Patents

Literature

3663 results about "Acid water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing powder formulation comprising an insulin

The present invention relates to a process for producing a therapeutic powder formulation, comprising (a) providing an acidic aqueous solution comprising an insulin or analoguc or derivative thereof and an enhancer; (b) adjusting the pH to a pH in the range of 4.5 to 7.4; (c) precipitating a product comprising the insulin or analogue or derivative thereof and the enhancer, wherein the precipitation is performed essentially without evaporation of the solution; and (d) removing the water.

Owner:NOVO NORDISK AS

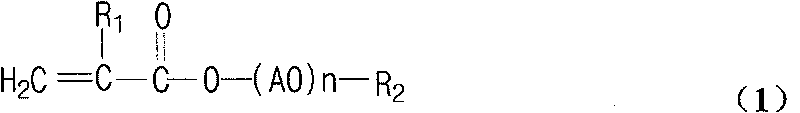

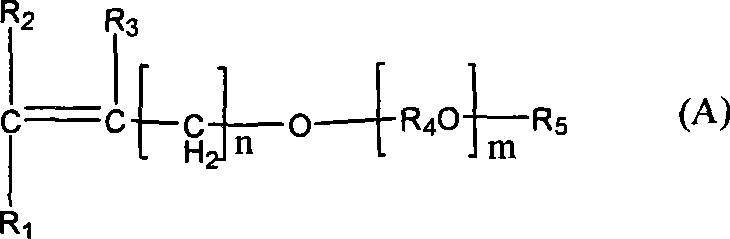

Normal-temperature synthesis method for polycarboxylic acid water-reducing agent

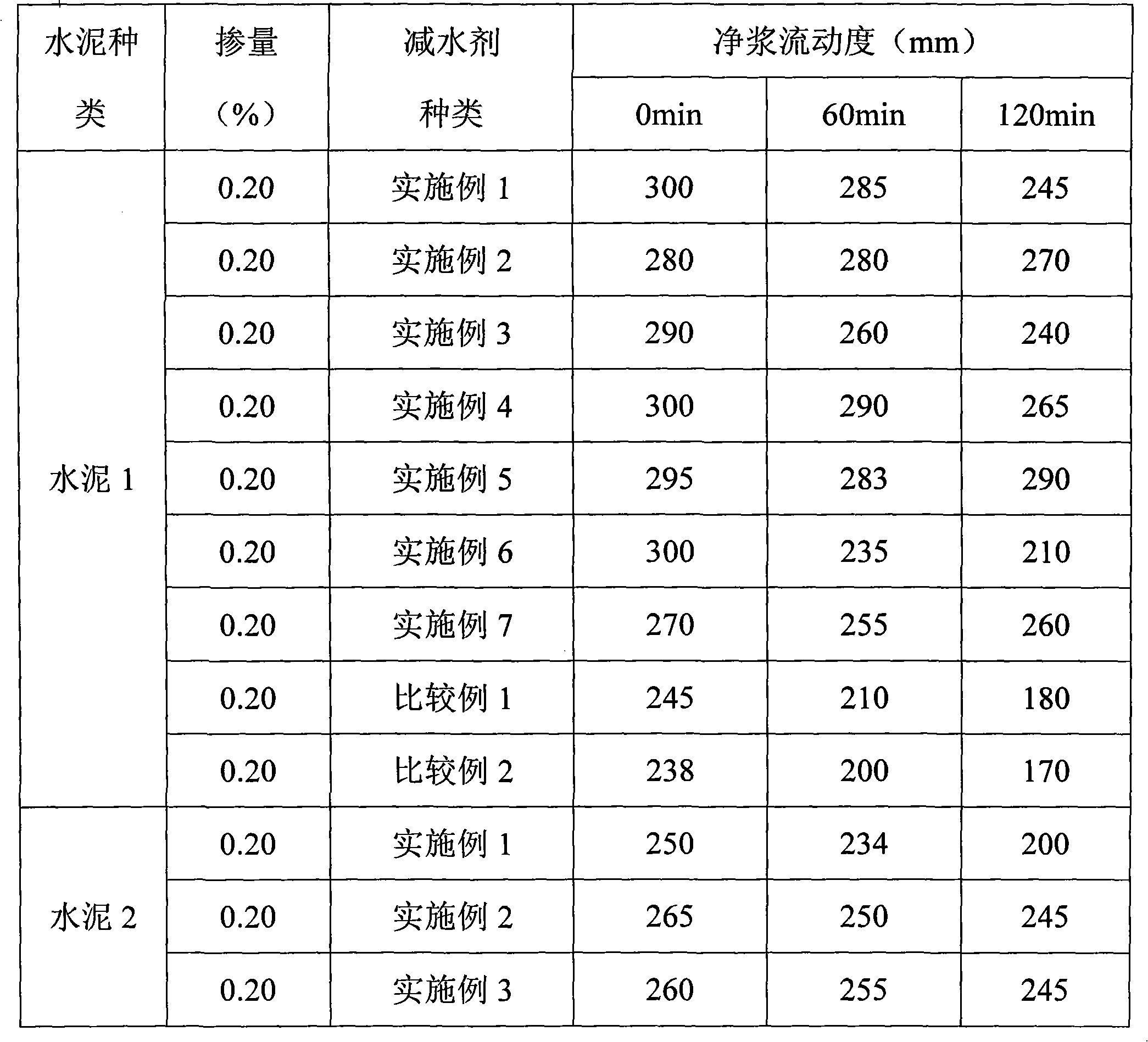

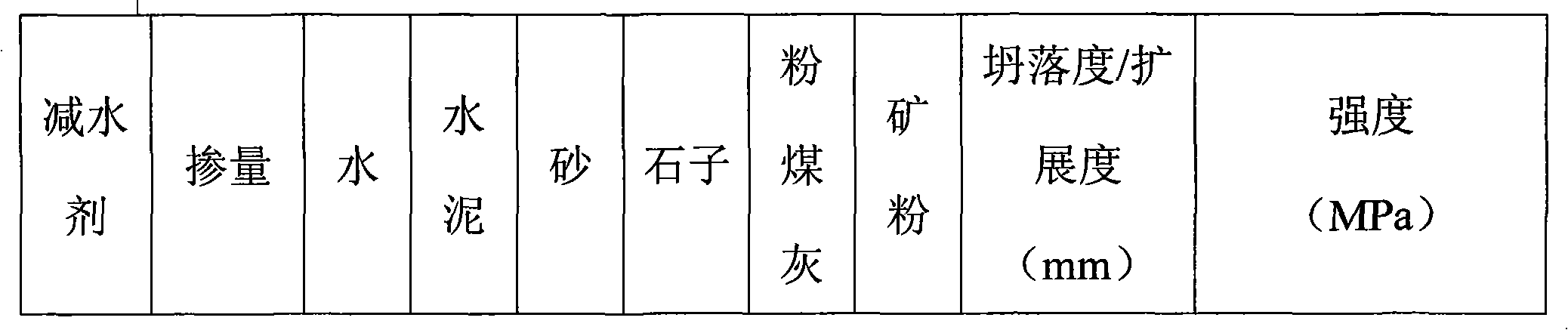

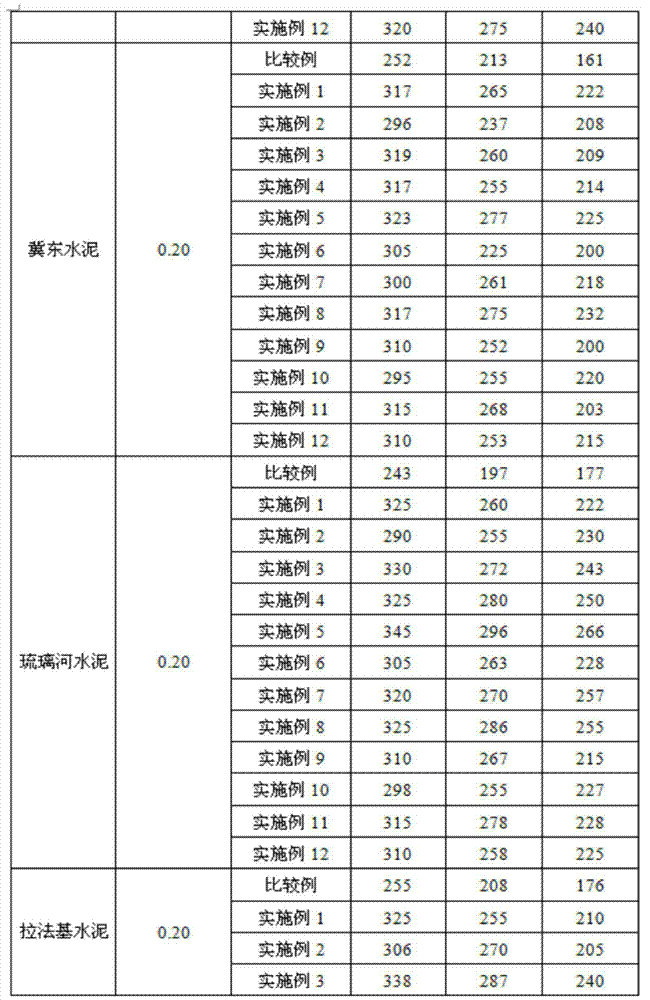

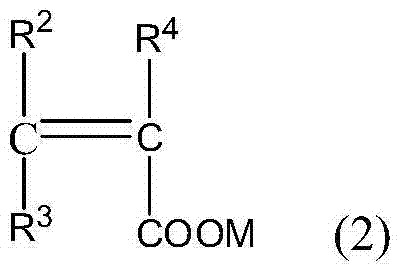

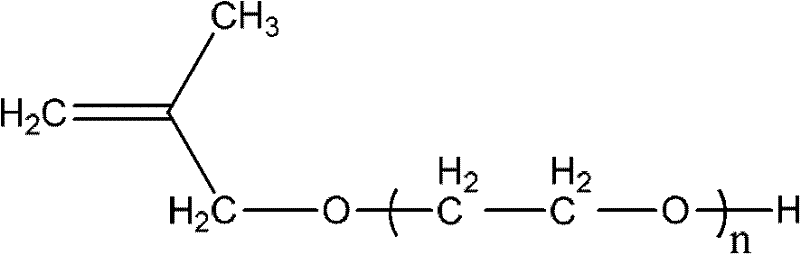

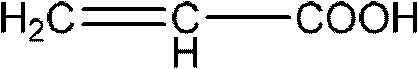

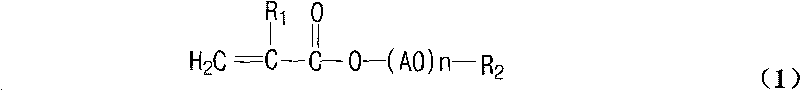

The invention discloses a normal-temperature synthesis method for a polycarboxylic acid water-reducing agent, and belongs to the field of cement concrete water-reducing agents. The water-reducing agent is prepared by the following steps of: copolymerizing polyoxyethylene ether monomer or polyoxyethylene ester monomer a containing unsaturated double bonds, unsaturated monocarboxylic acid and derivative monomer thereof b, unsaturated dicarboxylic acid c and unsaturated sulfonic acid or salt monomer thereof d in aqueous solution under the action of an oxidation reduction initiator, and finally neutralizing the solution by using alkali solution to obtain the water-reducing agent. The reaction can be performed at room temperature by adopting an oxidation reduction initiating system, and the appropriate reaction temperature is between 5 and 30 DEG C; and the synthesis process does not need heating, so energy is saved, and high-temperature side reaction is effectively controlled. The prepared polycarboxylic acid high-performance water-reducing agent has the characteristics of high water-reducing rate and good collapse protecting performance. The water-reducing agent has wide application range, and the method has low production process requirement and is suitable for industrialized large-scale production.

Owner:BEIJING UNIV OF TECH

Low-cost, user-friendly hardcoating solution, process and coating

InactiveUS6265029B1Excellent abrasion resistanceArticle accumulatePretreated surfacesCoatingsColloidal silicaSilanes

An improved, user-friendly silane / silica sol copolymer hardcoating composition for protecting optical plastic and other substrates (including wood, metals, glass, plastics and most coated articles) from scratching is able to be manufactured at lower costs and to provide much-improved ease of use in transportation, storage, dipbath (or other coating tank) stability, and blush resistance in ordinary cleanroom atmospheres. The silane / silica sol copolymer is formed as a direct reaction product of an acidic silica sol and monomethyltrialkoxysilane, preferably substantially monomethyltriethoxysilane, in ratios of 30:70 to 70:30, most preferably about 40:60. A tail solvent aids blush resistance, reduces internal stress and permits adhesion to unprimed polycarbonate. Optionally, colloidal silica sol dissolved in water-miscible solvent may be reacted in a second stage with acidic aqueous colloidal silica sol earlier silanized with monomethyltrialkoxysilane.

Owner:LEWIS WILLIAM

Polycarboxylic acid water reducing agent, preparation method and application thereof

The invention relates to a polycarboxylic acid water reducing agent, a preparation method and an application thereof, and belongs to the technical field of concrete additives. The polycarboxylic acid water reducing agent is prepared by using industrializedly produced isobutenol polyether or isoamylenol polyether with relatively good performances as a monomer A, unsaturated carboxylic acid, unsaturated acid anhydride or unsaturated ester as a monomer B and unsaturated sulfonic acid and salts thereof as a monomer C, according to a water reducing agent functional group theory and a polycarboxylic acid water reducing agent molecule design theory; and co-polymerizing the monomer A, B and C. A polycarboxylic acid water reducing agent product is obtained in a water solution via a one-step method, under initiation of a redox initiation system, by introducing carboxyls or ester groups having the functions of delayed coagulation and slump resistance, and the sulfonic acid groups having high water reducing effect into the molecular structure of the water reducing agent and controlling a material ratio and material-feeding modes. Besides, cost can be further reduced by selecting a proper redox system to make the polymerization carried out at a low temperature. The method is suitable for industrialize production.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

High-performance polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses a preparation method of a high-performance polycarboxylic acid water reducing agent. The preparation method of the high-performance polycarboxylic acid water reducing agent comprises the following steps of: adding an unsaturated polyether macromonomer A and water into a reactor, uniformly stirring and dissolving, and then adding an initiator F hydrogen peroxide; then respectively dropwise adding unsaturated carboxylic acid or an unsaturated carboxylic acid anhydride small monomer B, an unsaturated carboxylate ester small monomer C, an aqueous solution of an initiator D, an aqueous solution of an initiator E and an aqueous solution of a molecular weight regulator, and carrying out reaction for 3-5 hours at the room temperature of 10-40 DEG C, so as to obtain a copolymerization product; carrying out a neutralization reaction, namely regulating the pH value of the copolymerization production to be 6-7 by adopting sodium hydroxide, so as to obtain the high-performance polycarboxylic acid water reducing agent. The invention also discloses a high-performance polycarboxylic acid water reducing agent prepared by adopting the preparation method. By controlling a material adding manner, two initiators are compounded, initiated and synthesized to form the high-performance polycarboxylic acid water reducing agent, the synthesized high-performance polycarboxylic acid water reducing agent is environmentally-friendly, pollution-free and high in reaction conversion ratio, and concrete doped with the high-performance polycarboxylic acid water reducing agent has better water reducing property, slump loss resistant property, dispersibility and workability.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Preparation method of slow-setting polycarboxylic acid water reducing agent

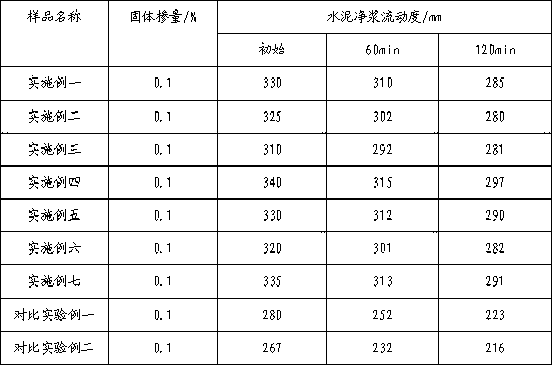

The invention relates to a preparation method of a slow-setting polycarboxylic acid water reducing agent, which is implemented by carrying out free radical copolymerization reaction on allylsulfonate monomers, acrylic monomers, polyethylene glycol nono-methyl ether methacrylate macromonomers and maleic anhydride grafted beta-cyclodextrin macromonomers. The invention is characterized in that a beta-cyclodextrin side chain is introduced into a polycarboxylic acid main chain, so that the polycarboxylate water reducing agent has favorable slow setting property, micro air-entraining property and better fluidity. The obtained polycarboxylic acid water reducing agent has the advantages of stable product performance, strong adaptability to cement and favorable compatibility; and the cement paste fluidity is up to higher than 290mm (W / C=0.29), the water reducing rate of concrete is up to 30-40%, and the slump protection time is 3-5 hours. The preparation method provided by the invention has the characteristics of unique technique, excellent product performance and the like.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

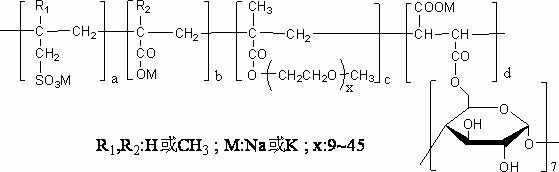

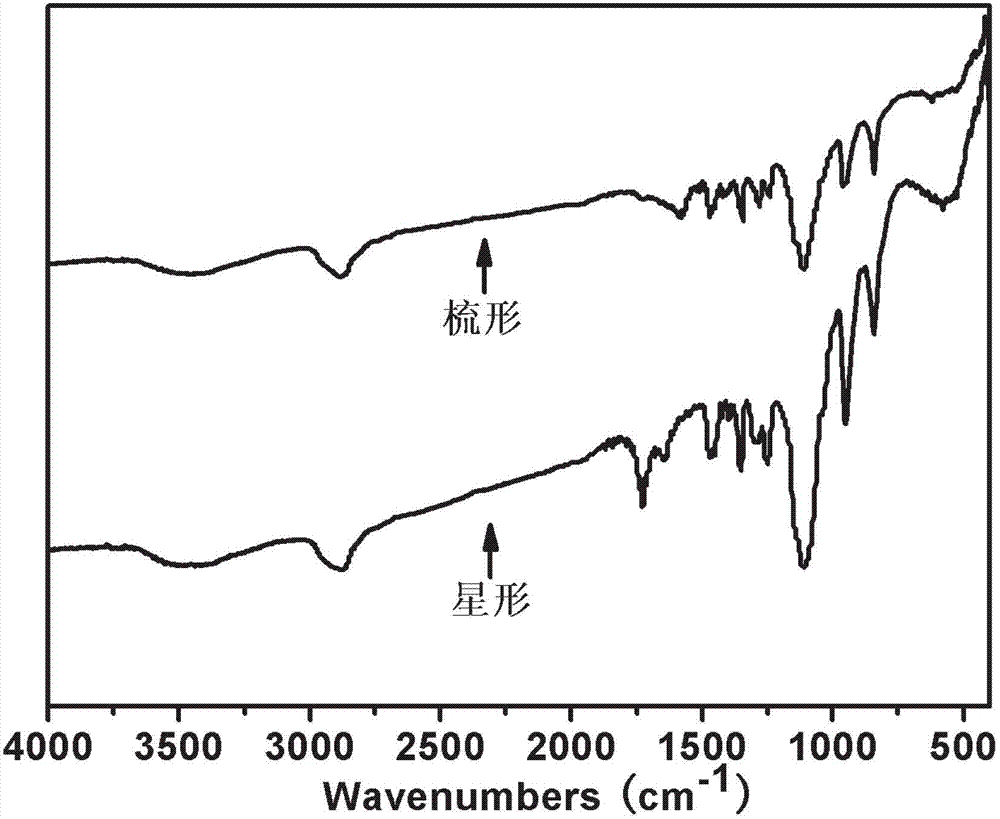

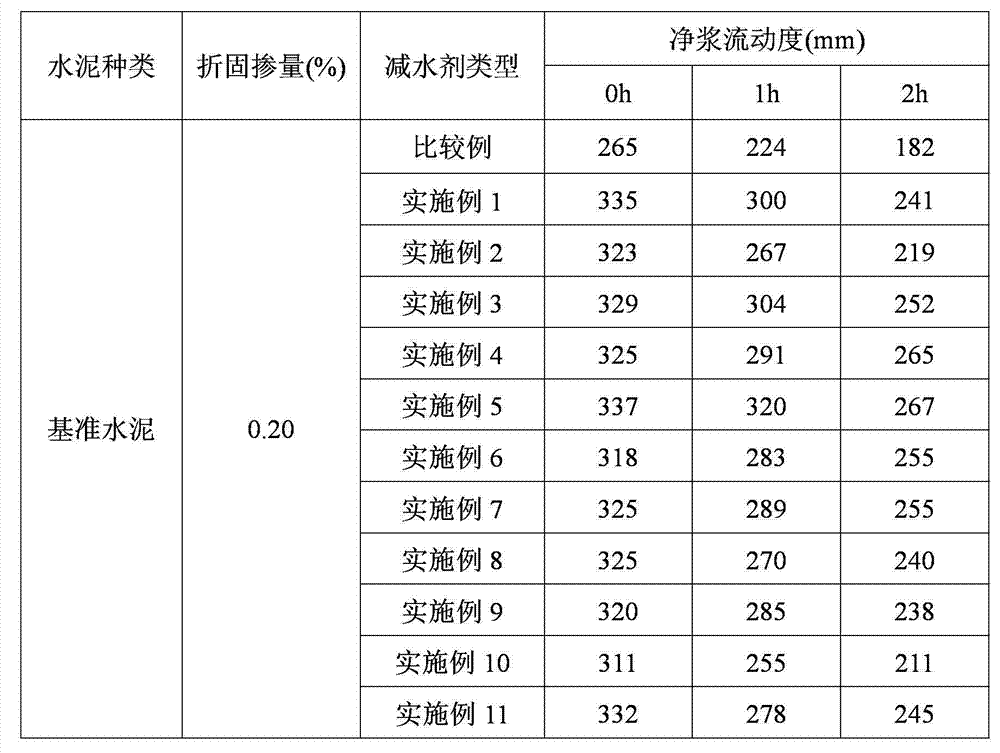

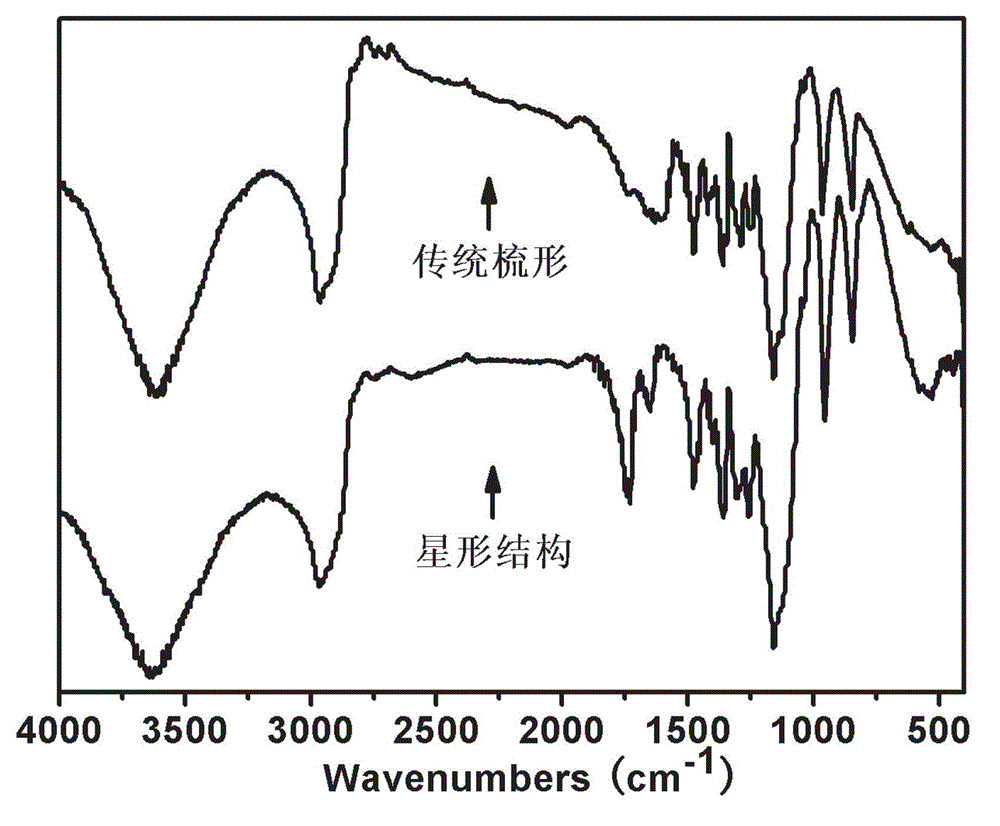

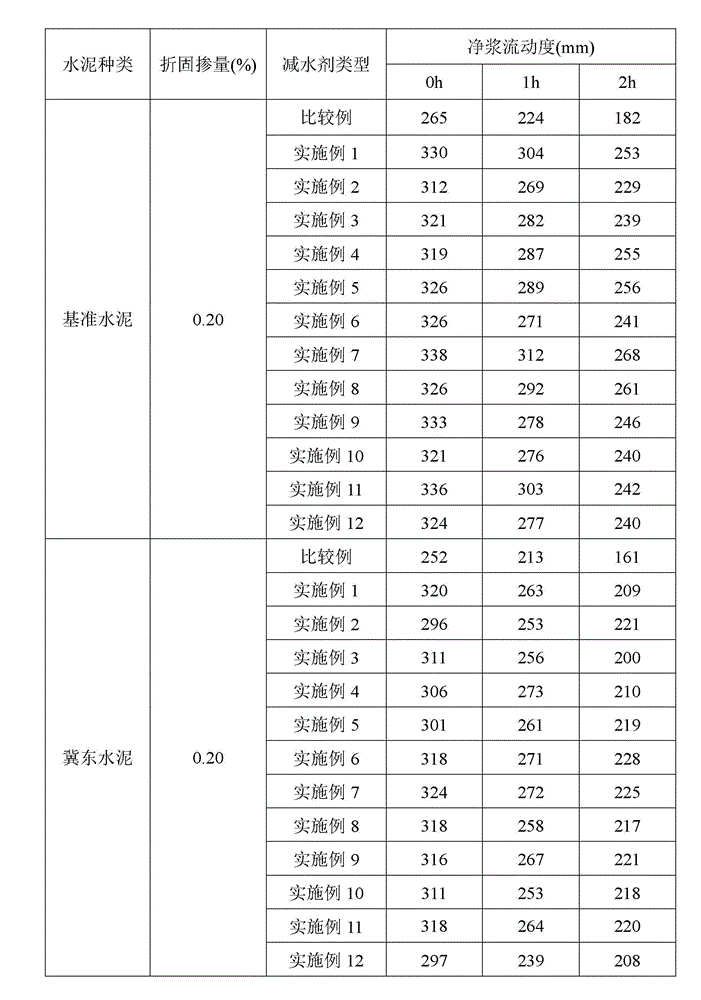

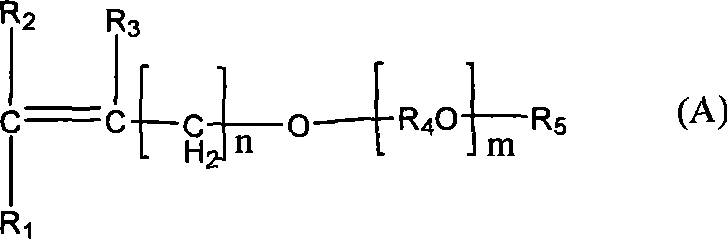

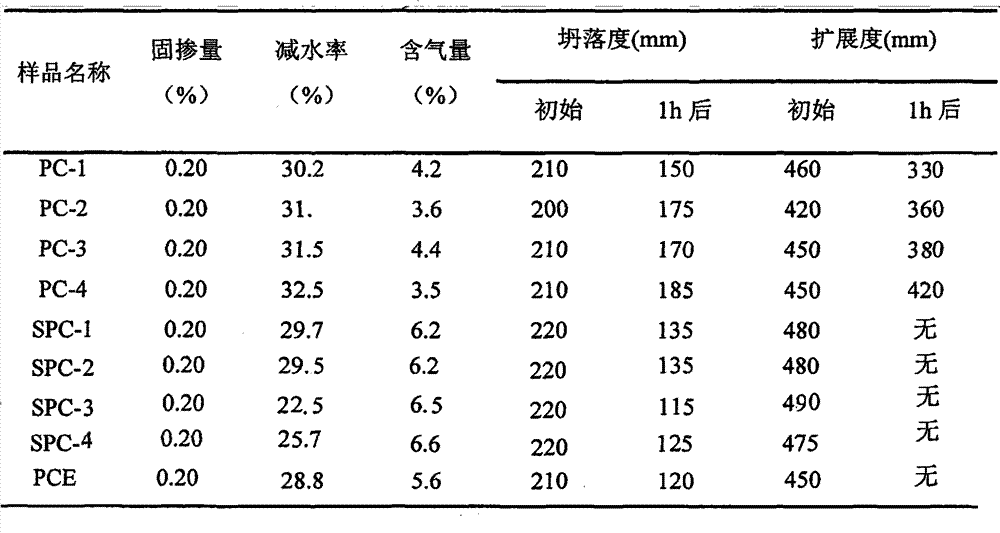

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

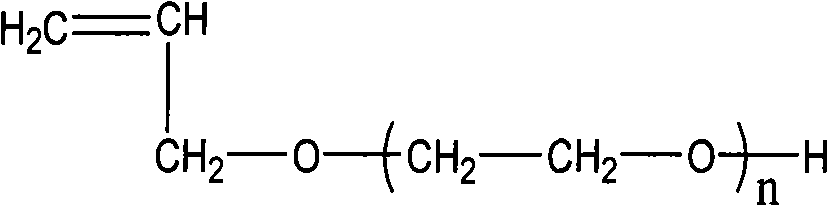

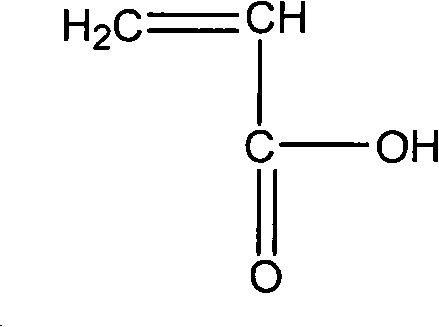

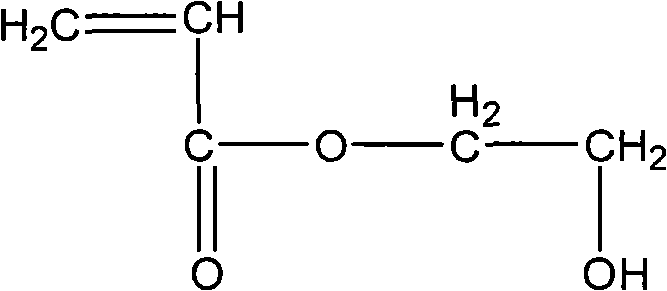

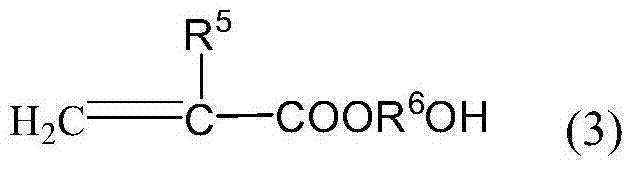

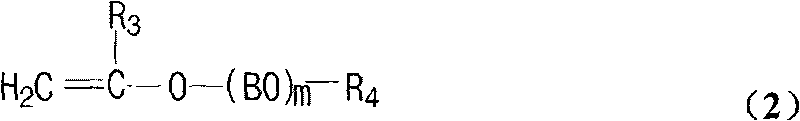

Ethers polycarboxylic acid water reducing agent and preparation

The invention discloses an ether polycarboxylic water reducing agent which is obtained through water solution copolymerization of three types of monomers of 10-70 percent of allyl polyxyethylated alcohol ether, 20-70 percent of acrylic acid and 10-30 percent of hydroxy-ethyl acrylate. Due to the introduction of hydroxy-ethyl acrylate, the ether polycarboxylic water reducing agent reduces the self-polymerization proportion of the acrylic acid, improves the copolymerization proportion, and greatly reduces the cost of the raw materials; in addition, the molecular weight of the polymer is controllable, the water reduction rate is high, the loss of slump constant with the time is low, and the prepared concrete has high fluidity, good workability, and enough early strength in the beginning of hardening. Besides, the preparation technique of the ether polycarboxylic water reducing agent is a one-step method, the operation is simple, the reaction conditions are easy to control, the production period is short, and the ether polycarboxylic water reducing agent is green and environment-friendly, has low cost and is applicable to industrial production on large scale.

Owner:杭州传化建筑新材料有限公司

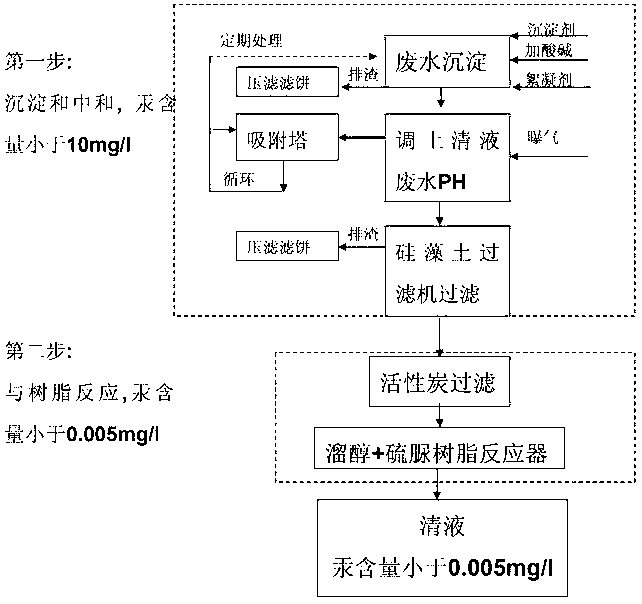

Method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through two-step process

InactiveCN102936070AEnsuring a circular economyImprove processing efficiencyMultistage water/sewage treatmentNature of treatment waterSlagGas phase

The invention discloses a method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through a two-step process. The method comprises the following steps of: firstly, completing primary removal of mercury, copper, ferrous and ferric iron, cadmium, zinc, manganese, lead and suspending impurities of above 10mg / l by using a precipitator and a flocculating agent, regulating PH to 6-8 and then adding the flocculating agent and stirring for 30 minutes, standing for above 1 hour, discharging slag and aerating, absorbing mercury carried away by a gas phase through a sulfide adsorber, purifying water by using a plate type kieselguhr filter, removing residual suspended matters; and 2, carrying out complete reaction on the mercury in the wastewater by using an active carbon and a mercaptan and thiourea resin combining method again for being removed, and finally reaching the standard that the content of the mercury is less than 0.005mg / l. The treated wastewater can be recycled to salt melting or an acetylene generator, so that zero emission of the treated wastewater is achieved; and the mercury-containing waste acid water of hydrochloric acid desorption in the industry of chlor-alkali can be treated, the consumption of acid is reduced, and the great popularization significance is achieved in the industry of chlor-alkali.

Owner:赵建军

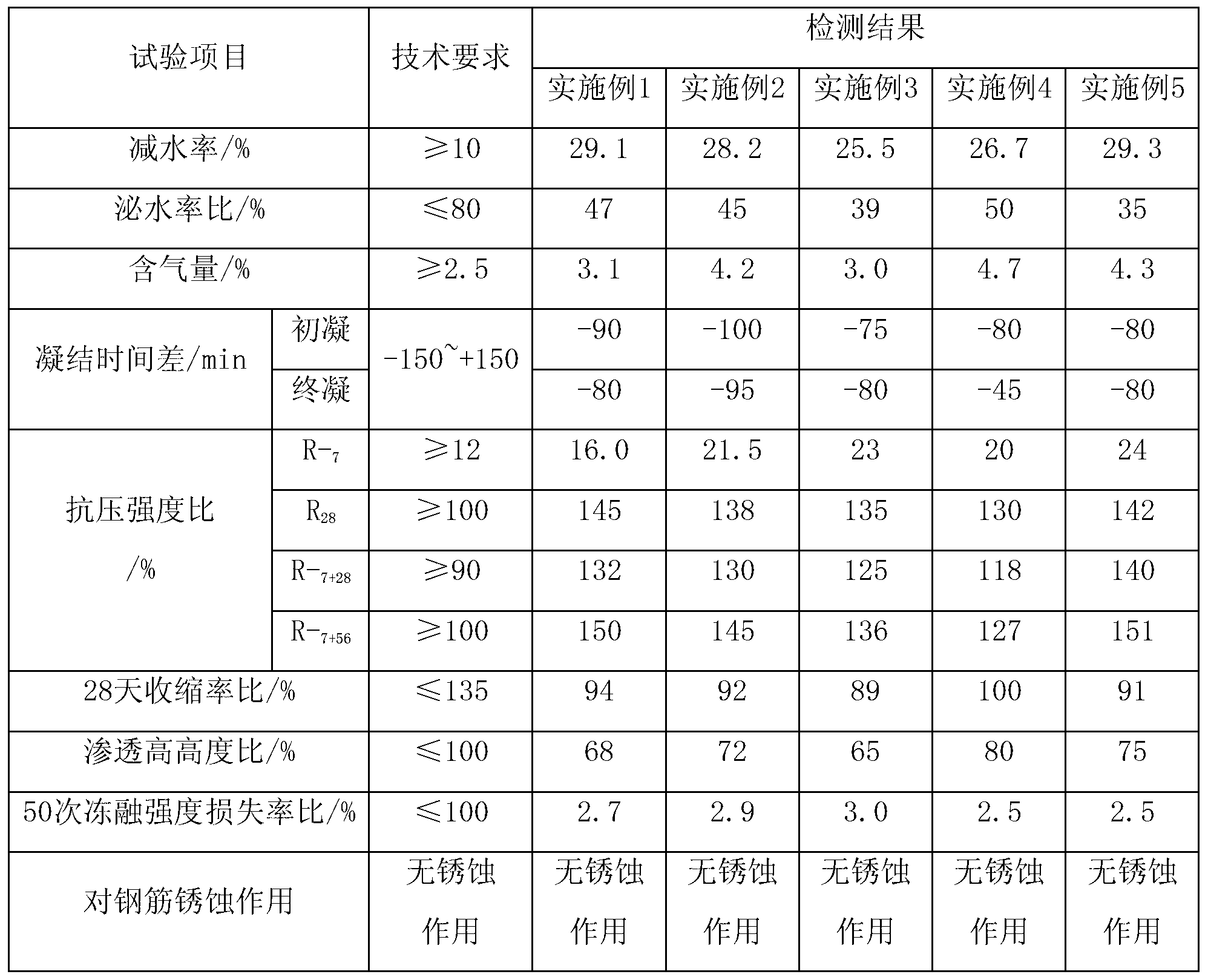

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

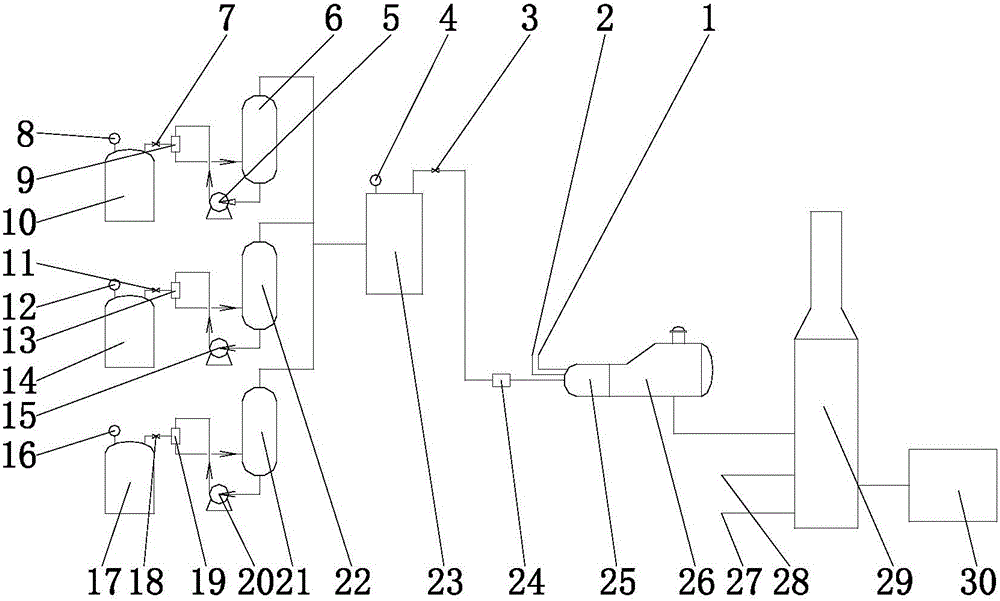

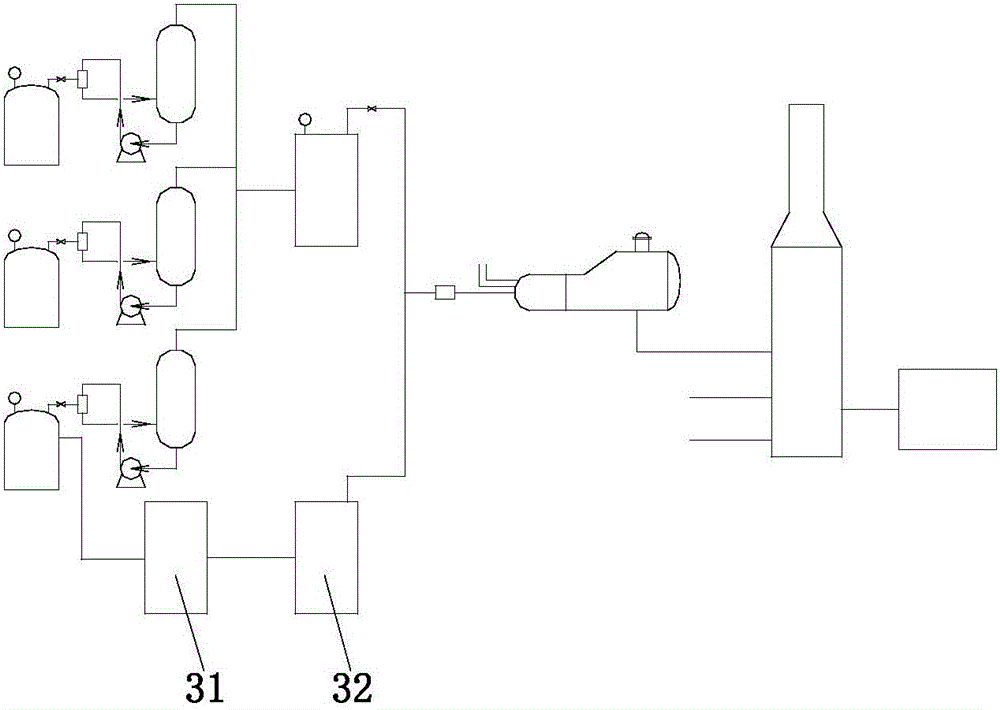

Integrated treatment method for malodorous VOCs gas of refining devices

InactiveCN105841168AReduce dosageSimple processDispersed particle separationIncinerator apparatusLiquid jetBurn units

The invention discloses an integrated treatment method for unorganized emission of malodorous VOCs gas from refining and chemical equipment, which collects VOCs gas emitted from refining and chemical storage tanks including residual oil tanks, intermediate product tanks, and acid water tanks. The VOCs gas outlet of the tank is connected to the injection fluid inlet of the liquid jet vacuum pump; the working fluid inlet of the liquid jet vacuum pump is connected to the outlet of the circulation pump, and the mixed fluid outlet is connected to the gas-liquid separation tank; the inlet of the circulation pump is connected to the The liquid outlet of the gas-liquid separation device is connected; the gas outlet of the gas-liquid separation device is connected with the buffer tank; the inlet of the incineration unit is also fed with combustion-supporting gas and air in addition to the VOCs gas in the gas storage buffer tank. , VOCs gas and malodorous gas are incinerated in the incineration unit, and the incineration temperature is 800-1000°C.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Method for preparing polyacrylonitrile-based carbon fiber protofilament

ActiveCN101165237AEfficient removalGood removal effectArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

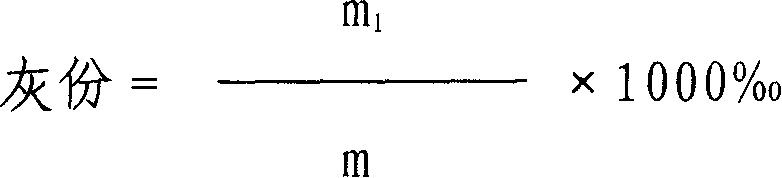

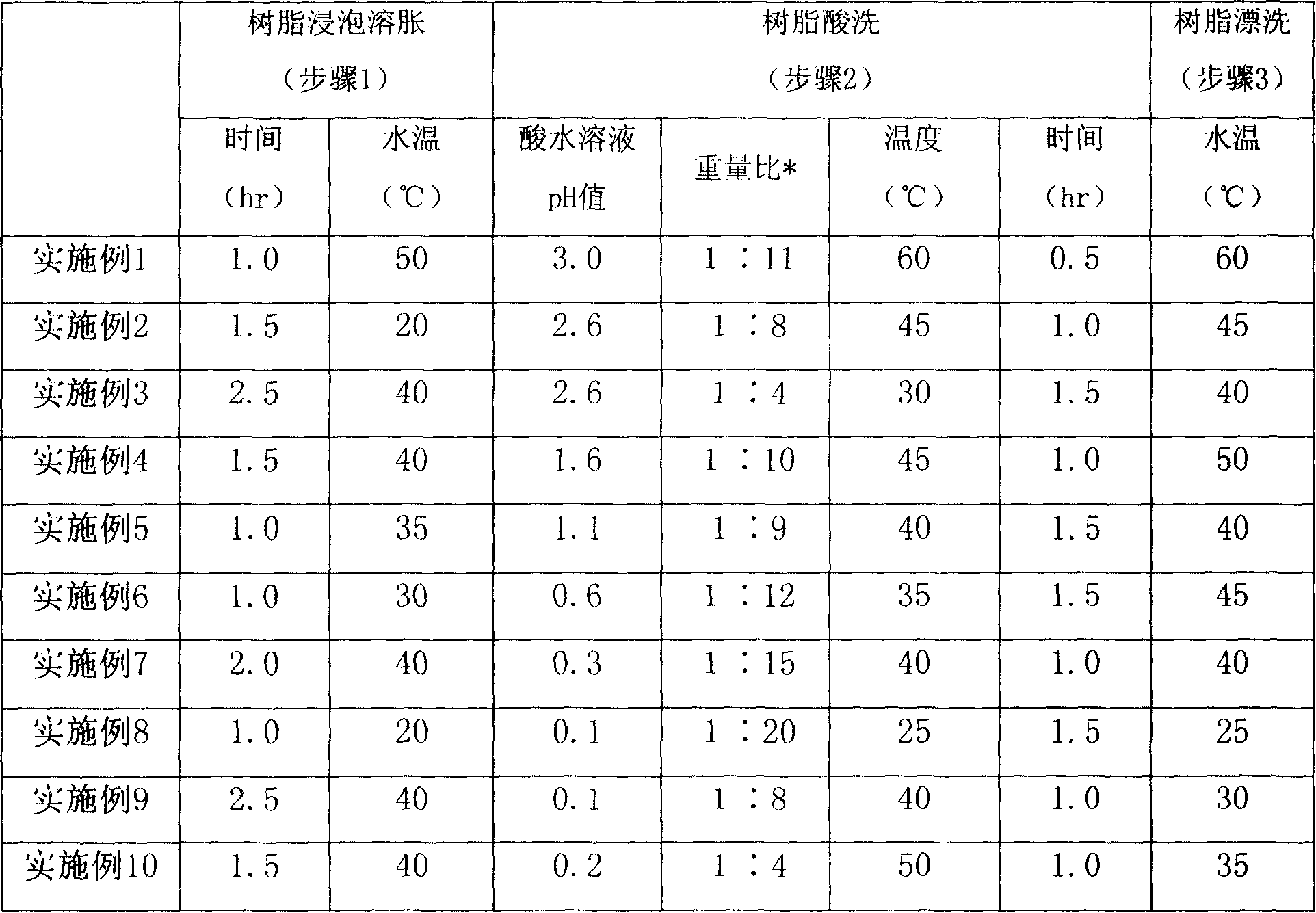

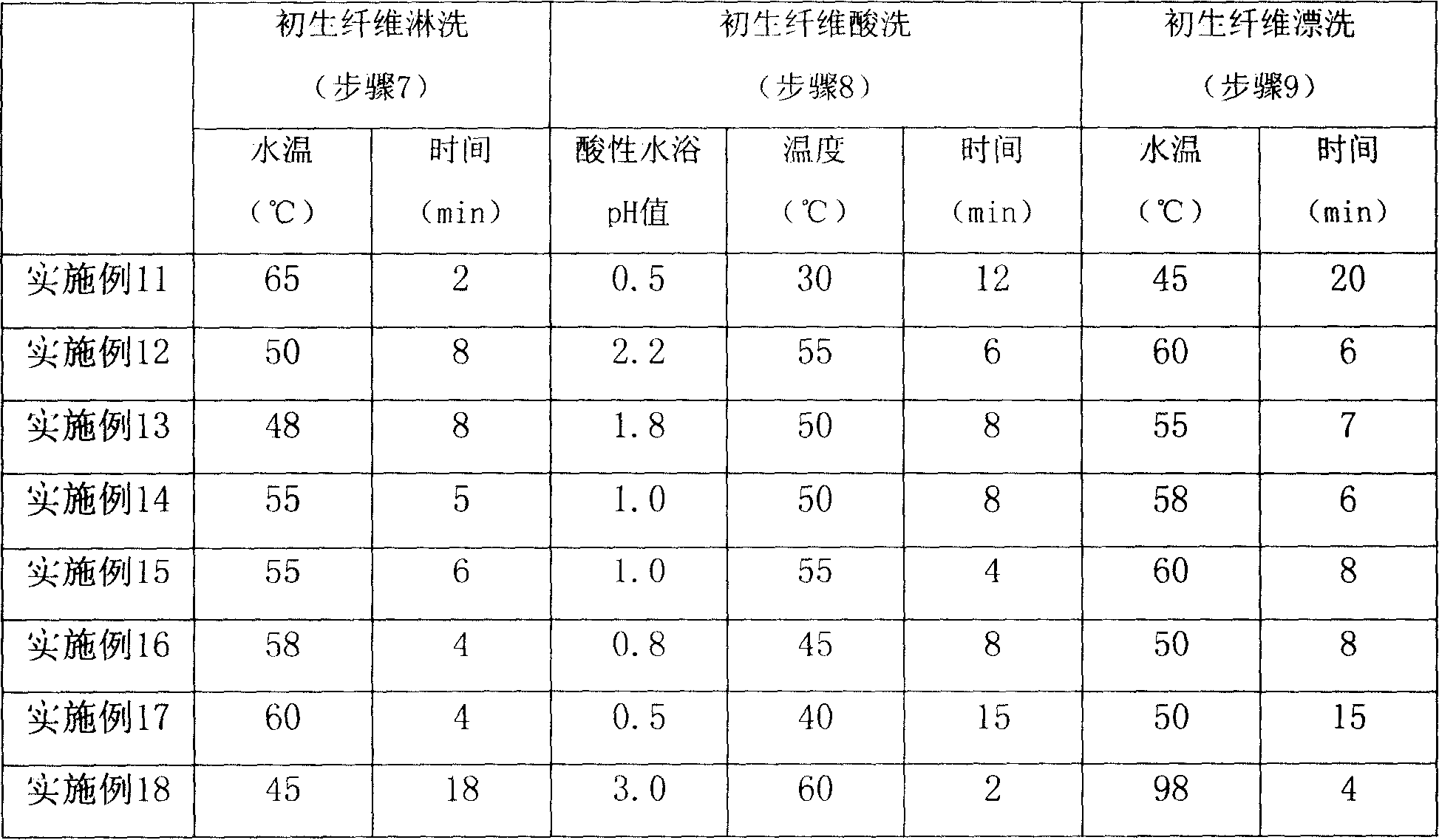

The process of preparing polyacrylonitrile fiber for carbon fiber includes the following steps: soaking resin in deionized water at 20-50 deg.c to swell for 1-2.5 hr; pickling in water solution of nitric acid or hydrochloric acid in pH 0.1-3.0 at 25-60 deg.c for 0.5-1.5 hr; rinsing with deionized water to neutral; dewatering and drying to water content lower than 3 %; dissolving in 35-58 wt% concentration NaSCN aqua to form spinning fluid in resin content of 8-16 wt%; debubbling and spinning to form initial fiber; washing with deionized water, acid aqua and hot water successively; drafting, oiling, drying, densifying, etc to produce polyacrylonitrile fiber for carbon fiber. The polyacrylonitrile fiber product has ash content not higher than 0.01% and alkali metal ion content not higher than 0.005%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

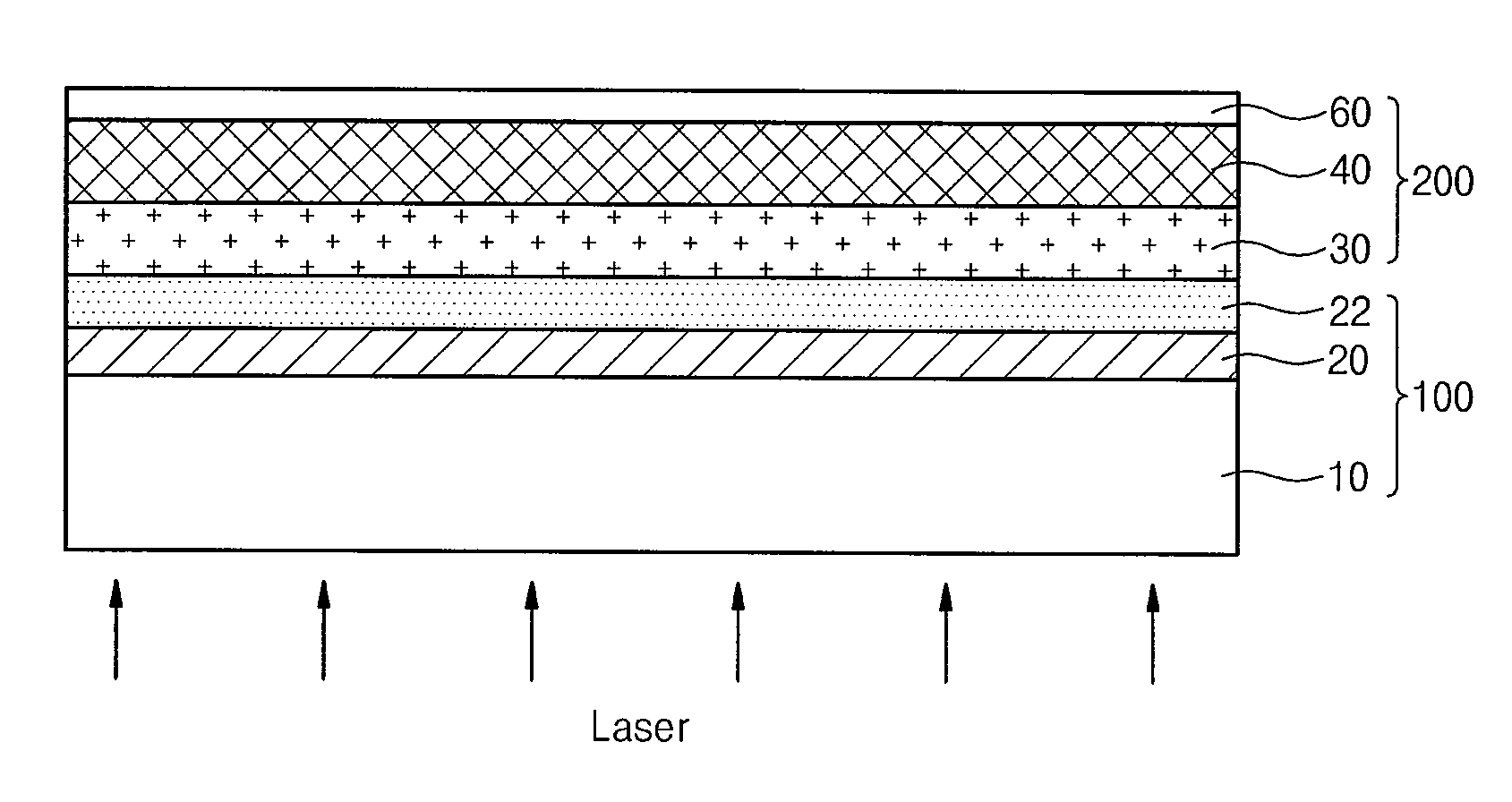

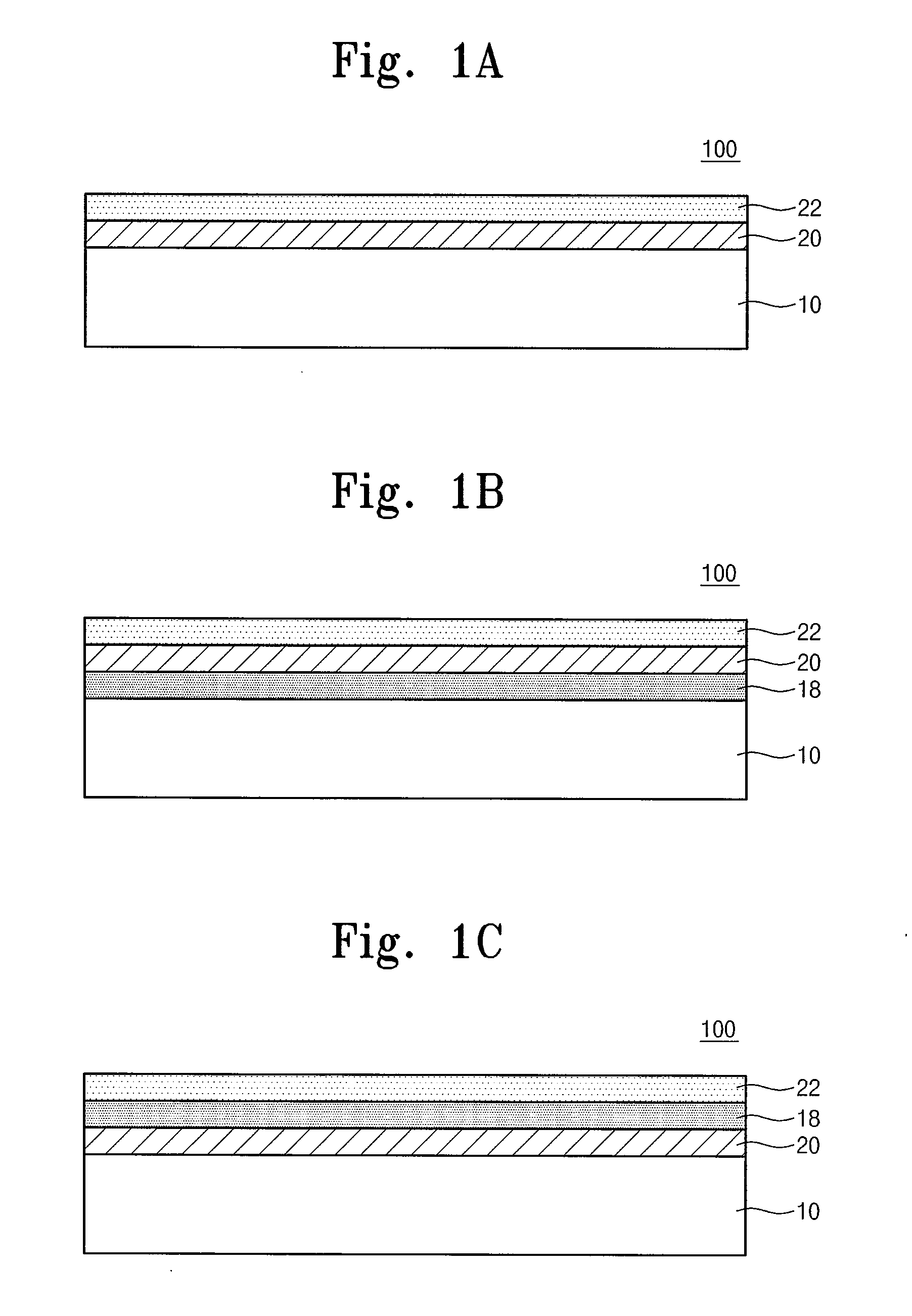

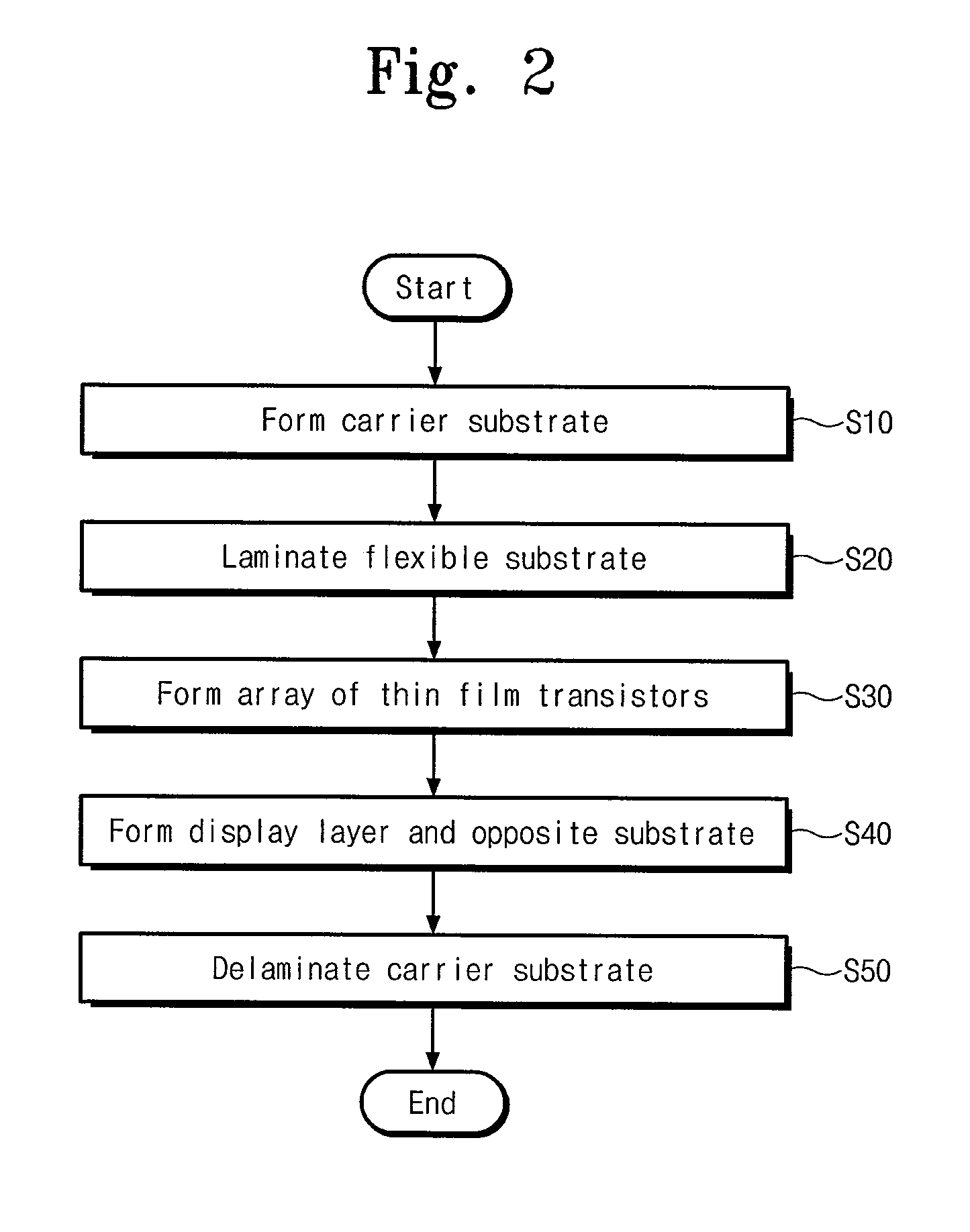

Carrier substrate and method of manufacturing flexible display apparatus using the same

InactiveUS20090261062A1Reduce manufacturing costOptical articlesRecord information storageAlkaline waterAcid water

Disclosed are a carrier substrate which can be recycled and a method of manufacturing a flexible display apparatus using the same. The carrier substrate includes a rigid substrate, an adhesive layer, and a sacrificial layer. The adhesive layer is formed on the rigid substrate and has an adhesive property. The sacrificial layer is interposed between the rigid substrate and the adhesive layer. The sacrificial layer includes a material selected from the group consisting of a transparent metal oxide, an alkaline water-soluble polymer compound, and an acid water-soluble polymer compound.

Owner:SAMSUNG DISPLAY CO LTD

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

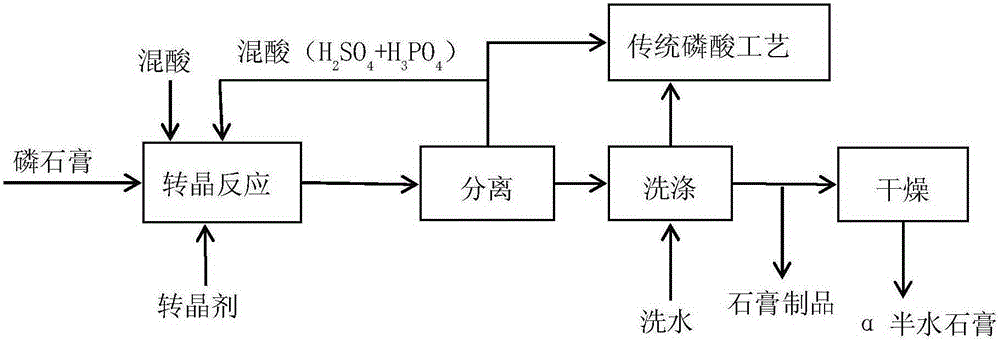

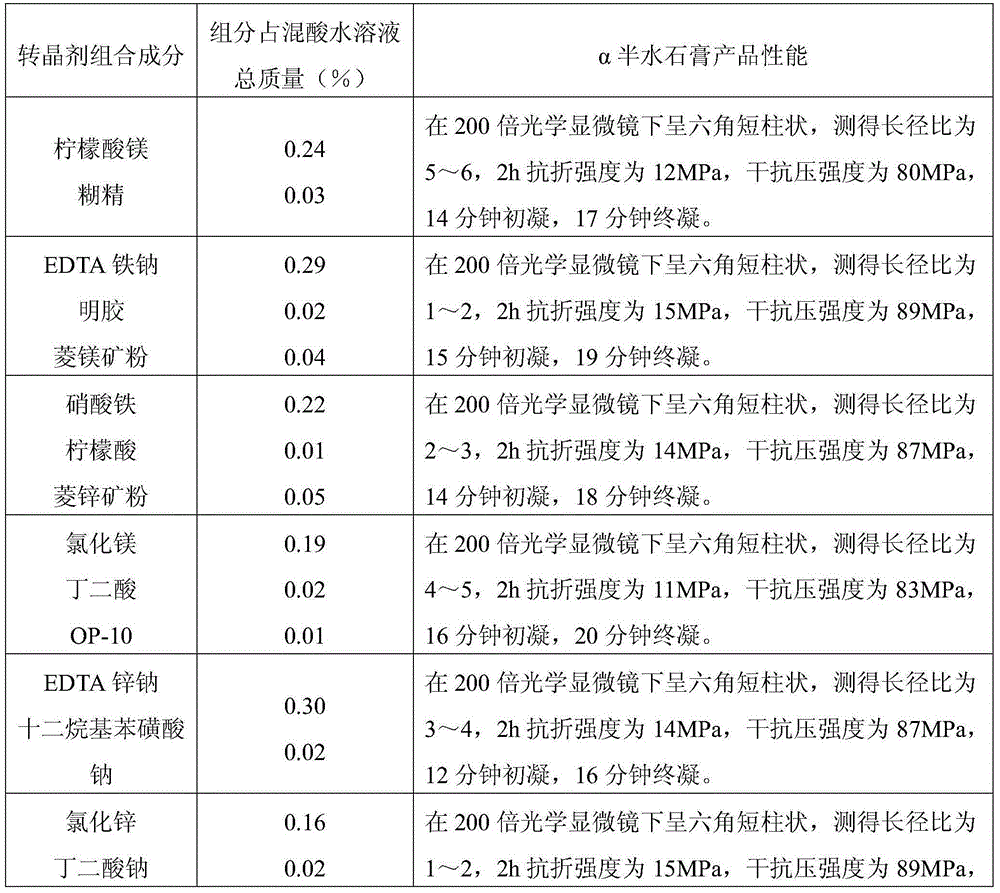

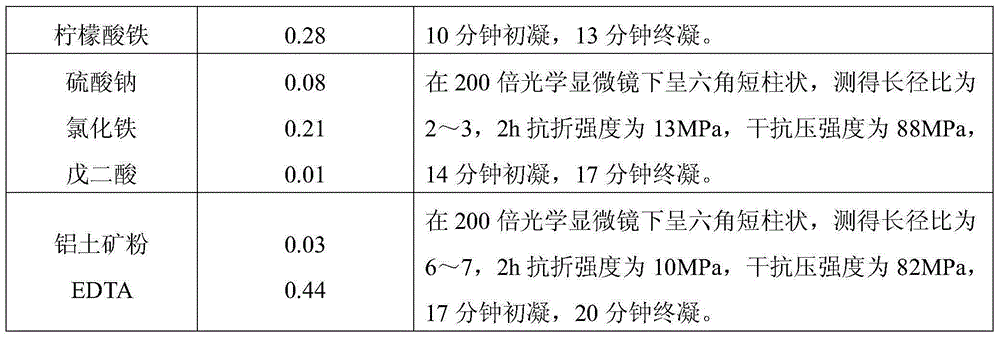

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

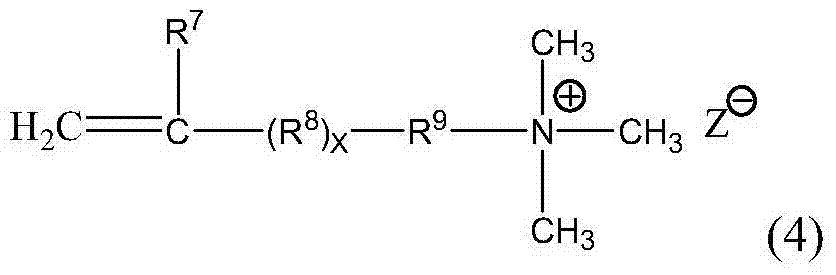

Mud-resistant polycarboxylic acid water-reducing agent and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water-reducing agent and a preparation method thereof. The mud-resistant polycarboxylic acid water-reducing agent disclosed by the invention is prepared by copolymerizing an unsaturated polyalkylene dialcohol ether monomer a, an unsaturated carboxylic acid monomer b, unsaturated acid hydroxyalkyl ester c and an ammonium salt cationic unsaturated monomer d through free radicals under the action of an initiator and a chain transfer agent; and the mol ratio of the monomer a to the monomer b to the monomer c to the monomer d is 1.0:(2.0-4.2):(0.2-1.0):(0.1-0.5). Under the condition that aggregates contain mud, the dispersion effect of the mud-resistant polycarboxylic acid water-reducing agent disclosed by the invention is obviously prior to that of the traditional water-reducing agent; and the mud-resistant polycarboxylic acid water-reducing agent not only has low amount of admixture but also has better keeping property.

Owner:HAISO TECH

Modified ether polycarboxylic acid water reducing agent and preparation method thereof

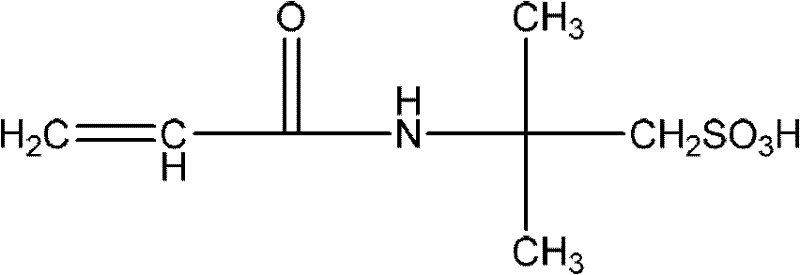

The present invention discloses a modified ether polycarboxylic acid water reducing agent, which is prepared by carrying out free radical induced copolymerization for three monomers, wherein the three monomers comprise 50-95% of methyl allyl polyoxyethylene ether, 4-40% of acrylic and 1-10% of 2-acrylamide-2-methylpro panesulfonic acid (AMPS). With the modified ether polycarboxylic acid water reducing agent of the present invention, the methyl allyl polyoxyethylene ether monomer is introduced, such that the synthesized water reducing agent product has higher water reducing rate and slump loss resistance than the conventional ether polycarboxylic acid water reducing agent; the water reducing rate of the synthesized water reducing agent product is further improved due to the introduced 2-acrylamide-2-methylpro panesulfonic acid (AMPS); the prepared concrete has characteristics of low dosage, high fluidity, low slump time losing, good workability and adequate early strength; with the synthesized water reducing agent, the adaptability of the product to raw materials with different sources is substantially improved.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Permeable crystalline waterproof coating

The invention discloses a permeable crystalline waterproof coating, which is prepared from the following components in percentage by weight: 30 to 65 percent of portland cement, 24 to 36 percent of quartz sand, 5 to 16 percent of filler, 1 to 4 percent of calcium ion compound, 1.5 to 4 percent of crystal precipitator, 1.5 to 3 percent of complexing aid, 1 to 3 percent of film forming aid, 0.4 to 1.6 percent of complexing agent, 0.4 to 2 percent of polycarboxylic acid water reducer and 0.2 to 0.4 percent of methylcellulose. The permeable crystalline waterproof coating has good penetration, and can grow insoluble crystals in capillary pores and microcracks on the surface of the concrete to block the capillary pore channels and the microcracks so as to improve the permeability of the concrete and fulfill the aims of resisting water and blocking leakage. The permeable crystalline waterproof coating can be widely applied to anti-permeability and waterproof construction of cellars, tunnels, subways, swimming pools, roof squares, toilets and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

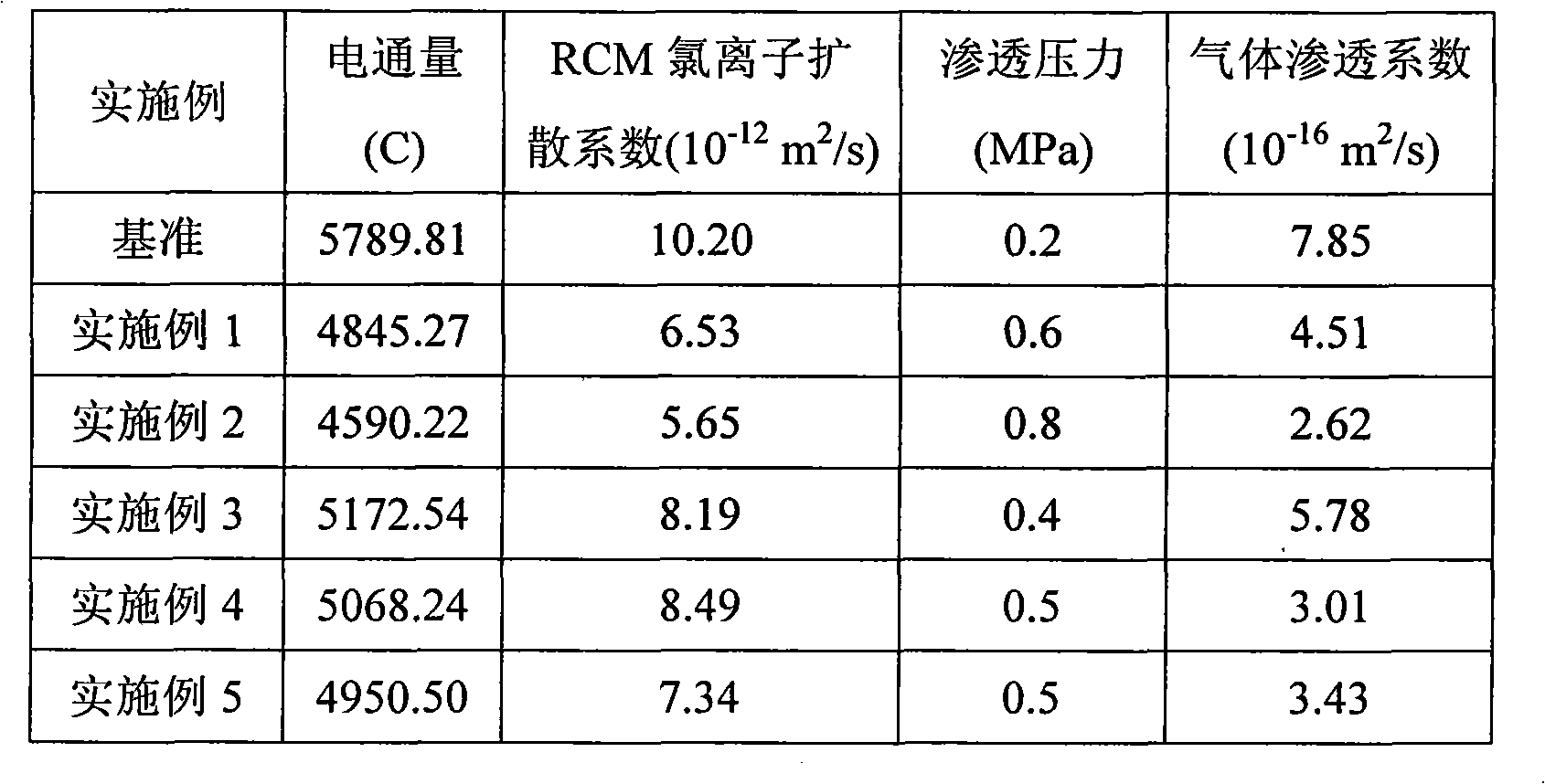

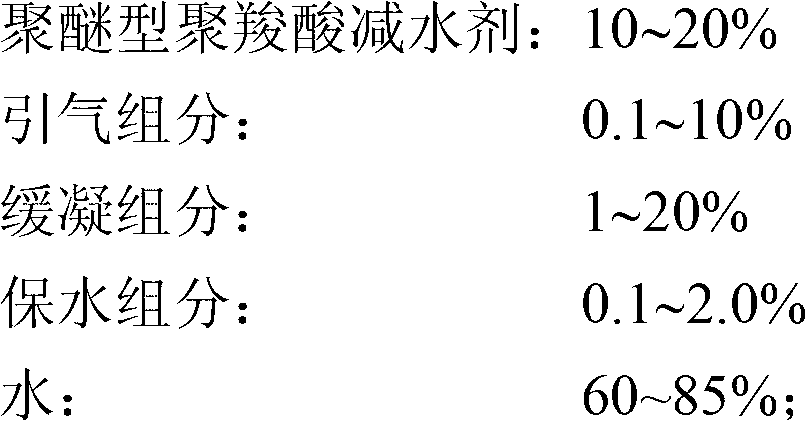

Water-based mortar modifier, its preparation method and application

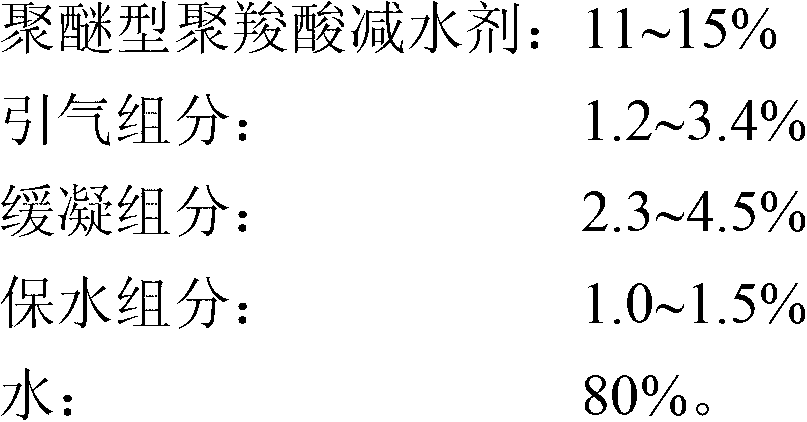

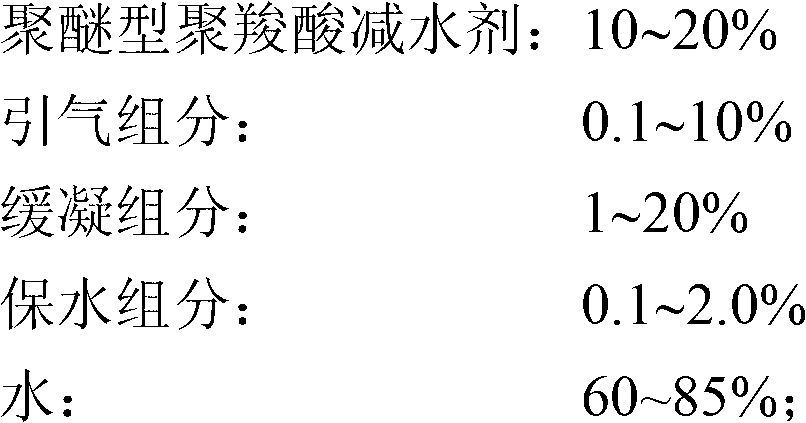

The invention discloses a water-based mortar modifier, its preparation method and application. The modifier comprises the following preparation raw materials by mass: 10-20% of polyether polycarboxylic acid water reducing agent, 0.1-10% of air entraining components, 1-20% of coagulation retarding components, 0.1-2% of water retention components and 60-85% of water. The polyether polycarboxylic acid water reducing agent is prepared by the method of: dissolving an enol polyether macromonomer, acrylic acid, and maleic anhydride in water, conducting heating to raise the temperature to 60-70DEG C, then adding a persulfate water solution dropwisely, carrying out heat preservation under 60-65DEG C for 2-4h, then performing cooling to a temperature of 45DEG C, and adjusting the pH value of the system to 7-8, thus obtaining the polyether polycarboxylic acid water reducing agent. The modifier provided in the invention can form a protective film on a cement particle surface, and at the same time can produce uniform and tiny bubbles, as well as reduce the friction between the particles in the system, thus effectively improving the workability and plasticity of the mortar system. Furthermore, the mortar modifier provided in the invention is a water-based multifunctional building mortar modifier, and is convenient to use. Doping of the modifier can significantly improve the workability and vicidity of mortar, and can maintain the properties effectively for 8-16 hours.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for producing epoxy plasticizer dirty oil and vegetable and animal waste oil

A method for producing epoxy plasticizer from refused animal and vegetable oil is carried out by adding refused oil 97-99.8wt% and porous carrier solid acid 0.2-3wt% into reactor, inducing into gas-phase methanol at 95-130degree, agitating for 1-4hrs, esterification reacting, separating out solid acid, adding liquid 70-80wt%, methanol 15-25wt% and solid alkali catalyst 1-5wt% into reactor, agitating at 50-65degree and normal pressure for 0.5-2hrs, separating out to obtain aliphatic acid methoxy-carbonyl, adding hydrogen peroxide 25-5wt%, methane acid 2.5-10wt% and sodium tripolyphosphate 0-1wt% into aliphatic acid methoxy-carbonyl 55-70wt%, agitating for 8-10hrs at 60+-5degree, reacting, separating out acid water, neutralizing, washing and dewatering to obtain the final product. It's simple, cheap and has less consumption.

Owner:江苏悦达卡特新能源有限公司

Process for treating metal surfaces

ActiveUS20080280046A1Pretreated surfacesMetallic material coating processesHydrofluoric acidAqueous solution

The corrosion resistance of a metal substrate surface treated with an acidic aqueous composition to form a conversion coating is improved by first contacting the surface with an oxidizing acidic pre-rinse, such as an aqueous solution of nitric acid and hydrogen peroxide, or nitric acid and hydrofluoric acid, or Fe+3 cations and hydrofluoric acid.

Owner:HENKEL KGAA

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

Method for synthesizing polycarboxylic acid high-property water reducer by copolymerization of amidated active monomers

InactiveCN102181020AReduce dependenceEnrich the means of synthesizing polycarboxylate high-performance water reducerCarboxylic acidControllability

The invention discloses a method for synthesizing polycarboxylic acid high-property water reducer by copolymerization of amidated active monomers, belonging to the field of water reducer. In the invention, the polycarboxylic acid high-property water reducer material is prepared by a method of first amidation and second copolymerization, namely, taking a (methyl) acrylic monomer and methoxyl polyoxyethylene ether with the other end containing amino as reactant, preparing a polymerizable monomer by amidation reaction under the action of catalyst, then copolymerizing the polymerizable monomer with the (methyl) acrylic monomer and a chain transfer monomer in water solution under the action of initiator, and then neutralizing with alkaline solution, thus preparing the polycarboxylic acid high-property water reducer. The method is low in cost, environment-friendly and free from pollution and achieves high polymerization degree and strong controllability; by copolymerization of amidated active monomer, an amide structure is introduced into the molecular structure of polycarboxylic acid water reducer, cement can obtain good flowing property, the flowing capacity maintaining capability of neat cement paste is improved obviously, excellent cement adaptivity is shown, and excellent flowing effect can be obtained under low doping quantity and low water-ash ratio.

Owner:BEIJING UNIV OF TECH

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Water-plastic retaining polycarboxylic acid water reducer and method for preparing same

The invention provides water-plastic retaining polycarboxylic acid water reducer and a method for preparing same, belonging to the technical field of the cement dispersant. The water-plastic retaining polycarboxylic acid water reducer is characterized by being prepared in nature through copolymerizing a big water-plastic retaining monomer and a small water-plastic retaining monomer, wherein the big water-plastic retaining monomer is prepared by mixing a big ester monomer with a small ester monomer. Prepared from the big water-plastic retaining monomer, the water-plastic retaining polycarboxylic acid water reducer can well retain the water and the plastic of concrete which is prepared through stirring different cement and different aggregate, and the ubiquitous problems of the segregation due to water bleeding and the quick slump loss are effectively solved. The water is used as solvent for the polymerization reaction, which is good for the industrial production and ensures the safe and environmental-friendly production process.

Owner:山东华伟银凯建材科技股份有限公司

Polycarboxylic acid water reducing agent

The invention discloses a polycarboxylic acid water reducing agent which is prepared by copolymerizing 10-25 wt% of monomer A, 50-65 wt% of monomer B, 1-10 wt% of monomer C and 21-30 wt% of monomer D in a 50-100 DEG C water solution in the presence of an initiator and a chain-transfer agent, wherein the sum of the weight percents of the monomers A, B, C and D is 100%; the monomer A is unsaturated polyether; the monomer B is unsaturated acid, unsaturated acid anhydride or mixture thereof; the monomer C is unsaturated siloxane; and the monomer D is a unsaturated monomer with double bond, excluding the monomers A, B and C. When being used in mortar or concrete, the water reducing agent has the advantages of high water reducing rate, high slump holding capacity and low gas content.

Owner:北京慕湖新材料技术有限公司

Watersoluble fluor resin non-stick paint and manufacture method thereof

InactiveCN101245209AHigh hardnessGood temperature distribution areaSpecial surfacesEmulsion paintsWater basedPerfluorooctanoic acid

The invention relates to a waterborne fluororesin nonstick coating, which is formed by 40 to 70 portions of modified polyte-trafluoroethylene (PTFE) water base resin, 10 to 30 portions of high temperature resistance pigment, 1 to 5 portions of fluororesin additive, 1 to 5 portions of surfactant and 20 to 40 portions of antiwear filler. The waterborne fluororesin nonstick coating uses synthesis propylene acid water base resin for modifying trafluoroethylene PTFE water base resin, adopts acrylic acid fat second polymerization method and does not use an addition agent, the entire fluorine caprylate compound which is harmful to human body in the modification process; the modified resin forms mosaic and perforating network structure, has good temperature dispersing region, solves the problem of the adhesiveness of the coating and the base material and the problems of baking and cracking, thus improving the hardness of nonstick coating. The NU aqueous fluorine resin of the invention does not stick to coating, can be coated on the surfaces of a microwave oven, an electric cooker, a nonstick pan and an electromagnetic pan, etc. to play the roles of protecting the surfaces from being stuck with food, and causing food and aluminum and other metals to be isolated.

Owner:TIANJIN COLOROAD COATING & CHEM

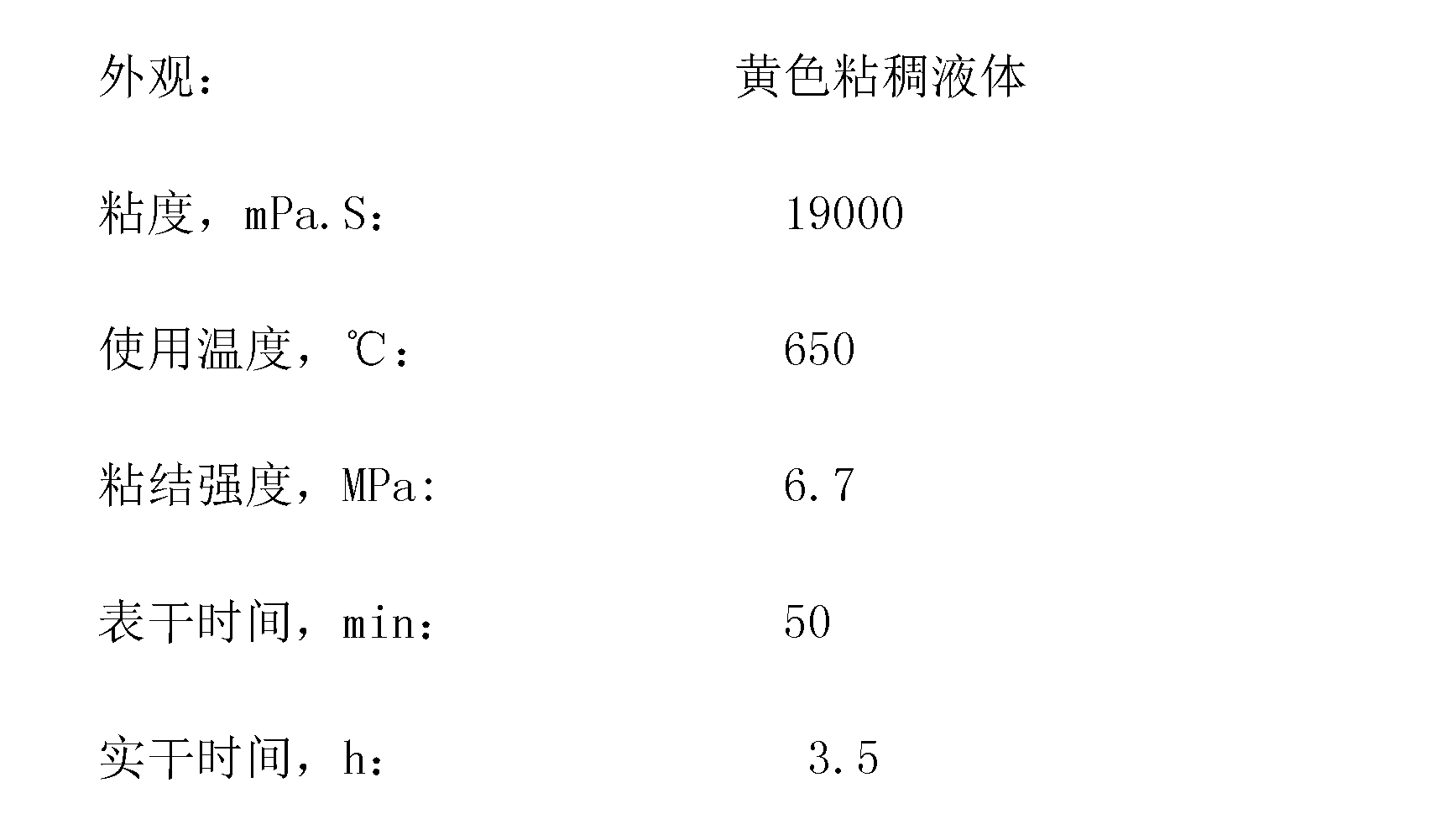

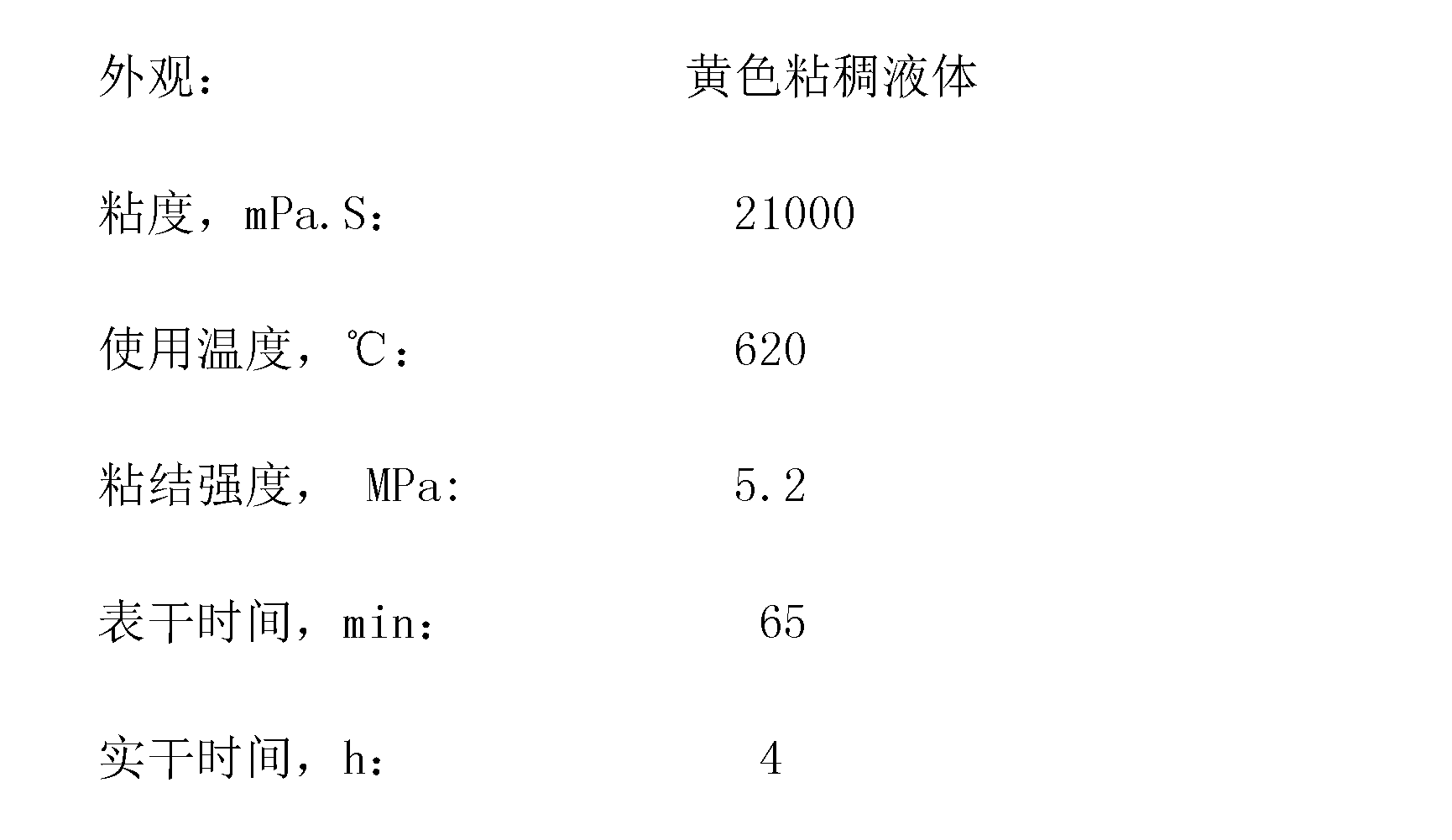

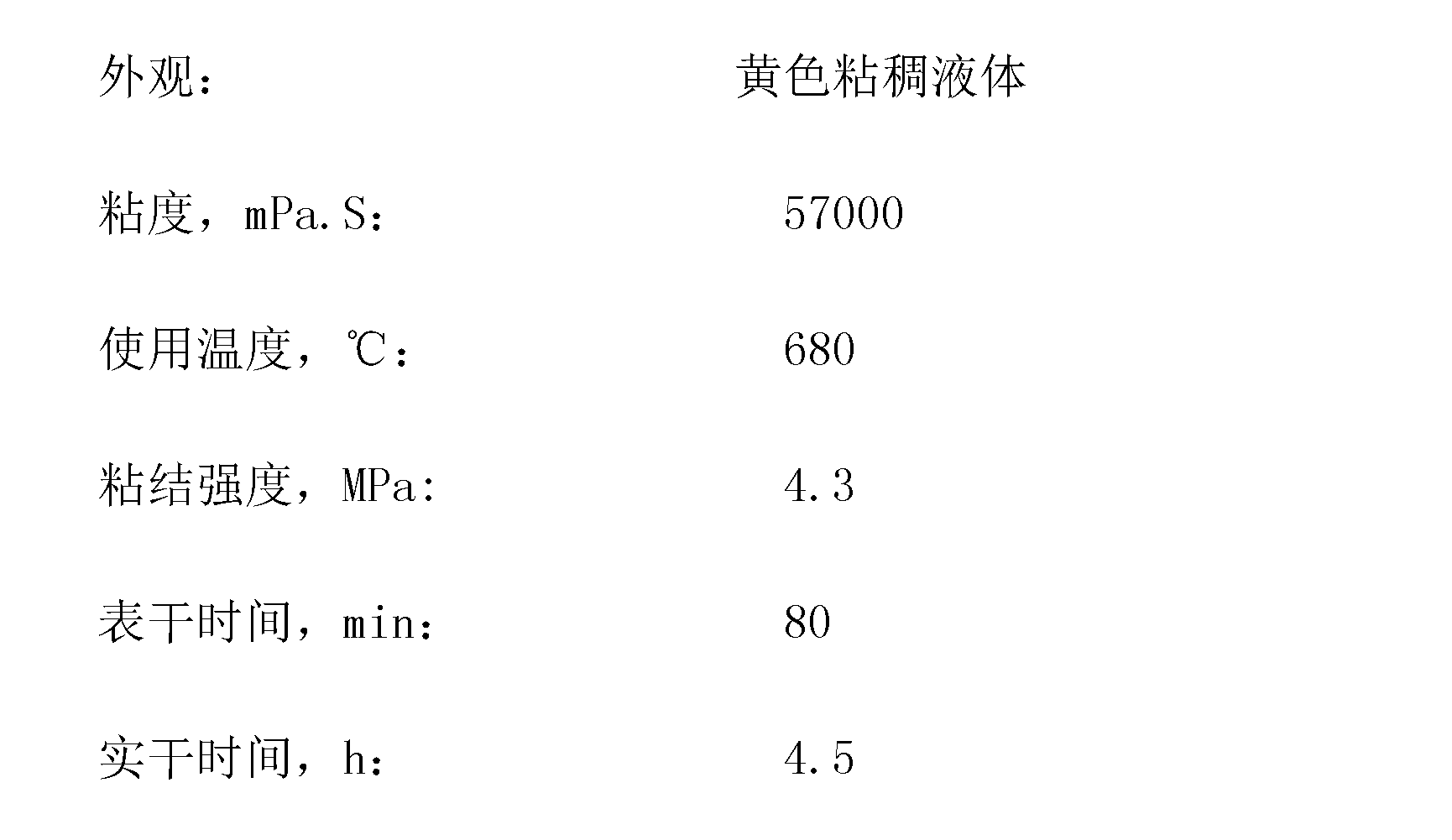

Borosiloxane and preparation method thereof

The invention relates to borosiloxane and a preparation method thereof. According to the method, a hydrolysis solvent and a boron compound are mixed proportionally and added to a reactor, the temperature keeps from 10 DEG C to 35 DEG C, and a mixed monomer is slowly dropwise added under the stirring condition for a hydrolysis reaction; the dropwise-adding time is controlled in 3-6 hours, the reactor is slowly heated to the temperature ranging from 55 DEG C to 65 DEG C after the dropwise-adding is finished, a stirring reaction is performed for 1 hour, and still standing is performed; acid water on the lower layer is separated and neutralized to be neutral, a saturated NaCl solution is used for washing, and an oil phase material is obtained; reduced pressure distillation is performed to remove the solvent, a catalyst I is added, the mixture is heated to 110-130 DEG C, and the rearrangement reaction is performed for 3-5 hours; the mixture is heated to 150-160 DEG C, the splitting cyclization reaction is performed for 2-5 hours, the reaction is finished, the mixture is cooled, and a polyborosiloxane prepolymer is obtained; an end-capping reagent and a catalyst II are added to a system and heated to 110-130 DEG C, and react for 2-4 hours; and pressure is reduced to remove a low-boiling-point substance, and a polyborosiloxane resin is obtained. The borosiloxane and the preparation method have the advantages of good temperature resistance, ageing resistance, impact resistance, toughness and low-temperature flexibility, high adhesion and the like.

Owner:上海爱世博有机硅材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com