Patents

Literature

65 results about "Construction 3D printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction 3D Printing (c3Dp) or 3D Construction Printing (3DCP) refers to various technologies that use 3D printing as a core method to fabricate buildings or construction components. Alternative terms are also in use, such as Autonomous Robotic Construction System (ARCS) Large scale Additive Manufacturing (LSAM), or Freeform construction (FC), also to refer to sub-groups, such as '3D Concrete', used to refer to concrete extrusion technologies.

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

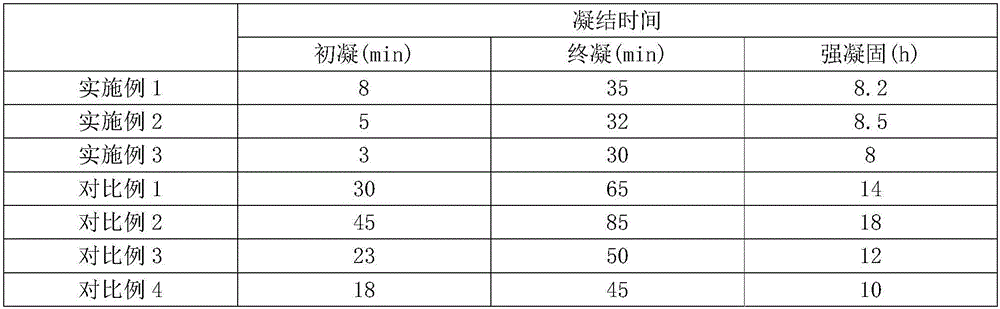

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Cement-based material used for building 3D (three-dimensional) printing

InactiveCN105753404AImprove early strengthAdjustable plasticityAdditive manufacturing apparatusFiberFoaming agent

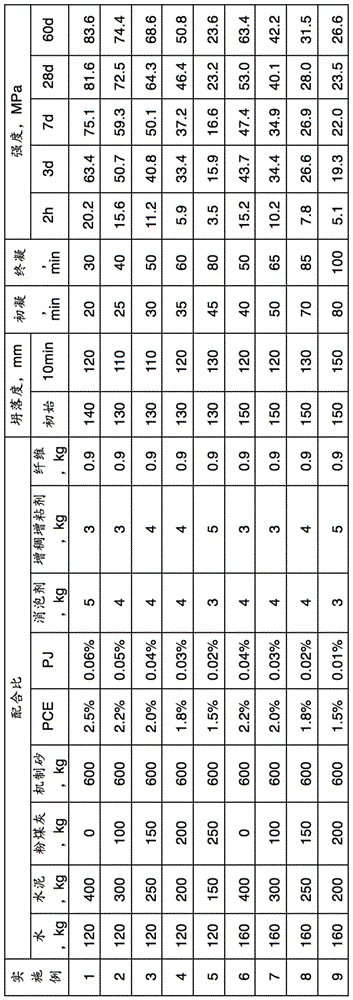

The invention provides a cement-based material used for building 3D (three-dimensional) printing; the cement-based material is high in plasticity and early strength, can be timely adjusted in setting time according to raw material composition and temperature of a construction environment, and is suitable for printing building components different in marks. The cement-based material used for building 3D printing is prepared from the following materials in mixing composition ratios: 400 kg of cementing material, 600 kg of machine-made sand, 3 to 5 kg of de-foaming agent, 3 to 5 kg of thickening agent, 0.9 to 1.0 kg of polypropylene staple fiber, a water reducing agent and a retarder; a water-binder ratio is 0.35 to 0.50, wherein the cementing material is prepared from 150 to 400 kg of sulphate aluminium cement and 0 to 250 kg of coal ash; the machine-made sand is 0.075 to 5 mm in grain size; the polypropylene staple fiber is 3 to 6 mm long; 10 min slump degree of the cement-based material is 90 to 110 mm, initial setting time is 15 to 80 min, and final setting time is 30 to 100 min.

Owner:LINYI UNIVERSITY

Reducing spray head and extrusion device for building 3D printing

ActiveCN107042632ALarge caliberNo need to extend the stayCeramic shaping apparatusApplying layer meansSpray nozzleEngineering

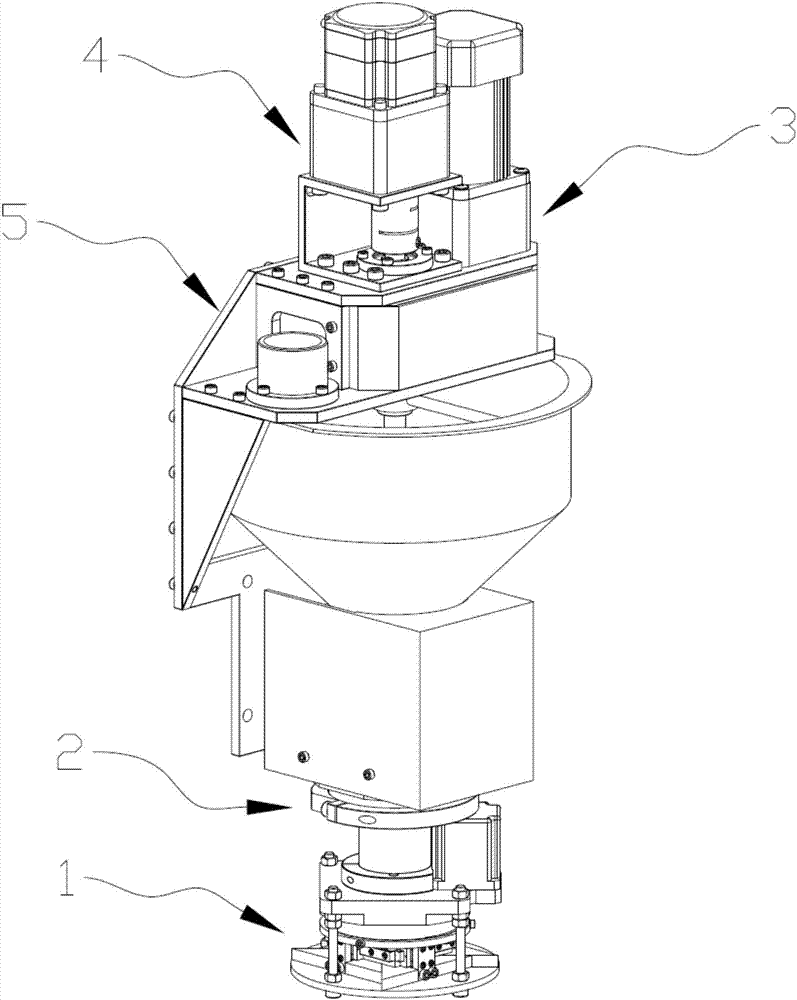

The invention discloses a reducing spray head for building 3D printing. The reducing spray head comprises a rotary shifting disc, a bottom plate, four linear guide rails, four sliding blocks and four right-angle moving sheets; when relative rotation occurs between the rotary shifting disc and the bottom plate, the rotary shifting disc drives four driving parts to rotate synchronously through four driving grooves, and then drives the four sliding blocks to synchronously slide along the four linear guide rails, and the four sliding blocks drive the four right-angle moving sheets to synchronously make relative movement, thereby changing the size of a square nozzle by changing relative positions of the four right-angle moving sheets in a printing process. A large-area region is printed, the size of the square nozzle can be enlarged and a discharge speed is raised, so that no repeated printing is required, the dwell time of the reducing spray head at such place is not required to be prolonged, and the printing efficiency is improved accordingly.

Owner:HUAZHONG UNIV OF SCI & TECH

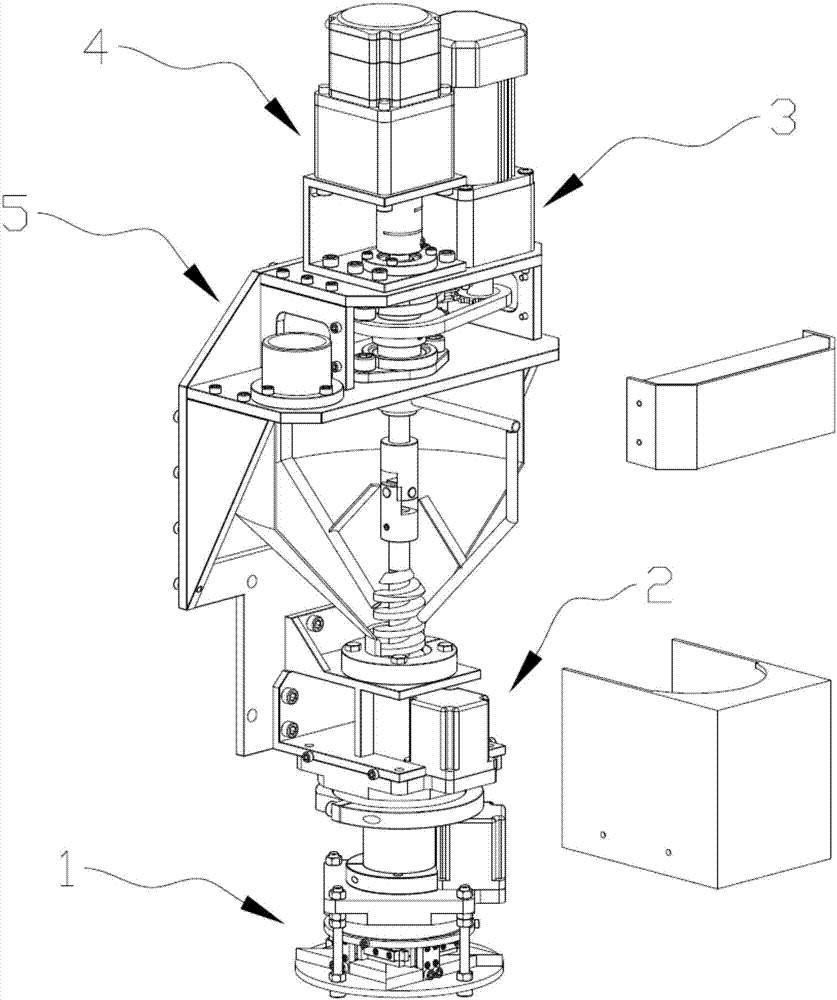

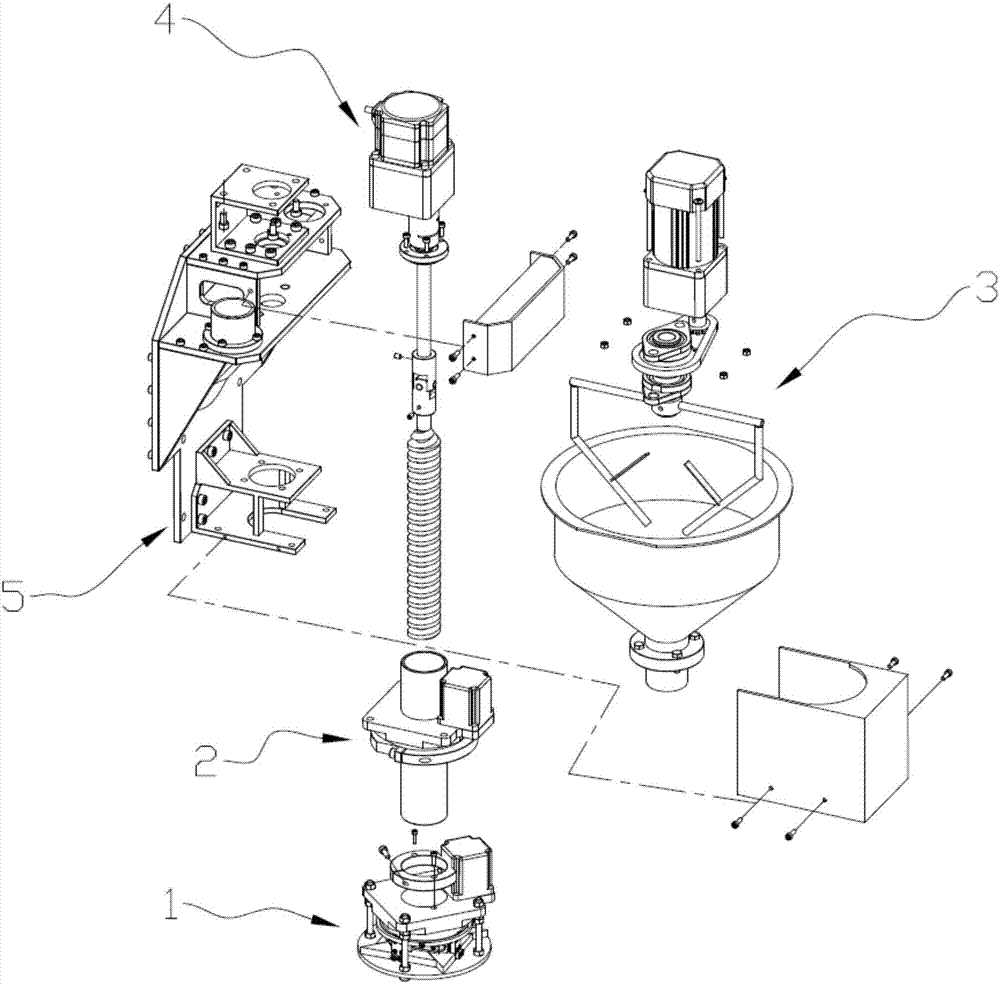

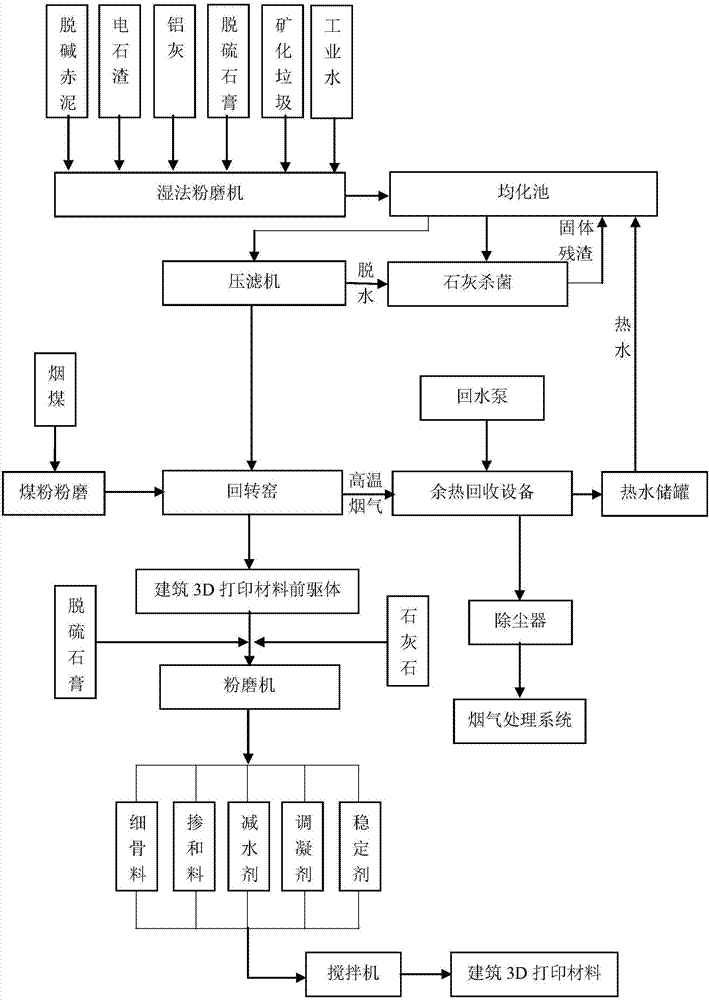

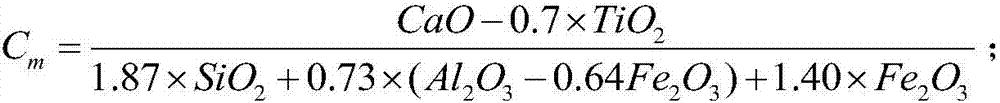

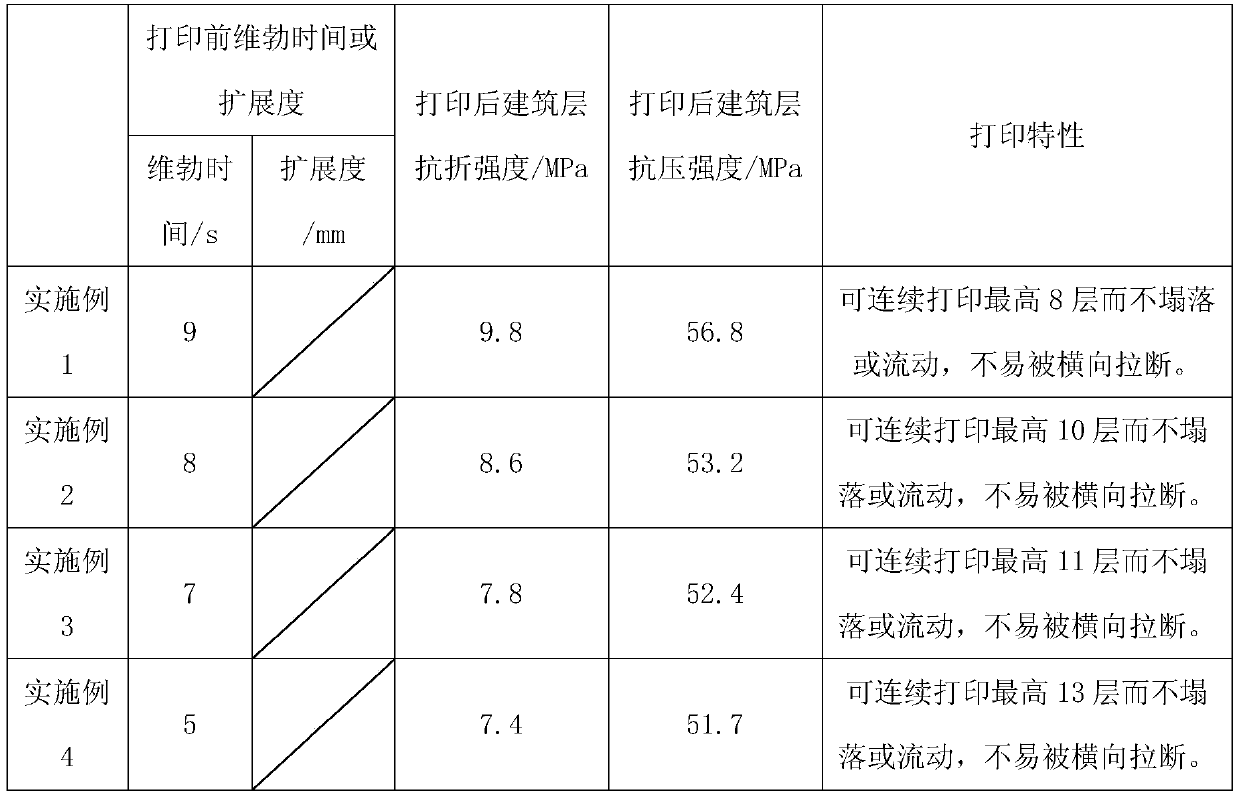

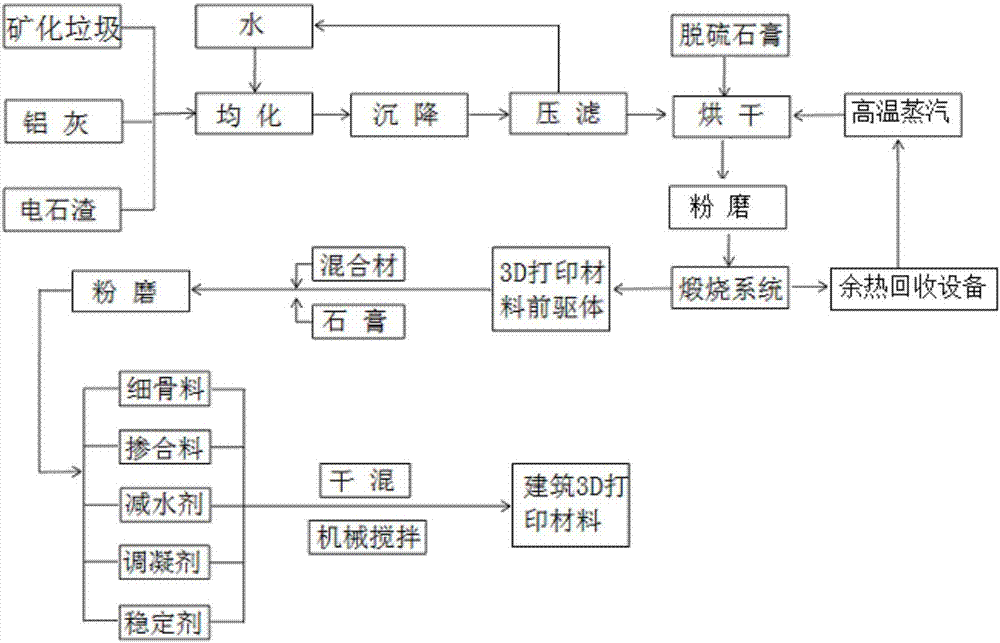

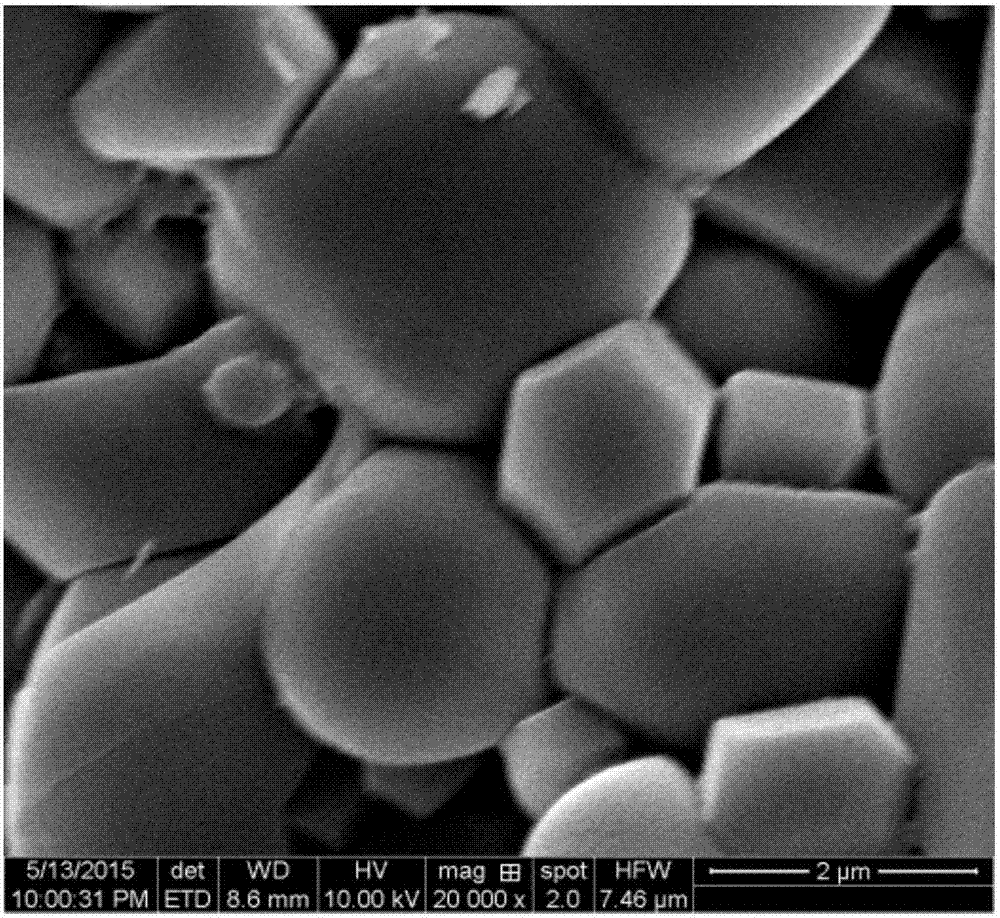

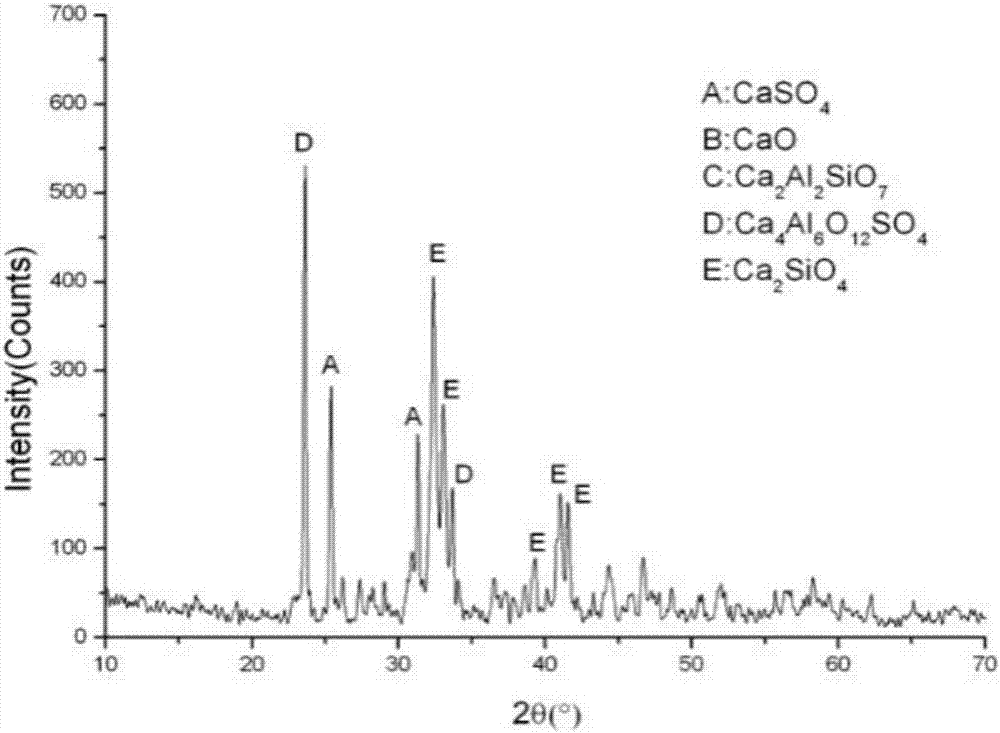

System and method for preparing building 3D printing material by using municipal waste and industrial solid waste

ActiveCN106904924ALow costReduce energy consumptionAdditive manufacturing apparatusSolid waste managementDry weightRed mud

The present invention discloses a system and a method for preparing a building 3D printing material by using municipal waste and industrial solid waste. The system comprises a homogenization pool, a wet powder mill, a filter press, a rotary kiln, a powder mill and a hot water storage tank. According to the method, wet sludge produced from an urban sewage treatment plant is directly mixed with mineralized garbage, red mud, desulfuration gypsum, carbide slag and industrial water to form a mixed solution without dewatering, a dry weight ratio of the wet sludge to the mineralized garbage to the red mud to the desulfuration gypsum to the carbide slag in the mixed solution is 5-10:5-10:15-30:10-20:30-60, the solid-liquid ratio in the mixed solution is maintained at 1:3-1:4, the mixed solution is sequentially subjected to wet milling, homogenization treatment and alkali removing, the homogenization treatment temperature is 60-70 DEG C, the homogenized material is subjected to mechanical pressure filtration dehydration, and the filtered material is subjected to high temperature calcination to obtain the building 3D printing material precursor.

Owner:SHANDONG UNIV

Building 3D printing head with function of automatic injecting of additive

InactiveCN106988535AWell mixedIncrease printing speedAdditive manufacturing apparatusBuilding material handlingPropellerEngineering

The invention discloses a building 3D printing head with a function of automatic injecting of additive, and belongs to the technical field of building engineering 3D printing. A material feeding pipe is connected with a material pushing pipe, a propulsion motor is arranged at one end of the material pushing pipe, the propulsion motor is connected with a propeller located in the material pushing pipe, the other end of the material pushing pipe communicates with a stirring chamber, an additive storage device is connected with the stirring chamber through an additive conveying pipe, stirring blades for stirring are arranged in the stirring chamber, the stirring blades are located on a stirring shaft, and the stirring shaft is connected with a stirring shaft motor. According to the building 3D printing head with the function of automatic injecting of the additive, the additive conveying pipe is connected to the printing head, uniform mixing of the additive and printing materials is achieved by a rotary stirring mode, so that the materials printed from the printing head are initially congealed in 2 minutes, and the printing speed and efficiency are improved.

Owner:都书鹏

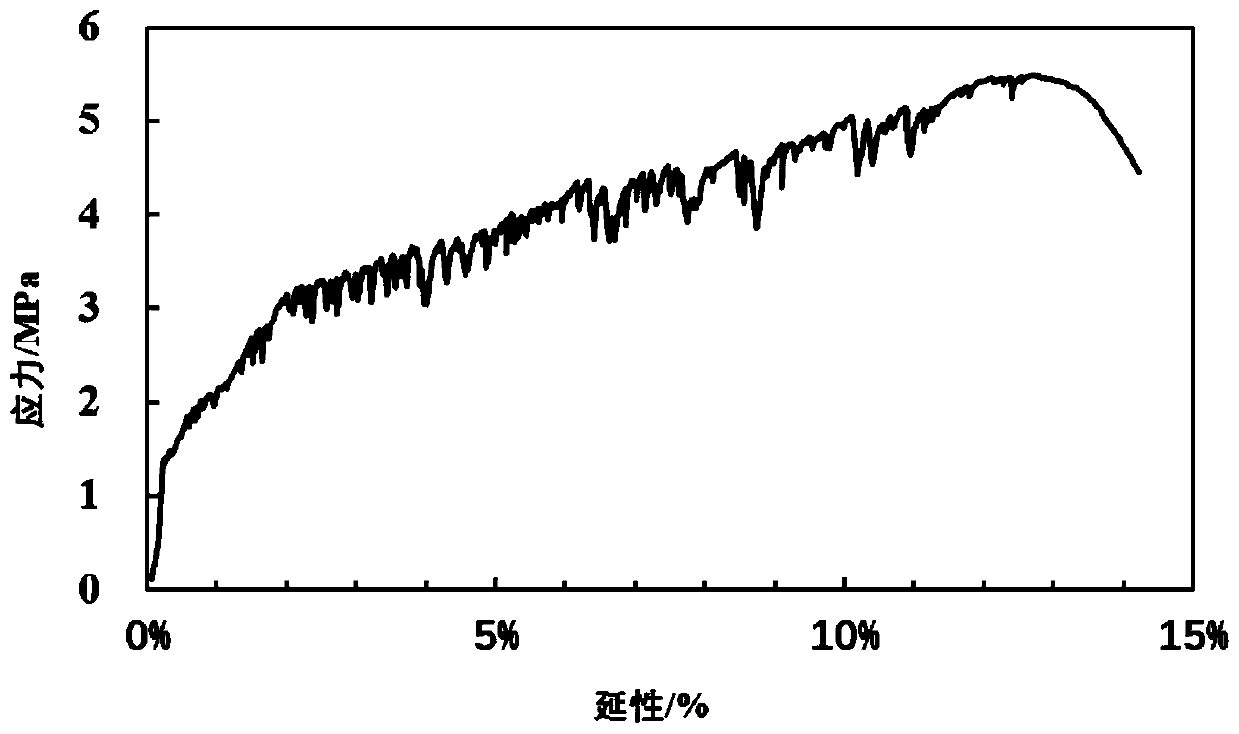

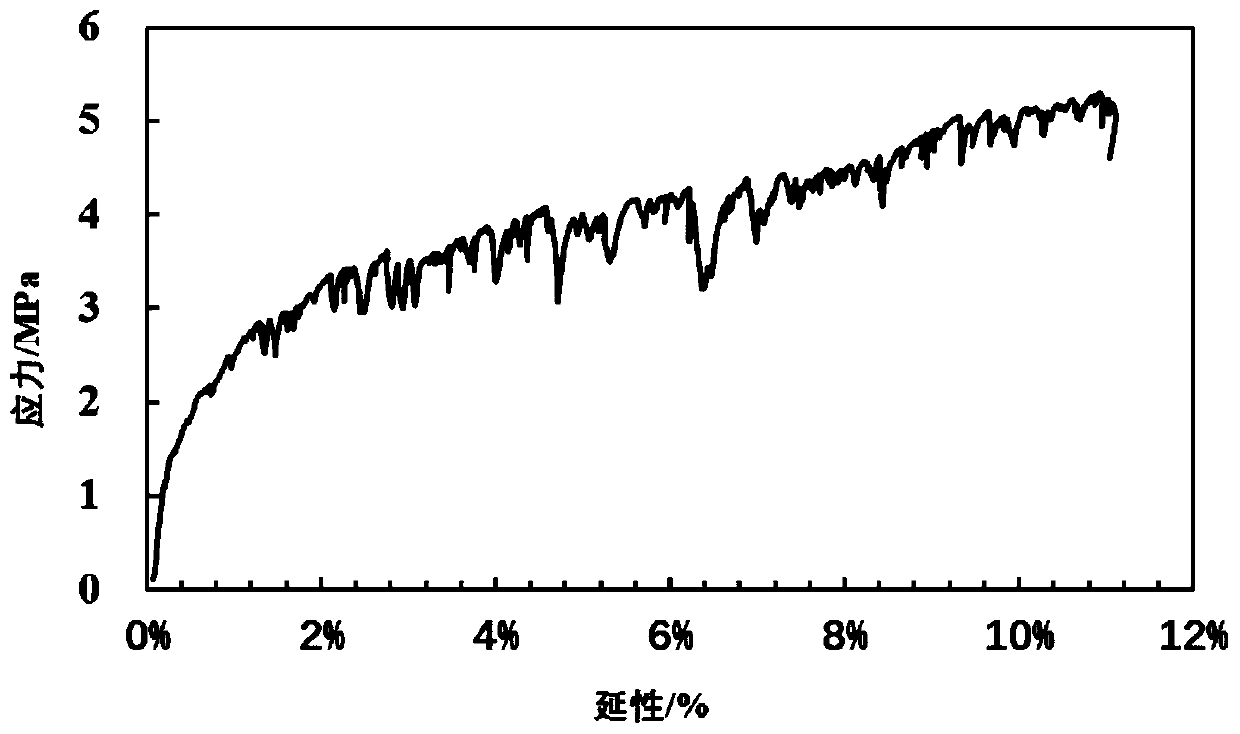

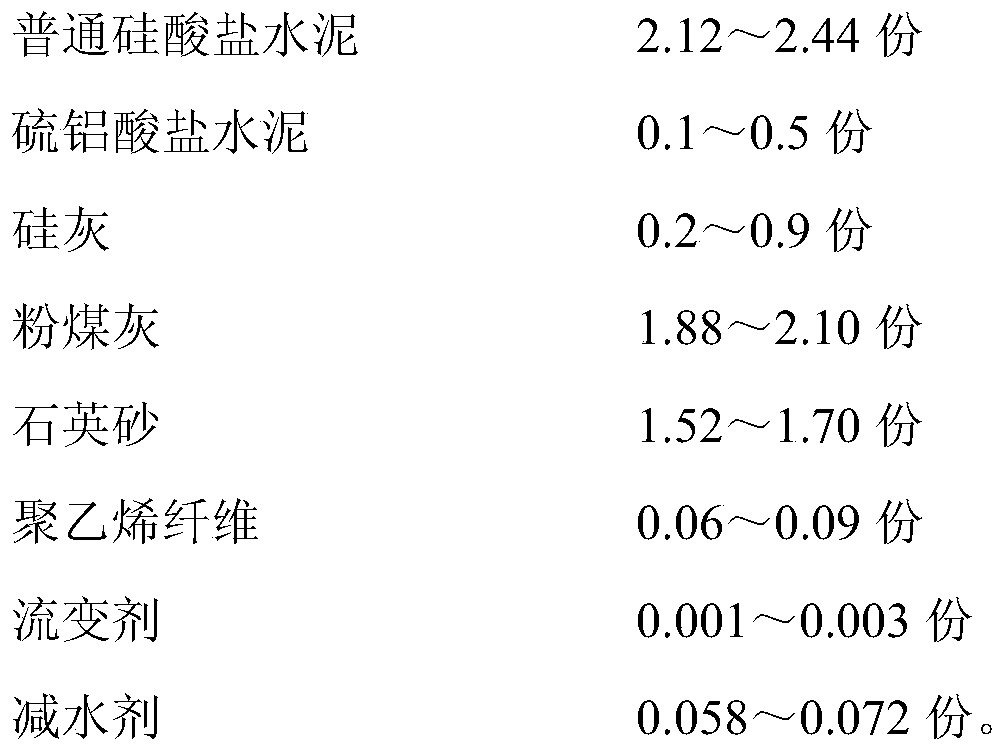

Fiber reinforced cement-based material for 3D printing, preparation, performance evaluation and application

ActiveCN109942262AHigh tensile ductilityImprove bending strengthAdditive manufacturing apparatusFlow propertiesSocial benefitsHigh energy

The invention discloses a fiber reinforced cement-based material (ECC) for 3D printing, preparation, performance evaluation and an application. The cement-based material is prepared by taking sulfatealuminum cement produced by industrial solid wastes fully as an early strength agent and doping polyethylene fiber relatively high in tensile strength and modulus. The cement-based material is introduced to 3D printing concrete and is applied to building 3D printing and a concrete structure or ribless construction of a member or pouring of the concrete structure, has the characteristics of strainstrengthening and multi-crack cracking under action of stretching and bending, has high ductility and high energy consumption, and solves the problem that a 3D printing concrete member is low in mechanical property. The fiber reinforced cement-based composite material is simple in preparation method, low in cost and low-carbon and environment-friendly, and has certain engineering demonstration meaning and social benefits. The invention also provides a 3D printing performance evaluation method of the material, including micro slump test, flowability test and rheological property test.

Owner:SOUTHEAST UNIV +1

Cement-based composite for 3D (three dimensional) building printing and preparation method of cement-based composite

InactiveCN107619243AImprove thixotropyHigh densityAdditive manufacturing apparatusConstruction 3D printingUltimate tensile strength

The invention discloses an environment-friendly cement-based composite for 3D (three dimensional) building printing. The composite comprises the following raw materials by mass percentage: 25-35% of cement, 2-8% of a reinforced rheologic material, 40-60% of quartz sand, 0.02-0.2% of a mixture improving material, 0.1-0.2% of a water reducer, 8-14% of blended water, 0.05-0.1% of fiber and 0-5% of perlite. Building waste broken powder replaces part of the quartz sand; and the composite is directly conveyed into a 3D building printer for 3D building printer construction by on-site mixing and addition of an accelerator, a thickening rheologic agent and the like into a printing tail end. According to the composite, the building waste and industrial waste can be applied greatly; the composite islow in cost and environmentally friendly; the strength, cost and forming time of the composite can be flexibly controlled; the composite can be used for the 3D printing of common buildings and landscape buildings under different environment scenes and requirements, and meets the requirements on the efficiency under different building strength conditions; and the development, popularization and application of a 3D building printing technology are greatly promoted.

Owner:南京嘉翼数字化增材技术研究院有限公司

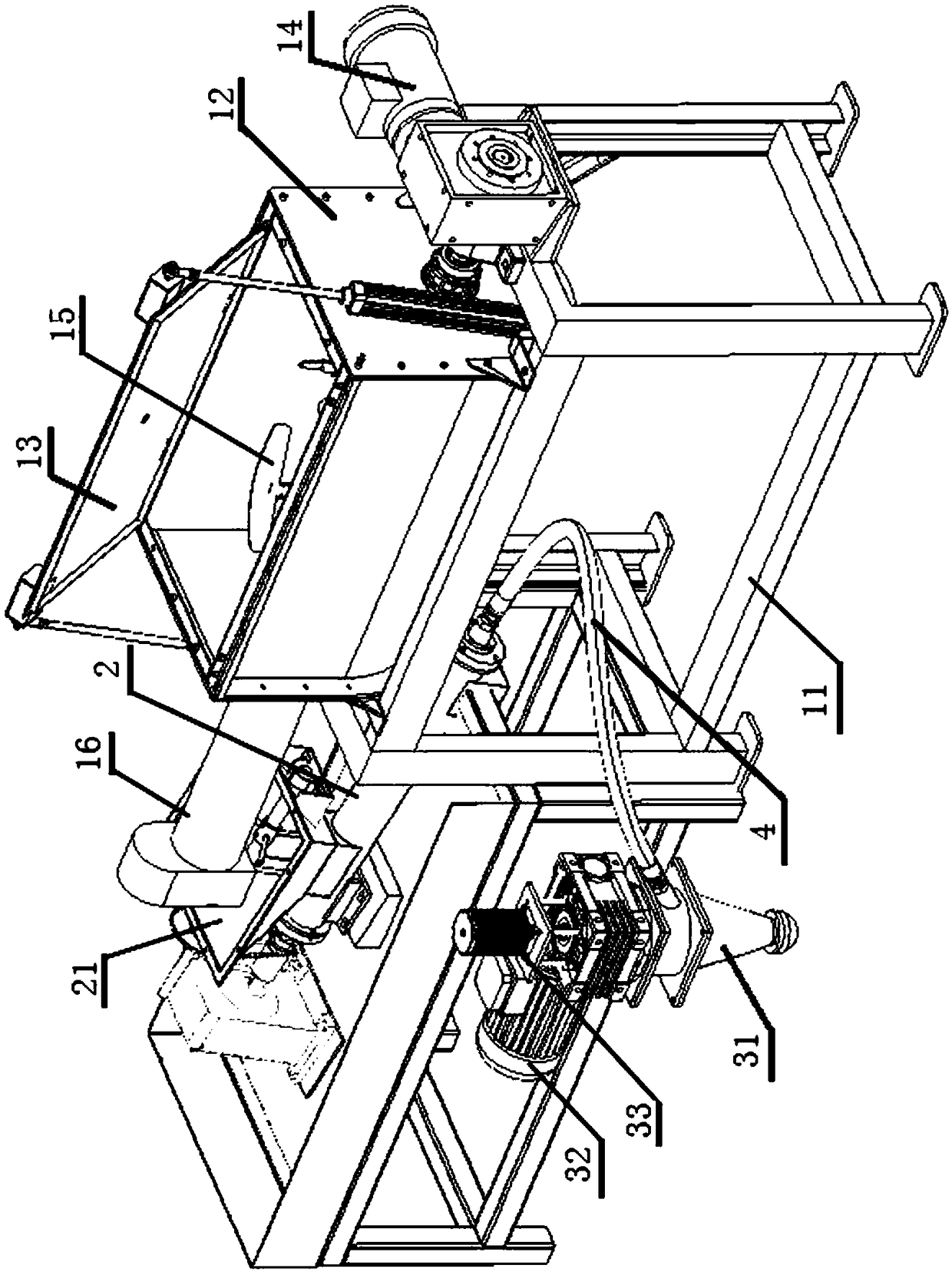

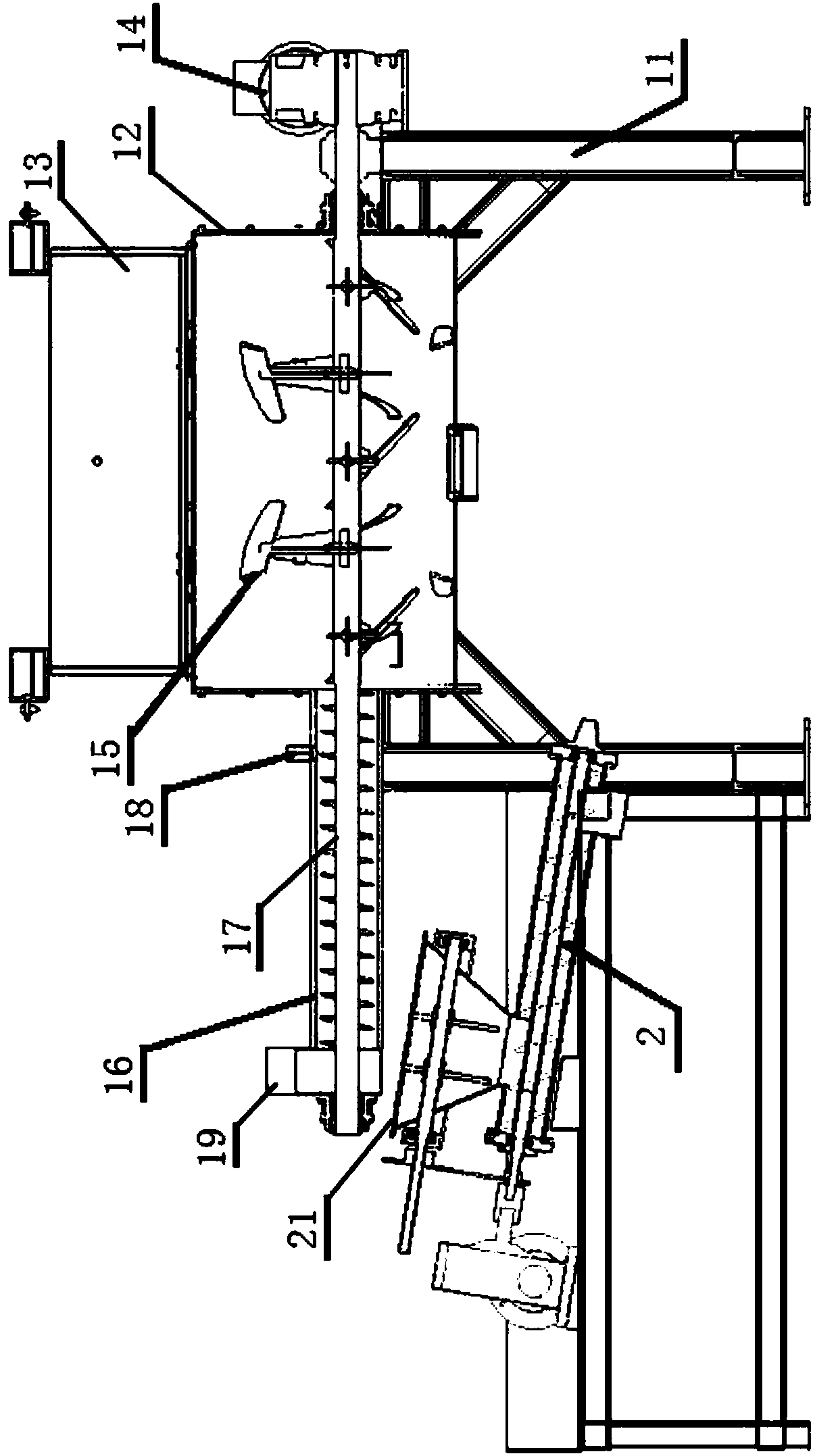

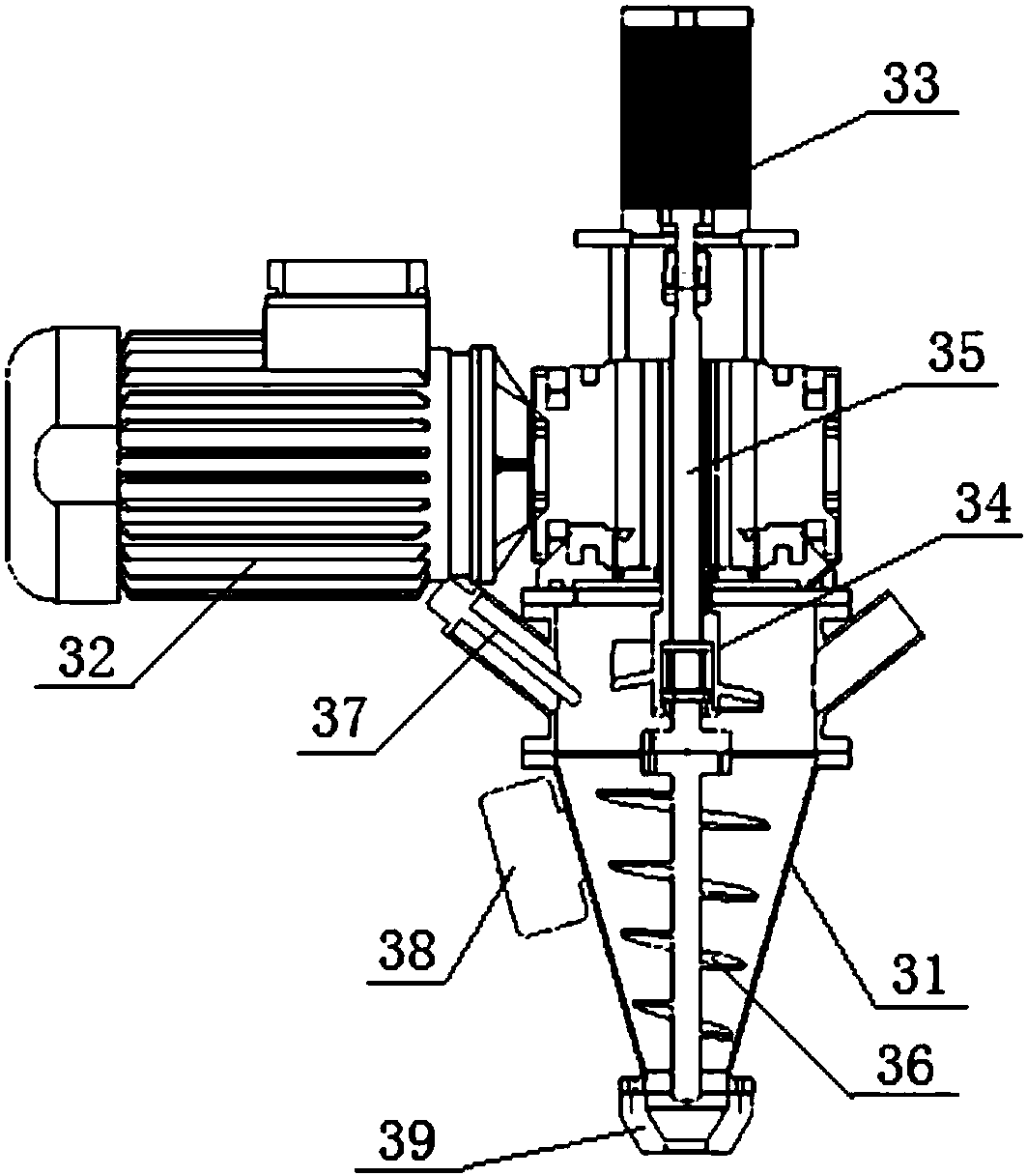

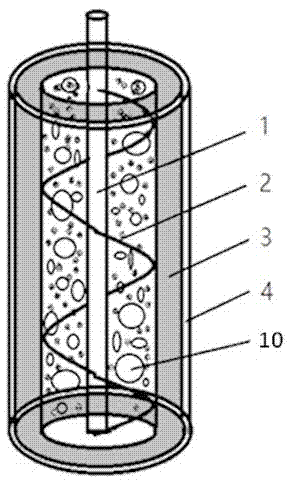

Continuous feeding system for building 3D printer

PendingCN108407042AExtrude evenly and continuouslyImprove printing qualityAdditive manufacturing apparatusCeramic shaping apparatusContinuous/uninterruptedPulp and paper industry

The invention discloses a continuous feeding system for a building 3D printer. The system comprises a continuous pulper, a spiral pumper and a stirring spiral extruder, wherein the continuous pulper comprises a stirring stock bin and a spiral discharge pipeline communicating to the stirring stock bin; the discharge port of the spiral discharge pipeline is connected to the feed inlet of the spiralpumper, and the feed inlet of the spiral pumper is connected to the feed inlet of the stirring spiral extruder; and the stirring spiral extruder comprises a stirring stock bin and a stirring blade shaft and a cone-shaped screw arranged in the stirring stock bin. Continuous intermittent feeding of the printer is achieved by efficient pulping by the continuous pulper and multi-level buffering of thestirring stock bin of the continuous pulper, the spiral pumper and a stirring hopper of the stirring spiral extruder.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

Layered bionic building element used for 3D printing and preparation method thereof

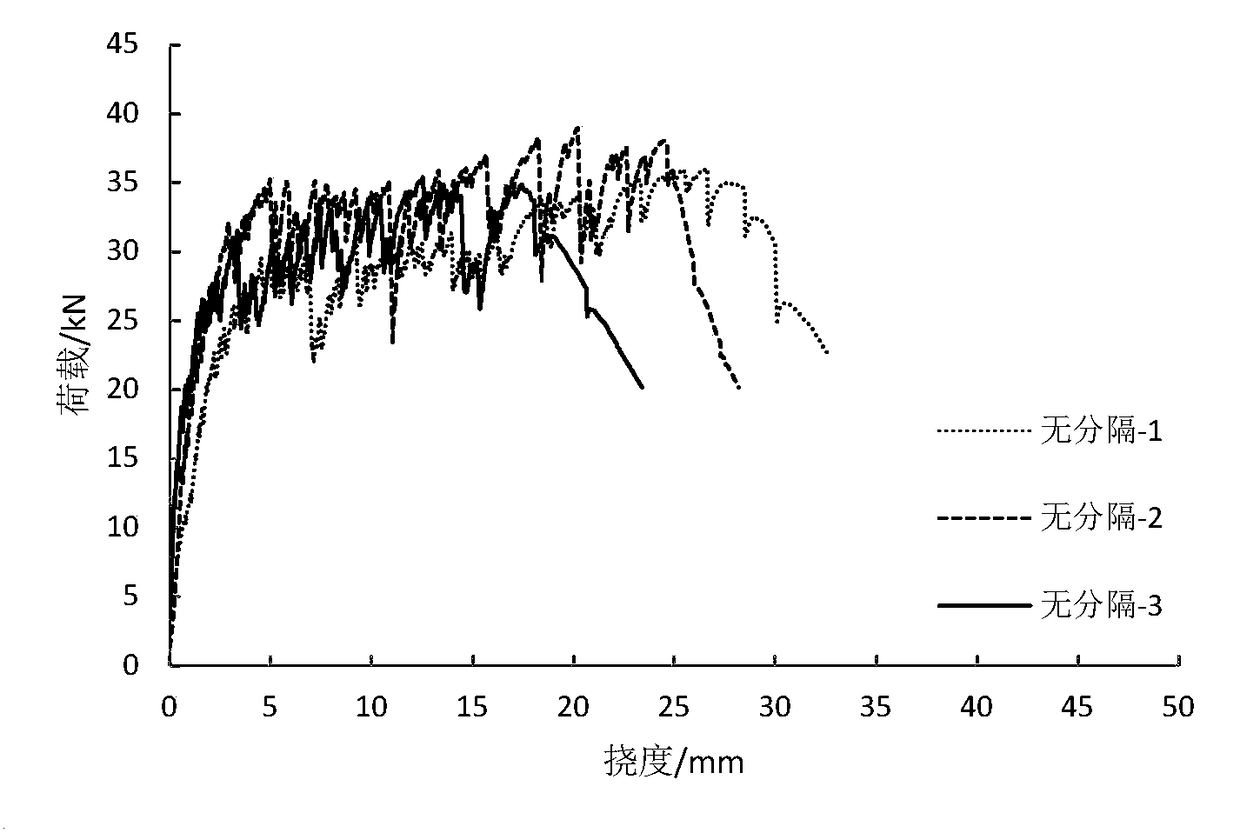

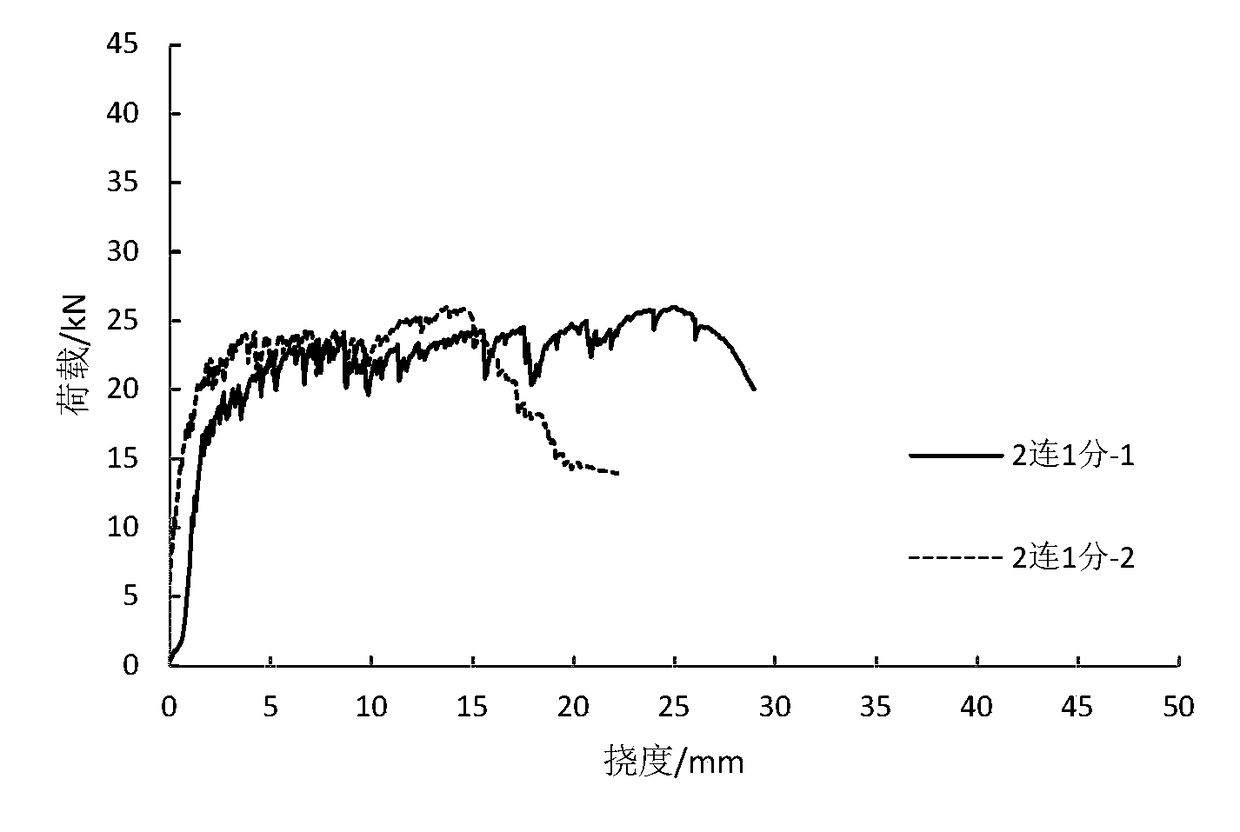

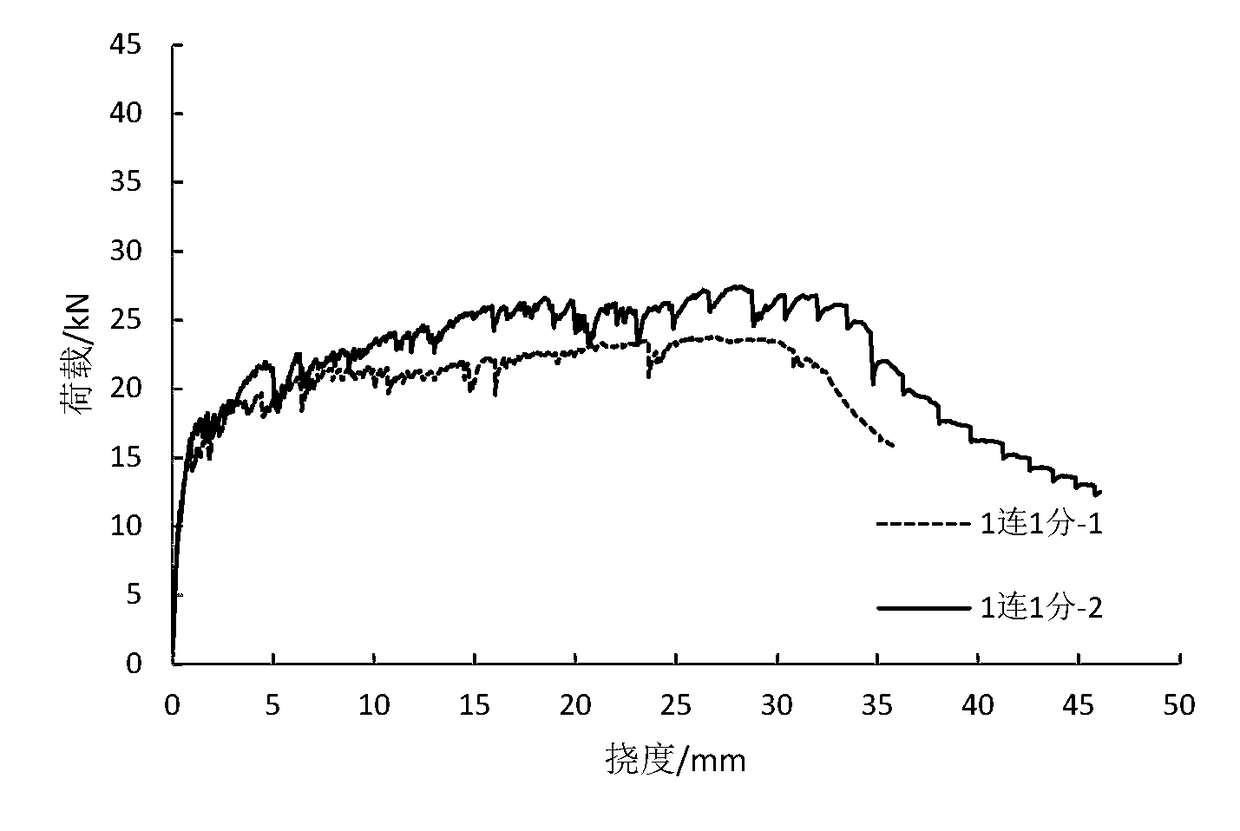

ActiveCN108178582AHigh bending ductilityIncreased ultimate deflection-span ratioAdditive manufacturing apparatusCeramic shaping apparatusFiberSlurry

The invention relates to a layered bionic building element used for 3D printing and a preparation method thereof. The building element is prepared by layered casting of concrete. The concrete comprises the following components in parts by weight: 590-600 parts of cement, 470-480 parts of quartz sand, 710-720 parts of fly ash, 3-5 parts of a water reducer, 320-330 parts of water, and 15-20 parts ofultrahigh molecular weight polyethylene fiber. The prepration method comprises the following steps: adding dry powder in a mixer and uniformly stirring the material, adding water in the mixer and stirring a slurry, adding polyethylene fiber and stirring the material, and performing layered casting moulding. According to the layered casting, a separation layer is arranged between layers, and bonding and slipping adjustment between the layers can be realized. Compared with the prior art, the bending strength of layered beams is high, bending deformation capability is obviously increased, crackdeflection and bifurcation in a layered structure are realized, the building element has good deformation capability and dissipating energy performance, and can be used for a layered construction modecomprising building 3D printing.

Owner:TONGJI UNIV

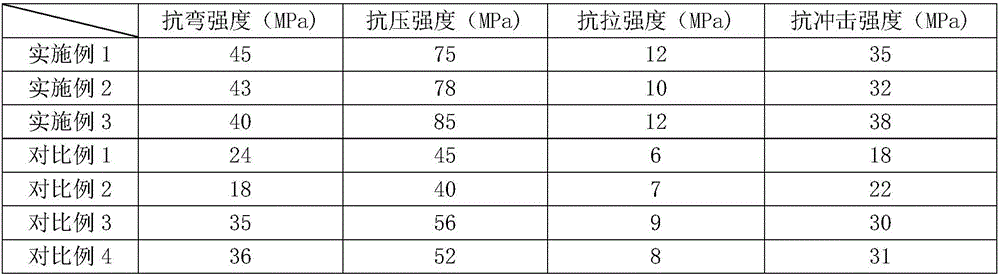

Building 3D printing ink and use thereof

InactiveCN106699039AShort initial setting timeHigh initial setting strengthAdditive manufacturing apparatusFiberParticulates

The invention provides a building 3D printing ink; the building 3D printing ink contains a fiber, a coagulating agent and solid small particles, the weight of the fiber accounts for 1 wt%-6 wt% of the total weight of the ink, the weight ratio of the coagulating agent to the solid small particles is (1-6) to (0-6), the slump ratio K of the 3D printing ink is in a range of 20%<=K<=50%, and the average volume of the solid small particles is 1*10<-3>-0.9 cm<3>. The 3D printing ink is used for 3D printing of buildings, and enhances the bending strength, the compressive strength, the tensile strength and / or the impact strength of the buildings.

Owner:马义军

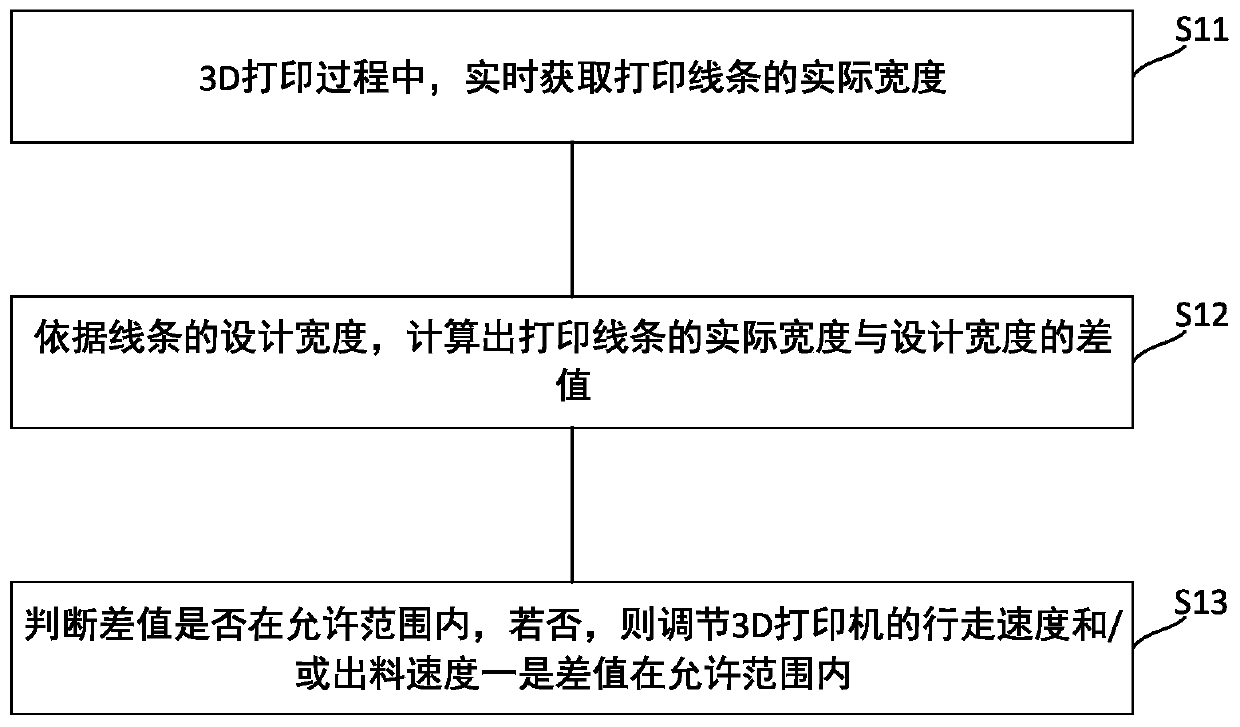

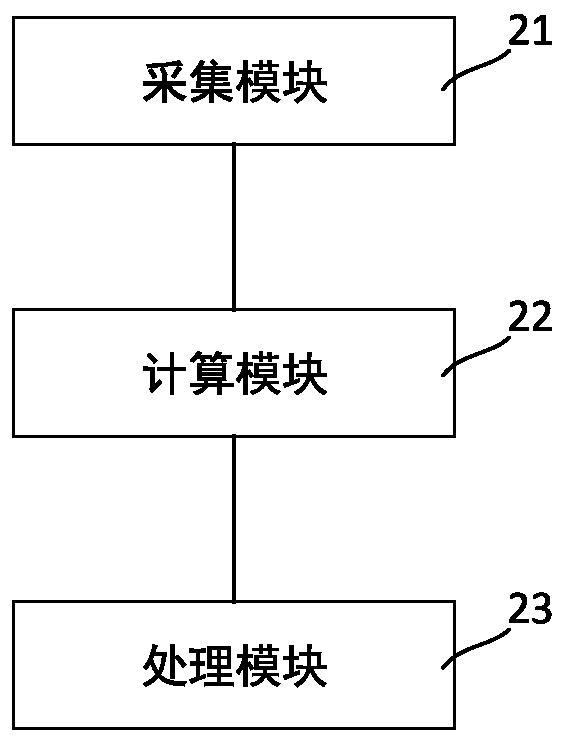

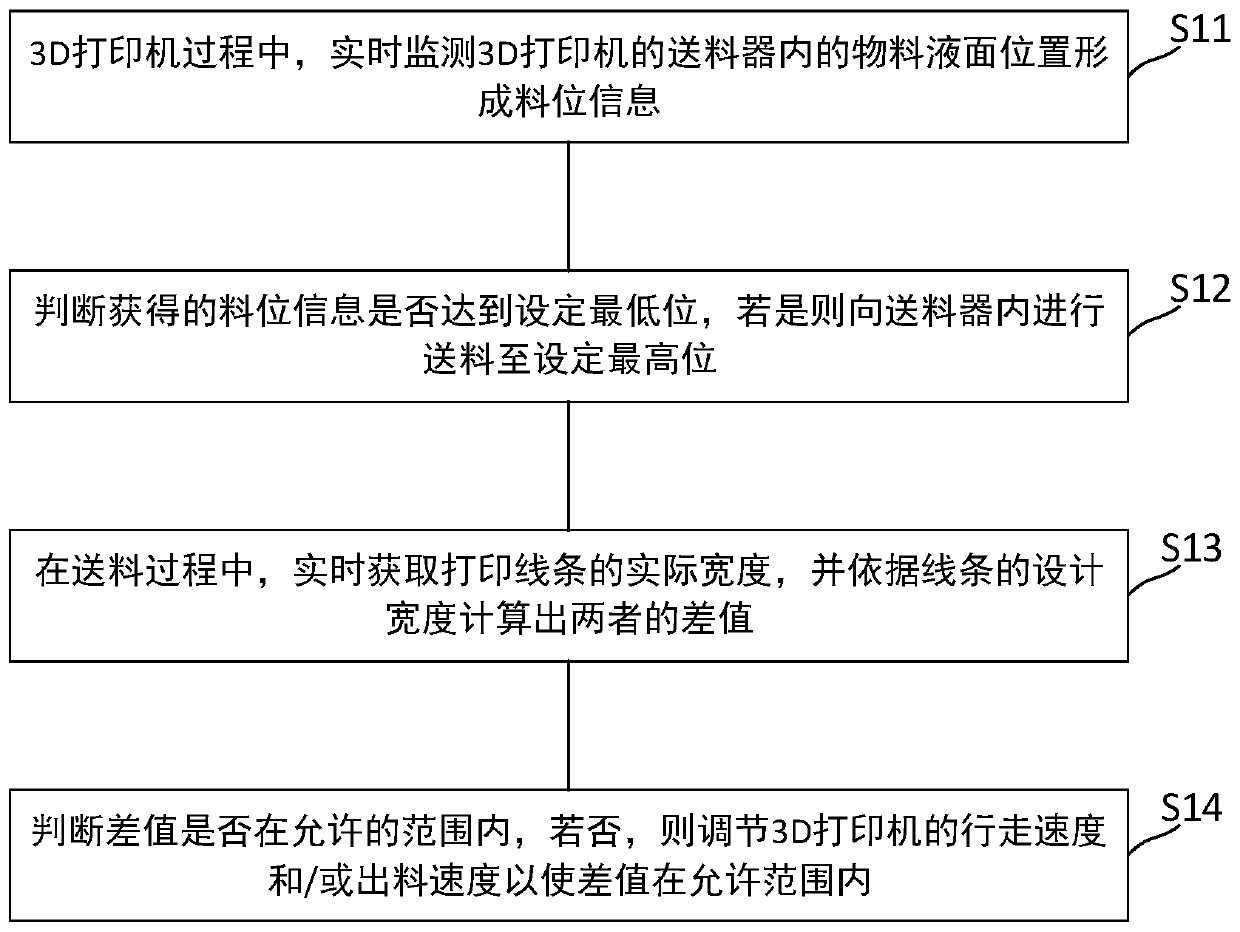

Line width compensation method and system for 3D printing of buildings

ActiveCN110281345AQuality improvementHigh precisionAdditive manufacturing apparatusCeramic shaping apparatusLine width3d printer

The invention relates to a line width compensation method and system for 3D printing of buildings. The method includes the following steps that in the process of 3D printing, the actual width of a printed line is obtained in real time; according to the designed width of the line, a difference value between the obtained actual width of the printed line and the designed width of the line is calculated; and whether the calculated and obtained difference value is within an allowed range or not is judged, if not, a travelling speed and / or a discharging speed of a 3D printer are / is adjusted so that the difference value can be within the allowed range. According to the line width compensation method for 3D printing of the buildings, the actual width of the printed line is monitored in real time, the designed width and the actual width are compared, when the difference value of the designed width and the actual width exceeds the allowed range, the travelling speed and / or the discharging speed of the 3D printer are / is automatically adjusted so that the actual width of the 3D printed line approaches the designed width, real-time detecting is achieved, real-time printing is achieved, real-time adjusting is achieved, and therefore the quality and the precision of a component formed due to printing are improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

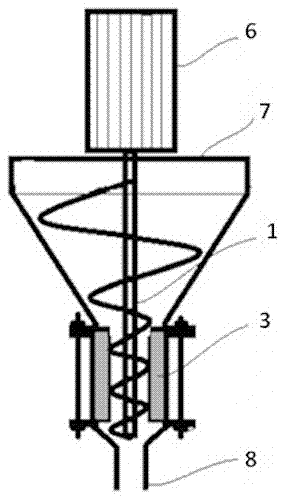

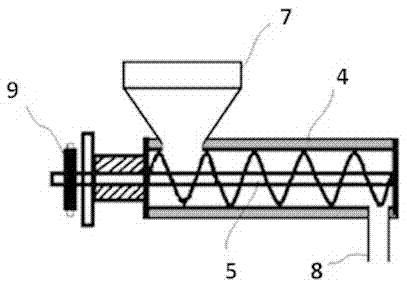

Sandwich compound building 3D printing material, preparing method and preparing device thereof

PendingCN108638290AMaximize the reinforcement effectImprove crack resistanceAdditive manufacturing apparatusCeramic shaping apparatusFiber bundleSlurry

The invention discloses a sandwich compound building 3D printing material, a preparing method and a preparing device thereof. The device comprises a hopper, a hollow spiral rod and a rotating motor; the hollow spiral rod is arranged in the hopper, a spiral structure is arranged outside the hollow spiral rod, a cavity allowing a flexible fiber bundle to axially pass through is formed in the hollowspiral rod, a fiber bundle inlet and a fiber bundle outlet are formed in the two ends of the cavity, the fiber bundle outlet is aligned with and narrower than a discharging opening, and the rotating motor is connected to the hollow spiral rod. The flexible fiber bundle penetrates the cavity in the hollow spiral rod, 3D printing slurry is added from the hopper, the hollow spiral rod rotates, the 3Dprinting slurry is extruded, the flexible fiber bundle is evenly wrapped by the 3D printing slurry, and the brand-new sandwich compound building 3D printing material is formed; the anti-cracking ability, the tensile strength and anti-shear performance of the 3D printing material are reinforced, the flexible fiber bundle is arranged in an orientation manner in the length direction, the fiber spacedirection is distributed in the direction most beneficial to tensile strength improving, and the enhancement effect of fibers can be maximized.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

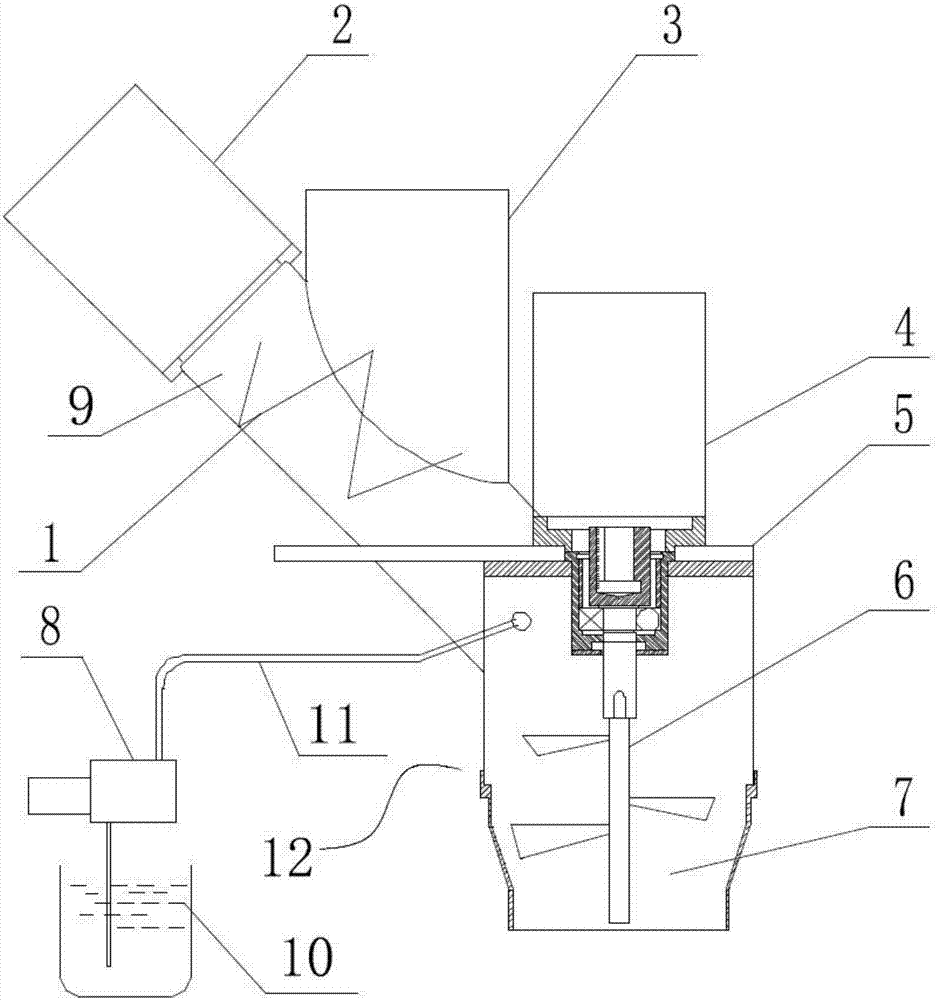

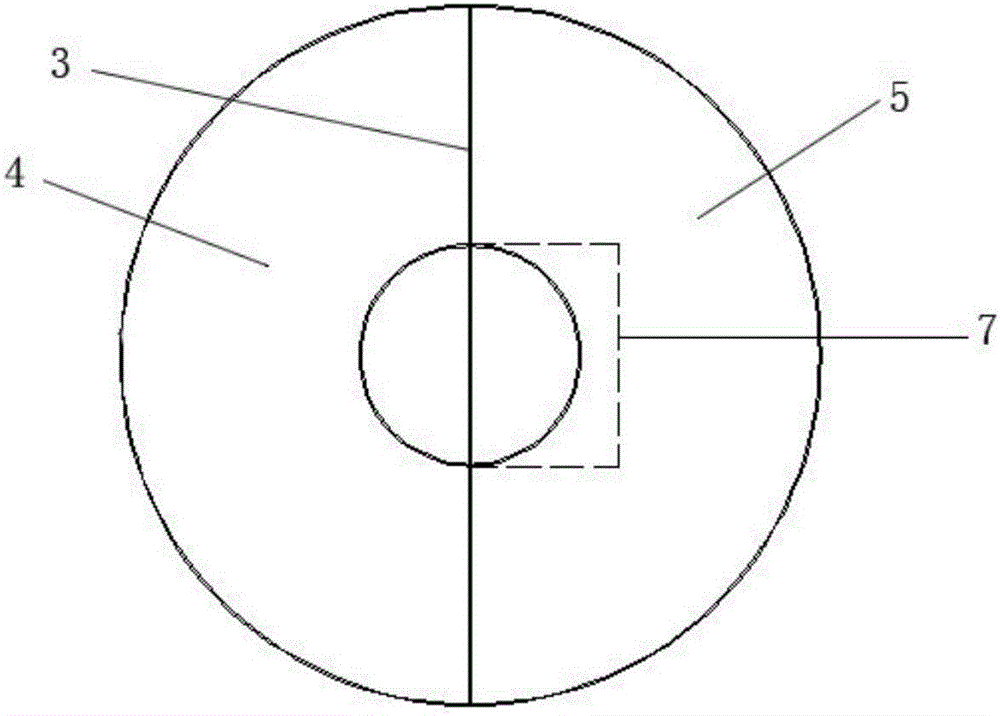

Quantitative detection device and method for the extrusion performance of 3D printed mortar

InactiveCN110243724AReflect extrusionSimple and fast operationFlow propertiesSpray nozzleEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

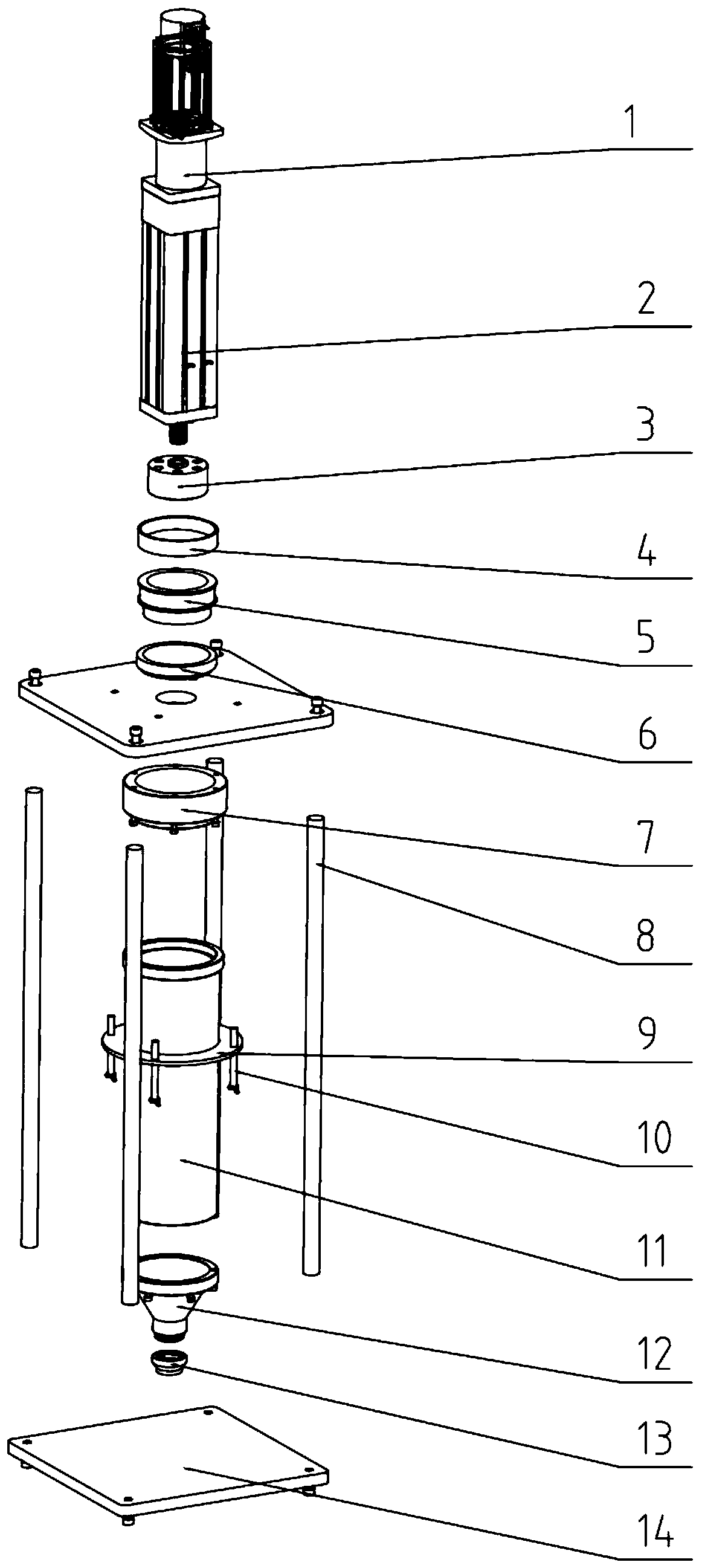

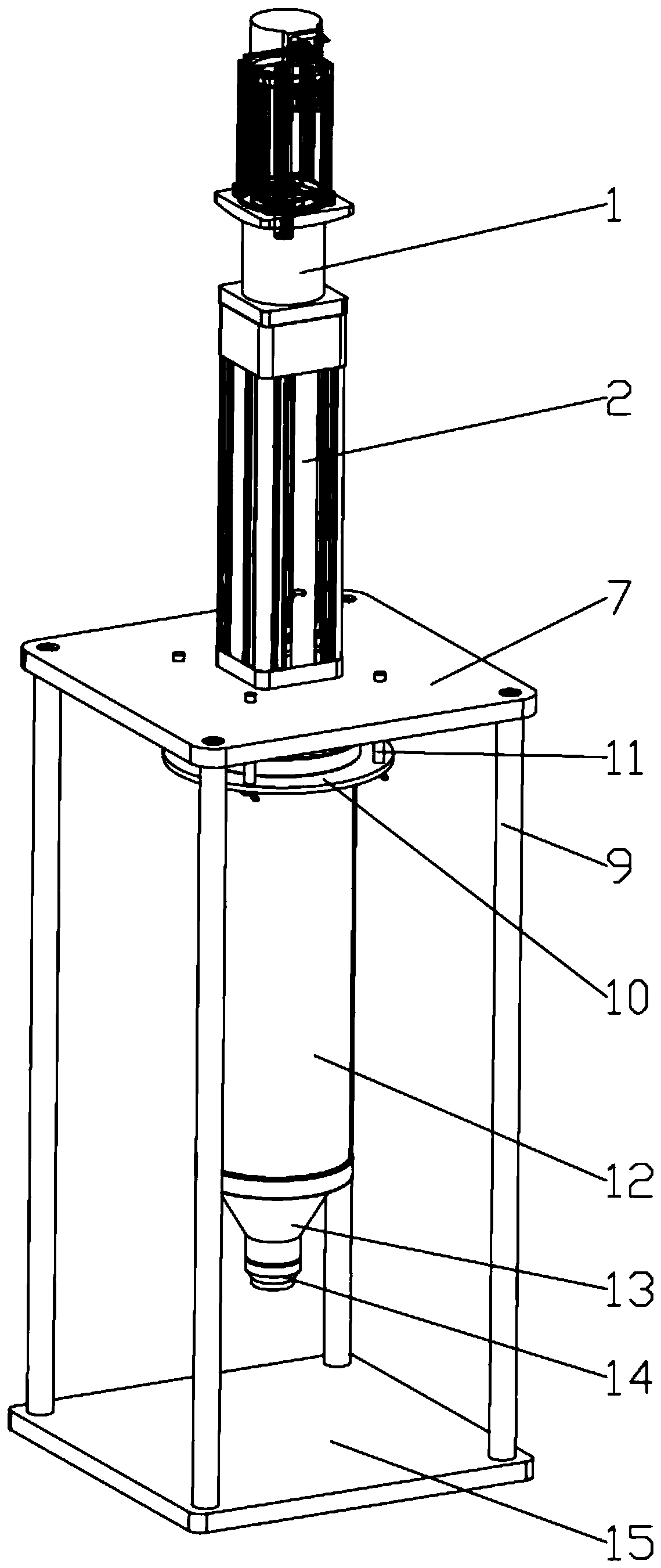

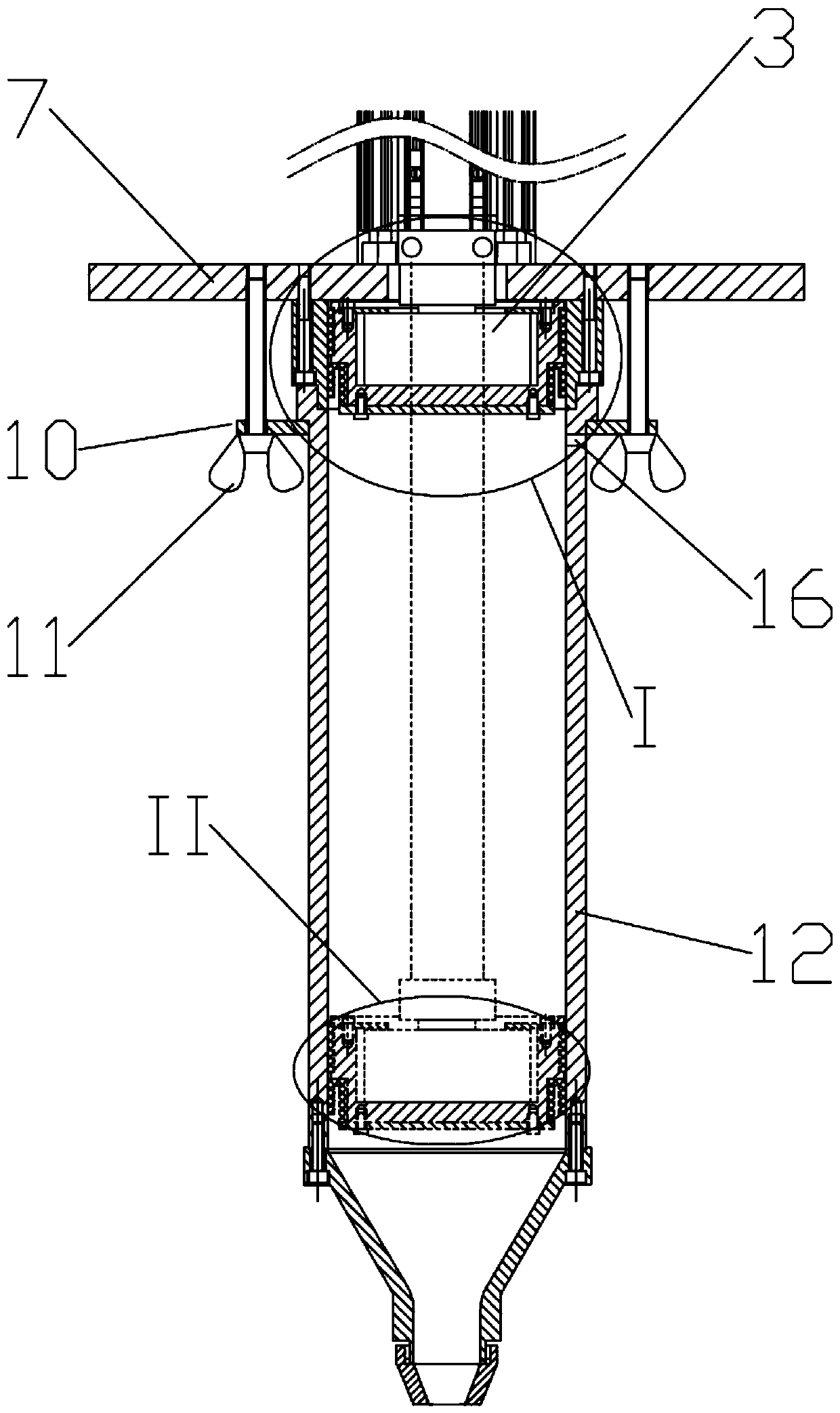

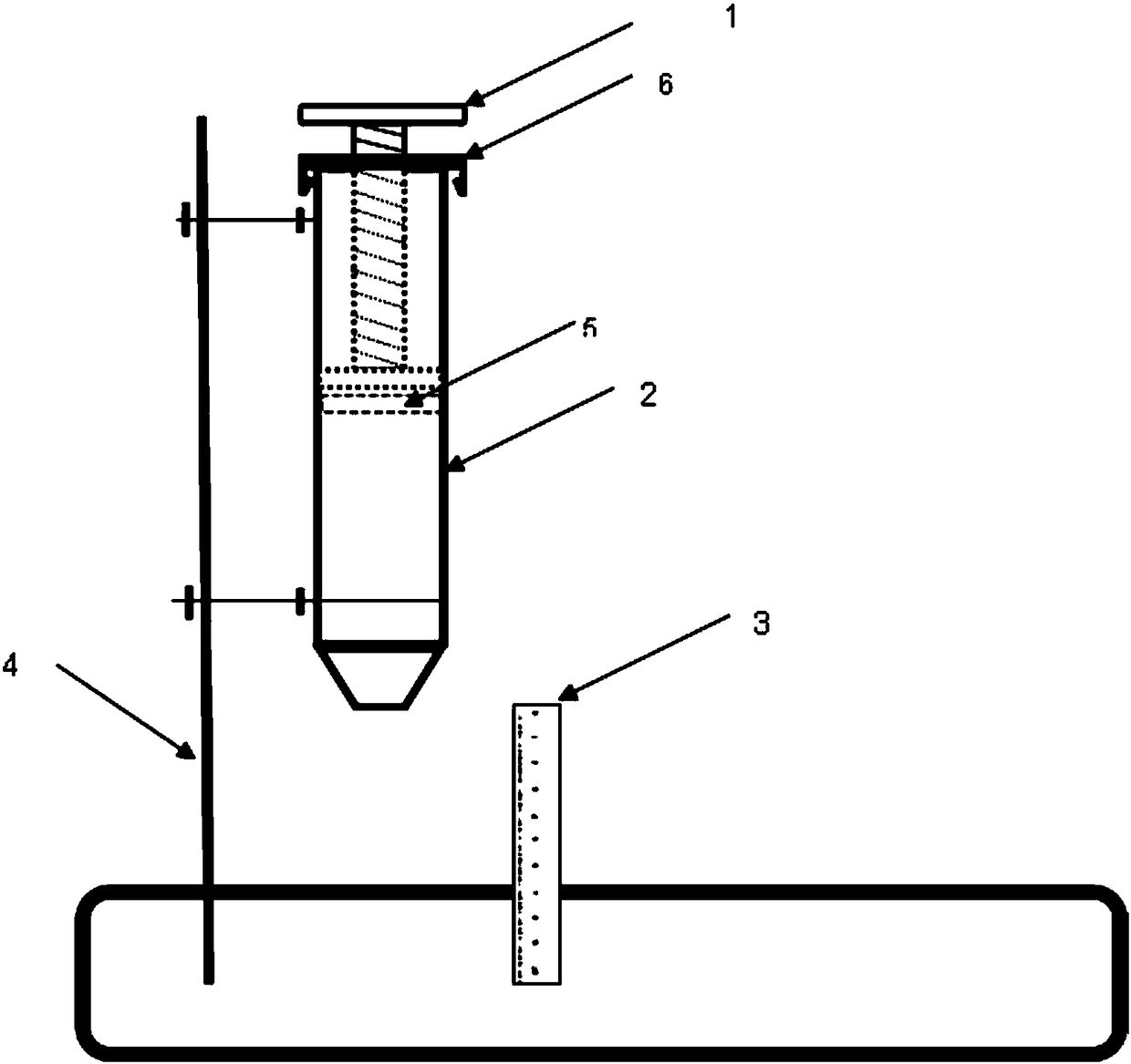

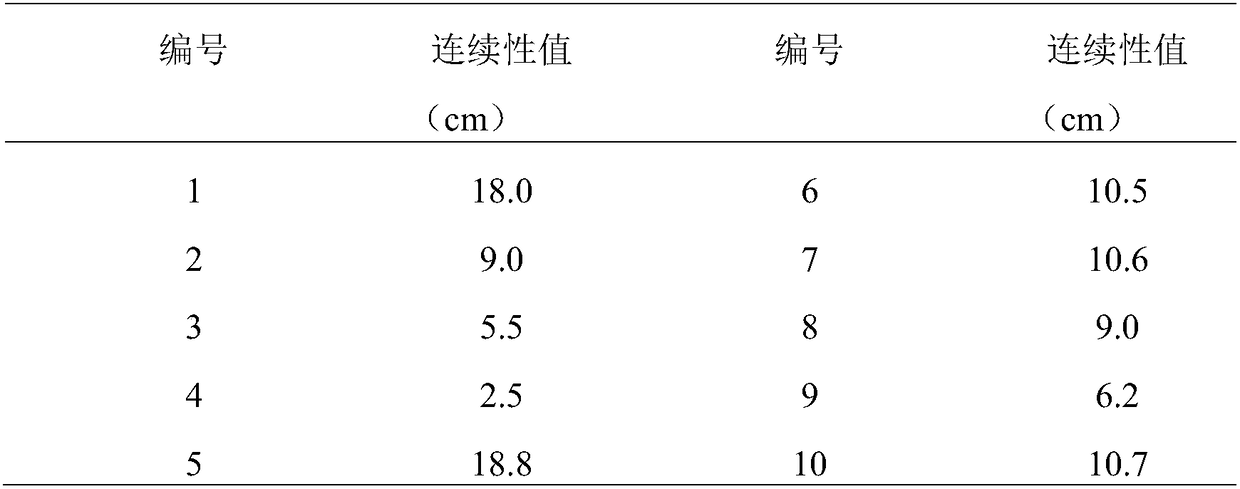

Continuity testing method of cement mortar for 3D (Three Dimensional) printing of building

InactiveCN108444867AExtrude evenlySolving Continuity Testing IssuesFlow propertiesContinuity testConstruction 3D printing

The invention provides a continuity testing method of cement mortar for 3D (Three Dimensional) printing of a building. A device for the continuity testing method is vertically arranged and comprises apushing rod (1) in an extruding barrel and a rear cover (6) which sleeves the pushing rod (1), wherein the pushing rod (1) is pushed into the extruding barrel (2); a gasket (5) is put into the extruding barrel (2) before the pushing rod (1) is put; the rear cover (6) is fixed at the upper end of the extruding barrel (2); the extruding barrel (2) is fixed on a fixed bracket (4); a straight ruler (3) is fixed on the fixed bracket (4); a zero scale line of the straight ruler (3) and the lower end of an extruding nozzle of the extruding barrel are located on the same horizontal line. Compared with the prior art, the cement mortar for the 3D printing of the building is tested and a quantification numerical value index related to continuity performance can be obtained; the continuity of the mortar for the 3D printing is accurately evaluated. The continuity testing method has the advantages that the proportion of the cement mortar for the 3D printing is easy to design, the blending time of amaterial before printing is shortened, wastes of the material are reduced and the working efficiency is improved.

Owner:BEIJING UNIV OF TECH

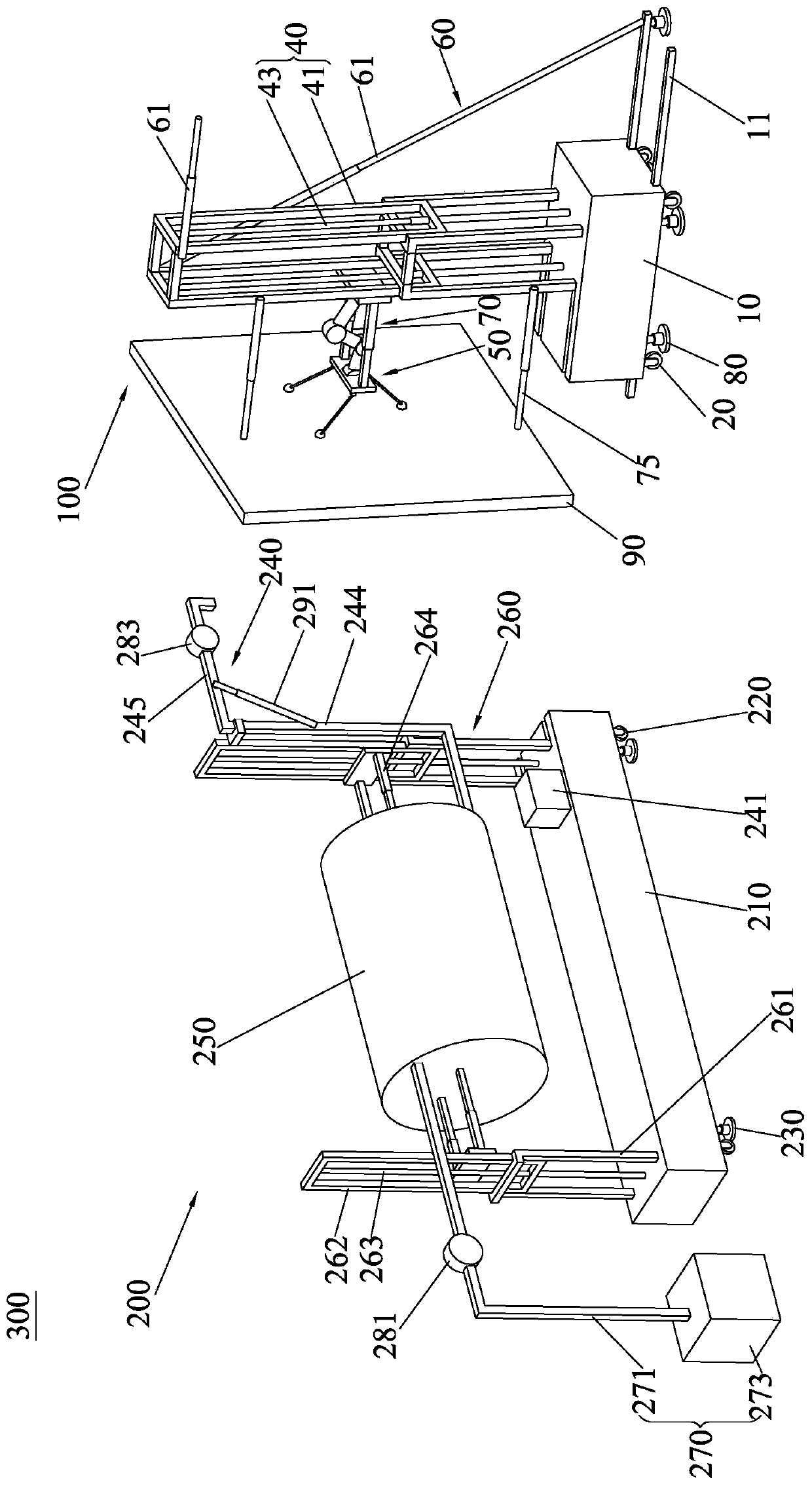

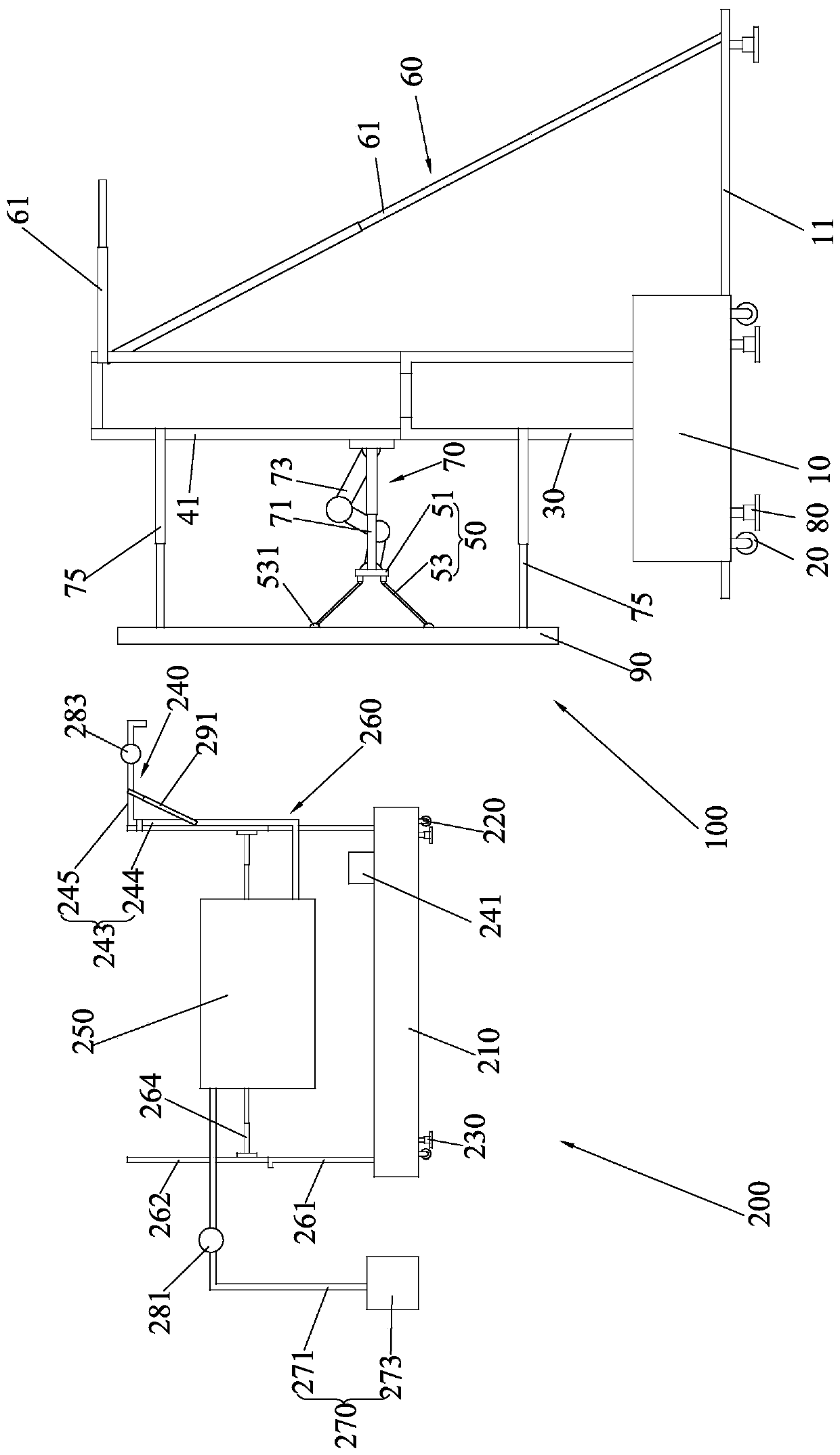

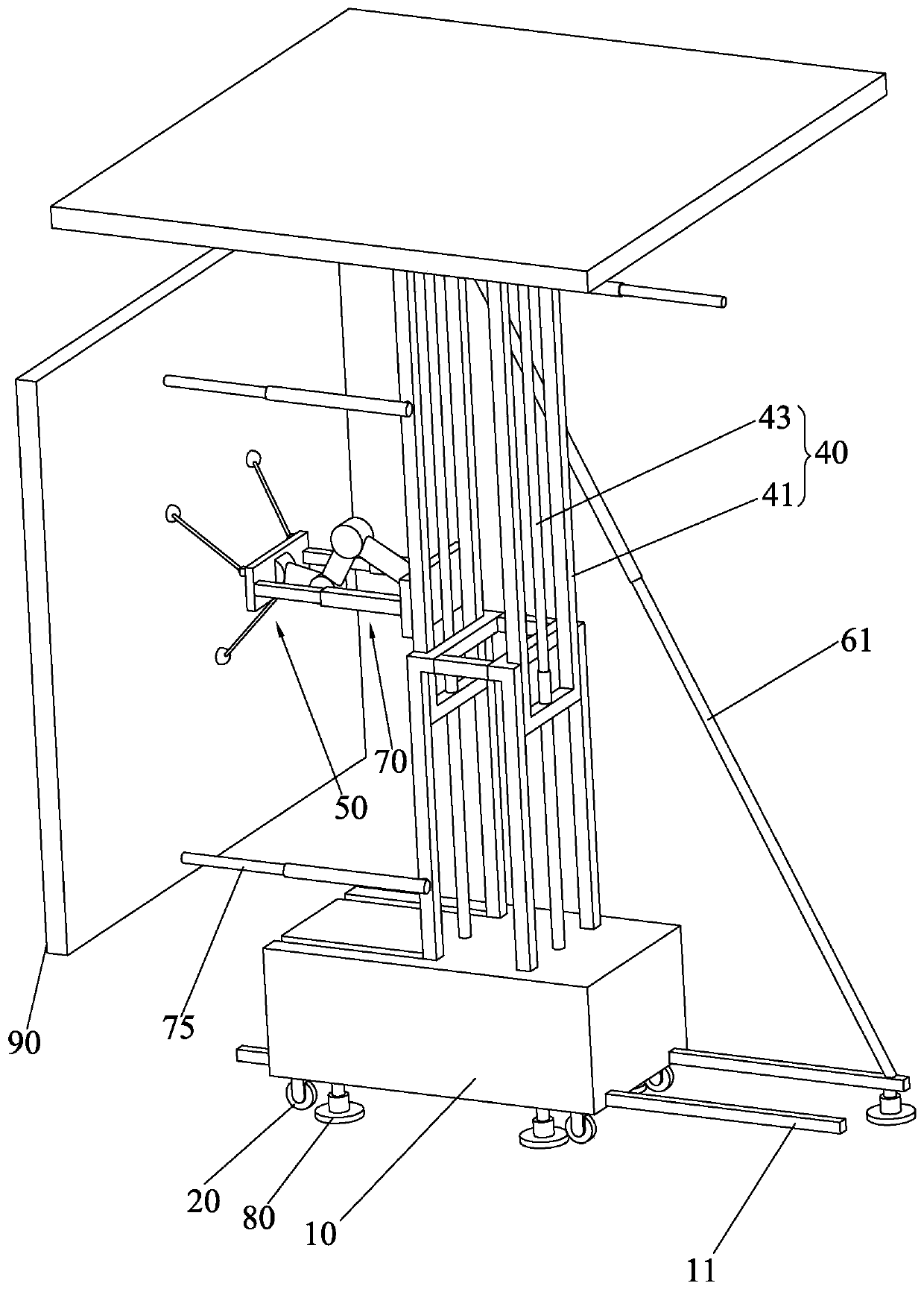

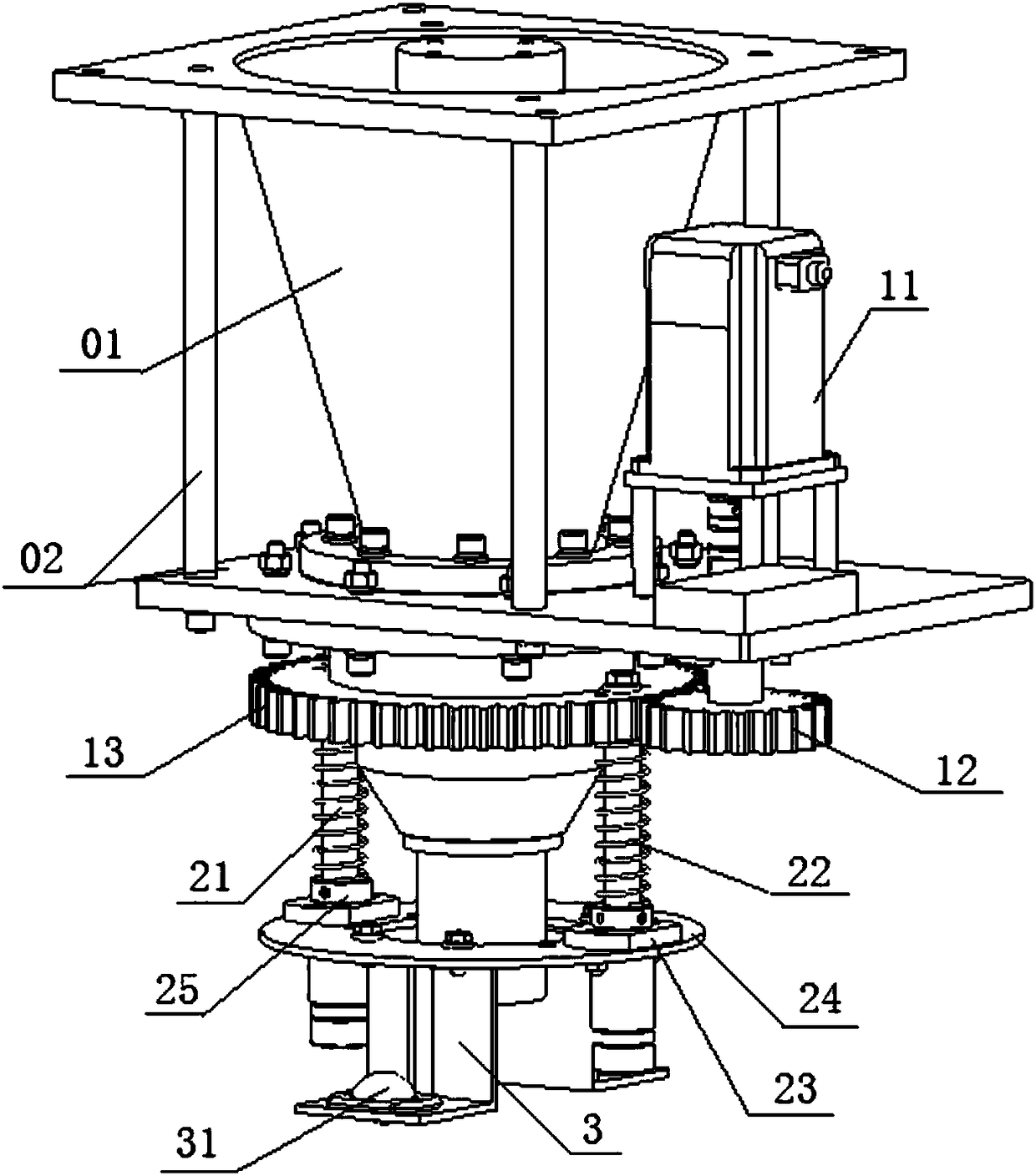

Building component molding robot module and building component molding method

PendingCN110125902AHigh forming precisionAvoid condensationGripping headsForm treatmentSupporting systemHybrid system

The invention discloses a building component molding robot module. The building component molding robot module comprises a building component molding robot (100) for forming mold plates into a mold cavity and a building 3D printing robot (200) for conveying building cementing materials to the mold cavity, wherein the building component molding robot (100) comprises a base (10), first travelling systems (20), a first rack body (30), a lifting system (40), at least one grabbing leveling system (50), at least one auxiliary support system (60) and first fixing systems (80), and the building 3D printing robot comprises a bottom rack (210), a conveying system (240), a mixing system (250) and a climbing system (260). By means of the building component molding robot module and a building componentmolding method, automation assembling of the mold plates used by vertical and horizontal components is realized and automatic pouring is performed, molding of building components is realized, and comprehensive efficiency improvement and cost reduction are realized. The invention further discloses the method for performing the building component molding adopting the building component molding robot module.

Owner:LANBEIWAN GUANGDONG SCI & TECH CO LTD

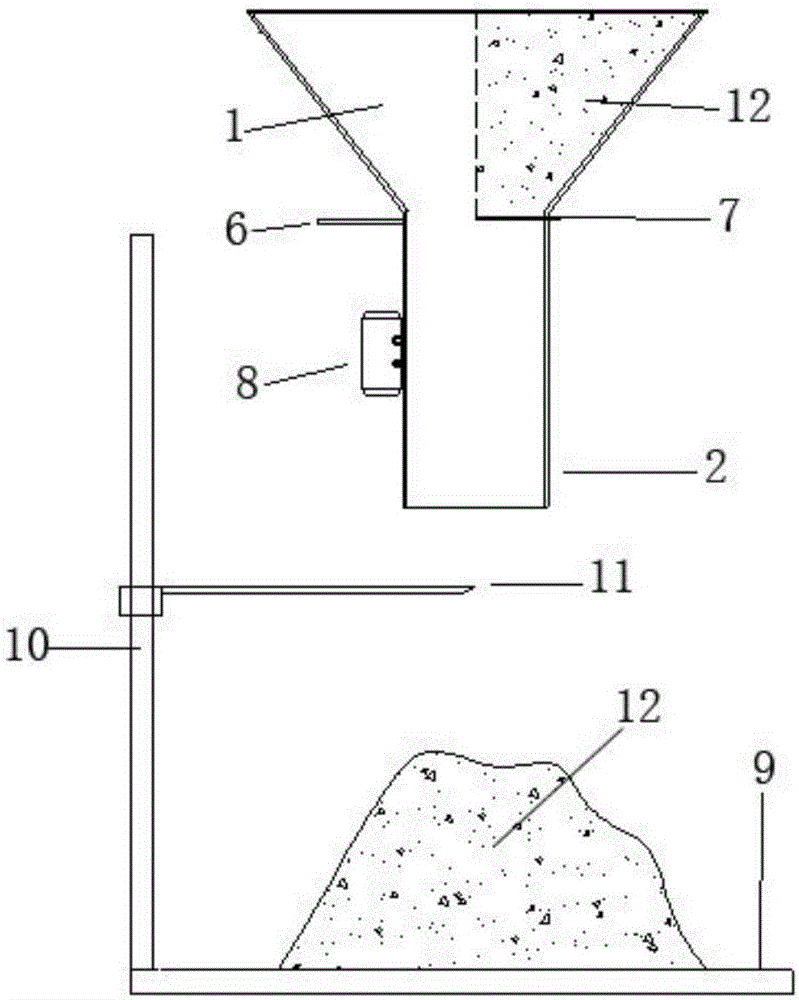

Testing device and testing method of building performance of 3D print material of building

The invention provides a testing device and testing method of the building performance of a 3D print material of a building. The testing device comprises a test tube, a stack height measurer and an extended measurement plate, wherein the test tube is suspended through a bracket; the stack height measurer comprises a measurement rod and a measurement needle; the measurement rod is vertically arranged at one side of the test tube; the measurement needle is horizontally arranged and one end of the measurement needle is connected with the measurement rod; and the extended measurement plate is arranged at the lower part of an outlet of the test tube. According to the testing device and the testing method, quantitative evaluation of the building performance of the 3D print material of the building can be achieved, the detection effect is good and the accuracy of the detection result is high.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

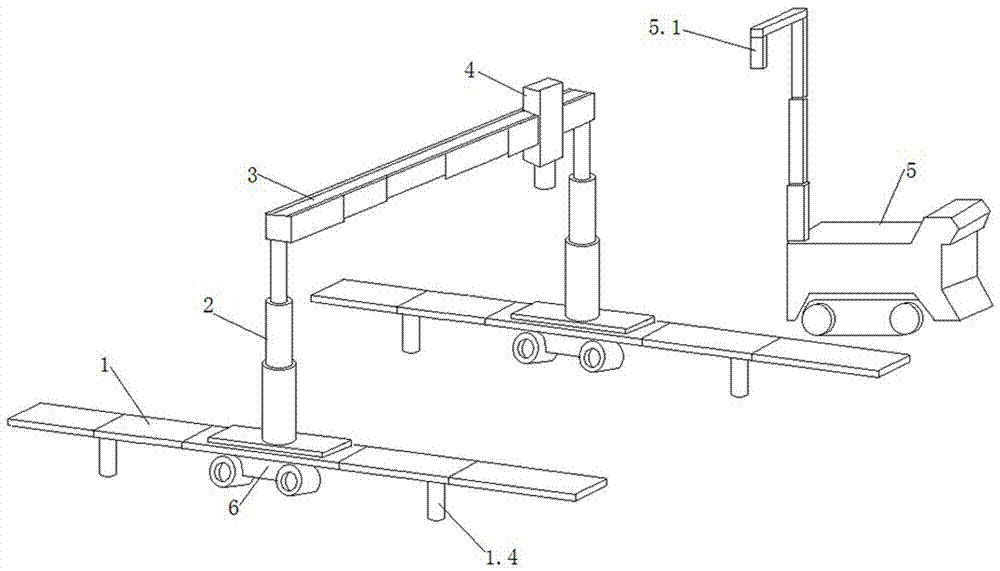

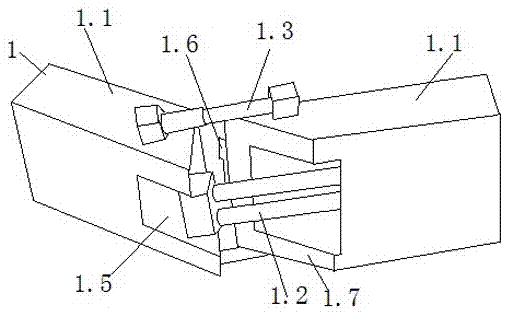

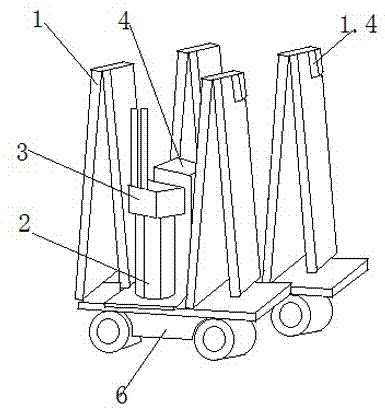

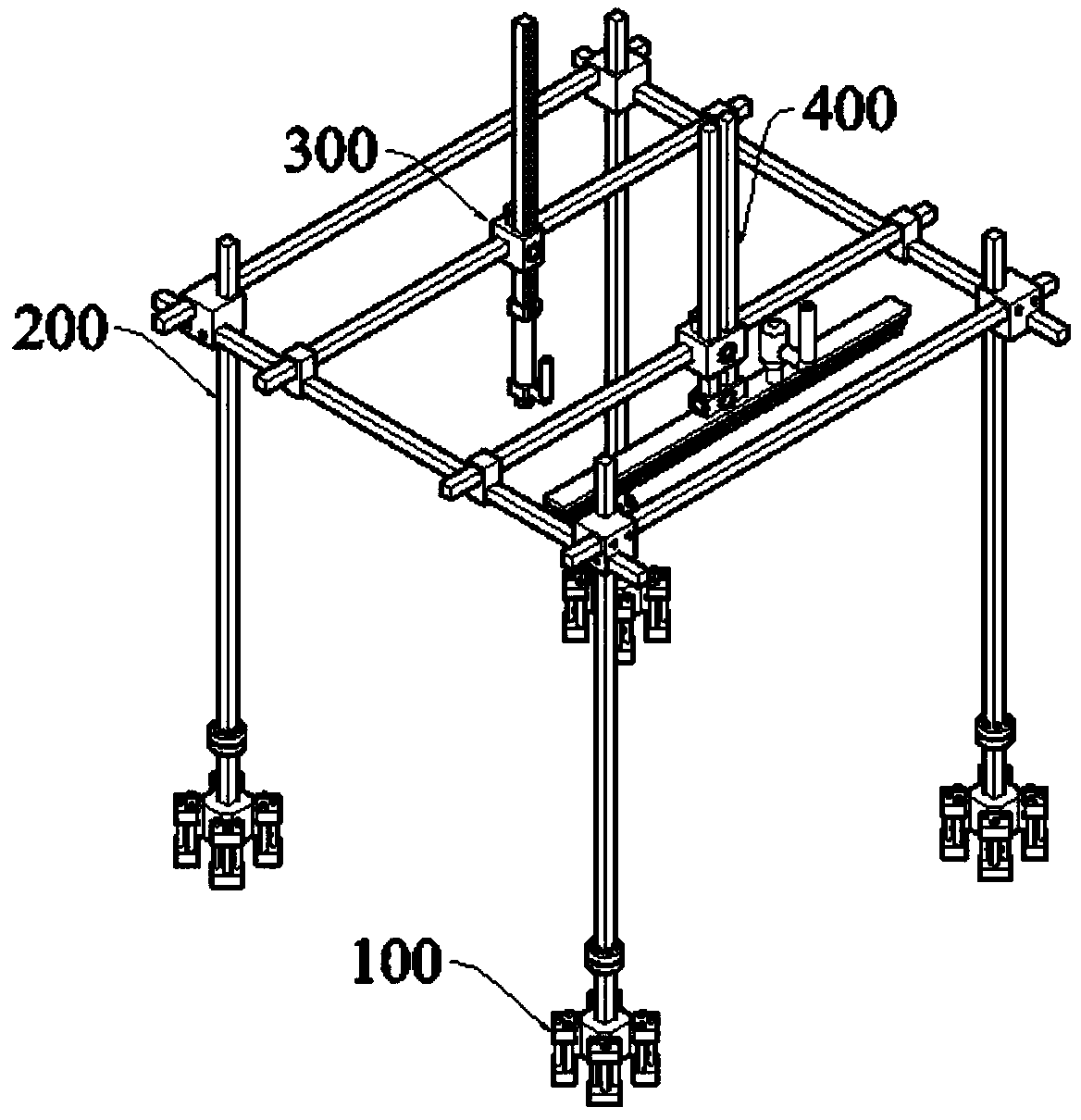

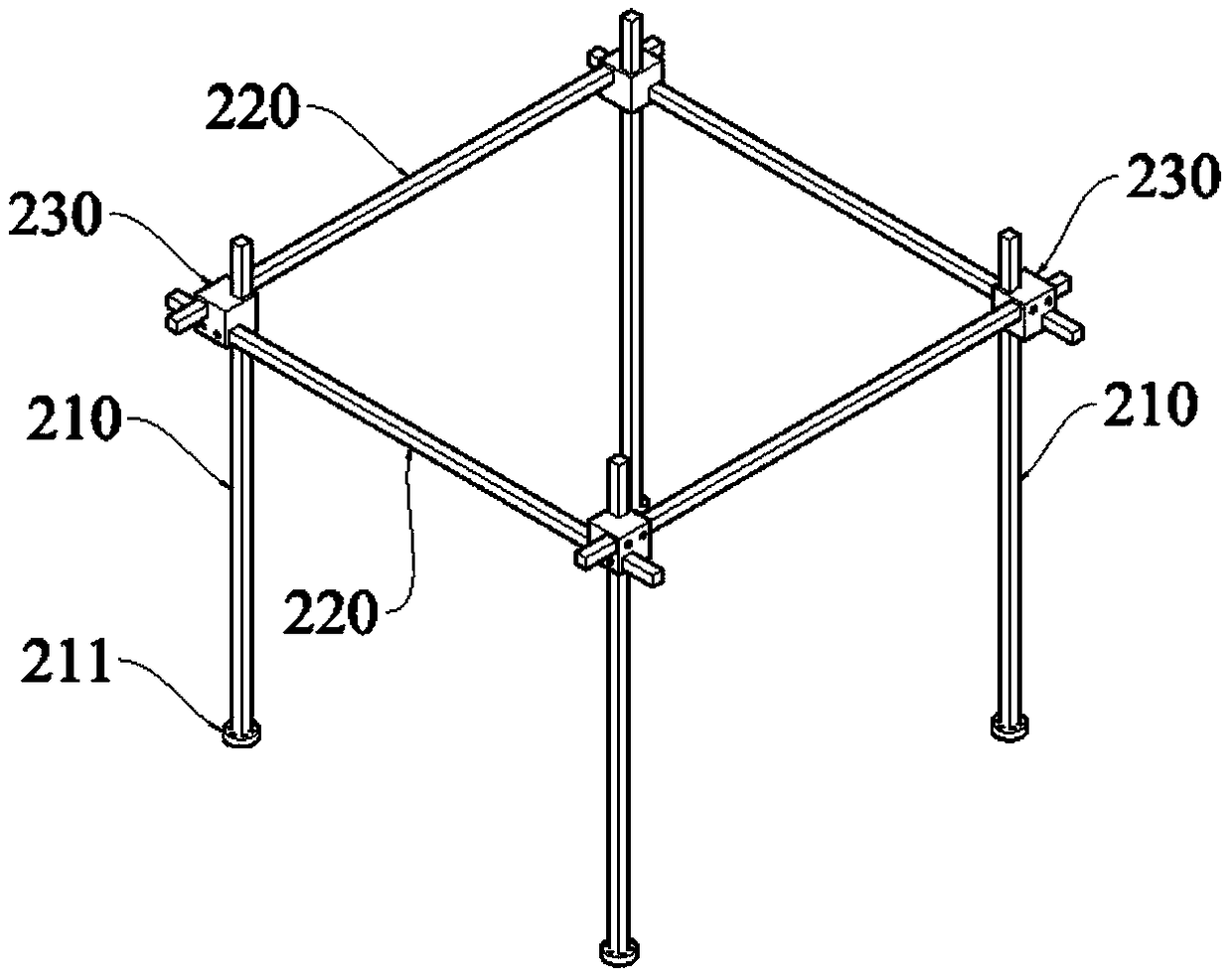

Foldable moving building 3D printing system

PendingCN107351385AReasonable structureEasy to transportManufacturing platforms/substrates3D object support structuresEngineeringConstruction 3D printing

The invention discloses a foldable moving building 3D printing system comprising a pair of transverse folding rails. Vertical telescopic uprights are mounted on the transverse folding rails correspondingly; after the transverse folding rails are unfolded, the vertical telescopic uprights can slide on the transverse folding rails; a telescopic cross beam is mounted between the pair of telescopic uprights; a telescopic material extruding printing head capable of sliding along the telescopic cross beam is assembled on the telescopic cross beam; and a bottom plate power device is mounted at the bottom of each transverse folding rail. According to the foldable moving building 3D printing system, the modularized design and folding moving are adopted, the transportation efficiency and space of the printing system are increased, and accordingly the construction cost is saved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Building 3D printer follow-up trowelling mechanism

ActiveCN108340469ARealize the function of automatic smoothing and smoothingAdditive manufacturing apparatusCeramic shaping apparatusControl systemEngineering

The invention discloses a building 3D printer follow-up trowelling mechanism which comprises a follow-up rotating mechanism, an automatic scraper blade height lifting mechanism, an adjustable scraperblade and a follow-up scraper blade control system, wherein the follow-up rotating mechanism is connected to a printing extruding machine, the automatic scraper blade height lifting mechanism is connected with the follow-up rotating mechanism, the adjustable scraper blade is connected to the automatic scraper blade height lifting mechanism, and the follow-up scraper blade control system is connected with the follow-up rotating mechanism to control an angle of the adjustable scraper blade. The building 3D printer follow-up flattening mechanism disclosed by the invention can automatically followa motion curve of a printer spray head to further rotate the position of the scraper blade in real time, so that the horizontal line of a vertical scraper blade face of the scraper blade is always parallel to a motion straight line curve or parallel to the tangential direction of a curve track; thus, a function of automatically flattening printing lines in a printing process is achieved, surfacequality of building 3D printer printing members is effectively improved, a subsequent manual modifying technology is reduced, and the efficiency of the 3D printer is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

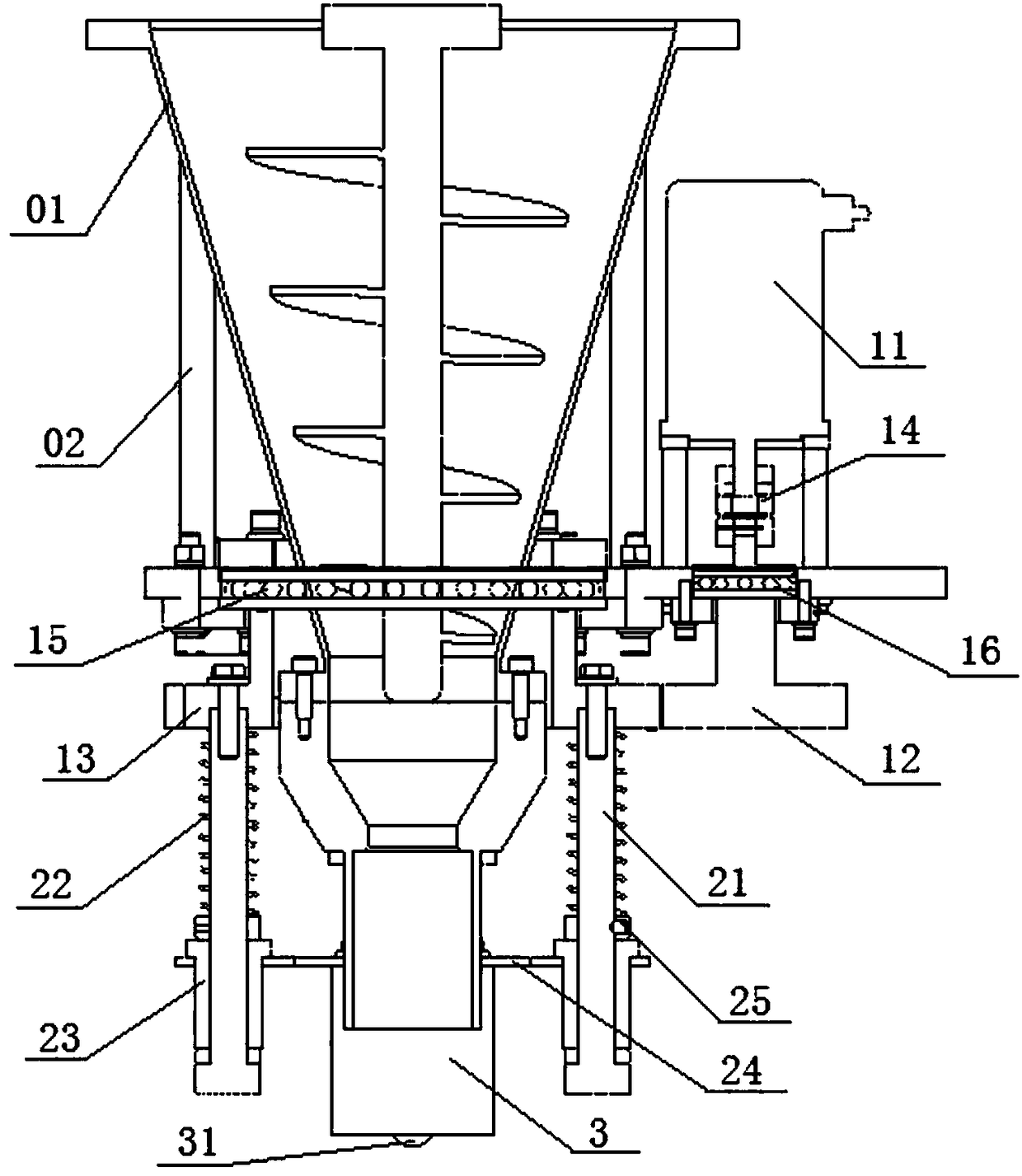

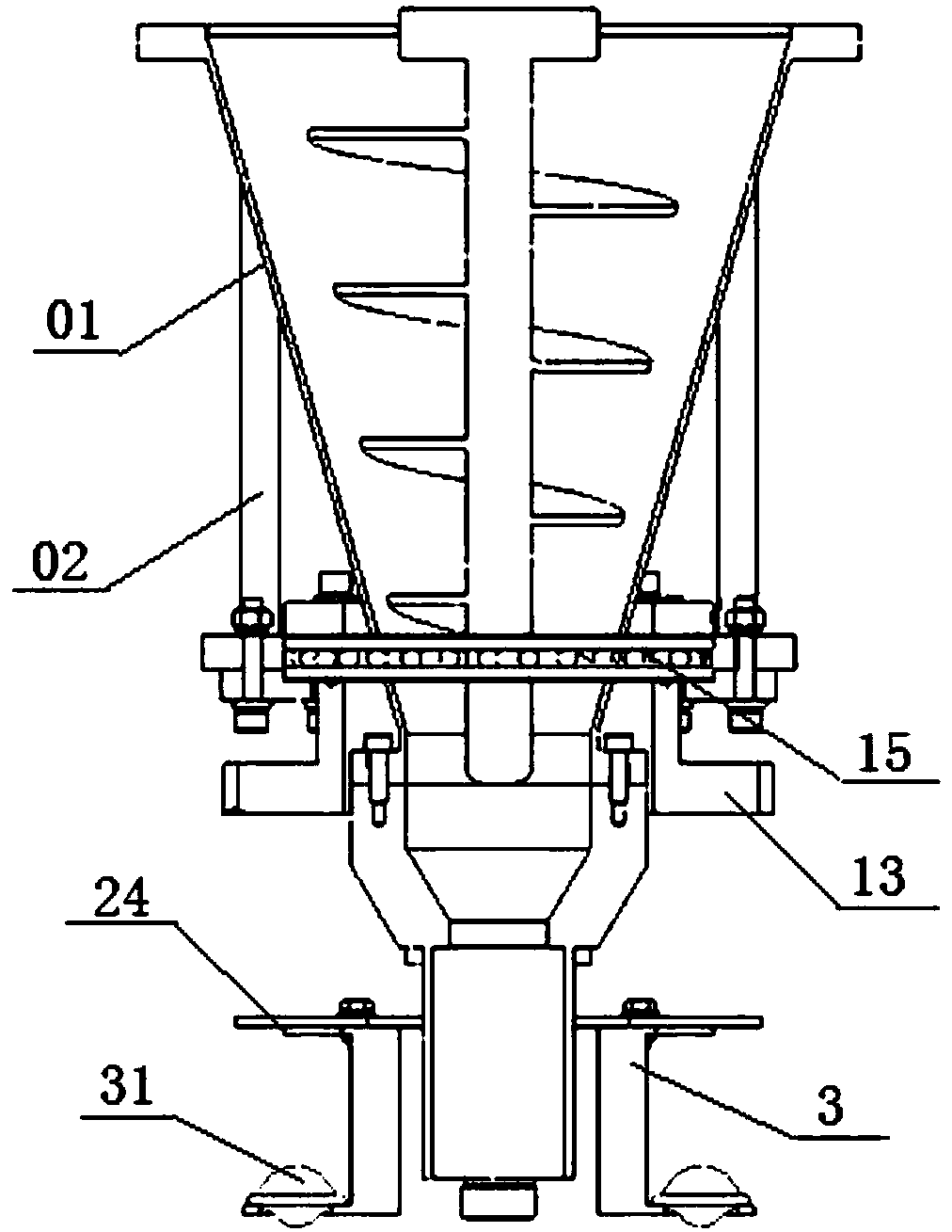

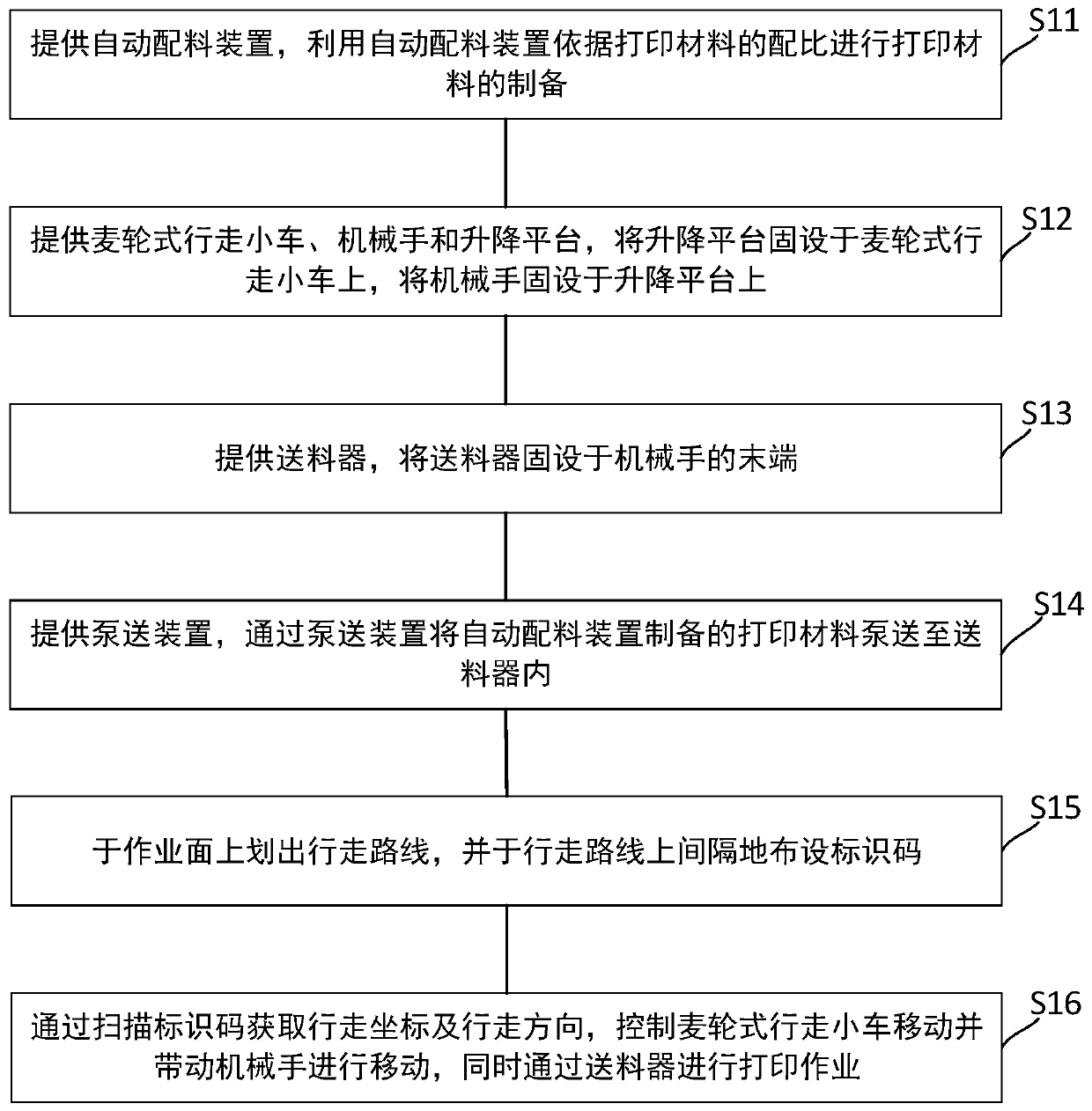

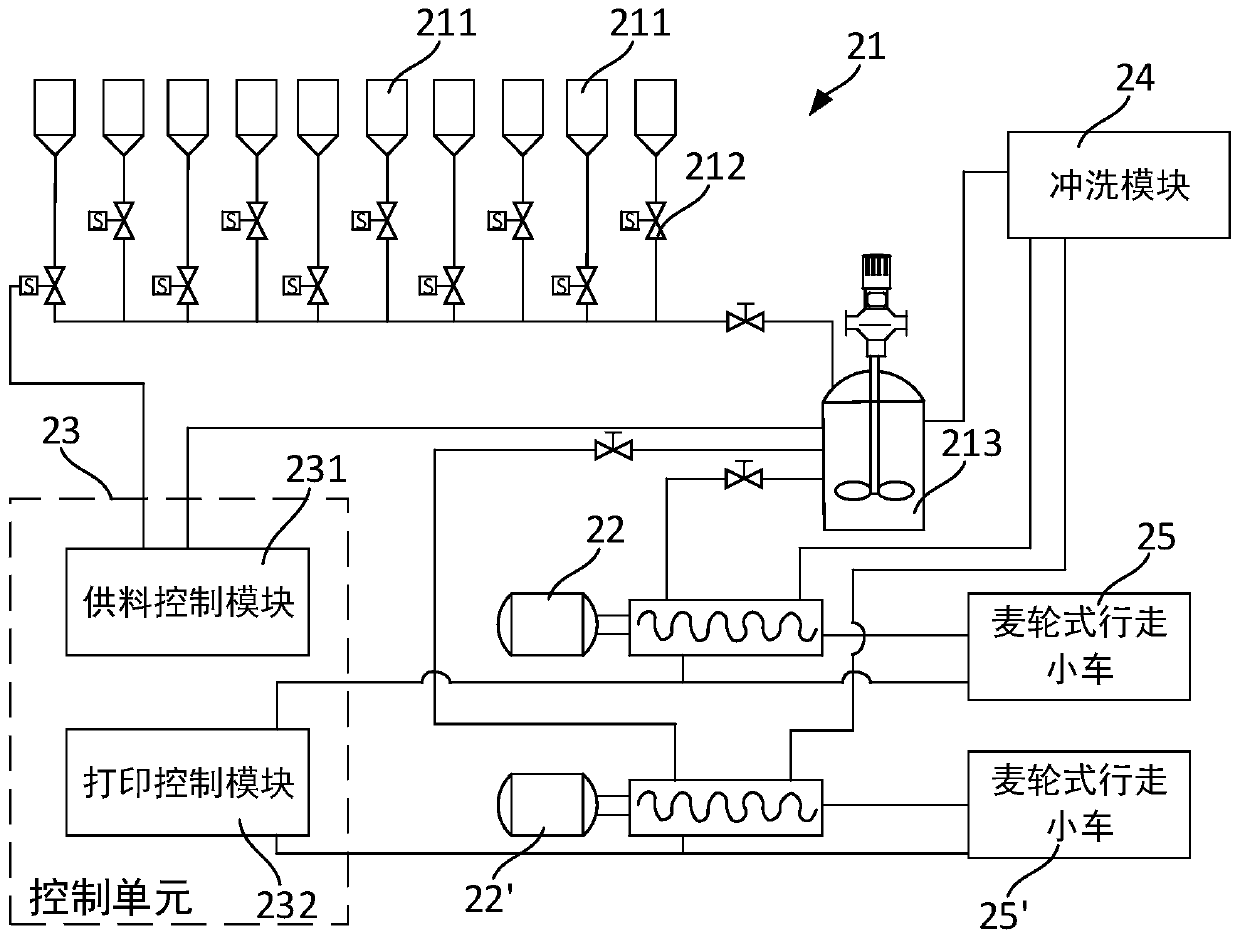

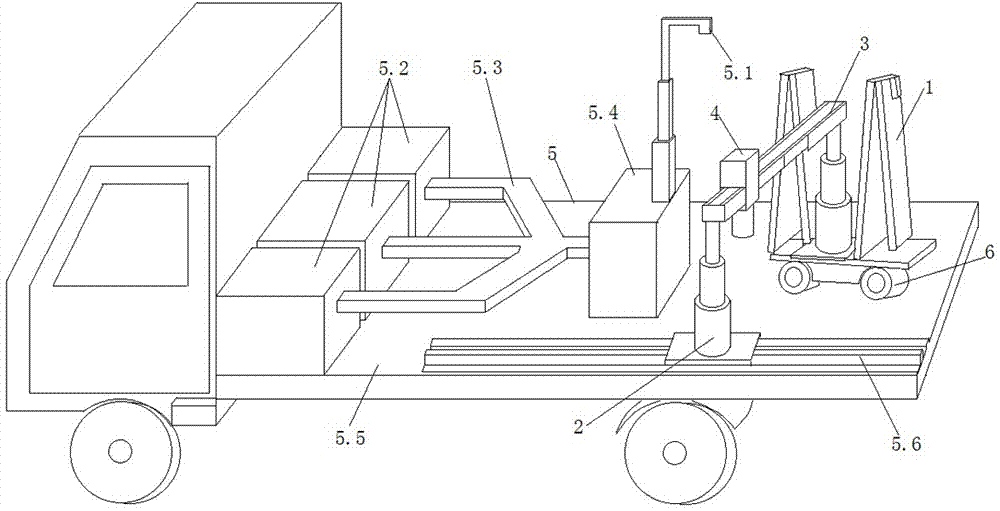

Control method of walking-type building 3D printing process

ActiveCN110421681AReduce pollutionHigh positioning accuracyAdditive manufacturing apparatusFeeding arrangmentsControl systemEngineering

The invention relates to a control method of a walking-type building 3D printing process. The control method comprises the steps of providing an automatic batching device, and preparing printing materials according to the proportion of the printing materials; providing a pumping device for pumping the printing materials into a feeder; providing a Mecanum wheel type walking trolley, and using the Mecanum wheel type walking trolley to drive a mechanical arm and the feeder to move; drawing out a running route on a working surface, and arranging identification codes on the running route at intervals; and scanning the corresponding identification code to obtain a walking coordinate and a walking direction so as to drive the mechanical arm to move, and carrying out printing at the same time. According to the control method, the automatic batching device is adopted to achieve automatic preparation of the printing materials, unmanned feeding is achieved, work intensity is reduced, and environmental pollution is reduced; and by means of the Mecanum wheel type walking trolley, the positioning accuracy of 3D printing is improved, the Mecanum wheel type walking trolley can move laterally at any angle, and is stable and reliable in operation, and a turning radius does not need to be set.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

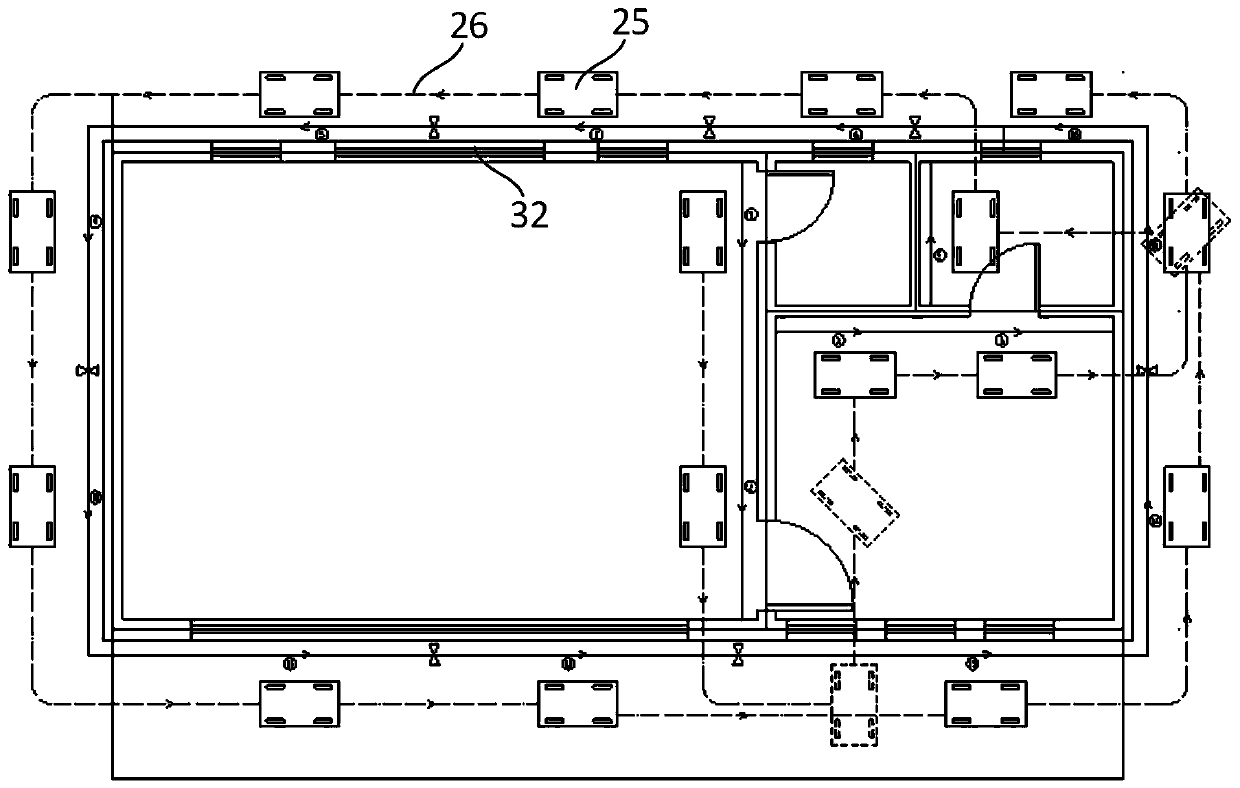

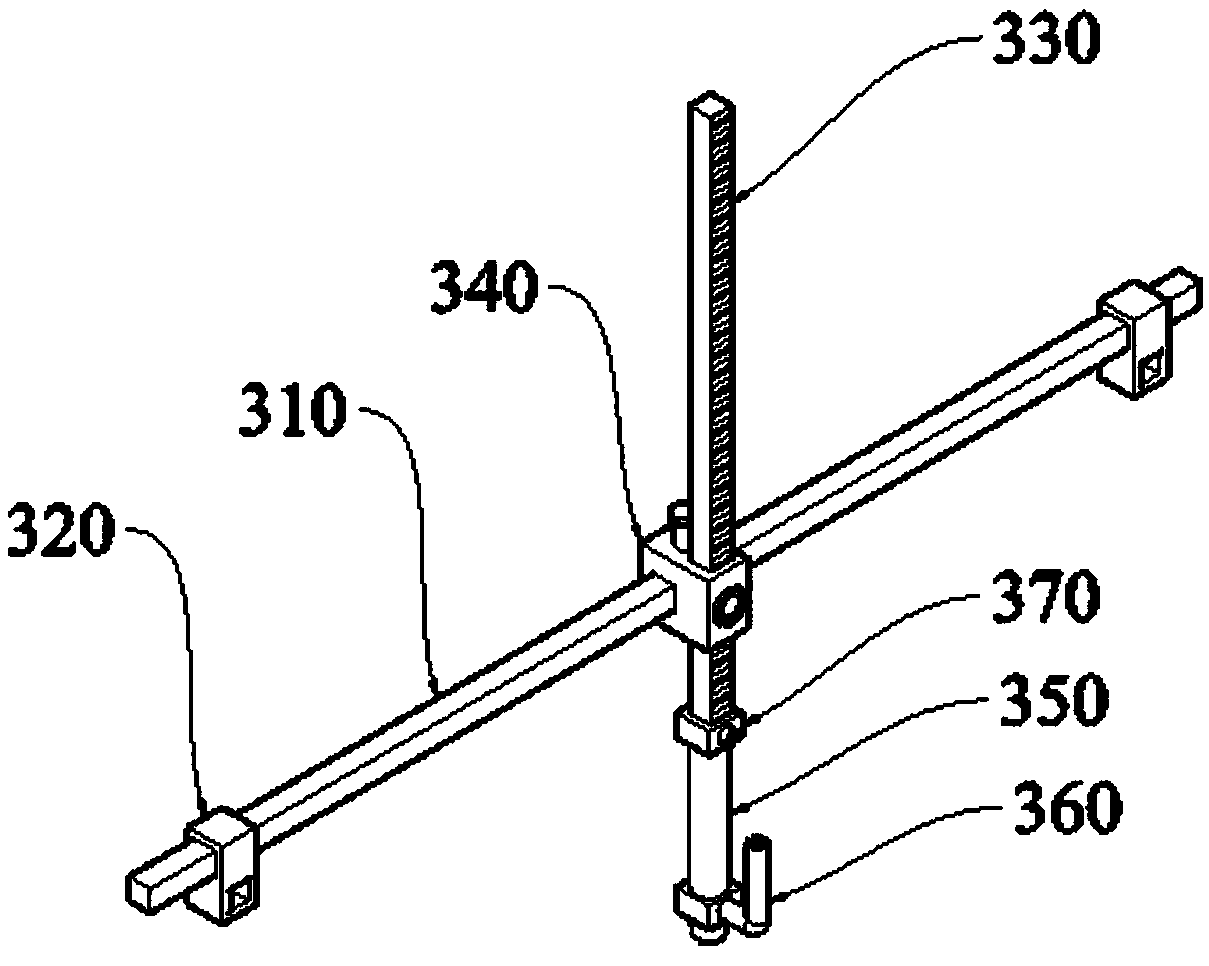

Dismountable easy-to-clean pipeline system for conveying building 3D printing material

ActiveCN105804405AAvoid cloggingEasy to moveBuilding material handlingEngineeringConstruction 3D printing

The invention discloses a dismountable easy-to-clean pipeline system for conveying a building 3D printing material. The system comprises two first guide rail mechanisms, two second guide rail mechanisms, a third guide rail mechanism, a fourth guide rail mechanism, a first connection mechanism, a second connection mechanism and a plurality of feeding pipes, wherein the two first guide rail mechanisms are arranged parallel to a first horizontal direction; the two second guide rail mechanisms are arranged along a vertical direction and are respectively connected with the two first guide rail mechanisms in a sliding manner along the first horizontal direction; the third guide rail mechanism is arranged along a second horizontal direction vertical to the first horizontal direction, is erected between the two second guide rail mechanisms and is connected with the two second guide rail mechanisms in a sliding manner along the vertical direction; the fourth guide rail mechanism is arranged along the second horizontal direction, is arranged at the upper part of the third guide rail mechanism and is fixedly connected between the two second guide rail mechanisms; the first connection mechanism is connected with a printer head and is connected with the third guide rail mechanism in a sliding manner along the second horizontal direction; the second connection mechanism is connected with the fourth guide rail mechanism; the feeding pipes are connected with each other via a bent pipe bearing, are communicated with the printer head and are used for conveying the printing material to the printer head; the feeding pipes are connected with each other via the bent pipe bearing, so that the feeding pipes are capable of freely rotating and are low in possibility of damage.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

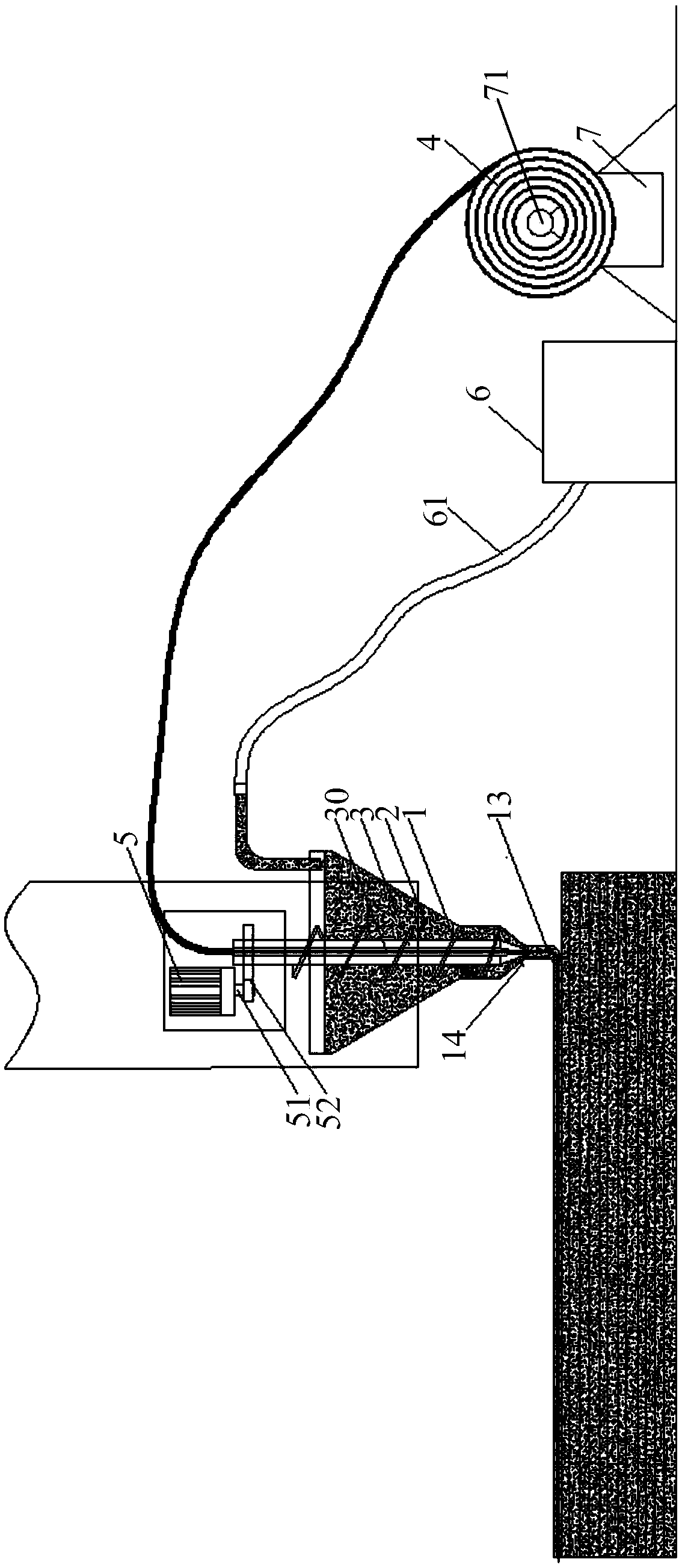

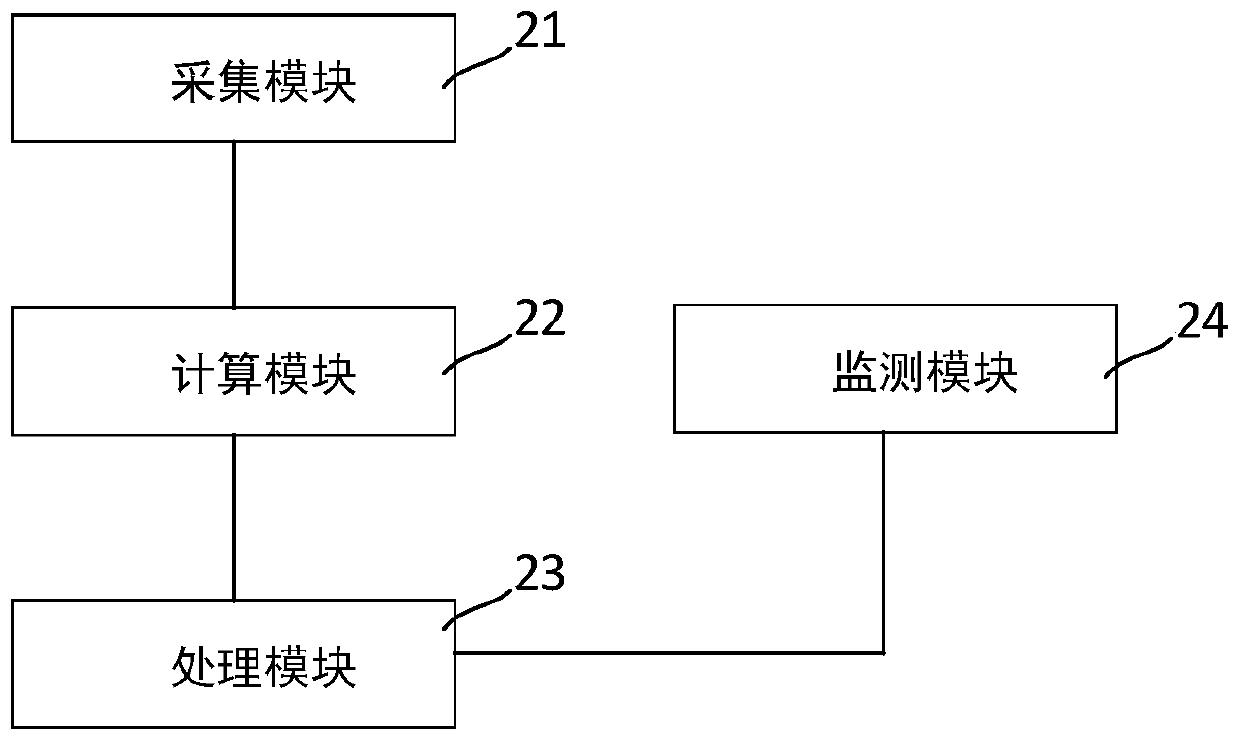

Building 3D printing circulating feeding control method and system

ActiveCN110281346AReal-time monitoring of actual widthHigh precisionAdditive manufacturing apparatusCeramic shaping apparatus3d printerConstruction 3D printing

The invention relates to a building 3D printing circulating feeding control method and system. The method comprises the following steps of in the 3D printing process, monitoring in real time the material liquid level position in a feeding device of a 3D printer and forming material level information; judging whether the obtained material level information reaches the set lowest position or not, and if yes, feeding material to the feeding device until the material level information reaches the set highest position; in the feeding process, acquiring in real time the actual width of printing lines, and calculating the difference value between the actual width of the obtained printing lines and the designed width of the lines according to the designed width of the lines; and judging whether the calculated difference value is within an allowable range or not, and if not, adjusting the travelling speed and / or the discharging speed of the 3D printer so as to enable the difference value to be within the allowable range. According to the control method, real-time detecting, real-time printing and real-time adjusting are realized, so that the quality of 3D printing can be improved by the feedback, and the precision of components formed by printing is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Printing head screw rod device suitable for coarse aggregate concrete 3D printing

InactiveCN107165831AReasonable structureConsistent extrusion pressureSpecific fluid pumpsPump componentsSpiral bladeEngineering

The invention discloses a printing head screw rod device suitable for coarse aggregate concrete 3D printing. The device comprises a stator and a rotor; the rotor is arranged in the stator, and comprises a straight rod and spiral blades; the spiral blades are uniformly distributed on the straight rod; the stator is a combined piece of a steel pipe and a flexible sleeve; the flexible sleeve is arranged between the spiral blades and the steel pipe; and the spiral blades on the rotor are tightly combined with the flexible sleeve on the stator. The printing head screw rod device can be applied to a concrete 3D printing head; a storage hopper on the printing head is arranged above the printing head screw rod device; and an extrusion port is positioned under the printing head screw rod device. The printing head screw rod device suitable for coarse aggregate concrete 3D printing is reasonable in structure; a wear-resistance rubber sleeve is arranged between the spiral blades of the rotor and a cover of the steel pipe; the blades are tightly combined with the rubber sleeve to guarantee consistent extrusion force, so that the discharge uniformity is improved; and the device can extrude concrete containing aggregates, and effectively widens the application range of a building 3D printer.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

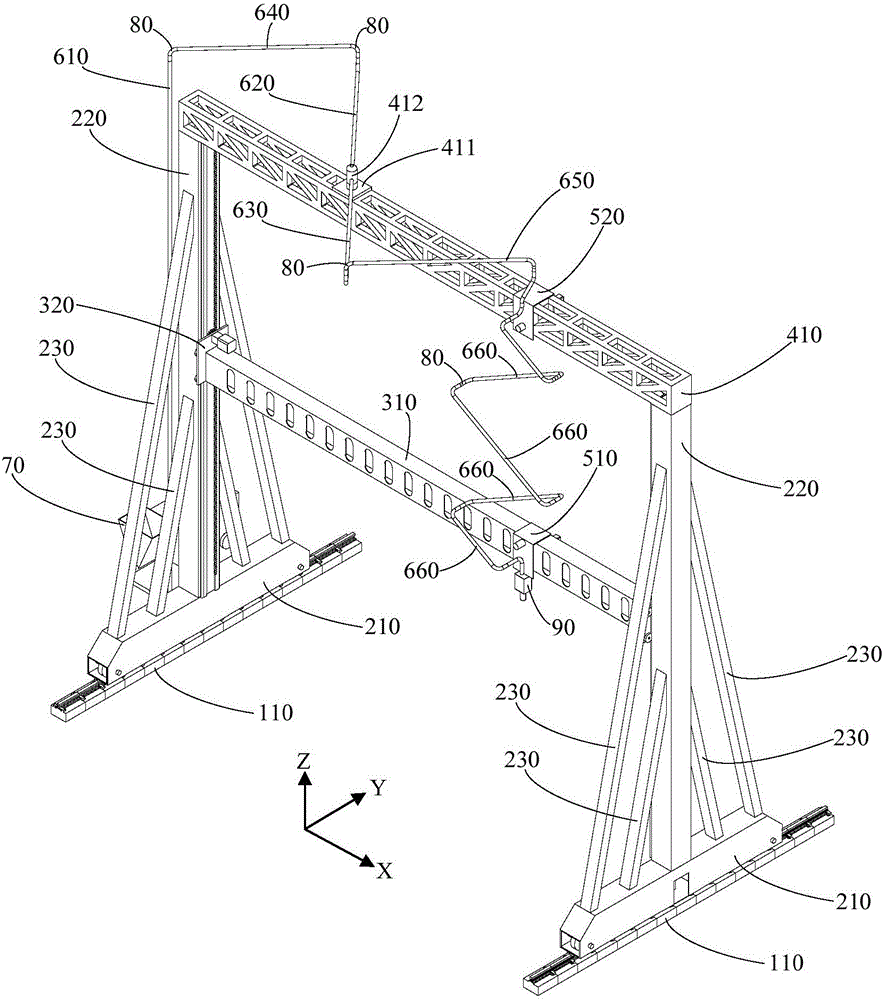

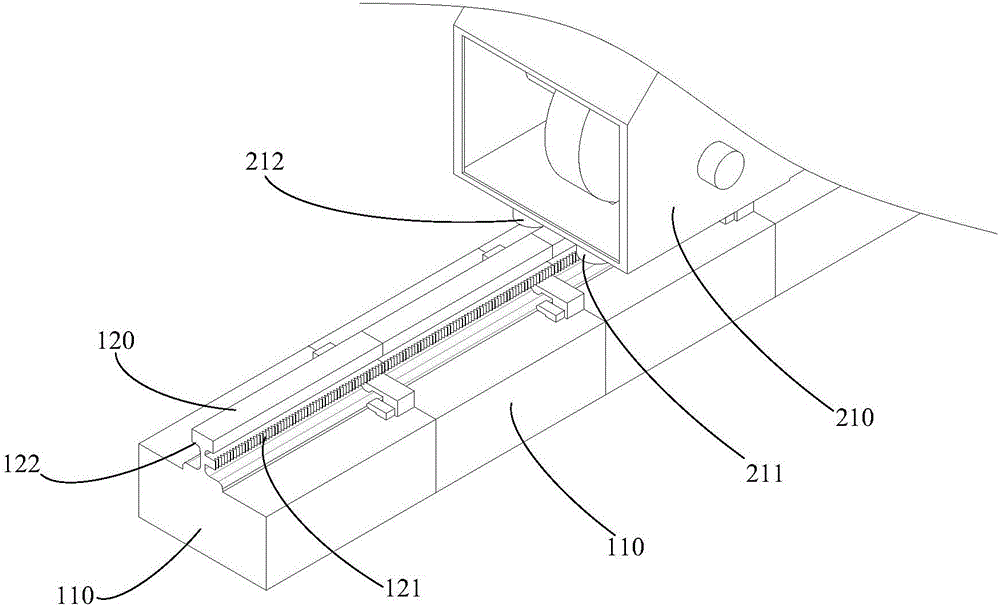

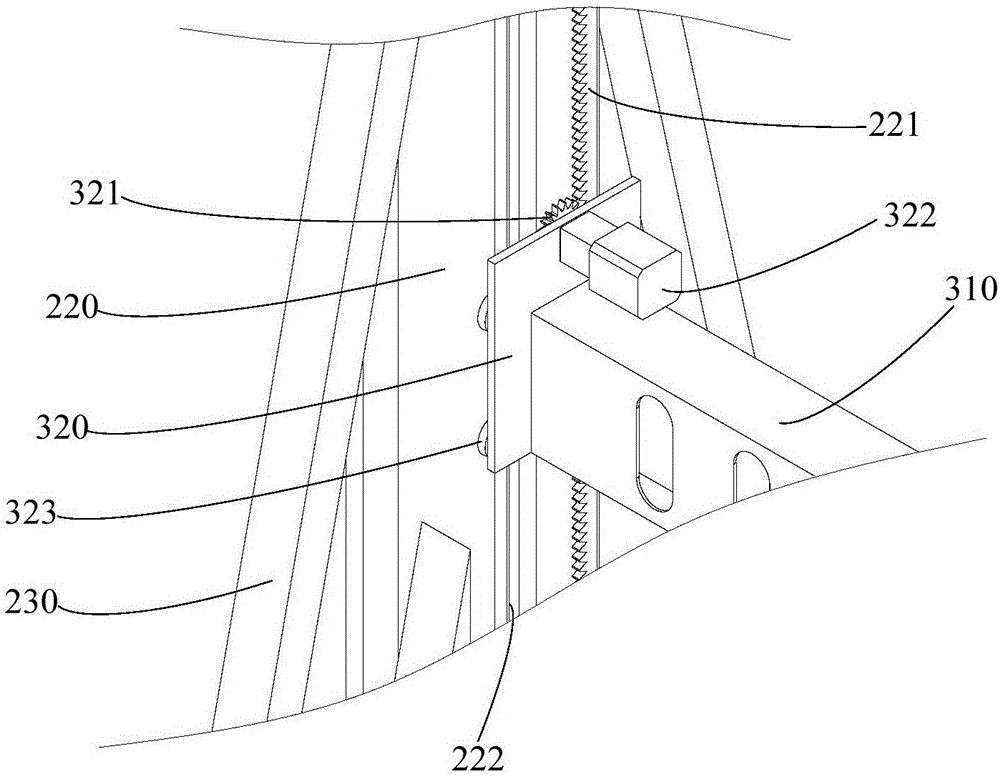

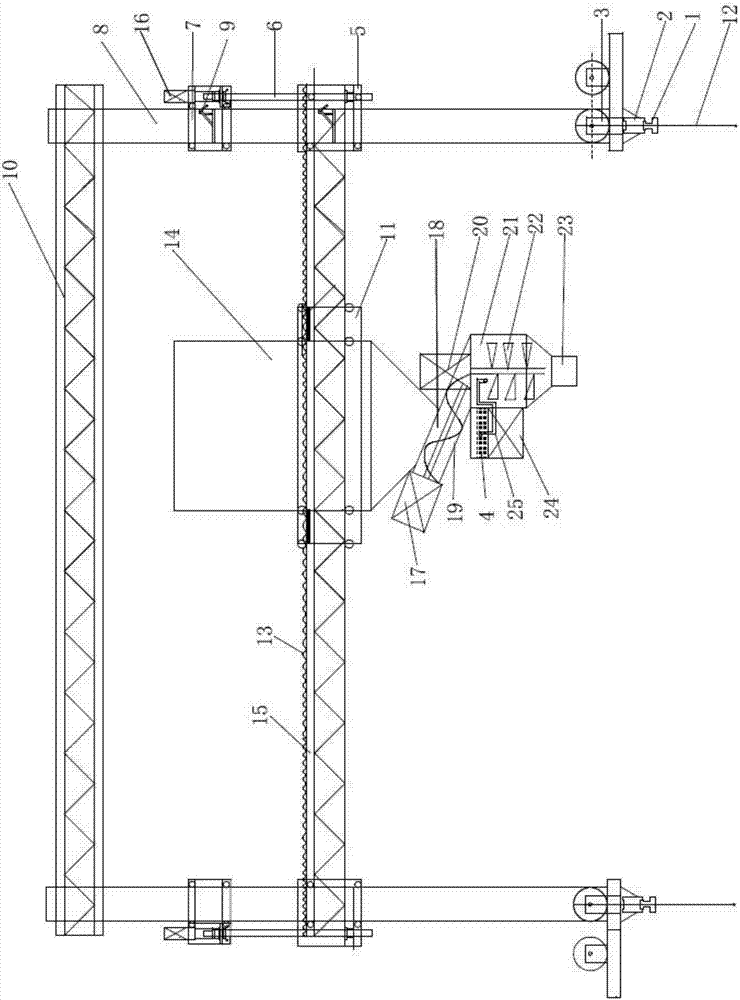

Portal type building 3D printer achieving integral and alternate lifting

PendingCN107053428AAchieve orienteeringRealize the print jobCeramic shaping apparatusControl systemLocking mechanism

The invention discloses a portal type building 3D printer achieving integral and alternate lifting and belongs to the technical field of constructional engineering 3D printing. The two ends of a supporting frame of the printer are connected with Z-axis slide rails, so that a portal type supporting structure is formed. The bottom of each Z-axis slide rail is connected to a Y-axis rail through a Y-axis drive mechanism and a guide wheel in a sliding manner. A pulley a and a pulley b are connected to each Z-axis slide rail in a sliding manner, wherein each pulley a and each pulley b are provided with locking mechanisms. The pulleys b are connected with the two ends of an X-axis slide rail. A sliding trolley is driven by an X-axis drive motor to be connected with the X-axis sliding rail in a sliding manner. The sliding trolley is connected with a printing mechanism. The Y-axis drive mechanisms, the X-axis drive motor, an alternate lifting mechanism, the printing mechanism and the locking mechanisms are connected with a control system. The portal type building 3D printer achieving integral and alternate lifting has the beneficial effects that the Y-axis rails can be prolonged, and outstanding advantages existing when an ultra-long building or a townhouse building is printed; in addition, the portal rail manner is adopted, so that the mechanism and the structure are greatly simplified, the manufacturing cost is greatly reduced, and conversion of a scientific and technological achievement is facilitated.

Owner:都书鹏

Two-component cement-based composite material for 3D printing and its preparation method and use

A two-component cement-based composite material for 3D printing and its preparation method and application, including two components A and B, A containing 34% to 40% sulfoaluminate cement, 0% to 6% inorganic powder, 40% to 44% tailings machine-made sand and 2.5% to 3% polymer, and the rest are retarder, water reducer, volume stabilizer, defoamer and water. Its pumping performance is good and the maintenance time is long. Realize the industrialization process of ready-mixed production-transportation-construction site use of mixing station; B includes coagulant, thixotropic agent, defoamer and water, and its stable form can be stored for a long time or concentrated production. A and B are pumped into the 3D printer and then mixed by the high-speed stirring extrusion head to extrude the composite printing material, which has short coagulation time, high strength, good cohesiveness, and strong stability, which meets the construction continuity and construction requirements of architectural 3D printing. Strength requirements, facilitate the industrial production and promotion of cement-based 3D printing materials, and effectively promote the application of 3D printing technology in construction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Hybrid fiber cement-based composite material for 3D printing and preparation method thereof

ActiveCN109384437AEmission reductionReduce manufacturing costAdditive manufacturing apparatusPolyvinyl alcoholPortland cement

The invention discloses a hybrid fiber cement-based composite material for 3D printing and a preparation method thereof. The hybrid fiber cement-based composite material comprises, by weight, 3.81 to4.76 parts of ordinary Portland cement, 0 to 0.21 parts of sulphoaluminate cement, 0 to 0.95 parts of silica fume, 3.81-4.35 parts of sand stone, 0.10-0.20 part of calcium carbonate whiskers, 0.005-0.007 part of polyvinyl alcohol fiber, 0.005-0.02 part of a rheological agent, 1.30-1.45 parts of water and 0.032-0.042 part of a water reducing agent. The hybrid fiber cement-based composite material is green and environmentally friendly in building 3D printing construction, has good printability, can significantly improve the mechanical properties, and is beneficial to popularize the application of 3D printing technology in civil engineering.

Owner:SOUTHEAST UNIV +1

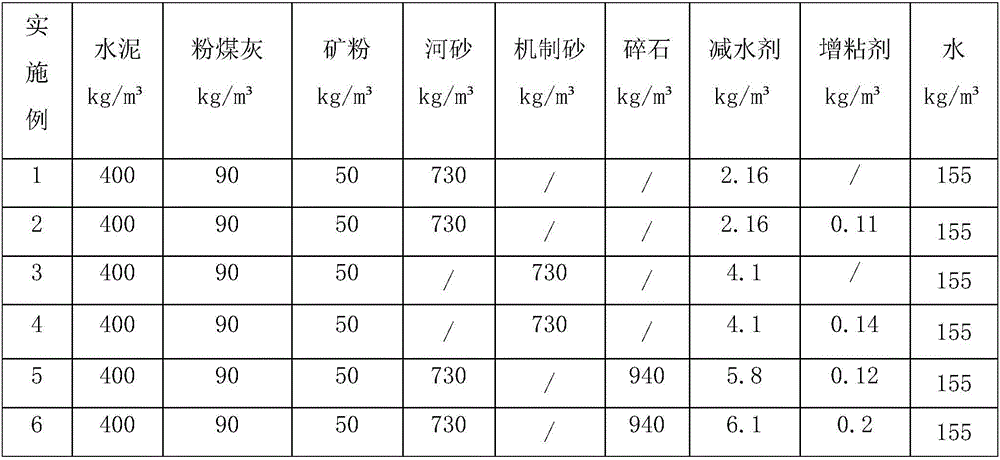

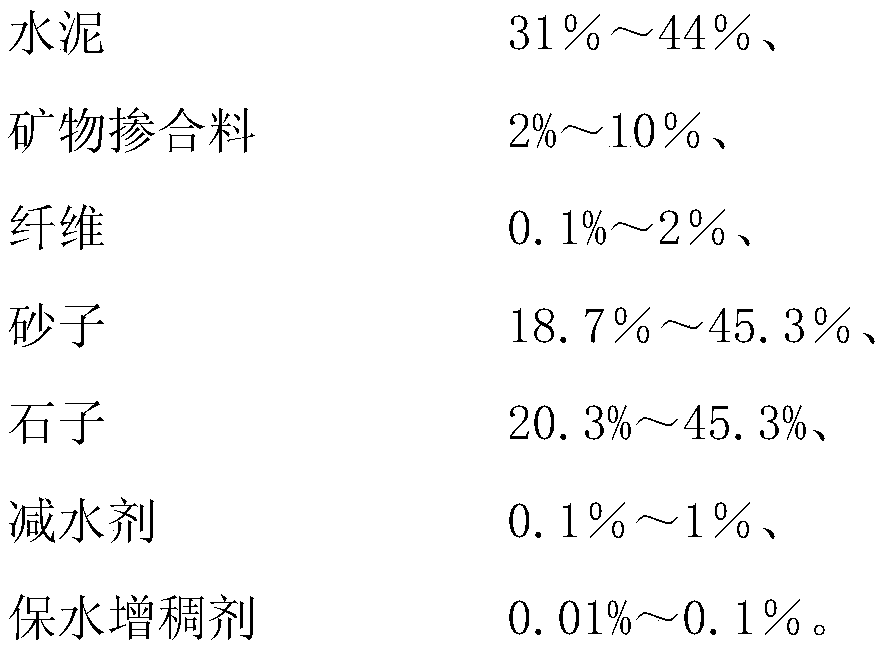

Coarse aggregate concrete ink material for 3D printing and application thereof

InactiveCN110228976AMeet pumping requirementsInhibition of contractionAdditive manufacturing apparatusUltimate tensile strengthConstruction 3D printing

The invention discloses a coarse aggregate concrete ink material for 3D printing and an application thereof. The material comprises the following components in percentage by weight: 31%-44% of cement,2%-10% of a mineral admixture, 0.1%-2% of fibers, 18.7%-45.3% of sand, 20.3%-45.3% of gravel, 0.1%-1% of a water reducer and 0.01%-0.1% of a water-retaining thickener. The coarse aggregate concrete ink material and mixing water are uniformly stirred for 3D printing of buildings. According to the invention, the skeleton and filling effects of the gravel are utilized, shrinkage of concrete is inhibited, and strength of a concrete wet blank is remarkably improved. Requirements of pumping and printing on a concrete material can be both taken into consideration, and the phenomenon of gushing or blockage during pumping before printing can be avoided. After printing, sufficient wet blank strength is achieved, and standing performance is achieved. In addition, tearing and early-stage cracks of aconcrete layer can be avoided through good cementing strength and good internal fiber drawing effect of the coarse aggregate concrete ink material.

Owner:SOUTHEAST UNIV

System and method for preparation of building 3D printing material from mineralized refuse

ActiveCN106866091AAchieve recyclingReduce wasteAdditive manufacturing apparatusSolid waste managementSlagFiltration

The invention discloses a system and method for preparation of a building 3D printing material from mineralized refuse. The method includes the steps of: 1) putting mineralized refuse, aluminum ash, carbide slag and water into a homogenization pool according to a set ratio to be blended into a paste, conducting heating homogenization, and the homogenization time at 2-4h; 2) conducting pressure filtration on the homogenized material, and performing drying to obtain a mixed material, heating desulfurized gypsum for dehydration to convert it into semi-hydrated gypsum; 3) mixing the mixture and the semi-hydrated gypsum evenly in ratio, and then performing powder grinding; 4) calcining the ground material, adding pulverized coal into the mixture during calcination to perform oxygen-enriched combustion so as to obtain a 3D printing material precursor, wherein the mineralized refuse, aluminum ash, carbide slag and desulfurized gypsum are in a mass ratio of 7-15:30-45:30-45:15-20; and 5) mixing the 3D printing material precursor, desulfurized gypsum and limestone in certain ratio and performing grinding, then conducting compounding with fine aggregate, an admixture, a water reducer, a composite coagulation regulator and a stabilizer, thus obtaining the building 3D printing material.

Owner:SHANDONG UNIV

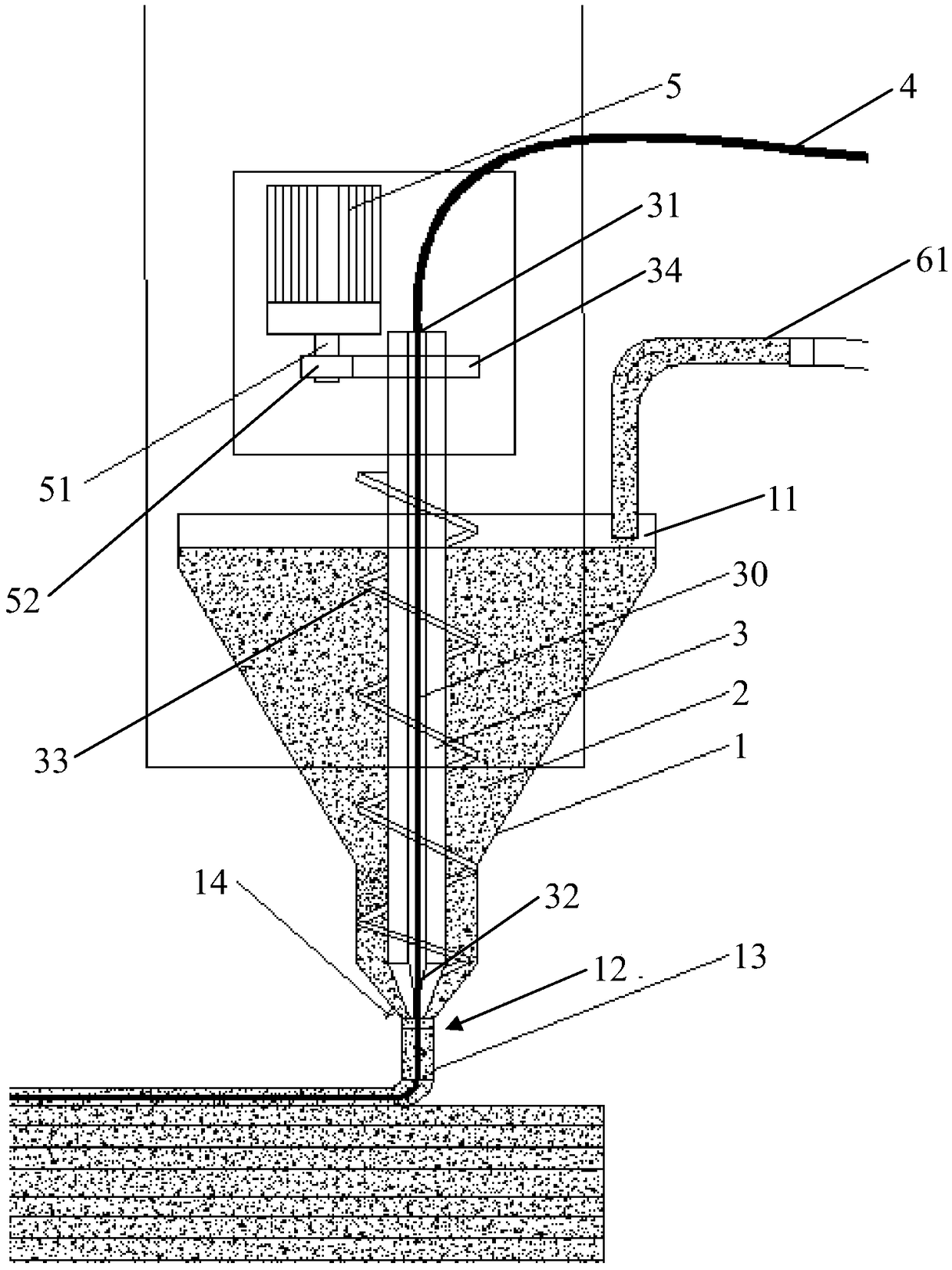

High-rise building 3D printing device connected with steel platform and construction method thereof

ActiveCN109025256AImprove construction efficiencyEasy to installAdditive manufacturing apparatusForms/shuttering/falseworksAutomatic controlHigh rise

The invention discloses a high-rise building 3D printing device connected with a steel platform and a construction method thereof. The 3D printing device comprises a platform connecting base, a driving guiding rack, a main body 3D printing mechanism and a decorative structure 3D printing mechanism. The platform connecting base is detachably connected with the steel platform. The bottom of the driving guiding rack is fixed to the steel platform. The driving guiding rack is provided with the main body 3D printing mechanism and the decorative structure 3D printing mechanism. The high-rise building 3D printing device can synchronously realize 3D printing of the building body structure and the decorative structure and finishes automatic control to 3D printing construction and improves 3D printing precision. The construction method can realize synchronous printing of the body structure and the decorative structure and can realize printing of the corner between the body structure and the decorative structure. The 3D printing device and the construction method have advantages of simple operation, wide application and high construction speed.

Owner:SHANGHAI CONSTRUCTION GROUP

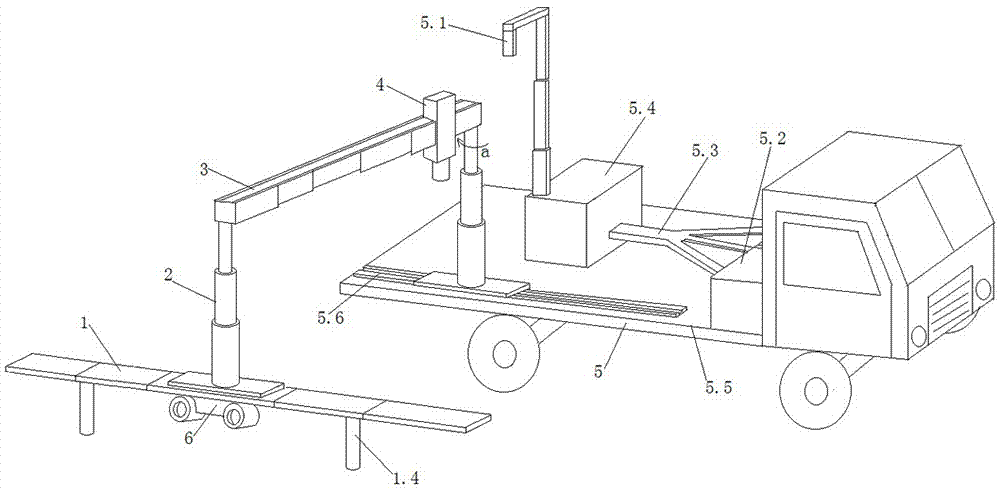

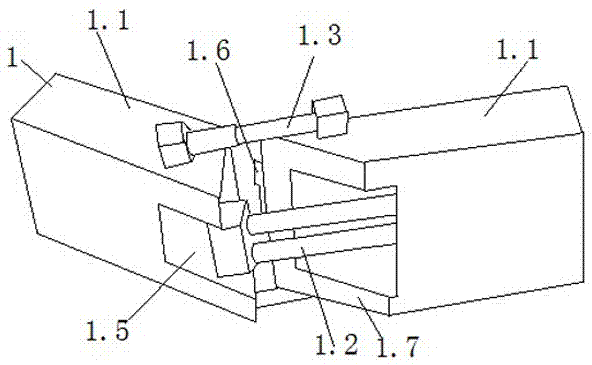

Vehicle-mounted building 3D printing equipment

ActiveCN107443735AReasonable structureEasy to transportAdditive manufacturing apparatusIncreasing energy efficiencyModular designArchitectural engineering

The invention discloses vehicle-mounted building 3D printing equipment. The vehicle-mounted building 3D printing equipment comprises a transportation stirring system and a pair of vertical telescopic stand columns. A telescopic beam is arranged between the vertical telescopic stand columns. A telescopic extrusion printing head capable of sliding along the telescopic beam is assembled on the telescopic beam and can rotate relative to the vertical telescopic stand columns. A first sliding rail is arranged in the transportation stirring system, the bottom of one of the pair of vertical telescopic stand columns is assembled to the first sliding rail, the bottom of the other vertical telescopic stand column is assembled on a transverse folding track, and a base plate power device is arranged at the bottom of the transverse folding track. According to the vehicle-mounted building 3D printing equipment, a vehicle-mounted structure and modular design are adopted, the transportation efficiency and space of the printing system are increased, and accordingly the construction cost is saved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com