Patents

Literature

4273 results about "Retention time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

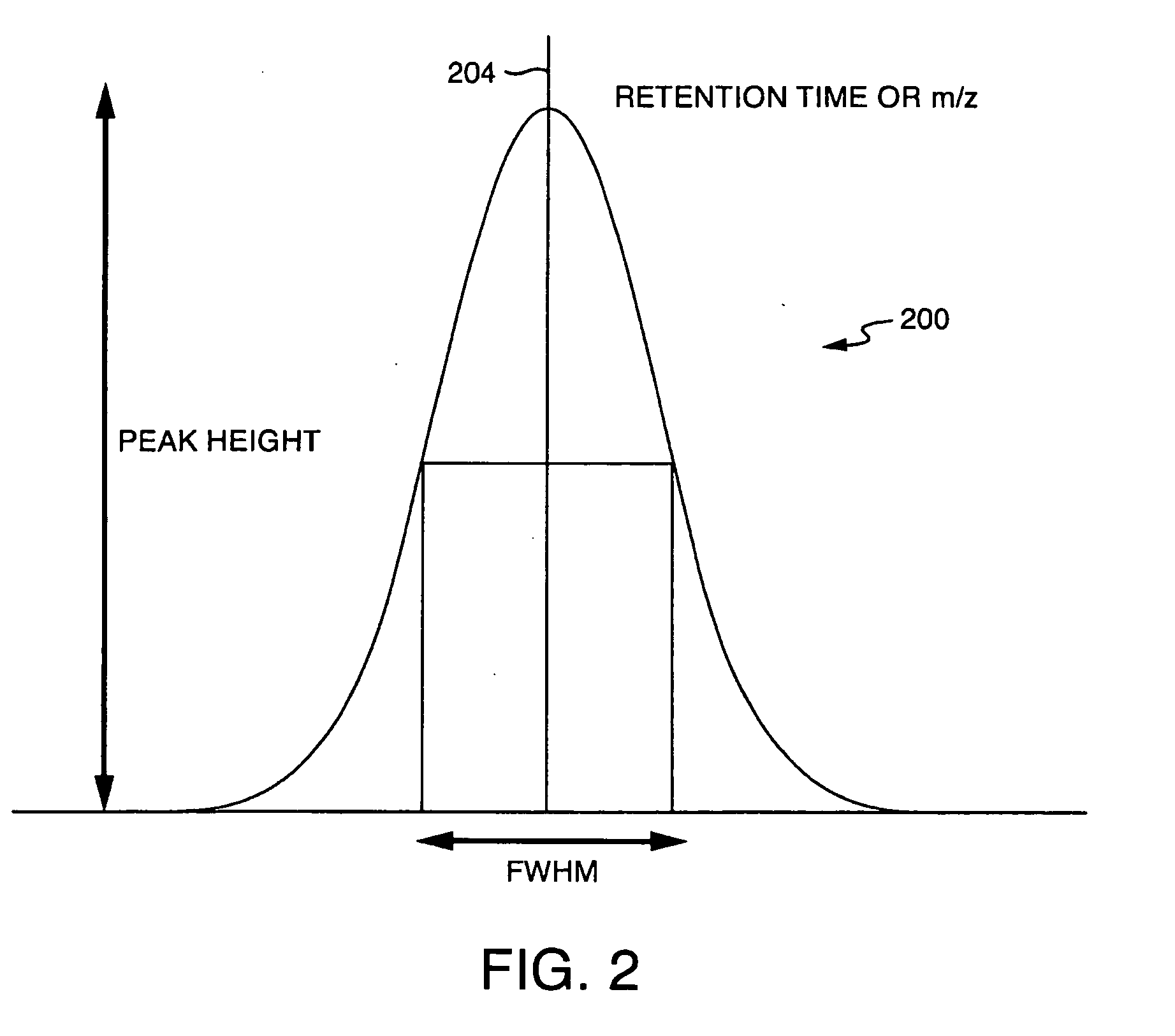

Techniques for mass spectrometry peak list computation using parallel processing

InactiveUS20130080073A1Particle separator tubesComponent separationRetention timeMass Spectrometry-Mass Spectrometry

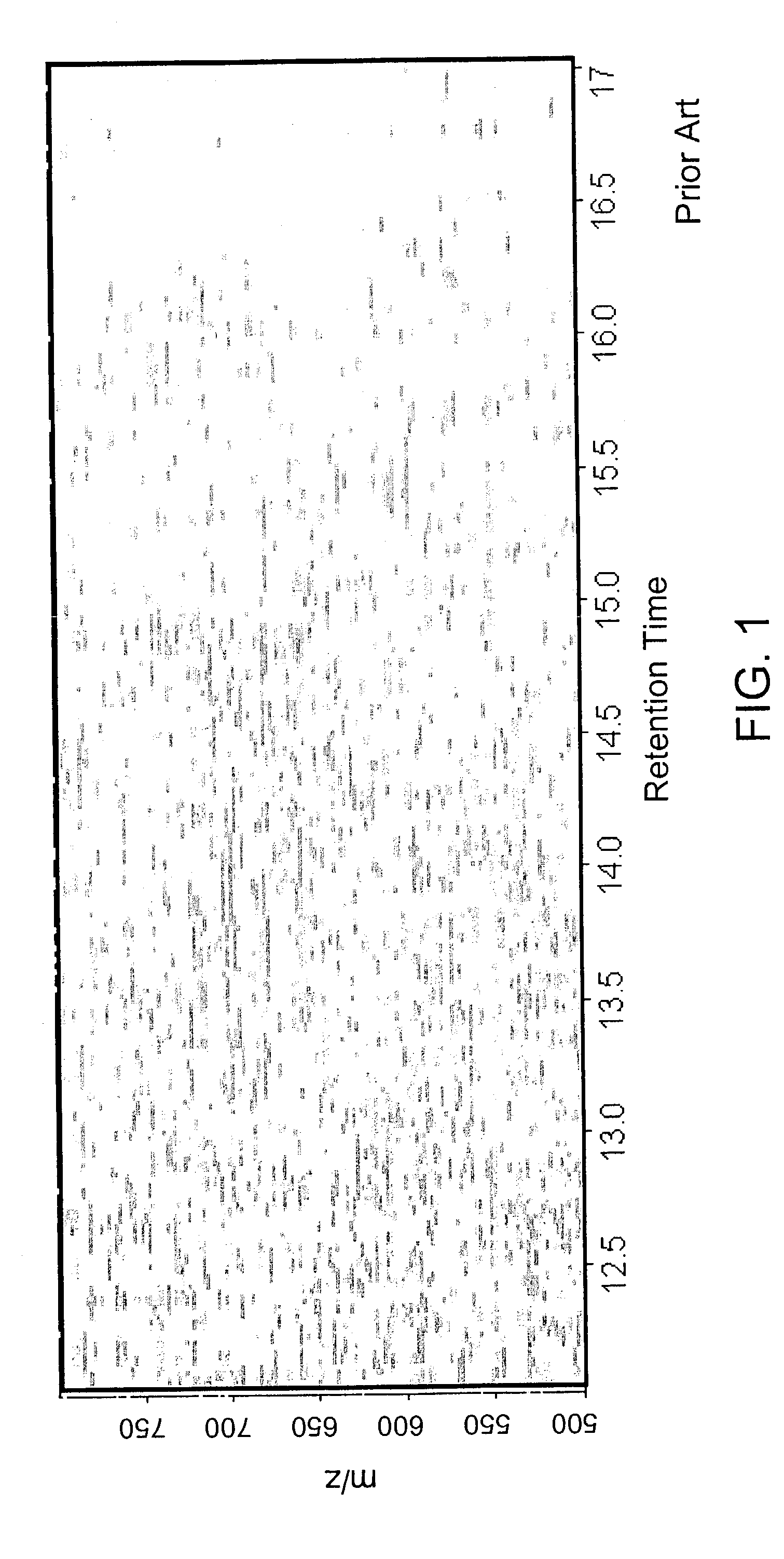

Described are techniques for processing data. Sample analysis is performed generating scans of data. Each scan comprises a set of data elements each associating an ion intensity count with a plurality of dimensions including a retention time dimension and a mass to charge ratio dimension. The scans are analyzed to identify one or more ion peaks. Analyzing includes filtering a first plurality of the scans producing a first plurality of filtered output scans. The filtering including first filtering producing a first filtering output, wherein the first filtering includes executing a plurality of threads in parallel which apply a first filter to the first plurality of scans to produce the first filtering output. Each of the plurality of threads computes at least one filtered output point for at least one corresponding input point included in the plurality of scans. Analyzing includes detecting one or more peaks using the filtered output scans.

Owner:WATERS TECH CORP

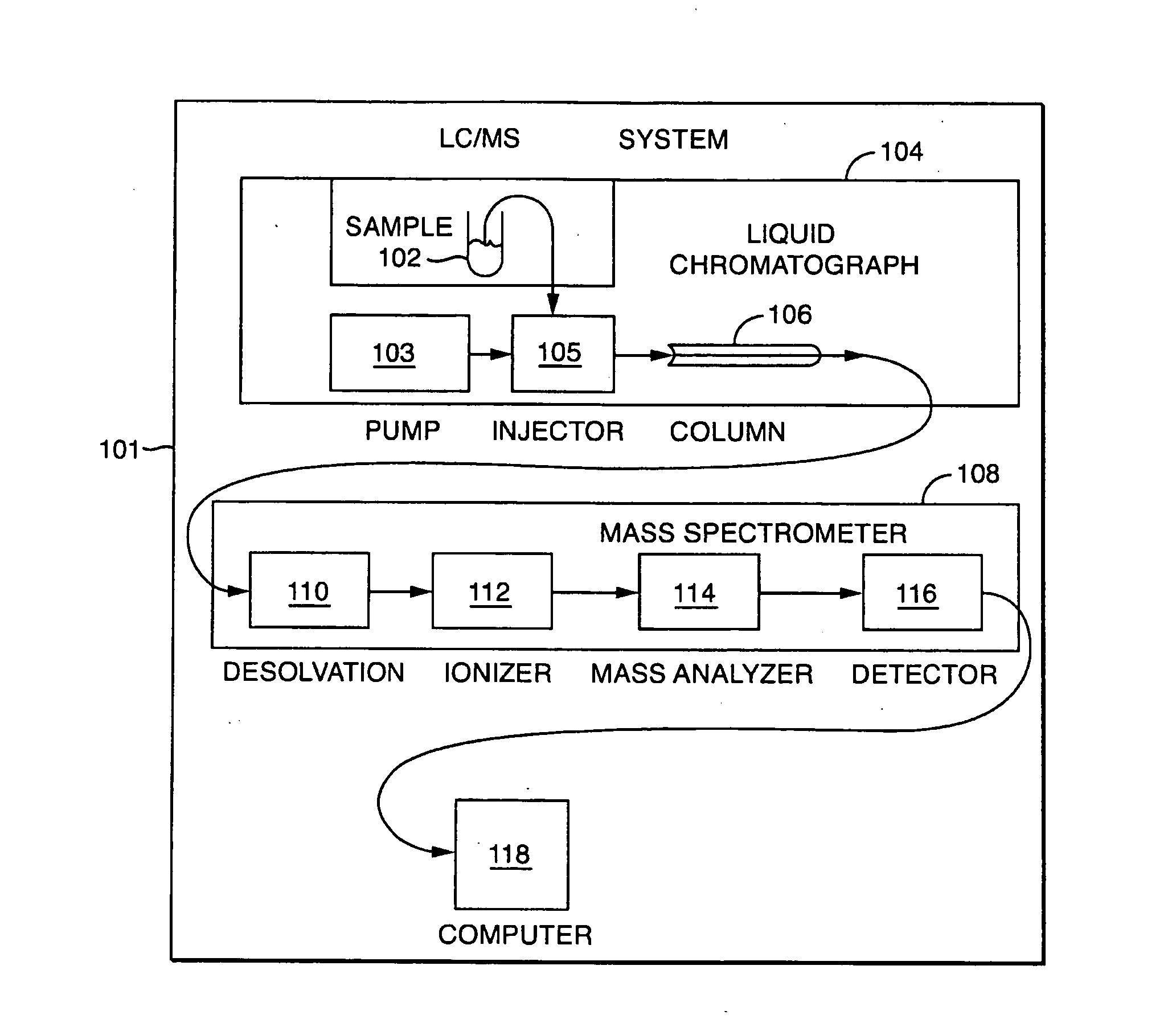

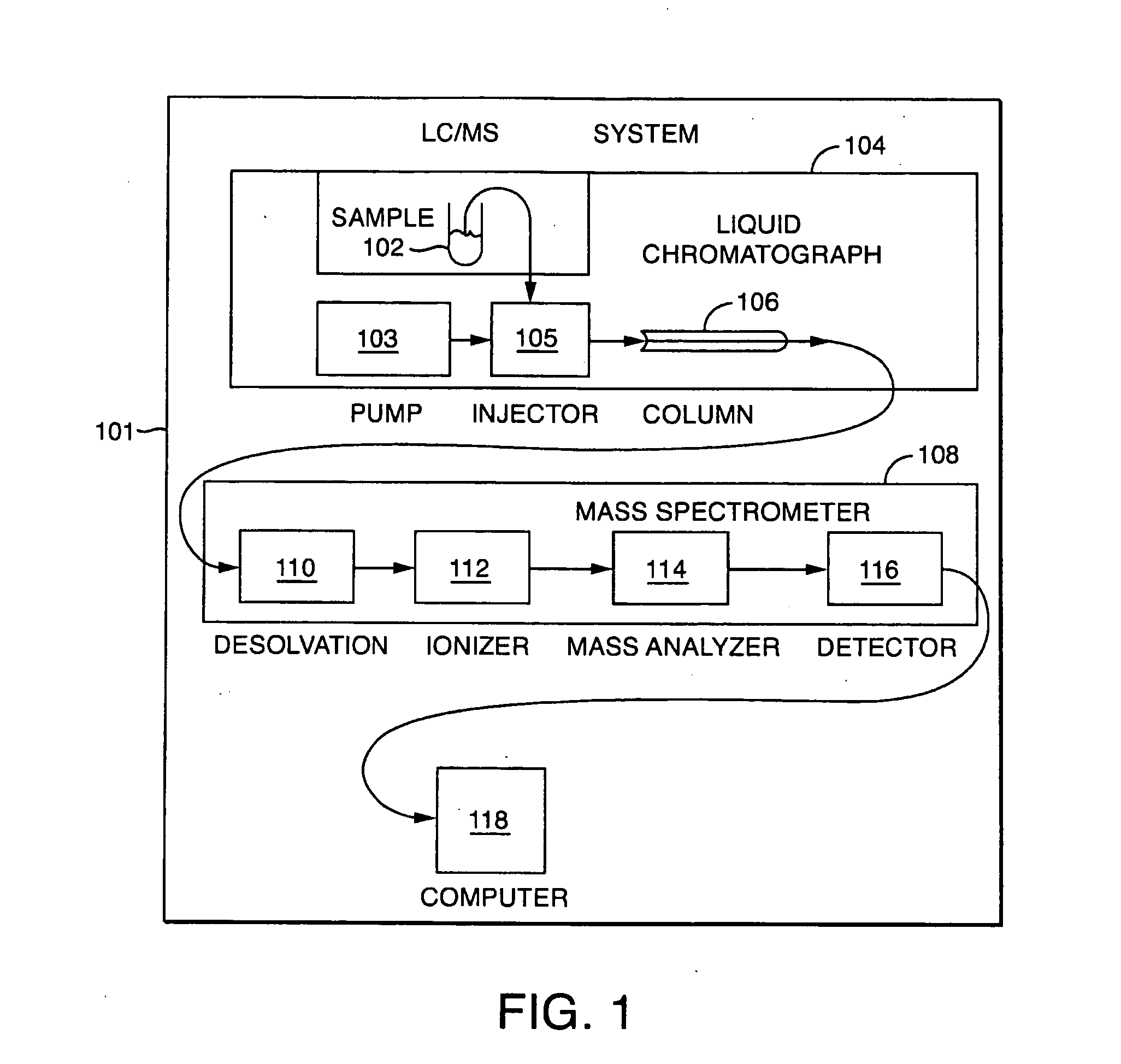

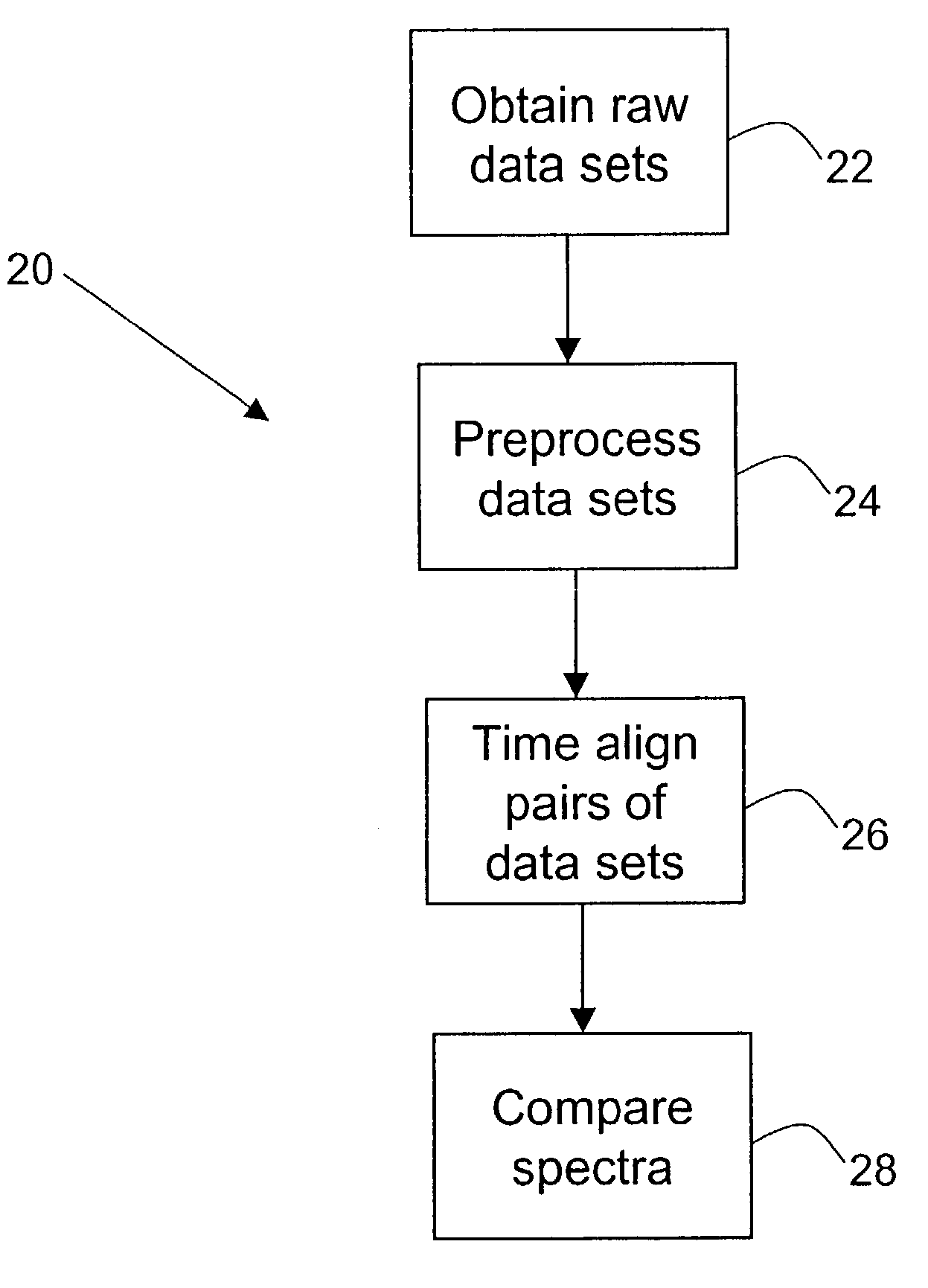

Methods for time-alignment of liquid chromatography-mass spectrometry data

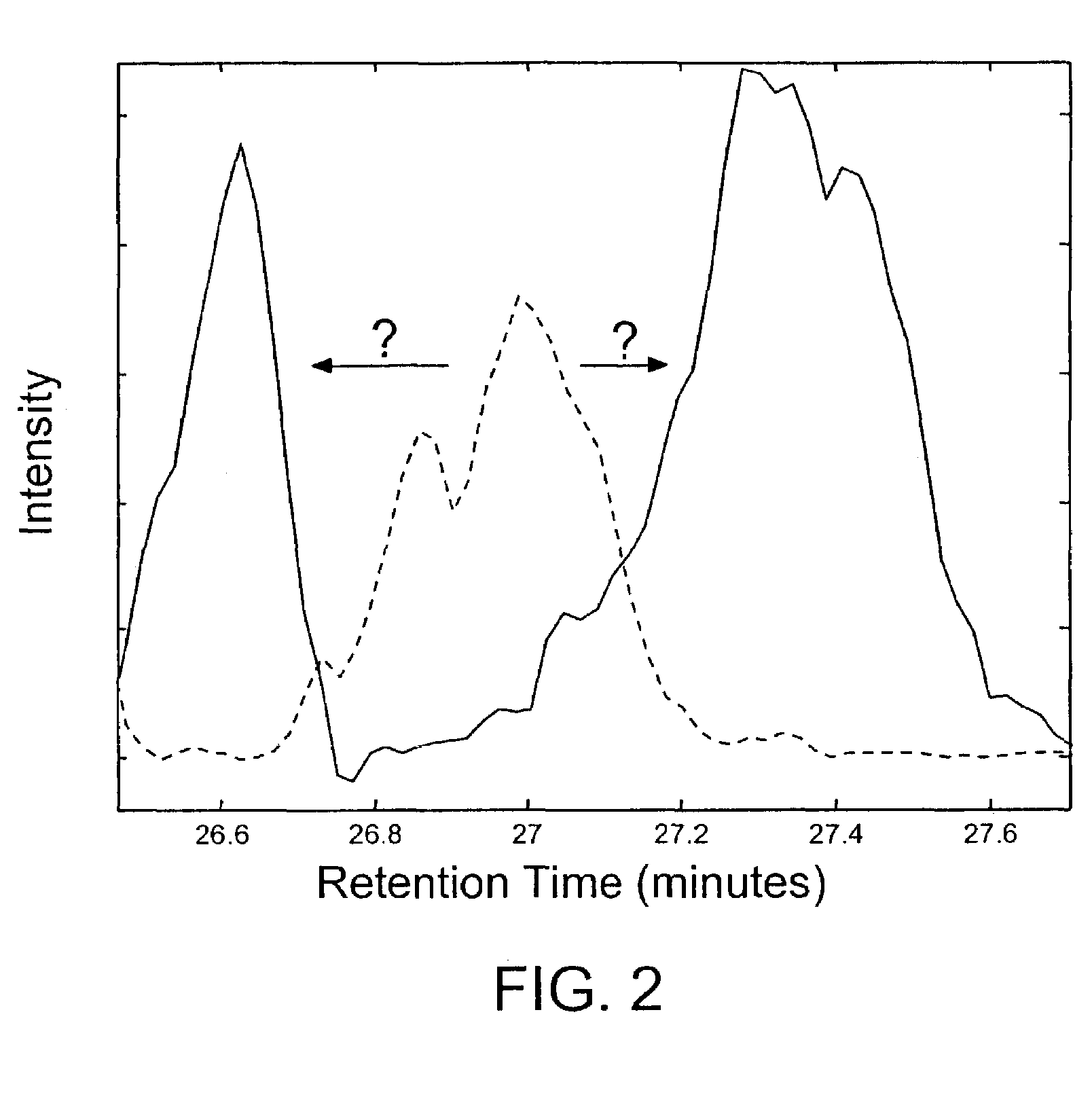

Nonlinear retention time variations in chromatography-mass spectrometry data sets are adjusted by time-alignment methods, enabling automated comparison of spectra for differential phenotyping and other applications.

Owner:CAPRION PROTEOMICS INC

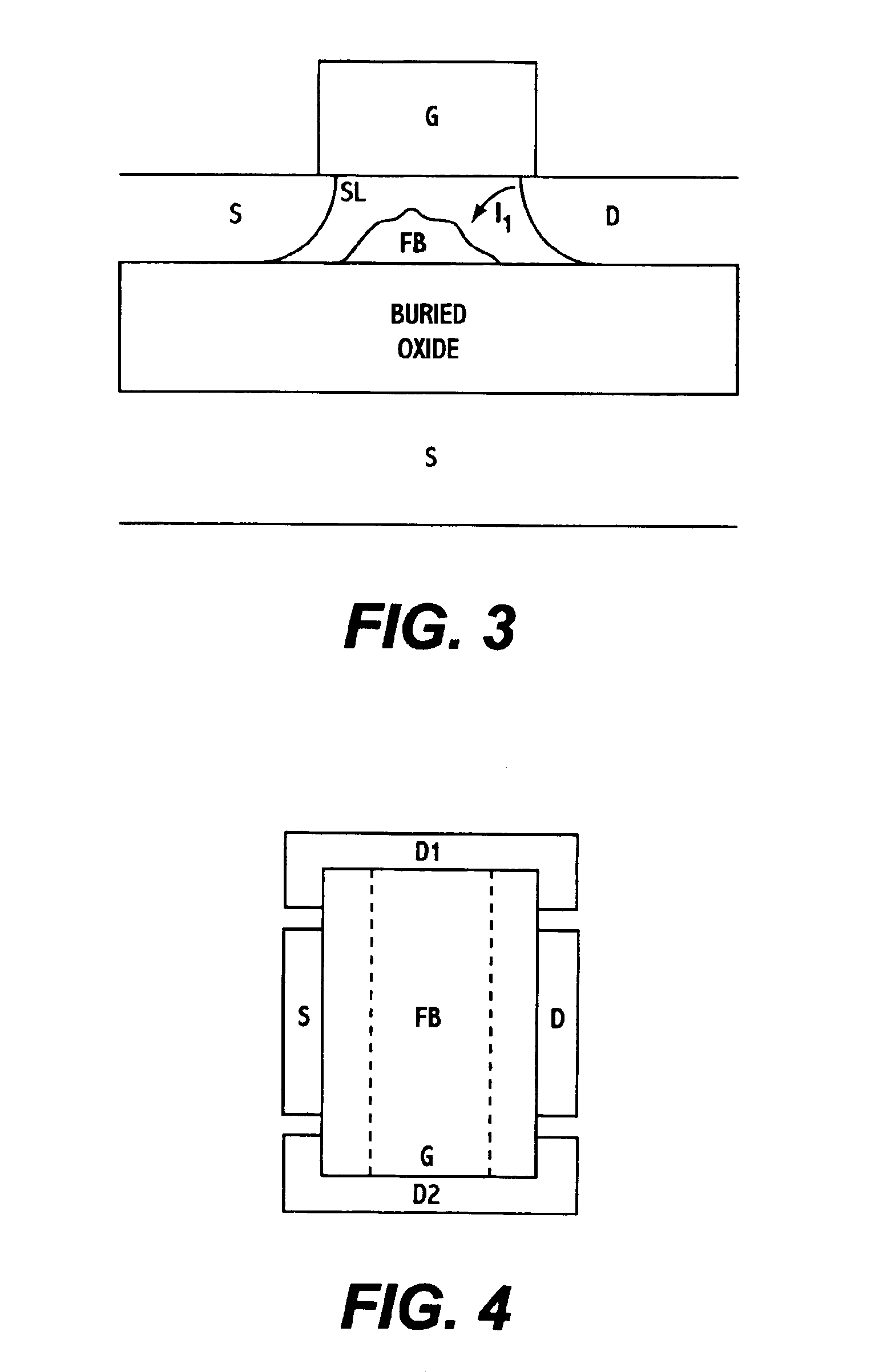

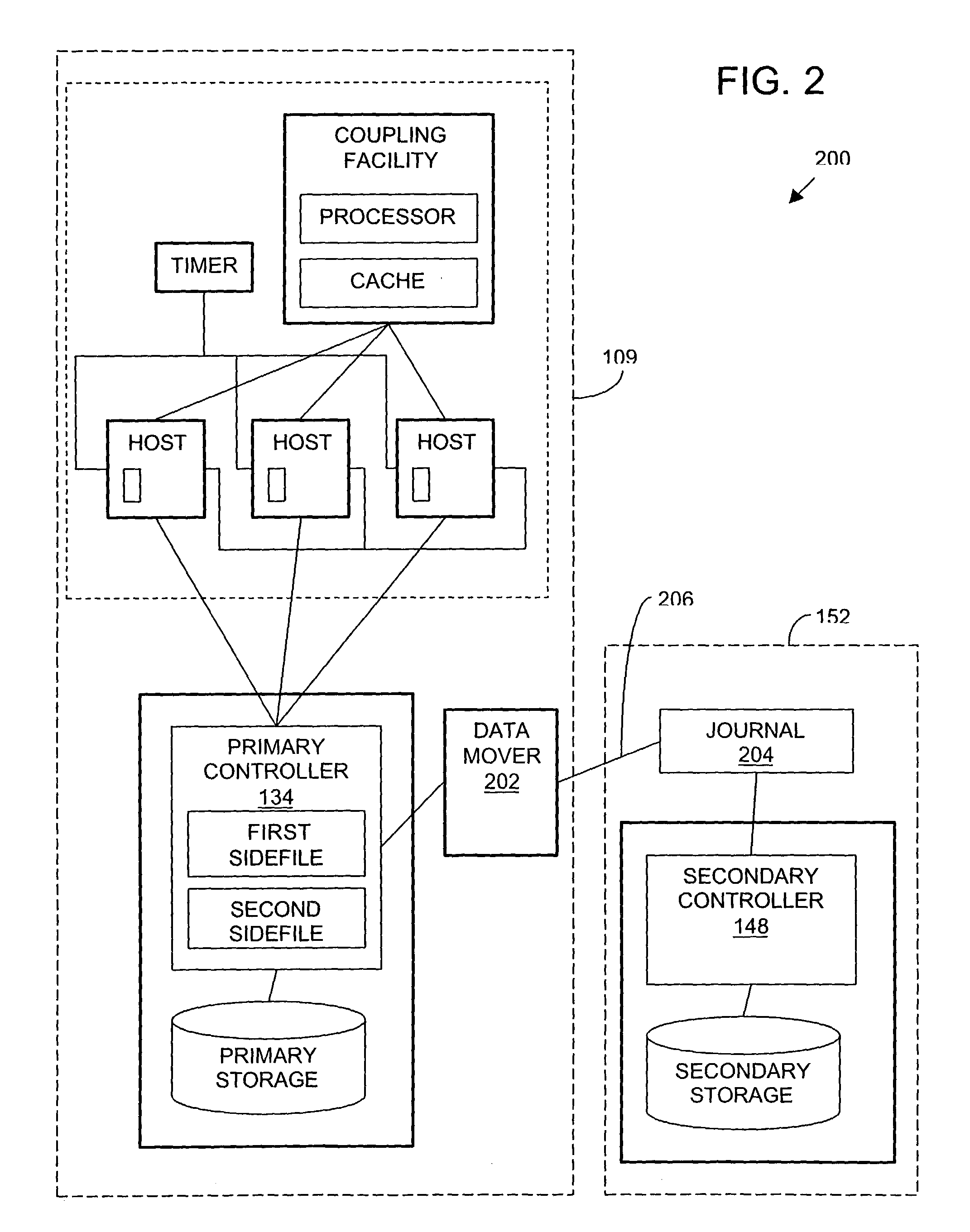

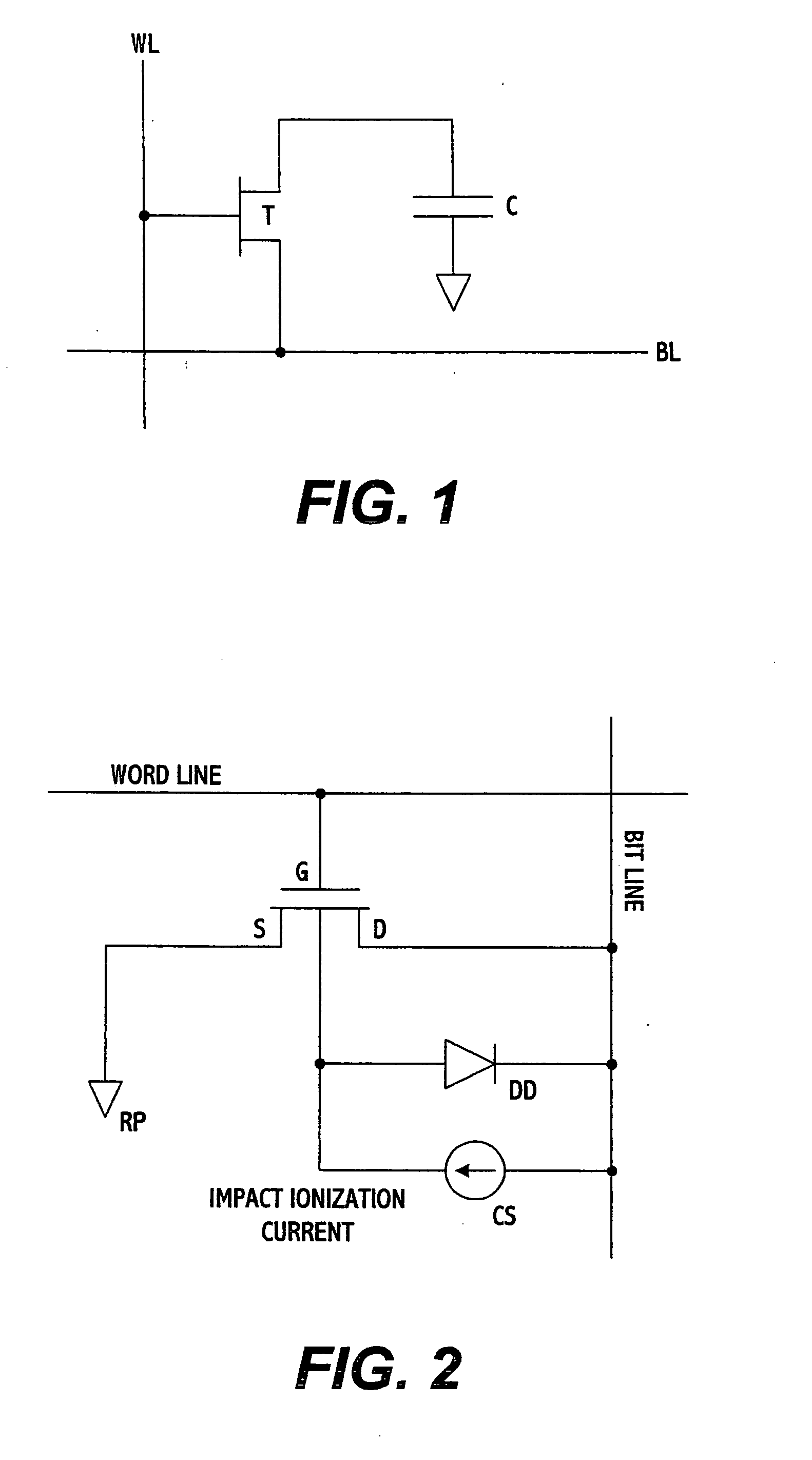

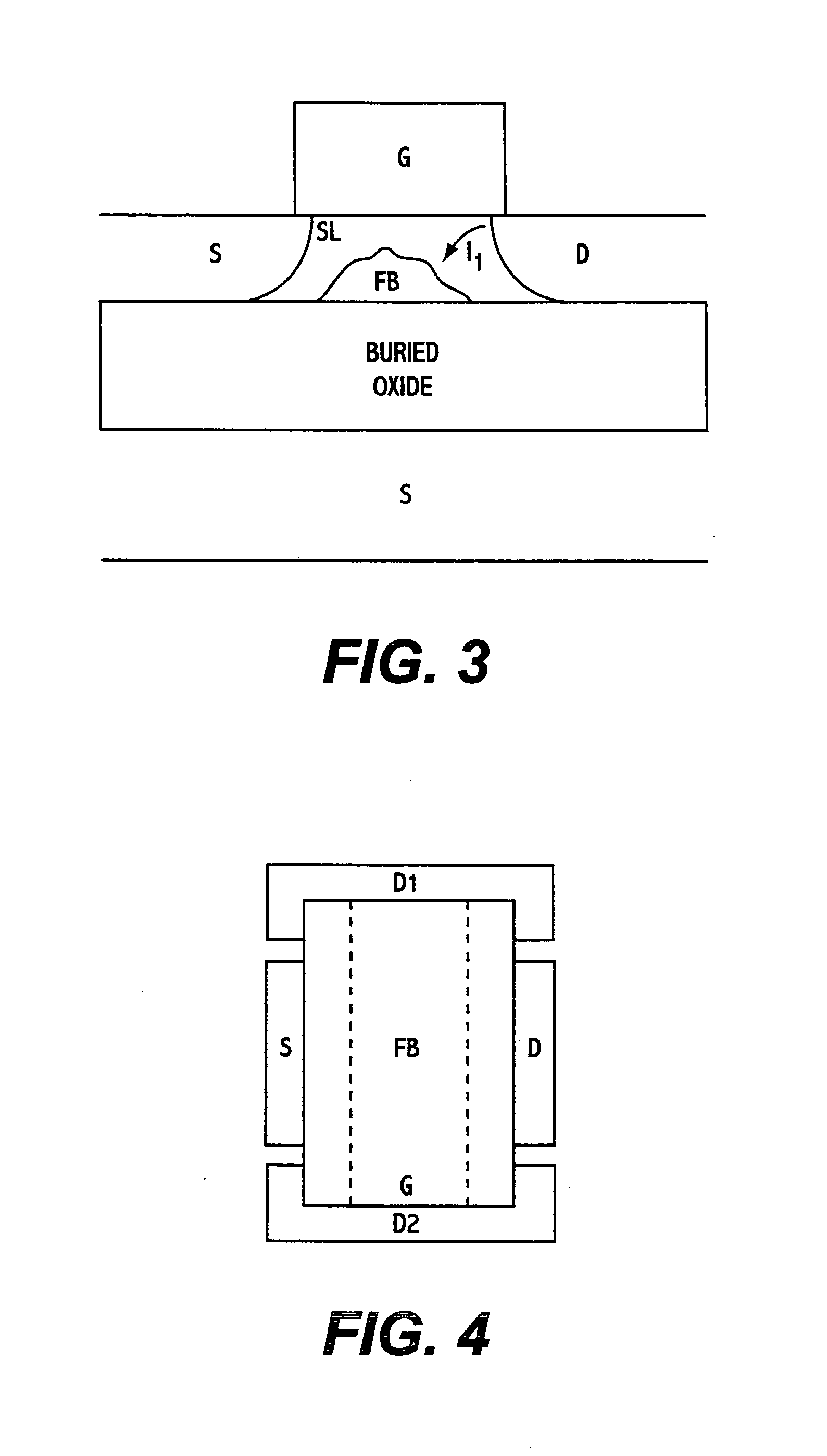

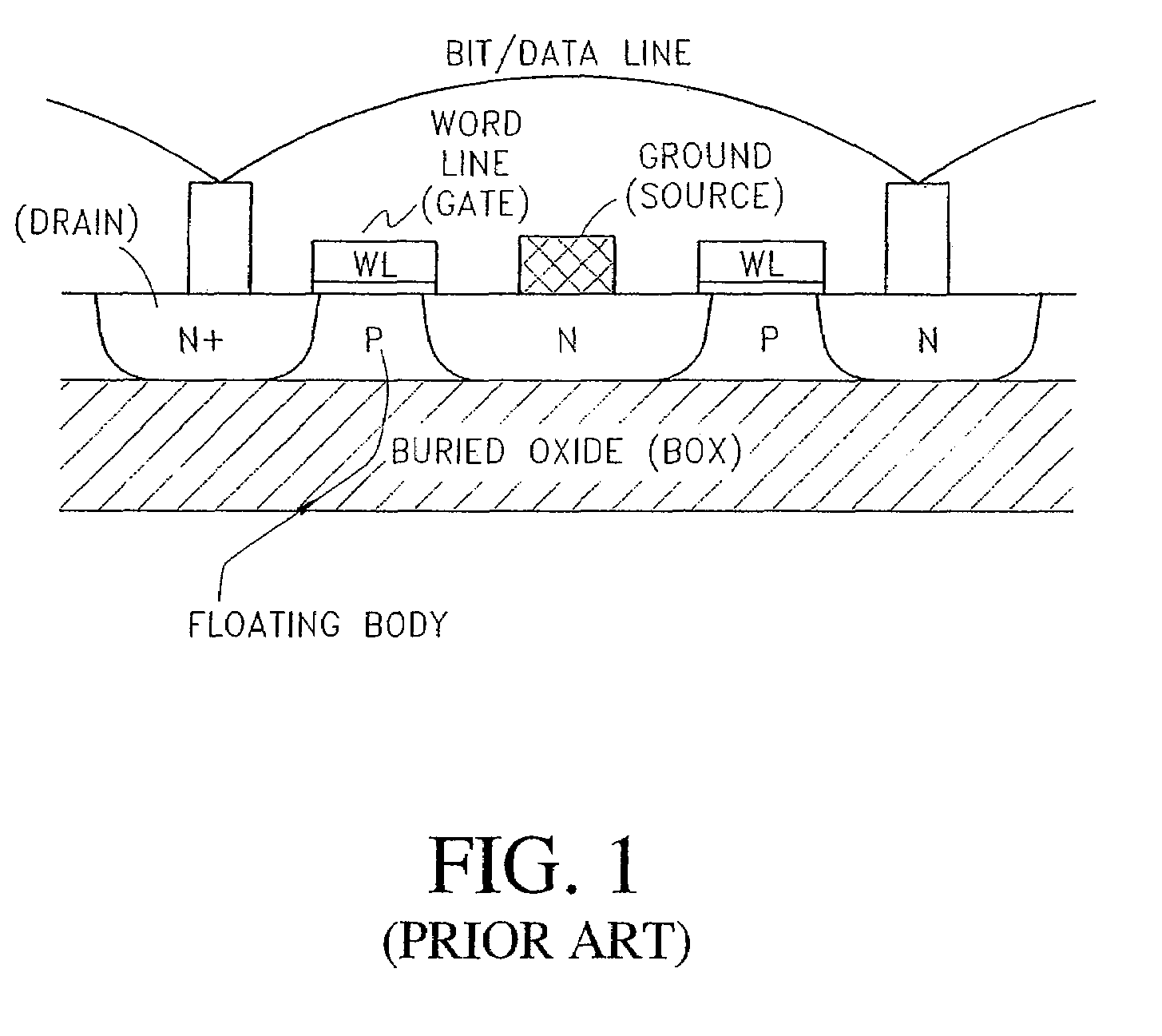

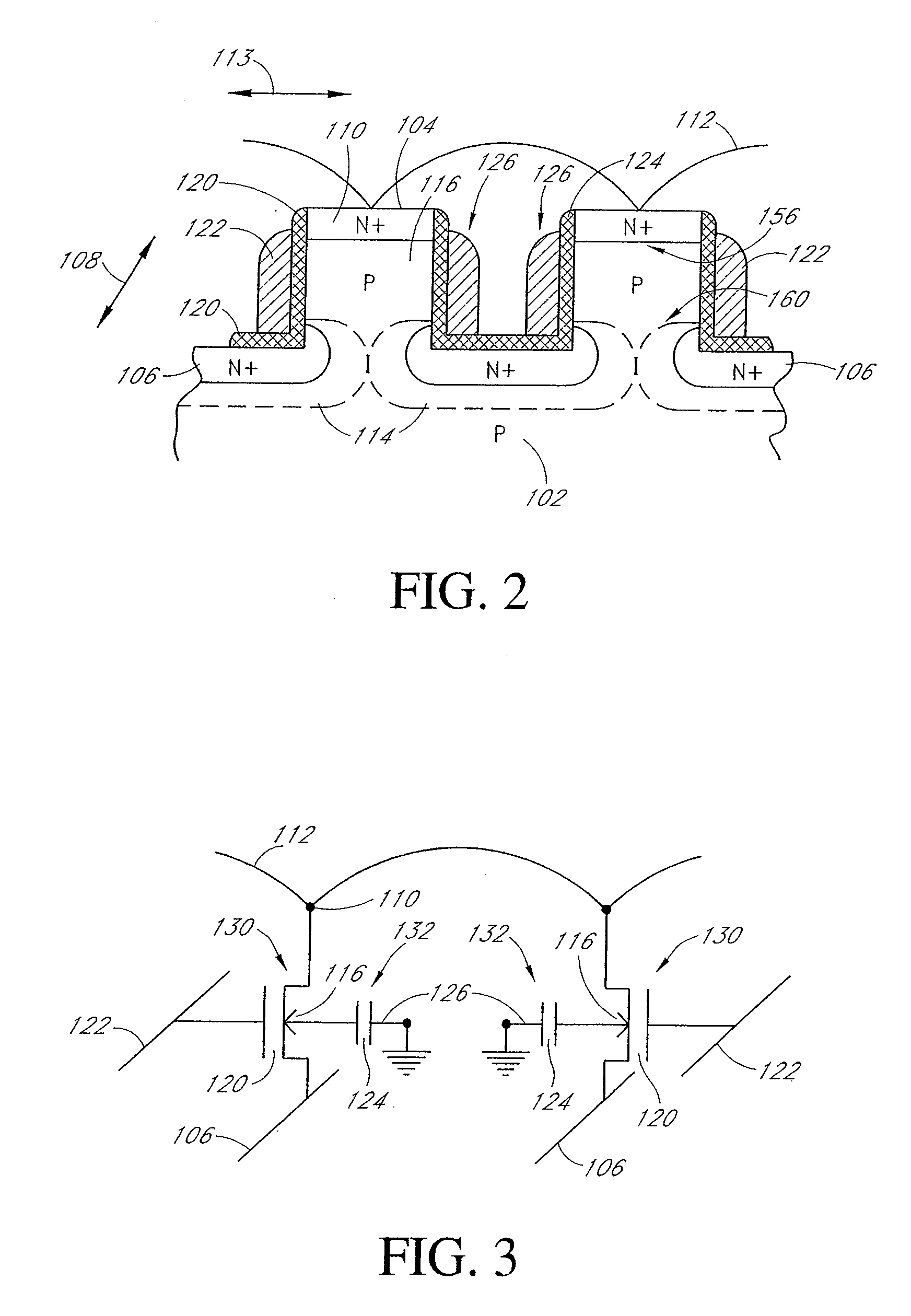

Floating-body DRAM using write word line for increased retention time

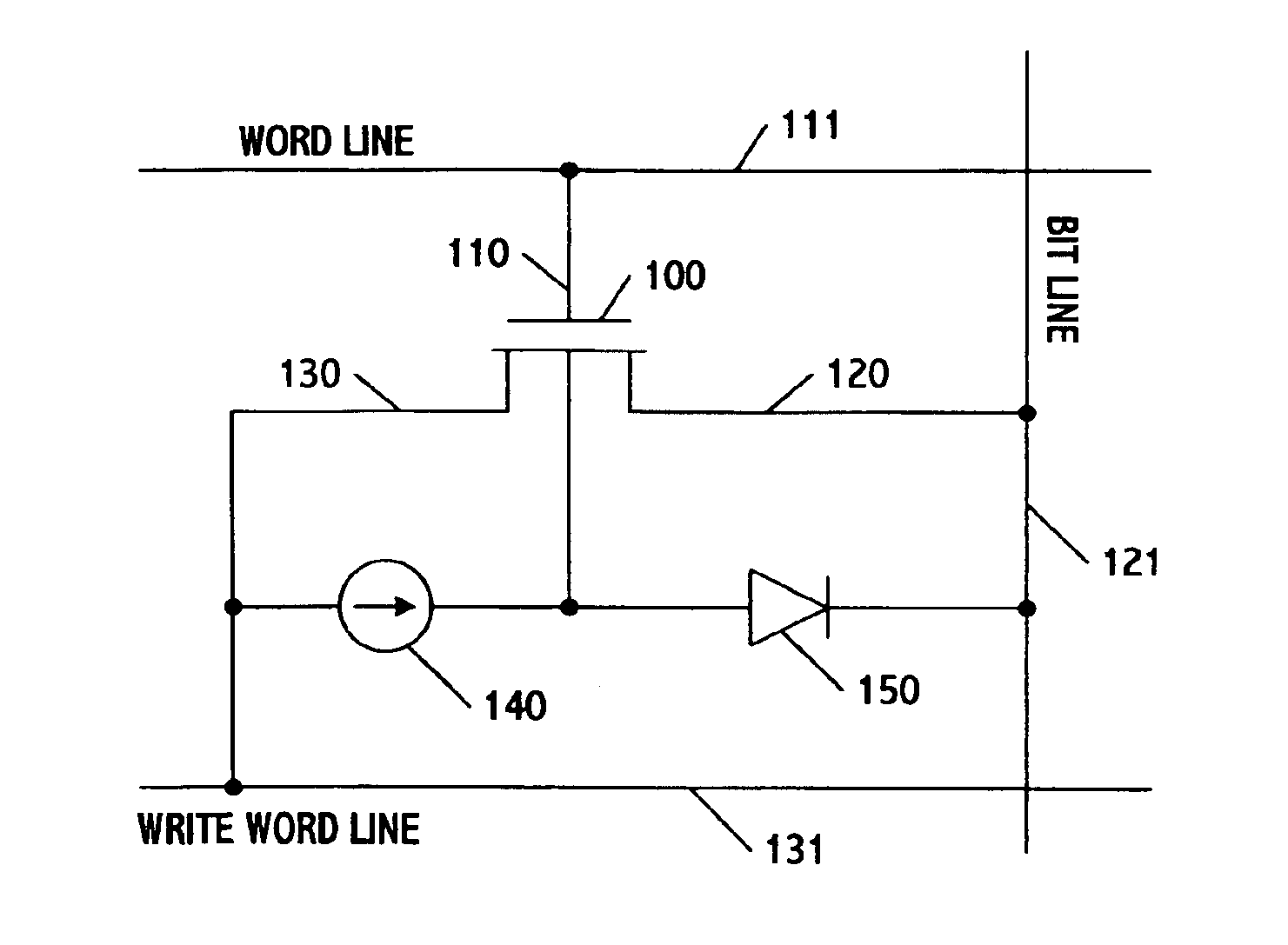

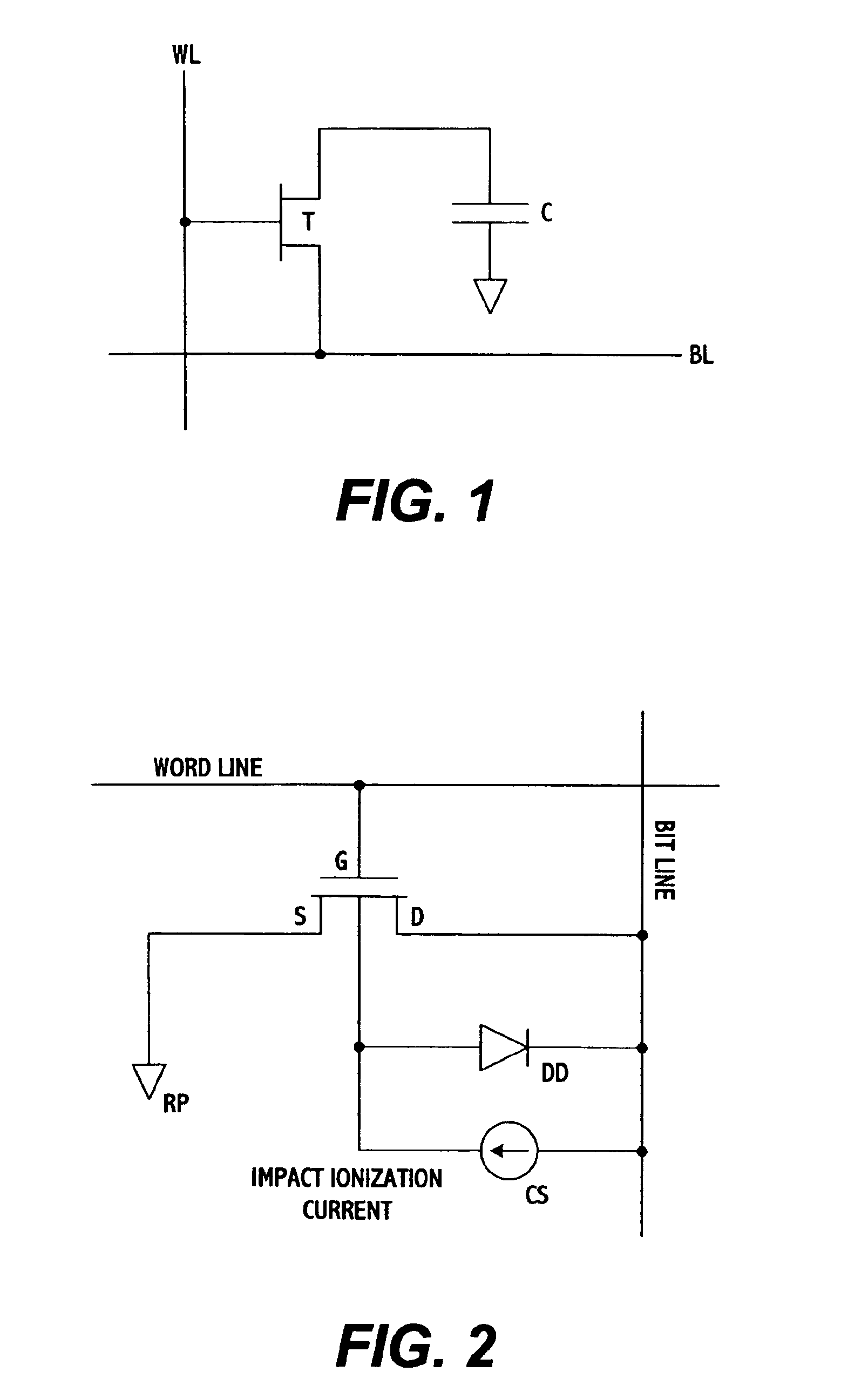

A DRAM memory cell uses a single transistor to perform the data storage and switching functions of a conventional cell. The transistor has a floating channel body which stores a potential that corresponds to one of two digital data values. The transistor further includes a gate connected to a first word line, a drain connected to a second word line, and a source connected to a bit line. By setting the word and bit lines to specific voltage states, the channel body stores a digital one potential as a result of impact ionization and a digital zero value as a result of forward bias of body-to-source junction.

Owner:INTEL CORP

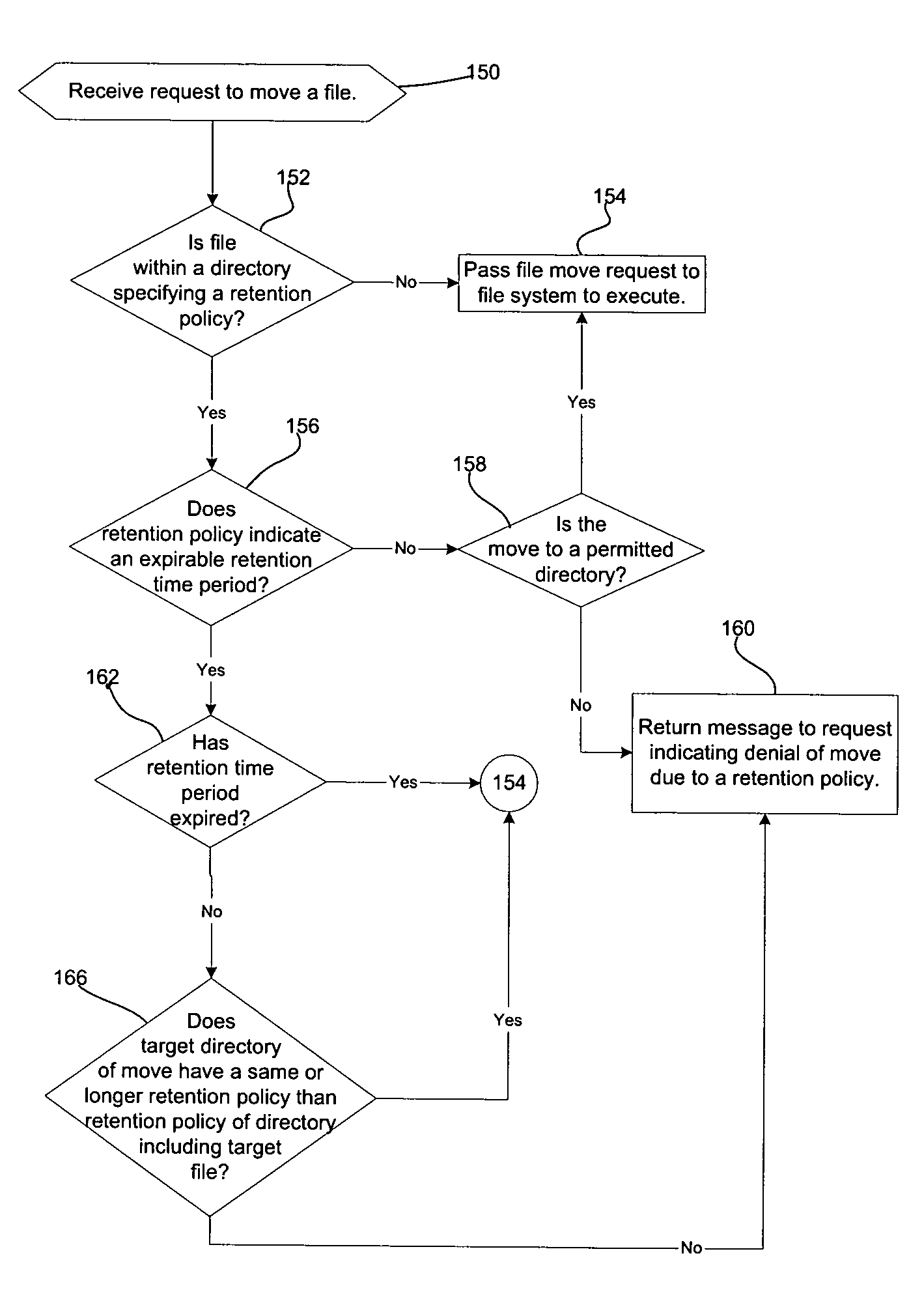

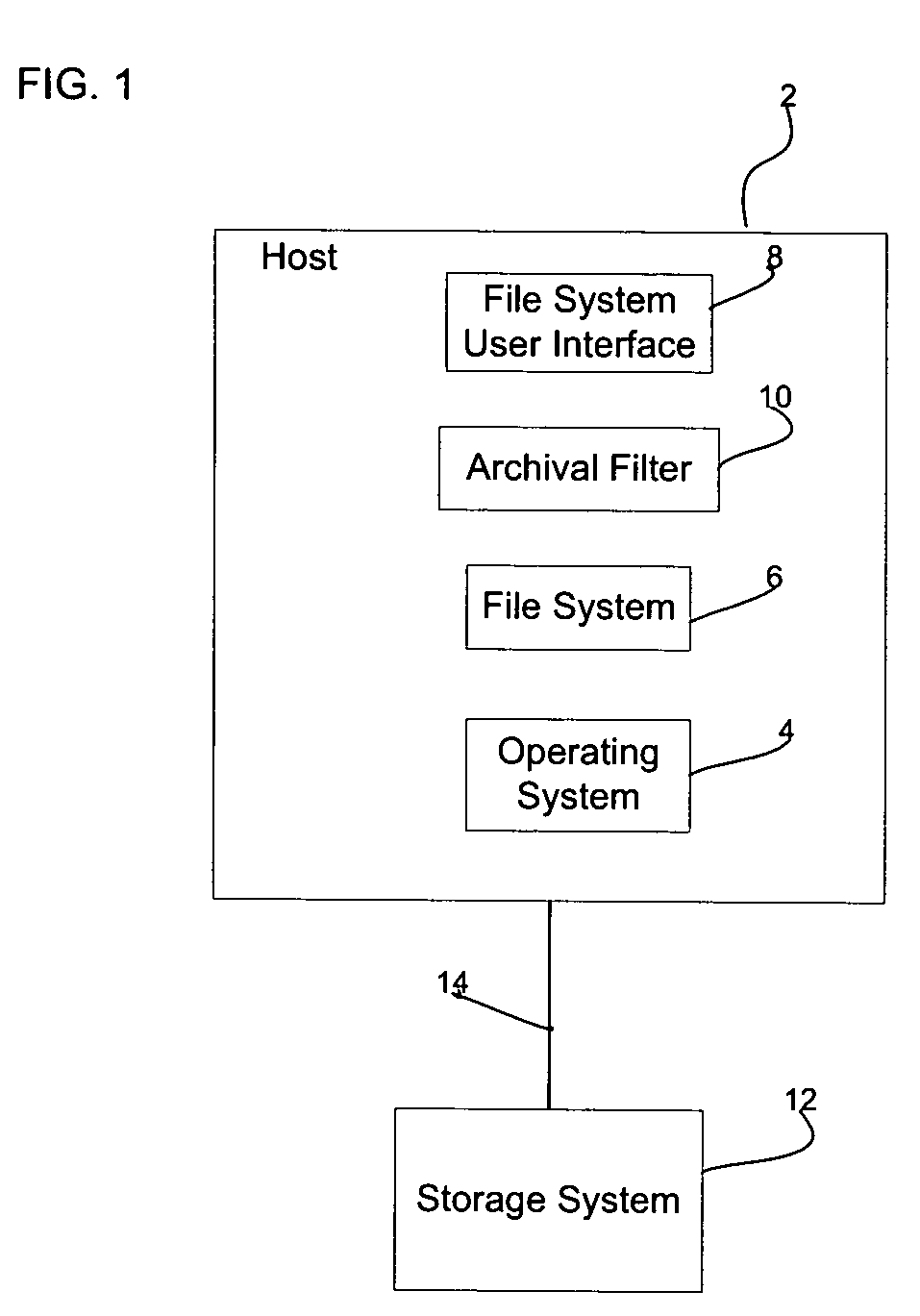

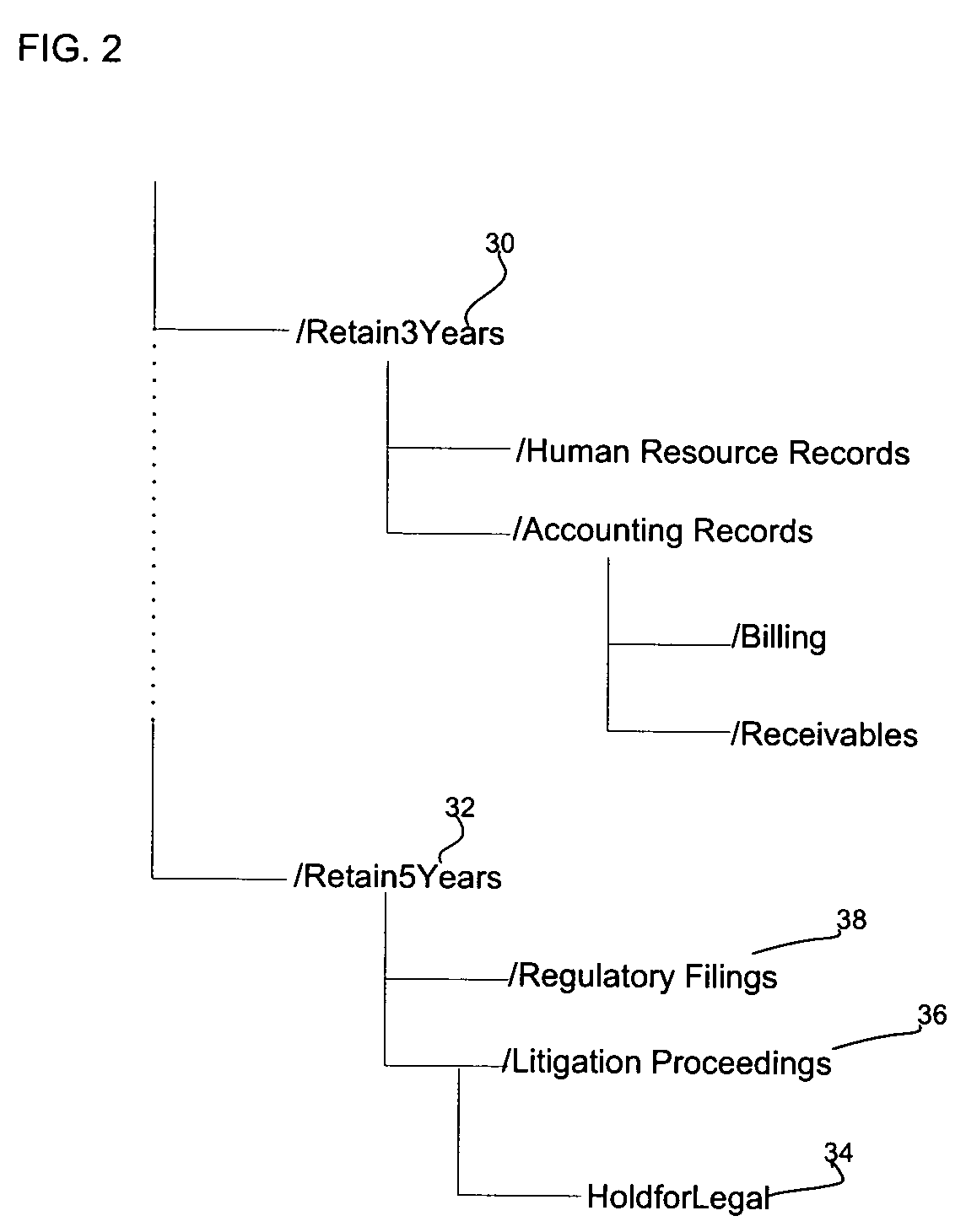

Method, system, and program for archiving files

Provided are a method, system, and program for archiving files. A hierarchical file system having directories is provided. An archival retention policy is associated with at least one of the directories in the hierarchical file system, wherein the retention policy applies to files included in the associated directory, and wherein the retention policy specifies a retention time indicating a time period during which a file is subject to the retention policy.

Owner:GOOGLE LLC

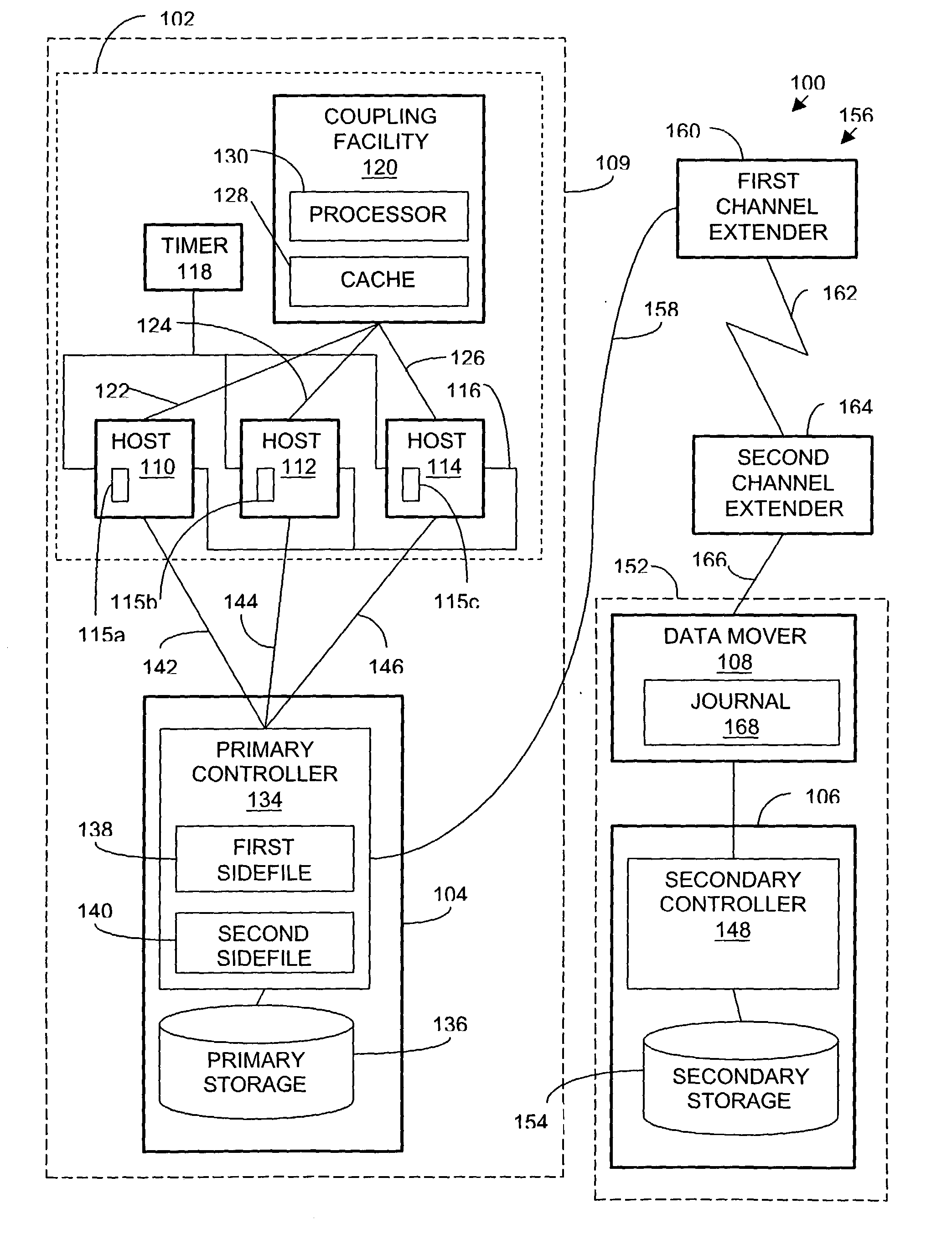

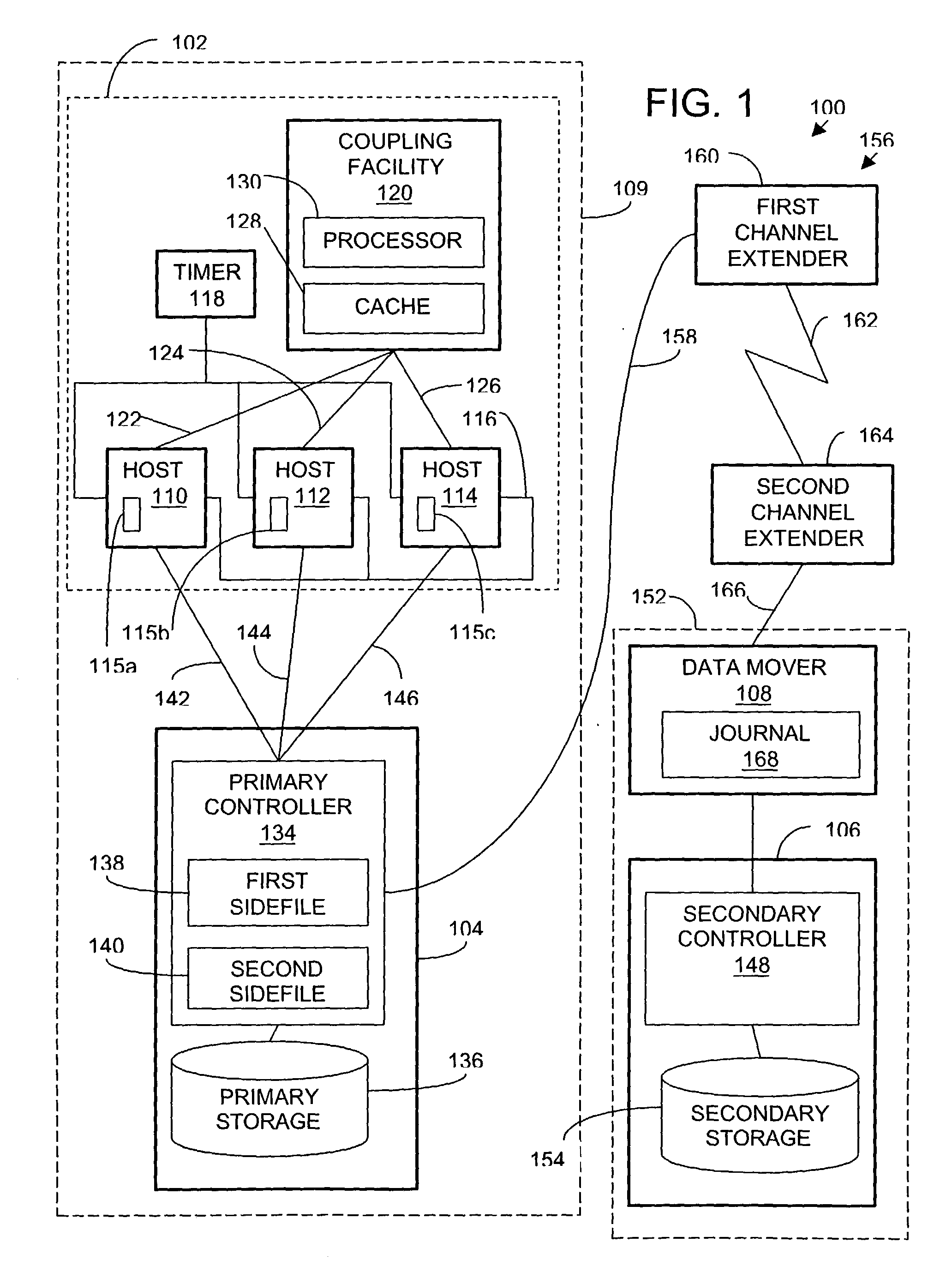

Adjusting timestamps to preserve update timing information for cached data objects

InactiveUS20040030837A1Quick storageEasy maintenanceData processing applicationsInput/output to record carriersTimestampRetention time

In a system including a host, a primary storage subsystem coupled to the host, a cache coupled to the host and separate from the primary storage system, a secondary storage subsystem, and a data mover coupling the primary and secondary storage systems, data is temporarily cached for future storage in the primary storage subsystem so as to preserve timestamp information and maintain data consistency for asynchronously mirroring the data at a secondary subsystem.

Owner:IBM CORP

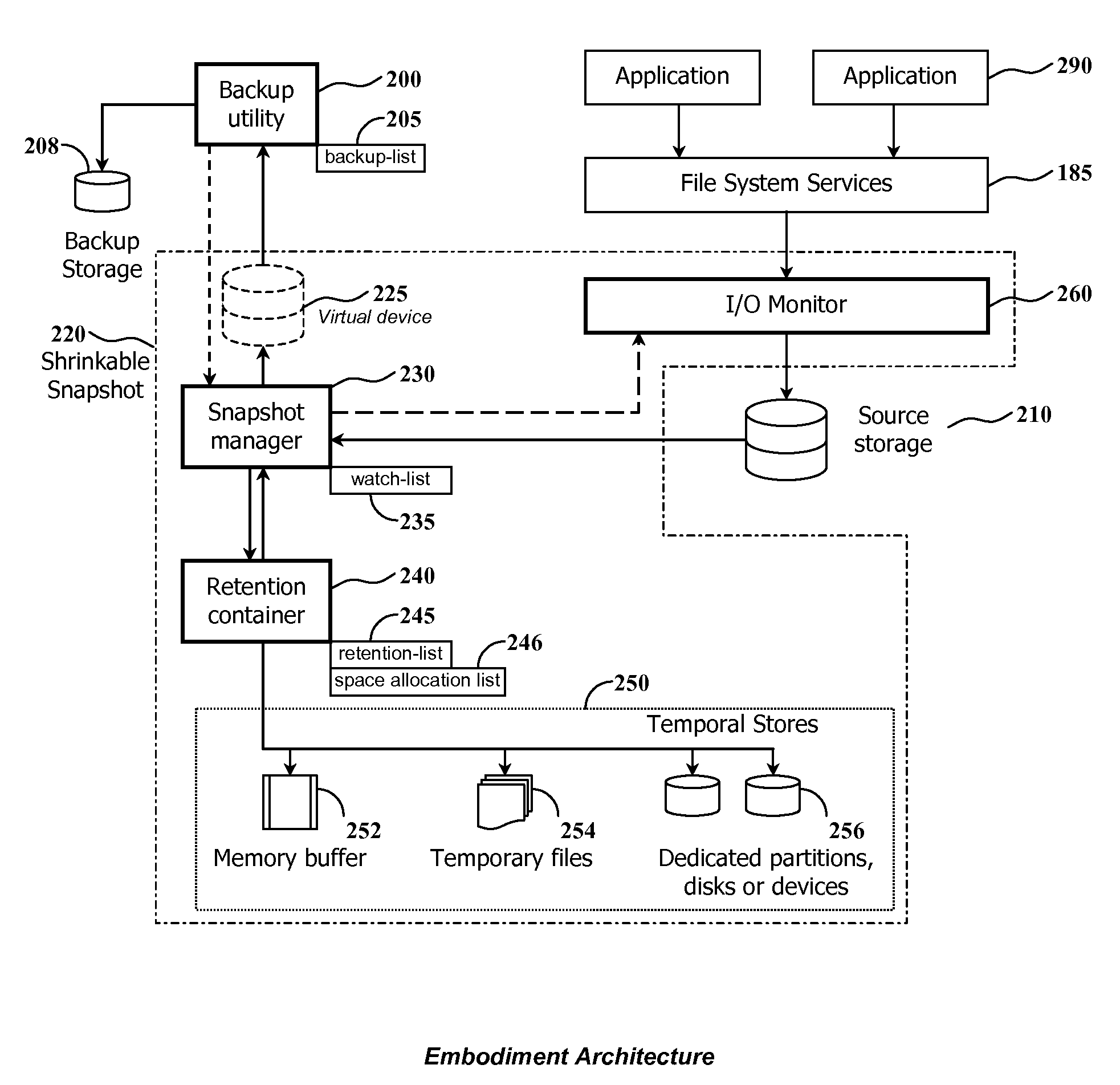

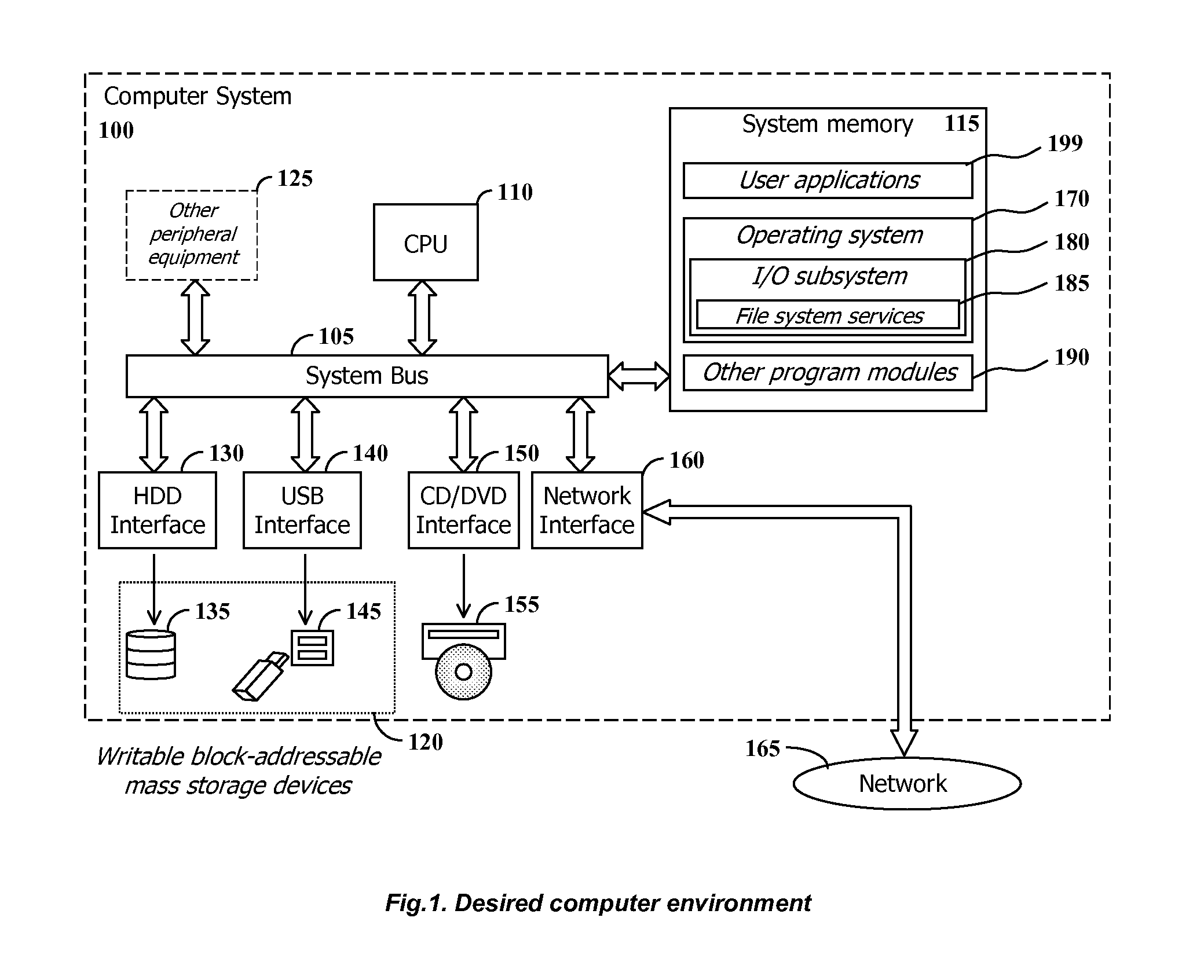

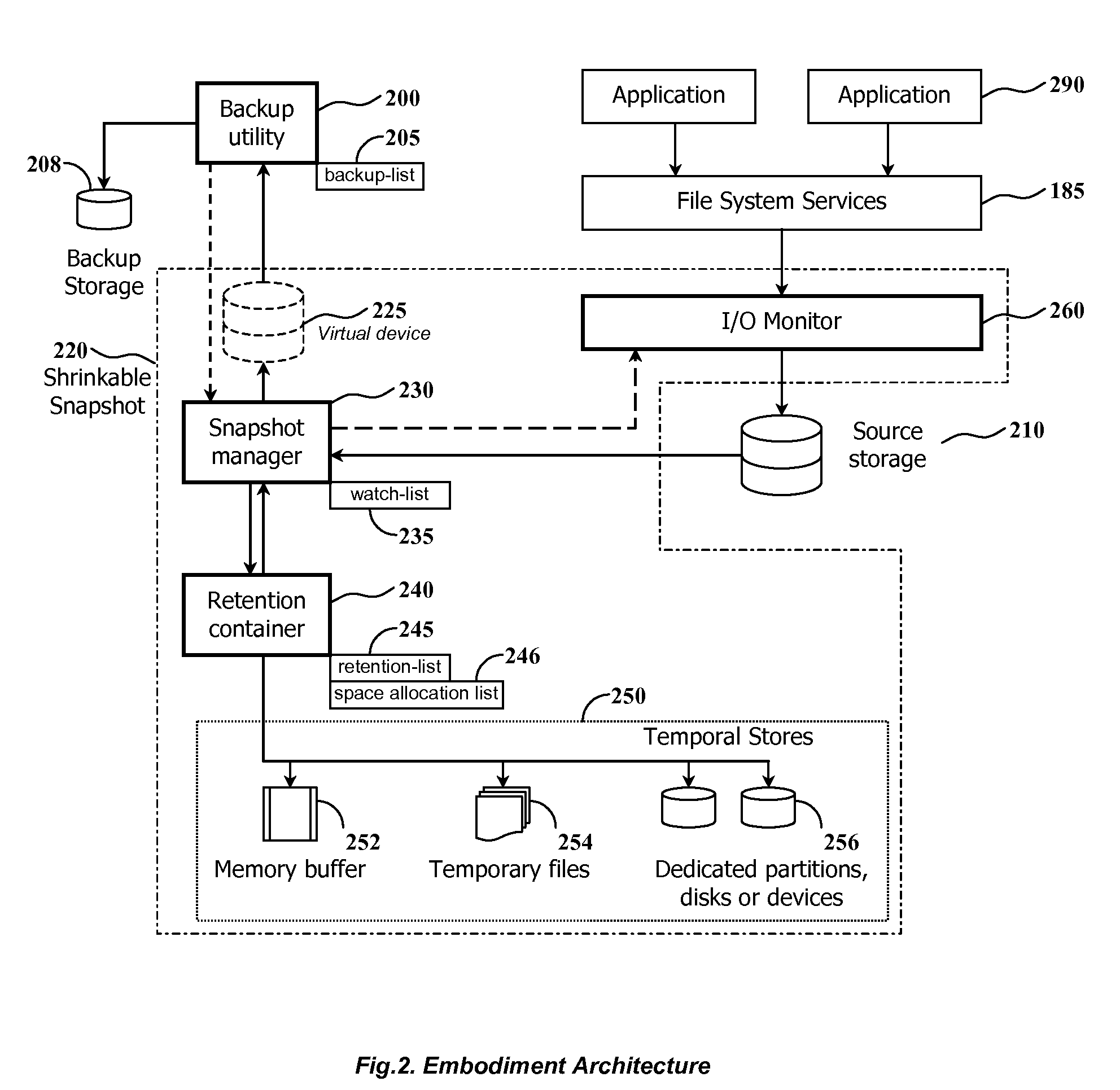

Using shrinkable read-once snapshots for online data backup

InactiveUS20080082593A1Improve performanceEasy to useDigital data information retrievalError detection/correctionRetention timeWatch list

The present invention discloses a method and system for snapshot-based online backup operations permitting reduced requirements to storage capacity and computational overhead for snapshot function.At the beginning of an online backup operation, the backup software system creates a snapshot of source data storage. The snapshot includes a watch-list used for identifying blocks of a source storage which are watched by snapshot management means for update. If a block included into the watch-list was requested for update, the snapshot management means preserve original contents of that block in a retention container for the purpose of temporary store. The retention container includes a set of temporal stores dedicated for transient storing of blocks until they are backed up.The essence of the invention is enabling to exclude blocks from the watch-list and the retention container at any moment within the period of snapshot operation. Therefore it is possible to exclude unnecessary blocks from the scope of blocks managed by the snapshot management means, for the purpose of preserving point-in-time data.Backed up blocks can be operatively excluded from the snapshot so that unchanged blocks are excluded from the watch-list and updated blocks are removed from the retention container. In the latter case temporal stores are shrunk as well. This technique allows to reduce progressively storage expenses and computational overheads required for maintenance of a snapshot being used in the online backup routine.When a volume-level online backup is performed the snapshot is switched to the read-once mode at the beginning of the data copying stage. A backup utility performs sequential read of blocks from the snapshot. The snapshot management means automatically exclude requested blocks from the scope of managed blocks.

Owner:PARAGON SOFTWARE GMBH

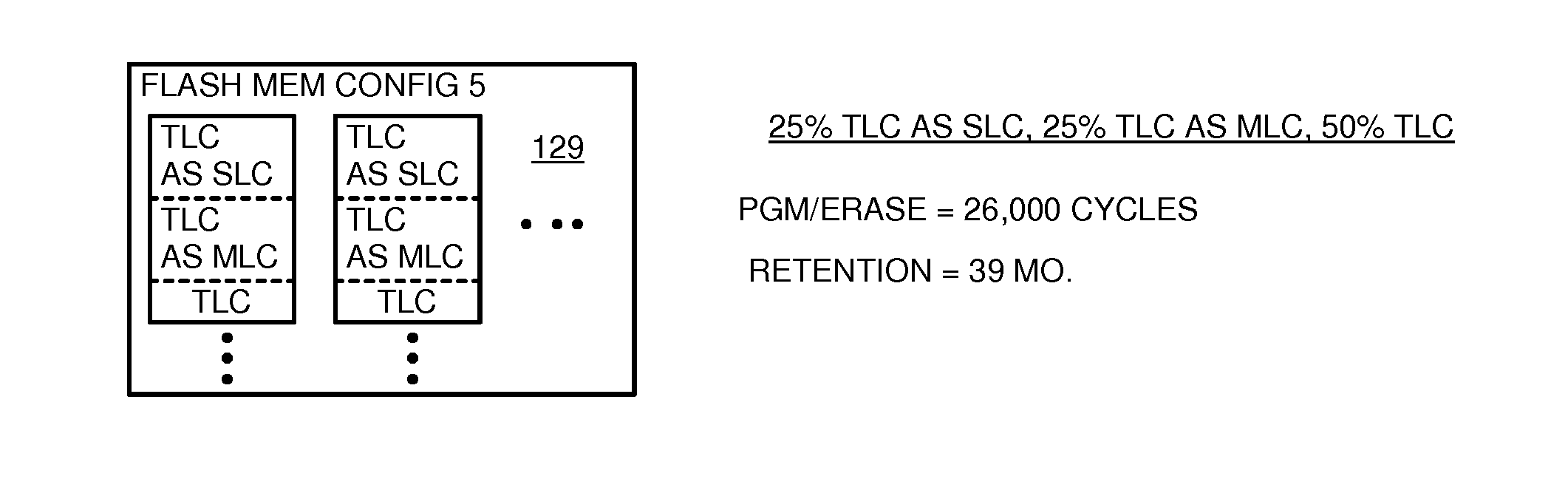

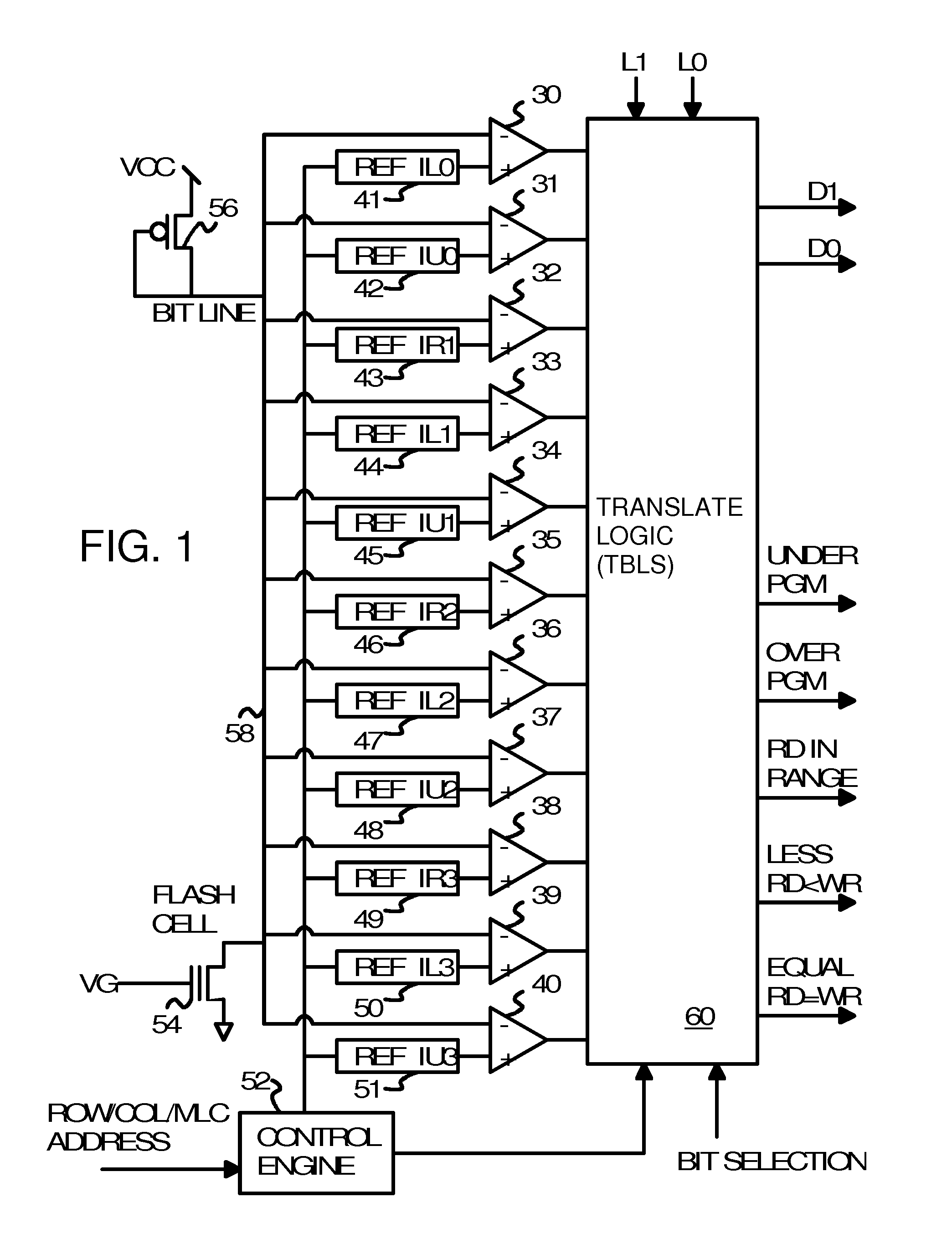

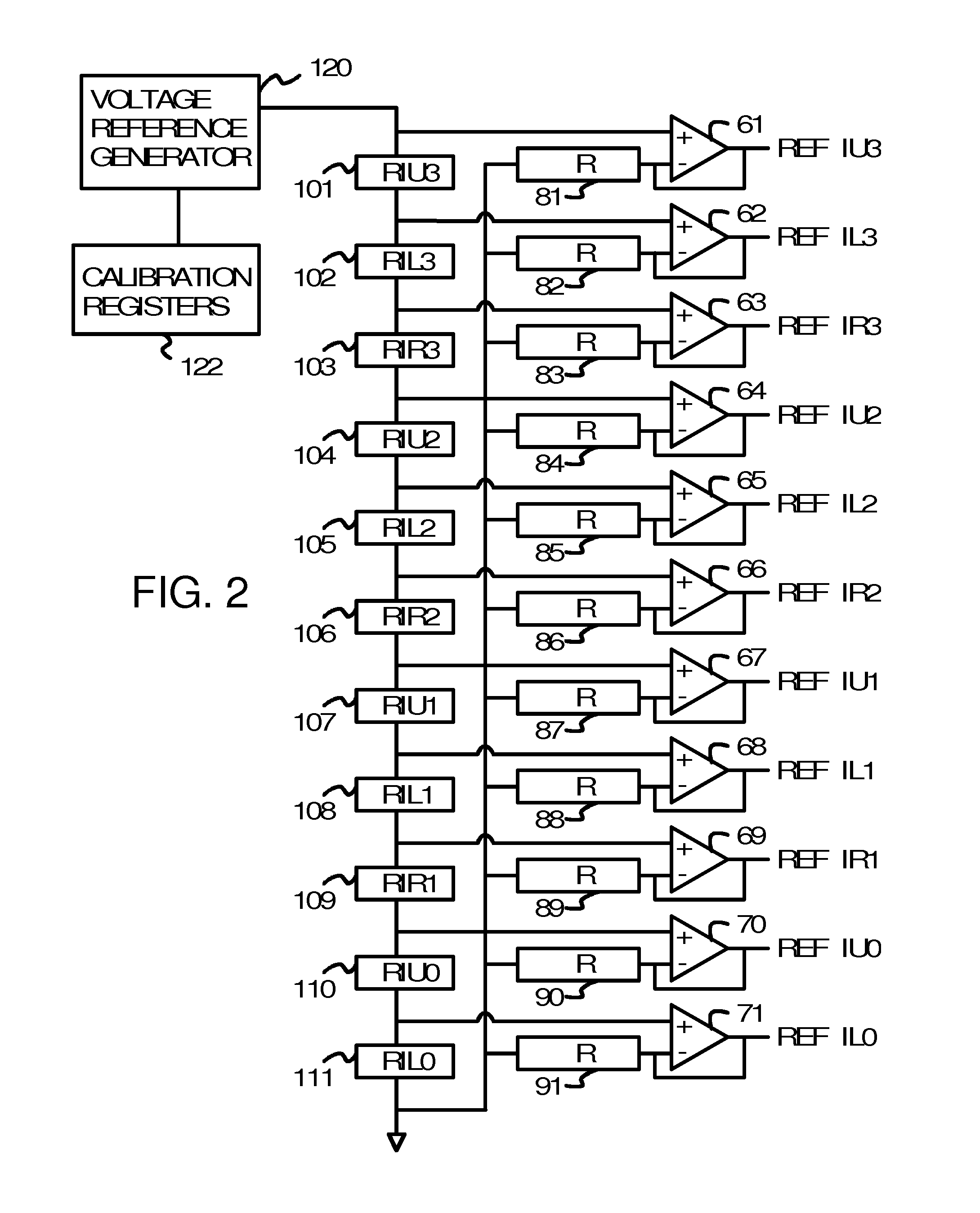

Endurance and retention flash controller with programmable binary-levels-per-cell bits identifying pages or blocks as having triple, multi, or single-level flash-memory cells

InactiveUS9123422B2Memory architecture accessing/allocationMemory adressing/allocation/relocationTruth valueRetention time

An retention flash controller reads assigned-level bits from a bad block / erase count table or from a page status table that indicate when flash memory cells operate as Triple-Level-Cell (TLC), Multi-Level-Cell (MLC), or Single-Level-Cell (SLC). Pages that fail as TLC or MLC are downgraded for use as SLC pages by changing the assigned-level bits. The level bits adjust truth tables used by translation logic that receives inputs from voltage comparators reading a bit line. The range of voltages for each logic level may be adjusted by the truth tables or by programmable registers. The programming voltage or programming pulses may be adjusted to increase endurance and the number of permitted program-erase cycles while reducing retention times before a refresh is needed of the flash cells. Mixed configurations of flash memory have MLC blocks and MLC as SLC blocks, or other combinations.

Owner:SUPER TALENT TECH CORP

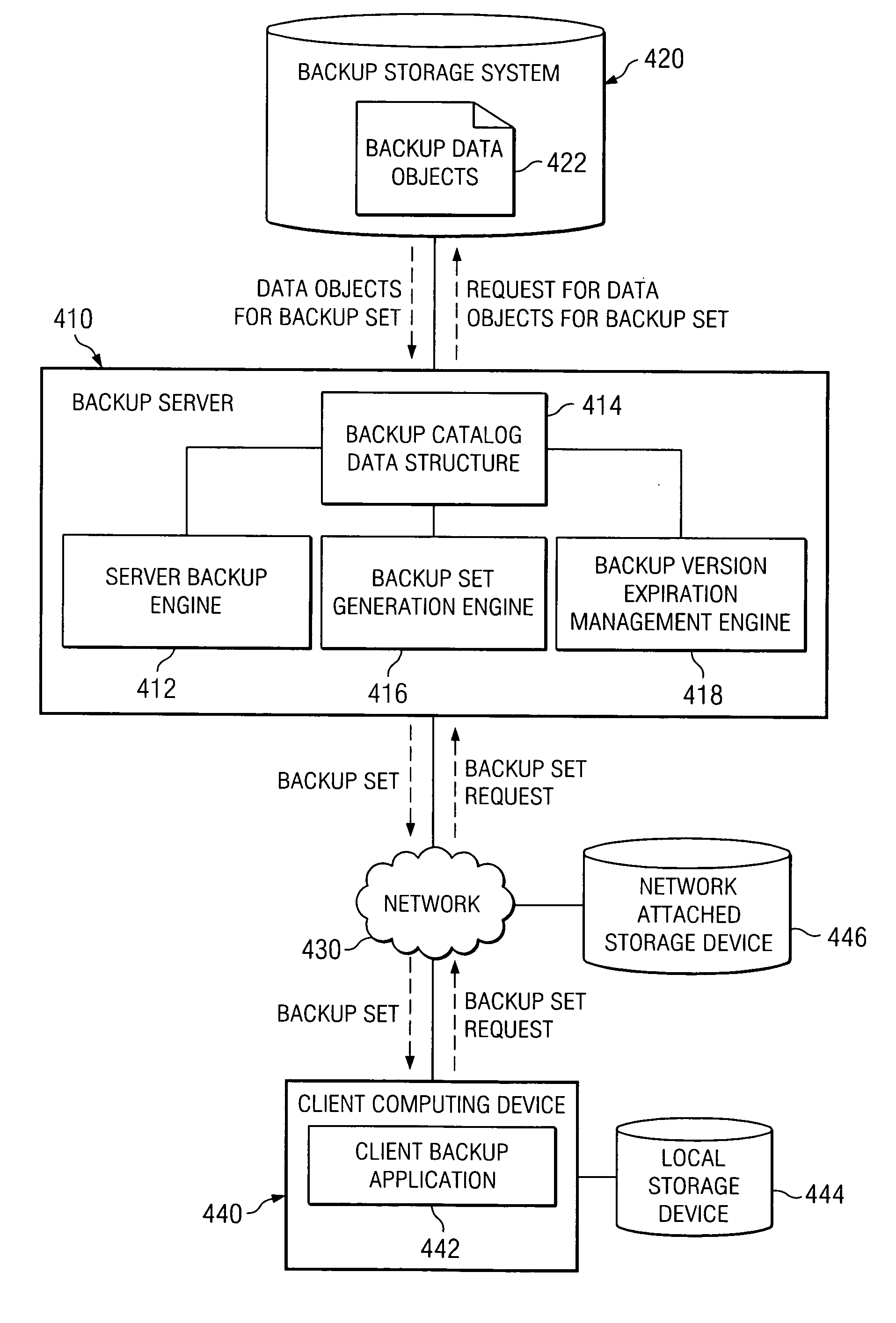

Generating backup sets to a specific point in time

InactiveUS20070136381A1Minimal amountDigital data processing detailsError detection/correctionObject basedTimestamp

A system, method and computer program product are provided for generating backup sets for a specific point in time from backup data stored in a backup storage device. A backup set, in accordance with an illustrative embodiment, is a collection of the files and data that would have been the most recently backed-up version of a computer's files and data at the particular point in time if the backup set had been created at that point in time. In order to generate the backup set, versions of data objects are identified in the backup storage system that have backup timestamps equal to or prior to the designated point in time and that have deactivation times that are after the designated point in time. In addition, a mechanism for deleting versions of data objects based on a retention time and an inactive version limit is provided.

Owner:IBM CORP

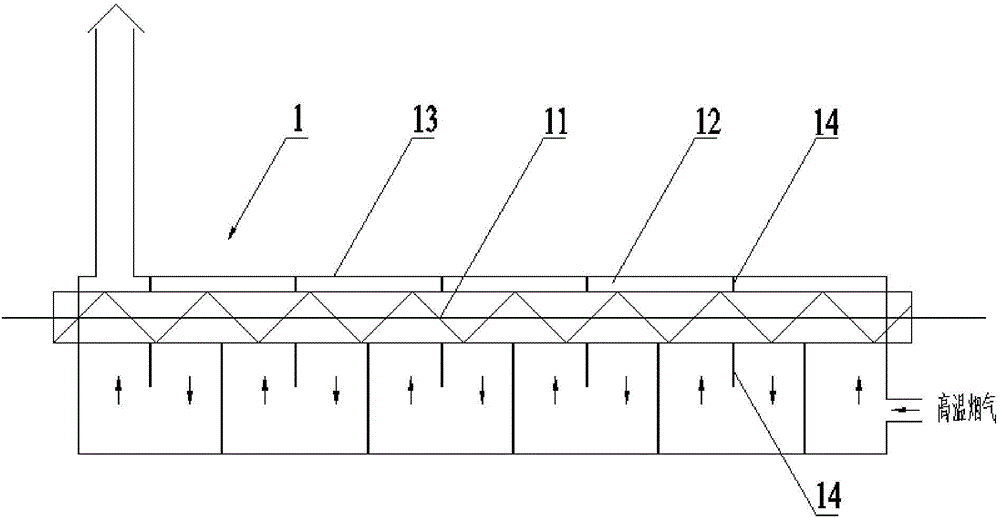

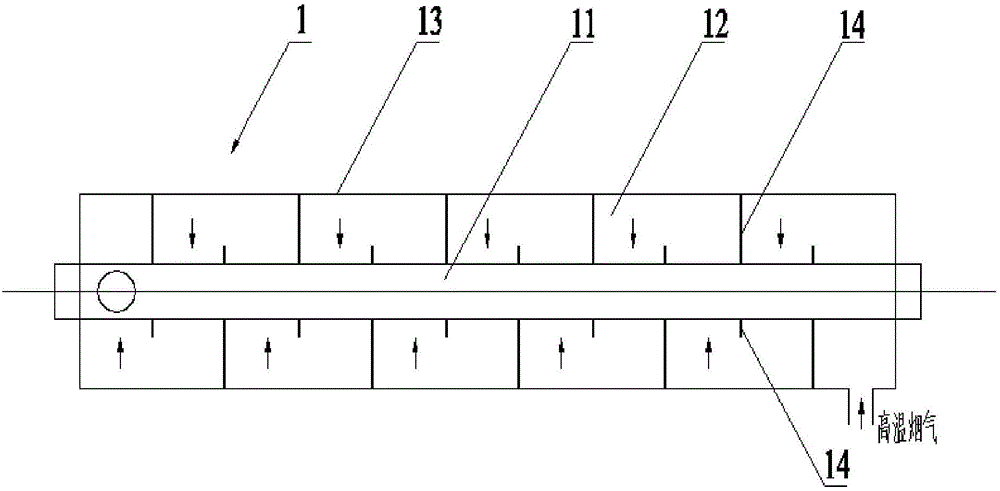

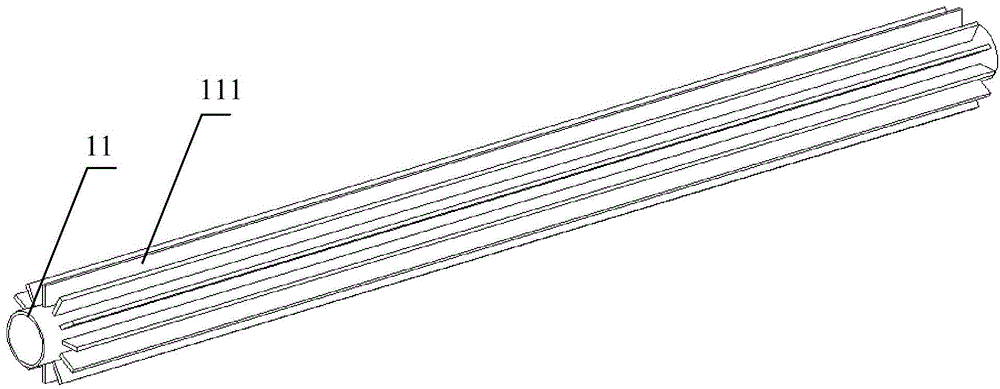

Thermal decomposition device of oil field waste

InactiveCN104402185AImprove heat transfer efficiencyEnhanced turbulence effectWaste water treatment from quariesSludge treatment by pyrolysisRetention timeOil field

The embodiment of the invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue. The oil field waste thermal decomposition device is characterized in that a plurality of partitioning plates are arranged on the inner wall of the casing; the flue is of a snakelike structure through the adoption of the partitioning plates. Through the adoption of the partitioning plates on the inner wall of the casing of the thermal decomposition device disclosed by the invention, the flue inside the casing is of the snakelike structure, so that the flowing direction and the flowing speed of fume are changed, the turbulent flow effect is improved, the retention time is prolonged, and the heat exchange efficiency of the heating cavity and the fume is improved.

Owner:JEREH ENERGY SERVICES

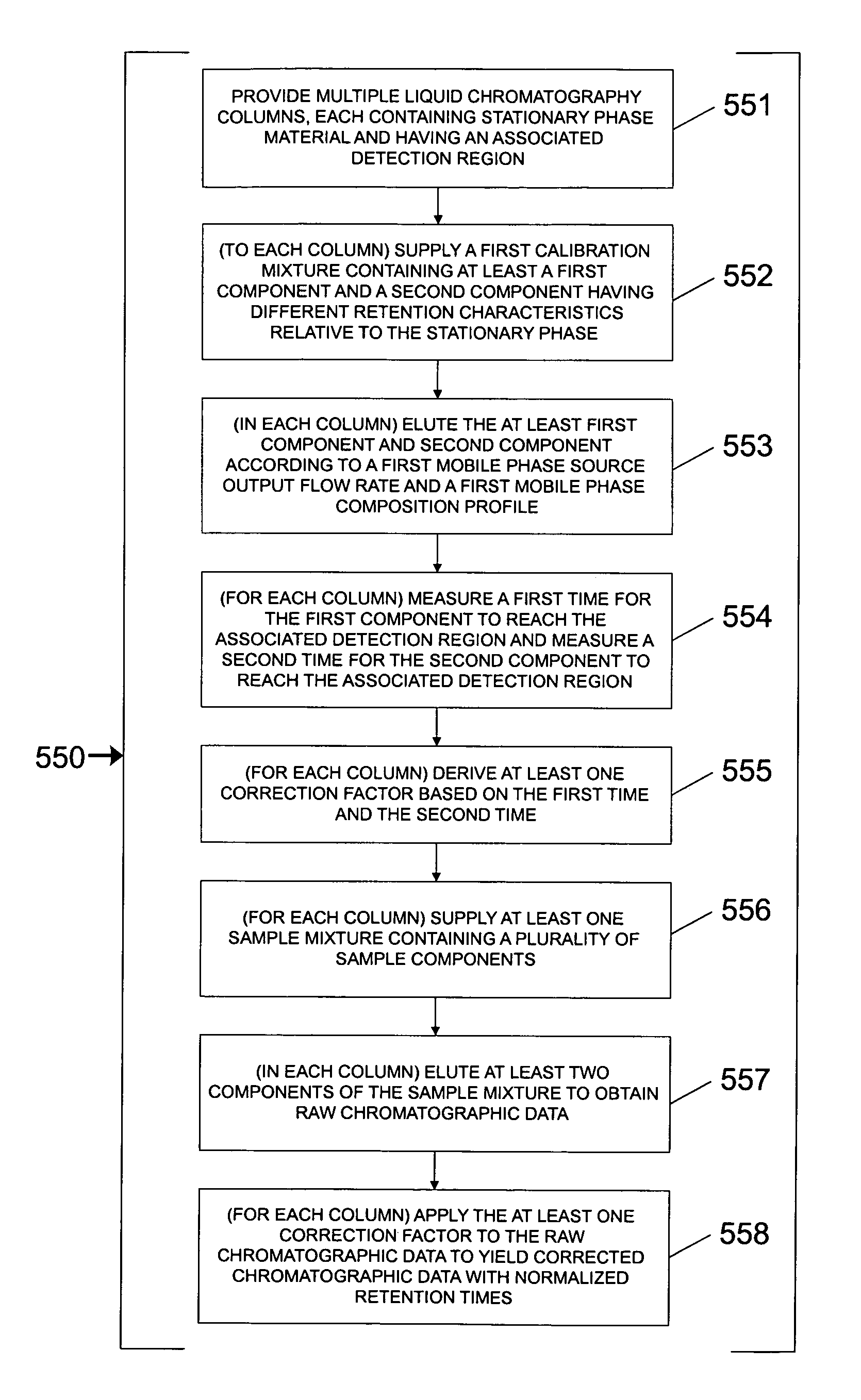

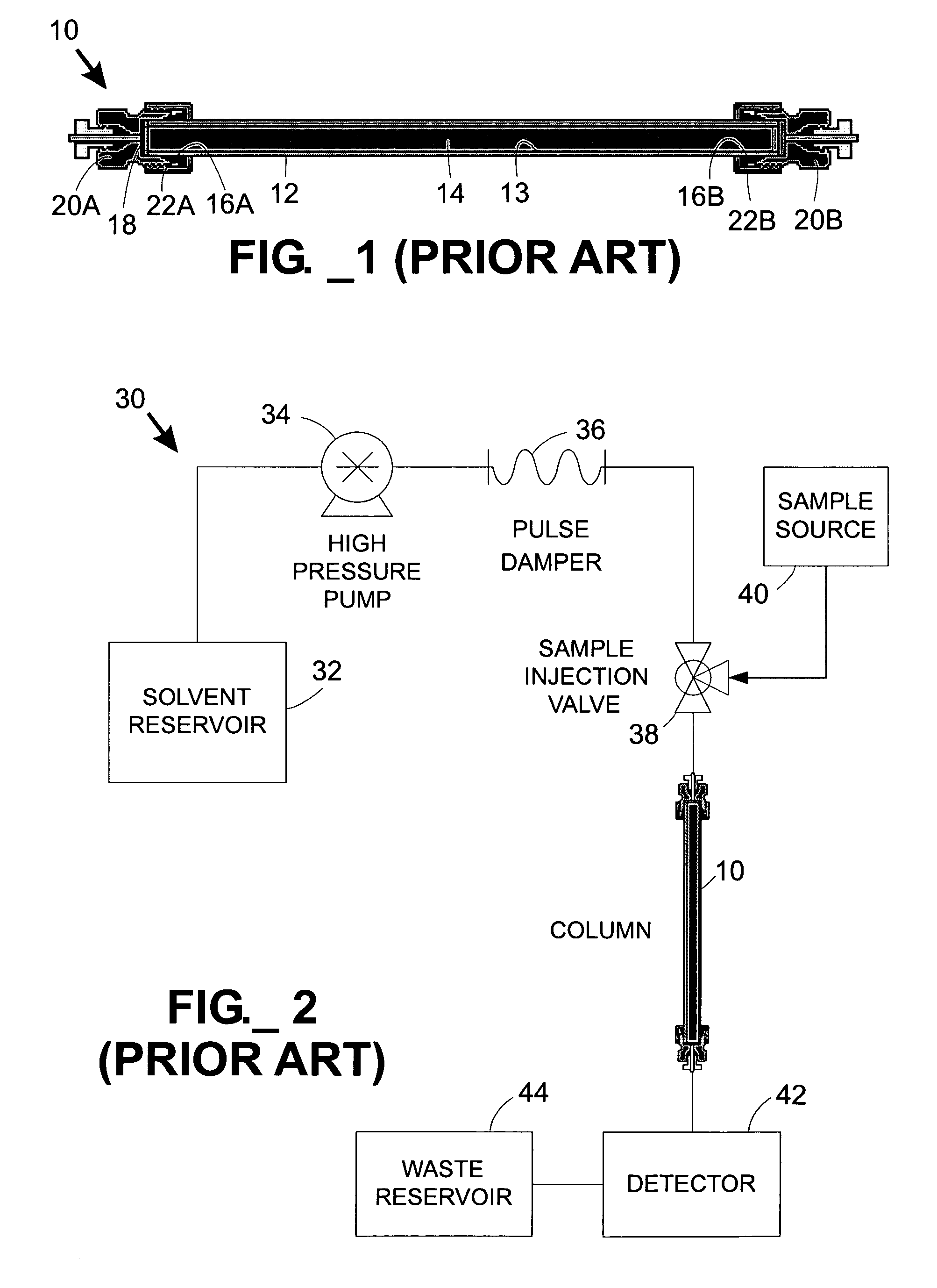

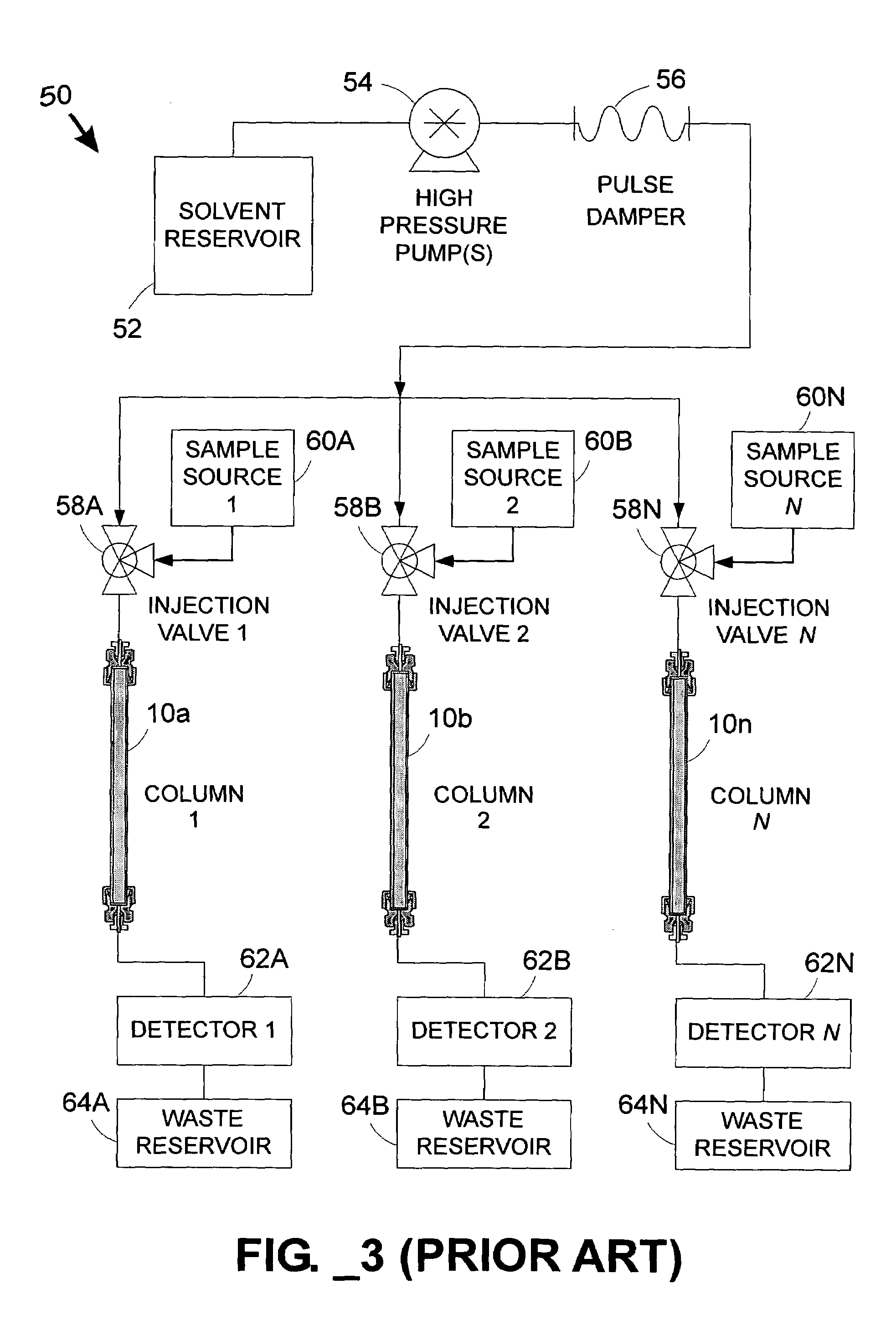

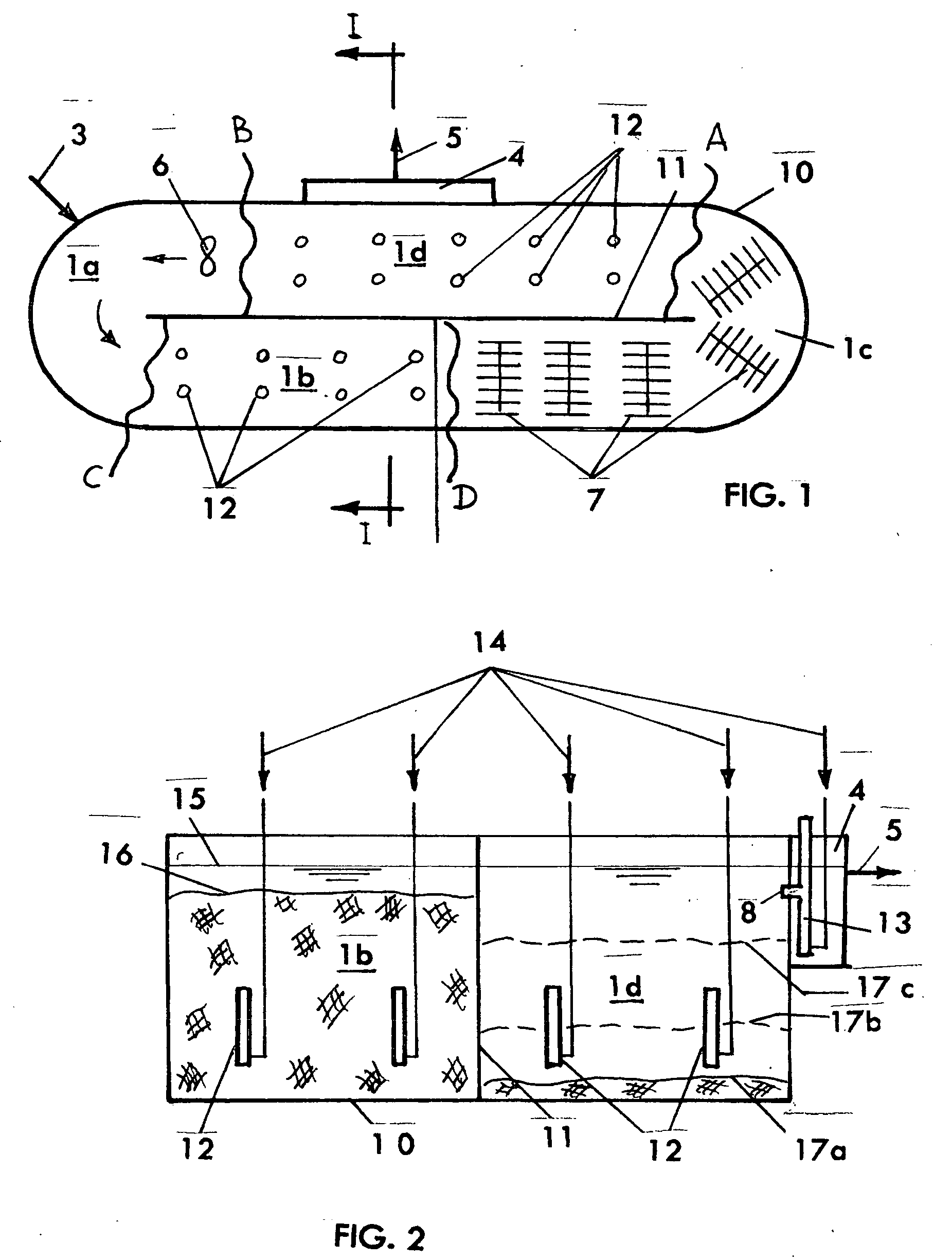

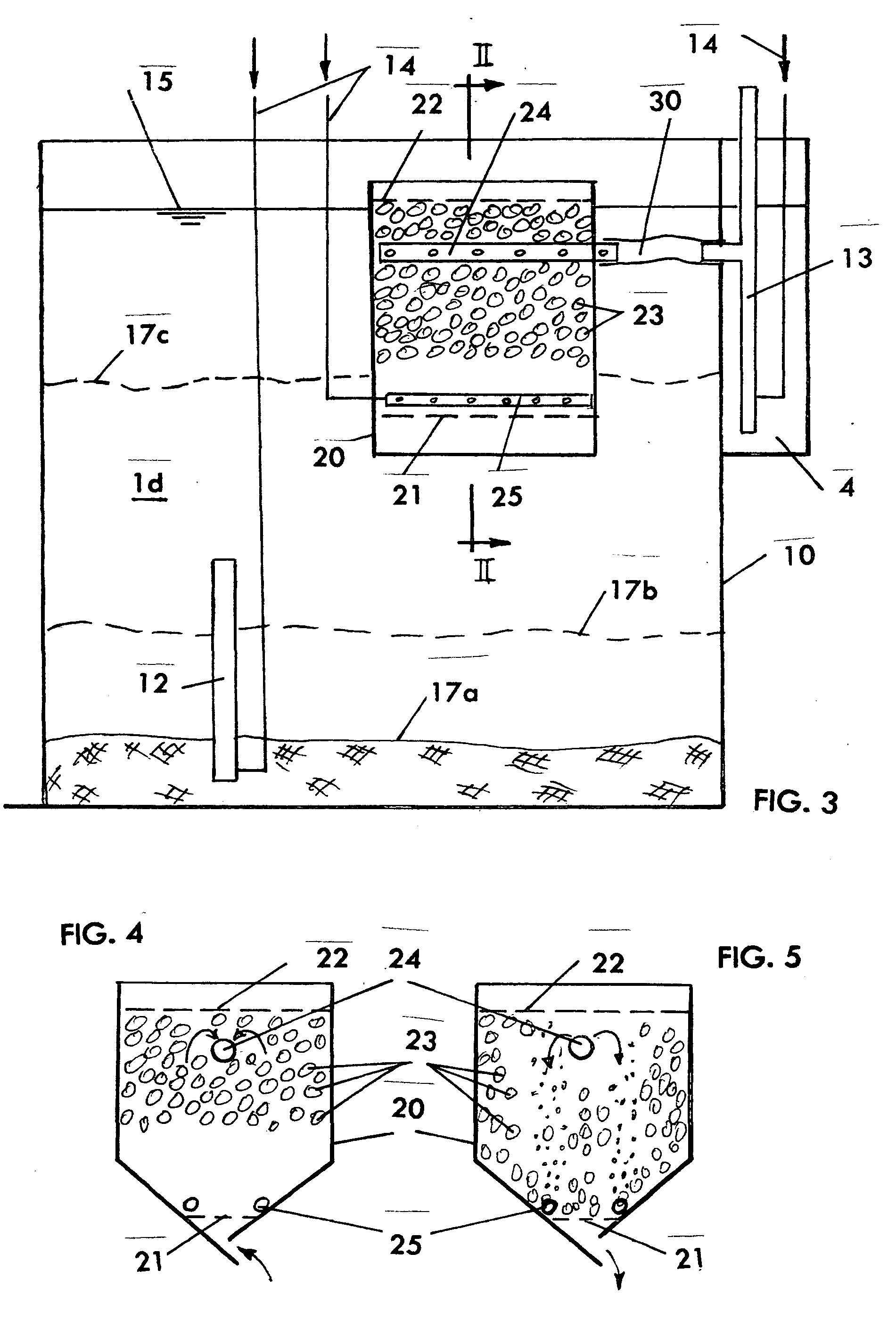

Parallel fluid processing systems and methods

ActiveUS7178386B1Ion-exchange process apparatusWave based measurement systemsFactor baseRetention time

A parallel fluid processing system including multiple fluid process regions containing solid material in fluid communication with a common first fluid source may be used to conduct analyses and / or synthesis in parallel. A parallel fluid processing data correction method includes supplying and processing a calibrant in each fluid process region, measuring a first physical parameter and deriving at least one correction factor based on the parameter, supplying and processing at least one second fluid in each fluid process region, and then applying the correction factor to yield corrected process data. Retention time correction, peak area correction, and other useful data corrections may be performed. Parallel fluid processing may be performed with microfluidic devices and systems. A system for correcting retention times in parallel liquid chromatography is further provided.

Owner:AGILENT TECH INC

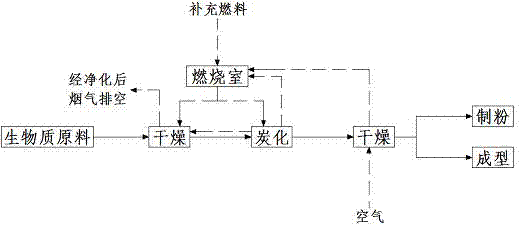

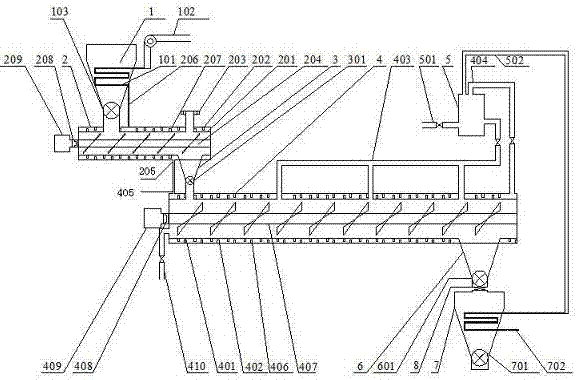

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

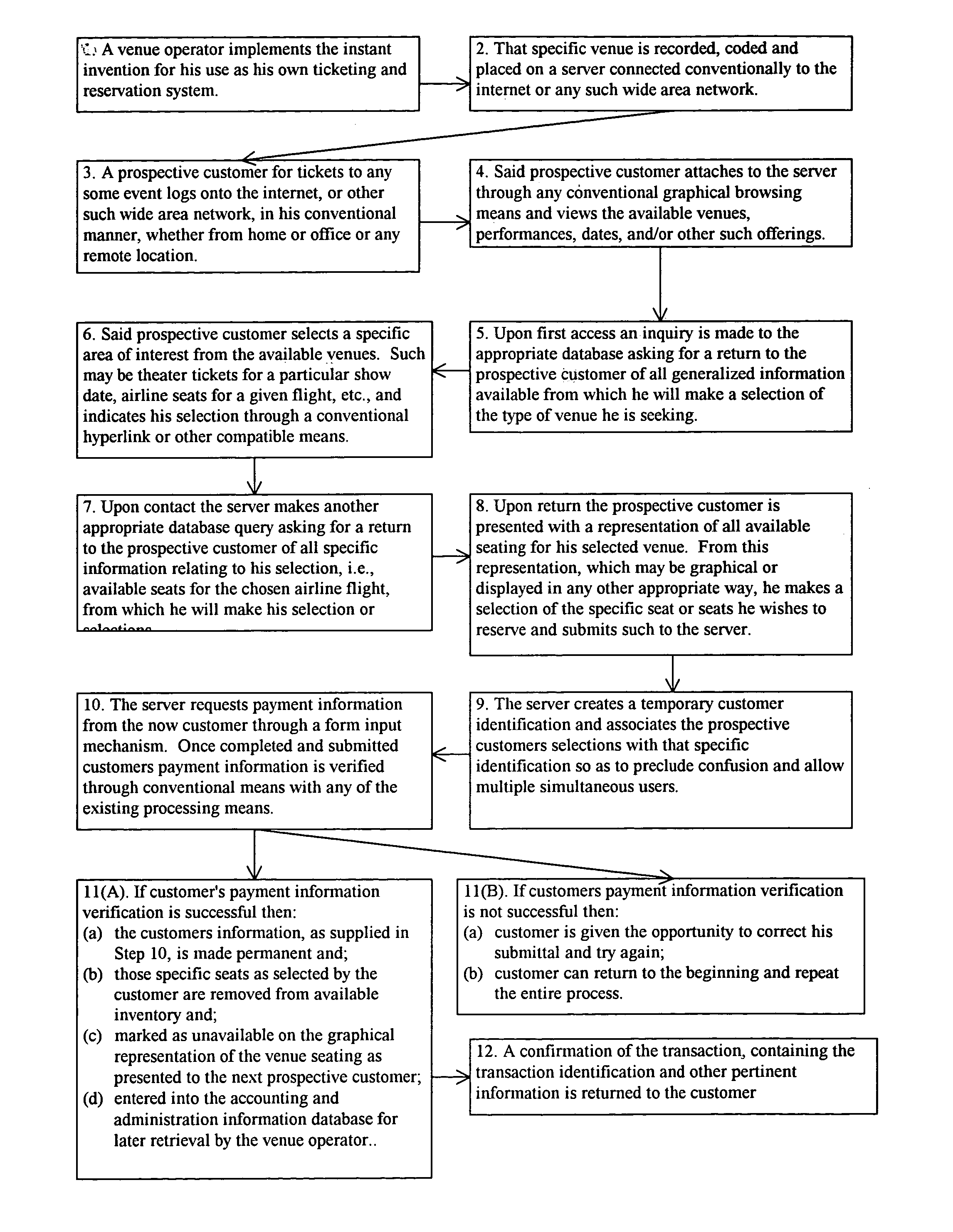

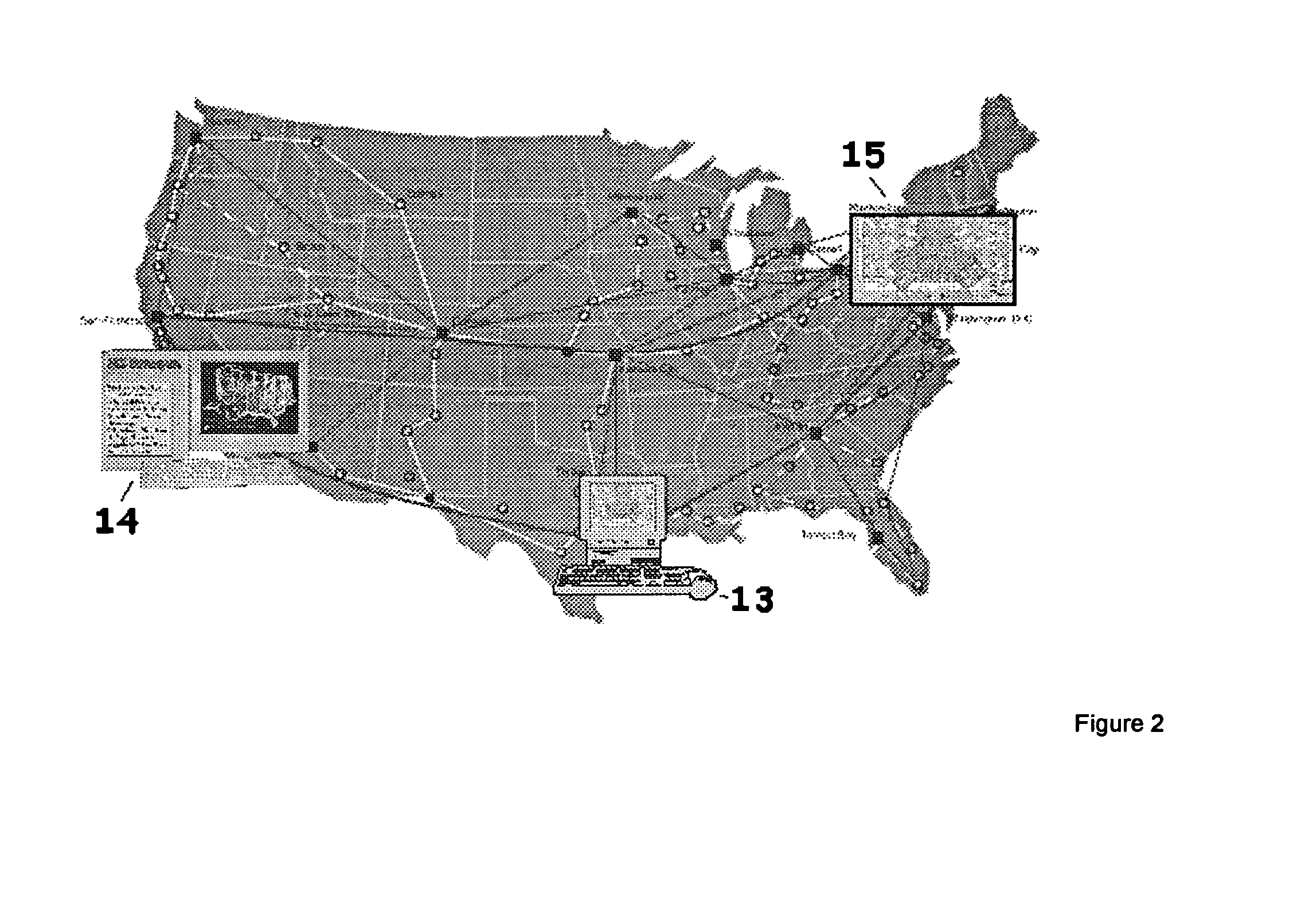

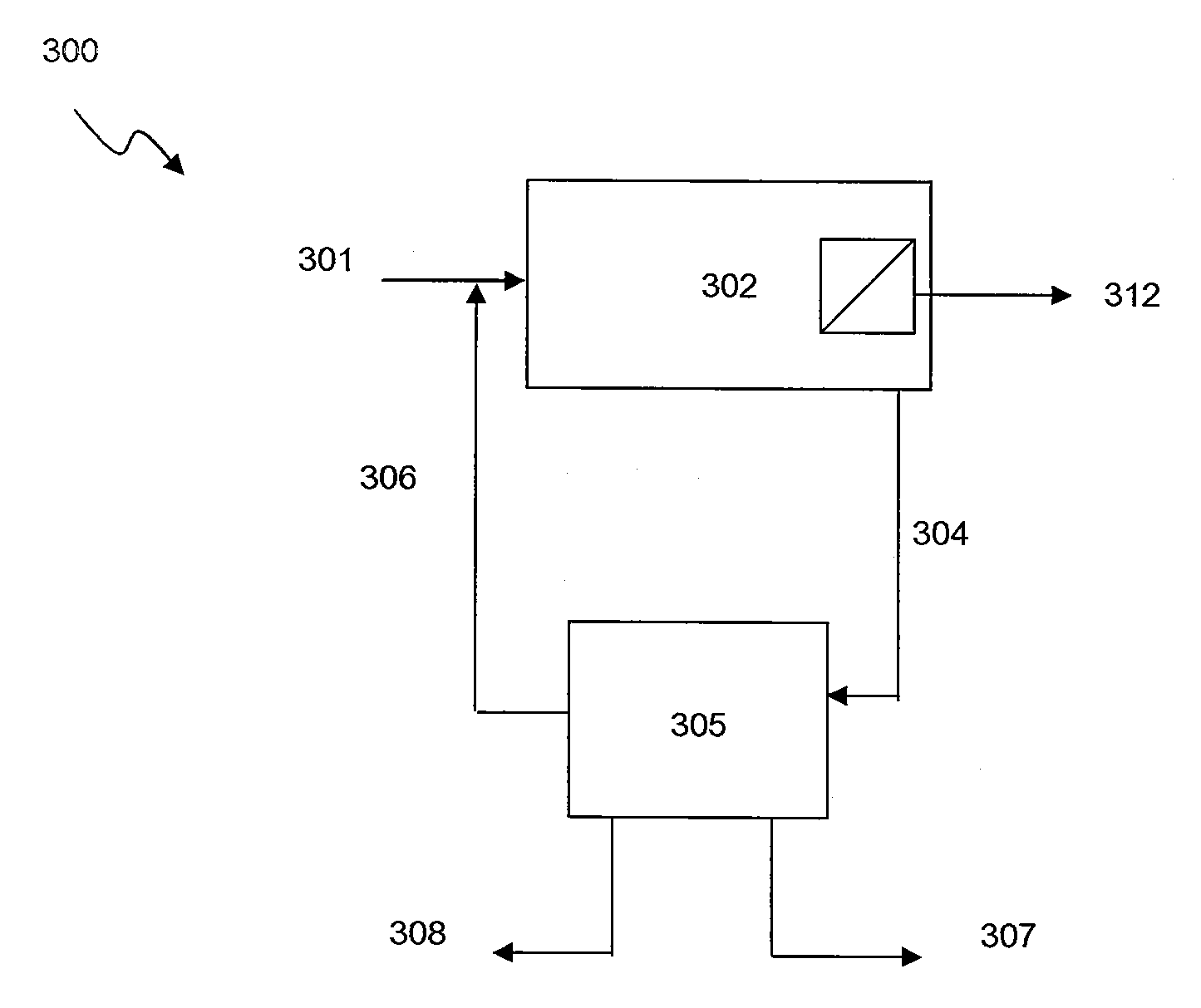

Individual seat selection ticketing and reservation system

This invention relates to an electronic means by which people can select the exact seat or seats they want for any type of event or reserve an appointment for any activity such as a doctor or dentist appointment or even an appointment to have their car lubed. More specifically, a customer or a ticket re-seller or a venue operator can go, for example, to the internet and select the event or activity for which they want a ticket or tickets or reserve a time and reserve and order the exact seat or seats or the time of their choosing directly online. The seat or seats or reserved time they select is then removed from the inventory for that activity or event and made not available for any other buyer and such is so indicated by a graphical representation or other such indicator on the online map or picture representing availability of seating or time for that event. For an appointment reservation, the user connects to the internet or other wide area network, such as a bulletin board, from his home of office computer and connects to a page that displays a reservation calendar where he can interact such as to reserve a specific time period for himself.

Owner:CEATS

High performance, energy efficient system and method for wastewater treatment with resource recovery and reduced residual solids generation

ActiveUS20080223783A1Treatment with anaerobic baffled reactorsWater treatment parameter controlRetention timeCell mass

A wastewater treatment system is provided including an aerobic membrane bioreactor and an anaerobic digester system connected to receive wasted solids continuously from the aerobic membrane bioreactor and also connected to return effluent from the anaerobic digester system continuously to the aerobic membrane bioreactor. Further, a process is provided for treating wastewater including the step of wasting a volume fraction of organic cell mass from an aerobic membrane bioreactor to an anaerobic digester system and maintaining a solids retention time (SRT) in the bioreactor that is (1) greater than a time needed to achieve growth of organisms suitable for converting carbonaceous biochemical oxygen demand (CBOD) into cell mass and (2) less than a time at which substantial decay of the organisms occurs. The system and process may further include optional pretreatment and / or phosphorus and / or nitrogen removal downstream of the membrane bioreactor system.

Owner:HSBC BANK

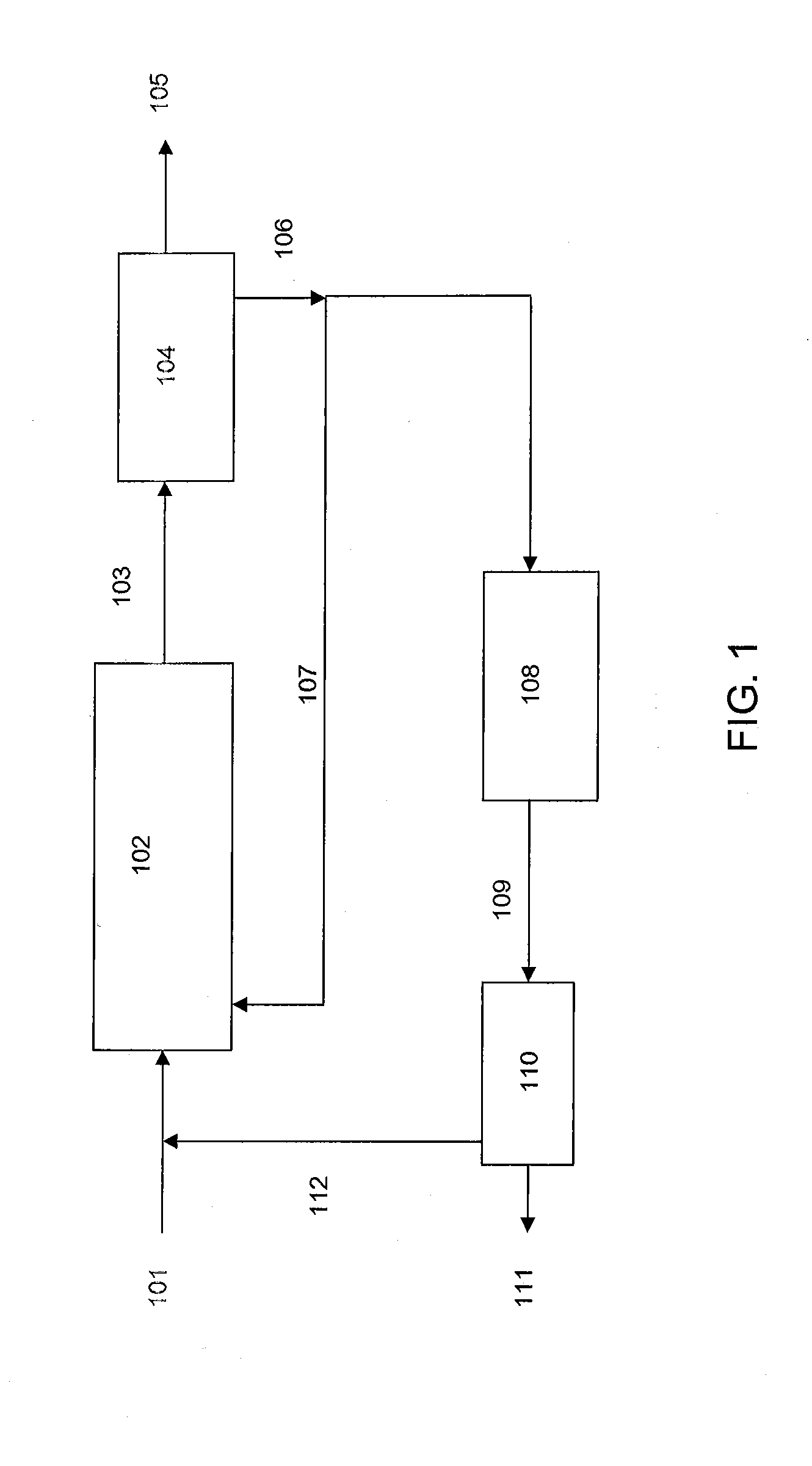

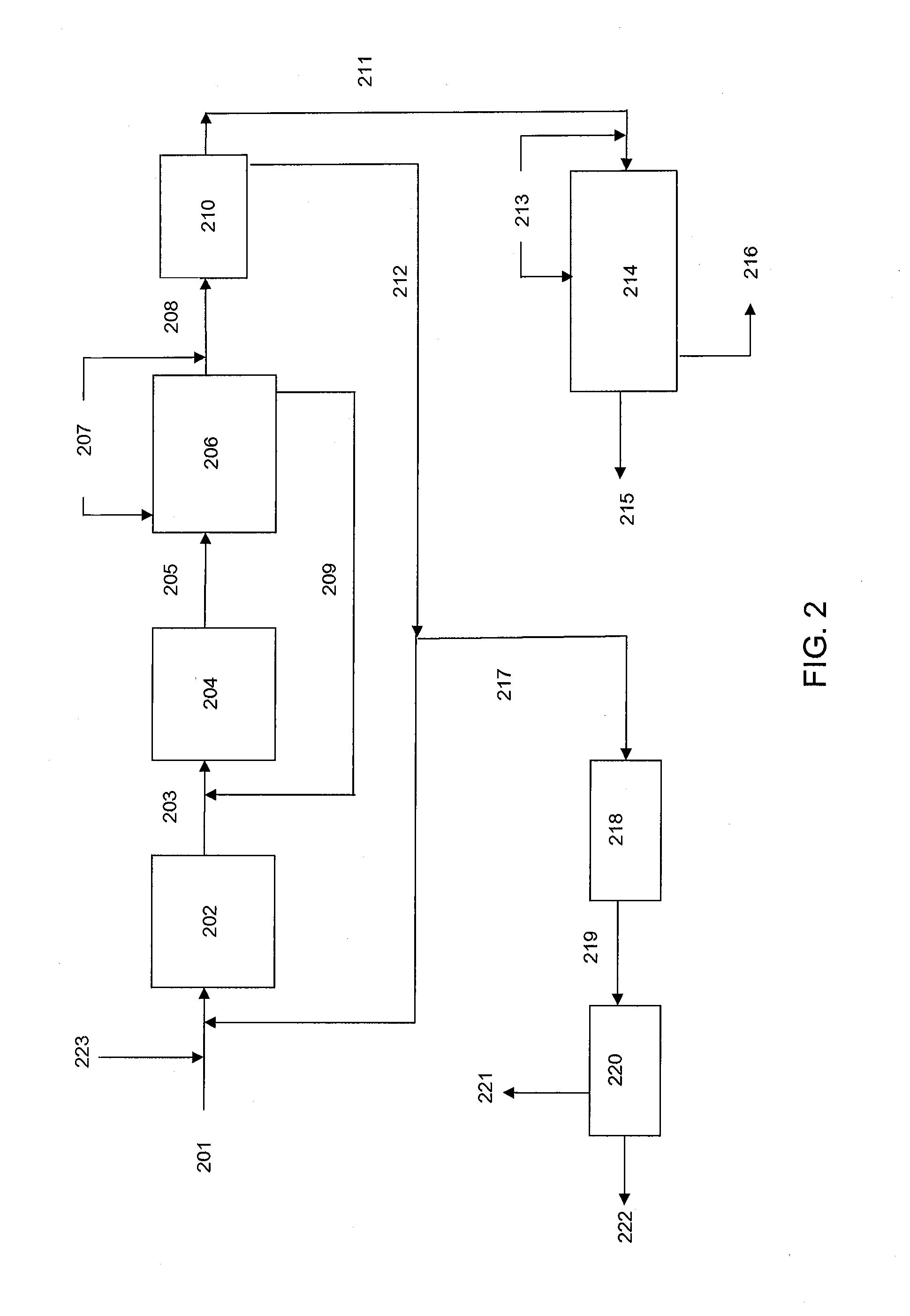

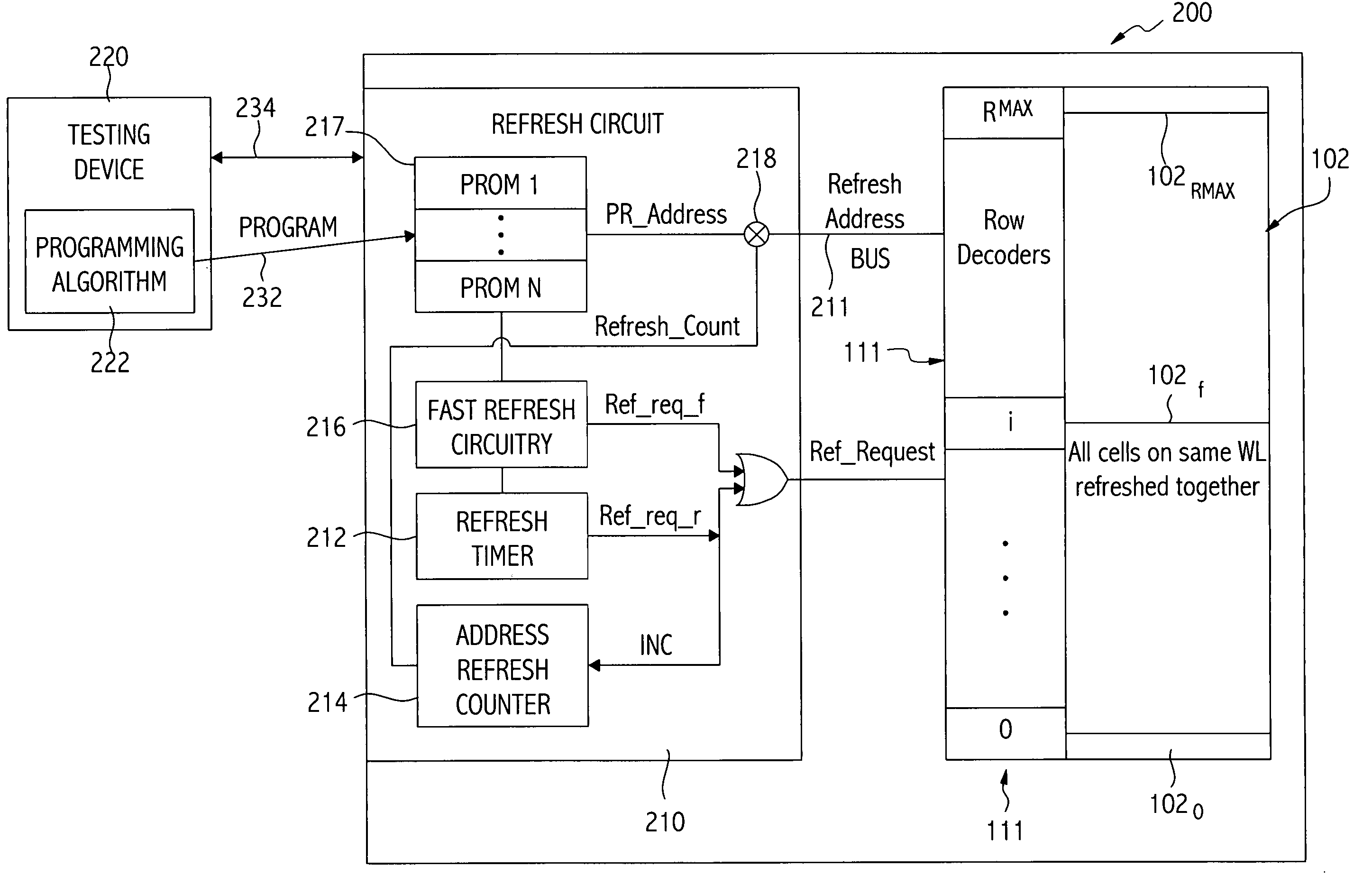

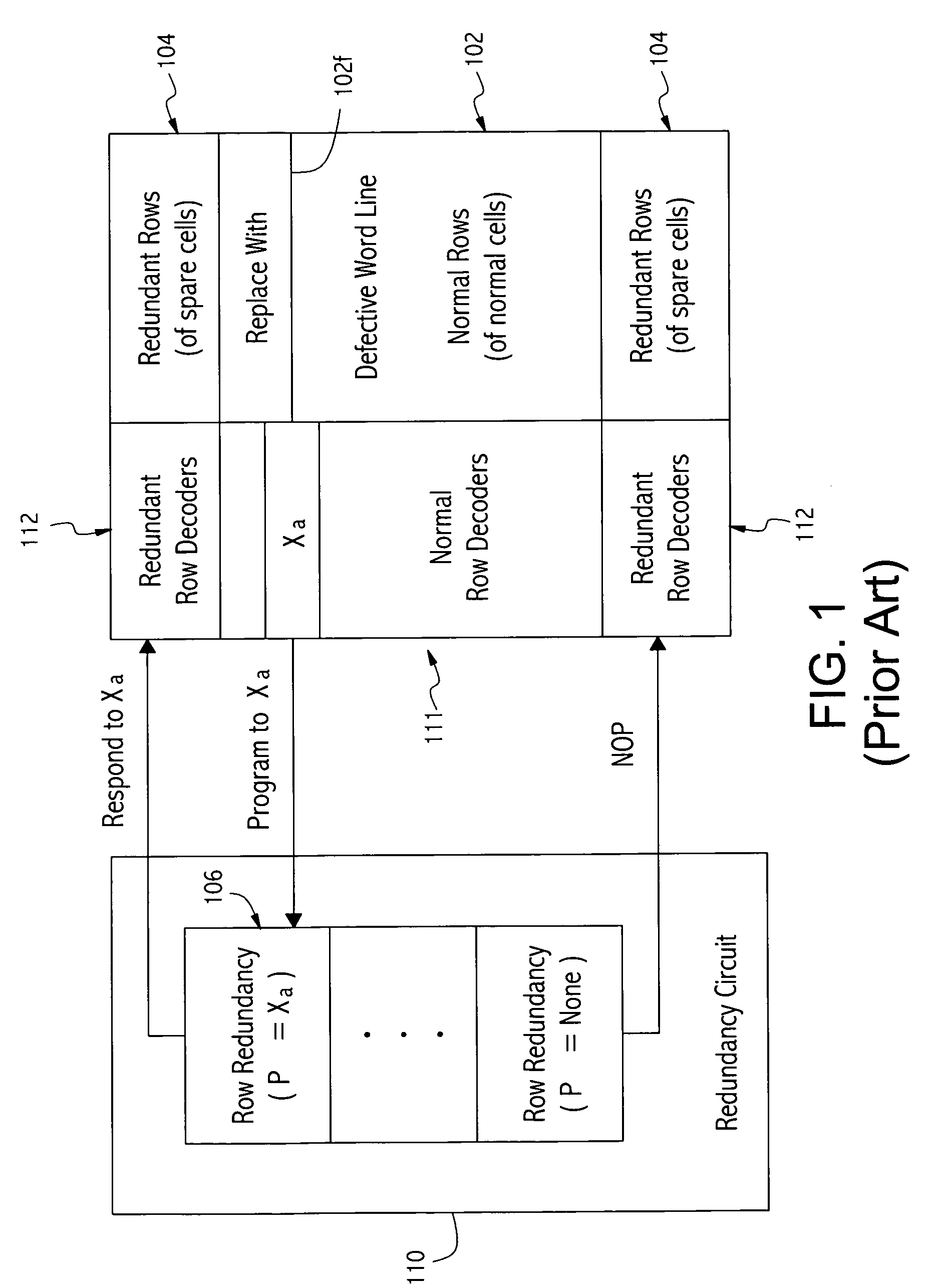

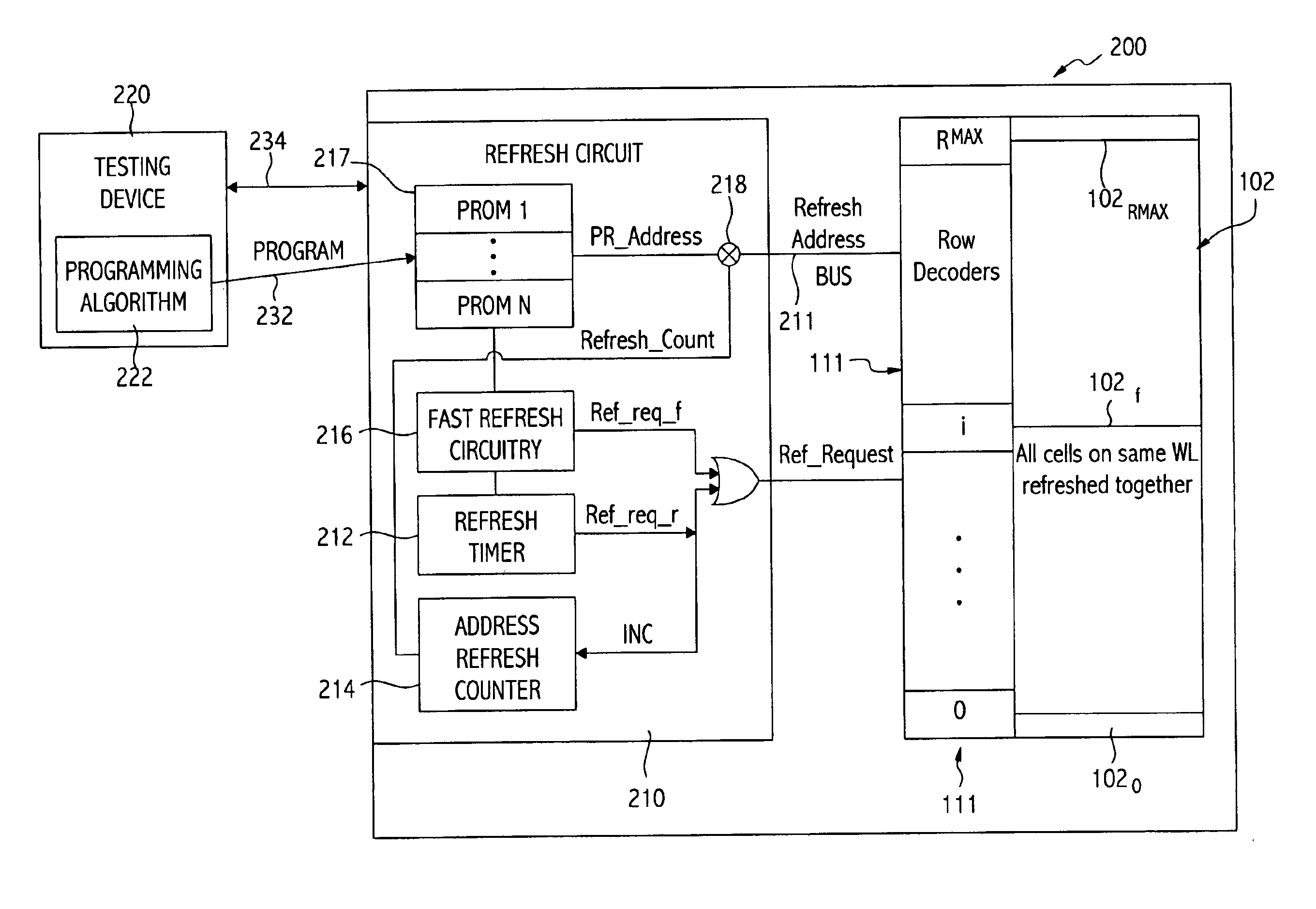

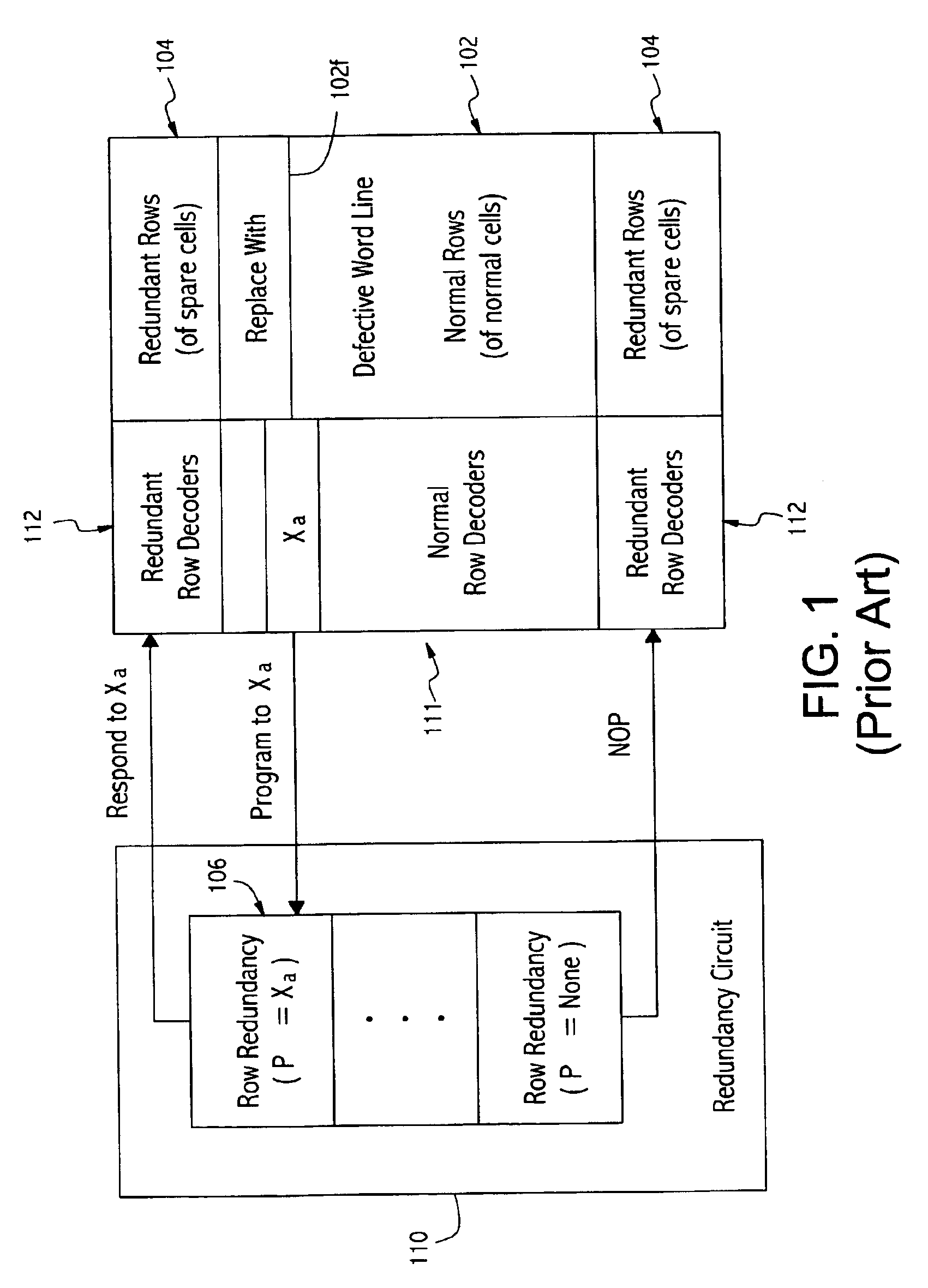

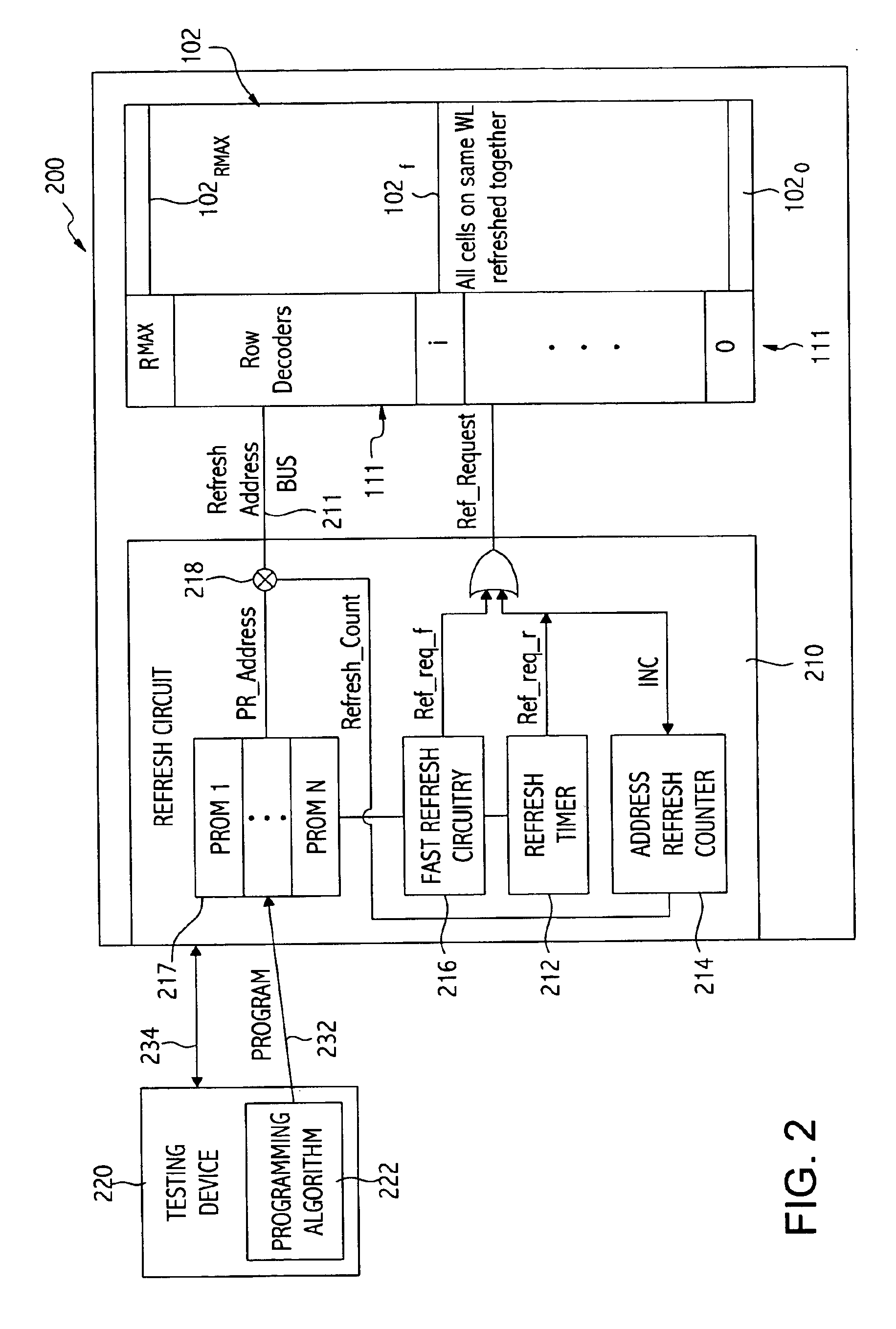

Refresh for dynamic cells with weak retention

Methods and circuit configurations for utilizing memory cells having weak retention times are provided. For some embodiments, rows identified as having weak retention cells may be refreshed more often than “normal retention” cells. As an example, if a normal refresh period is TREF, weak retention cells may be refreshed every TREF / 2 or TREF / 4 (possibly depending on the actual measured retention time).

Owner:POLARIS INNOVATIONS LTD

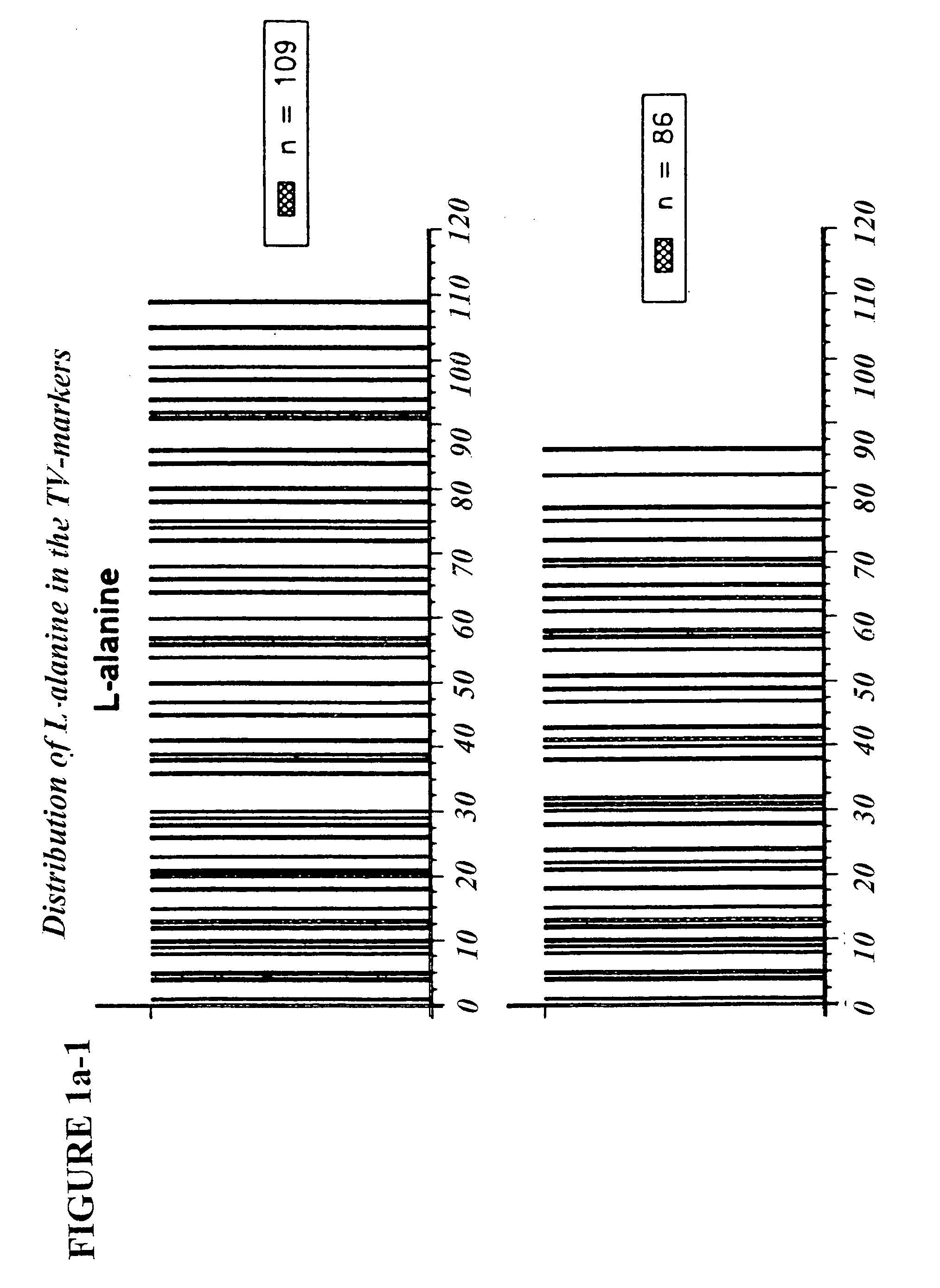

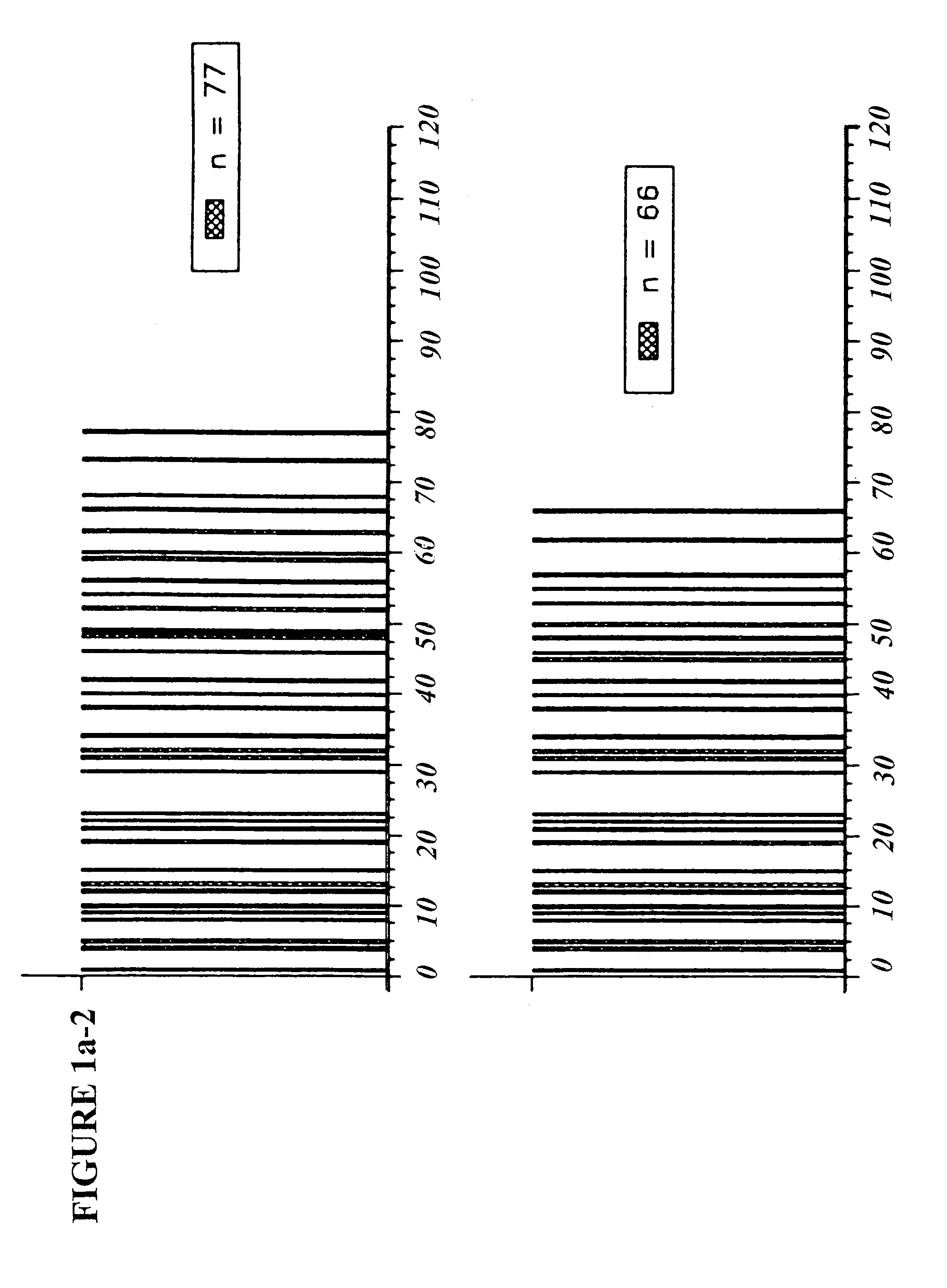

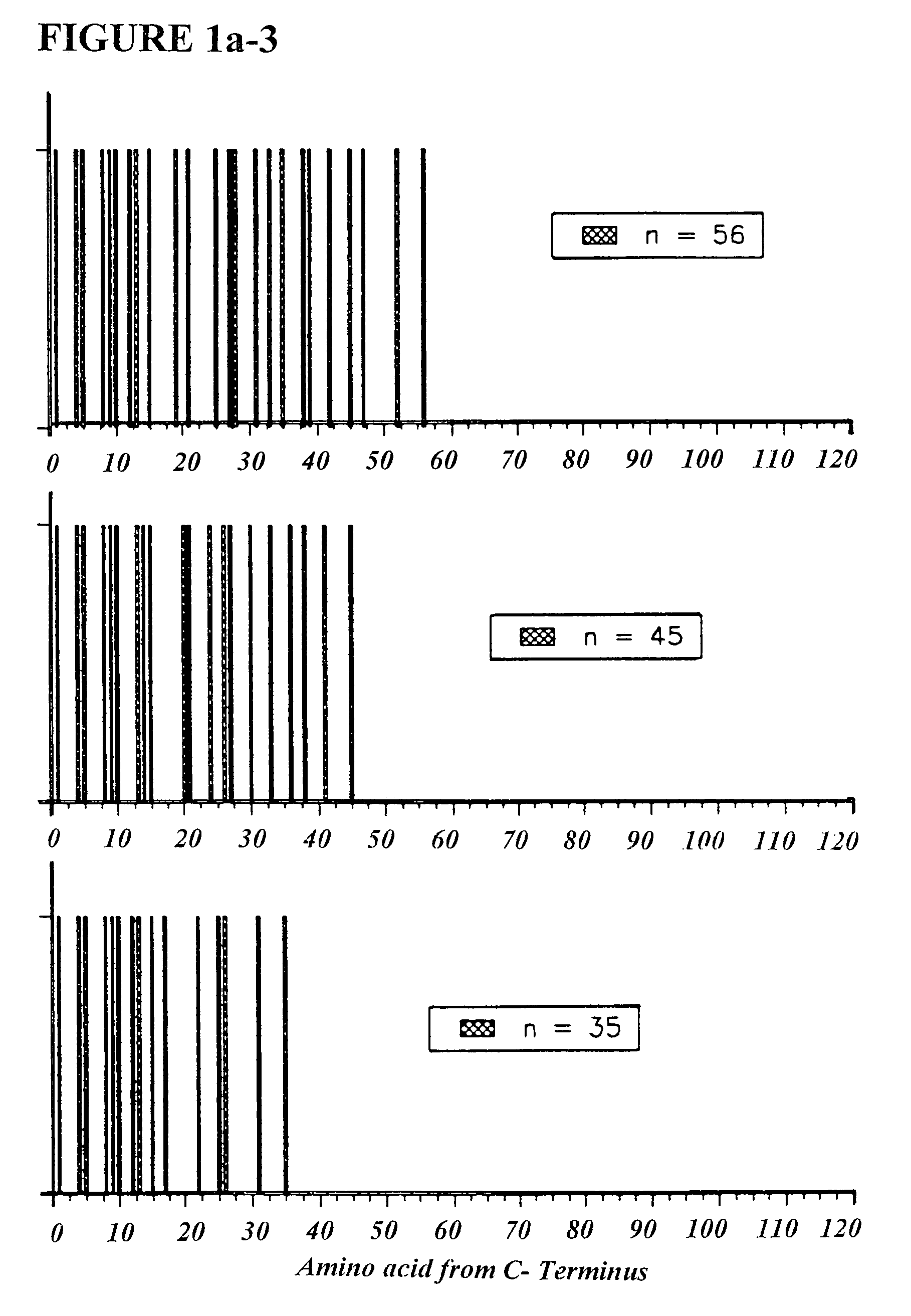

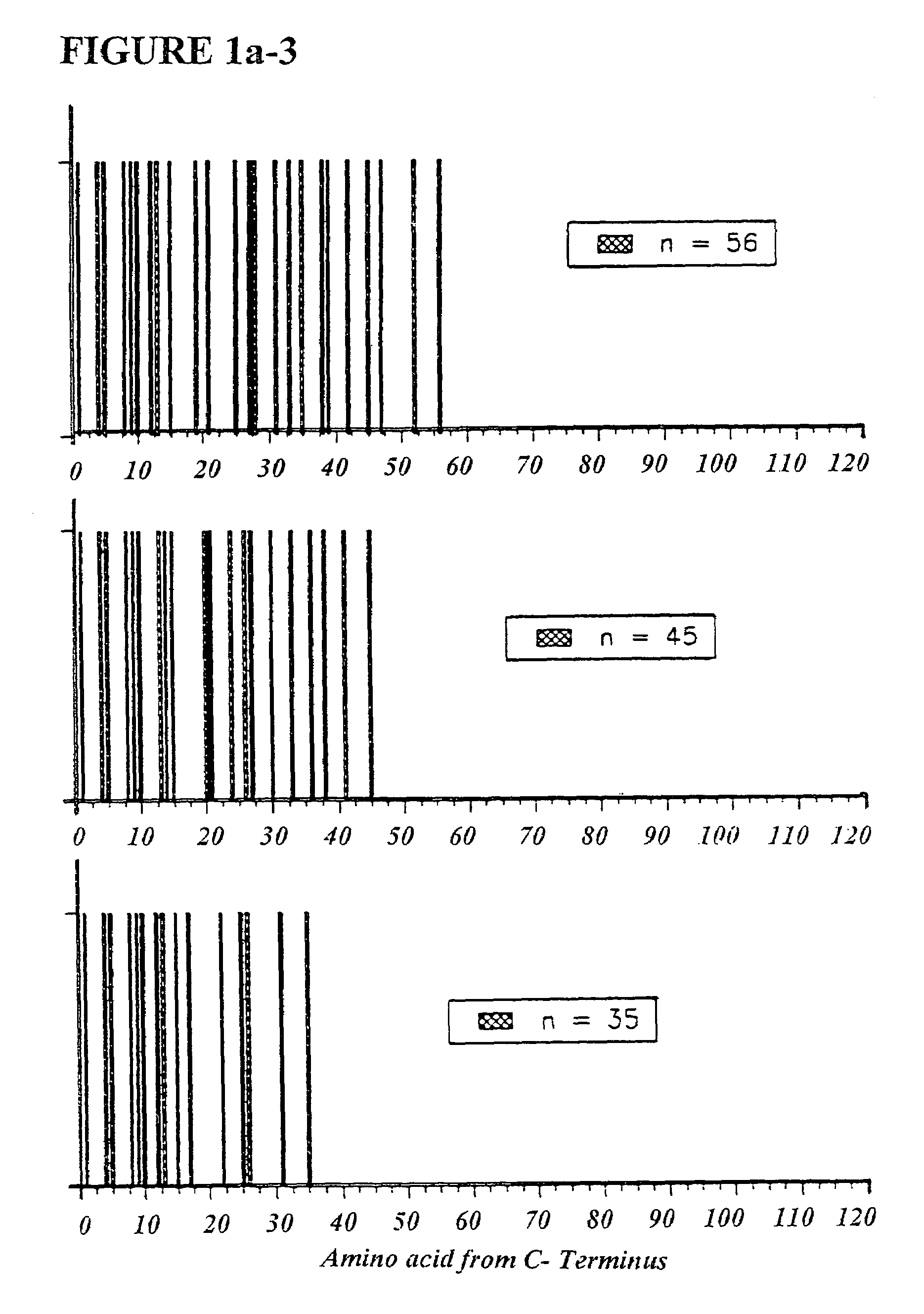

Copolymer 1 related polypeptides for use as molecular weight markers and for therapeutic use

InactiveUS7074580B2Accurate and robust calibration setTherapeutic utilityPeptide/protein ingredientsDisease diagnosisRetention timeLinear relationship

The present invention provides processes for determining the molecular weight of glatiramer acetate and other copolymers using molecular weight markers. The present invention further provides a plurality of molecular weight markers for determining the molecular weight of glatiramer acetate and other copolymers which display linear relationships between molar ellipticity and molecular weight, and between retention time and the log of the molecular weight. The molecular weight markers also optimally demonstrate biological activity similar to glatiramer acetate or corresponding copolymers and can be used for treating or preventing various immune diseases.

Owner:YEDA RES & DEV CO LTD

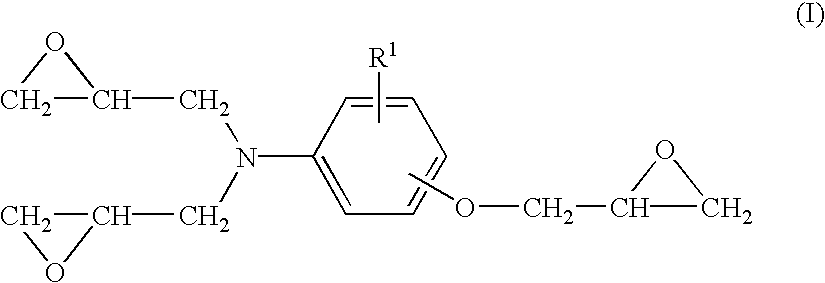

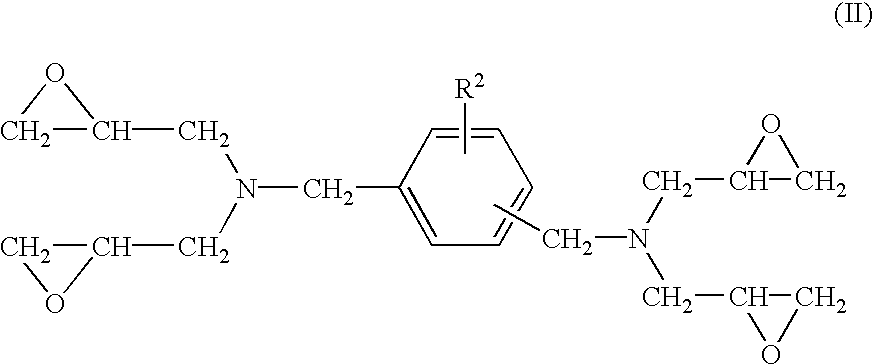

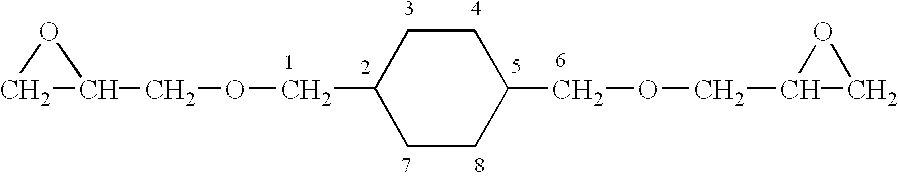

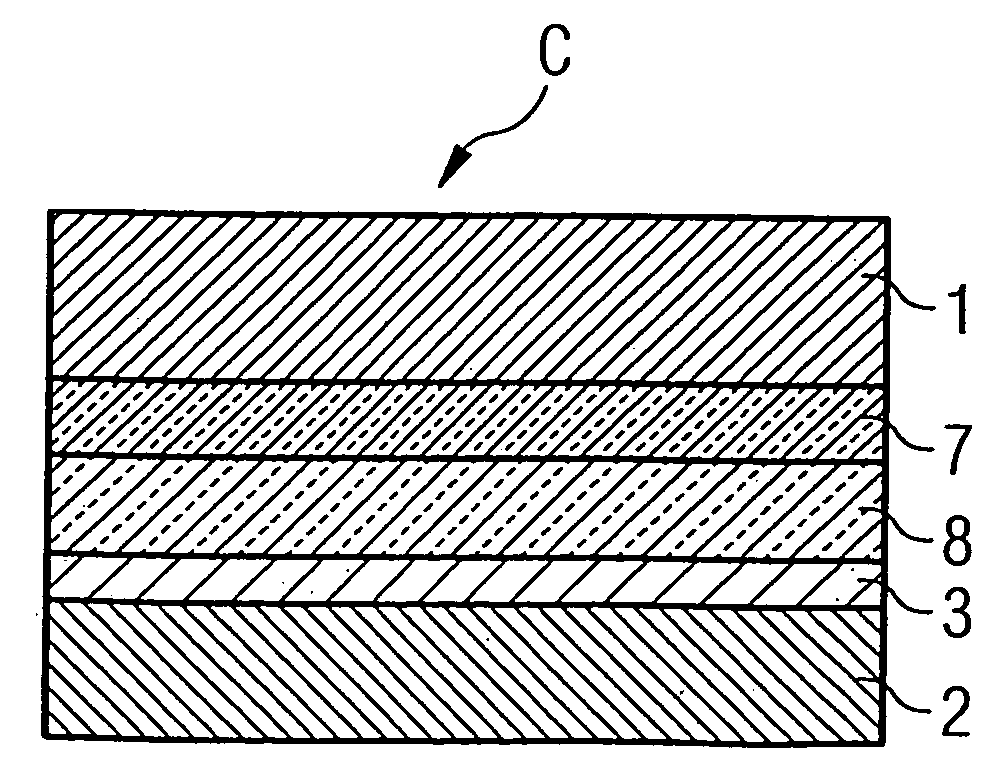

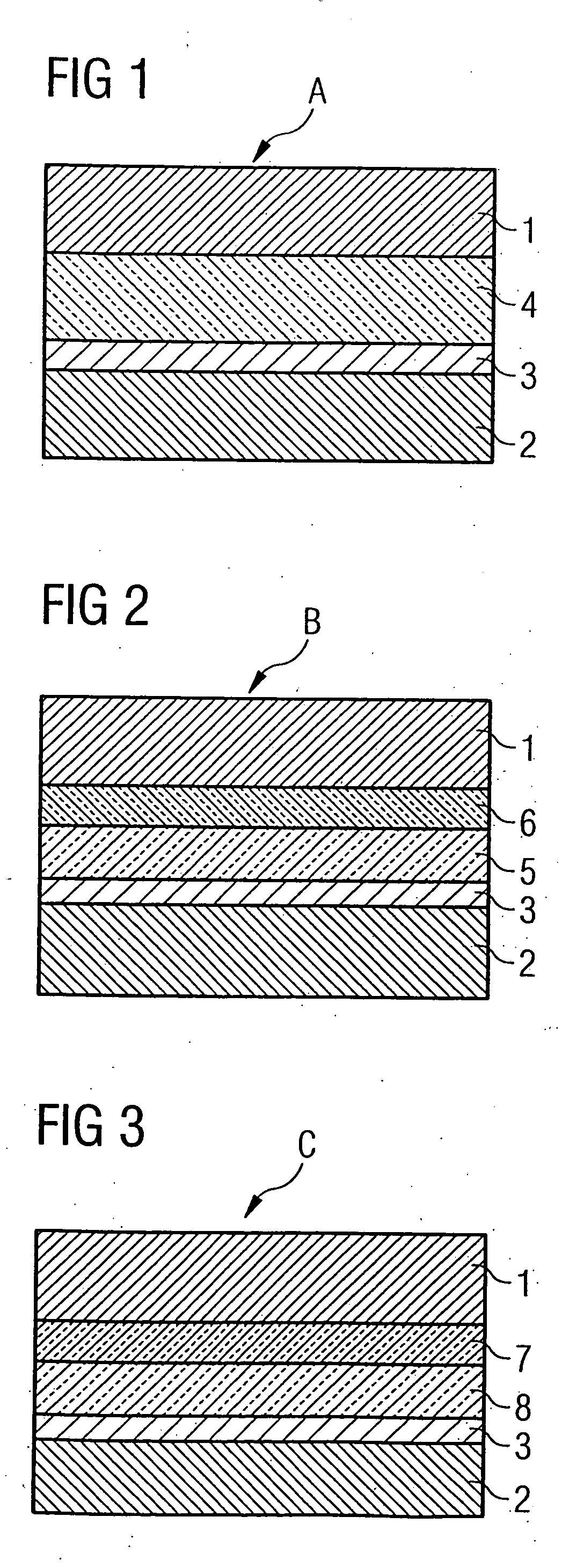

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

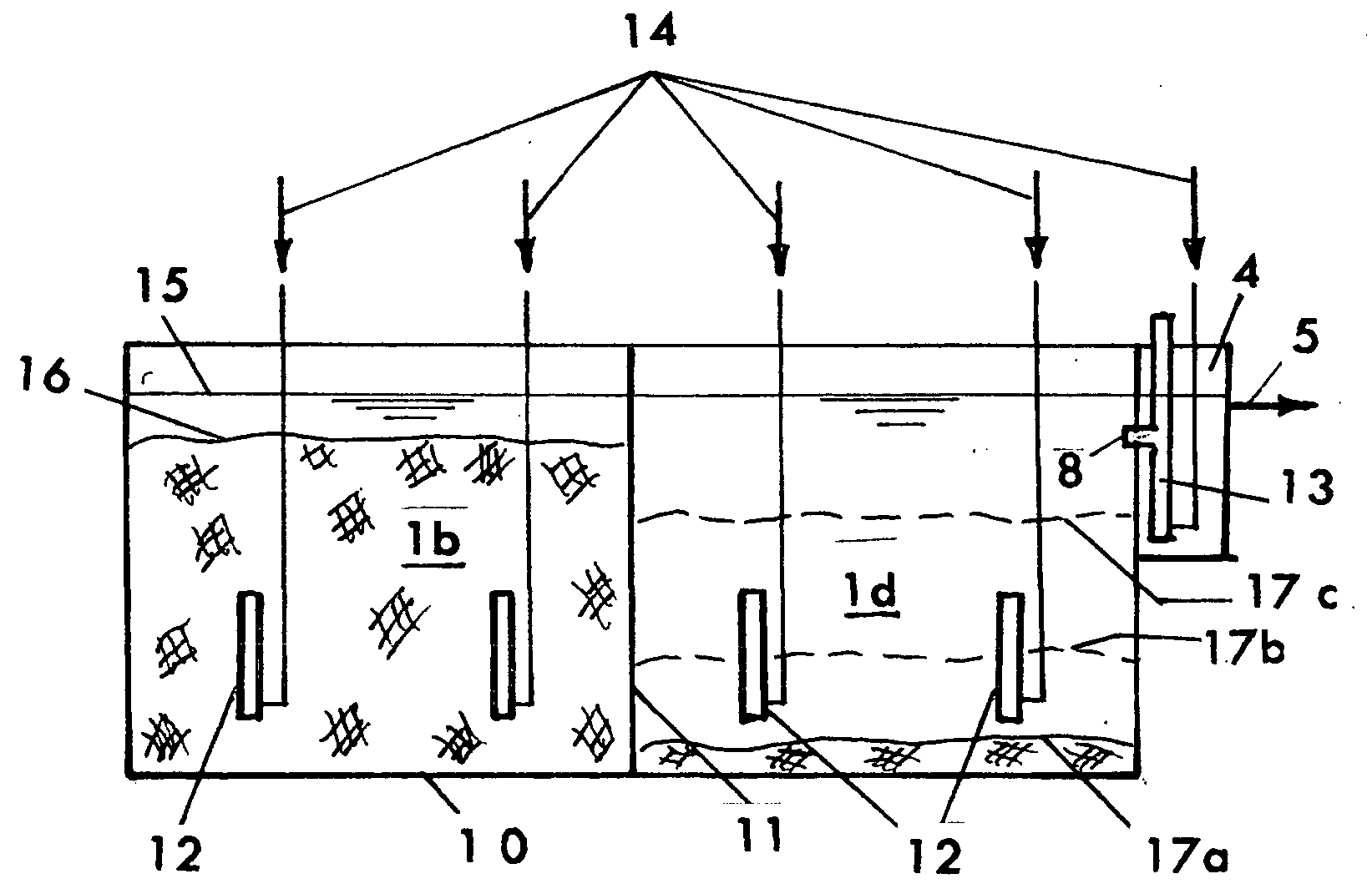

Batch-continuous process and reactor

InactiveUS20060081533A1Precise positioningTreatment using aerobic processesMultistage water/sewage treatmentRetention timeWastewater

This is a method of batch-continuous operation for treatment and separation of liquid-solid mixtures in a reactor with reactive solids comprising steps of continuously feeding the liquid in the reactor, contacting (possibly, mixing) liquid with the solids in at least a portion of the reactor, periodically separating the liquid from the solids in unmixed, or predominantly unmixed, portion of the reactor, discharging at least a portion of the separated liquid from the reactor, and retaining the separated solids in the unmixed portion of the reactor, and periodically resuspending the solids in the unmixed portion of the reactor and transferring the resuspended soilds into the portion of the reactor for contacting liquid with the solids. The contacting and / or mixing of the liquid with the solids in the mixed portion of the reactor can be continuous or periodic mixing. The unmixed zone differs from the quiescent zone in conventional clarifiers. It is a flow-through zone with a noticeably high velocity of flow as in aeration tanks of biological treatment systems. The retention time in unmixed zones is much shorter than in clarifiers. The method and apparatus can be used to treat water and wastewater, and in various chemical, biochemical, and pharmaceutical processing operations.

Owner:KHUDENKO BORIS M

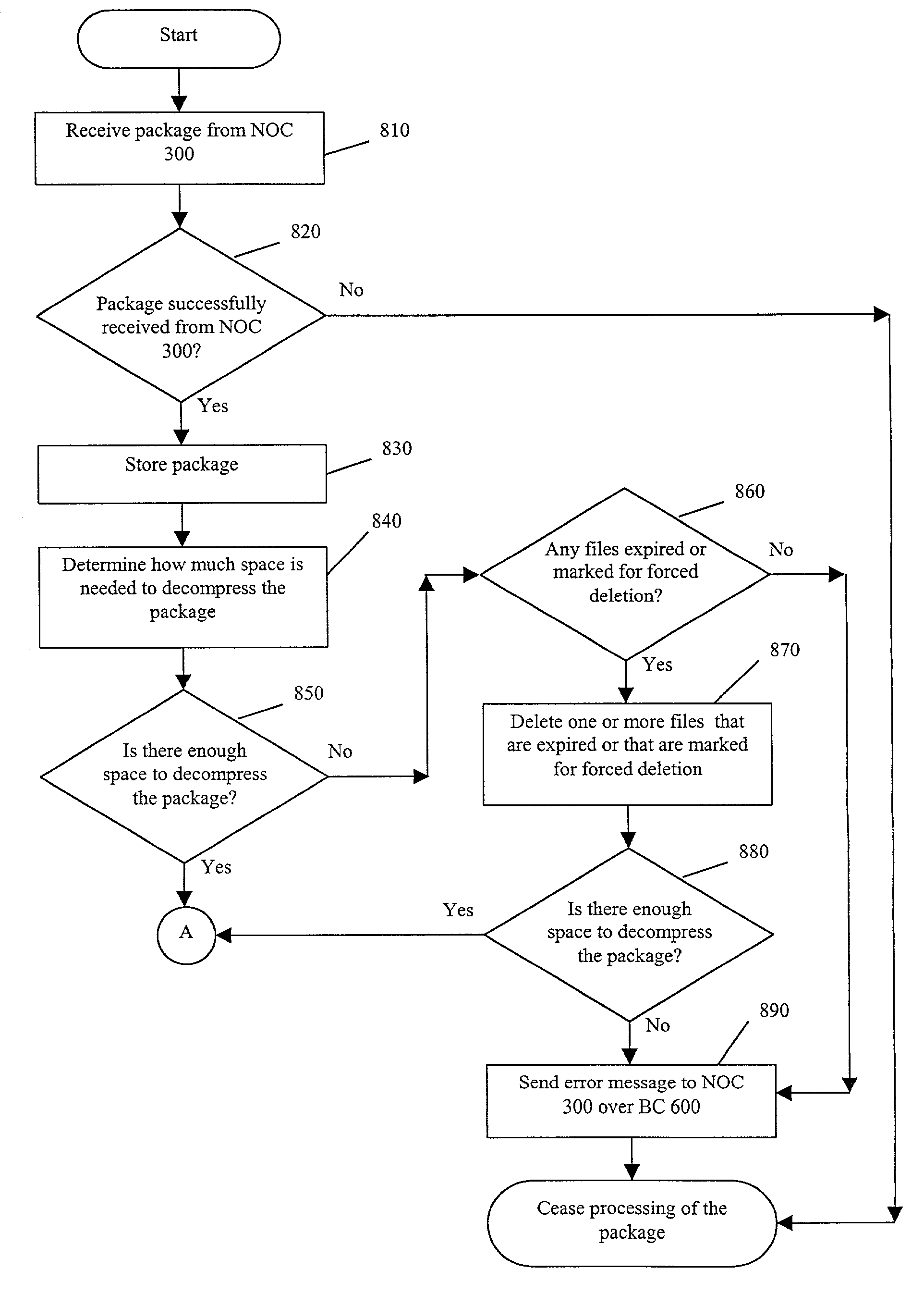

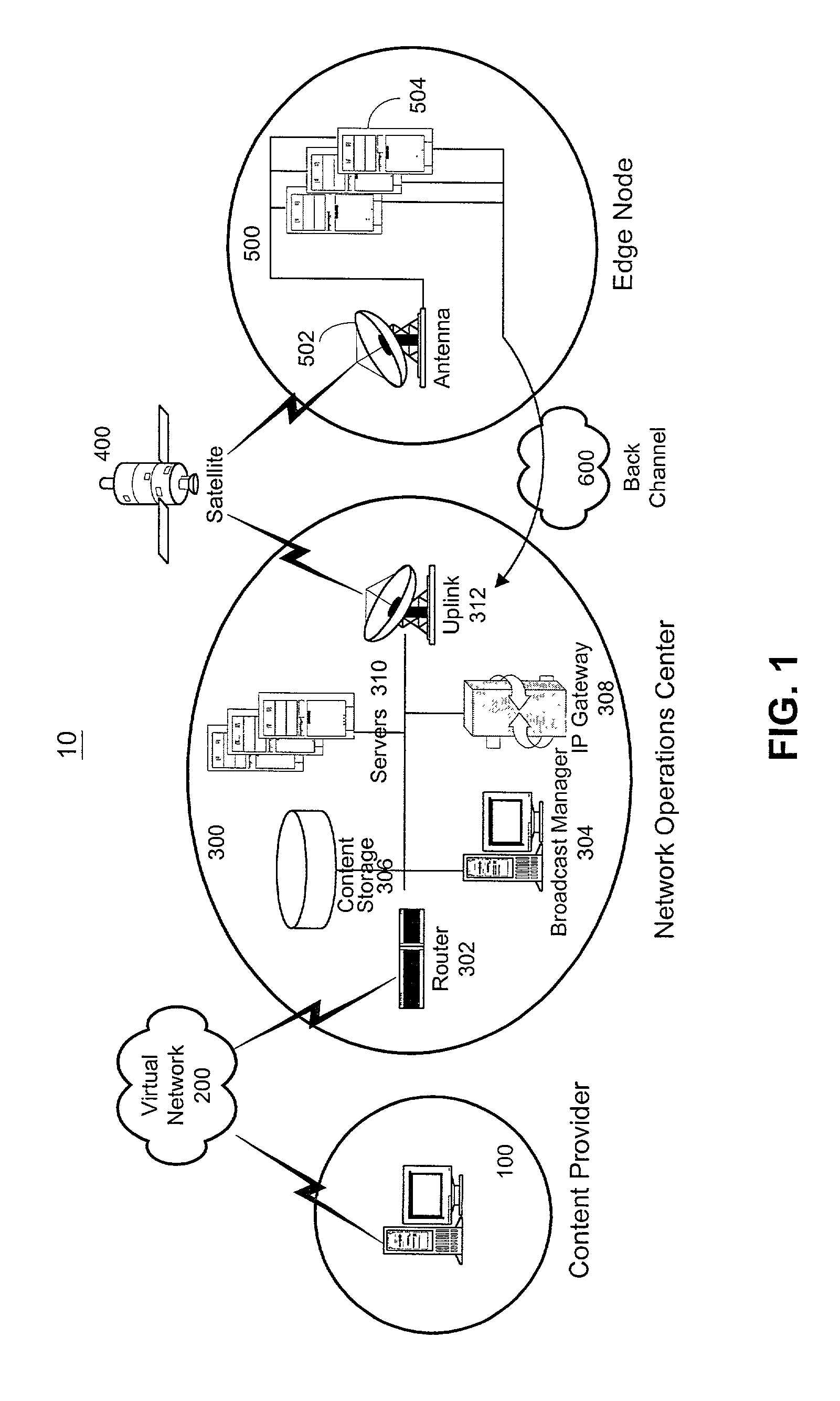

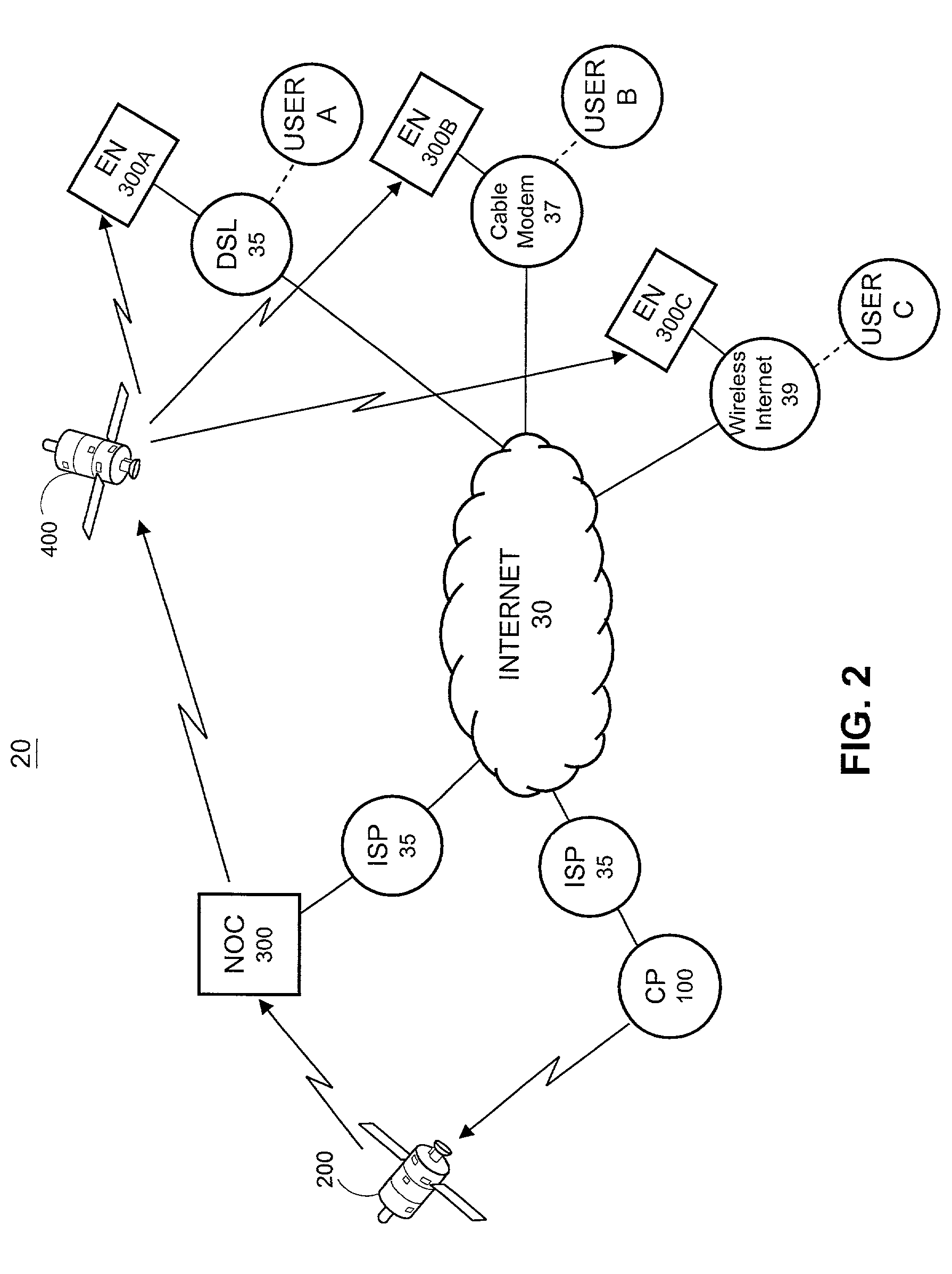

Forward cache management between edge nodes in a satellite based content delivery system

A method and system for storing data at edge nodes that receive content, such as video, from an uplink center, such as a network operation center (“NOC”), via a satellite for redelivery to a last mile service provider. Data is stored at the edge nodes in caches along with metadata, which determines how long data is to be kept. The NOC also sends messages to the edge nodes to require deletion of files and data.

Owner:BANK OF NEW YORK THE AS COLLATERAL TRUSTEE +1

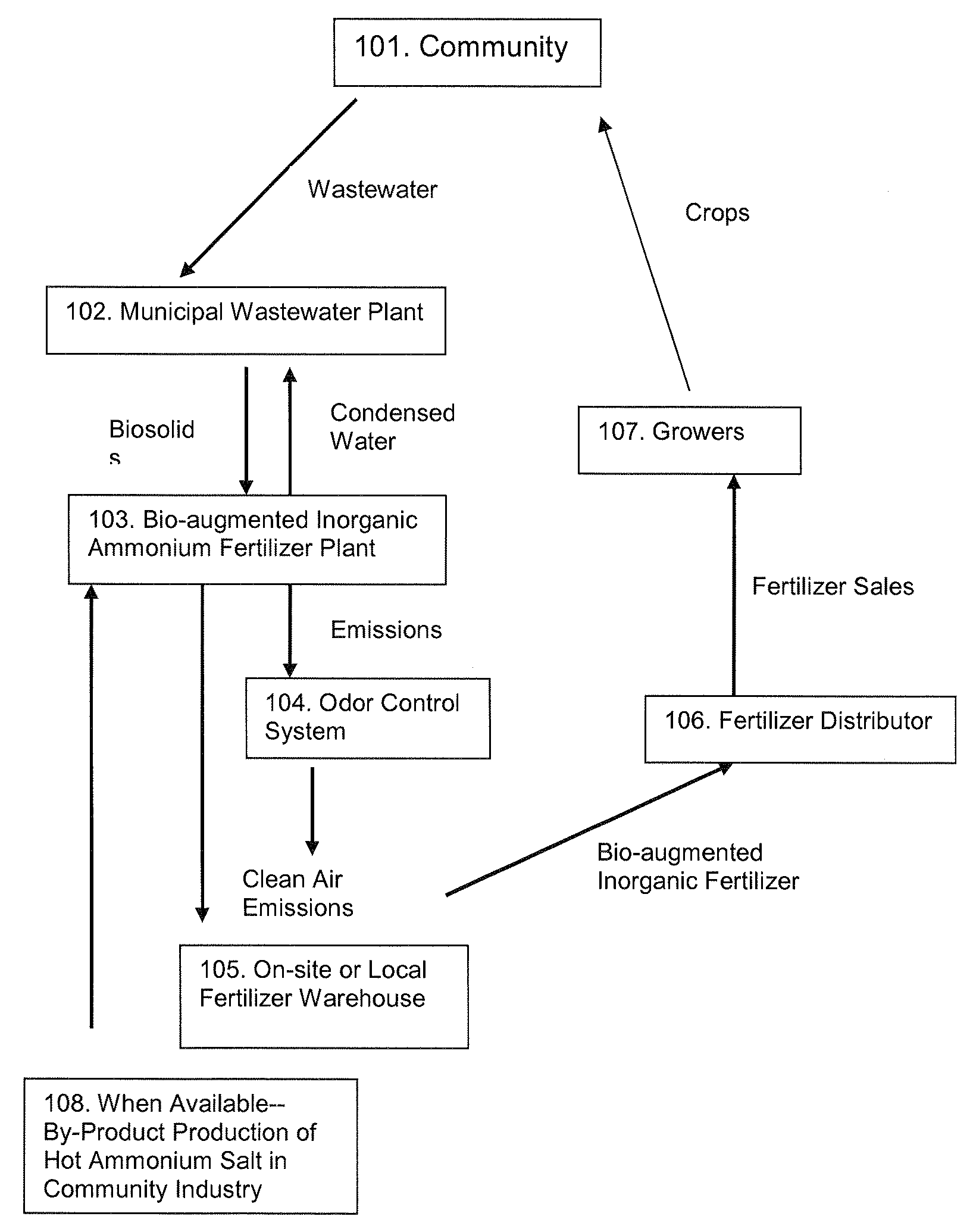

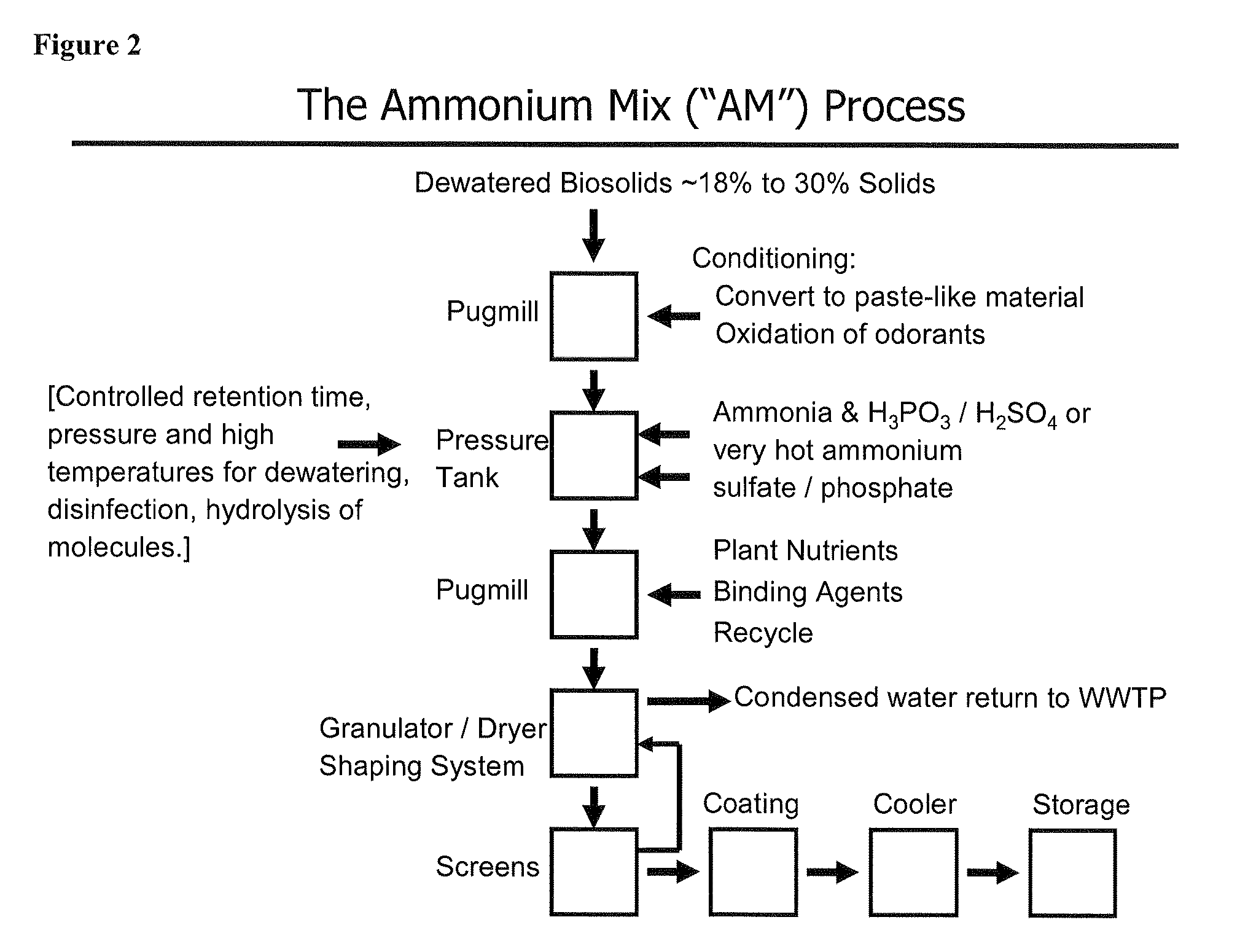

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

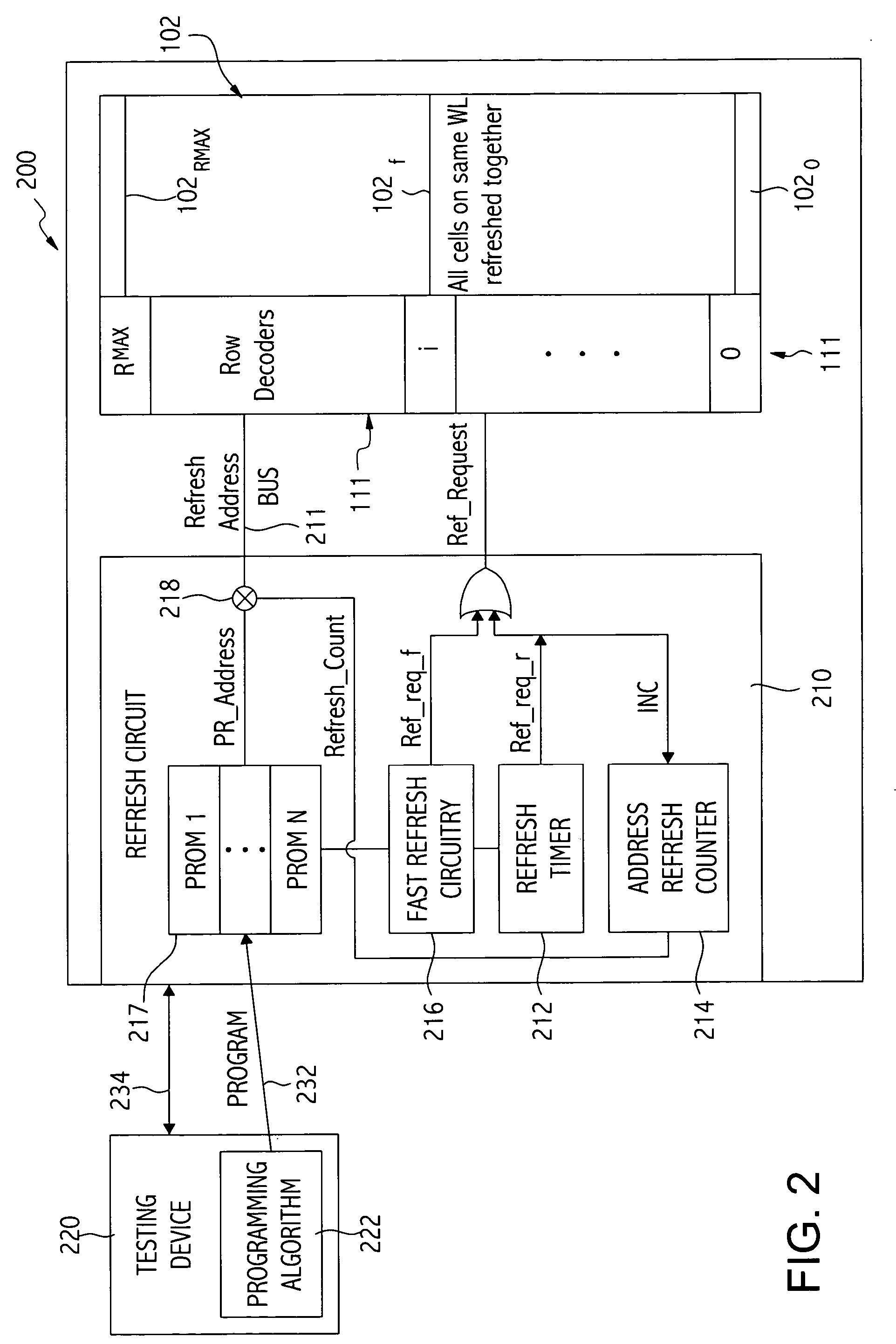

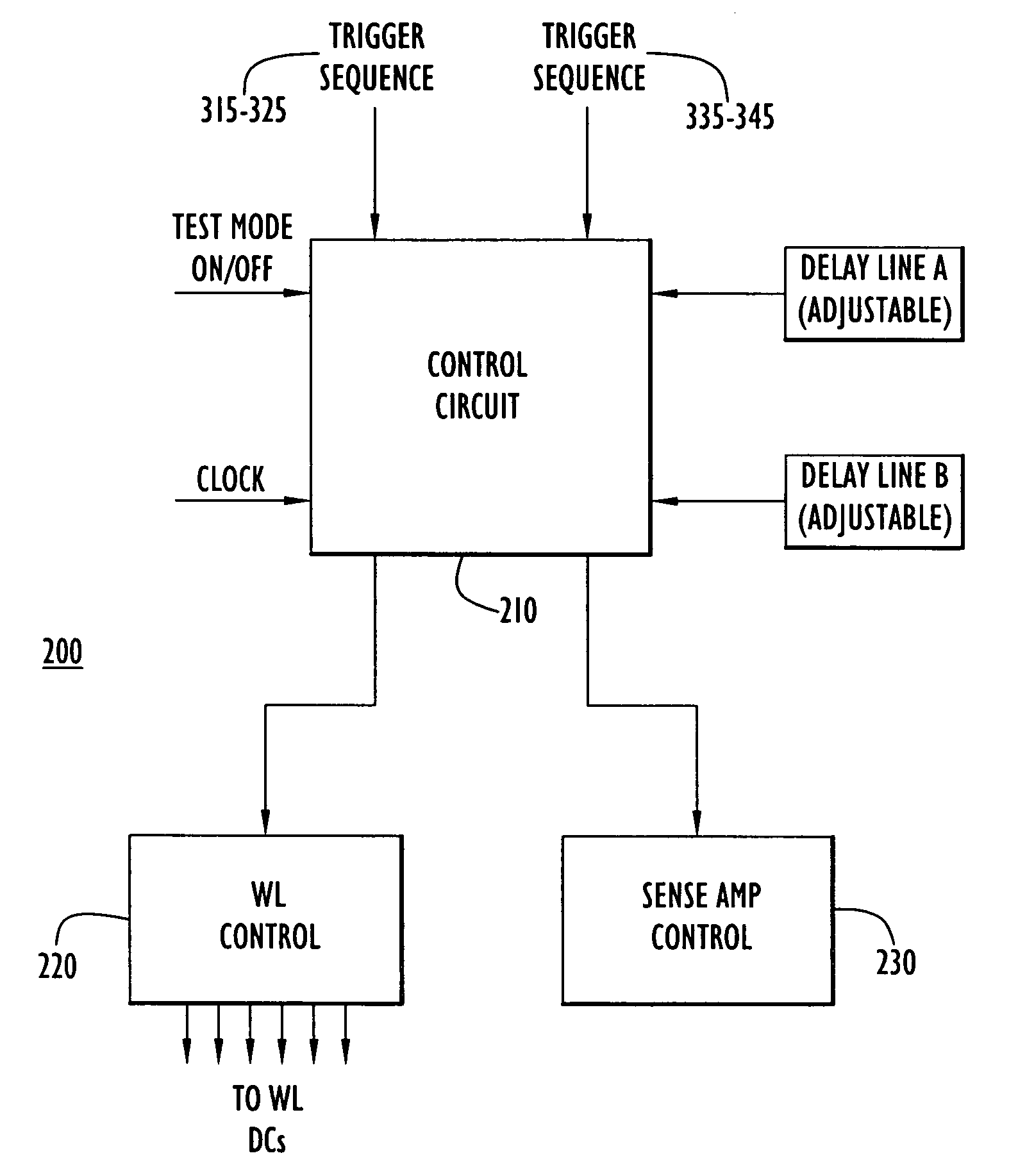

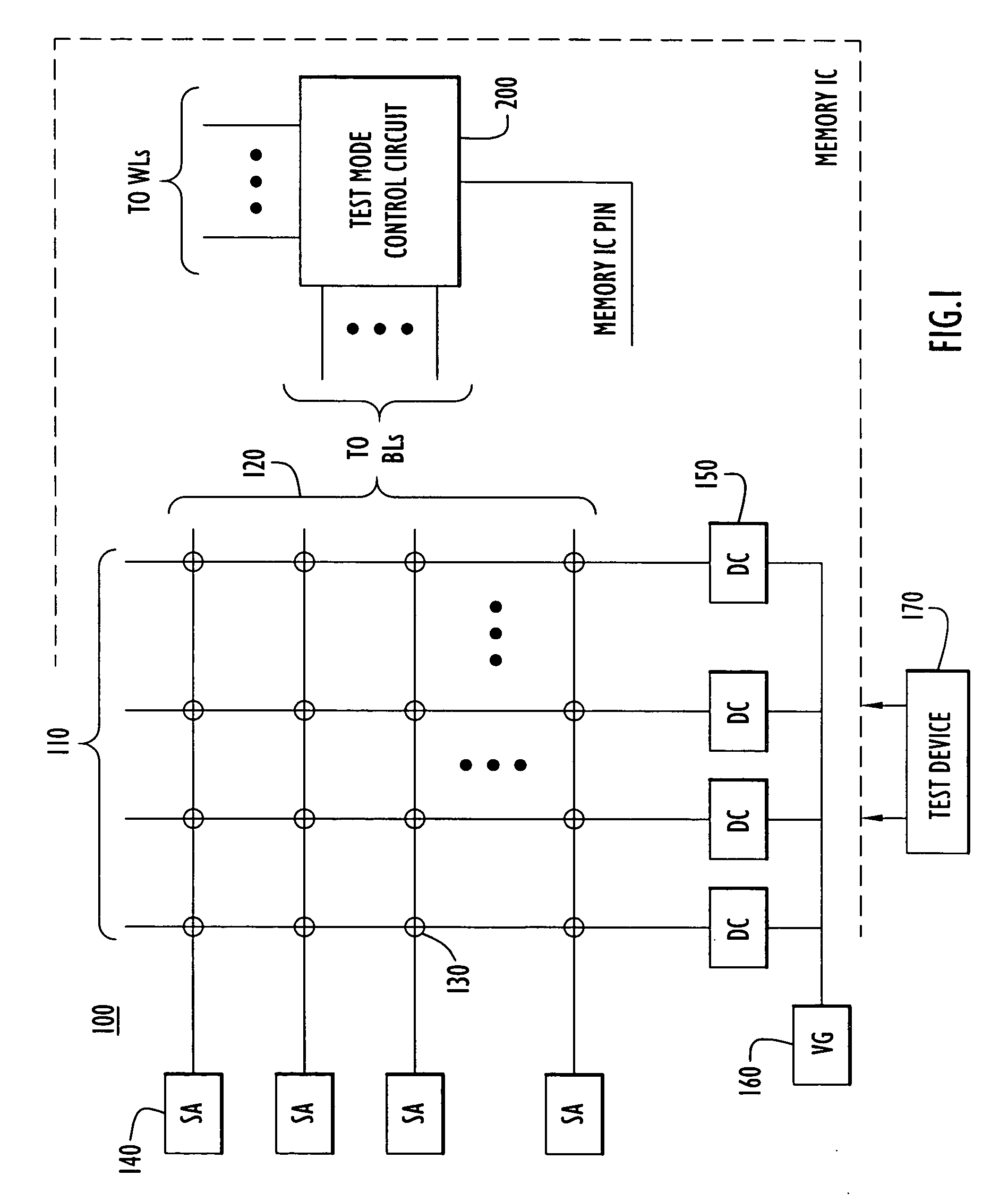

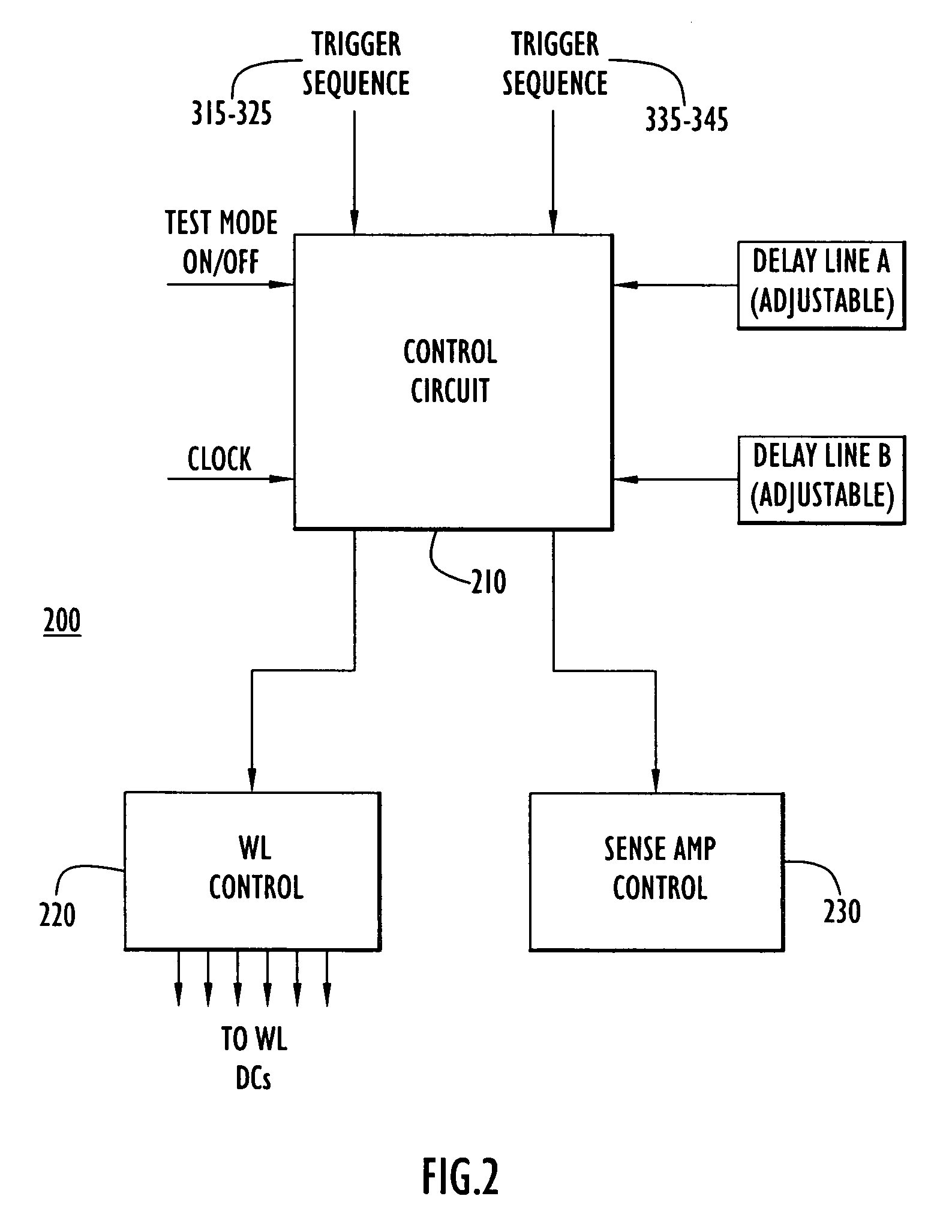

Test method, control circuit and system for reduced time combined write window and retention testing

A method, test mode circuit and system for a combined write window and retention test for a memory device that is faster than techniques heretofore known. The combined write window and retention test procedure involves controlling time intervals during which wordlines are activated and deactivated and bitlines are grounded or connected to a bitline high voltage such that the wordlines are activated while bitlines are either grounded or at the bitline high voltage. During a first time interval after the wordlines are activated a first value (e.g., 0 V) is written to storage cells associated with the activated wordlines. During a second time interval after a second activation of the wordlines, a second value (a non-zero logic “1” V) is written to storage cells associated with activated wordlines. The second time interval has a duration that establishes write window test conditions. After expiration of a third time interval corresponding to a retention time interval, the storage cells are read and a determination is made whether a storage cell has passed or failed a combined write window and retention test based on a value read from the storage cell.

Owner:INFINEON TECH AG

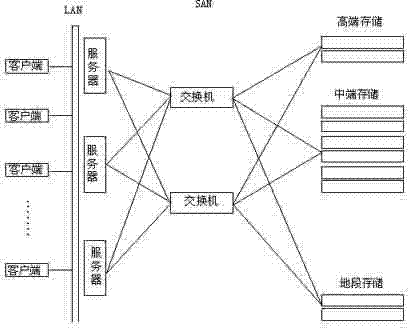

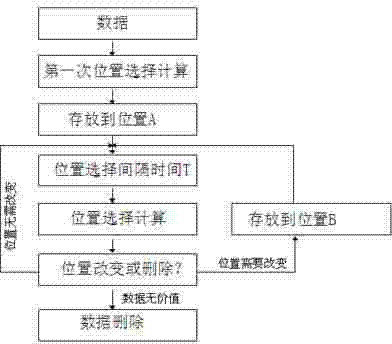

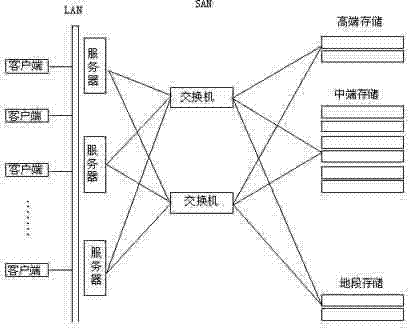

Grading storage method for system

InactiveCN102508789AReduce business costsImprove performanceMemory adressing/allocation/relocationRetention timePerformance index

The invention provides a grading storage method for a system. According to the importance, the visiting frequency, the retention time and the performance index of data, the data is stored in storage devices with different performances by adopting different storage modes, so as to realize automatic migration of data objects among the storage devices; and the data which is not visited frequently is automatically transferred to lower layers in storage layers, so that storage space with higher cost can be released for the data with higher visiting frequency, so that better cost performance is obtained, further, the space occupied by the non-important data in primary local disks can be greatly reduced, and the storage performance of the whole system is quickened.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

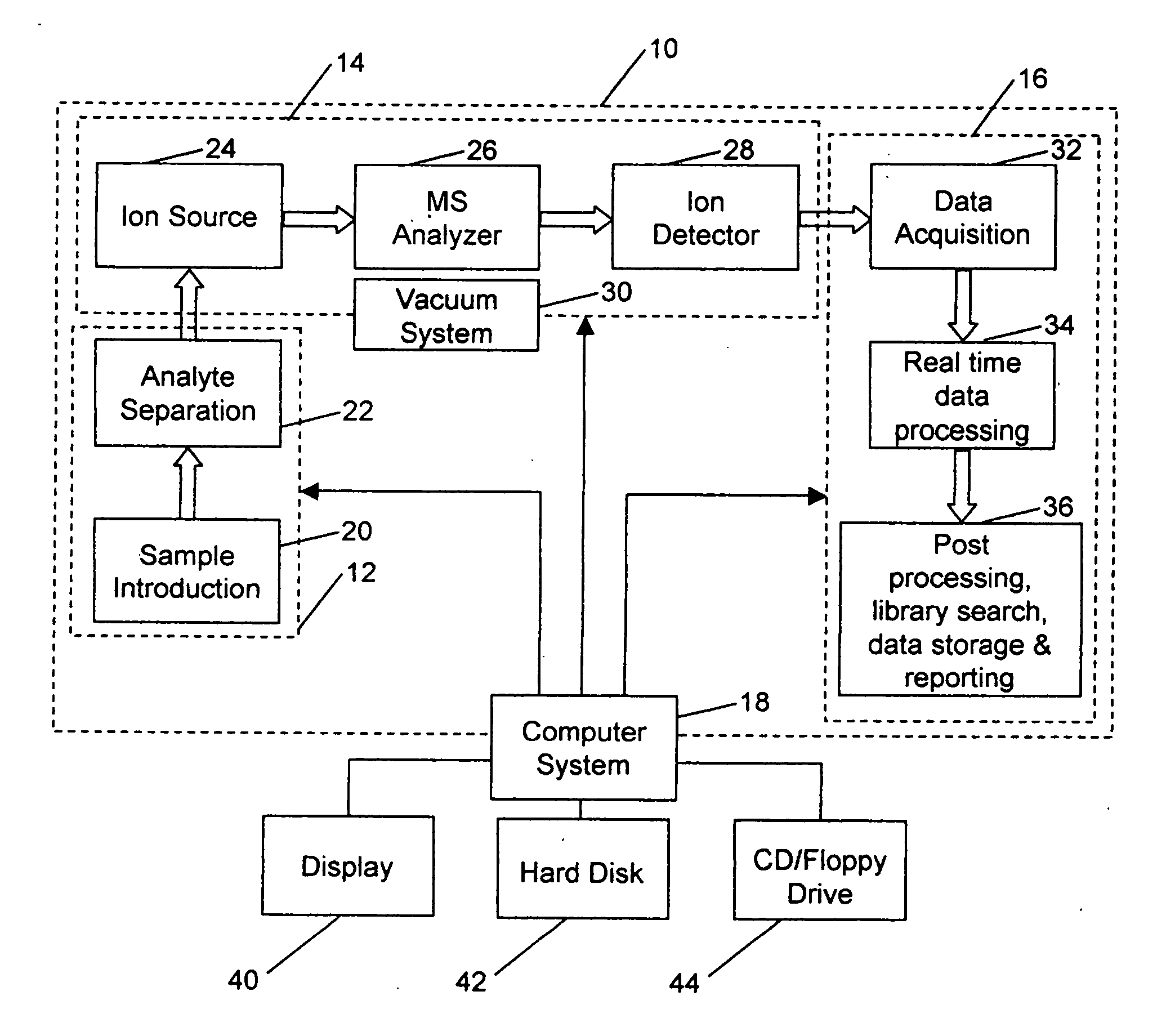

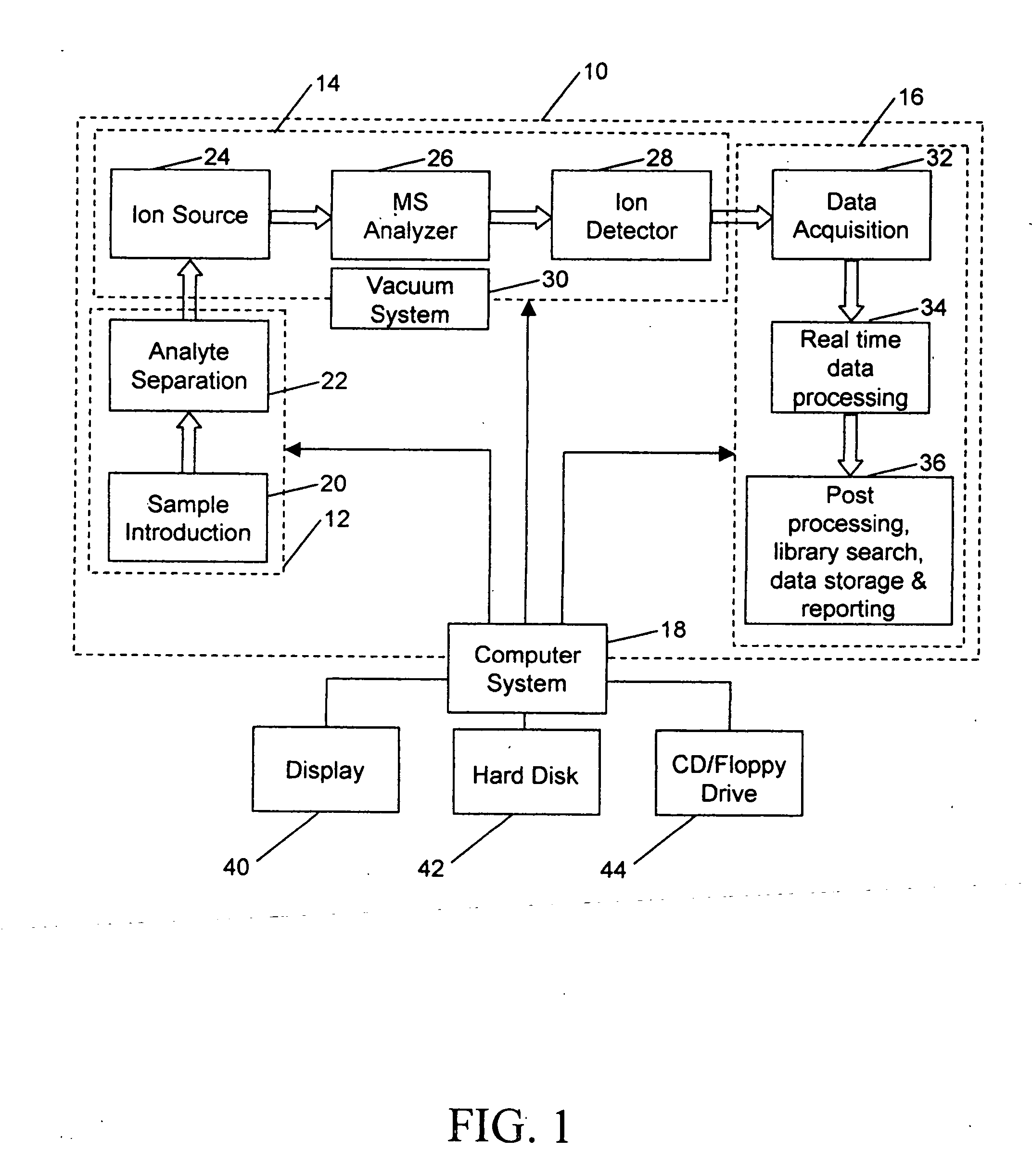

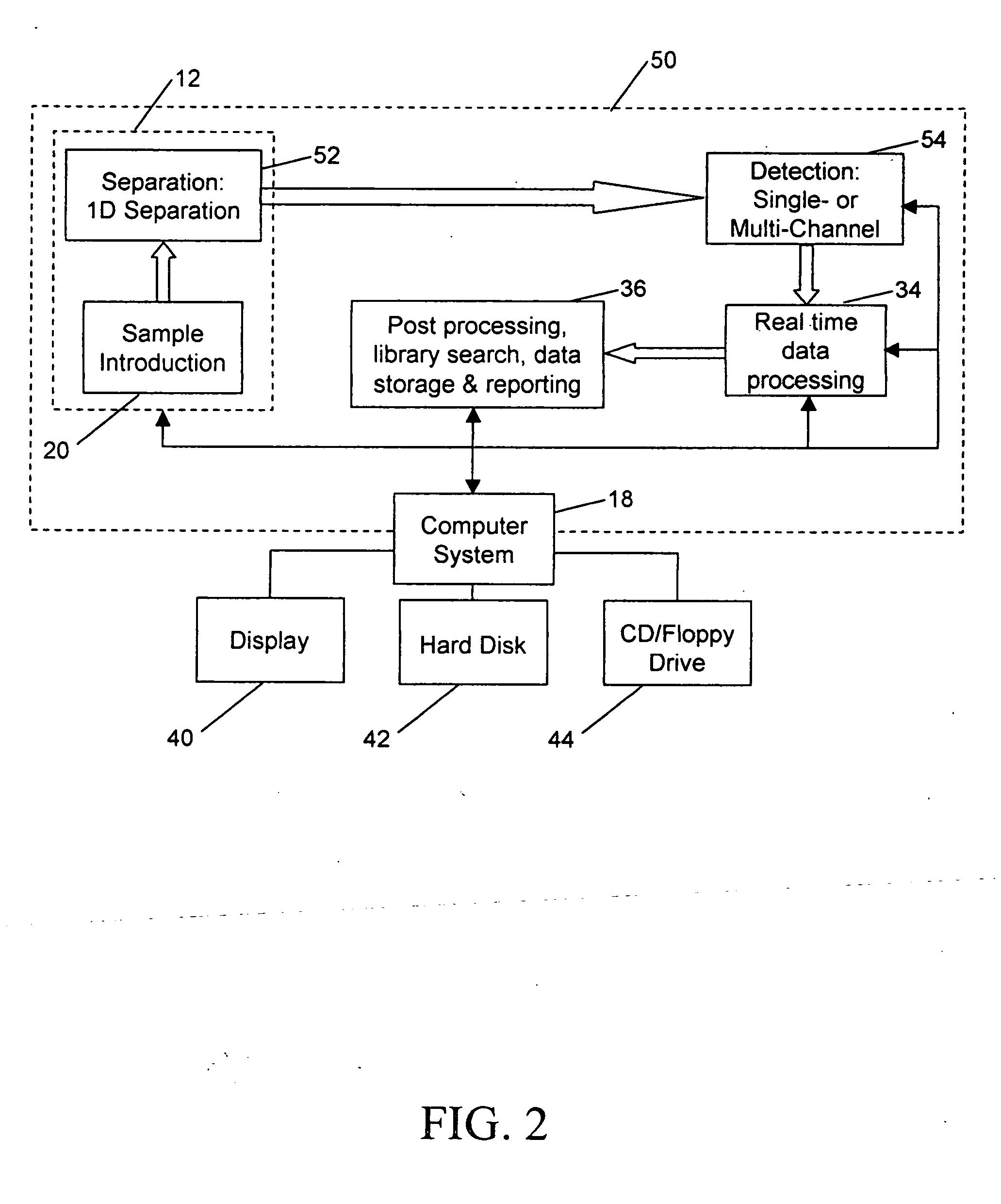

Chromatographic and mass spectral date analysis

InactiveUS20060255258A1Improve accuracyEasy to quantifyParticle separator tubesComponent separationAnalyteRegression analysis

Apparatus, methods, and computer readable media having computer code for calibrating chromatograms to achieve chromatographic peak shape correction, noise filtering, peak detection, retention time determination, baseline correction, and peak area integration. A method for processing a chromatogram, comprises obtaining at least one actual chromatographic peak shape function from one of an internal standard, an external standard, or an analyte represented in the chromatogram; performing chromatographic peak detection using known peak shape functions with regression analysis; reporting regression coefficients from the regression analysis as one of peak area and peak location; and constructing a calibration curve to relate peak area to known concentrations in the chromatogram. A method for constructing an extracted ion chromatogram, comprises calibrating a low resolution mass spectrometer for both mass and peak shape in profile mode; performing mass spectral peak analysis and reporting both mass locations and integrated peak areas; specifying a mass defect window of interest; summing up all detected peaks with mass defects falling within the specified mass defect window to derive summed intensities; and plotting the summed intensities against time to generate a mass defect filtered chromatogram.

Owner:CERNO BIOSCI

Semiconductor memory

InactiveUS20060076549A1Short switching timeLow programming voltageDigital storageBulk negative resistance effect devicesSilicon matrixRetention time

The object of providing a non-volatile semiconductor memory that stands out by good scalability and a high retention time as well as ensures low switching voltages at low switching times and achieves a great number of switching cycles at good temperature stability is solved by the present invention with a semiconductor memory whose memory cells comprise at least one silicon matrix material layer with open or disturbed nanocrystalline or amorphous network structures and structural voids which has a resistively switching property between two stable states, utilizing the ion drift in the silicon matrix material layer. The memory concept suggested in the present invention thus offers an alternative to the flash and DRAM memory concepts since it is not based on the storing of charges, but on the difference of the electric resistance between two stable states that are caused by the mobility of ions in the amorphous silicon matrix material with an externally applied electric field.

Owner:POLARIS INNOVATIONS LTD

Copolymer 1 related polypeptides for use as molecular weight markers and for therapeutic use

InactiveUS7163802B2Accurate and robust calibration setTherapeutic utilityPeptide/protein ingredientsDisease diagnosisRetention timeLinear relationship

The present invention provides processes for determining the molecular weight of glatiramer acetate and other copolymers. The present invention further provides a plurality of molecular weight markers for determining the molecular weight of glatiramer acetate and other copolypmers which display linear relationships between molar ellipticity and molecular weight, and between retention time and the log of the molecular weight. The molecular weight markers also optimally demonstrate biological activity similar to glatiramer acetate or corresponding copolymers and can be used for treating or preventing various immune diseases. In addition, the subject invention provides pharmaceutical compositions for the treatment of immune diseases comprising a polypeptide having an identified molecular weight and an amino acid composition corresponding to glatiramer acetate or a terpolymer.

Owner:YEDA RES & DEV CO LTD

Refresh for dynamic cells with weak retention

Methods and circuit configurations for utilizing memory cells having weak retention times are provided. For some embodiments, rows identified as having weak retention cells may be refreshed more often than “normal retention” cells. As an example, if a normal refresh period is TREF, weak retention cells may be refreshed every TREF / 2 or TREF / 4 (possibly depending on the actual measured retention time).

Owner:POLARIS INNOVATIONS LTD

Method for directly converting synthetic gas into low-carbon olefins

ActiveCN102234212AExcellent thermal effectStable temperatureHydrocarbon from carbon oxidesBulk chemical productionRetention timeSlurry

The invention discloses a method for preparing low-carbon olefins from synthetic gas, and belongs to the field of olefins. In order to solve the problems that due to a backmixing phenomenon, the retention time is inconsistent, reaction products are widely distributed, and side reactions of olefin secondary reaction and water gas reaction and the like are intensified so as to influence the economy of the process in the traditional process for preparing low-carbon olefins from synthetic gas, a rotating packed bed reactor is used as a reactor, a solid Fischer-Tropsch synthesis catalyst is used or a catalyst is prepared into slurry, and the synthetic gas is converted into the low-carbon olefins. By the method, the selectivity of the low-carbon olefins can be greatly improved, and reaction heat can be quickly removed to stabilize the temperature of a reaction bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

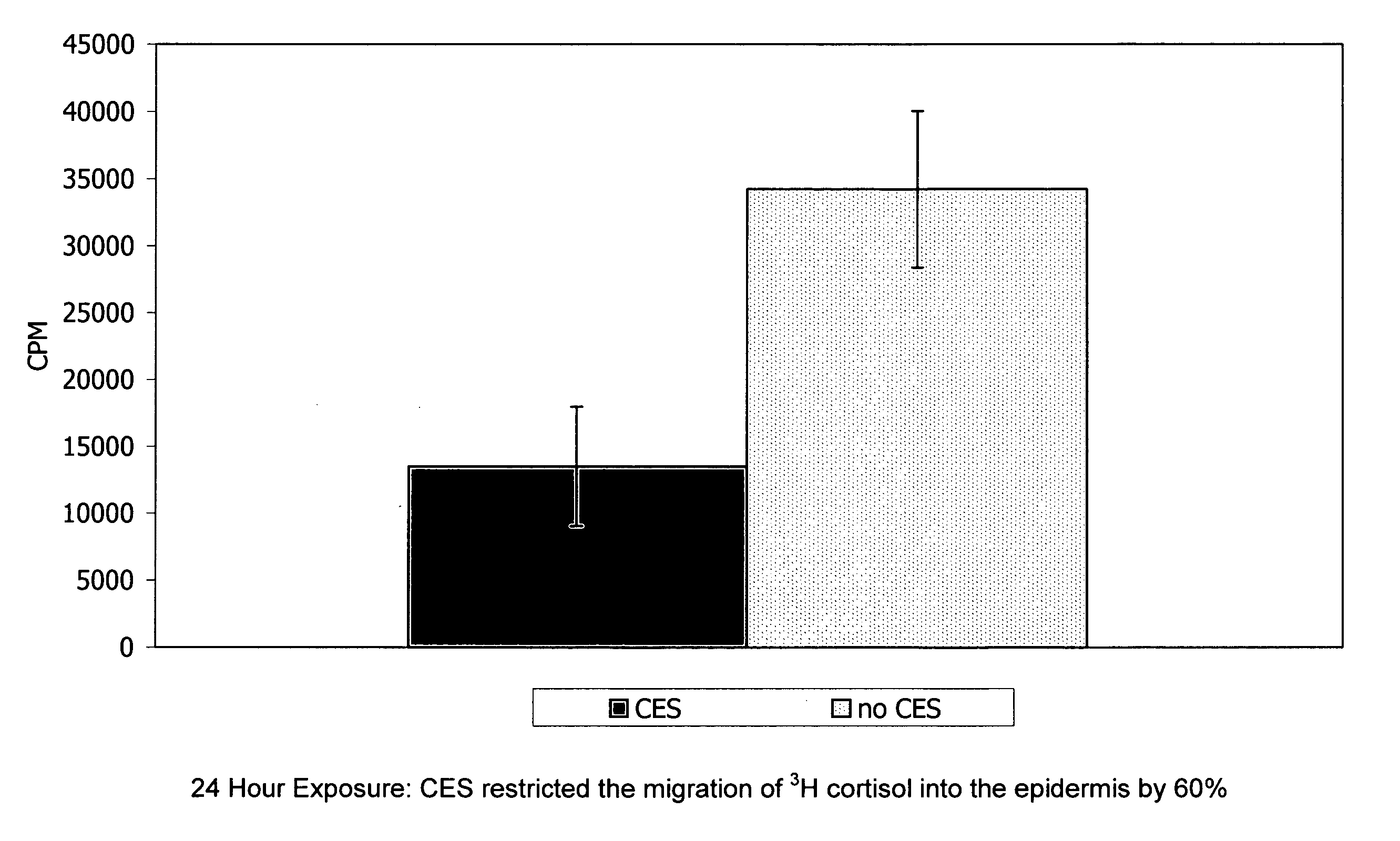

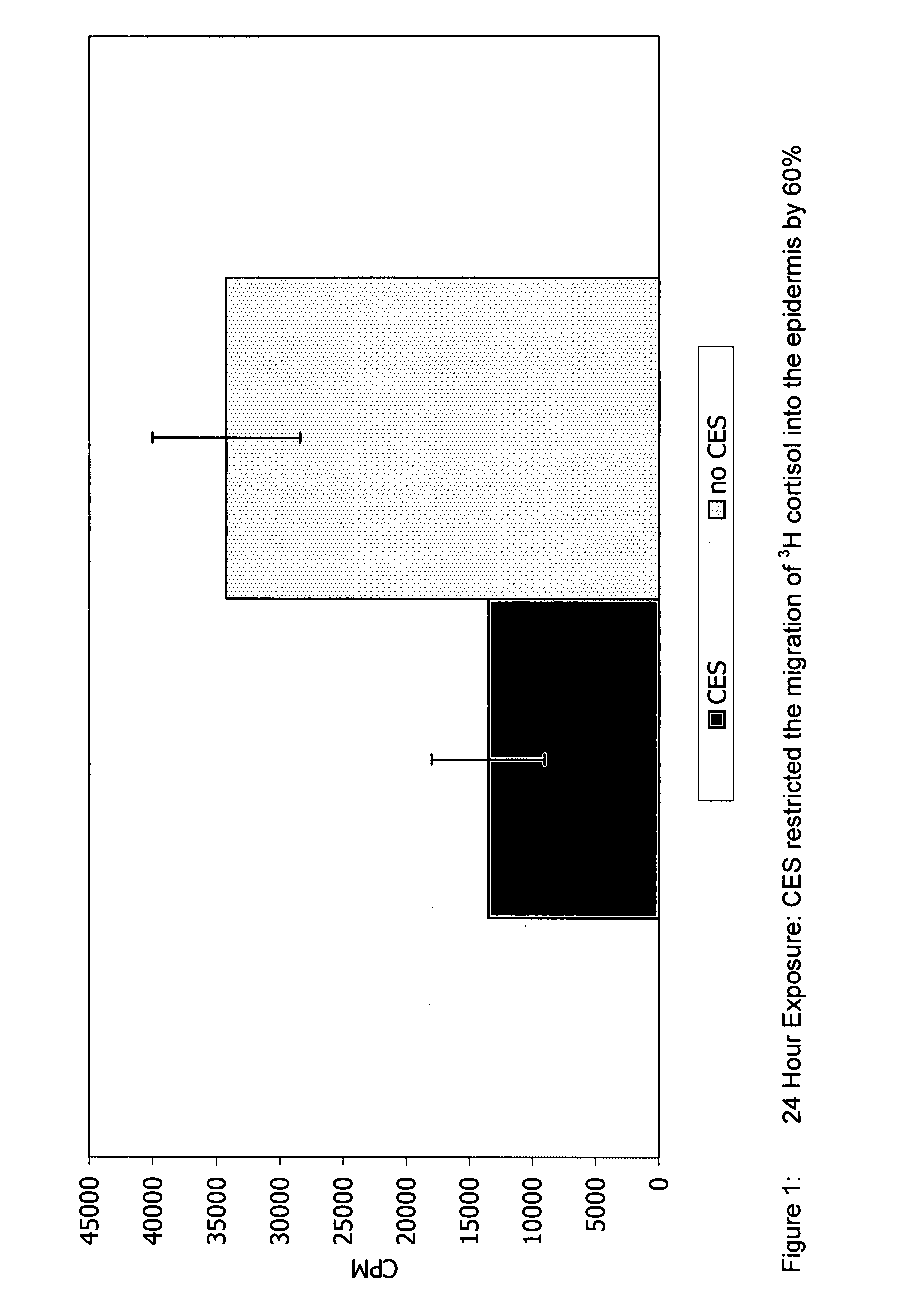

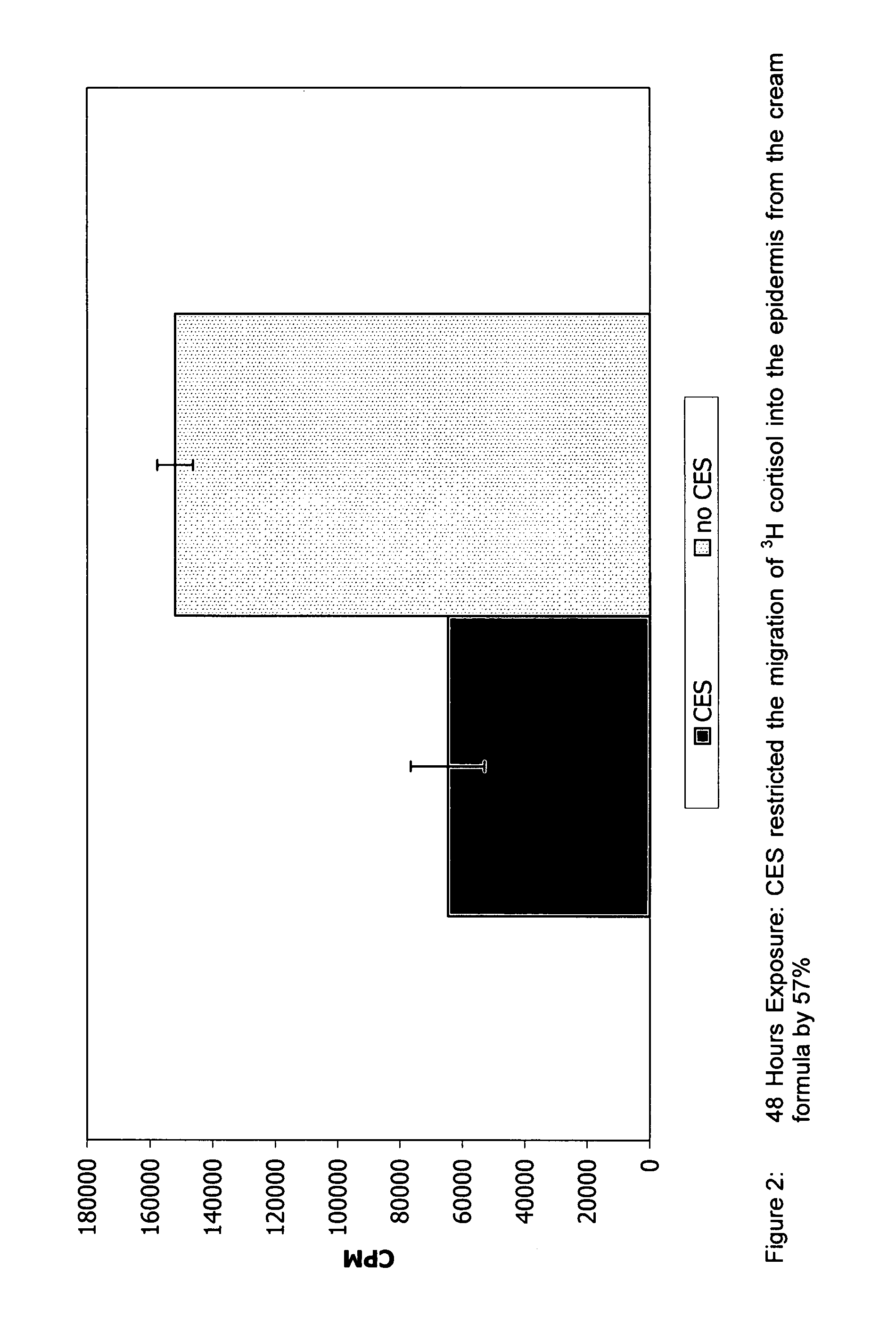

Modification of percutaneous absorption of topically active materials

InactiveUS20080039405A1Cut skinExtended retention timeBiocideHydrocarbon active ingredientsAdditive ingredientRetention time

The present invention relates to methods of influencing the flux or surface retention time of a topically active pharmaceutical ingredient through skin and formulations relating thereto.

Owner:CRODA

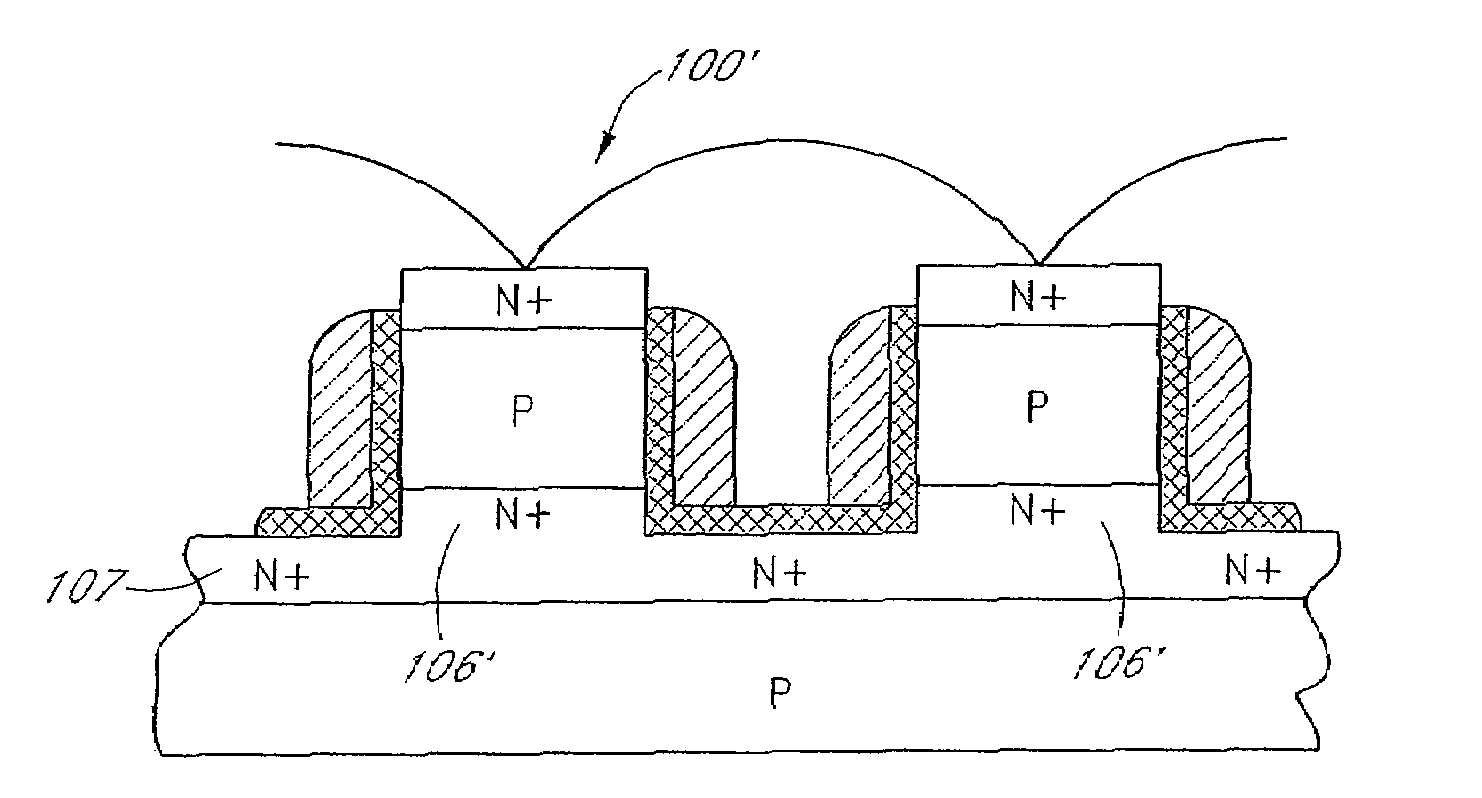

Long retention time single transistor vertical memory gain cell

ActiveUS7271052B1High band gap energyAvoid excessive leakage currentTransistorSolid-state devicesHigh cellRetention time

A single transistor vertical memory gain cell with long data retention times. The memory cell is formed from a silicon carbide substrate to take advantage of the higher band gap energy of silicon carbide as compared to silicon. The silicon carbide provides much lower thermally dependent leakage currents which enables significantly longer refresh intervals. In certain applications, the cell is effectively non-volatile provided appropriate gate bias is maintained. N-type source and drain regions are provided along with a pillar vertically extending from a substrate, which are both p-type doped. A floating body region is defined in the pillar which serves as the body of an access transistor as well as a body storage capacitor. The cell provides high volumetric efficiency with corresponding high cell density as well as relatively fast read times.

Owner:MICRON TECH INC

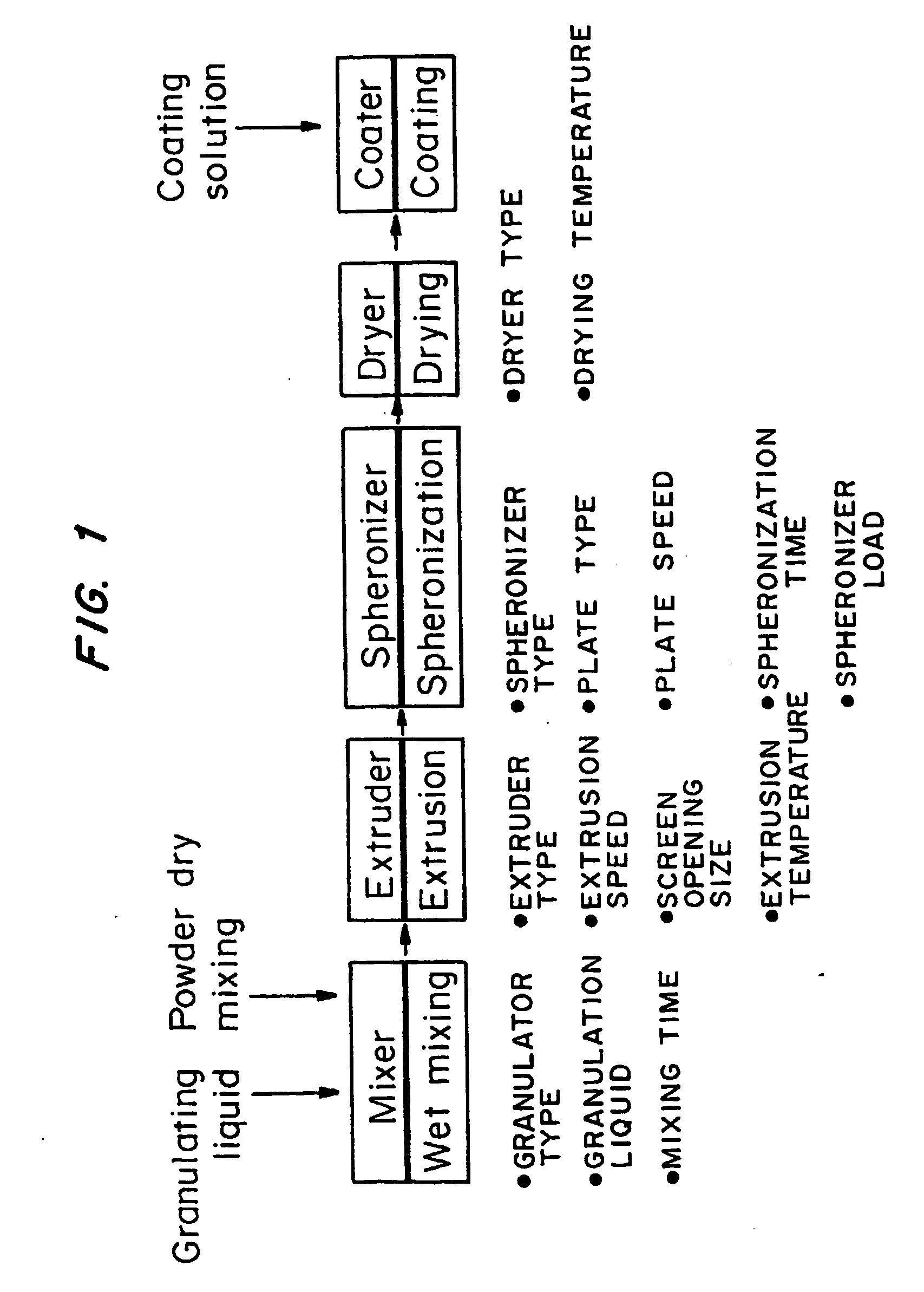

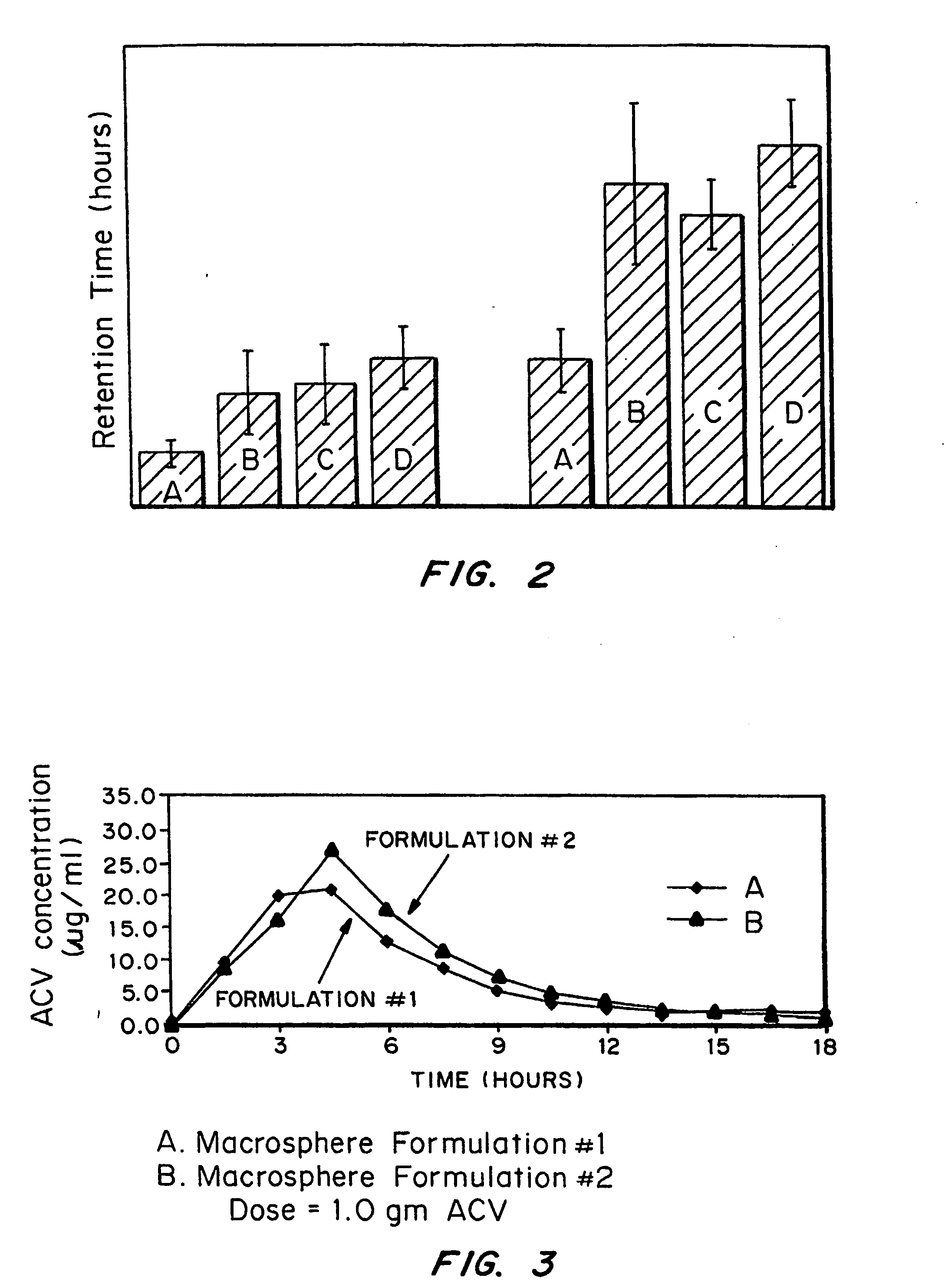

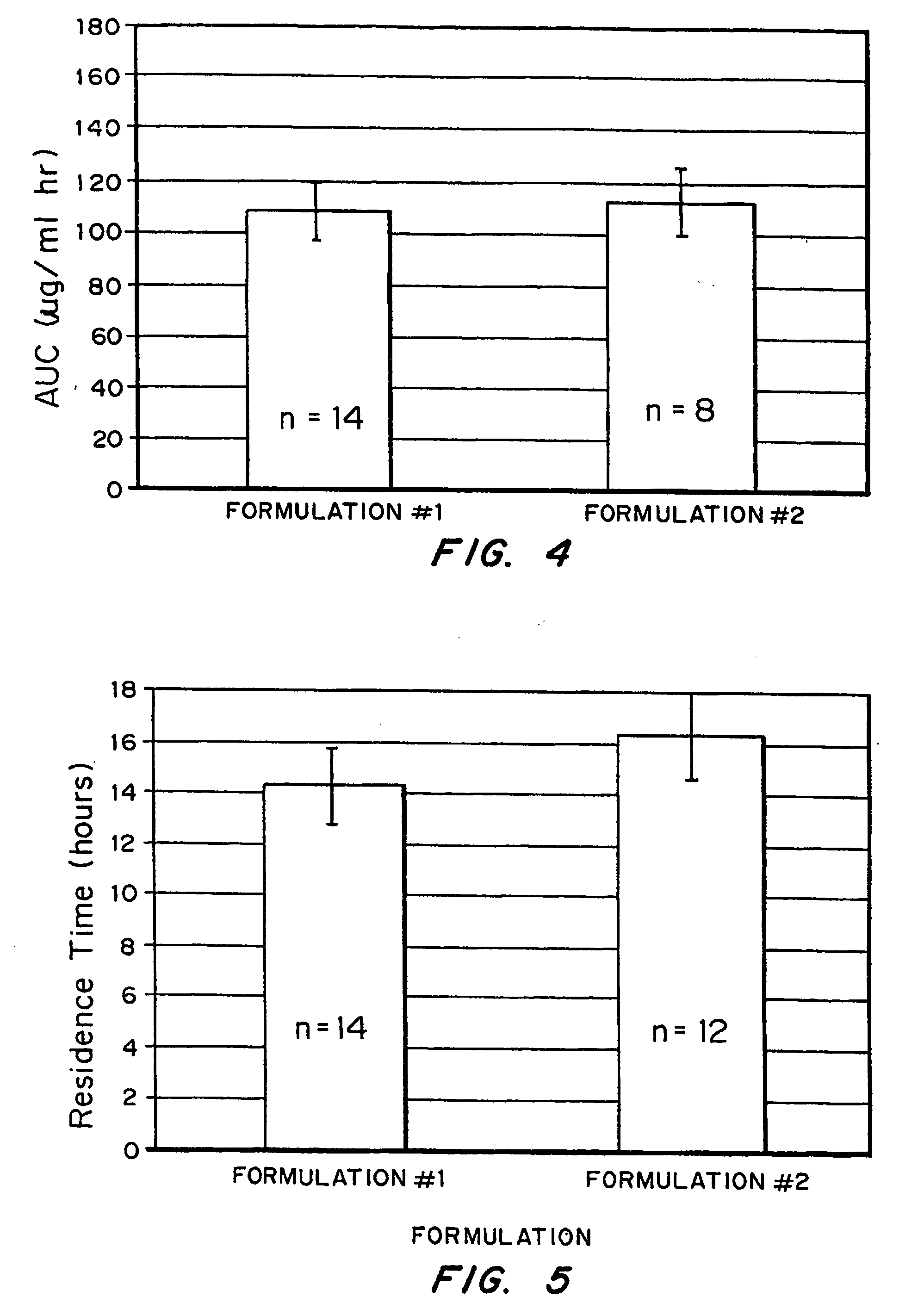

Bioadhesive drug delivery system with enhanced gastric retention

InactiveUS20050064027A1Prolonged gastric retention timeHigh retention rateBiocideCosmetic preparationsWhole bodyRetention time

Bioadhesive macrosphere delivery systems (“BDDS”) having prolonged gastric retention time due to bioadhesion rather than physical density or size are described. In general, the macrospheres have diameters that are greater than 200 microns, more preferably greater than 500 microns. The bioadhesive macrospheres are released in the stomach where they reside in close proximity to the gastric mucosa for a prolonged period of time. Increased residence of BDDS in the upper GI can lead to increased systemic absorption of drug in the preferred site of systemic absorption, namely the upper GI tract (upper to mid-jejunum). The BDDS may be engineered either as a capsule with drug delivery controlled by a diffusion-limited membrane or degradable shell, or as a solid matrix system with drug delivery controlled by a combination of diffusion and polymer degradation kinetics.

Owner:SPHERICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com