Exterior wall cladding and technique for producing the same

A production process and hanging board technology, applied in layered products, synthetic resin layered products, covering/lining, etc., can solve problems such as easy aging, complicated processing technology, and non-fireproof plastic hanging boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

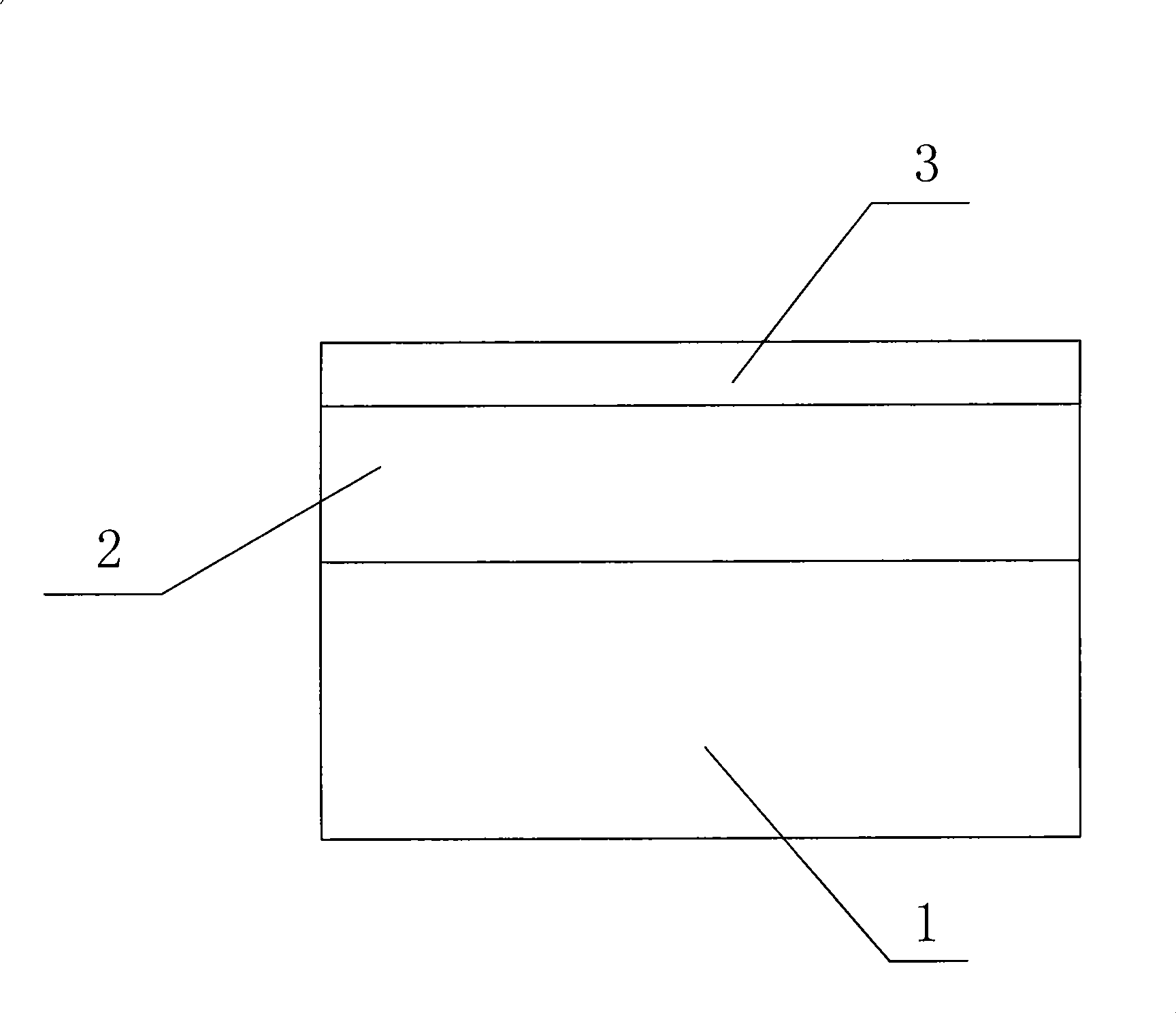

[0018] This embodiment is a kind of external wall hanging board, its layered structure is as follows figure 1 As shown, from bottom to top are extruded board layer 1, glass magnesium board layer 2 and metal paint layer 3. The extruded board layer 1 is an XPS extruded board with a thickness of 20-100 cm, the thickness of the glass magnesium board layer 2 is 6-12 cm, the metal paint layer 3 is a fluorocarbon metal paint layer, and the surface of the glass magnesium board layer 2 is There is a flat surface layer mixed with magnesium oxide and putty powder. The flat surface layer is integrated with the glass magnesium board layer 2, and a fluorocarbon metal paint layer is sprayed on the flat surface layer of the glass magnesium board layer 2. The extruded board layer 1 and the glass magnesium board layer 2 are firmly bonded by epoxy resin.

[0019] The production process of the external wall hanging board of the present embodiment comprises the following steps:

[0020] (1) When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com