Patents

Literature

1267 results about "Superstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A superstructure is an upward extension of an existing structure above a baseline. This term is applied to various kinds of physical structures such as buildings, bridges, or ships having the degree of freedom zero (in the terms of theory of machines).

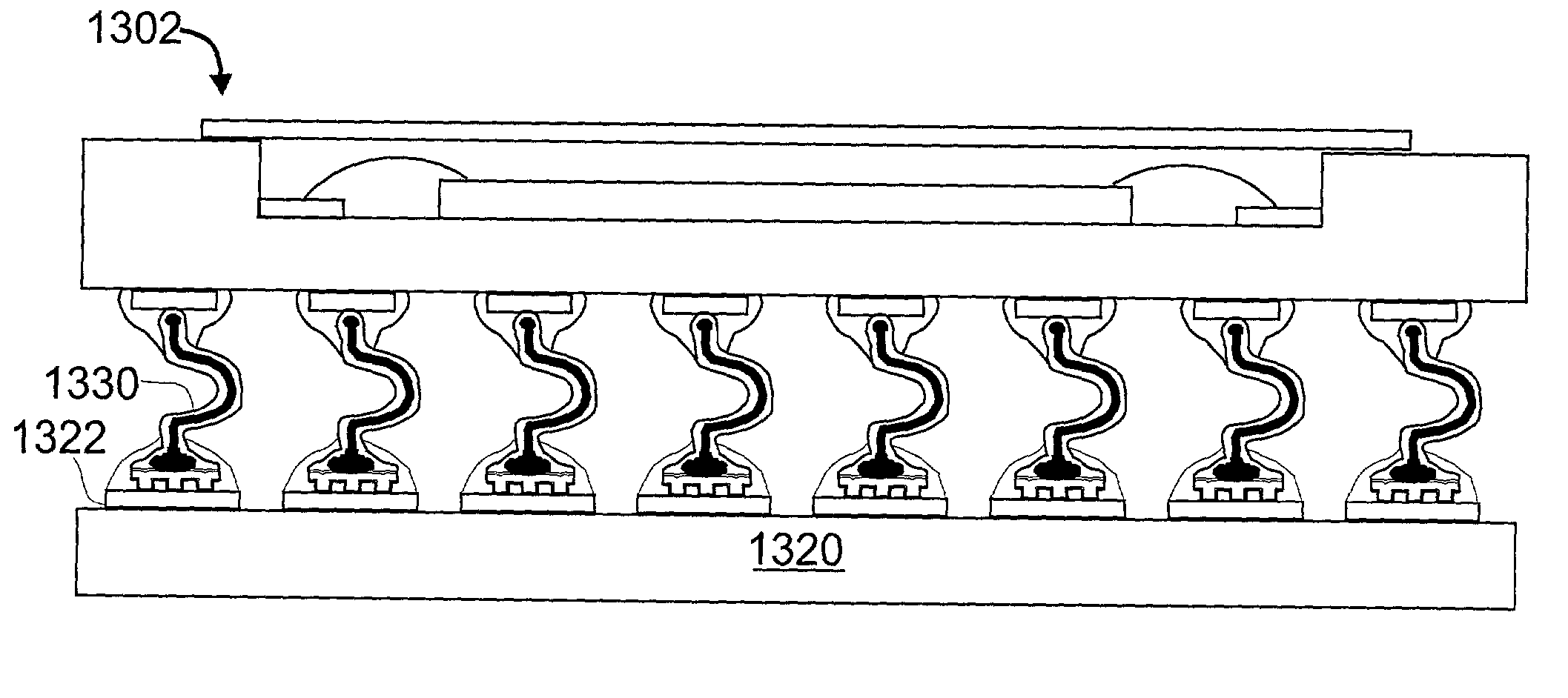

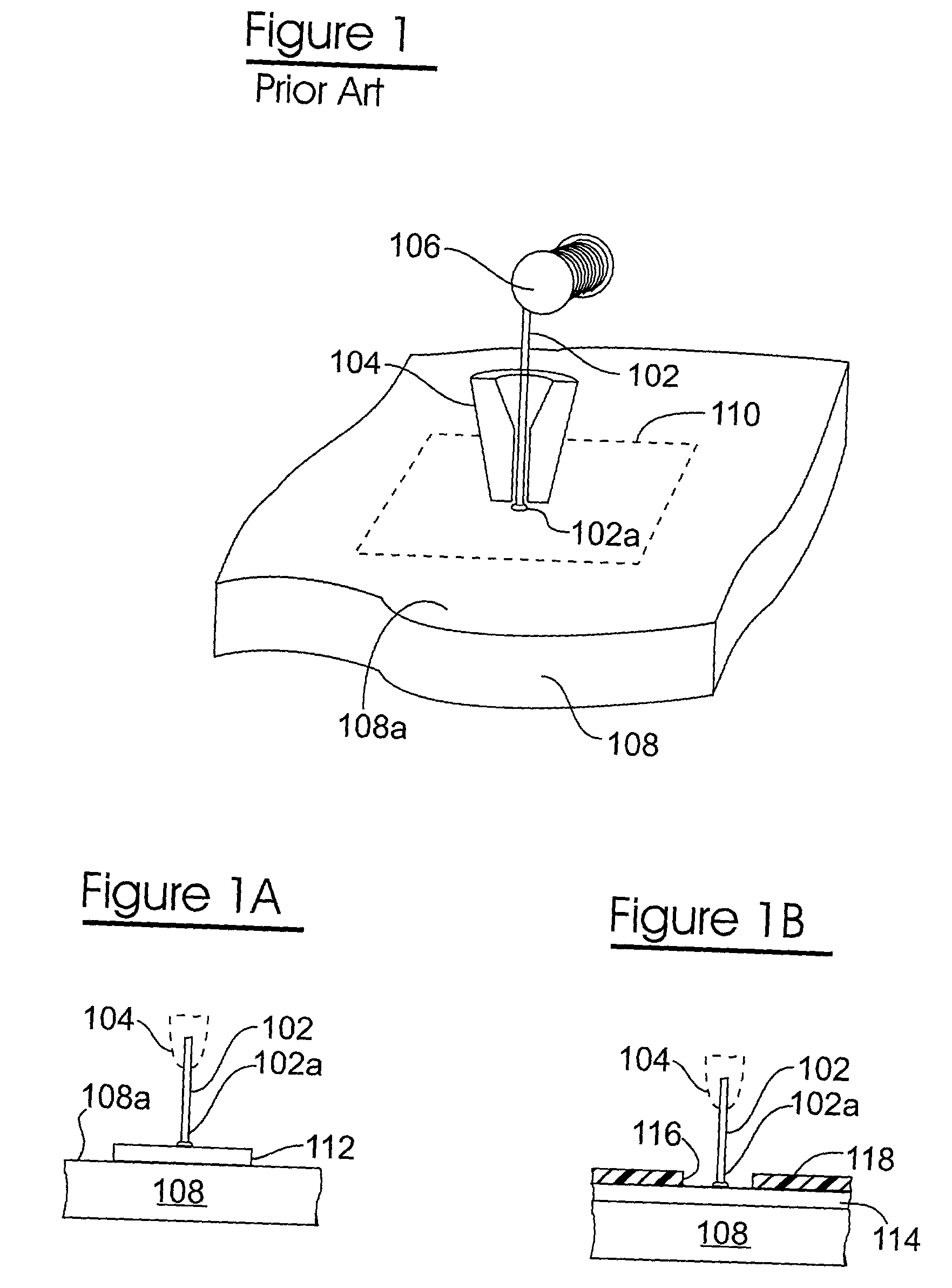

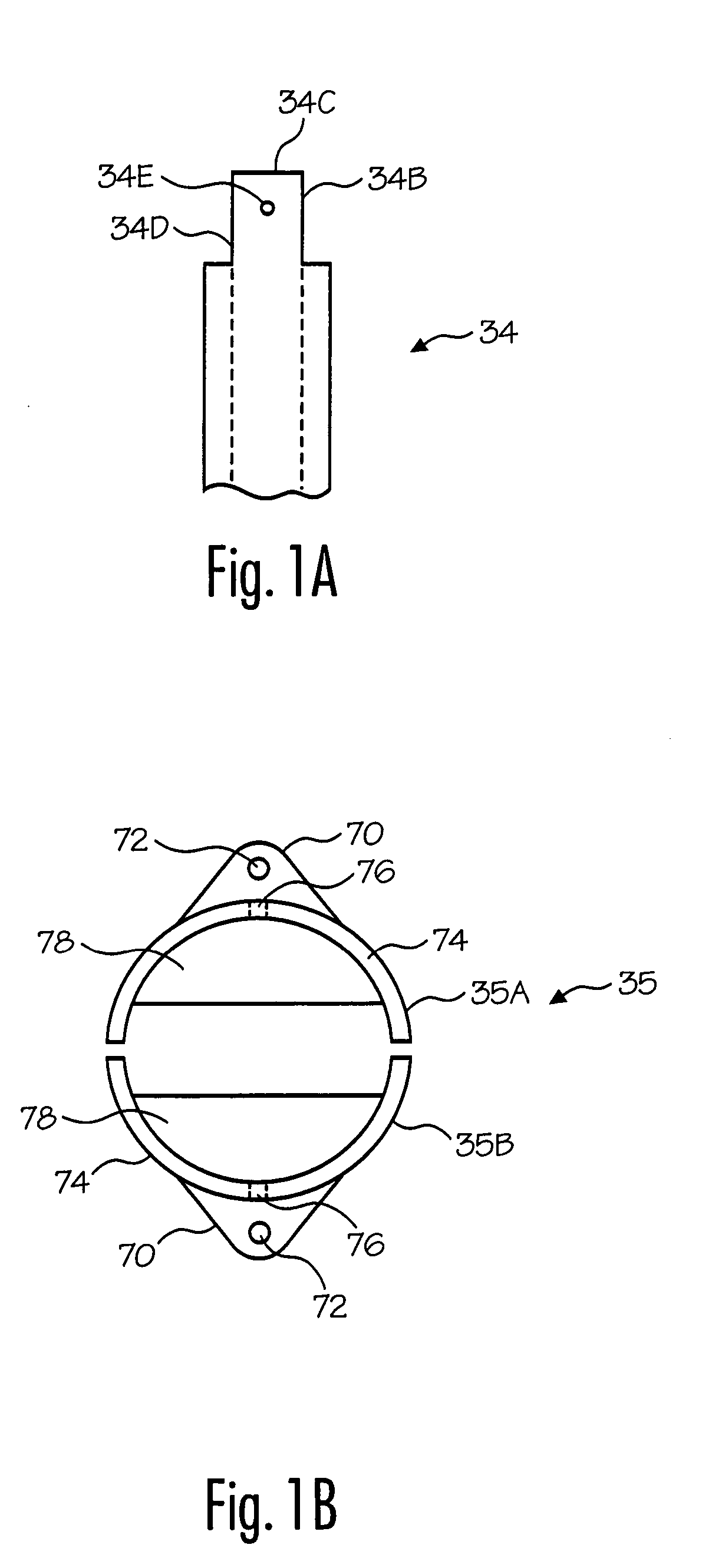

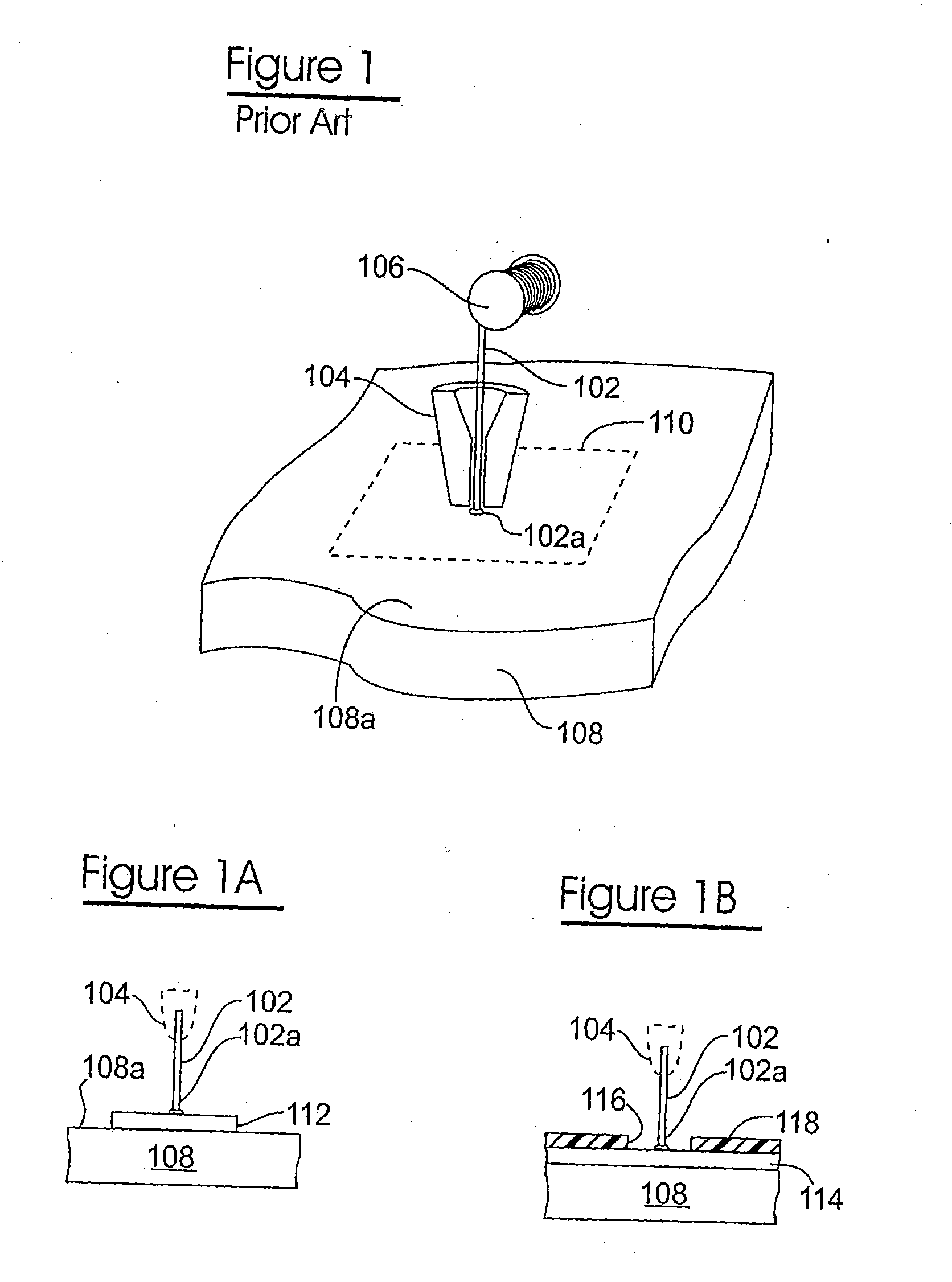

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

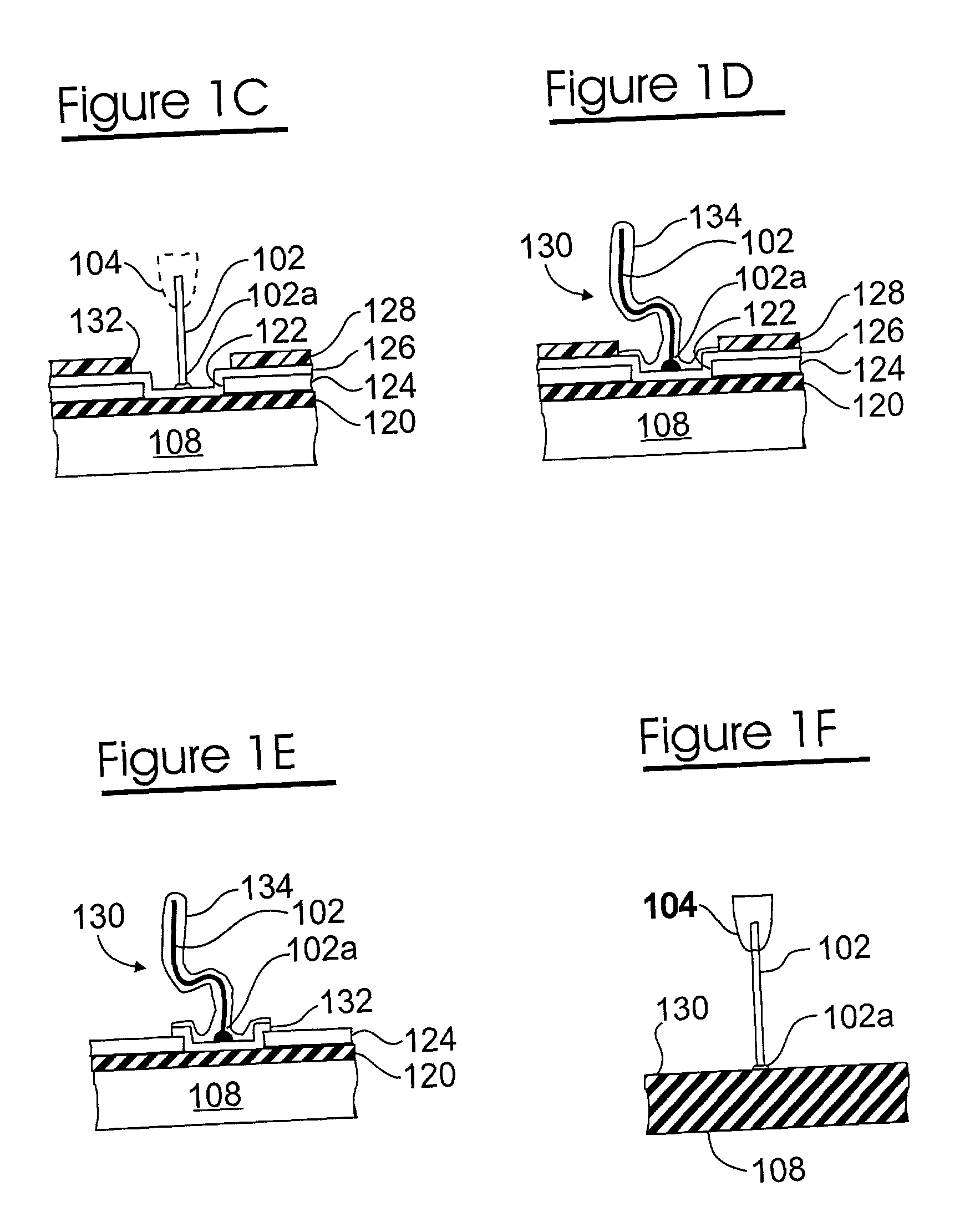

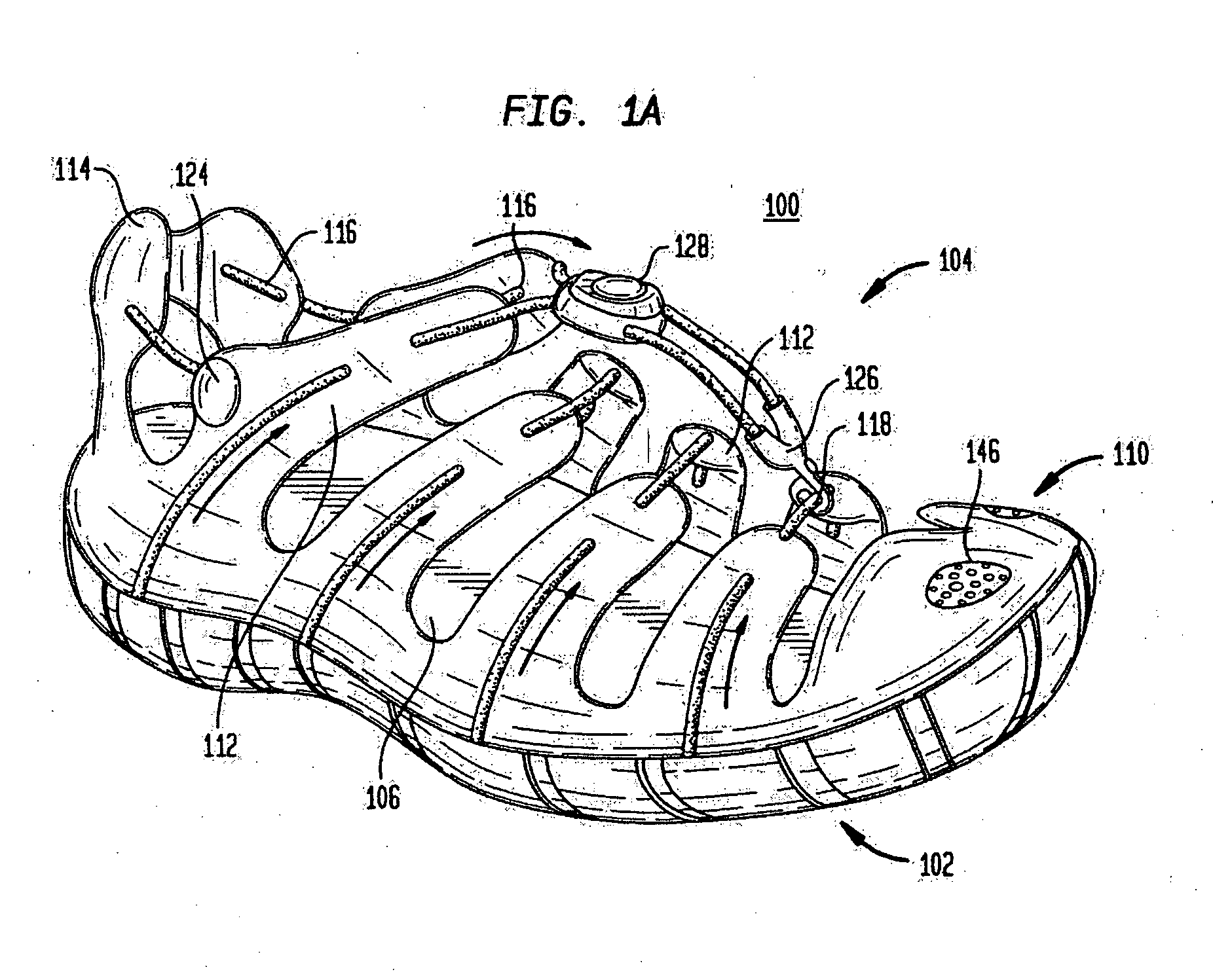

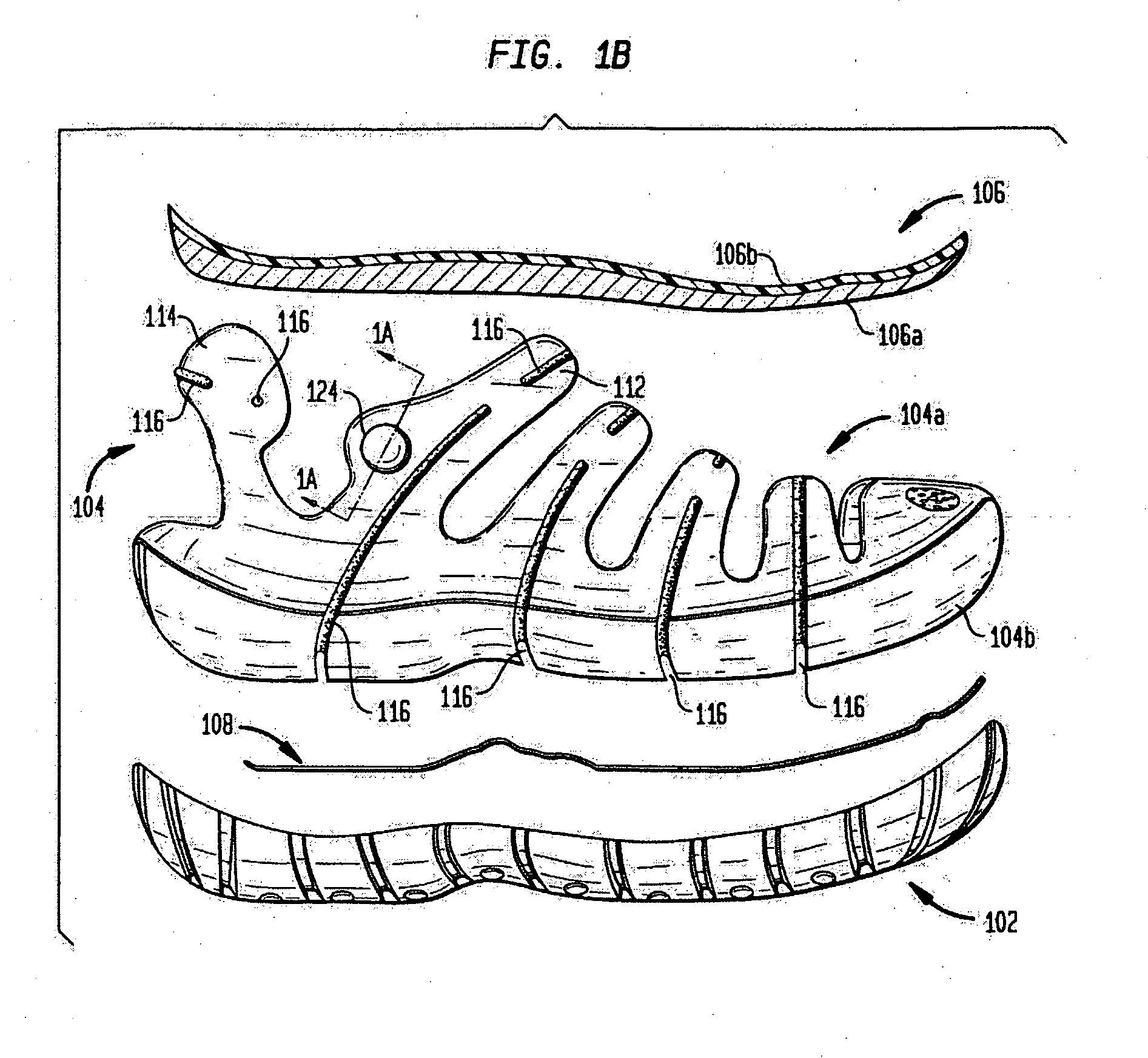

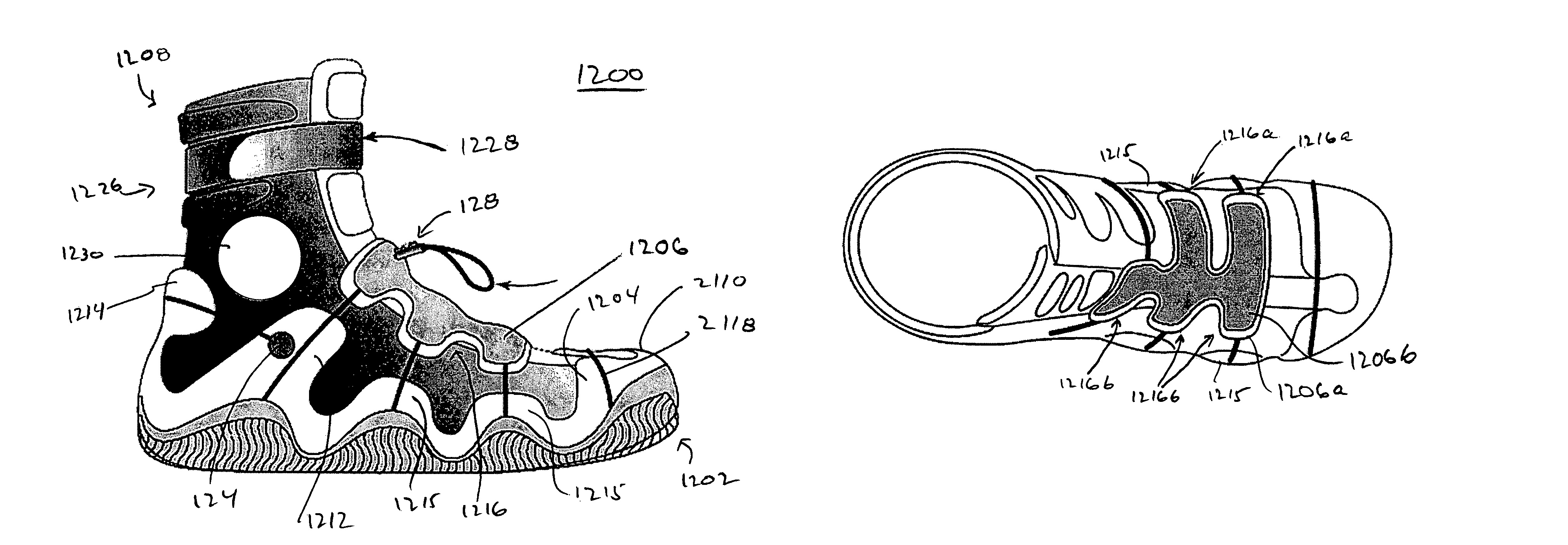

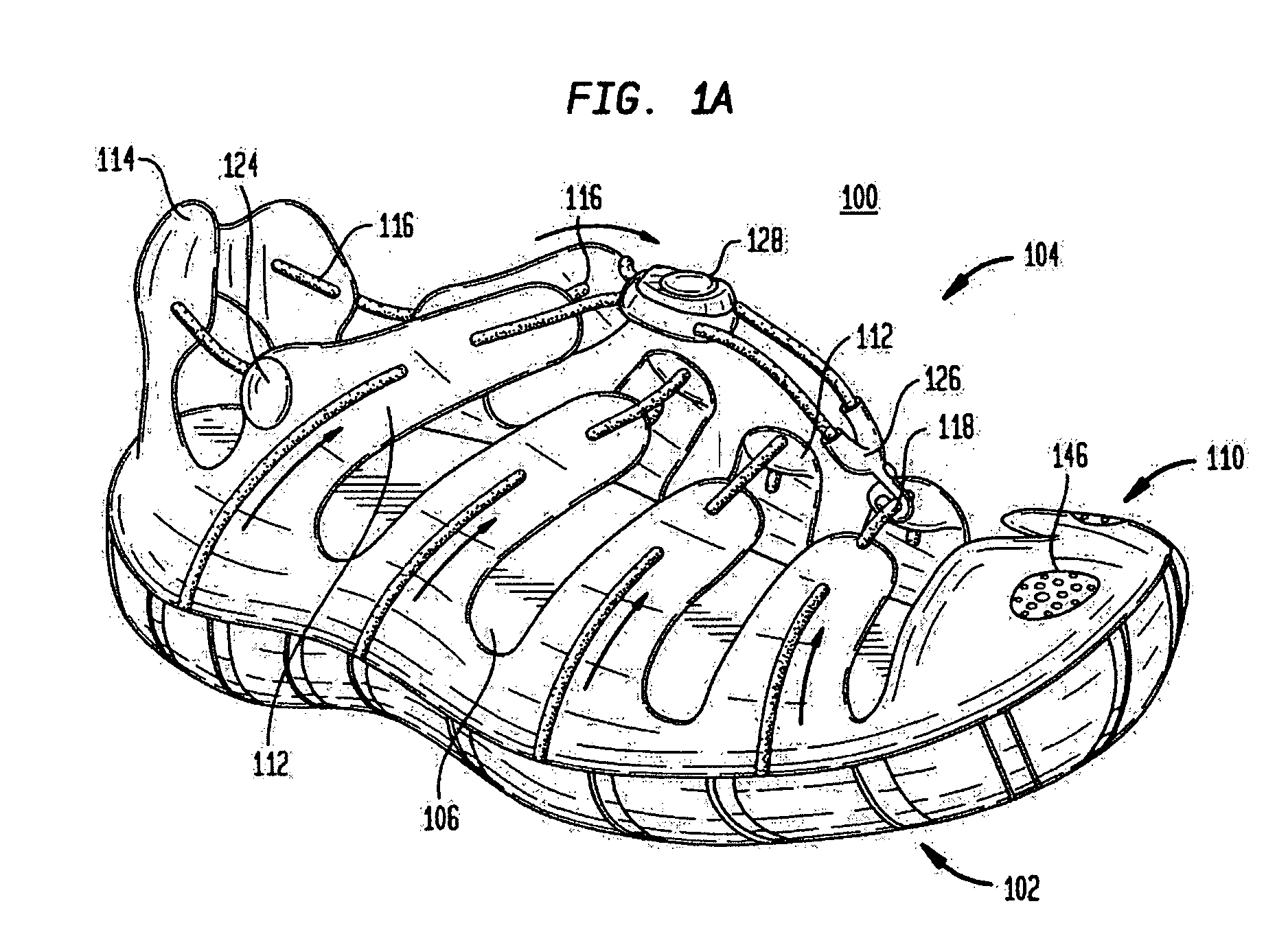

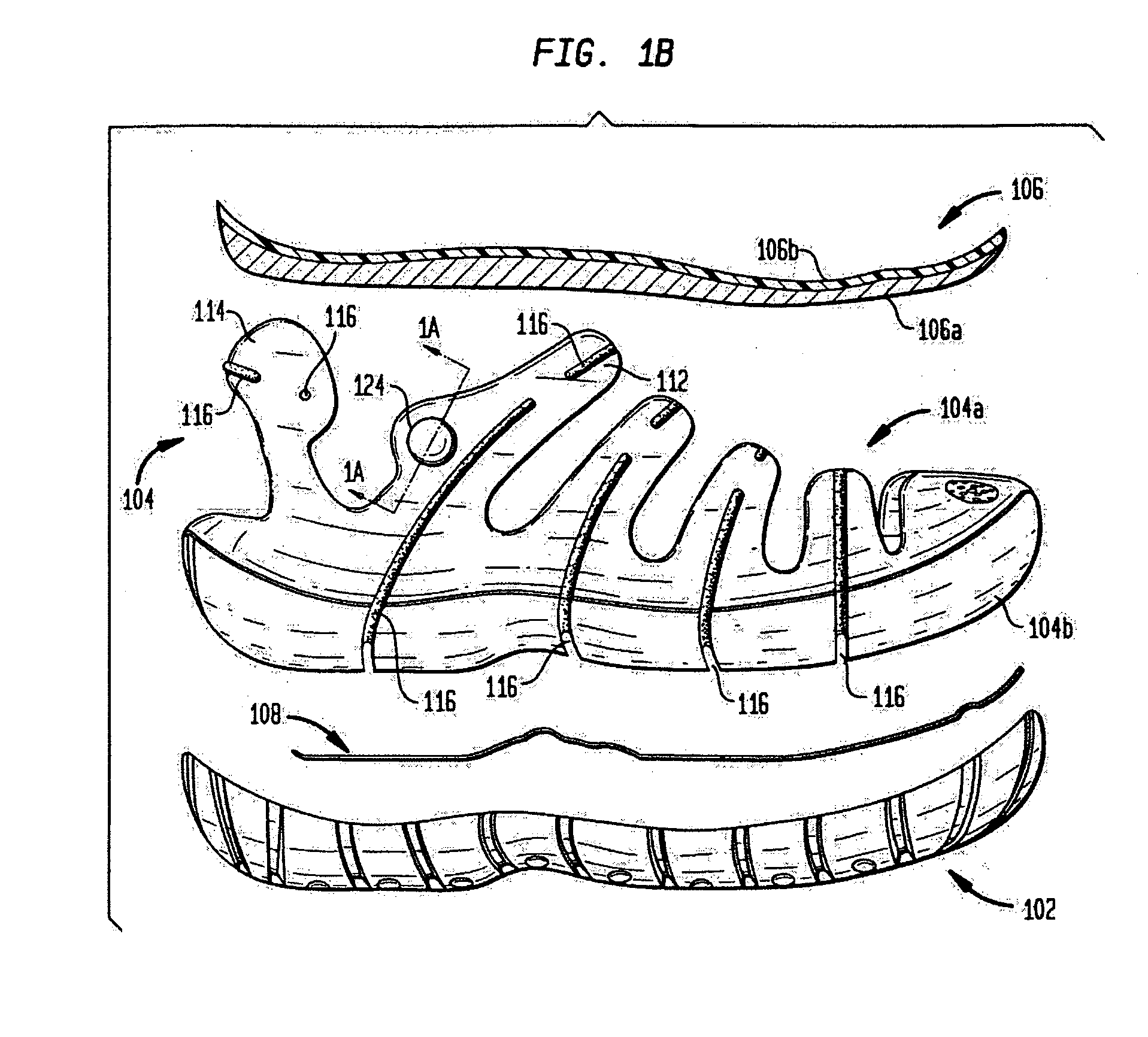

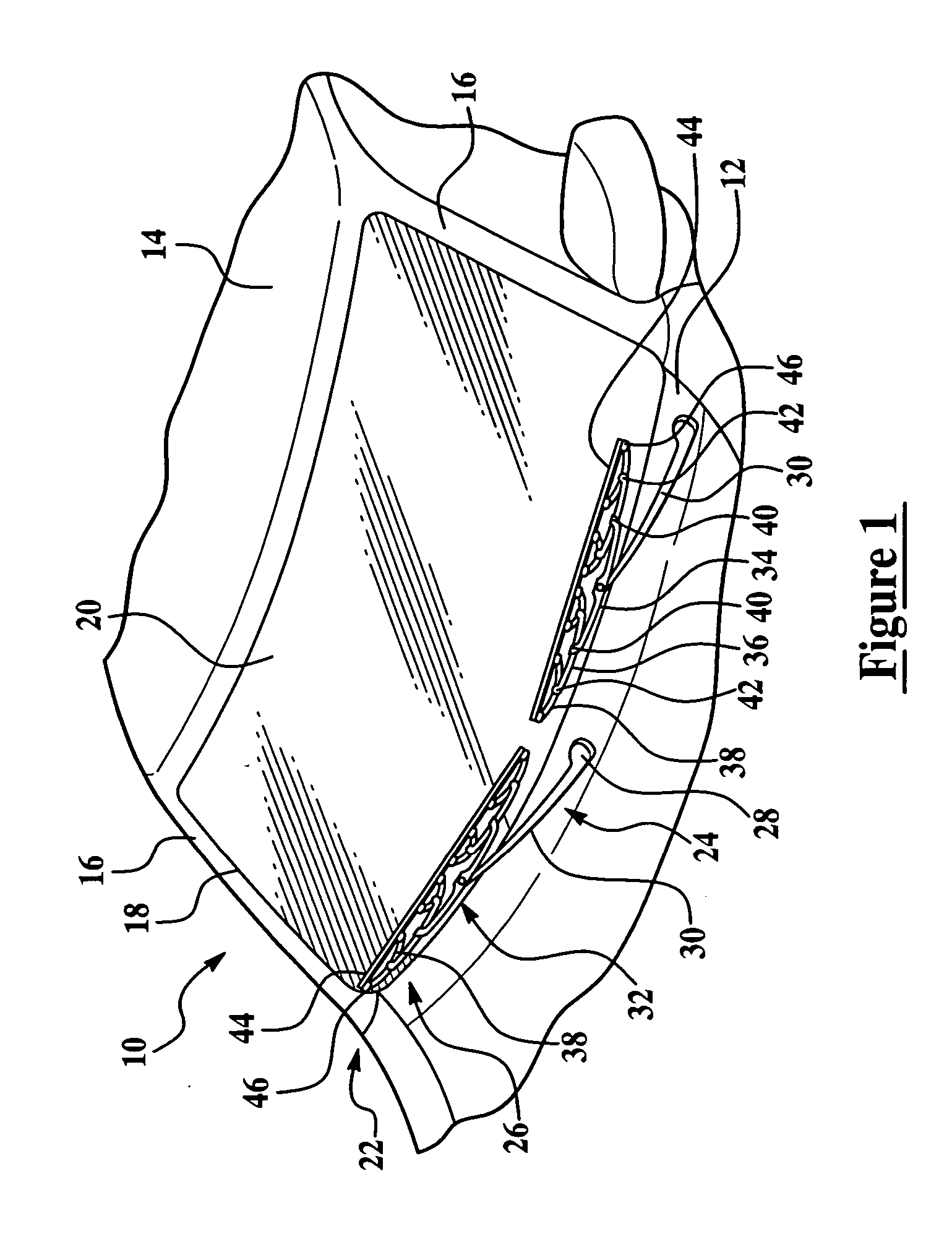

Shoe with anatomical protection

ActiveUS20070011914A1Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

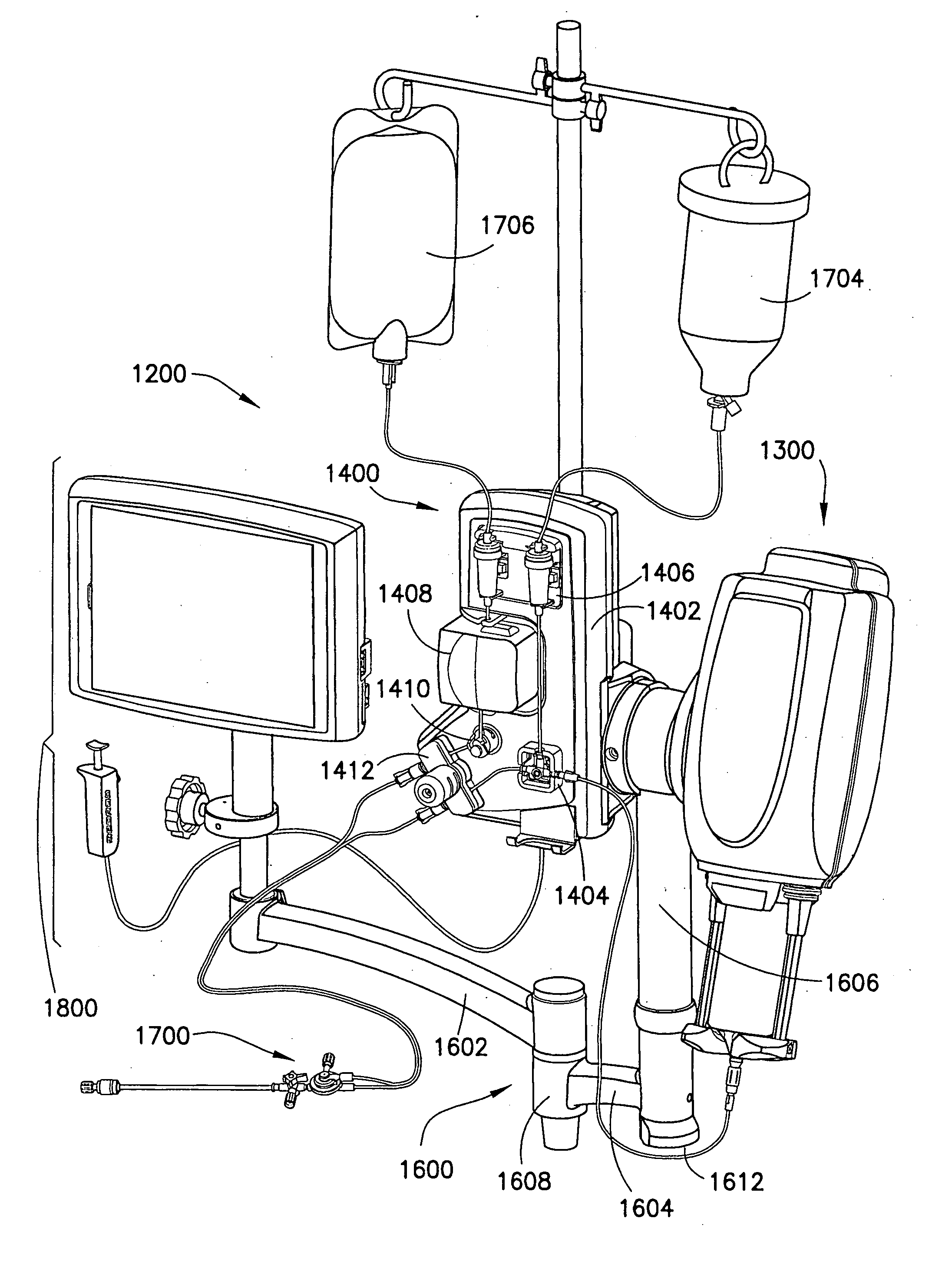

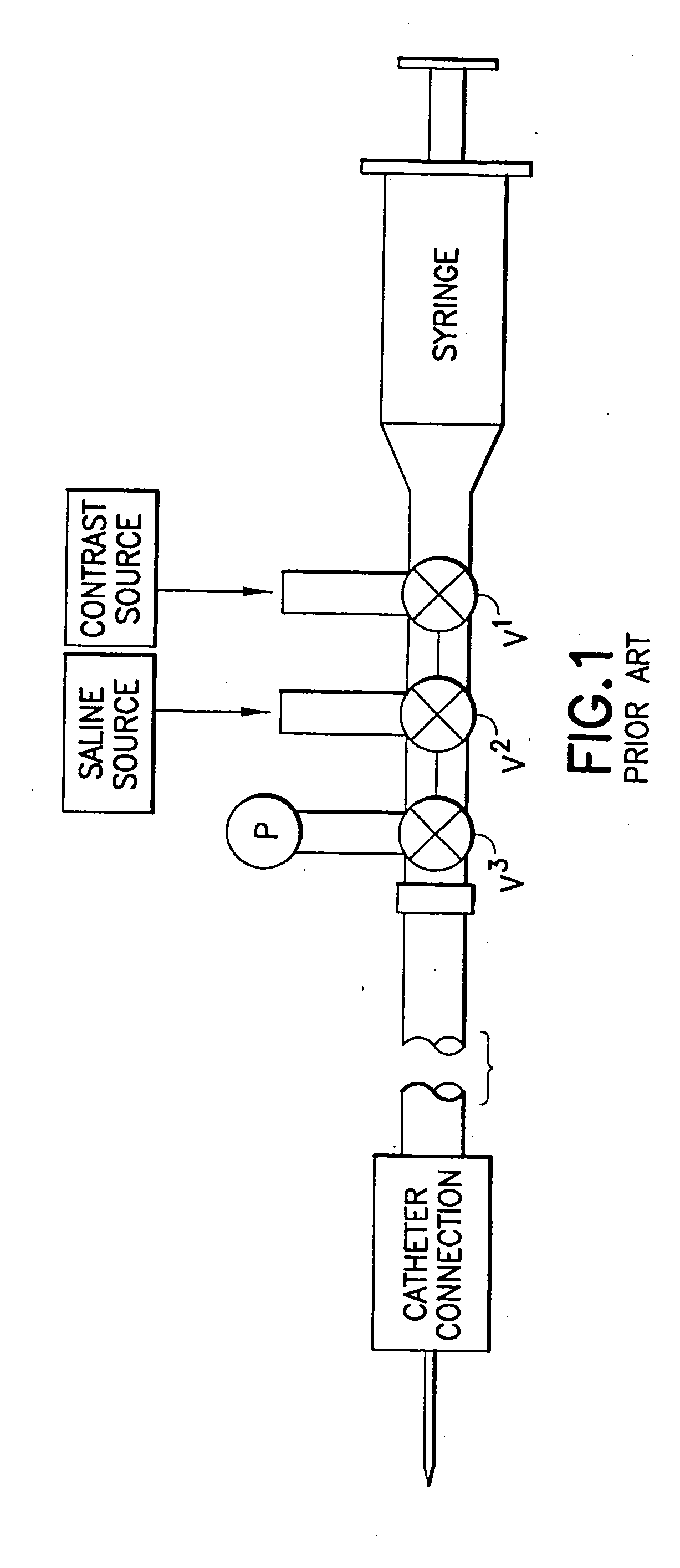

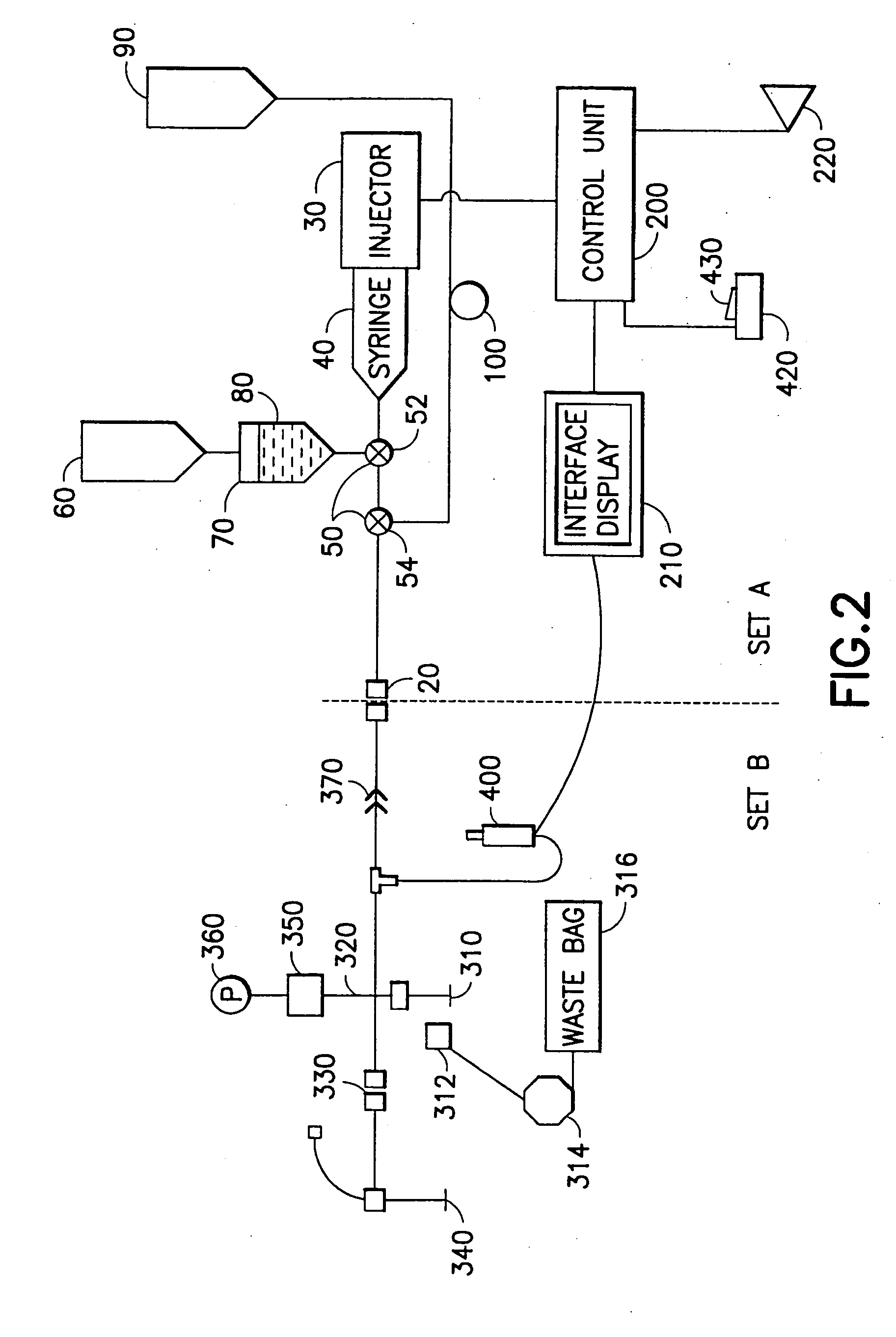

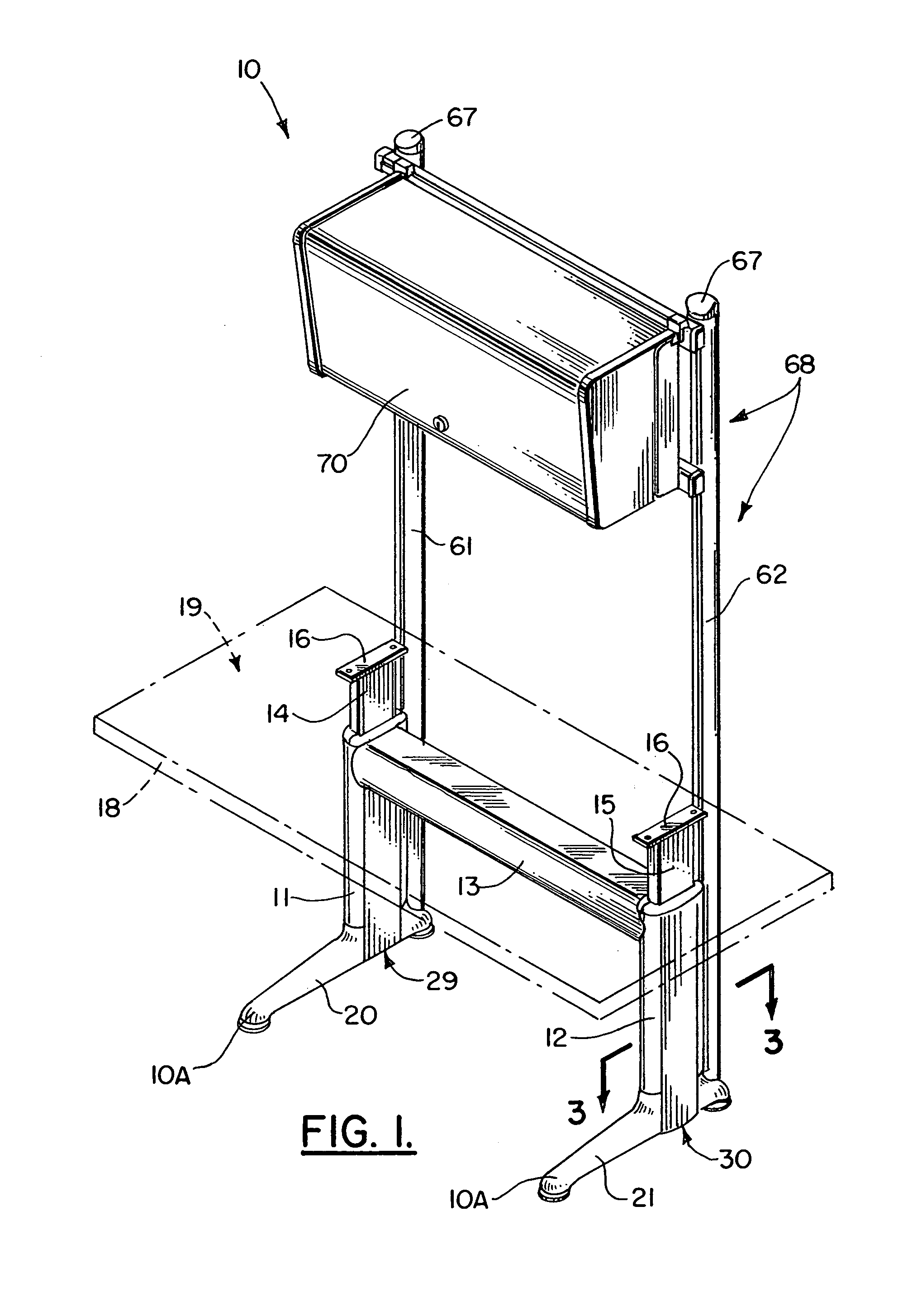

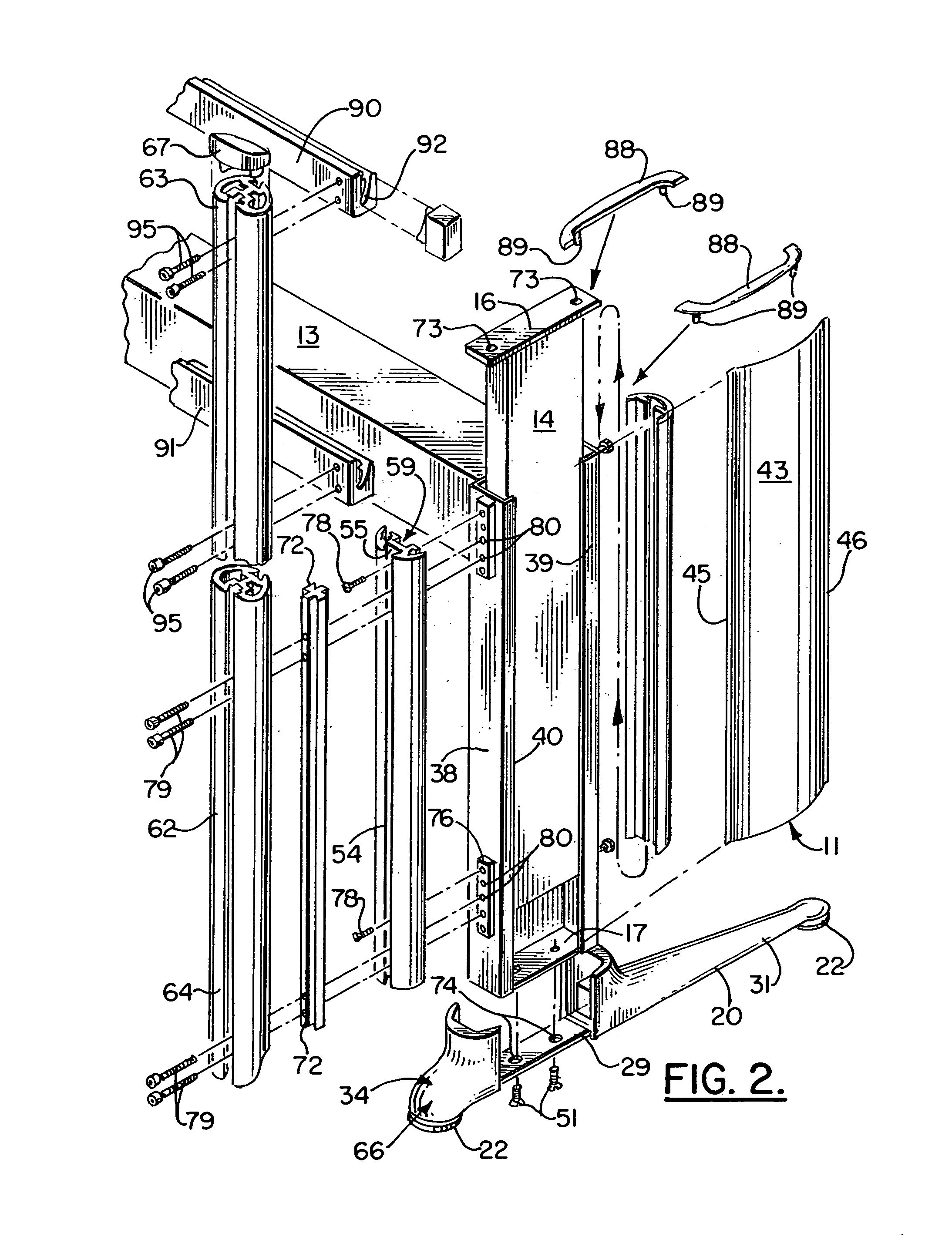

Mobile fluid delivery system with detachable pedestal

InactiveUS20050230575A1Reduce fluid pressureReduce and eliminate flowInfusion syringesMedical devicesFluid controlBiomedical engineering

The mobile fluid delivery system includes a mobile pedestal and a fluid delivery superstructure detachably connected to the pedestal. The fluid delivery superstructure includes a pump device and a fluid control device. A fluid path set operatively associates the pump device with the fluid control device. The superstructure is further adapted to detachably connect to a patient examination platform. A rail mount is used to provide the interface between the superstructure and the patient examination platform. The rail mount attaches to a rail of the patient examination platform and includes a main body defining an elongated recess for engaging the rail of the patient examination platform. The superstructure detachably connects to the main body. Locking devices are used to secure the rail mount to the patient examination platform and the superstructure to the rail mount. A spacer may be inserted into the elongated recess to accommodate different sized rails.

Owner:ZELENSKI KAREN M +4

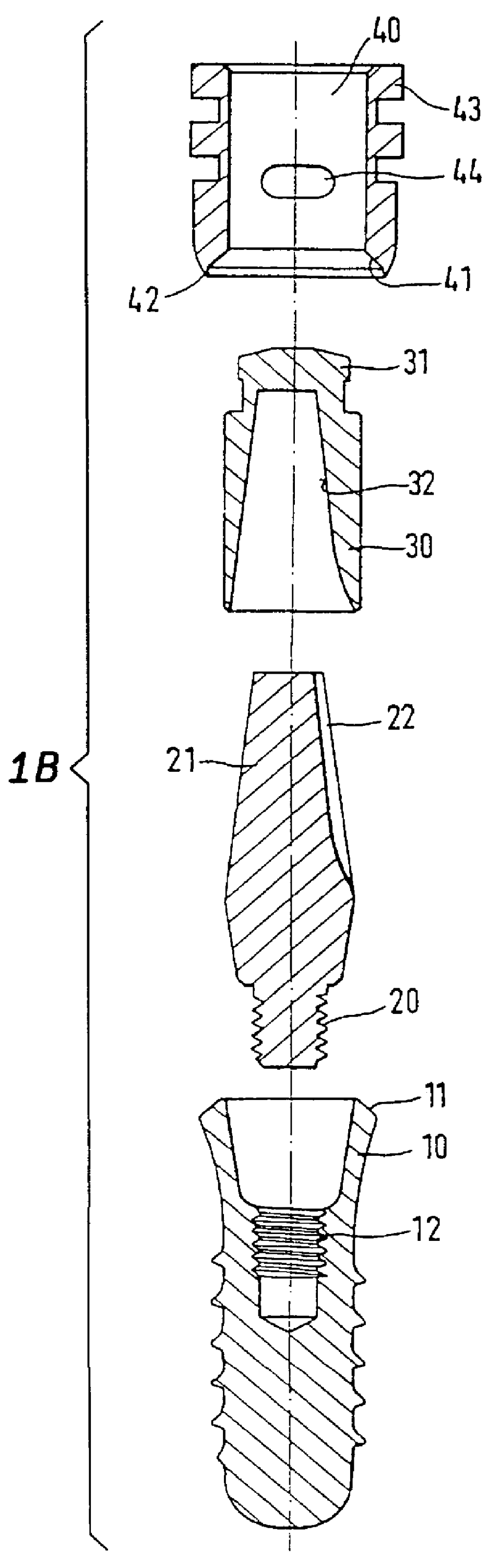

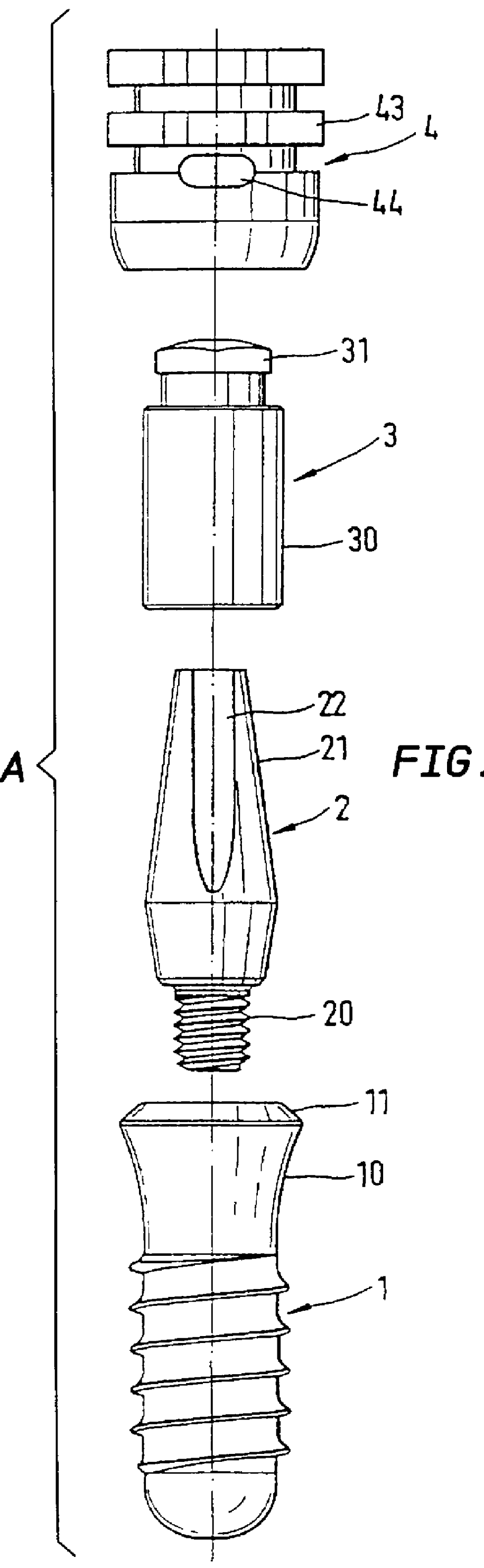

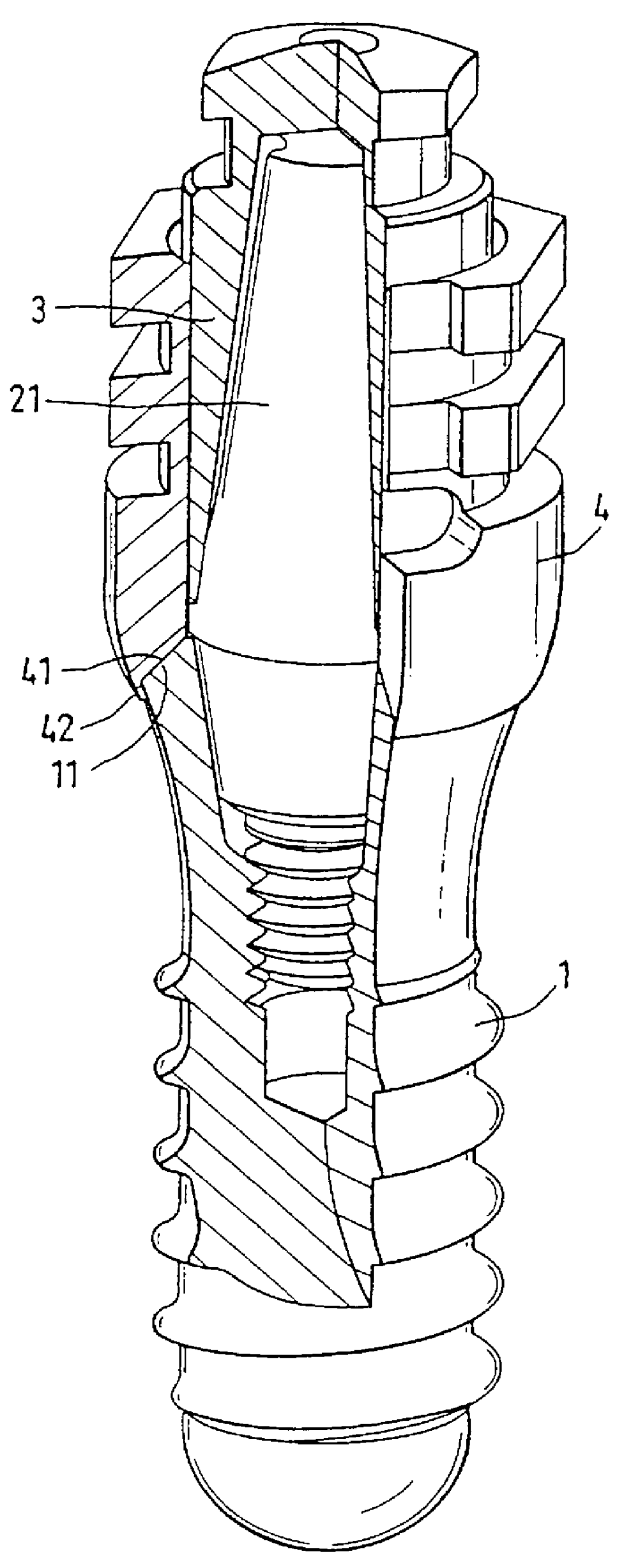

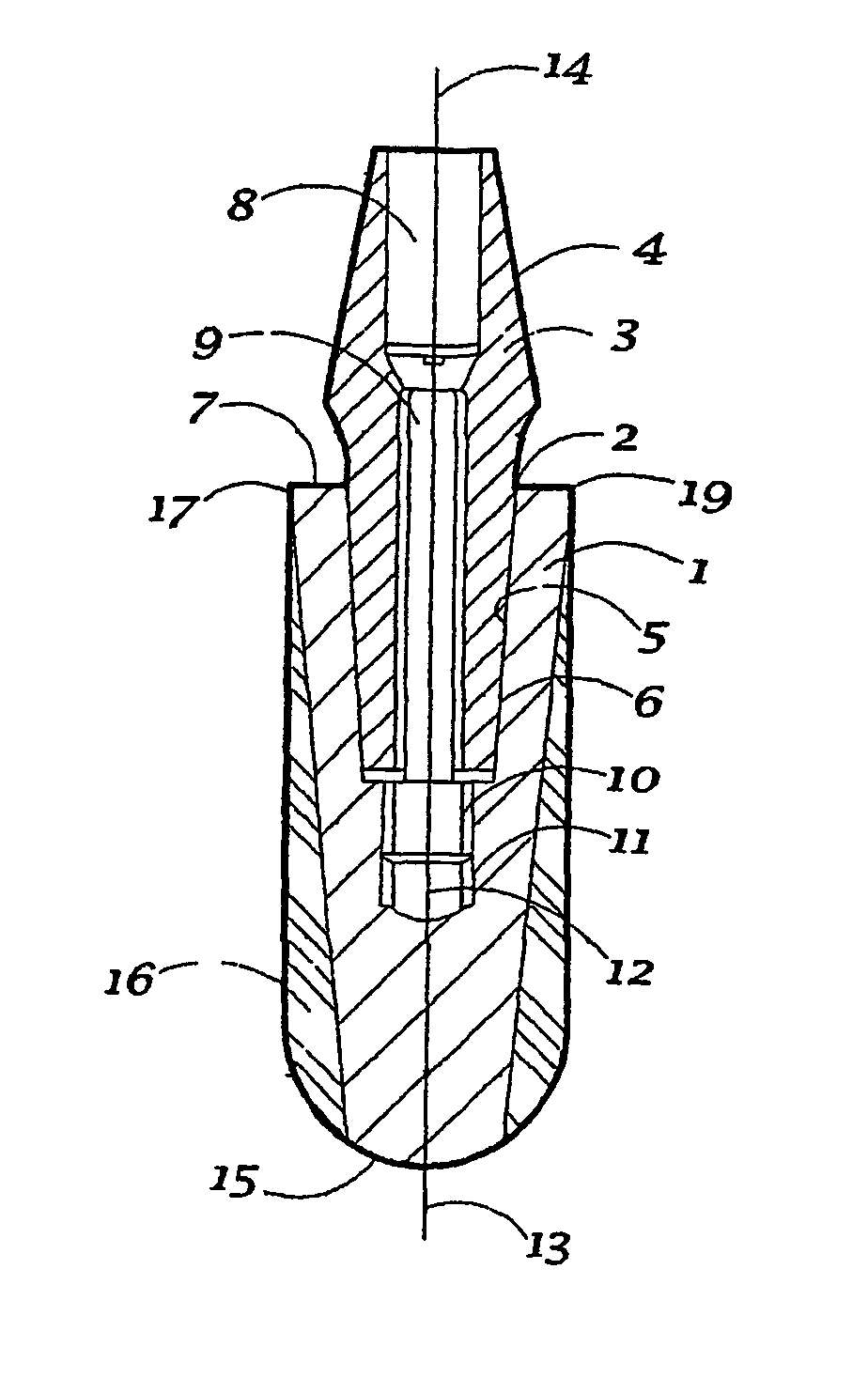

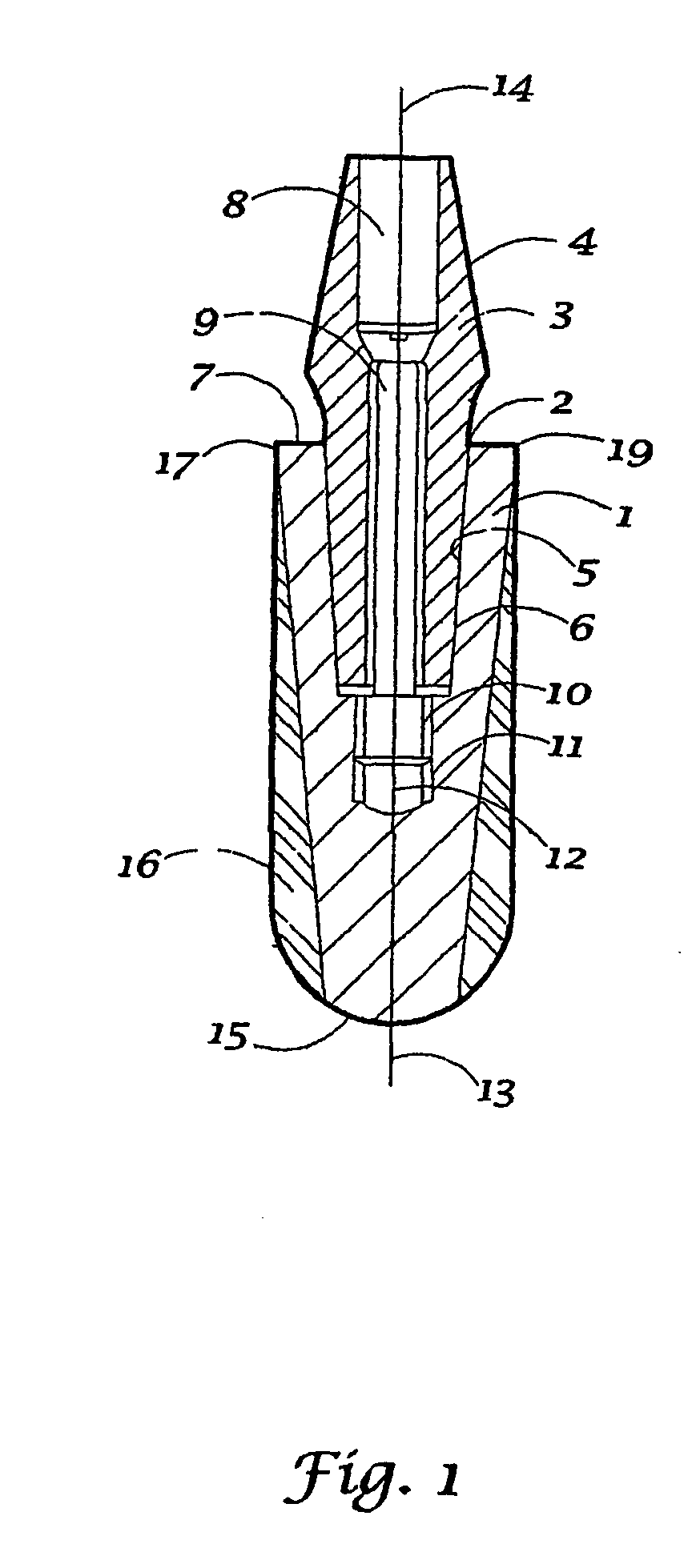

Impression system for an end of an implant projecting from a human tissue structure

InactiveUS6068478AEasy to manufactureAccurate transferDental implantsImpression capsHuman bodyEngineering

PCT No. PCT / CH97 / 00031 Sec. 371 Date Apr. 28, 1998 Sec. 102(e) Date Apr. 28, 1998 PCT Filed Jan. 31, 1997 PCT Pub. No. WO97 / 28755 PCT Pub. Date Aug. 14, 1997An impression system includes an impression cap (4) for transferring an end, protruding from a human tissue structure, of an implant (1) which is fitted in the human body, including possible superstructures, to a master cast. The outwardly directed implant end has an undercut contour on its outside, and the impression cap (4) has a geometry which complements the undercut contour and engages therein. The undercut contour is formed either by an implant geometry tapering in a trumpet shape towards the implant bed, or by a recess near the implant end. Taking an impression and producing a master cast are greatly simplified with the impression system. In addition, the actual geometrical situation on the patient can be transferred to the master cast with greater precision.

Owner:STRAUMANN HLDG AG

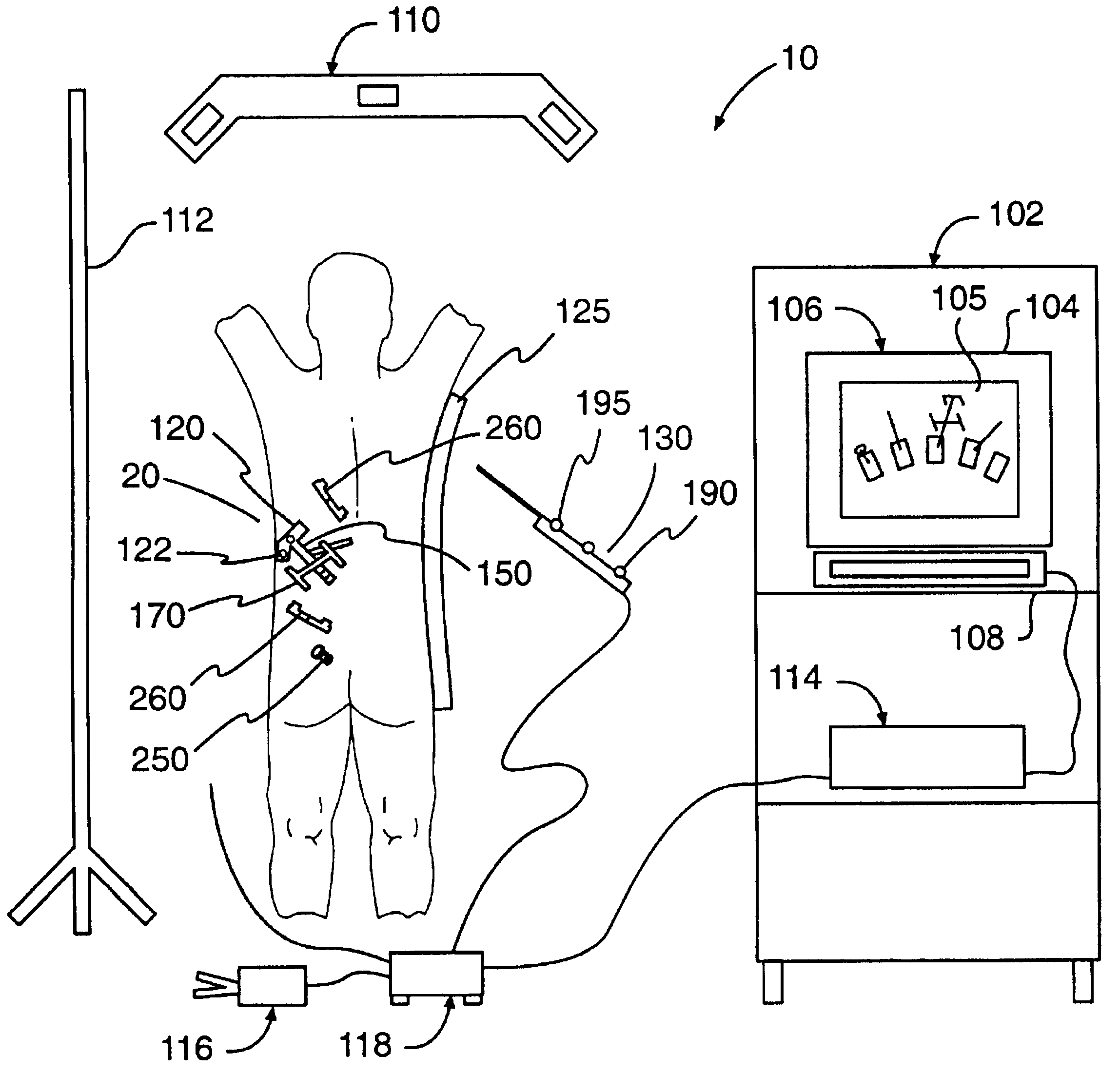

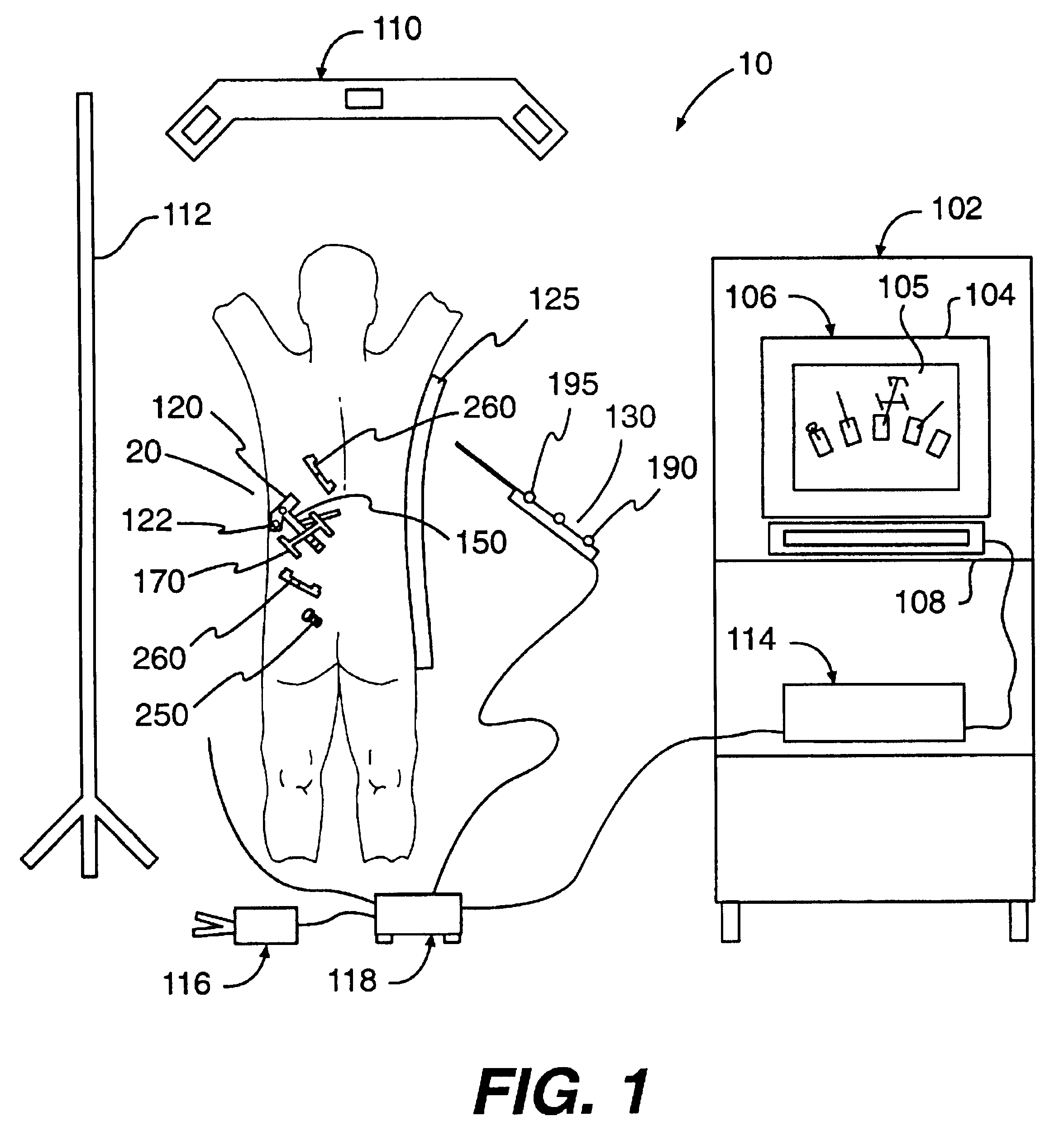

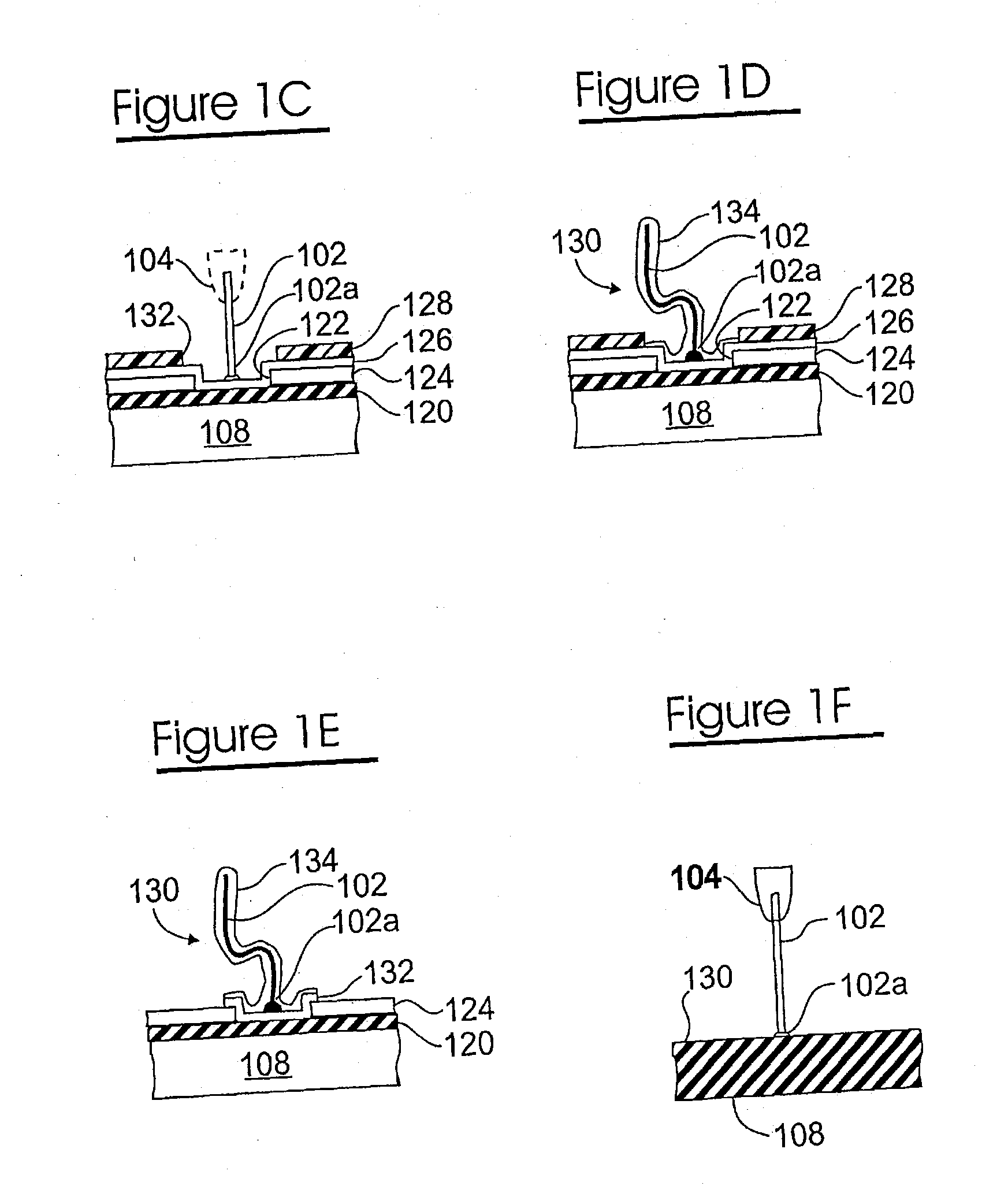

Percutaneous registration apparatus and method for use in computer-assisted surgical navigation

InactiveUSRE42194E1Internal osteosythesisSurgical navigation systemsSurgical operationComputer-assisted surgery

An apparatus and procedures for percutaneous placement of surgical implants and instruments such as, for example, screws, rods, wires and plates into various body parts using image guided surgery. The invention includes an apparatus for use with a surgical navigation system, an attaching device rigidly connected to a body part, such as the spinous process of a vertebrae, with an identification superstructure rigidly but removably connected to the attaching device. This identification superstructure, for example, is a reference arc and fiducial array which accomplishes the function of identifying the location of the superstructure, and, therefore, the body part to which it is fixed, during imaging by CAT scan or MRI, and later during medical procedures.

Owner:MEDTRONIC NAVIGATION INC

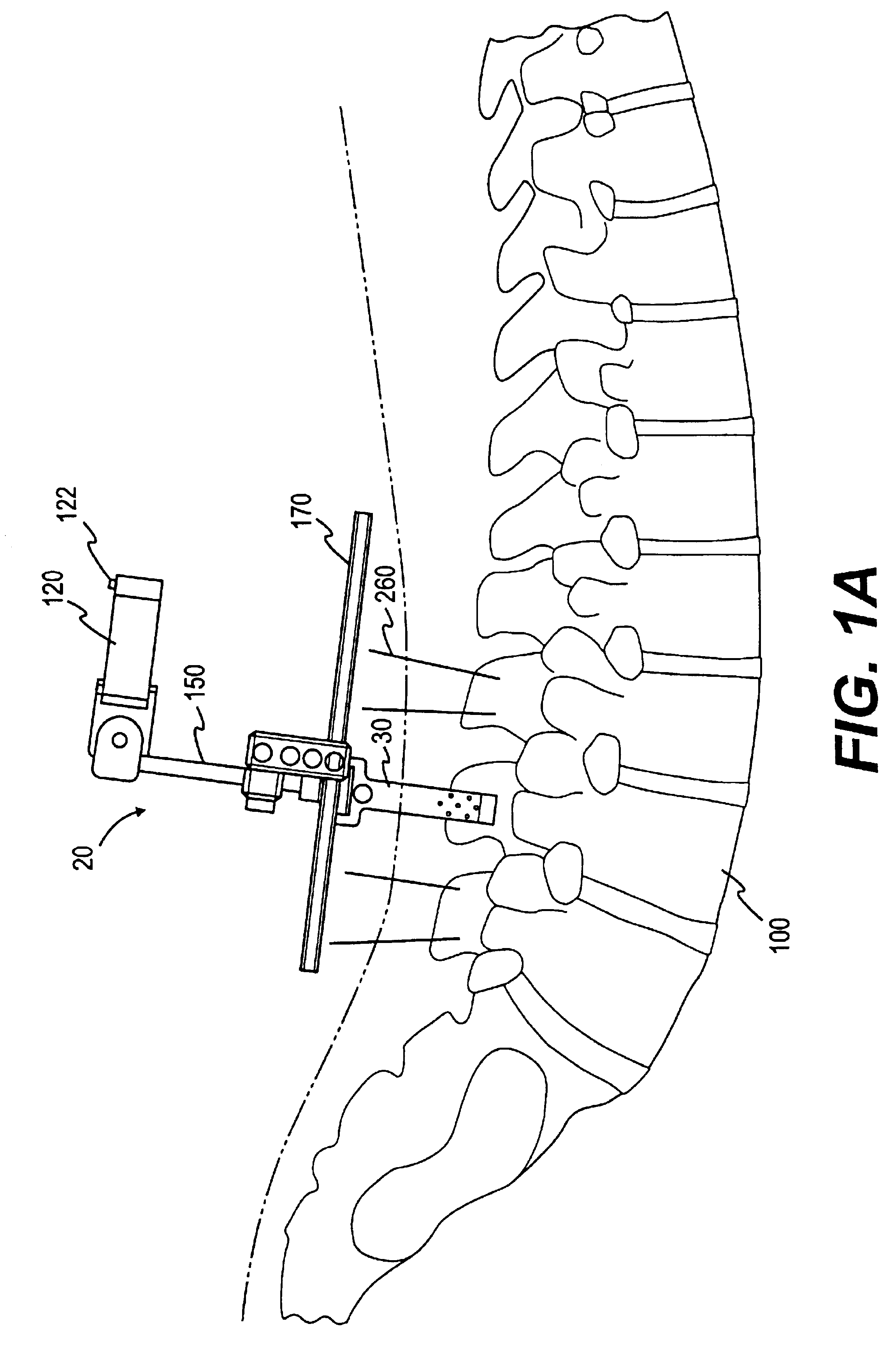

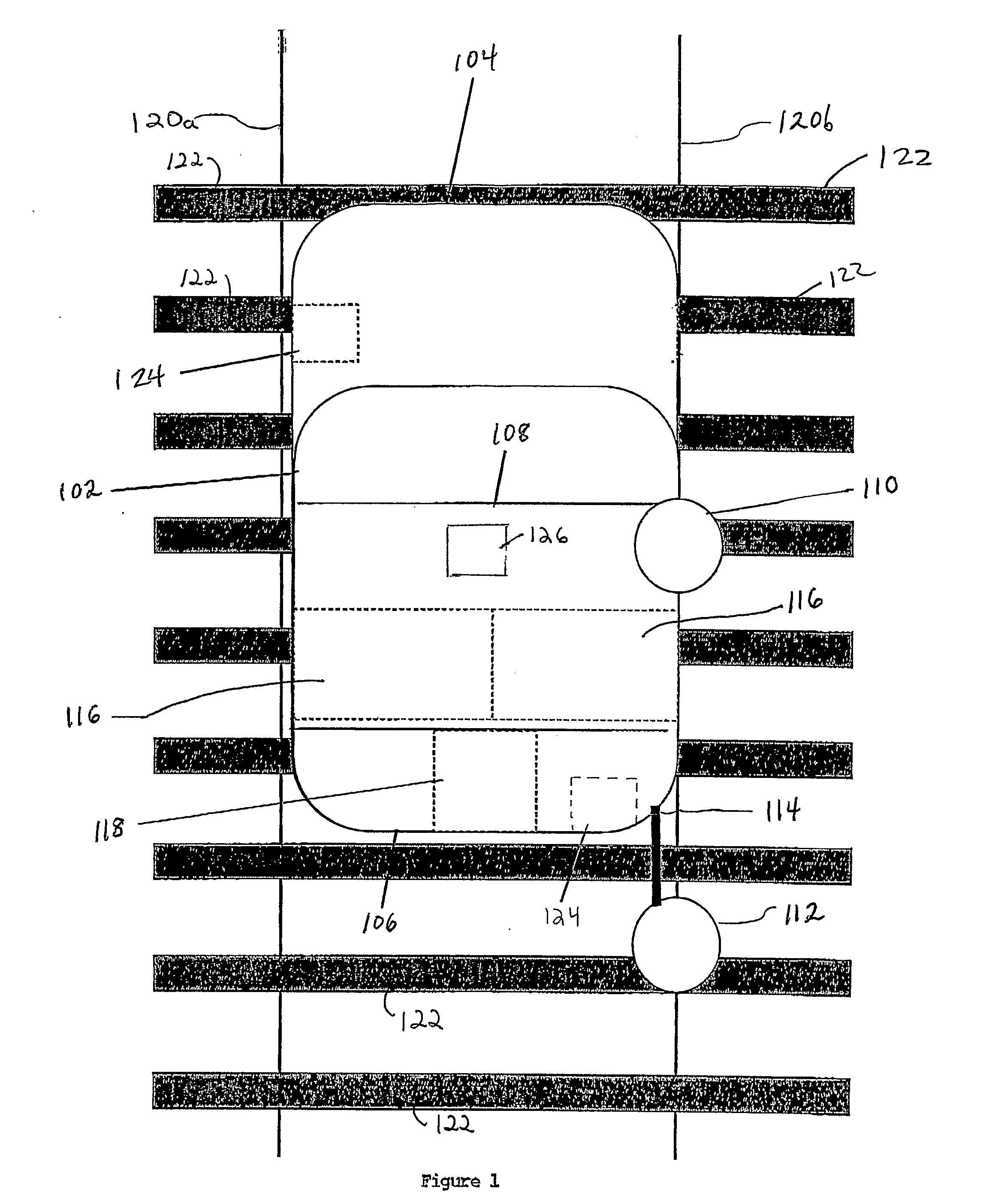

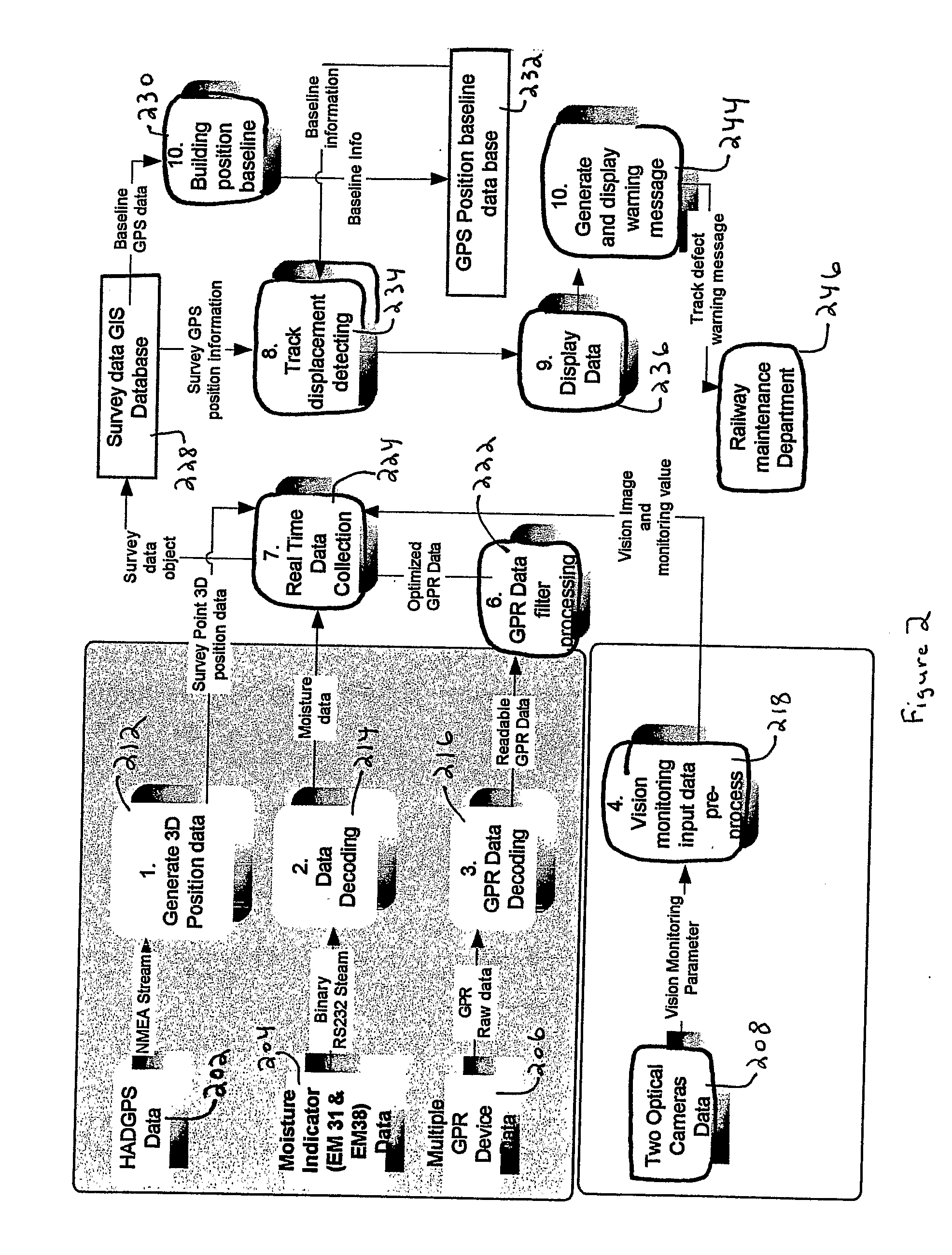

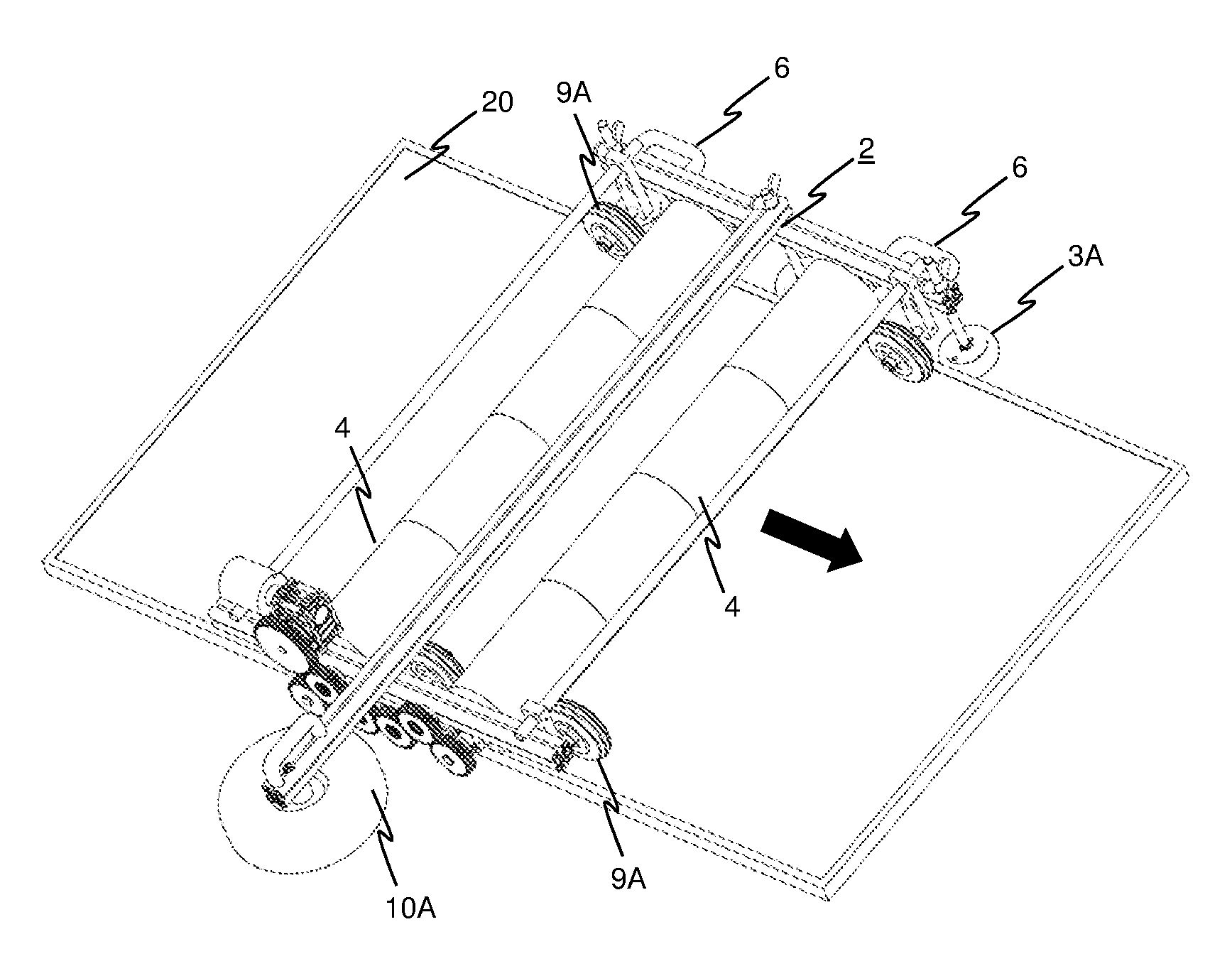

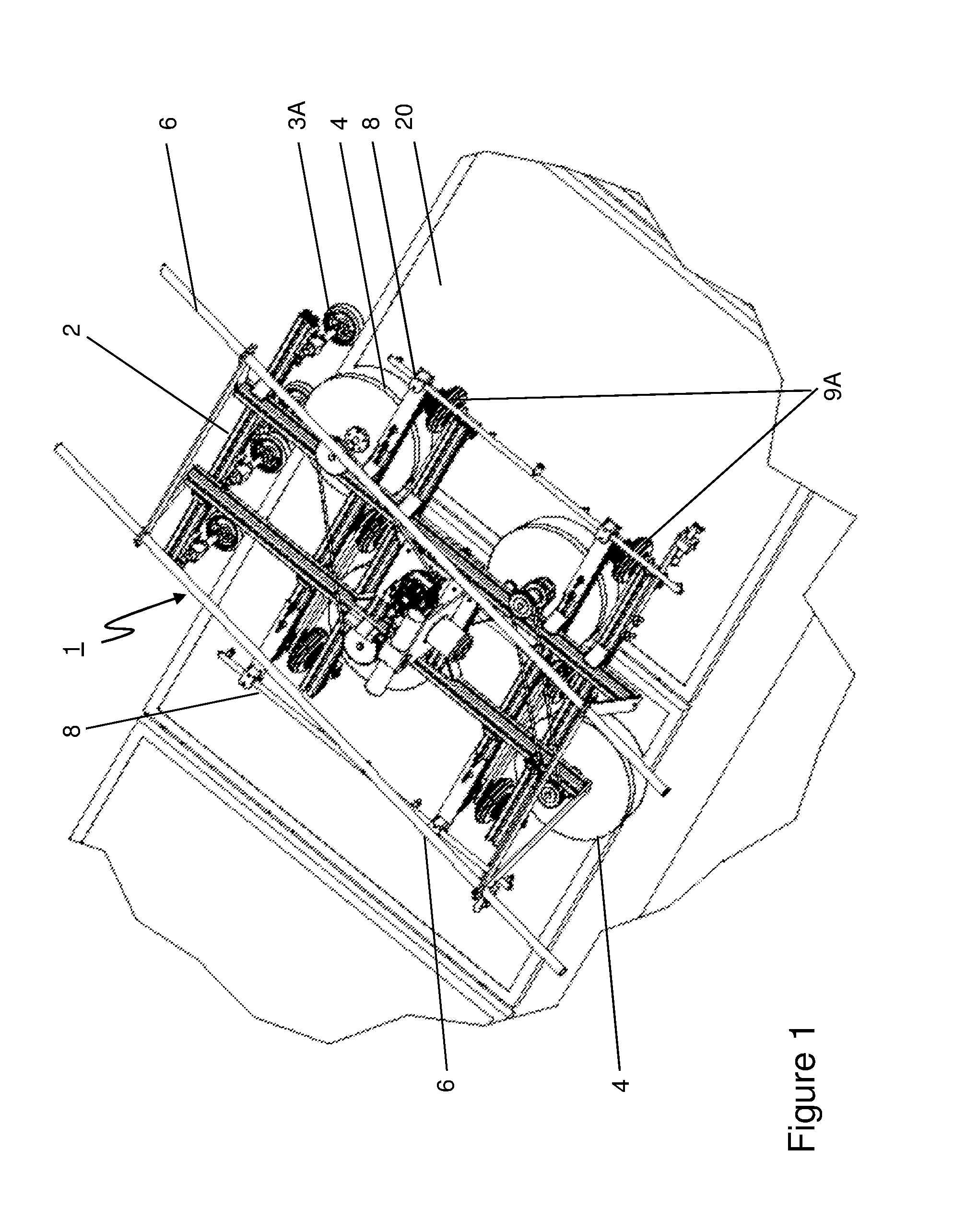

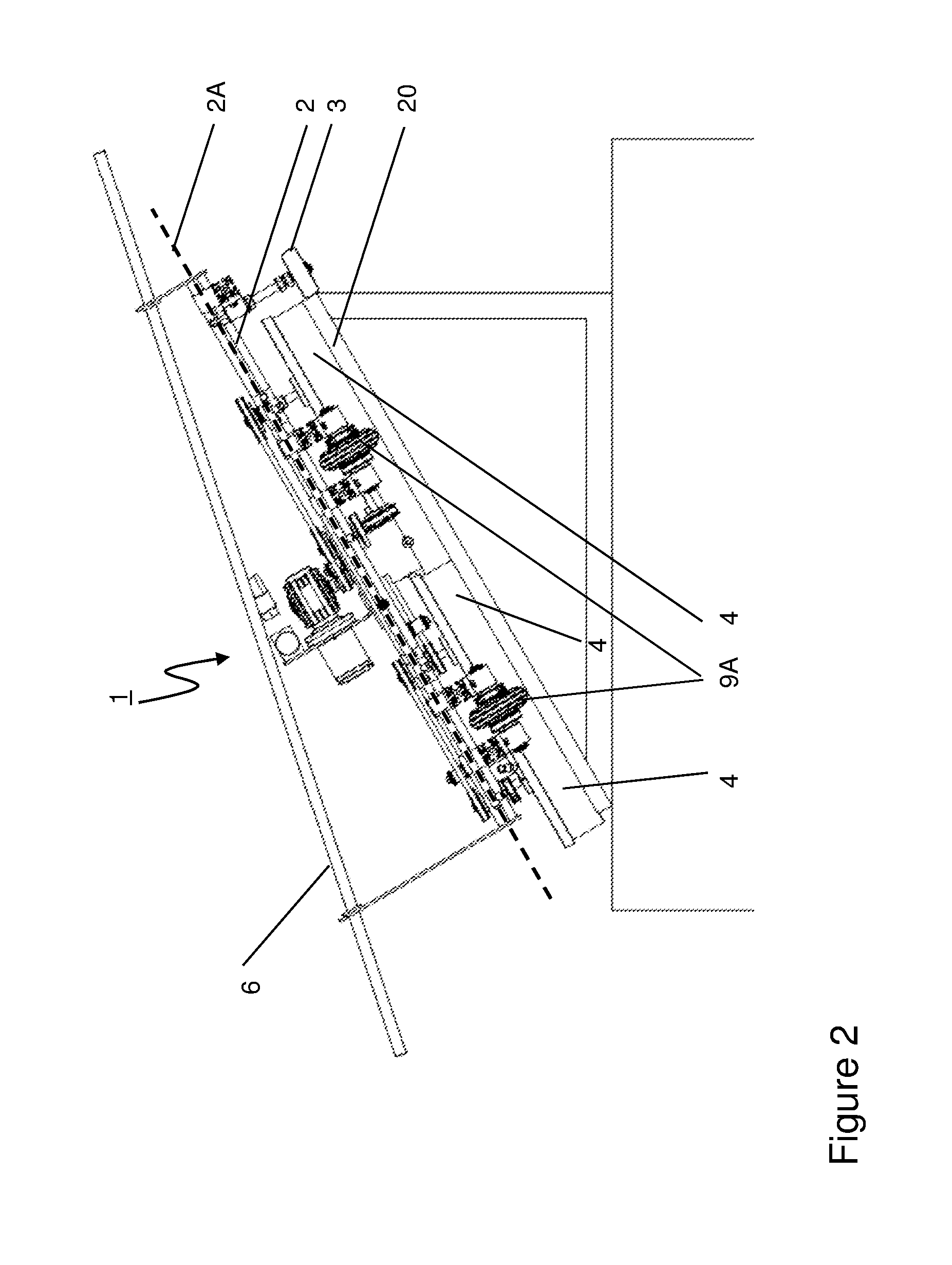

Railroad surveying and monitoring system

InactiveUS20100026551A1Easy to adaptOptimizationPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTerrainLandform

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

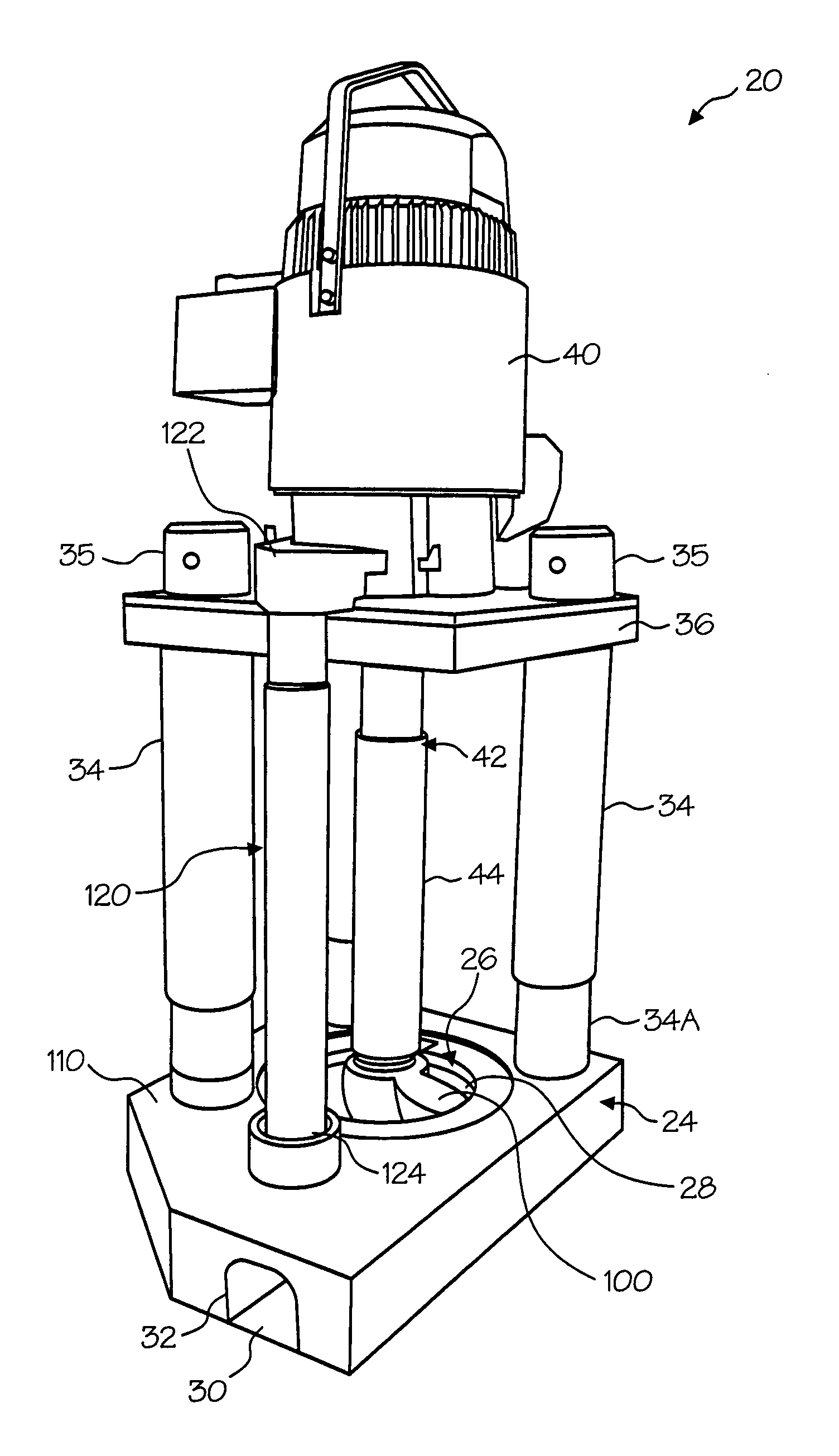

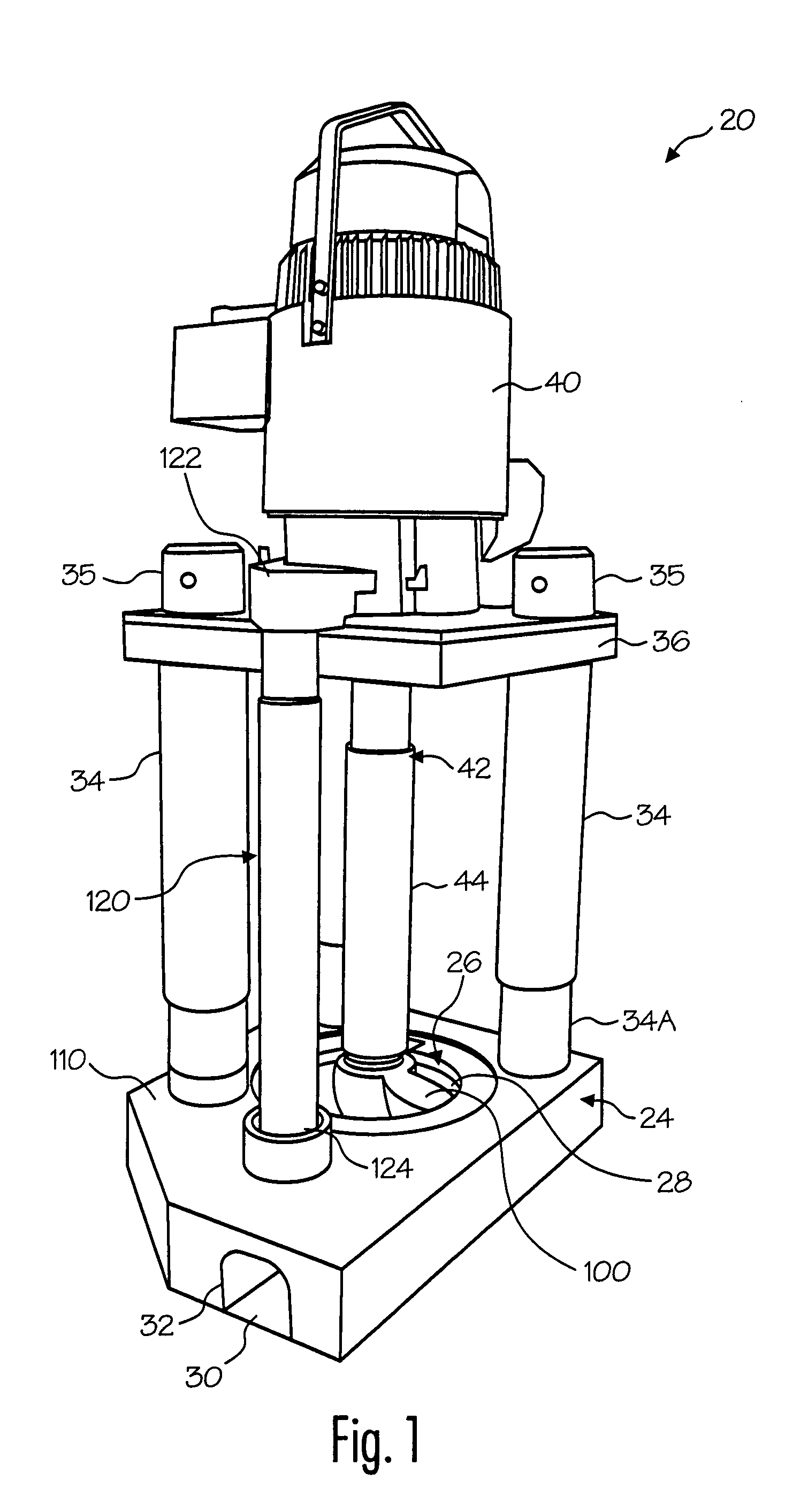

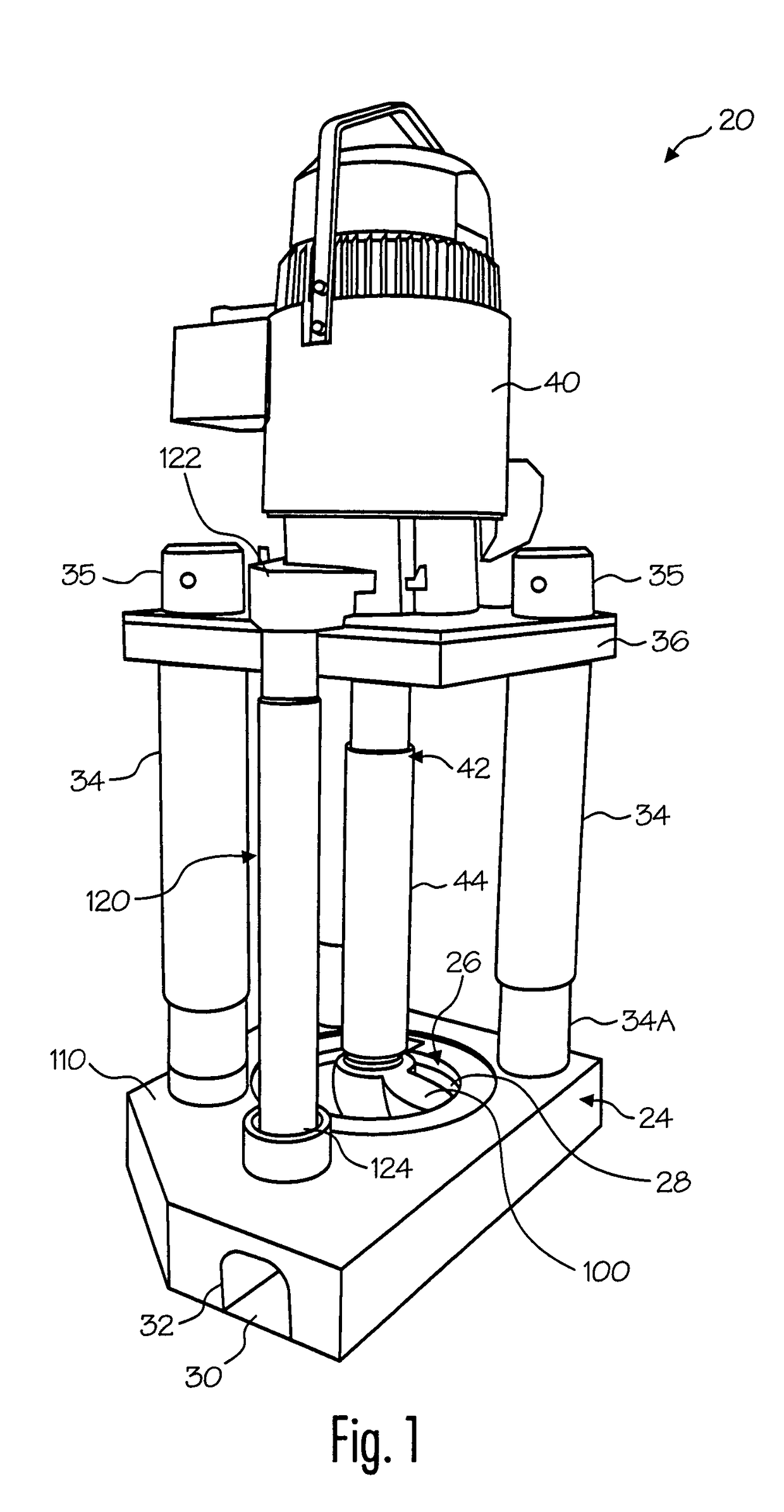

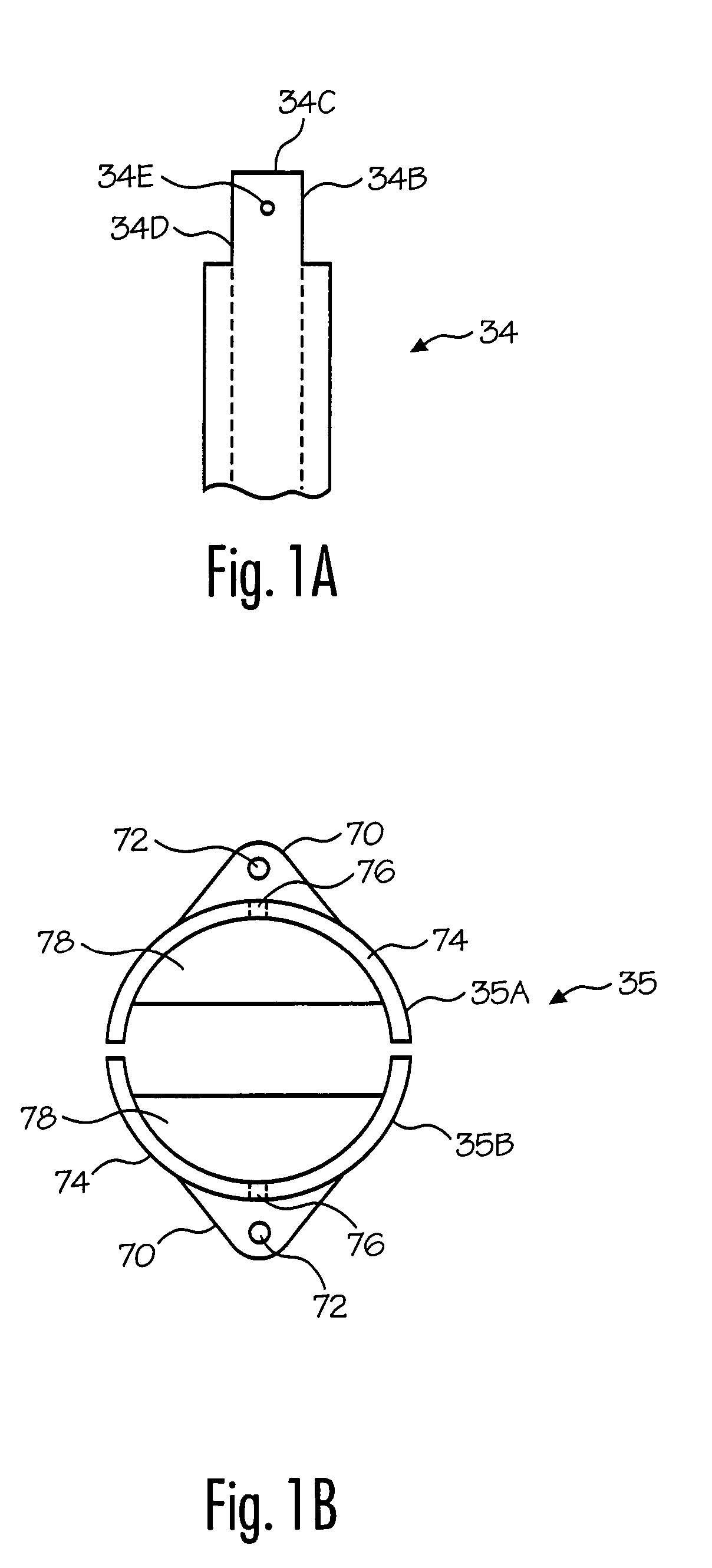

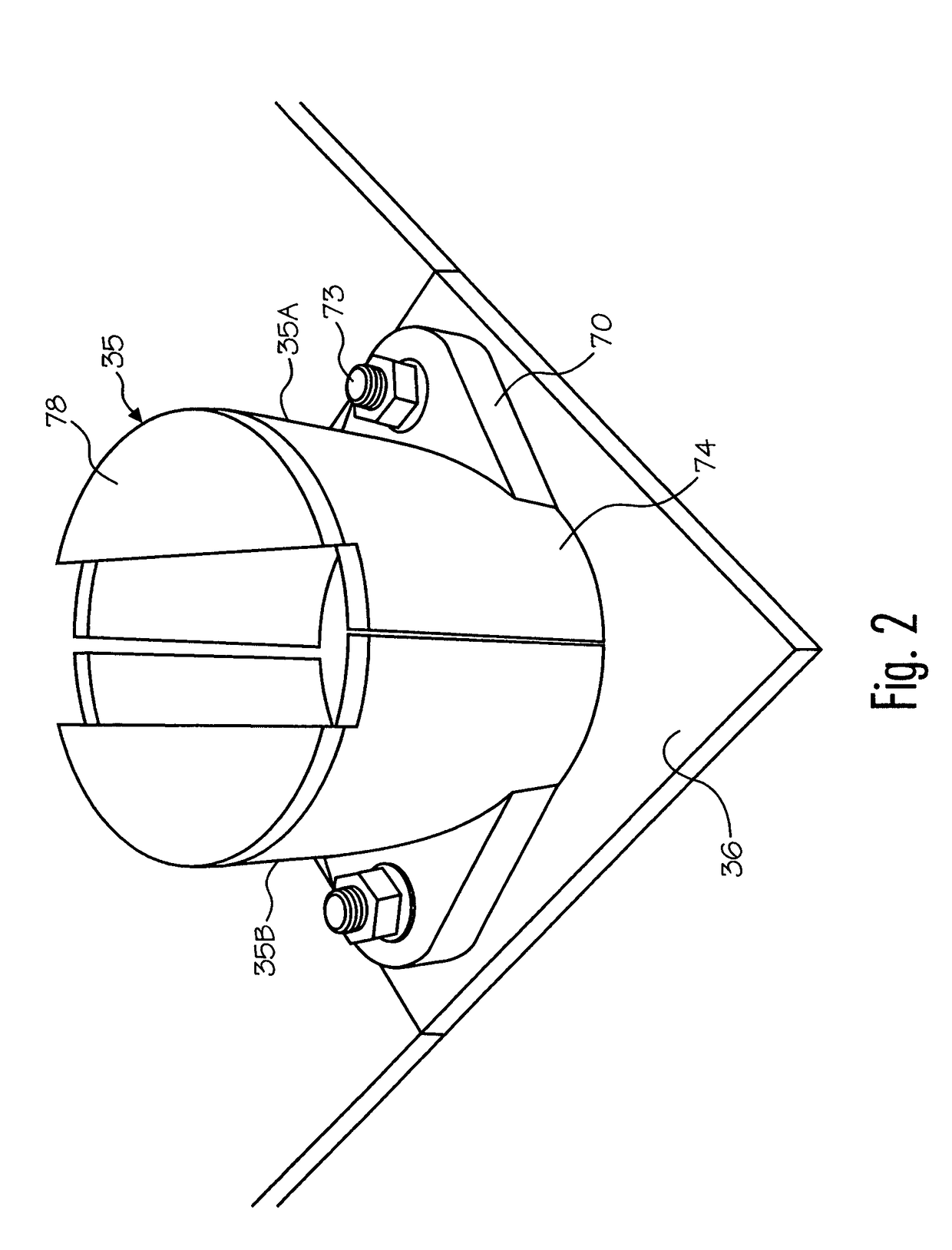

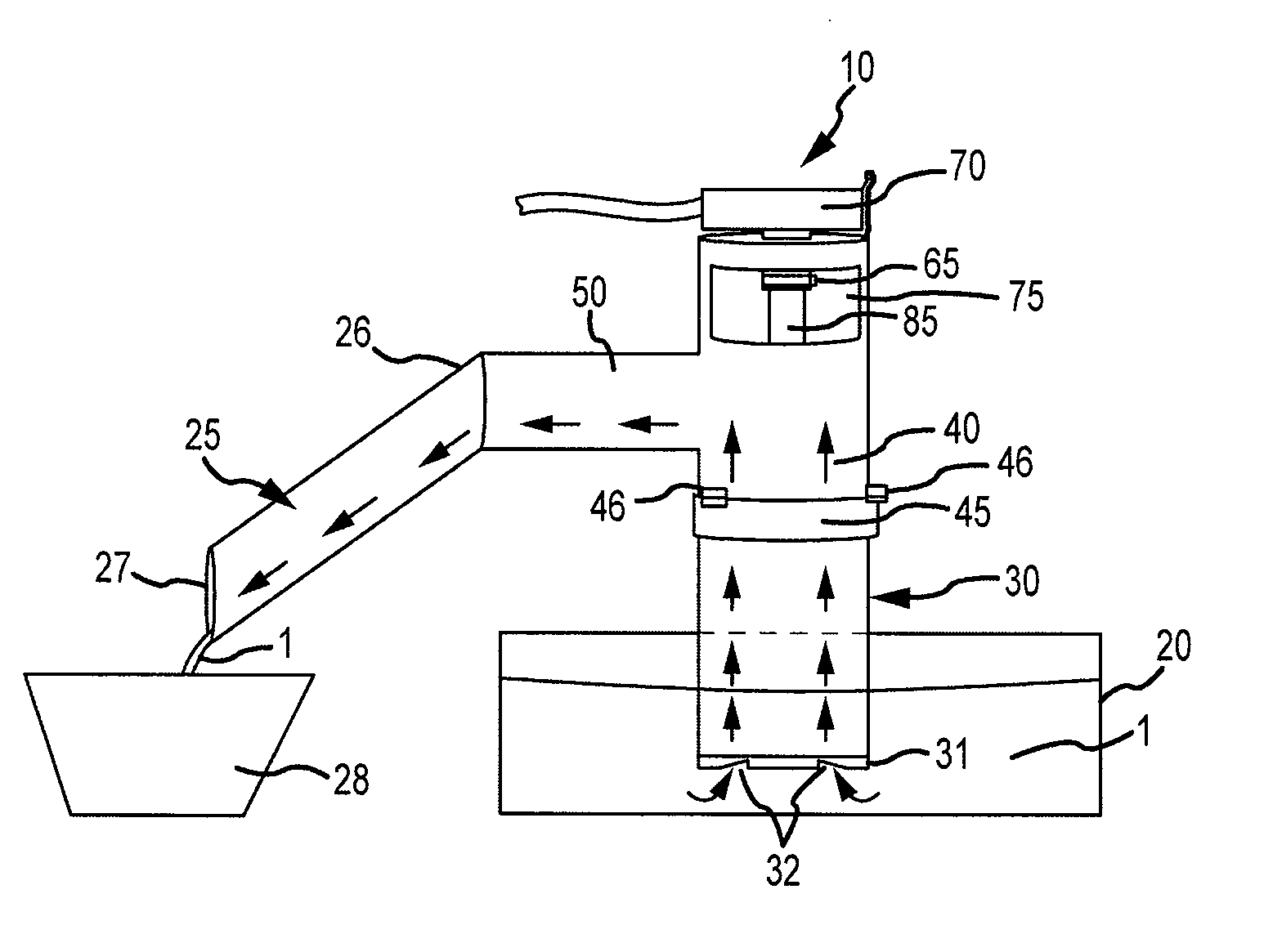

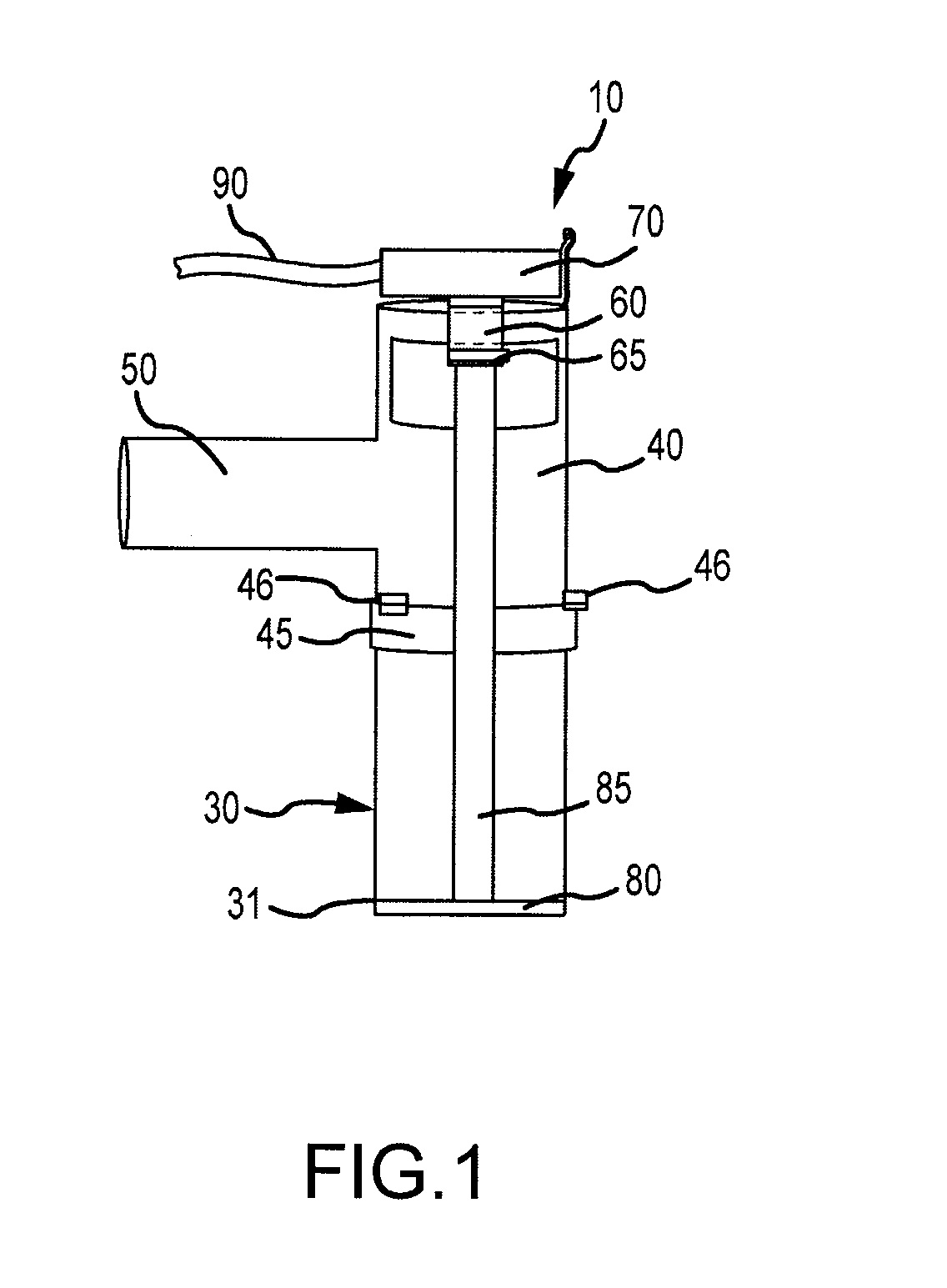

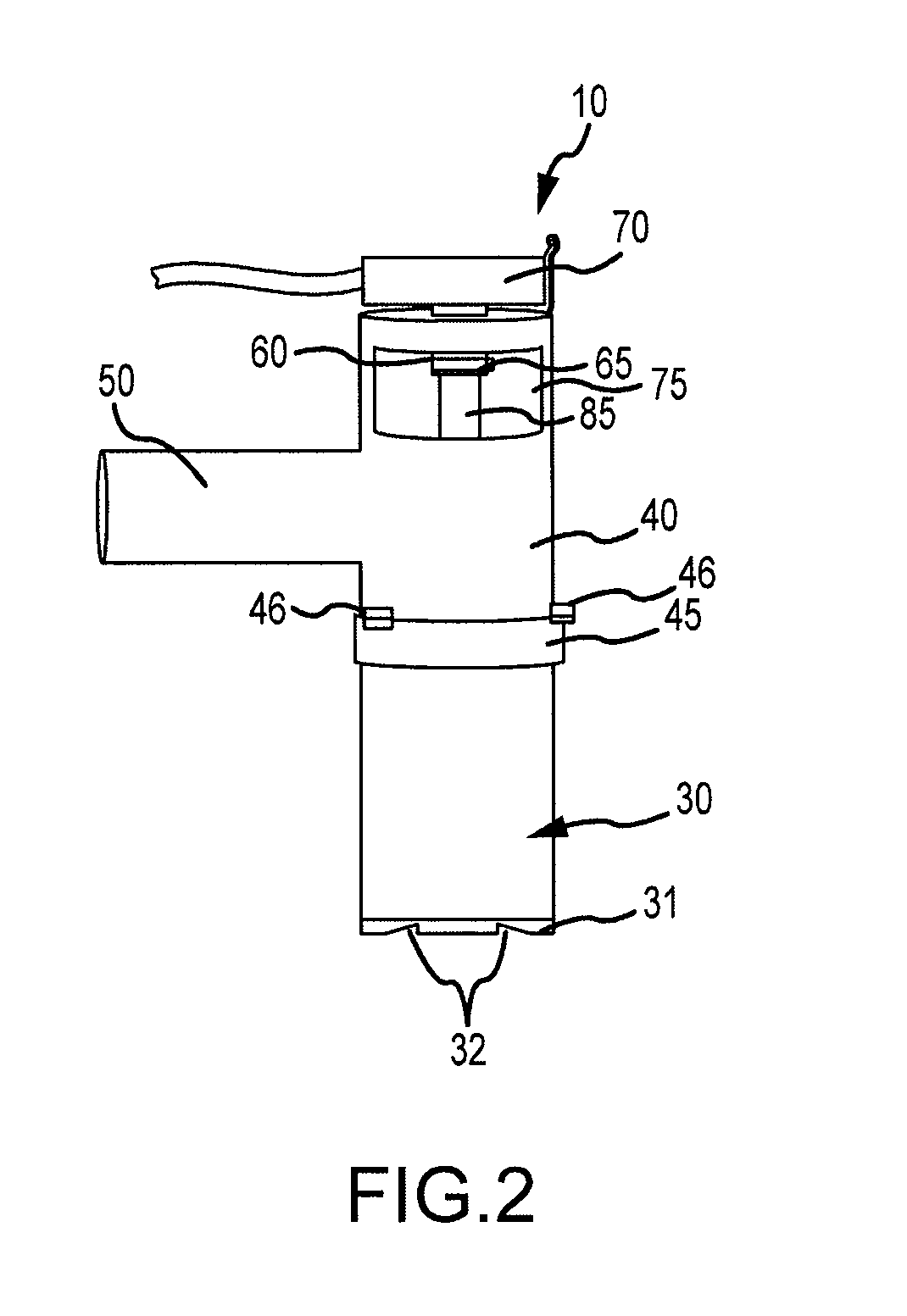

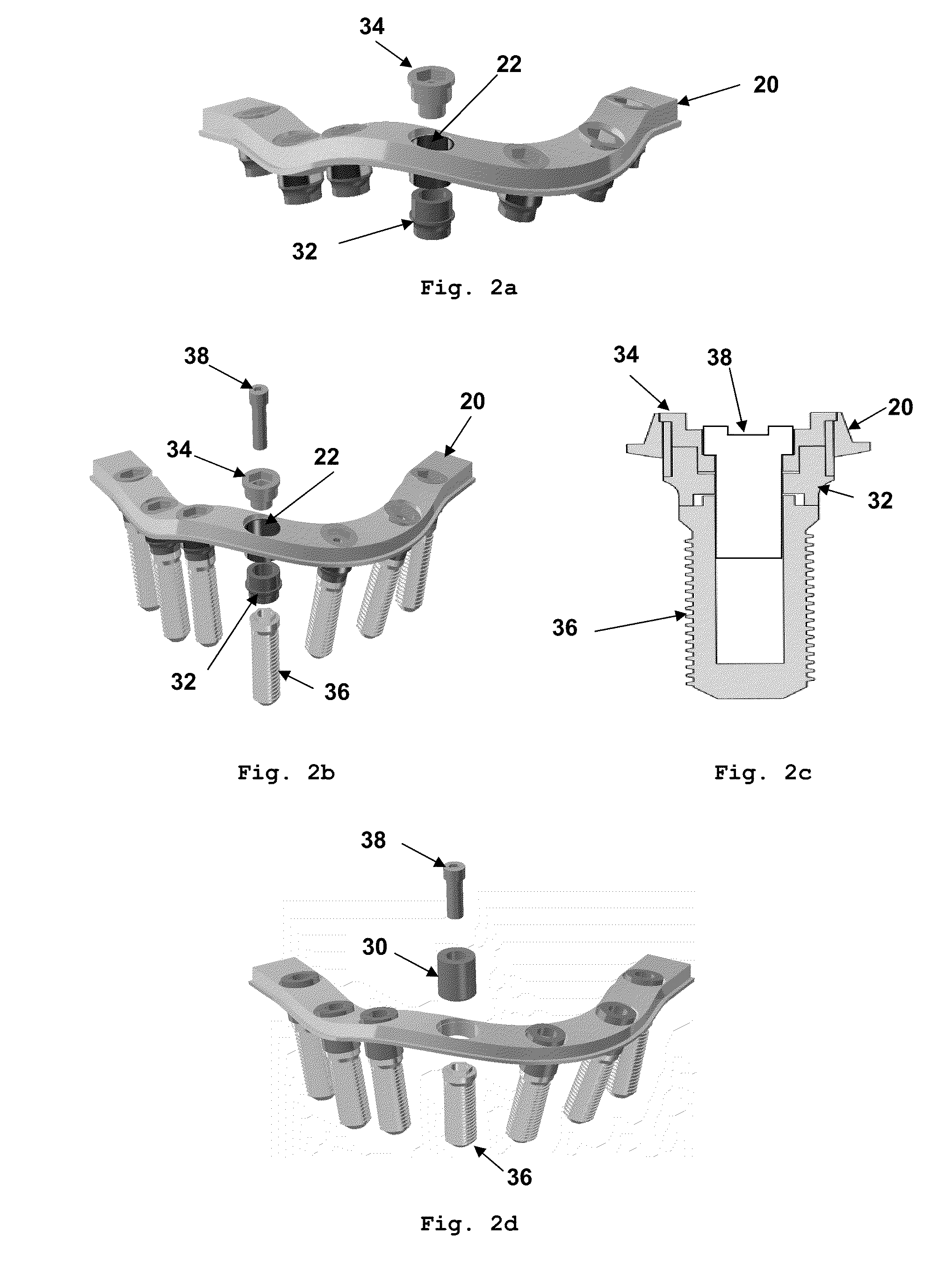

Support post system for molten metal pump

ActiveUS20050053499A1Specific fluid pumpsPositive displacement pump componentsEngineeringMechanical engineering

An improved post clamp for a molten metal pump includes a support post clamp that supports the weight of a pump superstructure on the top of the support posts. The clamp preferably includes (a) a bottom flange for connecting to the pump superstructure, (b) a cavity for receiving an end of a support post, wherein the end has a top surface, and (c) a top flange for being positioned above the top surface. In operation the top flange rests on the top surface of the support post thereby supporting at least part of the weight of the superstructure. It is preferred that a plurality of support posts and post clamps according to the invention be used with a molten metal pump wherein the top surface of each support post supports some of the weight of the superstructure. Also disclosed are novel support posts that may be used with the post clamp, and a pump in which the post clamp and / or support posts may be used.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Shoe with anatomical protection

ActiveUS7631440B2Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

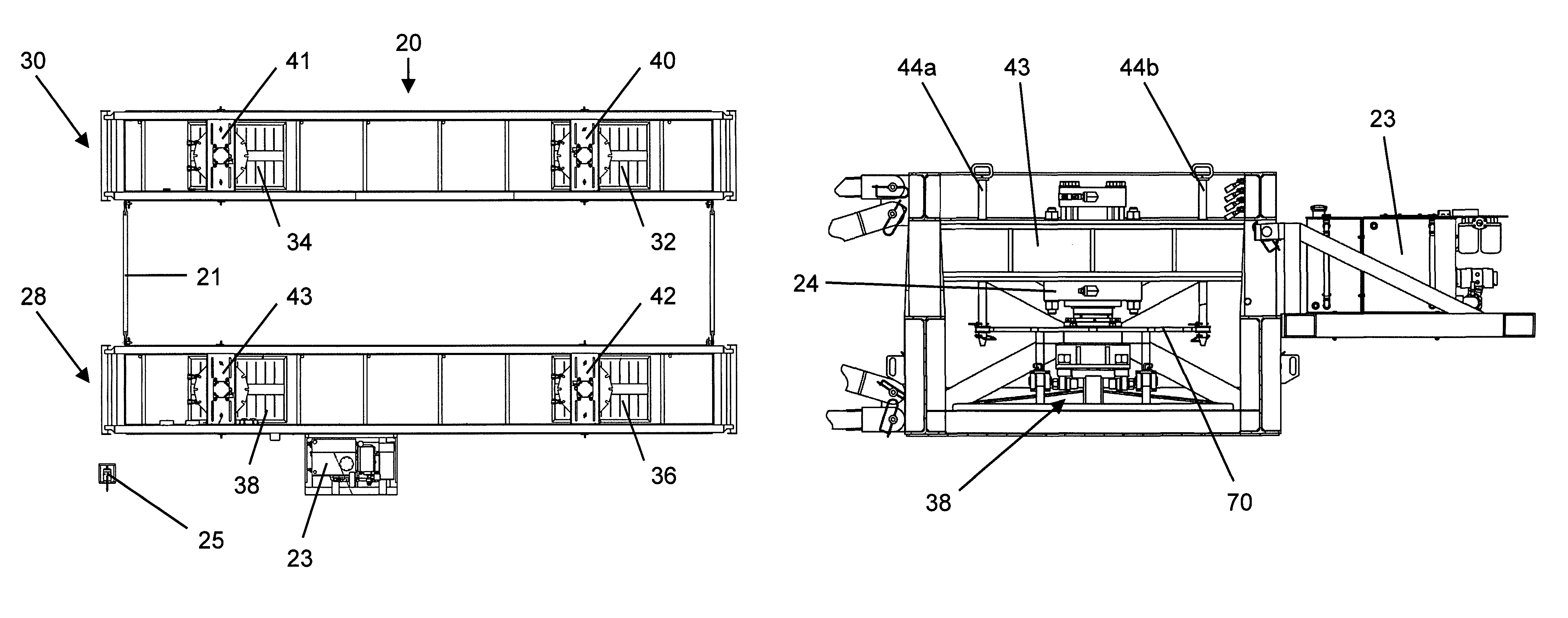

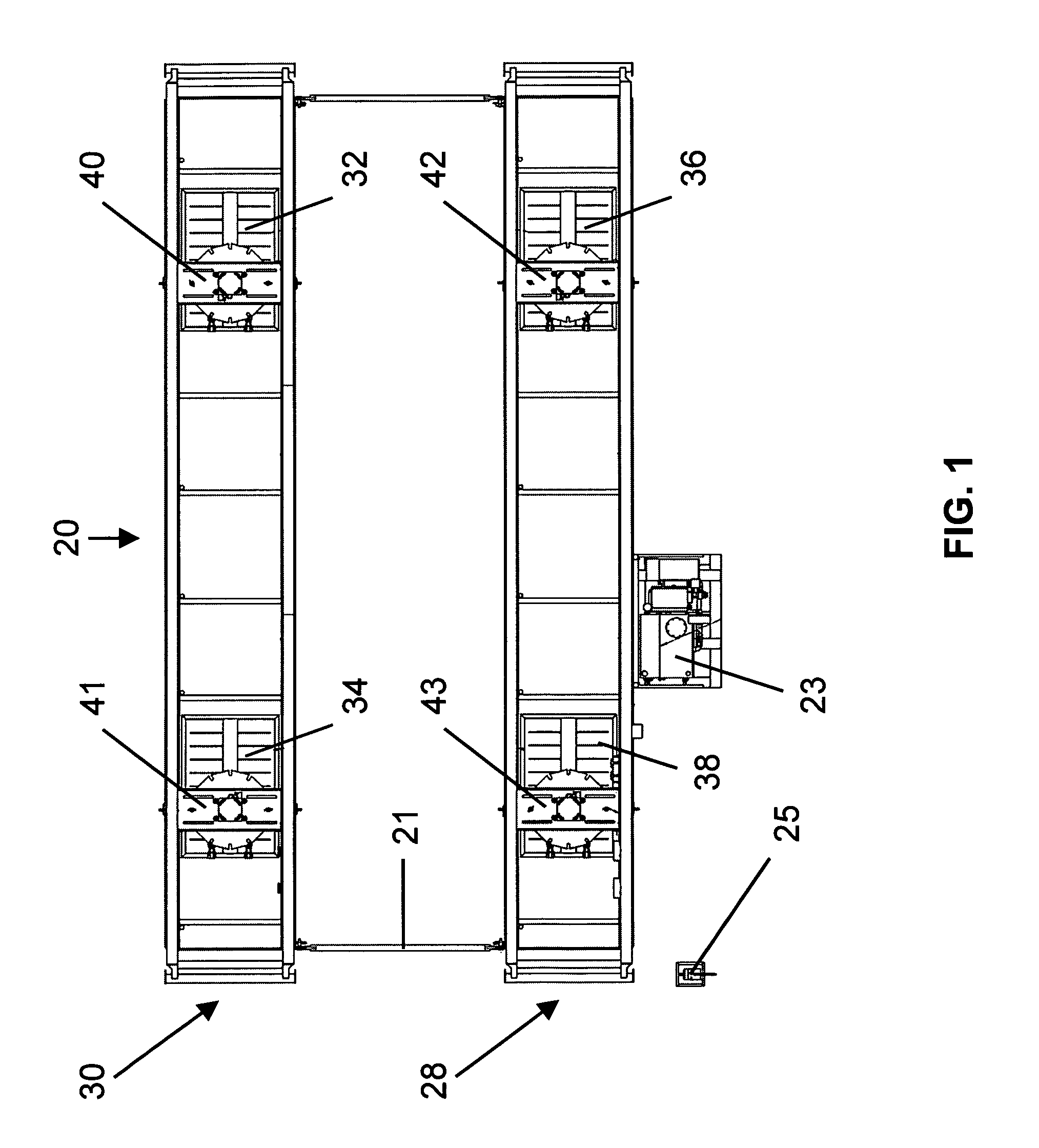

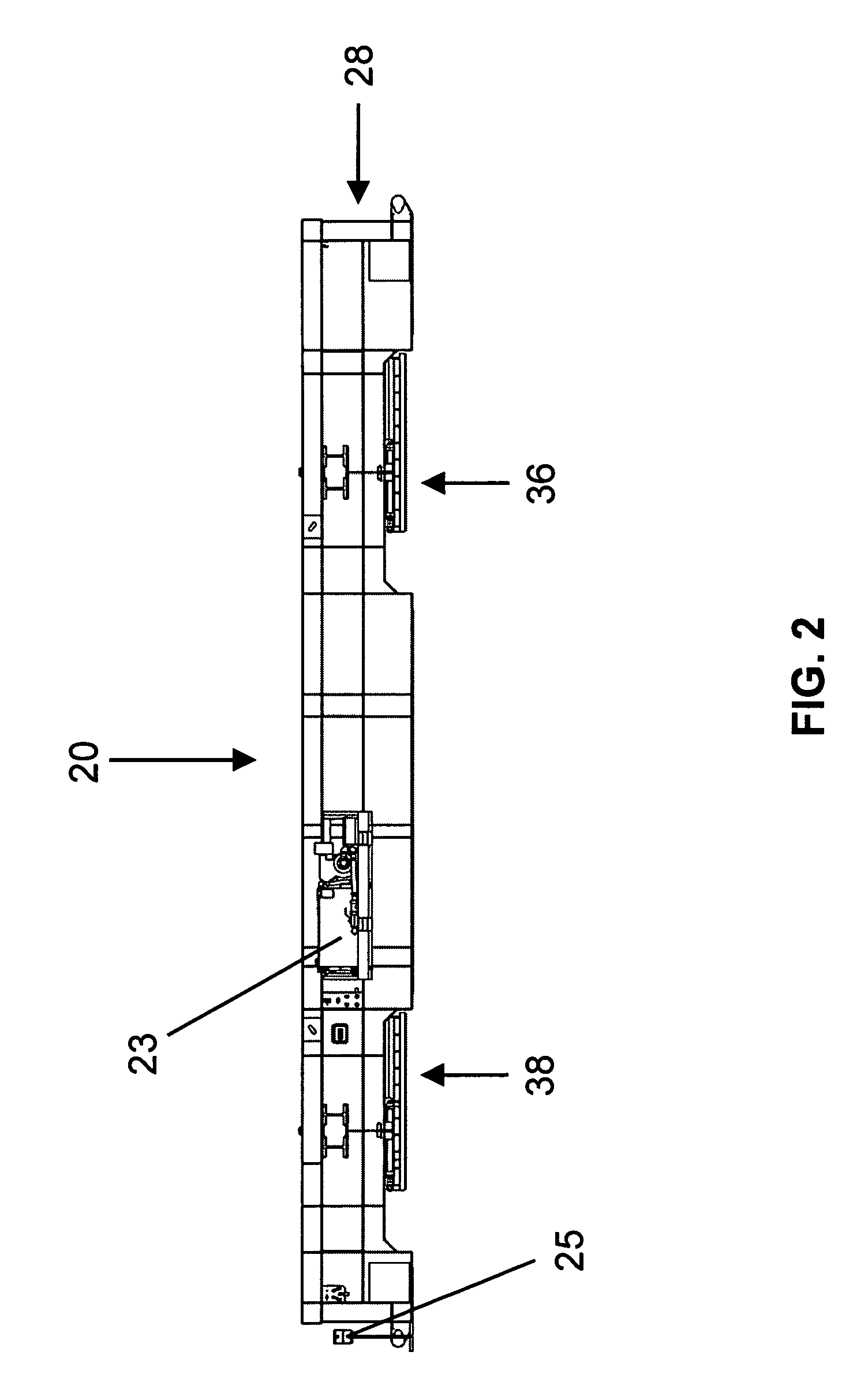

Guided transport unit

A guided transport unit and methods of guiding the transport unit for moving a superstructure in precise angular movements over a surface are disclosed. The guided transport unit comprises a skid pad, a vertical displacing member engaged with the skid pad, a base operatively associated with the vertical displacing member, and a directional actuator. The base includes a planar element for engaging the surface over which the superstructure is transported, and a carrier for moving the vertical displacing member and skid pad relative to the surface. The directional actuator controls and secures the relationship among the vertical displacing member, the base, and the skid pad for positioning the base in a predetermined direction to engage the surface, setting the carrier to move each skid pad in a predetermined direction across the planar element of the base, and repositioning the base in another direction for movement of the guided transport unit.

Owner:AXIS ENERGY SERVICES LLC

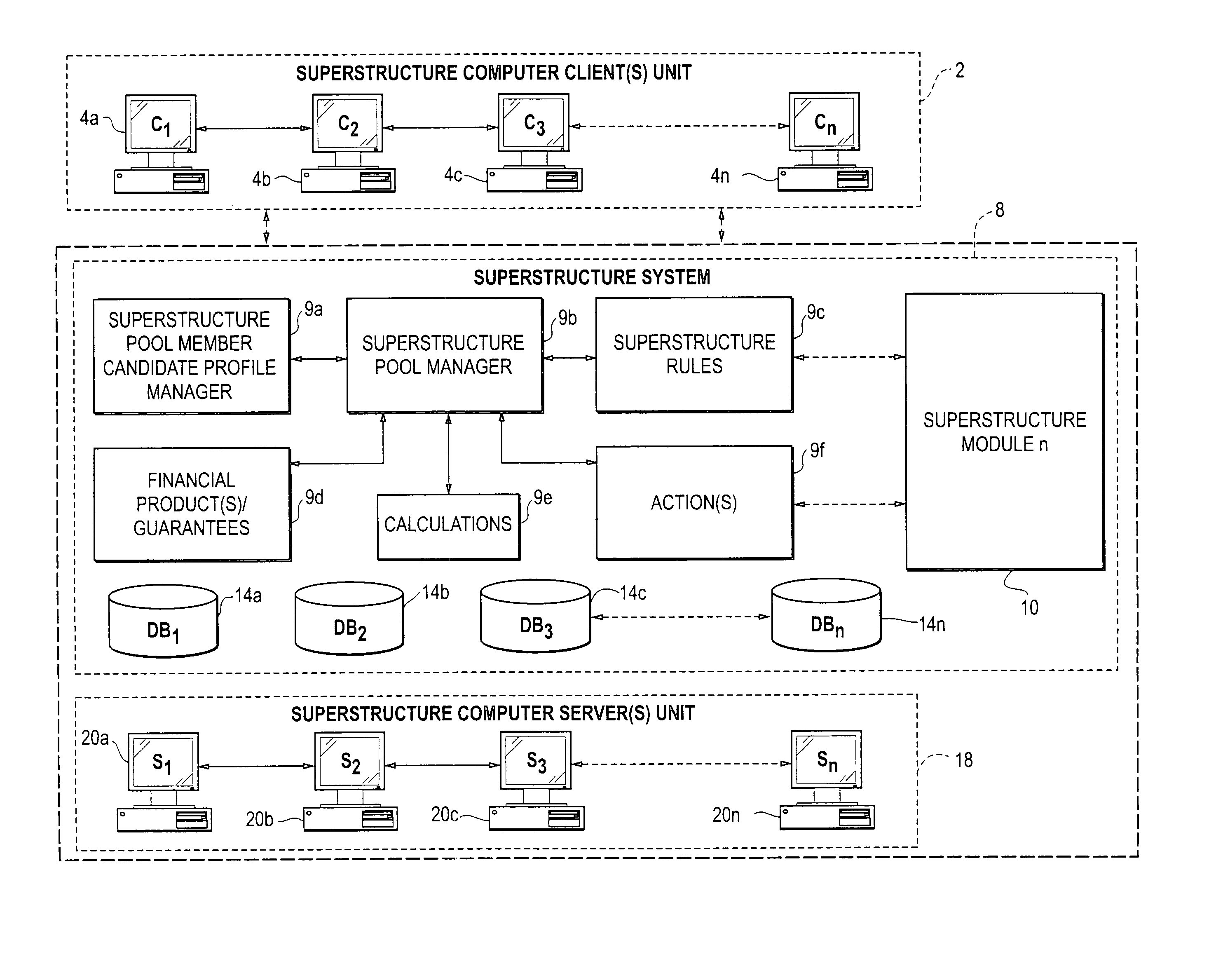

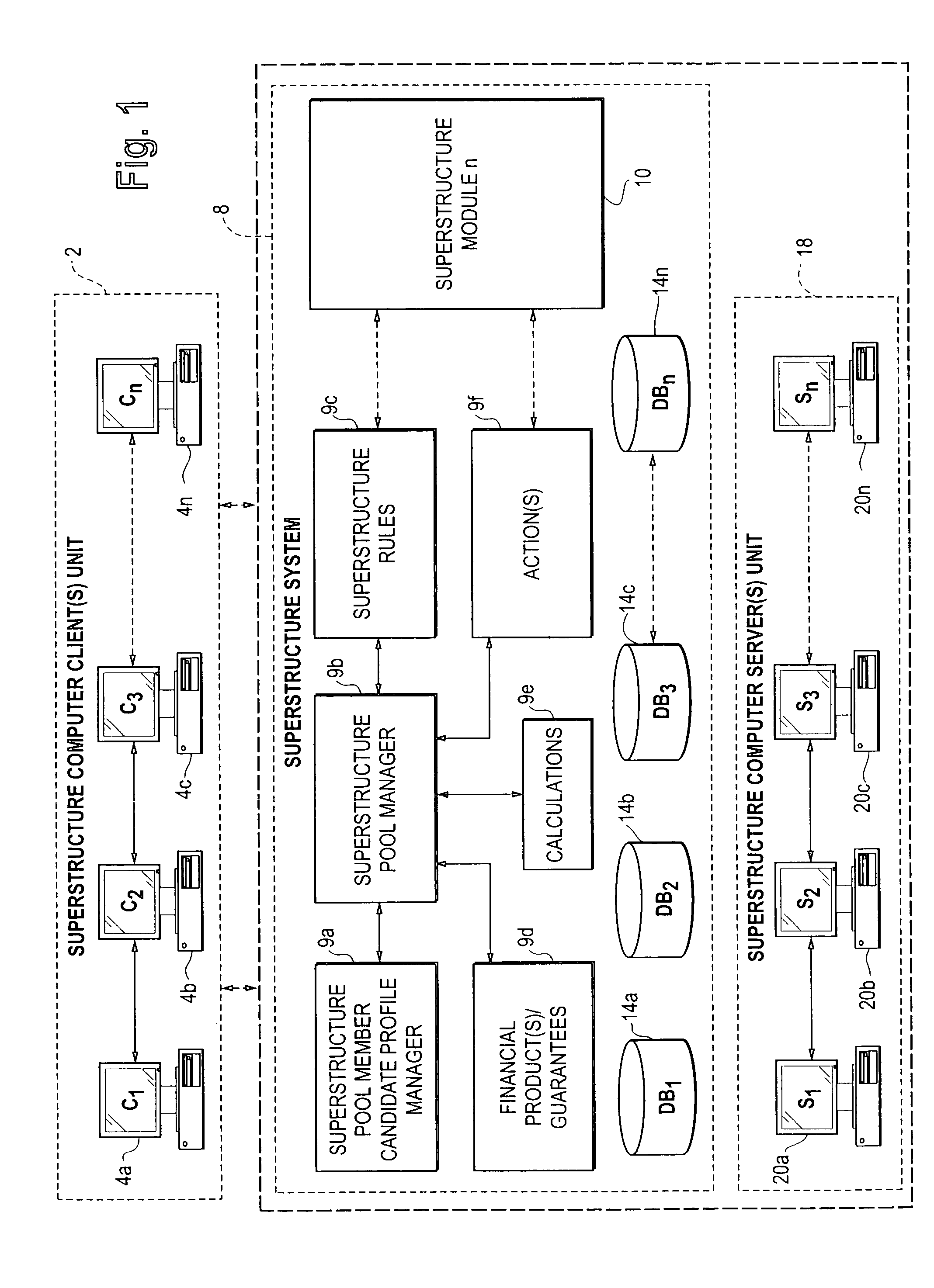

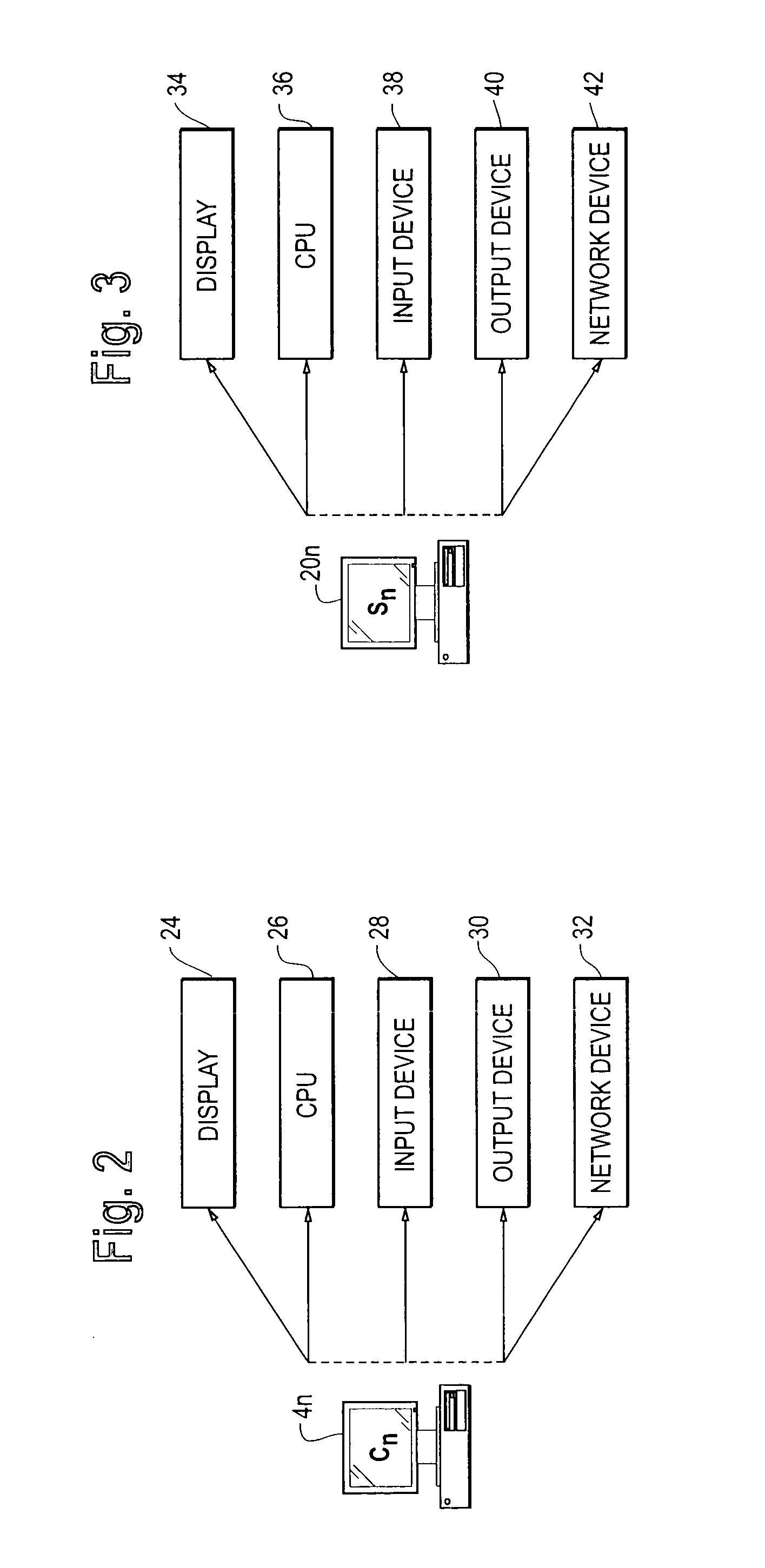

Superstructure pool computer system

InactiveUS20040225536A1FinanceSpecial data processing applicationsComputerized systemComputer science

In the computer method variant of the invention, a computer system is programmed for adjusting participation in a pool, the method including the steps of: forming a pool to handle a monetary obligation over a period of time; storing, in a computer rules, for participation in the pool over the period of time; and using the computer to carry out the step of adjusting the participation periodically within the period of time and in accordance with the rules. In the method, the step of adjusting the participation can include changing membership in the pool, changing responsibility for the obligation respectively for a member of the pool, or both.

Owner:CONCEPT HEDGING

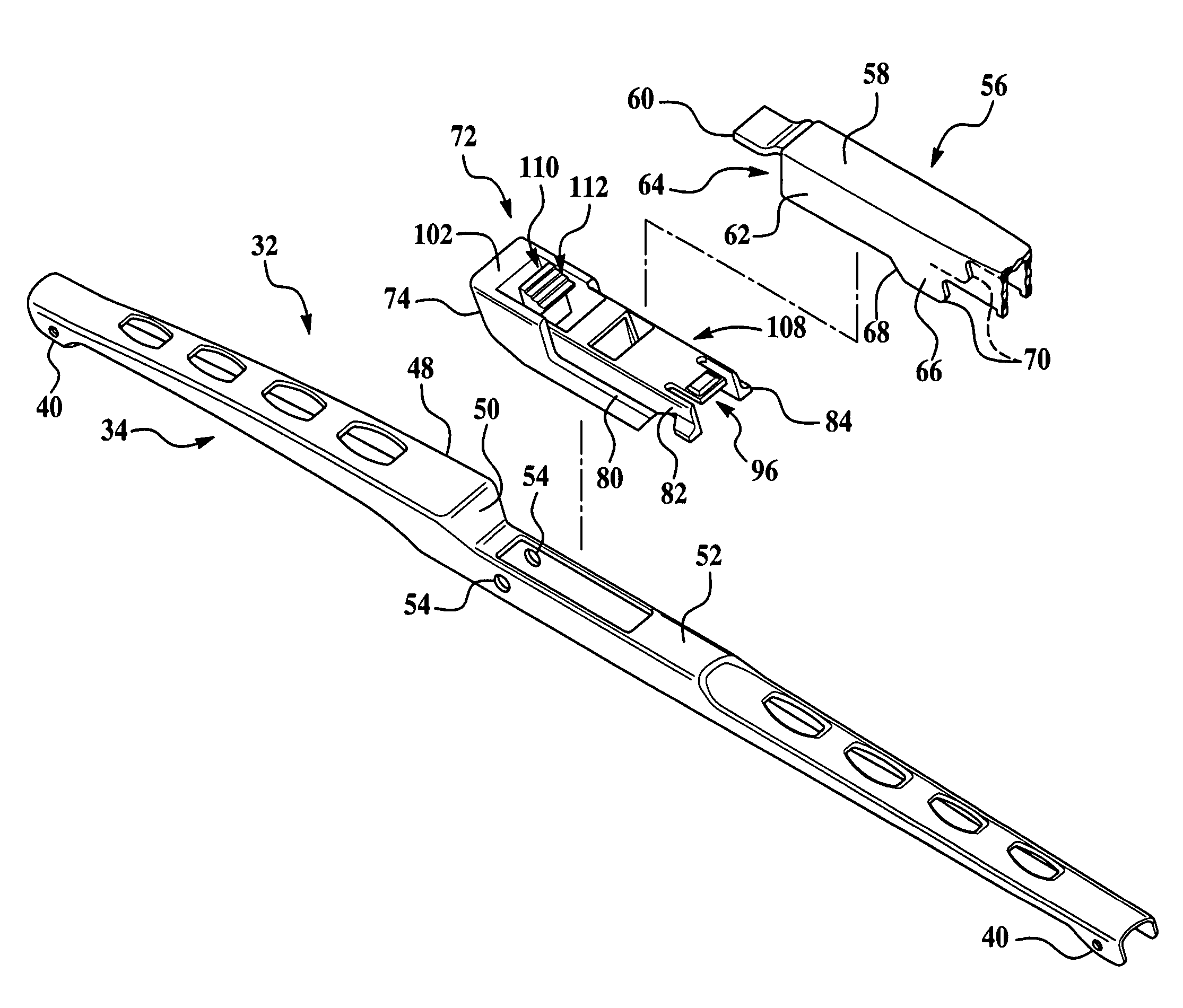

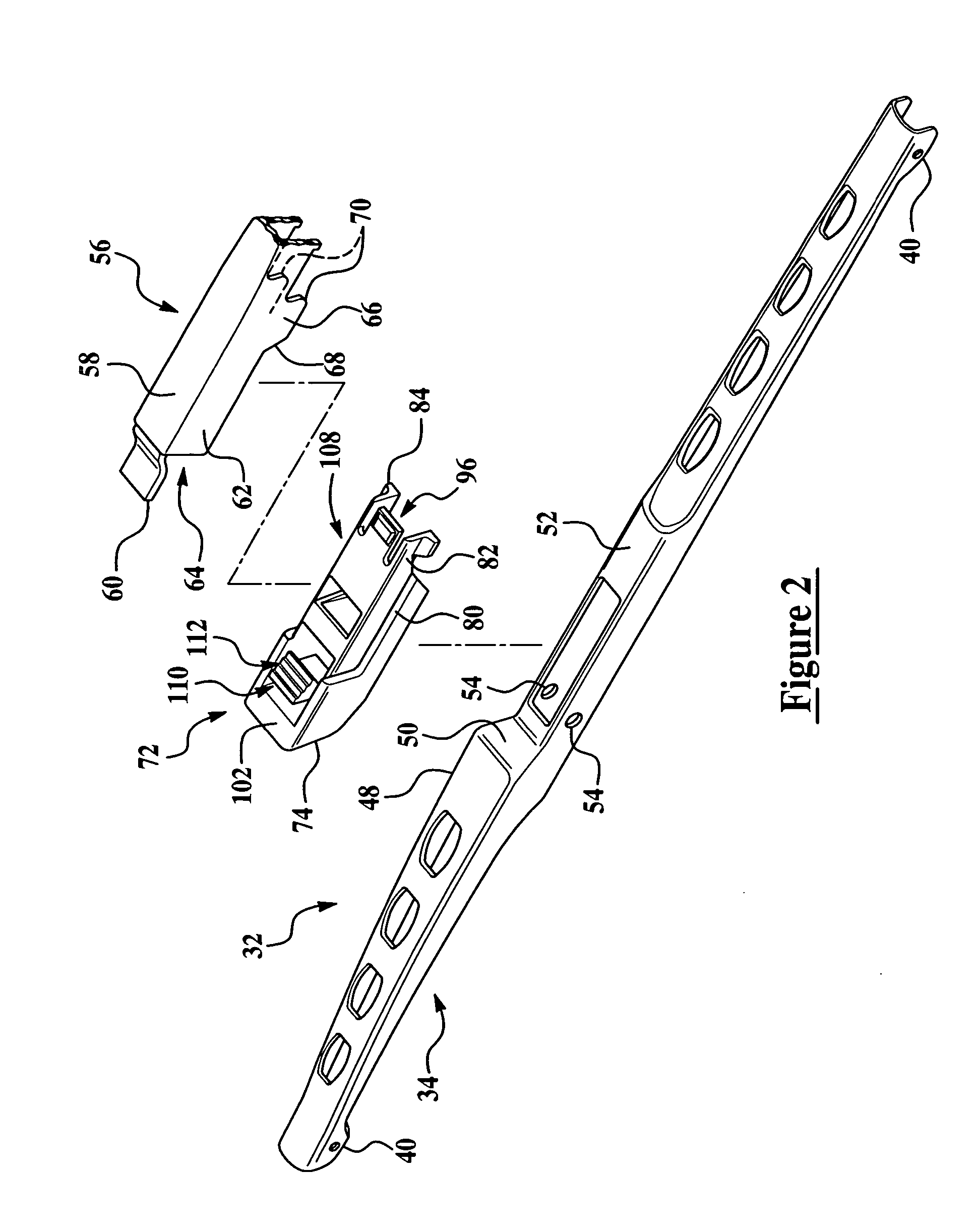

Wiper coupler and wiper assembly incorporating same

The present invention relates to a wiper coupler and wiper assembly that includes a wiping element and a tournament-style superstructure to support the wiping element. The wiper assembly further includes a wiper coupler that releasably attaches the superstructure to a wiper arm attachment member. The wiper coupler includes a pair of sidewalls each having a flange to engage a portion of the guides of the attachment member and further includes an elevated platform and a deck each disposed between the sidewalls. The deck and a portion of the sidewalls define a rest to receive the track of the attachment member. The wiper coupler further includes an aperture between the elevated platform and the deck. The aperture receives a portion of the bent tab of the attachment member to facilitate attachment between the superstructure and the attachment member conventionally employed for use with a beam blade-style wiper assembly.

Owner:TRICO PROD CORP

Support post system for molten metal pump

ActiveUS7906068B2Specific fluid pumpsPositive displacement pump componentsSupporting systemEngineering

An improved post clamp for a molten metal pump includes a support post clamp that supports the weight of a pump superstructure on the top of the support posts. The clamp preferably includes (a) a bottom flange for connecting to the pump superstructure, (b) a cavity for receiving an end of a support post, wherein the end has a top surface, and (c) a top flange for being positioned above the top surface. In operation the top flange rests on the top surface of the support post thereby supporting at least part of the weight of the superstructure. It is preferred that a plurality of support posts and post clamps according to the invention be used with a molten metal pump wherein the top surface of each support post supports some of the weight of the superstructure. Also disclosed are novel support posts that may be used with the post clamp, and a pump in which the post clamp and / or support posts may be used.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Quick submergence molten metal pump

A pump for transferring molten metal includes an intake tube, a motor, a rotor positioned at least partially within the bottom end of the intake tube, a rotor shaft positioned at least partially in the intake tube, the rotor shaft having a first end attached to the motor and a second end attached to the rotor. An overflow conduit is attached to the intake tube. The pump does not include a pump housing and preferably does not include a superstructure, so it is relatively small, light and portable. In use, the motor drives the rotor shaft and rotor to generate a flow of molten metal upward into the intake tube and into the overflow conduit where it is discharged.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

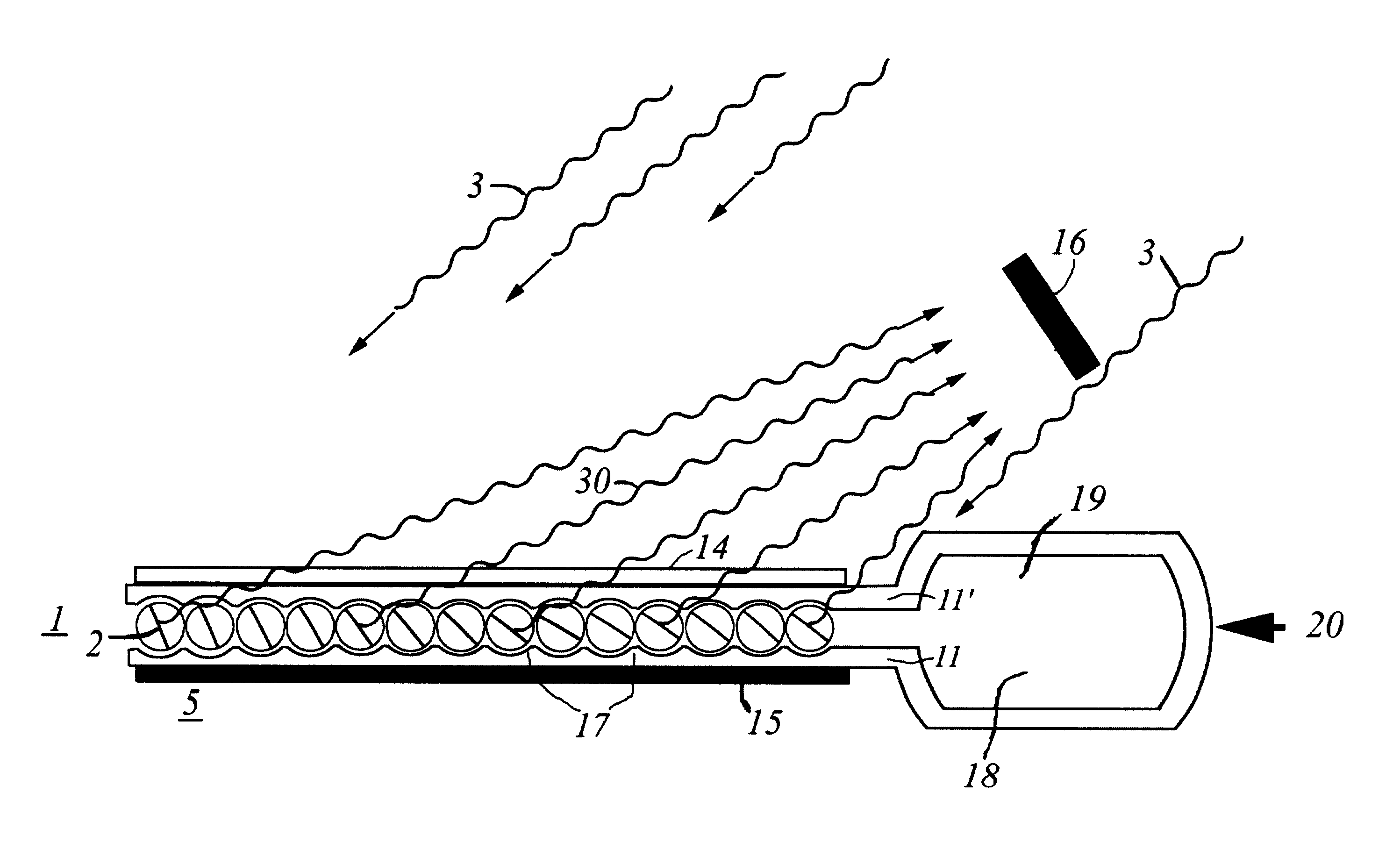

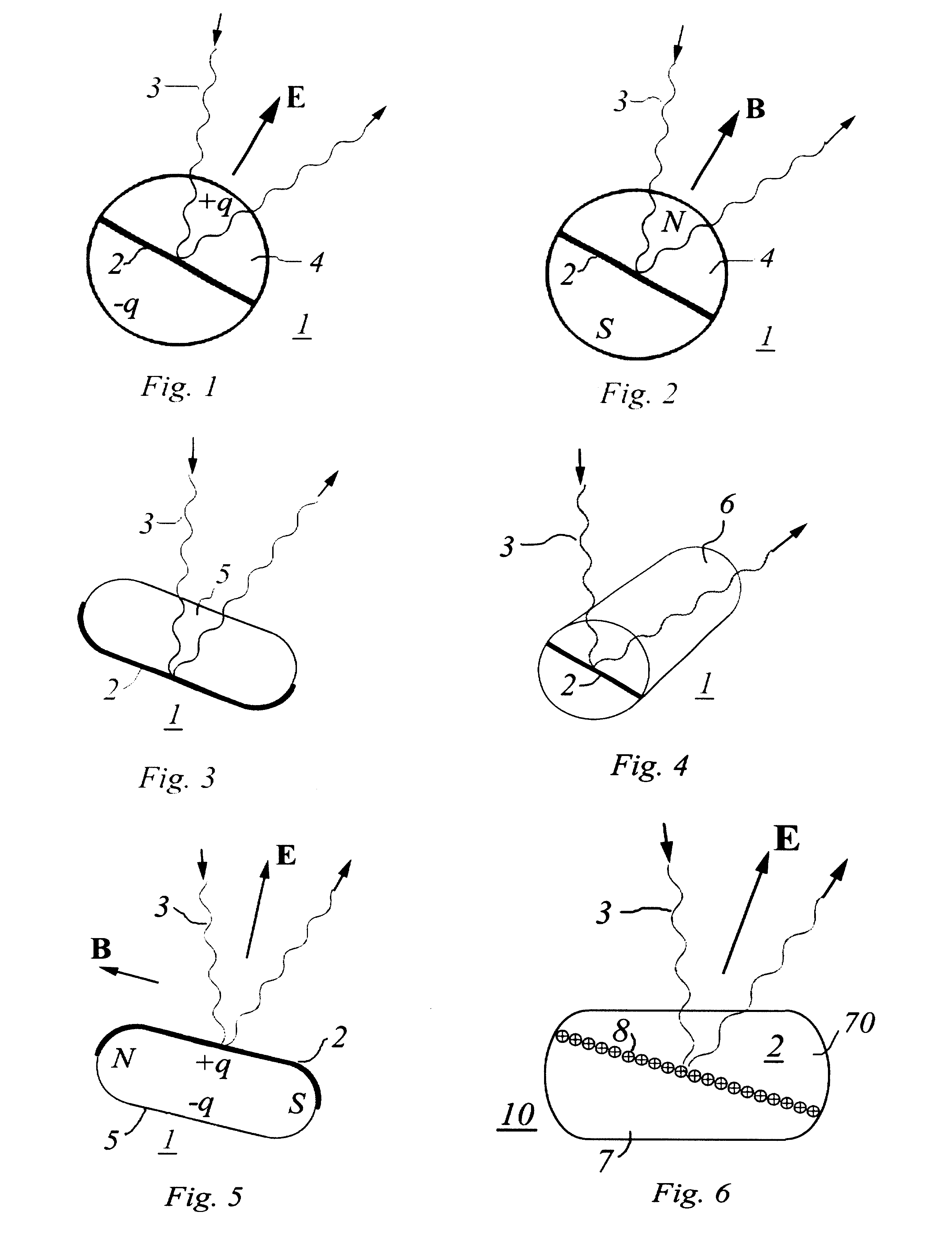

Mini-optics solar energy concentrator

This invention deals with the broad general concept for focussing light. A mini-optics tracking and focussing system is presented for solar power conversion that ranges from an individual's portable system to solar conversion of electrical power that can be used in large scale power plants for environmentally clean energy. It can be rolled up, transported, and attached to existing man-made, or natural structures. It allows the solar energy conversion system to be low in capital cost and inexpensive to install as it can be attached to existing structures since it does not require the construction of a superstructure of its own. This novel system is uniquely distinct and different from other solar tracking and focussing processes allowing it to be more economical and practical. Furthermore, in its capacity as a power producer, it can be utilized with far greater safety, simplicity, economy, and efficiency in the conversion of solar energy.

Owner:DAVIDSON MARK +1

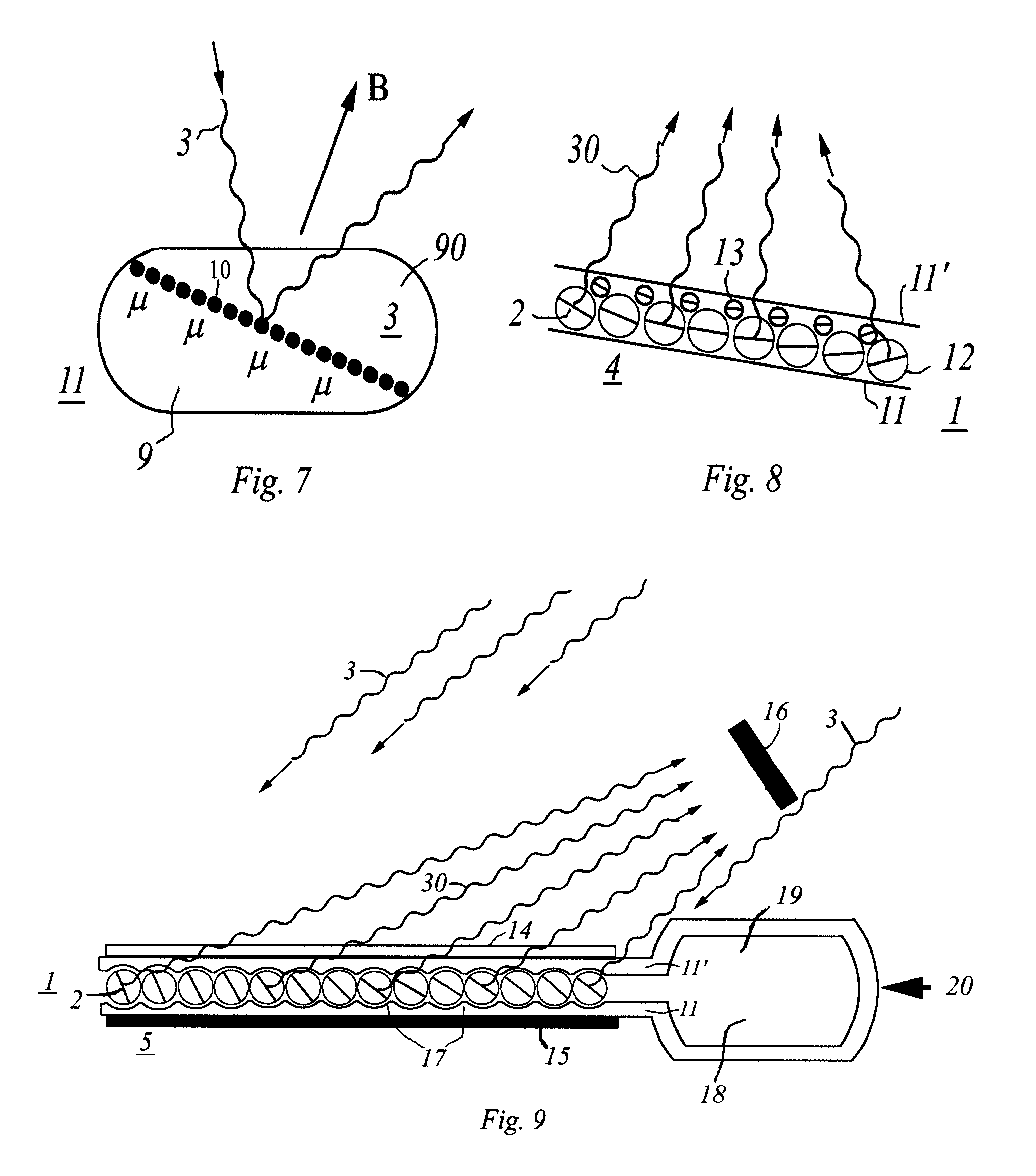

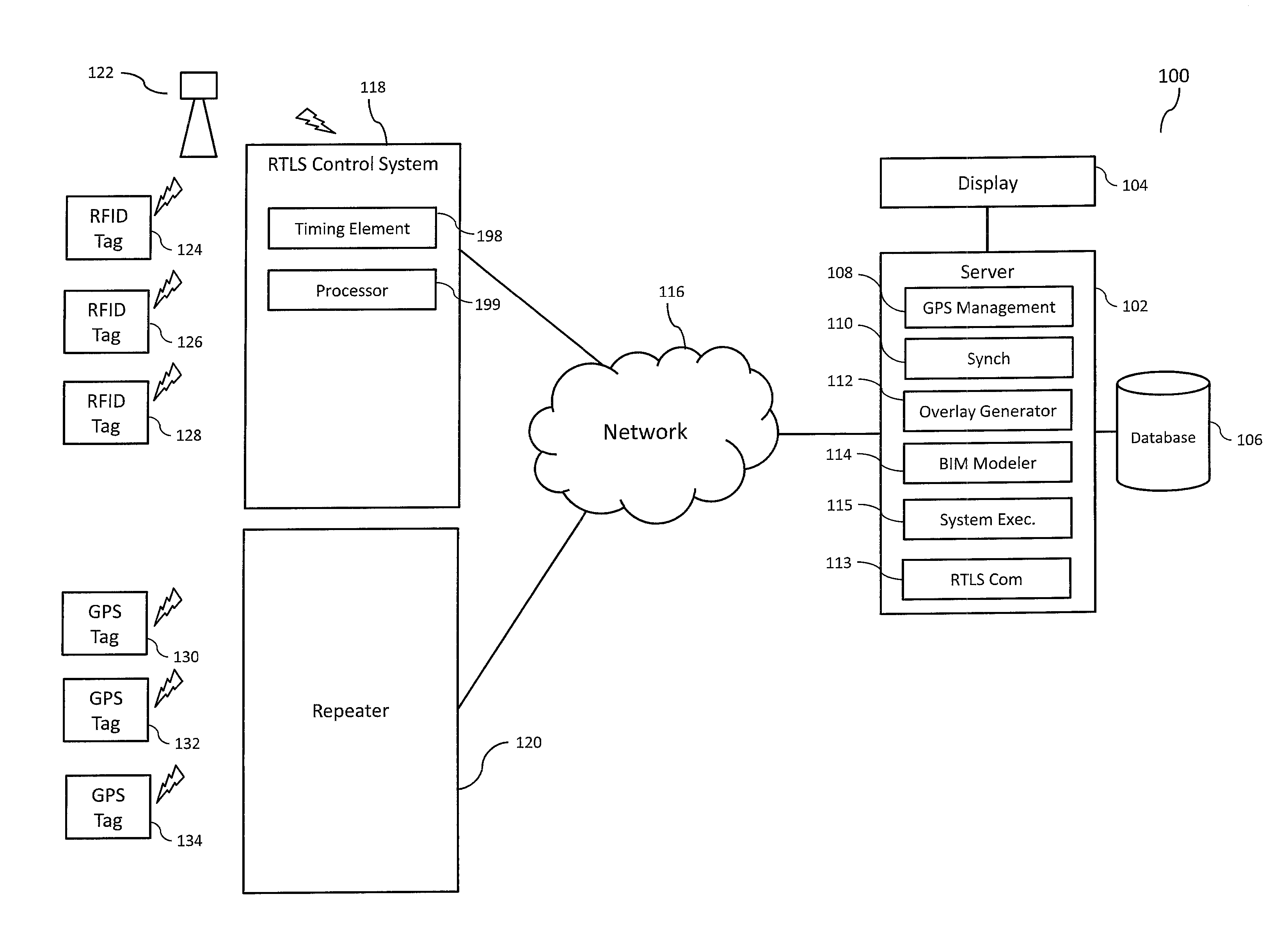

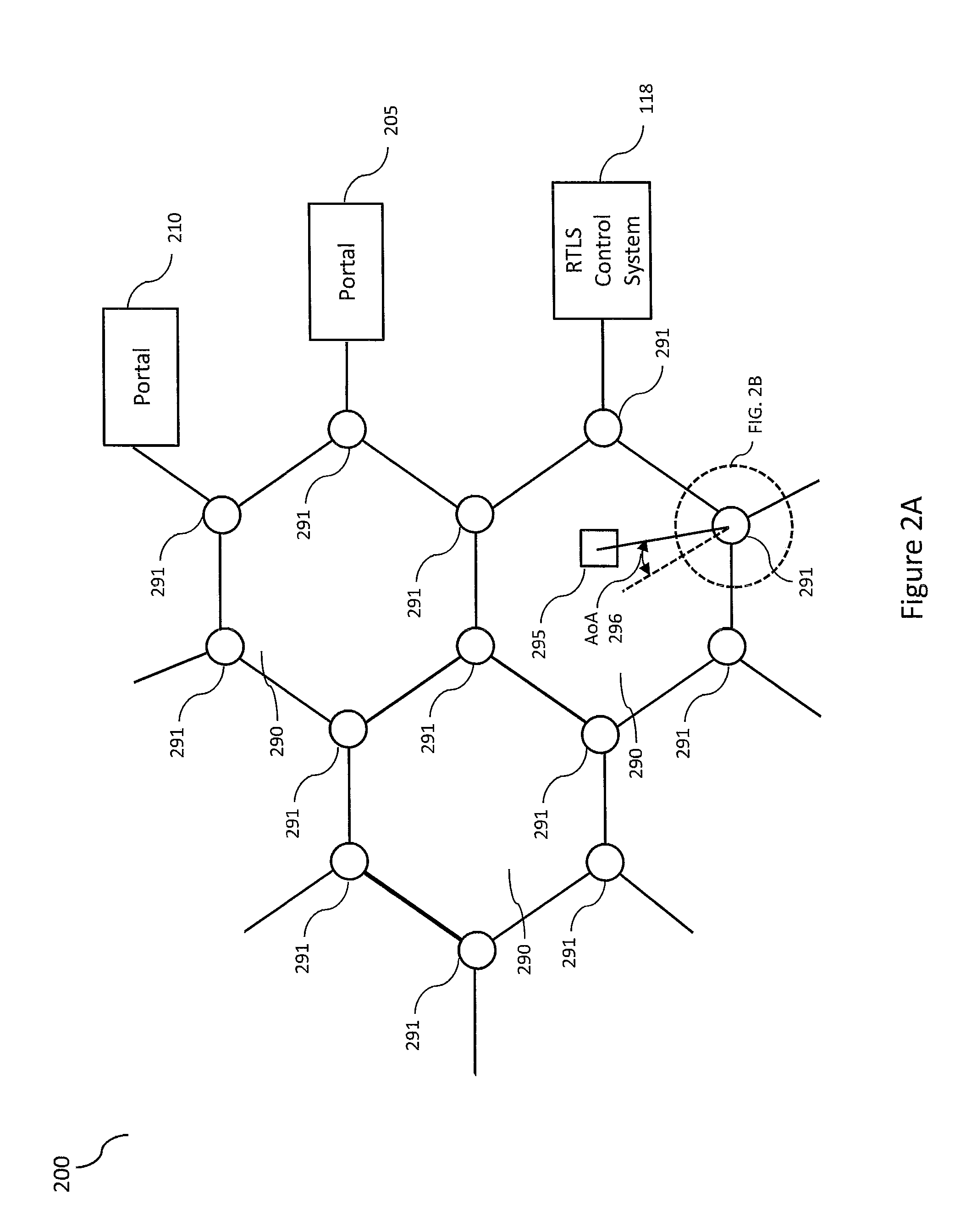

Method and apparatus for multi-mode tracking and display of personnel locations in a graphical model

The preferred embodiment provides an ultra-wide band radio frequency real-time location system (RTLS), synchronized with a GPS location system to provide reliable location data, in and around concrete and steel superstructures to a BIM graphic model system, to gather and display worker location data and coordinate its display for use. The RTLS system continuously locates each participant through the use of an active RFID tag and / or GPS location device, which may be placed in a personnel badge and verified. The location system logs the participant locations in a database for real-time information retrieval and upload into a BIM display system.

Owner:SPECIALTY ELECTRICAL

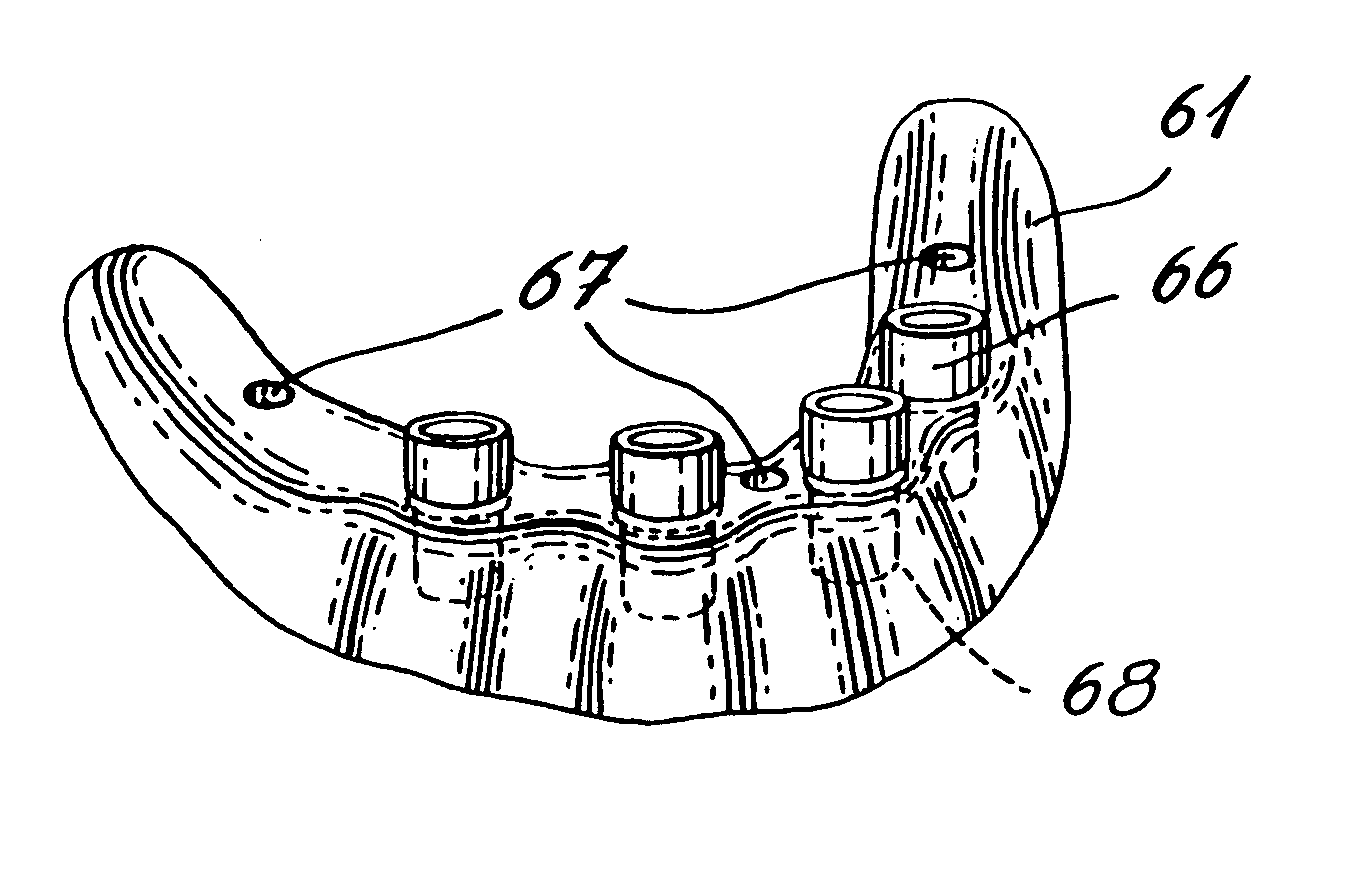

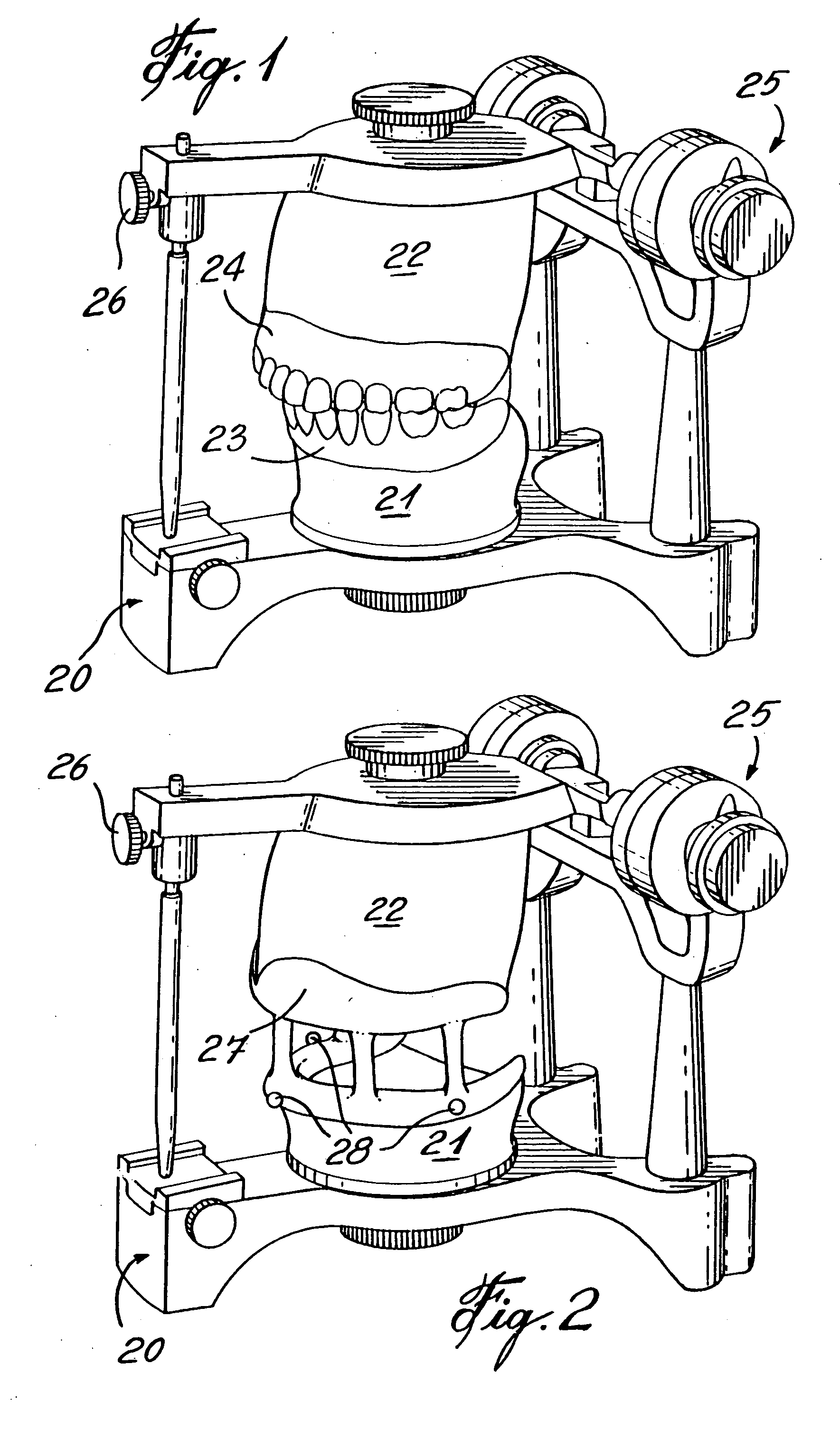

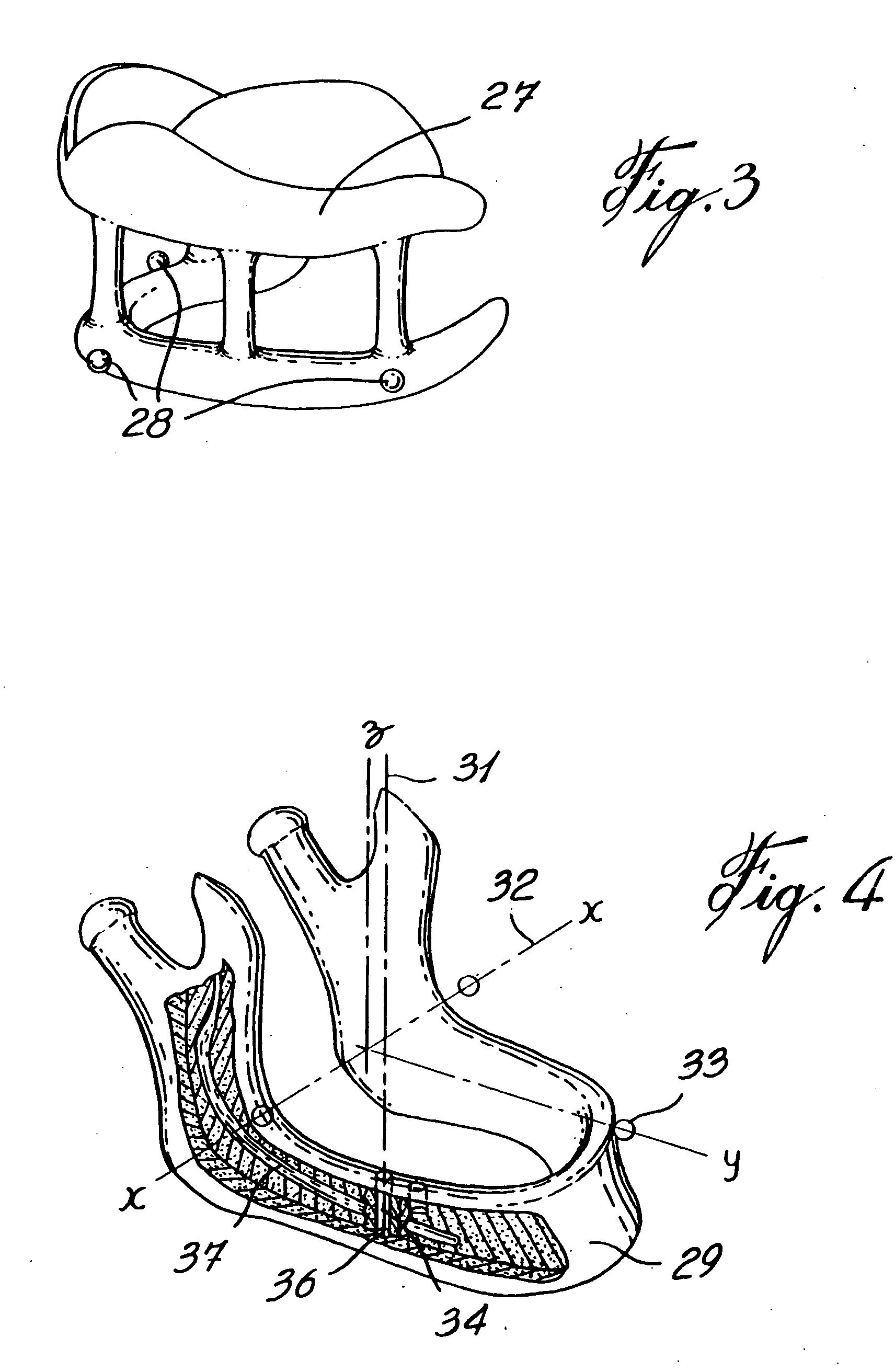

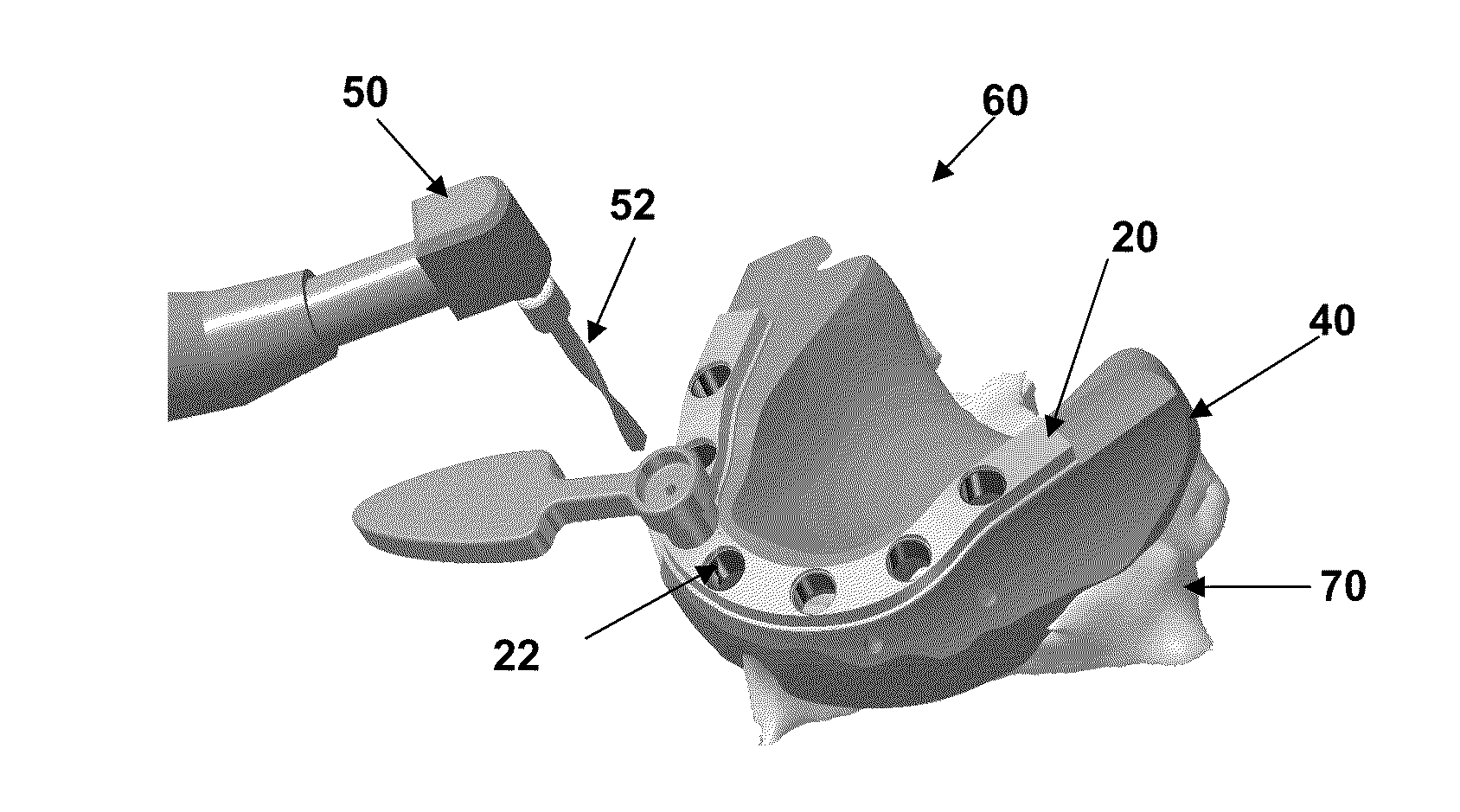

Manufacturing a dental implant drill guide and a dental implant superstructure

InactiveUS20050037320A1Good choiceExact referenceDental implantsImpression capsBone structureDental implant

Dental implant drill holes and the shape of a dental implant superstructure are chosen by creating a computer model giving jawbone structural details, gum surface shape information and proposed teeth or dental prosthesis shape information. The computer model shows the bone structure, gum surface and teeth images properly referenced to one another so that implant drill hole positions can be selected taking into consideration proper positioning within the bone as well as proper positioning with respect to the dental prosthesis. Similarly, manufacture of the dental implant superstructure used for fixed dental prosthesis or overdentures can be designed based on knowledge of the actual implant positions referenced to an image of the gum surface and proposed dental prosthesis.

Owner:TECHN DUSINAGE SINLAB

Mobile cleaning device for solar panels

InactiveUS20130206173A1Easy to carryEasy to cleanSolar heating energySolar heat devicesMechanical engineeringSuperstructure

The invention concerns a mobile cleaning device suitable for displacing along and cleaning a series of adjacent tilted solar panels aligned in a row and requiring therefor no superstructure fixed to the row of solar panels. The device includes a supporting frame defining a cleaning plane, on which are mounted a cleaning device suitable for cleaning a surface parallel to the cleaning plane, a support device for maintaining the supporting frame substantially parallel to the surface to be cleaned during the displacement of the cleaning device along a row of solar panels; and a guiding device for guiding the displacement of the cleaning device along a row of solar panels. The guiding device includes at least two, preferably at least three, separate guiding wheels, which are aligned along a straight line parallel to the cleaning plane and adjacent to a first edge of the frame. Each guiding wheel is mounted such as to rotate about an axis substantially normal to the cleaning plane and suitable for resting and rolling on the upper edge of the aligned solar panels with the cleaning device in cleaning contact with the surface to be cleaned.

Owner:SOLAR CLEAN

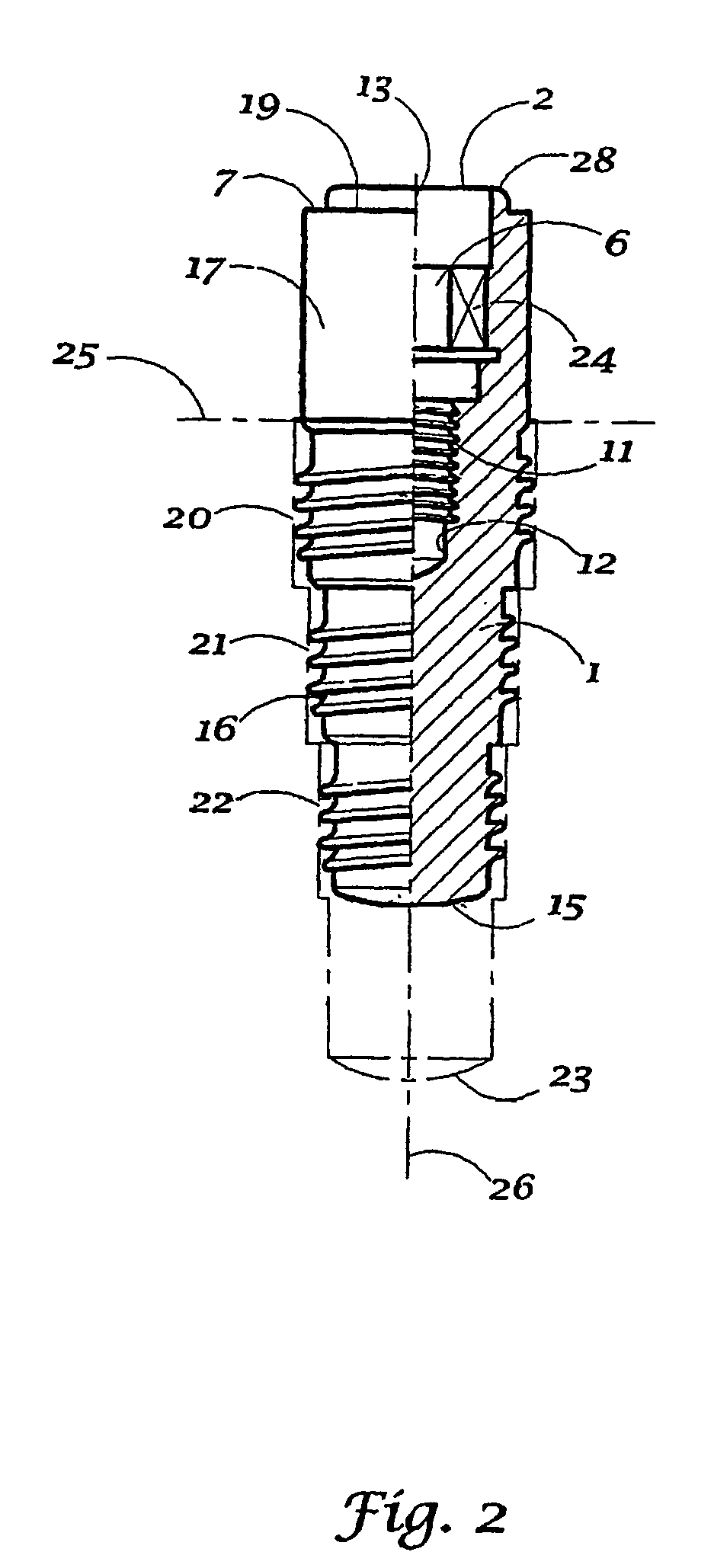

Multi part non metal implant

InactiveUS20060246397A1Good effectGood flexibilityDental implantsDental prostheticsAbutmentBiomedical engineering

An implant is disclosed comprising a fixture component (1) intended for insertion into a bone, and at least one further abutment component (3) for providing a base for a prosthetic superstructure, and a connecting element (9) for mechanically securing the abutment (3) to the fixture (1), wherein the fixture (1) comprises an external thread (16) or other protrusions for improving engagement between the fixture (1) and the bone, wherein the connecting element (9) detachably interconnects the fixture (1) and the abutment (3), and wherein at least the fixture (1) and the abutment (3) are made of non-metal material, and method of making the same.

Owner:FRIADENT

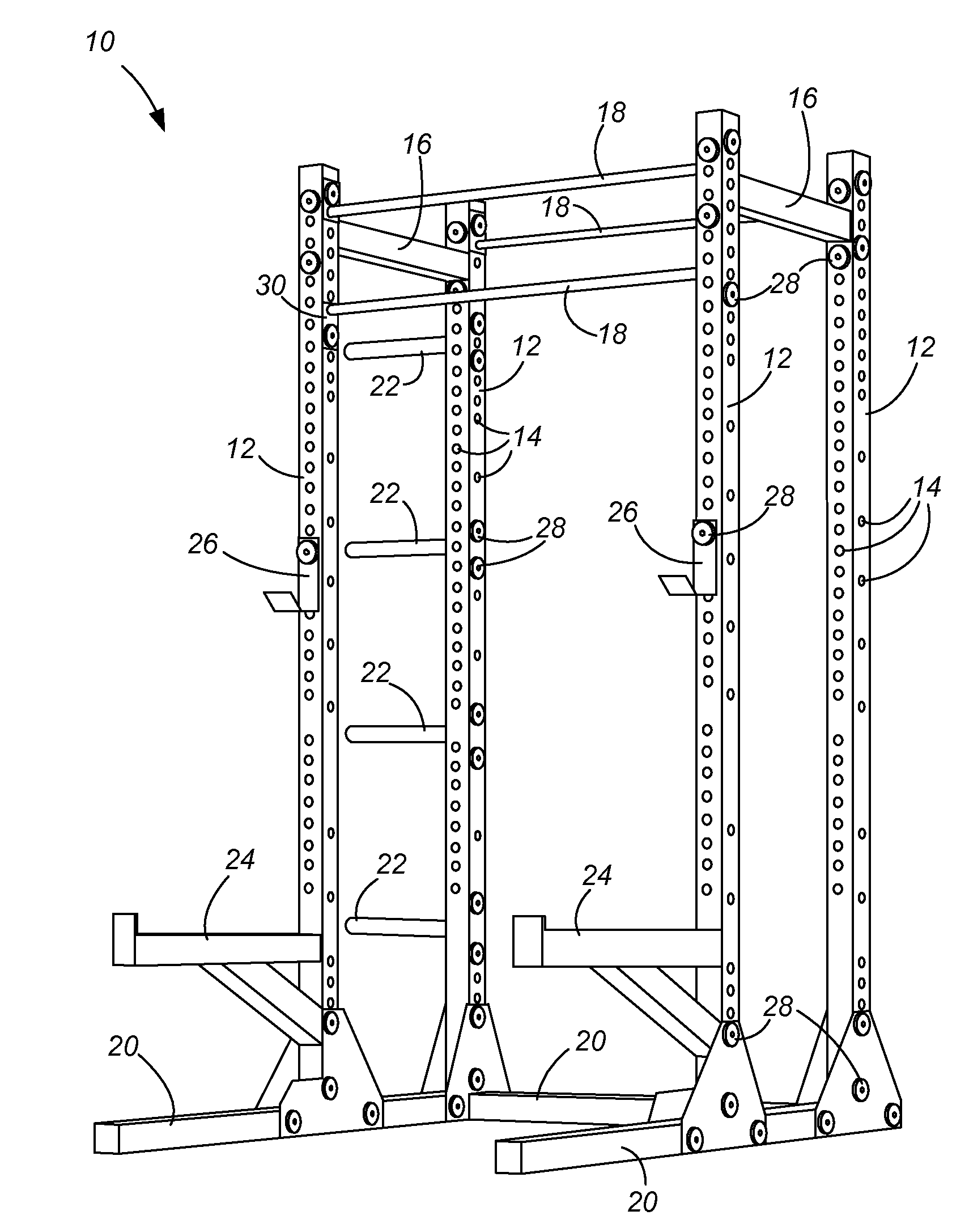

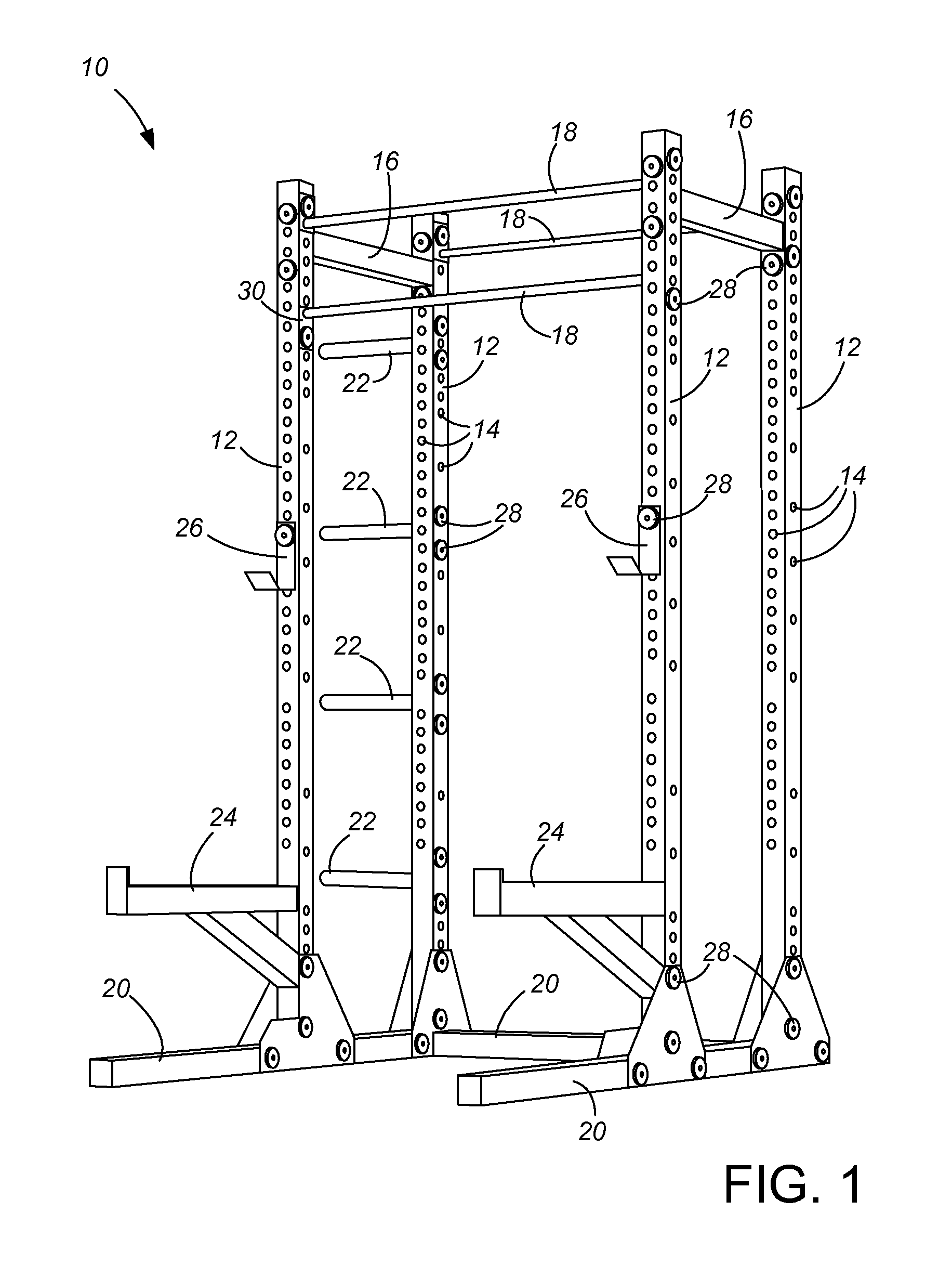

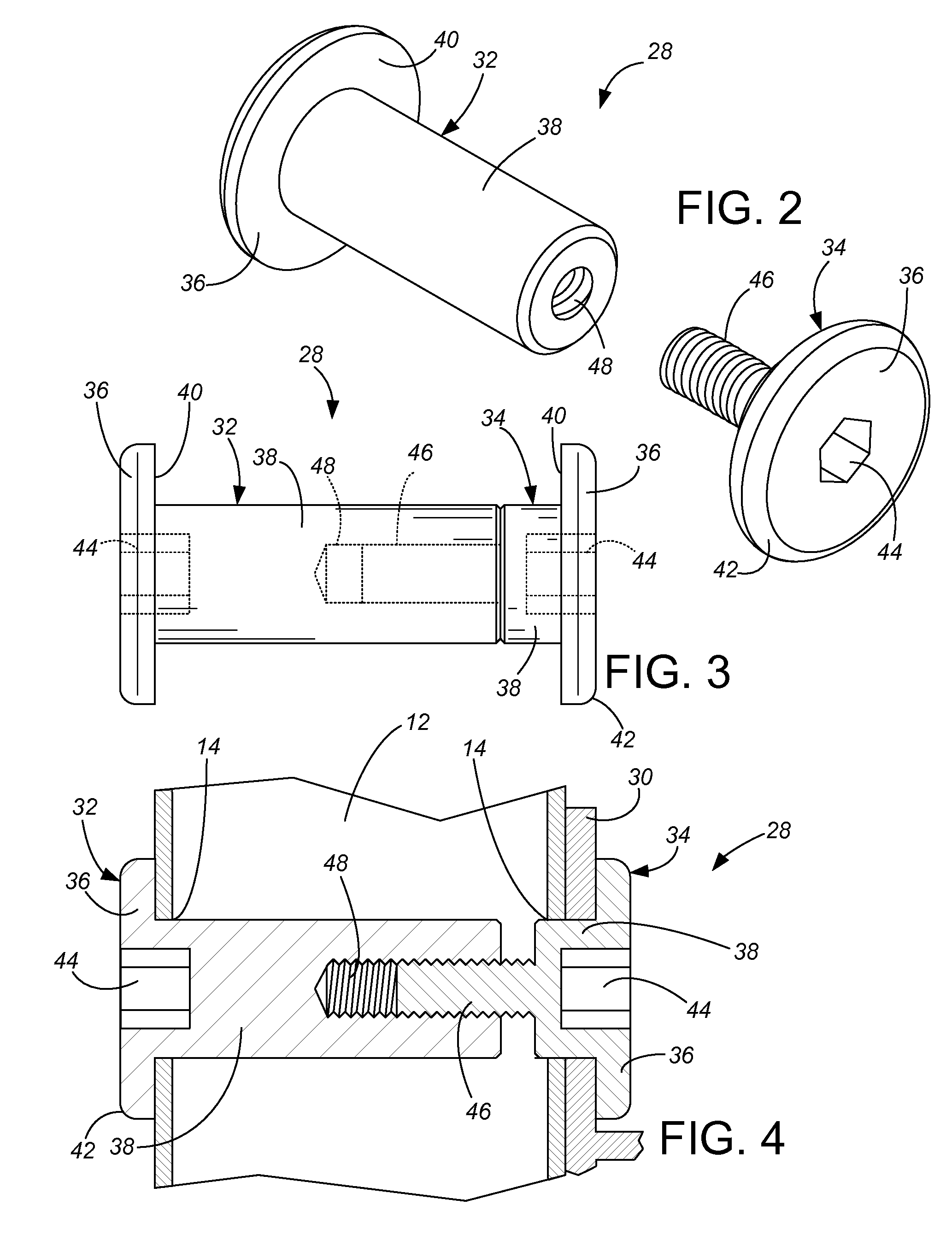

Fastener For Fitness Apparatus

InactiveUS20150016919A1Less likely can be damagedAvoid security issuesNutsBoltsScrew threadExercise machine

A fastener for a fitness equipment superstructure includes a stud member and a peg member, both of which include a head and a body. The body is sized to be received in holes on uprights of the superstructure to attach one or more accessories thereto. The head is significantly larger in diameter than the body, but thin with a circular profile and radiused corner. The stud member includes a thread portion which mates into a threaded recess in the body of the peg member, with the heads opposing each other on opposite sides of the upright.

Owner:DYNAMIC FITNESS & STRENGTH

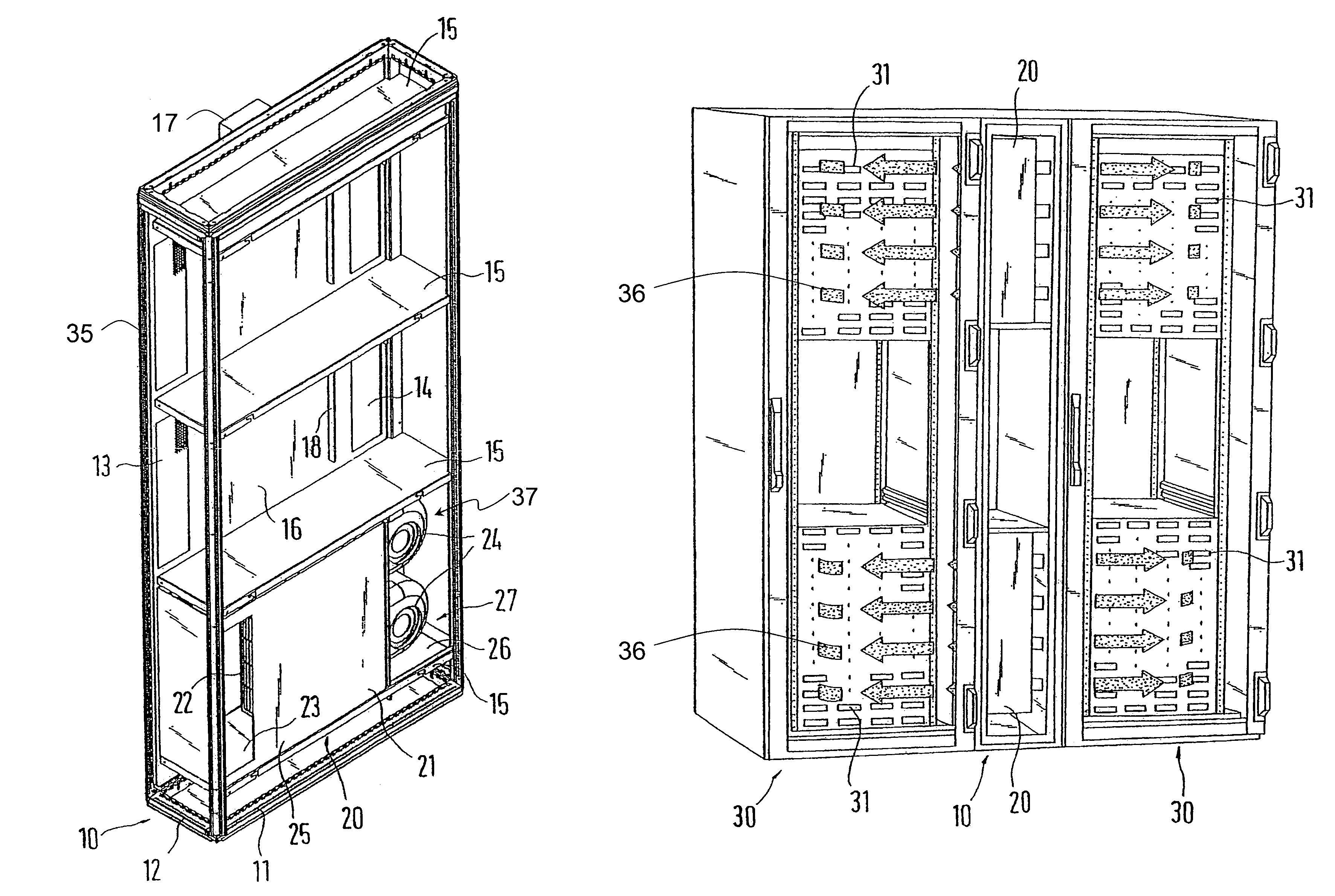

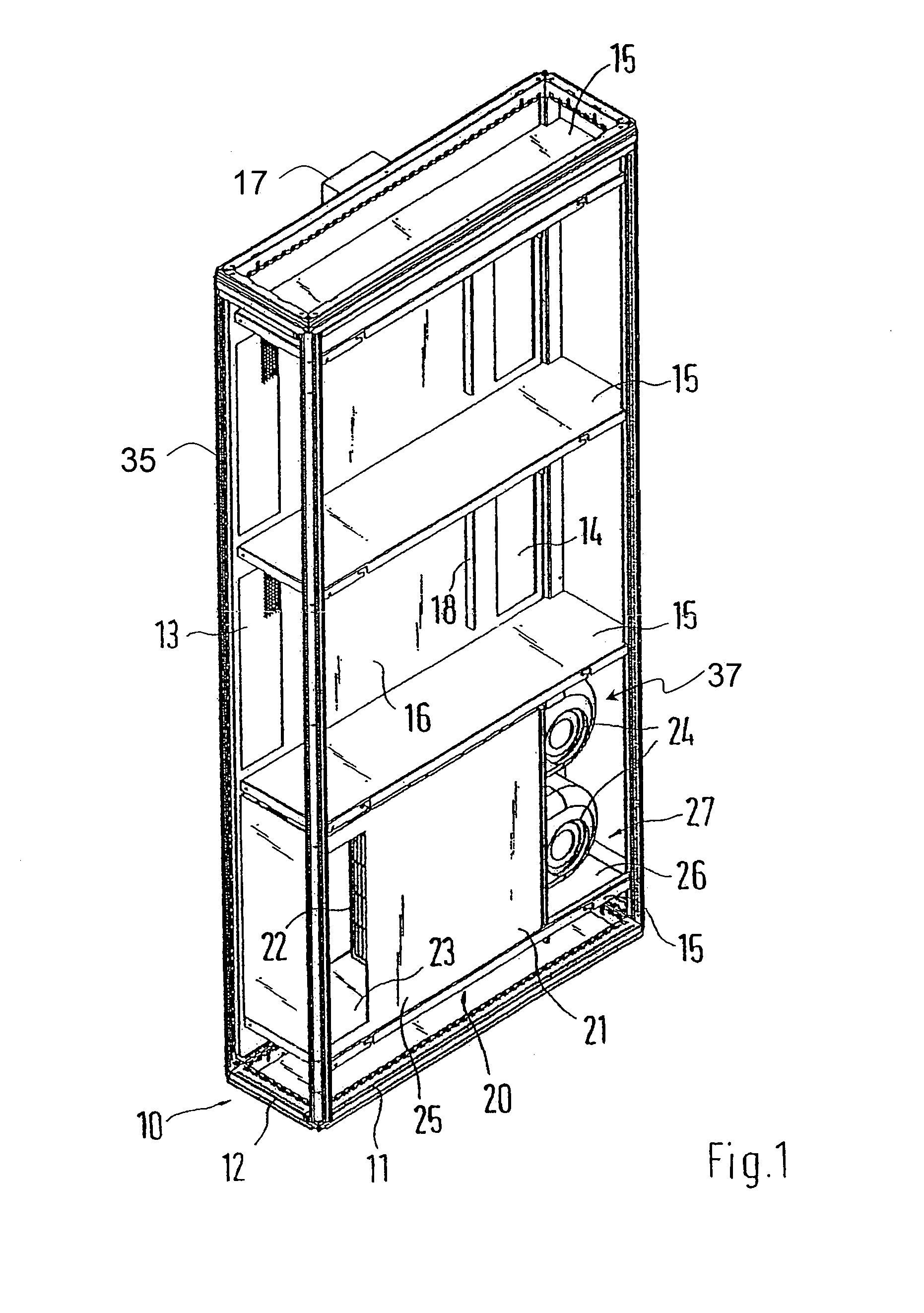

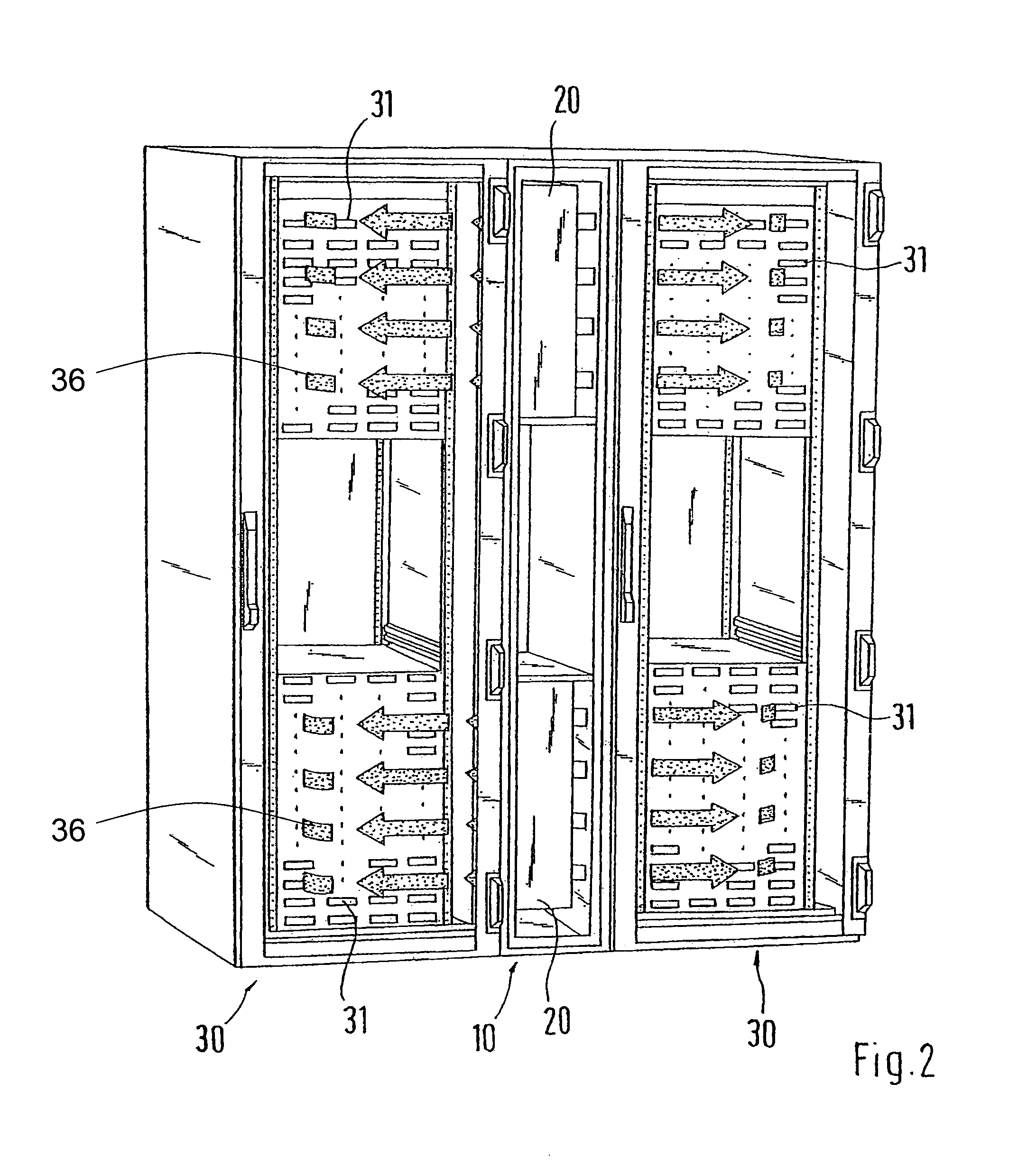

Assembly of devices

InactiveUS7319594B2Easy to adaptAvoid areaNon-enclosed substationsDigital data processing detailsComputer moduleEngineering

An assembly of devices including at least one switchgear cabinet and a cooling device. The switchgear cabinet has a closed interior, in which electric installations can be housed. The cooling device is attached in the vicinity of or near a lateral surface of the switchgear cabinet that runs vertically with respect to the front face, extending at least over part of the height of the switchgear cabinet and having a spatial connection with the interior via at least one air inlet and at least one vent outlet. The cooling device includes a receiving chamber that houses at least one heat exchanger. This invention facilitates the adaptation of the cooling device in superstructures of this type to modified cooling requirements. To achieve this, at least sections of the receiving chamber of the cooling device are divided into two or more receiving sub-chambers that are situated one above the other and a cooling module is housed in at least one of the receiving sub-chambers.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

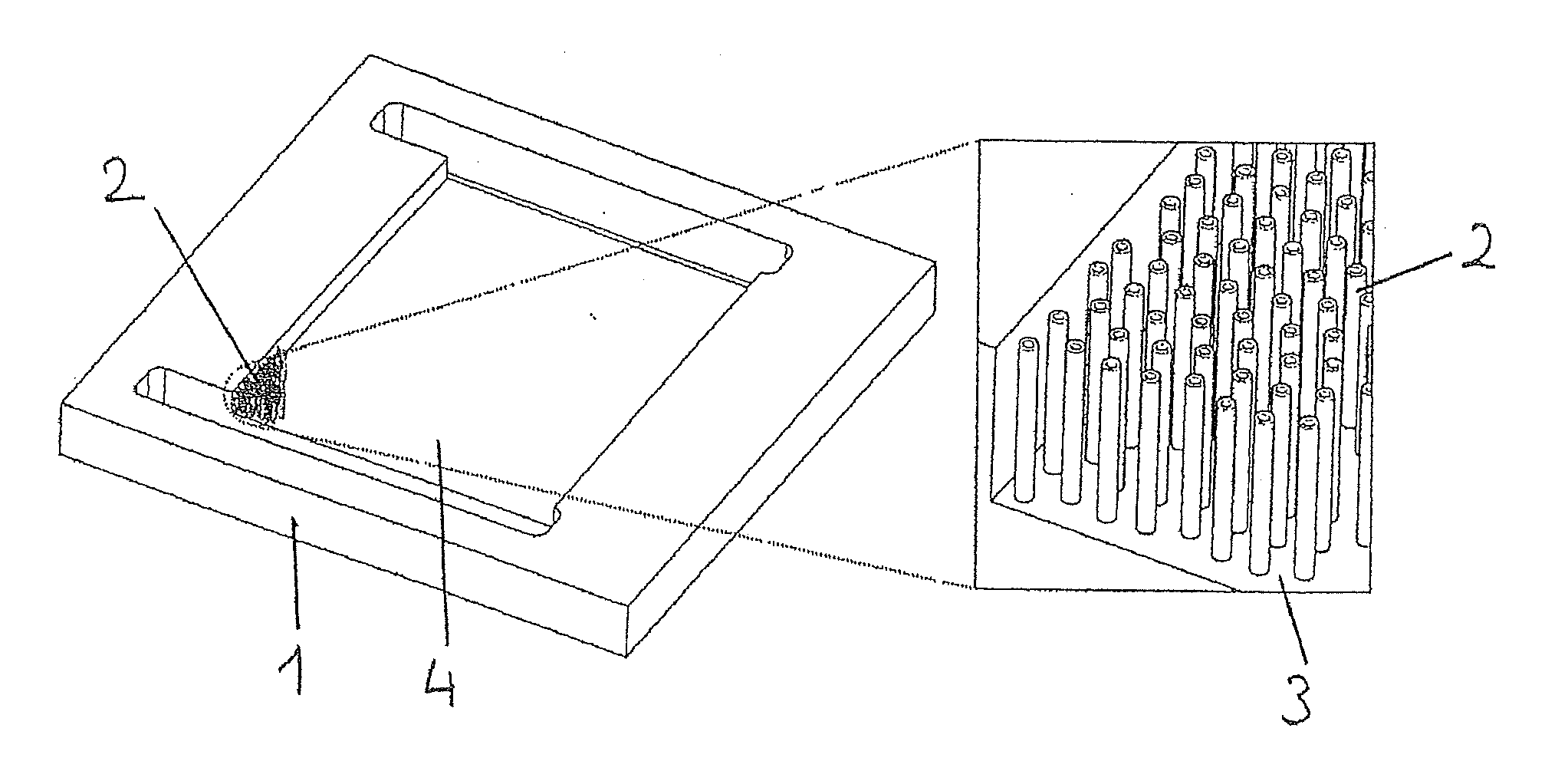

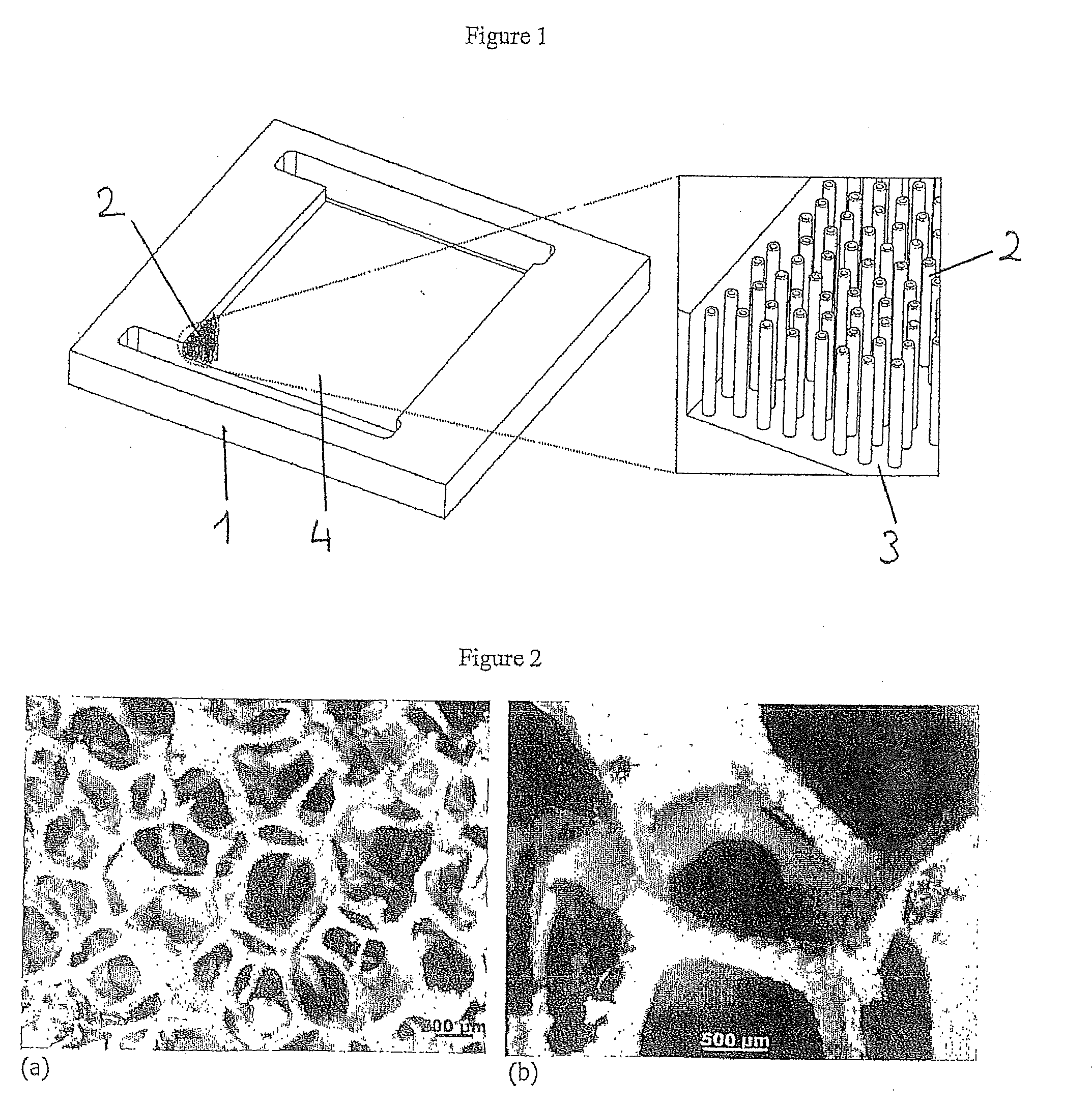

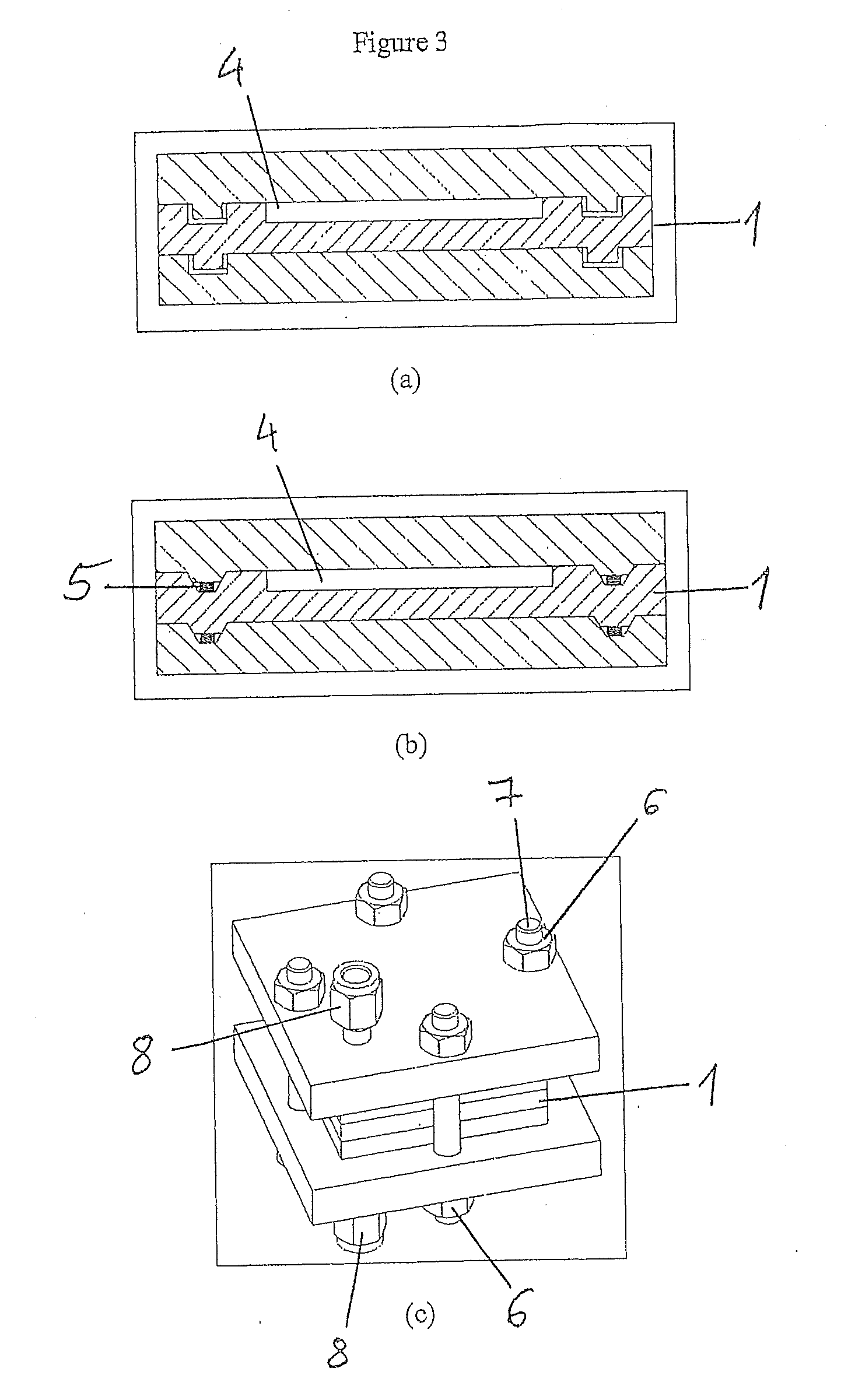

Chemical reactor with nanometric superstructure

InactiveUS20110123409A1Good choiceInhibition formationAnodisationMaterial nanotechnologyGlass fiberCarbon fibers

The invention relates to a chemical reactor with a nanometric superstructure, comprising at least one member wherein at least one reaction chamber is arranged, and said reaction chamber being filled at least partially with a high specific surface area material having a specific surface area greater than 5 m2 / g, and characterised in that said high specific surface area material is selected from nanotubes or nanofibres.These nanotubes or nanofibres are preferably selected in the group consisting of carbon nanofibres or nanotubes, β-SiC nanofibres or nanotubes, TiO2 nanofibres or nanotubes.They may be deposited on an intermediate structure selected in the group consisting of glass fibres, carbon fibres, SiC foams, carbon foams, alveolar β-SiC foams, said intermediate structure filling the reaction chamber of said reactor at least partially.

Owner:CENT NAT DE LA RECHERCHE SCI +1

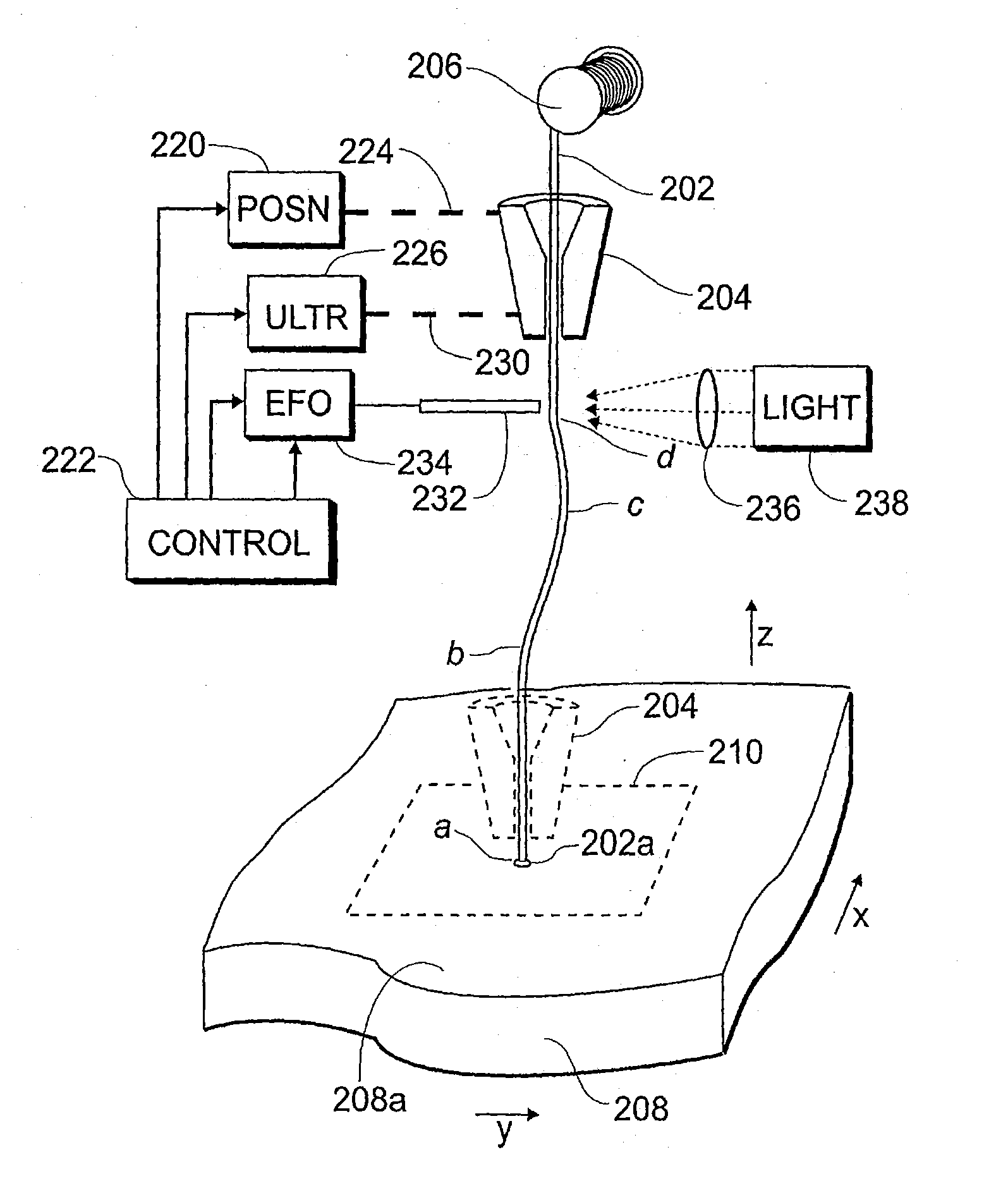

Method Of Wirebonding That Utilizes A Gas Flow Within A Capillary From Which A Wire Is Played Out

InactiveUS20070228110A1Simple technologyImprove bindingElectrical testingPrinted circuits structural associationsPrinted circuit boardTopography

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring the wire into a wire stem having a springable shape, severing the wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, severing, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to have a springable shape, the wire stem is severed to be free-standing by an electrical discharge, and the free-standing wire stem is overcoated by plating. A variety of materials for the wire stem (which serves as a falsework) and for the overcoat (which serves as a superstructure over the falsework) are disclosed. Various techniques are described for mounting the contact structures to a variety of electronic components (e.g., semiconductor wafers and dies, semiconductor packages, interposers, interconnect substrates, etc.), and various process sequences are described. The resilient contact structures described herein are ideal for making a “temporary” (probe) connections to an electronic component such as a semiconductor die, for burn-in and functional testing. The self-same resilient contact structures can be used for subsequent permanent mounting of the electronic component, such as by soldering to a printed circuit board (PCB). An irregular topography can be created on or imparted to the tip of the contact structure to enhance its ability to interconnect resiliently with another electronic component. Among the numerous advantages of the present invention is the great facility with which the tips of a plurality of contact structures can be made to be coplanar with one another. Other techniques and embodiments, such as wherein the falsework wirestem protrudes beyond an end of the superstructure, or is melted down, and wherein multiple free-standing resilient contact structures can be fabricated from loops, are described.

Owner:FORMFACTOR INC

Dental prosthesis system

The present disclosure relates to a dental prosthesis system and a method of using same comprising a prosthesis, a primary bar, and a base-plate. The primary bar is adapted to be received on the implants and to be used as a superstructure for supporting the prosthesis, a verification jig and / or an impression matrix. The base-plate has a shape adapted to be received on the patient's gum surface, comprising at least one hole each in alignment with a corresponding one of the aperture of the primary bar when the primary bar is seated on the base-plate, each hole of the base-plate correspond to the position of each implant hole, the base-plate supporting the primary bar to form a drilling guide for guiding the drilling of implants holes in the patient's gum surface.

Owner:INSTITUT STRAUMANN AG

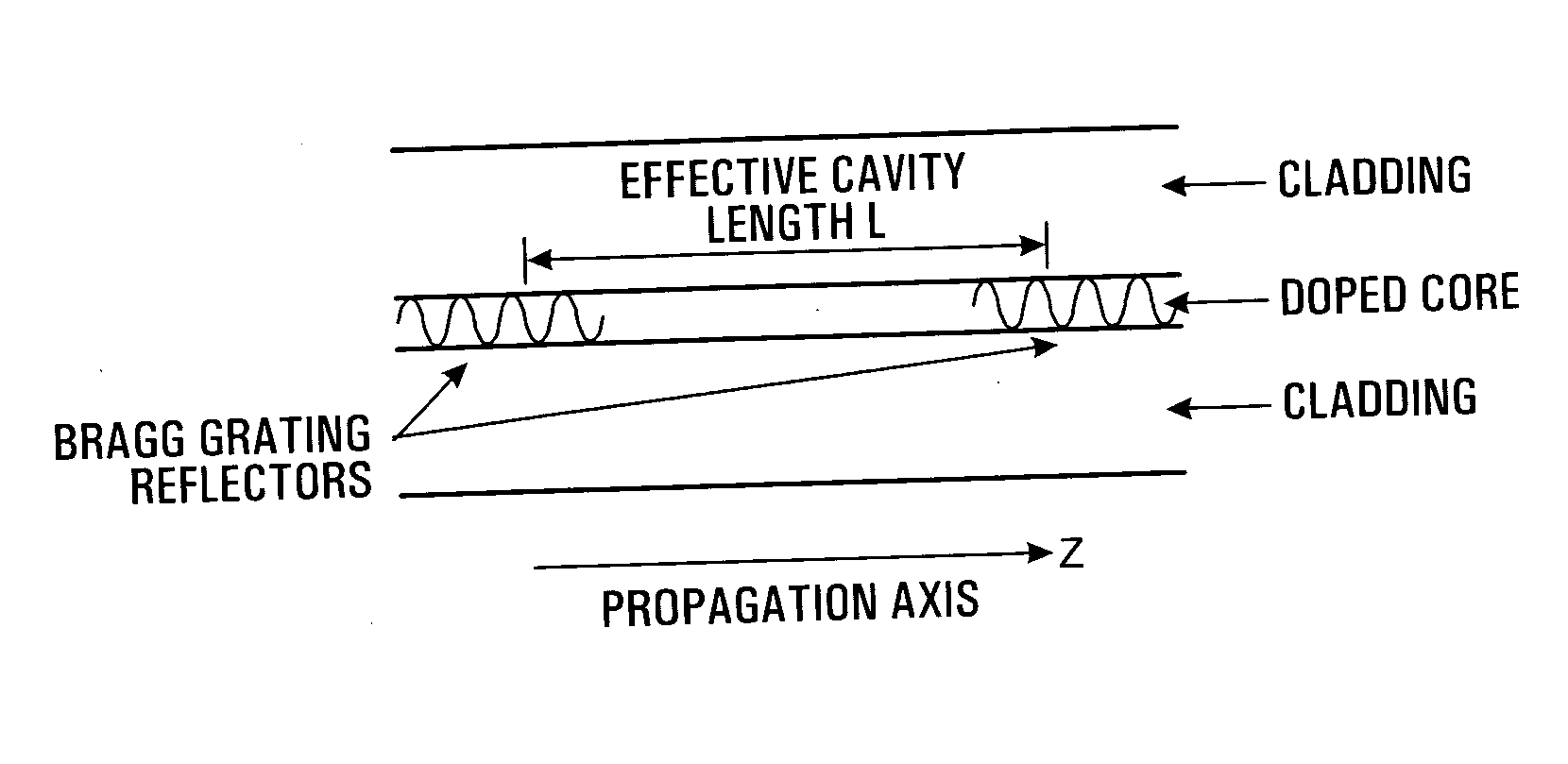

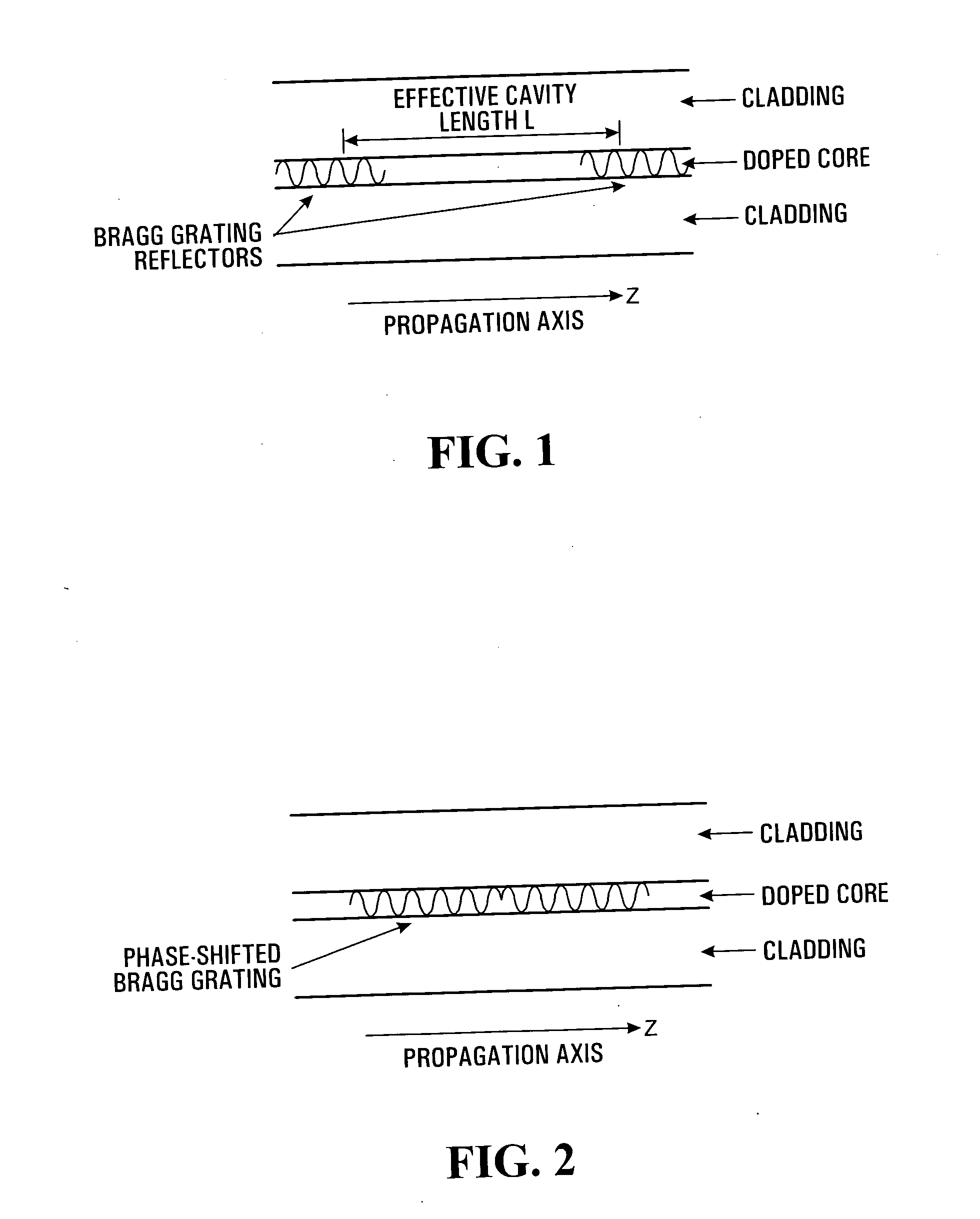

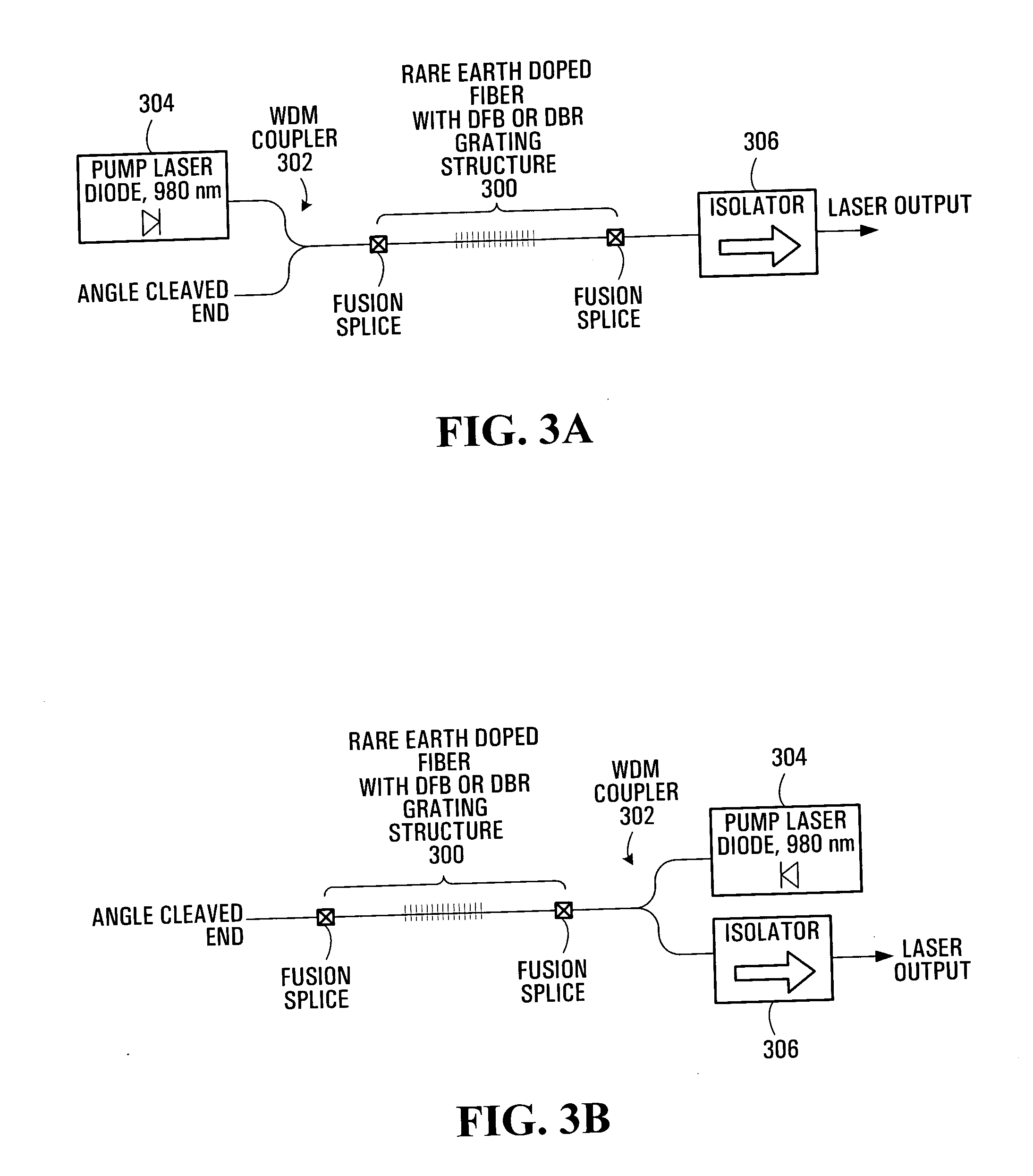

Multi-wave length laser source

InactiveUS20050063430A1Laser using scattering effectsOptical resonator shape and constructionGratingLaser source

A multi-wavelength laser source is provided including a pump laser unit, a gain section and an output. The pump laser unit generates an energy signal, which is applied to the gain section. The gain section includes a gain medium with having a superstructure grating forming a distributed Fabry-Perot-like structure. The superstructure grating causes a multi-wavelength laser signal to be generated when the energy signal is applied to the gain medium. The multi-wavelength laser signal is then released at the output.

Owner:UNIV LAVAL

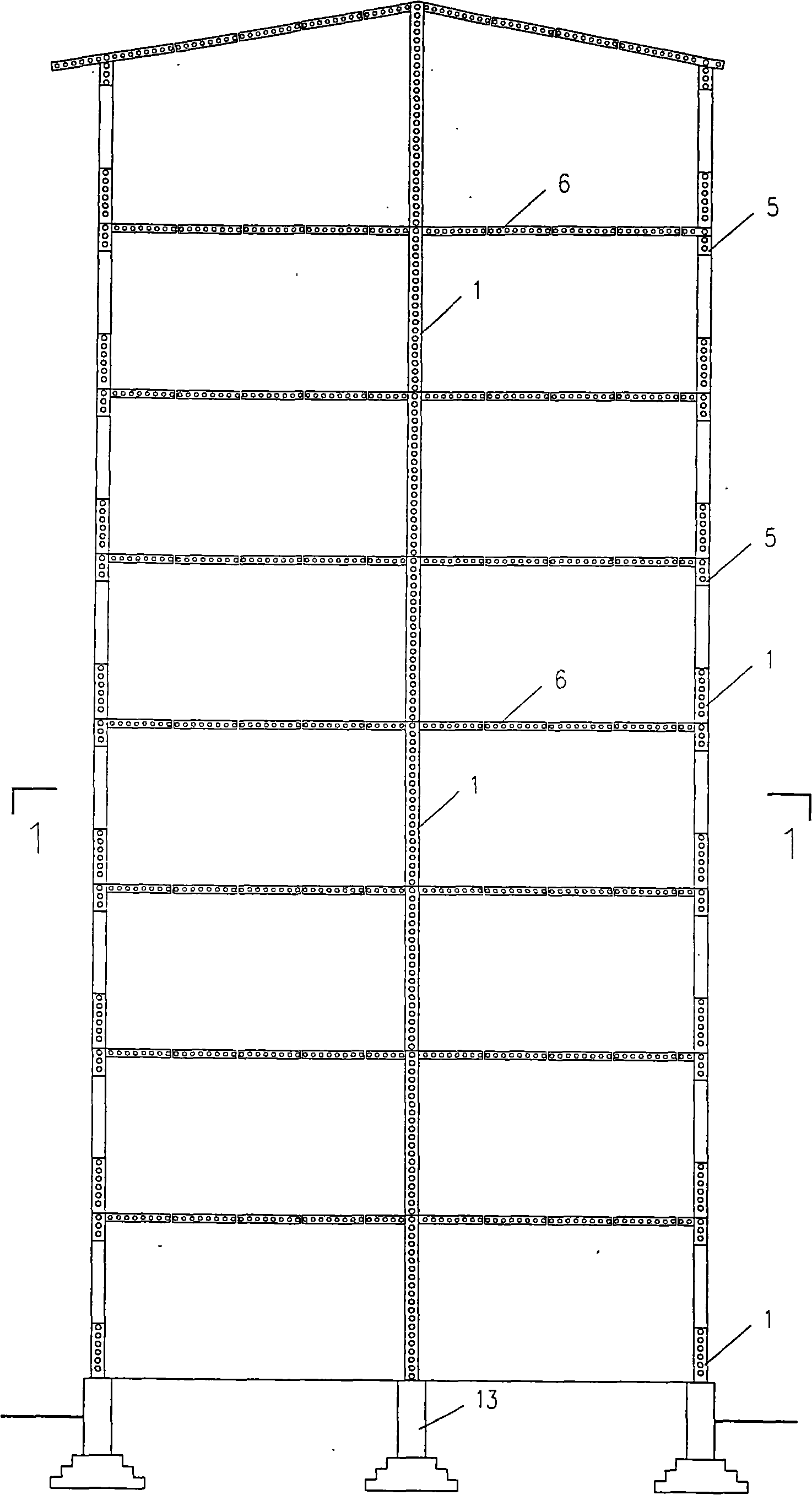

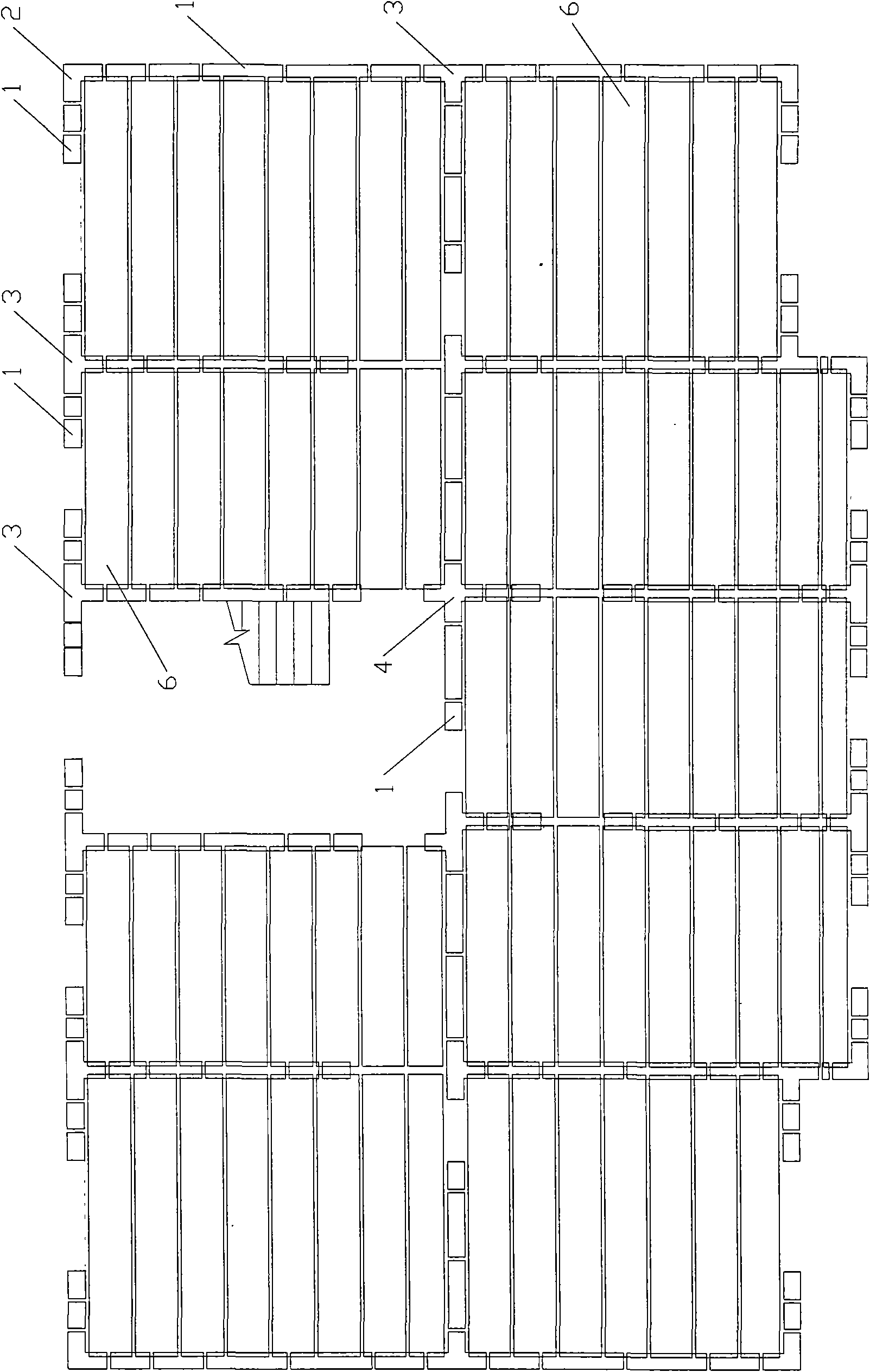

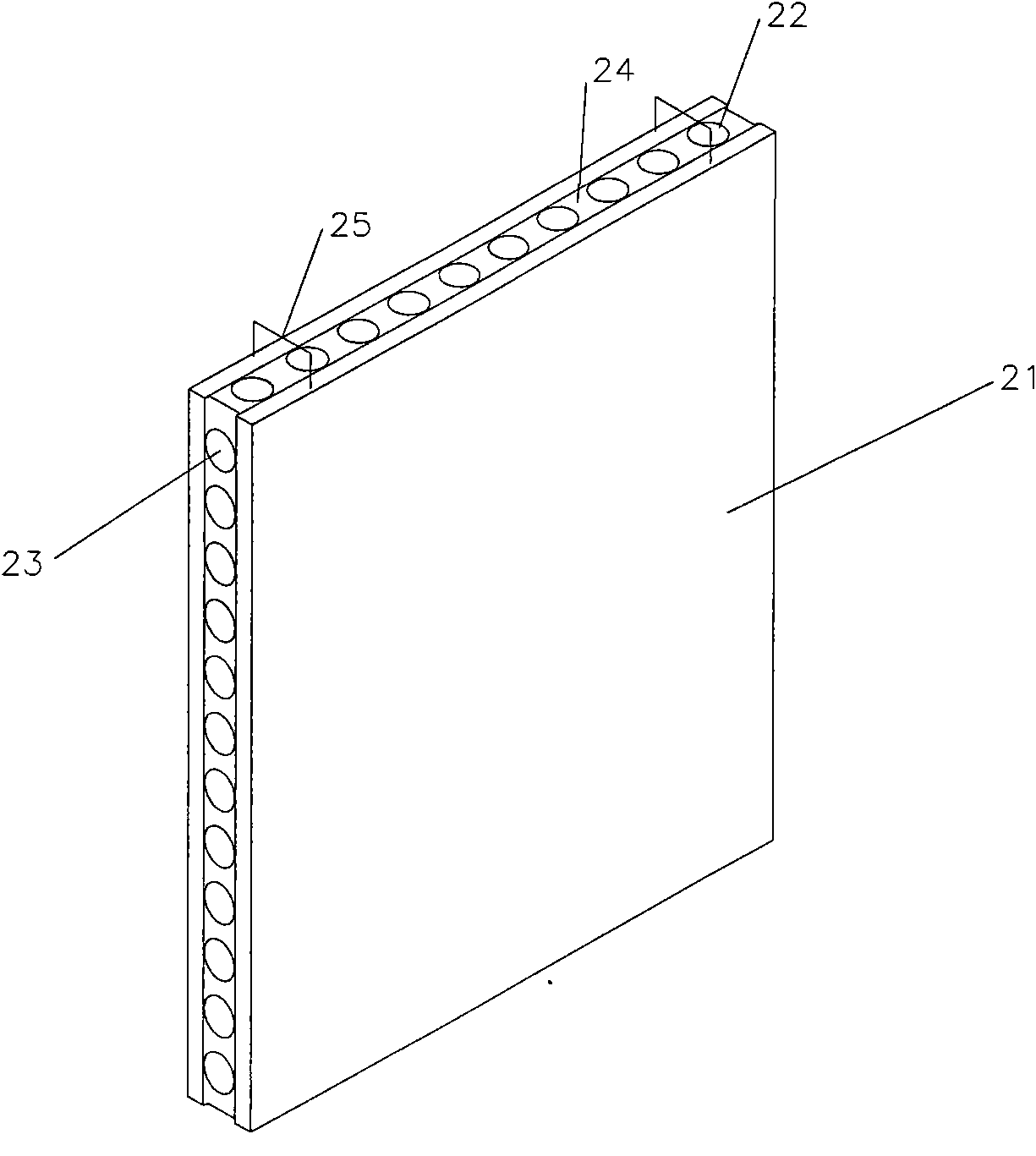

Shear wall structure building based on cross-hole prefabricated reinforced concrete template and construction method thereof

ActiveCN102061803AFlatness is easy to guaranteeReduce weightWallsBuilding reinforcementsRebarBuilding unit

The invention relates to a shear wall structure building based on a cross-hole prefabricated reinforced concrete template and a construction method thereof, belonging to the technical field of buildings and construction thereof. In the building, a wall template, an L-shaped column template, a T-shaped column template, a rectangular column template, a cruciform column template, a coupling beam template and a superstructure template which are free of removal are mutually connected to form a polyhedral space template system; all templates are the cross-hole prefabricated reinforced concrete templates; a longitudinal through hole and a lateral through hole, which are parallel to the surface, are arranged in the templates to form hollow hole paths in all directions; reinforcing steel bars and filling concrete are alternately inserted in the hollow hole paths to form a one-layer building unit or a single-layer building with the cast-in-place concrete shear wall structure; and multiple-layer building units are lapped and combined to form the multiple-layer building with the cast-in-place concrete shear wall structure. The shear wall structure building disclosed by the invention has the advantages of simpleness of processing, low production equipment investment, reduced construction working procedures, quickened construction speed, labor saving and the like.

Owner:ZHONGQINGDA TECH HLDG CO LTD

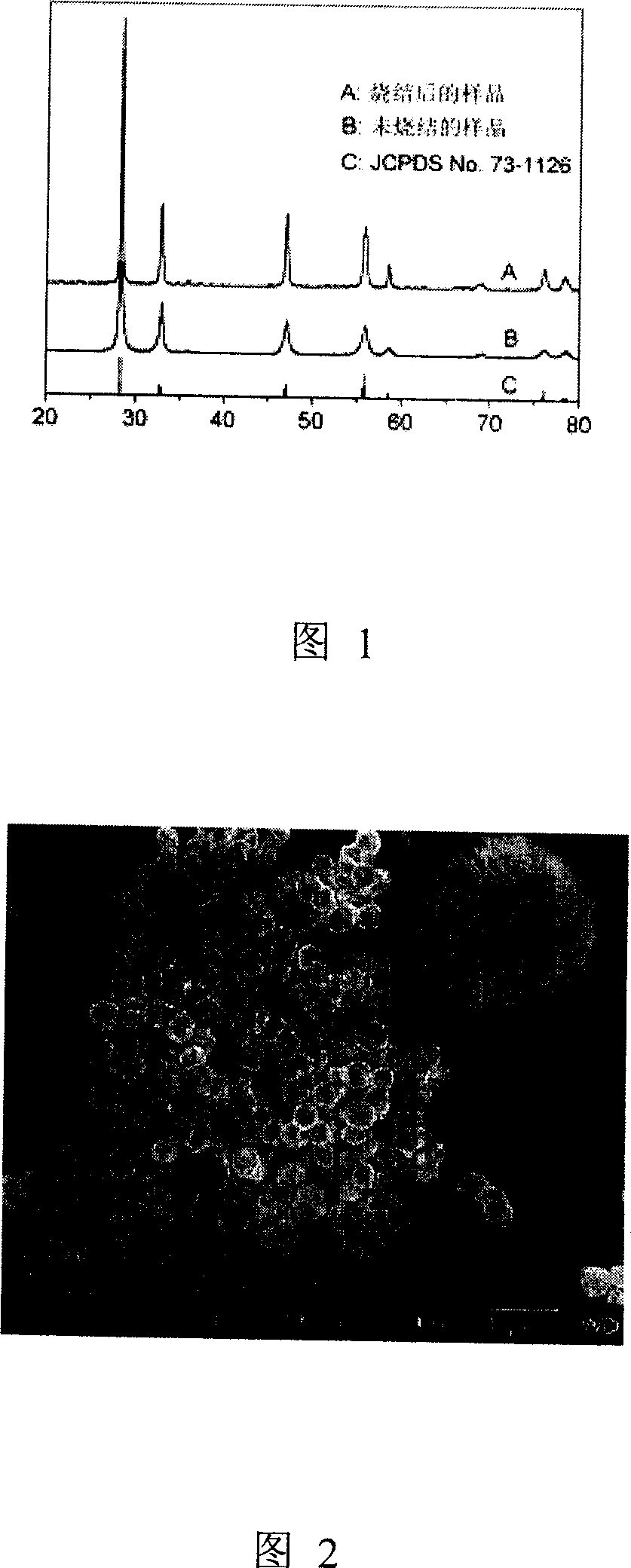

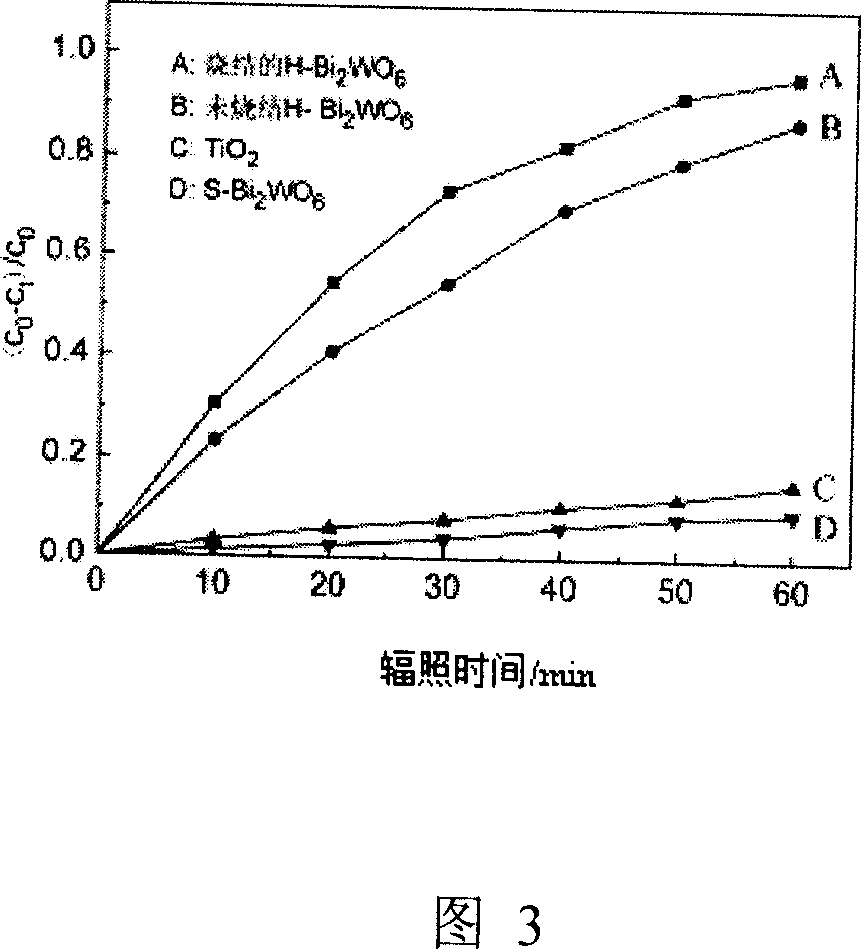

Hydrothermal method for preparing superstructure visible light responsive Bi2WO6 photcatalyst

InactiveCN1951557ALow costEasy to operateMetal/metal-oxides/metal-hydroxide catalystsLight responsiveNanometer size

The invention relates to a method for preparing Bi2WO6 optical catalyst which can respond visible light. Wherein, said method comprises that (1), preparing the forward body with Bi2WO6 structure at nanometer size that mixing the reactants or adding surface activator (P123, PVP, CTAB), mixing uniformly; (2), under 120-240Deg. C, reacting the forward body in water heating condition for 4-24h, eccentrically separating the product, washing and drying at 30-150Deg. C, to obtain the powder; then sintering the powder at 300-750Deg. C for 1-10h, to obtain the final catalyst. The invention has low cost, while the inventive catalyst high tens time degrade efficiency than TiO2 (P25).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

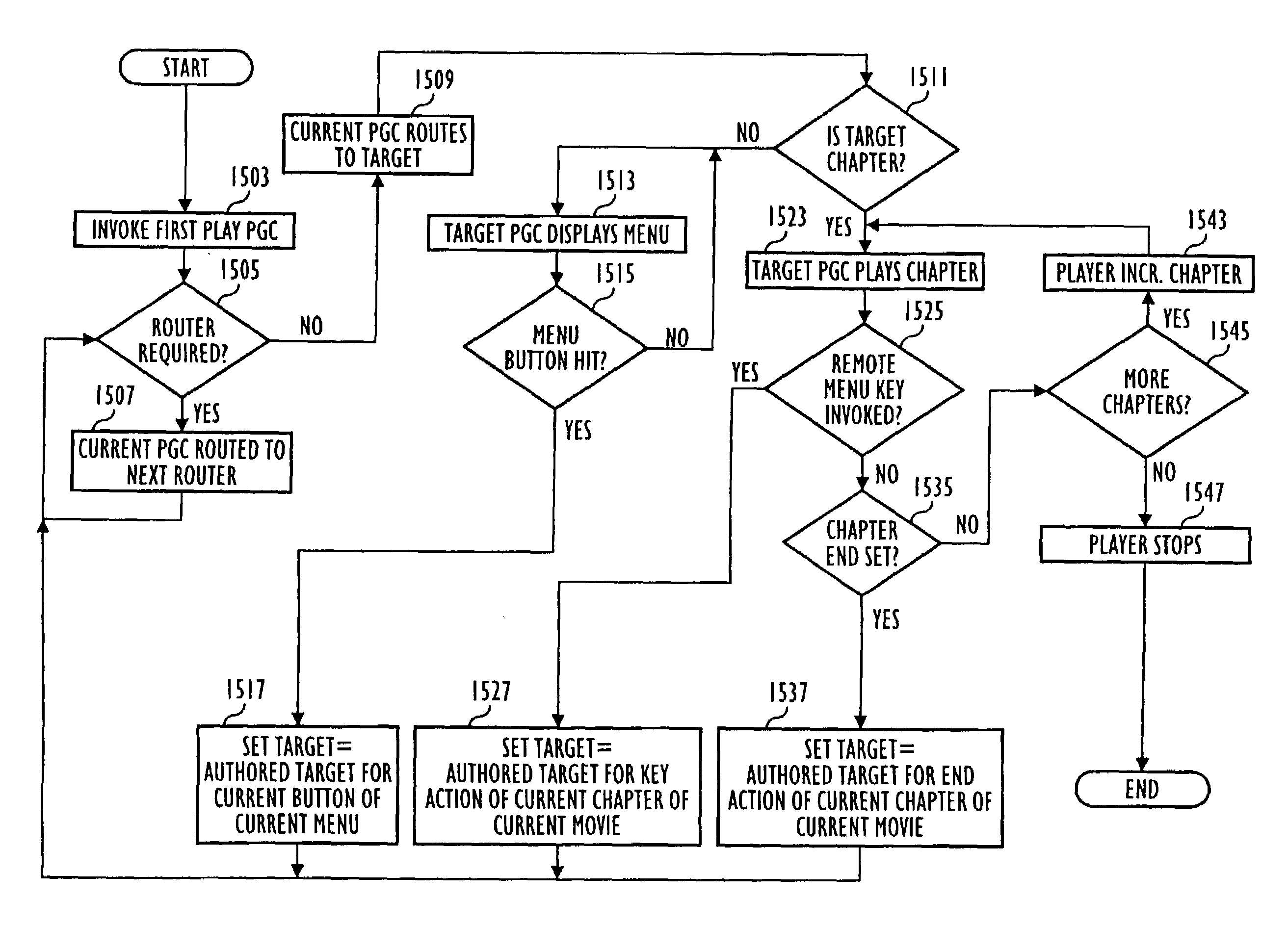

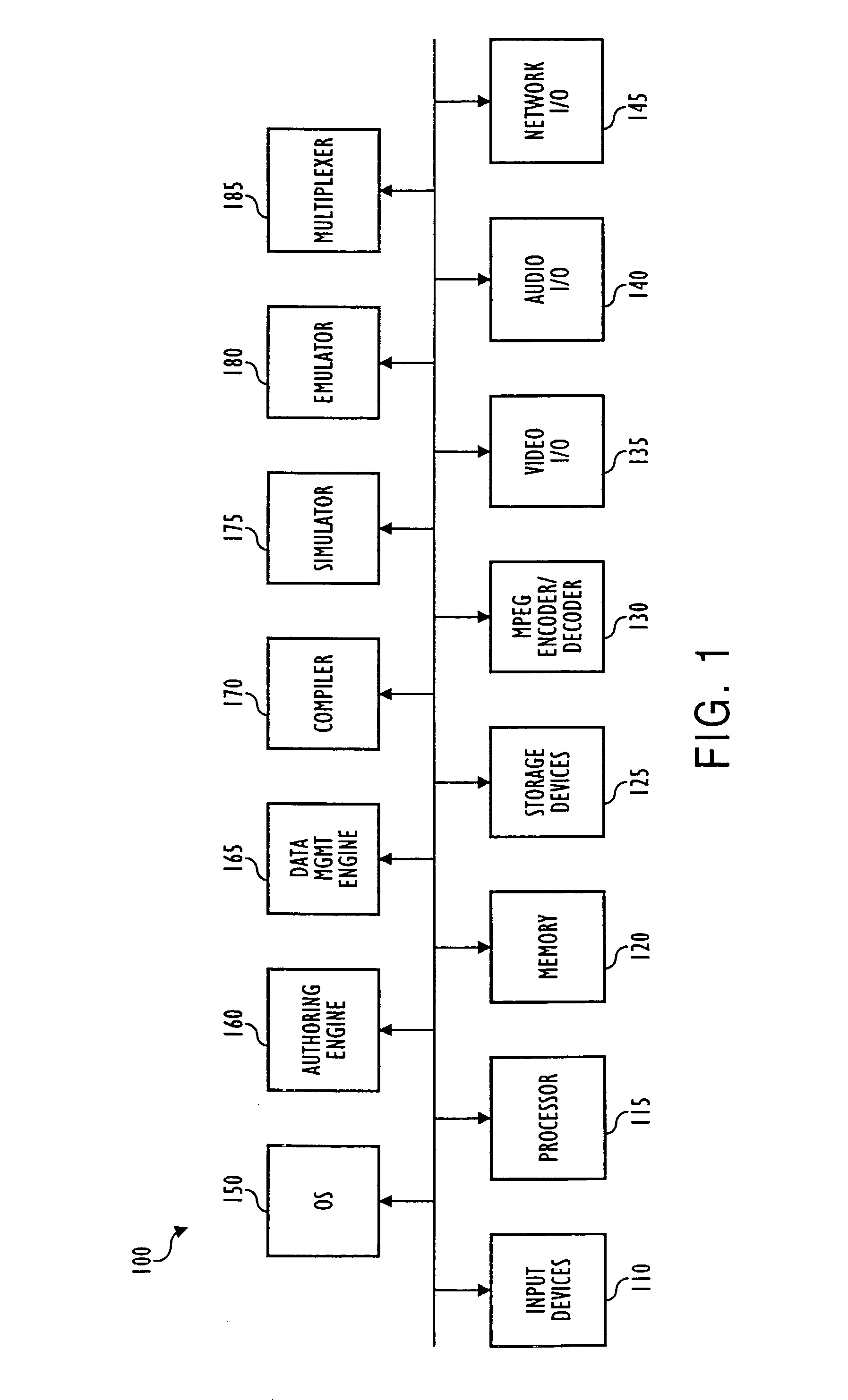

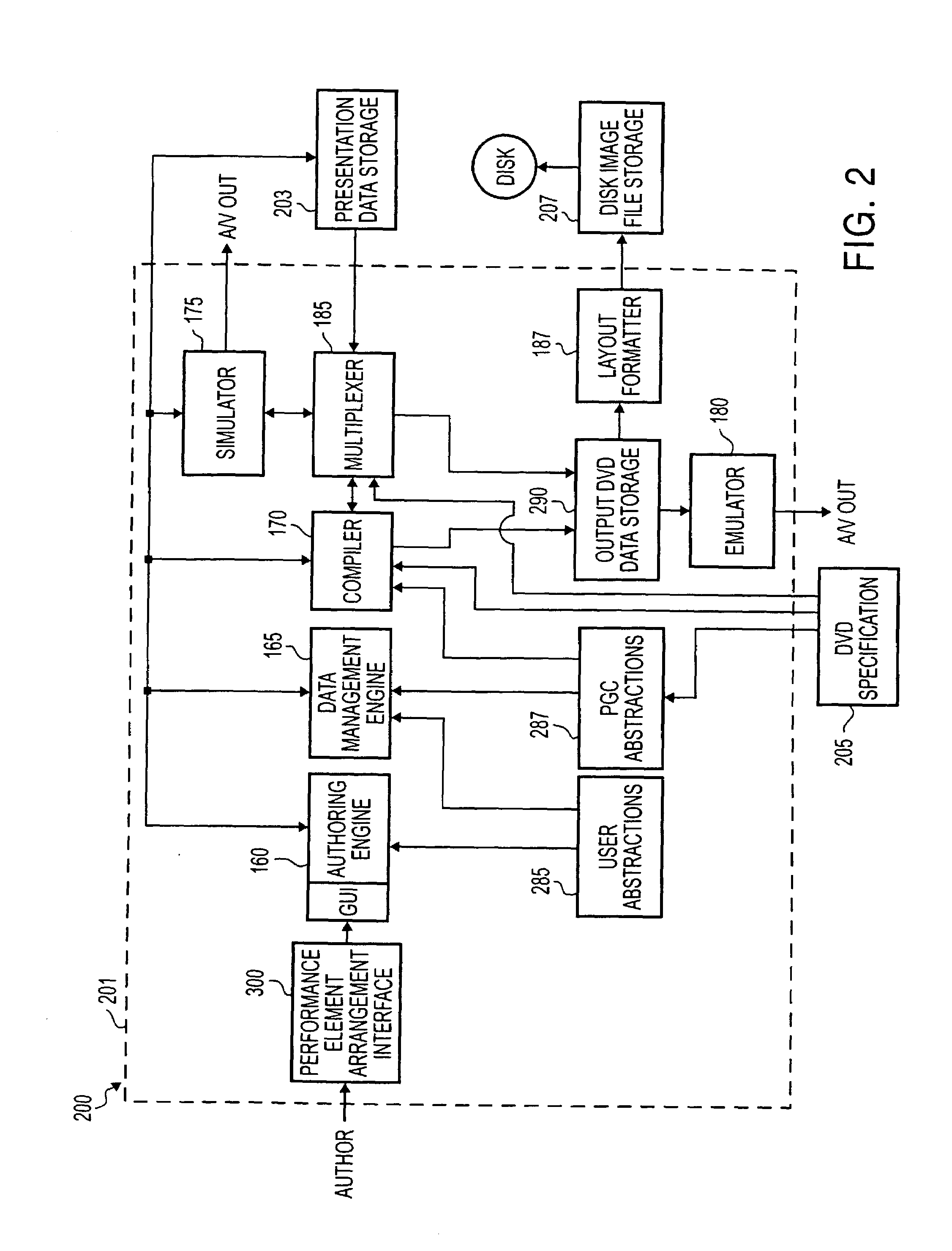

Menu authoring for automatically performing low-level DVD configuration functions

InactiveUS7200836B2Easy to createConnection specificationTelevision system detailsElectronic editing digitised analogue information signalsGraphicsMultiplexer

A DVD authoring system in a processor-based system removes an author from consideration of the DVD Specification during authoring. According to a preferred embodiment, the authoring system provides an authoring engine having an interactive graphical authoring interface, a data management engine, an emulator, a compiler, a multiplexer and a simulator. Using summary authoring data, the compiler builds a skeleton-form PGC layout structure comprising control PGC abstractions and router PGC abstractions. The compiler then resolves the PGC abstractions according to source-target connections. During playback on a DVD player, the PGC abstractions form elements in a connection-switching abstraction superstructure. Accordingly, in response to DVD-consumer and other control events, a source PGC preferably determines target PGC information and then transfers control, via virtual connections through necessary router PGC abstractions, to a target PGC abstraction. The target PGC abstraction then correspondingly initiates playback of a movie chapter or displays a menu.

Owner:APPLE INC

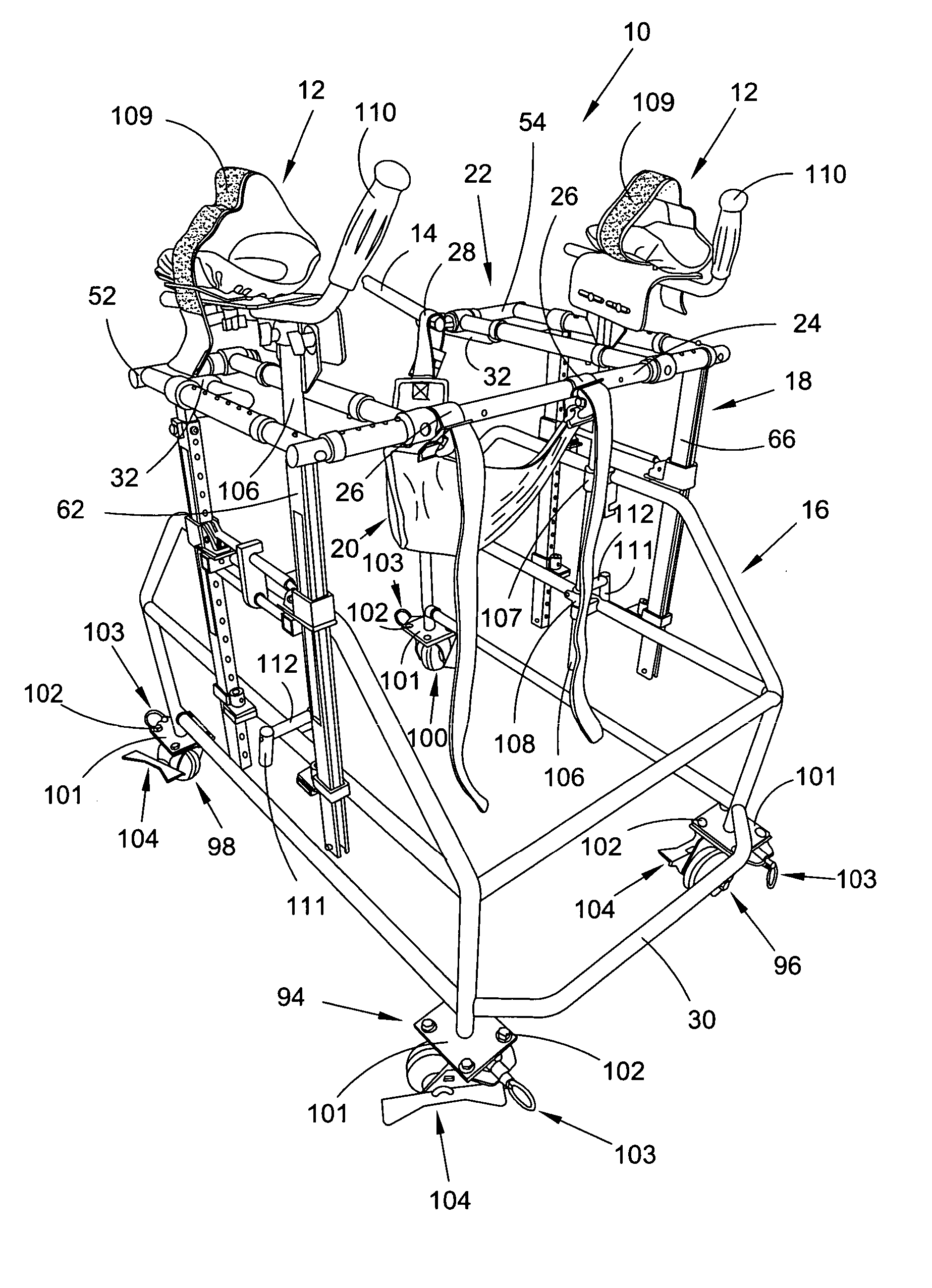

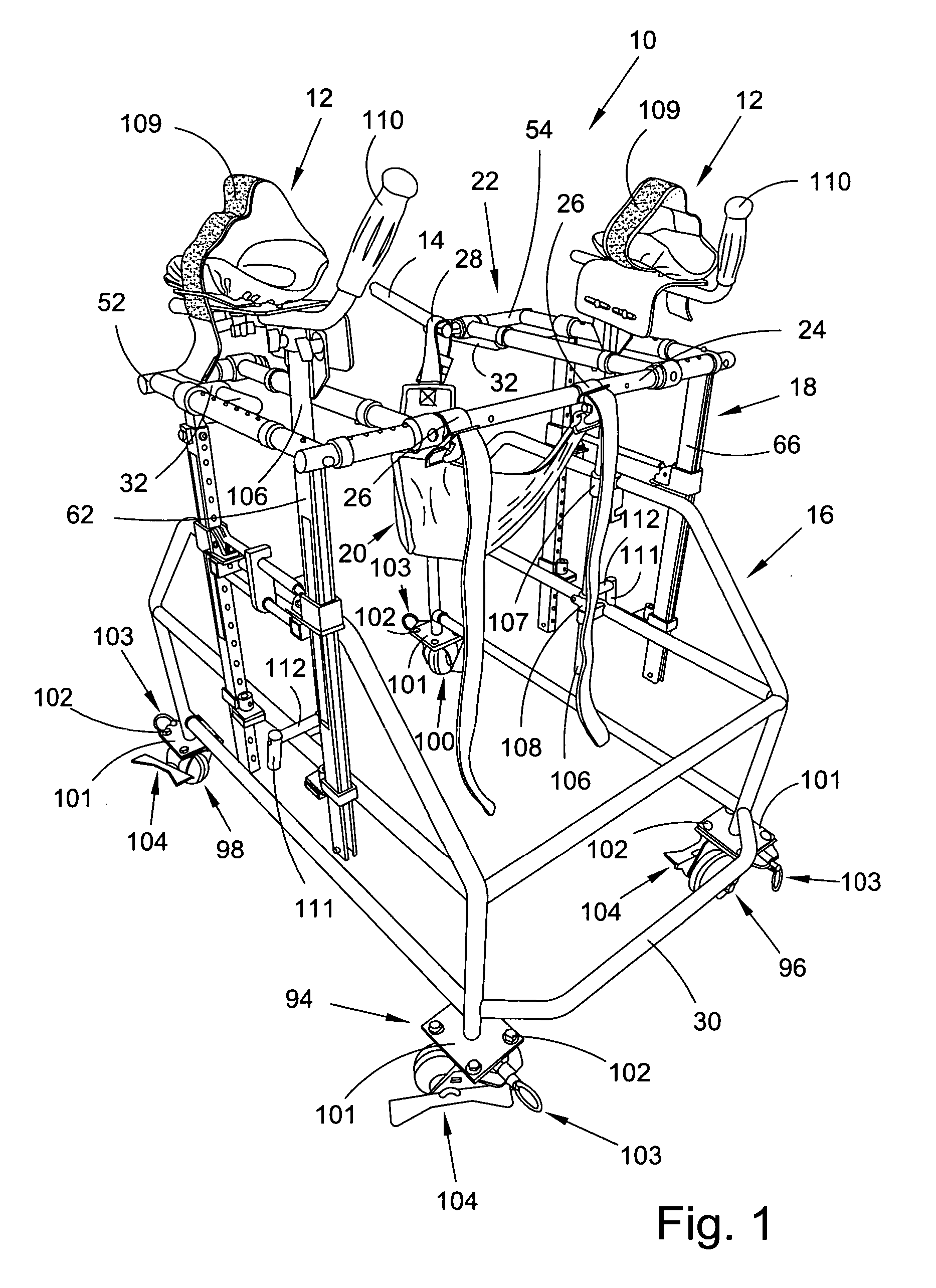

Height and width adjustable saddle sling seat walker with controllable directional tracking and optional arm supports

The invention relates to a walker having a main supporting frame, a superstructure frame and a body support means. The superstructure frame is operatively arranged for vertical adjustment relative to the main supporting frame and includes an adjustable interior opening for accommodating a user and an entrance gate operatively arranged to provide access to the adjustable interior opening. The body support means is secured to the superstructure frame and operatively arranged to support the user. Furthermore, the walker may include four wheels, each of which may include a directional locking apparatus and / or braking system, and the walker may include at least one arm support operatively arranged for supporting the user. The walker may also include at least one handle operatively arranged for transmission of the walker.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

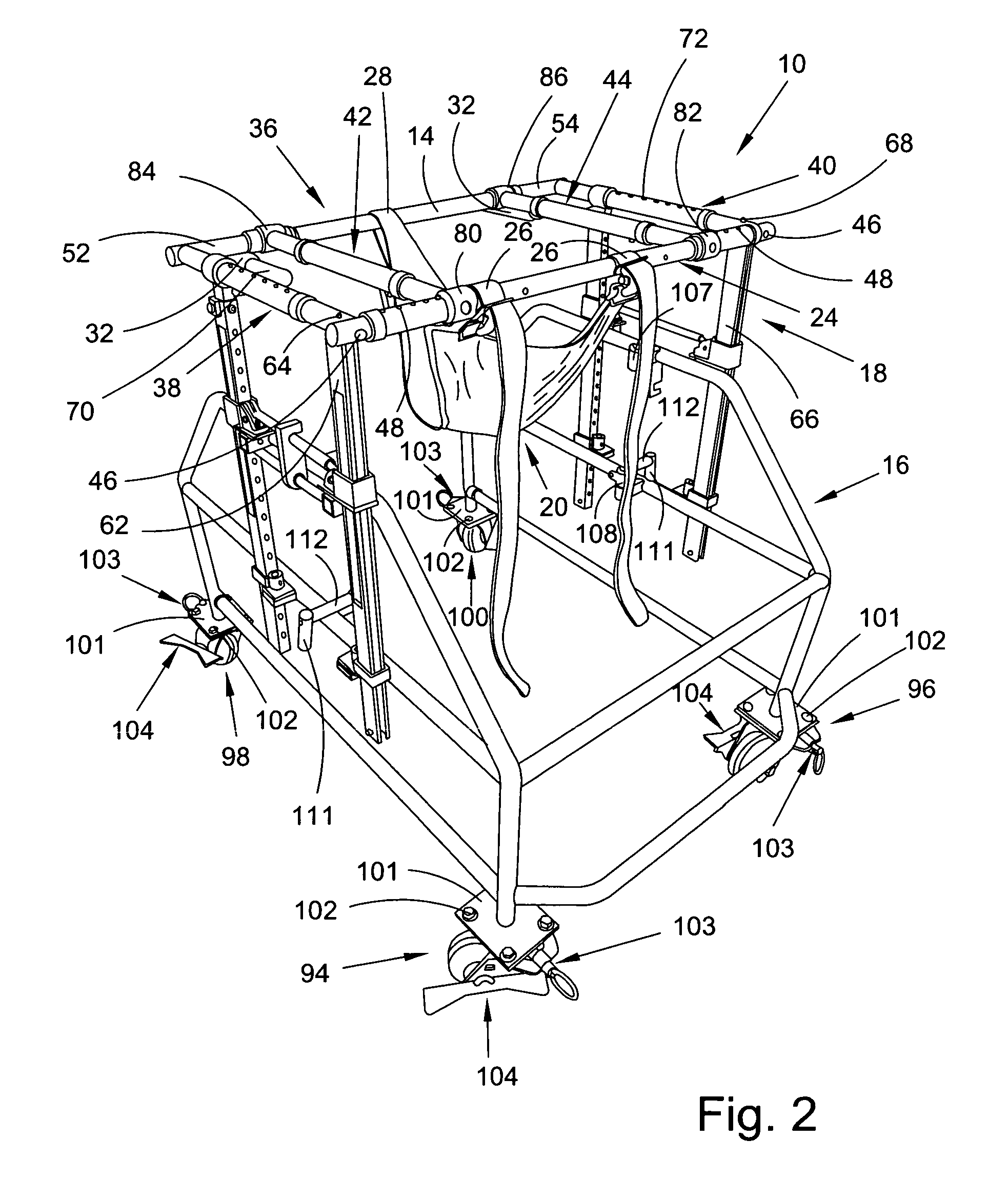

Height adjustable table

A height adjustable table includes a frame that has a pair of spaced apart, generally vertical frame sections, each supported upon a foot, a transverse, generally horizontal section that connects at its end portions to the vertical sections and a pair of lifts that are supported by the vertical frame sections to elevate between extended, higher elevational and retracted, lower elevational positions. The lifts support a table top with a work surface. The frame can be in the form of a universal base that accepts a number of different mechanism including, for example, a counterbalance mechanism, a motor drive mechanism, and a manually operable mechanism. These mechanisms can be selected by a user, depending upon the type of table that is to be manufactured. A plurality of panels are provided that cover the frame. These panels can also be selected by an end user to define an ornamental look and / or a selected color pattern. A superstructure extends from the frame upwardly to support a storage unit (e.g., cabinet, shelve, receptacle) at a position above the work surface.

Owner:BAKER MFG

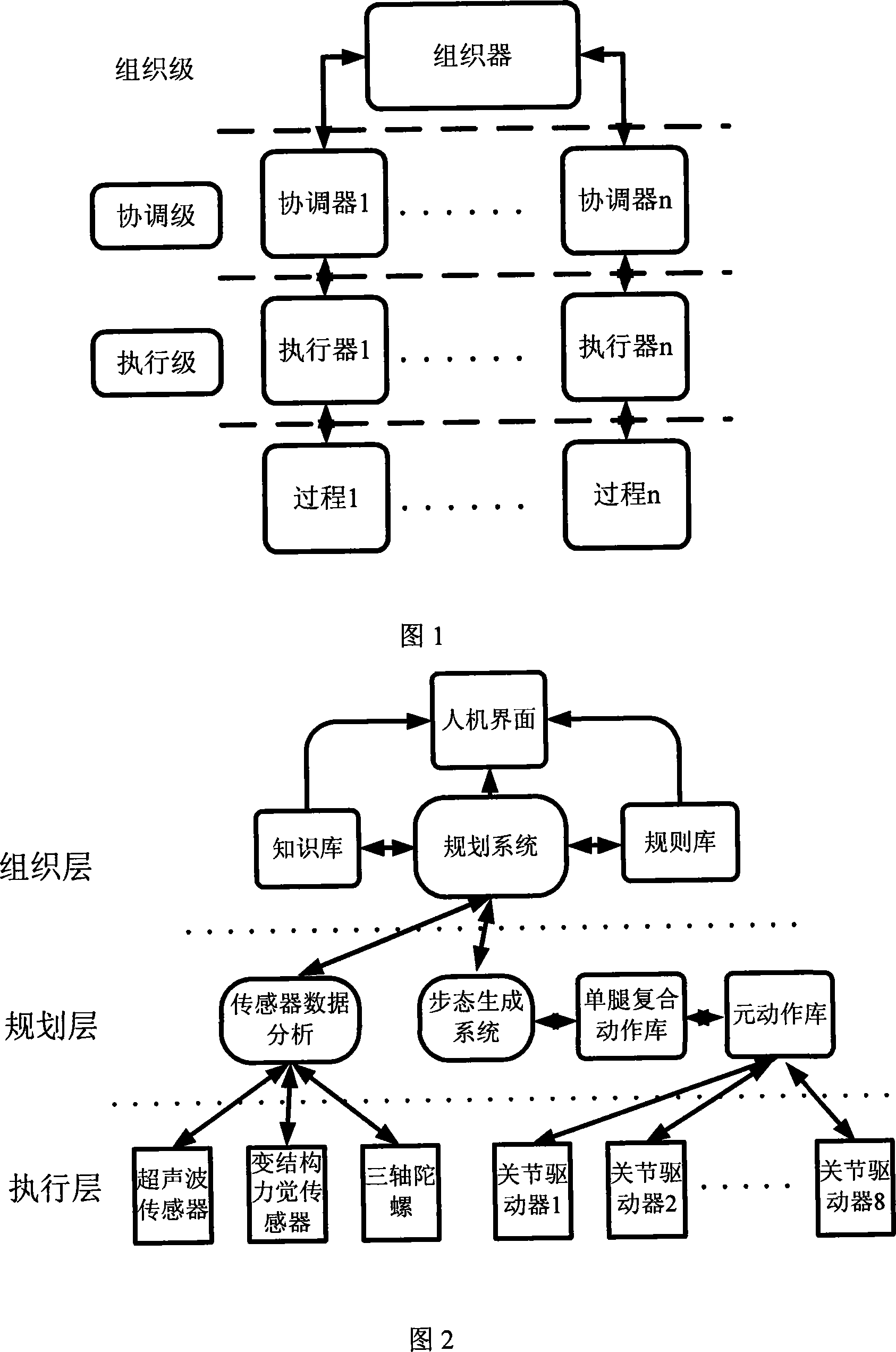

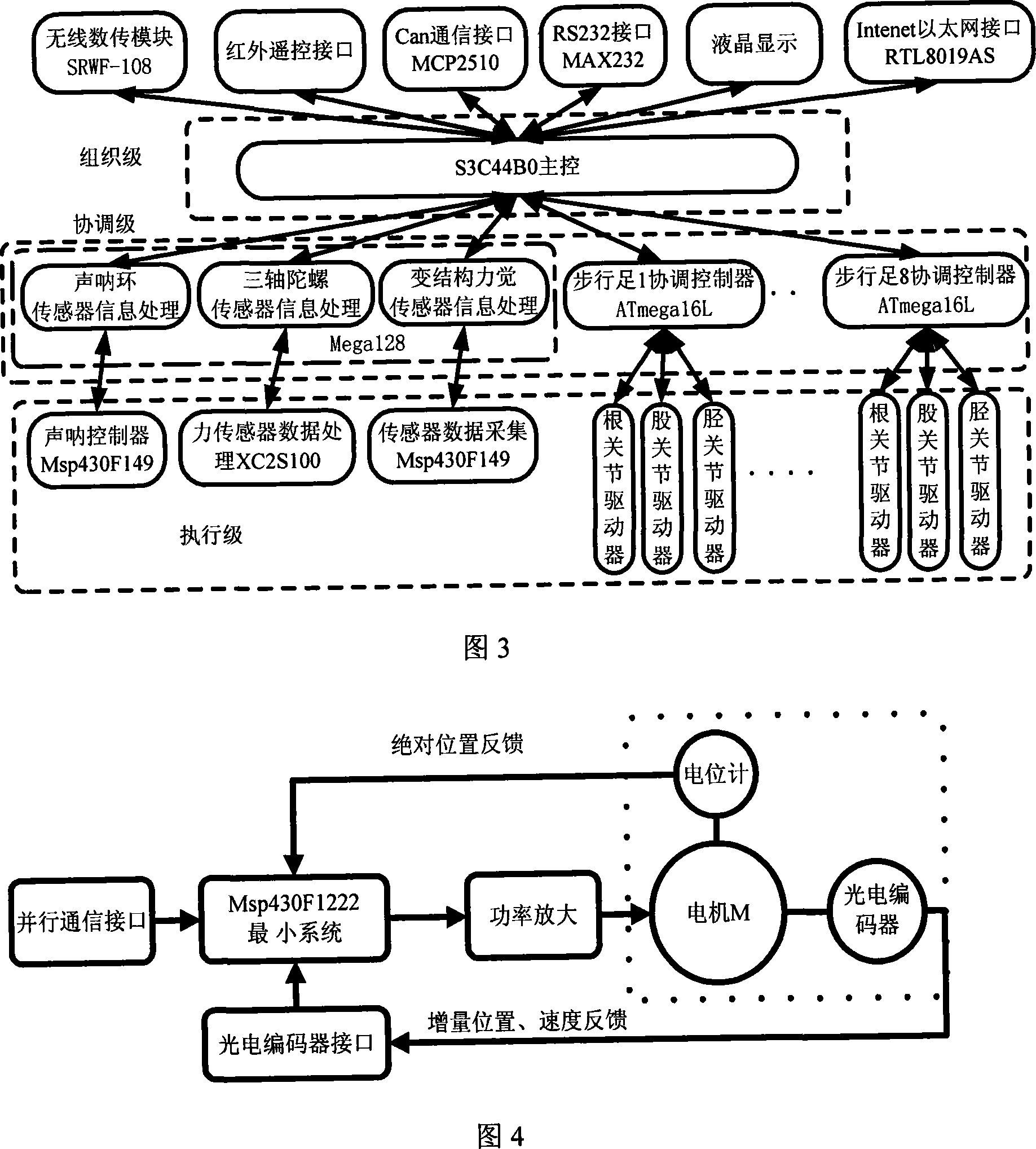

Amphibious mechanical crab step control device and control method

InactiveCN101216711AClear division of laborFast operationElectric controllersTotal factory controlControl signalNetwork Communication Protocols

The invention provides a hierarchical control device for an amphibian machinery crab and a control method thereof. The device comprises a superstructure-level control part composed of a B3C44B0-cored ARM system, a coordination-level control part composed of an AVR single chip computer ATmega128L, eight walking-leg drive modules and an execution-level control part which is composed of a multi-sensor signal collecting module; wherein control signals are input to the superstructure-level control part; the coordination-level control part is connected between the superstructure-level control part and the execution-level control part; and the execution-level control part communicates with joint drive units through bus communication protocols. The invention divides the system into superstructure level, monitoring coordination level and execution level based on the design principle of hierarchical distribution, each dispersed controller not only can work independently but also can communicate and exchange information with a higher level controller or a peer level controller through communication circuits. The hierarchical structure has the advantages of a centralized structure and a dispersed structure, thereby overall and partial control performances are high, and the operation is reliable.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com