Patents

Literature

1999results about How to "Reduce oxygen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

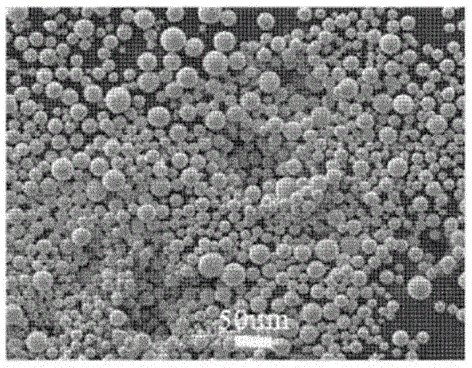

Metal powder for 3D printer and preparing method thereof

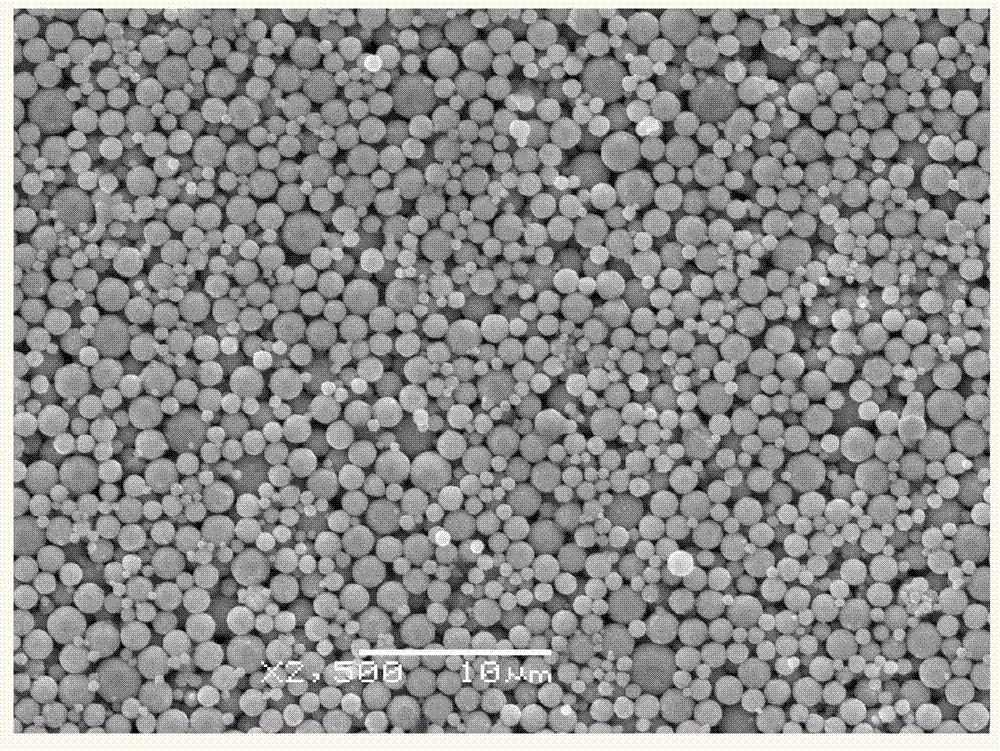

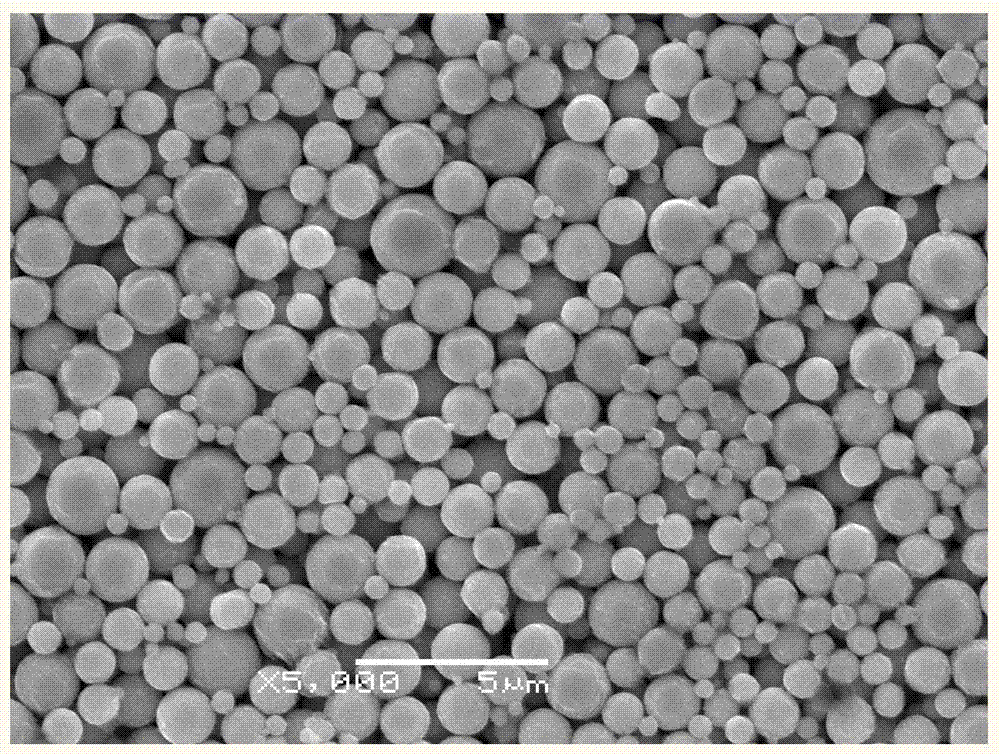

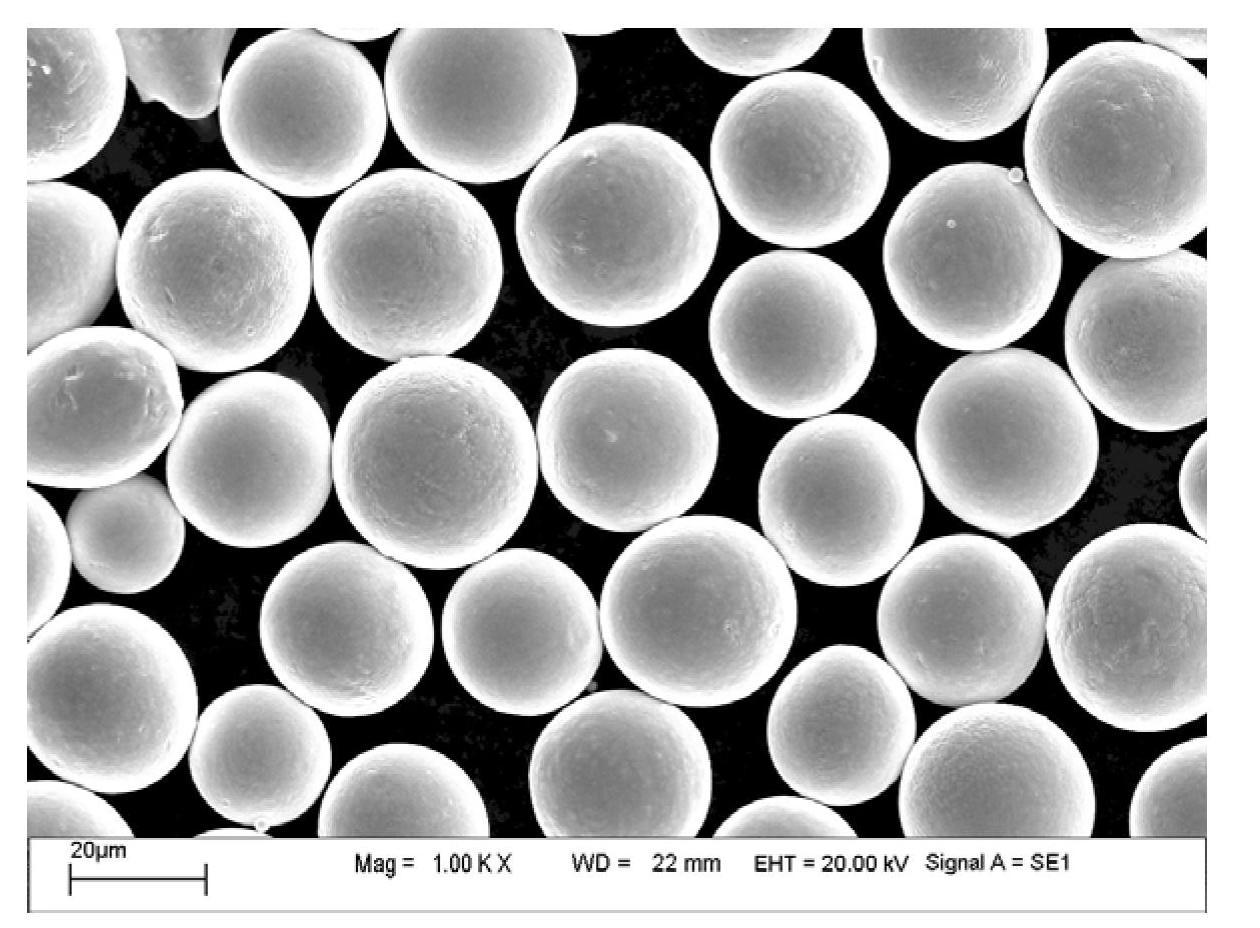

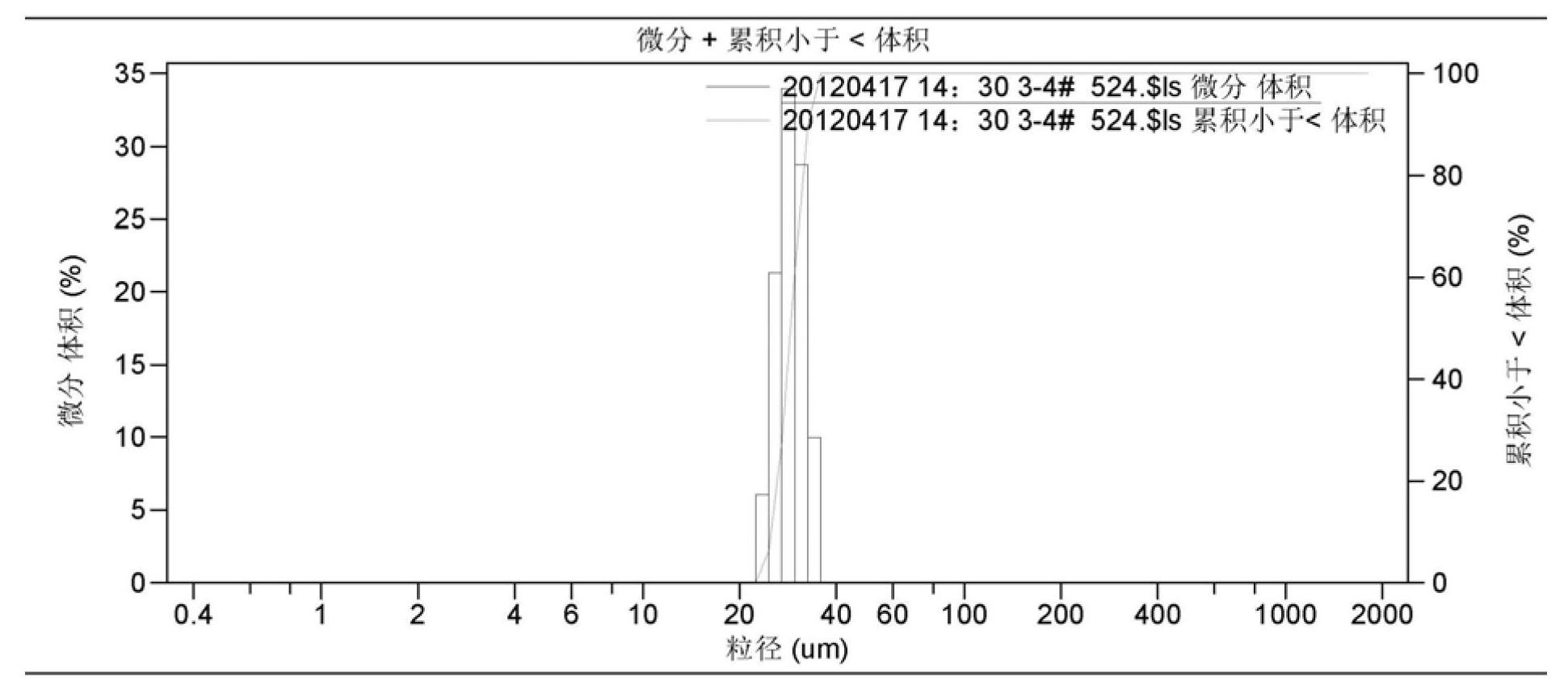

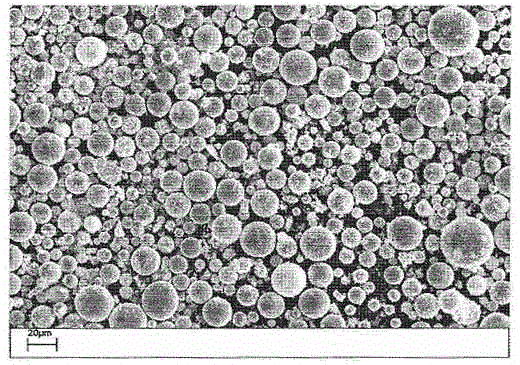

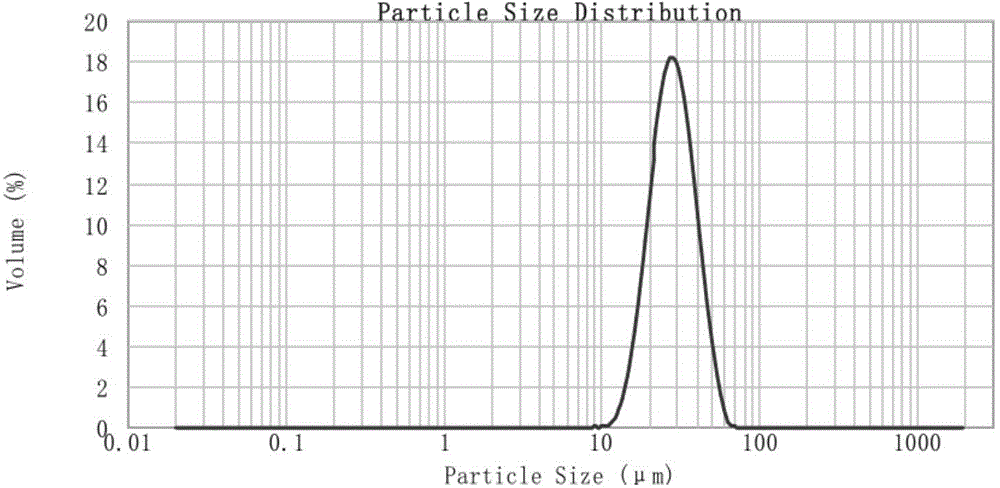

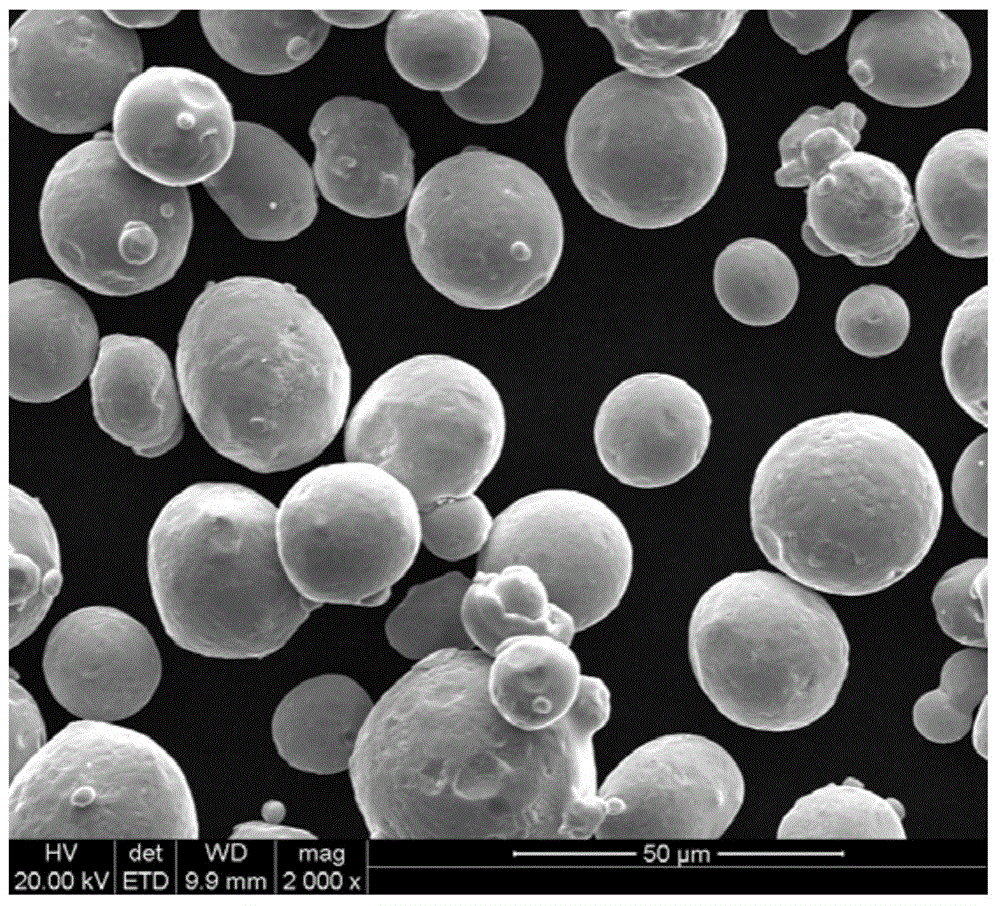

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

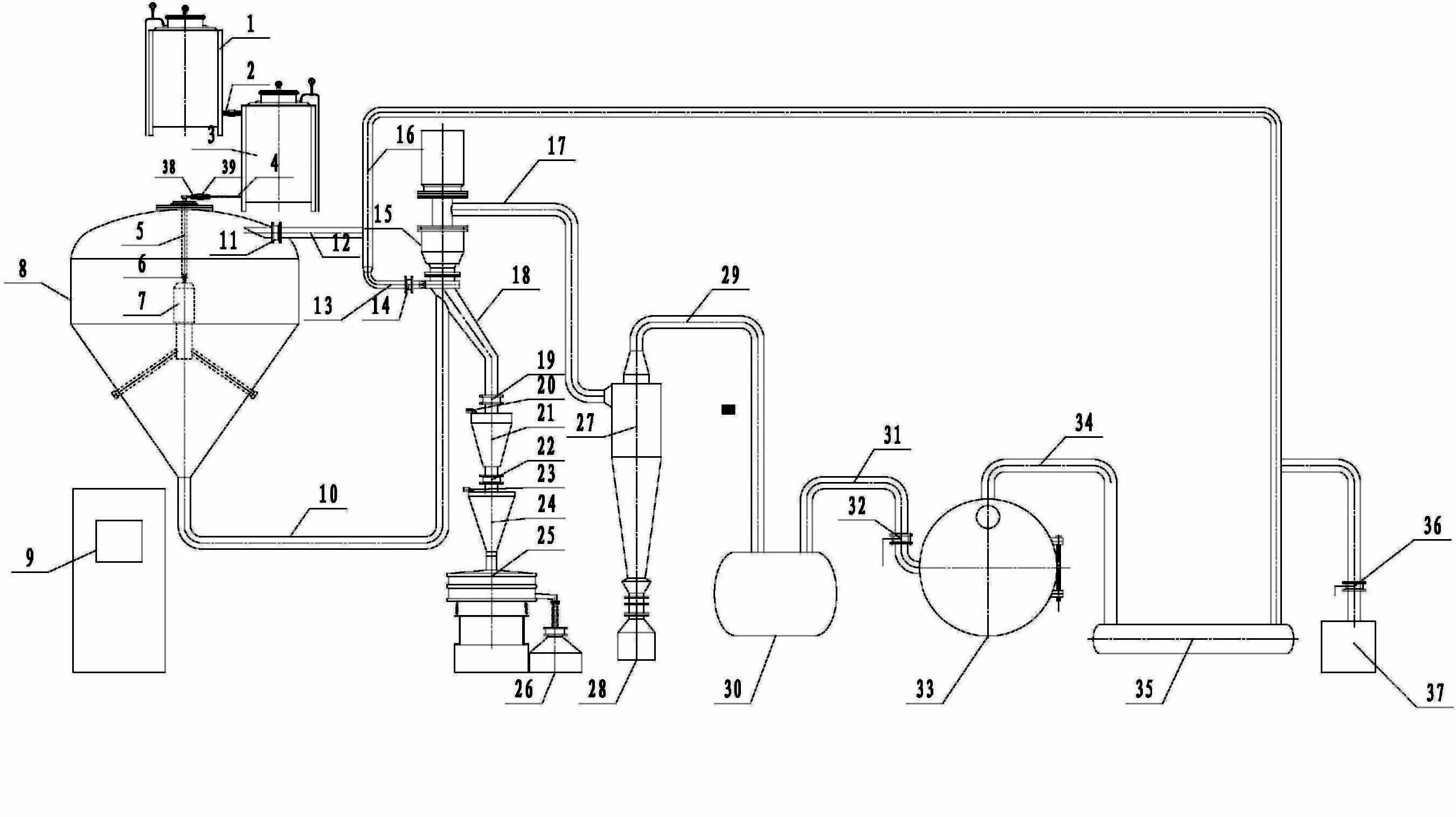

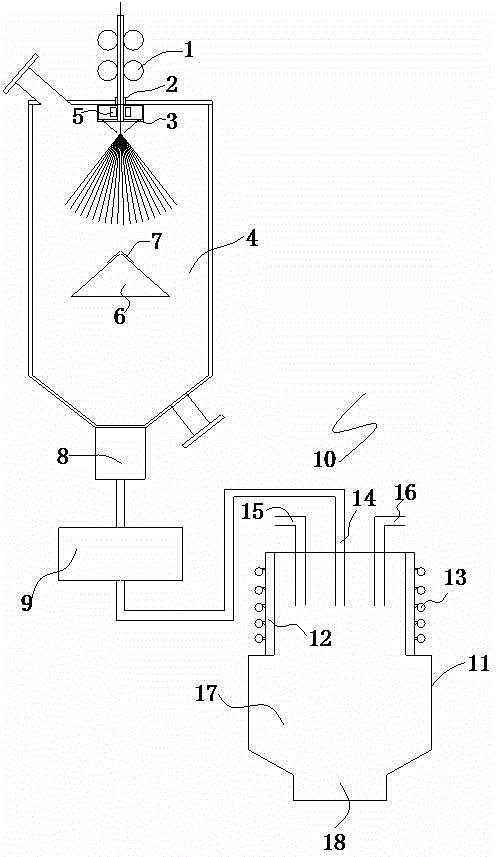

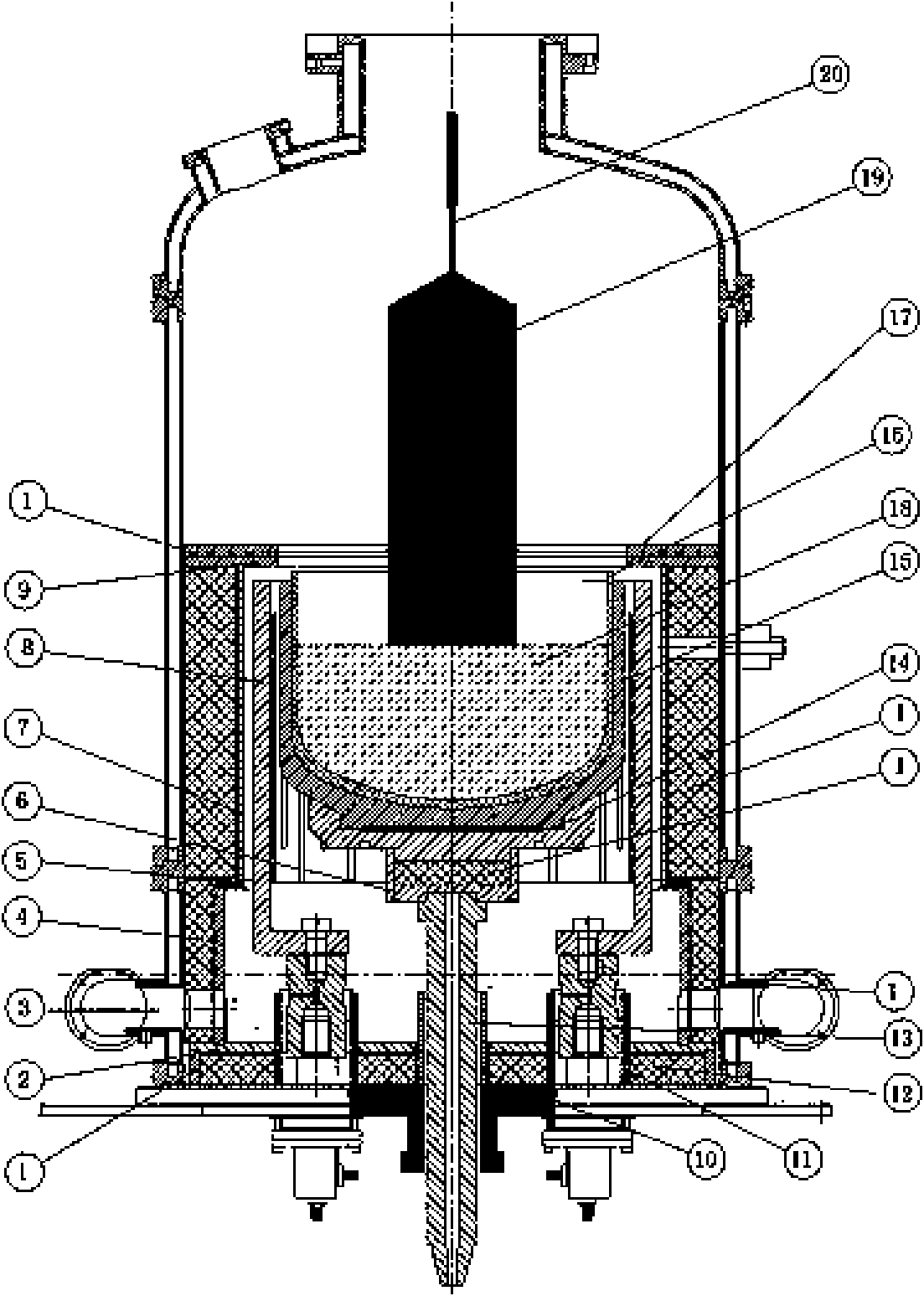

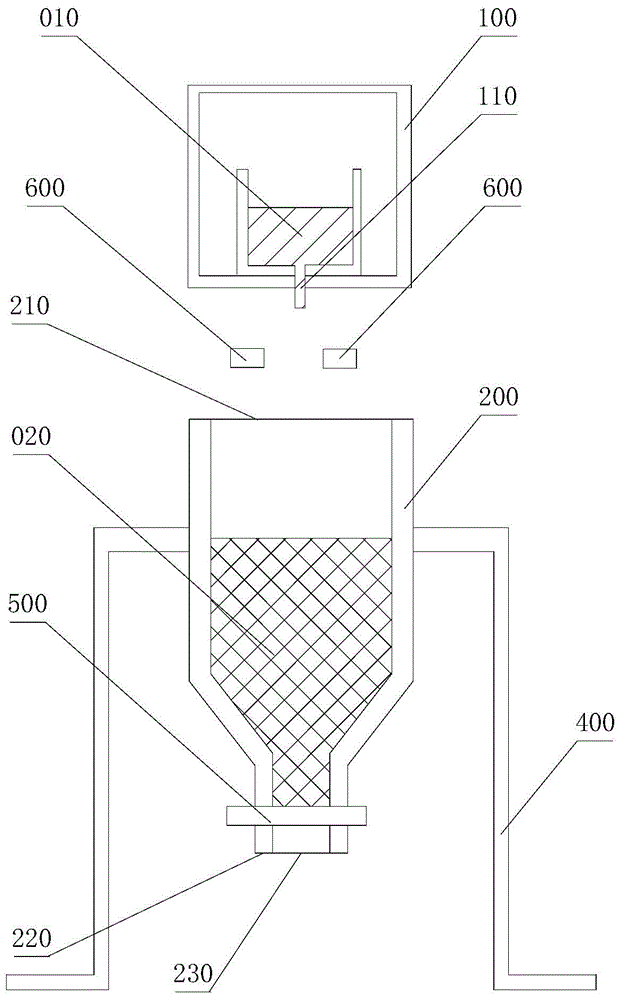

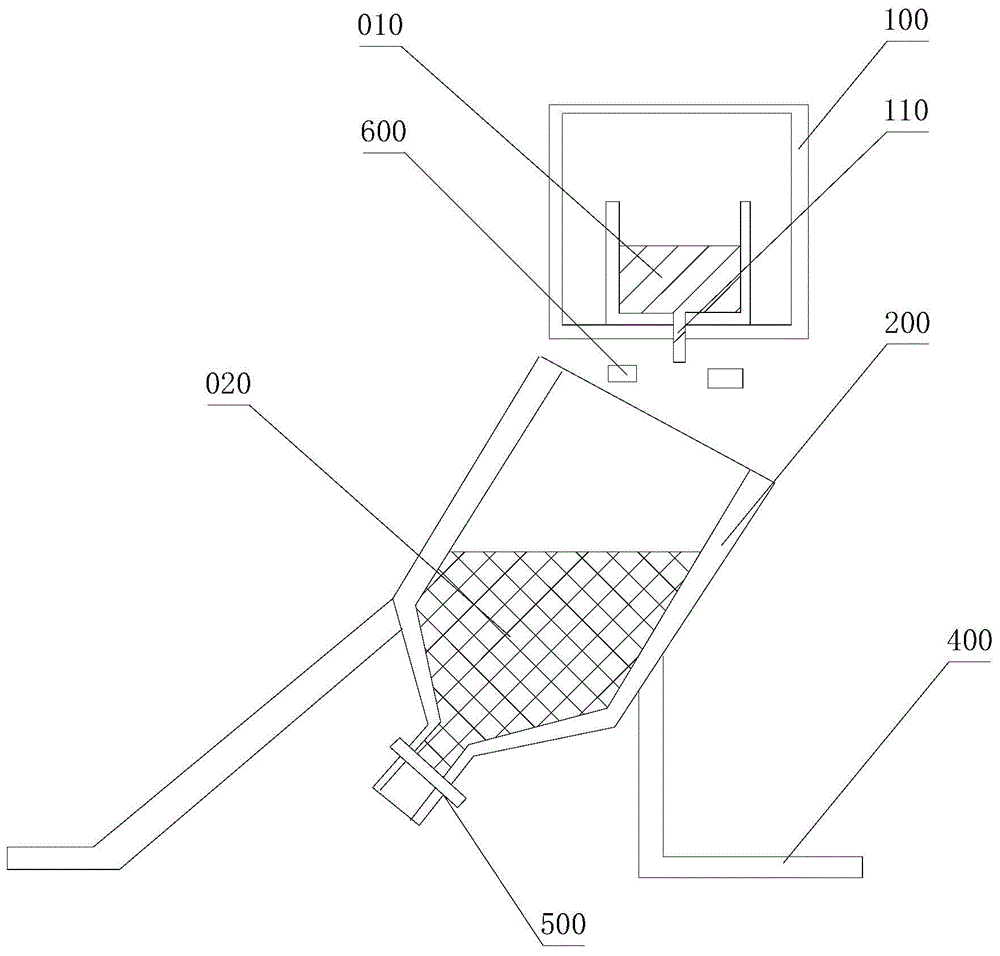

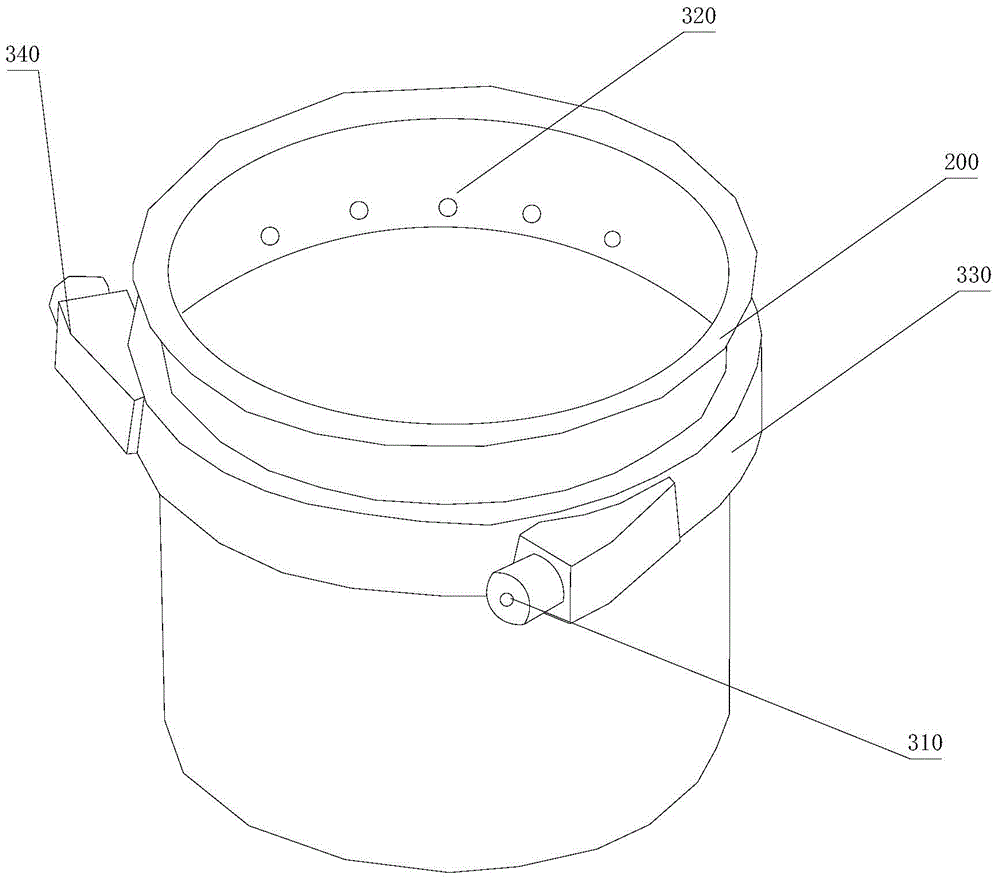

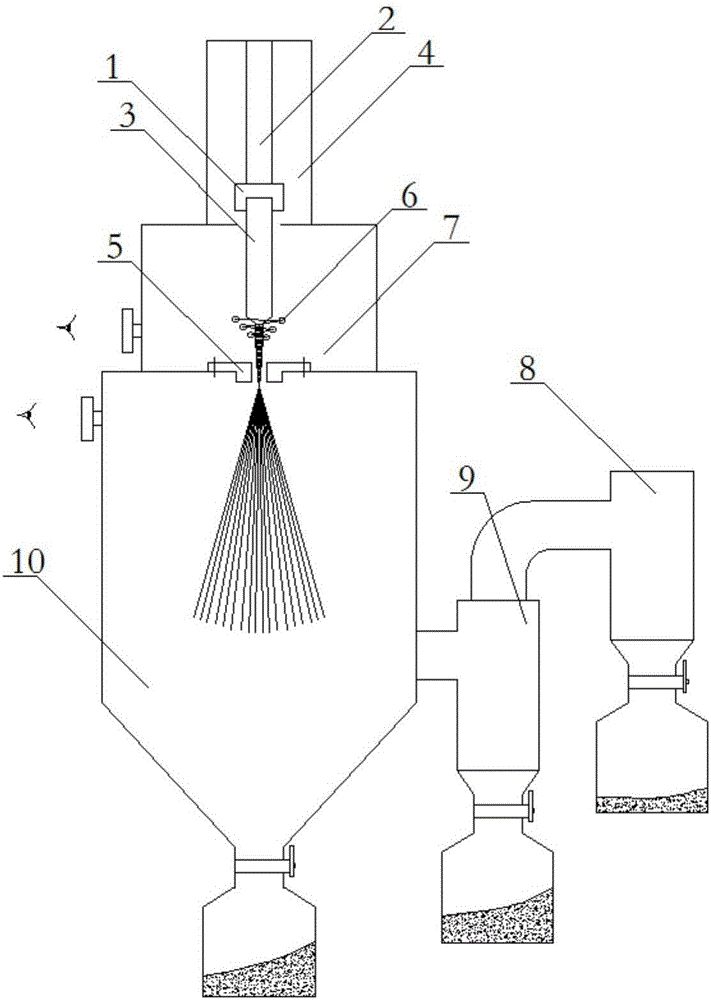

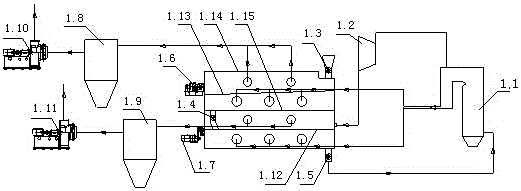

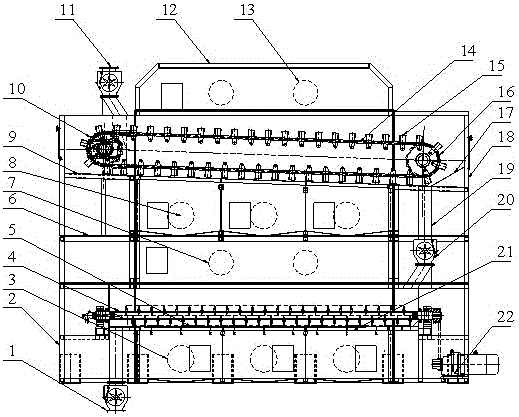

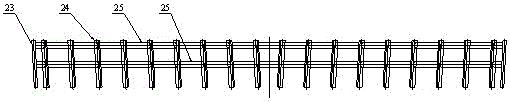

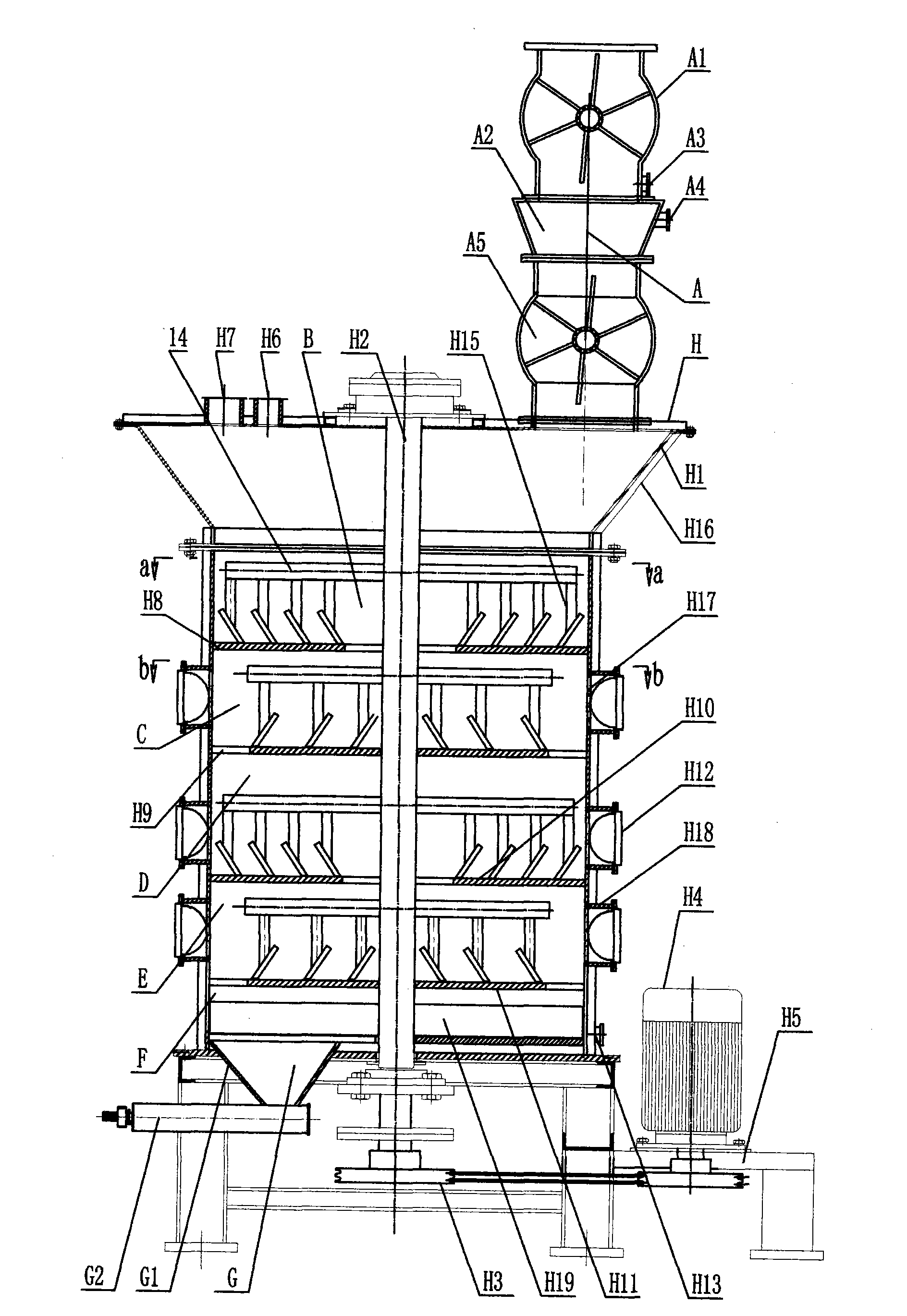

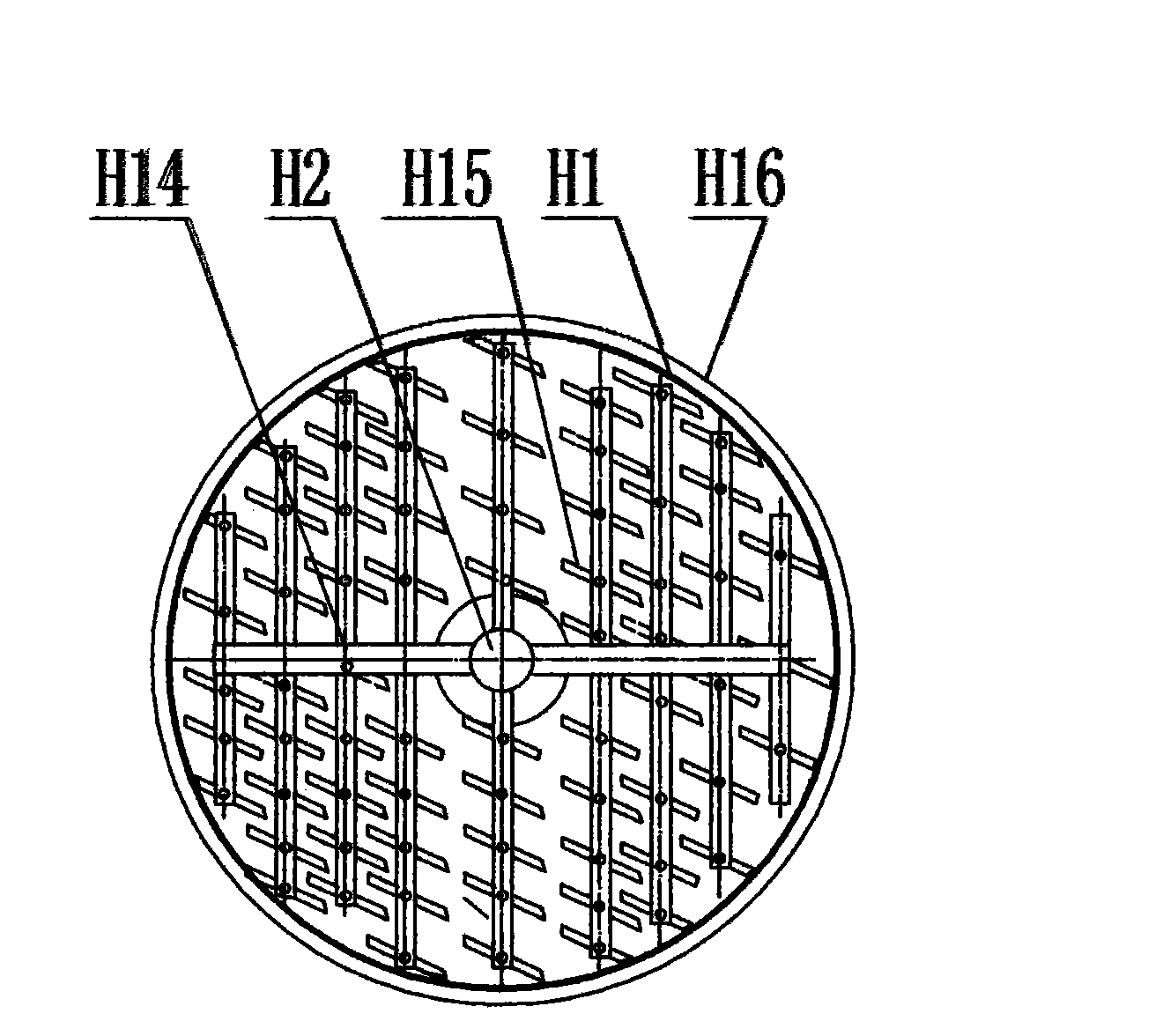

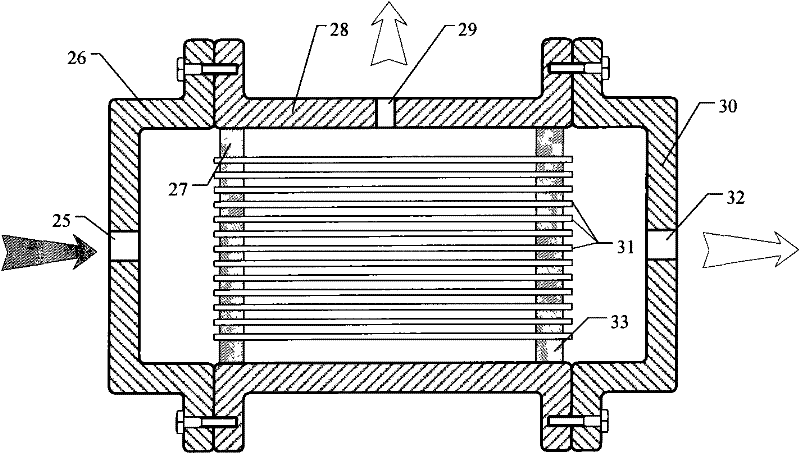

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

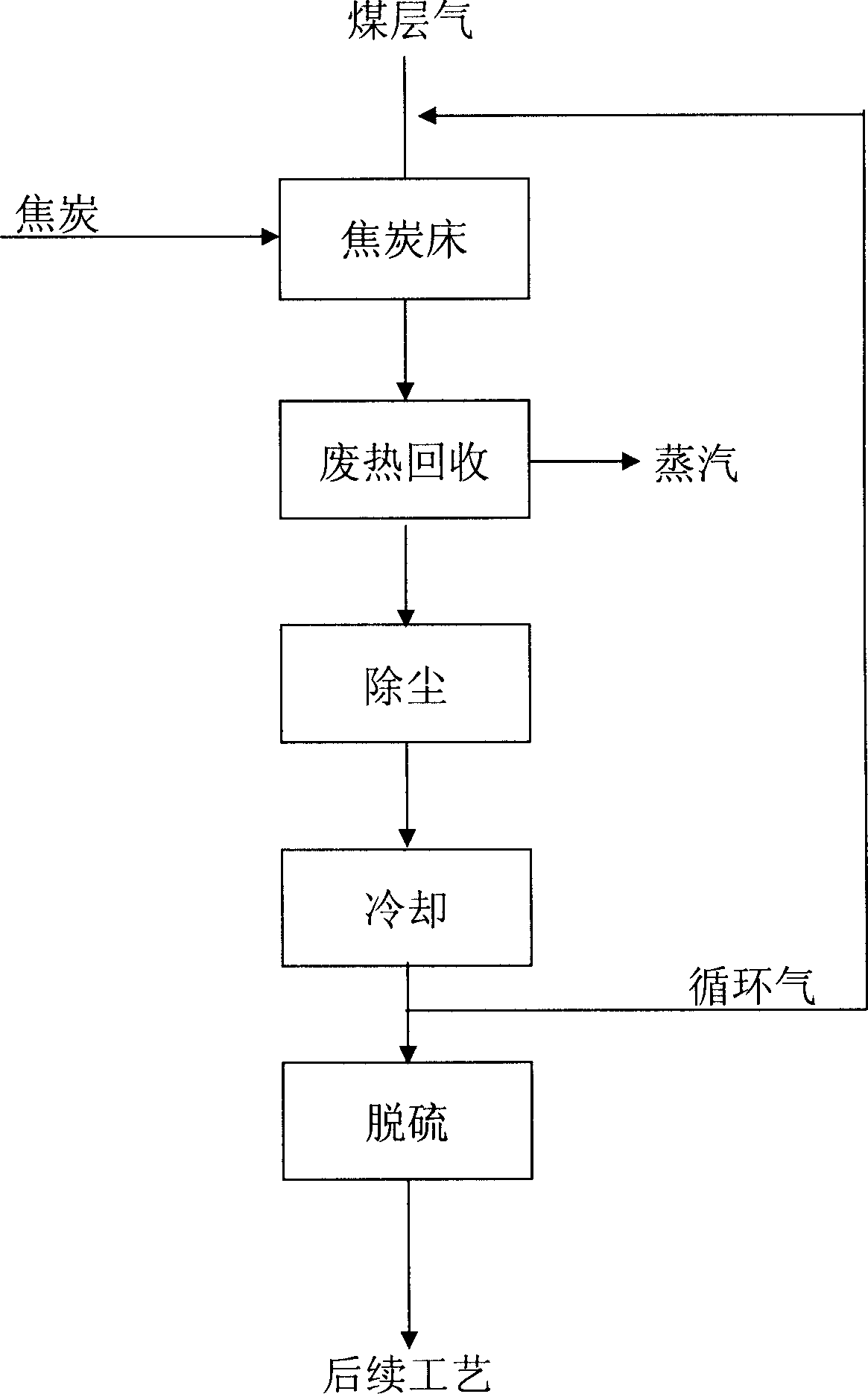

Coal bed gas coke deoxidization technique

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

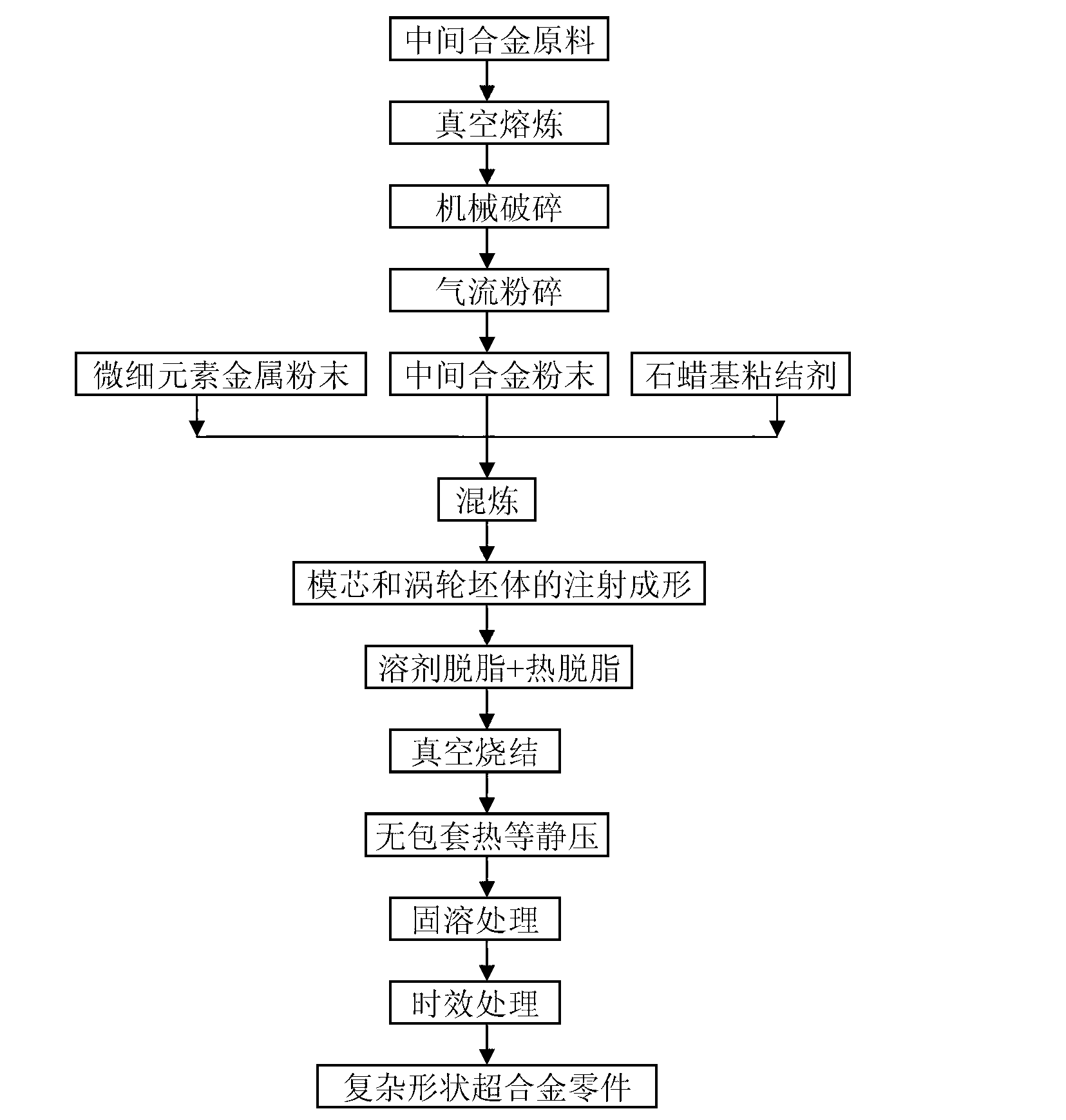

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

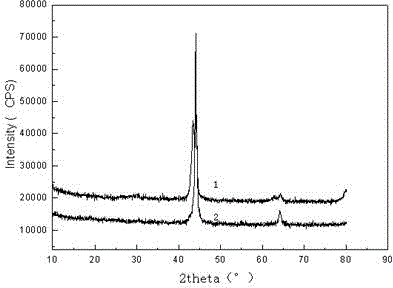

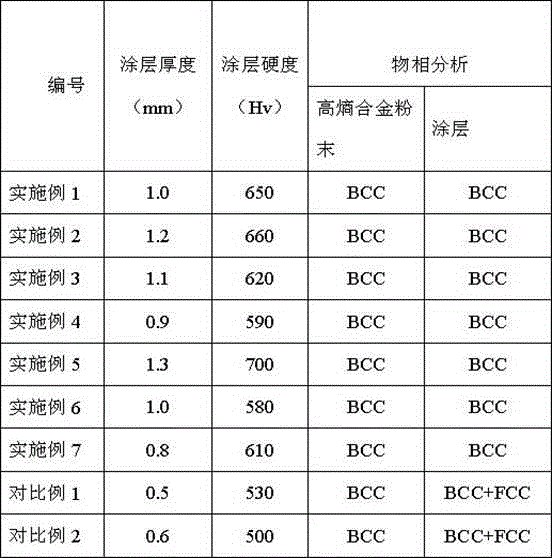

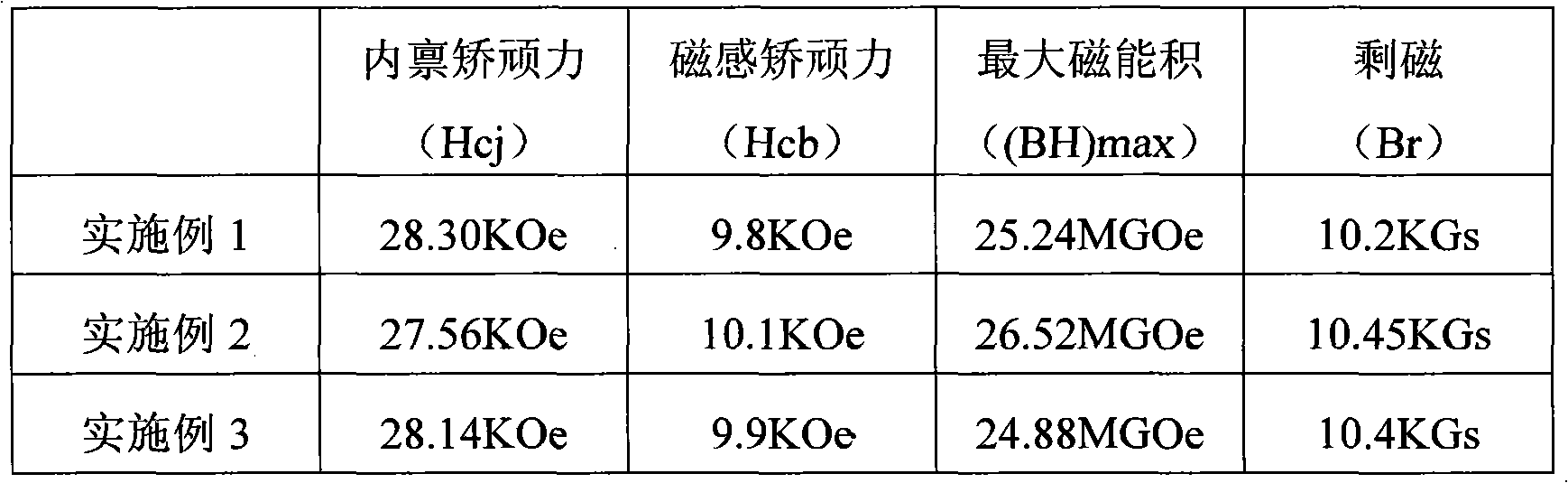

High-entropy alloy powder for spray coating and preparation method thereof, as well as composite material and preparation method thereof

InactiveCN104561878APurify the meltReduce oxygen contentMolten spray coatingRare-earth elementHigh entropy alloys

The invention provides high-entropy alloy powder for spray coating. The high-entropy alloy powder is composed of CraFebCocNidAleMfRg, wherein a, b, c, d, e, f, g are atomic percentages, a, b, c, d, e, f are nearly equal atomic percentages, g is larger than 0 and is smaller than 1, and a+b+c+d+e+f+g is equal to 100; M is at least one of Ti, HF, Mn and Cu; and R is at least one of rare earth elements. The invention further provides a preparation method of the high-entropy alloy powder, a composite material obtained by spray coating of the high-entropy alloy powder and a preparation method of the composite material. The high-entropy alloy coating provided by the invention has the advantages of high strength and low manufacturing cost, and has hardness and excellent adhesive force much better than those of traditional alloys, thereby being an excellent wear-resistant material and having a great application prospect.

Owner:BYD CO LTD

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

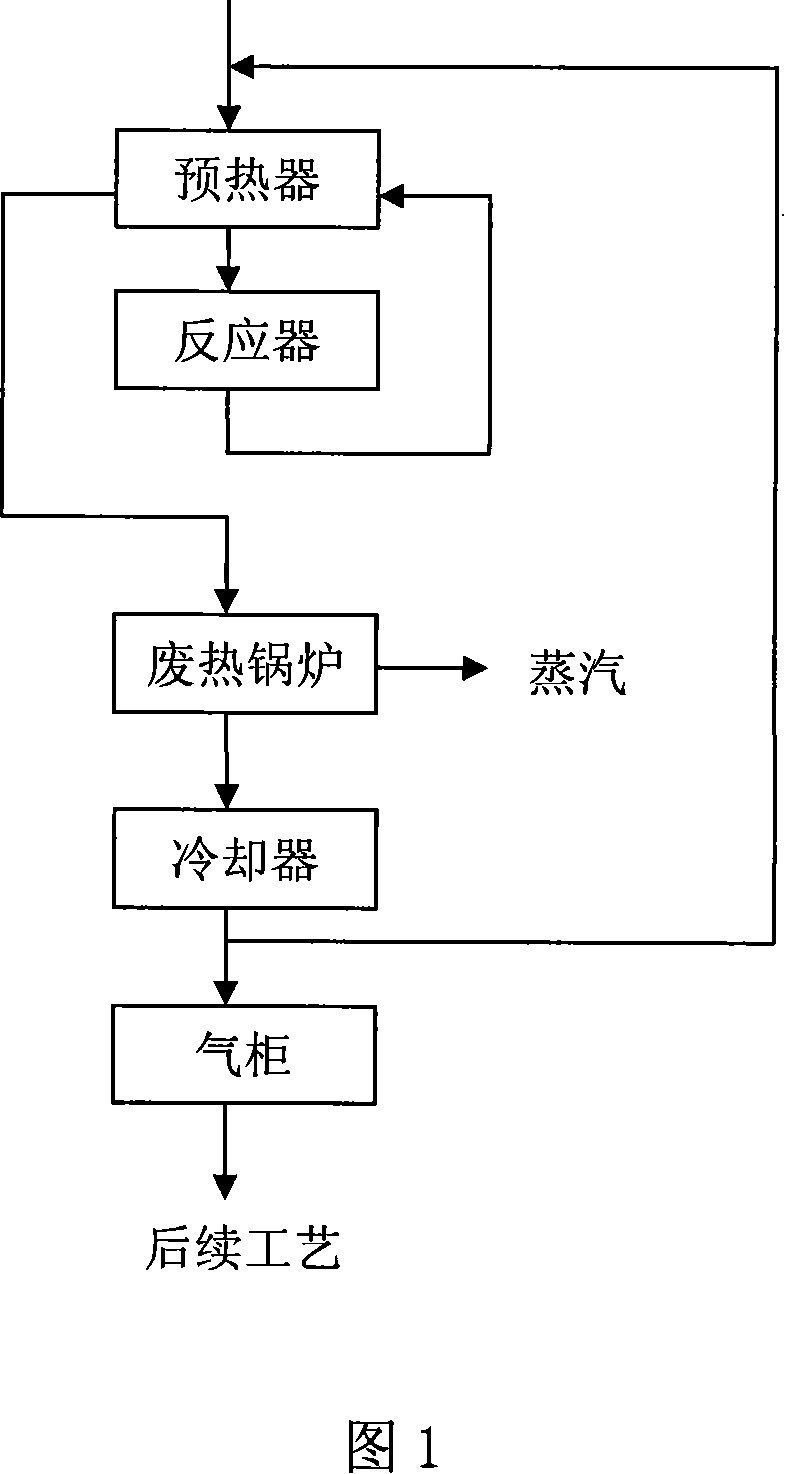

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

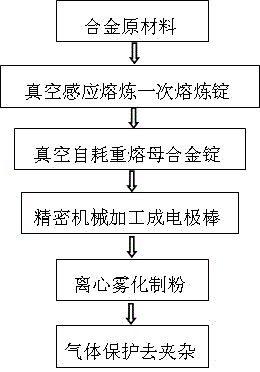

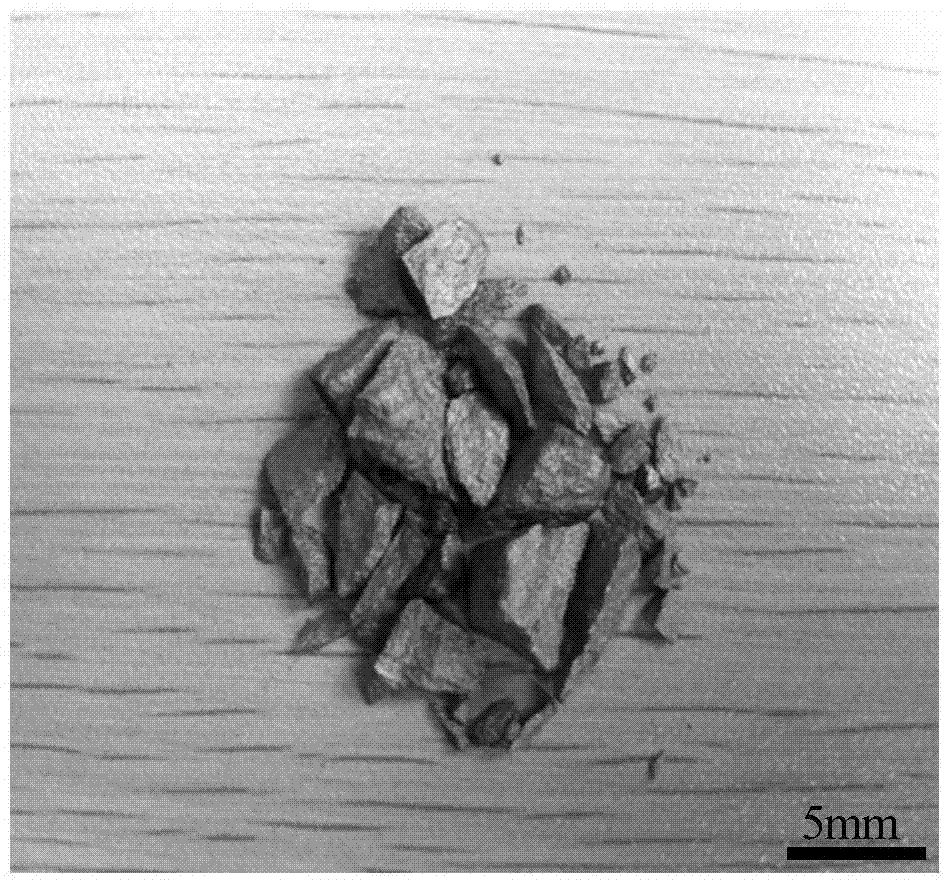

Preparation method of IN718 alloy spherical powder

InactiveCN104308167AReduce oxygen contentReduce contentElectrostatic separationNon-metallic inclusions

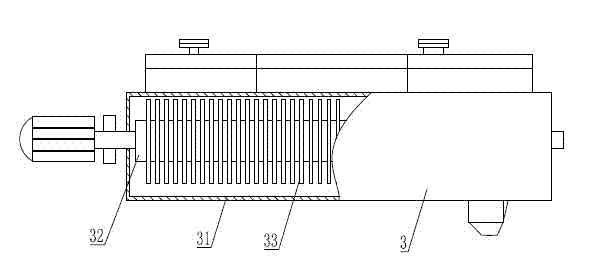

The invention discloses a preparation method of IN718 alloy spherical powder. The method comprises the following steps of step 1, smelting an IN718 alloy master ingot; step 2, processing the IN718 alloy master ingot into an IN718 alloy electrode bar with the diameter of 50 to 90mm and the length of 600 to 800mm, wherein the straightness of the electrode bar is controlled to be smaller than or equal to 0.1mm / m; step 3, placing the IN718 alloy electrode bar in a sealed furnace chamber protected by inert gas, rotating the IN718 alloy electrode bar at high speed, and heating the end part of the electrode bar by using a plasma gun to melt the electrode bar; step 4, atomizing the melted metal under the action of centrifugal force to enable melted metal to fly to form fine liquid droplets, wherein the liquid droplets are quickly cooled in inert gas to form spherical particles, and the spherical particles fall into a collector at the bottom of the furnace chamber to form the IN718 alloy spherical powder; step 5, under the protection of the inert gas, performing electrostatic separation processing on the prepared IN718 alloy spherical powder to remove non-metal impurities from the powder to obtain the pure IN718 alloy spherical powder. The method has the characteristics of good sphericity degree, fine particle size, low oxygen content and few impurities.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

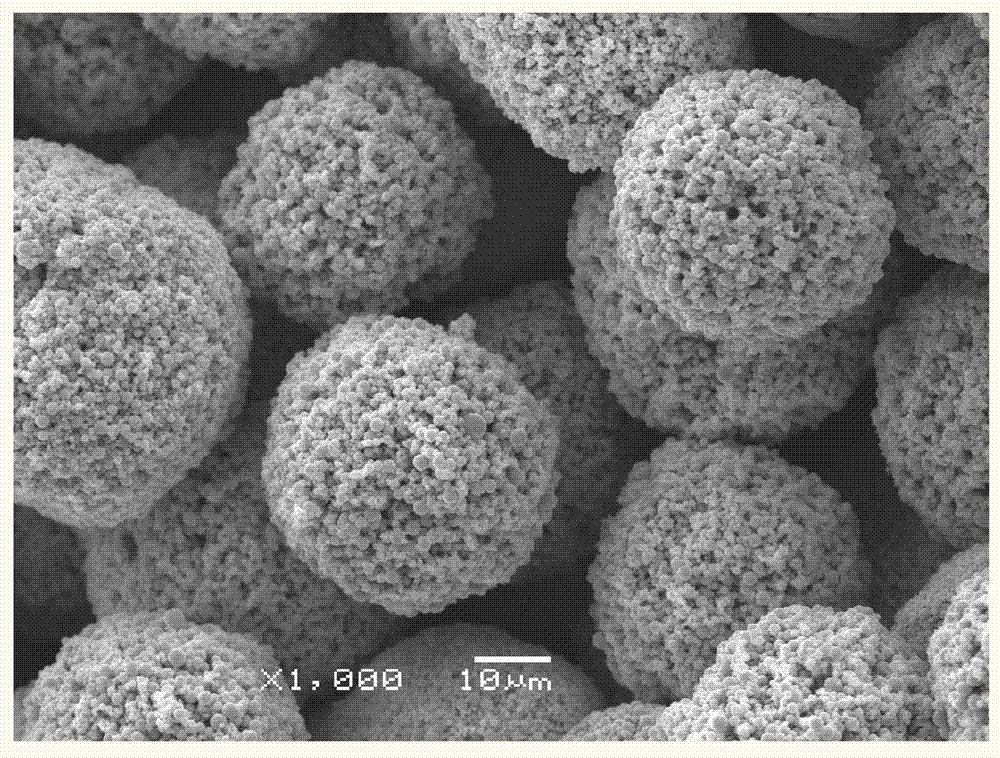

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

Preparation method of high-purity micro-fine low-oxygen titanium powder

The invention provides a preparation method of high-purity micro-fine low-oxygen titanium powder, which belongs to the technical field of powder preparation in the powder metallurgy process. The preparation method is characterized by combining hydrogenation and dehydrogenation with a jet milling process, firstly carrying out hydrogenation treatment on a titanium sponge to prepare titanium hydride powder, then utilizing a jet mill to break the titanium hydride, then carrying out vacuum dehydrogenation, and finally utilizing the jet mill to carry out breaking gradation and vacuum package and obtaining a titanium powder product. Compared with the traditional ball milling process, the jet milling process causes no pollution, and iron impurities caused by collision of steel balls in the ball milling process can be avoided; due to jet milling and high-vacuum dehydrogenation treatment, the content of oxygen can be controlled to be lowest, and the powder taking and packaging operations are respectively carried out in a glove box, so that the powder and the air are isolated in the whole process, and further, the prepared high-purity micro-fine low-oxygen titanium powder is prepared.

Owner:UNIV OF SCI & TECH BEIJING

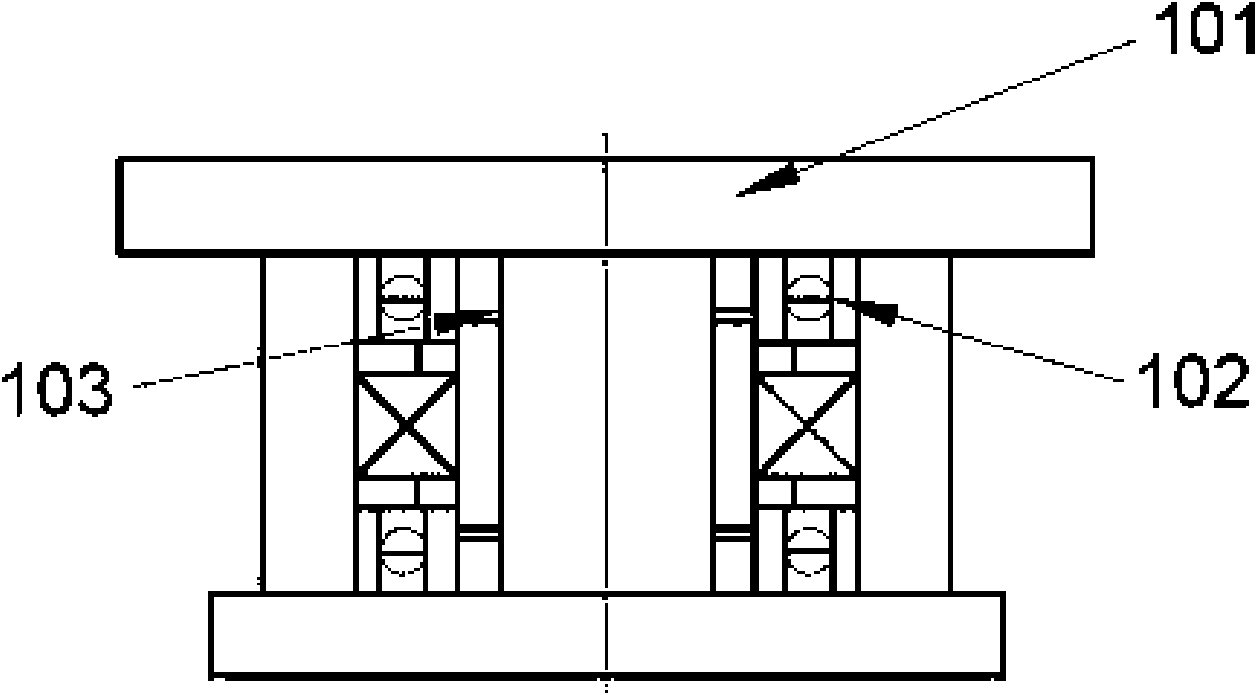

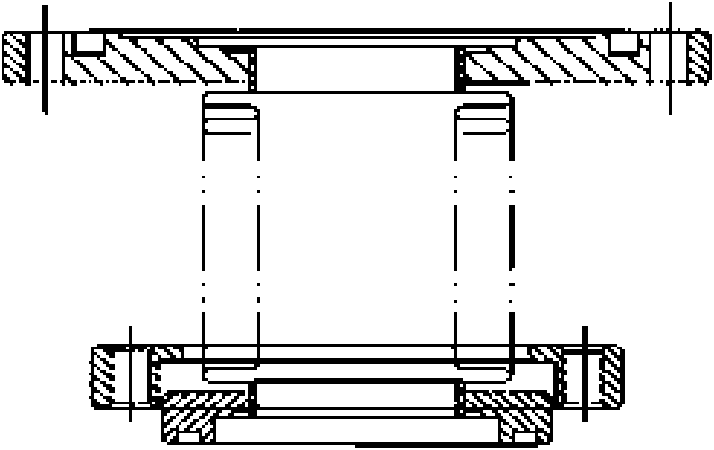

Process for growing phi 8'' solar-grade Czochralski silicon by using 18-inch thermal field

ActiveCN101798704AOptimize parameter conditionsImprove insulation effectBy pulling from meltSlagEvaporation

The invention discloses a process for growing phi 8'' solar-grade Czochralski silicon monocrystalline by using an 18-inch thermal field. By adopting the 18-inch thermal-shielding thermal field and an upper-shaft magnetic fluid sealing device with a cooling system and combining the optimized parameter conditions of crystal-pulling processes, the invention enables the thermal field to have good heat preservation and obviously reduced energy consumption, enables gas to smoothly flow to be beneficial for the exhaustion of volatile matter, stabilizes crystallization, prolongs the service life of equipment and reduces the production cost; and in addition, the invention reduces magnet demagnetization and the evaporation of a magnetic fluid to avoid the air leakage and the slag dropping of the sealing of the magnetic fluid affecting the growth of the Czochralski silicon monocrystalline, improves the sealing performance and prolongs the service life, thereby ensuring the crystal-pulling processes of crystal leading, diameter equalization, shoulder rotation and the like to be stable and improving production efficiency and yield.

Owner:峨嵋半导体材料研究所

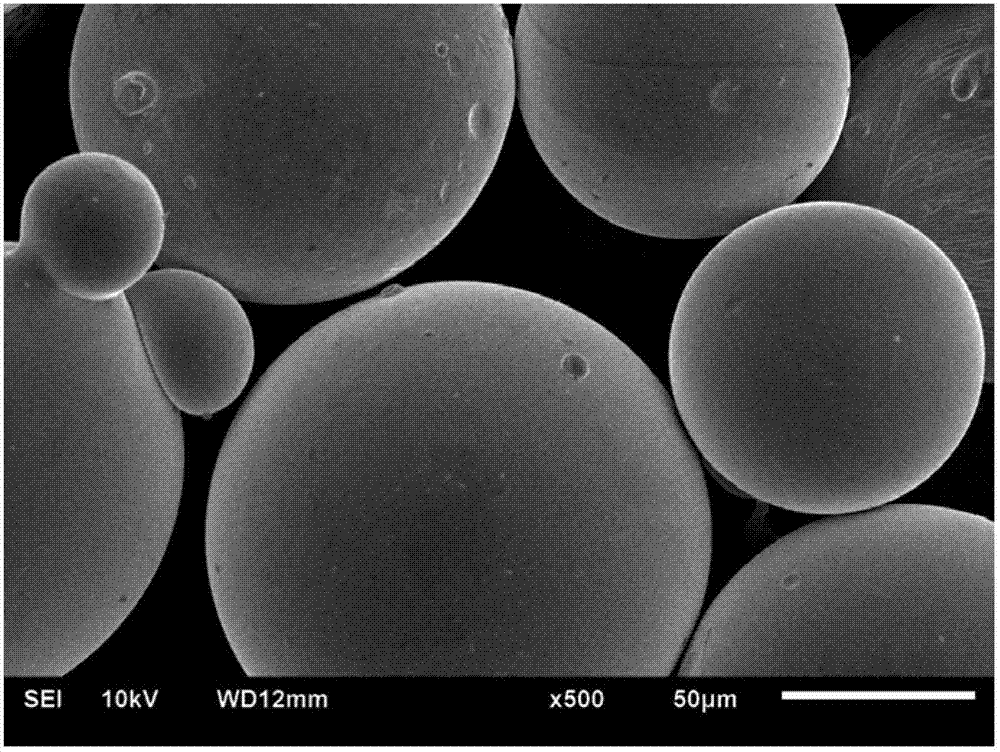

Preparation method for zirconium-based amorphous alloy as well as powder and large-sized block of zirconium-based amorphous alloy

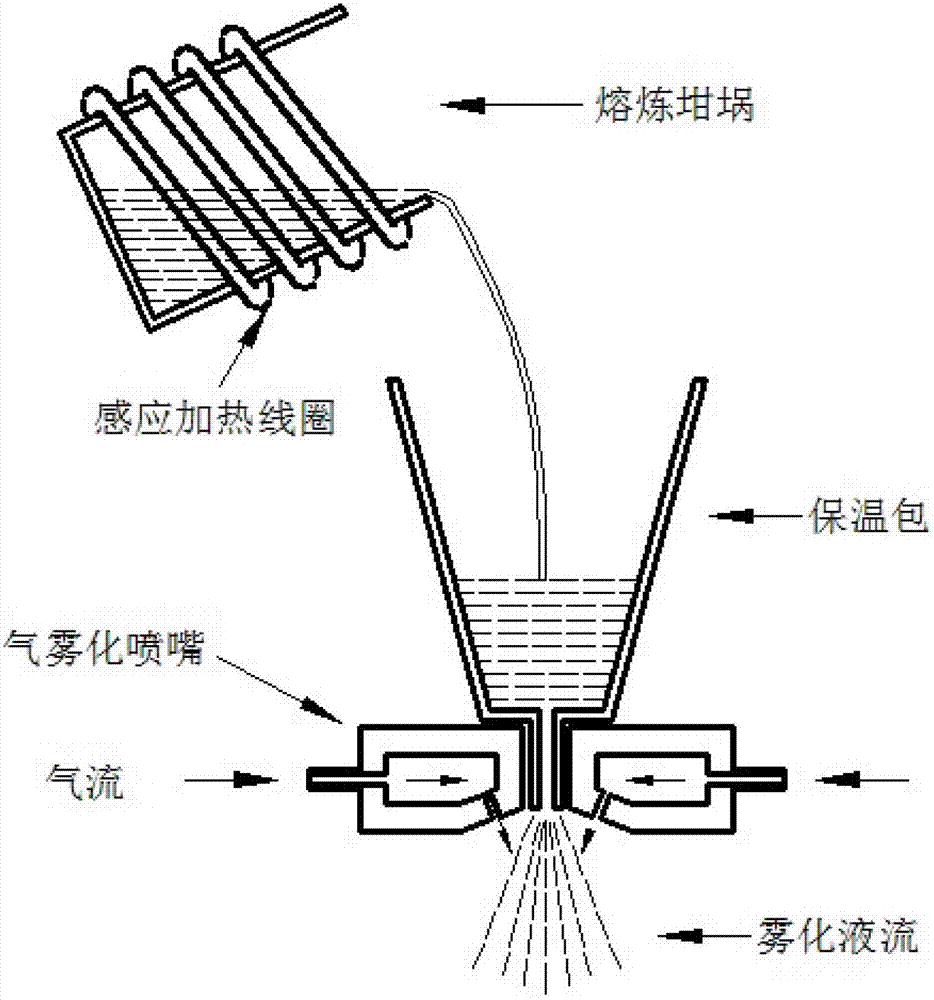

The invention relates to a preparation method for a zirconium-based amorphous alloy as well as powder and a large-sized block of the zirconium-based amorphous alloy, which belongs to the field of amorphous alloys, and is characterized by comprising the component of Zr61(Cu, Ni)27.5Al10Re1.5(at%), wherein Re is Y, La, Ce, Nd, Gd and Er, and adopting a manner of combination of the gas atomization powder milling technology and the spark plasma sintering technology. The preparation method comprises the following steps: preparing raw materials according to components of the amorphous alloy, and placing the raw materials into an induction crucible of gas atomization powder milling equipment; vacuumizing and filling inert gas for shielding; smelting to obtain an alloy solution with uniform components under the action of induction heating; pouring the alloy solution after smelting into an insulation bag at a constant speed slowly, and filling high-pressure inert gas as an atomizing medium at the same time; atomizing the alloy solution flow into small droplets under the impact of high-pressure airflow, and finally cooling to form amorphous alloy powder; collecting and screening the amorphous alloy powder; and under the protection of the inert gas, utilizing the spark plasma sintering technology to perform sintering on the amorphous alloy powder at different temperatures and pressure to obtain an amorphous alloy block.

Owner:UNIV OF SCI & TECH BEIJING

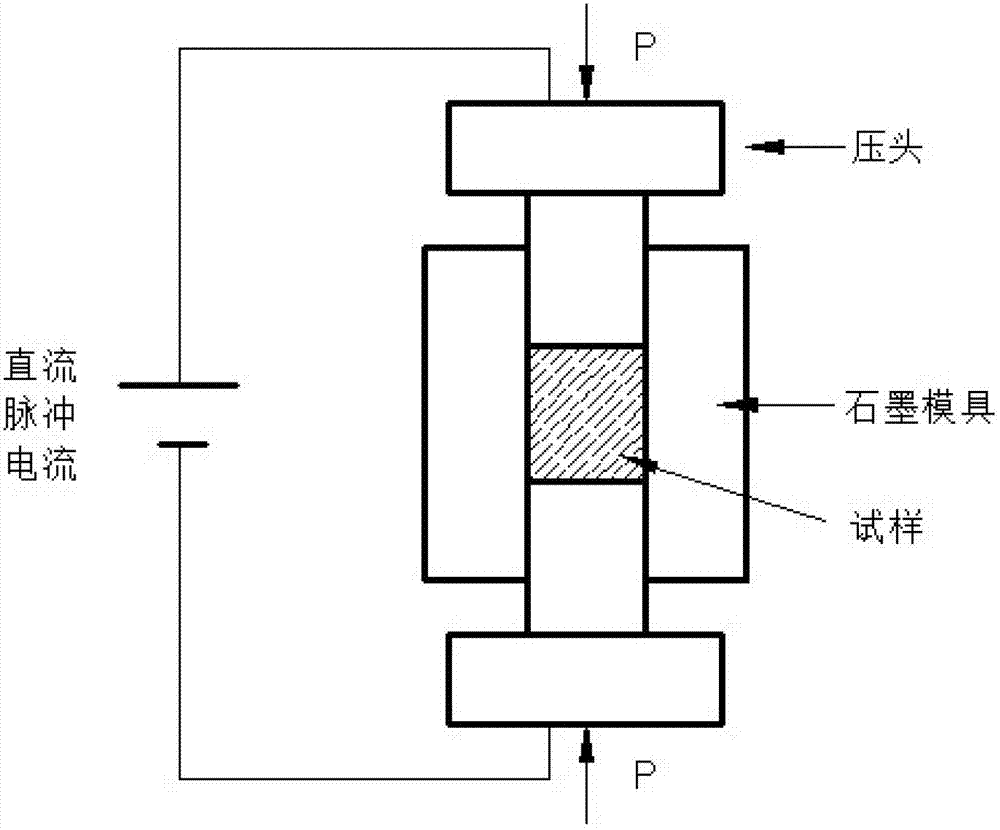

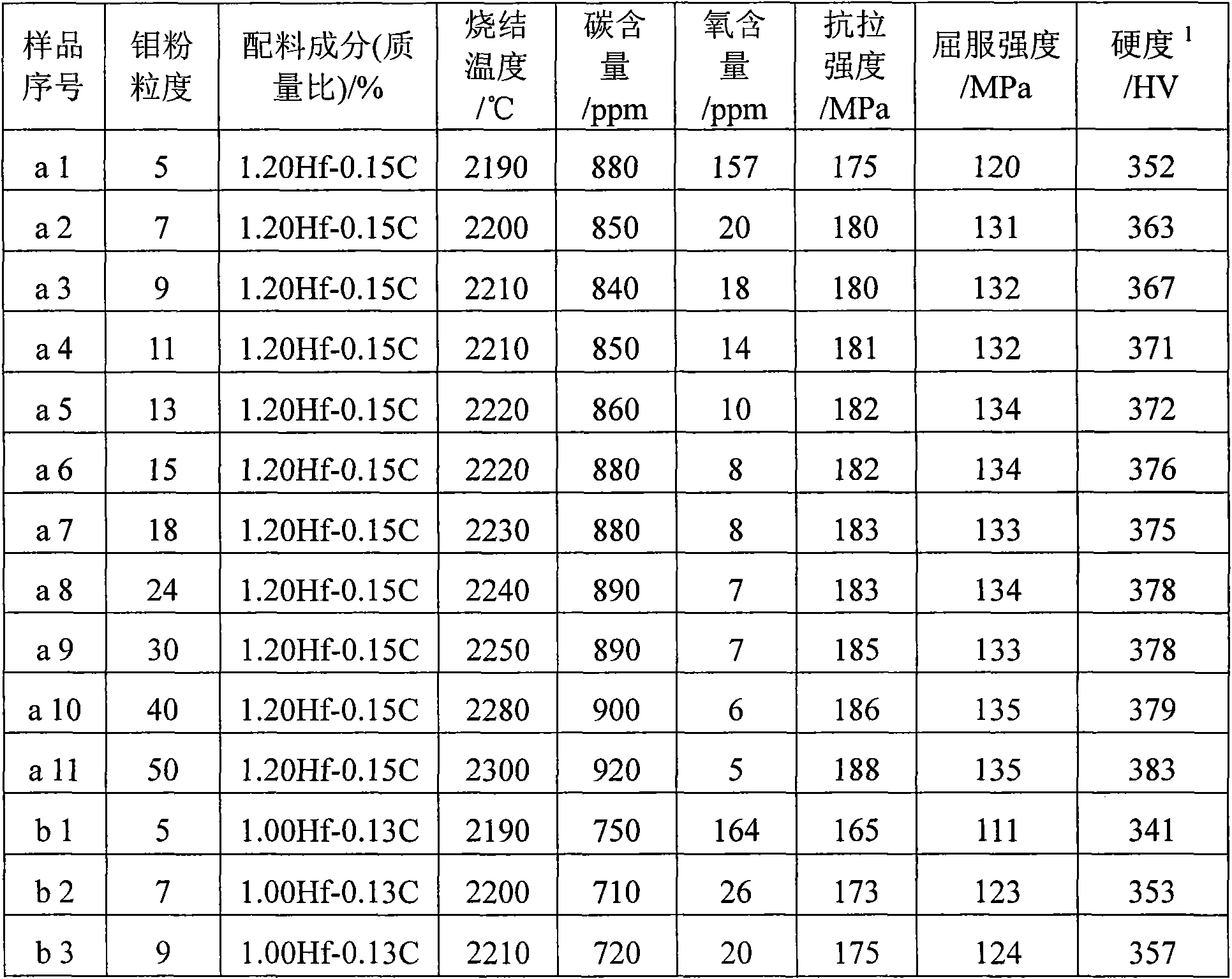

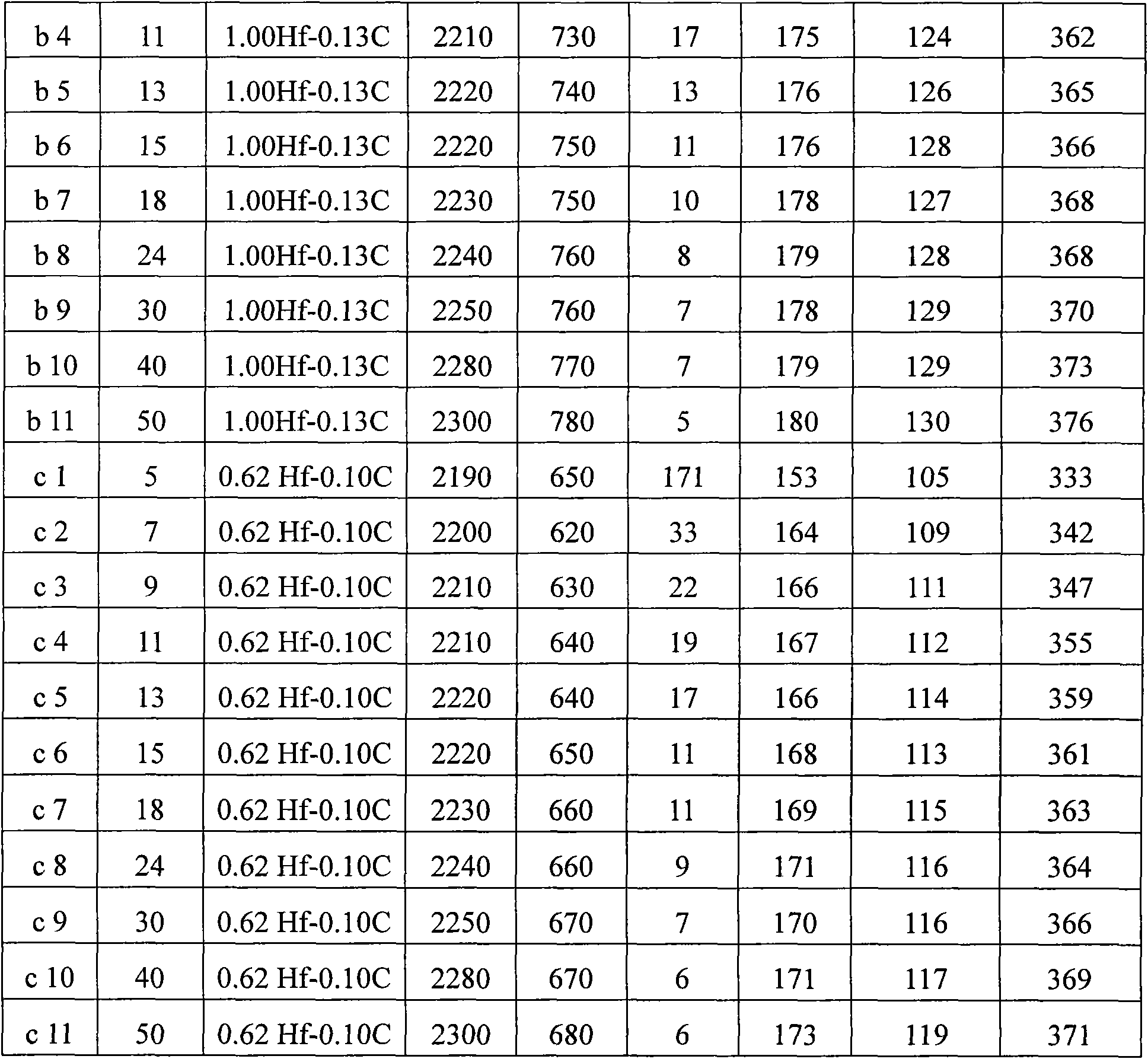

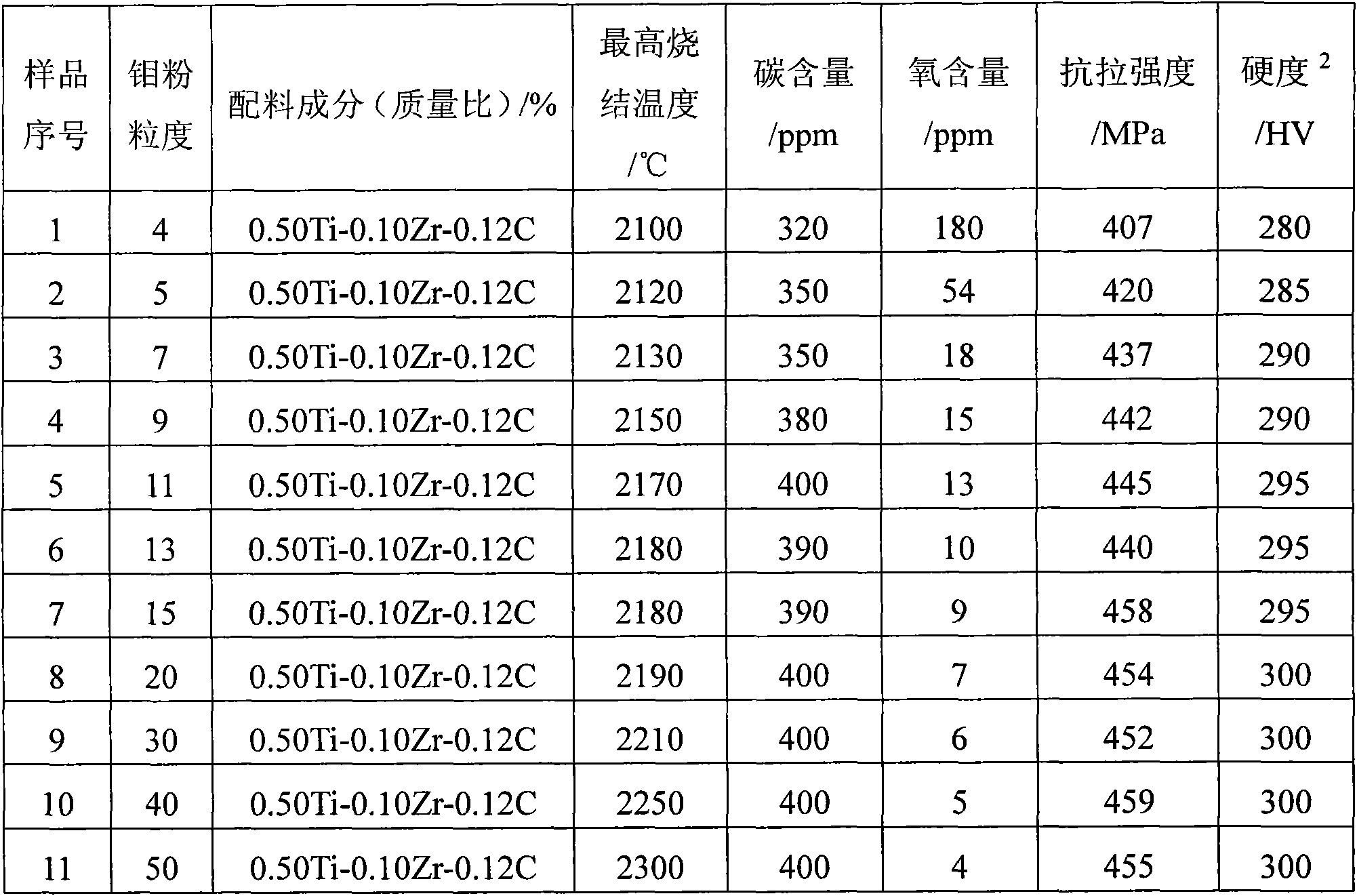

Preparation method of low-oxygen molybdenum alloy and application thereof

InactiveCN102041402AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesMass ratioAlloy

The invention provides a preparation method of a low-oxygen molybdenum alloy. The method comprises the following steps: 1) selecting raw materials: uniformly mixing industrial molybdenum powder with Fisher particle size of 3-100 mum, powder containing strengthening elements with Fisher particle size of 3-10 mum, and carbon simple substance powder with Fisher particle size of 0.1-3 mum at certain mass ratio; 2) forming the raw materials: performing static pressing or mould pressing treatment on the mixed raw materials under pressure of 100-300 MPa to obtain formed blank; and 3) sintering the raw materials: sintering the formed blank in vacuum, hydrogen or inert gas environment at the high temperature of between 1,800 and 2,300 DEG C for 5-15 h to obtain the low-oxygen molybdenum alloy. Through the invention, the problem of high oxygen content of the molybdenum alloy prepared by powder metallurgy is solved. The low-oxygen molybdenum alloy prepared by the method can be used for preparing an X-ray tube rotating anode target, a composite target-based target, a high-temperature crucible, a hot-forging die and a high-temperature ceramic gasket.

Owner:XIAN GEMEI METAL MATERIAL

Preparation method of Incone1625 nickel base alloy powder for selective laser melting technology

ActiveCN104923797AAppropriate ratioImprove purityAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention relates to a preparation method of Incone1625 nickel base alloy powder for a selective laser melting technology. The method combines a vacuum electrode induction smelting technology with an ultrasonic tight coupling atomization technology, applies methods of ultrasonic vibration separation and airflow classification, and matches powder with different particle sizes to prepare the Incone1625 nickel base alloy powder suitable for the selective laser melting technology. Compared with the prior art, the Incone1625 nickel base alloy powder, prepared by the method, has such performance characteristics as high sphericility, uniform particle size distribution, low oxygen content and low impurity content, satisfies the performance requirements of the selective laser melting technology on powder materials, and promotes the development of a metal material increase manufacturing technology.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

Sputtering target of magnetic material

ActiveUS20120241316A1Reduce oxygen contentReduce gas componentCellsVacuum evaporation coatingMaterials scienceImpurity

A magnetic sputtering target which contains B and is obtained by a melting and casting method, wherein the B content is 10 at % or more and 50 at % or less, and the remainder is one or more elements selected from Co, Fe, and Ni. Based on the method of the present invention, the sputtering target, in which gaseous impurities are few, there are no cracks and fractures, and segregation of its main constituent elements is minimal, is obtained. Consequently, when sputtered with a magnetron sputtering device comprising a DC power supply, this sputtering target yields a significant effect of being able to inhibit the generation of particles during sputtering, and improve the production yield upon forming thin films.

Owner:JX NIPPON MINING& METALS CORP

Method and device for manufacturing amorphous powder

The invention provides a method and device for manufacturing amorphous powder. The method for manufacturing the amorphous powder comprises the following steps that raw materials are fused to obtain fusion liquid; in the flowing-out and falling process, the fusion liquid interacts with atomized gas to be broken into droplets; the droplets move in the water at the high speed for a certain time to obtain first fluid; the first fluid is collected and separated to obtain the amorphous powder. The method for manufacturing the amorphous powder comprises a fusion device, a gas atomization device, a rotating water system and a discharge collection device. The gas atomization mode is adopted to enable the fusion liquid to be broken into the droplets, the final oxygen content of the power can be reduced, high-speed water flowing can break through a water steam film generated on the surface by droplet solidification in the water, the cooling rate is improved, and therefore the complete amorphous alloy powder with the larger grain diameter can be obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for producing tire cord steel wire by converter billet continuous casting process

ActiveCN102534094AGuaranteed surface qualityLow costManufacturing convertersMetal rolling arrangementsSlagSilicon alloy

The invention relates to a method for producing a tire cord steel wire according to a converter billet continuous casting process and belongs to the technical field of production of tire cord steel wires in the field of ferrous metallurgy. The method comprises the following process steps: desulfurizing by pre-treating molten iron, namely desulfurizing by spraying magnesium on a foundry ladle; smelting by using a converter, namely deoxidizing and alloying, modifying steel ladle slag, re-carburizing the molten iron and adding low-alkalinity pre-melted slag into the steel ladle after tapping; adding ferro-silicon alloy, manganese iron alloy and micronitrogen carburant in the tapping process and re-carburizing; and in the refining process and after the refining is finished, rolling the wire at high speed by adopting a two-stage steel ladle bottom blowing argon system and adopting billet continuous casting of 130mm*130mm or 160mm*160mm. The method has the advantages that: the production isreduced; the production efficiency is improved; and the method is particularly suitable for development and production of tire cord steel products in steel enterprises without big billet or rectangular billet continuous casting and without vacuum treatment equipment.

Owner:SHOUGANG CORPORATION

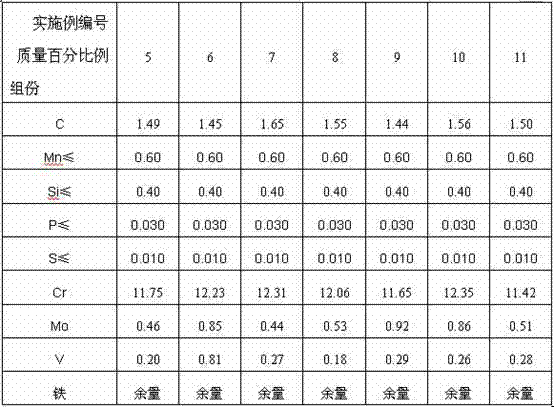

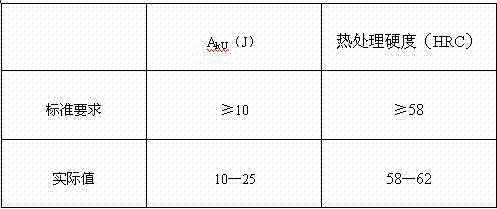

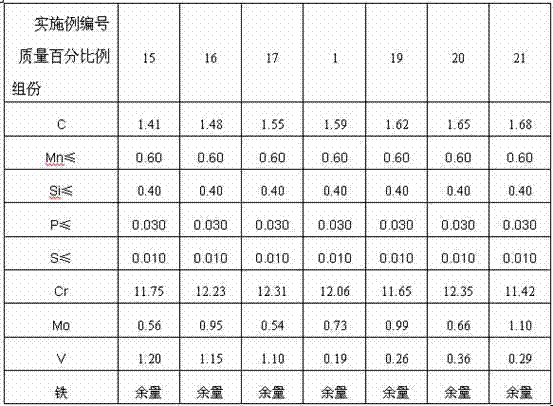

Method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel

The invention discloses a method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel. The method is characterized by comprising the following steps of: obtaining Cr12MoV or Cr12Mo1V1 steel by adopting primary smelting with an electric furnace, ladle refining and vacuum degassing process smelting; pouring the tapped steel to form a 6 to 9t octangular ingot; conveying the octangular ingot to a press at the temperature of more than or equal to 300 DEG C, forging the octangular ingot to a blank with the diameter of 300 to 700 millimeters, removing surface defects by annealing, polishing or turning and local grinding, performing cold saw cutting on the end face and blanking to form a cake blank; and heating the cake blank to the temperature of between 1,150 and 1,190 DEG C, upsetting and forging the cake blank by using the press, annealing and turning, and thus obtaining the large cake forgings of the high-carbon and high-chromium cold working die steel. By adopting the method, the yield is improved to 40 to 60 percent; and the manufactured large cake forgings of the high-carbon and high-chromium cold working die steel can comprehensively meet the requirements of hardness, impact toughness and the like and ultrasonic flaw detection quality.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

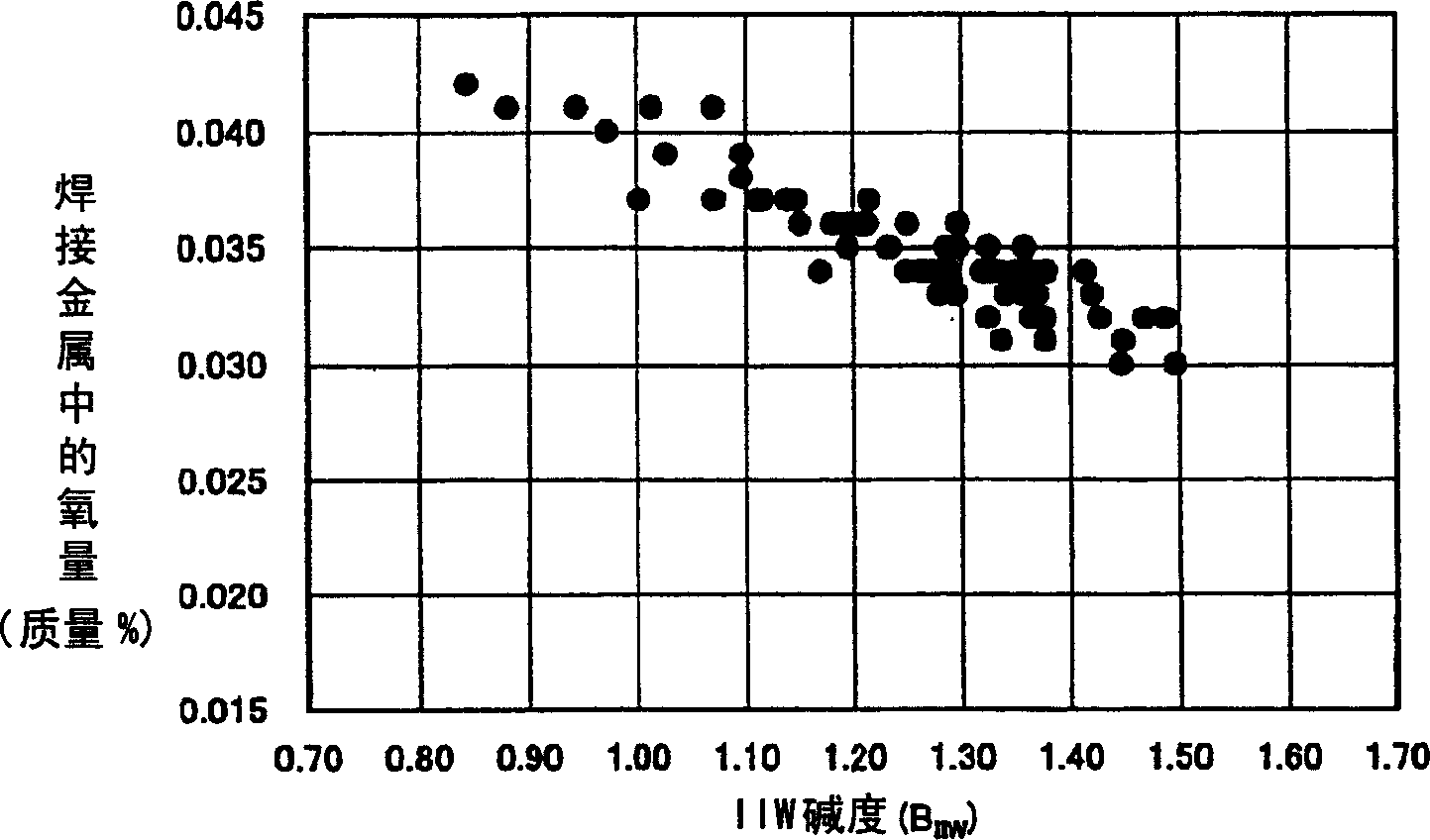

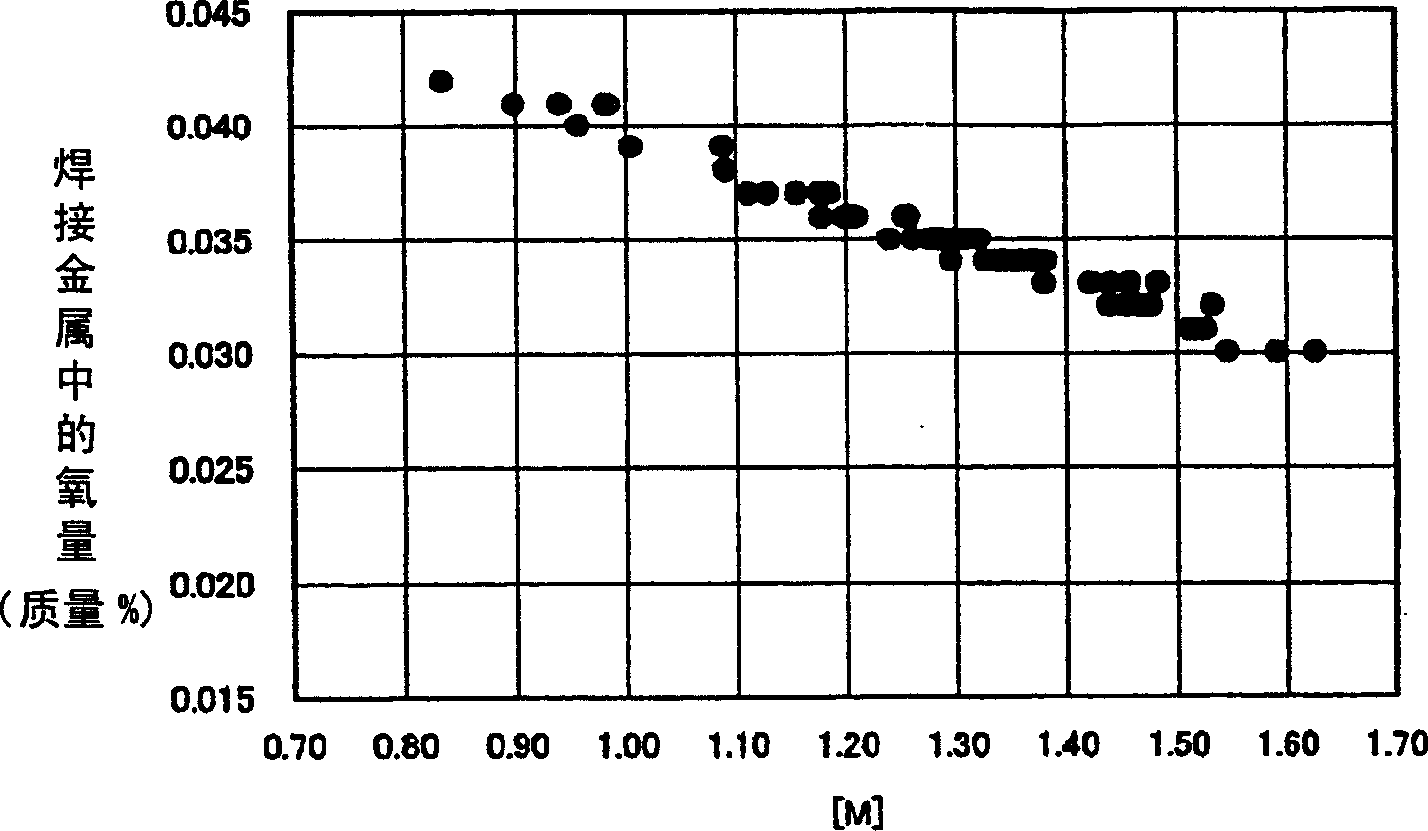

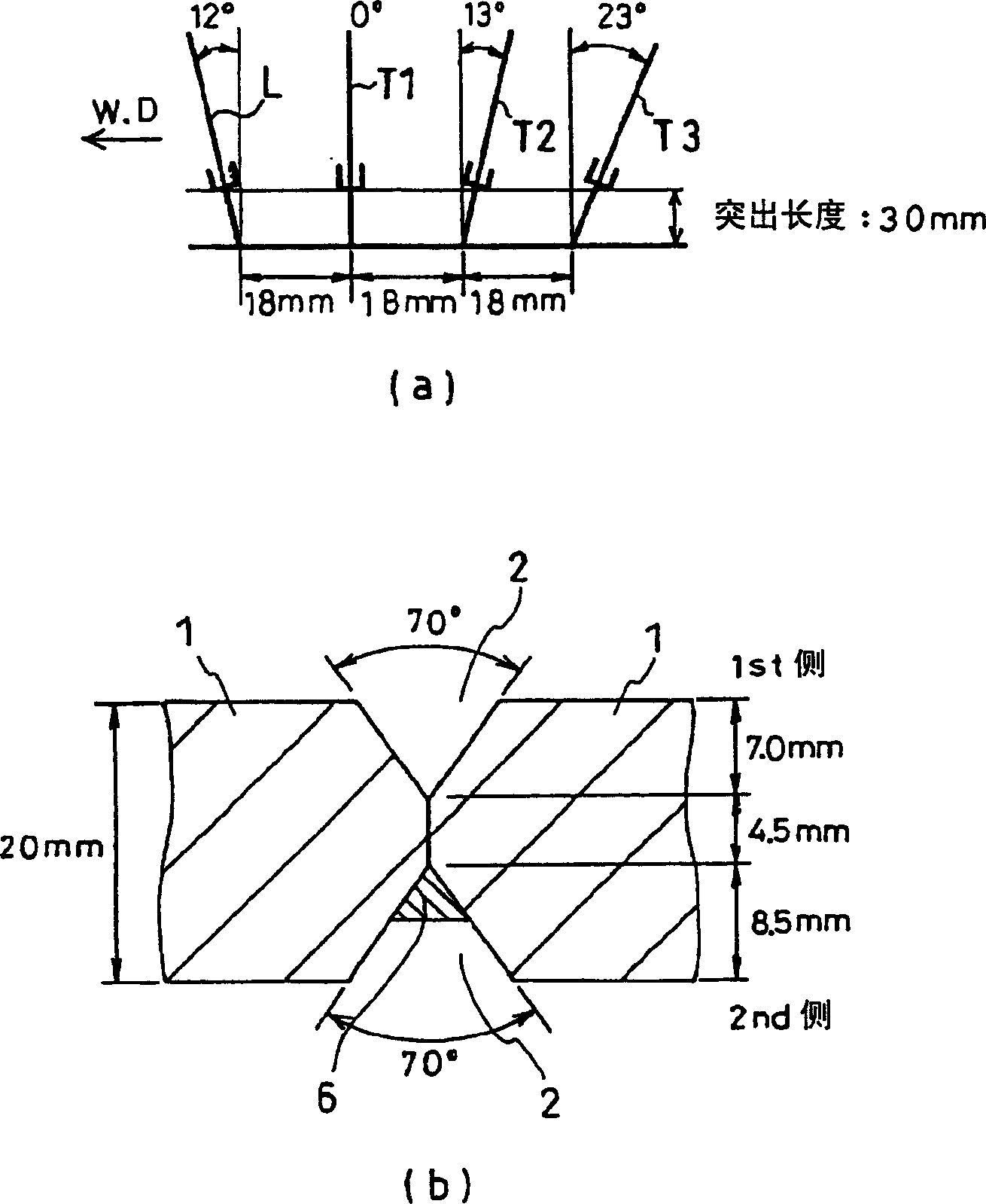

Melt flux for submerged-arc welding

ActiveCN1608791AIncrease contentImprove welding workabilityArc welding apparatusWelding/cutting media/materialsToughnessWeld metal

The fusible flux contains, in the total mass of the flux, 15-21 mass% CaO, 11-19 mass% CaF2, 7-14 mass% MgO, 28-35 mass% SiO2, 9-17 mass% Al2O3, 6-12 mass% MnO, 0.2-1.5 mass% FeO, 0.5-1.8 mass% in total of Na2O and K2O, and <=1.0 mass% B2O3, with TiO2prescribed at <=4 mass%. Also, a value [M] provided in the formula below is set at 1.00-1.50 in the fusible flux. To provide fusible flux for submerged arc welding, fusible flux that has superb low temperature toughness of weld metal and superior welding workability in two side / one layer high-speed welding.

Owner:KOBE STEEL LTD

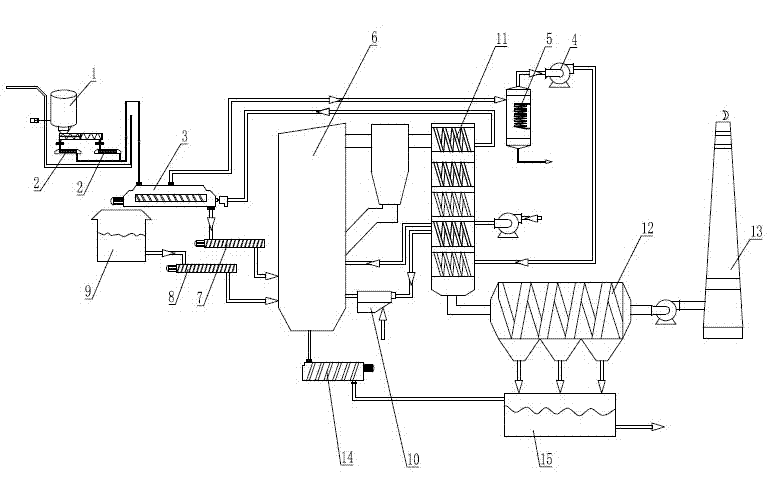

Water-containing sludge treatment method

InactiveCN102887619ANo protectionImprove operational reliabilitySludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeIncineration

The invention discloses a water-containing sludge treatment method which comprises the following steps of: conveying sludge into a sludge drying machine, heating and drying; conveying semi-dry sludge into a sludge incinerator; introducing air into the sludge incinerator after passing through an ignition device; enabling high-temperature smoke generated by incinerating sludge to pass through a waste heat recycling device, and then discharging the high-temperature smoke to the air through a smoke purifying and dust-removing system; and conveying residues generated by incinerating the sludge to an ash storage bunker. The semi-dry incineration of the sludge adopts the mode that the sludge directly passes through the sludge drying machine to reach a low-dryness and semi-dry degree and then enters the incinerator for being incinerated; and in the drying process, no full-dry sludge is generated, and the back-mixing operation is not needed. The water-containing sludge treatment method has the advantages that developed and reliable sludge drying and incineration devices are adopted, thus a system has high operation reliability; the dry sludge back-mixing operation is not needed for a semi-drying system, thus the dust quantity is low and the oxygen content and temperature are low during operation, the system is high in safety, and inert gas protection is not needed; and the whole system does not generate dust and odor during operation, and is environmental-friendly.

Owner:张开晓

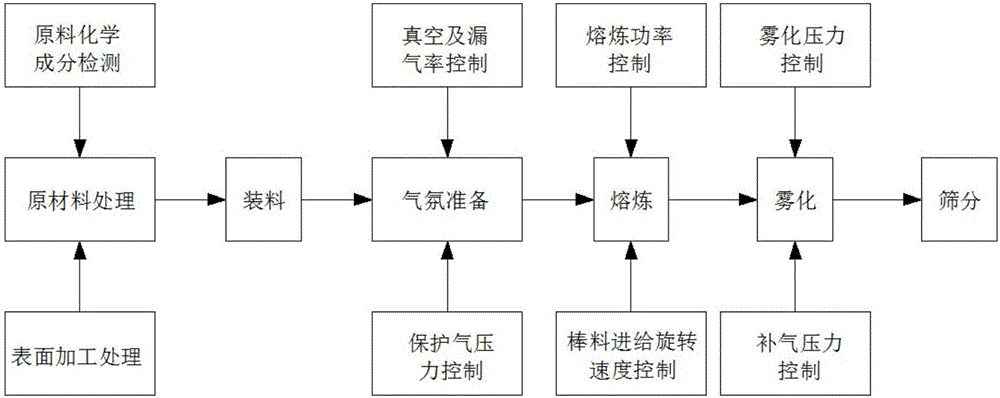

Preparation method of titanium alloy powder for 3D printing

ActiveCN106166617AEffective introductionIncrease productivityAdditive manufacturing apparatusTitanium alloyImpurity

The invention discloses a preparation method of titanium alloy powder for 3D printing, and belongs to the technical field of 3D printing / material additive manufacturing. The method comprises the specific steps that raw materials are loaded and clamped after being treated; pre-vacuum-pumping treatment is carried out on a smelting chamber and an atomization furnace, and high-purity argon is introduced into the smelting chamber and the atomization furnace when the vacuum degree reaches 10<-5>-10<-3> Pa; a gate valve is opened, a feeding mechanism is turned on, and bar materials are heated at the temperature of 1550-1700 DEG C; metal molten drop or liquid flow is atomized through a supersonic speed tight coupling gas atomization nozzle, and finally screening is carried out. The preparation method has the advantages that impurities introduced in the smelting and atomization process can be effectively reduced, and it is ensured that power oxygen content is controlled to be below 200 ppm; continuous production can be carried out after bar materials are replaced, and the powder is uniform in granularity, good in degree of sphericity and good in flowability.

Owner:中航迈特增材科技(北京)有限公司 +1

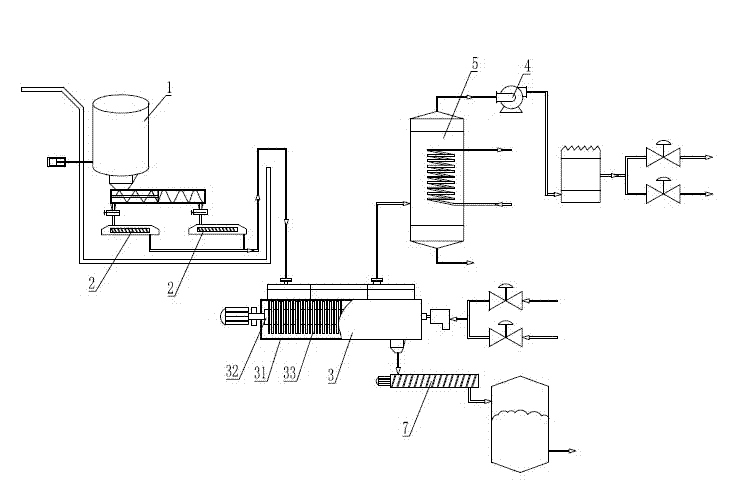

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

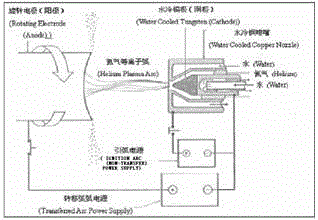

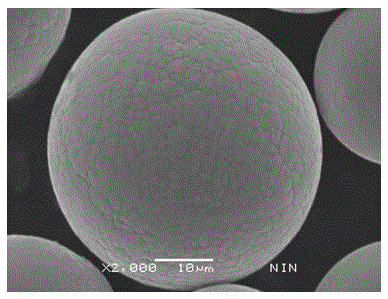

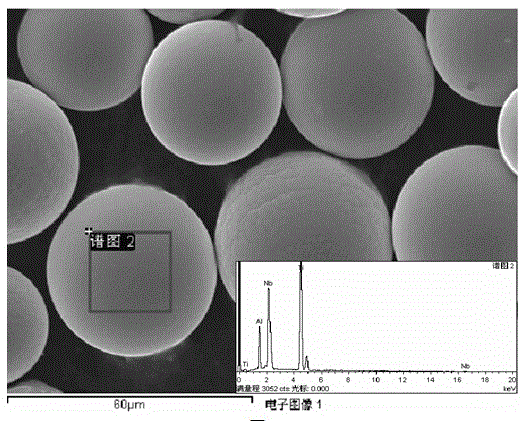

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

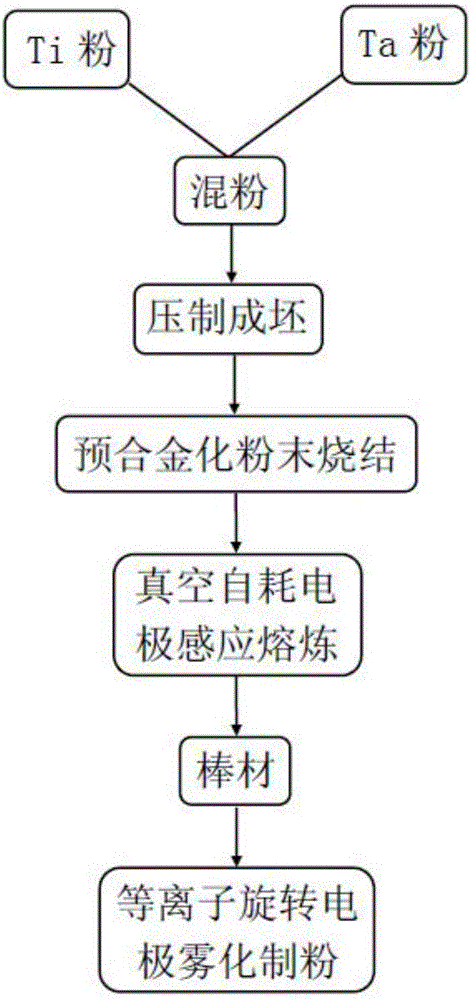

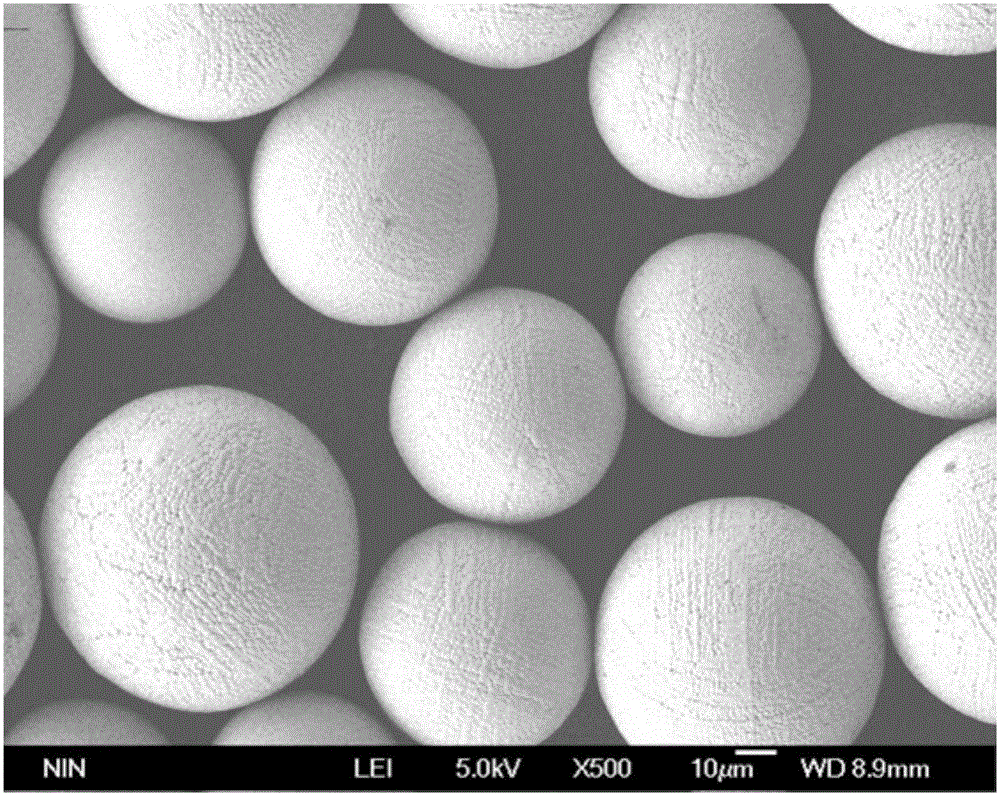

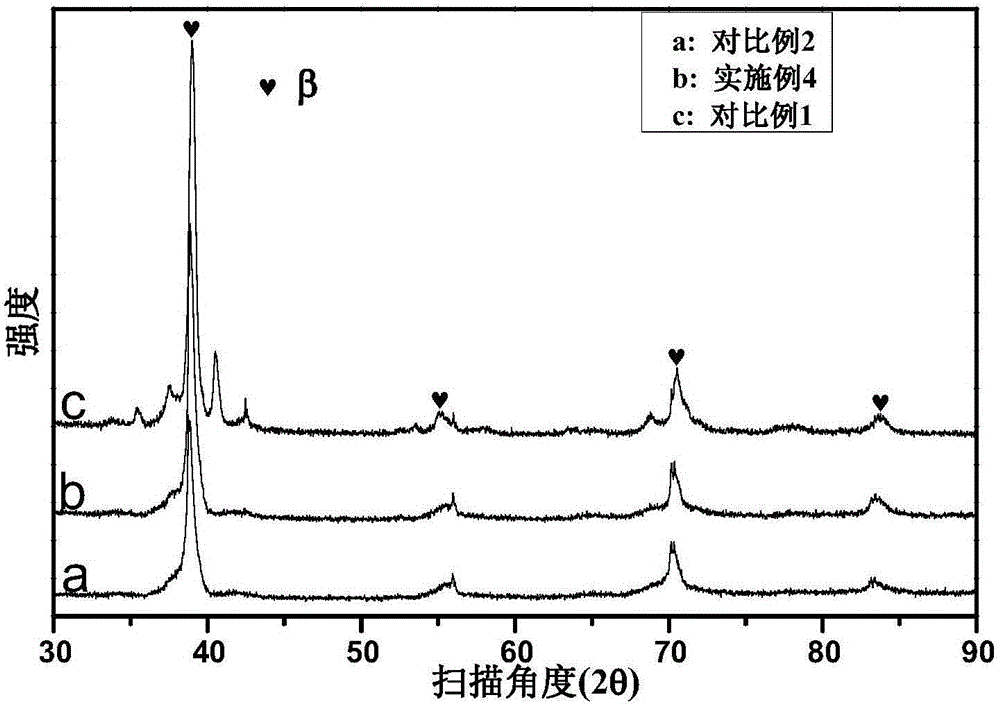

Preparation method of spherical TiTa alloy powder

ActiveCN106735280ASimple processIncrease productivityTransportation and packagingMetal-working apparatusElectric arc furnaceAlloy

The invention discloses a preparation method of spherical TiTa alloy powder. The preparation method comprises the following steps: 1, mixing Ti powder and Ta powder in a material mixing machine to obtain mixed powder; 2, pressing the mixed powder to prepare a blank; 3, pre-sintering the pressed blank; 4, putting the pressed blank into a vacuum consumable electrode electric arc furnace for smelting to obtain a sheared billet; 5, carrying out forging peeling, perforation and tapping, and machining an alloy rod finished product for atomization powdering of a plasma rotary electrode; and 6, preparing the spherical TiTa alloy powder from the alloy rod finished product in the step 5 through a plasma rotary electrode atomization process. The preparation method is simple in operation process and high in production efficiency; the pollution risk to the prepared TiTa alloy powder is reduced, and the oxygen content is less than or equal to 0.1 percent by weight; the raw materials are saved by at least 30 percent or above; the manufacturing cost of the spherical TiTa alloy powder can be effectively reduced by 50 percent; and therefore, low-cost and large-scale production of the high-quality spherical TiTa alloy powder can be met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

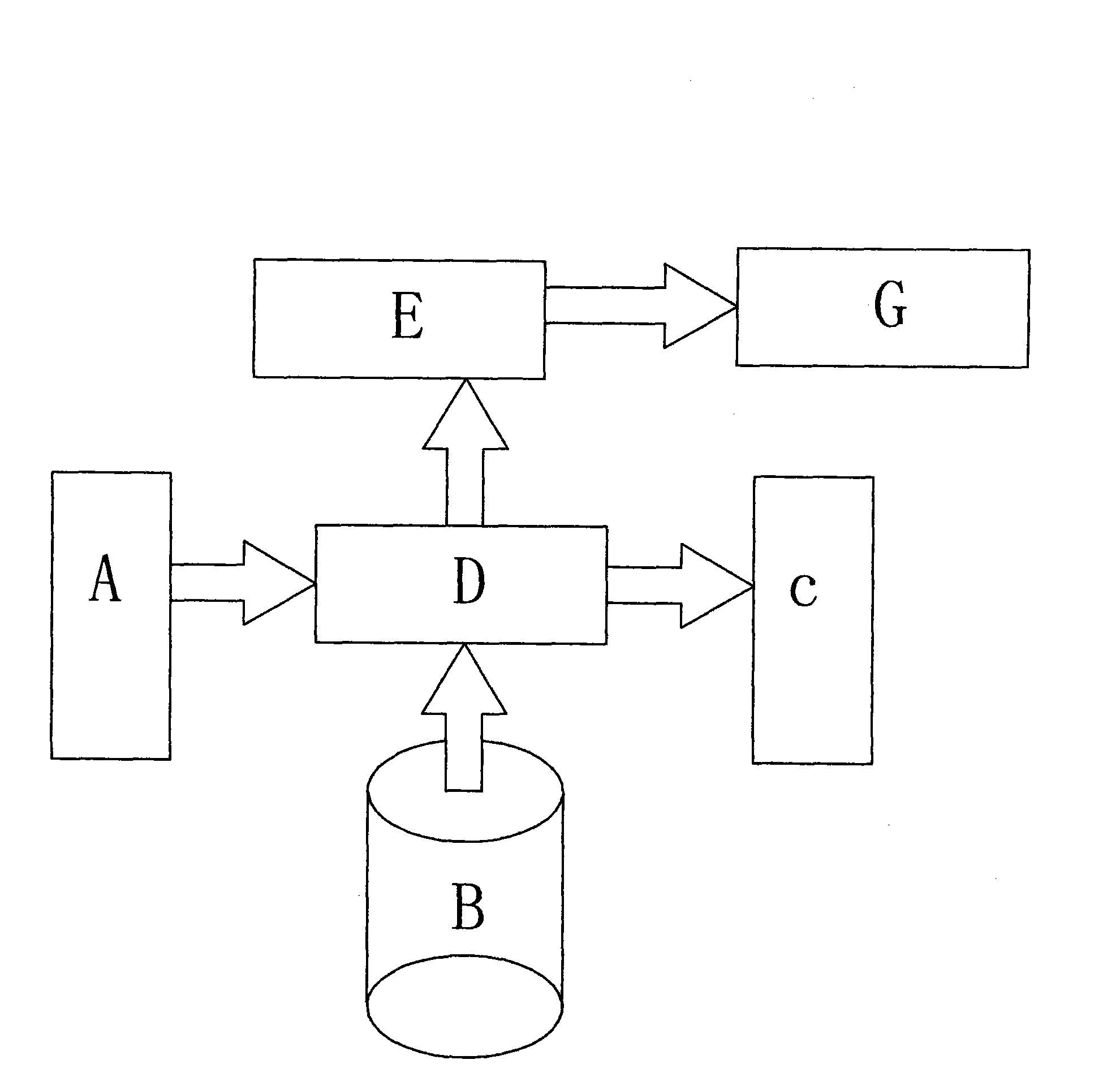

Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

InactiveCN101797578AReduce oxygen contentLower operating temperatureSolid waste disposalHydrocarbon distillationLiquid productFuel oil

The invention discloses a garbage microwave pyrolysis comprehensive treatment system and a method and equipment used by the same, aiming to solve the problems of microwave pyrolysis treatment, and the method and equipment used by the system. The comprehensive treatment system comprises a municipal solid waste (MSW) preprocessing system A, a vertical garbage continuous microwave heating low temperature cracking furnace B, a solid product activated carbon production system C, a pyrolysis gas preparation fuel gas system D, a liquid product distilled extraction light oil and fuel oil system F and a matched sewage treatment system G, wherein the MSW preprocessing system A, the solid product activated carbon production system C and the pyrolysis gas preparation fuel gas system D are respectively connected with the vertical garbage continuous microwave heating low temperature cracking furnace B; and the liquid product distilled extraction light oil and fuel oil system F is connected with the oil recovery pipeline of the pyrolysis gas preparation fuel gas system D. The invention has the advantage that: low carbon emission is realized in the treatment process under the reducing atmosphere, fixed carbon in the garbage is emitted without violent toxicity like dioxin and heavy metal solid powder, the treated wastewater can be recycled and max garbage resource recycling is realized.

Owner:深圳市兖能环保科技有限公司

Smelting method of ultra-low oxygen pure steel

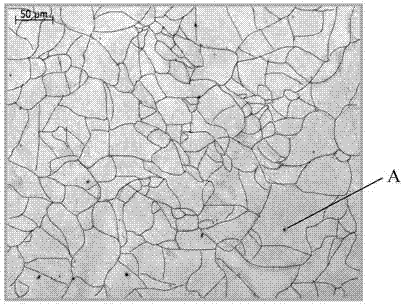

The invention relates to the field of smelting and specifically relates to a smelting method of ultra-low oxygen pure steel. A vacuum electric furnace or a vacuum induction furnace is adopted for smelting and vacuum pouring, and the vacuum degree is required to be 0.05-100Pa; after a metal charge is molten, a vacuum state is kept, molten metal is boiled for 5-30min, the oxygen content is reduced by vacuum carbon-oxygen reaction, and no deoxidizer or deoxidization alloy is added. The standing is performed for 20-30min after alloying, and the molten metal is boiled for 5-30min in the vacuum state. When the oxygen content is below 10ppm, 0.5-3kg / t of Si-Ca-Al-Mg-RE composite deoxidizer is added, the standing is performed for 1-10min after adding, then vacuum pouring is performed, and then the pure steel with the total oxygen content of below 4ppm can be obtained. The invention aims at solving the problems that existing steel ingots and cast blanks have more internal inclusions with relatively large sizes, the purity is not high and the channel segregation is serious. Simultaneously, by adopting a rare earth composite additive to perform modification treatment on the inclusions in the steel, the sizes of the inclusions are reduced, and the number of the inclusions in the steel is reduced, thus a new effective way is provided for pure smelting of molten steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

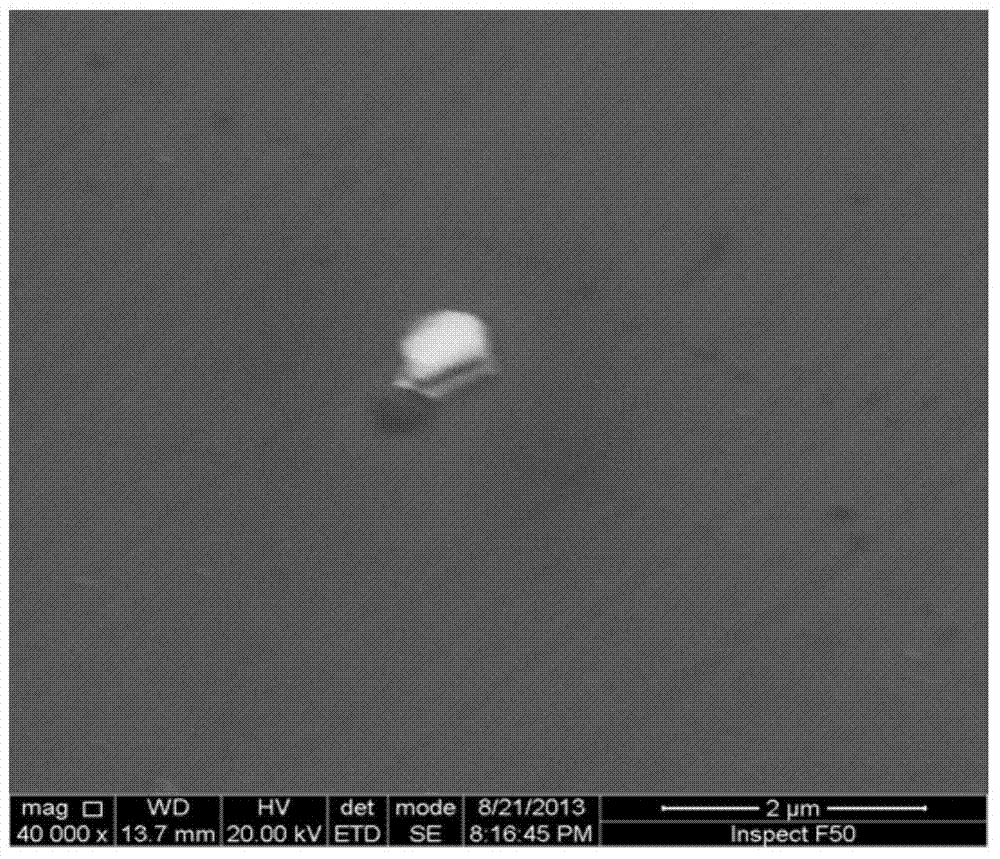

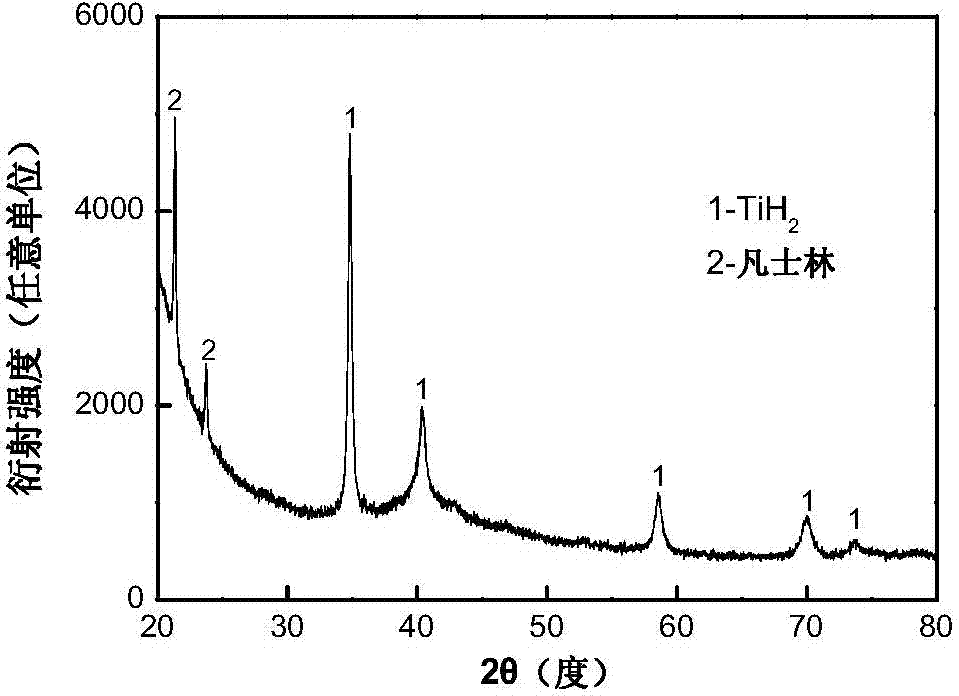

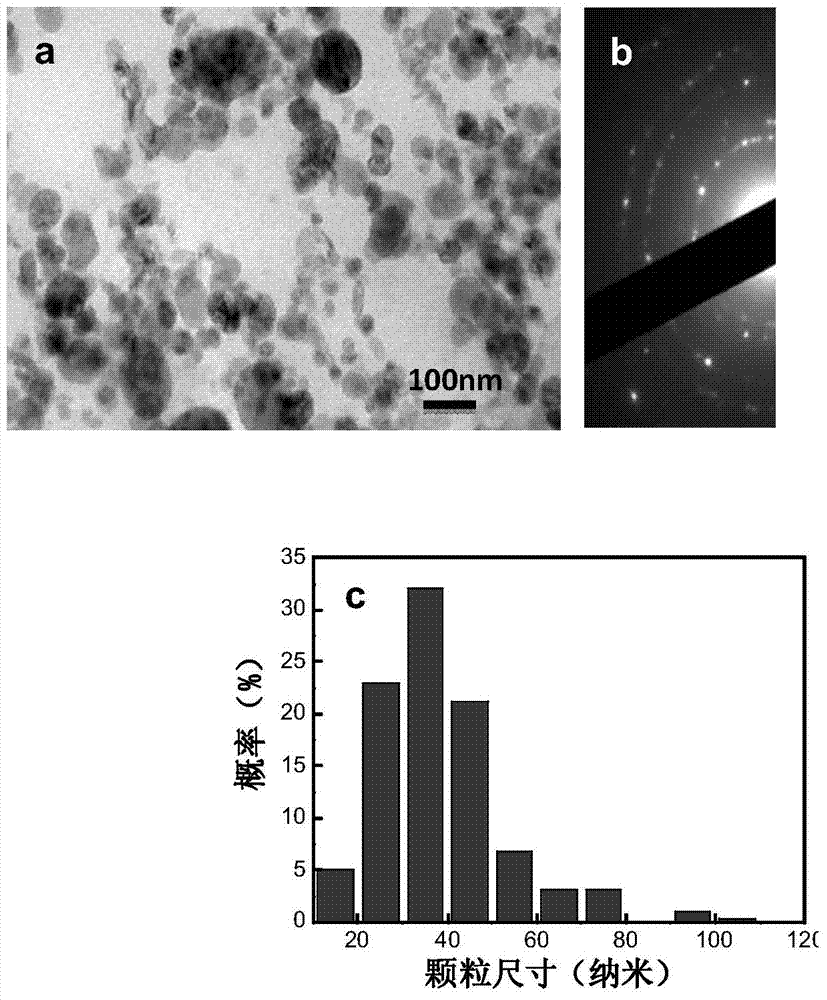

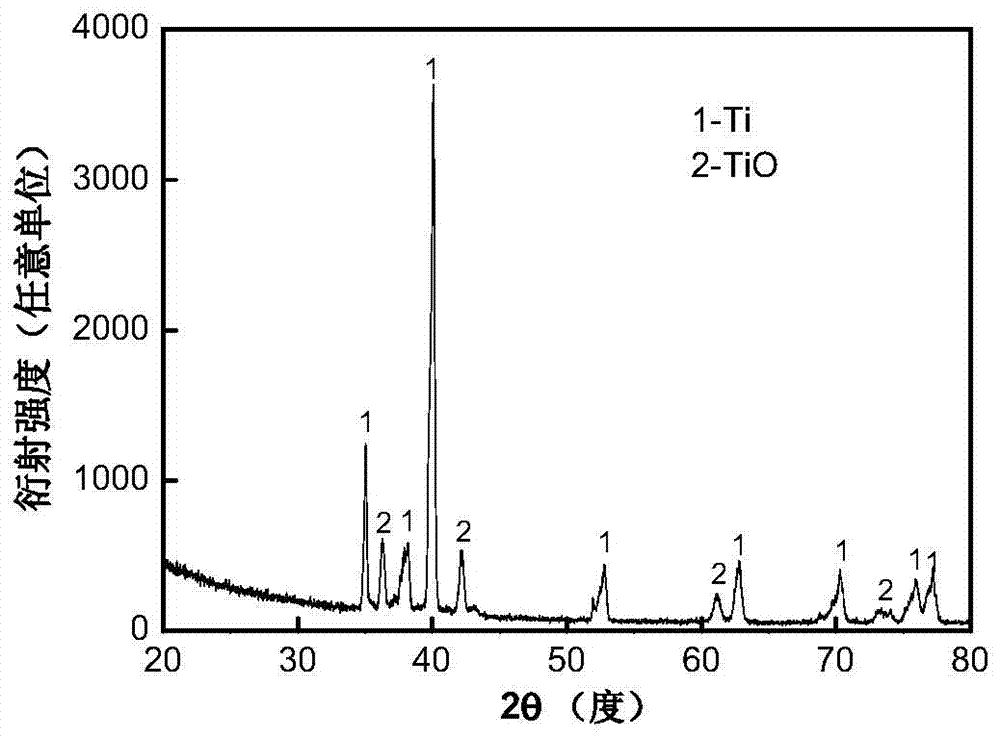

Preparation method of fine-particle spherical titanium powder for three-dimensional (3D) printing

The invention discloses a preparation method of fine-particle spherical titanium powder for three-dimensional (3D) printing and belongs to the technical field of preparation of metal powder. The method comprises the following steps: firstly, by using a high-purity titanium block material as a raw material, performing arc evaporation under an inert gas environment, and meanwhile, charging hydrogen to synthesize titanium hydride nano powder through a gas-phase reaction; secondly, agglomerating and granulating the titanium hydride nano powder to obtain micron-sized titanium hydride powder with higher density; finally, performing heat treatment on the granulated micron-sized titanium hydride powder, and performing degumming, dehydrogenation and compacted consolidation to obtain pure-titanium powder particles of which the particle size, the sphericity and the fluidity meet a 3D printing requirement. According to the method, the sphericity and the particle size distribution of the titanium powder particles are highly controlled; the process is simple, and the cost is low; metal titanium with great activity is stabilized in a new way of generating oxidation-resistant titanium hydride nano powder particles firstly, and the content of oxygen in the titanium powder particles which are finally prepared can be controlled.

Owner:BEIJING UNIV OF TECH

Decompressing fuel-oil floor washing device and method

InactiveCN101746508AGood effectReduced dissolved oxygenFuel tank safety measuresGround installationsTruckEnvironmental pressure

The invention discloses a decompressing fuel-oil floor washing device and a method, wherein, a vehicle nitrogen-manufacturing system is utilized to generate nitrogen-rich gas, firstly, the nitrogen-rich gas is adopted to wash the upper gas-phase space of the fuel-oil for an oil tank of a refueling truck, and then the oxygen content of the gas-phase space is decreased, and then, the nitrogen-rich gas is led into the fuel oil through a gas-oil mixer or a nitrogen-rich gas distributor which is arranged under fuel-oil liquid level, meanwhile, the pressure in the oil tank of the refueling truck isled to be lower than the environmental pressure through utilizing the suctioning of a vacuum suction device, thereby effectively increasing the treatment effect of fuel-oil washing inert; compared with the ordinary pressure washing, the oxygen content in the fuel-oil after decompressing washing is lower, therefore, the airplane can be ensured have no or have trace dissolved oxygen to escape when the airplane is at cruising altitude, thereby increasing the safety of the oil tank of the airplane. Additionally, after the washing is ended, the upper gas-phase space of the fuel-oil is filled with the nitrogen-rich gas of high purity, in order to ensure that the oxygen content can not increase caused by the mixing of external air in the fuel gas after the refueling truck is parked for a long period of time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

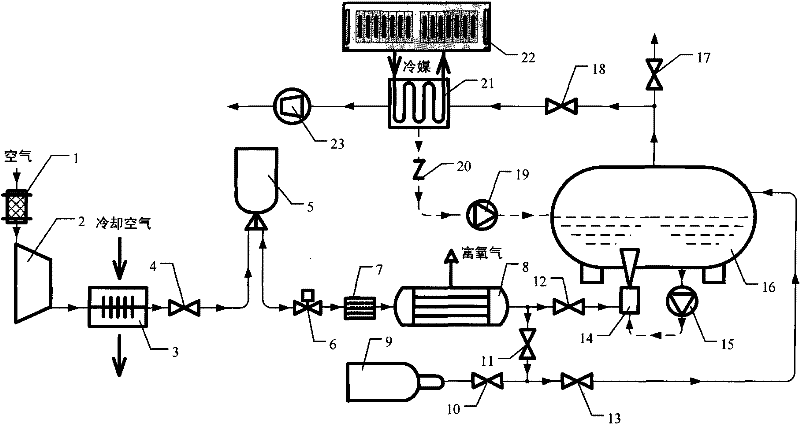

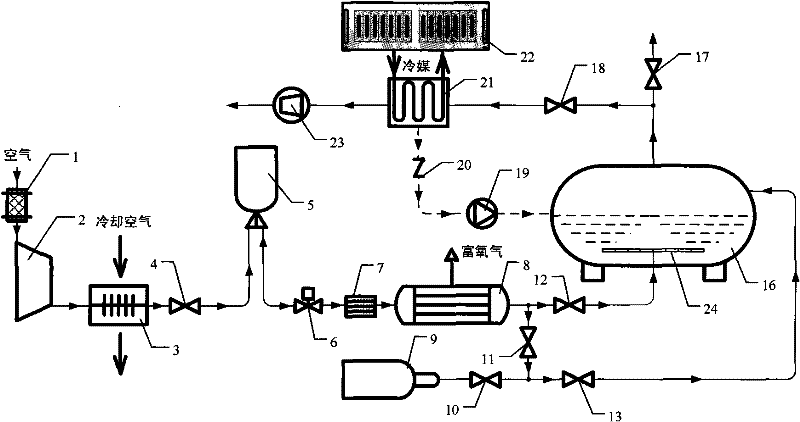

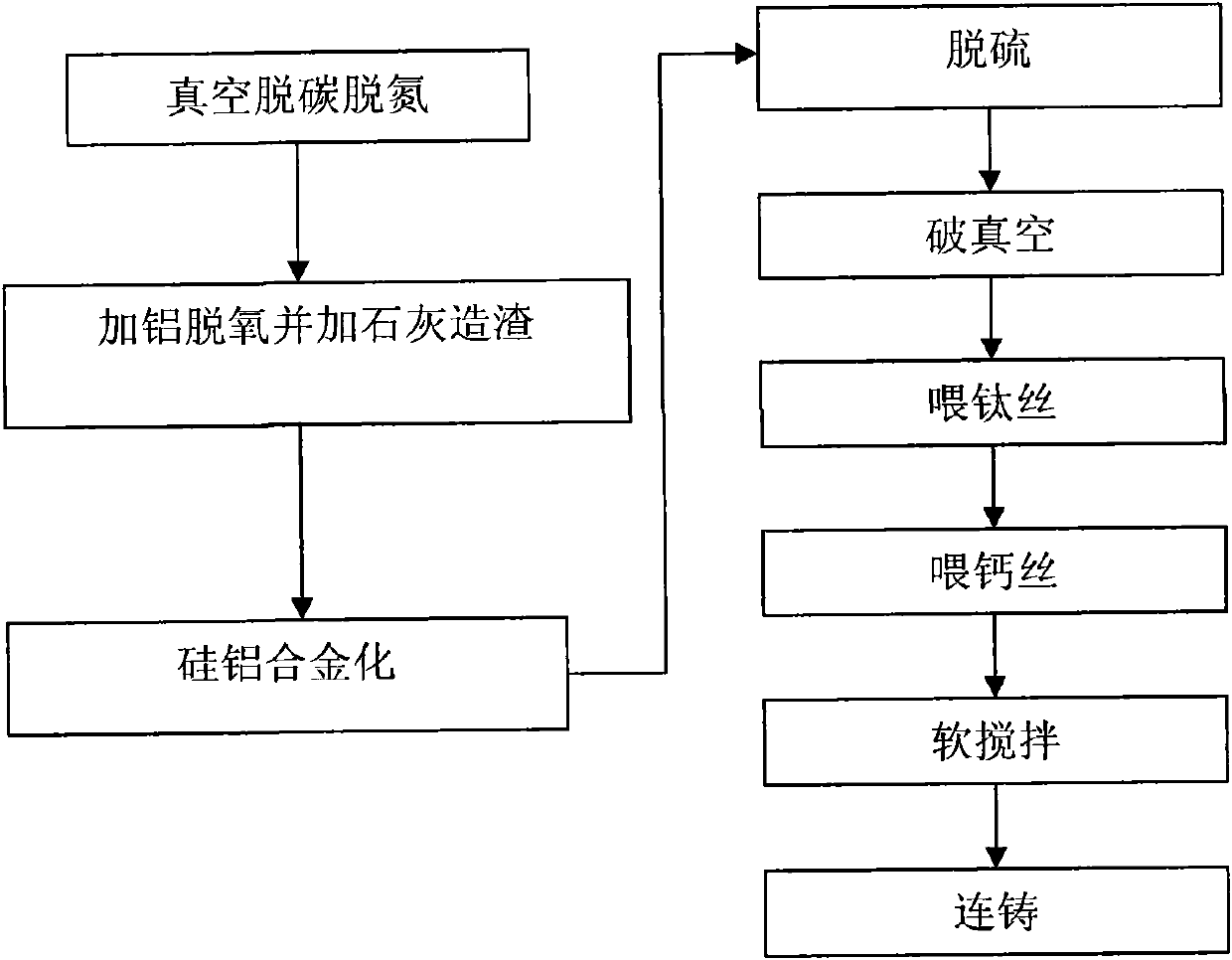

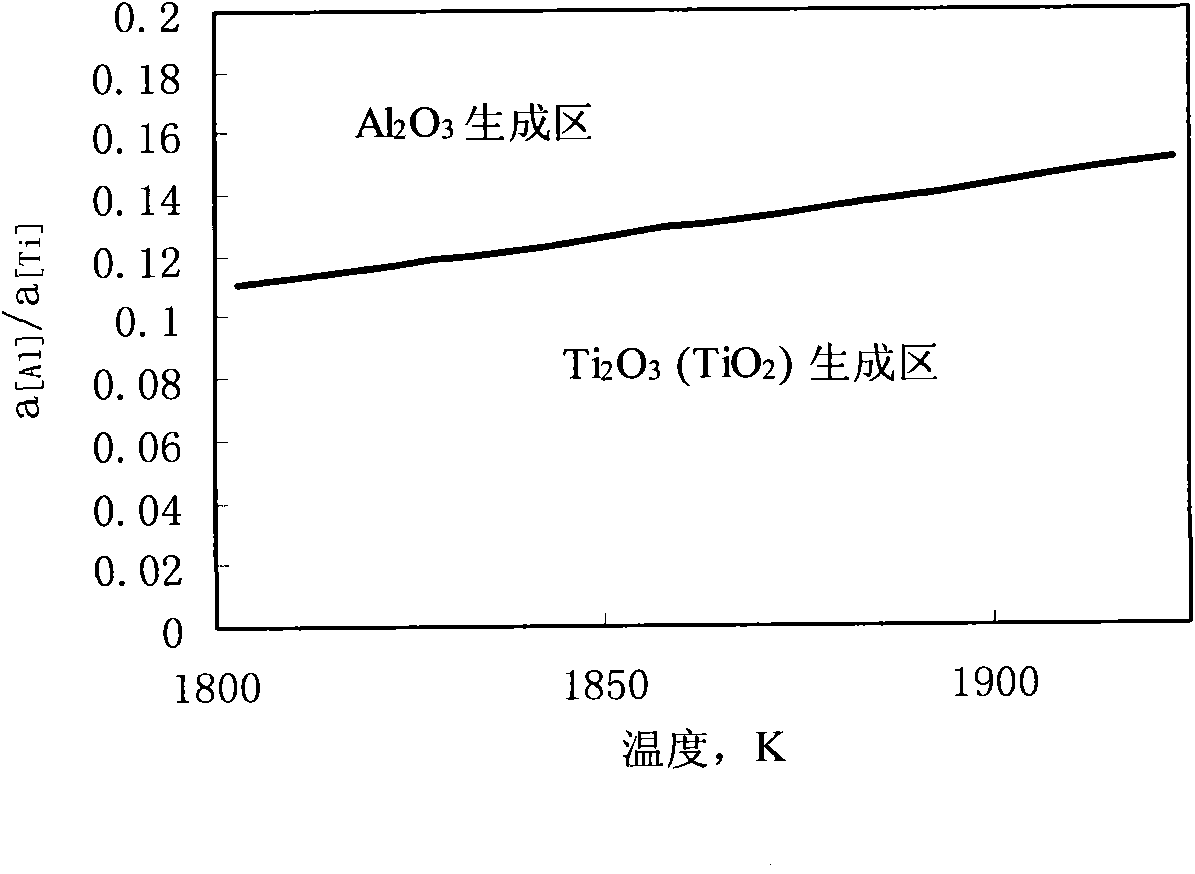

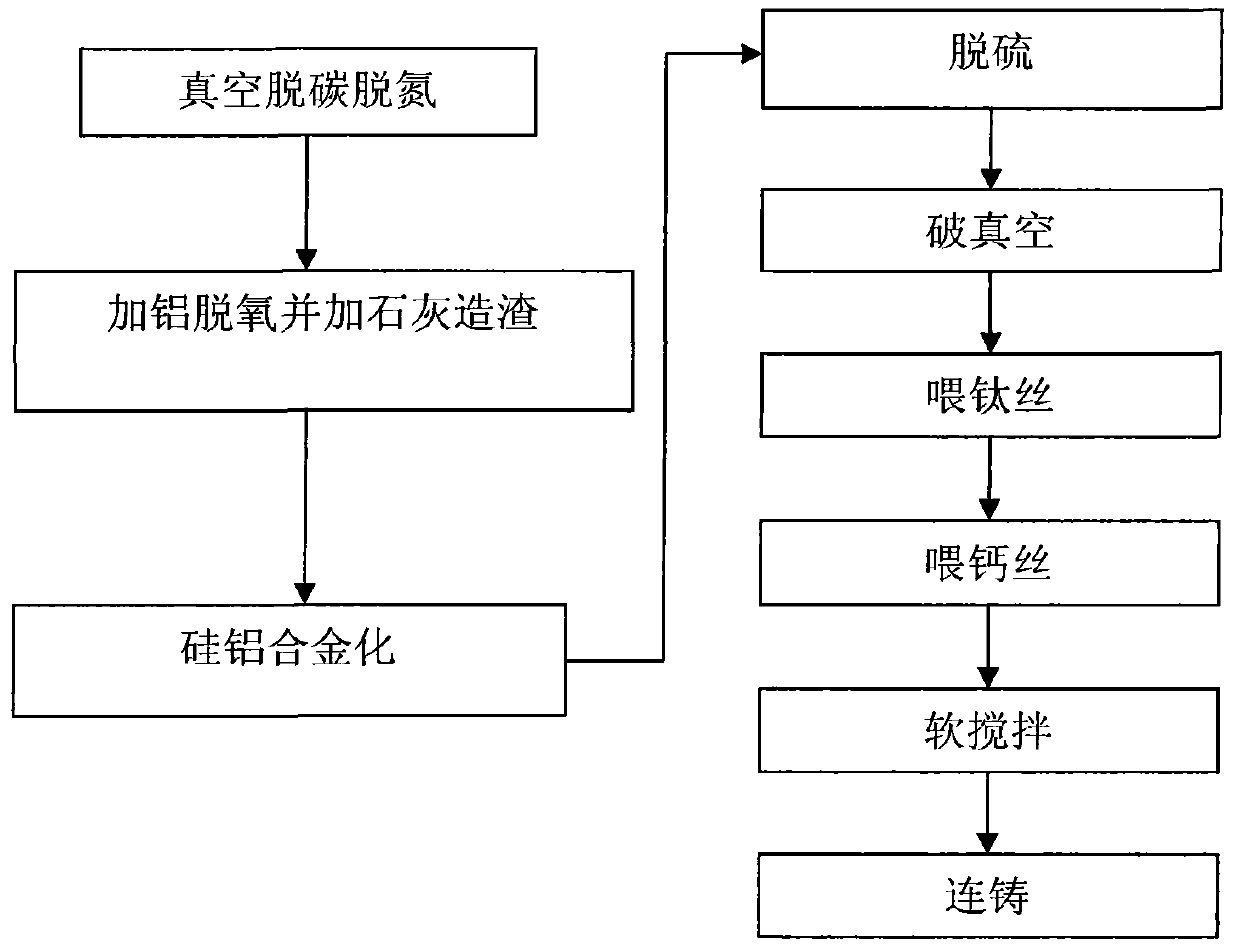

Production method of ultralow-oxygen titanium-containing ferrite stainless steel

The invention discloses a production method of ultralow-oxygen titanium-containing ferrite stainless steel, which comprises the following steps: 1) preparing molten ferrite stainless steel under a vacuum condition in a vacuum oxygen blowing decarburization furnace, wherein the carbon mass percentage content and nitrogen mass percentage content in the molten ferrite stainless steel are both less than 0.01 percent; 2) performing deoxidization, namely adding 6 to 12 kilograms of aluminum block or grains into each ton of steel and adding 10 to 28 kilograms of active lime into each ton of steel; 3) alloying silicon and aluminum, namely adding 2 to 9 kilograms of silicoferrite which contains 70 to 80 percent of silicon into each ton of steel and adding 0 to 1 kilogram of aluminum blocks or grains into each ton of steel, wherein the aluminum content is 0.02 to 0.1 percent; 4) performing desulphurization; (5) breaking vacuum; 6) softly stirring; 7) feeding titanium wires; 8) feeding silicon and calcium wires, wherein the calcium content is 5 to 30ppm; 9) softly stirring; and 10) continuously casting. The method can be used for producing ultralow-oxygen titanium-containing ferrite stainless steel, prevent or inhibit forming magnesia alumina spinel which are harmful impurities in a production process, improve product quality, prevent the water gap of tundish from being blocked in a continuous casting process and guarantee smooth production.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of low melting point spherical metal powder

A production method of low melting point spherical metal powder comprises the following working procedures: melting low melting point metal or alloy, mixing with hot oil, performing primary dispersion under pressure and inert gas, performing high-power ultrasonic dispersion and emulsification, performing filtering separation, etc. The production method of low melting point spherical metal powder is characterized by high production efficiency, narrow particle size distribution of the product, low oxygen content and no screening procedure. The method is suitable for the productions of the low melting point metal and alloy powder thereof of which liquid-phase temperatures are less than 300 DEG C, such as Pb-based alloy, Sn-based alloy, Sn-Zn based alloy or non-ferrous metals such as Bi, In and the like.

Owner:SHENZHEN FITECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com