Mud-resistant polycarboxylic acid water-reducing agent and preparation method thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixture preparation, can solve the problems of reducing the dispersion and retention effect of traditional water reducers, and achieve the effects of inhibiting the adverse effects of soil, reducing adsorption, and inhibiting adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

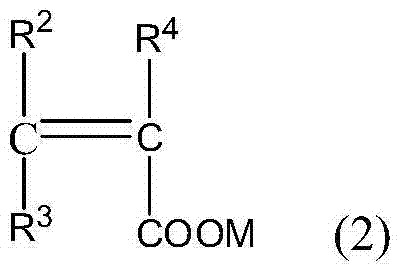

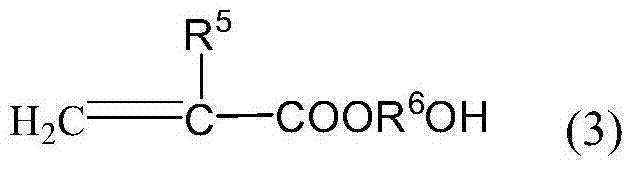

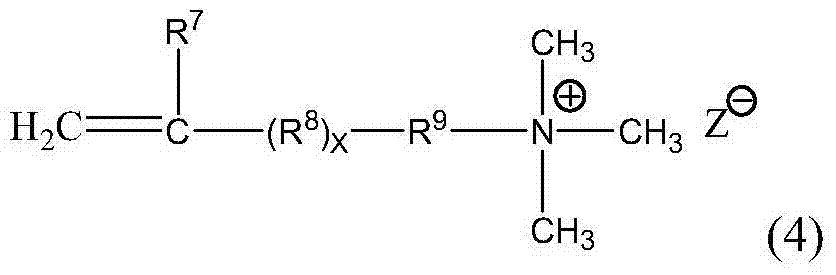

Method used

Image

Examples

Embodiment 1

[0042] Add 99.0g water, 240.0g (0.1mol) methallyl polyoxyethylene ether (average molecular weight 2400), 13.6g 50 % (0.05mol) of allyltrimethylammonium chloride aqueous solution, stirred and heated to 80°C. An aqueous solution obtained by dissolving 30.2 g (0.42 mol) of acrylic acid and 2.3 g (0.02 mol) of hydroxyethyl acrylate in 8.1 g of water was added dropwise within 2 h. While adding the monomer solution of acrylic acid and hydroxyethyl acrylate dropwise, an aqueous solution obtained by dissolving 1.04 g of mercaptopropionic acid and 4.47 g of ammonium persulfate in 104.7 g of water was added dropwise over 2.5 h. After the dropwise addition, keep warm for 2 hours to complete the polymerization reaction, then cool the reaction mixture, neutralize it with 30wt% NaOH solution to make pH = 6, and add water to adjust the solid content to 40wt%, that is, the mud-resistant polycarboxylate water reducer HSPC- KN1.

Embodiment 2

[0044] Add 99.3g water, 240.0g (0.1mol) 3-methyl 3-butene-1-alcohol polyoxyethylene ether (average Molecular weight 2400), 12.5g of 50% (0.03mol) 2-(methacryloyloxy) ethyltrimethylammonium chloride aqueous solution, stirred and heated up to 60°C, added 1.38g of 30% H 2 o 2 solution. An aqueous solution obtained by dissolving 23.0 (0.32 mol) of acrylic acid and 6.5 g (0.05 mol) of hydroxypropyl acrylate in 7.4 g of water was added dropwise within 2.5 h. While adding the monomer solution of acrylic acid and hydroxypropyl acrylate dropwise, an aqueous solution obtained by dissolving 0.89 g of mercaptopropionic acid and 0.53 g of L-ascorbic acid in 27.0 g of water was added dropwise over 3 h. After the dropwise addition, keep warm for 1.5h to complete the polymerization reaction, then cool the reaction mixture, neutralize it with 40wt% NaOH solution to make the pH = 6, and add water to adjust the solid content to 40wt%, that is, the mud-resistant polycarboxylate superplasticizer...

Embodiment 3

[0046] Add 50.0g of water, 120.0g (0.1mol) of allyl polyoxyethylene ether (average molecular weight 1200), 4.1g of 50% (0.01 mol) of (3-acrylamidopropyl) trimethylammonium chloride aqueous solution, stirred and warmed up to 60°C, added 1.64g of 30% H 2 o 2 solution. An aqueous solution obtained by dissolving 14.4 g (0.20 mol) of acrylic acid and 13.0 g (0.10 mol) of hydroxyethyl methacrylate in 6.9 g of water was added dropwise within 0.5 h. While adding the monomer solution of acrylic acid and hydroxyethyl methacrylate dropwise, an aqueous solution obtained by dissolving 1.37 g of thioglycolic acid and 0.60 g of L-ascorbic acid in 37.4 g of water was added dropwise over 1 h. After the dropwise addition, keep warm for 3 hours to complete the polymerization reaction, then cool the reaction mixture, neutralize it with 40wt% NaOH solution to make pH = 7, and add water to adjust the solid content to 40wt%, that is, the mud-resistant polycarboxylate superplasticizer HSPC- KN3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com