Patents

Literature

52results about How to "Flatness is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

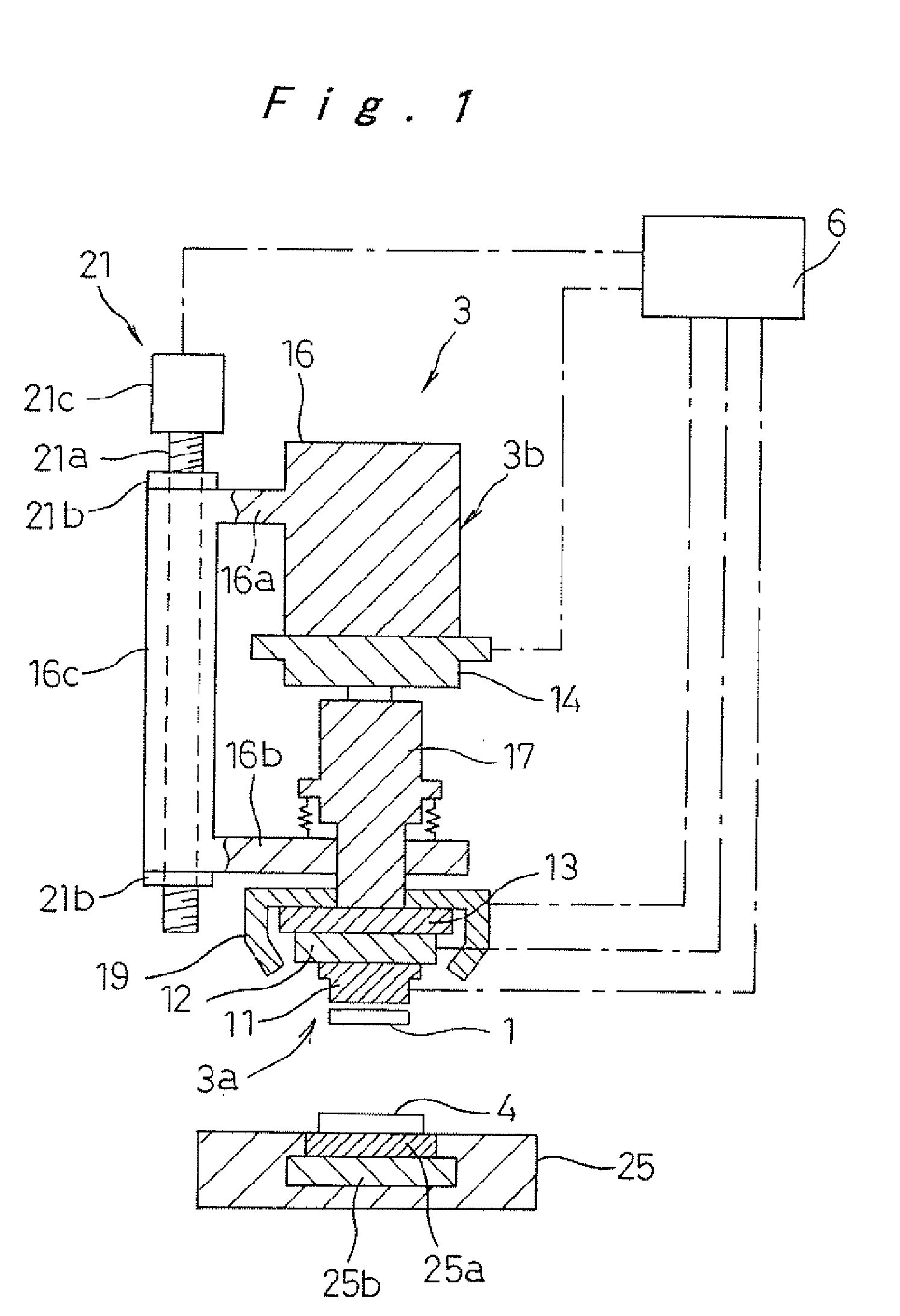

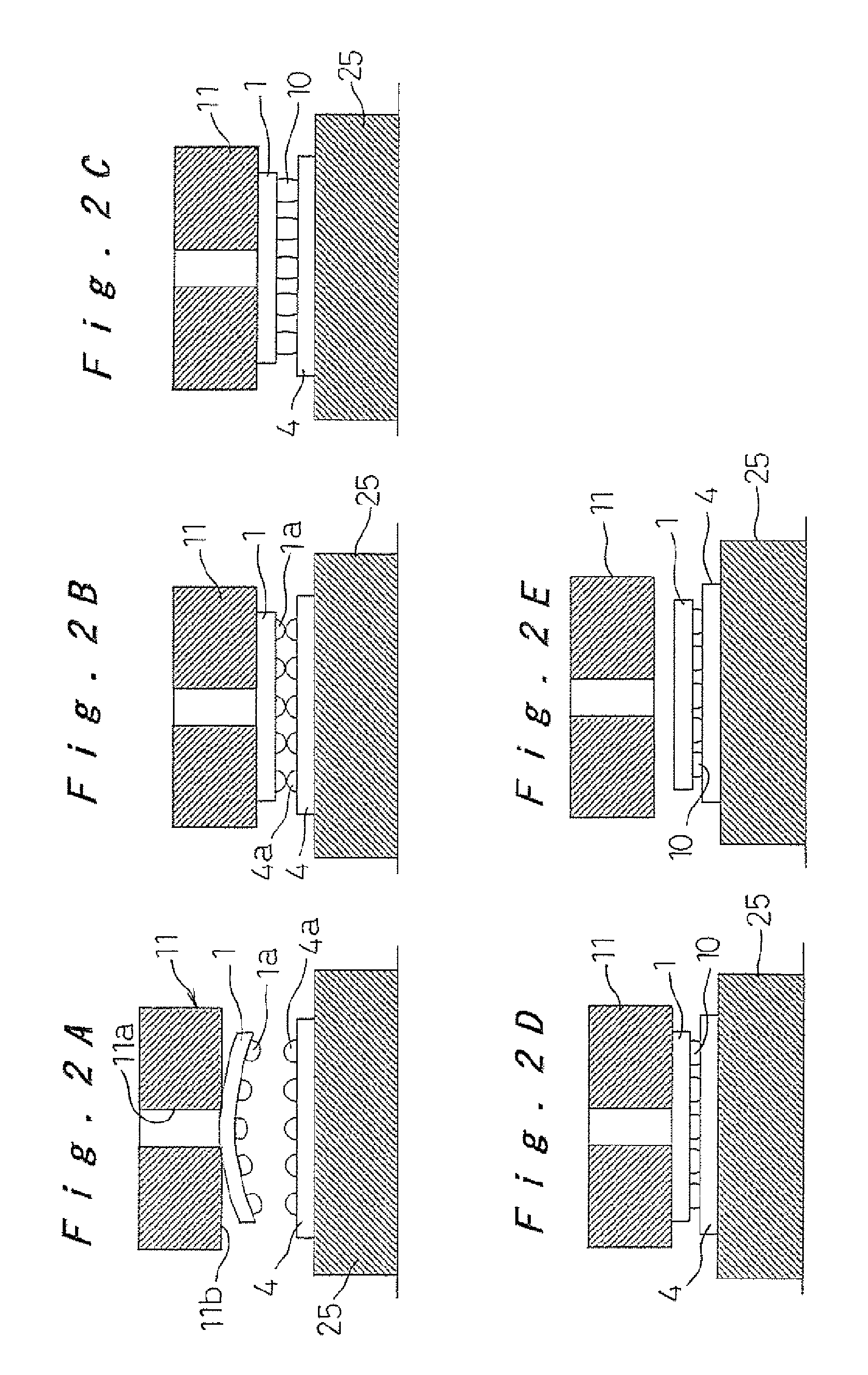

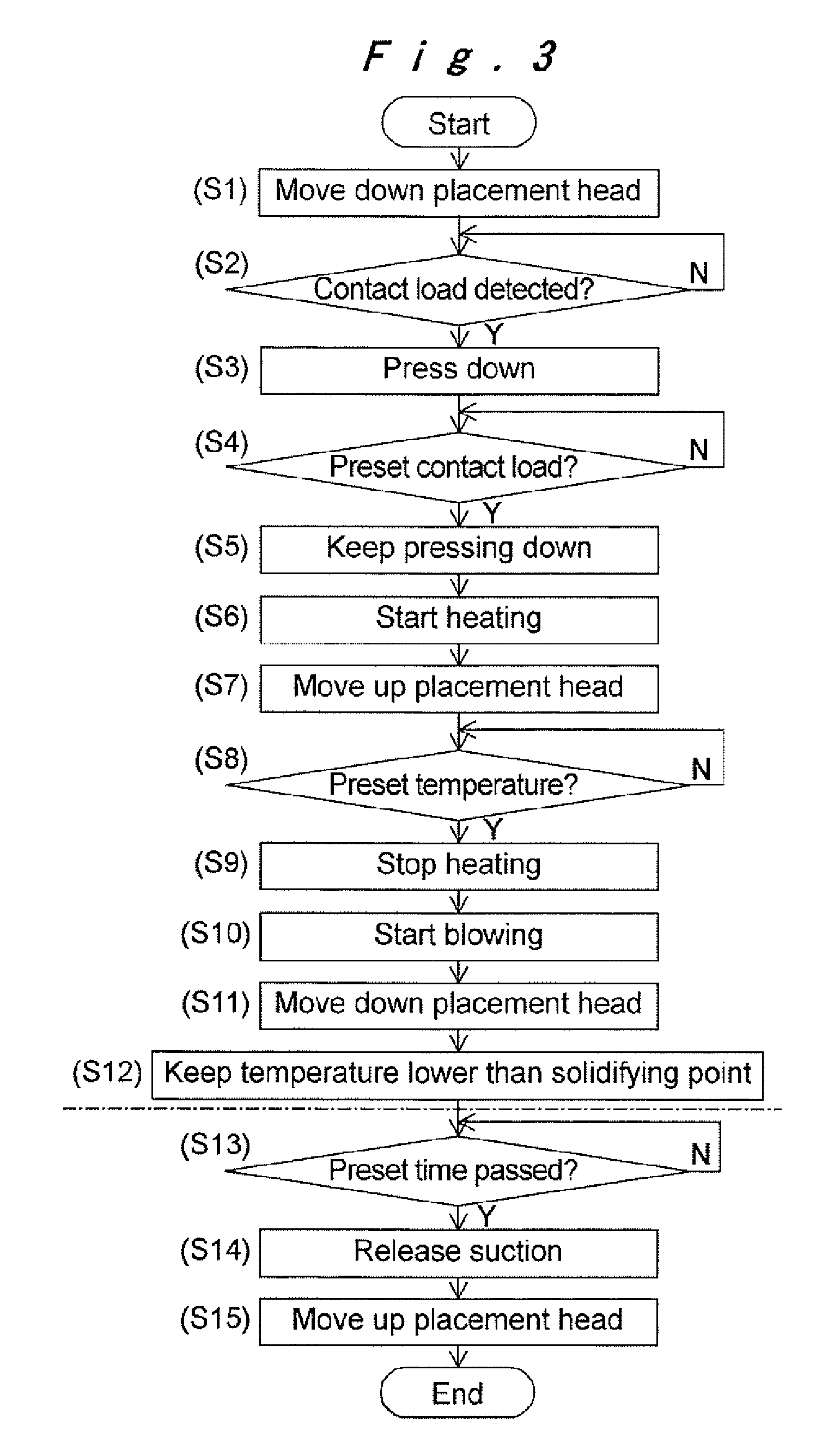

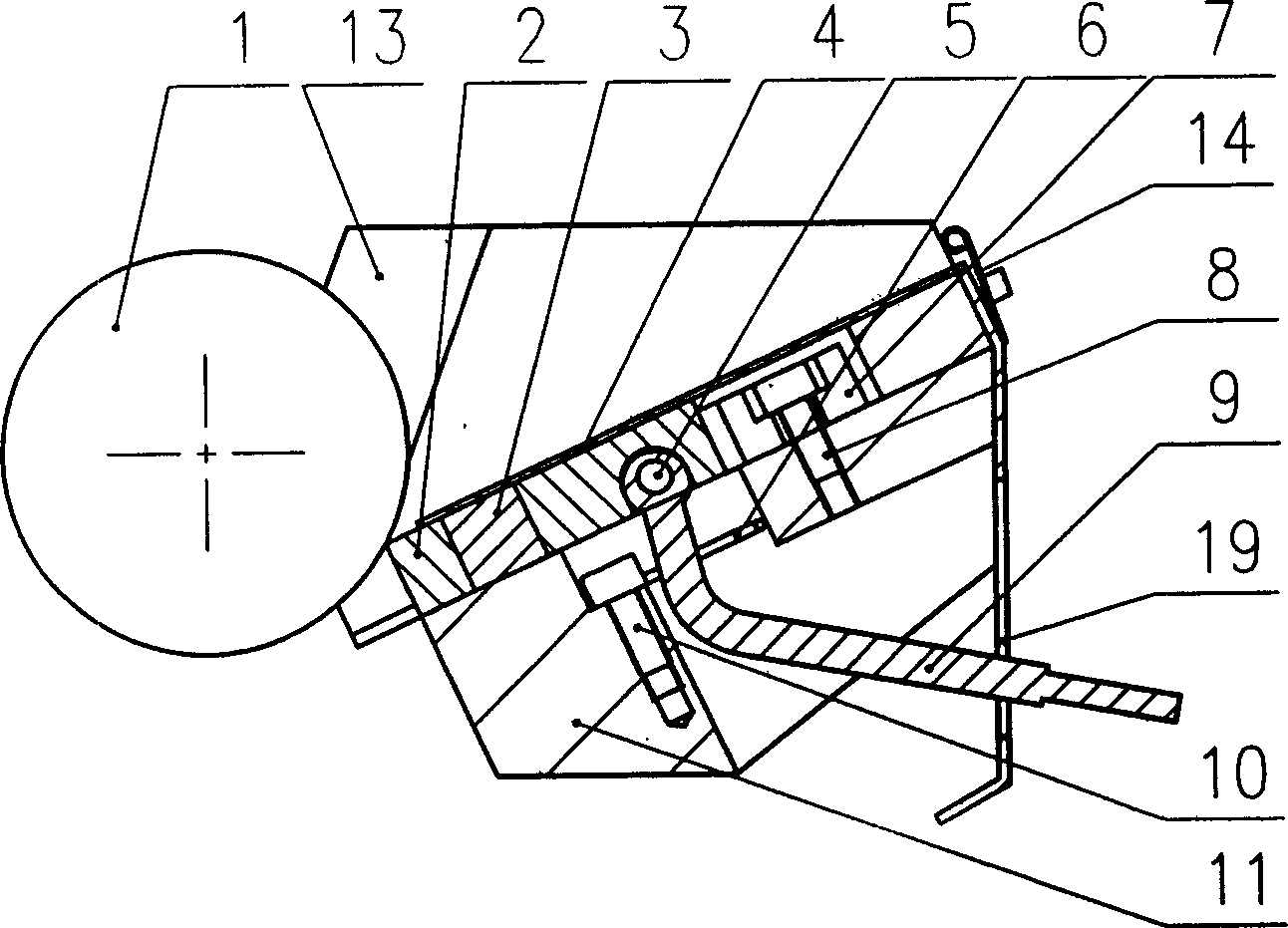

Component mounting method and component mounting apparatus

InactiveUS20070181644A1Avoid bond failureFlatness is easy to guaranteeCooking-vessel materialsPrinted circuit assemblingSuction stressEngineering

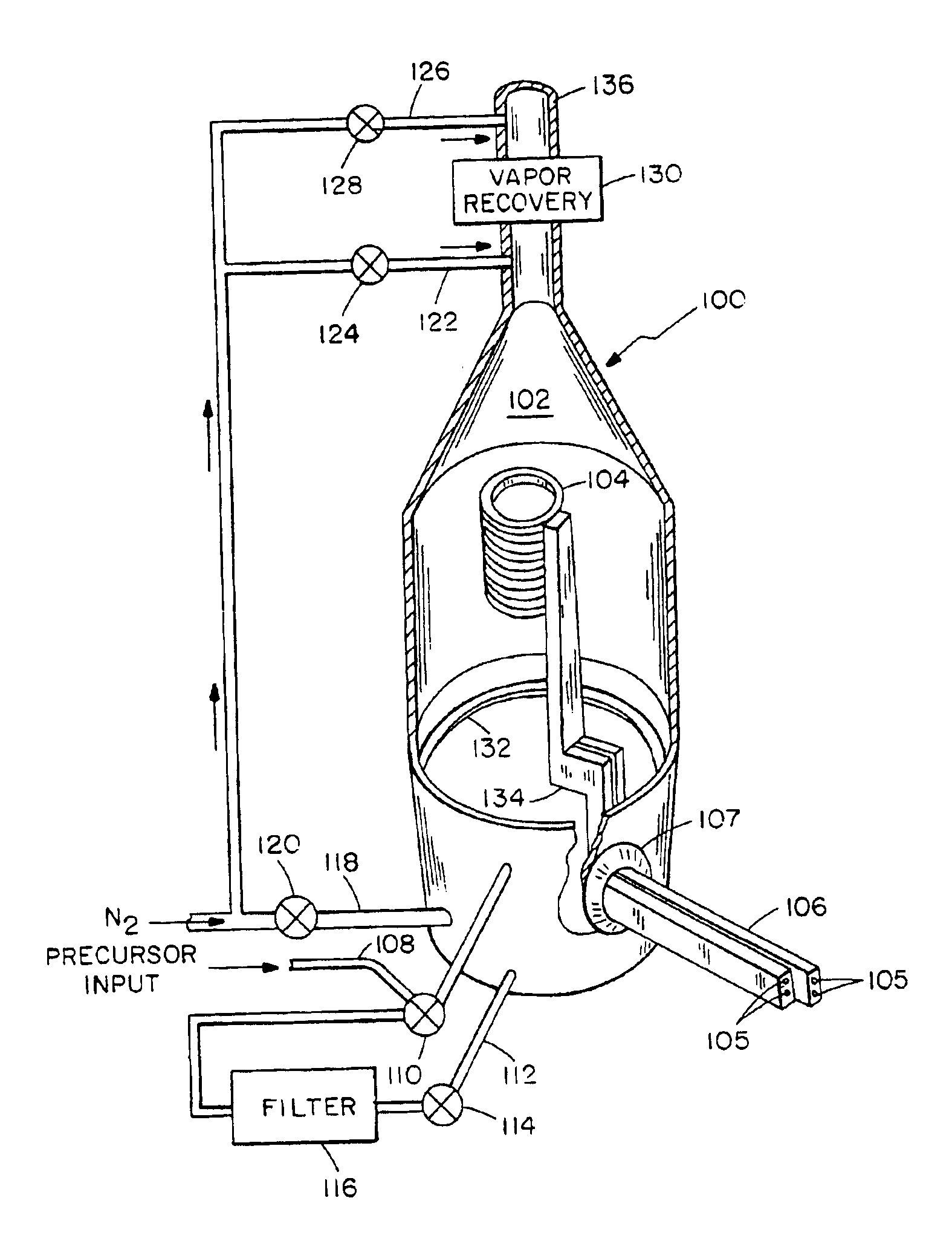

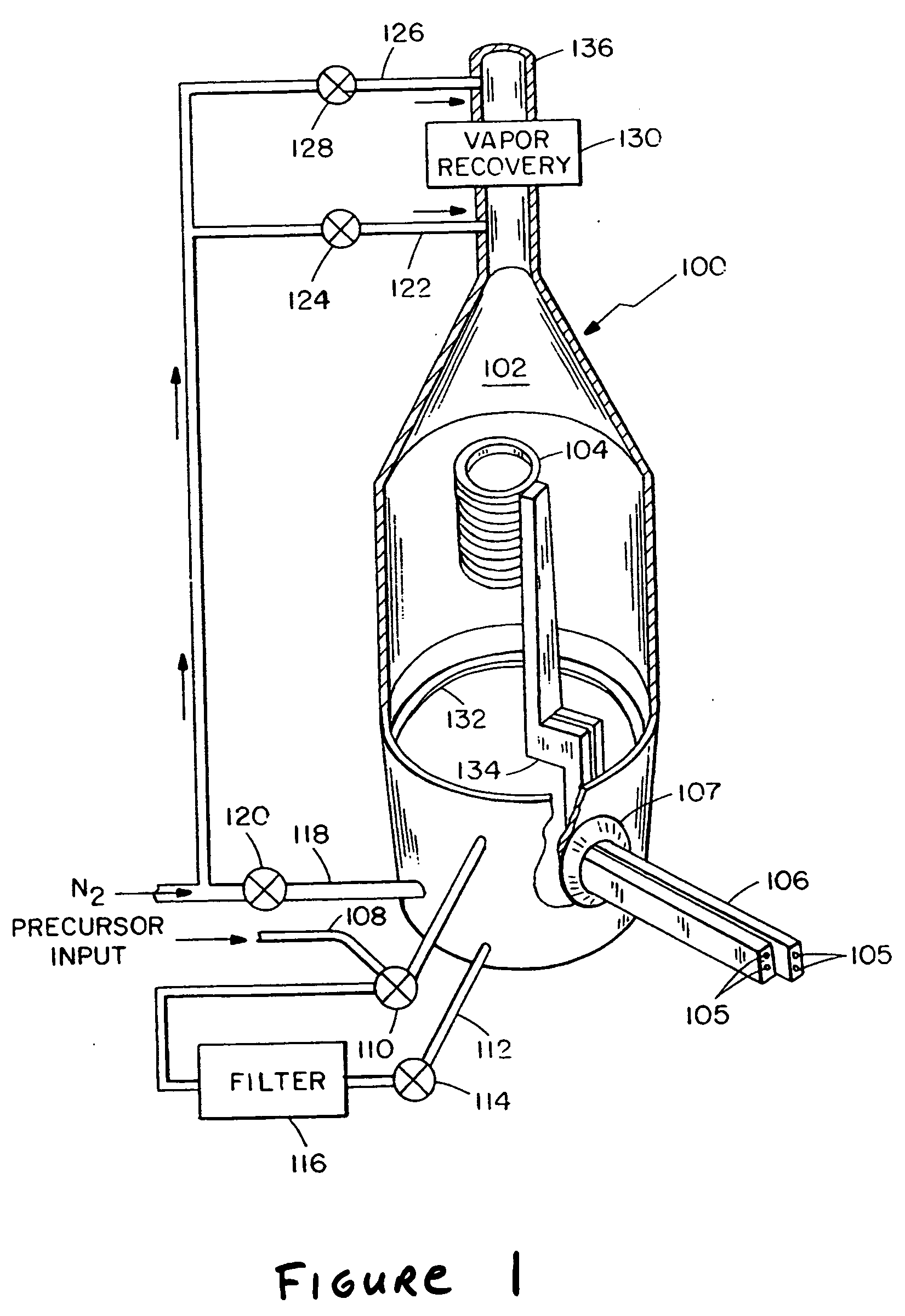

A method and an apparatus for mounting electronic components that enables precise mounting of electronic components, such as deformation-prone thin IC chips or fine-pitch and high-pin-count IC chips, on a substrate. Thin IC chips, which conventionally tend to lose flatness because of warping that occurs during production or deformation that occurs when picked up with a suction nozzle, are pressed against a substrate (4) with a preset load using a suction nozzle with a flat suction surface (11b) so as to correct deformation; the suction nozzle (11) is controlled to move up to make up for a decrease in the distance between the oppositely spaced IC chip and the substrate (4) that is caused by thermal expansion due to the heating for melting solder bumps (1a) on the electrodes; and the suction nozzle (11) is controlled to move down to mitigate the effect of a pulling-apart force applied to the molten parts as the thermally expanded parts cool down and contract.

Owner:PANASONIC CORP

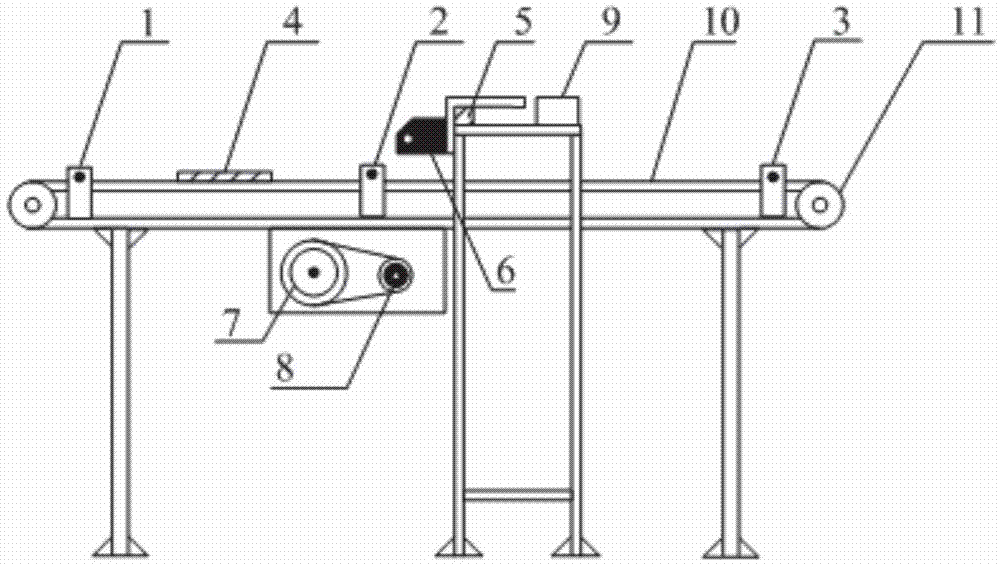

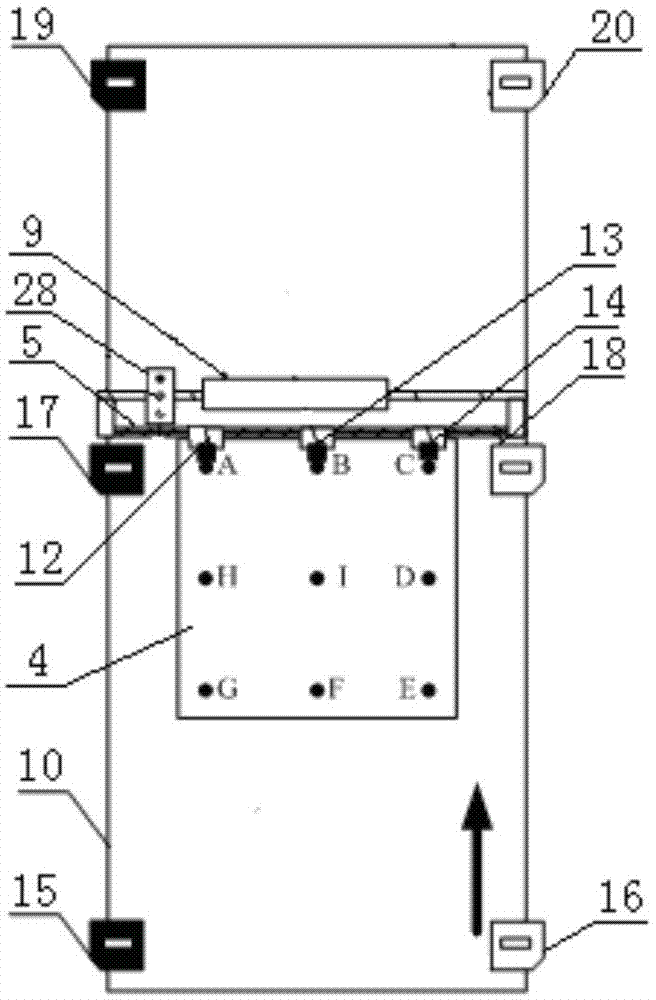

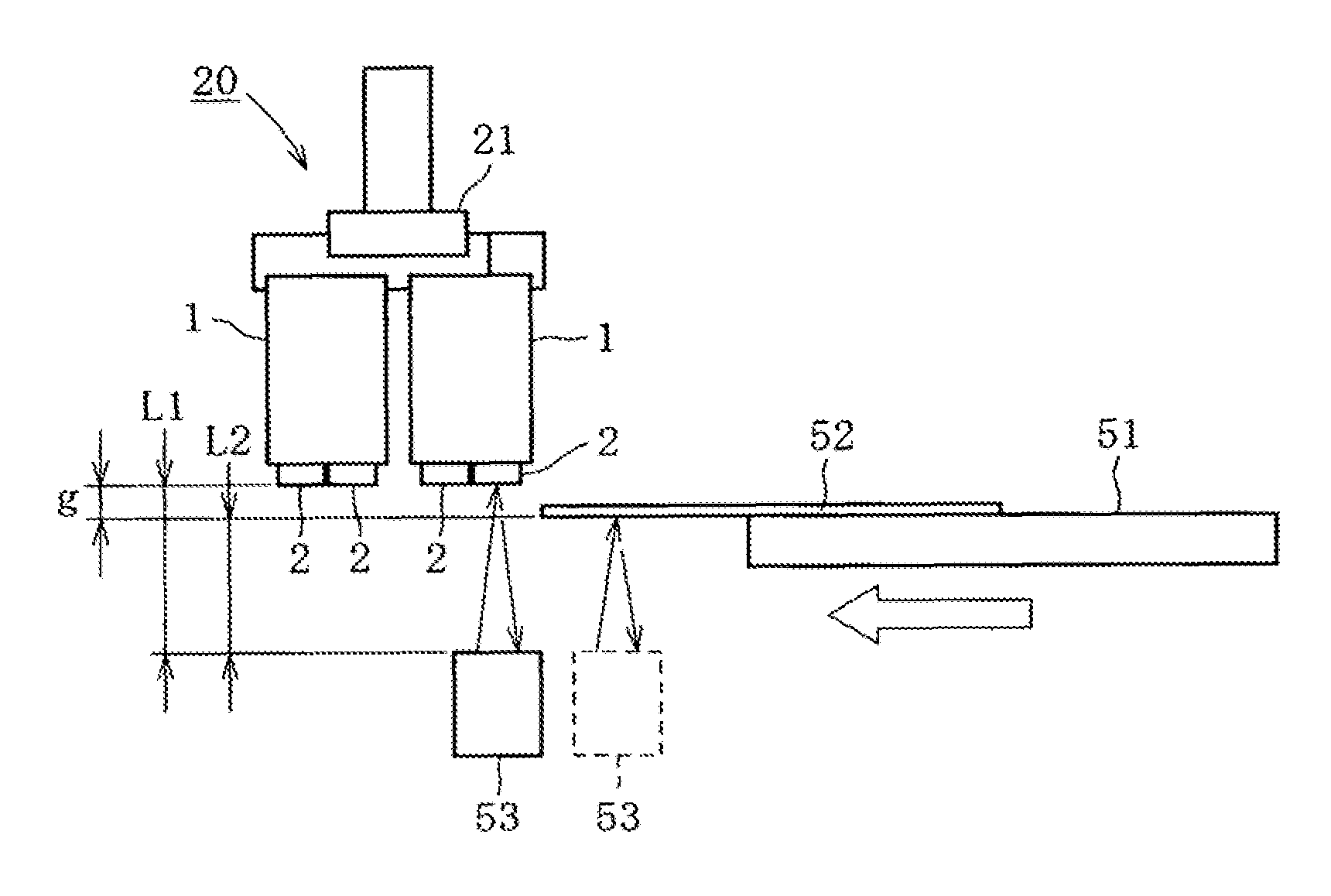

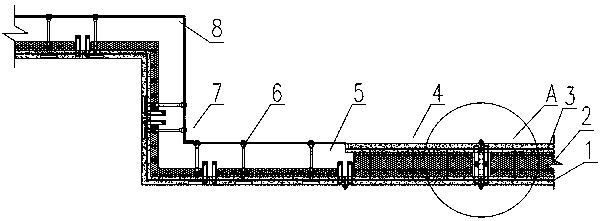

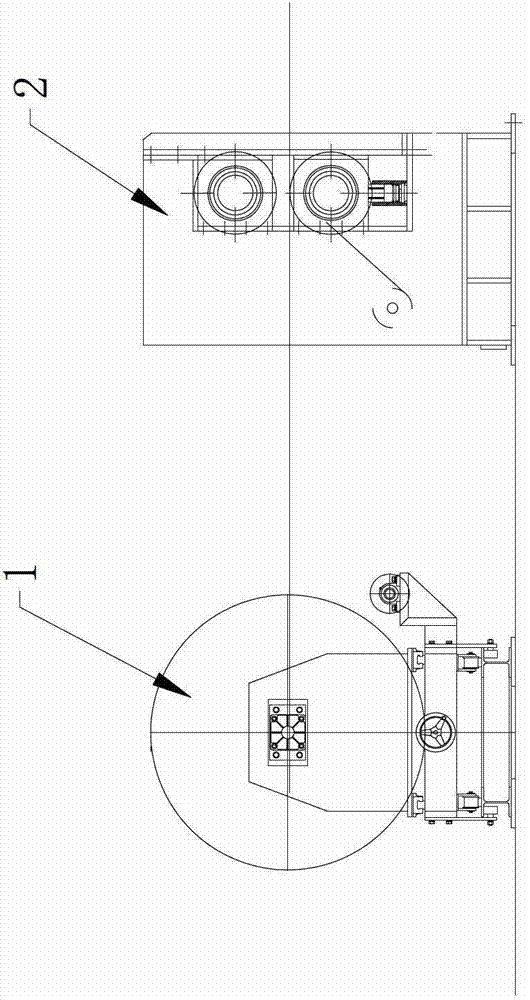

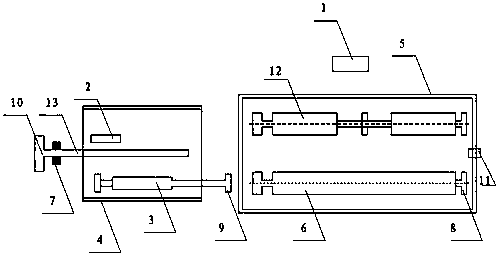

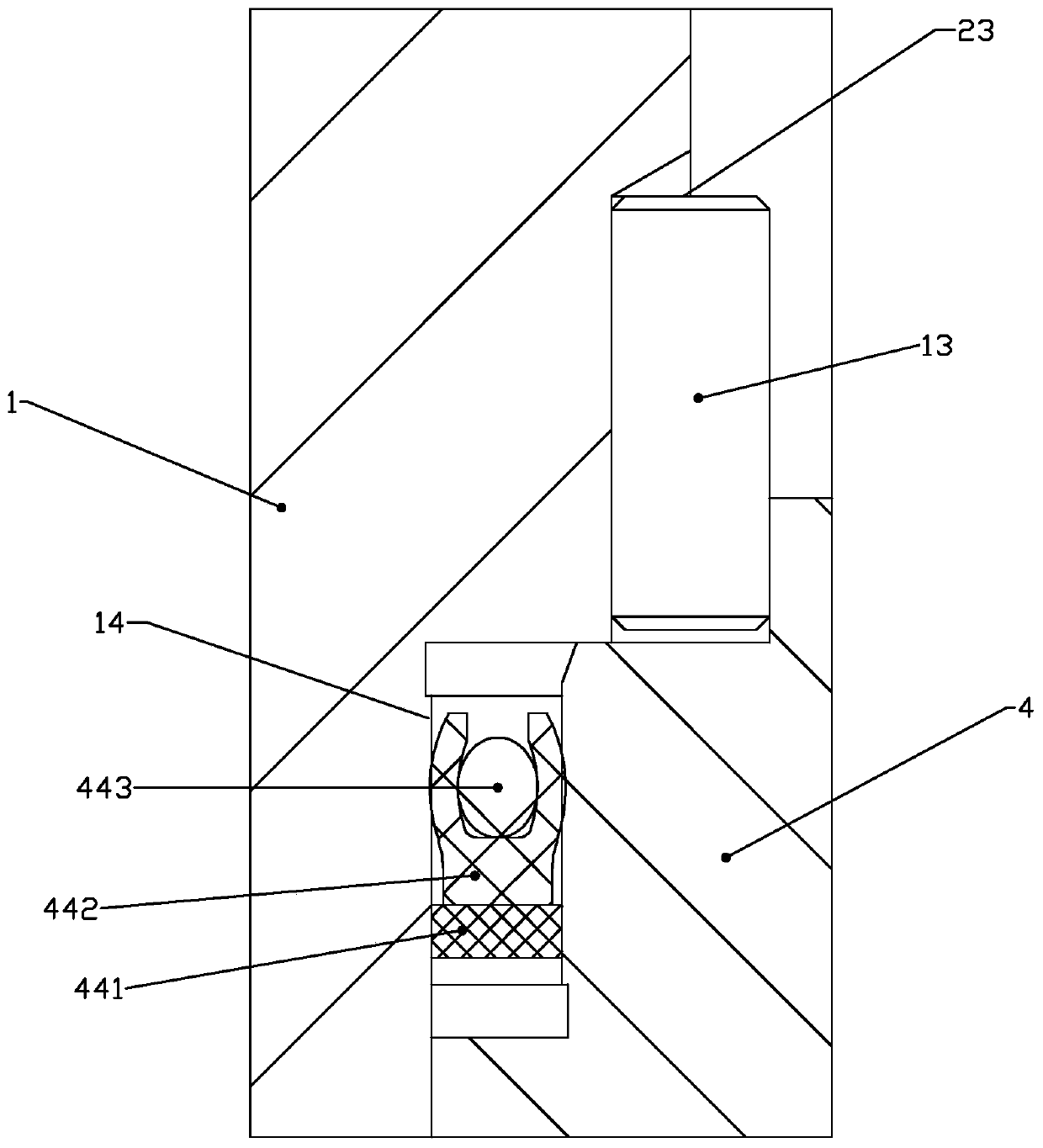

Sliding type ceramic tile surface flatness detection device and method thereof

InactiveCN104776817AFlatness is easy to guaranteeEasy to adjustUsing optical meansMetallurgyData treatment

The invention belongs to the technical field of ceramic tile surface flatness laser detection, and in particular discloses a sliding type ceramic tile surface flatness detection device and a method thereof. The sliding type ceramic tile surface flatness detection device comprises a laser emitting module, a sensing photoelectric triggering module, a ceramic tile transmission module and a data processing module, wherein the ceramic tile transmission module is used for conveying a tested ceramic tile; the laser emitting module is arranged above the ceramic tile transmission module and is connected with the data processing module; the laser emitting module is used for generating laser beams and used for acquiring the information of distance between the surface of the tested ceramic tile and the laser emitting module; the data processing module is used for processing and displaying the acquired surface characteristic point data of the tested ceramic tile and used for making a sound-light alarm; the sensing photoelectric triggering module is arranged on a side surface of the ceramic tile transmission module and is used for synchronizing the time that the laser emitting module emits the laser. The sliding type ceramic tile surface flatness detection device is convenient to adjust, convenient and rapid to mount and repair and stable and reliable to operate, and simple, rapid and precise detection on the flatness of ceramic tiles of different sizes and specifications can be achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

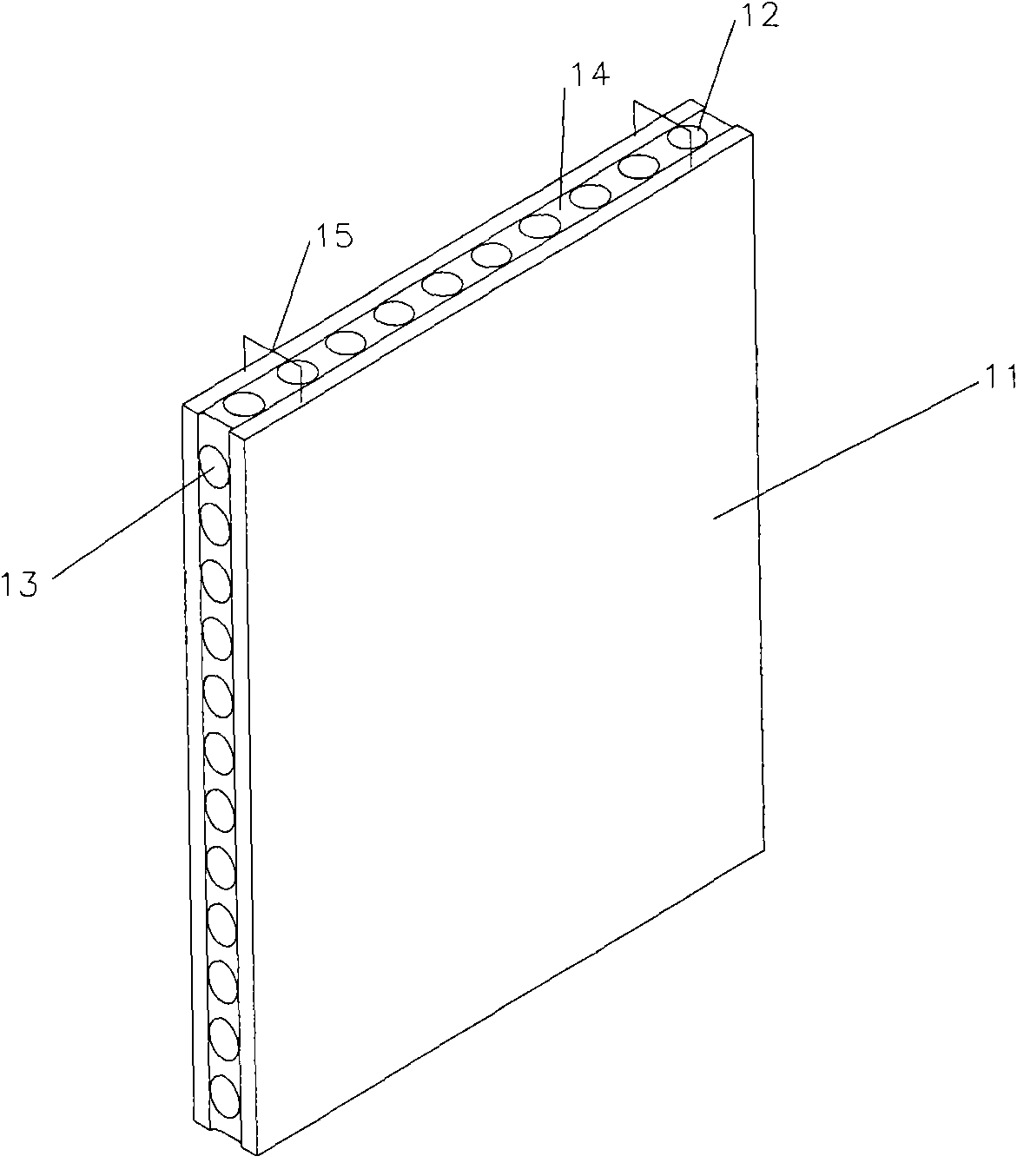

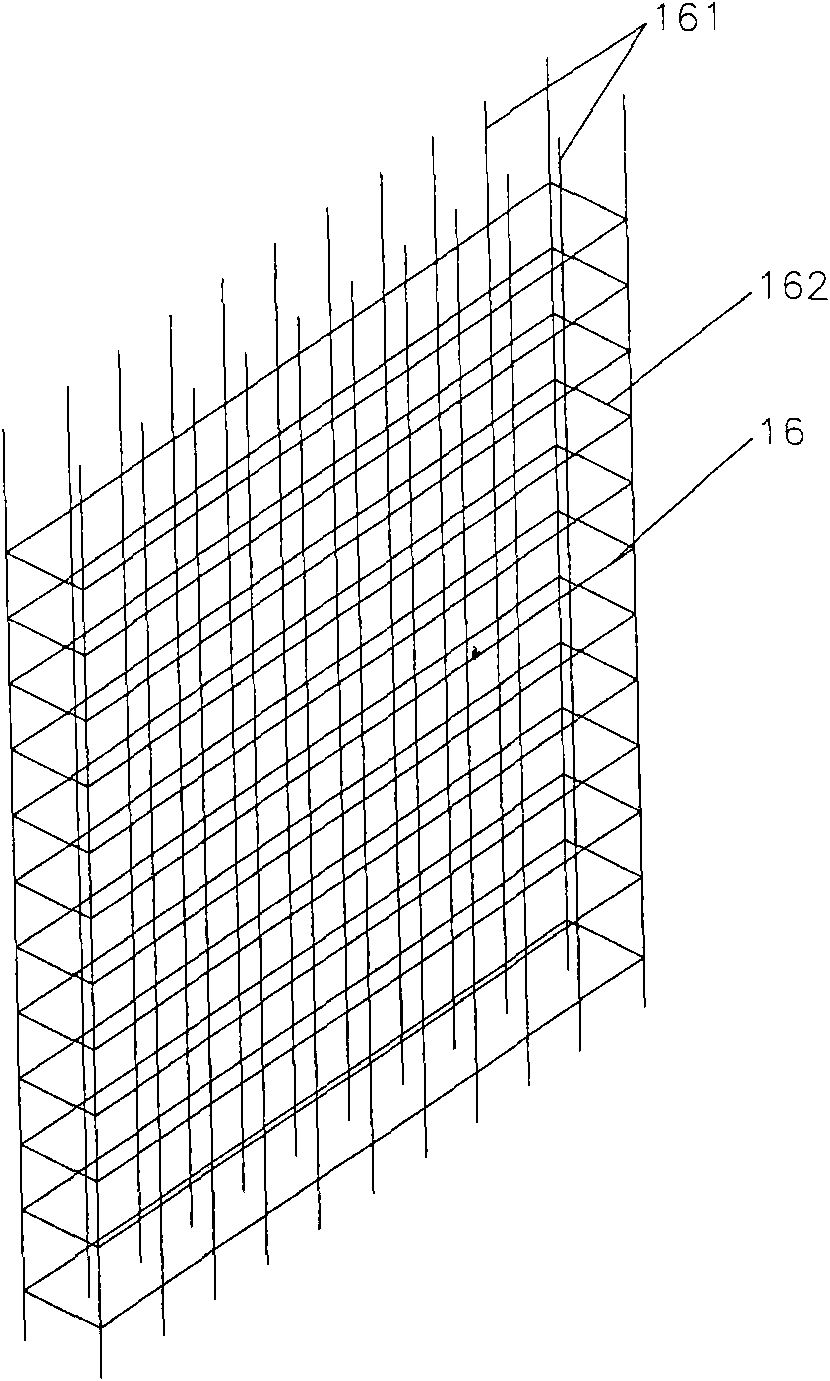

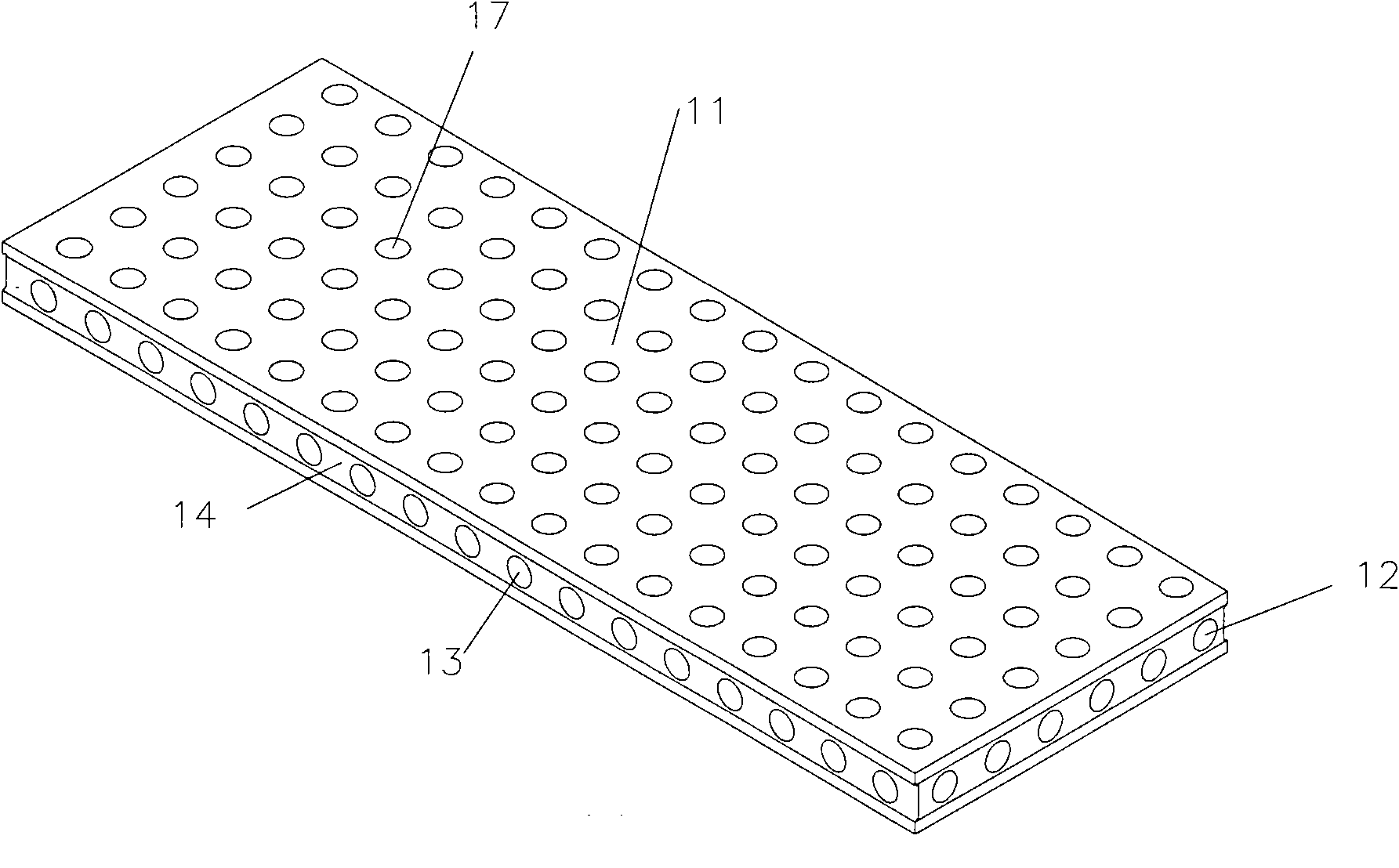

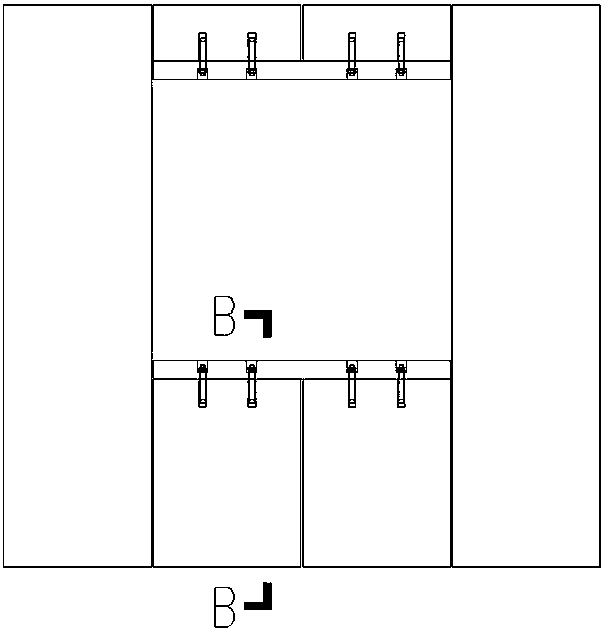

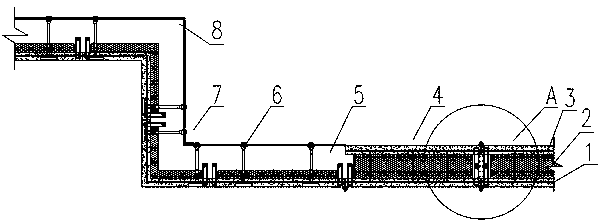

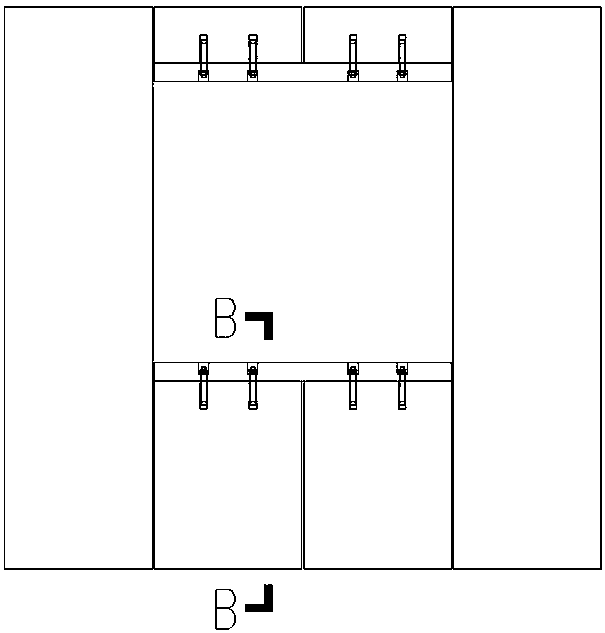

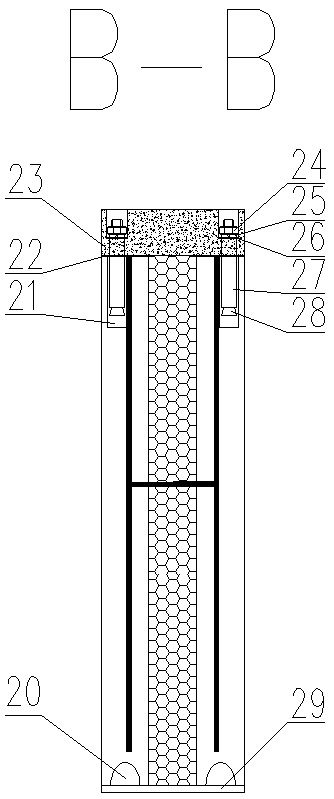

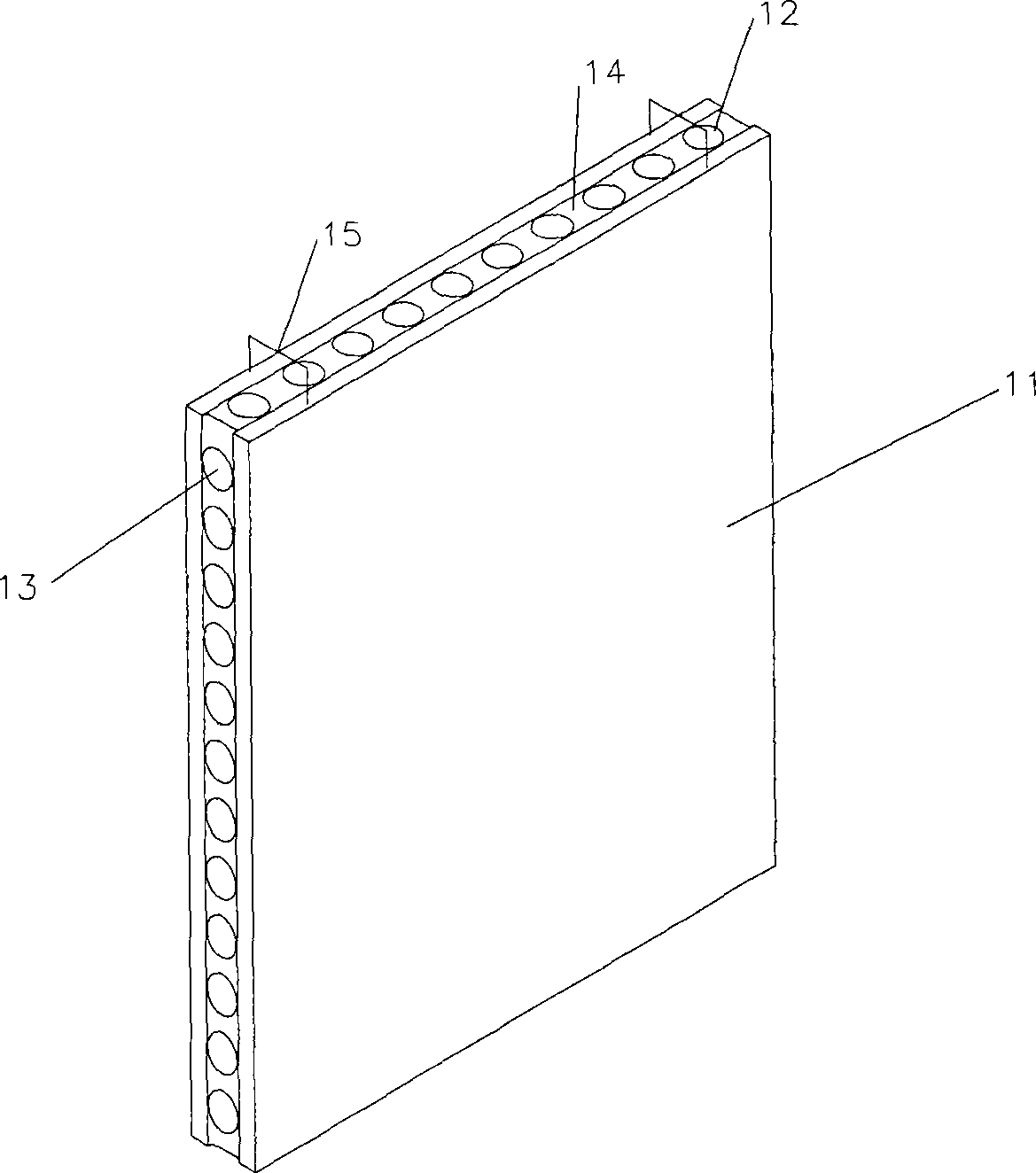

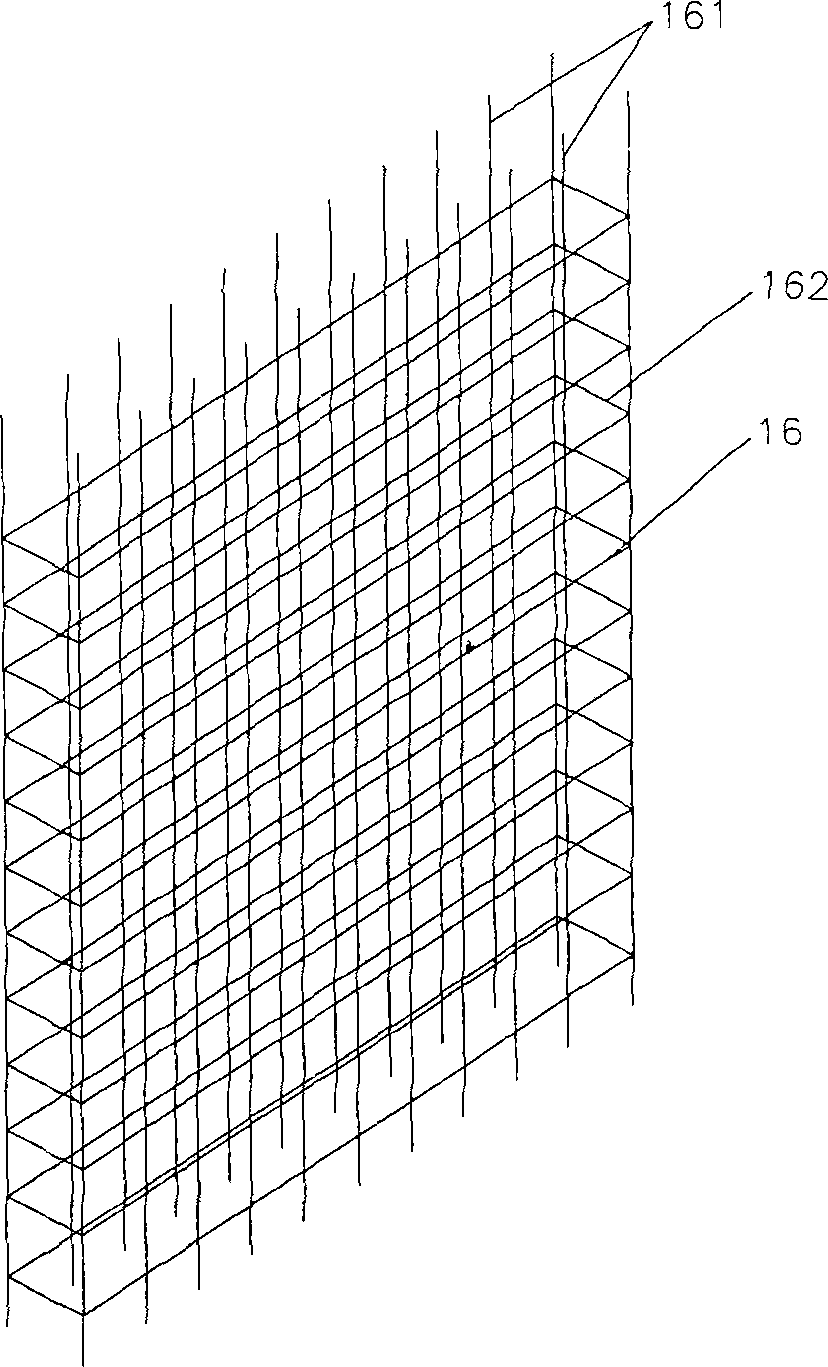

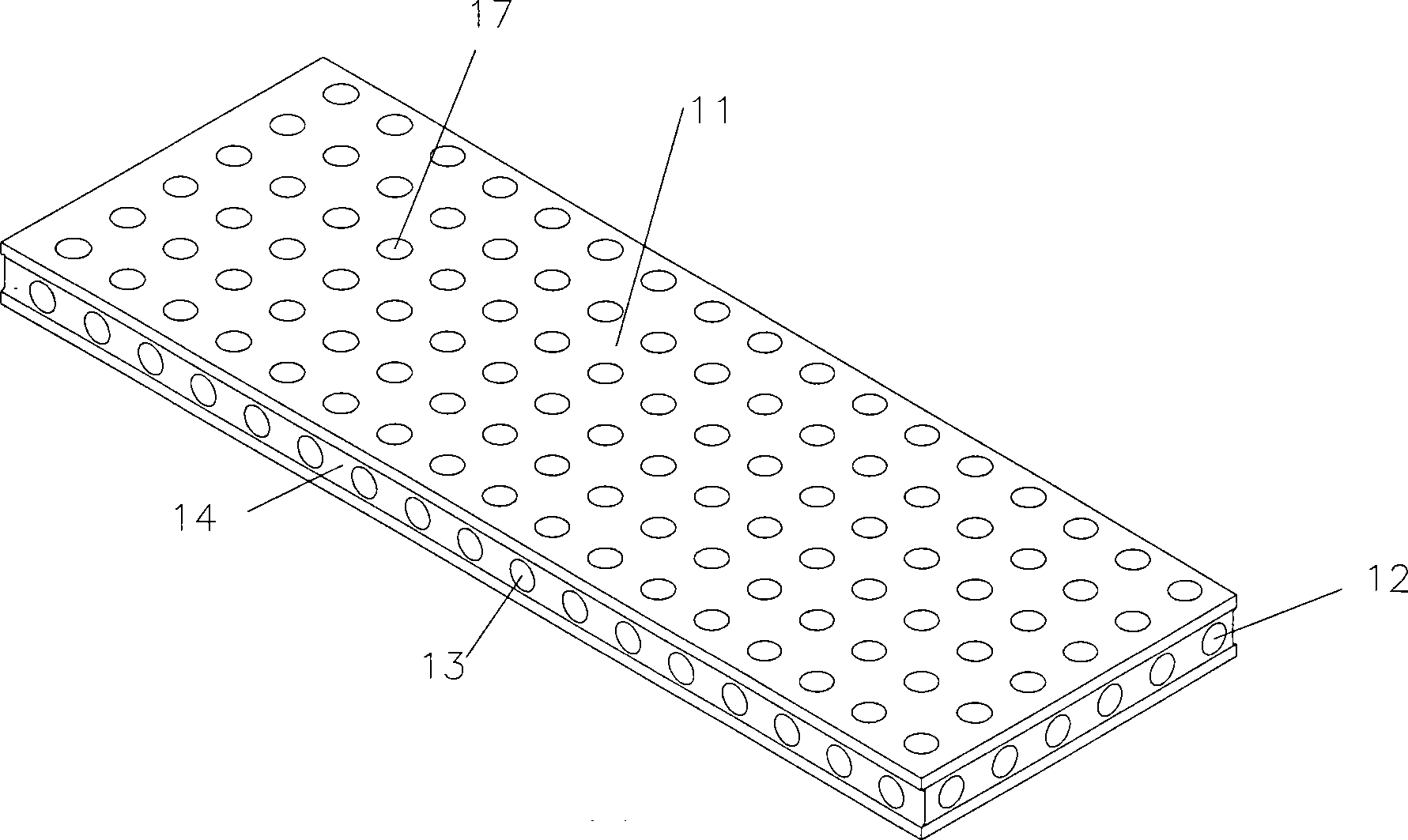

Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

ActiveCN101985856AConstruction quality is easy to guaranteeFlatness is easy to guaranteeForms/shuttering/falseworksForming/stuttering elementsEngineeringRebar

The invention relates to a removal-free prefabricated reinforced concrete template with cross holes inside. The template is a wall template, a floor template, a roof template, a T-shaped template, an L-shaped template, a cross template, a coupling beam template, a beam template or an upright template. A plurality of longitudinal through holes and a plurality of horizontal through holes parallel to the surface are arranged in the template. The plurality of longitudinal through holes and the plurality of horizontal through holes form cross channels. When the removal-free template is prefabricated in factories, 70-80% of stress reinforced concrete is prefabricated in the template, which facilitates industrialization production, transportation and hoisting, and realizes that each layer of house wall template and the floor template are supported once, the concrete is repoured, after the current layer of concrete is poured, the next layer construction is immediately carried out, the construction period of the house is shortened, meanwhile labour is saved, the construction speed is quickened and the house cost is reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

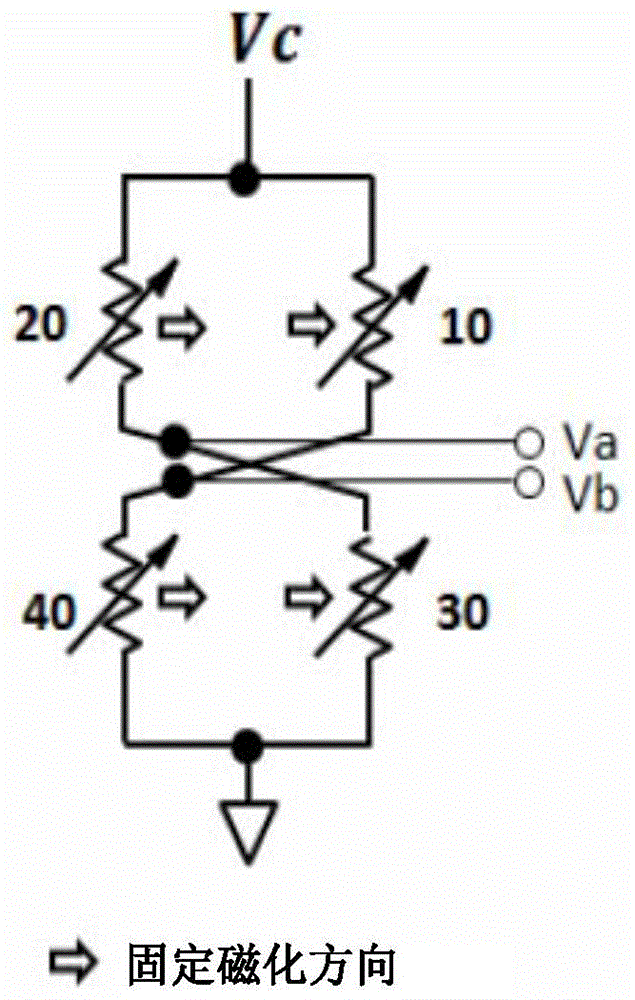

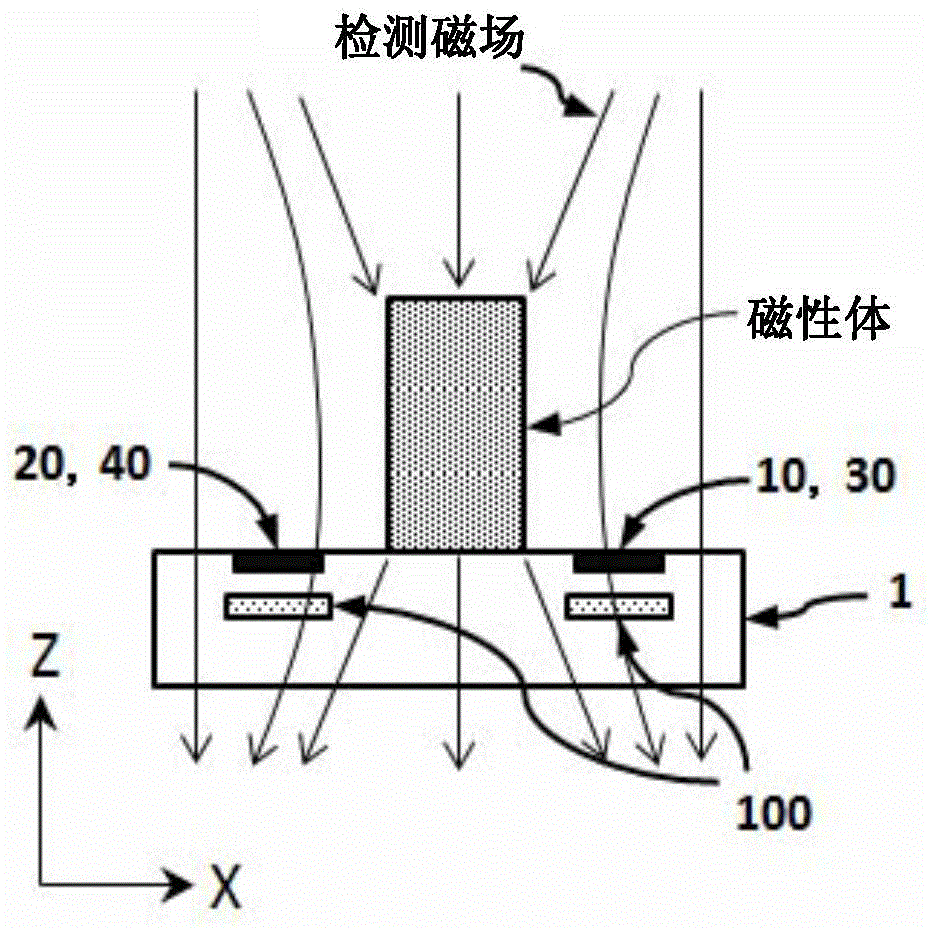

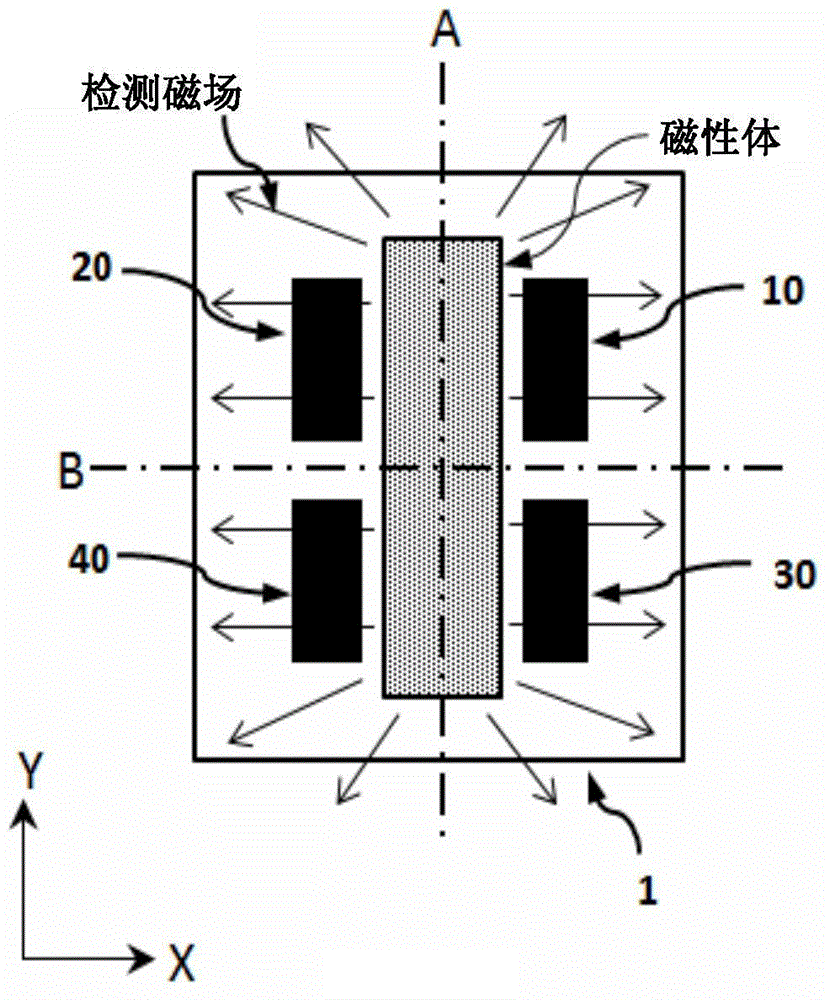

Magnetic field detecting sensor and magnetic field detecting apparatus using the same

ActiveCN105093138AImprove flatnessGuaranteed flatnessMagnetic measurementsElectrical resistance and conductancePower flow

A magnetic field detecting sensor includes a bridge circuit which is connected to multiple magnetoresistive effect elements and is capable of outputting a differential voltage between specified connection points, a magnetic field generating conductor for providing the magnetoresistive effect elements with a magnetic field in a direction opposite to that of the detection magnetic field by disposing a magnetic body near the center of the bridge circuit, a differential operation circuit which the differential voltage is input in and makes a feedback current flow to the magnetic field generating conductor, wherein the feedback current generates the magnetic field in a direction opposite to that of the detection magnetic field in the magnetic field generating conductor, and a voltage converting circuit for outputting the feedback current as a voltage value. The magnetic field generating conductor and the magnetoresistive effect elements are formed in the same stacked body.

Owner:TDK CORPARATION

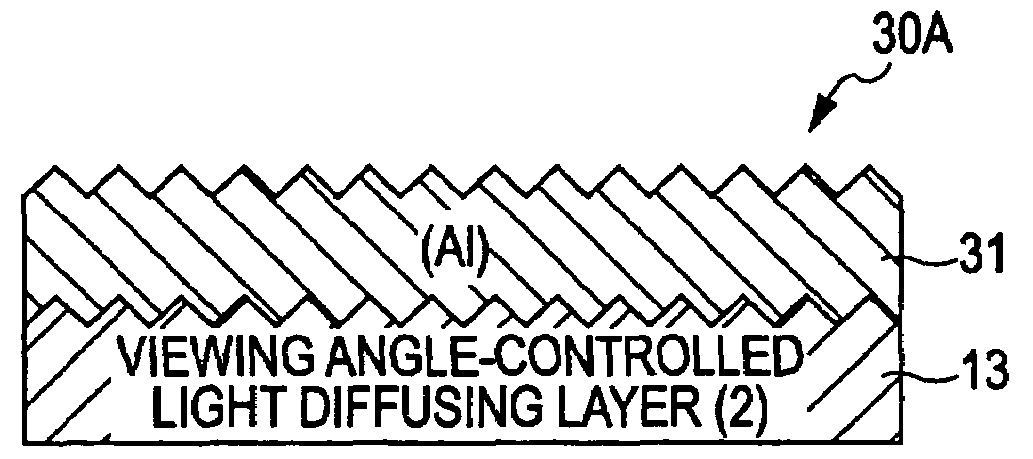

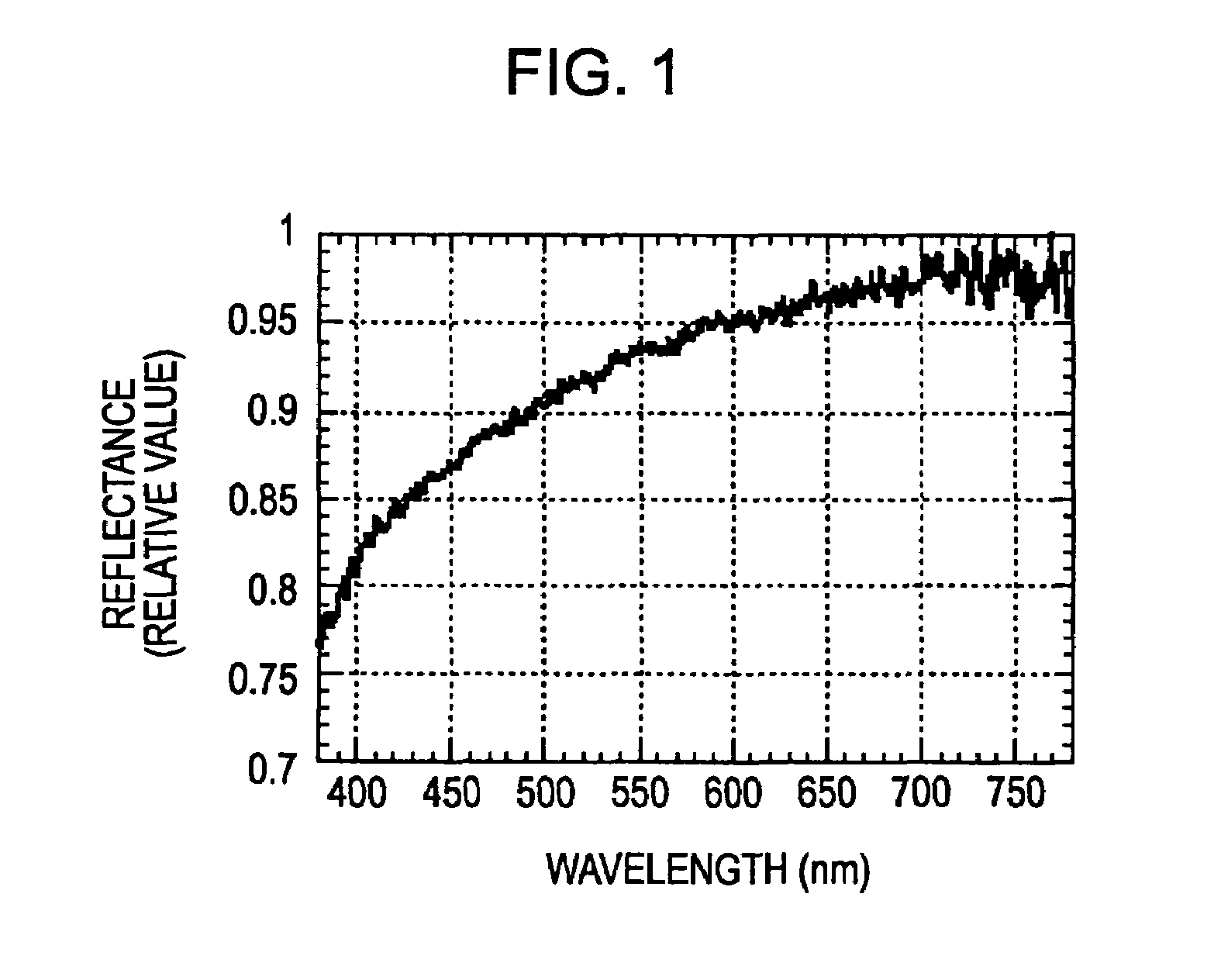

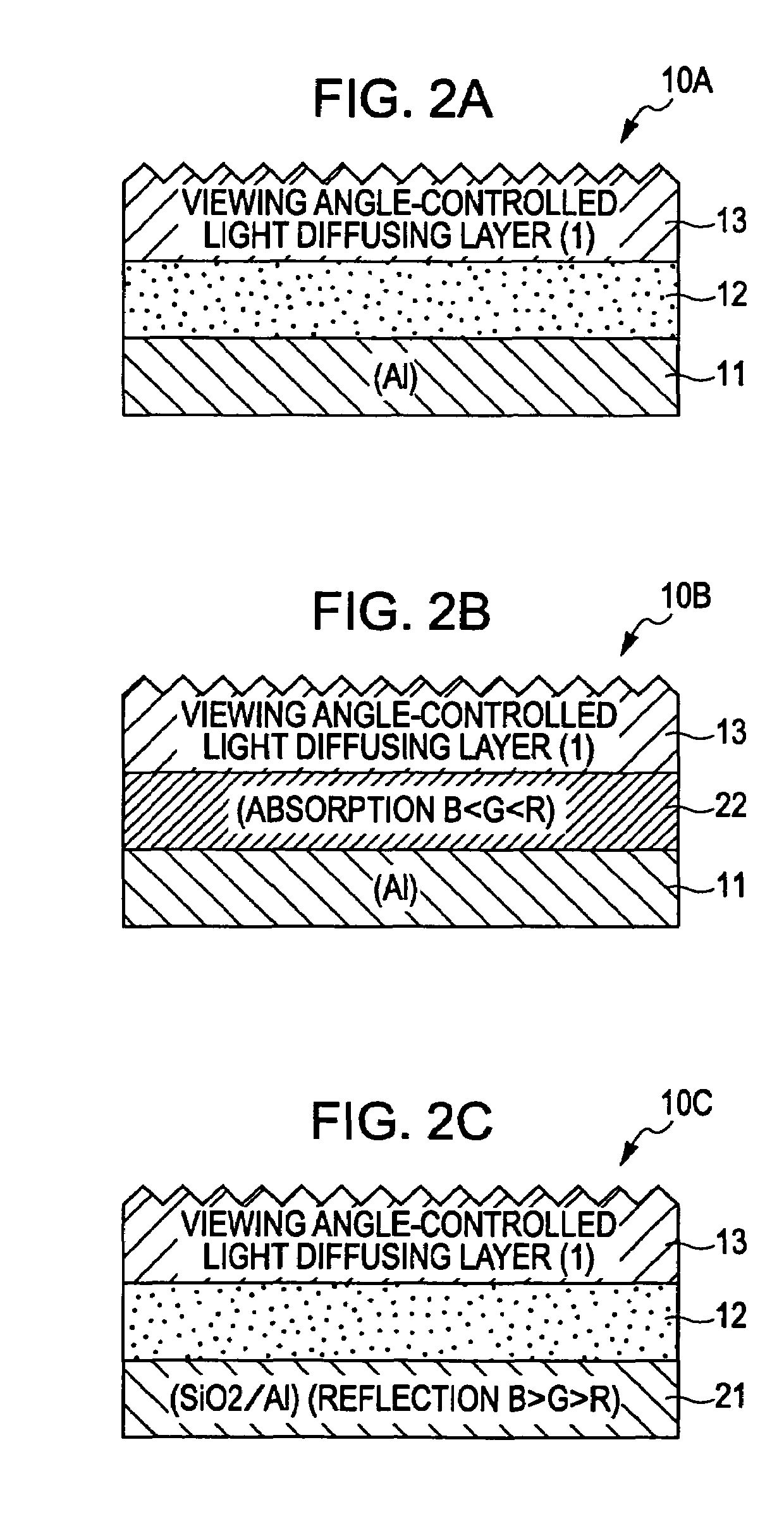

Reflective screen

InactiveUS7649687B2Increase contrastWell formedDiffusing elementsProjectorsLight reflectionLightness

A reflective screen includes a light reflecting layer, and a light diffusing layer provided on the light reflecting layer. The light diffusing layer has the diffusion property that in one (A axis) of two perpendicular axial directions on a light diffusion plane, a luminance distribution curve versus incidence angle is asymmetric with respect to the zero-incidence-angle axis, and the side on which the incidence angle (half-luminance incidence angle) with half of a peak luminance on the A axis in the normal direction to the screen plane is small faces in a direction in which external light has the highest strength.

Owner:SONY CORP

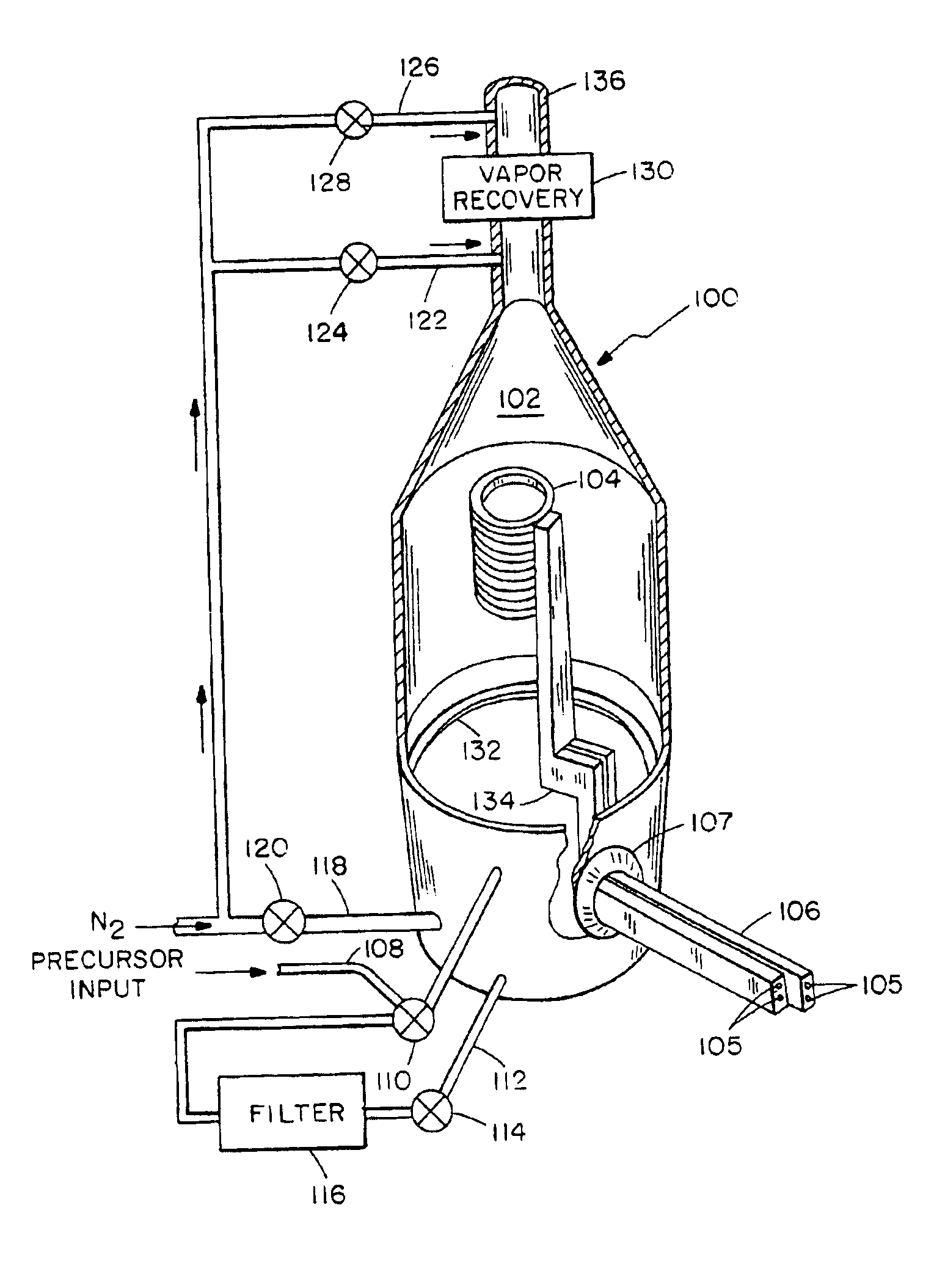

Composite articles

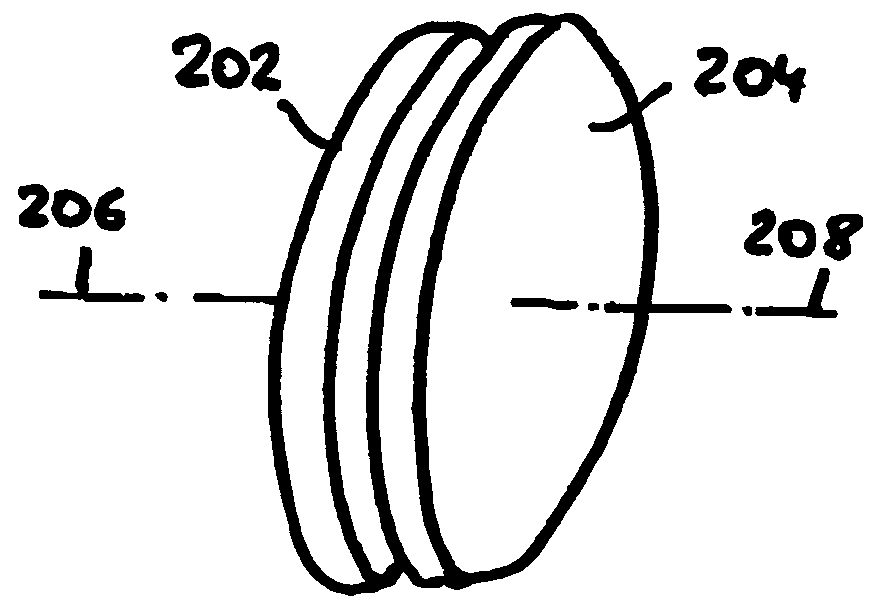

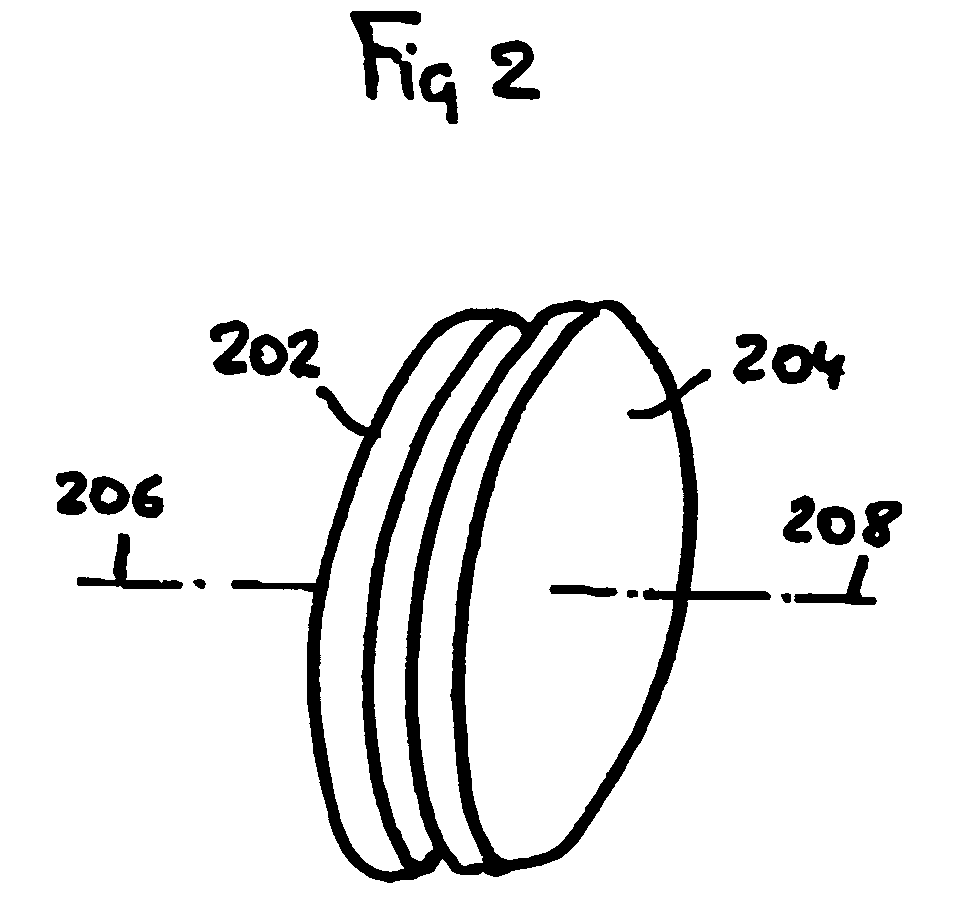

InactiveUS6858302B2Low costImprove permeabilityNatural mineral layered productsFriction liningCarbon compositesHigh density

A composite structure is formed by depositing a one or more coatings on an open-cell foam skeleton to form a higher-density composite foam. In accordance with one aspect of the invention, the composite foam can be a carbon / carbon composite formed by a rapid densification process. The composite structure is suitable for use, for example, as a friction material employed in clutch and brake devices.

Owner:SAFRAN LANDING SYSTEMS

Clutch or brake device formed of composite foam

InactiveUS20050115791A1Low costImprove permeabilityFriction clutchesFriction liningDevice formSolid density

An improved clutch or brake device in which at least two members are mounted for relative rotation and engagement, the members having friction material rotatable therewith, and the friction material of the members having surfaces confronting each other, characterized in that the friction material has a solid density of greater than 30% and includes an open lattice of carbon ligaments forming a network of three dimensionally interconnected cells; and a pyrolytic carbon coating on the open lattice of carbon ligaments.

Owner:SAFRAN LANDING SYSTEMS

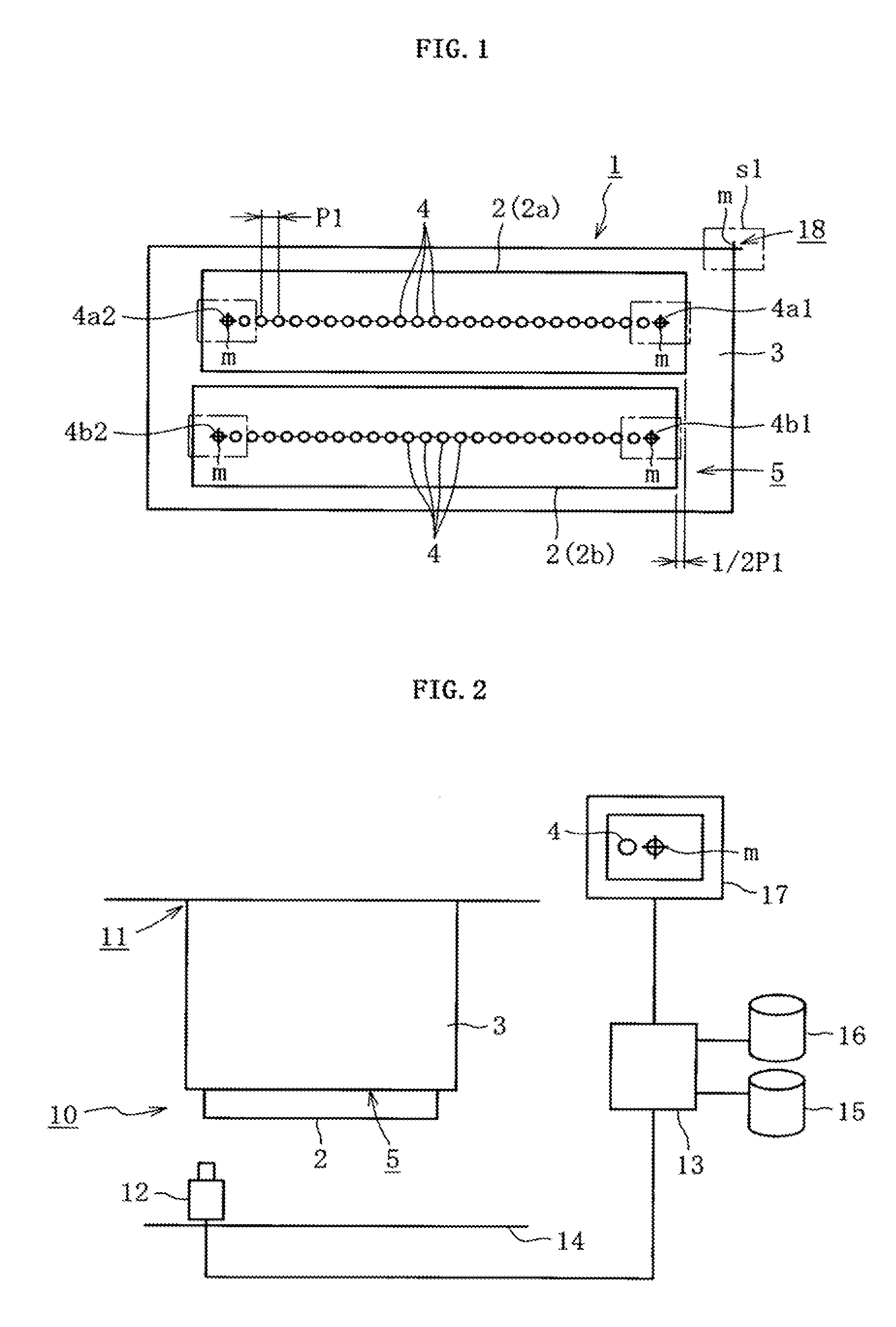

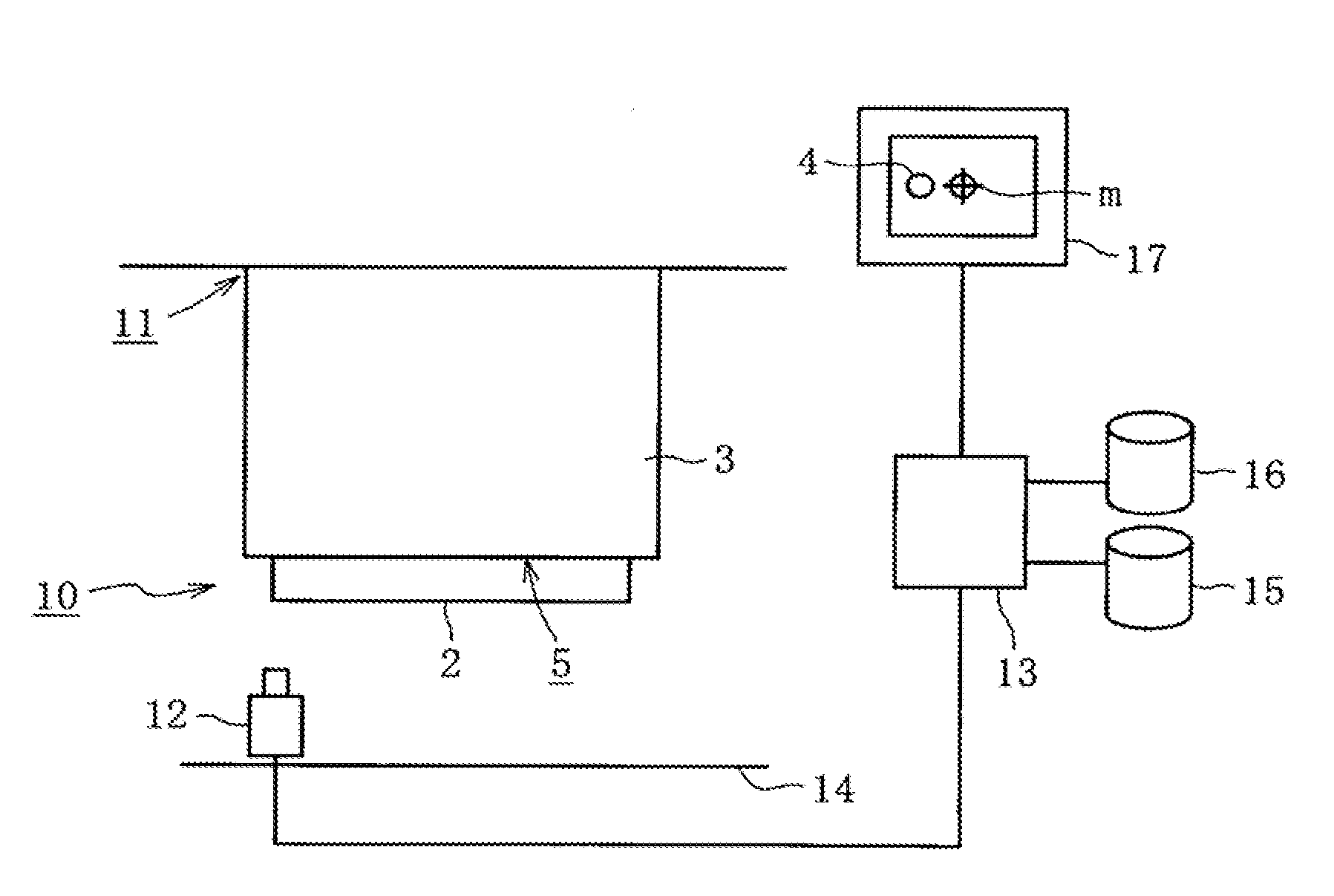

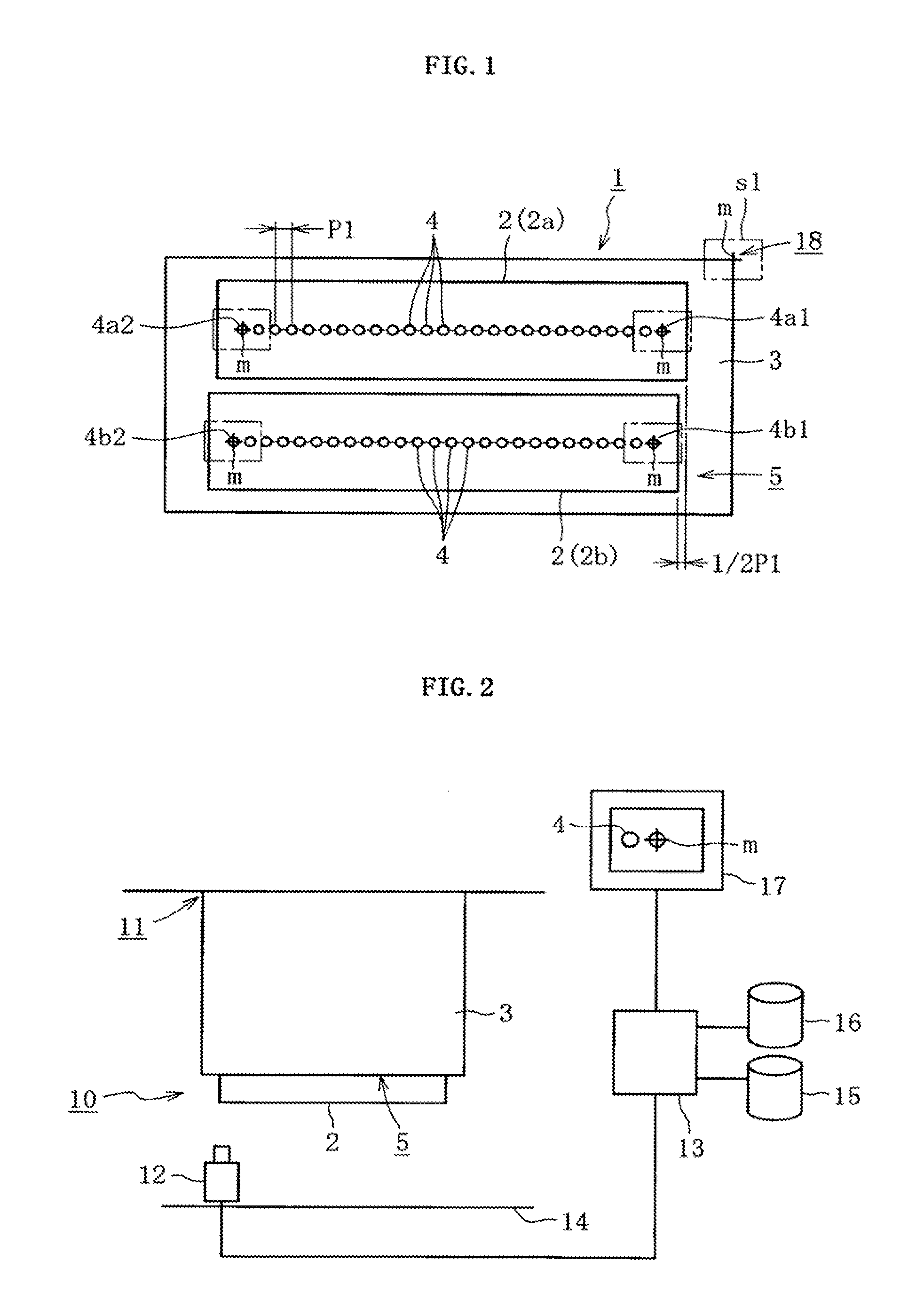

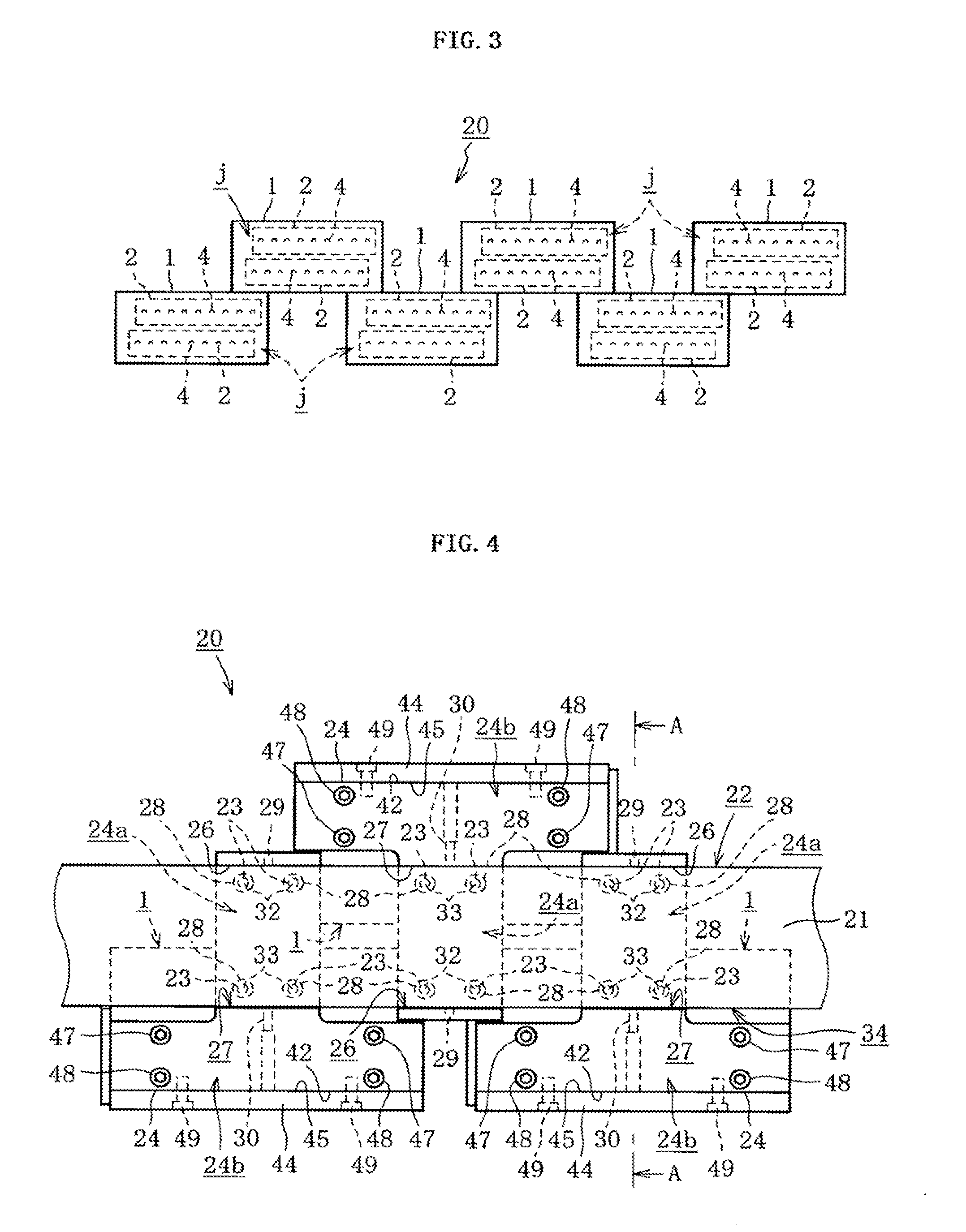

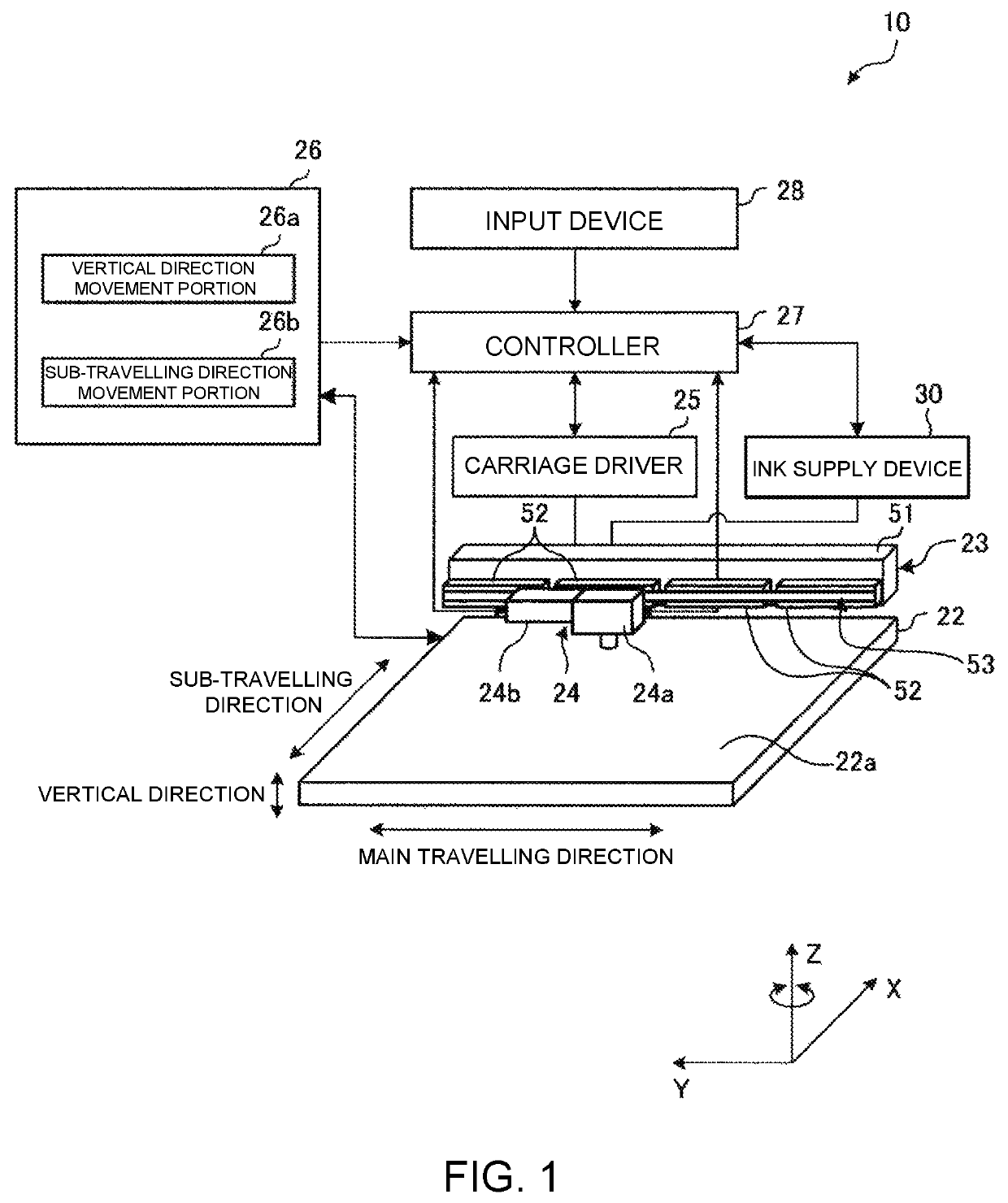

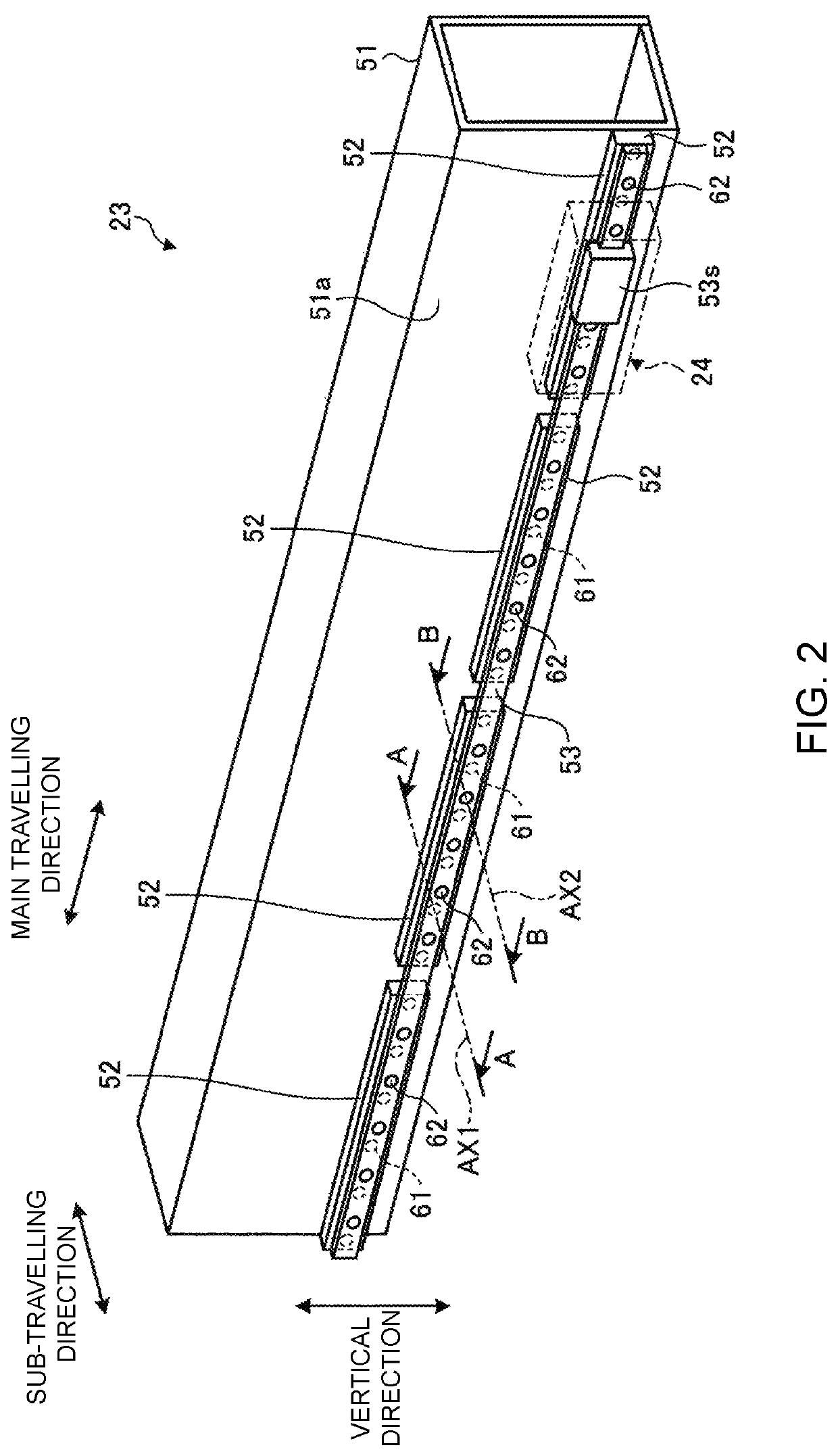

Inkjet head, method of detecting ejection abnormality of the inkjet head, and method of forming film

ActiveUS20130029047A1Flatness is easy to guaranteeStraightness be easilyPower drive mechanismsLiquid spraying apparatusEngineeringCoating

There are provided n number of line-type inkjet nozzles (2) which include nozzles (4) that eject a liquid material and are arranged in a row, and which are arranged in parallel with each other so that positions of the nozzles (4) are shifted from each other by 1 / n of a nozzle pitch (P1). Thus, an inkjet head (1) as a whole has a state equivalent to a state in which the nozzles (4) are arranged at 1 / n of a nozzle pitch of one line-type inkjet nozzle (2). The inkjet head (1) is capable of adjusting a timing of ejecting the liquid material for each line-type inkjet nozzle (2). Accordingly, adjustment of a dot pitch such as fine coating and rough coating can be performed with ease.

Owner:ISHII HYOKI

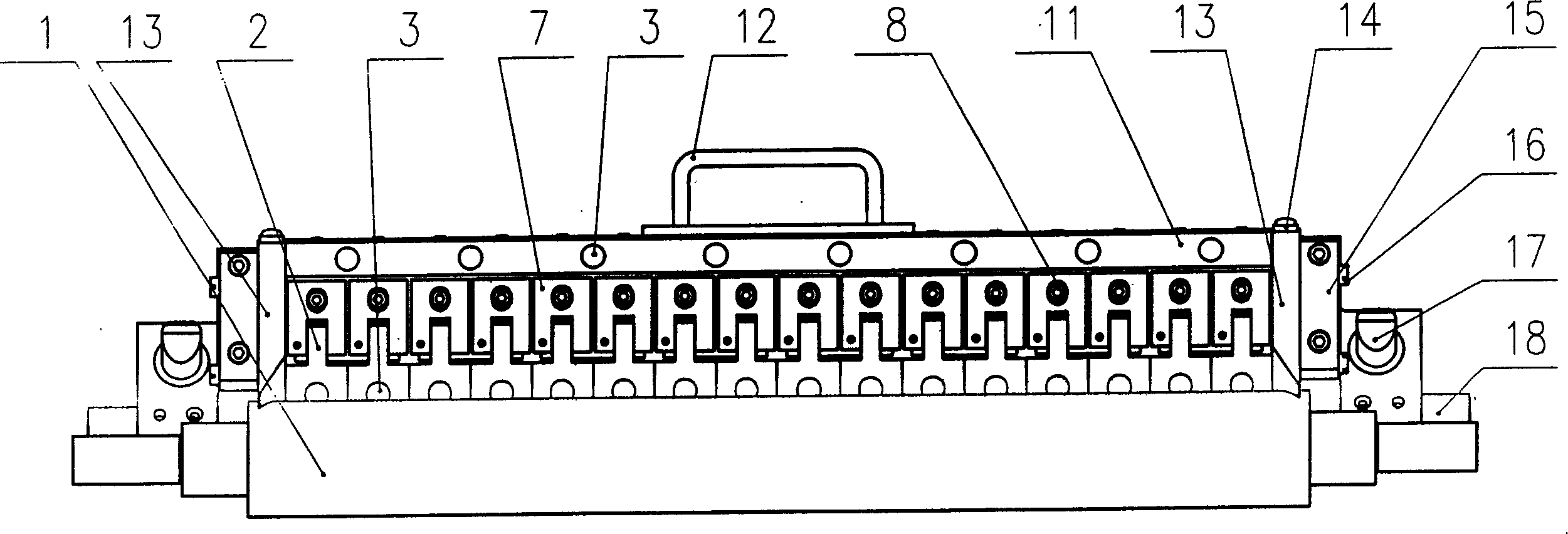

Zoning ink box for printer

InactiveCN1554532AMeet ink supply needsFlatness is easy to guaranteePrinting press partsEngineeringMetal sheet

The zoned ink box for printing machine has one ink box body, two side stoppers with front arced slot matching the ink roller, support shafts at two ends and connected to the wall boards of printing machine, one row of fixed blocks embedded parallelly to the upper side and with notch, one row of ink supplying blocks below the fixed blocks with lug inserted into the corresponding notch, cam levers installed onto the ink supplying blocks separately and with rotating shaft connected to the fixed block, and elastic metal sheets covering each of the ink box body, fixed blocks and ink supplying blocks separately. The zoned ink box has separately adjustable ink supply amount for each zone and thus homogeneous ink supply.

Owner:潍坊华光精工设备有限公司

Prefabricated fabricated type structure of external wall

ActiveCN107700697ASimple structureEconomically reasonableWallsHeat proofingAccessory structureEngineering

The invention discloses a prefabricated fabricated type structure of an external wall, and relates to the field of constructional engineering. The prefabricated fabricated type structure of the external wall is composed of a thermal insulating composite wall standard piece and an auxiliary structure; the thermal insulating composite wall standard piece comprises a prefabricated type external wallload-bearing wall standard piece, a prefabricated type external wall non-bearing wall standard piece and a prefabricated type external wall load-bearing wall internal and external corner standard piece; and the prefabricated type external wall load-bearing wall standard piece is provided with an assembly type oppositely-pulling rod which is used for positioning and installing of a load-bearing wall construction formwork. According to the prefabricated fabricated type structure of the external wall, the structure is simple, economical and reasonable, the technology is advanced, using is convenient, and the prefabricated fabricated type structure is the best construction method of a composite wall structure and has good popularizing value.

Owner:河南纽沃建筑科技有限公司

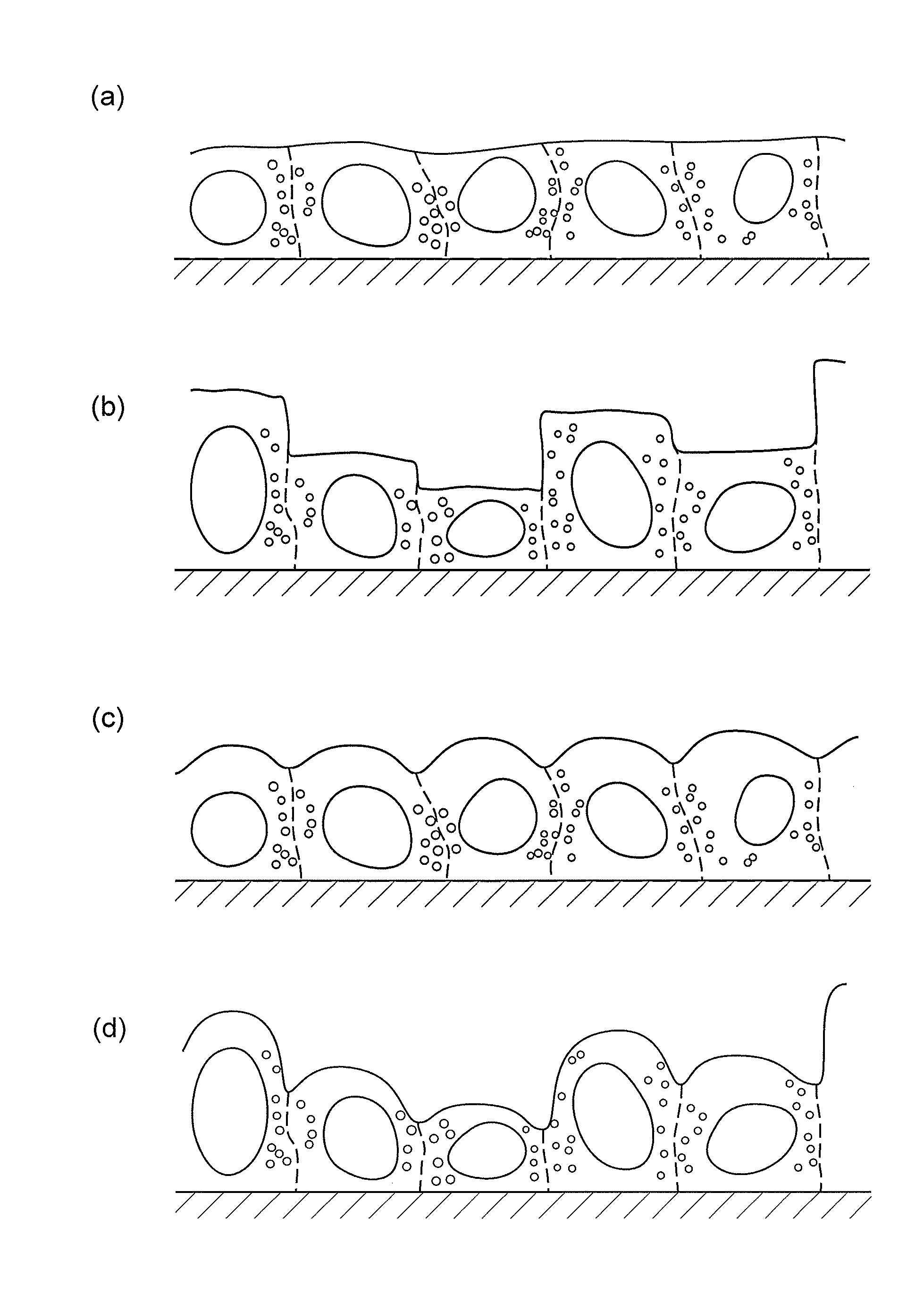

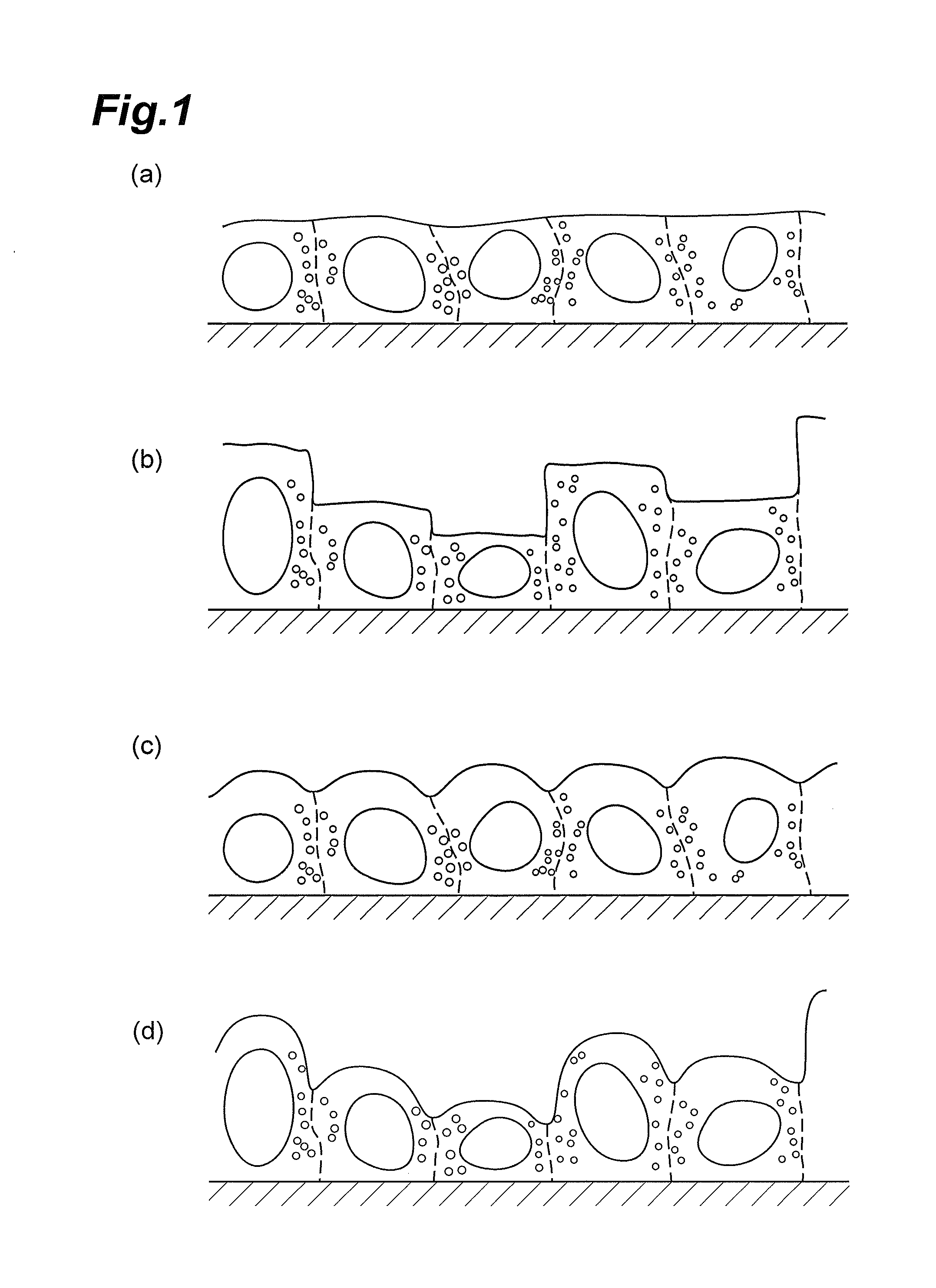

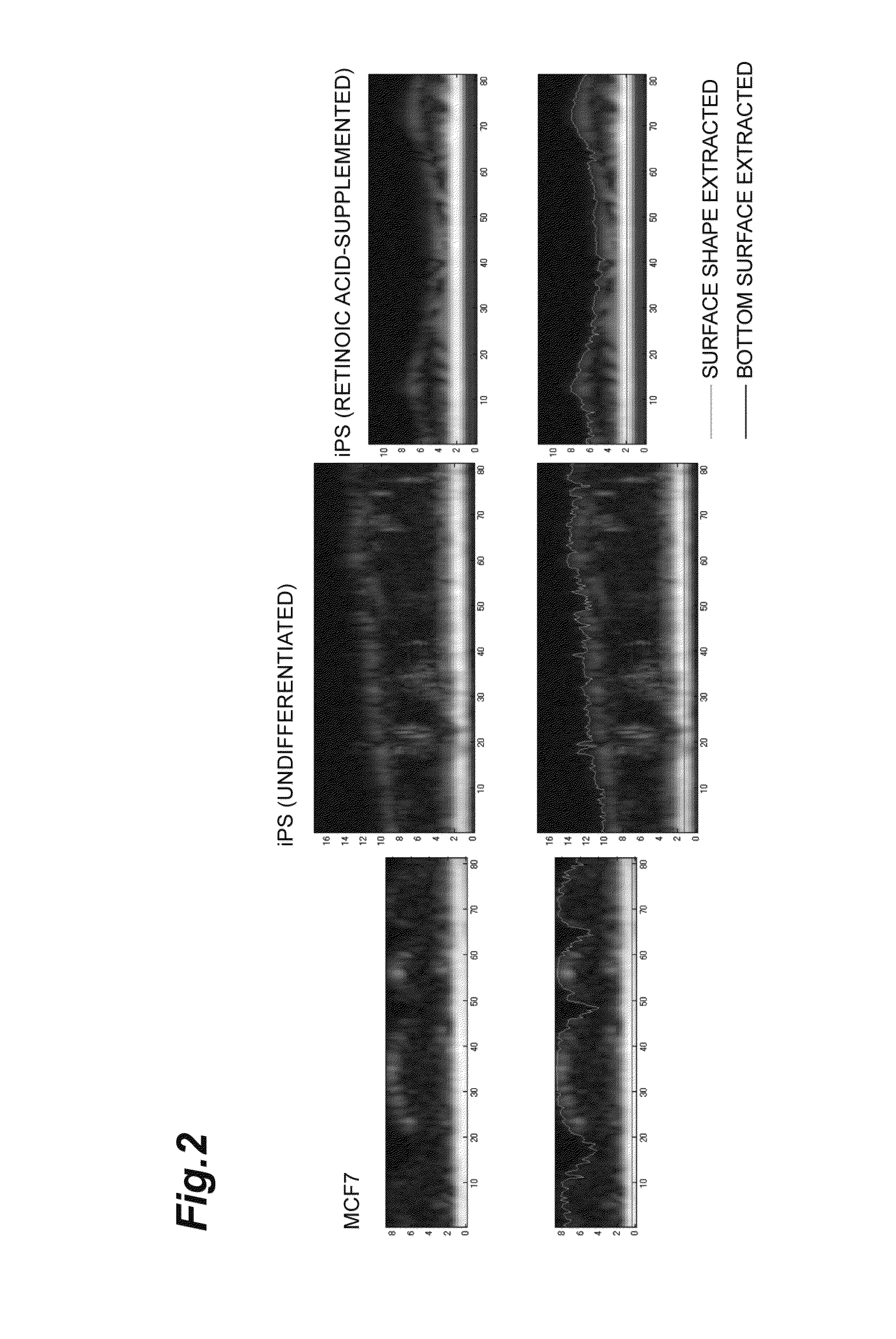

Method for determining differentiation level of pluripotent stem cells

ActiveUS20140073002A1Efficiently determinedEasily and effectively determineImage enhancementImage analysisMultipotent Stem CellStem cell

Owner:HAMAMATSU PHOTONICS KK

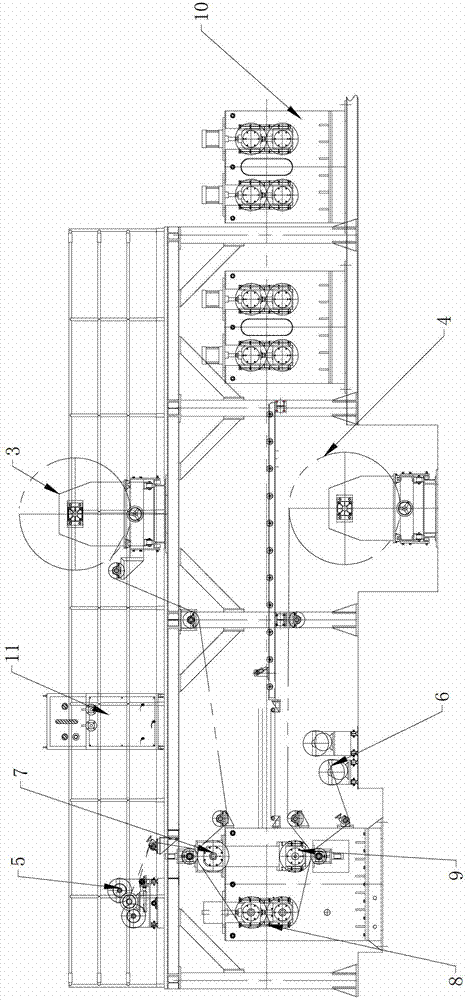

Automatic production technology of aluminum composite panel

InactiveCN103171228AGuaranteed StrengthReduce weightLamination ancillary operationsLaminationComposite plateAluminum composites

The invention discloses an automatic production technology of an aluminum composite panel. The automatic production technology comprises the following steps of: (1) respectively unreeling a core board, a surface board and a bottom board which are respectively made of aluminum through core board unreeling equipment, surface board unreeling equipment and bottom board unreeling equipment, unreeling an upper-layer hot melt adhesive membrane and a lower-layer melt adhesive membrane through first film releasing equipment and second film releasing equipment; (2) respectively carrying out heating pre-fitting on the surface board, the upper hot melt adhesive membrane, the bottom board and the lower-layer hot melt adhesive membrane on upper pre-fitting equipment and lower pre-fitting equipment; (3) continuously pressing the core board and pressing a plurality of bumps on the panel; (4) pressing and compounding the aluminum composite panel from the pressed core board, the pre-fit surface board and the pre-fit bottom board on the compound equipment; and (5) heating, fitting, cooling, leveling, trimming, drawing, cutting and feeding the aluminum composite panel. The aluminum composite panel can be continuously produced by the production technology; and the produced aluminum composite panel is high in strength and light in weight.

Owner:ZHANGJIAGANG MUZI MACHINERY TECH

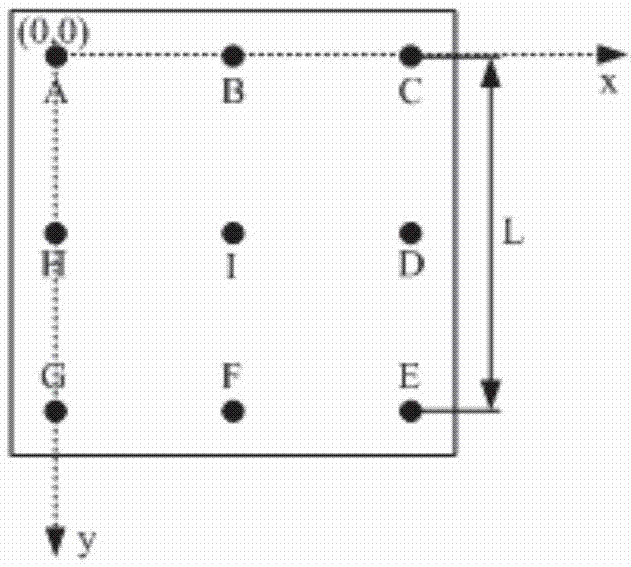

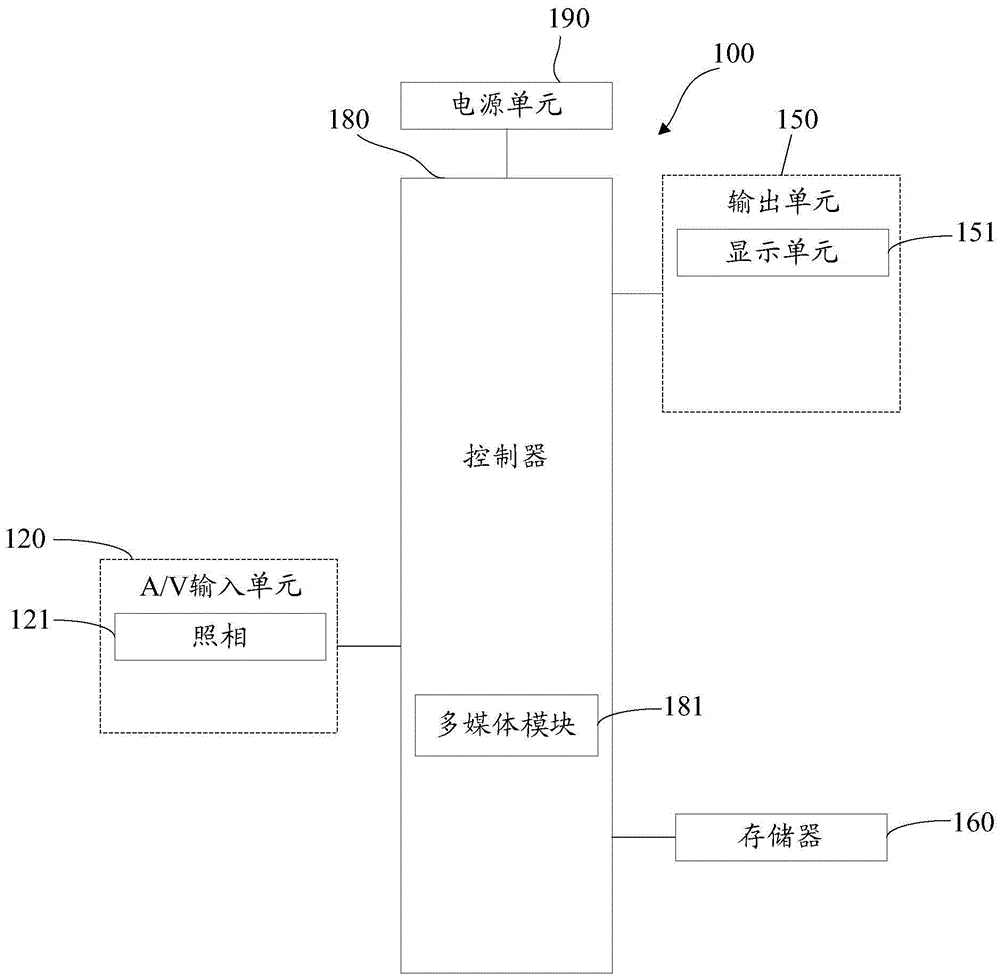

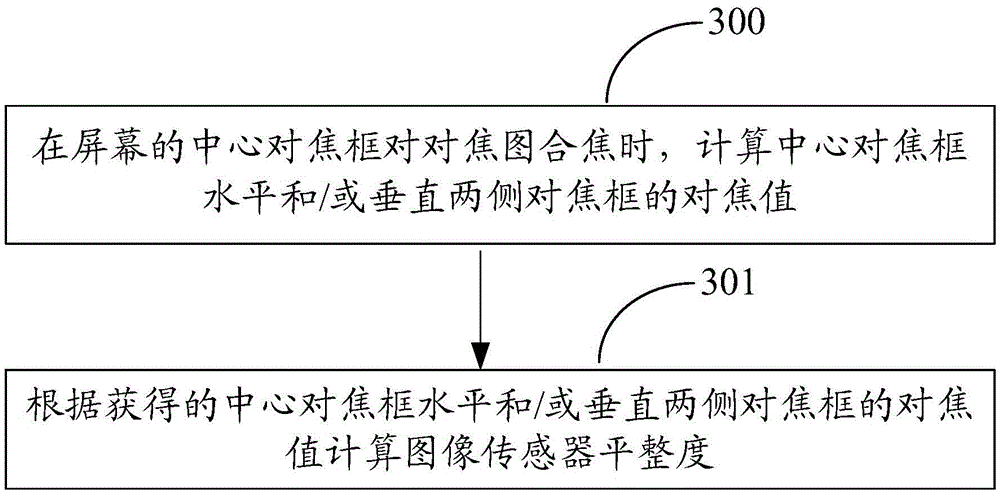

Method and device for obtaining smoothness of image sensor

InactiveCN105430379AFlatness is easyGuaranteed photo effectTelevision systemsCamera lensOptical axis

The invention discloses a method and a device for obtaining smoothness of an image sensor. The method comprises the following steps: when focusing a focus figure in a central focus frame of a screen, calculating focus values of focus frames on two horizontal and / or vertical sides of the central focus frame; wherein the focus figure is vertical to a primary optical axis of a lens module, and the distance between the focus figure and the lens module is smaller than the hyperfocal distance of the lens module; and calculating the smoothness of the image sensor according to the obtained focus values of the focus frames on the two horizontal and / or vertical sides of the central focus frame. By adopting the method and the device in the scheme of the invention, the smoothness of the image sensor is simply obtained by the focus figure, so that the photographing effect of a mobile terminal is guaranteed, and no special instrument is necessary for detection.

Owner:NUBIA TECHNOLOGY CO LTD

Inkjet head, method of detecting ejection abnormality of the inkjet head, and method of forming film

InactiveUS20130027452A1Flatness is easy to guaranteeStraightness be easilyPower drive mechanismsOther printing apparatusDot pitchCoating

There are provided n number of line-type inkjet nozzles (2) which include nozzles (4) that eject a liquid material and are arranged in a row, and which are arranged in parallel with each other so that positions of the nozzles (4) are shifted from each other by 1 / n of a nozzle pitch (P1). Thus, an inkjet head (1) as a whole has a state equivalent to a state in which the nozzles (4) are arranged at 1 / n of a nozzle pitch of one line-type inkjet nozzle (2). The inkjet head (1) is capable of adjusting a timing of ejecting the liquid material for each line-type inkjet nozzle (2). Accordingly, adjustment of a dot pitch such as fine coating and rough coating can be performed with ease.

Owner:ISHII HYOKI

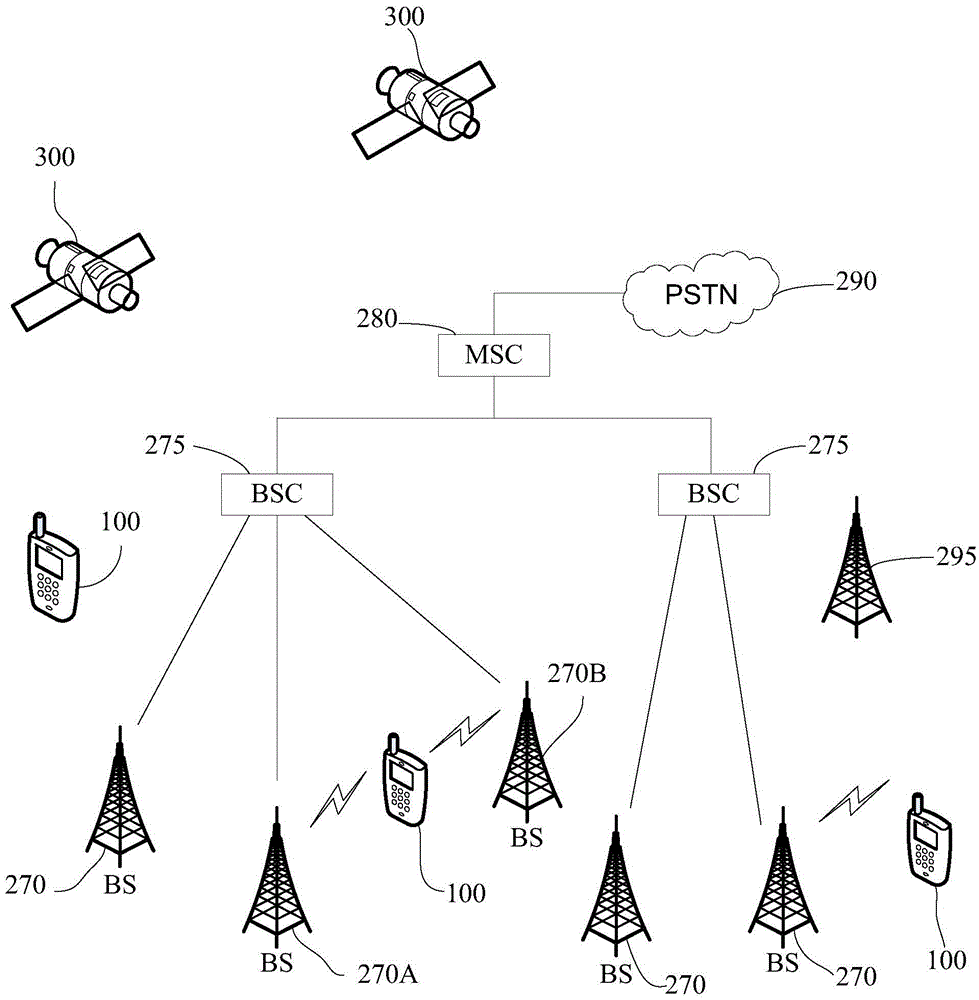

Waterproof and dampproof internet of things visual scale

PendingCN110332977AGuaranteed detection accuracyWaterproof, moisture-proof and breathableWeighing auxillary devicesSpecial purpose weighing apparatusComputer moduleLoad cell

The invention relates to a waterproof and dampproof internet of things visual scale. The waterproof and dampproof internet of things visual scale comprises an electronic scale base, a support rod andan electronic scale instrument, wherein the electronic scale base is provided with a sensor module group for weighing; the support rod is arranged on one side of the electronic scale base; the electronic scale instrument is connected with the top end of the support rod and is provided with a control circuit; the sensor module group is arranged below the electronic scale base and is electrically connected with the control circuit; a sensor module in the sensor module group is arranged in a waterproof and dampproof seal housing; the surface of the waterproof and dampproof seal housing is in sealing connection with a waterproof and dampproof ventilation assembly for adjusting the difference of the pressure inside and outside a cavity; a support plate is used for connecting a sensor and the waterproof and dampproof seal housing to form a weighing sensor module group. Both the sensor module group and the electronic scale instrument in the electronic scale adopt a full-seal design, have waterproof, dampproof and ventilation properties, and can ensure the detection precision of the sensor module; and the electronic scale improves multiple functional modules.

Owner:福州富日衡之宝电子有限公司

Exterior wall cladding and technique for producing the same

InactiveCN101457577AHigh strengthLow thermal conductivityCovering/liningsSynthetic resin layered productsEpoxySurface layer

The invention relates to a board and a production technology thereof, in particular to an exterior wall cladding and a production technology thereof. The exterior wall cladding sequentially comprises an extruded sheet layer, a bo-mei board layer and a metallic paint layer from bottom to top. The production technology comprises the following steps: the surface of the bo-mei board is added with a layer of mixture formed by magnesium oxide and putty powder, and the mixture is trowelled; the surface layer of the processed bo-mei board is polished to lead the surface to be level; the surface layer of the polished bo-mei board is coated with a layer of fluorocarbon metal paint; an XPS extruded sheet with the same size as the bo-mei board is processed; the underside of the processed bo-mei board is agglutinated with the processed XPS extruded sheet by epoxide resin. The exterior wall cladding has good heat preservation and insulation performance, is energy-saving and environment-friendly, has level and beautiful surface, and is convenient for construction.

Owner:南京高迪建筑科技研究院有限公司

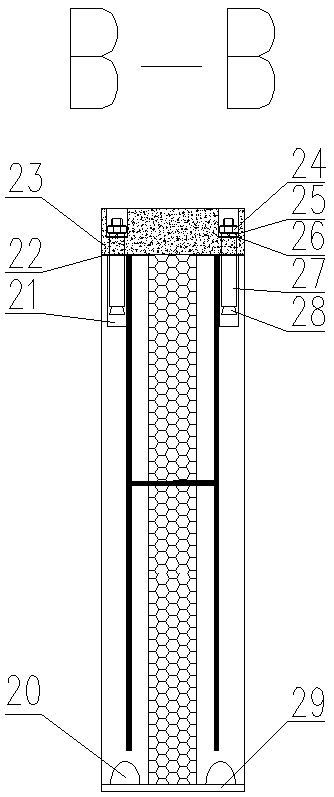

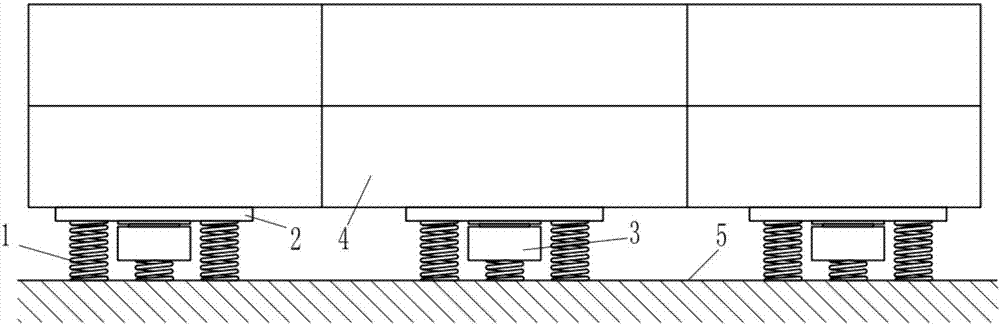

Pile grinding device for concrete pipe piles

InactiveCN111002174AFlatness is easyEven contactGrinding drivesGrinding machinesElectric machineryChain link

The invention discloses a pile grinding device for concrete pipe piles. The device comprises a first speed adjusting motor, a second motor, a grinder, a dovetail groove, a chassis, a driven support roller, a screw tilting fillet, a support roller bearing tilting fillet, a grinding disc, a screw hand wheel, a positioning bearing, a driving support roller and a lead screw. The first speed adjustingmotor is connected with the driving support roller through a chain; the second motor is connected with the grinder through a triangular belt; the grinder is mounted in the dovetail groove; the grinding disc of the grinder extends out of the dovetail groove; the screw hand wheel is fixedly connected with the lead screw; the screw tilting fillet supports the lead screw; the chassis is mounted on thepositioning bearing; the driven support roller and the driving support roller are arranged on the chassis; and the driven support roller is arranged on the support roller bearing tilting fillet. Compared with the prior art, the grinding disc of the pile grinding device for the concrete pipe piles and pipe sections are rotated at the same time; and the whole pipe wall end surfaces are uniformly contacted with the grinding disc, so that the flatness of the pipe wall end surfaces is easy to meet the standard requirement.

Owner:广水市浍洋科技有限公司

Large-size floor tile construction method

The invention discloses a large-size floor tile construction method including the following steps of (1) floor tile pretreatment, (2) ground treatment, (3) bottom ash plastering, (4) ground line-snapping setting-out, (5) paving and (6) seam plastering. Quick-drying thin cement mortar is smeared on the back faces of floor tiles, then the floor tiles are laid, the flatness of the ground tiles is easy to master, and the construction difficulty is greatly lowered; and the cement mortar is quickly solidified, the floor tiles and the ground are bonded more firmly, and the arching phenomenon can be effectively avoided.

Owner:宜兴市周铁镇生力钻探机械厂

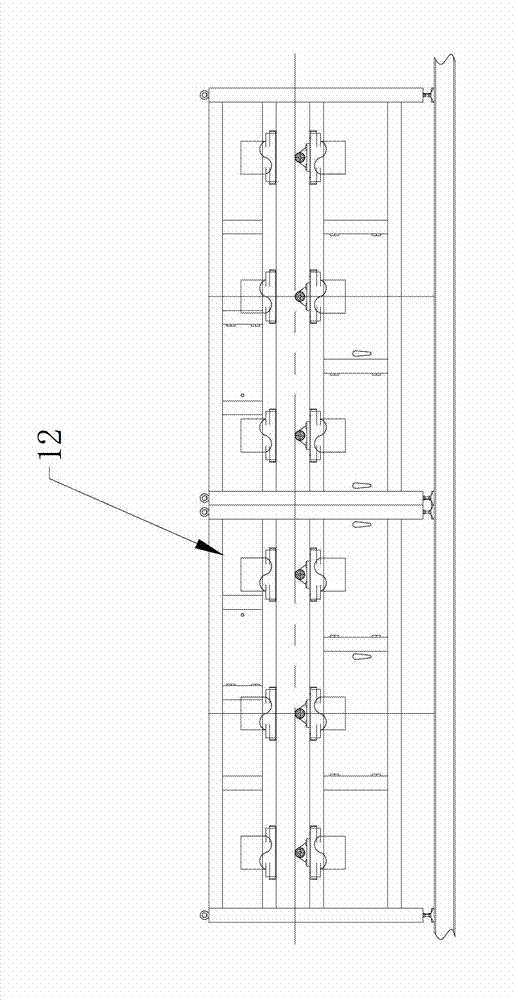

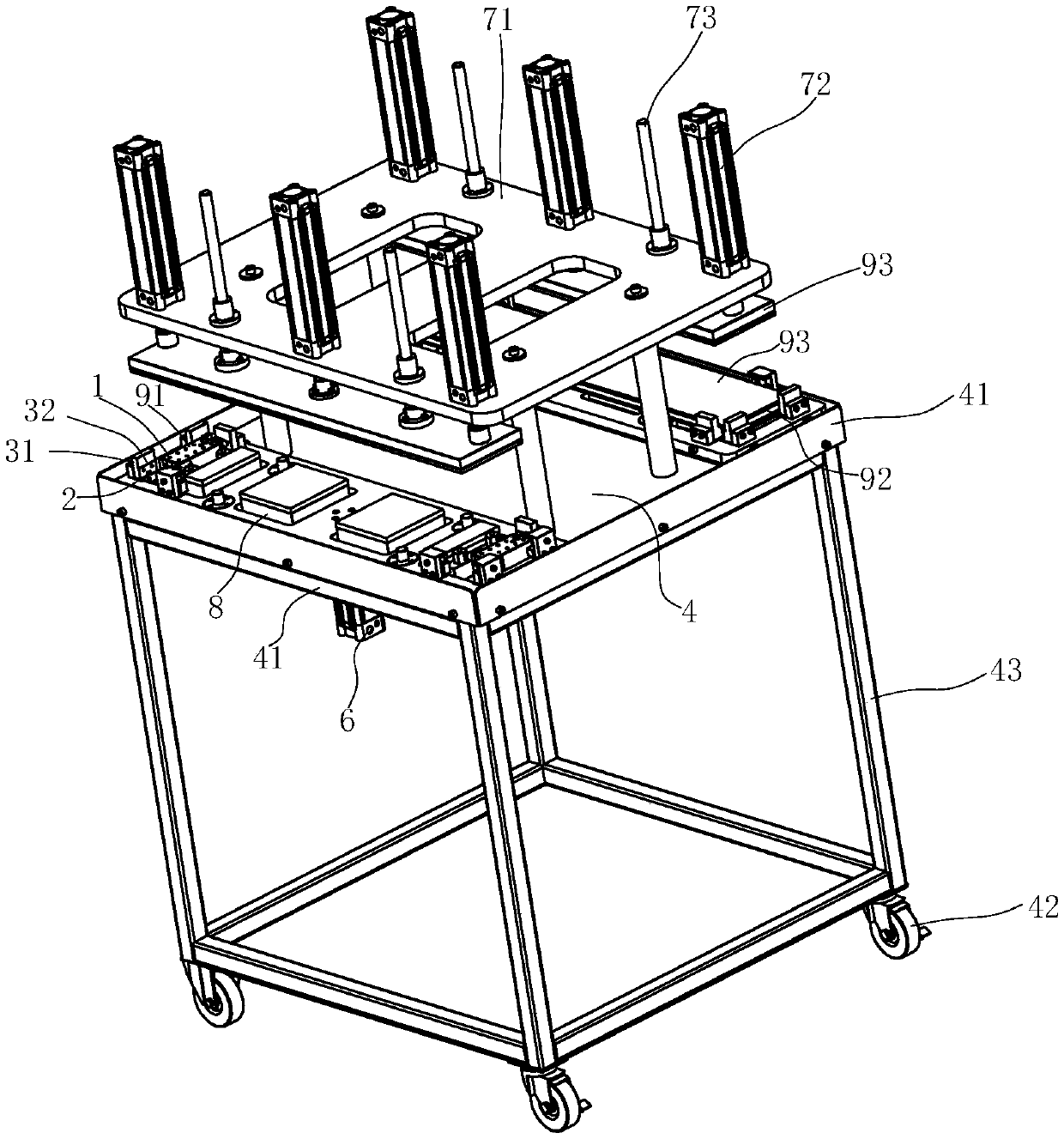

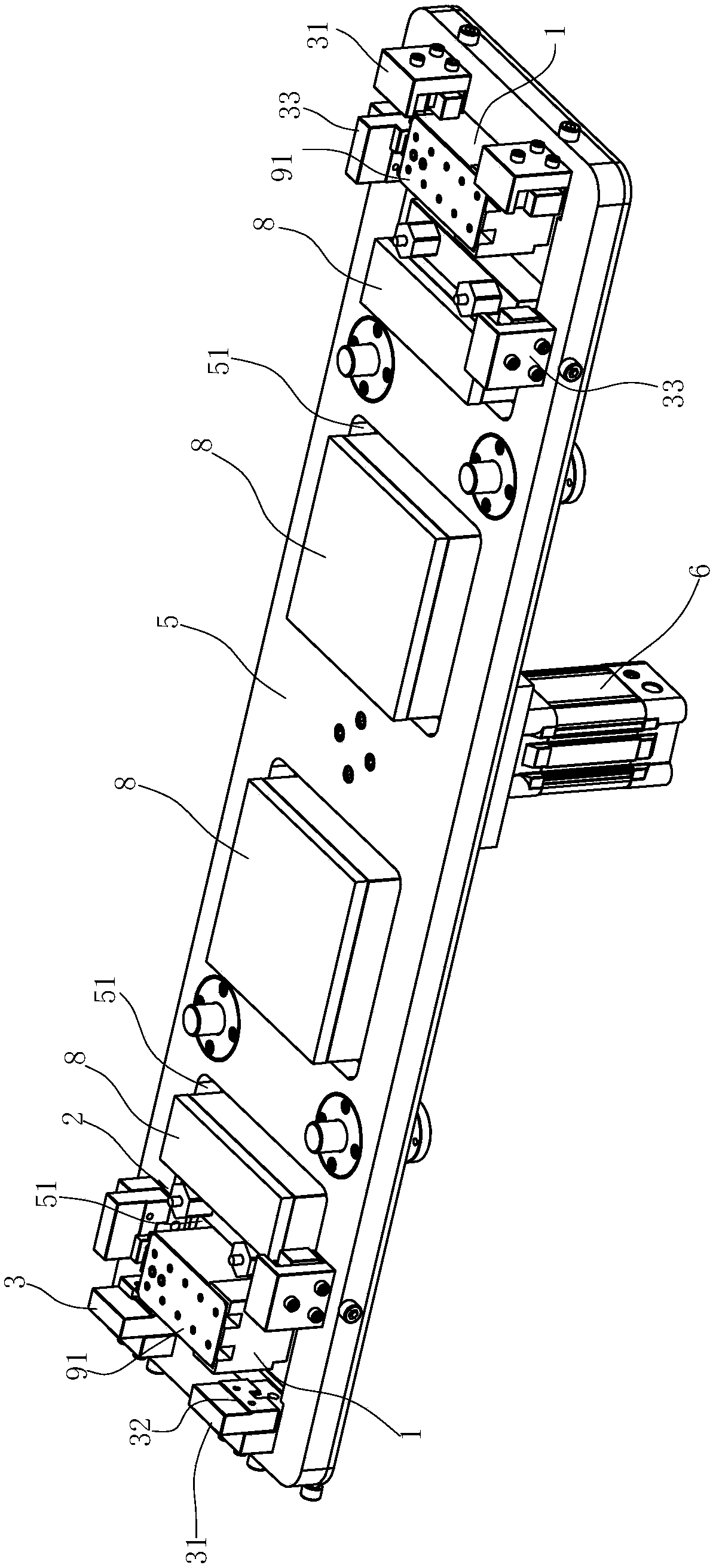

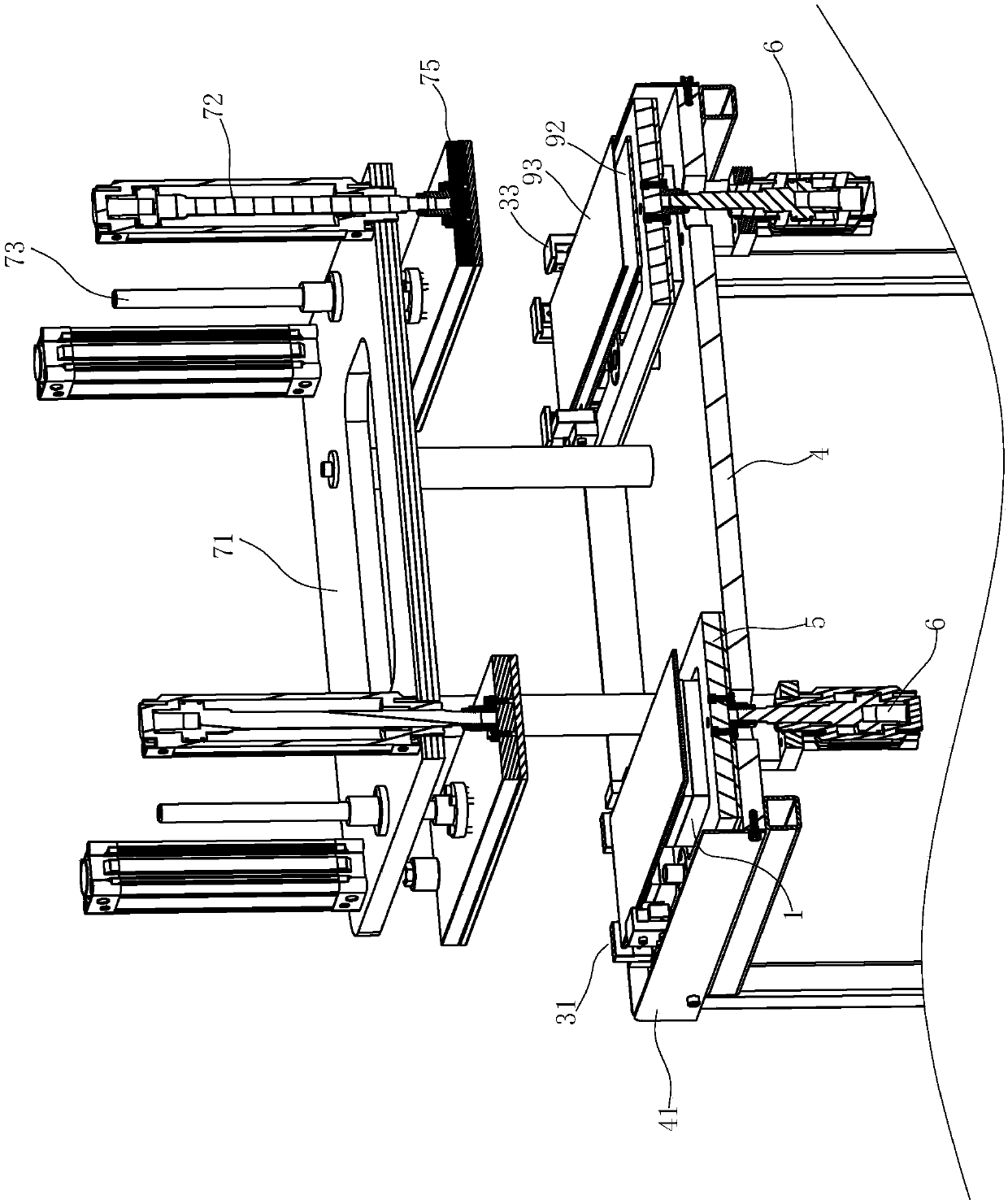

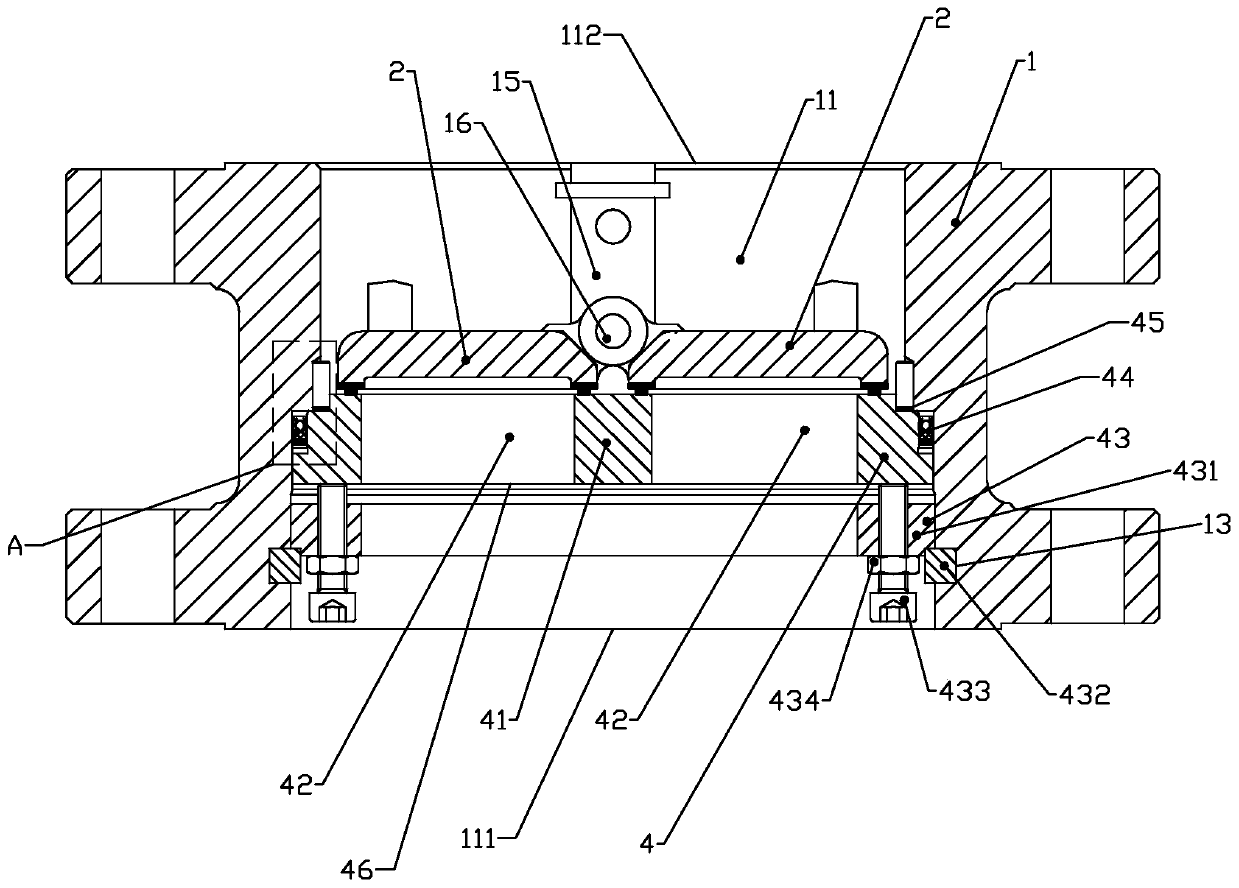

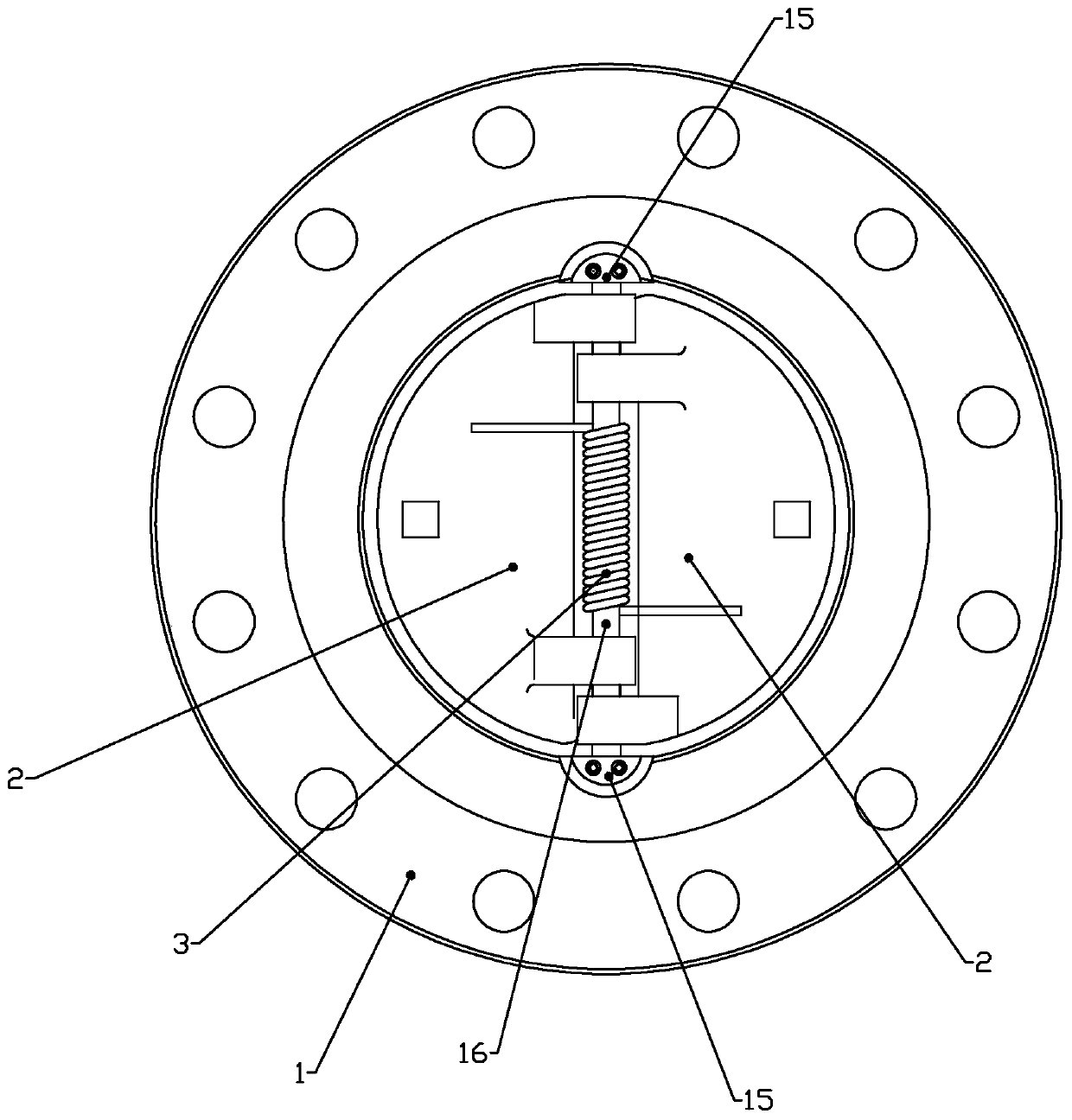

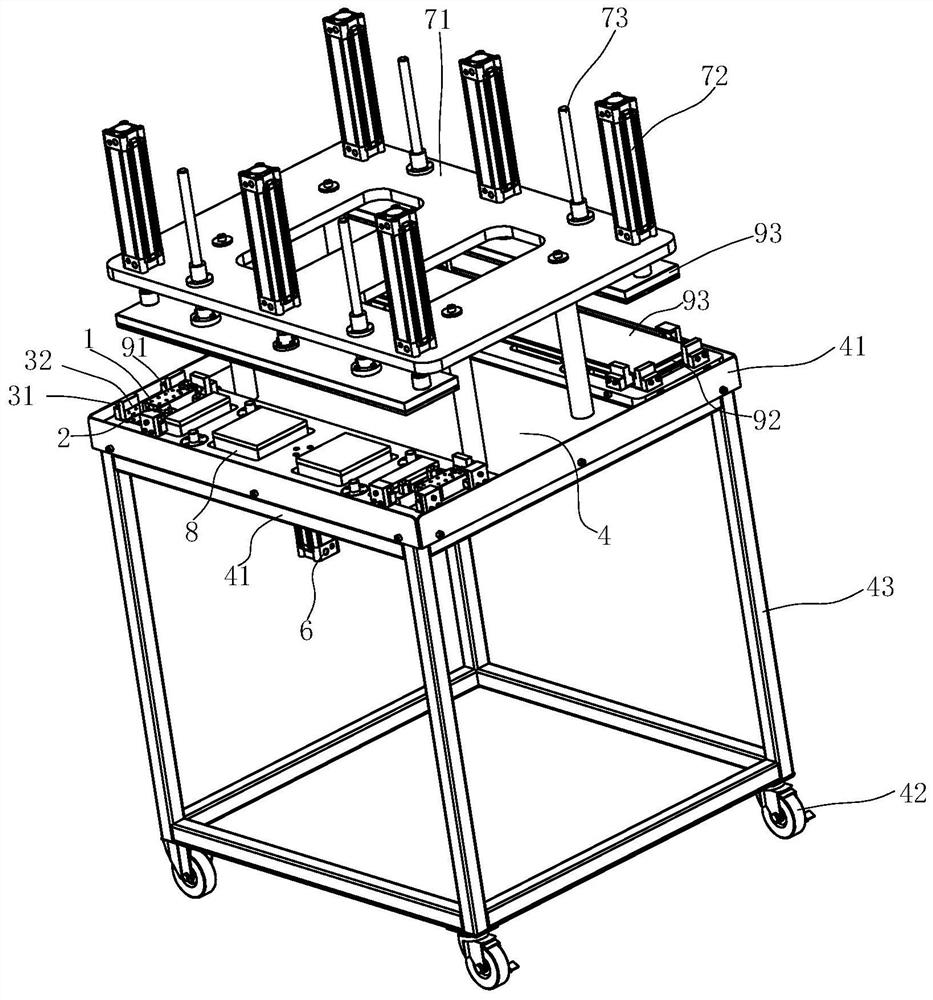

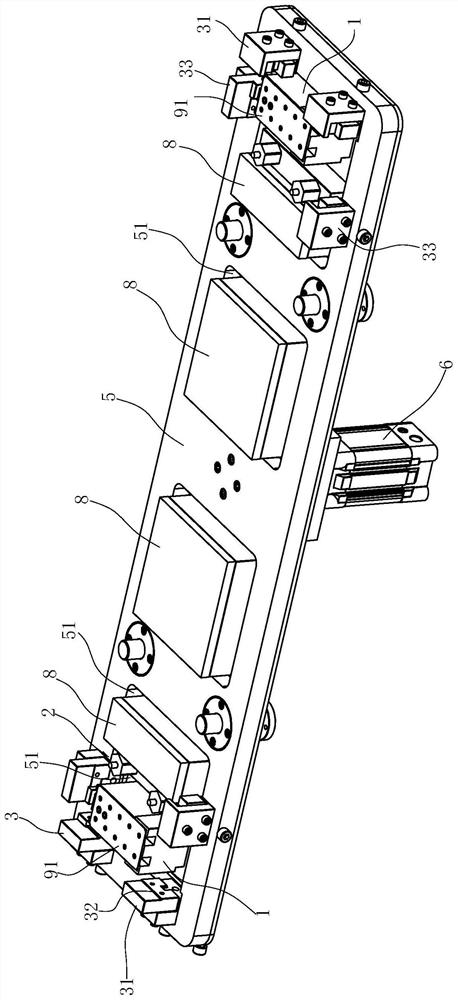

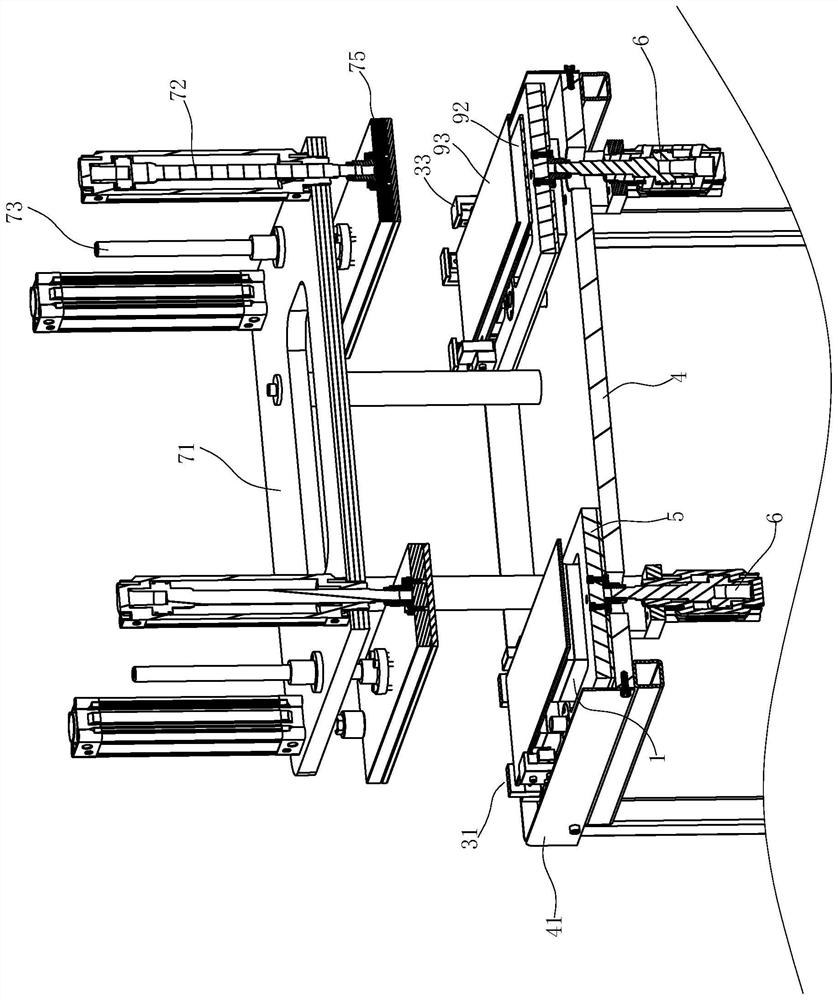

Three-workpiece simultaneous bonding tool

ActiveCN109931318APrecise positioningFlatness is easy to guaranteeFastening meansSupport surfaceEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

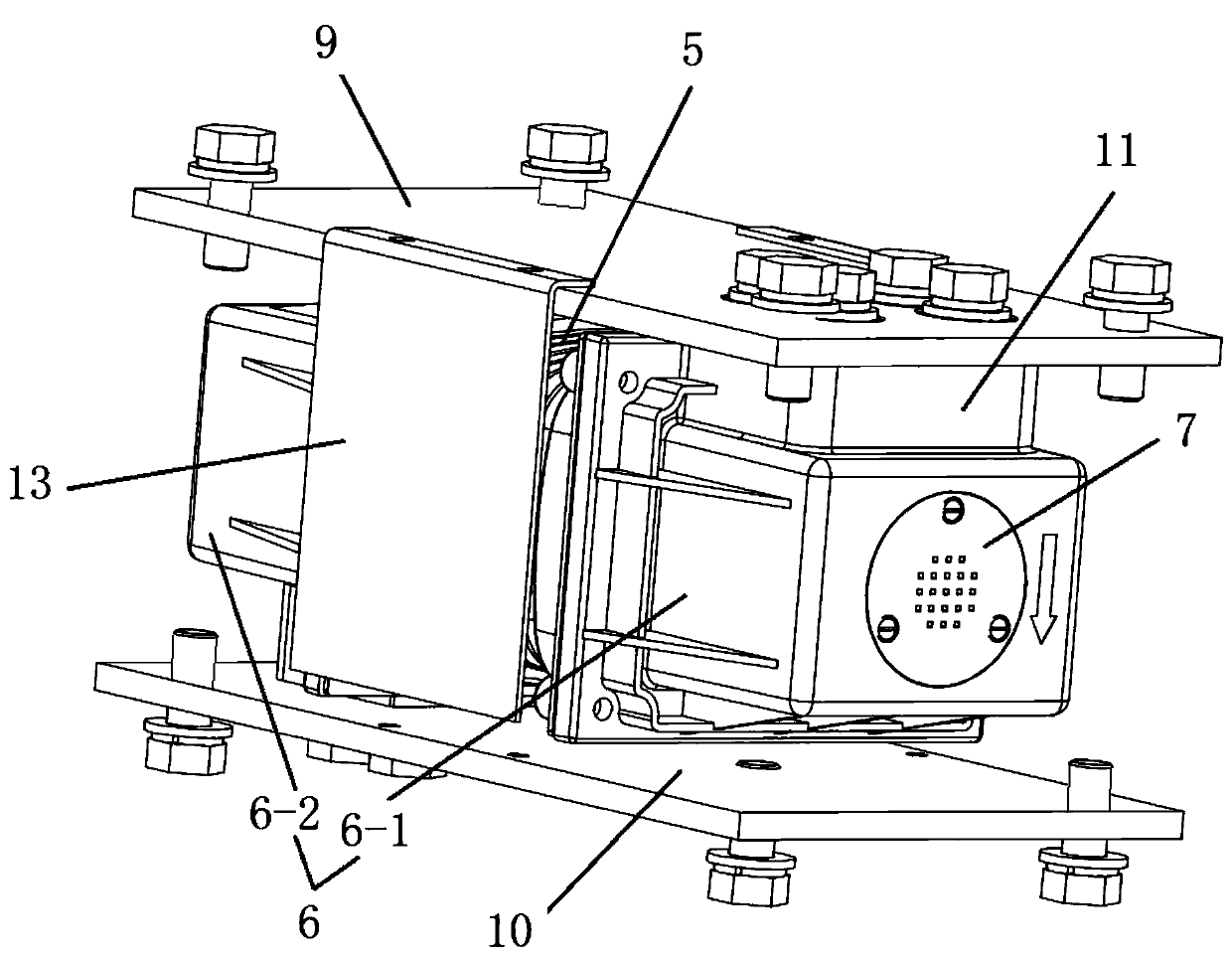

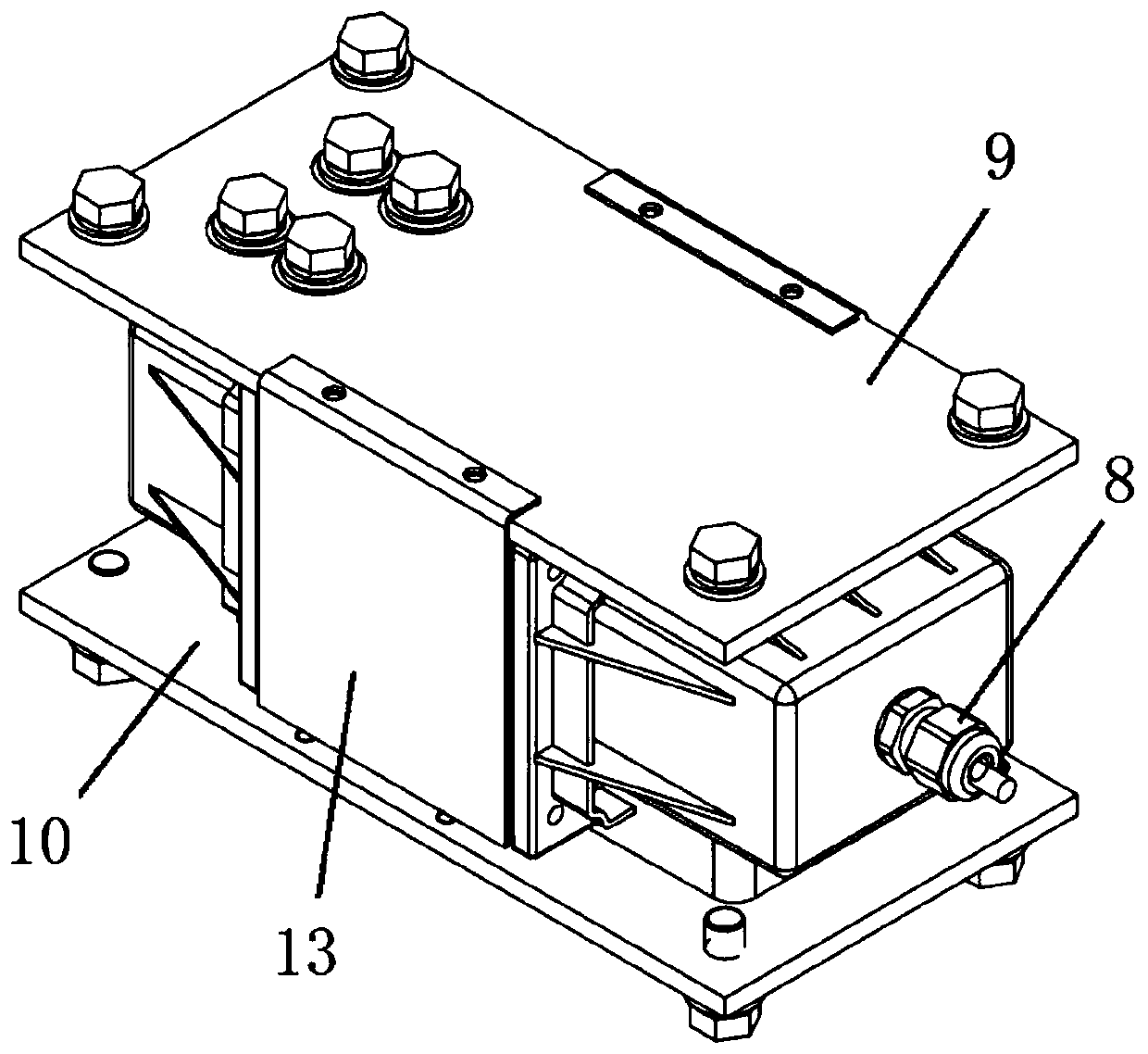

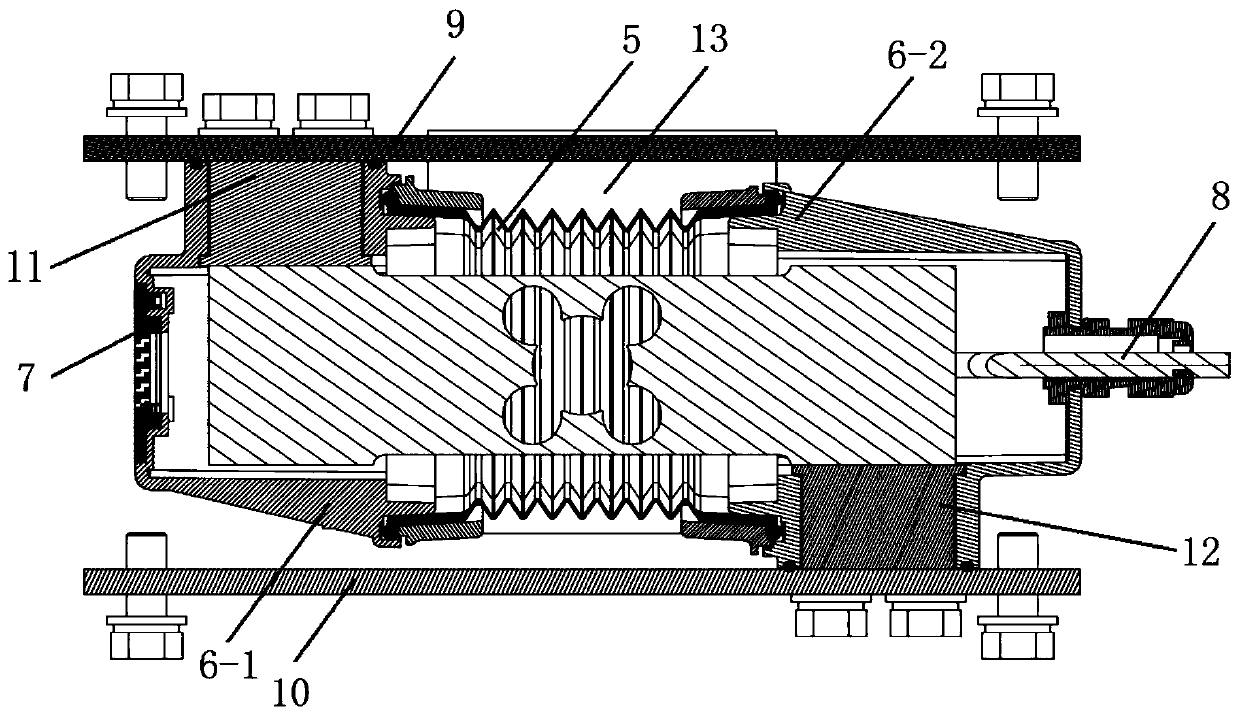

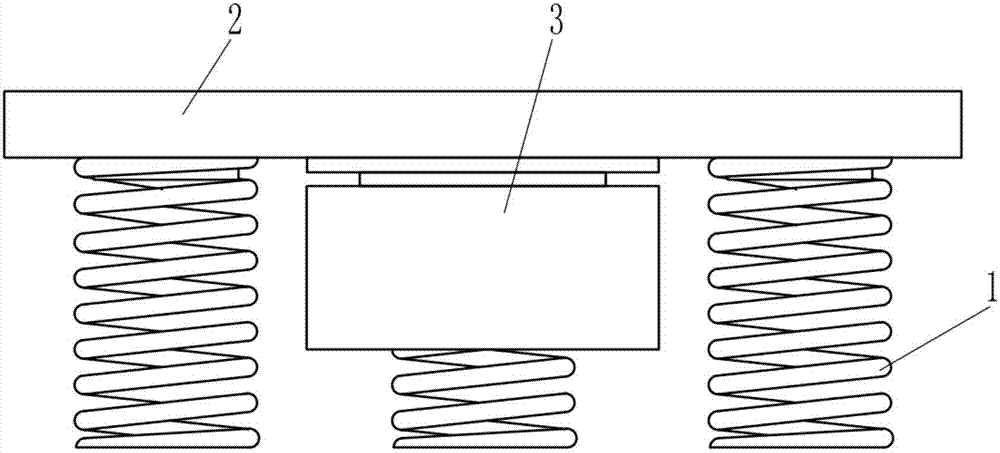

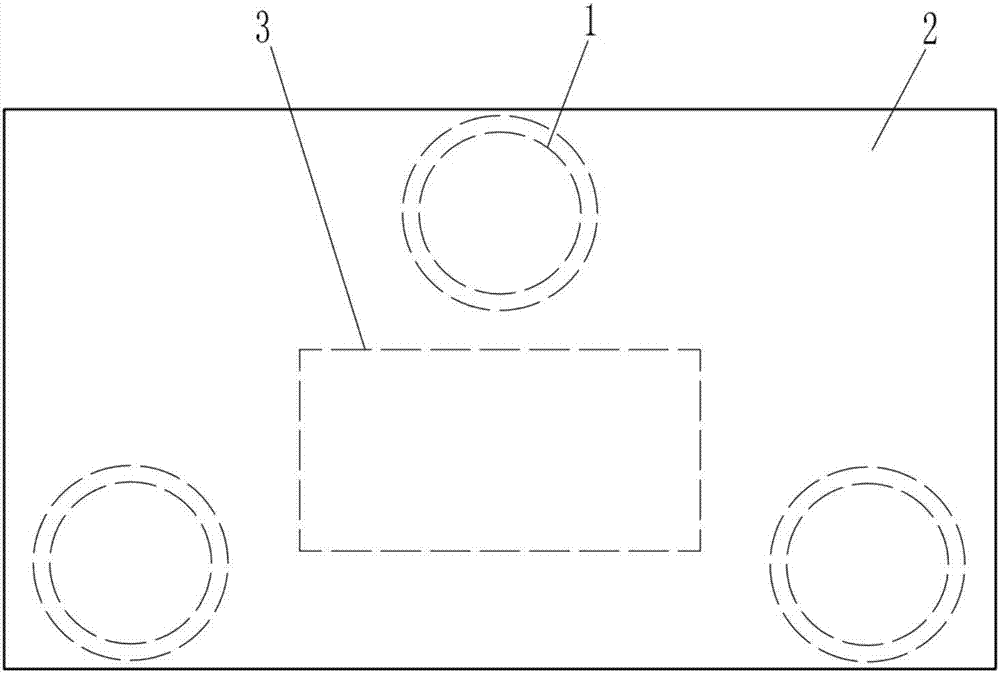

Low-noise vibration excitation support

The invention belongs to the field of concrete tamping devices, and discloses a low-noise vibration excitation support, which includes a vibration exciter, a connection base and an elastic element. The vibration exciter is tightly fixed on the connection base, and the elastic element is located under the connection base. And it elastically supports the connection base, and the elastic element is arranged around the exciter. In order to avoid the resonance of the connecting platform when the vibrator is working, the first-order structural modal frequency of the connecting platform is greater than 1.15 times the maximum operating frequency of the vibrator; the vibration system composed of the elastic element and the weight of the heavy object supported during operation The first-order natural frequency is less than half of the minimum working excitation frequency of the vibrator. The structure of the low-noise excitation support of the present invention is simple, easy to use, and high in vibrating efficiency; it has the characteristics of low working noise, health and environmental protection, each part is not easily damaged, and it is economical and environmentally friendly, and can be widely used in concrete prefabrication The vibrating production of parts can be applied to the vibrating production of castings.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +2

A prefabricated exterior wall structure

ActiveCN107700697BSimple structureEconomically reasonableWallsHeat proofingAccessory structureLoad-bearing wall

The invention discloses a prefabricated fabricated type structure of an external wall, and relates to the field of constructional engineering. The prefabricated fabricated type structure of the external wall is composed of a thermal insulating composite wall standard piece and an auxiliary structure; the thermal insulating composite wall standard piece comprises a prefabricated type external wallload-bearing wall standard piece, a prefabricated type external wall non-bearing wall standard piece and a prefabricated type external wall load-bearing wall internal and external corner standard piece; and the prefabricated type external wall load-bearing wall standard piece is provided with an assembly type oppositely-pulling rod which is used for positioning and installing of a load-bearing wall construction formwork. According to the prefabricated fabricated type structure of the external wall, the structure is simple, economical and reasonable, the technology is advanced, using is convenient, and the prefabricated fabricated type structure is the best construction method of a composite wall structure and has good popularizing value.

Owner:河南纽沃建筑科技有限公司

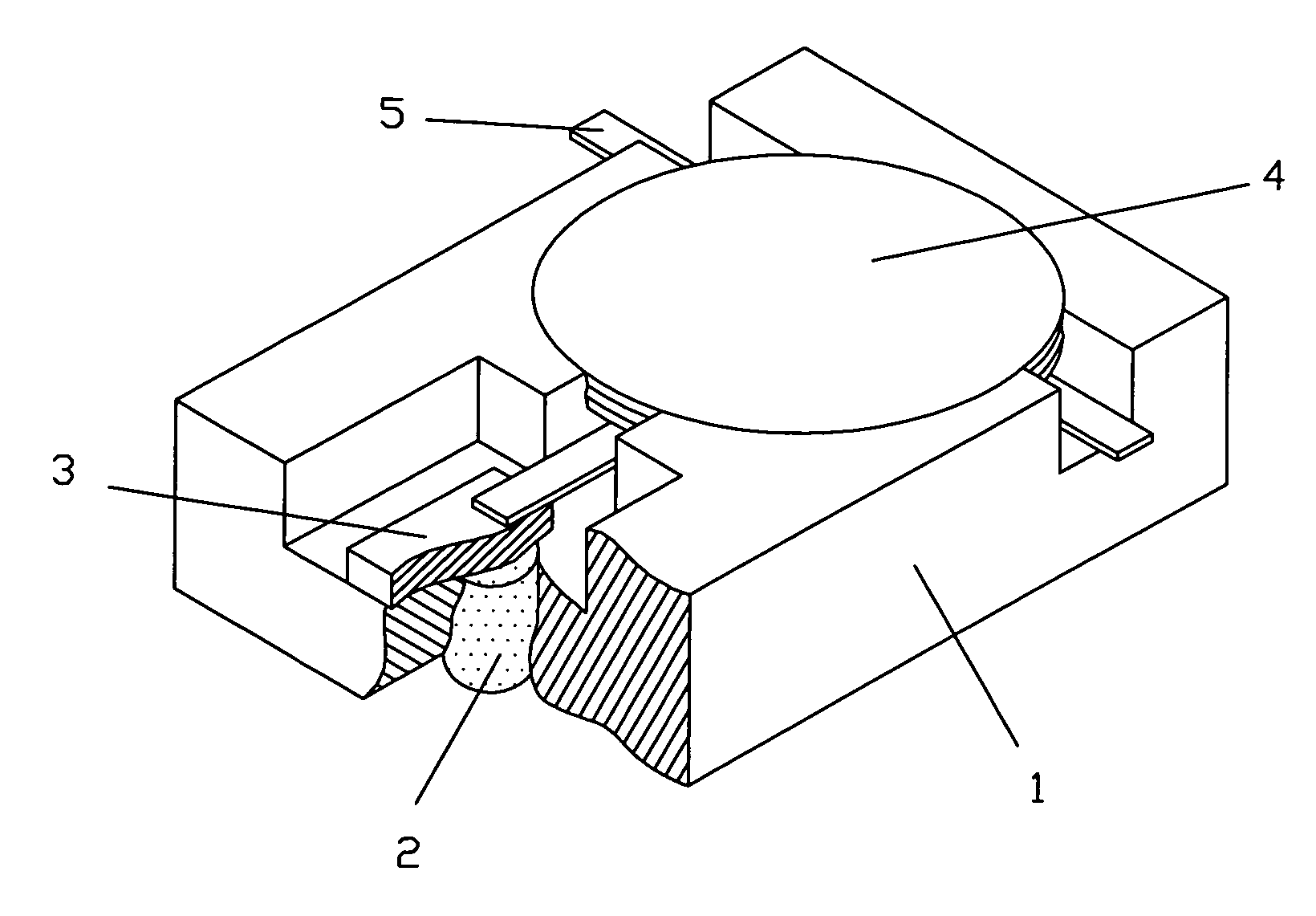

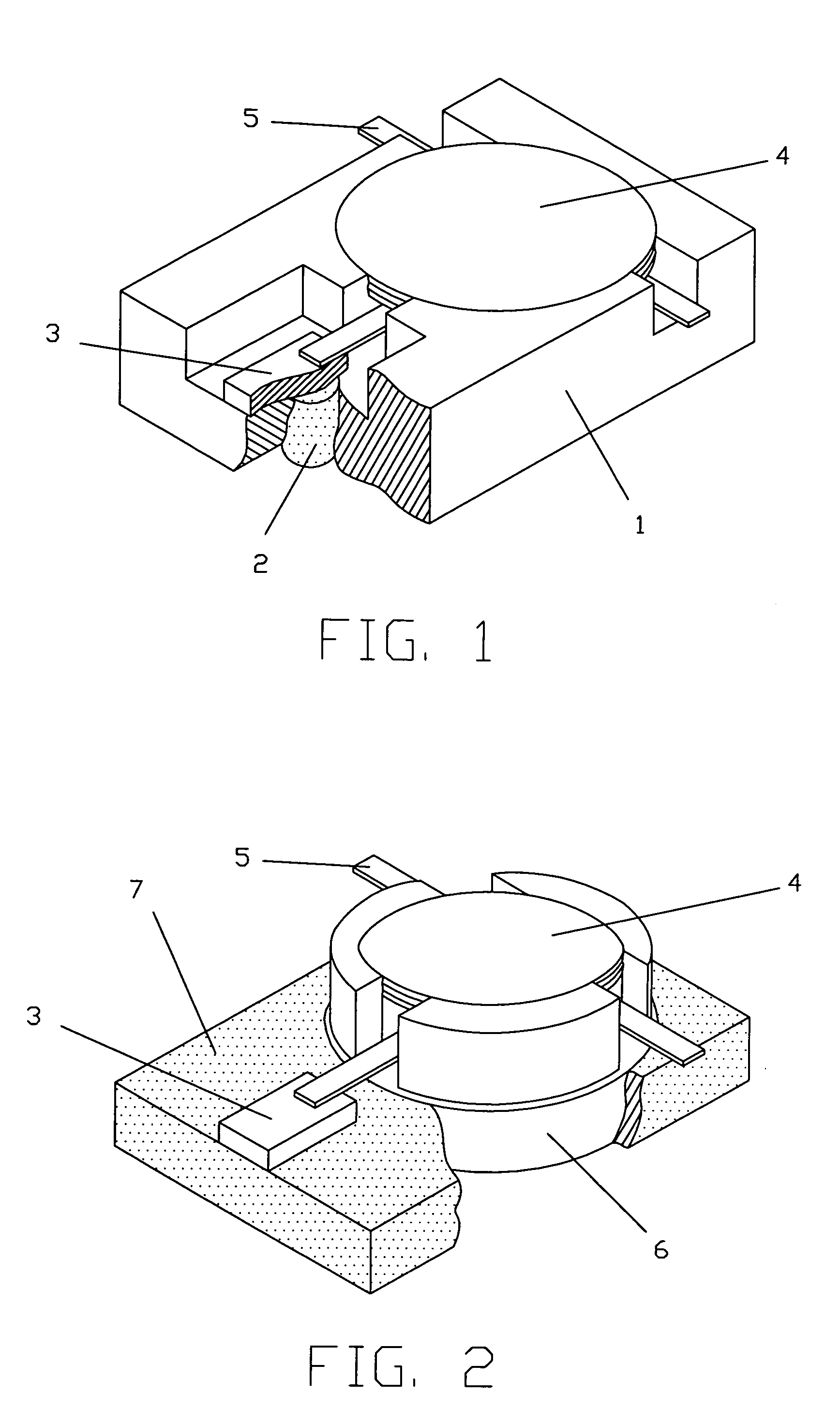

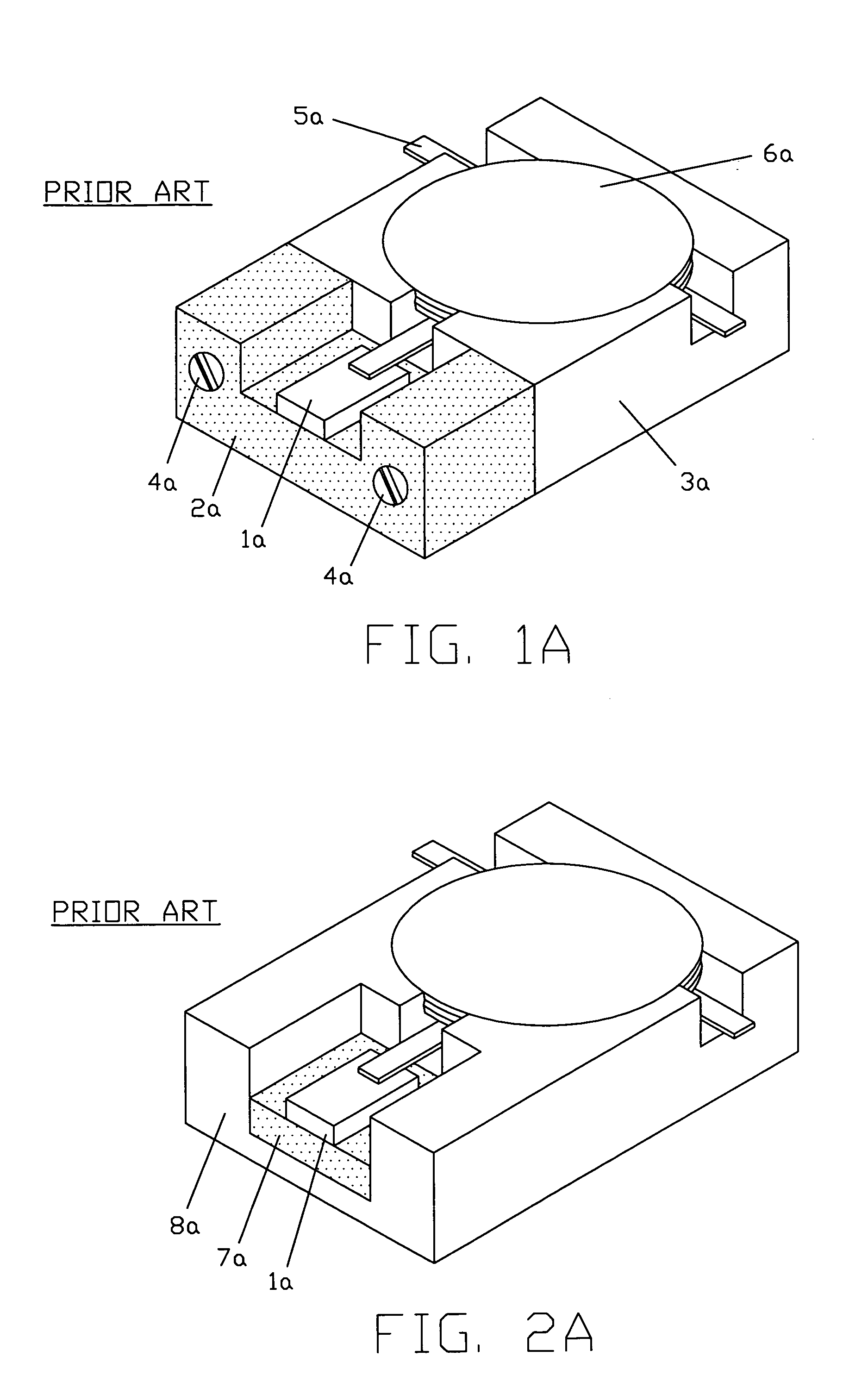

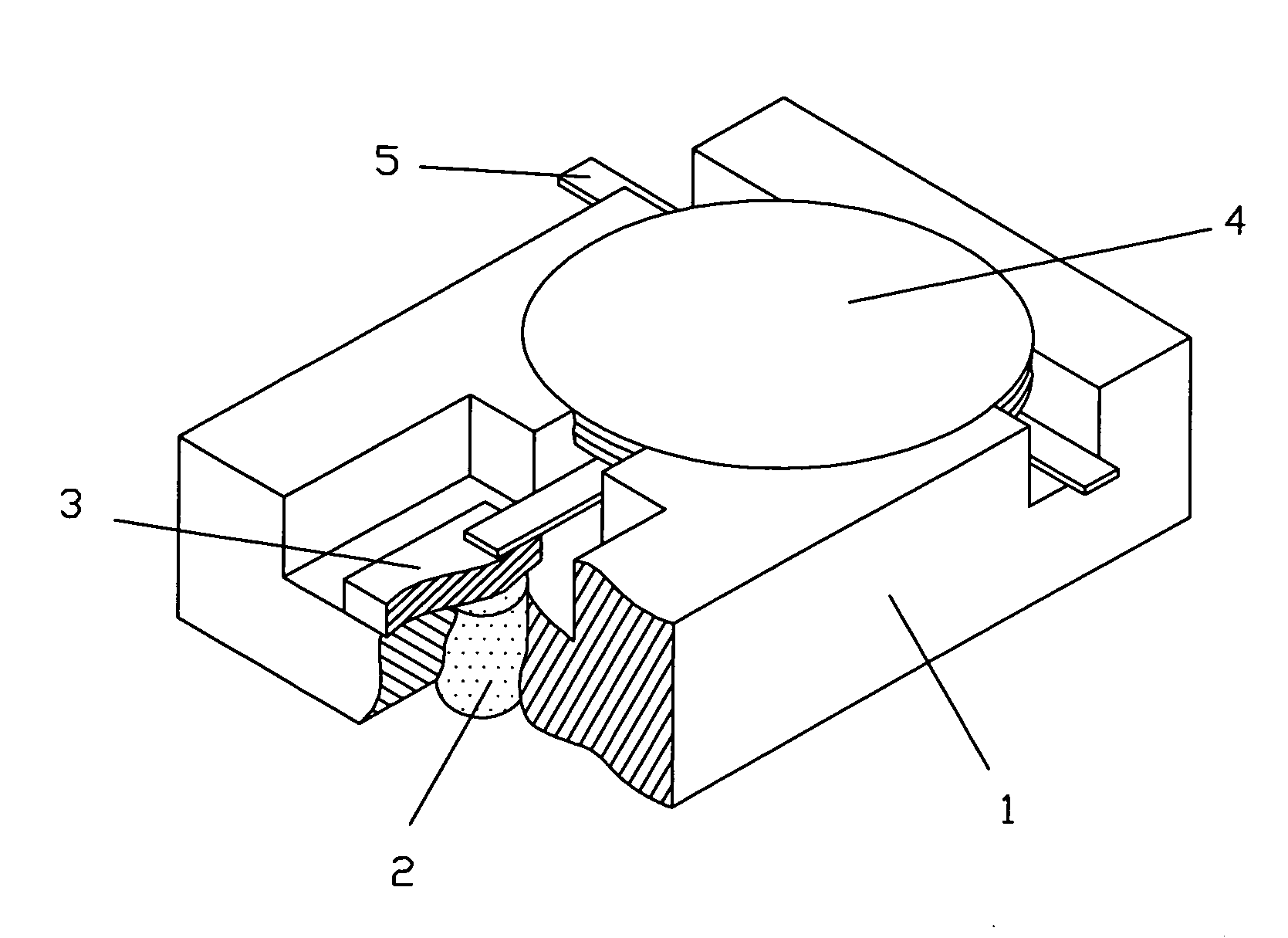

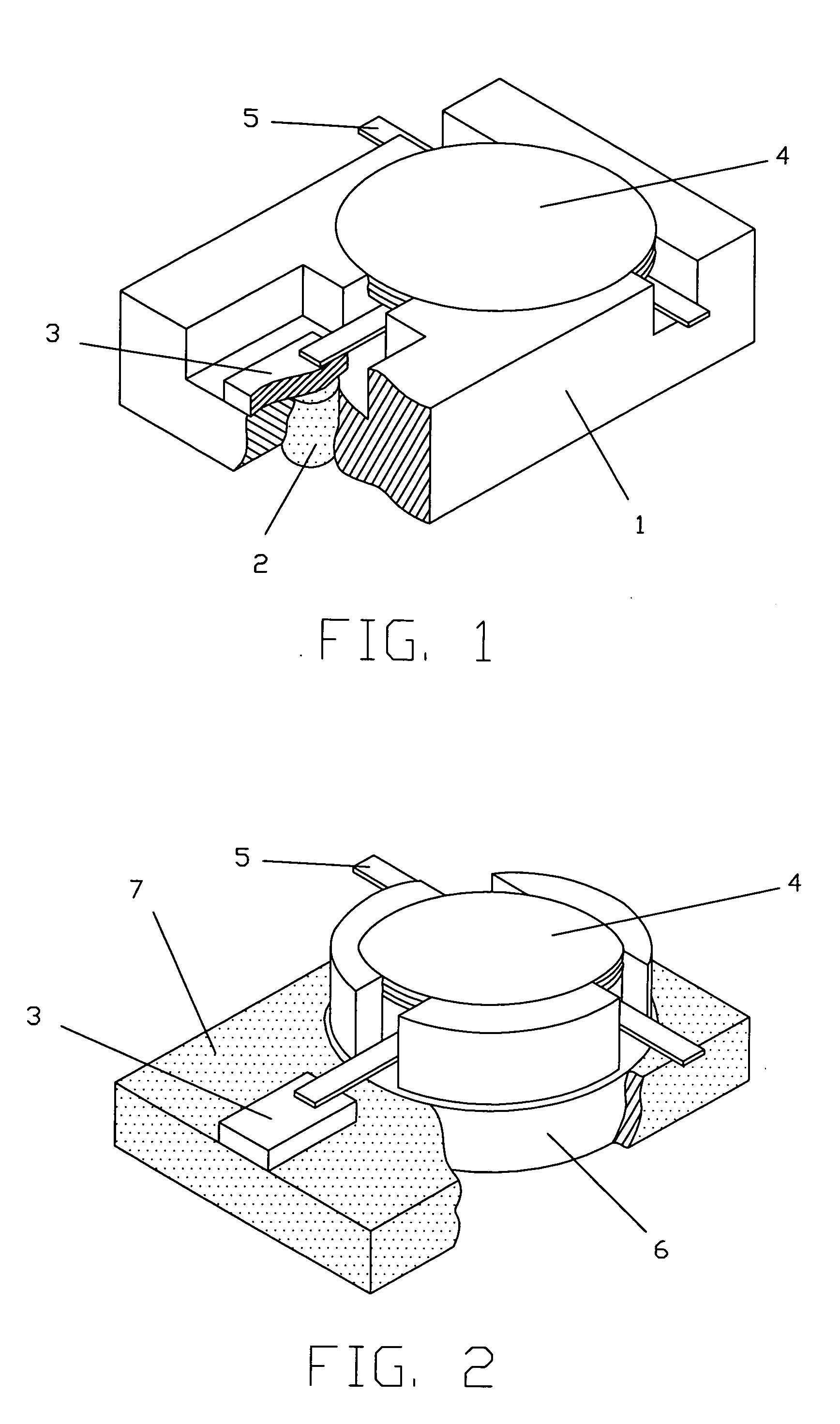

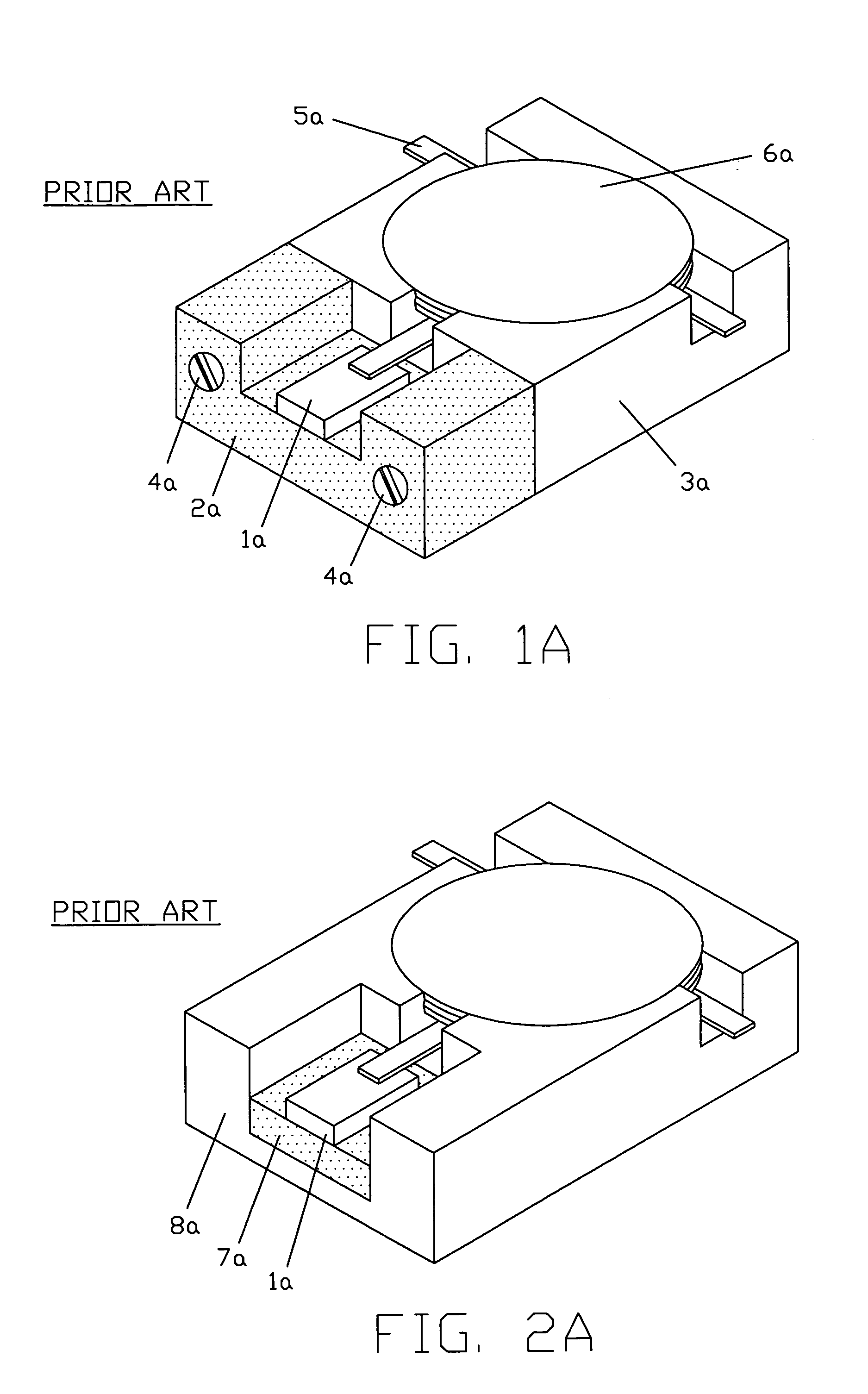

Nonreciprocal device having heat transmission arrangement

ActiveUS6956446B2Quality improvementTight toleranceWaveguide type devicesCooling/ventilation/heating modificationsMagnetic susceptibilityHeat transmission

Owner:RENAISSANCE ELECTRONICS & COMM LLC

Nonreciprocal device having heat transmission arrangement

ActiveUS20050134399A1Quality improvementTight toleranceWaveguide type devicesCooling/ventilation/heating modificationsMagnetic susceptibilityElectricity

An isolator with resistive termination and carbon steel housing wherein required magnetic performance is combined with improved efficiency of transmission of heat from termination to the heat sink. The improvement is achieved due to the copper / aluminum plug that mechanically and electrically connects the soldering base of termination to the base of isolator, which in operation is installed on the heat sink. The plug is pressed into the housing from the base side to provide tight coplanarity tolerance to exposed end of the plug and the base without any secondary machining. The termination is soldered to the opposite end of the plug, which is flush to or slightly above the top surface of the housing. Thus, magnetic flux required for operation of isolator is looped through a material having good magnetic susceptibility, and heat from the termination is transmitted to the heat sink through a material having high coefficient of heat transmission. Another embodiment of the structure is also described in this disclosure. In second embodiment, the entire housing is made of copper / aluminum, but a magnetic chamber of carbon steel supporting the magnetic loop is pressed into the housing. The termination is soldered directly to the housing and, therefore, the same efficiency for the heat dissipation as for the preferred embodiment is achieved.

Owner:RENAISSANCE ELECTRONICS & COMM LLC

Exterior wall cladding and technique for producing the same

InactiveCN101457577BHigh strengthLow thermal conductivityCovering/liningsSynthetic resin layered productsEpoxySurface layer

The invention relates to a board and a production technology thereof, in particular to an exterior wall cladding and a production technology thereof. The exterior wall cladding sequentially comprises an extruded sheet layer, a bo-mei board layer and a metallic paint layer from bottom to top. The production technology comprises the following steps: the surface of the bo-mei board is added with a layer of mixture formed by magnesium oxide and putty powder, and the mixture is trowelled; the surface layer of the processed bo-mei board is polished to lead the surface to be level; the surface layerof the polished bo-mei board is coated with a layer of fluorocarbon metal paint; an XPS extruded sheet with the same size as the bo-mei board is processed; the underside of the processed bo-mei boardis agglutinated with the processed XPS extruded sheet by epoxide resin. The exterior wall cladding has good heat preservation and insulation performance, is energy-saving and environment-friendly, has level and beautiful surface, and is convenient for construction.

Owner:南京高迪建筑科技研究院有限公司

Double flap check valve

The invention relates to a double flap check valve. The double flap check valve comprises a valve body, valve flaps and an elastic piece, wherein a flow channel is arranged in the valve body, the flowchannel has an inlet end and an outlet end, and the middle part of the flow channel is provided with a partition which divides the flow channel into two parts; the two valve flaps are both hinged tothe portions, located at the two ends of the partition, of the valve body or to the partition, and the two valve flaps correspondingly seal the two parts of the flow channel under the action of the elastic piece so as to form a cut-off for the flow channel; the portion, located in the flow channel, of the valve body is independently provided with a valve seat, wherein the valve seat is provided with a through hole which communicates with the flow channel so as to form a local flow channel, and the partition is located on the valve seat so as to divide the through hole into two parts; and the valve flaps are in sealing fit with the valve seat under the action of the elastic piece to form a cut-off for the through hole. Through adopting the above scheme, the double-flap check valve can improve the sealing performance.

Owner:FANGZHENG VALVE GRP

Simultaneous bonding tooling for three workpieces

ActiveCN109931318BPrecise positioningFlatness is easy to guaranteeWork holdersFastening meansSupport surfacePhysics

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

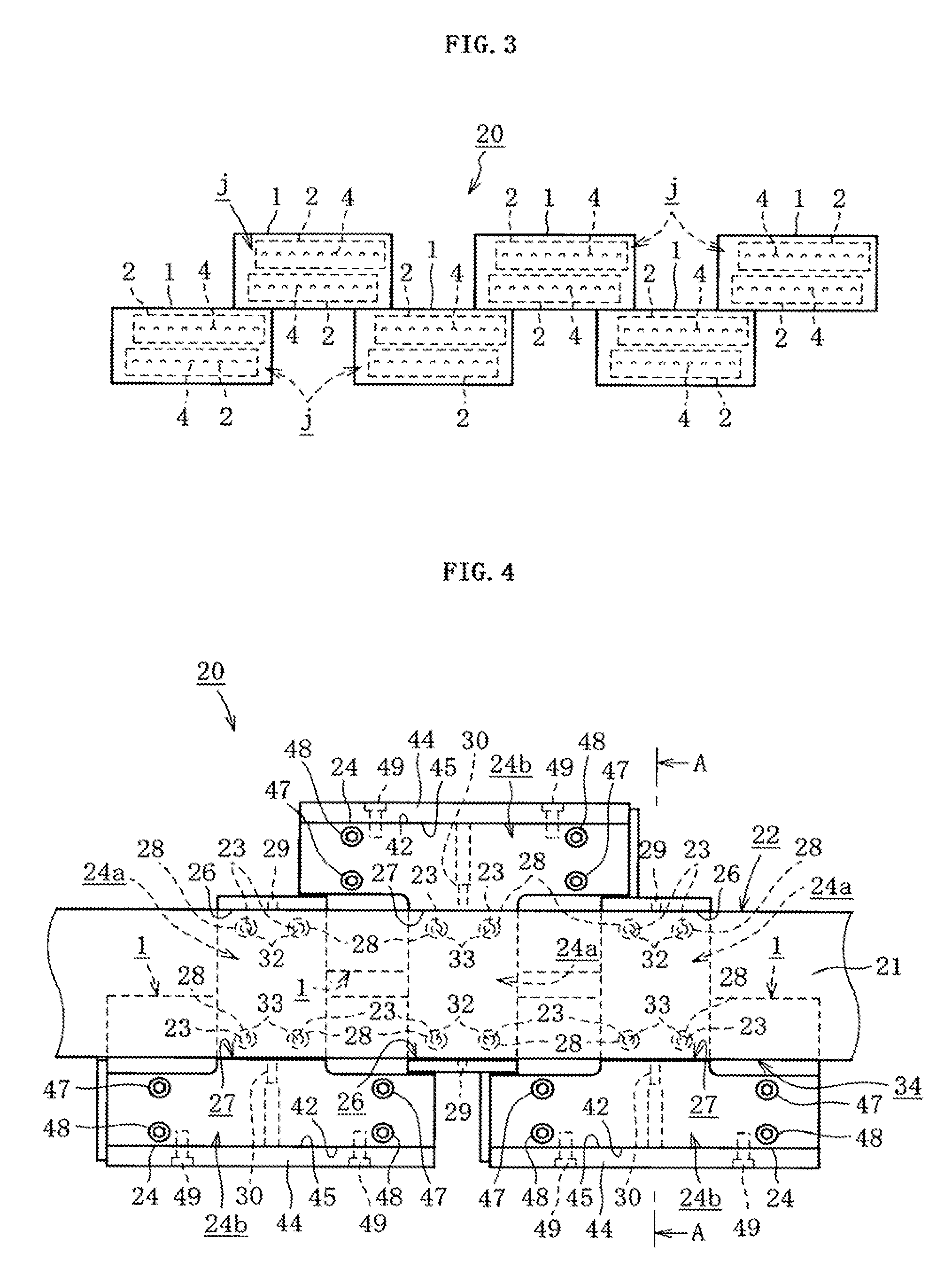

Manufacturing method of head leading member

ActiveUS20210252886A1Flatness is easy to guaranteeHigh precisionInking apparatusSpacing mechanismsPrinting pressMechanical engineering

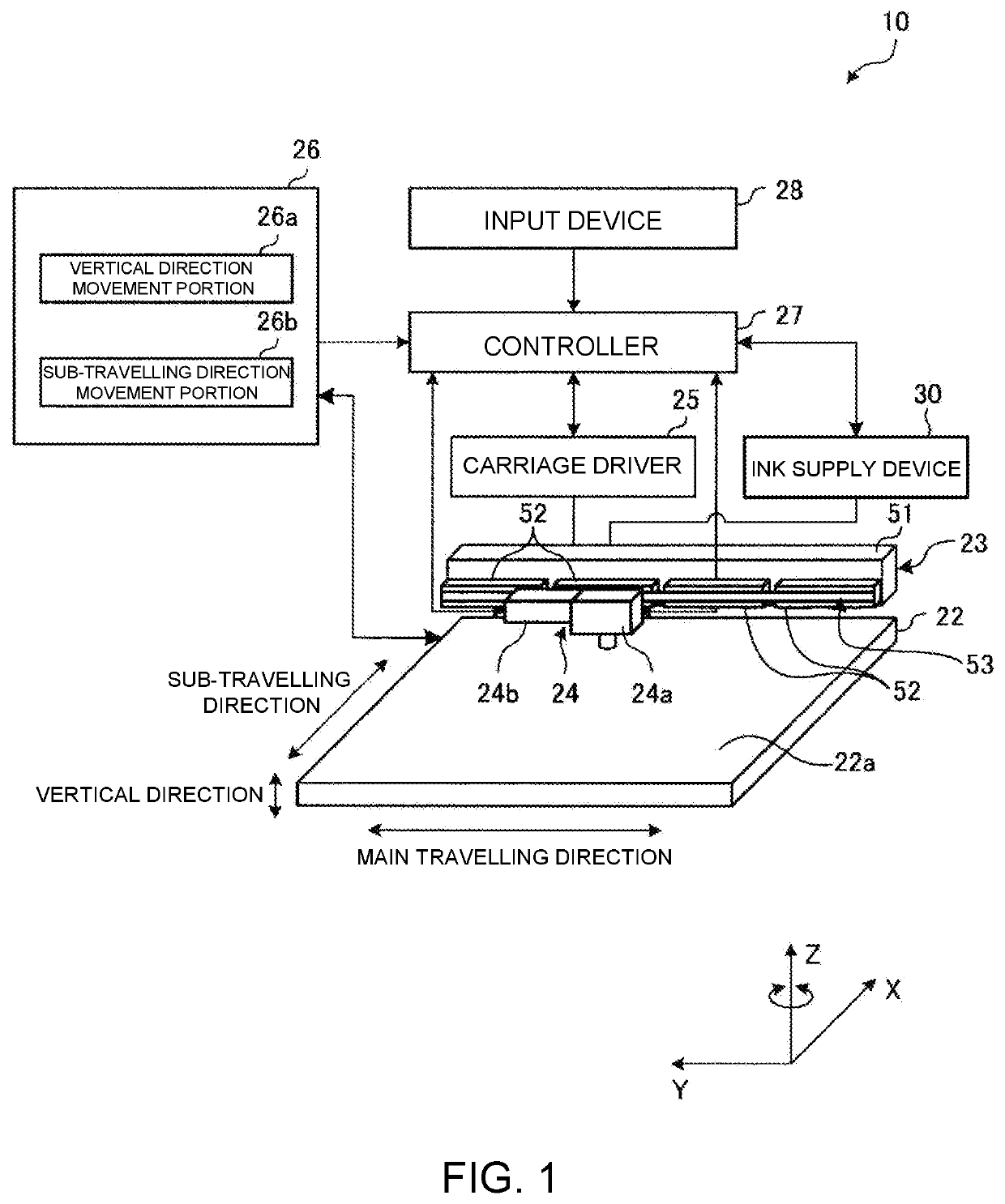

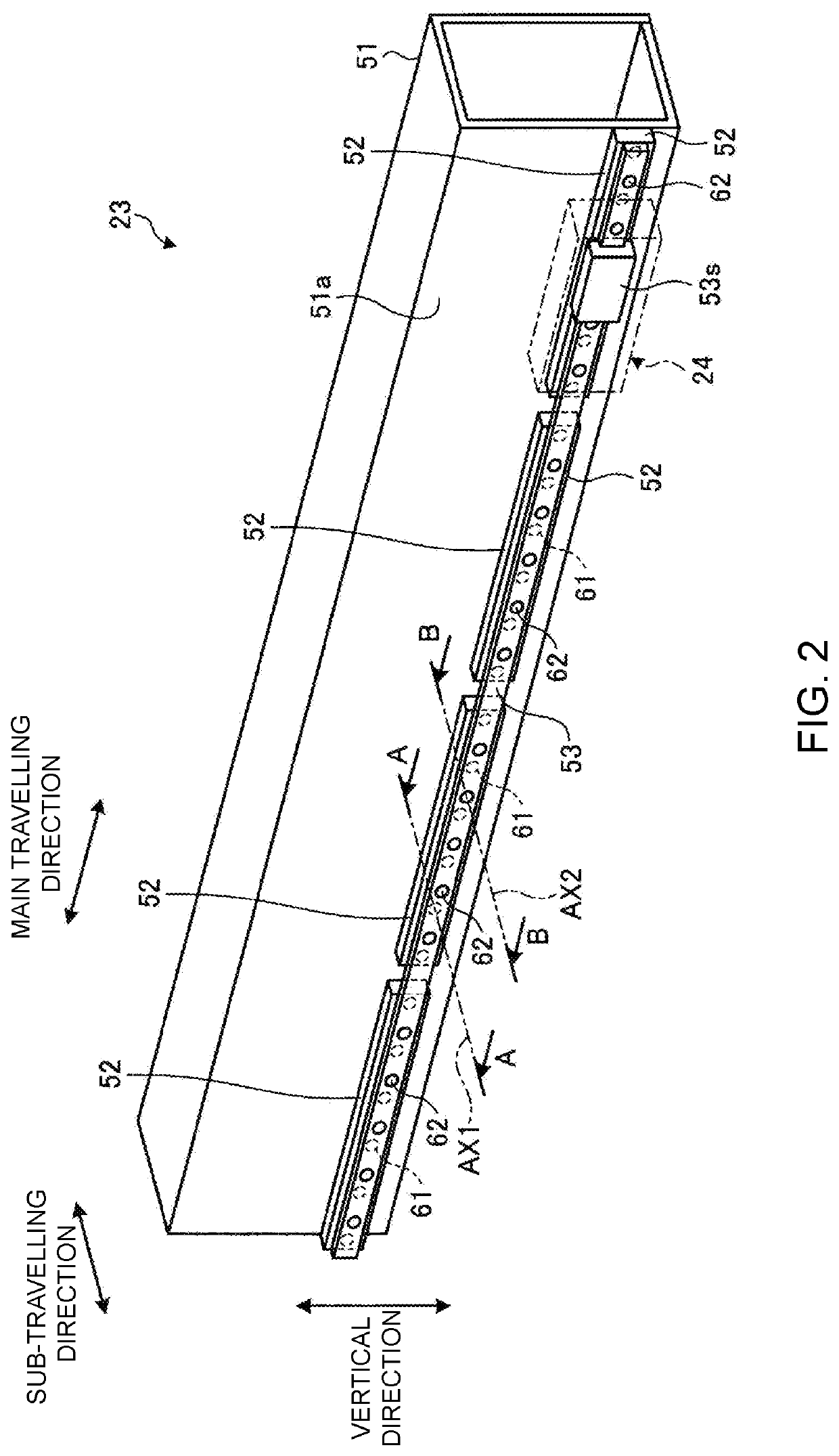

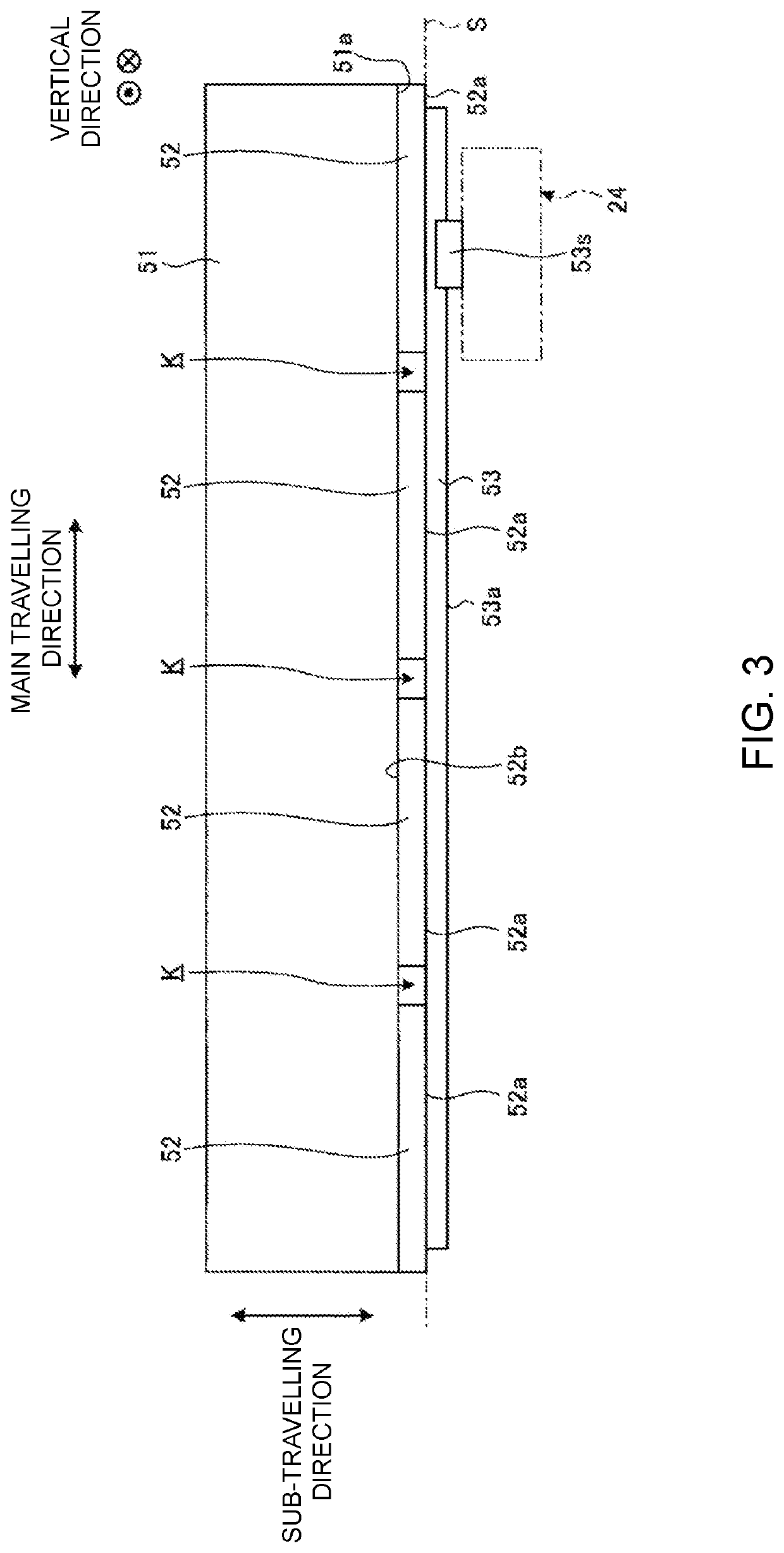

A manufacturing method of a head leading member, which is provided in a printing machine including a head for discharging an ink toward a working surface, in order to lead the head in a main travelling direction, and the manufacturing method of a head leading member including: a base member fixing step in which a base member, being like a plate, is fixed to a frame extending in the main travelling direction; a guiding reference surface shaping step in which a surface of the base member, in a state of being fixed to the frame, is so manufactured as to be a plane, being along the main travelling direction, in such a way as to shape a guiding reference surface; and a guide member supporting step in which a guide member for leading the head is set in such a way that the guiding reference surface supports the guide member.

Owner:MIMAKI ENG

Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

ActiveCN101985856BConstruction quality is easy to guaranteeFlatness is easy to guaranteeForms/shuttering/falseworksForming/stuttering elementsRebarCoupling beam

The invention relates to a removal-free prefabricated reinforced concrete template with cross holes inside. The template is a wall template, a floor template, a roof template, a T-shaped template, an L-shaped template, a cross template, a coupling beam template, a beam template or an upright template. A plurality of longitudinal through holes and a plurality of horizontal through holes parallel to the surface are arranged in the template. The plurality of longitudinal through holes and the plurality of horizontal through holes form cross channels. When the removal-free template is prefabricated in factories, 70-80% of stress reinforced concrete is prefabricated in the template, which facilitates industrialization production, transportation and hoisting, and realizes that each layer of house wall template and the floor template are supported once, the concrete is repoured, after the current layer of concrete is poured, the next layer construction is immediately carried out, the construction period of the house is shortened, meanwhile labour is saved, the construction speed is quickened and the house cost is reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

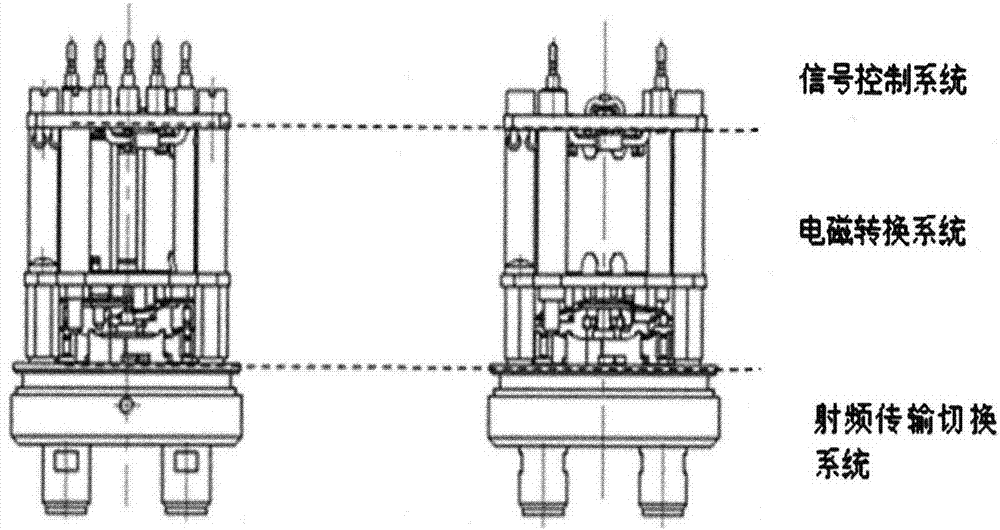

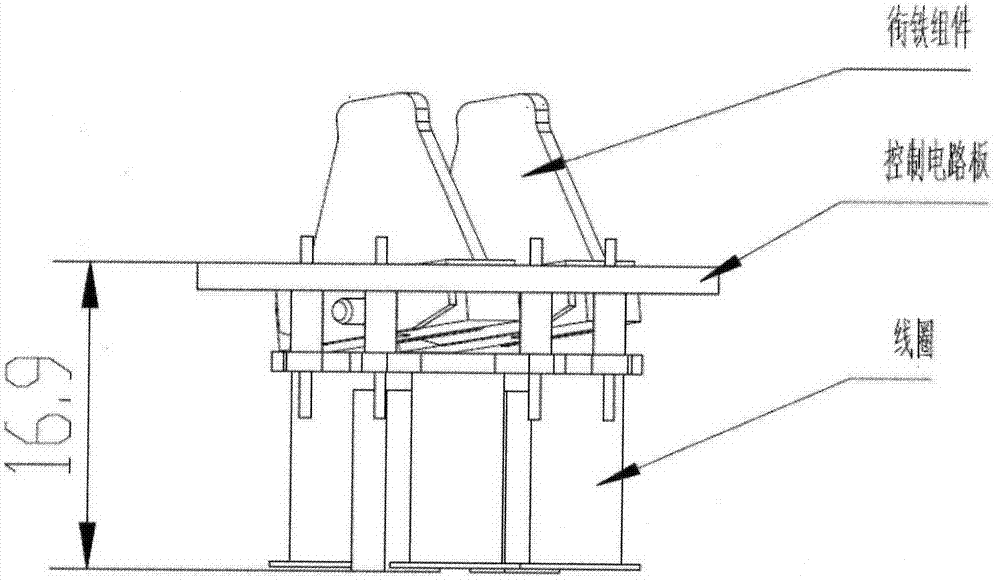

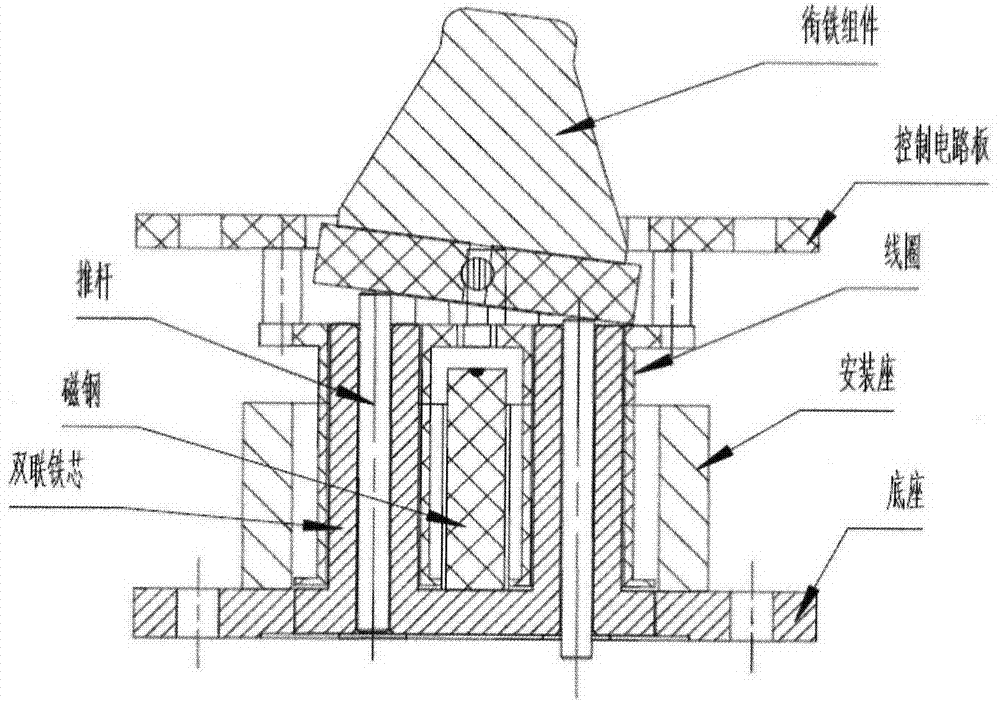

A Design of a Single Helix Type Transfer Switch

InactiveCN104821242BFlatness is easy to guaranteeReduce failure rateSwitch power arrangementsElectromagnetic relay detailsEngineeringFailure causes

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Head leading member, printing machine, and manufacturing method of head leading member

ActiveUS11020995B2Flatness is easy to guaranteeHigh precisionInking apparatusSpacing mechanismsEngineeringPrinting press

To provide a head leading member with which it is possible to inexpensively lead a head with a high level of accuracy. A head leading member is a head leading member, provided in a printing machine that includes a head to discharge ink toward a working surface, for leading the head in a main travelling direction; and the head leading member comprises; a frame extending in the main travelling direction; a base member fixed to the frame, and having a guiding reference surface that is performed with a manufacture so as to be planar along the main travelling direction, in a state of being fixed to the frame; and a guide member extending in the main travelling direction and being supported on the guiding reference surface of the base member, in order to lead the head in the main travelling direction.

Owner:MIMAKI ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com