Patents

Literature

286results about How to "Stable rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

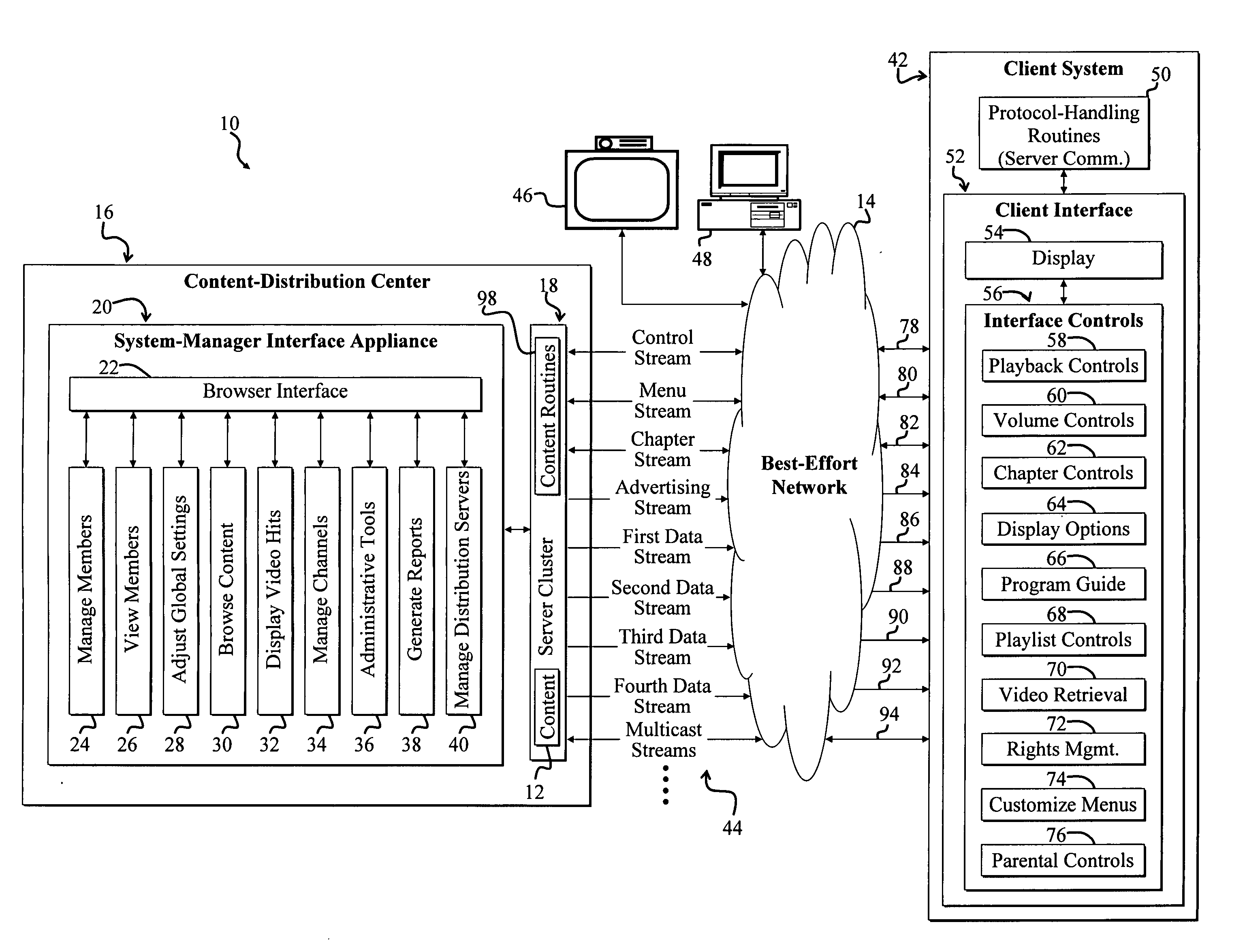

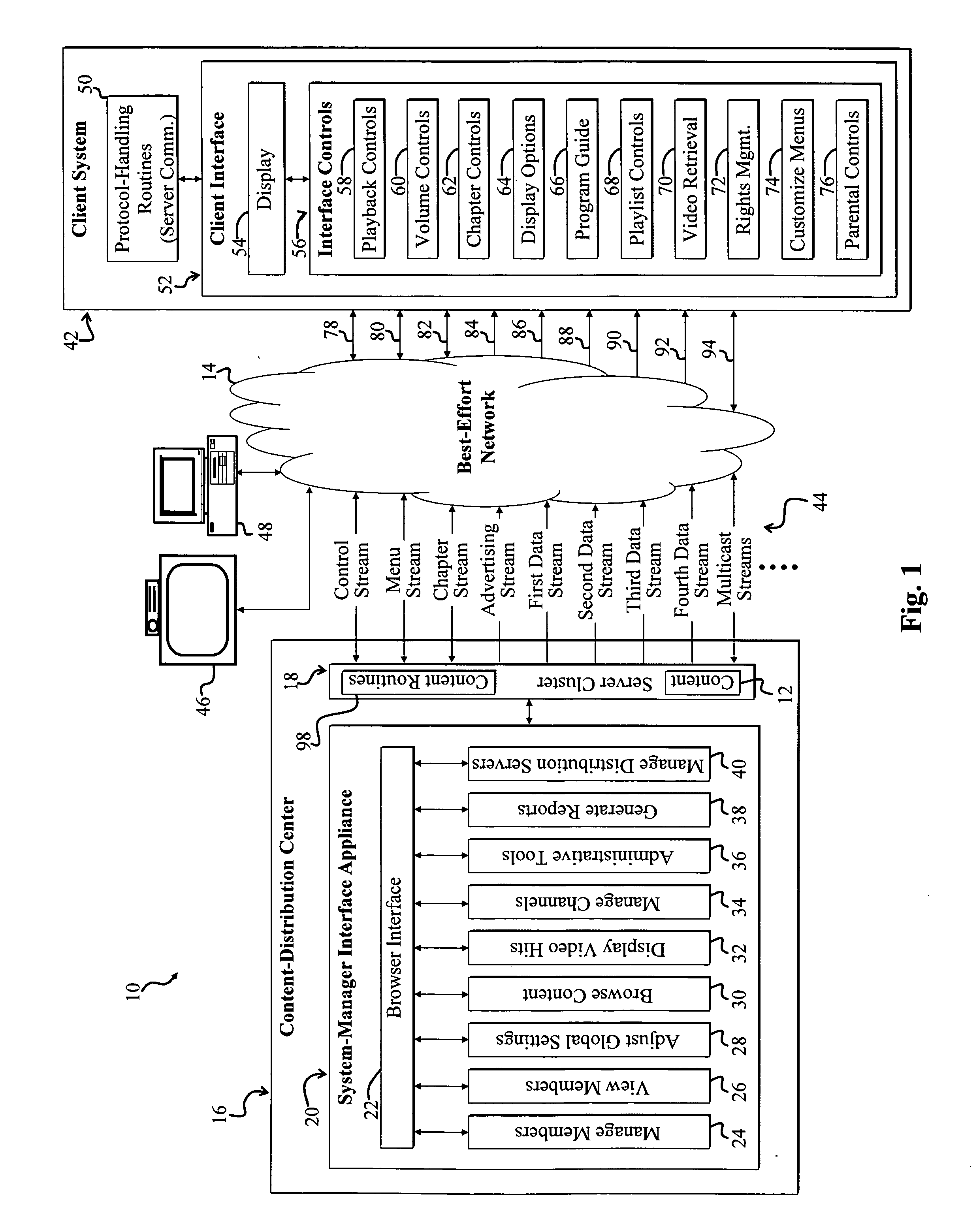

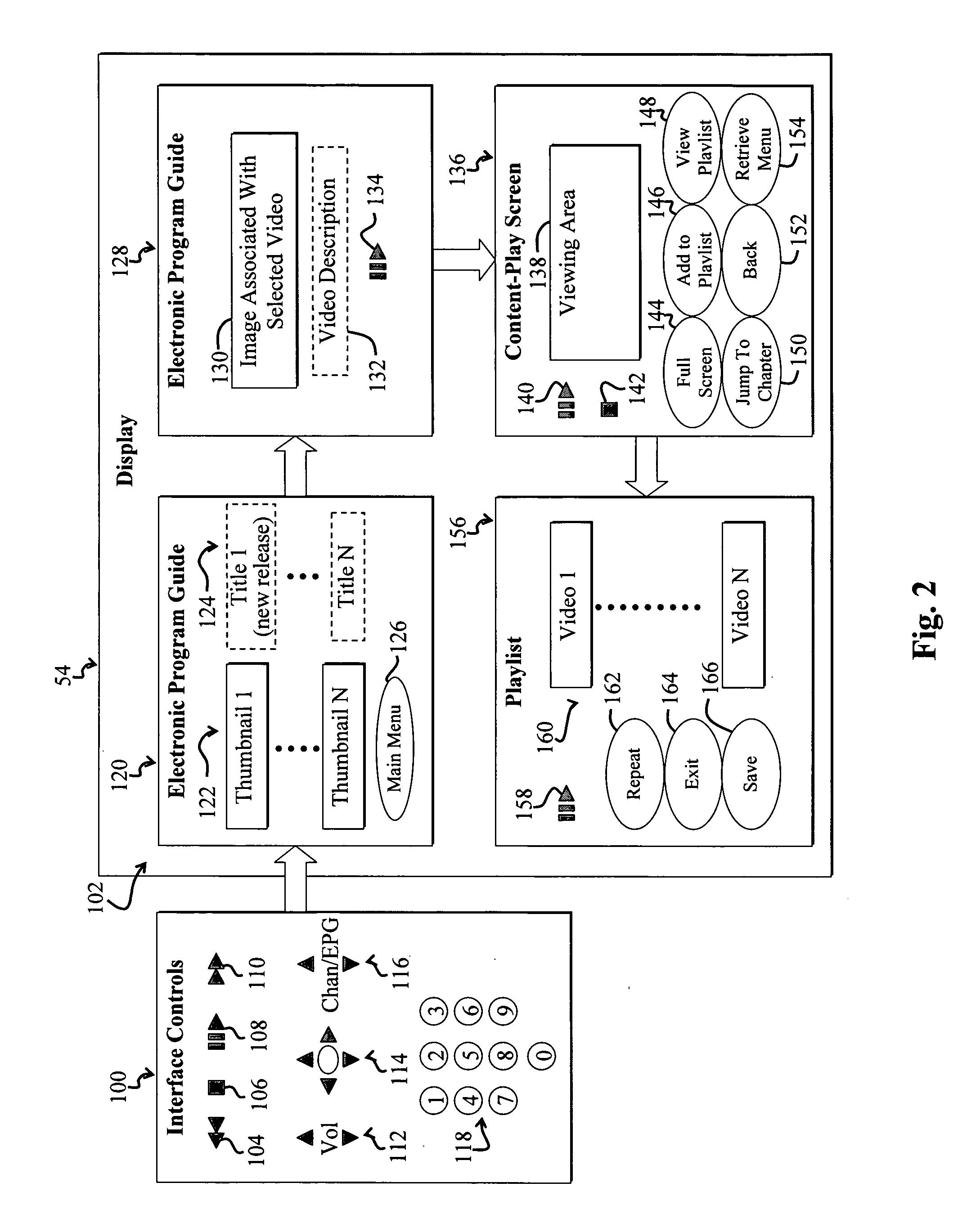

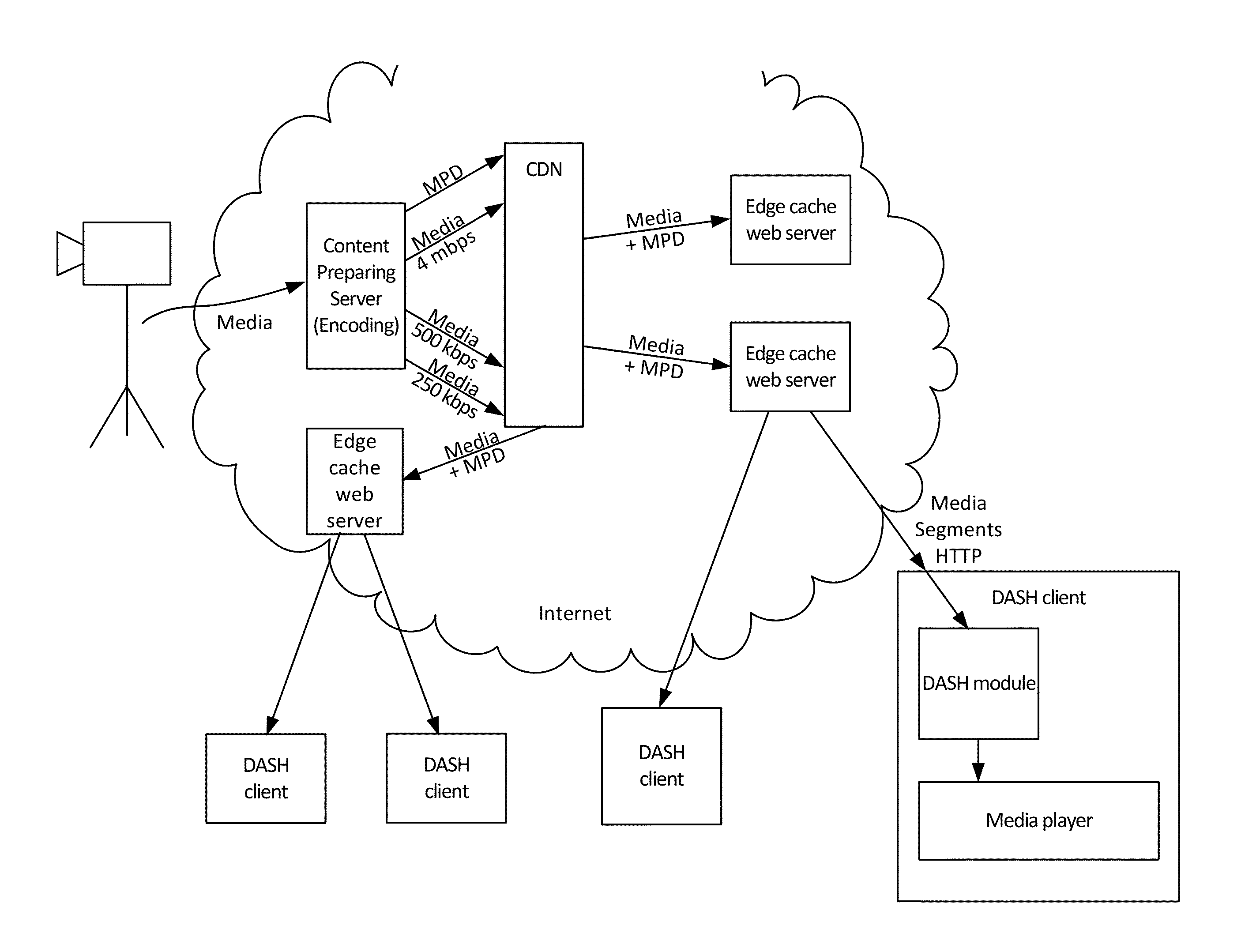

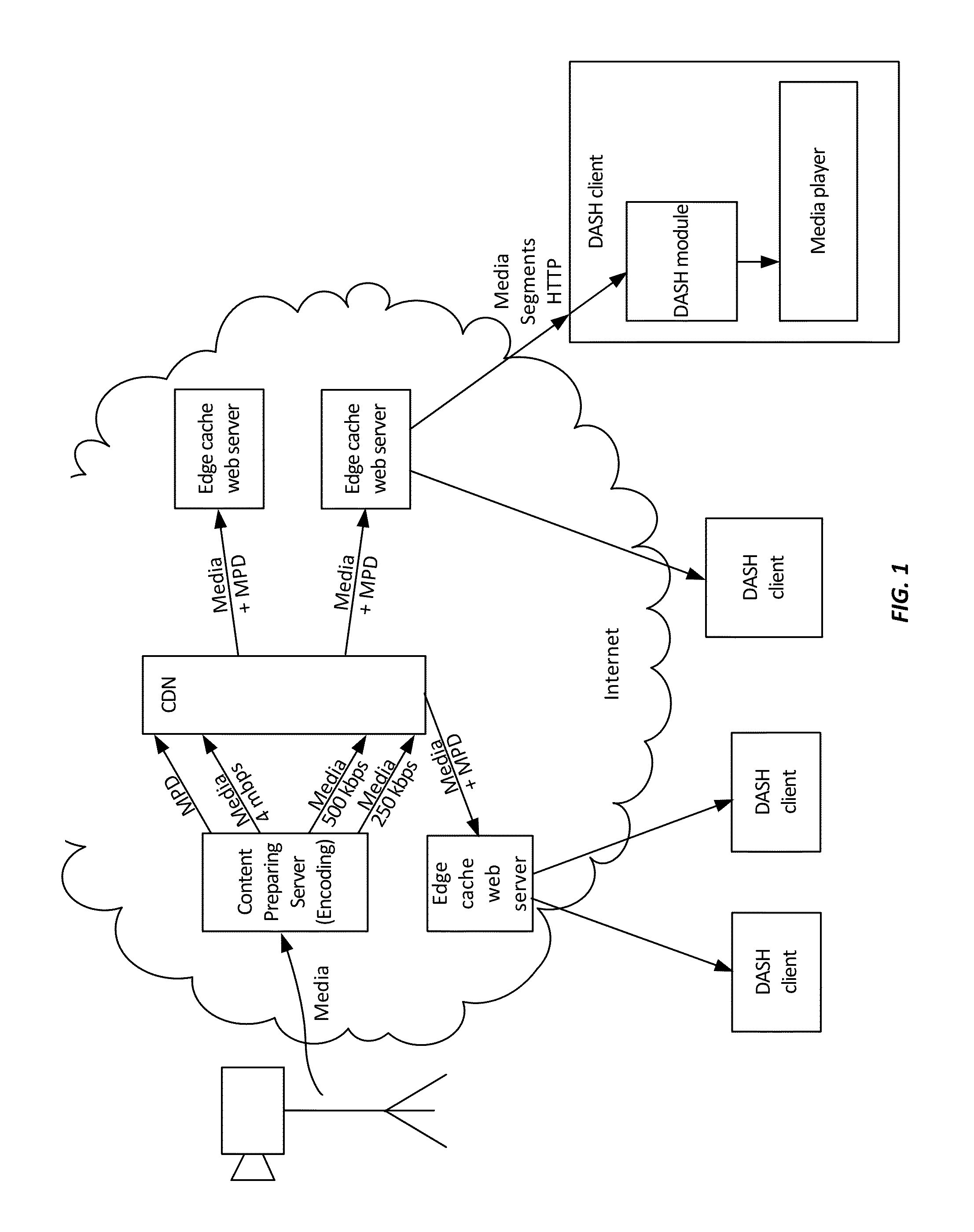

System and method for transferring content via a network

ActiveUS20060015637A1Reduce deliveryStabilize content-transfer rateMultiple digital computer combinationsTransmissionClient-sideClient system

A system for delivering content, such as video content, via a network. In an illustrative embodiment, the system includes a server system that is connected to the network and has access to the content. A client system is adapted to forward a request for the content to the server system via the network. One or more content-delivery routines in communication with the server system are adapted to initiate sending of the content to the client system via multiple streams over the network in response to the request.

Owner:MATRIXSTREAM TECH

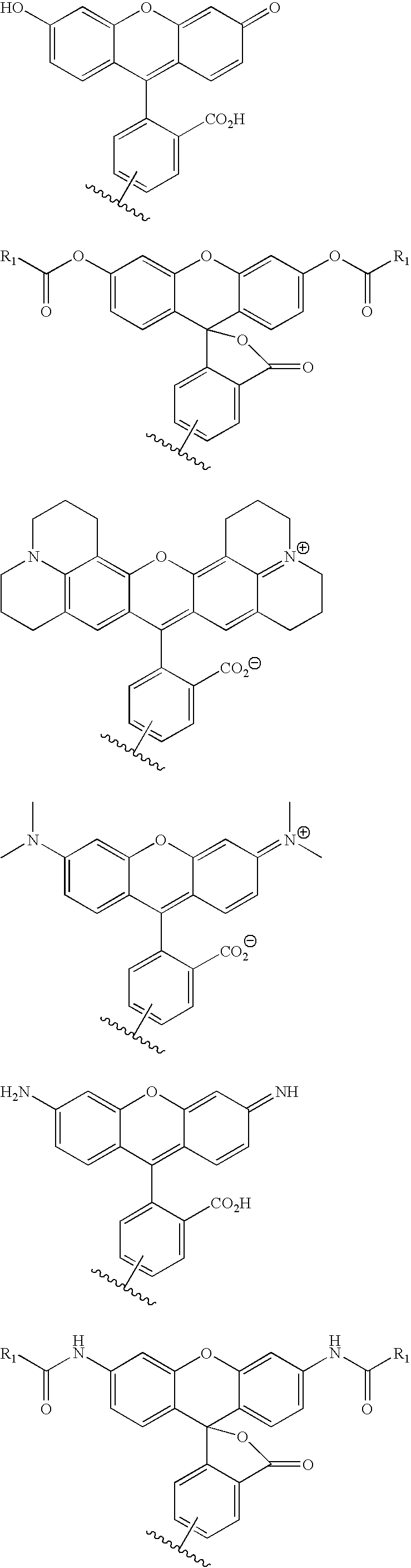

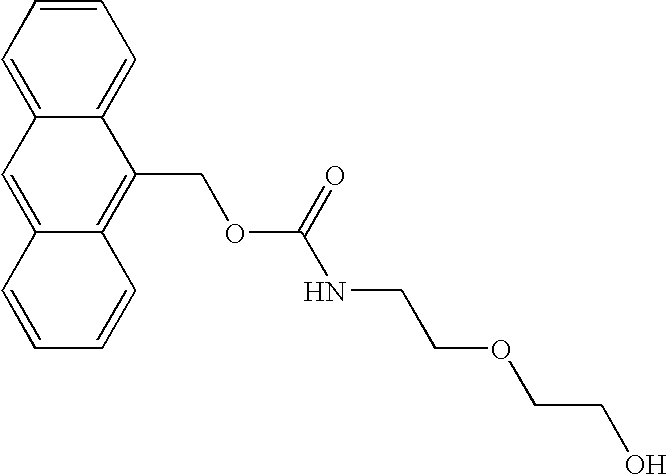

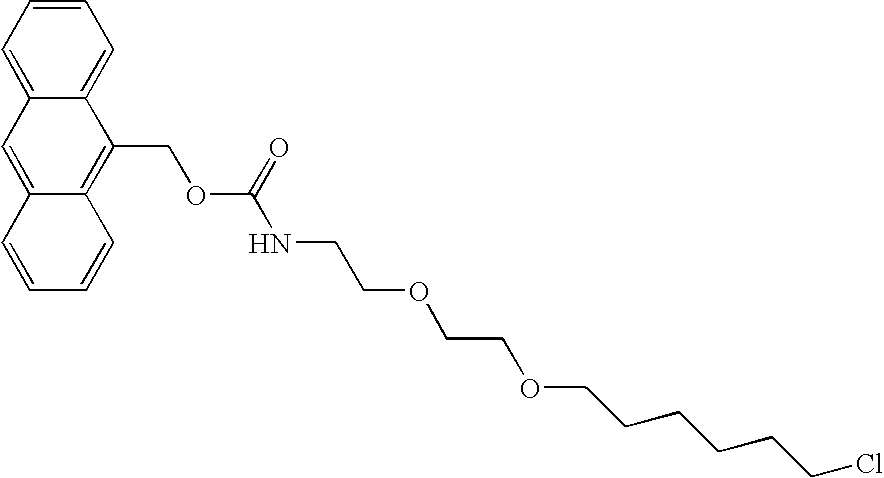

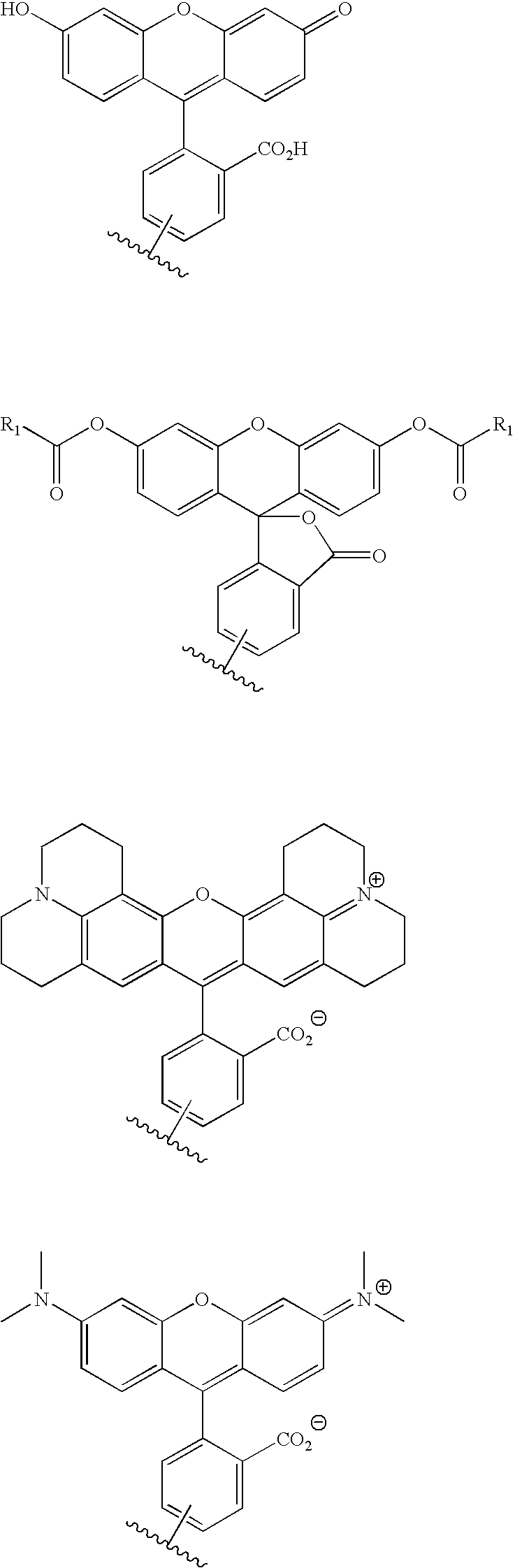

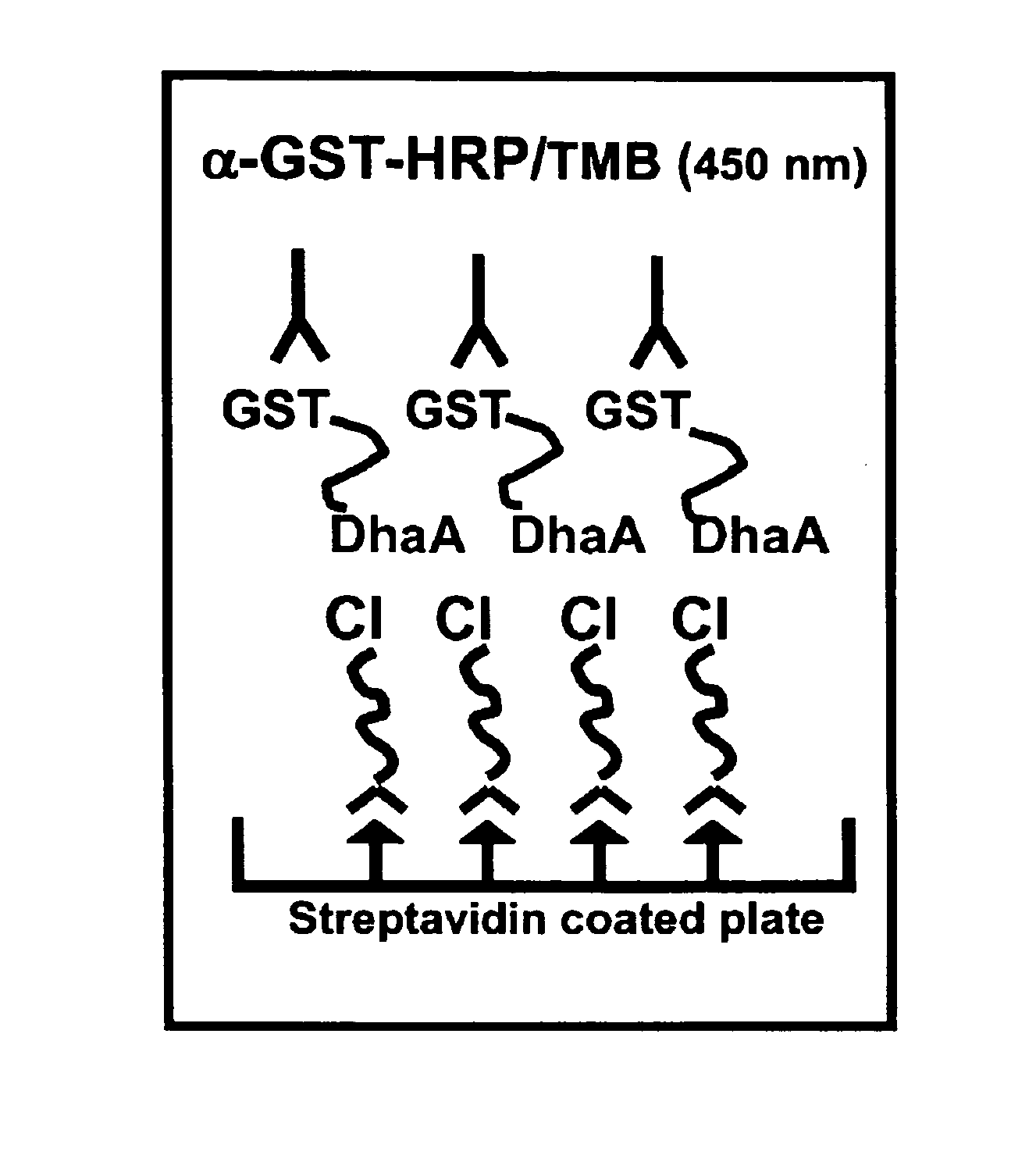

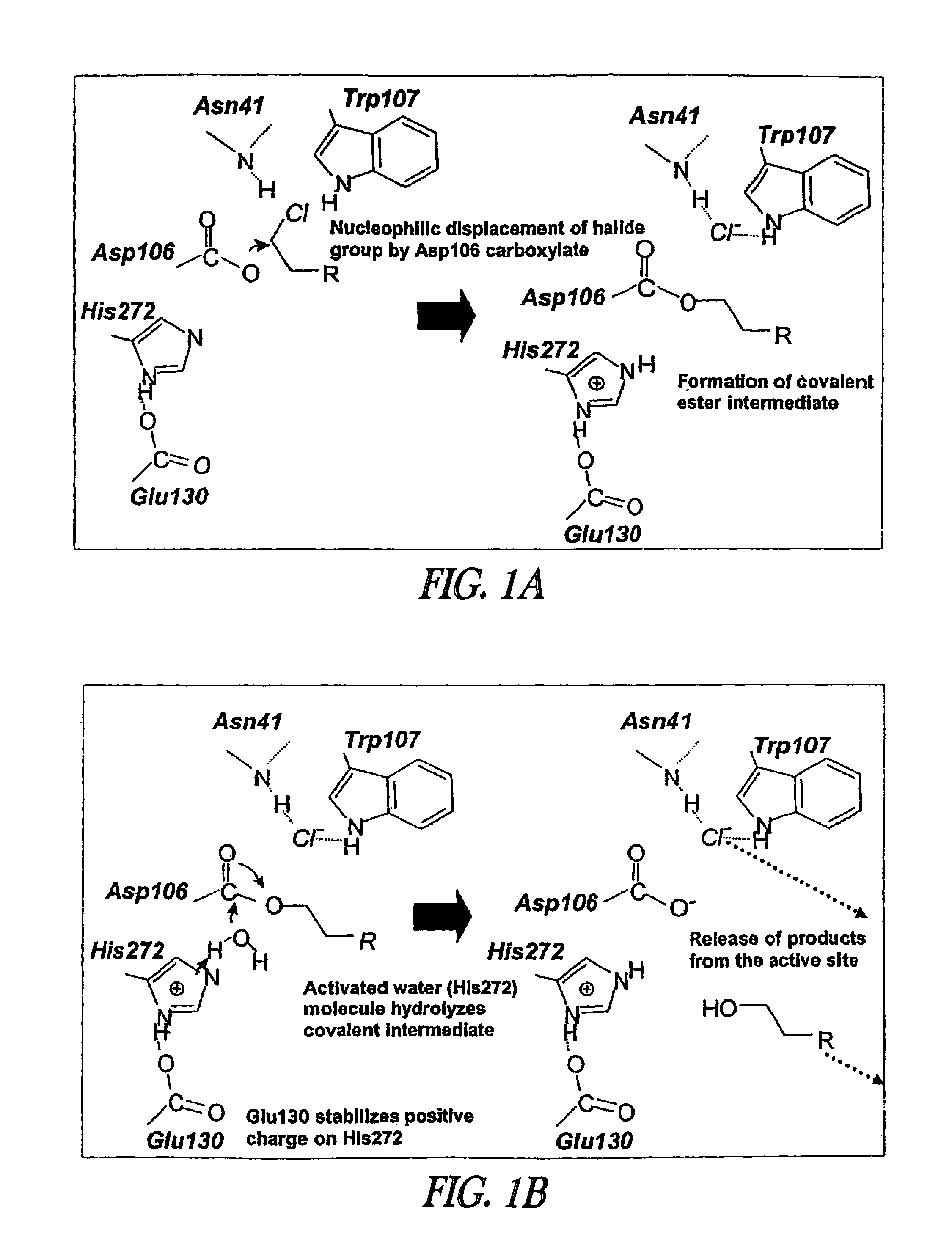

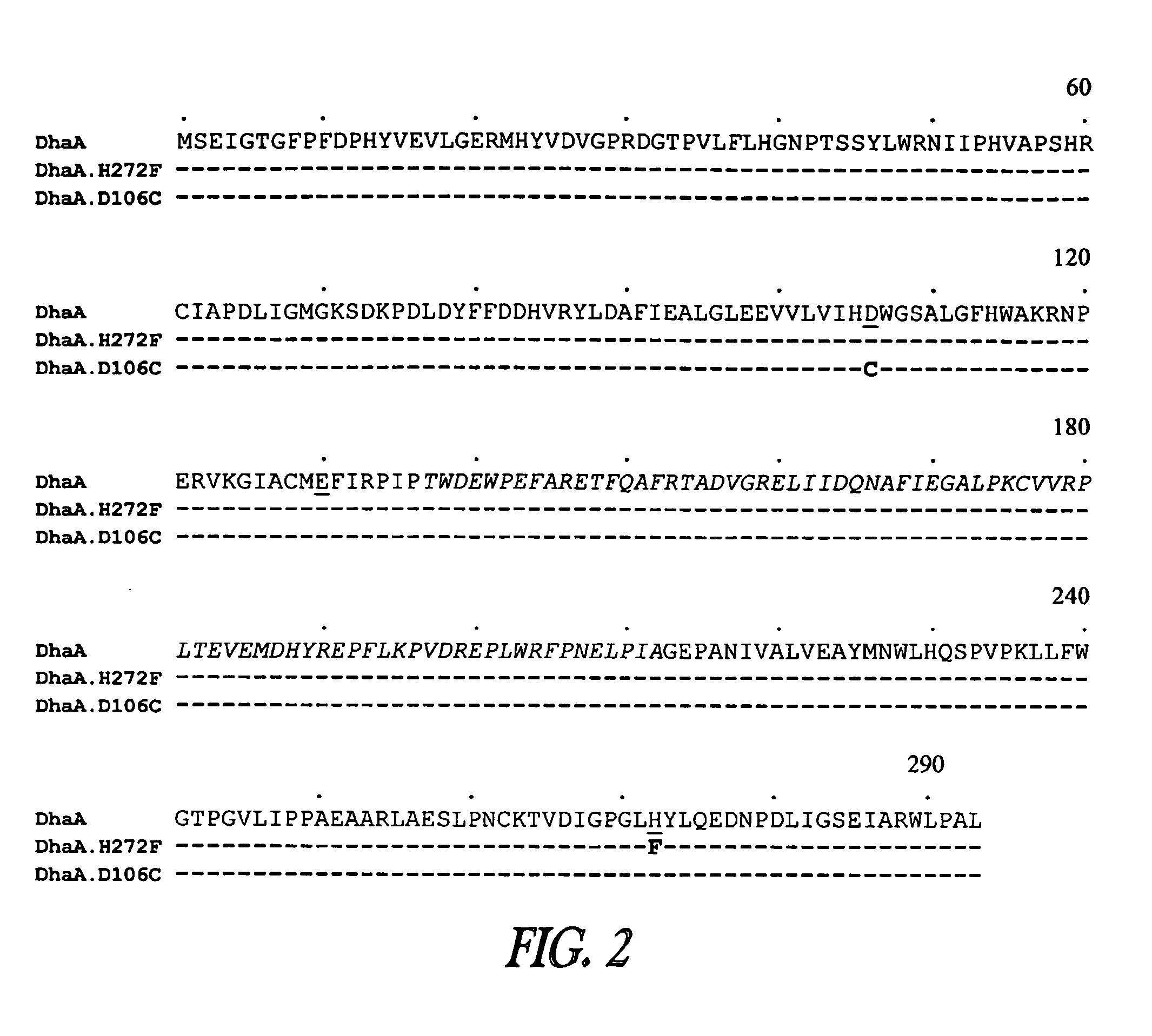

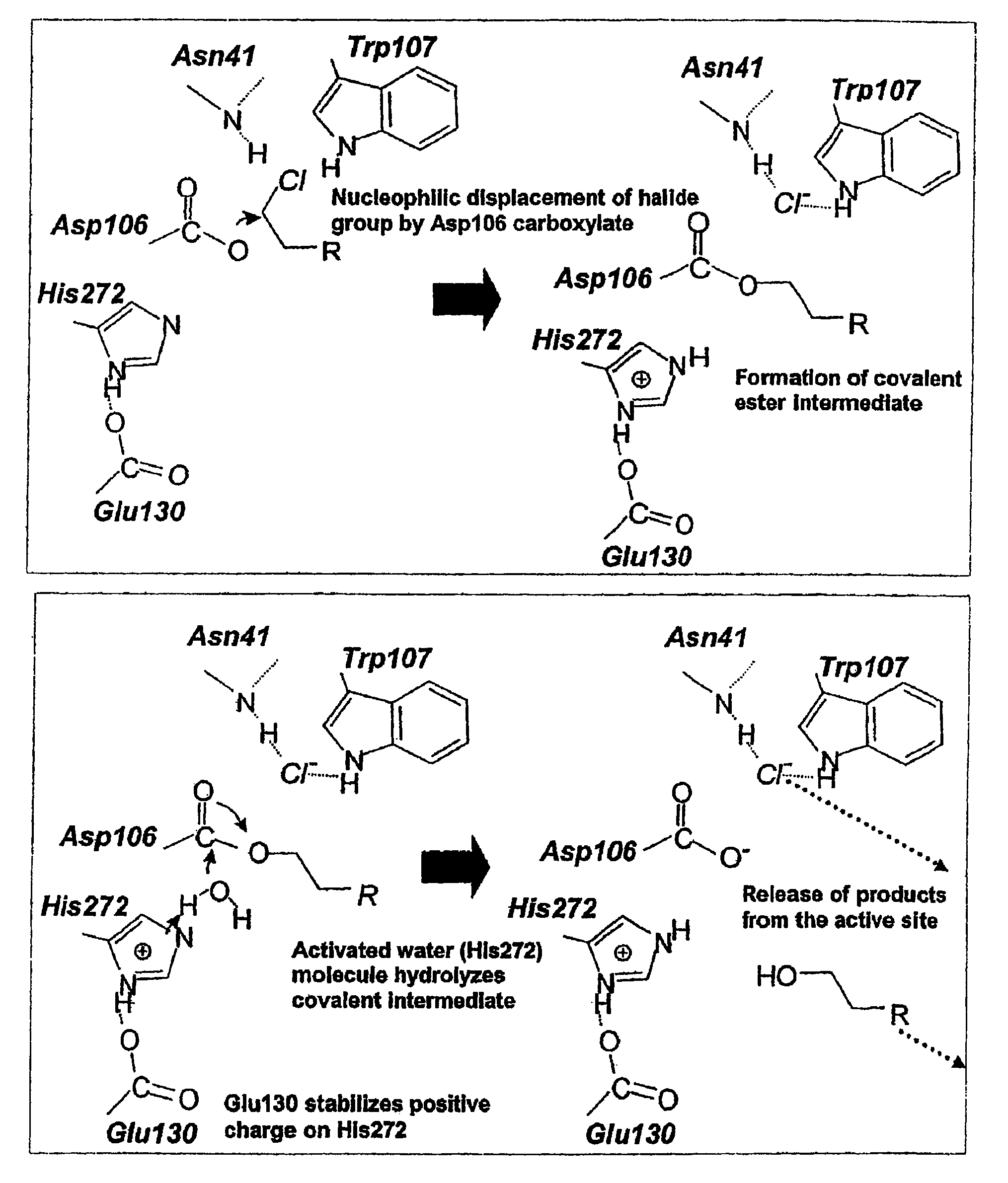

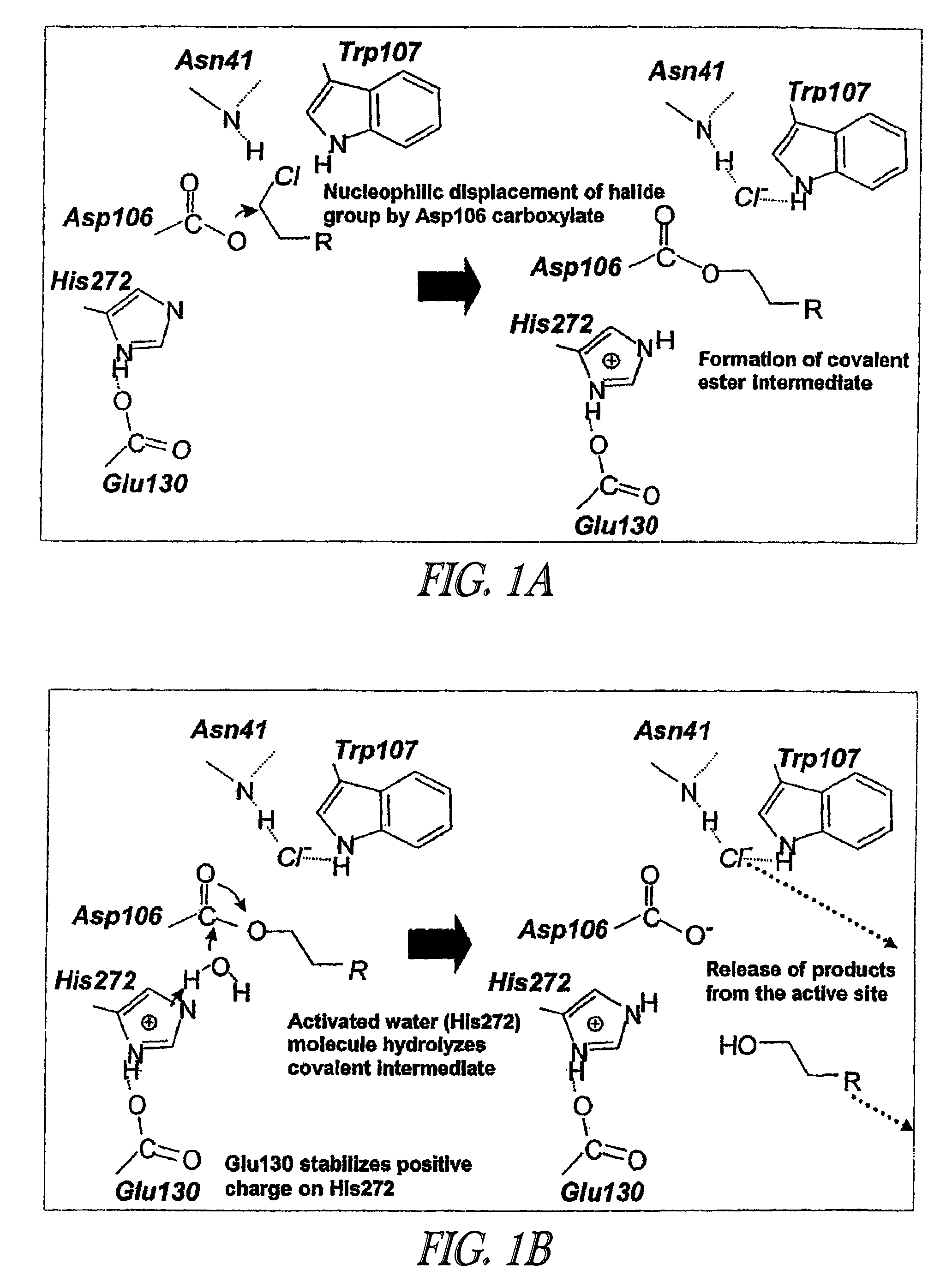

Covalent tethering of functional groups to proteins and substrates therefor

ActiveUS20060024808A1Rapidly and efficiently loaded into and washedStable rateMethine/polymethine dyesBacteriaAmino acid substitutionTethering

A mutant hydrolase optionally fused to a protein of interest is provided. The mutant hydrolase is capable of forming a bond with a substrate for the corresponding nonmutant (wild-type) hydrolase which is more stable than the bond formed between the wild-type hydrolase and the substrate and has at least two amino acid substitutions relative to the wild-type hydrolase. Substrates for hydrolases comprising one or more functional groups are also provided, as well as methods of using the mutant hydrolase and the substrates of the invention. Also provided is a fusion protein capable of forming a stable bond with a substrate and cells which express the fusion protein.

Owner:PROMEGA CORP

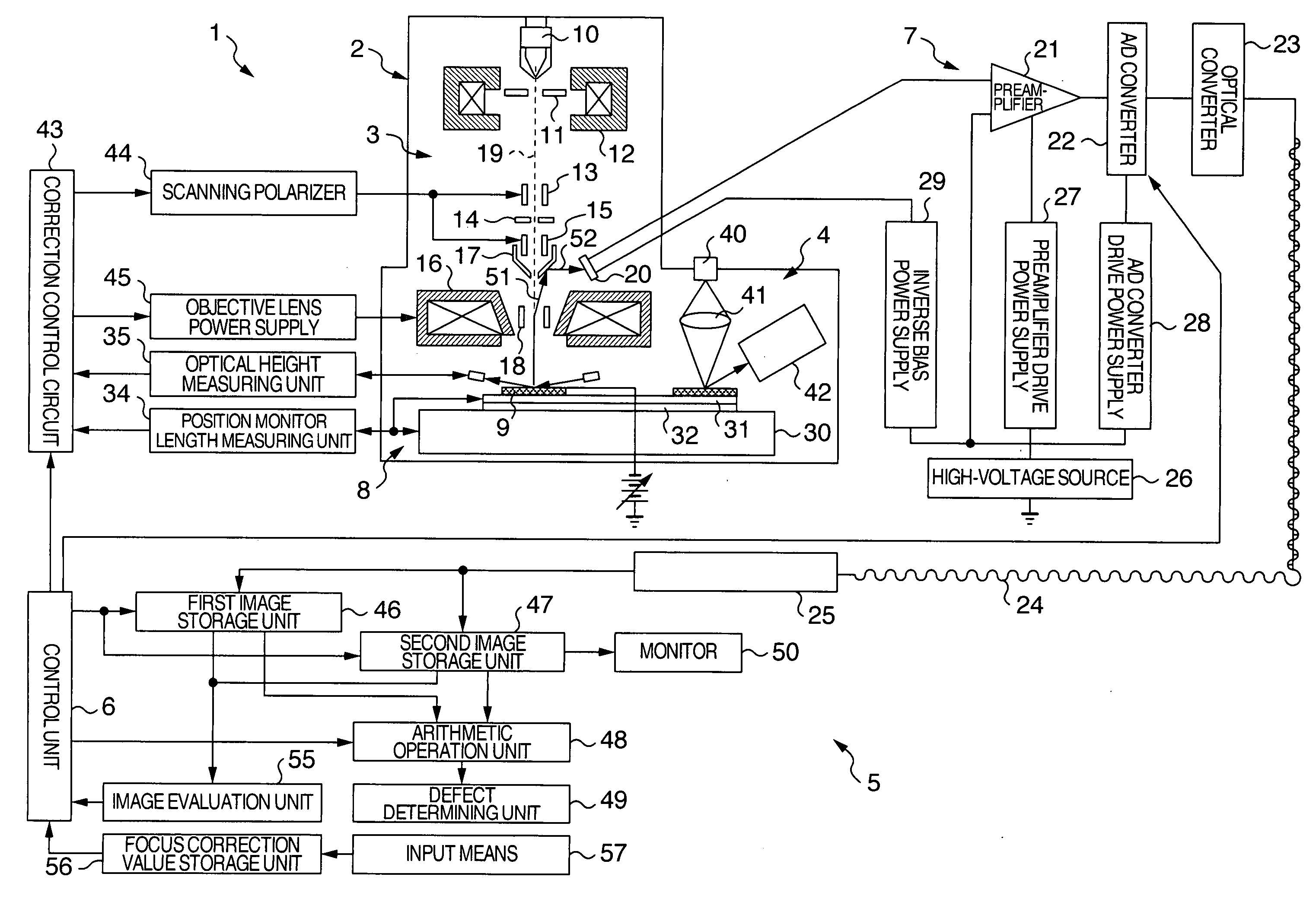

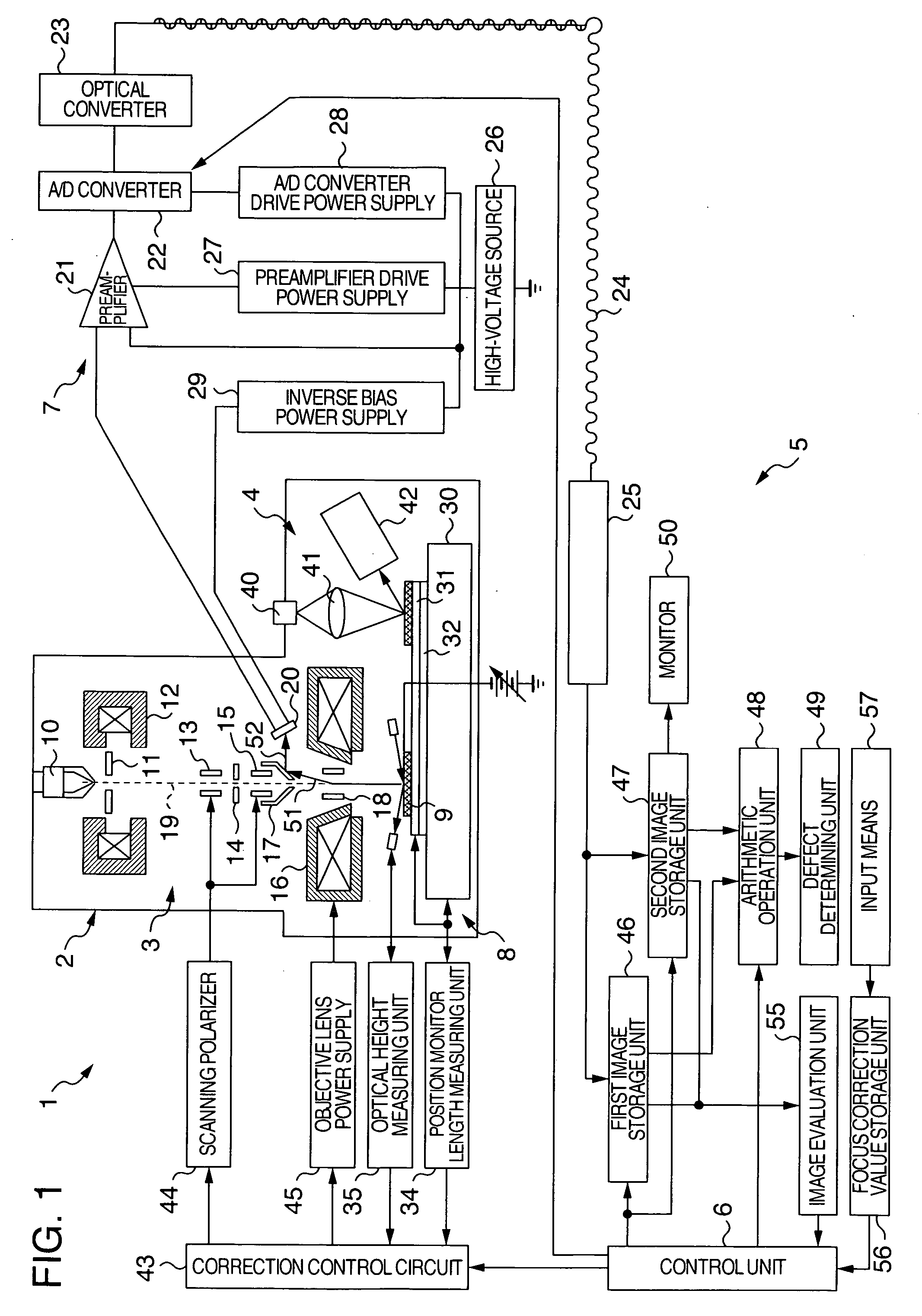

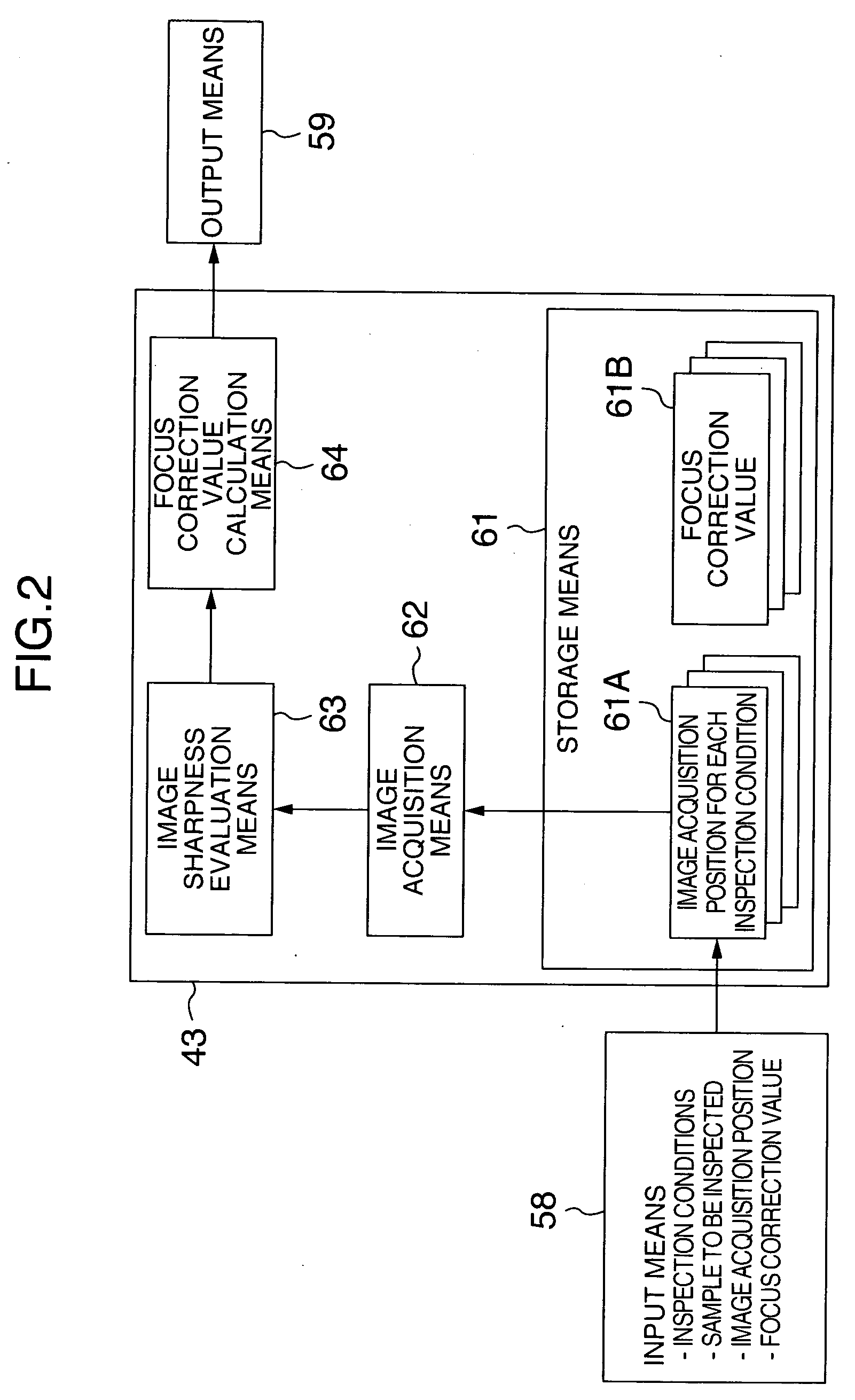

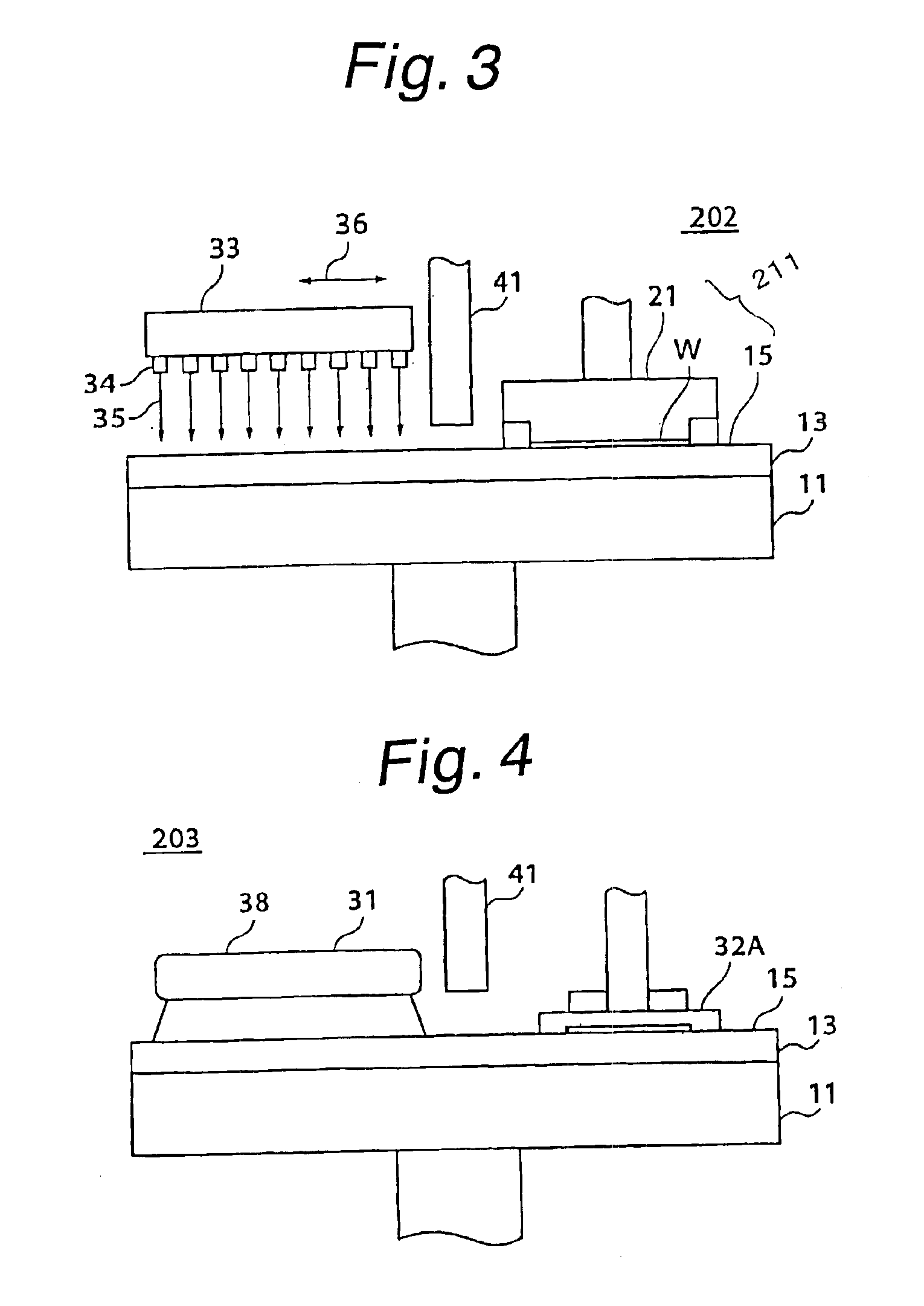

Focus correction method for inspection of circuit patterns

InactiveUS20060284088A1Avoid scrap rateReduce false informationMaterial analysis using wave/particle radiationElectric discharge tubesComputational physicsEngineering

A charged particle application circuit pattern inspection apparatus and method are disclosed, in which the reduction in the rejection rate attributable to an out-of-focus state due to the change in the charge condition on the sample surface is prevented and the false information is reduced to improve the apparatus reliability. The image acquisition position on a sample is stored in an image acquisition position storage unit, a focus correction value is stored in a focus correction value storage unit in accordance with the image acquisition position and the sample charge condition, the inspection conditions and the sample to be inspected are input from an input unit, the sample charge condition is evaluated in accordance with the image position acquisition position, and the focal point is corrected by a focus correction unit.

Owner:HITACHI HIGH-TECH CORP

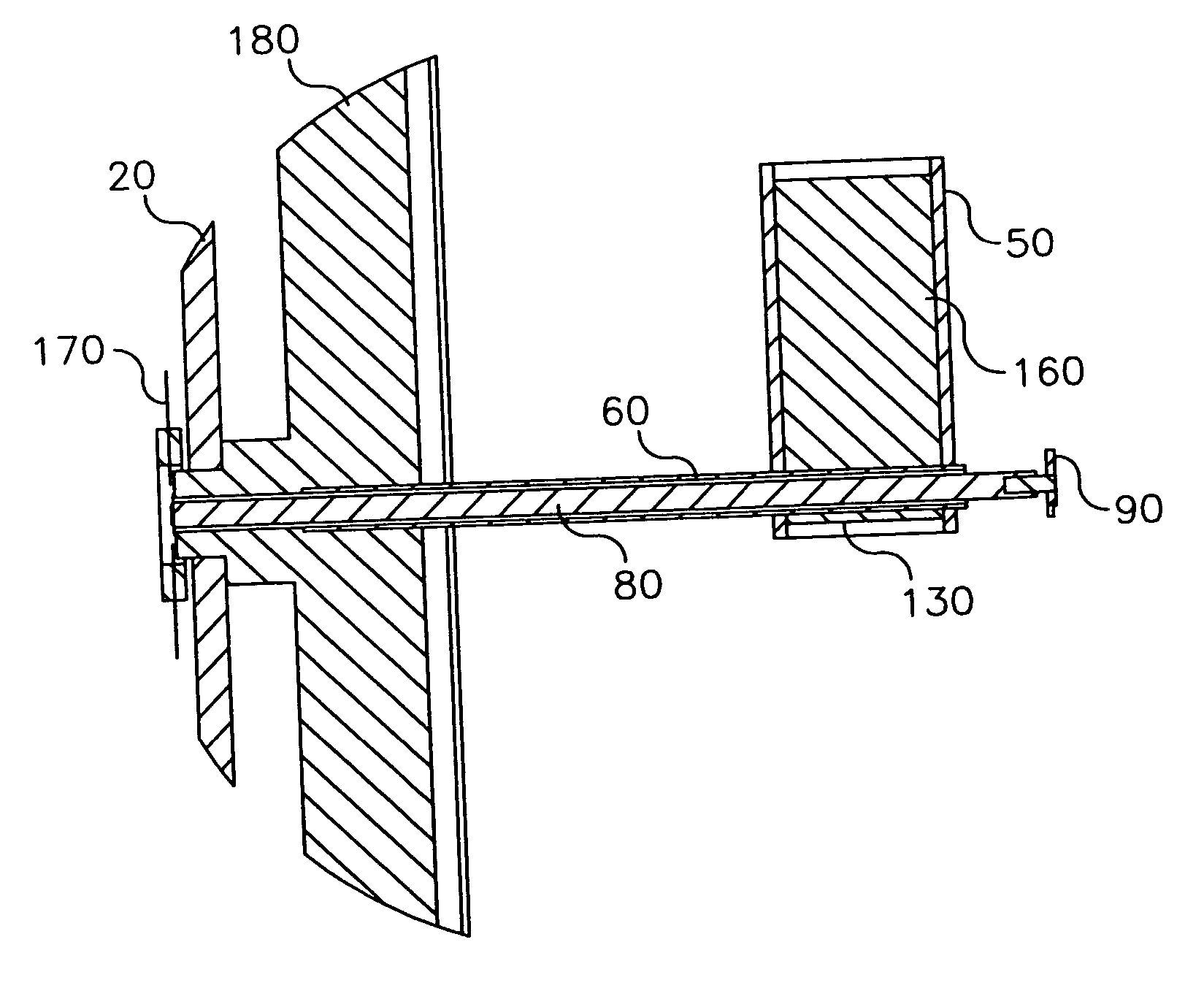

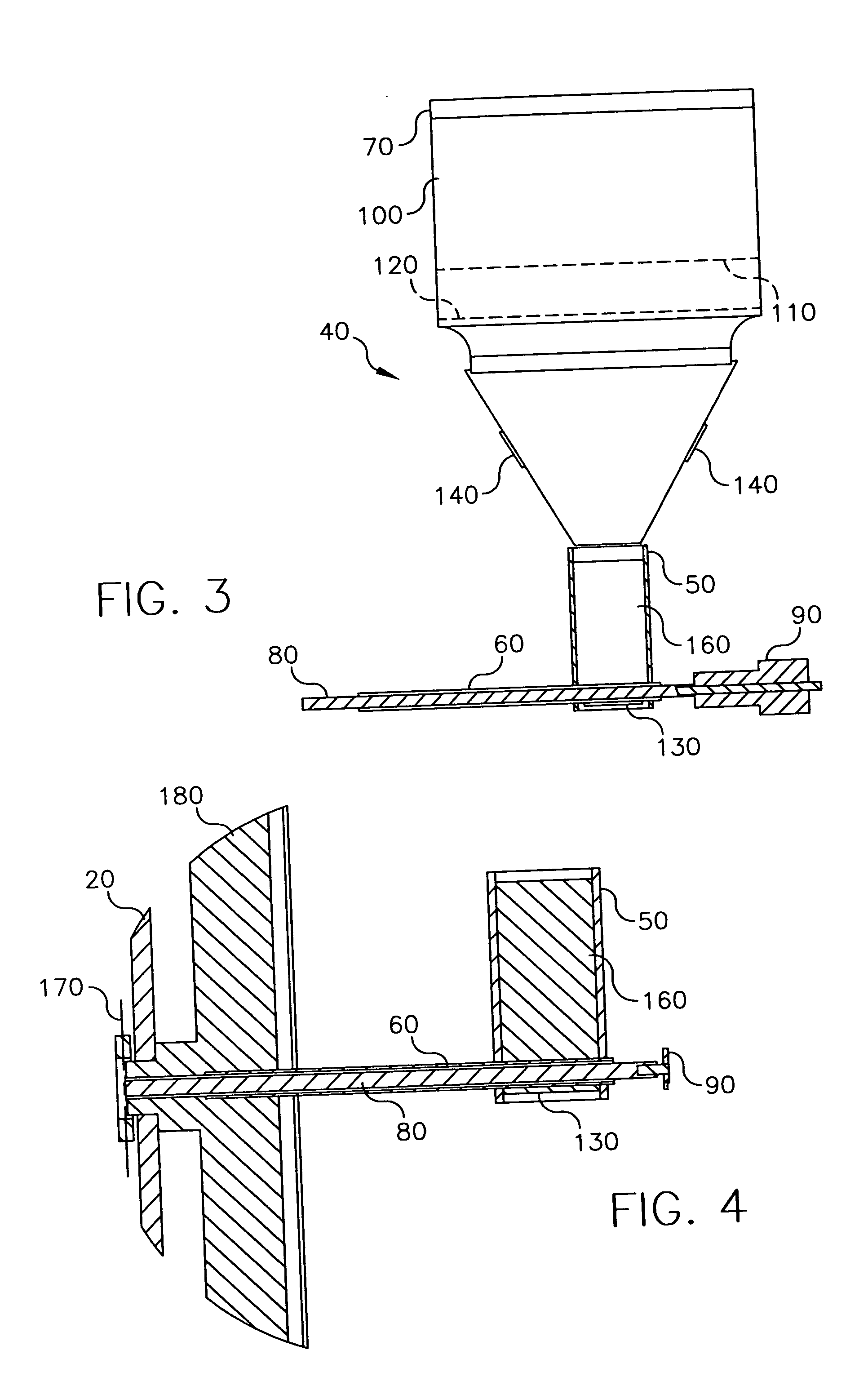

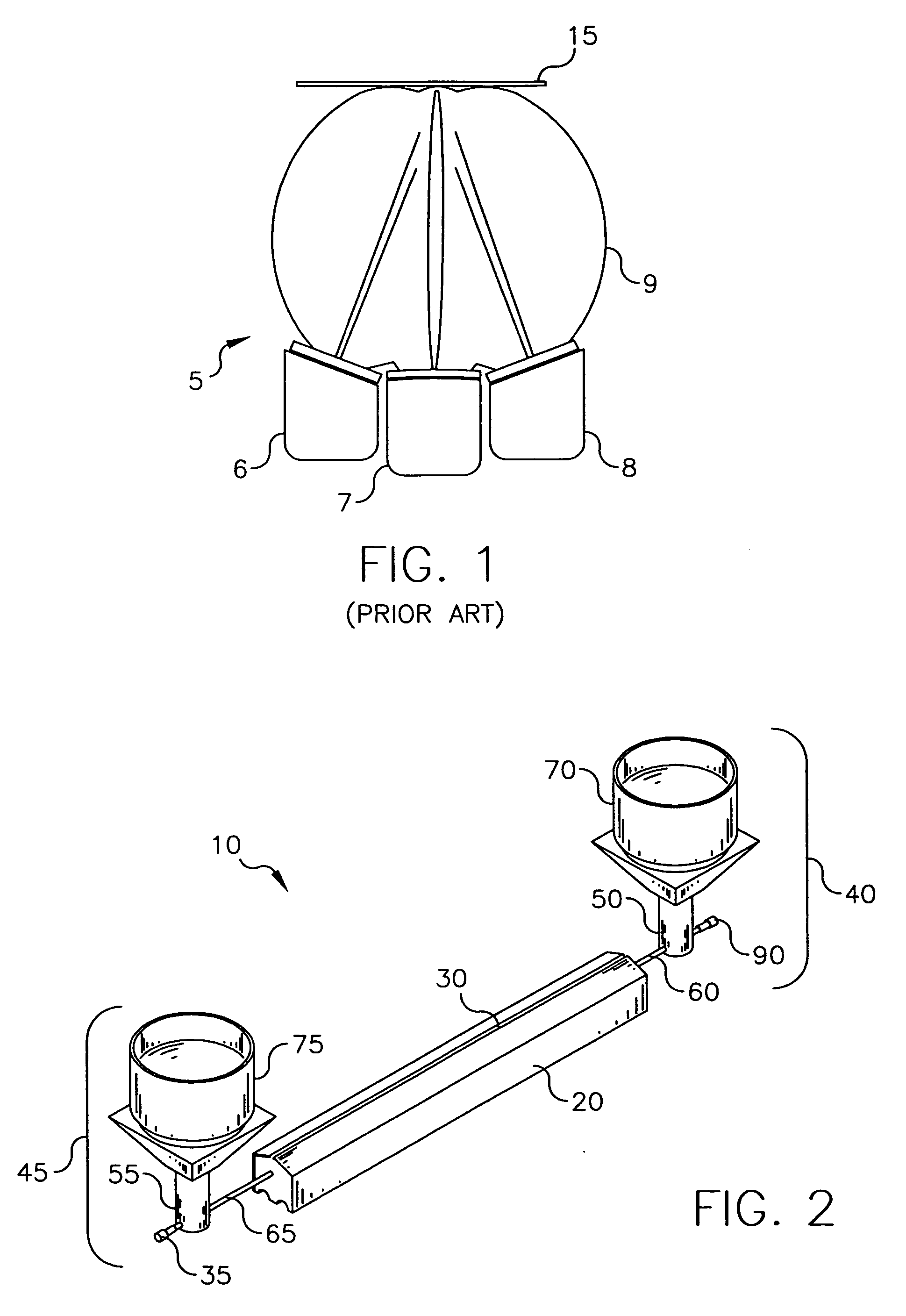

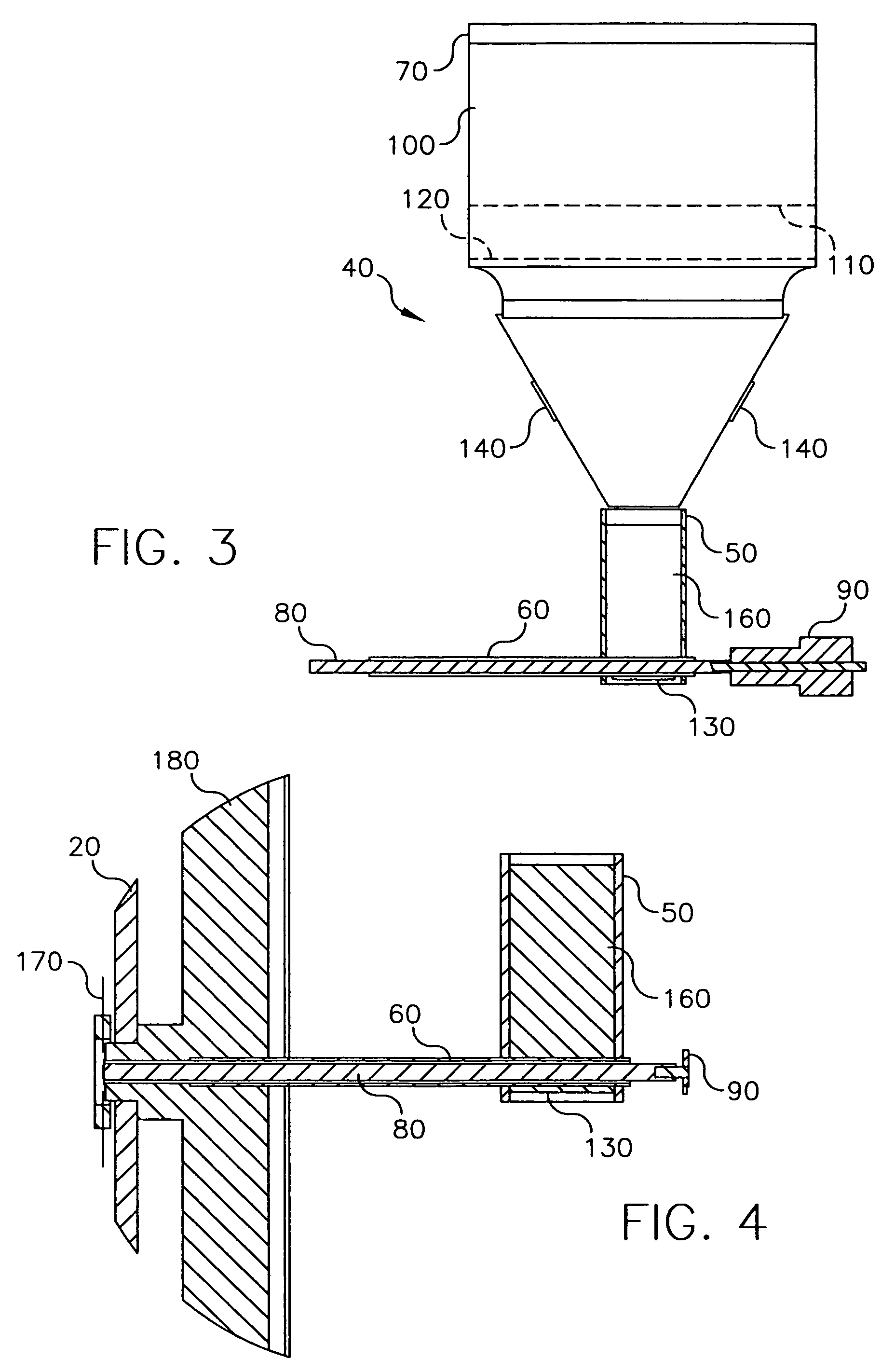

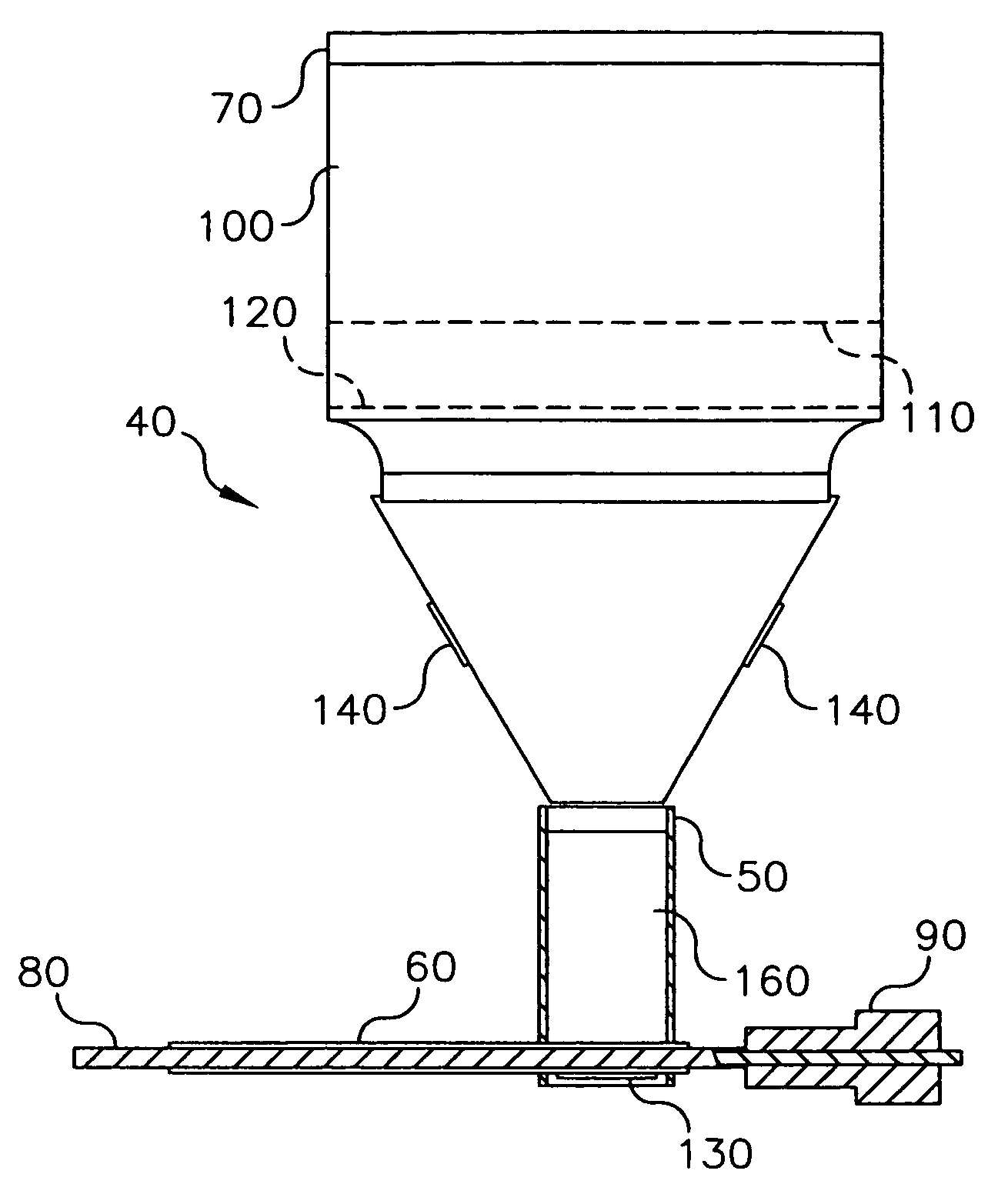

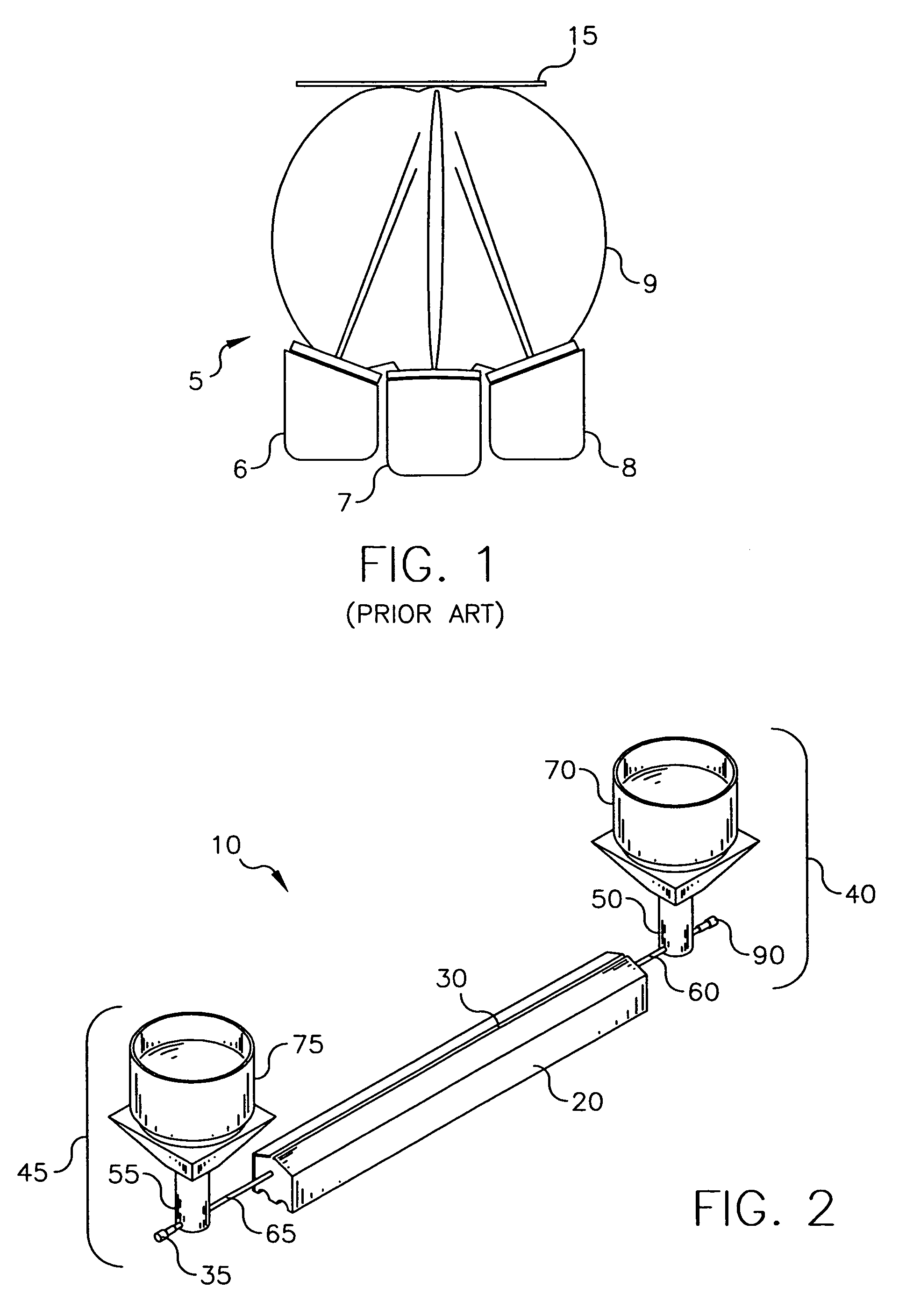

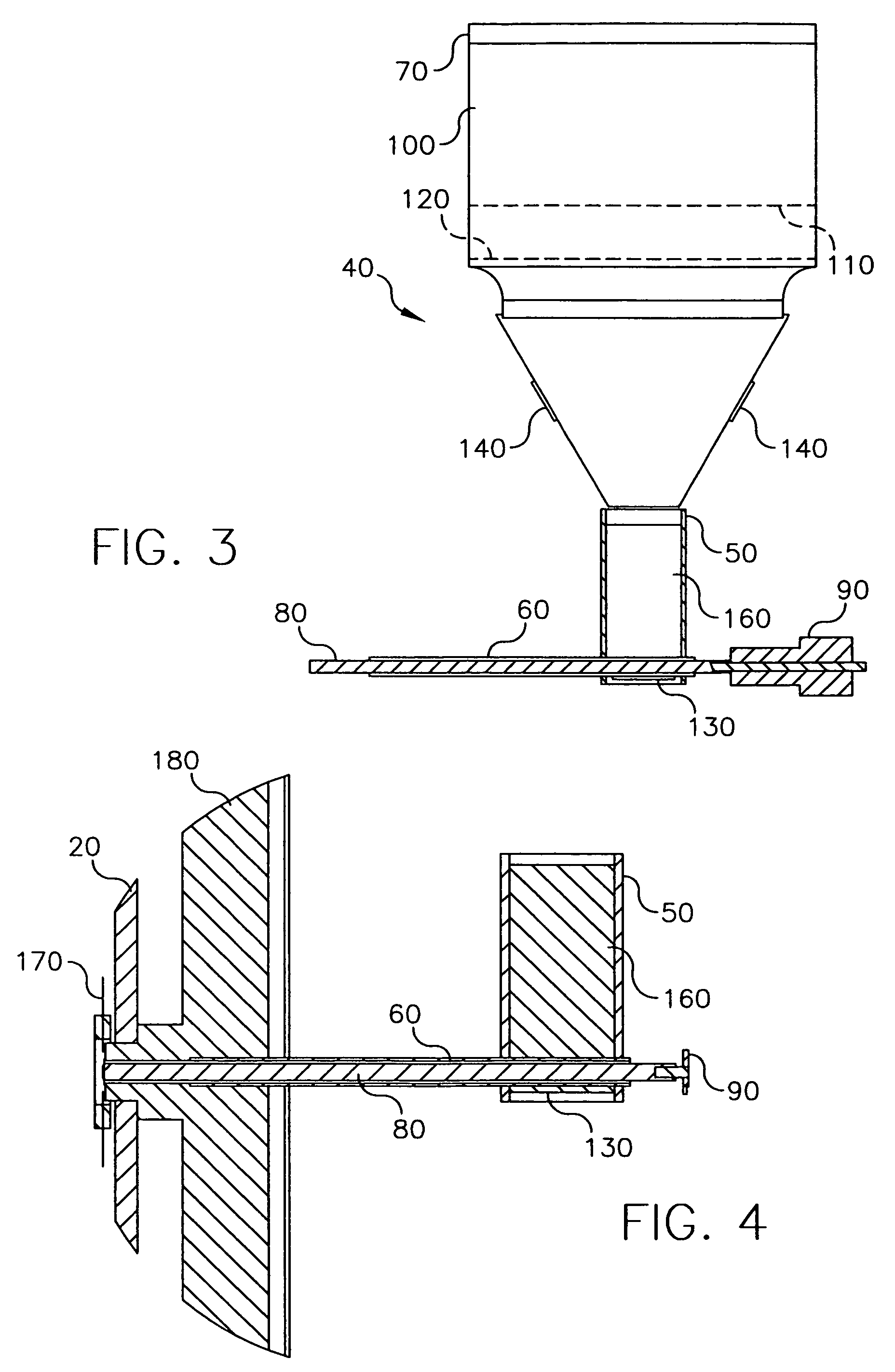

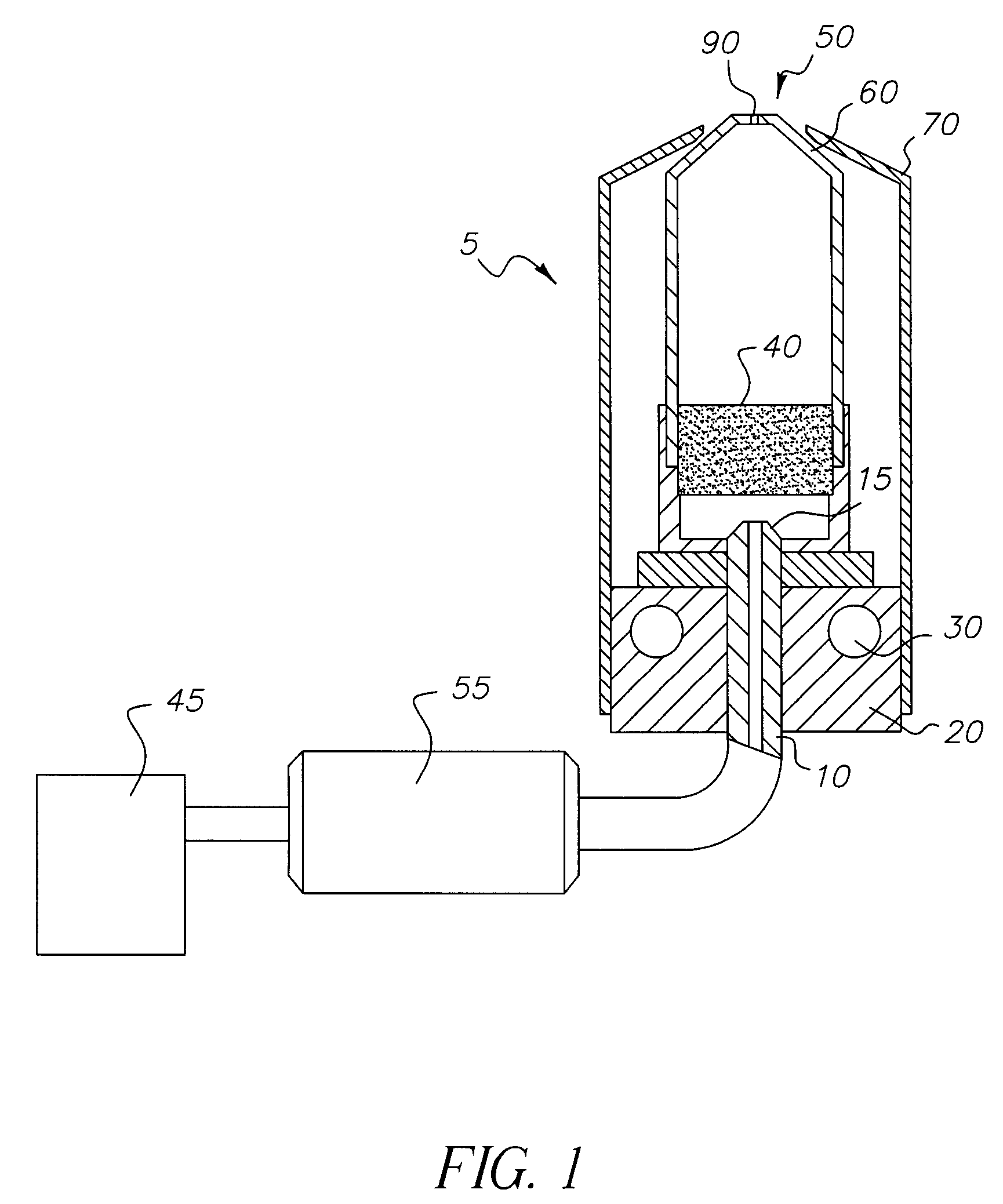

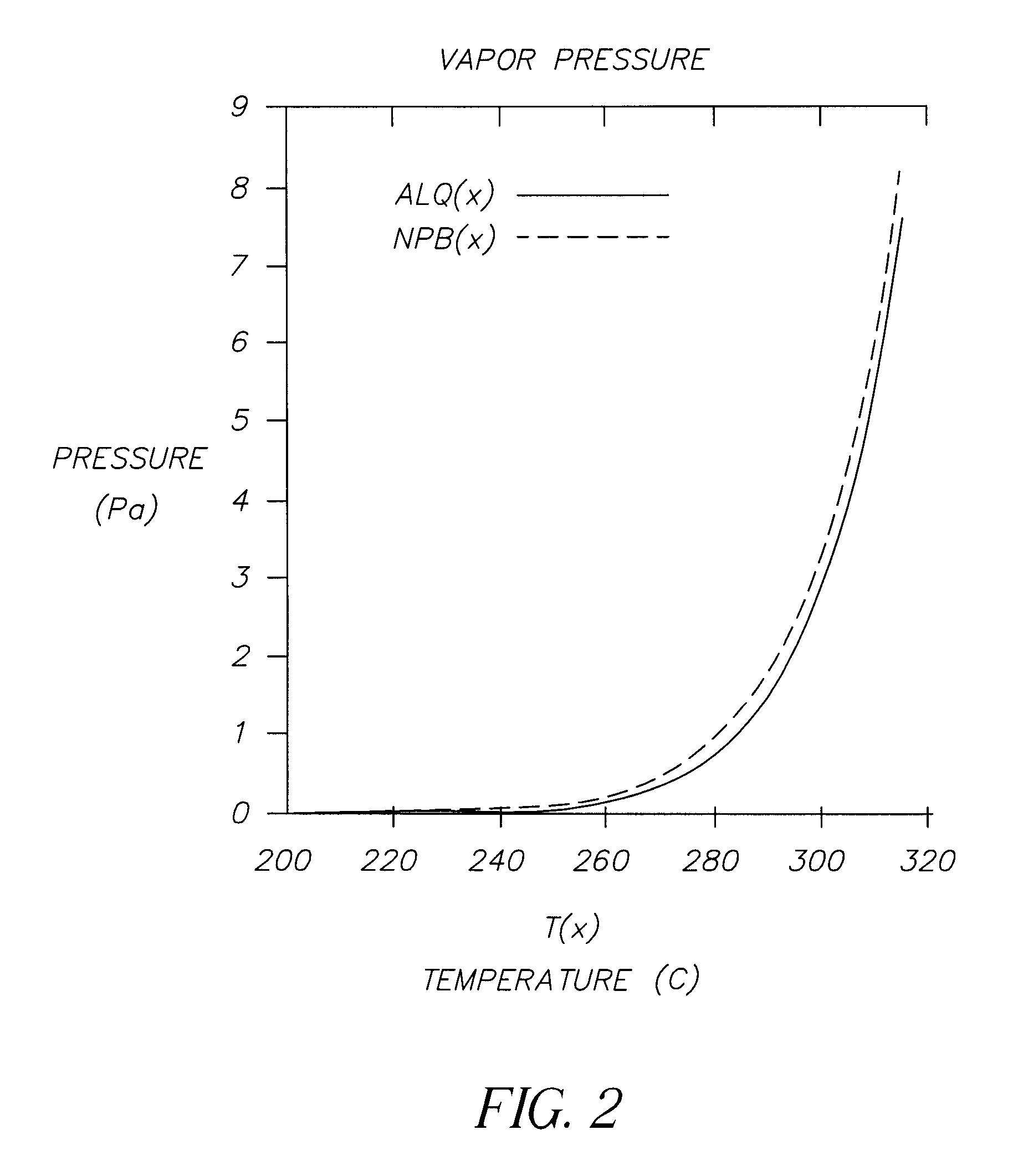

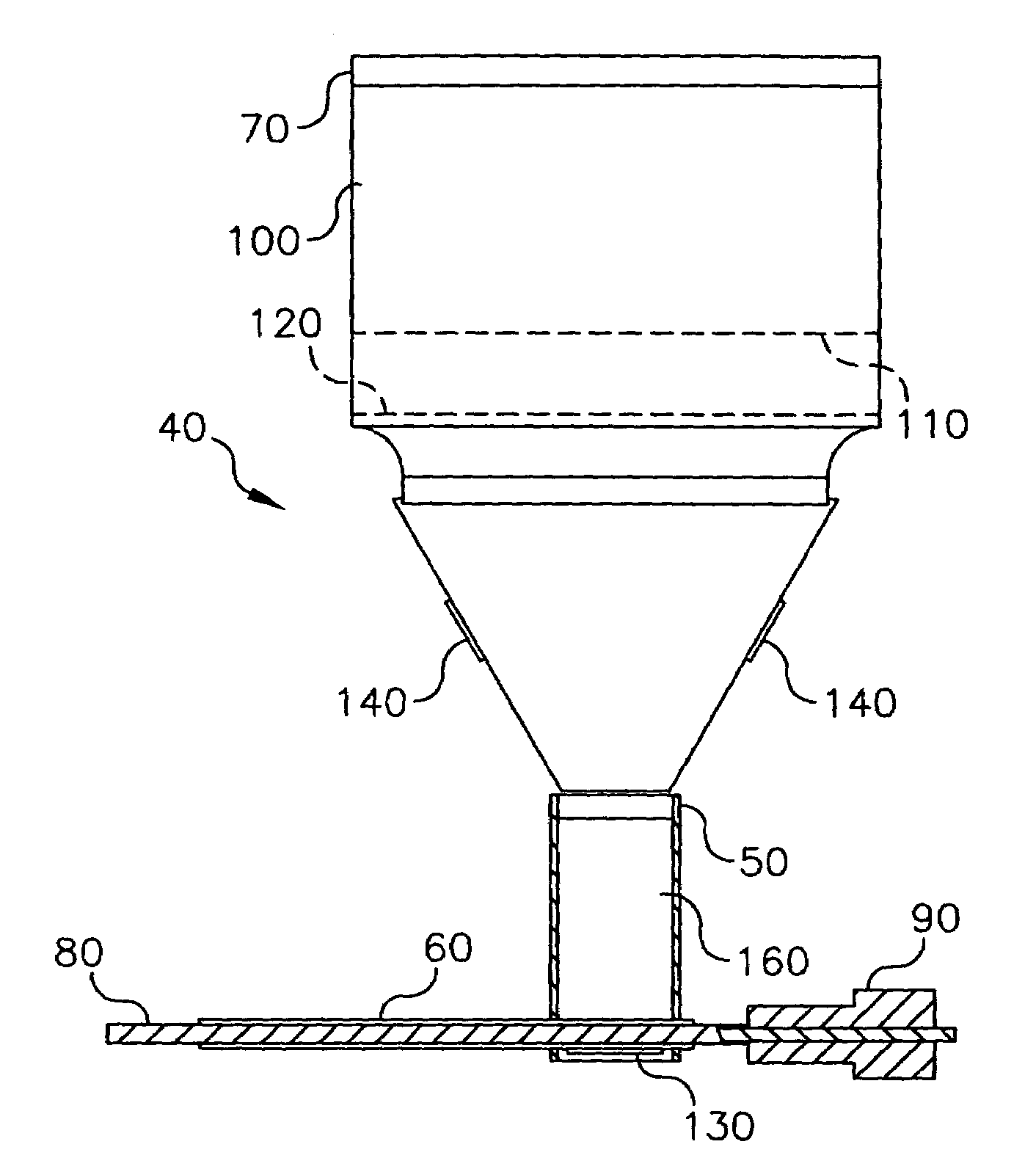

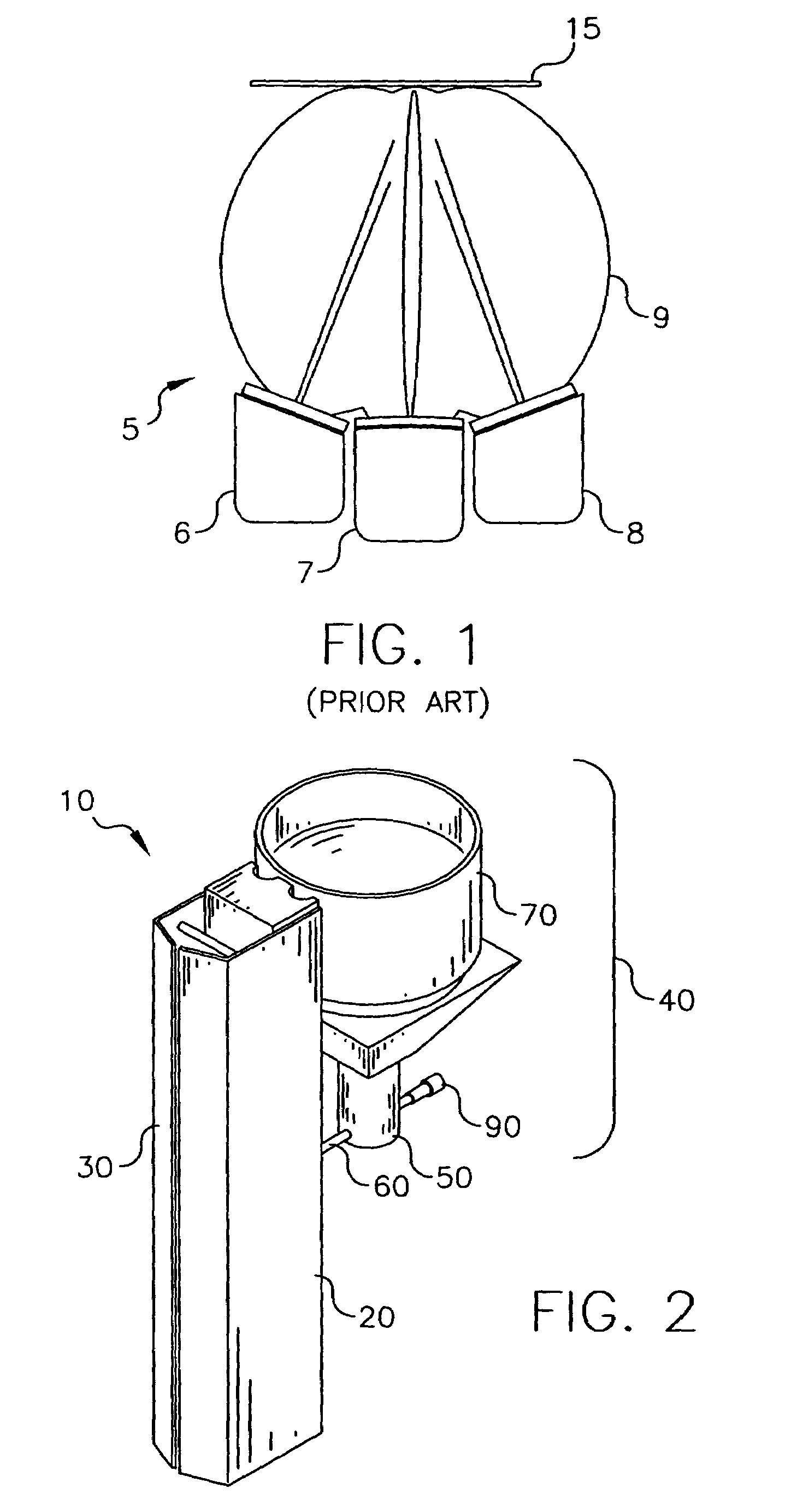

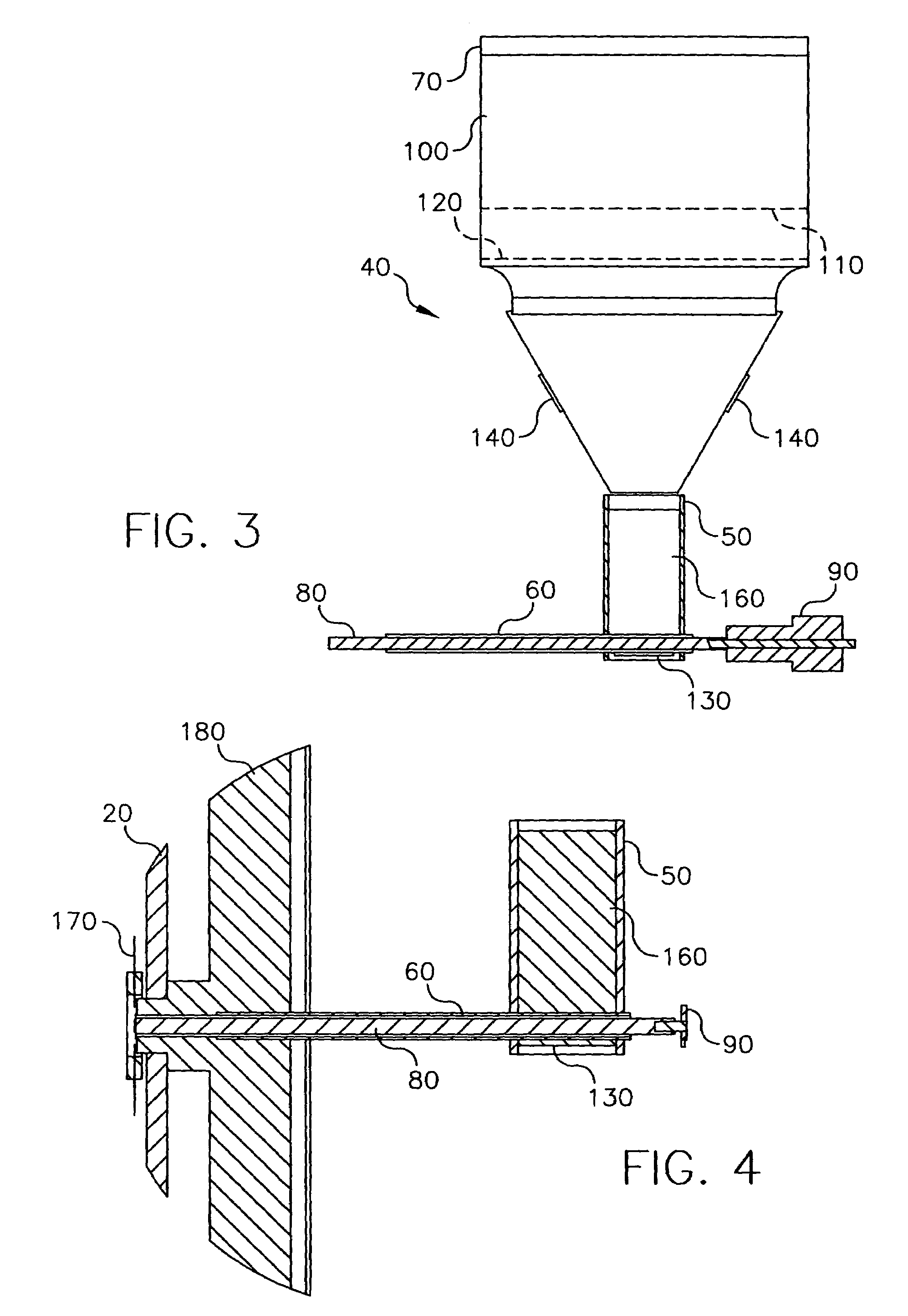

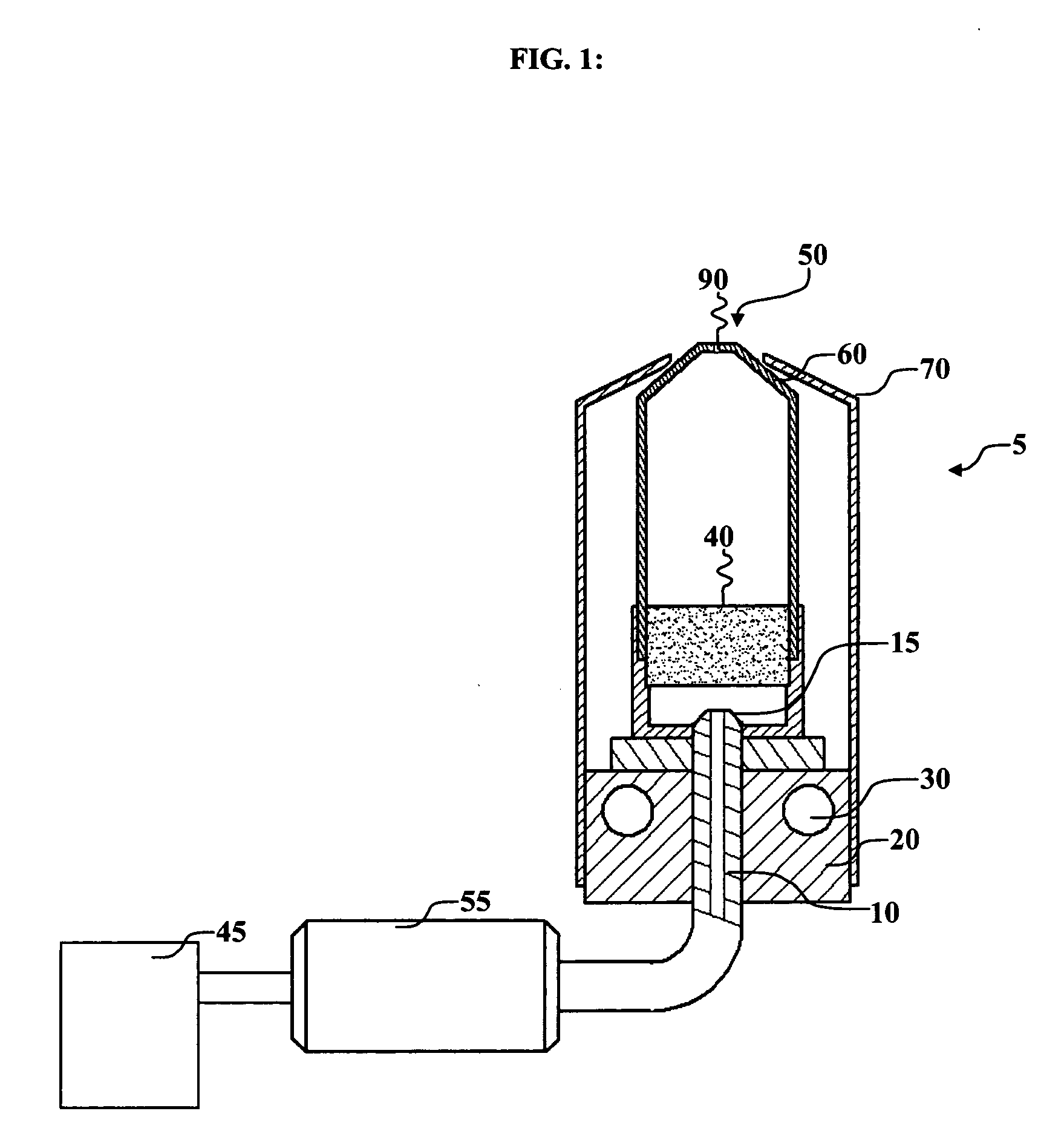

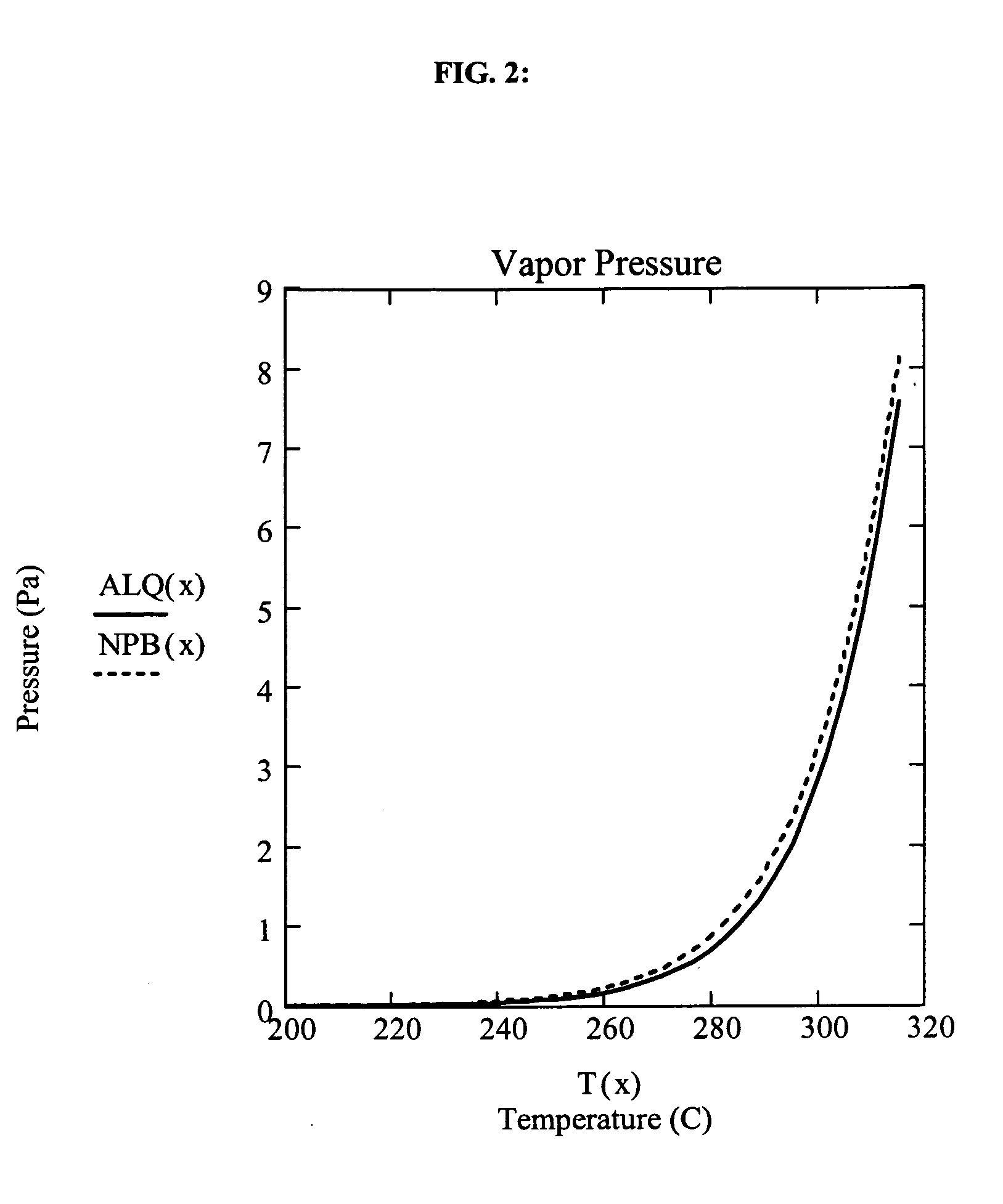

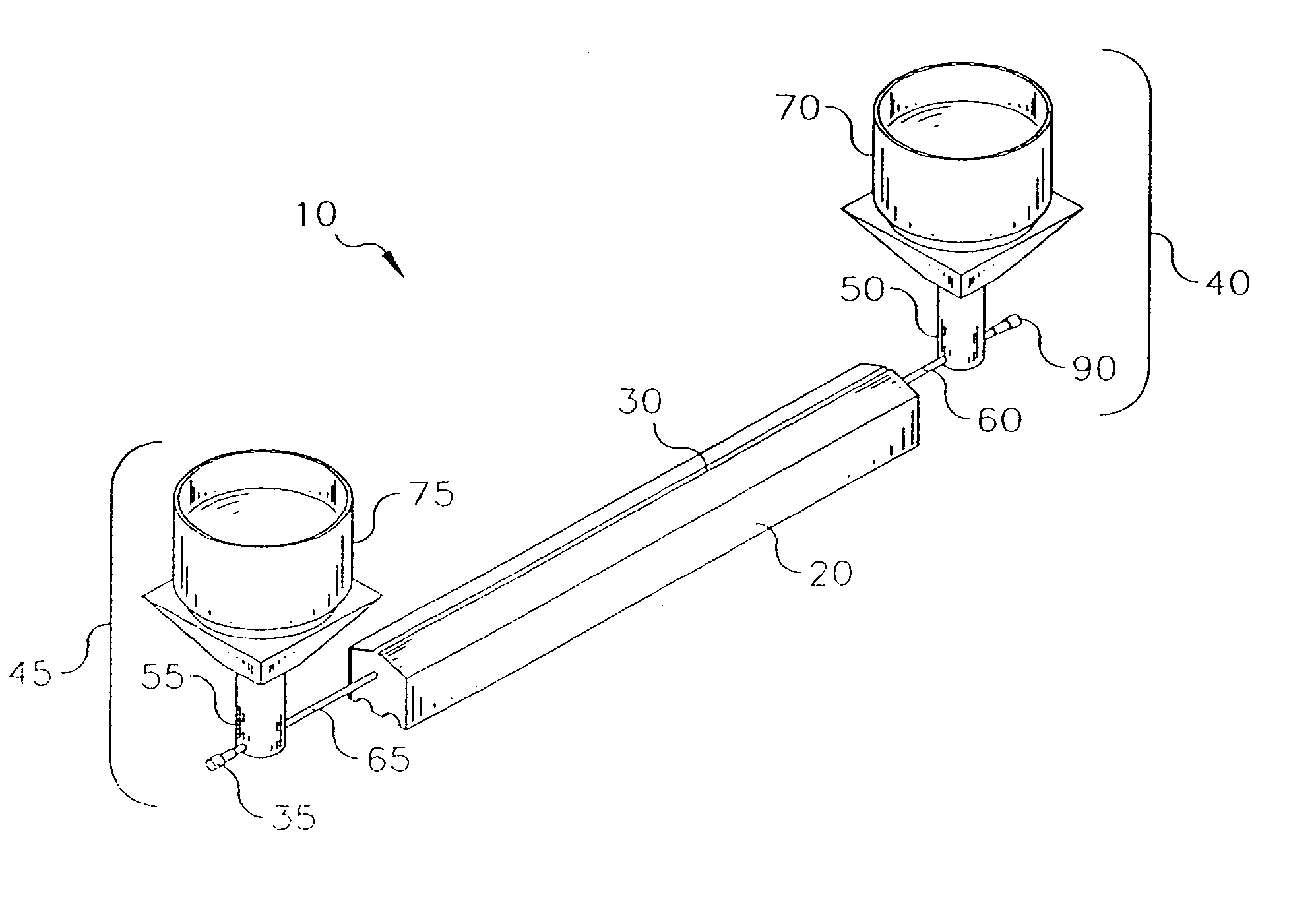

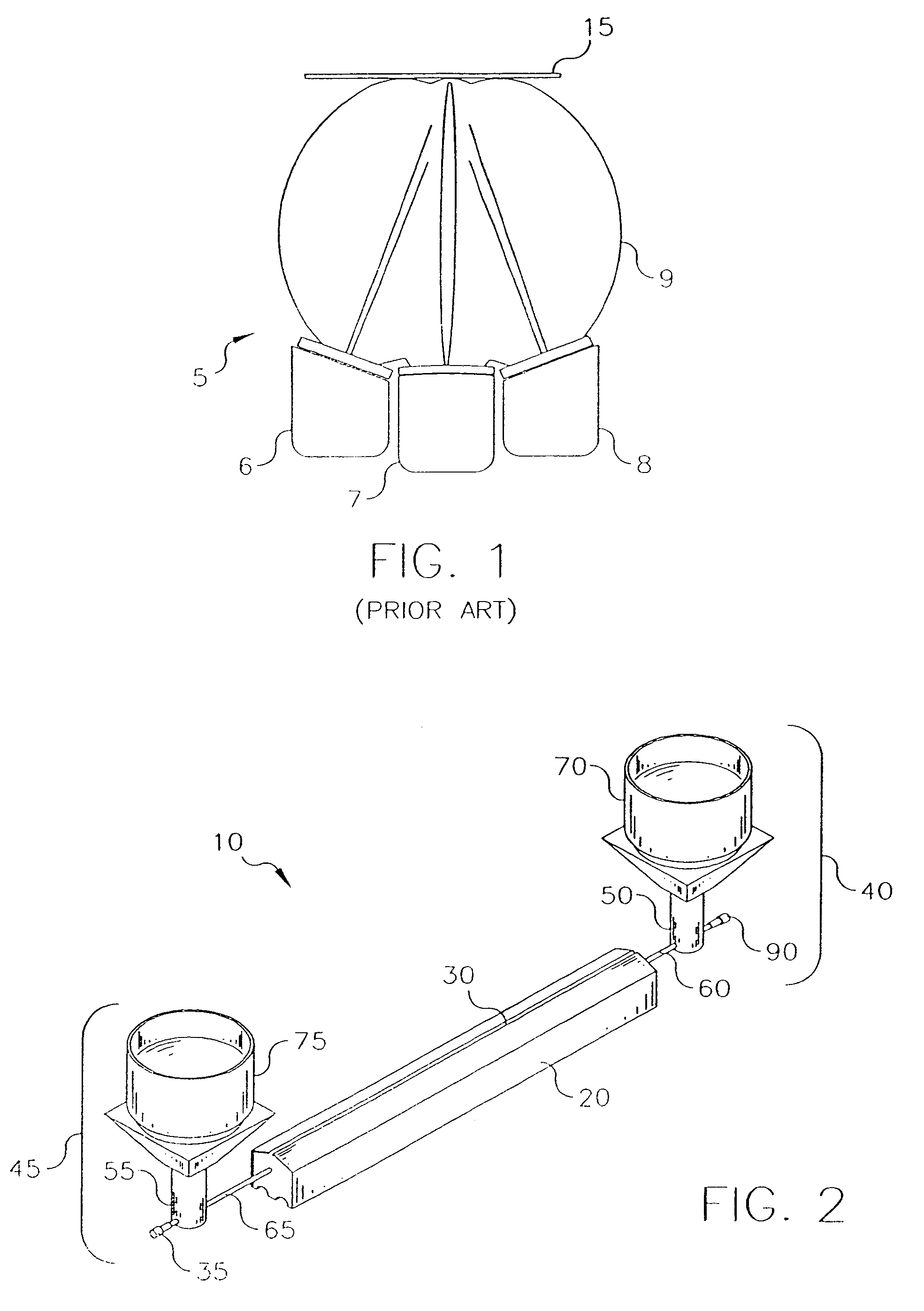

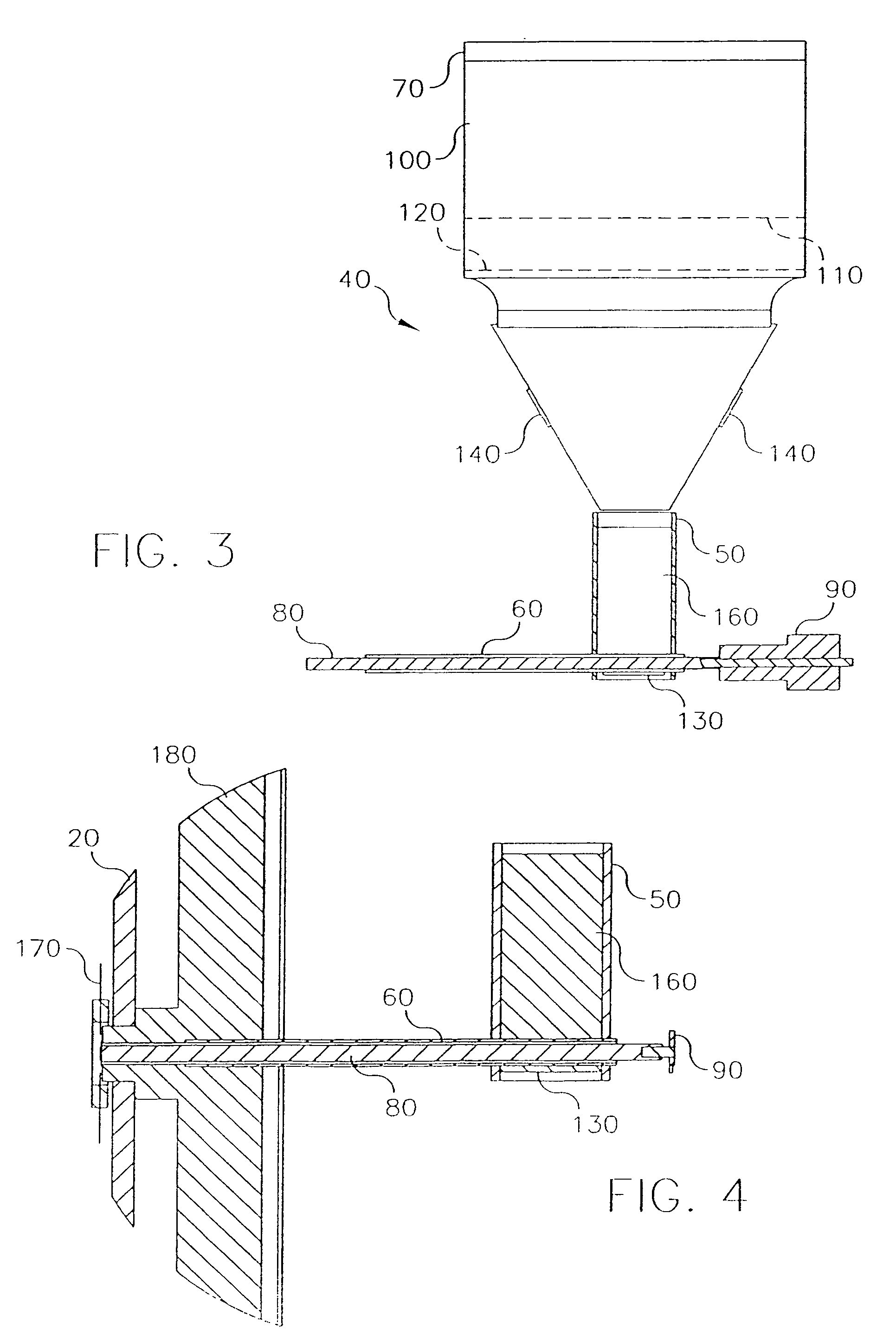

Delivering organic powder to a vaporization zone

ActiveUS20060062918A1Reduce riskSteady vaporization rateVacuum evaporation coatingSputtering coatingMaterial transferMaterials science

A method for vaporizing organic materials and condensing them onto a surface to form a layer, comprising: providing a quantity of organic material in a powdered form in a first container; fluidizing the organic material in the first container and transferring such fluidized material to an auger structure; and rotating at least a portion of the auger structure to transfer fluidized powder from the first container along a feeding path to a vaporization zone where such powder is vaporized and delivered to the substrate to form the layer.

Owner:GLOBAL OLED TECH

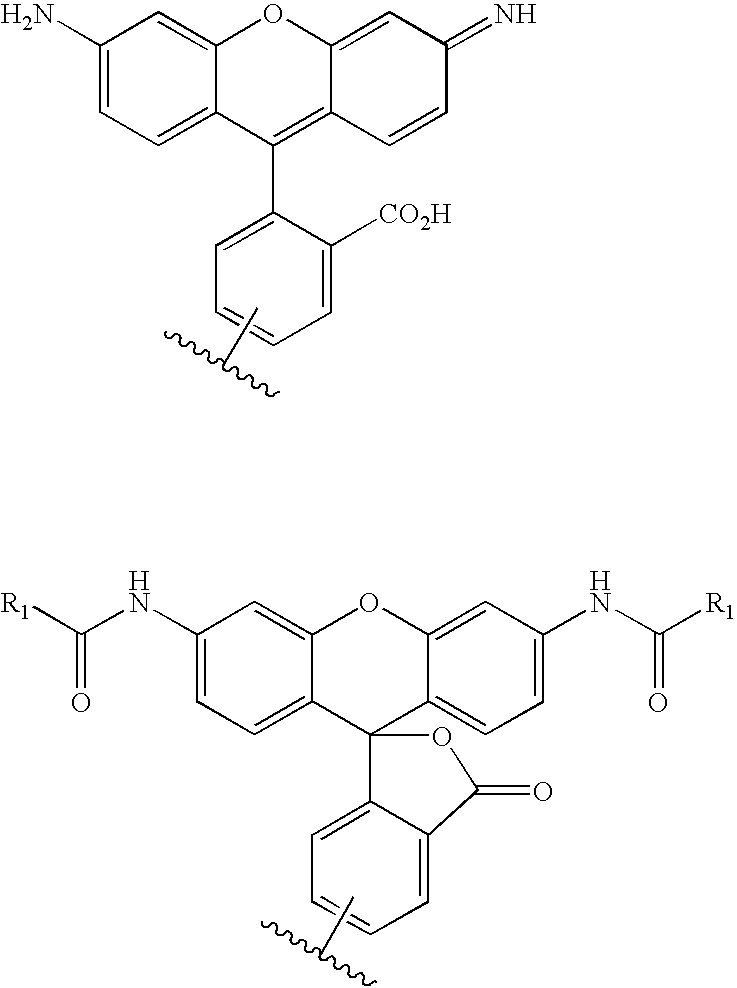

Substrates for covalent tethering to proteins

ActiveUS20050272114A1Efficient loadingLoad is outside loadMaterial nanotechnologyHydrolasesAmino acid substitutionWild type

A mutant hydrolase optionally fused to a protein of interest is provided. The mutant hydrolase is capable of forming a bond with a substrate for the corresponding nonmutant (wild-type) hydrolase which is more stable than the bond formed between the wild-type hydrolase and the substrate and has at least two amino acid substitutions relative to the wild-type hydrolase. Substrates for hydrolases comprising one or more functional groups are also provided, as well as methods of using the mutant hydrolase and the substrates of the invention. Also provided is a fusion protein capable of forming a stable bond with a substrate and cells which express the fusion protein.

Owner:PROMEGA

Delivering organic powder to a vaporization zone

ActiveUS20060062919A1Steady vaporization rateReduce riskVacuum evaporation coatingSolid-state devicesVaporizationSubstrate surface

A method for vaporizing organic material and condensing it onto a surface to form a layer, comprising: providing a quantity of first organic material in a powdered form in a first container and a quantity of second organic material in a second container spaced from the first container; fluidizing the first organic material in the first container, transferring the fluidized first organic material from the first container into a manifold, and vaporizing the first organic material in the manifold; fluidizing the second organic material in the second container, transferring the fluidized second organic material from the second container into the manifold, and vaporizing the second organic material in the manifold where the first and second vaporized organic materials are mixed; and delivering from the manifold the mixed vaporized materials to the substrate surface to form the layer.

Owner:GLOBAL OLED TECH

Method of immobilizing a protein or molecule via a mutant dehalogenase that is bound to an immobilized dehalogenase substrate and linked directly or indirectly to the protein or molecule

ActiveUS7429472B2Rapidly and efficiently loaded into and washedStable rateMaterial nanotechnologyPeptide/protein ingredientsAmino acid substitutionWild type

A mutant hydrolase optionally fused to a protein of interest is provided. The mutant hydrolase is capable of forming a bond with a substrate for the corresponding nonmutant (wild-type) hydrolase which is more stable than the bond formed between the wild-type hydrolase and the substrate and has at least two amino acid substitutions relative to the wild-type hydrolase. Substrates for hydrolases comprising one or more functional groups are also provided, as well as methods of using the mutant hydrolase and the substrates of the invention. Also provided is a fusion protein capable of forming a stable bond with a substrate and cells which express the fusion protein.

Owner:PROMEGA CORP

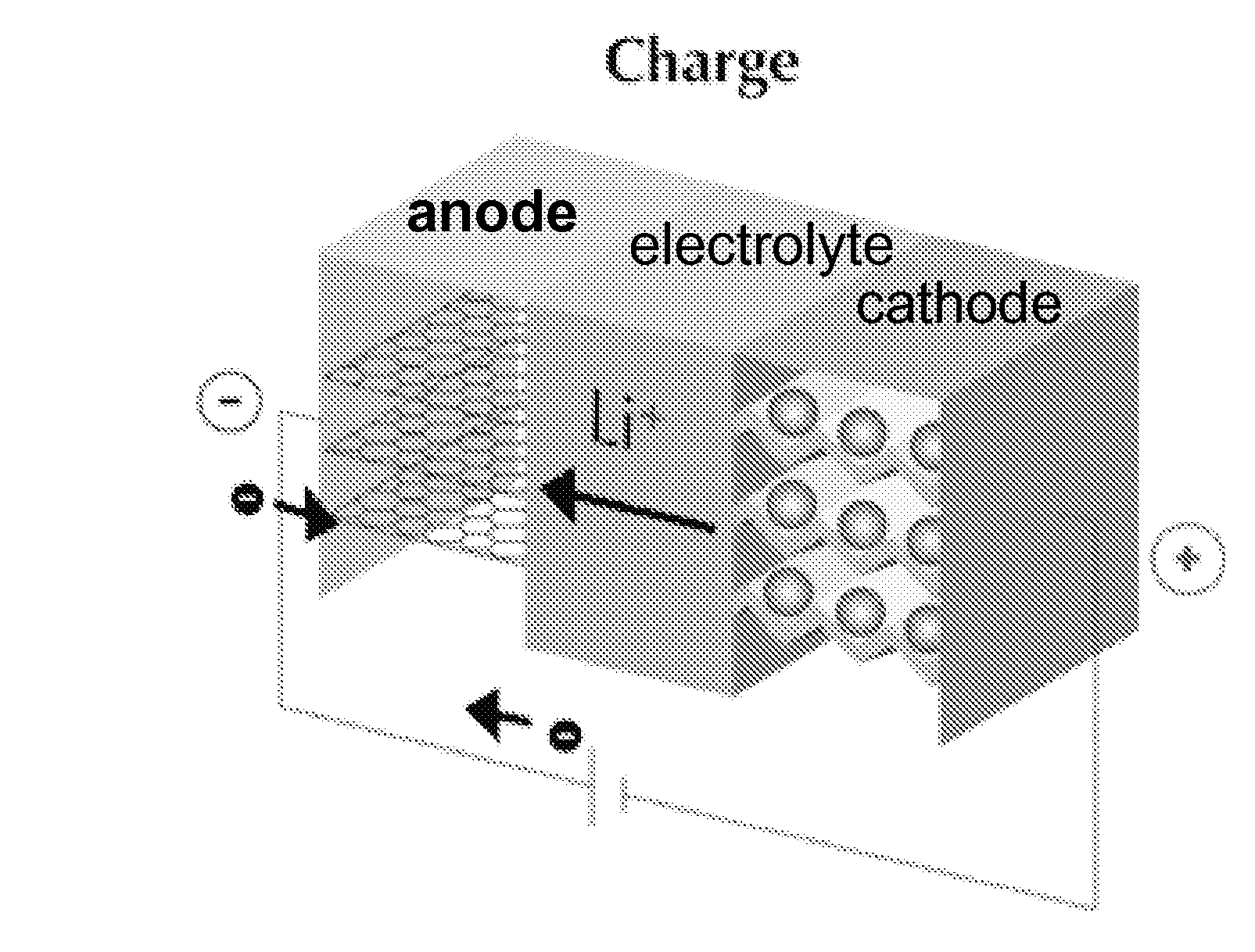

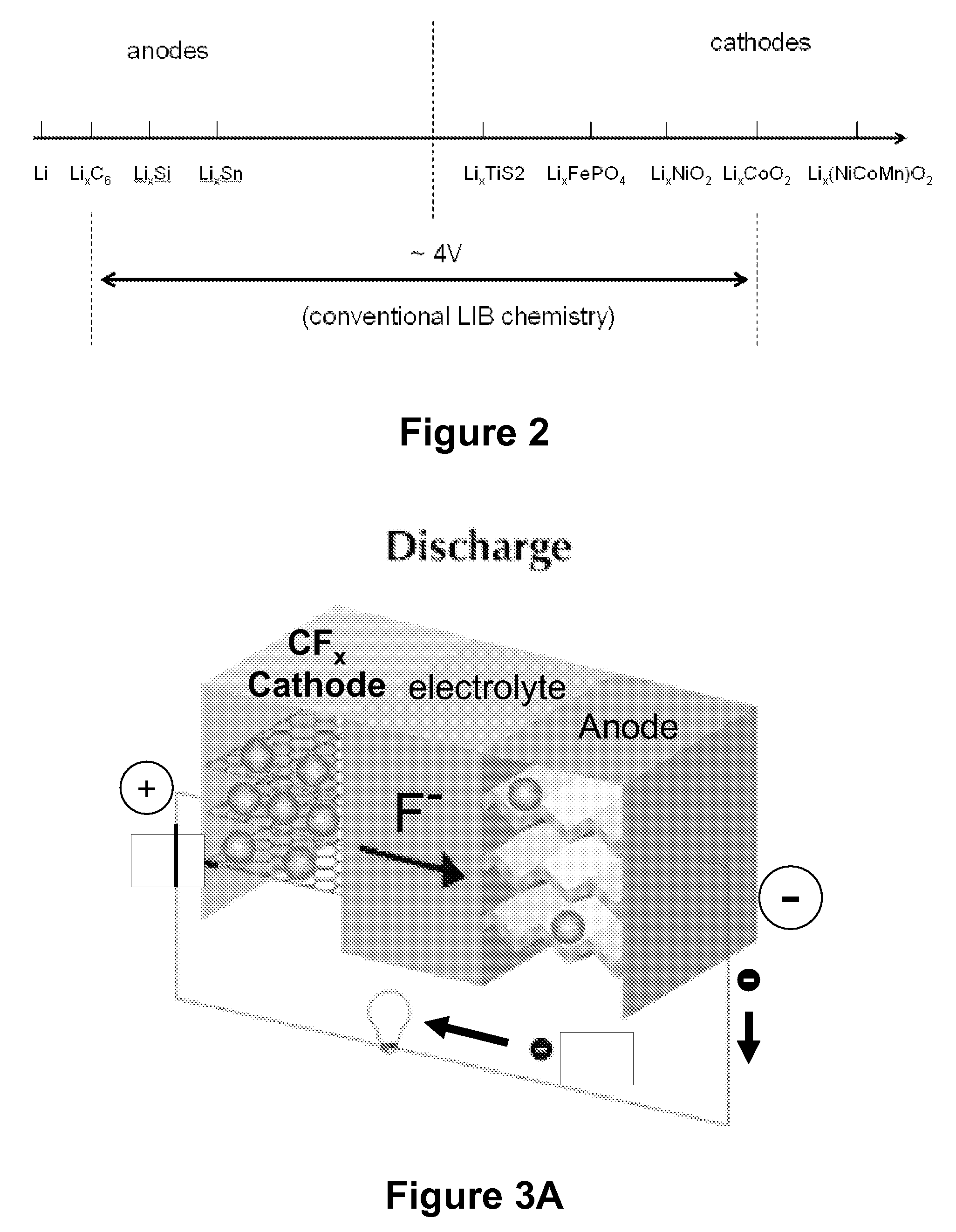

Fluoride ion electrochemical cell

ActiveUS20090029237A1Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

The present invention provides electrochemical cells capable of good electronic performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical cells of the present invention are versatile and include primary and secondary cells useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art primary lithium batteries and lithium ion secondary batteries. For example, electrochemical cells of the present invention include secondary electrochemical cells using anion charge carriers capable of accommodation by positive and negative electrodes comprising anion host materials, which entirely eliminate the need for metallic lithium or dissolved lithium ion in these systems.

Owner:CALIFORNIA INST OF TECH +1

Covalent tethering of functional groups to proteins and substrates therefor

ActiveUS7425436B2Rapidly and efficiently loaded into and washedStable rateMethine/polymethine dyesBacteriaTetheringAmino acid substitution

A mutant hydrolase optionally fused to a protein of interest is provided. The mutant hydrolase is capable of forming a bond with a substrate for the corresponding nonmutant (wild-type) hydrolase which is more stable than the bond formed between the wild-type hydrolase and the substrate and has at least two amino acid substitutions relative to the wild-type hydrolase. Substrates for hydrolases comprising one or more functional groups are also provided, as well as methods of using the mutant hydrolase and the substrates of the invention. Also provided is a fusion protein capable of forming a stable bond with a substrate and cells which express the fusion protein.

Owner:PROMEGA CORP

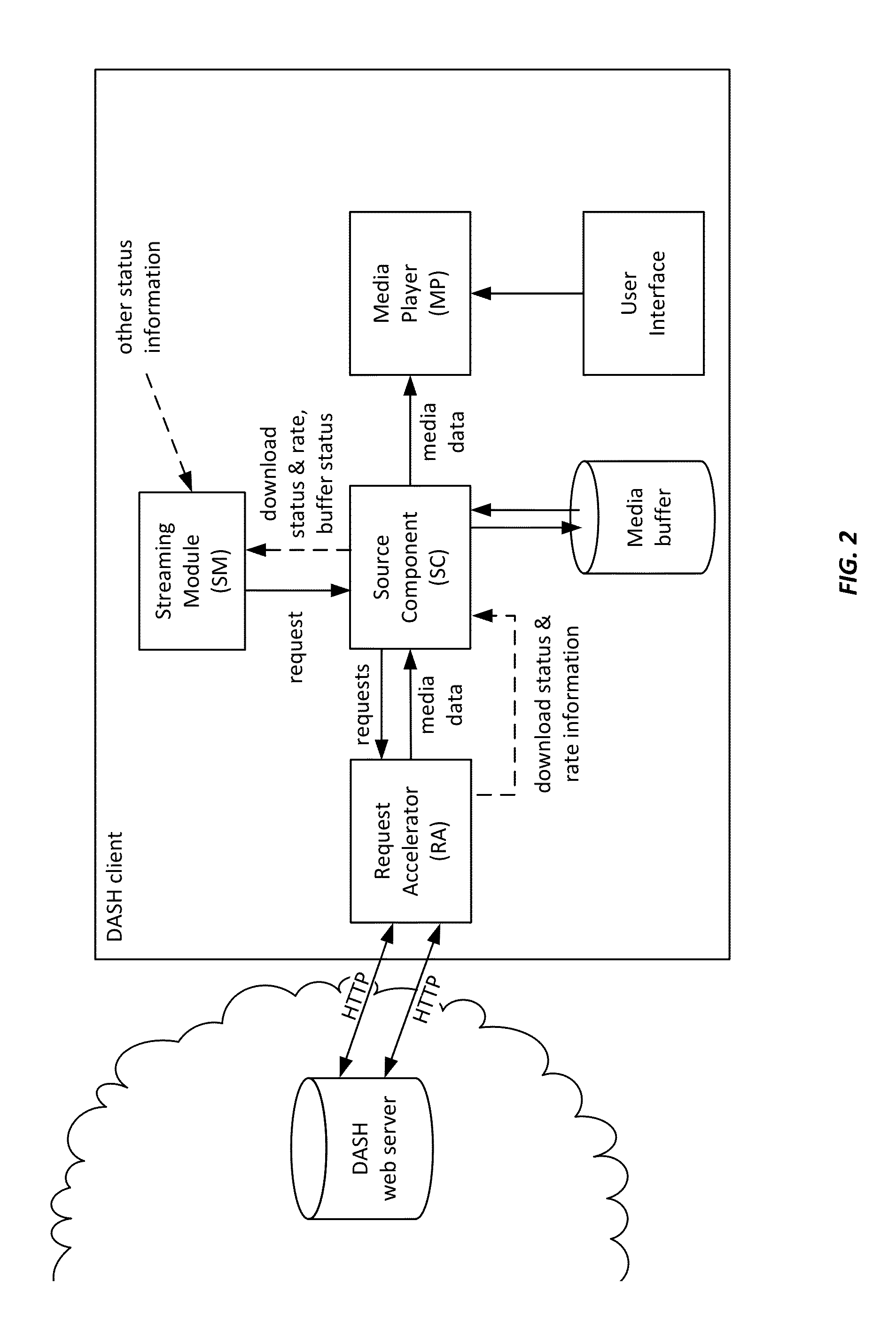

Dash client and receiver with playback rate selection

ActiveUS20130227080A1Efficiently streamedStable rateTelevision system detailsMultiple digital computer combinationsDownload rateShort Term Variability

A client device presents streaming media and includes a stream manager, a request accelerator, and a source component coupled to the stream manager and the request accelerator for determining which requests to make. A rate selection process can make rate decisions so that the buffer is filled when it is low, avoiding erratically changing rates and can choose the correct steady rate quickly. Multimedia download strategies can be used for HTTP that allow for accurate rate estimations, achieving link capacity even if network delays and packet loss rates are high, achieving timely delivery of the stream, and achieving relatively steady download rates with little short term variability. A receiver might use multiple HTTP connections, decompose media requests into smaller chunk requests, synchronize the connections using TCP flow control mechanisms, and request data in bursts. In addition, the receiver might use an HTTP pipelining process to keep the connections busy.

Owner:QUALCOMM INC

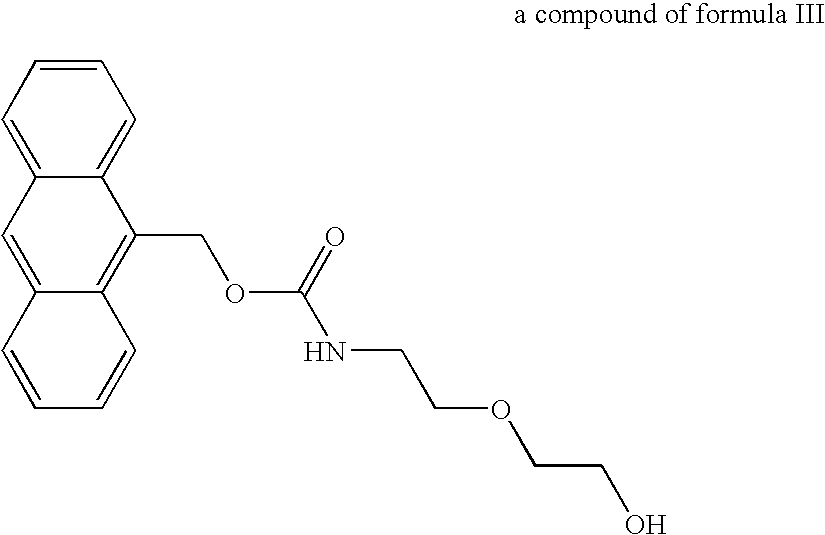

Delivering organic powder to a vaporization zone

ActiveUS7288286B2Reduce riskStable rateLiquid surface applicatorsVacuum evaporation coatingVaporizationSubstrate surface

A method for vaporizing organic material and condensing it onto a surface to form a layer, comprising: providing a quantity of first organic material in a powdered form in a first container and a quantity of second organic material in a second container spaced from the first container; fluidizing the first organic material in the first container, transferring the fluidized first organic material from the first container into a manifold, and vaporizing the first organic material in the manifold; fluidizing the second organic material in the second container, transferring the fluidized second organic material from the second container into the manifold, and vaporizing the second organic material in the manifold where the first and second vaporized organic materials are mixed; and delivering from the manifold the mixed vaporized materials to the substrate surface to form the layer.

Owner:GLOBAL OLED TECH

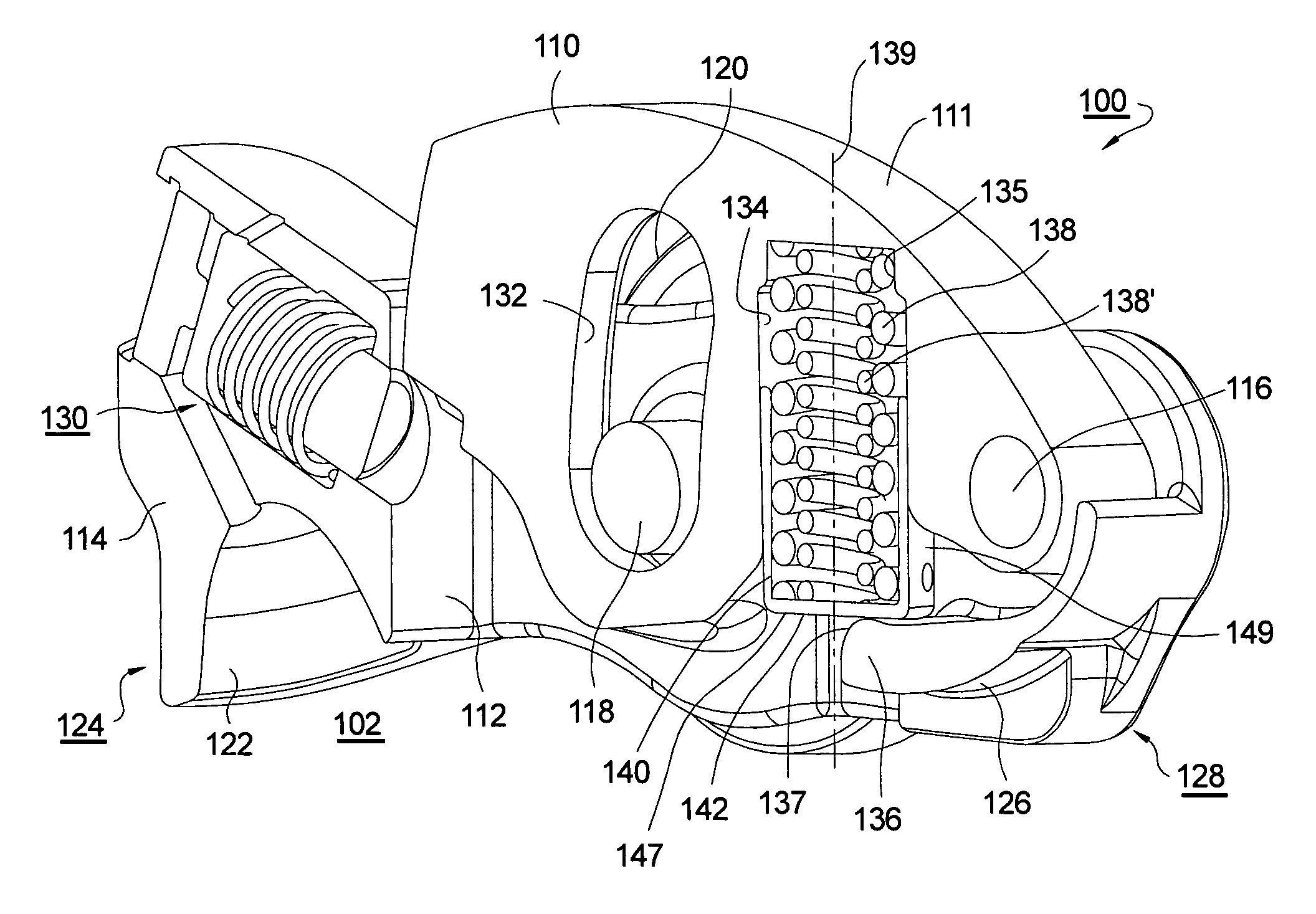

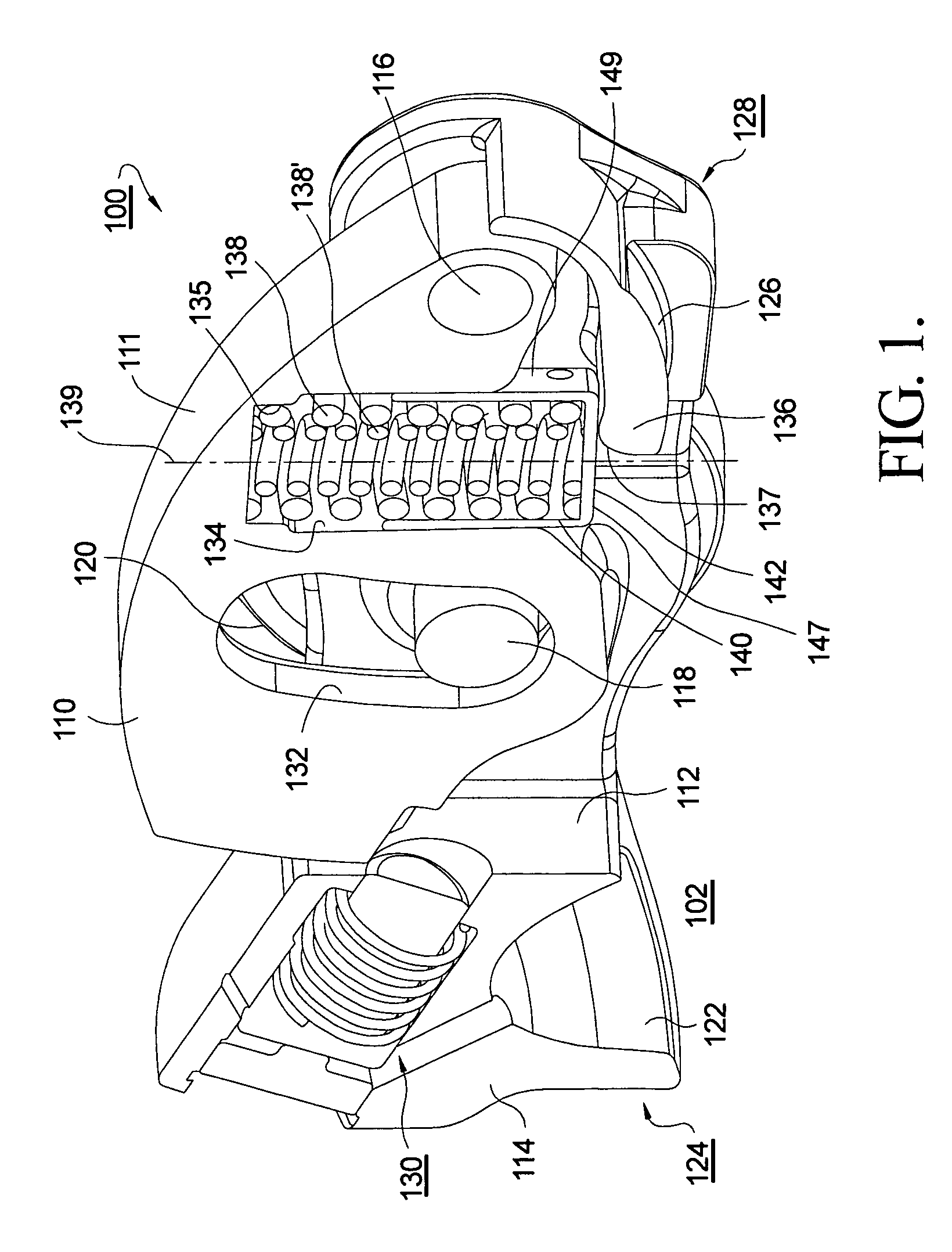

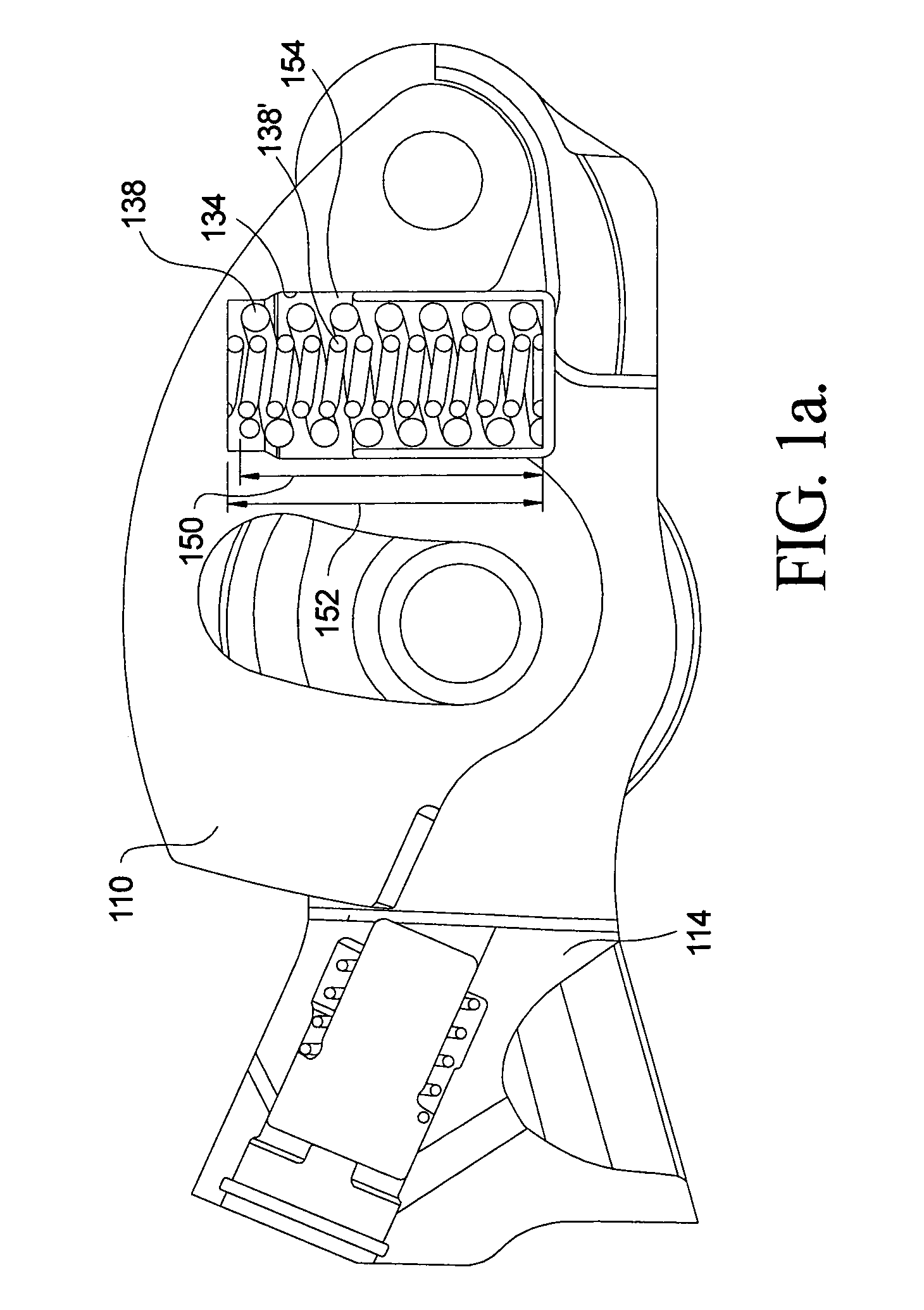

Two-step roller finger follower

A two-step roller finger follower having a high-lift follower portion that rotates relative to a low-lift follower portion about a pivot shaft, including a lost-motion compression spring disposed in a linear bore formed in the high-lift portion to exert force against an curved pad on the back side of the valve pallet of the low-lift portion. The spring is retained and guided in its bore by a spring retainer having a planar bottom for engaging the curved pad. Preferably the retainer is a cup positioned in the spring bore such that the stroke of the cup is limited, to prevent leak-down of the associated hydraulic lash adjuster. Driving the spring by a linear-acting retainer in a linear bore causes the spring to be compressed linearly, resulting in a highly stable and predictable spring rate.

Owner:DELPHI TECH IP LTD

Vaporizing fluidized organic materials

A method for vaporizing organic materials onto a surface, to form a film includes providing a quantity of organic material in a fluidized powdered form; metering the powdered organic material and directing a stream of such fluidized powder onto a first member; heating the first member so that as the stream of fluidized powder is vaporized; collecting the vaporized organic material in a manifold; and providing a second member formed with at least one aperture in communication with the manifold that permits the vaporized organic material to be directed onto the surface to form a film.

Owner:GLOBAL OLED TECH

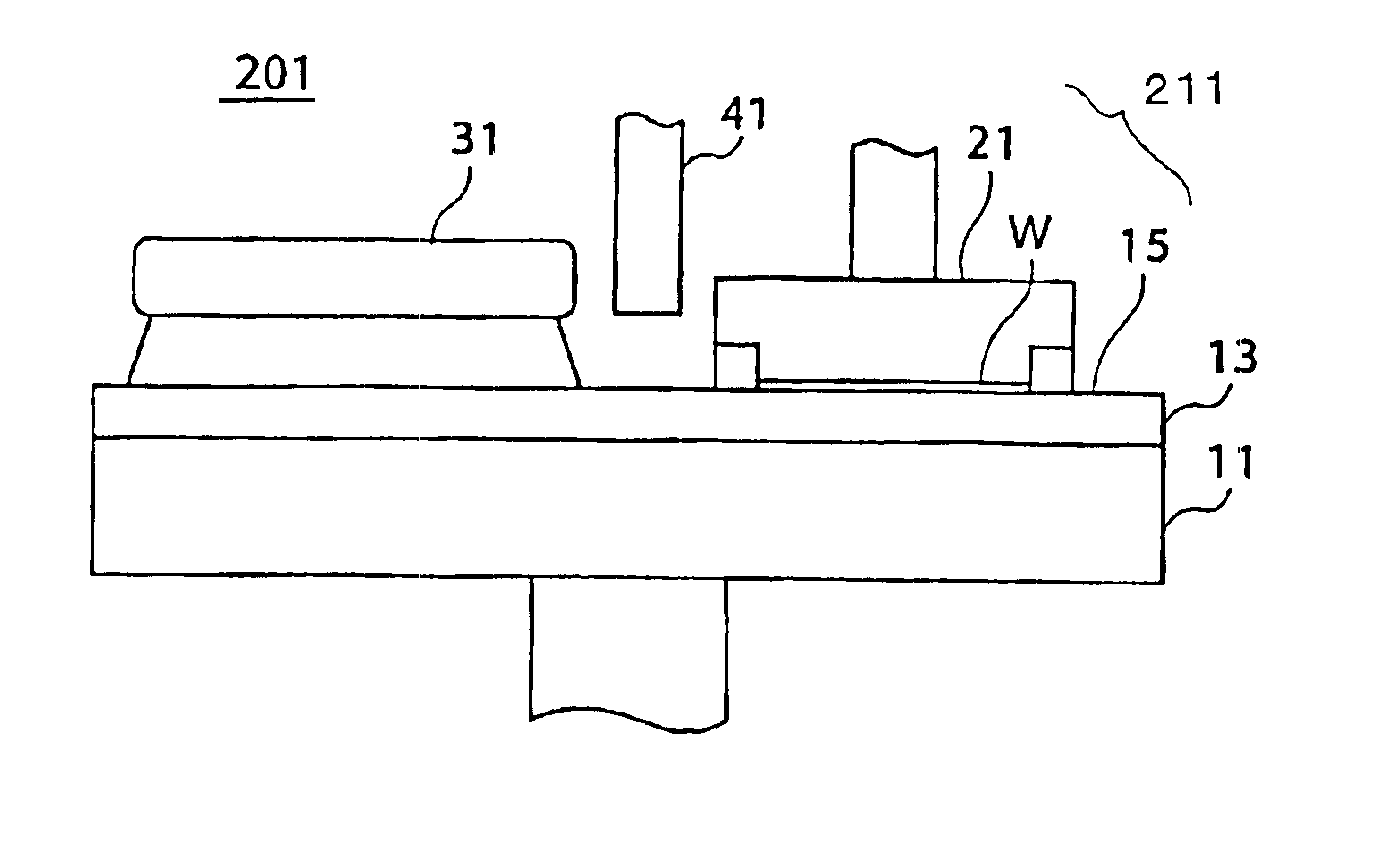

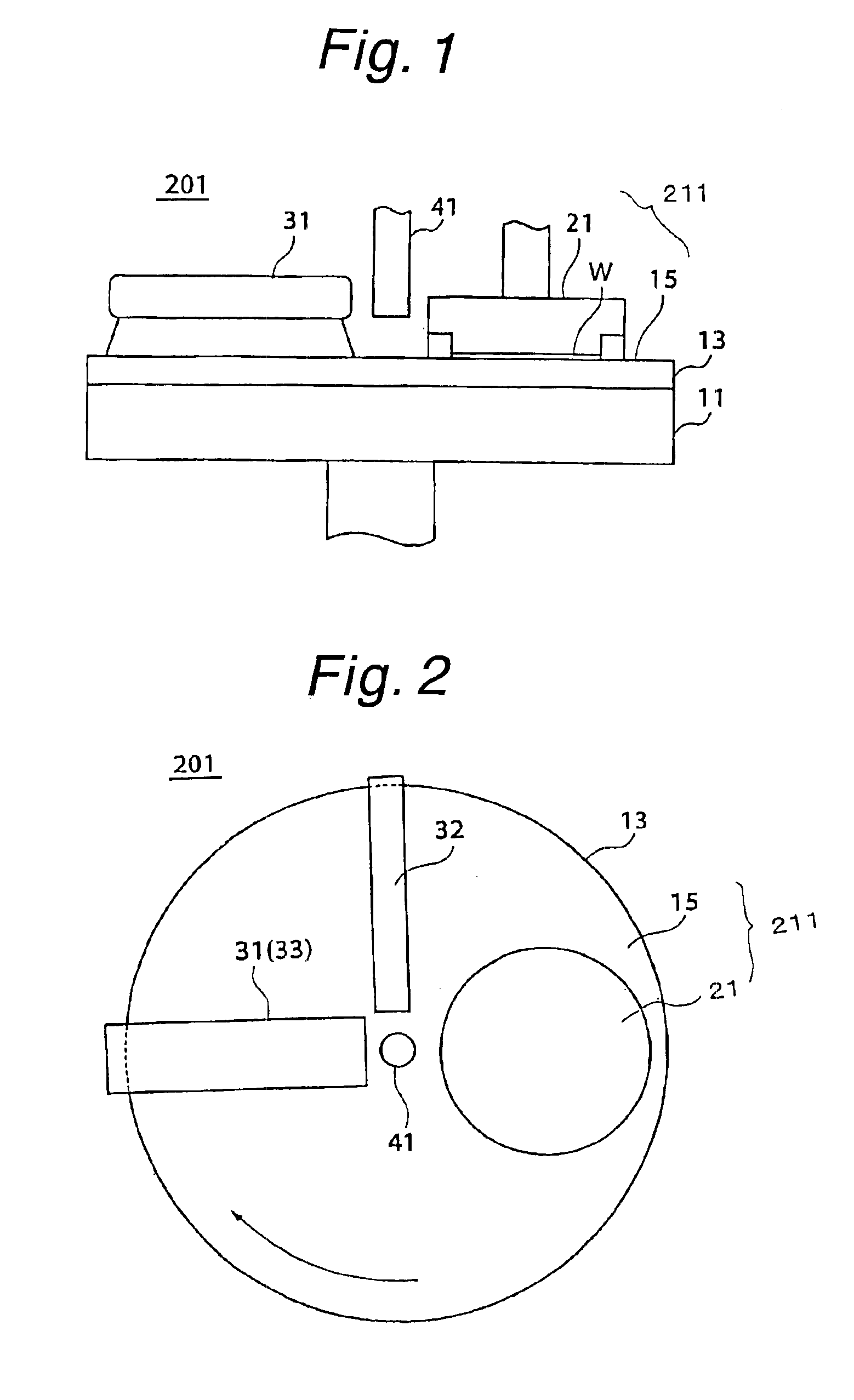

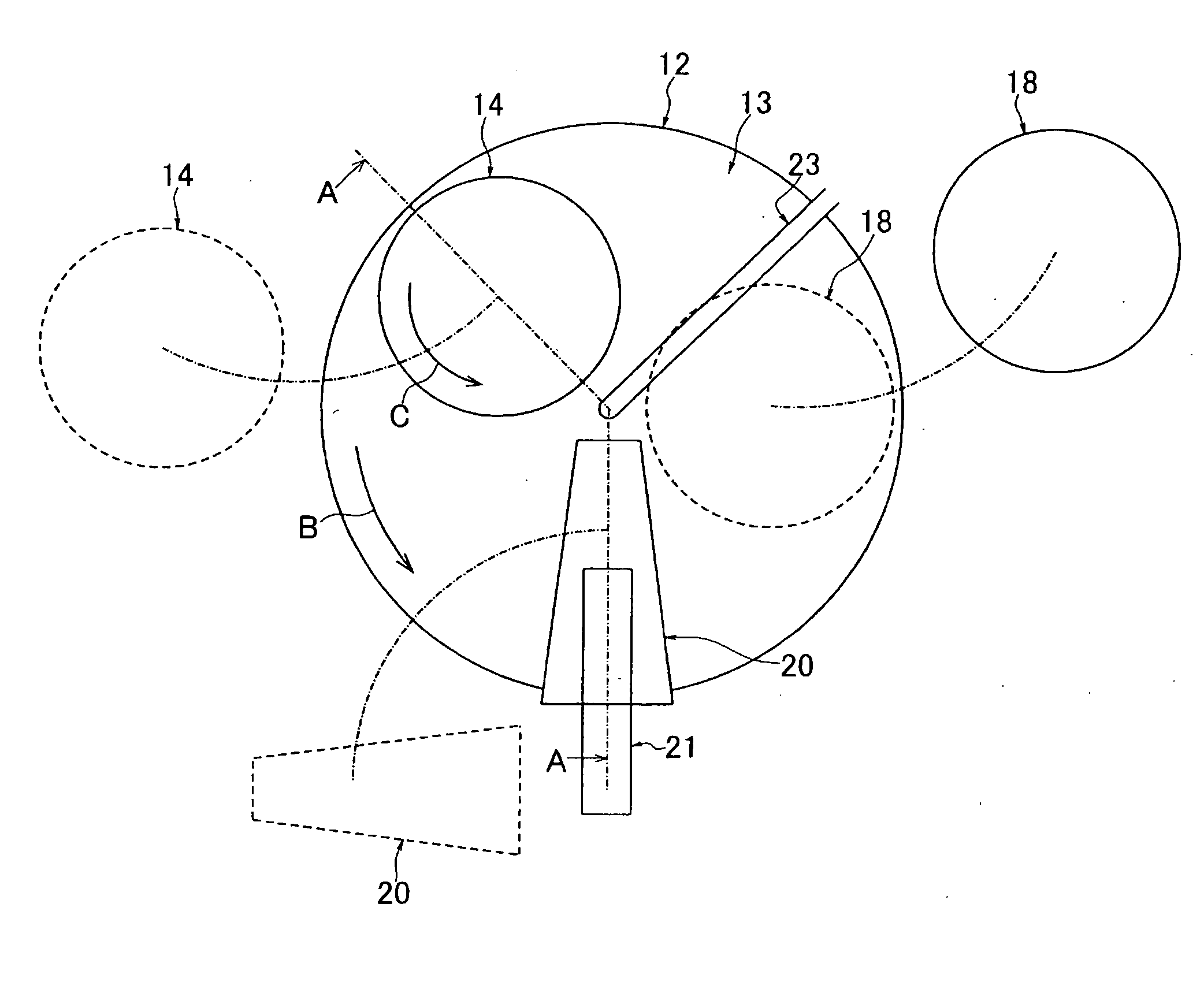

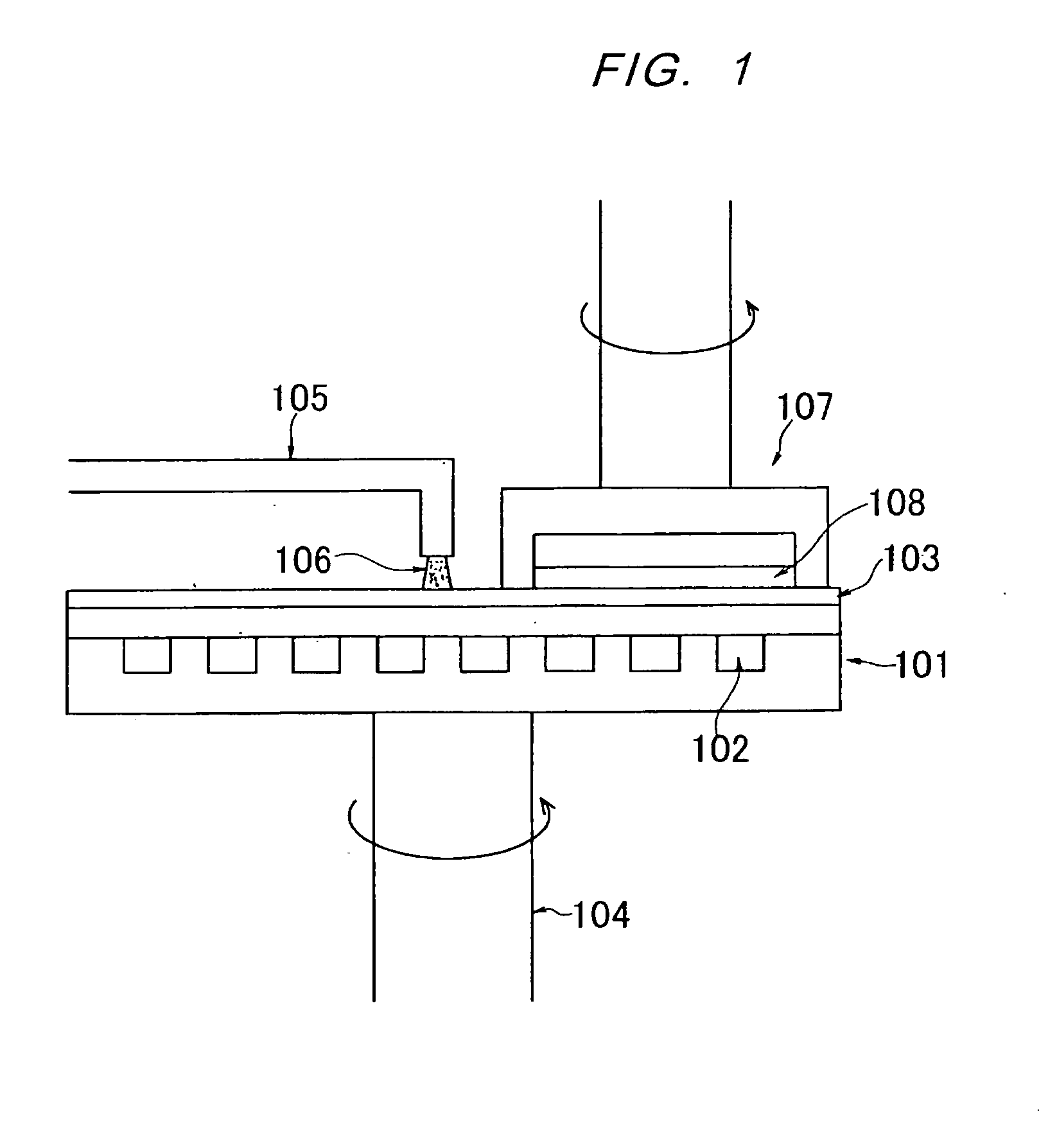

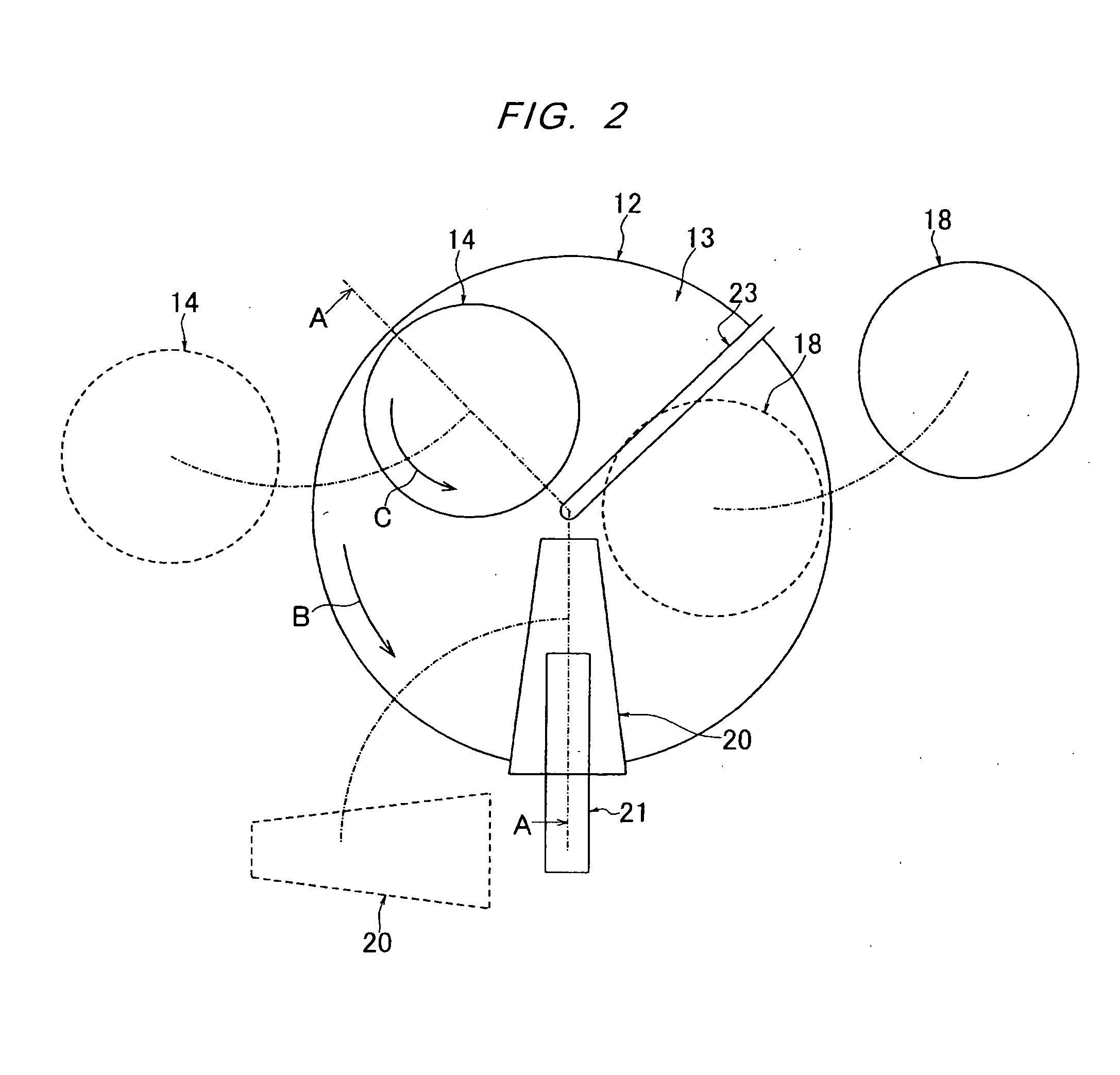

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

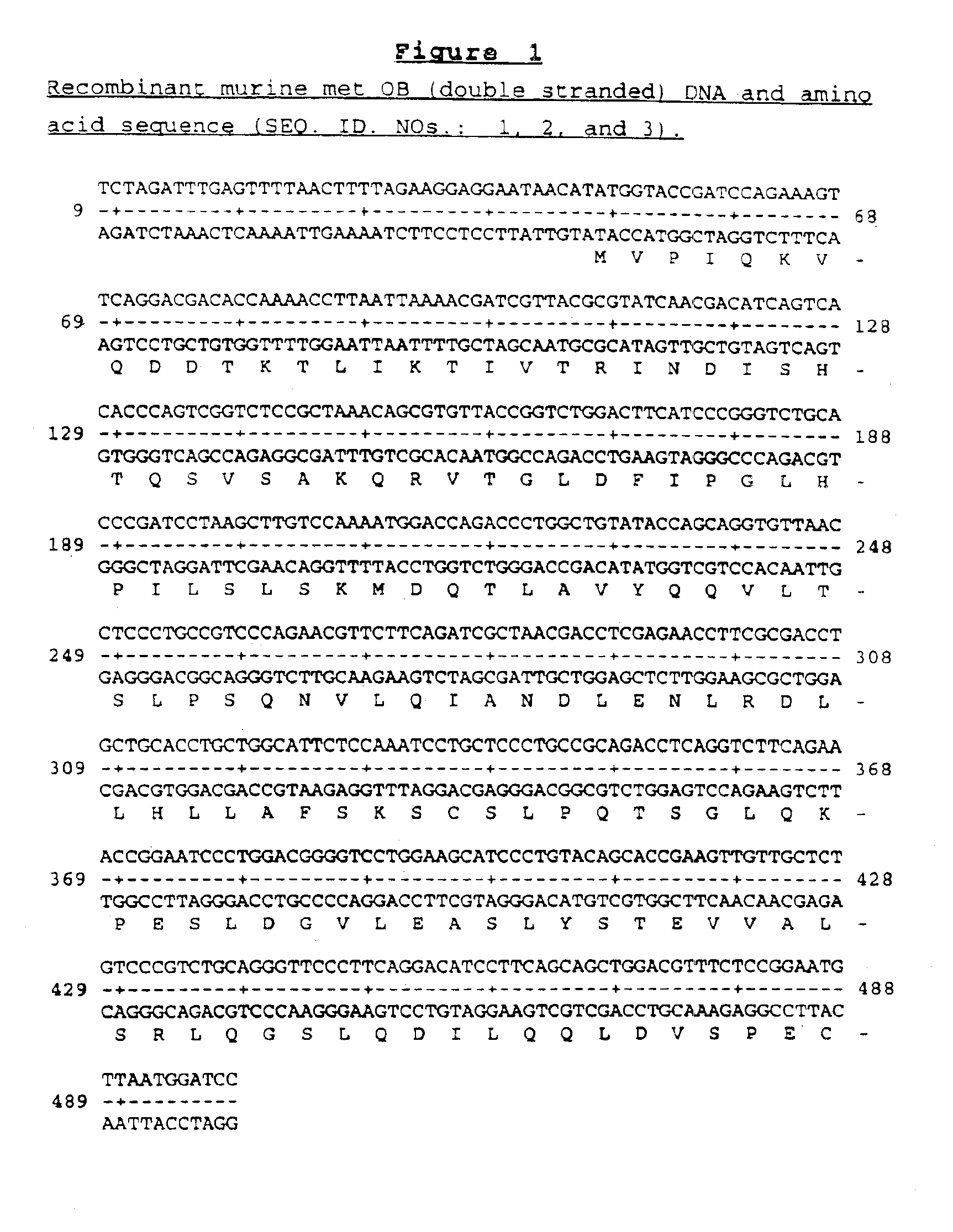

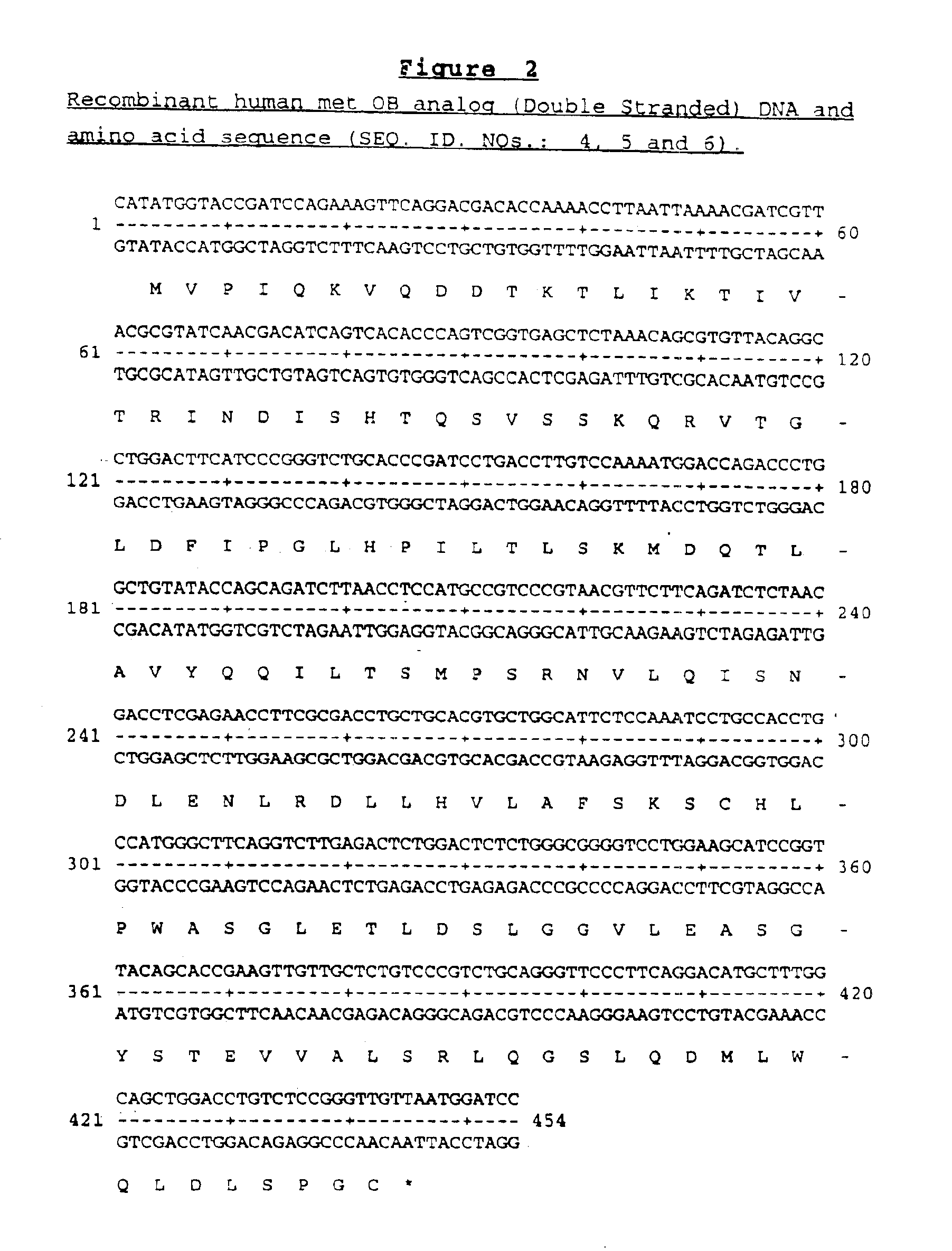

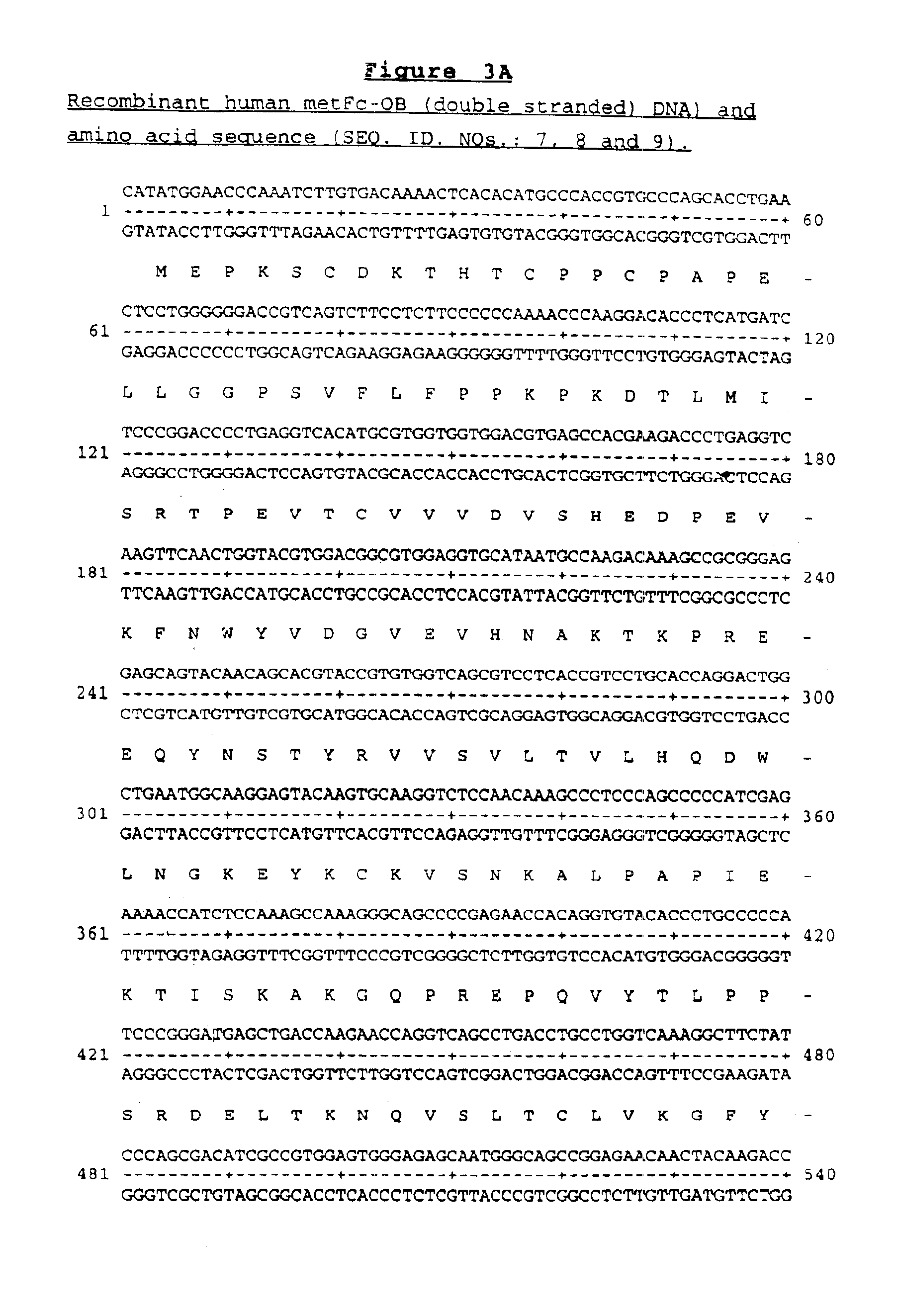

OB fusion protein compositions and methods

InactiveUS6936439B2Stability advantageStable rateObesity gene productsBacteriaImmunoglobulin regionOb Protein

Owner:AMGEN INC

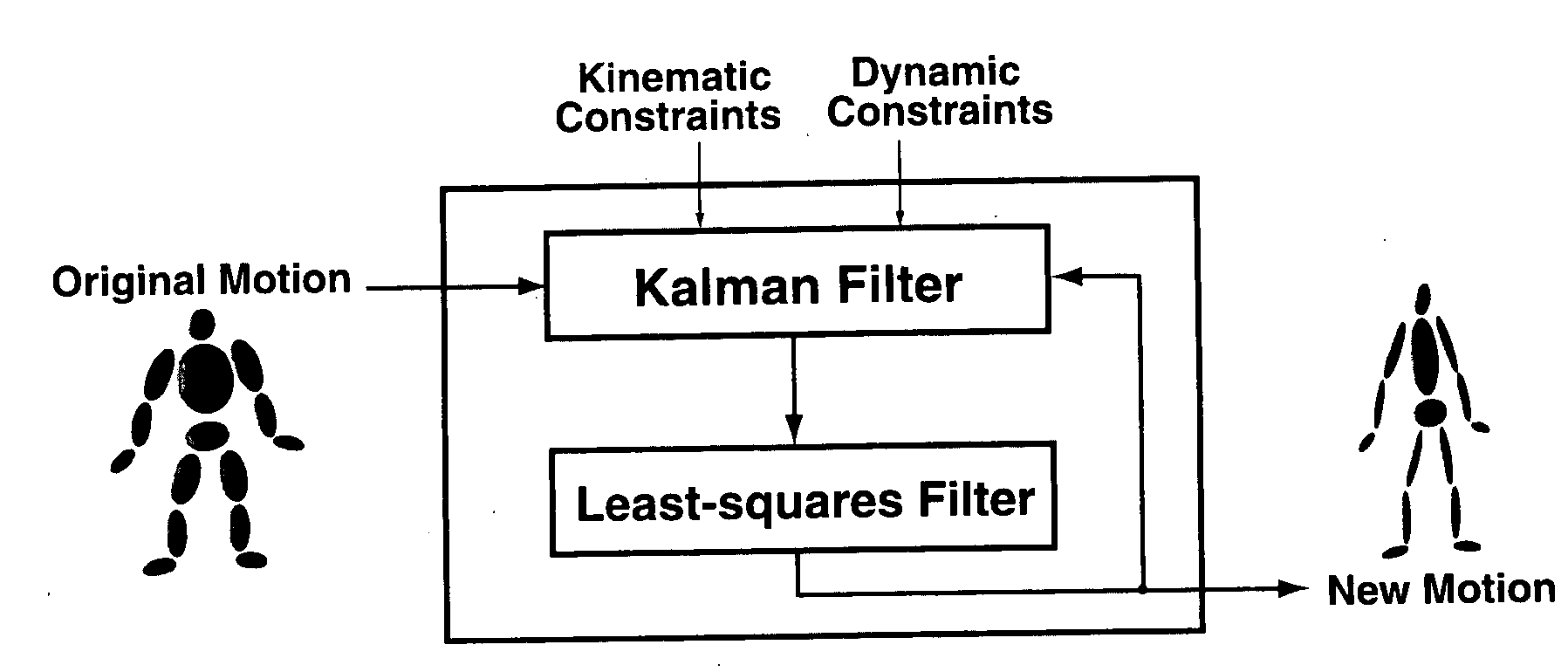

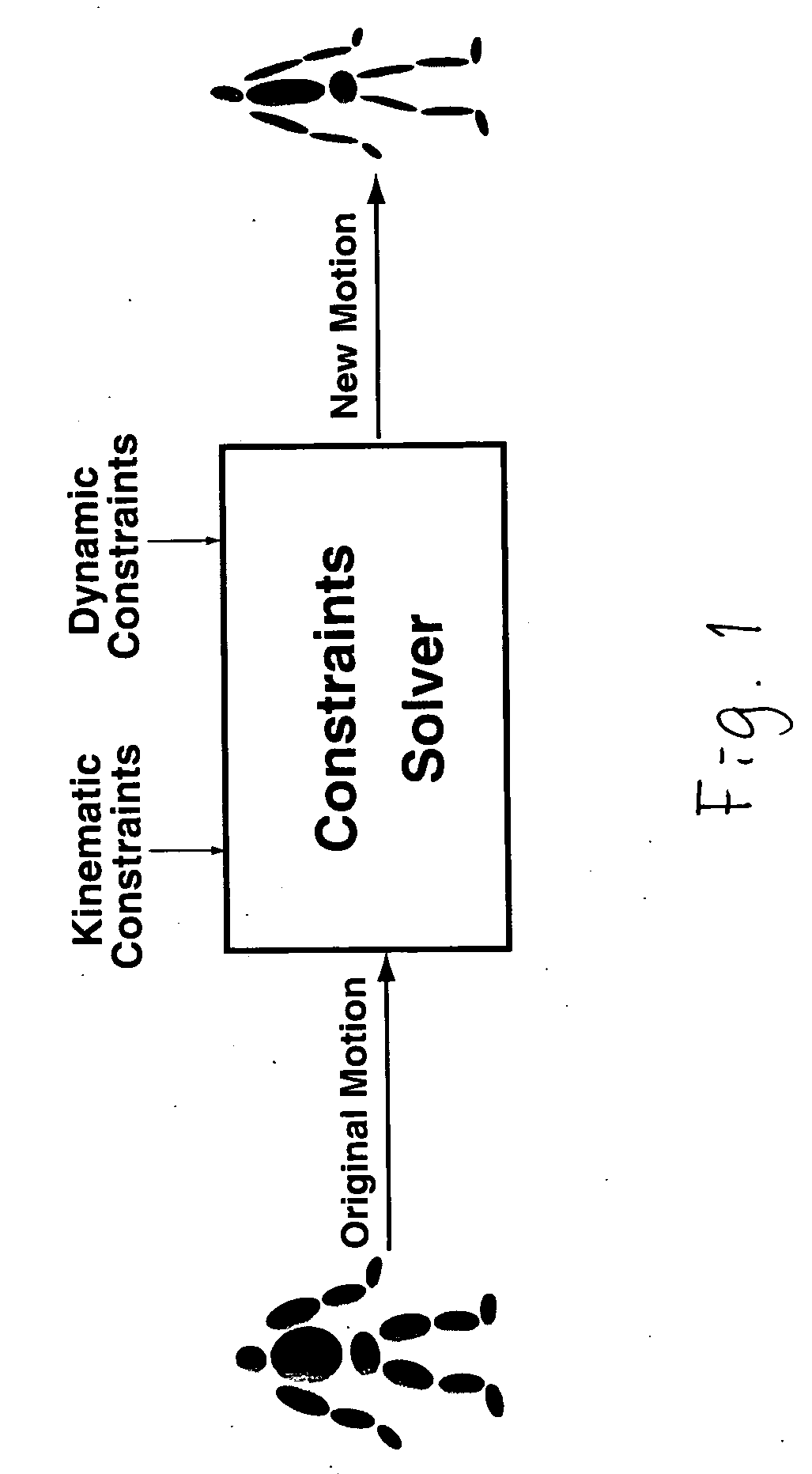

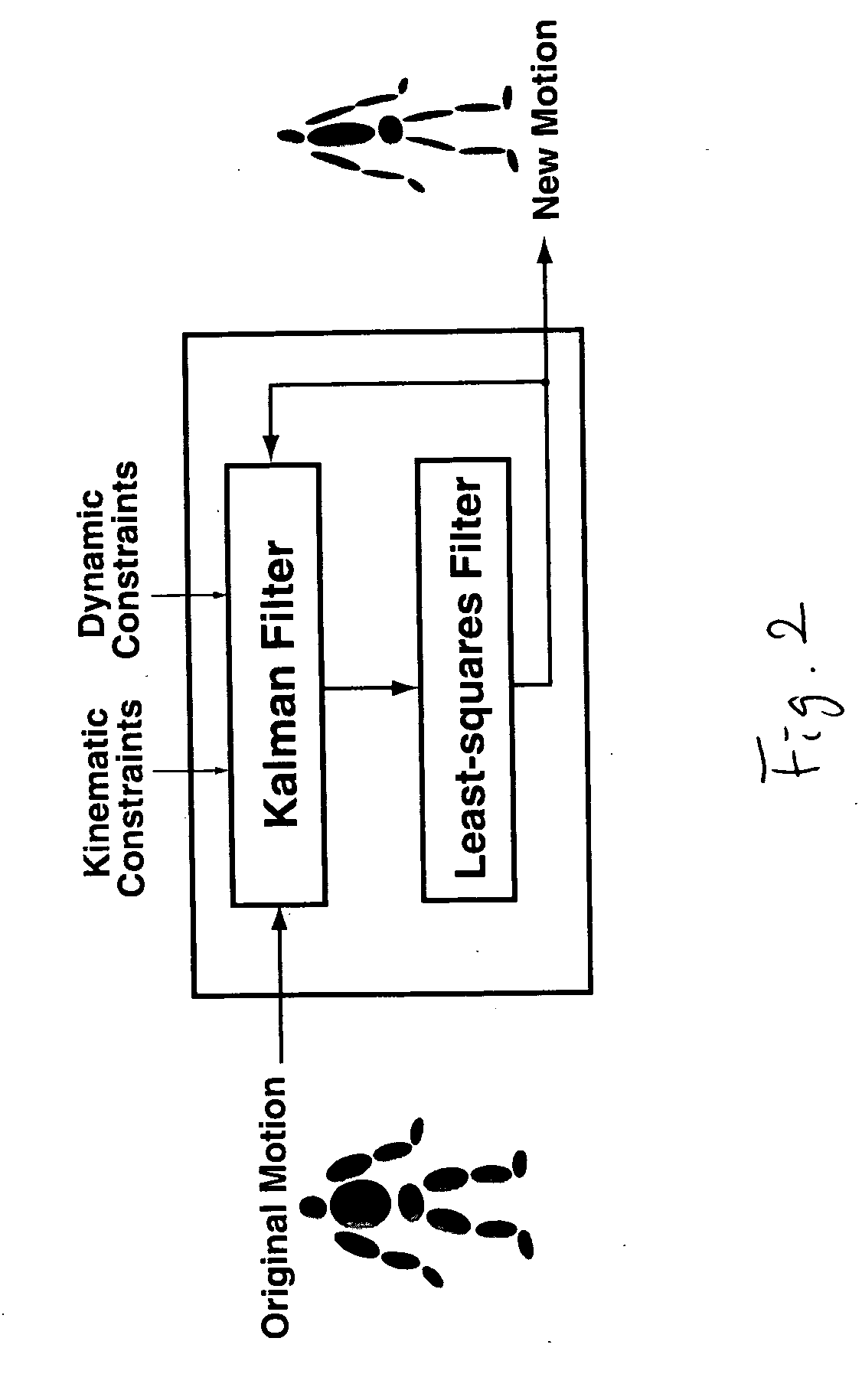

Physically based motion retargeting filter

InactiveUS20060139355A1Stable interactive rateStable rateAnimation3D-image renderingKaiman filterKinematics

A method for editing motion of a character includes steps of a) providing an input motion of the character sequentially along with a set of kinematic and dynamic constraints, wherein the input motion is provided by a captured or animated motion; b) applying a series of plurality of unscented Kalman filters for solving the contraints; c) processing the output from the unscented Kalman filters with a least-squares filter for rectifying the output; and d) producing a stream of output motion frames at a stable interactive rate. The steps are applied to each frame of the input motion The method may further include a step of controlling the behavior of the filters by tuning parameters and a step of providing a rough sketch for the filters to produce a desired motion. The Kalman filter includes per-frame Kalman filter. The least-squares filter is applied only to recently processed frames

Owner:SEOUL NAT UNIV R&DB FOUND

Delivering organic powder to a vaporization zone

ActiveUS7288285B2Reduce riskStable rateVacuum evaporation coatingSputtering coatingVaporizationMaterial transfer

A method for vaporizing organic materials and condensing them onto a surface to form a layer, comprising: providing a quantity of organic material in a powdered form in a first container; fluidizing the organic material in the first container and transferring such fluidized material to an auger structure; and rotating at least a portion of the auger structure to transfer fluidized powder from the first container along a feeding path to a vaporization zone where such powder is vaporized and delivered to the substrate to form the layer.

Owner:GLOBAL OLED TECH

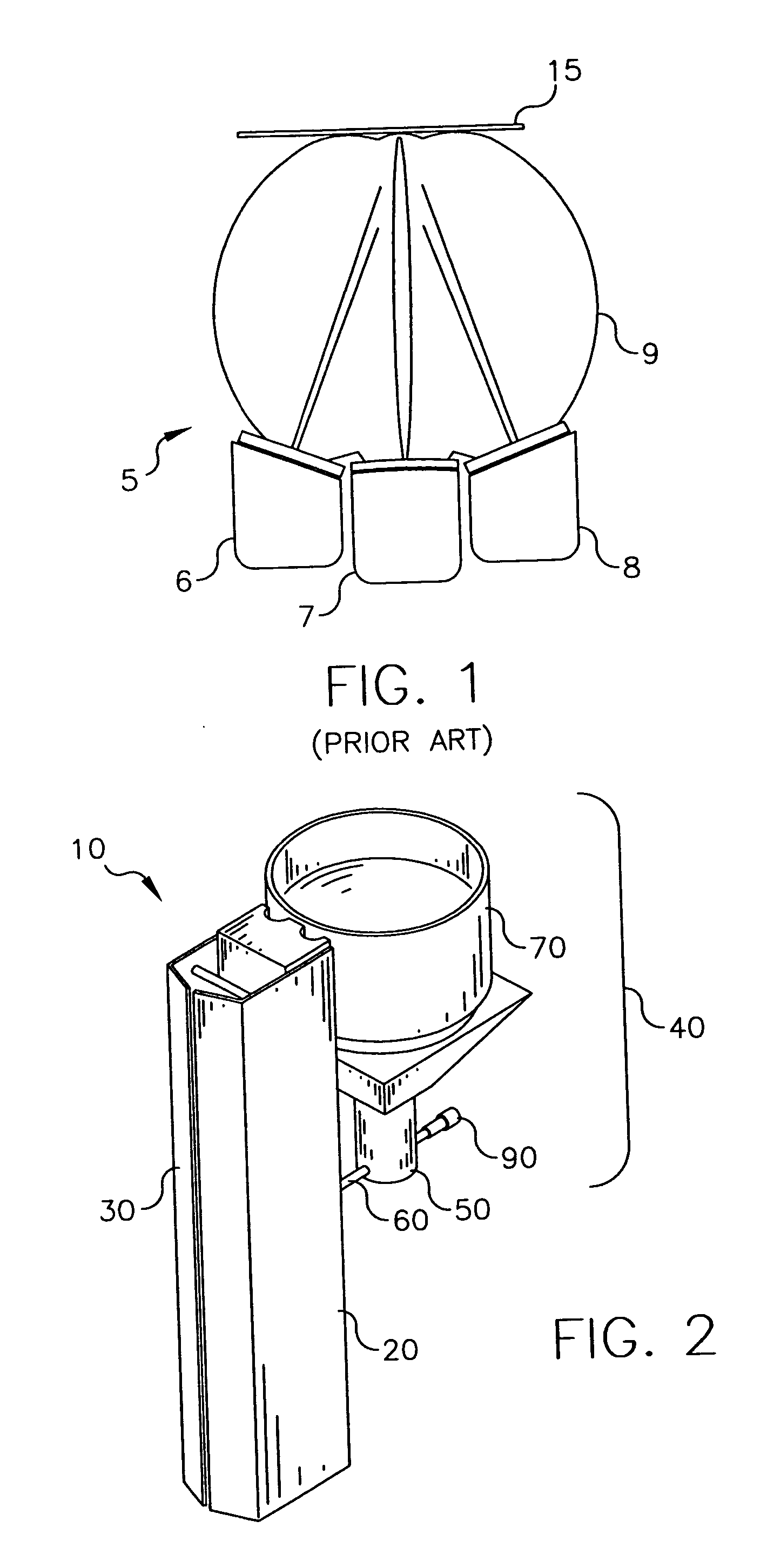

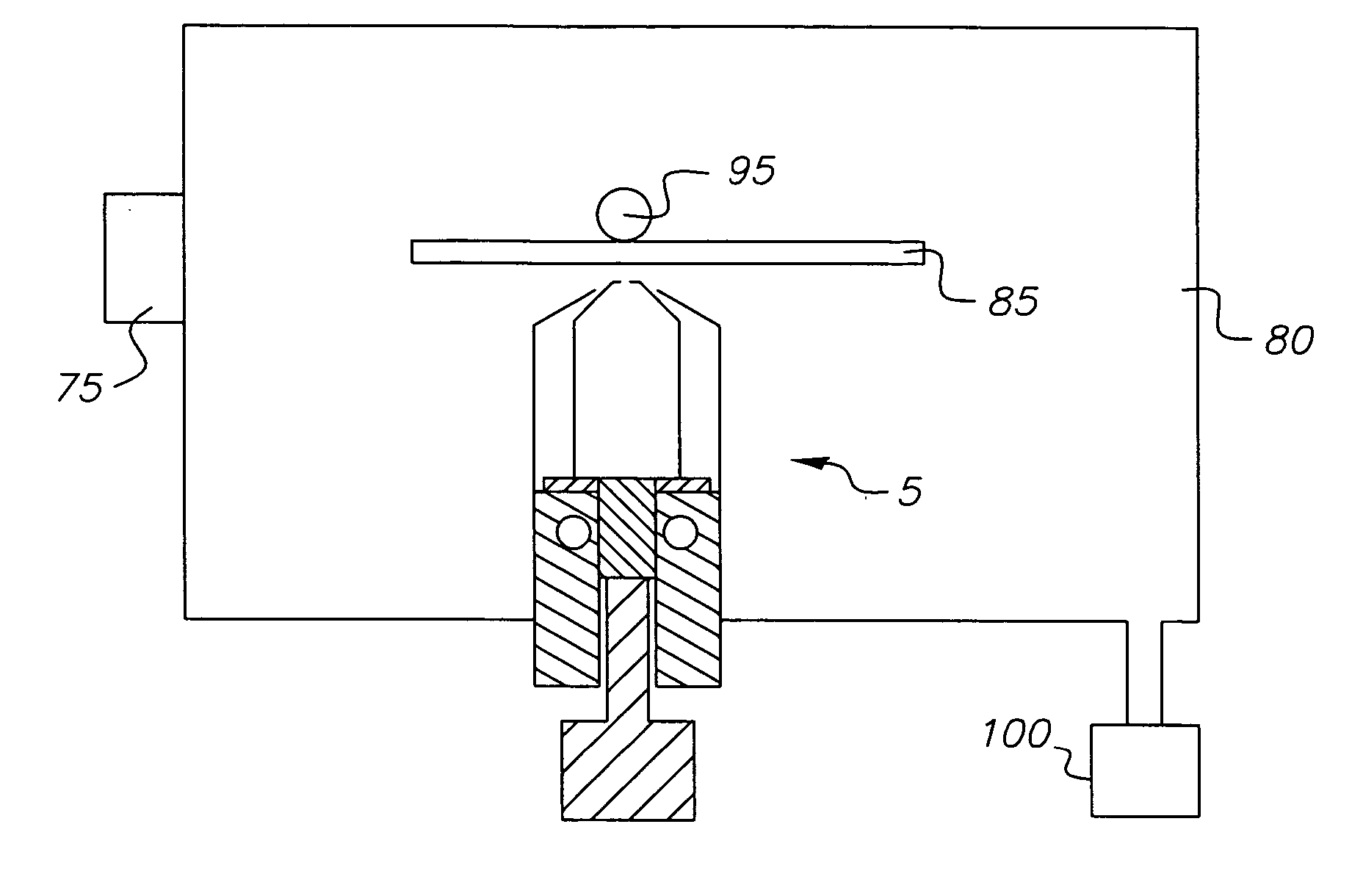

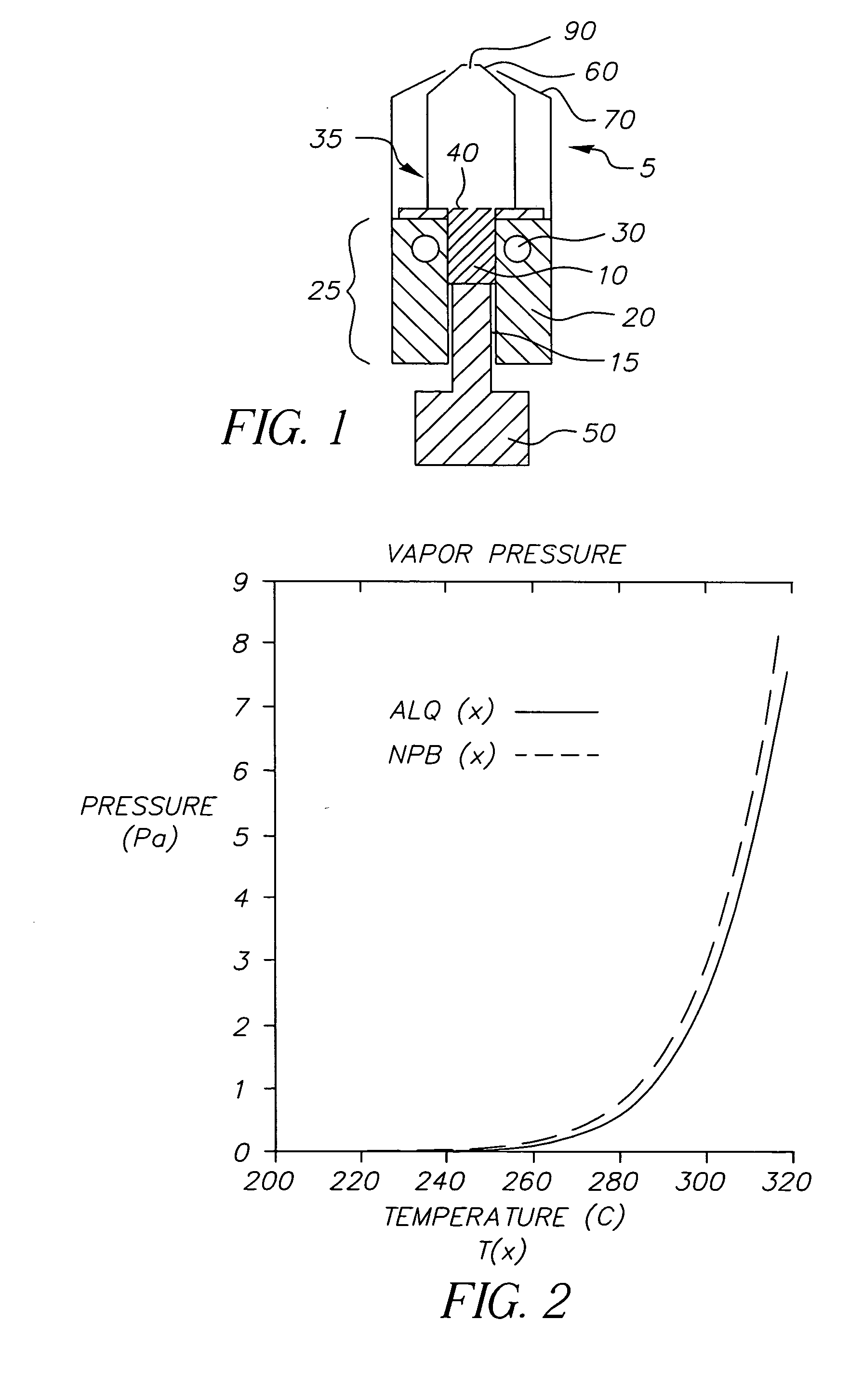

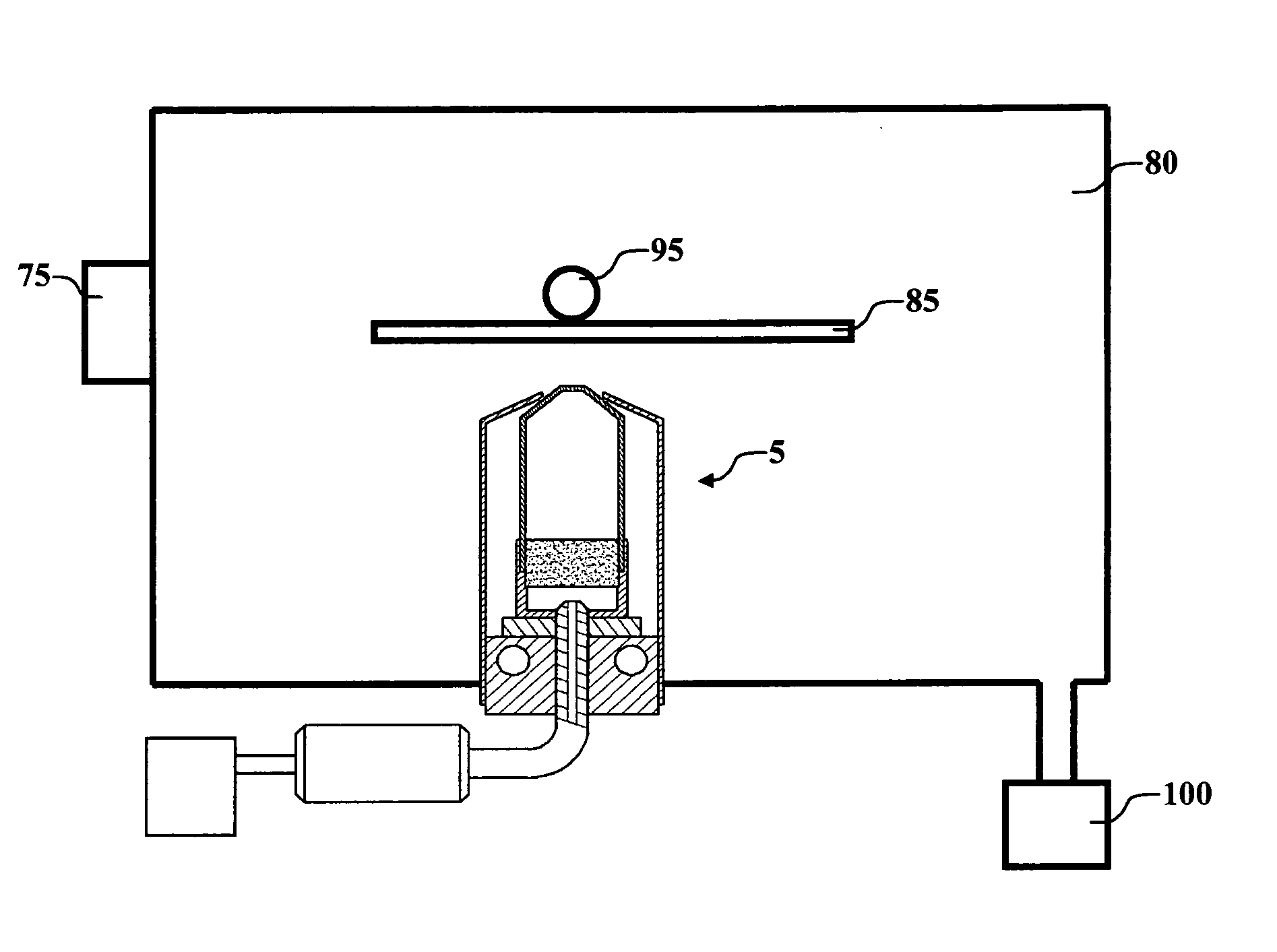

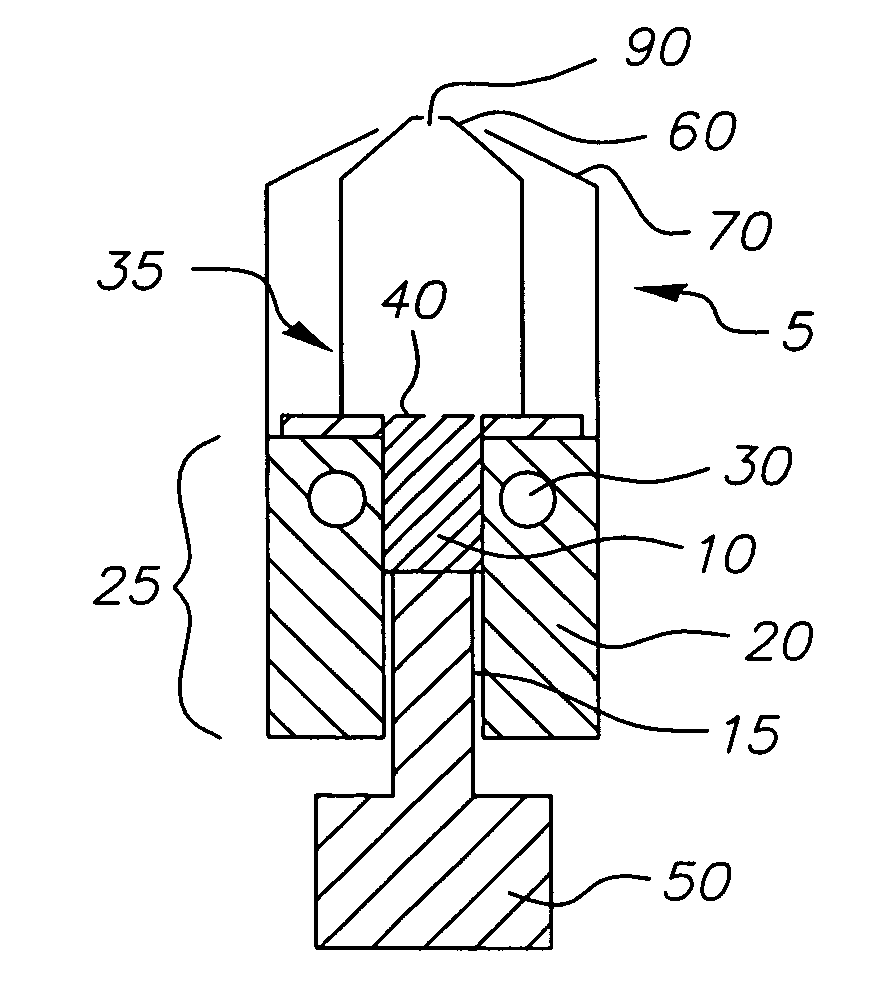

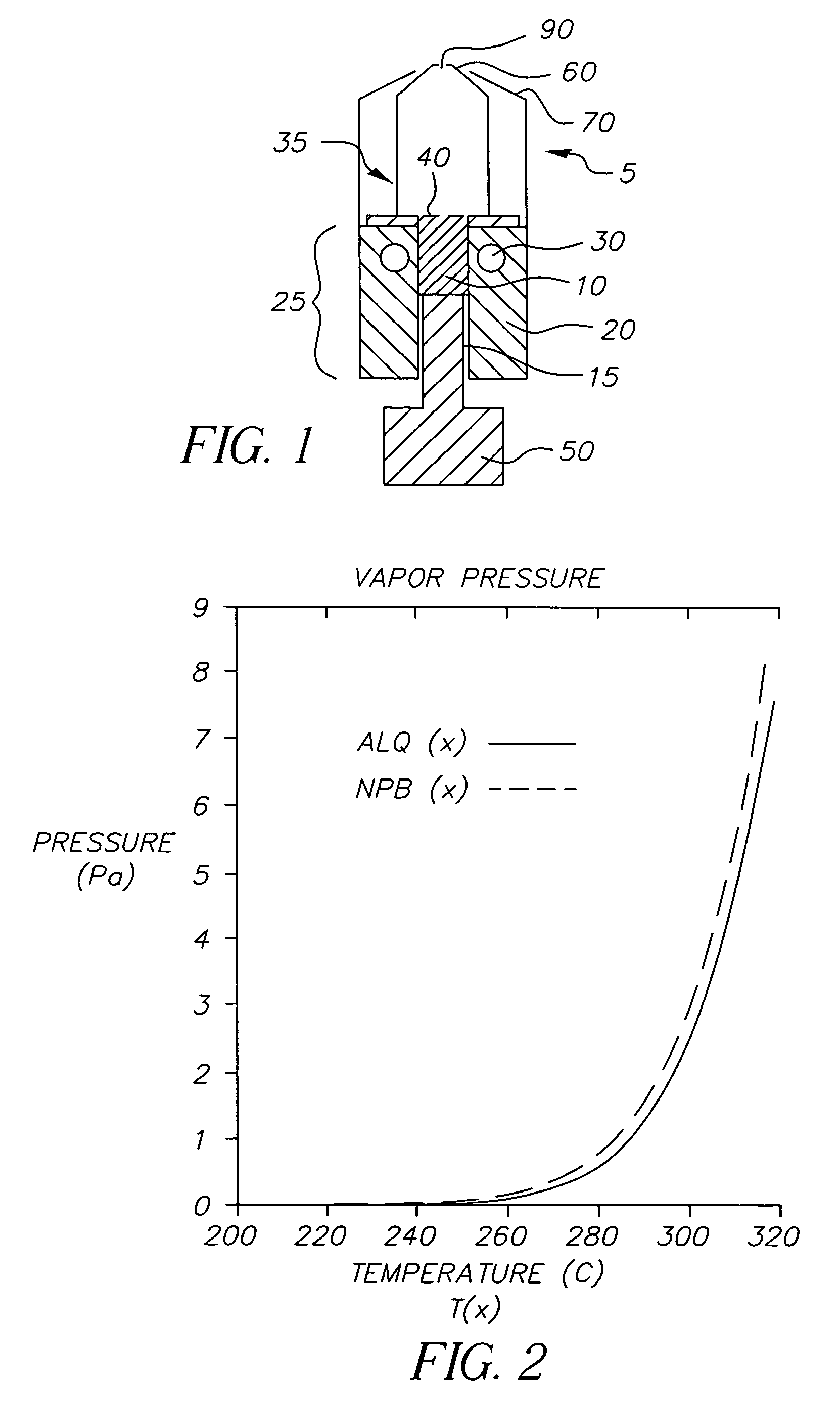

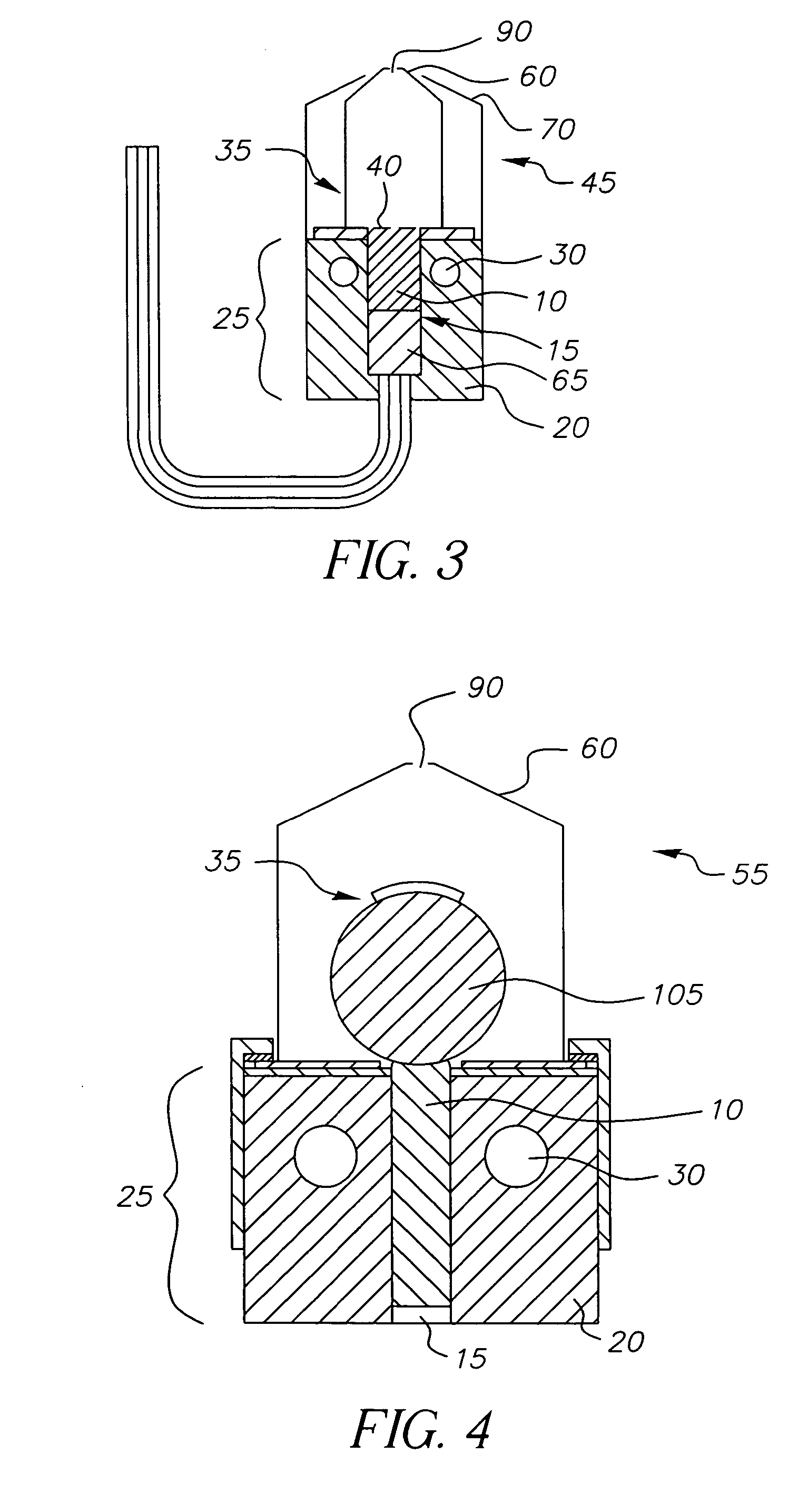

Device and method for vaporizing temperature sensitive materials

ActiveUS20050186340A1Steady vaporization rateReduce riskDischarge tube luminescnet screensElectroluminescent light sourcesMetallurgyVaporization

A method for vaporizing organic materials onto a substrate surface to form a film including providing a quantity of organic material into a vaporization apparatus and actively maintaining the organic material in a first heating region in the vaporization apparatus to be below the vaporization temperature. The method also includes heating a second heating region of the vaporization apparatus above the vaporization temperature of the organic material and metering, at a controlled rate, organic material from the first heating region into the second heating region so that a thin cross section of the organic material is heated at a desired rate-dependent vaporization temperature, whereby organic material vaporizes and forms a film on the substrate surface.

Owner:GLOBAL OLED TECH

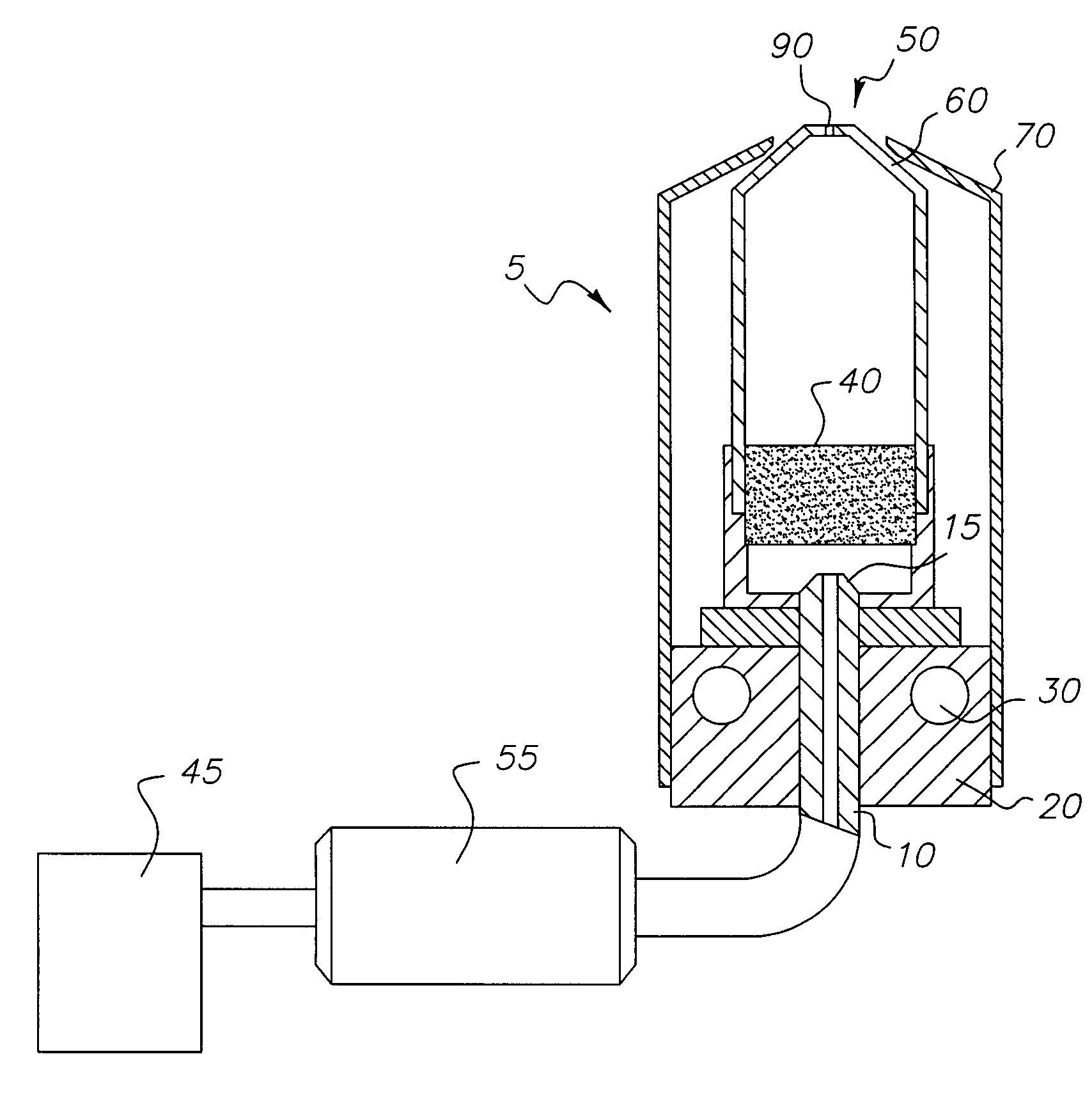

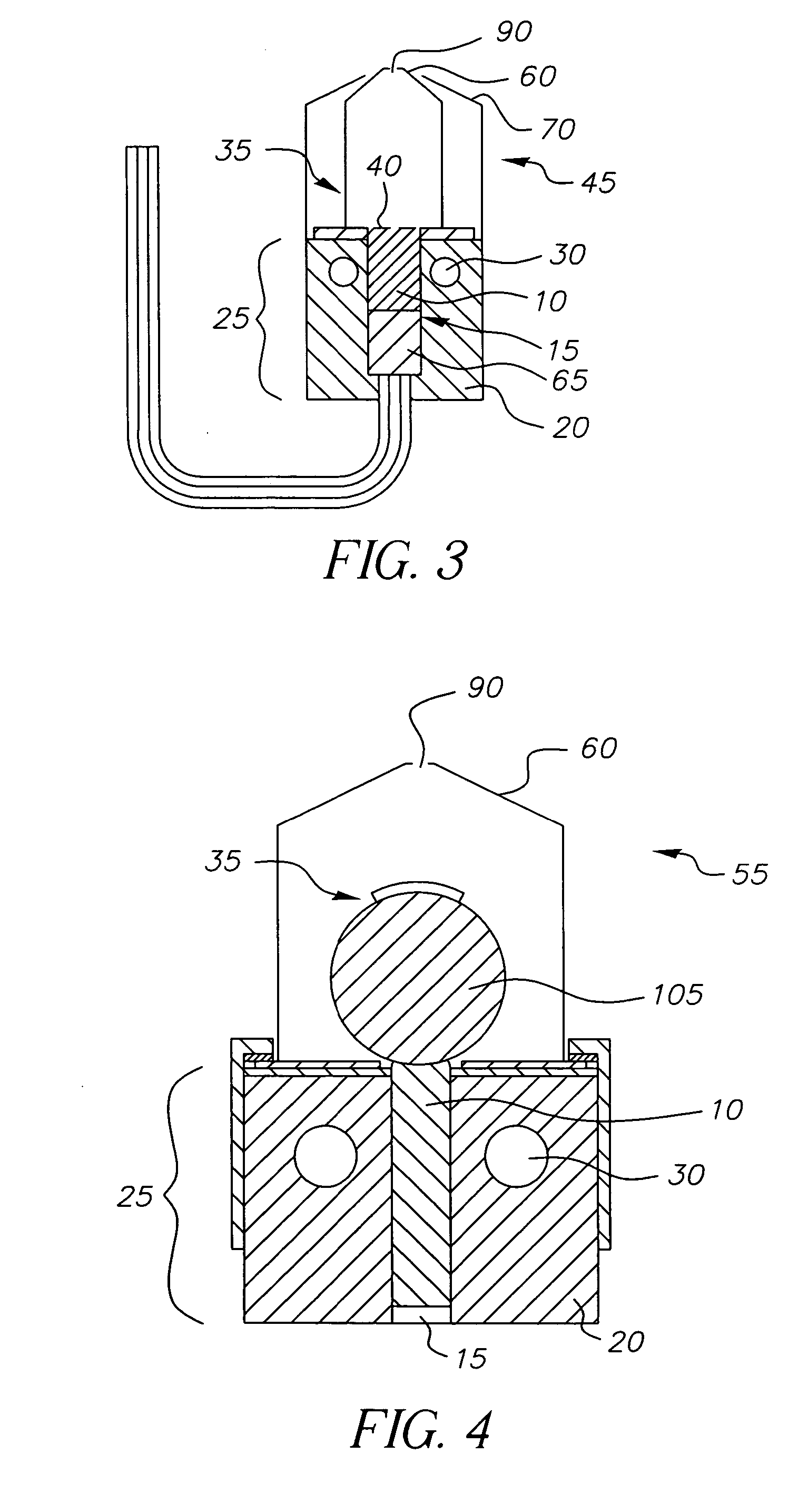

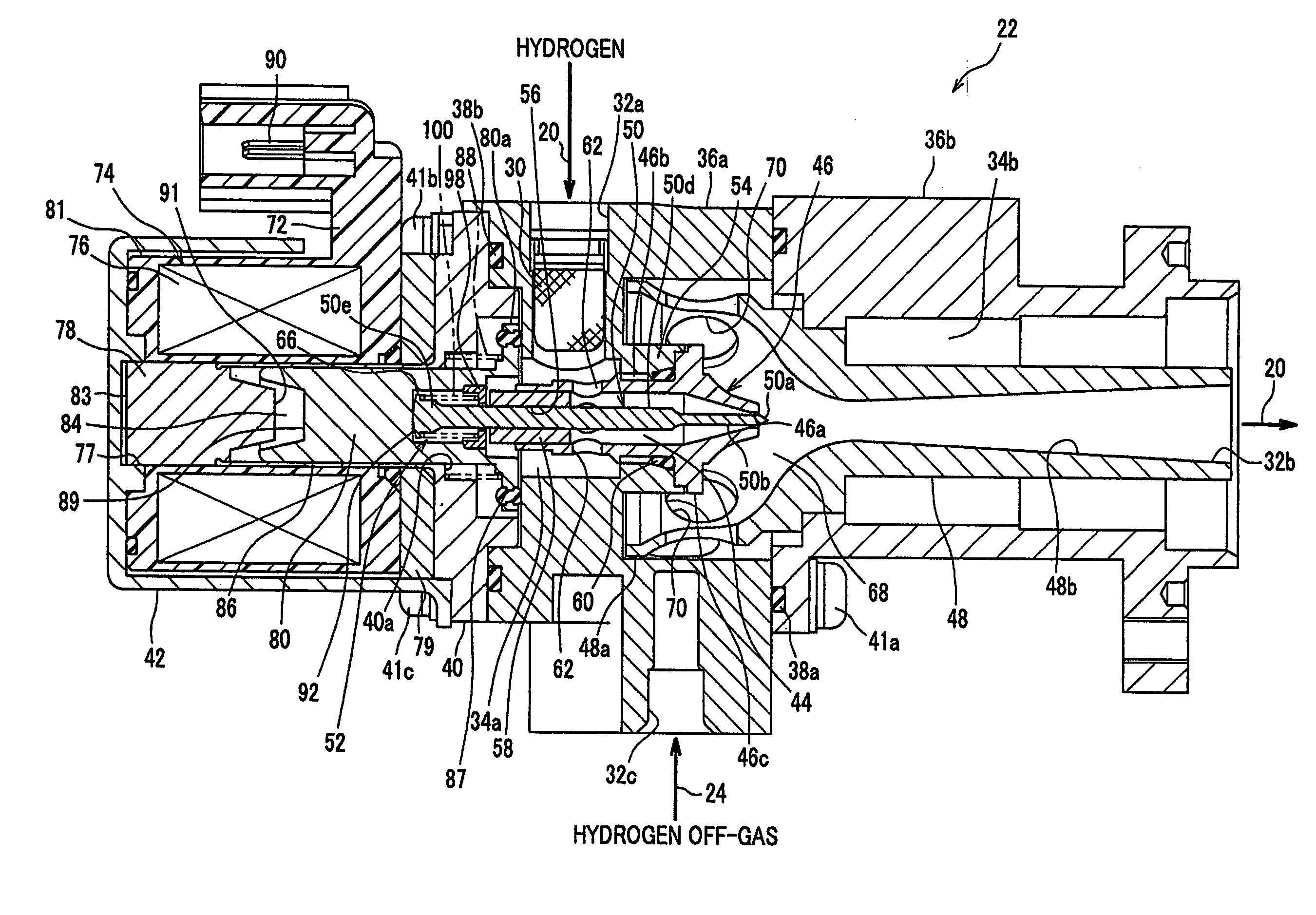

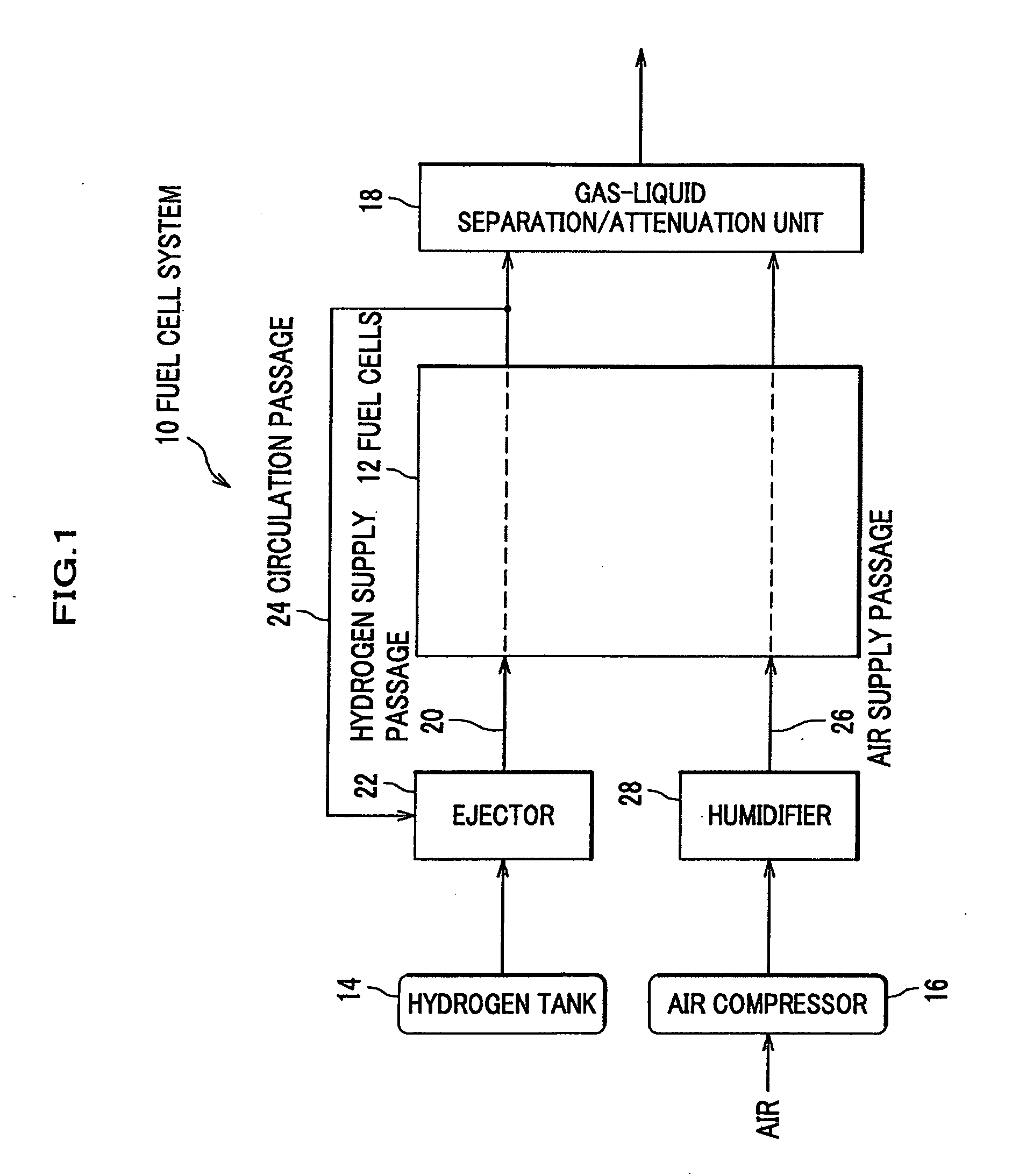

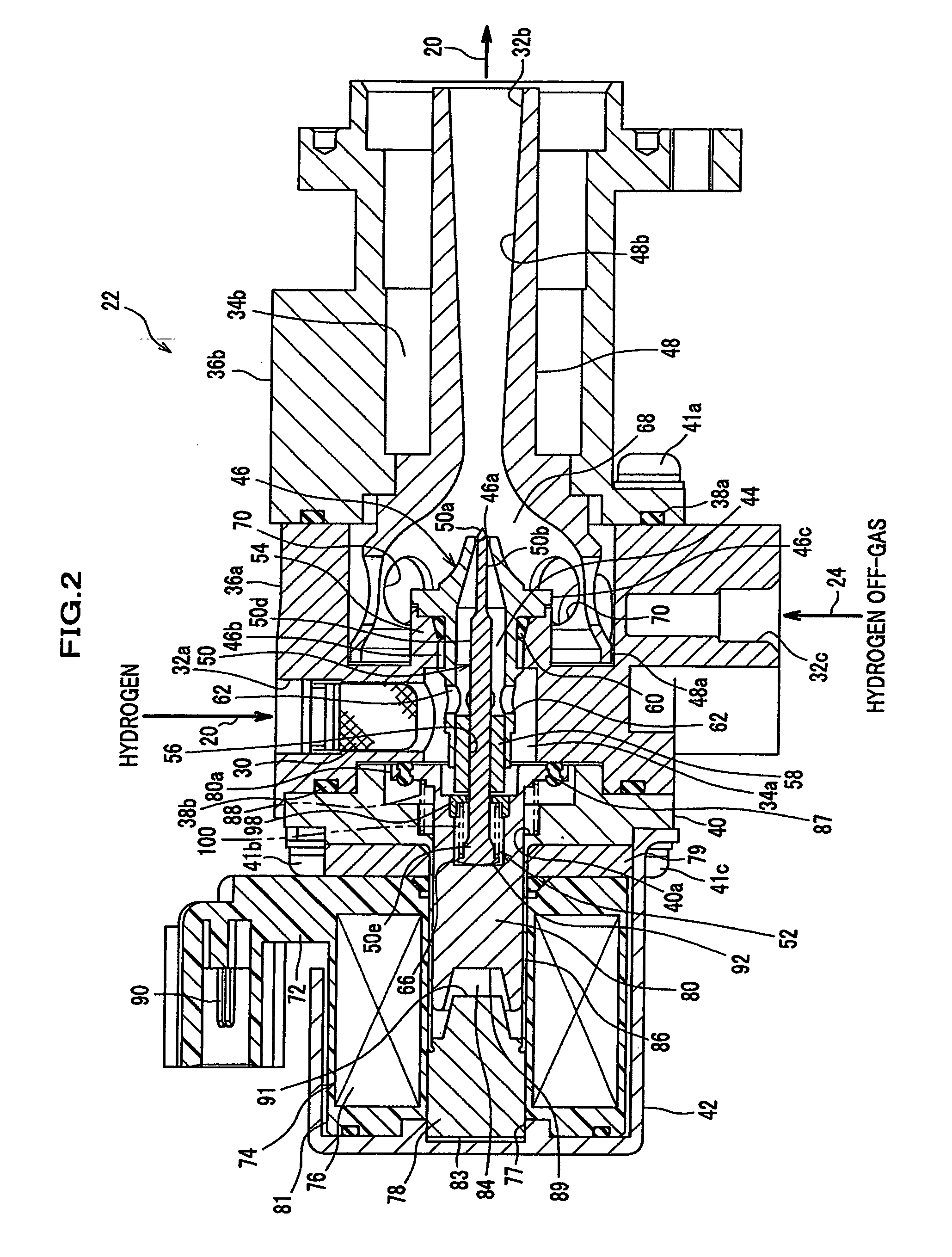

Ejector for fuel cell system

An ejector for a fuel cell system of the present invention includes a nozzle having a nozzle hole for discharging hydrogen supplied via an inlet port of an ejector body, a diffuser for mixing hydrogen discharged from the nozzle hole and hydrogen off-gas discharged and returned via a circulation passage from a fuel cell, a needle displacing in the axial direction by a driving force of a solenoid, and a bearing member held in a hollow portion of the nozzle, and having a through hole that movably supports the needle in the axial direction.

Owner:KEIHIN CORP

Vaporizing fluidized organic materials

ActiveUS20050208220A1Steady vaporization rateReduce riskDischarge tube luminescnet screensLamp detailsMetallurgy

A method for vaporizing organic materials onto a surface, to form a film includes providing a quantity of organic material in a fluidized powdered form; metering the powdered organic material and directing a stream of such fluidized powder onto a first member; heating the first member so that as the stream of fluidized powder is vaporized; collecting the vaporized organic material in a manifold; and providing a second member formed with at least one aperture in communication with the manifold that permits the vaporized organic material to be directed onto the surface to form a film.

Owner:GLOBAL OLED TECH

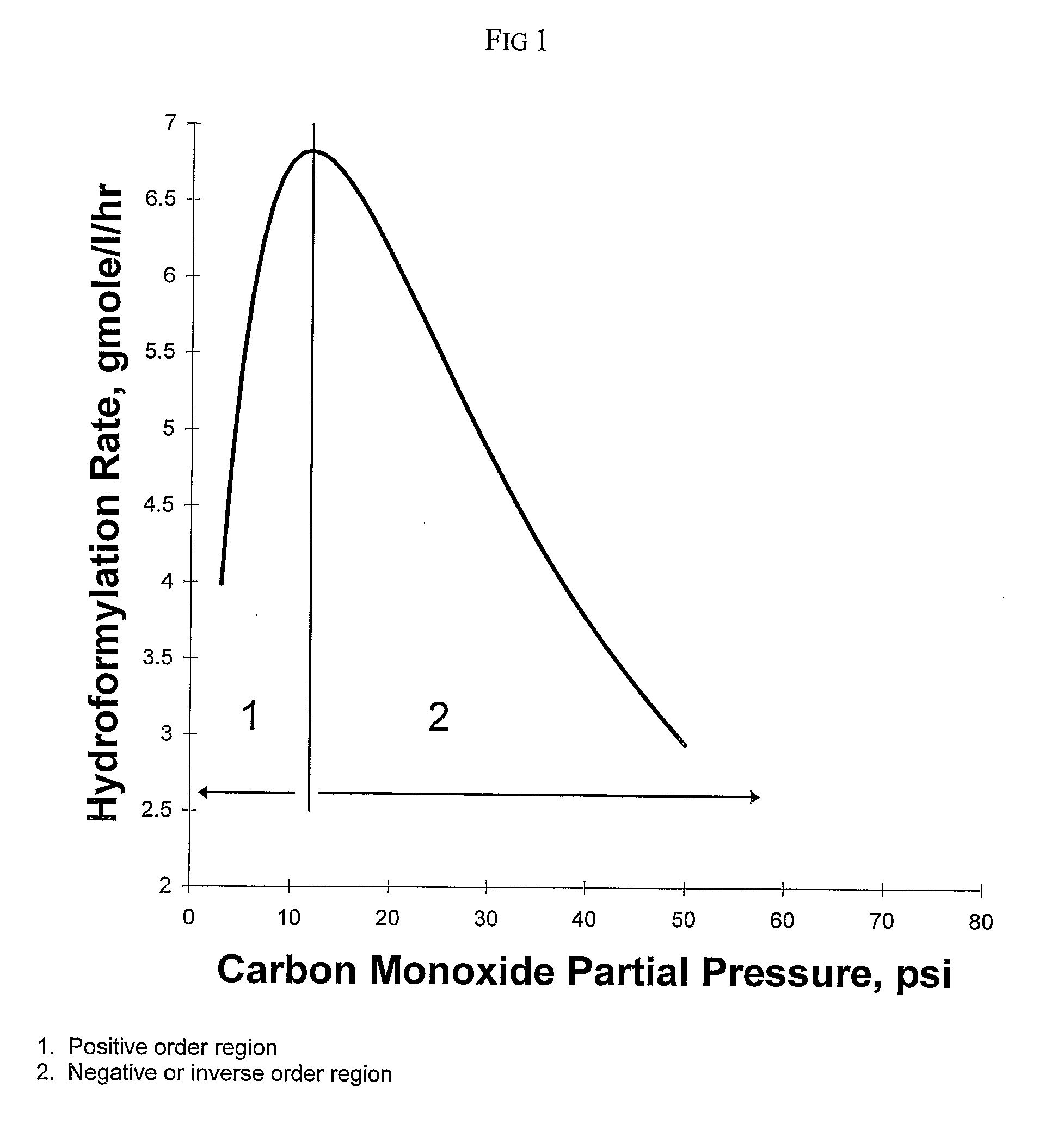

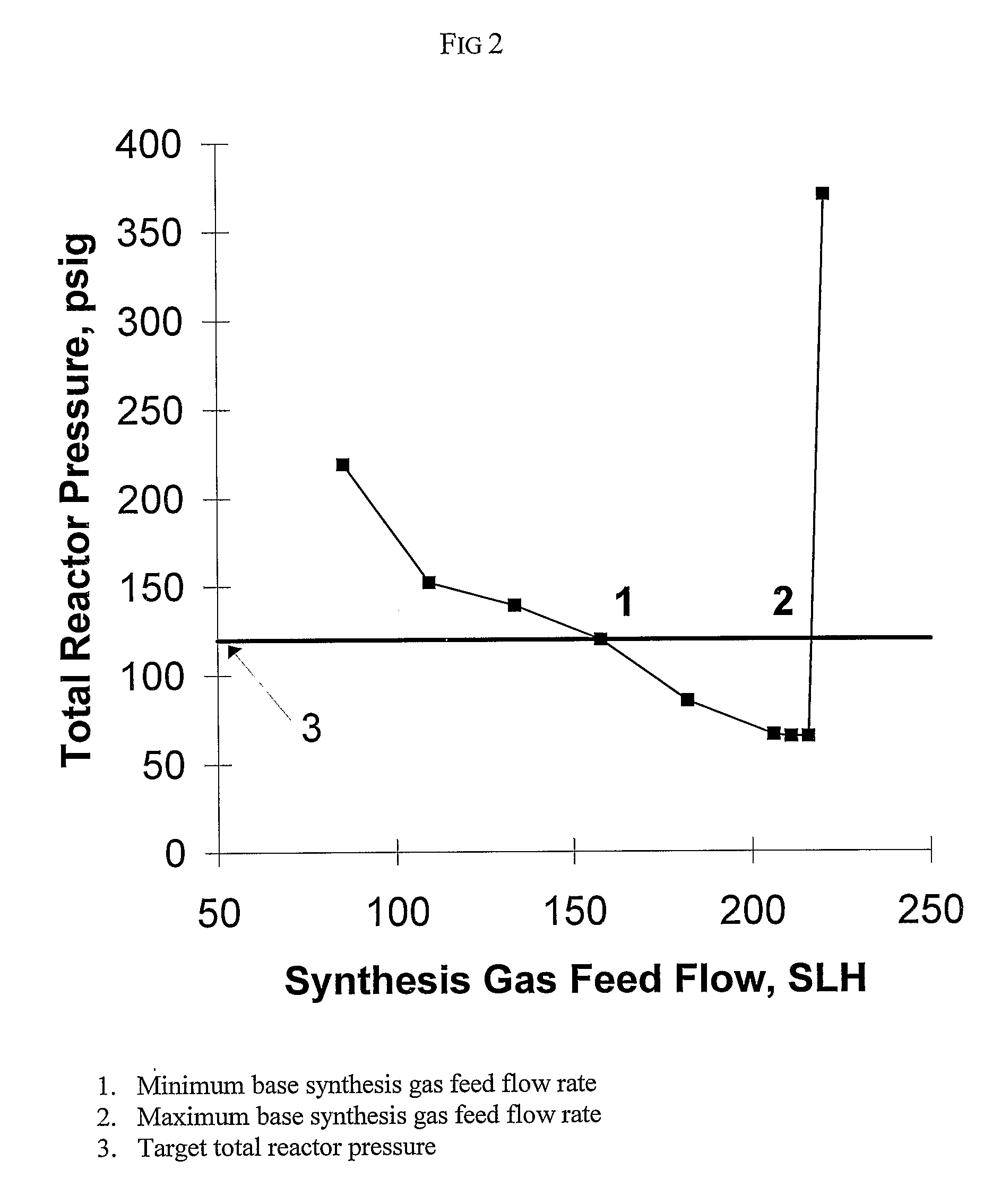

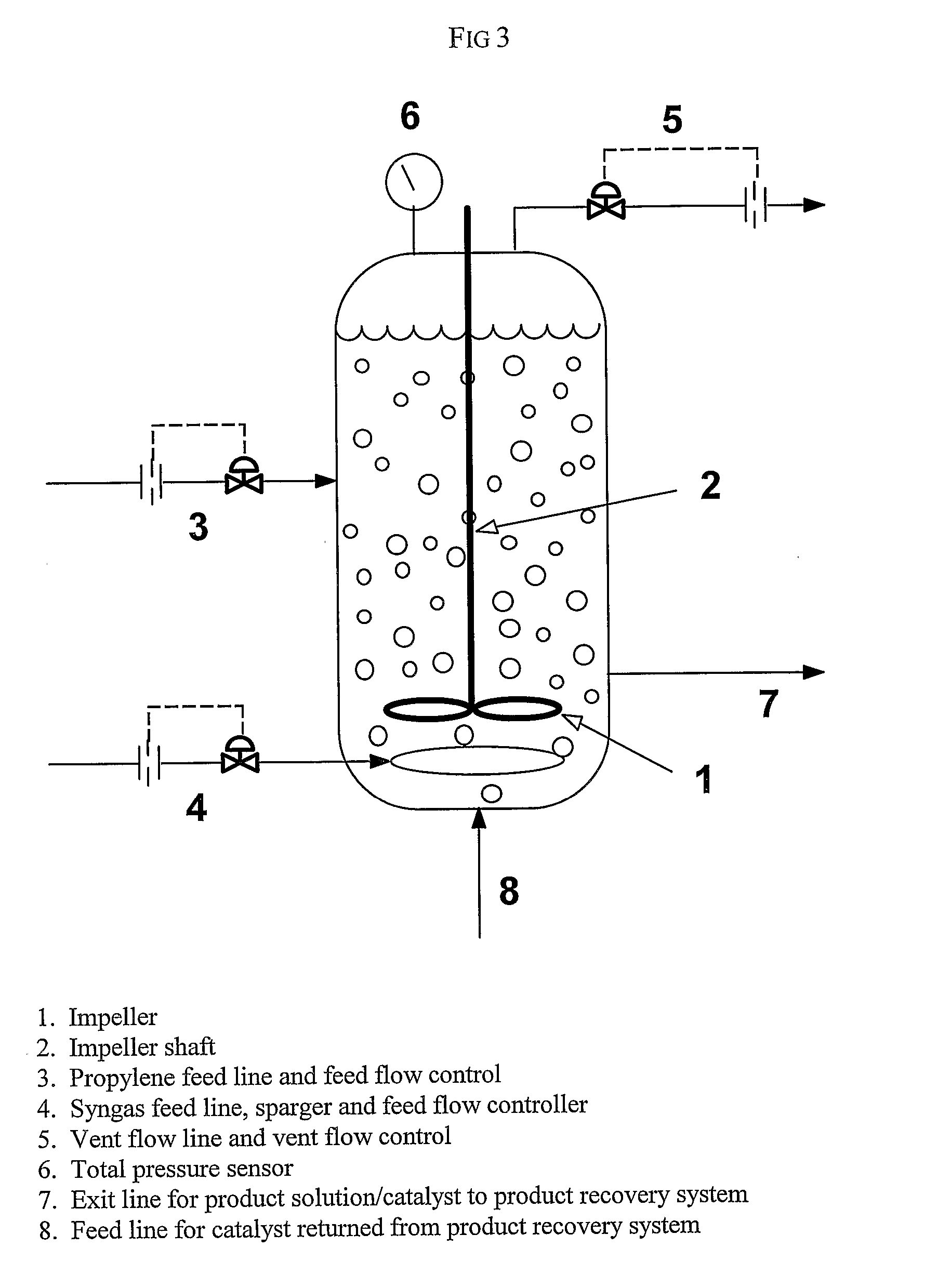

Stabilization of a hydroformylation process

ActiveUS7446231B2Improve efficiencyProcess stabilityLiquid degasificationOrganic compound preparationReaction rateRate curve

An improved hydroformylation process involving reacting one or more reactants, such as an olefin, with carbon monoxide and hydrogen in the presence of a hydroformylation catalyst, to produce a reaction product fluid comprising one or more products, preferably aldehydes; wherein said process is conducted in a region of the hydroformylation rate curve that is negative or inverse order in carbon monoxide, which is sufficient to prevent and / or lessen deactivation of the hydroformylation catalyst; and wherein total pressure is controlled at a predetermined target value and / or vent flow rate is controlled at a predetermined target value, by adjusting a flow of a carbon-monoxide containing inlet gas, so as to prevent and / or lessen cycling of process parameters, e.g., reaction rate, total pressure, vent flow rate, and / or temperature.

Owner:DOW TECH INVESTMENTS

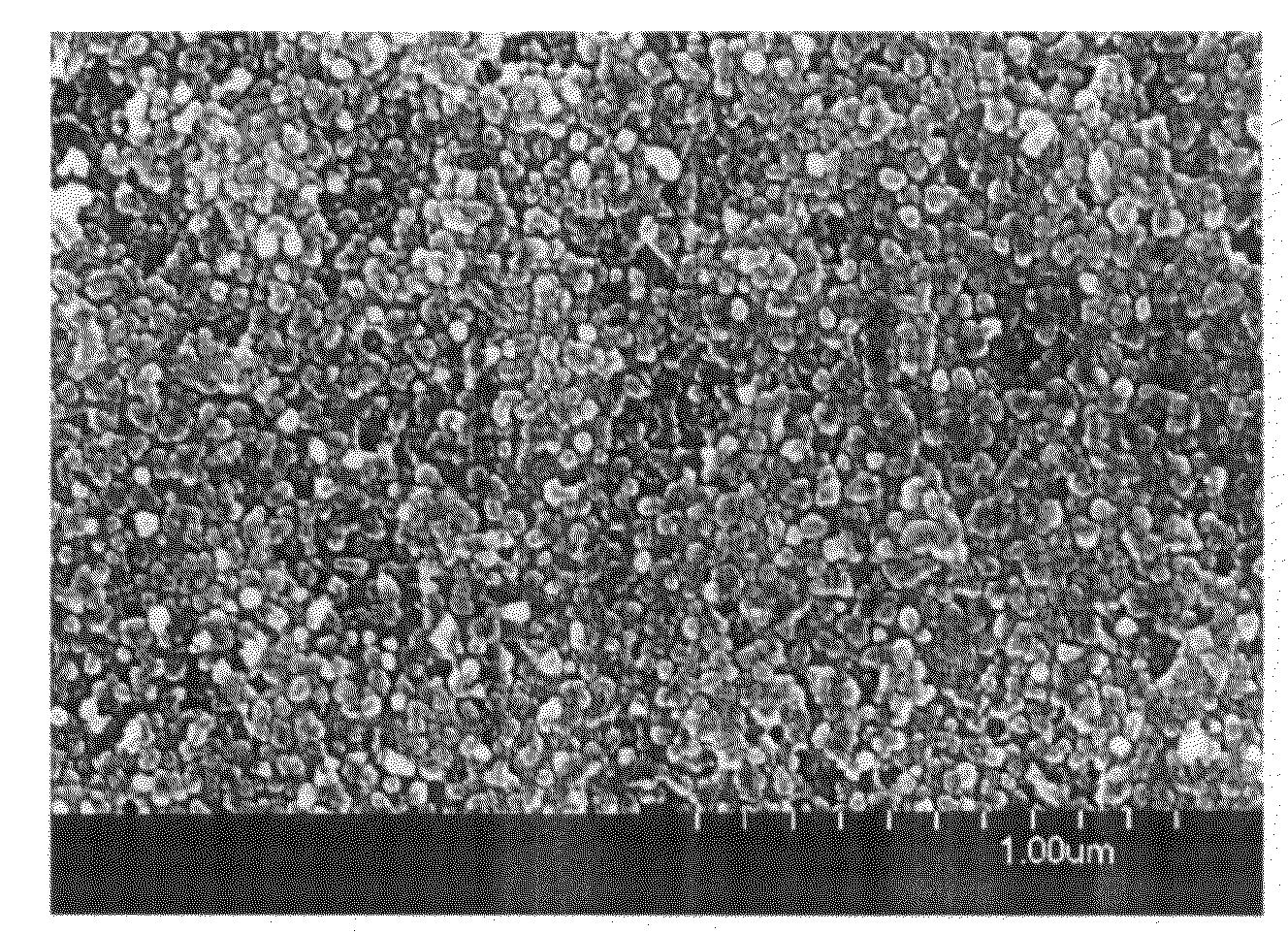

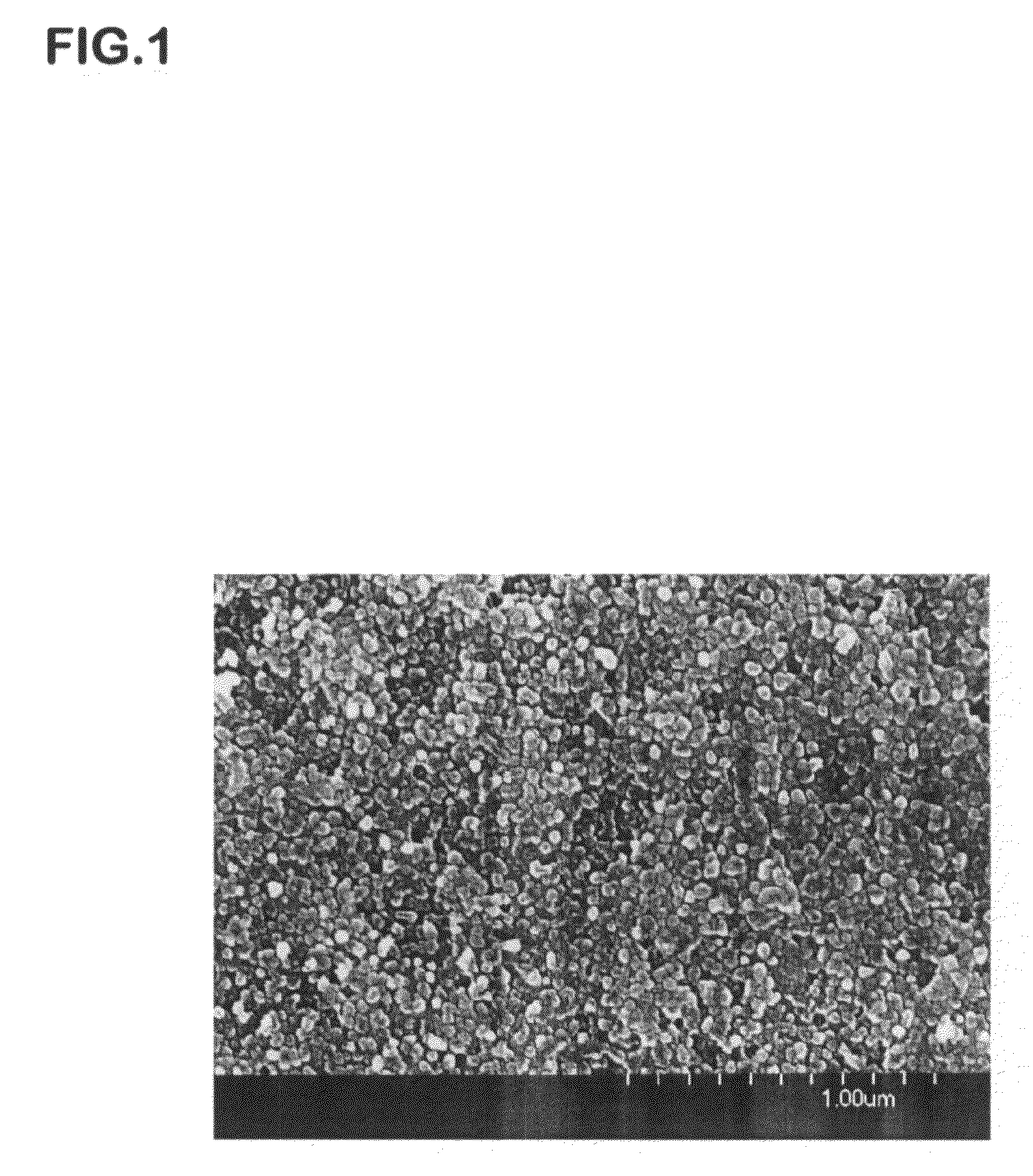

Polymer material, foam obtained from same, and polishing pad using those

ActiveUS20090298392A1Stable polishing rateHigh-precision polishingOther chemical processesSemiconductor/solid-state device manufacturingPolymer sciencePolymer

The subject is to provide a polymer material which enables to improve planarity and planarization efficiency of a polished surface and is useful as a polishing pad which generates only a few scratches. The said subject is solved by a polymer material having a tensile modulus at 50° C. after saturation swelling with 50° C. water of 130 to 800 MPa, a loss tangent at 50° C. of not more than 0.2, and a contact angle with water of not more than 80°.

Owner:KURARAY CO LTD

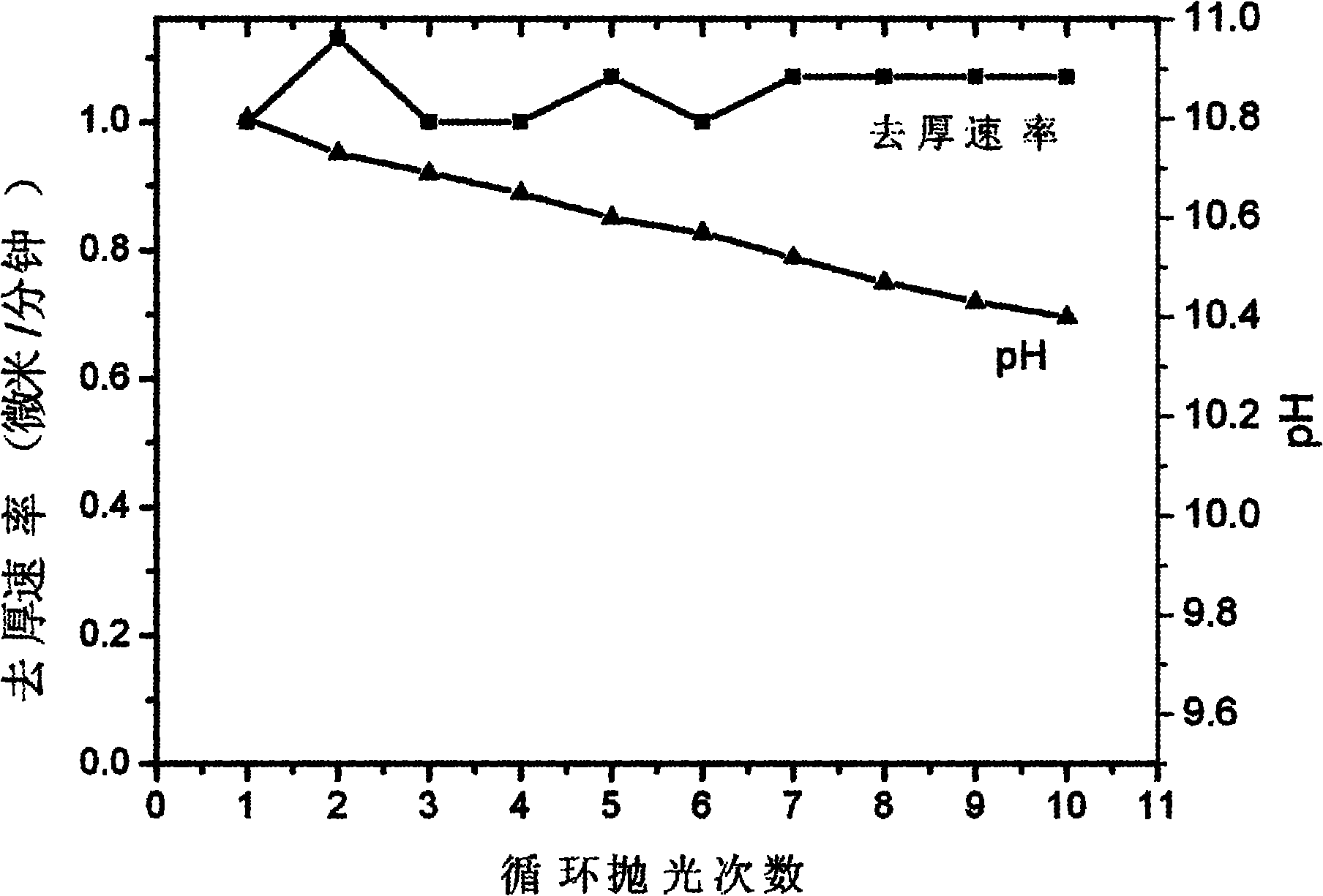

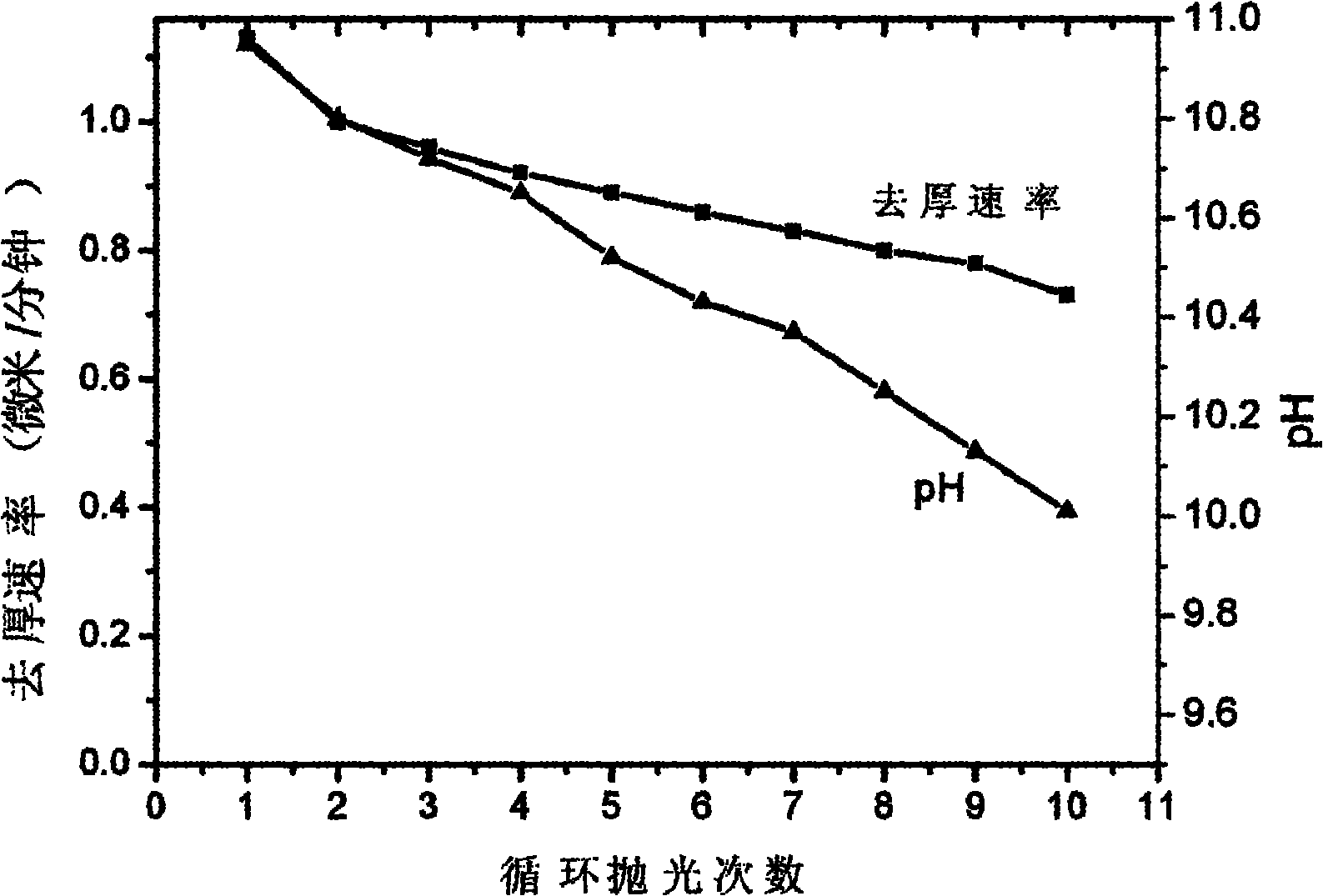

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

Device and method for vaporizing temperature sensitive materials

ActiveUS7232588B2Reduce riskStable rateDischarge tube luminescnet screensElectroluminescent light sourcesMetallurgyVaporization

A method for vaporizing organic materials onto a substrate surface to form a film including providing a quantity of organic material into a vaporization apparatus and actively maintaining the organic material in a first heating region in the vaporization apparatus to be below the vaporization temperature. The method also includes heating a second heating region of the vaporization apparatus above the vaporization temperature of the organic material and metering, at a controlled rate, organic material from the first heating region into the second heating region so that a thin cross section of the organic material is heated at a desired rate-dependent vaporization temperature, whereby organic material vaporizes and forms a film on the substrate surface.

Owner:GLOBAL OLED TECH

Polishing pad

InactiveUS6705934B1Reduce global step heightDepression depressionOther chemical processesSemiconductor/solid-state device manufacturingSurface layerHardness

The present invention relates to a polishing pad which is characterized in that it is of micro rubber A-type hardness at least 80°, has closed cells of average cell diameter no more than 1000 mum, is of density in the range 0.4 to 1.1 and contains polyurethane and polymer produced from a vinyl compound. When planarizing local unevenness on a semiconductor substrate with the polishing pad relating to the present invention, the polishing rate is high, the global step height is low, dishing does not readily occur at the metallic interconnects, clogging and permanent set of the surface layer region do not readily occur and the polishing rate is stable.

Owner:TORAY IND INC

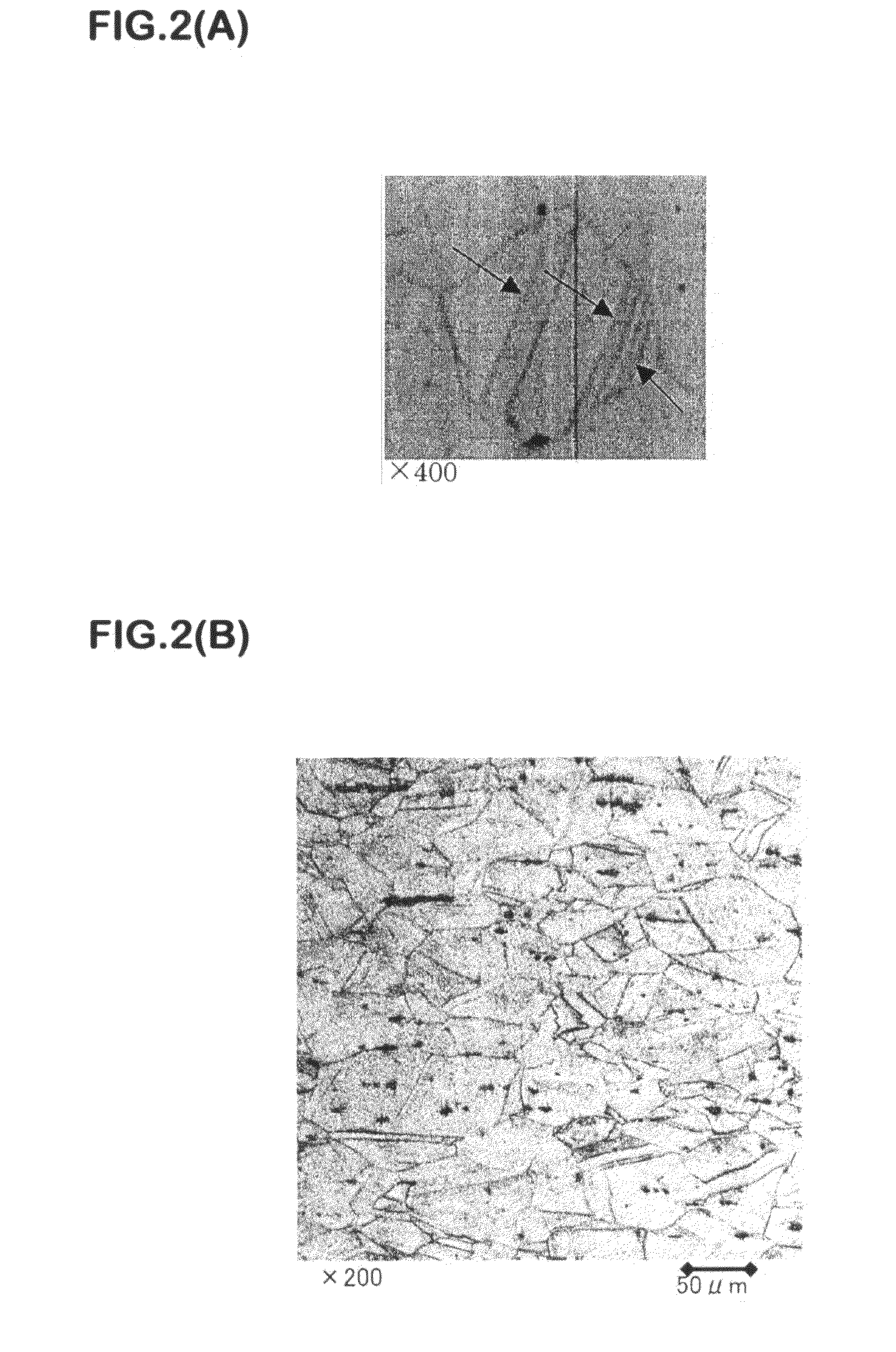

Heat-resistant alloy spring and Ni-based alloy wire therefor

A heat-resistant alloy spring is made of a Ni-based alloy material comprising in weight %: not more than 0.1% C; not more than 1.0% Si; not more than 1.50% Mn; 13.0 to 25.0% Cr; 1.5 to 7.0% Mo; 0.5 to 4.0% Ti; 0.1 to 3.0 % Al; {at least one optional element selected from the group consisting of 0.15 to 2.50% w, 0.001 to 0.020% B, 0.01 to 0.3% Zr, 0.30 to 6.00% Nb, 5.0 to 18.0% Co, and 0.03 to 2.00% Cu}; the balance being essentially Ni; and incidental impurities. The Ni-based alloy material is provided in its crystal structure with gamma prime phase [Ni3(Al, Ti)] or gamma prime phase [Ni3(Al, Ti, Nb)]. The gamma prime phase has an average grain diameter (d) of not less than 25 nanometers, and a hardness-diameter ratio (Hv / d) of a Vickers hardness Hv of a position at a depth of one-fourth of the entire thickness or the wire diameter from a surface of the Ni-based alloy material toward its center and the average grain diameter d(nanometer) is 5 to 25. The Ni-based alloy wire used as the Ni-based alloy material has a Hv hardness of 320 to 480 and a longitudinal elastic modulus of 150,000 to 230,000 N / sq.mm.

Owner:NIPPON SEISEN CO LTD +1

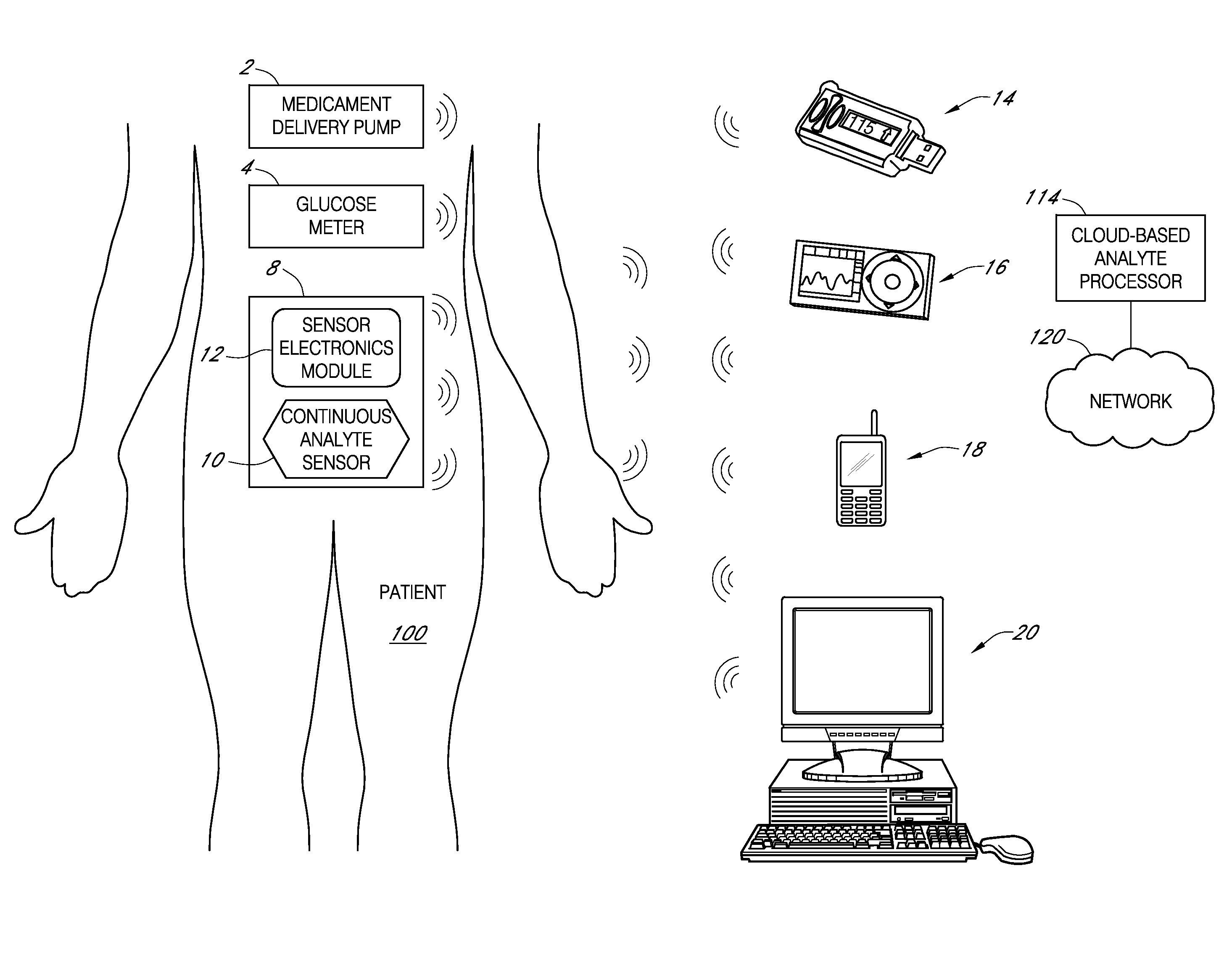

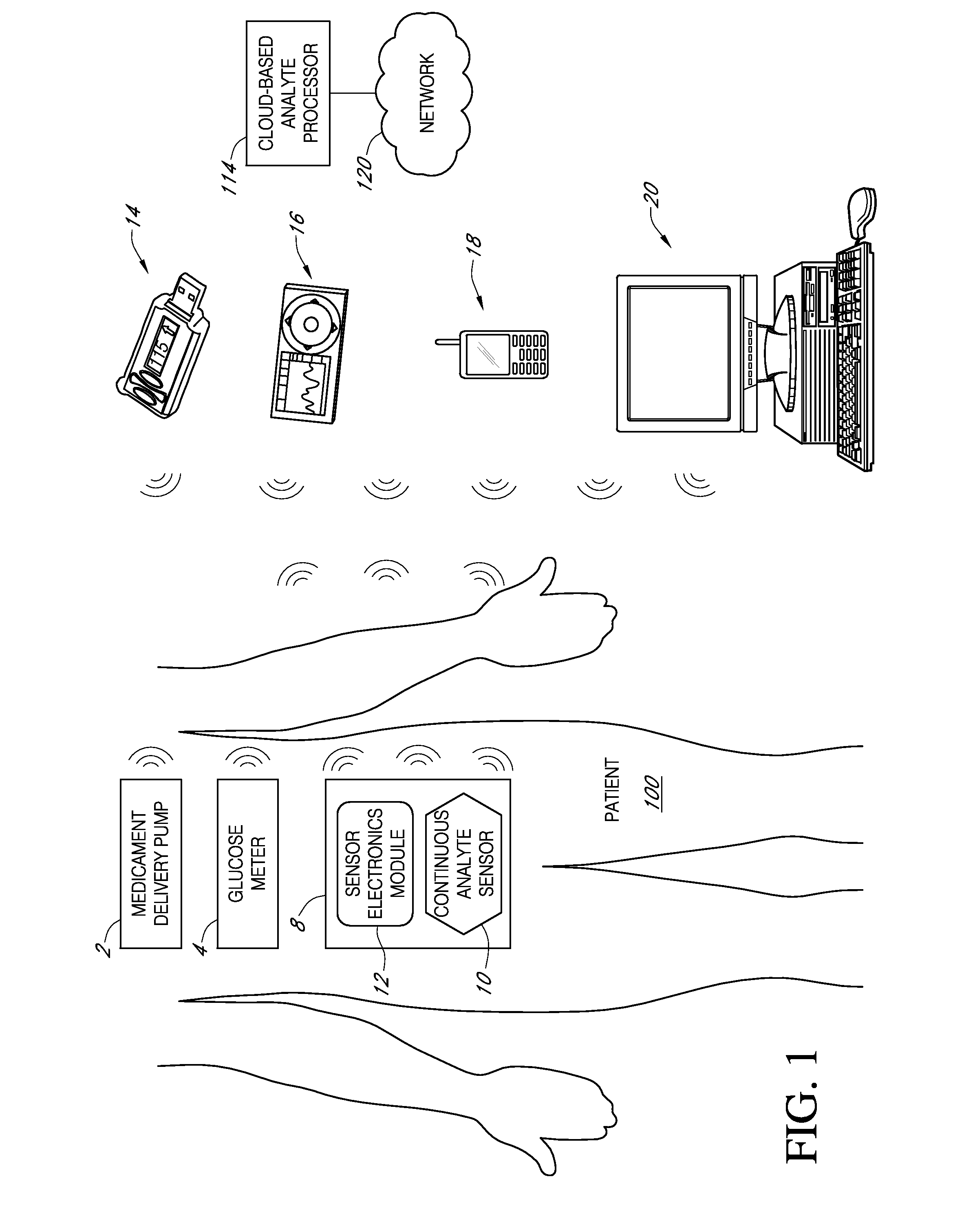

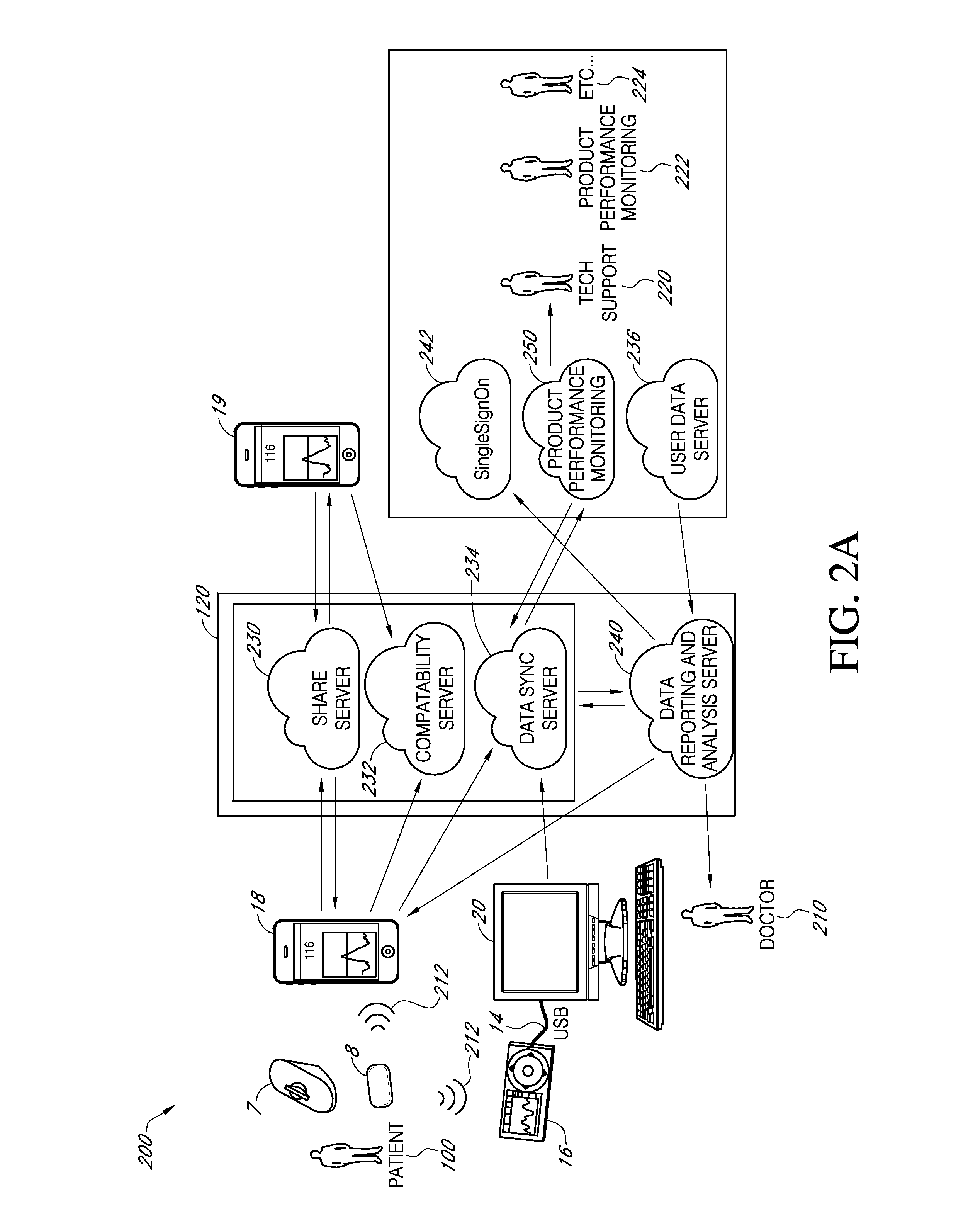

User interfaces for continuous glucose monitoring

ActiveUS20160119210A1Reduce riskReduce the chance of changeError preventionFrequency-division multiplex detailsSubject matterContinuous glucose monitoring

The subject matter disclosed herein provides methods for presenting glucose level data. Glucose data for a patient may be received. A current glucose level and a rate of change of the current glucose level may be determined based on the received glucose data. A first interface may be displayed on a screen of a device. The first interface may include a unitary icon. The unitary icon may display the current glucose level and a visualization of the rate of change. Related apparatus, systems, techniques, and articles are also described.

Owner:DEXCOM

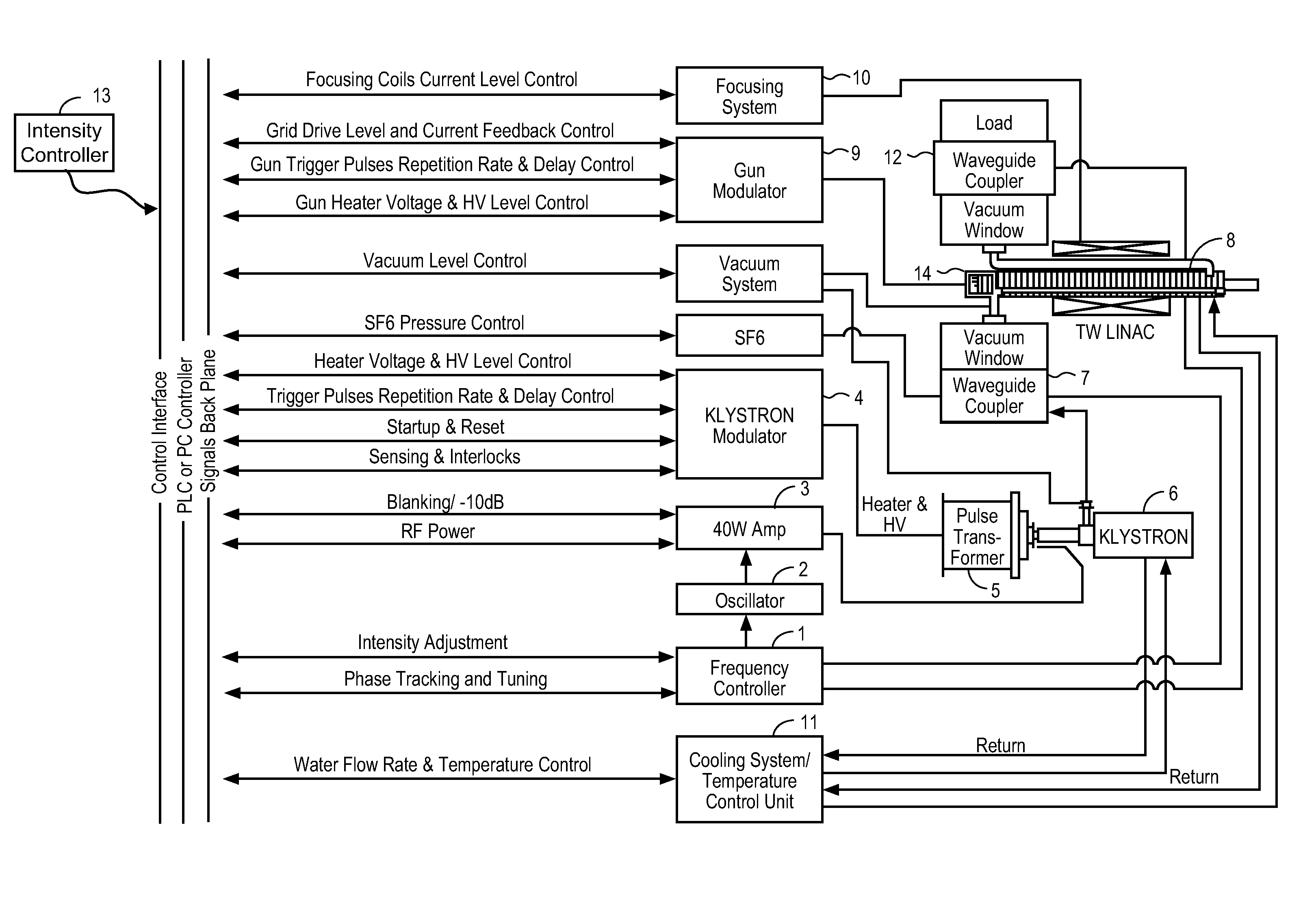

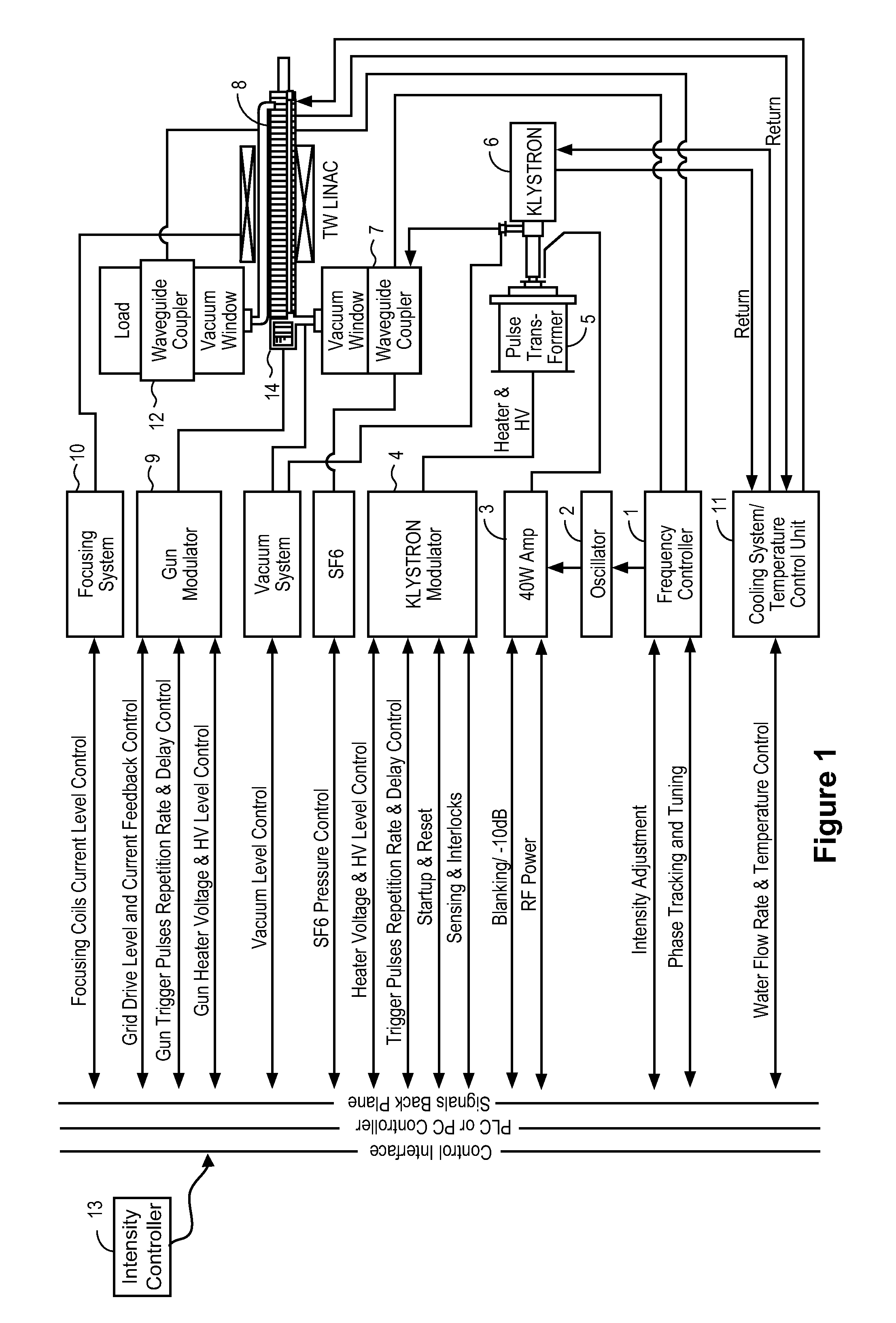

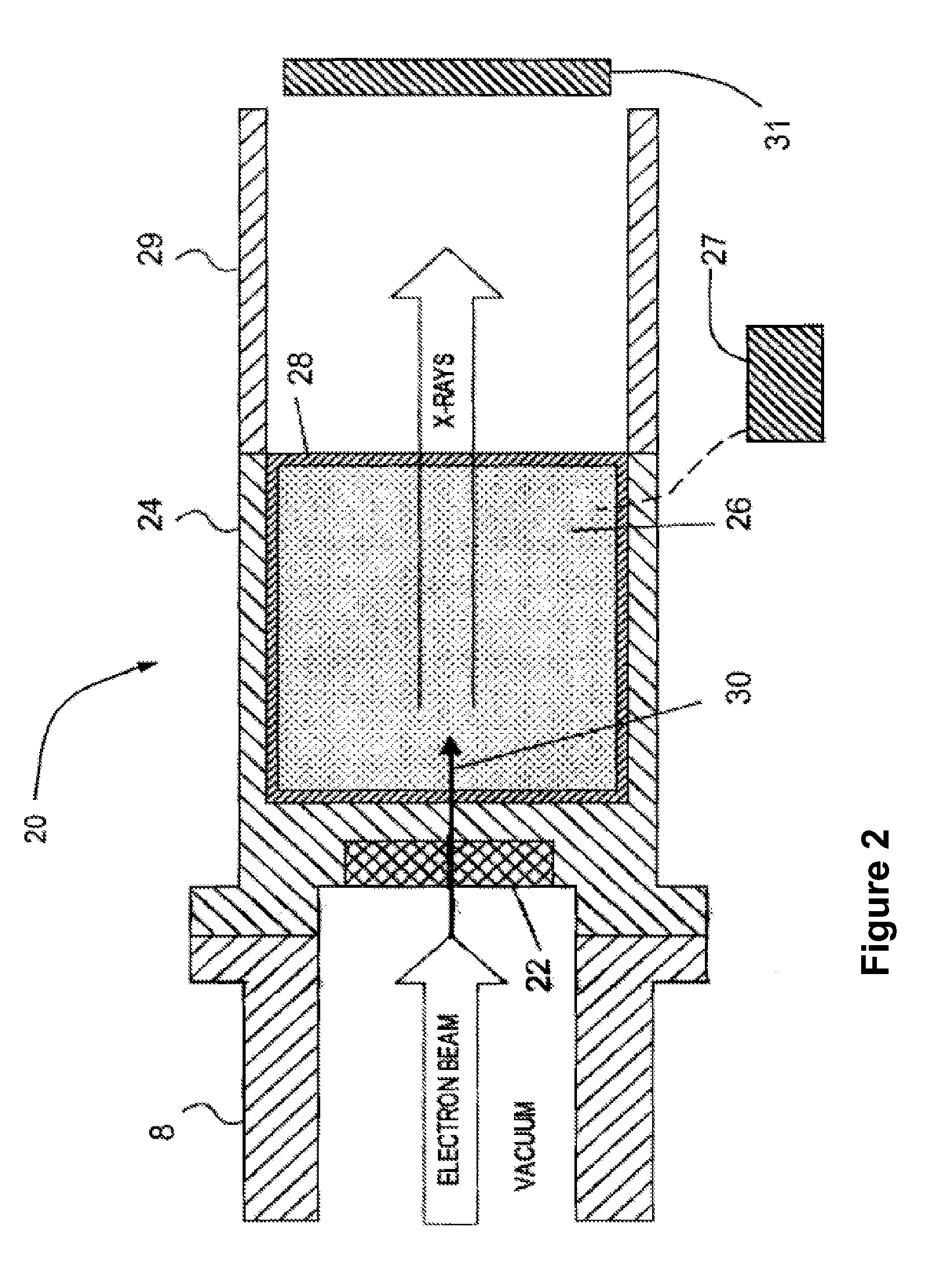

Traveling wave linear accelerator based x-ray source using current to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the electron beam current applied to an electron gun.

Owner:ACCURAY

Apparatus for heating or cooling a polishing surface of a polishing appratus

ActiveUS20080311823A1Reduce frictionAvoid excessive wearPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention provides an apparatus for heating or cooling a polishing surface. This apparatus includes a heat exchanger arranged so as to face the polishing surface when the workpiece is polished. The heat exchanger includes a medium passage through which a heat-exchanging medium flows, and a bottom surface facing the polishing surface. At least a part of the bottom surface is inclined with an upward gradient above the polishing surface such that a polishing liquid on the polishing surface generates a lift exerted on the bottom surface during movement of the polishing surface.

Owner:EBARA CORP

Delivering particulate material to a vaporization zone

ActiveUS20060062915A1Reduce riskStable rateVacuum evaporation coatingSputtering coatingParticulatesEngineering

A method for vaporizing particulate material and condensing it onto a surface to form a layer provides a quantity of first particulate material in a first container and a quantity of second particulate material in a second container spaced apart from the first container, the first and second containers respectively having first and second openings. The first particulate material is transferred through the first opening in the first container into a manifold and vaporized in the manifold. The second particulate material is transferred through the second opening in the second container into the manifold and vaporized in the manifold, whereby the first and second vaporized particulate materials are mixed. The mixed vaporized materials are delivered from the manifold to the surface to form the layer.

Owner:GLOBAL OLED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com