High-slump-resistance polycarboxylate water reducer

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete additives, can solve the problems of not being able to meet the needs of concrete super-long working performance, and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

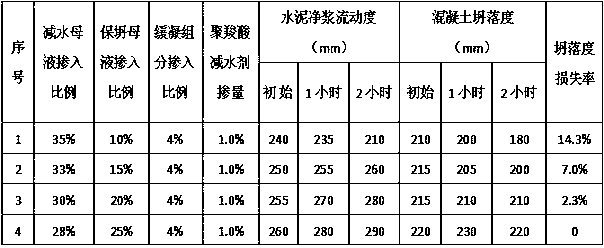

[0026] This embodiment provides a high slump retention polycarboxylate water reducer, which is composed of the following mass percentages: polycarboxylate slump retention mother liquor 10-25%, polycarboxylate water reducing mother liquor 28-35%, retarding component 4%, the balance is water.

[0027] The high slump retention polycarboxylate superplasticizer compounded with the polycarboxylate slump retention mother liquor provided by the present invention has low dosage, high water reduction, and high slump retention, and the slump retention time can be flexibly adjusted according to the transportation distance and time of engineering concrete. , The concrete slump retention time can be extended from 1 hour to 4 hours, and it has good adaptability to cement.

Embodiment 2

[0029] On the basis of Example 1, this embodiment provides a high slump retention polycarboxylate water reducer, the preparation process of the polycarboxylate retention mother liquor includes the following steps:

[0030] Step 1) Add unsaturated polyoxyethylene ether monomer and water into the reaction kettle, stir to dissolve and heat up to 20°C, and add chain transfer agent and initiator, wherein the mass of water accounts for the mass of unsaturated polyoxyethylene ether monomer 90-95%, the mass ratio of unsaturated polyoxyethylene ether monomer, chain transfer agent and initiator is 1000:10:5;

[0031] Step 2) Stir and dissolve the unsaturated acid monomer with a mass ratio of 1:(2.5-3):(1-2), molecular weight modifier A and water to prepare liquid A;

[0032] Step 3) Stir and dissolve the molecular weight regulator B with a mass ratio of 1: (50-60) and water to prepare liquid B;

[0033] Step 4) Add liquid A and liquid B dropwise in the reaction kettle at the same time,...

Embodiment 3

[0036] On the basis of Example 2, this embodiment provides a high slump retention polycarboxylate water reducer, the preparation process of the polycarboxylate retention mother liquor includes the following steps:

[0037] Step 1) Add unsaturated polyoxyethylene ether monomer and water into the reaction kettle, stir to dissolve and heat up to 20°C, and add chain transfer agent and initiator, wherein the mass of water accounts for the mass of unsaturated polyoxyethylene ether monomer 90%, the mass ratio of unsaturated polyoxyethylene ether monomer, chain transfer agent and initiator is 1000:10:5;

[0038] Step 2) Stir and dissolve the unsaturated acid monomer with a mass ratio of 1:2.5:1, molecular weight regulator A and water to prepare liquid A;

[0039] Step 3) Stir and dissolve the molecular weight regulator B with a mass ratio of 1:50 and water to prepare liquid B;

[0040] Step 4) Add liquid A and liquid B dropwise in the reaction kettle at the same time, control the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com