Patents

Literature

1381results about How to "Reasonable process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

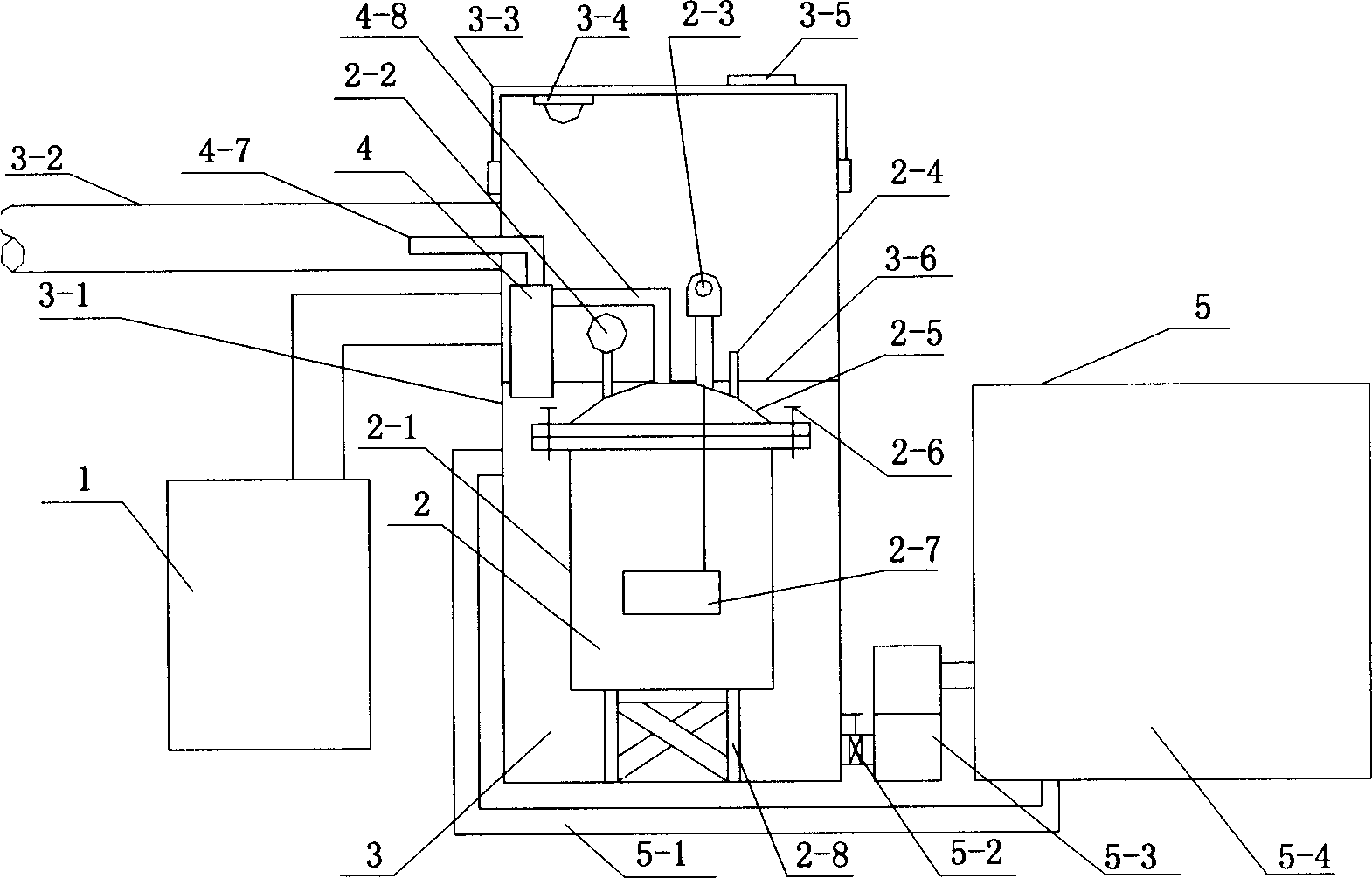

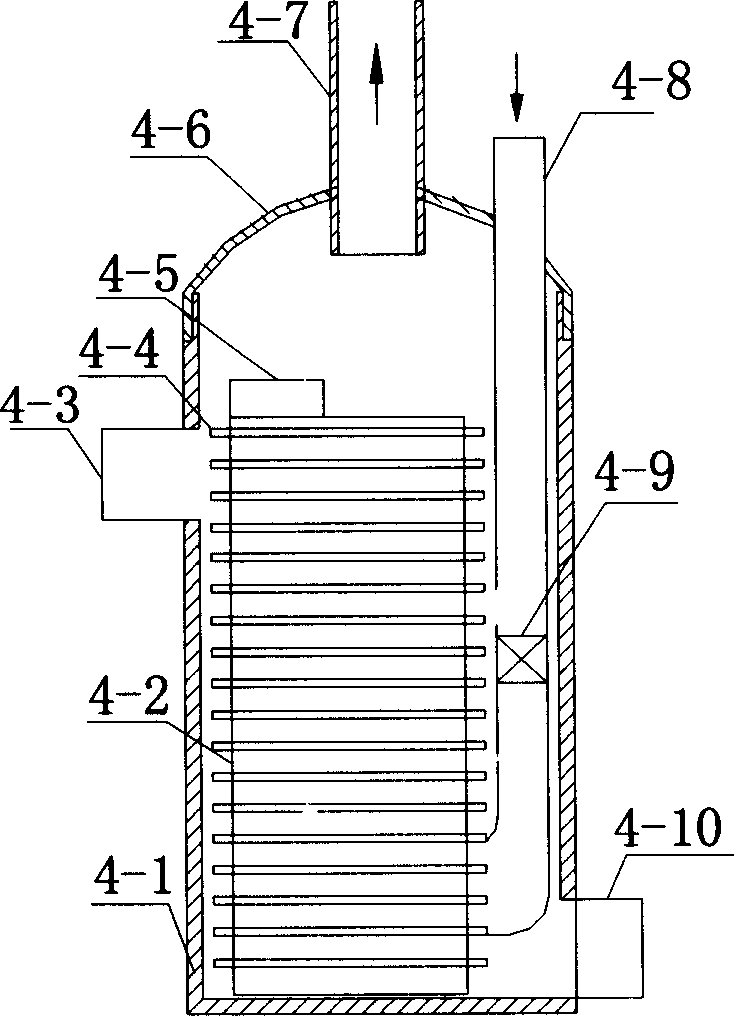

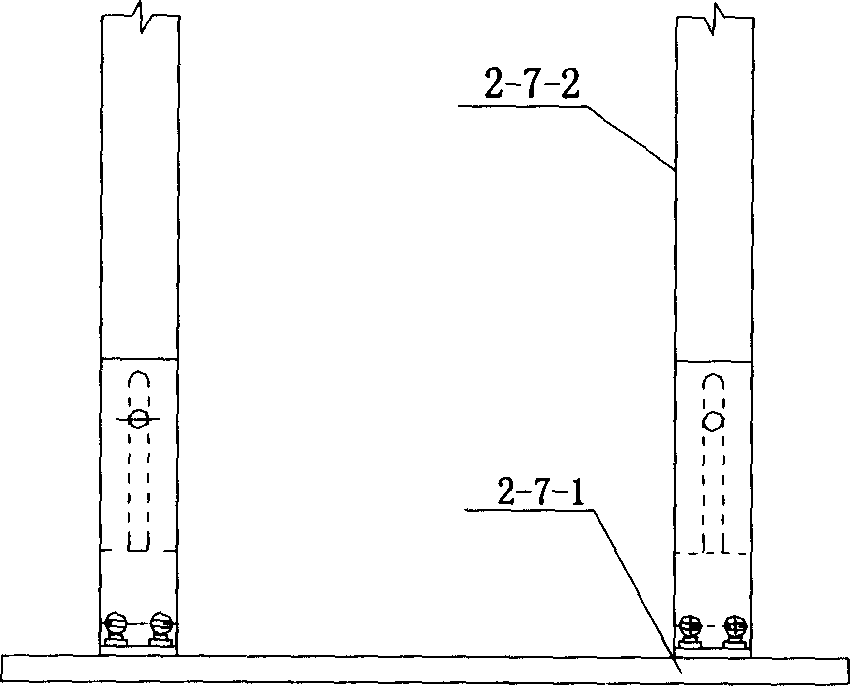

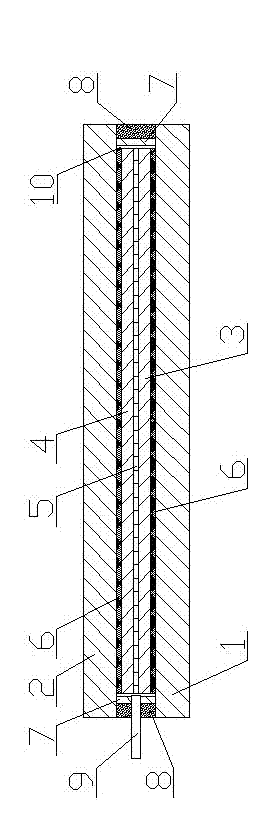

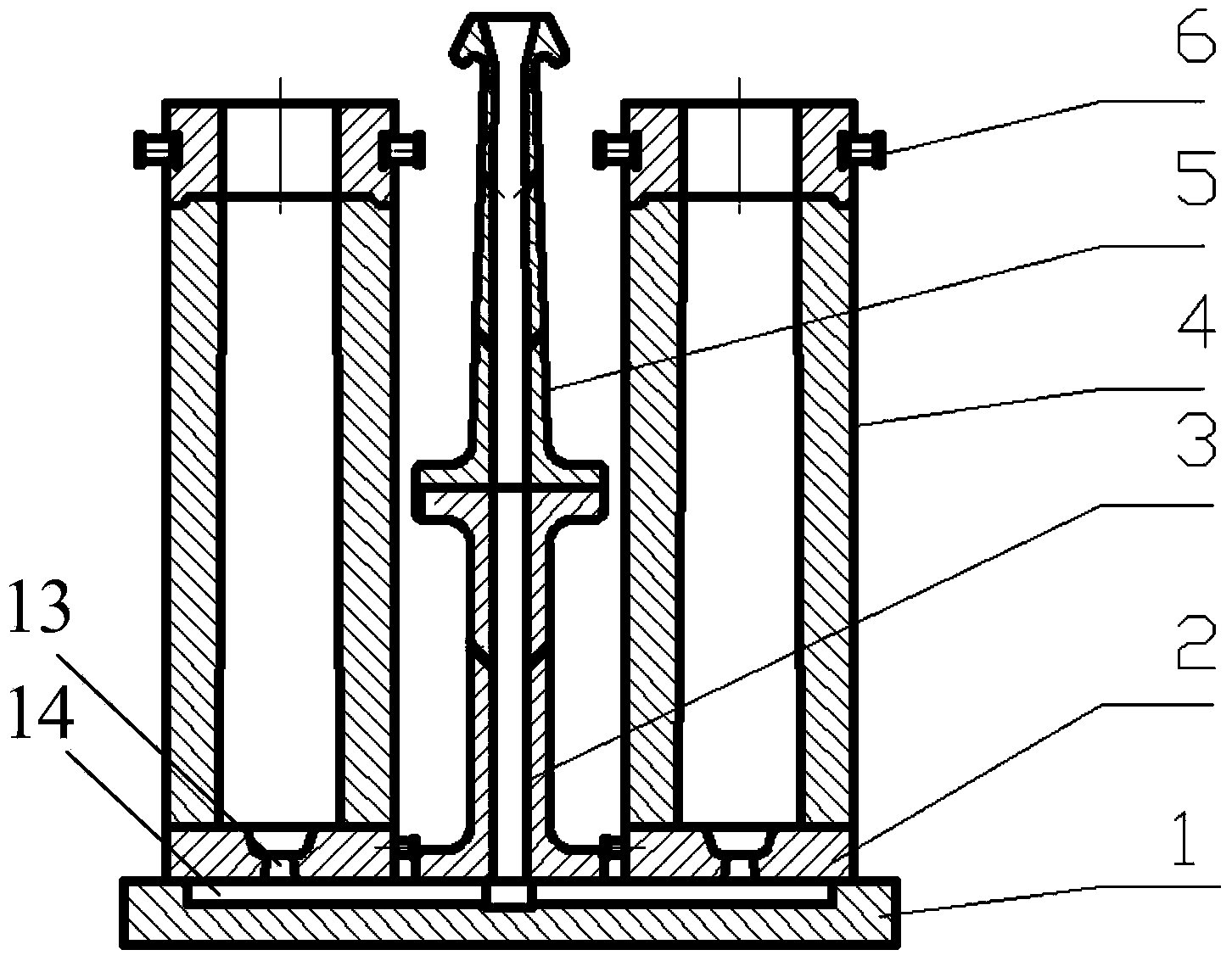

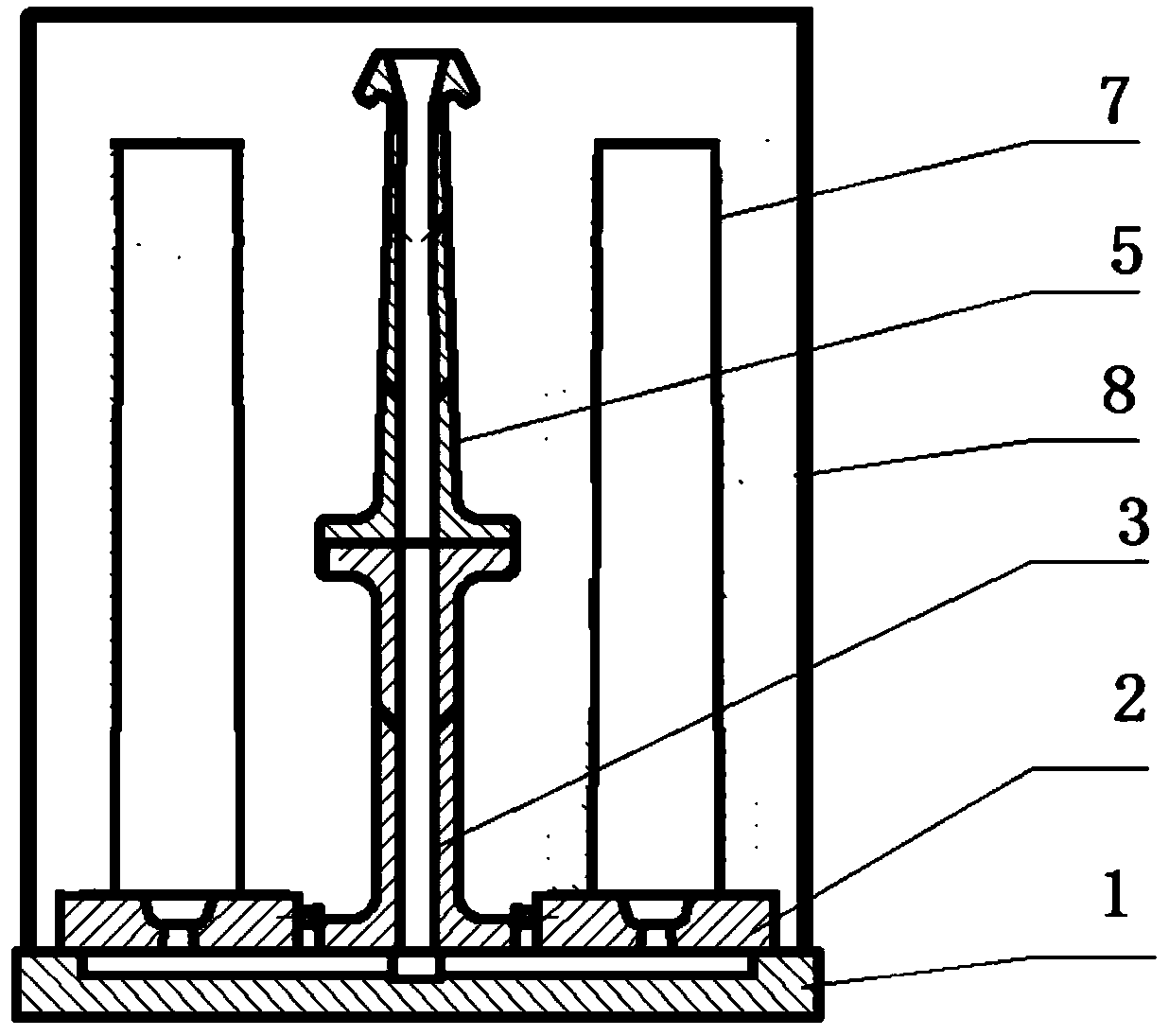

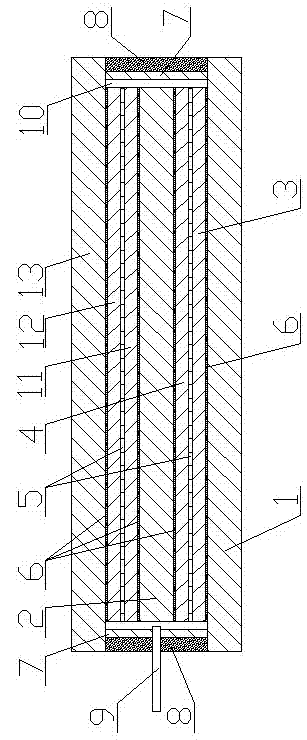

Apparatus and process for preparing carbon fiber reinforced silicon carbide composite material

The invention relates to equipment of producing carbon fiber enhanced carborundum composite material. The equipment is made up with controlling system, protection kettle system, working kettle system, security isolation system, and protection liquid circulating system. Controlling system connects to every part through leads. Security isolation and working kettle system are installed into protection kettle system. Security isolation connects to working kettle system through air intake duct. Protection liquid circulating system connects to protection kettle through pressure adjusting set. Technics of precast product are as follows: spraying protective layer material on precast product of carbon fiber, spraying strengthening layer material and getting production of precast product. Install the production into working kettle shell to produce carbon fiber enhanced carborundum composite material. The invention reduce producing period to several hours, which improves quality and efficiency and reduce production cost. It can operate in normal pressure and resist burning and exploding. Construction of the equipment is simple, technics reasonable and operation convenient.

Owner:UNIV OF JINAN

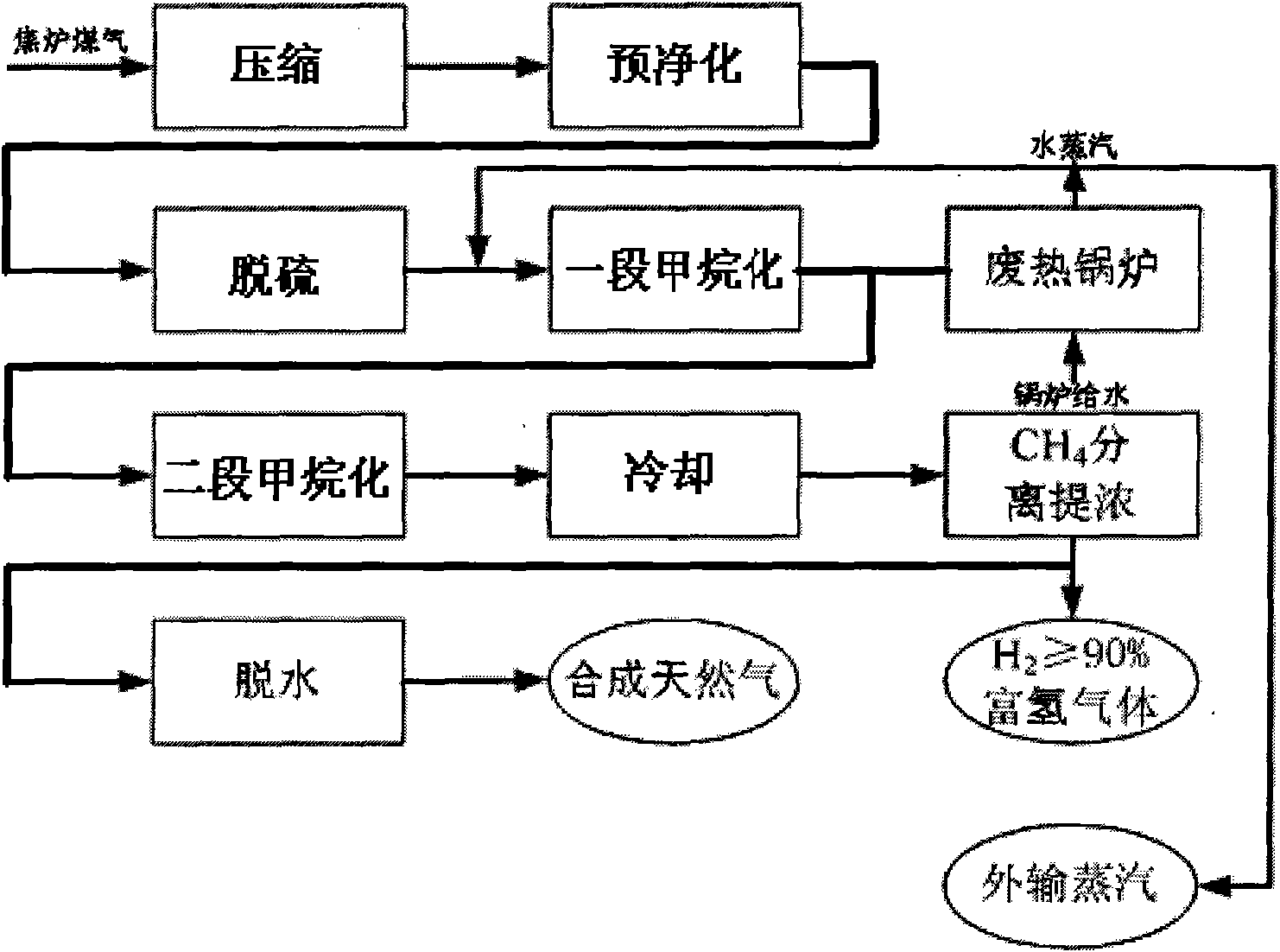

Synthesis process of natural gas employing methanation of coke oven gas

The invention relates to a comprehensive utilization synthesis process of natural gas employing methanation of coke oven gas, belonging to the technical field of new energy utilization. The process comprises the following steps: compressing coke oven gas, preliminary cleaning, removing sulfur, performing first section methanation, performing second section methanation and separating natural gas toprepare natural gas which reaches the grade A technological requirements of natural gas national standard (GB17820-1999). The synthesis process of natural gas employing methanation of coke oven gas reaches the aim of high effective comprehensive utilization of natural gas and provides a new way of preparing and synthesizing natural gas.

Owner:SHANDONG TIEXIONG METALLURGICAL TECH CO LTD +2

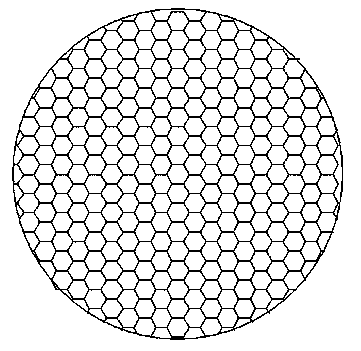

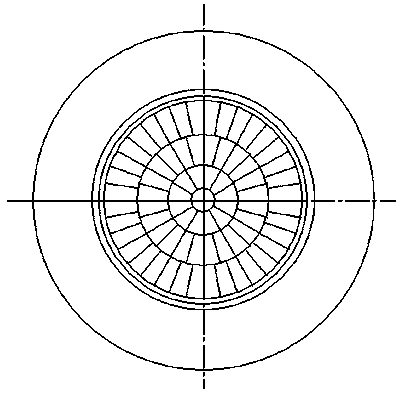

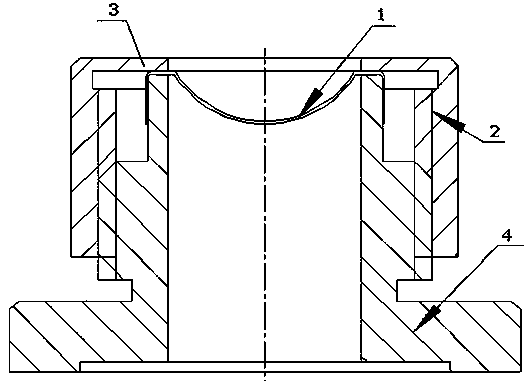

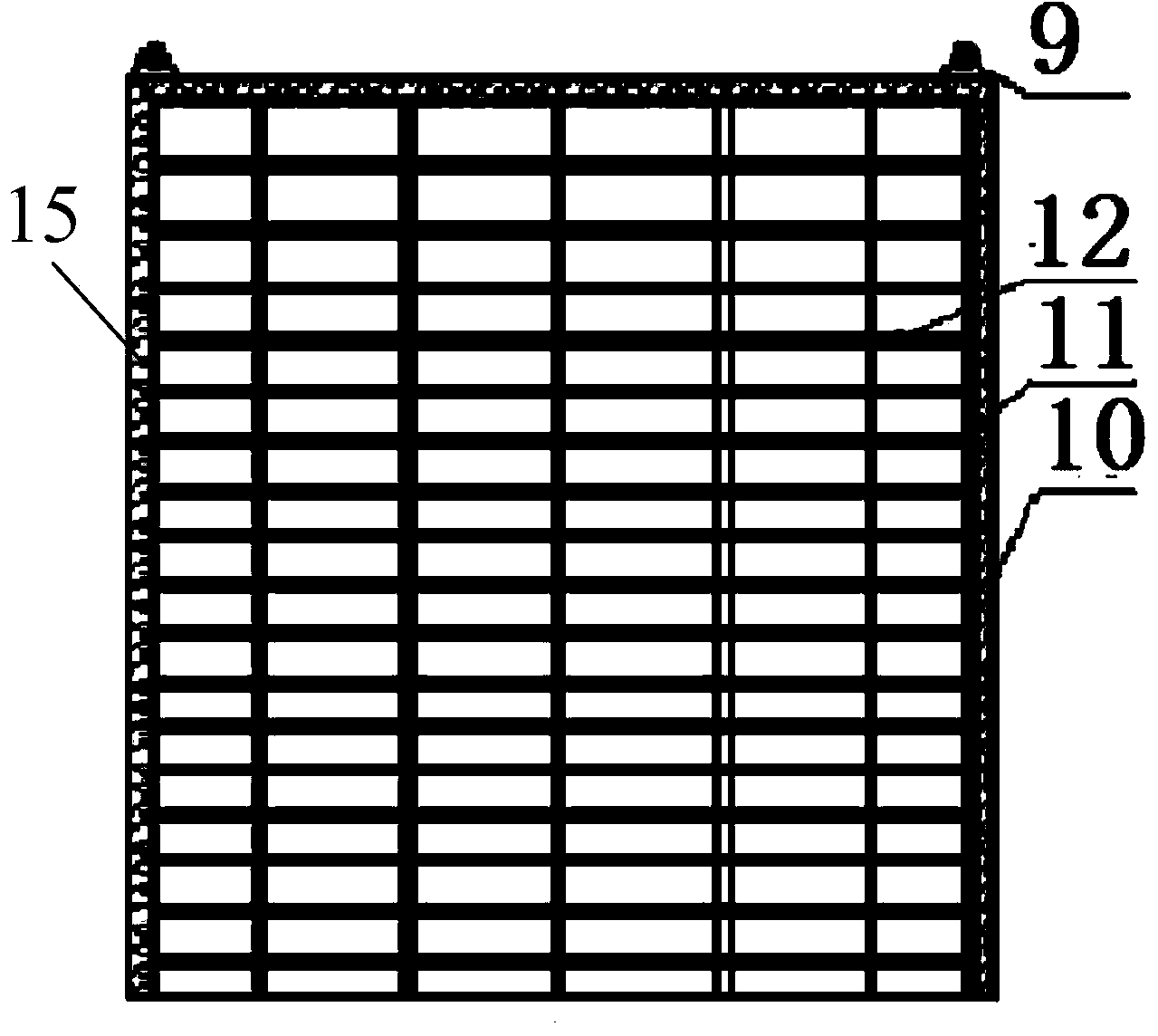

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

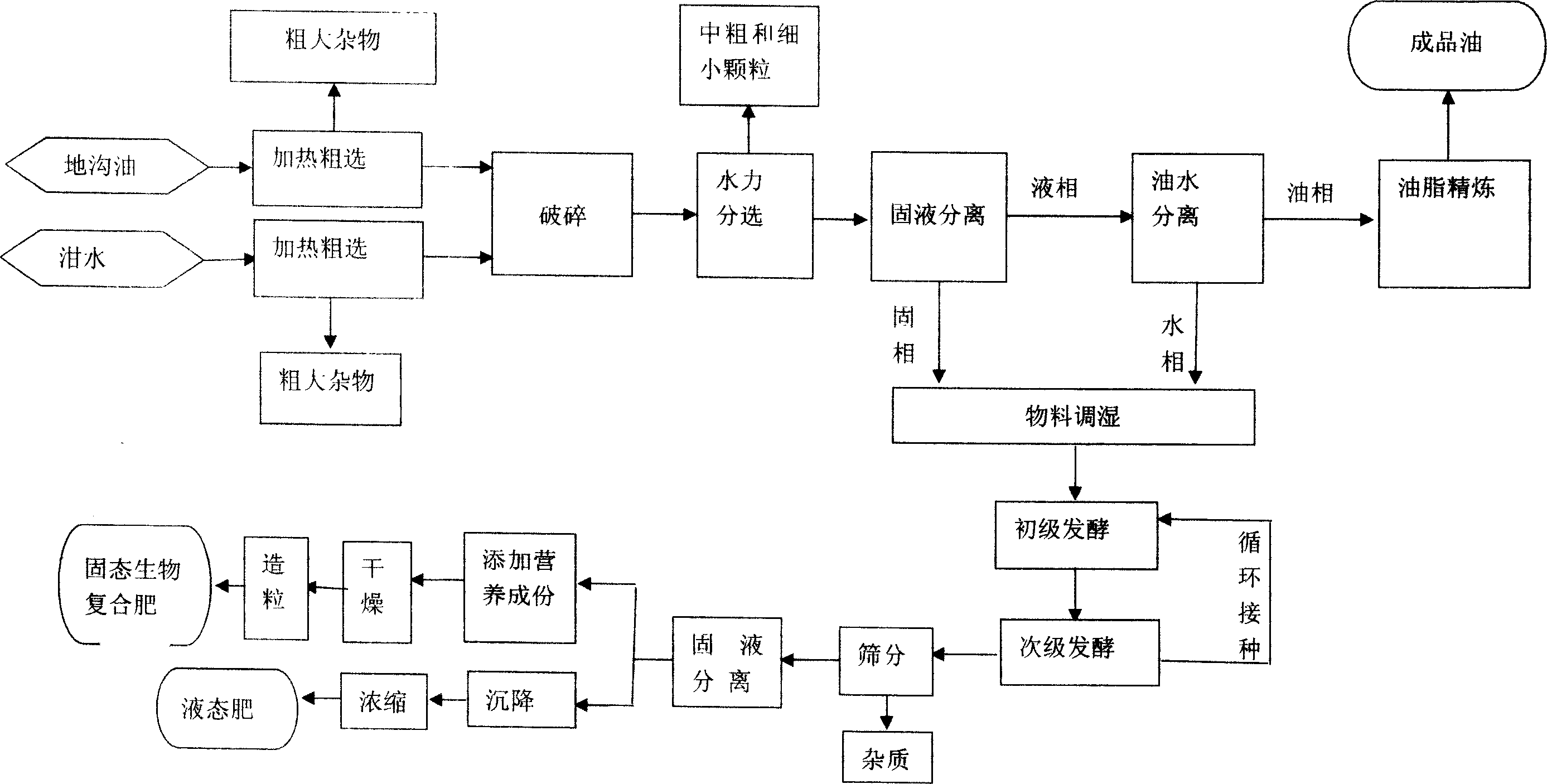

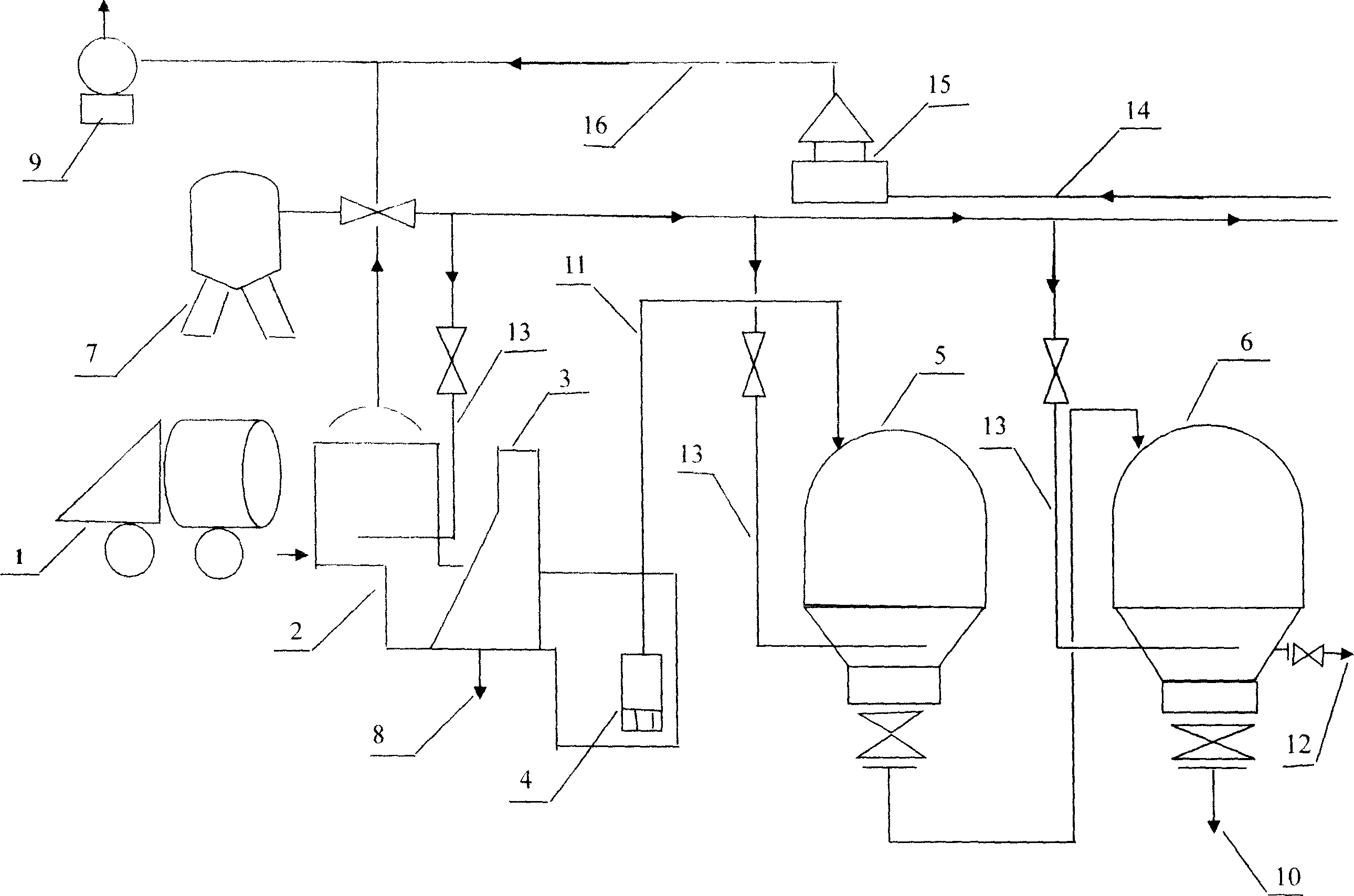

Comprehensive treatment technology of kitchen garbage

InactiveCN1903799AReasonable process designStrong controllabilityClimate change adaptationOrganic fertilisersOil waterThree stage

The present invention relates to a comprehensive treatment technique of restaurant kitchen garbage. Said technique includes the following steps: firstly, removing non-degradable components from said restaurant kitchen garbage, then breaking said garbage, making hydraulic separation to form cream liquor of organics. Said invention mainly includes three-stage high-speed centrifugal separation process, in which first stage centrifugal separation utilizes the cream liquor formed by hydraulic separator to produce solid dregs and oil-water mixture phase; second stage centrifugal separation utilizes the above-mentioned oil-water mixture phase to produce waste oil and clear water phase containing rich organics; the clear water phase and the above-mentioned cream liquor formed by blending solid dregs produced by first centrifugal separation are fed into fermentation tank, undergone the process of aerobic fermentation so as to form solid-liquid mixture, then the solid-liquid mixture is fed into third stage high-speed centrifugal machine to make solid-liquid separation to obtain heavy phase and light phase. Said heavy phase is solid fertilizer and the light phase is liquid biological organic fertilizer.

Owner:高鸿禄

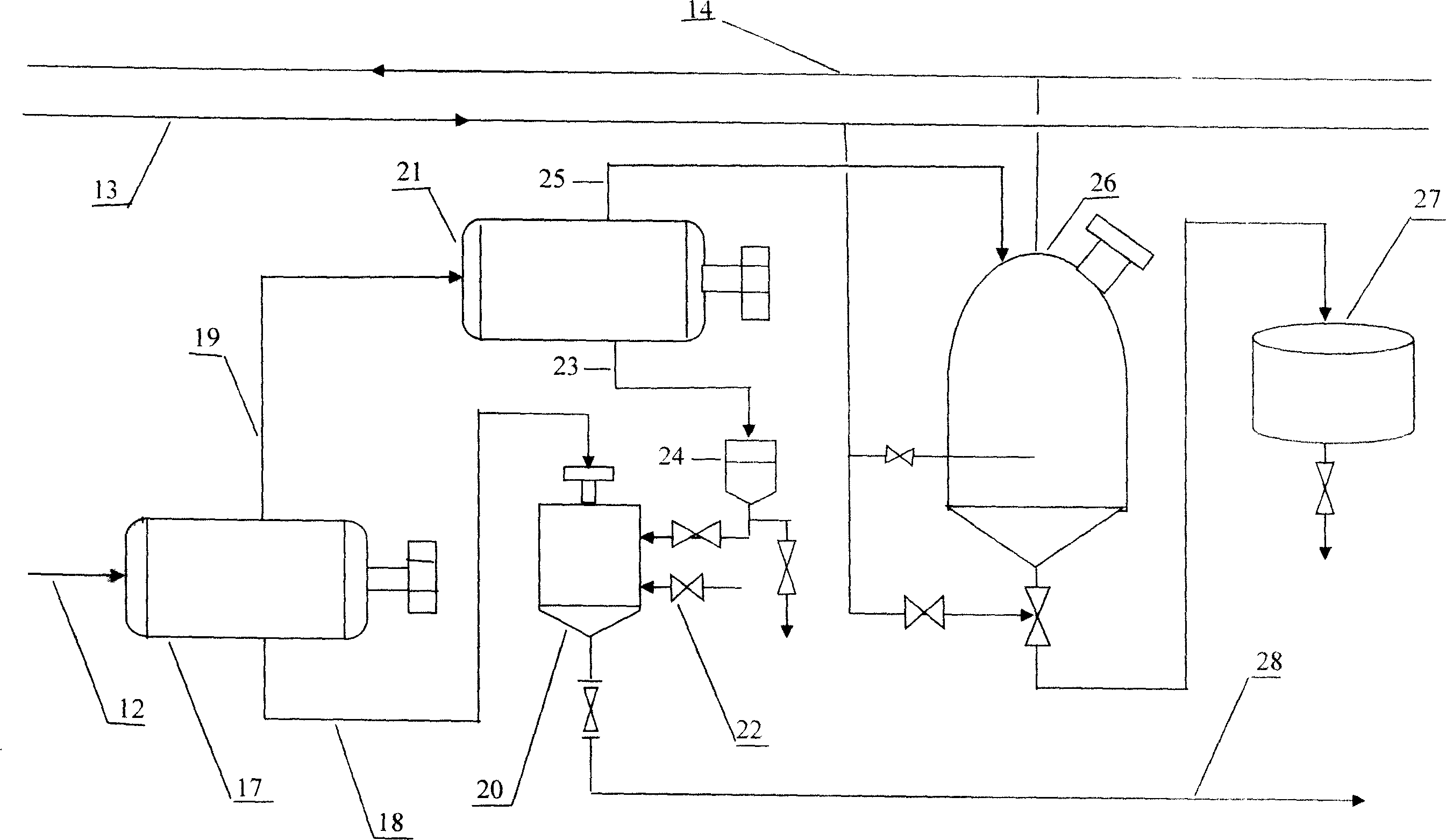

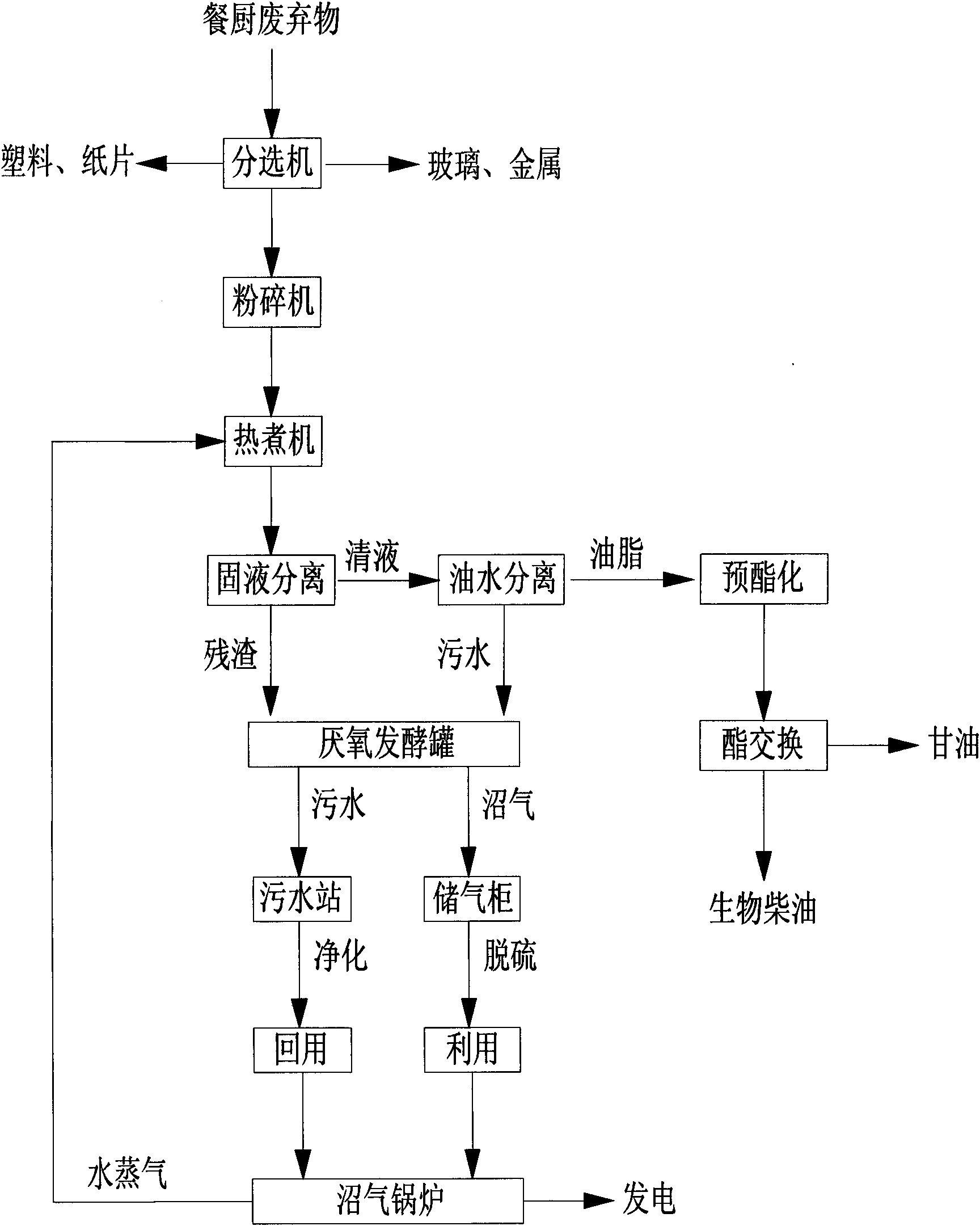

Urban kitchen waste recycling utilization and harmless treatment technology

ActiveCN102688881AReasonable process designSimple processBiological substance pretreatmentsFatty acid esterificationBiodieselWater vapor

The invention relates to an urban kitchen waste recycling utilization and harmless treatment technology. The urban kitchen waste recycling utilization and harmless treatment technology is characterized by grinding and sorting kitchen waste by a crushing sorting machine, separating out inorganic substances, carrying out high-temperature steam pyrolysis of organic matter slurry, and carrying out solid-liquid and oil-water separation, wherein separated residues and sewage are fed into a biogas fermentation tank and are subjected to anaerobic fermentation to produce biogas for power generation or civil heating; and separated waste oil undergoes an acid-base reaction to produce glycerin and biodiesel. The urban kitchen waste recycling utilization and harmless treatment technology realizes maximum recycle of active resources of kitchen waste, reduces the pollution and the damage on the environment, and has environmental, economic and social benefits.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

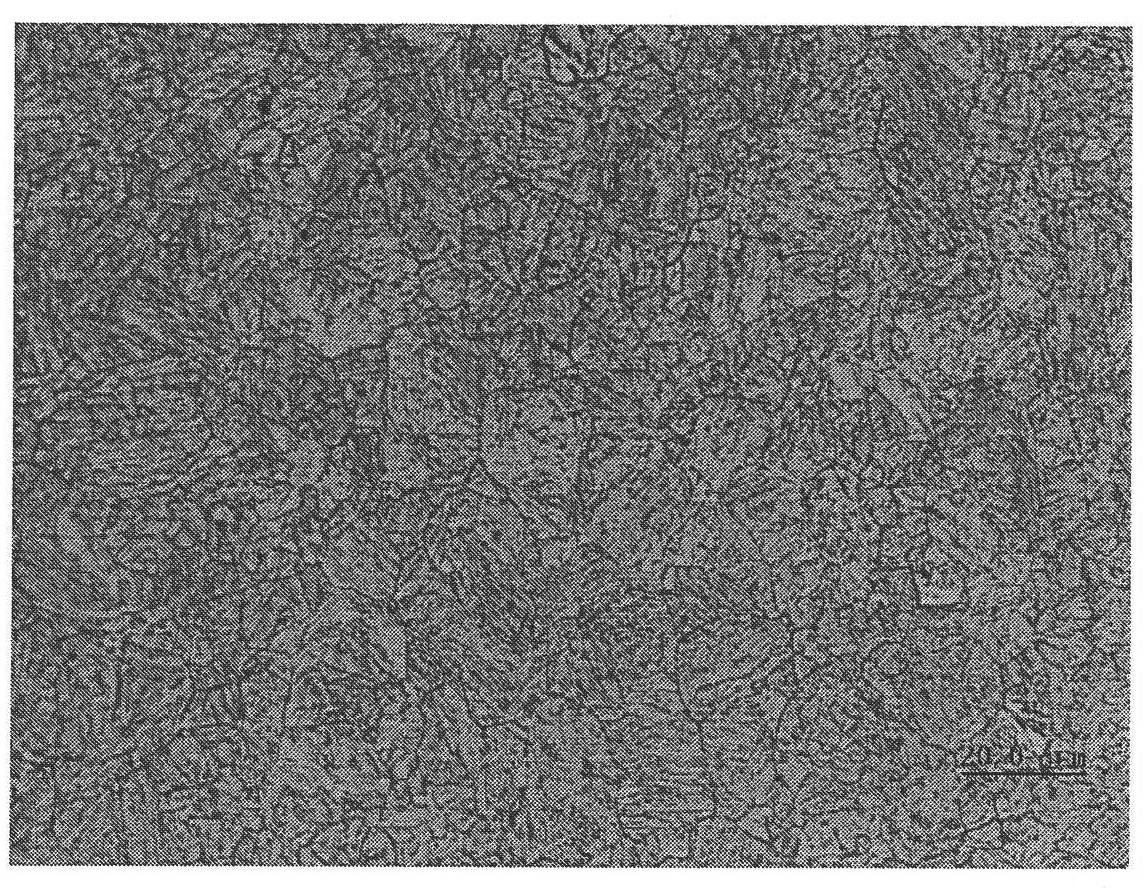

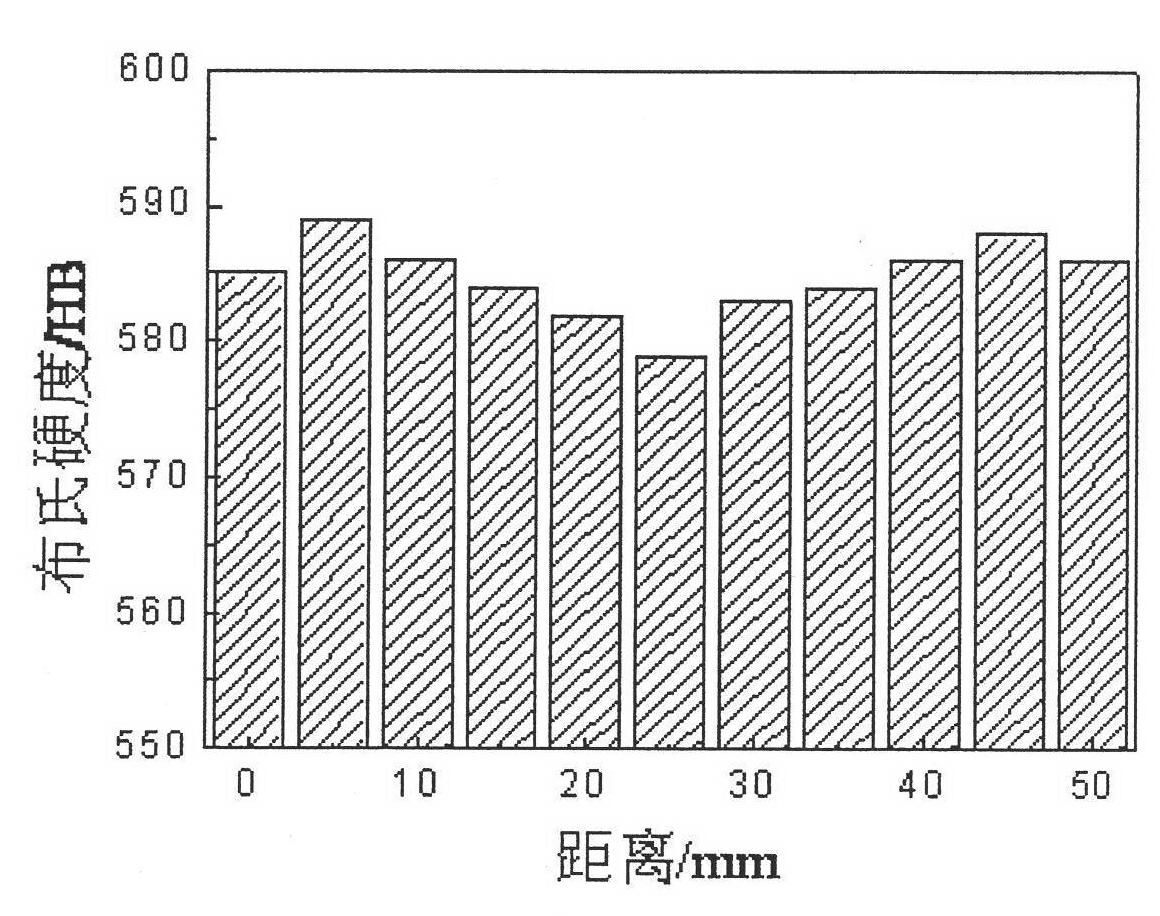

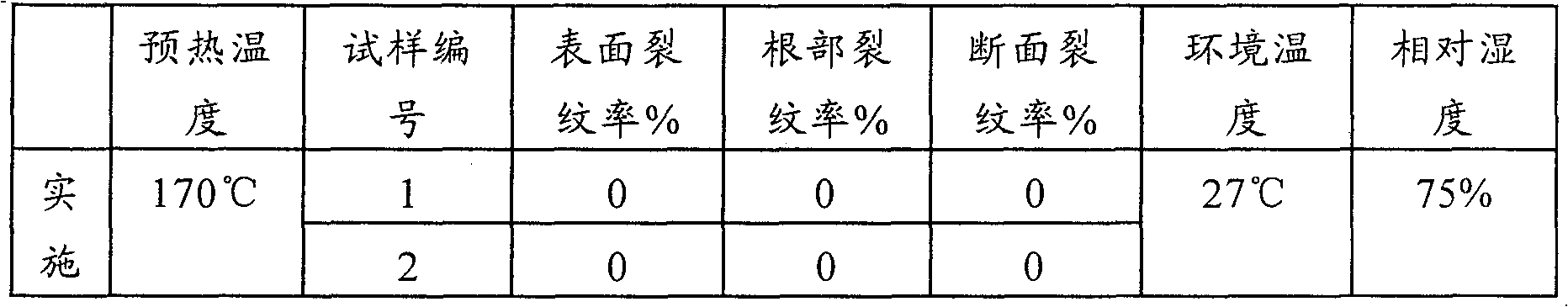

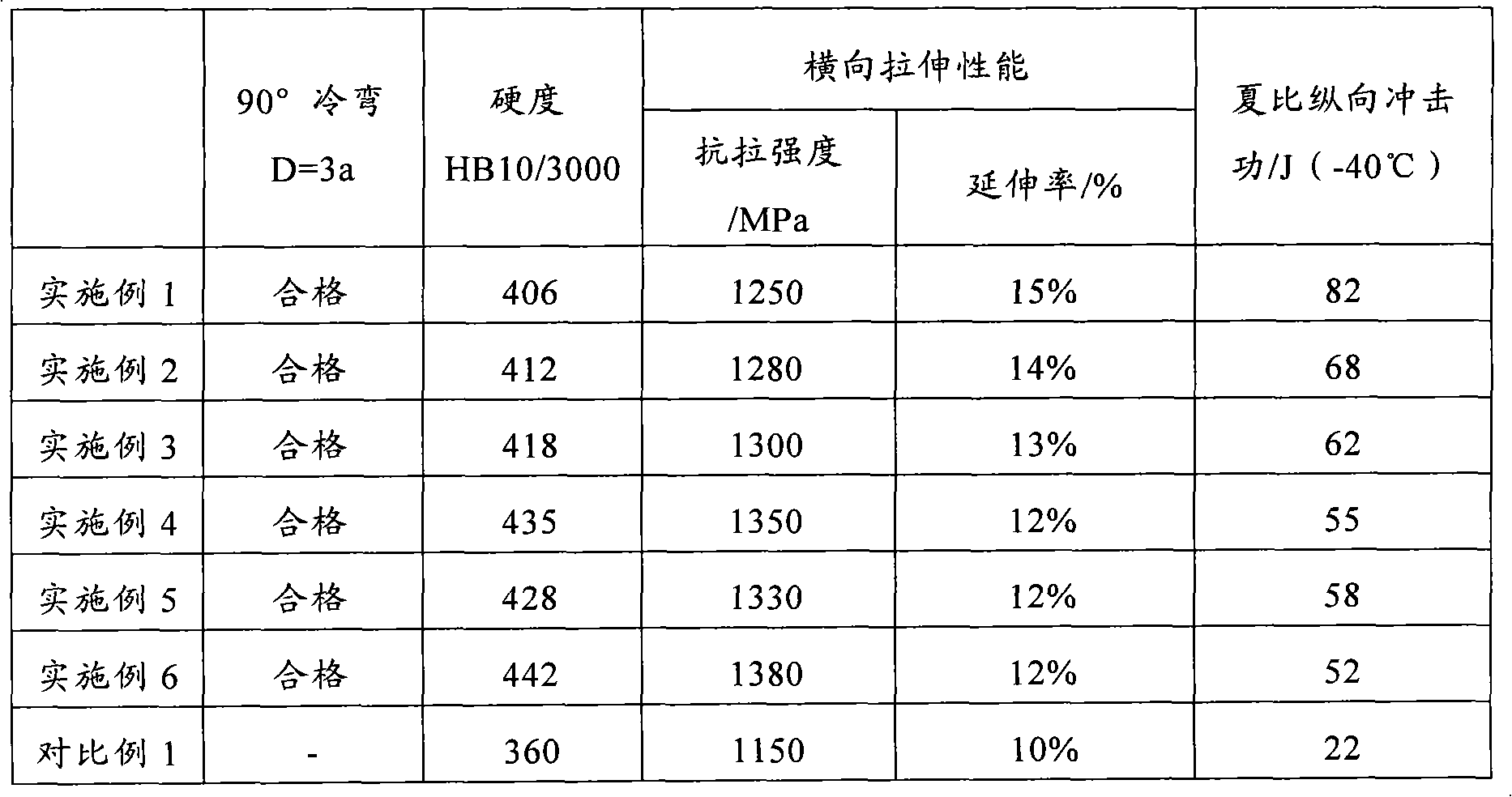

Wear resistant steel plate

The invention provides a wear resistance steel plate, which contains the chemical ingredients (by weight percent) of: 0.31 to 0.40% of C, 0.10 to 0.80% of Si, 0.20 to 1.50% of Mn, not more than 0.050% of P, not more than 0.030% of S, 0 to 1.50% of Cr, 0 to 0.80% of Mo, 0.02 to 0.20% of Al, 0.0005 to 0.0040% of B, 0 to 0.10% of Ti, 0 to 0.030% of Ca, the balance of Fe and unavoidable impurities, wherein Cr+Mo is not less than 0.10% and not more than 1.80%, and Al+Ti not less than 0.05% and not more than 0.18%. A manufacturing method of the wear resistance steel plate comprises the steps of smelting, refining, casting, rolling, quenching, tempering and the like. The 550 HB-level wear resistance steel plate, which is obtained from the ingredients and process, has high hardness (not less than550 HB), can be welded and bent, and includes the microstructure of martensite or martensite and residual austenite. The steel plate has superior wear resistance and is extremely suitable for workingunder strong wear environment, especially on vehicles or facilities, like buckets, loaders, mining electric wheel dump tracks and the like, which come into contact with high-hardness materials, such as high strength ore and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

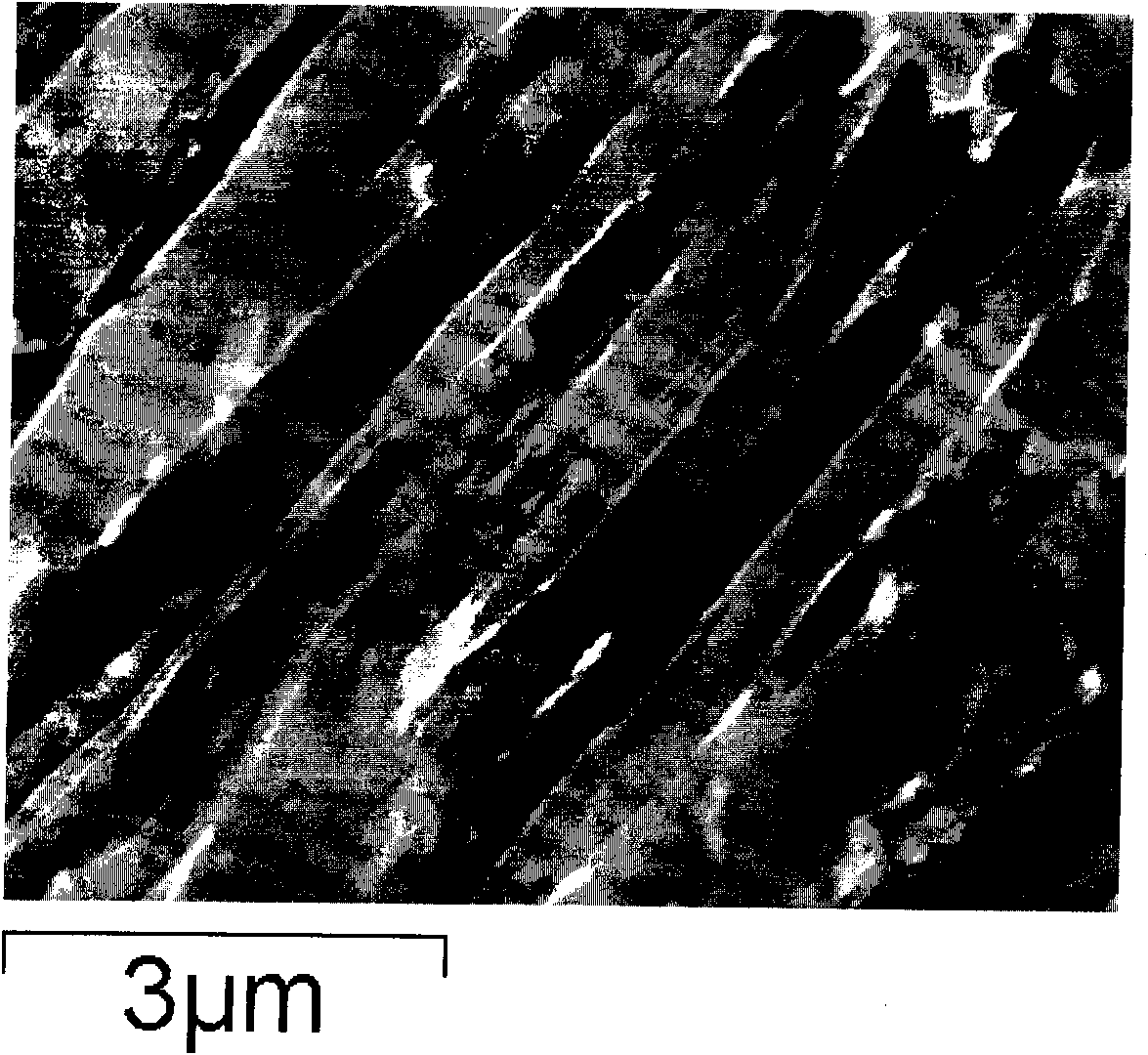

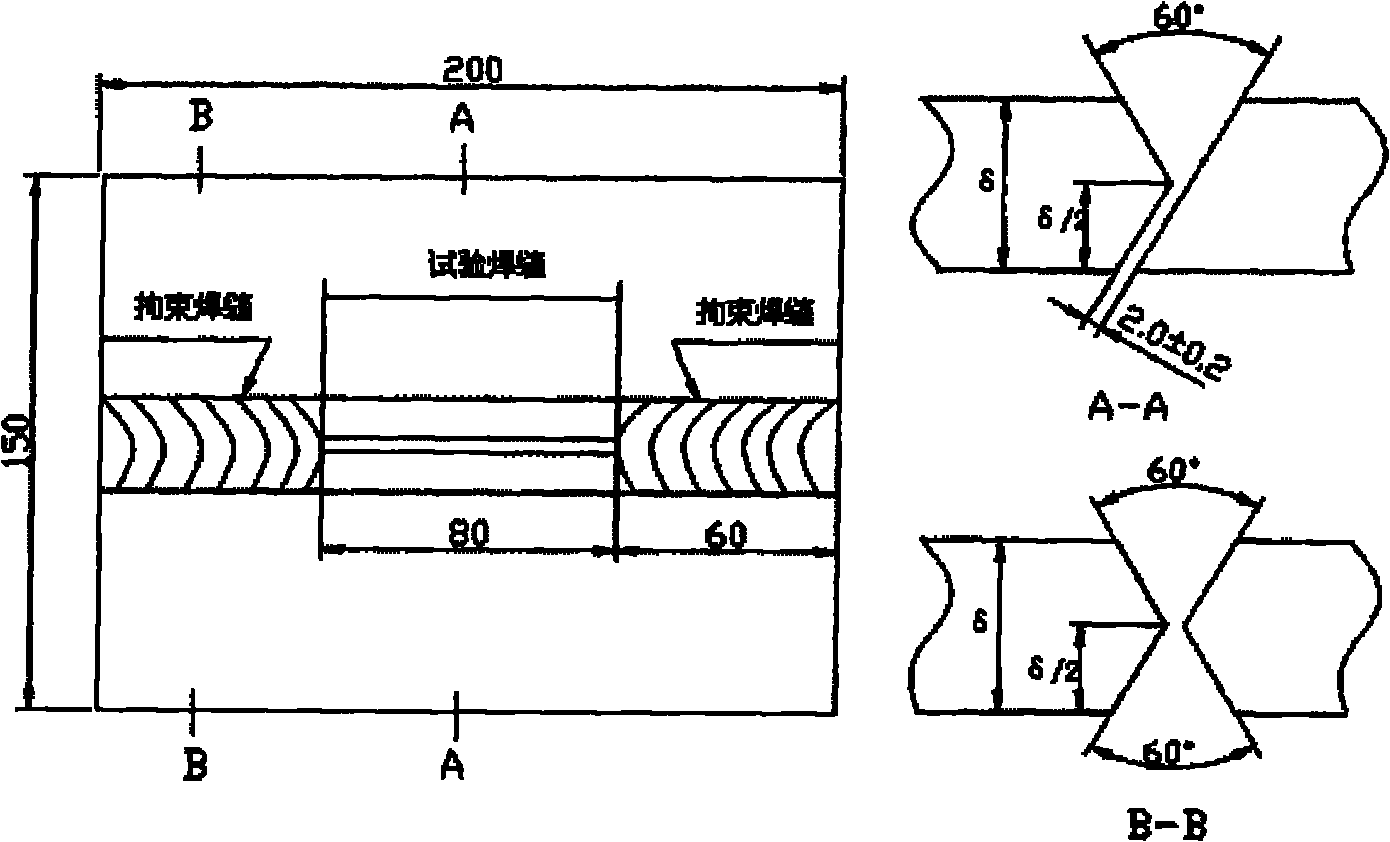

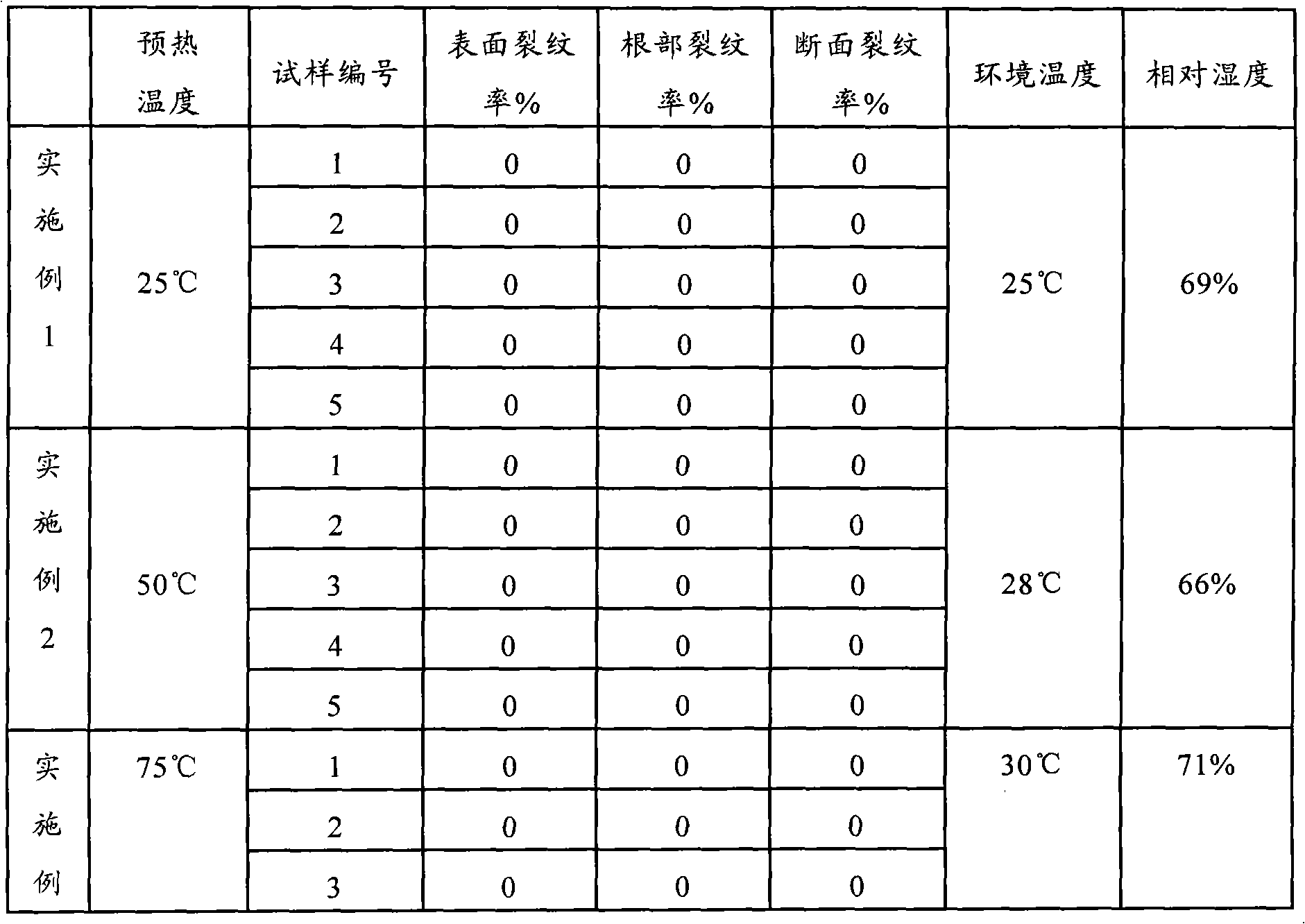

Ultrafine crystal bainite high-strength steel and manufacturing method thereof

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Owner:BAOSHAN IRON & STEEL CO LTD

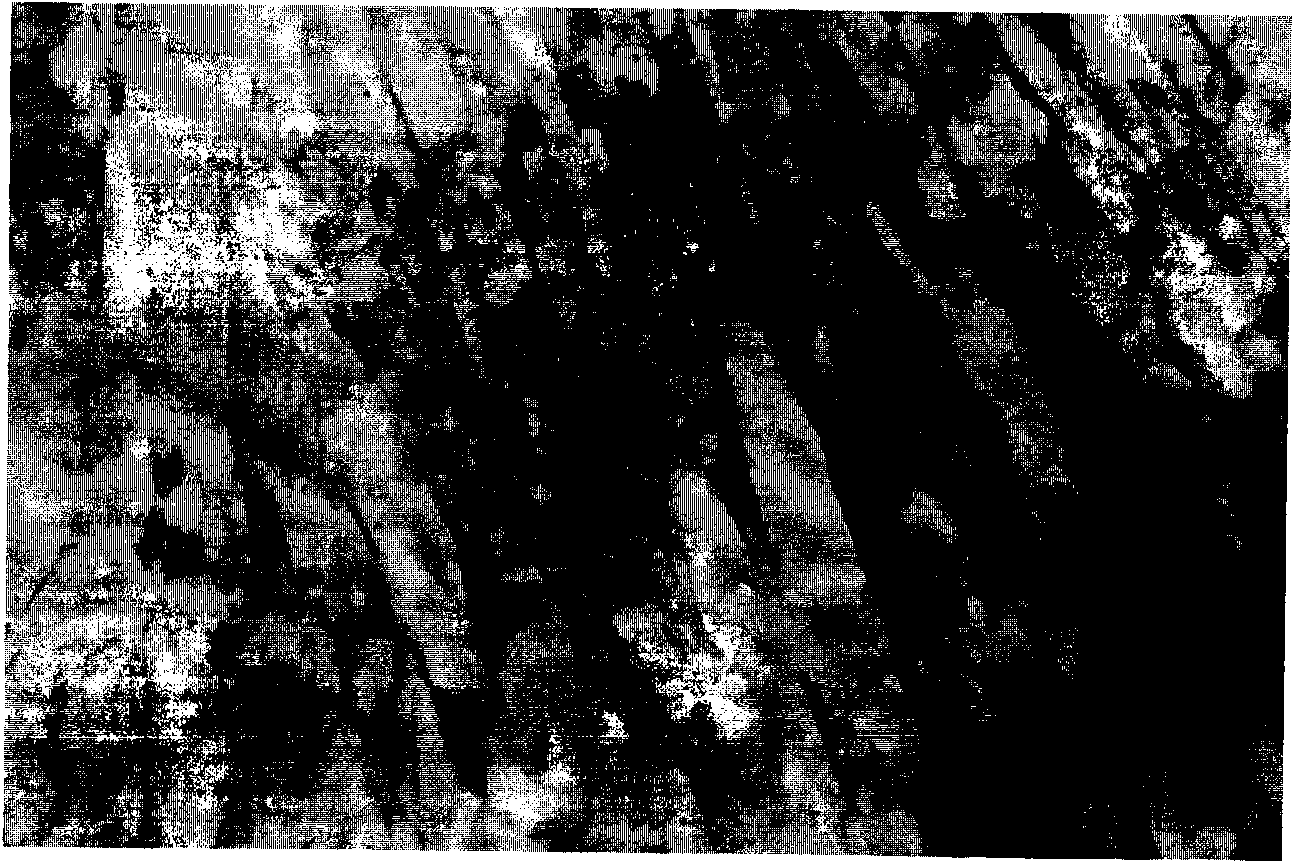

Micro-capsule essence with two-layer capsule wall and preparation method and application thereof

ActiveCN101649254AWell mixedHigh mechanical strengthFibre treatmentEssential-oils/perfumesEngineeringTwo layer

The invention discloses a micro-capsule essence with two-layer capsule walls and a preparation method and an application thereof. The essence comprises inner oil essence, a first micro-capsule wall inthe middle and an outer capsule wall located on outermost layer. The micro-capsule essence with two-layer capsule wall of the invention has two-layer capsule wall structure , good mechanical strengthand flexibitity; in addition, when used in cloth the micro-capsule essence has the advantage of strong washing resistance, long fragrance holding time and easy storage. The preparation method of themicro-capsule essence with two-layer capsule walls adopts complex coacervation phase separation method to prepare the essence, the technological design is seasonable, the maneuverability is strong, micro-capsule essence with different fragrances can be designed according to different demands; in the preparation process, the mechanical strength of the micro-capsule essence can be effectively controlled so as to control the duration time and degree of the frangrance of the micro-capsule essence; in addition, the finished product of the micro-capsule essence with two-layer capsule walls preparedin the invention has high qualification rate and the micro-capsule essence with two-layer capsule can realize industrialized production.

Owner:澳华达香精(广州)有限公司

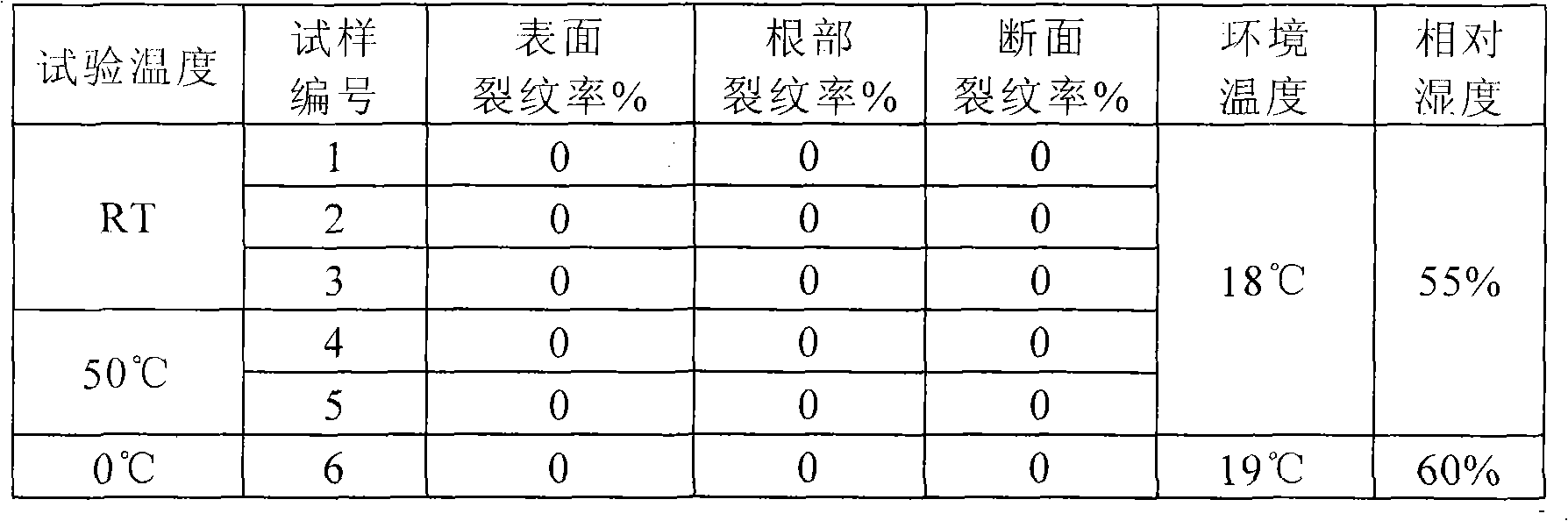

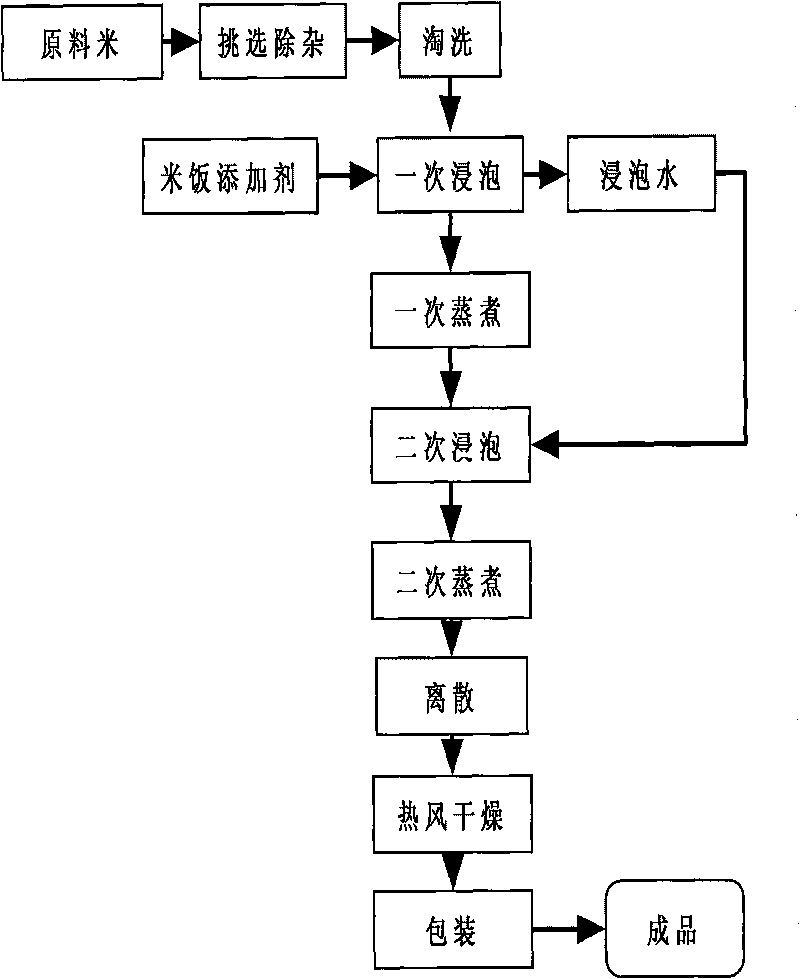

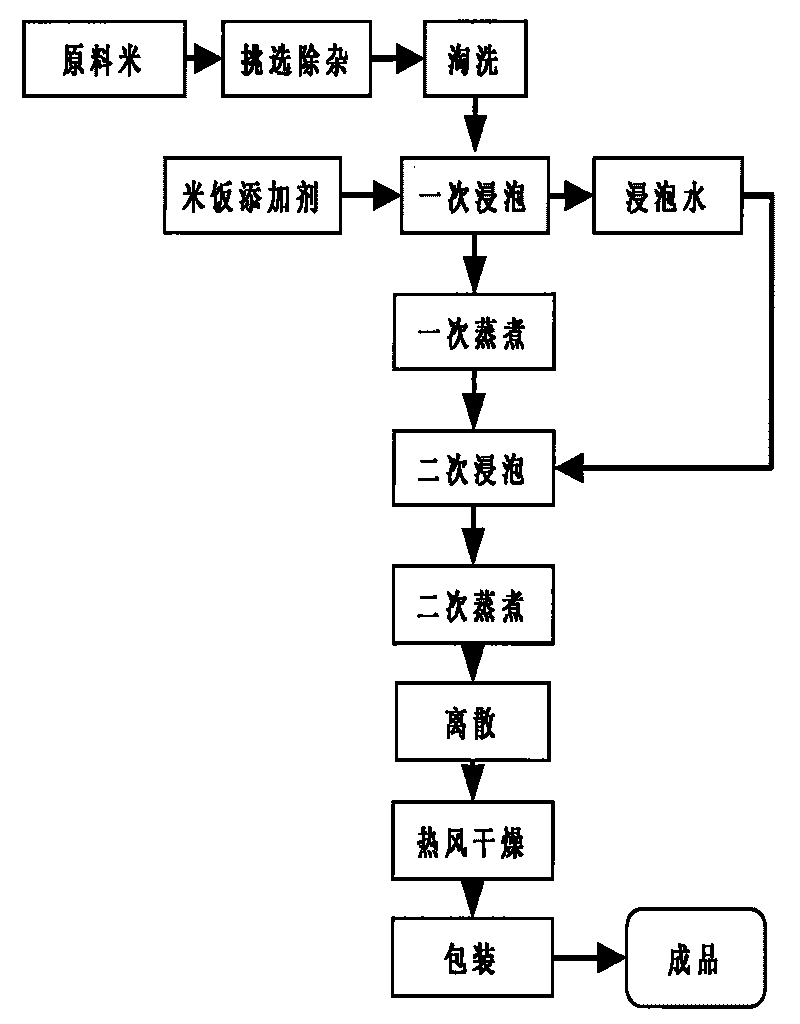

Preparation process of convenient rice

The invention relates to a preparation process of convenient rice, which comprises the following operational steps: A, washing rice; B, soaking the rice for the fist time; C, stewing the rice for the first time; D, soaking the rice the second time; E, stewing the rice for the second time; F, dispersing the rice; G, drying the rice to obtain finished products; and H, packaging the finished products, wherein soaking liquid contains 0.2 to 0.6 percent of citric acid, 0.1 to 0.3 percent of beta-cyclodextrin and 0.1 to 0.3 percent of sucrose fatty acid ester. The soaking liquid improves the edible quality of the convenient rice and strengthens the anti-retrogradation performance of the convenient rice while shortening the rehydration time of the convenient rice, so that the edible quality of the convenient rice is the same as that of fresh rice; and the gelatinization degree of the rice is improved by adopting the process of the two-time soaking and two-time stewing, so that the rehydration time of the convenient rice is shortened to 8 minutes. The preparation process has the advantages of reasonable process design, low equipment requirement, conveniently-eaten product, long quality guarantee period and good edible quality, and has the high popularization and use values.

Owner:HEFEI UNIV OF TECH

400HB-grade wear-resistant steel and method for manufacturing same

The invention provides a wear-resistant steel which comprises the following chemical components by weight percent (wt%): 0.08-0.24% of C, 0.10-0.30% of Si, 0.70-1.70% of Mn, 0.050% of P or less, 0.030% of S or less, 1.00% of Cr or less, 0.60% of Mo or less, 0.01-0.10% of Al, 0.0005-0.0040% of B, 0.005-0.06% of Ti and the balance of Fe and inevitable impurities, wherein the total weight percent of the Cr and the Mo is more than or equal to 0.15% and less than or equal to 1.20%, and the total weight percent of the Al and the Ti is more than or equal to 0.011% and less than or equal to 0.15%. A method for manufacturing the wear-resistant steel comprises the steps of smelting, casting, rolling, quenching and tempering. The 400HB-grade wear-resistant steel which is obtained by adopting the components and the process has high strength, good toughness and excellent machining performance, is easy to weld and bend and is suitable for the easily-worn equipment such as the bucket, the scraper conveyor and the mining electric-wheel dumper carriage of the engineering machinery.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

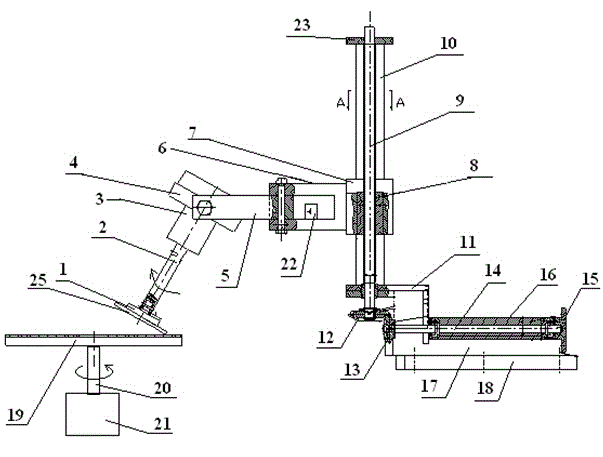

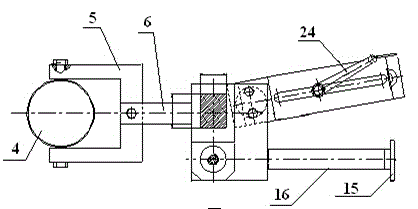

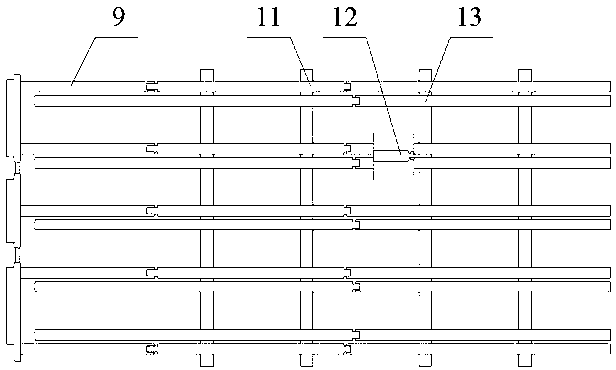

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

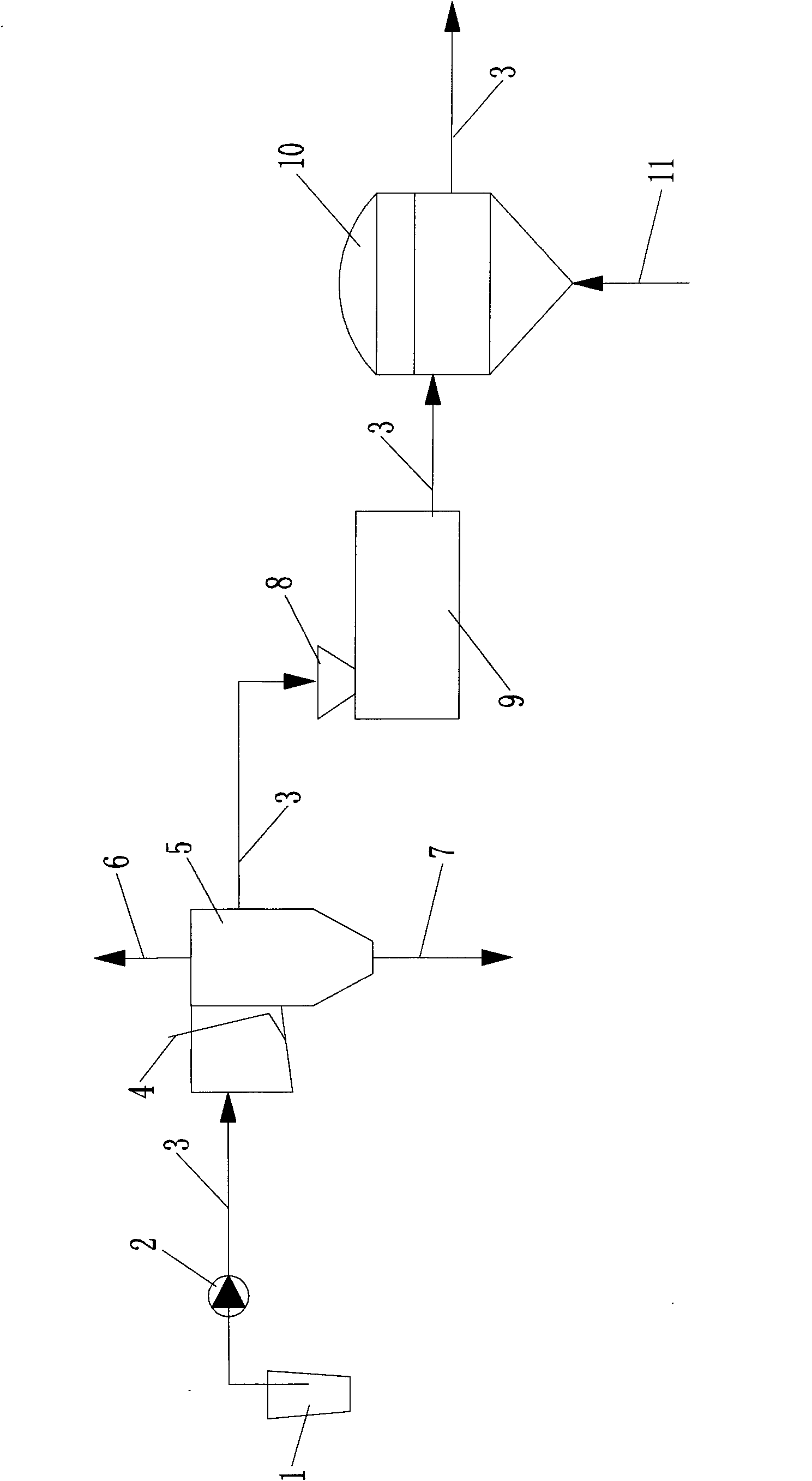

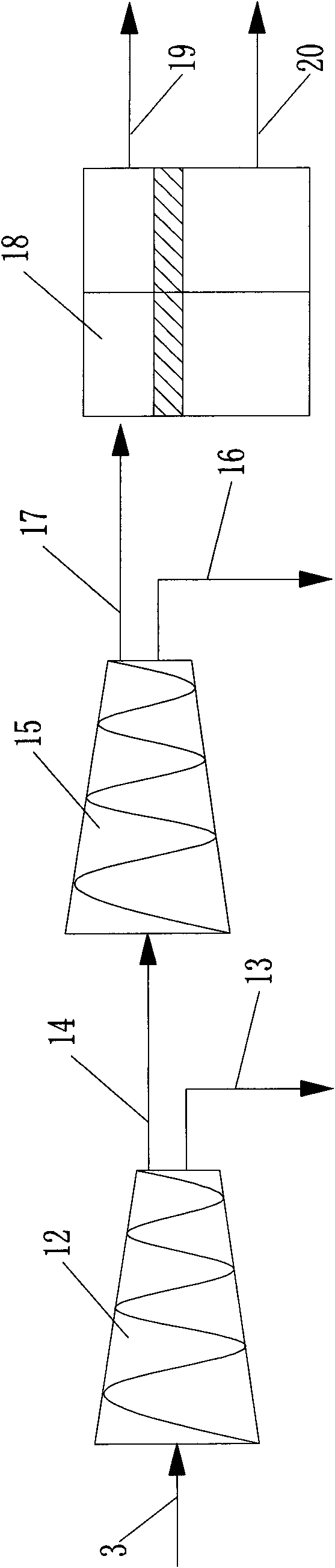

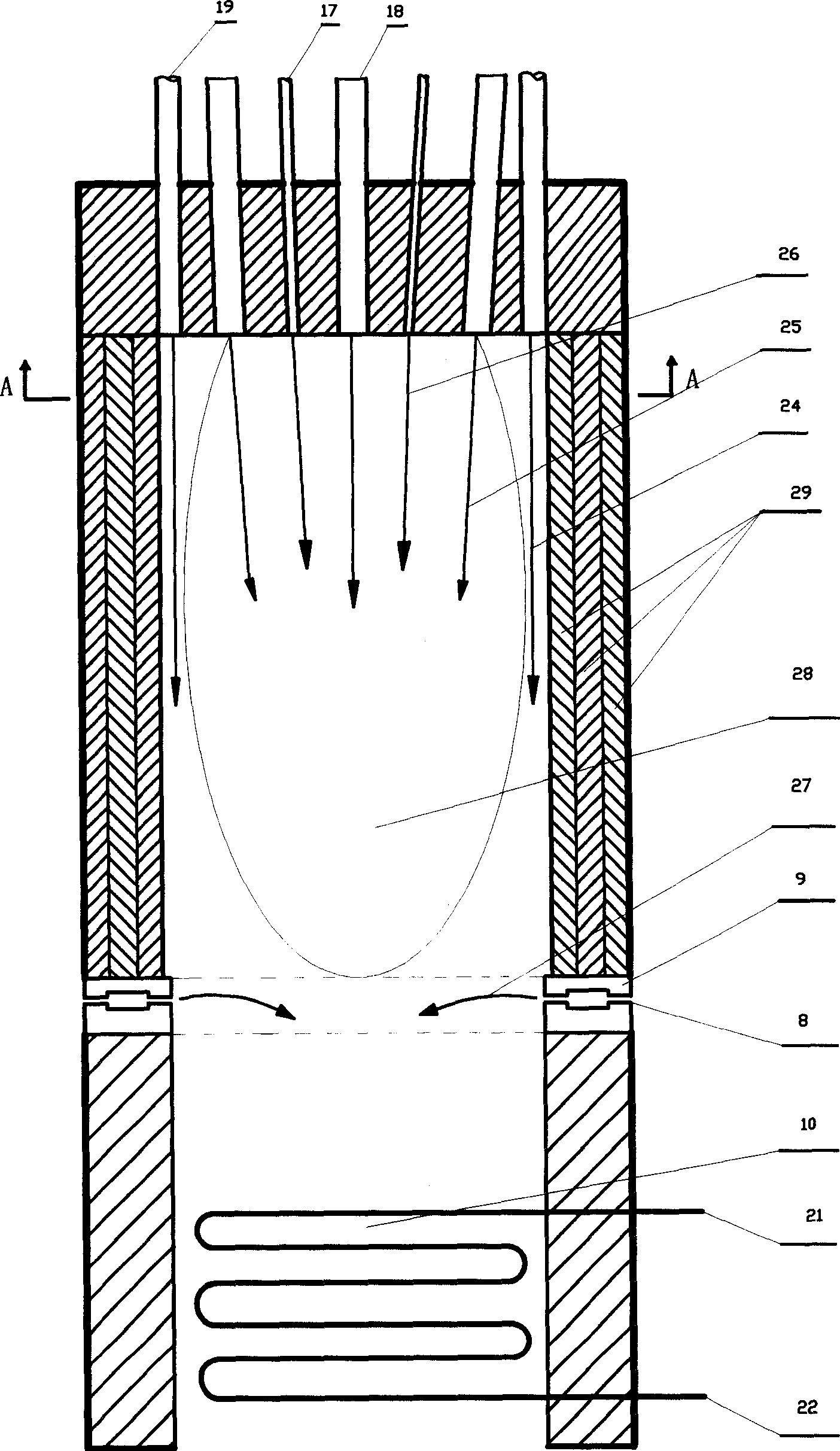

Apparatus and process for producing acetylene by plasma pyrolysis of coal and natural gas

Production of ethyne by coal and natural gas plasma pyrolyzation and its apparatus are disclosed. It is produced by spraying plasma, buggy steam current and natural gas protective gas in plasma reactor, reacting and generating mixed ethyne gas, cooling, separating, storing ethyne, passing gas into plasma generator and reutilizing, sprayed natural gas forming gas protective layer on plasma reactor wall to prevent carbon fragment from coking, and pyrolytic reacting to obtain mixed ethyne gas. It achieves high converting efficient and reacting efficient.

Owner:TAIYUAN UNIV OF TECH

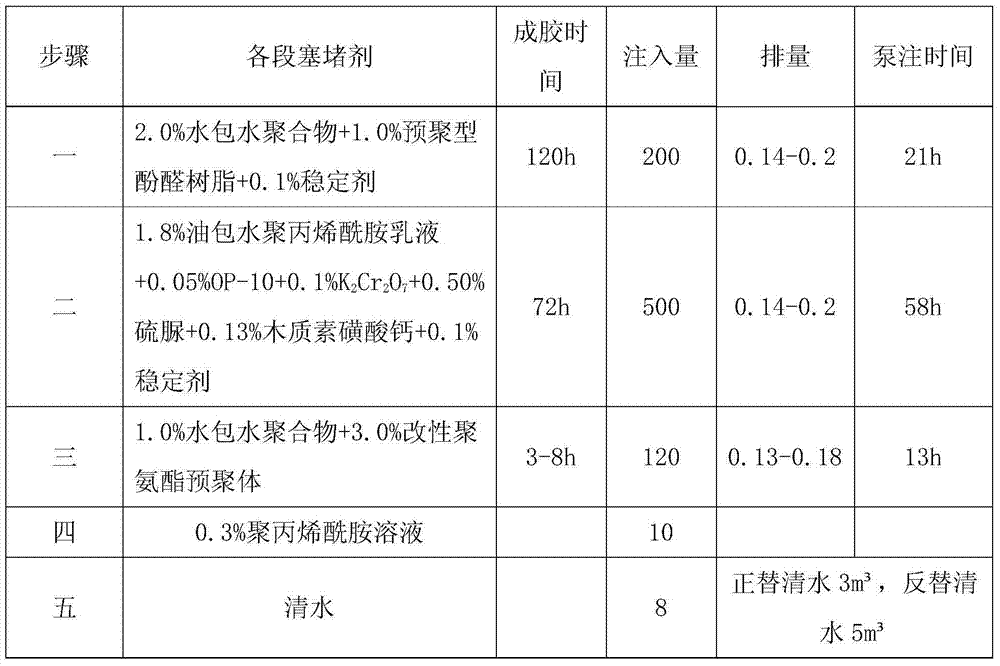

Composite slug deep water plugging method for oil pool with high water content

ActiveCN103498643ATo achieve the purpose of water controlReduce moisture contentDrilling compositionSealing/packingEnvironmental resistanceHigh intensity

The invention relates to a composite slug deep water plugging method for an oil pool with a high water content, and belongs to the technical field of oilfield development. The composite slug deep water plugging method for the oil pool with the high water content is characterized in that a composite slug is designed by using different plugging agent characteristics, high-strength plugging agents are filled into a near-wellbore zone slug, middle-strength plugging agents are filled into a transitional zone slug, and low-strength plugging agents are designed in a far-wellbore zone slug; foaming gel plugging agents are adopted as the high-strength plugging agents, inorganic chrome jelly plugging agents are adopted as the middle-strength plugging agents, and phenolic aldehyde jelly plugging agents are adopted as the low-strength plugging agents. The composite slug deep water plugging method has the advantages of being reasonable in process, easy to construct, long in water plugging validity period, free of poison, environmentally friendly, capable of achieving selective deep water storage, capable of plugging high-water-content zones and not damaging oil layers and long in water plugging validity period, effectively reducing the water content of oil well produced liquid, guaranteeing the normal production of an oilfield and the like.

Owner:陕西越洋石油技术服务有限公司

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

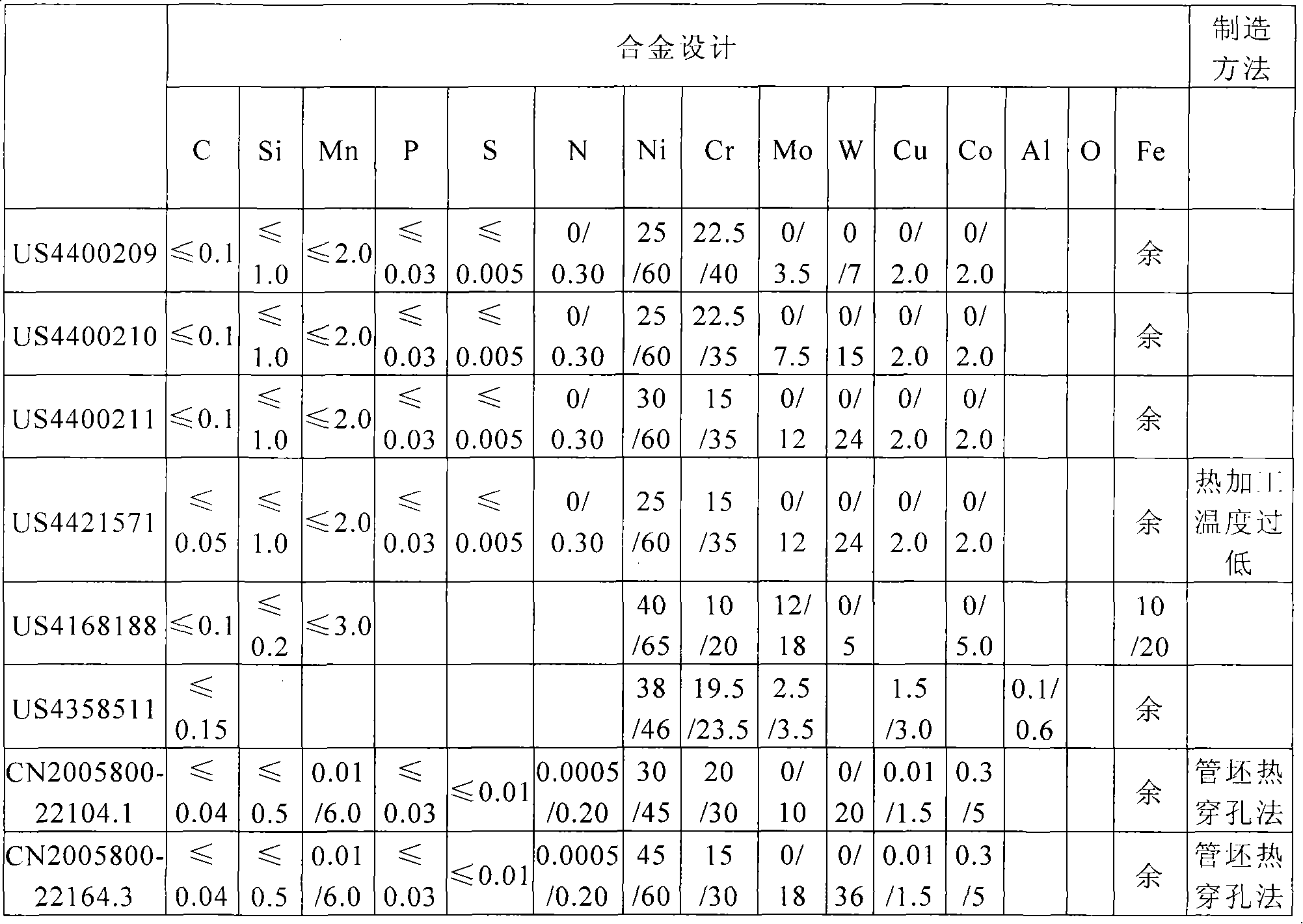

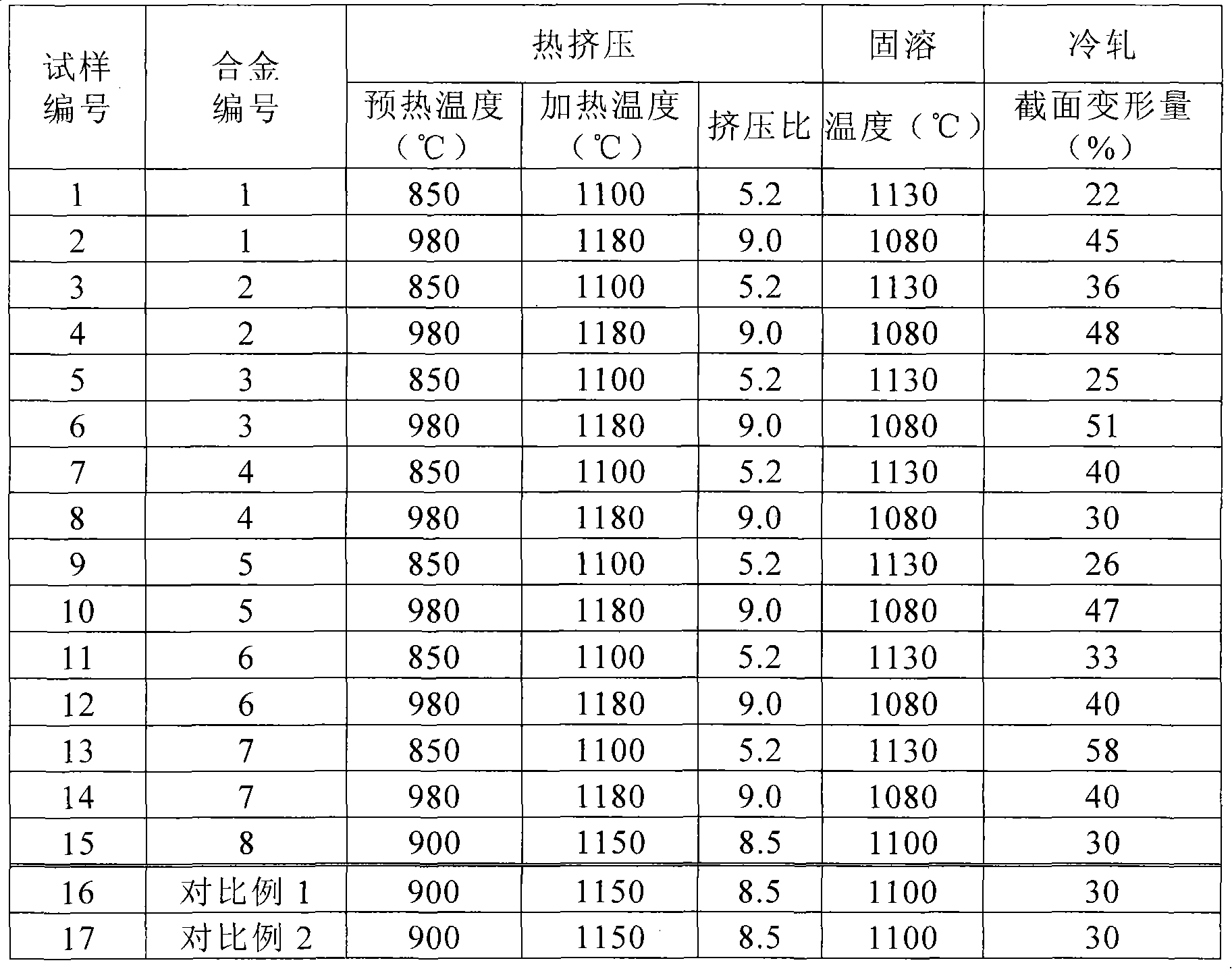

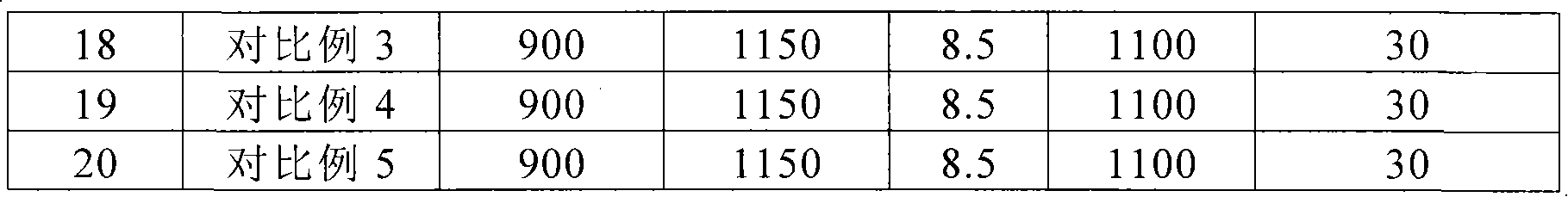

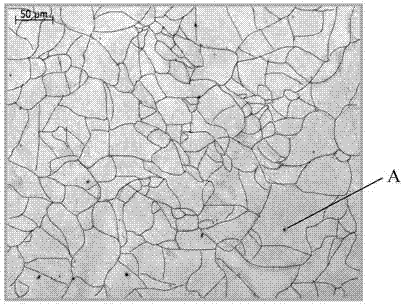

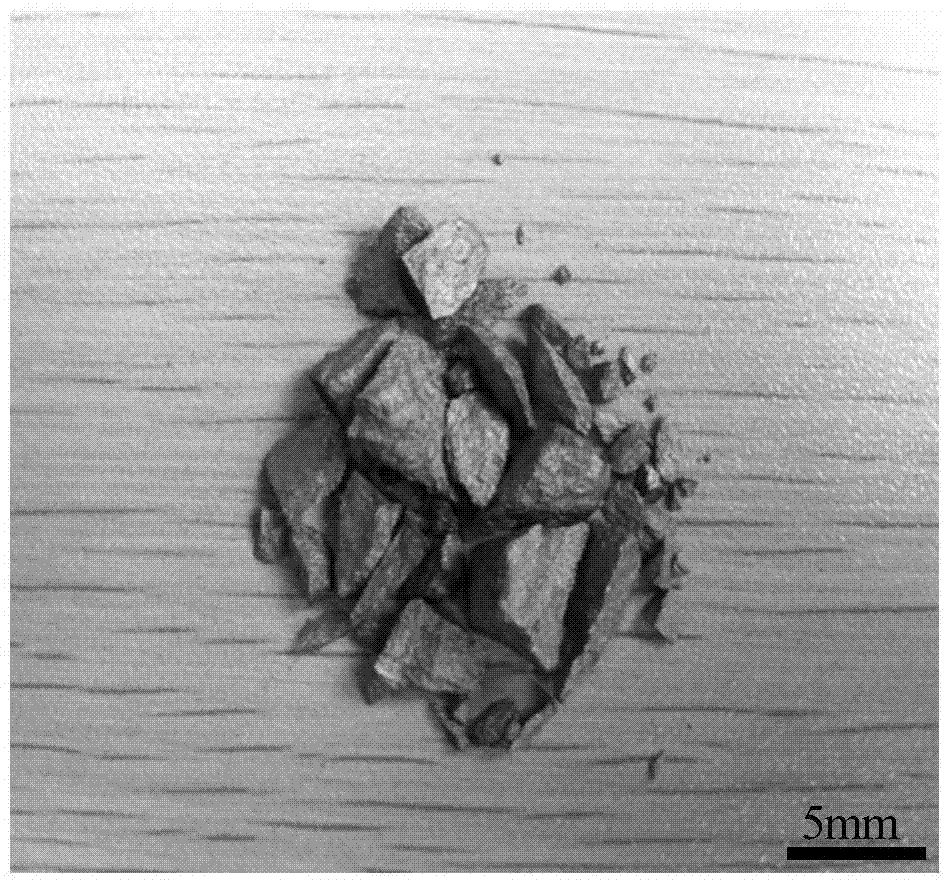

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Smelting method of ultra-low oxygen pure steel

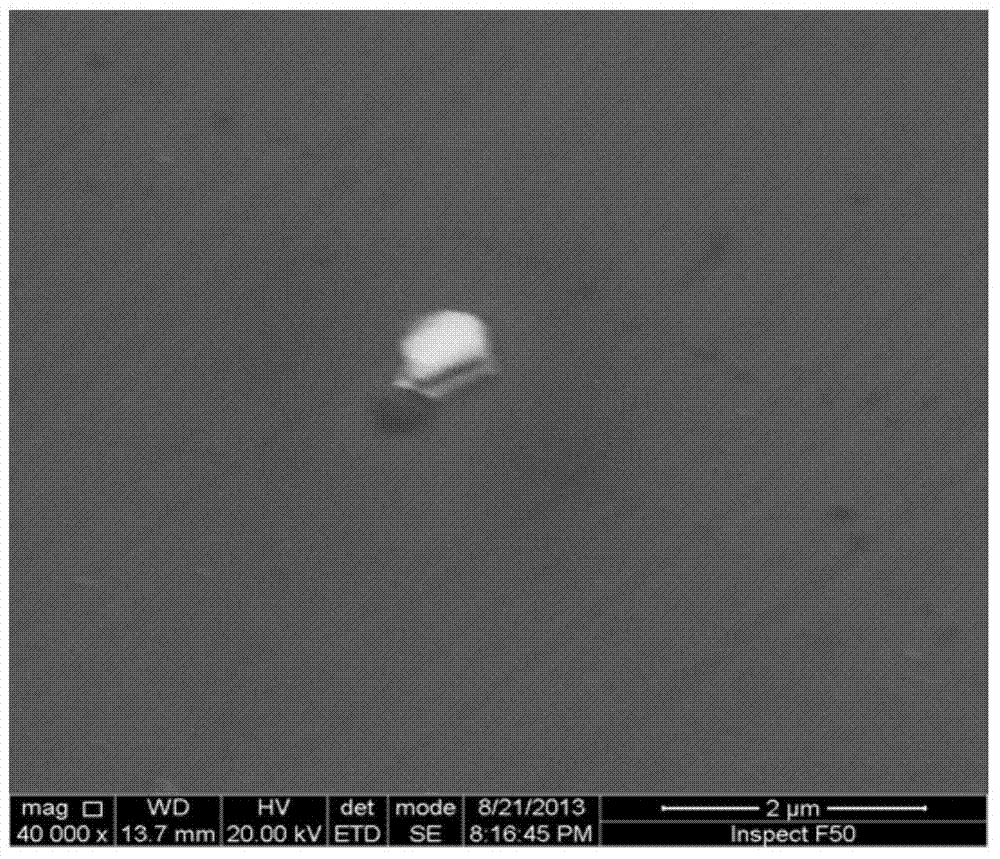

The invention relates to the field of smelting and specifically relates to a smelting method of ultra-low oxygen pure steel. A vacuum electric furnace or a vacuum induction furnace is adopted for smelting and vacuum pouring, and the vacuum degree is required to be 0.05-100Pa; after a metal charge is molten, a vacuum state is kept, molten metal is boiled for 5-30min, the oxygen content is reduced by vacuum carbon-oxygen reaction, and no deoxidizer or deoxidization alloy is added. The standing is performed for 20-30min after alloying, and the molten metal is boiled for 5-30min in the vacuum state. When the oxygen content is below 10ppm, 0.5-3kg / t of Si-Ca-Al-Mg-RE composite deoxidizer is added, the standing is performed for 1-10min after adding, then vacuum pouring is performed, and then the pure steel with the total oxygen content of below 4ppm can be obtained. The invention aims at solving the problems that existing steel ingots and cast blanks have more internal inclusions with relatively large sizes, the purity is not high and the channel segregation is serious. Simultaneously, by adopting a rare earth composite additive to perform modification treatment on the inclusions in the steel, the sizes of the inclusions are reduced, and the number of the inclusions in the steel is reduced, thus a new effective way is provided for pure smelting of molten steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

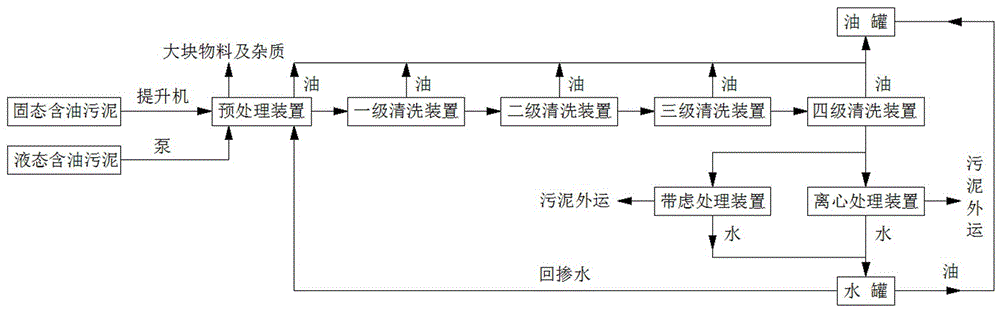

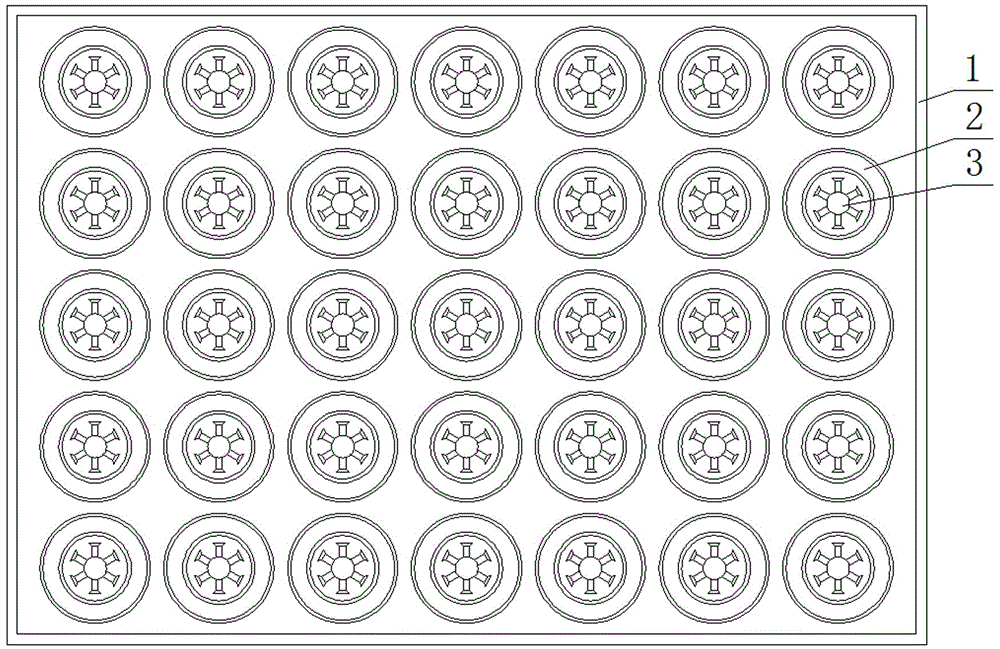

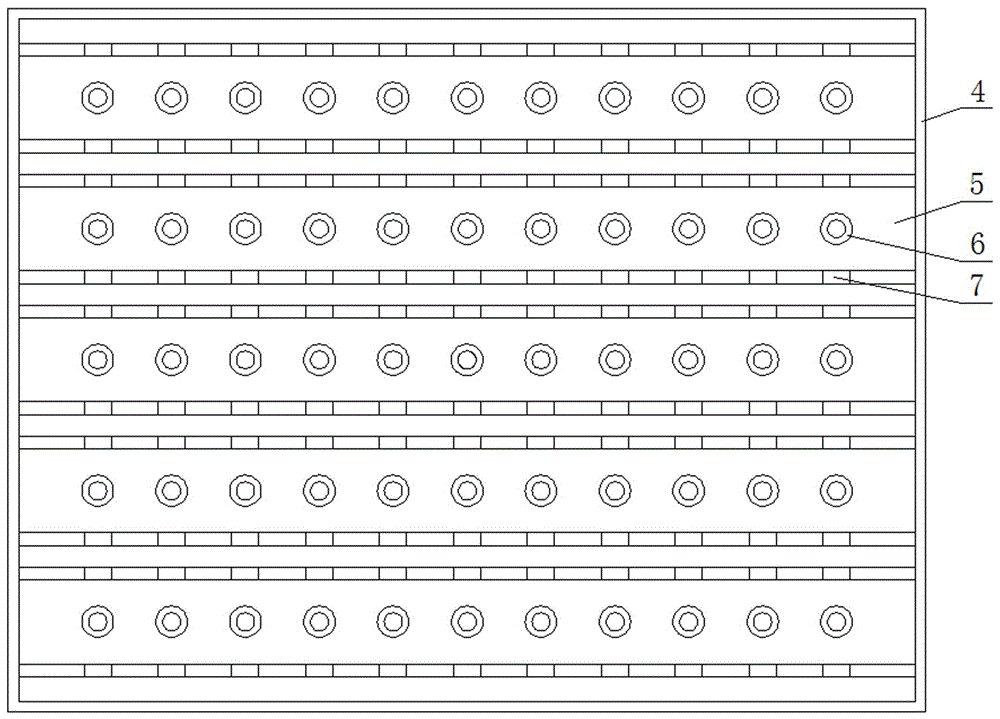

Technological method for treatment of oil field oil sludge

ActiveCN106242205AAvoid lossAvoid high temperature burnsSludge treatment by de-watering/drying/thickeningMelting tankFuel tank

Belonging to the technical field of oil sludge treatment, the invention specifically relates to a technological method for treatment of oil field oil sludge. The technological method consists of: solid oily sludge screening, solid oily sludge dry steam oil melting, solid oily sludge high-pressure water crushing, liquid oily sludge pretreatment, first level cleaning, second level cleaning, third level cleaning, fourth level cleaning, dehydration treatment and oil-water recovery. Specifically, an oil melting tank includes a box body, uniformly distributed ring cavity sieve columns and dry steam nozzles, the dry steam nozzles are located in the ring cavity sieve columns, the diameter of sieve pores on the inner and outer walls of the ring cavity sieve columns is 5mm, and the bottoms of the ring cavity sieve columns are provided with turnable discharge cover plates. A crushing box includes a shell, uniformly distributed material bins and high pressure water spray guns, the high pressure water spray guns are located at the top of the material bins, and both side walls of the material bins are provided with uniformly distributed round holes. The process involved in the invention has the advantages of reasonable design, safety and environmental protection, good treatment effect, high treatment efficiency, strong treatment capacity, and cost saving, and is economical and applicable.

Owner:大庆世纪新风环保科技有限公司

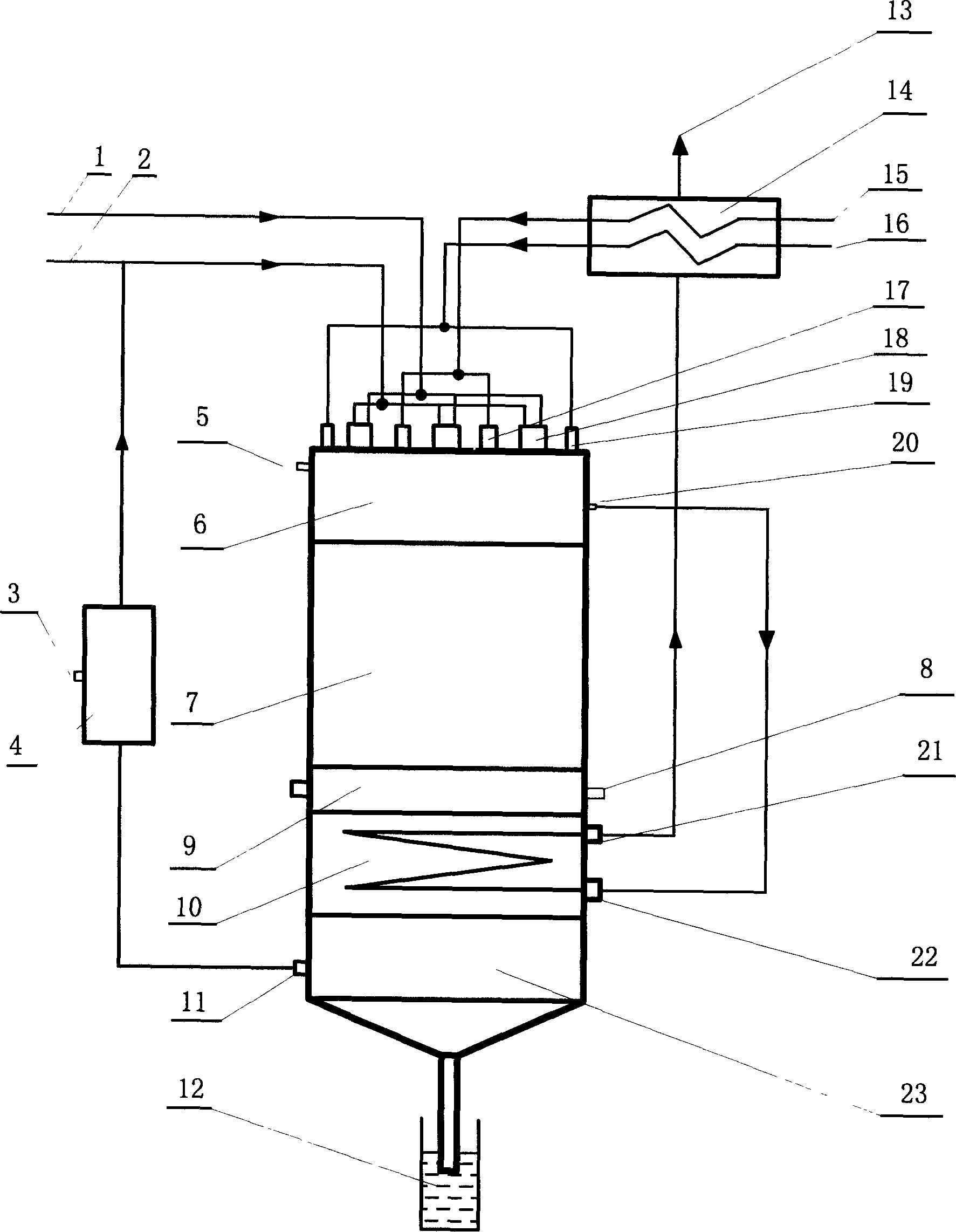

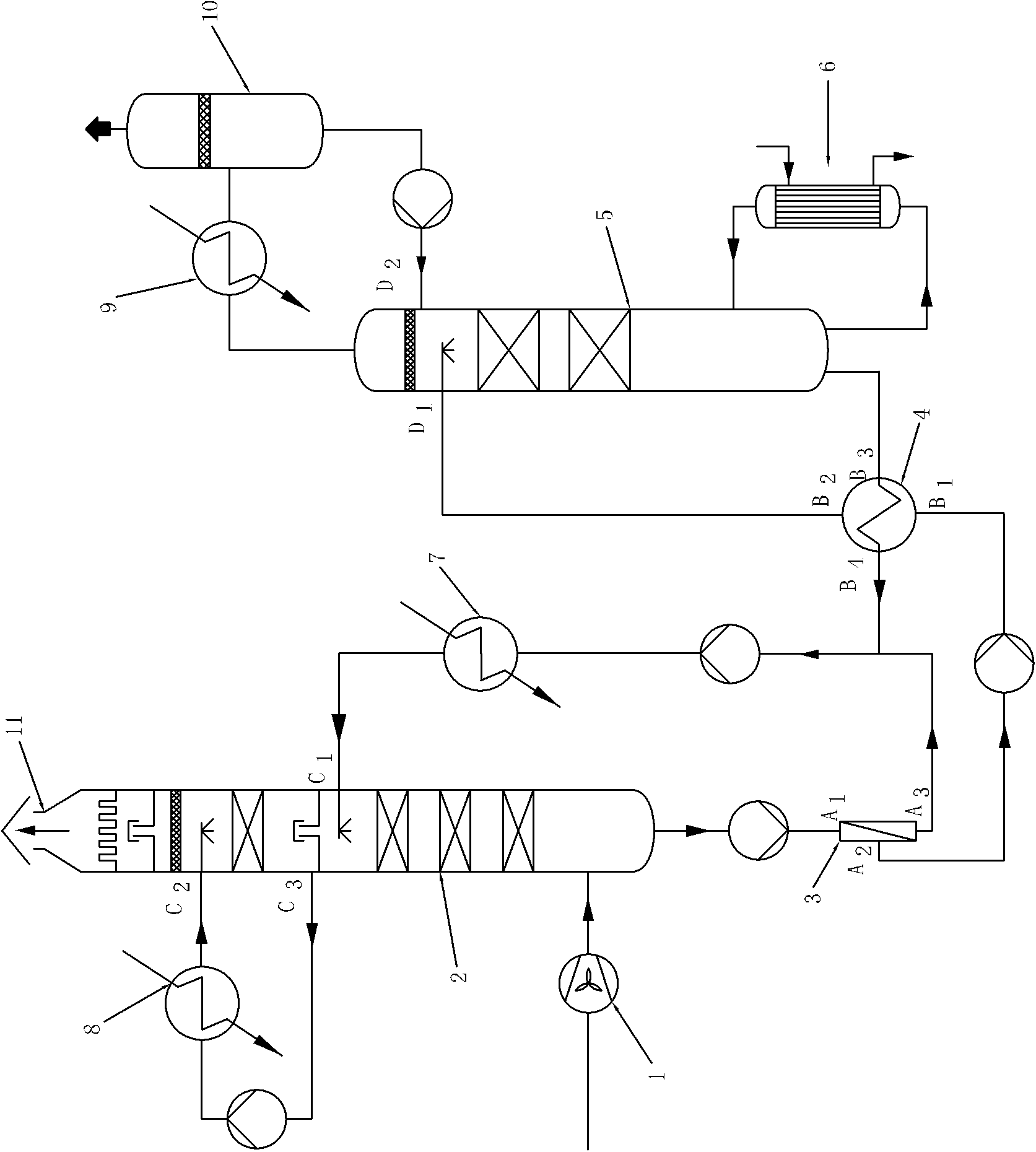

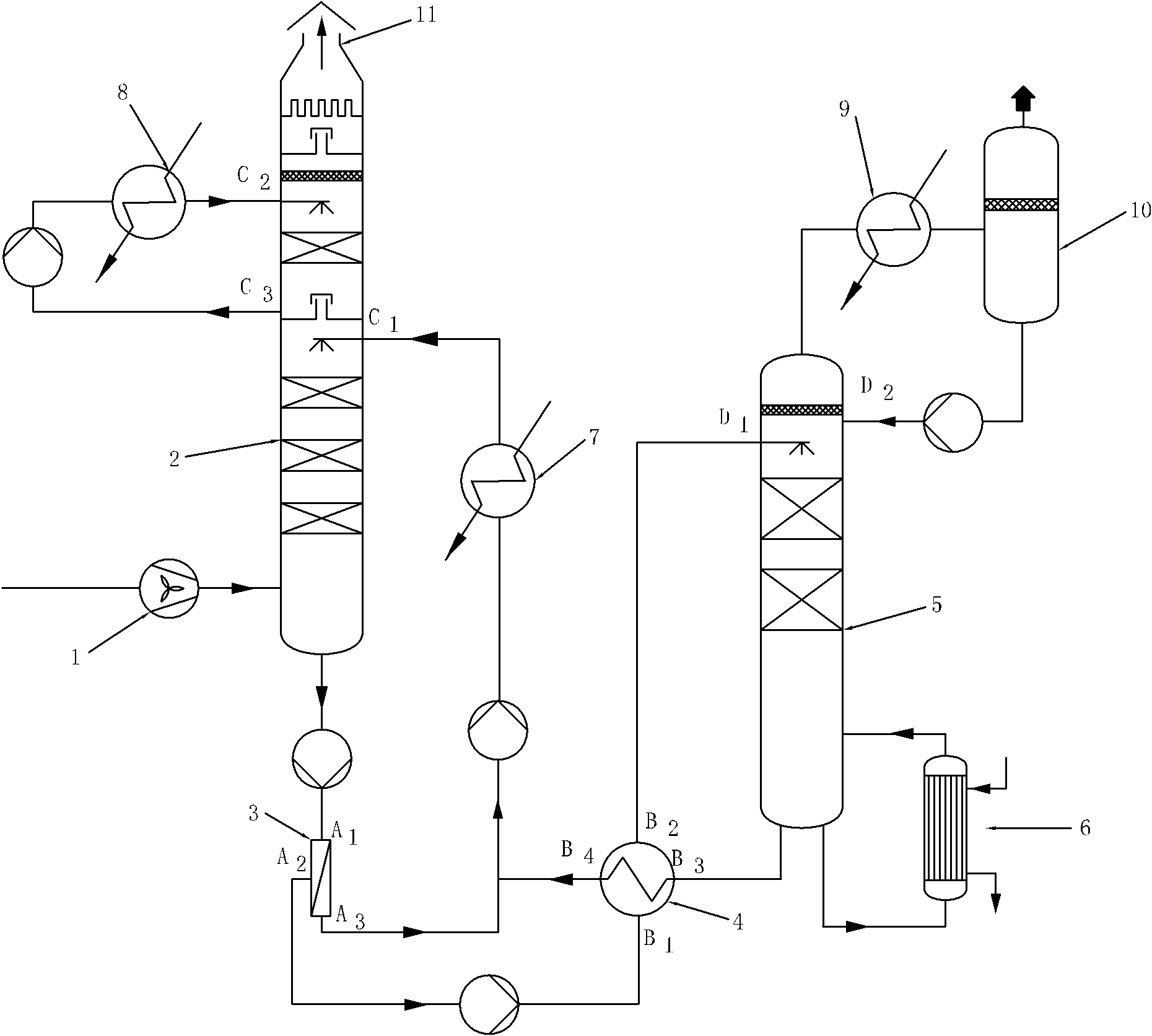

System and method for trapping acid gas in smoke

InactiveCN102133499AAvoid consumptionReduce energy consumptionDispersed particle separationVapor–liquid separatorReboiler

The invention relates to a system and a method suitable for trapping acid gas in smoke of a fired power plant by a chemical absorption method. The system comprises an absorption tower, a rich and barren liquor heat exchanger, a regenerating tower, a reboiler and a gas-liquid separator, and a liquid film concentrating device is arranged additionally, so that part of water in rich liquor is removed in the liquid film concentrating device before the rich liquor enters the rich and barren liquor heat exchanger, thus avoiding consumption of excessive unnecessary energy due to the heating of excessive water in the liquor when the rich liquor is regenerated. Removed water and barren liquor flowing out from the regenerating tower are combined, and enter the upper part of the absorption tower for spraying and recycling, so that the energy consumption of the whole system is reduced effectively.

Owner:杨东 +2

Supporting method for roadway fully-mechanized drivage operation without withdrawal of roadheader

InactiveCN103195457AImprove support qualityReasonable process designMine roof supportsAnchoring boltsProcess engineeringEngineering

The invention relates to a supporting method for a roadway fully-mechanized drivage operation without withdrawal of a roadheader, aiming to solve the problems of bad safe reliability and complex operating processes of conventional roadway fully-mechanized drivage operations with withdrawal of roadheaders. The supporting method includes providing temporary supporting for a new roof exposed in the roadway fully-mechanized drivage operation by an associated operation with the roadheader, and performing a supporting operation of laying metal nets and steel belts on a roadhead by a roadway drivage alternating supporting device; performing a permanent supporting operation of punching anchor rods on the roof and two sides of the roadway in a roadway zone behind the roadheader by a movable roof bolter supporting platform; and conveying coal cut by the roadheader through a bridge reversed loader and a belt conveyer. The process design is reasonable; supporting and moving is stable; a roadway empty operation is avoided; supporting is safe and reliable; the conventional operation method that the roadheader is needed to be withdrawn in each step and operation procedures are alternated frequently is changed, so that the roadheader can drivage continuously without being withdrawn. Synchronous mechanical operation of drivage and permanent supporting can be realized, and utilization rate and drivage efficiency of the roadheader can be increased remarkably.

Owner:LIAONING TIAN AN TECH CO LTD

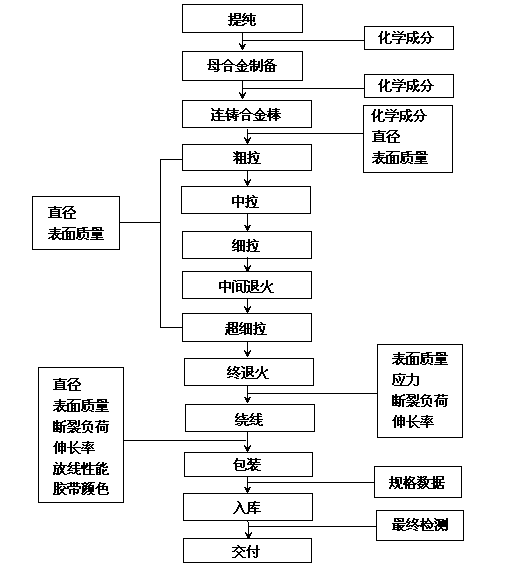

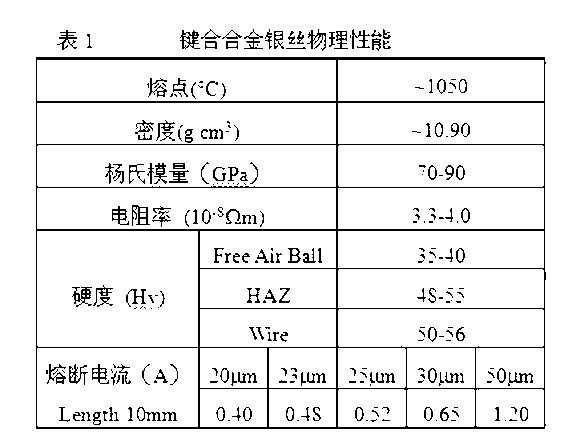

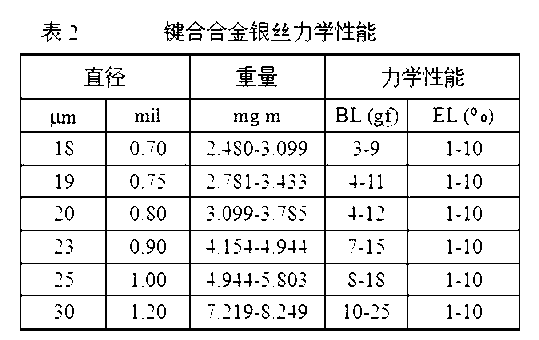

Bonding alloy filamentary silver and preparation method thereof

ActiveCN103194637AImprove conductivityAntioxidantSolid-state devicesSemiconductor devicesCeriumSemiconductor package

The invention relates to bonding alloy filamentary silver and a preparation method thereof, and belongs to the technical field of processing of a bonding wire. The bonding alloy filamentary silver comprises the following metal materials by mass ratio: less than 90wt% of silver, 3.0-10.0wt% of gold, and 3.0-8.0wt% of palladium; and the bonding alloy filamentary silver also comprises at least two of following metals of 10-100ppm of calcium, 4-10ppm of beryllium, 10-100ppm of cerium, and 50-500ppm of copper. The preparation method comprises the steps of 1) preparing materials; 2) smelting mother alloy; 3) continuously casting an alloy rod; 4) roughly working, intermediately drawing, and finely drawing; 5) carrying out middle annealing; 6) ultra-finely drawing; 7) finally annealing; 8) winding; and 9) packaging. The technology disclosed by the invention is specified and reasonable in design, and simple and convenient to operate; the obtained product is strong in electrical conductivity, has certain inoxidizability, good plasticity, high rupturing load, good elongation and low cost, can meet the demands of the semiconductor encapsulation industry and a light-emitting diode (LED) illumination technology on performance of the bonding alloy filamentary silver, and can be used as a substitute for a bonding alloy wire.

Owner:烟台招金励福贵金属股份有限公司

Method for preparing high-strength high-toughness magnesium alloy plate strip

InactiveCN102127725AImprove ductilityImprove the strengthening effectThermal deformationHigh intensity

The invention relates to a method for preparing a high-strength high-toughness magnesium alloy plate strip by cold deformation and artificial ageing, comprising the following steps of: placing a magnesium alloy in a thermal deformation state or a solid solution magnesium alloy cooled by water quenching after temperature preservation at the temperature of 400-540 DEG C for 1-15 hours into liquid nitrogen to be subjected to subzero treatment and cold deformation, or directly carrying out cold deformation on the original magnesium alloy in the thermal deformation state or the solid solution state, wherein the deformation is controlled to be 5-20%; and finally preserving the temperature of 100-250 DEG C for 5-100 hours and then carrying out artificial ageing, thus the high-strength high-toughness magnesium alloy is obtained. The method provided by the invention is reasonable in design, the equipment requirement is simple, the operation is convenient, and the problems that the cost is high, a large magnesium alloy is difficult to prepare and large-scale application is difficult to realize in the traditional high-strength high-toughness magnesium alloy preparation process can be effectively solved; and magnesium alloy plate strips with excellent comprehensive mechanical properties such as strength, stretchability and the like, thus the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

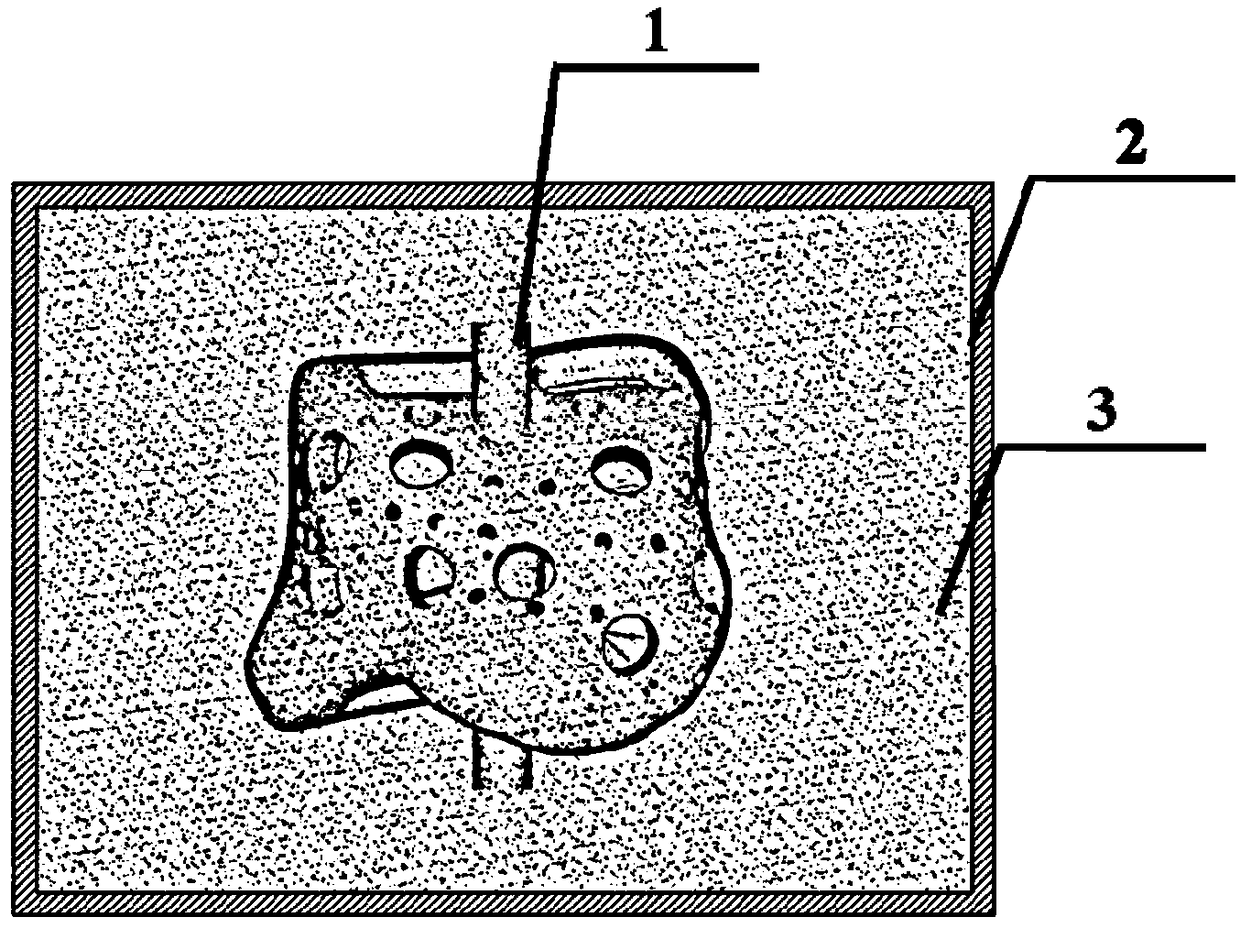

Preparation method of medical porous titanium or titanium alloy materials coated with tantalum coating on surfaces

ActiveCN109261958AImprove bindingSolve poor bondingAdditive manufacturing apparatusTransportation and packagingPorous titaniumTa element

The invention discloses a preparation method of medical porous titanium or titanium alloy materials coated with tantalum coatings on surfaces, which includes the following steps: firstly, preparing aporous titanium frame or a porous titanium alloy frame by adopting the 3D printing method; next etching the porous titanium frame or the porous titanium alloy frame, and cleaning and drying; then totally embedding the porous titanium frame or the porous titanium alloy frame in ultrafine tantalum powder in metal canning, vacuum sealing and diffusion sintering in low temperature; lastly taking out the frame, removing the powder and obtaining the medical porous titanium or titanium alloy materials coated with the tantalum coatings on surfaces. The preparation method of the medical porous titaniumor titanium alloy materials coated with the tantalum coatings on surfaces has the advantages that through embedding in powder and diffusion sintering in low temperature, tantalum coats the surfaces of the porous titanium frame or the porous titanium alloy frame, and metallurgical bonding is formed, thereby greatly enhancing the bonding force between tantalum and the surface of the porous titaniumframe or the porous titanium alloy frame, solving the difficulty of poor bonding force between the tantalum coatings and matrix, and overcoming the disadvantages of high cost and complicated processof the prior preparation method.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

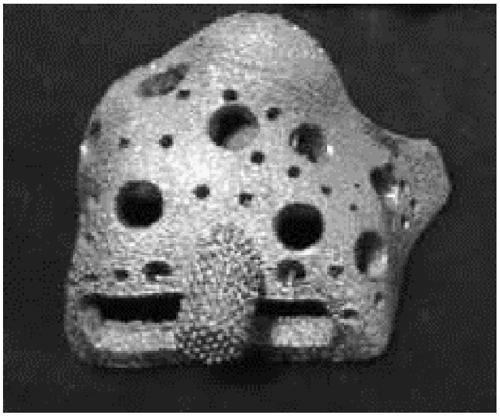

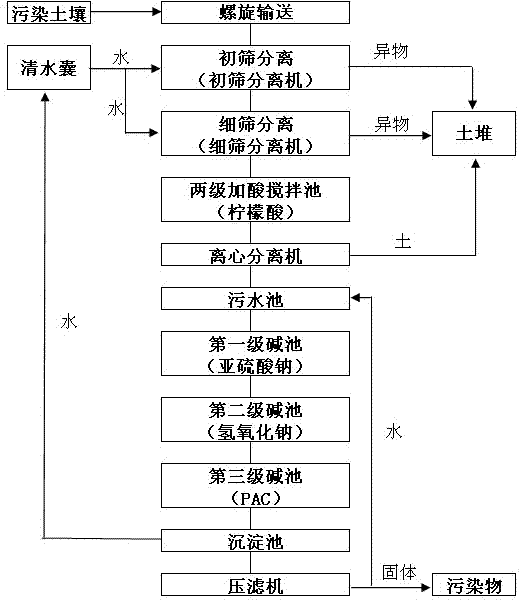

Elution-method soil remediation process

InactiveCN103861867AEnsure complete removalReasonable process designContaminated soil reclamationSoil remediationElution

The invention relates to an elution-method soil remediation process. The process comprises the steps of feeding, performing preliminary screening separation, performing fine screening separation, performing acid mixing pool oxidization, performing solid-liquid separation, reducing metal ions, precipitating metal ions, flocculating organic insoluble substances, performing precipitation separation and performing filter pressing treatment. The process has the beneficial effects of adopting preliminary screening eluting and fine screening eluting for separating heavy metal ions and other pollutants into water from soil, combining the metal ions and anions in acid through oxidization in two-stage acid mixing pool, dissolving the mixture in water, performing centrifugal separation, reducing pollutant-containing water through an alkali pool, reacting the water and hydroxyl to separate precipitates from sewage, flocculating the precipitates and settling the precipitates in a four-stage settling pond for solid-liquid separation, wherein the separated water can be recycled to be used for preliminary screening eluting and fine screening eluting, the pollutant-containing solids are discharged and then fed into a filter press for filter pressing recovery, and water, which is generated in the filter pressing process and contains a few of pollutants, is fed back to a sewage pool for treatment and separation again.

Owner:JIANGSU RISHENG ENVIRONMENTAL PROTECTION ENG

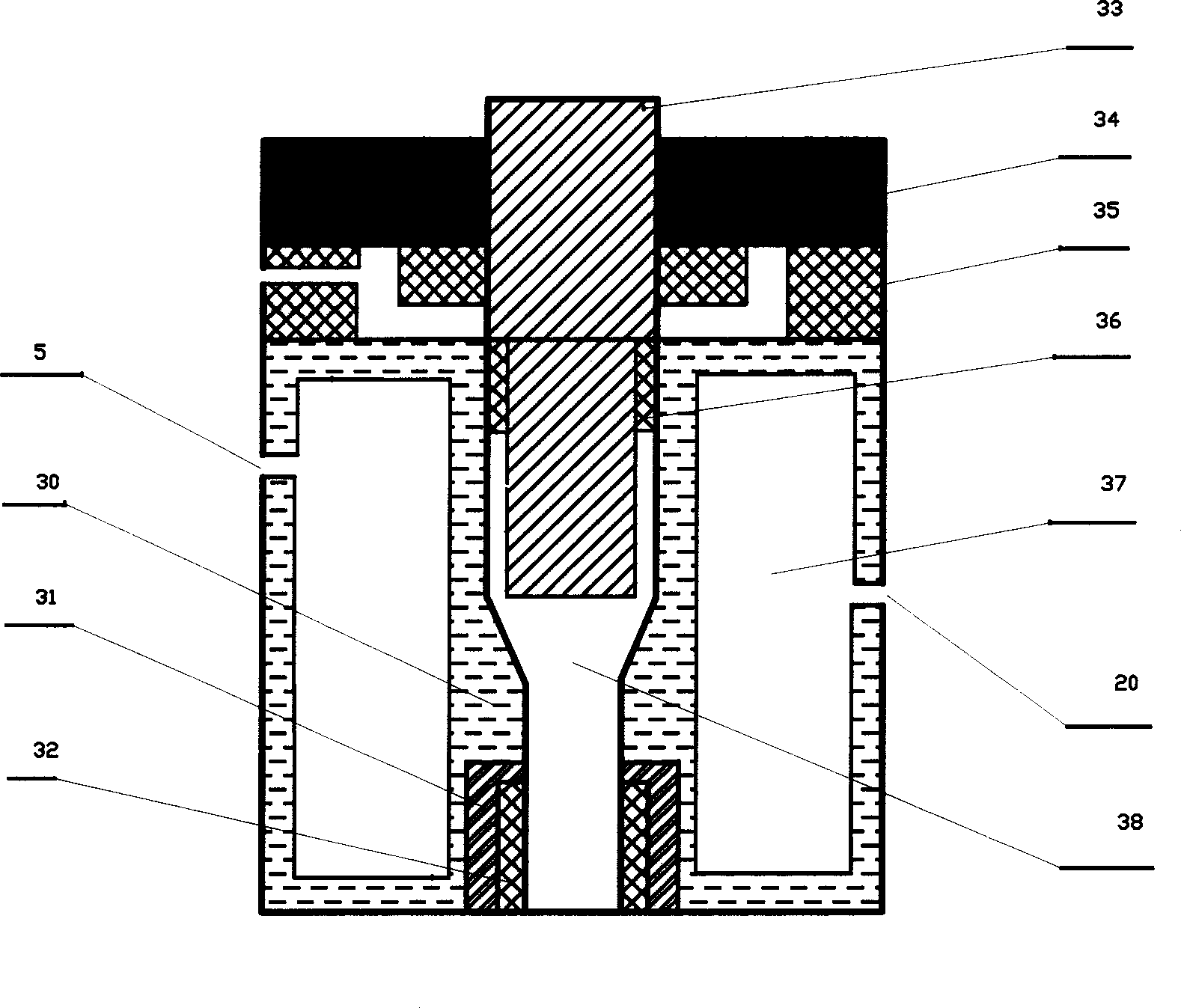

Manufacturing tooling and efficient production method of large height-diameter ratio circular casting billet

The invention relates to the field of manufacture of large height-diameter ratio circular casting billets, namely circular ingots, for shafts, particularly to a manufacturing tooling and an efficient production method of a large height-diameter ratio circular casting billet, namely a circular ingot. The problems of the quality problems of casting billet shrinkage cavity, porosity and cracks and the low manufacturing efficiency are solved. The manufacturing tooling is provided with a casting system, an ingot mould, a heat insulation feeder head, a heat insulation cover and a slow cooling pit. Before casting, the ingot mould, the casting system and a base plate are assembled in a ground pit and the heat insulation feeder head is preheated. The casting is performed in a slow casting mode. The mould release is performed after the casting in a high-temperature mould release mode and the heat insulation is performed on a steel ingot through the heat insulation cover. After the heat insulation, the steel ingot is hung into the slow cooling pit for slow cooling or directly enters a heat treatment work station through hot delivery to be heated and prepared to be forged. The manufacturing tooling and the efficient production method of the large height-diameter ratio circular casting billet are suitable for the efficient production of the circular casting billet and the high-quality casting billet is provided for the production of the shafts, barrel type forging parts and bar materials, wherein the diameter of the circular casting billet is more than Phi 200 mm and the height-diameter ratio of the circular casting billet is larger than 3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

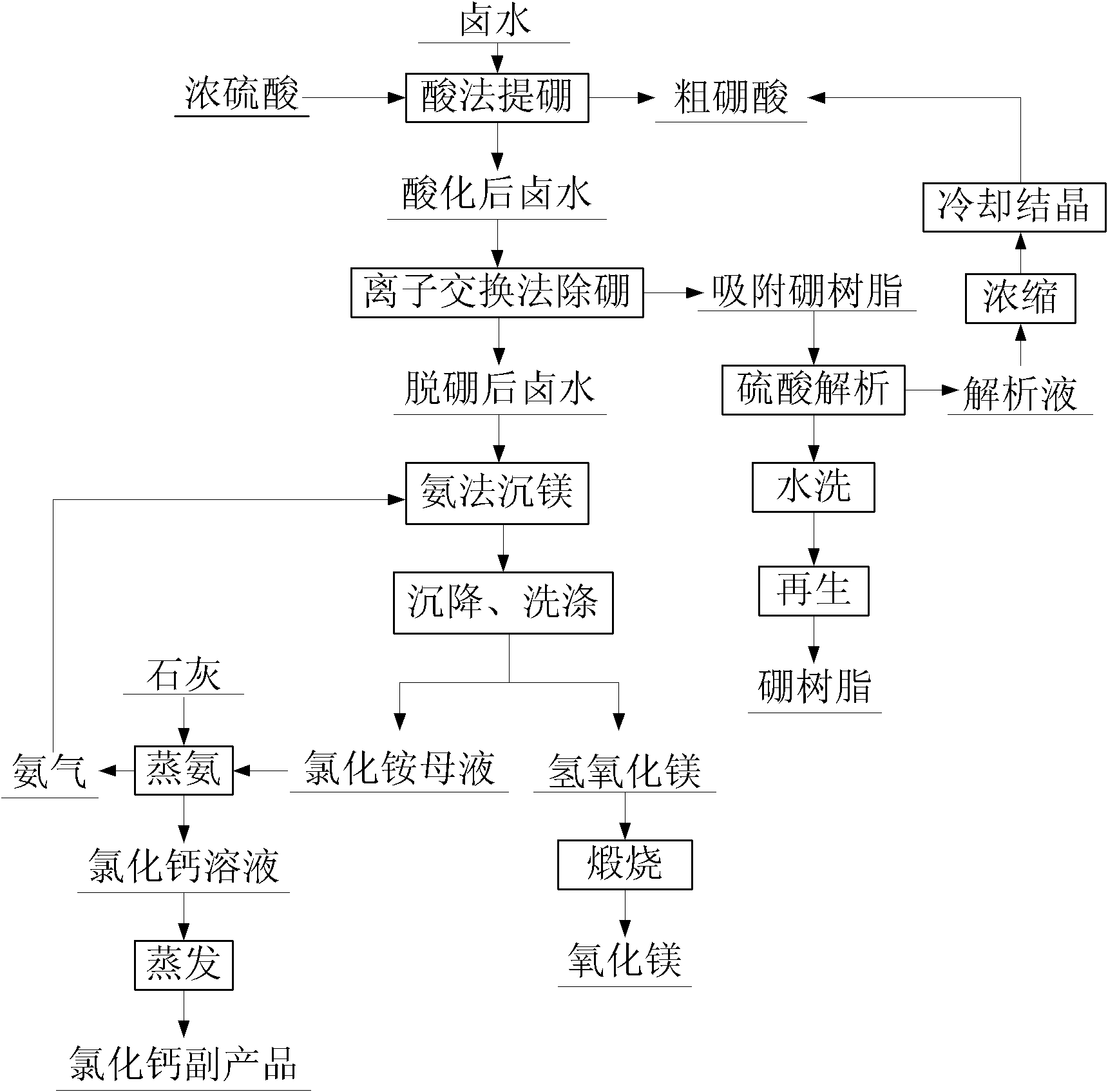

Method for preparing high-purity magnesium oxide with high boron salt lake brine

InactiveCN102491379ALarge particlesReduce extraction costsBoron-oxygen compoundsMagnesiaReaction temperatureIon-exchange resin

Provided is a method for preparing high-purity magnesium oxide with high boron salt lake brine. Salt lake brine is evaporated through a salt pan, concentrated to crystallize potassium sulfate, sodium chloride and potassium chloride and is drawn with lithium in adsorption mode so as to obtain master sauce brine containing magnesium and boron. Concentrated sulfuric acid is added into master sauce brine for reacting, and coarse boracic acid and acidized brine are obtained after cooling and filtering. Potential of hydrogen (pH) value of acidized brine is adjusted to be 5.5-6.5, and acidized brine passes through ion exchange resin adsorbing boron. When boron concentration in effluent liquid is higher than 5 mg / L, brine is not injected, boron-removed brine is obtained, then boron-removed brine and ammonium chloride solution are filled with ammonia for stirring and to produce magnesium sedimentation reaction, reaction temperature ranges from 60 DEG C to 80 DEG C, pH ranges from 7.5 to 8.0, the reaction is stopped when concentration of free ammonia reaches 1.8-2.2 mol / L, and magnesium hydroxide and magnesium sedimentation mother solution are obtained. Magnesium oxide is obtained by calcining magnesium hydroxide, content of magnesium oxide is larger than 99.8%, and magnesium extraction ratio is larger than 90%. Sedimentation mother solution adopts lime to steam ammonia, and generated ammonia circulates to magnesium sedimentation reaction. Mother solution after ammonia steaming is evaporated, concentrated and crystallized to obtain calcium chloride. Ion exchange resin adsorbing boron is washed, analyzed and regeneratively cycled for use. Boron-containing analysis solution is concentrated and cooled to pick up coarse boracic acid, and coarse boracic acid is recrystallized to obtain refined boracic acid with purity larger than 99%. High-purity magnesium oxide prepared by the method is high in purity, good in economic benefit, free of environment pollution, strong in operability and favorable for industrial production.

Owner:CENT SOUTH UNIV

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Corrugated paper board production technology

InactiveCN107263932AReasonable process designReduce manufacturing costMechanical working/deformationCardboardAdhesive

The invention discloses a production process of corrugated cardboard, which is characterized in that it is made of surface paper, inner paper and corrugated core paper through glue bonding, and has the functions of material preparation, corrugation, glue making, glued paper and coating. layers, drying and setting, cooling, creasing, slitting and cross-cutting, stacking and storage to make corrugated cardboard; the corrugated cardboard produced by the present invention has reasonable process design, low production cost, and extremely high functional performance. The use performance of the corrugated cardboard is improved, the value of the corrugated cardboard is further enhanced, the utility model has a great market prospect, and can be widely used in the technical field of corrugated cardboard boxes.

Owner:浙江新豪包装股份有限公司

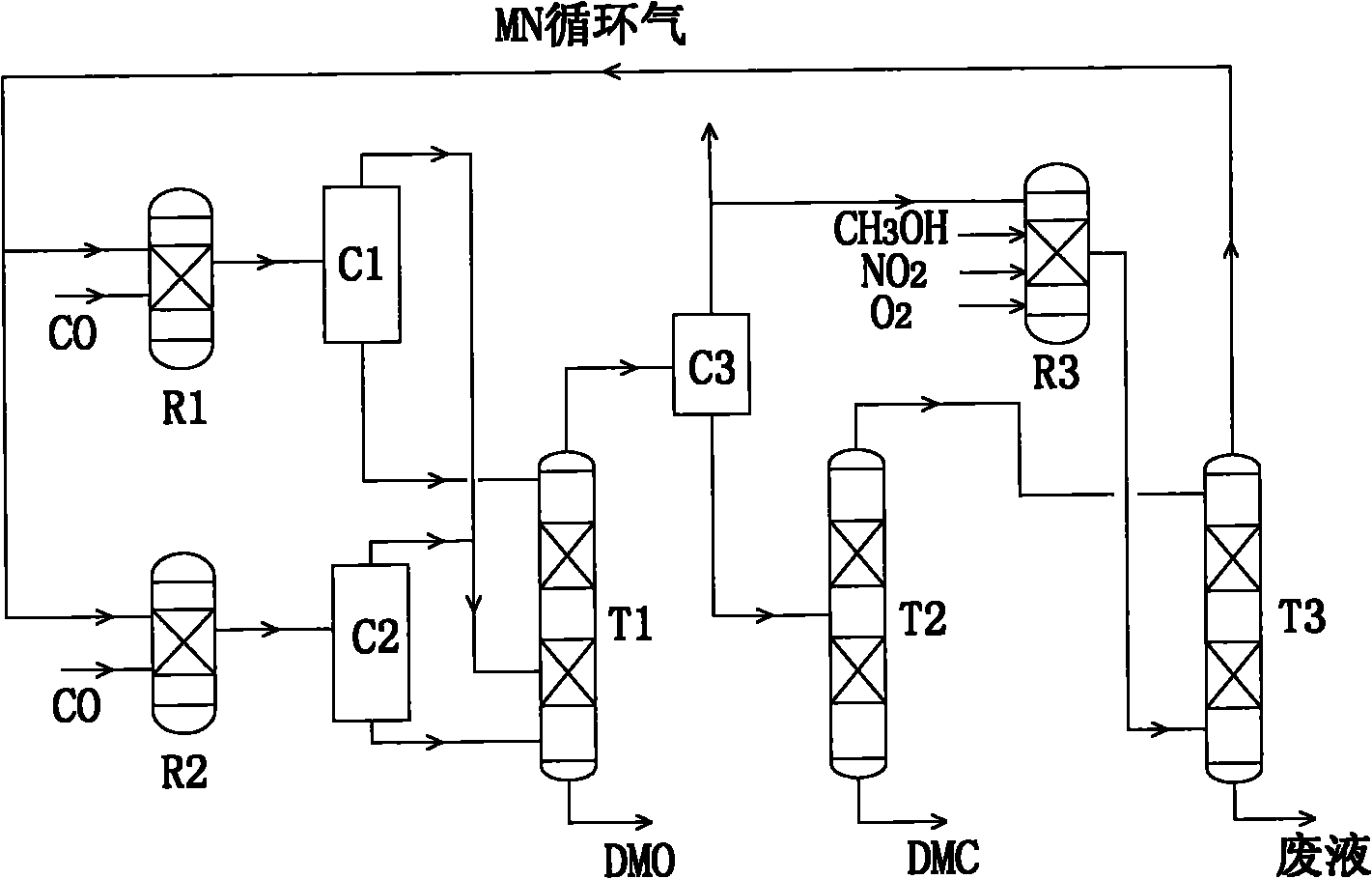

Method and device for co-producing dimethyl carbonate and dimethyl oxalate

ActiveCN101830806AReasonable deployment of productionLower energy requirementsOrganic compound preparationPreparation by carbon monoxide or formate reactionGas phaseTower

The invention discloses a method and a device for co-preparing di(C1-3) alkyl carbonate and di(C1-3) alkyl oxalate. The method comprises the following steps of: a) separating a product of a di(C1-3) alkyl carbonate synthesis reactor into a first liquid phase and a first gas phase; b) separating a product of a di(C1-3) alkyl oxalate synthesis reactor into a second liquid phase and a second gas phase; c) conveying the first liquid phase to a first rectifying tower from the tower top, conveying the combined first gas phase and second gas phase to the first rectifying tower from the middle lower part of the tower, conveying the second liquid phase to the first rectifying tower from the tower bottom, and generating basically pure di(C1-3) alkyl oxalate fraction from the bottom of the first rectifying tower during rectifying; d) separating the overhead fraction produced in the first rectifying tower into a third liquid phase and a third gas phase; and e) conveying the third liquid phase to a second rectifying tower from the middle part of the tower, and generating basically pure di(C1-3) alkyl carbonate from the bottom of the second rectifying tower. Only three rectifying towers are designed in the whole process through reasonable process design, so the energy requirement and operation expense are effectively reduced, and the equipment investment expense is saved.

Owner:PUJING CHEM IND SHA +1

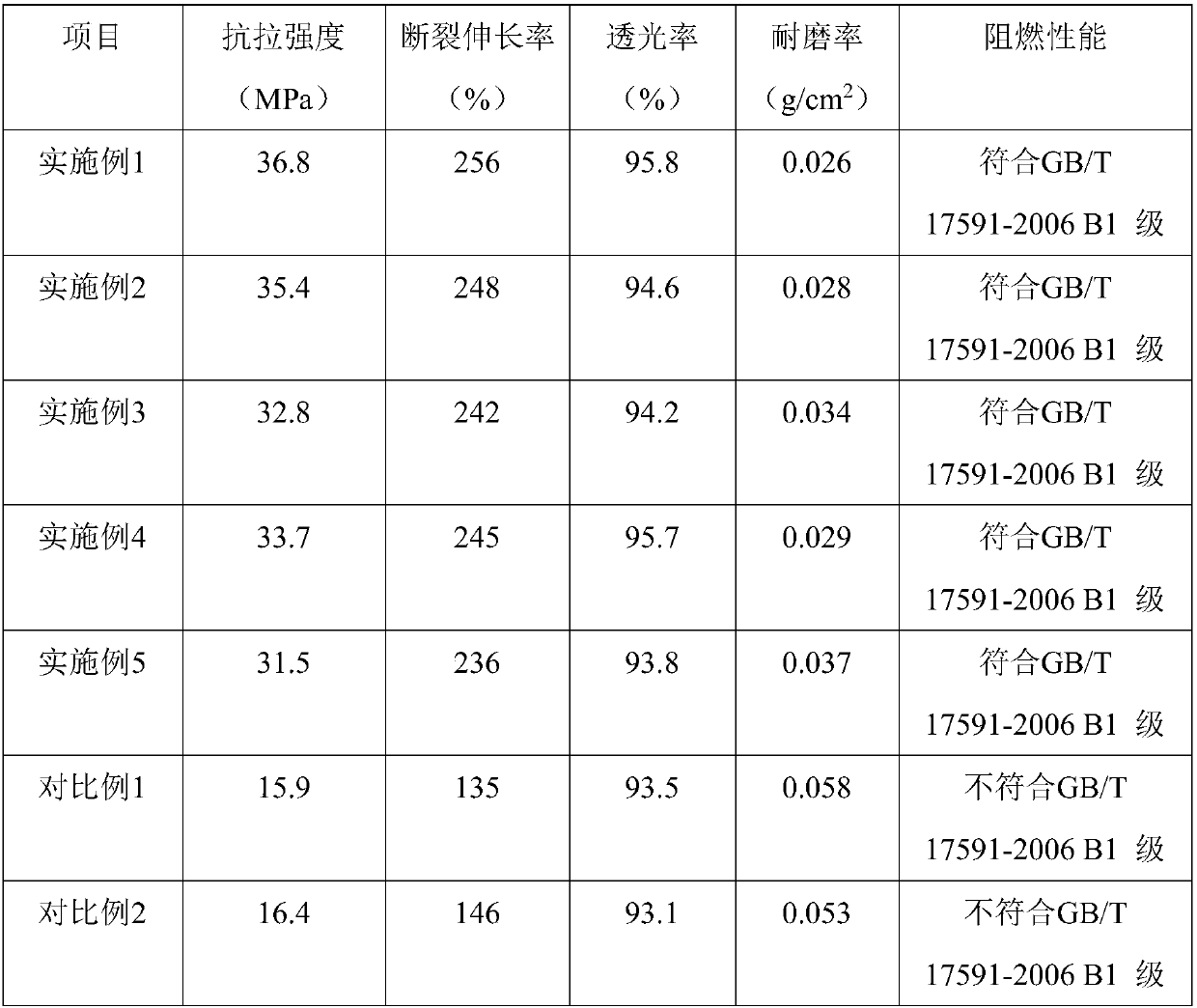

Technology for processing floor films

The invention discloses a technology for processing floor films, and relates to the field of floor film processing. The technology for processing the floor films includes steps of (1),mixing ingredients, to be more specific, weighing, by weight, PVC (polyvinyl chloride) resin powder, impact-resistant MBS (methyl methacrylate) resin, ACR (acrylamide) processing agents, di-iso-decylphthalate, internal lubricants, 3-10 parts of external lubricants and phosphate ester flame retardants, stirring the ingredients at the high speeds, and then carrying out cold stirring on the ingredients to obtain mixed materials; (2), carrying out extrusion, plasticization and calendaring molding on the mixed materials; (3), carrying out cooling and ageing treatment; (4), carrying out traction, winding and packaging. The technology has the advantages that the floor films are reasonable in composition proportion, high in light transmittance and suitable for large-scale industrial production, the technology isreasonable in design, and the toughness, the abrasion resistance, the flame retardance and the temperature resistance of the floor films can be enhanced.

Owner:安徽嘉阳新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com