Patents

Literature

6494results about How to "Stable temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

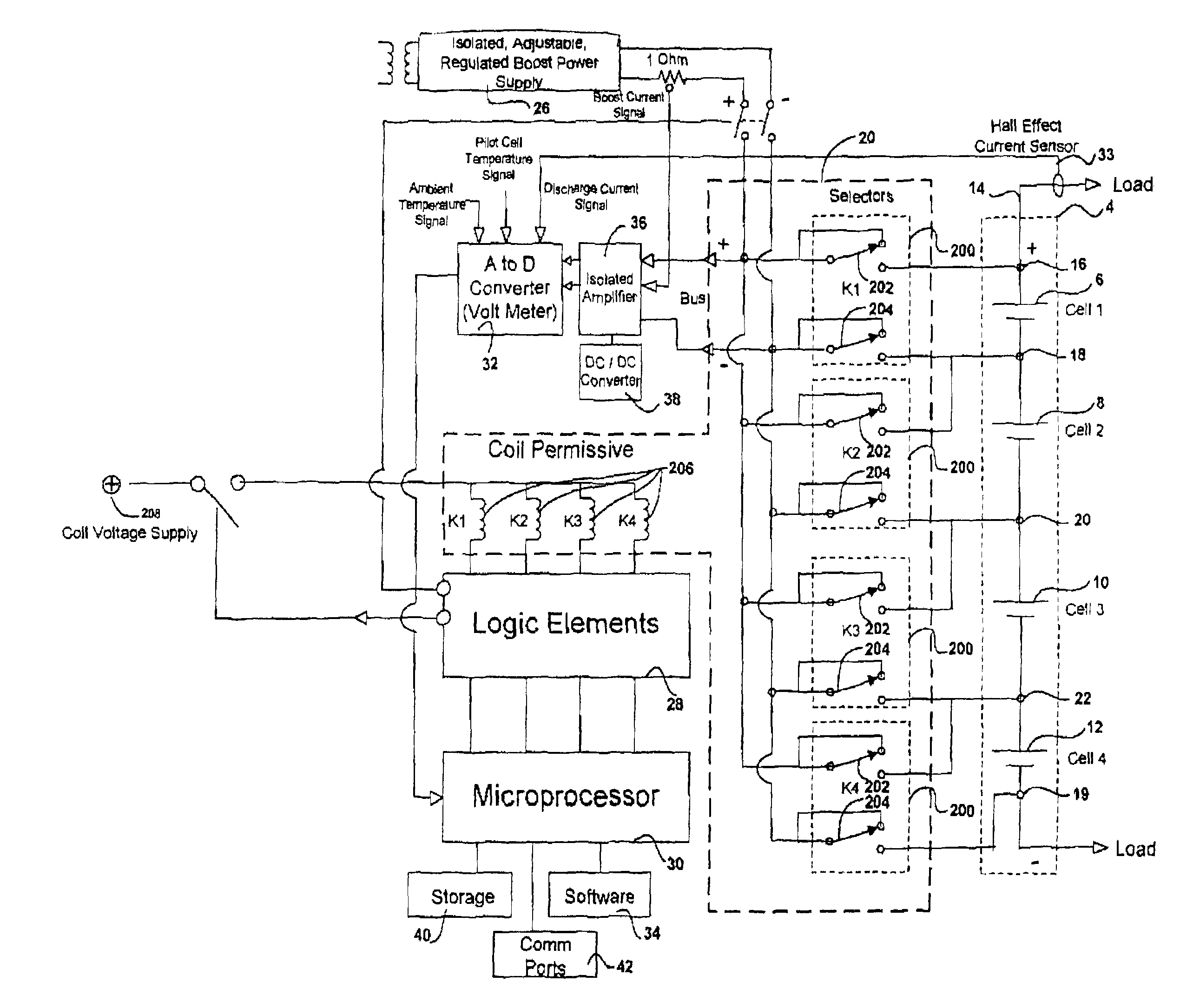

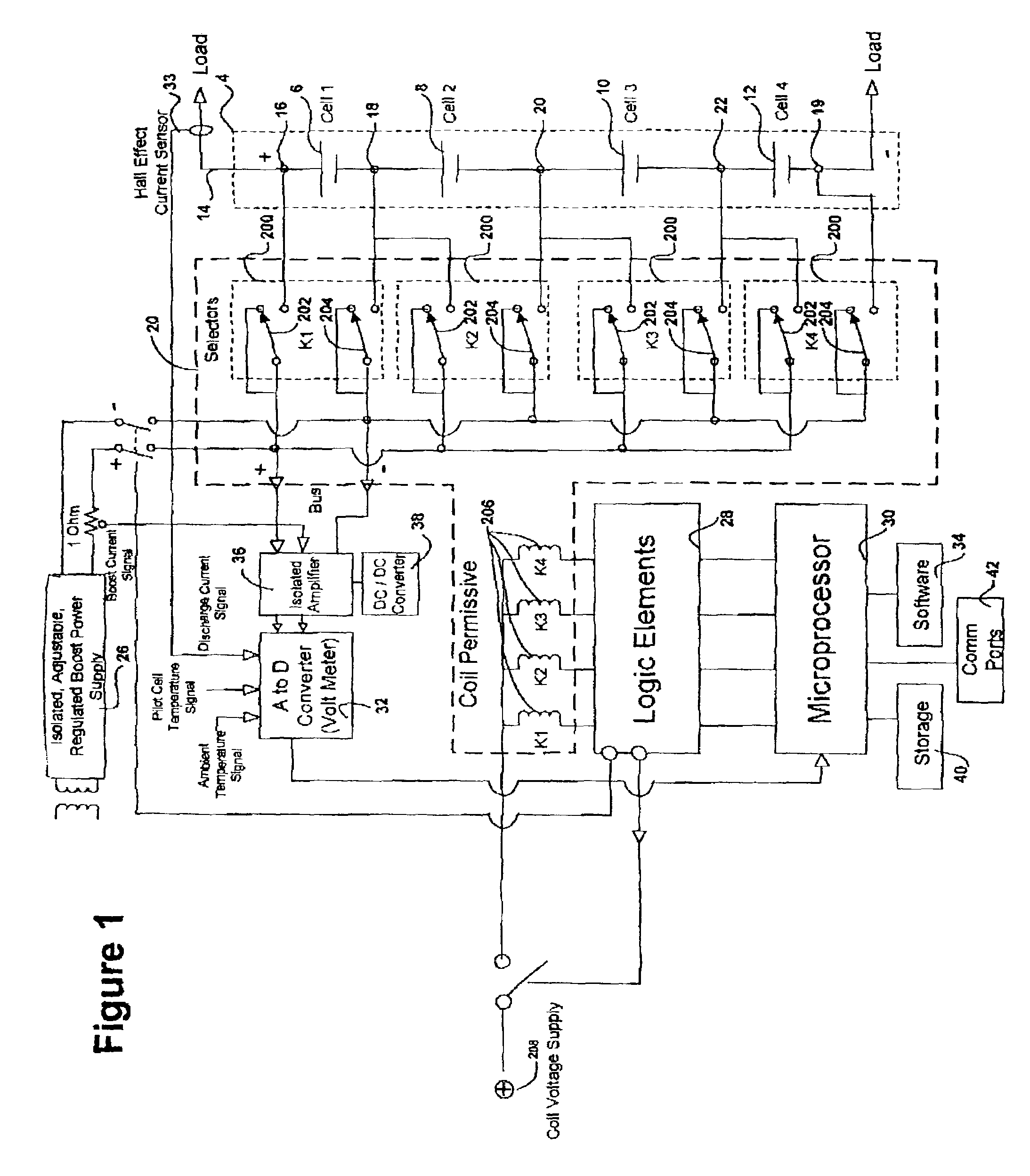

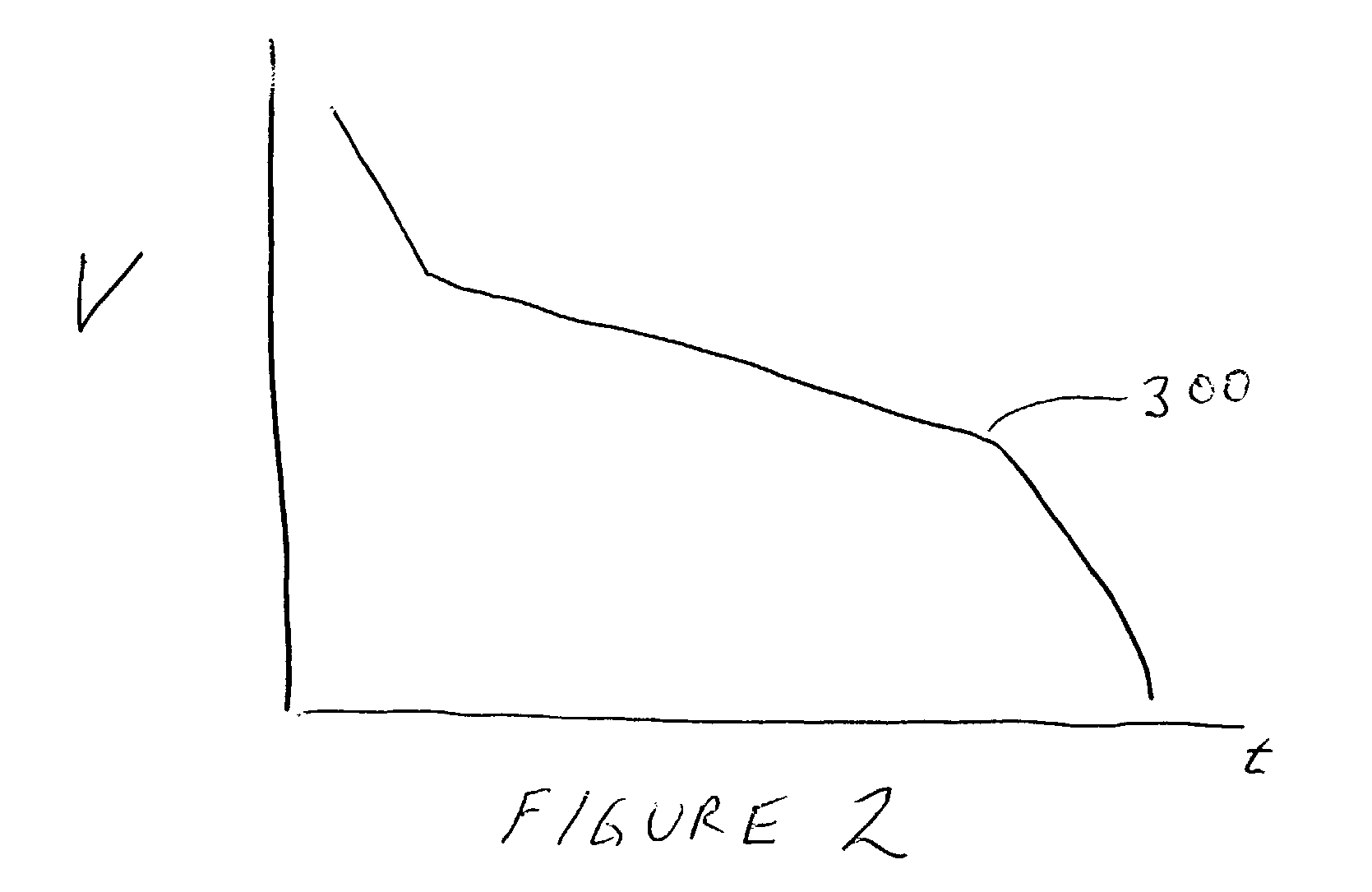

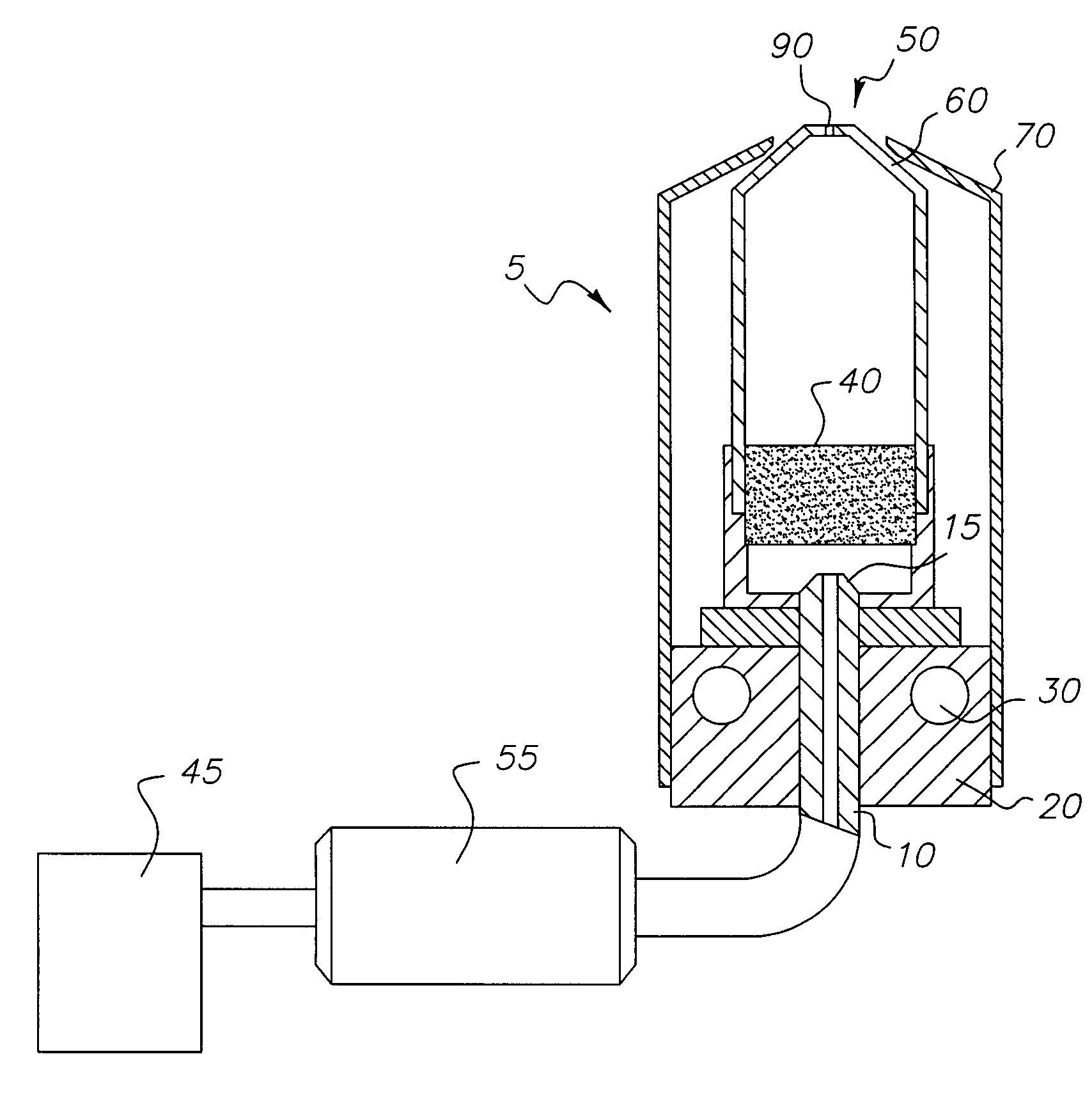

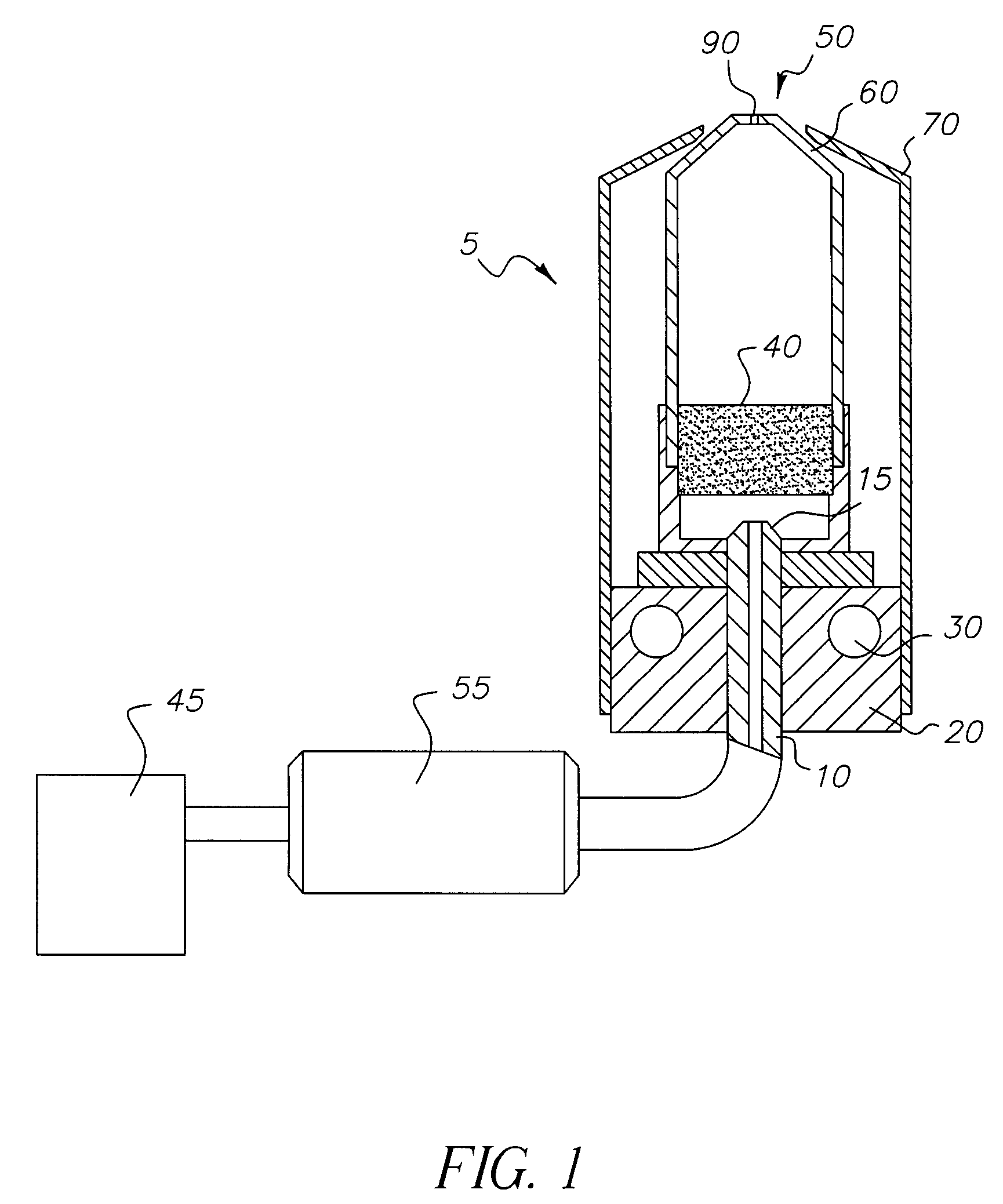

Battery management system and method

InactiveUS6983212B2Stable temperatureExtend battery lifeCircuit monitoring/indicationCharge equalisation circuitElectrical batteryVoltmeter

A battery management system is disclosed for control of individual cells in a battery string. The battery management system includes a charger, a voltmeter, a selection circuit and a microprocessor. Under control of the microprocessor, the selection circuit connects each cell of the battery string to the charger and voltmeter. Information relating to battery performance is recorded and analyzed. The analysis depends upon the conditions under which the battery is operating. By monitoring the battery performance under different conditions, problems with individual cells can be determined and corrected.

Owner:SCHNEIDER ELECTRIC IT CORP

Battery

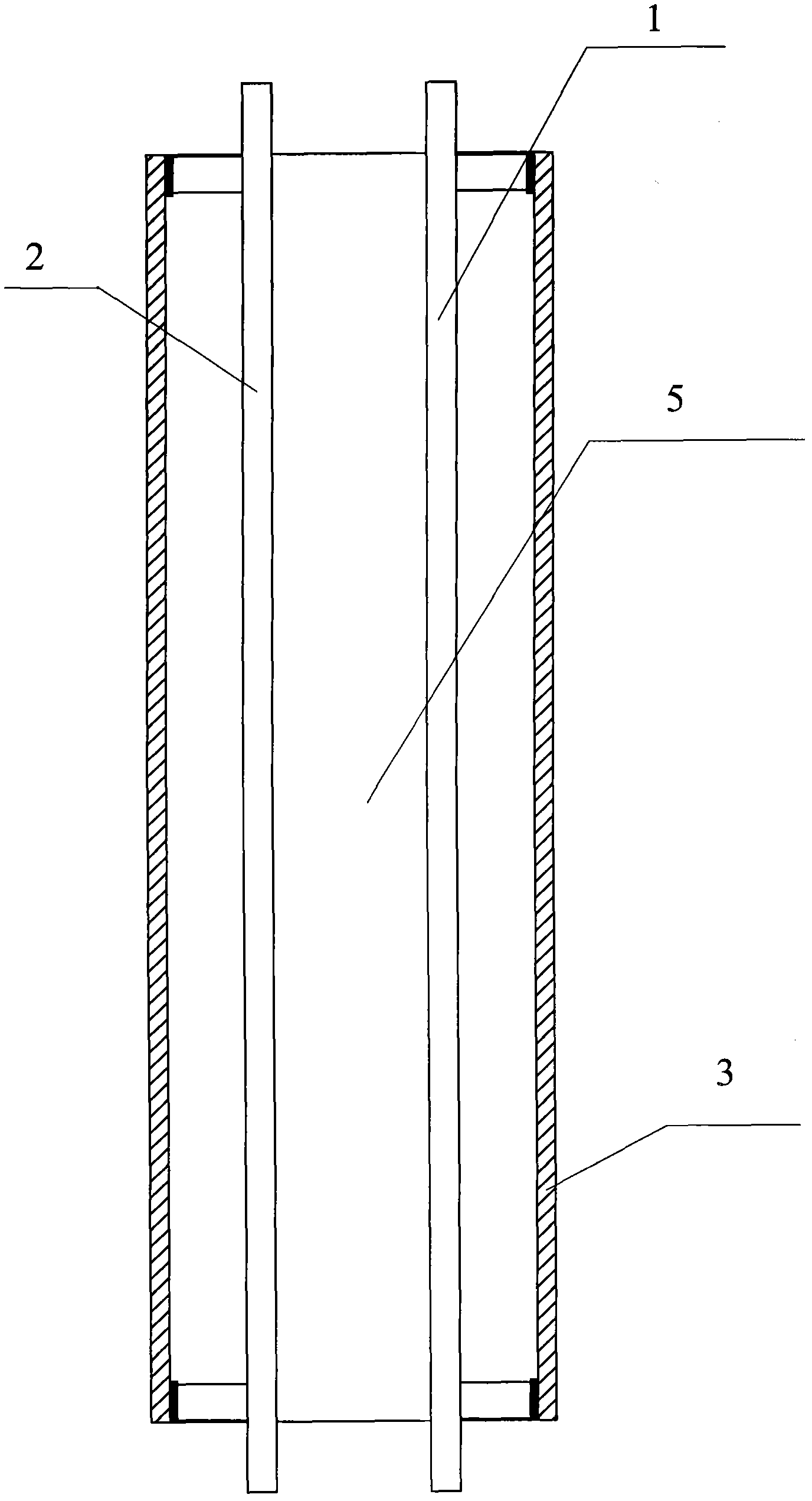

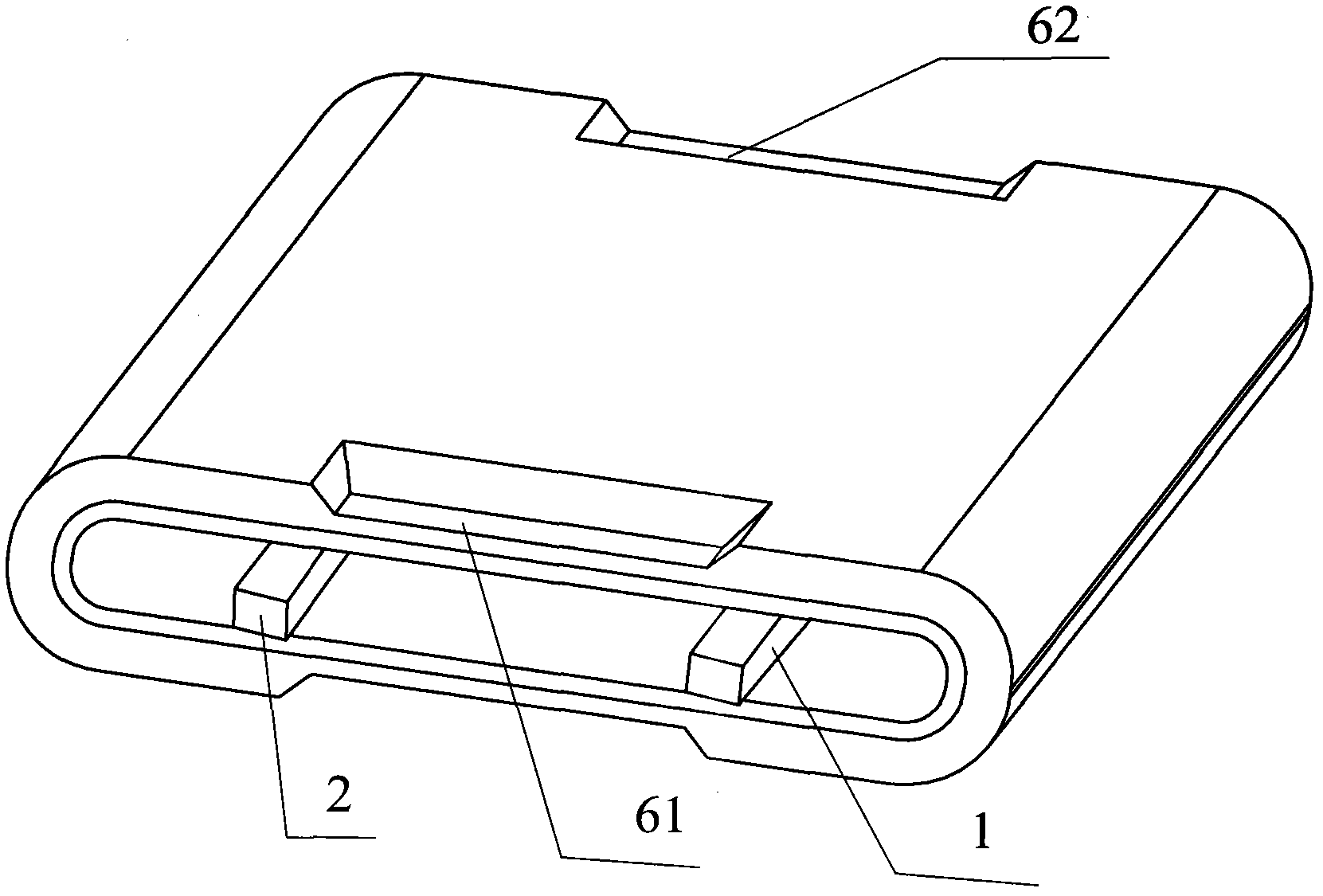

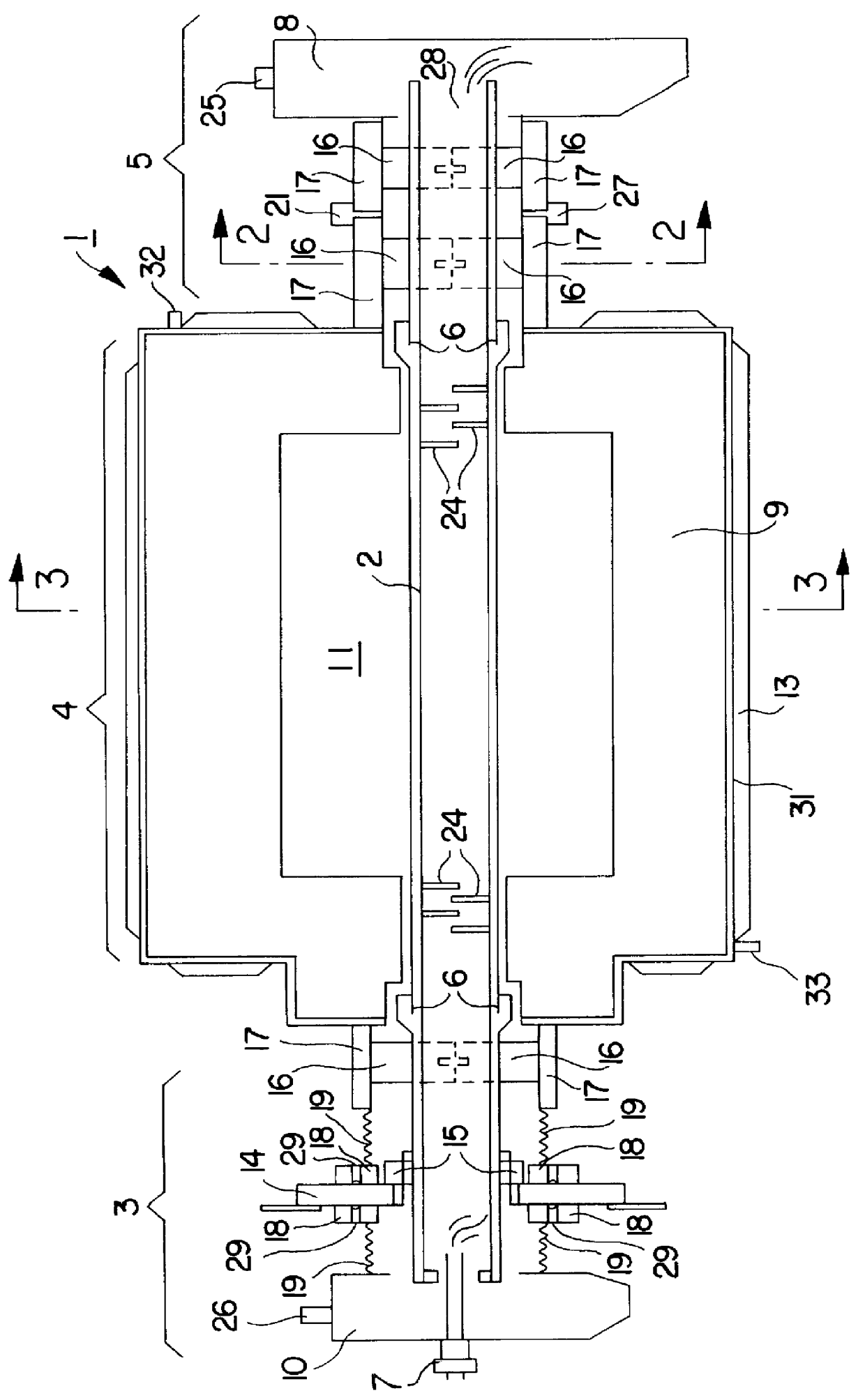

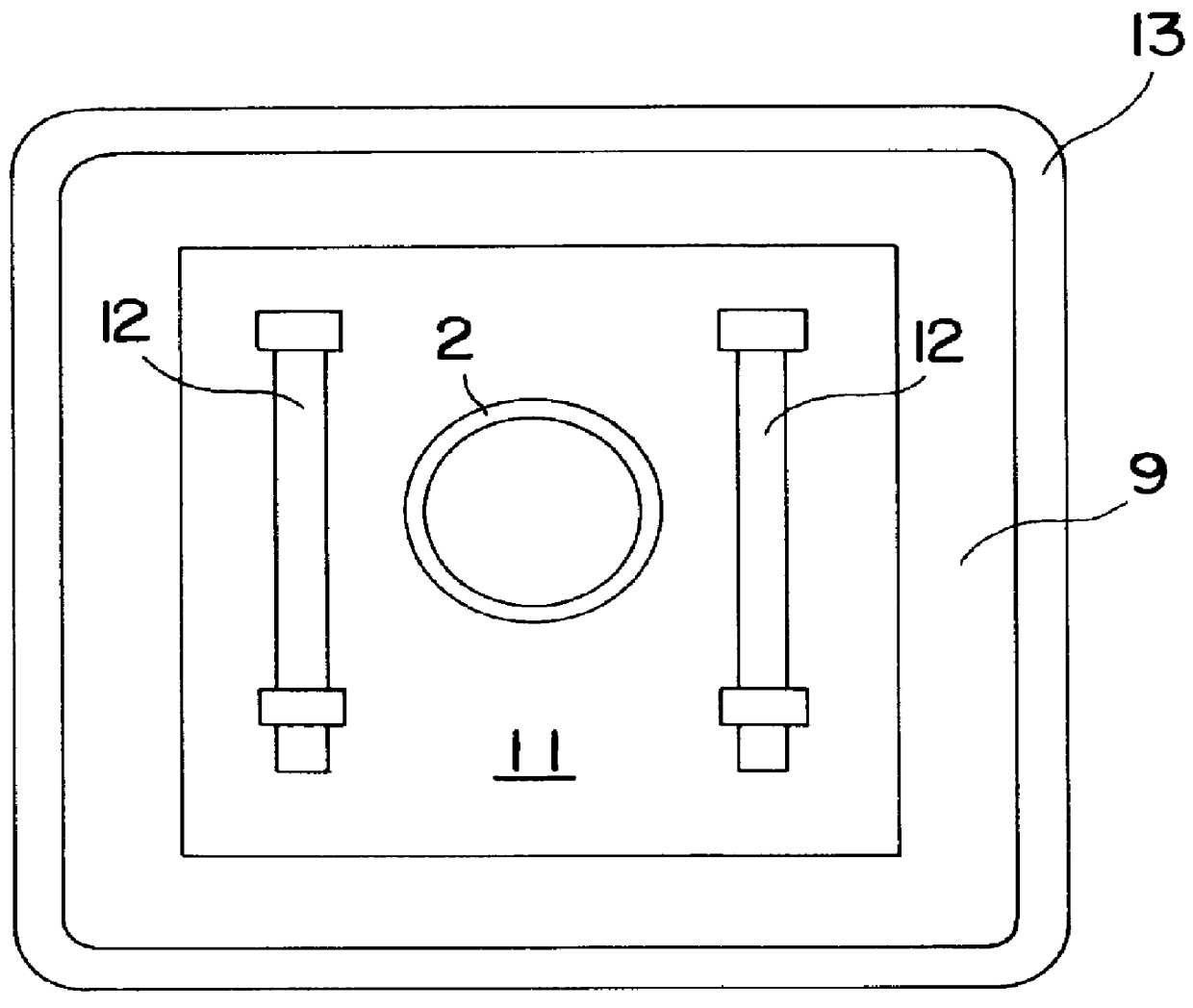

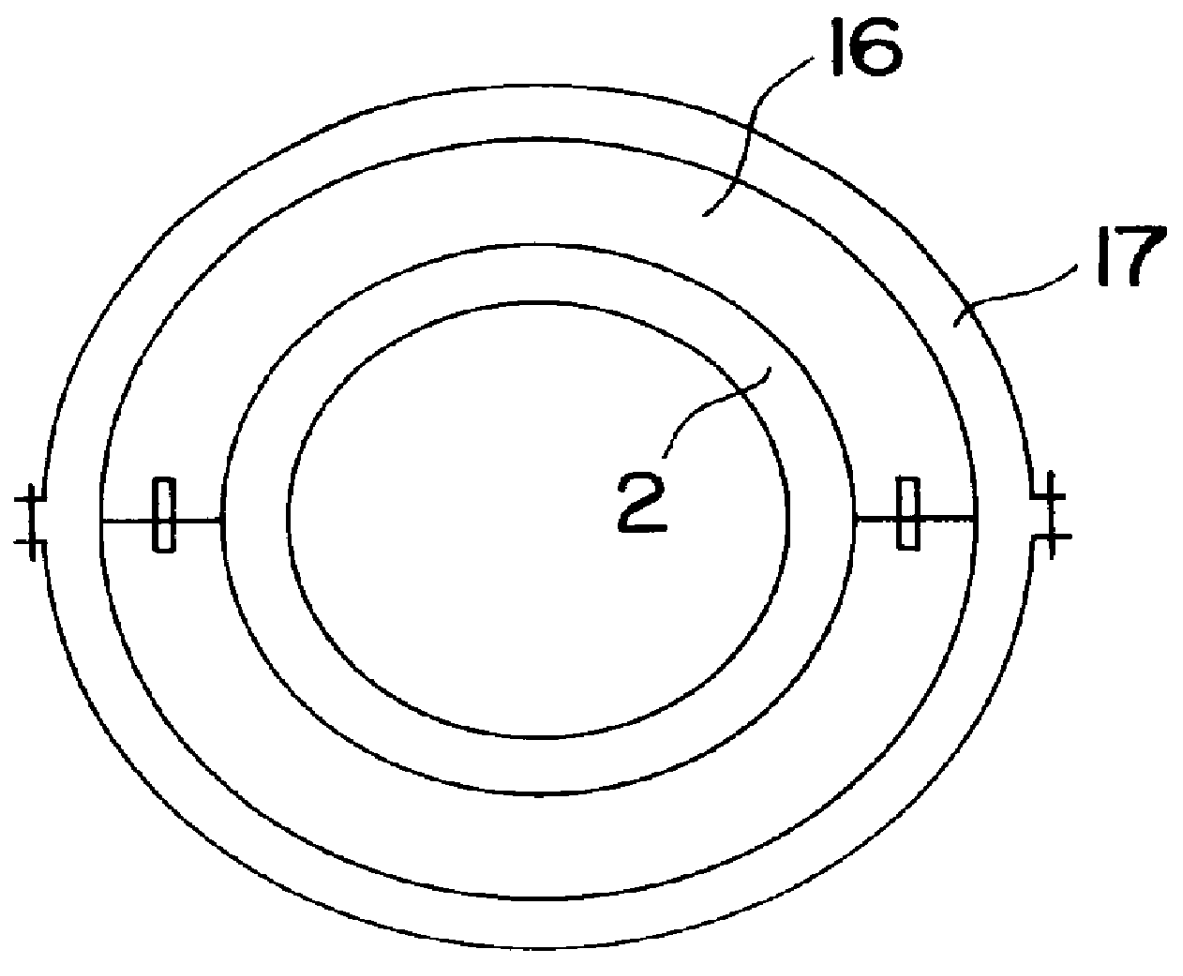

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

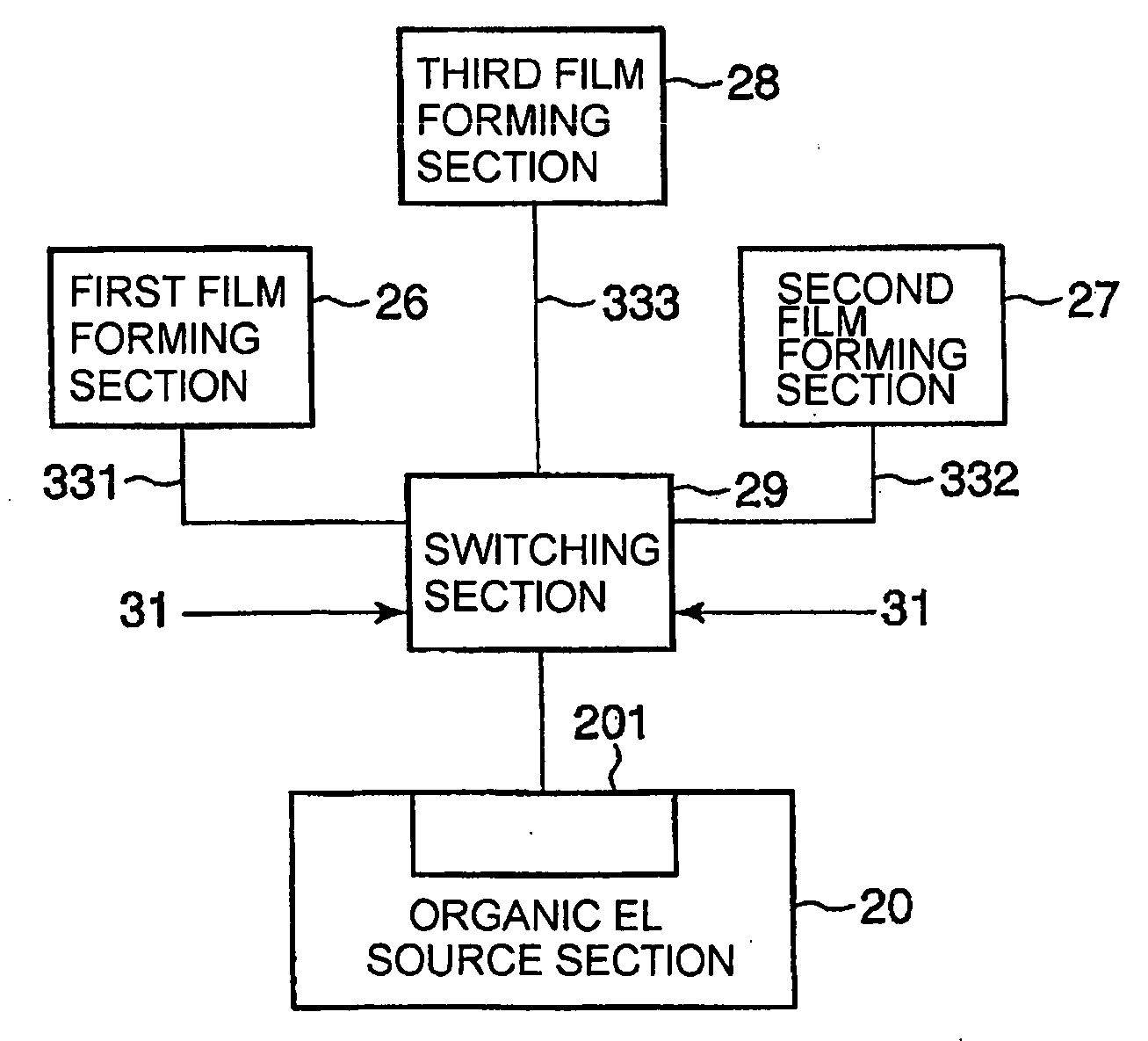

Vaporizing fluidized organic materials

A method for vaporizing organic materials onto a surface, to form a film includes providing a quantity of organic material in a fluidized powdered form; metering the powdered organic material and directing a stream of such fluidized powder onto a first member; heating the first member so that as the stream of fluidized powder is vaporized; collecting the vaporized organic material in a manifold; and providing a second member formed with at least one aperture in communication with the manifold that permits the vaporized organic material to be directed onto the surface to form a film.

Owner:GLOBAL OLED TECH

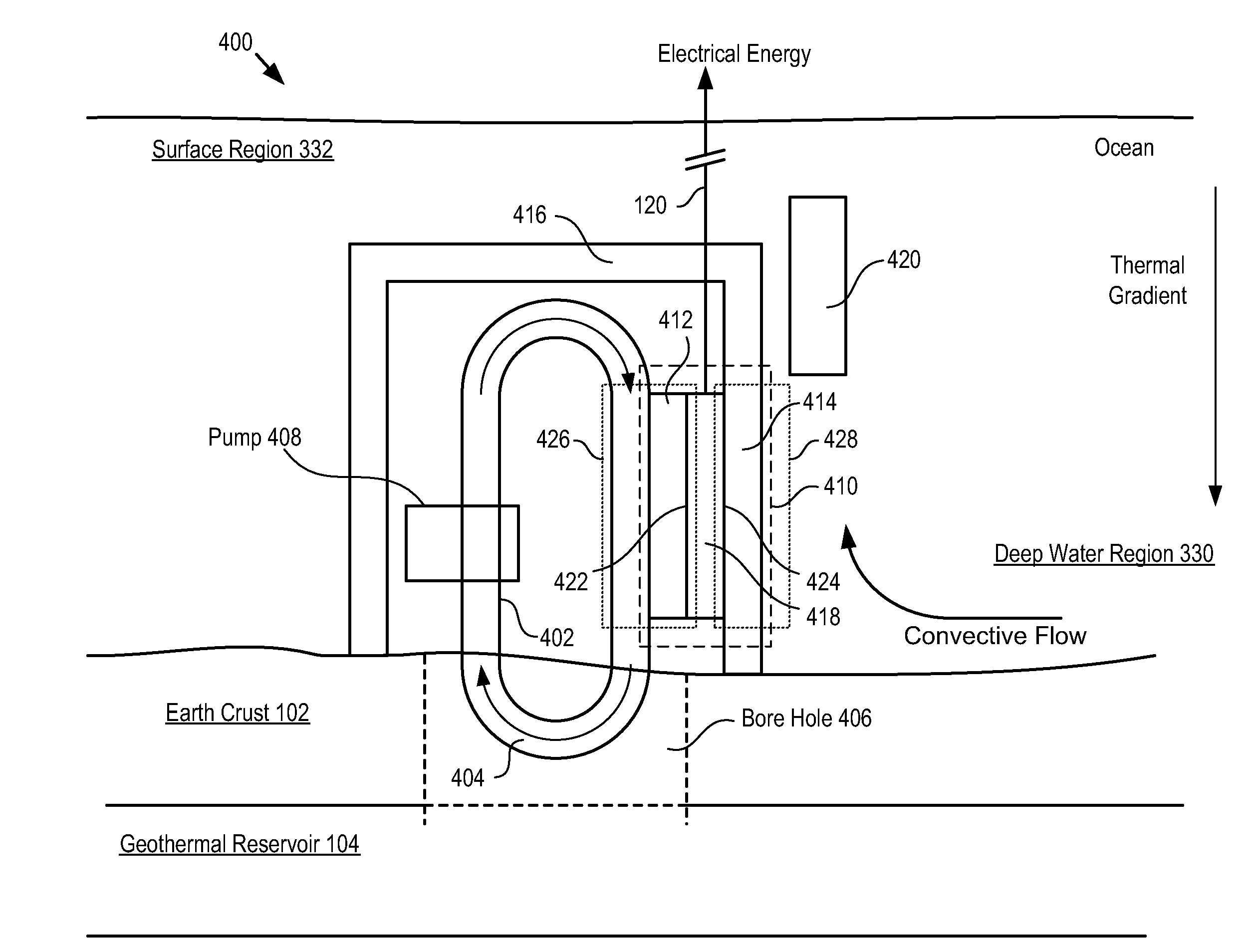

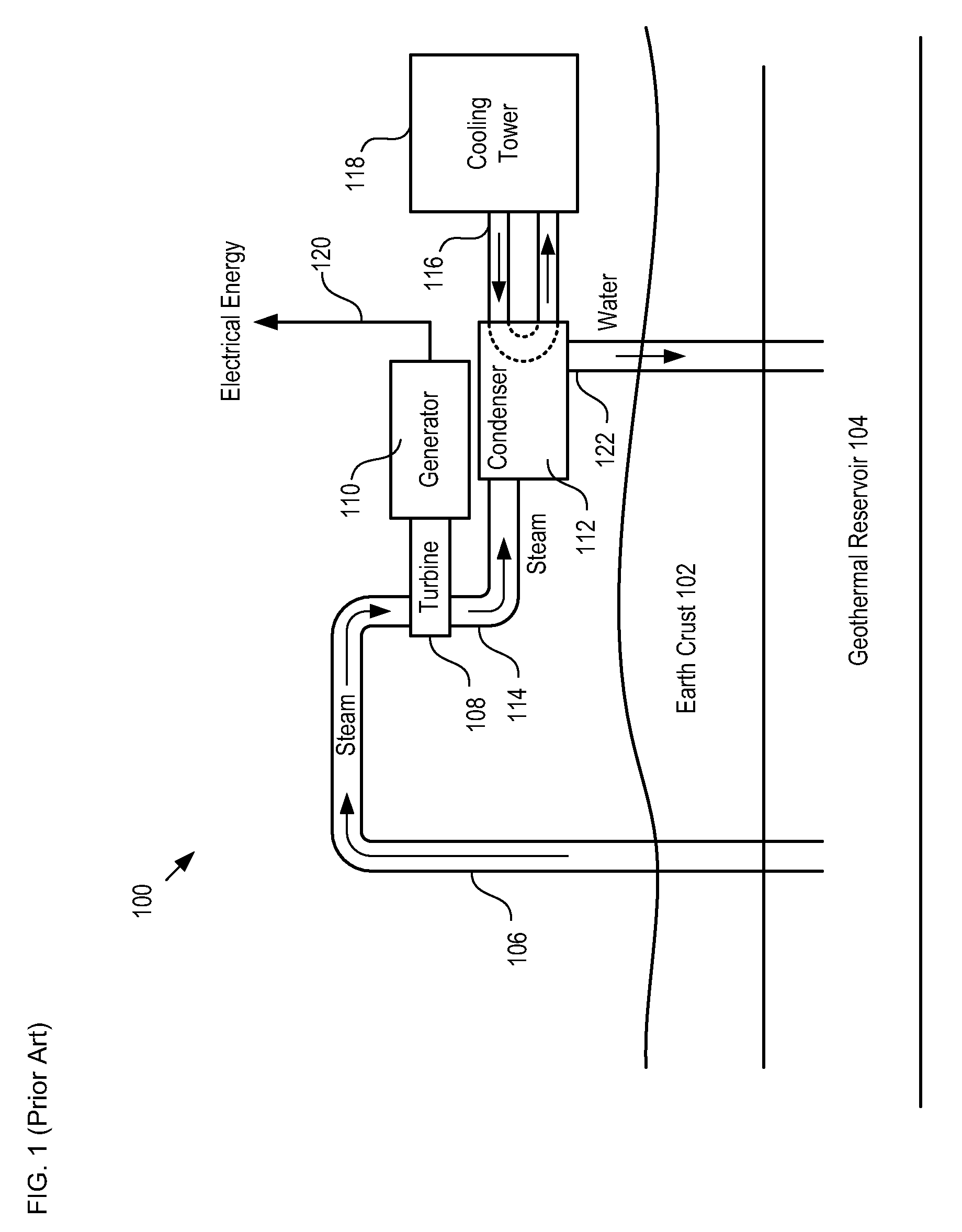

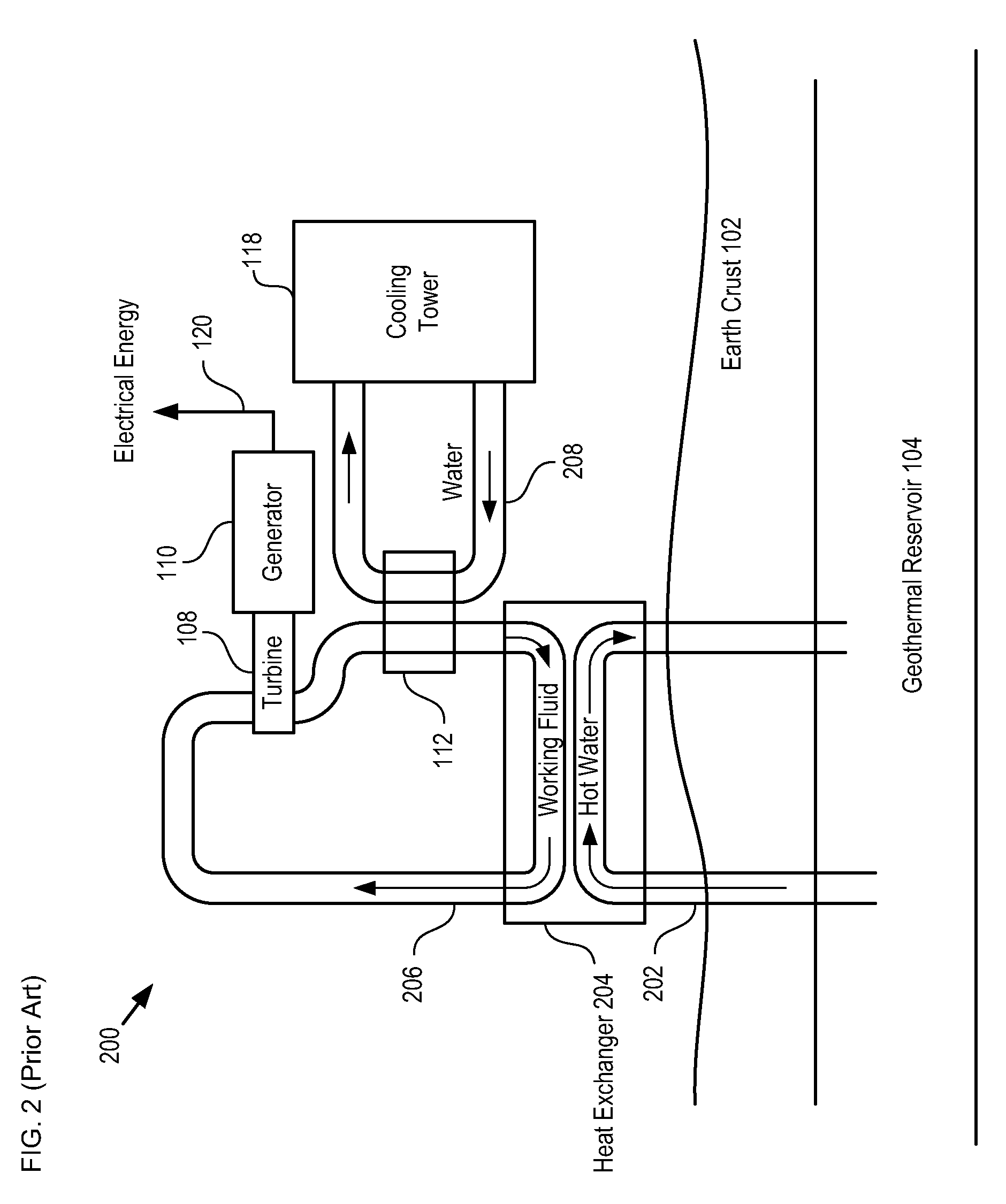

Submerged Geo-Ocean Thermal Energy System

InactiveUS20090217664A1Increase heating capacityStable temperatureGeothermal energy generationMachines/enginesDeep levelElectric energy

A system for generating electrical energy using a naturally occurring temperature difference is disclosed. The system provides electrical energy by thermally conduit a geothermal heat source and cold deep-level water to opposing sides of a thermoelectric element. The thermoelectric element generates electrical energy based on the temperature difference between these two surfaces.

Owner:LOCKHEED MARTIN CORP

Intelligent hot-air drying control device

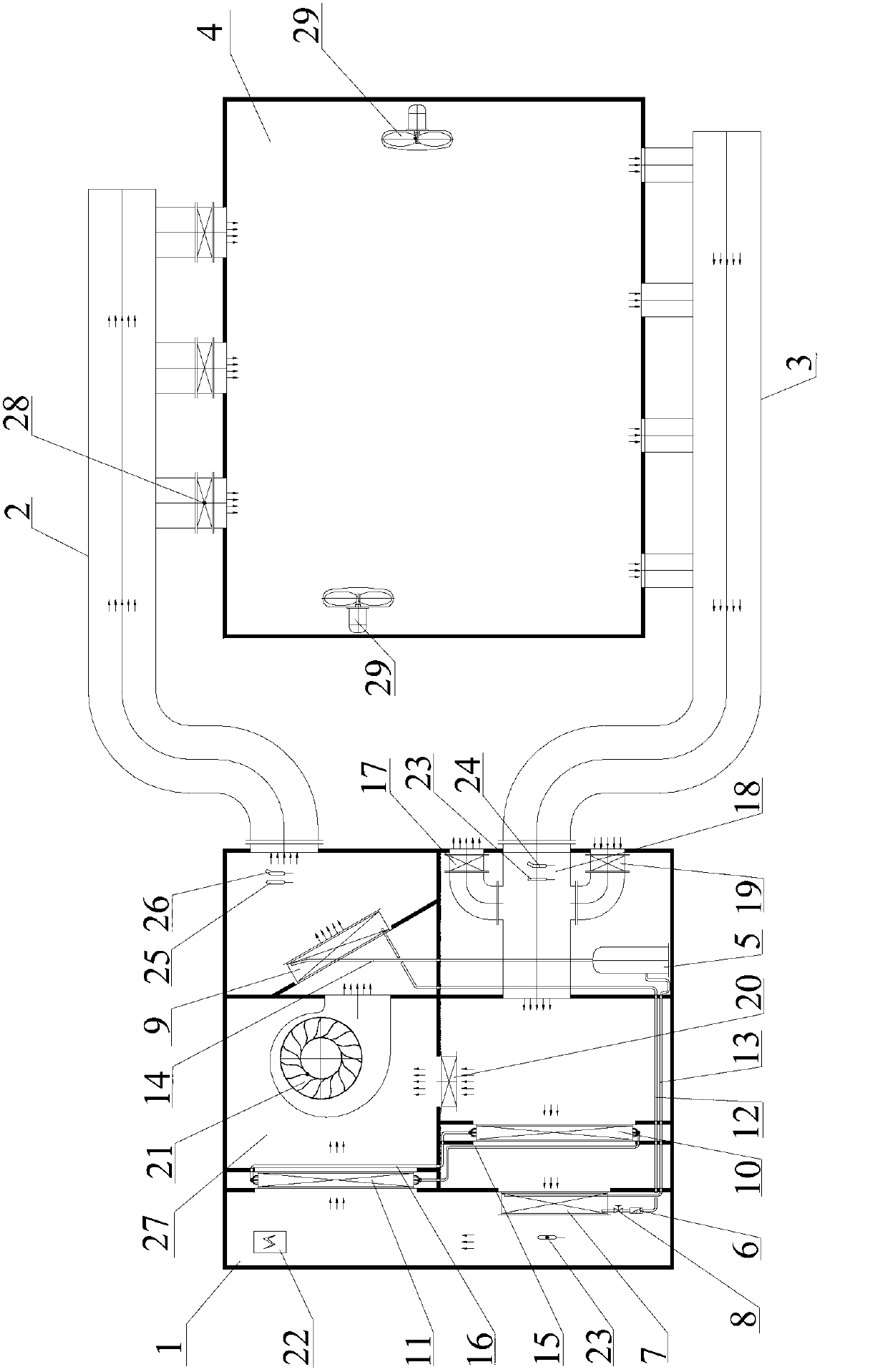

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

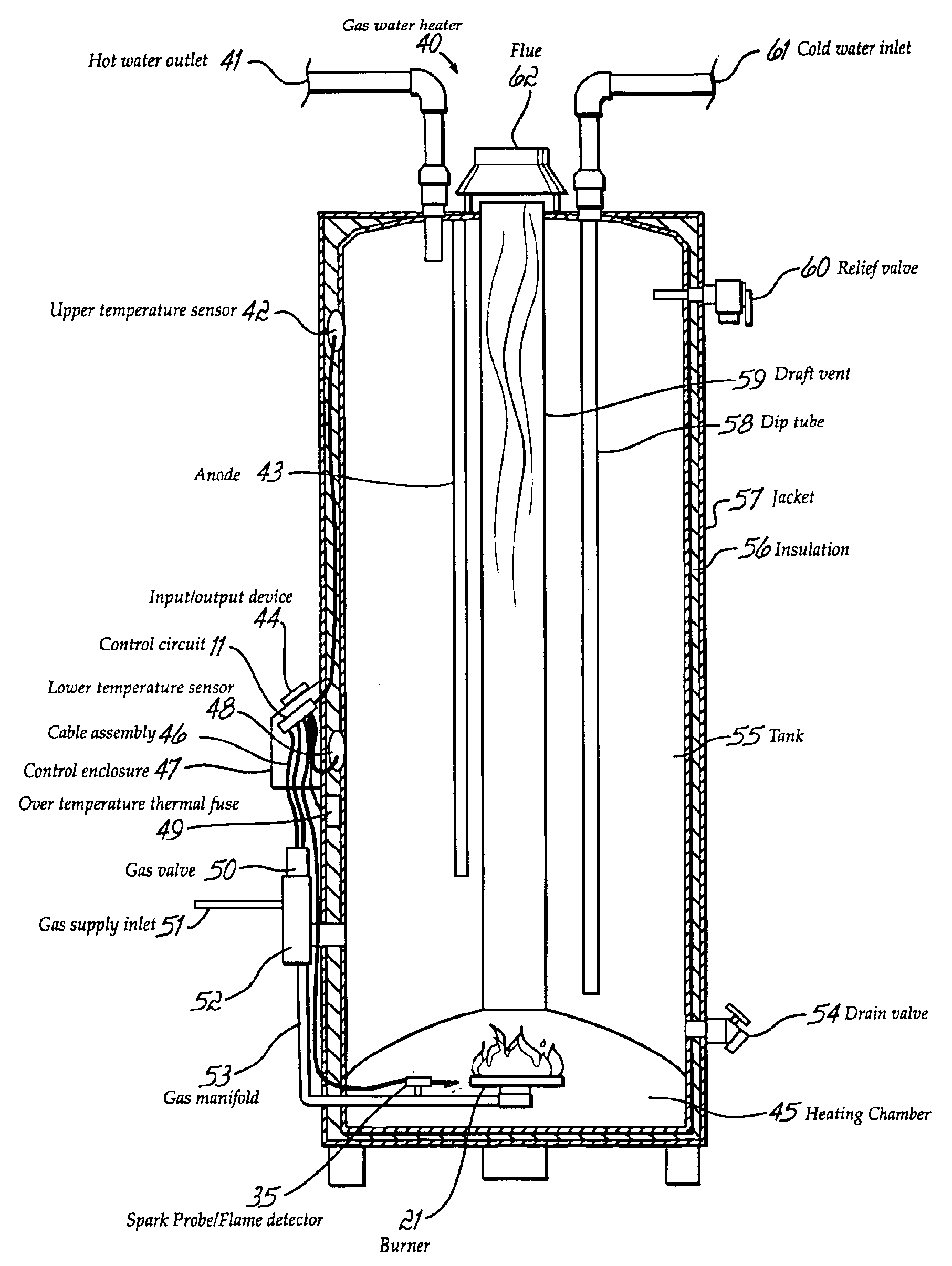

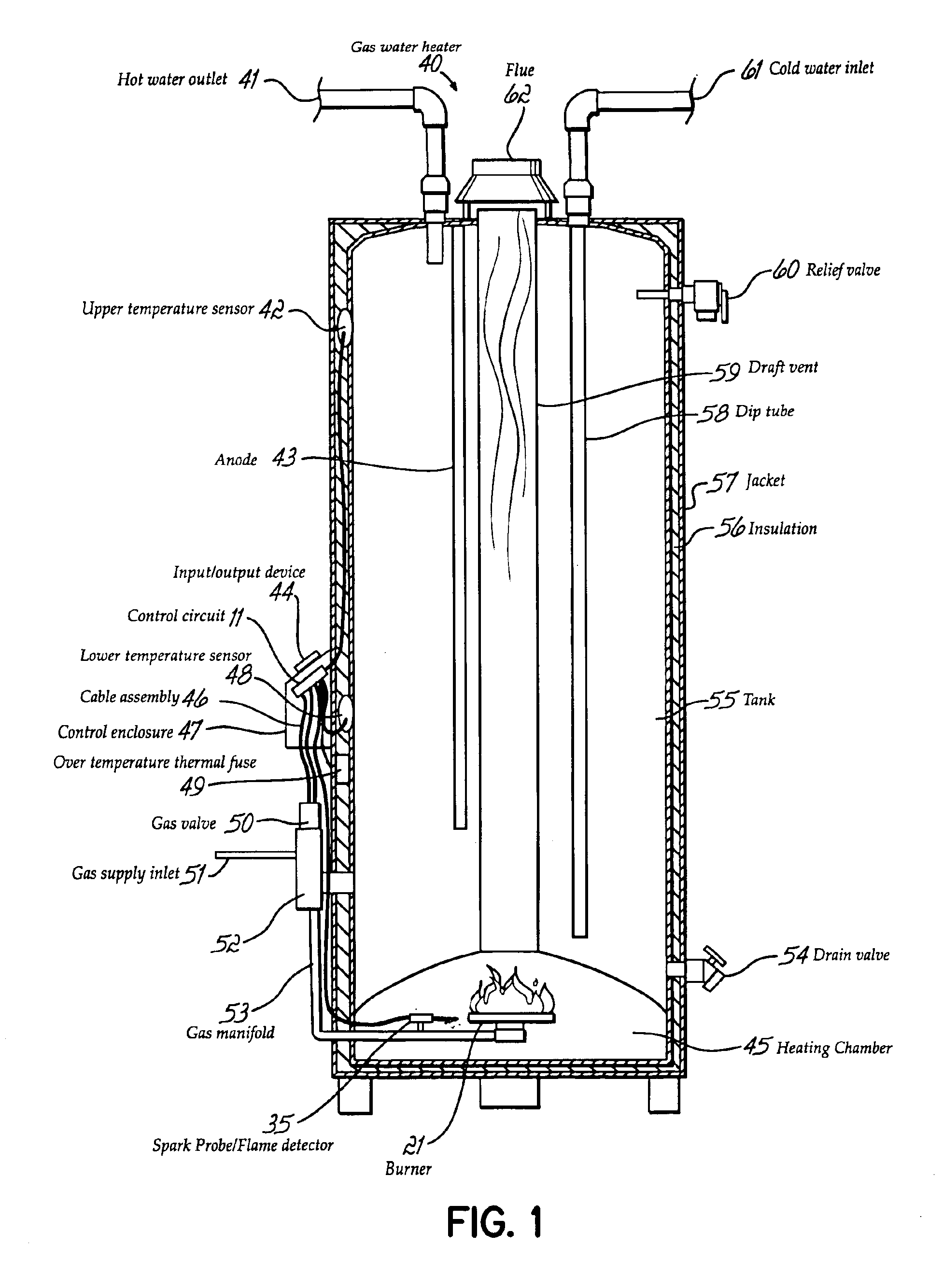

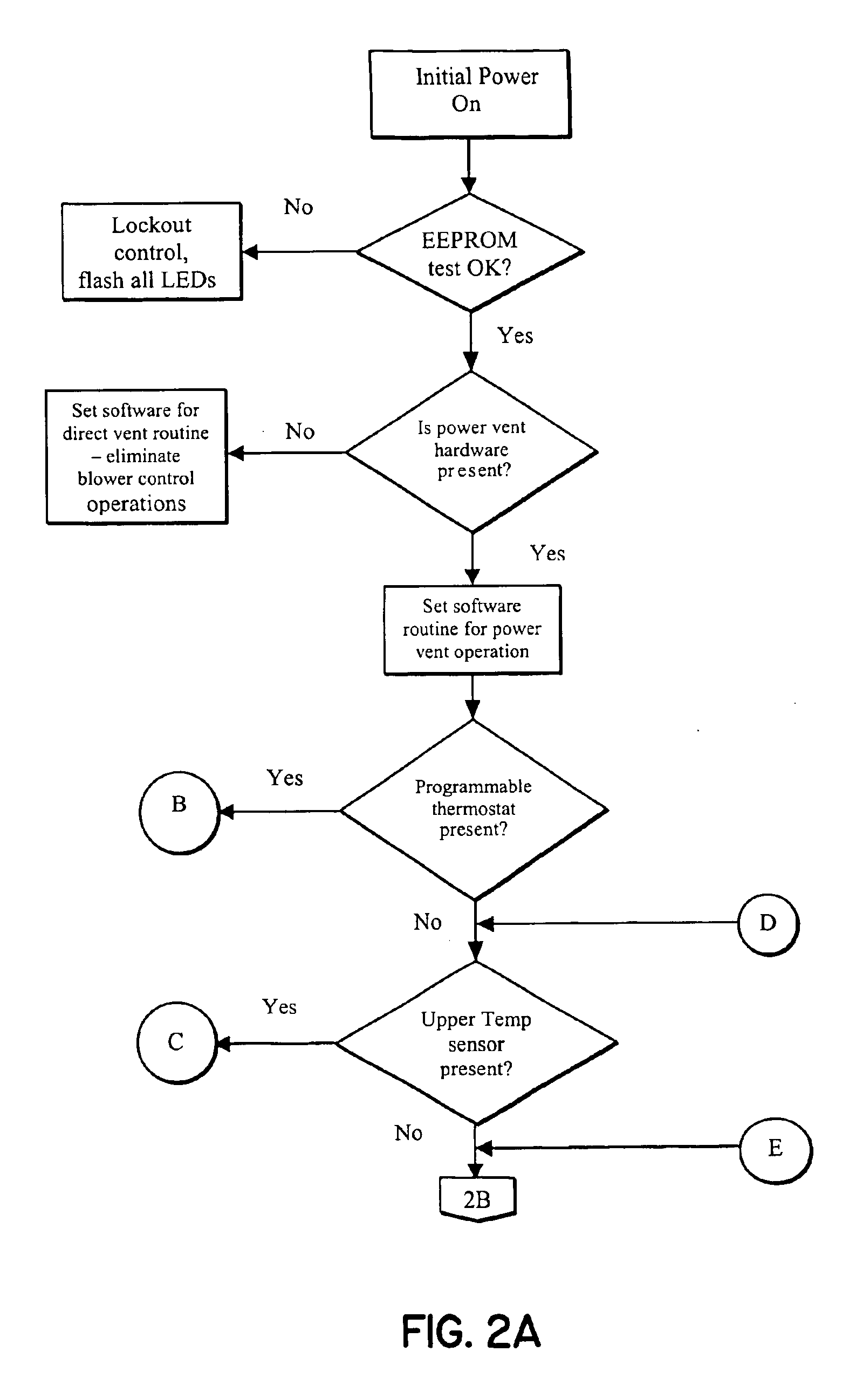

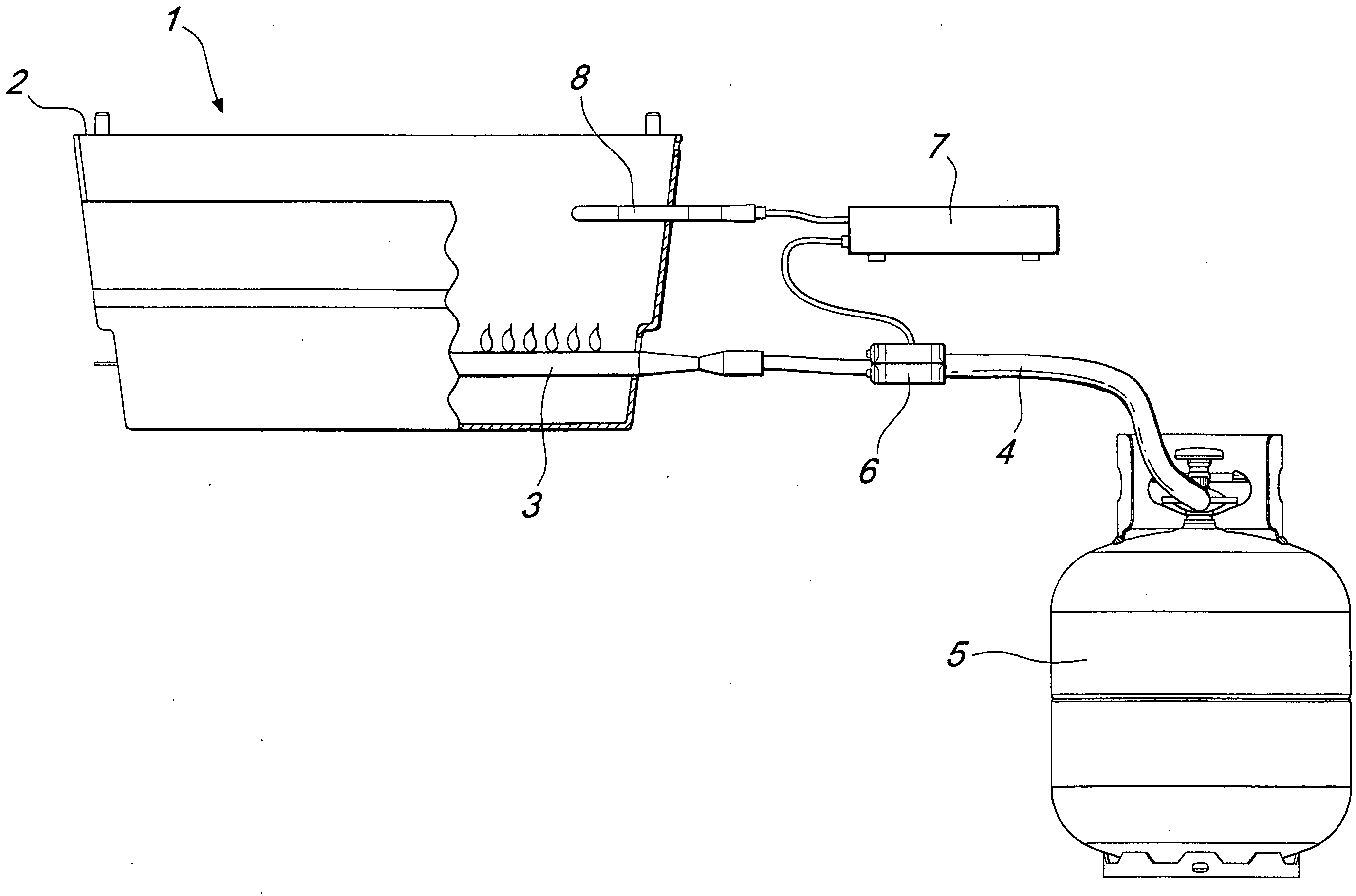

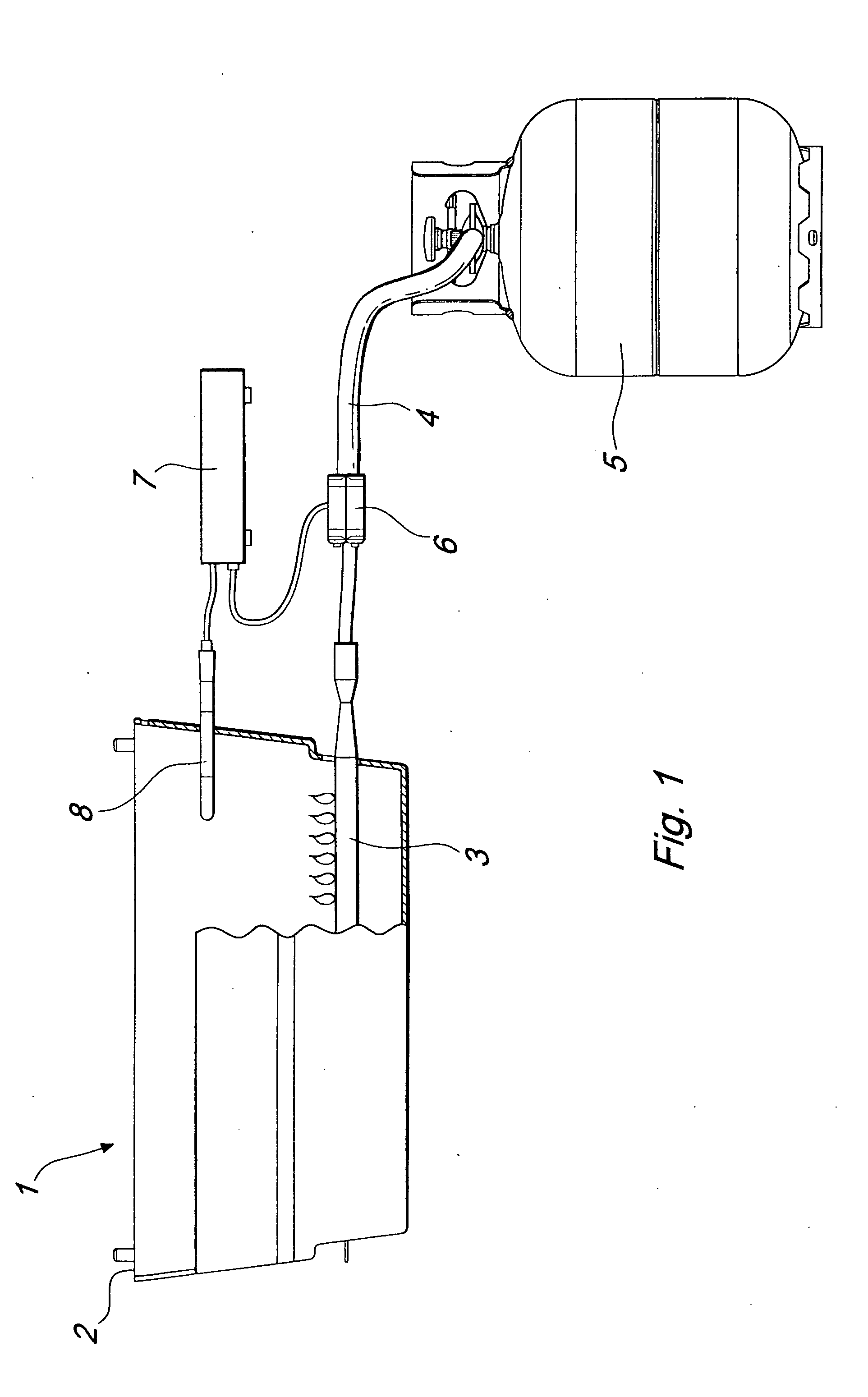

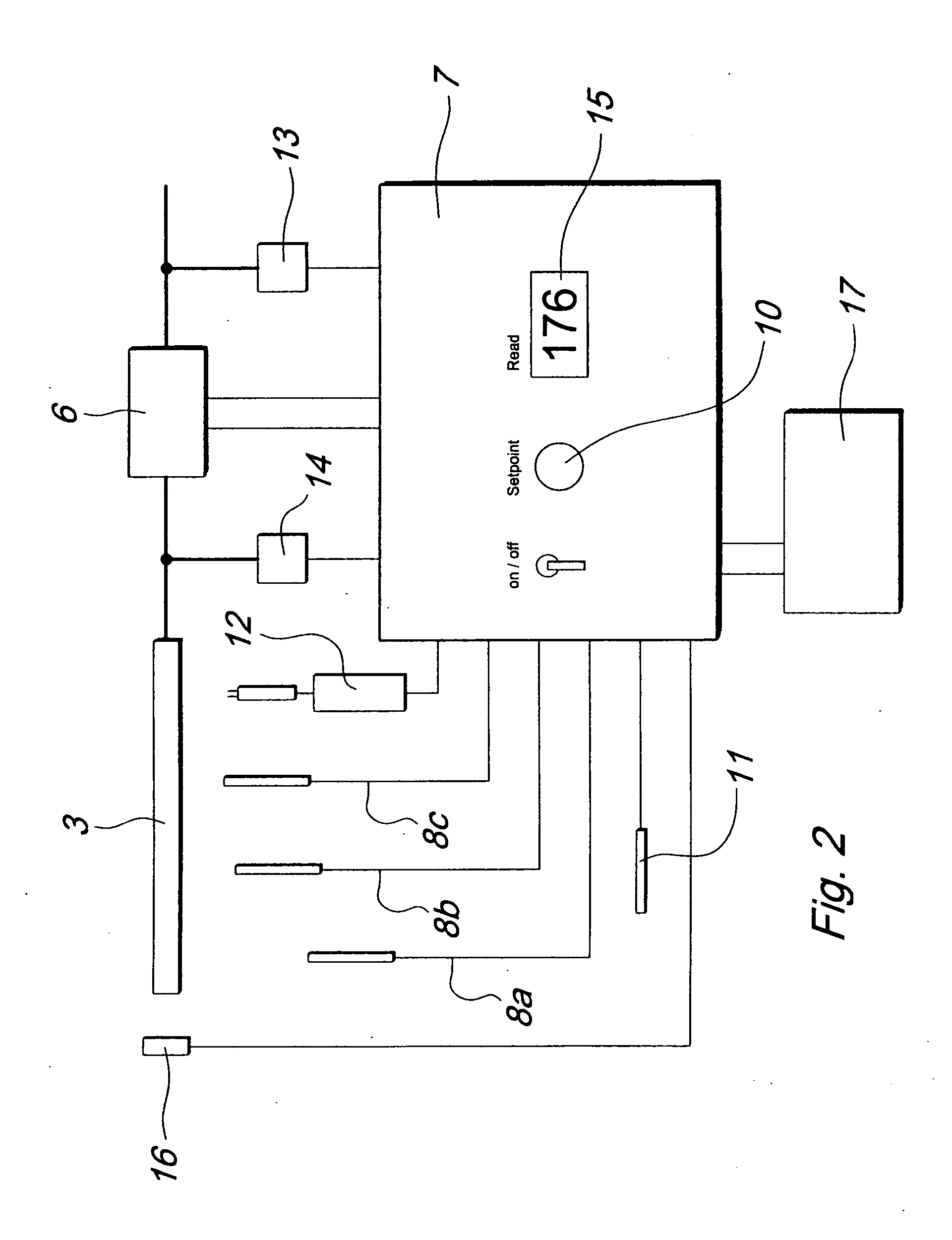

Gas water heater and method of operation

InactiveUS6880493B2Improve performanceStable temperatureFuel supply regulationElectric spark ignitersEngineeringProduct gas

A gas water heater with a tank for holding water including a gas valve mounted below the tank and in fluid communication with a supply of gas. A gas burner is fluidly connected to the gas valve. A first temperature sensor is mounted adjacent a lower portion of the tank and detects a temperature of the water in the lower portion of the tank, and a second temperature sensor is mounted adjacent an upper portion of the tank and detects a temperature of water in the upper portion of the tank. A control has inputs connected to the first and second temperature sensors and outputs connected to the gas valve. The control operates the gas valve in response to reading signals from the first and second temperature sensors such that water in the top and bottom portions of the tank stays within a desired temperature range.

Owner:CLIFFORD TODD W

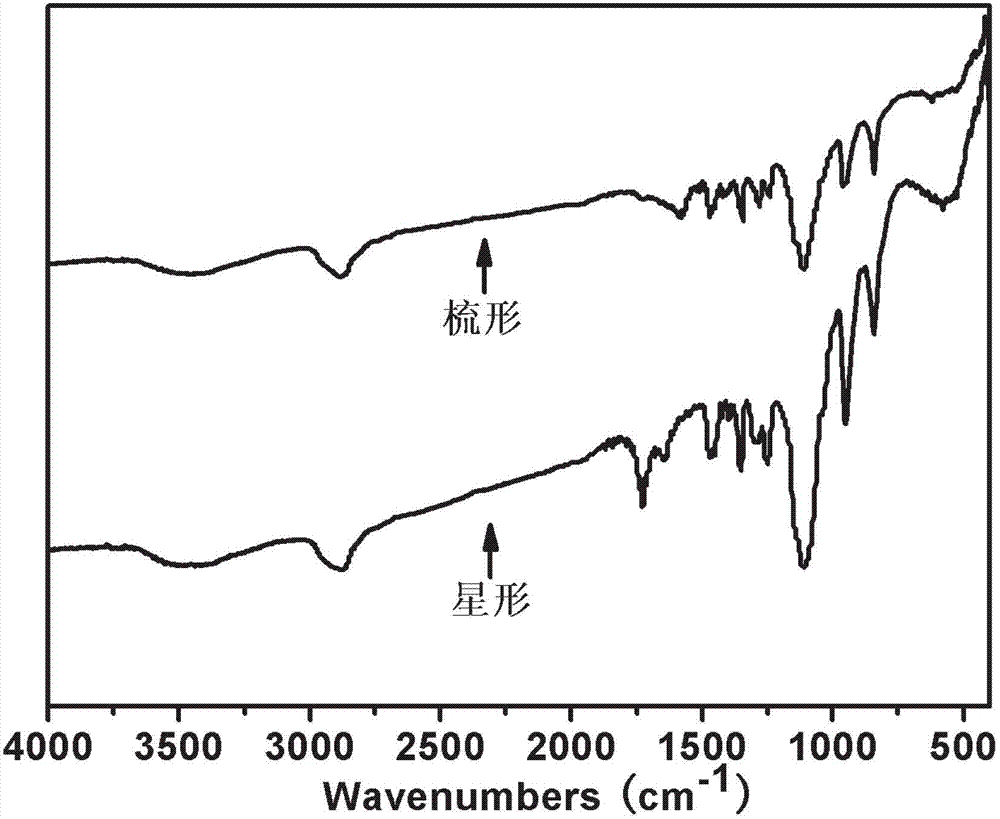

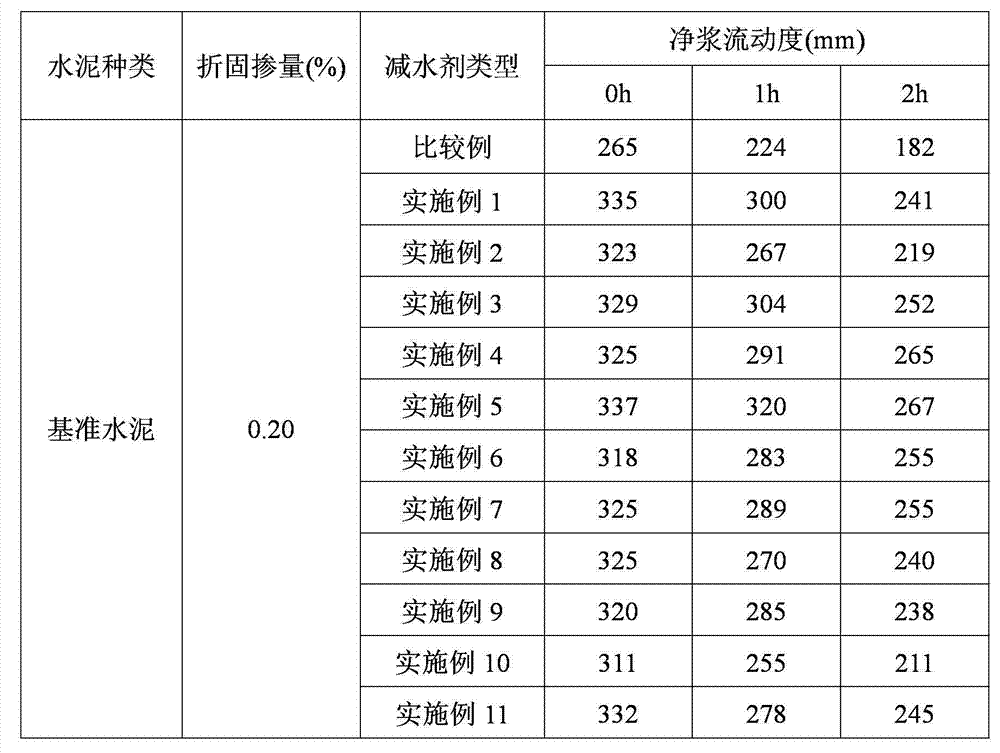

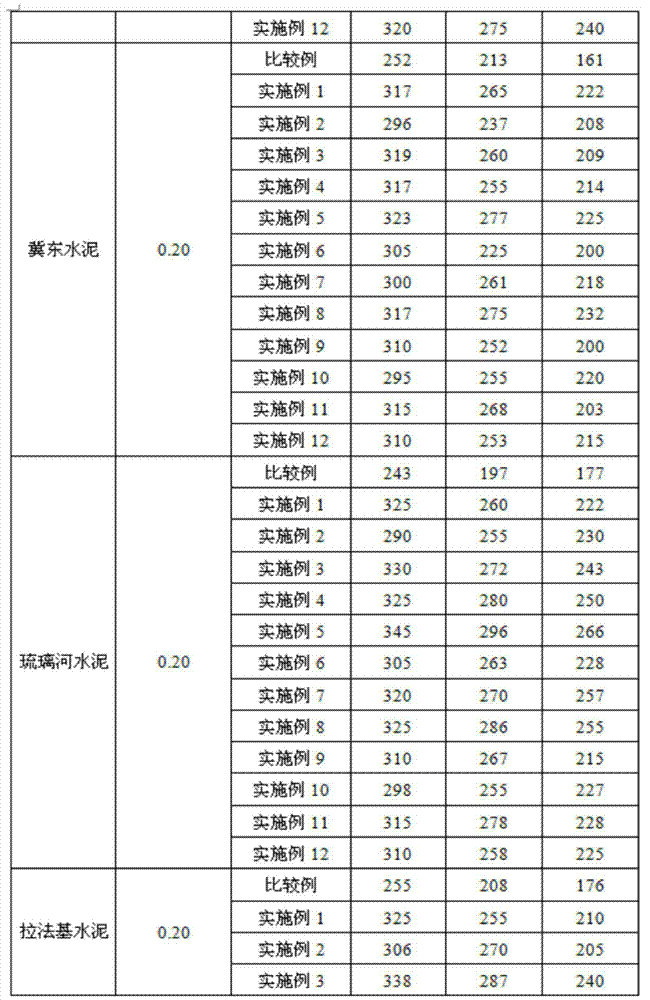

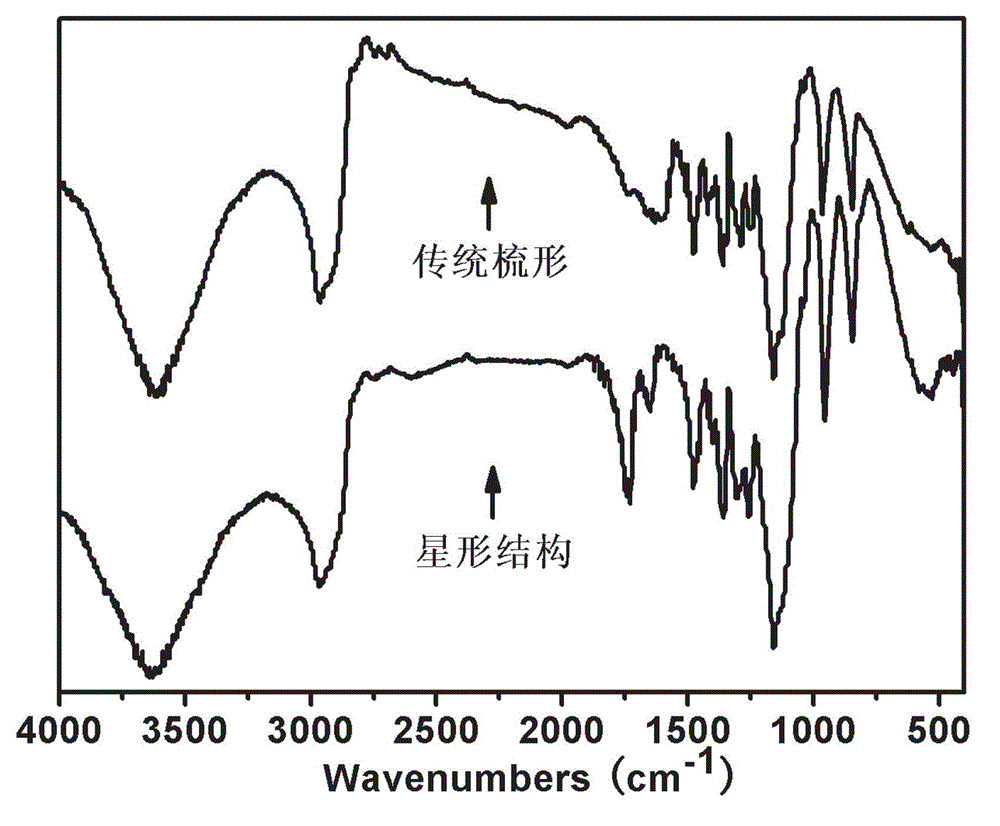

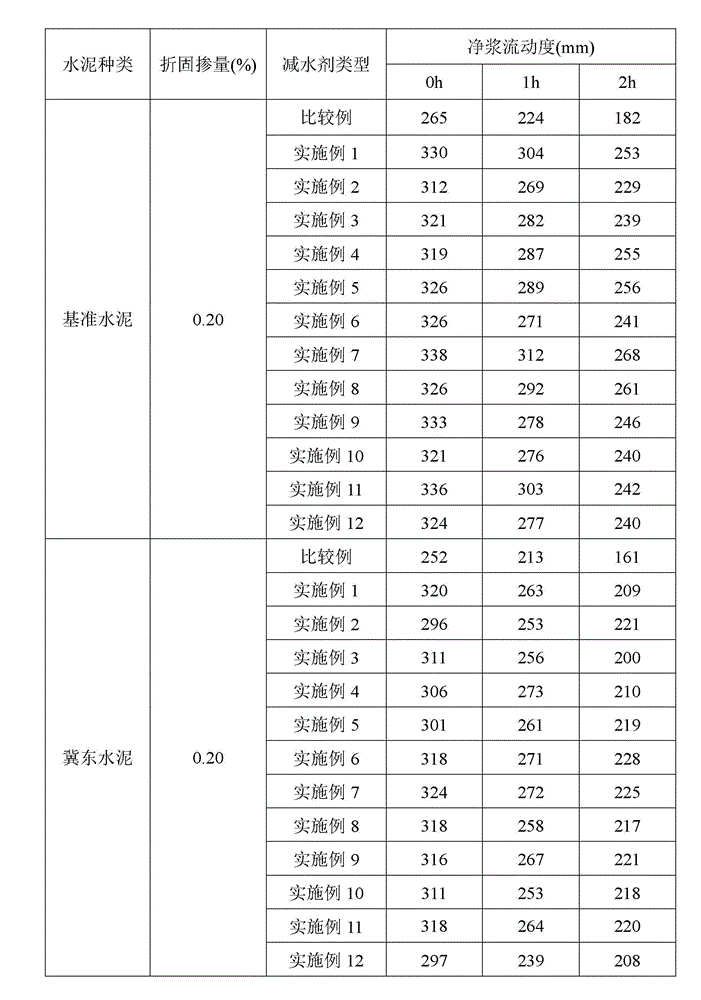

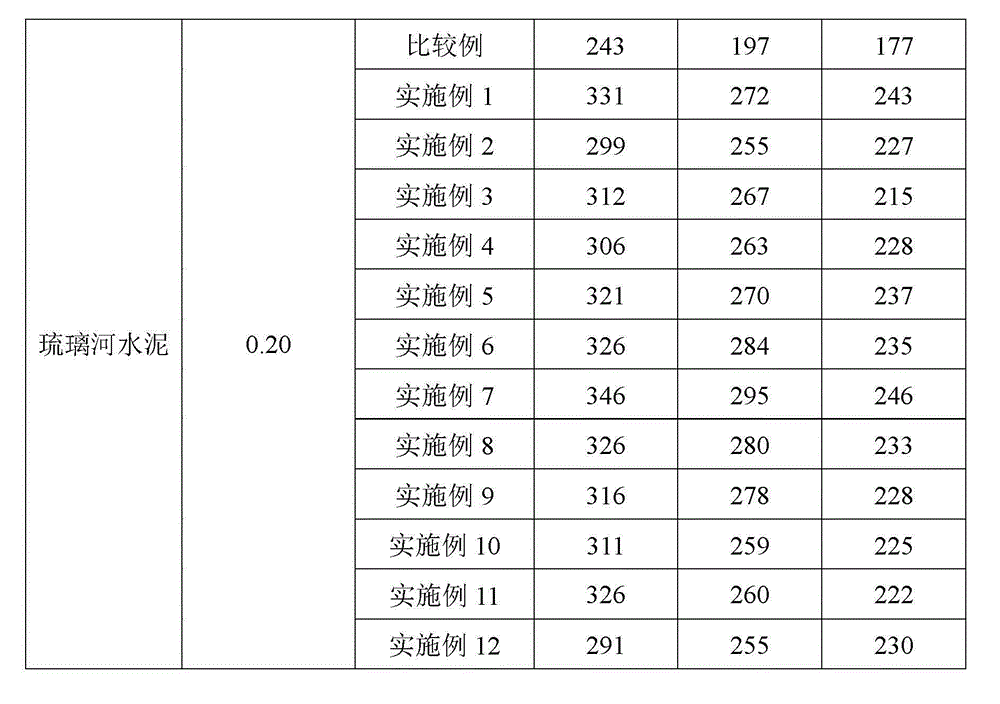

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

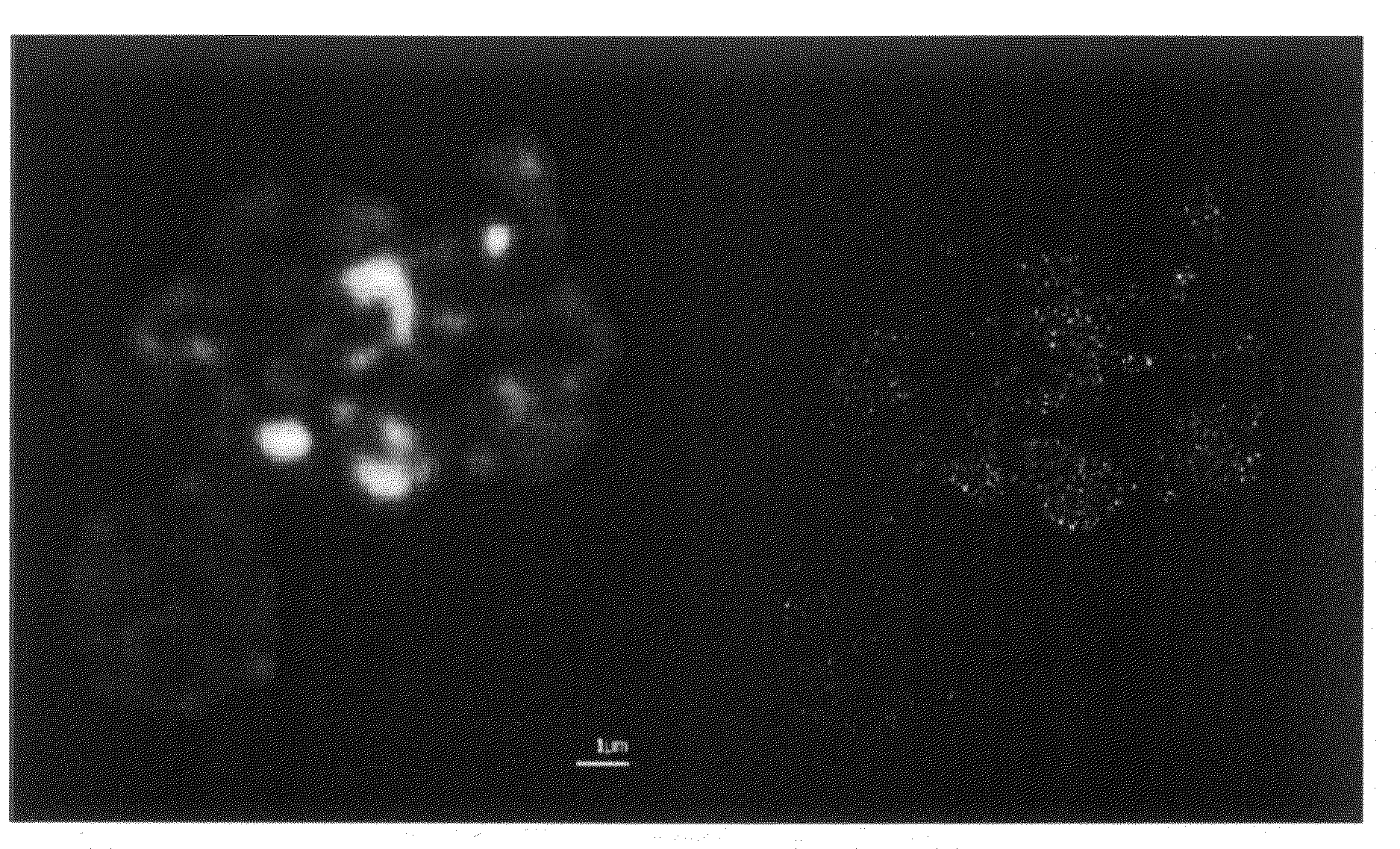

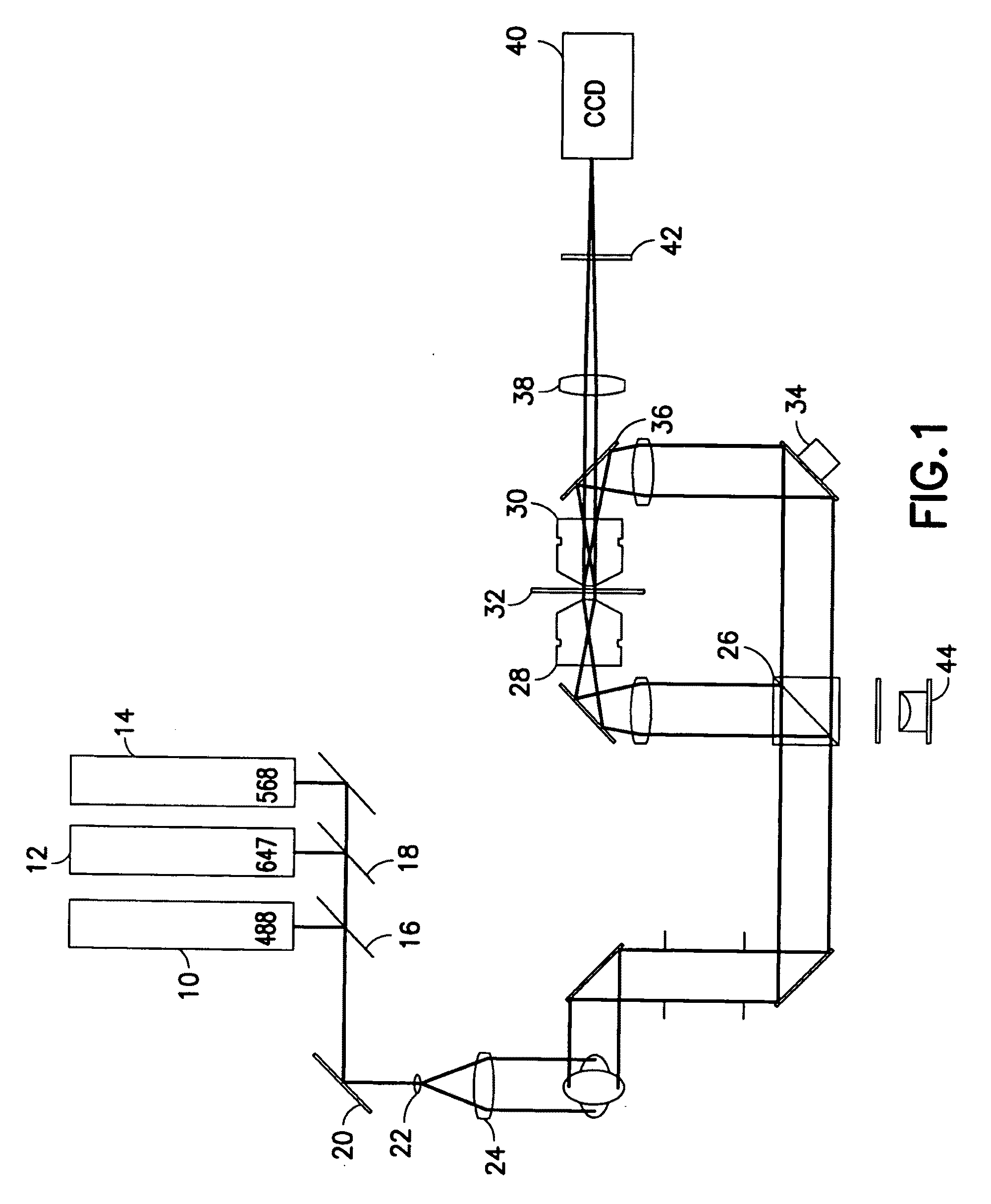

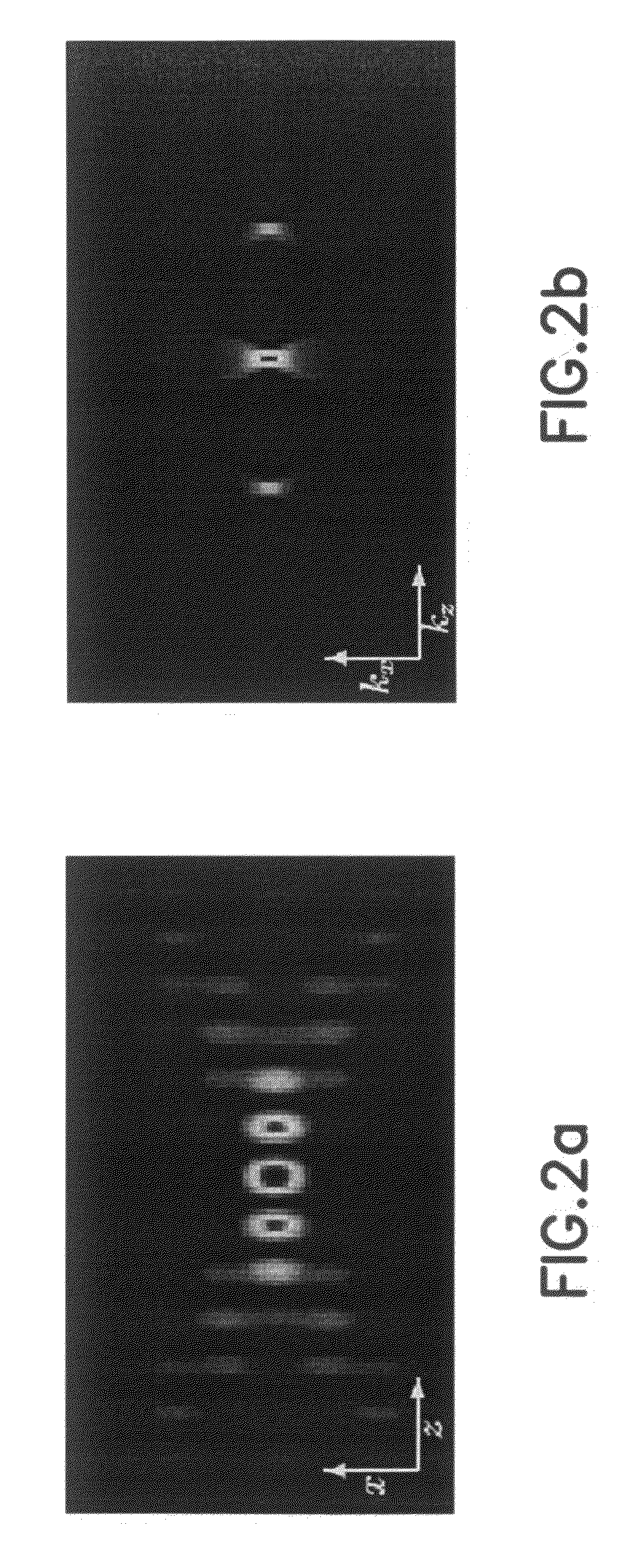

Wave field microscope with sub-wavelength resolution and methods for processing microscopic images to detect objects with sub-wavelength dimensions

The invention relates to a computer implemented method for processing of microscopic images to detect objects of interest. The method includes subjecting the microscopic image to a bandpass filtering to obtain a filtered image, wherein the bandpass filtering is such as to suppress the noise and any objects which are larger than a predetermined size; and processing the filtered image at a plurality of progressively decreasing threshold levels. The processing at each threshold level includes detecting the objects of interest using an object labelling algorithm and removing the detected objects detected at a given threshold level from the working image before proceeding to the next threshold level.

Owner:UNIVERSITY OF HEIDELBERG

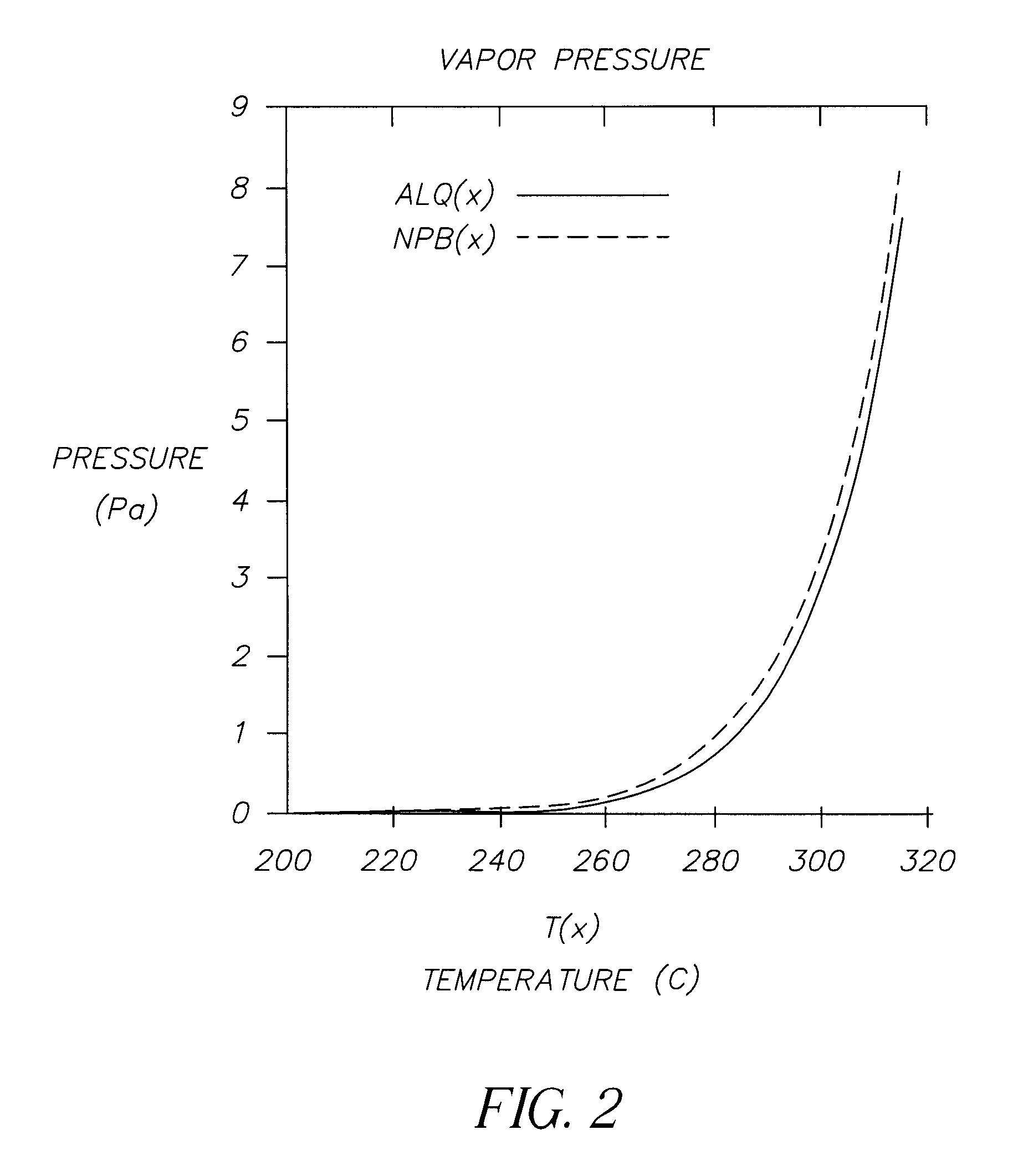

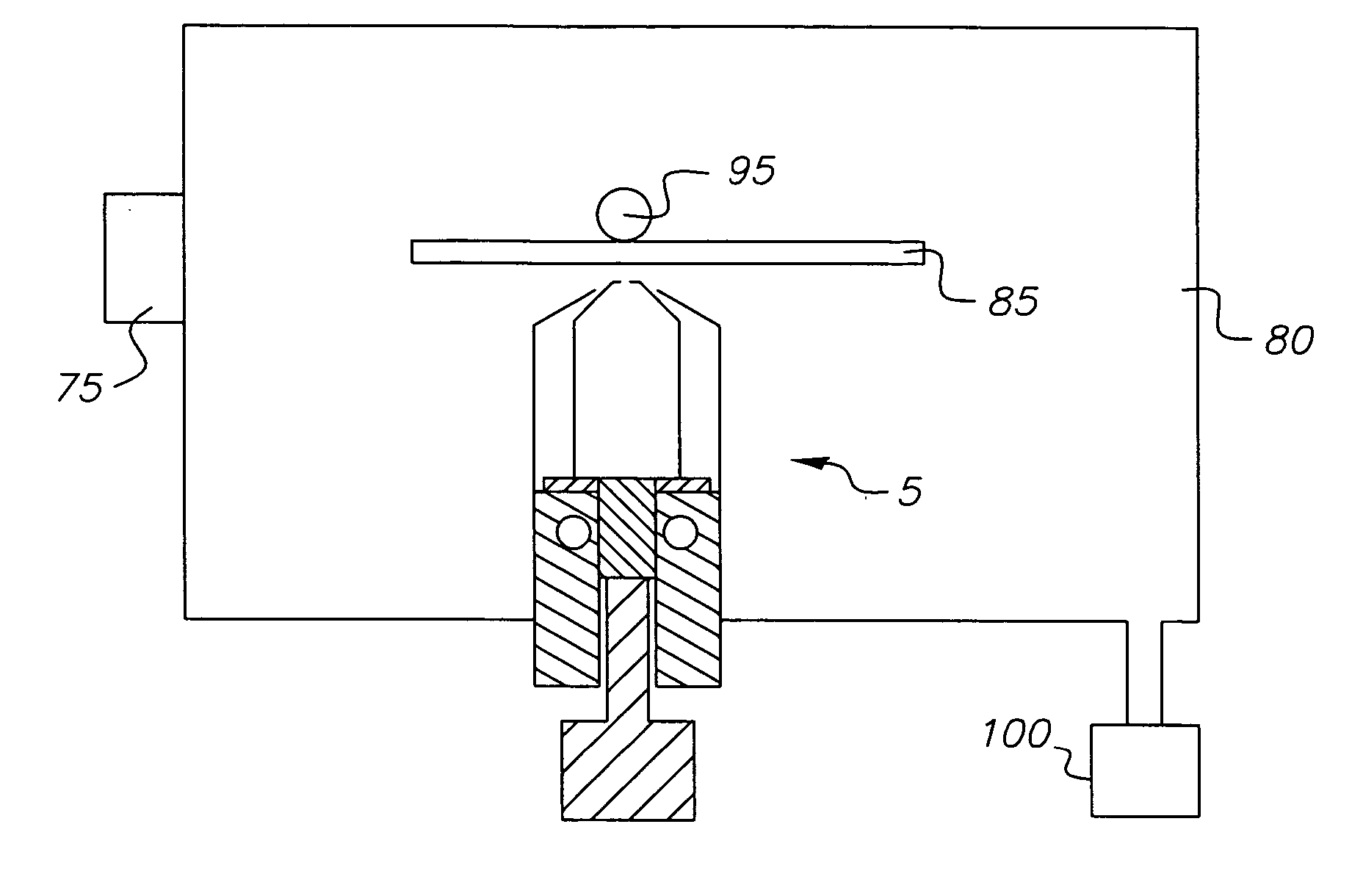

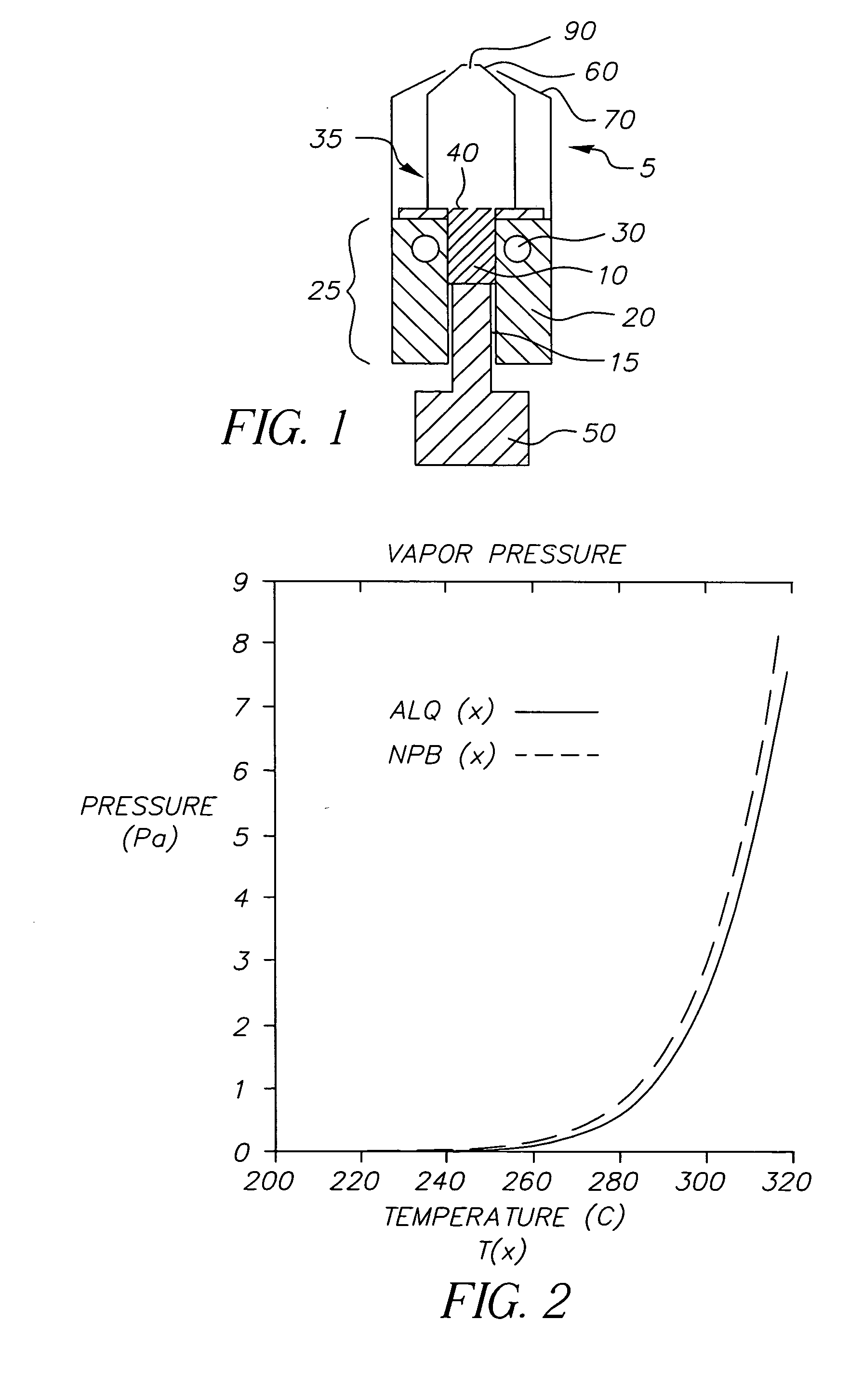

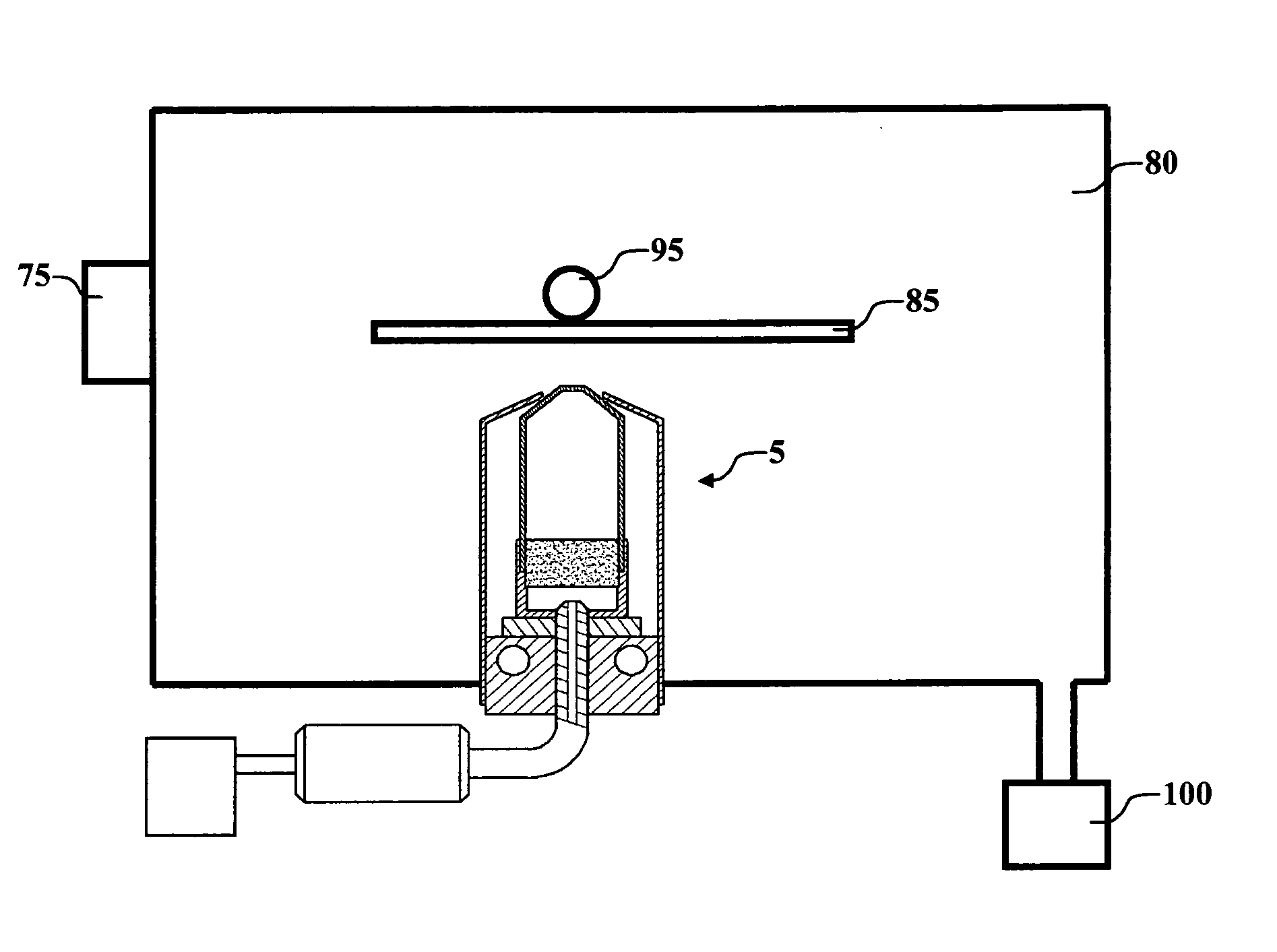

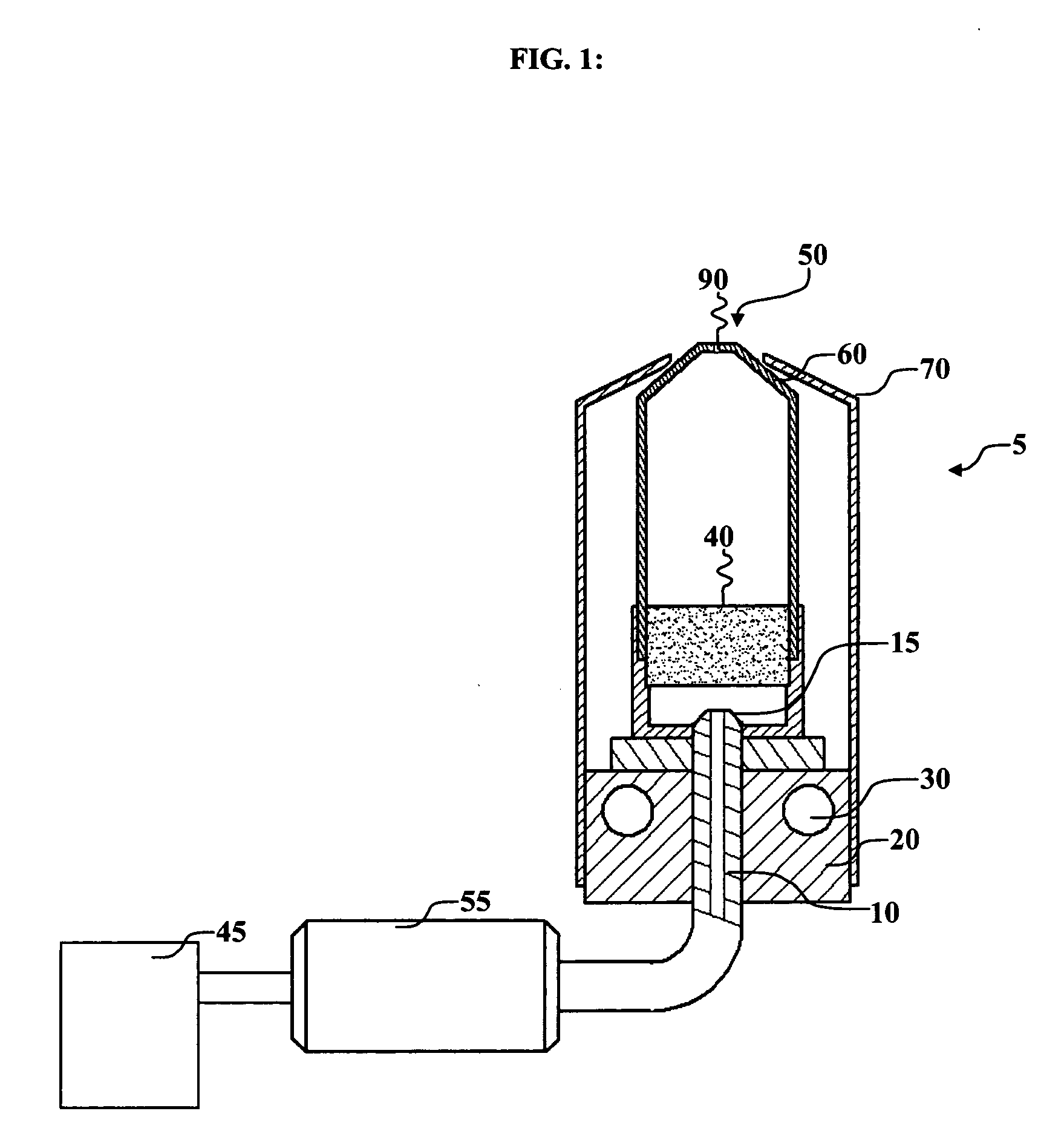

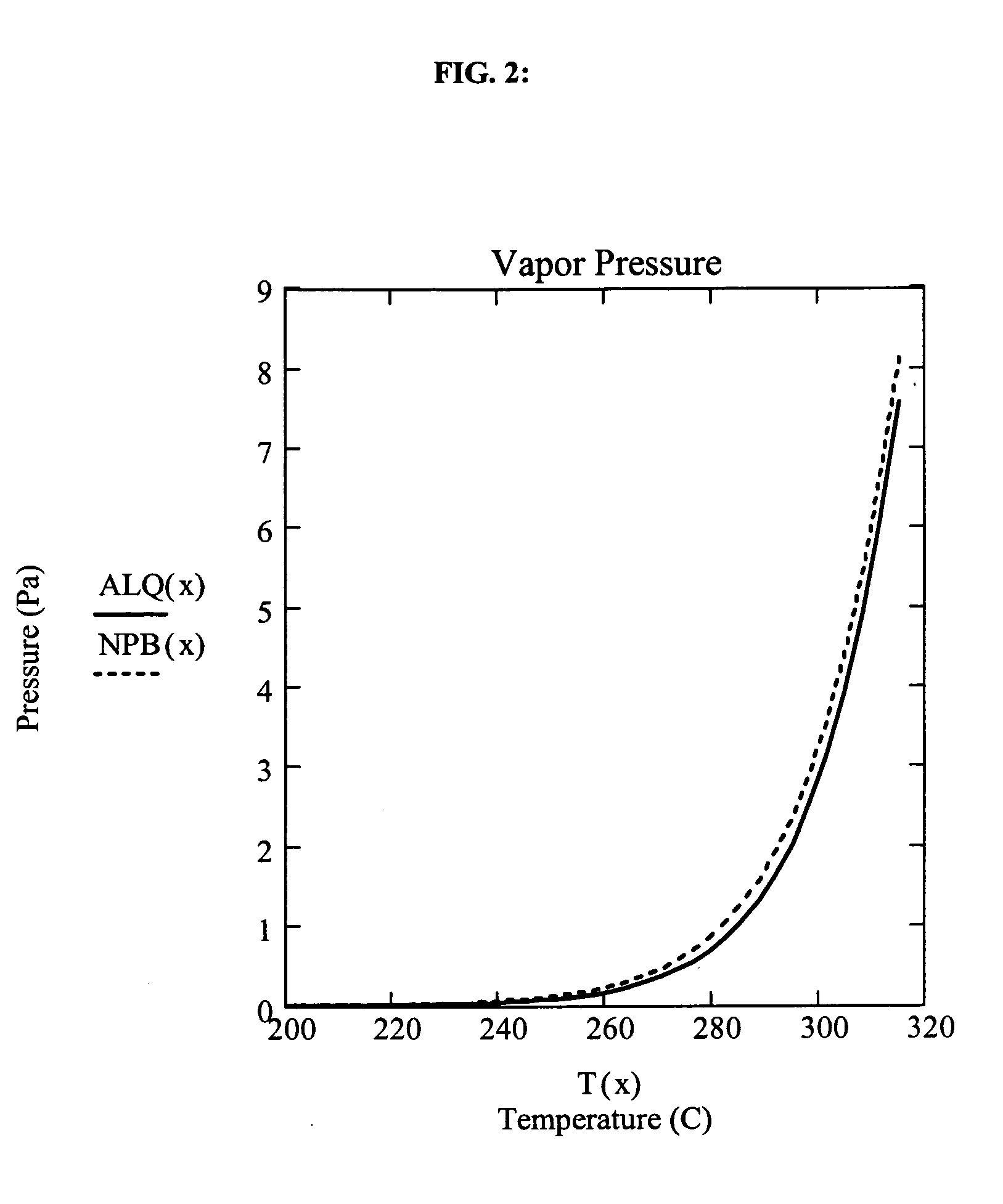

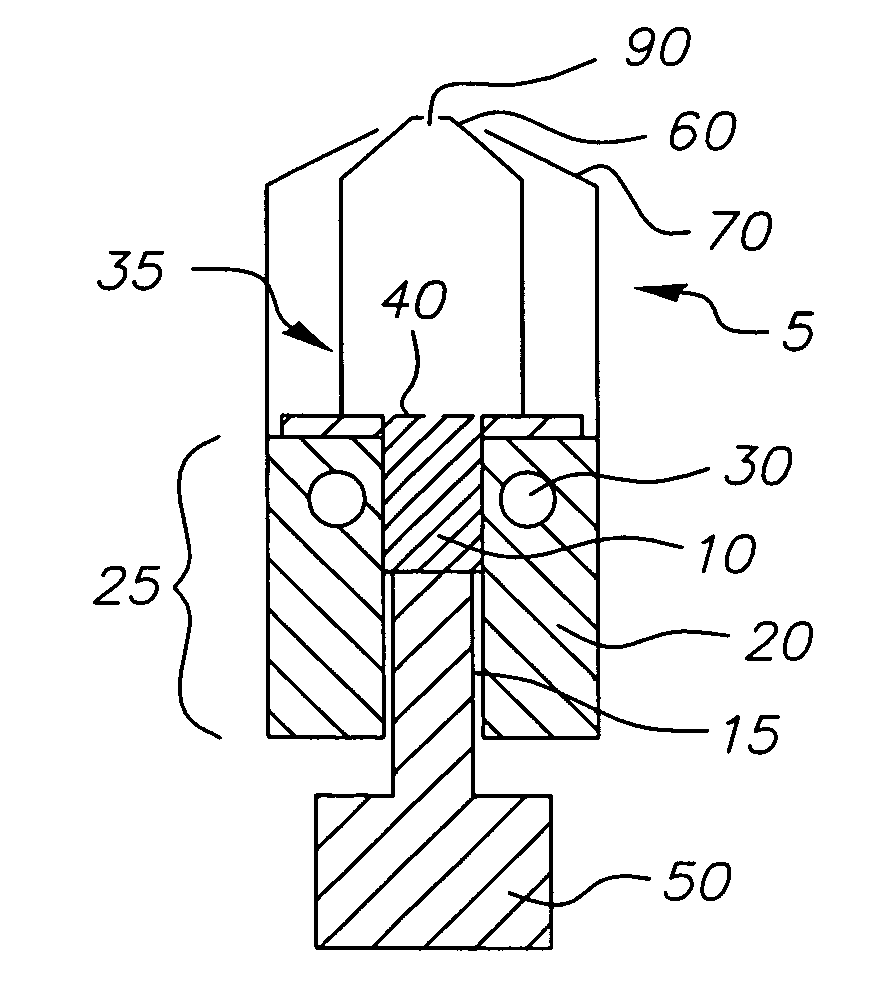

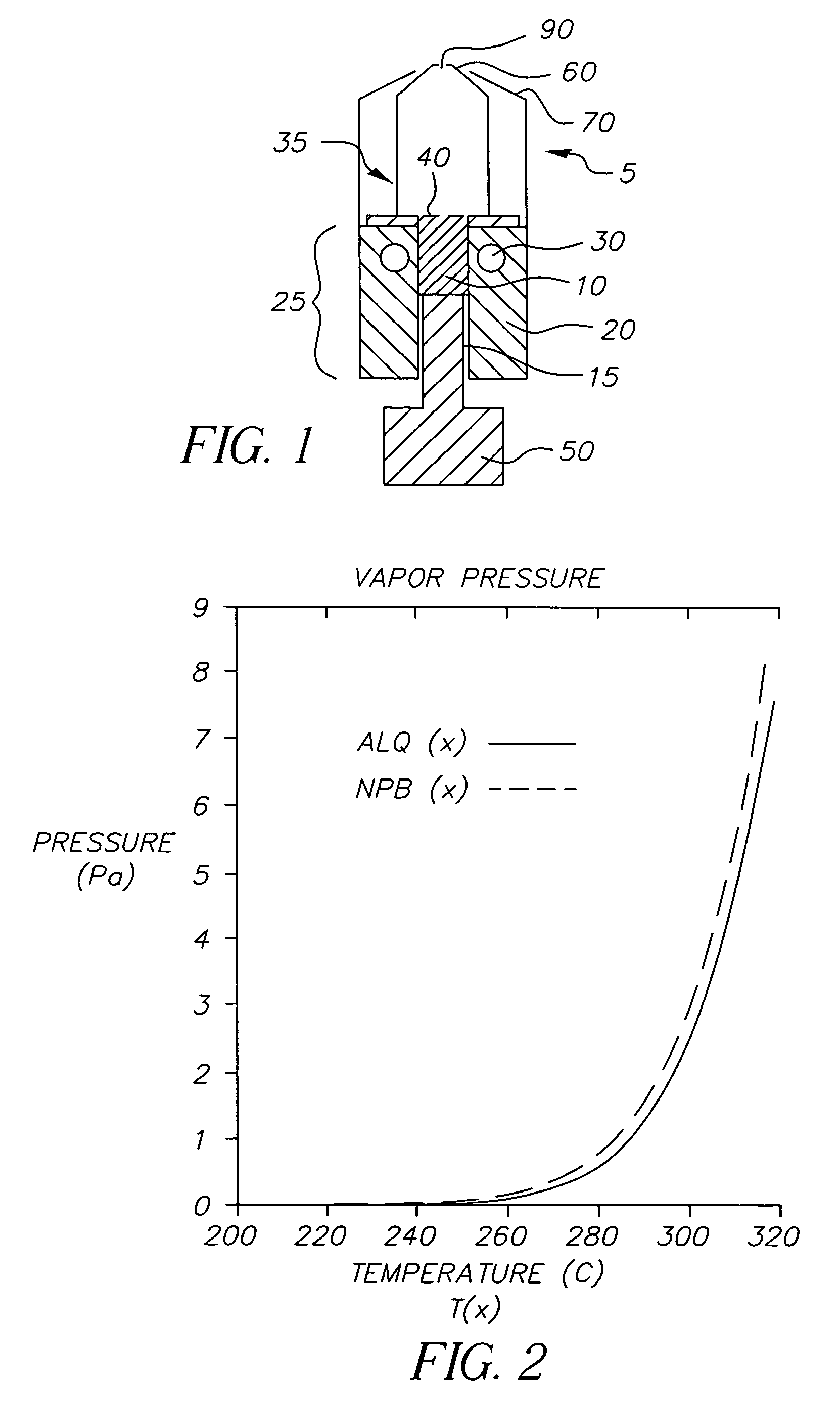

Device and method for vaporizing temperature sensitive materials

ActiveUS20050186340A1Steady vaporization rateReduce riskDischarge tube luminescnet screensElectroluminescent light sourcesMetallurgyVaporization

A method for vaporizing organic materials onto a substrate surface to form a film including providing a quantity of organic material into a vaporization apparatus and actively maintaining the organic material in a first heating region in the vaporization apparatus to be below the vaporization temperature. The method also includes heating a second heating region of the vaporization apparatus above the vaporization temperature of the organic material and metering, at a controlled rate, organic material from the first heating region into the second heating region so that a thin cross section of the organic material is heated at a desired rate-dependent vaporization temperature, whereby organic material vaporizes and forms a film on the substrate surface.

Owner:GLOBAL OLED TECH

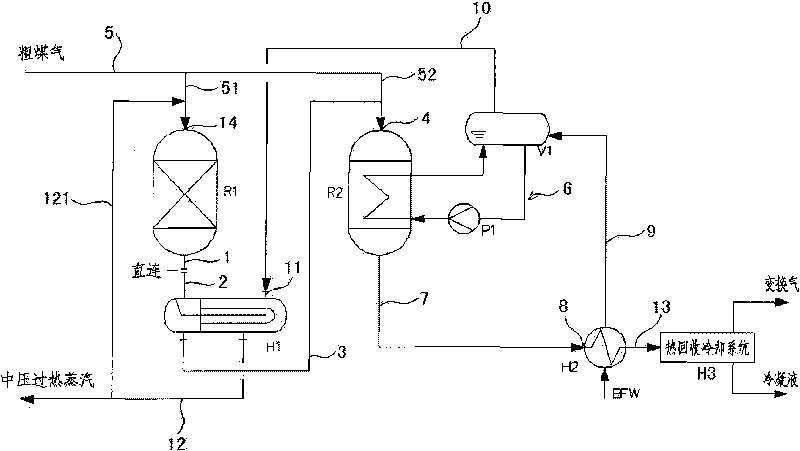

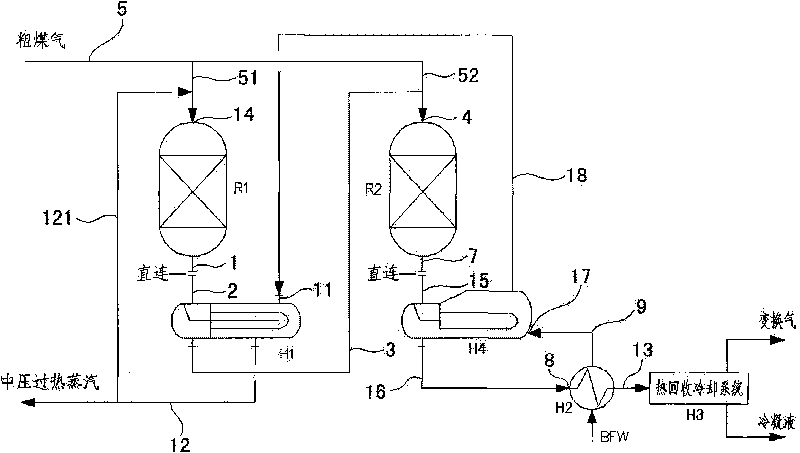

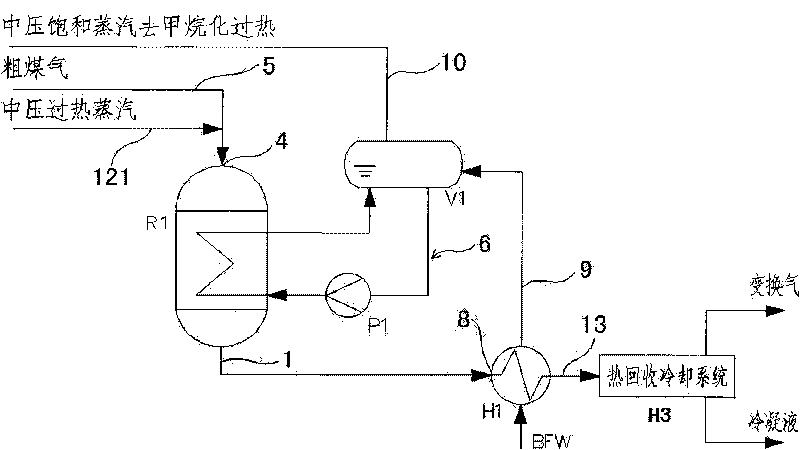

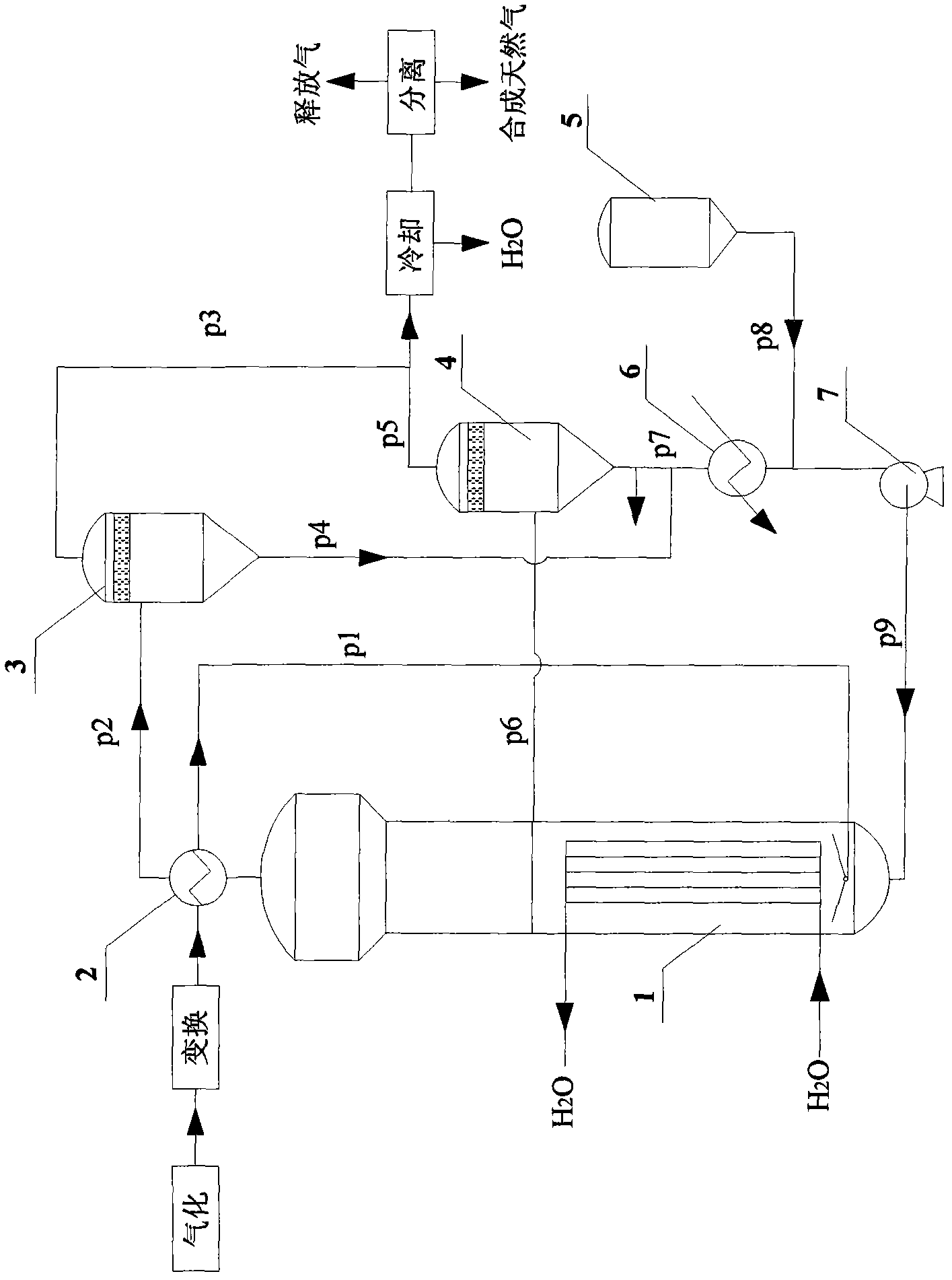

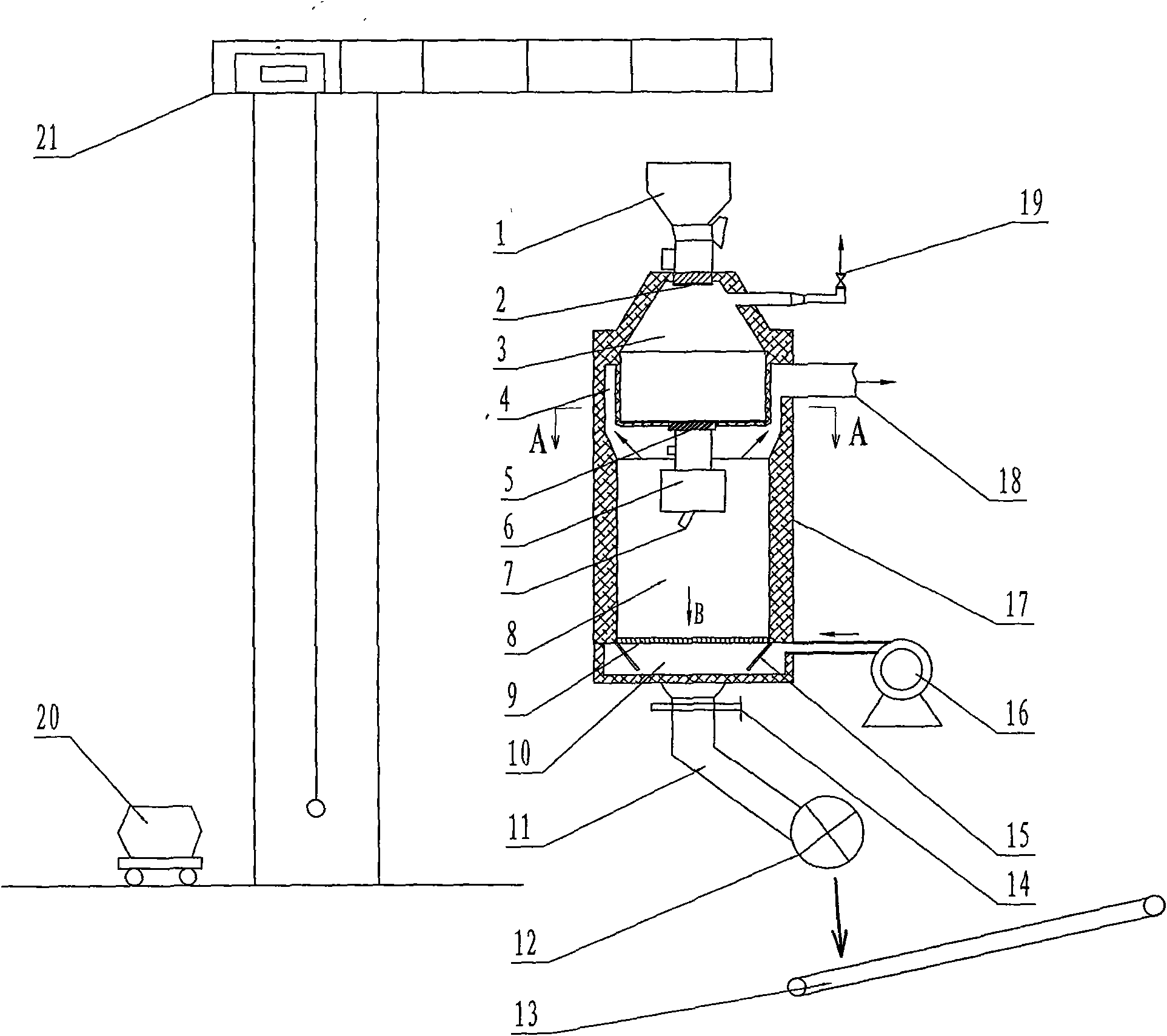

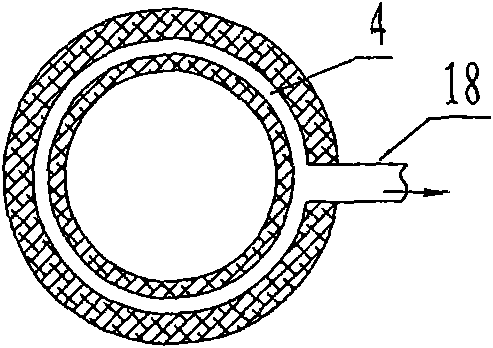

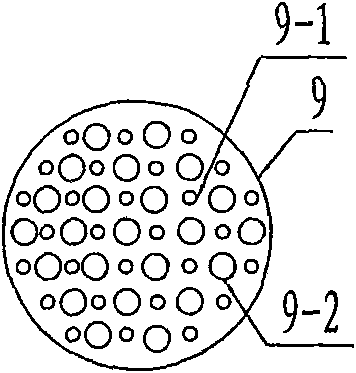

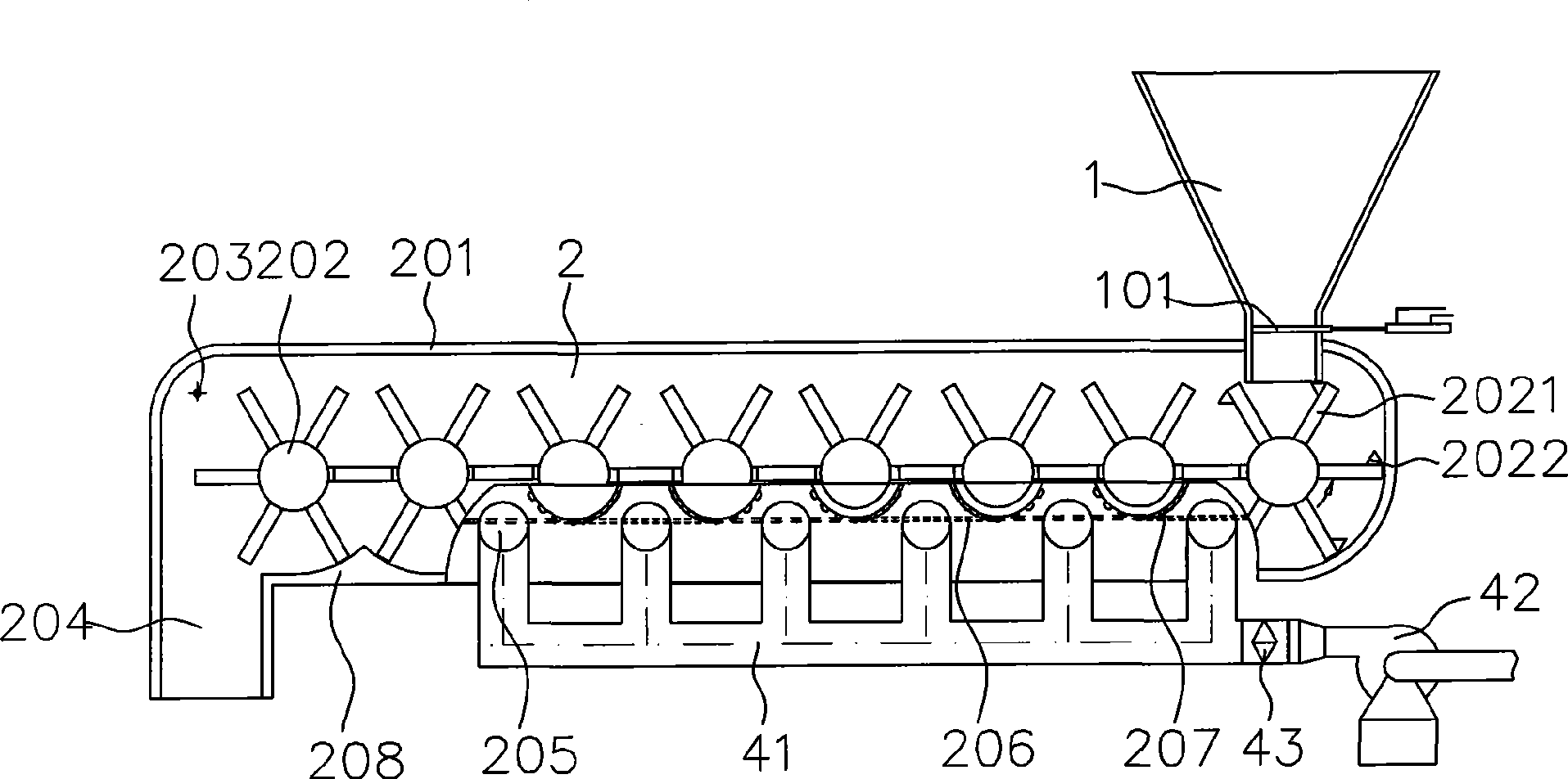

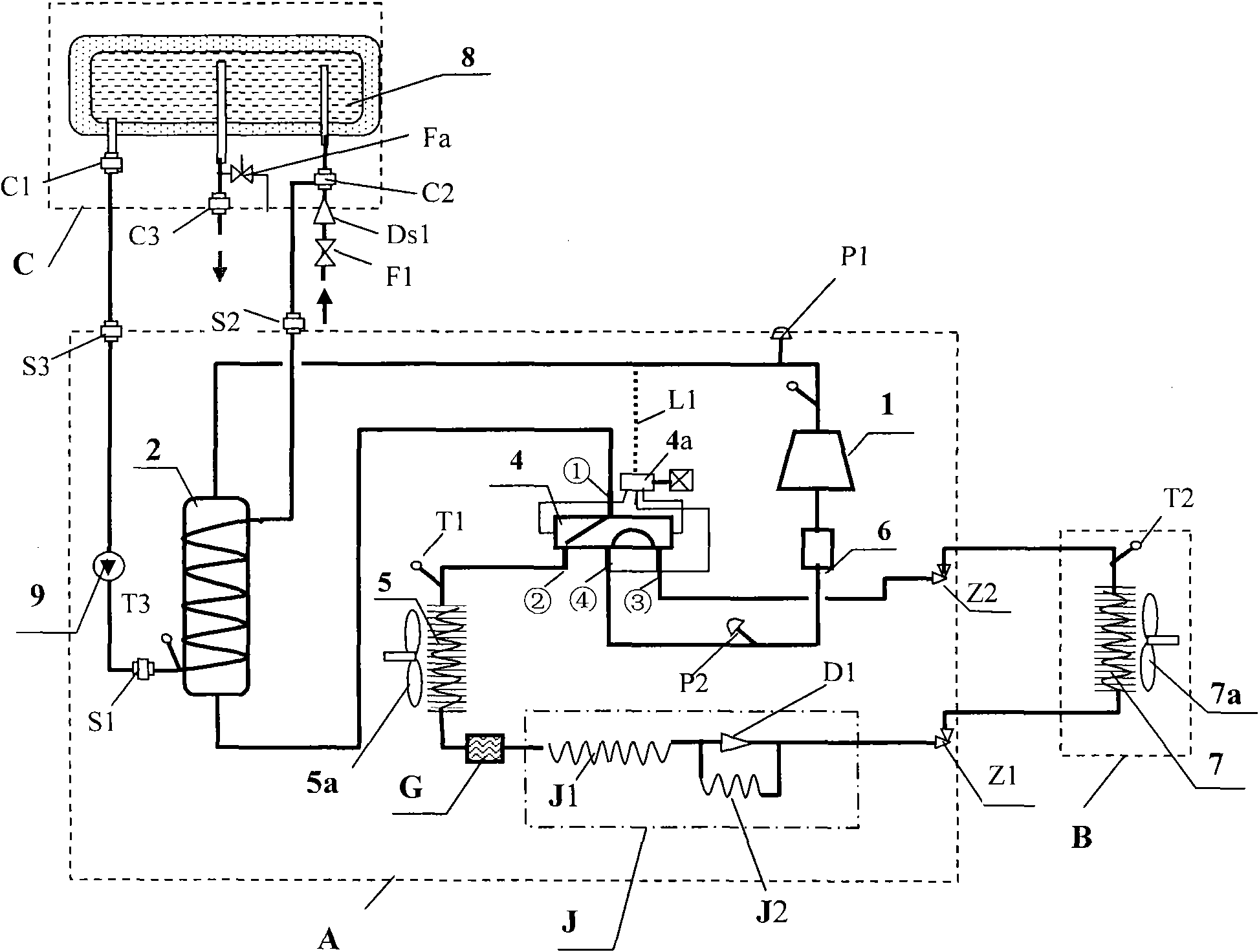

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

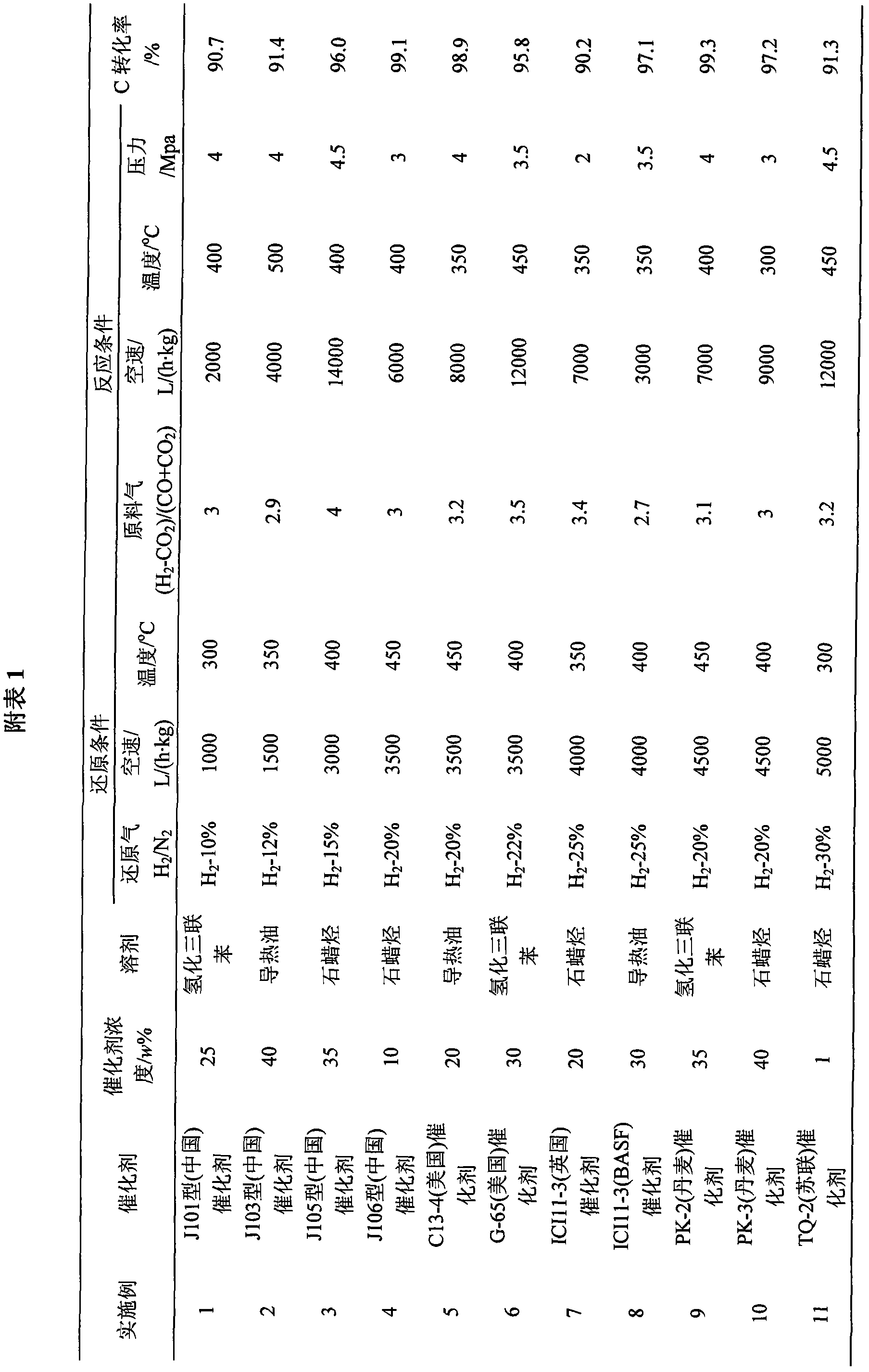

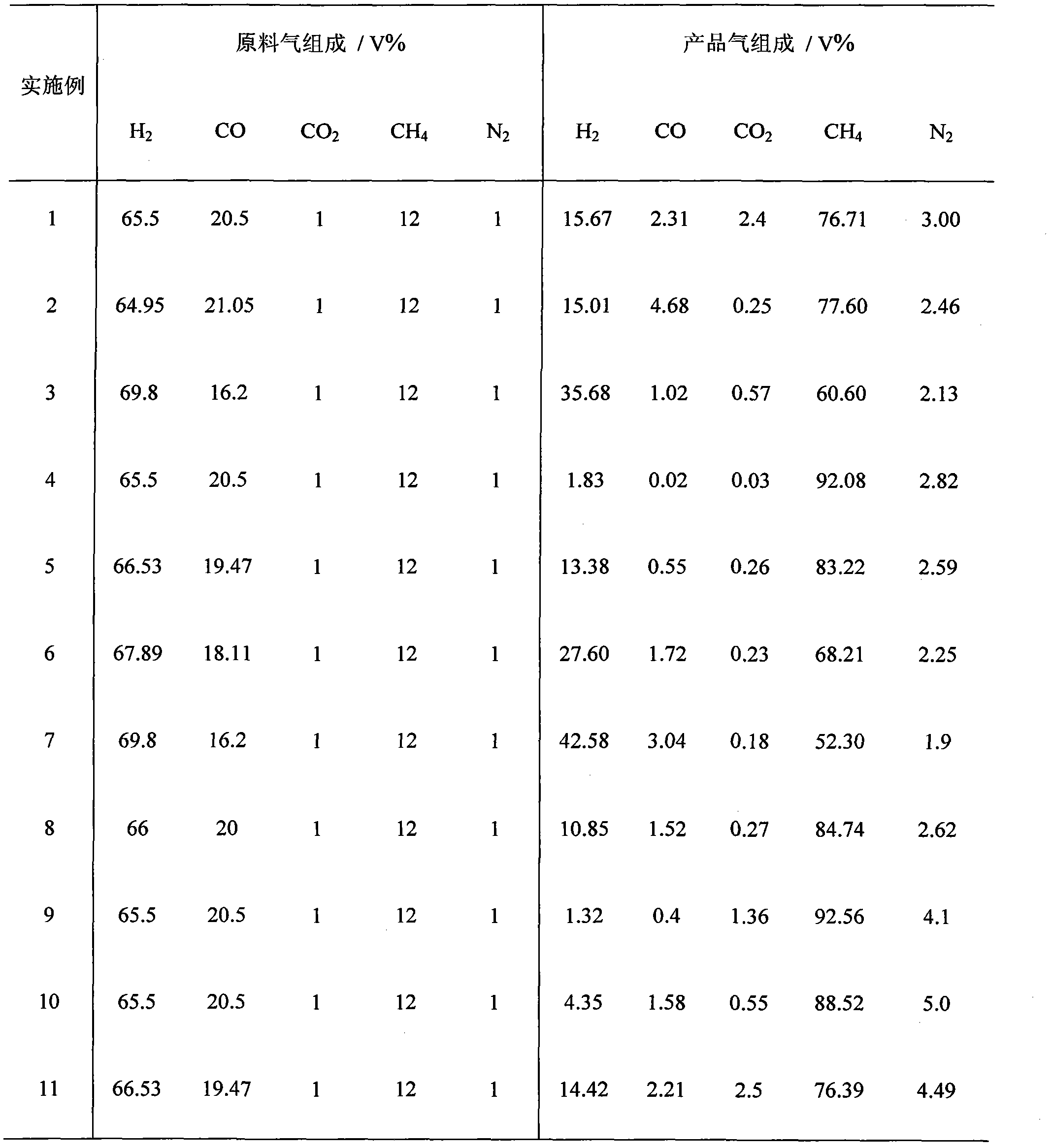

Process for synthesizing natural gas by methanation of coal synthesis gas

The invention discloses a process for synthesizing natural gas by methanation of coal synthesis gas, which comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid medium, delivering the medium into a slurry bed methanation reactor to perform reduction, performing methanation reaction on the transformed methanation raw gas after the reduction is finished, delivering the tail gas to a gas-liquid separator I, discharging the slurry liquid component and the catalyst in the tail gas from the bottom of the gas-liquid separator I, discharging the gas phase in the tail gas from the top of the gas-liquid separator I, delivering partial slurry liquid component containing the catalyst into a gas-liquid separator II, discharging the gas phase from the top of thegas-liquid separator II, merging the gas phases discharged from the tops of the gas-liquid separators I and II, cooling and purifying the gas phases to obtain synthesized natural gas, discharging theslurry liquid component containing the catalyst from the bottom of the gas-liquid separator II, merging the slurry liquid component discharged from the bottom of the gas-liquid separator II and the slurry liquid component and the catalyst discharged from the bottom of the gas-liquid separator I, discharging 1 to 5 percent of the weight sum of the slurry liquid component and the catalyst separatedfrom the two gas-liquid separators, and performing methanation reaction on the cooled rest slurry liquid component and catalyst and the fresh methanation catalyst dispersed into the insert liquid medium together. The process has the advantages of low power consumption and low equipment investment, and is easy to operate.

Owner:SEDIN ENG +1

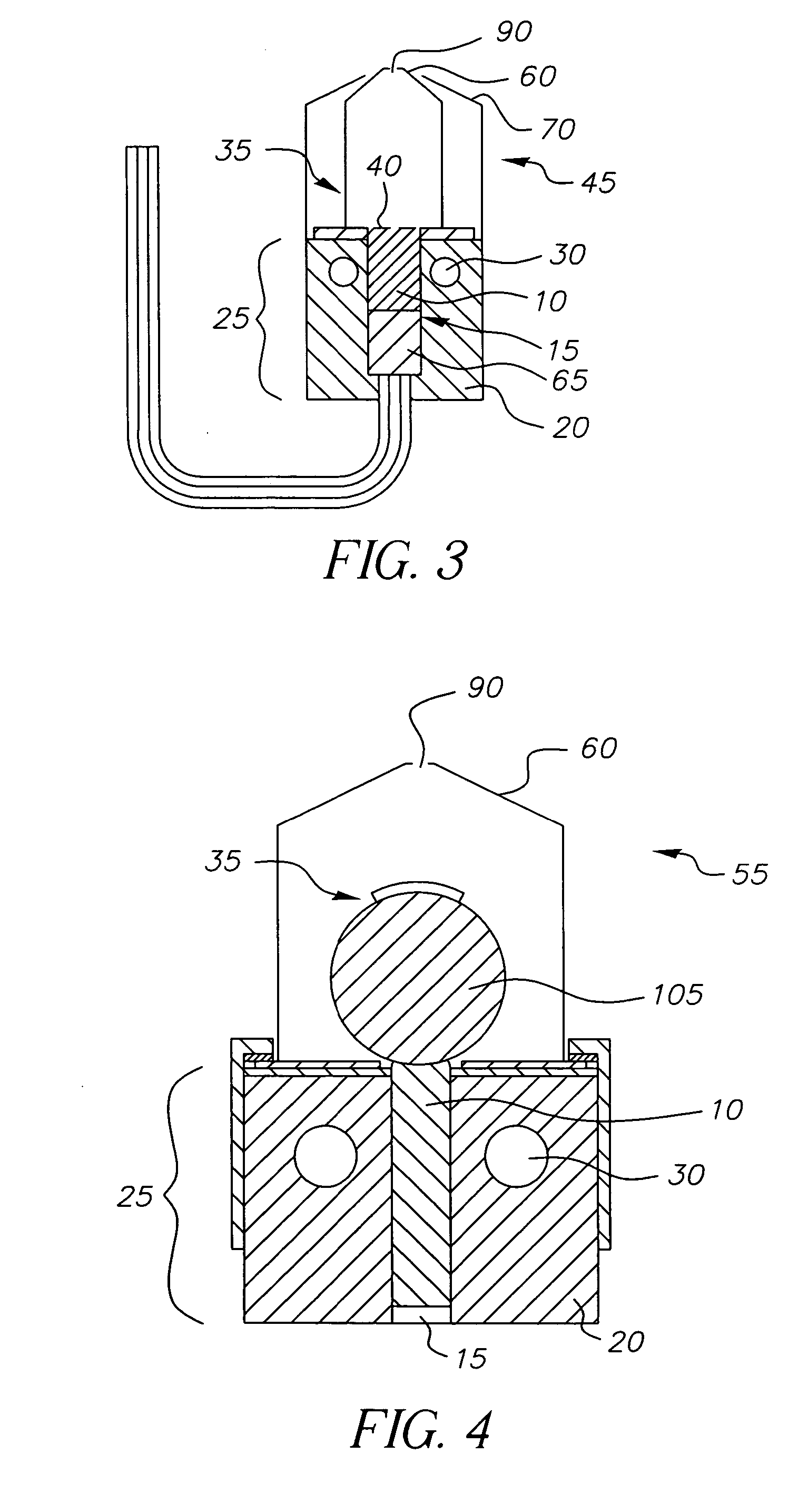

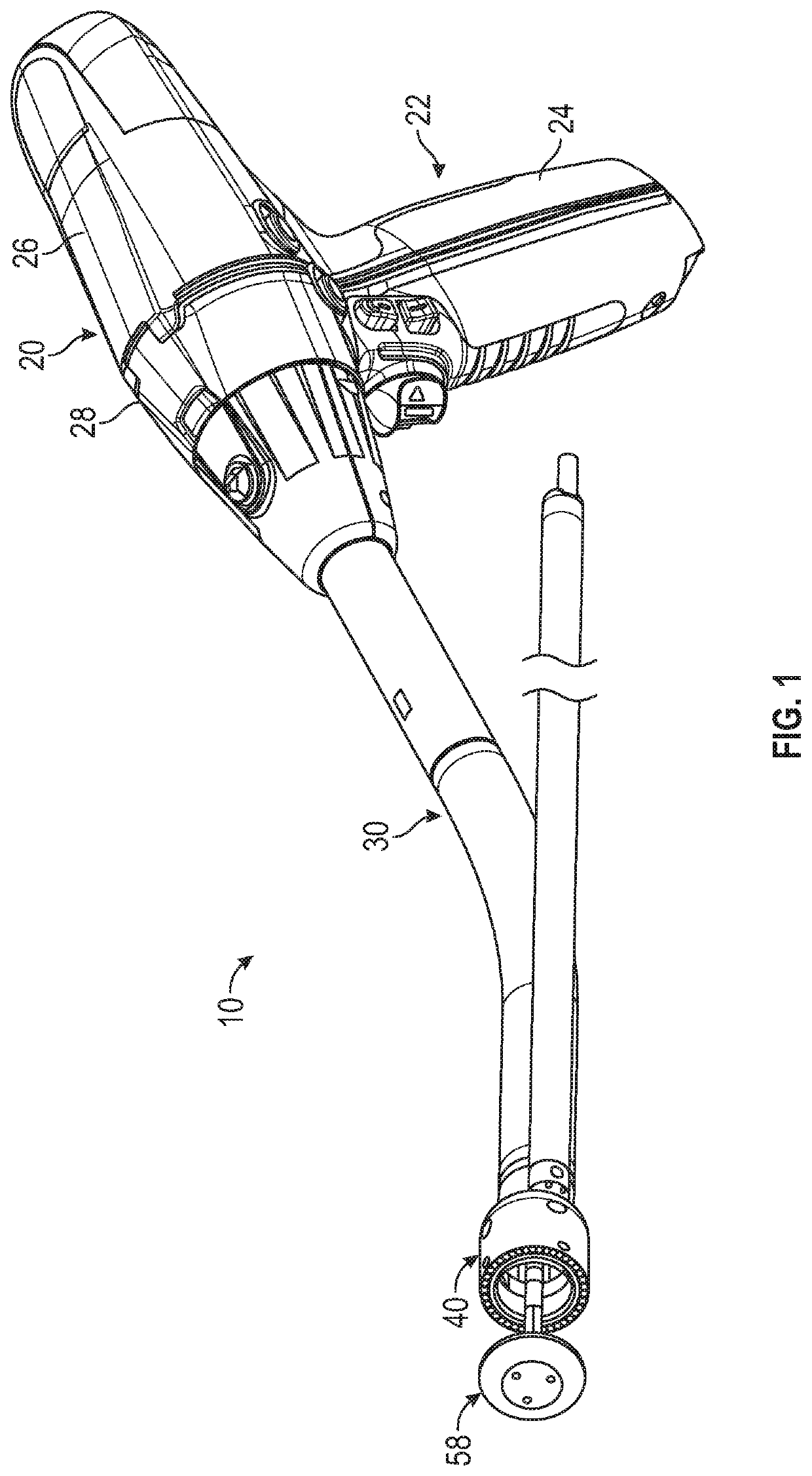

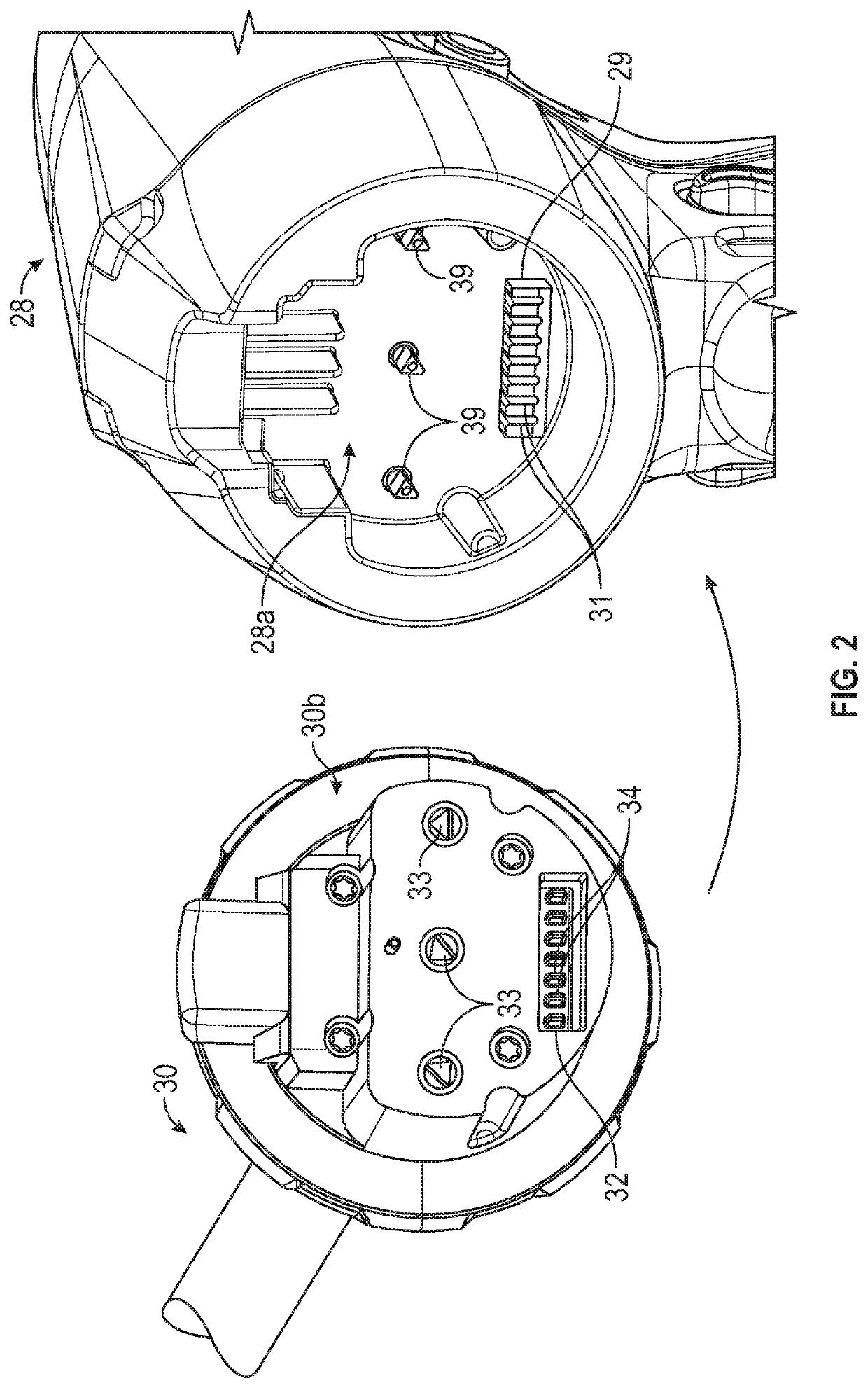

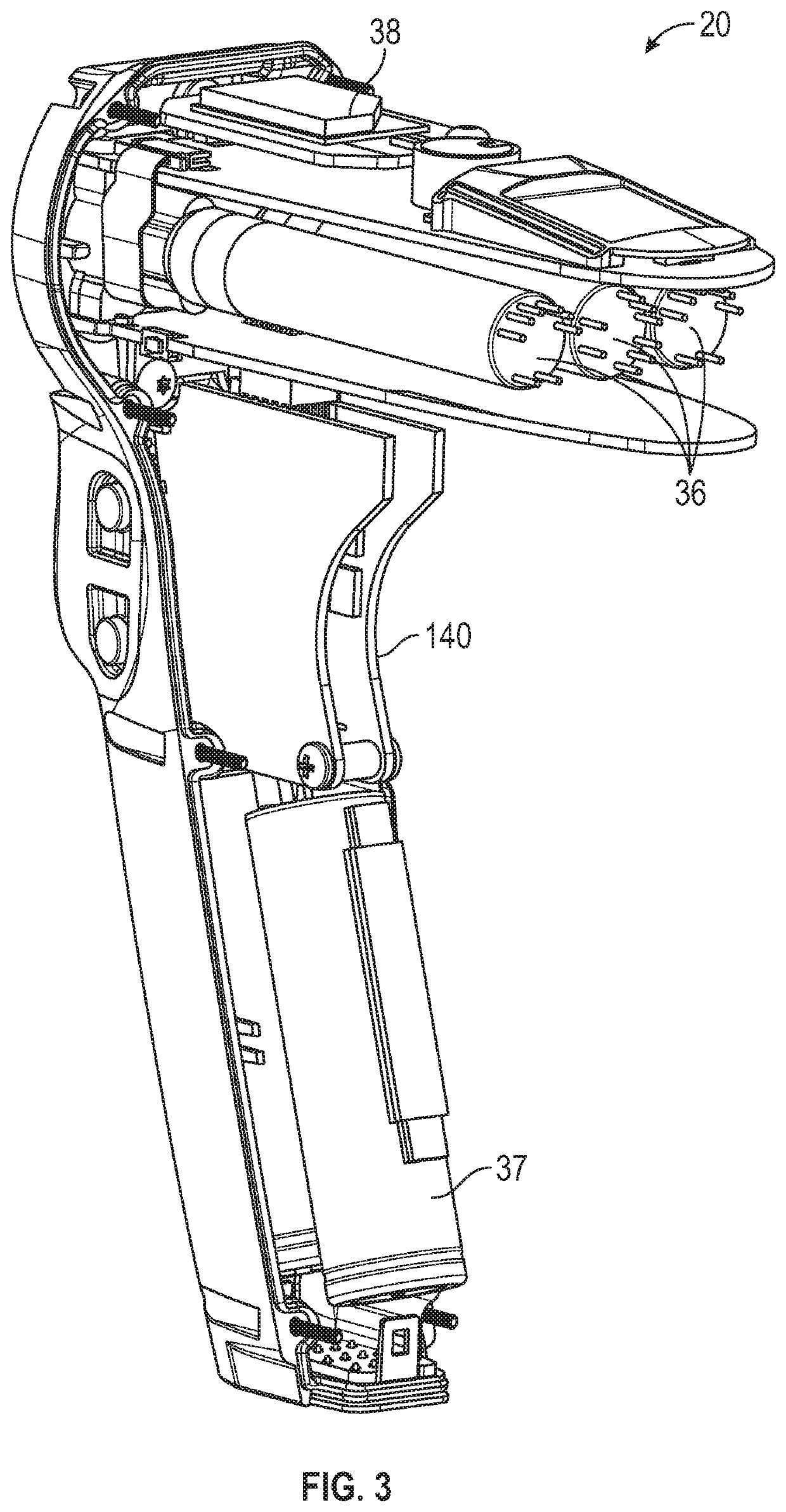

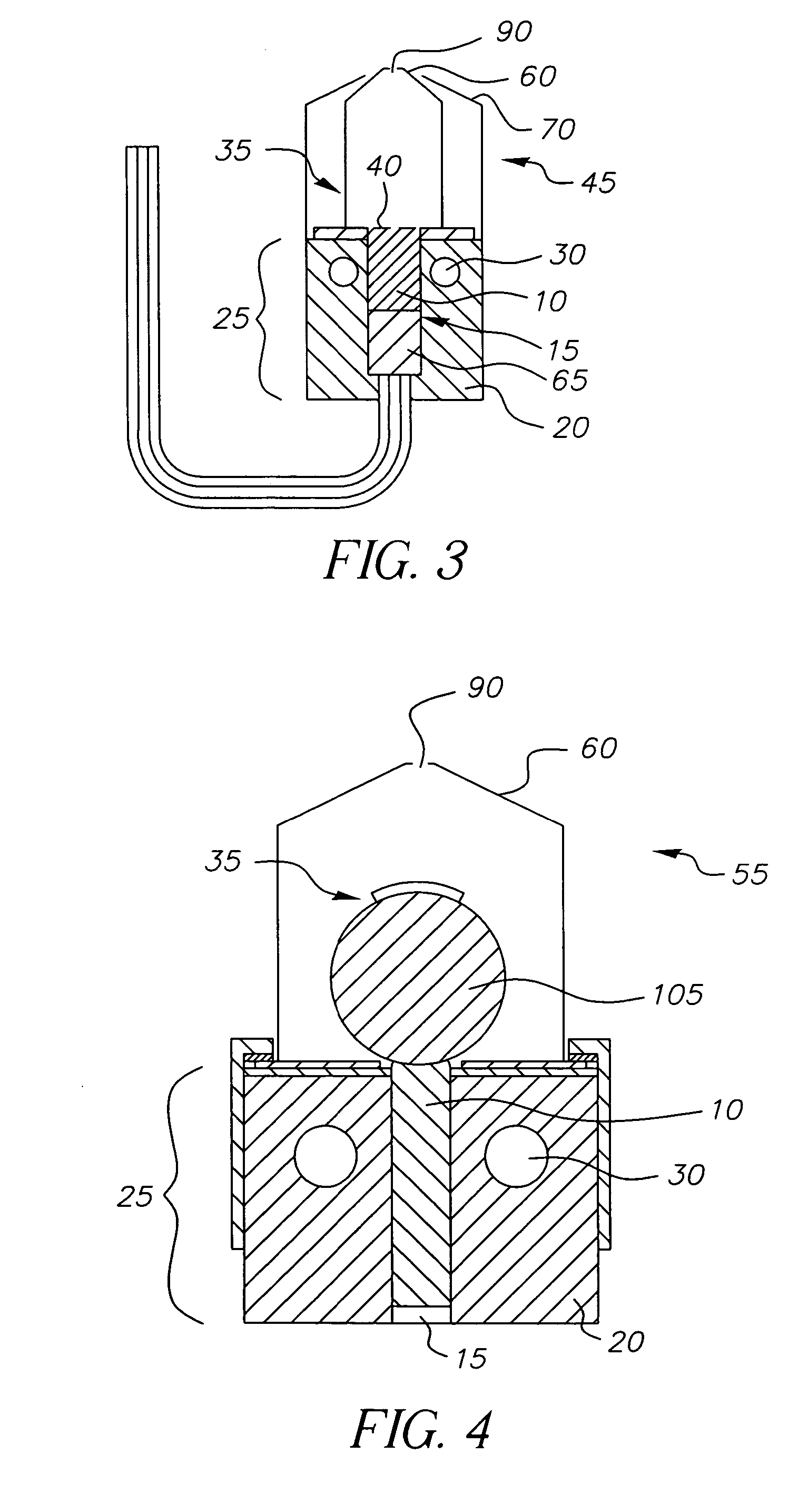

Strain gauge stabilization in a surgical device

ActiveUS20200315623A1Minimizes strain gauge errorStable temperatureDiagnosticsStrain gaugeSurgical operationSignal processing circuits

A surgical device includes an adapter assembly including a tubular housing having a proximal end portion configured to couple to a handle assembly, and a load sensing assembly disposed with the tubular housing. The load sensing assembly is configured to measure a load exerted on the tubular housing and includes: a sensor body including a pocket defined therein; a load sensor circuit disposed within the pocket and coupled to the sensor body; a signal processing circuit disposed within the pocket and electrically coupled to the load sensor circuit; a cover defining a cavity and disposed over the pocket and enclosing the load sensor circuit and the signal processing circuit therein, the cover being coupled to the sensor body thereby forming a first hermetic seal therebetween; and a thermal management material disposed within the cavity and in contact with the load sensor circuit and the signal processing circuit.

Owner:TYCO HEALTHCARE GRP LP

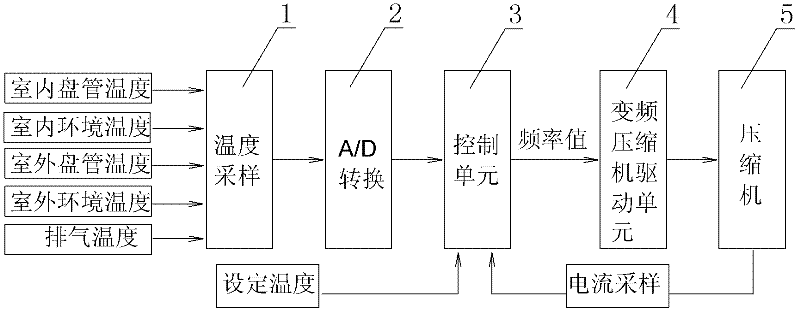

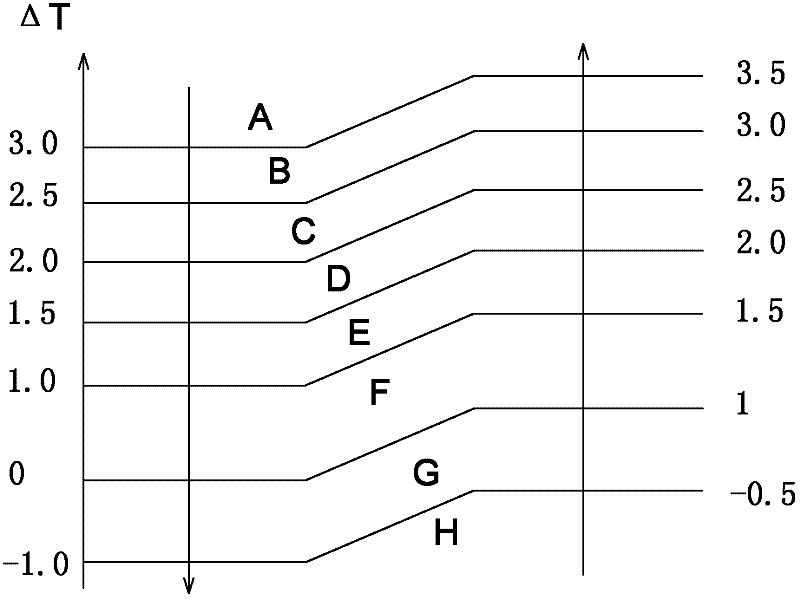

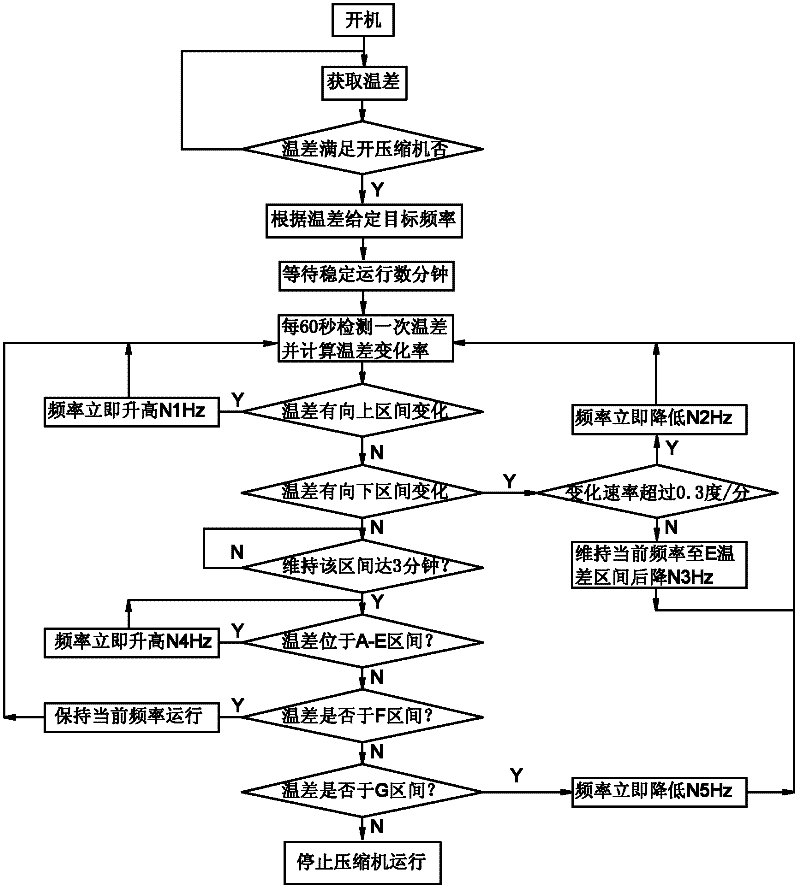

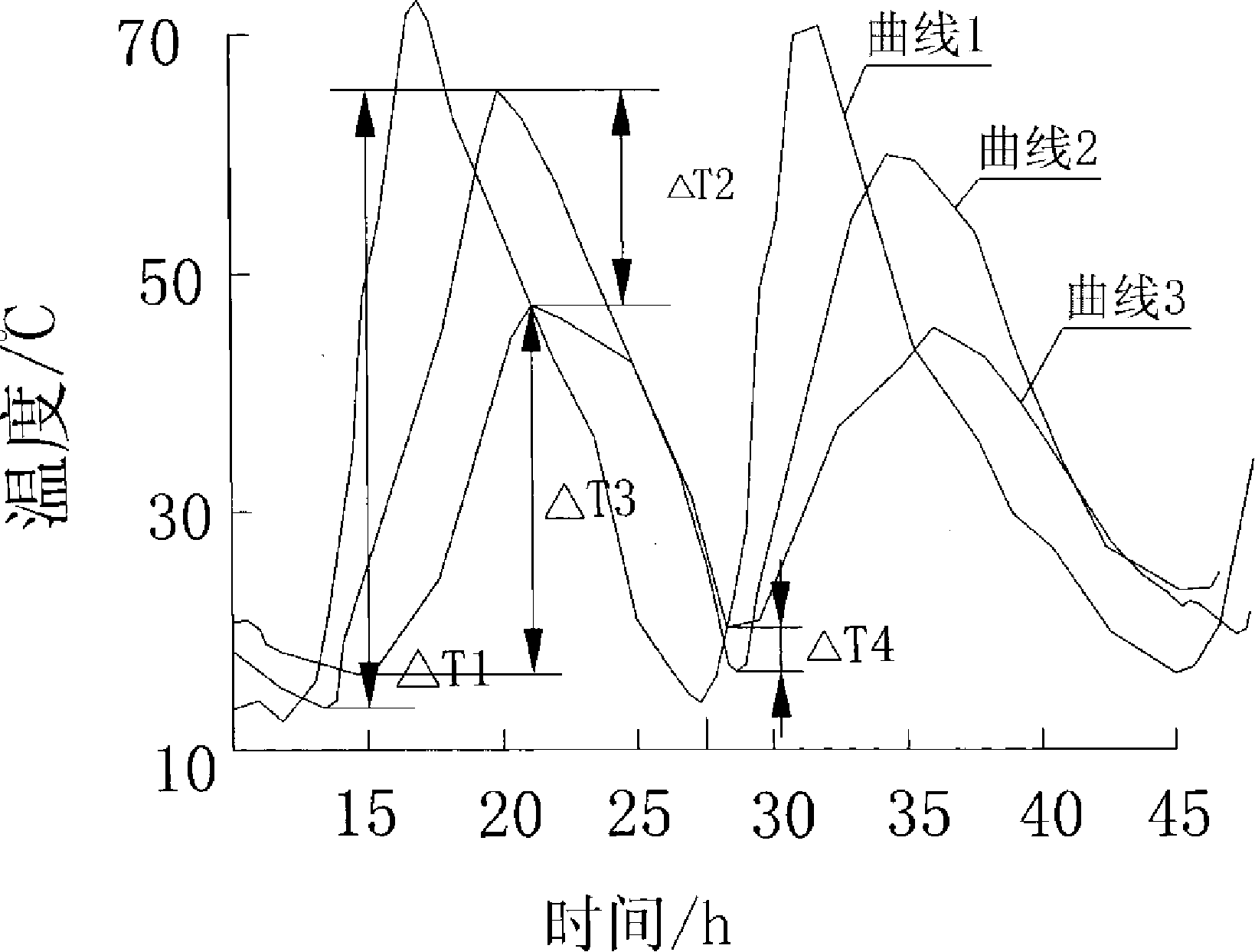

Method for controlling frequency of compressor of inverter air conditioner

InactiveCN102518579AStable temperaturePump controlPositive-displacement liquid enginesRoom temperatureTemperature difference

The invention discloses a method for controlling the frequency of a compressor of an inverter air conditioner, which comprises the following steps of: determining a plurality of continuous temperature difference intervals and a corresponding target frequency according to a set temperature and an environmental temperature; after the compressor is initially started, operating the compressor for m minutes towards the target frequency; and calculating the temperature difference and the temperature difference change rate Dt at intervals of n seconds and correcting the real-time operating frequency of the compressor according to the temperature difference and the temperature difference change rate. The method for controlling the frequency of the compressor of the inverter air conditioner, which is disclosed by the invention, can be used for accurately controlling the frequency of the compressor according to the actual output and the room load, so that the room temperature stably reaches the target temperature.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

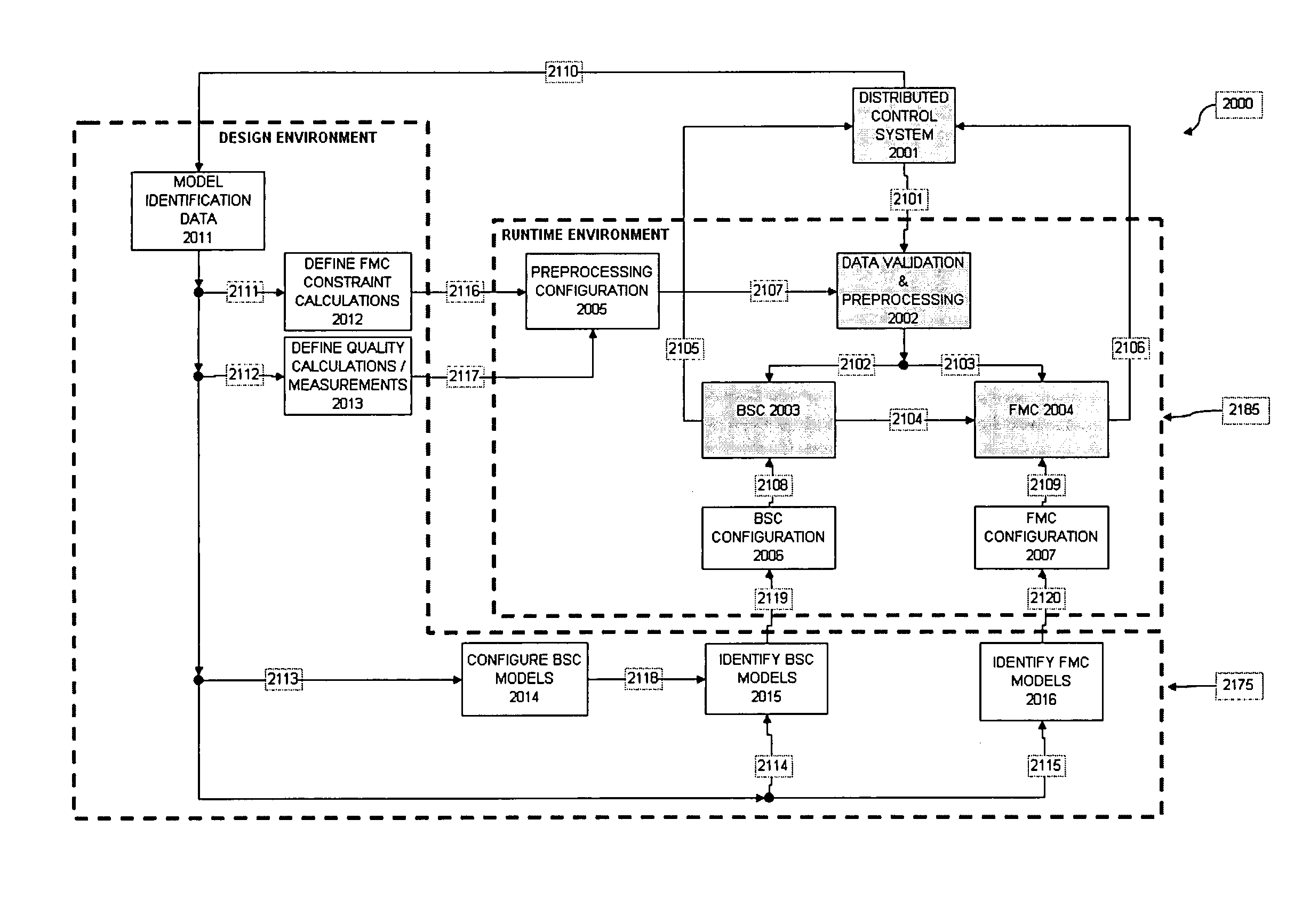

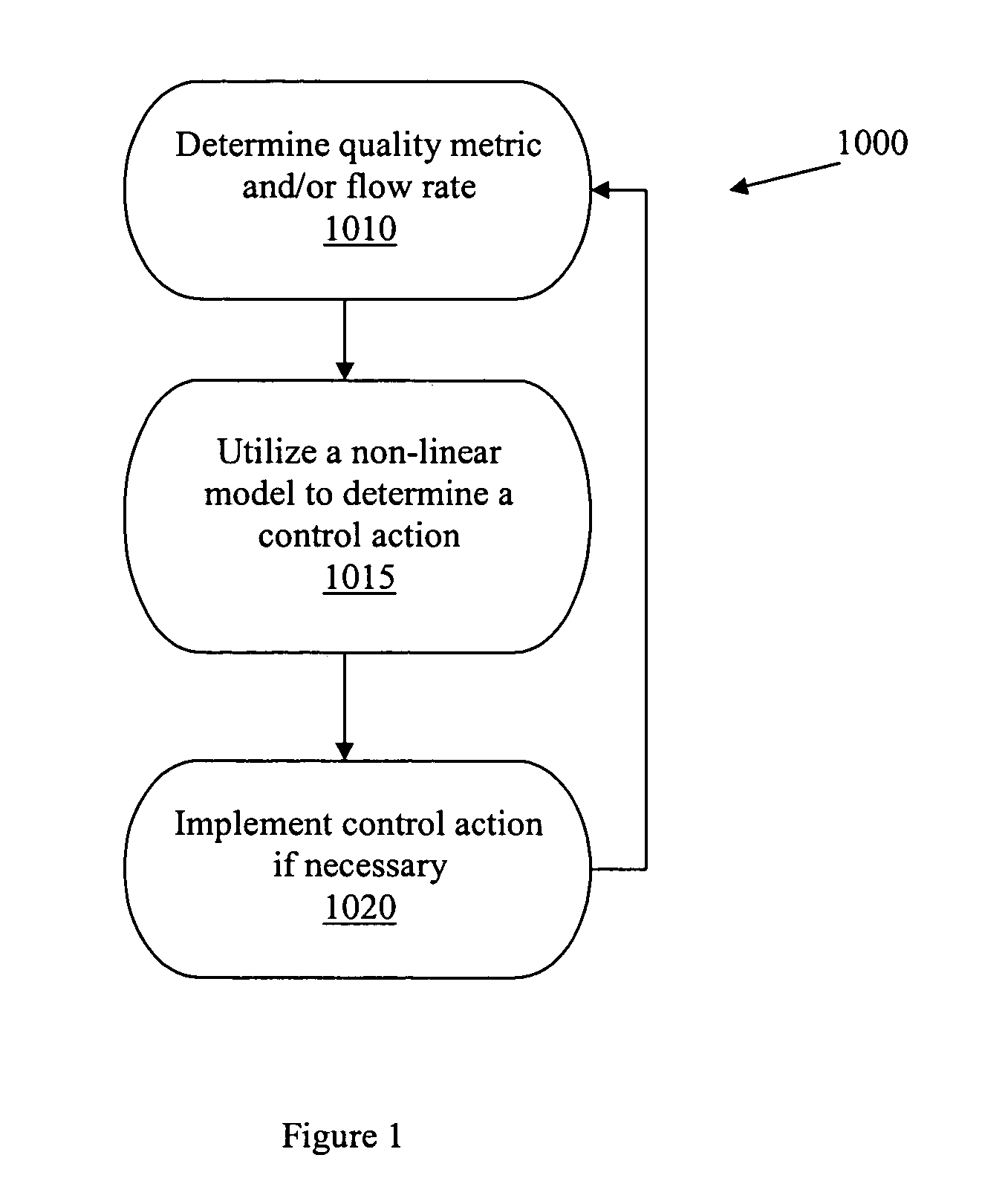

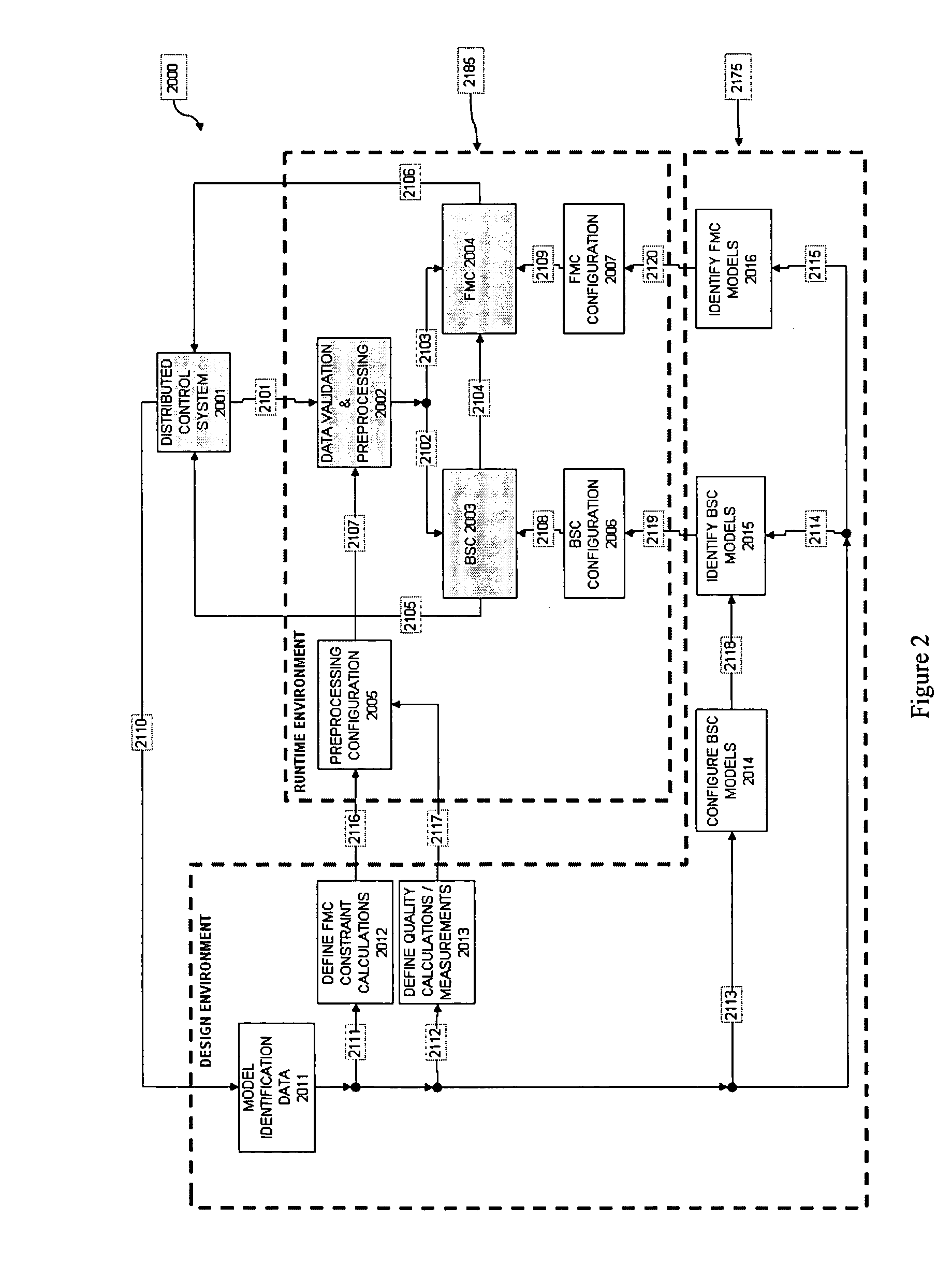

Methods, systems, and articles for controlling a fluid blending system

ActiveUS7188637B2Stable quantityQuality improvementControlling ratio of multiple fluid flowsPipeline systemsProduct gasEngineering

Described herein are methods, systems, and articles that are useful for controlling a fluid blending system, such as a fluid utility system. The methods, systems, and articles of this invention allow for the control of both a quantity metric (e.g., pressure) of the blended fluid the fluid blending system as well as at least one quality metric of a blended fluid in a fluid blending system. For example, the methods, systems, and articles of this invention provide for the simultaneous control of both the pressure and quality of fuel gas within a fuel gas header system.

Owner:ASPENTECH CORP

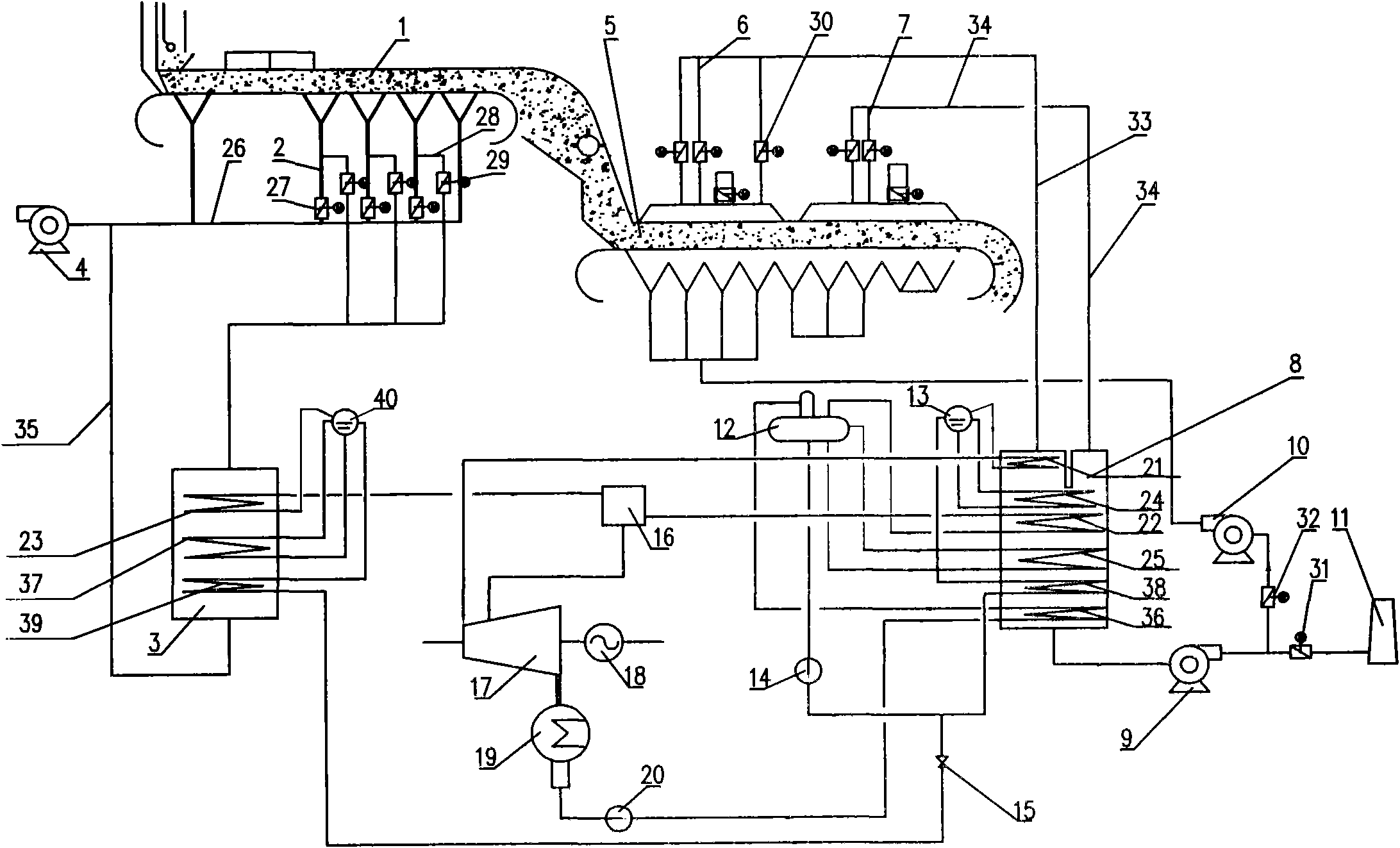

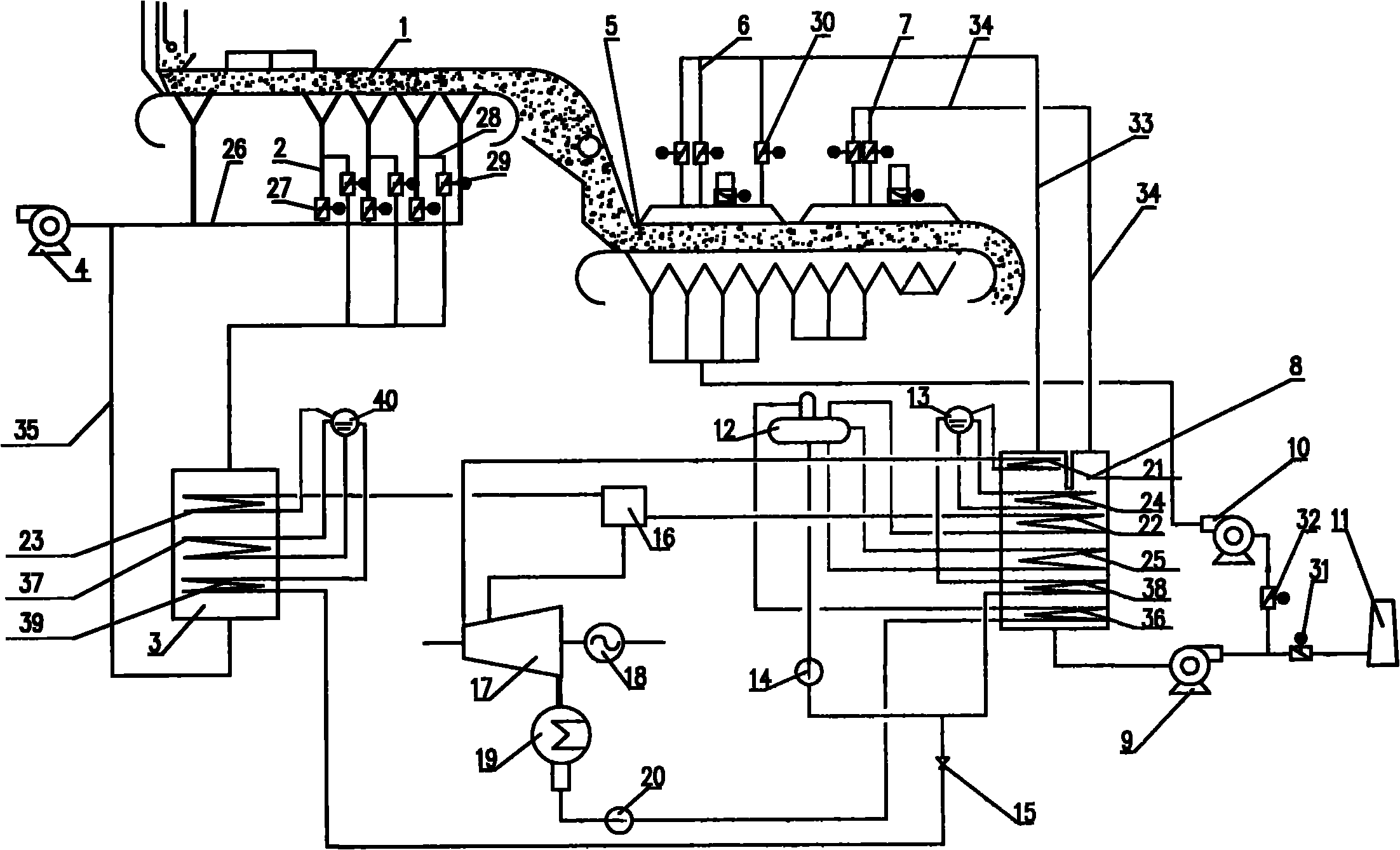

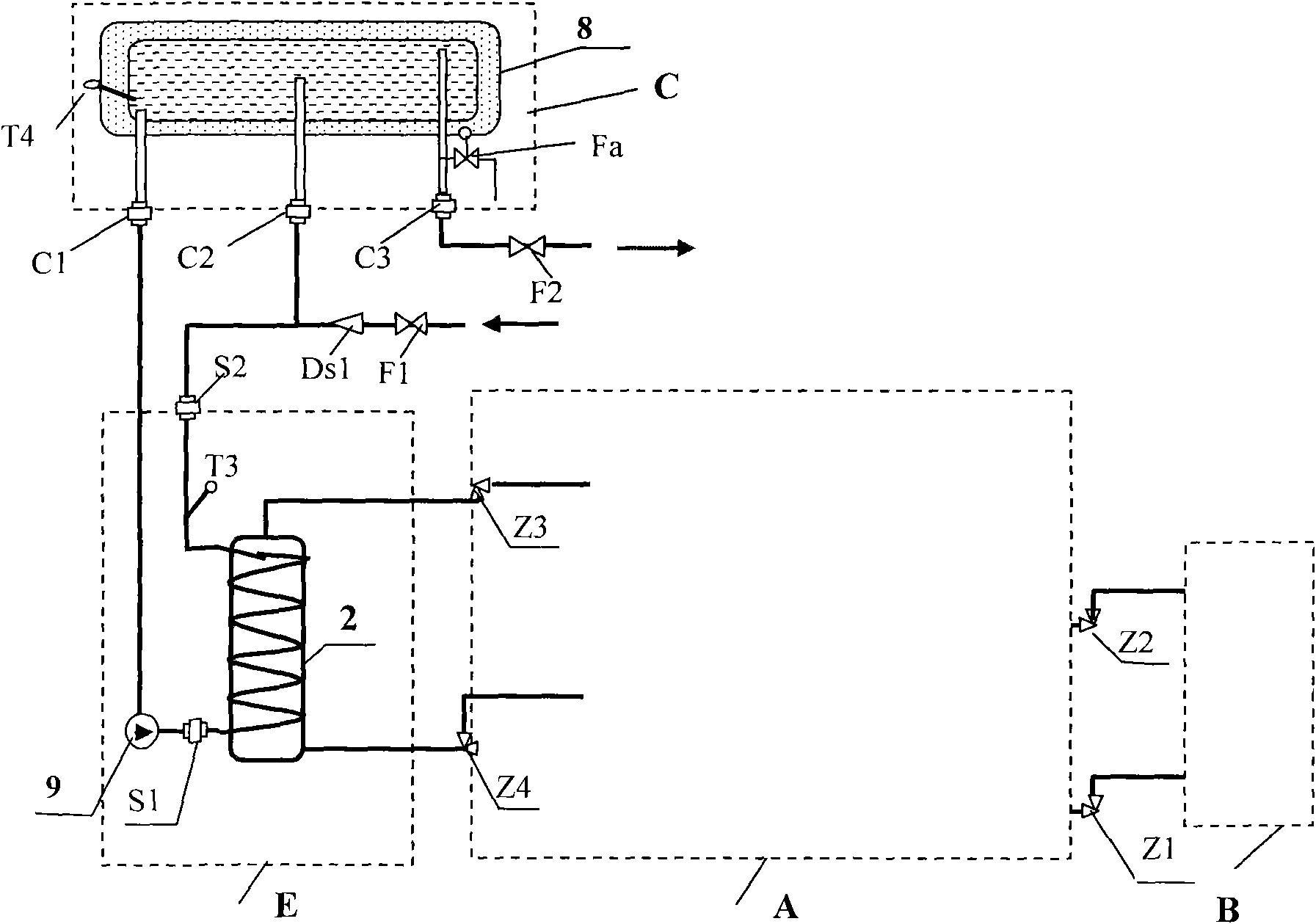

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

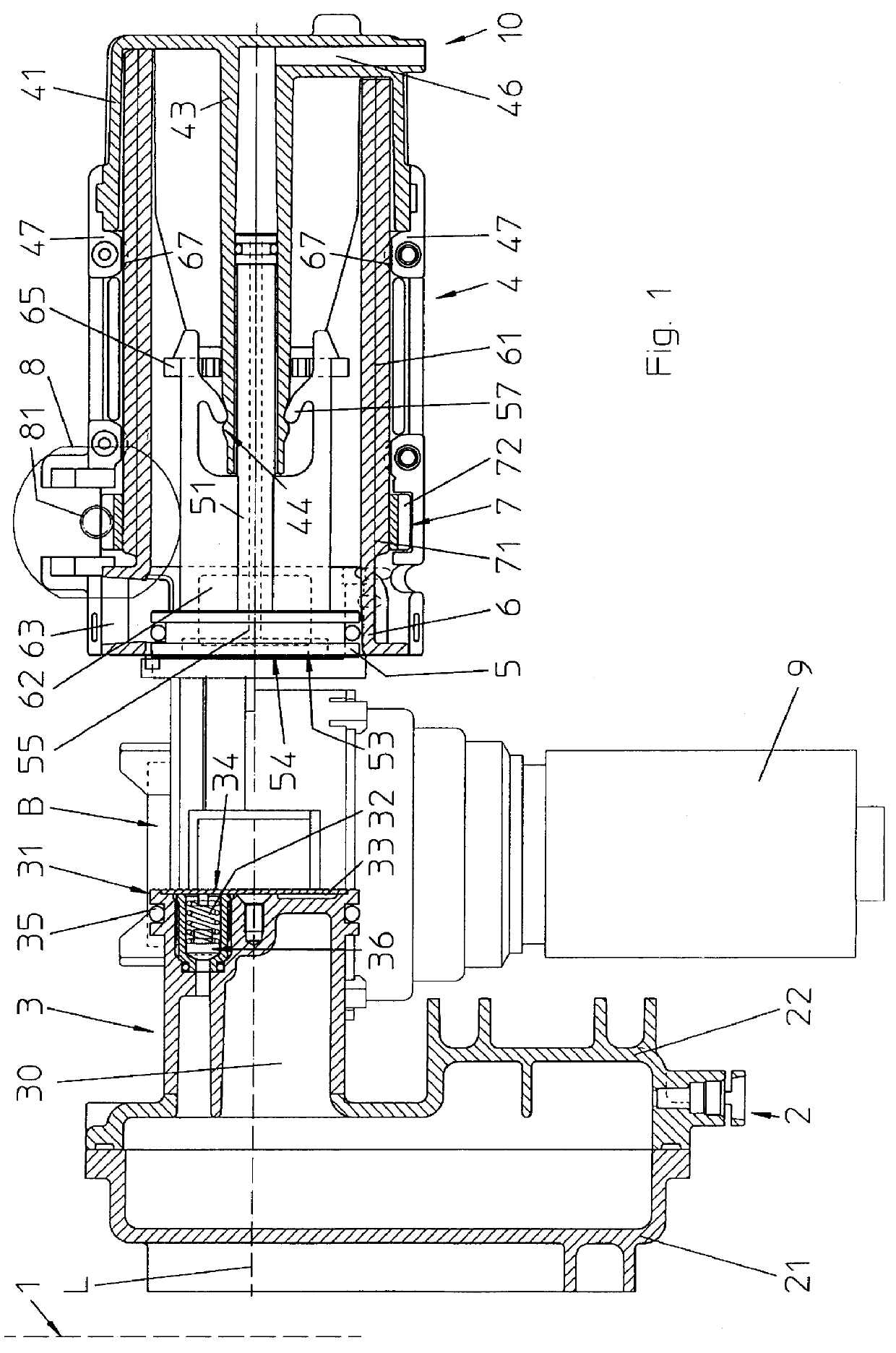

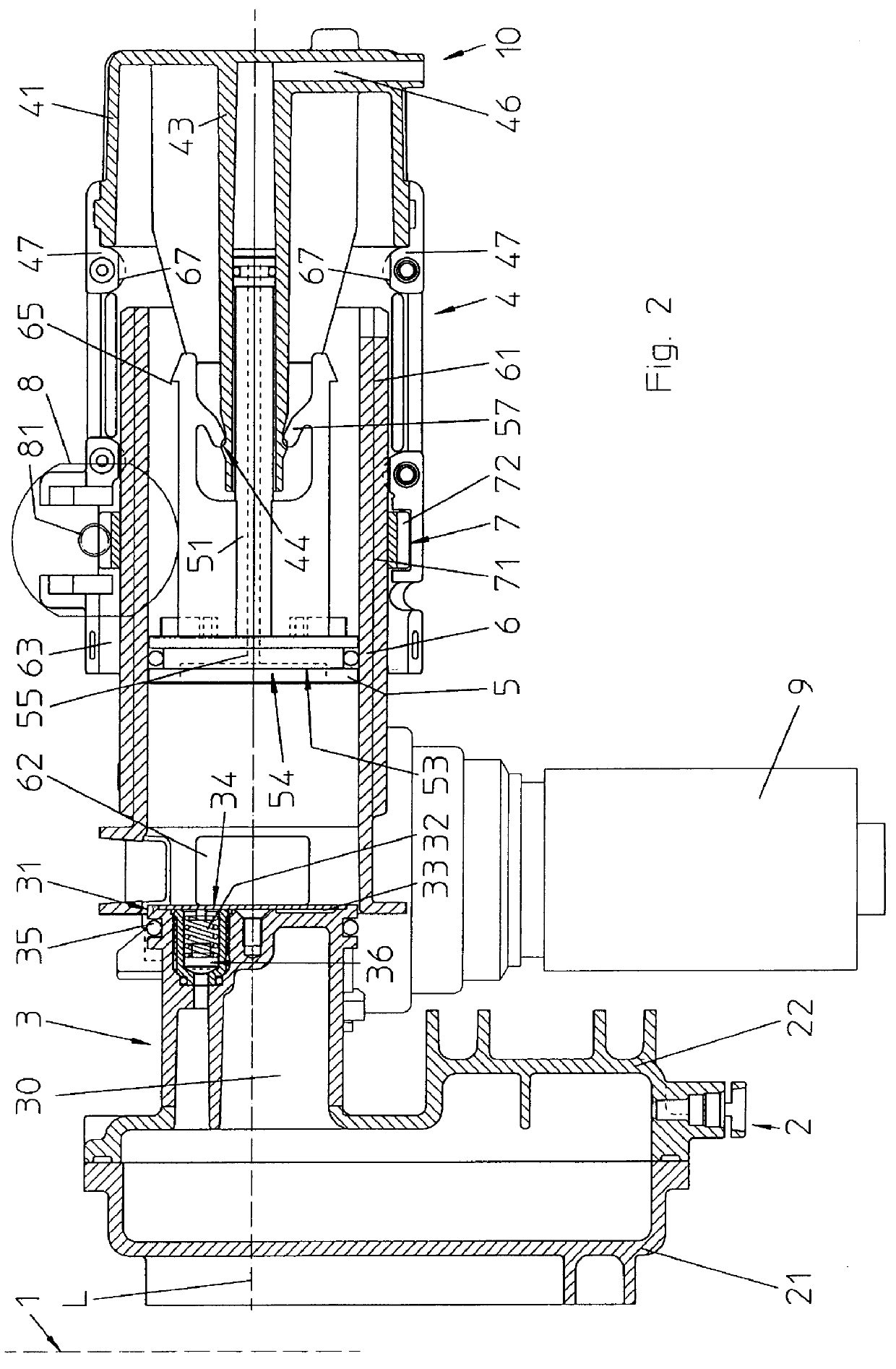

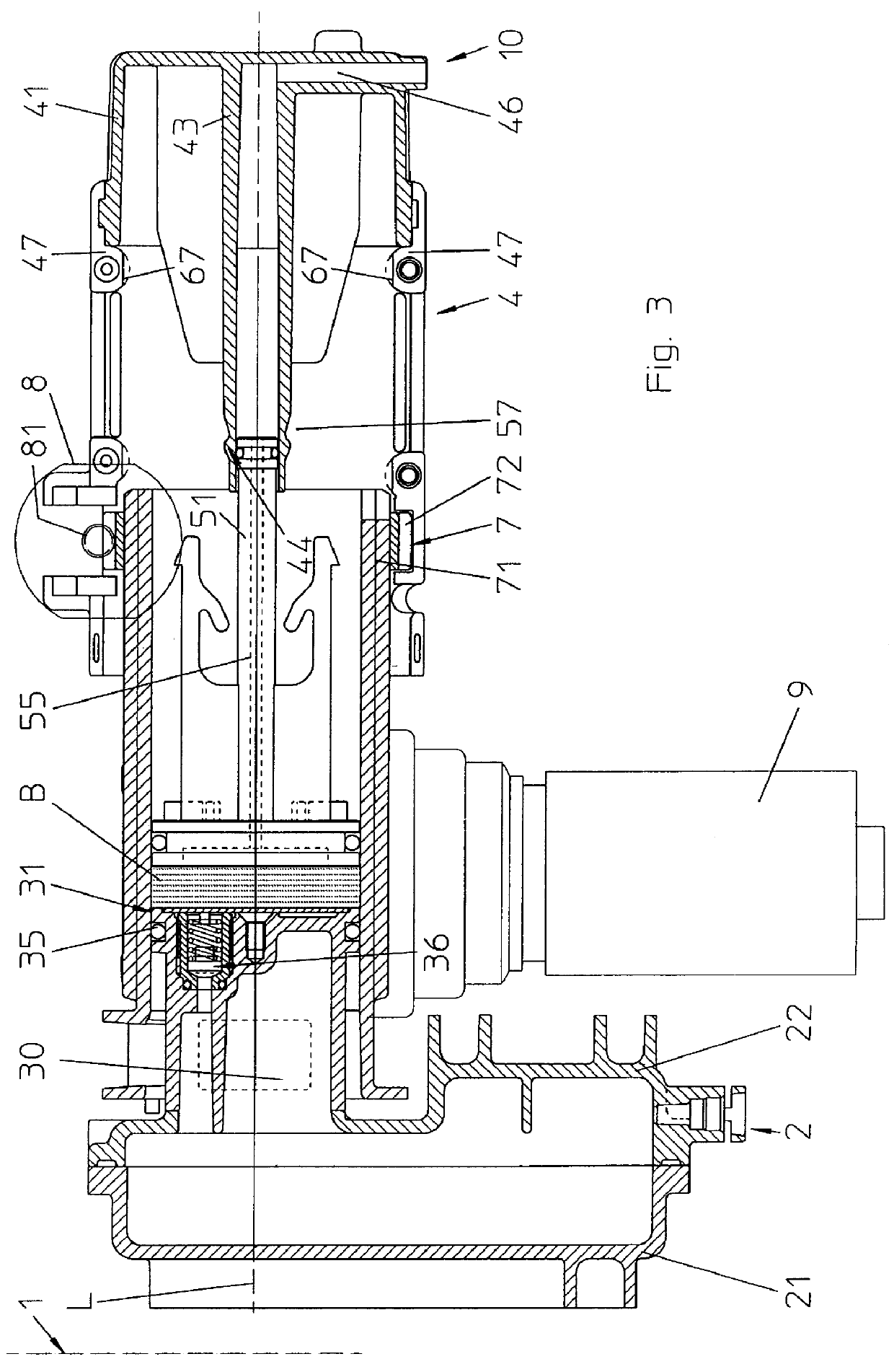

Coffee machine

InactiveUS6129006AQuality improvementSimple structure designBeverage vesselsEngineeringMechanical engineering

A coffee machine is provided with a boiler for heating brewing water, a brewing cylinder defining a brewing chamber, a closure piston for closing the one open end of the brewing cylinder as well as a brewing piston for compressing the coffee powder in the brewing cylinder and / or for ejecting the elutriated coffee powder cake, whereby the brewing piston is longitudinally movable in the brewing cylinder. The closure piston is integrally formed or rigidly connected to the housing of the boiler and firmly mounted to the housing of the coffee machine. Moreover, there is provided a brewing module that is removably inserted into the housing of the coffee machine and that includes at least the brewing cylinder and the brewing piston. The brewing cylinder and the brewing piston are movable in longitudinal direction, but cannot be rotated. Such a coffee machine can be designed very compactly. Moreover, the brewing module consists of only a few elements and, thus, can be manufactured at low costs and is very reliable in operation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

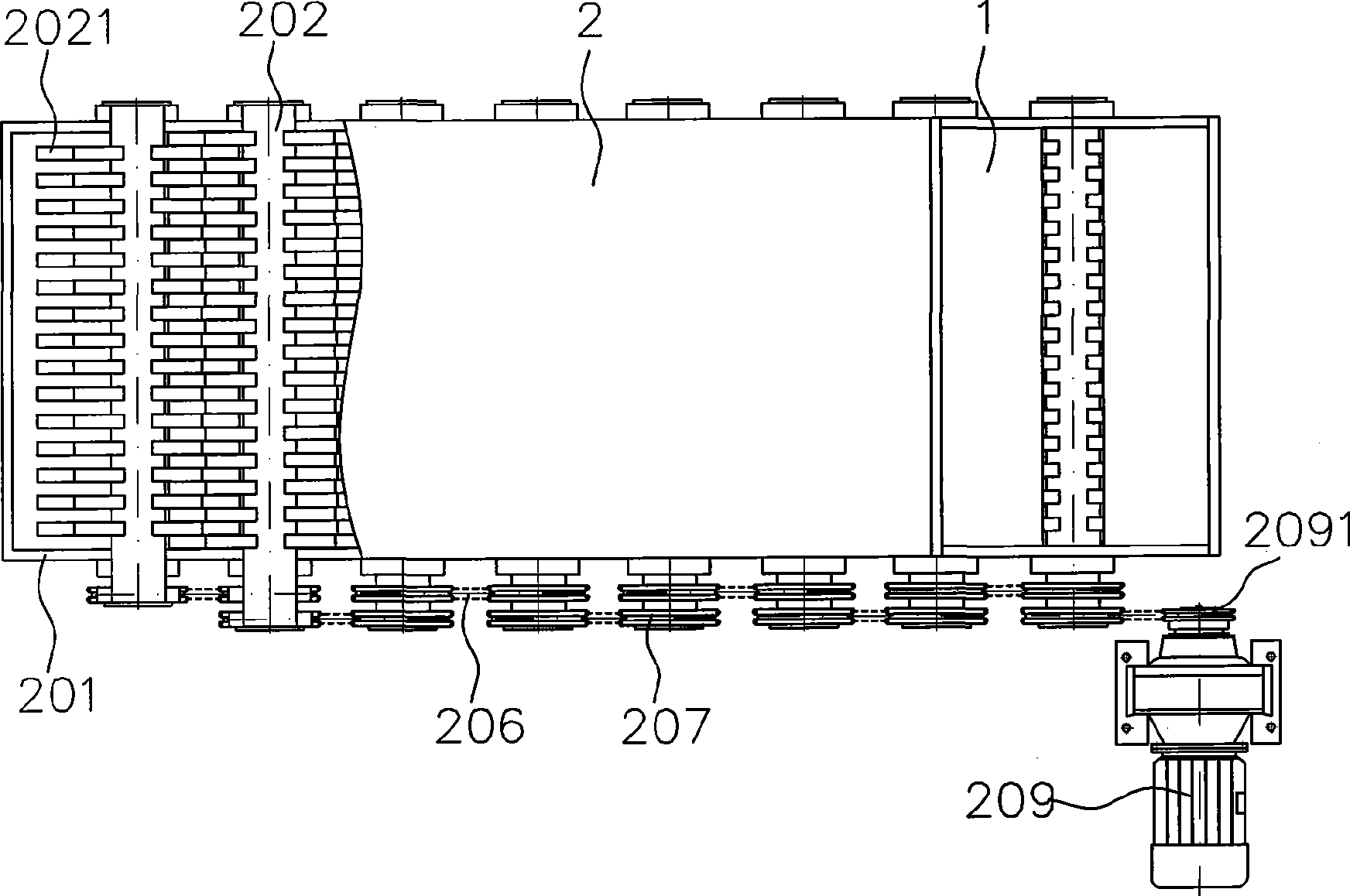

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

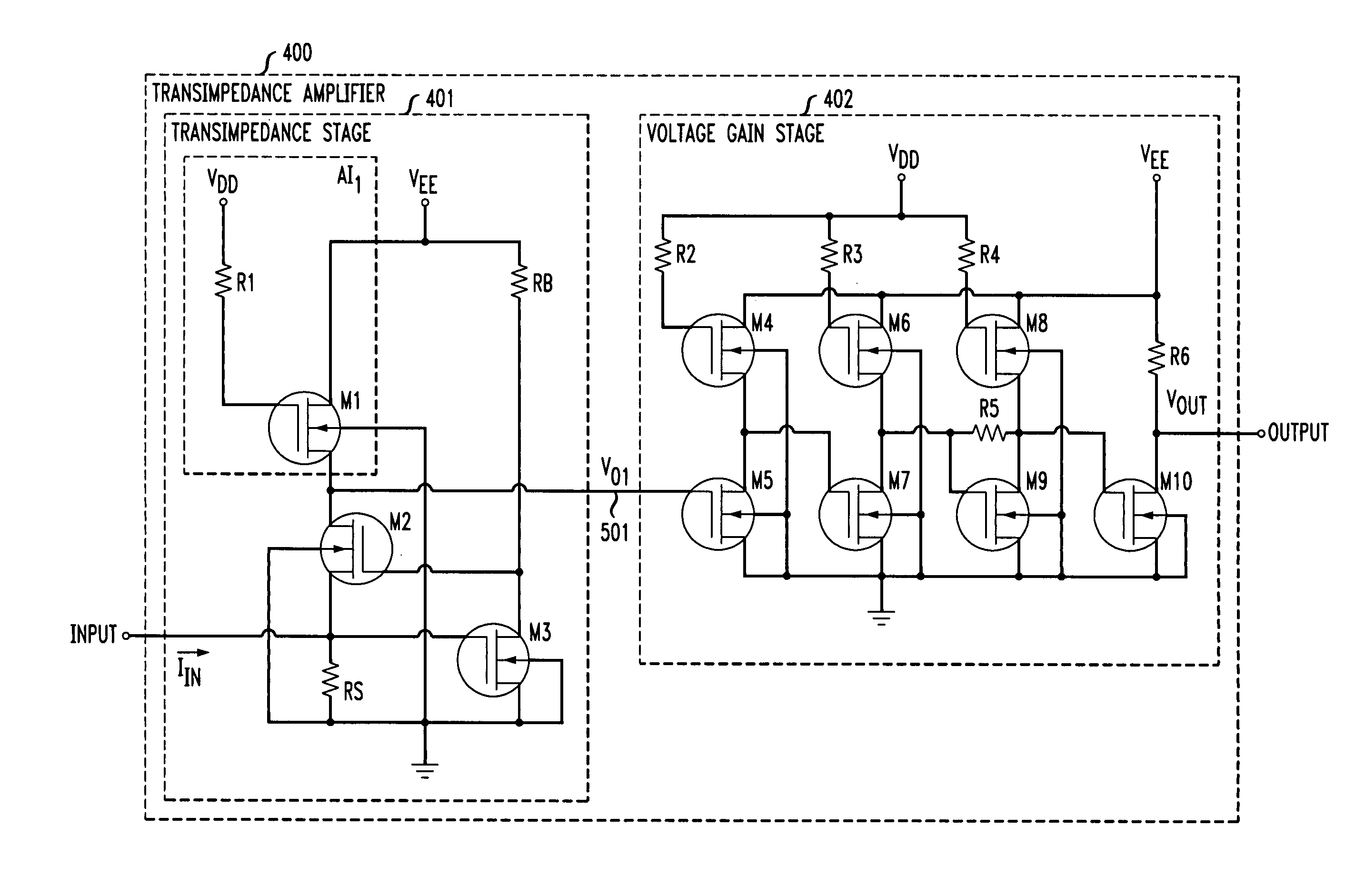

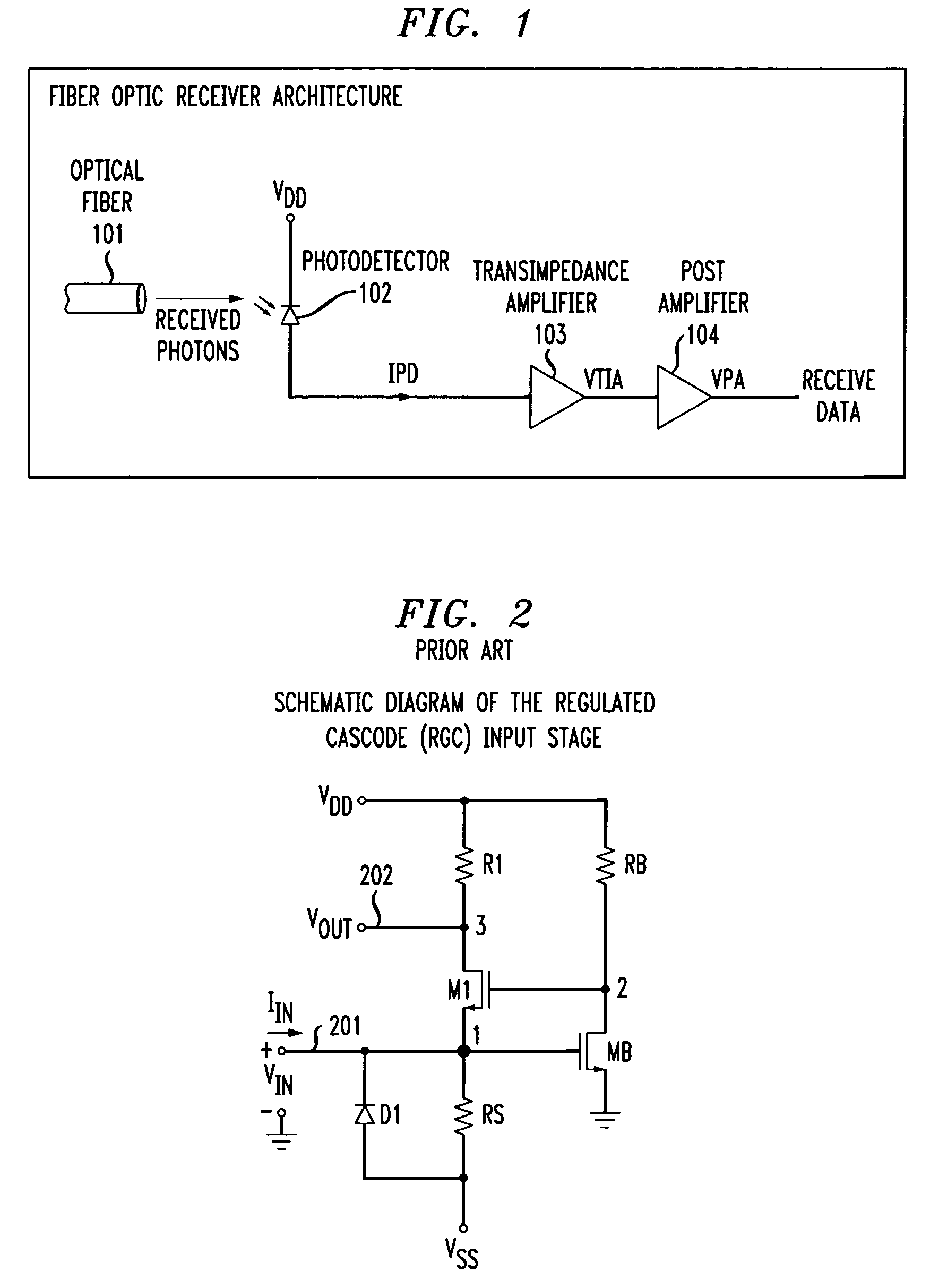

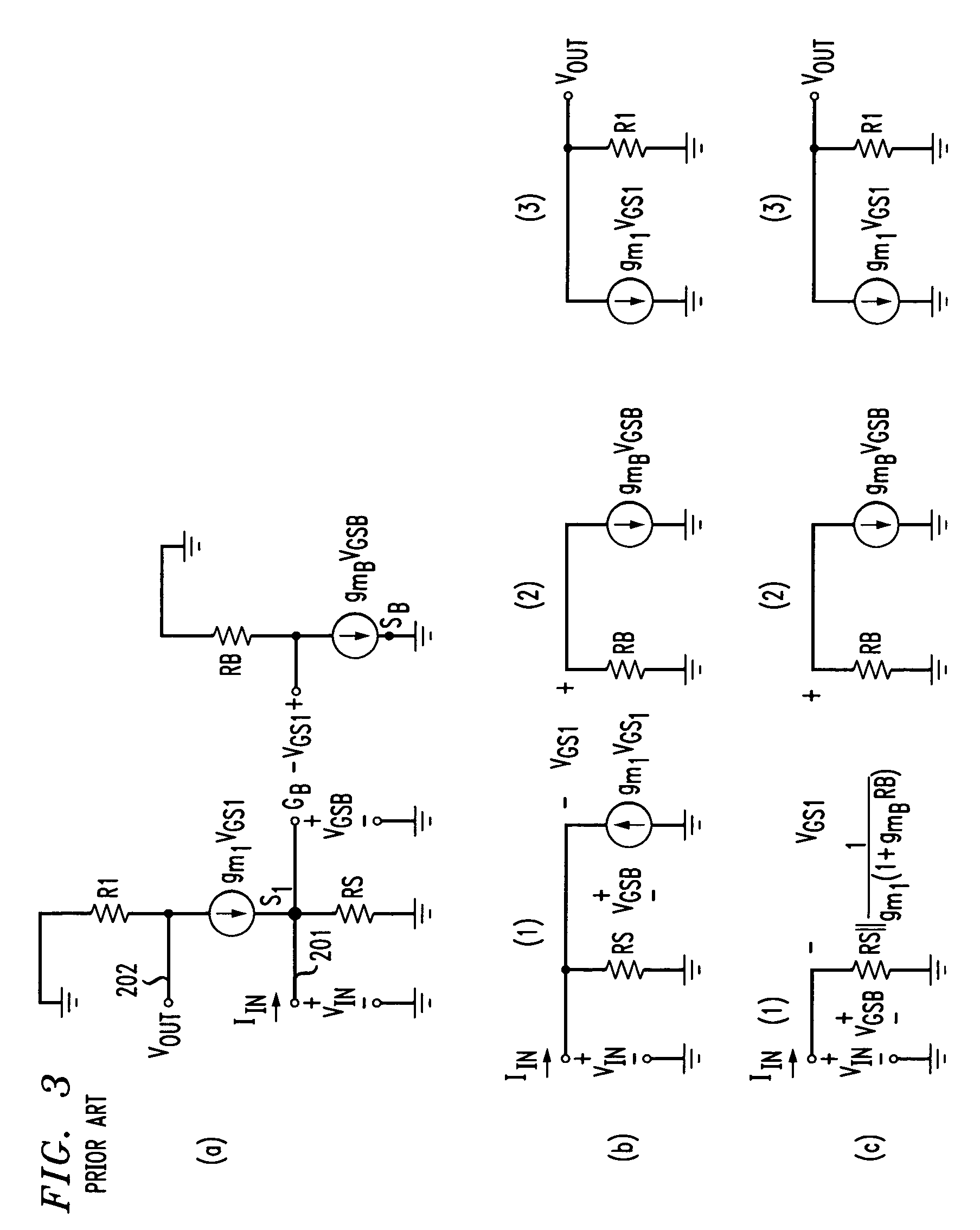

Transimpedance amplifier

InactiveUS7135932B2Minimise currentWide bandwidthAmplifier combinationsAmplifiers controlled by lightAudio power amplifierEngineering

A transimpedance amplifier, which is useful as an optical fiber preamplifier, is disclosed. The illustrative embodiment exhibits four characteristics. First, it minimizes the equivalent input noise current. Second, it has a wide bandwidth. Third, it has a reasonably large output voltage, and fourth, it is stable over wide temperature and voltage ranges. The illustrative embodiment comprises a transimpedance stage and a gain stage. Both stages employ a pure NMOS design which contributes to the above four advantages. Bandwidth is further increased over the prior art by the use of inductive loads. The inductive loads of the illustrative embodiment are not physical inductors, but transistor-based “active” inductors: the combination of a resistor connected in series with the gate of an NMOS transistor.

Owner:SIRES LABS

Vaporizing fluidized organic materials

ActiveUS20050208220A1Steady vaporization rateReduce riskDischarge tube luminescnet screensLamp detailsMetallurgy

A method for vaporizing organic materials onto a surface, to form a film includes providing a quantity of organic material in a fluidized powdered form; metering the powdered organic material and directing a stream of such fluidized powder onto a first member; heating the first member so that as the stream of fluidized powder is vaporized; collecting the vaporized organic material in a manifold; and providing a second member formed with at least one aperture in communication with the manifold that permits the vaporized organic material to be directed onto the surface to form a film.

Owner:GLOBAL OLED TECH

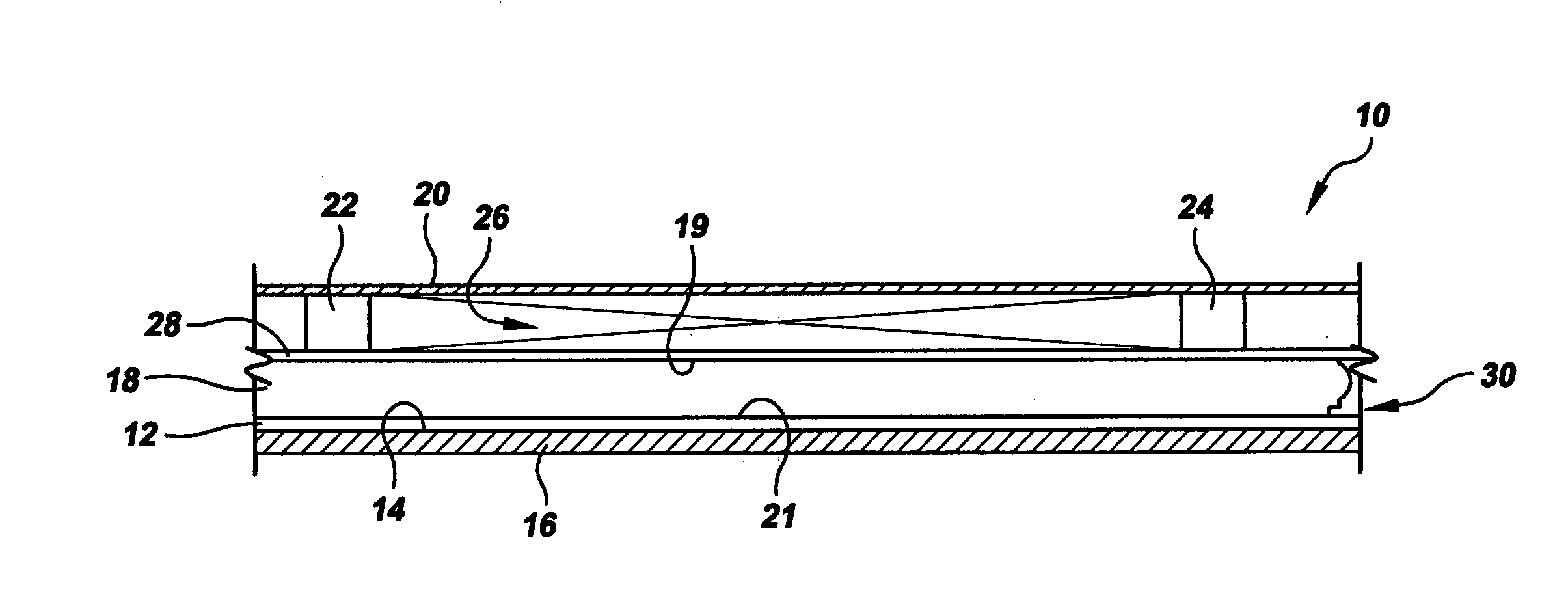

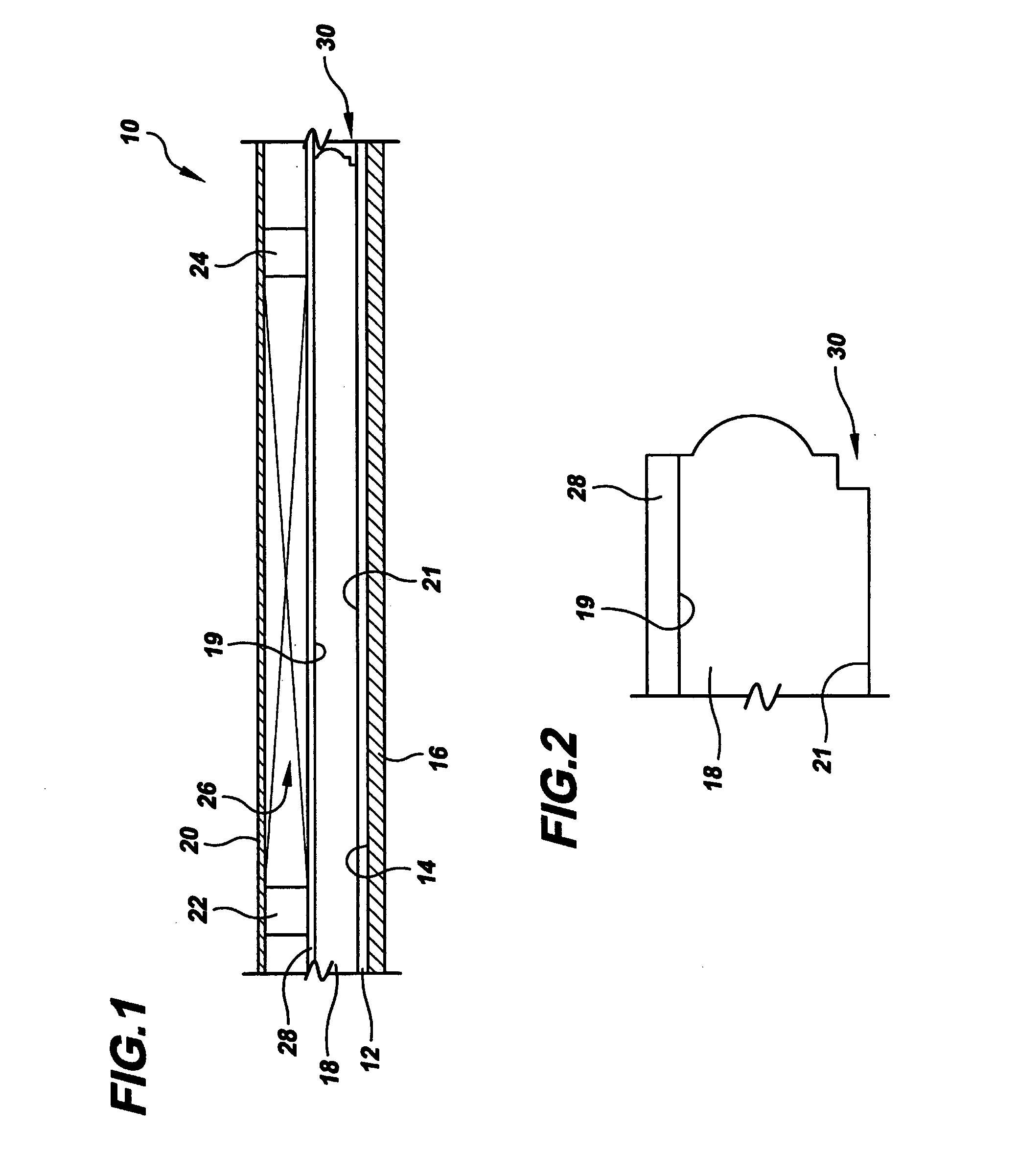

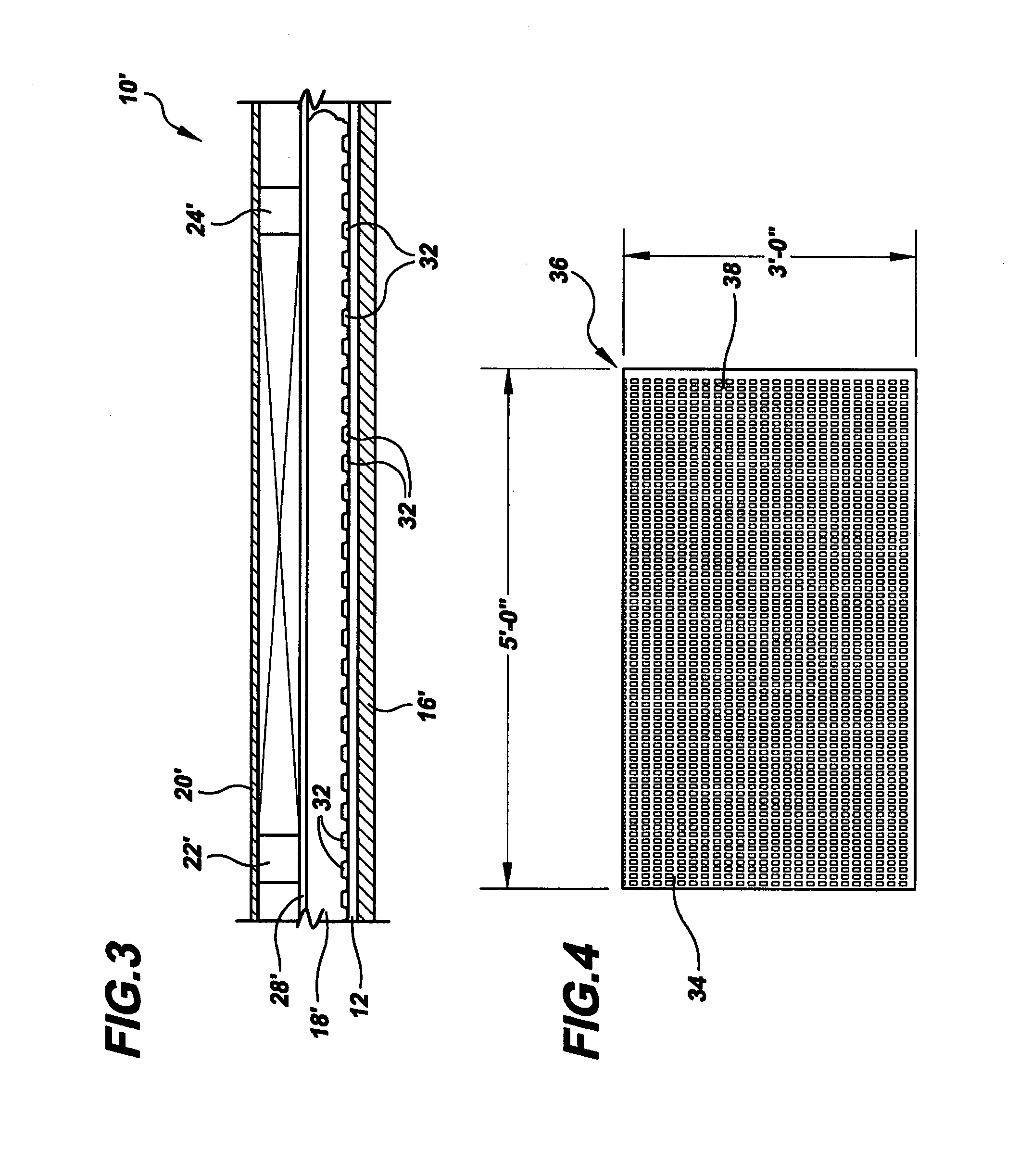

Photovoltaic roof-top components, a photovoltaic IRMA roofing system, and a photovoltaic roofing system

InactiveUS20070095388A1Improve performanceGood servicePhotovoltaic supportsSolar heating energyInsulation layerMinimum weight

An improved photovoltaic roofing system (10) includes a roofing membrane (12) overlying a top surface (14) of a roof deck (16), an insulation layer (18) above the roofing membrane (12) and a photovoltaic panel (20) above the insulation layer (18). The improved photovoltaic insulation layer (18) component defines a predetermined number of drainage channels (30) between the insulation layer (18) and the roofing membrane, and / or a predetermined insulation layer thickness, and the predetermined number of drainage channels (30) and / or thickness is a function of variable drainage requirements and / or variable insulation requirements of the roofing system (10). A photovoltaic IRMA roofing system (72) replaces traditional IRMA roofing system (73) ballast materials (79) with a combined weight of concrete topped (83) insulation layer and photovoltaic panels (80) to meet a predetermined minimum weight per unit area requirement of a specific roofing system (72).

Owner:MERGOLA THOMAS J +1

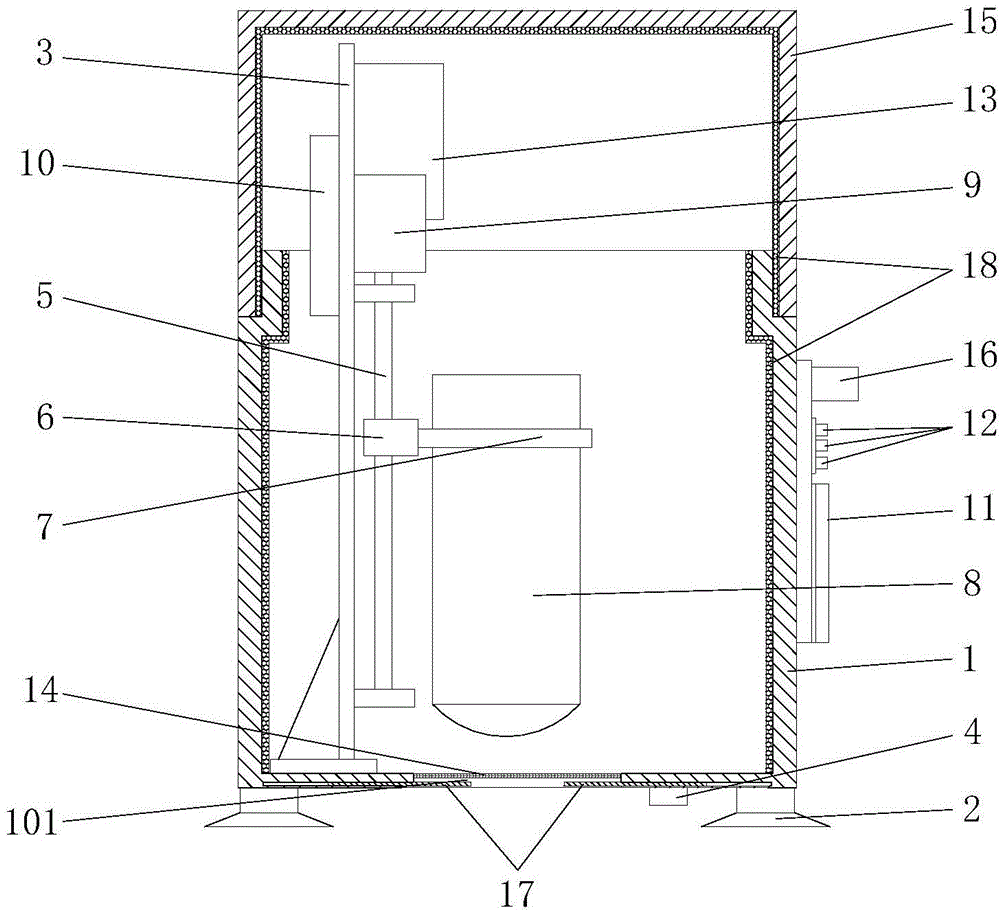

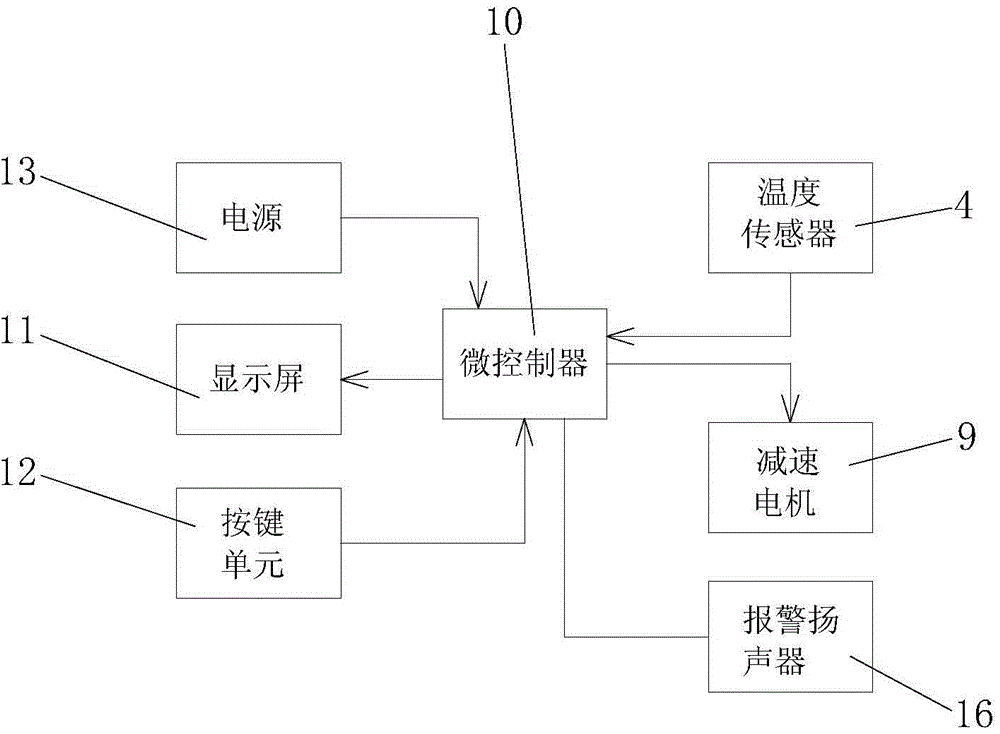

Novel temperature control moxibustion device

InactiveCN103550062AMaintain a constant temperatureKeep the moxibustion process temperature at the best constant temperatureDevices for heating/cooling reflex pointsTemperature controlTreatment effect

The invention discloses a novel temperature control moxibustion device which comprises a cylindrical moxibustion box and a box cover, wherein a moxibustion hole is formed in the bottom of the moxibustion box, and a detachable dust stop screen is arranged on the moxibustion hole. The temperature control moxibustion device further comprises a support frame and a temperature sensor, the support frame is fixed in the moxibustion box, and the temperature sensor is fixed on the bottom surface of the moxibustion box; a screw rod perpendicular to the bottom surface of the moxibustion box is arranged at the lower part of the support frame, a nut seat is in bolted connection with the screw rod, and a fixing ring corresponding to the moxibustion hole is fixed on one side of the nut seat and used for inserting moxa sticks; and the screw rod is driven by a reducing motor fixed on the support frame to rotate. According to the novel temperature control moxibustion device, the therapeutic temperature is regulated by controlling a distance between a moxa stick fire point and a moxibustion acupuncture point, the constant temperature of the moxibustion acupuncture point of a human body is maintained, and the whole device is portable and flexible, so that the temperature of the moxibustion acupuncture point of the human body can be accurately controlled, and an optimal curative effect is achieved.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

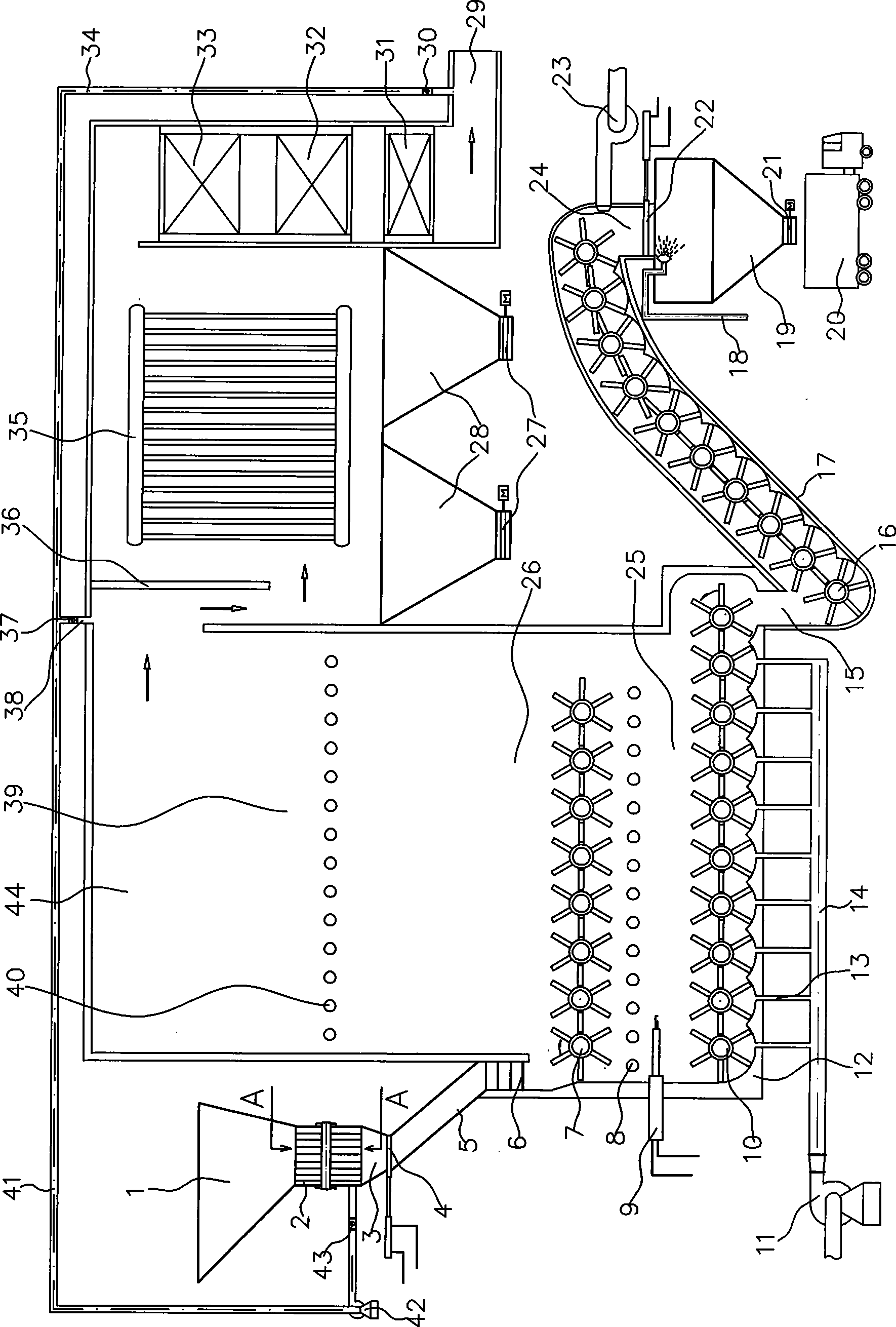

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

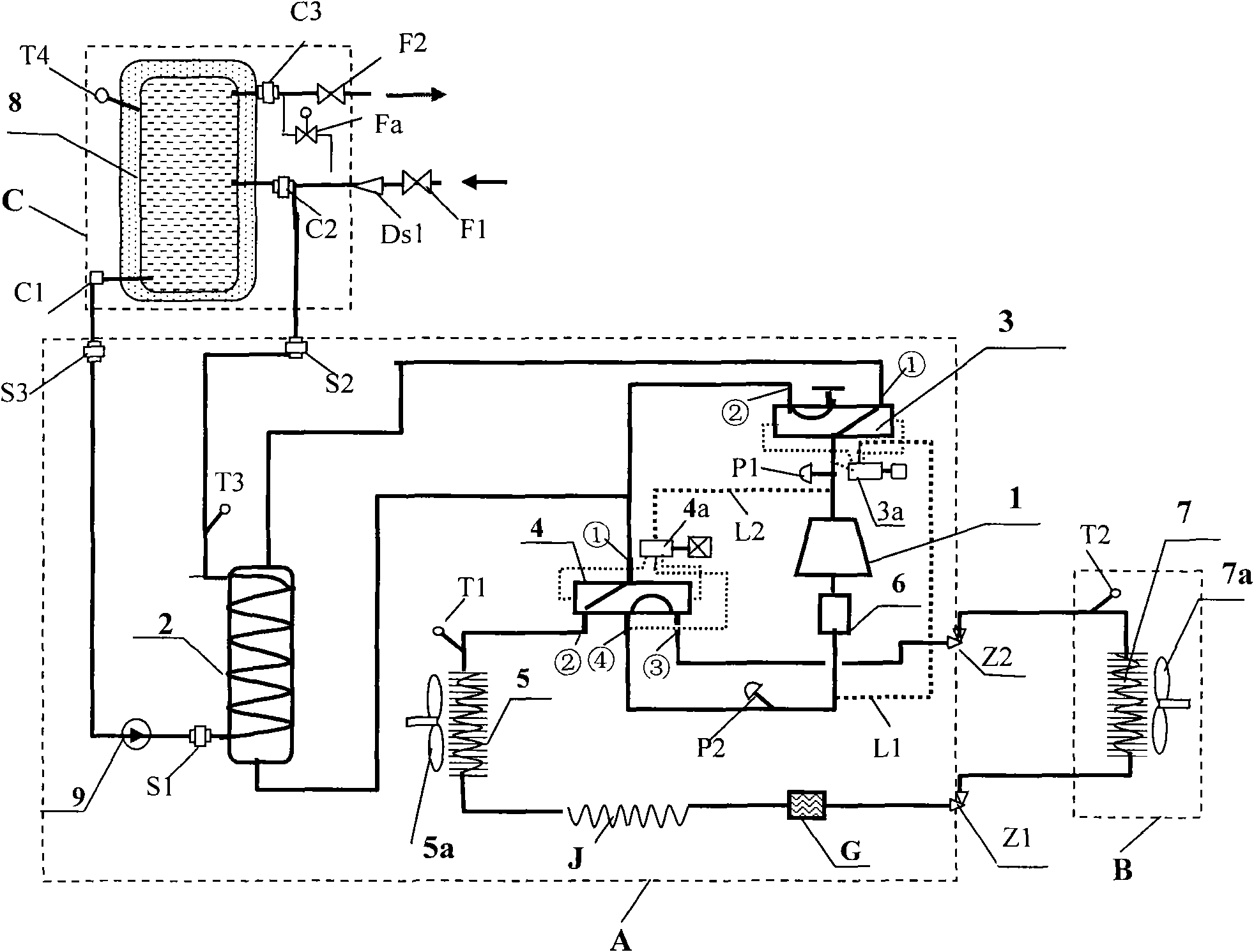

Simple, high-efficiency and reliable cold-warm air-conditioning water heater

InactiveCN102313326ASimple structureEasy to switchFluid heatersSpace heating and ventilation safety systemsFour-way valveLow voltage

The invention relates to a simple, high-efficiency and reliable cold-warm air-conditioning water heater, which comprises a refrigerant loop, a hot-water condensing heat exchanger, a hot-water storing box and a signal acquisition and circuit control system. A scheme I of the invention is characterized in that: an exhaust opening of a compressor is connected with an air inlet of a three-way valve; a first air outlet of the three-way valve is connected with a refrigerant inlet of the hot-water condensing heat exchanger, and a second air outlet is connected and communicated with a first interfaceof a four-way valve and a refrigerant outlet of the hot-water condensing heat exchanger; a second interface, a third interface and a fourth interface of the four-way valve are respectively connected with the upper ports of an outdoor-wind heat exchanger and an indoor-wind heat exchanger and an air inlet of an air-liquid separator, and a capillary is connected in series between the lower ports of the outdoor-wind heat exchanger and the indoor-wind heat exchanger; an air outlet of the air-liquid separator is connected with an air inlet of the compressor; and an electromagnetic guide-valve low-voltage air-outlet pipe of the three-way valve is communicated with an air-sucking pipe of the compressor, and an electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with an exhaust pipe of the compressor. A scheme II of the invention is characterized in that: the hot-water condensing heat exchanger is added between the exhaust opening of the compressor of a refrigerant-circulating loop of a cold and warm air conditioner and an air inlet of the four-way valve, and the electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with the exhaust pipe of the compressor; and the two technical schemes both have four functions of hot-water making and refrigerating, hot-water making, refrigerating and heating.

Owner:JIASHAN YONGNING PLASTICS

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

Gas-fired cooking apparatus with control of cooking temperature

ActiveUS20050098169A1Accurate and optimized controlEasy to manufactureDomestic stoves or rangesLighting and heating apparatusCombustorProcess engineering

A gas-fired cooking apparatus, comprising a cooking compartment inside which one or more burners are inserted, gas supply source being suitable to supply gas to the one or more burners, further comprising elements for regulating the flow of gas that arrives from the gas supply source arranged in series between the gas supply source and the one or more burners, a control element being adapted to detect internal and external temperature conditions of the cooking compartment in order to regulate the flow of gas through the regulator elements, to one or more burners, so as to maintain the cooking temperature constant at a value preset by the user.

Owner:CAVAGNA GROUP

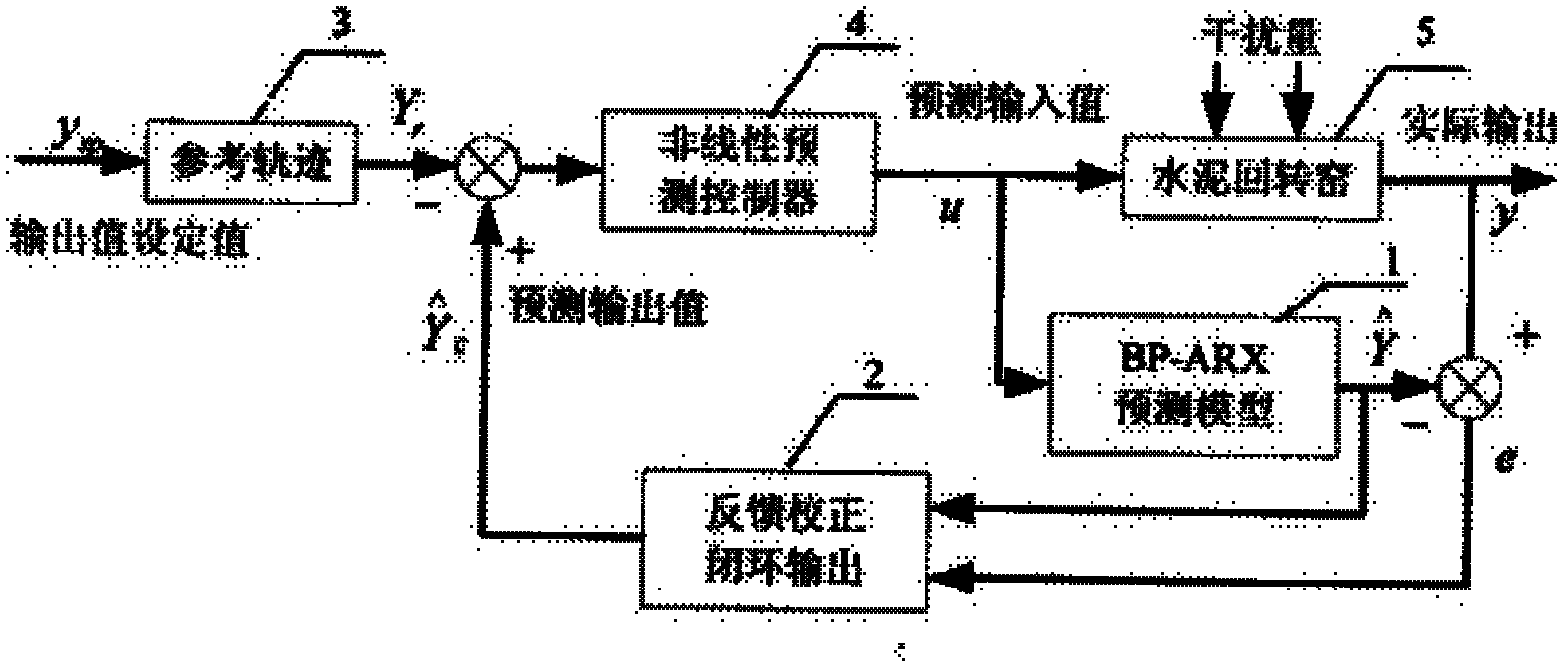

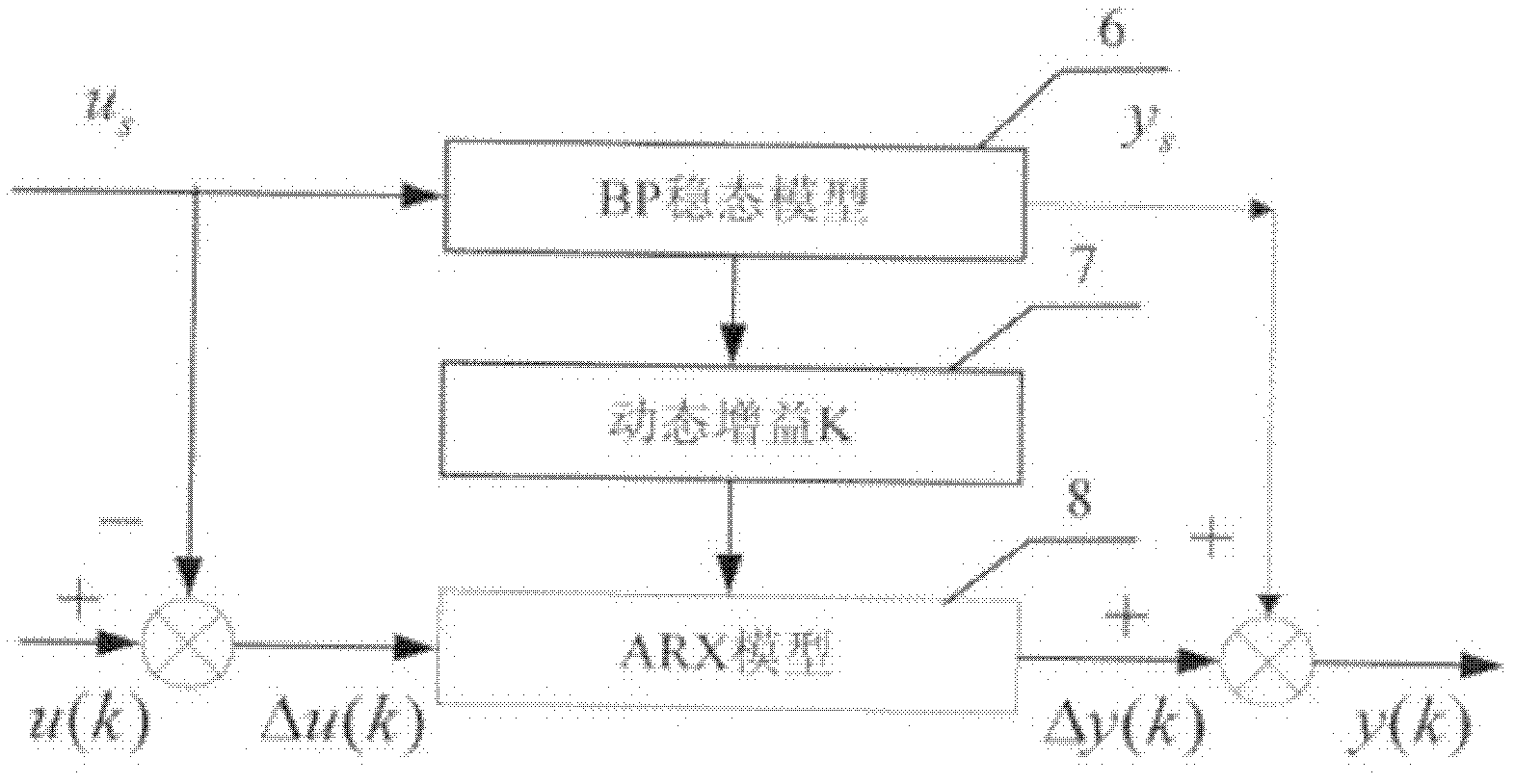

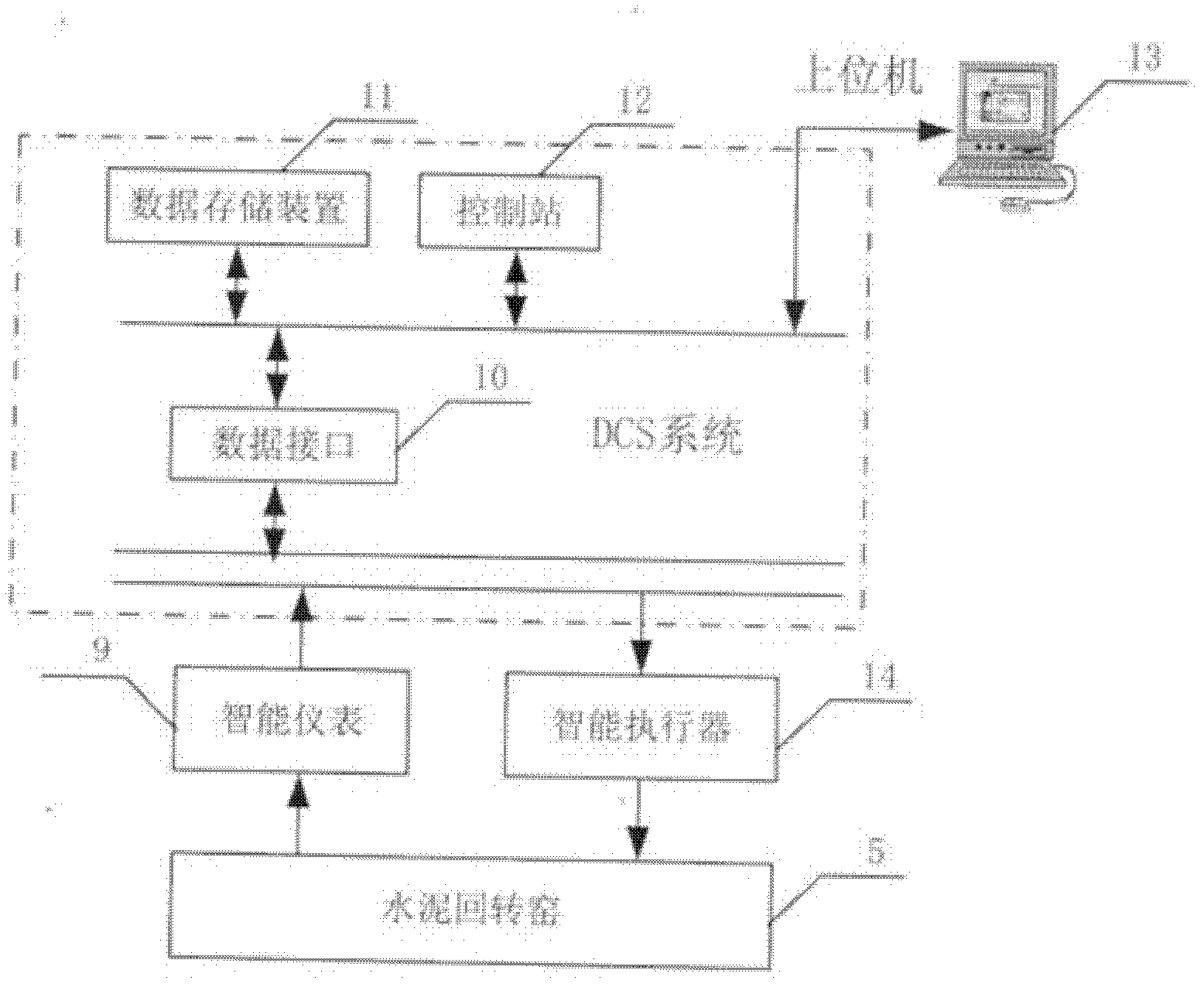

Calcination predictive control system and method for rotary cement kiln

InactiveCN102629104AStable temperatureTaking into account energy consumption per unit of productionRotary drum furnacesAdaptive controlData informationClosed loop

The invention relates to a calcination predictive control method and a calcination predictive control system for a rotary cement kiln. The method comprises the following steps of: (1) acquiring field data of the calcining process of the rotary cement kiln and classifying the field data; (2) respectively carrying out model identification on the data and organically combining the data to establish a prediction model; (3) carrying out prediction on historical and future data information on the calcining process by the prediction model to obtain an output of the calcining process and outputting error feedback correction by utilizing the model to obtain a closed-loop prediction output of the calcining process; and (4) according to the closed-loop prediction output and a reference output trace,constructing a non-linear target function and carrying out solution of a optimal solution on the target function by using a sequential quadratic programming method to obtain a predicted value of the calcination controlling quantity. The system comprises an intelligent detection instrument and an actuator which are connected with the rotary cement kiln, a data storage device and an upper computer,wherein a calcination predictive control algorithm is embedded in the upper computer. The calcination predictive control method and the calcination predictive control system for the rotary cement kiln can be suitable for the dynamism of the calcining process of the rotary cement kiln and the coupling, nonlinearity and obsoleteness between multiple variables, and obtain good control effect.

Owner:YANSHAN UNIV

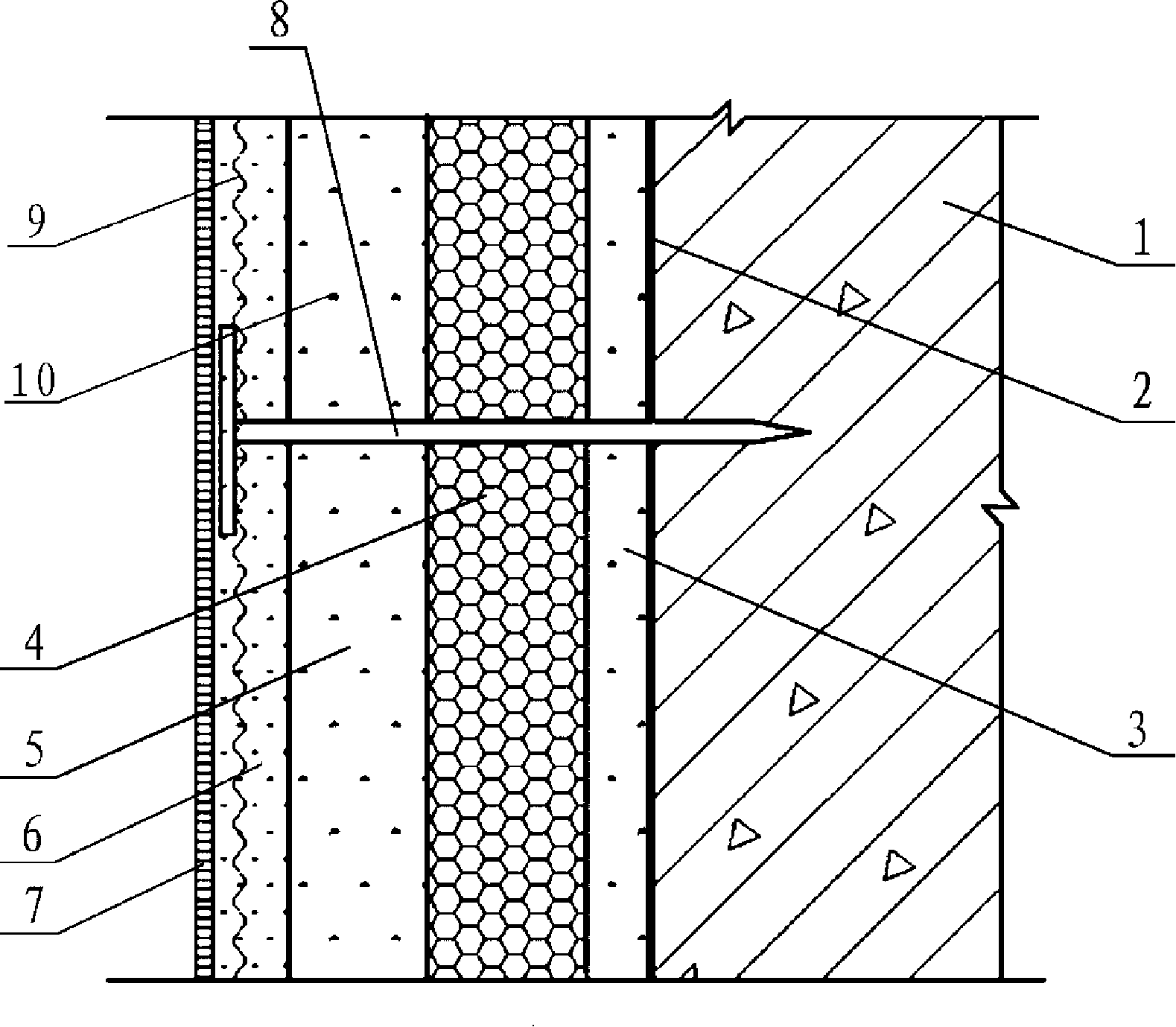

Phase-change thermal energy storage three-in-one exterior wall outer insulation system and construction method thereof

InactiveCN101177967ALow costReduce heat transferCovering/liningsInsulation layerThermal energy storage

The invention relates to a triad phase change and energy storage external thermal insulating system of an external wall and the job practice of the system. A boundary layer, an insulation layer, a crack shielding layer and a finishing coat are arranged from a basal wall to outside in sequence. The insulation layer comprises three layers, including a bonding insulation layer which is an insulation mortar layer, a stable insulation layer which is an insulation board and an active insulation layer which is a phase change and energy storage insulation mortar layer, which are bonded with each other from interior to exterior; wherein, the fine aggregate in the phase change and energy storage insulation mortar layer uses inorganic porous particle as vector, organic phase changed material is adsorbed and stored in the pore space, and the outside surface comprises the phase change and energy storage porous medium of polymer-based composite material film. The crack shielding layer comprises a crack shielding mortar with strengthened mesh inside, meanwhile, a clip is vertically penetrated into the basal wall from the outside of the strengthened mesh. The invention adopts a triad insulation structure as the structure and phase changeable energy-storage material as fixing material, which significantly improves the insulation effect of wall and is favorable for keeping stable indoor temperature and substantially saving the energy consumption of indoor air conditioner.

Owner:北京中远汇丽精细化工有限公司

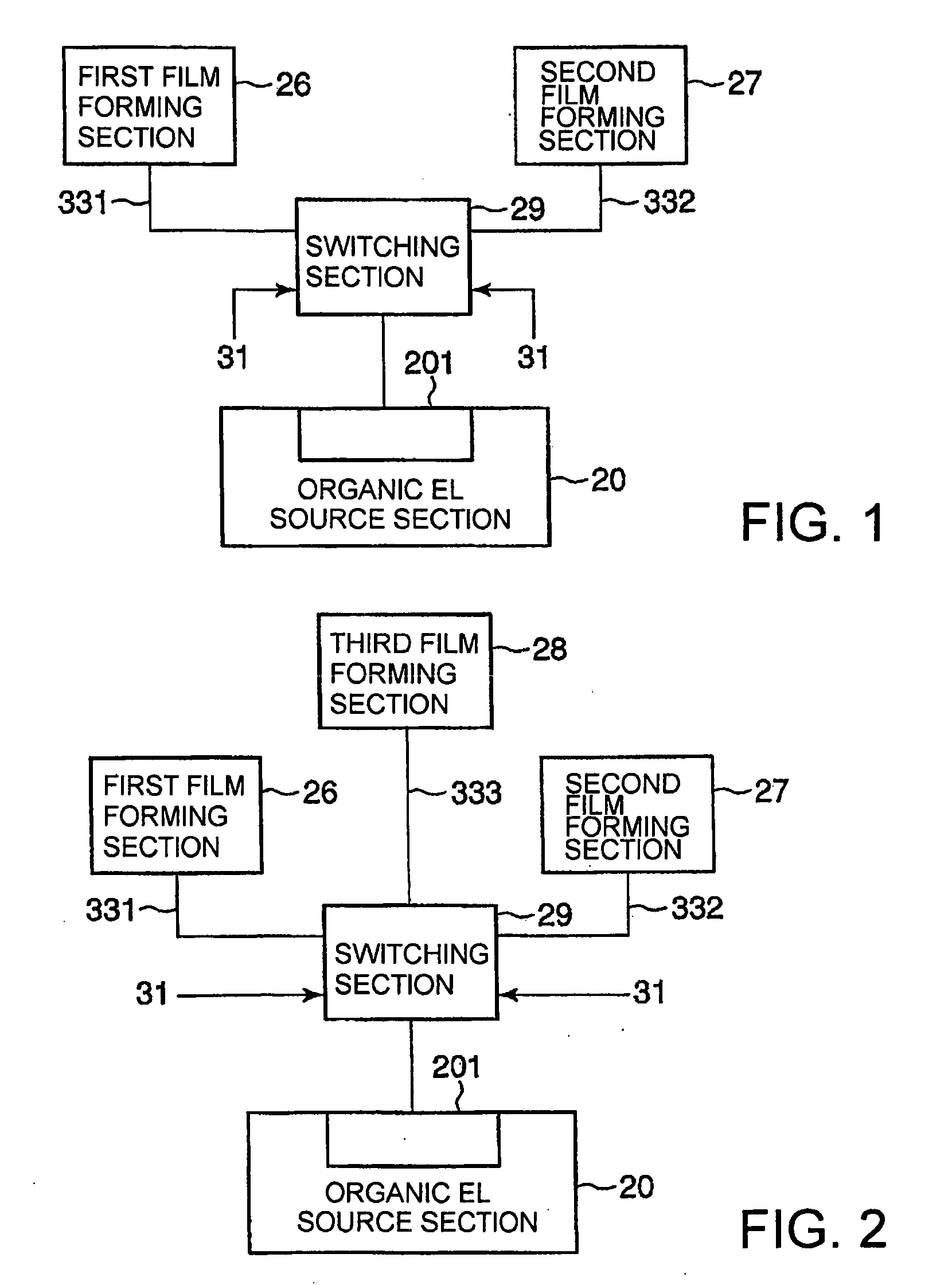

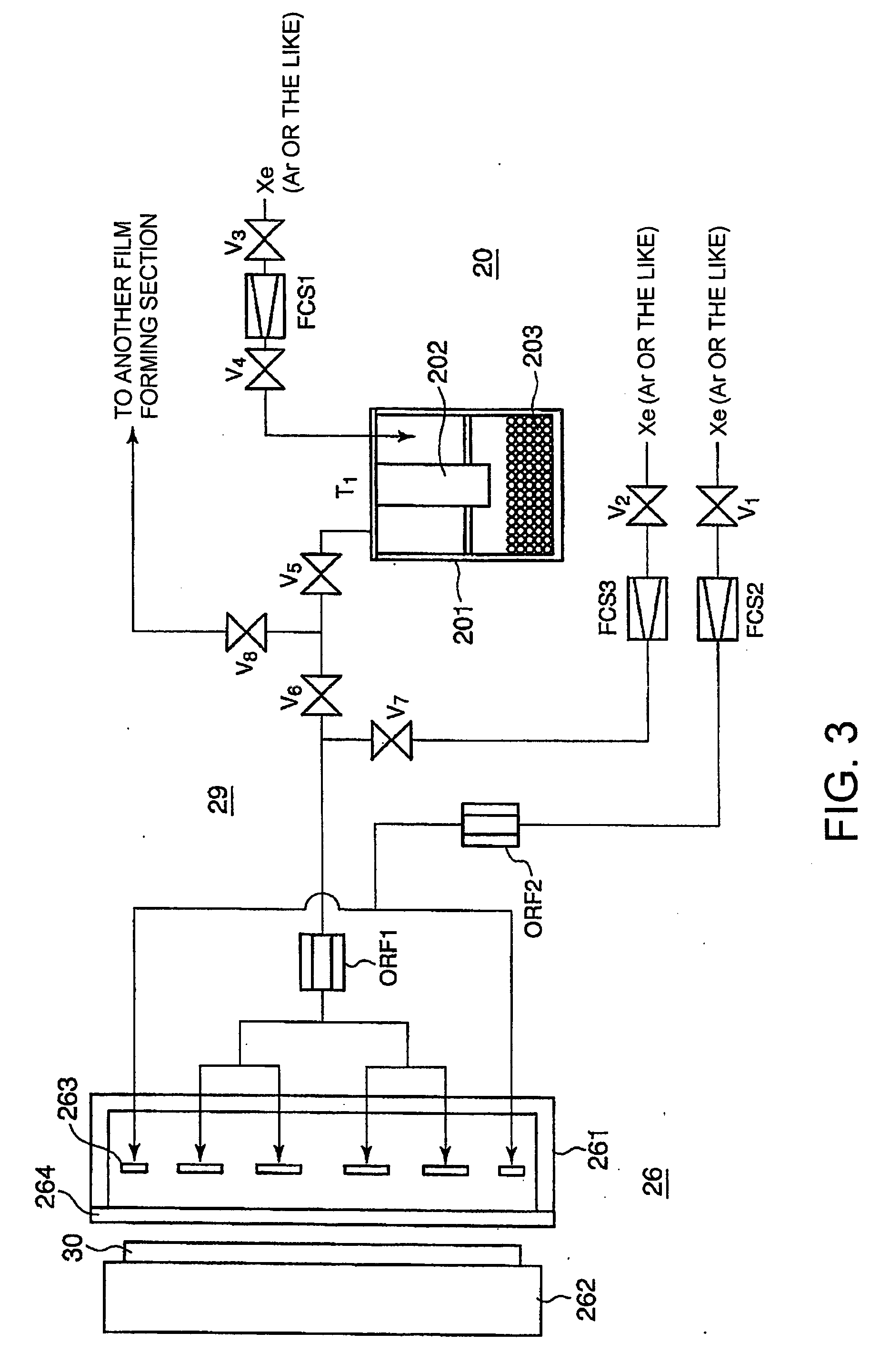

Film Forming Apparatus, Evaporating Jig, and Measurement Method

InactiveUS20090087545A1Improve efficiencyEasy to controlAnalysing fluids using sonic/ultrasonic/infrasonic wavesVacuum evaporation coatingEngineeringMechanical engineering

Owner:TOHOKU UNIV +1

Device and method for vaporizing temperature sensitive materials

ActiveUS7232588B2Reduce riskStable rateDischarge tube luminescnet screensElectroluminescent light sourcesMetallurgyVaporization

A method for vaporizing organic materials onto a substrate surface to form a film including providing a quantity of organic material into a vaporization apparatus and actively maintaining the organic material in a first heating region in the vaporization apparatus to be below the vaporization temperature. The method also includes heating a second heating region of the vaporization apparatus above the vaporization temperature of the organic material and metering, at a controlled rate, organic material from the first heating region into the second heating region so that a thin cross section of the organic material is heated at a desired rate-dependent vaporization temperature, whereby organic material vaporizes and forms a film on the substrate surface.

Owner:GLOBAL OLED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com