Phosphorus slag super-sulfate cement and preparation method thereof

A technology of super sulfate cement and phosphorus slag, which is applied in cement production, clinker production, etc., can solve the problems of low strength, unfavorable promotion and application of super sulfate cement, limited application and promotion, etc., and achieves low cost and shortened initial production. The effect of short setting and final setting time, initial setting and final setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

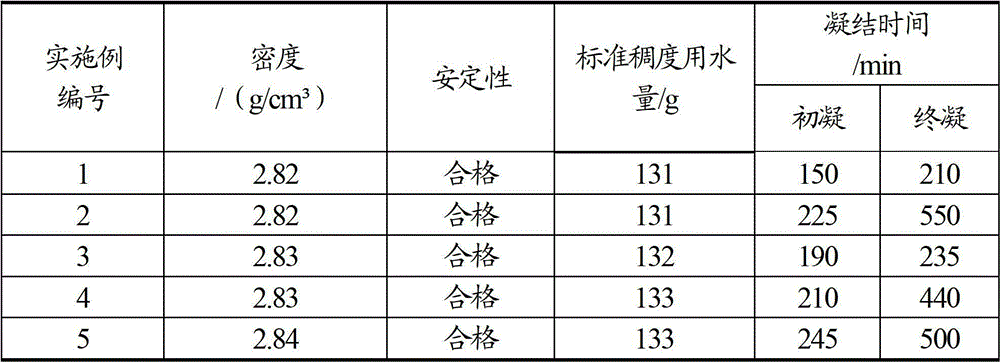

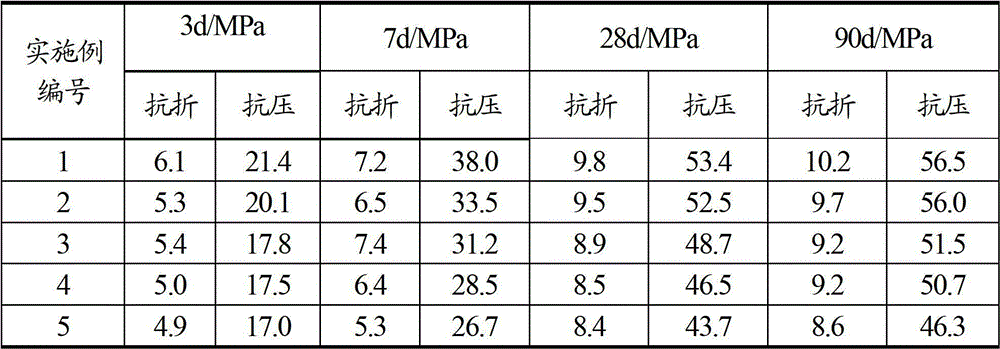

Embodiment 1

[0046] Weigh each substance according to the following weight ratio:

[0047] 50 parts of electric furnace phosphorus slag;

[0048] 25 slag;

[0049] 10 parts of dihydrate gypsum;

[0050] 1 part excipient;

[0051] 2 parts calcium hydroxide.

[0052] Example 1 was obtained after mixing and grinding the weighed material.

Embodiment 2

[0054] Weigh each substance according to the following weight ratio:

[0055] 50 parts of electric furnace phosphorus slag;

[0056] 50 slag;

[0057] 5 parts of anhydrite and 10 parts of modified phosphogypsum;

[0058] 3 accessories;

[0059] 3 parts cement clinker.

preparation Embodiment 2

[0061] A. Mix and grind electric furnace phosphorus slag and slag until the specific surface area is 500m 2 / kg of composite powder a;

[0062] B. Mix and grind gypsum, auxiliary materials and cement clinker until the specific surface area is 520m 2 / kg of composite powder b;

[0063] C. Mix the composite powders a and b to obtain the phosphorus slag super sulfate cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com