Patents

Literature

30results about How to "Gao Baotan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

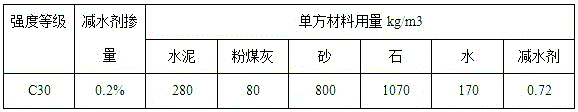

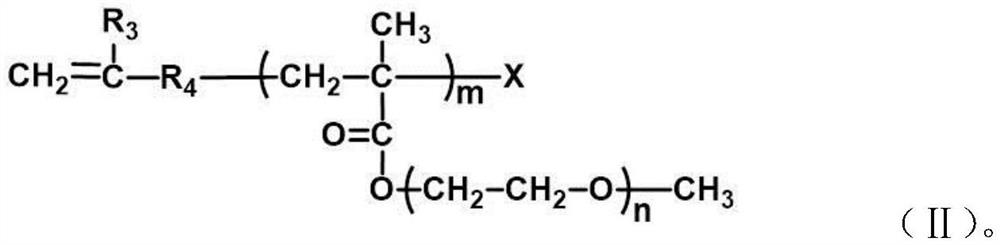

Method for preparing polycarboxylic acid retarding water reducer

The invention belongs to the technical field of methods for preparing polycarboxylic acid water reducers. A method for preparing a polycarboxylic acid water reducer comprises the following: a step 1 of esterification, in which a poly(ethylene glycol methyl ether)acrylate macromonomer is synthesized by using methoxy polyethylene glycol and acrylic acid in a molar ratio of 1:1.1 to 1:1.5 at 100 to 120 DEG C, water is separated out in a reaction process, and the molecular weight of the macromonomer is 1,250 to 3,000; and a step 2 of polymerization, in which aqueous solution of the macromonomer is prepared, an unsaturated monomer and a catalyst A are added in turn at 40 to 50 DEG C, the temperature is kept constant at 28 to 40 DEG C, aqueous solution of anhydrous sodium hydrogensulfite or vitamin c is dripped, the concentration of a solid content is kept between 35 to 45 percent by adjusting water content, stirring is stopped, and the solution is allowed to stand for 1 to 1.5 hours, the pH value is kept between 6 and 8 by alkaline reagent after the reaction is finished, and the catalyst A is peroxyacetic acid or potassium peroxydisulfate. The invention has the advantages of low cost, simple process and high product performance.

Owner:河北智胜工程技术有限公司

Anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and preparation method and application thereof

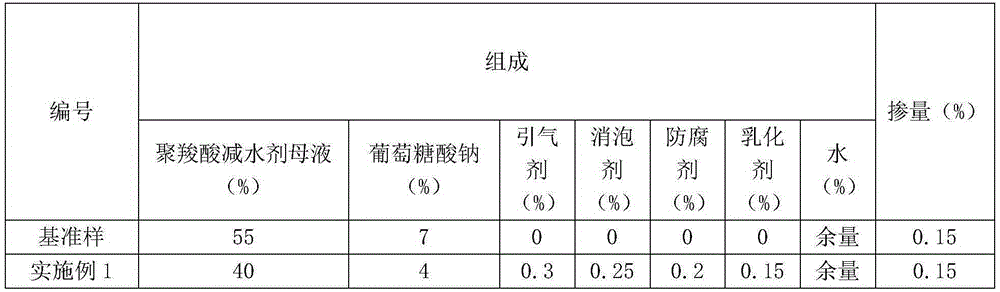

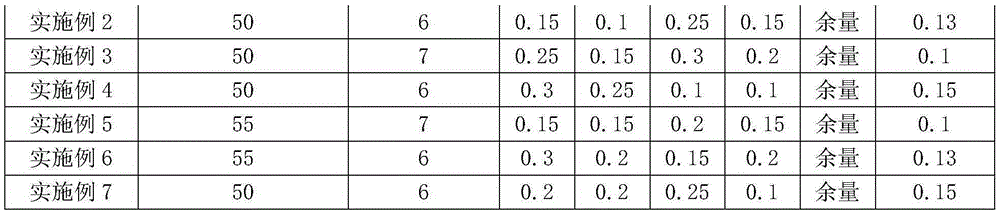

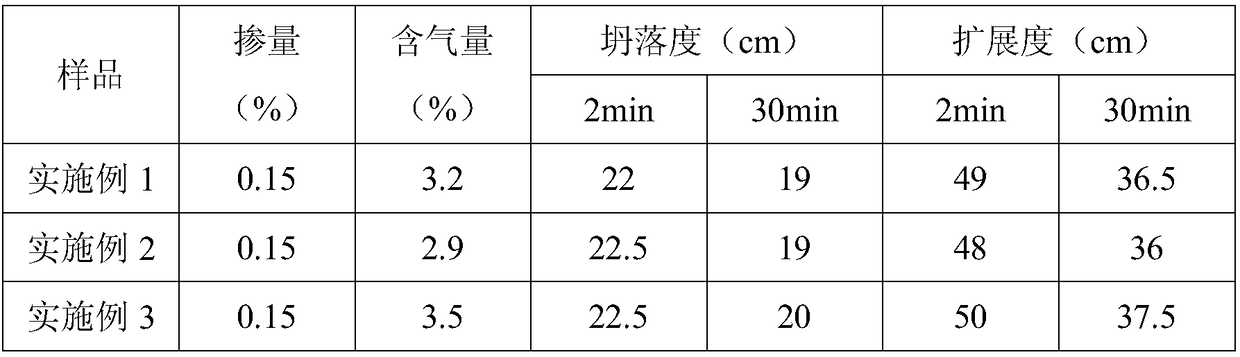

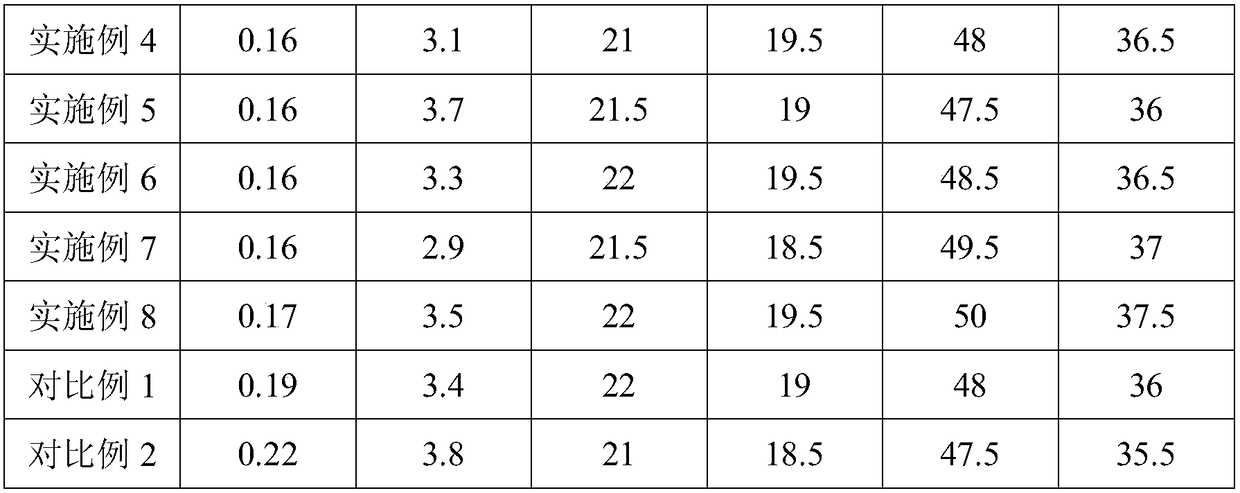

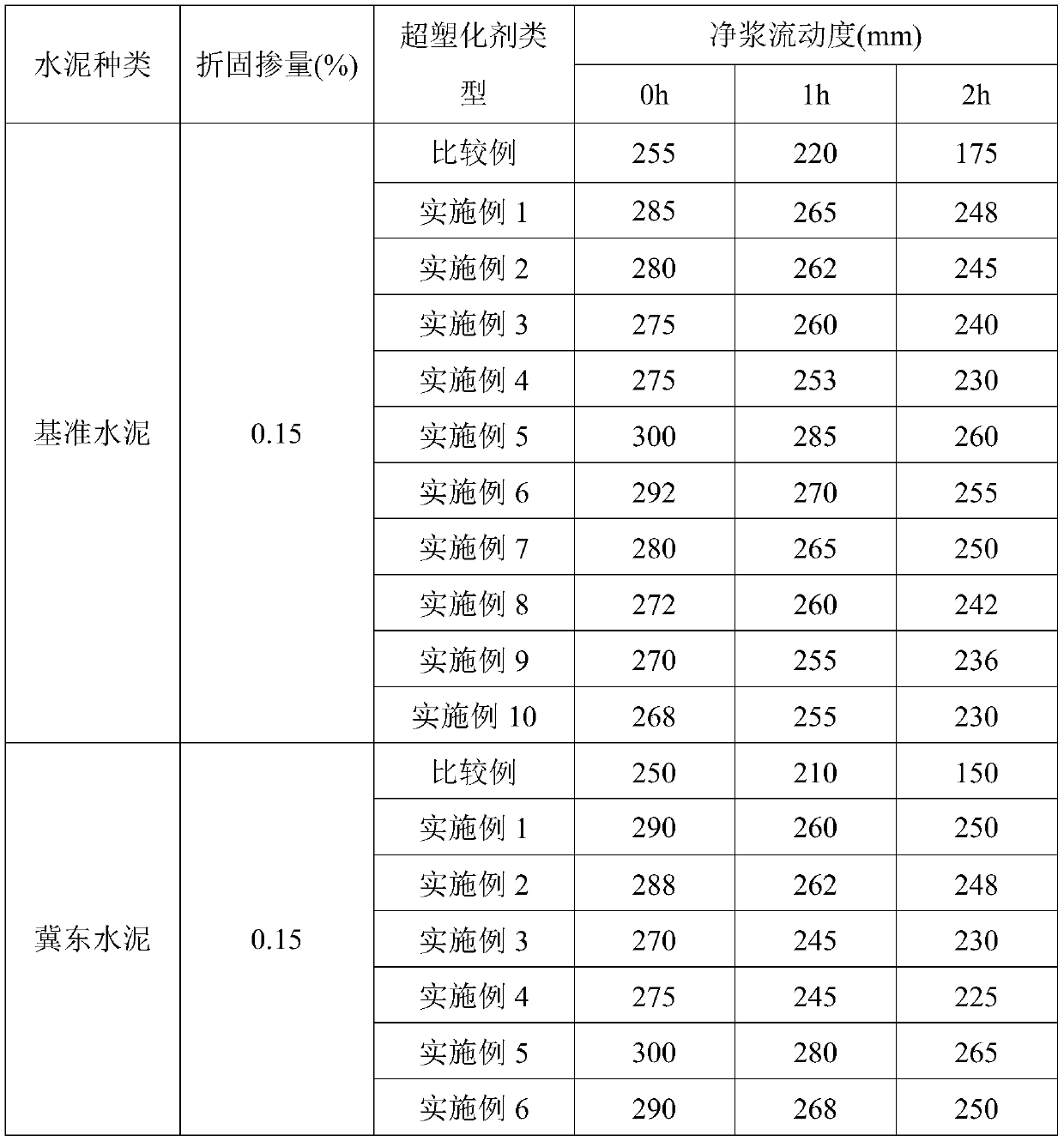

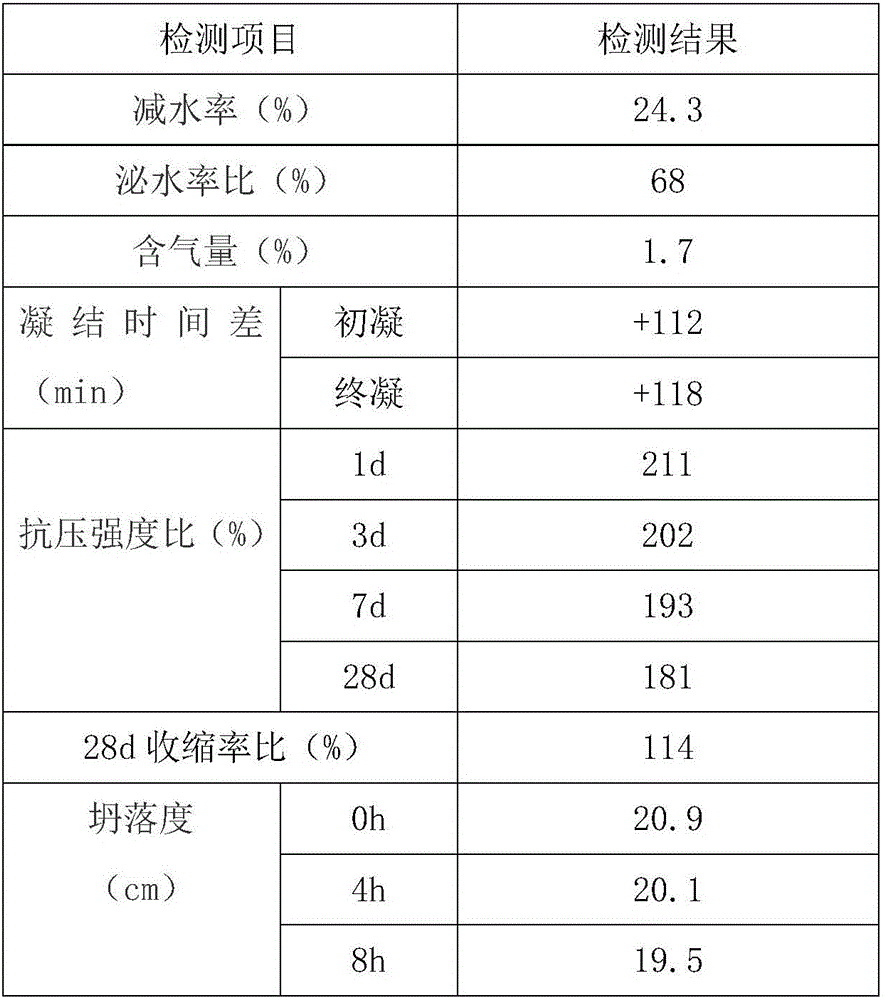

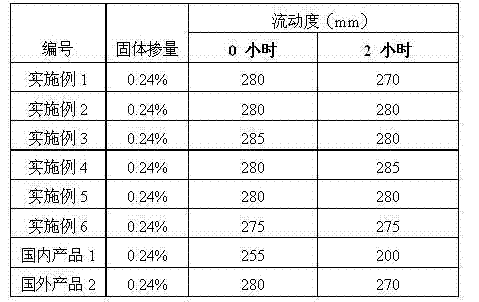

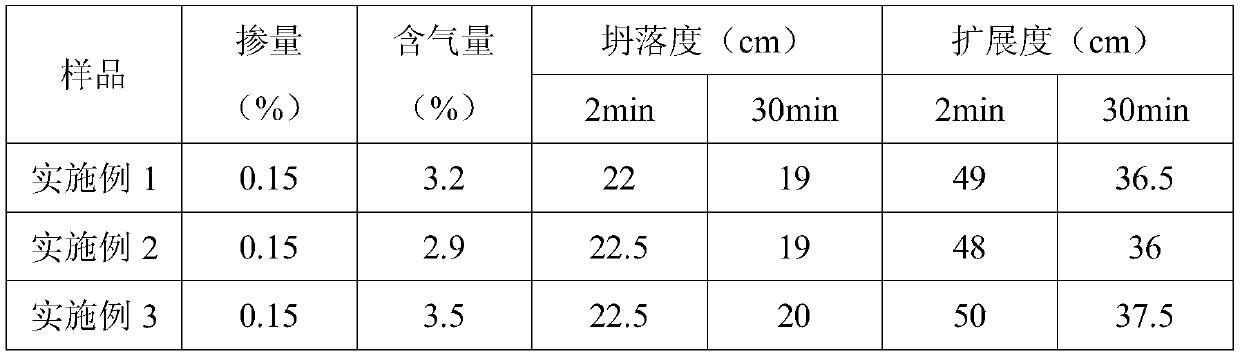

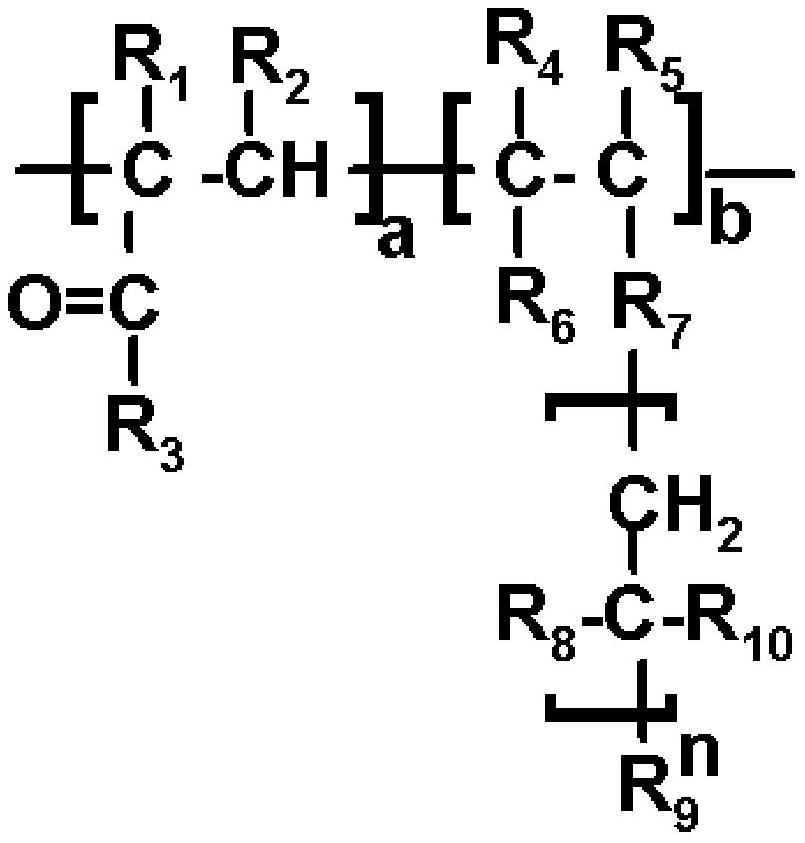

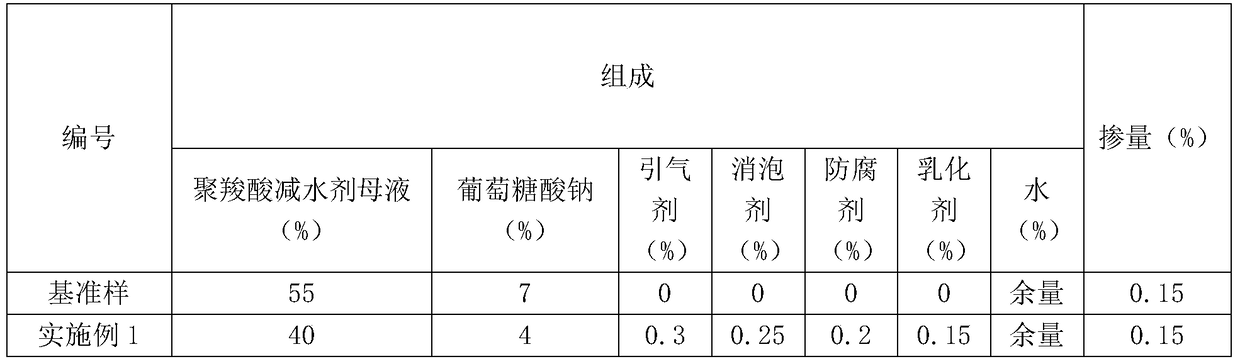

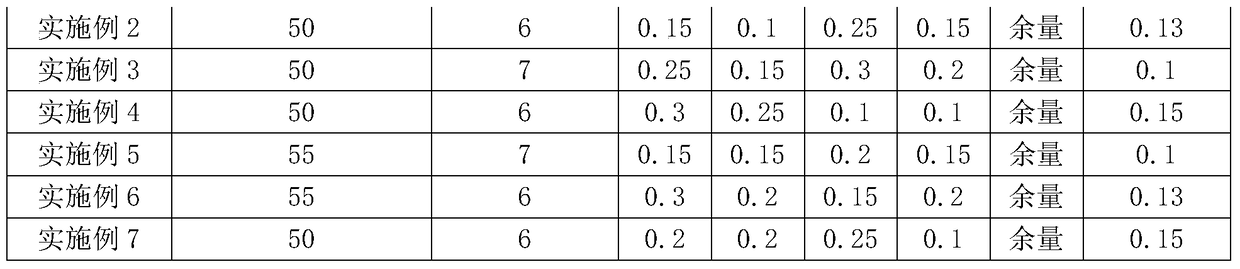

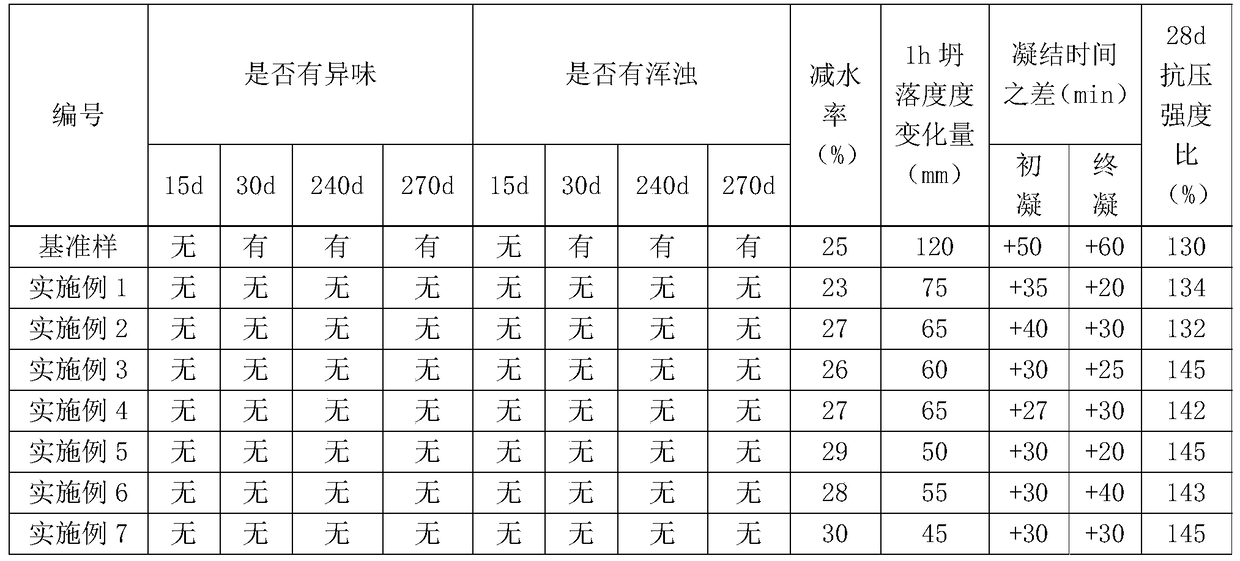

The invention relates to an anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and a preparation method and application thereof. The composite polycarboxylate superplasticizer comprises, by mass, 40 to 55% of mother liquor of a polycarboxylate superplasticizer, 4 to 7% of sodium gluconate, 0.15 to 0.3% of an air entraining agent, 0.1 to 0.25% of an antifoaming agent, 0.05 to 0.2% of an emulsifying agent and 0.1 to 0.3% of an anticorrosive bactericide, with the balance being water, wherein the mass percents of every component sum to 100%. The composite polycarboxylate superplasticizer is prepared by placing the mother liquor of the polycarboxylate superplasticizer, sodium gluconate, the air entraining agent, the antifoaming agent, the anticorrosive bactericide and the water in a container together according to the above-mentioned mass percents under the conditions of normal temperature and normal pressure and carrying out uniform mixing under stirring. In use, the composite polycarboxylate superplasticizer is added into a concrete cementing material according to a mass ratio of the composite polycarboxylate superplasticizer to the concrete cementing material of 0.1-0.15: 100. Compared with the prior art, the composite polycarboxylate superplasticizer provided by the invention has the advantages of convenience in usage, stable performance, no phenomena of mildew, smelliness and layering due to long-term storage, capacity of introducing small bubbles when used in fresh mixed concrete, and excellent water-reducing and slump-retaining performances.

Owner:TONGJI UNIV

Preparation method and application of mud-resistant polycarboxylate superplasticizer

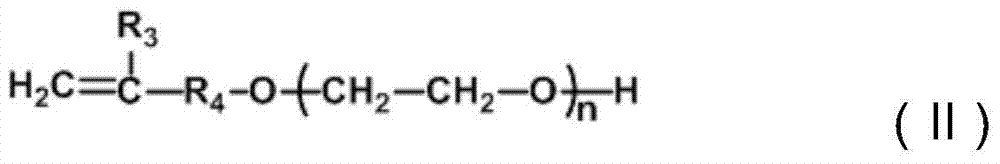

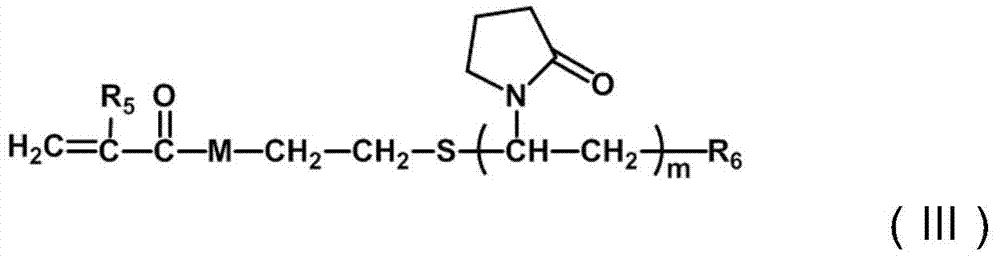

The invention provides a preparation method and application of a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer has the advantages of being low in mixing amount, high in water-reducing rate, long in slump resisting time and high in mud resistance when serving as a cement dispersing agent. The synthesis process is simple, the raw material utilization rate is high, a solvent is convenient to recycle, and production cost is low. According to the preparation method of the mud-resistant polycarboxylate superplasticizer, the mud-resistant polycarboxylate superplasticizer is obtained through the free radical polymerization reaction of specific unsaturated acid monomers, specific unsaturated polyether macromonomers and poly(N-vinyl pyrrolidone) chain containing PVP macromonomers, and the molar weight of the unsaturated polyether macromonomers is 50% to 100% that of the PVP macromonomers.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

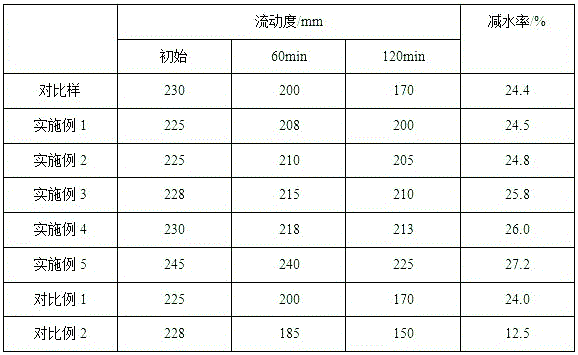

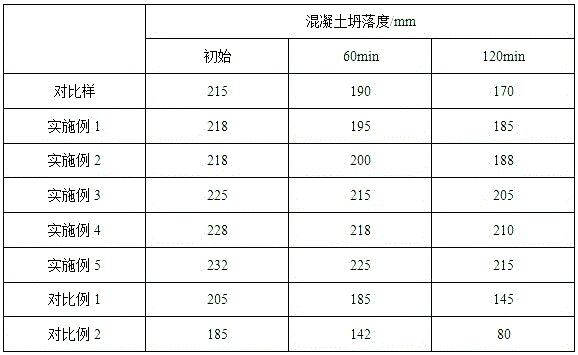

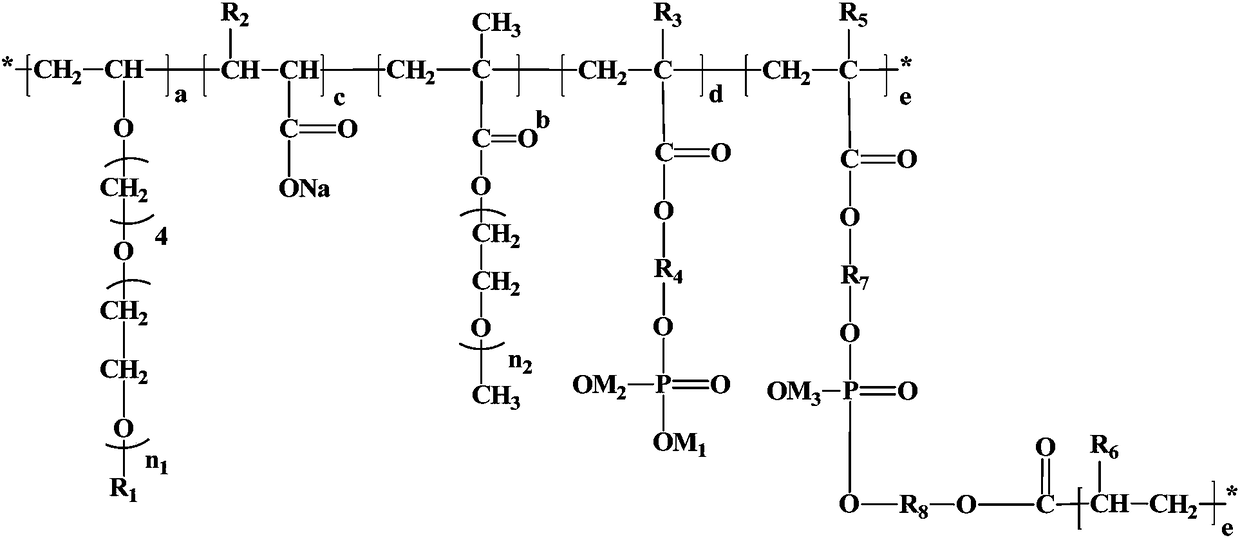

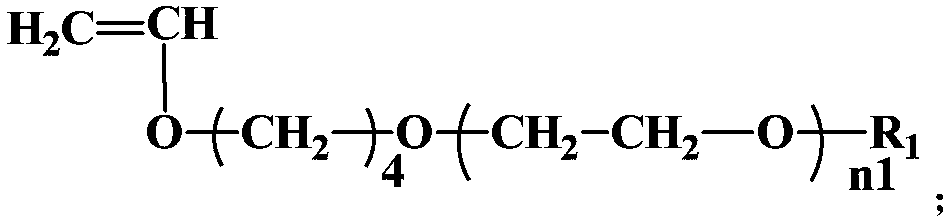

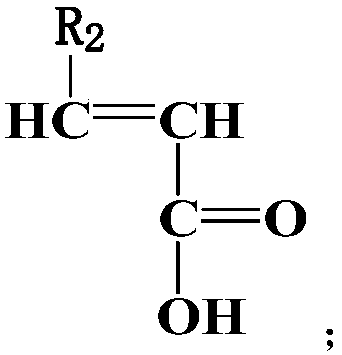

Crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and preparation method thereof

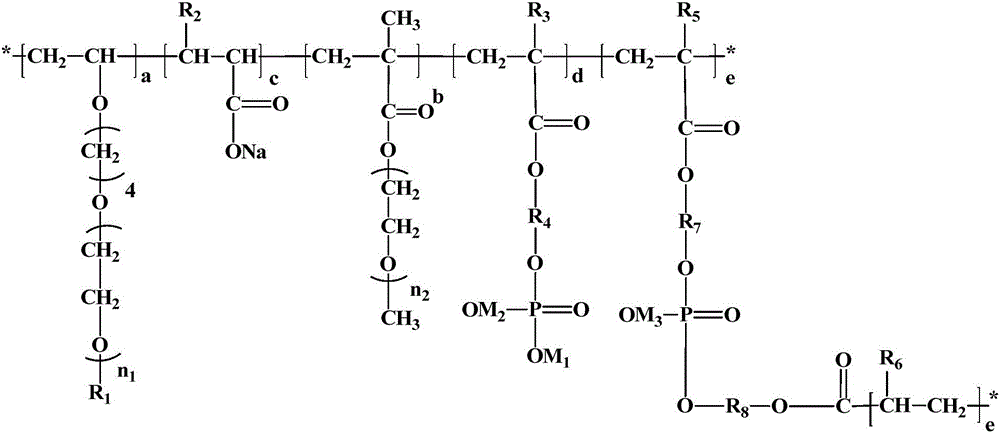

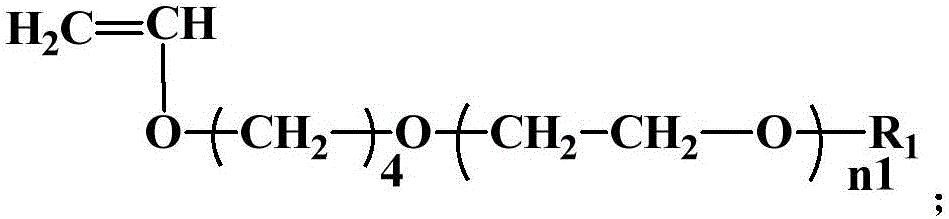

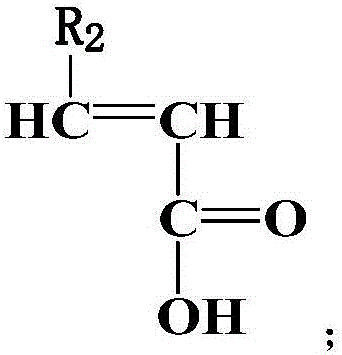

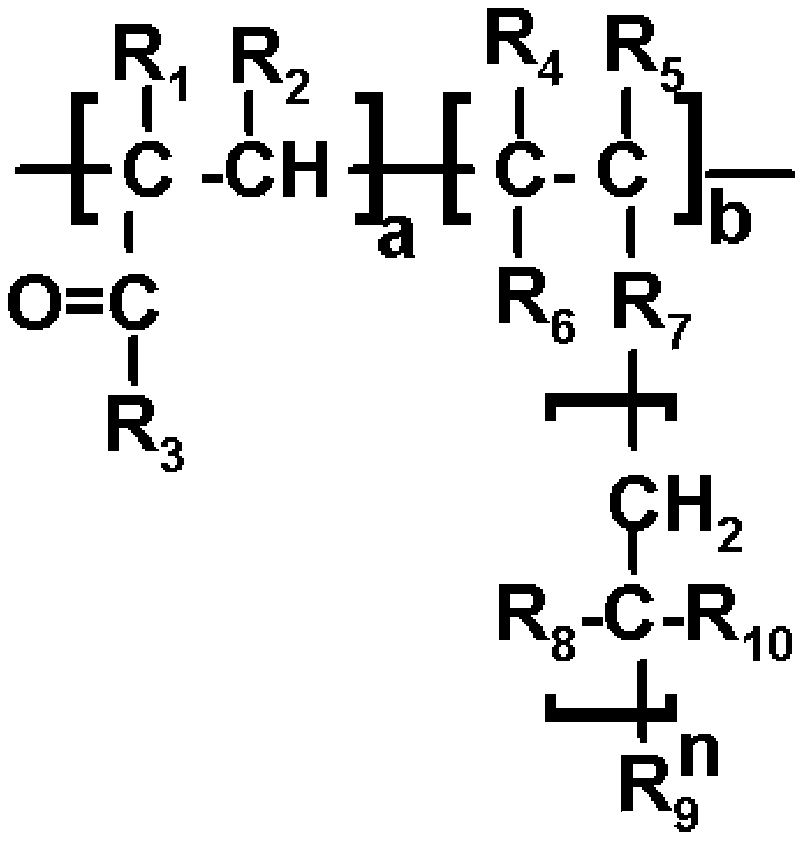

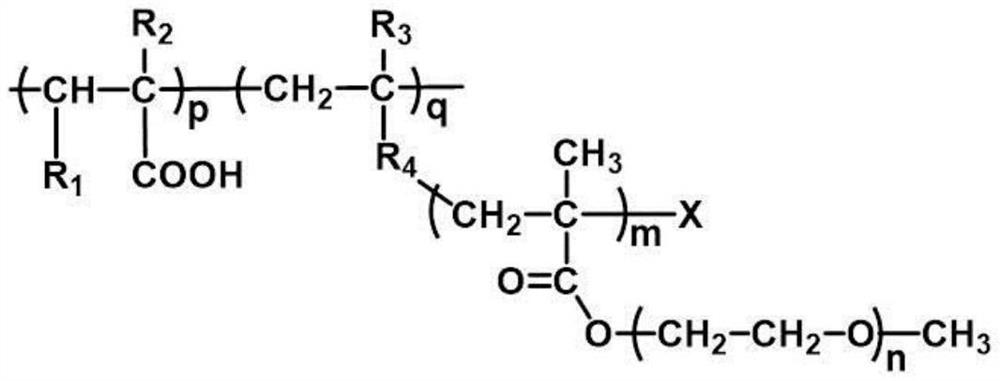

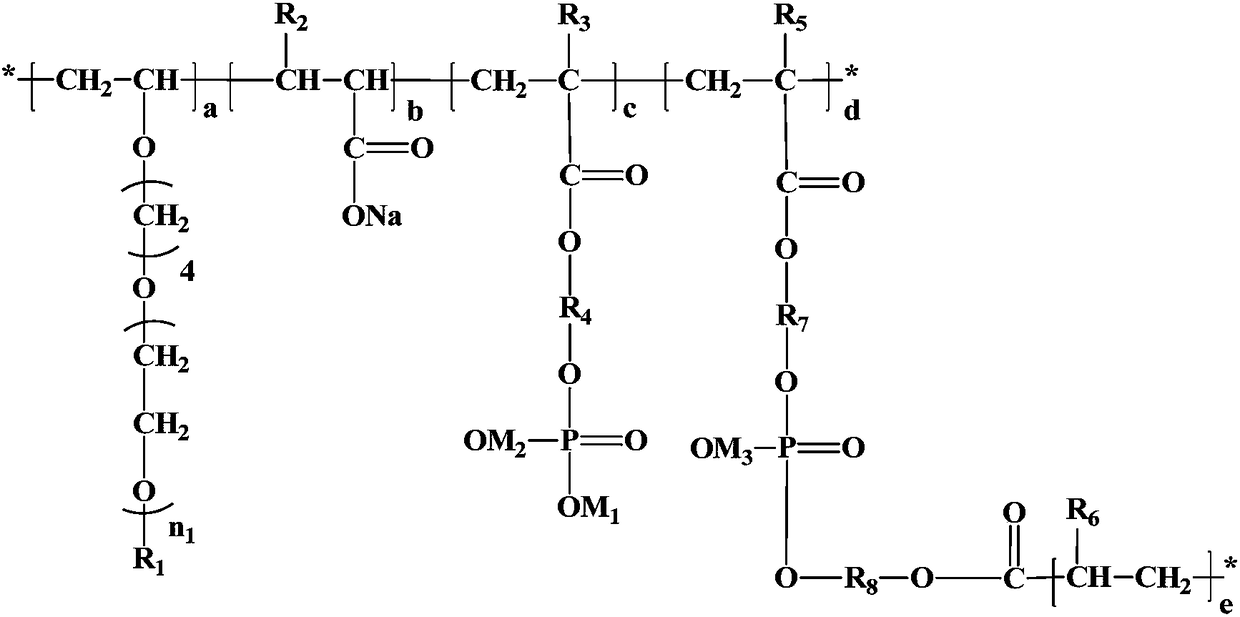

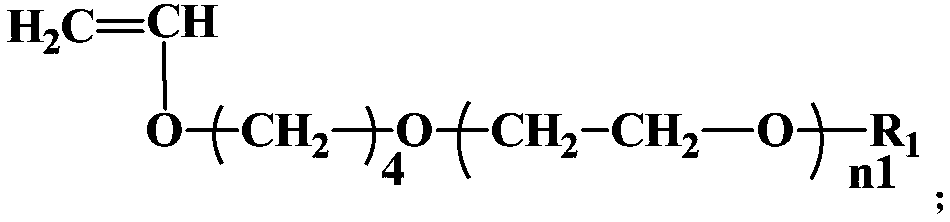

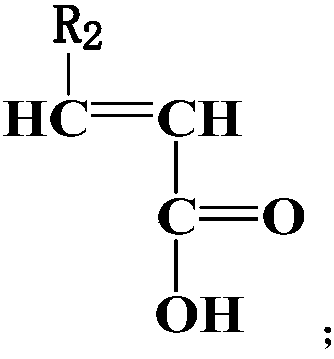

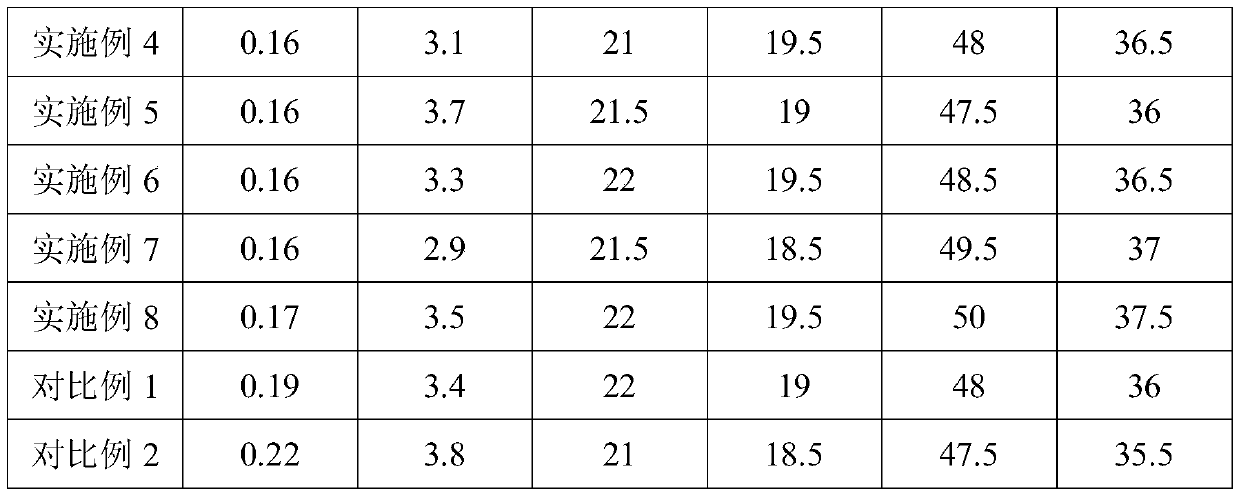

ActiveCN106046269AEven distribution of side chainsImprove workabilityPolymer sciencePhosphomonoesters

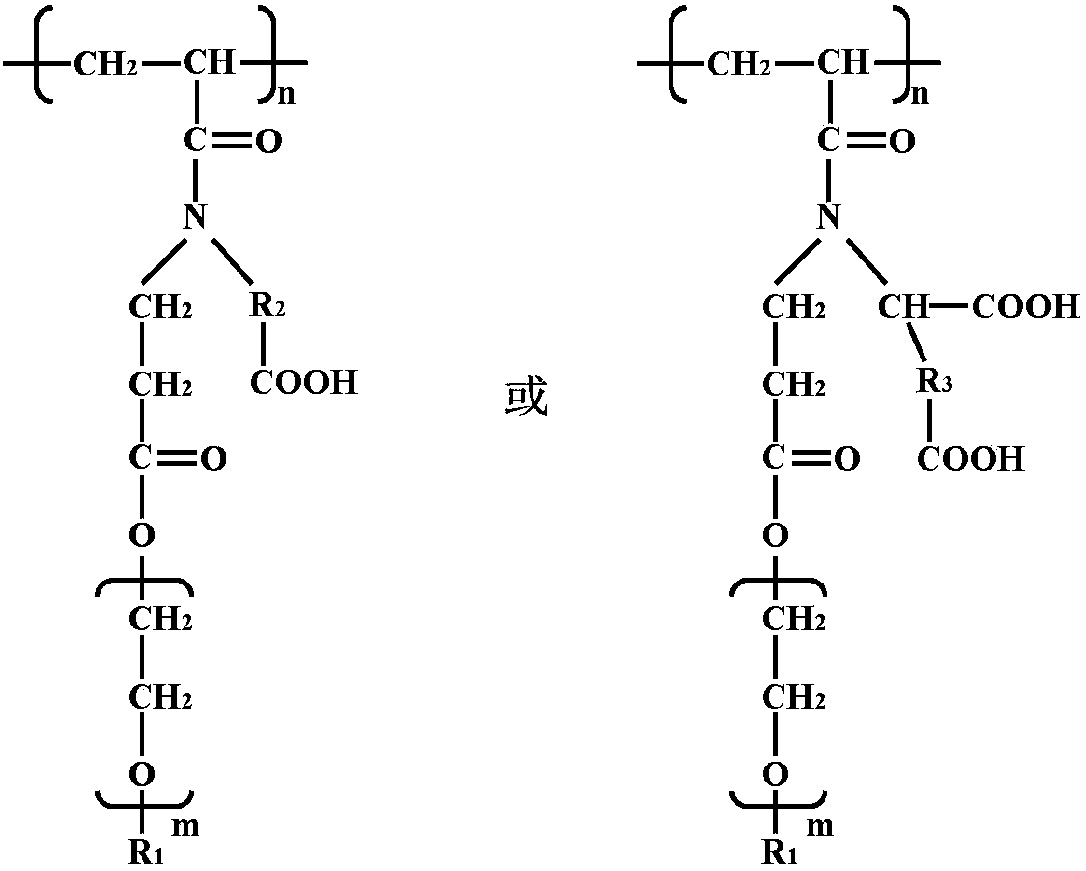

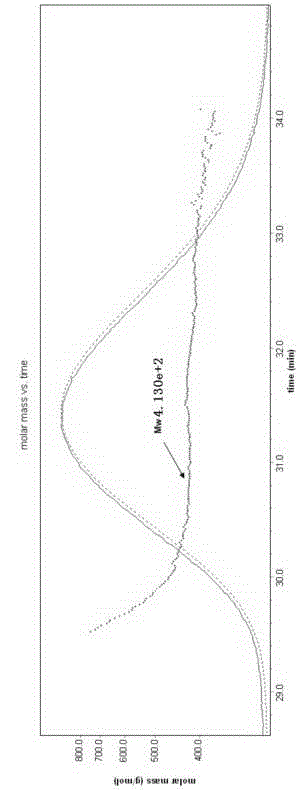

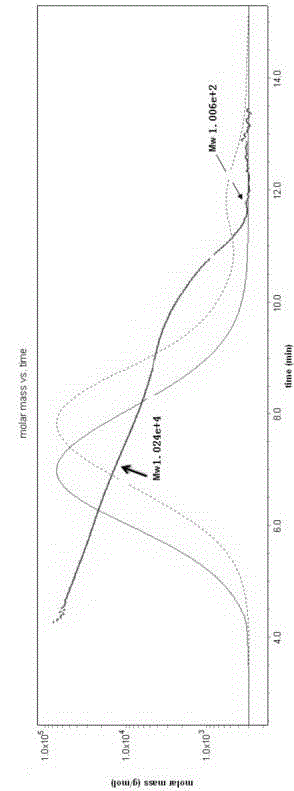

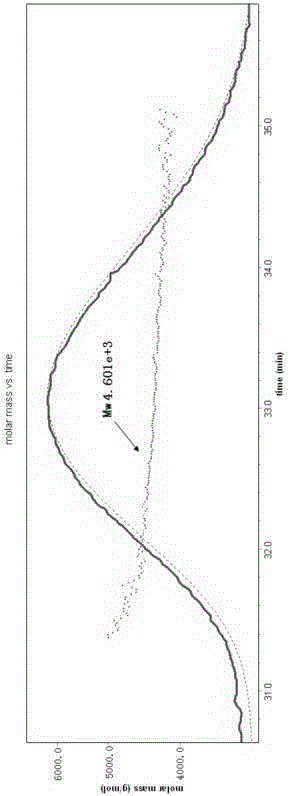

The invention discloses a crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and a preparation method thereof. The crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer has the number-average molecular weight of 10000-100000 and has a structural formula as shown in the specification. Under the synergistic effect of various groups, the polycarboxylate superplasticizer formed by copolymerization of 4-hydroxybutyl-vinyl polyoxyethylene ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester has the advantages of high water-reducing rate, high slump loss resistance, high peaceability, mud-resistant property and low dosage sensibility.

Owner:KZJ NEW MATERIALS GROUP CO LTD

High-slump-resistance polycarboxylate water reducer

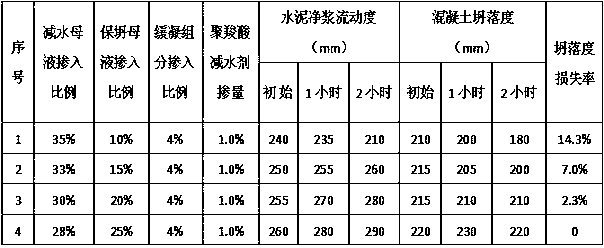

The invention provides a high-slump-resistance polycarboxylate water reducer. The high-slump-resistance polycarboxylate water reducer is composed of, by weight percentage, 10-25% of polycarboxylate slump-resistant mother liquor, 28-35% of polycarboxylate water reducing mother liquor, 4% of setting retarding components and water as balance. By adding in hydrophobic slow release ester groups, the high-slump-resistance polycarboxylate water reducer can avoid being adsorbed by cement particles during the early stage of cement hydration and meanwhile can be slowly released inside alkaline solutioninto water reducer molecules with water reducing effects to achieve water-reduced dispersion; the release speed can be adjusted according to requirements on environment, alkalinity and construction and by changing the number of slow release groups and the molar mass ratio of acid esters. By compounding the polycarboxylate slump-resistant mother liquor and the polycarboxylate water reducing motherliquor, the high-slump-resistance polycarboxylate water reducer is low in mixing amount and high in water-reducing and slump-resistant performance; the slump-resistant time can be flexibly adjusted according to the requirements on construction concrete transportation distance and time, the concrete slump-resistant time can be prolonged by 1-4 hours, so that high cement adaptability can be achieved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

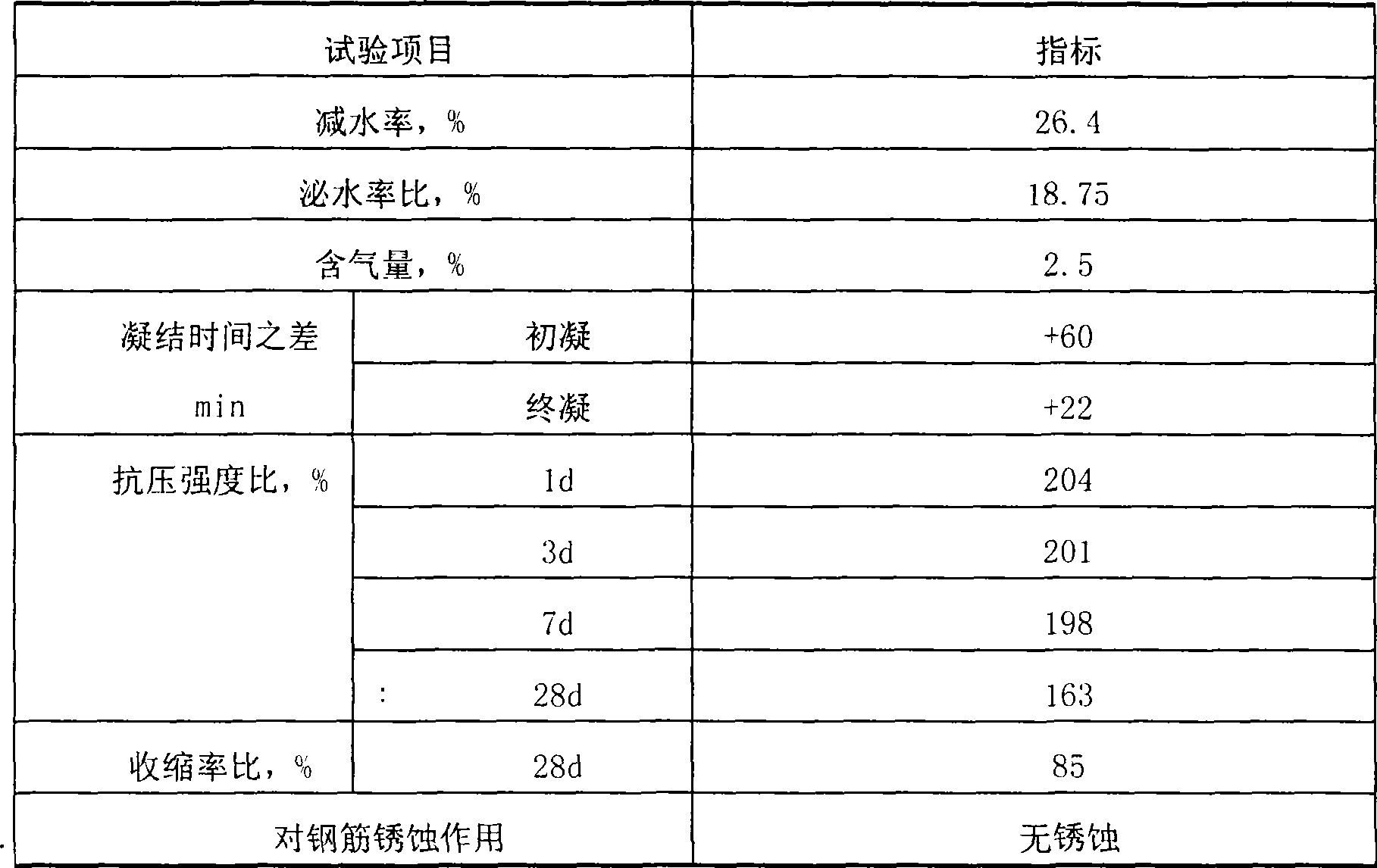

Amino sulfonic acid water reducing agent with very low alkali content and its production process

The amino sulfonic acid water reducing agent with very low alkali content is produced through: 1. mixing amino aryl sulfonating agent, phenol monomer and water, regulating the pH value of the reaction system to 7-9.5, dropping condensing agent and heating to 50-100 deg.c to react for 0.5-2 hr; 2. regulating the pH value of the reaction system to 8-11, adding compound containing amino radical and reaction at 70-100 deg.c for 2-10 hr; and 3. regulating the pH value of the reaction system to 8.5-13, reaction at 85-100 deg.c for 0.5-3 hr, lowering the temperature, discharging and spray drying. The material consists of amino aryl sulfonating agent 10.5-32 wt%, phenol monomer 3.2-16 wt%, compound containing amino radical 0-10.5 wt% and water 17.5-65 wt%. The present invention has the feature of low total alkali amount of 0-1.0 wt%.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

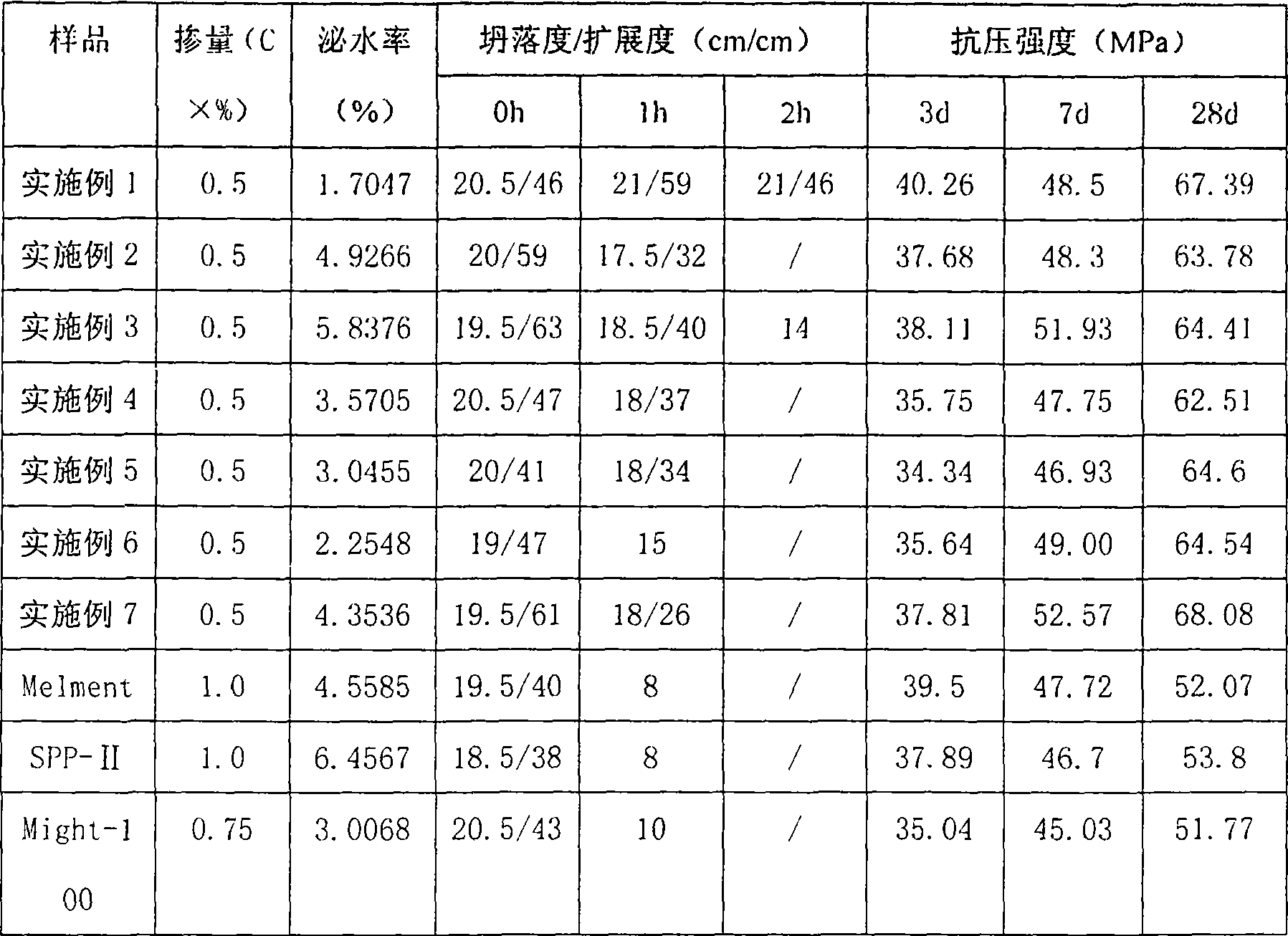

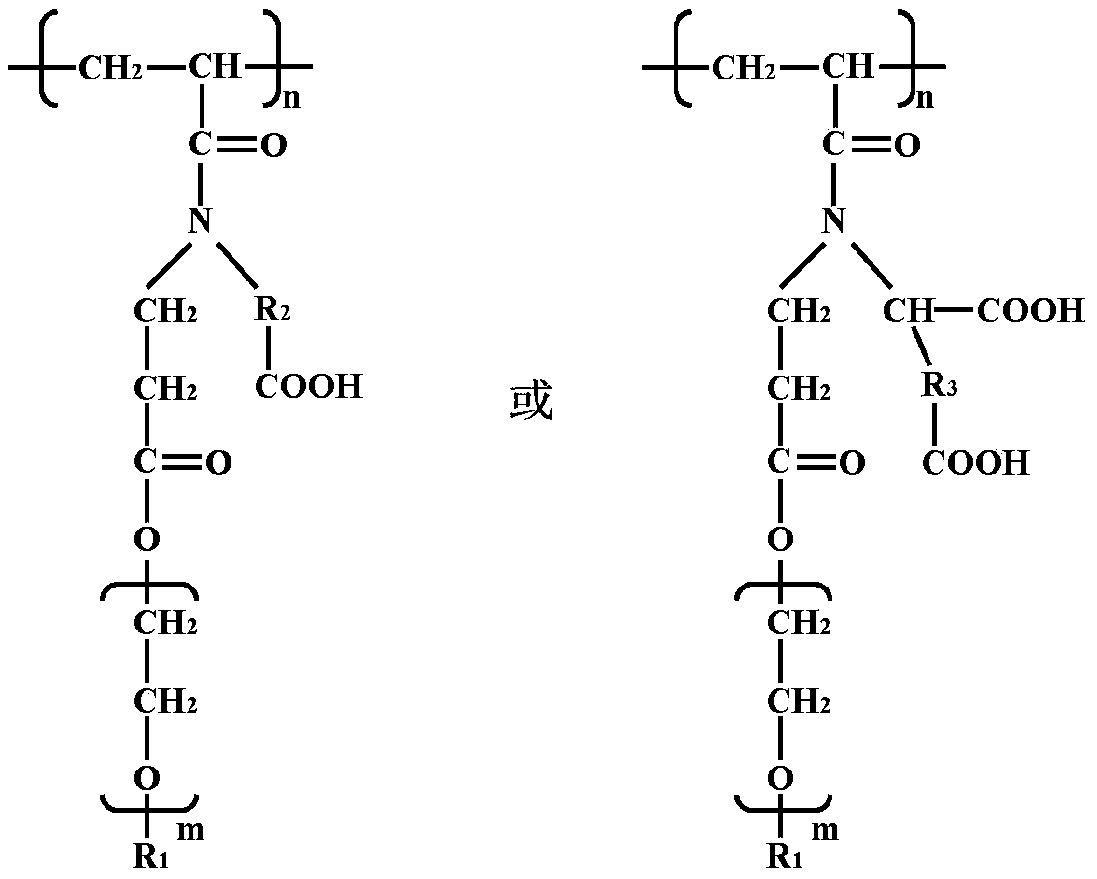

Ternary random copolymer and its preparation method

ActiveCN103183790AReasonable main and side chain density distributionAdaptablePolymer scienceSide chain

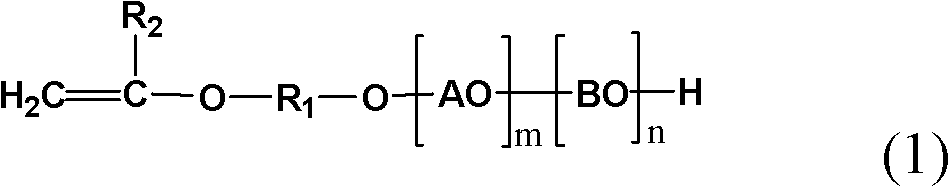

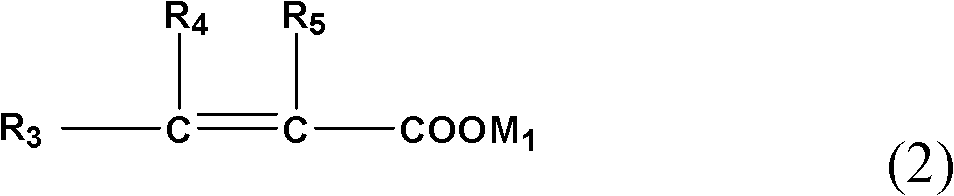

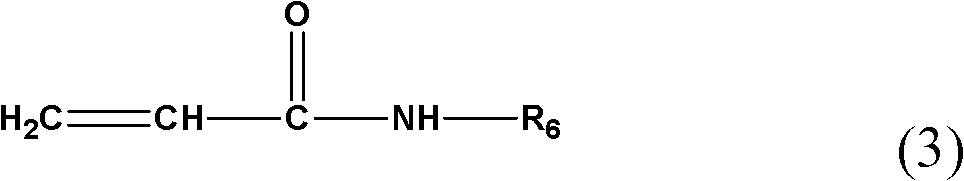

The invention discloses a ternary random copolymer and its preparation method. The ternary random copolymer is composed of the structural units of three monomers, i.e. X, Y and Z respectively shown in formula (1)-(3). The mole ratio of the three structural units, i.e. X:Y:Z is 1:2-5:0.4-1, and the copolymer has a weight average molecular weight of 10000-30000, with the meaning of each symbol in the formulas being shown in the specification. The copolymer is prepared from the three monomers through aqueous solution copolymerization in the presence of an initiator. The copolymer can be used as an early strength type concrete polycarboxylic water reducer. Because of the introduction of an amide structural unit, the water reducer can reduce the coagulation retarding effect of concrete and improve the early strength of concrete. In addition, as the copolymer has reasonable main and side chain density distribution, the water reducer also has the characteristics of high water reduction, high slump retaining and strong adaptability to cement.

Owner:LIAONING OXIRANCHEM INC

Method for preparing ether ester copolymer high-efficiency water reducer

The invention discloses a method for preparing an ether ester copolymer high-efficiency water reducer; methyl polyethenoxy ether, methyl methacrylate, polyethylene glycol and the like are taken as raw materials and go through ester condensation reaction, addition reaction and neutralization reaction to prepare the ether ester copolymer high-efficiency water reducer; and the preparation method is simple and the reaction conditions are easy to control. The weight percentages of the raw materials are as follows: 9 percent to 19 percent of methyl polyethenoxy ether, 45 percent to 60 percent of methyl methacrylate, 30 percent to 40 percent of polyethylene glycol; the technology of the preparation method is simple, the reaction is stable, the reaction condition is mild and the technological process is easy to control. The obtained ether ester copolymer high-efficiency water reducer has the advantages of high water reduction rate, good fluidity, high slump retaining ability, good plasticizing effect, low retardation, low shrinkage, high reinforcement and the like, thus meeting the technical requirements and construction requirements of modern high-performance concrete.

Owner:上饶市天佳新型材料有限公司

Cracking resisting concrete

The invention discloses cracking resisting concrete. The cracking resisting concrete comprises the following components in parts by mass: 230-420 parts of cement, 60-120 parts of mineral powder, 40-70 parts of pulverized fuel ash, 175-190 parts of water, 580-765 parts of sand, 1,080-1,090 parts of gravel and 3.6-6.96 parts of a high-performance polycarboxylate admixture. The cracking resisting concrete disclosed by the invention has high ultimate strain capacity and high cracking resistance and is low in production cost, less cement is used, and less energy is consumed.

Owner:JIANGSU GUANGYA BUILDING MATERIAL

Preparation method of poly carboxylic acid water reducing agent with regular sequence structure

The invention discloses a preparation method of a poly carboxylic acid water reducing agent with a regular sequence structure. The preparation method comprises the following steps of performing Michael addition reaction on a polyethylene glycol ester acrylate macromer A and amino group containing carboxylic acid B for 5-12h, then cooling the temperature to 0 DEG C, dropwise adding acryloyl chloride slowly at a constant speed, and continuously performing reaction for 12h under the condition with normal temperature after dropwise addition is finished to obtain a carboxyl group containing polyether macromer C; and fully mixing the carboxyl group containing polyether macromer C, a small molecular RAFT reagent, an initiator and water, keeping the polymerization mass concentration be 30-60 percent, rising the temperature to 60-80 DEG C at the atmosphere of N2, and performing reaction for 2-5h to obtain the poly carboxylic acid water reducing agent with the regular sequence structure. The poly carboxylic acid water reducing agent prepared by the preparation method is suitable for regions with high mud content of sandstone aggregates and has the advantages of low mixing amount, high waterreducing ability and high slump loss resistance. The preparation method provided by the invention is simple in preparation technology as well as is environmentally friendly and is low in cost in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Building water reduction agent

The invention provides a water reduction agent, belonging to the field of building material additives. The building water reduction agent comprises the following components in parts by weight: 4-20 parts of acetone, 10-15 parts of calcium lignosulphonate, 10-14 parts of urea, 4-7 parts of formaldehyde, 1-2 parts of sodium hydroxide, 2-5 parts of melaminen and 1-5 parts of phenol. According to the technical scheme, a preparation method of the water reduction agent comprises the following steps: mixing calcium lignosulphonate, urea and acetone, heating to be 55-65 DEG C, further feeding acetone, formaldehyde, sodium hydroxide, melaminen and phenol, and continuously stirring uniformly, thereby obtaining a product, wherein the products with different solid content can be prepared according to practical demands. The water reduction agent provided by the invention is wide in resource, simple in preparation method, free of toxicity or pollution and low in energy consumption.

Owner:QINGDAO WINCHANCE TECH

Making method for low-cost concrete water-reducing agent

The invention provides a making method for a low-cost concrete water-reducing agent. The making method comprises the following concrete contents: (1) cement mortar is allowed to form a flocculation structure under the action of molecular gravitation of cement particles, 10 to 30% of mixing water is allowed to be wrapped in the cement particles instead of participating in free flowing and exerting lubrication effect, so the fluidity of a concrete mixture is influenced, and raw material quality is stabilized at a constant level by using a waste material homogenizing and purifying apparatus developed under self-dependent innovation; (2) molecules of cement mortar aqua can directionally adhere on the surfaces of the cement particles, and the surfaces of the cement particles are allowed to carry same charges (usually negative charges) so as to form electrostatic repulsion effect, so the cement particles are dispersed, the flocculation structure is destroyed, and water wrapped in the cement particles is released and participated in flowing; and (3) the doping amount of the water-reducing agent is 0.4 to 2.0% of the gross weight of cementing materials, and a frequently-used doping amount is 0.4 to 1.2%. Concrete trial mix test should be carried out before usage of the water-reducing agent so as to determine an optimal doping amount.

Owner:HARBIN RUNDE WEIYE TECH DEV

Method for preparing polycarboxylic acid retarding water reducer

The invention belongs to the technical field of methods for preparing polycarboxylic acid water reducers. A method for preparing a polycarboxylic acid water reducer comprises the following: a step 1 of esterification, in which a poly(ethylene glycol methyl ether)acrylate macromonomer is synthesized by using methoxy polyethylene glycol and acrylic acid in a molar ratio of 1:1.1 to 1:1.5 at 100 to 120 DEG C, water is separated out in a reaction process, and the molecular weight of the macromonomer is 1,250 to 3,000; and a step 2 of polymerization, in which aqueous solution of the macromonomer is prepared, an unsaturated monomer and a catalyst A are added in turn at 40 to 50 DEG C, the temperature is kept constant at 28 to 40 DEG C, aqueous solution of anhydrous sodium hydrogensulfite or vitamin c is dripped, the concentration of a solid content is kept between 35 to 45 percent by adjusting water content, stirring is stopped, and the solution is allowed to stand for 1 to 1.5 hours, the pH value is kept between 6 and 8 by alkaline reagent after the reaction is finished, and the catalyst A is peroxyacetic acid or potassium peroxydisulfate. The invention has the advantages of low cost, simple process and high product performance.

Owner:河北智胜工程技术有限公司

Aqueous solution retarder

The invention provides an aqueous solution retarder. The aqueous solution retarder is prepared from, by weight, 70-85 parts of a polycarboxylate superplasticizer, 1-10 parts of polyphosphate, 5-20 parts of organic acids, 1-5 parts of an anti-freezing agent and 1-10 parts of a calcium increasing agent, wherein the polyphosphate refers to sodium hexametaphosphate or sodium tripolyphosphate, and thecalcium increasing agent refers to calcium hydroxide, calcium oxide and calcium carbonate. The problem of environmental pollution caused by adding of various auxiliary agents in high quantity due to apurpose of improving a retarding function of a water reducing agent in the prior art is solved. A product has advantages of high slump loss resistance, high water reducing rate, high strength, retarding and the like, concrete workability is improved, various mechanical performances of concrete are improved, and high adaptability to various types of cement is achieved. Concrete prepared from the aqueous solution retarder is free of surface bleeding line and bubbles, low in color difference and high in appearance quality, low environment temperature influences are realized, convenience in construction is achieved, and a preparation method is simple and easy to operate.

Owner:南京友西科技集团股份有限公司

Slump retaining type polycarboxylic acid water reducing agent, and preparation method and application thereof

The invention discloses a slump retaining type polycarboxylic acid water reducing agent, and a preparation method and application thereof. The water reducing agent is prepared from the following raw materials in parts by weight: 27 to 35 parts of polymethylacrylic acid, 1 to 5 parts of polyepoxysuccinic acid, 7 to 15 parts of casein, 5 to 12 parts of polyethylene glycol adipate and 3 to 10 parts of calamine; the calamine is smashed; absolute ethyl alcohol is added for heat stirring treatment; the polyepoxysuccinic acid is added, and heat stirring treatment is performed; then, the casein solution is added, and heat stirring treatment is performed; the polymethacrylic acid and the polyethylene glycol adipate are added; heat treatment, ultrasonic treatment and centrifugal treatment are performed; filter liquor is taken; heat stirring treatment is performed; the water reducing agent is obtained. The water reducing agent has the advantages of high slump retaining performance, excellent dispersion performance and good adaptability; the preparation process is simple; the control is easy; the reaction period is short; no pollution exists; the energy consumption is low; a good effect is also achieved on reducing the slump loss of concrete under the condition of low mixing content; the concrete water loss and evaporation due to long-time transportation and high temperature can be reduced; the industrial production is easily realized.

Owner:江苏润天建材(集团)有限公司

Synthetic method of side-chain adsorption type concrete super-plasticizer

The invention relates to a synthetic method of a side-chain adsorption type concrete super-plasticizer. By using an unsaturated monomer, an unsaturated initiator, a transition metal complex, a carboxylic small monomer and the like as main raw materials and through the method of auto-polymerization, hydrolysis and graft copolymerization, the side-chain adsorption type concrete super-plasticizer issynthesized. The synthetic method specifically comprises the following steps: the unsaturated monomer, which is used as a reactant, is subjected to atom transfer radical polymerization (ATRP) in an initiating system composed of the unsaturated initiator, transition metal halide and a ligand so as to obtain an unsaturated macromonomer; then, the macromonomer is subjected to hydrolysis to obtain ananionic macromonomer; and the anionic macromonomer and the carboxylic small monomer are subjected to radical graft copolymerization under the action of an initiator and a chain transfer agent to prepare the side-chain adsorption type concrete super-plasticizer. The synthetic method of the invention has controllable process and simple step, is convenient and efficient, and is energy-saving and environmentally-friendly. Through innovative design of the molecular structure, the side-chain adsorption type concrete super-plasticizer is synthesized, multiple excellent effects of water reduction andslump retaining and the effect of inhibiting side effect of clay are realized, and the types of the concrete super-plasticizer are enriched.

Owner:BEIJING UNIV OF TECH

Efficient compound water reducing agent for concrete and preparation method of efficient compound water reducing agent

The invention discloses an efficient compound water reducing agent for concrete and a preparation method of the efficient compound water reducing agent. The efficient compound water reducing agent comprises, by weight, 13-18 parts of aromatic sulfamic acid formaldehyde condensate sodium salt, 11-16 parts of sulfonated humic acid-formaldehyde-sulfonated acetone polymer, 10-15 parts of polymer of 4-amino-sodium benzene sulfonate, formaldehyde and methylphenol, 7-11 parts of alkali lignin, 8-13 parts of sodium polystyrenesulfonate, 5-10 parts of calcium gluconate, 6-12 parts of propylene glycol alginate, 4-7 parts of mannitol, 4-8 parts of sodium lauryl sulfate and 5-10 parts of polyvinyl pyridine. The water reducing agent prepared by the method has the advantages that the water reducing agent is excellent in comprehensive performance, high in water reducing performance, high in early strength, high in reinforcing performance, low in shrinkage, high in slump loss resistance, and the like; the water reducing agent is suitable for high-durability concrete, self-leveling concrete, high-strength pump-delivery commodity concrete, underwater bored pile grouting concrete, bare concrete with high facing requirements, steam-cured concrete and the like.

Owner:安徽炎胜新材料科技有限公司

High water reduction high collapse protection type polycarboxylate high-performance water reducer and pyrogen-free preparation method thereof

The invention belongs to the technical field of concrete additives in building materials. The high water reduction high collapse protection type polycarboxylate high-performance water reducer mainly comprises the following monomer components: unsaturated methyl vinyl polyoxyethylene ether (A), a chain transfer agent (B), a mixture (C) of one or more of unsaturated acid and unsaturated acid derivatives, an oxidant (D) and a reducing agent (E), wherein the molar ratio A: B: C: D: E of the monomers is 1:0.01-0.5:2-8:0.08-0.5:0.02-0.3. The high water reduction high collapse protection type polycarboxylate high-performance water reducer is prepared by regulating the polymer mass concentration to between 20 and 40 percent by using water, and polymerizing a redox initiator system at normal temperature. The water reducer has the advantages of low doping amount, high water reducing ratio, excellent slump retaining capacity, and high cement adaptability, and the technology has the advantages of no need of extra heat source, implementation at normal temperature, low equipment investment, low cost and suitability for large area popularization and application.

Owner:大连华建科技有限公司

Amino sulfonic acid water reducing agent with very low alkali content and production process thereof

Ultra-low-alkali sulfamic acid-based water reducer, 1) After mixing the aminoaryl sulfonating agent, phenolic monomer and water, adjust the pH value of the reaction system to 7-9.5 with an alkaline regulator, drop Add a condensing agent, heat up to 50-100°C and react for 0.5-2h; 2) Adjust the pH value of the system to 8-11 with an alkaline regulator, add a compound containing an amide group, and react at 70-100°C for 2 -10h; 3) Adjust the pH value of the system to 8.5-13 with an alkaline regulator, react at 85-100°C for 0.5-3.0h, cool down and discharge, and then spray dry. The dosage of each raw material is: aminoaryl sulfonating agent: 10.5-32%, phenolic monomer: 3.2-16%, compound containing amide group 0-10.5%, condensing agent: 9.5-61.0%, basic regulator : 0.7-11.5%, water: 17.5-65%. The outstanding feature of the present invention is that the total alkali content is less than 1.0%, or even zero.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

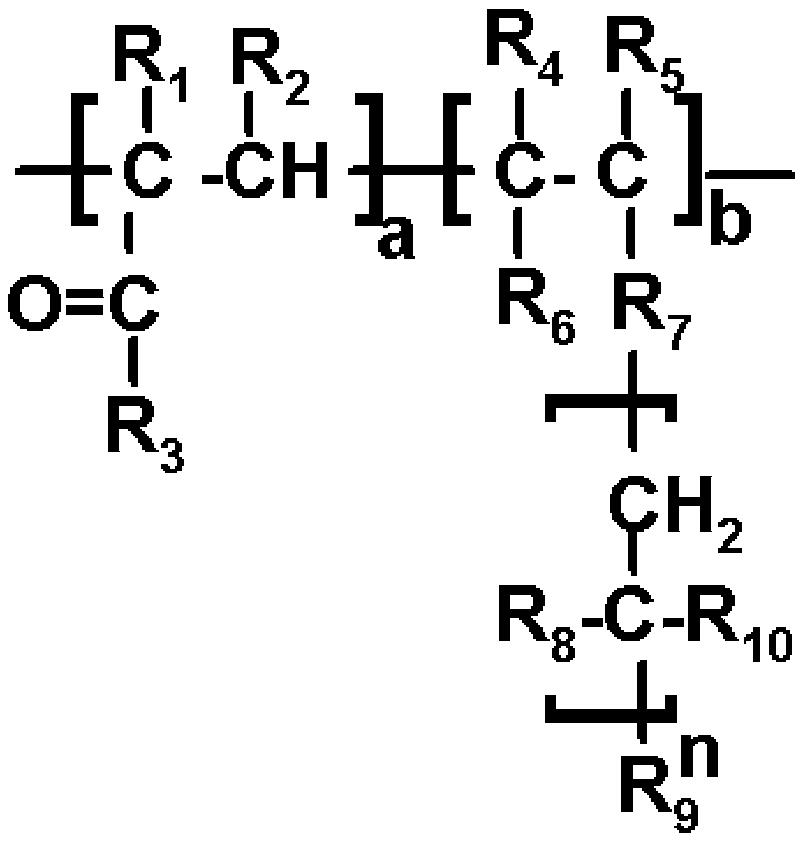

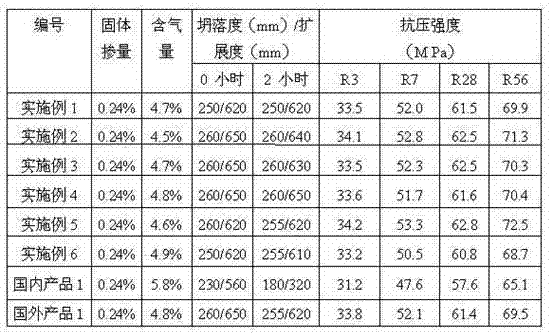

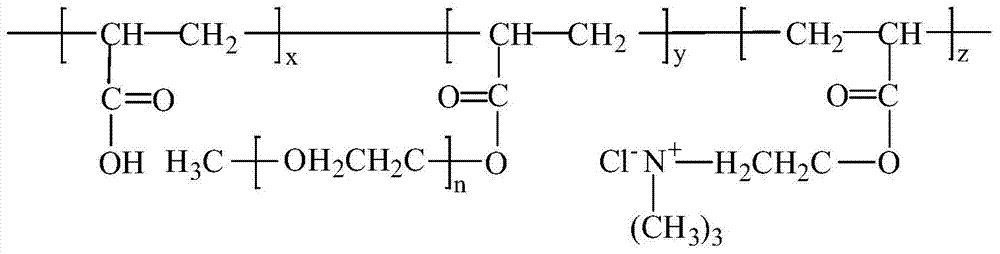

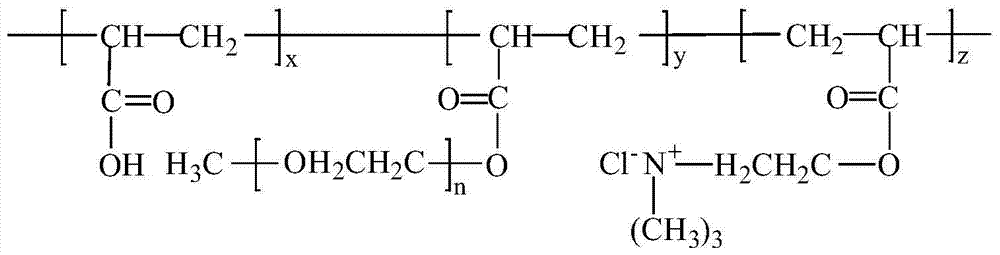

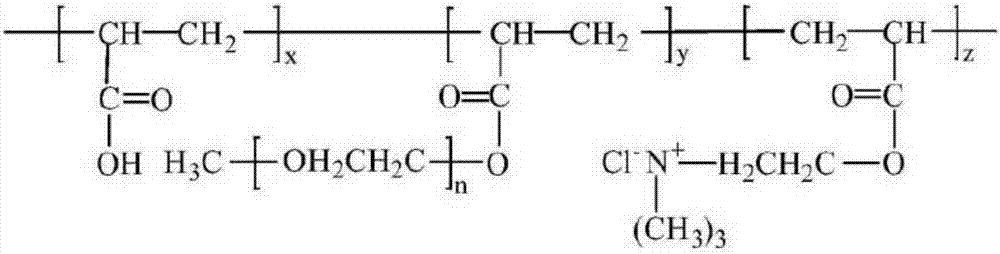

A kind of amphoteric high-performance polycarboxylate water reducer and its preparation method

The invention discloses an amphiplilic high-performance polycarboxylate water reducer which has a structure as shown in the formula, wherein n is a natural number between 10-60, and x, y and z are positive integers; the invention further discloses a preparation method of the amphiplilic high-performance polycarboxylate water reducer, and the preparation method comprises the steps of preparing a cationic active organic monomer and preparing the amphiplilic high-performance polycarboxylate water reducer. The amphiplilic high-performance polycarboxylate water reducer provided by the invention is domestic in synthetic raw materials, safe in synthetic process, mild in reaction condition and free of environmental pollution; besides, when used in concrete, the obtained product has the characteristics of low dosage, high dispersion, high slump loss resistance, high water reduction, high early compressive strength and the like.

Owner:LIMING VOCATIONAL UNIV

Preparation method and application of mud-resistant polycarboxylate superplasticizer

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Preparation method of phenolic ether polycarboxylate concrete slushing agent

The invention relates to a preparation method of a concrete slushing agent, in particular to a preparation method of a phenolic ether polycarboxylate concrete slushing agent. The preparation method comprises the following steps of: polymerizing a raw material A with high copolymerization activity and ethylene oxide and / or epoxypropane under base catalysis ro obtain polyether macromonomer, and introducing the synthesized polyether macromonomer into the main chain of polycarboxylic acid in the manner of free radical polymerization to finally obtain the phenolic ether polycarboxylate concrete slushing agent of which the main chain is provided with the benzene ring. The slushing agent has the advantages of high slushing, high collapse perversion and good concrete adaptability.

Owner:贵阳格瑞林建材科技有限公司

A kind of polycarboxylate water reducing agent, its preparation method and application

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A cross-linked low-sensitivity ester ether copolymerization polycarboxylate water reducer and its preparation method

ActiveCN106046269BEven distribution of side chainsImprove workabilityPolymer sciencePhosphomonoesters

Owner:KZJ NEW MATERIALS GROUP CO LTD

A kind of cross-linked low-sensitivity polycarboxylate water reducer and preparation method thereof

ActiveCN106117455BEven distribution of side chainsHigh polymerization activityAcid waterPhosphomonoesters

The invention discloses a cross-linking type low-sensitivity polycarboxylate water reducing agent and a preparation method thereof. The structural formula of the polycarboxylate water reducing agent is as shown in the specification. The polycarboxylate water reducing agent is synthesized by copolymerization of 4-hydroxybutyl vinyl polyethenoxy ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester, and has high water-reducing rate, high slump loss resistance, mud resistance and low dosage sensibility under the synergetic effect of various groups.

Owner:KZJ NEW MATERIALS GROUP CO LTD

A kind of low-temperature synthesis method of multi-branched polycarboxylate water reducing agent

The invention discloses a low-temperature synthesis method of a multi-branched polycarboxylate superplasticizer. 1) Put a base material composed of unsaturated polyoxyethylene ether and water into a reaction kettle under a set temperature and stirring conditions; 2) After the base material is completely dissolved, put in the initiator, and add the pre-configured A and B materials dropwise at the same time; 3) The dropping time of A and B materials is controlled at 0.5‑1.5h, and the reaction is continued for 0.5 hours after the dropping ‑1.5h, dilute with water and neutralize with liquid caustic soda to pH 6‑8, and obtain that; wherein, the A material includes unsaturated carboxylic acid, unsaturated quaternary ammonium salt monomer and water; the B material includes a reducing agent , chain transfer agent and water. The synthesis method of polycarboxylate water-reducer provided by the present invention can synthesize multi-branched polycarboxylate water-reducer in one step within the range of 5-30°C, the selected initiator and reducing agent are low-temperature polymerization initiation system, and water As a solvent, the reaction process does not require external heat energy, the preparation process is simple, the reaction time is short, and it is environmentally friendly and economical.

Owner:JIANGSU ZHONGKAI NEW MATERIALS

A preparation method of polycarboxylate water reducer with regular sequence structure

The invention discloses a preparation method of polycarboxylate water reducer with regular sequence structure. The preparation method of the present invention comprises: performing Michael addition reaction on macromonomer A of poly(ethylene glycol ether ester) of acrylate and carboxylic acid B containing amino group, after reacting for 5-12 hours, then cooling down to 0°C, slowly adding propylene dropwise at a uniform speed Acyl chloride, after the dropwise addition, continue to react at normal temperature for 12 hours to obtain carboxyl-containing polyether macromonomer C; fully mix carboxyl-containing polyether macromonomer C, small molecule RAFT reagent, initiator and water, Keep the polymerization mass concentration at 30~60%, in N 2 Under the atmosphere, raise the temperature to 60-80°C, and react for 2-5 hours to obtain a polycarboxylate superplasticizer with a regular sequence structure. The polycarboxylate water reducer prepared by the invention is suitable for areas with high mud content in sand and gravel aggregates, and has the advantages of low dosage, high water reduction and high slump retention; the preparation process of the invention is simple, and the production process is green and environmentally friendly ,low cost.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Synthesis method of side chain adsorption type concrete superplasticizer

The invention relates to a synthesis method of a side chain adsorption type concrete superplasticizer, which uses unsaturated monomers, unsaturated initiators, transition metal complexes, small carboxylic acid monomers, etc. The method of graft copolymerization synthesizes the side chain adsorption type concrete superplasticizer, that is, the unsaturated monomer is used as the reactant, and the atom transfer radical polymerization ( ATRP) to obtain unsaturated macromonomers, and then hydrolyze the macromonomers to obtain anionic macromonomers, and then carry out free radical graft copolymerization reaction with small carboxylic acid monomers under the action of initiator and chain transfer agent to prepare have to. The process of the invention is controllable, the steps are simple, convenient, fast, energy-saving and environmentally friendly. Through the innovative design of the molecular structure, a side-chain adsorption concrete superplasticizer is synthesized, which realizes multiple functions such as excellent water reduction and slump protection, and suppression of side effects of clay. The variety of concrete superplasticizers has been enriched.

Owner:BEIJING UNIV OF TECH

A kind of slump-preserving polycarboxylate water reducer and its preparation method and application

The invention discloses a slump retaining type polycarboxylic acid water reducing agent, and a preparation method and application thereof. The water reducing agent is prepared from the following raw materials in parts by weight: 27 to 35 parts of polymethylacrylic acid, 1 to 5 parts of polyepoxysuccinic acid, 7 to 15 parts of casein, 5 to 12 parts of polyethylene glycol adipate and 3 to 10 parts of calamine; the calamine is smashed; absolute ethyl alcohol is added for heat stirring treatment; the polyepoxysuccinic acid is added, and heat stirring treatment is performed; then, the casein solution is added, and heat stirring treatment is performed; the polymethacrylic acid and the polyethylene glycol adipate are added; heat treatment, ultrasonic treatment and centrifugal treatment are performed; filter liquor is taken; heat stirring treatment is performed; the water reducing agent is obtained. The water reducing agent has the advantages of high slump retaining performance, excellent dispersion performance and good adaptability; the preparation process is simple; the control is easy; the reaction period is short; no pollution exists; the energy consumption is low; a good effect is also achieved on reducing the slump loss of concrete under the condition of low mixing content; the concrete water loss and evaporation due to long-time transportation and high temperature can be reduced; the industrial production is easily realized.

Owner:江苏润天建材(集团)有限公司

A kind of anticorrosion high slump retention polycarboxylate composite water reducing agent and its preparation method and application

The invention relates to an anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and a preparation method and application thereof. The composite polycarboxylate superplasticizer comprises, by mass, 40 to 55% of mother liquor of a polycarboxylate superplasticizer, 4 to 7% of sodium gluconate, 0.15 to 0.3% of an air entraining agent, 0.1 to 0.25% of an antifoaming agent, 0.05 to 0.2% of an emulsifying agent and 0.1 to 0.3% of an anticorrosive bactericide, with the balance being water, wherein the mass percents of every component sum to 100%. The composite polycarboxylate superplasticizer is prepared by placing the mother liquor of the polycarboxylate superplasticizer, sodium gluconate, the air entraining agent, the antifoaming agent, the anticorrosive bactericide and the water in a container together according to the above-mentioned mass percents under the conditions of normal temperature and normal pressure and carrying out uniform mixing under stirring. In use, the composite polycarboxylate superplasticizer is added into a concrete cementing material according to a mass ratio of the composite polycarboxylate superplasticizer to the concrete cementing material of 0.1-0.15: 100. Compared with the prior art, the composite polycarboxylate superplasticizer provided by the invention has the advantages of convenience in usage, stable performance, no phenomena of mildew, smelliness and layering due to long-term storage, capacity of introducing small bubbles when used in fresh mixed concrete, and excellent water-reducing and slump-retaining performances.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com