Patents

Literature

134results about How to "Controlled contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

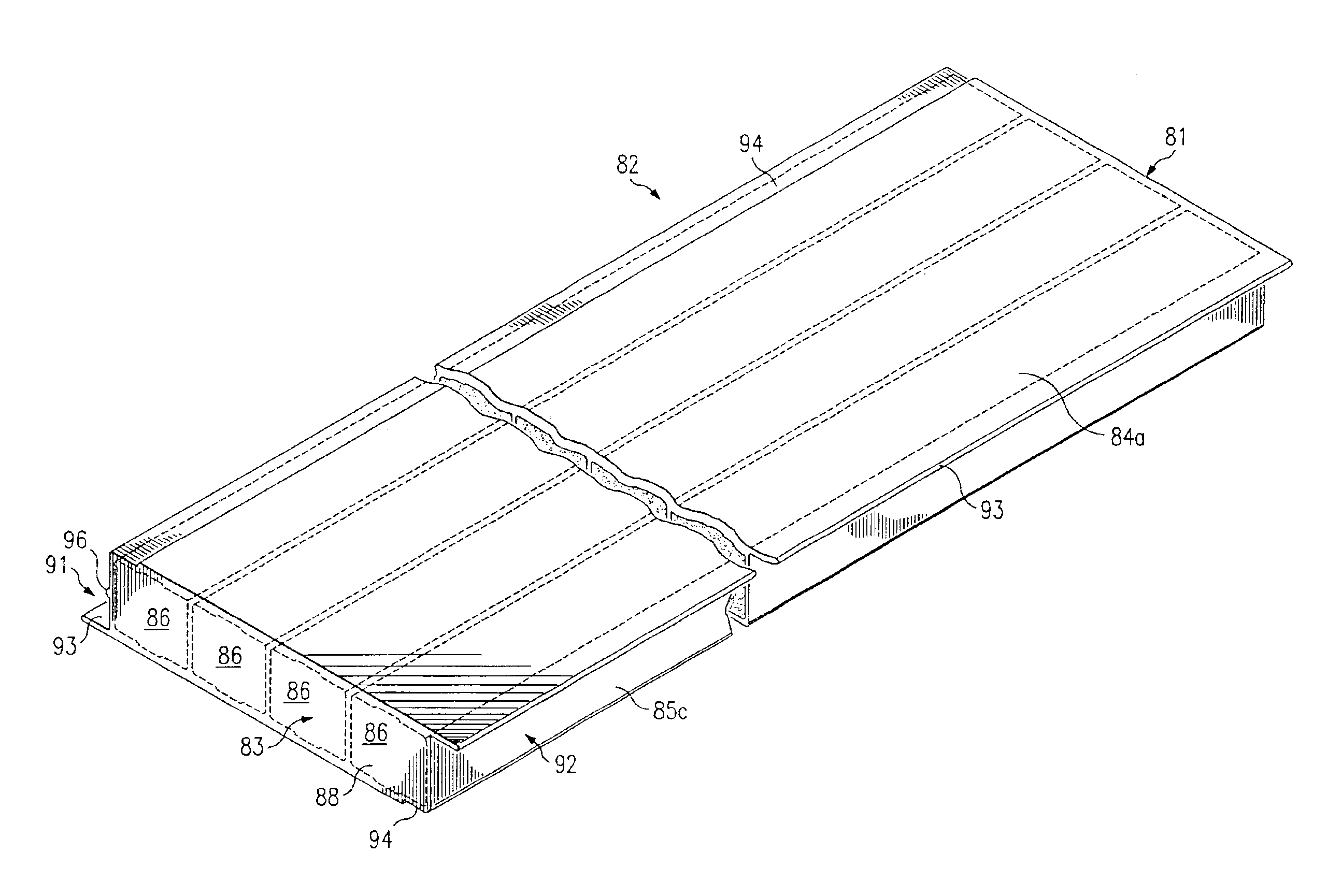

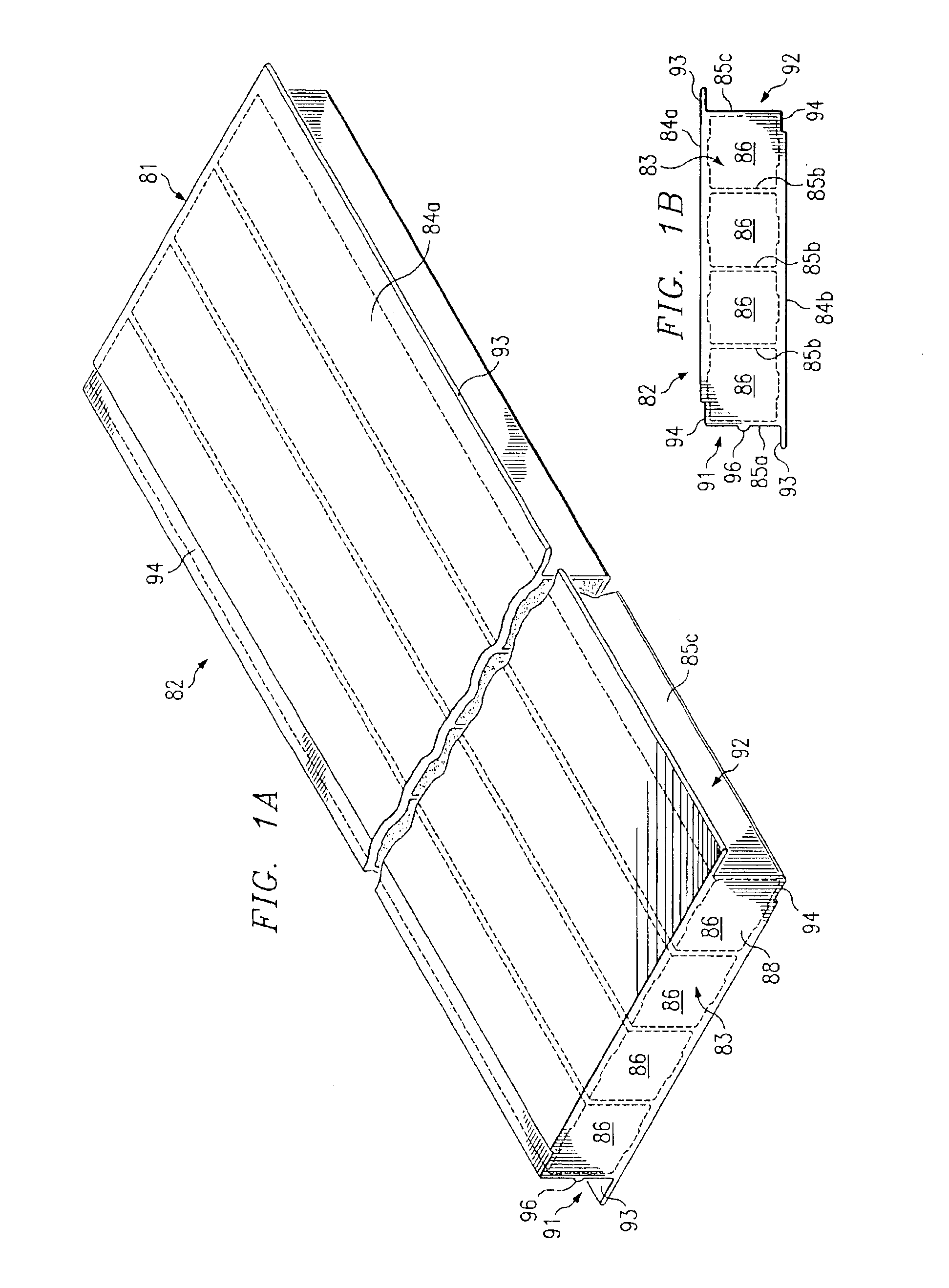

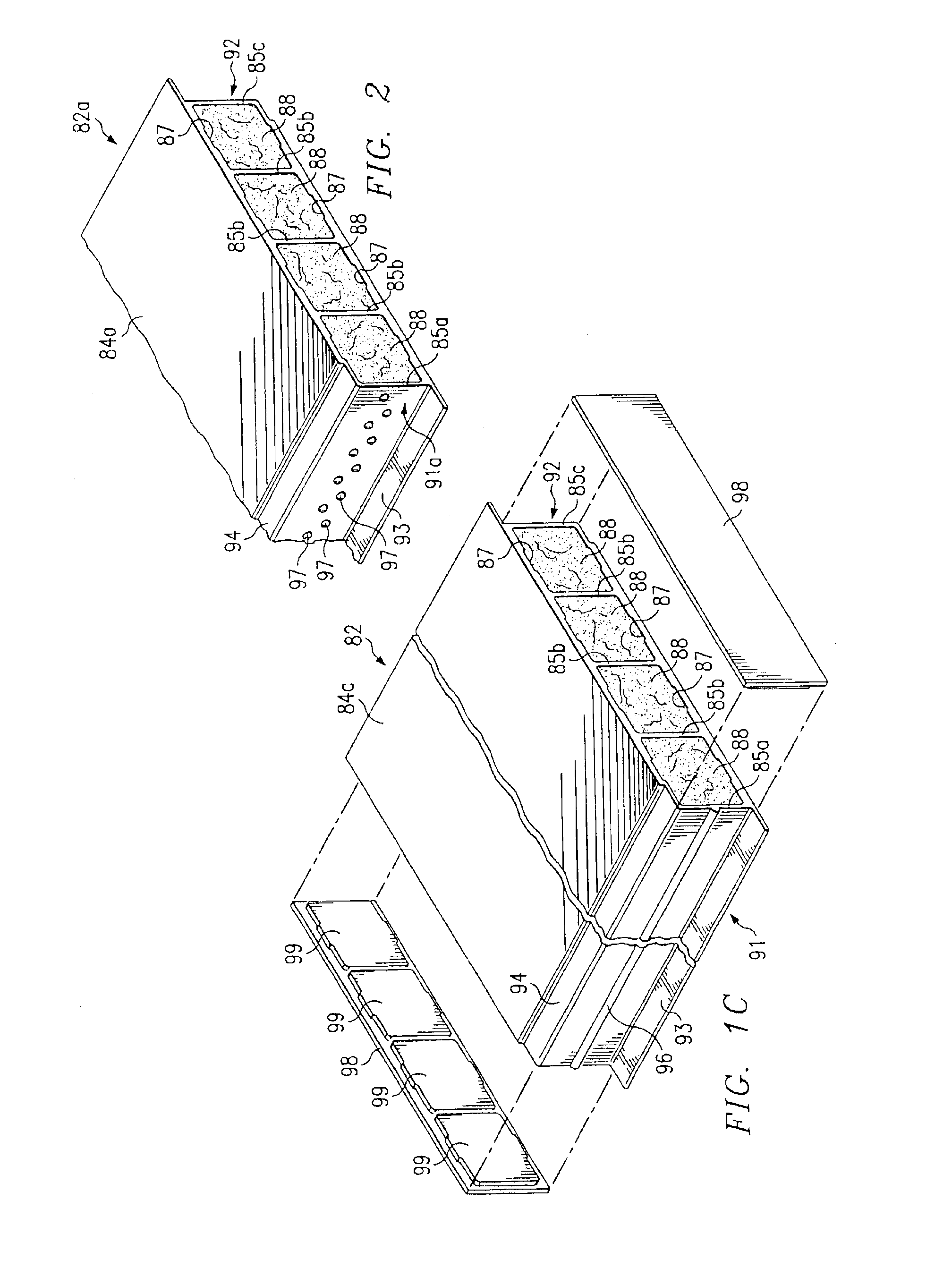

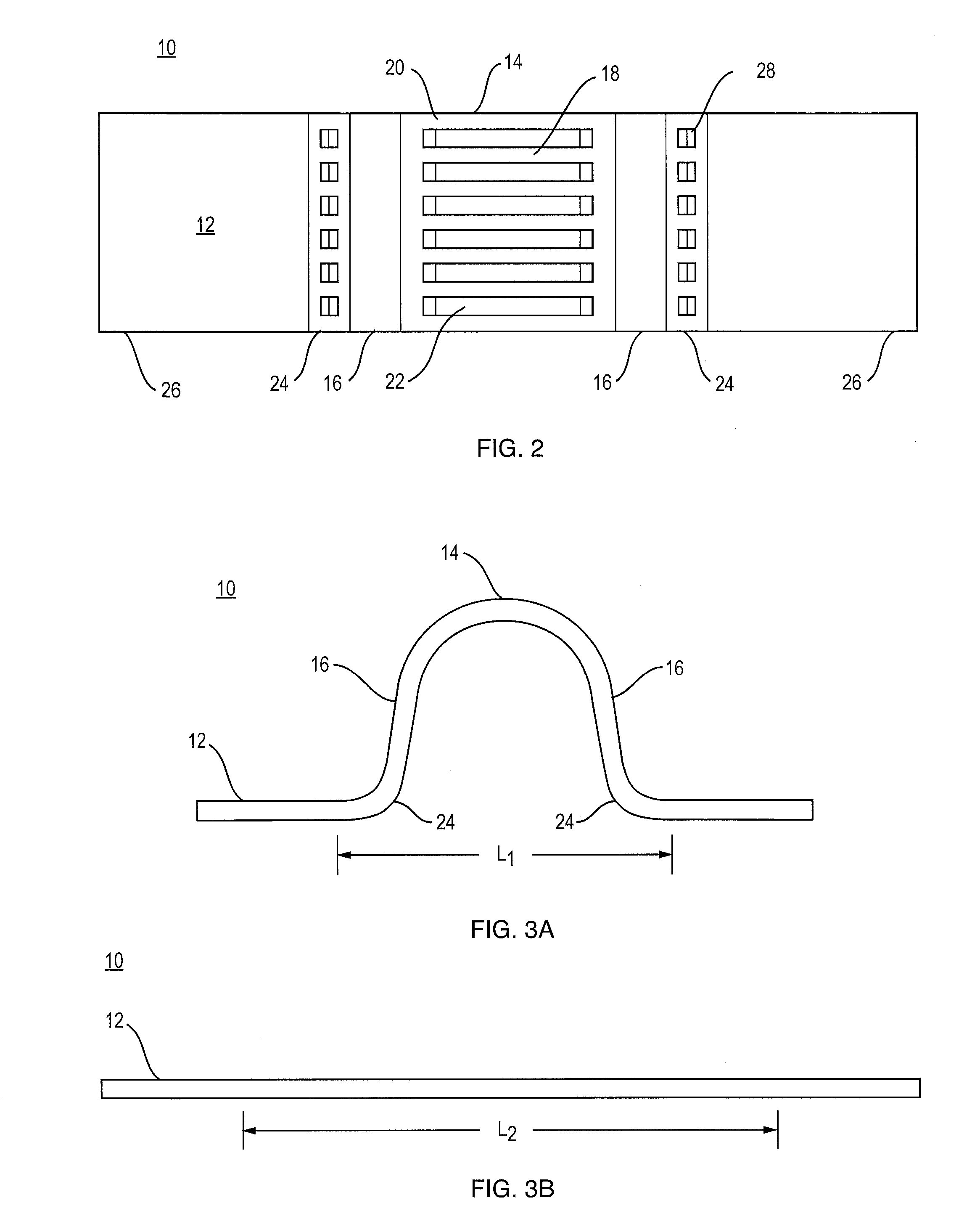

Pultruded panel

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

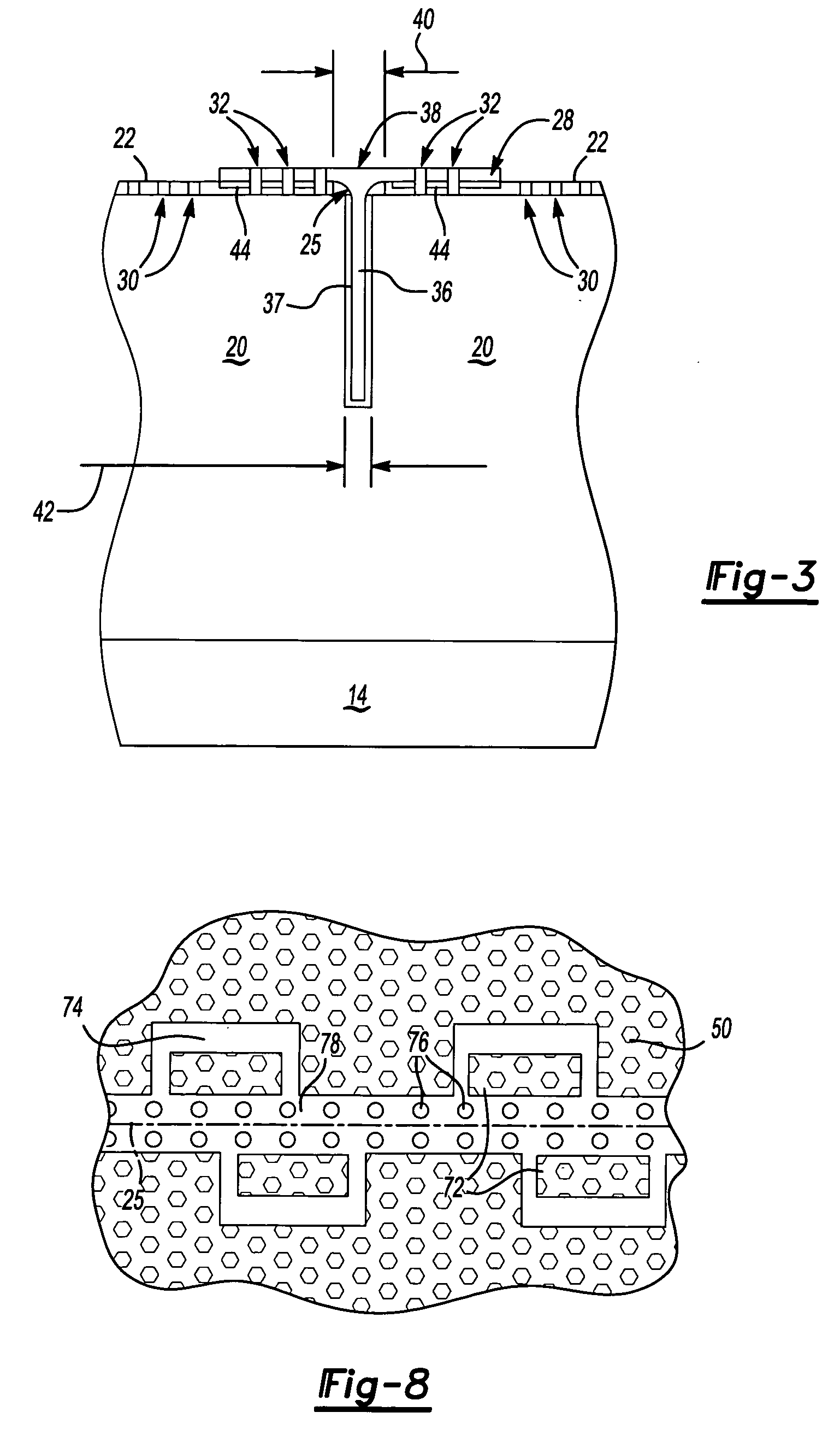

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

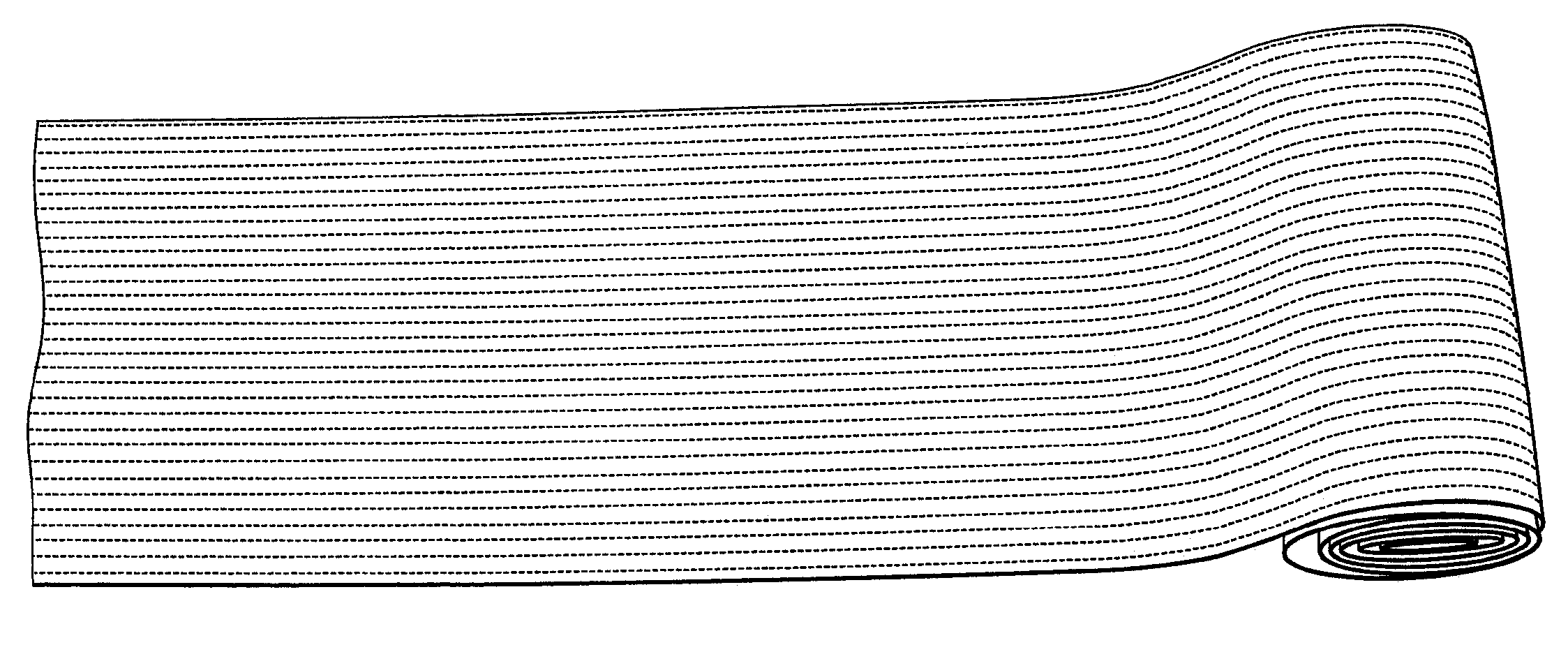

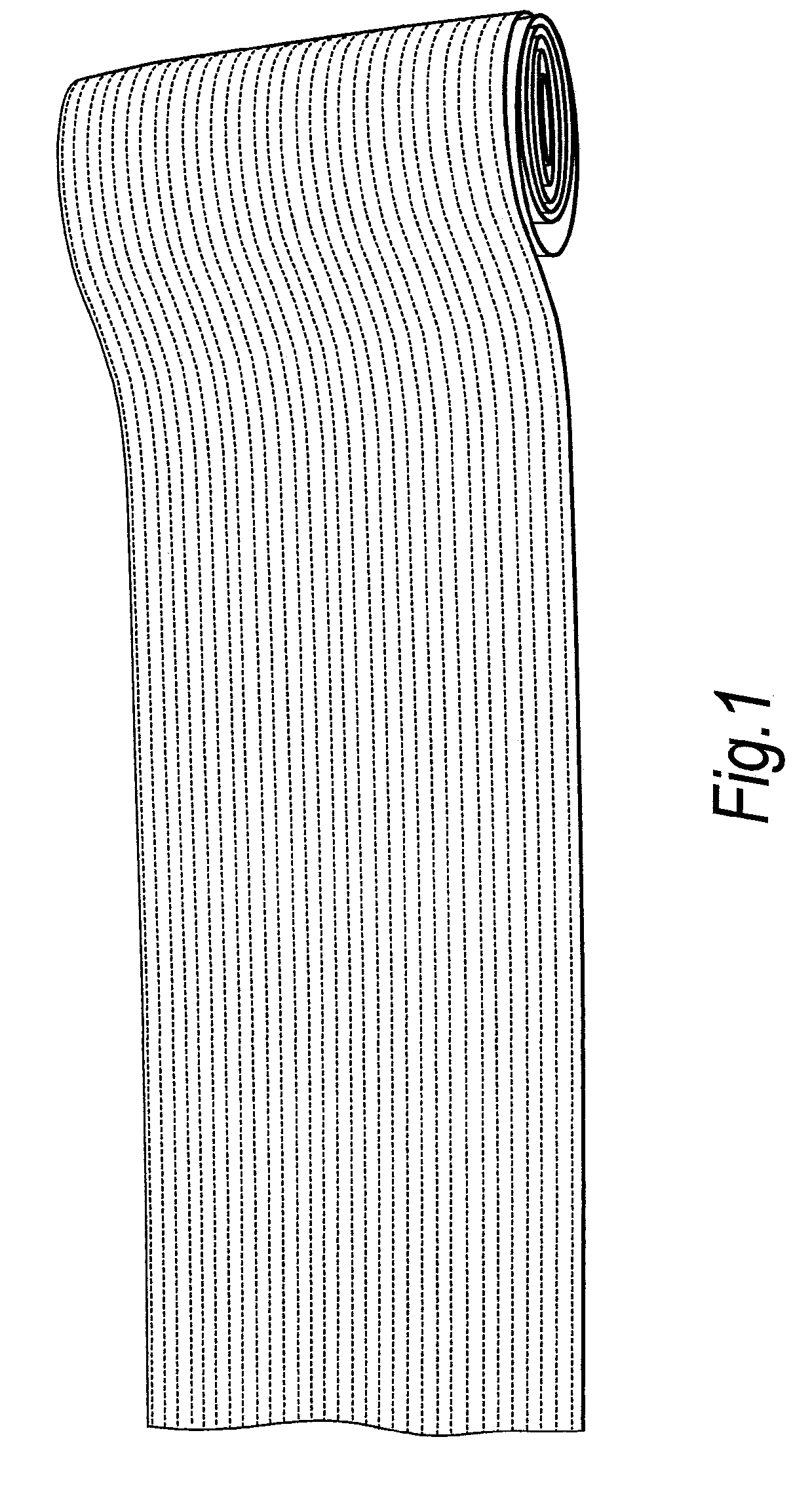

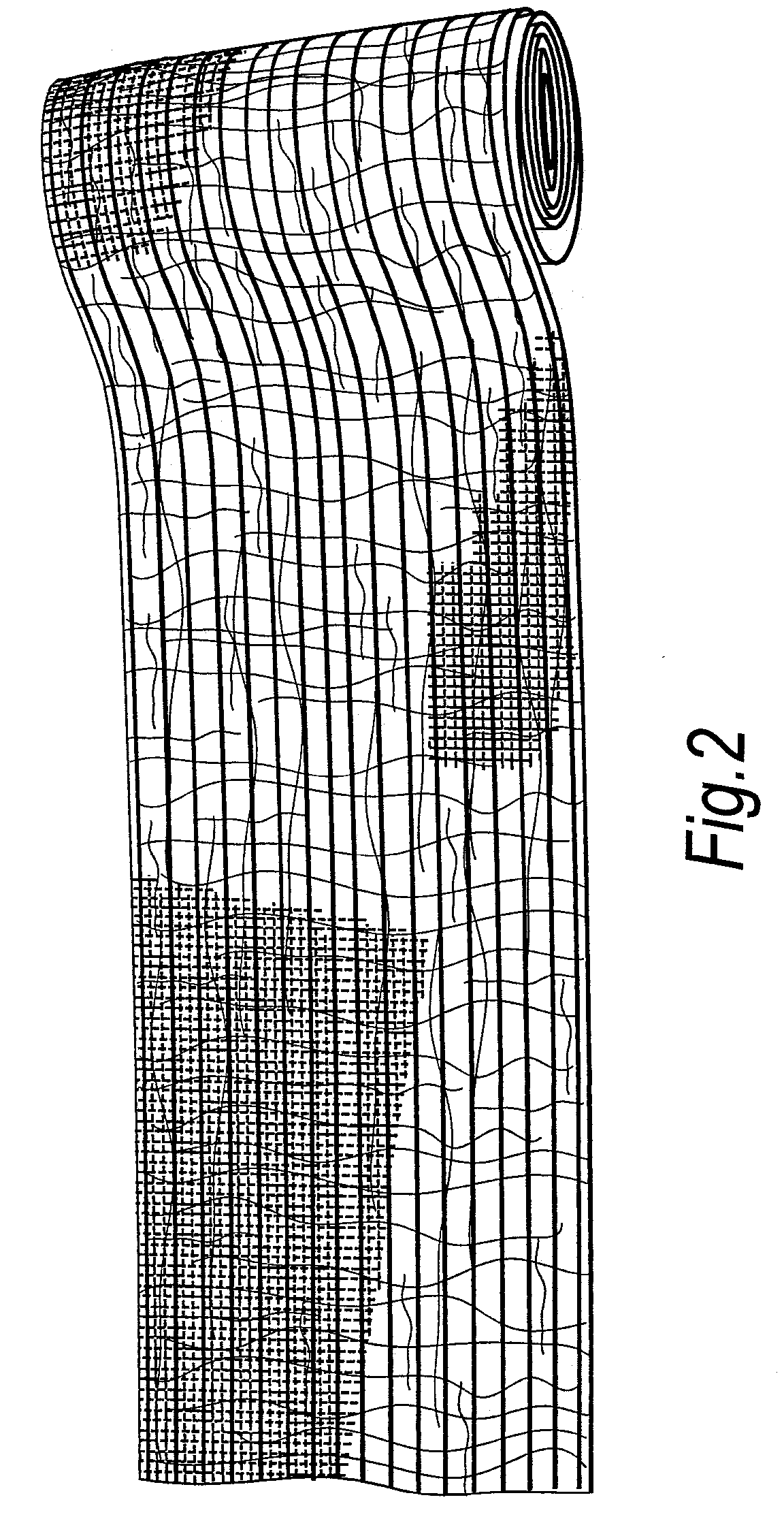

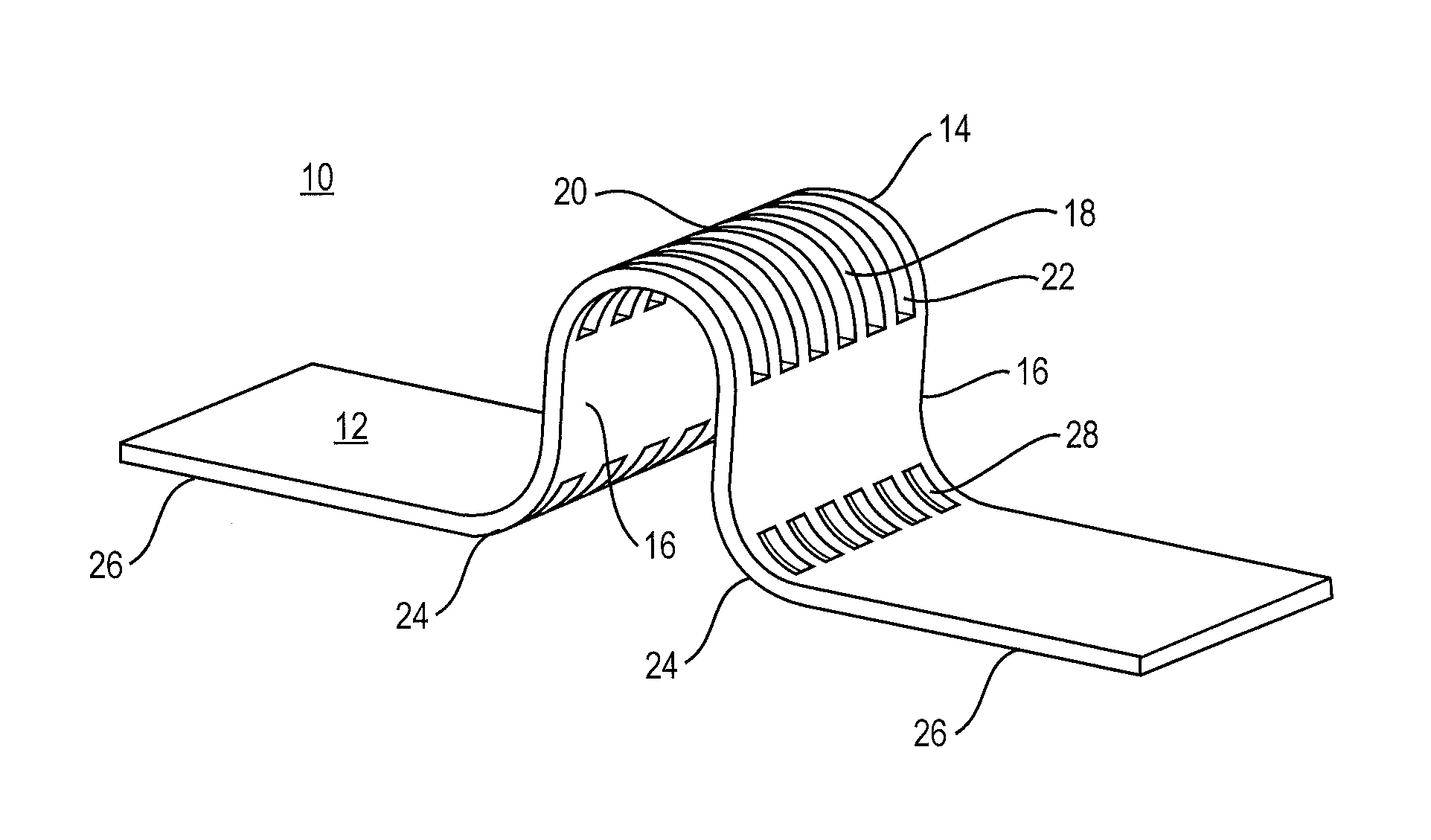

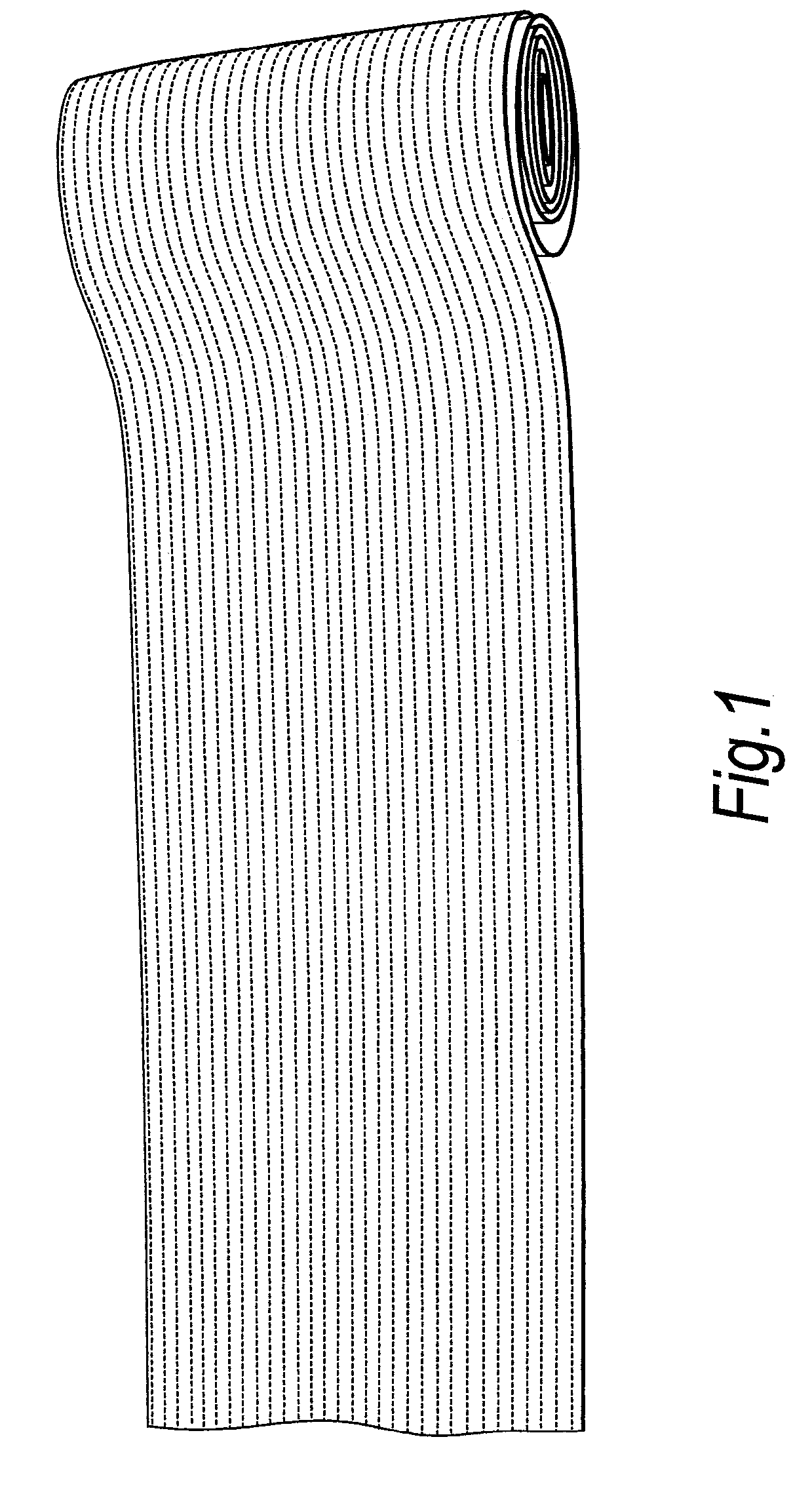

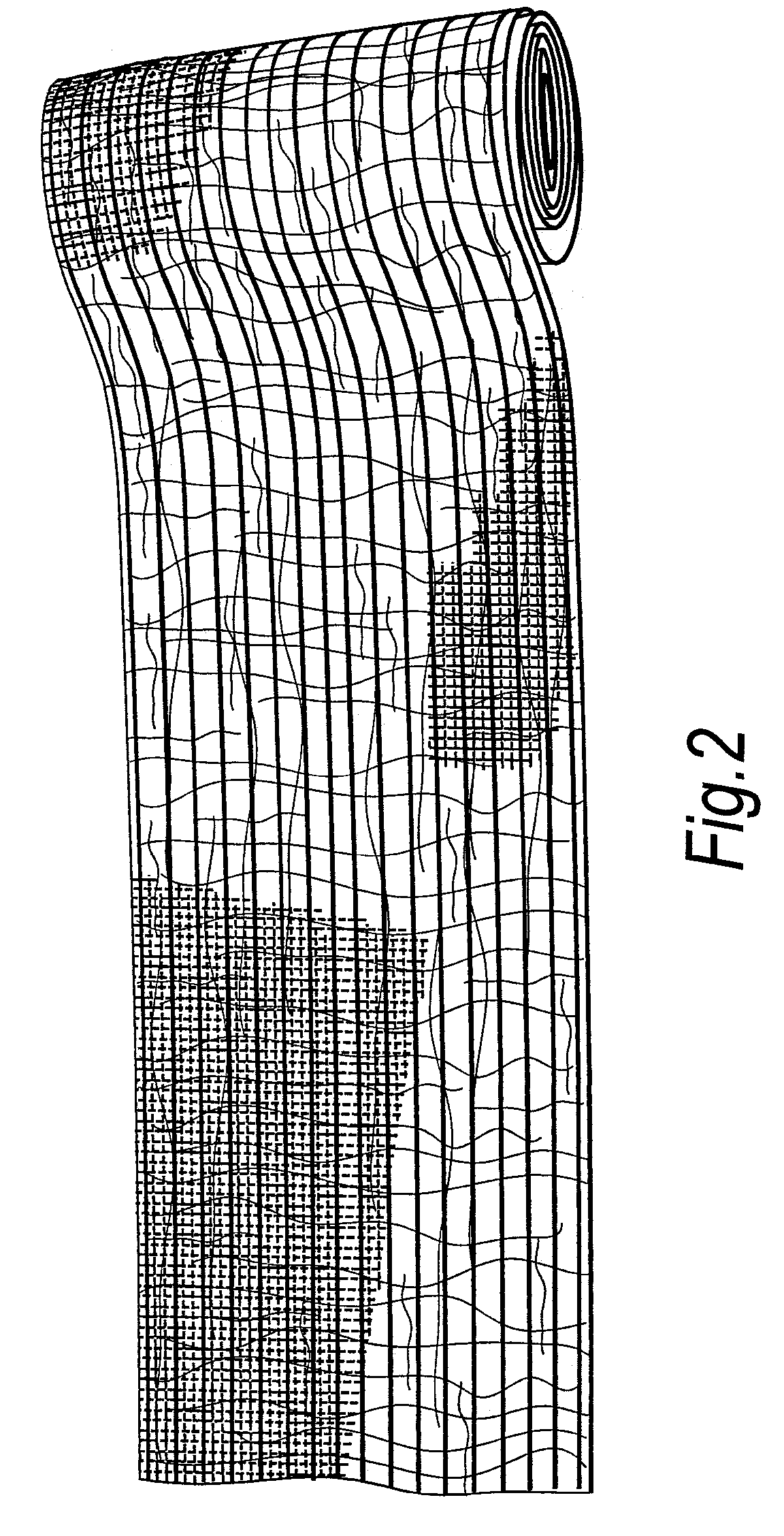

Wound dressing material

ActiveUS20070042024A1Easily placed in intimate contact woundEasily in surrounding skinNon-adhesive dressingsSynthetic resin layered productsFiberWound dressing

A material for use as a wound dressing, the material being in the form of a roll and comprising gel forming fibers and the material having lines of longitudinal stitching.

Owner:CONVATEC TECH INC

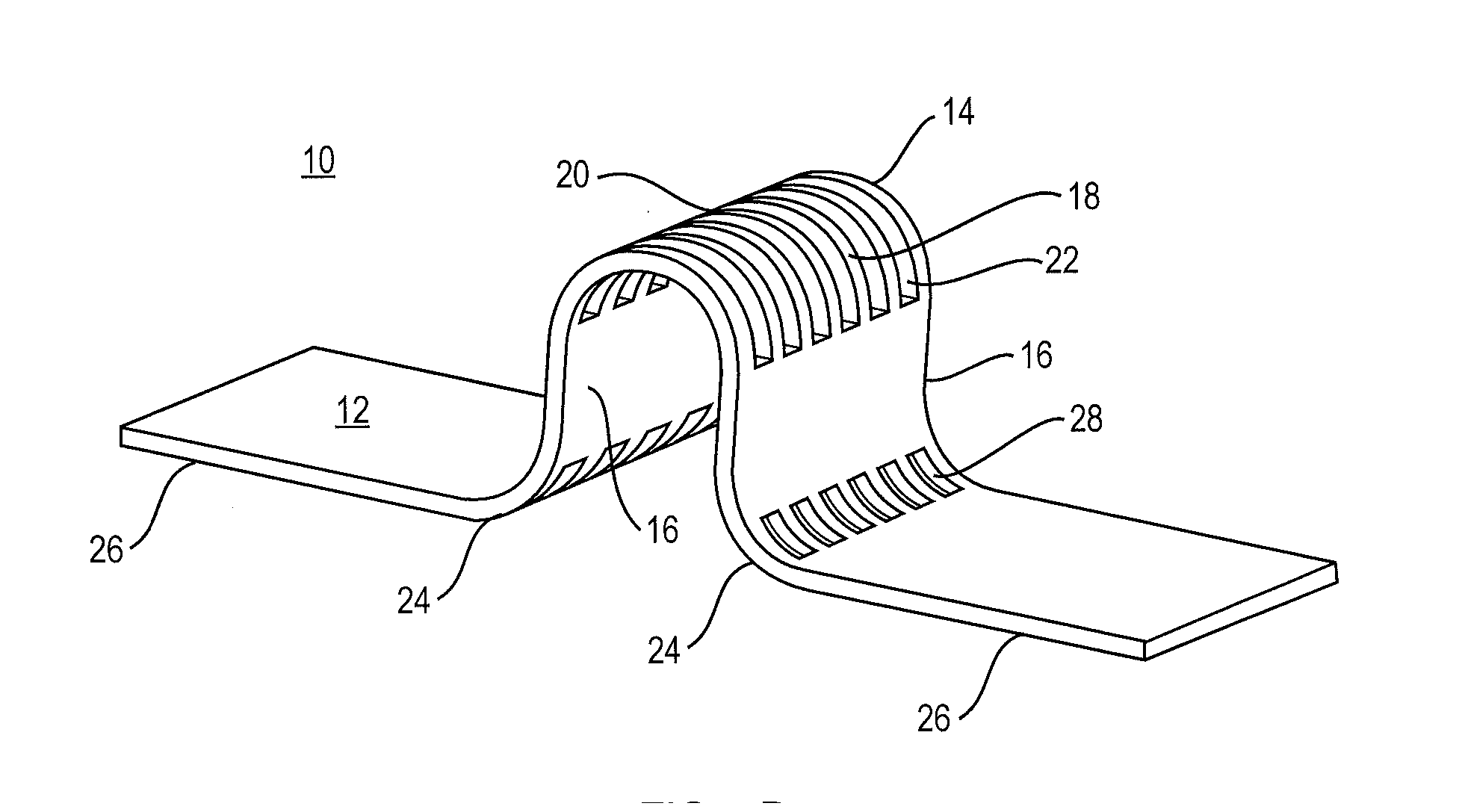

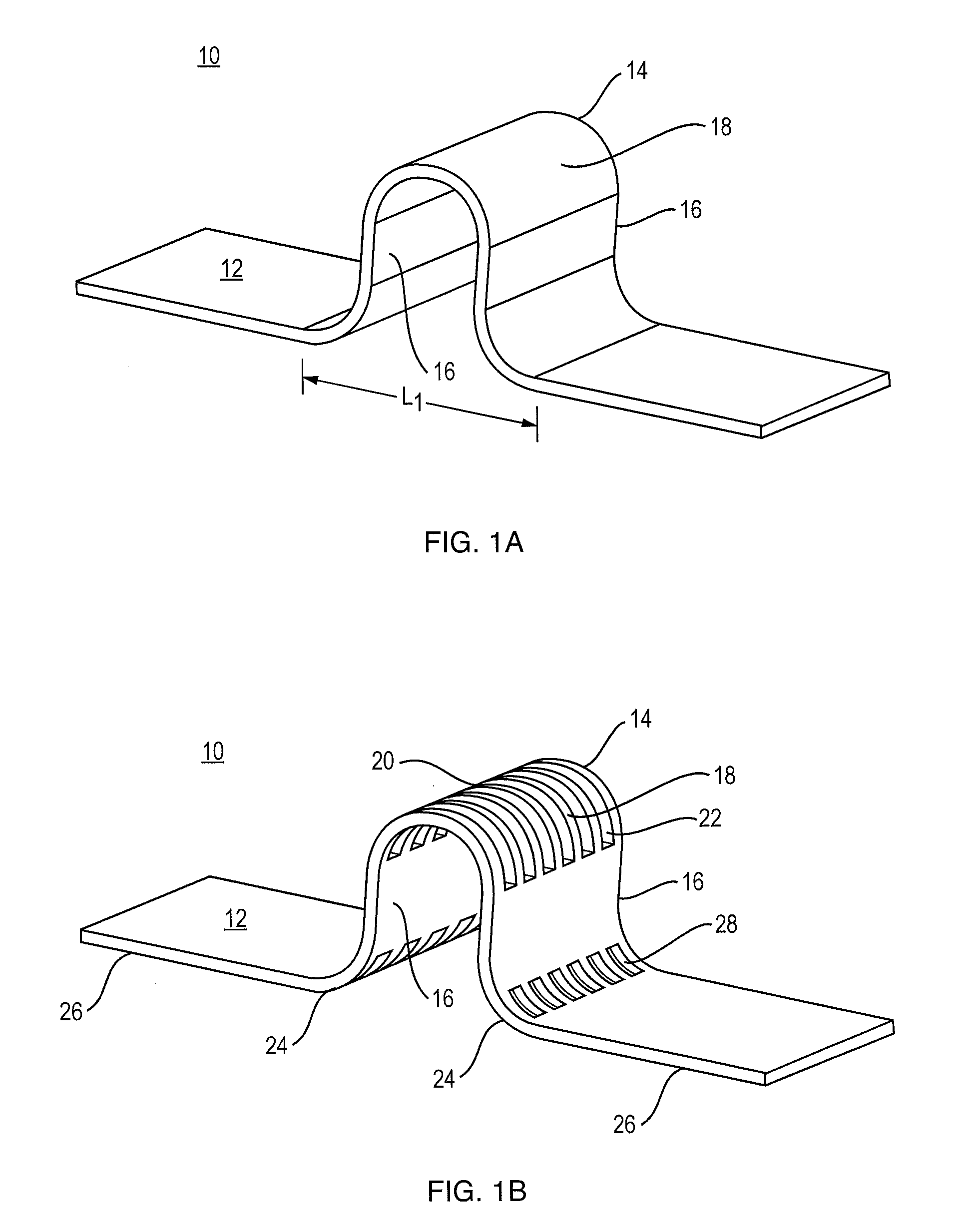

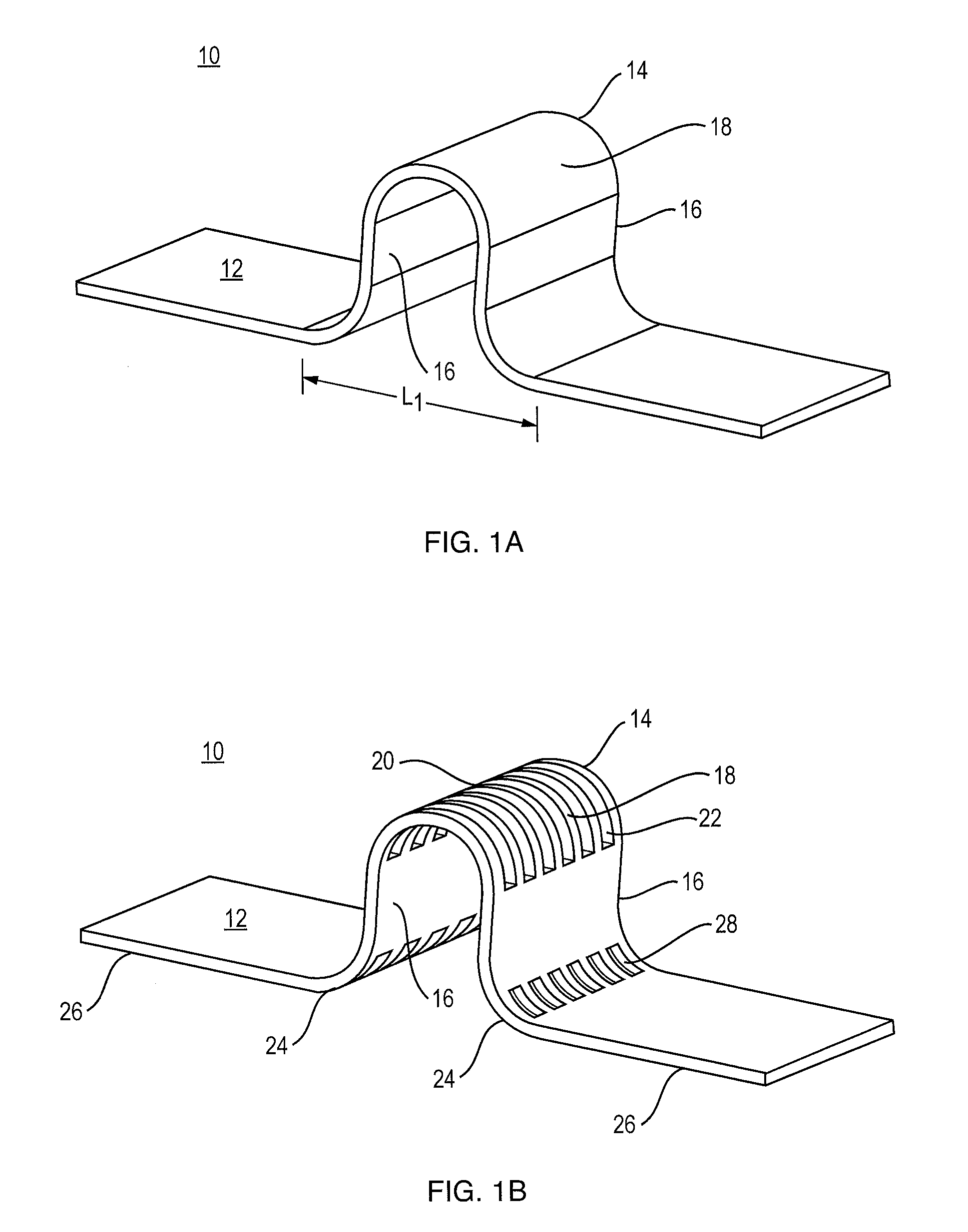

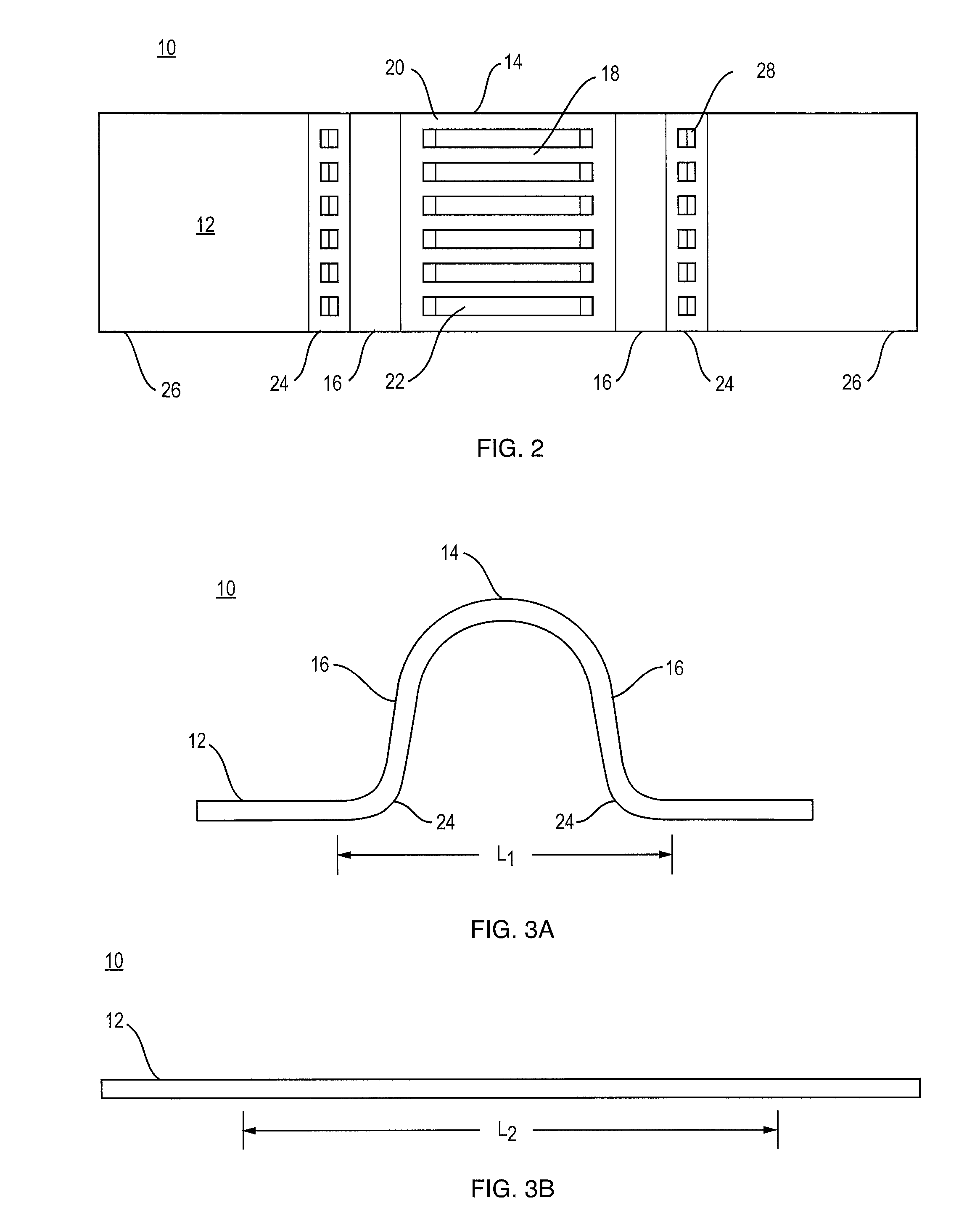

Flexible actuator based on shape memory alloy sheet

InactiveUS20110173970A1Raise the ratioReduce the cross-sectional areaMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceElectricity

A flexible unit-cell actuator includes a shape memory alloy sheet having a fold between adjacent legs in one state and a heat source that upon activation concentrates heating of the shape memory alloy sheet at the fold relative to the legs to change the fold between one state and another state. The heat source may include resistive heating due to an electric current passing through the shape memory alloy sheet. The fold typically includes a reduced cross-sectional area and may include slits to increase electrical resistance at the fold relative to the adjacent legs. An actuator array includes a plurality of flexible unit-cell actuators formed in a sheet, each unit-cell actuator mechanically coupled to at least one other unit-cell actuator at a coupling region. Plural unit-cell actuators may be mechanically coupled in series, in parallel, or both, may be electrically connected in series, and may move along a defined curve or surface. A linear or curvilinear actuator includes a guide, a plurality of bearings or support elements slidable along the guide, and an array of actuators coupled between adjacent bearings and circumferentially about the bearings. An actuator includes a plurality of segments fanning from a hinge and shape memory alloy actuators coupled between adjacent segments to cause the segments to fan in an out about the hinge.

Owner:MASSACHUSETTS INST OF TECH

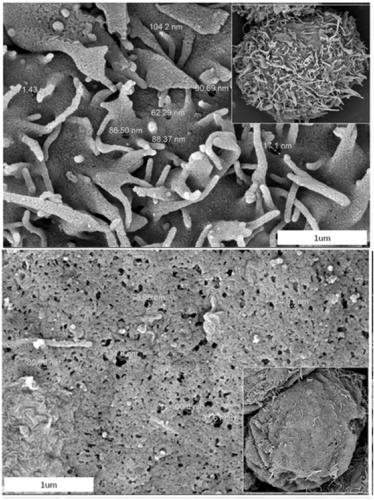

Pigment-containing artificial skin detection model and preparation method thereof

The invention relates to a pigment-containing artificial skin detection model and a preparation method thereof. The artificial skin detection model is an epidermal layer structure with activity, which is constructed by compositely inoculating cutin formative cells and melanophores to the surface of a support membrane made from a biodegradable material through culture and comprises a stratum basale, a stratum spinosum, a stratum granulosum and a stratum corneum, and a basilar membrane structure is formed between the epidermal layer and the biodegradable material positioned below the epidermal layer. Compared with the conventional product, the invention can better simulate the pigment components of natural skin and more accurately reflect the whitening and sunscreen effect of cosmetics because of containing the melanophores, nourish the cutin formative cells by using the support membrane made from the biodegradable material as an enderonic layer, control the contraction of the epidermal layer with the strength and enhance the stability of the detection model and has low raw material cost, short manufacturing period and mass production; and in addition, the prepared artificial skin detection model can be directly used for the efficacy detection of the cosmetics and the skin irritation detection of textiles, the cosmetics and chemicals.

Owner:GUANGDONG BOXI BIO TECH CO LTD

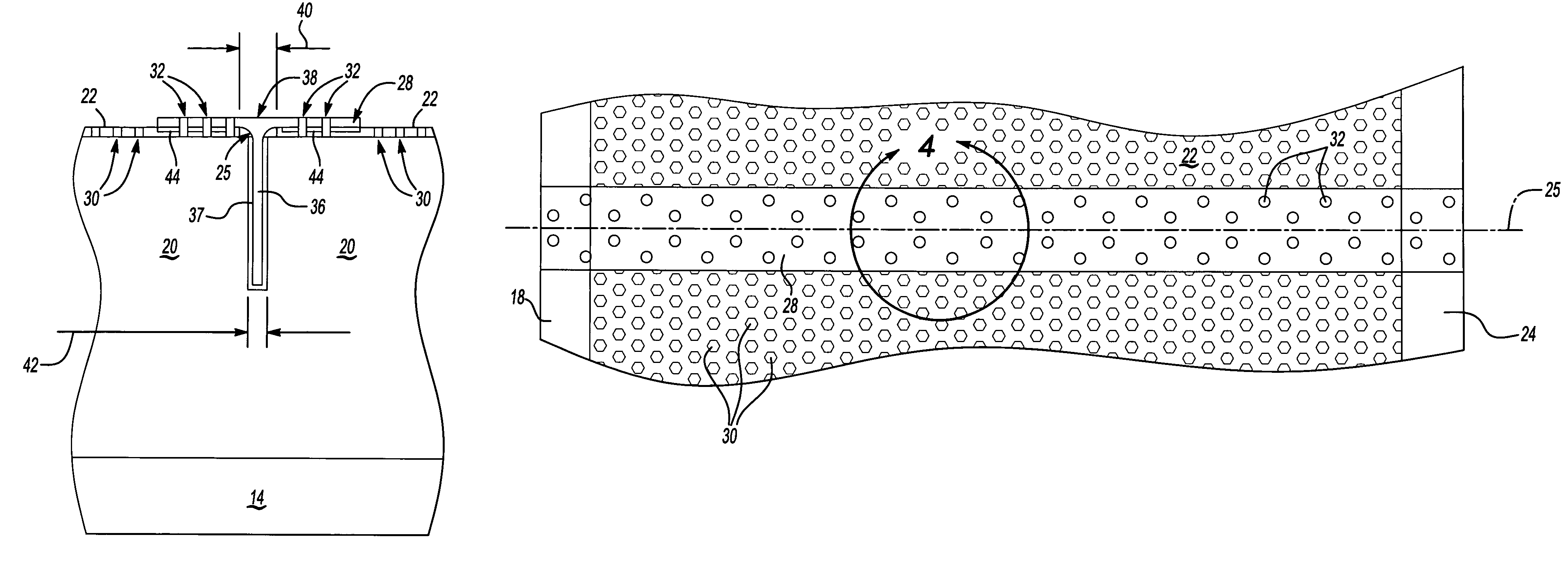

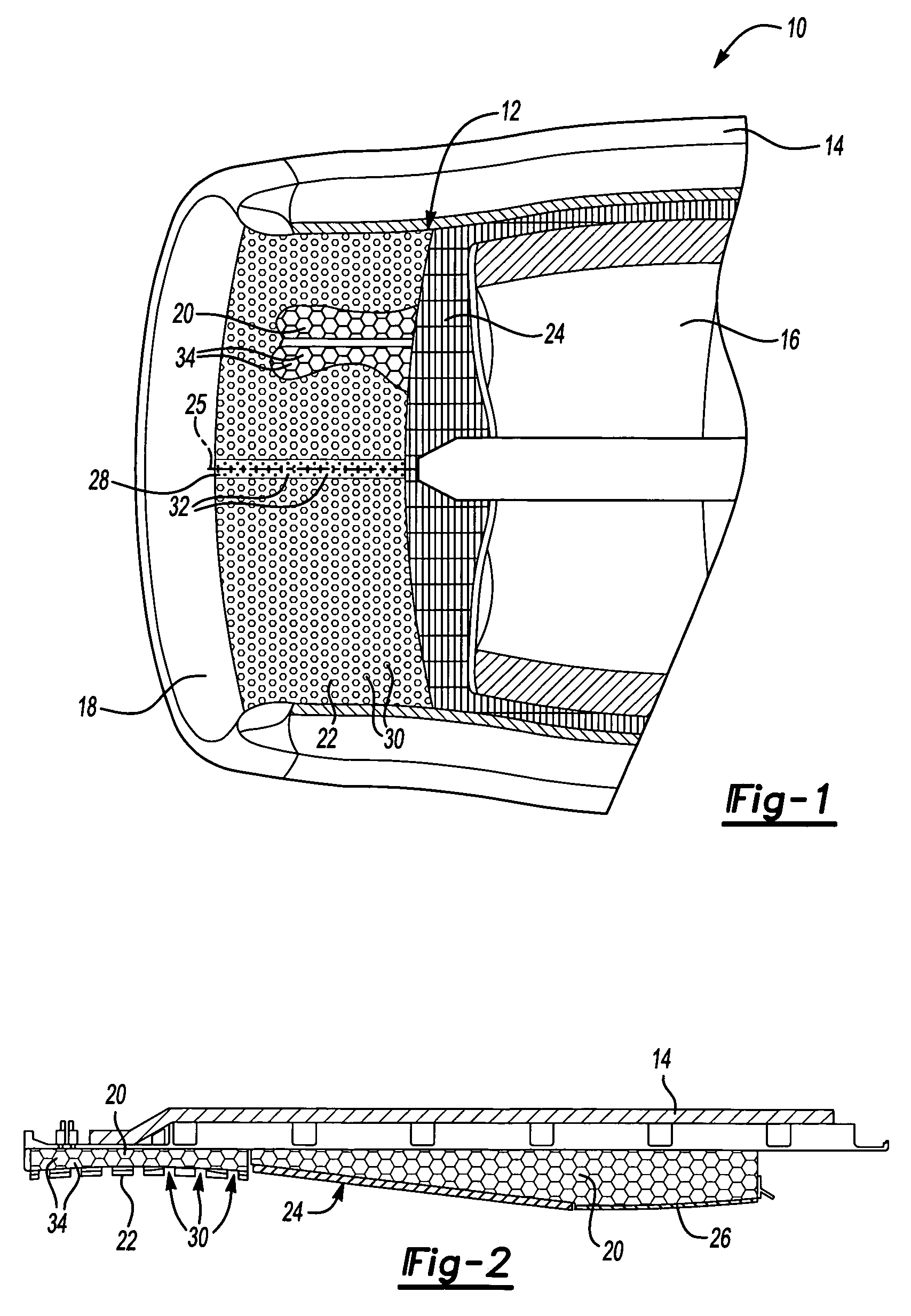

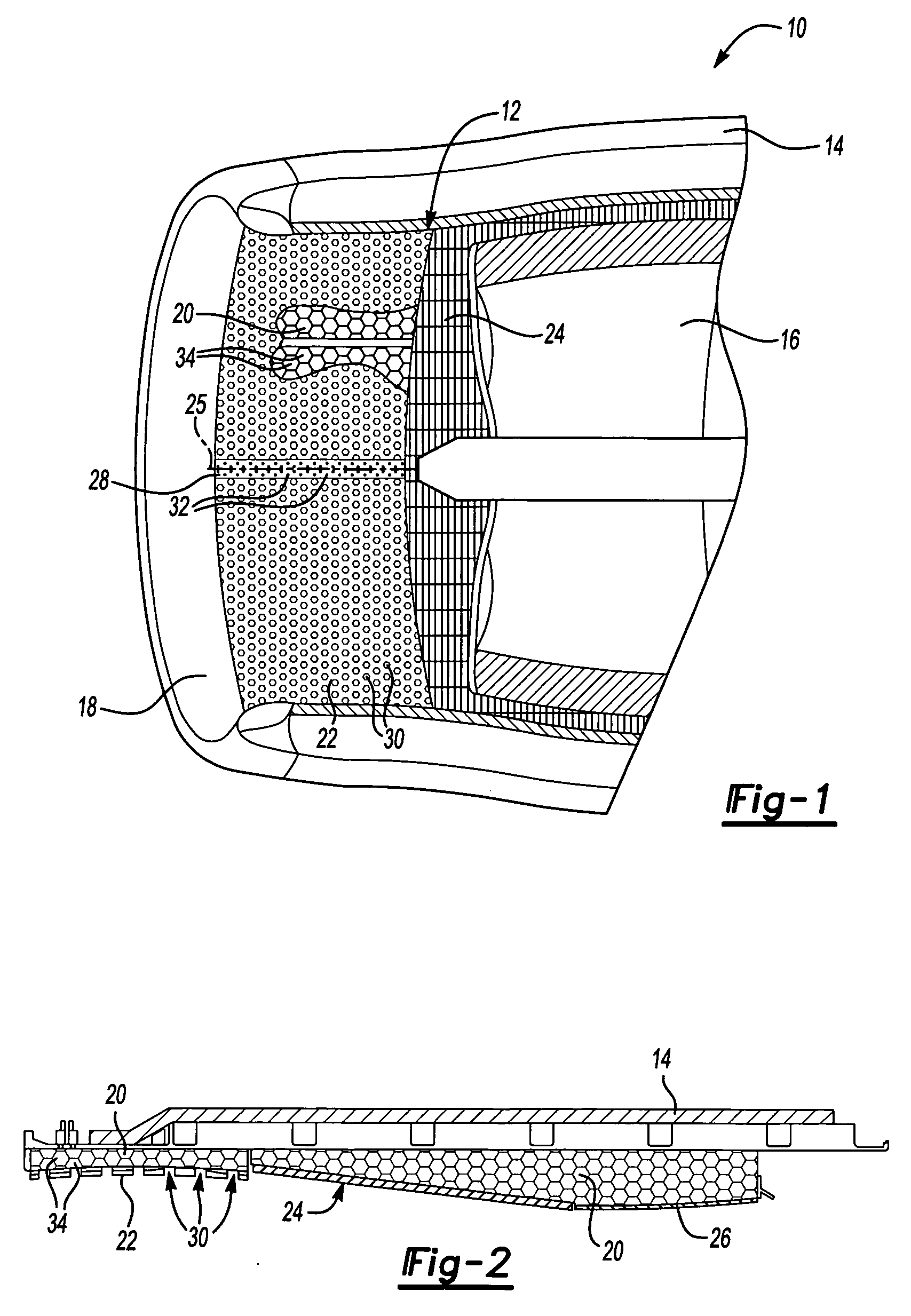

Acoustic mechanical retainer

ActiveUS7296656B2Improved noise attenuation performanceReduce sound levelFuselage framesNoise reduction installationsEngineeringFace sheet

A fan case assembly includes a noise attenuation layer that is covered by a face sheet. The face sheet includes a first plurality of openings. The noise attenuation layer includes a plurality of individual cells that are in communication with at least one of the first plurality of openings. Noise energy is communicated through the first plurality of openings into the individual cells and dissipated to reduce noise emissions. A seam in the face sheet is covered to protect the underlying noise attenuation layer from damage by a retainer. The retainer is bonded to the face sheet over the seam and includes a second plurality of holes that communicates noise energy through the retainer to the noise attenuation layer. Communication of noise energy through the retainer provides an acoustically active seam that aids in the dissipation of noise energy and thereby reduces the level of sound emitted from the engine.

Owner:RTX CORP

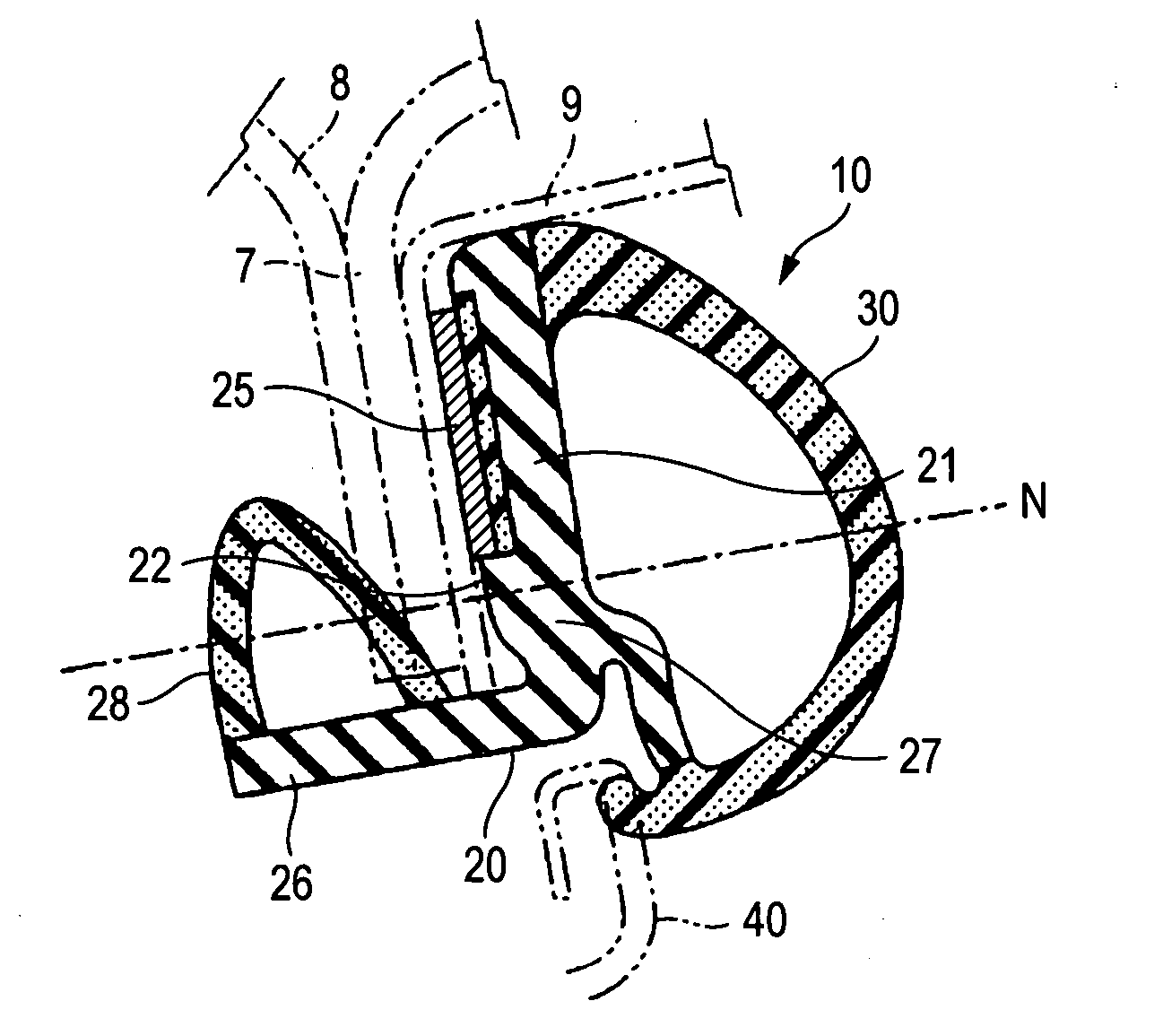

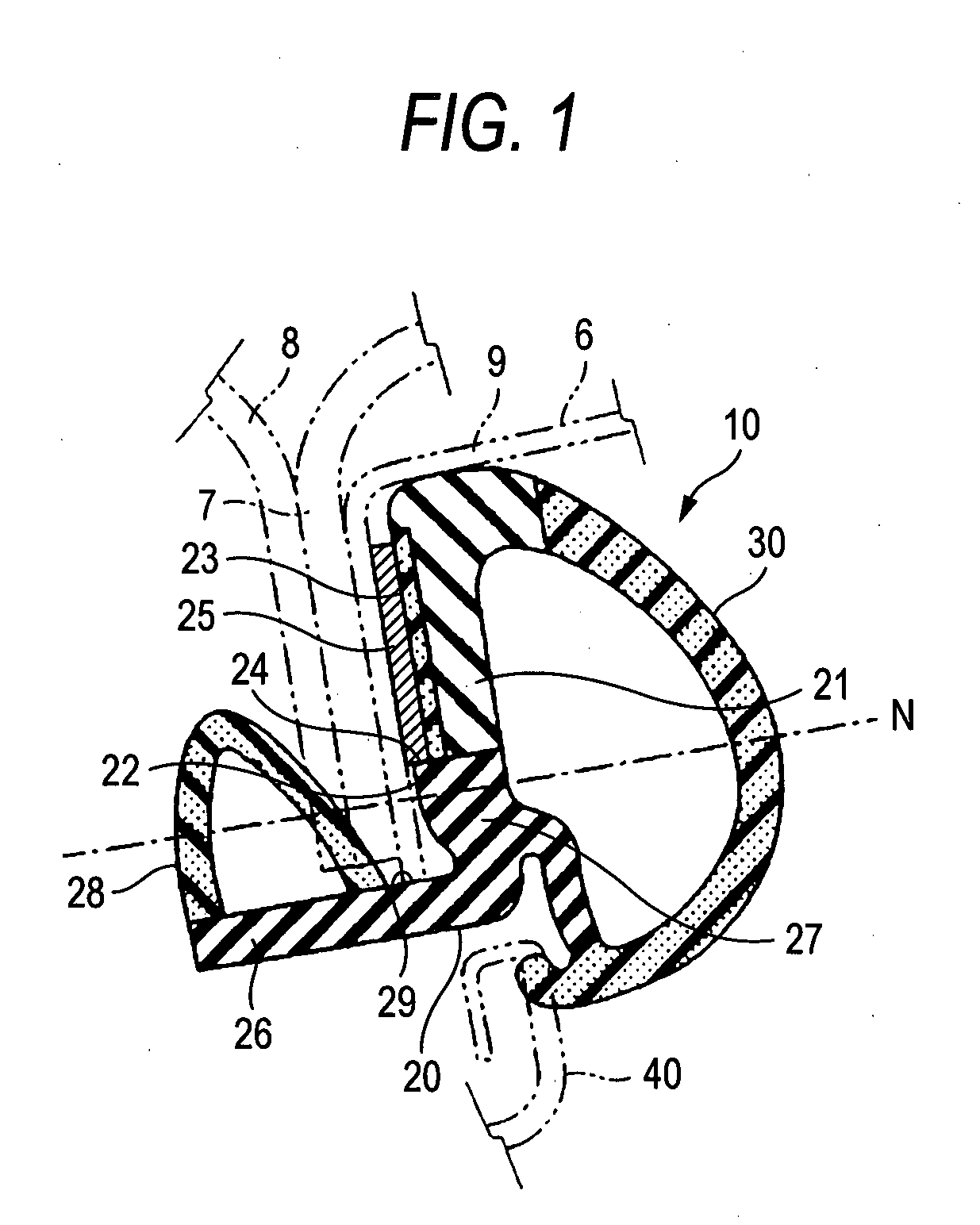

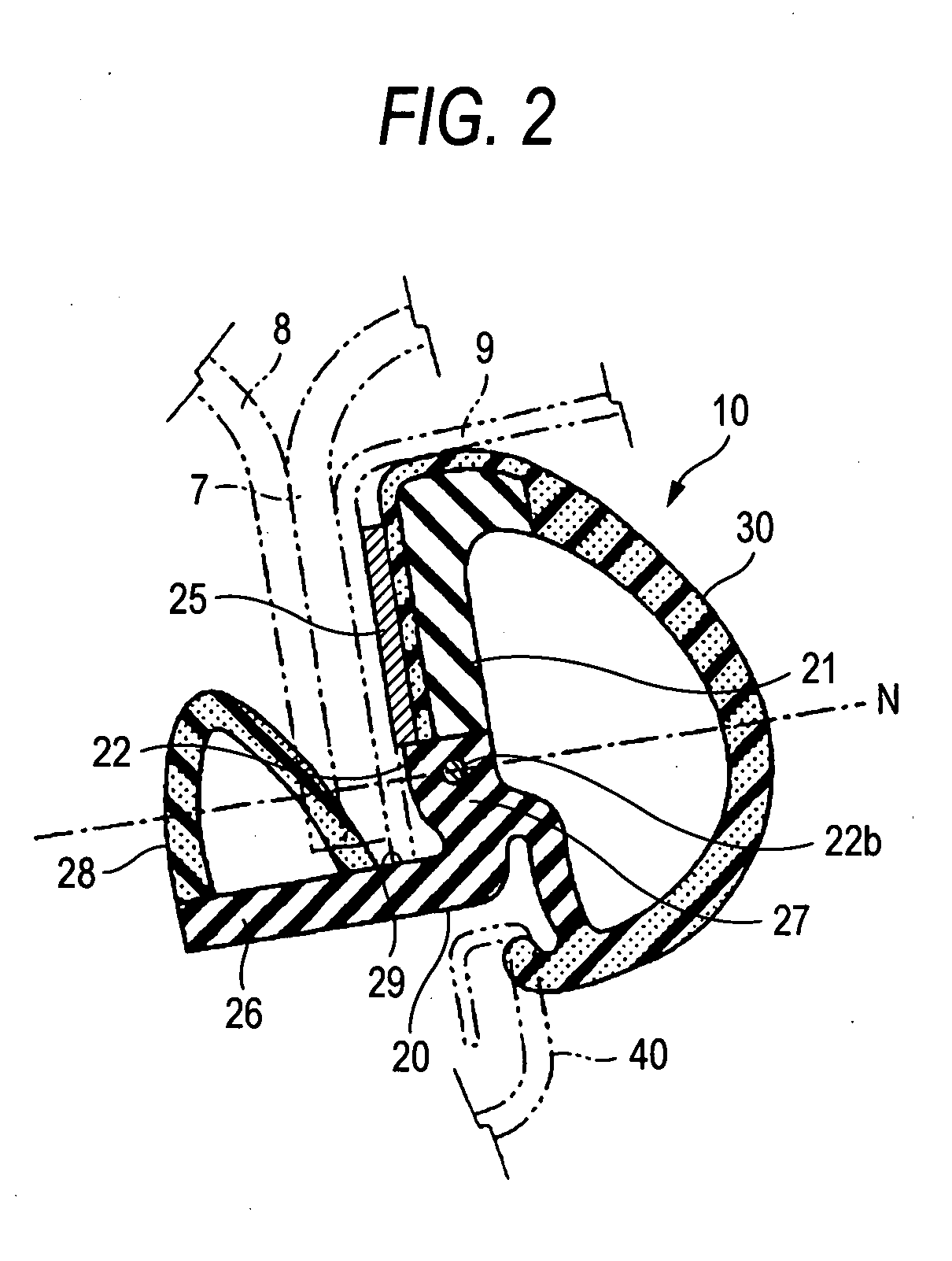

Weather strip

InactiveUS20070245634A1Prevent intrusionGood flexibilityVehicle sealing arrangementsSealing arrangementsNeutral planeMechanical engineering

There is provided a weather strip in which a mounting base portion of the weather strip includes a portion formed into a substantially L-shape in cross section which has at least a bottom wall and an exterior side wall. A pressure sensitive adhesive double coated tape is securely affixed to an internal surface of the exterior side wall. A stretch and contraction prevention portion is formed on the exterior side wall in a position which lies more centrally in a width direction of the exterior side wall than a connecting portion where the exterior side wall and the bottom wall are connected together. When the mounting base portion is curved in the width direction, a neutral plane of the curve is made to reside within the stretch and contraction prevention portion.

Owner:TOYODA GOSEI CO LTD

All-silver electronic paste and preparation method thereof

ActiveCN101620893AGuaranteed electrical performanceEffectively fill the gapNon-conductive material with dispersed conductive materialMetal/alloy conductorsSolventFineness

The invention relates to an all-silver electronic paste and a preparation method thereof, and the all-silver electronic paste comprises the following components by weight percent: 86-90wt% of silver powder, 3-7wt% of organic solvent, 4-6wt% of polymer resin and 1-3wt% of inorganic additive. The preparation method comprises the following steps: (1) weighing the polymer resin and a solvent according to proportion, placing in a container, placing the container in a constant temperature water bath, carrying out dispersion and stirring on the resin and the solvent for 120 plus or minus 10 minutes, evenly mixing, keeping the water temperature of the water bath at 80 plus or minus 5 DEG C, using a 200-mesh nylon filter screen for removing impurities and then preparing an organic carrier; (2) weighing the silver powder and the inorganic additive according to the proportion, adding into the organic carrier obtained in the step (1), using a three-roller rolling machine for grinding and rolling, obtaining the all-silver electronic paste with the average fineness of less than 5mu m and further using a 500-mesh filter cloth or filter screen for removing the impurities. The obtained all-silver electronic paste has the advantages of good dispersion, superior performance and great environmental protection. The preparation method is simple and the production efficiency is high.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

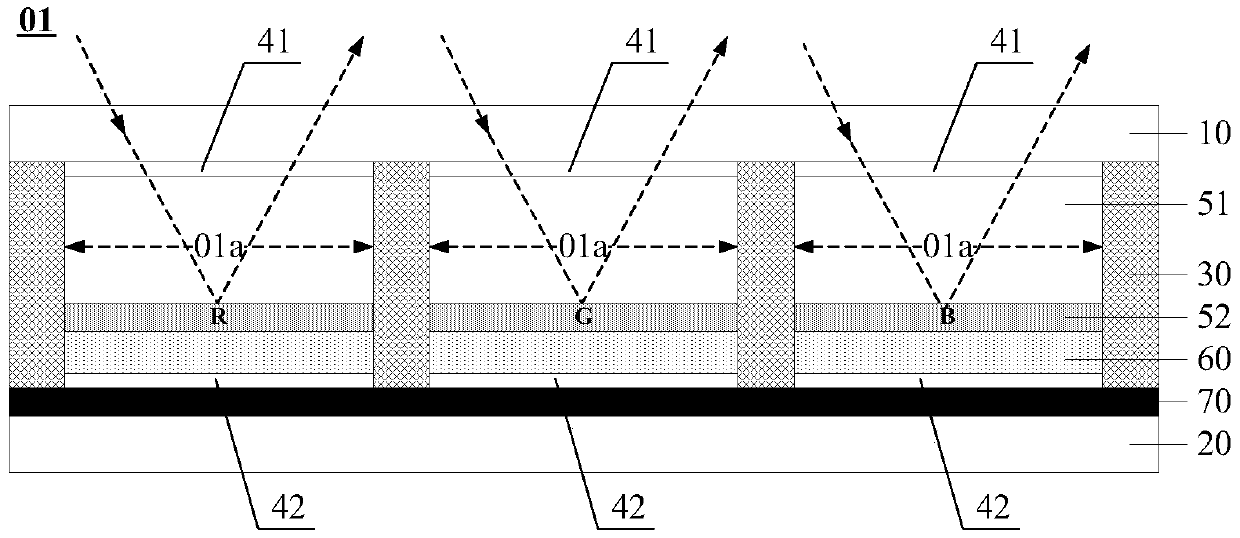

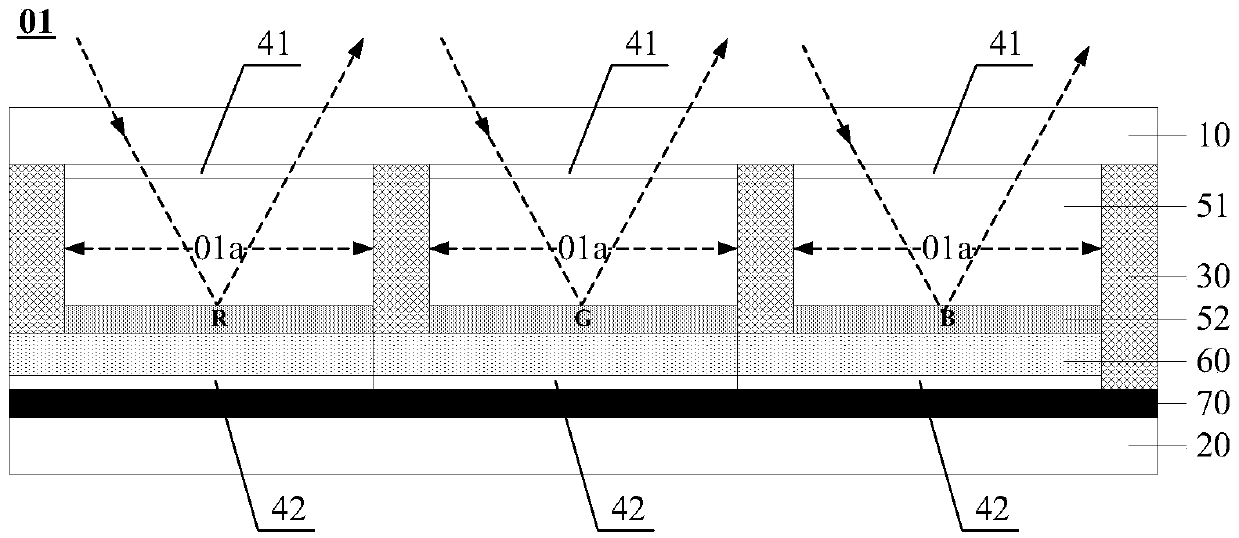

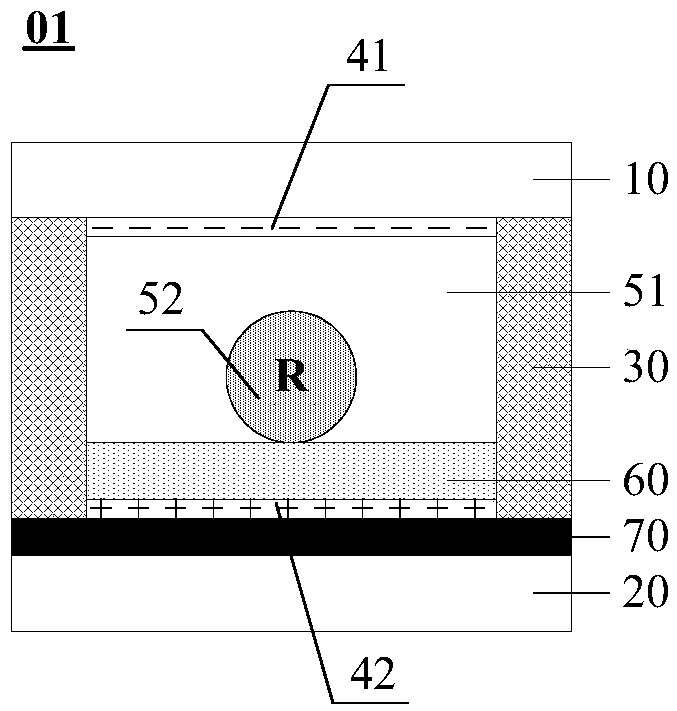

Display panel

The embodiment of the invention provides a display panel and relates to the technical field of display. According to the display panel, color display can be achieved without a backlight source or colored filter layer. The display panel comprises pixel separating walls arranged between a first substrate and a second substrate, wherein the space between the first substrate and the second substrate is divided into a plurality of sub-pixel areas by the pixel separating walls, and a first electrode, a first fluid layer, a second fluid layer, a hydrophobic dielectric layer, a second electrode and a black light absorption layer are arranged in any sub-pixel area in sequence in the direction from the first substrate to the second substrate; the first fluid layer is formed by transparent hydrophilic liquid, the second fluid layer is formed by colored printing ink, the second fluid layer is spread on the surface of the hydrophobic dielectric layer when no electric field exists between the first electrode and the second electrode, and the second fluid layer contracts to make the hydrophobic dielectric layer exposed when an electric field exists between the first electrode and the second electrode.

Owner:BOE TECH GRP CO LTD

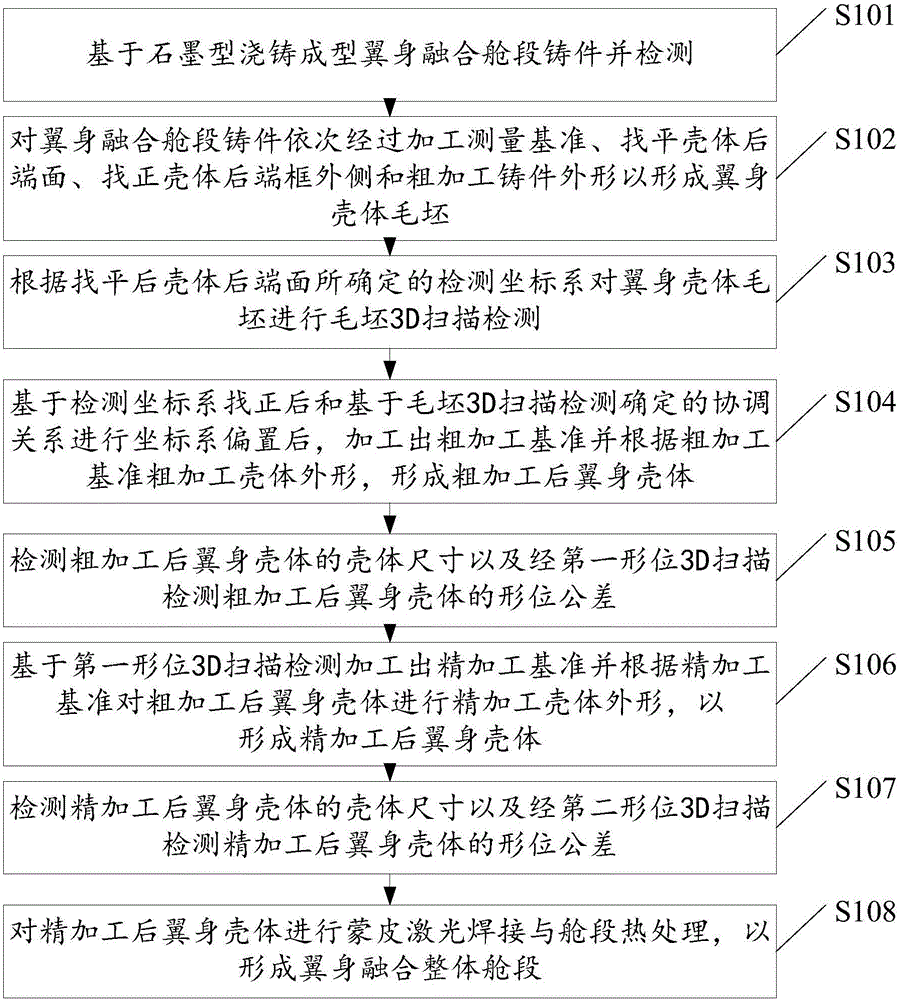

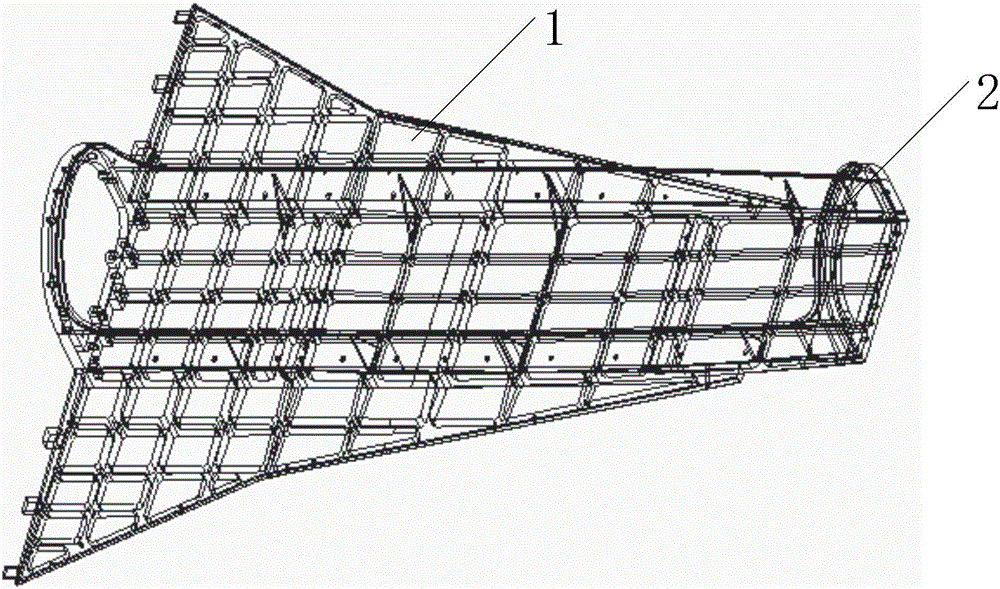

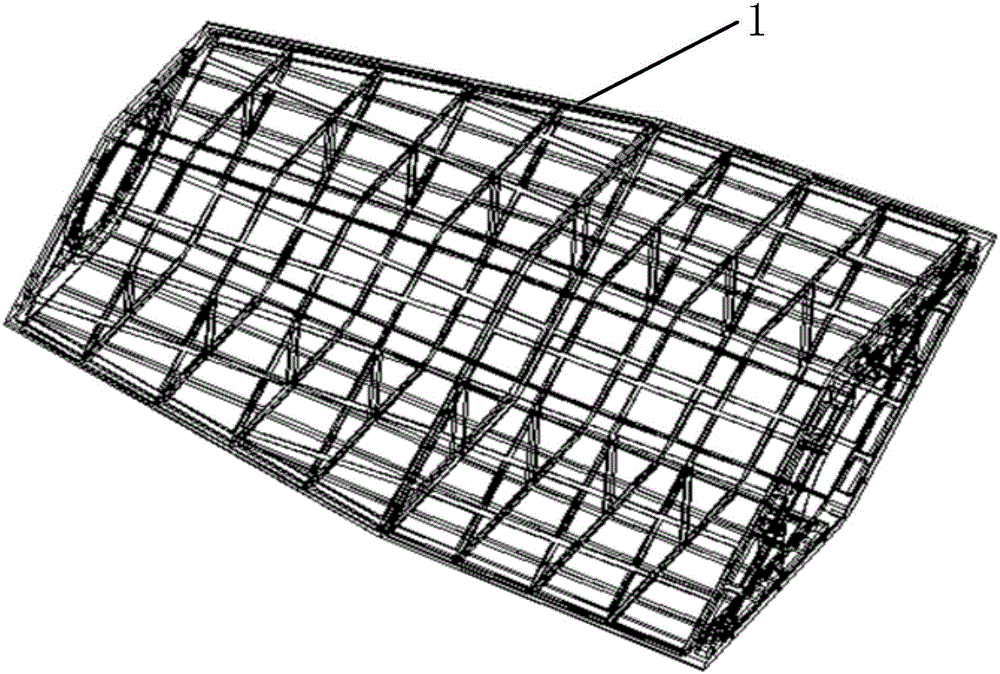

Manufacturing method for integral wing-body-fused cabin

ActiveCN106002088AQuality assuranceAvoid deformation accumulationAircraft componentsGraphite3d scanning

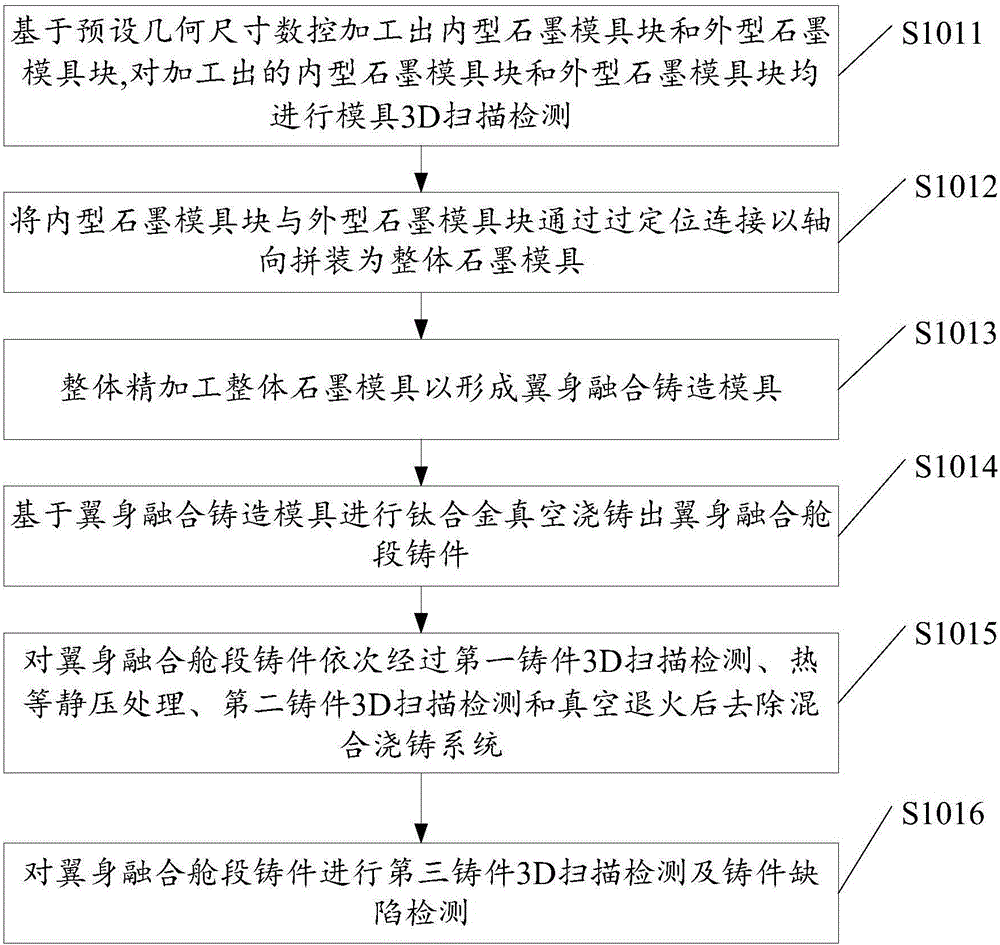

The invention discloses a manufacturing method for an integral wing-body-fused cabin. The manufacturing method comprises the steps that a wing-body-fused cabin casting is cast and formed based on the graphite type and detected; the wing-body-fused cabin casting is sequentially subjected to machining, datum measuring and the like, a wing body shell blank is formed, and blank 3D scanning detection is conducted; a rough machining datum is machined, and the shell appearance is roughly machined according to the rough machining datum; the shell size of the roughly-machined wing body shell is detected, and the form and location tolerance of the roughly-machined wing body shell is detected through first shape and location 3D scanning; a finish machining datum is machined based on the first shape and location 3D scanning, shell appearance finish machining is conducted on the roughly-machined wing body shell according to the finish machining datum, the shell size of the wing body shell subjected to finish machining is detected, and the form and location tolerance of the wing body shell subjected to finish machining is detected through second shape and location 3D scanning; and skin laser welding and cabin heat treatment are conducted on the wing body shell subjected to finish machining. The manufacturing method effectively solves the technical problem that machining of existing integral wing-body-fused cabin products is hard to control, and accordingly the overall quality of the integral wing-body-fused cabin is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

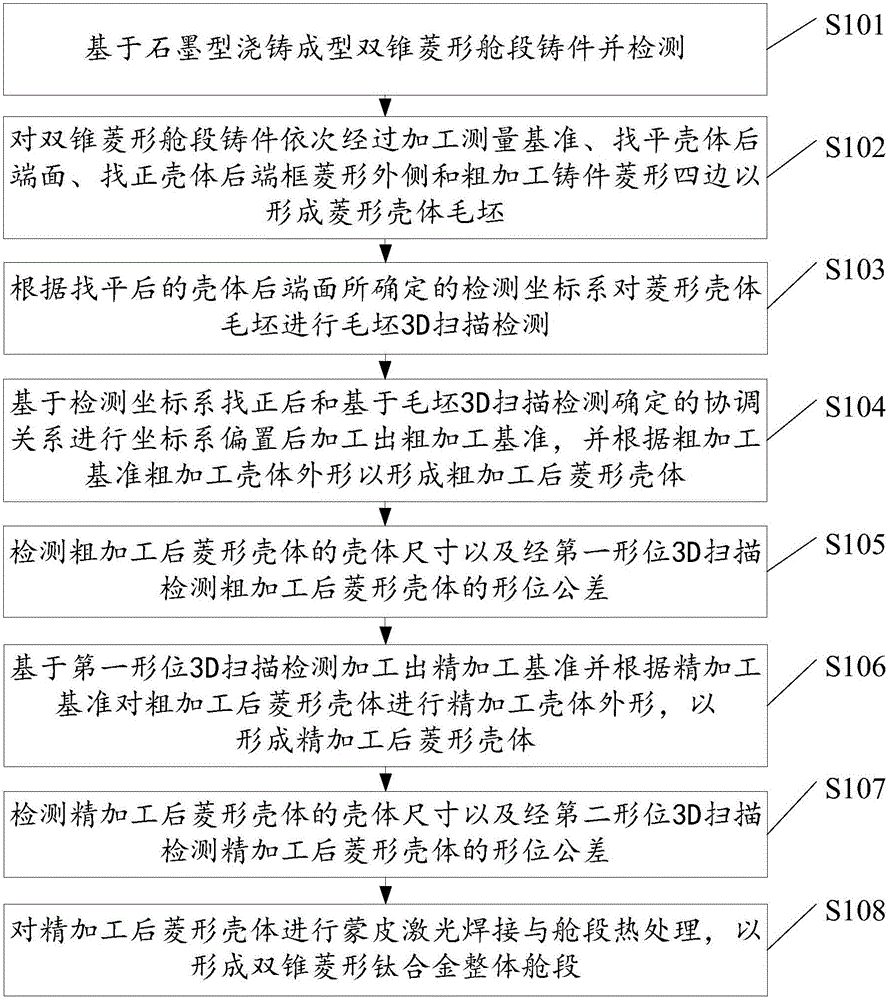

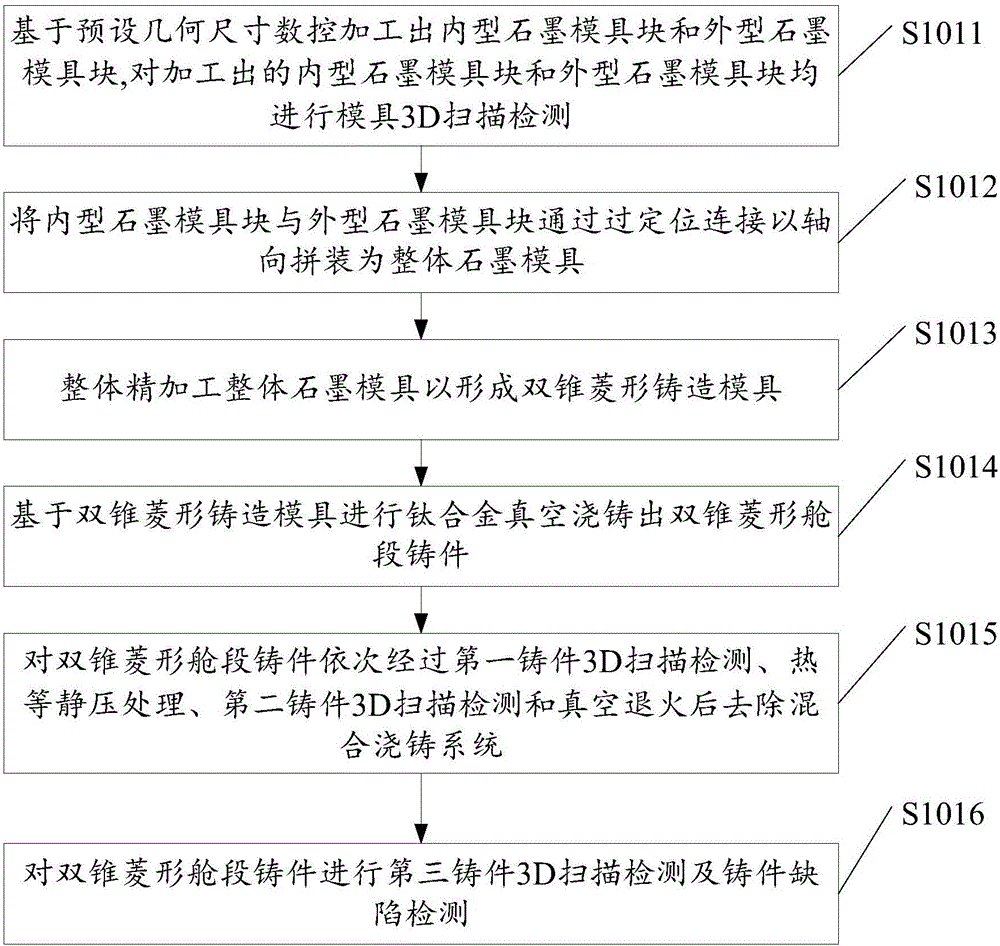

Double-cone rhombic titanium alloy overall cabin manufacturing method

The invention discloses a double-cone rhombic titanium alloy overall cabin manufacturing method. The method comprises the following steps: a double-cone rhombic cabin casting is molded based on graphite pouring and detected; a rhombic shell blank is formed by performing machining, standard measurement and the like for the double-cone rhombic cabin casting in sequence; a rough-machined rhombic shell is formed by roughly machining a shell appearance according to the rough machining reference after deviation of a coordinate system; the shell size of the rough-machined rhombic shell is detected; the form and location tolerance of the rough-machined rhombic shell is detected by the first form and location 3D scanning; the shell appearance of the rough-machined rhombic shell is finished based on the finishing reference; the shell size of the finished rhombic shell is detected; the form and location tolerance of the finished rhombic shell is detected by the second form and location 3D scanning; and the cover laser welding and the cabin heat treatment are performed for the finished rhombic shell. The method effectively solves the technical problem of difficult control of machining of a traditional double-cone rhombic titanium alloy overall cabin product, and guarantees the total quality of the double-cone rhombic titanium alloy overall cabin.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

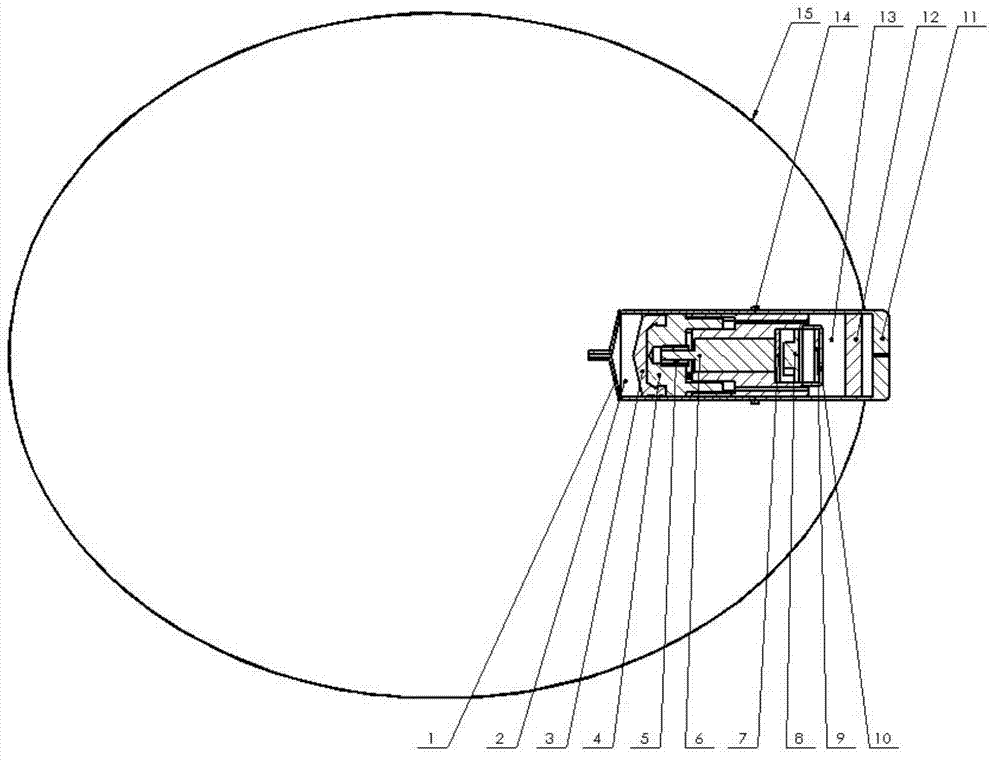

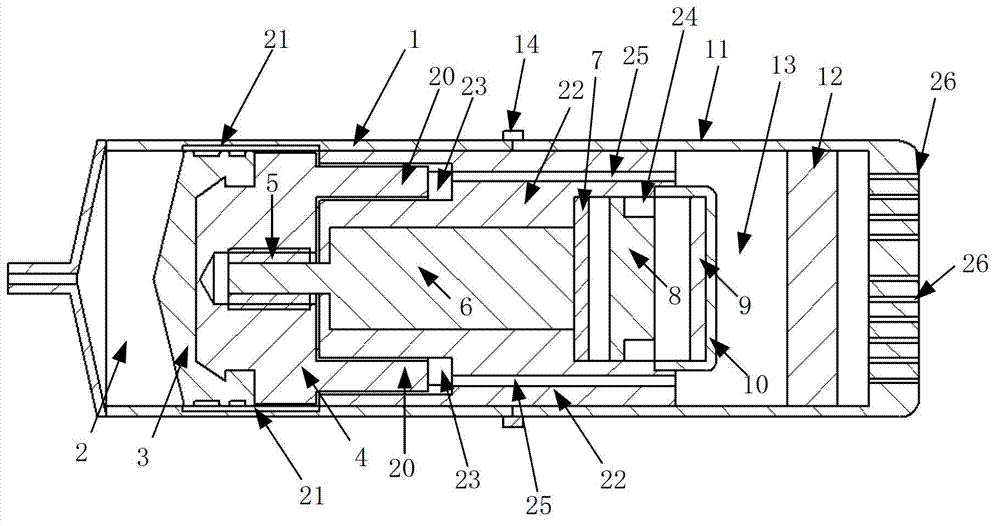

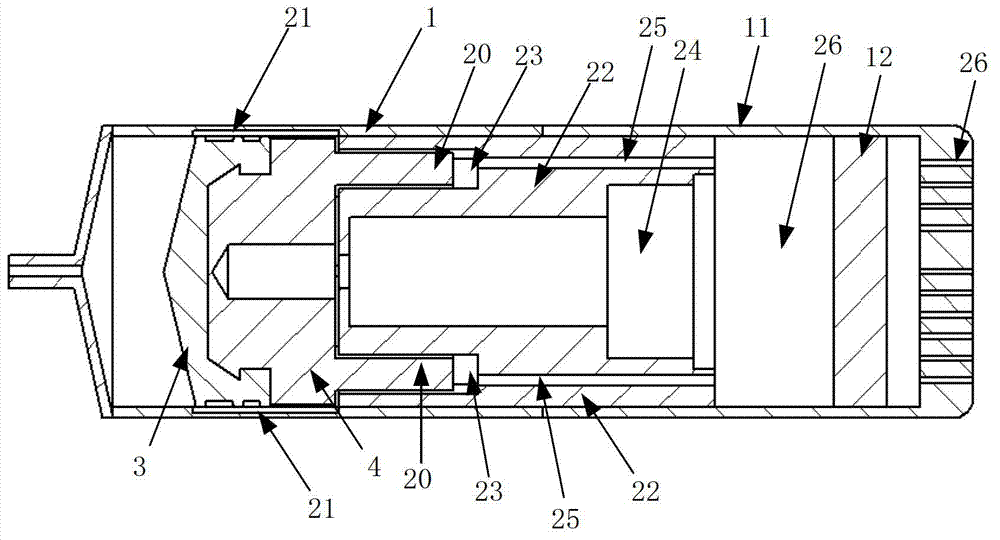

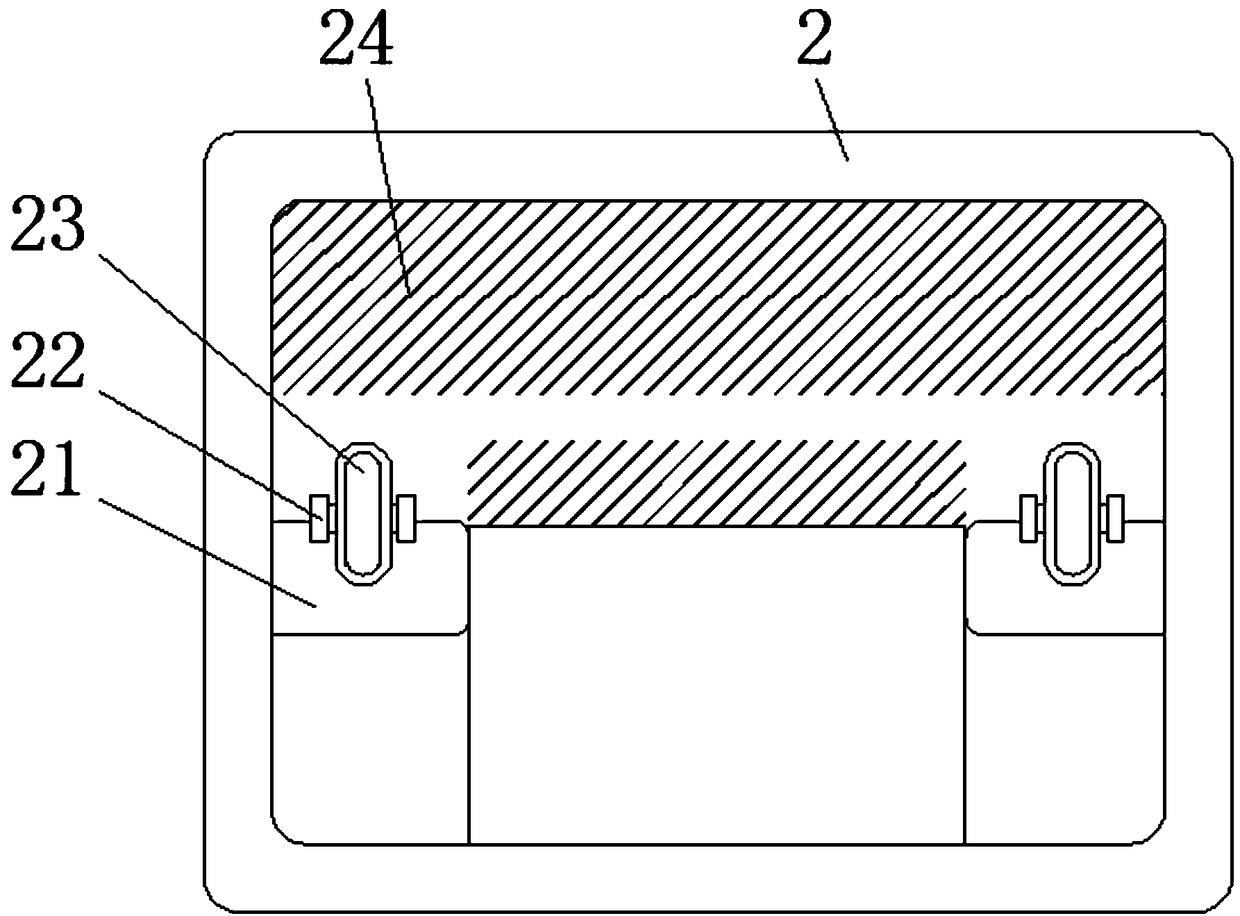

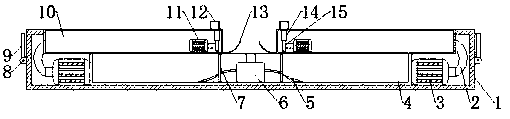

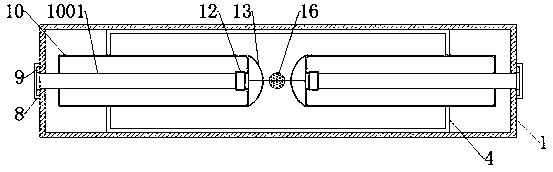

Modularization miniature weight-losing capsule robot based on wireless power supply and communication

InactiveCN103083049AReduce volumeEliminate discomfortEnergy efficient ICTSurgeryTherapeutic DevicesNon invasive

The invention discloses a modularization miniature weight-losing capsule robot based on wireless power supply and communication and provides novel weight-losing treatment equipment which conducts wireless type energy supply by using a resonance principle and removes power source equipment to reduce the size of capsules, conducts expansion and shrinkage by wireless communication control equipment, and has modularization design. The modularization miniature weight-losing capsule robot solves the problems that the guiding process and the aerating process of traditional stomach inside balloon weight-losing equipment greatly damage a patient, the size of existing ingested treatment equipment without auxiliary guiding is difficult to reduce due to power supply demands of a power source, and repeated use of a whole machine is low. Compared with a similar product, the modularization miniature weight-losing capsule robot is small in size, can be normally taken or drained, is low in patient damage and pain, has treatment effectiveness and economy, and is outstanding in feature. The modularization miniature weight-losing capsule robot provides a novel scheme for non-invasive obesity treatment, provides a solution for sufficient energy supply of miniature internal medical equipment and small size contradictory, and simultaneously modularization design saves treatment cost and creates conditions for product commercialization.

Owner:BEIHANG UNIV

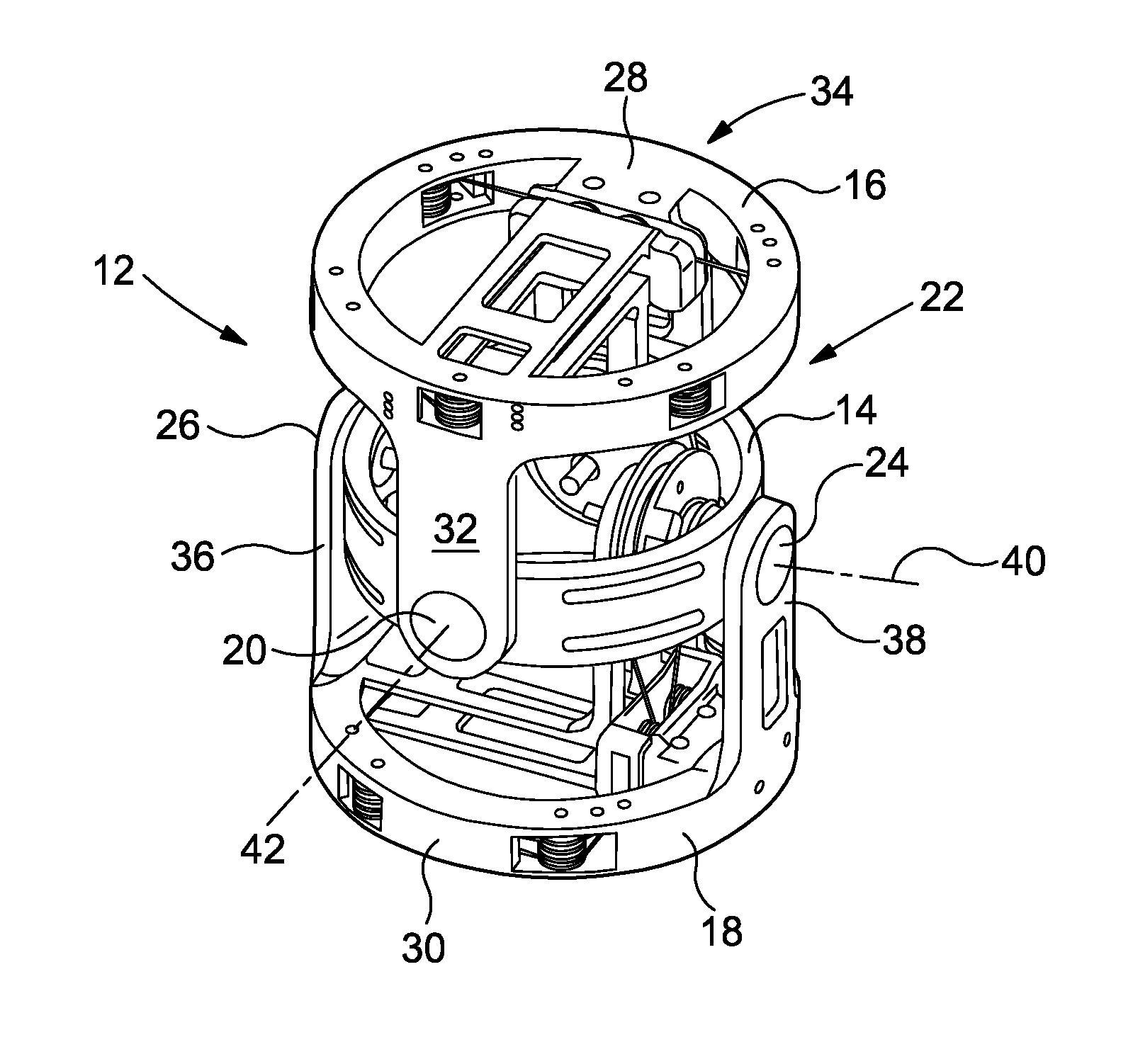

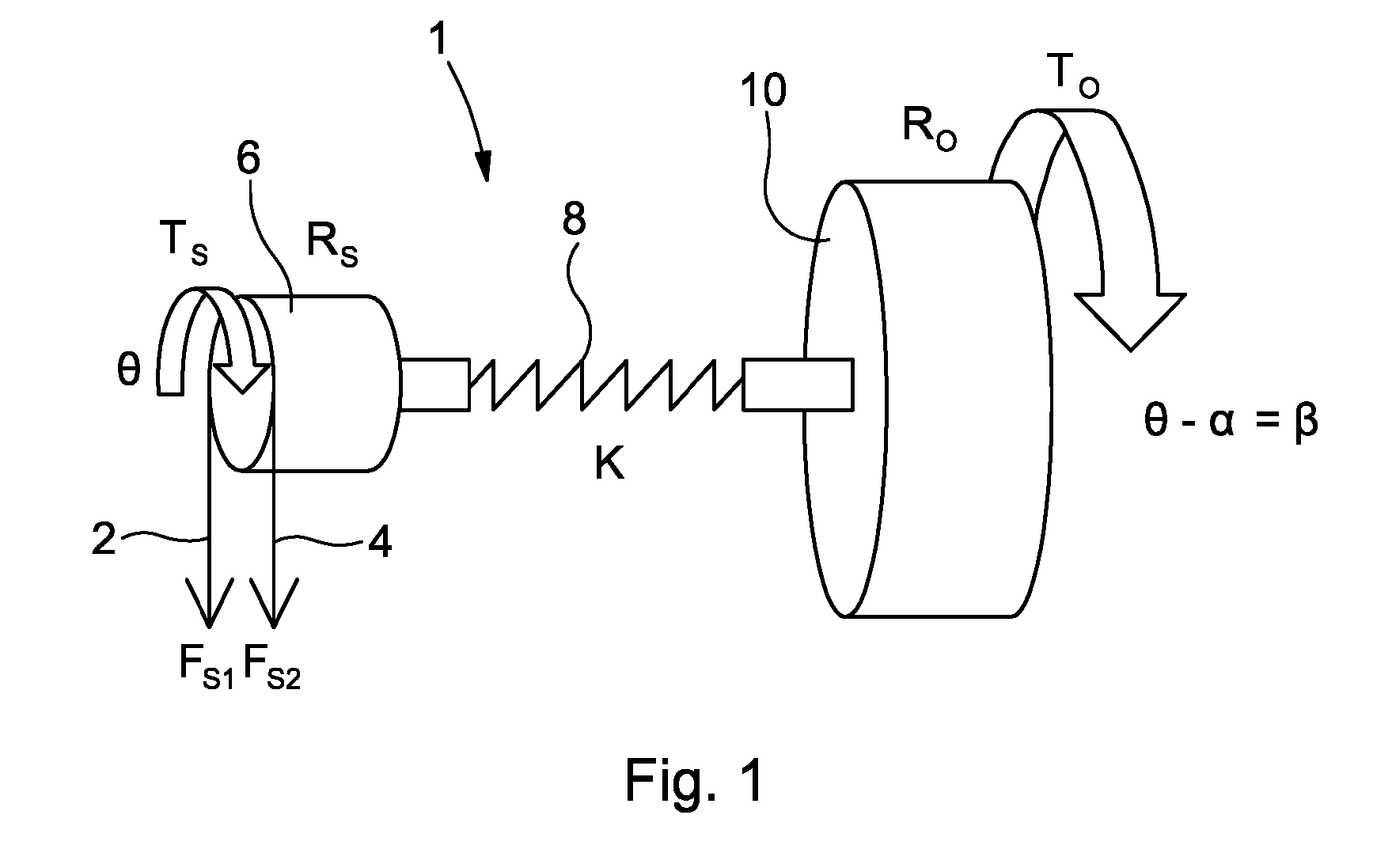

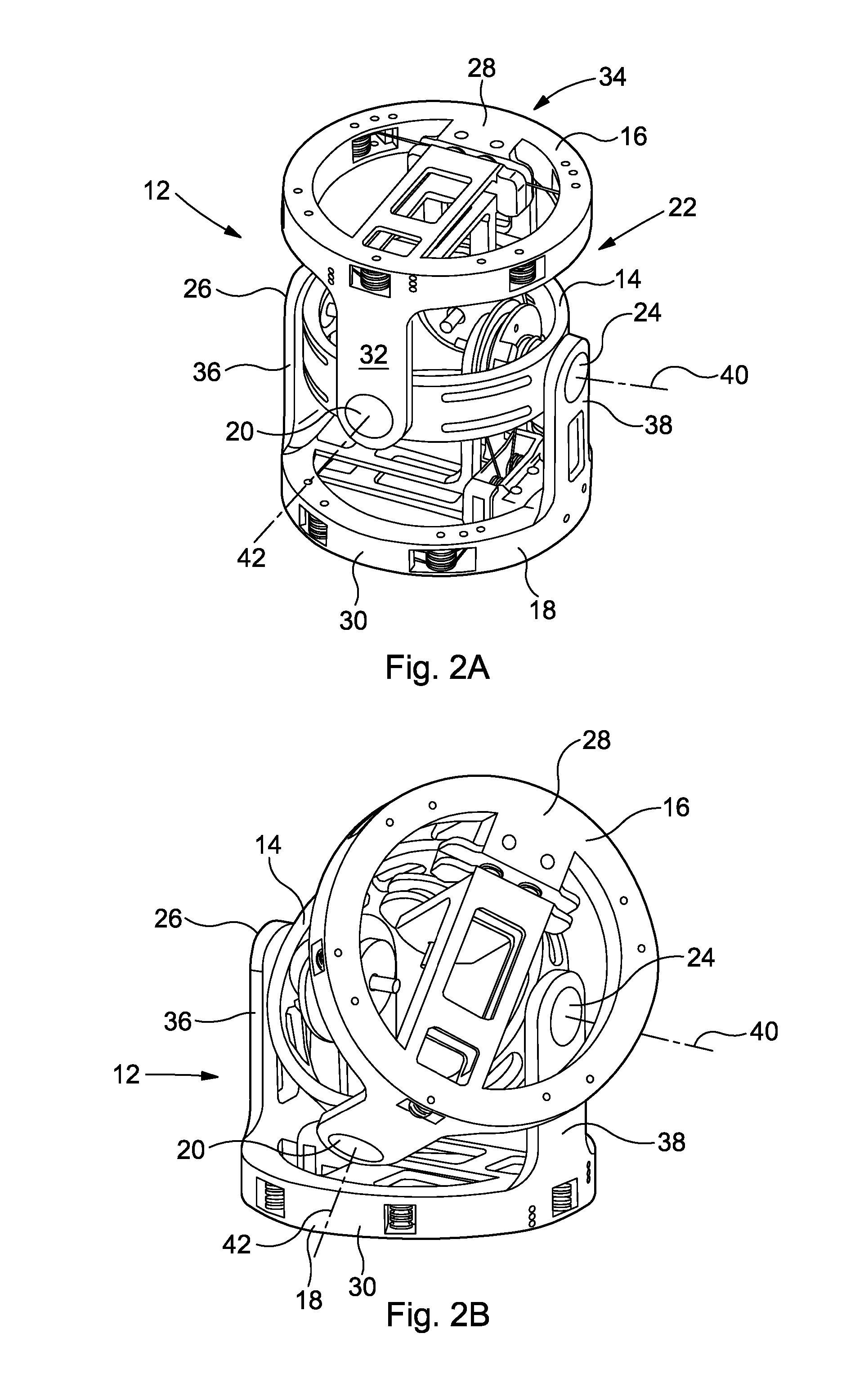

Complaint actuator

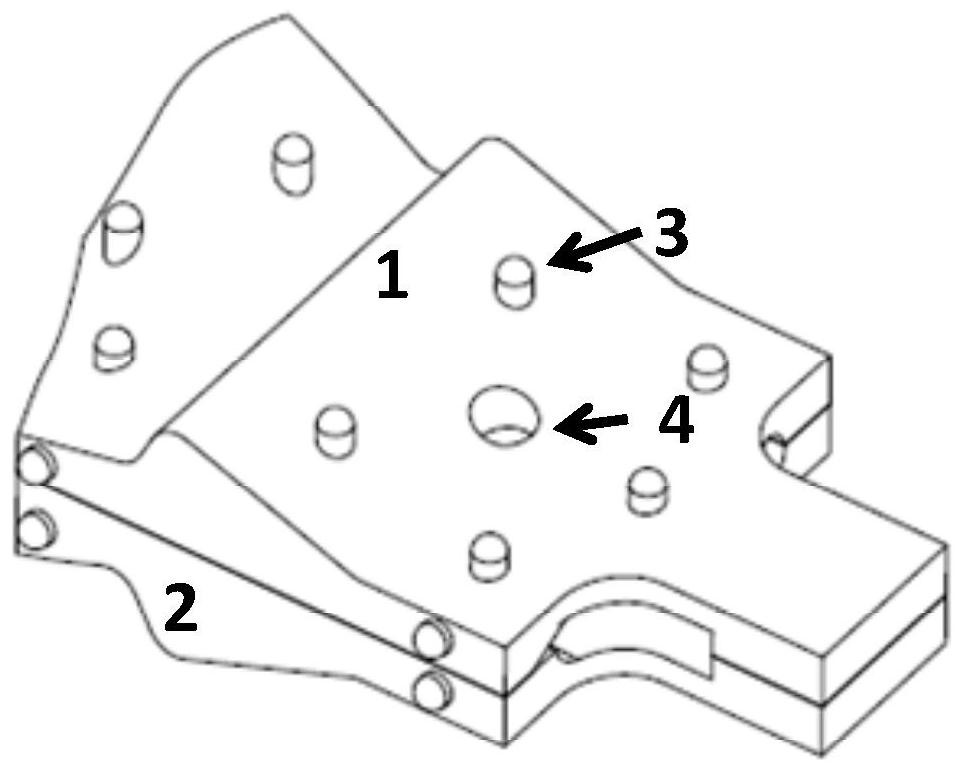

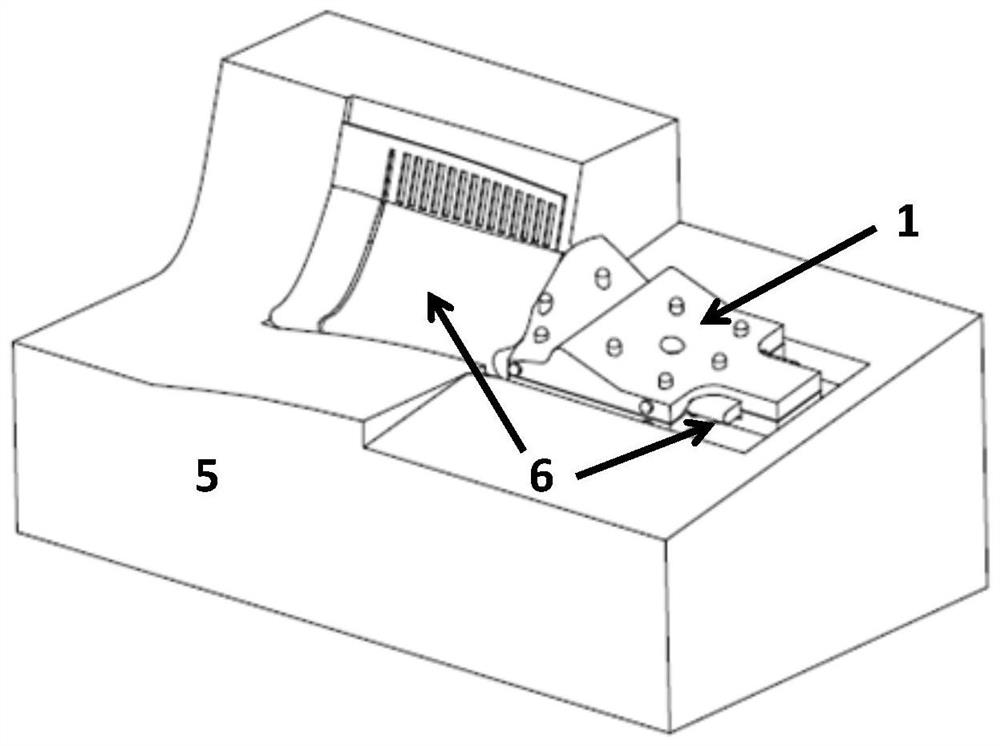

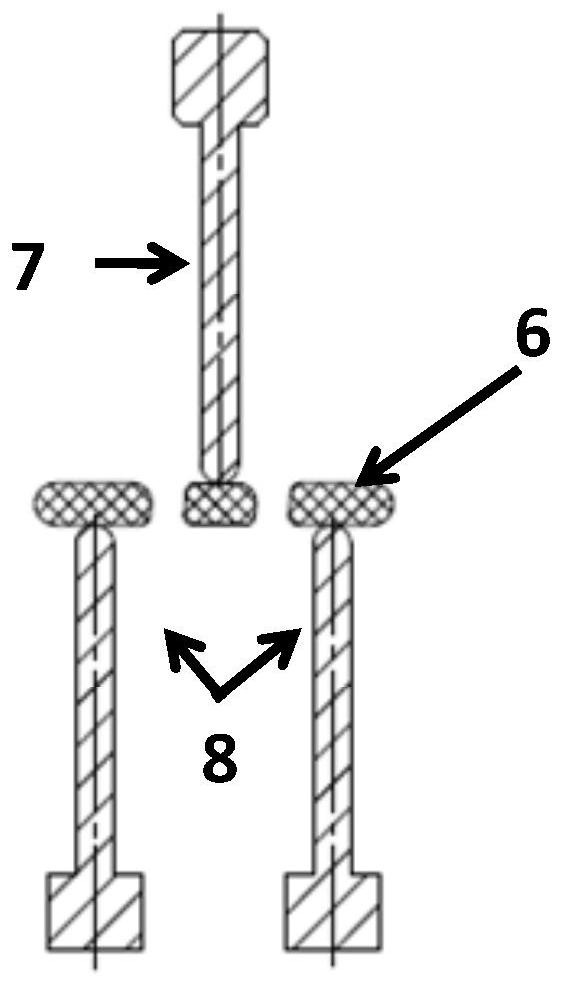

ActiveUS20170051729A1Improve energy efficiencyLow heat generationEndoscopesMachines/enginesShape-memory alloyActuator

An actuator (12) includes a moving member (18) pivotally connected to a base unit (14) for rotation about an axis. The driving force for rotation of the moving member (18) relative to the base unit (14) is provided by a pair of antagonistically operating shape memory alloy (SMA) wires (48, 50) and transmitted via a torsional spring (56). An endoscope, or a snake-like robot (66), may include one or more of the actuators (12).

Owner:UNIVERSITY OF DUNDEE

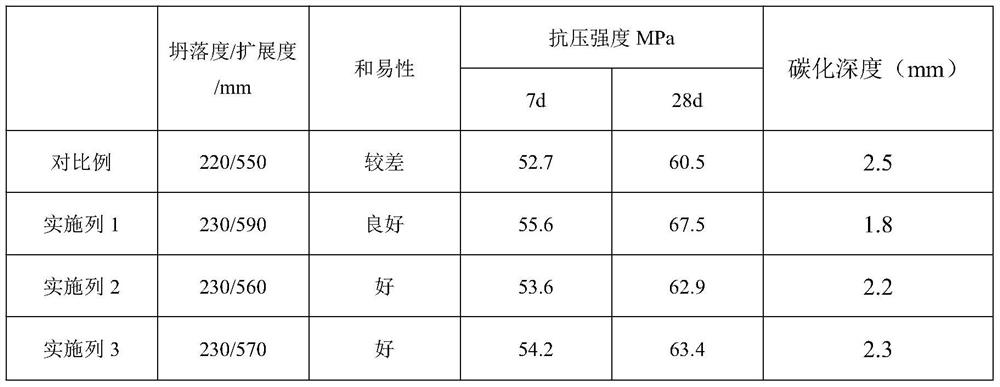

Machine-made sand concrete using synergist and preparation method of machine-made sand concrete

InactiveCN111943605AReduce porosityPromotes the hydration processNatural sandGeotechnical engineering

The invention discloses machine-made sand concrete using a synergist and a preparation method of the machine-made sand concrete. The concrete comprises the following components and a formula: 395-435parts of cement; 0-30 parts of fly ash; 0-30 parts of mineral powder; 900.15-920.55 part of machine-made sand; 864.85-884.45 parts of broken stone; 9.1-9.9 parts of an additive; 2.73-2.97 parts of a synergistic agent; and 153-170 parts of water. The synergist component comprises a reinforcing agent, a dispersing agent, nano calcium carbonate, a foaming agent, a foam stabilizer and water. Accordingto the invention, the inherent advantages of the machine-made sand are brought into full play, and the problem of shortage of natural sand resources is effectively relieved; use amount of cement in the same grade of machine-made sand concrete can be reduced and the strength of the machine-made sand concrete is not changed or even higher, the durability of the machine-made sand concrete is improved, the cost of the machine-made sand concrete is reduced, and the cracking risk of the concrete can be reduced.

Owner:中建西部建设贵州有限公司 +1

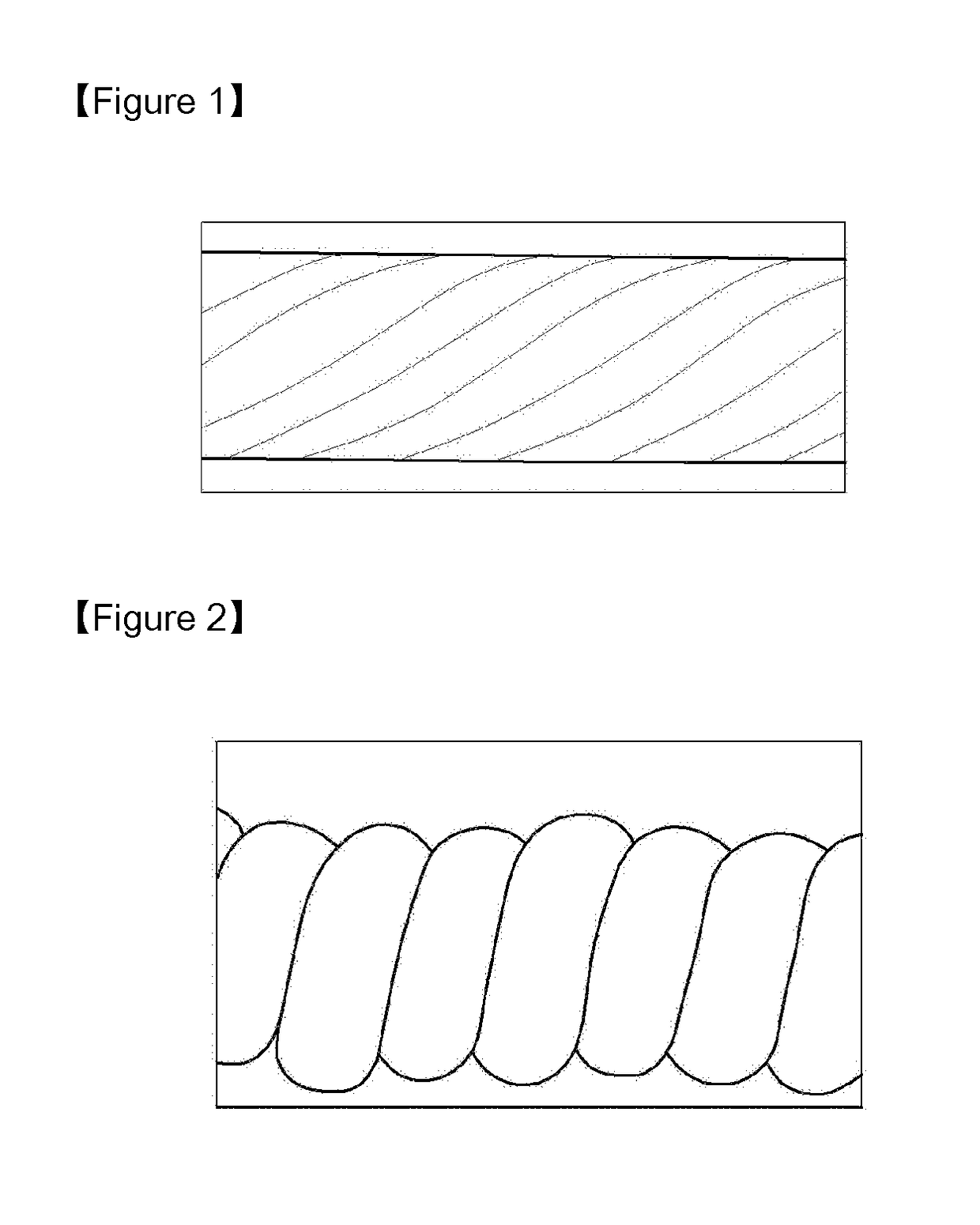

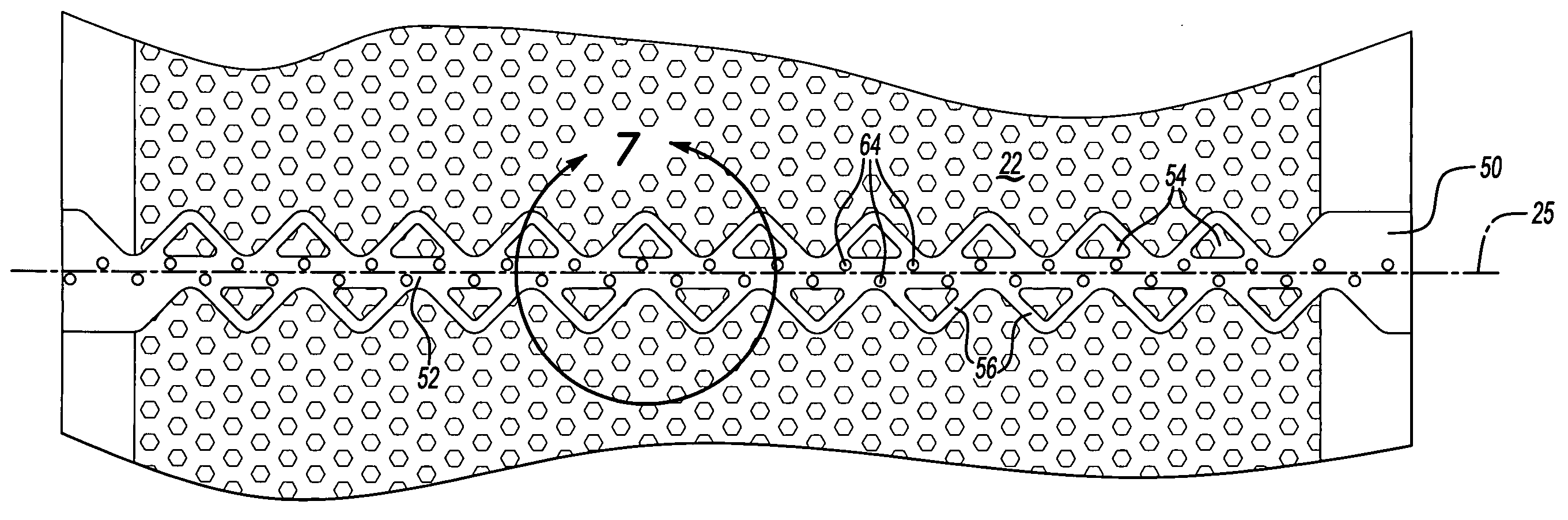

Flexible actuator based on shape memory alloy sheet

InactiveUS8733099B2Raise the ratioReduce the cross-sectional areaMechanical power devicesClosed-cycle gas positive displacement engine plantElectricityPower flow

A flexible unit-cell actuator includes a shape memory alloy sheet having a fold between adjacent legs in one state and a heat source that upon activation concentrates heating of the shape memory alloy sheet at the fold relative to the legs to change the fold between one state and another state. The heat source may include resistive heating due to an electric current passing through the shape memory alloy sheet. The fold typically includes a reduced cross-sectional area and may include slits to increase electrical resistance at the fold relative to the adjacent legs. An actuator array includes a plurality of flexible unit-cell actuators formed in a sheet, each unit-cell actuator mechanically coupled to at least one other unit-cell actuator at a coupling region. Plural unit-cell actuators may be mechanically coupled in series, in parallel, or both, may be electrically connected in series, and may move along a defined curve or surface. A linear or curvilinear actuator includes a guide, a plurality of bearings or support elements slidable along the guide, and an array of actuators coupled between adjacent bearings and circumferentially about the bearings. An actuator includes a plurality of segments fanning from a hinge and shape memory alloy actuators coupled between adjacent segments to cause the segments to fan in an out about the hinge.

Owner:MASSACHUSETTS INST OF TECH

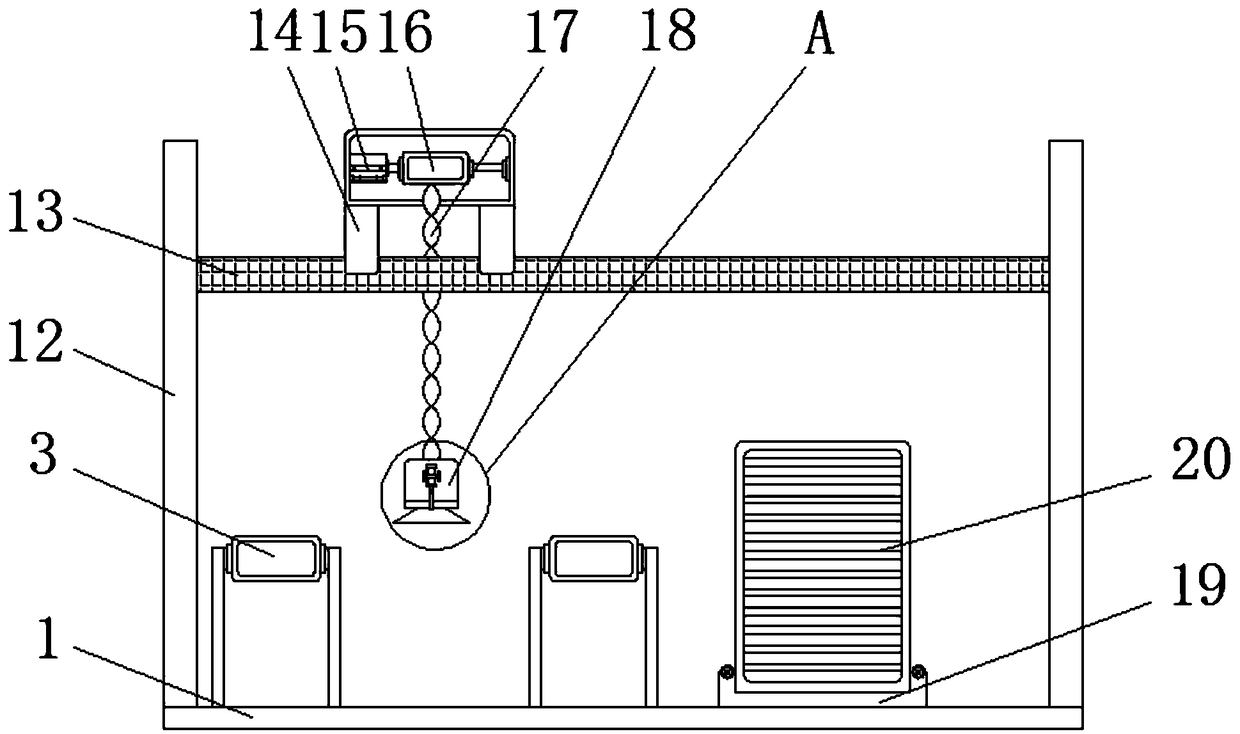

Cleaning and abrasion preventing storage device for tempered glass production

ActiveCN108817013APrevent movementReduce contact areaDrying gas arrangementsFlexible article cleaningEngineeringToughened glass

The invention relates to a cleaning and abrasion preventing storage device for tempered glass production. The cleaning and abrasion preventing storage device comprises a bottom plate, a support and abase plate. A feeding port is formed in the left side of the upper end of the bottom plate, a control box is arranged on the right side of the upper end of the feeding port, and a water tank is arranged on the left side in the control box. The cleaning and abrasion preventing storage device has the beneficial effects that conveying belts are arranged on the two sides below the control box correspondingly and support and convey fed glass, the tempered glass moves towards a storage box, carrying of the tempered glass through manpower is avoided, a certain gap distance is formed between the two conveying belts, the contact area between the conveying belts and the tempered glass is reduced, the situation that after the tempered glass makes contact with water, the tempered glass is sucked to the conveying belts, and consequently a suction cup sucks up the tempered glass in the later period is avoided; the conveying belts can be prevented from staining the tempered glass as well; and the bottom end of the tempered glass is hollow, the bottom can make contact with a spraying head and a sponge wiper, accordingly, the bottom of the tempered glass is cleaned, and flexibility of the device isembodied.

Owner:江苏伟恒玻璃制造有限公司

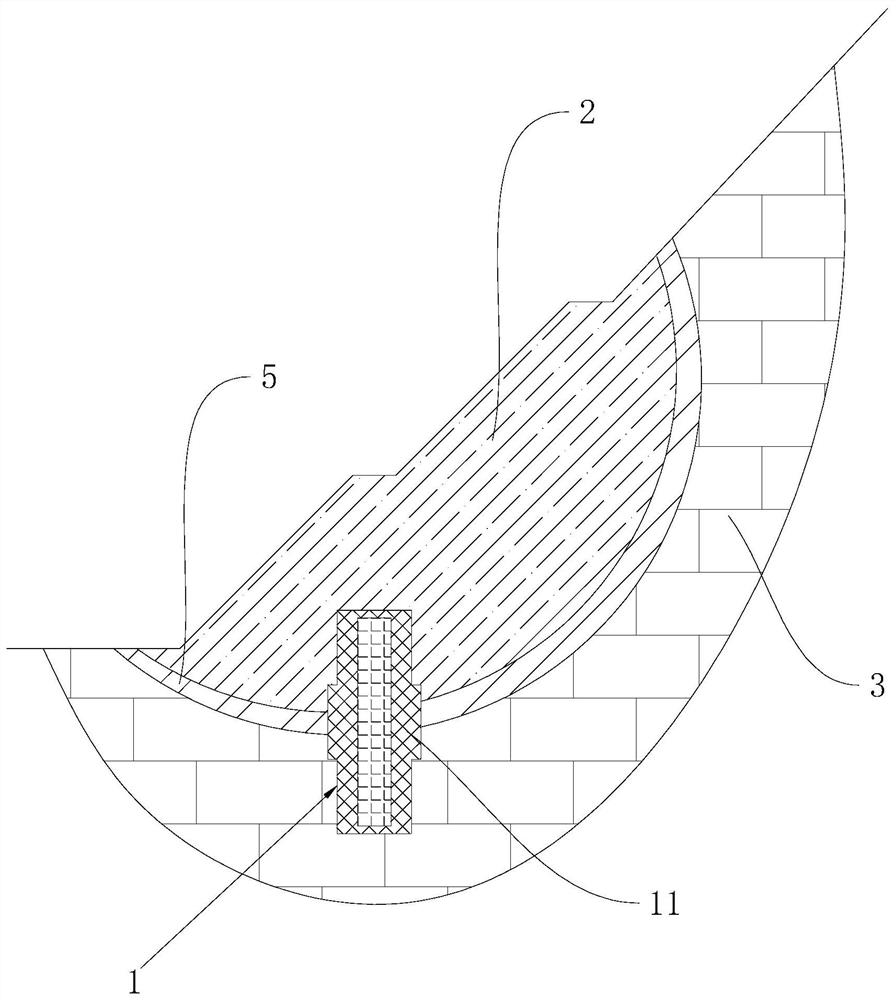

Stiffened variable cross section high-pressure jet grouting pile antiskid wall construction method

ActiveCN111648387AStable anti-skid effectNot easy to produce relative displacementExcavationsBulkheads/pilesSoil scienceLandslide

The invention relates to a stiffened variable cross section high-pressure jet grouting pile antiskid wall construction method. An antiskid wall comprises multiple high-pressure jet grouting piles which are engaged mutually, the high-pressure jet grouting piles penetrate slip soil in the vertical direction, the two ends of the high-pressure jet grouting piles are located on an undisturbed soil bodylocated below the slip soil and a landslide body located above the slip soil correspondingly. The top ends of the high-pressure jet grouting piles are located in the landslide body, and the tops of the high-pressure jet grouting piles are filled with backfill soil. The stiffened variable cross-section high-pressure jet grouting pile antiskid wall construction method has the effects that a soil arch effect is easily achieved on the slip soil, and the slip soil is not likely to be deformed.

Owner:广东省工程勘察院

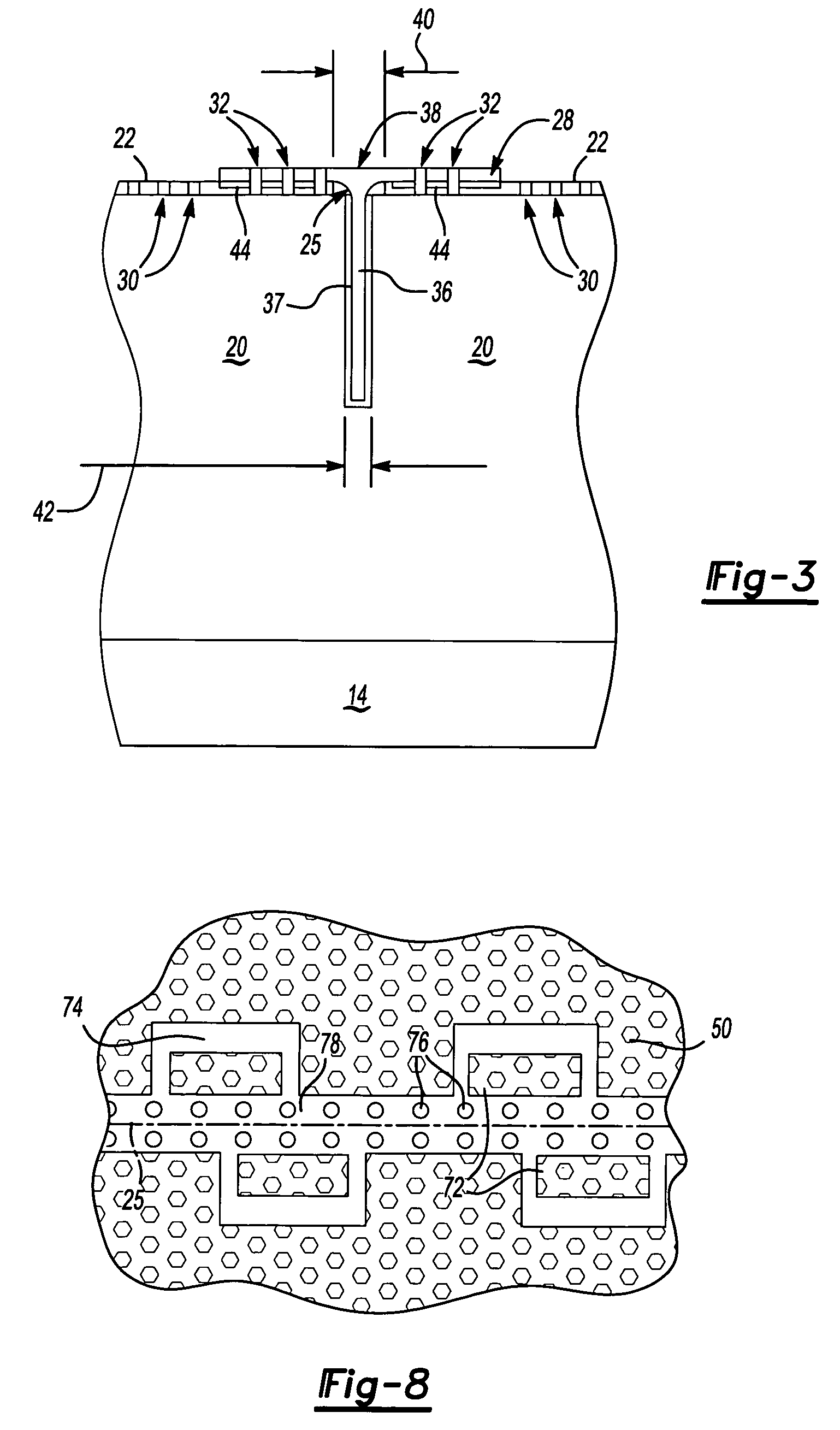

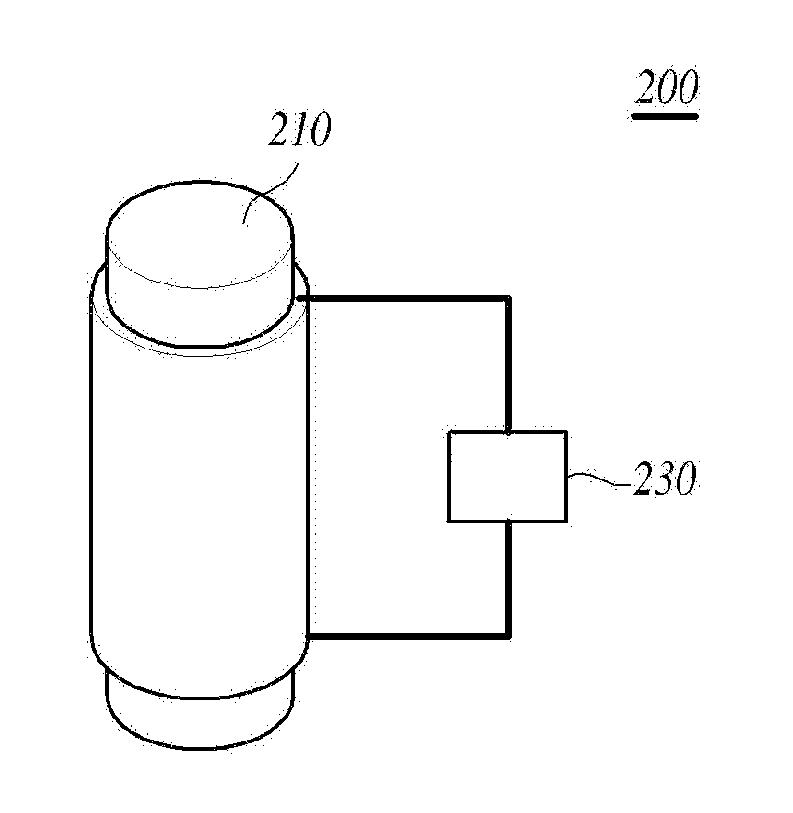

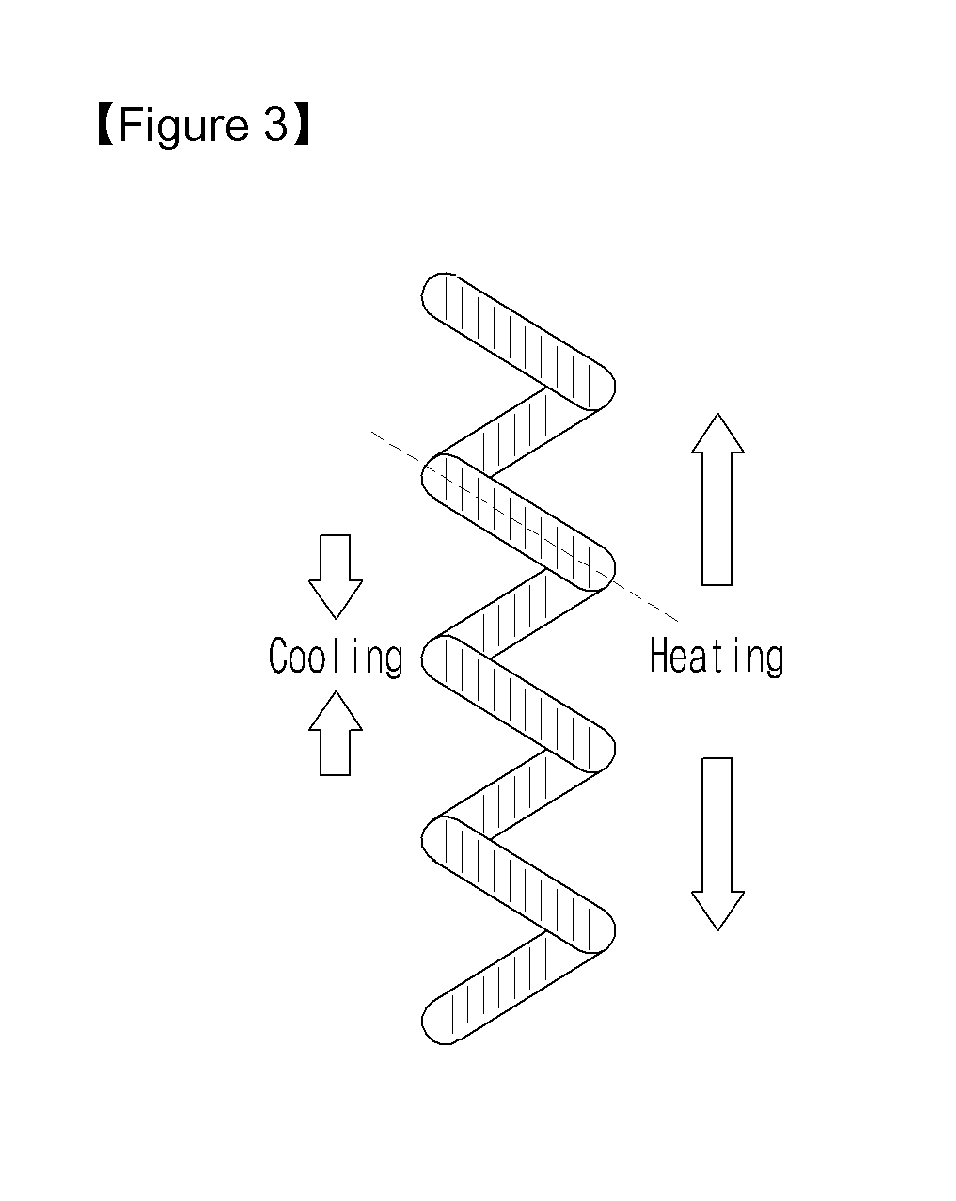

Soft actuator using thermoelectric effect

ActiveUS20180058429A1Reduce operation response timeControlled contractionThermoelectric device with peltier/seeback effectChiropractic devicesThermoelectric effectSoft actuator

The present invention relates to a soft actuator moving linearly against external stimuli whose expansion and contraction can be actively controlled, suggesting that the actuator of the invention overcomes the problems of the conventional soft actuators, The soft actuator of the present invention can be repetitively driven quickly and accurately by controlling heating and cooling by using thermoelectric effect and, the soft actuator of the present invention can realize bending, tensioning, compression, and rotational driving of a tubular device containing a driver.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

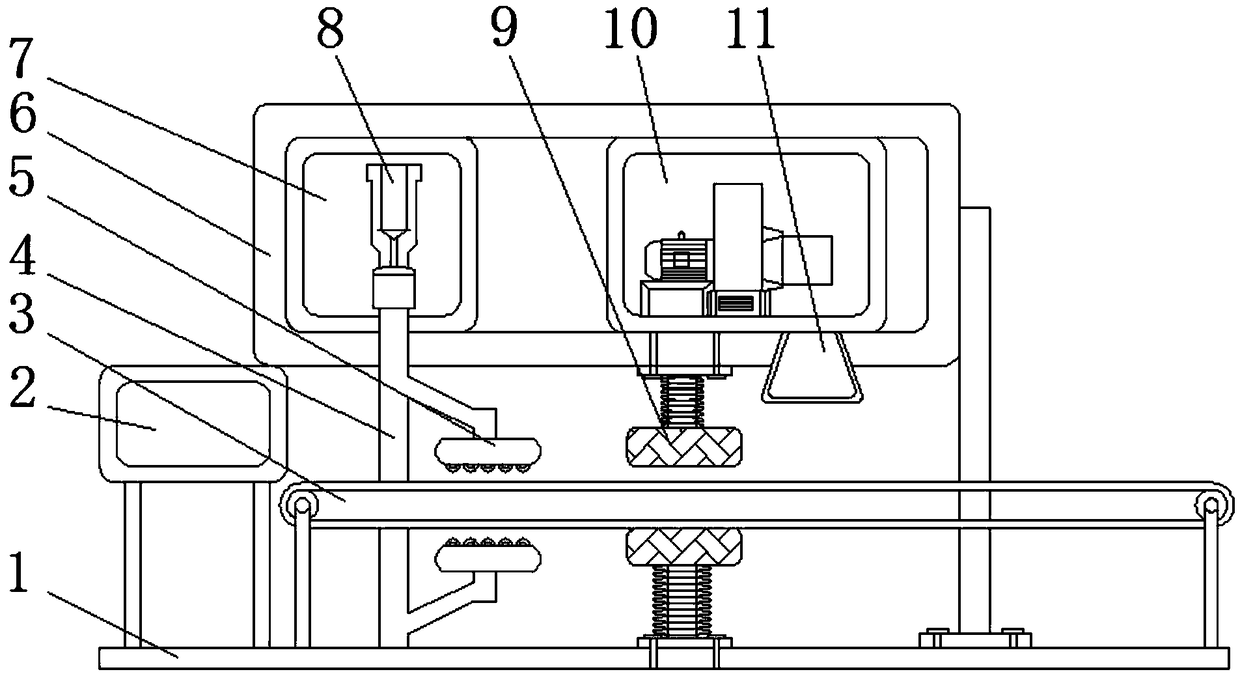

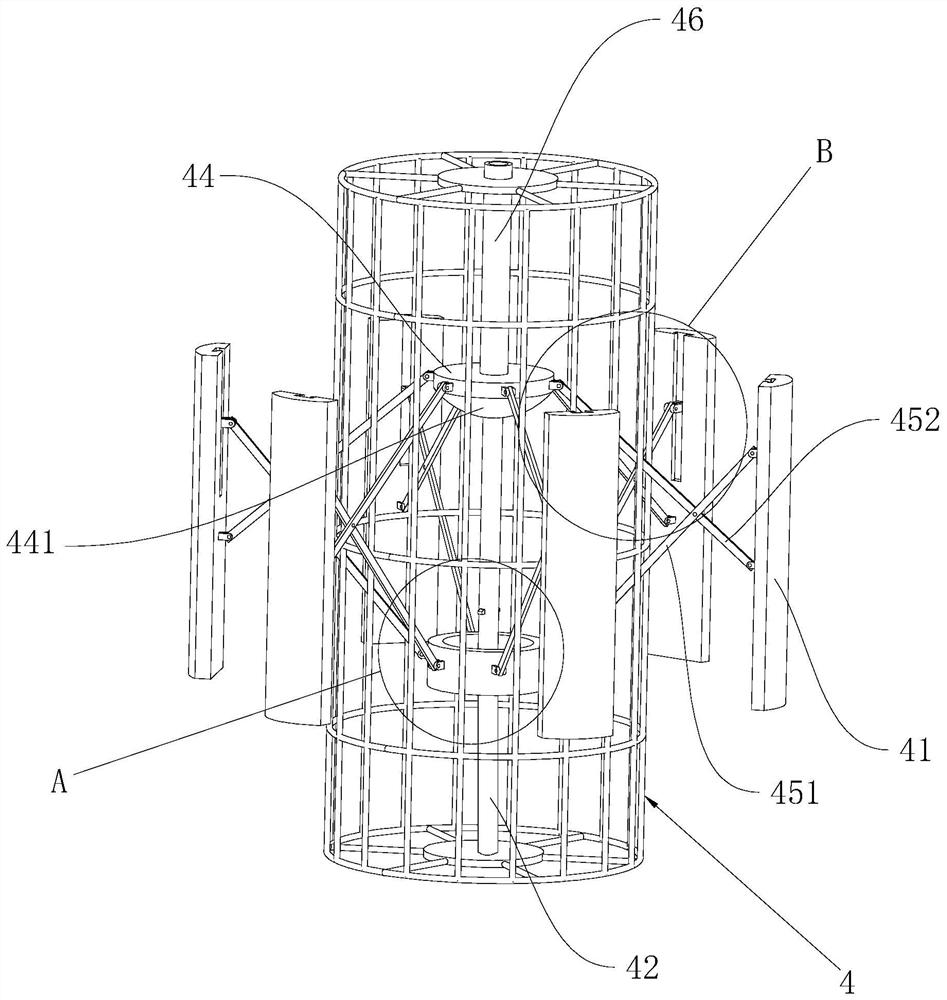

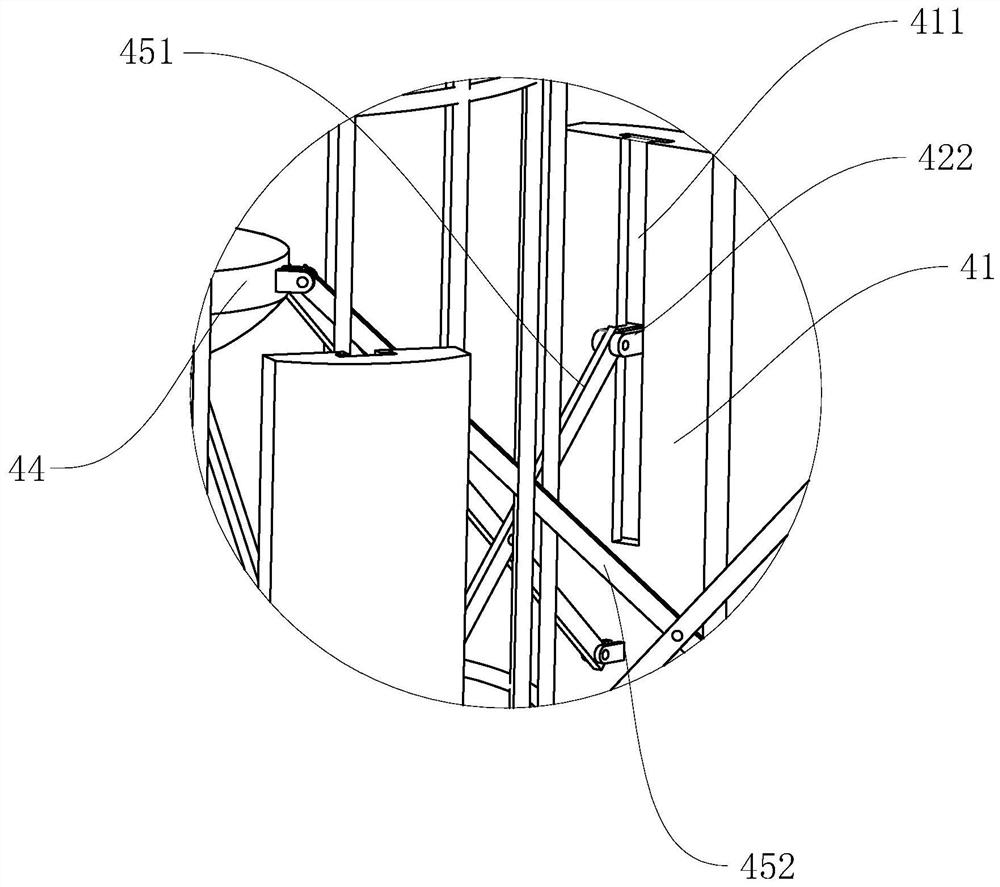

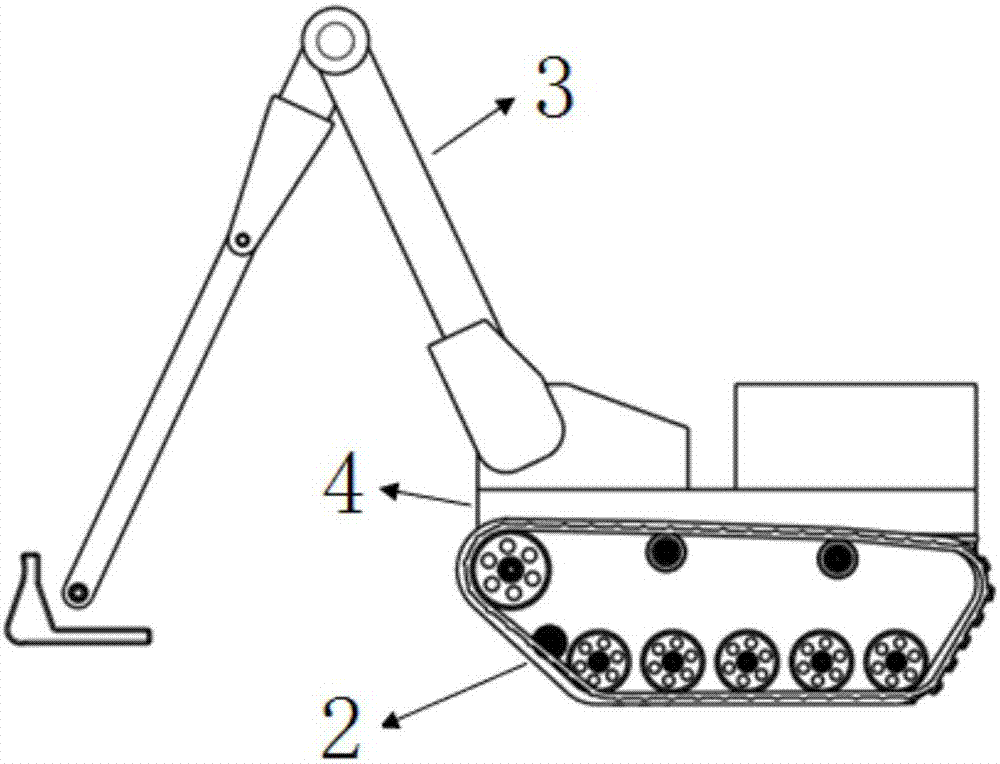

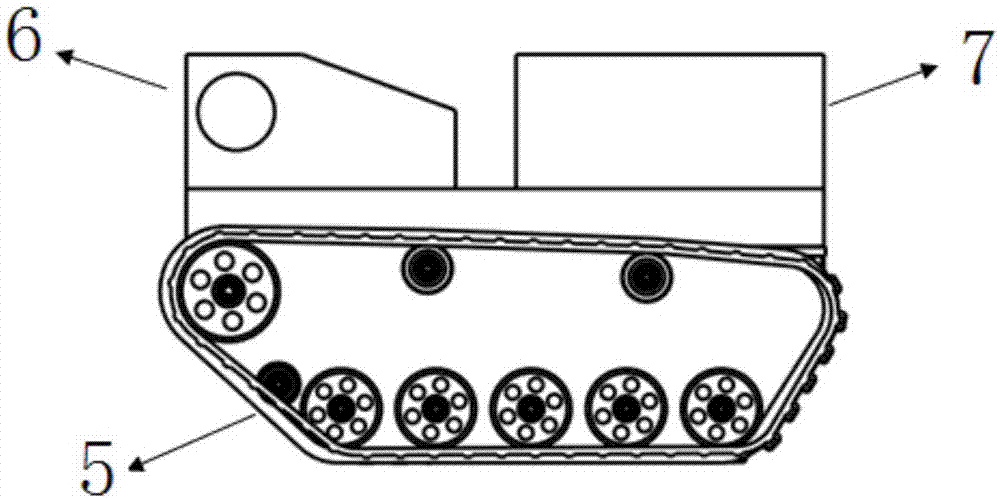

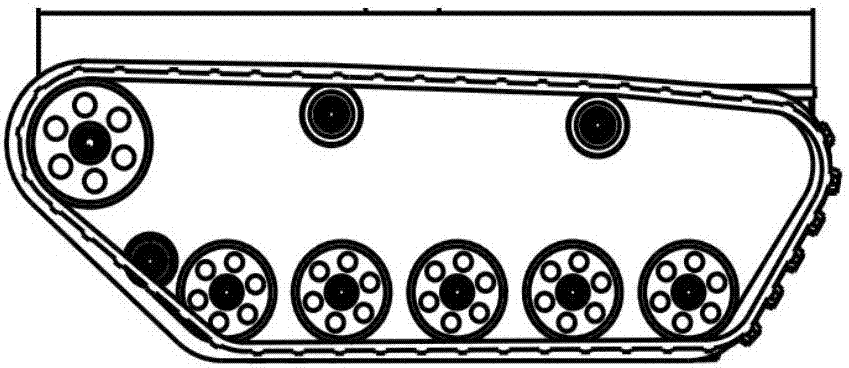

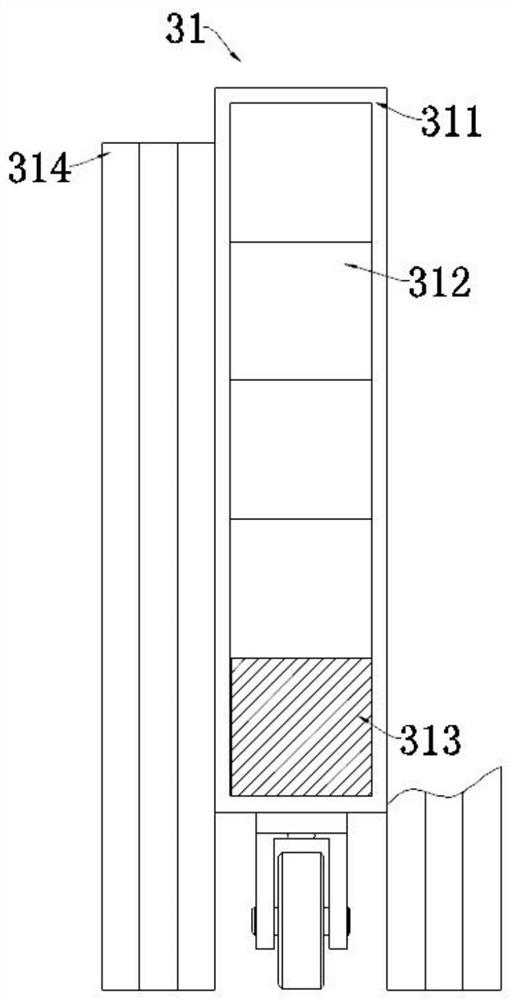

Autonomous type mine detection robot system and mine detection method

InactiveCN107328308AReasonable path planningImprove operational efficiencyDefence devicesPosition/course control in two dimensionsRobotic systemsControl system

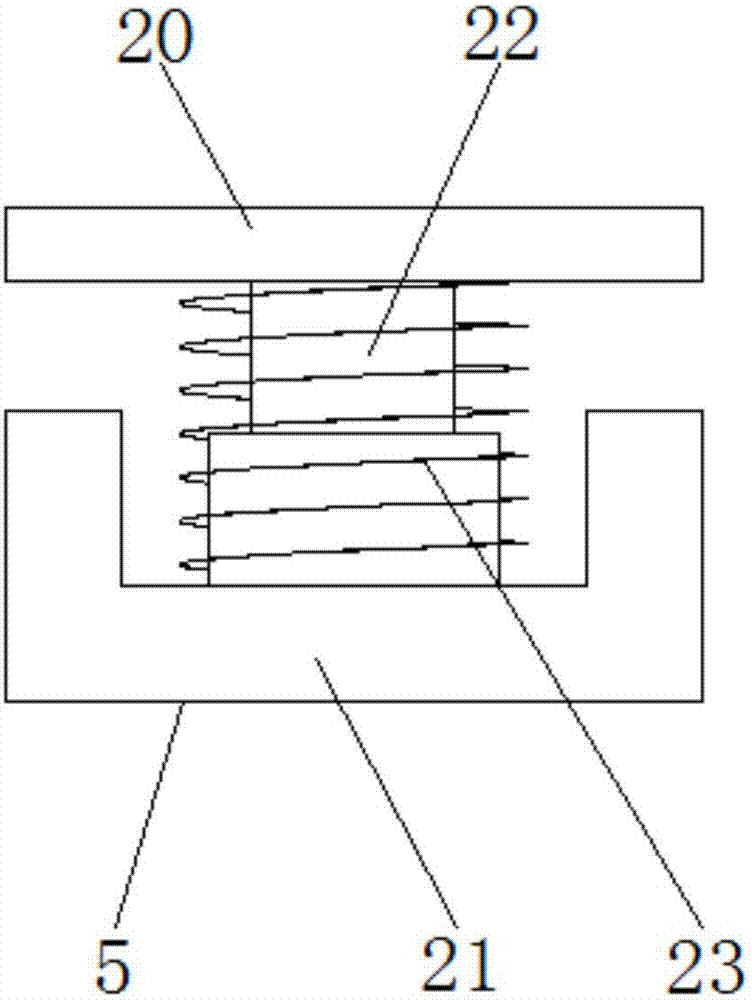

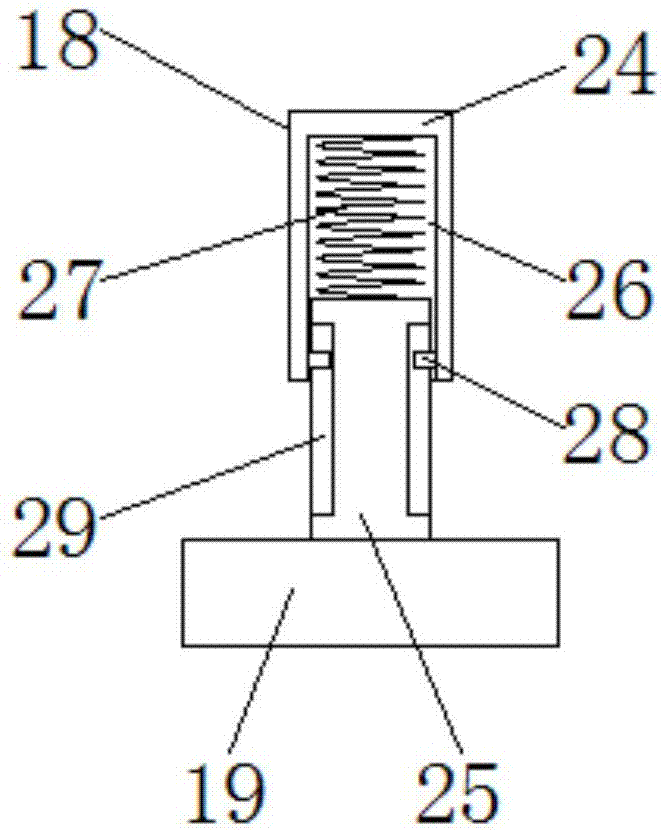

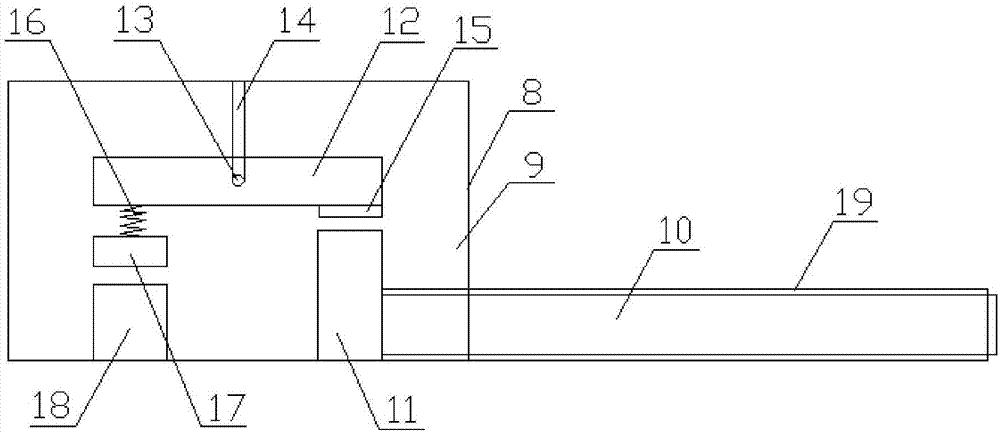

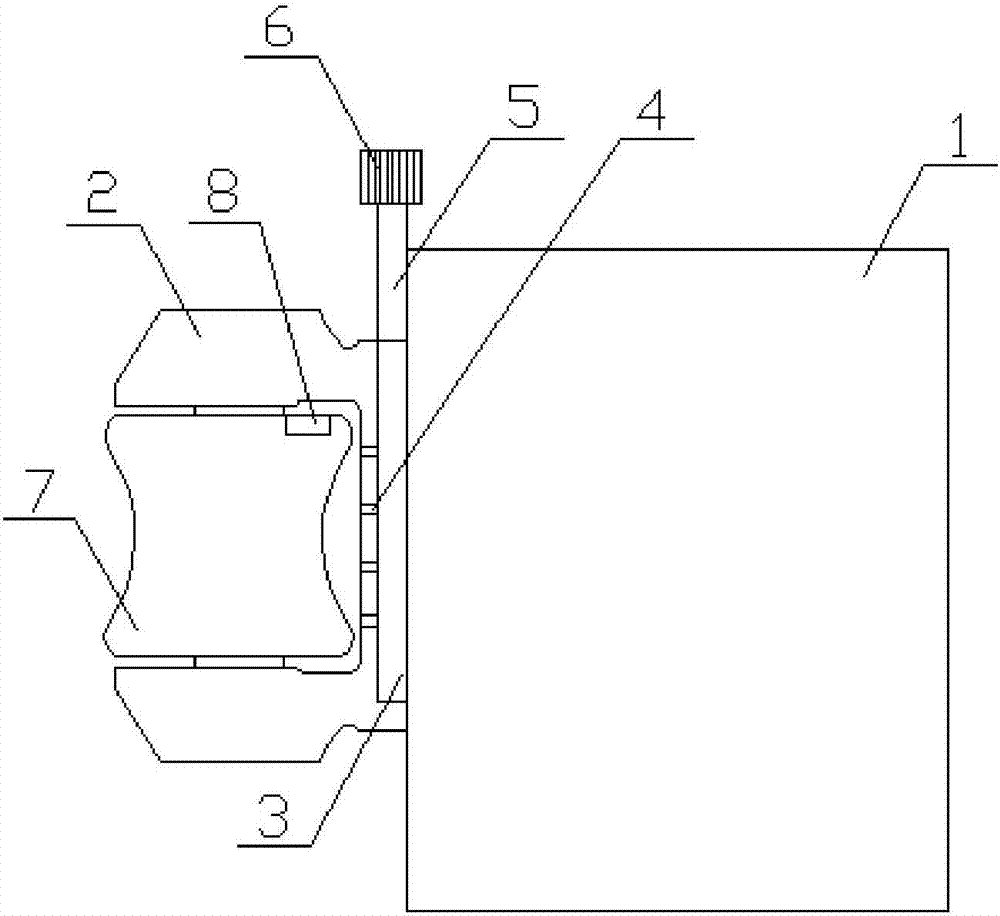

The invention discloses an autonomous type mine detection robot system and a mine detection method. The autonomous type mine detection robot system comprises a vehicle body. A moving chassis system 2, a mechanical arm detection system 3 and a coating system 4 are arranged on the vehicle body. The moving chassis system 2 is connected with the mechanical arm detection system 3 and the coating system 4. The moving chassis system 2 comprises a moving platform system 5, a power system 6 and a control system 7. The mechanical arm detection system 3 comprises a mechanical arm movement system 8 and a detection system 9. The power system 6 is installed at the back end of the movement platform system 5, provides the power source for the whole device and is used as a counter weight. The control system 7 is connected with the power system 6 and the detection system 9. The detection system 9 is arranged at the front end of the mechanical arm movement system 8. The autonomous type mine detection robot system can intelligently, accurately and efficiently detect and mark mine points of a mine area in a non-destructive manner, and therefore the safe and reliable guarantee is provided for follow-up mine removal. The autonomous type mine detection robot system conducts mine detection and marking and is long in service life.

Owner:上海圭目机器人有限公司

Acoustic mechanical retainer

ActiveUS20060237261A1Improved noise attenuation performanceReduce sound levelFuselage framesNoise reduction installationsEngineeringFace sheet

A fan case assembly includes a noise attenuation layer that is covered by a face sheet. The face sheet includes a first plurality of openings. The noise attenuation layer includes a plurality of individual cells that are in communication with at least one of the first plurality of openings. Noise energy is communicated through the first plurality of openings into the individual cells and dissipated to reduce noise emissions. A seam in the face sheet is covered to protect the underlying noise attenuation layer from damage by a retainer. The retainer is bonded to the face sheet over the seam and includes a second plurality of holes that communicates noise energy through the retainer to the noise attenuation layer. Communication of noise energy through the retainer provides an acoustically active seam that aids in the dissipation of noise energy and thereby reduces the level of sound emitted from the engine.

Owner:RAYTHEON TECH CORP

Cold wax block for controlling wall thickness of tenon teeth of hollow turbine working blade and casting method implemented by applying cold wax block

InactiveCN112338139AControlled contractionUniform wall thicknessFoundry mouldsFoundry coresStructural engineeringMechanical engineering

The invention discloses a cold wax block for controlling the wall thickness of tenon teeth of a hollow turbine working blade and a casting method implemented by applying the cold wax block, and belongs to the technical field of precision casting. In the wax pressing process, the cold wax block with the precisely-designed shape is adopted to control the shrinkage amount of a wax mold. An upper moldblock and a lower mold block of the cold wax block can be buckled, a ceramic core is limited and protected, the problems that the ceramic core deviates and breaks due to wax material impacting in thewax pressing process of the ceramic core are avoided, and meanwhile the problem that the sizes of the thick and large parts of the tenon tooth wax mold are too small due to the large wax material shrinkage amount is solved. In order to further accurately position the core, an ejector pin of a shape mold is adopted to directly position the minimum wall thickness measurement part of the tenon teethof the core so as to ensure the relative position relationship between the core and the shape. By means of the method, the problem that the wall thicknesses of the tenon teeth are out of tolerance due to improper shrinkage control and / or core deviation in the working casting process of a hollow turbine can be effectively solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

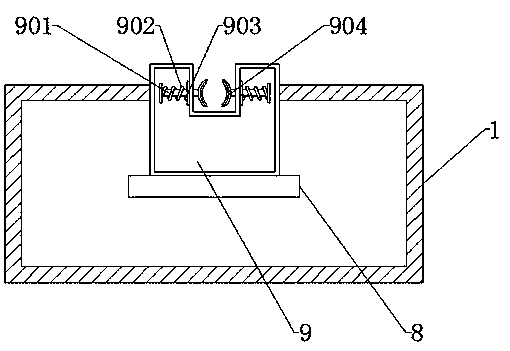

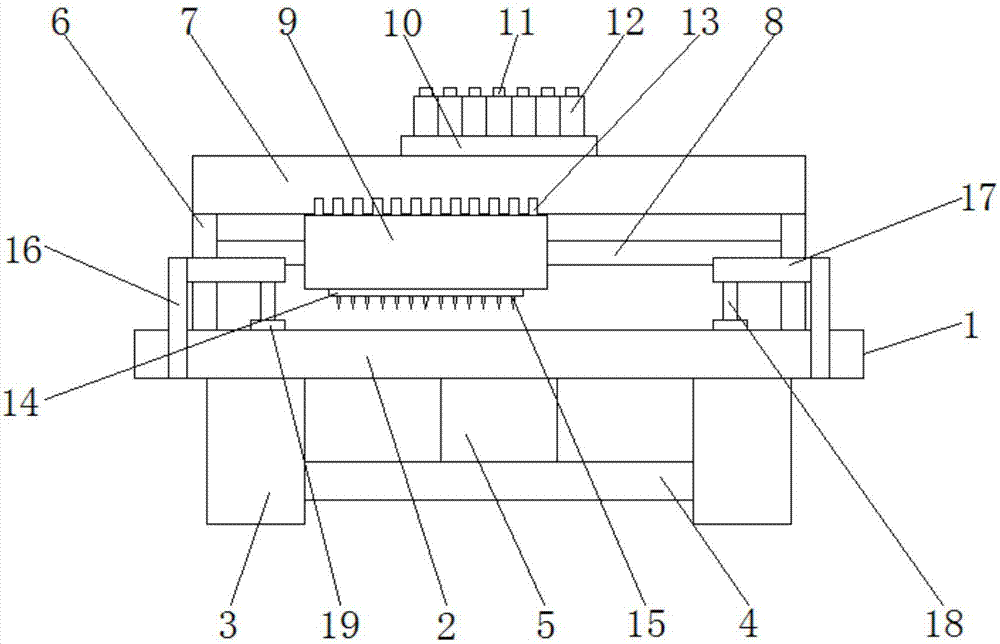

Steel bar welding platform for construction engineering

PendingCN110480216AImprove cooling effectControlled contractionWelding/cutting auxillary devicesAuxillary welding devicesStationary caseArchitectural engineering

The invention belongs to the technical field of construction engineering, and particularly relates to a steel bar welding platform for construction engineering. The steel bar welding platform aims tosolve the technical problem that the welding steel bar needs to be quickly cooled after rust and welding of a welding head need to be removed; the following scheme is provided, the steel bar welding platform comprises a main body, a water tank is fixedly connected to the inner wall of the bottom end of the main body, and an atomizing nozzle is fixedly arranged in the middle of the inner wall of the bottom end of the water tank; a strip-shaped through hole is formed in the top end of the main body, the main body is fixedly connected with two fixing boxes at the strip-shaped through hole, motorsare fixedly installed on one sides of the inner walls of the bottom ends of the two fixing boxes, first through holes are formed in one sides of the top ends of the fixing boxes, and grinding structures are arranged at the position of the first through holes, the and the grinding structures comprises fixing plates. According to the steel bar welding platform, the edge and the cross section of thewelding head can be ground through the grinding structures, so that the rust on the surface of the steel bar can be removed, so that the welding of the steel bar welding platform is more stable, andthe spraying can be blown upward through the blowing, so that the cooling of the welding head is accelerated.

Owner:中建河图建设有限公司

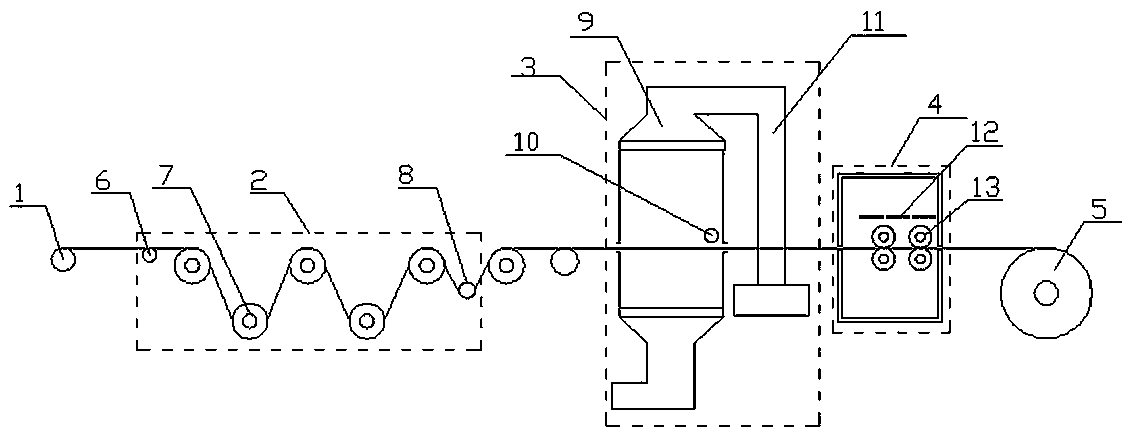

Continuous carbon fiber thermoplastic prepreg preparation system

The invention provides a continuous carbon fiber thermoplastic prepreg preparation system. The prepreg preparation system comprises a creel, a fiber spreading device, a coating device, a hot pressingdevice and a winding device; a carbon fiber bundle is arranged on the creel, the carbon fiber bundle is drawn out of the creel and then enters the coating device after being uniformly spread by the fiber spreading device, after the coating device is used for spraying resin with the carbon fiber bundle, heating and rolling of the hot pressing device are carried out to form a prepreg tape with complete impregnation, and finally the prepreg tape is rolled through the winding device. The continuous carbon fiber thermoplastic prepreg preparation system has the beneficial effects that the size of awhole set of equipment is small, the whole set of equipment is less than 5m, and the occupied space is small; the equipment with modularization design, and the fiber spreading and the preimpregnatingcan be carried out separately; a fiber tape with uniform width and thickness can be obtained; a hot pressing module can control the shrinkage in the heating process of a bonding body, so that the prepreg tape with uniform thickness can be obtained.

Owner:大工碳鼎科技洛阳有限公司

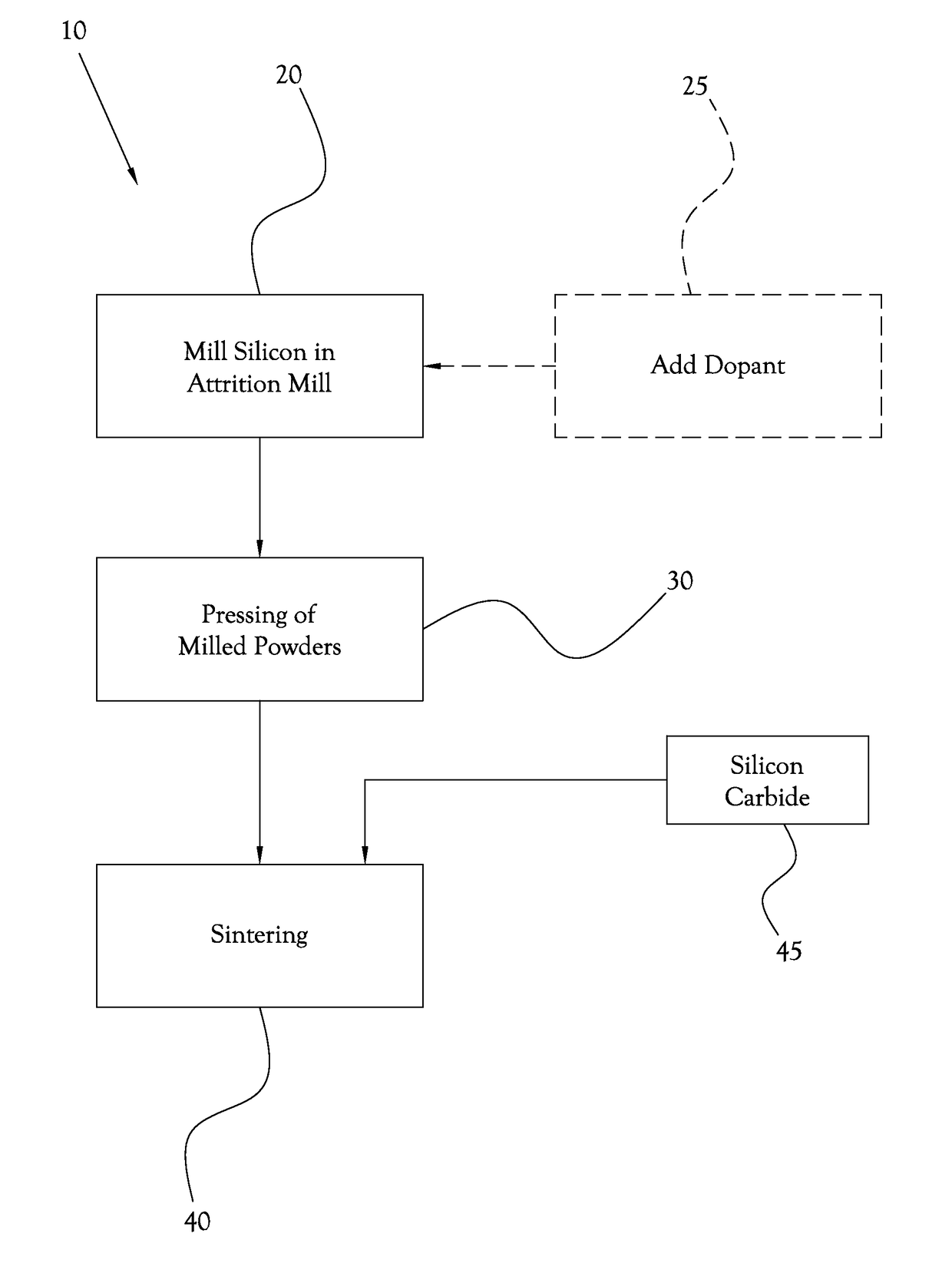

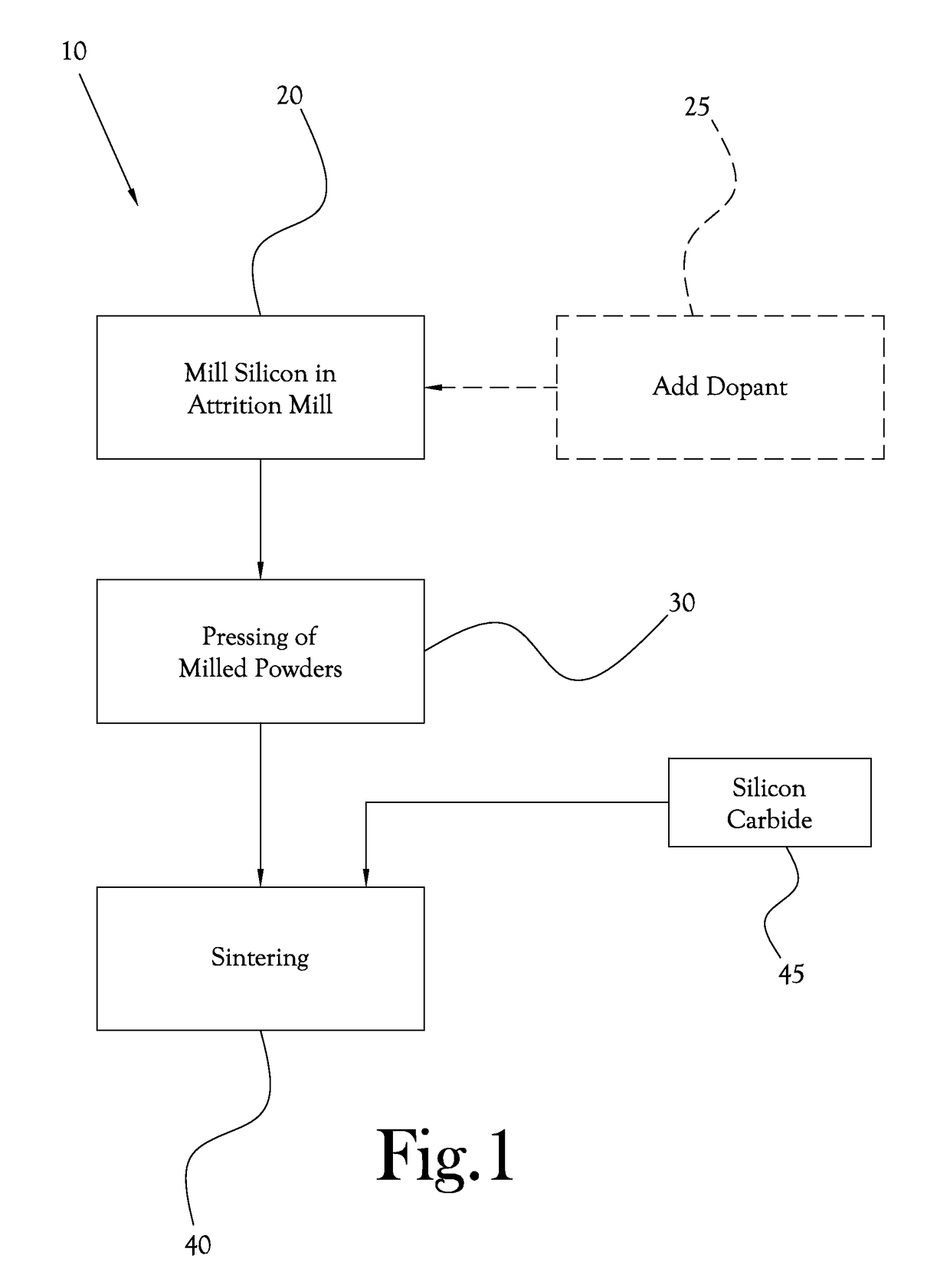

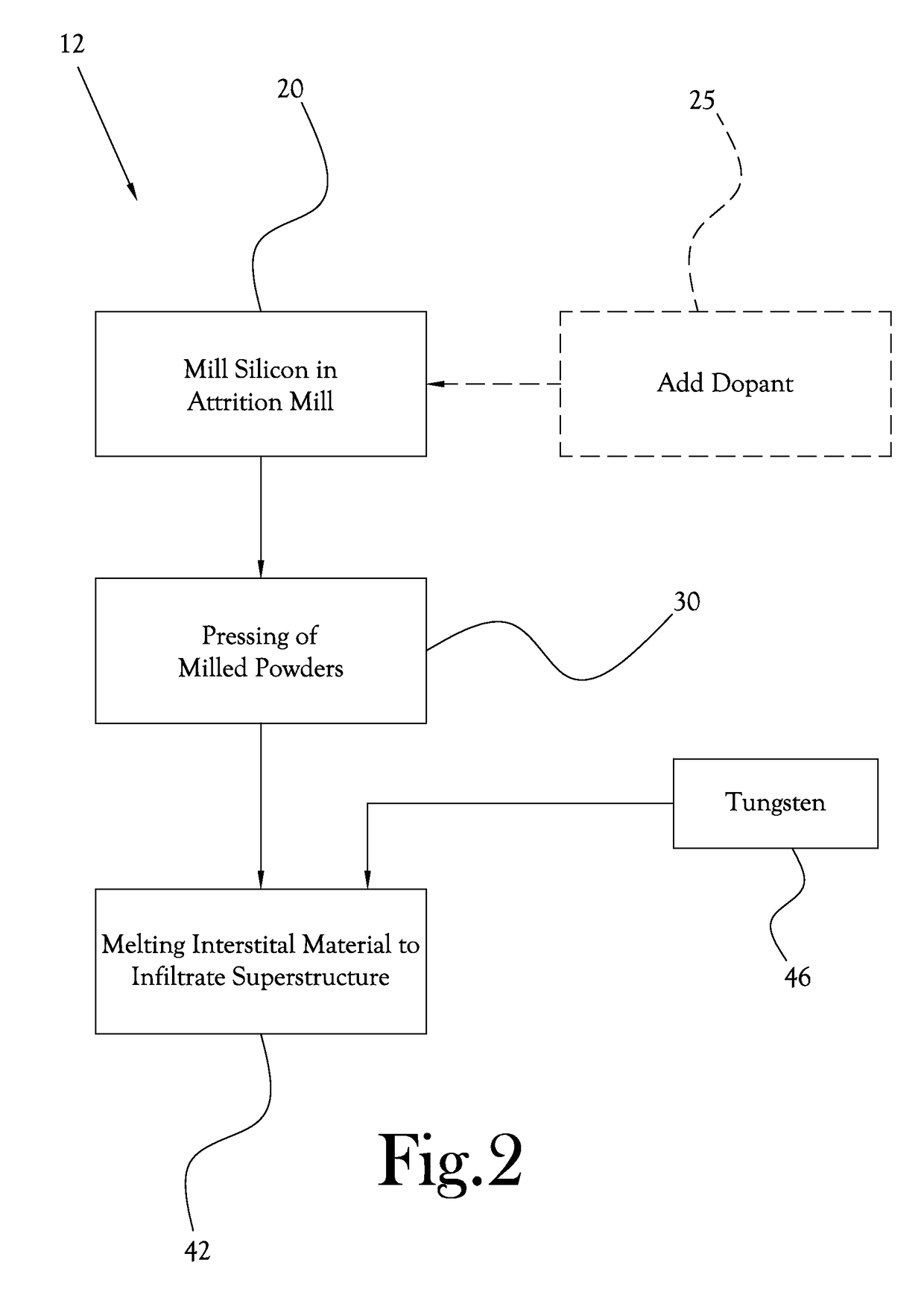

Porous Sintered Superstructure with Interstitial Silicon for Use in Anodes for Lithium Batteries

InactiveUS20170125805A1High lithiation capacityProvide durabilityElectrode thermal treatmentElectrode carriers/collectorsSiliconTungsten

Anodes for the lithium secondary batteries include a strong, electrically conductive, porous superstructure filled with a milled or melted interstitial material, such as nano-scaled silicon; the milled or melted interstitial material provides high lithiation capacity, and the superstructure provides durability and controls the anode's electromechanical expansion and contraction during the lithiation and de-lithiation cycle. Embodiments include porous superstructures comprised of silicon carbide, tungsten, and other materials, many of which offer capability of lithiating.

Owner:MOSSEY CREEK TECH

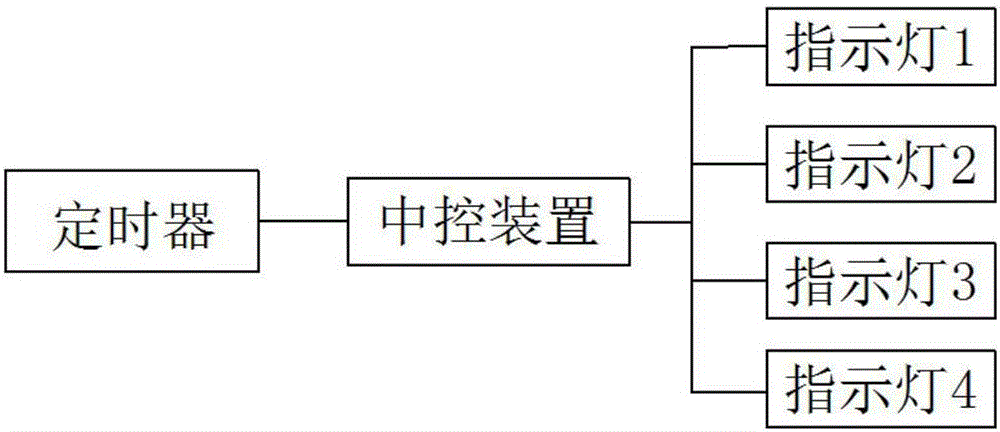

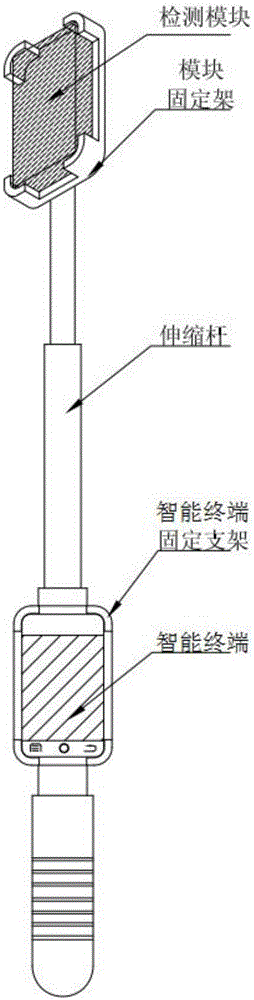

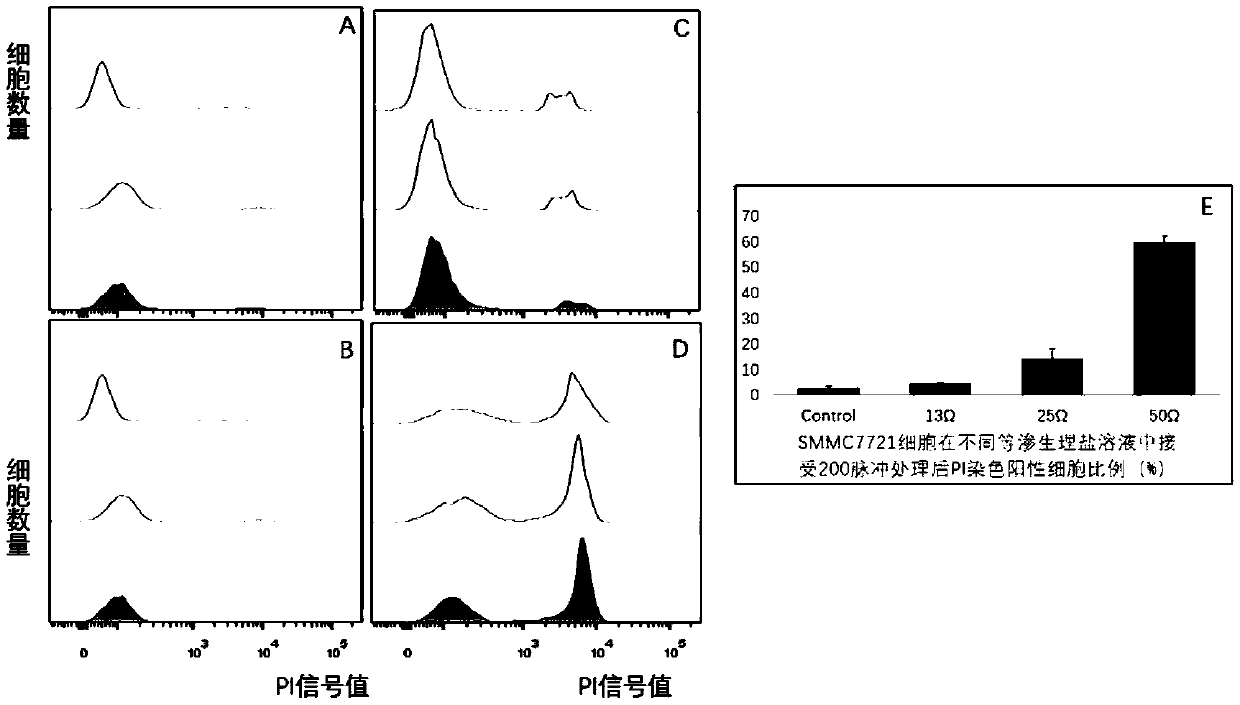

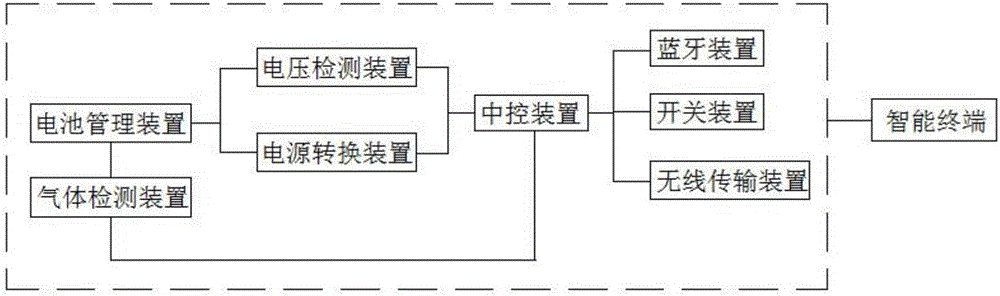

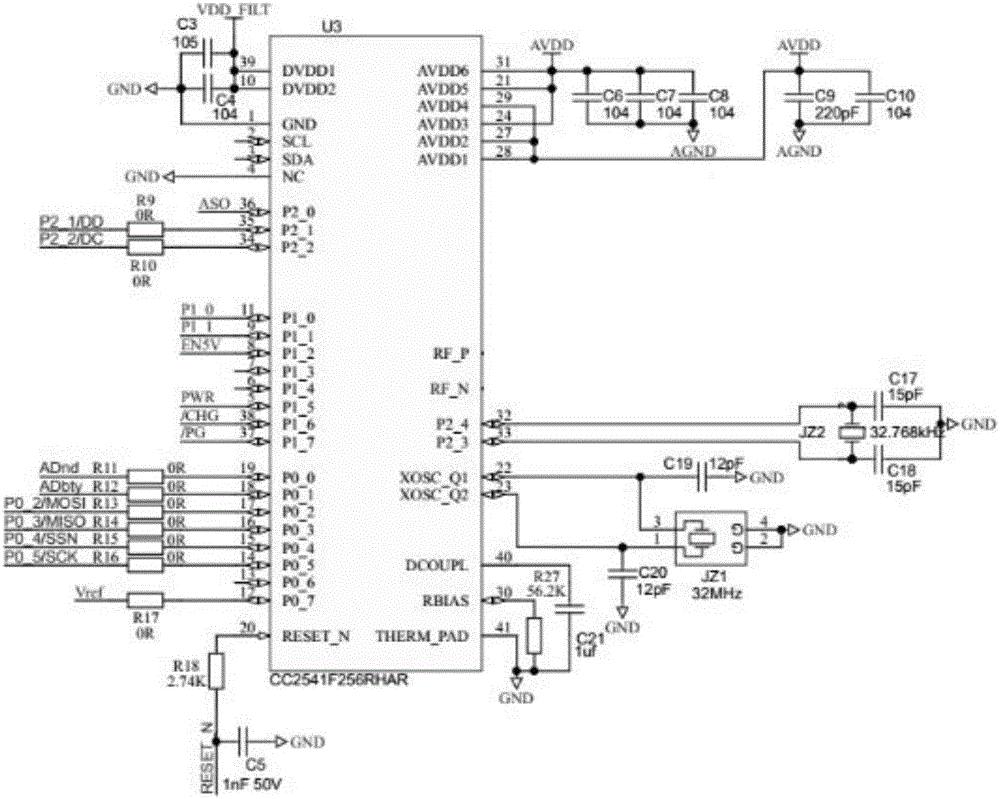

Indicating device of portable combustible gas detector, and display method and indicating method of portable combustible gas detector

ActiveCN106501177AExpress Repair ProgramSimple structureMaterial analysis by optical meansCombustible gasEngineering

The invention discloses an indicating device of a portable combustible gas detector. The indicating device comprises a timer arranged on the portable combustible gas detector, a central control device and an indicating lamp, wherein both the timer and the indicating lamp are connected with the central control device. The invention further discloses a display method and an indicating method of the portable combustible gas detector, and the portable combustible gas detector. The indicating device can display nine operation states including startup operation, shutdown operation, normal operation, concentration alarm, sensor fault, battery under voltage, battery charging, battery full and Bluetooth connection whether by any mode.

Owner:山东罗伯特能源装备有限公司

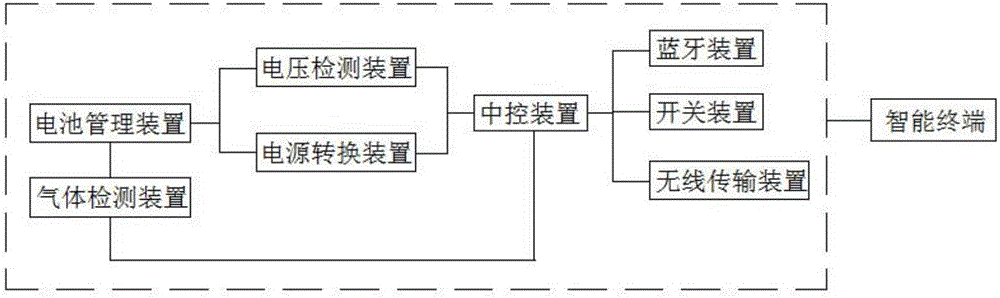

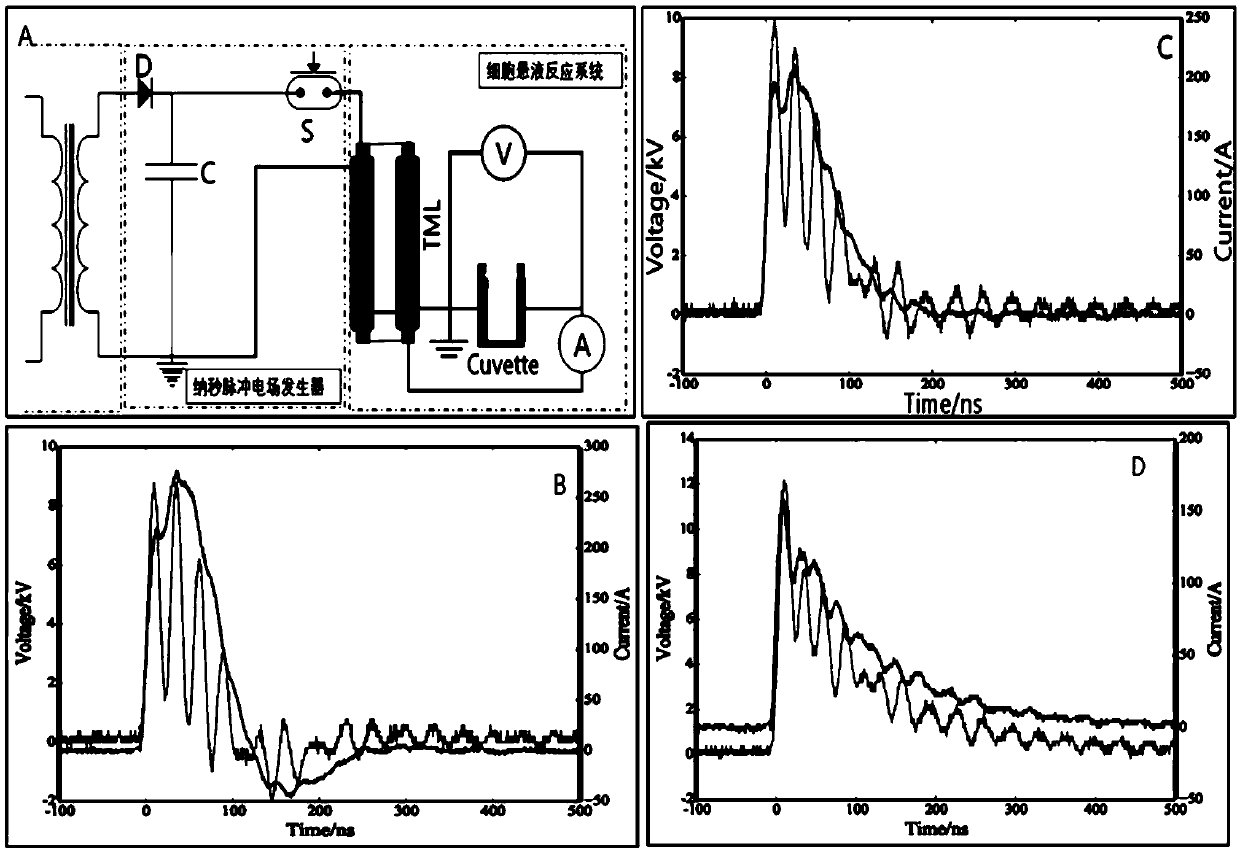

Method for improving electroporation efficiency of electric energy induced living cell membrane

InactiveCN109593753AImprove permeabilityImprove the efficiency of electroporationOther foreign material introduction processesElectrical/wave energy microorganism treatmentCapacitanceCell membrane

The invention discloses a method for improving electroporation efficiency of an electric energy induced living cell membrane. Electric energy stored in a capacitor is released into an iso-osmia normalsaline solution in a mode of index waveform nanosecond electric pulse through a conduction wire, and then cell membranes of living cells in the normal saline solution have electroporation. When the impedance of the normal saline solution is greater than the characteristic impedance of the conduction wire, as charges are reflected in the conduction wire, the voltage released into the loaded electric pulse is higher than that loaded at a capacitor discharge start point, then when same single pulse energy stored in the capacitor is released into living cells suspended in the normal saline solution, the voltage of the pulse has a higher highest peak value, and the efficiency that induced living cells have functional electroporation is improved. Living cells of a greater ratio can be induced to have cell membrane electroporation by outputting less total energy.

Owner:ZHEJIANG UNIV

Wound dressing material

ActiveUS8691266B2High tensile strengthControlled contractionNon-adhesive dressingsSynthetic resin layered productsFiberWound dressing

Owner:CONVATEC TECH INC

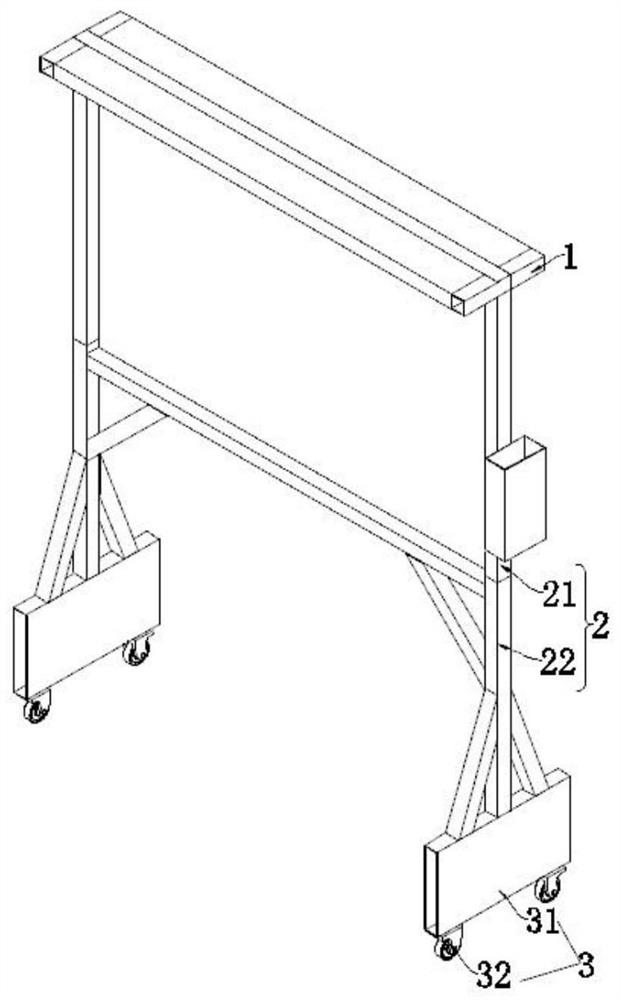

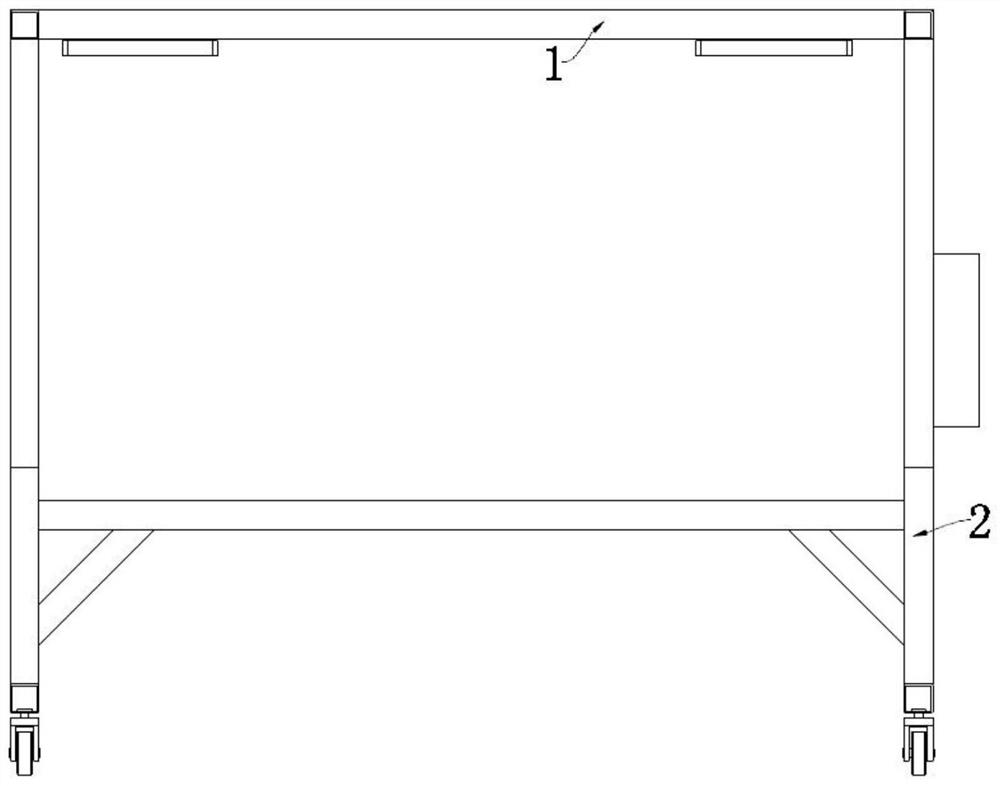

Spinning embroidery machine for textile processing and convenient to use

InactiveCN107338589AStable supportEasy to moveAutomatic machinesAuxillary devicesArchitectural engineeringTextile processing

The invention discloses a textile embroidery machine for textile processing which is convenient to use, comprising a textile embroidery machine body, the textile embroidery machine body including a textile work embroidery table, the front of the textile work embroidery table is fixedly connected with a fixing frame, the An extension frame is fixedly connected to the top of the fixing frame, a compression rod is fixedly connected to the bottom of the extension frame, and a compression plate is fixedly connected to the bottom of the compression rod. The present invention provides shock-absorbing support for the textile embroidery machine body by arranging a shock-absorbing support seat, thereby ensuring the stability of the textile embroidery machine body, thereby facilitating the embroidery operation of the textile embroidery machine body, improving the embroidery quality, and providing compression by setting a compression rod. force, so that the pressing plate can press the embroidery cloth placed on the textile work embroidery table, which is convenient for the embroidery equipment to carry out embroidery processing, and achieves the advantage of convenient use, thus effectively solving the inconvenient use of the existing textile embroidery machines. Problems with textile embroidery operations.

Owner:梅明会

Smart city lighting integrated controller, control method and intelligent street lamp

PendingCN113301683AGood lighting effectEasy to maintainMechanical apparatusElectrical apparatusColor temperatureIntegrated controller

The invention discloses a smart city lighting integrated controller, a control method and an intelligent street lamp, and relates to the technical field of lighting equipment. The controller comprises a first module, a second module, a third module and a fourth module. The first module is arranged to identify foggy days, and the second module is arranged to adjust the color temperature of a lighting lamp. The third module is arranged to be capable of adjusting the brightness of the lighting lamp, the fourth module is arranged to be capable of sensing the light intensity of the environment, and the intelligent street lamp comprises a lighting system and supporting equipment; the supporting equipment is arranged to support the lighting system at one end; wherein the lighting system comprises a sliding rail, at least two lighting lamps connected with the sliding rail in a sliding mode and a driving assembly for driving the lighting lamps to move along the sliding rail, the intelligent street lamp has the better lighting effect, the position of a light source can be adjusted, and workers can conveniently move and maintain the intelligent street lamp.

Owner:南京瑞思其智能科技有限公司

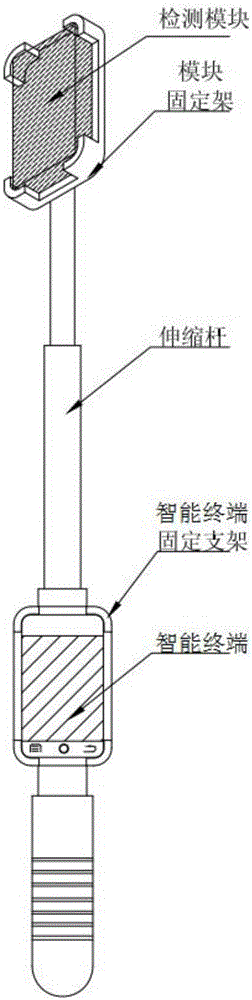

Portable combustible gas detector and application method thereof

ActiveCN106290780AExpress Repair ProgramControlled contractionTransmission systemsFuel testingFixed frameCombustible gas

The invention relates to a portable combustible gas detector. The portable combustible gas detector comprises an intelligent terminal, a stretchable rod and a detection module, wherein the top of the stretchable rod is provided with a module fixing frame for fixing the detection module, four corners of the module fixing frame are respectively provided with an infrared sensor, the infrared sensors are connected with the detection module, the bottom of the stretchable rod is provided with a handle, an intelligent terminal fixing support for fixing the intelligent terminal is arranged above the handle, a button is arranged below a handle fixing frame, and the stretchable rod is formed by connecting a plurality of connecting rods; and the detection module is connected with the intelligent terminal. The invention also relates to an application method of the portable combustible gas detector. The portable combustible gas detector can realize an automatic stretchable function and a function for judging a combustible gas overflow opening.

Owner:山东罗伯特能源装备有限公司

Guide unit guide roller cooling system

InactiveCN107377639AControlled contractionControl liftTemperatue controlGuiding/positioning/aligning arrangementsTemperature controlWater resources

The invention discloses a guide unit guide roller cooling system. The guide unit guide roller cooling system comprises a guide unit, a guide roller supporting arm is fixedly arranged on one side of the guide unit, a cold water pipe is arranged at the top of the guide roller supporting arm and is fixedly connected with the guide unit, a spraying head is arranged on the cold water pipe, one end of the cold water pipe is connected with a water inlet pipe, a water pump motor is arranged on one side of the water inlet pipe, a guide roller is arranged on the guide roller supporting arm, and a temperature control device is arranged on the guide roller. According to the guide unit guide roller cooling system, a heat conduction bar and a shape memory alloy are arranged, and therefore the heat conduction bar can better transmit the temperature of the guide roller to the shape memory alloy, and the shape memory alloy is controlled to extend and contract; and a supporting frame, an electrode plate and an electric contact bar are arranged, and therefore the shape memory alloy can better deform to control the supporting frame to ascend and descend, the supporting frame ascends and descends to control contact between the electrode plate and the electric contact bar, starting and stopping of the water pump motor are controlled, constant work of the water pump motor is avoided, energy resources are saved, and the water resource is saved.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com