Patents

Literature

37results about How to "Sulfur resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

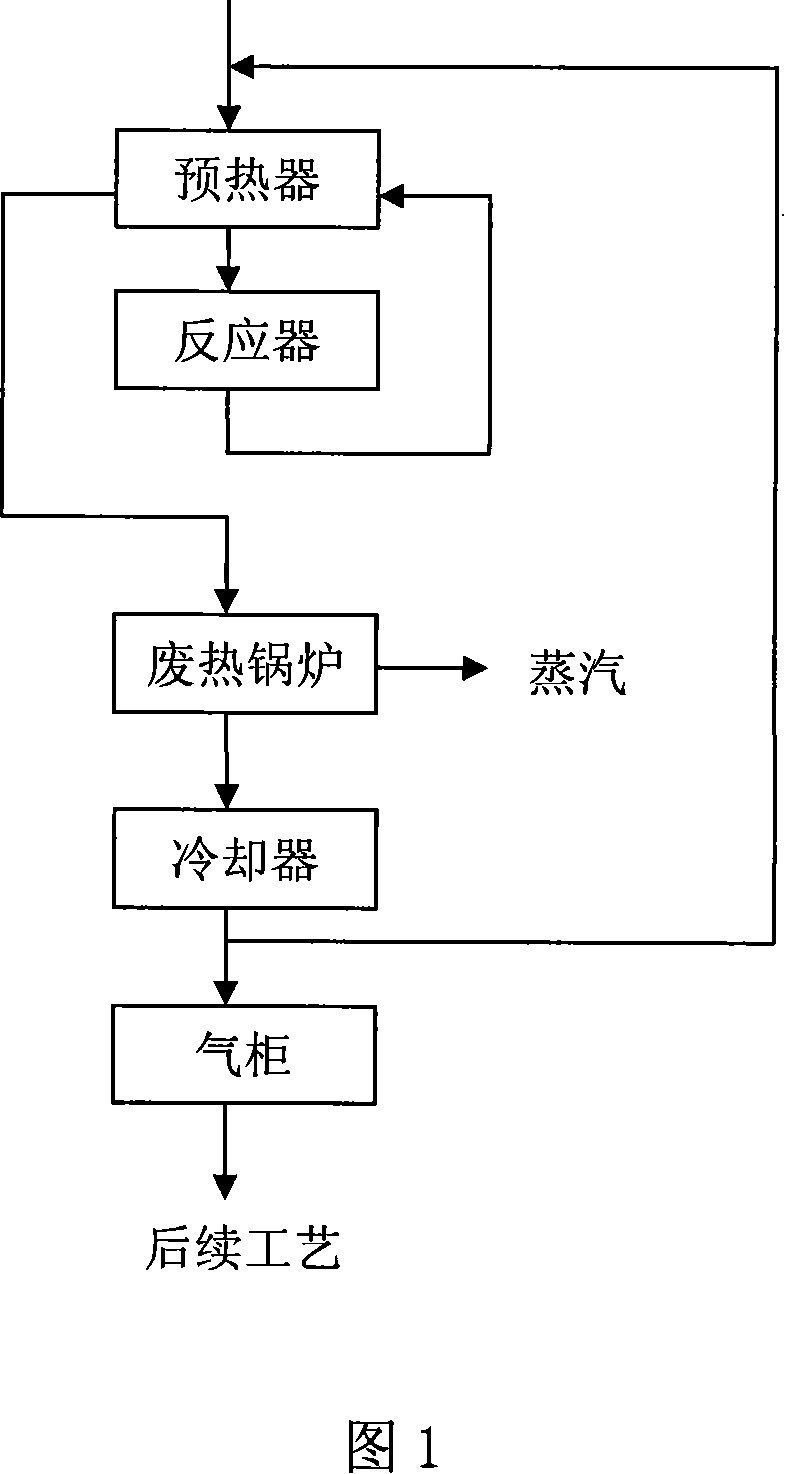

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

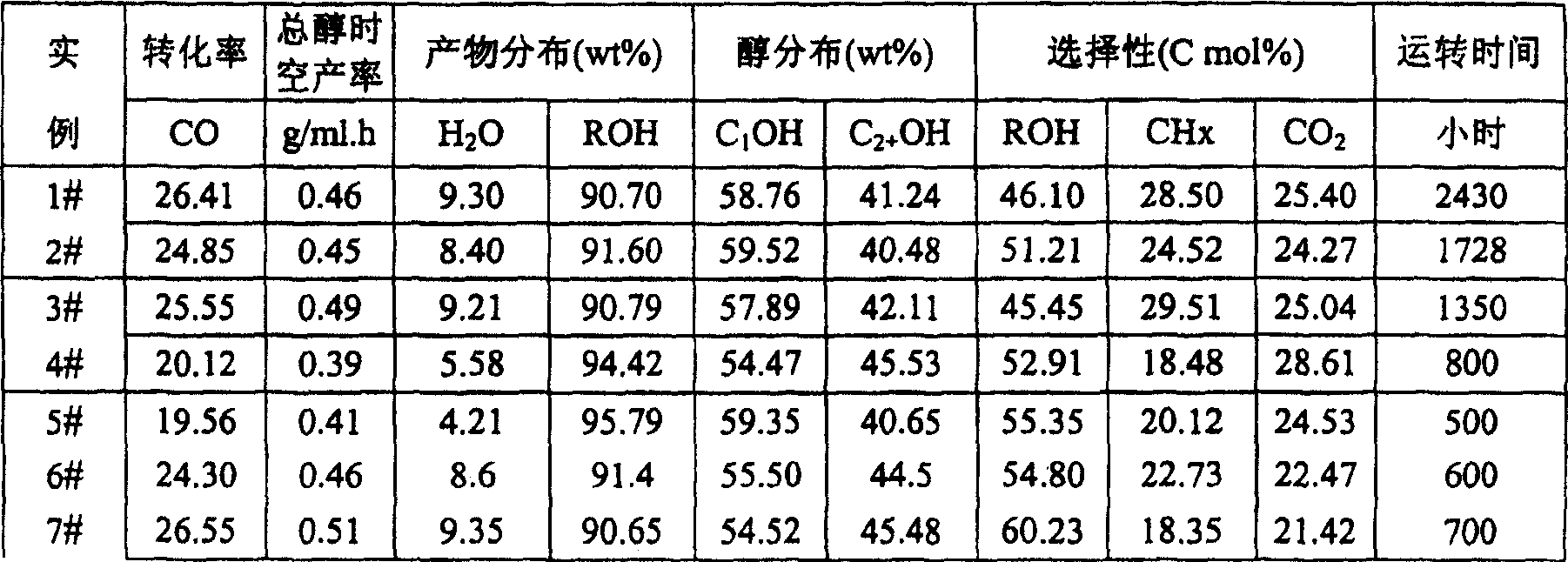

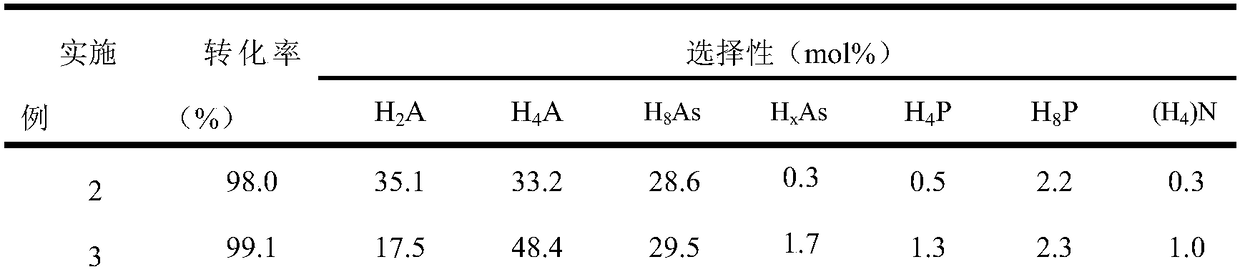

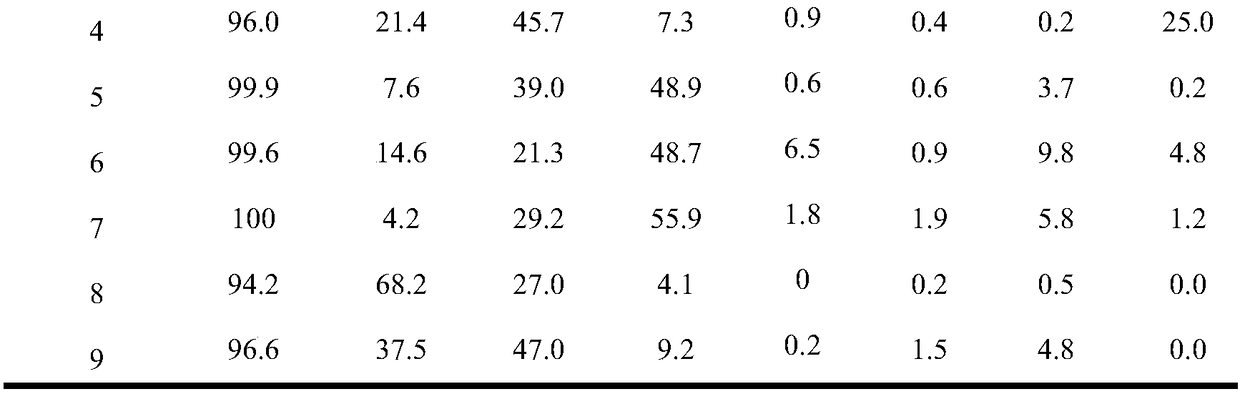

Catalyst for synthesizing low carbon mixed alcohol by synthetic gas and its preparation method

InactiveCN1631527AHas low hydrocarbon selectivityHigh activityOrganic compound preparationHydroxy compound preparationAcetic acidAlcohol

This is about a kind of catalyst to make complexes ether of low carbon, whose weight rate is: Mo: 20--40%, soil: 15--30%, Ma: 5--20%, K: 5--15%, S: 20--40%. Take the changing S reactivity to the S hua ammonia solution and Mo acid ammonia, add heavy Acetic acid, filter, dry, and make S dai Mo acid ammonia ether solution: make Ma salt ether solution, mixing them and take supersonic reaction, then get the precipitation, wash, dry and mix with K salt, crash, fire after taking protection air, add soil, mix, press to sheet, shape. The way of the invention is simple, easy to operate, high activity, high choosing ability of ether and low choosing ability of Hydrocarbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Solid oxide fuel battery anode and its production

InactiveCN1897337AOvercome carbon depositsOvercome stabilityCell electrodesCerium(IV) oxideMaterial physics

A solid oxide fuel battery anode and the preparation method, the characteristic is: adulterates the titanic mine cadmium acid lanthanum or the titanate compound oxide as the anode structure framework and the main electron conducting phase, uses the ion infusing method, the macromolecule modeling board method, the sol-gel method, or the suspending grain pulp spreading method, prepares the nanometer grain anode active substance multi-hole film with the thickness of 0.05-5 micron in the inner and outer hole surface of the multi-hole anode structure framework; the anode active substance includes the ceric oxide, or the adulterating ceric oxide, or the zirconia based oxygen ionic conductor electrolyte, or the cerate based proton conductor electrolyte, or the mixture of the above active substance, or the above active substance adding a small quantity of Ni or Ni-Cu and V2O5. The invention is structure stabilization, high conducting rate, high catalyzing activity of the fuel oxidation, matching with the closing material at physics and chemistry, structure size stabilization, anti-carbon deposition, is fit for the fuel operation of the hydrocarbon directly.

Owner:UNIV OF SCI & TECH OF CHINA

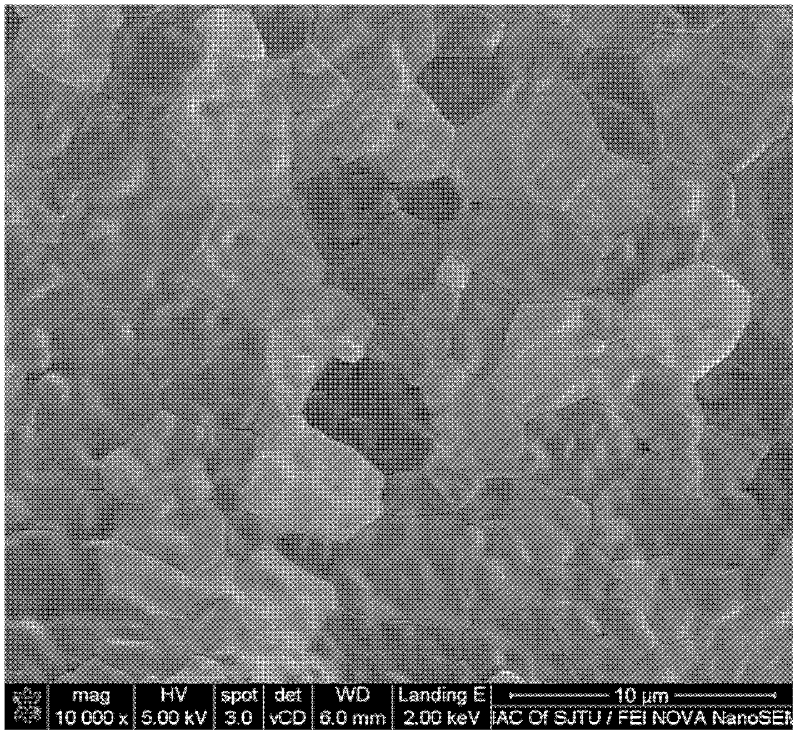

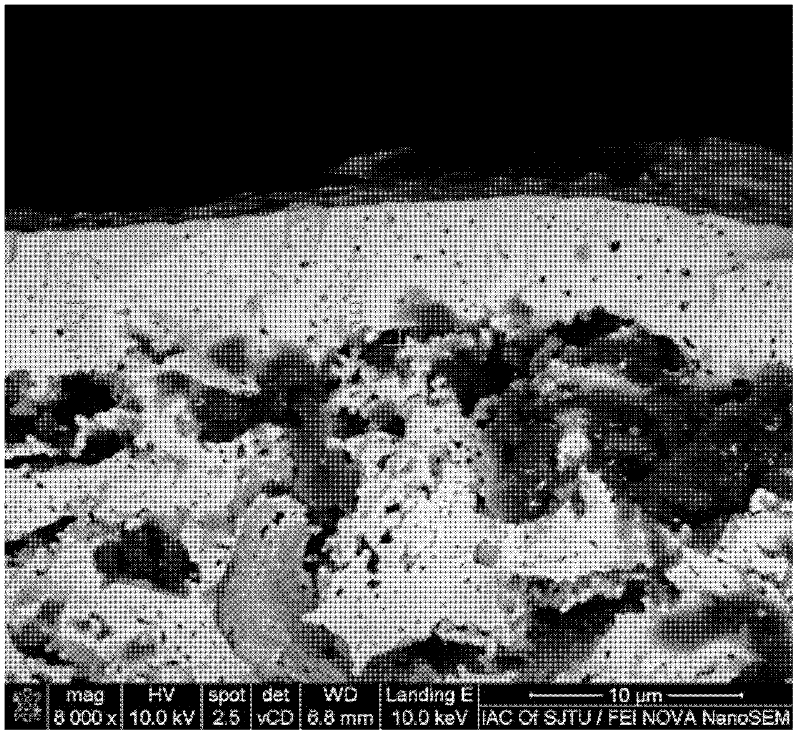

Solid oxide fuel cell anode/electrolyte bilayer membrane and preparation method thereof

The invention relates to a solid oxide fuel cell anode / electrolyte double-layer membrane and a preparation method thereof. The porous yttrium oxide stabilized zirconia (YSZ) anode structure thick film green body is prepared by a tape casting method, and the screen printing method is used here. Thick-film deposited electrolyte layer, co-sintered at a certain temperature to obtain a porous YSZ structure skeleton / dense electrolyte double-layer film, using the impregnation method to deposit nano-electrocatalysts on the inner and outer surfaces of the anode structure skeleton, and calcining at a lower temperature. Anode / electrolyte bilayer membrane. The advantages of the present invention are that the formed porous anode support has a long-term structural stability in a reducing atmosphere, has high electronic conductivity, can withstand multiple oxidation-reduction cycles, is resistant to carbon deposition, and has sulfur resistance. Low cost and scalable preparation process, multilayer films of various sizes can be prepared, and have good industrialization prospects.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst for preparing low-carbon mixed alcohol by synthetic gas, its preparation method and application

ActiveCN1663683AImprove stability and longevityImprove stabilityPhysical/chemical process catalystsOrganic compound preparationAmmonium molybdateAmmonium sulfide

The invention is composition gasifying low-carbon mixing alcohol catalyst and its preparation method and utilization. The weight percentages of the catalyst are: Mo: 20-40%, Ni: 4-10%, Mn: 0.1-1.0%, K: 5-15%, Fe: 5-10%, S: 20-40%, the cohesive agent: 10-20%. The preparation method is to add ammonium molybdate to ammonium sulfide solution to react to get thiosulfate ammonium molybdate solution; drop in nickel and manganese salt solution and the thiosulfate ammonium molybdate solution, and through heating, filtering, cleaning, depositing and drying to get molybdenum nickel manganese multi-sulfur compound; mix molysite with citric acid and carry out heating reaction to get molysite C; mix molybdenum nickel manganese multi-sulfur compound, kali salt and molysite C, abrade them, lead in indifferent protective gas to burn to get molybdenum nickel manganese kalium sulfur compound; add cohesive agent to mix, press and form. The catalyst of the invention has high activity, high selectivity and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

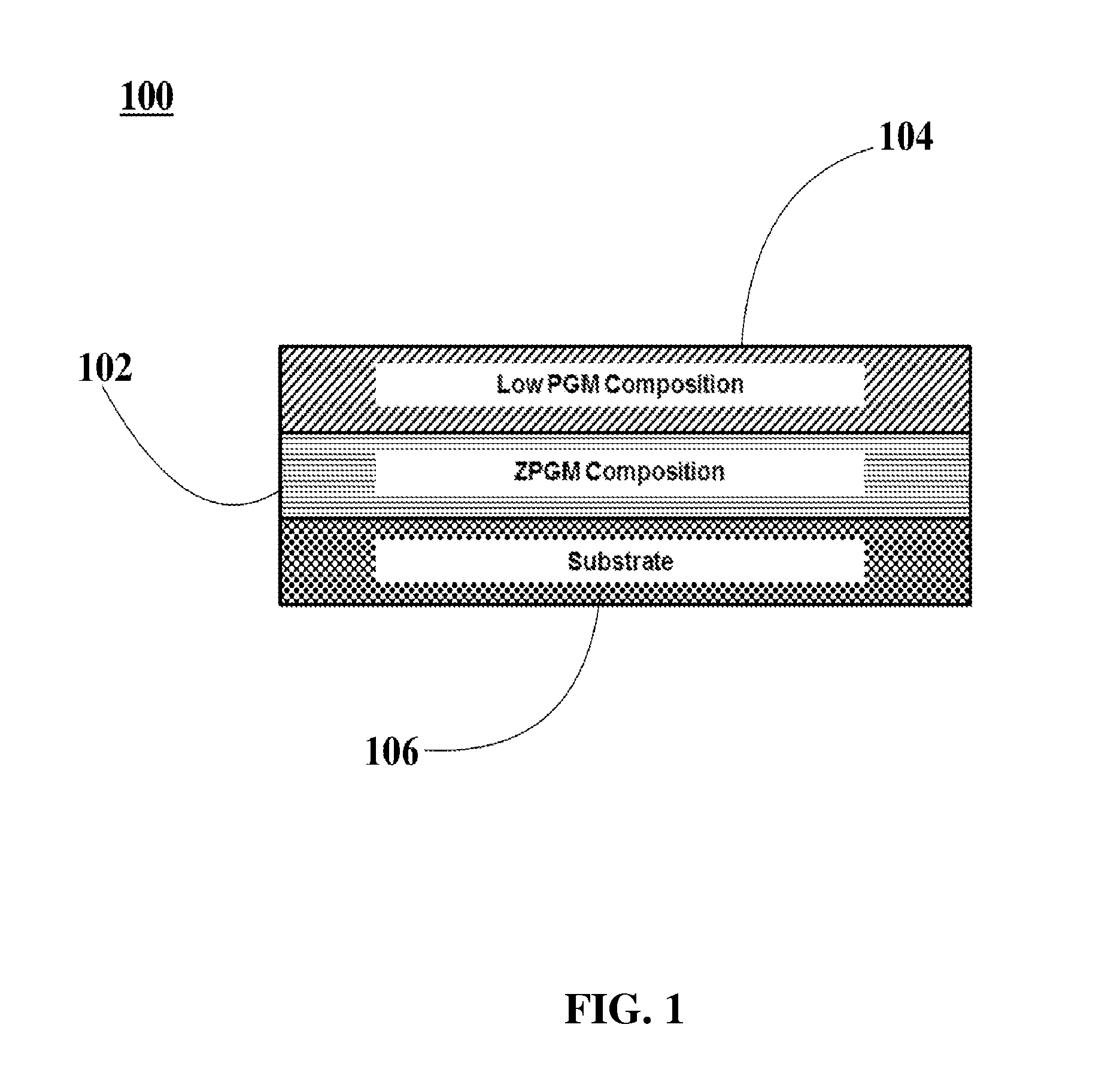

Combination of Pseudobrookite Oxide and Low Loading of PGM as High Sulfur-Resistant Catalyst for Diesel Oxidation Applications

InactiveUS20160346765A1High activityIncrease resistanceHeterogenous catalyst chemical elementsDispersed particle separationPseudobrookiteSulfur

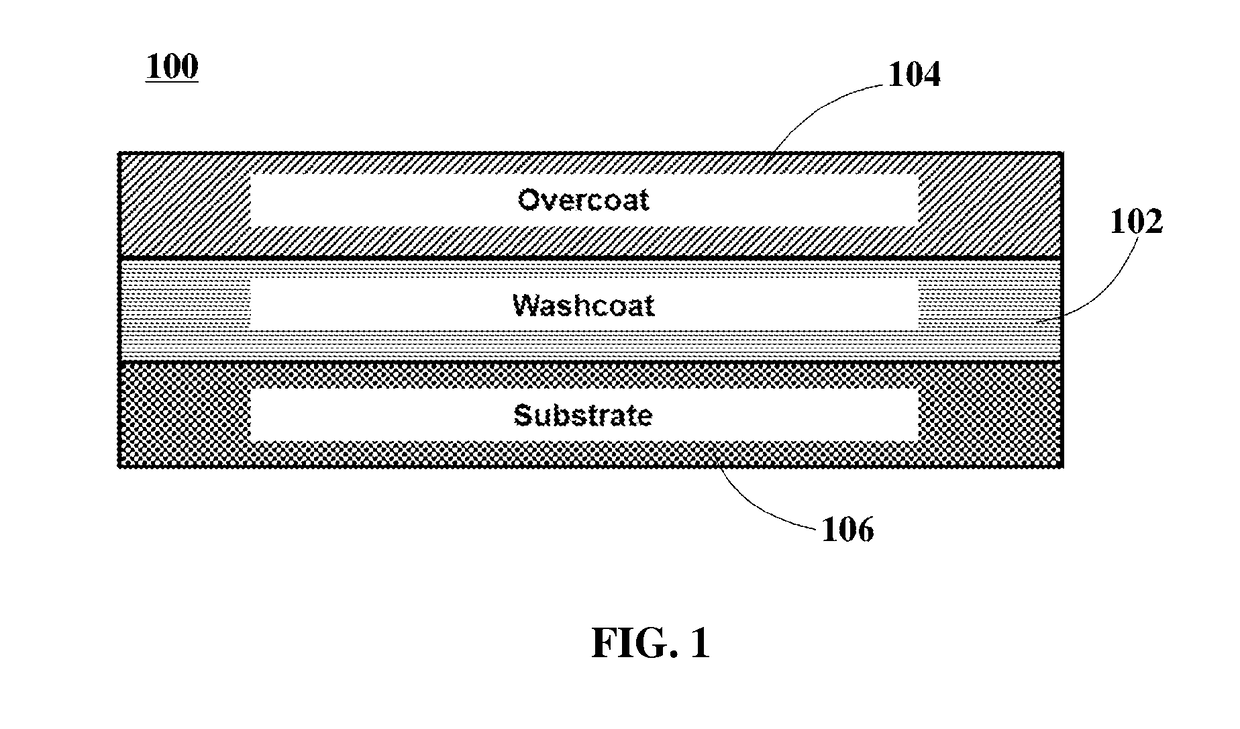

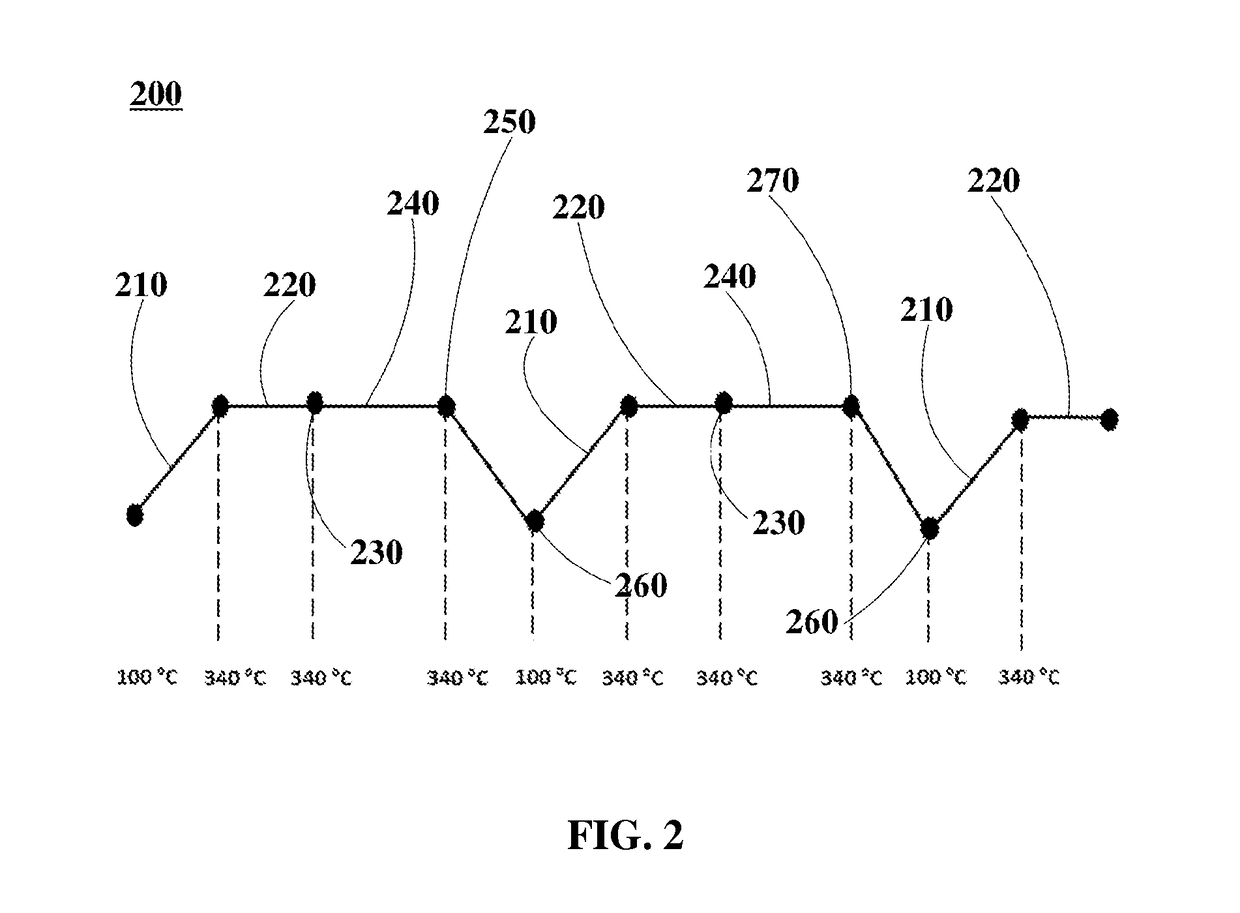

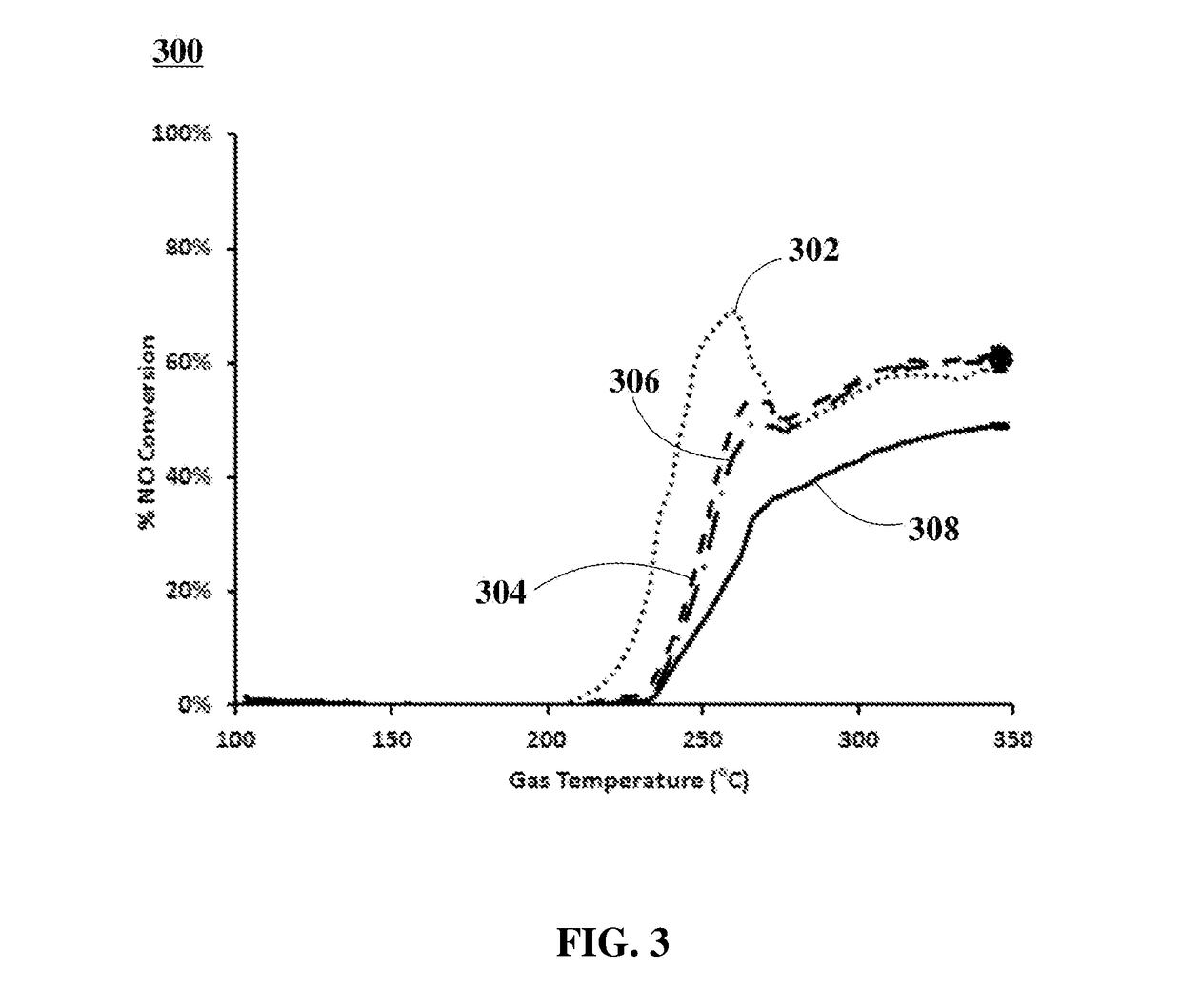

Sulfur-resistant synergized platinum group metals (SPGM) catalysts with significant oxidation capabilities are disclosed. Catalytic layers of SPGM catalyst samples are prepared using conventional synthesis techniques to build a washcoat layer completely or substantially free of PGM material. The SPGM catalyst includes a washcoat layer comprising YMn2O5 (pseudobrookite) and an overcoat layer including a Pt / Pd composition with total PGM loading of at or below 5.0 g / ft3. Resistance to sulfur poisoning and catalytic stability is observed under 5.2 gS / L condition to assess significant improvements in NO oxidation, and HC and CO conversions.

Owner:CLEAN DIESEL TECHNOLOGIES

Preparation method for hydrogenation catalyst for polycyclic aromatic hydrocarbons, catalyst and application thereof

ActiveCN105772034ASulfur resistanceImprove hydrodesulfurization activityPhysical/chemical process catalystsMolybdenum sulfidesPolycyclic aromatic hydrocarbonSulfur

The invention provides a hydrogenation catalyst for polycyclic aromatic hydrocarbons. The hydrogenation catalyst is a molybdenum disulfide (MoS2) catalyst prepared in a microemulsion system. The molybdenum disulfide catalyst provided by the invention has the advantages of sulfur tolerance, high hydrodesulfurizing activity, high polycyclic-aromatic-hydrocarbon hydrogenation activity, simplicity in process operation, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

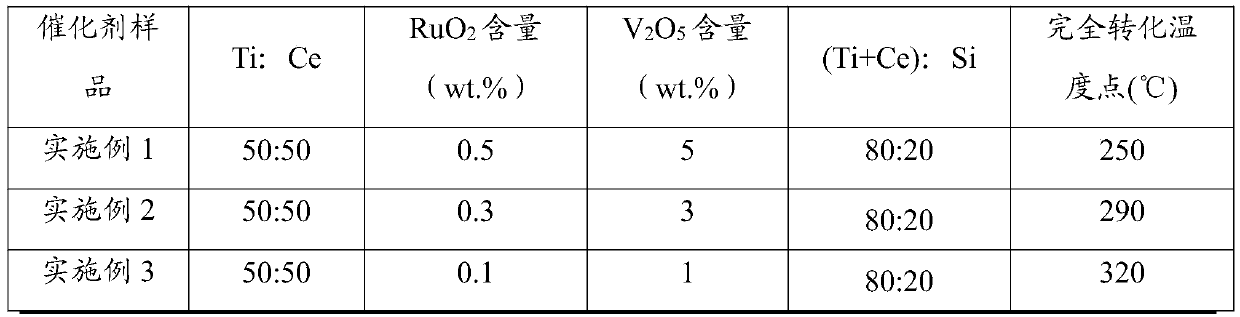

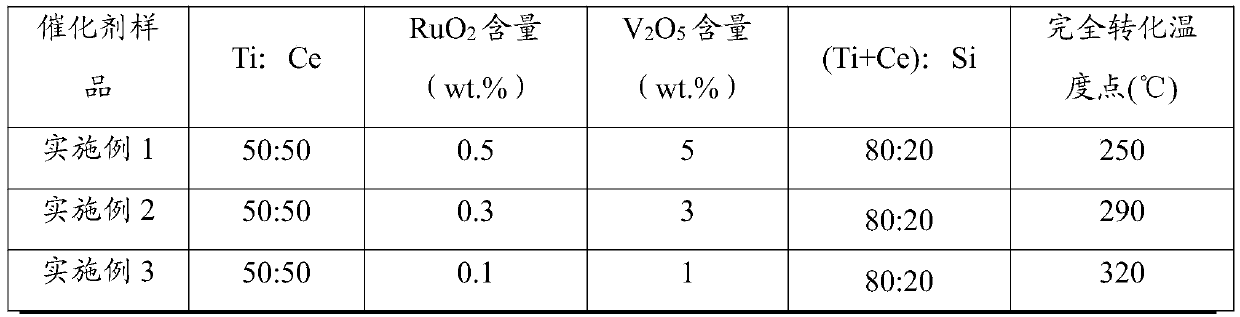

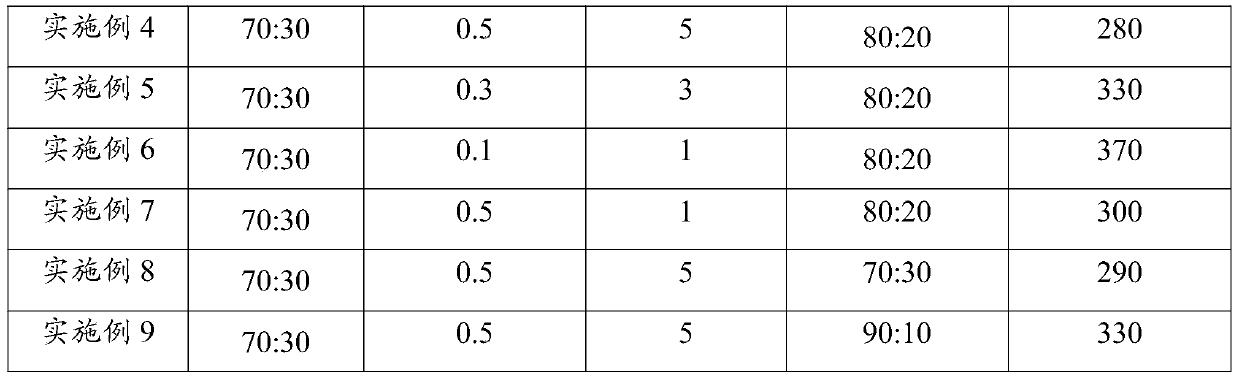

Catalyst for catalytic combustion of VOCs as well as preparation method and application thereof

ActiveCN110479317AGood oxygen mobilityImprove redox abilityPhysical/chemical process catalystsIncinerator apparatusCatalytic oxidationOxygen

The invention provides a catalyst for catalytic combustion of VOCs and a preparation method and application thereof, and belongs to the field of catalyst preparation. The invention particularly provides a core-shell type catalyst which is formed by covering, with a SiO2 shell, a catalyst taking a sulfuric acid modified TiO2-CeO2 composite oxide as a carrier and loaded with noble metal ruthenium oxide and / or transition metal vanadium oxide as active components. The CeO2 has good oxygen mobility and can significantly enhance the oxidation-reduction performance of the catalyst, so that the catalyst has efficient VOC catalytic oxidation activity; the carrier is soaked in sulfuric acid; the surface acidity is enhanced to inhibit adsorption of acidic impurity components such as SO2, HCl and H2S,the active components RuO2 and V2O5 also have sulfur resistance, so that the sulfur poisoning resistance of the catalyst is remarkably improved, the silicon shell can inhibit contact between chlorideand the active components, and inactivation of the active components of the catalyst due to chlorine poisoning is avoided; or honeycomb ceramic can be used as a matrix to prepare a coated type catalyst.

Owner:KUNMING UNIV OF SCI & TECH

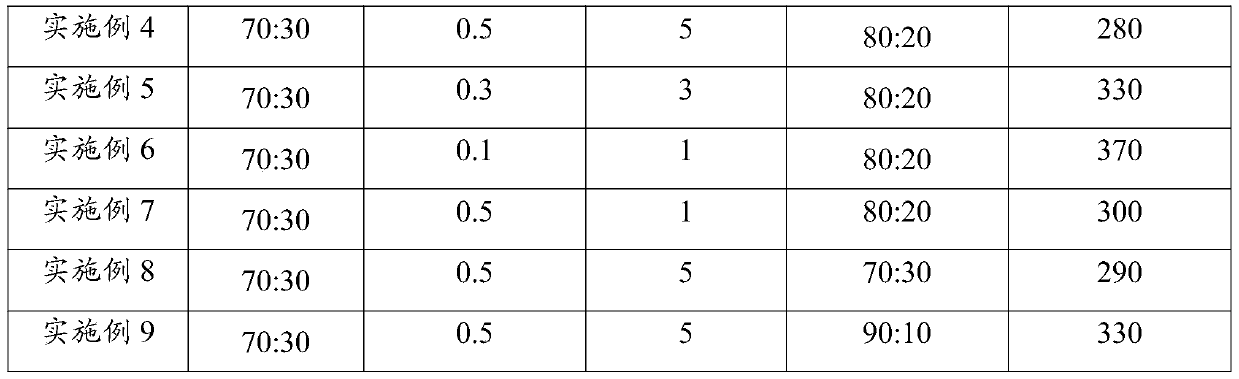

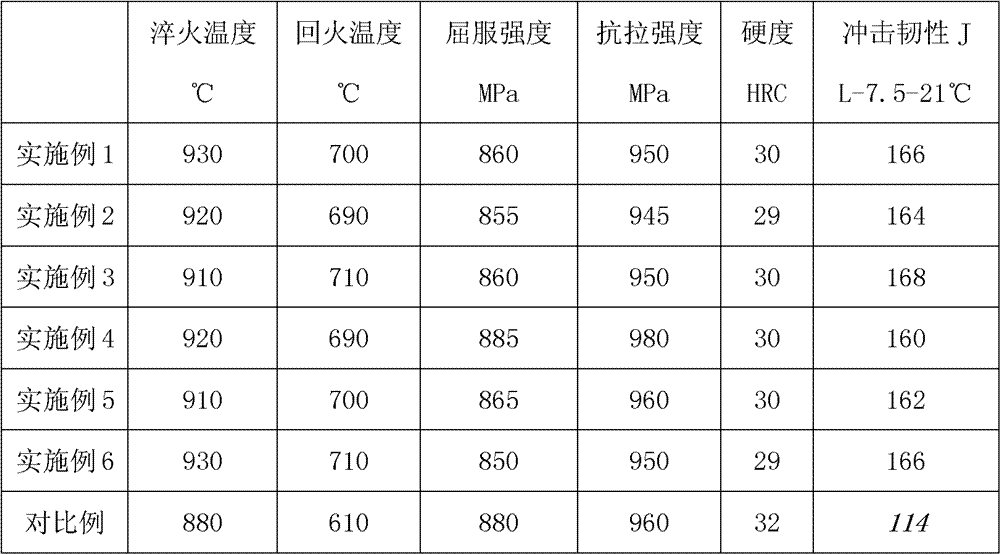

120ksi primary grade sulfur-resistant drill pipe and manufacturing method thereof

ActiveCN102330027ASulfur resistanceLow costFurnace typesHeat treatment furnacesChemical elementUltimate tensile strength

The invention discloses a 120ksi primary grade sulfur-resistant drill pipe, which comprises the following chemical elements in percentage by weight: 0.24 to 0.30 percent of C, 0.1 to 0.5 percent of Si, 0.8 to 1.4 percent of Mn, 0.8 to 1.4 percent of Cr, 0.5 to 0.8 percent of Mo, 0.05 to 0.10 percent of V, 0.01 to 0.05 percent of Nb, 0.002 to 0.007 percent of Ca, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also provides a manufacturing process of the 120ksi primary grade sulfur-resistant drill pipe, wherein the 120ksi primary grade sulfur-resistant drill pipe has a certain capability of sulfur resistance while maintaining the strength of 120ksi grade by controlling a quenching step and a tempering step. Furthermore, the primary sulfur-resistant drill pipe has the advantage of low cost.

Owner:BAOSHAN IRON & STEEL CO LTD

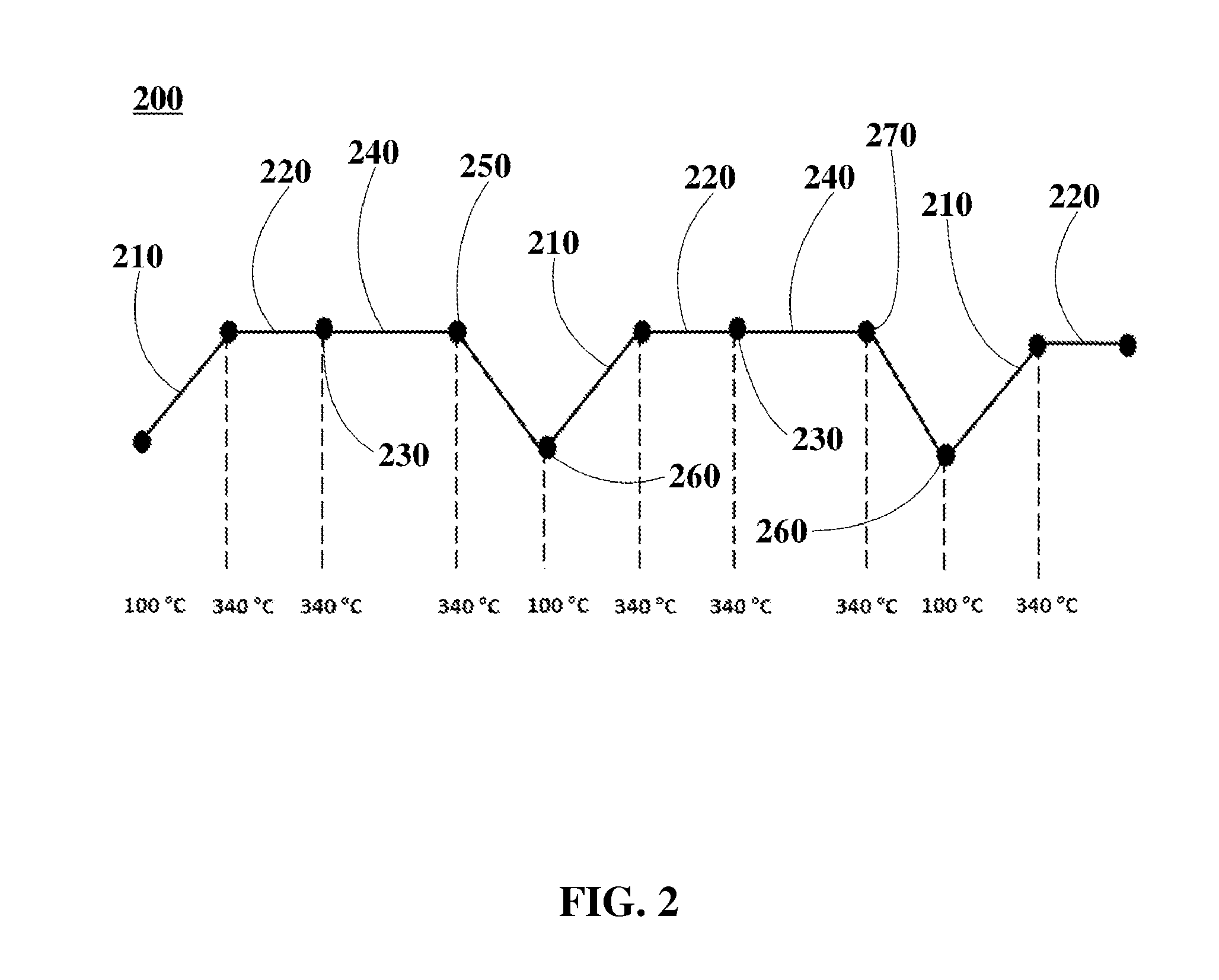

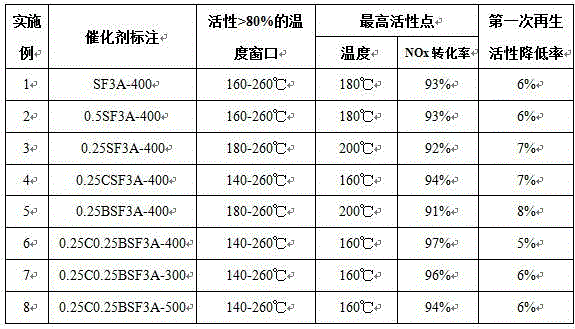

Method for preparing low-temperature SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103537289ALow priceIncrease surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlcoholNitrate

The invention relates to a method for preparing a low-temperature SCR (Selective Catalytic Reduction) denitration catalyst. The catalyst comprises the following raw materials: attapulgite, tetrachlorostannane pentahydrate, iron nitrate nonahydrate, cerium nitrate hexahydrate, barium nitrate, citric acid and ethyl alcohol. The method comprises the following three steps of: (1) pretreatment of the attapulgite; (2) composite deposition of active constituents and the attapulgite; and (3) calcination of the composite catalyst, wherein an intermittent stirring acid treatment method is adopted in the pretreatment step; the method for preparing the composite catalyst is a sol-hydrothermal method; and a temperature programmed calcination method is adopted in the catalyst calcining step. The method is low in production cost and simple in operation and the prepared denitration composite catalyst is good in low temperature performance, high in efficiency and renewable.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

Preparation method of sulfur-tolerant methanation catalyst

InactiveCN104998669AAvoid uneven loadSpray evenlyHydrocarbon from carbon oxidesCatalyst activation/preparationSyngasMethanation

The invention discloses a sulfur-tolerant methanation catalyst used for production of methane from synthetic gas. The catalyst is an impregnation catalyst mainly adopting oxides of Mo, Ni and W as active components, Al2O3 as a carrier and P2O5 as an assistant. The catalyst is used for synthetic gas with the H2S content being smaller than 400ppm, and realizes a good methanation reaction and good selectivity under a pressure of 1-4Mpa at a temperature of 300-550DEG C on the premise of no deep evolution of the synthetic gas. The invention also discloses a preparation method of the sulfur-tolerant methanation catalyst.

Owner:BEIJING UNIV OF CHEM TECH +1

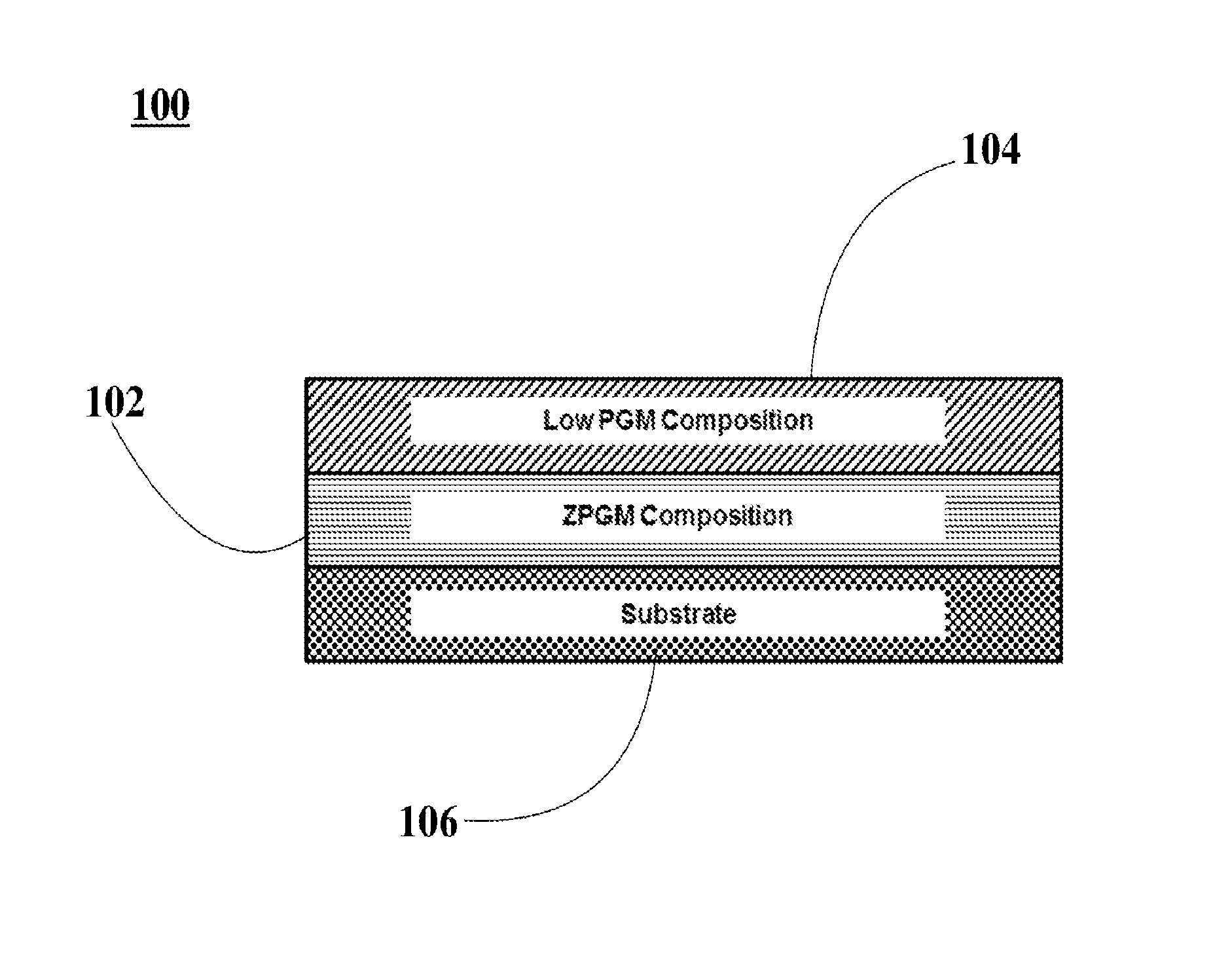

Effect of Type of Support Oxide on Sulfur Resistance of Synergized PGM as Diesel Oxidation Catalyst

InactiveUS20170095803A1More efficiencyMore stabilityGas treatmentInternal combustion piston enginesSulfurPlatinum group

Sulfur-resistant synergized platinum group metals (SPGM) catalysts with significant oxidation capabilities are disclosed. Catalytic layers of SPGM catalyst samples are produced using conventional synthesis techniques to build a washcoat layer completely or substantially free of PGM material. The SPGM catalyst includes a washcoat layer comprising YMnO3 perovskite and an overcoat layer including a Pt composition deposited on a plurality of support oxides with total PGM loading of about 5 g / ft3. Resistance to sulfur poisoning and catalytic stability is observed under 1.3 gS / L condition to assess the influence that selected support oxides have on the DOC performance of the SPGM catalysts. The results indicate SPGM catalysts produced to include a layer of low amount of PGM catalyst material deposited on a plurality of support oxides added to a layer of ZPGM catalyst material are capable of providing significant improvements in sulfur resistance of SPGM catalyst systems.

Owner:CLEAN DIESEL TECHNOLOGIES

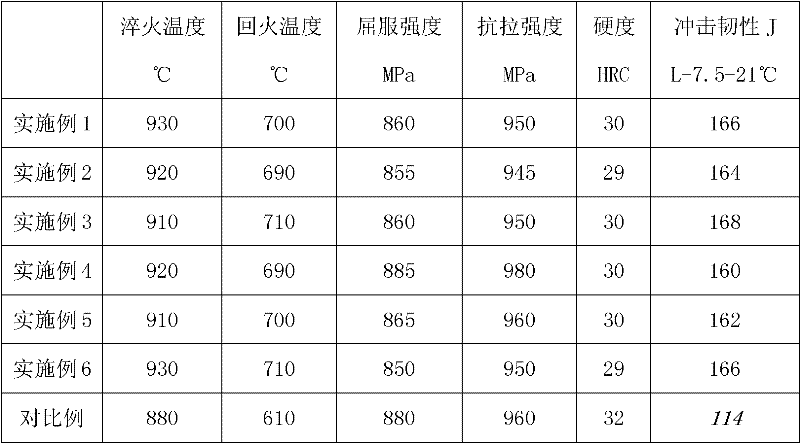

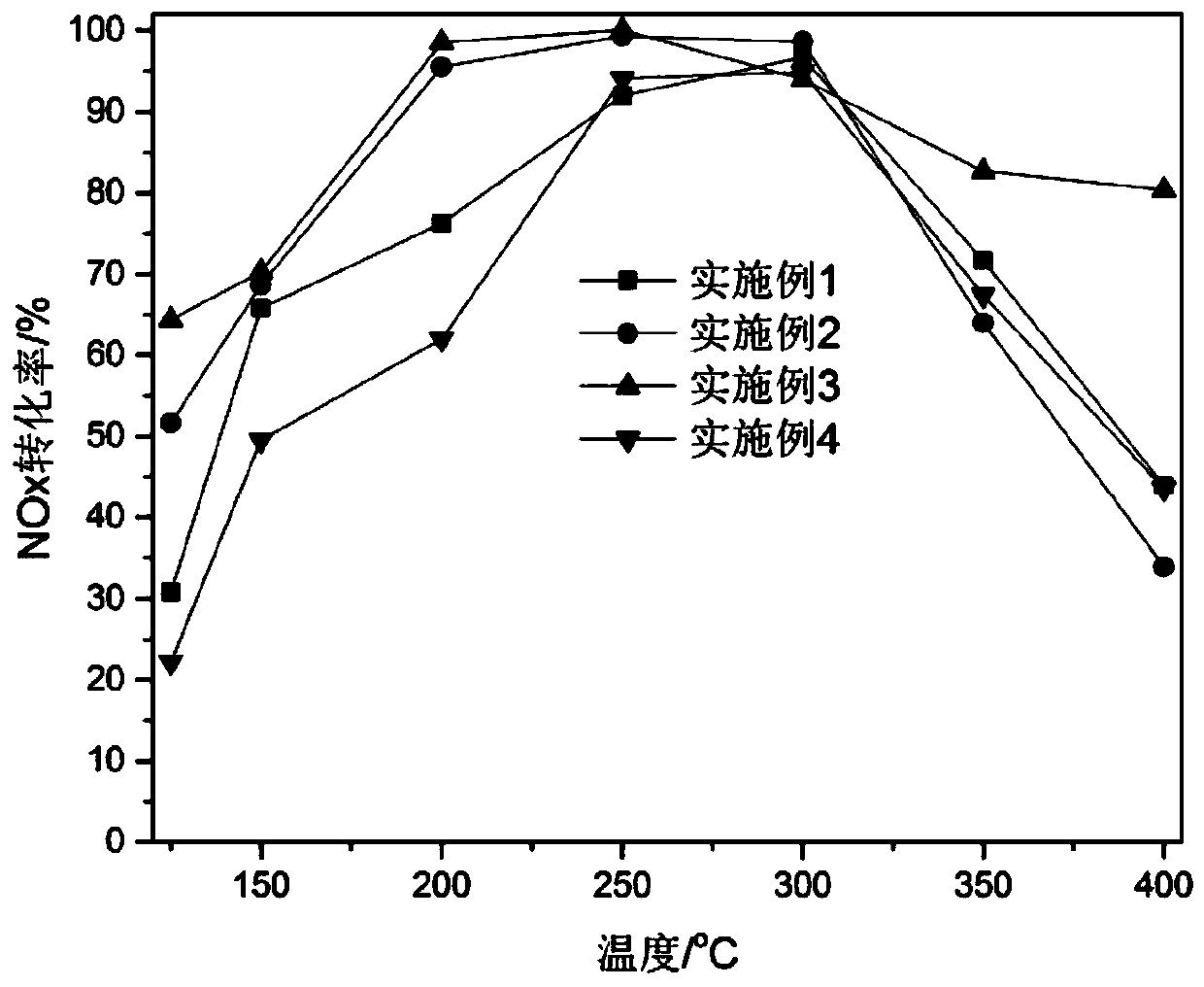

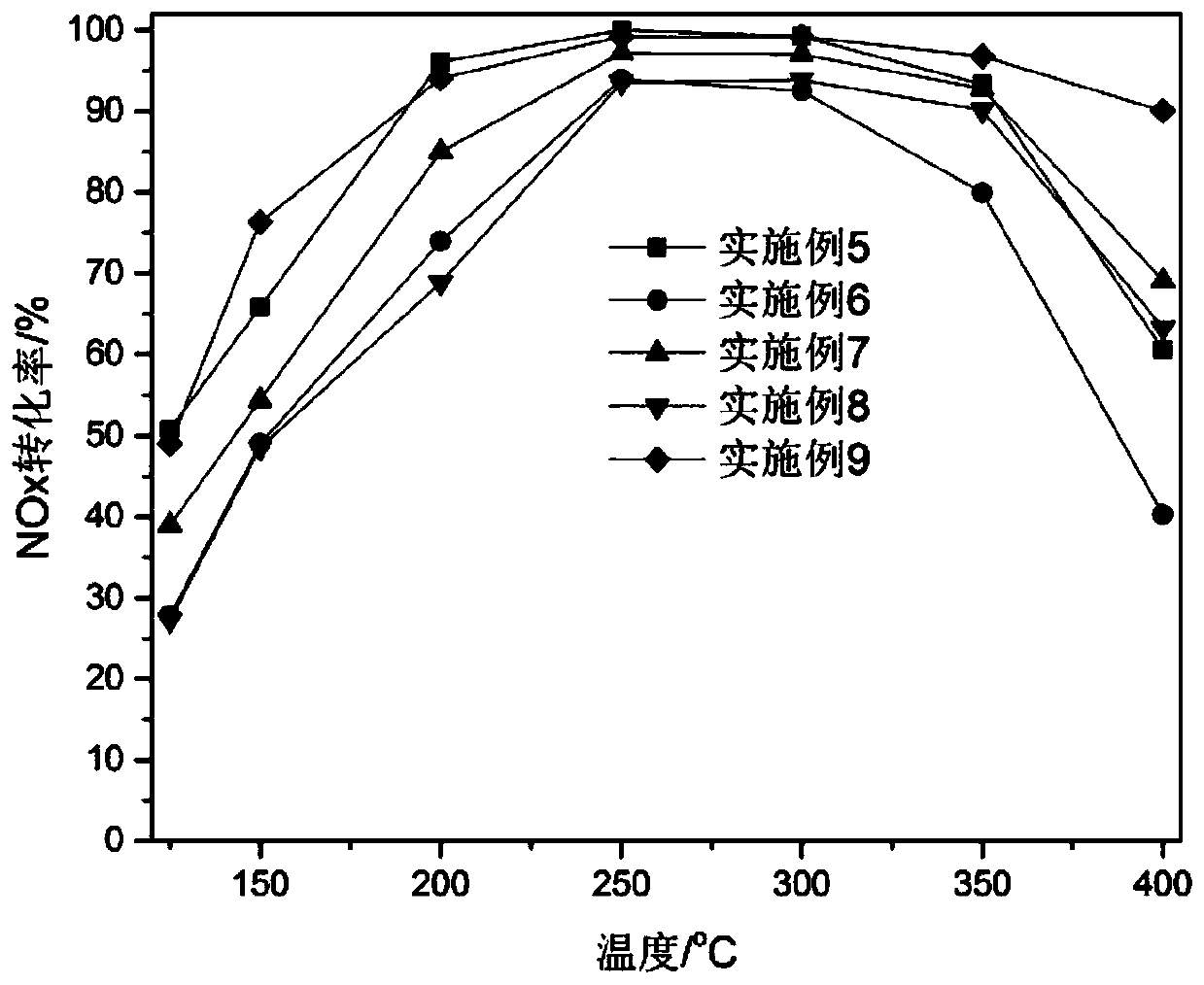

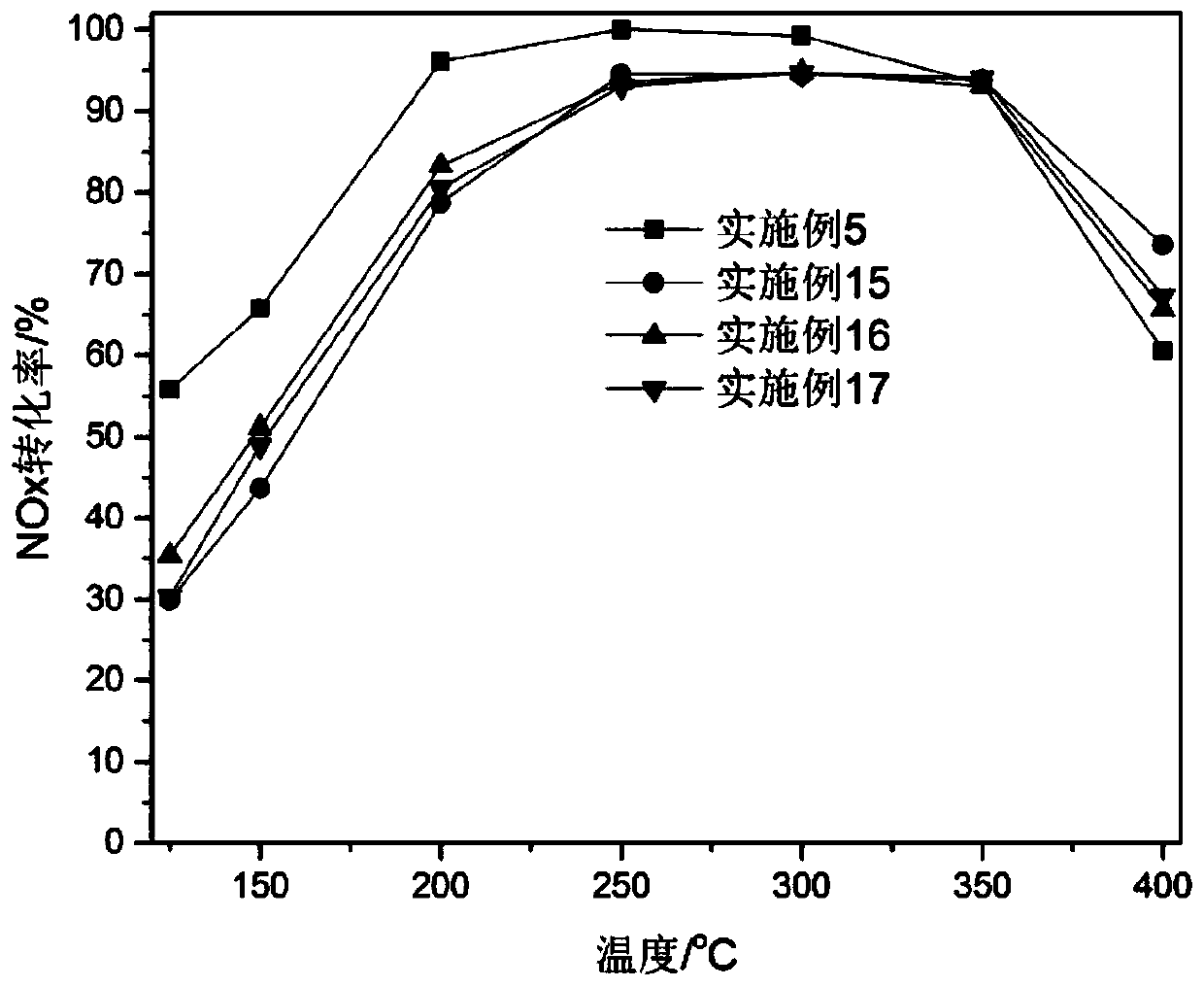

Cu-SAPO-34 molecular sieve, preparation method thereof and application of Cu-SAPO-34 molecular sieve in selective catalytic reduction denitration

PendingCN111437878ANo SCR activityWide active temperature windowMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention provides a Cu-SAPO-34 molecular sieve, a preparation method thereof and application of the Cu-SAPO-34 molecular sieve in selective catalytic reduction denitration. The invention also provides an SAPO-34 molecular sieve containing copper metal ions through one-step hydrothermal synthesis and a preparation method of the SAPO-34 molecular sieve. The Cu-SAPO-34 molecular sieve comprisesthe following components in parts by weight: a) 21-35.5 parts of SiO2; b) 38.5 to 47.5 parts of Al2O3; c) 22.5 to 27.5 parts of P2O5 (phosphorus pentoxide); and d) 2.5-6 parts of a copper-ammonia complex. The method provided by the invention can regulate and control the copper content and the silica-alumina ratio, and has the characteristics of low cost, simple process, environmental friendlinessand the like. The Cu-SAPO-34 molecular sieve catalyst provided by the invention has relatively high NOx removal efficiency, good low-temperature activity and a relatively wide active temperature window, and can still maintain excellent reaction activity at a relatively high space velocity.

Owner:DALIAN UNIV OF TECH PANJIN INST OF IND TECH

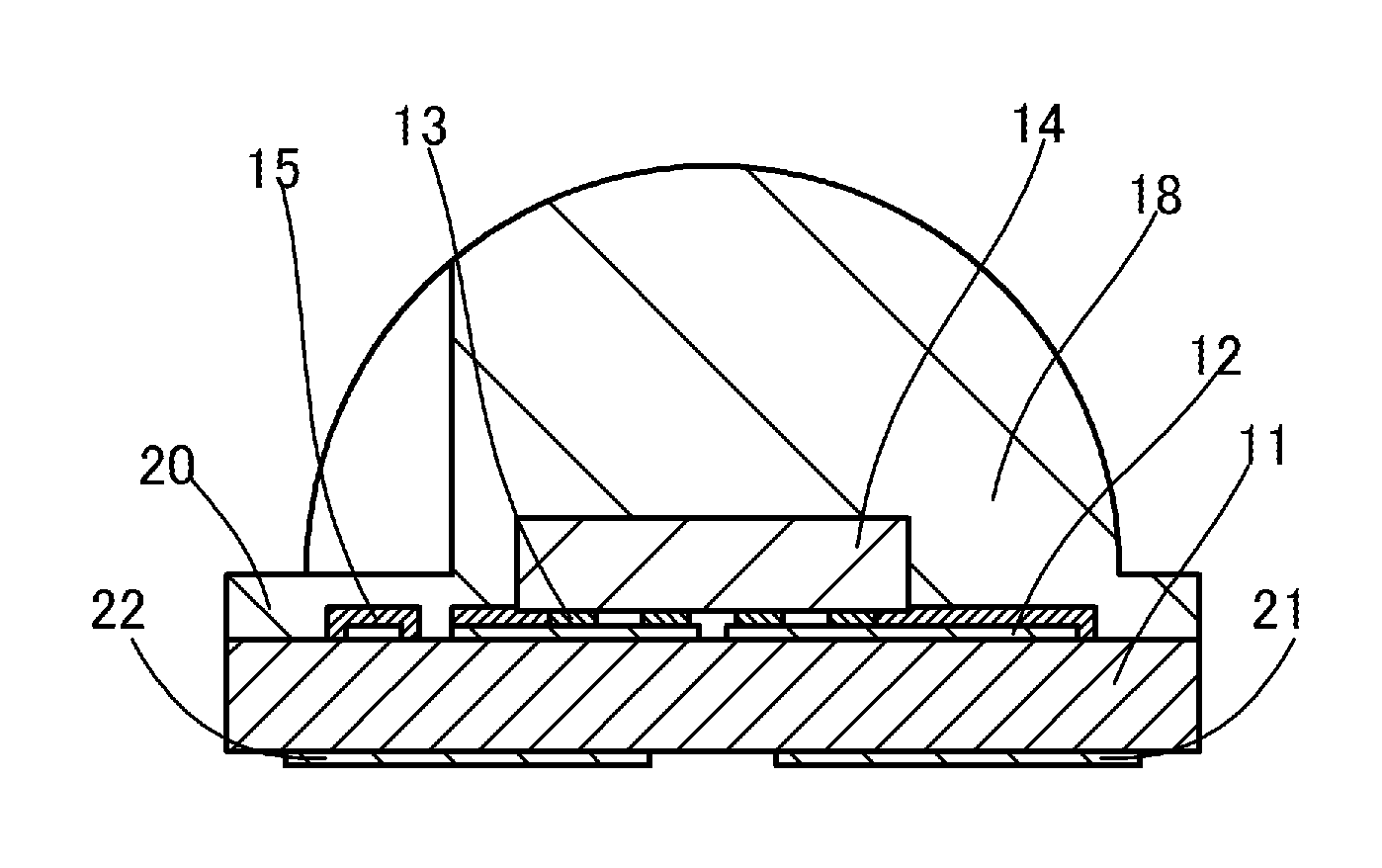

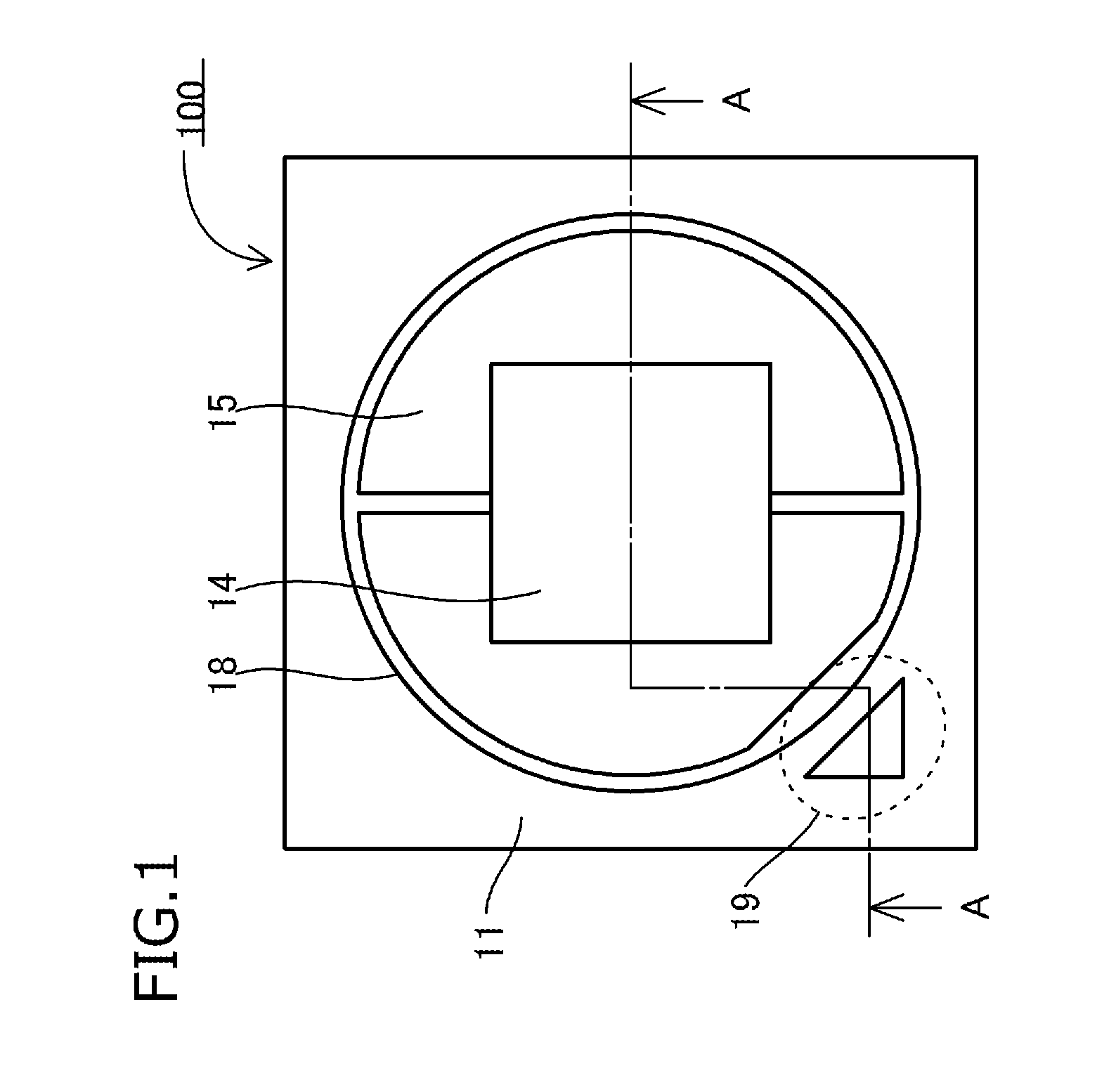

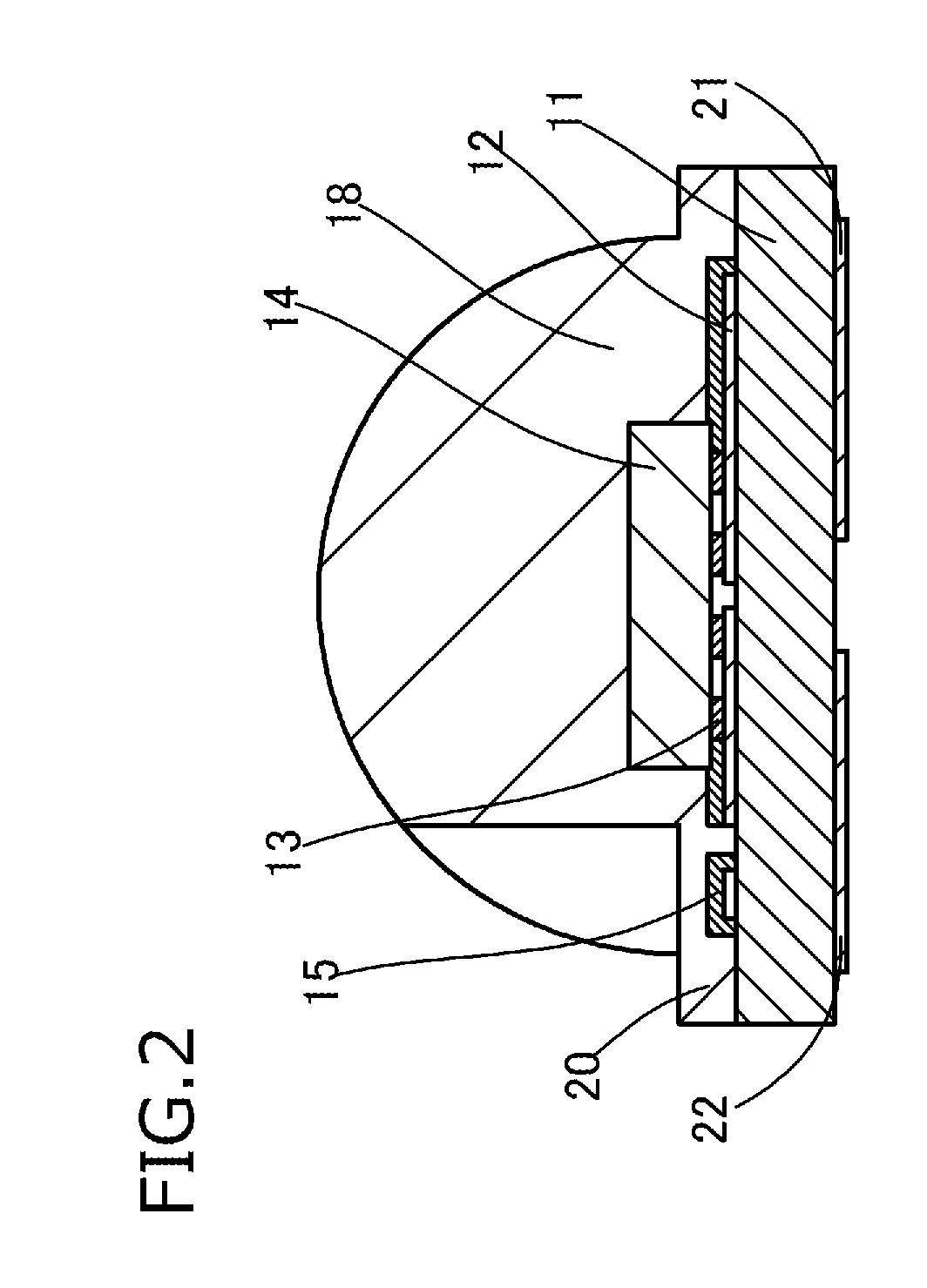

Light-emitting device

ActiveUS9559267B2Sulfur resistanceIncrease contrastSemiconductor/solid-state device detailsSolid-state devicesInsulation layerConductive materials

A light-emitting device includes a support body having a quadrangle planar shape, a wiring pattern on the support body, a light-emitting element on the wiring pattern, a recognition target portion on a corner portion of the support body, the recognition target portion including a conductive material, an insulation layer reflecting light emitted from the light-emitting element and covering a periphery of the recognition target portion, and a light-transmissive member including a lens portion covering the light-emitting element and a flange portion on a periphery of the lens portion and covering a portion of the recognition target portion that is covered with the insulation layer. The portion of the recognition target portion covered by the flange portion is arranged in a non-point symmetry around a center of the support body, and a difference in reflectivity between the support body and the insulation layer is larger than between the support body and the recognition target portion.

Owner:NICHIA CORP

Solid oxide fuel battery anode and its production

Owner:UNIV OF SCI & TECH OF CHINA

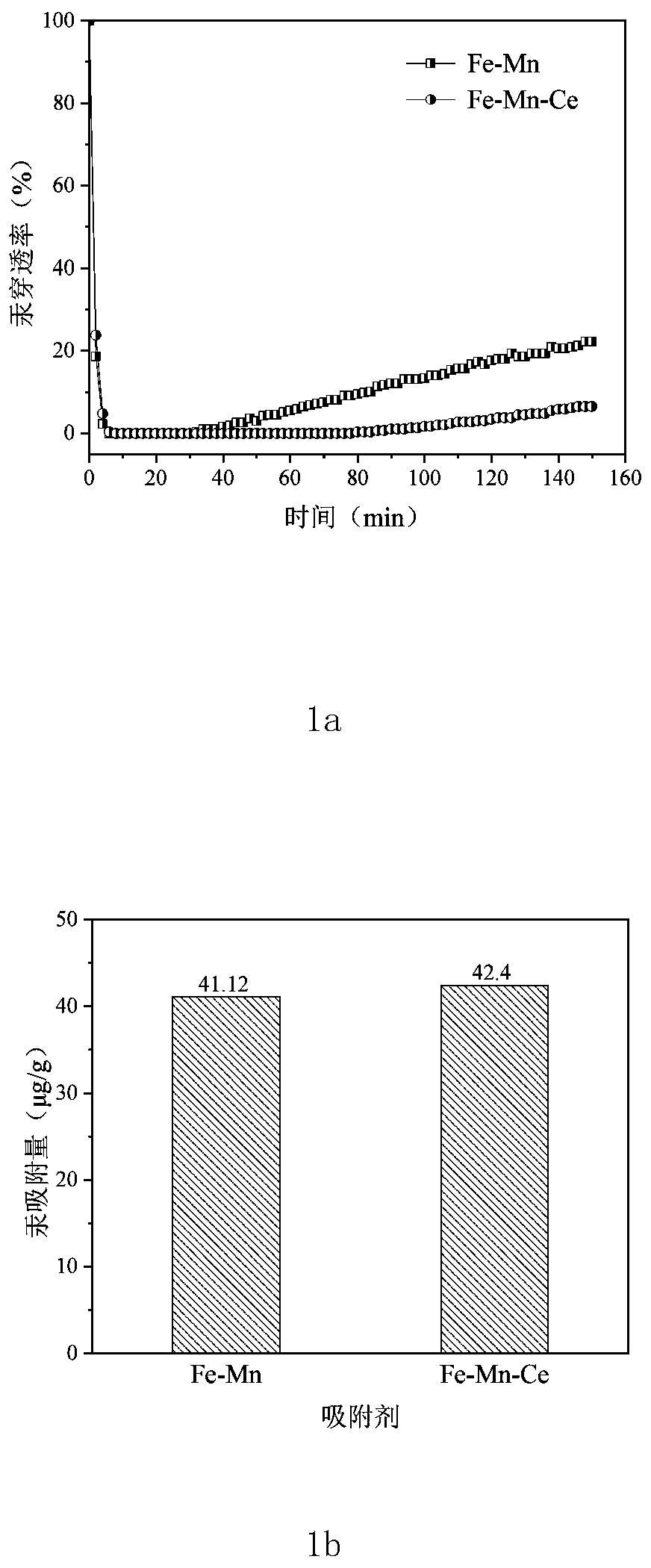

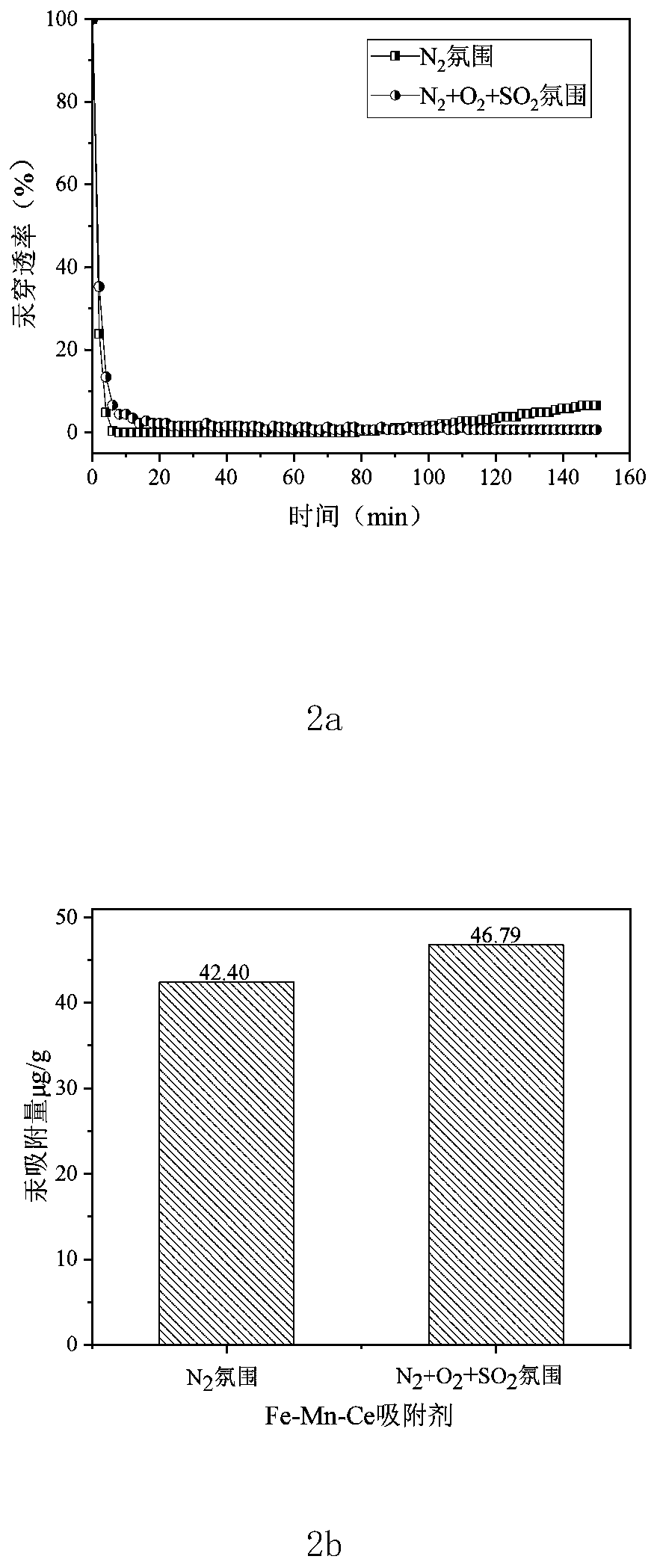

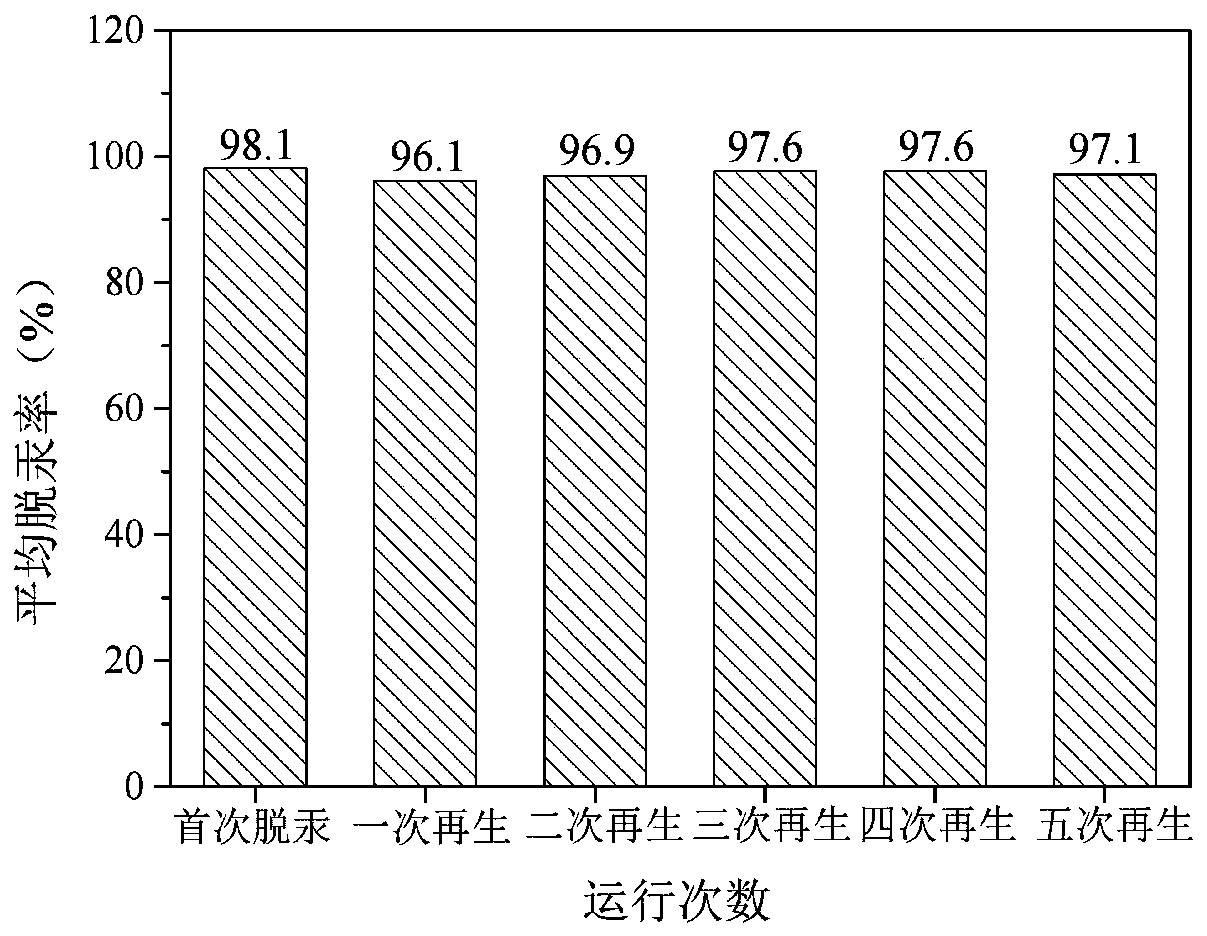

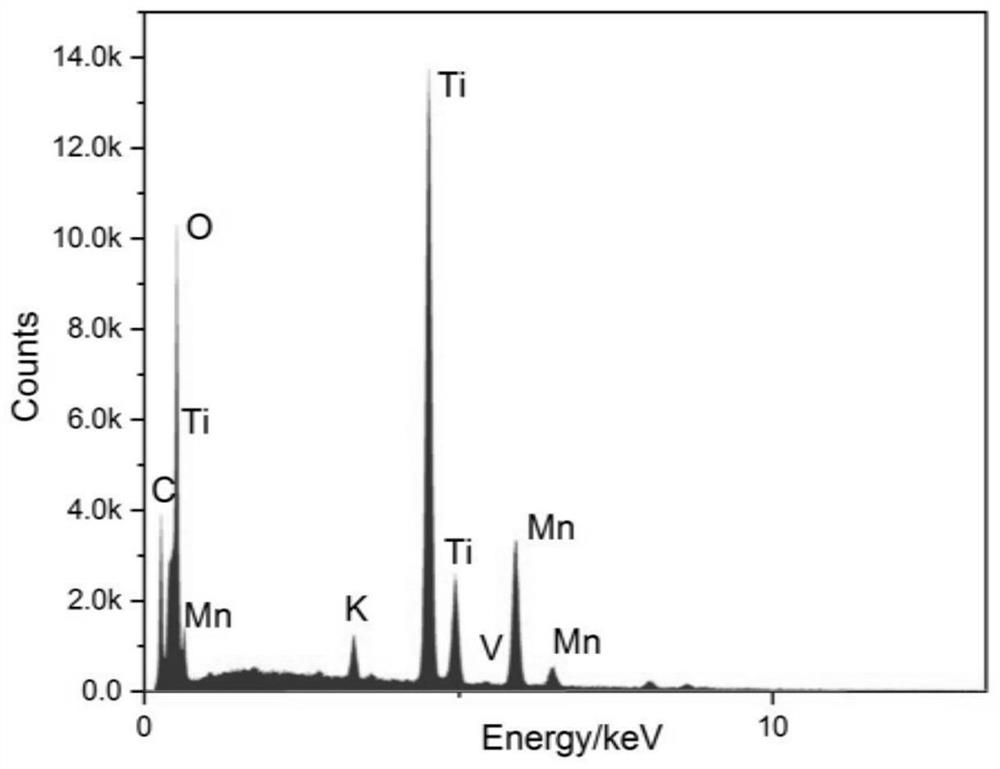

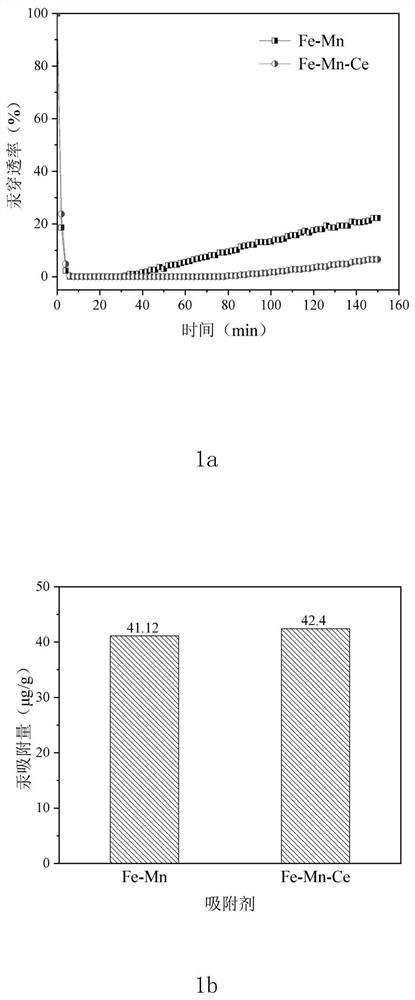

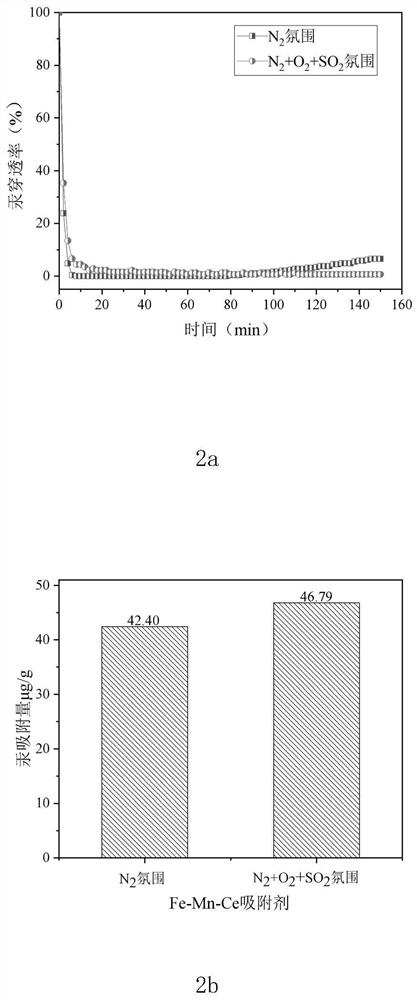

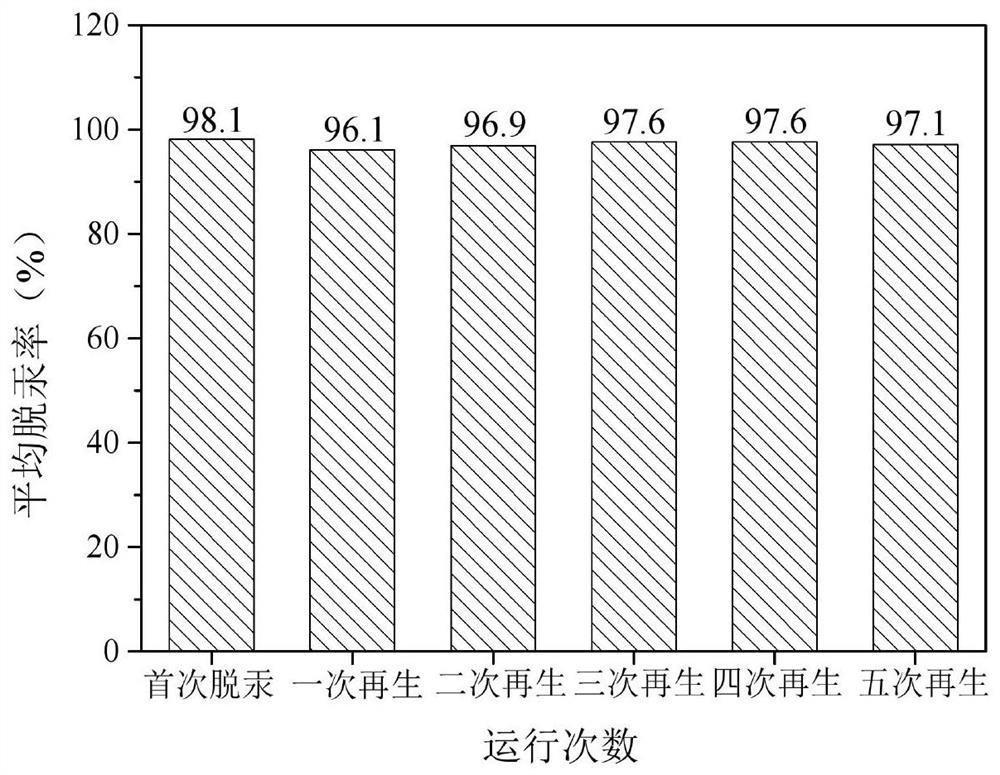

Preparation process of renewable sulfur-resistant Fe-Mn-Ce magnetic adsorbent for flue gas demercuration

ActiveCN111282540AImprove mercury removal efficiencyImprove oxygen storage capacityGas treatmentOther chemical processesPhysical chemistryMercury adsorption

The invention relates to a preparation process of a renewable sulfur-resistant Fe-Mn-Ce magnetic adsorbent for flue gas demercuration. The demercuration adsorbent prepared by a coprecipitation methodis an efficient demercuration adsorbent aiming at a coal-fired power plant flue gas demercuration technology, has the advantages of strong demercuration performance, separability in magnetism, renewability, SO2 poisoning resistance and the like, and can realize efficient demercuration and cyclic utilization of coal-fired flue gas.

Owner:NANJING NORMAL UNIVERSITY

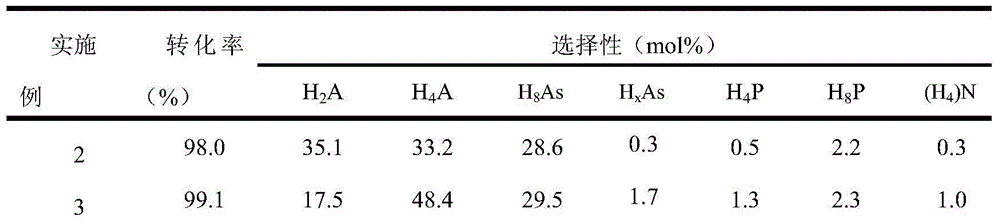

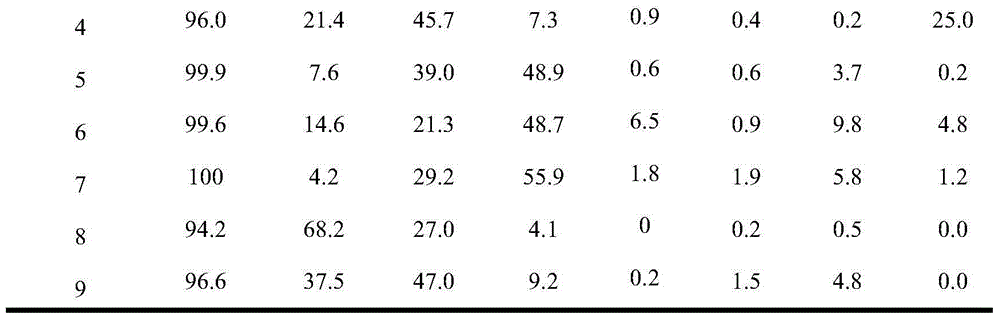

Catalyst for preparing mixed alcohol with low carbon from synthesis gas and its preparing process

InactiveCN1167502CImprove stabilityHigh selectivityOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammonium sulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

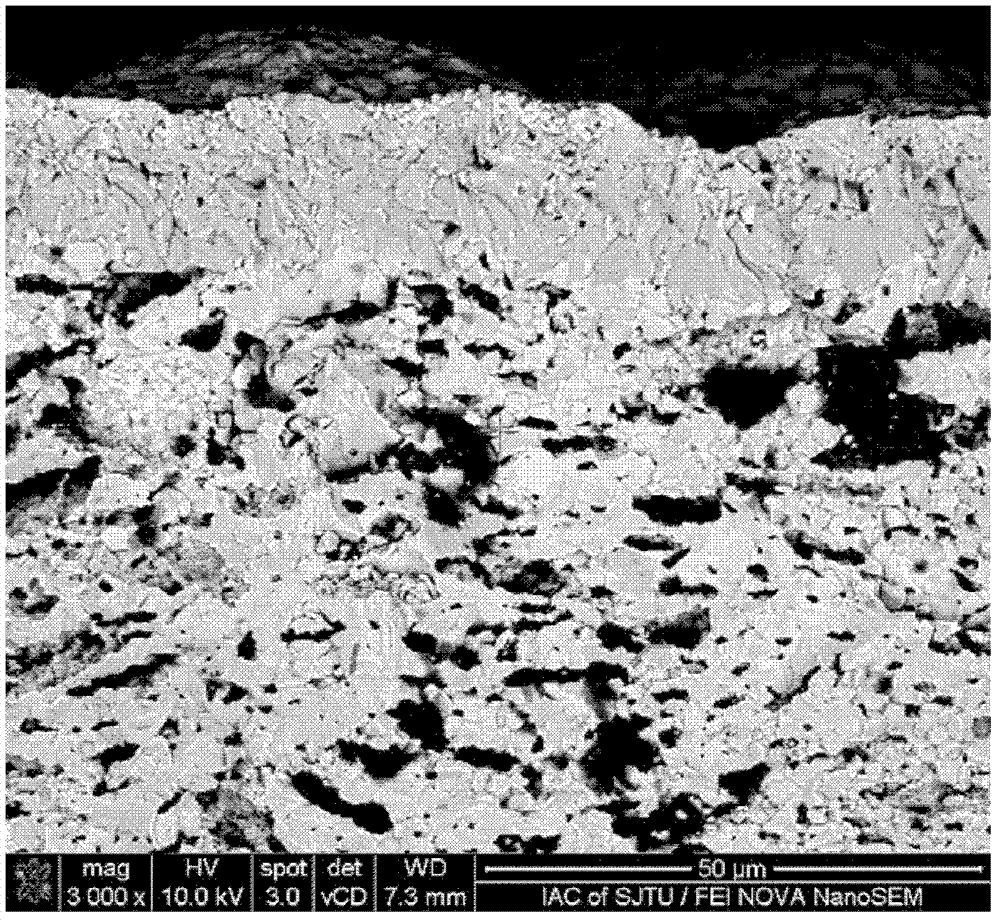

Lignin modified filter material loading denitration and sulfur-resistant catalyst with double-layer core-shell structure and preparation method of lignin modified filter material

ActiveCN107694338AImprove toughnessExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCarbon–carbon bondSulfur

The invention discloses a lignin modified filter material loading a denitration and sulfur-resistant catalyst with a double-layer core-shell structure and a preparation method of the lignin modified filter material. According to the preparation method, a PPS filter material is modified by virtue of lignin, and the lignin is formed by mutually connecting three phenylpropane units through ether bonds and carbon-carbon bonds, has a three-dimensional network structure and can be firmly adsorbed to the surface of the PPS filter material through a benzene ring conjugate effect. The molecular structure of the lignin contains multiple active groups of alcoholic hydroxyl groups, phenolic hydroxyl groups, carbon-base conjugated double bonds and the like, so that the surface activity of the filter material is substantially improved. The denitration and sulfur-resistant catalyst with the double-layer core-shell structure is loaded to the surface of the modified filter material by virtue of an electrostatic incorporation effect of the lignin, so as to form the lignin modified filter material loading the denitration and sulfur-resistant catalyst with the double-layer core-shell structure. Testsshow that the composite filter material modified by the lignin has relatively high denitration activity and very excellent sulfur resistant.

Owner:FUZHOU UNIV

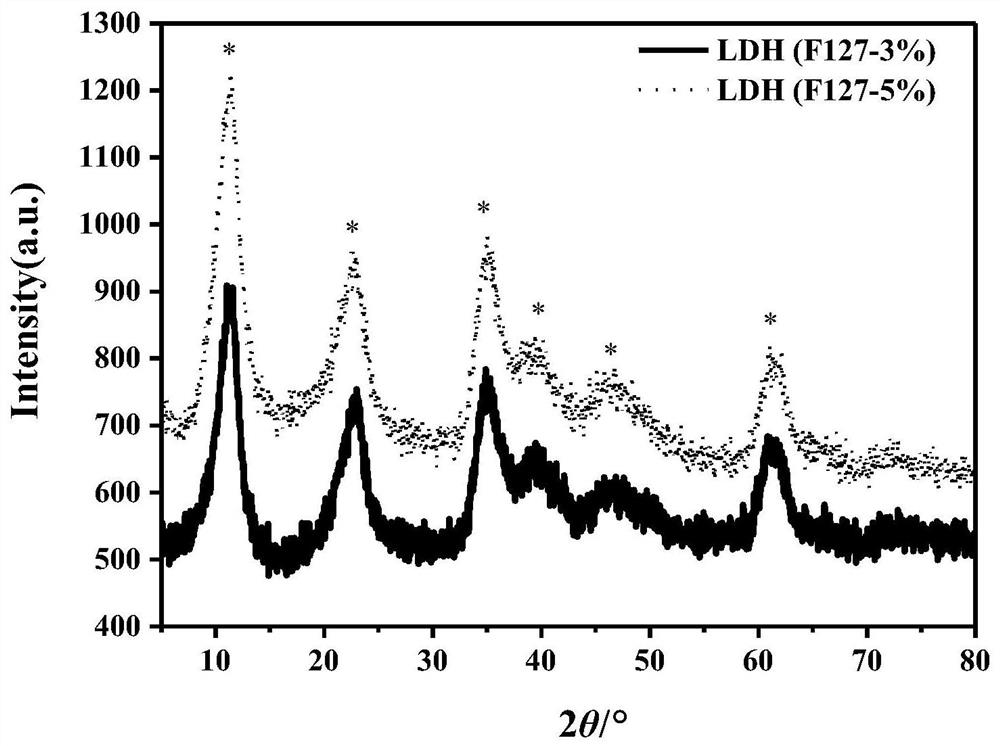

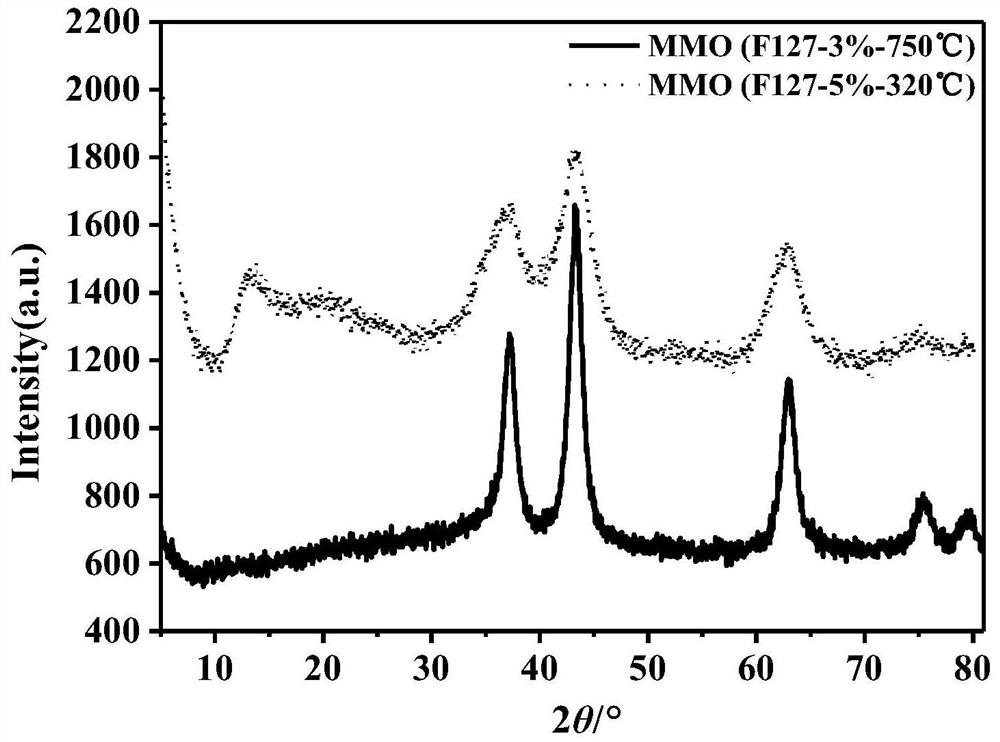

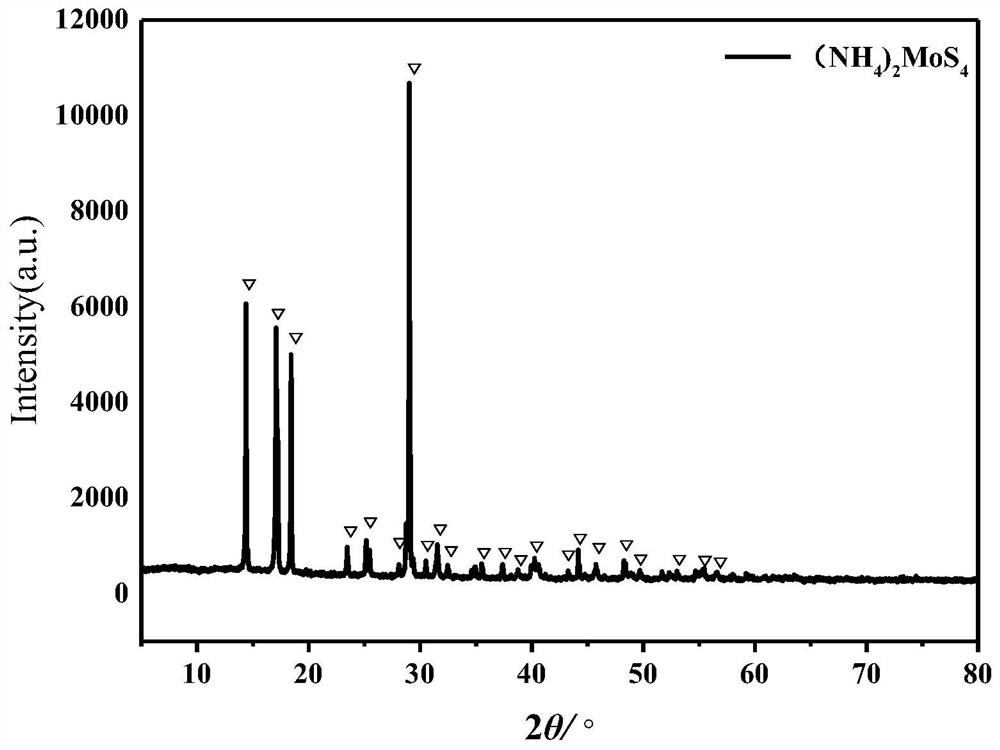

Molybdenum-based catalyst for preparing low-carbon alcohol from synthesis gas by taking alkaline carrier material mesoporous NiO-Al2O3 as carrier and preparation method of molybdenum-based catalyst

ActiveCN112844418AUniform particlesAchieve modulationOrganic compound preparationHydroxy compound preparationPtru catalystAlcohol

The invention discloses a molybdenum-based catalyst for preparing low-carbon alcohol from synthesis gas by taking an alkaline carrier material, namely mesoporous NiO-Al2O3 as a carrier and a preparation method of the molybdenum-based catalyst, belonging to the technical field of catalysts. The catalyst is prepared by the following steps: synthesizing a precursor NiAl-LDH; subjecting the obtained NiAl-LDH is to heating calcination to a obtain a calcined material NiO-Al2O3; preparing MoS2-NiO-Al2O3 by dissolving (NH4)2MoS4 in concentrated ammoniacal liquor, adding NiO-Al2O3, conducting continuous stirring, performing drying in the air, and successively carrying out grinding, firing and cooling to obtain MoS2-NiO-Al2O3; and subjecting MoS2-NiO-Al2O3 and K2CO3 to grinding, mixing and tabletting, and carrying out sieving so as to obtain K-Mo-S / NiO-Al2O3. The catalyst has the advantages of excellent activity for preparing low-carbon alcohol from synthesis gas, high alcohol selectivity and operation stability, low cost and convenience in preparation.

Owner:INNER MONGOLIA UNIVERSITY

A kind of vocs catalytic combustion catalyst and its preparation method and application

ActiveCN110479317BGood oxygen mobilityImprove redox abilityPhysical/chemical process catalystsIncinerator apparatusPtru catalystCatalytic oxidation

The invention provides a VOCs catalytic combustion catalyst and its preparation method and application, belonging to the field of catalyst preparation. The invention provides a TiO modified with sulfuric acid 2 ‑CeO 2 The composite oxide is used as the carrier, the precious metal ruthenium oxide and / or the transition metal vanadium oxide is supported as the catalyst as the active component, and finally SiO is wrapped 2 Shell, formed core-shell catalyst; CeO 2 It has good oxygen mobility, which can significantly enhance the redox performance of the catalyst, thus having efficient VOCs catalytic oxidation activity; and after the carrier is soaked in sulfuric acid, the enhanced surface acidity inhibits SO 2 , HCl, H 2 Adsorption of acidic impurity components such as S, active component RuO 2 and V 2 O 5 It also has sulfur resistance, thereby significantly improving the catalyst's ability to resist sulfur poisoning. The silicon shell can inhibit the contact between chloride and active components, avoiding the deactivation of chlorine poisoning of the active components of the catalyst; honeycomb ceramics can also be used as the matrix to make a coating type catalyst.

Owner:KUNMING UNIV OF SCI & TECH

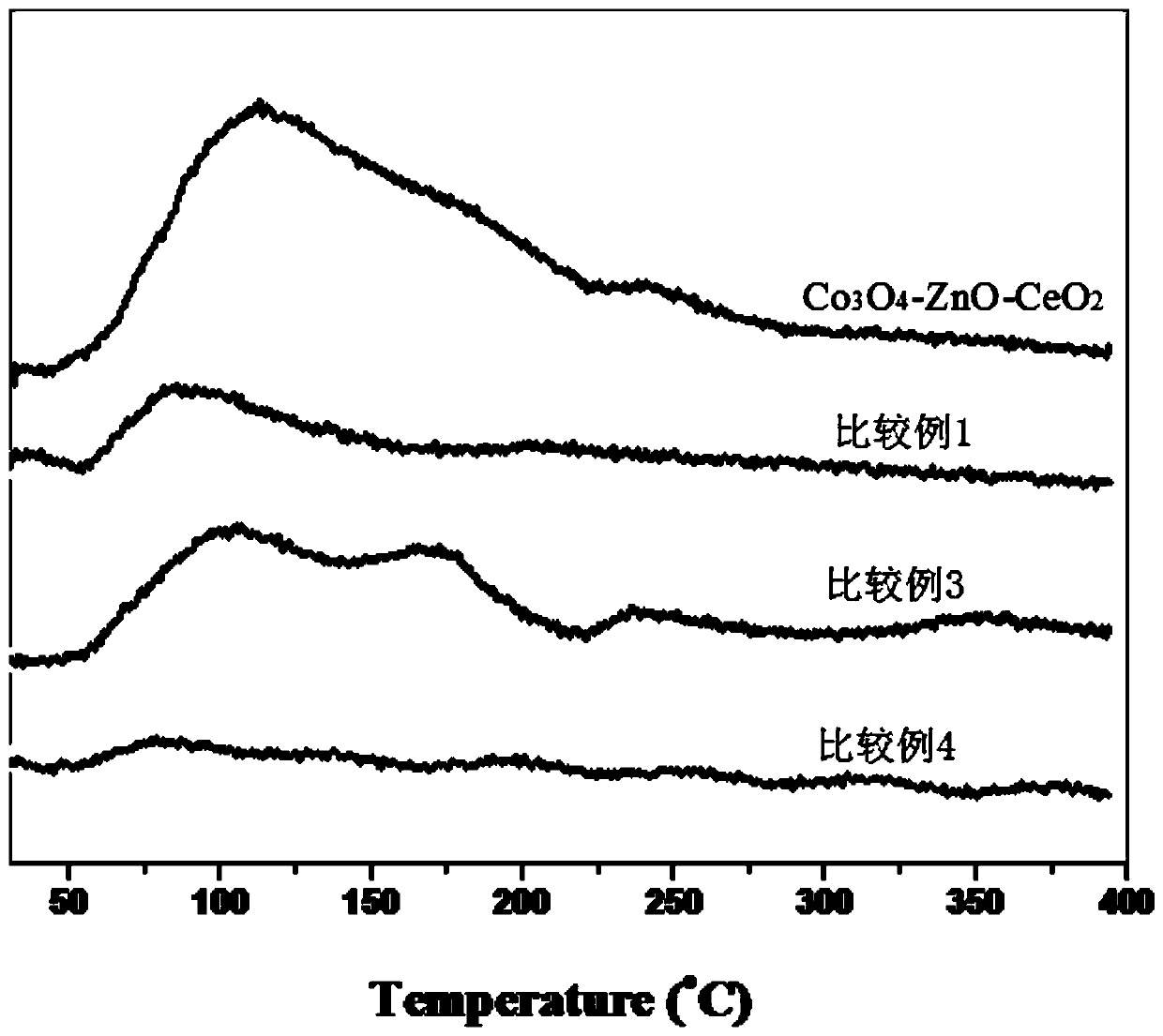

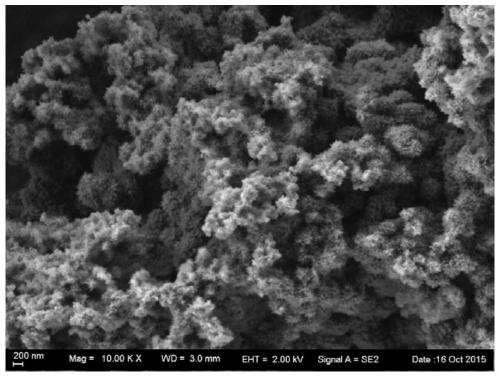

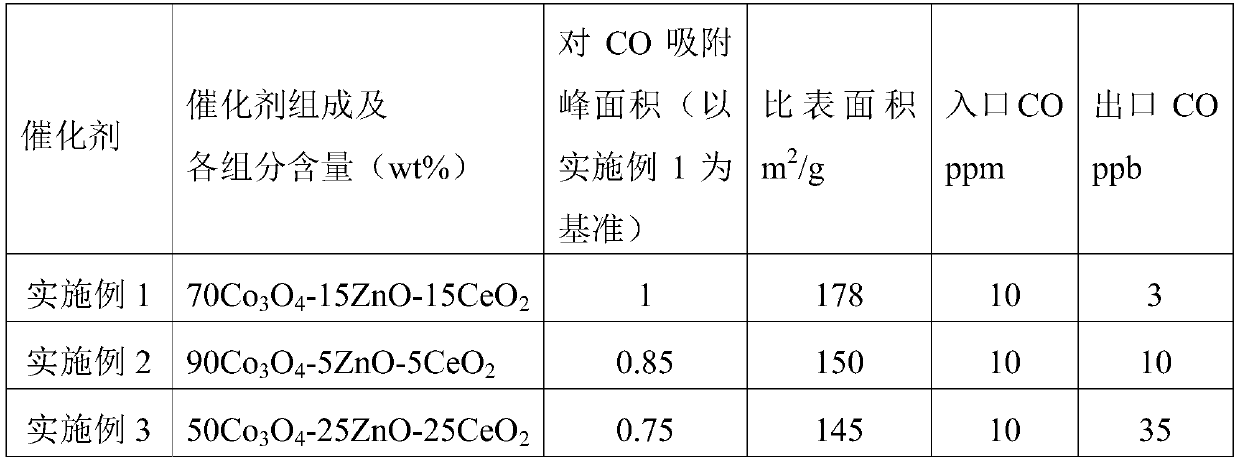

Catalyst for deep purification and removal of impurities in olefin stream at room temperature and its preparation and application

ActiveCN106378142BRealize deep oxidation removalImprove performanceAdsorption purification/separationMetal/metal-oxides/metal-hydroxide catalystsOxidation stateCerium

Owner:SHANGHAI RES INST OF CHEM IND

Catalyst for preparing low-carbon mixed alcohol by synthetic gas, its preparation method and application

ActiveCN100471563CImprove stabilityExtend your lifePhysical/chemical process catalystsOrganic compound preparationAlcoholAmmonium sulfide

The invention is composition gasifying low-carbon mixing alcohol catalyst and its preparation method and utilization. The weight percentages of the catalyst are: Mo: 20-40%, Ni: 4-10%, Mn: 0.1-1.0%, K: 5-15%, Fe: 5-10%, S: 20-40%, the cohesive agent: 10-20%. The preparation method is to add ammonium molybdate to ammonium sulfide solution to react to get thiosulfate ammonium molybdate solution; drop in nickel and manganese salt solution and the thiosulfate ammonium molybdate solution, and through heating, filtering, cleaning, depositing and drying to get molybdenum nickel manganese multi-sulfur compound; mix molysite with citric acid and carry out heating reaction to get molysite C; mix molybdenum nickel manganese multi-sulfur compound, kali salt and molysite C, abrade them, lead in indifferent protective gas to burn to get molybdenum nickel manganese kalium sulfur compound; add cohesive agent to mix, press and form. The catalyst of the invention has high activity, high selectivity and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942BLow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is oneor more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percentby deoxidization.

Owner:HAO HUA CHENGDU TECH

Mixed titanate support solid electrolyte multilayer film of solid oxide fuel cell and manufacturing method thereof

InactiveCN102593480BLong-term structural stabilityImprove electronic conductivityFinal product manufactureFuel cell detailsEngineeringElectronic conductivity

The invention relates to a mixed titanate support solid electrolyte multilayer film of a solid oxide fuel cell and a manufacturing method of the mixed tianate support solid electrolyte multilayer film of the solid oxide fuel cell. The multilayer film is formed by a transition layer film and an electrolytic layer film which are sequentially formed through depositing on an anode main electronic conduction phase and a structural framework increase phase; the anode main electronic conduction phase is porous perovskite type mixed titanate composite oxides; and the structural framework increase phase is aluminum oxide or mixed zirconium oxide or mixture of the aluminum oxide and the mixed zirconium oxide. The manufacturing method provided by the invention comprises the steps: combining the casting method and the screen printing method, adopting the casting method to manufacture a support green body, adopting the screen printing method to respectively form the transition layer and the electrolytic layer on the support green body through depositing, and firing the support green body, the transition layer and the electrolytic layer at certain temperature to obtain the multilayer film with different dimensions. Compared with the prior art, the porous anode support formed in the invention keeps stable structure in reducing atmosphere for a long time, has high electronic conductivity, can be subjected to oxidation-reduction circulation for many times, resists carbon deposition and has sulfur resisting property.

Owner:SHANGHAI JIAOTONG UNIV

A kind of preparation method of low-temperature SCR denitrification catalyst

InactiveCN103537289BLow priceIncrease surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlcoholNitrate

The invention relates to a method for preparing a low-temperature SCR (Selective Catalytic Reduction) denitration catalyst. The catalyst comprises the following raw materials: attapulgite, tetrachlorostannane pentahydrate, iron nitrate nonahydrate, cerium nitrate hexahydrate, barium nitrate, citric acid and ethyl alcohol. The method comprises the following three steps of: (1) pretreatment of the attapulgite; (2) composite deposition of active constituents and the attapulgite; and (3) calcination of the composite catalyst, wherein an intermittent stirring acid treatment method is adopted in the pretreatment step; the method for preparing the composite catalyst is a sol-hydrothermal method; and a temperature programmed calcination method is adopted in the catalyst calcining step. The method is low in production cost and simple in operation and the prepared denitration composite catalyst is good in low temperature performance, high in efficiency and renewable.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

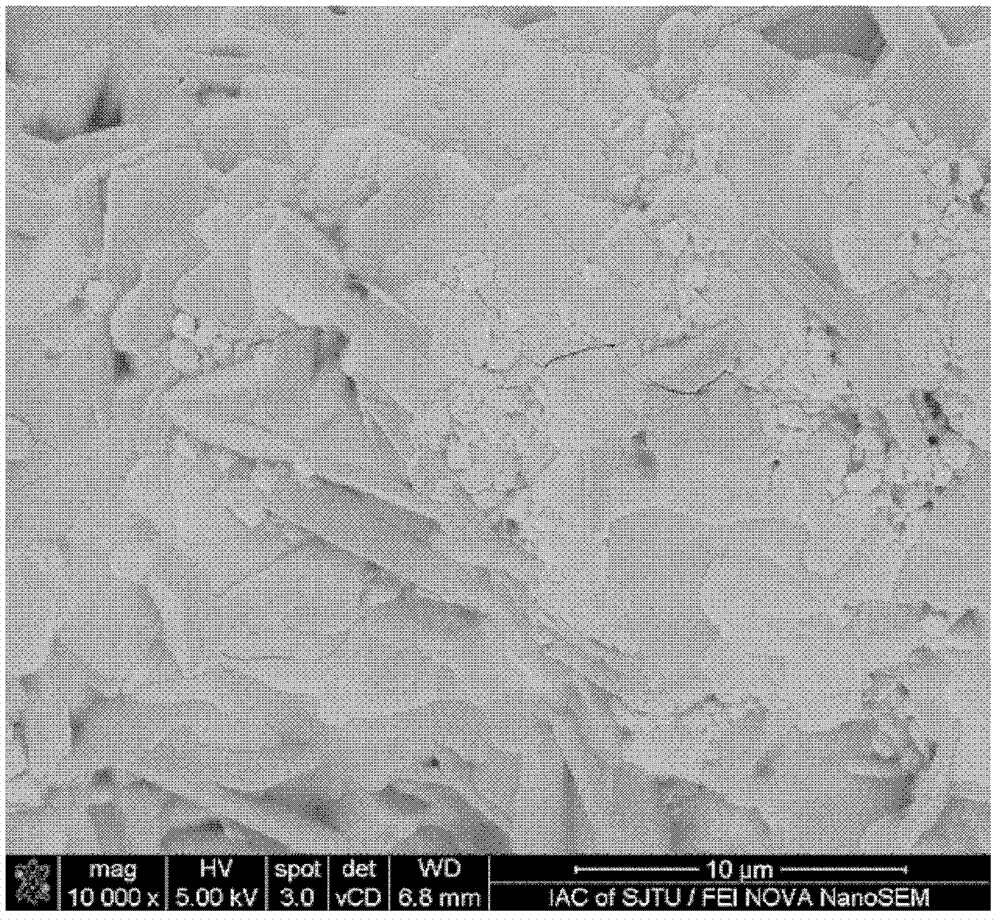

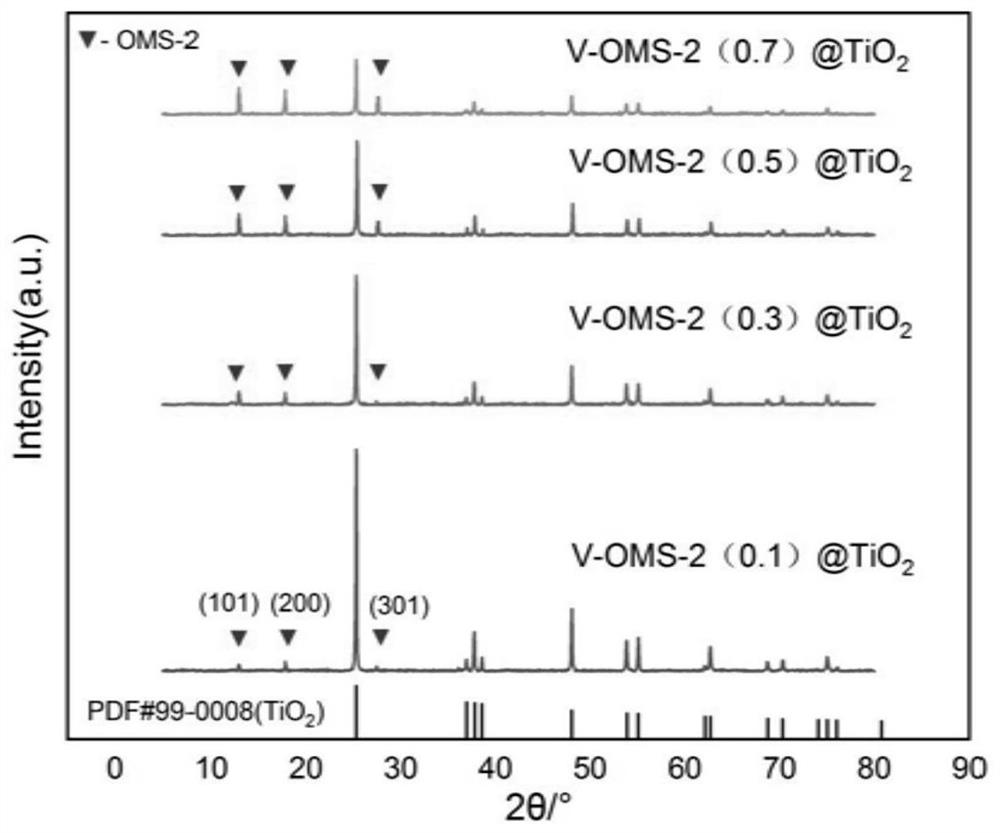

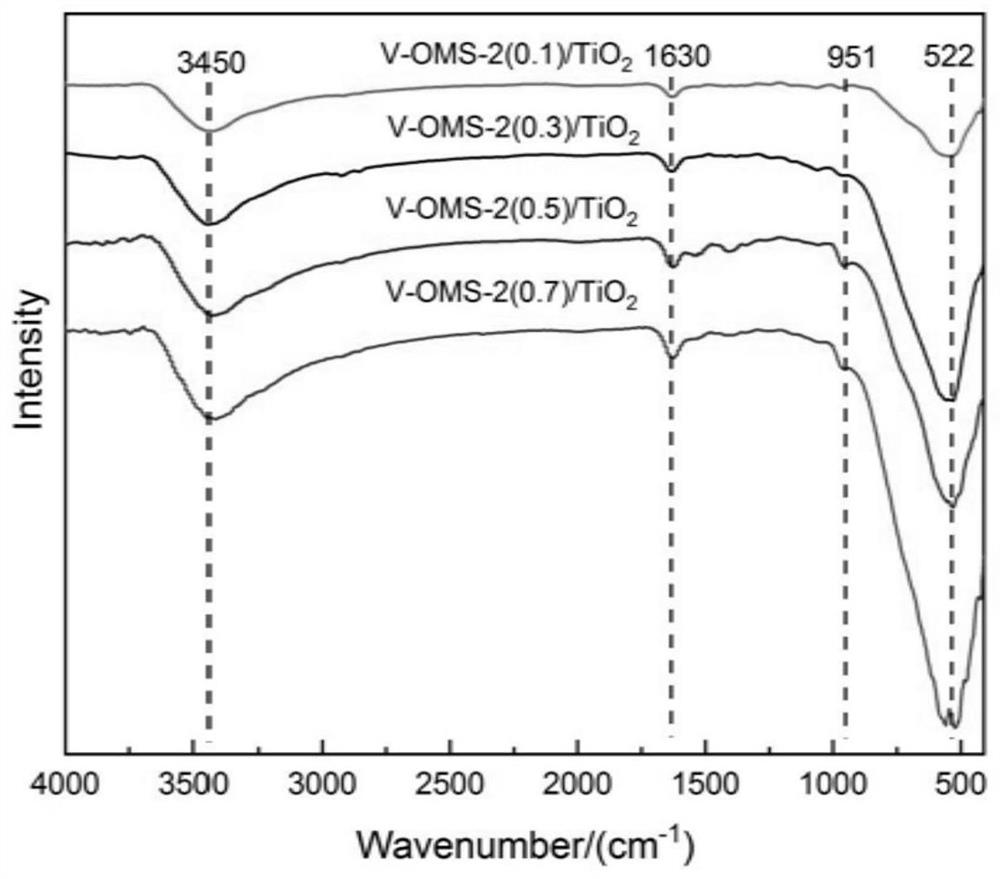

Vanadium-doped OMS-2 loaded TiO2 material as well as preparation method and application thereof

PendingCN114308112AImprove denitrification rateEfficient denitrificationMolecular sieve catalystsDispersed particle separationToxic gasPtru catalyst

The invention discloses a vanadium-doped OMS-2 loaded TiO2 material as well as a preparation method and application thereof, titanium dioxide, a vanadium source, potassium permanganate and a manganese source are dispersed or dissolved in deionized water, and a product V-OMS-2 (at) TiO2 is formed through a hydrothermal method. The OMS-2 loaded TiO2 catalyst can catalyze two toxic gases of nitric oxide and carbon monoxide in flue gas to react at low temperature to generate two non-toxic gases of nitrogen and carbon dioxide, so that the purposes of low-temperature denitration and waste control by waste are achieved, the denitration rate can reach 80% or above at the temperature of 150 DEG C, the denitration rate can reach 90% or above at the temperature of 300 DEG C, and the denitration rate can reach 90% or above at the temperature of 300 DEG C. And the obtained catalyst material has sulfur dioxide resistance, and can maintain a denitration rate of 62.3% at 150 DEG C and a denitration rate of 87.8% at 300 DEG C in the presence of SO2.

Owner:王俊英 +1

120ksi primary grade sulfur-resistant drill pipe and manufacturing method thereof

ActiveCN102330027BSulfur resistanceLow costFurnace typesHeat treatment furnacesChemical elementUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation process of renewable sulfur-resistant fe-mn-ce magnetic adsorbent for mercury removal from flue gas

ActiveCN111282540BImprove mercury removal efficiencyImprove oxygen storage capacityGas treatmentOther chemical processesSorbentPhysical chemistry

The invention relates to a preparation process of a renewable anti-sulfur Fe-Mn-Ce magnetic adsorbent for flue gas demercuration. A high-efficiency mercury removal adsorbent for mercury technology, with strong mercury removal performance, magnetic separation, renewability, and anti-SO 2 Poisoning and other advantages, can achieve efficient mercury removal and recycling of coal-fired flue gas.

Owner:NANJING NORMAL UNIVERSITY

Preparation method, catalyst and application of polycyclic aromatic hydrocarbon hydrogenation catalyst

ActiveCN105772034BSulfur resistanceImprove hydrodesulfurization activityPhysical/chemical process catalystsMolybdenum sulfidesPolycyclic aromatic hydrocarbonPtru catalyst

The present invention provides a polycyclic aromatic hydrocarbon hydrogenation catalyst, which adopts molybdenum disulfide (MoS2) catalyst prepared in a microemulsion system. The molybdenum disulfide catalyst provided by the invention has the advantages of sulfur resistance, high hydrodesulfurization activity, high hydrogenation activity of polycyclic aromatic hydrocarbons, simple process operation and the like for the hydrogenation reaction of polycyclic aromatic hydrocarbons.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com