Patents

Literature

221 results about "Mercury adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury adsorbents compatible as cement additives

InactiveUS20080134888A1Efficient removalReduce distractionsGas treatmentOther chemical processesAluminateSorbent

Solid adsorbents, following their use for mercury removal from flue gas, that do not interfere with the ability of air-entraining additives (such as surfactants) to form stable bubbles when added to fly ash containing the adsorbents. The interference is overcome by heating the materials used in the manufacture of the adsorbent so that magnesium hydroxide and / or one or more alkali compounds containing one or more silicate, aluminate, and / or phosphate moiety, added or already present in the materials, binds multivalent cations present in the materials that could otherwise interfere with the surfactant activity.

Owner:PRAXAIR TECH INC

Regenerative process for removal of mercury and other heavy metals from gases containing H2 and/or CO

ActiveUS20080184884A1Increase release rateRaise regeneration temperatureGas treatmentIsotope separationSorbentCarbonyl sulfide

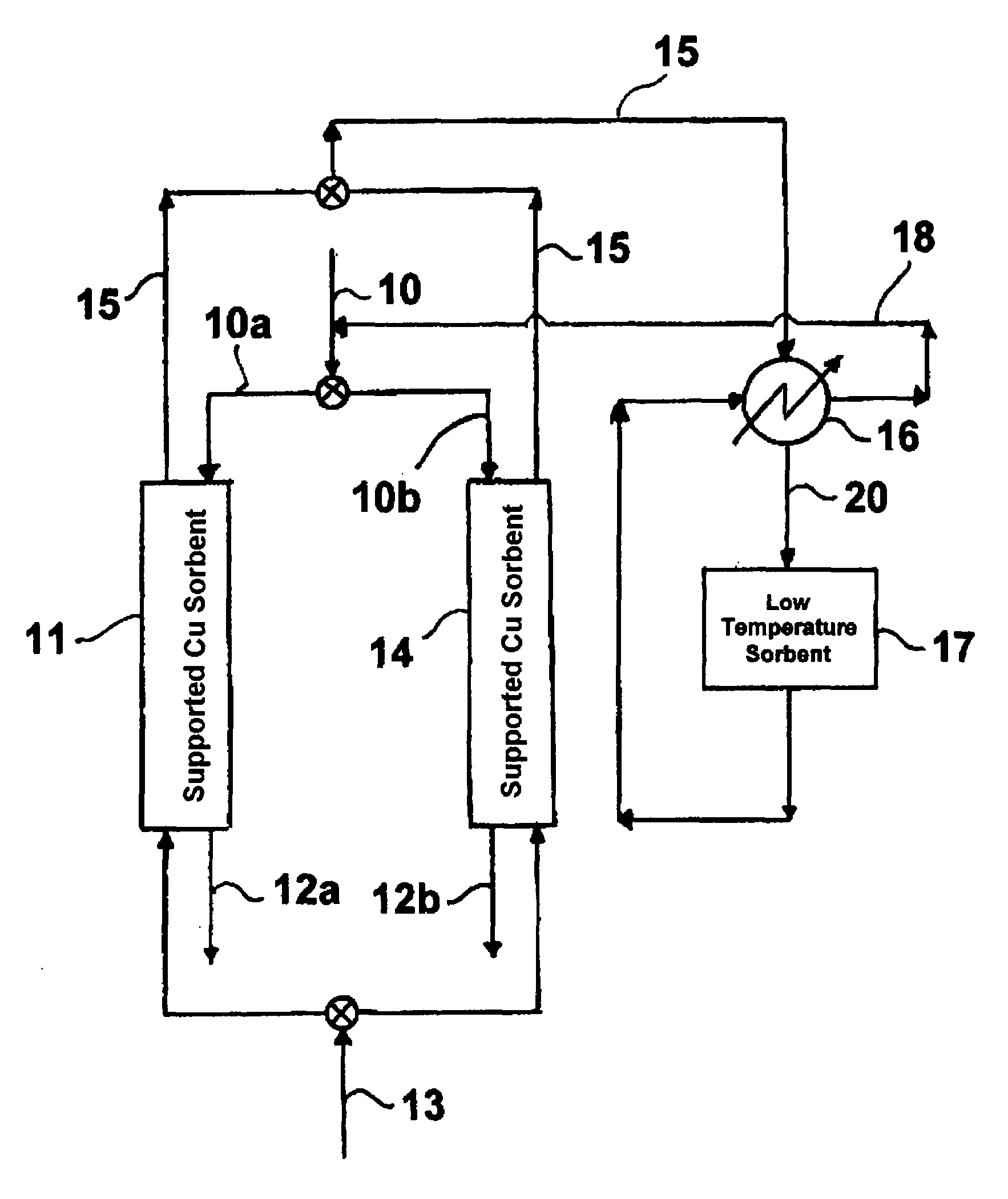

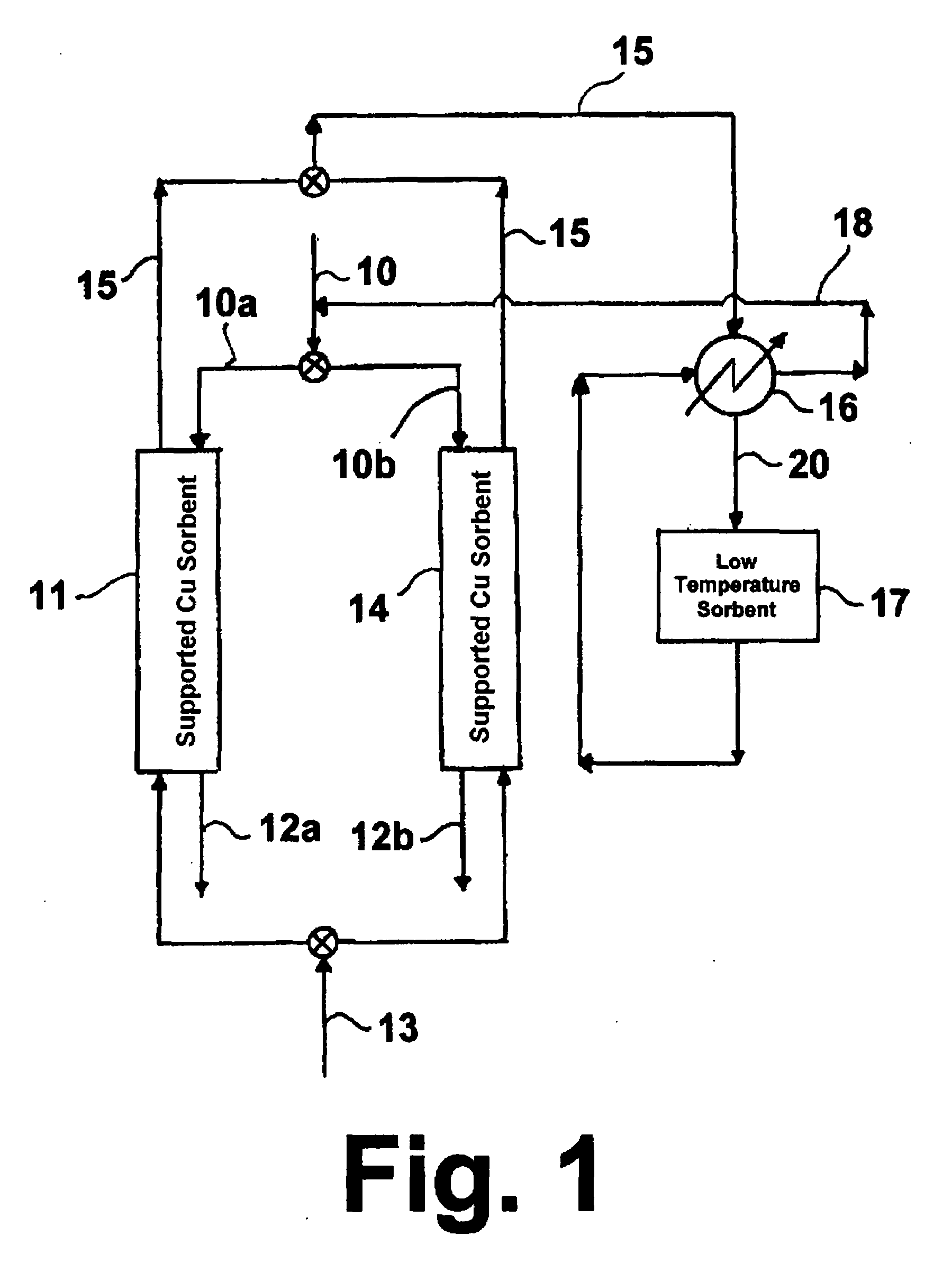

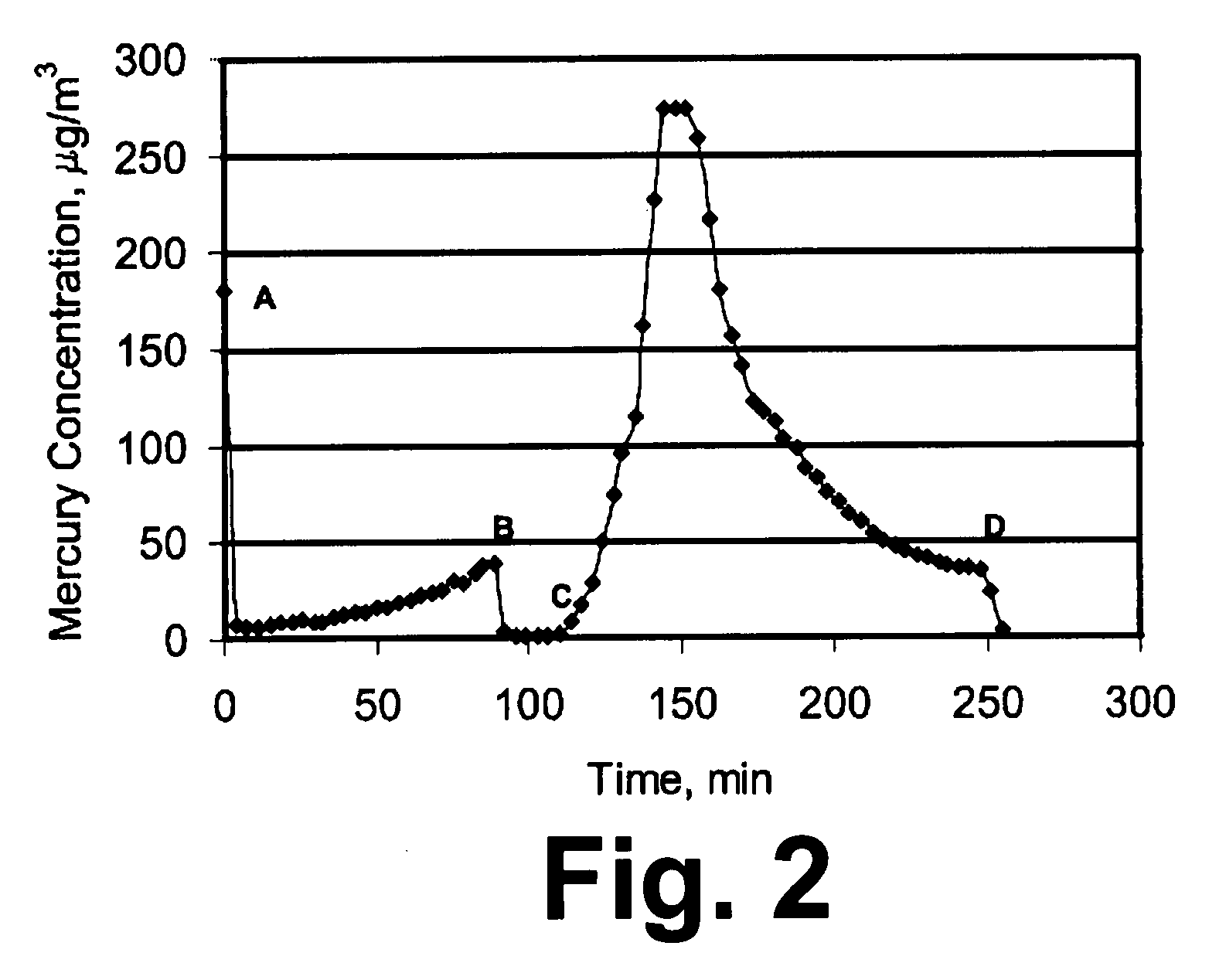

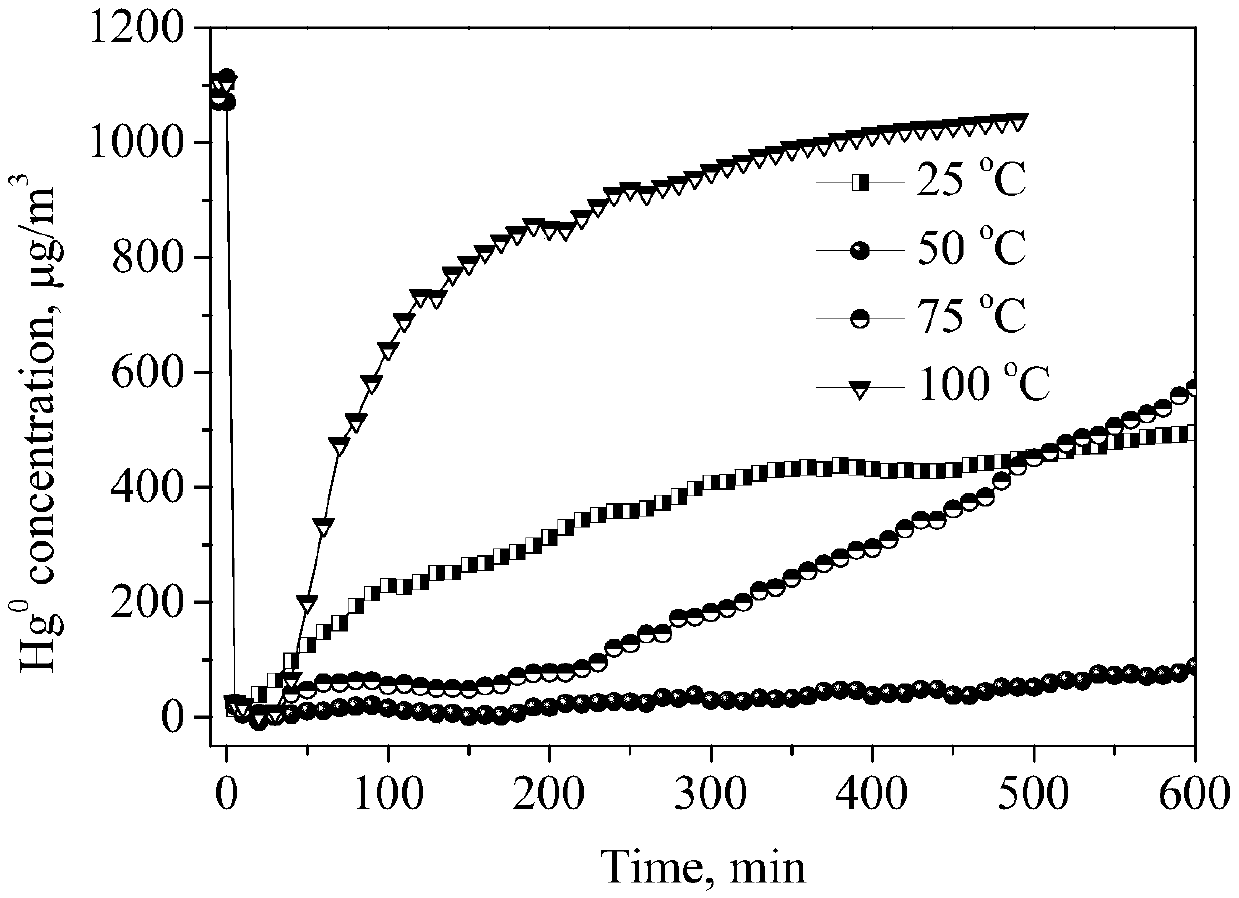

A method for removal of mercury from a gaseous stream containing the mercury, hydrogen and / or CO, and hydrogen sulfide and / or carbonyl sulfide in which a dispersed Cu-containing sorbent is contacted with the gaseous stream at a temperature in the range of about 25° C. to about 300° C. until the mercury concentration in the gaseous stream after contacting the sorbent exceeds a predetermined breakthrough level, signaling a spent sorbent. Arsenic, cadmium and selenium present in the gaseous stream may also be captured along with the mercury. The spent sorbent is then contacted with a desorbing gaseous stream at a temperature equal to or slightly higher than the temperature at which the mercury adsorption is carried out, producing a regenerated sorbent and an exhaust gas comprising released mercury. The released mercury in the exhaust gas is then captured using a high-capacity sorbent, such as sulfur-impregnated activated carbon, at a temperature less than about 100° C. The regenerated sorbent may then be used to capture additional mercury from the mercury-containing gaseous stream. The process may be carried out at pressures in the range of about 1 bar to about 200 bar.

Owner:GAS TECH INST

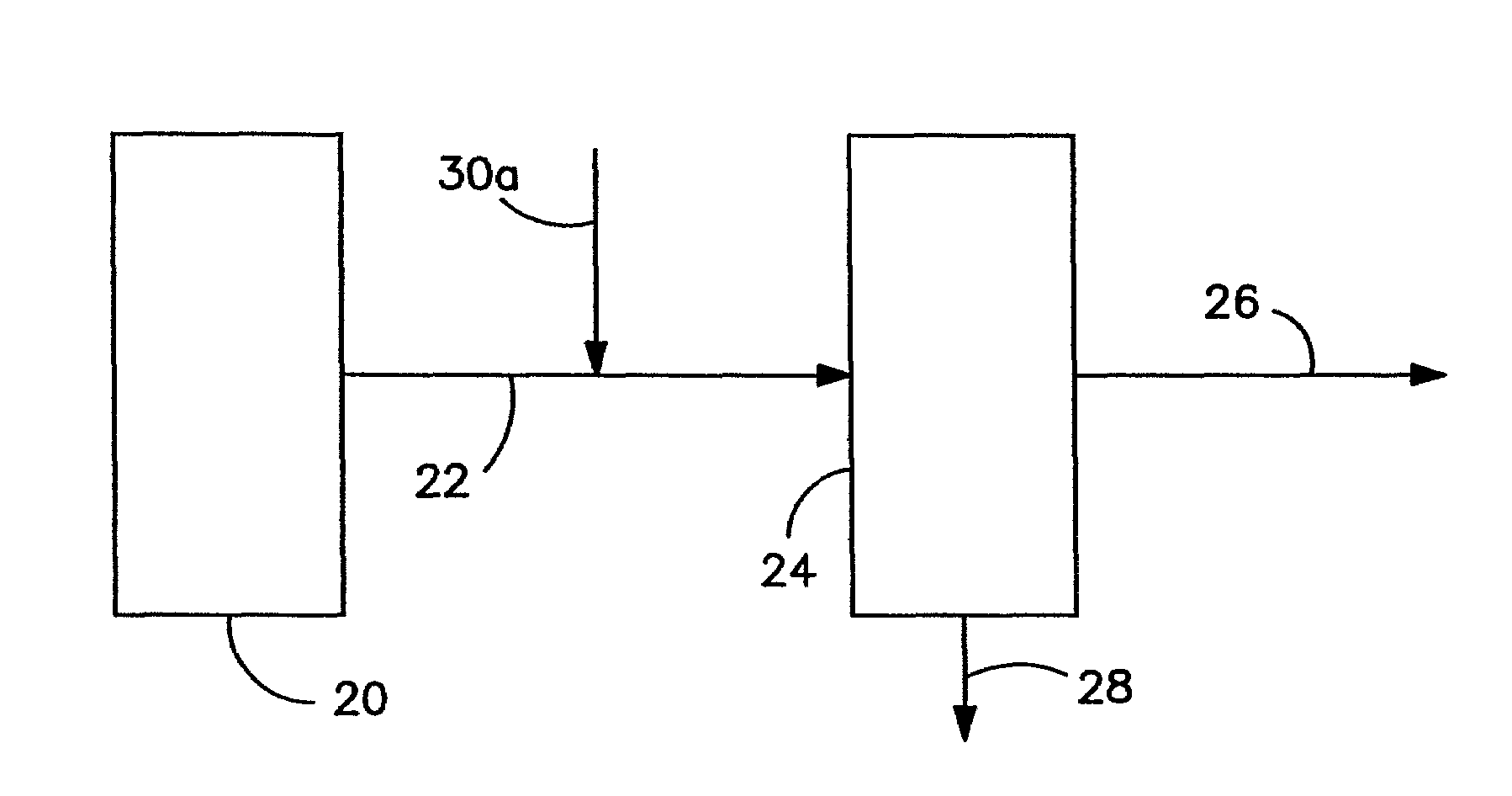

Mercury-removal adsorbent ,method of producing mercury-removal adsorbent, and method of removing mercury by adsorption

InactiveUS20100025302A1Reduce concentrationIncrease volumeGas treatmentOther chemical processesSorbentPotassium iodine

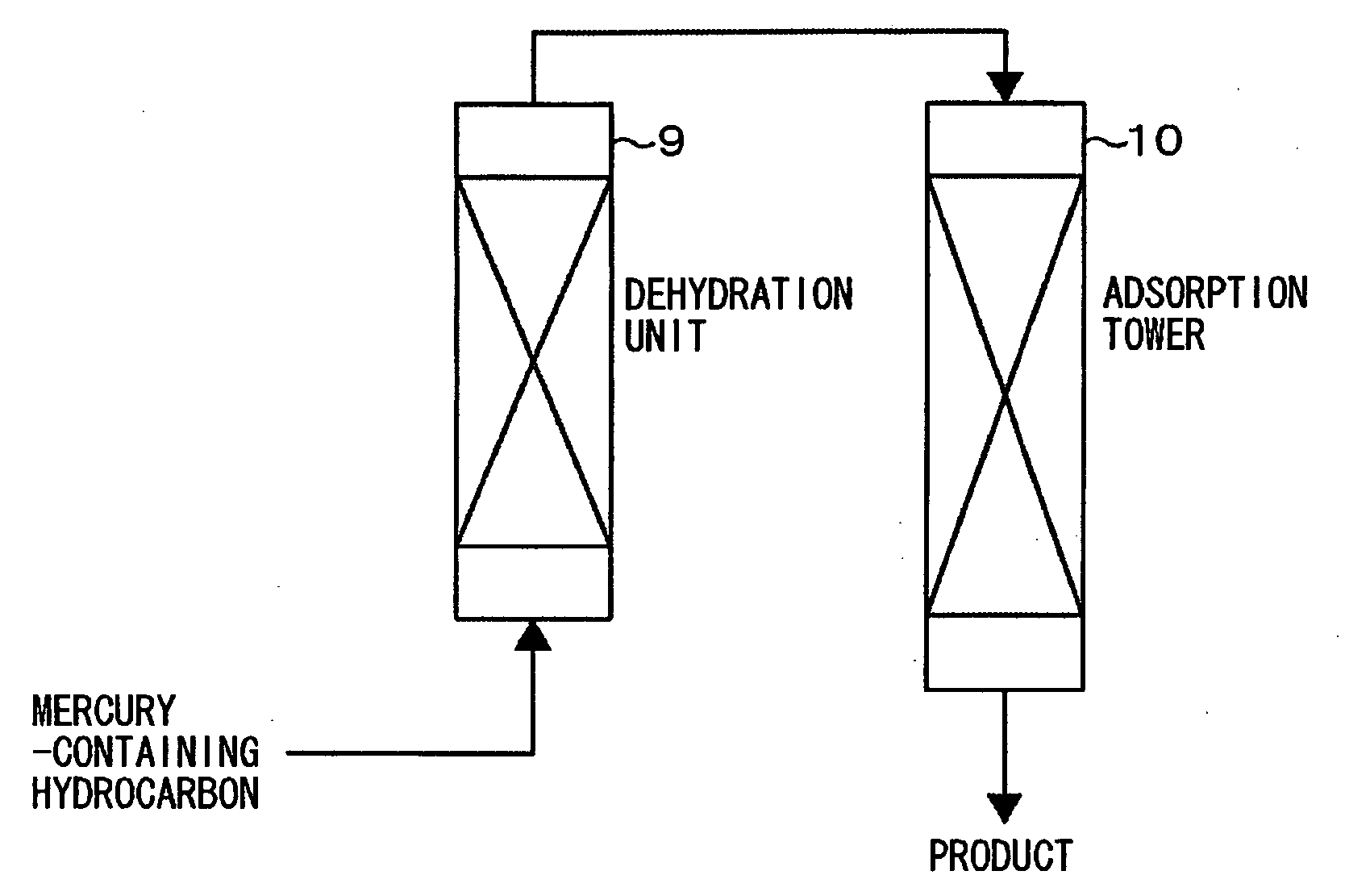

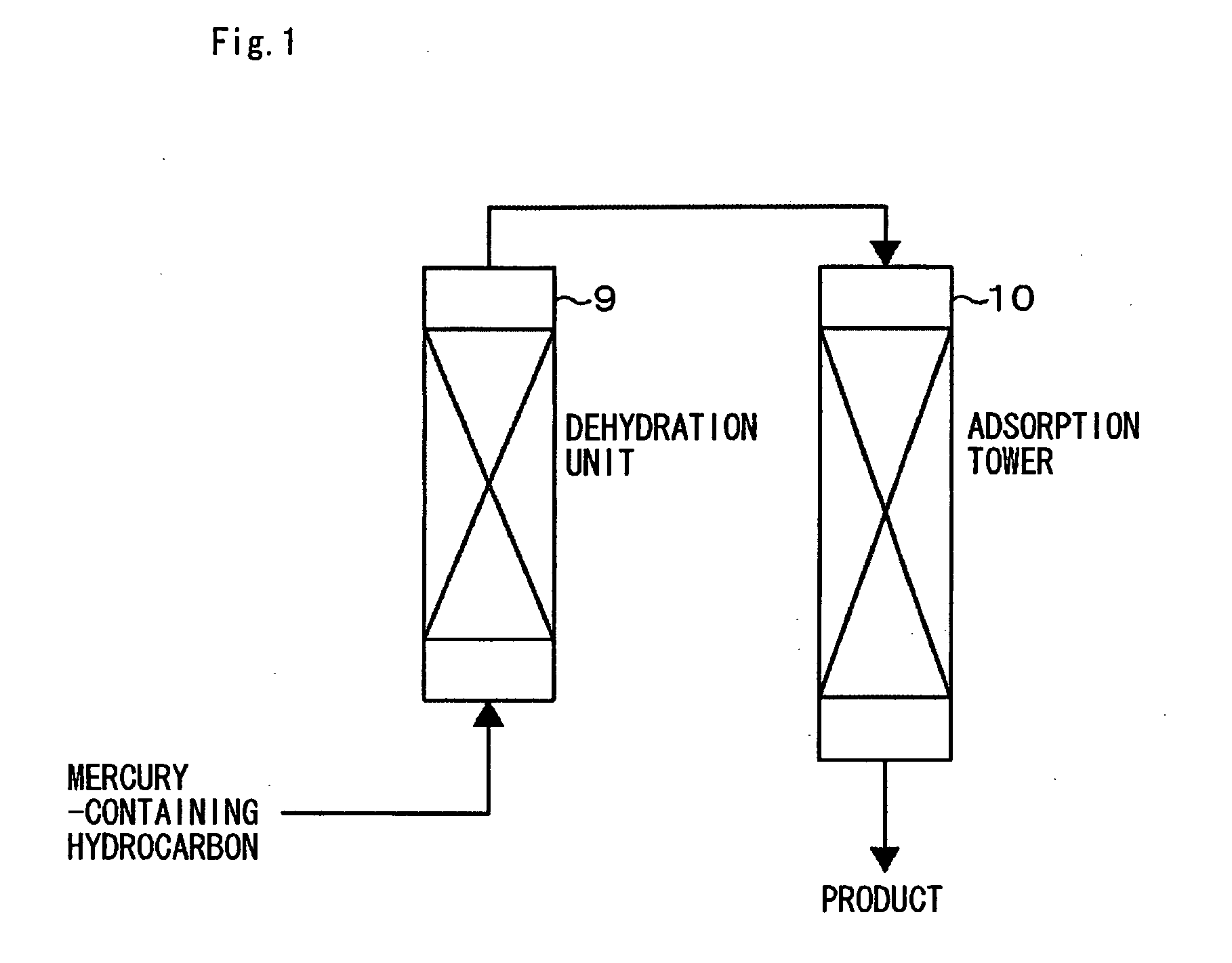

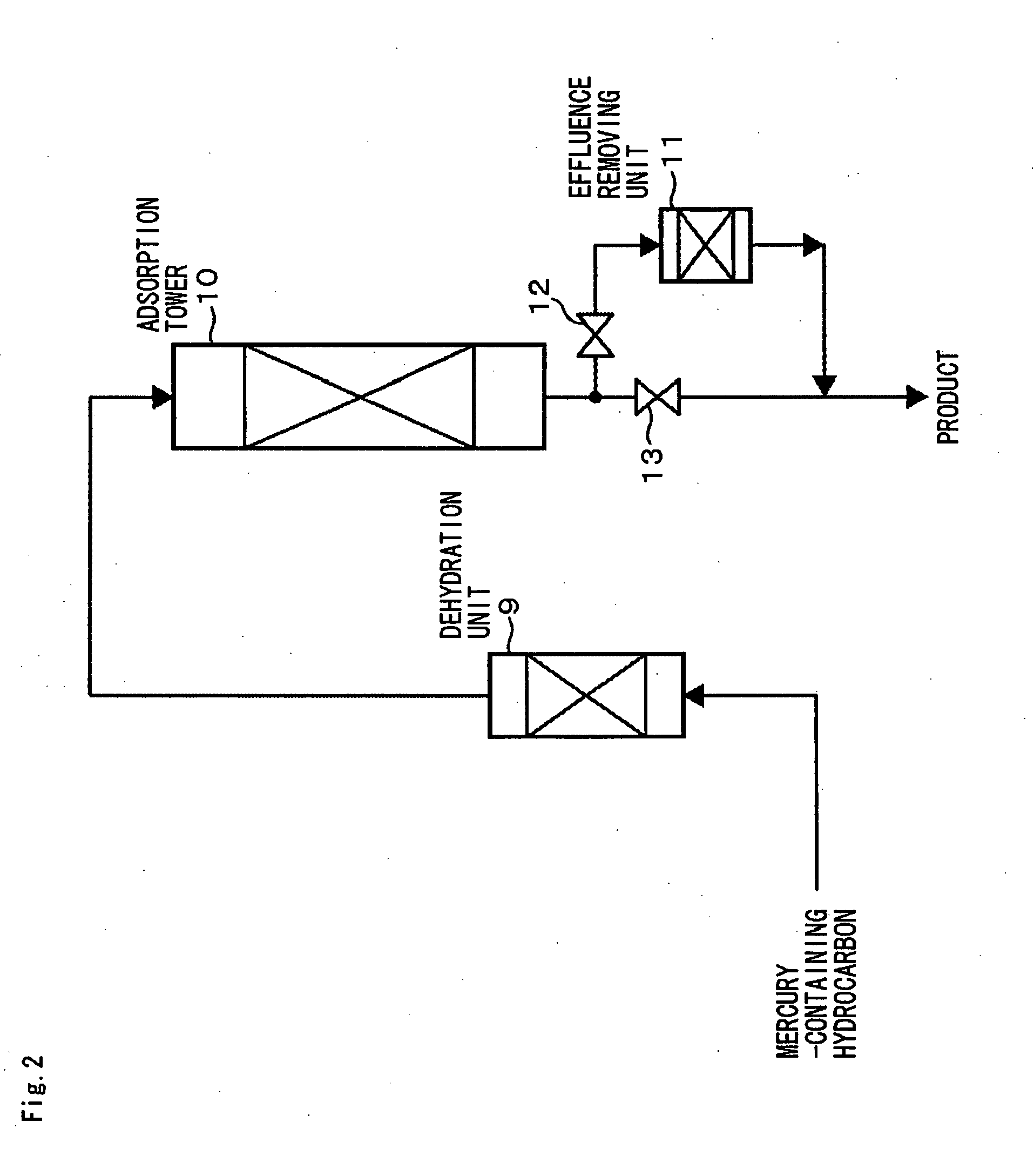

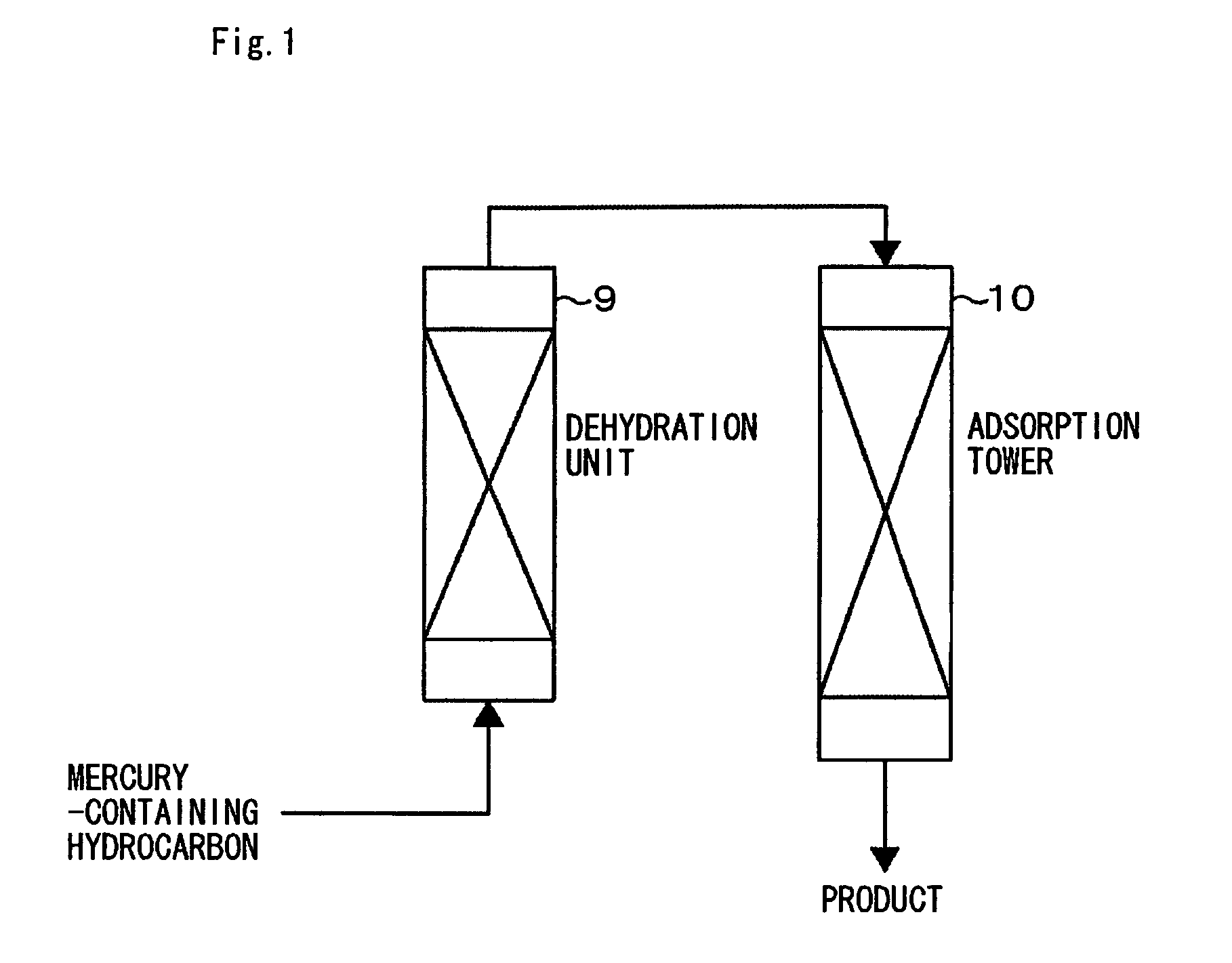

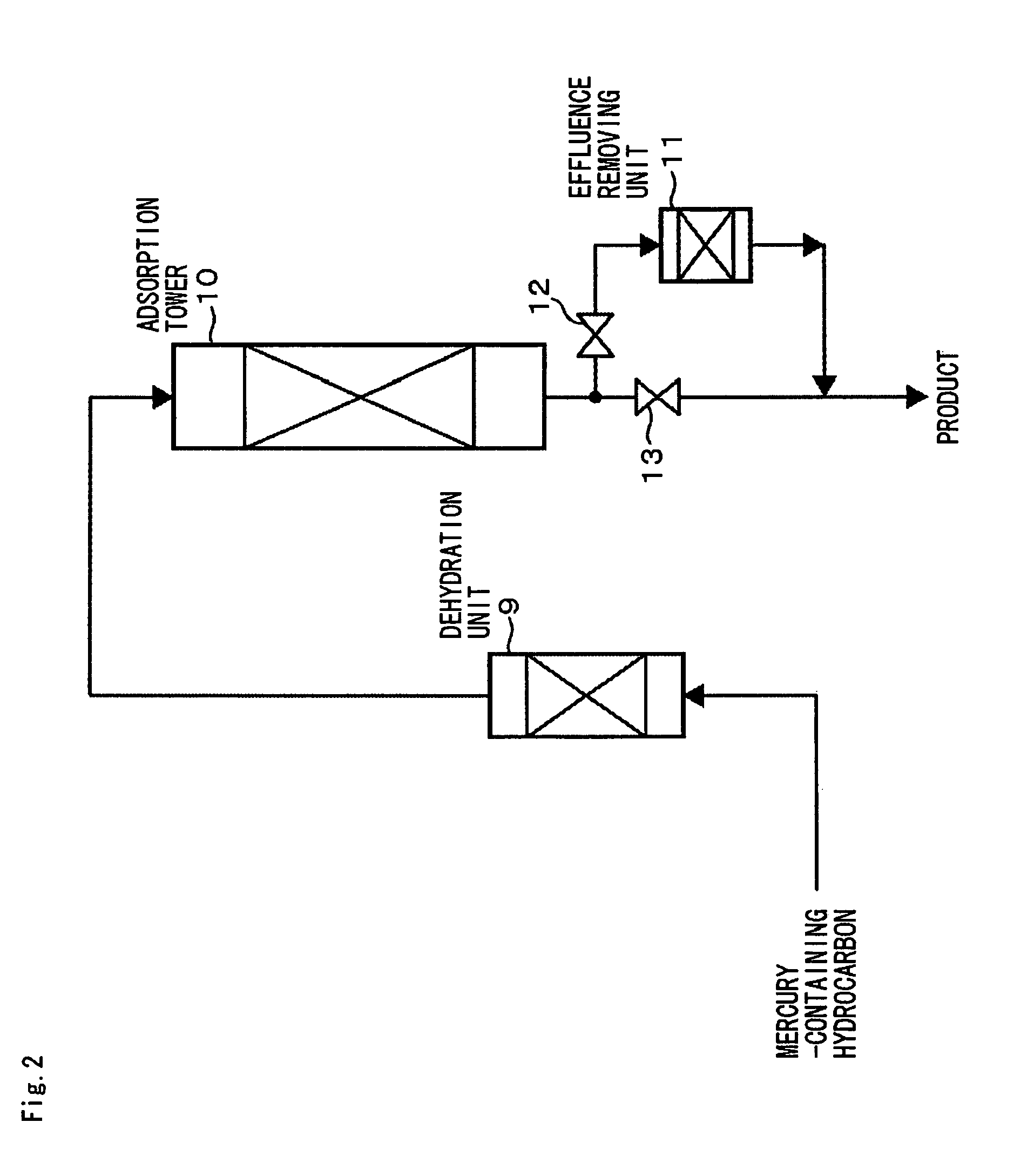

To provide mercury-removal adsorbents, a method of producing mercury-removal adsorbents, and a method of removing mercury by adsorption which are capable of realizing efficient removal of mercury by adsorption from liquid hydrocarbon, thermal power station exhaust combustion gas, natural gas, off gas of various process plants, and so on which contain mercuries in various forms such as elemental mercury, ionic mercury, and organic mercury, and a concomitant hindering mercury adsorption.Mercury-removal adsorbents carrie potassium iodide in an amount of 27 to 70% of a total adsorbent weight, and a volume of pores with a 1 μm pore diameter or more in the mercury-removal adsorbents is 0.6 mL / g or more. These mercury-removal adsorbents are filled in, for example, an adsorption tower 10, and a hydrocarbon liquid is passed therethrough (mercury removal step). In a case where the hydrocarbon liquid contains saturated water, a dehydration unit 9 or the like is installed on a preceding stage of the adsorption tower 10 to dehydrate the hydrocarbon liquid (dehydration step).

Owner:JGC CORP

Promoted ammonium salt-protected activated carbon sorbent particles for removal of mercury from gas streams

ActiveUS20170100692A1Reduce disposalLow costGas treatmentOther chemical processesActivated carbonSorbent

Promoted ammonium salt-protected activated carbon sorbent particles for removal of mercury from gas streams. A method of separating mercury from a mercury-containing gas stream includes contacting a mercury-containing gas stream with an activated carbon sorbent including promoted ammonium salt-protected activated carbon sorbent particles, to form a mercury-sorbent composition. The method also includes separating at least some of the mercury-sorbent composition from the mercury-containing gas stream, to give a separated gas.

Owner:MIDWEST ENERGY EMISSIONS CORP

Modified vermiculite mercury removal adsorbent, preparation method and application thereof

InactiveCN104888717AIncrease the areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionMicrowaveSorbent

Belonging to the technical field of wastewater treatment, the invention in particular relates to a modified vermiculite mercury removal adsorbent, a preparation method and application thereof. The method includes: taking vermiculite as the main raw material, soaking vermiculite with thickness of 0.6-1mm and a particle size of 7-8mm with 25% hydrogen peroxide, performing heating, then placing the vermiculite in certain power microwave to perform heating, thus obtaining expanded vermiculite, grinding the expanded vermiculite to less than 100 meshes, then conducting further modification with a certain amount of chitosan to obtain the modified vermiculite adsorbent with a chitosan loading capacity of 0.01g / g-0.05g / g, and applying the adsorbent for treatment of mercury-containing wastewater. The modified vermiculite mercury removal adsorbent prepared by the method provided by the invention has the advantages of low price, simple operation and the like, and mercury removal examples prove that the adsorbent has fast adsorption speed and strong adsorption capacity to mercury ions, and can be used for treatment of mercury-containing wastewater with a wide concentration range.

Owner:SHIHEZI UNIVERSITY

Solid-phase synthetic procedure for attapulgite-crosslinked chitosan composite adsorbent

ActiveUS9914111B1Improve adsorption capacityLow priceOther chemical processesAluminium silicatesCrosslinked chitosanSolubility

The present invention relates to a mercury-containing wastewater treatment technology field, in particular to an attapulgite-crosslinked chitosan composite adsorbent and its solid-phase synthetic method. The attapulgite-crosslinked chitosan composite mercury adsorbent in the invention is synthesized by the method of adding chitosan and glutaraldehyde in batches. In consideration of the limited solubility of chitosan, batch addition can not only dissolve chitosan, but also minimize the use of organic acid, resulting in less discharge of wastewater and waste gas, which is suitable for large-scale industrial production. The prepared mercury adsorbent can be applied to the removal of mercury ions in the wastewater owing to the excellent adsorptive property and regeneration performance. Meanwhile, the solid-phase synthetic procedure for preparing the mercury adsorbent is simple, easy to handle and environmental-friendly. Moreover, the product cost is greatly reduced due to the use of attapulgite.

Owner:WUHU GEFENG GREEN TECH RES CENT CO LTD +1

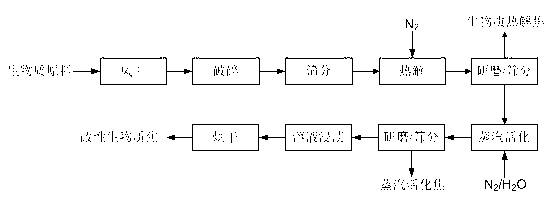

Biomass carbon-based flue gas demercuration adsorbent and preparation method thereof

InactiveCN103252212AControl pollution dischargeRealize the double effect of protectionOther chemical processesDispersed particle separationMercury pollutionNitrogen gas

The invention discloses a biomass carbon-based flue gas demercuration adsorbent and a preparation method thereof. Based on comprehensive utilization of biomass resources and control of flue gas mercury pollutants, the emission of flue gas mercury is controlled by using modified biomass tar as the adsorbent. The biomass carbon-based flue gas demercuration adsorbent with a developed pore structure and abundant surface functional groups is prepared through treating processes of pyrogenic decomposition (at 400-800 DEG C in a nitrogen atmosphere) and steam activation (at an activation temperature of 800 DEG C with an N2-to-H2O mole ratio of 1: 1) of biomass raw material, modified reagent (H2O2, ZnCl2, NaCl or NaBr) solution dipping, and the like; and the biomass carbon-based flue gas demercuration adsorbent has the characteristics of wide adsorbent raw material source, simple preparation process, low cost, high demercuration efficiency and the like, and is suitable for coal-fired power plants and management of flue gas mercury emission in the fields of waste incineration and the like. The carbon-based flue gas demercuration adsorbent is prepared by adopting biomass, so that the emission reduction of mercury pollution can be realized, and the renewable resource of biomass can be utilized efficiently in a large scale; and the biomass carbon-based flue gas demercuration adsorbent has obvious economic benefit, environmental benefit and social benefit.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing rare-earth element doped composite metal oxide mercury removal catalyst

InactiveCN101602018AImprove adsorption capacityImprove catalytic performanceOther chemical processesDispersed particle separationRare-earth elementTrapping

The invention relates to a method for preparing rare-earth element doped composite metal oxide mercury removal catalyst in the technical field of chemical engineering and environmental protection. The method prepares a mercury removal catalyst by rare-earth element doped composite metal oxide to realize double functions of zero-valent mercury adsorption trapping and catalytic oxidation, which not only can be sprayed into smoke gas in a powder mode to trap the zero-valent mercury onto the mercury removal material, but also can be embedded with smoke gas in a static bed mode to cooperate with oxidant to catalytically oxidize the zero-valent mercury into divalent mercury, and can be absorbed by downstream desulfurization equipment. The mercury removal material prepared by the method has better adsorption capability, catalytic function and sulfur resistance on the zero-valent mercury, and has simple application process, convenient operation and maintenance.

Owner:SHANGHAI JIAO TONG UNIV +1

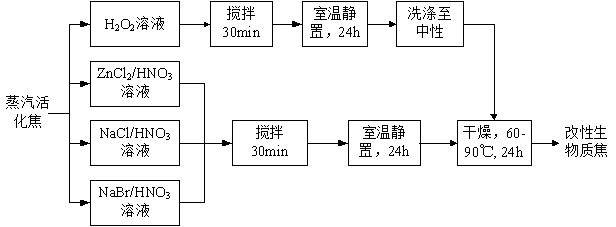

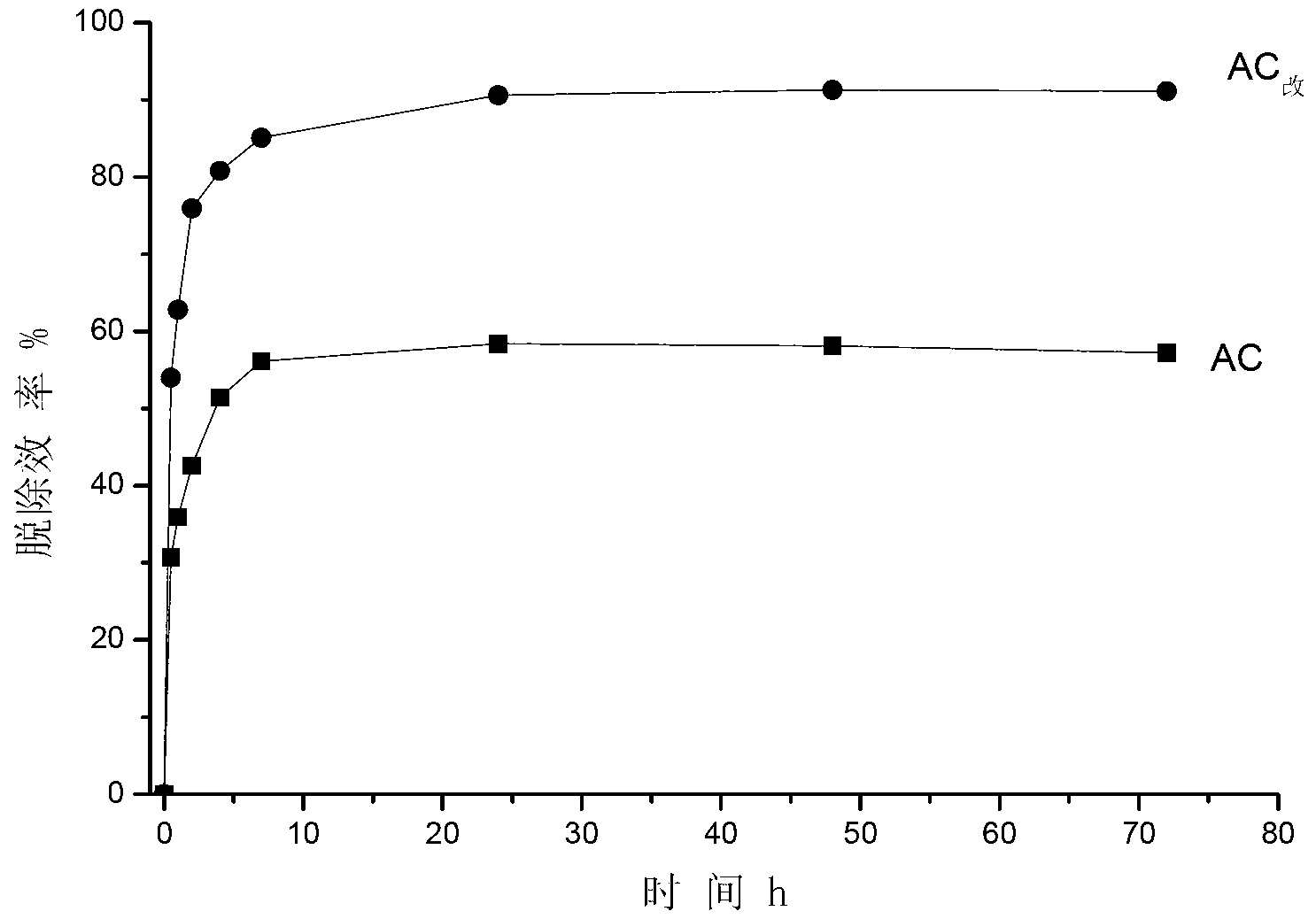

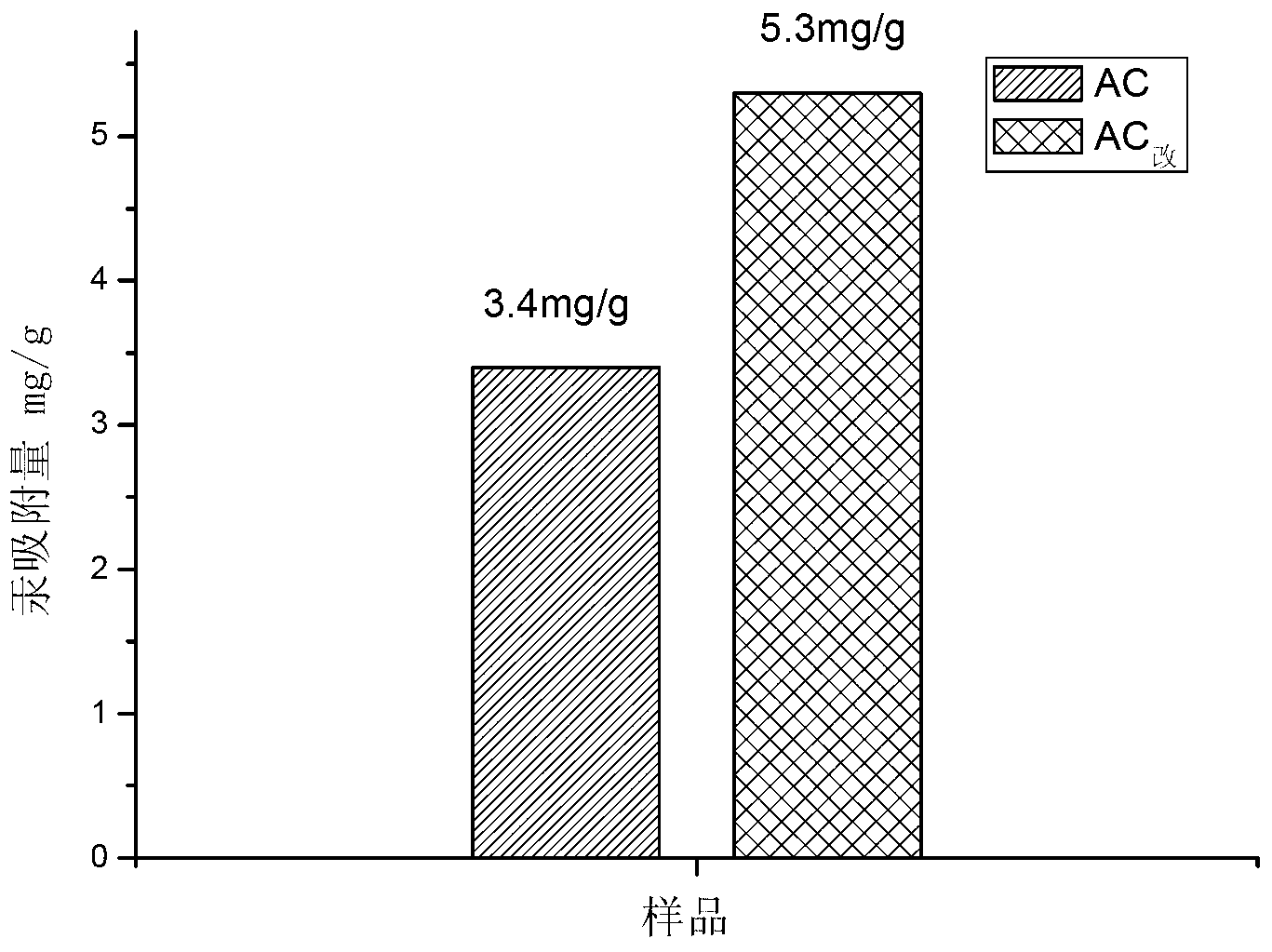

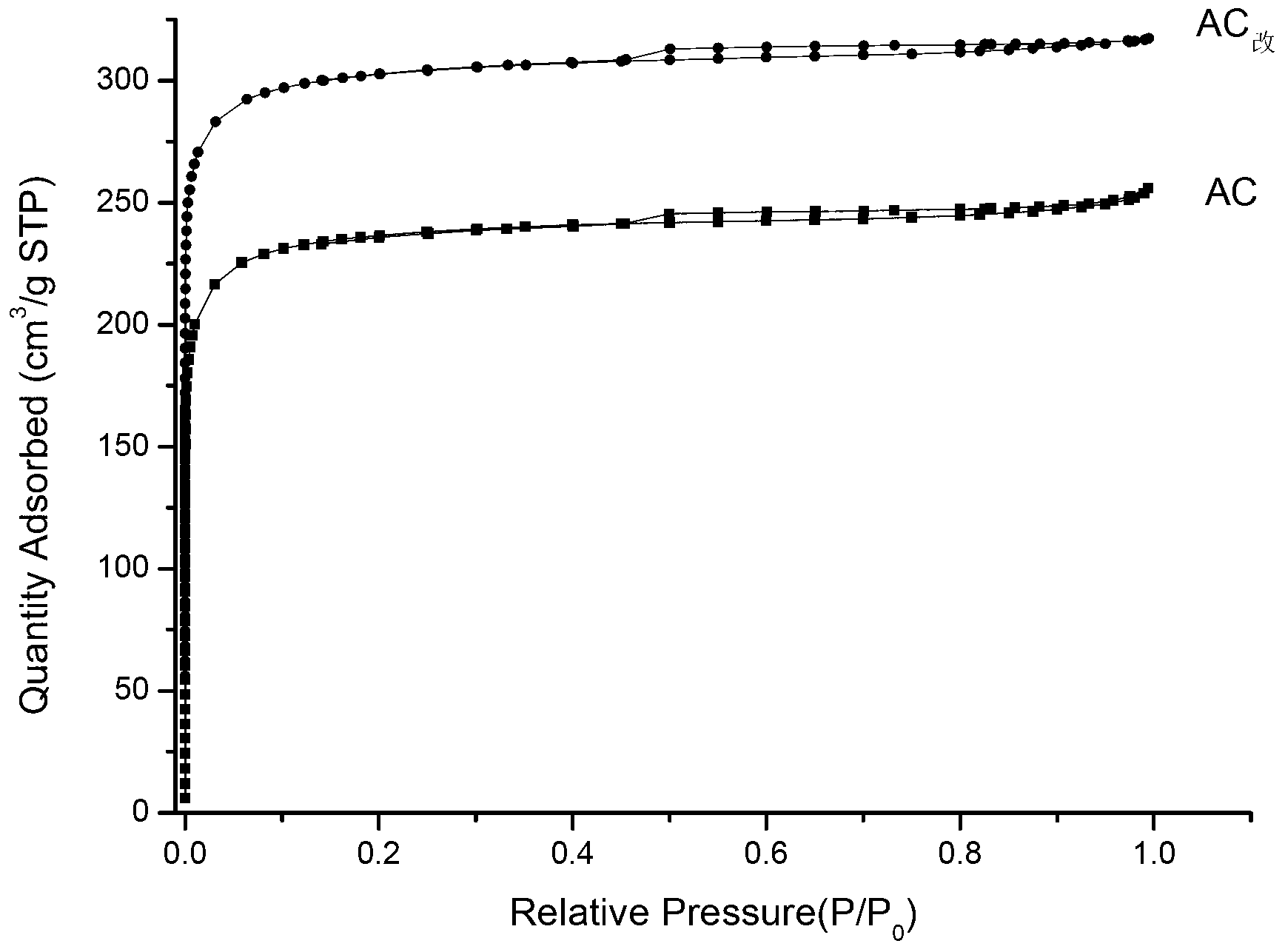

Preparation method of special modified active carbon for removing mercury

ActiveCN103223330AImprove mercury removal performanceSimple operation processOther chemical processesDispersed particle separationDistilled waterMercury adsorption

The invention discloses a preparation method of special modified active carbon for removing mercury. The method comprises the following steps of: washing wooden particle active carbon through hydrochloric acid and distilled water, and then drying the washed wooden particle active carbon to standby; heating the active carbon and the hydrogen peroxide with the concentration being 25 to 30wt% at the temperature of 50 to 70 DEG C for 2 to 4h according to the mass-to-volume ratio of 6g:(15-10)ml, and then carrying out the ultrasonic treatment on the active carbon for 20 to 40min; and standing, filtering, drying, washing and drying the active carbon to obtain the special modified active carbon for removing the mercury. The special modified active carbon has high mercury removal efficiency, and the maximal mercury adsorption volume can reach 5.3mg / g and is 1.5 times that of unmodified active carbon.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

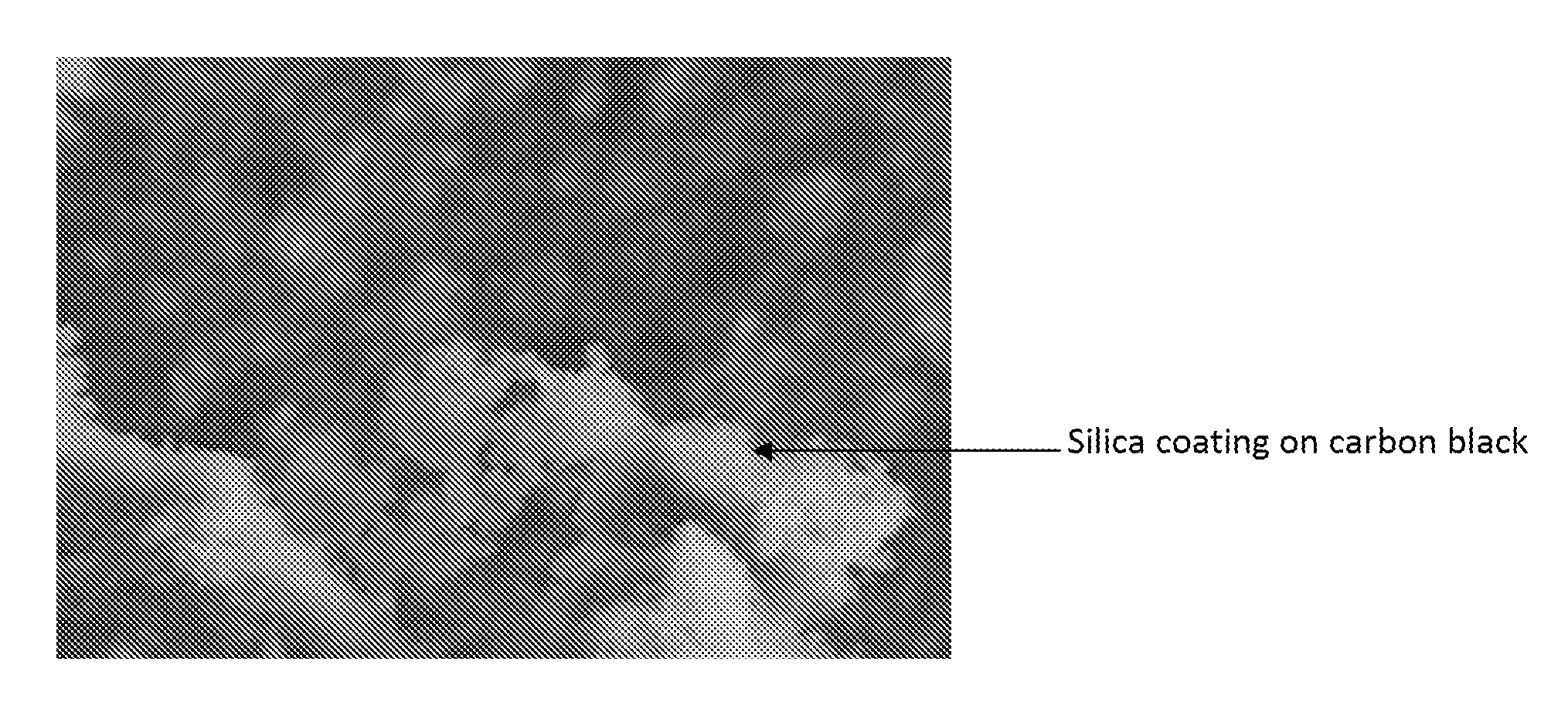

Nanoparticle sorbent for efficient mercury remediation from contaminated water

A new class of sorbents for the removal of mercury from contaminated water. The optimum structure of the sorbent particles and a method to produce the same is described. The newly developed carbon-based particles are differentiated from other sorbent particles by their high accessible surface area and high affinity towards mercury ions that leads to faster and higher mercury adsorption. The sorbent is based on carbon particles with a metal-oxide coating on the surface. The metal-oxide is coated on the surface of carbon, using a solution-based method. The metal-oxide coated carbon was further modified with sulfur molecules, to increase its mercury removal capacity.

Owner:NORTHERN ENG IND PLC

Modified biomass activated coke mercury removal adsorbent and preparation method thereof

ActiveCN103480336ADoes not affect the high-efficiency physical mercury adsorption capacityImprove chemical mercury adsorption conversion capacityOther chemical processesDispersed particle separationPhosphoric acidMercury adsorption

The invention discloses a modified biomass activated coke mercury removal adsorbent and a preparation method thereof. The mercury removal adsorbent is biomass activated coke undergoing phosphoric acid activation and halogenated ammonium salt modification dual treatment. The preparation method includes: immersing biomass particles into a phosphoric acid solution to conduct continuous stirring impregnation, performing filtering and drying, then under an N2 atmosphere, carrying out pyrolysis activation on the biomass particles subjected to phosphoric acid impregnation treatment; then conducting washing till the filtrate has a pH value of 6-7, and performing drying under 45-50DEG C; immersing the biomass activated coke into a halogenated ammonium salt solution, and carrying out continuous stirring impregnation for 1-2h; and conducting filtering and drying so as to obtain the modified biomass activated coke mercury removal adsorbent, which has the advantages of convenience and simplicity, less pollution, easy industrial popularization and the like.

Owner:SOUTHEAST UNIV

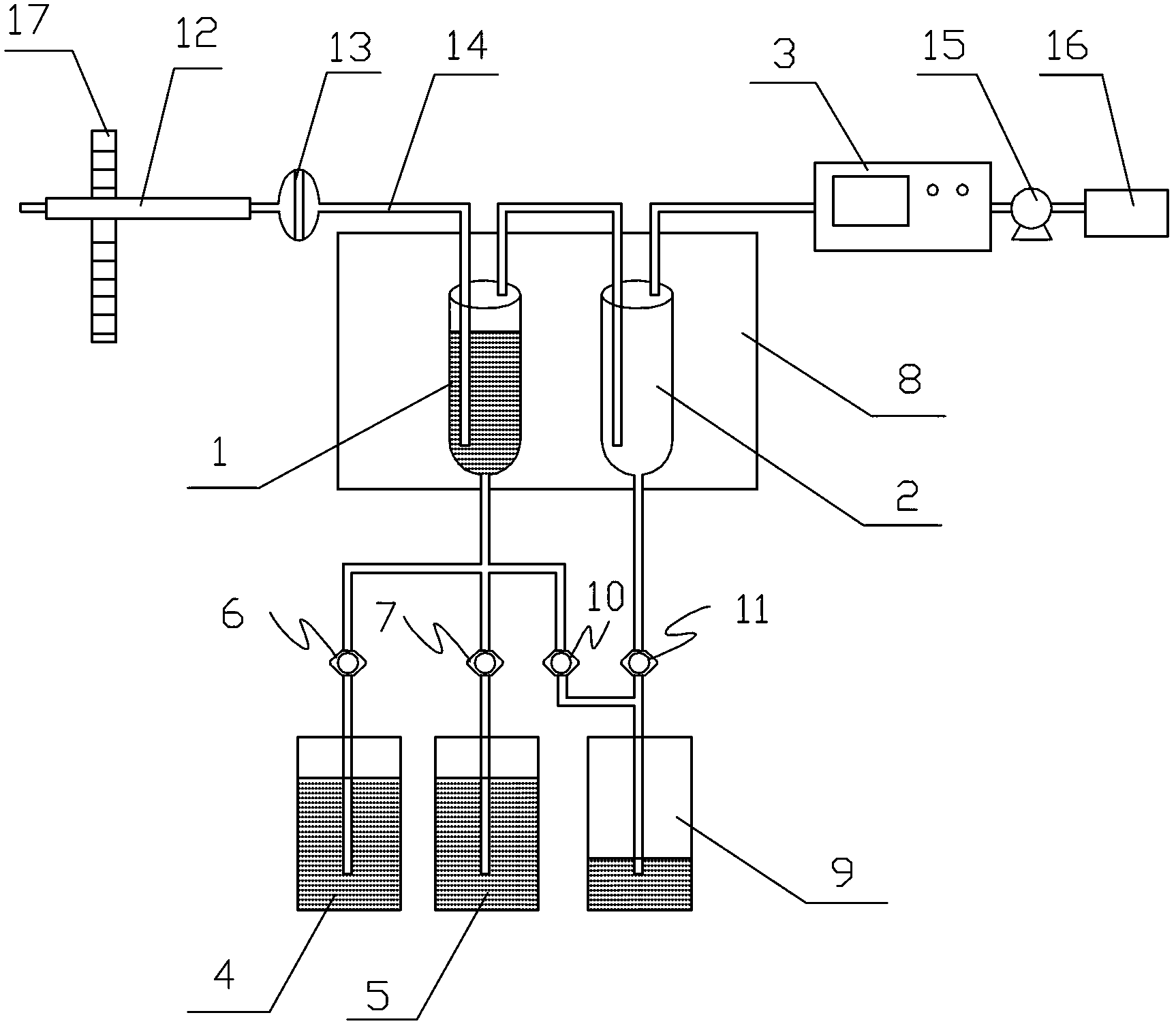

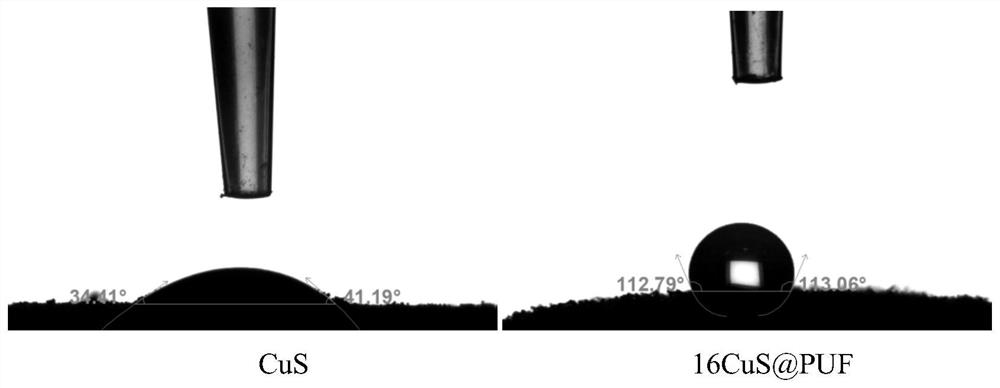

A mercury-containing fumes emission continuous monitoring system and a monitoring method thereof

InactiveCN103293326AFew samplesRealize online automatic continuous monitoringMaterial analysisElectricityPeristaltic pump

Owner:HANGZHOU AADTECH

Mercury adsorbents compatible as cement additives

InactiveUS7767007B2Promote formationImprove adsorption capacityGas treatmentSolid waste managementAluminatePhosphate

Solid adsorbents, following their use for mercury removal from flue gas, that do not interfere with the ability of air-entraining additives (such as surfactants) to form stable bubbles when added to fly ash containing the adsorbents. The interference is overcome by heating the materials used in the manufacture of the adsorbent so that magnesium hydroxide and / or one or more alkali compounds containing one or more silicate, aluminate, and / or phosphate moiety, added or already present in the materials, binds multivalent cations present in the materials that could otherwise interfere with the surfactant activity.

Owner:PRAXAIR TECH INC

Modified organic metal framework used for efficiently adsorbing elemental mercury in flue gas

InactiveCN105294749AHigh-efficiency and high-capacity adsorptionGroup 4/14 element organic compoundsOther chemical processesTetrachlorideMetal framework

The chemical formula of a modified organic metal framework used for efficiently adsorbing elemental mercury in flue gas is Zr6O4(OH)4[C6H2M2(CO2)2]6 or Zr6O4(OH)4[C6H3M(CO2)2]6, wherein M is Br or Cl or I. A preparation method includes the steps that zirconium tetrachloride serves as an MOF metal center, terephthalic acid series ligands provided with a mercury affine substituent group serve as active organic ligands, and a mercury affine active MOF series is synthesized; the modified organic metal framework can be used for efficiently removing elemental mercury in the flue gas. The modified organic metal framework has the advantages that 2-chlorine terephthalic acid with mercury affine functional group and the other three organic ligands are adopted for synthesizing an active MOP series, a mercury static adsorption experiment represents that the demercuration efficiency of active MOF elemental mercury is larger than 90%. By means of the modified organic metal framework, the efficient and high-amount elementary mercury adsorption characteristic is given, and the modified organic metal framework is a flue gas demercuration adsorption material with good application prospects.

Owner:HEBEI UNIV OF TECH

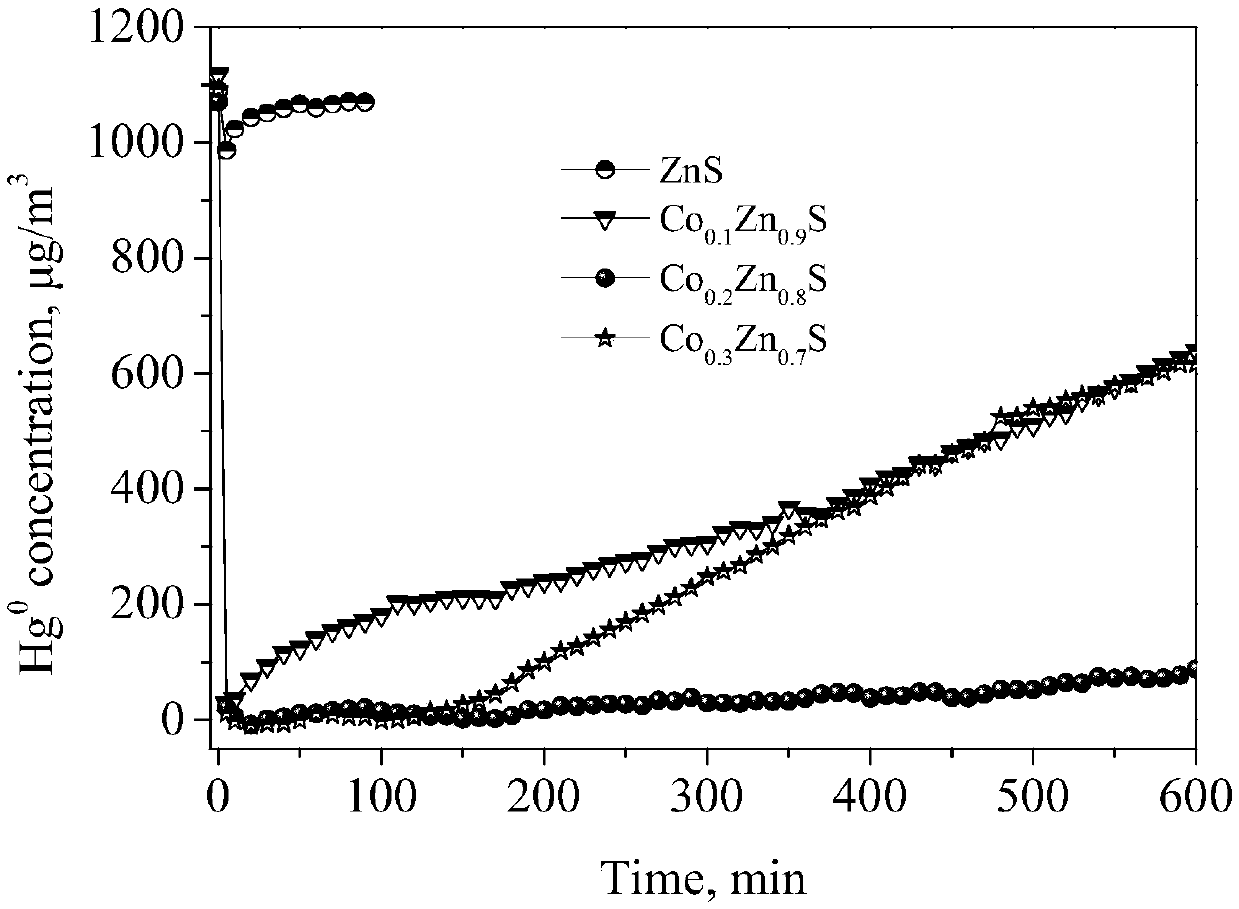

Zinc sulfide based mercury adsorbent for flue gas zero-valent mercury capturing and preparation method of zinc sulfide based mercury adsorbent

ActiveCN109092239ASimple processMild operating conditionsGas treatmentOther chemical processesSorbentFlue gas

The invention relates to a zinc sulfide base mercury adsorbent for flue gas zero-valent mercury capturing and a preparation method of the zinc sulfide based mercury adsorbent. The adsorbent is a cobalt-doped zinc sulfide mercury adsorption material CoxZn1-xS, in the formula, x represents the stoichiometric ratio of cobalt in a solution, and the stoichiometric ratio is 0.1-0.3. The preparation method comprises the following steps: (1) dissolving a cobalt salt and a zinc salt of a certain mole ratio into deionized water so as to obtain a mixed solution; (2) mixing and stirring the mixed solutionwith a precipitant; (3) putting a suspension liquid into a reactor, and carrying out heating treatment on the reactor in a baking oven; (4) repeatedly washing the obtained precipitate with deionizedwater, and drying, thereby obtaining the zinc sulfide based mercury adsorbent. Compared with the prior art, the preparation method is wide in raw material source, simple and controllable in preparation process and gentle in reaction condition, and the prepared adsorbent has a mercury adsorption capability which is improved by dozens of times when being compared with pure zinc sulfide, in additionhas a very good anti-SO2 influence property, is capable of maintaining certain high activity within a long time, and is particularly applicable to adsorption and removal of zero-valent mercury in a metallurgical flue gas.

Owner:SHANGHAI JIAO TONG UNIV

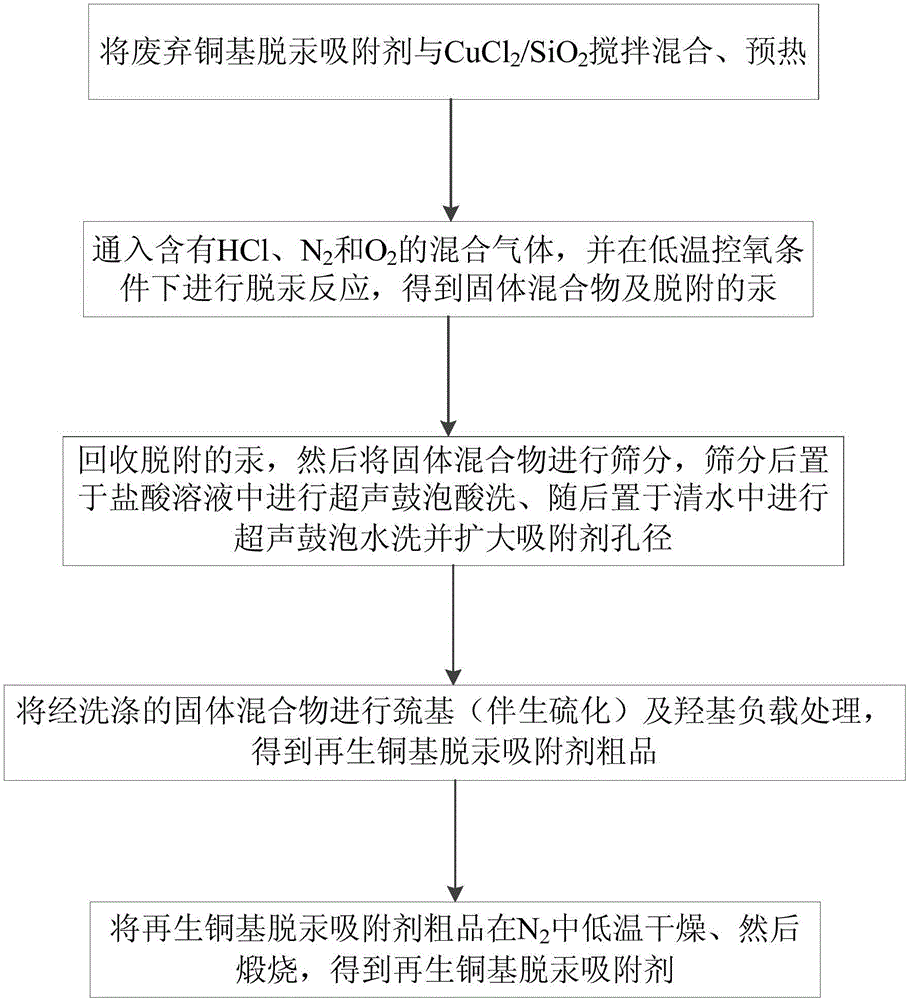

Demercuration and regeneration method for copper-based demercuration adsorbent

ActiveCN106215845AAchieve regenerationSolve the problem that cannot be recycledOther chemical processesGaseous fuelsSorbentShielding gas

The invention provides a demercuration and regeneration method for a copper-based demercuration adsorbent. The demercuration and regeneration method for the copper-based demercuration adsorbent includes the following steps that the used copper-based demercuration adsorbent and a catalyst are mixed and preheated, then mixed gas containing oxygen, hydrogen chloride and shielding gas is introduced, a demercuration reaction is carried out, and a solid mixture and desorbed mercury are obtained; the solid mixture is screened and ultrasonically washed, and a crude regenerated copper-based demercuration adsorbent is obtained; the crude copper-based demercuration adsorbent is dried and calcined, and the regenerated copper-based demercuration adsorbent is obtained. The catalyst contains chloride and silicon dioxide, or the catalyst contains sulfide and silicon dioxide. Based on the mass of the mixed gas being 100%, the mass ratio of hydrogen chloride to oxygen to the shielding gas is (5%-10%):(1%-2%):(88%-94%); the ultrasonic washing frequency ranges from 1 MHz to 1.5 MHz.

Owner:PETROCHINA CO LTD

Normal-temperature and normal-pressure preparation method and application of metal selenide mercury adsorbent

PendingCN113231004AImprove adsorption capacityIncrease speedGas treatmentOther chemical processesSorbentCobalt

The invention discloses a normal-temperature and normal-pressure preparation method and application of a metal selenide mercury adsorbent. The metal selenide mercury adsorbent is prepared at normal temperature and normal pressure by adopting a precipitation method. The metal selenide mercury adsorbent comprises a compound formed by selenium and one or more of chromium, manganese, iron, copper, cobalt, nickel, zinc, molybdenum, silver and cadmium and a composite of the compound, unstable mercury is converted into stable mercury selenide, mercury in industrial tail gas or by-products of fire coal, metallurgy, waste incineration, cement production and the like is removed, mercury enriched in mercury-containing articles for daily use is absorbed, the recovery and reutilization of mercury resources are realized, and mercury to be treated can exist in the forms of a simple substance state, a free state and / or a compound state and the like. As the metal selenide has extremely high mercury adsorption capacity and adsorption rate, realization of large-scale preparation of the metal selenide under normal temperature and pressure conditions has great significance on mercury pollution prevention and control, and the corresponding technology has wide market application prospects.

Owner:CENT SOUTH UNIV

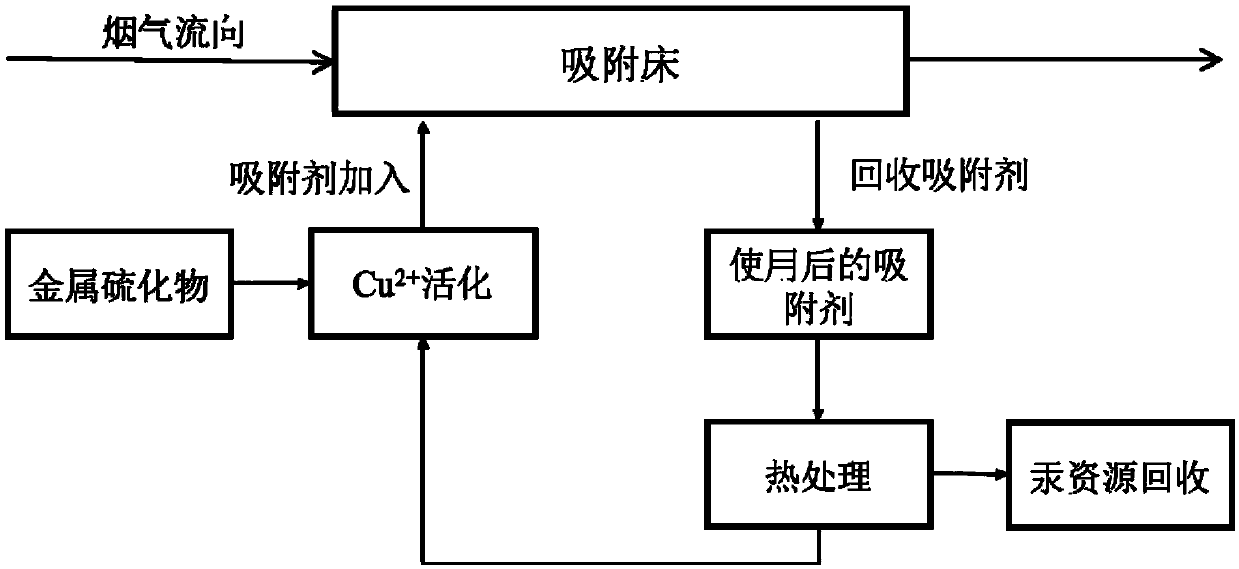

Activation and regeneration method for metal sulfide mercury removal adsorbing agent

The invention relates to an activation and regeneration method for a metal sulfide mercury removal adsorbing agent. The activation and regeneration method comprises the following steps: moderately soaking a metal sulfide main body inside an activate fluid consisting of a cupric salt solution, and then separating, washing and drying to complete the activation for the adsorbing agent, and then usingthe adsorbing agent to adsorb mercury inside an airflow. After the adsorbing agent is inactivated due to adsorption and saturation for mercury, and the adsorbed mercury is released through thermal treatment, and resource recovery is carried out on the mercury. The adsorbing agent after thermal treatment is put in the activate fluid again for soaking to complete the regeneration of a metal sulfide. Compared with the prior art, besides the synthetic metal sulfide, low-cost natural metal sulfide ores can be directly used as the adsorbing agent main body. The mercury adsorption property of the metal sulfide can be greatly strengthened through activation, and simultaneously, the regeneration of the metal sulfide after mercury adsorption can be realized. The using amount of the adsorbing agentis greatly reduced while efficient trapping of flue gas mercury is realized, so that the consumption cost of the adsorbing agent and the implementation difficulty of adsorption mercury removal technology are reduced.

Owner:SHANGHAI JIAO TONG UNIV

Novel demercuration catalyst

InactiveCN102764655AImprove mercury removal efficiencyLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBiological bodyMercury adsorption

Disclosed is a novel demercuration catalyst. As mercury has extremely high accumulation performance in the environment and in organisms, it has very strong toxicity for mankind and wild animals and plants even the concentration is very low. In recent years, mercury is considered as another pollution problem in the world. Present existing demercuration catalysts have disadvantages of poor anti-poisoning capability and high cost, and are difficult to realize industrialization. In order overcome these advantages, a novel demercuration catalyst is invented. The product is prepared from TOx (T is Cu, Fe and V) and ROy (R is La and Ce) with the addition of titanium dioxide pillared montmorillonite. The invention belongs to the technical field of separation. The demercuration catalyst can be used for elemental mercury removal from flue gas. The invention is characterized in that the catalyst has high mercury adsorption capability and mercury oxidation catalysis capability. The catalyst has very strong anti-poisoning capability.

Owner:YANCHENG INST OF TECH

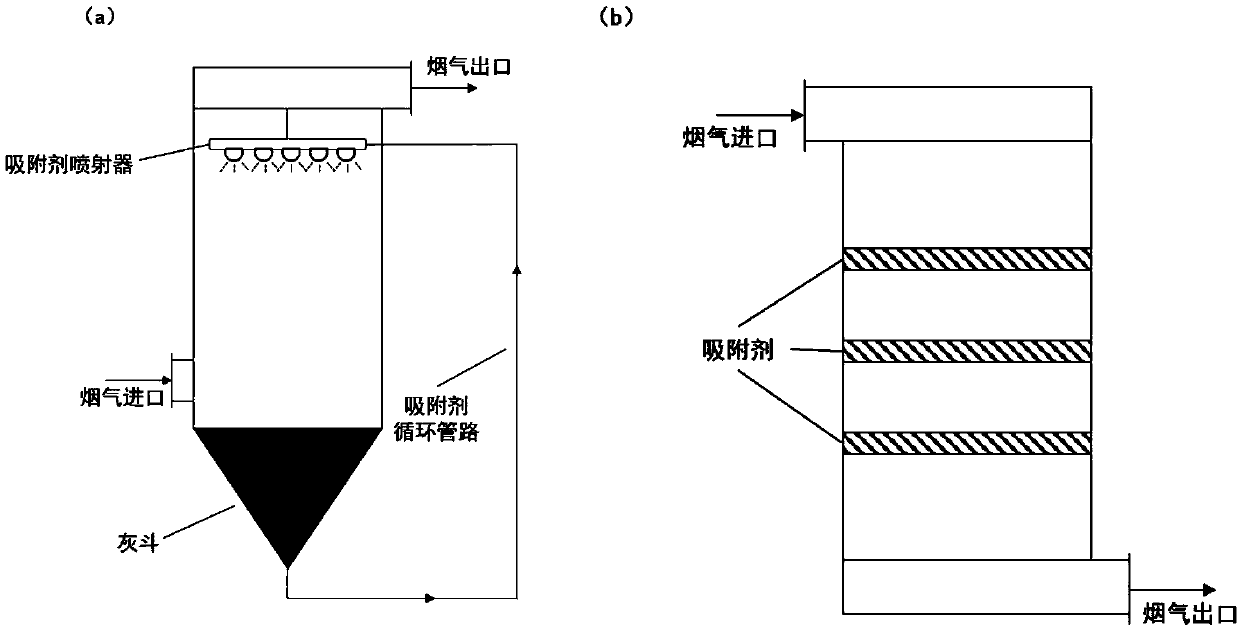

Method for efficiently removing elemental mercury in flue gas

InactiveCN109603410AEasy to synthesizeEasy access to raw materialsGas treatmentOther chemical processesFixed bedMercury adsorption

The invention discloses a method for efficiently removing elemental mercury in flue gas. A metal selenized mineral is utilized as a demercuration medium, contains selenium-copper ores (CuSe), selenium-molybdenum ores (MoSex) and selenium-zinc ores (ZnSe) and is in contact with mercury in the flue gas, in a fixed bed reactor or a jet tower, and accordingly volatile gaseous elemental mercury in theflue gas is converted into stable solid mercury selenide; the natural reserve of the metal selenized mineral is large, synthesis is relatively easy, and metal selenized mineral has very high mercury adsorption capacity and adsorption rate. Therefore, the method has the advantages of high efficiency, low investment, simple, easy operation and the like and has wide market application prospects.

Owner:CENT SOUTH UNIV

Straw-based selective mercury removal material, preparation method and applications thereof

InactiveCN106237985AHigh removal rateFast removalOther chemical processesWater contaminantsNitrogen gasHigh selectivity

The present invention provides a straw-based selective mercury removal material preparation method, which comprises: (1) carrying out a steam explosion treatment on straws, and then treating at a temperature of 400-800 DEG C under vacuumizing and nitrogen atmosphere; (2) placing the product obtained in the step (1) into a reductive sulfur group-containing mixing liquid, carrying out stirring mixing, filtering, and drying, wherein the reductive sulfur group-containing mixing liquid is a mixing liquid of ammonium thiocyanate, ammonium thiosulfate and thioglycolic acid; and (3) mixing the product obtained in the step (2) and sublimed sulfur, heating under vacuumizing and nitrogen introducing conditions to achieve a temperature of 450 DEG C, maintaining for 2 h, carrying out program heating to 600-1000 DEG C, maintaining the vacuumizing and nitrogen introducing for 2 h, cooling, and grinding so as to obtain the straw-based selective mercury removal material. The invention further provides the mercury removal material prepared through the method and applications of the mercury removal material in mercury removal. According to the present invention, the straw-based selective mercury removal material has advantages of high mercury adsorption capacity, high mercury removal rate, rapid mercury removal, high selectivity, cheap and easily available raw materials, simple and feasible preparation process, environmental protection, economy, and good application prospect.

Owner:SICHUAN NORMAL UNIVERSITY

Preparation method and applications of gaseous mercury adsorbent

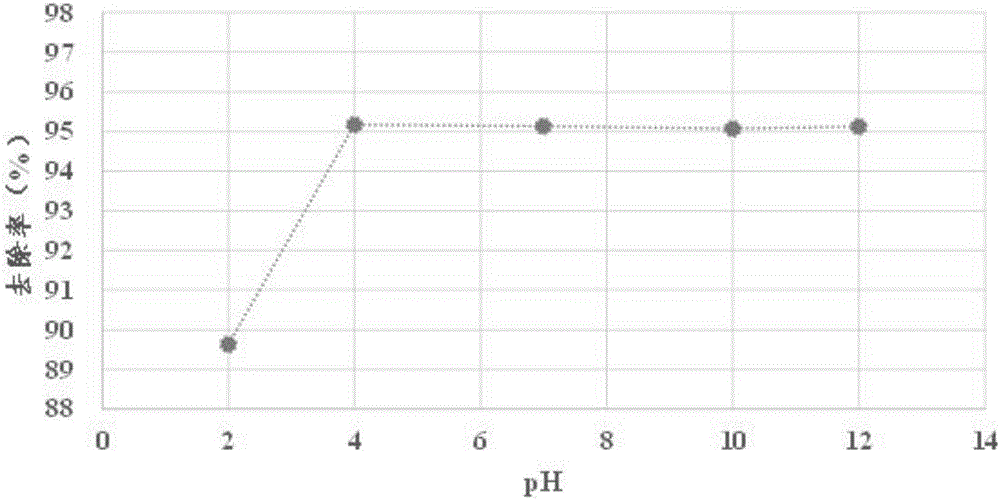

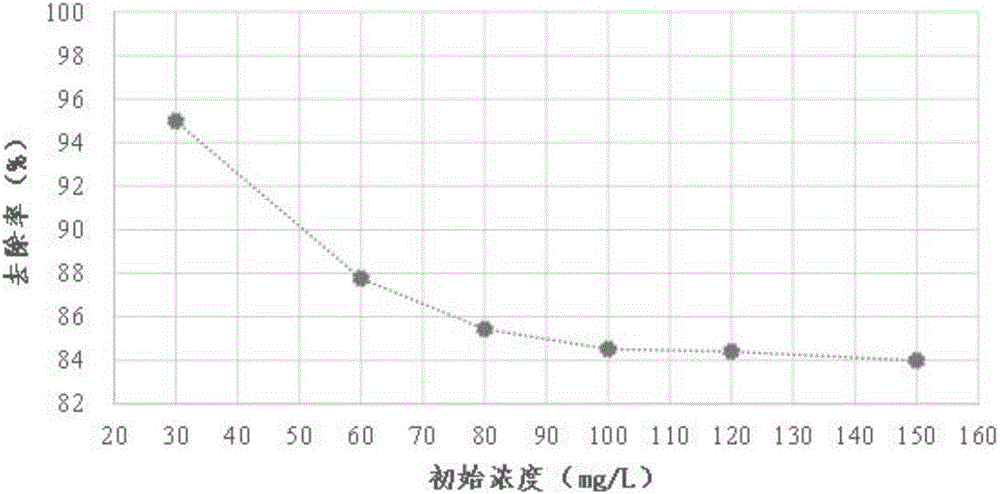

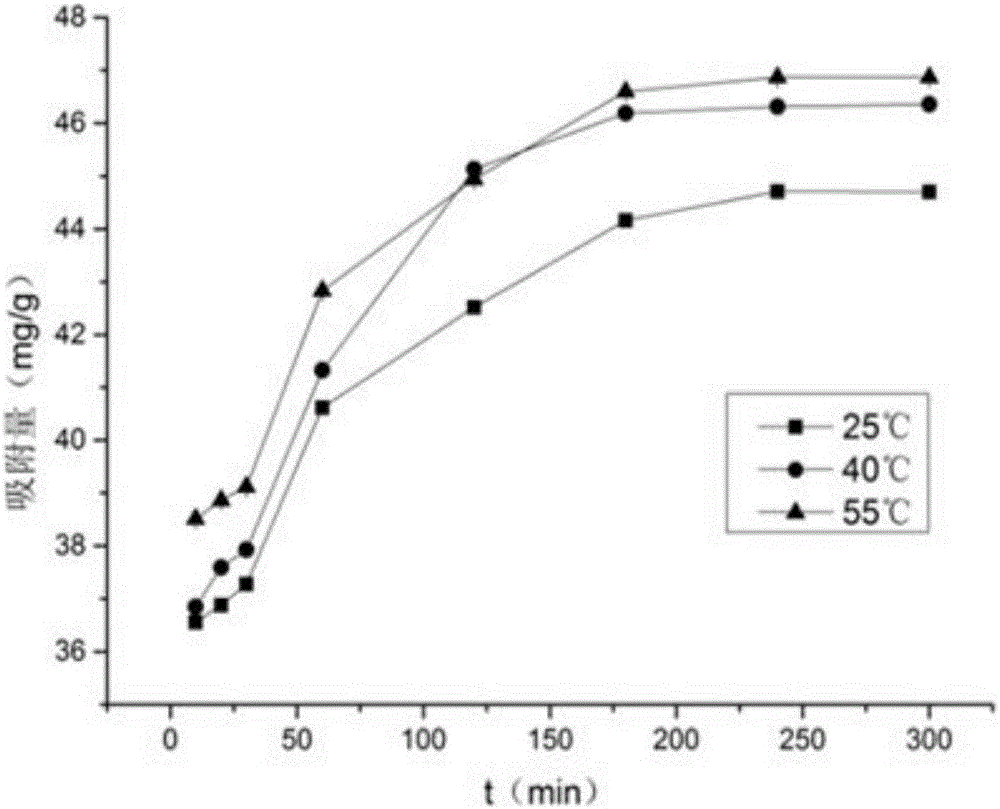

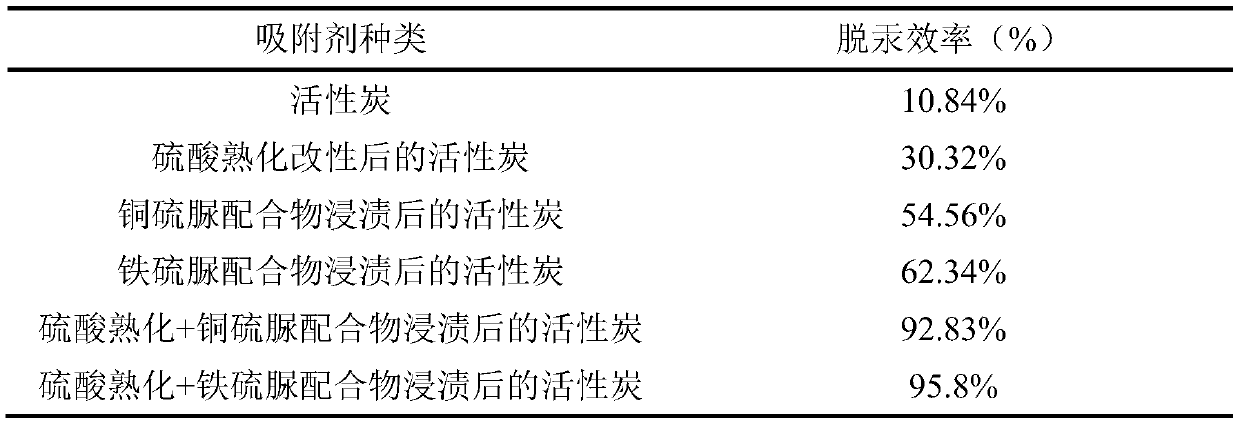

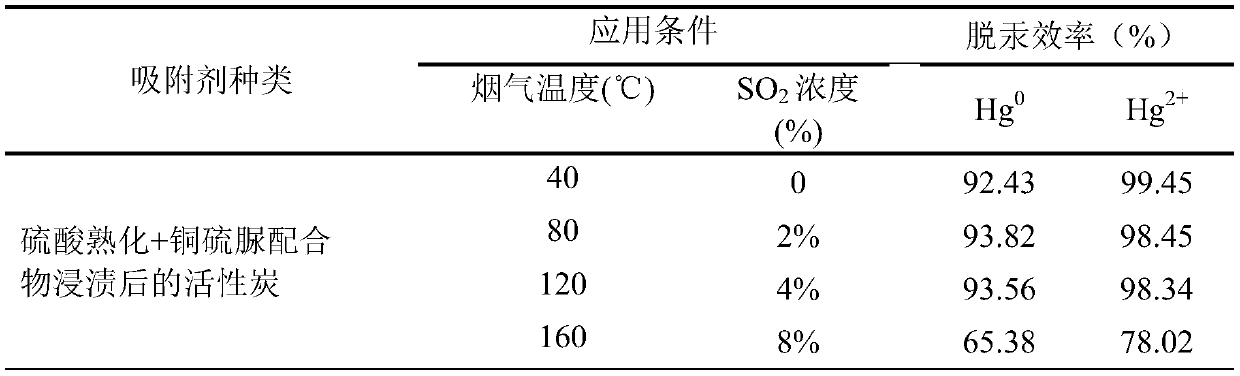

ActiveCN110252255AImprove sulfur resistanceImprove removal efficiencyGas treatmentOther chemical processesSorbentThiourea

The invention discloses a preparation method of a gaseous mercury adsorbent. The preparation method comprises following steps: (1) mixing active carbon and concentrated sulfuric acid, aging, filtering, and washing to obtain modified active carbon; (2) mixing thiourea and metal salts to obtain a metal thiourea mixed solution, wherein the metal ions of the metal thiourea mixed solution are copper ions and / or iron ions; and (3) mixing modified active carbon and the metal thiourea mixed solution to impregnate modified active carbon, and after impregnation, drying obtained materials in vacuum to obtain the gaseous mercury adsorbent. The invention also discloses an application of the gaseous mercury adsorbent on absorbing gaseous mercury in high sulfur smelting exhaust gas. The prepared gaseous mercury adsorbent can absorb gaseous mercury and divalent mercury in flue gas, has an excellent sulfur-resistant performance, and has high mercury removing efficiency, even if the concentration of sulfur dioxide is high.

Owner:JIANGXI UNIV OF SCI & TECH

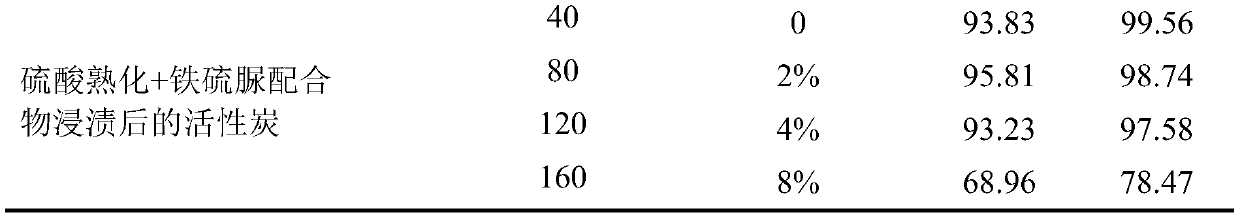

Macroporous skeleton hydrophobic mercury removal material, preparation method and application thereof

ActiveCN112934197ASolve pollutionTurn waste into treasureGas treatmentOther chemical processesSorbentActive agent

The invention discloses a macroporous skeleton hydrophobicmercury removal material, a preparation method and application thereof. A simple one-step precipitation method is adopted, a surfactant is used for regulating and controlling the crystal size of metal sulfide, the metal sulfide is fixed on a macroporous skeleton hydrophobic material, and a novel mercury removal material is obtained. The preparation method of the macroporous skeleton hydrophobic mercury removal material is simple, the contact area of metal sulfide minerals and mercury is increased, and the resistance of an adsorbent to flue gas is reduced. The macroporous framework hydrophobic mercury removal material has extremely high mercury adsorption capacity and adsorption rate, the hydrophobic performance of pure metal sulfide is improved, and the obtained mercury removal material can be used as a mercury removal medium to be applied to a fixed bed or a liquid phase (such as a wet dust removal device) to be in contact with gaseous elemental mercury; and volatile gaseous elemental mercury is converted into stable solid mercuric sulfide, and the material has the advantages of being flexible in application, high in efficiency, environmentally friendly and the like.

Owner:CENT SOUTH UNIV

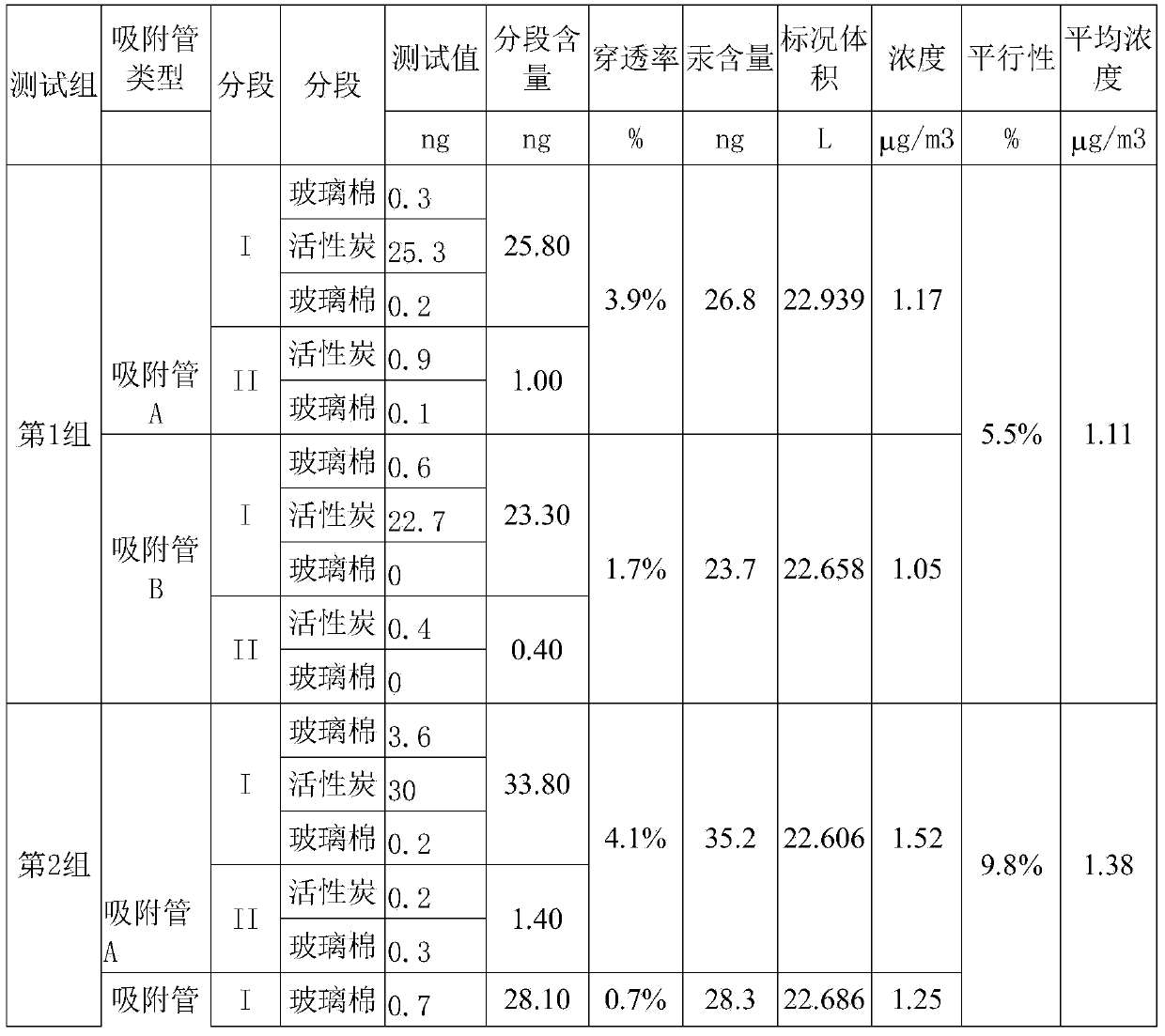

System for simultaneously sampling and detecting flue gas NO and mercury

ActiveCN105300744ARealize concentration monitoringAchieve separationWithdrawing sample devicesPreparing sample for investigationLine tubingFlue gas

The invention relates to a system for simultaneously sampling and detecting flue gas NO and mercury. The method comprises an off-line mercury detection apparatus and a sampling probe gun used for stretching into a flue, a flue gas pipeline of the sampling probe gun is several independently arranged quartz pipelines, an outlet of the quartz pipeline is communicated to a flue gas dedusting, acid-removal and dehumidifying apparatus, a flow control apparatus and a NO detector, the flow control apparatus and the NO detector are connected to a computer; a heating layer used for keeping the sampling probe gun at temperature of more than 120 DEG C is arranged on an inner wall of a housing of the sampling probe gun, an active carbon adsorption pipe is arranged on each quartz pipeline, and the active carbon adsorption pipe is filled by an adsorbent, the adsorbent is divided into the adsorbent which is a mercuric oxide capture layer of KCl and a simple substance mercury adsorption layer of mercury-removal active carbon according to a flue gas passing sequence. The system can simultaneously realize sampling and detection of NO and mercury pollutants at a same sampling point in the flue gas, and can realize flow parallel sampling and constant current sampling, the detection results can be mutually calibrated.

Owner:HUANENG POWER INTERNATIONAL +2

Mercury-removal adsorbent, method of producing mercury-removal adsorbent, and method of removing mercury by adsorption

InactiveUS8598072B2Increase volumeSolution value is not highGas treatmentOther chemical processesSorbentPotassium iodine

To provide mercury-removal adsorbents, a method of producing mercury-removal adsorbents, and a method of removing mercury by adsorption which are capable of realizing efficient removal of mercury by adsorption from liquid hydrocarbon, thermal power station exhaust combustion gas, natural gas, off gas of various process plants, and so on which contain mercuries in various forms such as elemental mercury, ionic mercury, and organic mercury, and a concomitant hindering mercury adsorption.Mercury-removal adsorbents carrie potassium iodide in an amount of 27 to 70% of a total adsorbent weight, and a volume of pores with a 1 μm pore diameter or more in the mercury-removal adsorbents is 0.6 mL / g or more. These mercury-removal adsorbents are filled in, for example, an adsorption tower 10, and a hydrocarbon liquid is passed therethrough (mercury removal step). In a case where the hydrocarbon liquid contains saturated water, a dehydration unit 9 or the like is installed on a preceding stage of the adsorption tower 10 to dehydrate the hydrocarbon liquid (dehydration step).

Owner:JGC CORP

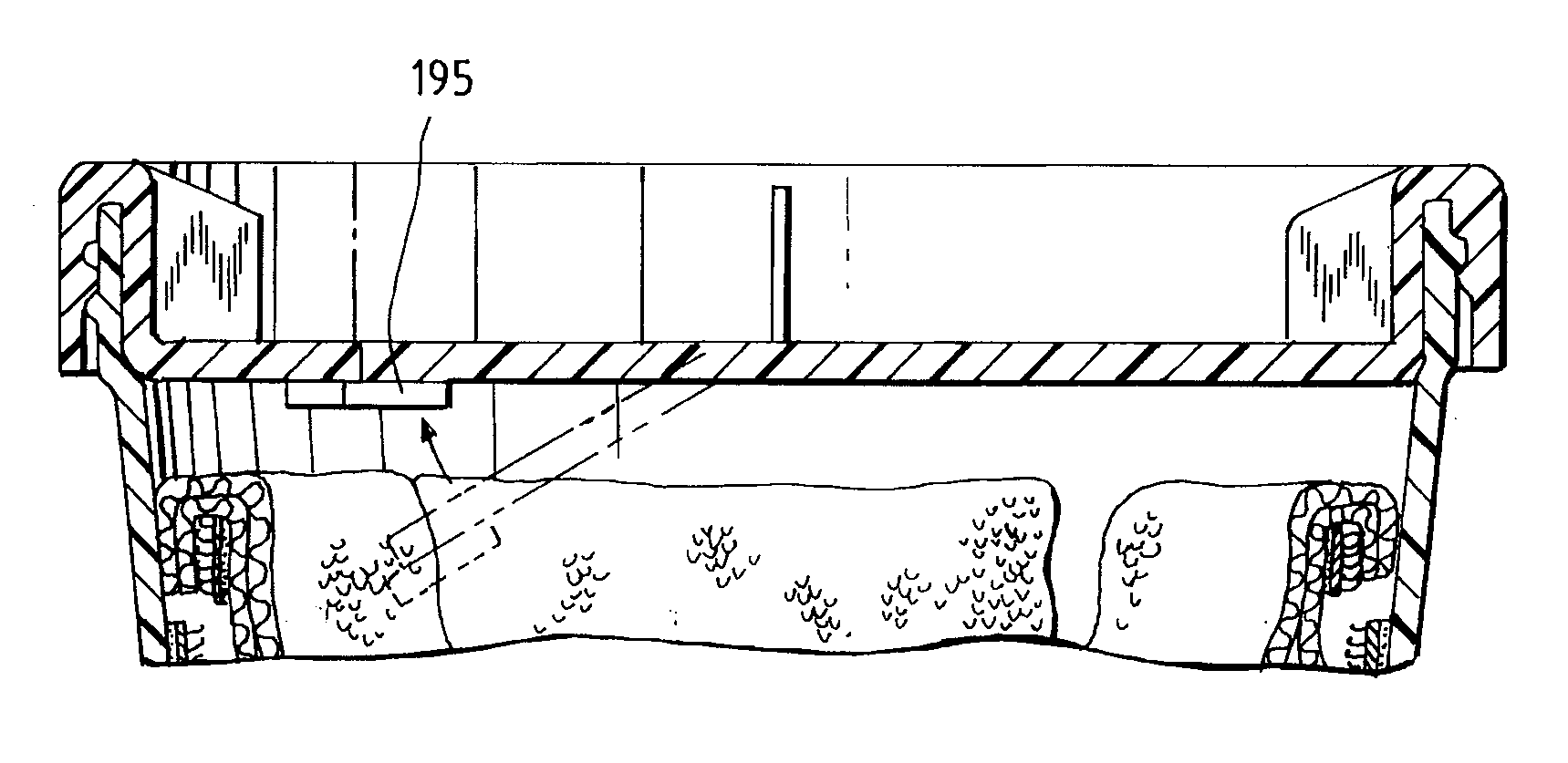

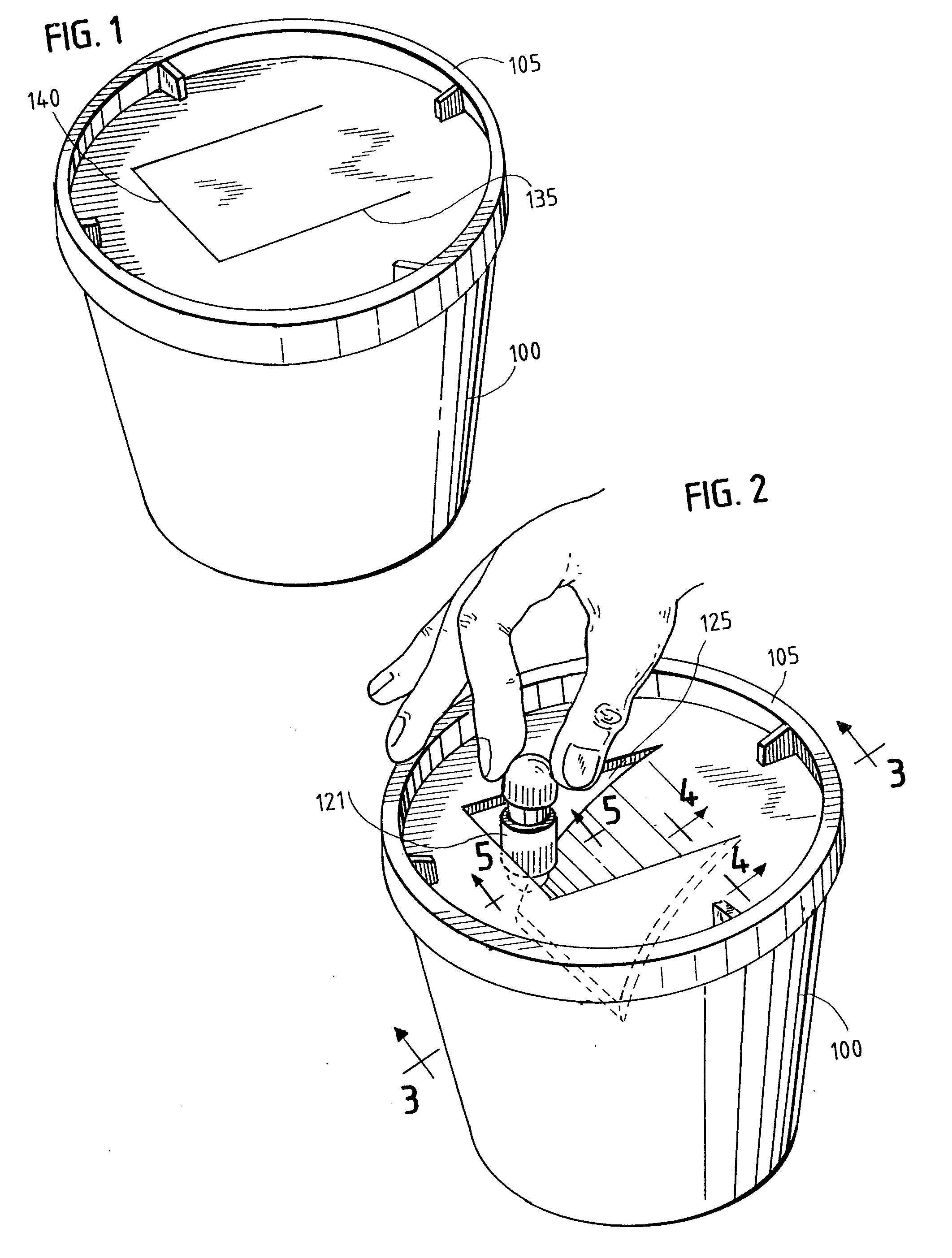

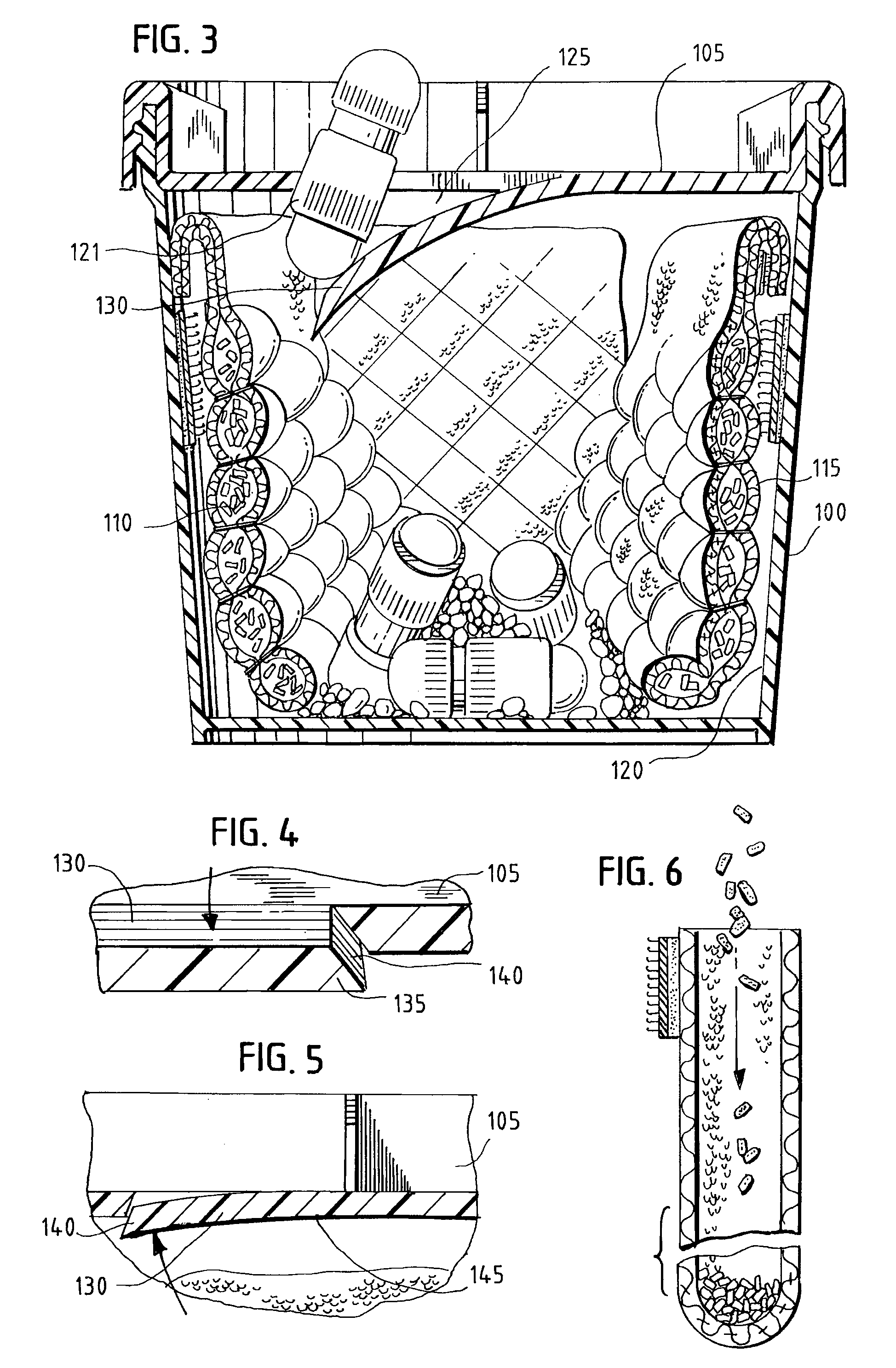

Recycling container for the collection and temporary storage of mercury contaminated wastes in dental facilities

InactiveUS20080257759A1Prevents and reduce releaseReduce releaseDiagnosticsSurgeryWaste treatmentEngineering

The present invention is directed to a container for the collection and temporary storage of amalgams and other mercury wastes. The container can include a hollow body with air-tight lid, and one or more mercury sorbents contained in a filter bag. The filter bag covers the inside surface of the hollow body and has holes that allow air exchange between the air in the hollow body and the sorbents. As air exchange occurs, mercury vapors released from dental wastes binds to the mercury binding materials. A self-closing door was made on the lid, which automatically closes after each waste disposal.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Mercury removal adsorbent with core-shell structure, and preparation method thereof

InactiveCN110665455AImprove mercury removal efficiencyThe process is simple and easy to controlGas treatmentPhysical/chemical process catalystsThioureaPhysical chemistry

The invention discloses a mercury removal adsorbent with a core-shell structure. The mercury removal adsorbent is characterized in that Fe3O4 nanoparticles are used as a carrier, and MoS2 nanosheets are grown on the surface of Fe3O4 in situ to form a Fe3O4@MoS2 core-shell structure in order to obtain the mercury removal adsorbent with the core-shell structure. The Fe3O4 nanoparticles are taken asa raw material, and are dispersed into deionized water, ammonium molybdate tetrahydrate and thiourea are added, and the mercury removal adsorbent, namely the MoS2 Fe3O4 nano-composite material, is prepared by using a hydrothermal technology. The composite material has the advantages of good crystallinity, controllable morphology and size, and excellent adsorption performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

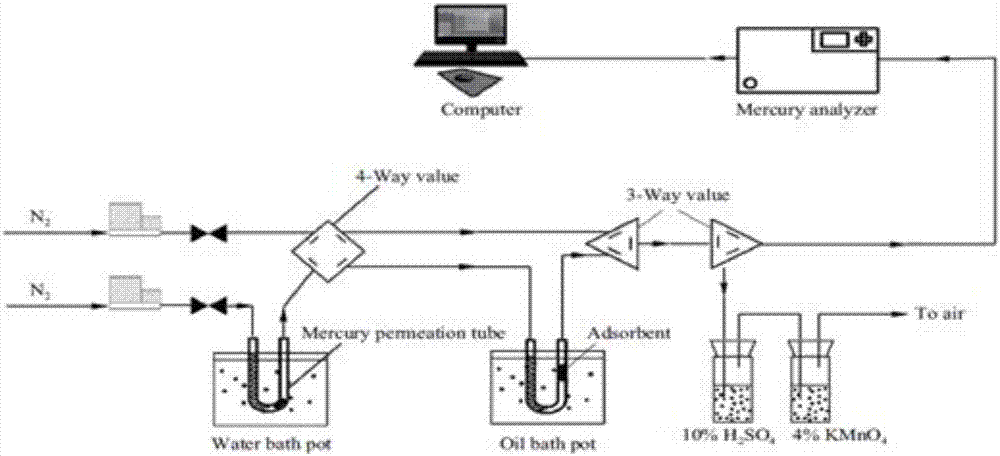

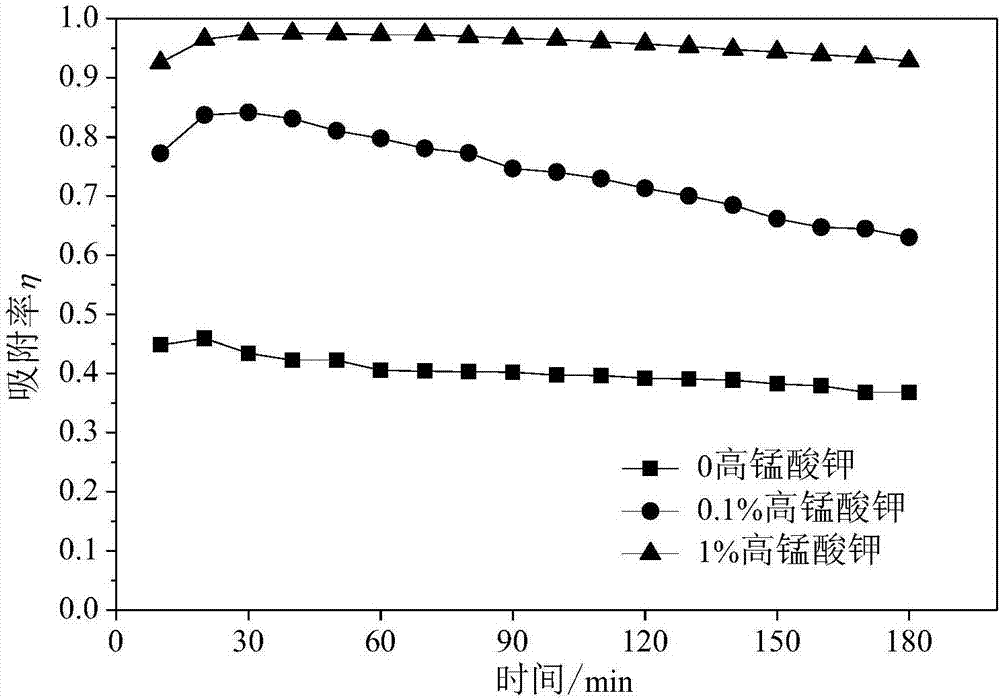

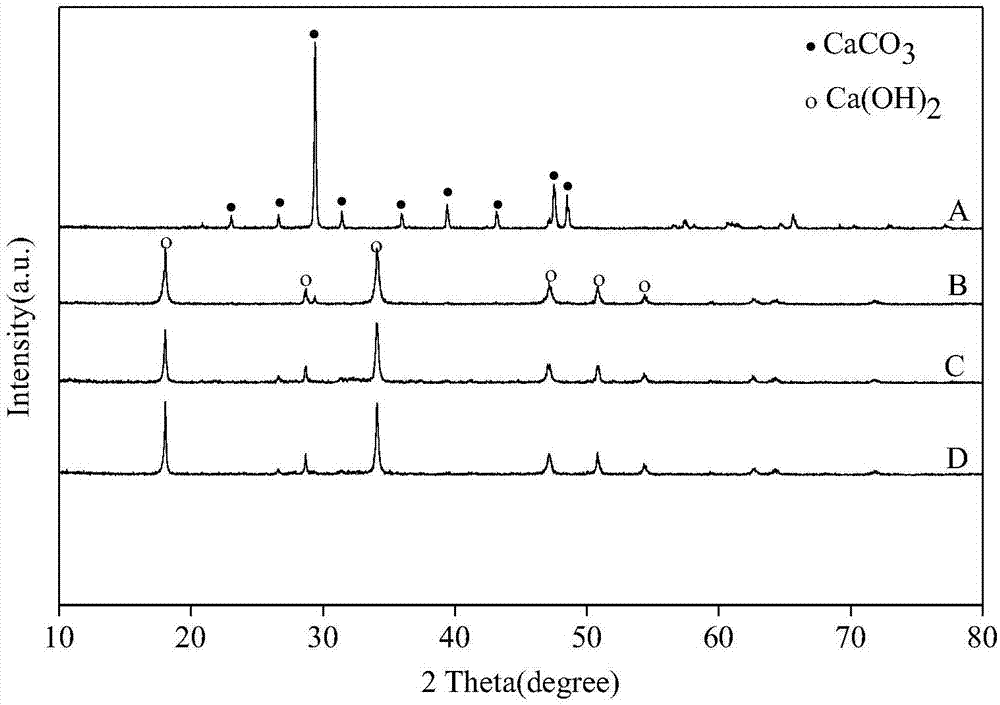

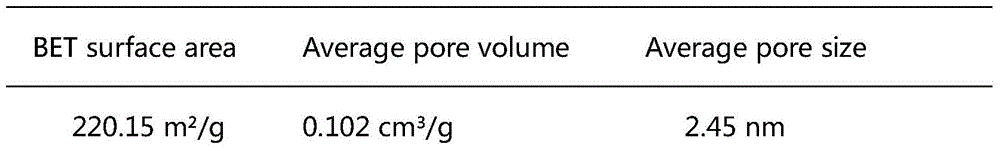

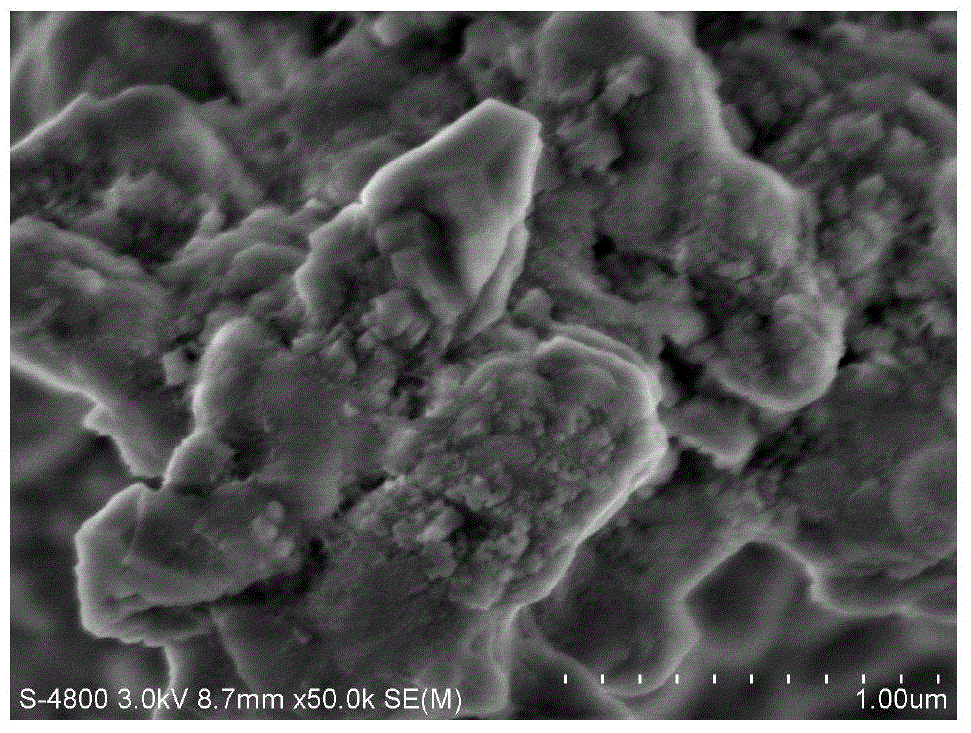

Preparation method of mercury removal adsorbent for Indonesian oil sand tailings

InactiveCN107008222AHigh adsorption rateRealize resource utilizationGas treatmentOther chemical processesEconomic benefitsMercury adsorption

The invention provides a preparation method of a mercury removal adsorbent for Indonesian oil sand tailings. The method includes: taking Indonesian oil sand tailings as raw materials, subjecting to high-temperature firing and digestion in water to obtain the mercury removal adsorbent for the Indonesian oil sand tailings. The mercury removal adsorbent has a certain mercury removal rate, the mercury removal rate is greatly increased after addition of a strong oxidant in a preparation process, and when the mass percent of the added strong oxidant reaches 1%, the mercury removal rate of the obtained mercury removal adsorbent reaches 95% or above. The preparation method of the mercury removal adsorbent for the Indonesian oil sand tailings is simple, free of secondary pollution in a manufacturing process and high in mercury adsorption rate, recycling of the oil sand tailings is realized, the problem of treatment of oil sand tailings which are hazardous solid wastes is solved, and remarkable economic benefits and environmental protection benefits are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

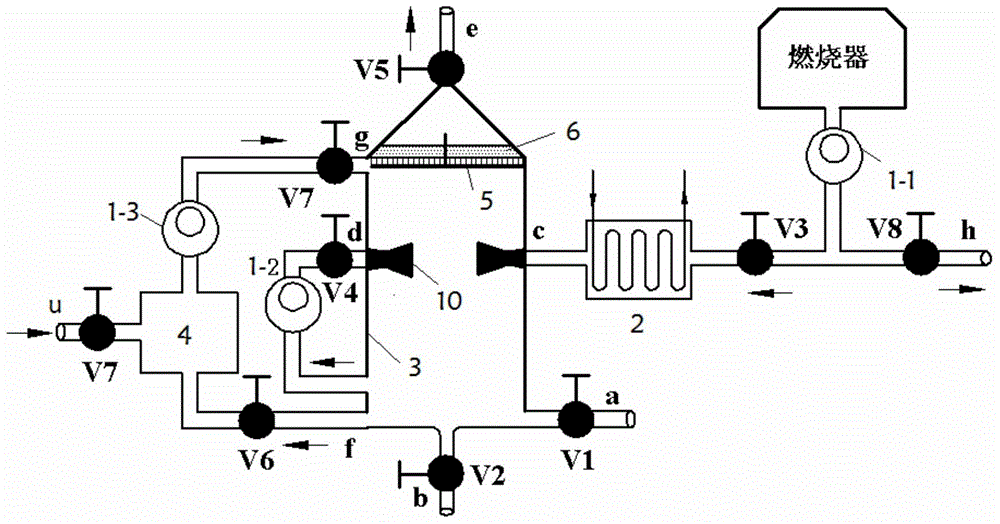

Algae-char-impact-tower-based mercury removal method and preparation method of algae char

InactiveCN104436994AImprove protectionEmission reduction benefits are obviousOther chemical processesDispersed particle separationFlue gasMercury adsorption

The invention relates to an algae-char impact-tower-based mercury removal method. The method comprises the following steps: performing pyrolysis on algae to prepare biomass char as a flue gas mercury removal adsorbent, and adsorbing and removing mercury in one impact tower reactor; recycling mercury resource and regenerating the adsorbent in a separator; cooling mercury-containing flue gas from a burner and spraying the flue gas into the impact tower reactor through a Laval spray pipe, spraying the algae char adsorbent into the impact tower reactor through the Laval spray pipes which are coaxially and oppositely arranged, and enabling two strands of gas flows to have opposite impact in the impact tower reactor so as to realize the adsorption and removal of mercury. When regeneration is performed in one impact tower reactor, flue gas from the burner is automatically switched and flows into the other impact tower reactor. The two impact tower reactors are alternatively used for performing regeneration. According to the method and the device, the biomass char is prepared by utilizing pyrolysis of algae and used for adsorbing and removing mercury, the removal process has no secondary pollution, the raw material of the adsorbent is a regenerative resource with wide reserves, and wide application prospects can be achieved.

Owner:南京朗洁环保科技有限公司

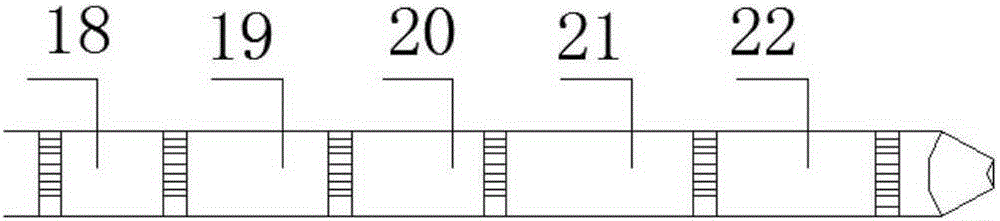

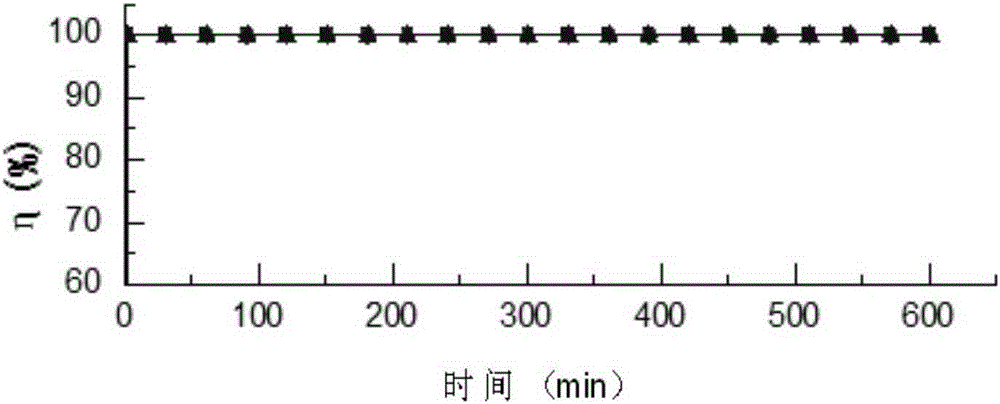

Iodized activated carbon and preparation method and application thereof

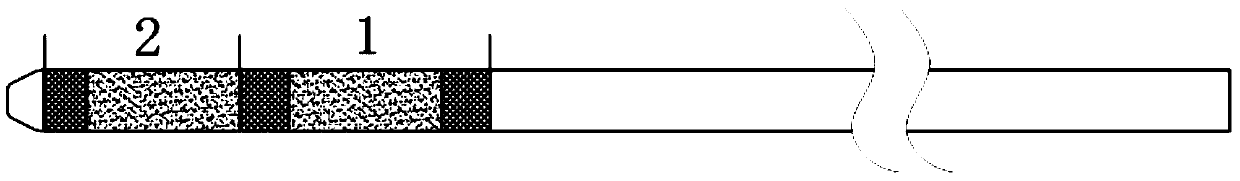

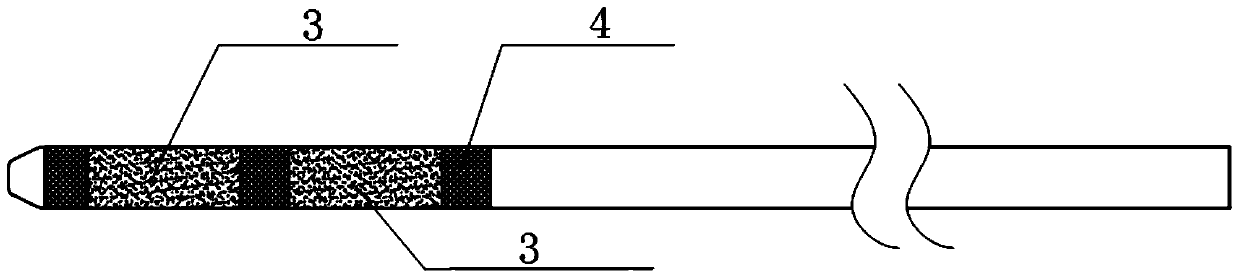

InactiveCN103721676ALarge specific surface areaLow costOther chemical processesDispersed particle separationGlass fiberMercury adsorption

The invention discloses iodized activated carbon and a preparation method and application thereof and belongs to the field of preparation of activated carbon. The preparation method for the iodized activated carbon comprises the steps of treating the activated carbon by a pickling treatment mode and iodizing the activated carbon by using an iodine compound. The application method of the iodized activated carbon comprises the steps of canning the iodized activated carbon into a hollow pipe, wherein the bottom and the top of the hollow pipe are not sealed; filling the front end and the rear end of the activated carbon with glass fiber cotton in order to prevent leakage of the iodized activated carbon, wherein a mutual isolation function is realized during filling of multiple sections of the activated carbon. Due to the adsorption performance of the activated carbon to mercury in smoke, a mercury adsorption pipe can be applied to smoke monitoring and has the same performance as that of a foreign imported adsorption pipe, and the cost is low; the adsorption performance of the adsorption pipe can meet a technical requirement of EPA30B. The technical method is simple, is easy to operate and is low in cost and is suitable for monitoring the mercury in the smoke of a fixed pollution source.

Owner:NANJING ASSEN ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com