Water-soluble coagulant for cement-based cementing material and preparation method of water-soluble coagulant

A technology of cementitious material and early setting agent, which is applied in the field of building materials, can solve the problems of lag in setting time and low early strength of cement cementitious materials, and achieve the effect of shortening the interval between initial setting and final setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For cement A, polysilicic acid flocculant component a is polymeric silicic acid: polyaluminum iron silicate = 8: 2 (mass ratio), and then polysilicic acid flocculant: enhancer: stabilizer: dispersant = 60: The mass ratio of 25:10:5 is to add enhancer, stabilizer, and dispersant, add a certain amount of water, and mix well to obtain a water-soluble early setting agent; the components of the enhancer are: calcium formate: calcium fluoride: silicon Sodium sulfate: aluminum sulfate=40:30:20:10 (mass ratio); wherein the stabilizer is magnesium fluorosilicate; wherein the dispersant is fatty alcohol polyoxyethylene ether, wherein the quality of water is the quality of water-soluble early setting agent 92%.

Embodiment 2

[0033] For cement B, the polysilicate flocculant component a is polyaluminum ferric silicate: polysulphate ferric silicate = 5:5 (mass ratio), and then polysilicate flocculant: enhancer: stabilizer: dispersant = The mass ratio of 70:20:7:3 is added to enhancer, stabilizer, dispersant, add a certain amount of water, mix evenly, and then get water-soluble early setting agent; the additive components are: calcium fluoride: silicic acid Sodium: sodium methyl silicate: aluminum nitrate: iron nitrate = 40:25:15:10:10 (mass ratio); the stabilizer is zinc fluorosilicate; the dispersant component is N-methyl taurine Hydrogenated tallow acid amide: fatty alcohol polyoxyethylene ether = 2:1 (mass ratio), wherein the mass of water is 96% of the mass of the water-soluble early setting agent. .

Embodiment 3

[0035] For cement C, polysilicic acid flocculant component a is polymeric silicic acid: polymeric ferric sulfate sulfate = 6:4 (mass ratio), and then polysilicic acid flocculant: enhancer: stabilizer: dispersant = 55: Add additives, stabilizers, and dispersants in a mass ratio of 25:15:5, add a certain amount of water, and mix well to obtain a water-soluble early setting agent; the additive components are: calcium nitrate: calcium fluoride: silicon Potassium acid: sodium methyl silicate: aluminum sulfate = 20:30:15:15:20 (mass ratio); the stabilizer is ammonium hexafluoroaluminate; the dispersant is N-(2-hydroxypropyl) hydrogenation Tauric acid, wherein the quality of water is 98% of the water-soluble early setting agent quality. .

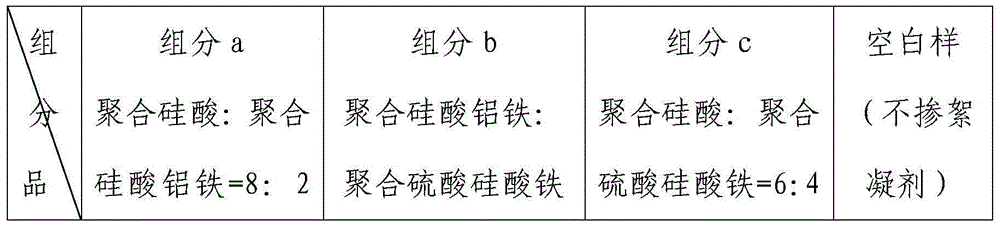

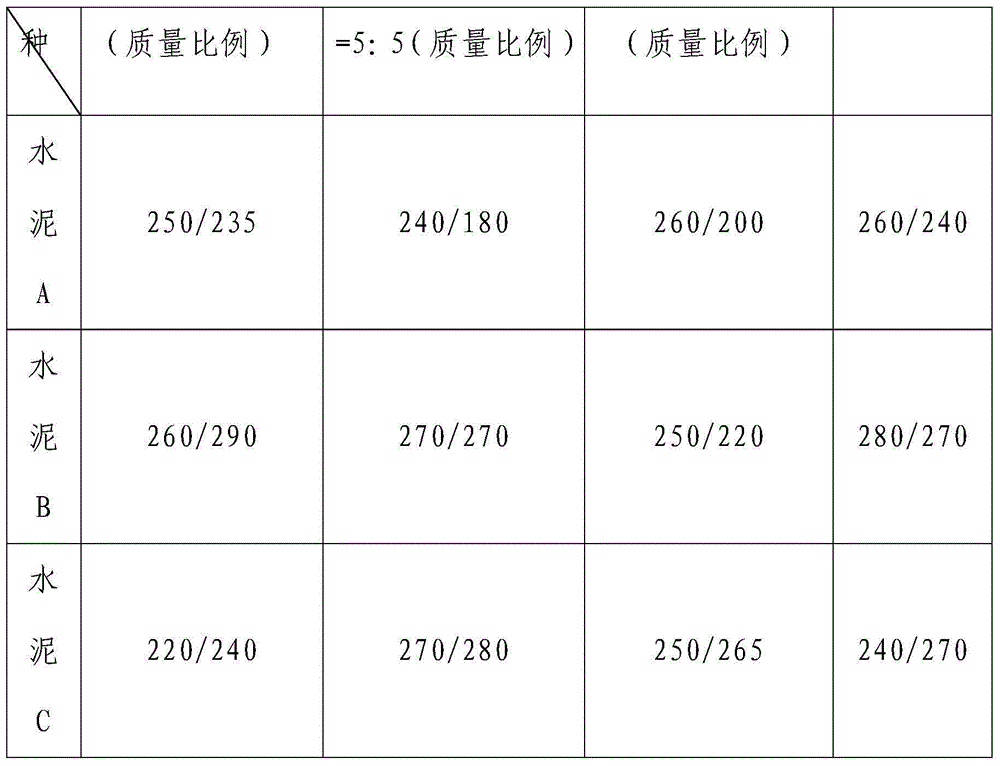

[0036] Table 1 Fluidity index of cement slurry mm

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com