Bridge bearing mortar and production method thereof

A bridge support mortar and quartz sand technology, which is applied in the field of bridge support mortar, can solve the problems of low strength stability and durability, failure to develop strength, and inability to retard setting in the later stage, so as to achieve early expansion stability and reduce The effect of the initial and final setting time interval and good self-leveling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

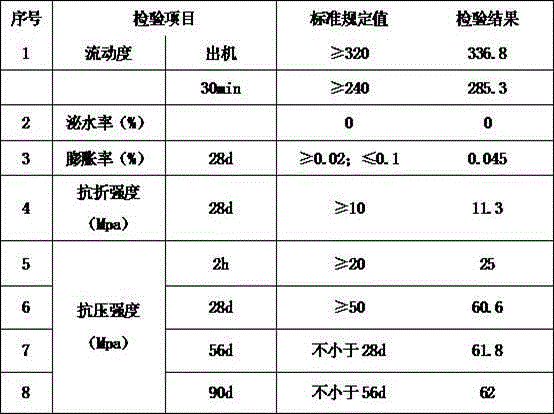

Examples

Embodiment 1

[0029] (1) Raw material and weight:

[0030] 45 parts of graded quartz sand, 40 parts of 42.5 sulfoaluminate cement, 15 parts of 42.5 ordinary silicon cement, 10 parts of U-shaped expansion agent, 1 part of water reducing agent, 0.5 part of water retention agent, 0.1 part of early strength agent, retarder 1 part, 0.03 parts of defoamer:

[0031] The water reducer is a high-performance polycarboxylate water reducer with a polyester structure; the U-shaped expansion agent includes anhydrous calcium sulfoaluminate, alumite, gypsum and surfactants; the water retention Agents include sodium bentonite and low-viscosity hydroxypropyl methylcellulose; the above-mentioned accelerators include calcium formate, ferric sulfate, calcium chloride, bentonite, triethanolamine, citric acid; the retarder includes molasses , borax, sodium gluconate and aluminum sulfate; the defoamer is organic silicon, isooctyl alcohol and diisobutyl carbinol.

[0032] (2) Production

[0033] After weighing t...

Embodiment 2

[0035] (1) Raw material and weight:

[0036] 50 parts of graded quartz sand, 35 parts of 42.5 sulfoaluminate cement, 10 parts of 42.5 ordinary silicon cement, 4 parts of U-shaped expansion agent, 0.5 part of water reducing agent, 0.2 part of water retaining agent, 0.05 part of early strength agent, retarder 0.5 parts, 0.02 parts of defoamer:

[0037]The water reducer is a high-performance polycarboxylate water reducer with a polyether structure; the U-shaped expansion agent includes anhydrous calcium sulfoaluminate, alunite, gypsum and surfactants; the water retention Agents include sodium bentonite and low-viscosity hydroxypropyl methylcellulose; the above-mentioned accelerators include calcium formate, ferric sulfate, calcium chloride, bentonite, triethanolamine, citric acid; the retarder includes molasses , borax, sodium gluconate and aluminum sulfate; the defoamer is organic silicon and dipalmitoyl ethylenediamine.

[0038] (2) Production

[0039] After weighing the gra...

Embodiment 3

[0041] (1) Raw material and weight:

[0042] 55 parts of graded quartz sand, 38 parts of 42.5 sulfoaluminate cement, 12 parts of 42.5 ordinary silicon cement, 8 parts of U-shaped expansion agent, 0.8 part of water reducing agent, 0.4 part of water retaining agent, 0.08 part of early strength agent, retarder 0.8 parts, 0.02 parts of defoamer:

[0043] The water reducer is a high-performance polycarboxylate water reducer with a polyester structure; the U-shaped expansion agent includes anhydrous calcium sulfoaluminate, alumite, gypsum and surfactants; the water retention Agents include sodium bentonite and low-viscosity hydroxypropyl methylcellulose; the above-mentioned accelerators include calcium formate, ferric sulfate, calcium chloride, bentonite, triethanolamine, citric acid; the retarder includes molasses , borax, sodium gluconate and aluminum sulfate; the defoamer is organic silicon, isooctyl alcohol, diisobutyl carbinol and distearyl ethylenediamine.

[0044] (2) Produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com