Single-component lightweight sound-insulating heat-preserving mortar material and construction method thereof

A technology of thermal insulation mortar and thermal insulation mortar layer, which is applied in the field of building materials, can solve problems such as difficult control of construction quality, complex construction technology, and unsatisfactory conditions, and achieve large market space and development prospects, reasonable process design, and simple and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A single-component lightweight sound-insulating and heat-insulating mortar material, which is made of the following raw materials in parts by weight:

[0031] 350 parts by weight of Portland cement, 500 parts by weight of light porous slag, 6 parts by weight of redispersible latex powder, 3 parts by weight of cellulose ether, 20 parts by weight of sound-absorbing foam glass particles, 10 parts by weight of sound-insulating filler, shale 20 parts by weight of pottery sand, and 1 part by weight of reinforcing fiber.

Embodiment 2

[0033] A single-component lightweight sound-insulating and heat-insulating mortar material, which is made of the following raw materials in parts by weight:

[0034] 700 parts by weight of Portland cement, 1000 parts by weight of light porous slag, 12 parts by weight of redispersible latex powder, 6 parts by weight of cellulose ether, 40 parts by weight of sound-absorbing foam glass particles, 20 parts by weight of sound-insulating filler, shale 40 parts by weight of pottery sand, 2 parts by weight of reinforcing fiber.

Embodiment 3

[0036] 1. The construction method of the household floor slab of the thermal insulation system in the lightweight sound insulation and thermal insulation mortar provided by the invention, it comprises the following steps:

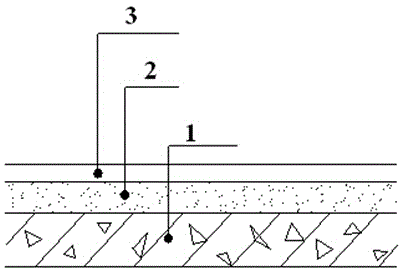

[0037] a. First erect steel bars on the building formwork, and then pour concrete to obtain a concrete floor (1);

[0038] b. Then pour the single-component lightweight sound-insulating and heat-insulating mortar material described in Example 1 on the reinforced concrete floor (1) to obtain the sound-insulating and heat-insulating mortar layer (2);

[0039] c. Brush a layer of plain cement surface layer slurry on the sound insulation and thermal insulation mortar layer (2) in step b, and compact and roughen it (3). Such as figure 1 shown.

[0040] 2. Performance test:

[0041] The household floor slabs prepared above were taken for various performance tests. The test results are as follows: compressive strength ≥ 10.0MPa (GB / T 5486-2008); thermal condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com