Patents

Literature

1045results about How to "High water reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and preparation method thereof

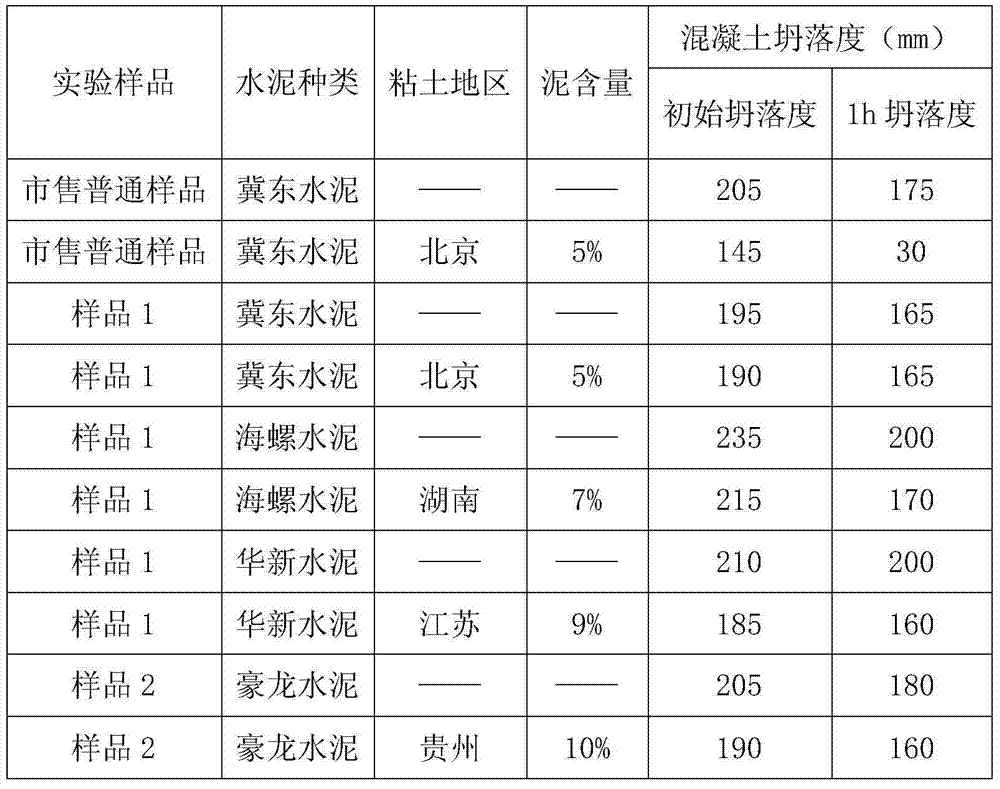

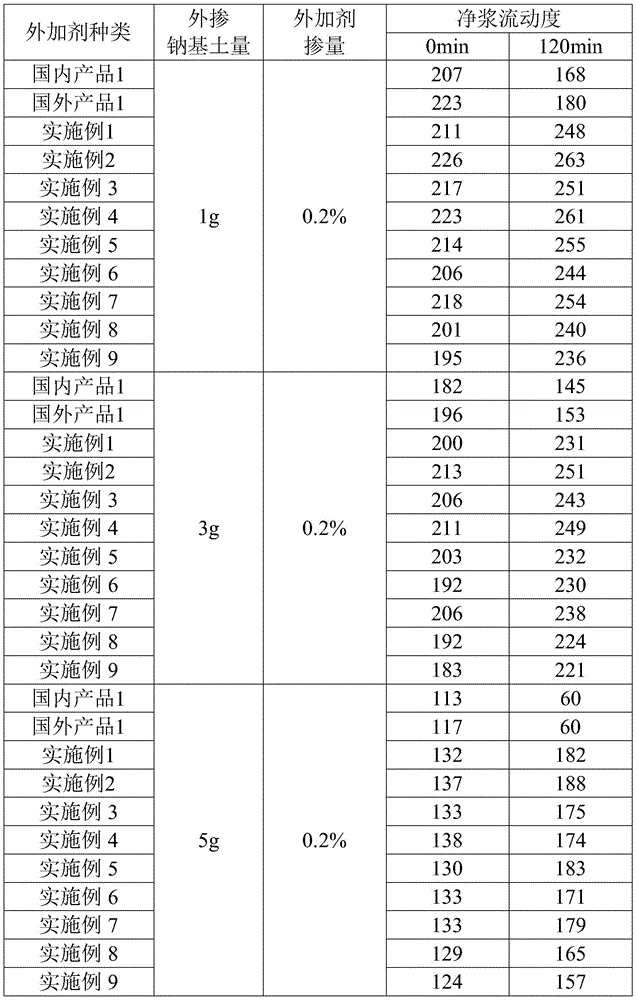

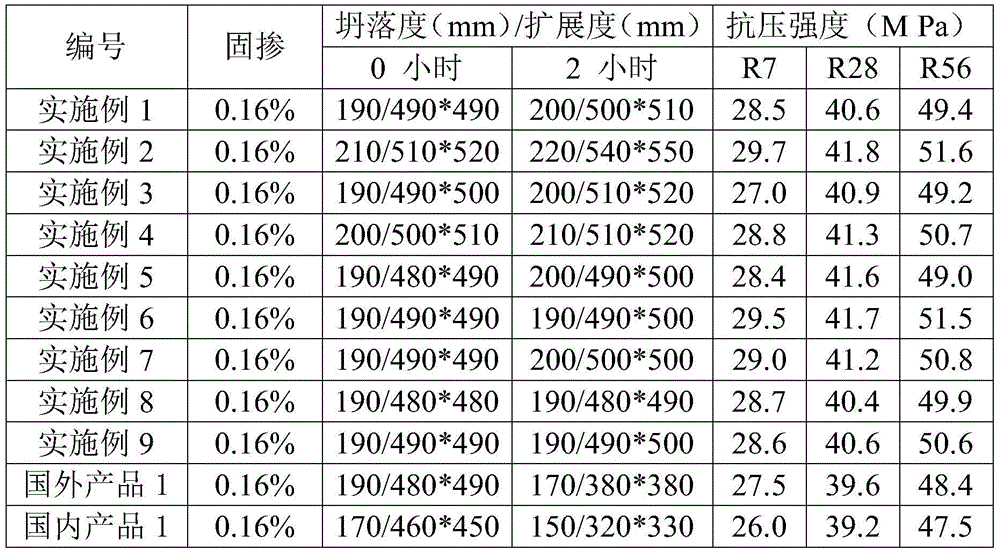

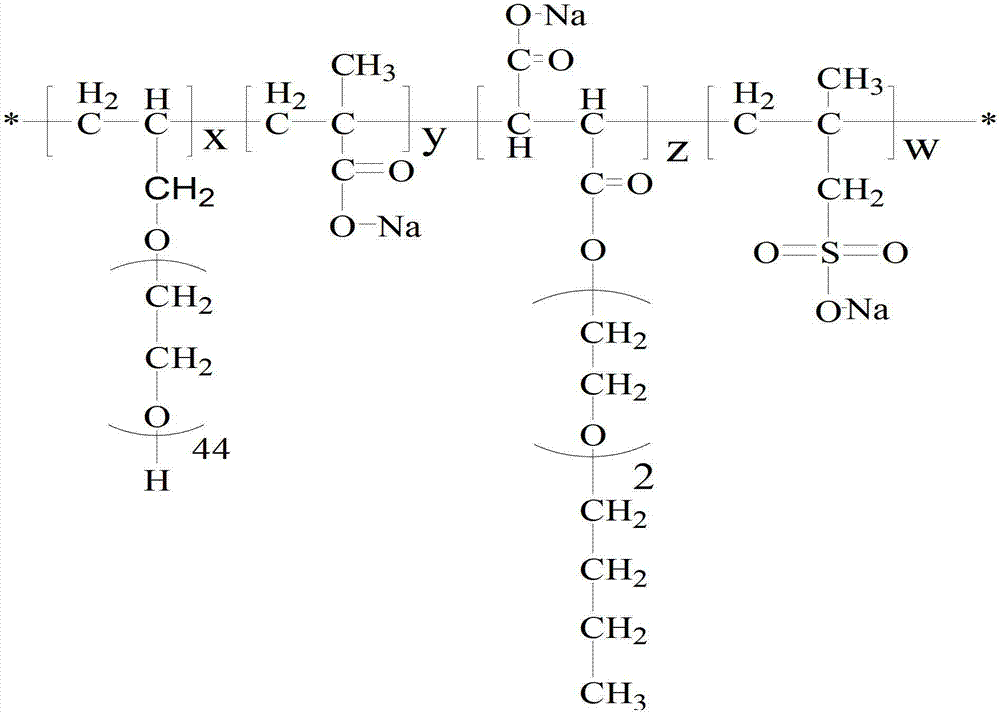

The invention discloses a plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and a preparation method thereof, mainly being applicable to the field of building materials. The water reducing agent is obtained in the following method: with the action of initiating agent, copolymerizing unsaturated polyalkyl ether monomer (A), unsaturated monocarboxylic acid and derivative monomer thereof (B), unsaturated dicarboxylic acid and derivative monomer thereof (C) and unsaturated sulfonic acid or salt monomer (D) in water solution for 2-8h at 50-80 DEG C and then reducing temperature to 35-45 DEG C, using alkaline solution to neutralize the mixture to a pH value of 5-7, thus obtaining the water reducing agent. The synthesized water reducing agent of the invention features changeable molecular structure, high water reducing ratio, high dispersion property under low dosage and fine slumps-retaining property, good adaptability to concrete raw material; in addition concrete with the water reducing agent added enjoys good peaceability; with the one-step method synthesis technology employed, the preparation method has the advantages of simple operation, low energy consumption in production and freedom from pollution.

Owner:CNBM ZHONGYAN TECH

High-early strength antifreezing polycarboxylate high performance water reducing agent and preparation

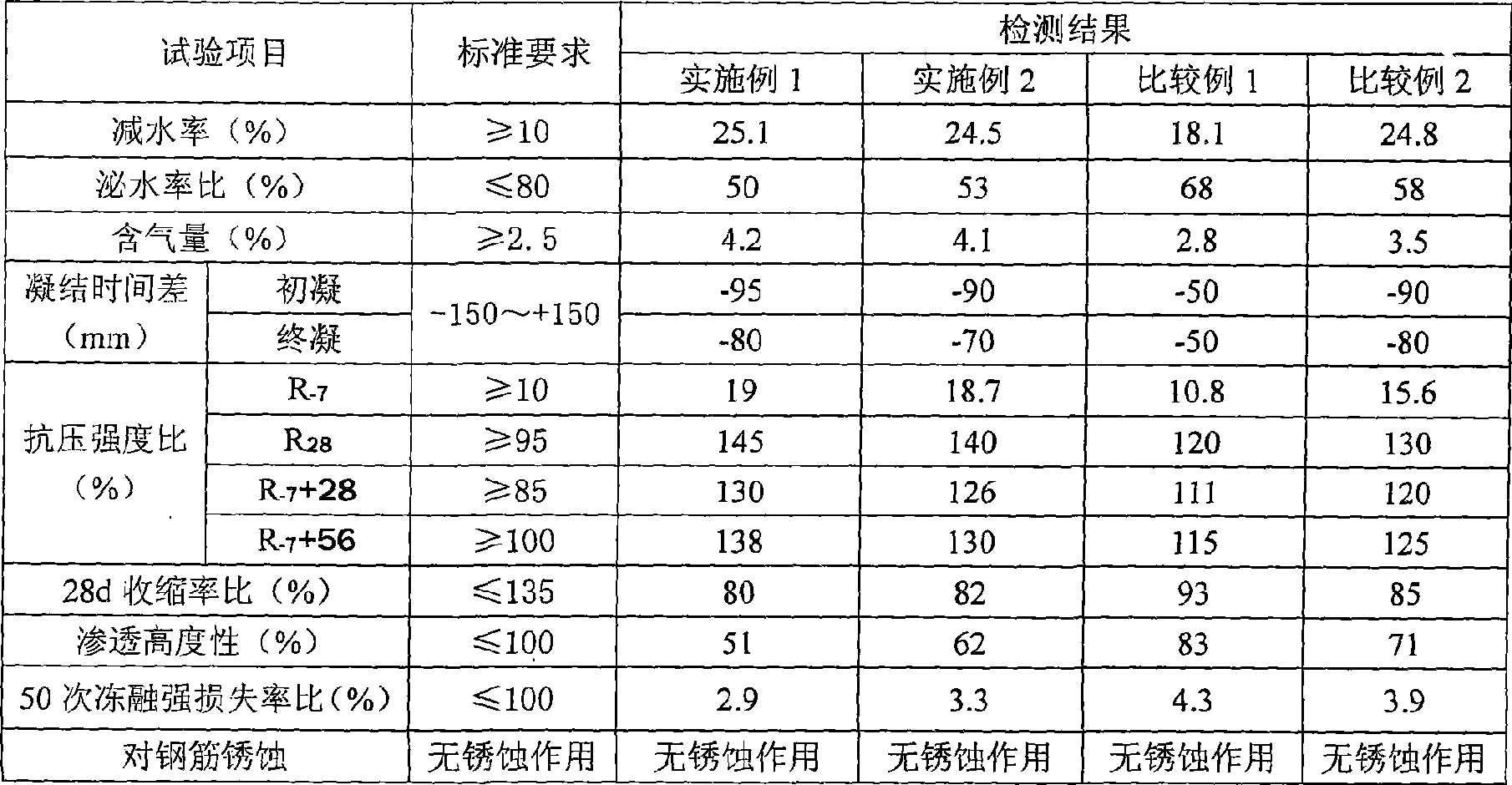

The invention discloses an early-strength antifreezing polycarboxylate high-performance water reducing agent and a method for preparing the same. The early-strength antifreezing water reducing agent is prepared from a polycarboxylate water reducing agent, an early-strength antifreezing agent, an air entraining agent and water. The method comprises the following steps: A, the synthesis of the polycarboxylate high-performance water reducing agent: (1) esterification reaction; adding methacrylic acid, and the like to a reaction kettle, and (2) polymerization reaction; heating big monomer methoxy polyethyleneglycol methacrylic ester; B, the preparation for the solution of an early-strength antifreezing agent: a, weighing water and adding the same to the reaction kettle, and adding calcium formate to the reaction kettle, and b, adding triethanolamine, and the like to the reaction kettle to prepare the early-strength antifreezing agent solution; C, the preparation of the air entraining agent: weighing water and adding the same to the reaction kettle, and adding powdered three-level colophony to the reaction kettle to obtain the air entraining agent; and D, the preparation of the finished product: weighing the polycarboxylate water reducing agent and adding the same to the reaction kettle, and adding the air entraining agent and the early-strength antifreezing agent solution to the reaction kettle. The early-strength antifreezing polycarboxylate high-performance water reducing agent has higher water reducing rate and remarkable enhancing effect, and is suitable to prepare various common concrete and high-performance concrete at a negative temperature range of between 20 DEG C below zero and 0 DEG C.

Owner:武汉市联合石油化工有限责任公司

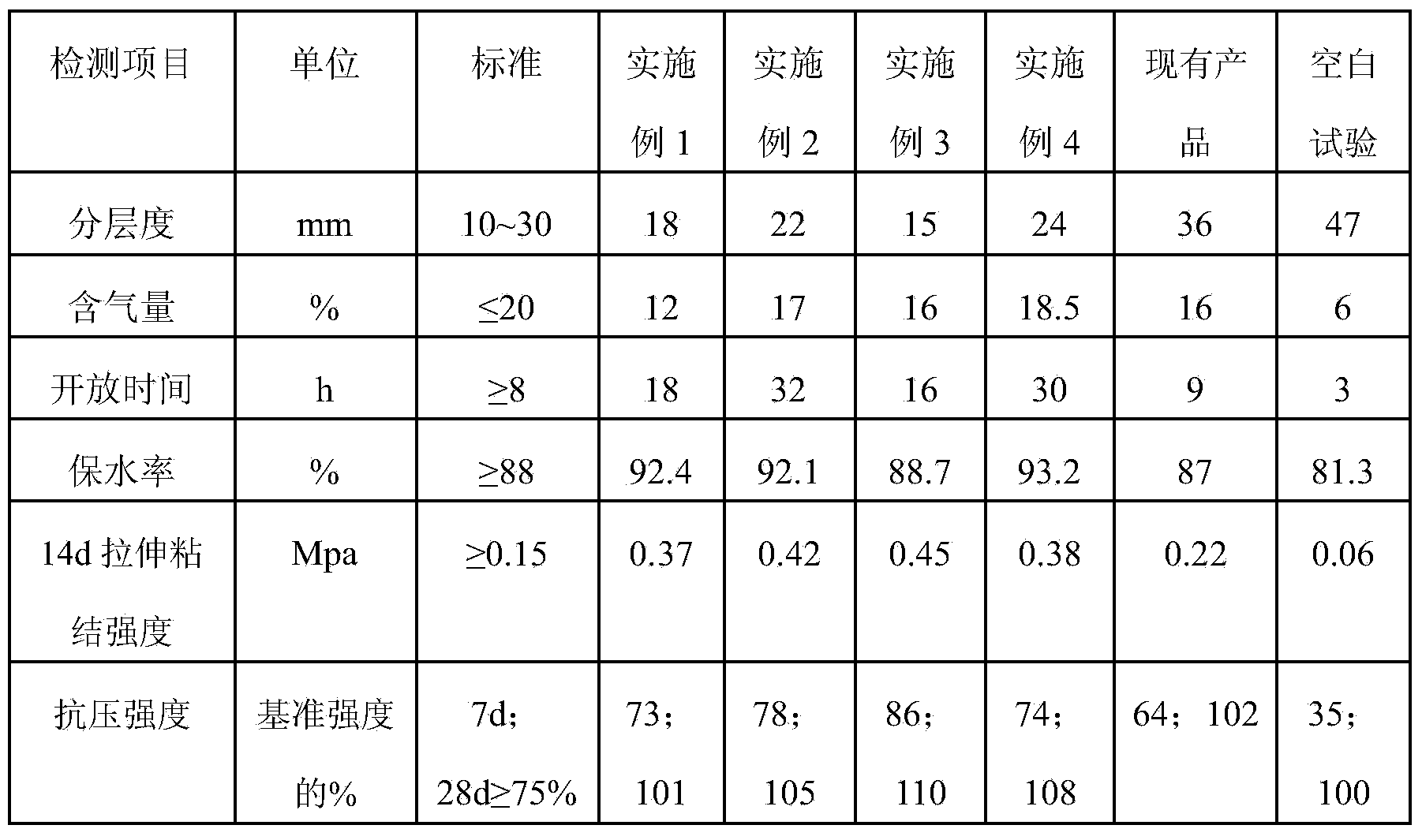

Wet-mixed mortar admixture as well as preparation method and application thereof

ActiveCN104129943AHigh water reduction rateGood material adaptabilityMaterials scienceCompressive strength

The invention relates to a wet-mixed mortar admixture as well as a preparation method and application thereof, and belongs to the technical field of building mortar. For solving technical problems, the invention provides the wet-mixed mortar admixture consisting of a material A and a material B, wherein the material A consists of the following components in percentage by weight: 0.8-2% of air entraining agent, 2-4% of retarder, 0.06-0.15% of anti-cracking agent, 0.6-1.2% of reinforcing agent, 0.3-0.7% of water retaining agent and the balance of water; the material B consists of the following components in percentage by weight: 3-12% of water reducing agent, 0.2-0.5% of shrinkage reducing agent and the balance of water. The wet-mixed mortar admixture disclosed by the invention is high in water reducing rate, environment-friendly, and can be used for improving the open time, workability and water retaining rate of mortar and improving the compressive strength and the bonding strength; by adopting a double-mixing manner of the materials A and B, the consumption of the material A or B can be effectively adjusted according to the performance of the mortar, and the performance of the mortar can be easily controlled.

Owner:四川恒泽建材有限公司

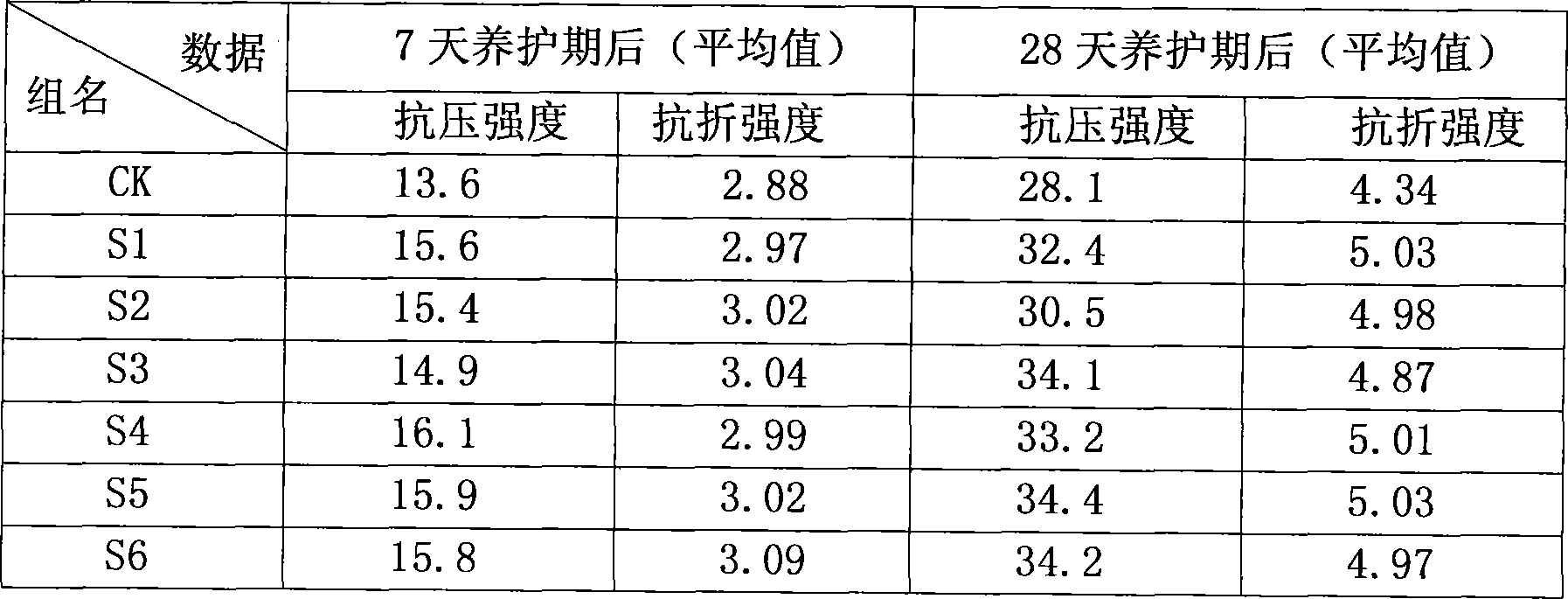

Concrete inner curing agent and preparing method thereof

The invention relates to an internal concrete curing compound and manufacturing method thereof. The ingredients include de-ionized water, non-metallic minerals, sodium hydroxide, acrylic acid and / or derivative monomer, water-soluble initiators of free radical polymerization, water-soluble cross-linker of free radical polymerization and addictive. The preparing method for the internal curing compound of solution-type concrete is characterized in that the following procedures are applied: 1) preparation of raw materials; 2) mixing of de-ionized water, sodium hydroxide, acrylic acid and / or derivative monomer; 3) the mixed solution is added and mixed with and in order of cross-linker, initiator, non-metallic minerals, epoxy ethane, rust retardant agent; the internal concrete curing compound can be obtained following a homogeneous mixing and heating with recycled hot air. The invention can save curing water, reduce manpower / material input, minimize addictive cost, effectively control water evaporation, reduce the cost for late concrete curing and enhance the comprehensive performance of concrete addictives, which proves to be environment friendly with respect to environmental impact.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

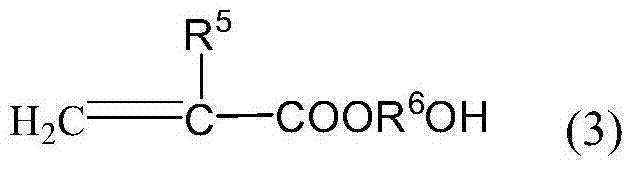

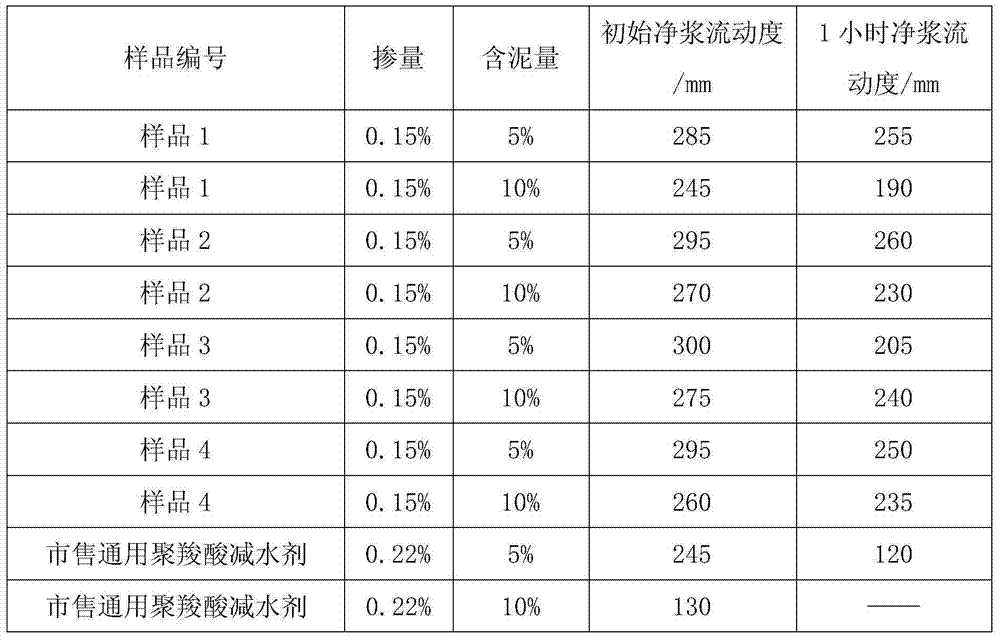

Mud-resistant polycarboxylic acid water-reducing agent and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water-reducing agent and a preparation method thereof. The mud-resistant polycarboxylic acid water-reducing agent disclosed by the invention is prepared by copolymerizing an unsaturated polyalkylene dialcohol ether monomer a, an unsaturated carboxylic acid monomer b, unsaturated acid hydroxyalkyl ester c and an ammonium salt cationic unsaturated monomer d through free radicals under the action of an initiator and a chain transfer agent; and the mol ratio of the monomer a to the monomer b to the monomer c to the monomer d is 1.0:(2.0-4.2):(0.2-1.0):(0.1-0.5). Under the condition that aggregates contain mud, the dispersion effect of the mud-resistant polycarboxylic acid water-reducing agent disclosed by the invention is obviously prior to that of the traditional water-reducing agent; and the mud-resistant polycarboxylic acid water-reducing agent not only has low amount of admixture but also has better keeping property.

Owner:HAISO TECH

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

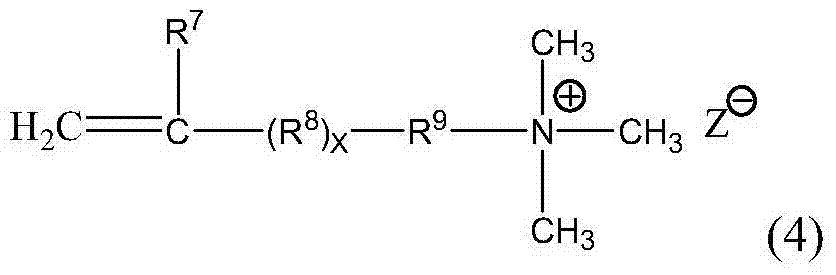

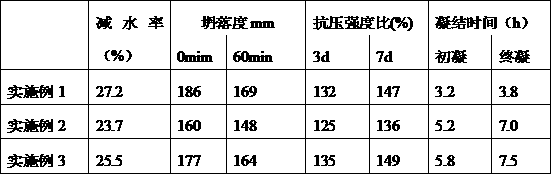

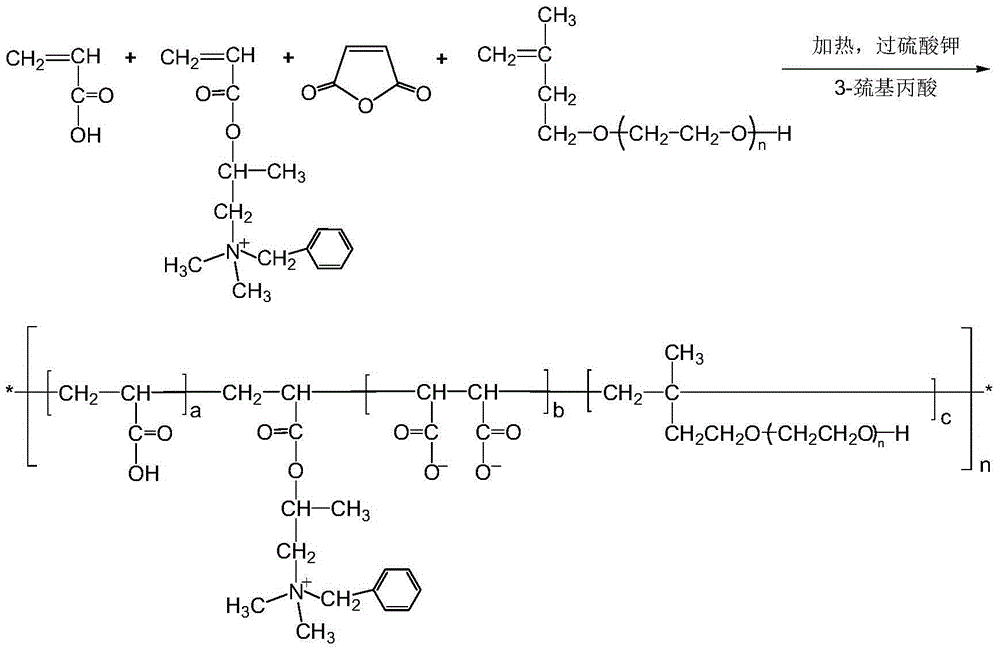

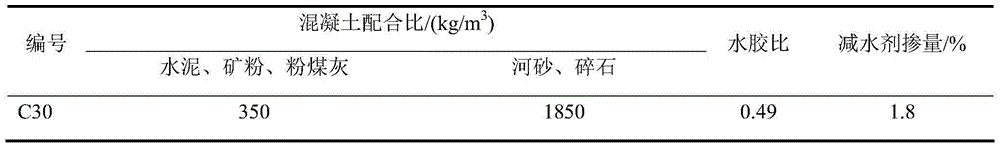

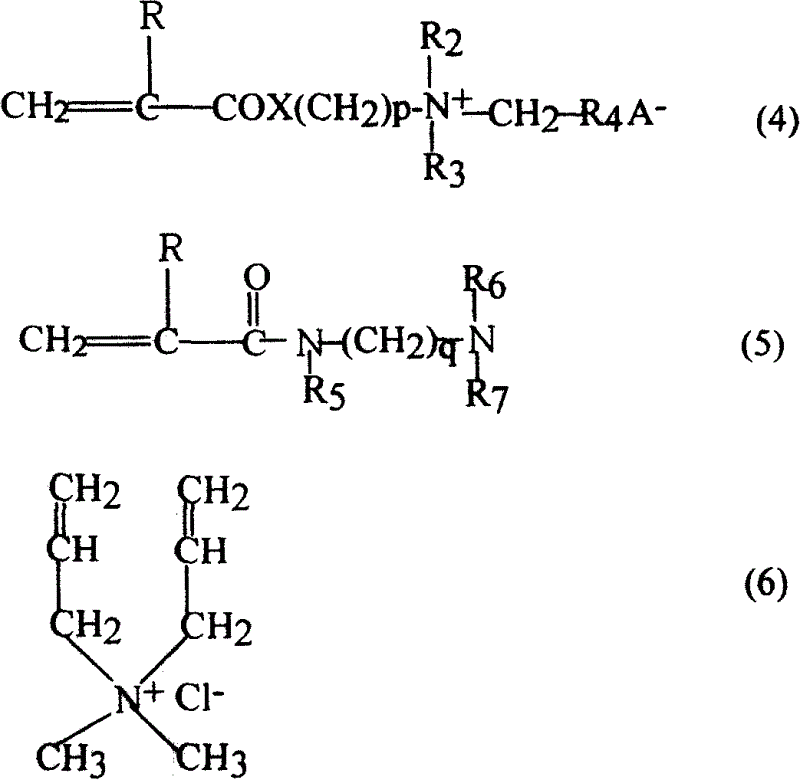

Cation modified polycarboxylate superplasticizer and preparation method thereof

The invention discloses a cation modified polycarboxylate superplasticizer which is characterized by being prepared from isoamyl alcohol polyoxyethylene ether monomer a, unitary unsaturated carboxylic acid and a derivative monomer b thereof, cationic monomer c as well as binary unsaturated carboxylic acid and a derivative monomer d thereof through copolymerization in a 7-70 DEG C water solution for 3-8h under the action of an initiator e and a chain transfer agent f and addition of alkali to realize neutralization until the pH is 5-8. Compared with the traditional anionic polycarboxylate superplasticizers, the cation modified polycarboxylate superplasticizer can be adsorbed on the surfaces of cement minerals with positive charge and negative charge when being added into concrete as a cation group is introduced into the molecular structure, and undergoing molecular chain extension in cement paste alkaline environment due to the existence of antipolyelectrolyte effect to make the adsorption form more stretch, so that the water reducing rate of the superplasticizer is higher and the cement particles can be dispersed more sufficiently.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

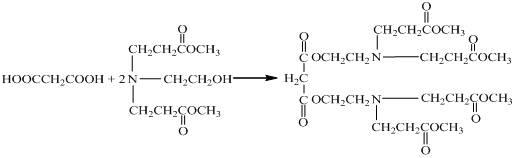

Hyperbranched polymer, hyperbranched type water reducing agent of polycarboxylic acid series and preparation method and application thereof

ActiveCN102002134AGood dispersionAvoid reunionAtom-transfer radical-polymerizationPolyethylene glycol

The invention provides a hyperbranched polymer and a preparation method thereof, wherein the preparation method comprises the steps of taking methyl acrylate, ethanolamine, 2-bromoethanol and propandioic acid as raw materials to synthesize a hyperbranched poly (amine-ester) nuclear molecule comprising a bromine terminal group; taking cuprous bromide and 2,2-bipyridyl as a catalyst and a coordinating agent; respectively grafting acrylic acid and single methyl oxygen radical sealed allyl polyethylene glycol into the hyperbranched poly (amine-ester) comprising bromine terminal group by means of an atom transfer radical polymerization method so as to obtain a hyperbranched polymer. The invention further provides a hyperbranched type water reducing agent of polycarboxylic acid series mainly comprising the hyperbranched polymer and the application thereof, wherein the water reducing agent improves the faults of existing water reducing agent of which the adding quantity is large and the cement adaptability is bad and the like,. and has the advantages that the adding quantity is low, the water reducing efficiency is high, the loss of slump is less, the compatibility to the cement is good, the frozen resistance is strong and the like, the properties of the product are stable, and the water reducing agent has no tendency of layering and precipitating and has no toxicity and pollution after storing for a long time.

Owner:江苏超力建材科技有限公司

Retardation setting type polycarboxylic acids series water reducing agent

The invention belongs to the technical field of architectural materials, specifically relating to a retarded polycarboxylic acids series water reducing agent. The compounded components are polycarboxylic acids series water reducing agent employing allyl group polyethylene glycol as raw material, sodium lignosulphonate, gluconic acid sodium salt, sodium citrate, sodium pyrophosphate, sucrose and water which are added to a mixing machine under normal temperature. After full agitation and dissolution, then the invention is prepared. The raw materials of the invention are low in price, the performance of the products is stable, and the invention has good market prospect.

Owner:TONGJI UNIV

Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

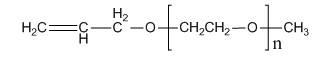

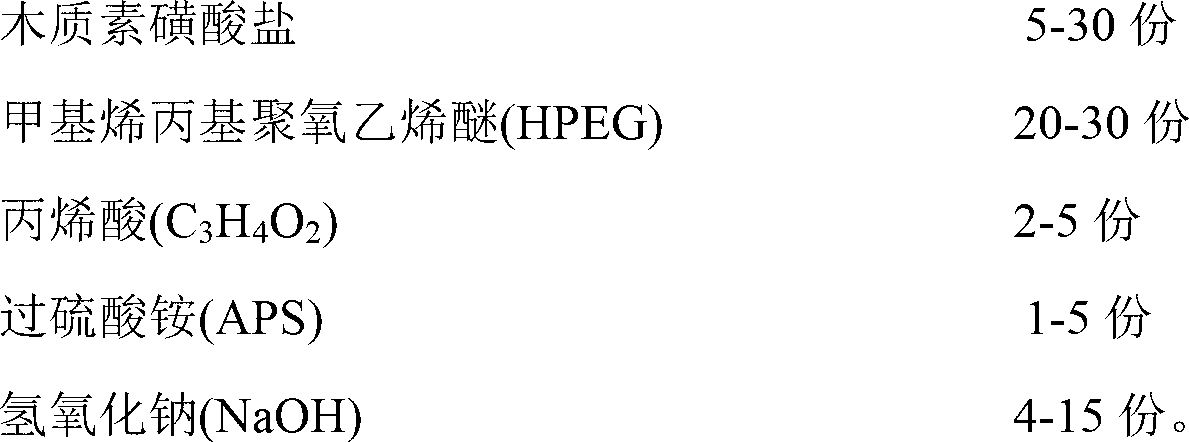

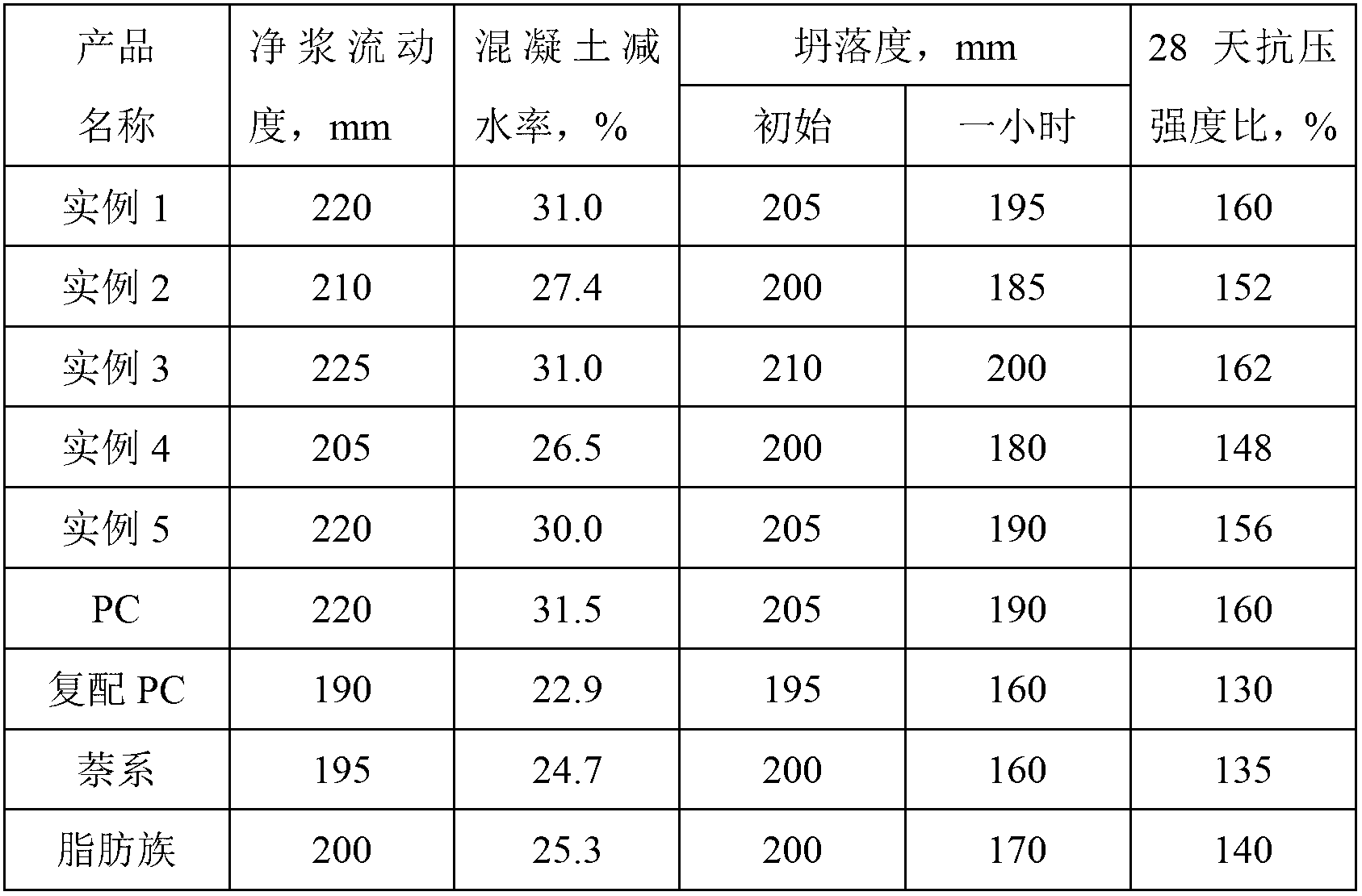

The invention discloses a lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and a preparation method thereof. The high-performance water reducer comprises the components in parts by weight: 5-30 parts of lignosulfonate, 20-30 parts of methyl allyl polyethenoxy ether, 2-5 parts of acrylic acid, 1-5 parts of ammonium persulfate, 4-15 parts of sodium hydroxide and water. The preparation method comprise the steps as follows: lignosulfonate, methyl allyl polyethenoxy ether and acrylic acid are directly synthesized under the action of ammonium persulfate, and the mixture is neutralized by sodium hydroxide to obtain the high-performance water reducer. As the high-performance water reducer is made from natural recycled materials, the high-performance water reducer is low in price, stable in performance, high in water-reducing rate, good in collapse prevention property, remarkable in improved effect, and is unlikely to bleed, separate and deposit after concrete is added, the quality problems of sand leakage, honeycomb-like phenomenon and leakage due to cracking in the middle and low-strength concretes are effectively avoided, and the safety performance is improved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer is prepared from the following components: vinyl polyoxyethylene ether, sodium p-styrenesulfonate, an acrylic acid and acrylamide compounds as monomers as well as an alkaline neutralizer, an initiator and a molecule modulator as auxiliary materials through copolymerization. The mud-resistant polycarboxylic acid water reducer disclosed by the invention is high in water-reducing rate, small in slump loss, good in mud-resistant effect, free of formaldehyde pollution in a production process, and especially adapts to sand concrete with relatively high mud content.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Slow-release cationic anti-mud polycarboxylic-type high performance water reducer and preparation method thereof

The present invention discloses slow-release cationic anti-mud polycarboxylic-type high performance water reducer and a preparation method thereof. The slow-release cationic anti-mud polycarboxylic-type high performance water reducer is successfully synthesized from an unsaturated carboxylic acid, a polyether macromonomer, a cationic unsaturated monomer, an unsaturated esters, a crosslinking agent, a chain transfer agent, an oxidizing agent and a reducing agent as raw materials at room temperature without heat source. By introduction of the long-chain-ester crosslinking agent and the cationic unsaturated monomer, the slow-release cationic anti-mud polycarboxylic-type high performance water reducer has good slow-release and anti-mud effects, is low in admixing volume, high in water-reducing rate, excellent in slump retention ability, and not sensitive to mud contained in sand and stones, and the process does not require an additional heat source, an be carried out at room temperature, and is low in investment, low in cost, and suitable for large scale promotion and application.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) free radical copolymerizing reaction of four kinds of monomers in certain proportion in water soluble medium; 2) crosslinking reaction through introducing crosslinking agent after the polymerization. The present invention proposes that the amphoteric ionic polymer can raise the saturated added amount of concrete super-plasticizing agent, and introduces amphoteric ion concept into the molecular design of concrete admixture. The concrete super-plasticizing agent of the present invention has high water reducing rate, can eliminate the environmental pollution caused by concrete water reducing agent and reduce the added amount while ensuring the outstanding dispersivity and slump maintaining capacity.

Owner:JIANGSU SOBUTE NEW MATERIALS

Polycarboxylic superplasticizer, synthesis method thereof and application method thereof

The invention discloses a synthesis method of a polycarboxylic superplasticizer. The raw materials for synthesis of the polycarboxylic superplasticizer are APEG of two types of molecular weight (respectively 500-1000 and 1600-2200), MPEGMA of two types of molecular weight (respectively 800-1400 and 2000-2500), maleic anhydride, acrylic acid, alkylphenol ethoxylate, hydrogen peroxide, ascorbic acid, ferrous sulfate, sodium persulfate, sodium hydroxide and deionized water. Since the APEG and MPEGMA of different types of molecular weight are simultaneously adopted as crossing branch chains, the invention not only has a high water-reducing rate, but also maintains good water-reducing rate, has good adaptability to sands and stones with high clay contents, and improves the strength of concrete, Compared with the prior art, the invention has the advantages that the raw materials of the product are easily available, the synthesis process can be easily controlled, the performance of the reaction product is stable, and the cost is reduced by 5-10 percent.

Owner:GUANGDONG REDWALL NEW MATERIALS

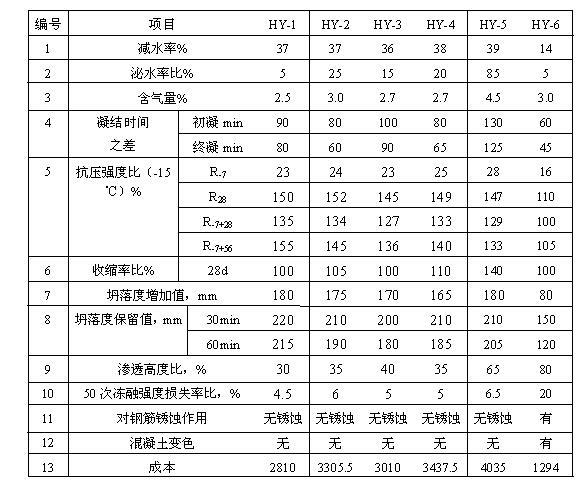

Low-cost concrete antifreezing pumping aid and preparation method thereof

The invention relates to the concrete pumping aid field, in particular to a low-cost concrete antifreezing pumping aid and a preparation method thereof. The concrete pumping aid comprises the following raw materials by weight percent: 20-30% of polycarboxylic acid water reducing agent of which solid content is 40%, 0.3-0.4% of air entraining agent, 0.9-2% of retarder, 11-15% of sulfonated acetone-formaldehyde condensate of which solid content is 36%, 6-10% of sodium lignin sulfonate, 2-4% of antifreezing component and the balance of water. The preparation method comprises the following steps: adding water, air entraining agent, polycarboxylic acid water reducing agent and sulfonated acetone-formaldehyde condensate in a container to heat to 45-55 DEG C, and stirring evenly; adding sodium lignin sulfonate in the container to stir, centrifuging to remove precipitate; and adding retarder and antifreezing component to stir evenly. The low-cost concrete antifreezing pumping aid has good performance; the composite indicators such as the antifreezing property, the pumping property, the water reducing ratio and the ratio of compressive strength are better than that of the antifreezing pumping aid which uses polycarboxylic acid water reducing agent or sulfonated acetone-formaldehyde condensate alone; and the antifreezing pumping aid in the invention has higher adaptability and good cost performance.

Owner:安徽海螺材料科技股份有限公司

Cross-linked polycarboxylic acid water reducing agent and preparation method thereof

The invention relates to a preparation method of a cross-linked polycarboxylic acid water reducing agent. The molecular weight of the cross-linked polycarboxylic acid water reducing agent is 10000-100000. The preparation method comprises the following steps: sequentially adding methylallylalcohol polyethenoxy ether, polyethyleneglycol dimethyl acrylate, sodium methylacrylsulfonate and deionized water into a reaction kettle with good leak tightness while continuously stirring, heating to 45-50 DEG C, stirring for 10 minutes, continuing heating to 60-62 DEG C, adding oxydol, slowly and dropwisely adding an acrylic acid solution and a chain-transfer agent within 3-3.5 hours, keeping the temperature for 1-1.5 hours, cooling to 50 DEG C after the reaction finishes, supplementing water, and adding liquid alkali to neutralize until the pH value reaches 6.5-7, thereby obtaining the cross-linked polycarboxylic acid water reducing agent of which the solid content is 40%. The invention has the advantages of simple reaction equipment, easily controlled reaction, low cost and the like; and the prepared cross-linked polycarboxylic acid water reducing agent has the advantages of high water reducing rate, favorable workability and high slumping retention.

Owner:ZHUZHOU KAMILE SU BUILDING MATERIALS

Preparation method for high performance water reducer made from high water reducing solid polycarboxylic acid

The present invention relates to a preparation method for high performance water reducer made from high water reducing solid polycarboxylic acid. The prepartion method specifically comprises the following steps: performing heat fusion on two unsaturated polyoxyethylene ether composite macromonomers with different molecular weights; then dropwise adding a mixed liquid of an unsaturated carboxylic micromonomer, an unsaturated amide micromonomer and a chain transfer agent under the reaction of an initiator; and preparing the water reducer through a free radical polymerization reaction, and after the reaction, using a neutralizing agent to adjust a pH value to 5-6 and then cooling and grinding the water reducer in a solid particulate shape. The preparation method provided by the present invention has advantages of being simple in process, high in conversion rate and environmental-friendly and free of pollution, and has the characteristics of high water reduction and low adulterate amount in concrete and dry-mixed mortar, and the transportation cost in long distance transportation is greatly lowered.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

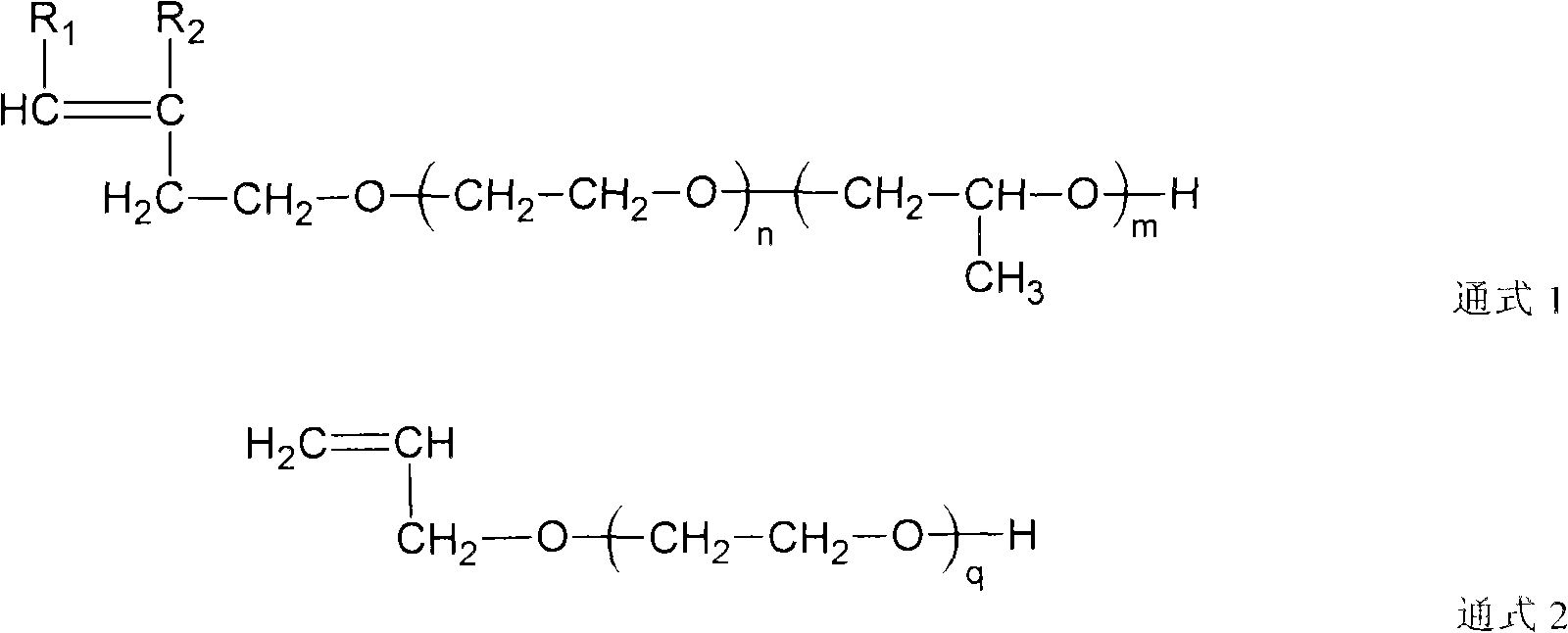

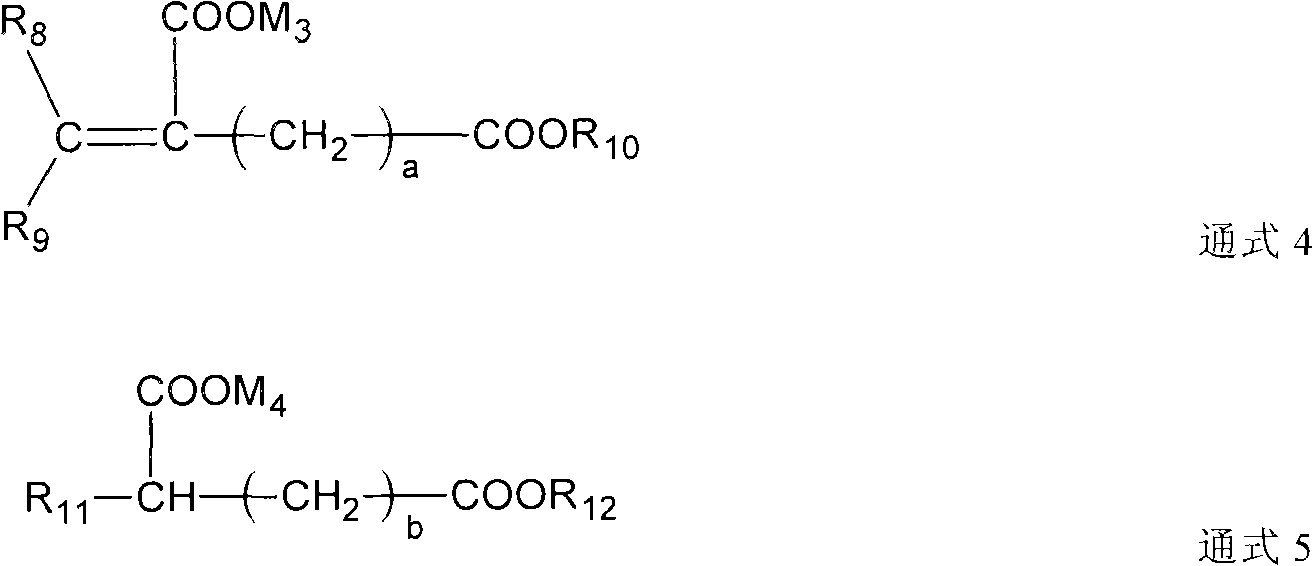

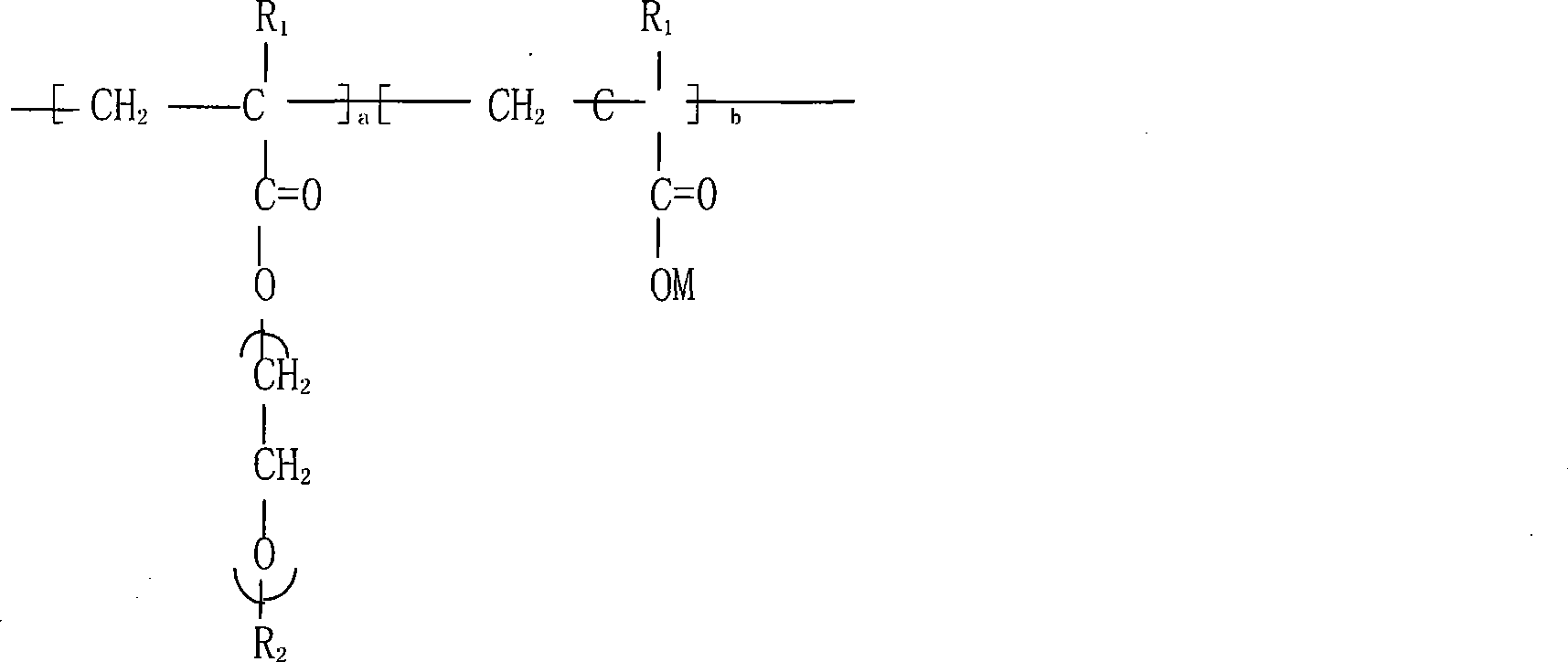

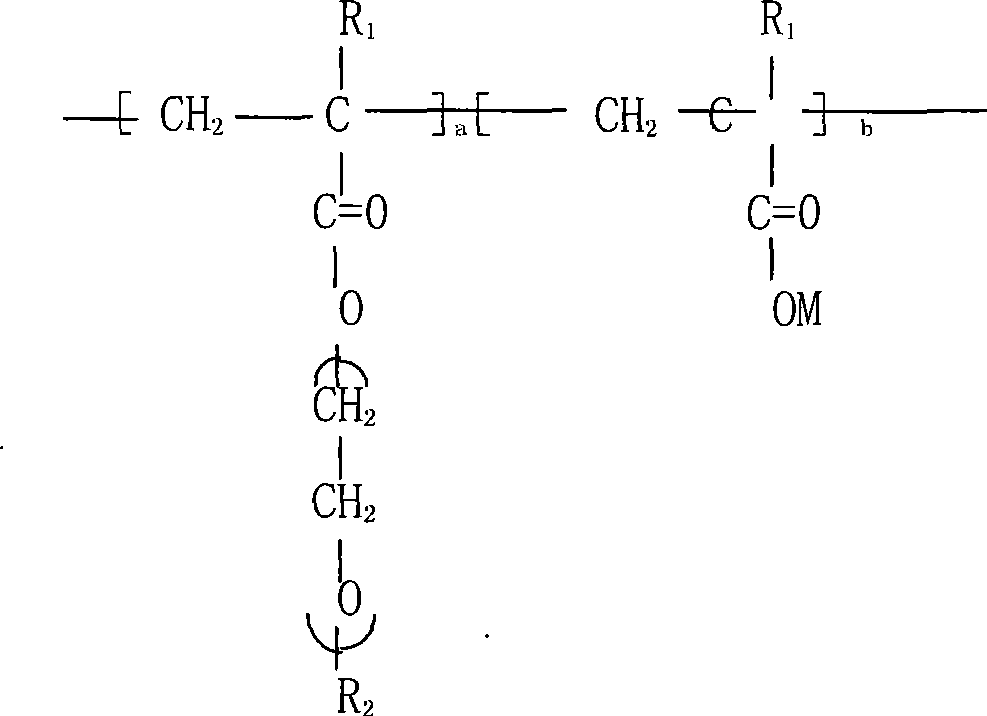

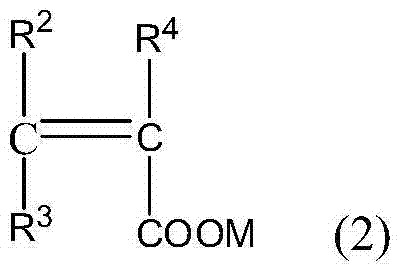

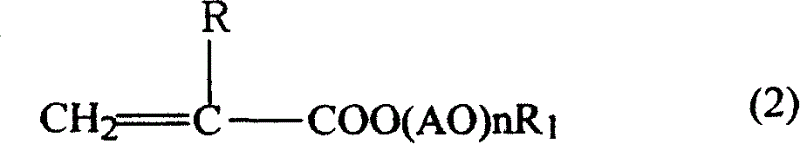

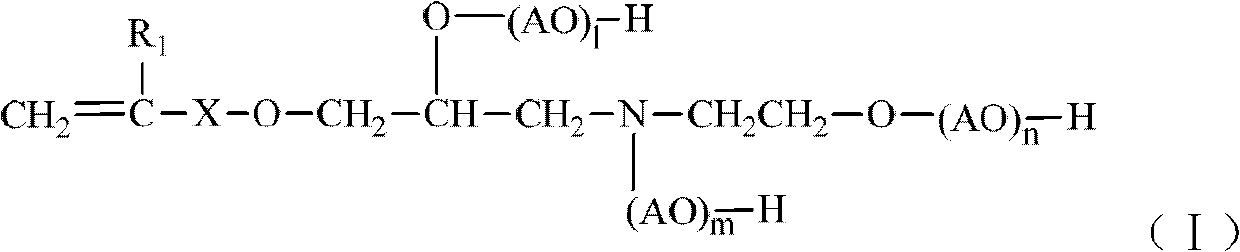

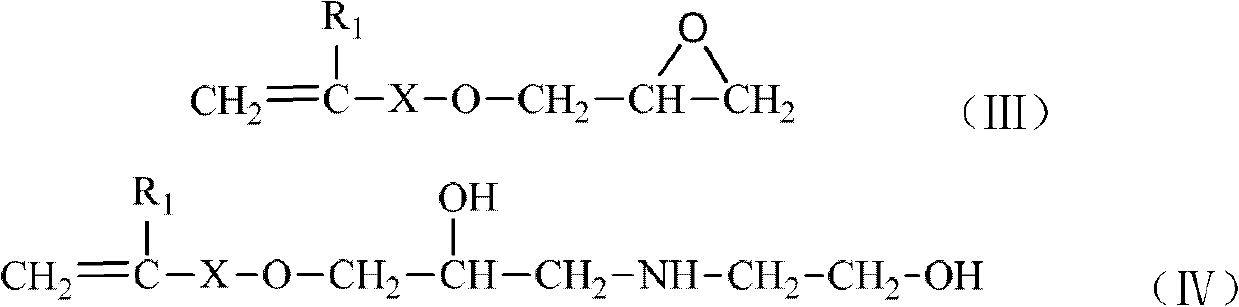

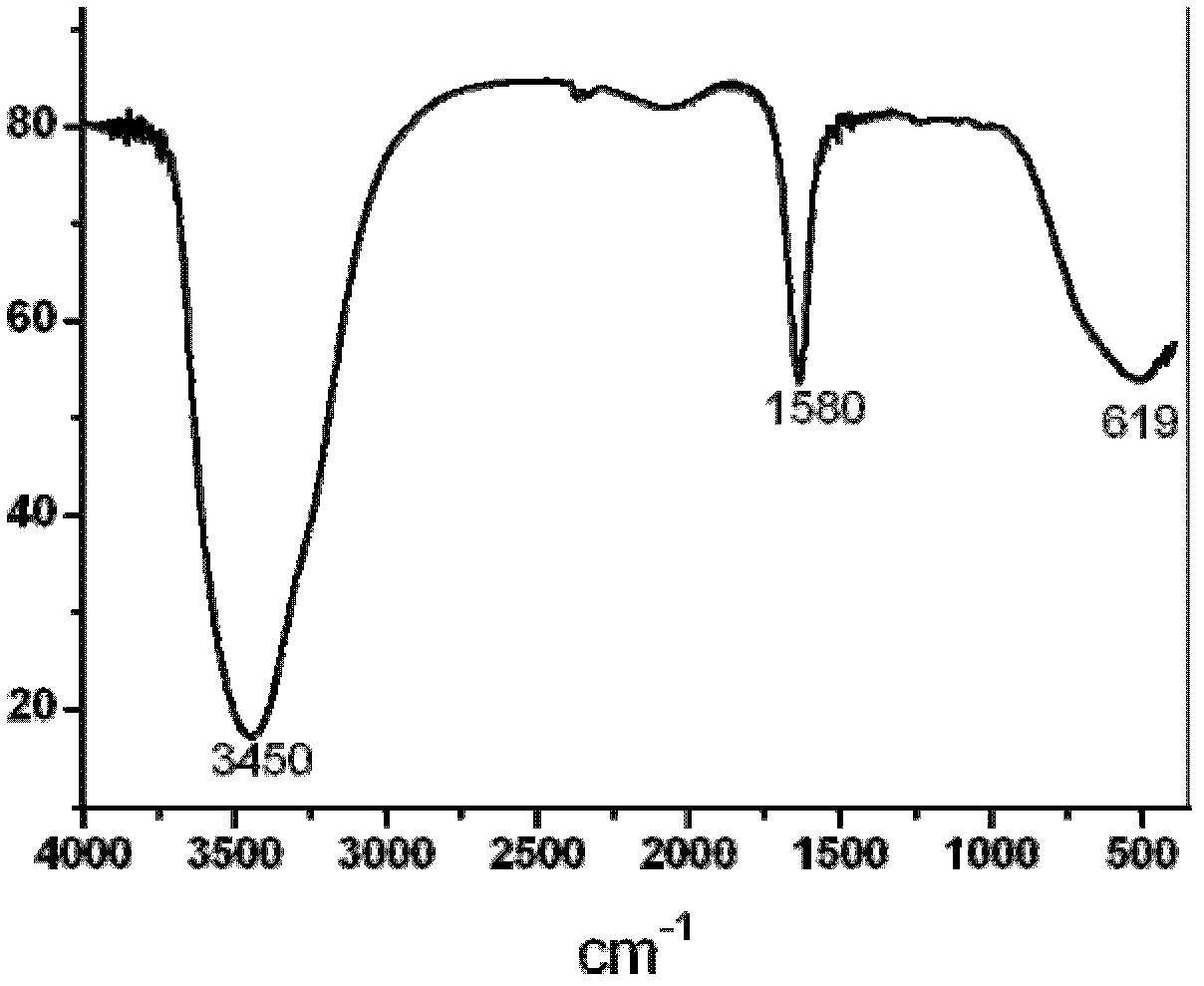

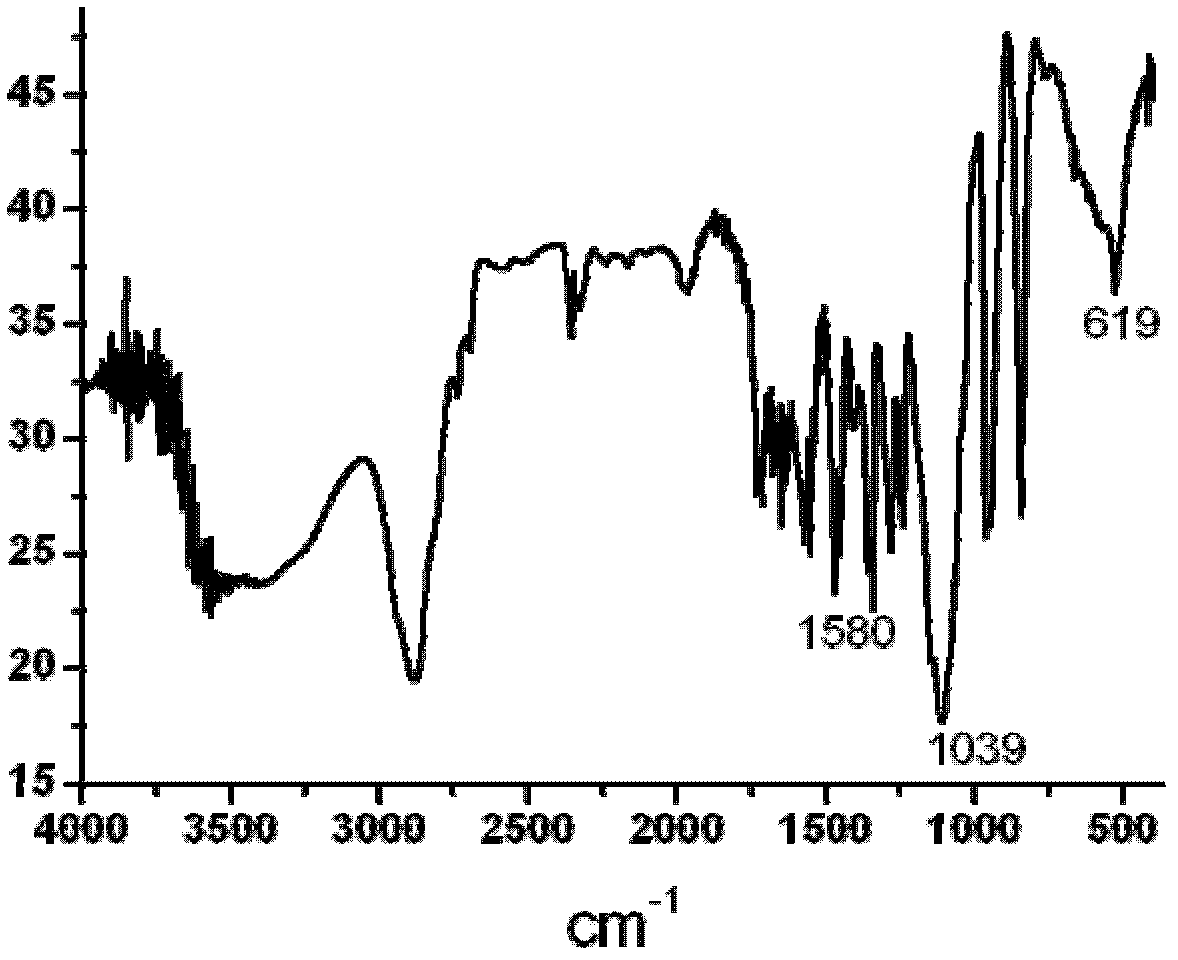

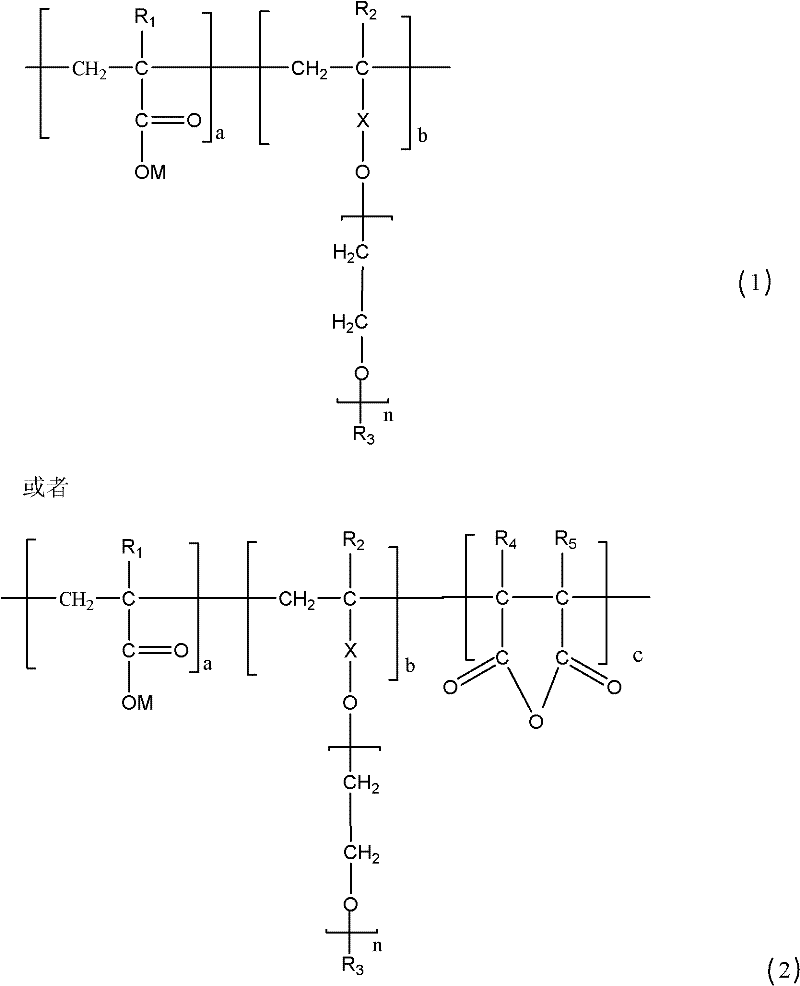

Unsaturated polyether monomer, comb-like branched copolymer cement dispersant prepared by the same, and preparation method thereof

The invention relates to an unsaturated polyether monomer, a comb-like branched copolymer cement dispersant prepared by the monomer, and preparation methods of the monomer and the dispersant. The unsaturated polyether monomer has the general formula (I), wherein R1 is H or -CH3; X is a linking group selected from -CH2-, -CH2CH2-, -OCH2CH2-, -OCH2CH2CH2CH2-; AO is ethylene oxide group and / or propene oxide group; l, m and n are all repeating units of AO; and the sum of l, m and n is an natural number of 10 to 50. The dispersant has the following chemical structure (VI), wherein x, y and z represent mole percentages of three structural units in the copolymer, and the sum of x, y and z is 100%. Preferably, x is 10% to 50%, y is 40% to 80% and z is 0% to 30%. The preparation method of the dispersant is simple and does not need organic solvents or complex esterification. The dispersant is advantageous in low dosage, good dispersibility and small slump loss.

Owner:连云港苏博特新材料有限公司 +2

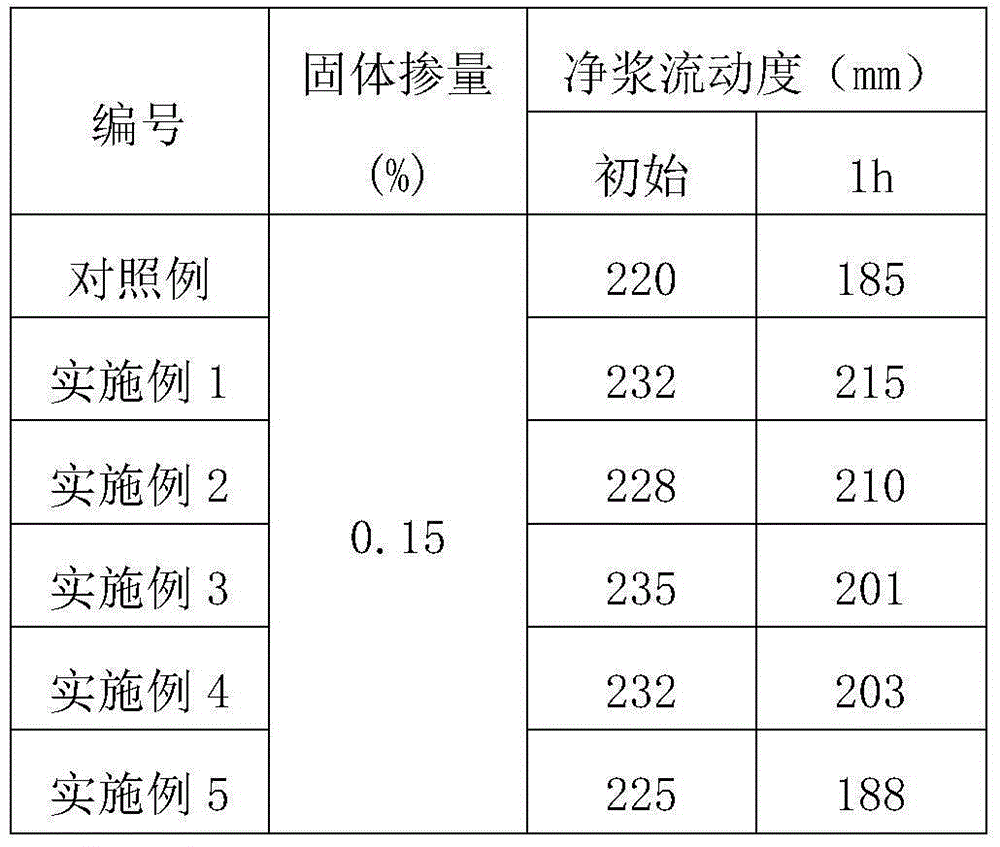

Sustained-release polycarboxylic high-performance water reducing agent and preparation method thereof

The invention relates to a sustained-release polycarboxylic high-performance water reducing agent and a preparation method thereof. The water reducing agent comprises: 0.13mol of monomer methyl alkenyl polyoxyethelene or allyl polyoxyethylene ether or polyoxypropylene ether, 0.32mol of monomer acrylic acid or methacrylic acid, 0.01mol of monomer sodium methallyl sulfonate, 0.12mol of monomer acrylamide or 2-acrylamide-methylpropanesulfonic acid, and 0.05mol of monomer ethyl acetate or styrene. Deionized water is adopted as a reaction medium, and the materials are subjected to a reaction with an initiating agent and a chain transfer agent for 4-6h with a maintained temperature of 58-62 DEG C. Copolymerization is carried out, such that a polymer with a molecular weight of 50000-120000 is obtained; the temperature is reduced to below 40 DEG C, and an alkali solution is added for regulating the pH of the system to 6-8, such that the water reducing agent is obtained. The sustained-release polycarboxylic high-performance water reducing agent provided by the invention has high water reduction rate. When an equivalent solid dosage is 0.2%, a water reduction rate can reach 35%. A slump performance is good. Concrete slump and extension degree have no loss in 3h. The water reducing agent is widely adaptable with concrete raw materials.

Owner:广西云鹰新材料科技有限公司

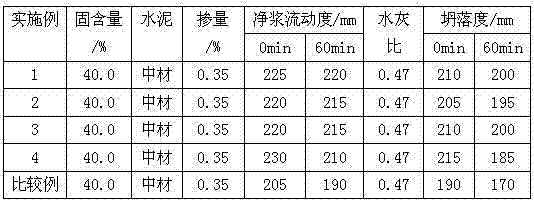

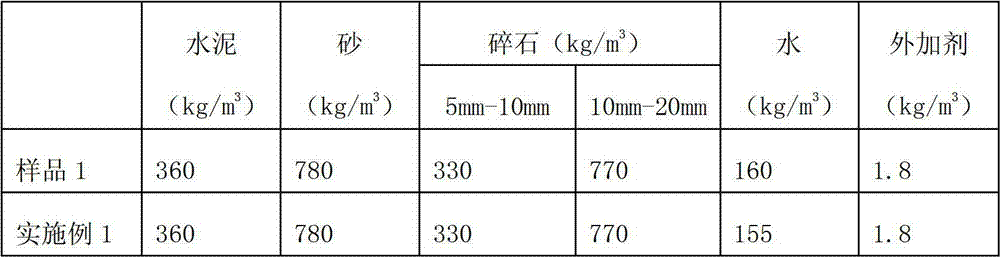

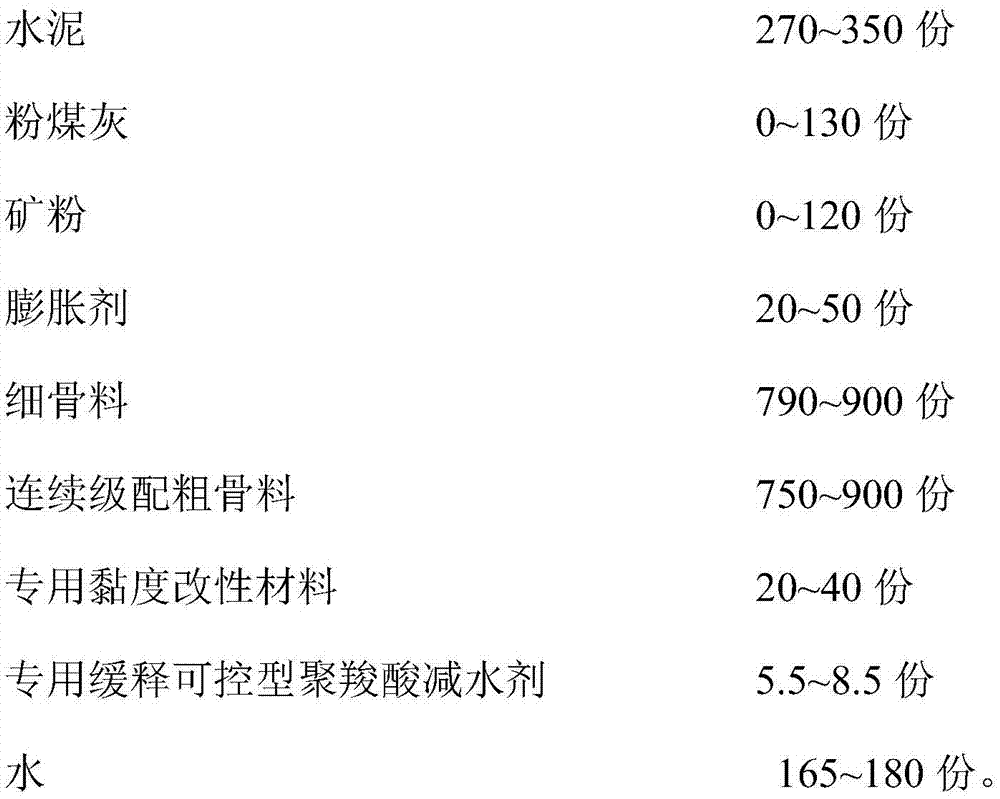

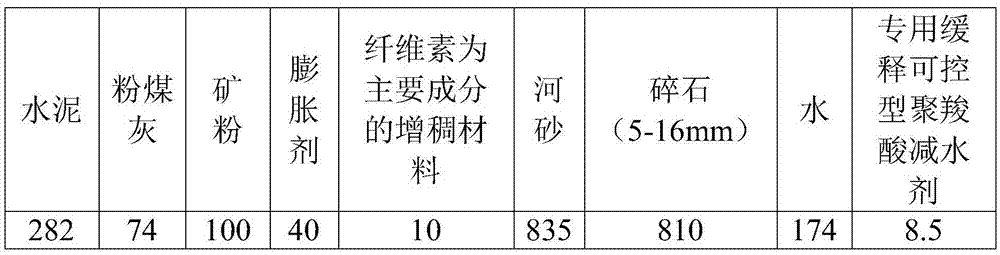

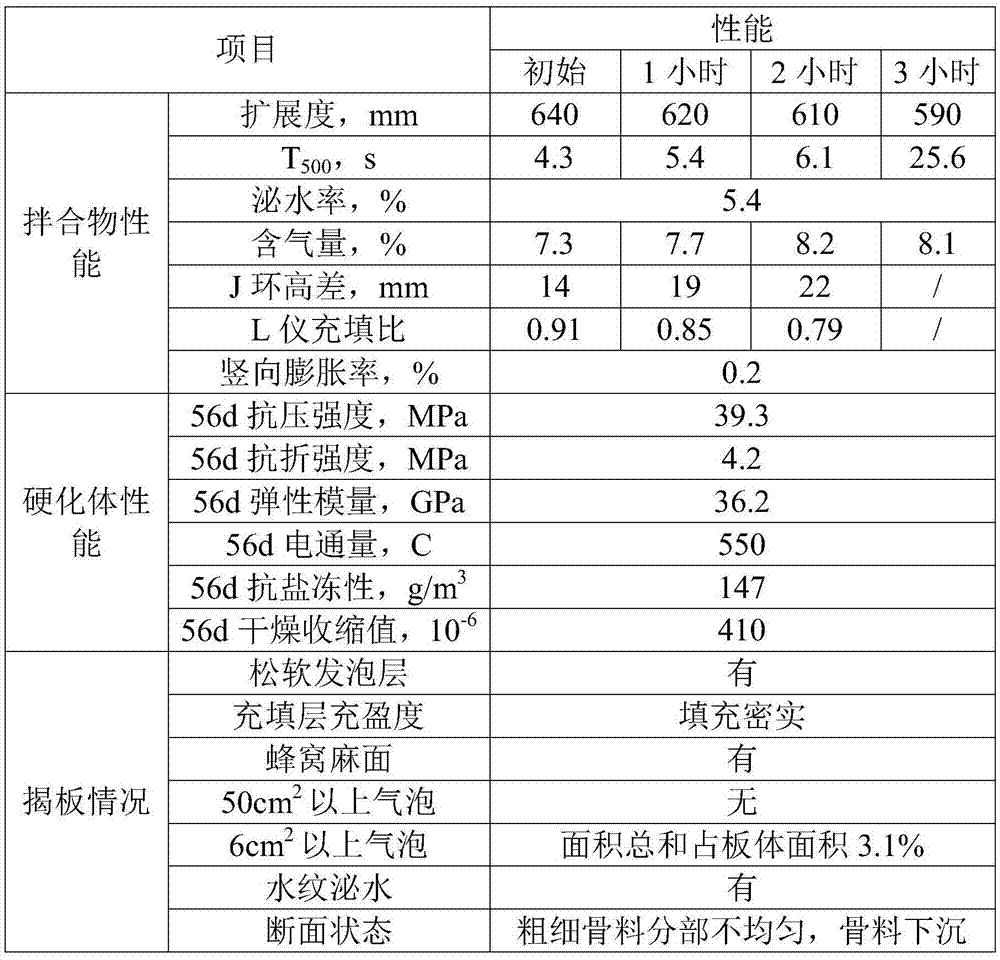

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

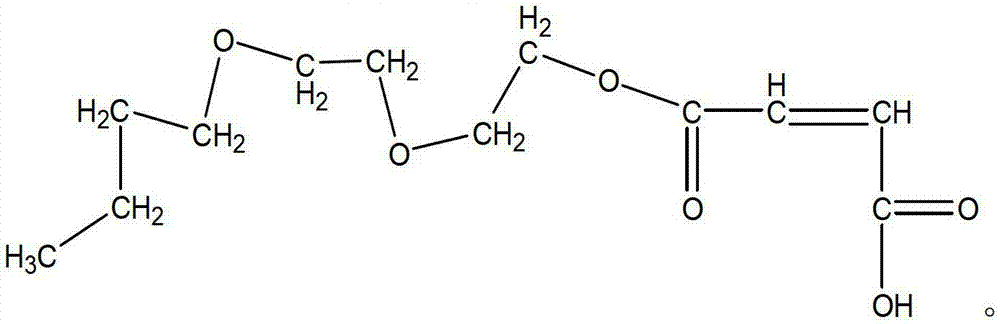

Shrinkage-reducing poly carboxylic acid water reducing agent and preparation method

InactiveCN103193410ALarge physical space hindrance effectGood water reduction effectPolyethylene glycolCarboxylic acid

The invention discloses a method for preparing a poly carboxylic acid water reducing agent. According to the method, sodium methallyl sulfonate, allyl polyethylene glycols, methacrylic acid, diethylene glycol dimethyl monobutyl ether maleic monoester and water are mixed according to an appropriate proportion and are subjected to thermostatic reaction for 3-7 hours under the temperature of 50-100 DEG C under the initiation of the initiator ammonium persulfate, the reaction products are cooled and then the pH value is adjusted to 6-8 by using a NaOH solution to obtain the water solution of macromolecule copolymer, i.e. the shrinkage-reducing poly carboxylic acid water reducing agent. The invention further discloses a novel shrinkage-reducing poly carboxylic acid water reducing agent. The raw materials of the shrinkage-reducing poly carboxylic acid water reducing agent of the invention are abundant in source, and the synthesis process is simple and easily operated; the shrinkage-reducing poly carboxylic acid water reducing agent has good water reducing and shrinkage reducing functions when the mixing amount is lower, can appropriately entrain air, and has better market prospect and economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

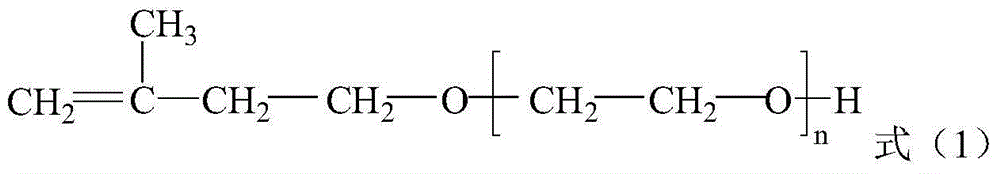

Composite method of isopentenol polyoxyethylene ether

InactiveCN101928392AStrong dispersion retention abilitySimple processEther preparation from oxiranesPolymer scienceEthylene oxide

The invention discloses a preparation method of isopentenol polyoxyethylene ether. Isopentenol and ethylene oxide are served as raw materials; in the presence of catalyst, the raw materials react for 5-40 hours to obtain the isopentenol polyoxyethylene ether at the reaction temperature of 70-160 DEG C. The isopentenol polyoxyethylene ether has the molecular weight of 200-6000 and the iodine value of 3.9-123; the mass ratio of isopentenol to ethylene oxide in the raw materials is 1:0.0143-0.754; and the mass of the catalyst is 0.03-0.5% of total mass of the raw materials of isopentenol and ethylene oxide. The invention has simple and reasonable technology. Because the invention has the structural particularity of branched chain methyl, molecular space steric hindrance is increased, and the composite polycarboxylic acid high-efficiency water reducer has strong cement particle dispersibility holding capacity. Thus, the product has the advantages of low dosage, high water-reducing ratio, good strengthening effects, good durability and the like, does not erode reinforcing steel bars and protects environment.

Owner:ZHEJIANG HUANGMA TECH

Pumping agent and application thereof

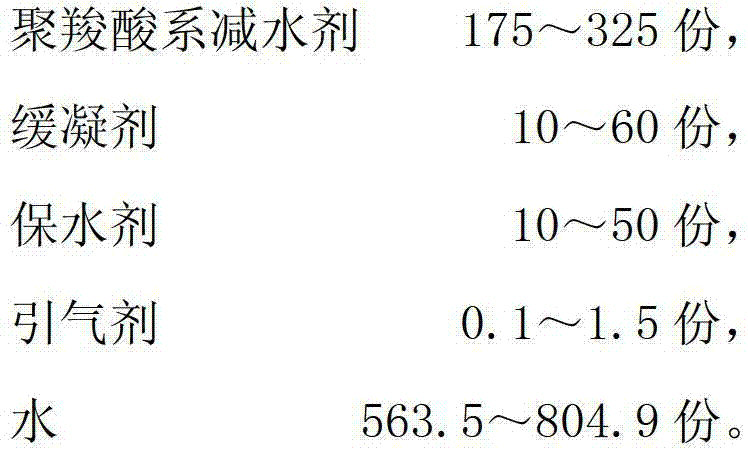

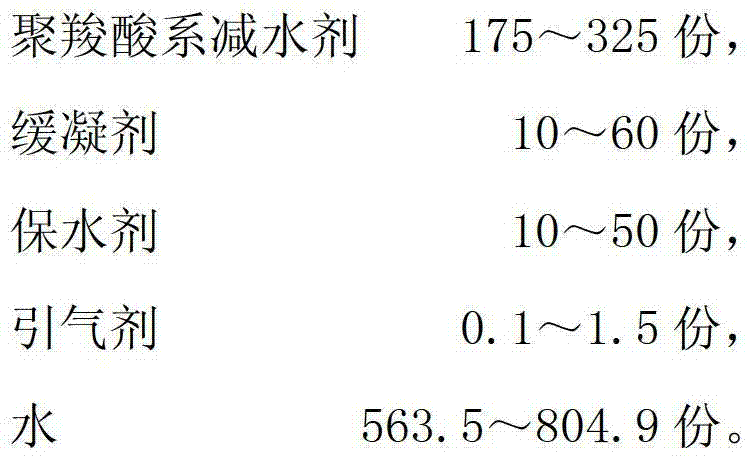

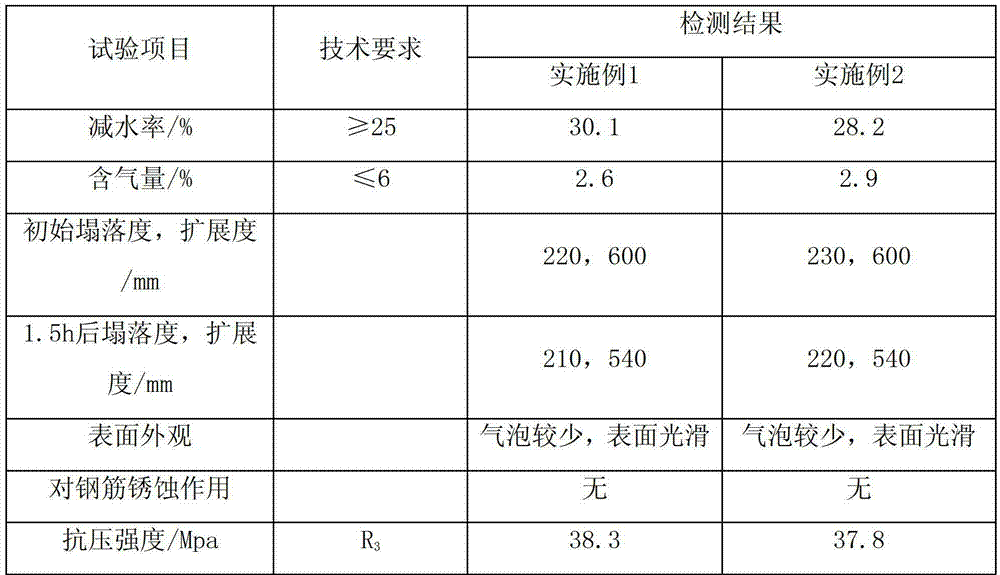

The invention relates to a pumping agent and application thereof, belonging to the field of construction materials. The invention aims to provide the pumping agent and the application thereof. The pumping agent provided by the invention comprises 175-325 parts by weight of polycarboxylic acid water reducing agent, 10-60 parts by weight of retarder, 10-50 parts by weight of water retention agent, 0.1-1.5 parts by weight of air entraining agent and 563.5-804.9 parts by weight of water. The invention also relates to the application of the pumping agent in C15-C70 concrete. The addition amount of the pumping agent accounts for 0.9-2.2 wt% of a cementing material in the concrete. The pumping agent prepared by the invention has the advantages of favorable material adaptability, low addition amount, high water reducing rate, low air content, high concrete strength contribution and the like, mainly solves the problem that the polycarboxylic acid pumping agent is easily subjected to over-addition in practical situations, can effectively prevent the defects of the concrete such as weepage, isolation and the like, and ensures the quality of the concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Green preparation method of slow-release polycarboxylic-acid high-performance water reducing agent

The invention relates to a green preparation method of a slow-release polycarboxylic-acid high-performance water reducing agent, which comprises the following steps: firstly, dissolving unsaturated polyethenoxy ether in water, adding an oxidant solution, and evenly stirring; then, respectively and dropwisely adding a reducer / chain-transfer agent mixed solution and a comonomer solution, and polymerizing; and finally, adding an alkaline regulator to neutralize and age the solution, thereby obtaining the slow-release polycarboxylic-acid high-performance water reducing agent. In the invention, hydrogen on the terminal hydroxyl group of the original unsaturated polyethenoxy ether is substituted by an allyl group containing unsaturated bond, so that the terminal group of methoxypolyethylene glycol is converted from the original active hydroxyl group into the inert methoxy group at present; and thus, the byproducts of the copolymerization product are greatly reduced, and the molecular weight distribution is narrow, so that the synthesized water reducing agent has the advantages of high water reduction rate and slump resistance. The redox system with low activation energy is used for initiating the monomer copolymerization, so that the polymerization can be implemented at normal temperature, thereby implementing the production of the product by a no heat source method, simplifying the production equipment and lowering the energy consumption and cost.

Owner:NANJING RUIDI HIGH TECH

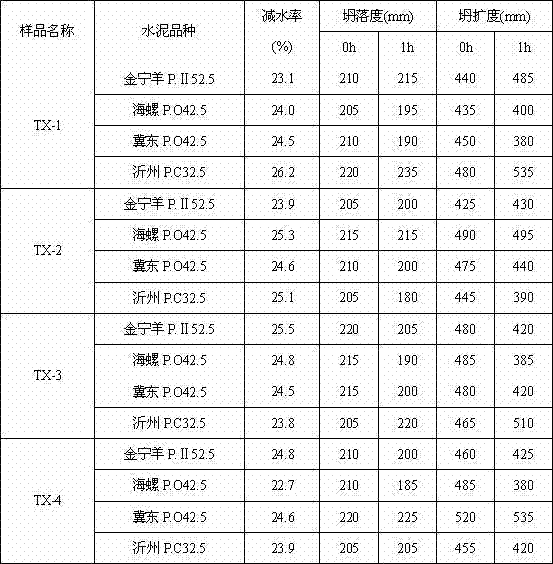

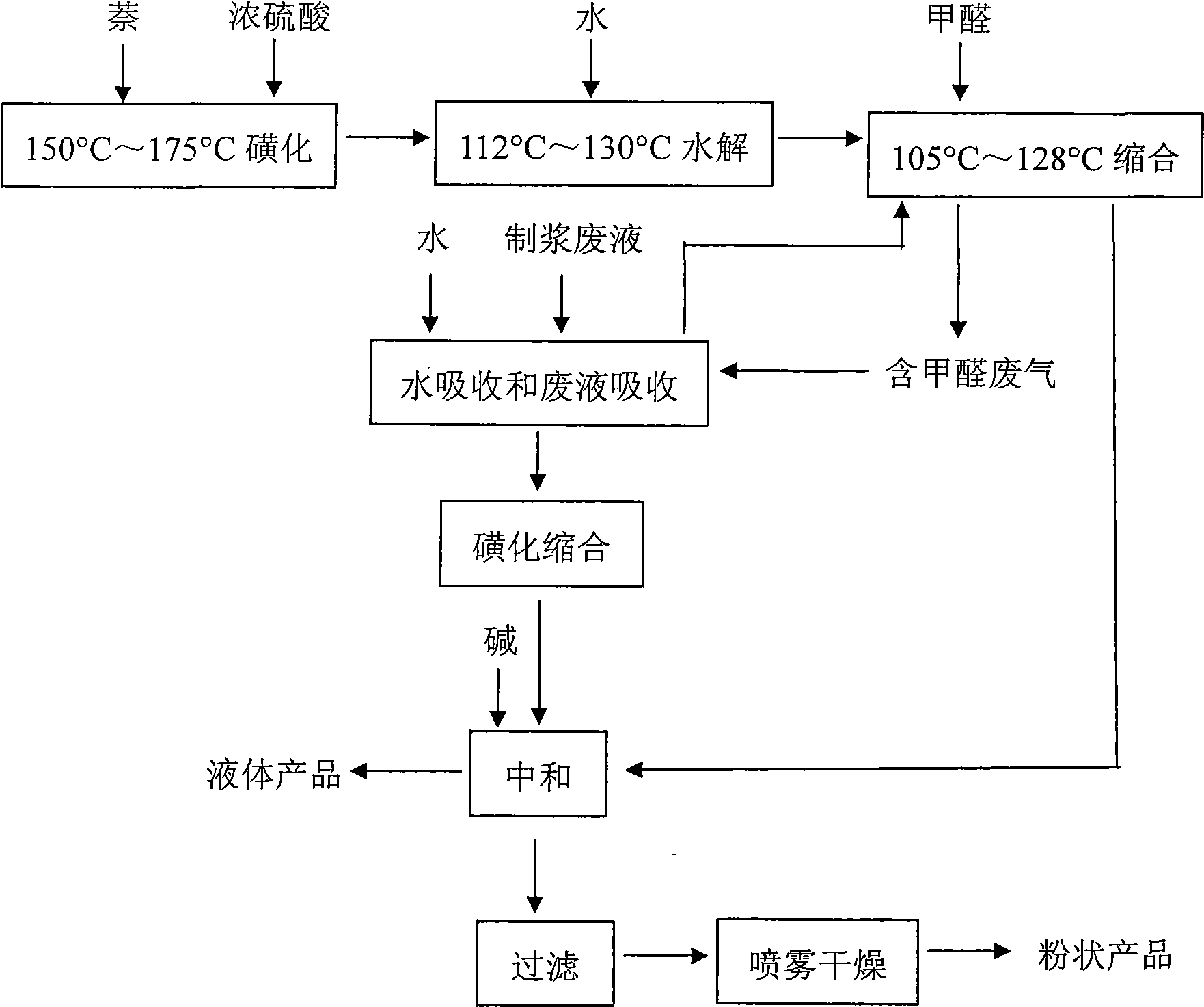

Process for preparing modified naphthalene series water reducing agent

InactiveCN101497506AReduce dosageHigh water reduction rateDispersed particle separationChemistryZero emission

The invention discloses a method for preparing a modified naphthalene water reducing agent, which comprises the following steps: A, adding industrial naphthalene to a glass lining reaction kettle to be melted, and adding industrial concentrated sulfuric acid to the reaction kettle; B, sampling and measuring the acid number to determine the water quantity to be added to a hydrolysis reaction; C, adding industrial formaldehyde to the mixture to perform reaction so as to obtain a naphthalene sulfonic acid formaldehyde condensation compound; D, adding pulping waste liquor and water to the mixture respectively from the top and the middle part of a formaldehyde absorption tower while adding the formaldehyde to the mixture, using a pump to perform circulating spraying on the waste liquor and the water on the upper section and the lower section of the adsorption tower respectively, and adding the waste gas generated by a condensation reaction to the lower part of the formaldehyde absorption tower so as to have a counter current contact with the water and obtain a waste liquor containing the formaldehyde; E, adding a diluted formaldehyde solution to a condensation reaction material, reducing the viscosity of the material and reclaiming the formaldehyde; F, delivering the formaldehyde pulping waste liquor to a waste liquor reaction kettle to perform sulphonation and condensation reactions; and G, preparing the modified naphthalene water reducing agent. The method achieves the zero emission of the formaldehyde with less usage; the water reducing rate of the water reducing agent is improved by 3 to 8 percent compared with the conventional product, and the utilization of an environmental pollutant pulping waste liquor is achieved.

Owner:武汉市联合石油化工有限责任公司

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

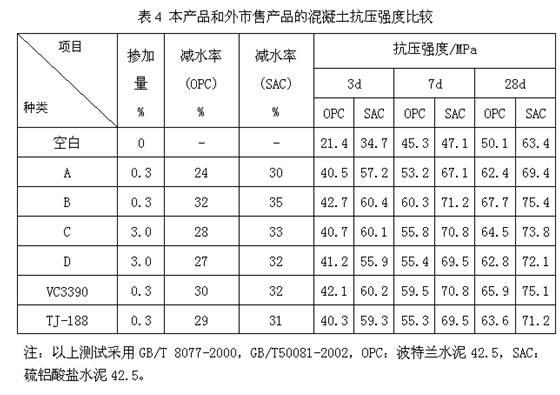

Hyperbranched polymer, hyperbranched polycarboxylic acid-series super plasticizer and preparation method thereof

ActiveCN102504247AEasy to getSimple processSulfonic acids salts preparationEthylene diaminePolymer science

The invention provides a hyperbranched polymer, a hyperbranched polycarboxylic acid-series super plasticizer and a preparation method thereof. The preparation method comprises the following steps of: undergoing an addition reaction and an ammonolysis reaction on alkenyl amine, polymethylmethacrylate, ethylene diamine and 2-acrylamide-2-sodium methylacrylsulfonate serving as raw materials to obtain a hyperbranched polymer with a structure shown as a formula (I), (II), (III) or (IV); undergoing a polymerization reaction on the hyperbranched polymer, an esterification monomer and a crosslinking agent; and preparing a hyperbranched polycarboxylic acid-series super plasticizer with a two-step process. The preparation method provided by the invention has the advantages of simple process, easiness for controlling a preparing process and operating, readily-available raw materials, low production cost and suitability for industrial production. Due to the adoption of the hyperbranched polycarboxylic acid-series super plasticizer, the comprehensive performance of concrete is improved. As proved by an experiment result, the hyperbranched polycarboxylic acid super plasticizer provided by the invention has high slump loss resistance, high water-reducing rate and high compressive strength.

Owner:安徽海螺材料科技股份有限公司

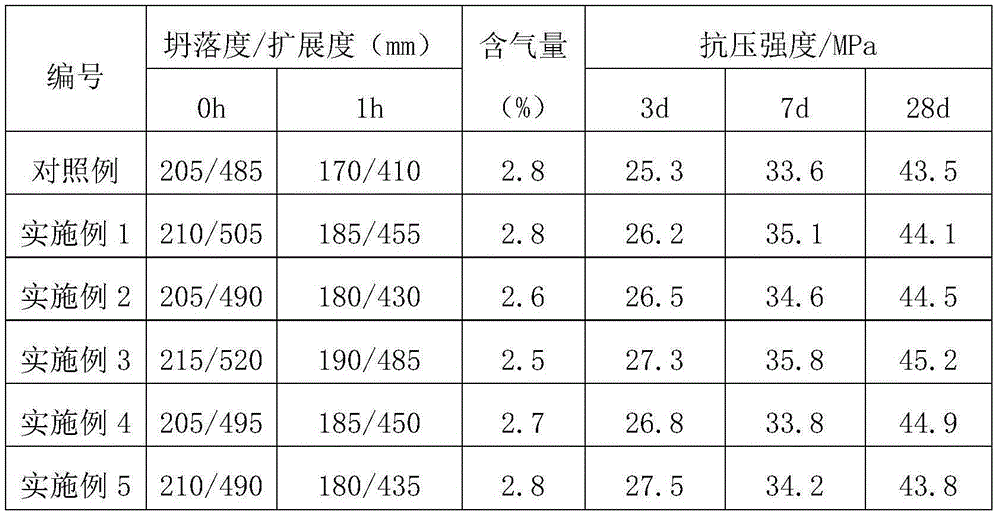

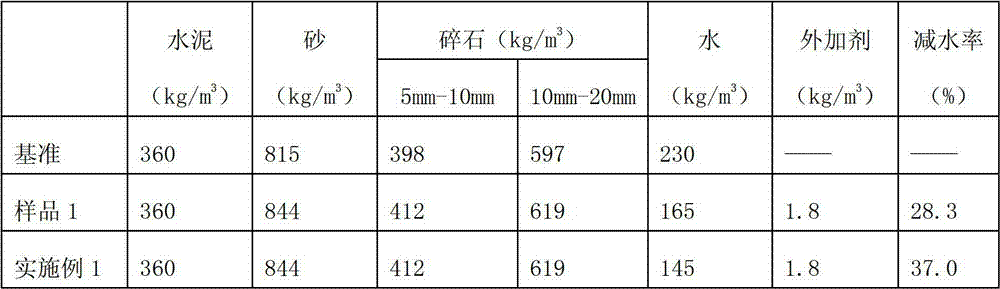

A polycarboxylate water reducer with high water reducing rate and high slump retention, its synthesis method and its use

The invention belongs to the technical field of building materials, and specifically relates to a polycarboxylic acid water reducer with a high water-reducing rate and high slump constant holding capacity, and its synthetic method and use method. The polycarboxylic acid water reducer comprises 2-methallyl polyoxyethylene ether (TPEG), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methacrylic acid (MAA), ammonium persulfate (APS), sodium hydroxide and water. The synthetic method comprises the following steps that 1, TPEG, AMPS and MAA are prepared respectively into mixed solutions with concentrations in a range of 20 to 50%; 2, simultaneously, APS is added with a proper amount of water and is dissolved in the water; 3, the TPEG and AMPS monomer mixed solutions prepared by the step 1 are added into a reactor; nitrogen is fed into the mixture in the reactor; a condenser tube is mounted; the mixture is heated to a temperature of 60 to 100 DEG C with stirring; the MAA monomer solution prepared by the step 1 and the APS solution prepared by the step 2 are respectively added dropwisely into the heated mixture, wherein dropwise addition time of the MAA monomer solution is in a range of 1 to 5 hours and dropwise addition time of the APS solution is in a range of 1.5 to 5.5 hours; and after the dropwise addition is finished, the mixture with the MAA monomer solution and the APS solution undergoes a reaction at a constant temperature for 1 to 2 hours; 4, reaction products obtained by the step 3 are cooled and are neutralized by a NaOH solution to form desired products. The synthetic method of the polycarboxylic acid water reducer is a one-step synthetic method and has simple processes. Products prepared through the synthetic method have the advantages of stable performances, low doping quantity, high water-reducing rate, high slump constant holding capacity and good market prospects.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Dry powder of active powder concrete and use method of dry powder

The invention relates to dry powder of active powder concrete and a use method of the dry powder. The dry powder comprises the following components by weight percent: 25%-55% of concrete, 5%-20% of blending stock, 30%-60% of fine aggregate, 5%-20% of micro powder, 2-5% of super plasticizing agent powder, 1-3% of air entraining agent powder, 0.2-1% of defoamer powder, and 0%-25% of fibers. According to the invention, through industrial production, water, of which the weight is 5%-10% of the weight of the dry powder, is added into the products on site, a conventional stirring technology and equipment are used for uniformly stirring, and a mixture meets a certain fluidity of construction performance and is used for easily preparing an active powder concrete prefabricated part or meets the requirement of cast in situ. The dry powder of active powder concrete and the use method of the dry powder have the advantages of stable and reliable quality, small air-entraining volume, excellent homogeneity and convenience in construction, can be widely applied to the engineering fields, such as petroleum, railway, nuclear power, municipal administration, ocean, military facilities and the like, and have excellent economic benefits.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

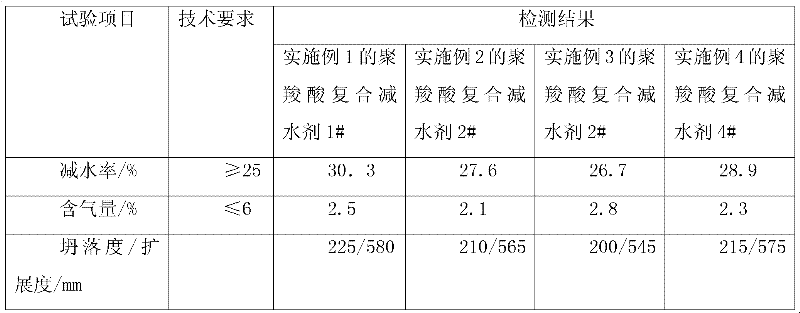

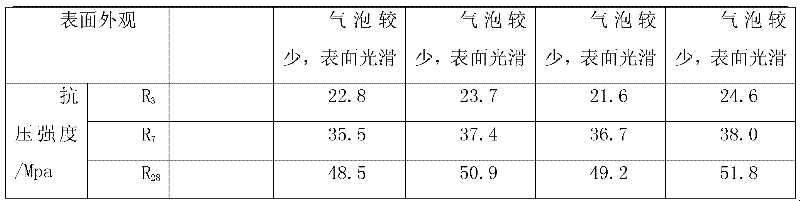

Composite polycarboxylic acid water reducing agent

The invention belongs to the technical field of concrete additives, in particular relates to a water reducing agent, and more particularly a composite polycarboxylic acid water reducing agent. The composite polycarboxylic acid water reducing agent is characterized by being prepared from the following components in percentage by mass: 8-28.6 percent of polycarboxylic acid high-performance water reducing agent, 0.5-7.36 percent of inhibiting agent, 0.001-0.15 percent of functional aid, 0.01-0.65 percent of preservative and the balance of water, wherein the total mass percentage of the components is 100 percent. The composite polycarboxylic acid water reducing agent is applied to freshly mixed concrete. After a template coated with waste engine oil or rosinate soap is dismantled, the surface of hardened concrete is smooth, air bubbles are reduced remarkably, and the construction requirement is fully met. By adopting the composite polycarboxylic acid water reducing agent, the problem of a large quantity of air bubbles on the surface of concrete, produced after the use of demolding agents such as waste engine oil or rosinate soap and the like is solved.

Owner:CHINA STATE CONSTR ENG CORP TIANJIN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com