Patents

Literature

1564results about How to "Fireproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

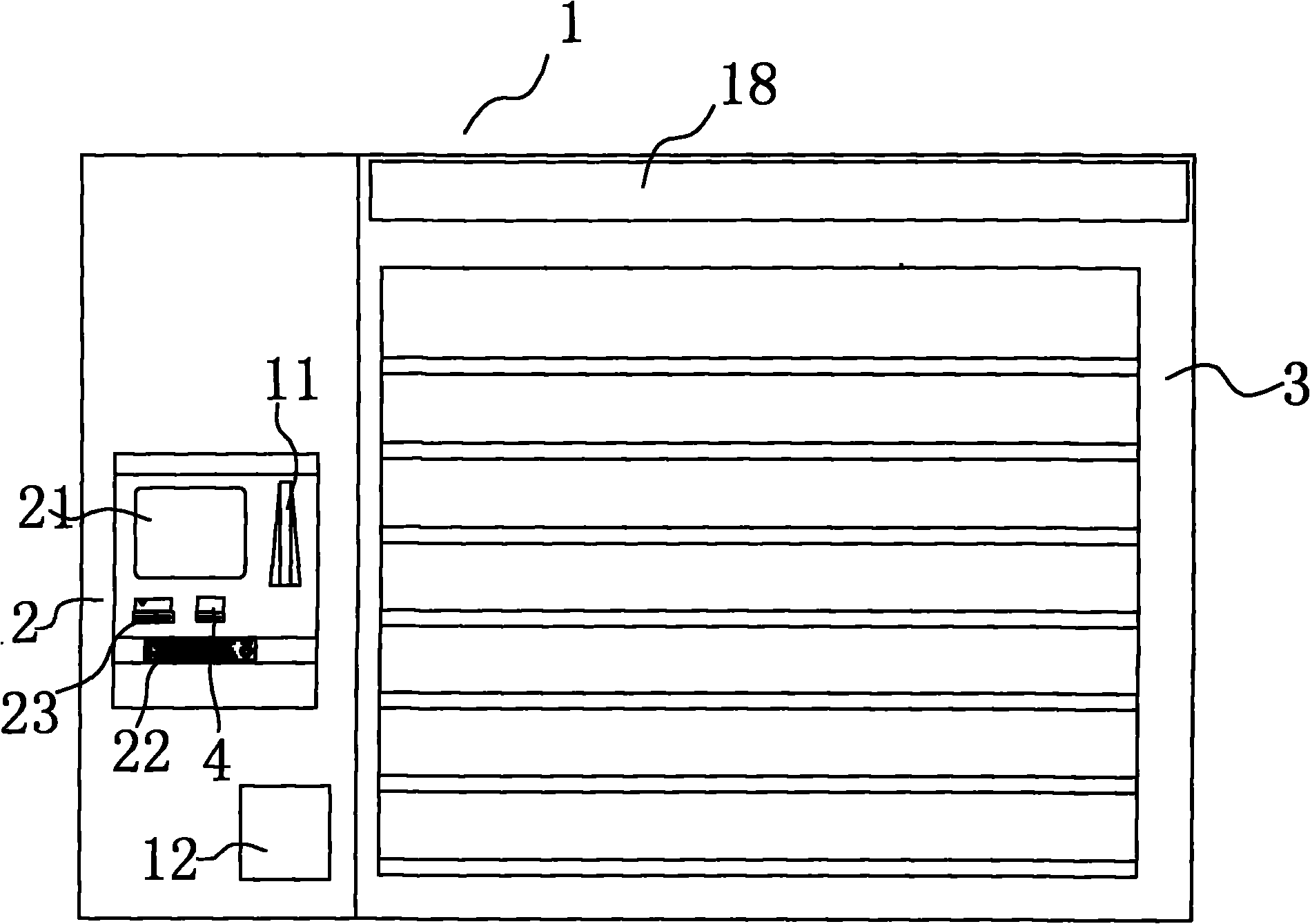

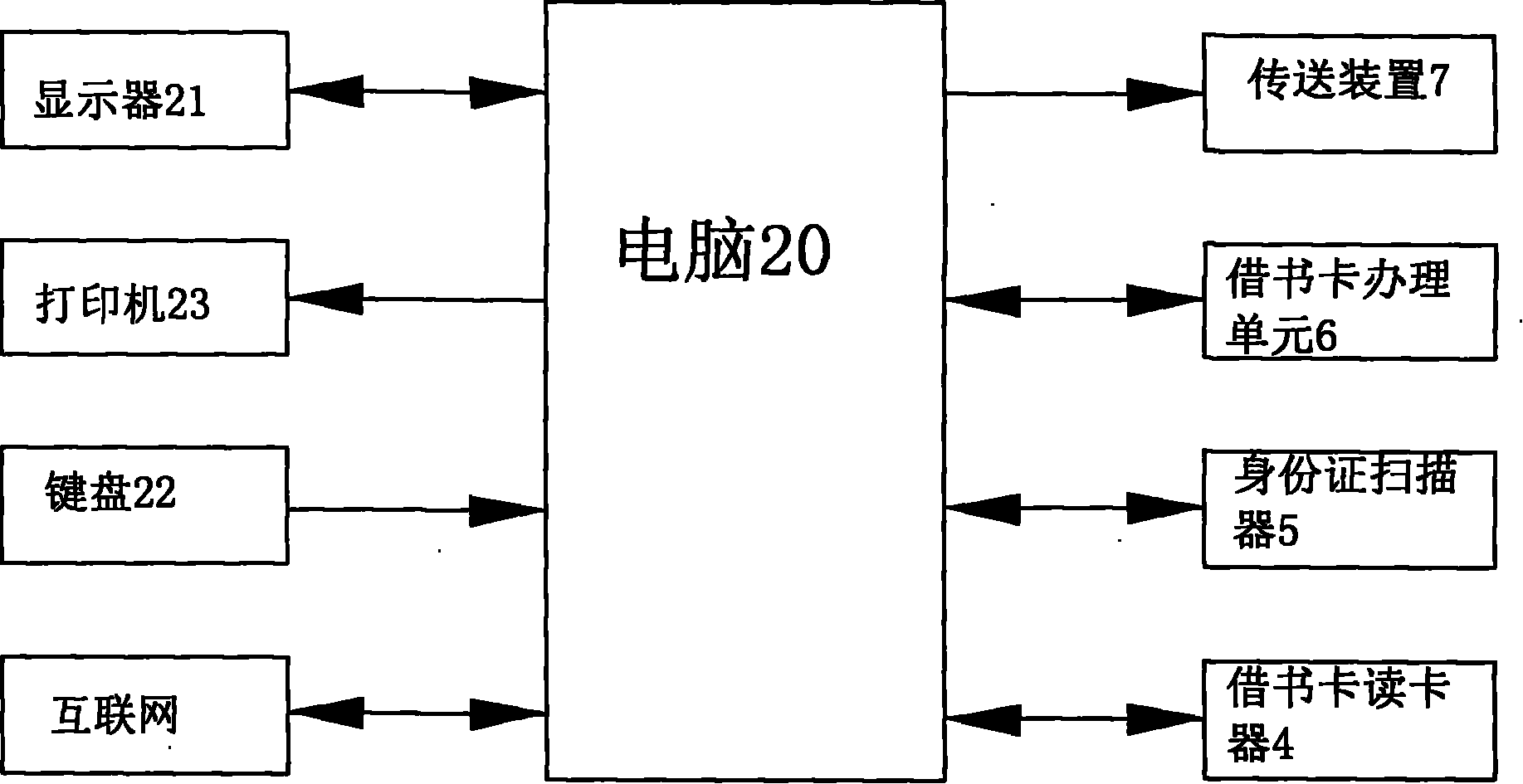

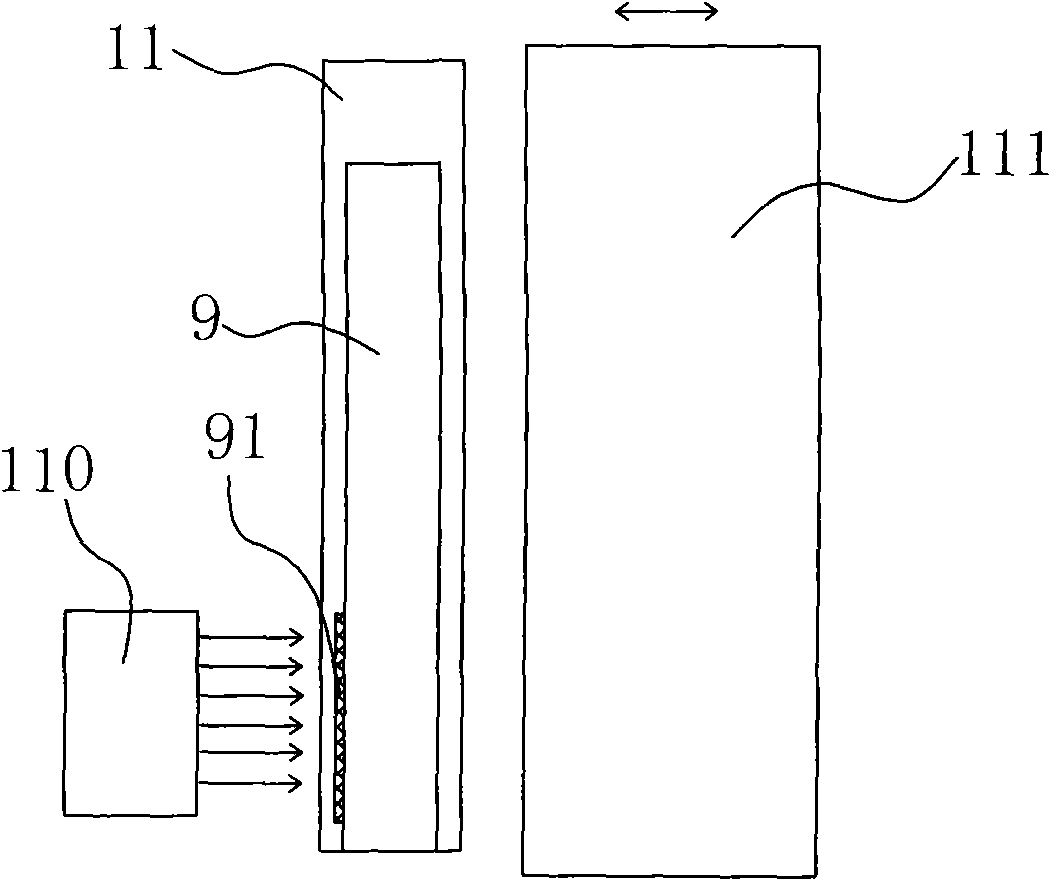

Full-automatic library service station and operation method thereof

InactiveCN101908251AUnderstand the status of the collectionAnti-smashGripping headsCash registersLibrary cardLibrary services

The invention provides a full-automatic library service station and an operation method thereof. The service station comprises a computer, a displayer, a printer, a keyboard, a library card reader, an identification card scanner, a library card transaction unit and a mechanical conveying device, wherein the computer serves as a main control unit; the displayer and the printer serve as information output units; the keyboard serves as an information input unit; the library card reader and the identification card scanner serve as information input equipment; the library card transaction unit is connected with the computer; the mechanical conveying device is controlled by the computer; the service station main body is a sealed cabinet body which comprises an operation platform and book shelves; the displayer, the keyboard, the printer, the library card reader, the identification card scanner and the library card transaction unit are positioned on the operation platform which is also provided with a book inlet and a book outlet; book separation columns are formed on the book shelves by clapboards; each book separation column corresponds to a piece of position information; under the control of the computer, the conveying device conveys books between the book inlet, the book outlet and the shelves by manipulators arranged per se.

Owner:东莞市树煜智能图书设备科技有限公司

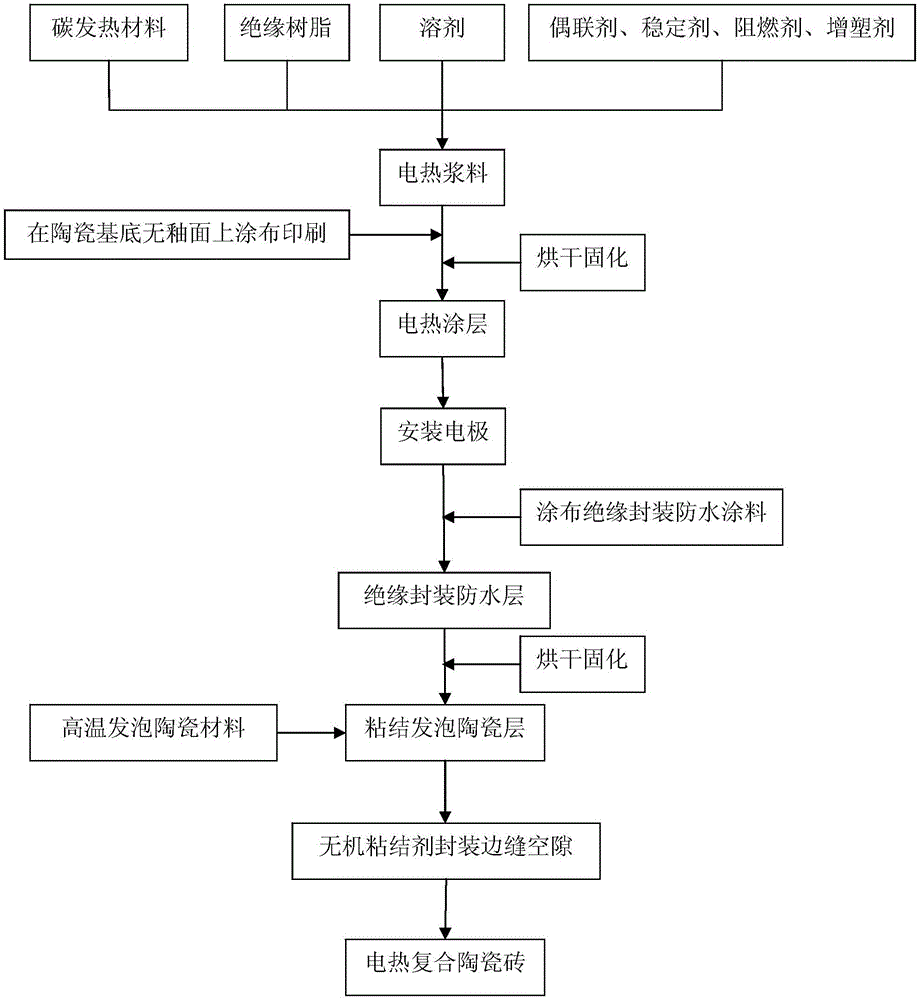

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

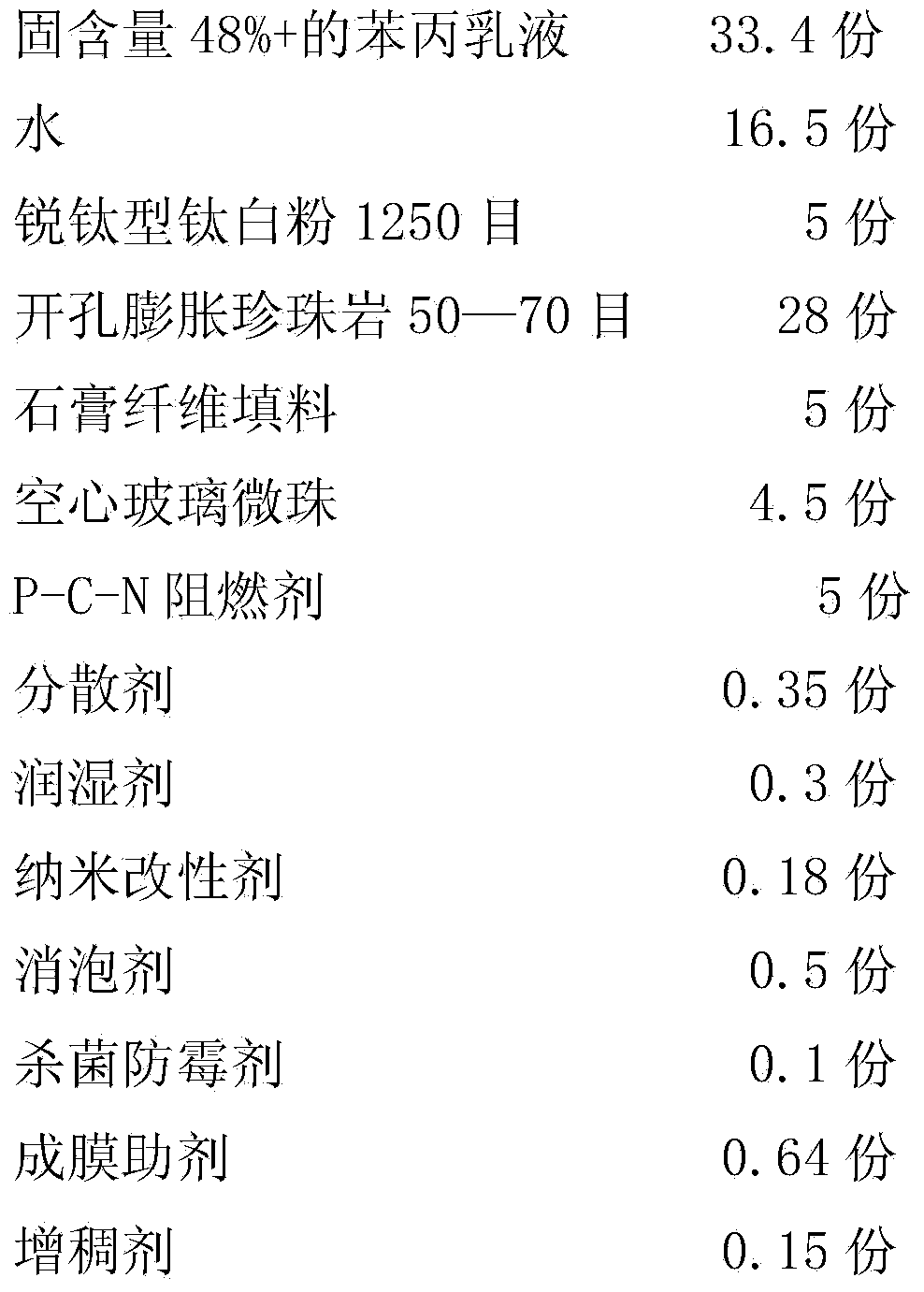

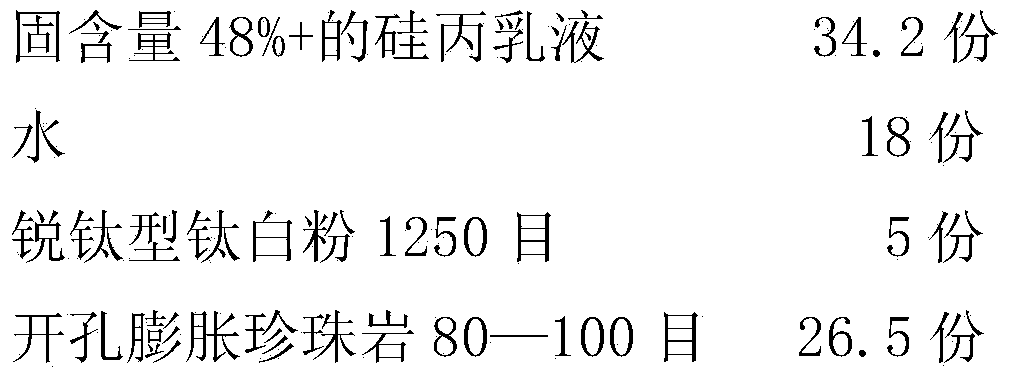

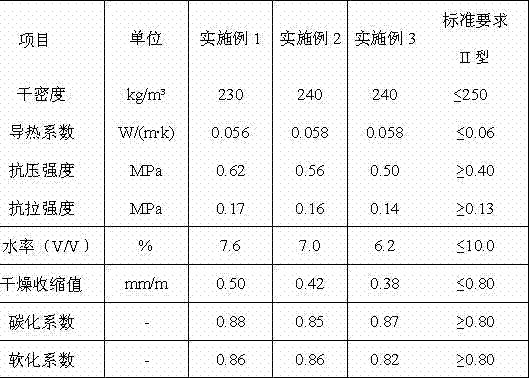

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

Composite foamed cement heat retaining panel using high-volume fly ash and preparation method thereof

The invention discloses a composite foamed cement heat retaining panel using high-volume fly ash and a preparation method thereof; the composite foamed cement heat retaining panel is prepared by 60-80 parts of cement, 20-40 parts of fly ash, 0.6-3.0 parts of moisture repellent, 0.12-0.30 part of a water reducing agent, 0.8-3.0 parts of an exciting agent, 0.3-0.50 part of anti-crack fiber, 30-60 parts of water and 4-8 parts of a foaming agent (by weight); the preparation method comprises the following steps: weighing each raw material; adding the water, the anti-crack fiber, the moisture repellent, the cement, the fly ash, the water reducing agent; stirring a mixture; adding the exciting agent; stirring the mixture; adding the foaming agent; stirring the mixture so as to prepare mixed slurry; then, injecting the mixed slurry into a mould; putting the mould statically for 4-5 hours; removing the mould; after 24 hours, cutting and packaging a product; and maintaining the product until age is 28 days. According to the invention, a part of the cement is substituted by fly ash; cost is low; environment pollution is reduced; and social efficiency and economic benefit are obvious.

Owner:JIANGSU NIGAO SCI & TECH +1

Foam cement insulation board containing industrial solid waste and preparation method thereof

he invention relates to a foam cement insulation board and a preparation method thereof, and provides a foam cement insulation board containing industrial solid wastes and a preparation method thereof. The foam cement insulation board is composed of a mixture A and a mixture B. The mixture A comprises 55-65% of cement, 10-20% of gypsum powder, 8 -15% of hydrogen peroxide,3-4% of a flocculant, 1-2% of a water reducing agent, 1-2% of a coagulant, 2-3% of a cement waterproof agent, 1-2% of lithium carbonate, 1-2% of fiber, and 1-2% of solid master batch. The mixture B comprises 35-47% of a base material, 35-39% of a magnesium chloride solution, 10-15% of magnesium oxide, 2-5% of a binding agent, 2-3% of industrial hydrogen peroxide, 1-2% of lanthanide rare earth and 5-7% of an additive. The Foam cement insulation board provided by the invention has advantages of fireproof, waterproof, light weight, compressive and flexural resistance and high strength, and effectively utilizes industrial solid waste, facilitates environmental protection, and truly realizes turning wastes into treasures.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

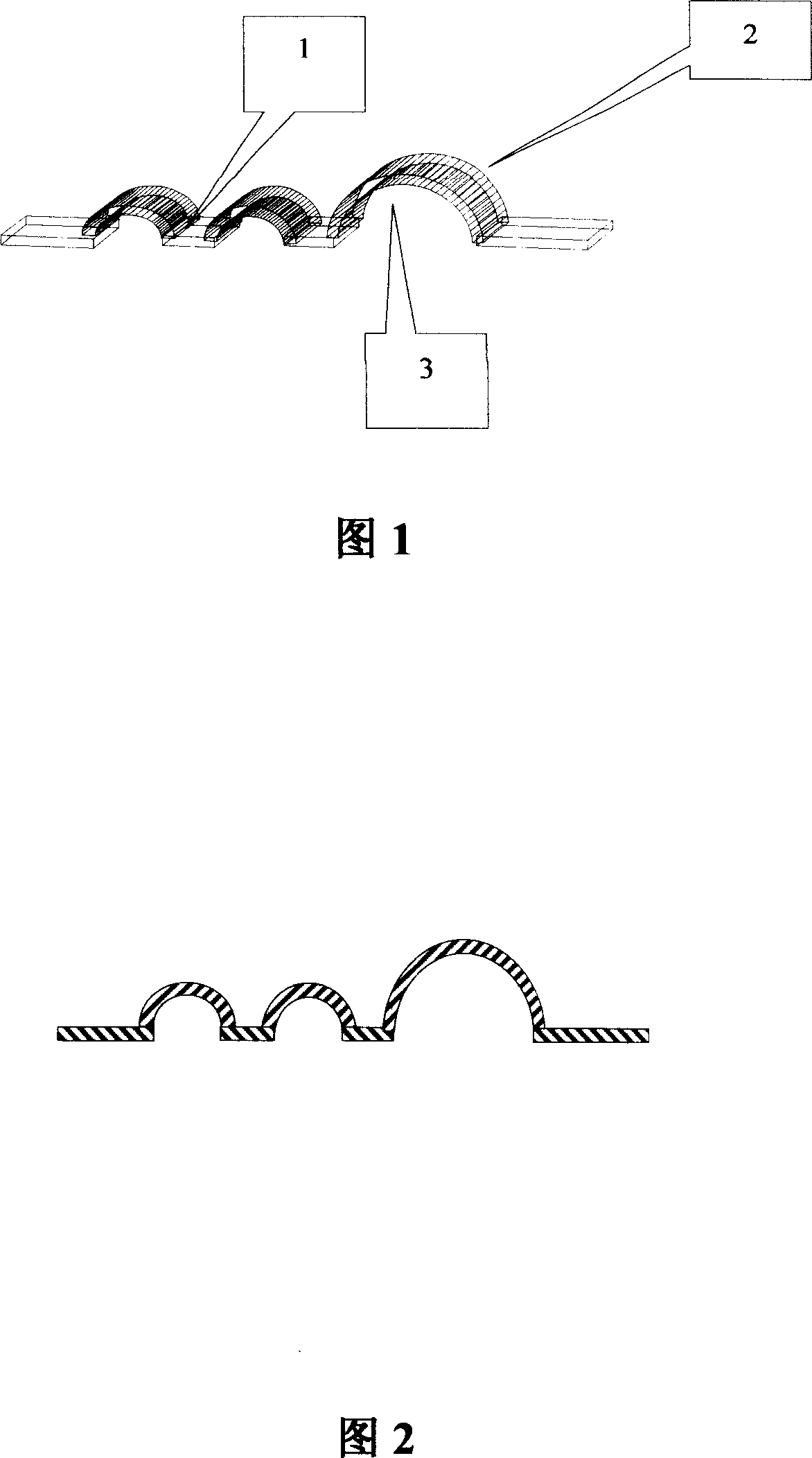

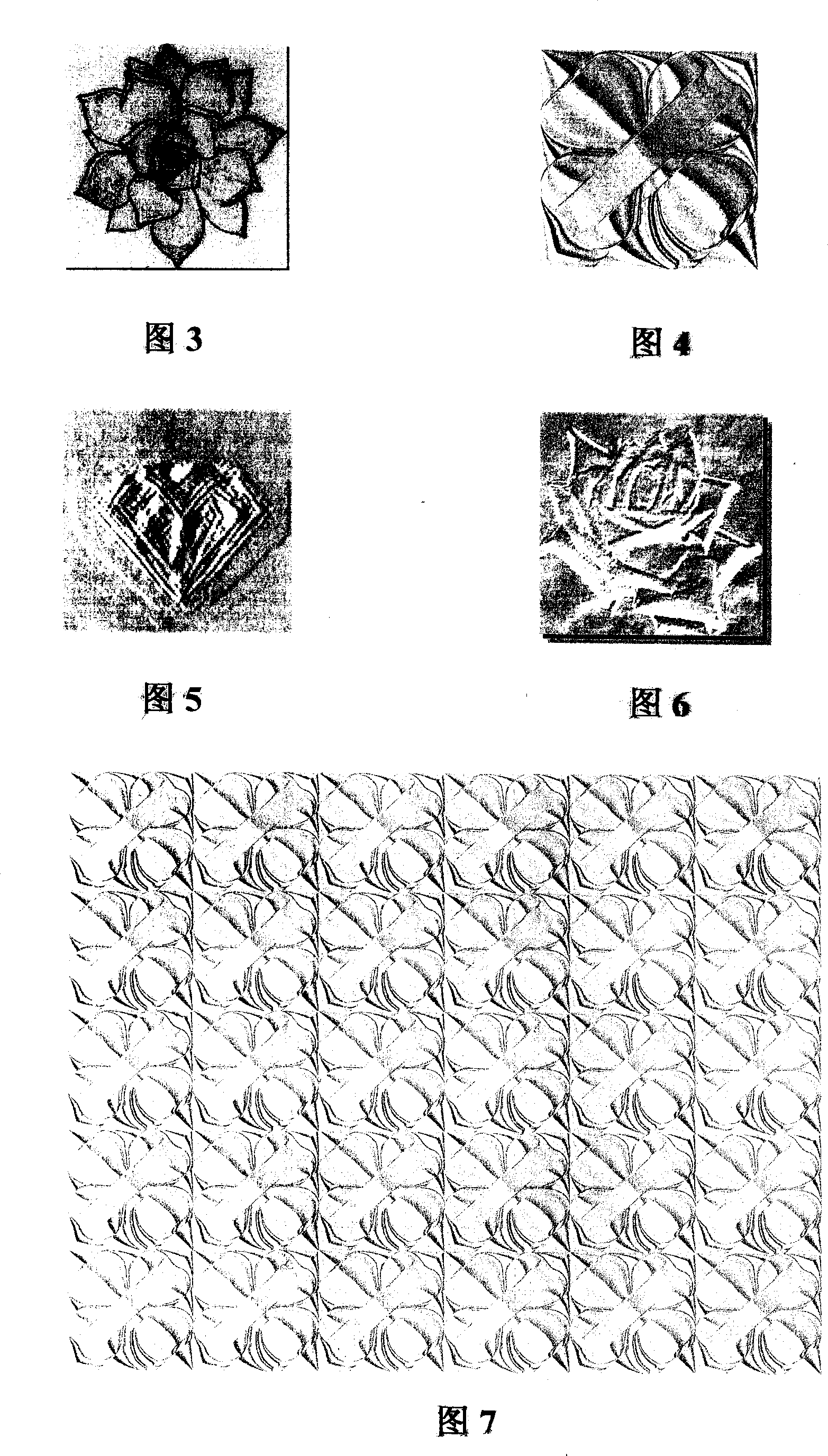

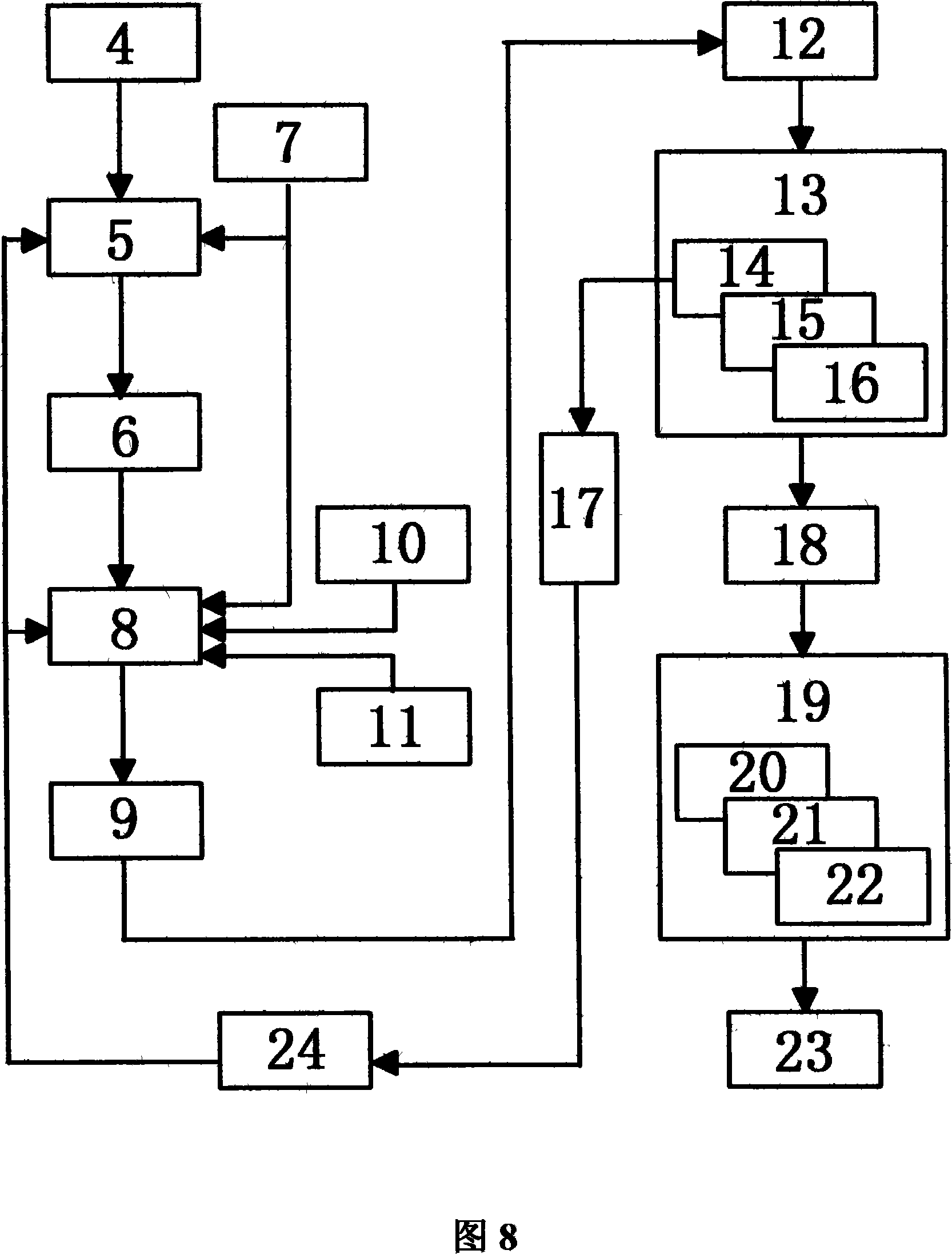

Solid wall paper and its production method and use

InactiveCN101100832APromote environmental protectionFireproofSpecial paperPaper/cardboardWoolSurface finishing

The invention discloses a new type solid wall paper, its manufacturing method and application. Its feature is that pulpwood formed three-dimensional bass-relief pattern and colorful plate type is used to form the solid wall paper which has various design and color, geometry by monomer jointing, assembling, and arranging. The method includes the following steps: adding solid filling and additive, or any one of wood pulp, bamboo pulp, or their mixture into paper making pure wool pulp; using pulp molding plant and die to product; pulping; forming; drying; shaping; ginning; scratching; brush coating or surface overlaying film to obtain the solid wall paper. It can be used in the decoration for bedroom, drawing room, and public occasion.

Owner:BEIJING TONGLANHAI TECH CO LTD

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

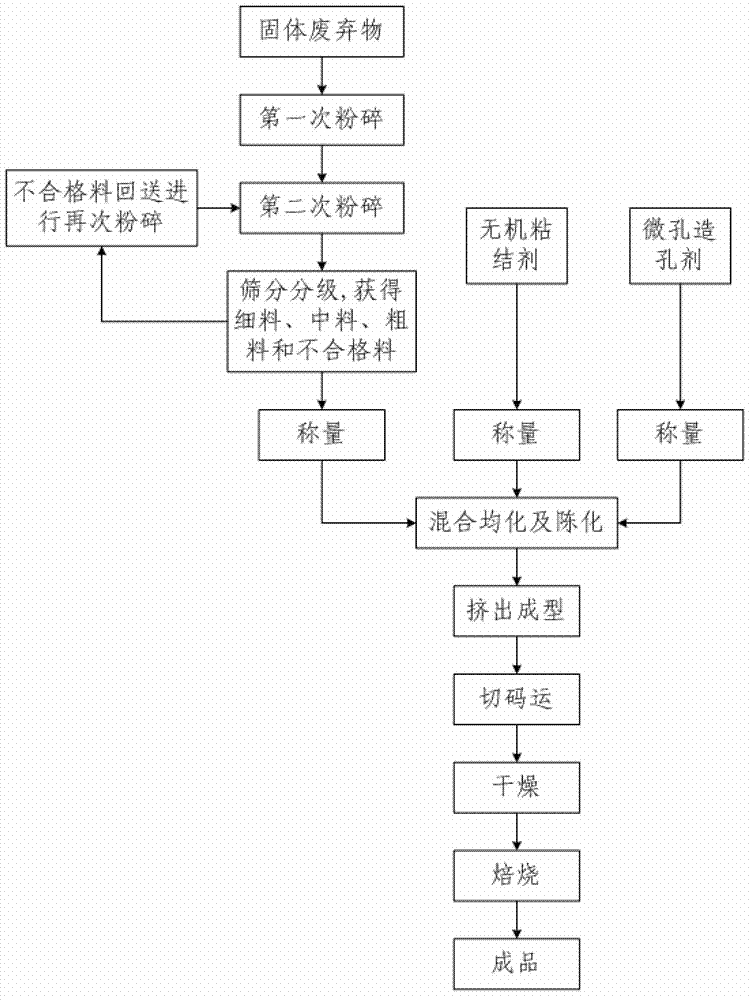

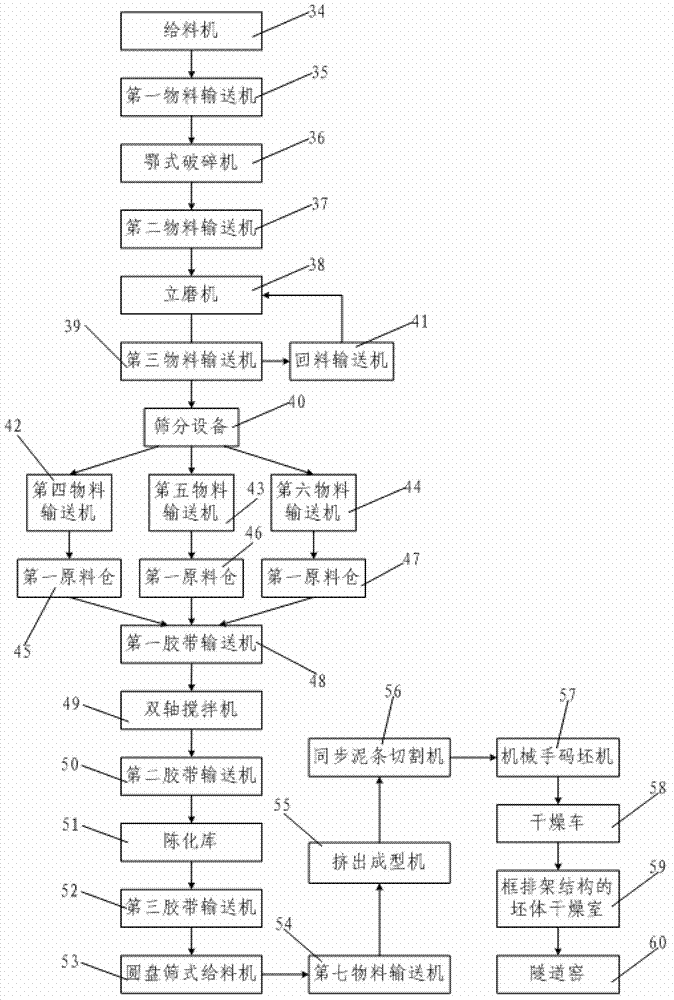

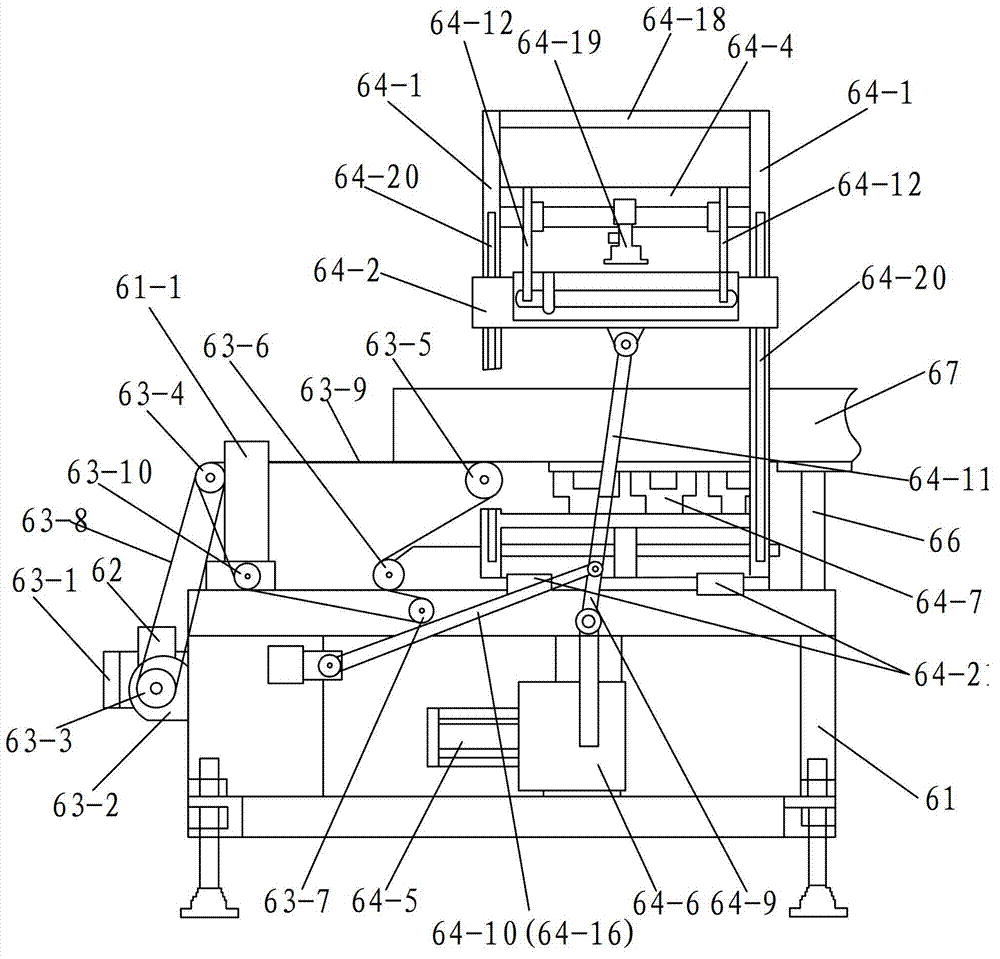

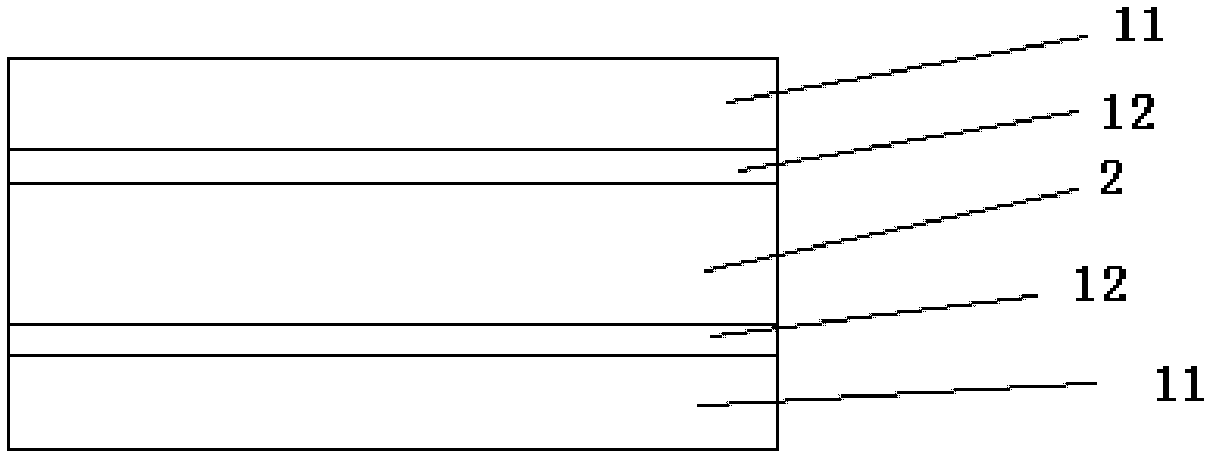

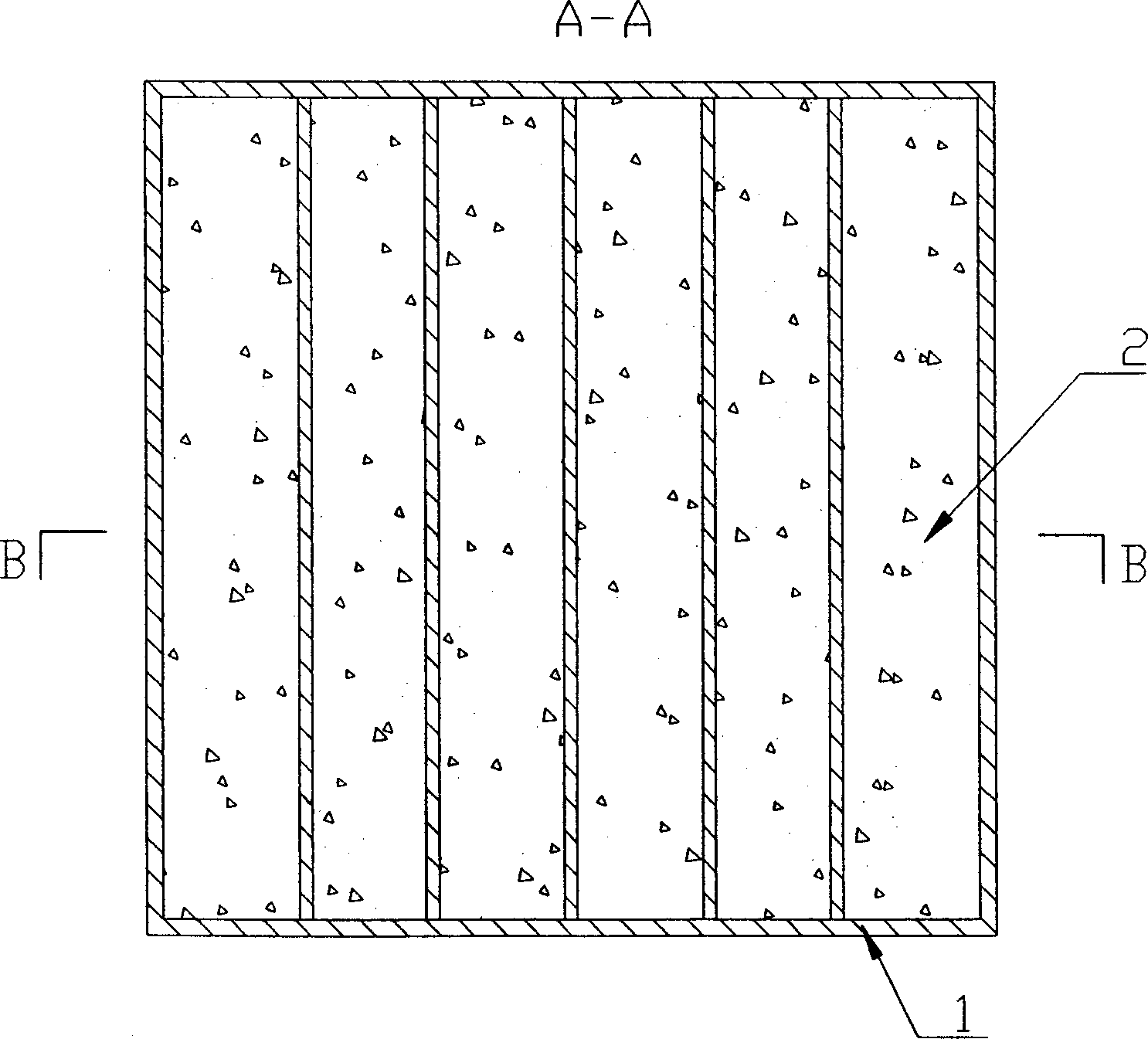

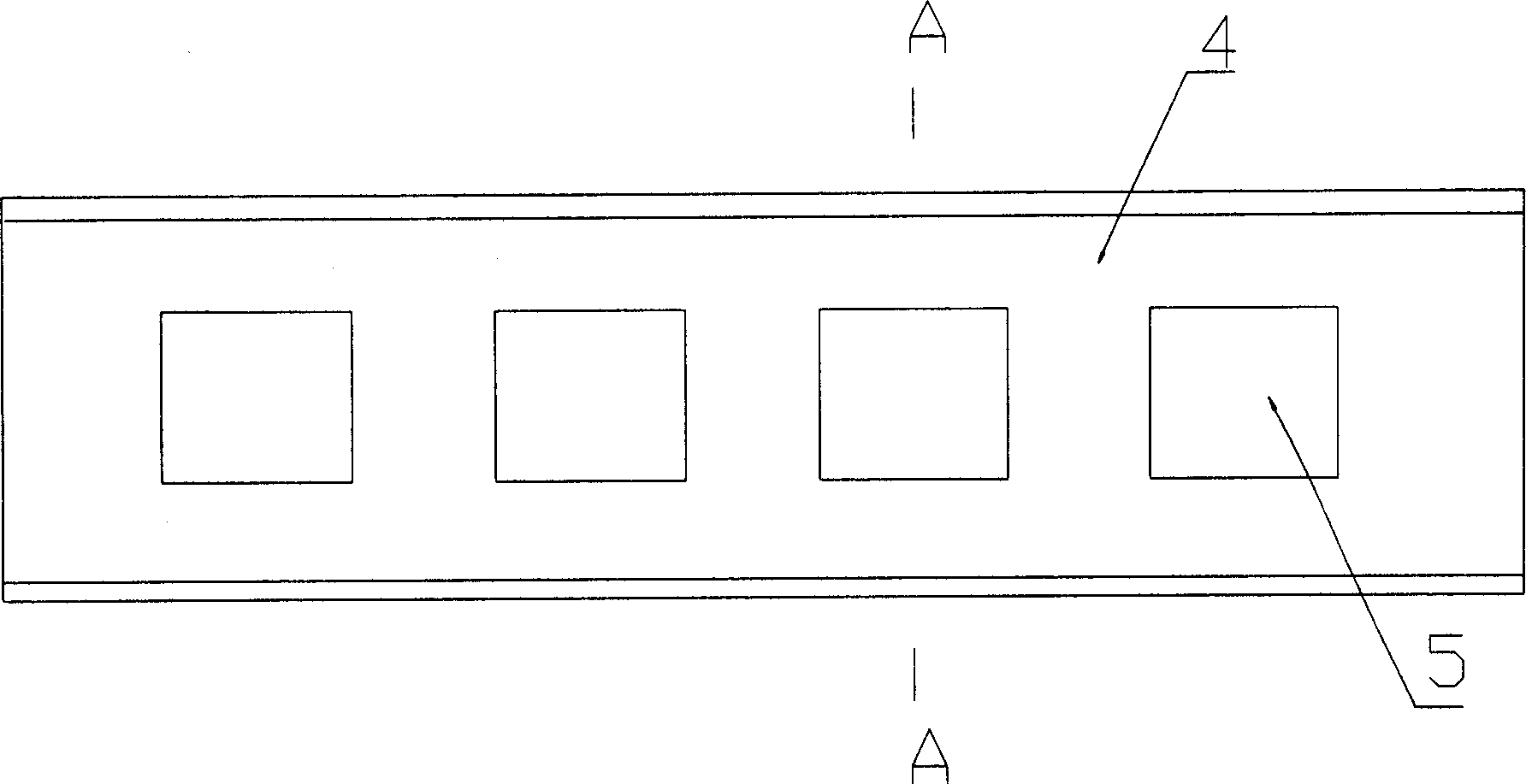

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

Stalk light body energy-saving heat preserving building blocks and manufacturing method thereof

InactiveCN101476365AImprove insulation effectLow water absorptionBuilding componentsPolymer scienceThermal insulation

The invention discloses a straw light-weight energy-saving insulated building block and a method for producing the same. The method comprises the following steps: using broken straw segments processed by a surface modifier, high strength low-alkali cement, fly ash, superfine active mixed materials and the like as main raw materials; adding various additives such as a waterproof impermeable agent, a preservative, a high-efficiency water reducing agent, an excitant and the like and modified materials to the main raw materials, mixing all the materials evenly, and adding water to the mixture and blending the mixture evenly; molding, demolding and maintaining the mixture to mold the building block (a reinforcing rib of which the surface is provided with a plurality of transverse lug bosses), and coating cement waterproof fluid on the outside; and making protection layers on two sides of the building block with ordinary Portland cement, sand, slag, additives and water so as to obtain the straw light-weight energy-saving insulated building block. The straw light-weight energy-saving insulated building block has the characteristics of light weight, high strength, good thermal insulation property, low water absorption rate, high freeze-melt resistance, fire prevention, water prevention, seepage prevention, insect and mouse damage prevention and the like, and saves 50 percent of energy for a single wall body material in the northern cold areas. Besides, the straw light-weight energy-saving insulated building block can be widely popularized and applied to the field of construction, in particular to the village and small town dwelling constructions in the northern cold areas.

Owner:肖力光

Lightweight ceramic material and process for manufacturing same

The present invention is one kind of light ceramic material and its production process, and belongs to building material technology. The ceramic material is produced with waste slag from polishing ceramic product, ceramic clay, high temperature sand and low temperature sand and through material compounding, crushing, forming, drying, sintering in kiln and packing. The produced ceramic material has the features of light weight, high strength, heat insulation, sound insulation, fireproofing, waterproofing and long service life. The present invention raises the utilization of ceramic raw material, reduces environmental pollution, and the produced ceramic material may be used in decorating outer and inner walls of building, as tunnel sound insulating material, house ceiling decoration, etc.

Owner:聂曼云

Light-weight and high-strength thermoplastic composite material sandwich board and production method thereof

InactiveCN103568396ALight in massLightweight and high-strength qualitySynthetic resin layered productsLaminationSandwich boardHoneycomb

The invention relates to a light-weight and high-strength thermoplastic composite material sandwich board and a production method thereof. The light-weight and high-strength thermoplastic composite material sandwich board comprises two panels and a sandwich layer, wherein the sandwich layer is fixedly arranged between the two panels. The preparation method comprises the following steps: putting the sandwich layer between the two panels; and sticking the two panels on the front and rear faces of the sandwich layer by a thermoplastic glue film through a hot pressing process and a cold pressing process to produce the thermoplastic composite material sandwich board. The panels are continuous fiber enhanced thermoplastic composite material boards and the sandwich layer is made of a honeycomb aluminum material. Compared with the prior art, the thermoplastic composite material sandwich board has the advantages of light weight, high strength, heat preservation, fireproof prevention, moisture prevention, corrosion prevention and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

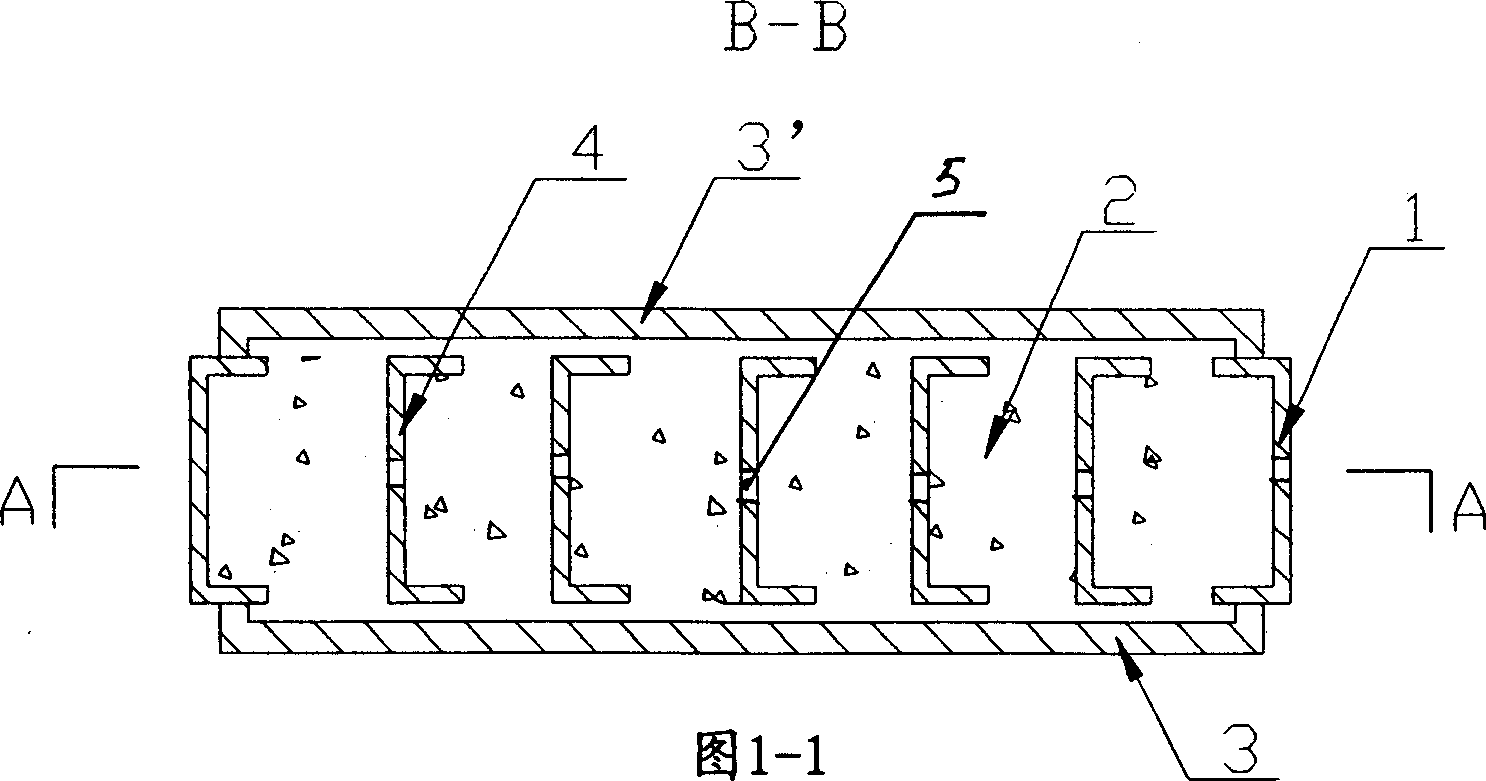

Composite building board material capable of load bearing and its productioin method

InactiveCN1478971AFireproofWith sound insulationMouldsBuilding componentsSteel columnsLoad-bearing wall

A composite building plate able to bear load is composed of the external frame, foamed cement layer filled into the frame, and surfacial layers, and features that several steel columns or beams are unidirectionally arranged in the frame, which have through holes for allowing the foamed cement to penetrate through them. Its advantages are light weight, high weatherability, insulation to heat and sound, and resistance to water, acid and alkali, and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

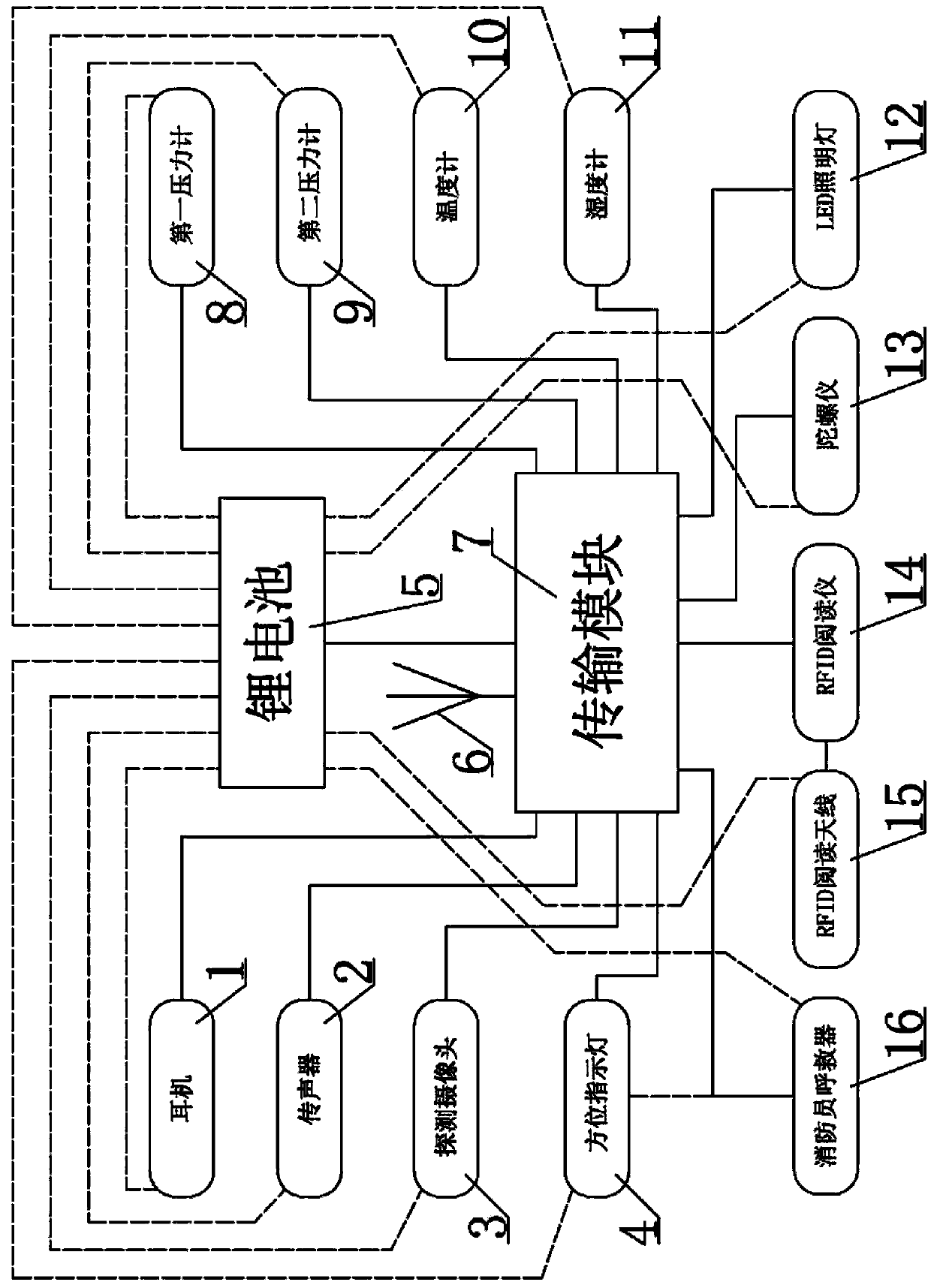

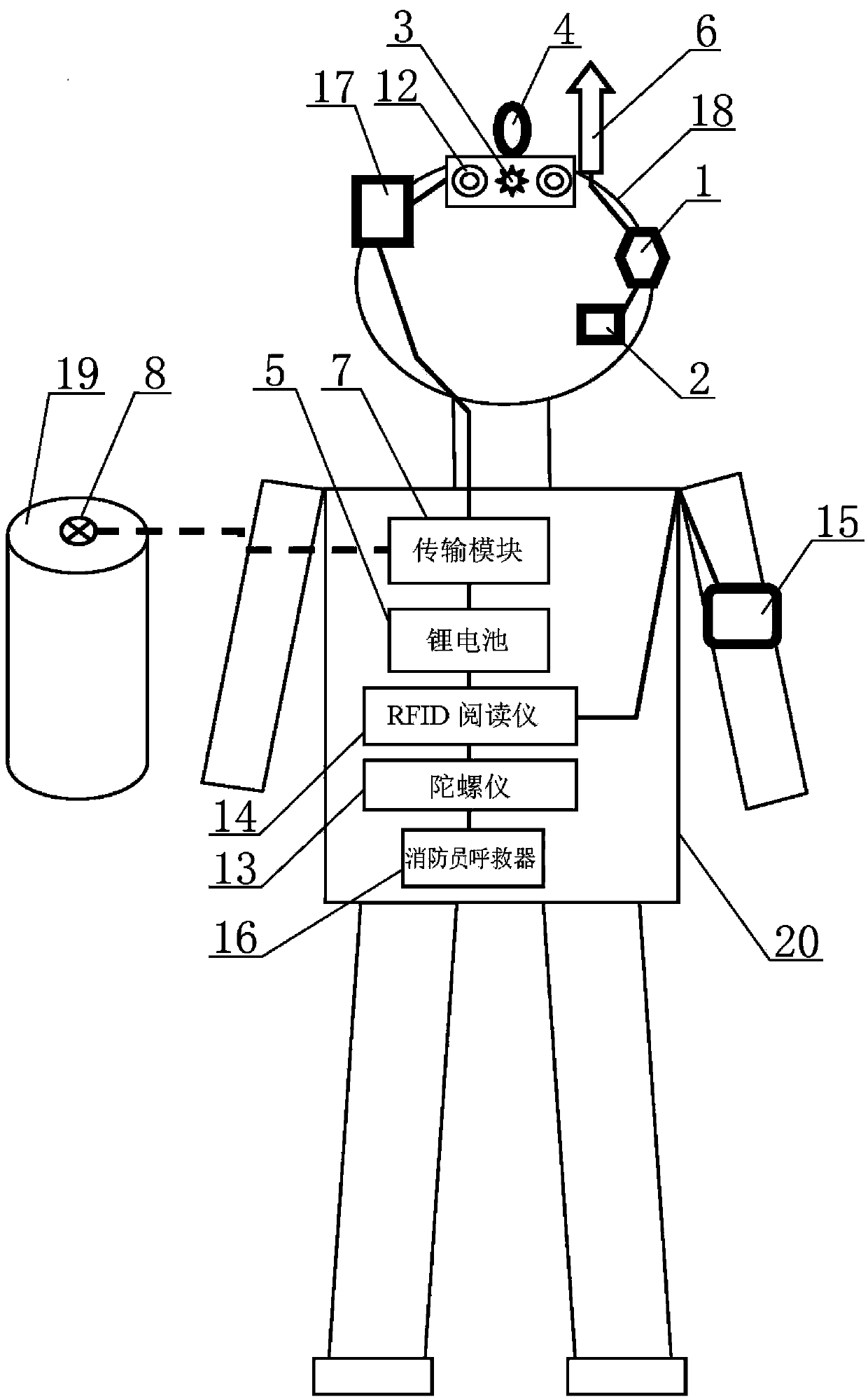

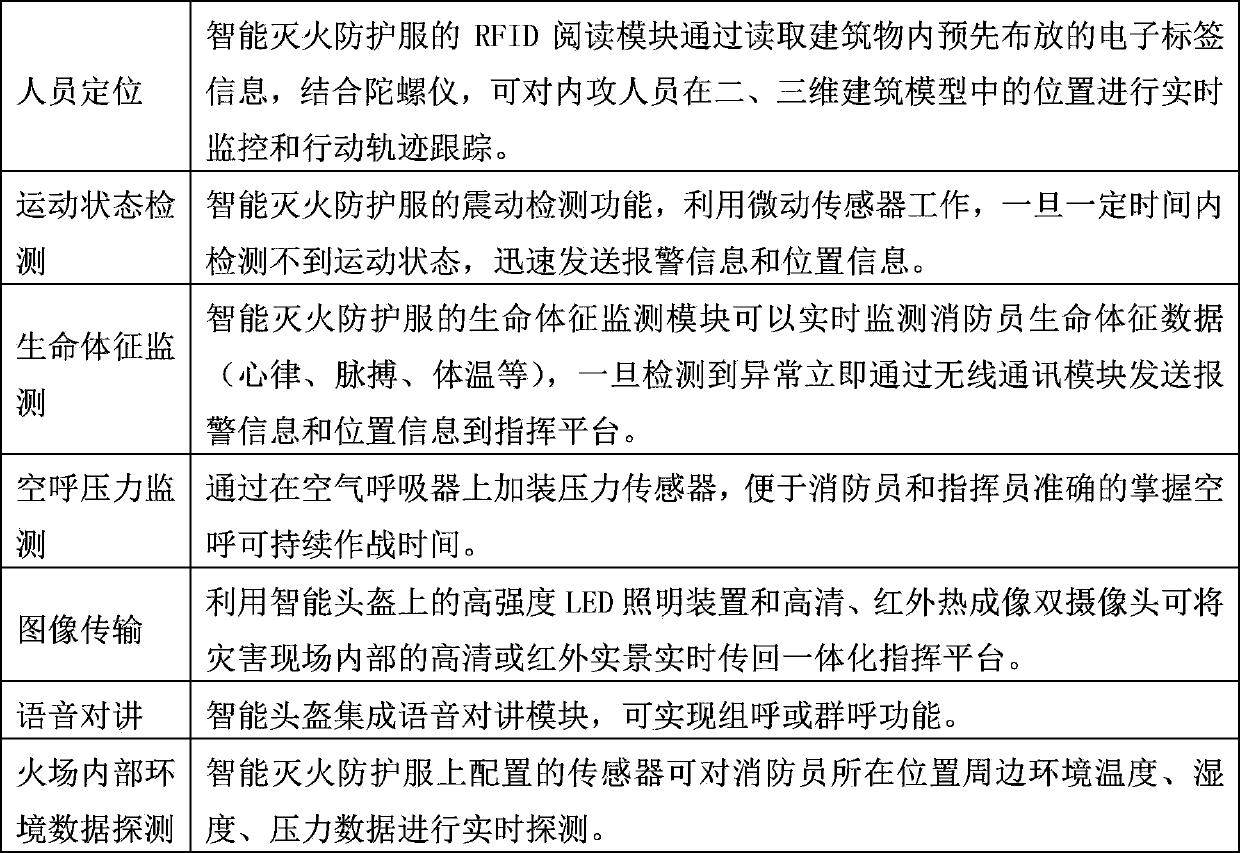

Intelligent information collecting device on disaster site

ActiveCN103622203ADecision-making command is real and intuitiveFireproofChemical protectionHeat protectionGyroscopeFire protection

The invention discloses an intelligent information collecting device on a disaster site. A communication module, a temperature and pressure sensor, a micro sensor, an RFID reading instrument, a gyroscope, a vital sign detector and the like are designed to be additionally arranged. The several innovative functions of man positioning, telecommunication, motion state detection, air respirator pressure monitoring, external environment (temperature and pressure) detection, vital sign monitoring and the like inside a building are further achieved, and all detecting parameters can be transmitted to a field managing rescue platform in real time. The intelligent information collecting device on the disaster site is reasonable in structure, improves the fire protection and rescue efficiency, lowers the life and property loss to the minimum degree, and improves the life safety guarantee level.

Owner:新疆中睿电子科技有限公司 +1

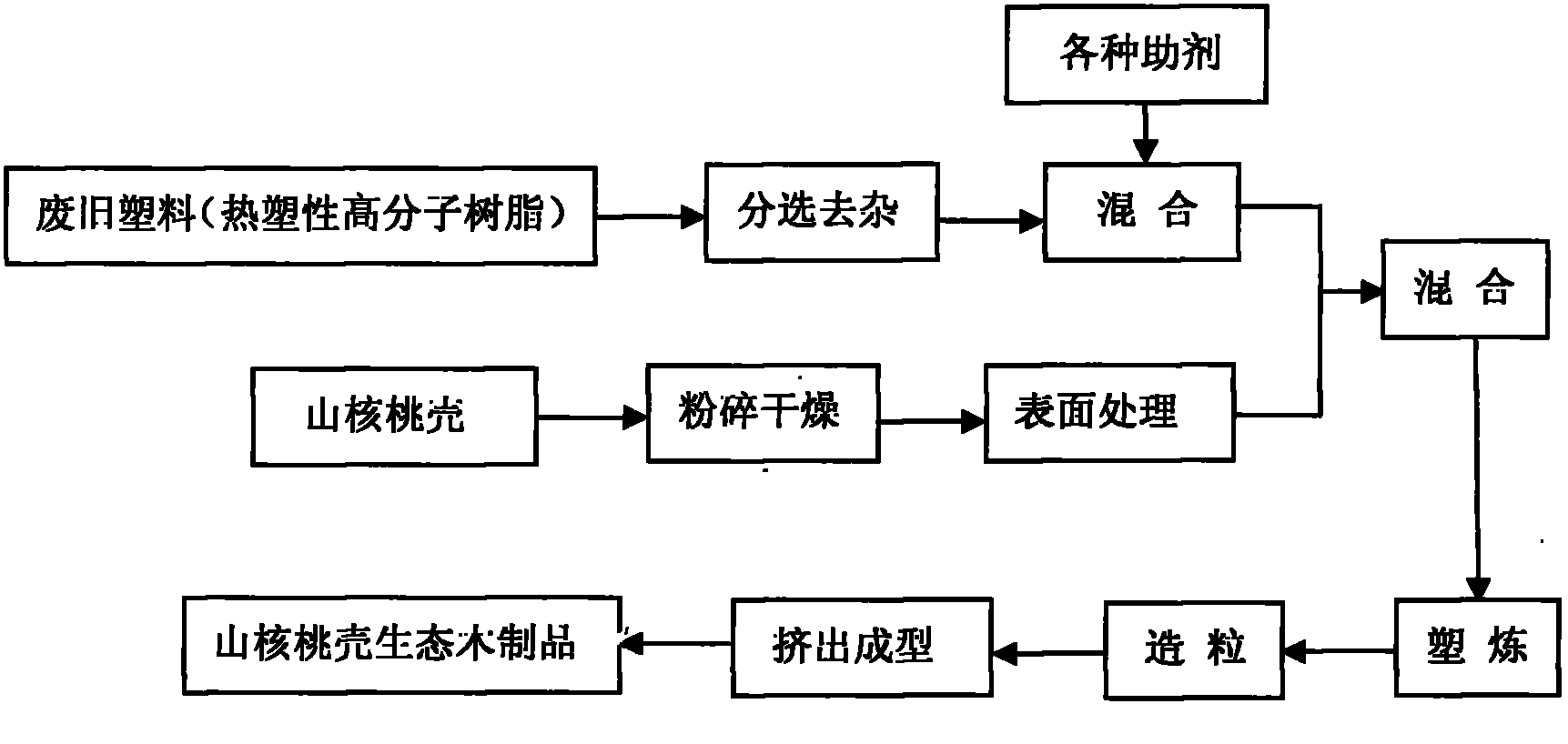

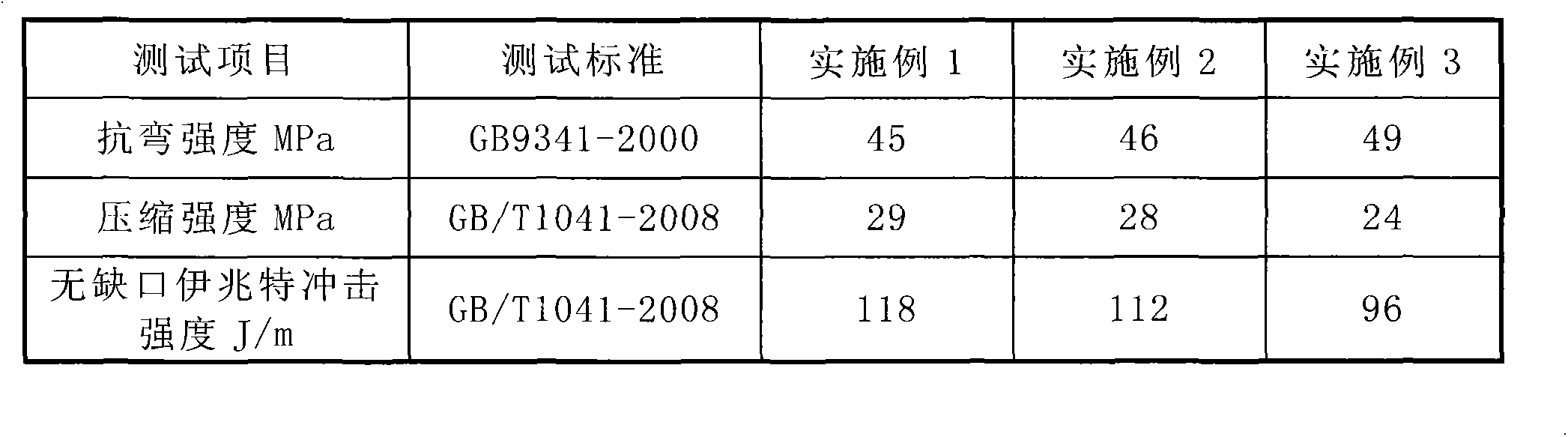

Hickory nut shell ecologic wood composite material and preparation method thereof

The invention relates to a plastic-wood composite material and provides a hickory nut shell ecologic wood composite material and a preparation method thereof. The hickory nut shell ecologic wood composite material is prepared from following components including, by weight, 50-60 parts of a thermoplastic high-molecular resin, 40-50 parts, or 30-40 parts, of hickory nut shell powder, 10-20 parts of wood powder, 8-10 parts of light calcium carbonate, 10-14 parts of a compatilizer, 2-4 parts of a thermal stabilizer, 2-4 parts of a lubricant, 2-3 parts of a plasticizer, and 1-3 parts of an antioxidant and an ultraviolet stabilizer. A comprehensive technology comprising deep process of raw materials and extrusion moulding and the like is employed. Deep process waste of wild hickories and waste plastic resources are employed. The composite material in the invention has dual-characteristics, which exist in common plastic-wood, of wood and plastic, is better in mechanical performances and is more rigid, durable, wear-resistant and weather-resistant. The method is simple and convenient, is low in manufacturing cost, can be recovered and recycled, can save energy resources and can protects environment.

Owner:LIAONING CHANGBAIXIANZI BIOTECH

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin andthe like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

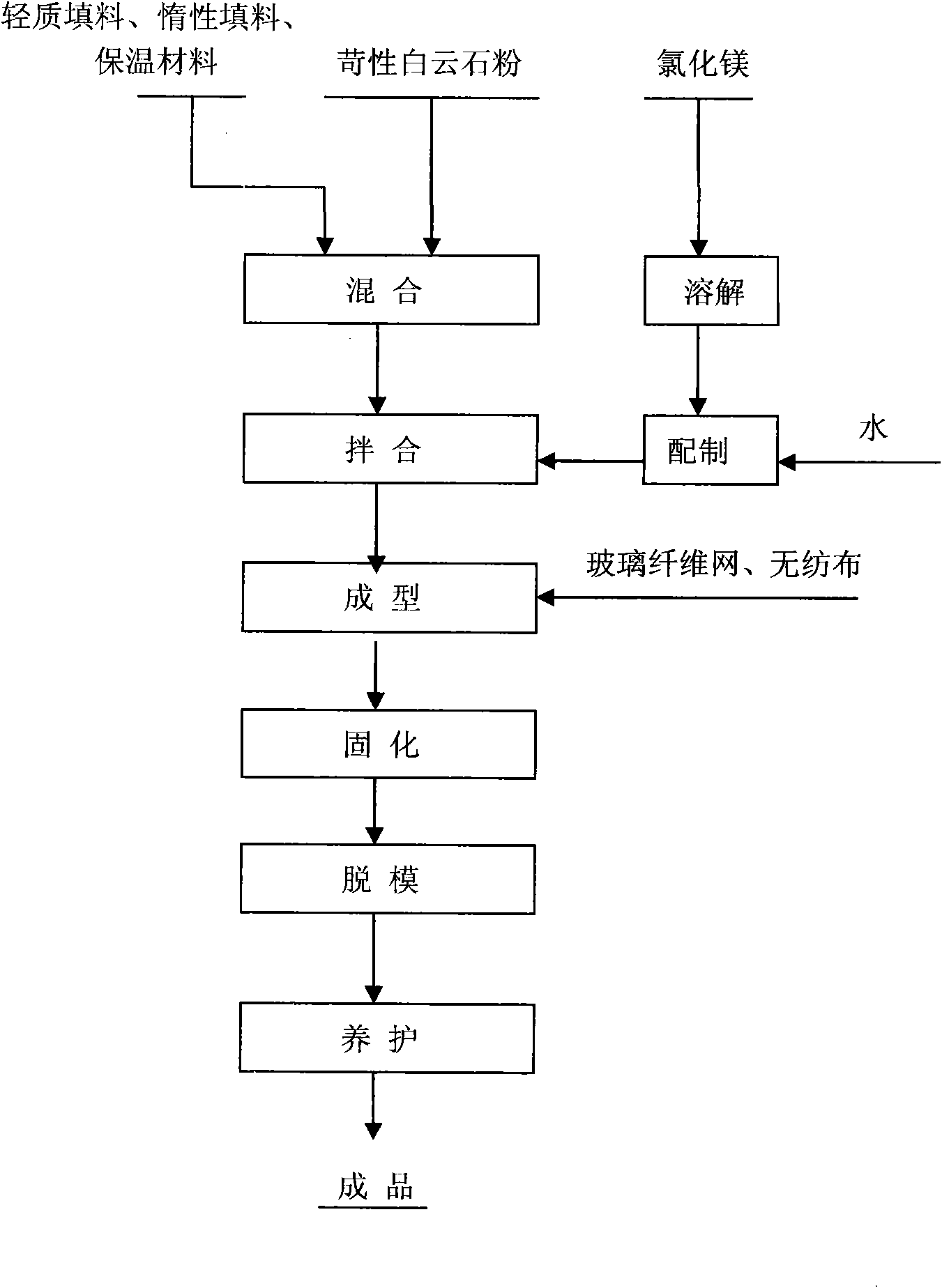

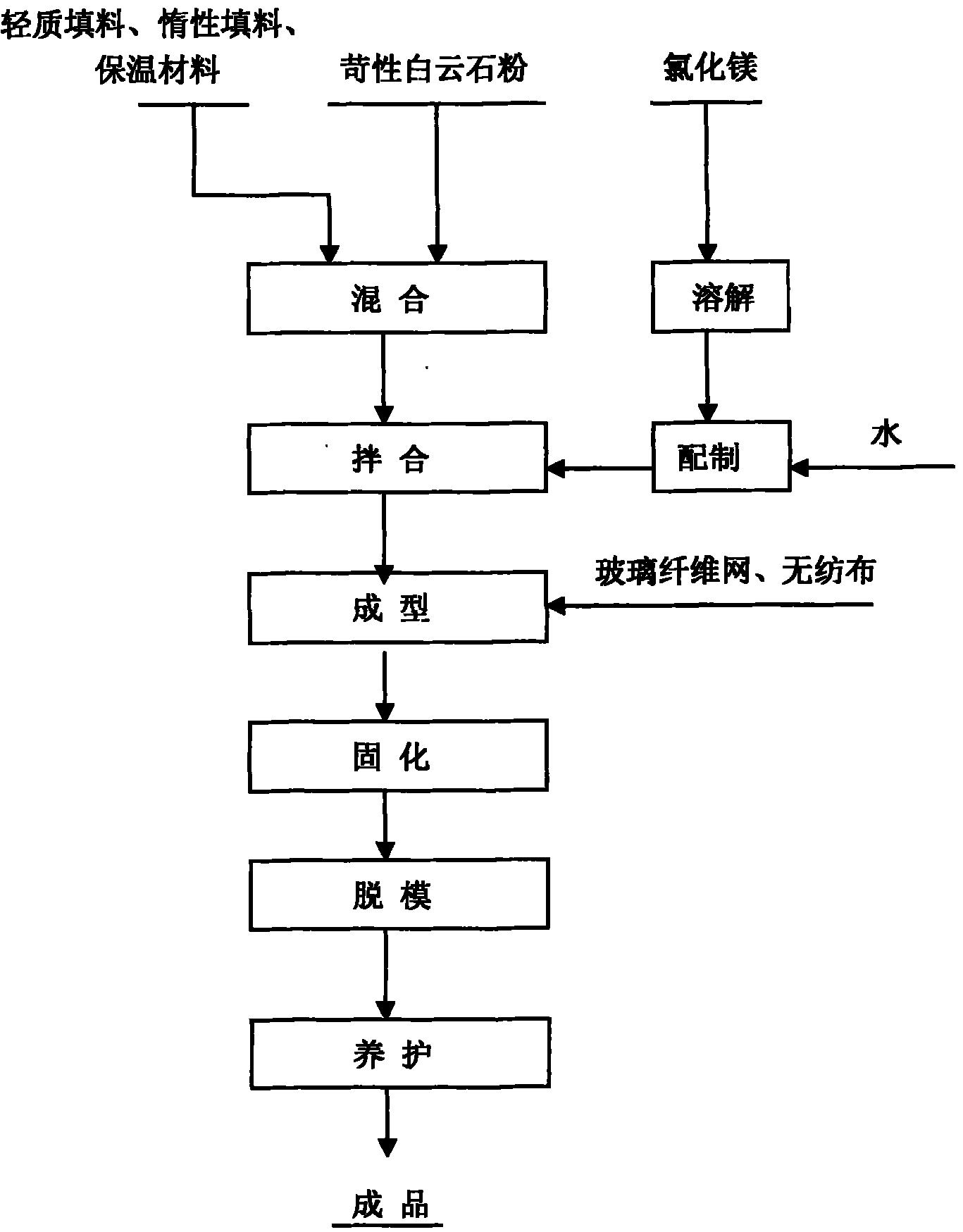

Light dolomite magnesium cement partition plate and manufacturing method thereof

The invention relates to a light dolomite magnesium cement partition plate and a manufacturing method thereof, and belongs to the field of chemical building materials. The light dolomite magnesium cement partition plate consists of caustic dolomite powder, magnesium chloride, light filler, inert filler, water and a heat insulating material in a mass ratio of 1.00:(0.12-0.40):(0.10-0.60):(0.05-0.30):(0.44-1.20):(0.05-0.30); and an appropriate amount of reinforcing material is added into the materials; and the manufacturing method of the light dolomite magnesium cement partition plate comprises the following steps of: stirring and mixing slurry, molding and solidifying, and curing. The light dolomite magnesium cement partition plate for building, which is produced by the manufacturing method, has the advantages of fire protection, heat preservation, high strength and water tolerance, anticorrosion, vibration resistance, sound insulation, easiness in construction, environmental-friendliness, energy conservation, simple production process and low consumption, and the like, is a generation-substituting product which can replace various plates, such as color steel light partition plates, portland cement partition plates and the like, belongs to environmental-friendly building materials and can be widely applied to a building industry.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

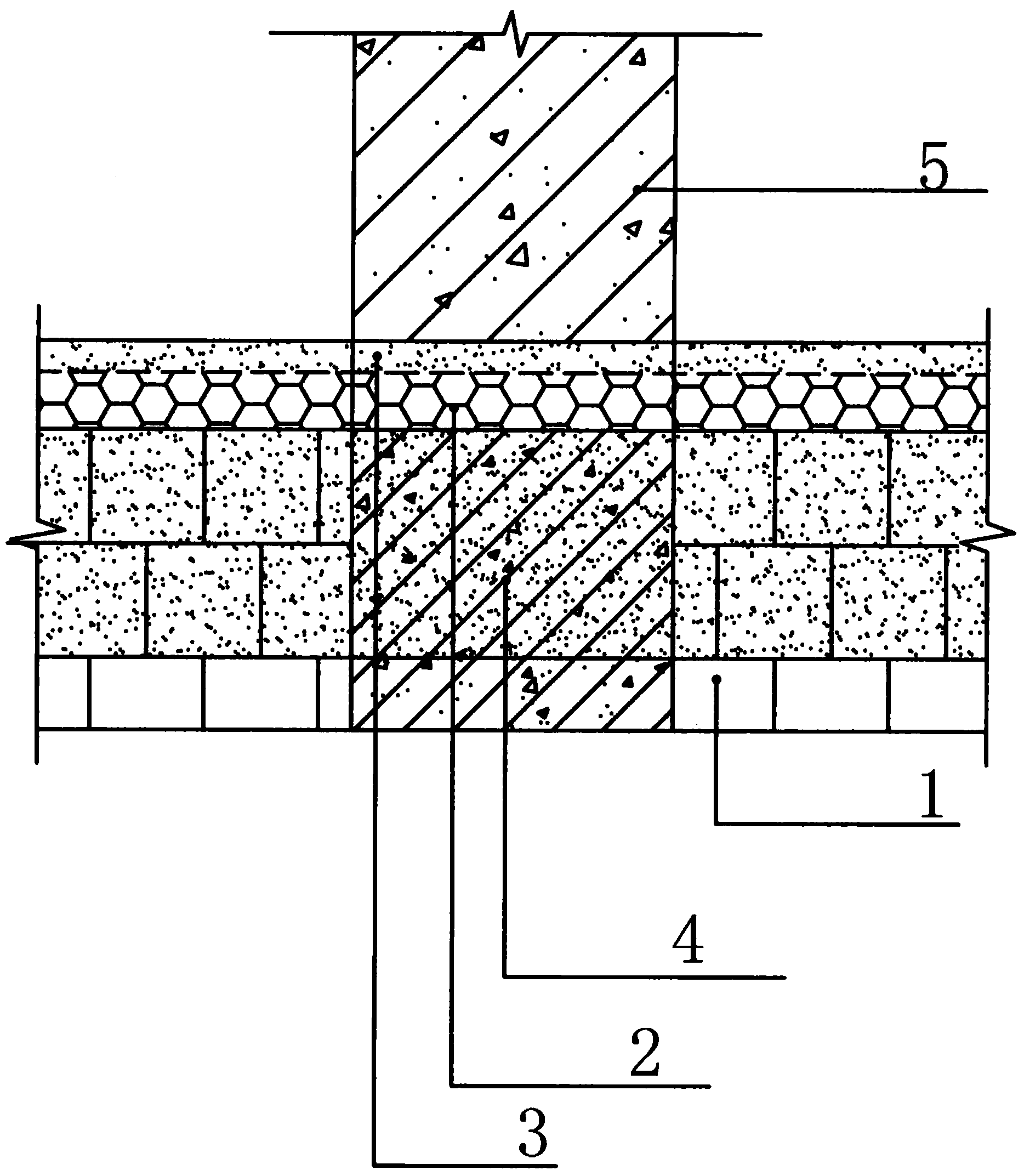

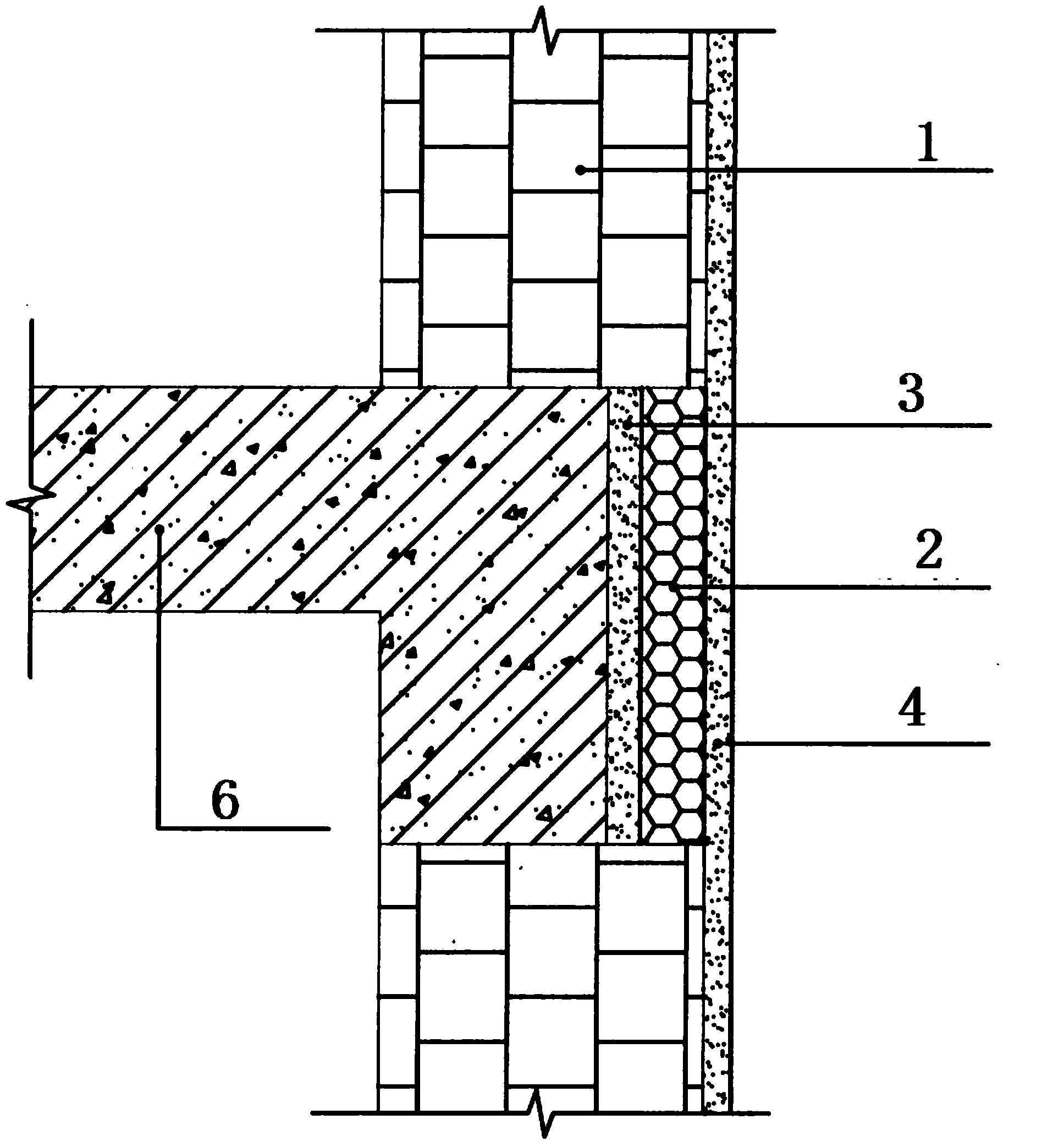

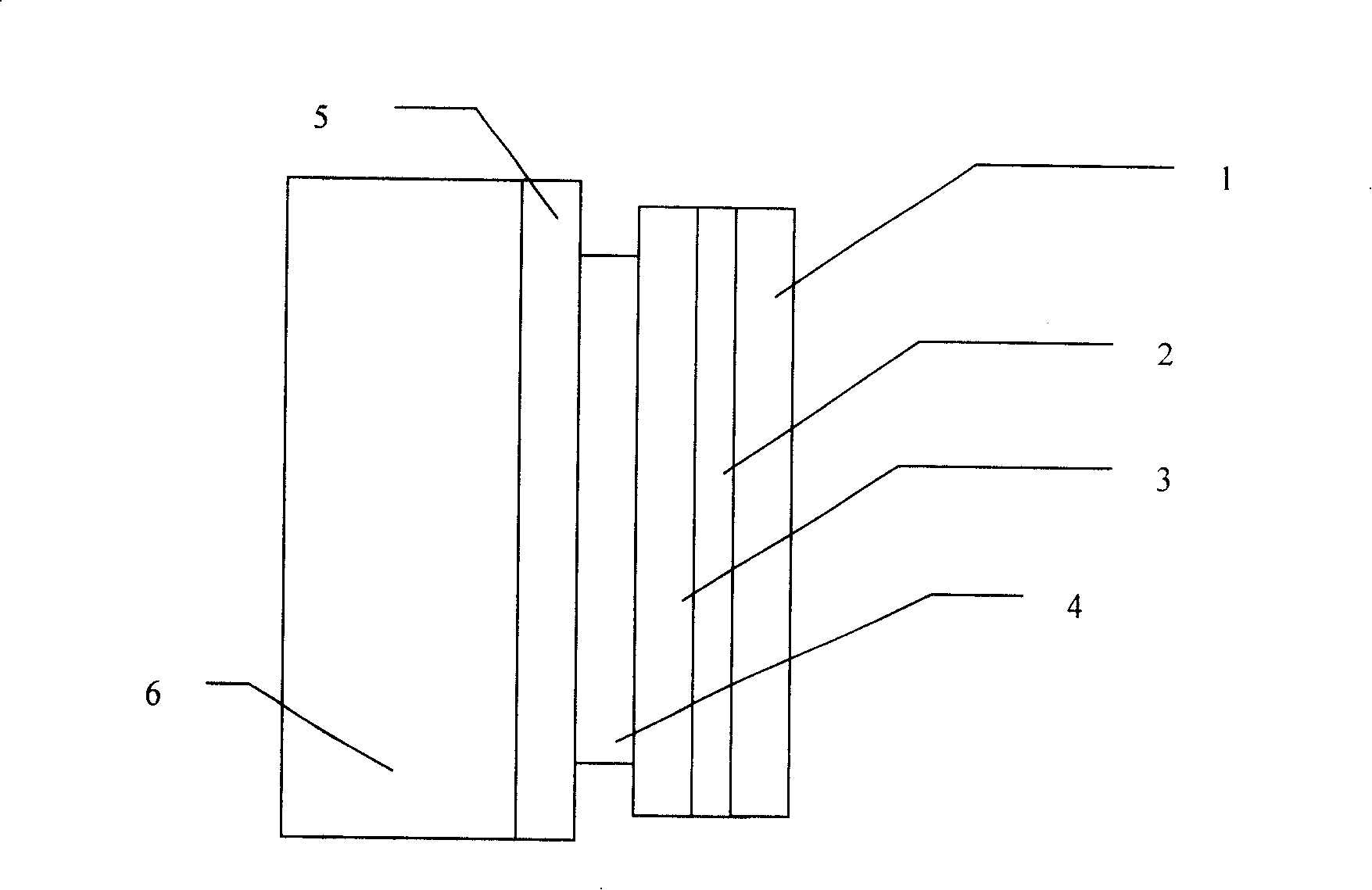

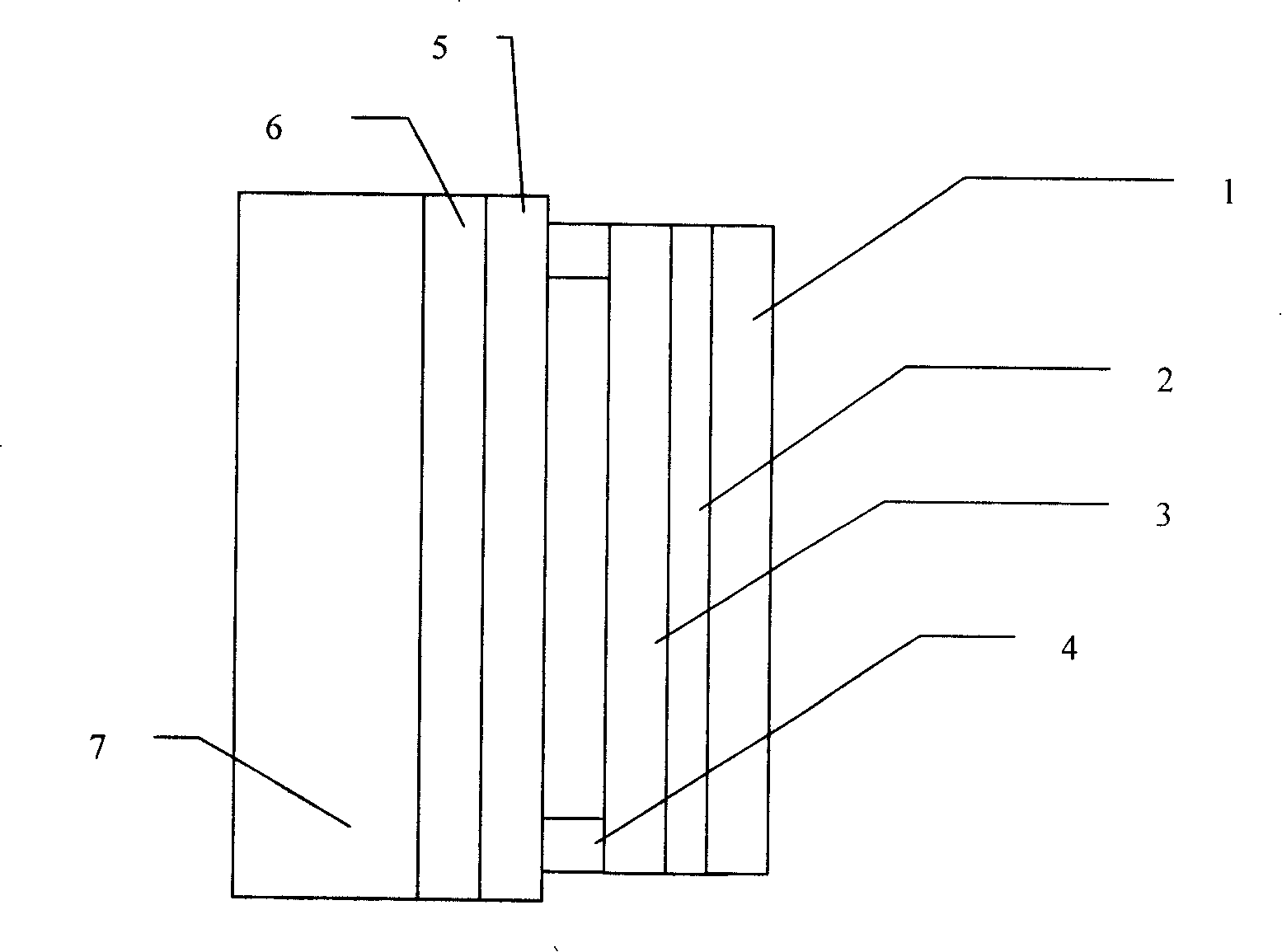

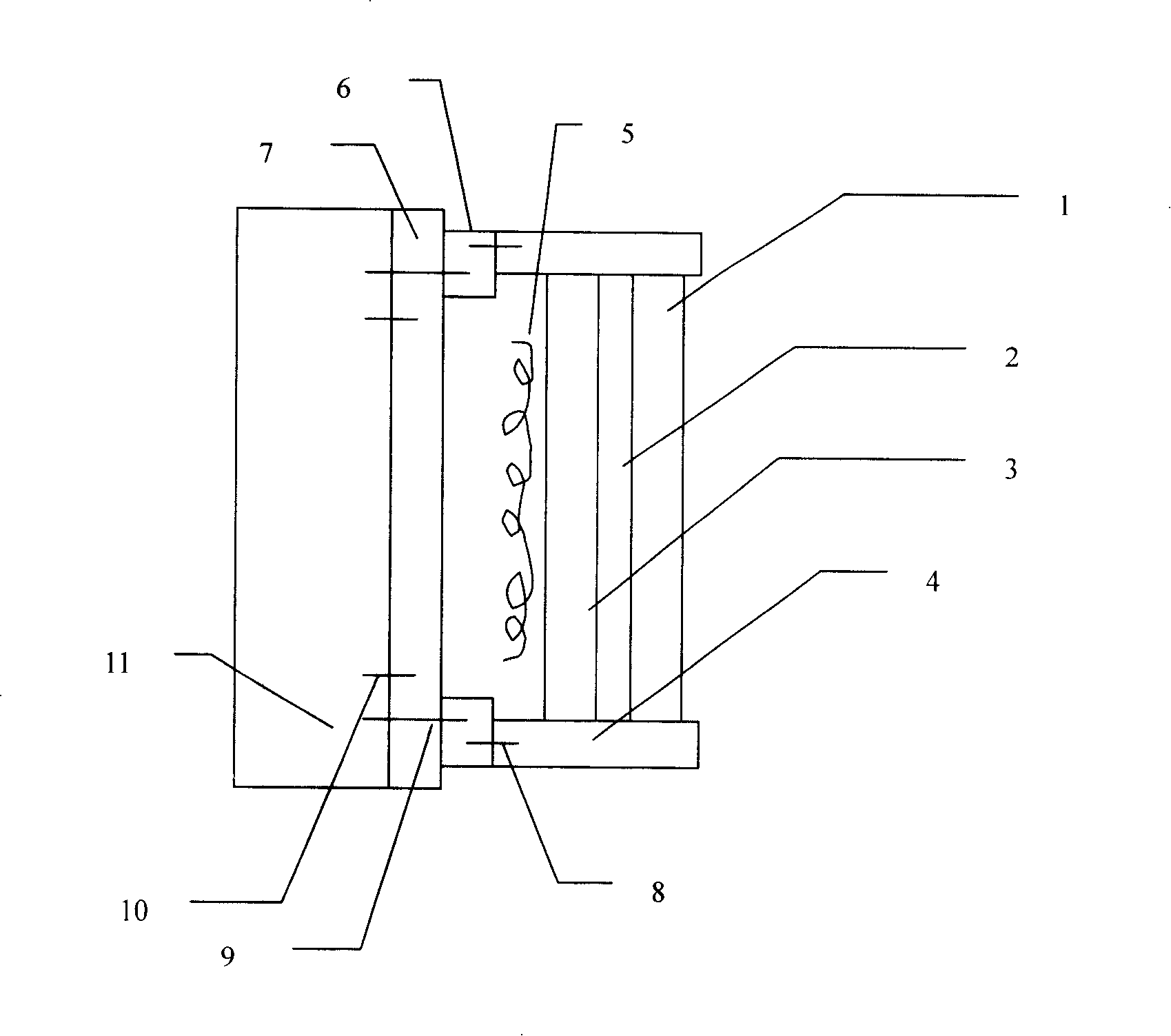

Grade-A fireproof self-heat-insulation wall body and manufacturing method thereof

ActiveCN103755287AEasy to solidifyShorten molding timeSolid waste managementUltimate tensile strengthMaterials science

The invention discloses a grade-A fireproof self-heat-insulation wall body and a manufacturing method thereof. The wall body comprises a grade-A fireproof self-heat-insulation wall body building block, a heat-insulation plate, a plastic rivet bolt, a masonry mortar layer and a heat-insulation anti-crack mortar layer, wherein the heat-insulation plate is adhered to a beam column of a frame structure through the masonry mortar layer; heat-insulation anti-crack mortar wraps each surface of the combination of the heat-insulation plate and the masonry mortar layer; the grade-A fireproof self-heat-insulation wall body building block, the heat-insulation plate, the plastic rivet bolt, the masonry mortar layer and the heat-insulation anti-crack mortar layer adopt an integrated structure; moreover, manufacturing methods for each part are introduced in detail. According to the grade-A fireproof self-heat-insulation wall body and the manufacturing method thereof, the product strength is greatly improved, the volume-weight is reduced on the basis that the product strength meets requirements, and the labor intensity is further reduced; the load of a building is reduced, the weight is light, the strength is high, and the fireproof, waterproof and heat-insulation effects are good; one-time construction is performed, the masonry of a main wall body is completed, the requirement for saving 65 percent of energy is also met, heat-insulation construction is not required to be performed, and the service life of the wall body is the same as that of the building.

Owner:环秀(青岛)建材科技有限公司

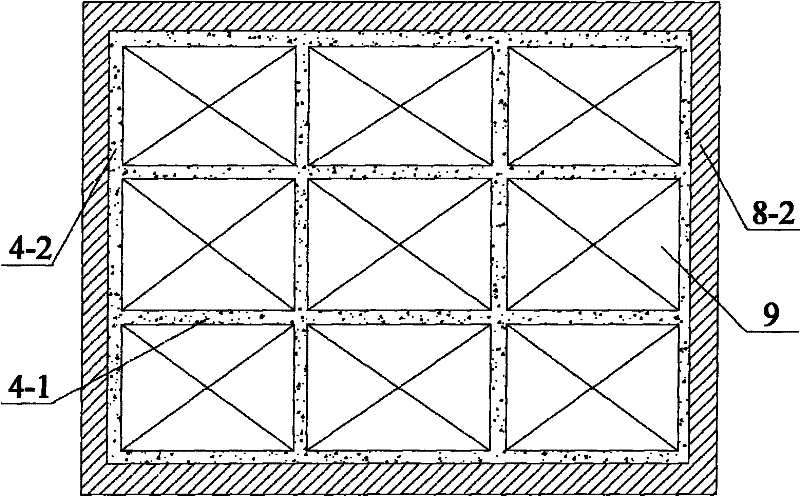

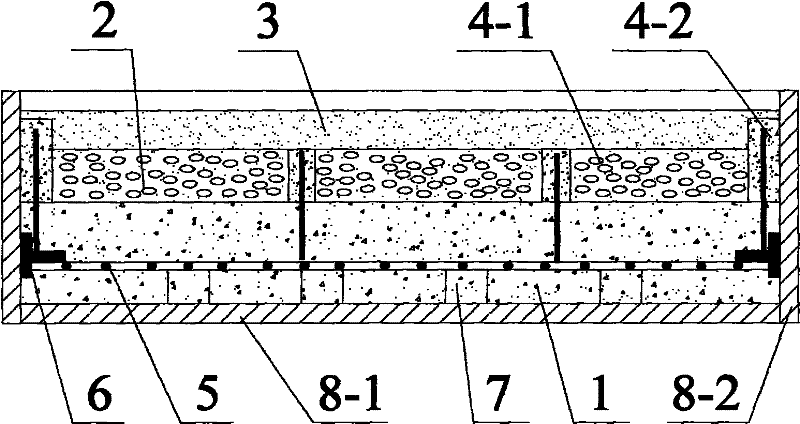

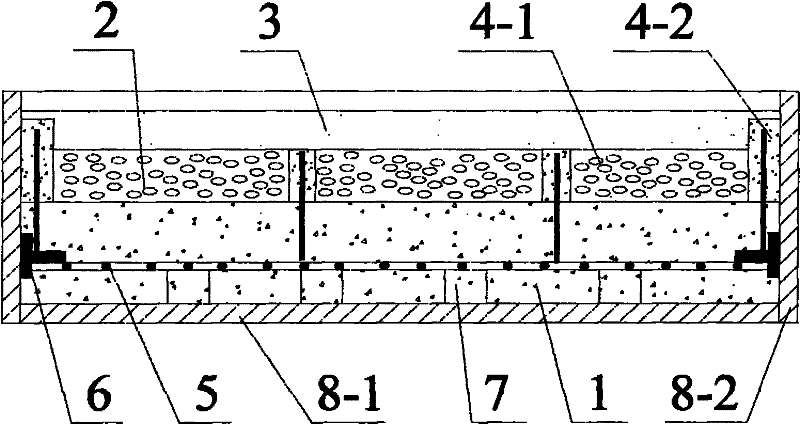

Cast-in-place process for ultra light foamed cement-based bearing heat insulation wallboard

ActiveCN102251662AReduce weightWith insulationRoof covering using slabs/sheetsWallsReinforced concreteSurface layer

The invention discloses a cast-in-place process for an ultra light foamed cement-based bearing heat insulation wallboard. The process for preparing the bearing wallboard in a mode of directly pouring ultra light foamed cement on site comprises the following steps of: paving a bottom template and side templates to form a concrete forming die; paving a concrete protection layer cushion block on thebottom template, and then pouring fine stone concrete into the concrete forming die to form a reinforced concrete bearing layer; placing a plate frame for sizing and a reinforcing rib combined inner die on the initially non-set concrete of the bearing layer according to the design positions; pouring fine stone concrete into the combined inner die to form a frame and reinforcing ribs; pouring an ultra light foamed cement core material into a groove formed by the reinforced concrete bearing layer, the frame and the reinforcing ribs, forming an ultra light foamed cement heat insulation core layer after initial setting, and reserving the thickness of a waterproof surface layer; pouring waterproof fast hardened cement-based self-leveling mortar to the upper part of the ultra light foamed cement heat insulation core layer before initial setting to form the waterproof surface layer; and detaching the forming die after the waterproof fast hardened cement-based self-leveling mortar is hardened.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Flame retardant polystyrene foamed hard wood-imitating material and preparation method thereof

The invention discloses a flame retardant polystyrene foamed hard wood-imitating material and a preparation method thereof. The hard wood-imitating material comprises, by weight, 50-70 parts of recovered polystyrene, 55-75 parts of high impact polystyrene, 35-45 parts of flame retardant masterbatch for a core layer, 30-40 parts of special flame retardant masterbatch for a surface layer, 0.5-0.9 parts of a foaming agent, 1-4 parts of a flexibilizer, 0.1-0.5 parts of a plasticizer, and 0.5-0.9 parts of a coloring agent. The flame retardant polystyrene foamed hard wood-imitating material of the present invention has high intensity flame retardation, is a hard foamed wood-imitating material with certain toughness and low density, and simultaneously has the advantages of fireproofing, waterproofing, oil resistance, insect prevention, mildew resistance, weatherproofing, light weight and the like.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

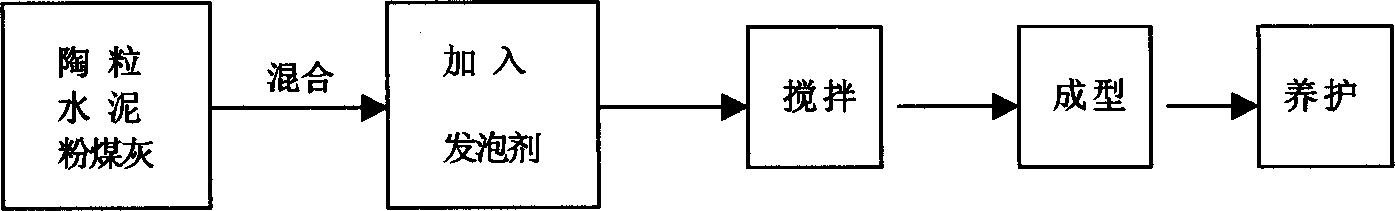

Sound-absorbing material for subway and its preparing process

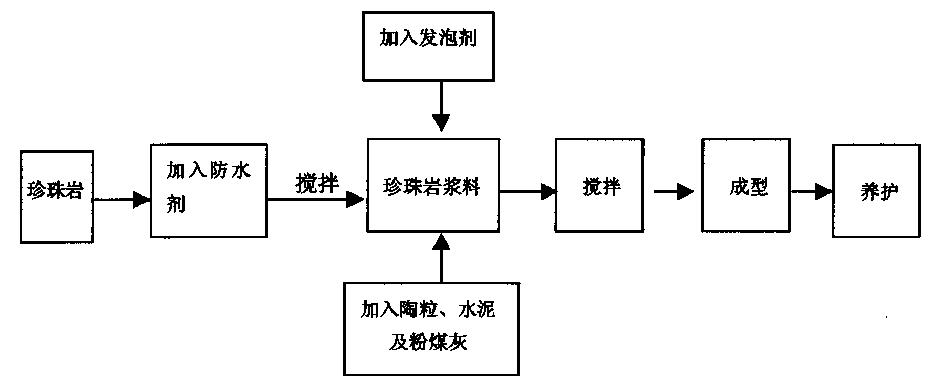

InactiveCN1346814AFireproofWaterproofSolid waste managementSound proofingFoaming agentExpanded clay aggregate

A sound-absorbing material for subway is prepared from haydite (40-70%), cement (20-48%) flyash (0-10%) and foaming agent (1-2%) through diluting foaming agent with water, mixing the others, adding the deluted foaming agent to the mixture and shaping. Its advantages are broad audio band, high sound absorptivity, low volume weight, high strength, resisting fire and water, no toxicity, and low cost.

Owner:曾令可

Aerated concrete wall material containing river silt and preparation method thereof

ActiveCN102910889AFireproofWaterproofCeramic shaping apparatusCeramicwareCompressive resistanceAluminium powder

The invention relates to an aerated concrete wall material and a preparation method thereof, in particular to an aerated concrete wall material containing river silt and a preparation method thereof. The aerated concrete wall material comprises the following main components in percentage by weight: 60-75% of river silt, 1-10% of cement, 13-28% of lime, 1-2% of gypsum powder, 6-10% of aluminum powder and 2-11% of foam stabilizing agent, and the sum of weight percentages of the components is 100%. In the invention, river silt dug out by regulating the Yangtze River can be effectively utilized, energy is saved, emission is reduced, the ecological environment is protected, and the processed aerated concrete wall material also has high compressive strength and high bending strength.

Owner:HUAHONG GROUP YIXING HUAHONG NEW WALL BUILDING MATERIALS

Multifunctional composite ornamental board

InactiveCN101220702AReduce generationEasy to useCovering/liningsMoisture absorptionVibration isolation

The invention discloses a multifunctional compound decorative board, which includes a decoration surface, a gluing layer, a plate bottom and a functional material and is characterized in that the decoration surface and the plate bottom are compounded with one or more functional materials (the various functional materials can be mutually overlapped, covered, permeated or mixed); the decoration surface is bonded on the plate bottom and the plate bottom is bonded on the functional material; the functional material can be selected from heat insulating material, sound-proof material, vibration isolation material, damping material, hazardous material or gasses adsorption material, beneficial matters releasing material, flame retardant and fireproof material, sound absorbing material, moisture absorption and moistureproof material, etc., therefore, a compound multifunctional heat-insulating, sound-insulating, vibration-isolating, noise-absorbing, environment-protective, flame-retardant, fire-fighting, moisture-absorbing and moistureproof decorative board can be produced.

Owner:刘涛

Nano intelligent health powder coating

InactiveCN108610817AWith heat insulationWith sound insulationFireproof paintsAntifouling/underwater paintsFiberSlurry

The invention relates to a nano intelligent health powder coating. The nano intelligent health powder coating is prepared from the material components: dispersible film-forming materials, inorganic functional element materials, negative ion powder, sea-foam powder, diatomite, titanium dioxide, germanite powder, carbon fiber powder, nano titanium dioxide, nano-silica, nano-zinc oxide, microcapsules, cellulose, dispersan, antifoaming agents and the like; the nano intelligent health powder coating is prepared by the following steps of preparation of activated microporous materials, nano-slurry dispersion and powdering, mixing and stirring, melt extrusion, ball milling separation and sieving and the like; interior wall powder coating, exterior wall powder coating, thermosetting powder coating;in addition to fully complying with national standards, the coating also has new functions of temperature regulation, humidity control, sound insulation, heat preservation, air purification, anti-corrosion, antibacterial sterilization, anti-mold, anti-condensation, anti-radiation, anti-static, permanent release; negative ions, trace elements, far-infrared, bio-current, and permanent adsorption offormaldehyde, benzene, odor, smoke and harmful gases; the coating can be widely used for wall painting of habitable rooms, classrooms, offices, hospitals and the like.

Owner:胡春宇

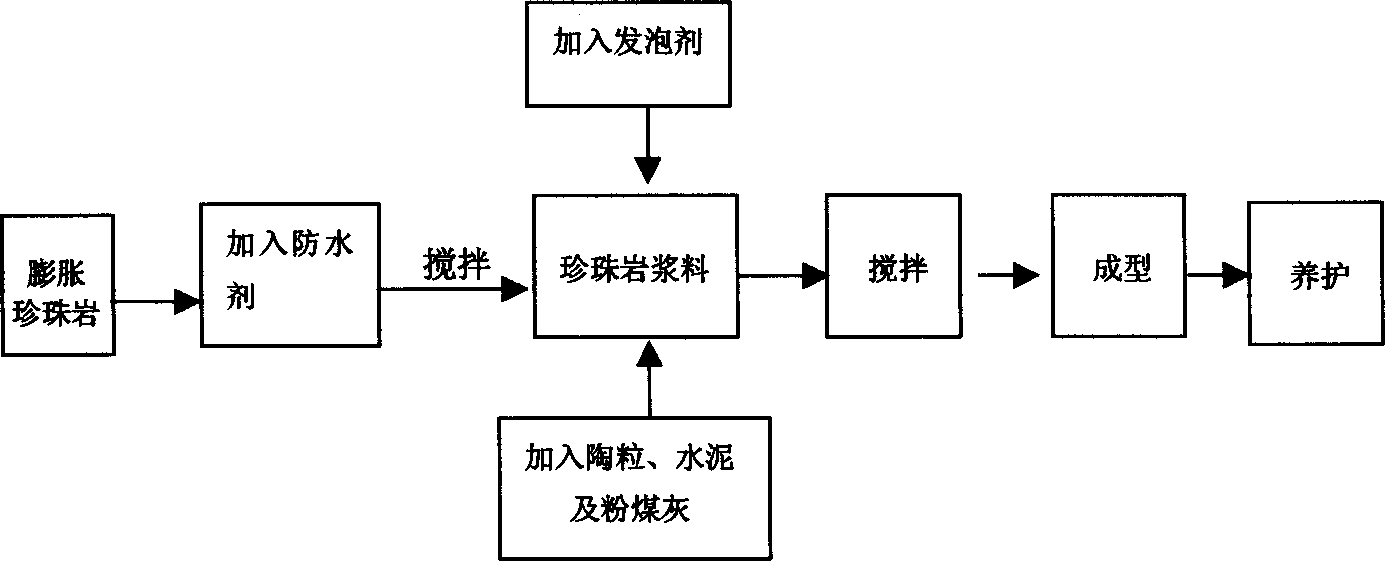

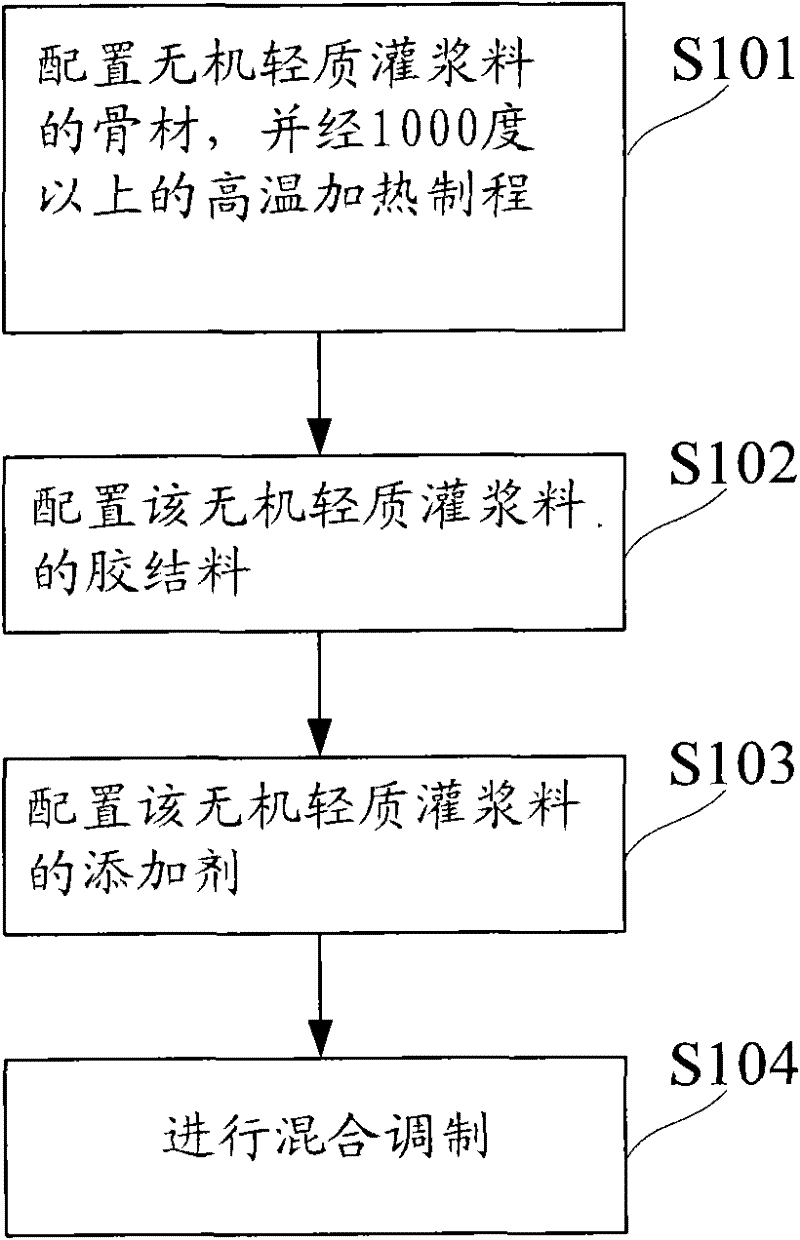

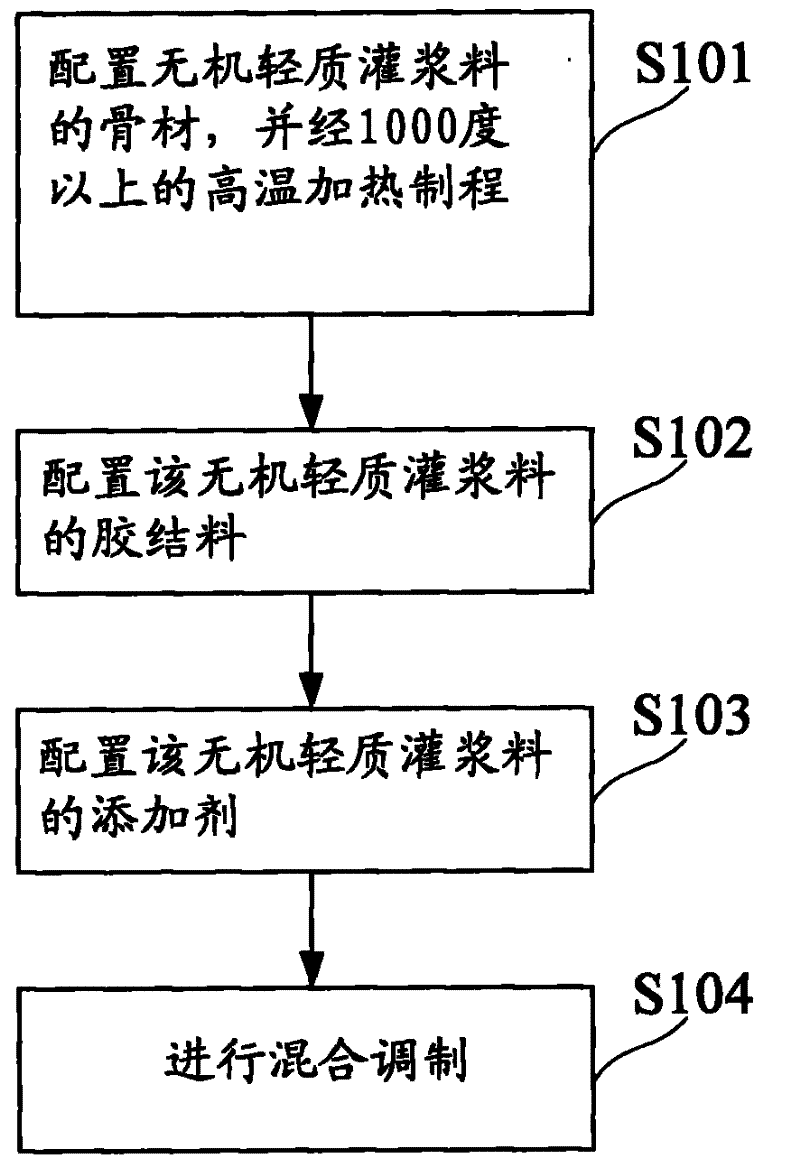

Inorganic lightweight grouting material, and manufacture method thereof

The invention discloses an inorganic lightweight grouting material, and a manufacture method thereof. The inorganic lightweight grouting material provided by the invention is manufactured from a low-density, surface-sealed and inside-hollow granular expanded ore such as pitch stone or perlite as main raw material, a powdery adhesive, an additive and the like through blending at a proper ratio. The inorganic lightweight grouting material is practically used by adding water according to a certain ratio, uniformly stirring, pouring into building wall and carrying out hydration reaction to form the grouting material for wall filling. The grouting material has the advantages of slight expansion, low specific gravity (smaller than water), good heat preservation and fireproof effects, strong high-temperature resistance, good sound absorbing property, low cost, etc.

Owner:古金盛 +1

Single-component lightweight sound-insulating heat-preserving mortar material and construction method thereof

The invention discloses a single-component lightweight sound-insulating heat-preserving mortar material. The material is prepared from the following raw materials by weight: 350 to 700 parts of Portland cement, 500 to 1000 parts of lightweight porous slag, 6 to 12 parts of redispersible latex powder, 3 to 6 parts of cellulose ether, 20 to 40 parts of foam glass particle, 10 to 20 parts of a sound-insulating filling material, 20 to 40 parts of shale pottery and 1 to 2 parts of reinforced fiber. The single-component lightweight sound-insulating heat-preserving mortar material provided by the invention has scientifically and reasonably proportioned components, is extensively applicable to handling of walls, household floors and the like having requirements on sound insulation and heat preservation during building and brushing of the walls, casting of the household floors, etc., and has the advantages of sound insulation, heat preservation, fire prevention, water resistance, anti-freezing performance, good adhesion, no occurrence of cracking and hollowing, etc. The construction method for the material is reasonably designed, can mold a sound-insulating and heat-preserving system in a building wall or household floor in one shot and has the advantages of convenient construction, high efficiency, low cost, high quality, etc.

Owner:YANCHENG SHENXING IND

Flame retardant environmentally friendly adhesive and producing method of plant fiberboard

ActiveCN105331294ARaw materials are easy to getFlame retardantNon-macromolecular adhesive additivesWood working apparatusFire retardantFiberboard

The present invention provides a flame retardant environmentally friendly adhesive, and the raw materials comprise magnesium sulfate, magnesium chloride, water, magnesium oxide, sodium dihydrogen phosphate, boric acid, and methyl cellulose. The flame retardant environmentally friendly adhesive is a formaldehyde-free environmentally friendly inorganic adhesive, not only has flame-retardant effect, but also can make a plant fiberboard highly stable in fiber structure and high in mechanical properties, and also allows the plant fiberboard to have waterproof, moistureproof, fireproof, rot-resistant, pest control and other functions; in addition, the flame retardant environmentally friendly adhesive has readily available raw materials, and cheap in price, so that the production cost of the flame retardant environmentally friendly adhesive is relatively low. The present invention also provides a producing method of the plant fiberboard by use of the flame retardant environmentally friendly adhesive.

Owner:河南国信联投环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com