Patents

Literature

387 results about "Coagulation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coagulation time. noun. : the time required by shed blood to clot that is a measure of the normality of the blood.

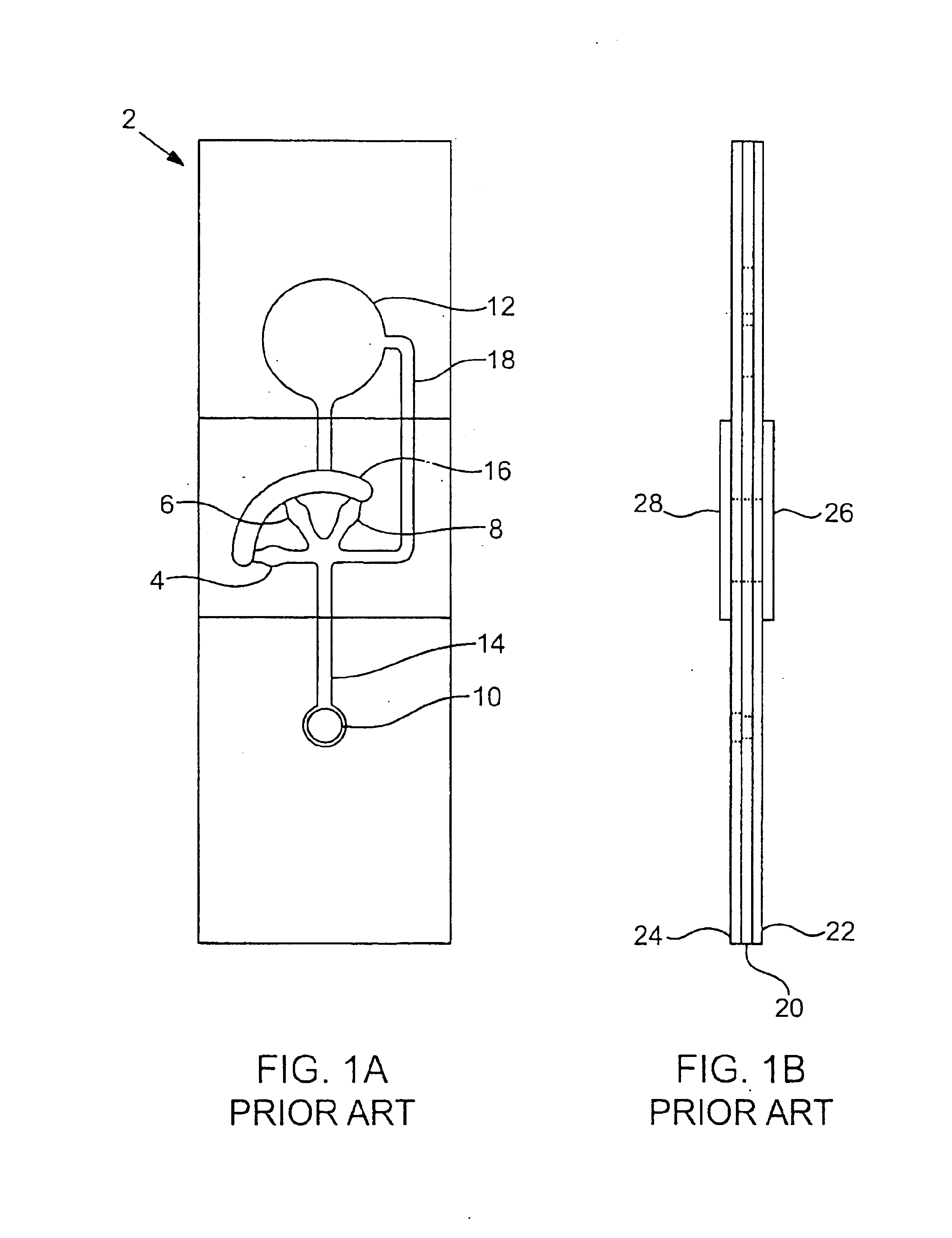

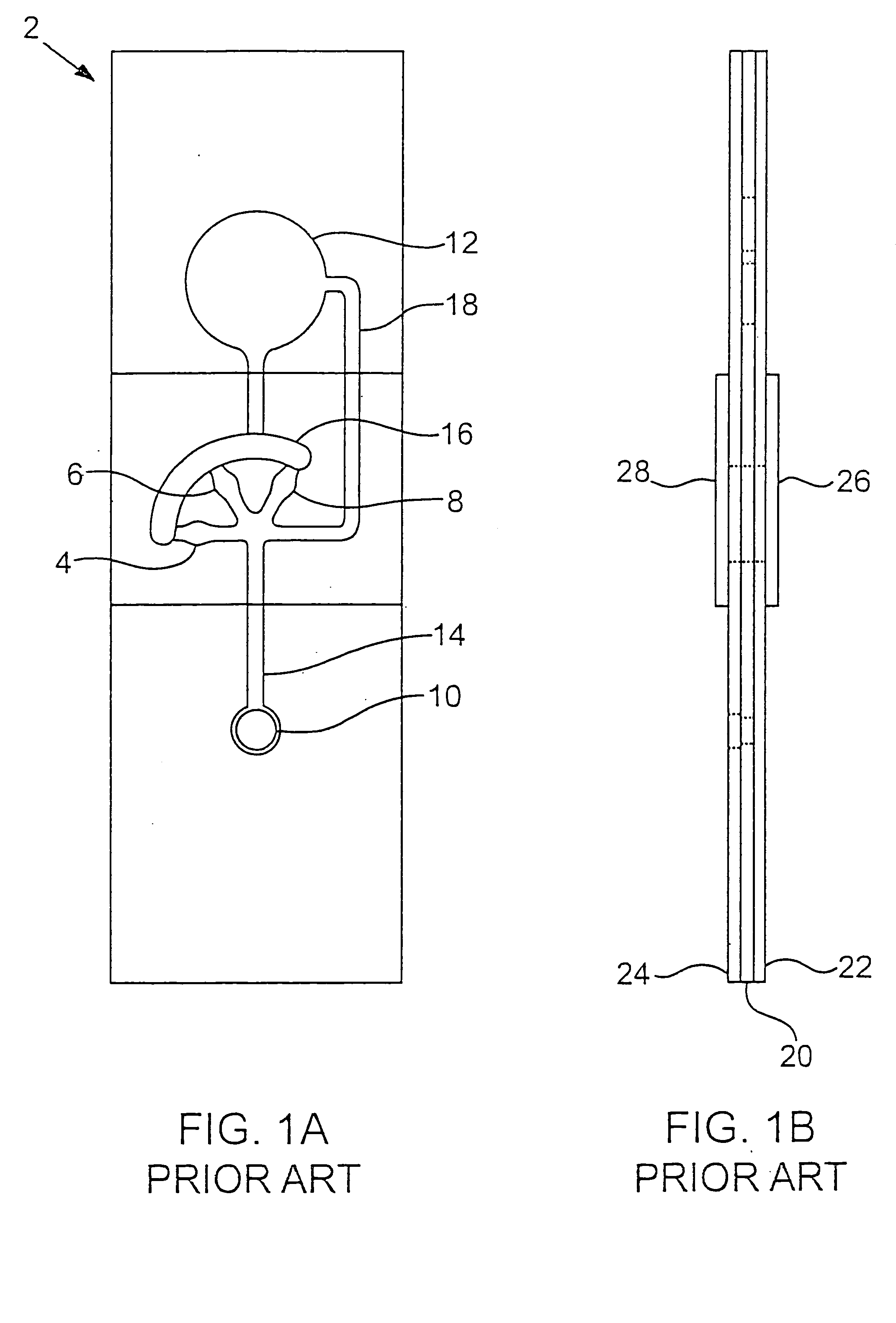

Fluidic device for medical diagnostics

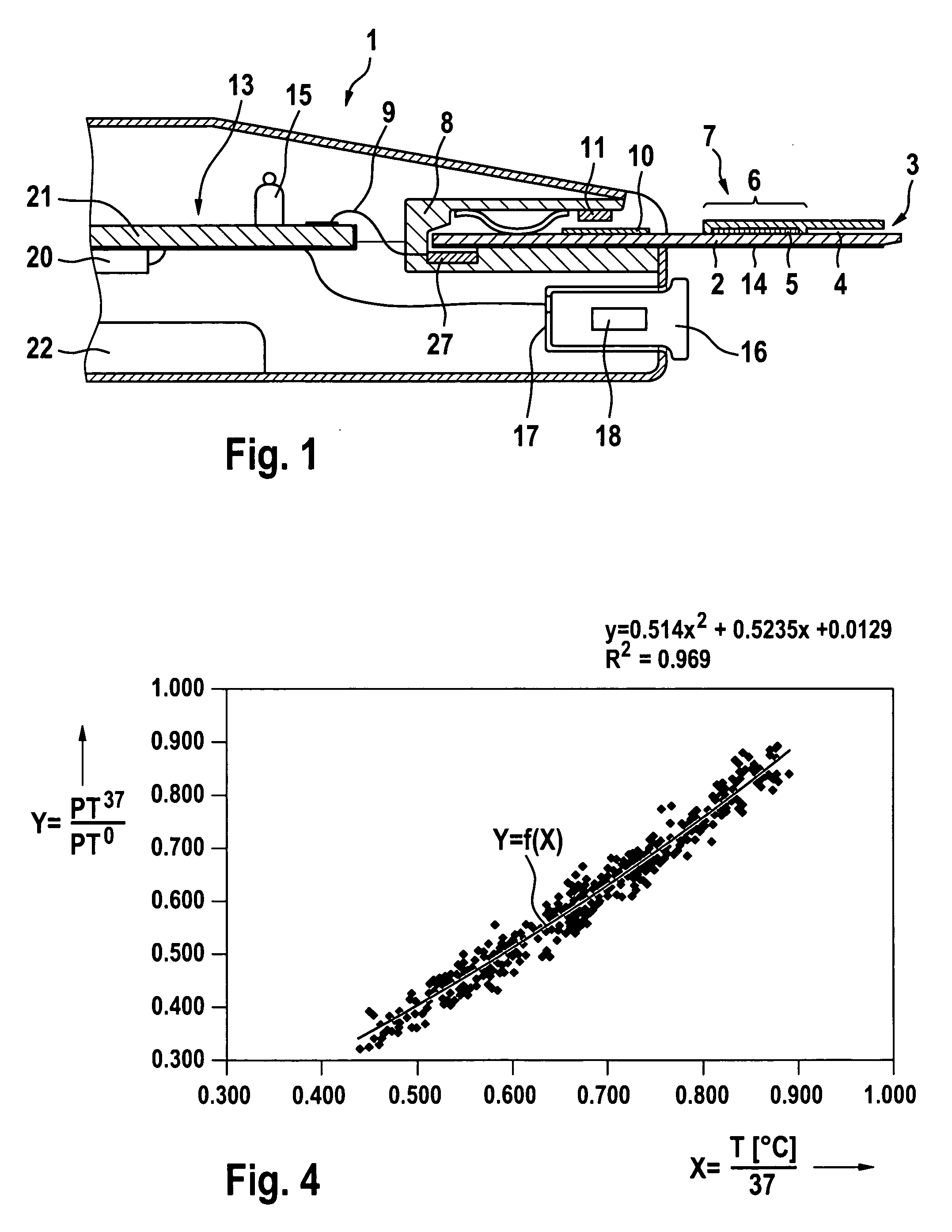

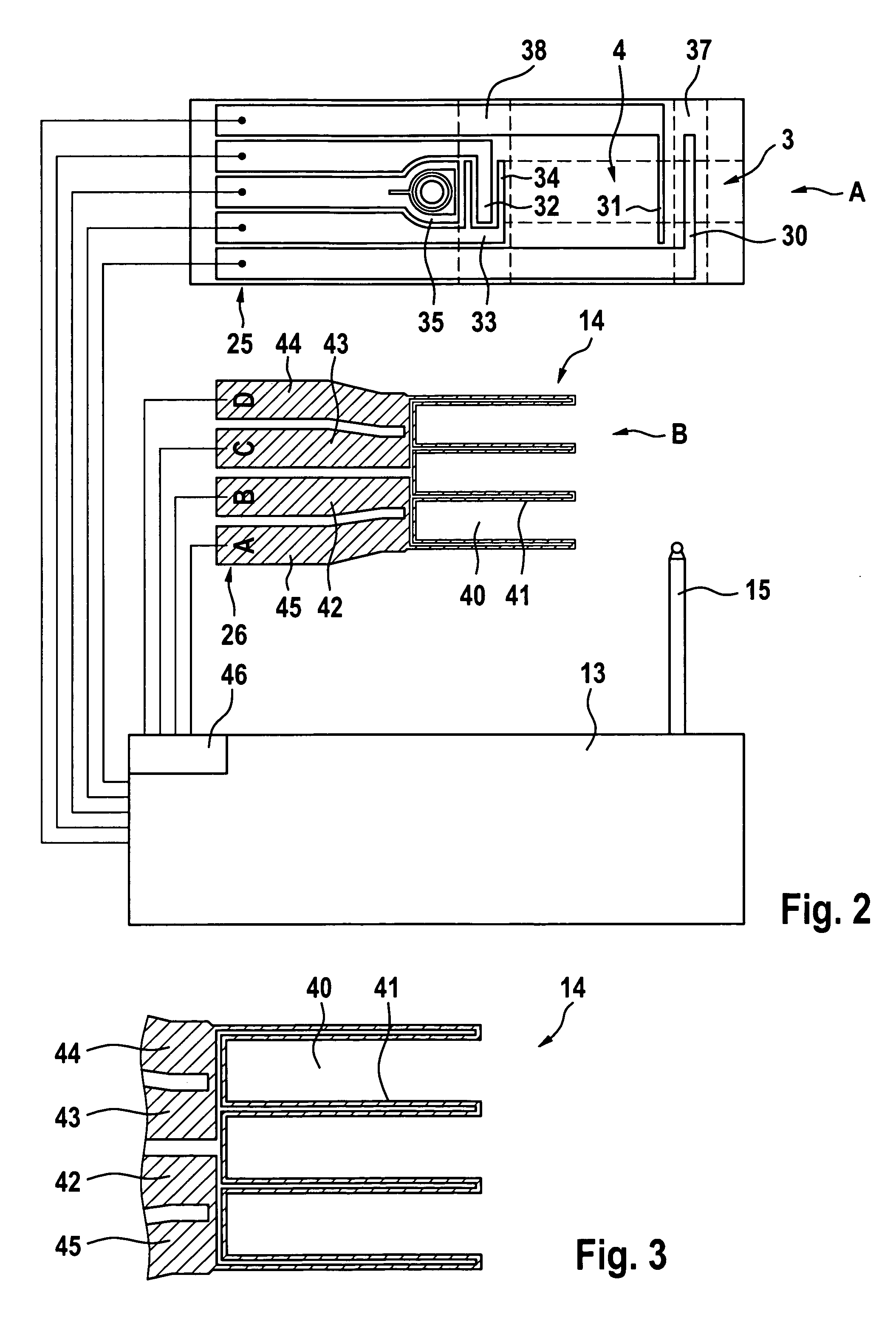

InactiveUS7022286B2Analysis using chemical indicatorsLaboratory glasswaresAnalyteOptical transmittance

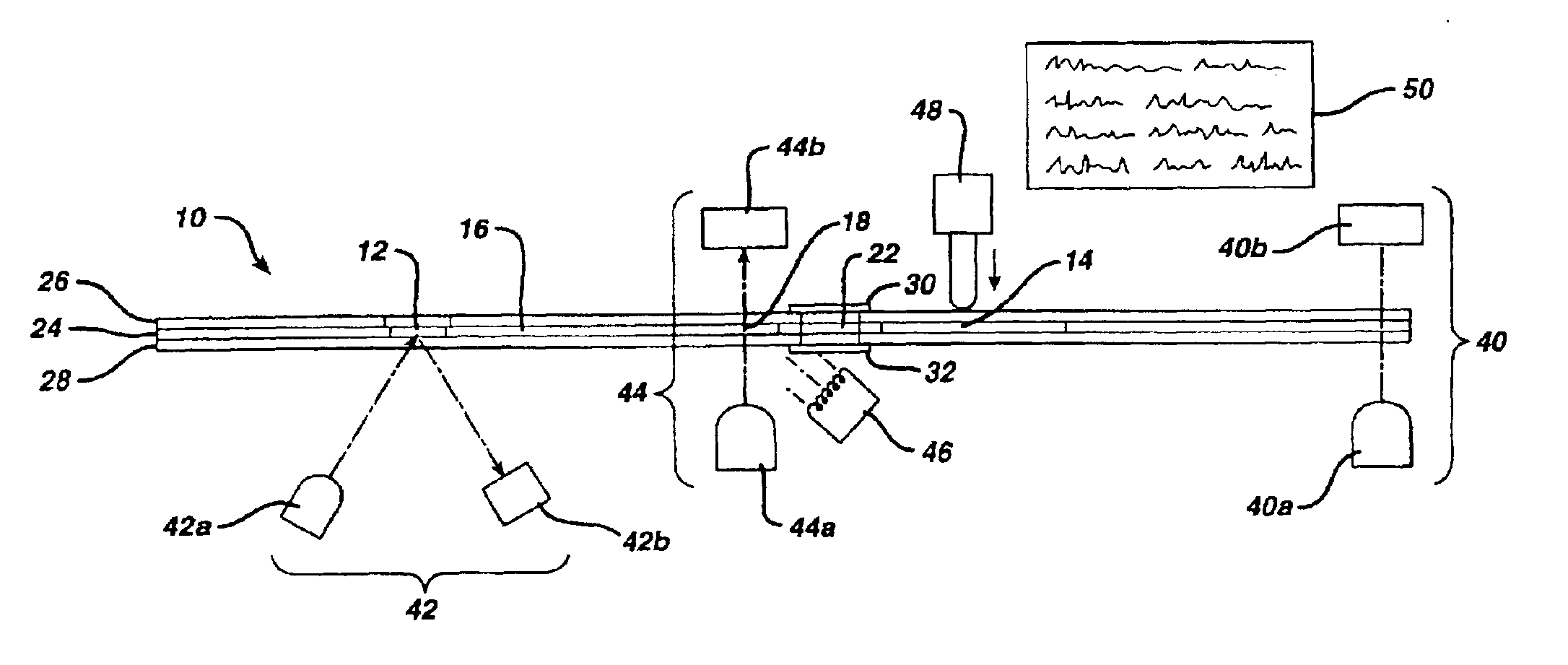

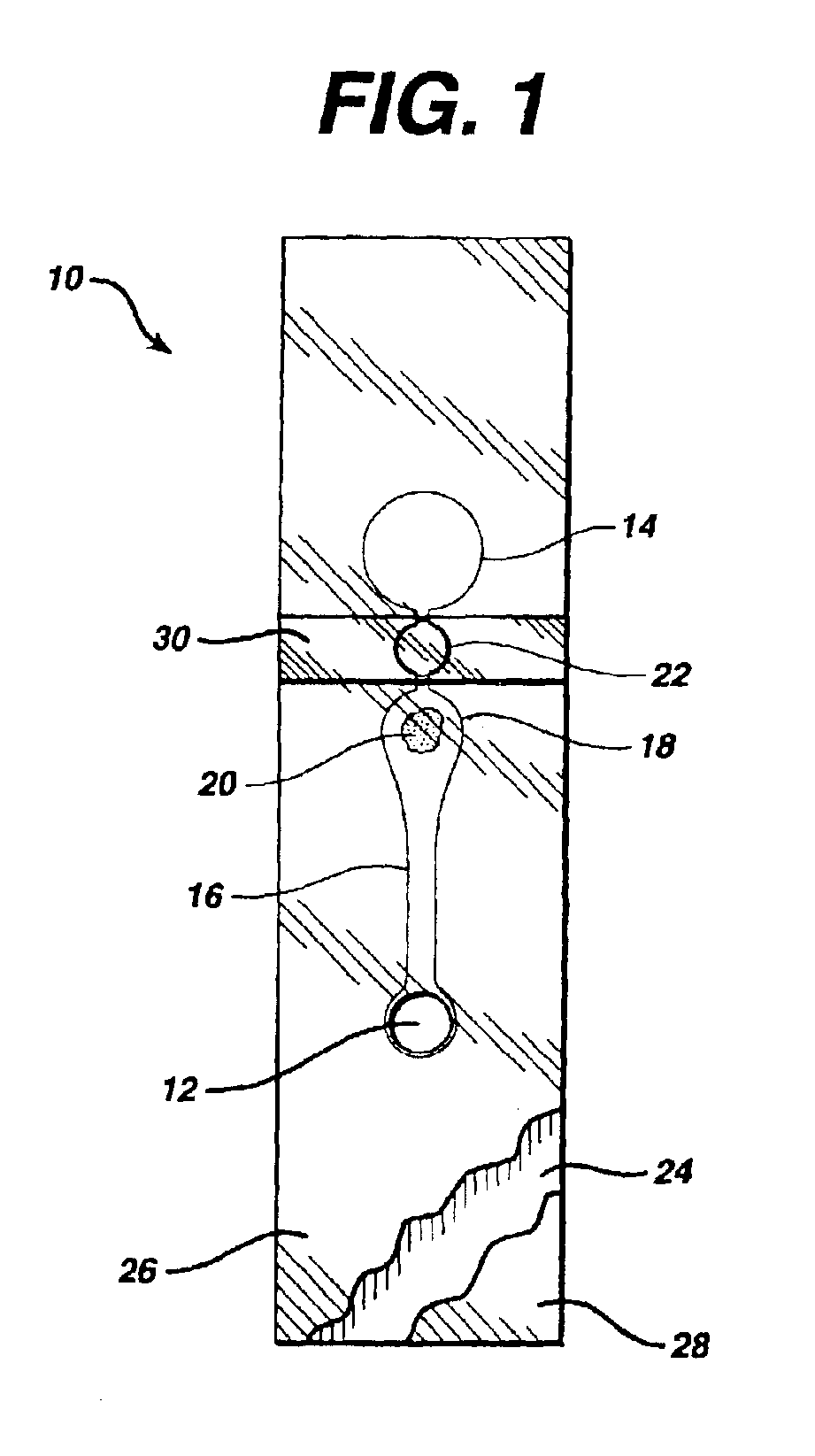

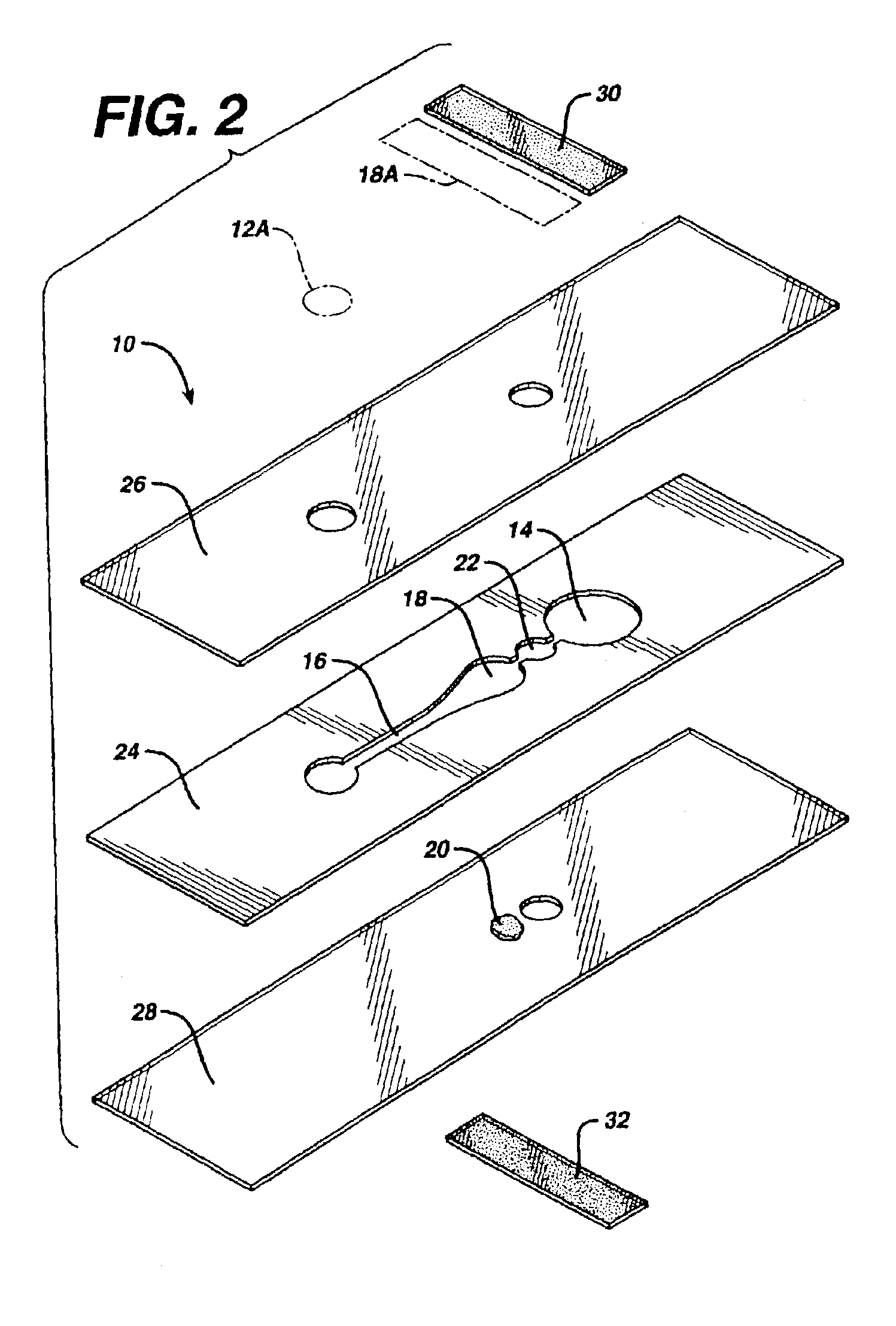

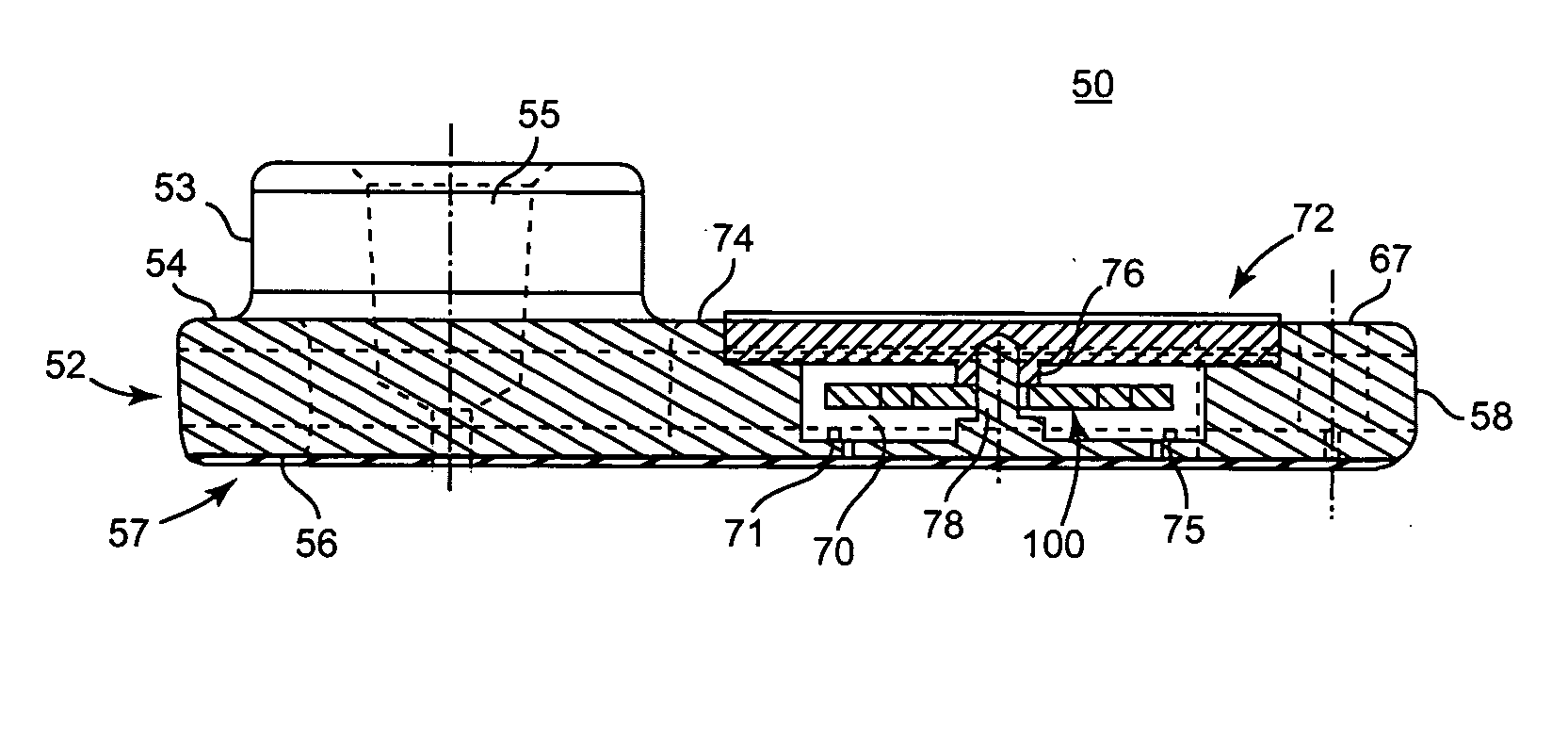

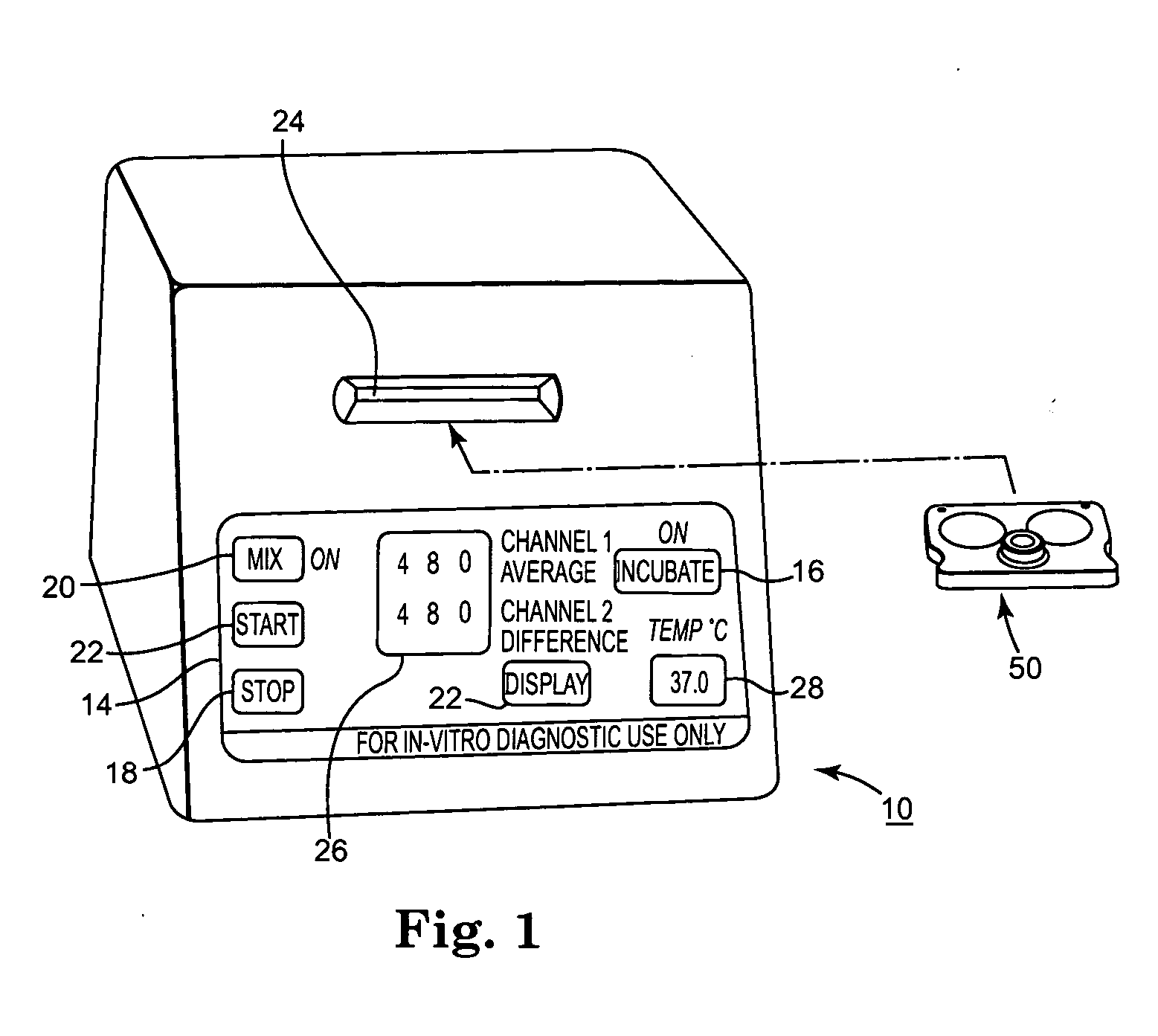

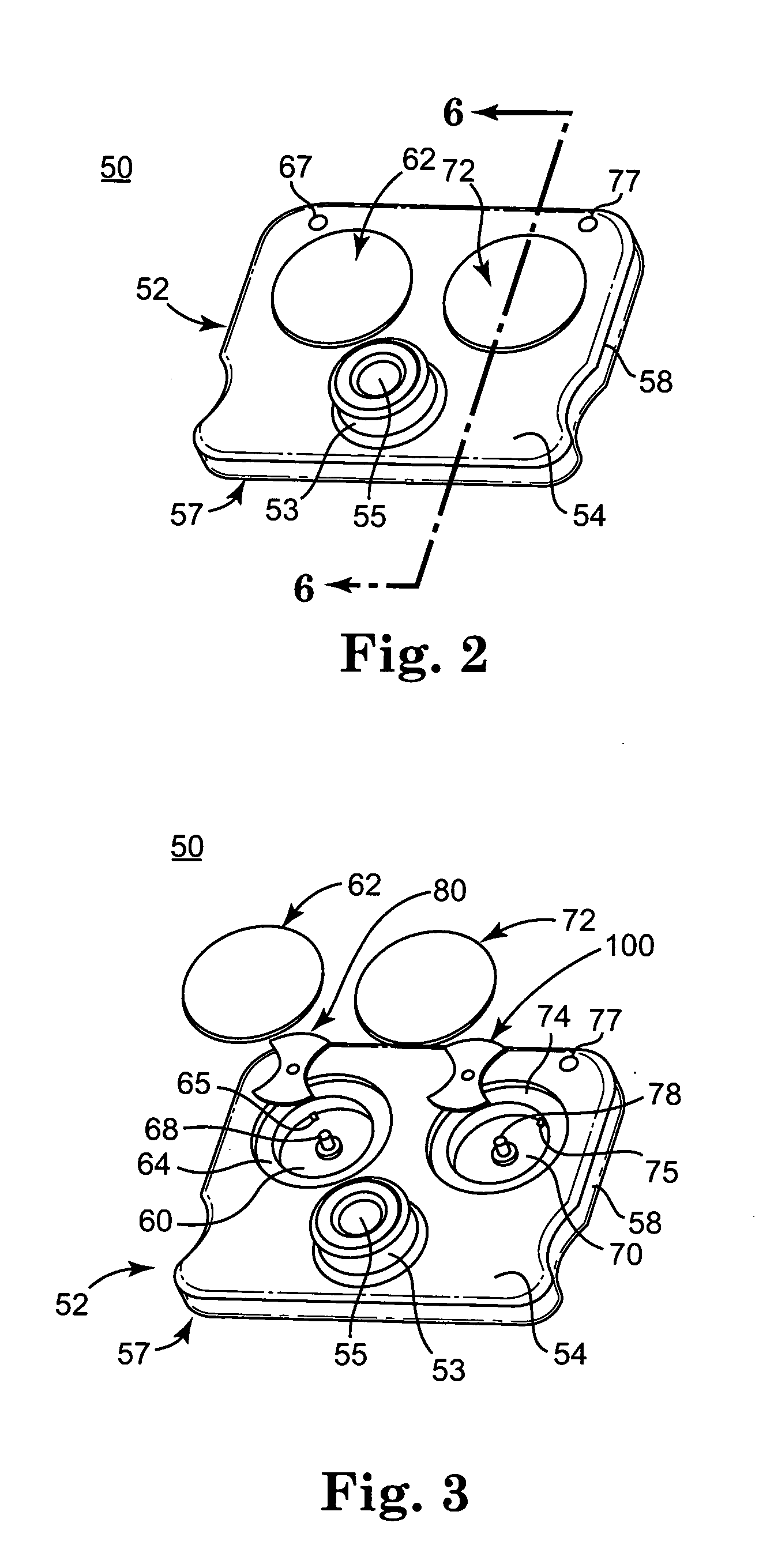

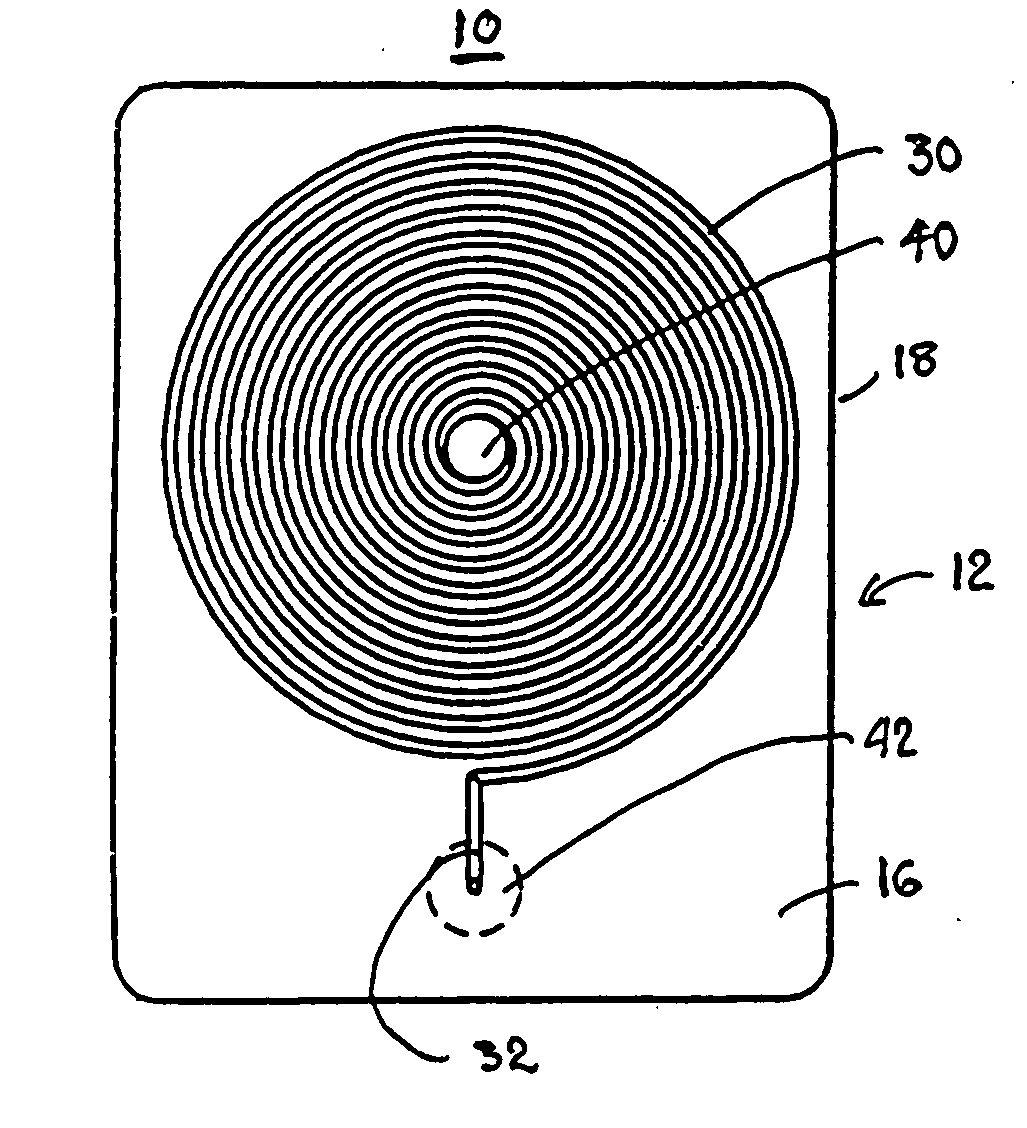

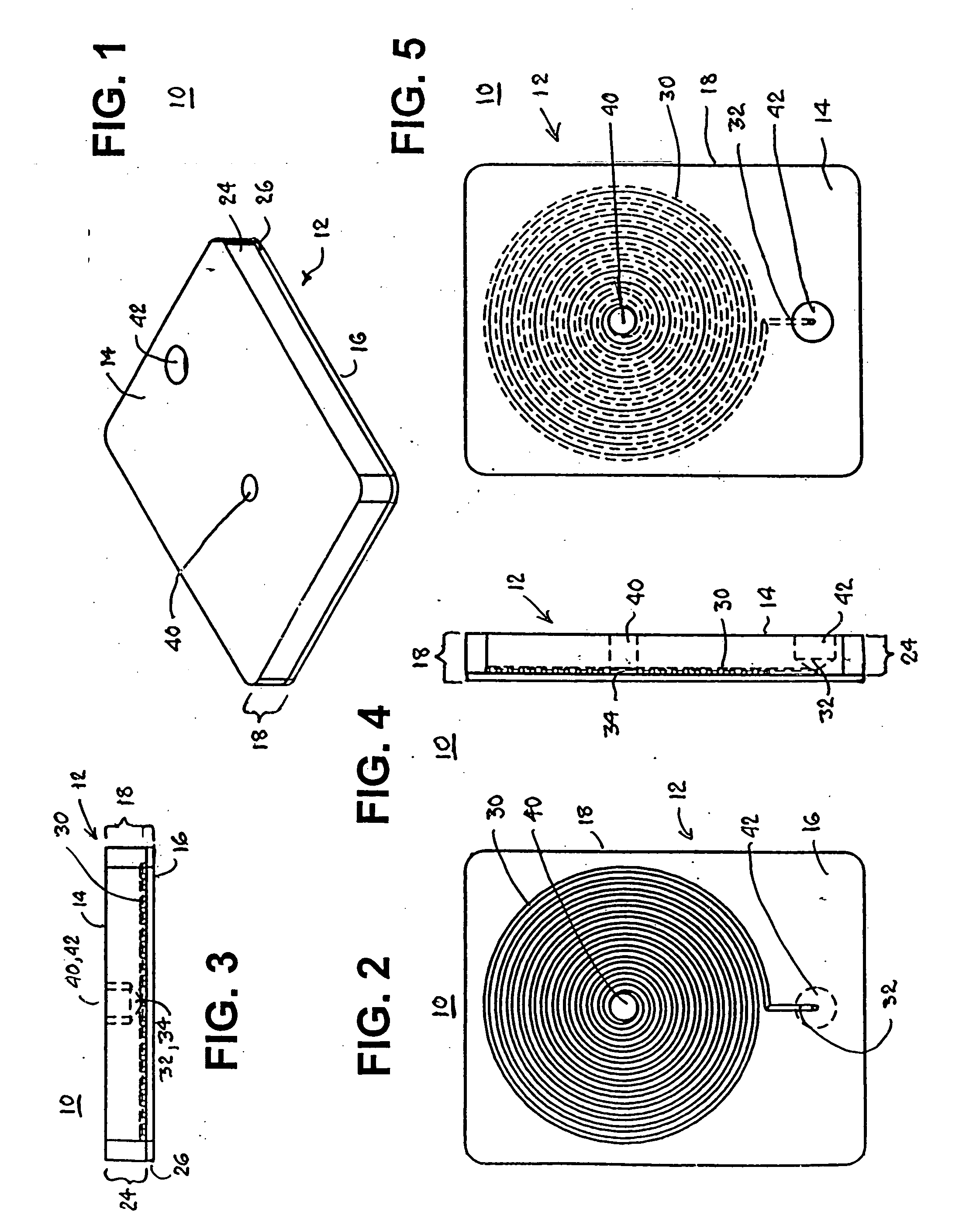

A fluidic medical diagnostic device permits measurement of analyte concentration or a property of a biological fluid, particularly the coagulation time of blood. The device has at one end a sample port for introducing a sample and at the other end a bladder for drawing the sample to a measurement area. A channel carries the sample from the sample port to the measurement area, and a stop junction, between the measurement area and bladder, halts the sample flow. The desired measurement can be made by placing the device into a meter which measures a physical property of the sample—typically, optical transmittance—after it has interacted with a reagent in the measurement area.

Owner:LIFESCAN IP HLDG LLC

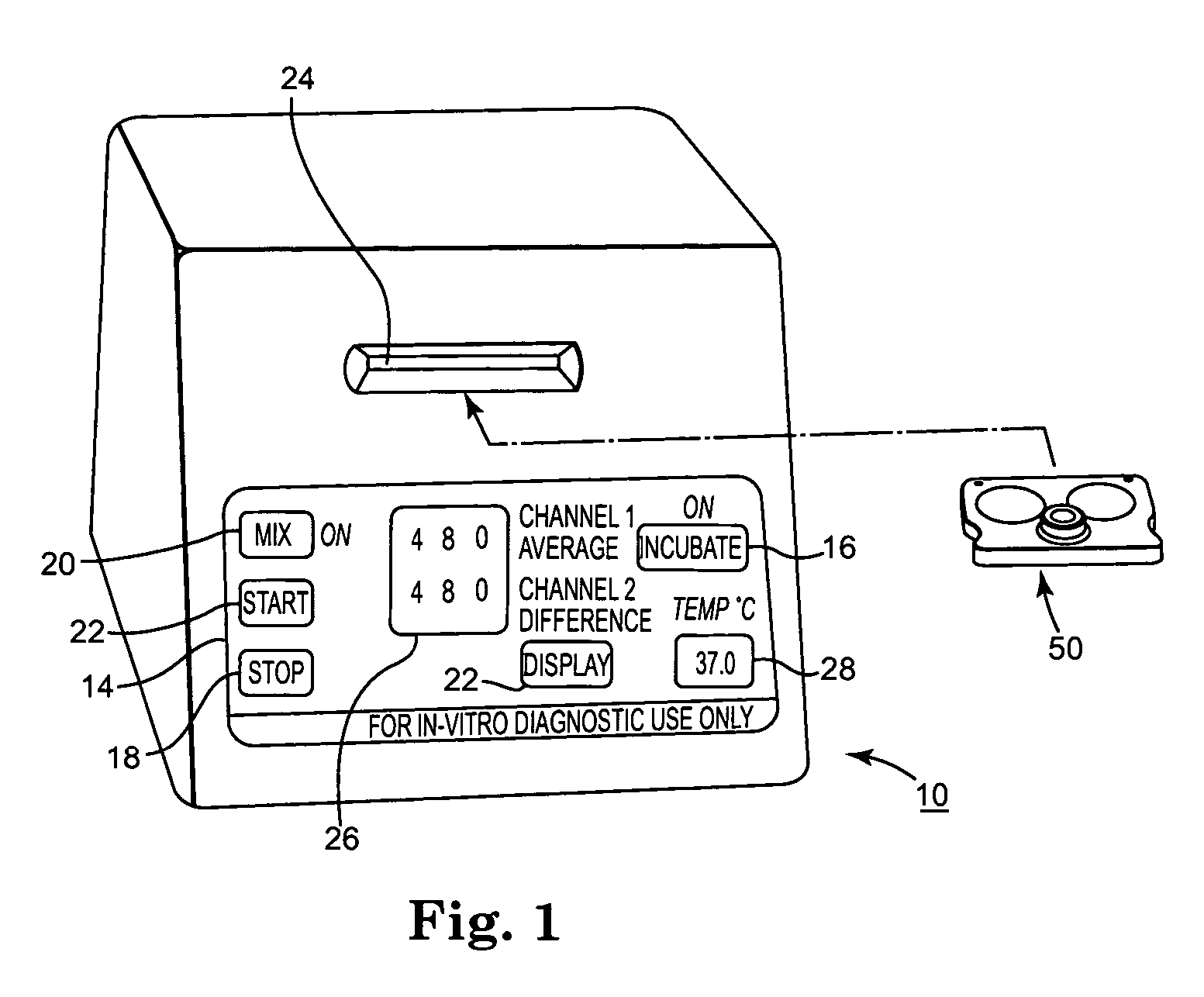

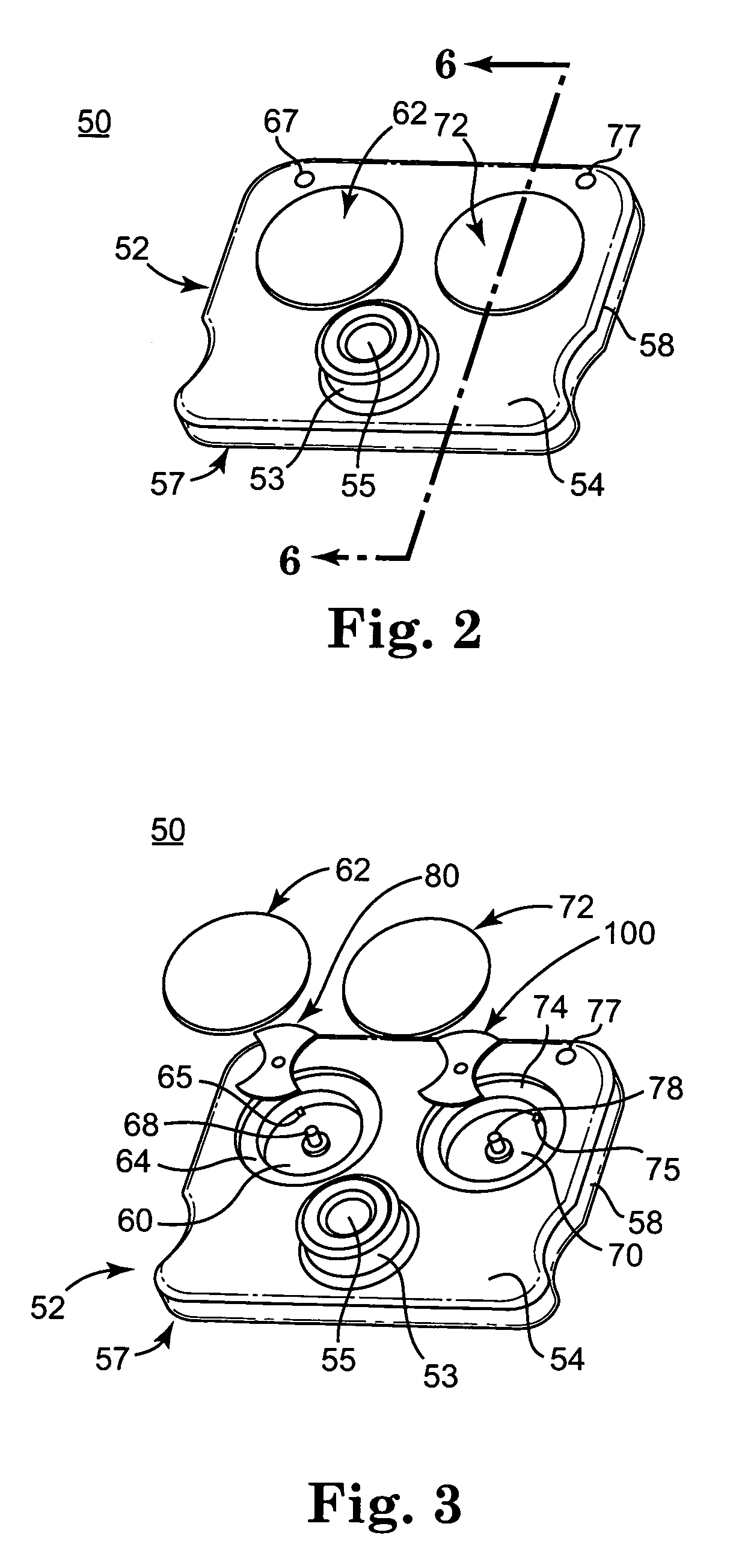

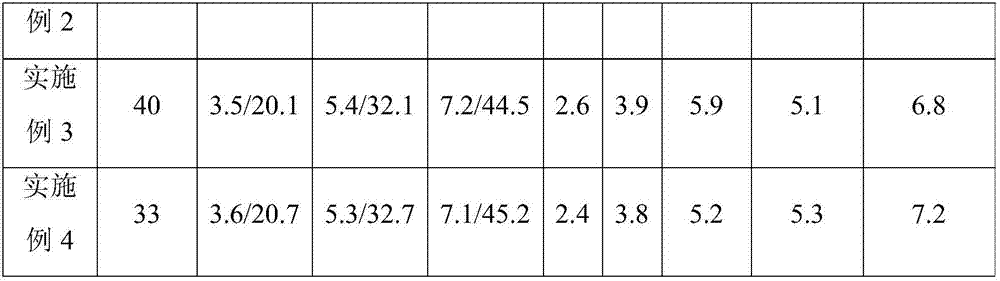

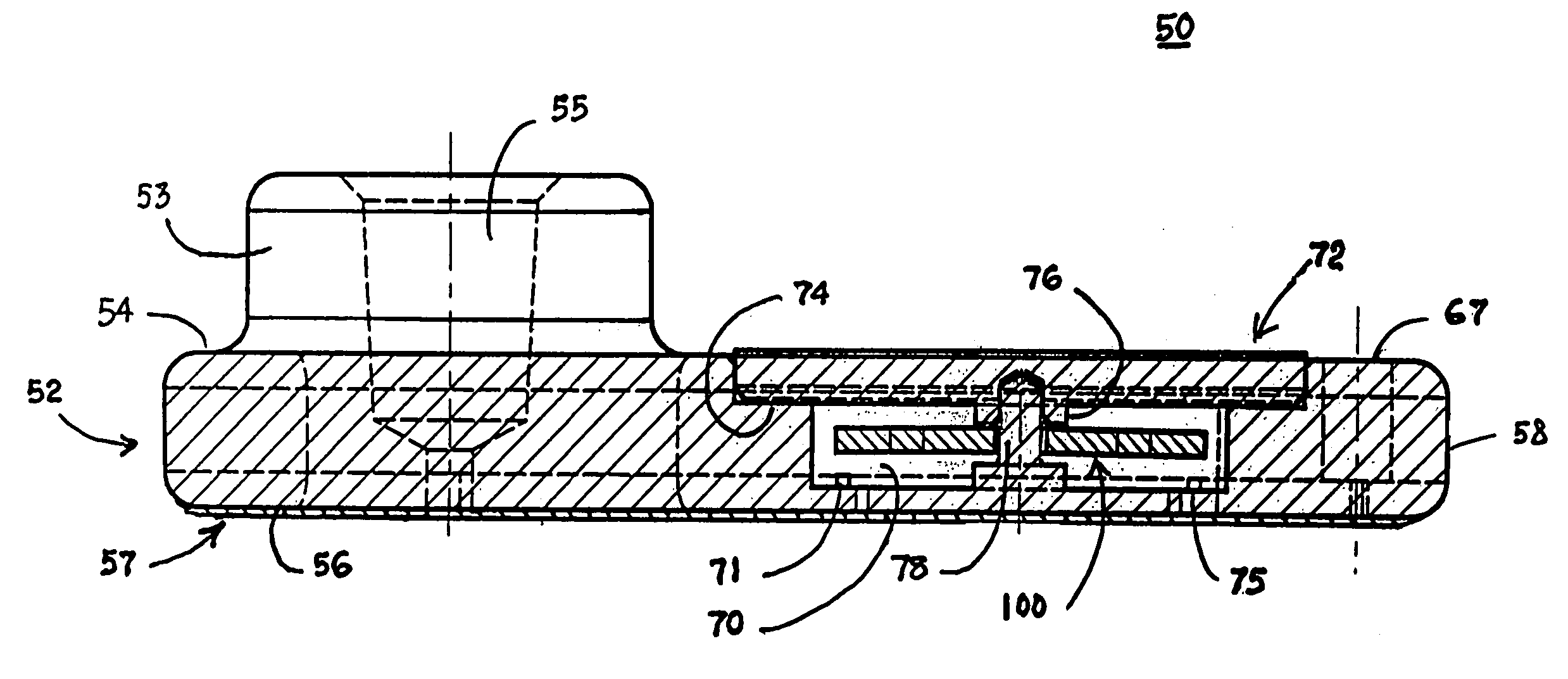

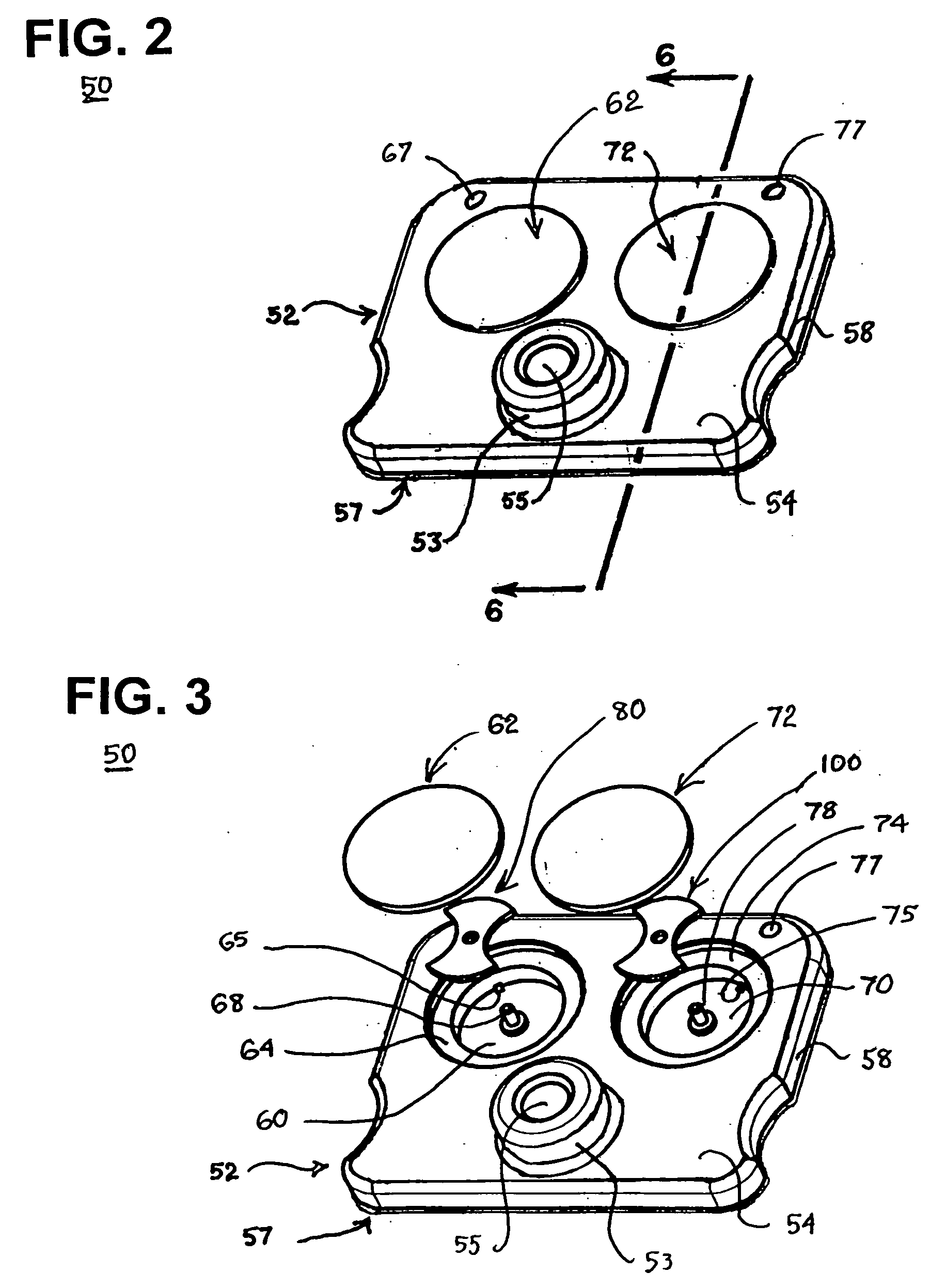

Blood coagulation test cartridge, system, and method

ActiveUS7399637B2Practical and convenientRapid and reliableAnalysis using chemical indicatorsMicrobiological testing/measurementBlood testTest sample

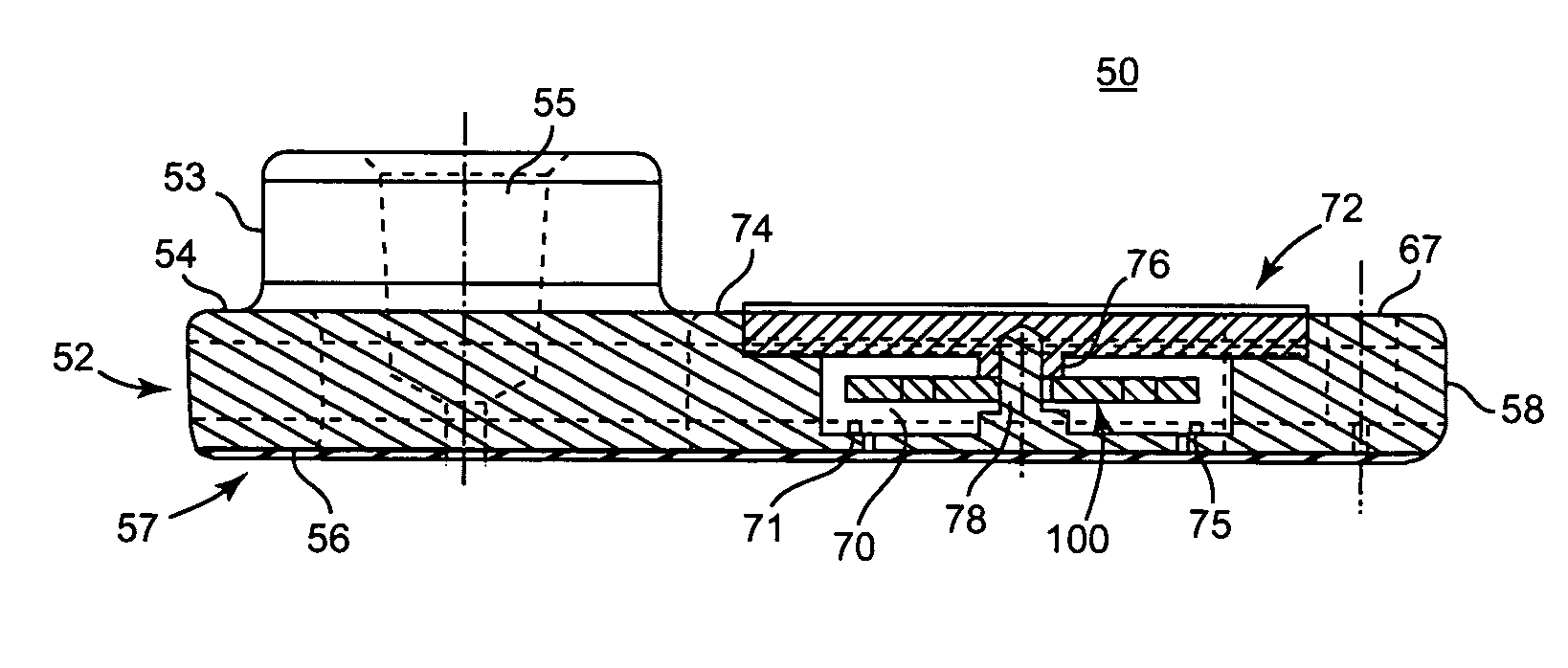

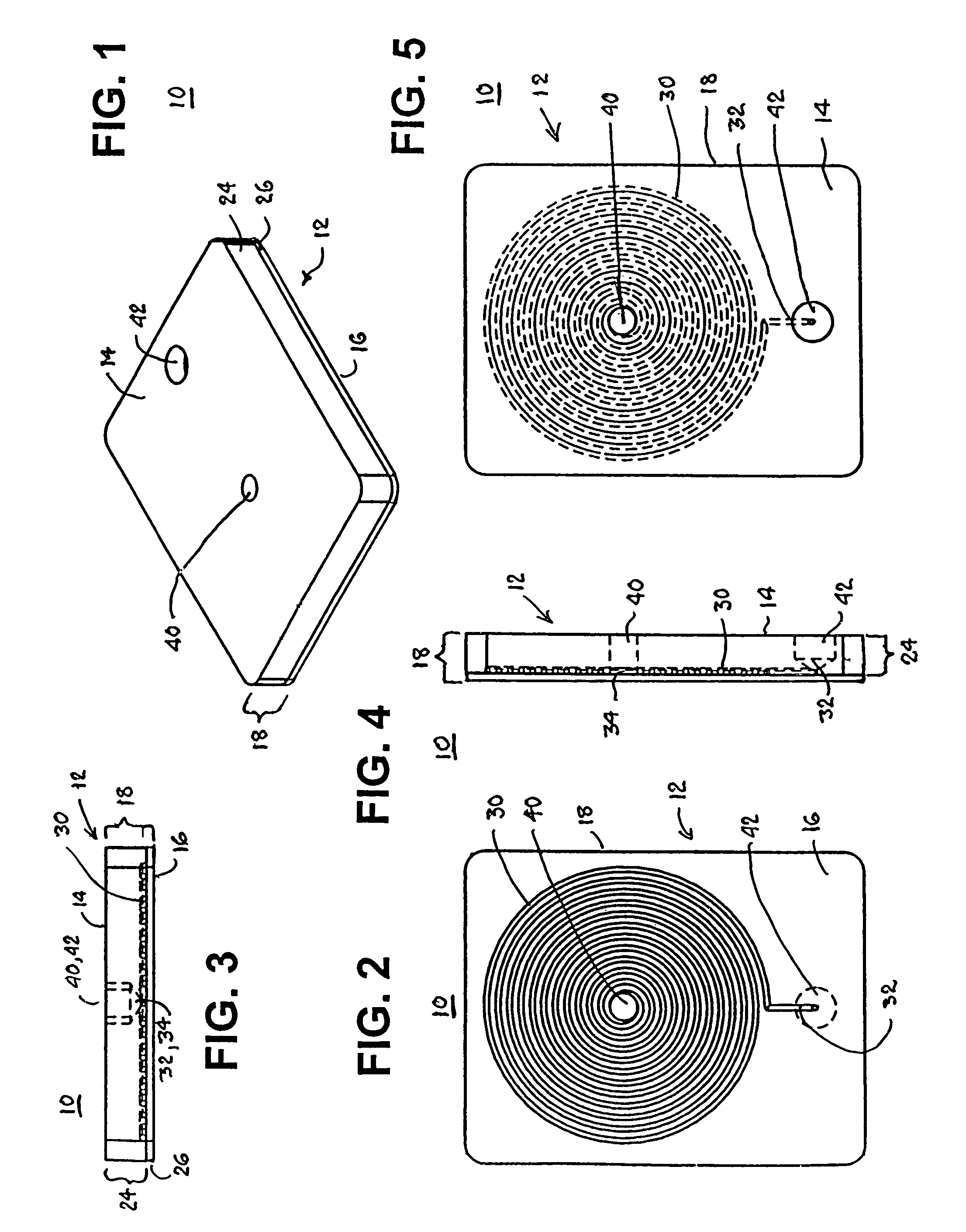

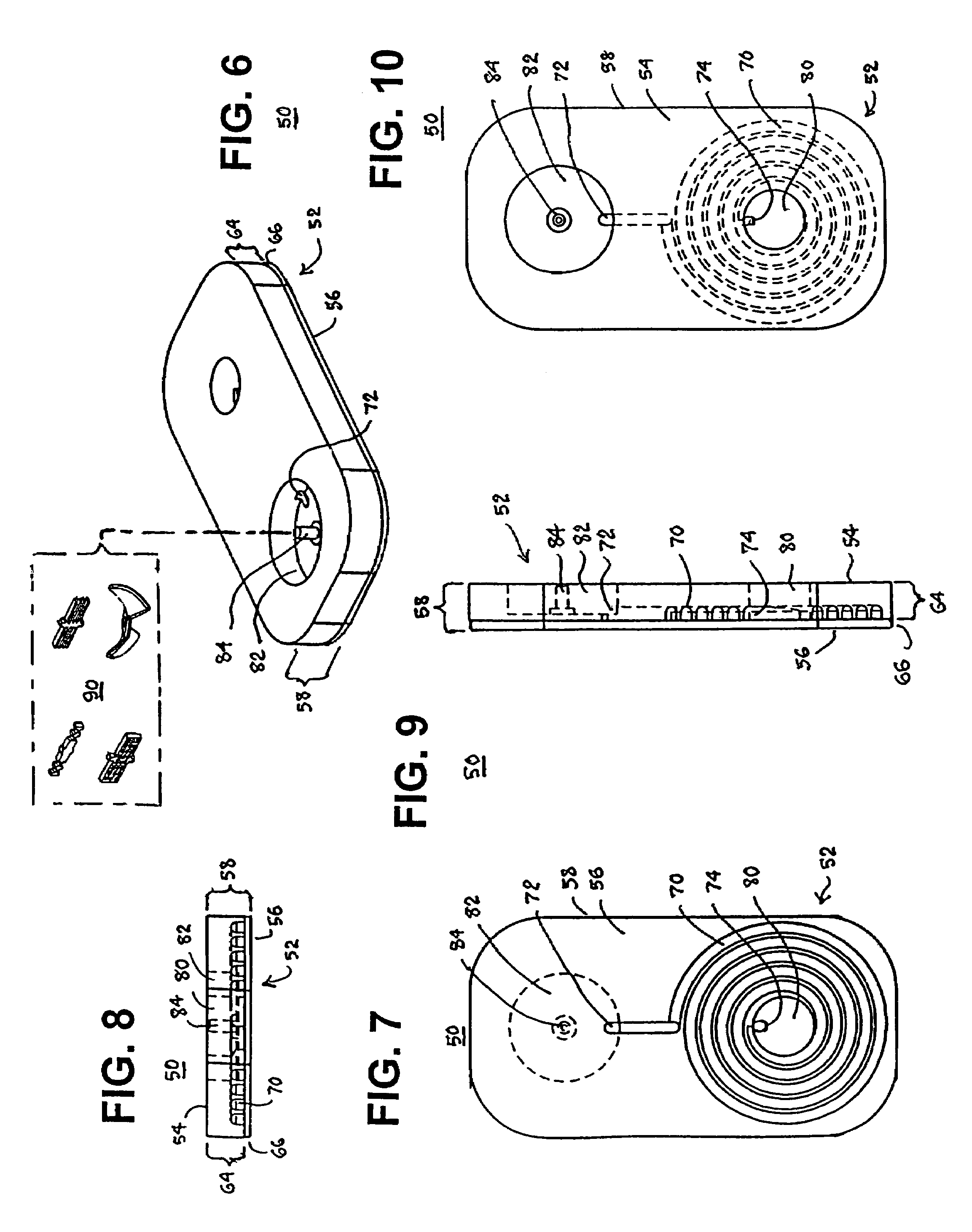

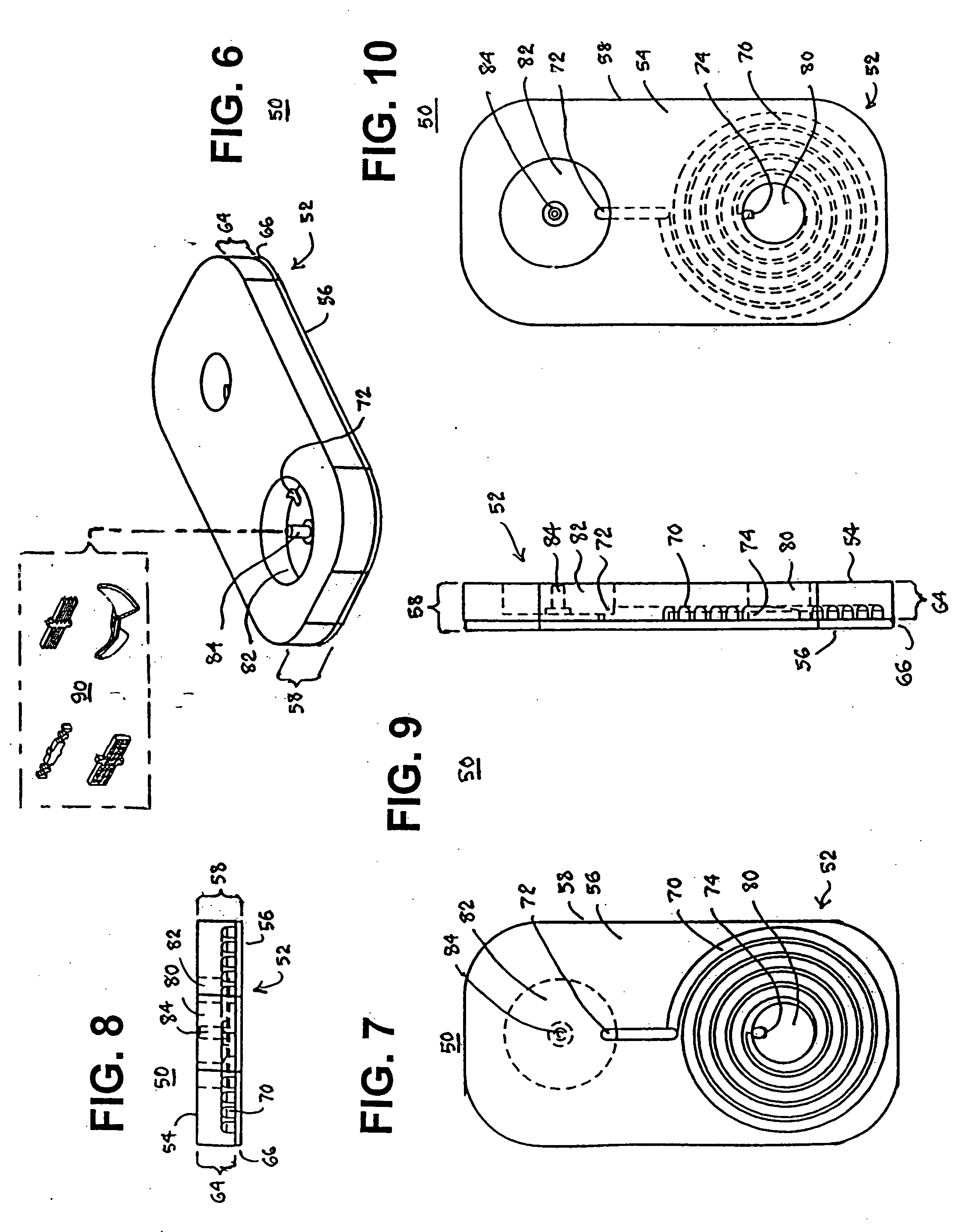

A system and method for determining a coagulation time, e.g., TT, PT, aPTT, and ACT, of a blood test sample deposited in a test cartridge is disclosed. A cartridge housing having upper and lower major sides and a minor sidewall encloses a test chamber having a test chamber pivot element and is provided with a cartridge port for introducing a test sample into the test chamber,. Ferromagnetic agitator vane leaflets extend from an agitator pivot element supported by the test chamber pivot element intermediate the upper and lower major sides for rotational motion. The agitator vane leaflets can be swept, in response to an external magnetic field, through the test sample in the absence of coagulation. A timer is started when the agitator movement is commenced whereupon the agitator moves freely. Resistance to agitator movement due to coagulation is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

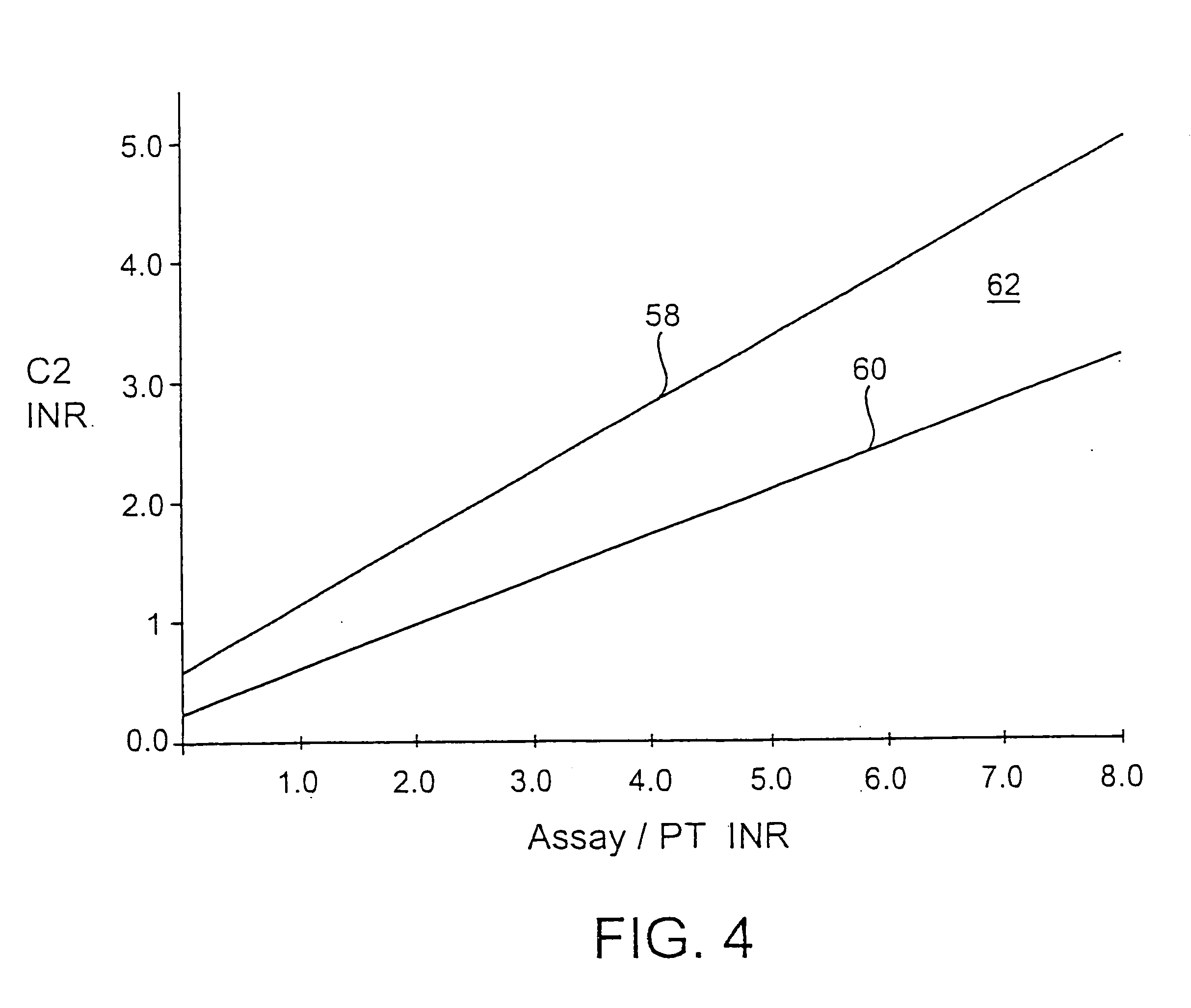

Test strip qualification system

InactiveUS6849456B2Microbiological testing/measurementDiagnostic recording/measuringEngineeringTest strips

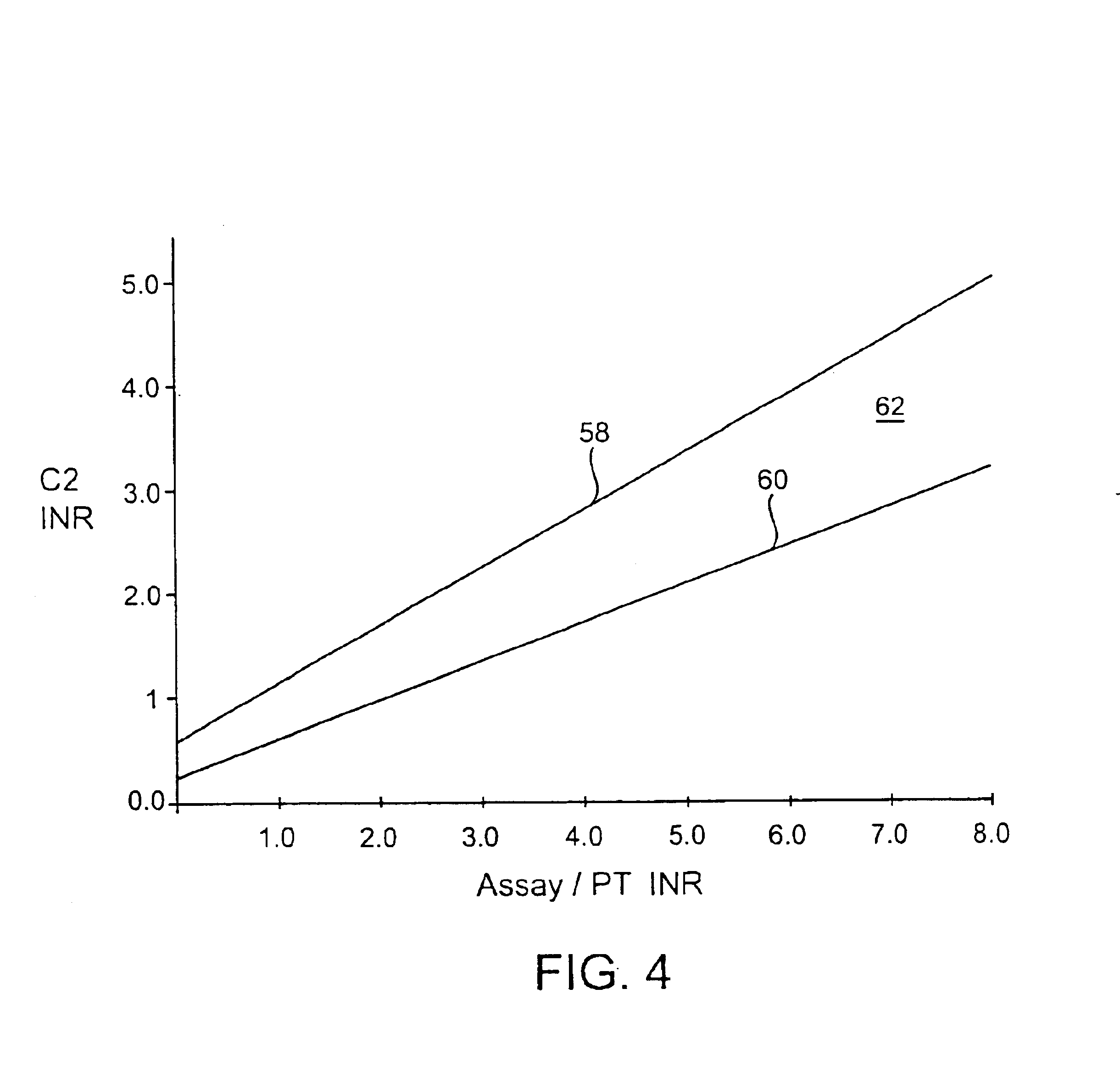

In connection with a fluidic medical diagnostic device that permits measurement of the coagulation time of blood, software, methods and associated devices for quality control are provided. The fluidic device preferably includes a test strip with one end having a sample port for introducing a sample and a bladder at the other end for drawing the sample to a measurement area. A channel carries sample from the sample port to an assay measurement area and first and second control measurement areas. Preferably a stop junction, between the measurement areas and bladder, halts the sample flow for measurement. If results from measurements taken for each control fall within a predetermined zone or defined limits, the assay measurement is qualified. If not, an error is registered and the test strip is counted as unfit.

Owner:LIFESCAN IP HLDG LLC

Blood coagulation test cartridge, system, and method

ActiveUS20050233466A1Practical and convenientRapid and reliableAnalysis using chemical indicatorsFlow propertiesBlood testTest sample

A system and method for determining a coagulation time, e.g., TT, PT, aPTT, and ACT, of a blood test sample deposited in a test cartridge is disclosed. A cartridge housing having upper and lower major sides and a minor sidewall encloses a test chamber having a test chamber pivot element and is provided with a cartridge port for introducing a test sample into the test chamber,. Ferromagnetic agitator vane leaflets extend from an agitator pivot element supported by the test chamber pivot element intermediate the upper and lower major sides for rotational motion. The agitator vane leaflets can be swept, in response to an external magnetic field, through the test sample in the absence of coagulation. A timer is started when the agitator movement is commenced whereupon the agitator moves freely. Resistance to agitator movement due to coagulation is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

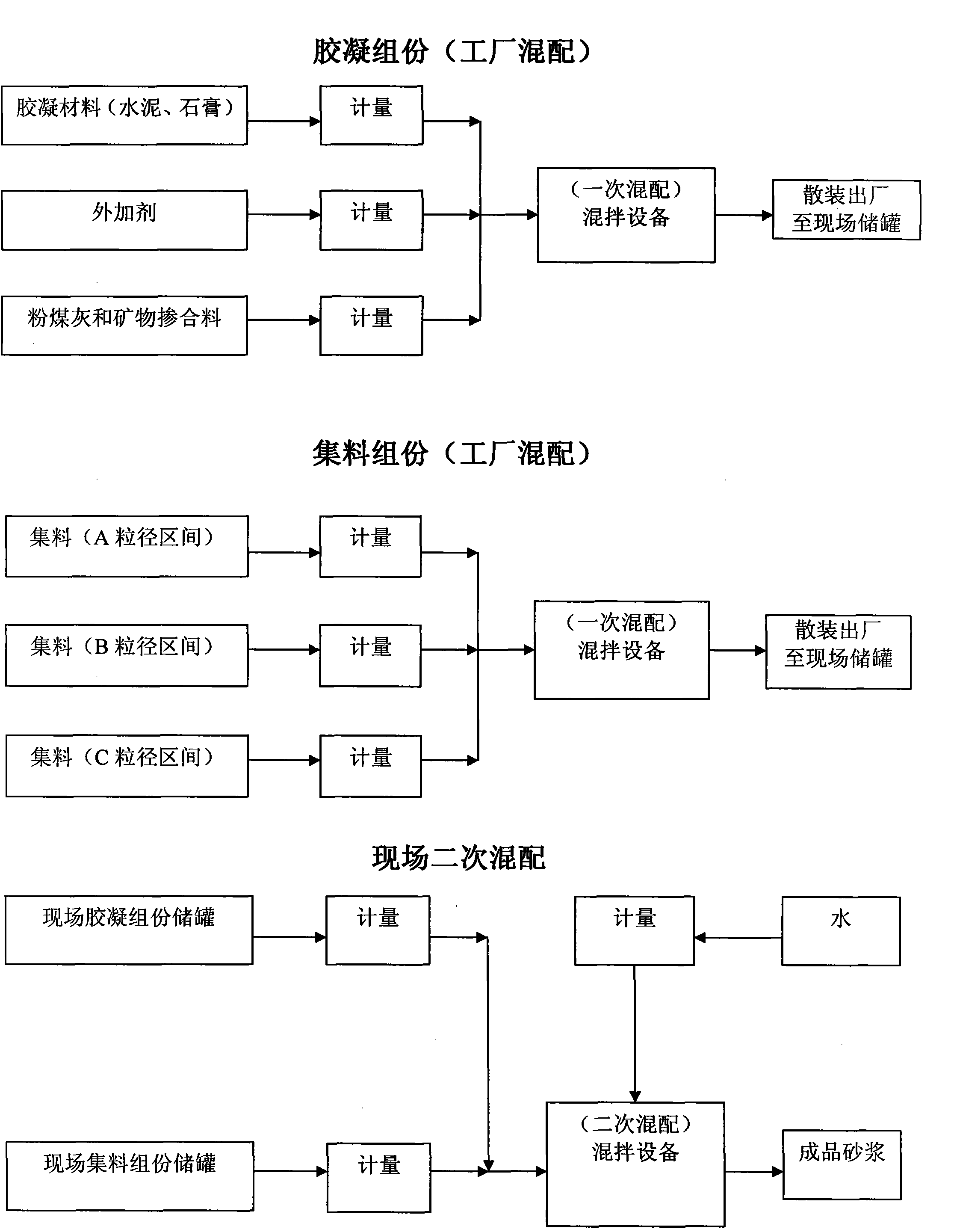

Blood coagulation test cartridge, system, and method

InactiveUS7439069B2Practical and convenientRapid and inexpensiveMicrobiological testing/measurementWithdrawing sample devicesBlood capillaryEngineering

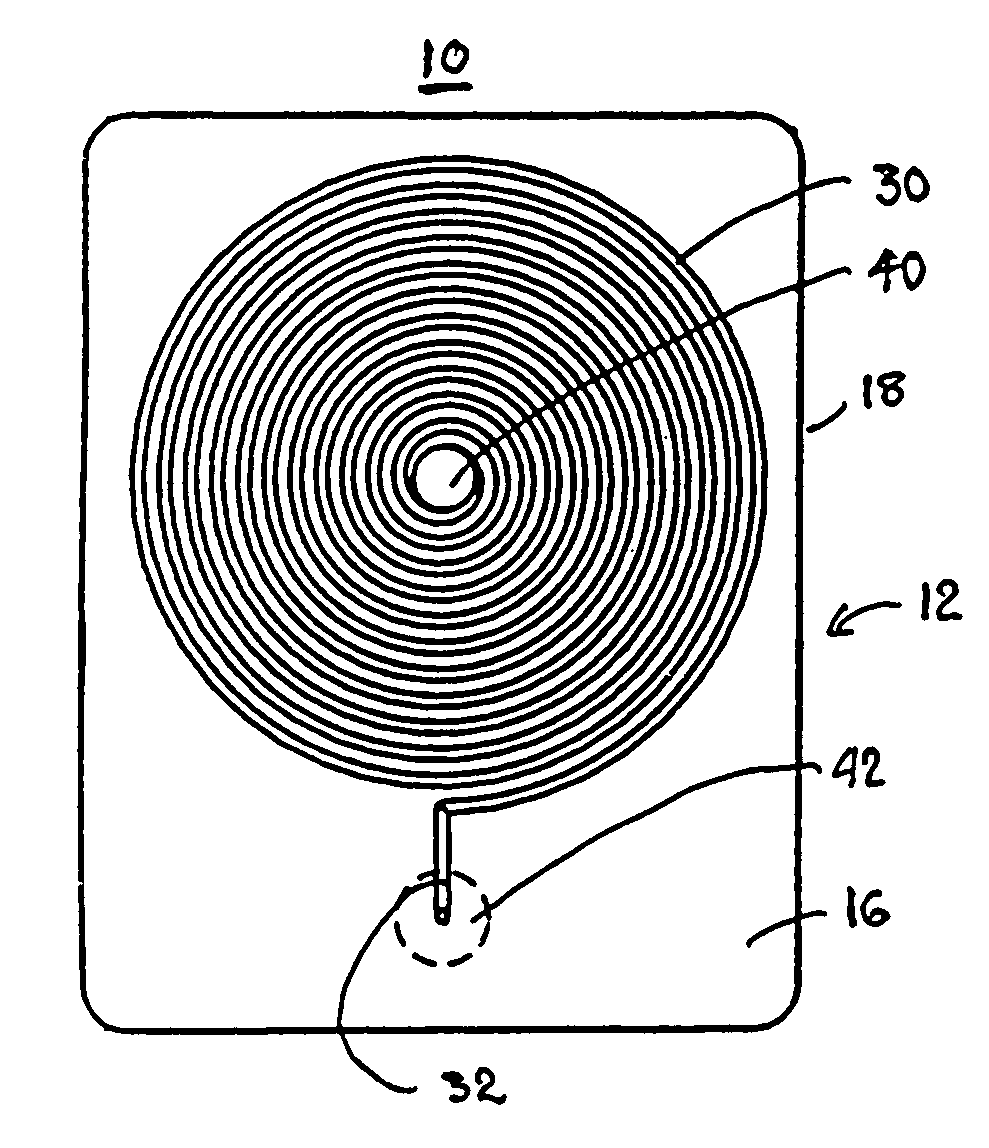

A system and method for determining a coagulation time, e.g., thrombin time, PT, aPTT, and ACT, of a blood sample deposited in a test cartridge is disclosed. The test cartridge includes a blood receptacle that is open to the atmosphere into which a blood sample is to be deposited, a vacuum port that is open to atmosphere, and a spiral capillary within the test cartridge having a capillary length and cross-section area, a first capillary end of the spiral capillary open to the blood receptacle and a second capillary end of the spiral capillary open to the vacuum port, whereby the spiral capillary is closed to atmosphere. When a blood sample is deposited in the blood receptacle, a vacuum is drawn through the vacuum port and the blood is drawn through the spiral capillary until coagulation occurs. A pressure change is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

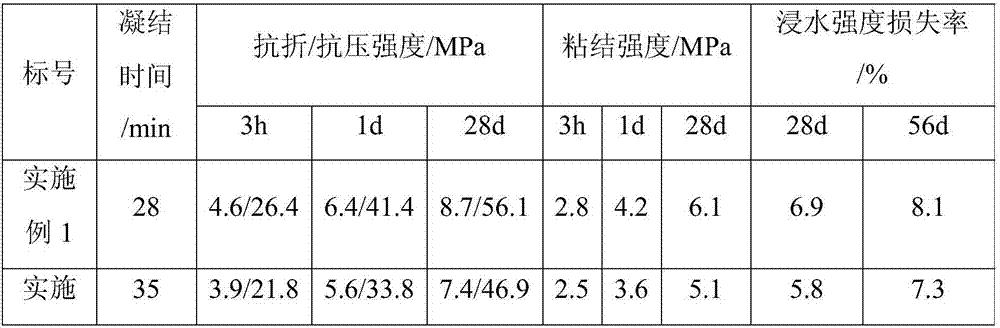

Magnesium phosphate cement based rapid repair mortar and preparation method thereof

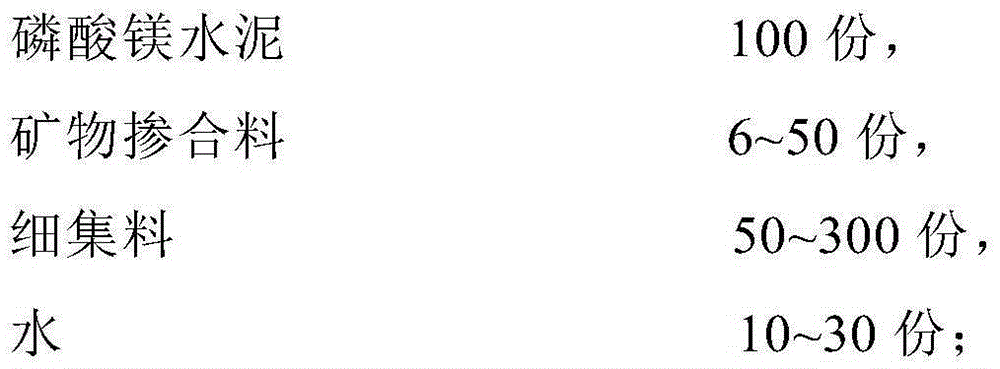

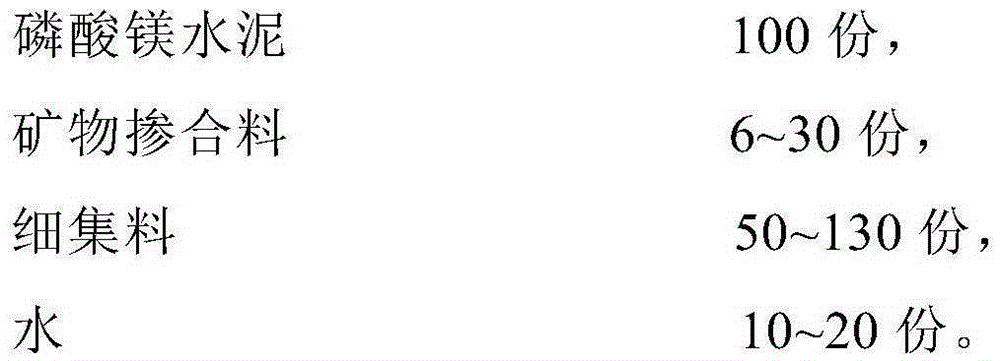

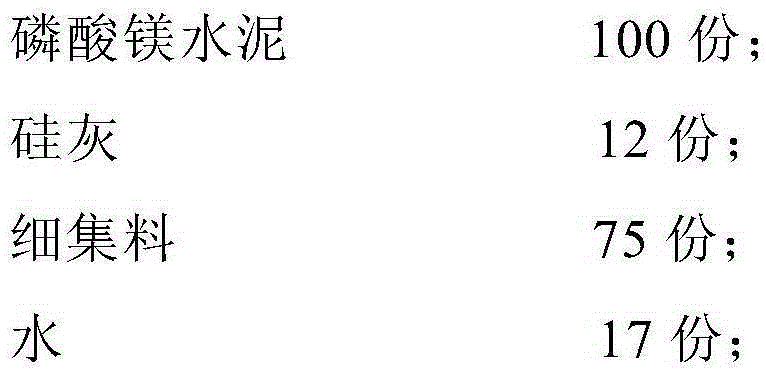

ActiveCN105272138AGuaranteed water resistanceImprove performance indicatorsMagnesium phosphateMagnesium orthophosphate

The invention relates to a magnesium phosphate cement based rapid repair mortar and a preparation method thereof. The rapid repair mortar includes the following components by weight: 100 parts of magnesium phosphate cement, 6-50 parts of a mineral admixture, 50-300 parts of fine aggregate, and 10-30 parts of water. The magnesium phosphate cement is obtained by mixing of, by weight, 60-70 parts of metal oxide powder, 20-28 parts of phosphate, 3-6 parts of a retarder and 4-6 parts of a coagulation regulating component. The magnesium phosphate cement based rapid repair mortar is prepared by adopting magnesium phosphate cement as the cementing material, adopting dipotassium phosphate for coagulation regulating modification, and using sand as the fine aggregate, then adding a proper amount of mineral admixture, and performing mixing with water. Compared with the prior art, the magnesium phosphate cement based rapid repair mortar provided by the invention has the advantages of controllable coagulation time, high bonding strength, good stability and high water resistance, etc.

Owner:TONGJI UNIV

Geopolymeric concrete based on recycled aggregate and preparation method of geopolymeric concrete

InactiveCN103601424AReduce consumptionImprove thermal stabilitySolid waste managementCement productionAdhesiveRoad surface

The invention relates to geopolymeric concrete based on recycled aggregate, and a preparation method of the geopolymeric concrete. The concrete is prepared by taking construction waste as aggregate and inorganic geopolymer as an adhesive through an alkali activation process. The recycled aggregate geopolymeric concrete prepared by using the method has the characteristics that the concrete can be rapidly dried, the compressive strength, particularly the early-stage compressive strength is high, the volume shrinkage in the coagulation process is extremely low, the coefficient of volume expansion is approximate to 0, and acid-base corrosion resistance is good. Due to the adoption of the method, the defects that the conventional concrete is low in early-stage strength and the coagulation time is long are overcome; a method for rapidly repairing concrete pavement is provided, and problems of recycling and reusing construction waste aggregate and environment problems caused by the construction waste aggregate are solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

Blood coagulation test cartridge, system, and method

ActiveUS20050233460A1Practical and convenientRapid and reliableAnalysis using chemical indicatorsMicrobiological testing/measurementTest sampleEngineering

A system and method for determining a coagulation time, e.g., TT, PT, aPTT, and ACT, of a test sample deposited in a test cartridge is disclosed. A cartridge housing having upper and lower major sides and a minor sidewall encloses a test chamber having a test chamber pivot element and is provided with a cartridge port for introducing a test sample into the test chamber,. Ferromagnetic agitator vane leaflets extend from an agitator pivot element supported by the test chamber pivot element intermediate the upper and lower major sides for rotational motion. The agitator vane leaflets can be swept, in response to an external magnetic field, through the test sample in the absence of coagulation. A timer is started when the agitator movement is commenced whereupon the agitator moves freely. Resistance to agitator movement due to coagulation is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

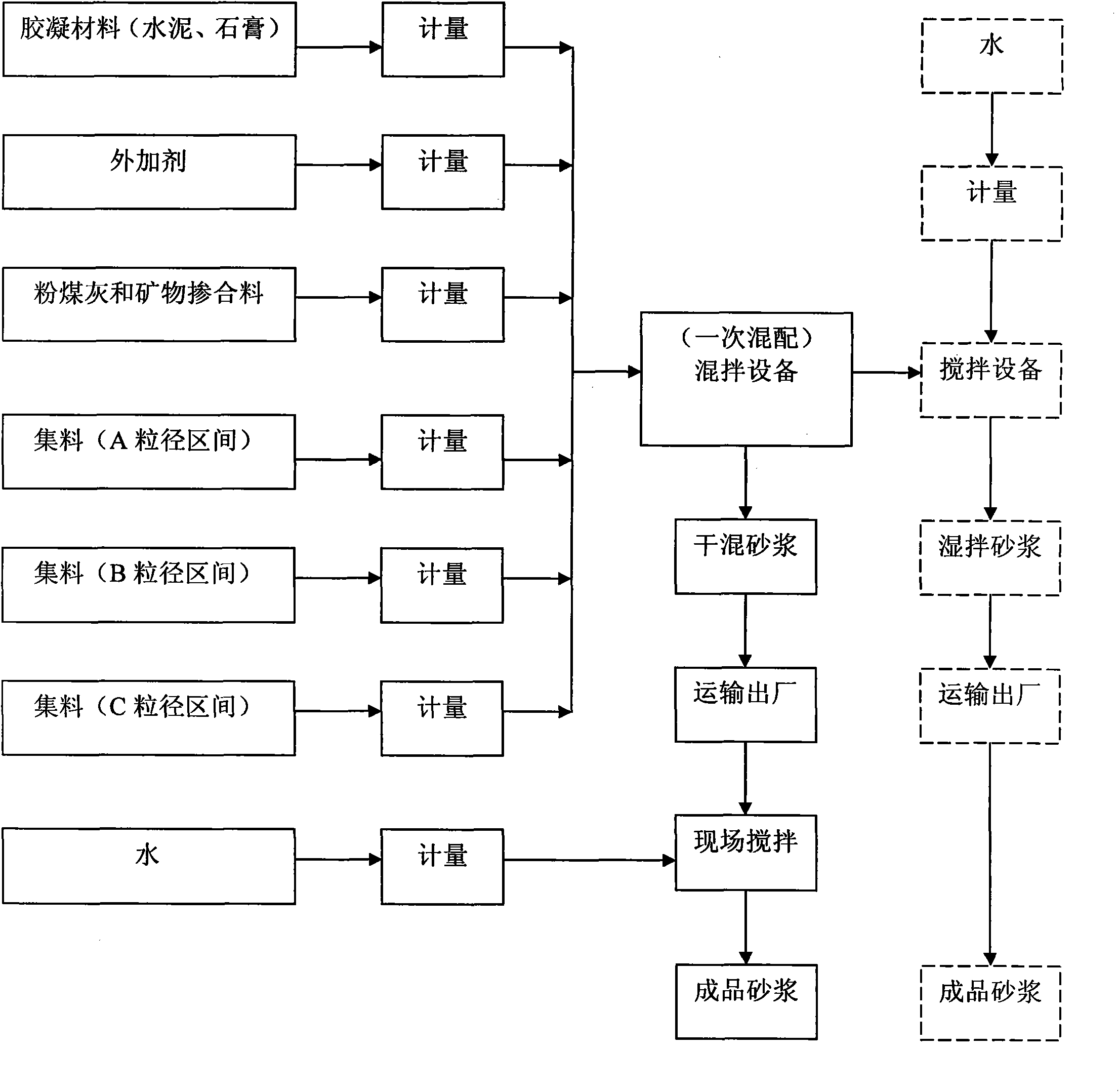

Method for preparing two-component pre-mixed mortar by mixing twice

InactiveCN102030504AGive full play to application advantagesAvoid quality fluctuationsSolid waste managementFly ashMaterials science

The invention provides a method for preparing two-component pre-mixed mortar by mixing twice, which comprises the following steps of: 1. weighing a cementing material, an additive, fly ash, silica ash and a mineral admixture in a certain proportion and mixing to obtain a cementing component; 2. Weighing weighing aggregates distributed by different grain sizes in a certain proportion and mixing to obtain an aggregate component; 3. Respectively respectively transporting the cementing component and the aggregate component in bulk or in bags to a construction site; performing secondary mixing in a sealed condition to mixing the cementing component and the aggregate component together to obtain the two-component pre-mixed mortar prepared by mixing twice, wherein the cementing material accounts for 15%-35%, the aggregate component accounts for 65%-85%, and water addition is determined by the type of the mortar. By the invention, quantity fluctuation of the mortar caused by the segregation and layering of the mortar in the processes of production, transportation, storage and use can be avoided, mismatching between consumption and transport loadage and between construction period and mortar coagulation time in the use process of the mortar can be solved thoroughly, and bulk utilization rate can be improved greatly.

Owner:张斌

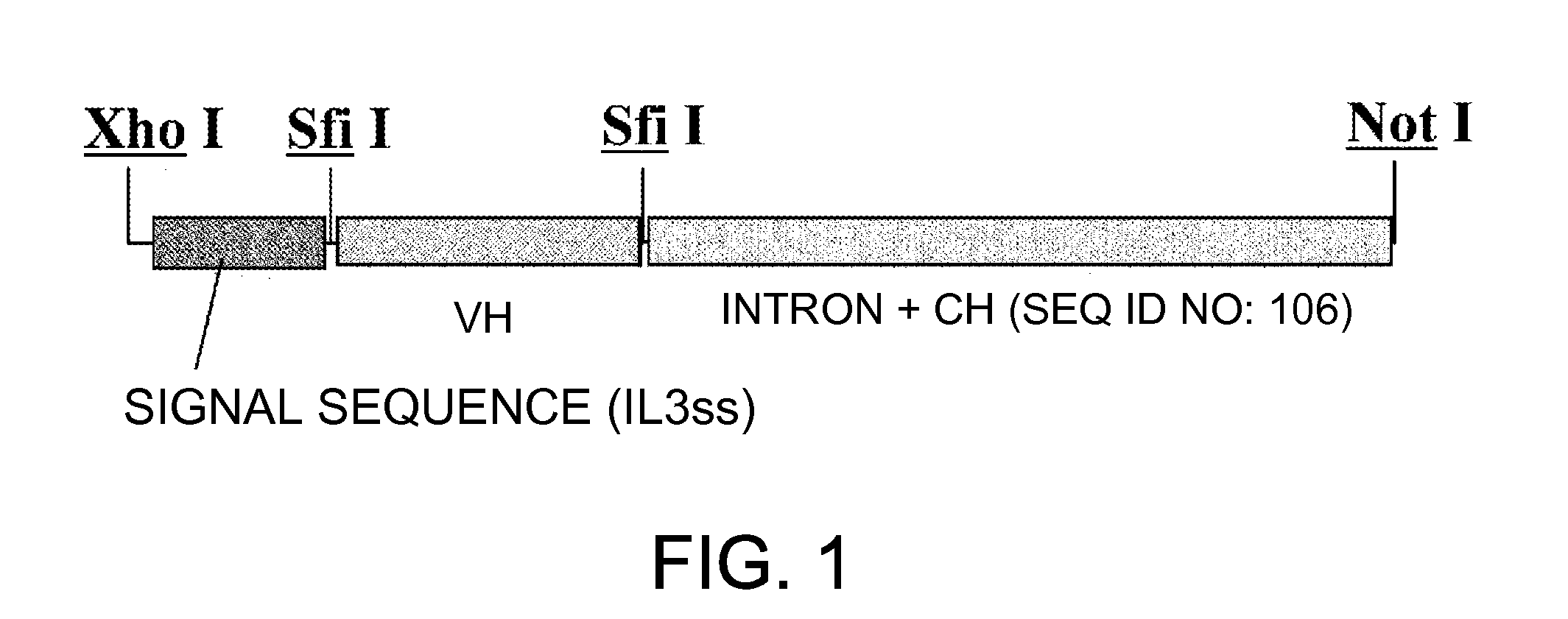

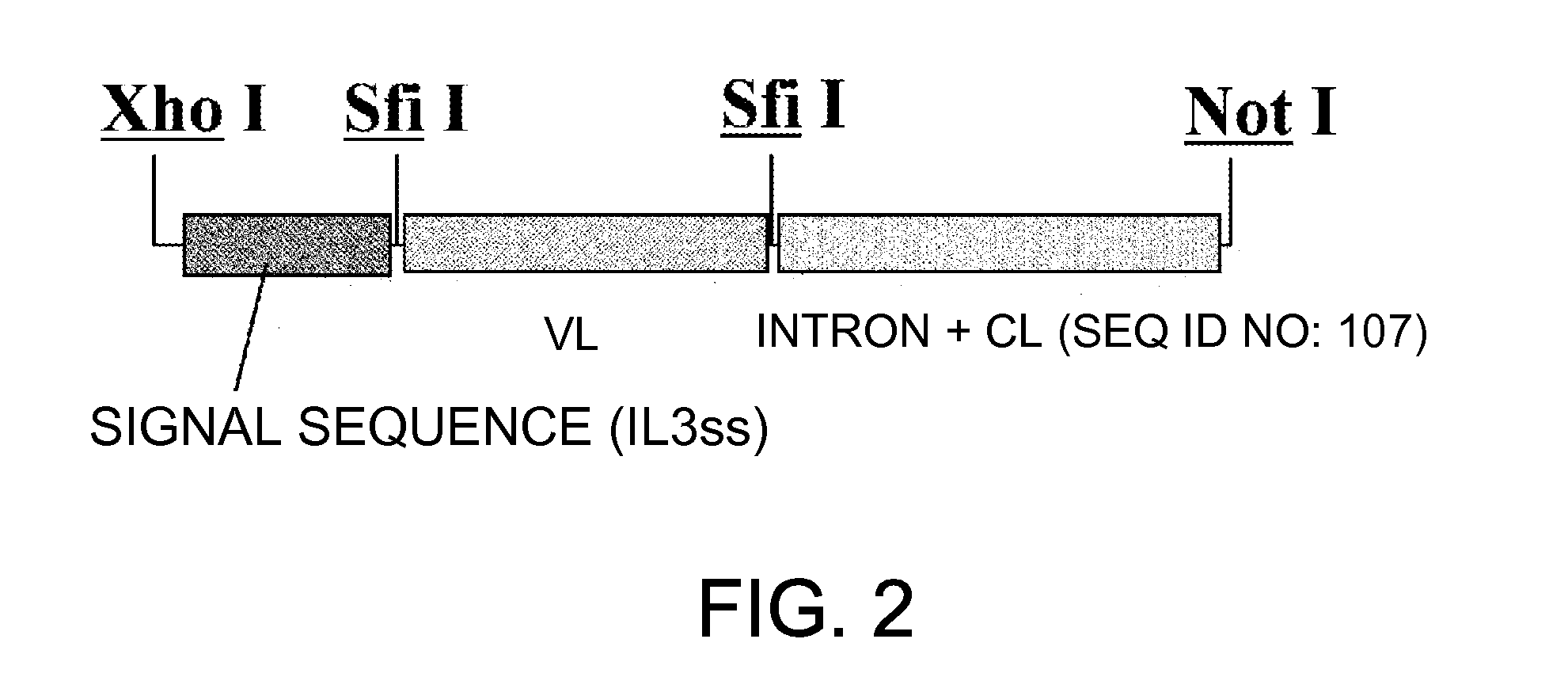

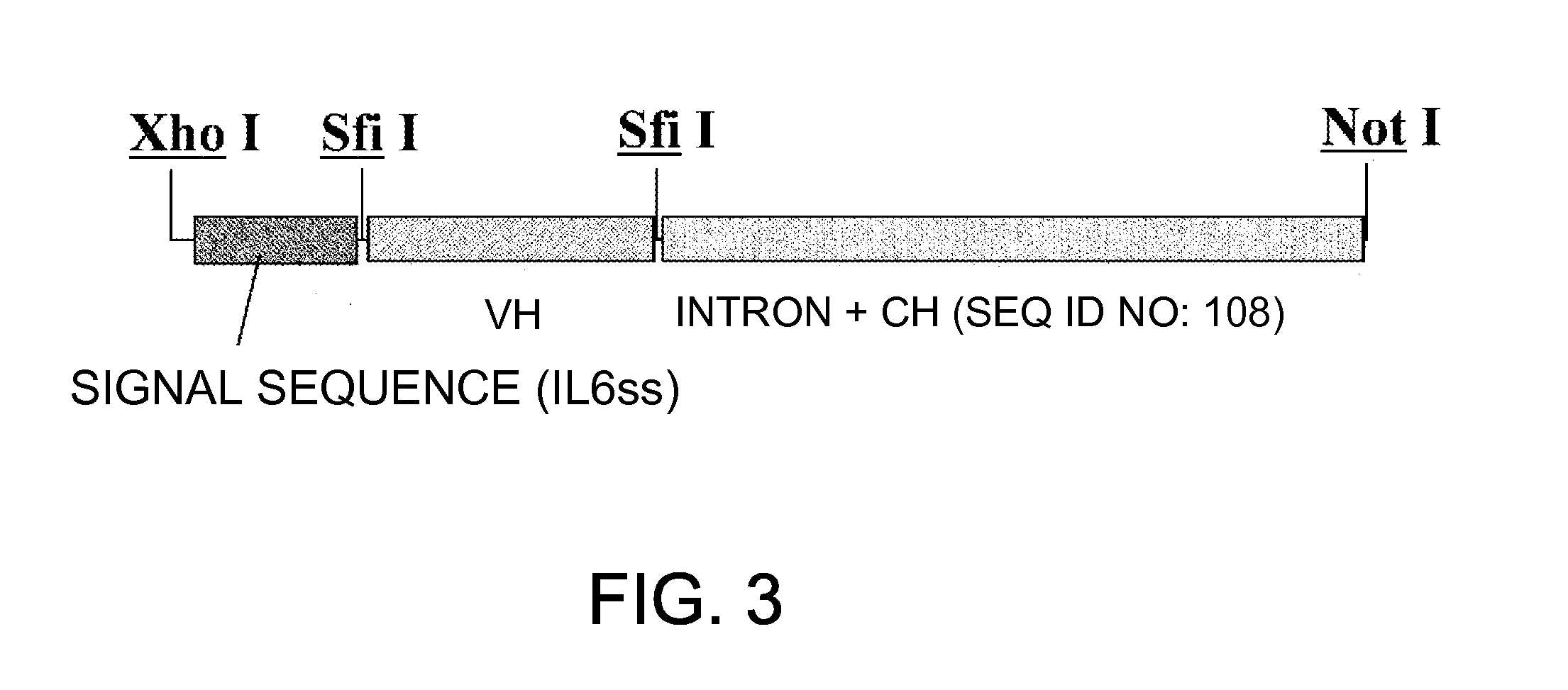

Antibody Substituting for Function of Blood Coagulation Factor VIII

InactiveUS20120237517A1Shorten clotting timeImmunoglobulins against blood coagulation factorsAntibody ingredientsBlood coagulation factor VIIIBispecific antibody

The present inventors produced a variety of bispecific antibodies that specifically bind to both F. IX / F. IXa and F. X, and functionally substitute for F. VIIIa, i.e., have a cofactor function to promote F. X activation via F. IXa. Among these antibodies, the antibody A44 / B26 reduced coagulation time by 50 seconds or more as compared to that observed when the antibody was not added. The present inventors produced a commonly shared L chain antibody from this antibody using L chains of A44, and showed that A44L can be used as commonly shared L chains, although the activity of the resulting antibody is reduced compared to the original antibody (A44HL-B26HL). Further, with appropriate CDR shuffling, the present inventors successfully produced highly active multispecific antibodies that functionally substitute for coagulation factor VIII.

Owner:CHUGAI PHARMA CO LTD

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

Aggregate-free cement-based grouting material

InactiveCN102173708AObvious beneficial effectImprove liquiditySolid waste managementEnvironmental resistancePlasticizer

The invention belongs to the technical field of inorganic cement-based grouting materials, in particular relating to an aggregate-free cement-based grouting material. The grouting material comprises the following components in parts by weight: 700 parts of cement, 0-40 parts of gypsum, 50-80 parts of expanded material, 0.5-1 part of thickener, 3-6 parts of super-plasticizer, 0-5 parts of coagulation regulating agent and 160-200 parts of admixture. In the invention, mainly aiming at gap width less than or equal to 15mm, when in grouting, the aggregate-free cement-based grouting material has the advantages of good self-flowability and adjustable coagulation time; water is not secreted in the process of grouting; and after coagulation, the grouting material has the characteristics of no shrinkage, micro-expansion, no crack and high strength. Simultaneously, the aggregate-free cement-based grouting material has the advantages of low cost, easiness for construction and environmental friendliness.

Owner:URUMQI MUNICIPAL BUILDING MATERIALS SCI RES INST

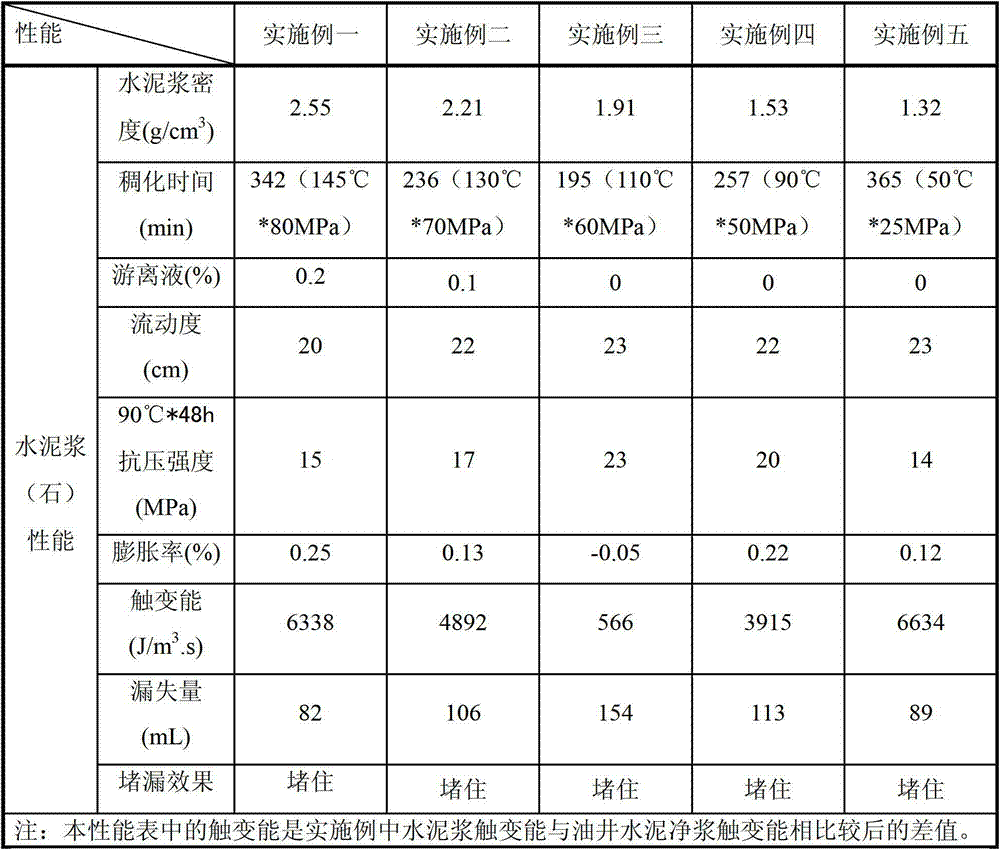

Plugging thixotropic cement paste for oil-gas well and preparation method for same

InactiveCN103045214ARaw materials are easy to getSimple processDrilling compositionCement pasteMaterials science

The invention relates to a plugging thixotropic cement paste for an oil-gas well and a preparation method for the same. The plugging thixotropic cement paste is composed of the following constituents in parts by weight: 100 parts of oil-gas cement, 0.5-10 parts of a thixotropic agent, 0-200 parts of a density regulator, 0-35 parts of a stabilizer, 0-6 parts of a coagulation time regulator, 0-5 parts of an expander, 0.5-3 parts of a dispersant, 0-2 parts of a defoamer, and 60-150 parts of water. Via the plugging thixotropic cement paste disclosed by the invention, the technical problem of loss during the well construction process and the production process of the oil-gas well can be effectively solved on the premise of meeting the various engineering performances needed by the plugging cement paste for the oil-gas well, thus providing a guarantee on the subsequent drilling and completion as well as the safety production of the oil-gas well.

Owner:SOUTHWEST PETROLEUM UNIV

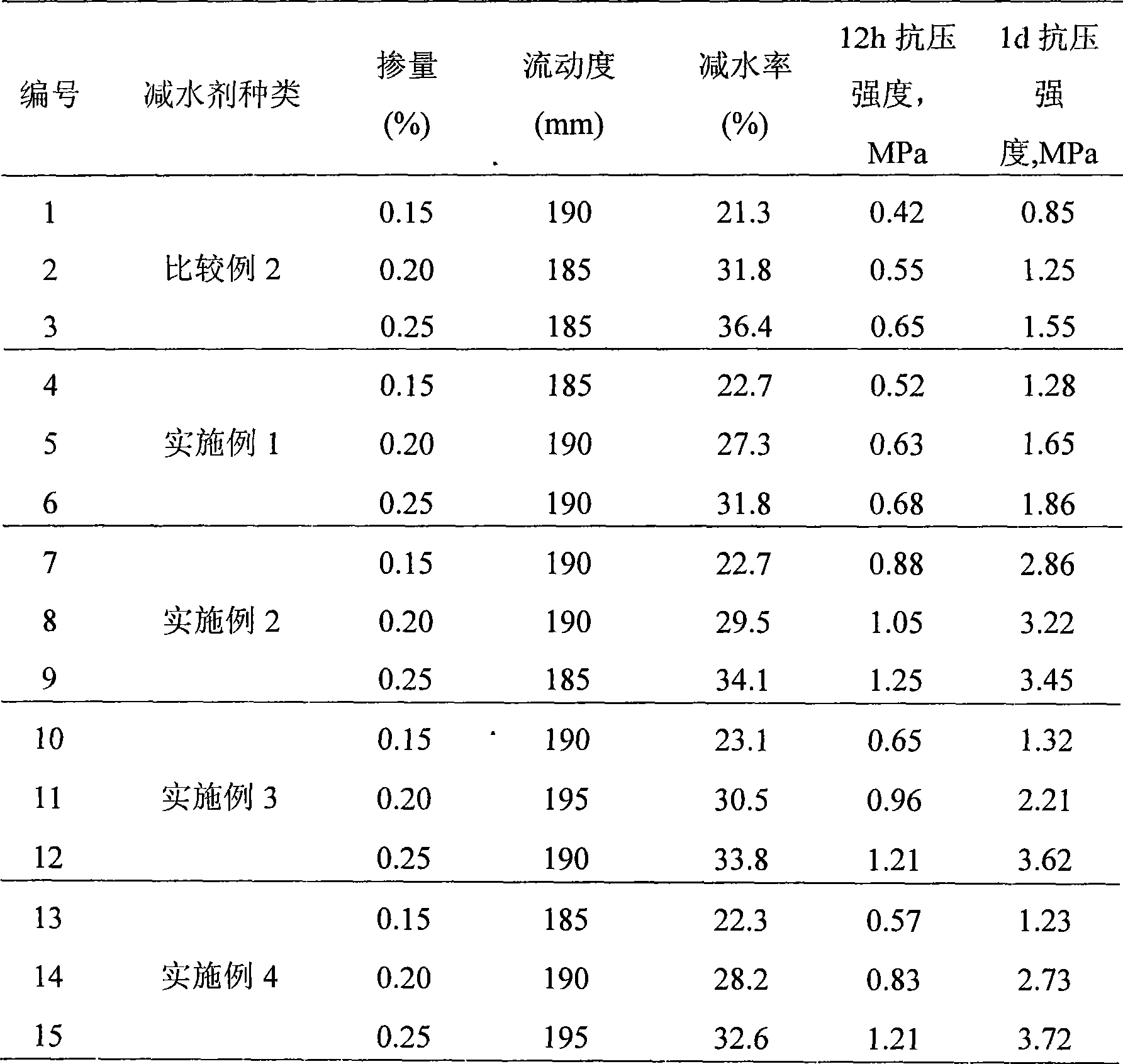

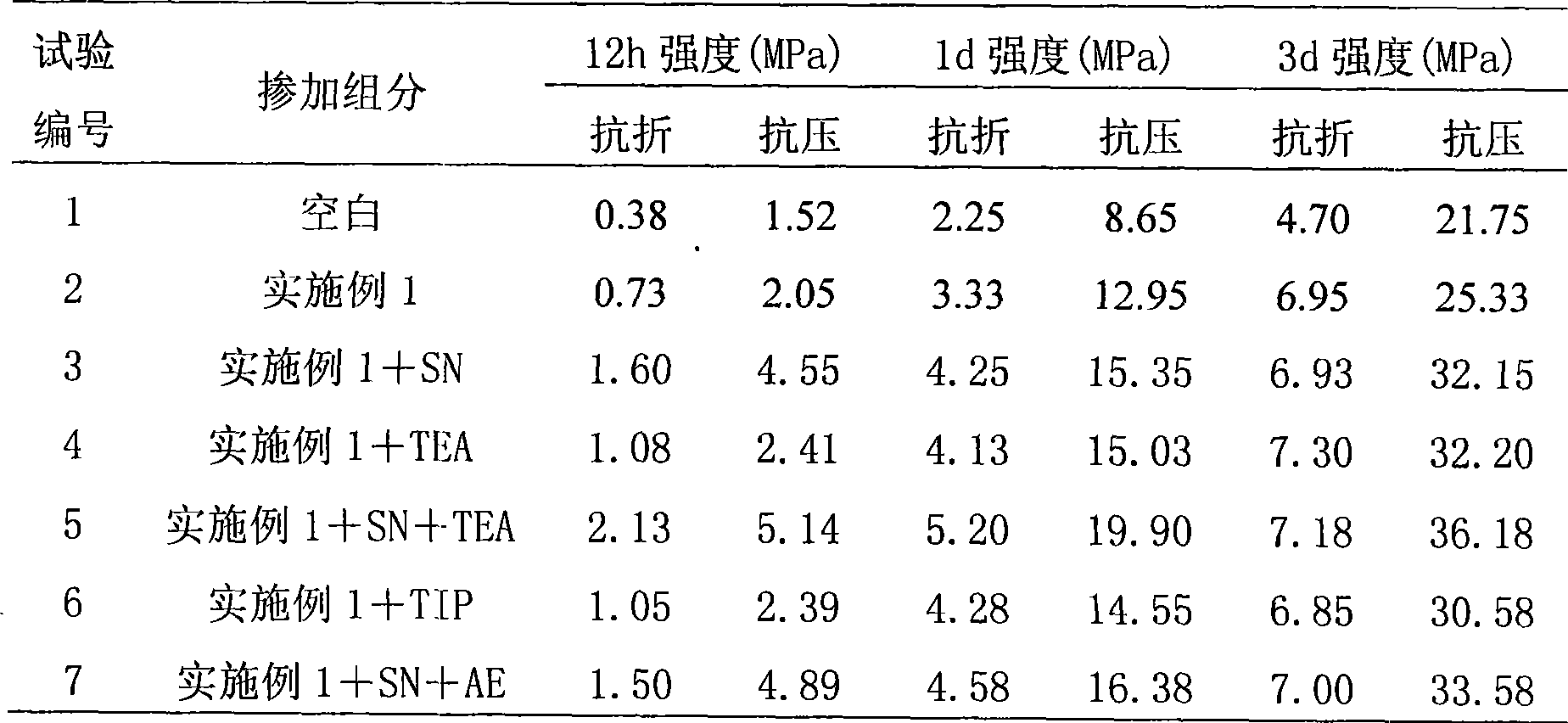

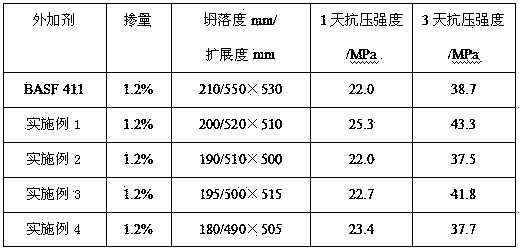

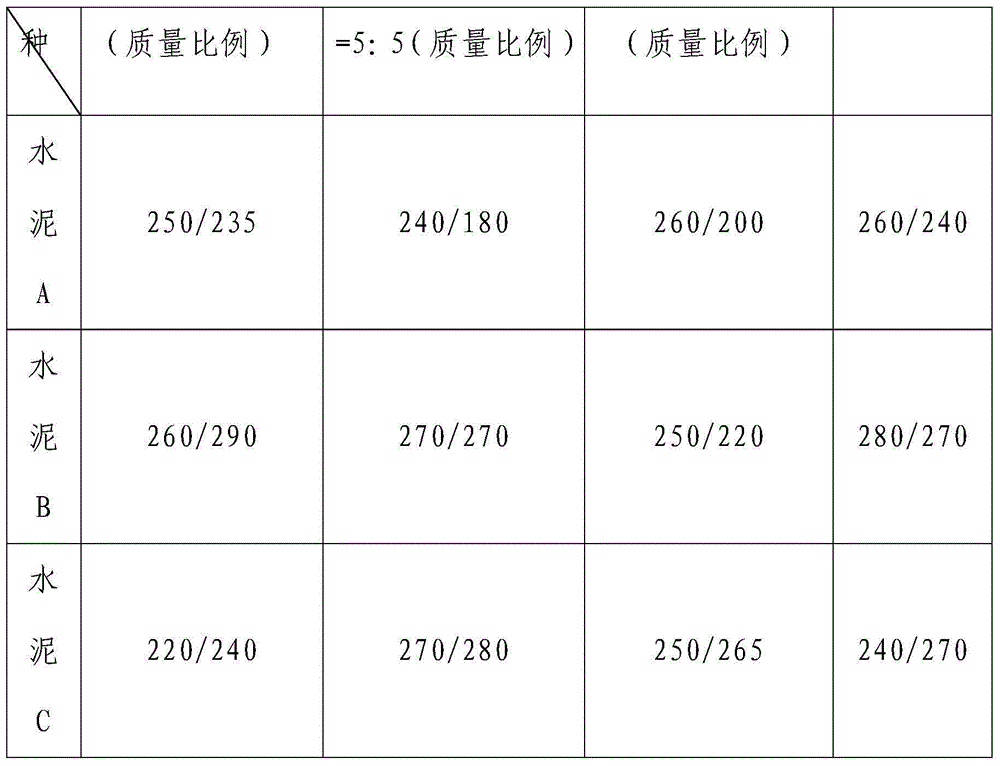

Preparation of polycarboxylic acid water reducing agent for prefabricated part

The invention discloses a preparation method for a polyocarboxy acid water reducing agent for precast units, which belongs to the field of water reducing agent. Under the action of a persulphate initiator, methoxypolyethylene glycol acrylate, acrylic acid, unsaturated sulfonic acid or a salt monomer b thereof, unsaturated amide or a salt monomer c thereof are copolymerized in an aqueous solution; a terminator is used to process the rest initiator of the reaction at a later polymerization stage; and finally alkaline solution is used for neutralization and the water reducing agent is obtained. The methoxypolyethylene glycol with high polymerization degree is introduced as a grafting side chain, thereby making the prepared water reducing agent effectively shorten the concrete coagulation time without reducing the concrete initial fluidity and improving the concrete compression strength. The early strength type polyocarboxy acid high performance water reducing agent can be widely applied to the construction of various concrete projects with a low temperature or early strength requirements, in particular to the low energy consumption production process of precast concrete units. The water reducing agent has wide generalization space.

Owner:HUIZHOU JIANKE IND

High-early-strength polycarboxylate water reducer and preparation method thereof

The invention discloses a high-early-strength polycarboxylate water reducer and a preparation method thereof. The high-early-strength polycarboxylate water reducer is a liquid, and has a solid content of 40%. The water reducer containing an esterified alcohol amine group, a sulfonic group, an amido group, a carboxyl group and a methylallyl polyoxyethylene ether side chain is prepared through polymerizing monomers comprising methylallyl polyoxyethylene ether, acrylamide, sodium methylallyl sulfonate, acrylic acid or methacrylic acid, acrylated amine and the like under the action of a molecular weight chain initiator and a chain transferring agent, and neutralizing. The high-early-strength polycarboxylate water reducer has the advantages of low alkali content, high water reduction rate, short coagulation time, suitableness for the construction of prefabricated components, pile tubes, duct pieces and bridges, simple production technology, easily controlled reaction condition, and no environmental pollution.

Owner:湖南加美乐素新材料股份有限公司

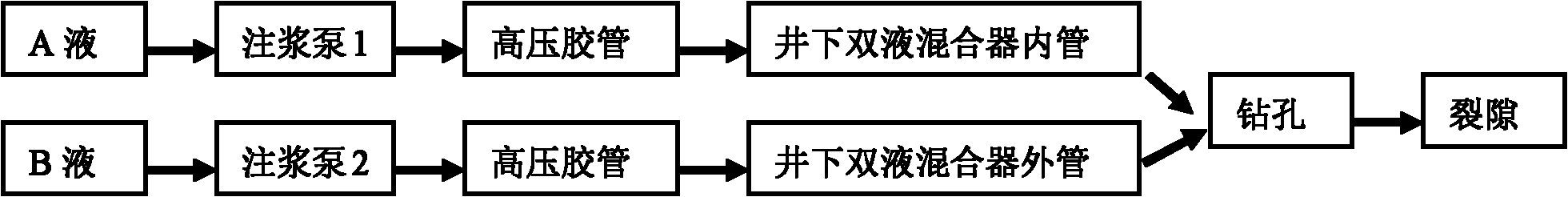

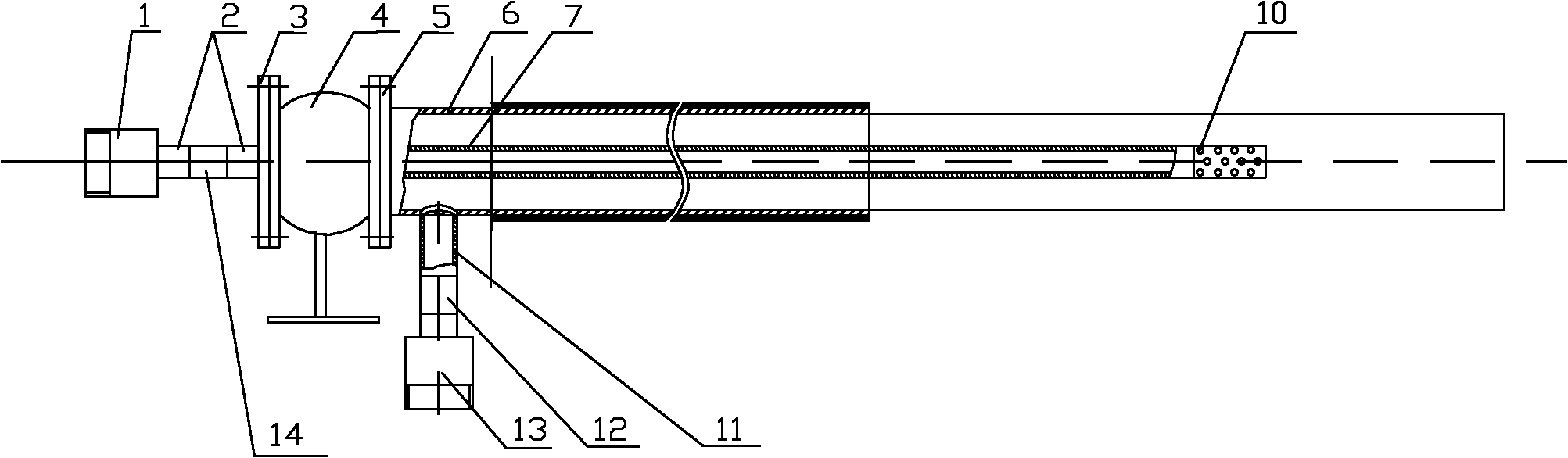

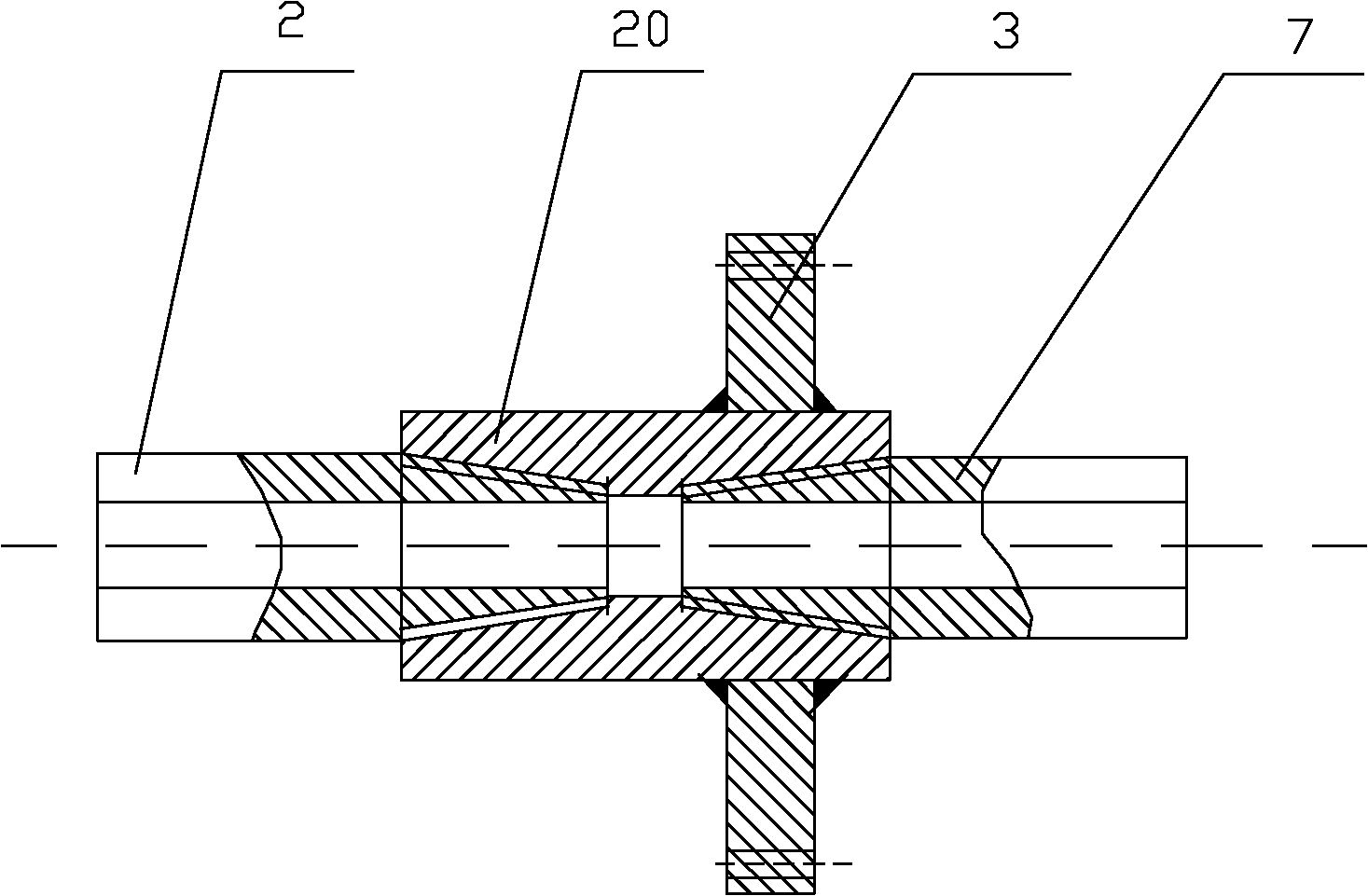

Underground double liquid grouting process and underground double liquid grouting machine thereof

ActiveCN102080552AEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersTunnel liningSlurryPulp and paper industry

The invention relates to an underground double liquid grouting process, which comprises the following steps: (1) making preparations for implementing the double liquid grouting process and judging whether the grouting conditions are met; and (2) implementing the double liquid grouting process. The invention also discloses an underground double liquid grouting machine. An underground double liquidgrouting machine comprises an inner grouting tube and an outer grouting tube which are nested together, wherein the inner and outer grouting tubes are two independent airtight tubes. According to theinvention, a drill rod and a drill hole water-stopping casing pipe are respectively used as a grout conveying pipeline, the double pipeline grouting is realized, and the position for mixing two grouts and the running time of the grouts in the drill hole after the grouts are mixed are both adjusted by changing the depth of the grouting tubes in the drill hole, thus achieving the purpose of adjusting the coagulation time of the double grouts in the deeper drill hole and eliminating the disastrous effect of blocking the drill hole with the grouts, thereby ensuring a better grouting effect.

Owner:SHANDONG UNIV

Desulfurated gypsum self-leveling material and preparation method thereof

InactiveCN101054284ASufficient construction timeHigh strengthSolid waste managementEmulsionPortland cement

The invention discloses a desulfurizing plaster self-leveling material, which main component weight percent are as follows: 30-65% desulfurizing plaster, 25-60% high-alumina cement, 0-30% ordinary portland cement, 0-20% fly ash, 0-8.0% redispersing emulsion powder. The material comprises an amount of additive and fine aggregate. Blending each component at determined weight percent fully and uniformly in a blender, packing to get self-leveling material. The invention can prepare self-leveling material by desulfurizing plaster massively, has more simple manufacturing technique, less energy consumptions, low cost, moderate coagulation time, strong and better water resistance, microswelling performance, can be widely applied to kinds of leveling execution.

Owner:ZHEJIANG UNIV

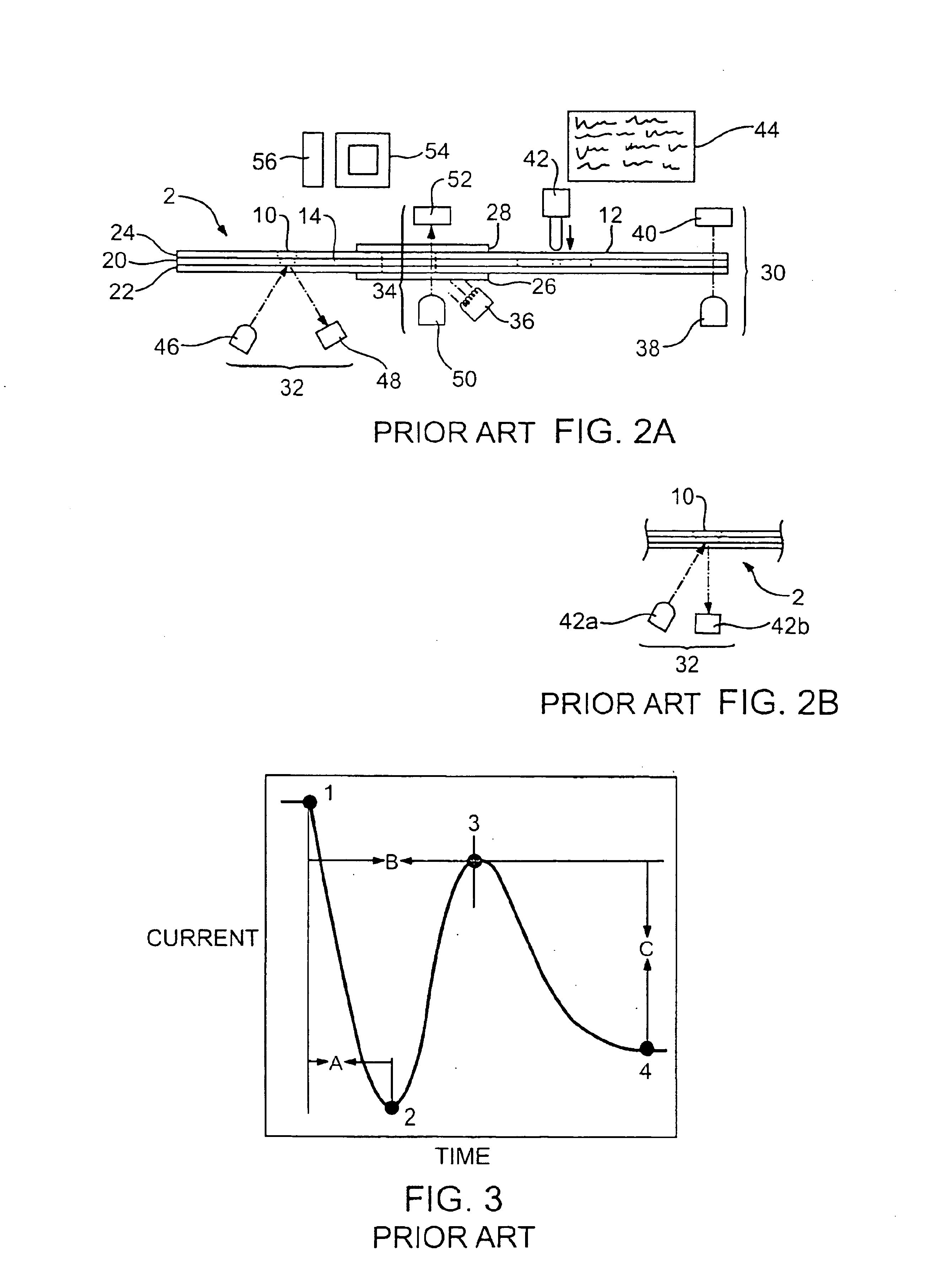

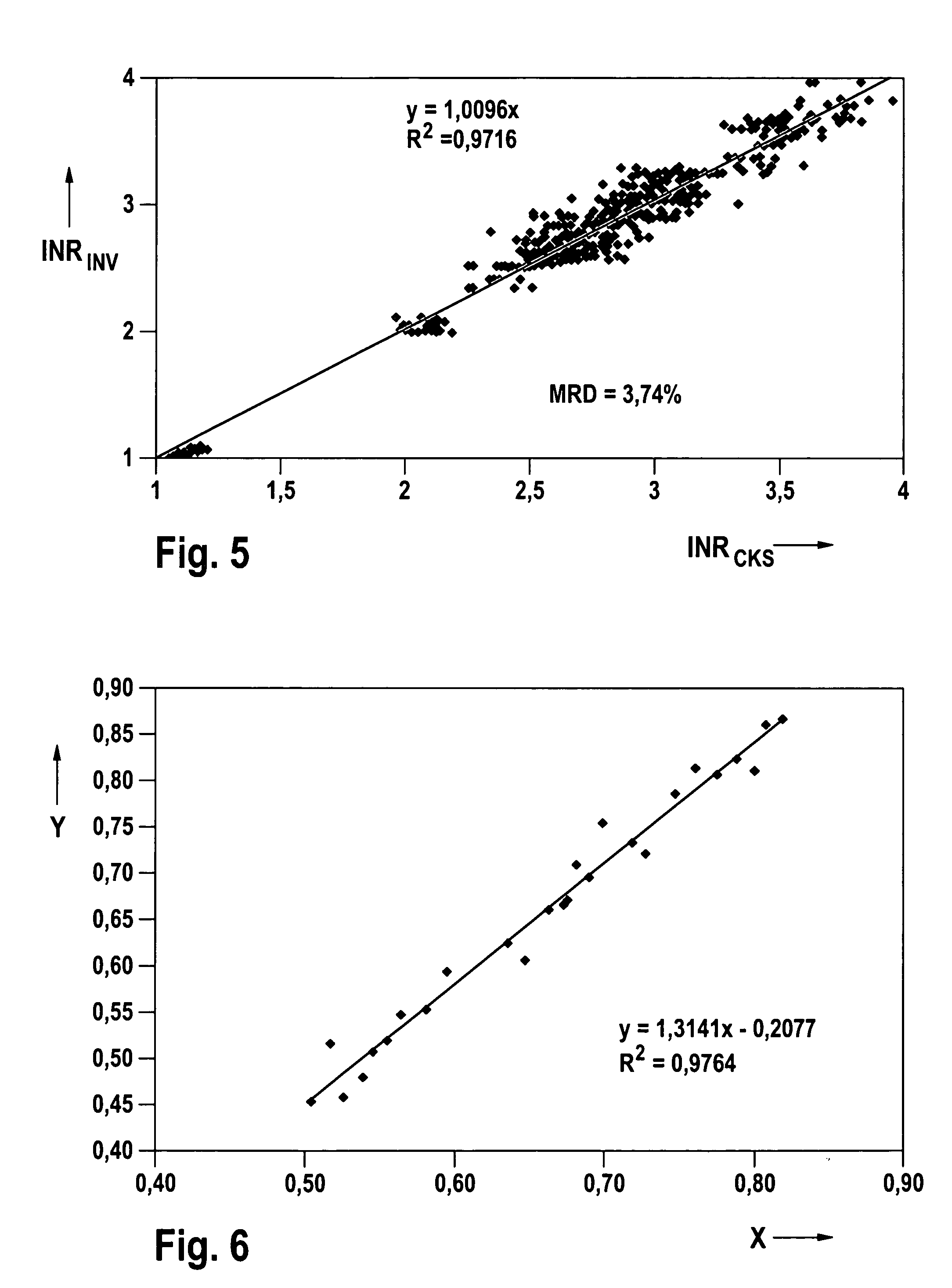

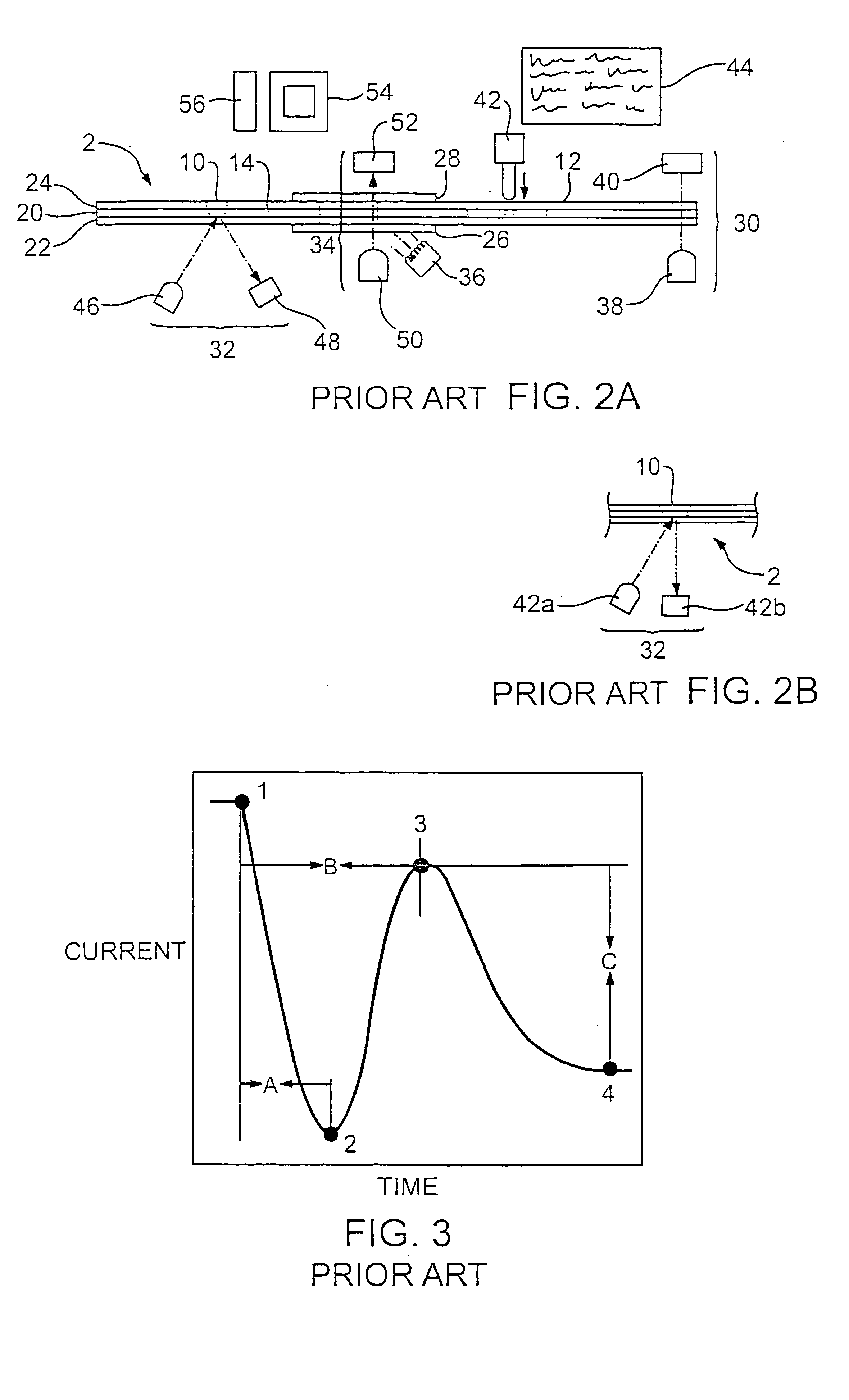

System and method for determining a coagulation parameter

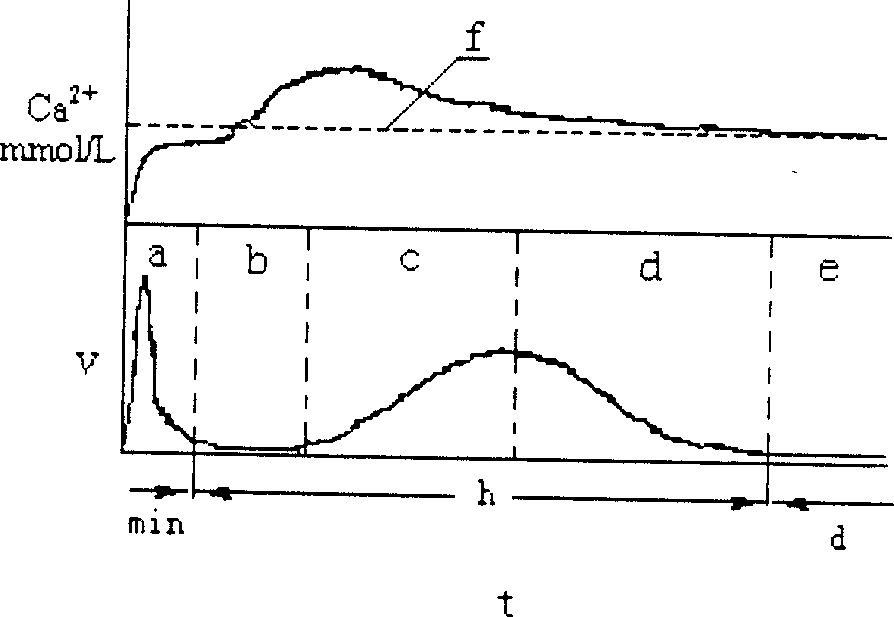

InactiveUS20060035298A1Simple designMaintenanceMicrobiological testing/measurementBiological testingEngineeringTest element

System and method for the determination of a coagulation parameter comprising a disposable test element and an instrument for evaluation thereof. The coagulation time is determined at a non-standard temperature different from a standard temperature for the respective coagulation parameter, the non-standard temperature being measured by a temperature measurement device of the instrument, the instrument has a non-volatile memory containing data which define a mathematical relationship of coagulation time versus temperature which relationship is independent of the individual patient whose blood is examined, and the coagulation parameter for the standard temperature is calculated from the coagulation time measured at the non-standard temperature, using the mathematical relationship.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

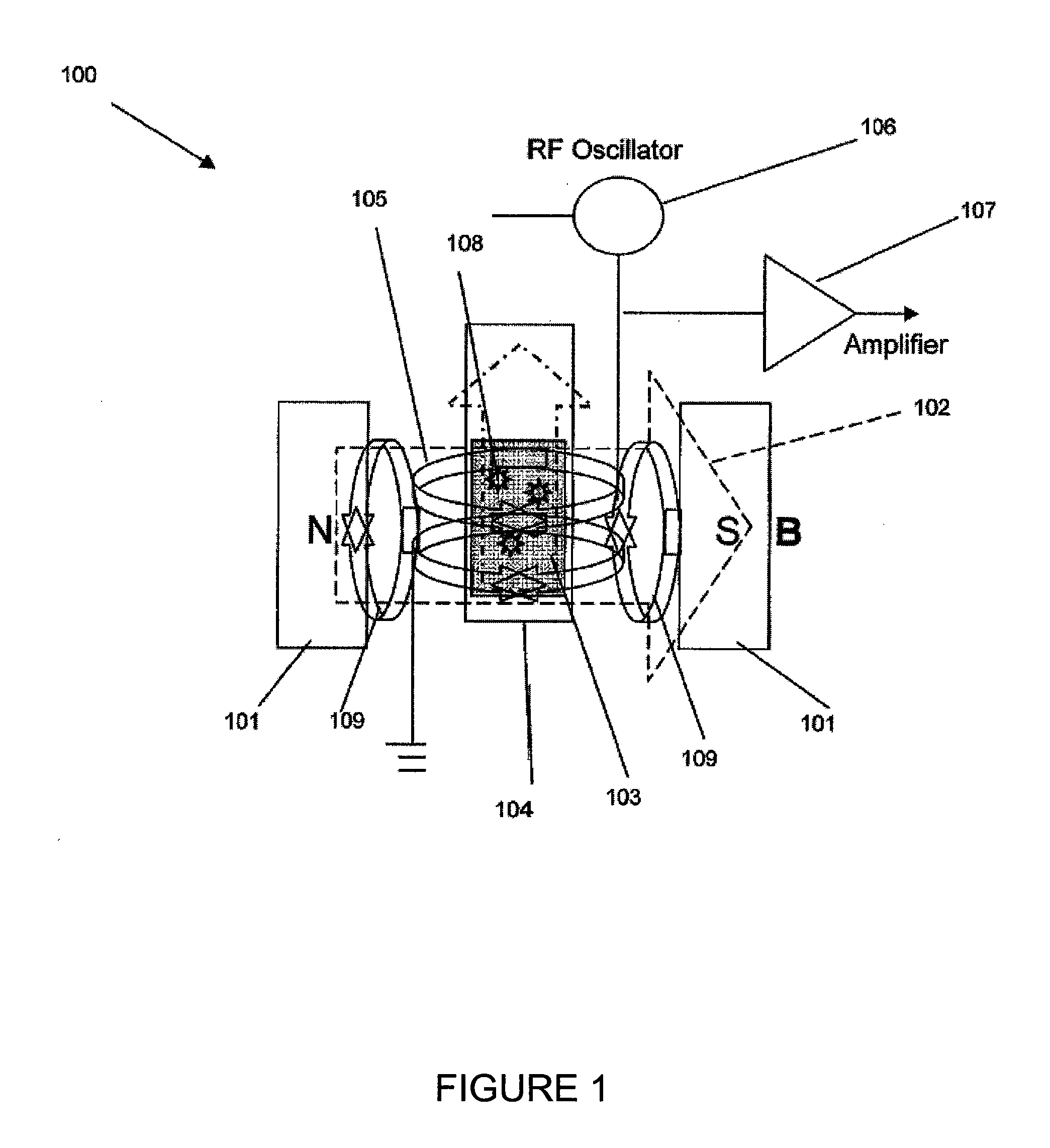

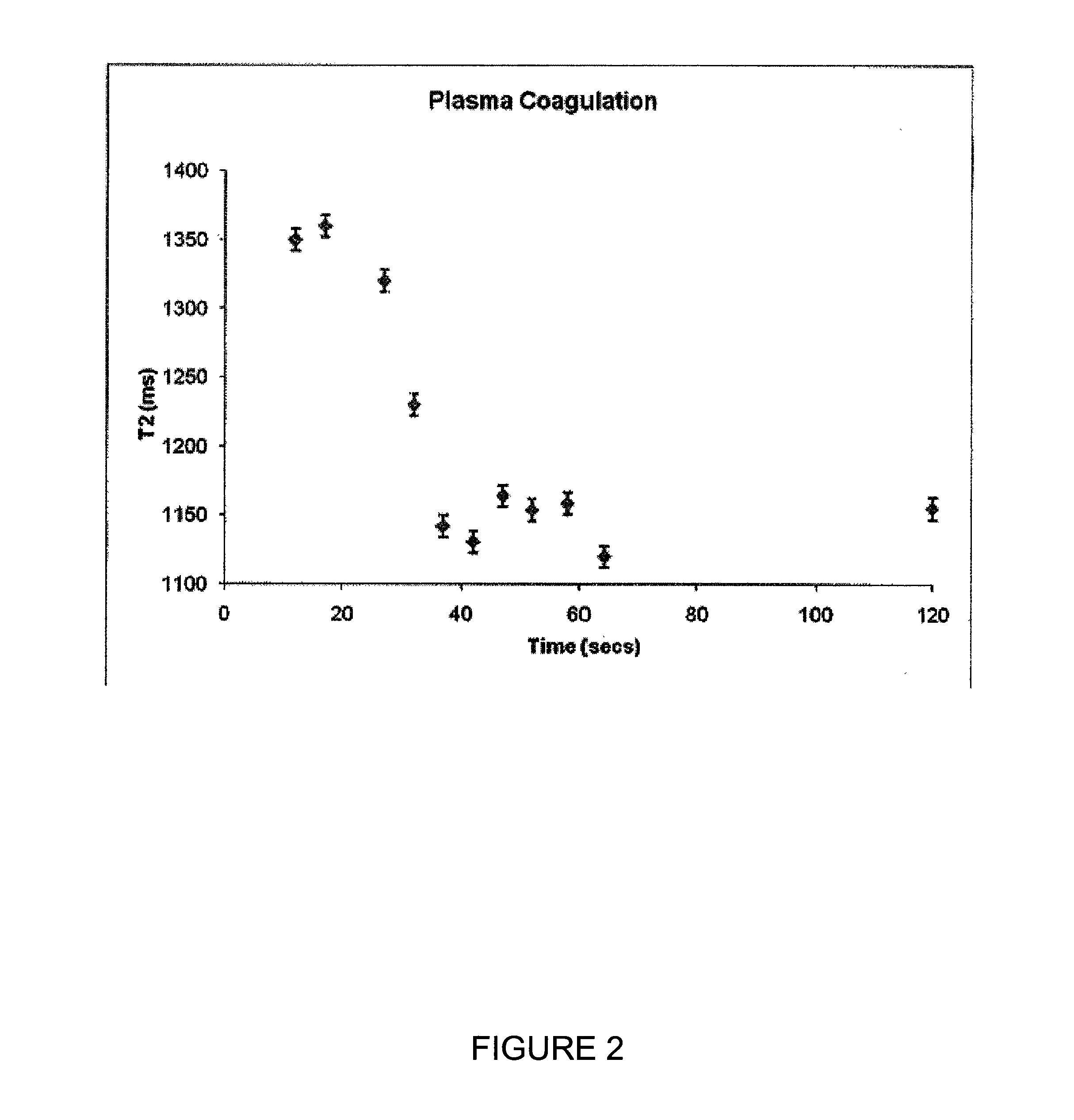

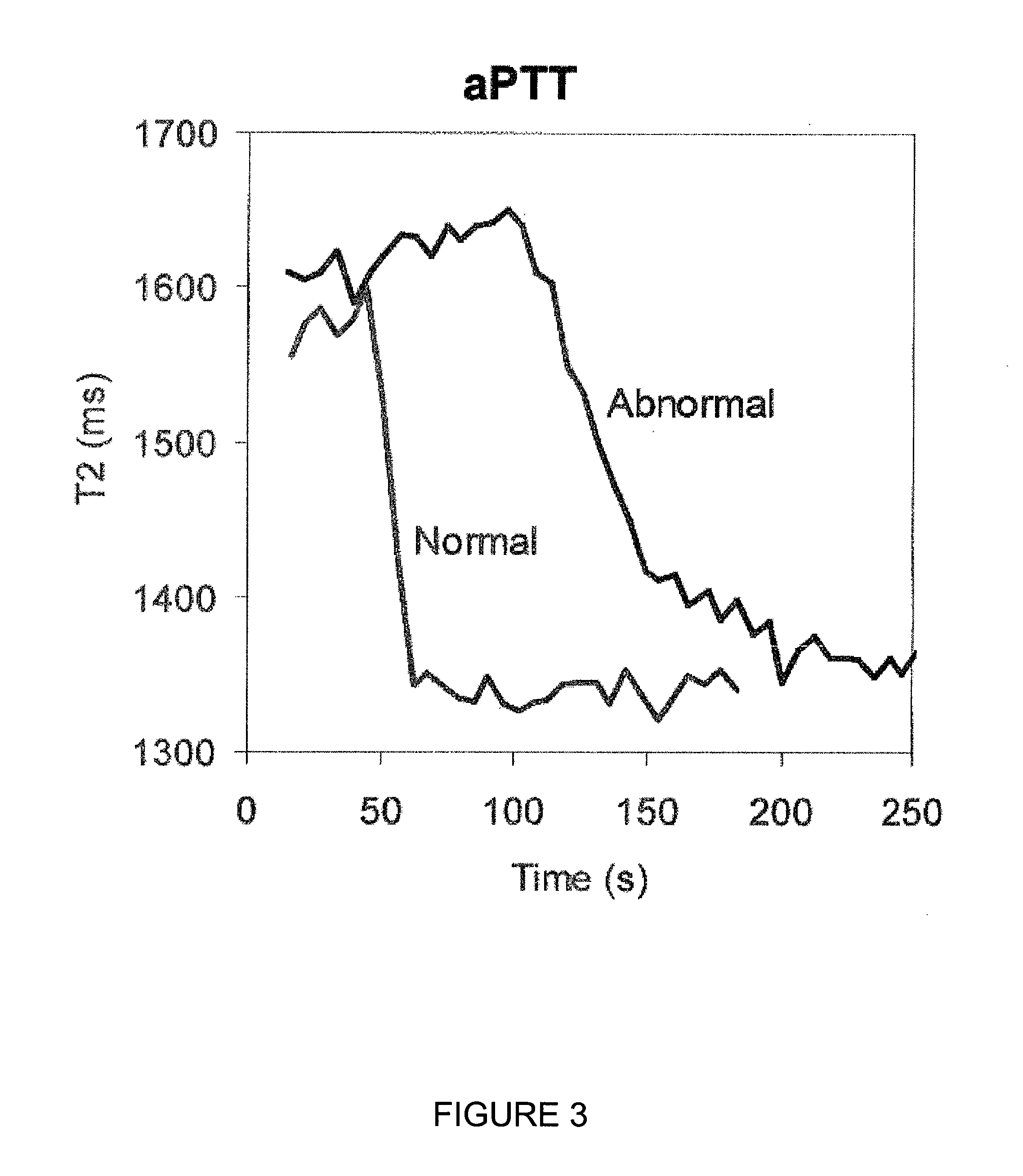

Nmr detection of coagulation time

ActiveUS20110312002A1Correction accuracyPointing accuratelyMicrobiological testing/measurementMeasurements using NMR imaging systemsCoagulation timeFibrinolysis

The invention relates to detecting coagulation and coagulation-related activities including agglutination and fibrinolysis of samples. More particularly the invention relates to methods and apparatus for monitoring coagulation and / or obtaining a coagulation time of a sample using NMR-based detectors.

Owner:T2 BIOSYST

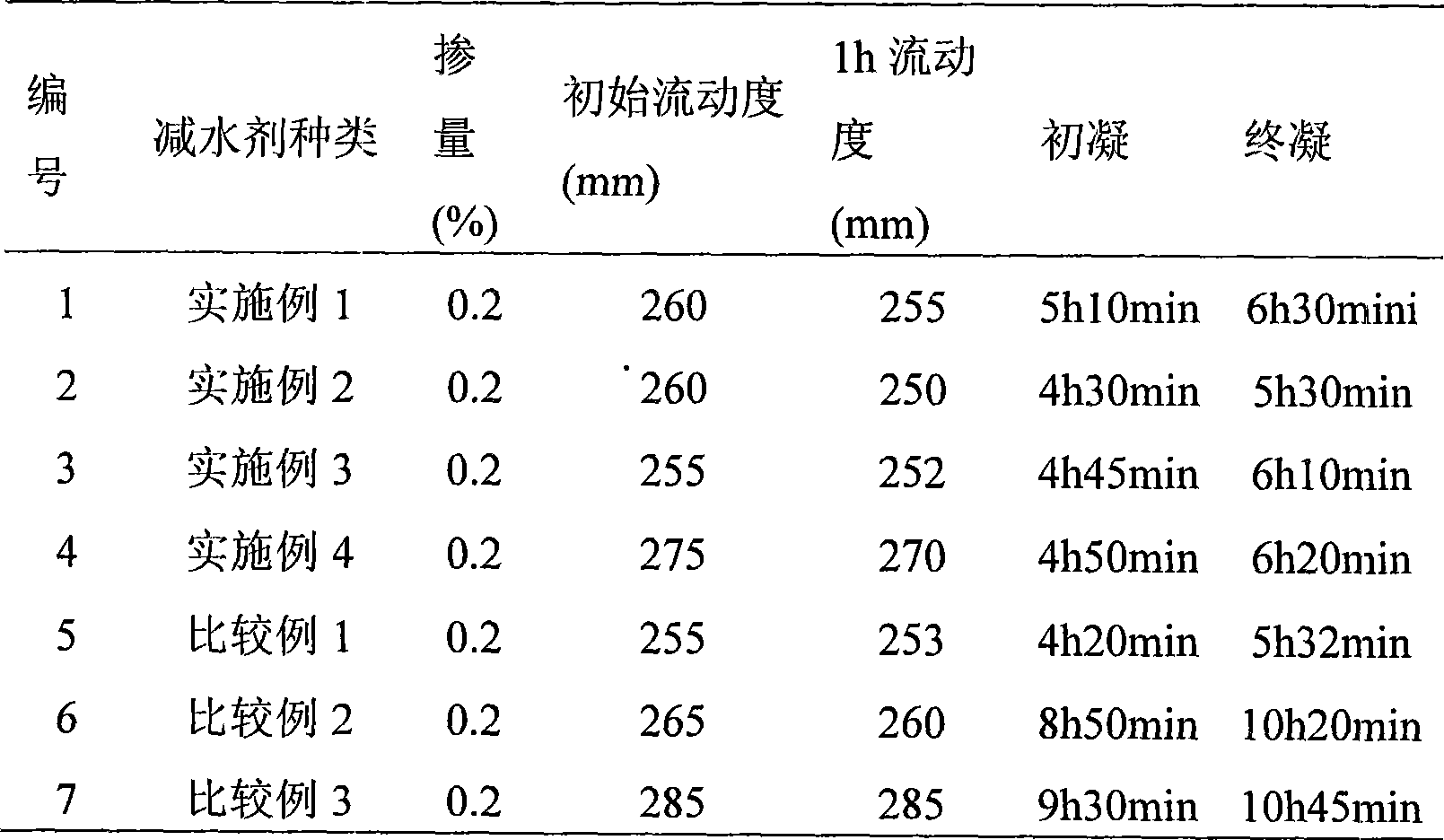

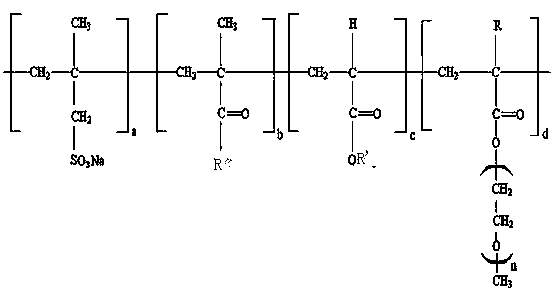

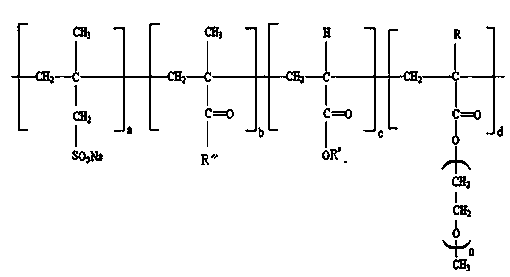

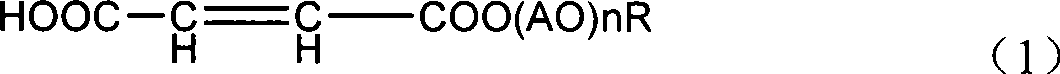

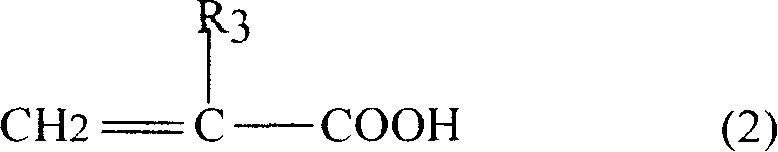

Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

The invention relates to the design and synthesis of a poly carboxylic acid water reducing agent, the coagulating time of which can be controlled. The poly carboxylic acid water reducing agent is prepared by co-polymerize the following three monomers in water: the monomer a occupying 30 to 70 percent and indicated by a general expression 1, the monomer b occupying 10 to 50 percent and indicated by the general expression 2, and the monomer c occupying 10 to 40 percent and indicated by the general expression 3. The coagulating time is controlled by the monomer a which is made by condensing maleic anhydride and polyoxyethylene monoalkyl ether. The length of a polyoxyethylene monoalkyl ether chain controls the change of the coagulating time: the longer the chain, the shorter the coagulating time is; and the shorter the chain is, the longer the coagulating time is. The monomer a does not contain inhibitive substances in the process of synthesis, therefore, the water reducing agent is easy to be controlled in the coagulating process. The poly carboxylic acid water reducing agent is suitable for the construction of concrete under different temperature conditions: under higher temperature, the water reducing agent with longer coagulating time can be adopted, and under lower temperature, the water reducing agent with shorter coagulating time can be adopted. The poly carboxylic acid water reducing agent has good adaptability to cement and admixtures and has the advantages of low mixing quantity, good slump constant hold facility and water segregation resistance, and the like.

Owner:武汉格瑞林建材科技股份有限公司

Blood coagulation test cartridge, system, and method

InactiveUS20050255601A1Practical and convenientRapid and inexpensiveMicrobiological testing/measurementWithdrawing sample devicesBlood capillaryEngineering

A system and method for determining a coagulation time, e.g., thrombin time, PT, aPTT, and ACT, of a blood sample deposited in a test cartridge is disclosed. The test cartridge comprises a blood receptacle that is open to the atmosphere into which a blood sample is to be deposited, a vacuum port that is open to atmosphere, and a spiral capillary within the test cartridge having a capillary length and cross-section area, a first capillary end of the spiral capillary open to the blood receptacle and a second capillary end of the spiral capillary open to the vacuum port, whereby the spiral capillary is closed to atmosphere. When a blood sample is deposited in the blood receptacle, a vacuum is drawn through the vacuum port and the blood is drawn through the spiral capillary until coagulation occurs. A pressure change is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

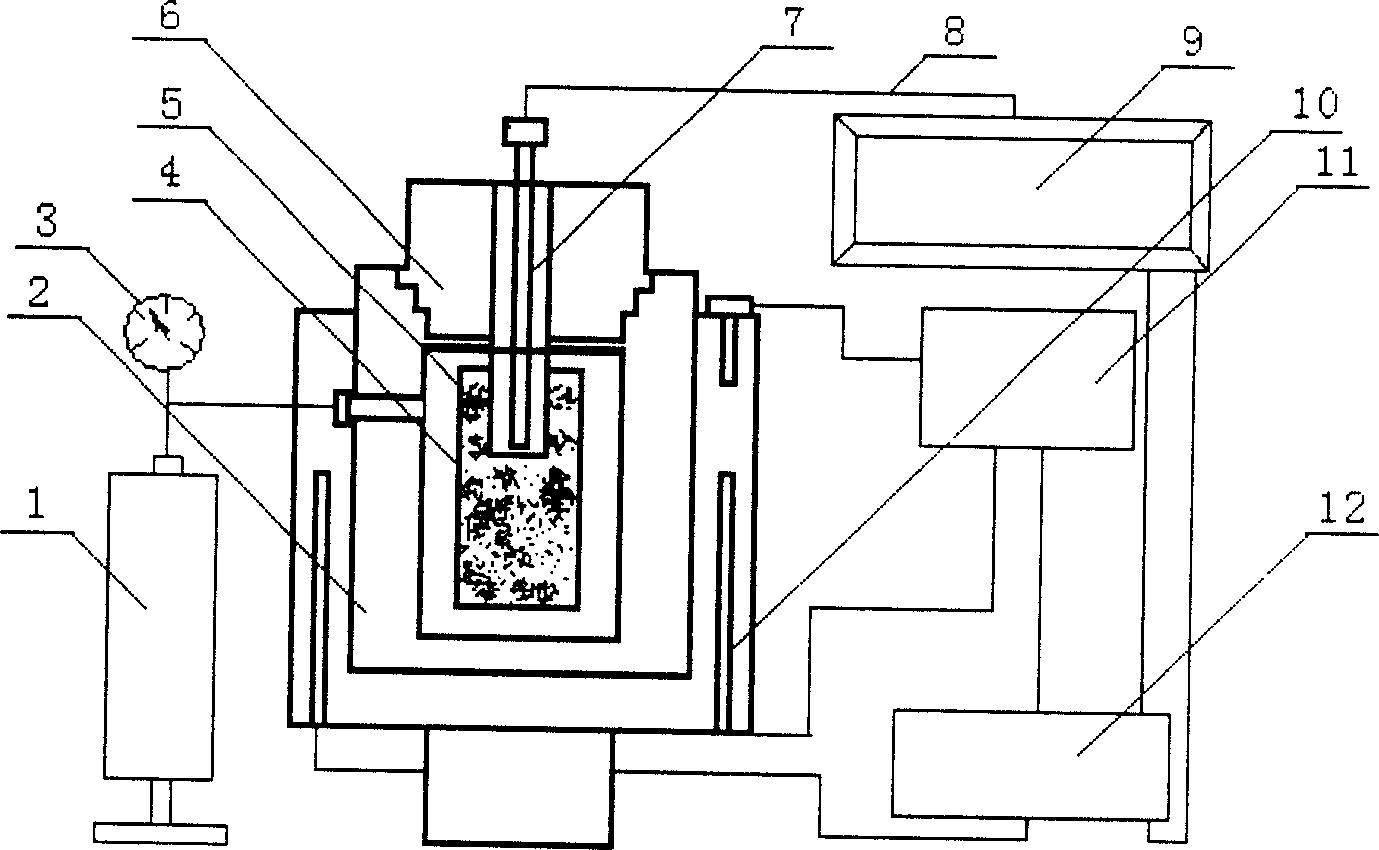

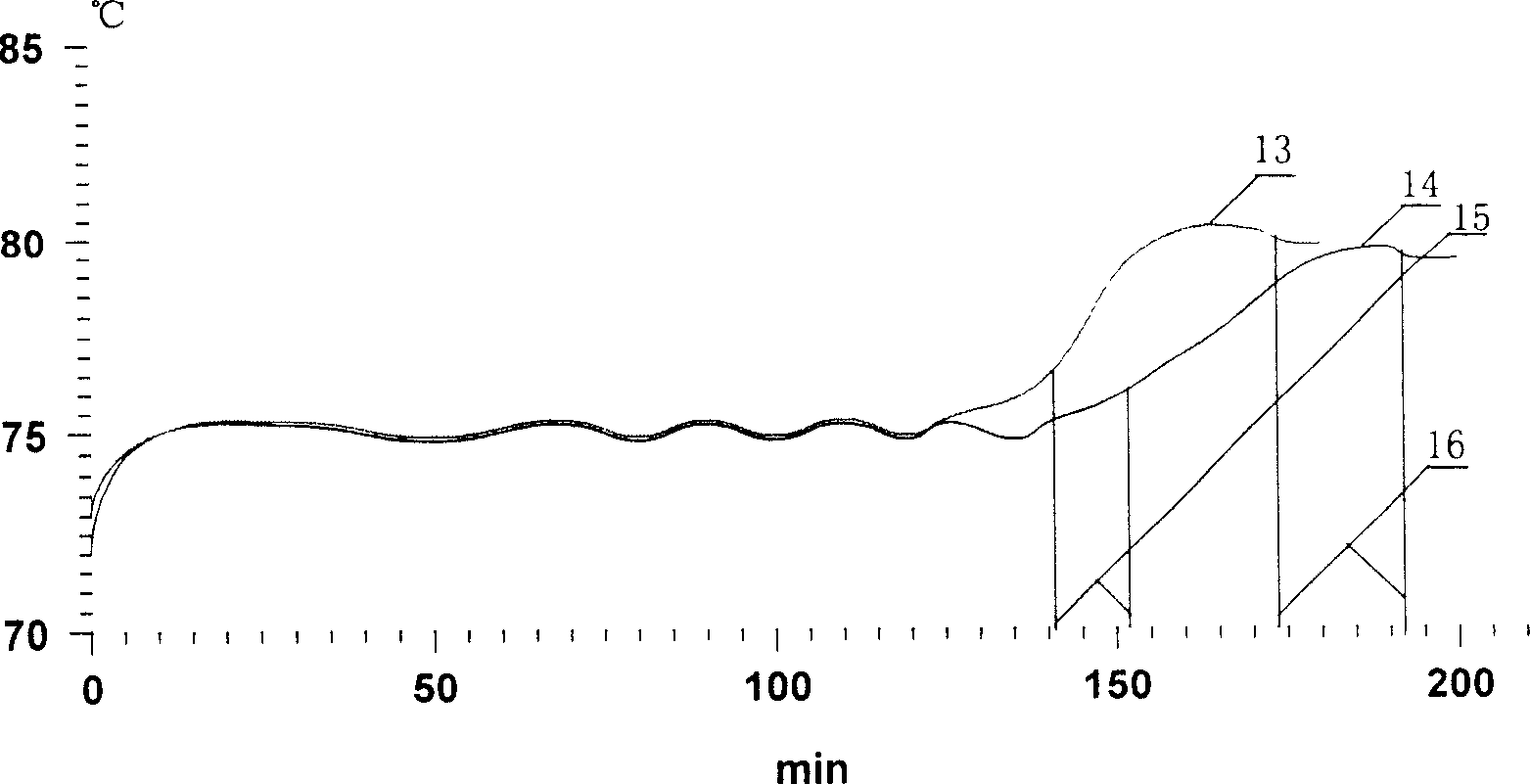

High temperature high pressure oil well cement paste coagulation instrument and its coagulation time measuring method

InactiveCN1676873AMeet the required conditionsEasy to operateSurveySealing/packingDepth in a wellData treatment

The invention is a method which surveys the coagulation status and its relevant time of annular cement under high pressure and high temperature, while simulating different depths and static conditions. It is adaptive to activities such as petroleum well and gas well reinforcement, squeezing cement, pouring cement seal and leakage repairing. The invention provides with the ability of surveying starting and ending time of different coagulation periods, in cement liquor under high temperature and high pressure, by surveying the variation of heat released by cement hydrating. First pre-heat the kettle to a experiment temperature, then put in it with a cup filled with prepared cement liquor in a reactor, seal reactor and increase the pressure to experiment value after the temperature is stable both outside and inside; initiate data processing system so to record the temperature variation automatically with a computer; finally figure out the coagulation starting and ending time by time-temperature curve line. The problem that surveying is difficult under high temperature and high pressure, is resolved with the invention which is adopted with the indirect contacting continuous survey of temperature variation.

Owner:SOUTHWEST PETROLEUM UNIV

Modified starch water reducing agent and preparation method and use method thereof

The invention discloses a modified starch water reducing agent and a preparation method and a use method thereof; with natural starch as a main raw material, the modified starch water reducing agent is prepared through oxidative degradation and grafting copolymerization reaction with a mixed monomer and has the characteristics of high water reducing rate, strong adaptability, good delayed coagulation effect and good compatibility with other additives, the water reducing rate can reach 26-28%, and the delayed coagulation time is 3-4 hours. When the product prepared by the method is in cooperation use with a polycarboxylate-type water reducing agent, can increase the delayed coagulation time of the polycarboxylate-type water reducing agent to reach 4-5 hours, can effectively prevent the polycarboxylate-type water reducing agent from generating water overflowing, segregation and other phenomena, and improves the adaptability of the polycarboxylate-type water reducing agent on mud-containing dinas.

Owner:FUSHUN LUTONG CHEM

Novel phosphorus and magnesium based cement grouting material and preparation method

The invention discloses a novel phosphorus and magnesium based cement grouting material and a preparation method and belongs to the field of technical application of grouting materials. The grouting material is prepared from the following raw materials in parts by weight: a component A: 30 to 90 parts of a compound magnesium compound, 0.5 to 5 parts of a compound retarder, 0.2 to 0.7 part of a water reducer, 0.2 to 1.5 parts of an acid-alkali buffering agent, 1 to 5 parts of a compound stabilizer and 0.5 to 1.5 parts of a compound surfactant; a component B: 20 to 50 parts of phosphate and 0.2to 2 parts of a de-foaming agent. The preparation method comprises the following steps: accurately weighing materials of the component A and the component B according to the ratio and uniformly stirring; mixing with water according to the weight ratio of 100 to (20 to 50) and stirring to form slurry; after uniformly mixing, pressing a mixture into gaps or cracks and curing. The novel phosphorus and magnesium based cement grouting material disclosed by the invention has the beneficial effects of controllable coagulation time, large adjustable range, high early age strength, high bonding strength, good permeability, simplicity and convenience for construction, greenness and environment protection and low cost, and meets the requirements on three properties including injectability, controllability and permeability resistance.

Owner:山东塔罗斯智能装备有限公司

Test strip qualification system

InactiveUS20050153457A1Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorEngineeringTest strips

Owner:LIFESCAN INC

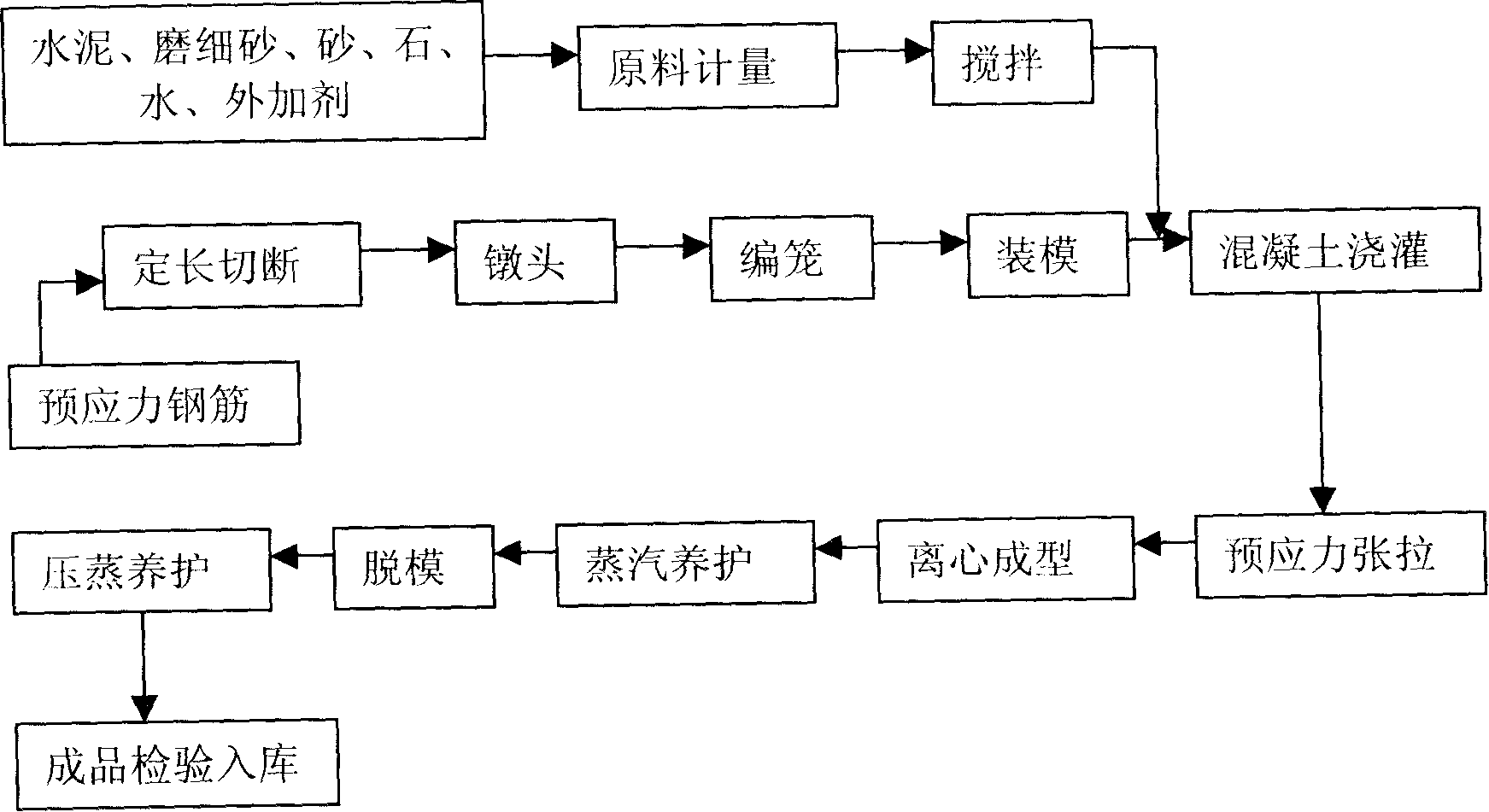

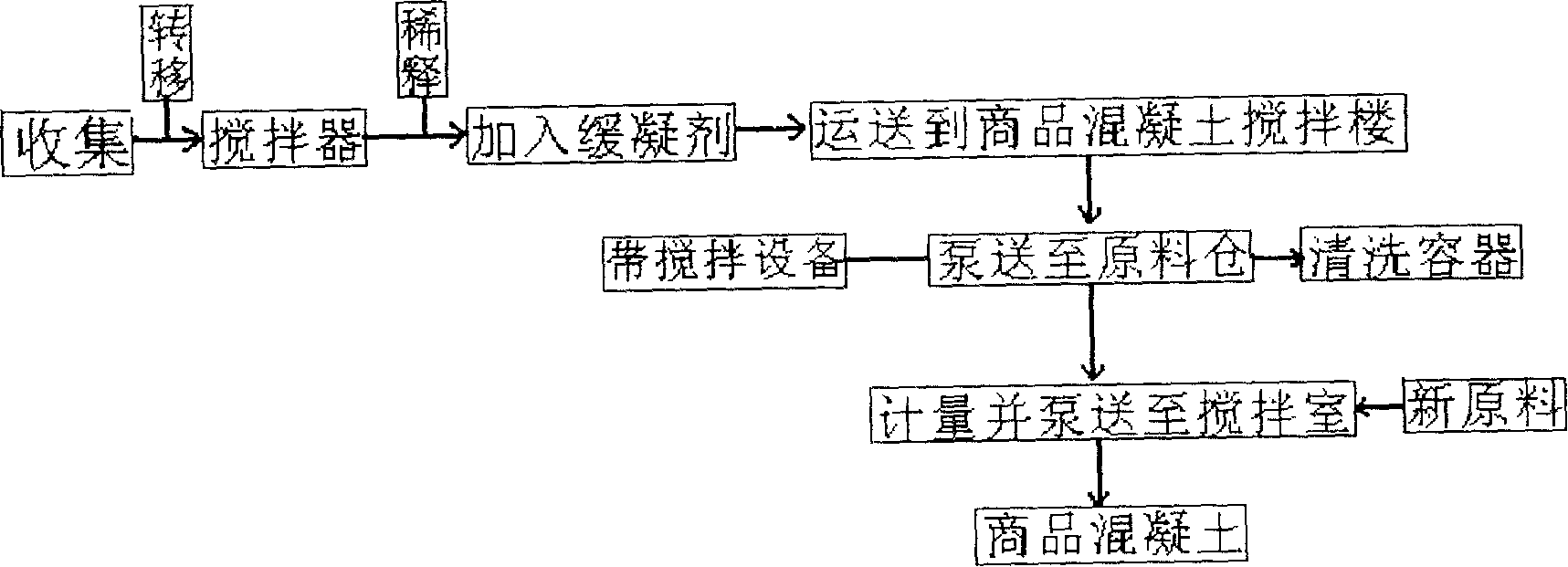

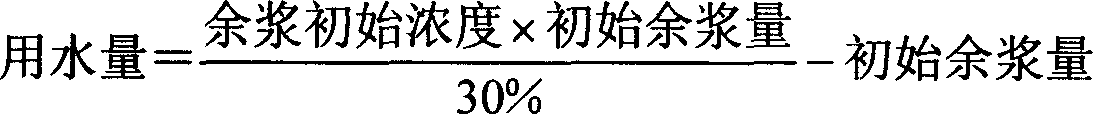

Method for producing concrete by reclaiming and reusing PHC pipe pile residual slurry

InactiveCN101168266AReduce pollutionWork lessMixing operation control apparatusCement mixing apparatusCentrifugationSlurry

The invention discloses a process for preparing concrete by recycling and utilizing PHC pile tube surplus slurry, which comprises collecting the surplus slurry produced by the centrifugation of the PHC pile tube in a ware, then calculating the proportion of the surplus slurry X and calculating solidity Y of the surplus slurry according to the mathematical formula Y=AX-B, and according to the solidity value of original surplus slurry, adding water into the surplus slurry for mixing and diluting into a fixed density or solidity, adding retarder into the surplus slurry and controlling the coagulation time of the surplus slurry in 4-6 hours, then adding the surplus slurry and the row material of commodity concrete into the blender for producing the mixture fitting for the relative strength gradation, and conducting commodity concrete production to the mixture with manufacturing technique of commodity concrete. The process for preparing concrete by recycling and utilizing PHC pile tube surplus slurry enables the effective components of the surplus slurry to be reutilized, which not only reduces the environmental contamination and saves resource, but also substantially improves both the service performance and the early strength and later strength of the produced commodity concrete.

Owner:富春控股集团有限公司

Grouting and hole-sealing material used for drilling of underground coal mine gas

InactiveCN105016677AAvoid the phenomenon of "air leakage"Accurate pH adjustmentSolid waste managementDrilling compositionPortland cementMetakaolin

The invention provides a grouting and hole-sealing material used for drilling of underground coal mine gas. The material comprises a dry grouting and hole-sealing material and water, wherein a weight ratio of the dry grouting and hole-sealing material to water is 1: 0.8-1.2; the dry grouting and hole-sealing material is composed of the following substances: Portland cement, fly ash, desulphurized gypsum, lime, aluminum powder paste, sodium chloride, metakaolin, and citric acid or sodium carbonate; and the substances composing the dry grouting-and-sealing material are required by weight as follows: 6 to 10 parts of the Portland cement, 0.5 to 3 parts of the fly ash, 0.5 to 3 parts of the desulfurized gypsum, 0.2 to 1 part of the lime, 0.0005 to 0.002 part of the aluminum powder paste, 0.05 to 0.15 part of the sodium chloride, 0.2 to 1.5 part of the metakaolin, and 0.0025 to 0.015 part of the citric acid or 0.005 to 0.03 part of the sodium carbonate. The grouting and hole-sealing material used fo drilling of underground coal mine gas provided by the invention has the advantages of adjustable coagulation time, improved air tightness of hole-sealing, improved hole-sealing efficiency and safety, lowered hole-sealing cost, simplified hole-sealing preparation work, etc.

Owner:HENAN TIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

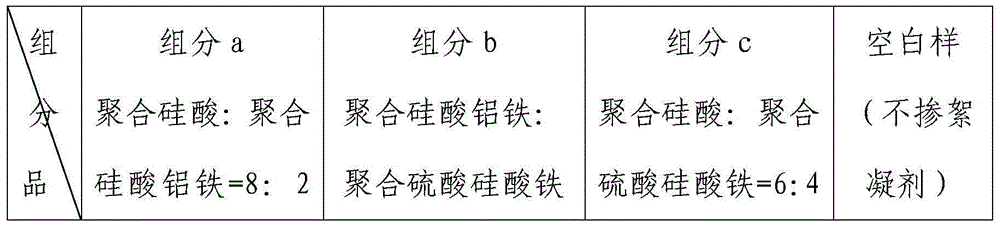

Water-soluble coagulant for cement-based cementing material and preparation method of water-soluble coagulant

The invention provides a water-soluble coagulant for a cement-based cementing material and a preparation method. A solid solute part of the coagulant comprises raw materials in parts by weight as follows: 40-60 parts of a poly-silicic acid flocculating agent, 20-25 parts of an inorganic salt enhancer, 5-15 parts of a stabilizer and 1-5 parts of a dispersing agent. The prepared water-soluble coagulant is high in cost-performance ratio, and the actual engineering problem that the final coagulation time of the cement-based cementing material lags due to the lower temperature in winter and delayed coagulation of a polycarboxylate superplasticizer is solved on the basis of the theory and the nature of cement mineral hydration under the actual condition that the construction period is affected due to the fact that the concrete coagulation time is longer during construction in winter. Compared with like products on the market, the water-soluble coagulant has the advantages that the compatibility of the water-soluble coagulant with the polycarboxylate superplasticizer is higher, liquidity and slump retaining property indexes are not affected, and development of early strength of concrete and reduction of the cost of the superplasticizer are facilitated.

Owner:HUBEI UNIV OF TECH

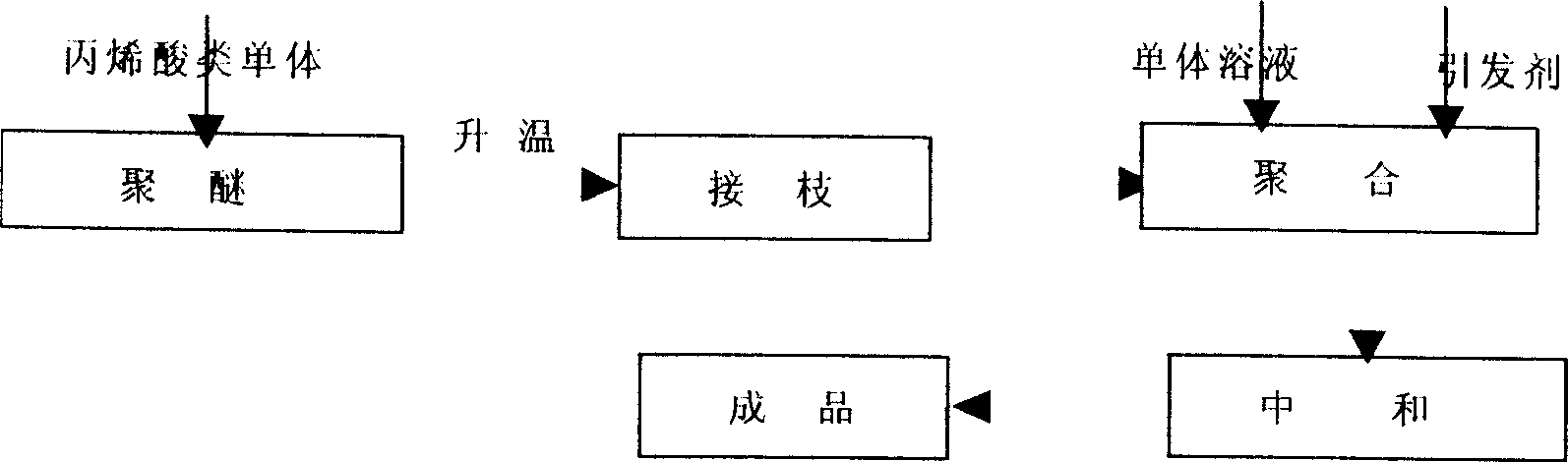

Carboxylic acids graft copolymer concrete strengthening agent

This invention is a carboxylic acids graft copolymer concrete bao tan agent. The procedures are that 1) single alkyl polyether or double hydroxy group polyether and their compound said by general formula (1) is grafting reacted to generate big monomer a with C=C with dyadic unsaturated carboxylic acid or anhydride in condition of acid catalyst. 2) Compound an and monomer b is compounded copolymerized with weight ratio is 70-90% and 3-30%. This invention can greatly improve the slump constant loss of traditional naphthalene system water reducing agent, and improve its dispersibility at the same time. Coagulation time of concrete doesní»t prolong, it has good plastic keeping effect to medium and low slump constant concrete or big degree of fluidity concrete. It has good adaptability to other high efficiency water reducing agent. Good degree of fluidity keeping ability is on it whether coordinated with traditional naphthalene system water reducing agent or melamine system water reducing agent or new style polyocarboxy acid system dispersibility. There is no three wastes during its procedure.

Owner:JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com