Patents

Literature

660results about How to "Enhanced pumpability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geopolymer composition and application in oilfield industry

ActiveUS20080028994A1Enhanced pumpabilityImprove stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

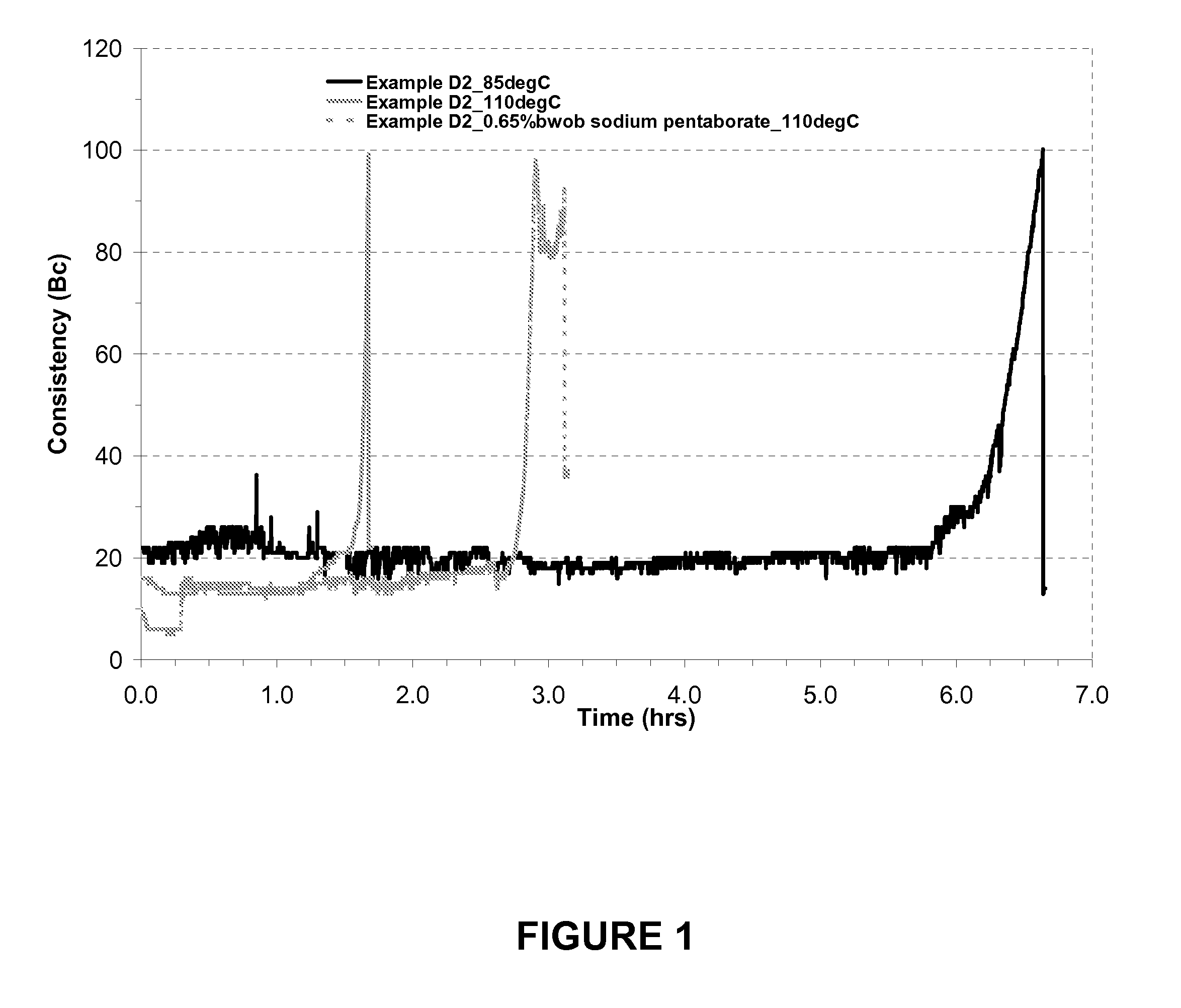

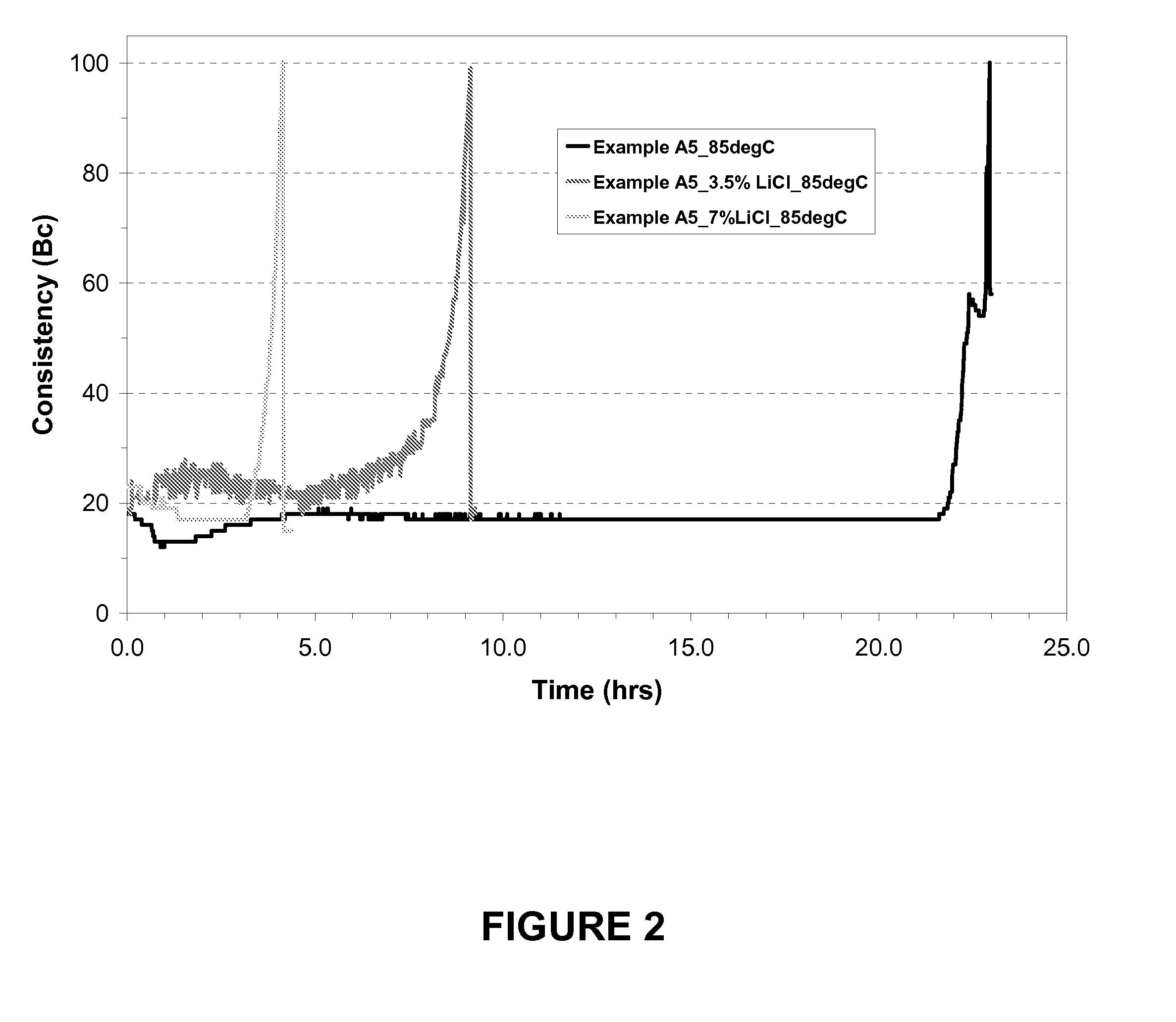

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

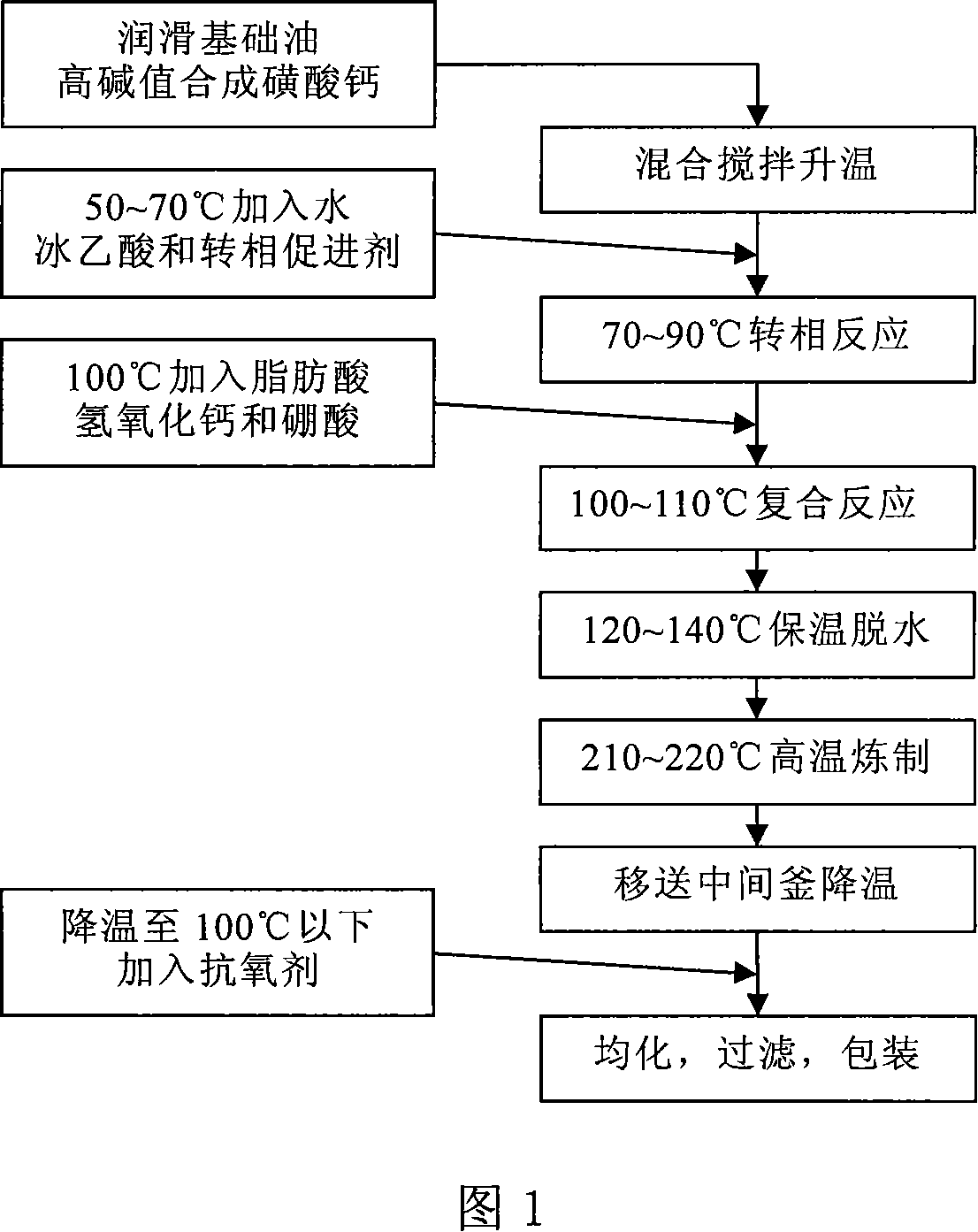

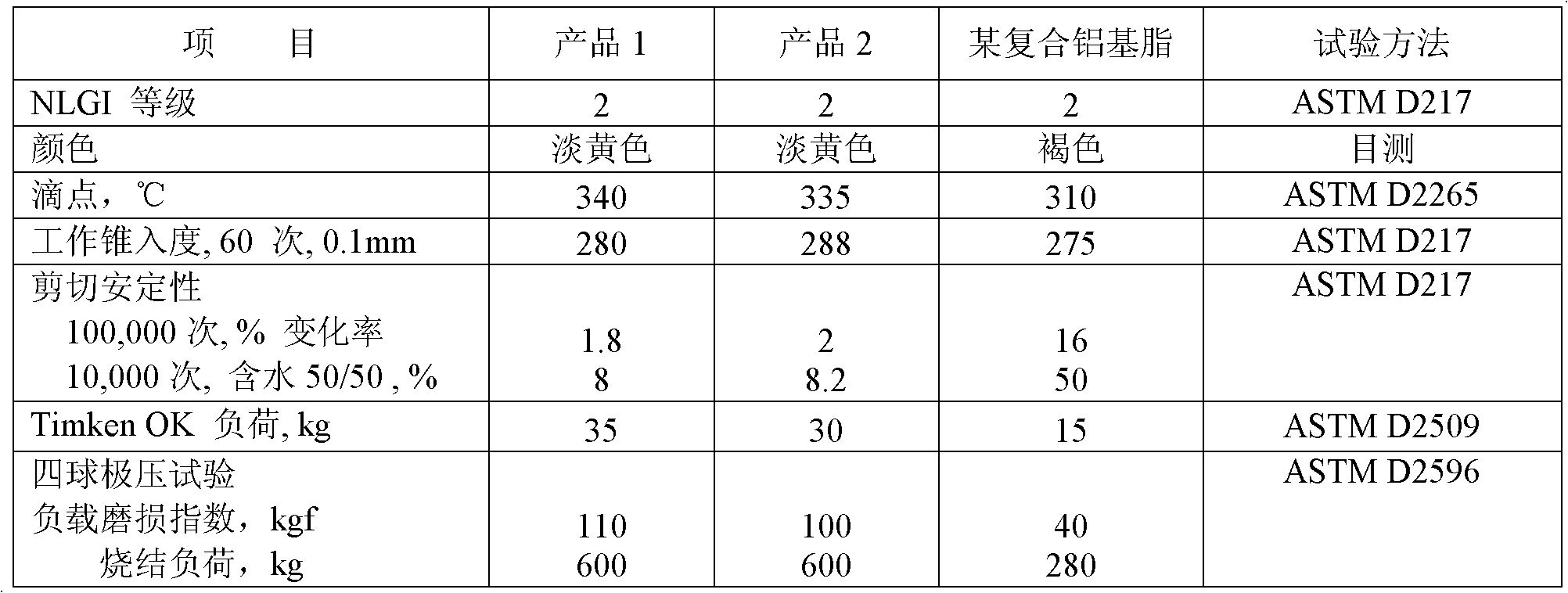

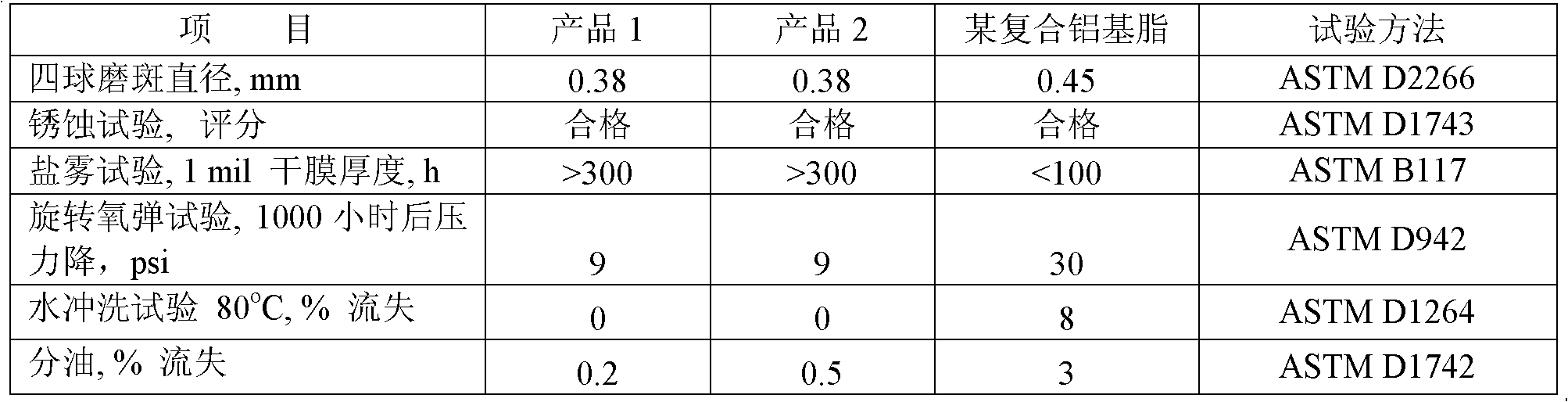

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

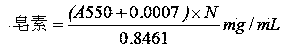

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

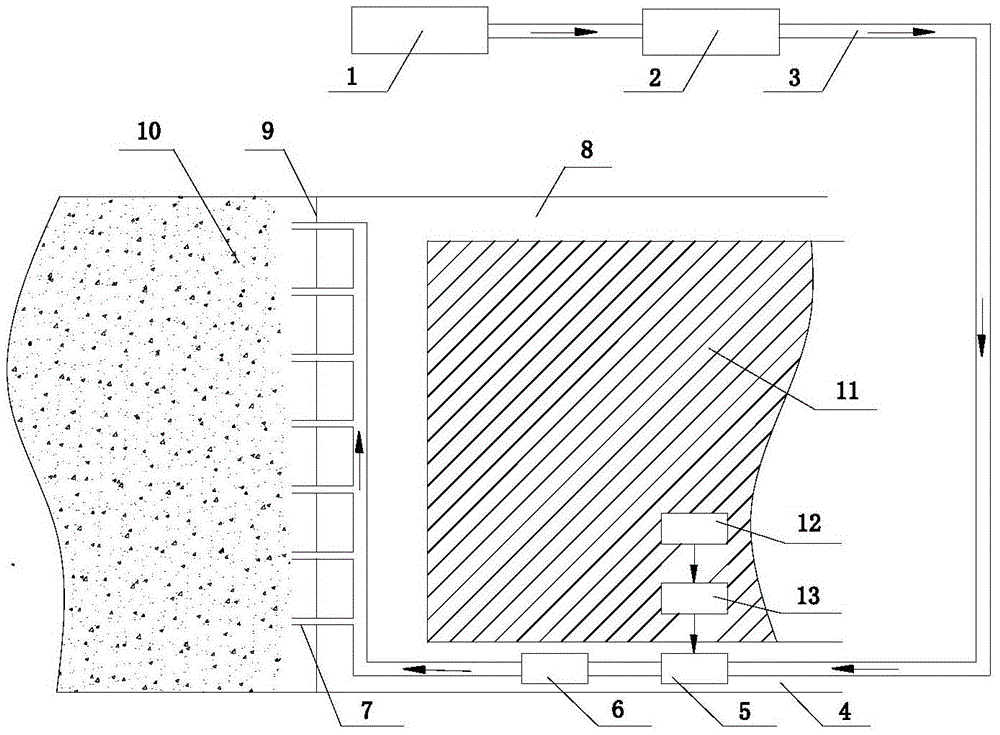

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Geopolymer composition and application for carbon dioxide storage

InactiveUS20080028995A1Enhanced pumpabilityImprove stabilityLiquid surface applicatorsSolid waste managementCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

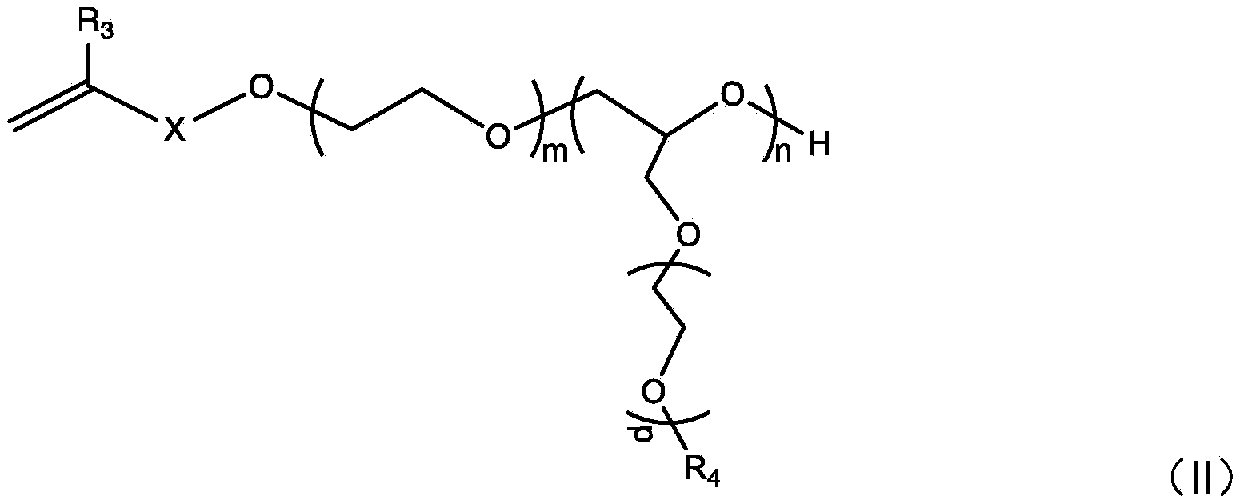

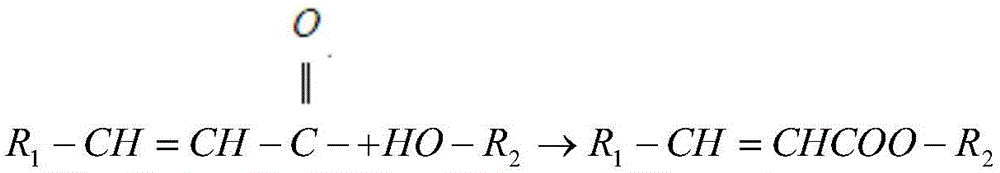

Method for preparing viscosity-reduction-type polycarboxylic acid superplasticizer and application of viscosity-reduction-type polycarboxylic acid superplasticizer

The invention provides a method for preparing a viscosity-reduction-type polycarboxylic acid superplasticizer and application of the viscosity-reduction-type polycarboxylic acid superplasticizer. The method is simple in operating process, and the prepared polycarboxylic acid superplasticizer is applied to high- and ultrahigh-strength concrete, can be used for effectively lowering the viscosity of concrete and improving the placeability and flow velocity of the concrete and is beneficial to pumping construction. According to the method, the viscosity-reduction-type polycarboxylic acid superplasticizer is prepared through carrying out free-radical copolymerization on a carboxylic monomer a, a branched side chain containing monomer b and a rigid cyclic group containing monomer c which are in the mole ratio of (4-15): 1: (0.5-2). The polycarboxylic acid superplasticizer prepared by the method provided by the invention can serve as a cement dispersant so as to greatly lower the water-cement ratio of concrete; and the polycarboxylic acid superplasticizer can be used for effectively lowering the viscosity of the high- and ultrahigh-strength concrete and improving the placeability and flow velocity of the concrete, so that the pumpability is excellent.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

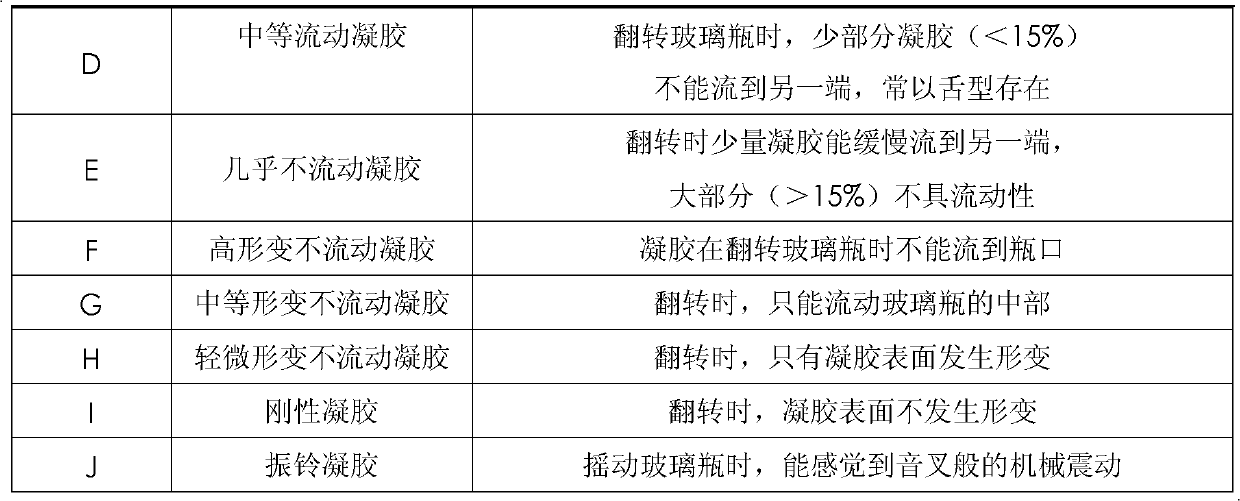

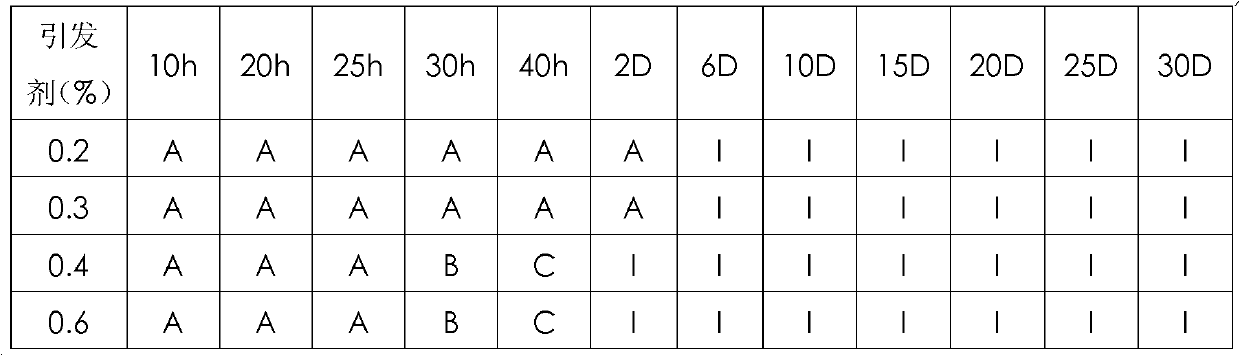

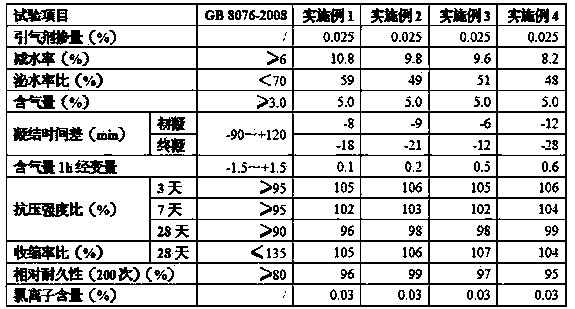

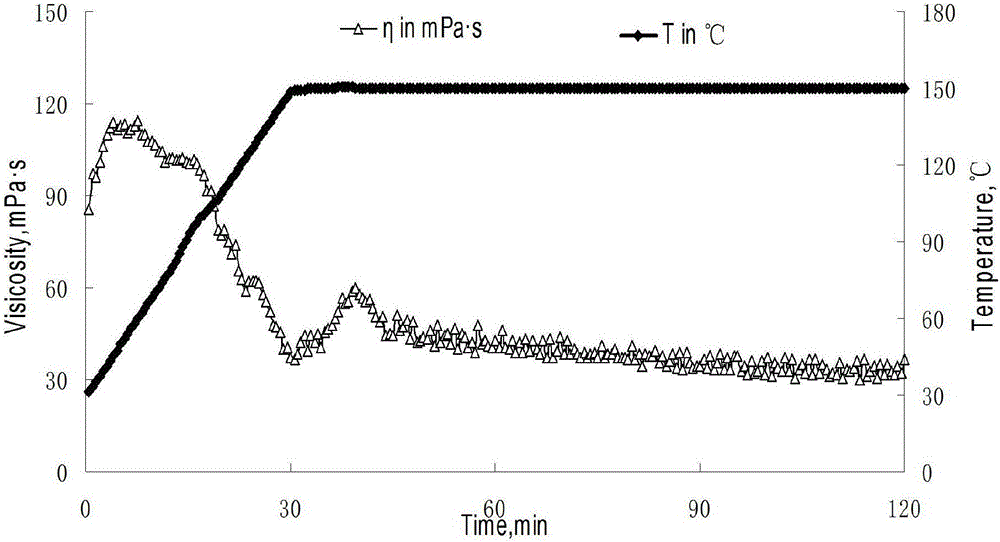

Gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs

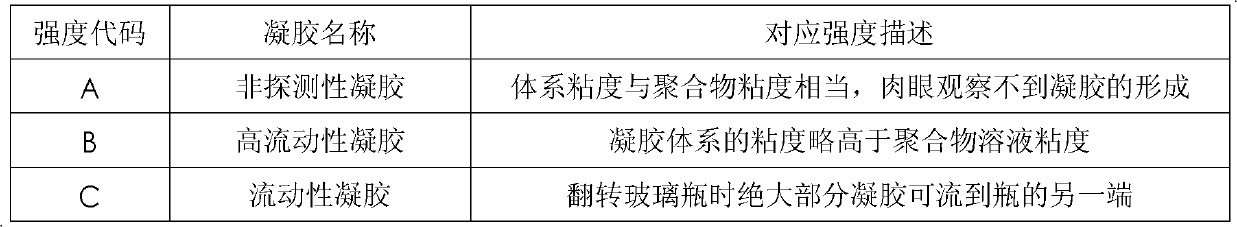

InactiveCN102382244AGood instant solubilityConvenient dispensing operationDrilling compositionSynaeresisVisual observation

The invention relates to a gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs, which consists of 5 to 7 percent by weight of main agent, 1 to 2 percent by weight of solubilizer, 1 to 2 percent by weight of cross-linking agent, 0.1 to 0.8 percent by weight of initiator and the balance of water, the main agent consists of monomer A and monomer B, the mass ratio of the monomer A to the monomer B is 3:1 to 5:1, the monomer A is acrylamide, and the monomer B is ester. Under high temperature, the pumping time of the gel is relatively longer, the gelation time canbe controlled at 20 to 72 hours under 120 DEG C, the final set strength can reach visual observation code level I, the synaeresis of the gel does not take place in 90 days, and the gel can be used inwater shutoff operation for high-temperature reservoirs under 90 DEG C to 140 DEG C. Because the gel has the advantages of good pumping property, high plugging strength, long service life, simple construction process and the like, the gel has a broad application prospect in chemical profile modification and water shutoff for oil fields.

Owner:SOUTHWEST PETROLEUM UNIV

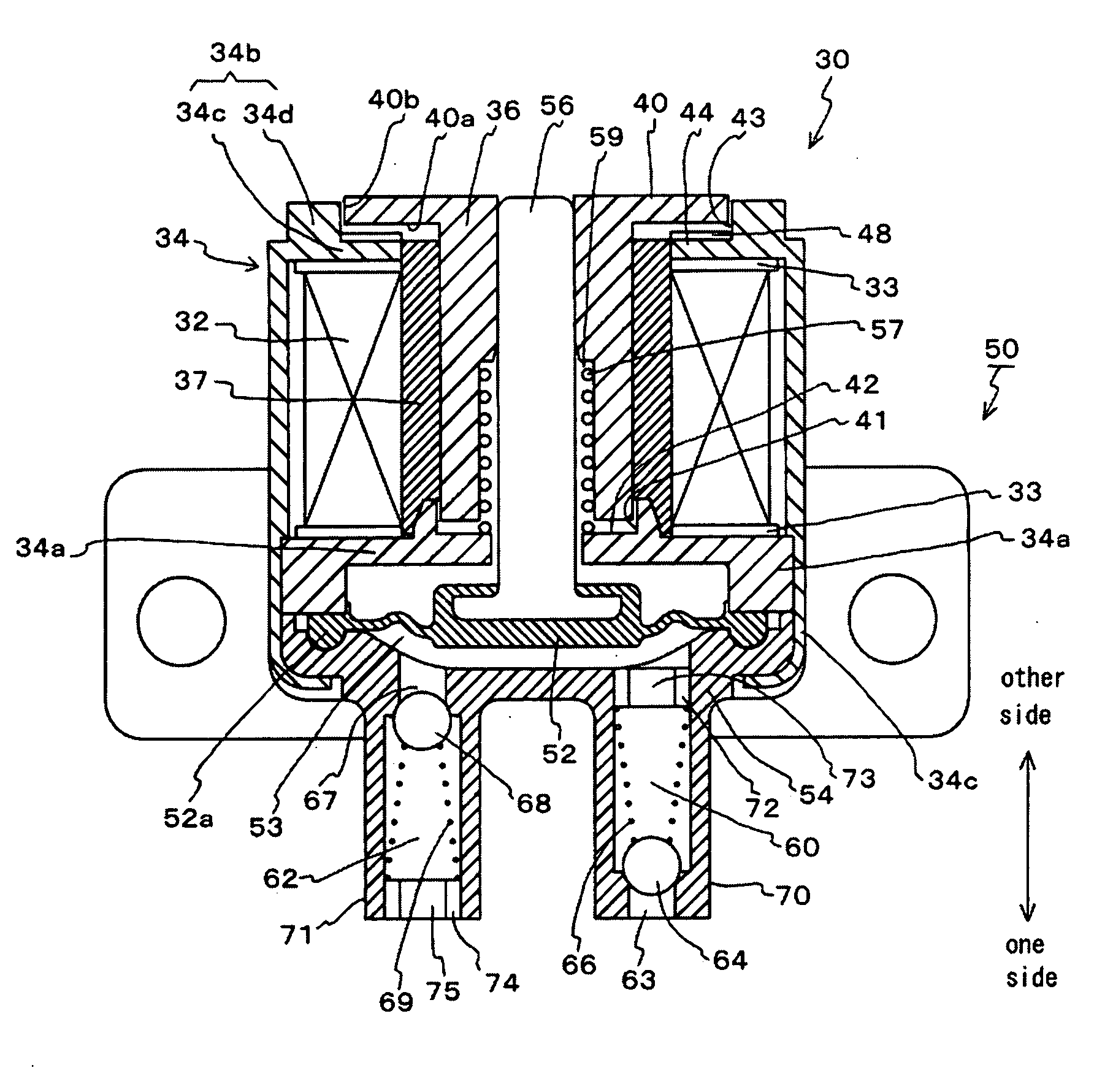

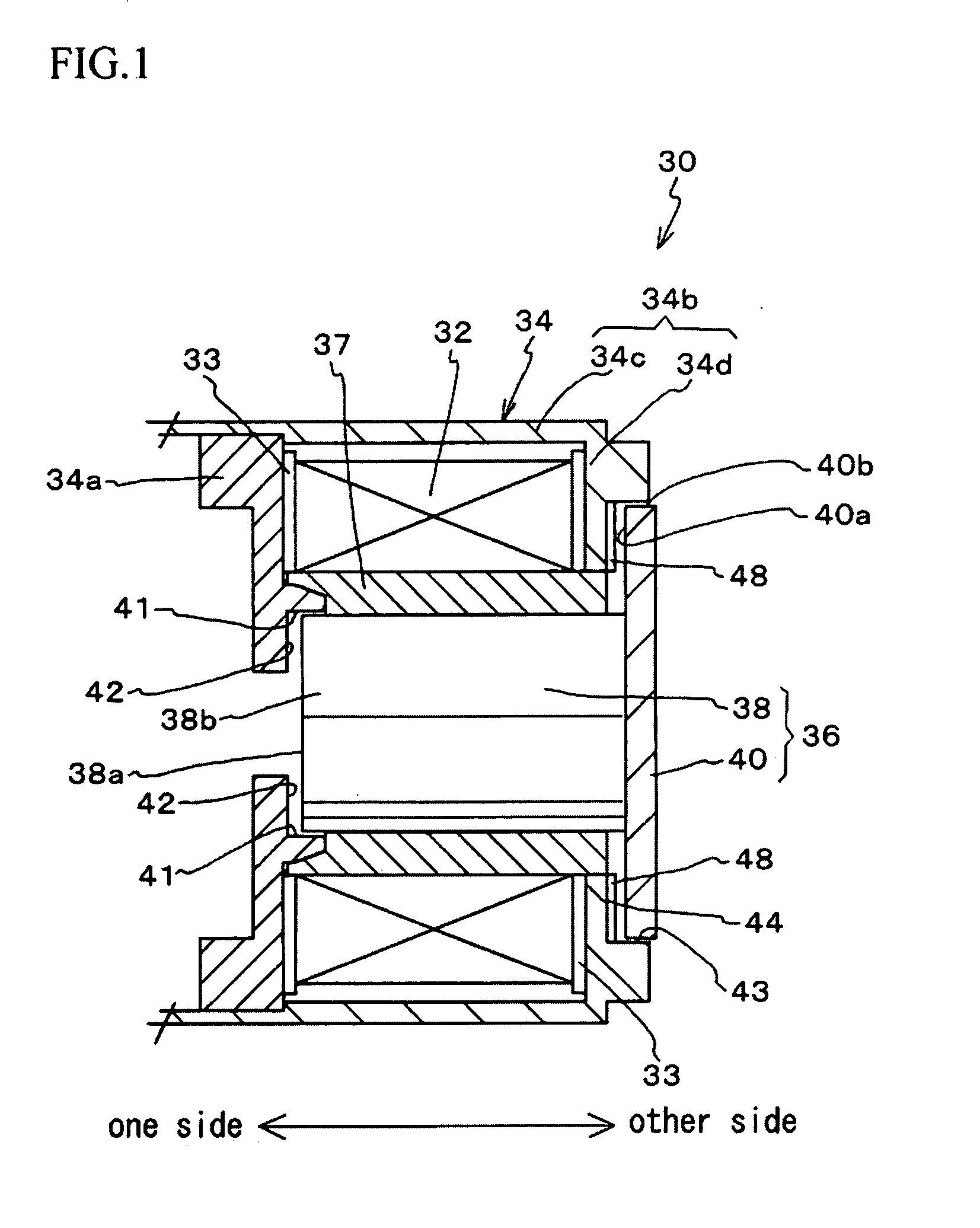

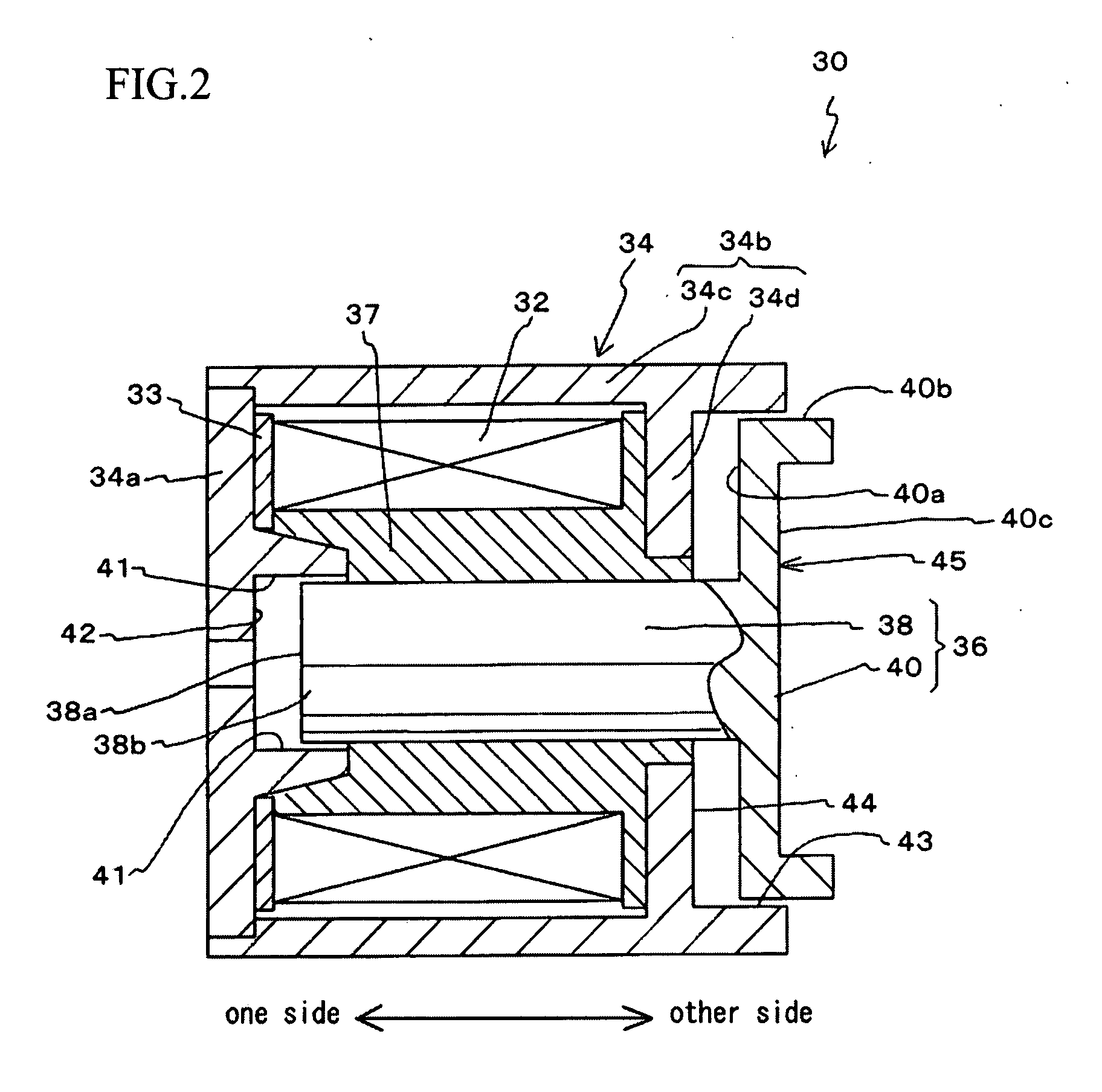

Solenoid and pump using the same

InactiveUS20070236089A1Enhanced pumpabilityImprove pumping capacityFlexible member pumpsPiston pumpsSolenoid valveEngineering

The solenoid is capable of generating great thrust and having broad-ranging thrust characteristics. The solenoid of the present invention comprises: a guide pipe formed into a cylindrical shape and provided inside of an excitation coil; a movable element having a small diameter section and a large diameter section; a first yoke part covering one end face of the excitation coil, the first yoke part having a first facing surface, which faces an outer circumferential face of the small diameter section of the movable element, and a second facing surface, which faces one end face of the small diameter section; and a second yoke part covering the other end face of the excitation coil, the second yoke part having a third facing surface, which faces an outer circumferential face of the large diameter section of the movable element, and a fourth facing surface, which faces one end face of the large diameter section.

Owner:SHINANO KENSHI

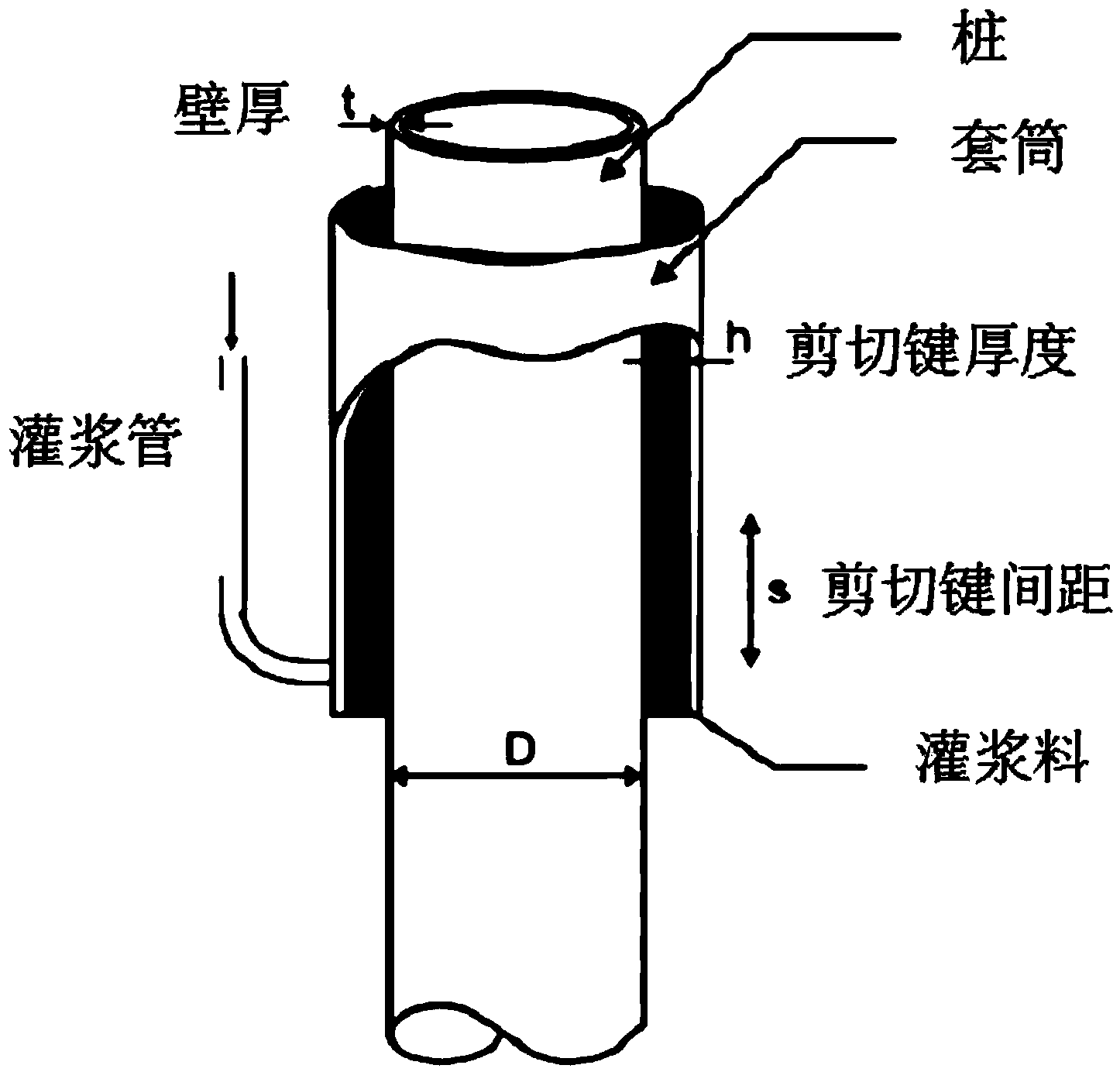

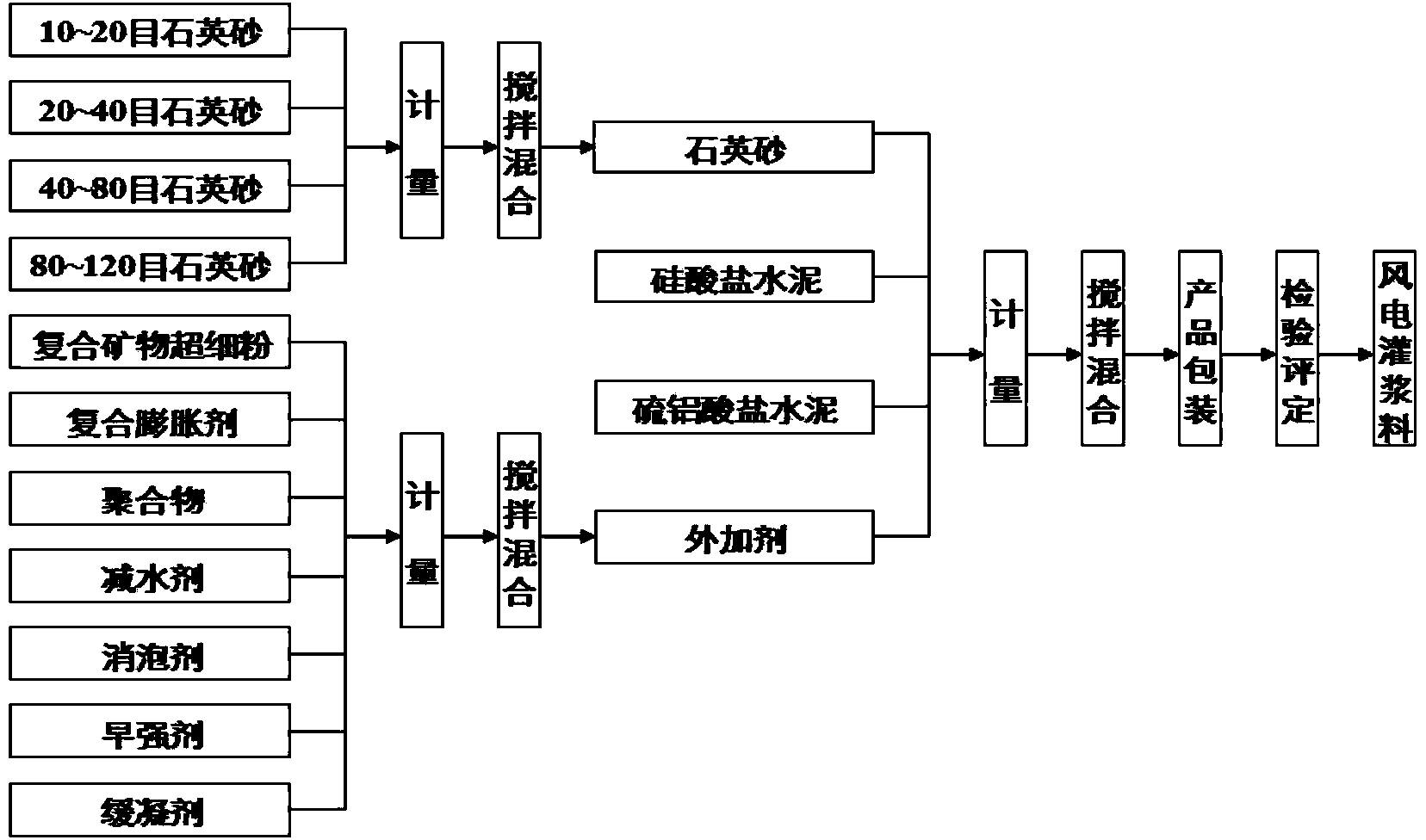

Offshore wind power duct rack grouting material and construction method thereof

ActiveCN104003681AMeet the index requirements for groutingImprove workabilityFoundation engineeringPortland cementOffshore wind power

The invention provides an offshore wind power duct rack grouting material which comprises a dry material and water, wherein the dry material comprises the following components in percentage by mass: 25.0-40.0 percent of Portland cement, 1.0-5.0 percent of sulphoaluminate cement, 45.0-55.0 percent of quartz sand and 5.0-15.0 percent of admixture; the addition amount of the water is proper. The invention further provides a construction method of the offshore wind power duct rack grouting material. According to the offshore wind power duct rack grouting material and the construction method thereof, the material has the characteristics of high liquidity, high pumpability, super-high early-strength, ultrahigh strength, high durability, good water dispersion resistance, zero shrinkage and high fatigue resistance, can be conveyed by a rubber pipeline by adopting a pumping and grouting construction mode, is suitable for underwater grouting and is also suitable for grouting connection between the offshore wind power duct rack and steel pipe pile foundation.

Owner:CCCC THIRD HARBOR ENG +2

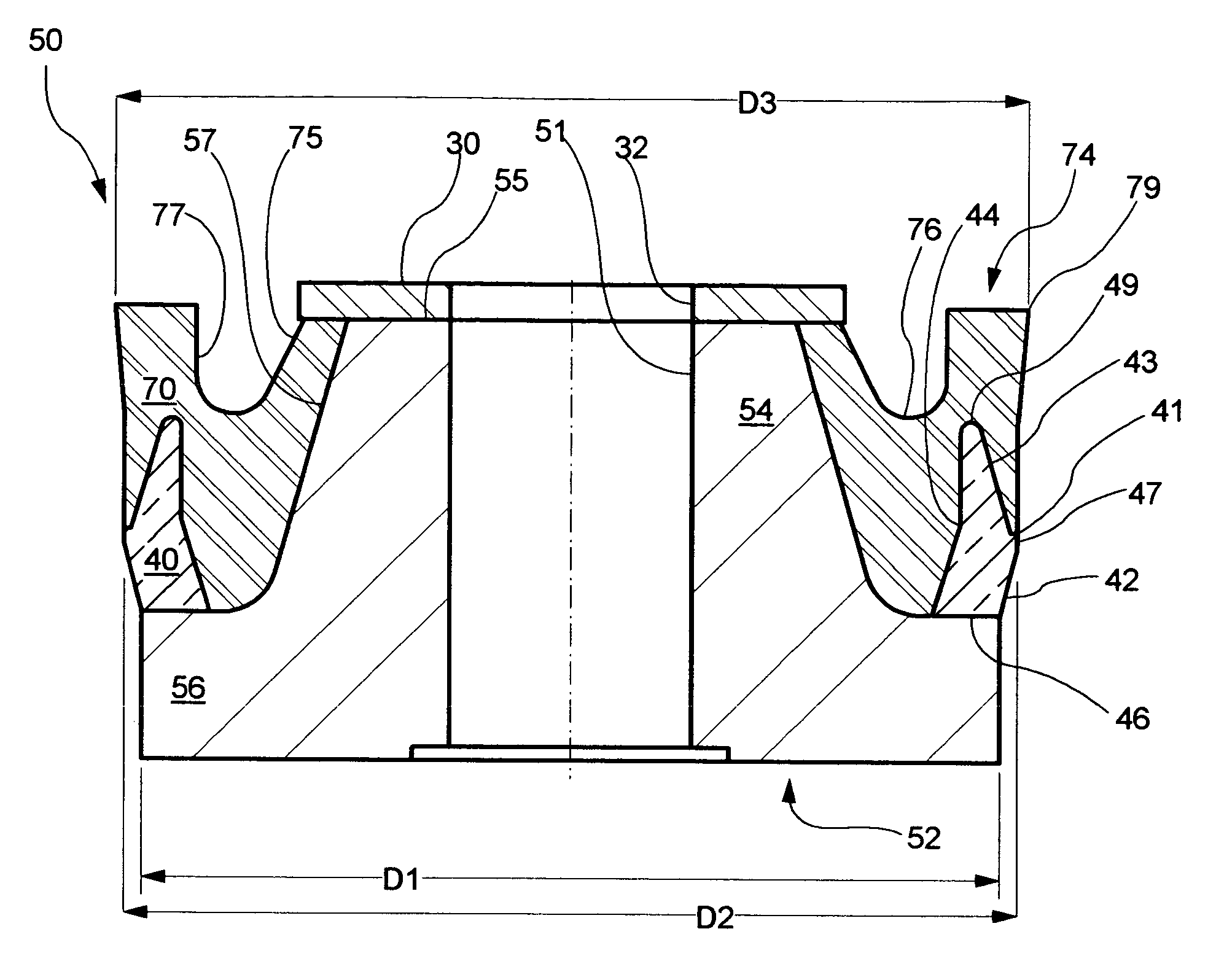

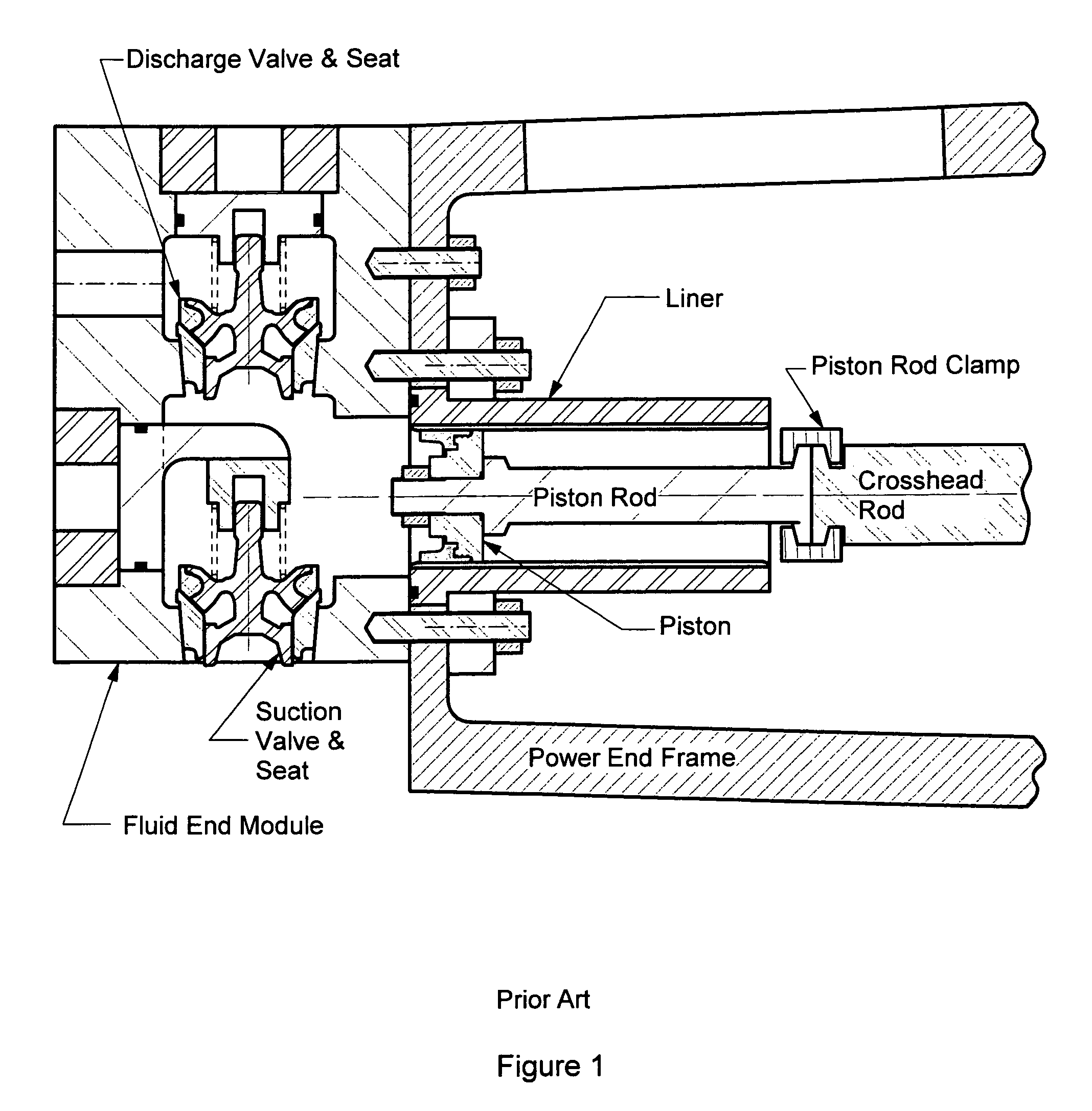

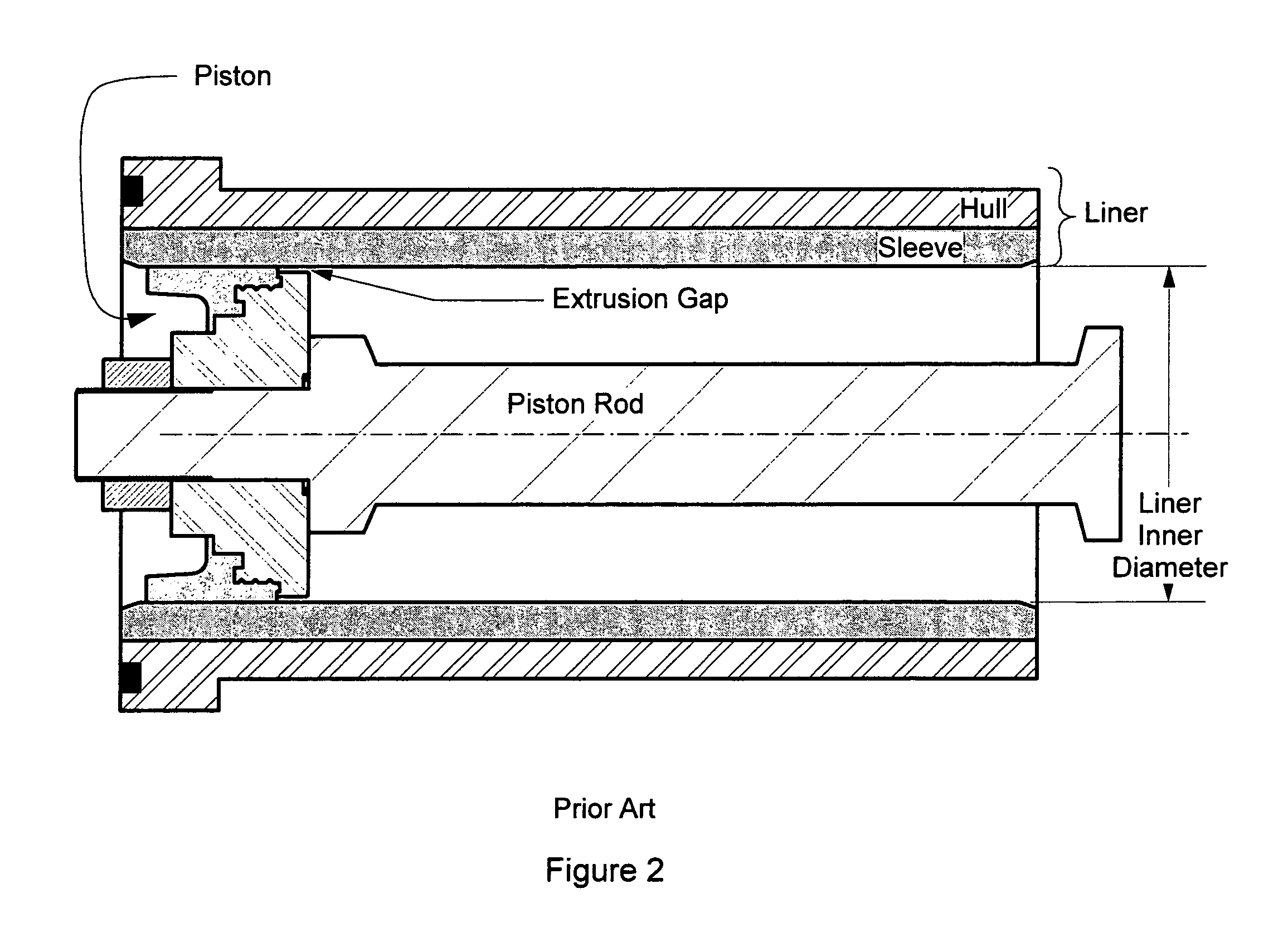

High pressure pump piston

InactiveUS6957605B1Easy maintenanceReduce the force per unit areaEngine sealsPiston ringsElastomerEngineering

A high pressure piston for use within a liner for a reciprocating pump comprises an elastomeric seal and a metallic annular bearing ring having relatively high heat conductivity compared to the liner and seal. During the pump's pressure stroke a portion of the bearing ring elastically expands radially to narrow or close the extrusion gap. Narrowing the gap decreases the tendency for extrusion of piston seal elastomeric material, while closing the gap tends to block elastomer extrusion and establish sliding contact between the bearing ring and the liner. Sliding contact between the bearing ring and liner prevents portions of the piston hub (e.g., a transverse flange) from contacting the liner and damaging it. The heat-conductive bearing ring improves scavenging of frictional heat near the extrusion gap, extending the service life of piston seal elastomer while reducing bearing ring and liner wear. Under reduced pressure on the pump's return stroke, the bearing ring elastically contracts radially, slightly widening the extrusion gap. On the pump's return stroke the slightly wider extrusion gap allows cooling water directed generally toward the proximal flange of the piston hub to better cleanse, as well as cool, the liner wall.

Owner:NOVATECH HLDG CORP

Tail sealing grease for shield tunneller

The invention discloses a sealing grease for a shield tail of a shield tunneller, which comprises by weight the following components: basic oil 17.5-19 portions, thickener 8-15 portions, waterproof sealing material 58-65 portions, lubricant 1.5-3 portions, antioxidant 1-2 portions, anti-rust agent 0.5-1.5 portions, and tackifier 4-6 portions. The invention is of low cost, strong adhesion, good sealing performance, good pumping effect, environmental friendliness, good lubrication and steadiness, is resistant to aging and oxidation, free from separation and dry contracting during the quality warranty period of the product.

Owner:刘延鹏

Sludge treatment method and sludge foaming lightweight concrete produced therefrom and use

InactiveCN101381191ASolve processing problemsNo pollutionSludge treatmentSolid waste managementFoaming agentFilling materials

The invention discloses a sludge treatment method, as well as sludge foamed lightweight concrete produced through the method and application thereof. In the method, sludge produced by sewage treatment first reacts with quicklime so as to form sludge hydrated lime; then the sludge hydrated lime is mixed with cement and water so as to form sludge concrete; foaming agent produces foam by utilizing a foaming system of a foaming machine; and the foam is mixed with the sludge concrete. The sludge treatment method can directly obtain the sludge foamed lightweight concrete. The sludge foamed lightweight concrete has a plurality of functions, which can be used as a filling material, a heat insulating material, a walling material, a sound insulation material, a mine tunnel filling material, an artificial landscape manufacturing material, a road recovery material, a pipe base filling material and the like. The sludge treatment method is low in cost and friendly to environment, can directly produce the sludge foamed lightweight concrete with a plurality of functions, and not only solves the sludge treatment problems in the sewage treatment industry, but also ensures the full utilization of the sludge.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Low-cost concrete antifreezing pumping aid and preparation method thereof

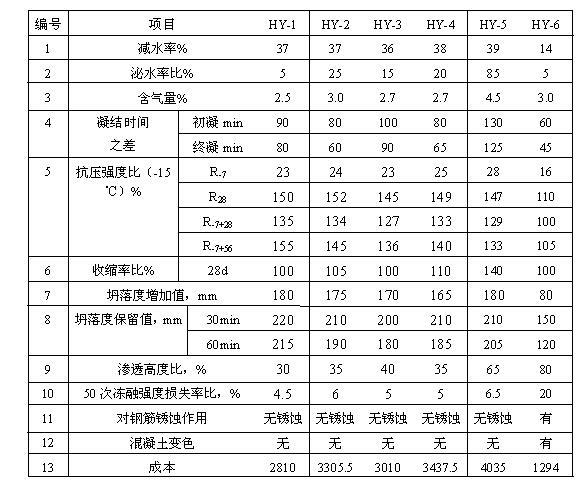

The invention relates to the concrete pumping aid field, in particular to a low-cost concrete antifreezing pumping aid and a preparation method thereof. The concrete pumping aid comprises the following raw materials by weight percent: 20-30% of polycarboxylic acid water reducing agent of which solid content is 40%, 0.3-0.4% of air entraining agent, 0.9-2% of retarder, 11-15% of sulfonated acetone-formaldehyde condensate of which solid content is 36%, 6-10% of sodium lignin sulfonate, 2-4% of antifreezing component and the balance of water. The preparation method comprises the following steps: adding water, air entraining agent, polycarboxylic acid water reducing agent and sulfonated acetone-formaldehyde condensate in a container to heat to 45-55 DEG C, and stirring evenly; adding sodium lignin sulfonate in the container to stir, centrifuging to remove precipitate; and adding retarder and antifreezing component to stir evenly. The low-cost concrete antifreezing pumping aid has good performance; the composite indicators such as the antifreezing property, the pumping property, the water reducing ratio and the ratio of compressive strength are better than that of the antifreezing pumping aid which uses polycarboxylic acid water reducing agent or sulfonated acetone-formaldehyde condensate alone; and the antifreezing pumping aid in the invention has higher adaptability and good cost performance.

Owner:安徽海螺材料科技股份有限公司

Degradable type shield tail sealing grease of shield excavation machine

InactiveCN102757839AGood pumping effectWide temperature rangeLubricant compositionFilling materialsOil and grease

The invention discloses a degradable type shield tail sealing grease of a shield excavation machine, belonging to the field of chemical grease. The degradable type shield tail sealing grease of the shield excavation machine is prepared by compounding the following raw materials in parts by weight: 16-20 parts of base oil, 10-16 parts of thickening agents, 68-76 parts of filling materials, 3-5 parts of lubricating agents, 0.5-2 parts of antioxidants, 0.3-1.7 parts of antirusting agents, 0.5-1.5 parts of antimildew agents, 5-7 parts of viscosity index modifying agents and 16-24 parts of plasticizing agents. The preparation method of the degradable type shield tail sealing grease comprises the following steps of: firstly adding the base oil, the thickening agents, the viscosity index modifying agents, the antirusting agents, the antimildew agents, lubricating agents and the antioxidants to an agitator according to weight ratio at normal temperature, and uniformly mixing and agitating; then adding the filling materials in batches, and uniformly mixing; finally adding fibers, and mixing and agitating for about 90 minutes. The degradable type shield tail sealing grease not only has property of the conventional shield tail sealing grease and the advantages of low cost, high adhesivity, good pumping effect and excellent sealing property, but also can be degraded by microbes contained in soil without polluting the soil and underground water, belongs to an environmental-friendly product.

Owner:上海茨夫新型建筑材料有限公司

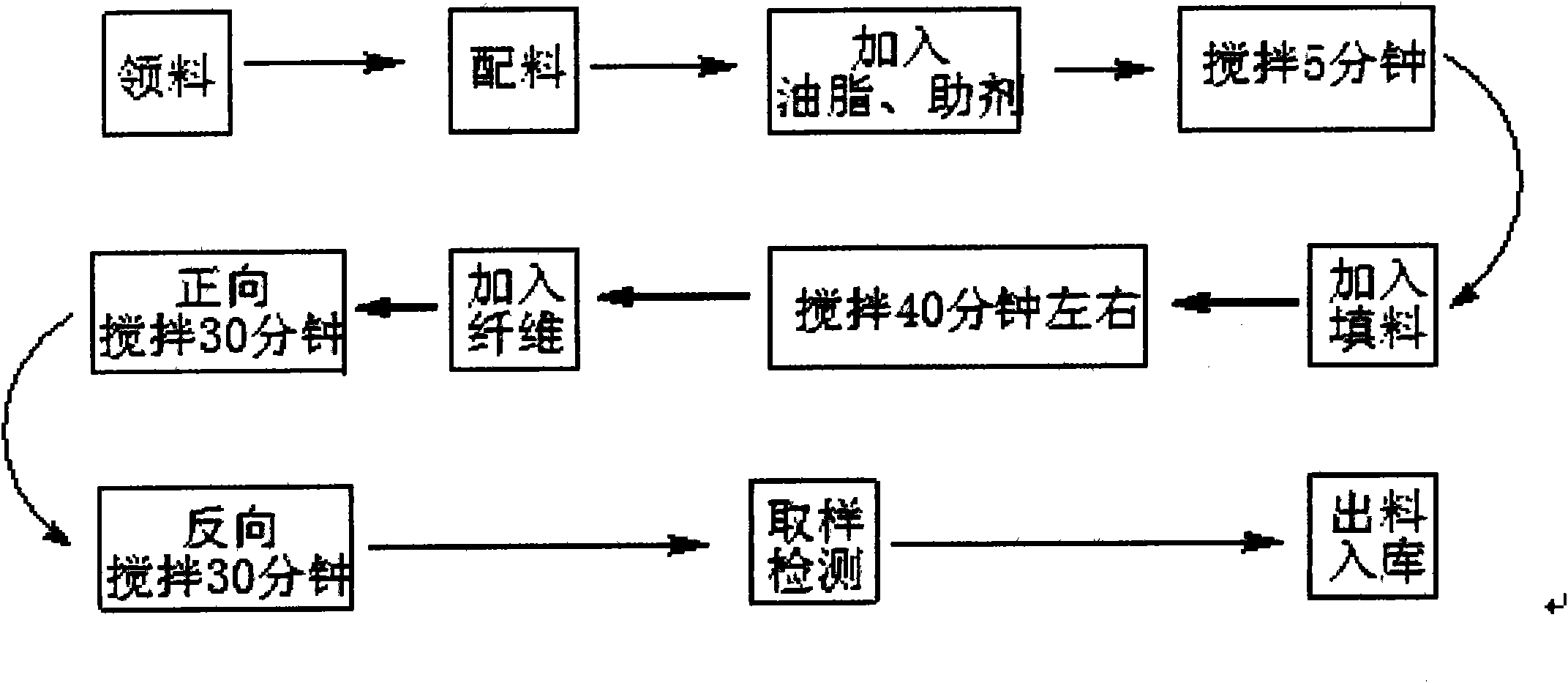

Shield tail sealing grease and preparation method thereof

The invention discloses shield tail sealing grease and a preparation method thereof. The shield tail sealing grease for tunnel construction tunneling equipment namely a shield tunneling machine consists of the following components: 15-30% of base oil, 10-20% of lubricating grease, 2-8% of a tackifier, 1-5% of an adhesion promoter, 5-10% of fibers, and 30-50% of a flour filler. The shield tail sealing grease is mainly formed by the combination of the base oil, the lubricating grease, the fibers and the filler, particularly the adhesion promoter is added, and the adhesion and the stability of a product are enhanced by the interaction force between the adhesion promoter and the surface of a base material; the product is stable in performance, avoids phenomena of segregation and sun crack when exposed in the air for a long time, does not generate sag and flow when encountering heat, and can still keep a relatively good pumping performance at a low temperature; and the shield tail sealing grease has relatively high impermeability, is convenient to operate and easy to pump, has excellent adhesion and certain corrosion resistance to metals, has outstanding water-stop and lubricating effects, and is easily biodegradable, environment-friendly and nontoxic.

Owner:XIAMEN NORNS TECH

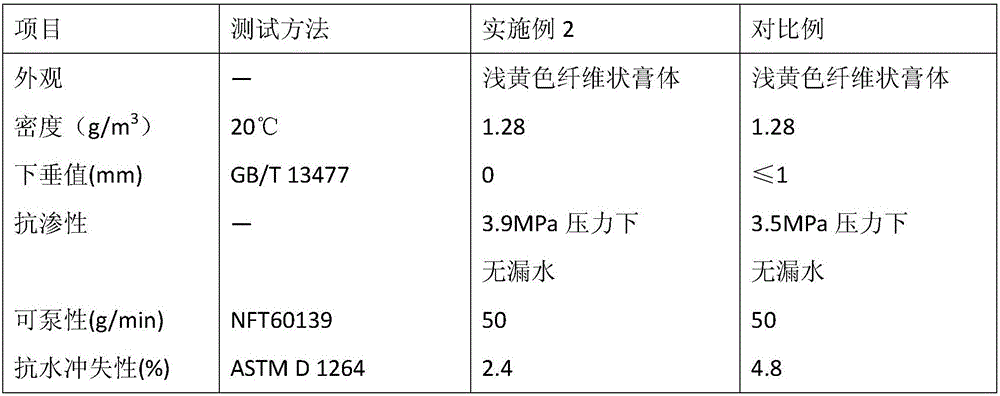

Preparation method and application of environment-friendly type shield tail sealing grease

The invention discloses a preparation method and an application of environment-friendly type shield tail sealing grease. The shield tail sealing grease mainly comprises the following components: 14-30% of lubricating oil, 7-22% of oil plasticizer, 3-15% of thickening agent, 3-12% of lubricating grease, 3-8% of natural degradable fiber, 35-60% of filling granular material, 1-3% of coloring agent and 0.1-2% of preservative. The environment-friendly type shield tail sealing grease prepared by using the method is used for sealing a shield tail of a shield tunneling machine in tunnel engineering, and has the advantages of good water pressure sealing performance, excellent pumping performance, high adhesivity, good lubrication, stable properties, no corrosion, antioxidation, wide raw material resources, environment-friendliness and simple preparation process.

Owner:东莞市明洁隧道建设材料有限公司

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Polyurethane polymer material for coal rock mass reinforcement and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a polyurethane high polymer material for coal rock mass reinforcement and a preparation method of the polyurethane polymer material. The polyurethane polymer material consists of component A and component B, wherein the component A is composed of a polyalcohol, a solvent, a catalyst and a fire retardant and the component B is composed of polyaryl polymethylene polyisocyanate. The polyurethane polymer material and the preparation method, disclosed by the invention, have the advantages that: through formulation design, foaming is carried out at a normal temperature, the curing rate is adjustable, the strength of consolidation body is high, compressive strength is more than 55MPa, the coal rock support force can be obviously increased; the consolidation body has very good toughness and can bear subsequent mining influence; the raw liquid is low in viscosity and has good permeability in the coal rock mass; and the caking property of the consolidation body and the coal rock mass is good; the related raw materials in the invention are green, pollution-free and harmless to human body, contain no volatile solvent and generate no any toxic gas, therefore, the use and environmental requirements for the coal rock mass reinforcement are completely satisfied; and the material is pressed and filled by using a double liquid grouting pump, therefore, the pumpability is good and the use is convenient.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Sealing grease and preparation method and application thereof

The invention discloses sealing grease, which is characterized by comprising the following components in percent by weight: 20 percent to 30 percent of base oil, 8 percent to 14 percent of fibers, 12 percent to 20 percent of tackifier, 10 percent to 18 percent of stabilizer and balance of powder filler. Compared with other like products, the sealing grease has the following advantages: (1) the low-temperature performance is excellent, i.e. tail sealing grease can be used in the northeastern area of China at the temperature of minus 20 degrees or so, and the grease does not harden or cake and keeps excellent pumpability; and (2) the sealing performance is strong, i.e. at normal temperature, the grease can bear the pressure of 0.80MPa, grease leakage and water leakage do not occur, and the grease shows excellent water resistance and water jet resistance.

Owner:上海翔威环境科技集团有限公司

High-performance reinforced mortar suitable for thick-layer spraying and preparation method thereof

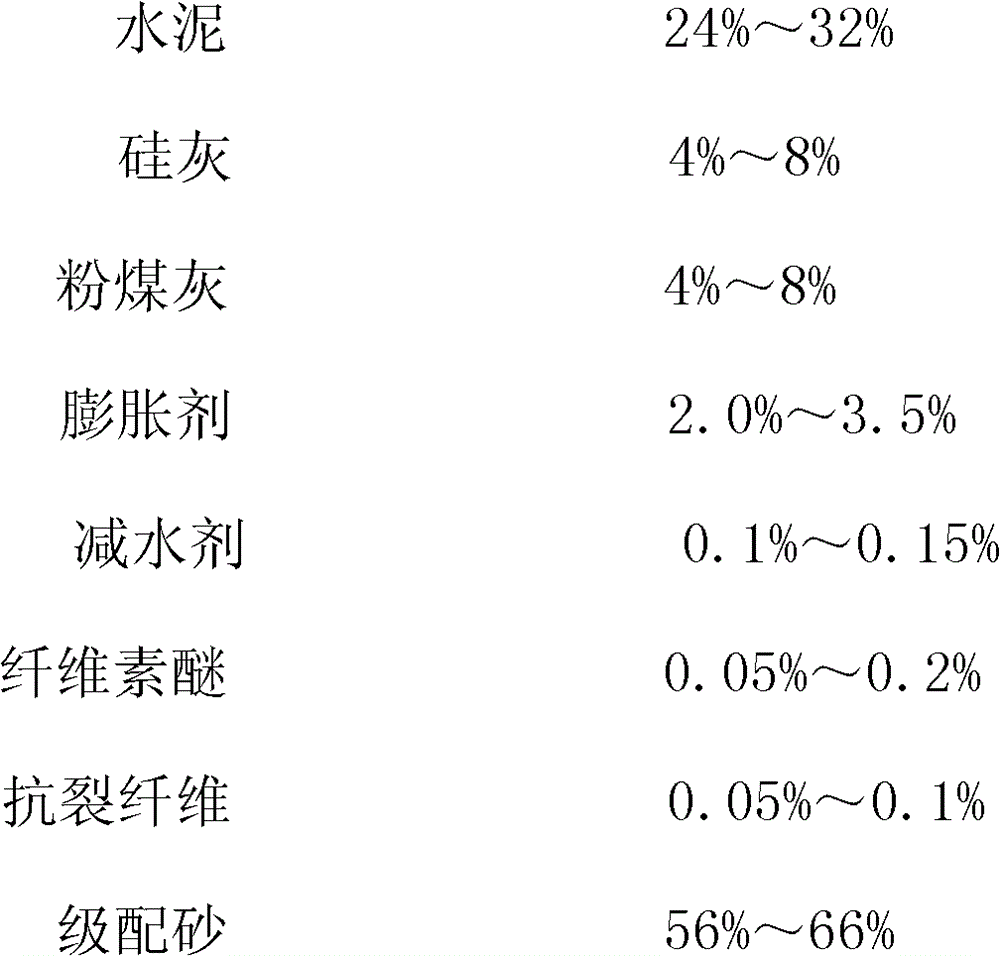

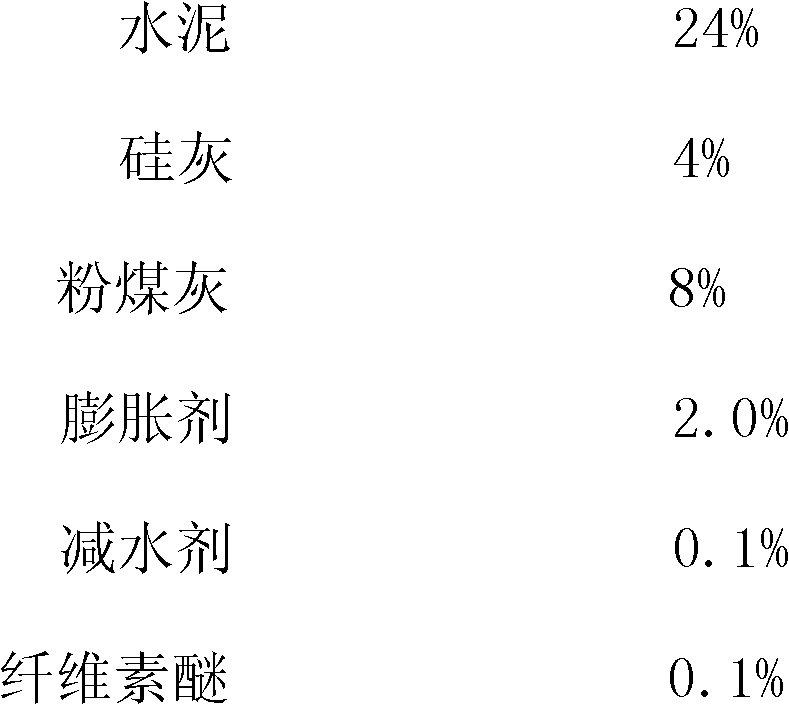

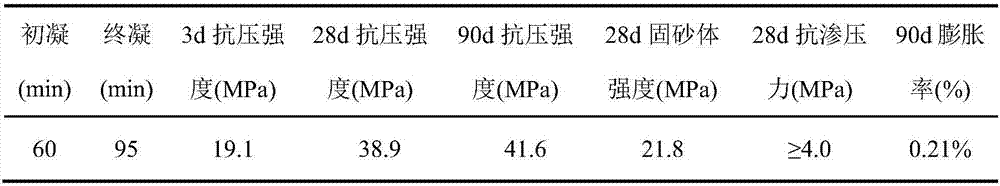

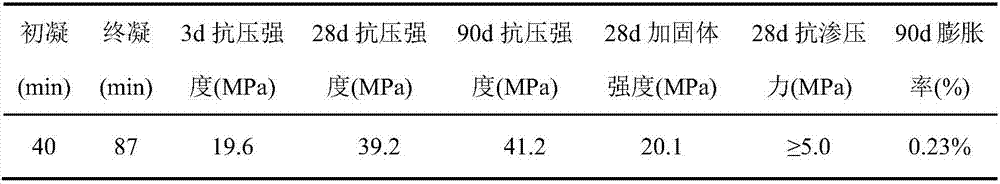

InactiveCN102718447AMeet reinforcement requirementsEnhanced pumpabilityHigh strength concreteCellulose

The invention discloses a high-performance reinforced mortar suitable for thick-layer spraying and a preparation method thereof. The high-performance reinforced mortar is mainly prepared from ordinary portland cement, silica fume, coal ash, an expanding agent, a water reducing agent, cellulose ether, anti-crack fibers, and graded sand in a certain mass percent, wherein the mass percent of each composition is as follows: the cement 24%-32%, the silica fume 4%-8%, the coal ash 4%-8%, the expanding agent 2.0%-3.5%, the water reducing agent 0.1%-0.15%, the cellulose ether 0.05%-0.2%, the anti-crack fibers 0.05%-0.1%, and the graded sand 56%-66%. The high-performance reinforced mortar of the invention has strength of M60-M80, and can be used to meet reinforcing requirements of high strength concrete of strength grade C60. The high-performance reinforced mortar has good pumping performance, and is suitable for mechanized spraying construction. Moreover, the high-performance reinforced mortar has excellent substituted performance and a single spraying construction thickness of 40mm, and can be used to meet construction requirements of large-size members and thick-layer reinforcement.

Owner:陈明中

Chemical composite resin mounting agent for oil-water well casing restoration

ActiveCN102516963AEnhanced pumpabilityStrong penetrating powerDrilling compositionBorehole/well accessoriesPrepolymerChemistry

The invention relates to a chemical composite resin mounting agent for the oil-water well casing restoration, which can be applied to reinforcing work for the oil-water casing damage restoration when the stratum temperature is 40-110DEG C. The agent is characterized in that the agent comprises, by weight, 60-75% of a phenol and formaldehyde prepolymer, 10-20% of an epoxy phenolic resin F-46, 5-30% of an epoxy resin 6101, 1-5% of ethylenediamine, 1-5% of triethanolamine, 0.5-2% of acetic anhydride, 1-3% of dibutyl phthalate, 2-5% of glycol, 2-5% of polyvinyl alcohol and 0.1-0.2% of an ultrafine acrylic staple fiber. The agent has the following effect: the production capacity of the oil-water well is restored by rebuilding a composite artificial casing on the damaged and deformed casing well segment through combining the restoration reinforcing work for the damaged and deformed casing in the oilfield exploitation with a drilling and milling technology. According to the mounted casing, the tensile strength is 10.8-13.1MPa, the compressive strength is 13-87MPa, and the shearing strength is 9.2-28.9MPa.

Owner:PETROCHINA CO LTD

Silicate modified polyurethane high molecular material and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a silicate modified polyurethane high molecular material for the reinforcing and plugging of coal-rock mass and a preparation method thereof. The silicate modified polyurethane high molecular material consists of a component A and a component B at a volume ratio of 1:1, wherein the component A is liquid sodium silicate water glass; and the component B consists of 40-50 parts of polyaryl polymethylene isocyanate, 40-50 parts of modified MDI and 0-10 parts of viscosity reducer by weight. The preparation method comprises the following steps of: adding the raw materials of the component B into a reaction kettle and stirring uniformly, and performing nitrogen displacement encapsulation; and mixing the component A and the component B and grouting by a double-liquid grouting pump to obtain the product. Through the invention, the product has good flame retardance; the raw material liquid has low viscosity and good permeability in the coal-rock mass; cohesiveness between the consolidating body and the coal-rock mass is good; the silicate modified polyurethane high molecular material is suitable for the quick reinforcing and plugging treatment of the broken coal bed and rock stratum in various coal mines and tunnels in poor ventilation; and the preparation method adopts the pressure grouting of a double-liquid grouting pump, realizes an excellent pumping property, and is convenient to use.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

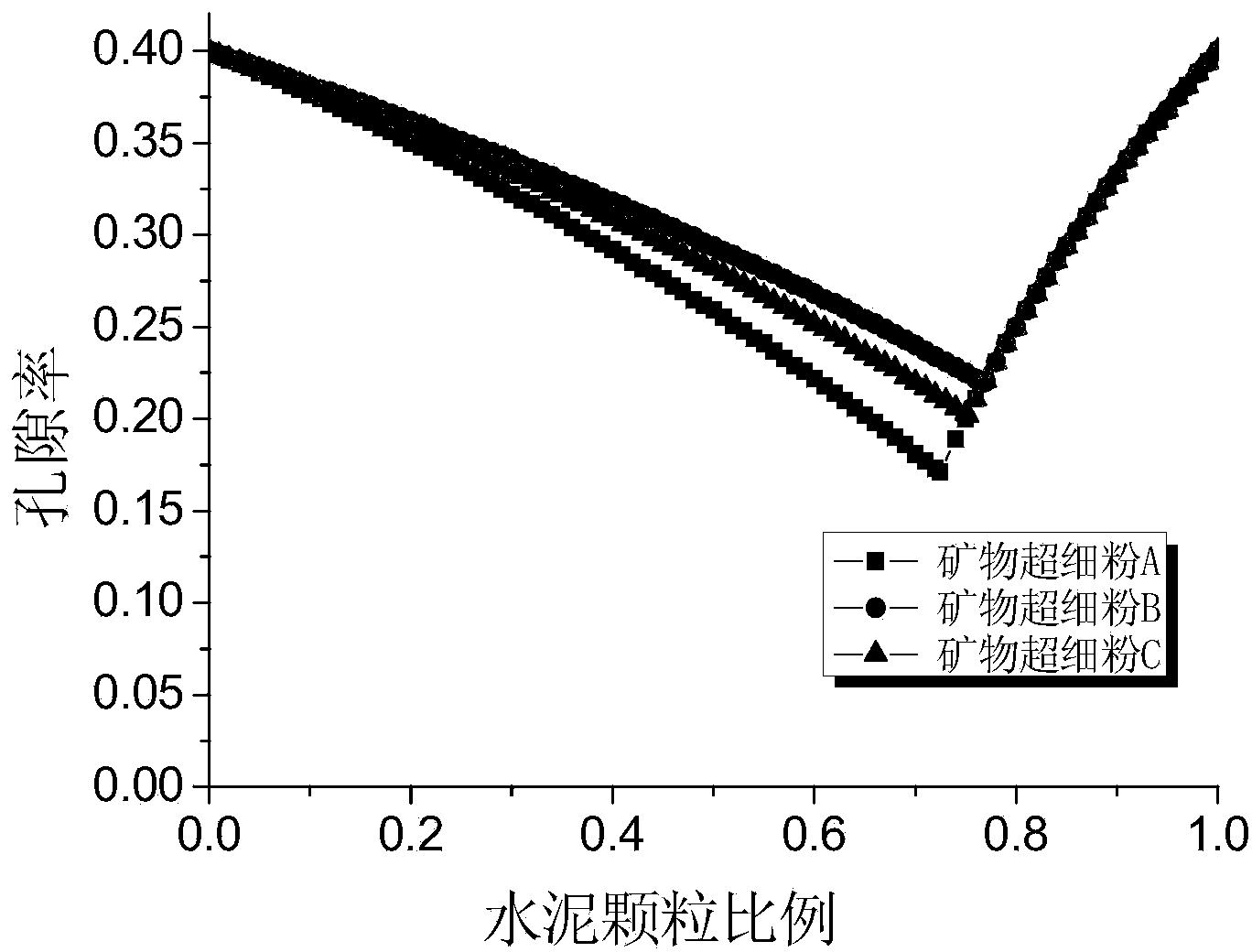

Efficient superfine cement based composite grouting material for grouting treatment of water-rich sand layer, preparation process and application

ActiveCN107572994AEasy to operateImprove applicabilityDrilling compositionSealing/packingMicrofine cementAluminate

The invention discloses an efficient superfine cement based composite grouting material for grouting treatment of a water-rich sand layer, a preparation process and application. The efficient superfine cement based composite grouting material is prepared from the following components in parts by weight: 40 to 80 parts of portland cement clinker, 10 to 45 parts of coal ash, 5 to 30 parts of superfine slag micro powder, 2 to 6.5 parts of desulphurization gypsum, 1 to 10 parts of silica fume, 0.51 to 2.10 parts of first mixed composite modifier, 0.4 to 2.4 parts of second mixed composite modifierand 5.5 to 8.9 parts of third mixed composite modifier; the coal ash is prepared from the following components in parts by weight: 50 to 100 parts of high-calcium coal ash and 0 to 50 parts of low-calcium coal ash; the first mixed composite modifier is prepared from the following components in parts by weight: 96 to 99 parts of super plasticizer and 1 to 4 parts of hydroxypropyl methyl cellulose;the second mixed composite modifier is prepared from the following components in parts by weight: 20 to 32 parts of sodium hydroxide, 21 to 28 parts of sodium carbonate, 18 to 32 parts of sodium sulfate and 18 to 36 parts of sodium metaaluminate; the third mixed composite modifier is prepared from the following components in parts by weight: 12 to 25 parts of calcium chloride, 8 to 21 parts of lithium chloride, 10 to 23 parts of triethanolamine and 32 to 68 parts of sulphoaluminate cement clinker.

Owner:SHANDONG UNIV

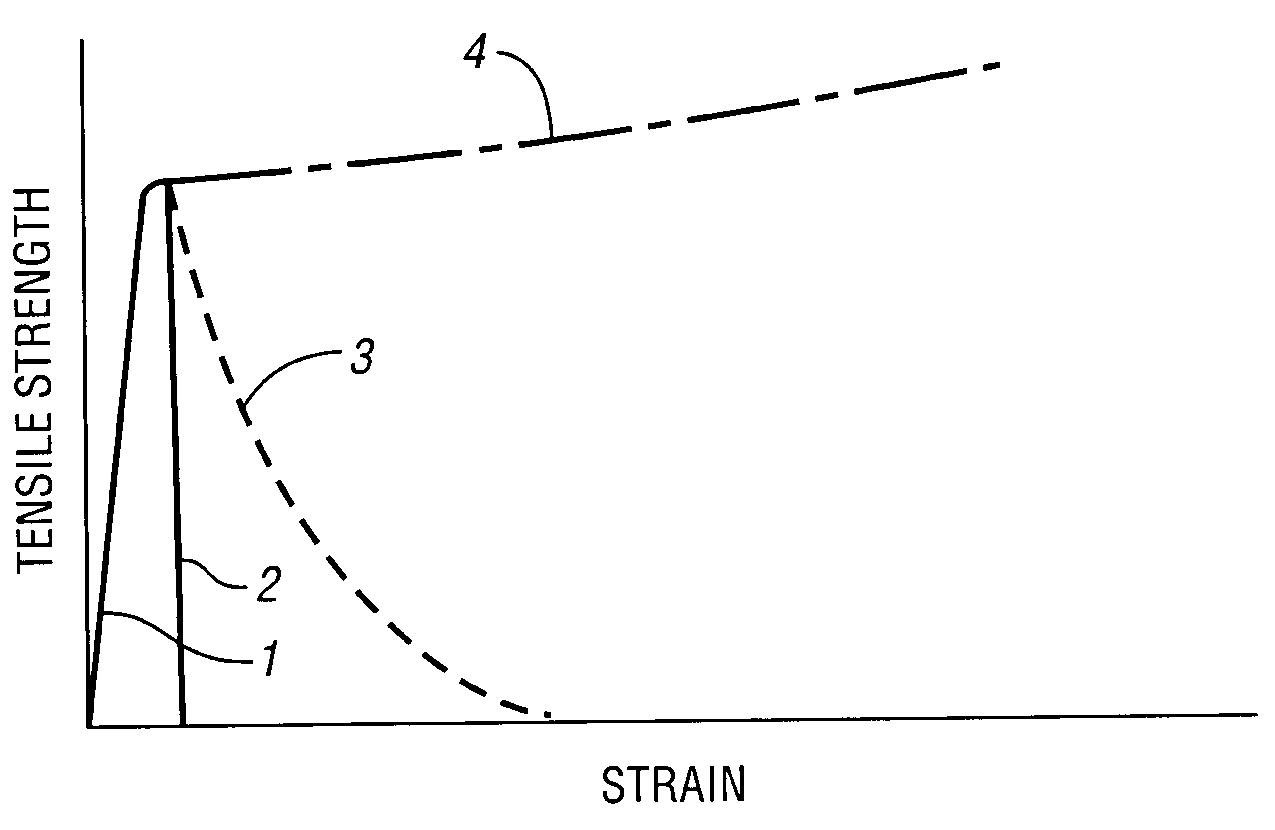

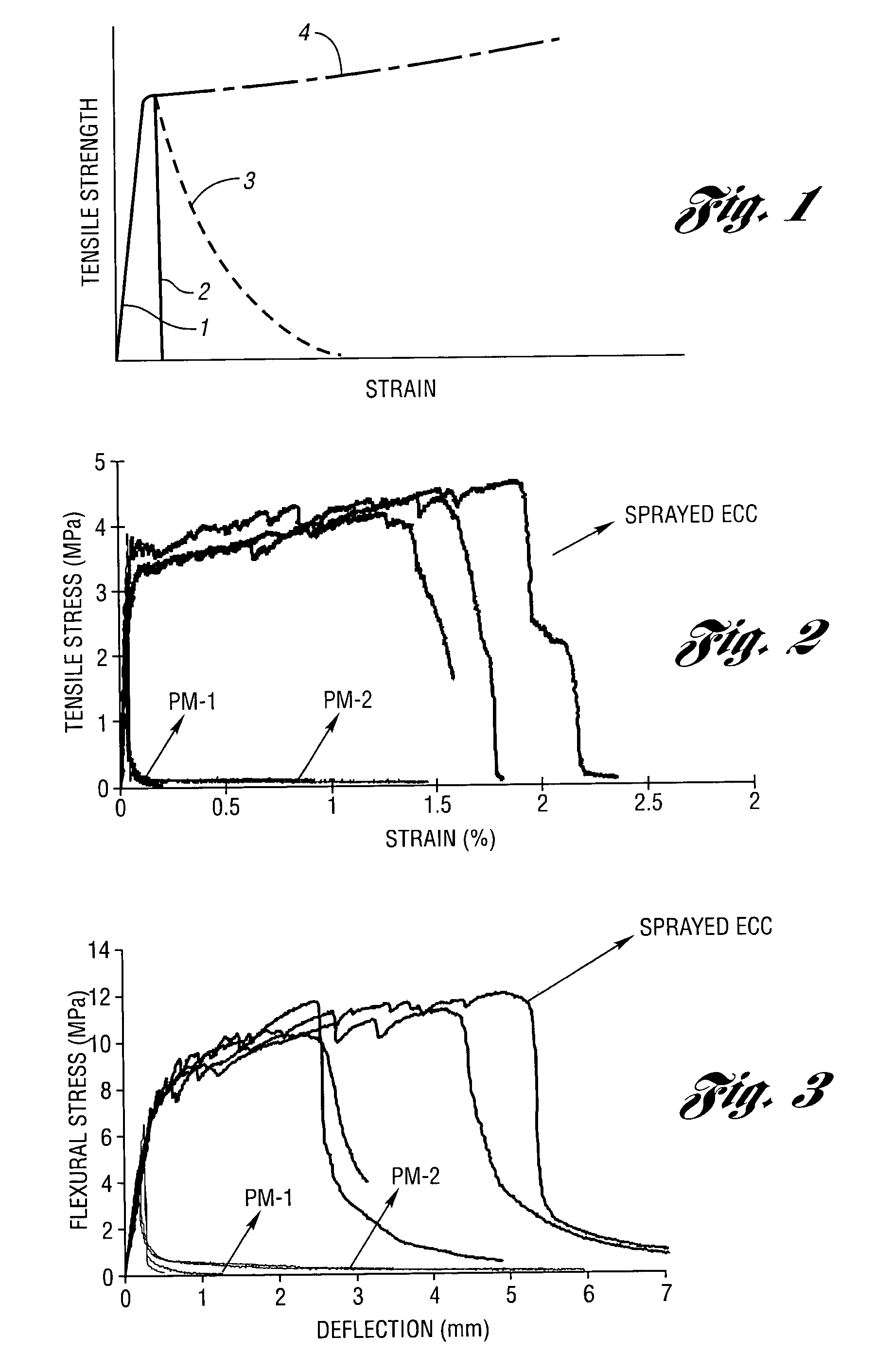

Sprayable, strain-hardening cementitious compositions

ActiveUS20050066858A1Improve tensile strain capacityImprove tensile strengthSolid waste managementNatural mineral layered productsSuperplasticizerFiber

Sprayable fiber reinforced hydraulically setting mortars exhibit strain hardening behavior, and comprise hydraulically setting cement, less than 4 weight percent matrix interactive fibers, a non-Newtonian additive, a superplasticizer, optionally a viscosity control agent, aggregate, and further additives. The ductile composites can be prepared by spraying in thicknesses higher than conventional sprayable mortars.

Owner:THE RGT OF THE UNIV OF MICHIGAN

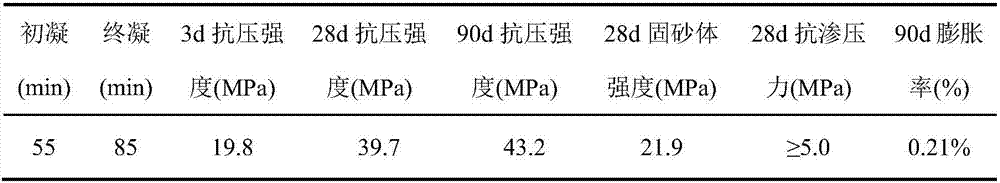

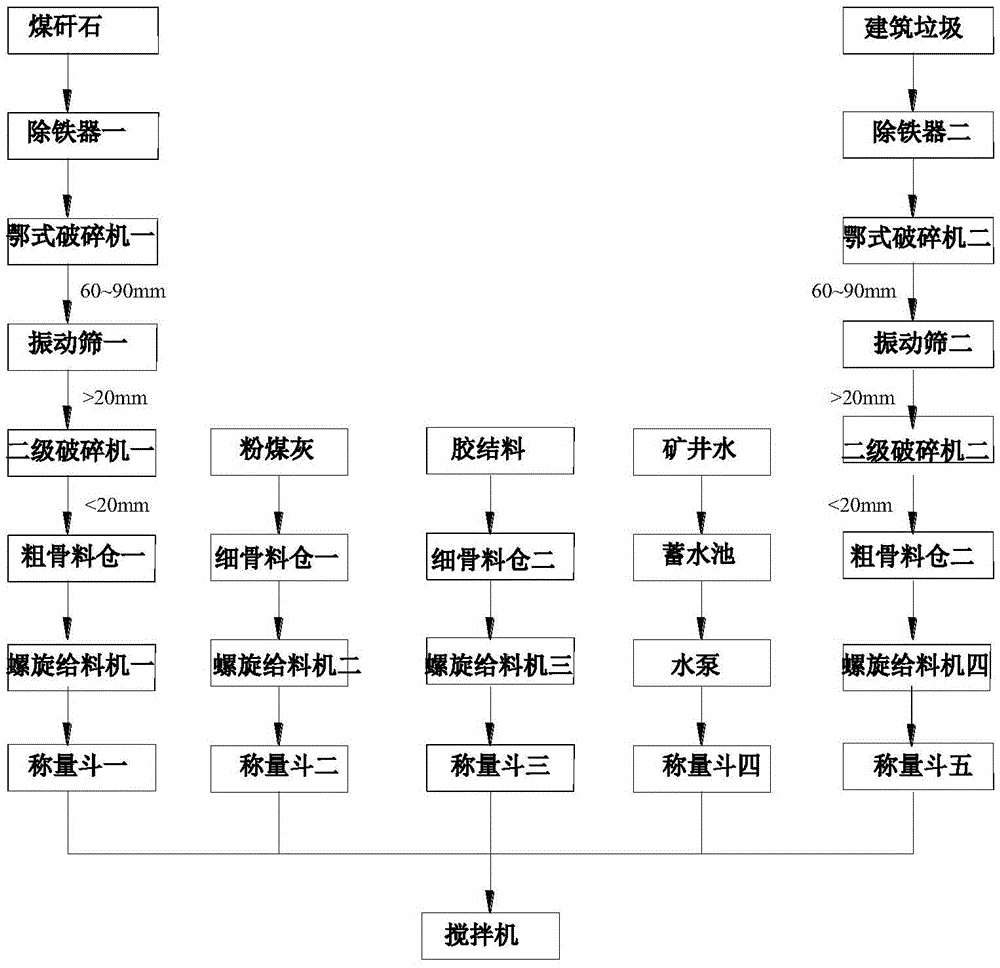

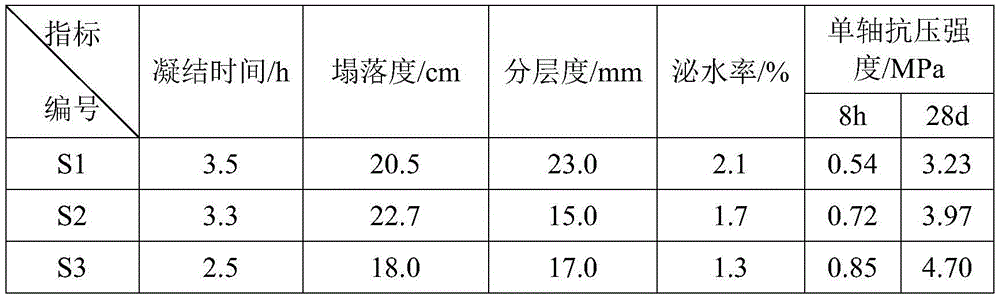

Coal mine paste-like filling material using construction waste, and preparation and filling method thereof

InactiveCN105481314AHigh strengthImprove stabilitySolid waste managementMaterial fill-upFilling materialsWater reducer

The invention provides a coal mine paste-like filling material using construction waste. The material comprises the following raw materials: a coarse aggregate containing 450-500Kg of construction waste and 400-450Kg of gangue; a fine aggregate containing 350-400Kg of fly ash and 200-250Kg of a binder; an admixture containing 6.0-12.5Kg of an accelerator and 2.0-7.5Kg of a water reducer; and 550-630Kg of mine water. According to the invention, construction waste, gangue and other wastes are used to prepare the paste-like filling material with good pumpability, low bleeding rate and degree of stratification, short setting time, high strength and stability, and low cost. The invention also provides a preparation and filling method of the coal mine paste-like filling material using construction waste.

Owner:ANHUI UNIV OF SCI & TECH

Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

InactiveCN102690716AStrong extreme pressureWear scar diameter is smallLubricant compositionAcetic acidCalcium hydroxide

The invention relates to superstrong extreme pressure antiwear lubricating grease and a preparation method thereof; particularly, a densifier is generated by calcium sulfonate with a high base number through a phase inversion reaction, and the lubricating grease is prepared by combining base oil with other functional additives, wherein the base oil is combined by base oil with high viscosity and medium viscosity. The method comprises the following steps: stirring and mixing the composite base oil and the calcium sulfonate in a reaction vessel, heating, adding a phase inversion promoter, glacial acetic acid, and water, heating and reacting at a constant temperature, adding calcium hydrate, aliphatic acid and boric acid after the phase inversion is completed, reacting at a constant temperature, heating and dehydrating, adding an anti-oxidant, refining, transferring the materials into a blending vessel, adding an eutectic rolling additive and an adhesion improver, dispersing and homogenizing the mixture, filtering, and degassing to obtain the finished product. The lubricating grease of the invention has excellent water sprinkling resistance, excellent high and low temperature performance, superstrong extreme pressure antiwear performance, excellent pumping performance, outstanding shearing stability, and antirust performance.

Owner:超美科技(深圳)有限公司

Thixotropic pasty grout containing clay slurry and preparation method thereof

The invention discloses a low-cost thixotropic pasty grout which is prepared by taking clay slurry (prepared from undisturbed soil by using a slurry making machine from clay) as a main raw material and taking general silicate cement, tetracalcium aluminoferrite, calcium sulphoaluminate, gypsum, sodium aluminate, calcium oxides, calcium hydroxides as main cementing materials through the steps of mixing the main raw material with the main cementing materials and stirring the obtained mixture. The thixotropic pasty grout can be used as a controllable grouting material and widely applied to the controllable anti-seepage and leaking-stoppage grouting projects performed in foundations in geotechnical projects such as water conservancy and hydropower projects, mine projects, tunnel projects, underground space projects, and the like, wherein the controllable anti-seepage and leaking-stoppage grouting projects comprise the operations of carrying out anti-seepage and leaking-stoppage grouting and project emergency reinforcement on high-permeability stratums.

Owner:湖南宏禹工程集团有限公司

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

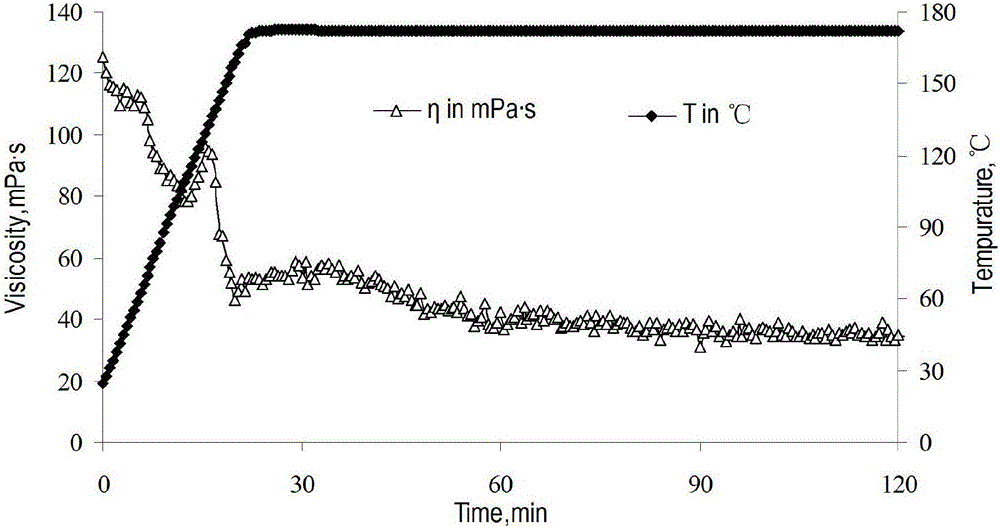

Supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C

The invention discloses supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C. The fracturing fluid is prepared from the following components in percentage by weight: 0.2 to 0.5 percent of thickening agent for the clean fracturing fluid, 0.1 to 0.5 percent of viscosity synergist, 0.2 to 0.4 percent of structural intensifier, 0.05 to 0.2 percent of deoxidant, 0.1 to 0.3 percent of metal ion chelating agent, 1 to 2 percent of clay stabilizer and the balance of fresh water. According to the clean fracturing fluid, a reversible supramolecular network structure is formed through the intermolecular interaction, and the thickening agent is low in use concentration and can be used for effectively controlling the viscosity of a base solution of the fracturing fluid and improving the pumping performance of the fluid; viscoelastic sand-carrying of the fracturing fluid is realized by low viscosity and high viscoelasticity; the temperature resistance can reach 170 DEG C under a long-term shear condition; the shear resistance is excellent, and the fluid viscosity and the structure after high shear can be effectively recovered; the construction friction is low, and the equipment load and the fracturing construction risk are reduced; the residue content is low, so that the damages to a reservoir stratum and prop fractures are greatly reduced, and the fracturing stimulation effect is greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

High-performance lightweight aggregate concrete

InactiveCN101747006AImprove the way of forceImprove mechanical propertiesSolid waste managementSlagExpanded clay aggregate

The invention discloses high-performance lightweight aggregate concrete. The high-performance lightweight aggregate concrete is characterized in that: high-performance porcelain granules are taken as lightweight aggregate; and the high-performance lightweight aggregate concrete is prepared by mixing the following raw materials in proportion: 400 to 430 kg / m<3> of cement, 500 to 570 kg / m<3> of high-performance porcelain granule, 40 to 55 kg / m<3> of fly ash, 40 to 55 kg / m<3> of grounded furnace slag, 540 to 565 kg / m<3> of sand, 180 to 185 kg / m<3> of water and 6 to 10 kg / m<3> of water reducing agent, wherein the performance indexes of the high-performance porcelain granule is that stacking density is less than and equal to 700 kg / m<3>, cylinder pressure strength is greater than and equal to 6.0 MPa, strength mark is greater than and equal to 35 MPa and water absorbing capacity is less than and equal to 1.0 percent. The high-performance lightweight aggregate has the advantages that the strength is high, and workability and pumpability can meet design and construction requirements.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com