Low-cost concrete antifreezing pumping aid and preparation method thereof

An antifreeze pump and concrete technology, applied in the field of concrete pumping agent, can solve the problems of darkening of the concrete surface, poor adaptability of the retarder, affecting the application promotion, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

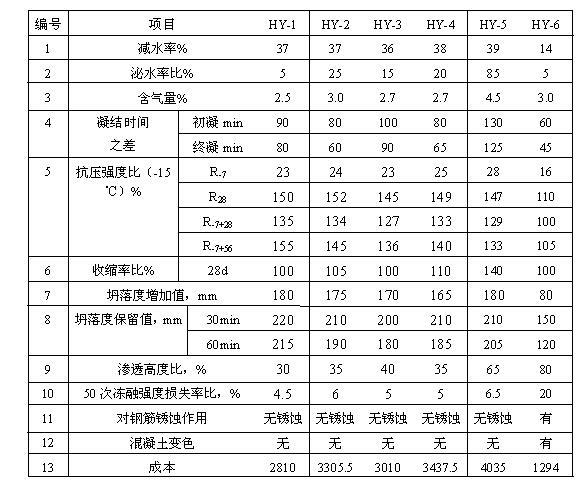

Examples

Embodiment 1

[0039] Put 380kg of deionized water and 180kg of methyl vinyl polyoxyethylene (TPEG) with a molecular weight of 2400 in the reactor, raise the temperature to 60°C, add 0.5kg of hydrogen peroxide and react for 8 minutes, then add 60kg of 50% acrylic acid aqueous solution dropwise And 5kg of 10% sodium thiosulfate aqueous solution. After 4 hours of dropping, keep warm for 2 hours, lower the temperature to below 40°C, neutralize with lye until the pH is 6~7, obtain the polycarboxylate water reducer, and adjust the solid content to 40%.

[0040] Add 506 kg of water, 200 kg of the obtained polycarboxylate superplasticizer, 4 kg of triterpene saponins, and 150 kg of 36% concentration of sulfonated acetone-formaldehyde condensate solution into the reaction kettle, and raise the temperature to 45-55°C. Add 100 kg of sodium lignosulfonate into the reaction kettle, stir thoroughly, and centrifuge at high speed to remove the precipitate after the dissolution is completed. The speed of ce...

Embodiment 2

[0042] Put 430kg of deionized water and 245kg of methyl vinyl polyoxyethylene (TPEG) with a molecular weight of 2400 in the reactor, raise the temperature to 70°C, add 0.8kg of hydrogen peroxide and react for 10 minutes, then add 80kg of 50% acrylic acid aqueous solution dropwise And 8kg of 10% sodium thiosulfate aqueous solution. After 5 hours of dropping, keep warm for 1 hour, lower the temperature to below 40°C, neutralize with lye until the pH is 6~7, and obtain the polycarboxylate water reducer, the molecular weight is between 5000~20000, and the solid content is adjusted to 40% .

[0043] Add 481 kg of water, 280 kg of the polycarboxylate superplasticizer obtained, 2 kg of fatty alcohol polyoxyethylene ether, 2 kg of triterpene saponin, and 110 kg of sulfonated acetone-formaldehyde condensate solution into the reactor, and raise the temperature to 45-55°C. Add 70 kg of sodium lignosulfonate into the reaction kettle, stir well, and centrifuge at high speed to remove the ...

Embodiment 3

[0045] Add 498 kg of water, 250 kg of polycarboxylate superplasticizer obtained in Example 2, 3 kg of triterpene saponins, and 130 kg of sulfonated acetone-formaldehyde condensate solution into the reactor, and raise the temperature to 45-55°C. Add 80 kg of sodium lignosulfonate into the reaction kettle, stir well, and centrifuge at high speed to remove the precipitate after the dissolution is completed. The speed of centrifugation is 950~1000r / min, and then transfer it into the reaction kettle. Put 15 kg of borax and 30 kg of ethylene glycol into the reaction kettle, stir evenly, and naturally cool to room temperature to obtain the finished product HY-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com