Patents

Literature

13874 results about "Cement Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement is often supplied as a powder, which is mixed with other materials and water. A cement is a binder, a substance used for construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together.

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

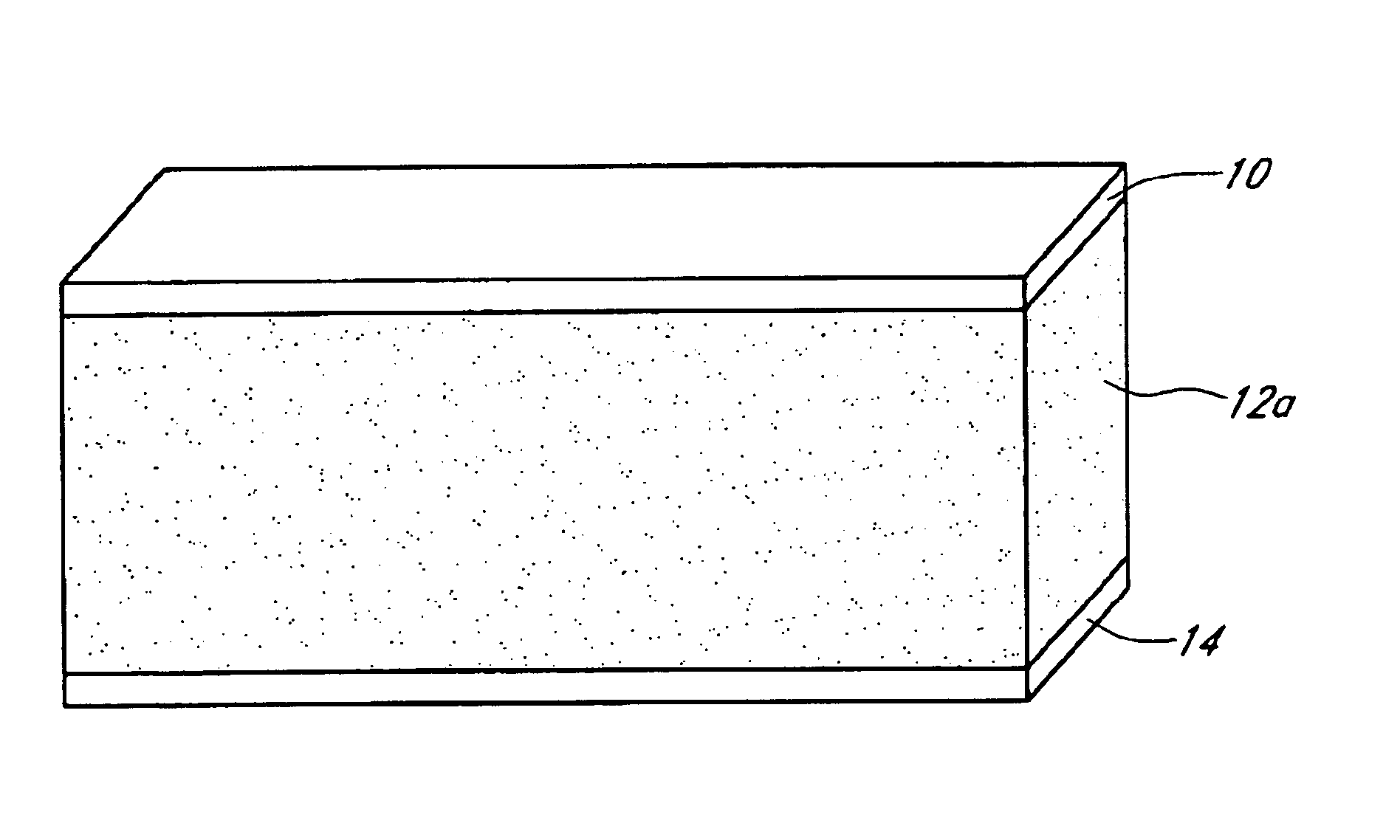

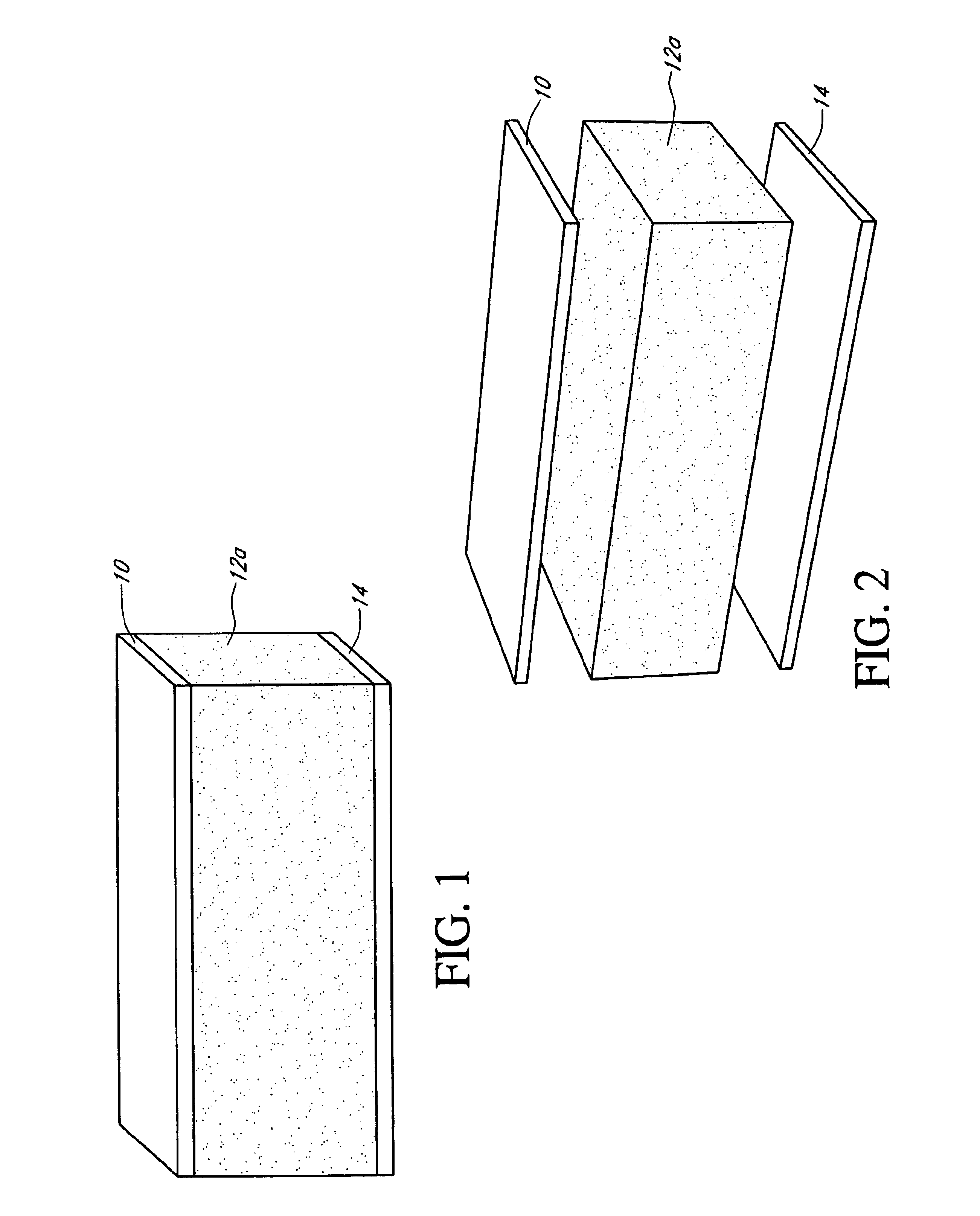

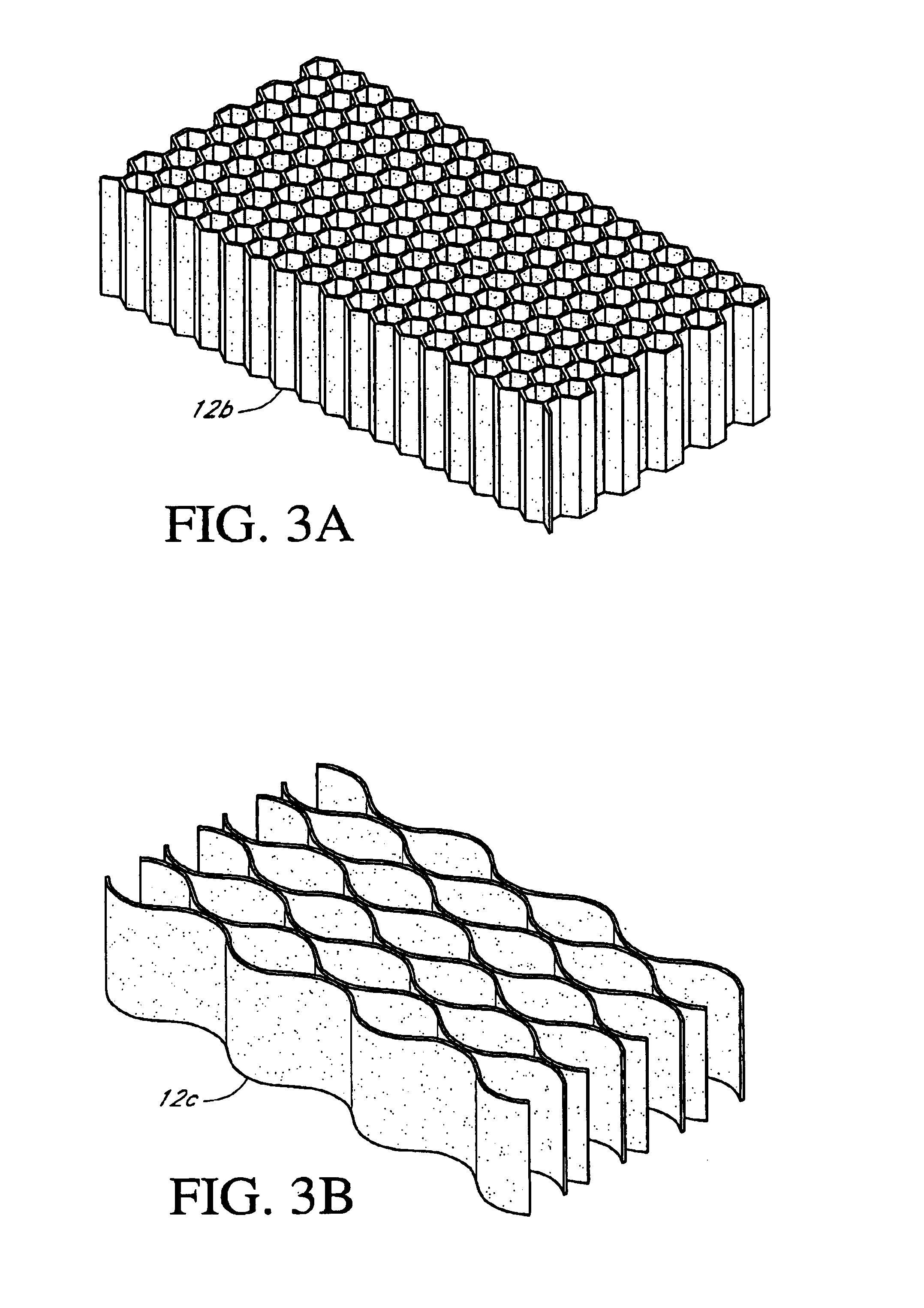

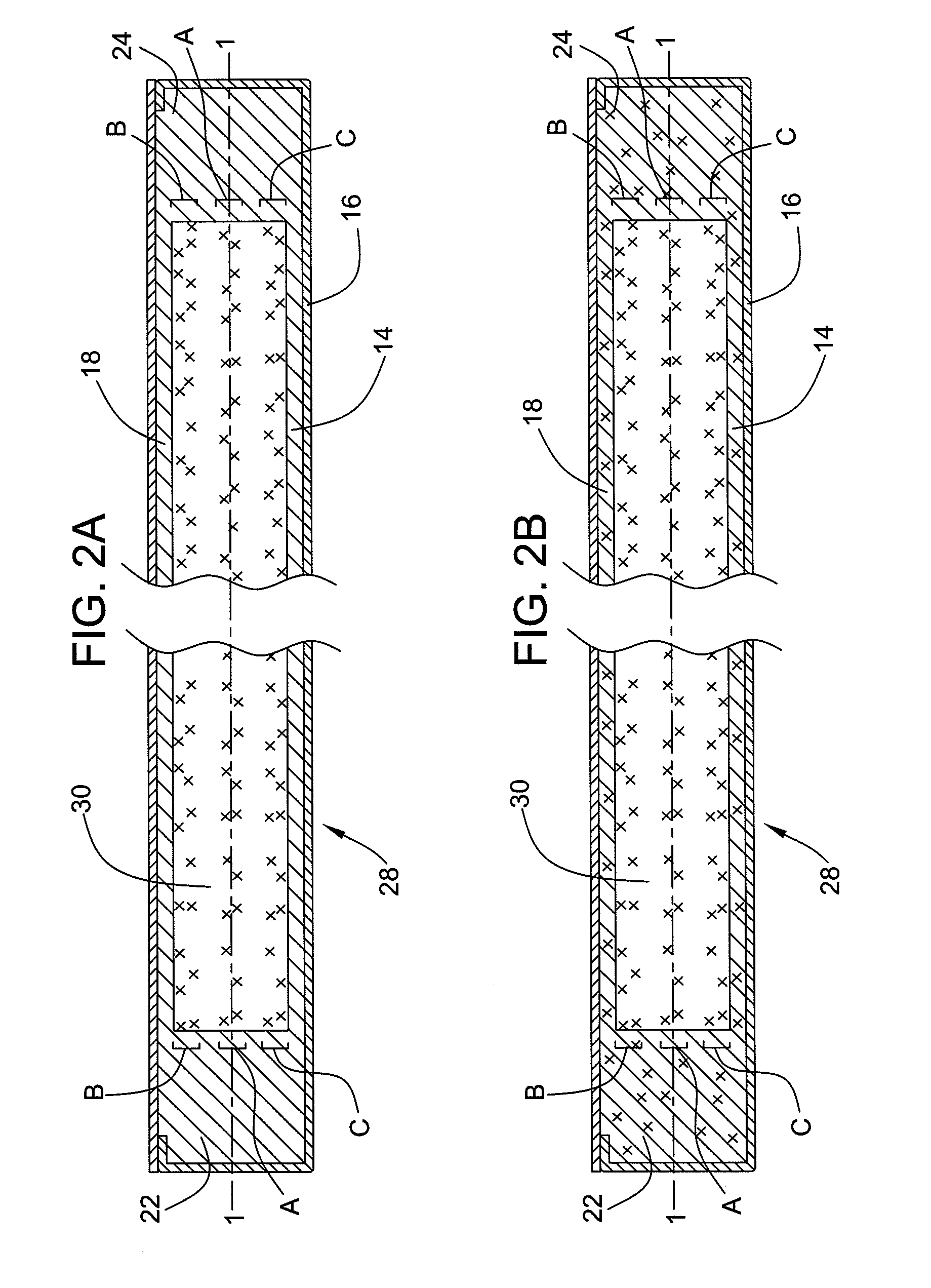

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

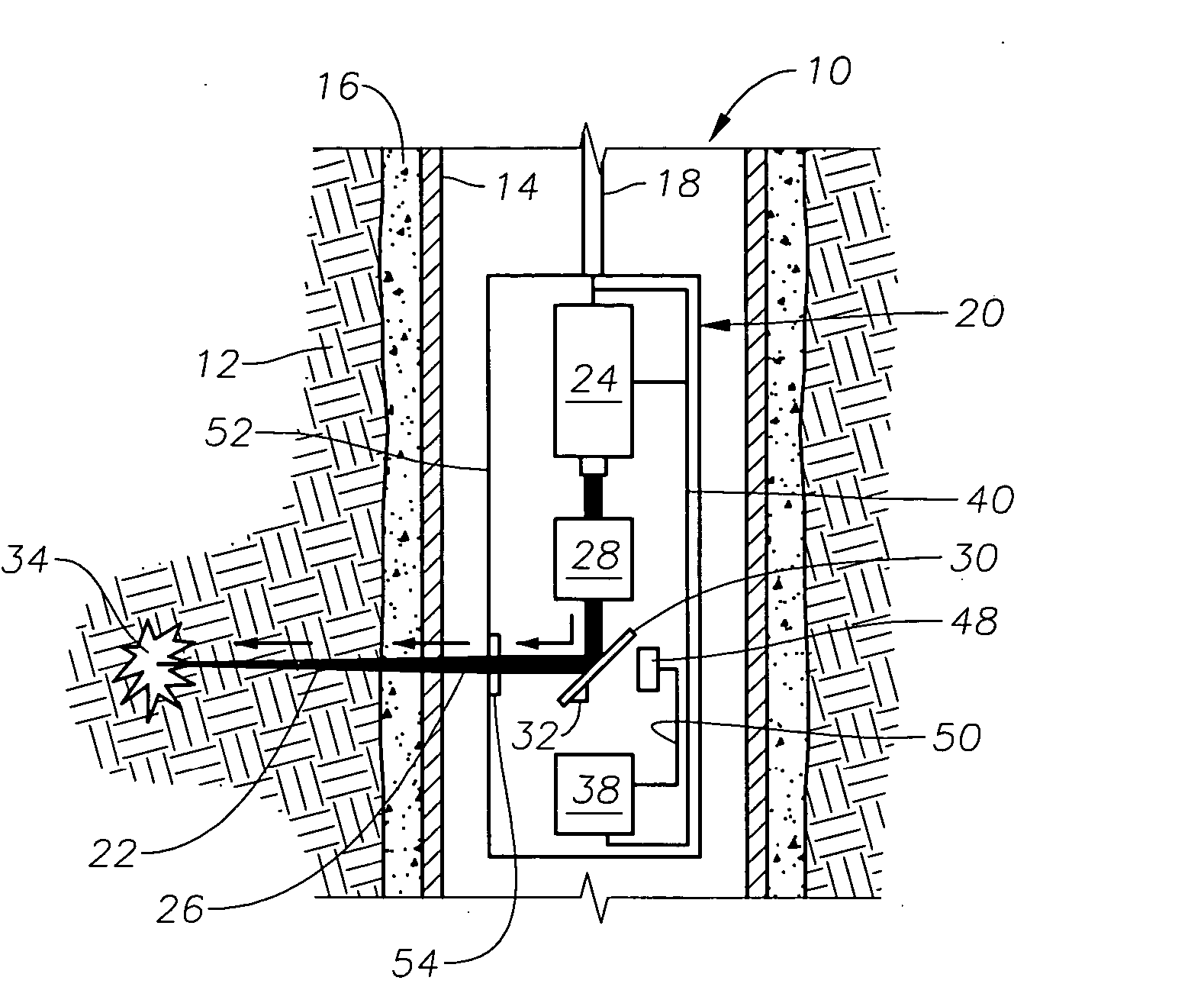

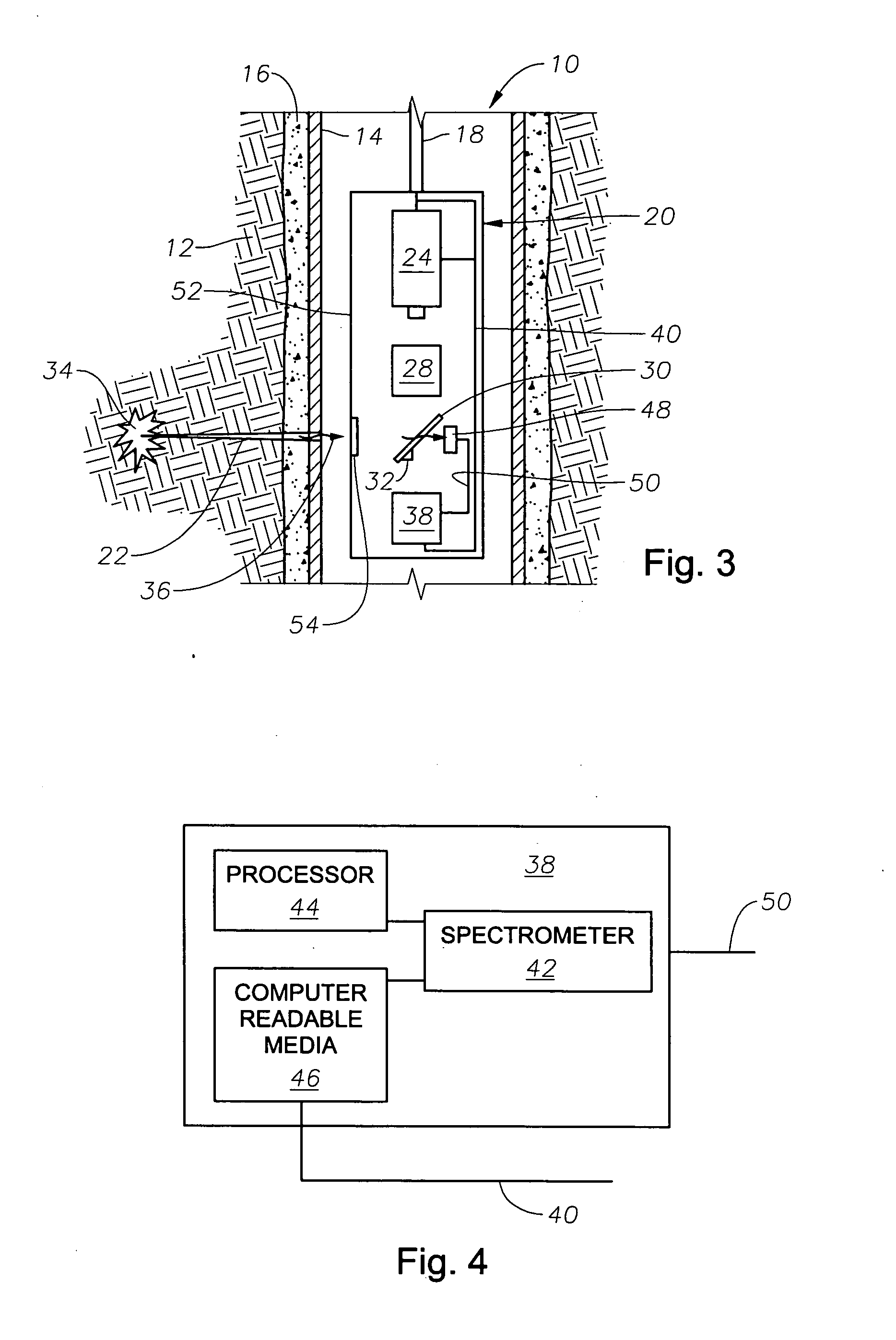

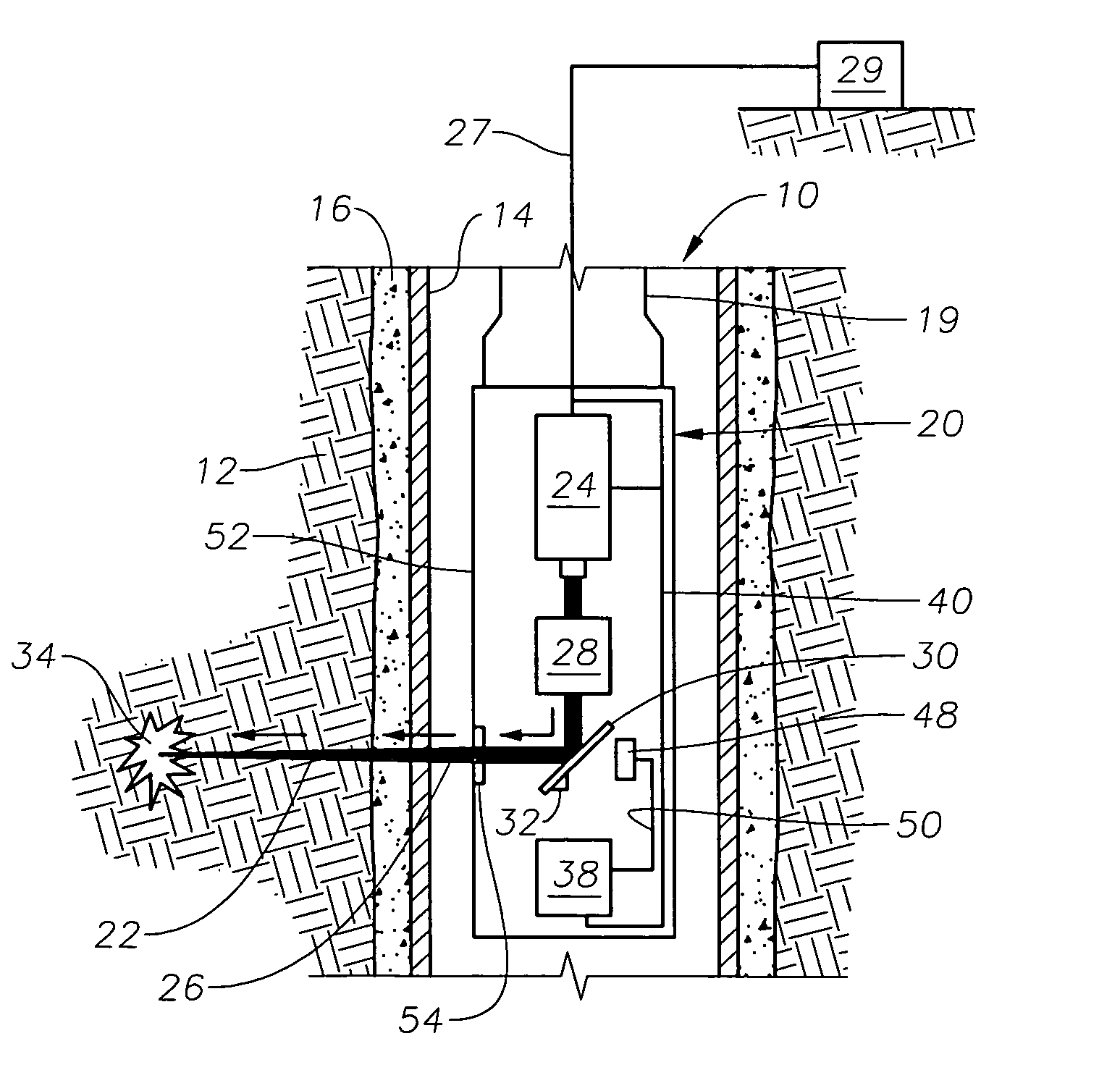

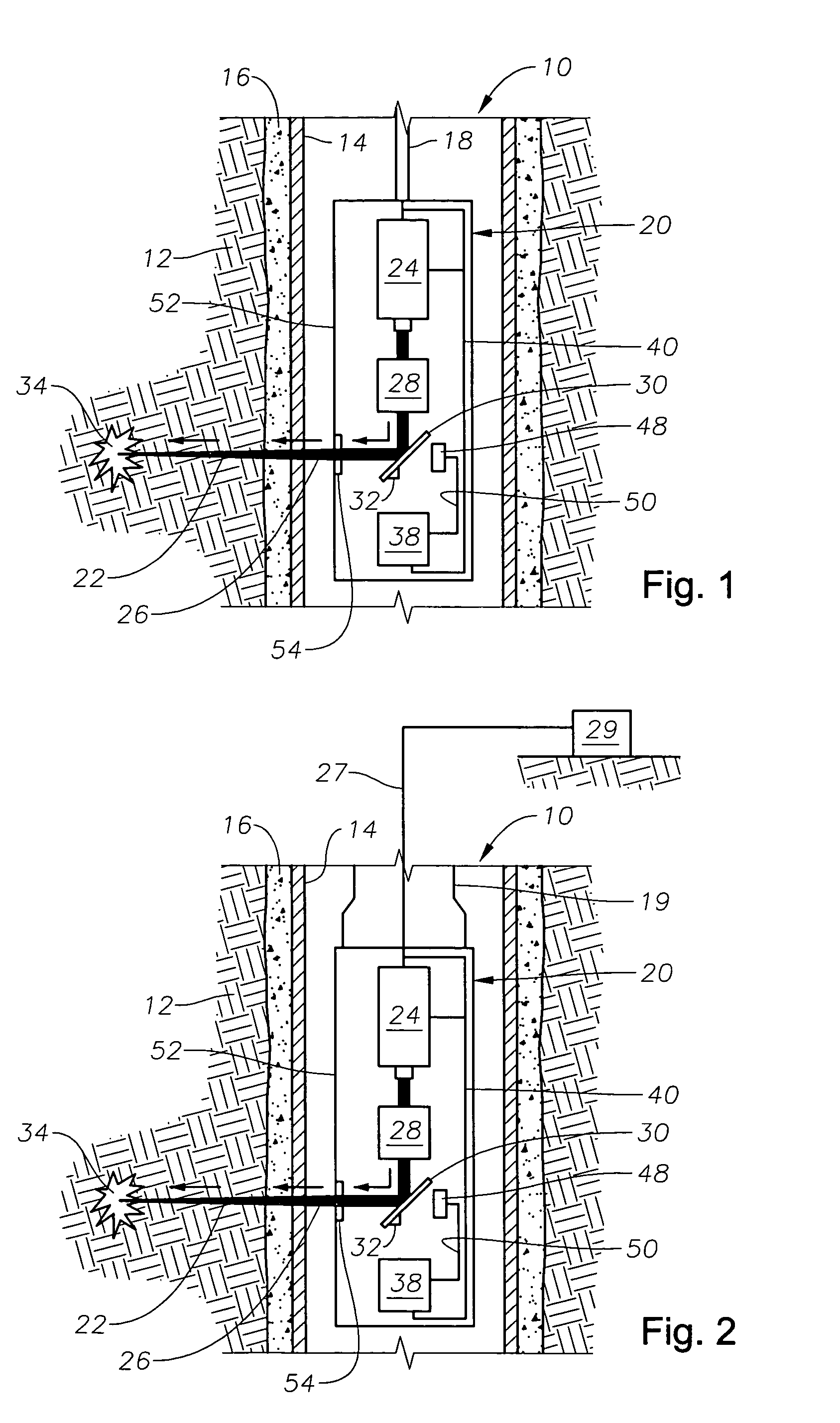

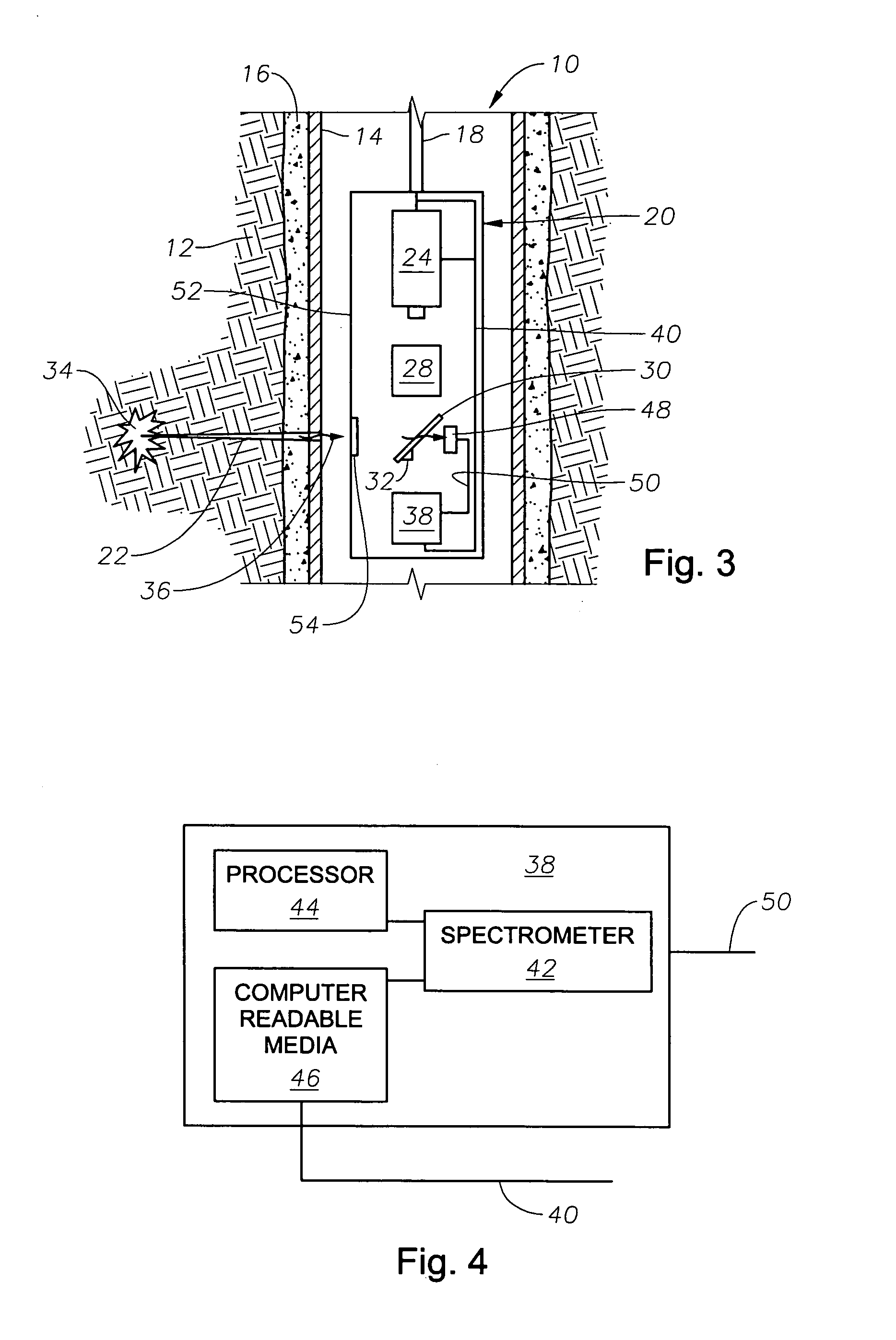

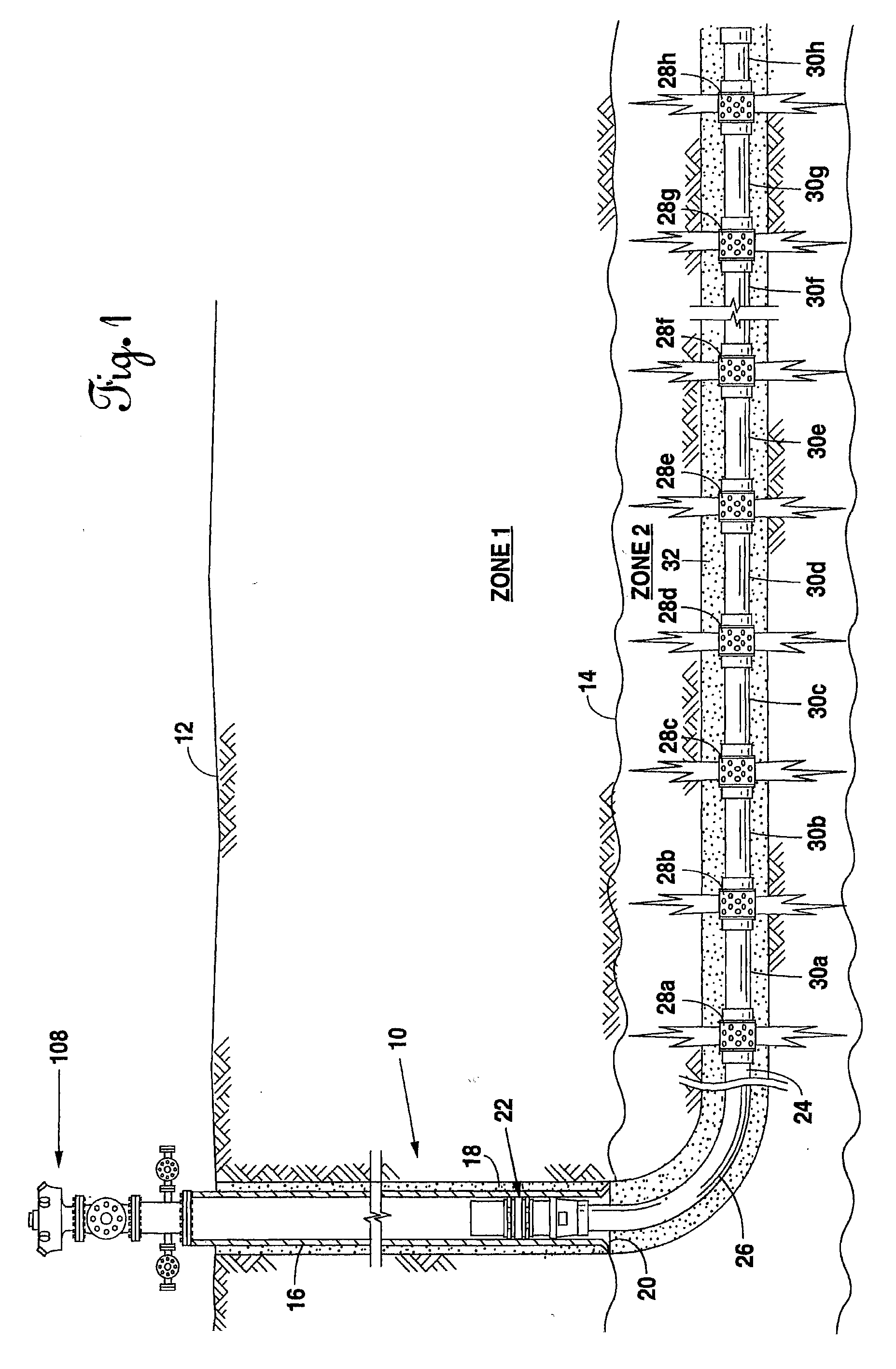

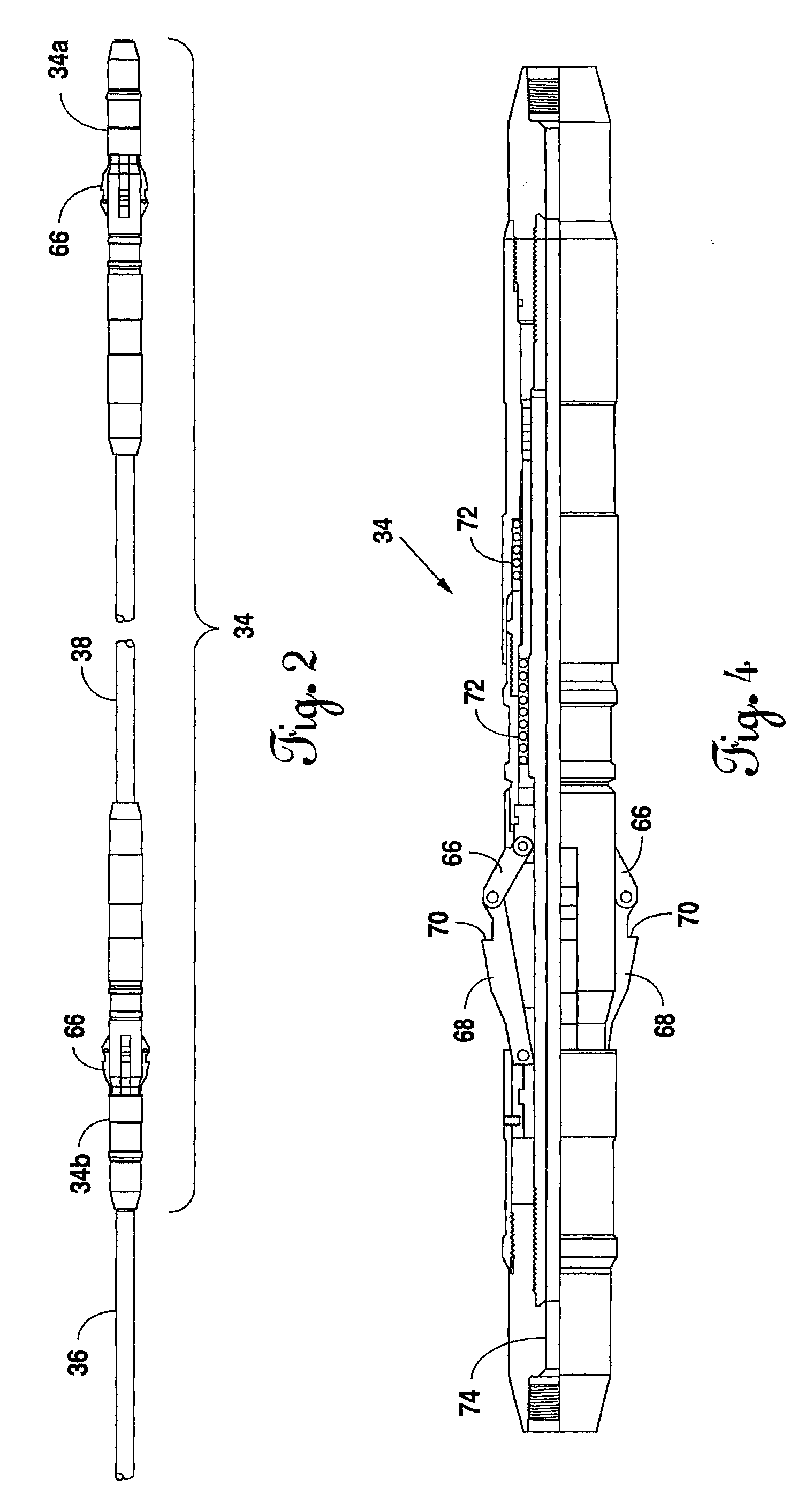

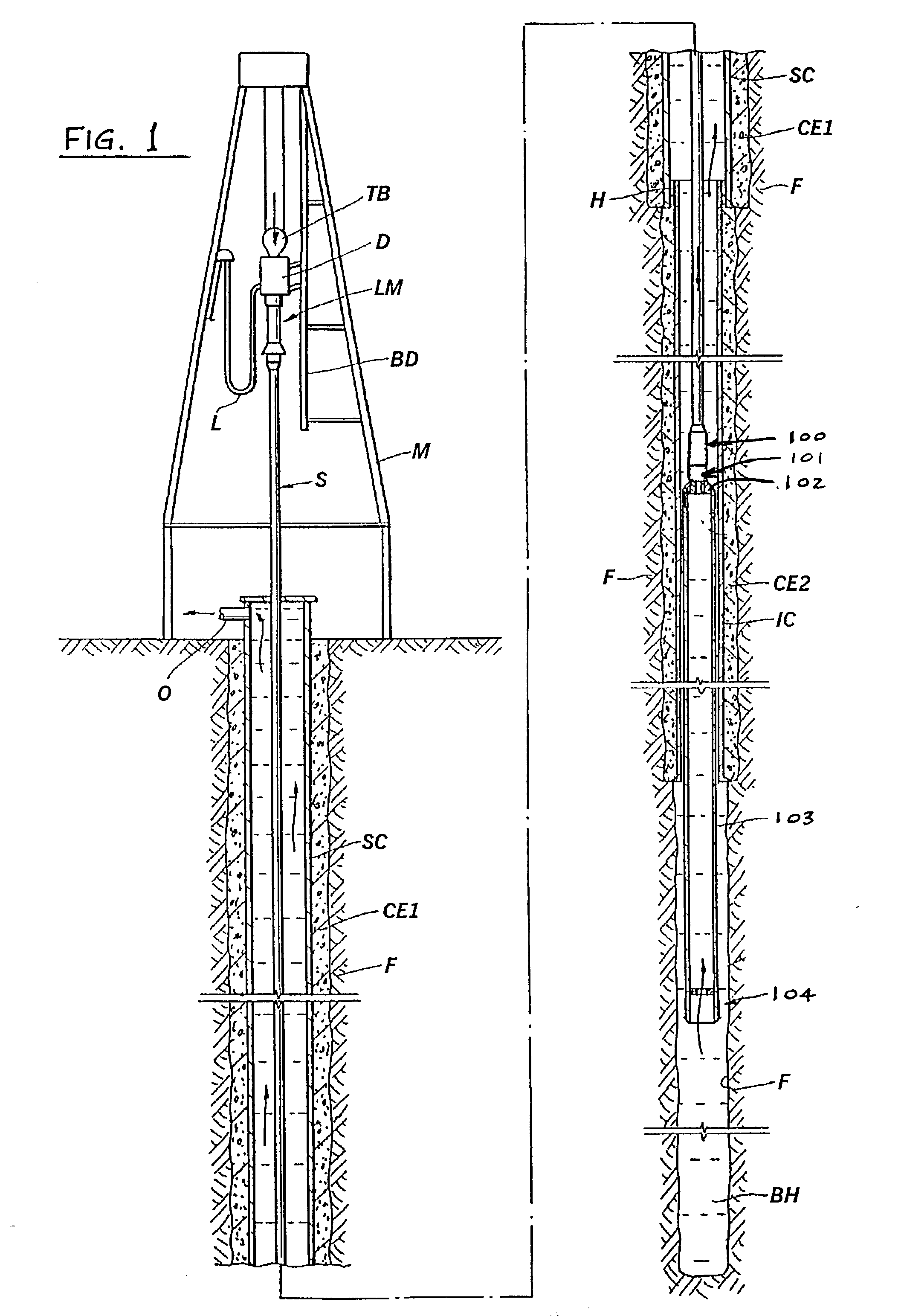

Drilling, perforating and formation analysis

ActiveUS20060102343A1Easy to useImprove breathabilitySpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

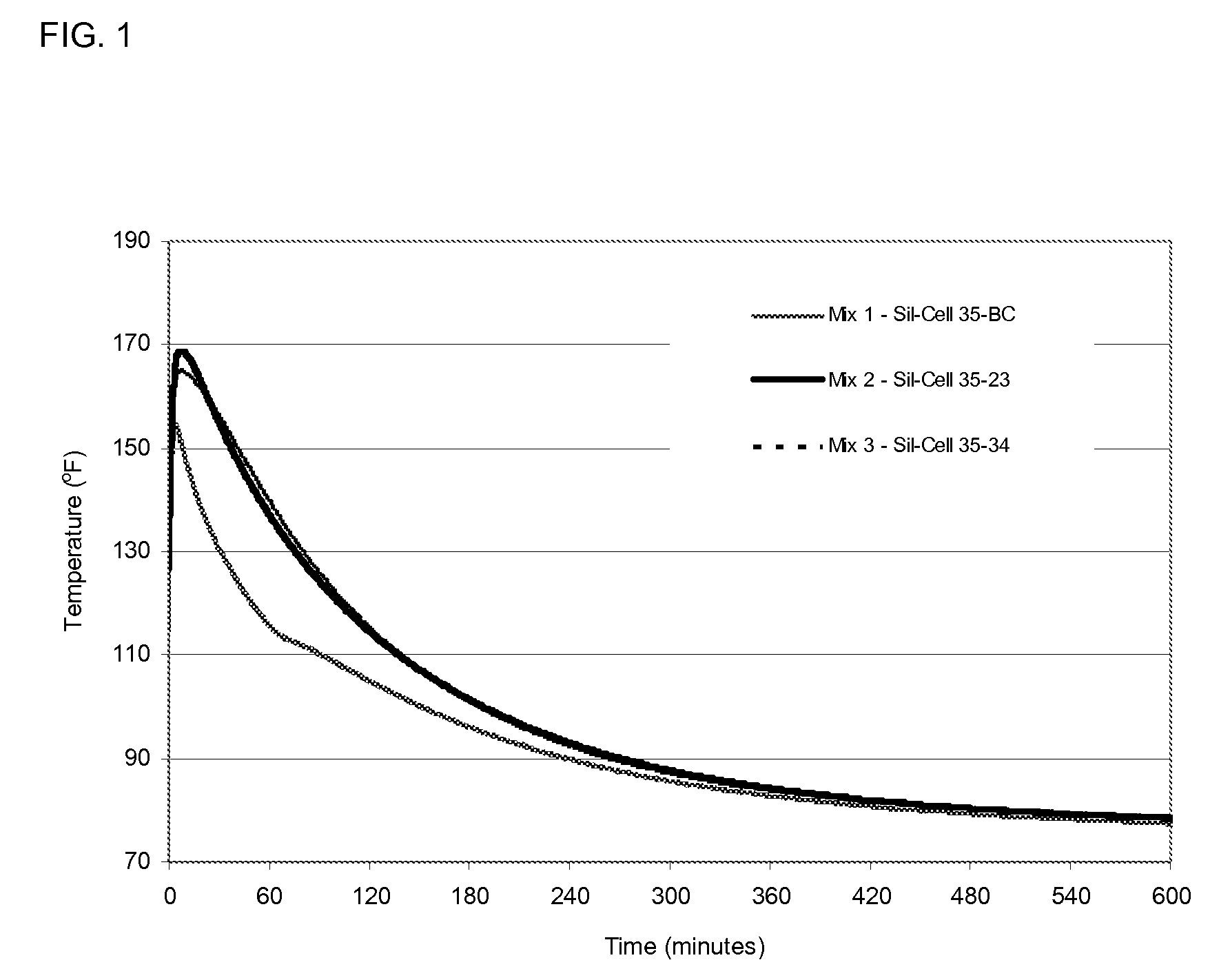

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

High early-strength cementitious composition

A high early-strength cementitious composition comprising a hydraulic cement; and a combination admixture system wherein the combination admixture system comprises a polycarboxylate high range water reducing dispersant in combination with an accelerator and a retarder. The admixture allows for acceptable workability and development of high early-strength in cementitious compositions without the use of an external heat source.

Owner:MBT HLDG +1

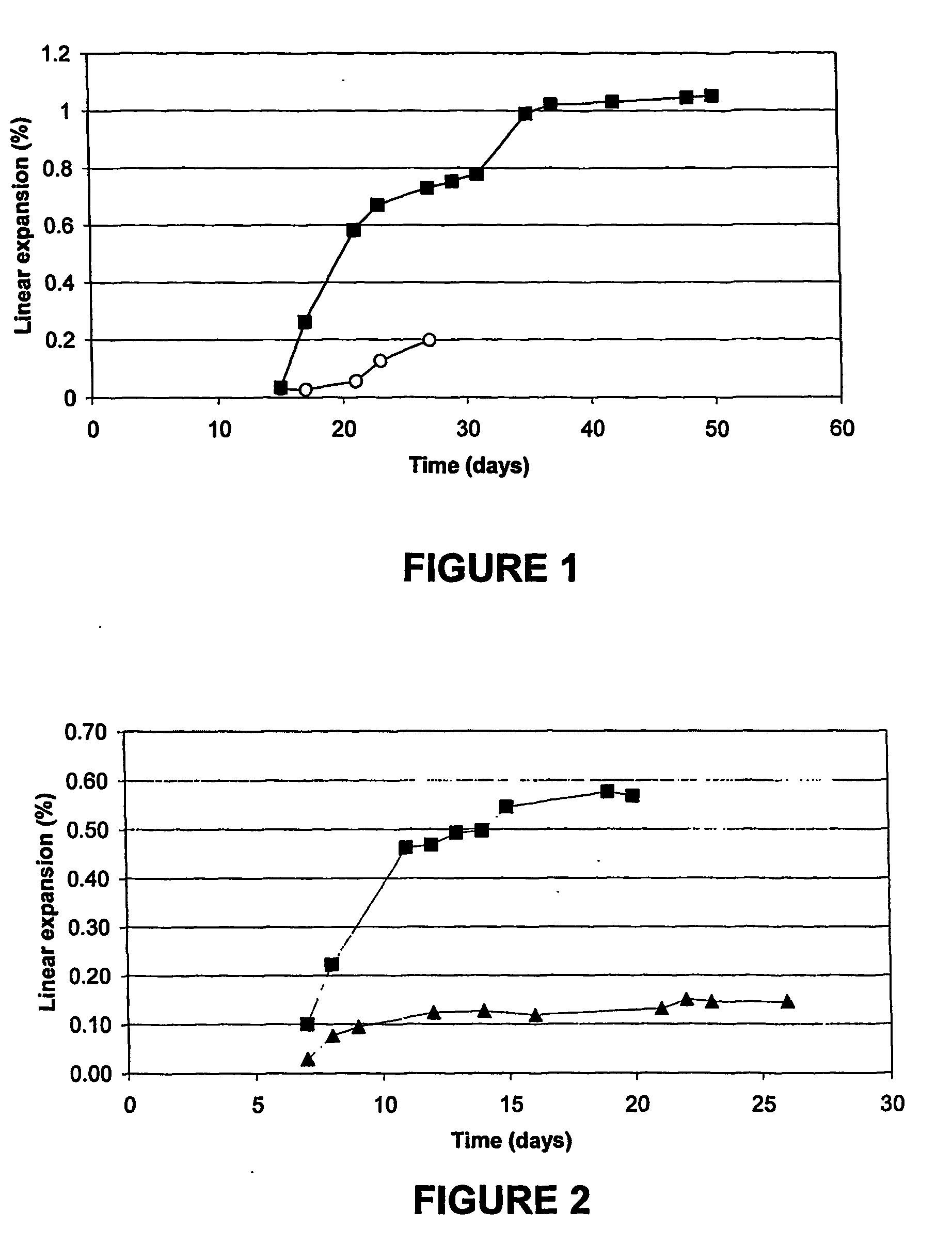

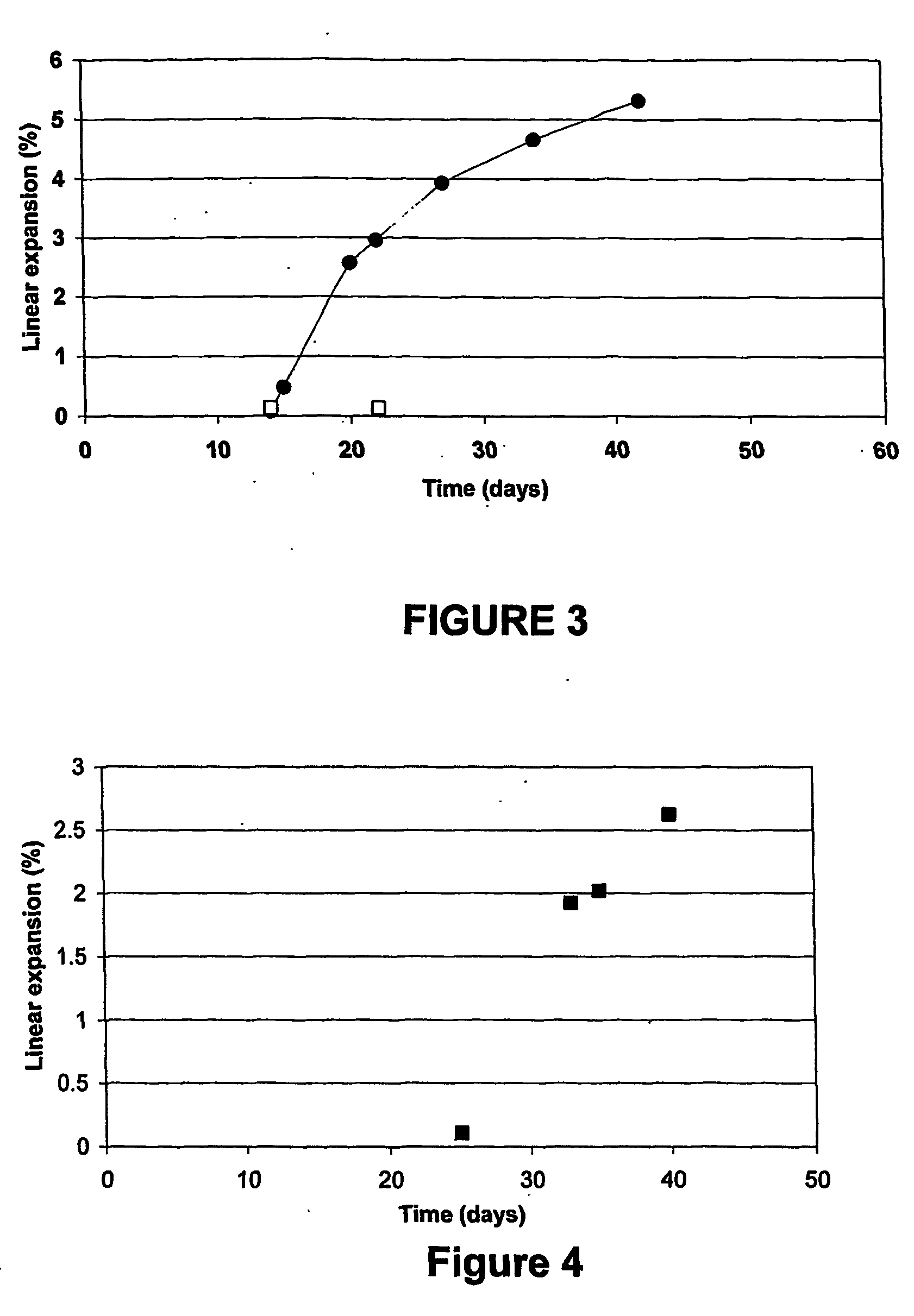

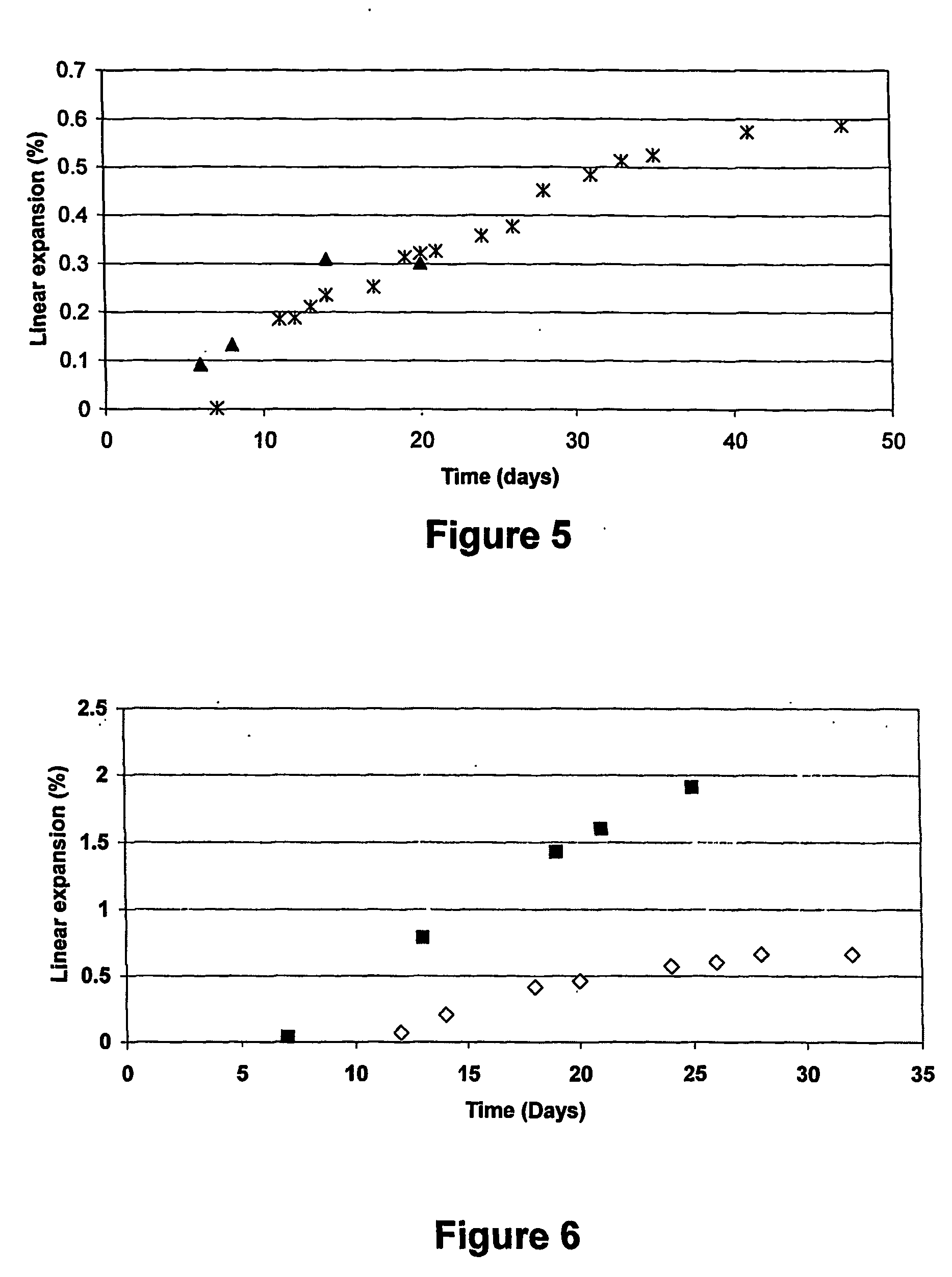

Self adaptive cement systems

InactiveUS20070137528A1Avoid seizuresInhibit migrationSolid waste managementDrilling compositionSelf-healingChemical products

A self-adaptive cement system includes cement, water and at least one additive that reacts or and expands in contact with oil and gas. Several chemical products have been identified including rubber alkylstyrene, polynorbornene, resins such precrosslinked substituted vinyl acrylate copolymers and diatomaceous earth. These additives have the effect of making the cement self-healing in the event of physical failure or damage such as micro-annuli. The self healing property is produced by the contact with subterranean hydrocarbon fluids, the potential repair mechanism is thus activated if and when needed in case of start of loss of zonal isolation. In another embodiment, the expansion is deliberately induced by pumping a hydrocarbon fluid in the vicinity of the set cement.

Owner:SCHLUMBERGER TECH CORP

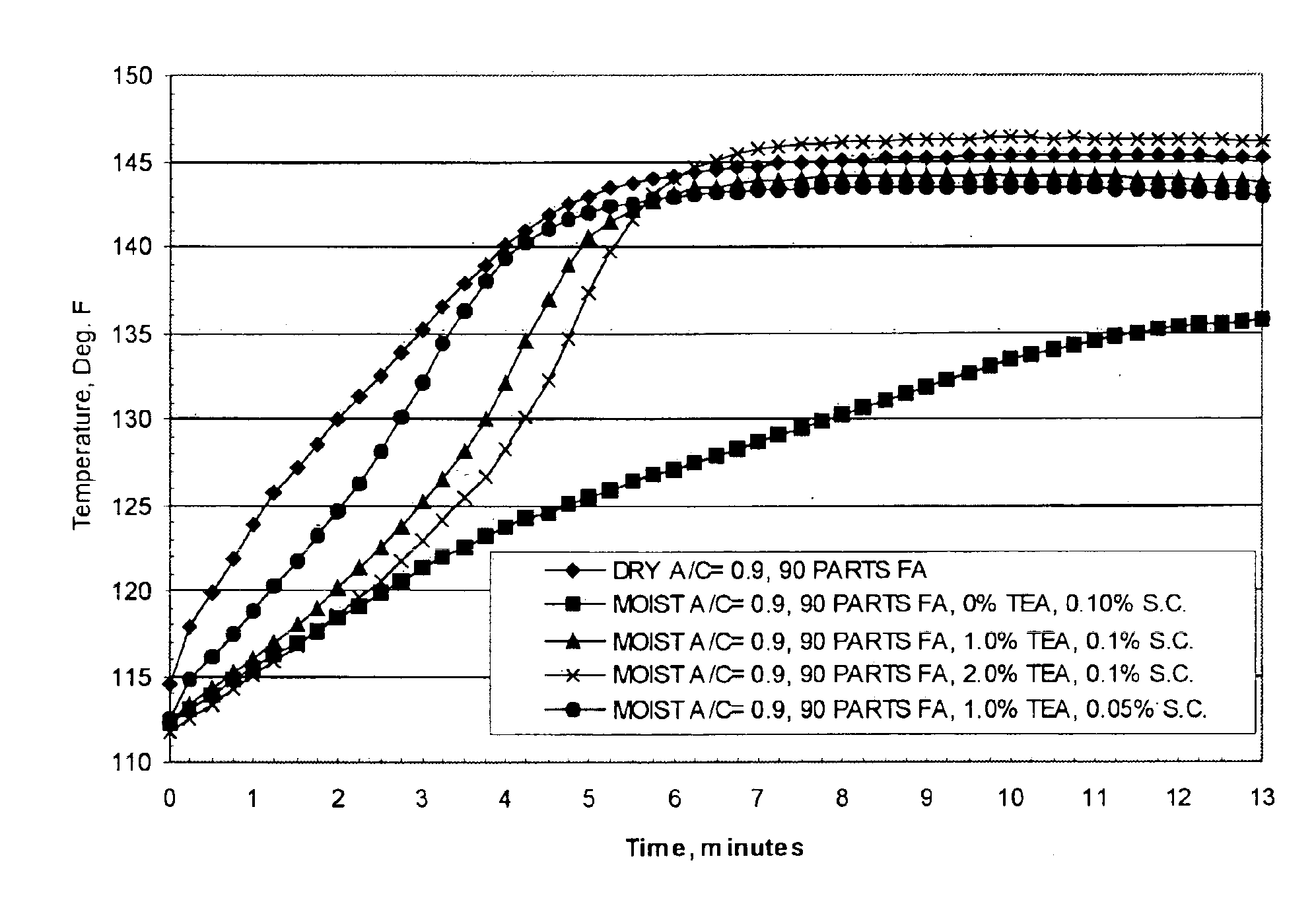

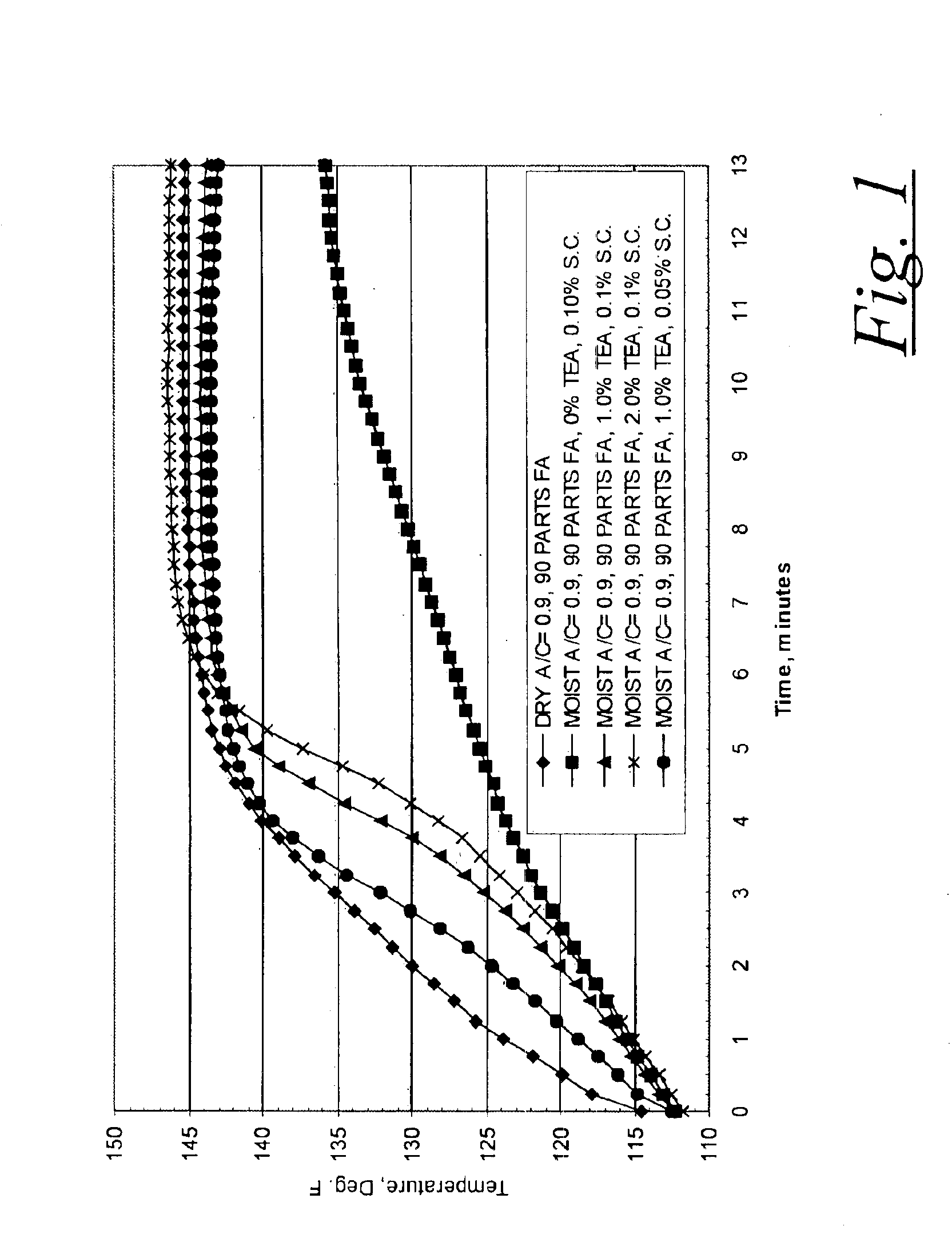

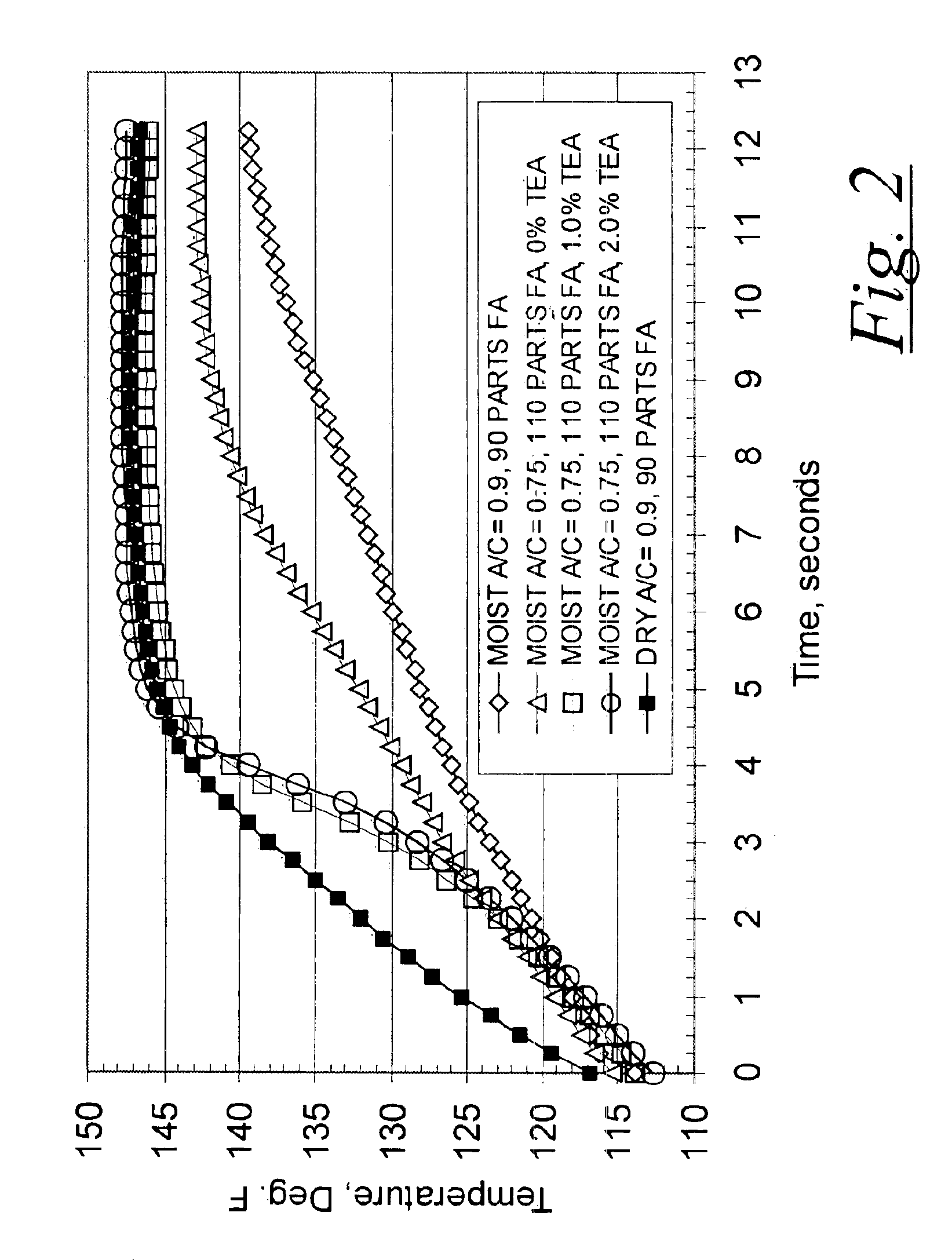

Very fast setting cementitious composition

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

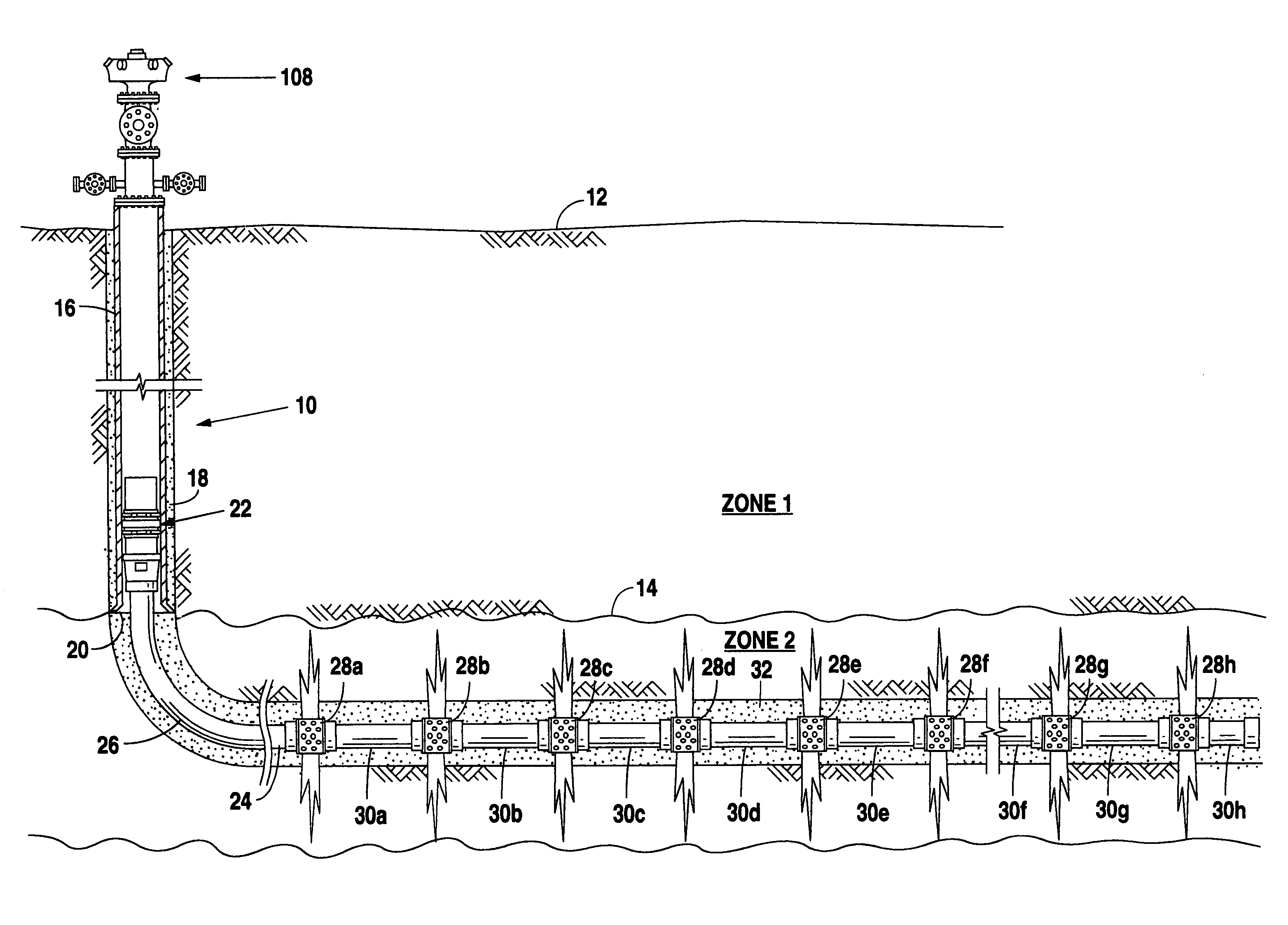

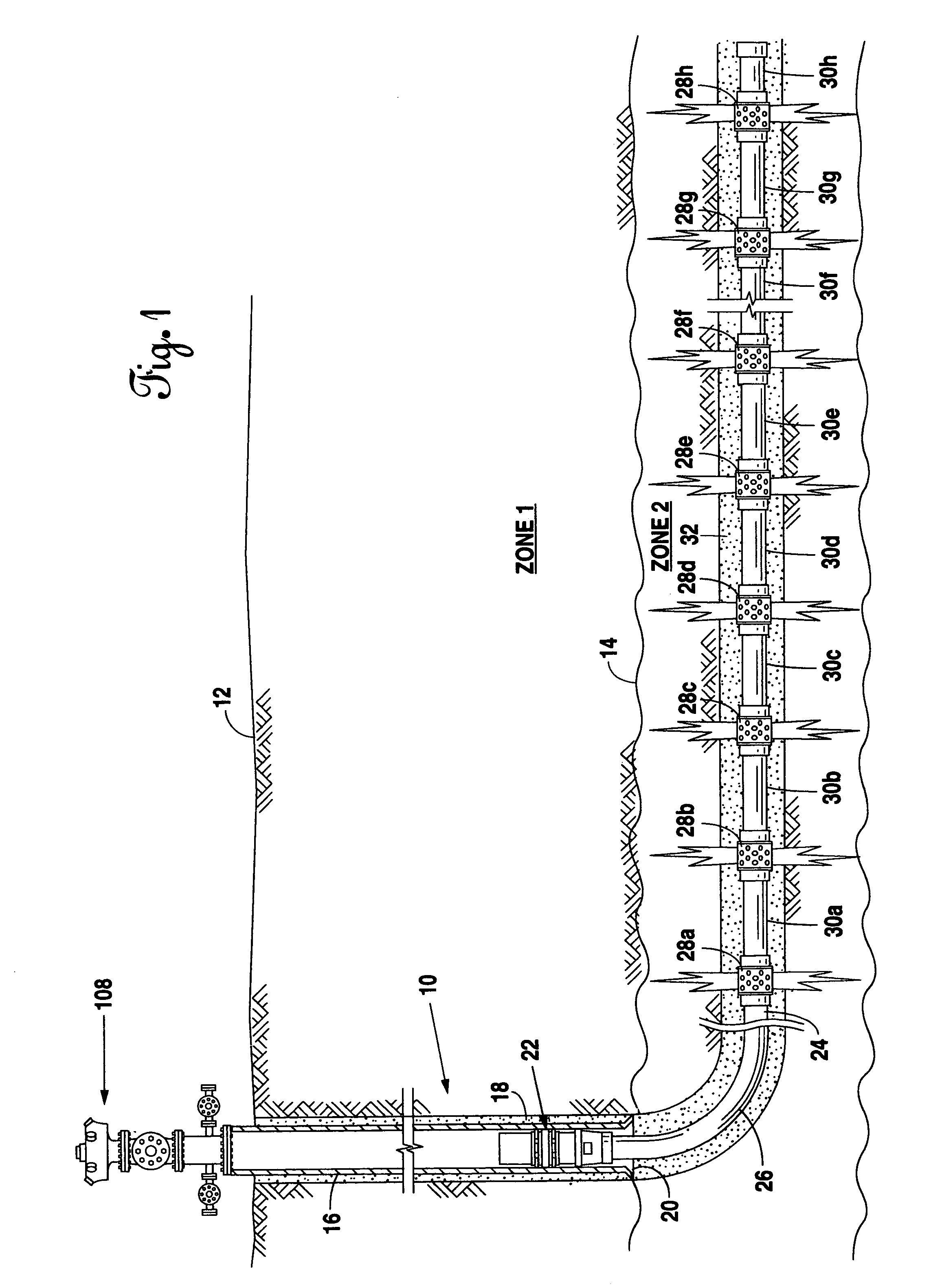

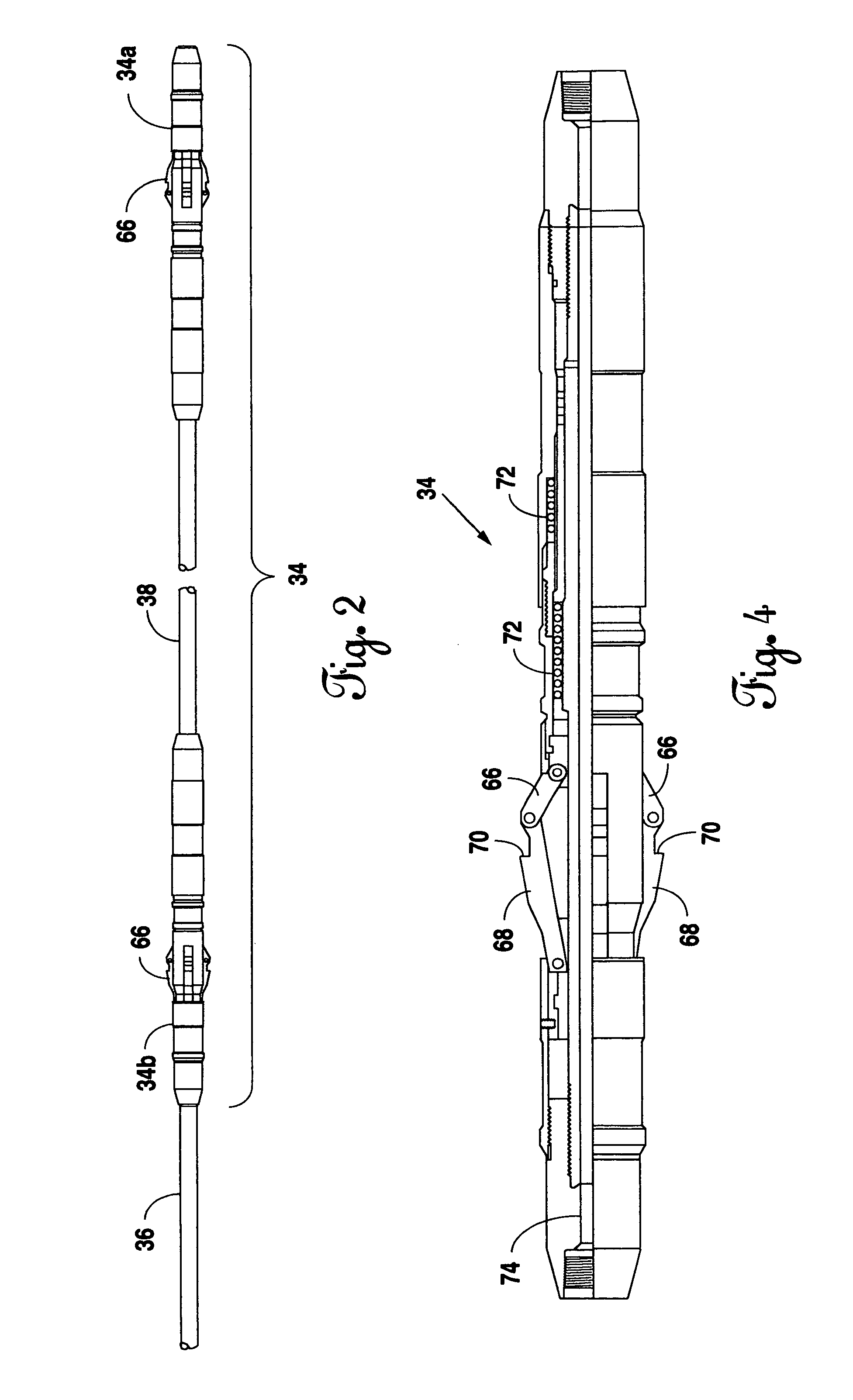

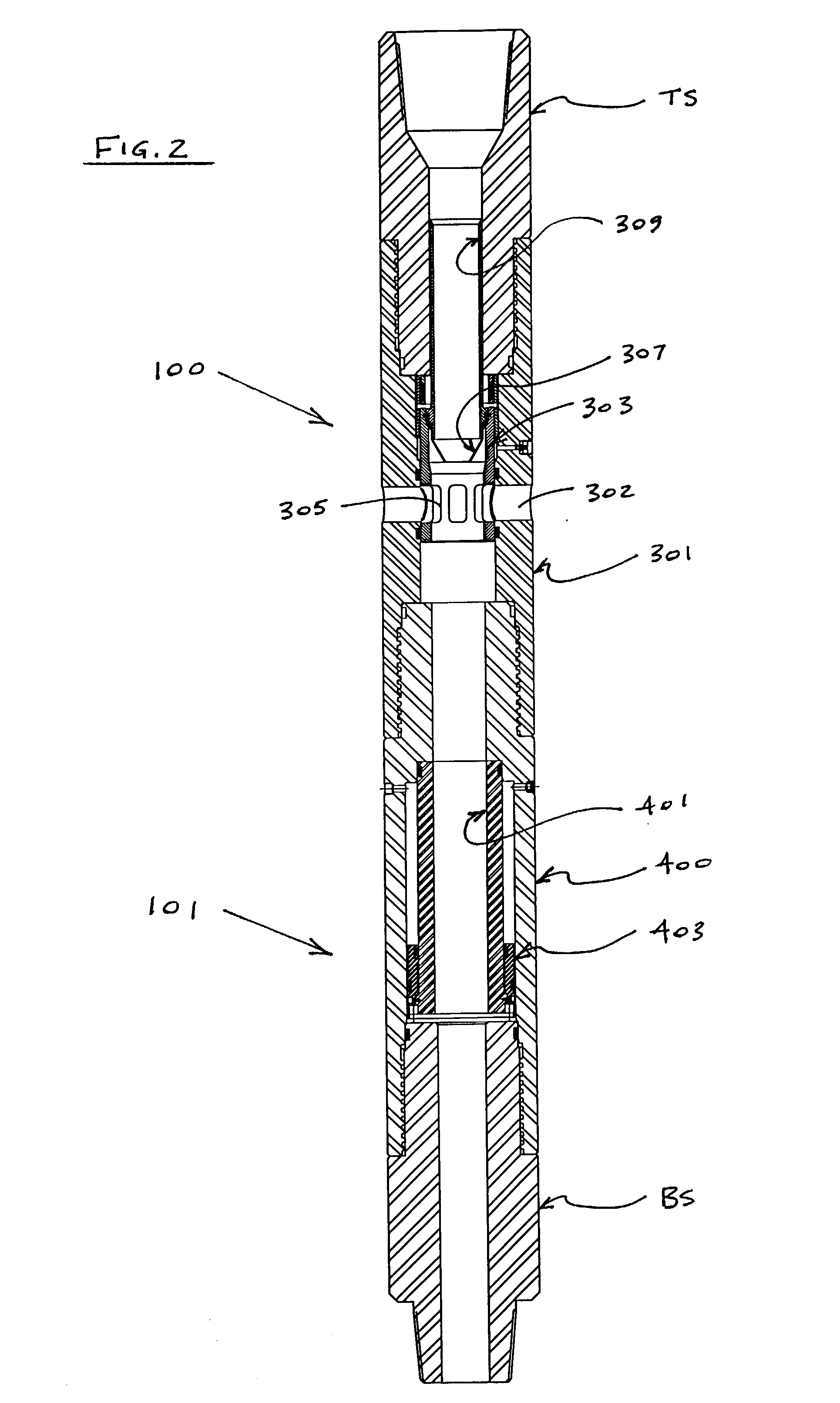

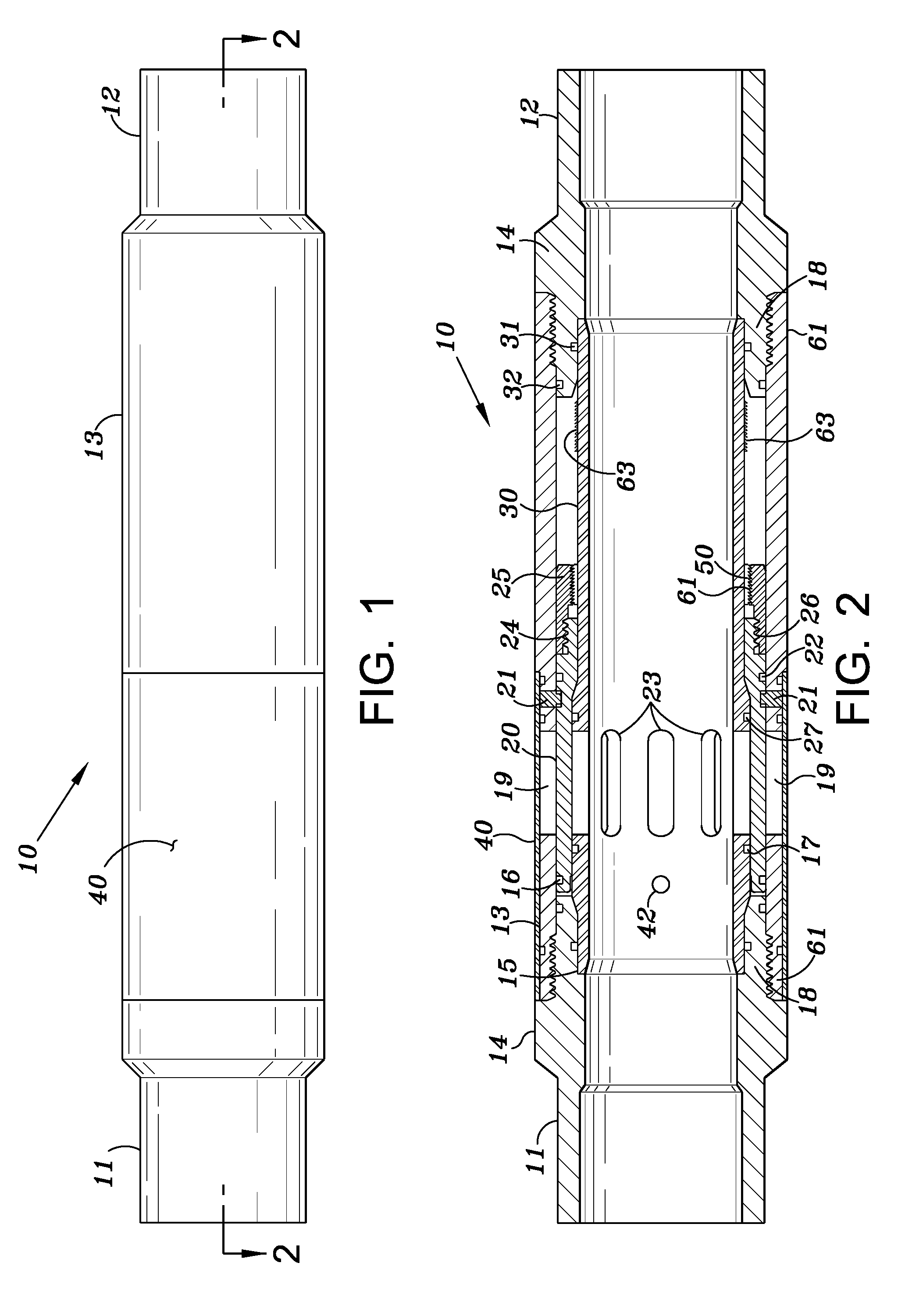

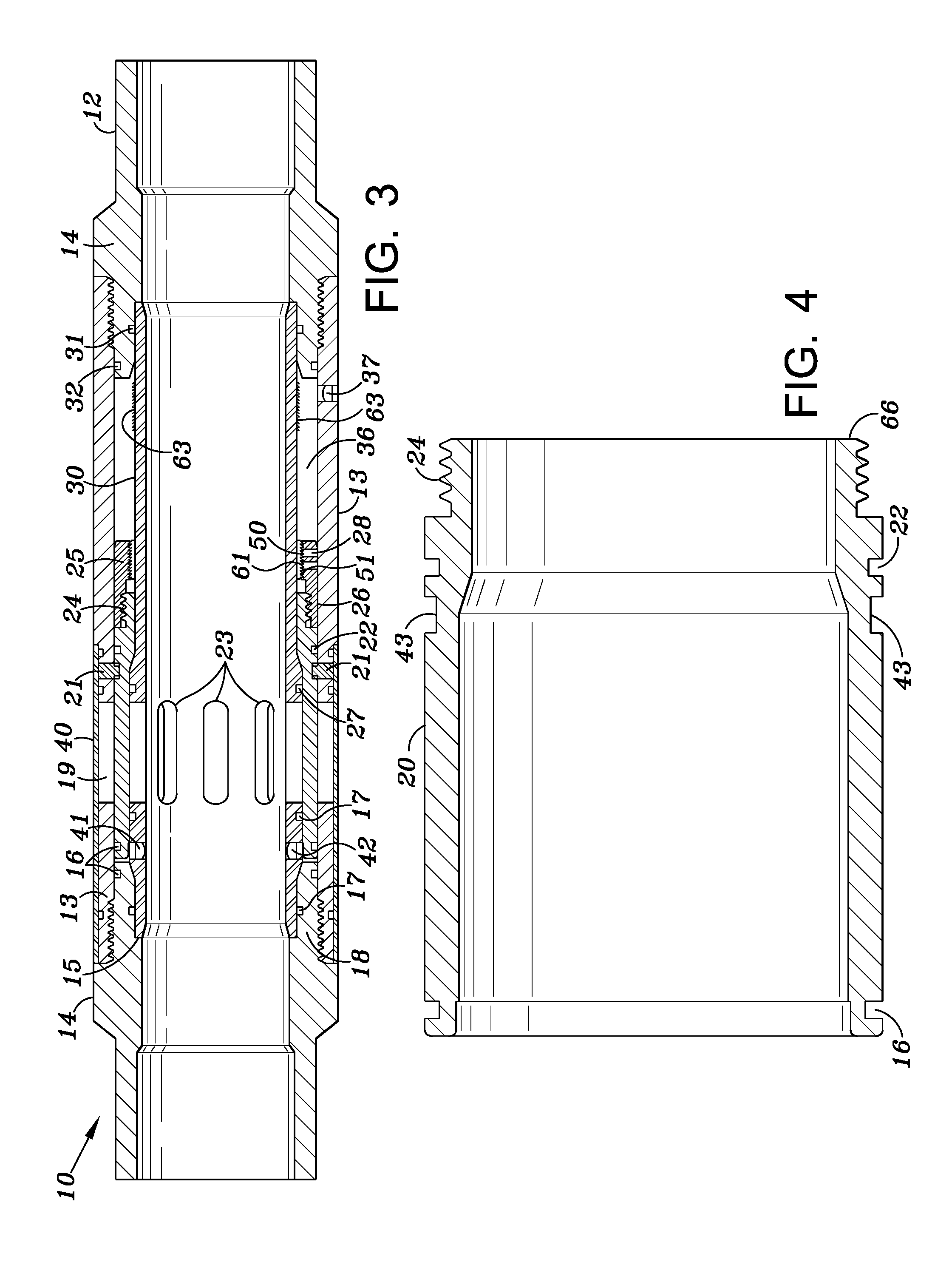

Cemented open hole selective fracing system

A cemented open hole selective fracing system is shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened by a shifting tool, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened with a switching tool, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETIONS TECH INC

Cementitious article and method for preparing the same

ActiveUS20100247937A1Solid waste managementSynthetic resin layered productsAcetic acidPolymer science

A cementitious article and a method of making a cementitious article are disclosed. The cementitious article comprises a cementitious component that comprises a polyvinyl acetate type polymer, a monobasic phosphate, and optionally boric acid. Cementitious articles, such as board, are prepared such that the polyvinyl acetate type polymer, the monobasic phosphate, and optionally boric acid can be present in the cementitious core, and / or in dense layers if present. The concentration of the polyvinyl acetate type polymer, monobasic phosphate, and optionally boric acid in the cementitious article can increase from a central region A to peripheral regions B and C, respectively. In some embodiments, the polyvinyl acetate type polymer is a polyvinyl alcohol and the monobasic phosphate is monoammonium phosphate.

Owner:UNITED STATES GYPSUM CO

Processes for incorporating inert gas in a cement composition containing spherical beads

ActiveUS20050098317A1High densityModifies its propertySolid waste managementFluid removalAl powderPhysical chemistry

The present invention provides a process for forming cement in a well bore. In this process, a cement composition is formed that comprises a cement and one or more beads mixed with the cement. The cement composition containing the beads is displaced into the well bore, and an inert gas phase is introduced to the cement composition to control a density of the cement composition. The inert gas phase can be introduced by adding a gas generating material to the cement composition and / or a porous material to the cement composition. In an embodiment, the gas generating material is a nitrogen generating material that may be activated by an oxidizing agent. In another embodiment, the gas generating material is a hydrogen generating material, e.g., an aluminum powder. The present invention further provides a cement composition comprising a cement, one or more beads combined with the cement, and an inert gas phase created by, e.g., a gas generating material and / or a porous material.

Owner:HALLIBURTON ENERGY SERVICES INC

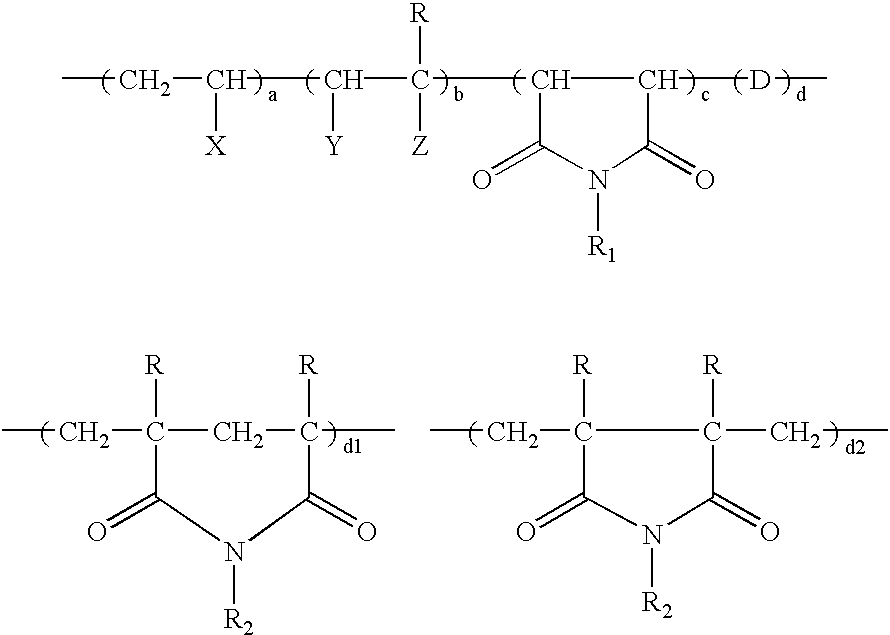

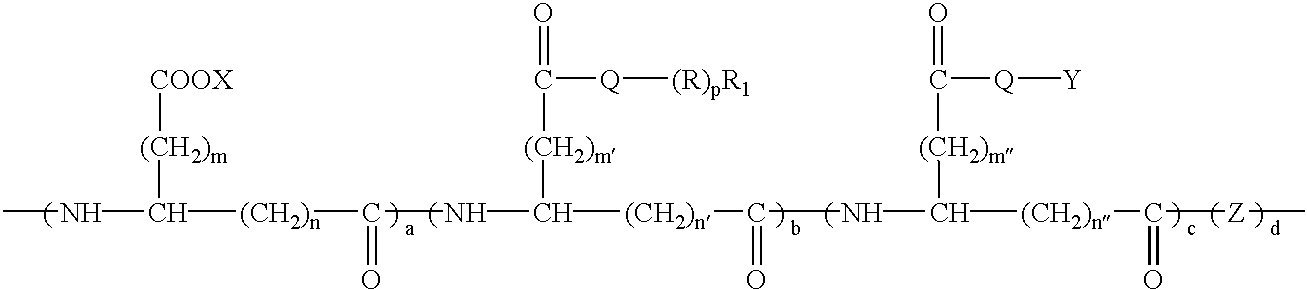

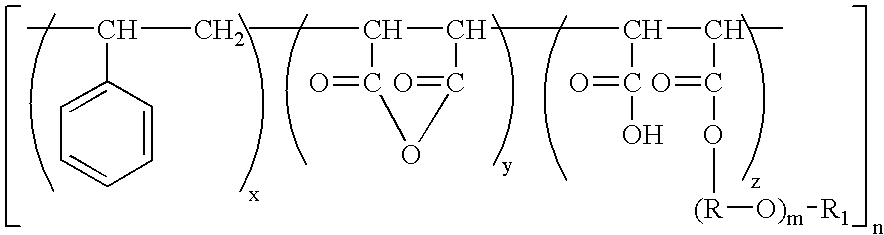

Cement dispersant, method for production thereof, and cement composition using the dispersant

InactiveUS6376581B1Delayed slump lossLowering of unit water contentPolymer sciencePolyethylene glycol

A cement dispersant having excellent ability to prevent slump loss and high water-reducing property which comprises a polycarboxylic acid type polymer having a specific molecular weight distribution, a method for the production thereof, and a cement composition using the dispersant are provided. The cement dispersant comprises as a main component thereof a polycarboxylic acid type polymer (A), having a weight average molecular weight in the range of 10,000 to 500,000 in terms of polyethylene glycol determined by gel permeation chromatography, and having a value determined by subtracting the peak top molecular weight from the weight average molecular weight in the range of 0 to 8,000.

Owner:MBT HLDG

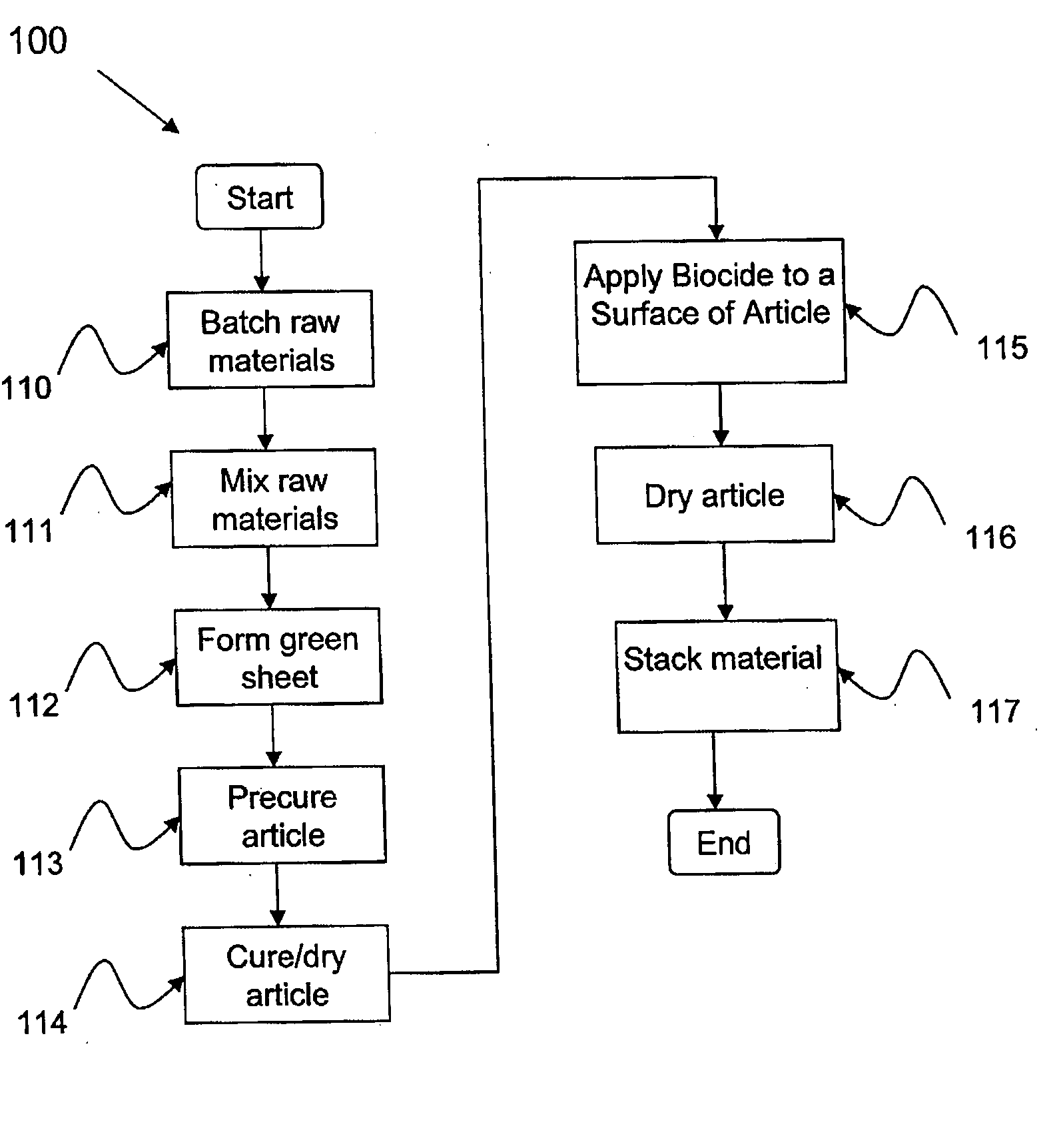

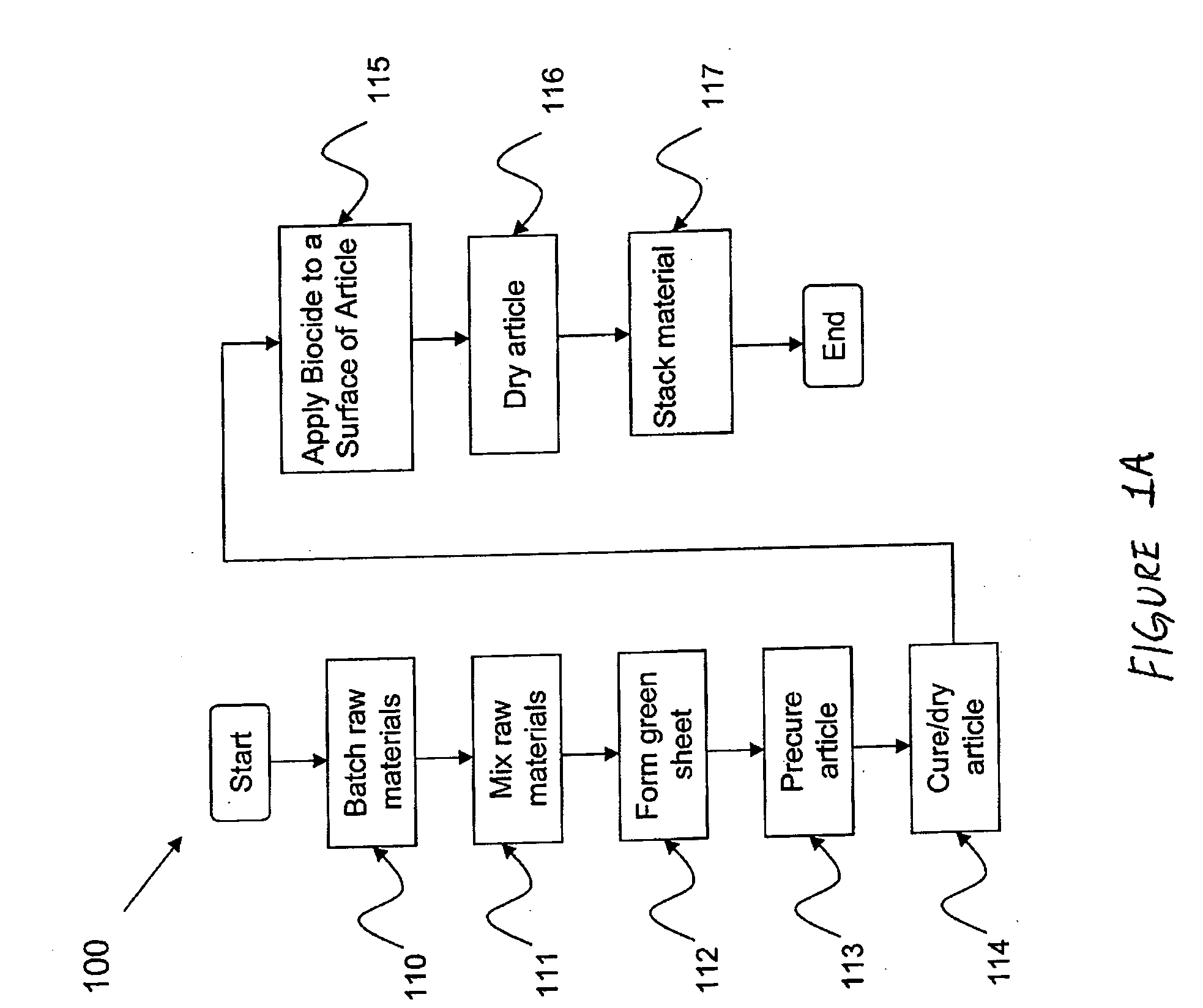

Building materials with bioresistant properties

InactiveUS20050126430A1Effective biocide treatmentAffecting performanceFireproof paintsAntifouling/underwater paintsFiberBiological resistance

A building article incorporating a biocidal agent, such as copper oxine, that inhibits the growth of mold, fungi, algae, mildew, bacteria, lichen, and other undesirable biological growth is provided. The biocidal agent can be a biocide, fungicide, germicide, insecticide, mildewcide, or the like. The biocidal agent can be interspersed throughout the matrix of the article; applied as a surface treatment to the article; or applied as a treatment to the fibers reinforcing the article. The building article can include tile backer boards, decks, soffits, trims, decking, fencing, roofing, cladding, sheathing, and other products. The building article can also include a variety of different composite materials such as cement, gypsum, wood, and wood / polymer composites.

Owner:JAMES HARDIE TECH LTD

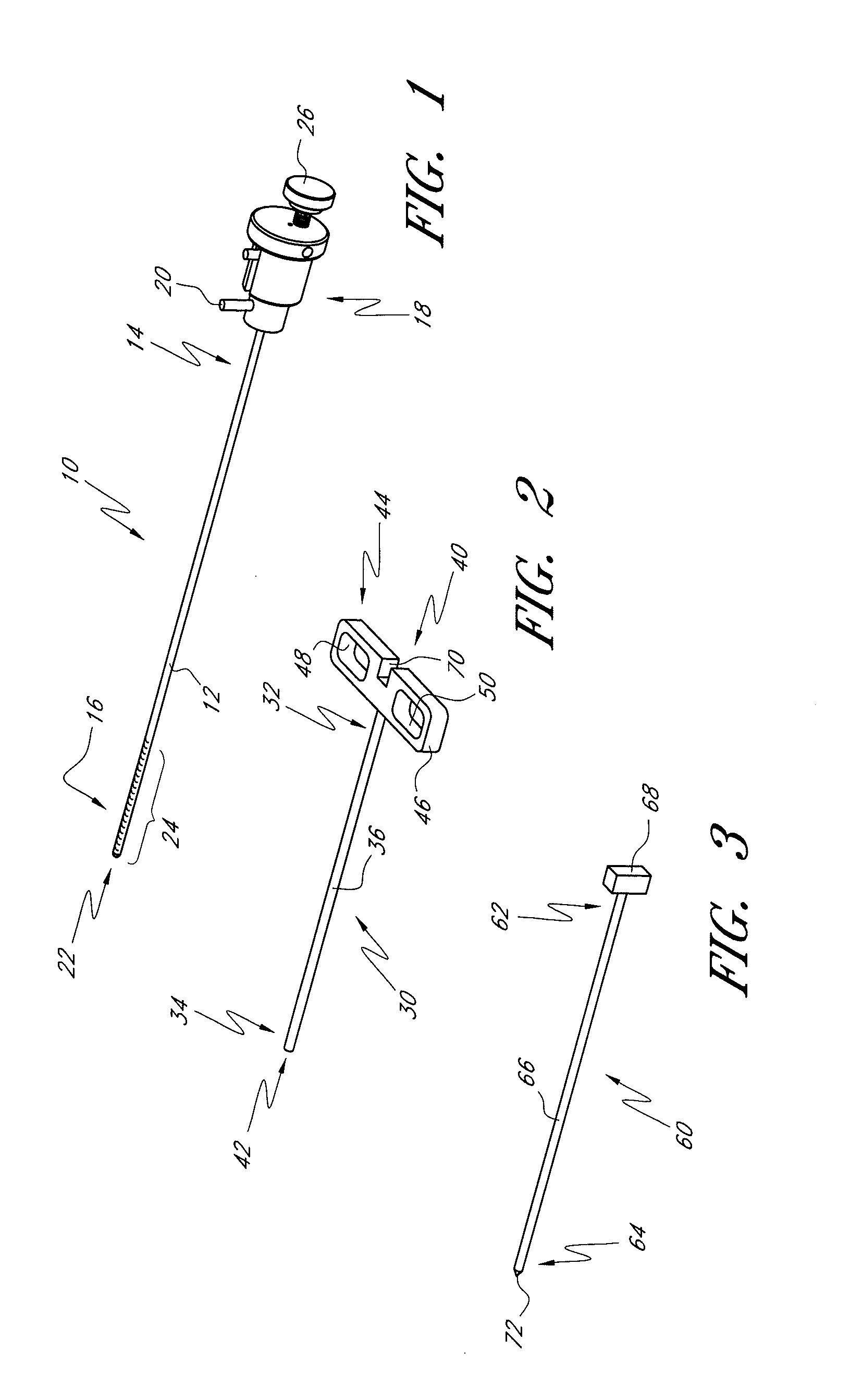

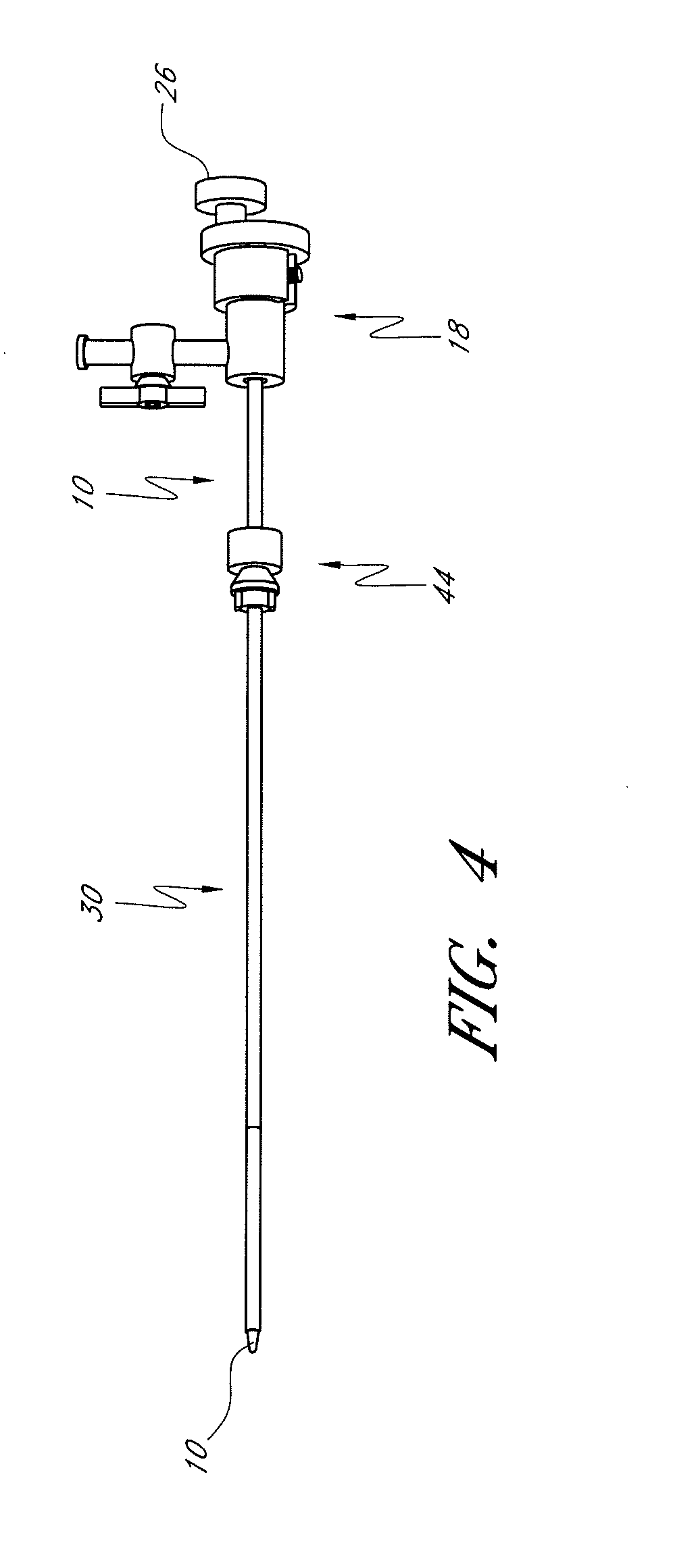

Steerable vertebroplasty system with a plurality of cavity creation elements

Methods and devices for augmenting bone, such as in performing vertebroplasty are disclosed. A bone cement injection needle is provided, having a laterally deflectable distal end. The distal end may be provided with one or two or more cavity creation elements, such as inflatable balloons. A cavity creation element may include one or more filament layers. Systems are also disclosed, including the steerable injection needle, introducer and stylet. The system may additionally include a cement delivery gun, one-time use disposable cement cartridges and a cement mixing chamber. Methods are also disclosed.

Owner:OSSEON THERAPEUTICS

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

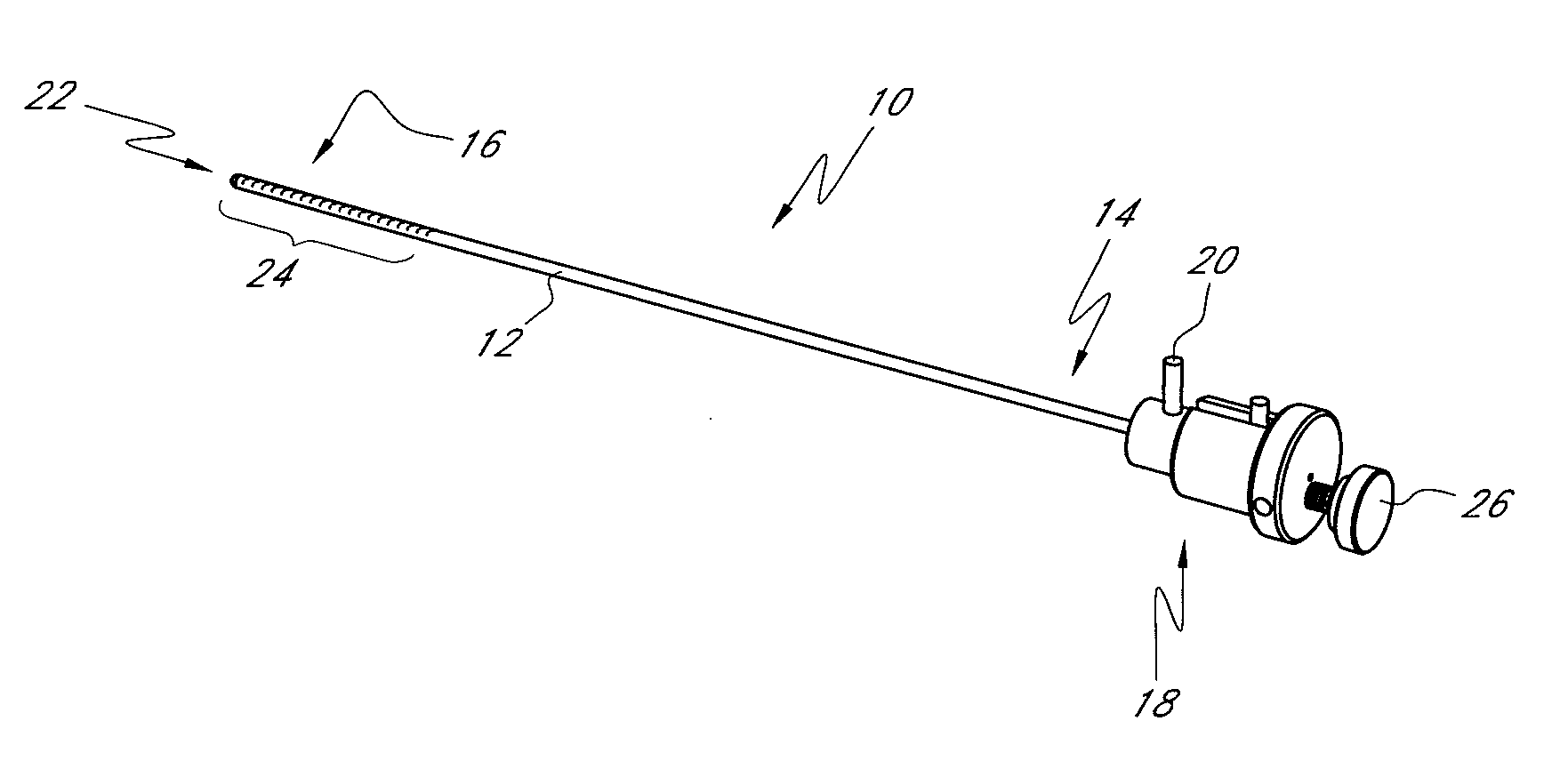

Drilling, perforating and formation analysis

ActiveUS7490664B2Easy to useWithout usingSpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

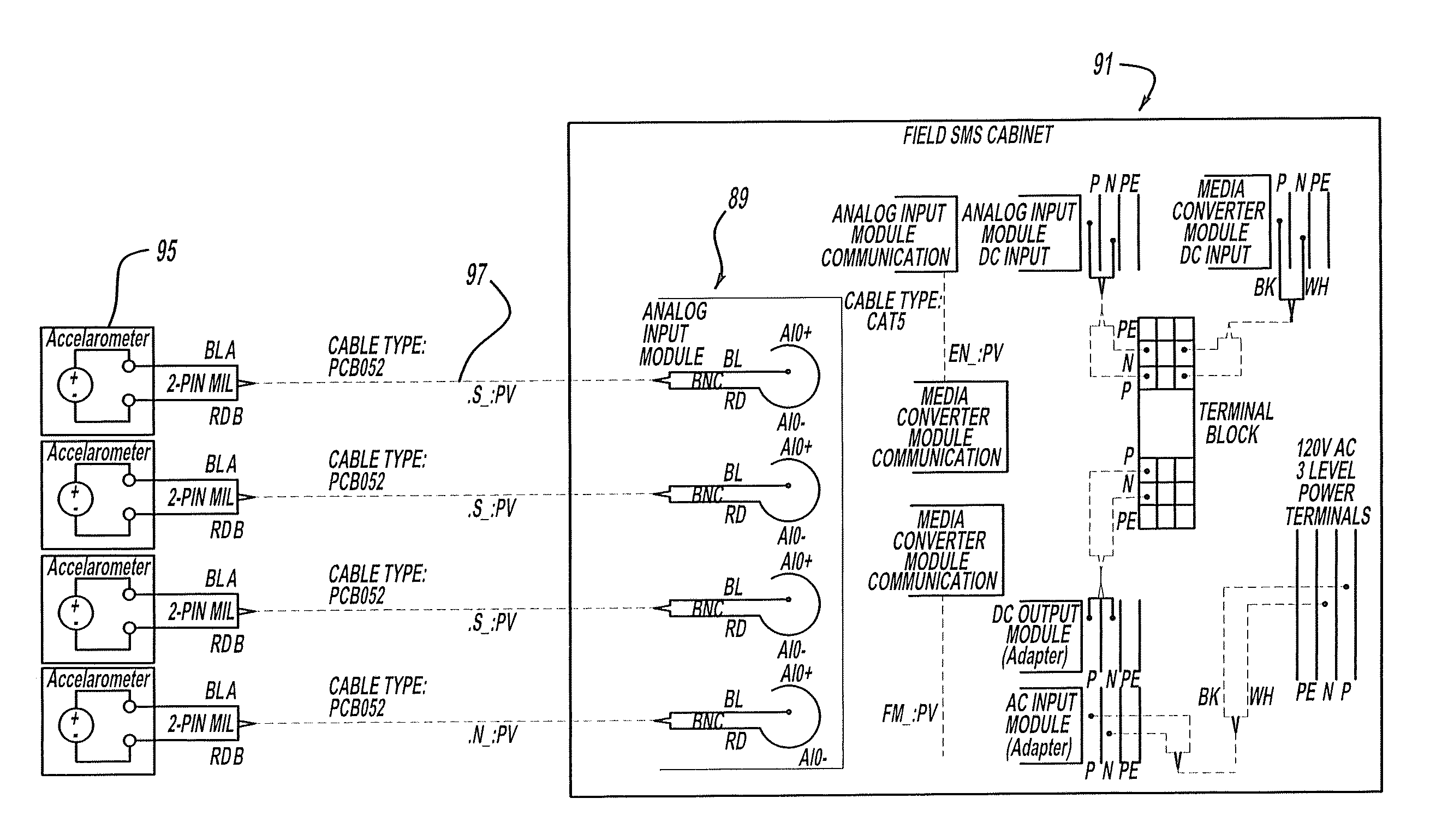

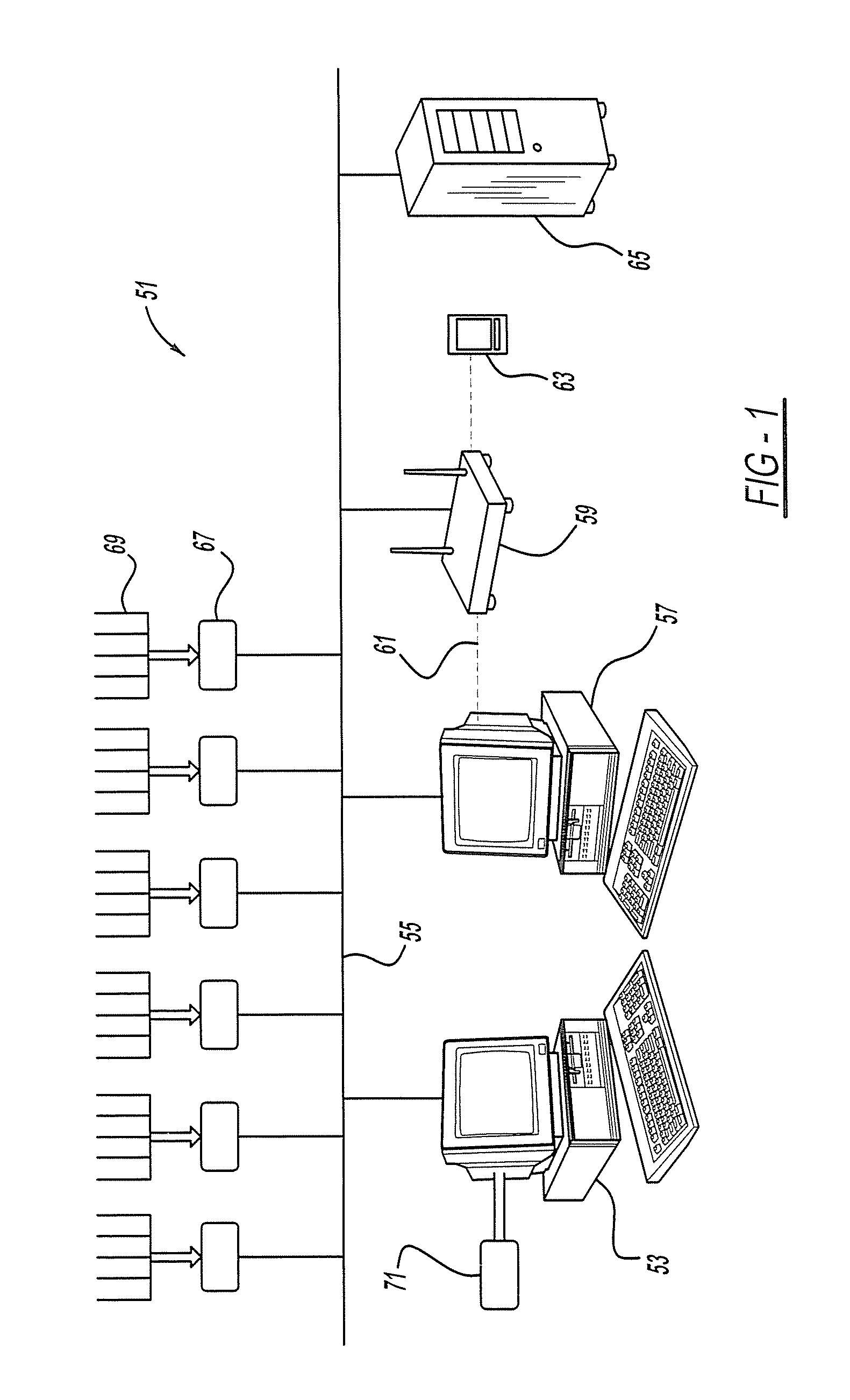

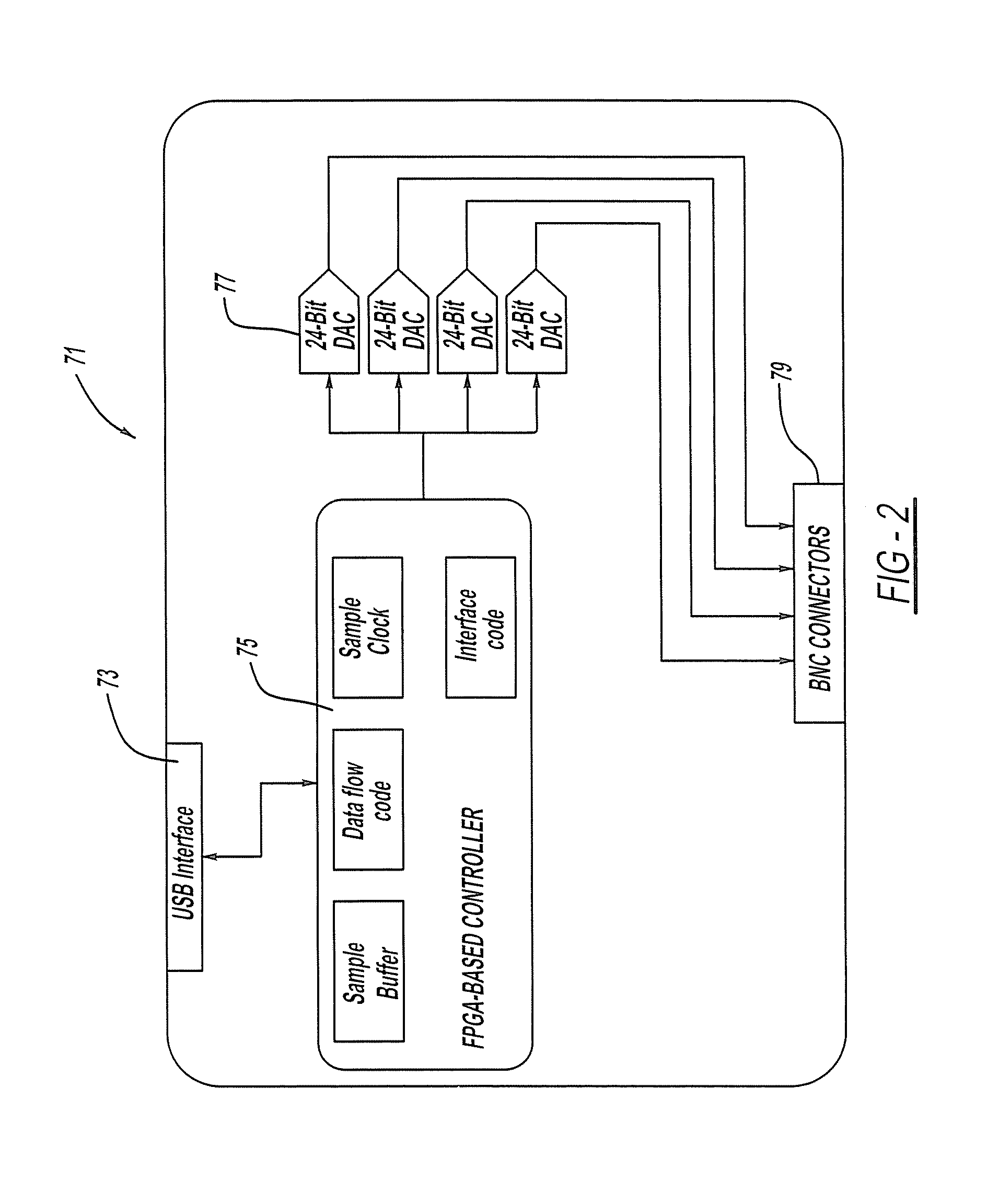

System for monitoring plant equipment

ActiveUS20110184547A1Improve sensed data analysisReduce hardware costsRotary drum furnacesRoads maintainenceCement manufacturingSoftware

A system for monitoring plant equipment is provided. Another aspect provides an automated analysis system wherein software instructions operably compare sensor data to predefined valves and determine mechanical problems in multiple machines. In another aspect, a cement manufacturing system includes sensors for sensing movement conditions of cement making machines. A further aspect provides a central computer connected to vibration sensors associated with cement making machines, where software instructions perform real-time comparisons and machine performance determinations, based at least in part on sensed signals.

Owner:HOLCIM US

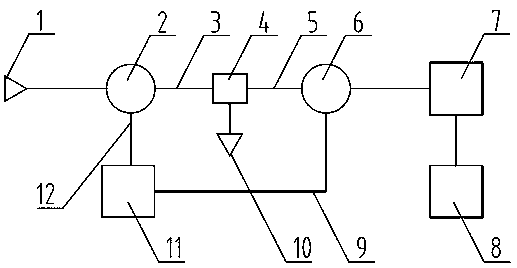

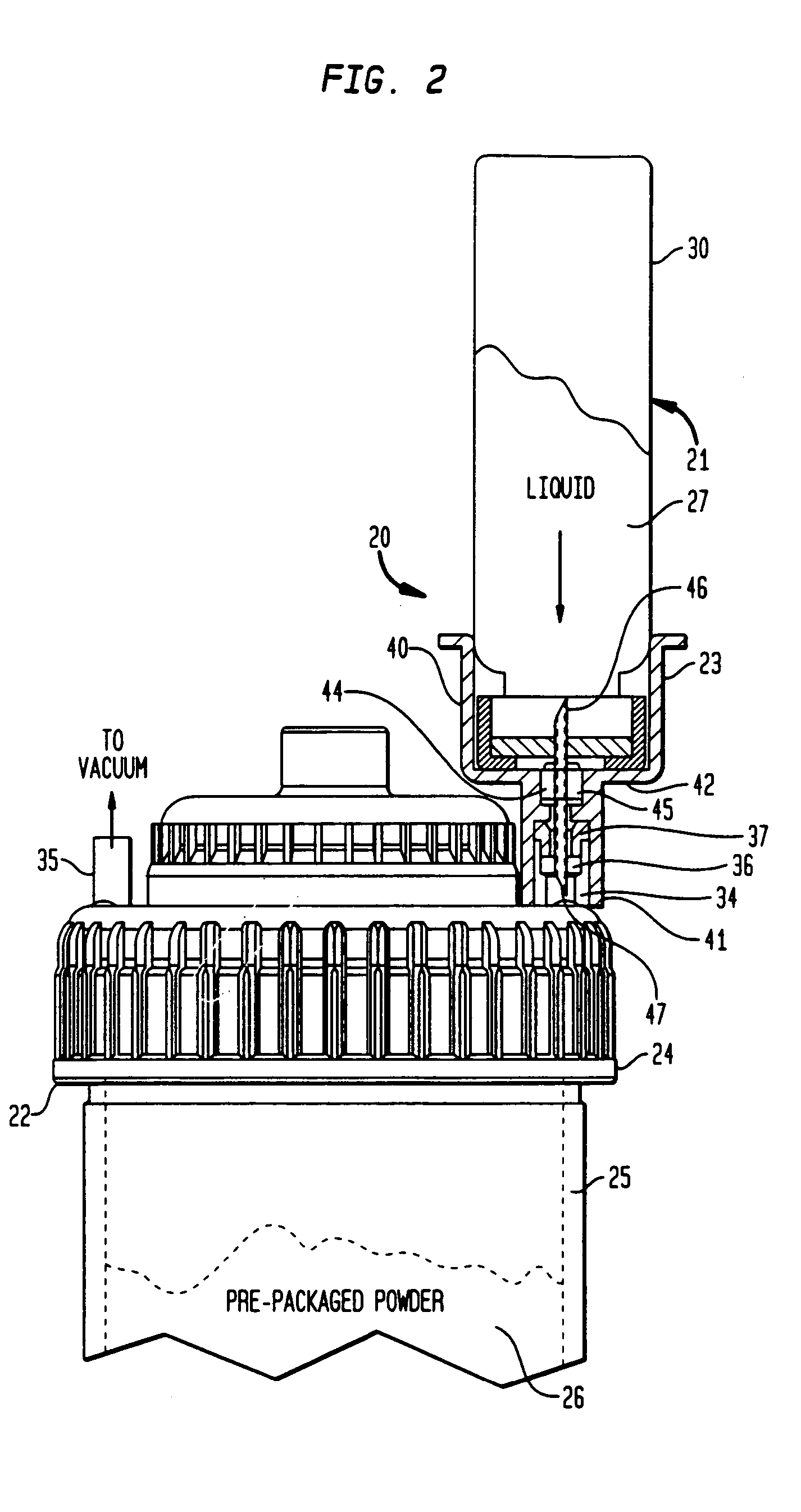

Cement truck densimeter automatic cleaning device and method

PendingCN110947681ASave cleaning laborWill not polluteCleaning using liquidsControl systemProcess engineering

The invention provides a cement truck densimeter automatic cleaning device and method. The cement truck densimeter automatic cleaning device comprises a liquid feeding pipeline, a centrifugal pump, atee joint, a densimeter mounting seat, a signal acquisition system, a control system and a cleaning tank, wherein the liquid feeding pipeline is connected with an inlet of the centrifugal pump, the tee joint is arranged between the centrifugal pump and the densimeter mounting seat, the third end of the tee joint is provided with a discharge pipeline in a connected manner; the densimeter mounting seat is connected with the cleaning tank; and the densimeter mounting seat is in electric signal connection with the signal acquisition system, and the signal acquisition system is electrically connected with the control system. According to the cement truck densimeter automatic cleaning device, the problem that cement adheres to the inner part of a densimeter is solved, the measuring precision ofthe densimeter is improved and the service life of the device is prolonged; cleaning liquid is automatically fed, the cleaning process is automatically circulated, the cleaning progress is automatically detected; and the cement truck densimeter automatic cleaning device is used for densimeter automatic cleaning, the operation is safer and more efficient, and on-site manpower is greatly saved.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG +1

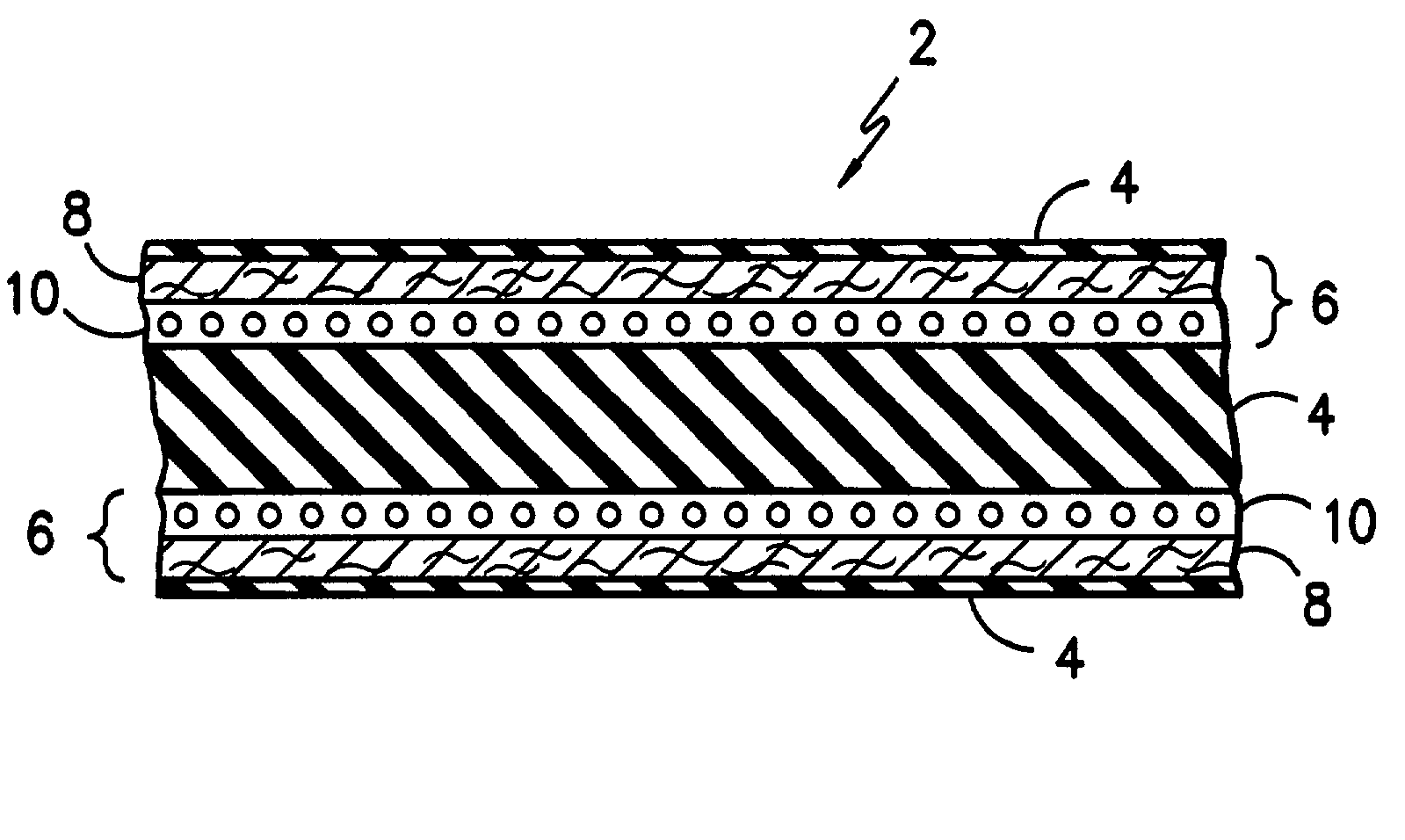

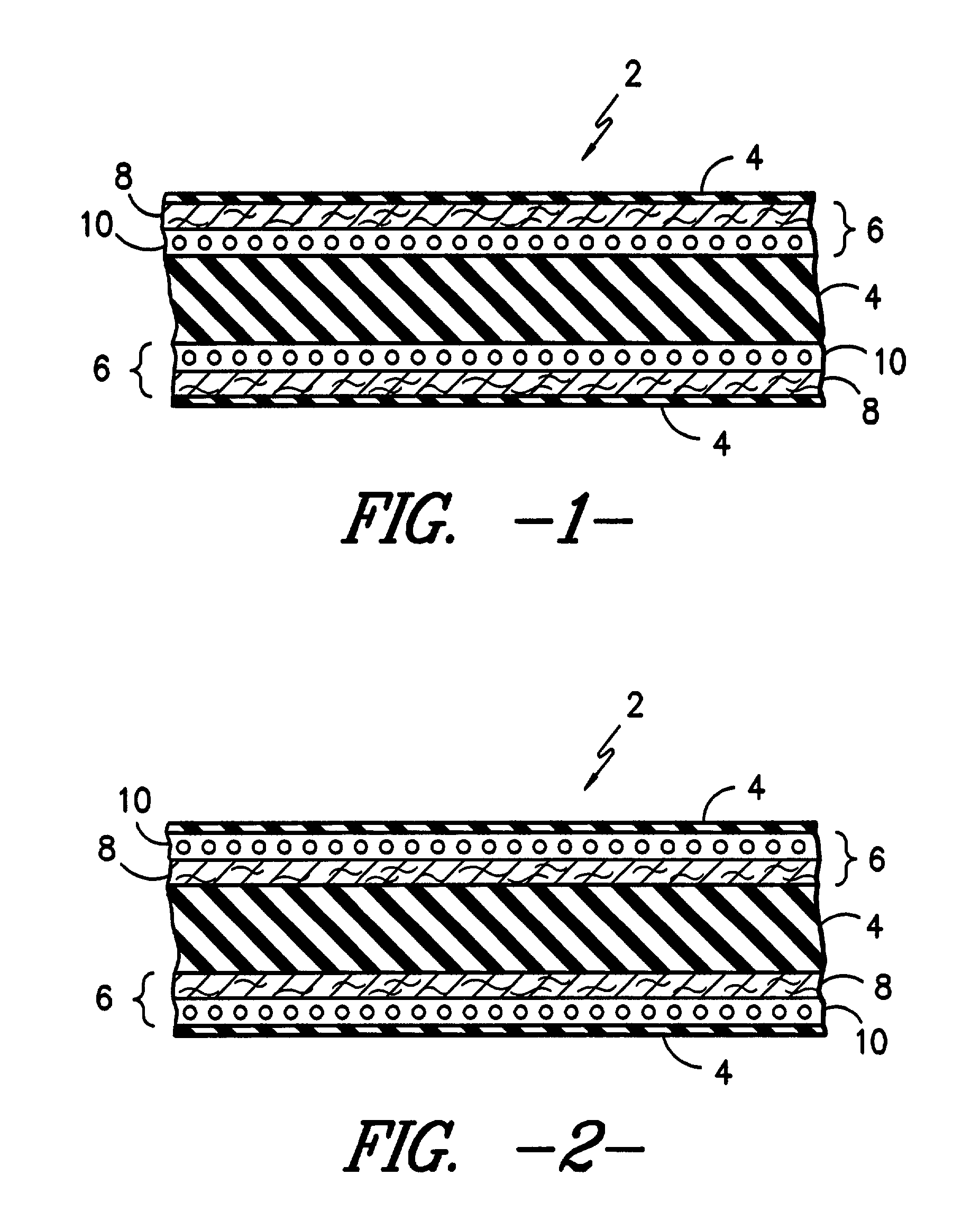

Composite facer for wallboards

InactiveUS20020151240A1Easy to foldReduce the possibilityMedical devicesPressure infusionSecondary layerPolyester

A composite facer material for use with cementitious wallboards, where the composite facer is embedded in a top and bottom face thereof. The composite facer material, in a most preferred embodiment, comprises two layers. The first layer is preferably a carded polyester nonwoven mat, which is bonded to a second layer comprising preferably a tri-directional laid scrim fabric reinforcement layer made of continuous glass fibers. The two layers are preferably bonded together using an acrylic adhesive, which offers superior adhesion between the layers as well as superior adhesion between the composite facing material and the cementitious core.

Owner:MILLIKEN & CO

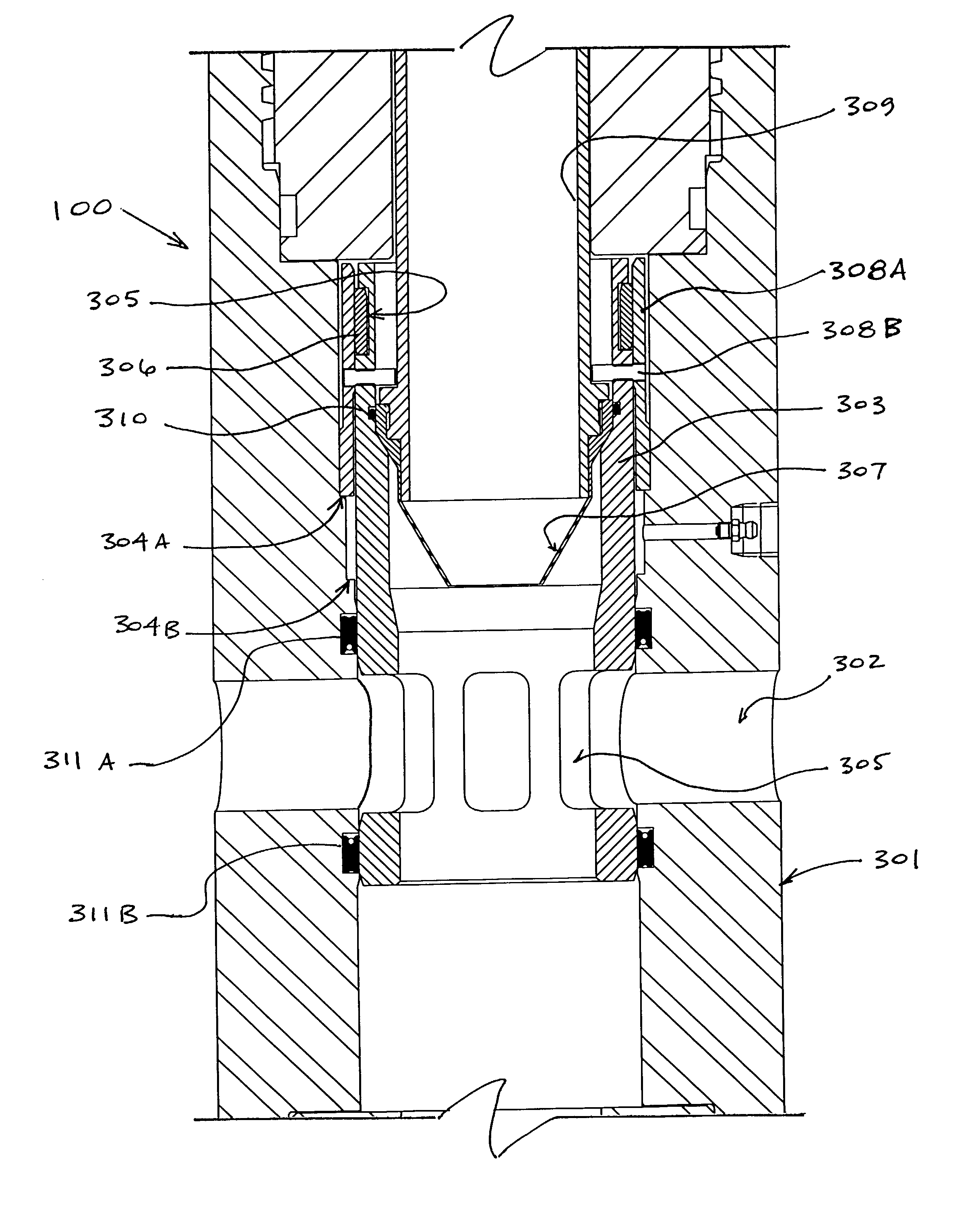

Cemented Open Hole Selective Fracing System

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

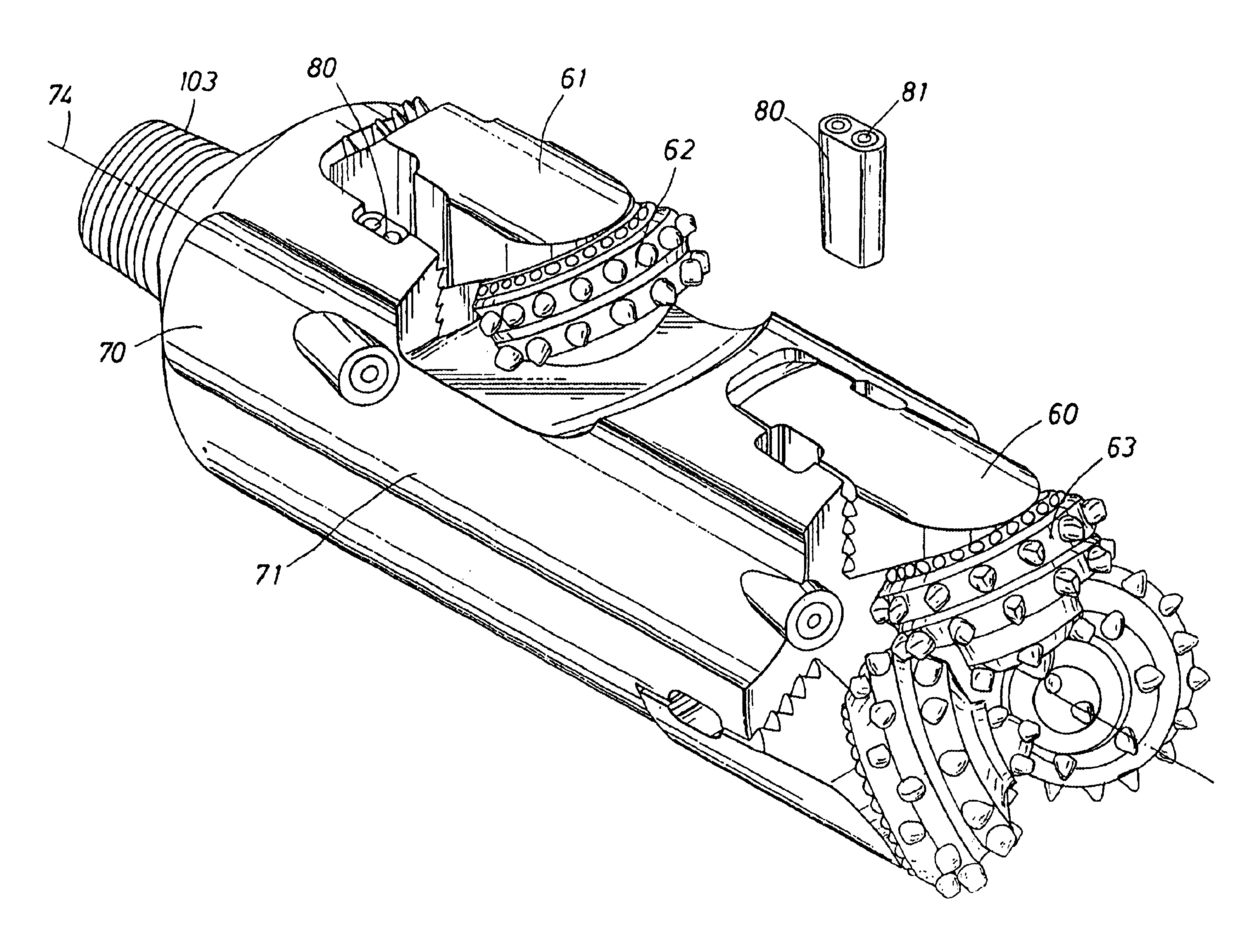

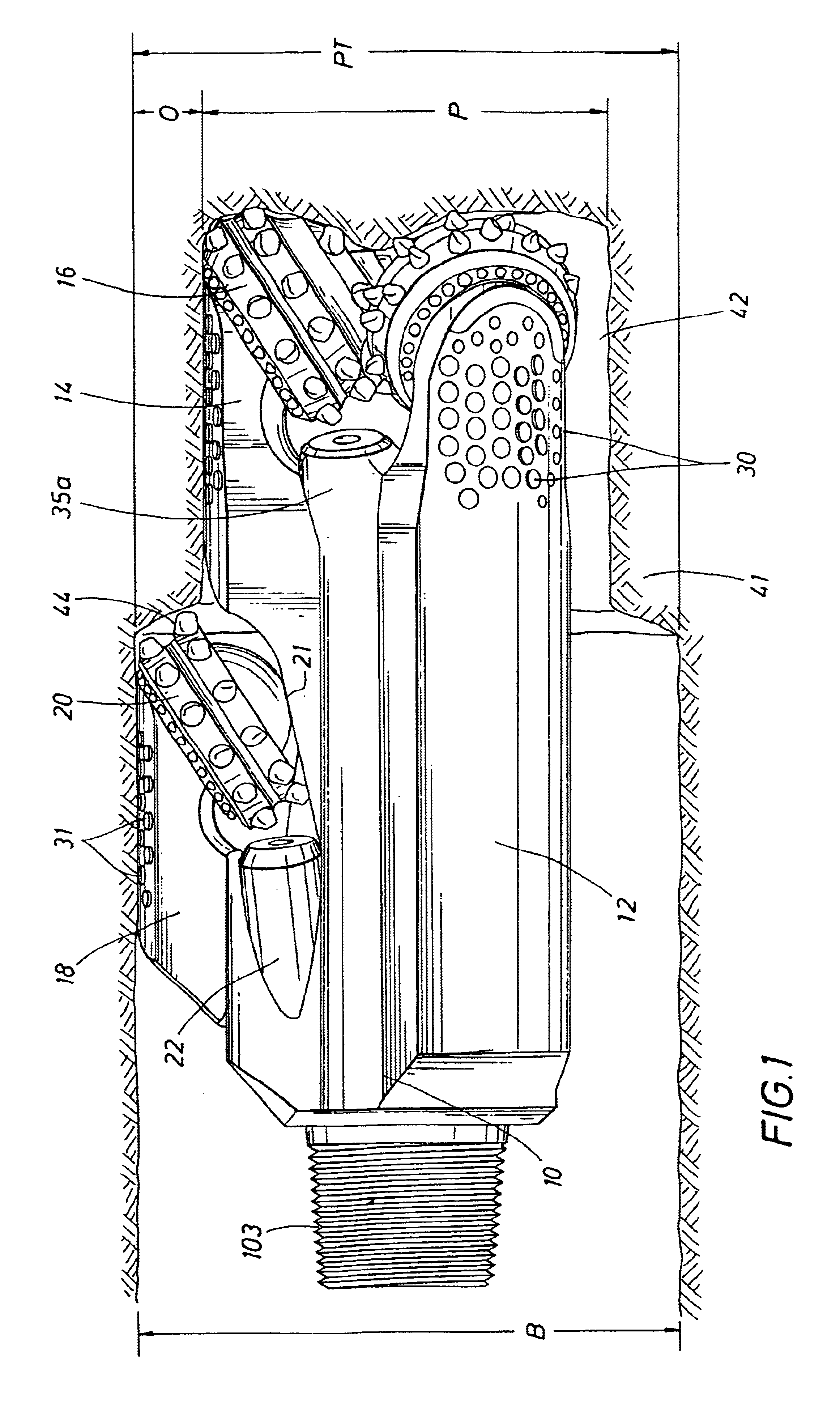

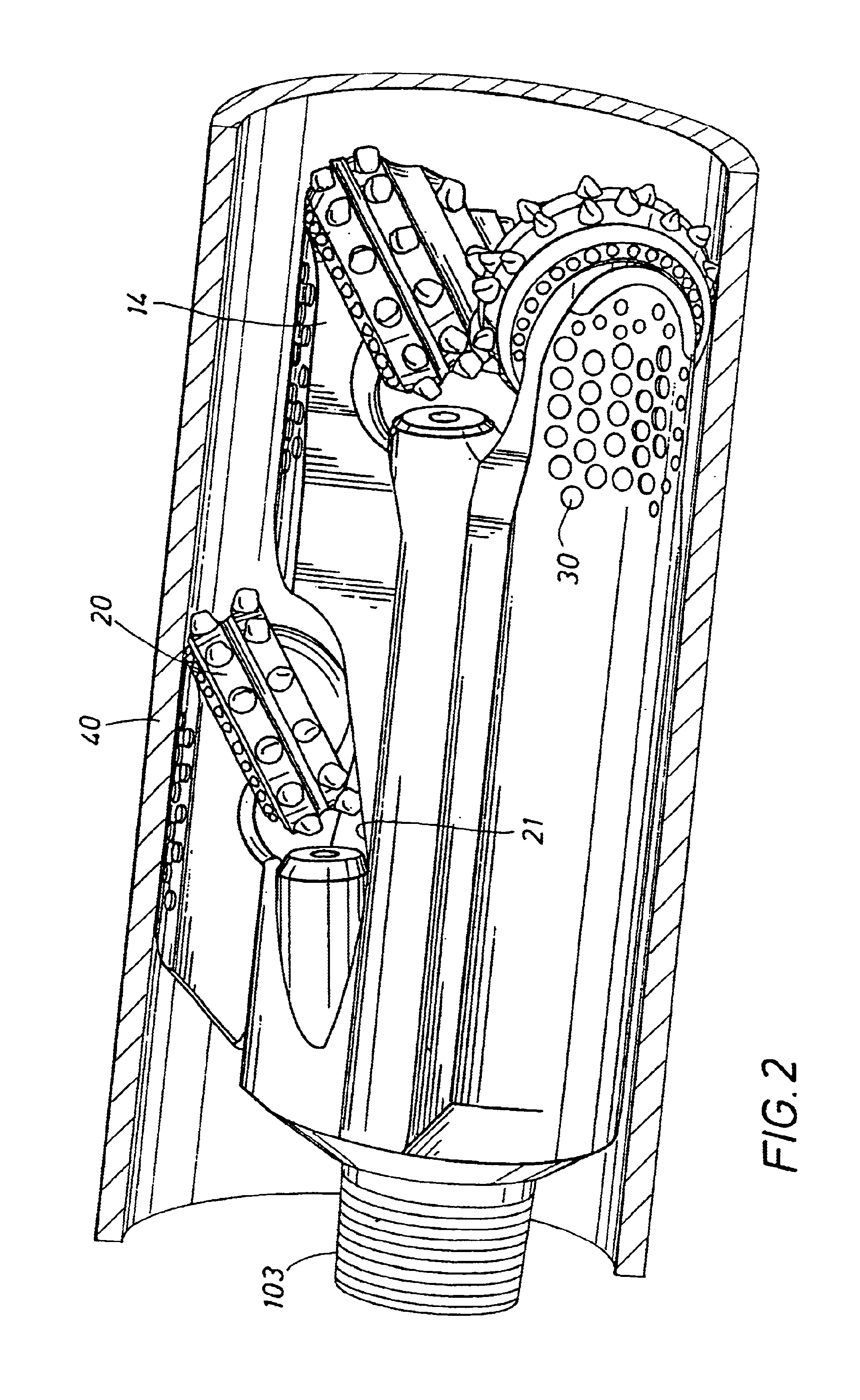

Roller cone bi-center bit

InactiveUS6902014B1Enhance drilling outEasy to disassemble and replaceDrill bitsCutting machinesEngineeringMechanical engineering

A roller cone bi-center bit for economically drilling an enlarged borehole below casing in earth formation is provided. The bi-center bit includes a rolling cone cutter or other appropriate cutter to enlarge a pilot bore also made by rolling cone or other type of cutters. The bit comprises a single-diameter body with a recess to accommodate the trailing cutter which enlarges the pilot bore. The bi-center bit may also provide the ability to change out the cutters efficiently in the field. The cutters are oriented to enhance drilling out the cement plug at the bottom of the casing. The cone cutter may be also be mounted on segments which are designed to be easily removed for replacement or adjustment in position in the field.

Owner:ROCK BIT INT +2

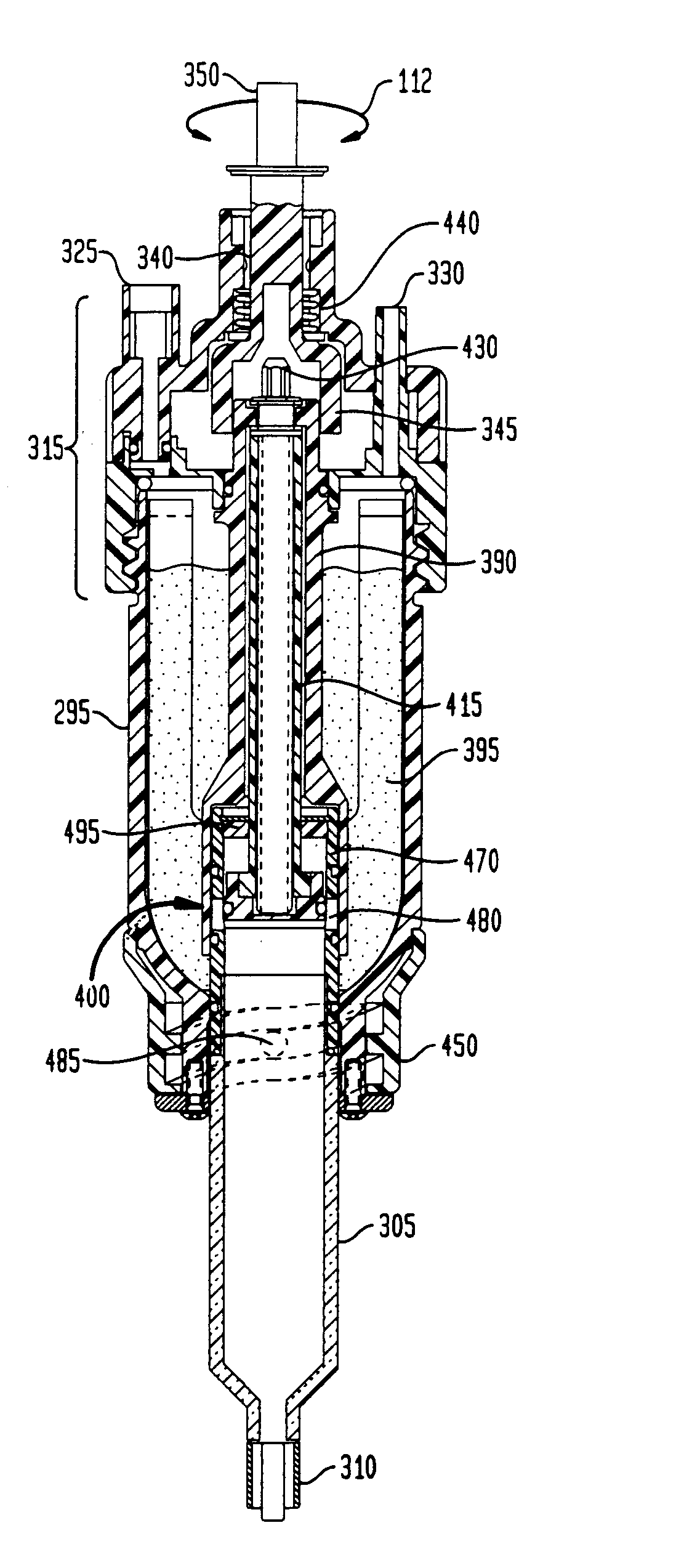

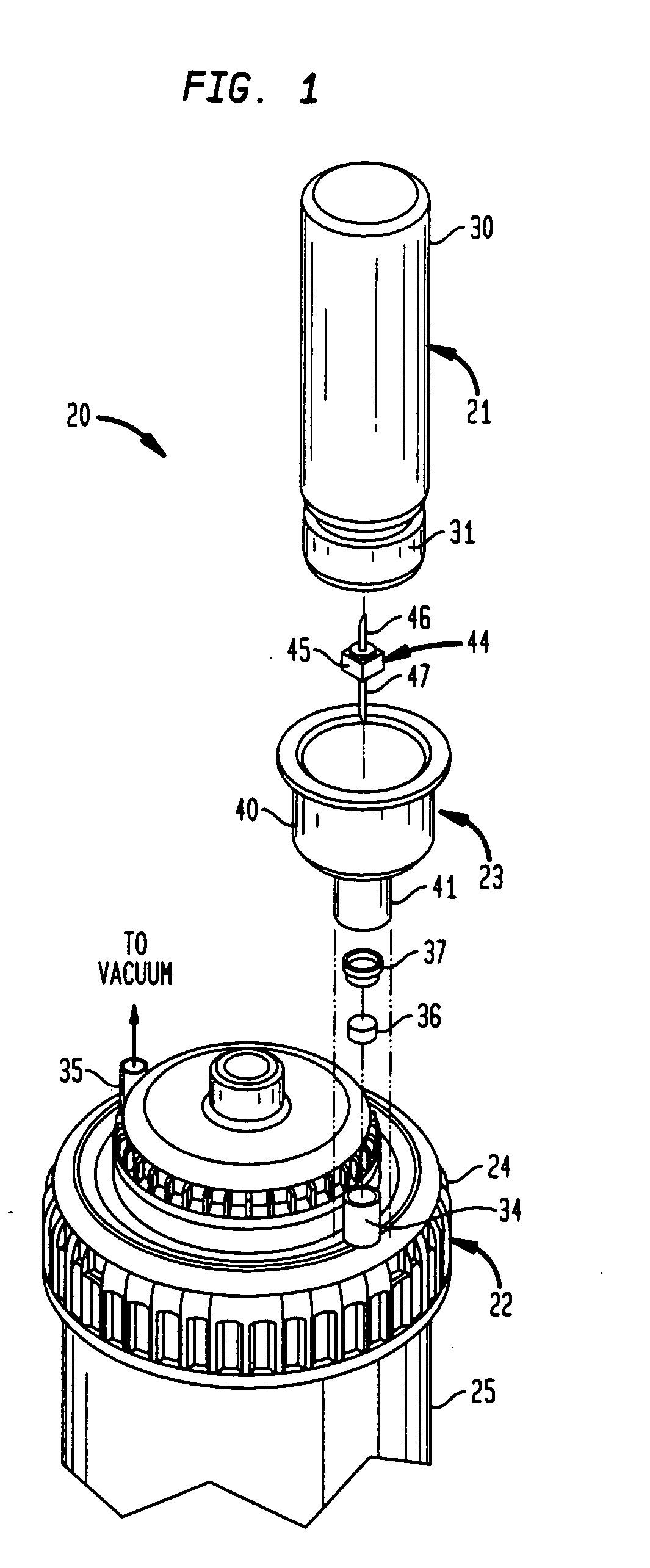

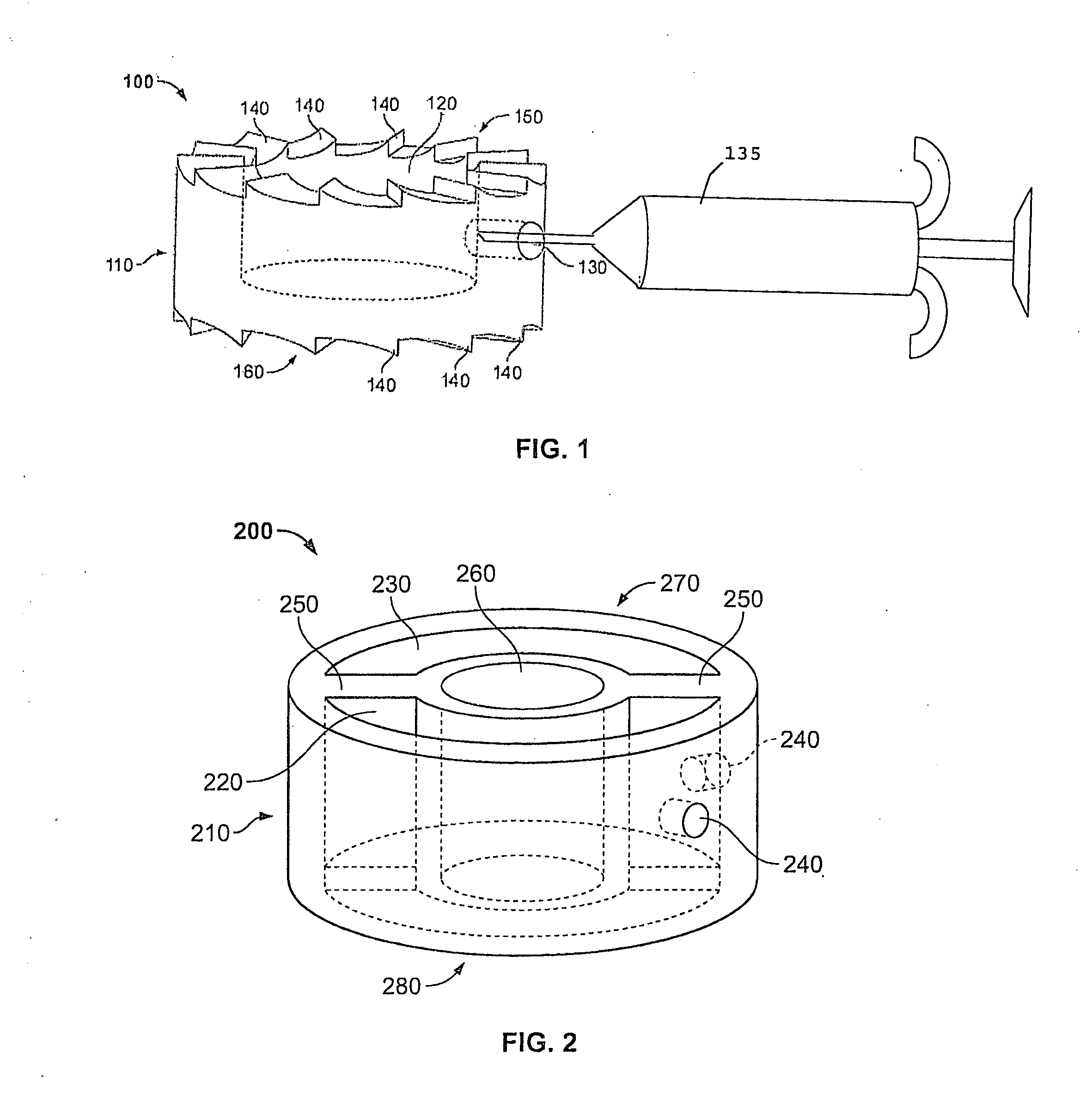

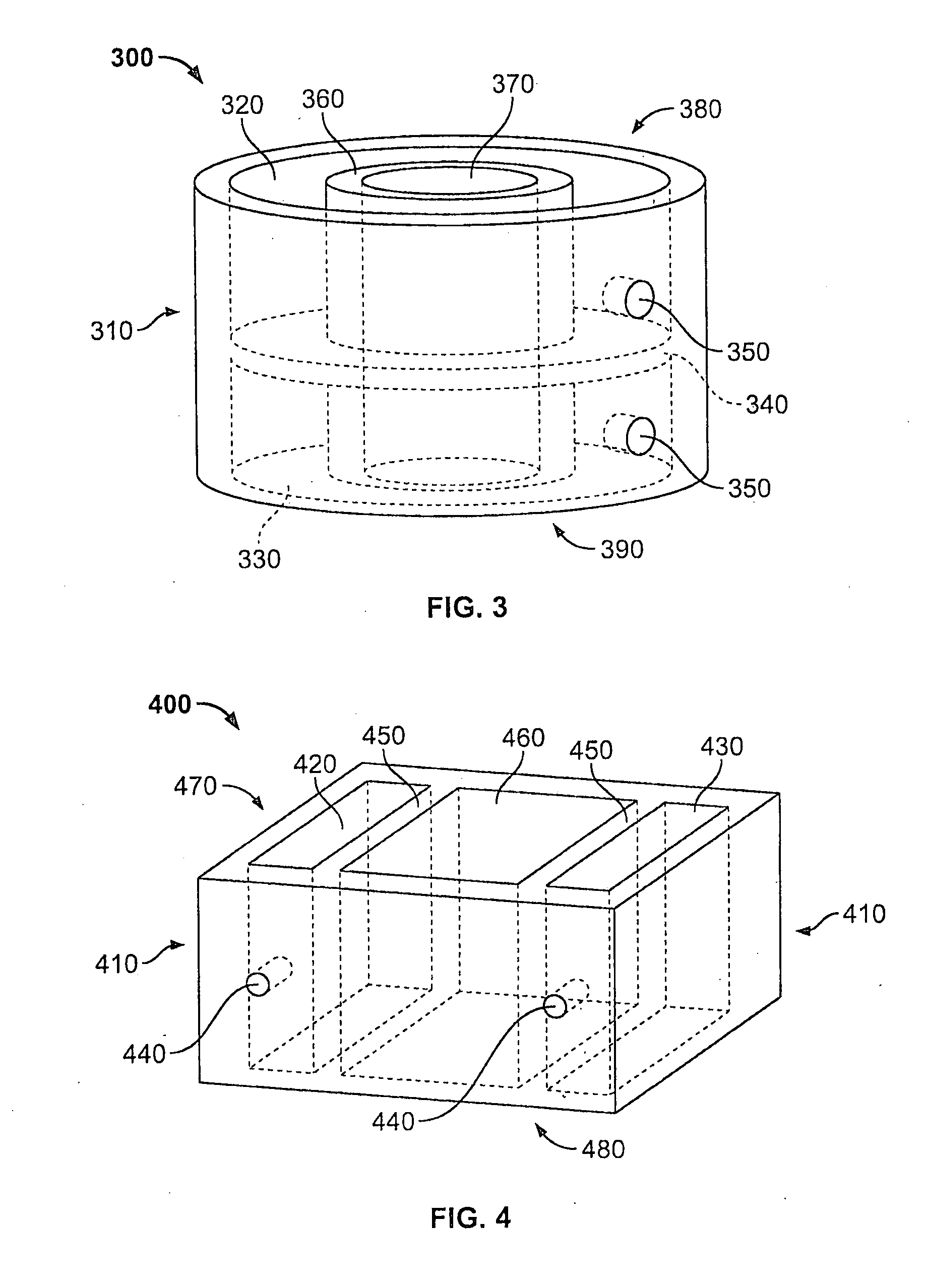

Apparatus for mixing and dispensing components

InactiveUS20040196735A1Exposure was also limitedReduce in quantitySurgical furnitureRotary stirring mixersEngineeringBone cement

Apparatus and methods for mixing and dispensing components. The methods and apparatus of the invention are particularly advantageous to manually mix the components of radiopaque bone cement and inject the resulting radiopaque bone cement into skeletal structures. The manually actuated apparatus of the invention comprises: (1) a sealed mixing chamber for mixing components; (2) a dispensing chamber isolated from the sealed mixing chamber; (3) a controllable portal to open a flow path between the sealed mixing chamber and the dispensing chamber so that the dispensing chamber can receive the mixed components after they are mixed; and (4) a drive mechanism associated with the dispensing chamber to force the mixed contents from the dispensing chamber.

Owner:GLOBUS MEDICAL INC

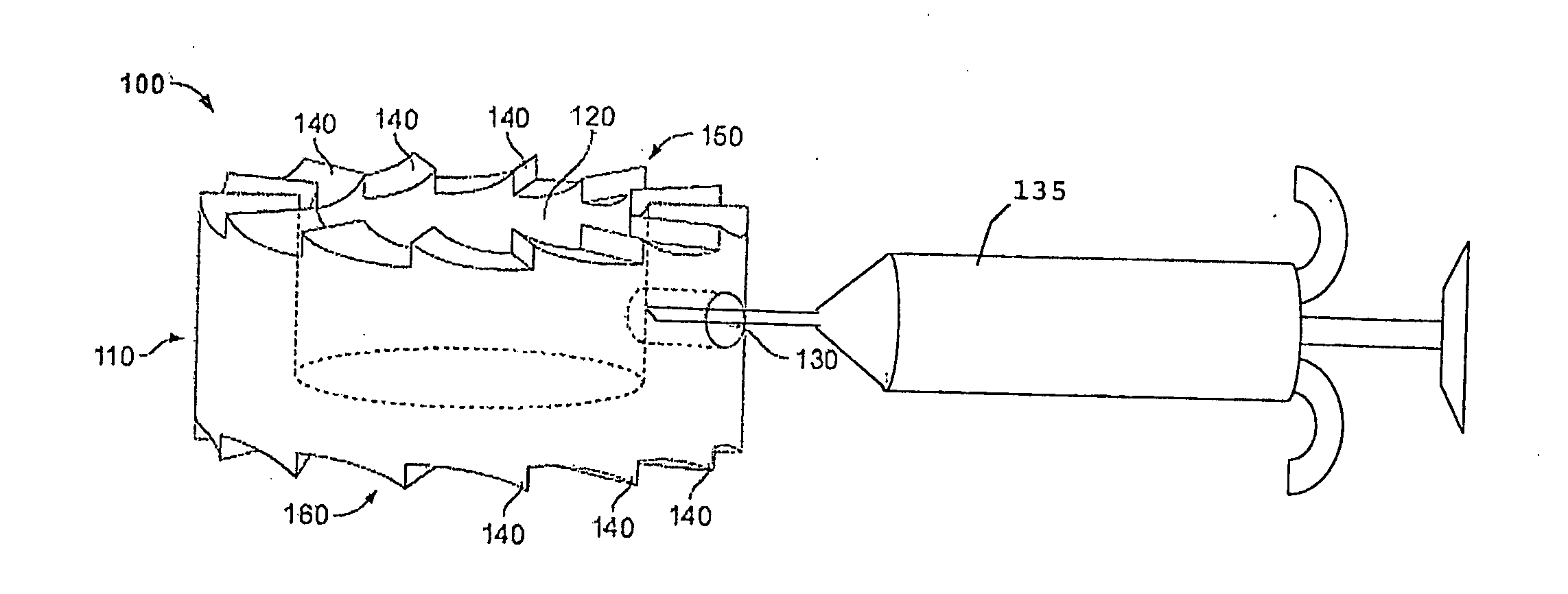

Fusion device, systems and methods thereof

InactiveUS20110004307A1Reduce and eliminate needPrecise deliveryInternal osteosythesisBone implantVertebraIntervertebral space

The spinal fusion device (100) of the invention is implanted within an intervertebral space between adjacent upper and lower vertebrae and secured to the vertebrae with cement. The fusion device includes upper and lower endplate facing surfaces (150, 160) each having at least one opening (120) for delivering cement material to adjacent contact surfaces of the vertebrae above and below the implant. Utilizing quick-setting cement compositions with the device <:an allow for almost immediate fusion of the vertebrae, thus, reducing or eliminating the need for adjuvant fixation devices such as screws, plates, and / or rods, while also simultaneously providing precise delivery of cement to contact surfaces between the fusion device and vertebrae.

Owner:PIONEER SURGICAL TECH INC

High water reduction high collapse protection type polycarboxylate high-performance water reducer and pyrogen-free preparation method thereof

The invention belongs to the technical field of concrete additives in building materials. The high water reduction high collapse protection type polycarboxylate high-performance water reducer mainly comprises the following monomer components: unsaturated methyl vinyl polyoxyethylene ether (A), a chain transfer agent (B), a mixture (C) of one or more of unsaturated acid and unsaturated acid derivatives, an oxidant (D) and a reducing agent (E), wherein the molar ratio A: B: C: D: E of the monomers is 1:0.01-0.5:2-8:0.08-0.5:0.02-0.3. The high water reduction high collapse protection type polycarboxylate high-performance water reducer is prepared by regulating the polymer mass concentration to between 20 and 40 percent by using water, and polymerizing a redox initiator system at normal temperature. The water reducer has the advantages of low doping amount, high water reducing ratio, excellent slump retaining capacity, and high cement adaptability, and the technology has the advantages of no need of extra heat source, implementation at normal temperature, low equipment investment, low cost and suitability for large area popularization and application.

Owner:大连华建科技有限公司

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

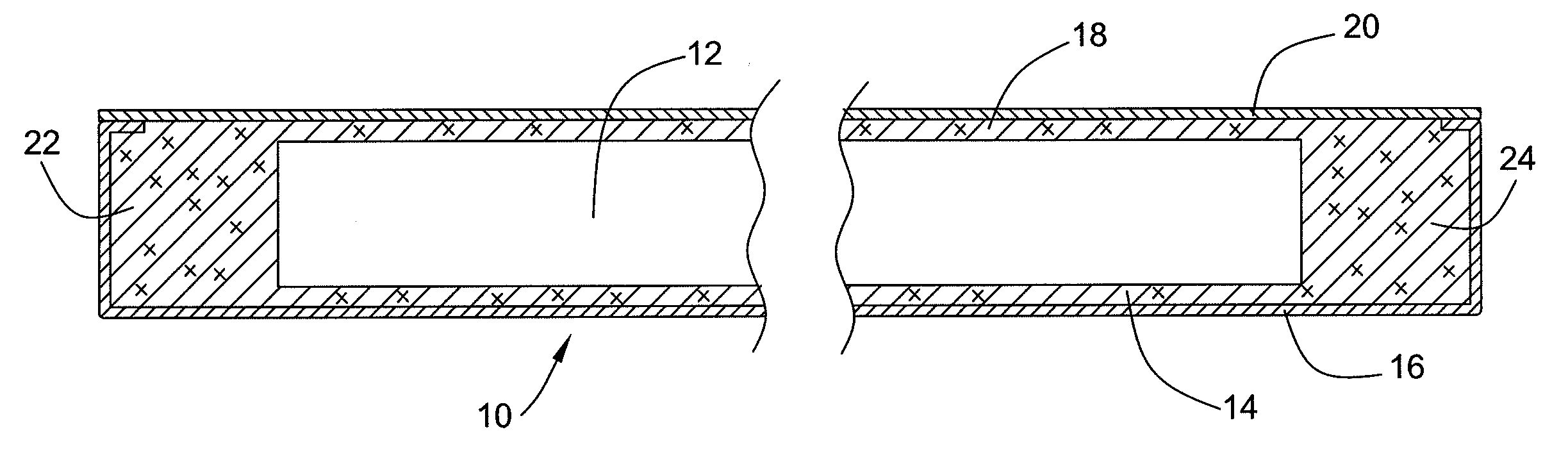

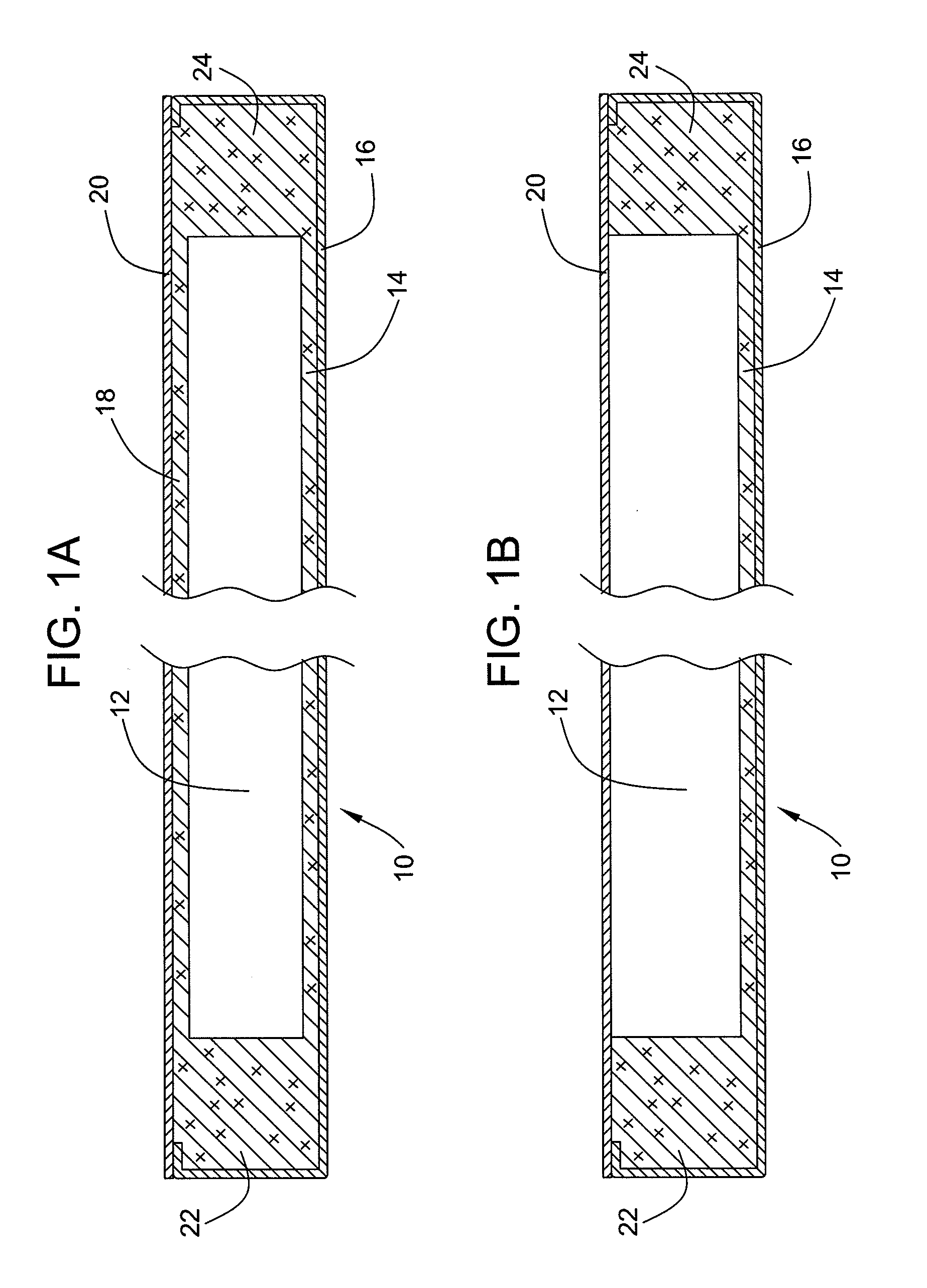

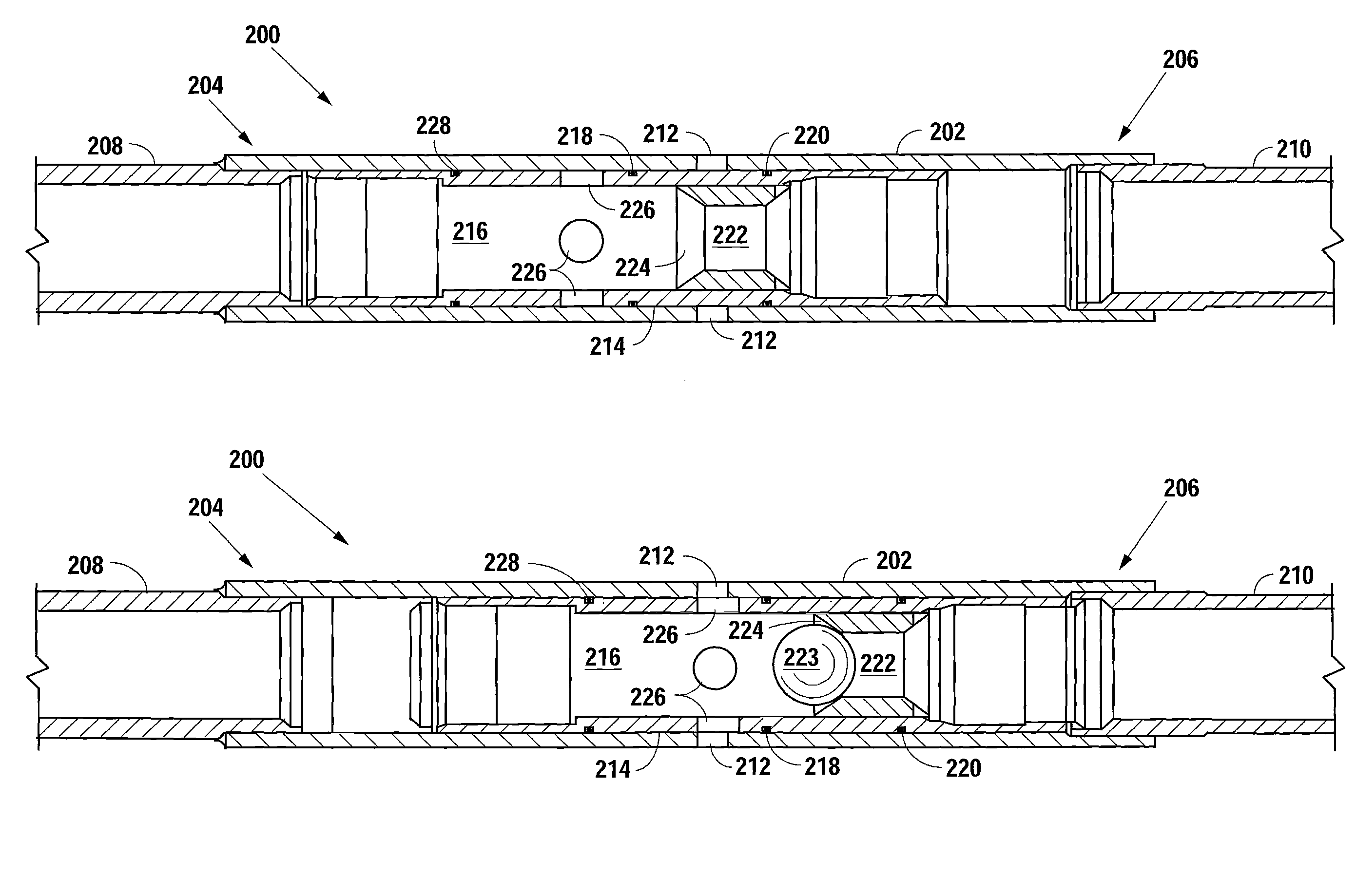

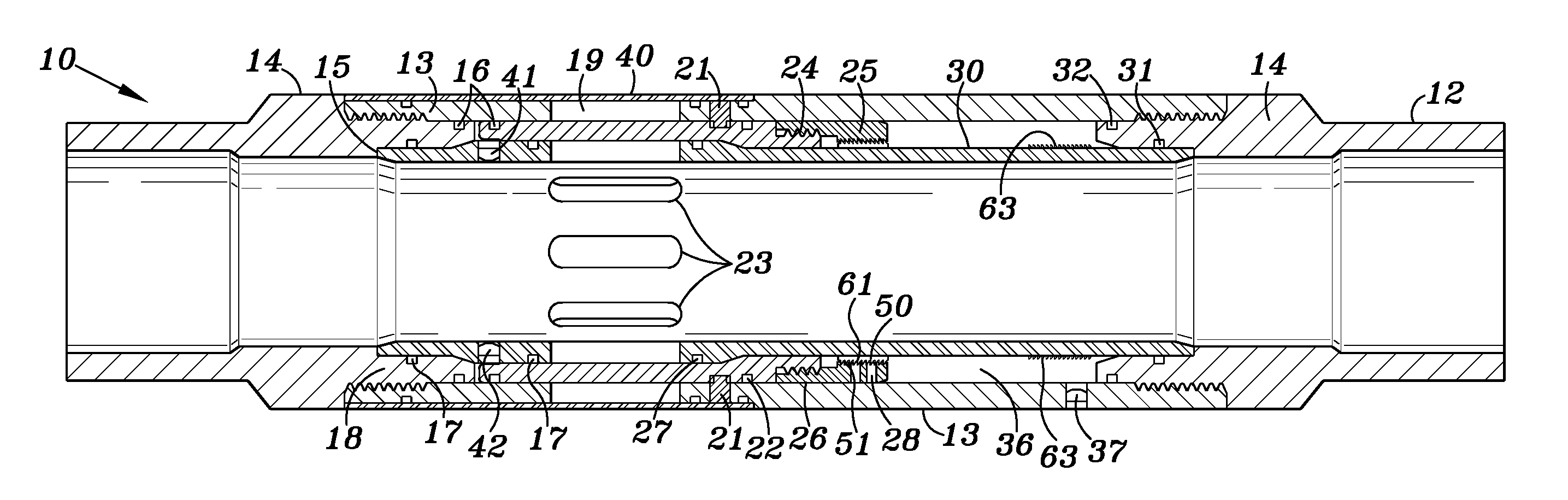

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

Valve for hydraulic fracturing through cement outside casing

A valve for use in fracing through cement casing in a well allows for flow of cement down the well during the cementing process and in the open position allows for fracing fluid to be directed through the cement casing for fracturing the formation adjacent the valve. The valve is constructed so as to reduce the likelihood of the valve to jam as a result of cement or other foreign material.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Storable water-microsphere suspensions for use in well cements and methods

Storable water-microsphere suspensions for use in well cements and methods of cementing well bores are provided. The storable water-microsphere suspensions are basically comprised of water, microspheres and an effective amount of a suspending agent selected from the group consisting of microfine or colloidal materials and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

Complex admixture and method of cement based materials production

The present invention relates to admixtures production and to a method of application of the admixtures in cement and concrete technology. The method allows production of high-strength and high durable cement based systems, as well as cement systems with specially designed properties or cheap high-volume mineral admixture cements.

Owner:SCI CON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com