR RICHARD ANTHONY

Temperature controlled railway car

InactiveUS7478600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingFiberTemperature control

Owner:TRINITY IND INC

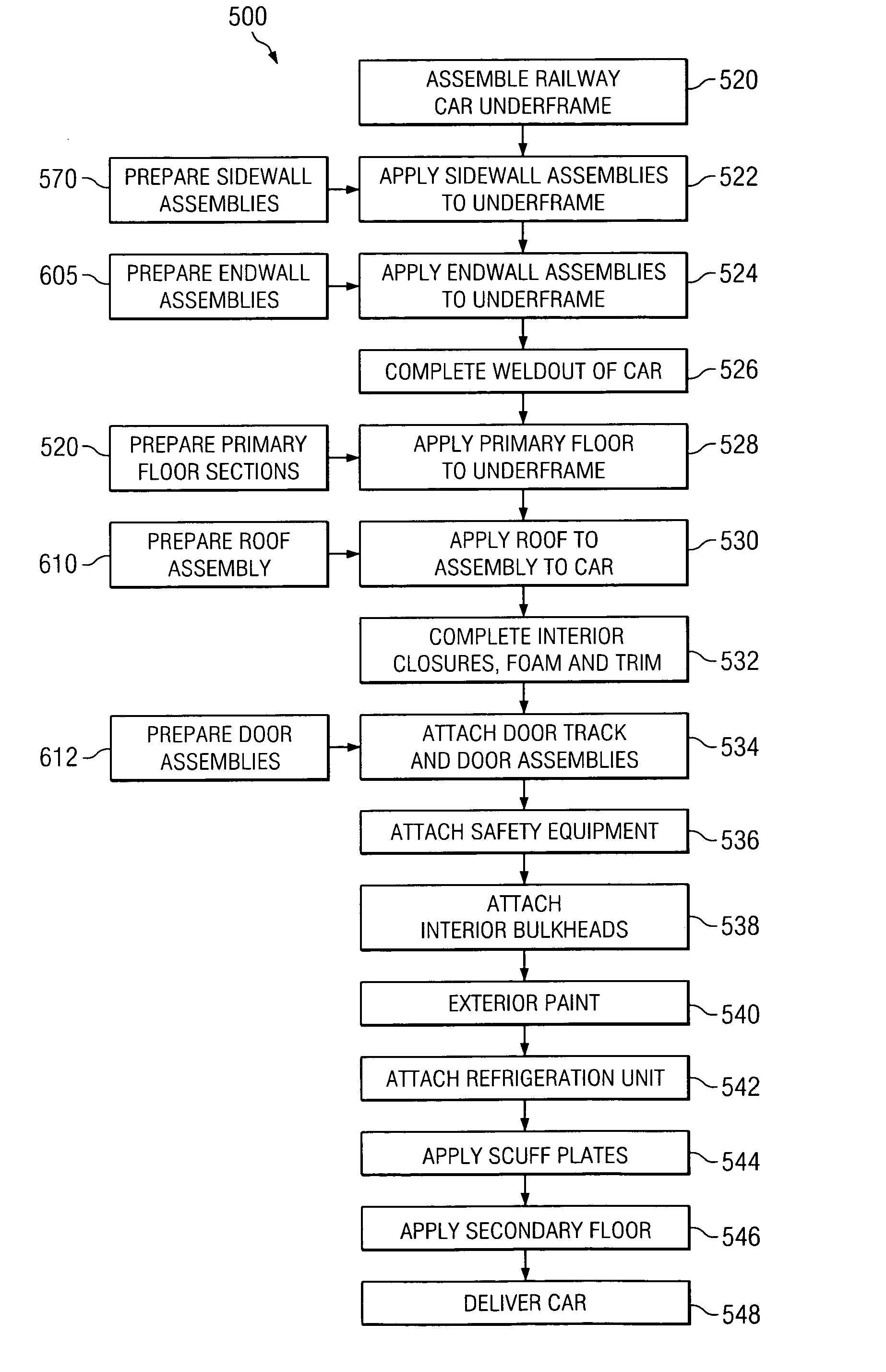

Manufacturing method of assembling temperature controlled railway car

InactiveUS6892433B2Low costShorten the timeRailway roofsRailway heating/coolingTemperature controlPlastic materials

A manufacturing facility and method for assembling a composite box structure on a railway car underframe are provided. The composite box structure may be defined in part by an exterior metal surface, interior side stakes attached to the exterior metal surface, foam insulation disposed between the side stakes and attached to the metal surface and at least one layer of reinforced plastic material forming an interior surface. The composite box structure preferably includes a pair of end walls, a pair of side walls, a floor assembly and a roof assembly. The composite box structure may be assembled on a railway car underframe to form a temperature controlled boxcar or on insulated boxcar.

Owner:TRINITY IND INC

Hair iron

InactiveUS20060201924A1Improve steam cutoff propertyEasy to disassembleCurling-ironsCurling-tongsEngineeringNormal conditions

A hair iron comprising a pair of openable / closable hair-sandwiching arms that each store in void spaces shielded by shielding members a heat-source plate and a hair-heating plate positioned adjacent to the heat-source plate and sandwiches hairs when the arms are closed; wherein the pair of arms are openably / closably connected on one end by a pivot, and spring pressure is used to maintain the pair or arms in opening directions in a normal condition; wherein the heating plates are installed so that they face each other; wherein tapered portions are provided in a base, on the void space side, of the heating plate, and a gasket is securely fitted in the formed tapered voids in order to improve the steam cutoff property of the void spaces; and wherein the temperature can be controlled easily at the operator's fingertips.

Owner:PHILD CO LTD

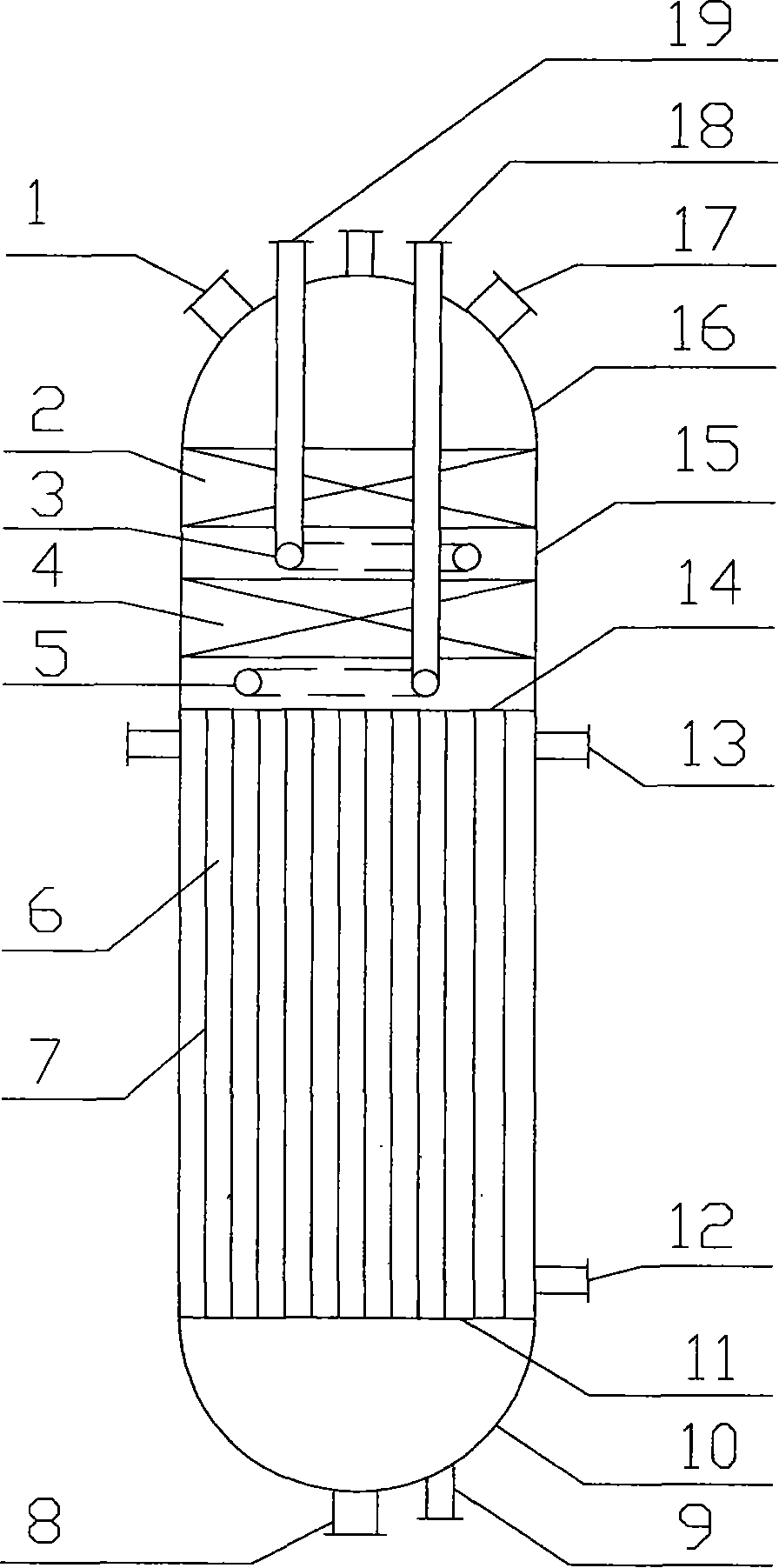

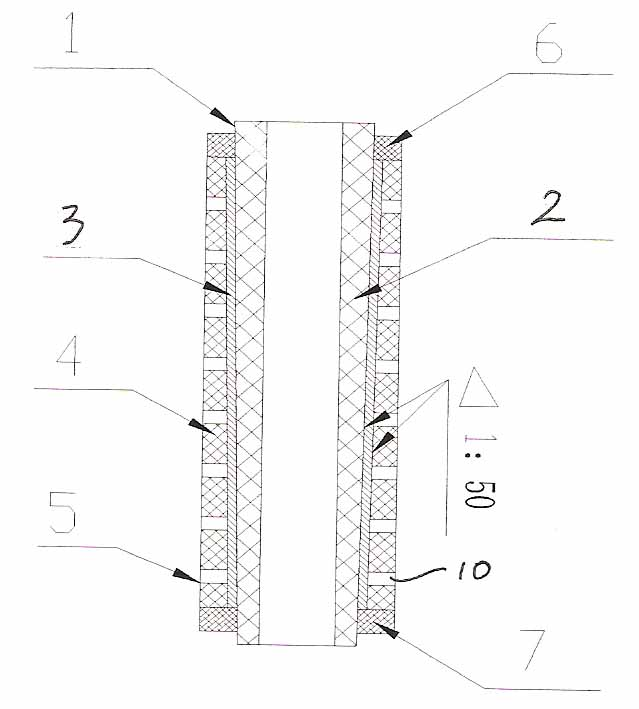

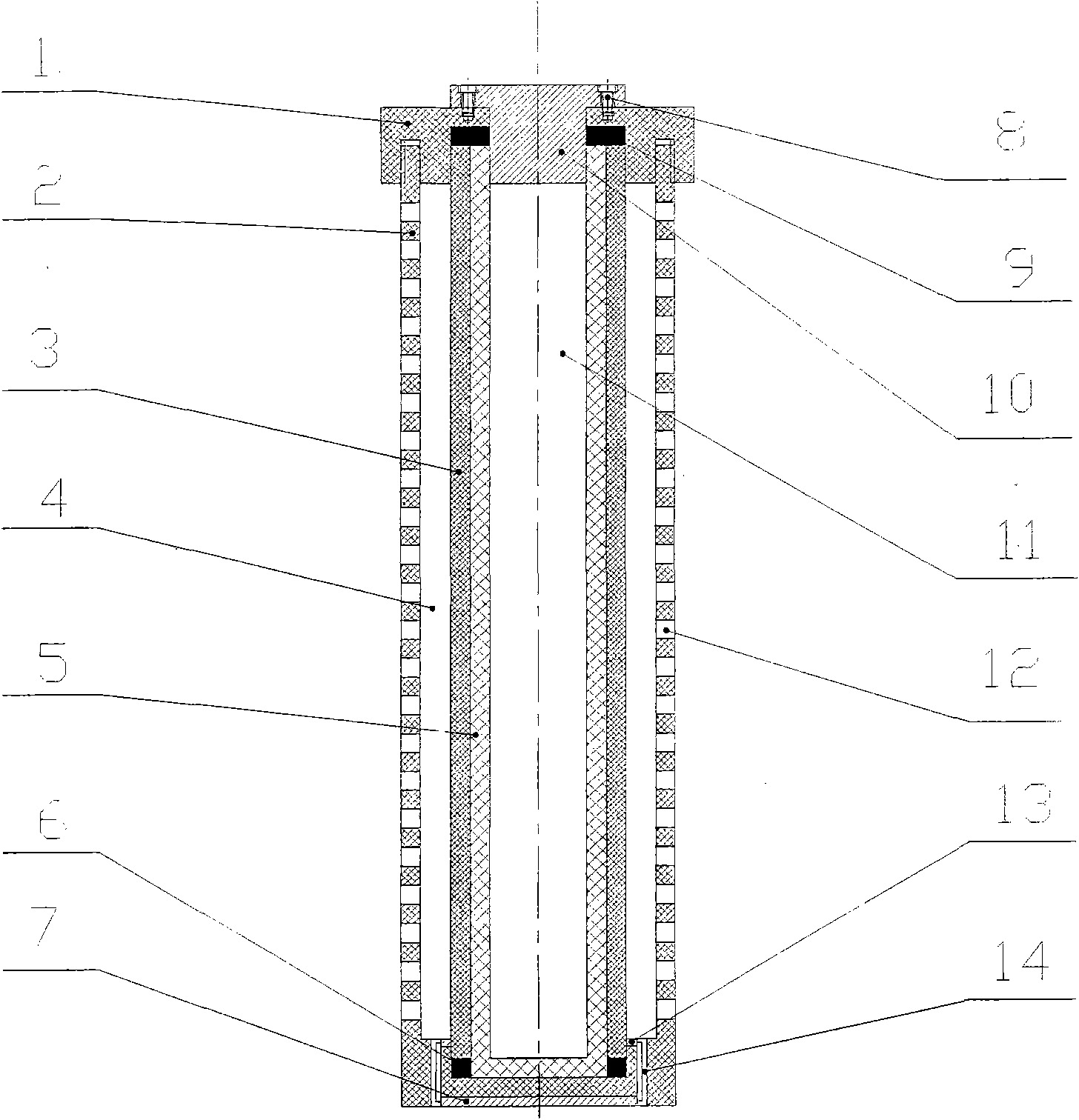

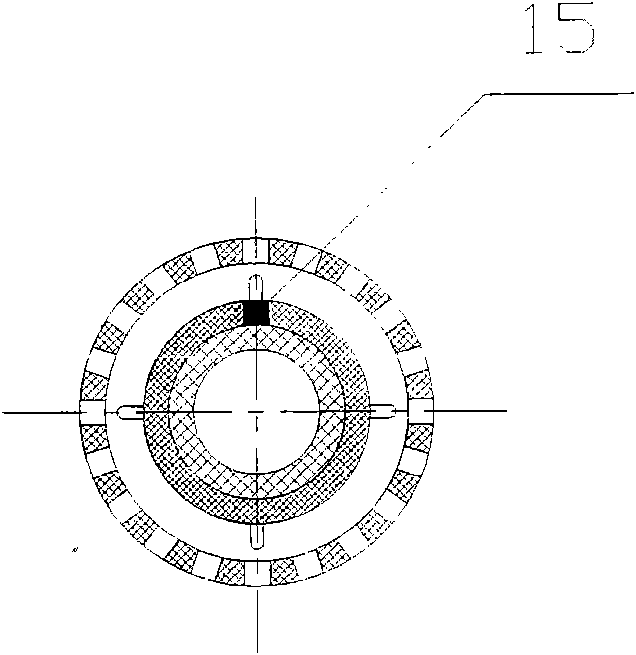

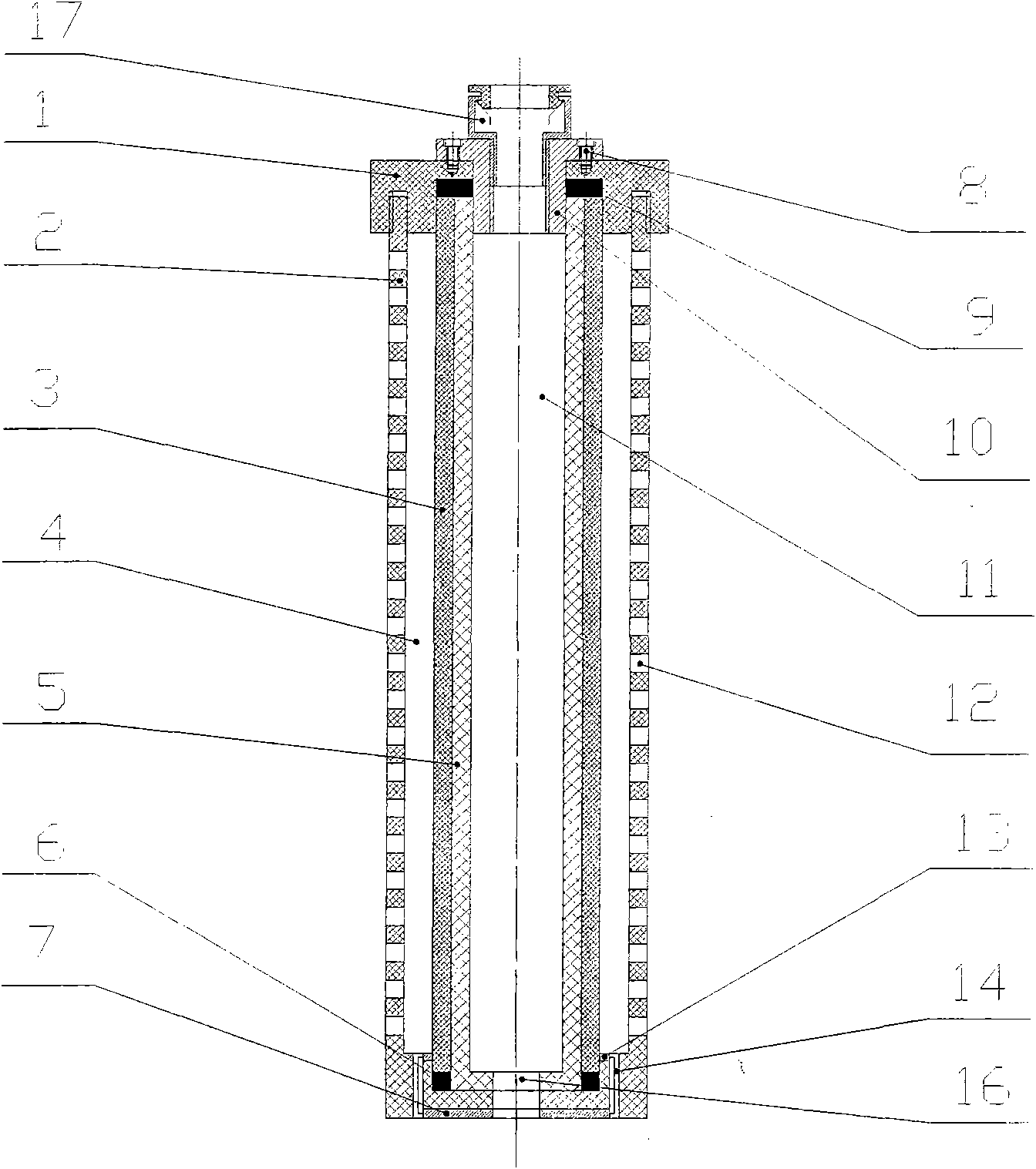

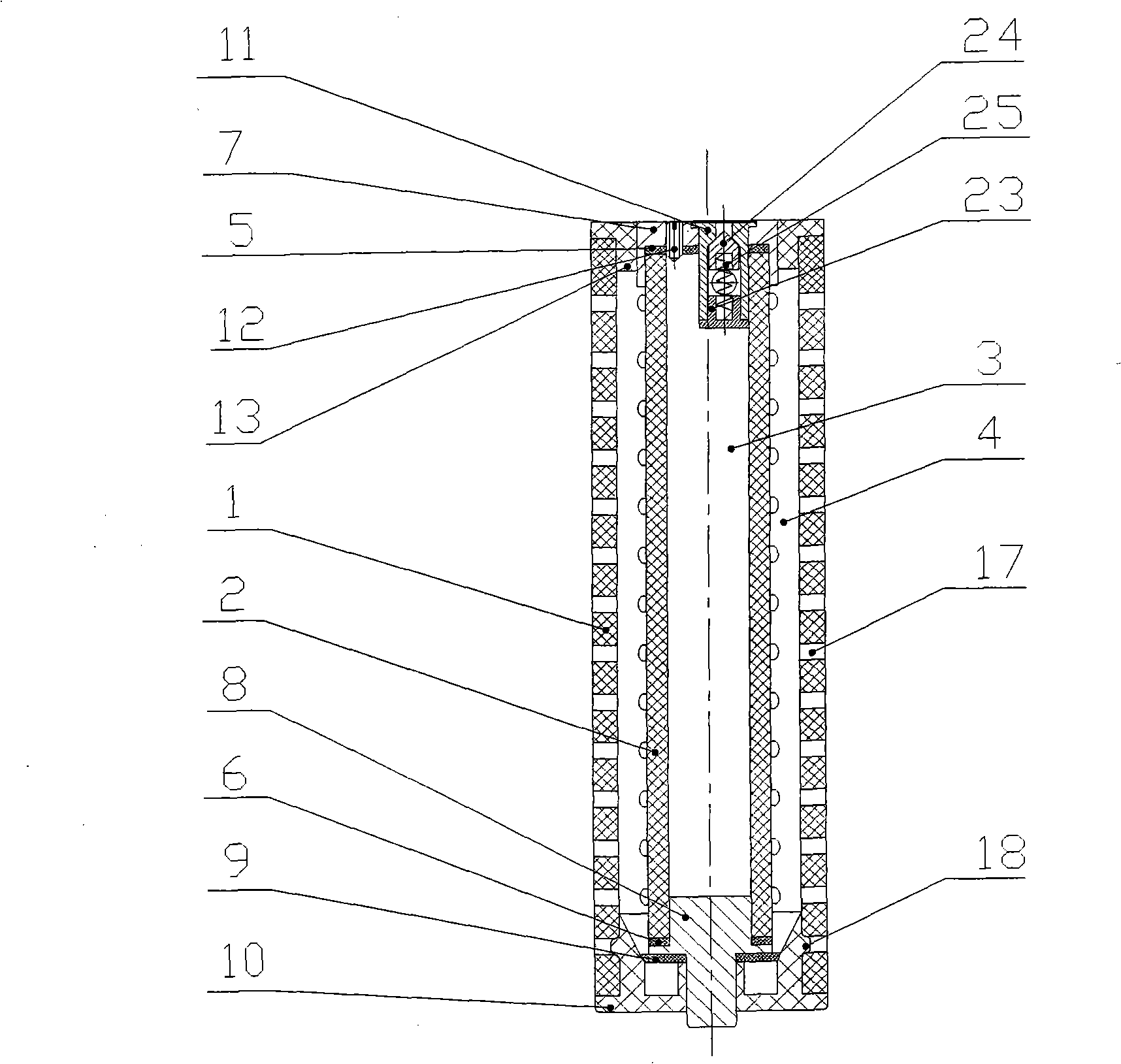

Heat insulation-cold stimulated-shell of pipe exterior cold combined gas solid phase fixed bed catalyst chamber

InactiveCN101249406AExtended service lifeEasy temperature adjustmentChemical/physical processesExothermic reactionHigh potential

A heat insulating-cold shocking-external cooling combined gas-solid phase fixed bed catalytic reactor comprises an upper end plate provided with a gas inlet and a manhole; a pipe shell external cooling section provided with an upper and a lower pipe plates, a group of heat exchangers, heat exchange medium inlet and outlet; and a low end plate provided with a gas outlet and a catalyst discharge port, wherein two heat insulating layers are disposed on a heat insulating reaction section; a material gas cold shocking device including a cold shocking distributor and a cold shocking pipe is disposed in the back of each adiabatic insulating layer; the height of the adiabatic reaction section is 5-30% total height of a reactor catalyst layer; catalyst is filled into the heat exchange pipe with a filling height 50-95% of total height of the reactor catalyst layer. The reactor is specially designed based on the characteristics of a reversible exothermic reaction, has the advantages of simple structure, convenient charge / discharge of catalyst; easy heating reduction of catalyst, simple temperature regulation of catalyst bed, recovery of high potential energy reaction heat and steam byproduct, and is suitable for large-scale chemical production.

Owner:EAST CHINA UNIV OF SCI & TECH

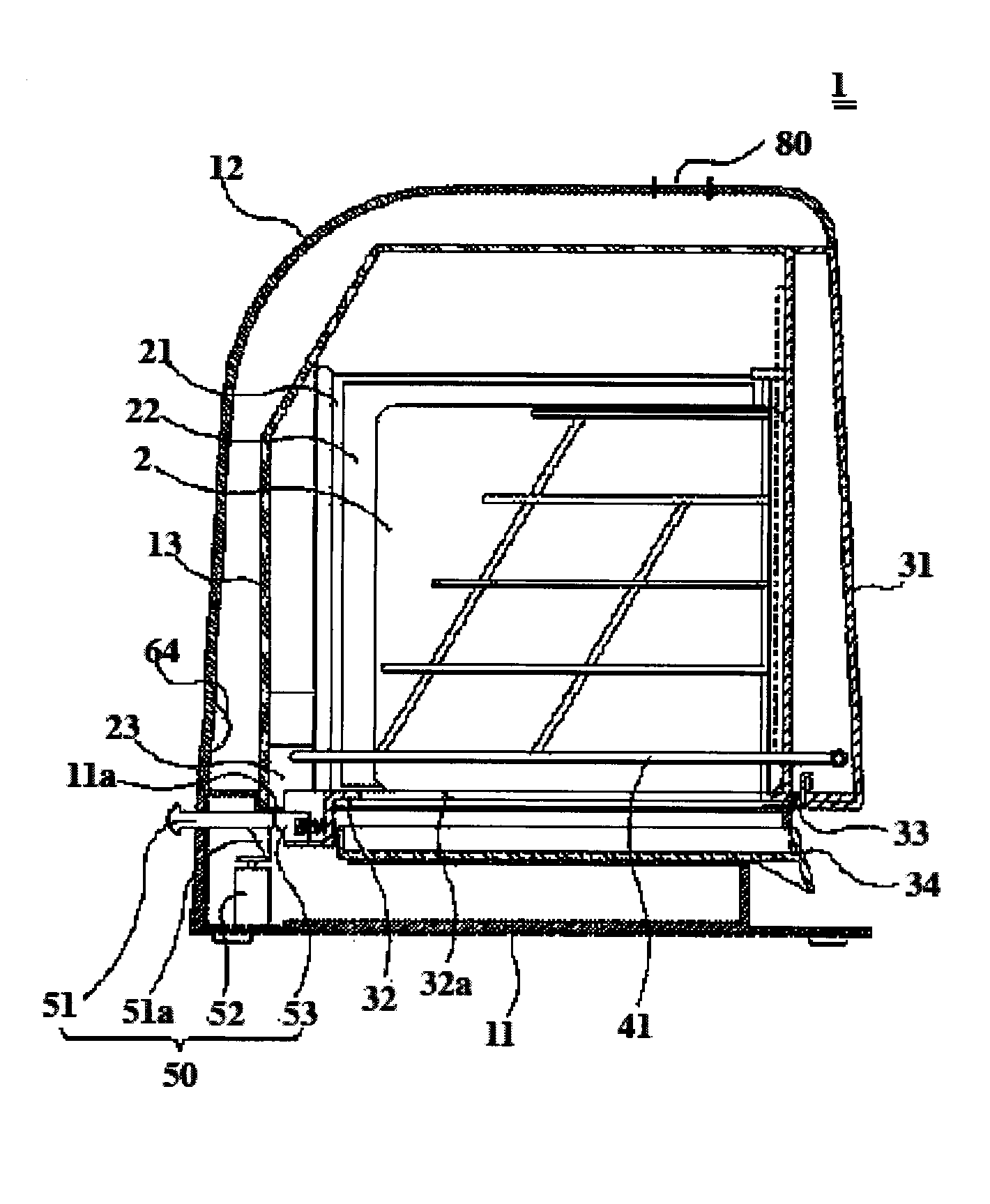

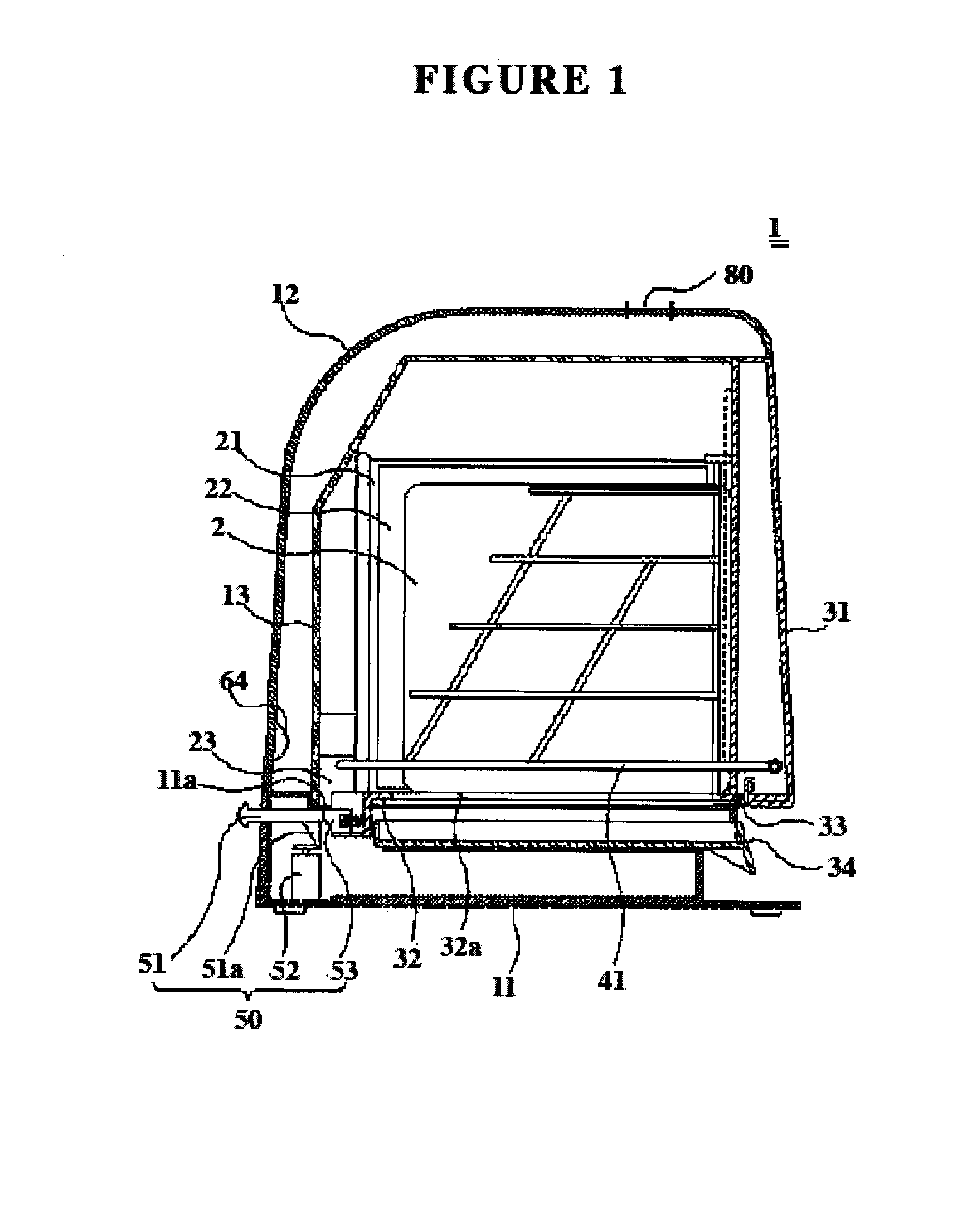

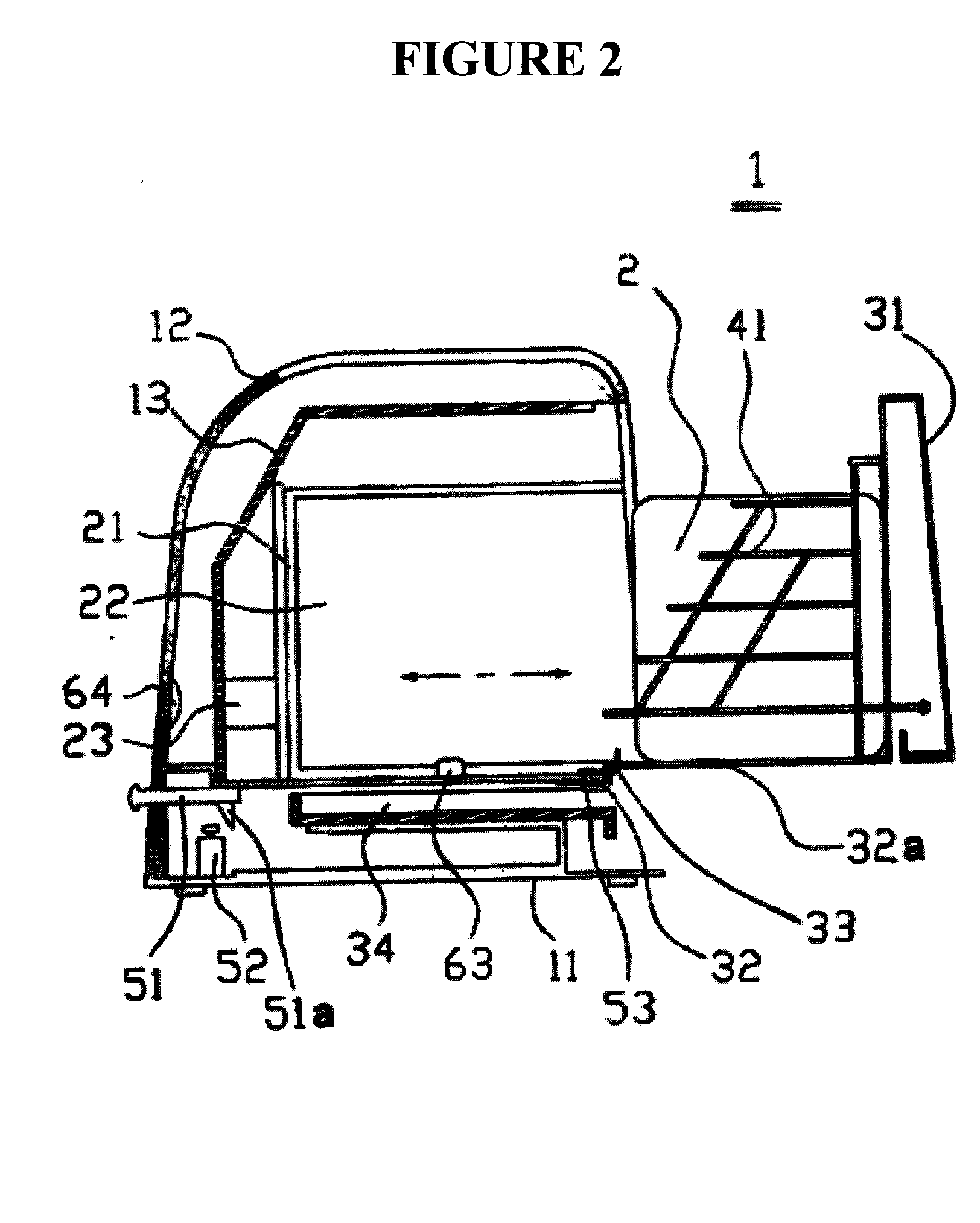

Toaster-and-Oven Device

InactiveUS20090288563A1Prevent warpNeat and easy to cleanMechanical apparatusDomestic lightingElectric heatingHinge angle

A toaster-and-oven device with visible interior, wherein bread or cooking ingredients are added and removed through the side, and wherein the bread can be gripped while toasting. The toaster of the present invention comprises: a housing located above the base and furnished with an internal dome wherein an internal space is formed; multiple toast holders that hold pieces of bread at a distance from one another, placed at specified intervals on the interior of the said internal dome and actually positioned in a vertical or horizontal direction with respect to the said base, on the surface whereof are furnished transparent surface heating elements; a door furnished with a door frame that connects to the interior of the said housing and wherein the lower edge is connected to the said housing by hinges so as to open and close at one side of the said internal dome and housing; and toast holders furnished on the said base and formed so as to contract so that if the said door is closed, the bread can be gripped between the aforementioned toast holders. The door swings left to right, and while the door is closed, the door is kept locked by the mechanical locking device (FIG. 6a); when electrified, it opens automatically in response to electric circuit signals or the operation of a solenoid or magnet, and is configured (FIGS. 6a, 6b, 6c) with a structure whereby the door can be automatically or manually opened at any time; it also includes a structure wherein if the door closes the sensor determines whether or not to toast based on whether or not electric heat is detected.

Owner:LIM JAESANG

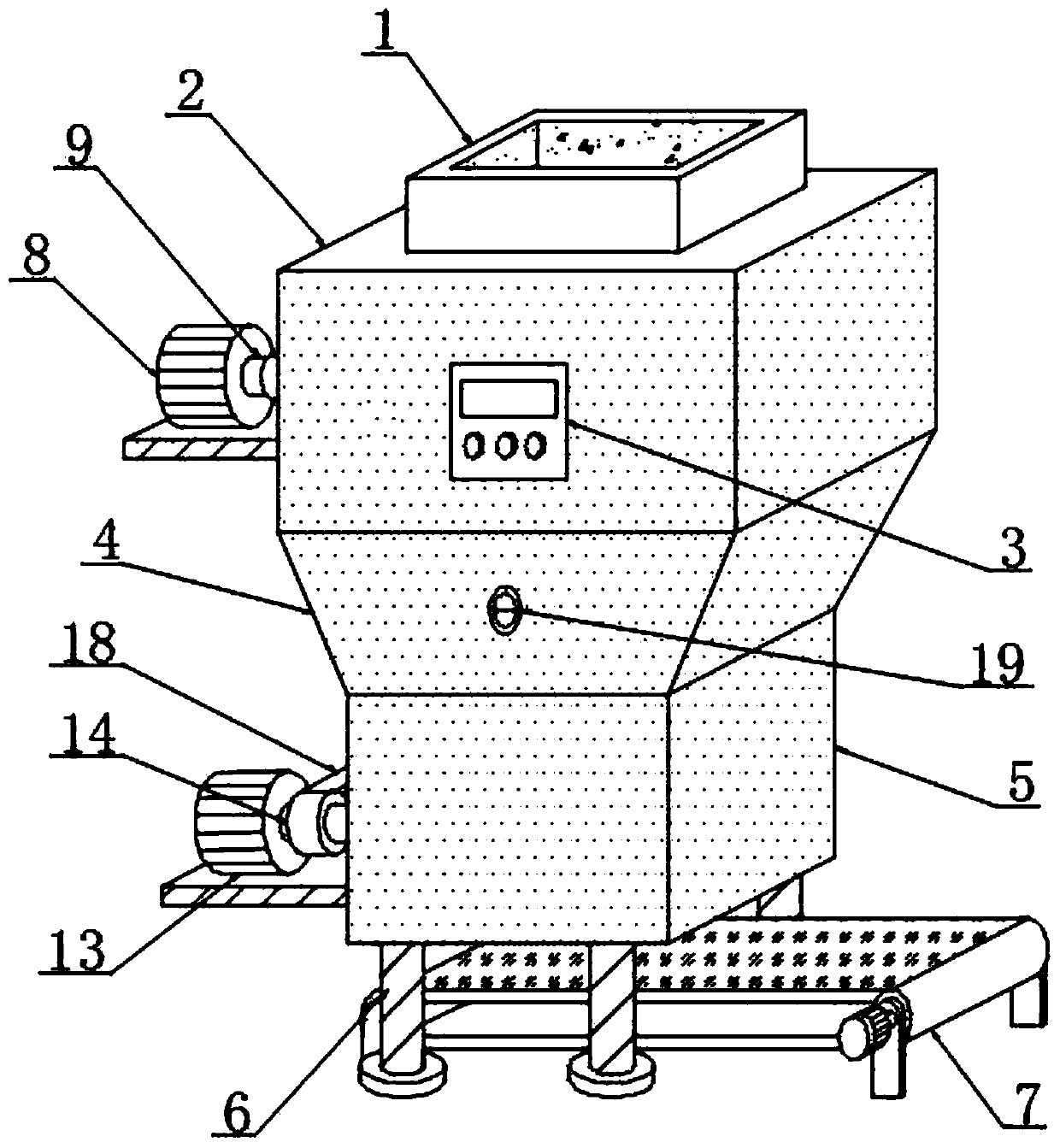

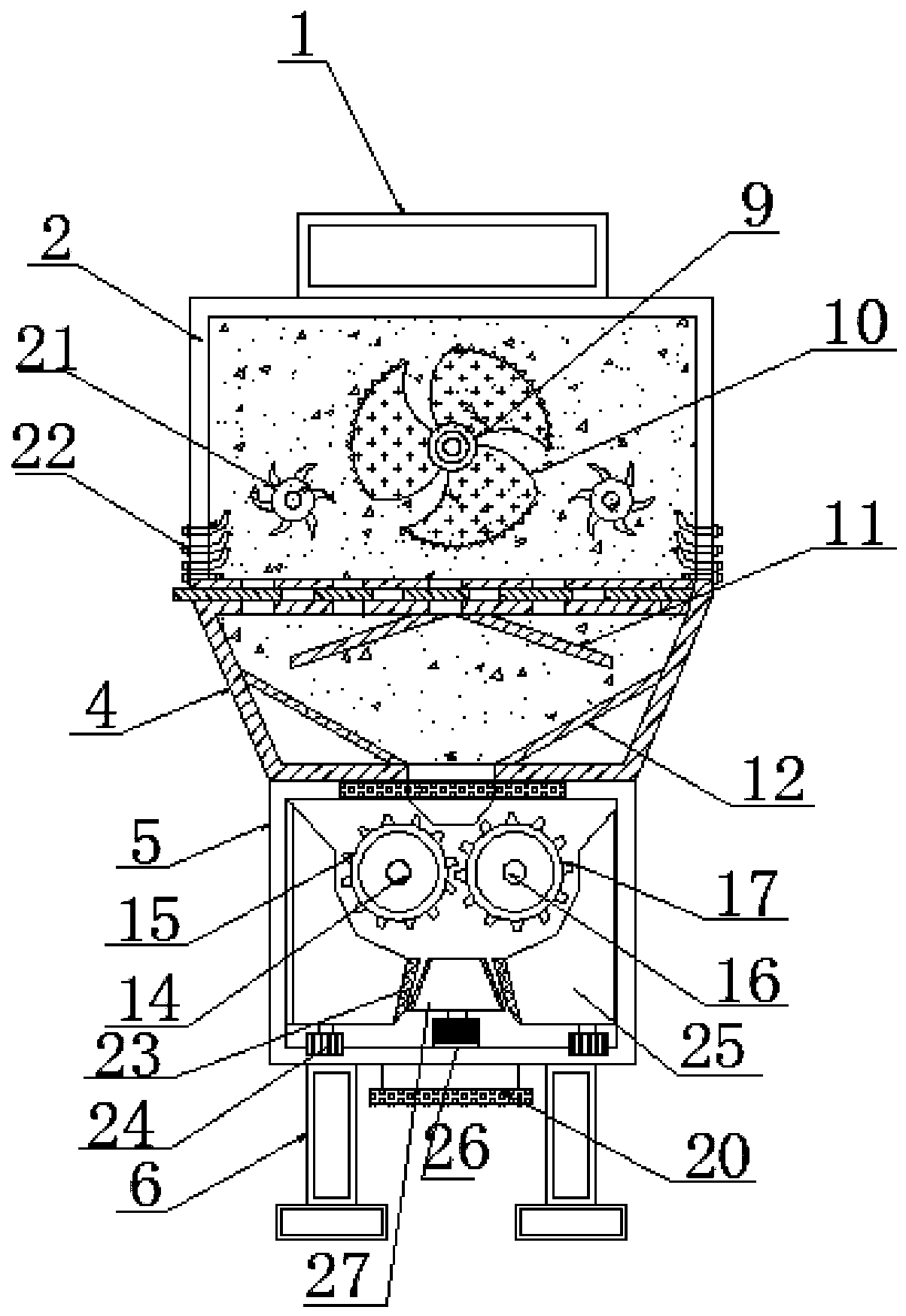

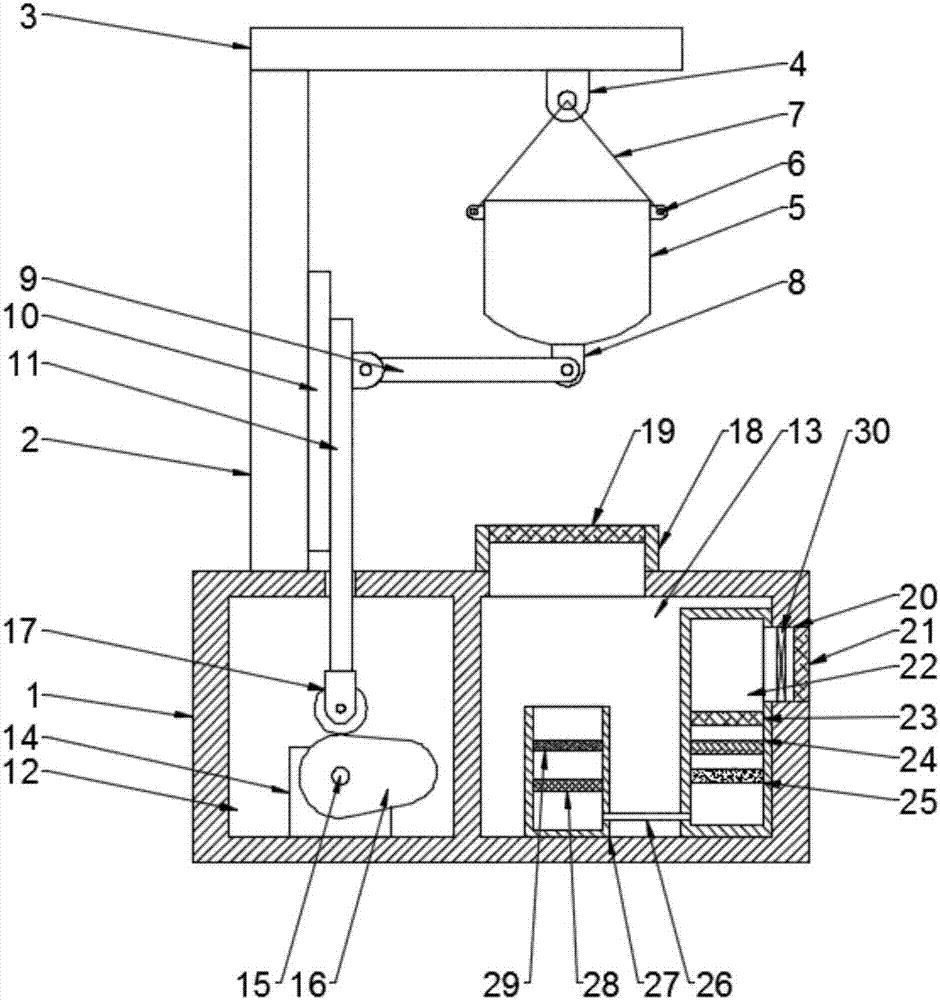

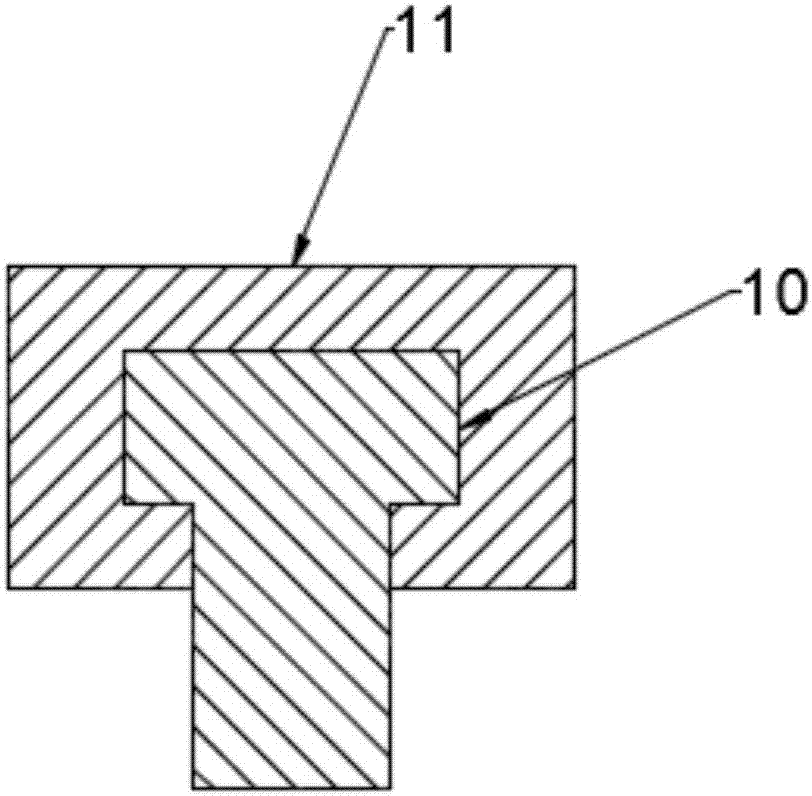

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

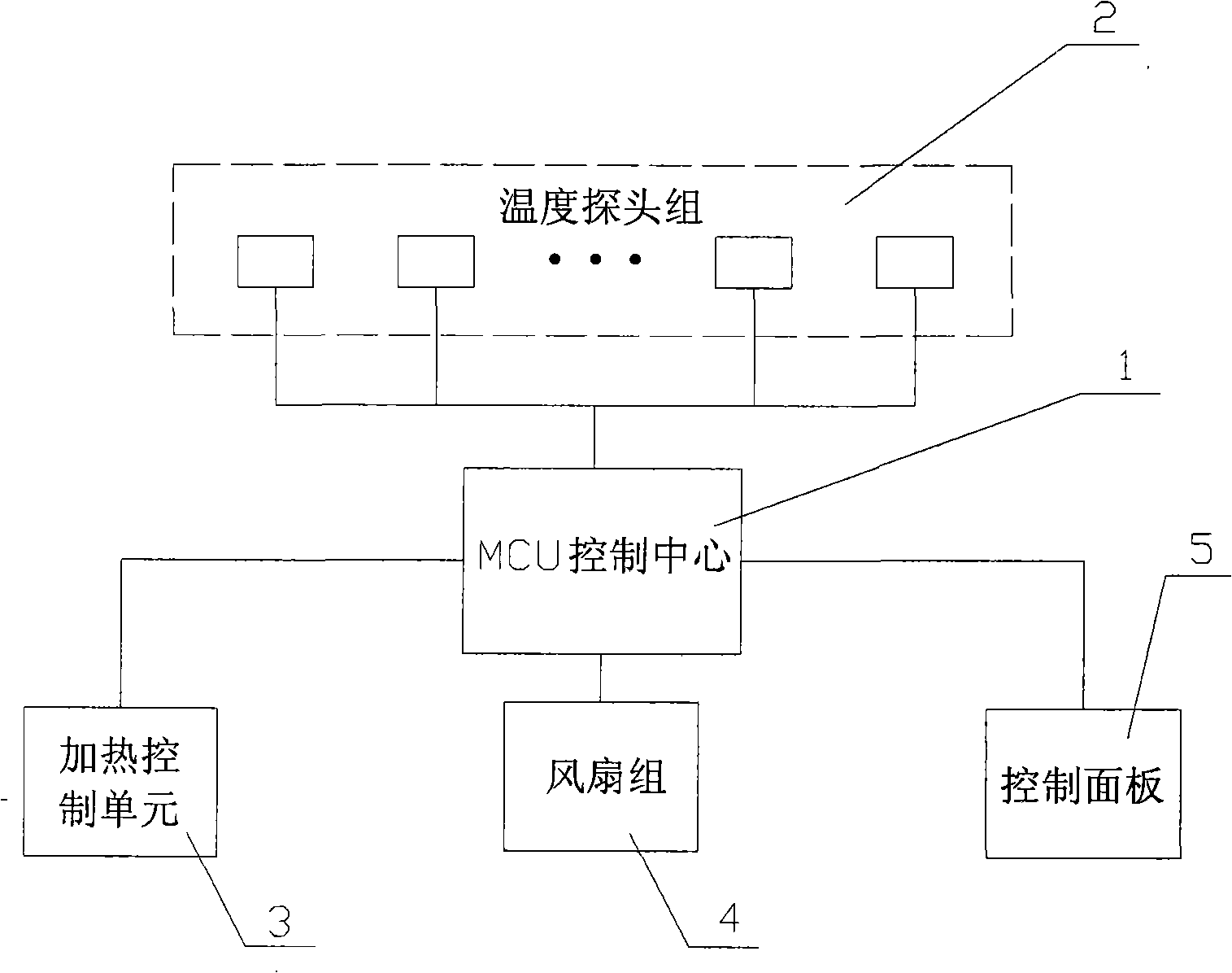

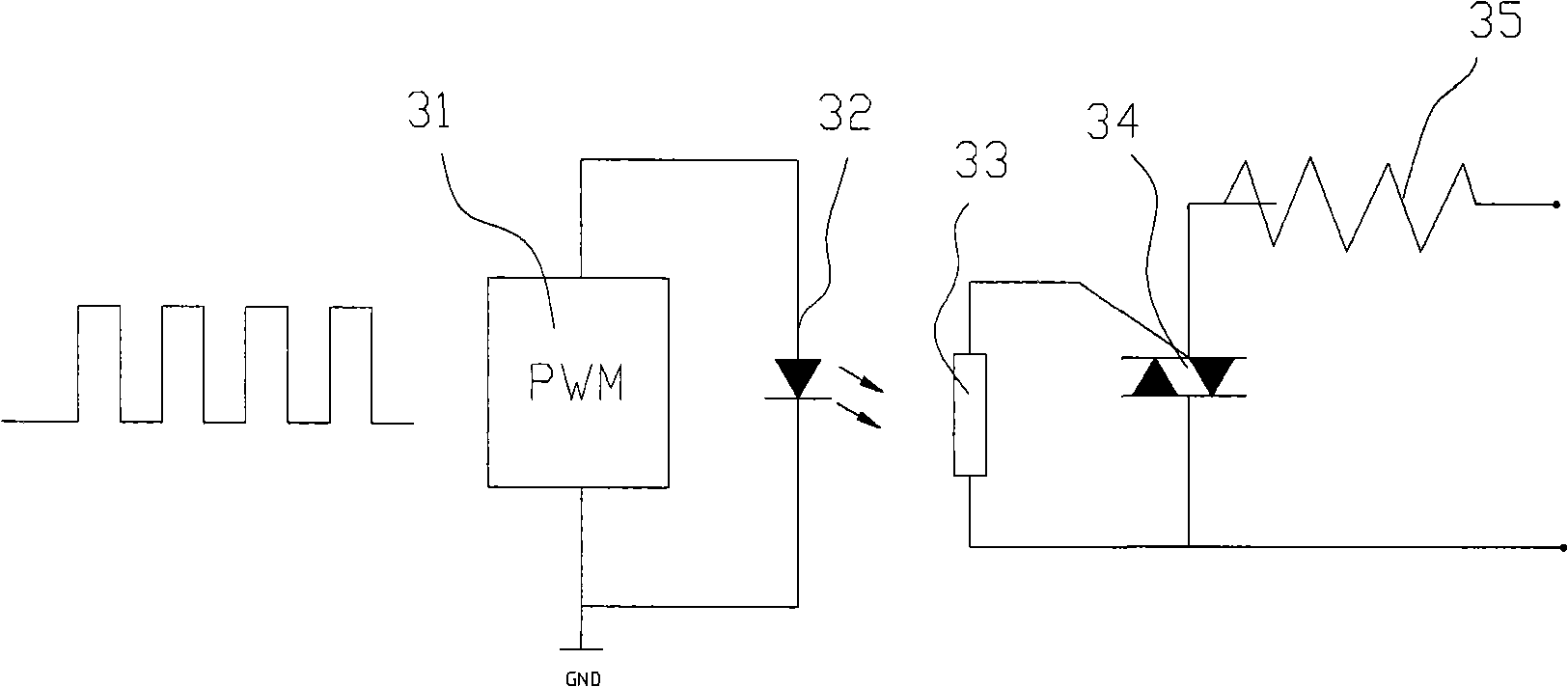

Multiplex temperature detect controller

InactiveCN101303608APrecise temperature regulationRealize real-time measurement and controlThermometer detailsTemperature control with auxillary non-electric powerEngineering

The invention discloses a multi-way temperature detecting controller, which is characterized in that the controller includes 4-8 one-wire temperature probes, a set of controlled heating units and an MCU control center; the temperature probes are connected with the heating units and geometrically distributed in a heating space to measure the peripheral temperature; the selected temperature probes are connected with the MCU control center by connecting wires and send measured temperature to the MCU control center, then the MCU control center compares the received temperature value with a stated reference temperature value, if the received temperature value is lower than the reference temperature value, the heating units are controlled for heating so as to maintain a point at a temperature constant state. The controller can realize the control precision that the target temperature fluctuates at a range of 1.5 DEG C to minus 1.5 DEG C.

Owner:黄竞

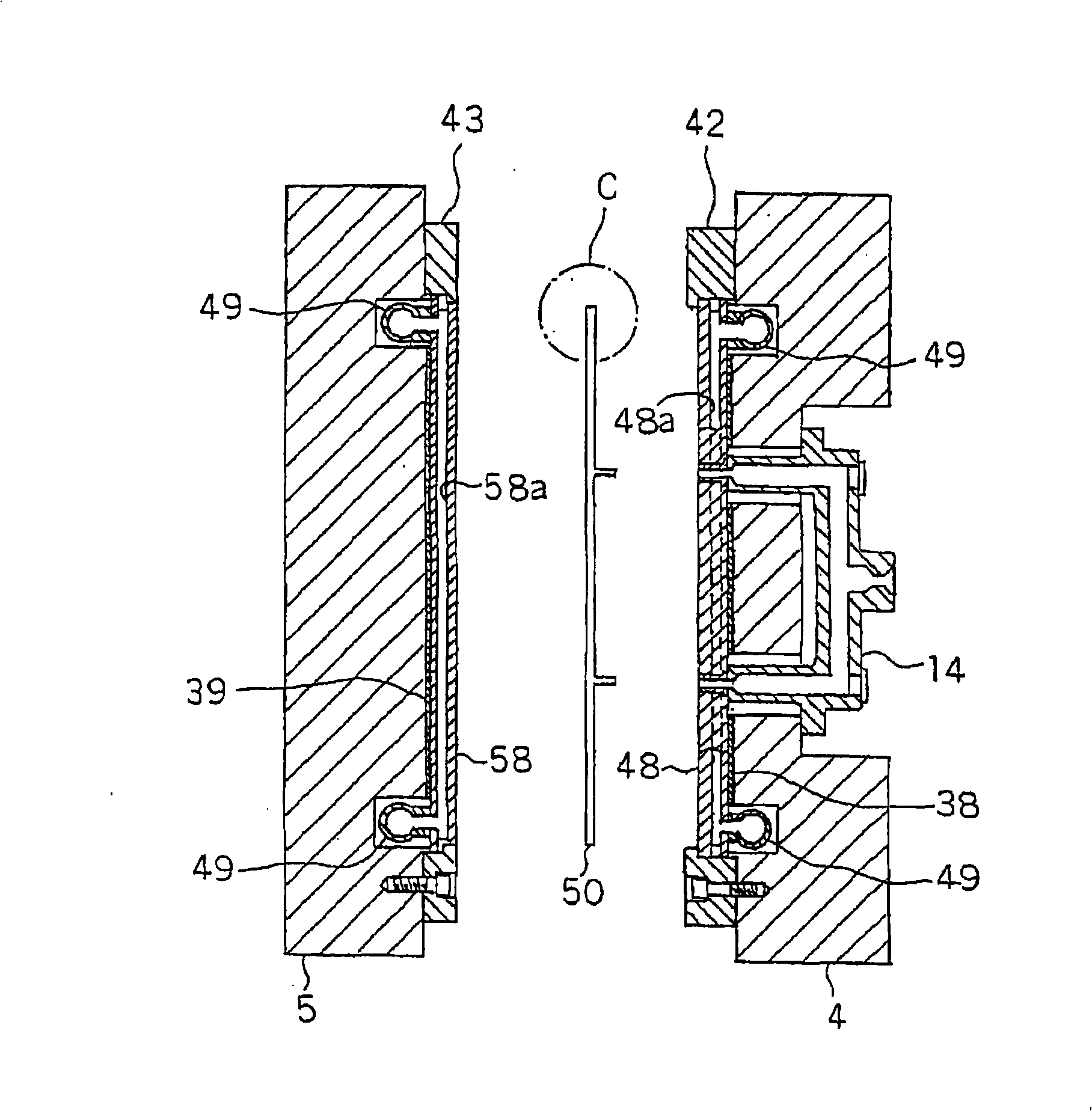

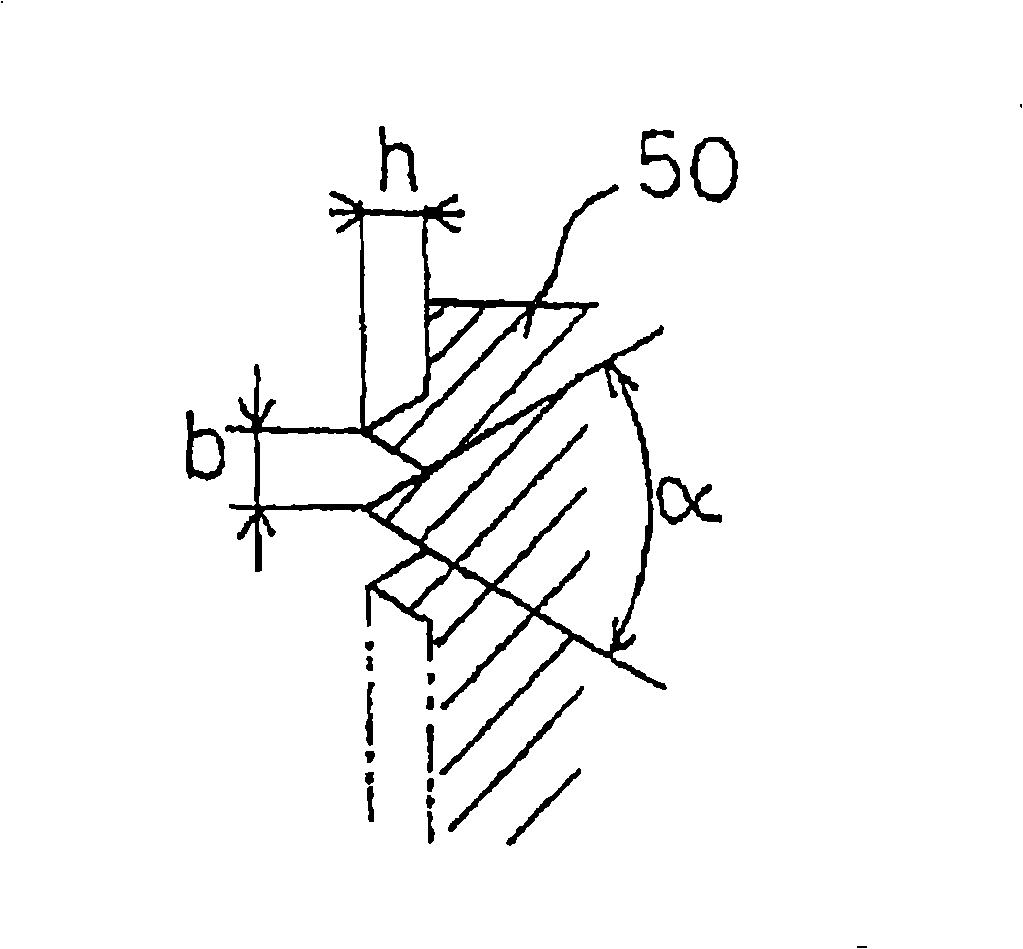

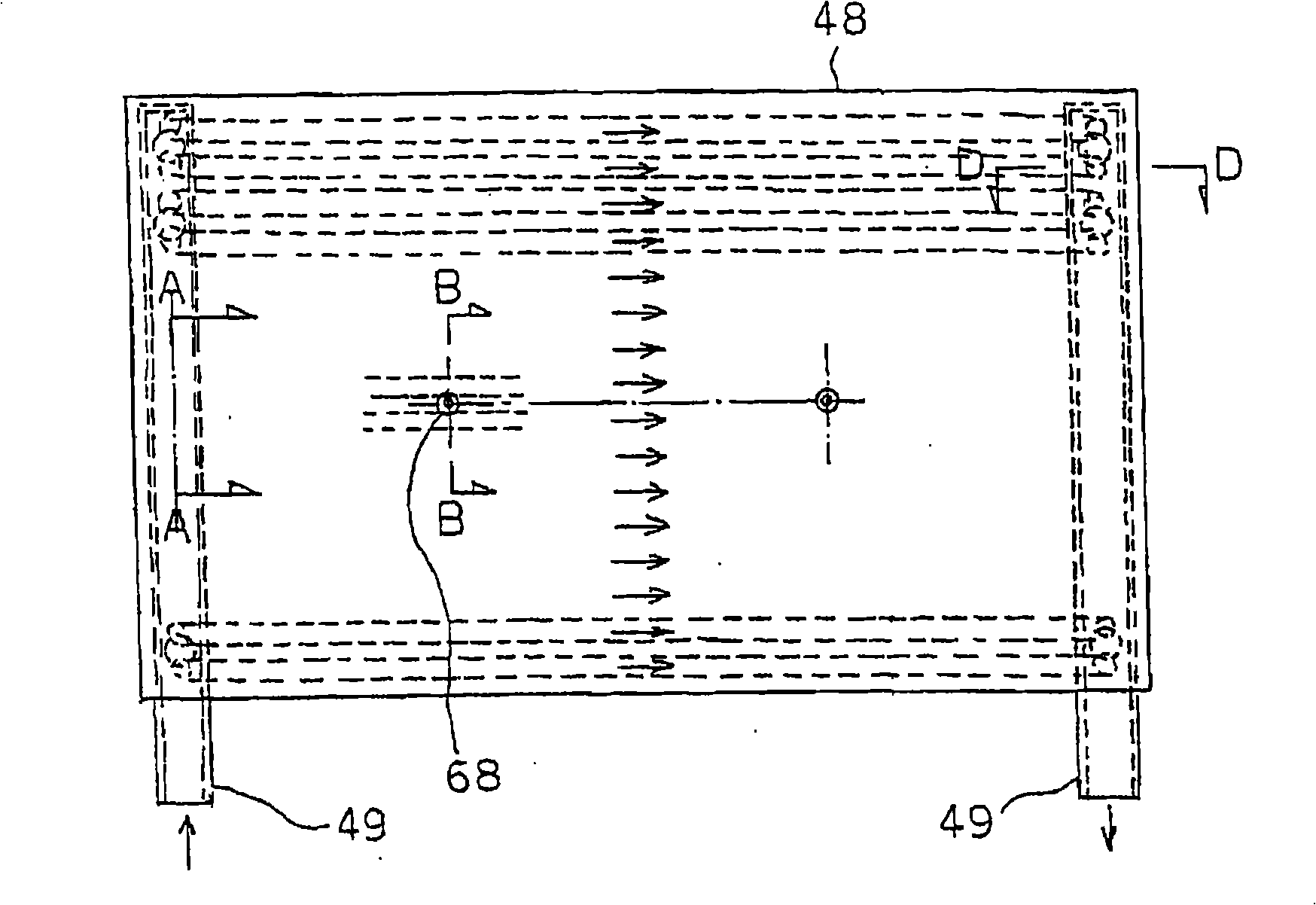

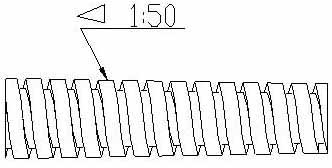

Mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet

The present invention provides a mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet, the mold made of by certain material can enhance the transferability of the surface of a molded product and can allow the molded product to be taken out immediately after the solidification, whereby molding cycle can be accelerated. In the mold, both a stationary side mold and a movable side mold are mounted within masters, and a cavity face is formed on a release side. A plurality of heating medium passages are bored at a position distant by a given distance from the cavity face. The mold comprises a 15 to 30 mm-thick rectangular bushes formed of a metal having a coefficient of thermal conductivity of 20 to 40 W / (m K), heat insulating plates having a coefficient of thermal conductivity of not more than 5 W / (m K) and held between the masters and the bushes, a pair of heating medium manifolds (mounted on both ends of the anticavity face of the bushes so as to be led to the heating medium passages of the bushes, and a plurality of pressing members for pressing four edges of the bushes to fix the bushes to the masters.

Owner:MITSUBISHI HEAVY IND LTD +1

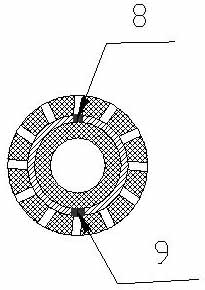

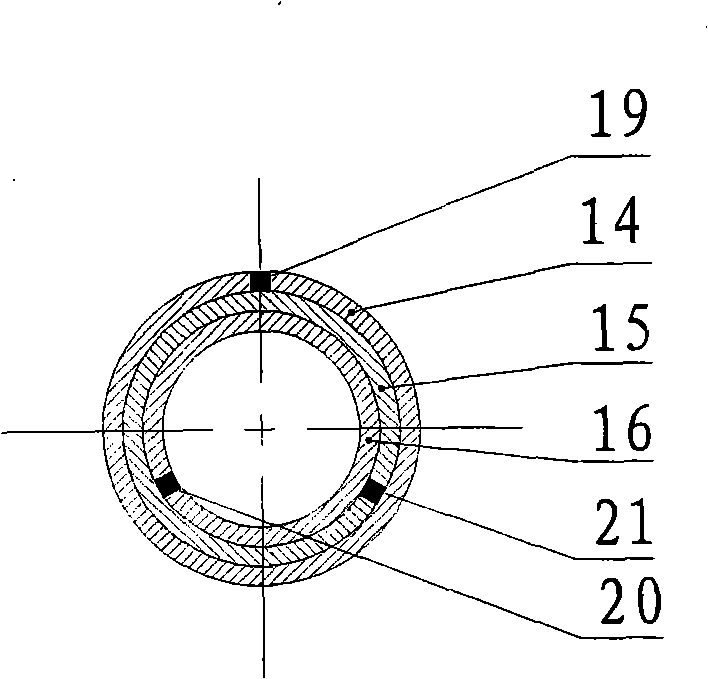

Tapered cylindrical membrane electrode for oxyhydrogen proton exchange membrane fuel cell

The invention discloses a tapered cylindrical membrane electrode for oxyhydrogen proton exchange membrane fuel cell, which is characterized by comprising an anode in contact with hydrogen, a composite membrane and a cathode in contact with air from inside to outside; the composite membrane is composed of a proton exchange membrane (which usually is a Nafion membrane), an output joint is arranged at a anode plate, a seal ring used for isolating the anode output joint from the composite membrane and the cathode is arranged at the anode output joint and a cathode output joint is arranged at the bottom of the cathode; and the anode is in a cone shape, the composite membrane is in a cone shape matched with the cone shape of the anode, the cathode is a hollow pipe, the outside surface of the cathode hollow pipe is cylindrical and the inner hole of the cathode hollow pipe takes a shape of a cone hole with the same conical degree as the cathode. In the invention, the structure is reasonable and crucially a conical structure is adopted to ensure that a problem of the close fit between the cylindrical oxyhydrogen proton exchange membrane fuel cell electrode and the composite membrane can be solved, therefore, the battery performance can be greatly enhanced, and the manufacture and the assembly can be convenient.

Owner:NANTONG UNIVERSITY

Inkjet printhead for full color pagewide printing

ActiveUS10293609B2Increase distanceMinimize color mixingInking apparatusPower drive mechanismsMechanical engineeringFull color

Owner:MEMJET TECH LTD

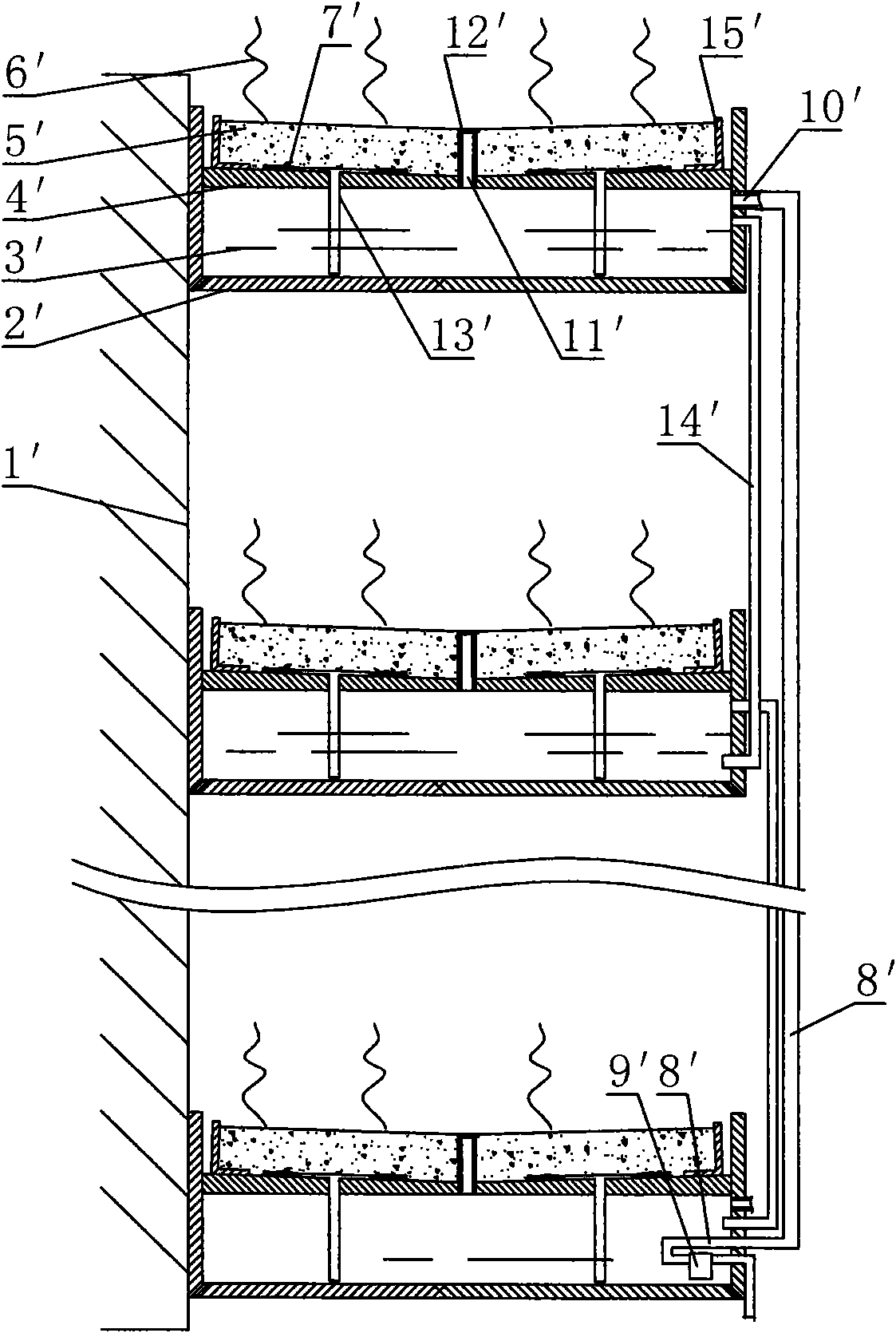

Ecological greening system of building

ActiveCN101828488AInexpensive to implement and maintainSave water costsSelf-acting watering devicesReceptacle cultivationNutrientSoil horizon

The invention discloses an ecological greening system of a building, which comprises a water storage layer, a soil isolation layer, a nutrient soil layer and a greening plant planted on the nutrient soil layer in turn from the bottom to the top, wherein the water storage layer is closed; the soil isolation layer is provided with a plurality of through holes, and water absorption materials are filled in the through holes; one end of the water absorption material is positioned below the water level of the water storage layer, while the other end is dispersedly arranged on the lower part of the nutrient soil layer on the upper surface of the soil isolation layer along four sides; and a water inlet pipe connected with a tap water pipe of the building is arranged in the water storage layer, a water level control valve is arranged at the outlet of the water inlet pipe, a water outlet is also formed in the water storage layer, and the water outlet is higher than the controlled water level of the water level control valve. Compared with the prior art, due to extremely low implementation cost and maintenance cost, the ecological greening system of the building has the advantages of low cost and easy maintenance.

Owner:王怀

Automatic cooking medium level control systems and methods

ActiveUS8689679B2Prevents overcyclingLess viscousCooking vesselsBread-toastersControl systemProcess engineering

An automatic cooking medium level control system for a cooking apparatus, e.g., a fryer, may include a cooking vessel having a first temperature sensor at a first level of the cooking vessel and a second temperature sensor at a second level of the cooking vessel. A reservoir holding a cooking medium, such as cooking oil, may be in fluid communication with the cooking vessel. A controller may monitor temperature data from the first and second temperature sensors to determine whether the level of cooking oil in the cooking vessel has lowered. Upon determining that the cooking oil level has lowered, the controller may actuate a supply mechanism, such as a pump, which may be disposed on a fluid communication path between the reservoir and cooking vessel, which may enable the introduction of cooking medium from the reservoir to the to the cooking vessel.

Owner:HENNY PENNY CORP

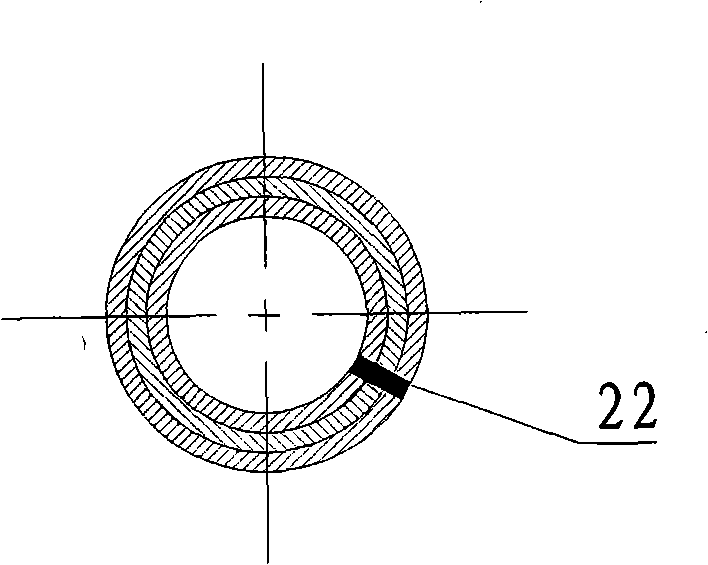

Cylindrical self-breathing prorton exchange membrane fuel cell

InactiveCN101587963ALower impedanceImprove power densityFuel cell heat exchangeCell electrodesEngineeringProton exchange membrane fuel cell

The invention discloses a cylindrical self-breathing prorton exchange membrane fuel cell, includes a shell, a membrane electrode, an anode tube, inside the membrane electrode is a fule chamber, between the shell and the membrane electrode is an air chamber, two ends of the membrane electrode are provided with insulation seal ring, a cathode output member and an anode output member are disposed on cathode end and anode end of battery separately, a water discharge device is disposed on the cathode output member. The invention has rensonable structure and good operation performance.

Owner:NANTONG UNIVERSITY

Tobacco curing barn taking air source heat pump as heat source

InactiveCN101940358BReduce labor intensityEasy temperature adjustmentTobacco preparationBusiness efficiencyHigh energy

The invention discloses a tobacco curing barn taking an air source heat pump as a heat source, which comprises a heating chamber with a fresh air opening, and a drying chamber with temperature and humidity probes. A dehumidifying opening is reserved above the curing barn. The tobacco curing barn further comprises the air source heat pump and a condenser fan. The ratio of the heat exchange area ofa condenser to the input power of a compressor is numerically 7 to 12 m<2> / kw. The condenser and the suction type air supply fan thereof are arranged in the heating chamber. The drying chamber and / orthe heating chamber are / is provided with a heat preservation layer. By taking the air source heat pump and solar energy as the novel heat sources, the tobacco curing barn of the invention has the characteristics of energy saving, normal and stable running of a system, high energy efficiency ratio, convenient operation, capability of providing hot air at relatively higher temperature and greatly expanding the application range of the air source heat pump and the solar energy, and positive role in saving energy sources and protecting the environment. Due to the large-scale popularization and utilization of the technology in tobacco production areas, the sulfur content of the air, soil and tobacco can be reduced and the quality of the tobacco can be improved.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO +1

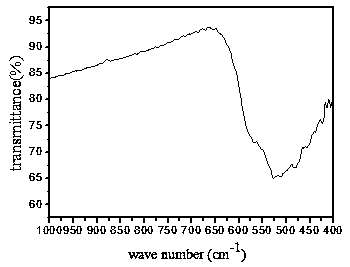

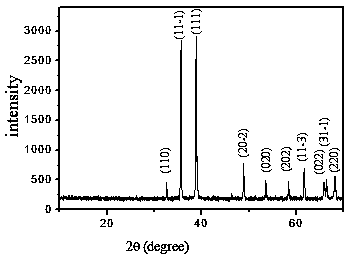

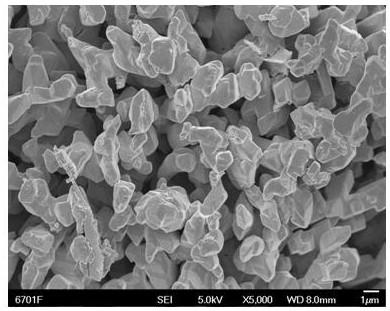

Preparation method and application of flaky nano copper oxide

ActiveCN110436508ASimple preparation processReduce manufacturing costNanotechnologyCopper oxides/halidesPhotocatalytic degradationCopper salt

The invention discloses a preparation method and application of flaky nano copper oxide. The preparation method of the flaky nano copper oxide mainly comprises the following steps: accurately weighingcopper salt and oxalic acid or oxalate, uniformly mixing the copper salt and the oxalic acid or the oxalate, then grinding, adding a proper amount of distilled water in the grinding process to enablethe mixture to be in a fluid state, heating, cleaning and drying after grinding to obtain a precursor copper oxalate, and calcining the precursor copper oxalate to obtain the flaky nano copper oxide.A preparation technology is simple, no organic solvent except ethanol is used in a preparation process, the preparation method is environment-friendly and safe, and prepared flaky nano copper oxide particles are uniform in size and small in particle size, and have good photocatalytic degradation performance on a methylene blue solution.

Owner:GANSU AGRI UNIV

Circular direct methanol fuel cell of high performance and low cost

InactiveCN101335362AEasy to cleanEasy maintenanceFuel cells groupingCell electrodesFuel cellsBiochemical engineering

The invention discloses a column direct methanol fuel cell with good performance and low cost. The cell comprises a shell, wherein, a membrane electrode is arranged in the shell. A battery liquid compartment is arranged in the membrane electrode, an air chamber is arranged between the shell and the membrane electrode, insulating sealing rings are arranged on both ends of the membrane electrode, and a cathode output device and an anode output device are respectively arranged on the cathode end and the anode end of the cell group, a water-diversion gas-barrier membrane is arranged on the exterior of the anode output device, a water collector is arranged on the exterior of the water-diversion gas-barrier membrane, and the cathode output device is provided with a check valve which is communicated with the cell liquid compartment and a pollutant output bolt device. The cell has the advantages of reasonable structure and good working performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

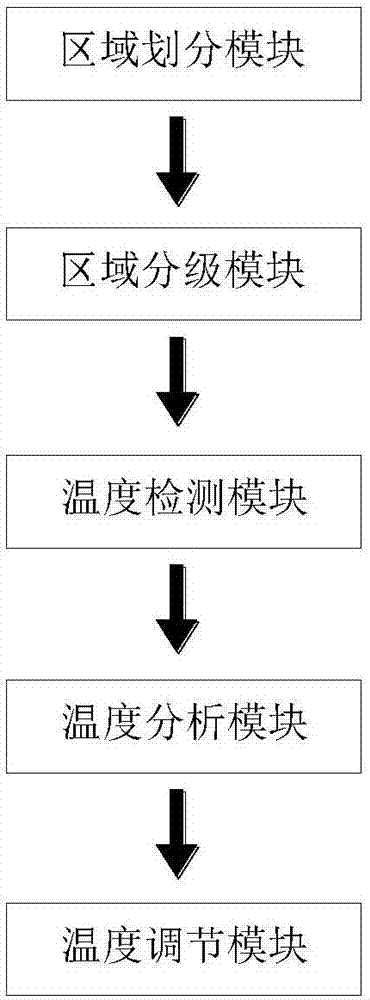

Intelligent temperature regulation system based on area classification

InactiveCN107238185AImprove targetingHigh precisionSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringStellar classification

The invention discloses an intelligent temperature regulation system based on area classification. The intelligent temperature regulation system comprises an area partition module, an area classification module, a temperature detection module, a temperature analysis module and a temperature regulation module, wherein the area partition module is used for partitioning a target area into n subareas; the area classification module is used for classifying each of the n subareas into a first area and a second area; the temperature detection module is used for detecting the temperature in the 2n areas; the temperature analysis module is used for analyzing the temperature in the 2n areas and outputting the analysis results; and the temperature regulation module is used for regulating the temperature in the n subareas according to the analysis results of the temperature analysis module. According to the intelligent temperature regulation system based on area classification, the target area is firstly partitioned into the plurality of subareas, each of the subareas is then classified, the range of each of the subareas is narrowed, the temperature in each of the subareas is collected, the actual temperature in each of the subareas is analyzed, and finally the temperature in the different subareas is regulated according to the analysis results. According to the intelligent temperature regulation system based on area classification, not only is the temperature regulation pertinence improved, but also the temperature regulation effect is effectively improved.

Owner:合肥亿迈杰软件有限公司

Full-automatic self-service pushing-type swing cradle

The invention discloses a full-automatic self-service pushing-type swing cradle. The full-automatic self-service pushing-type swing cradle comprises a base, a stand column, a cross rod and a cradle body, the stand column is arranged at one side of the top end face of the base, the top of the stand column is fixedly connected with the cross rod, a guide rail is arranged on the stand column, a lifting rod is slidably connected to the guide rail, a connecting rod is hinged to the hinging rod, the bottom of the lifting rod penetrates through the top wall of a power cavity and is fixedly connectedwith a top wheel, a power cavity and a temperature adjusting cavity are formed in the base, a motor is arranged on the bottom wall of the inner cavity of the power cavity, a motor shaft of the motor is fixedly connected with a rotary shaft, a cam which is matched with the top wheel is fixedly connected to the other end of the rotary shaft, an air exhausting pipe penetrates through the top of the temperature adjusting cavity, and an electric heating box and a filtering box are arranged in the temperature adjusting cavity. Through the cooperation of the motor, the cam, the lifting rod and the connecting rod, the whole process is automatically completed, manual operation is not needed, and parents conveniently complete other work; through the arrangement of the electric heating box and the filtering box, the temperature of surrounding air is adjusted, and the air quality is improved.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

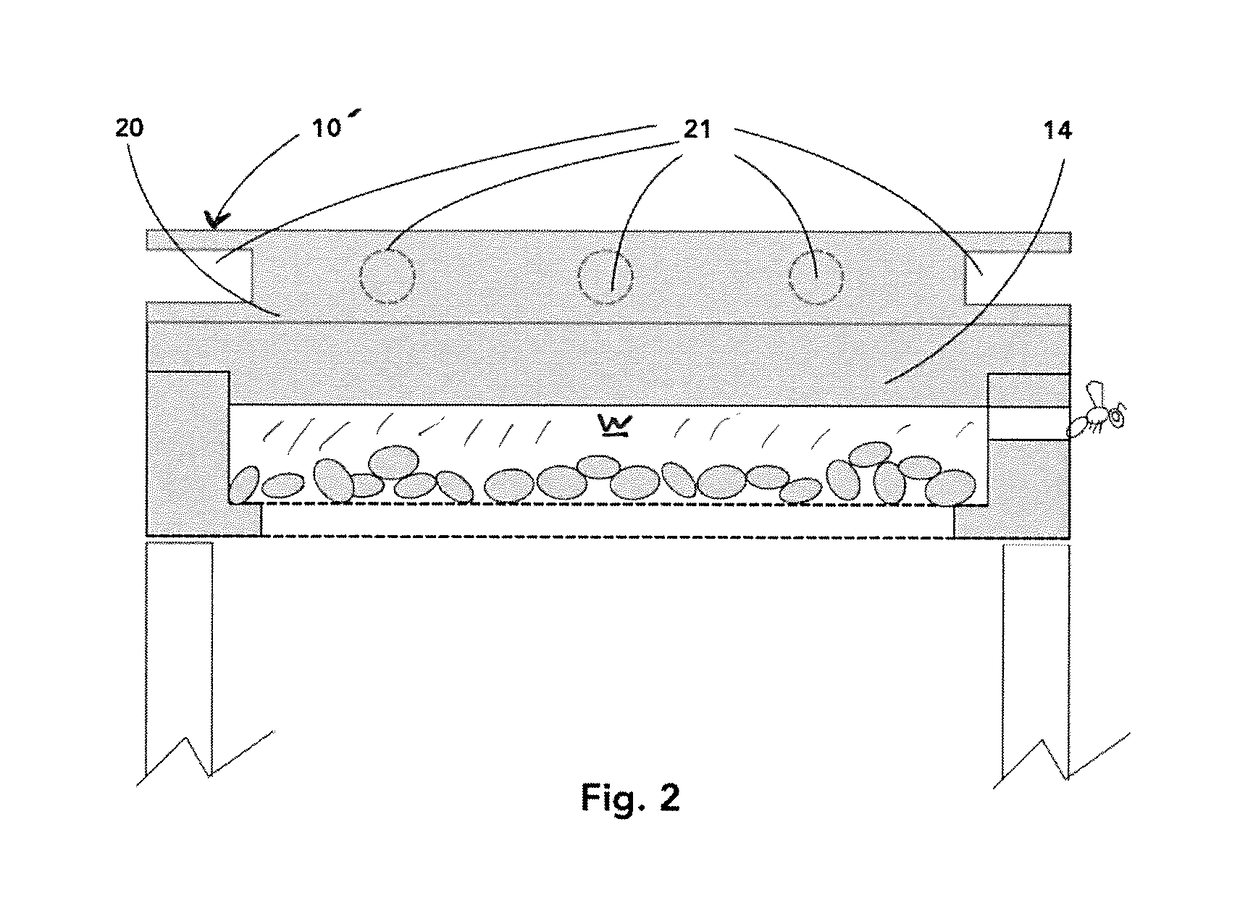

Method and apparatus for field incubation of bees

ActiveUS9801358B1Efficient transportEfficient and affective and profitable commercial pollination operationBeehivesField cropSolitary bee

A hivetop incubator stimulates dormant solitary bees to emerge at the appropriate time to pollinate orchard and field crops. The hivetop incubator utilizes the heat produced by a colony of honeybees. It comprises an insulated incubation chamber with a lid and a screened base. The hivetop incubator is placed over the open top of a beehive containing a honeybee colony. Heat generated by nurse honeybees to maintain temperatures within the brood nest rises into the incubation chamber. Dormant solitary bees in cocoons are placed within the incubation chamber and are stimulated by the warmth to emerge rapidly. The active bees leave the incubation chamber thru exits and are thus available in the orchard or field for pollination.

Owner:WONDERFUL ORCHARDS

Manufacturing facility and method of assembling a temperature controlled railway car

InactiveUS20050204536A1Improve heat transfer characteristicsSatisfied with useAssembly machinesAxle-box lubricationFiberTemperature control

A manufacturing facility and method for assembling a railway car having a composite box structure mounted on a railway car underframe are provided. The composite box structure may be defined in part by exterior metal sheets, side stakes attached to the exterior metal sheets, insulating materials disposed between the side stakes and the exterior metal sheets and at least one layer of fiber reinforced material. The composite box structure preferably includes a pair of endwalls, a pair of sidewalls, a floor assembly and a roof assembly.

Owner:TRINITY IND INC

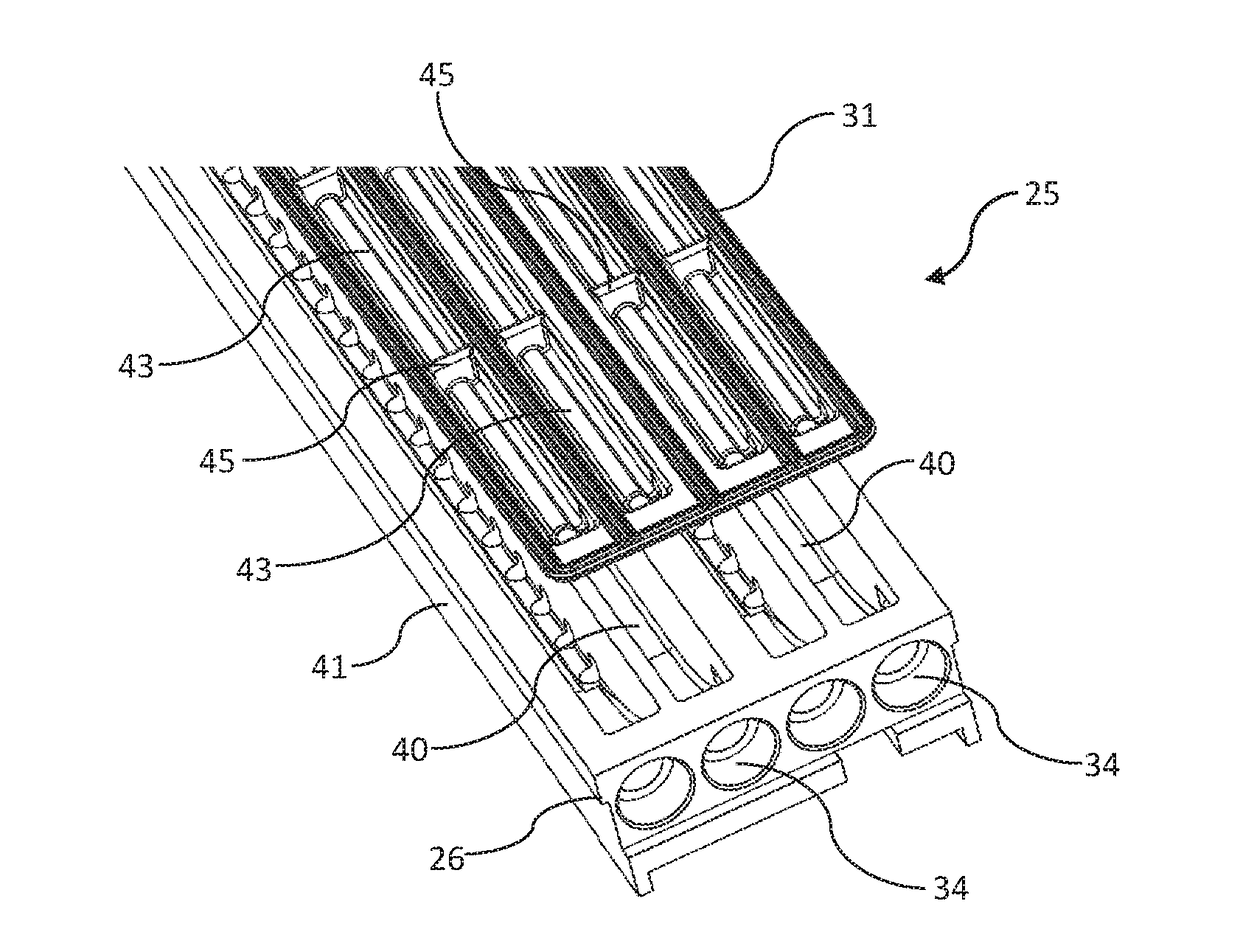

Roof assembly and airflow management system for a temperature controlled railway car

InactiveUS6904848B2Satisfied with useImprove insulation performanceRailway roofsRailway heating/coolingTemperature controlControl system

A roof assembly mounted on a composite box structure with an air plenum assembly attached to and extending from an interior surface of the roof assembly. The composite box structure includes a pair of end wall assemblies, a pair of side wall assemblies, a floor assembly and the roof assembly. An opening may be formed in one end of the end wall assemblies to allow installing a temperature control system. An airflow management system may be incorporated into the composite box structure. The composite box structure may be assembled on a railway car underframe to form a temperature controlled railway car or an insulated box car.

Owner:TRINITY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com