Patents

Literature

122results about How to "Control stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

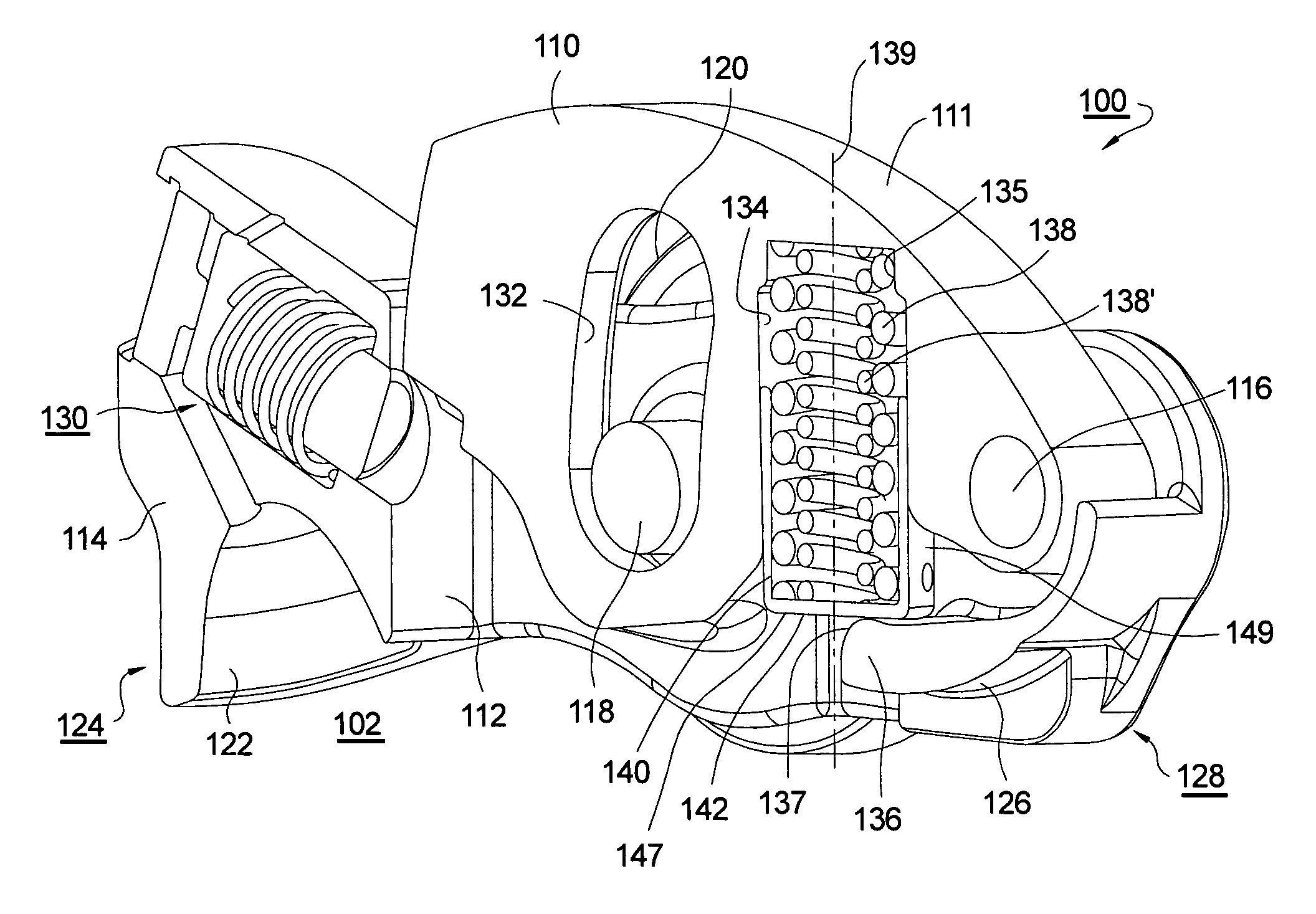

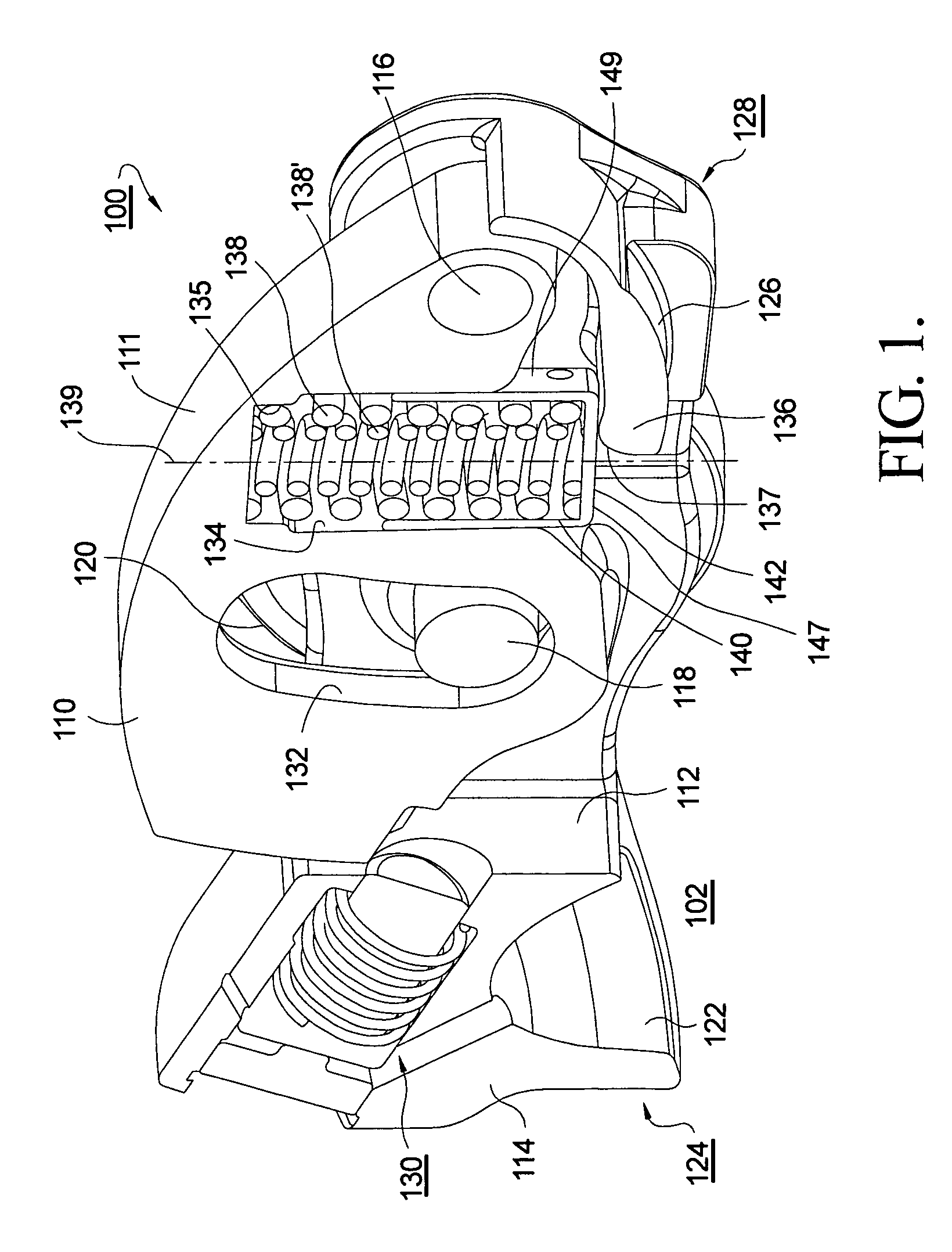

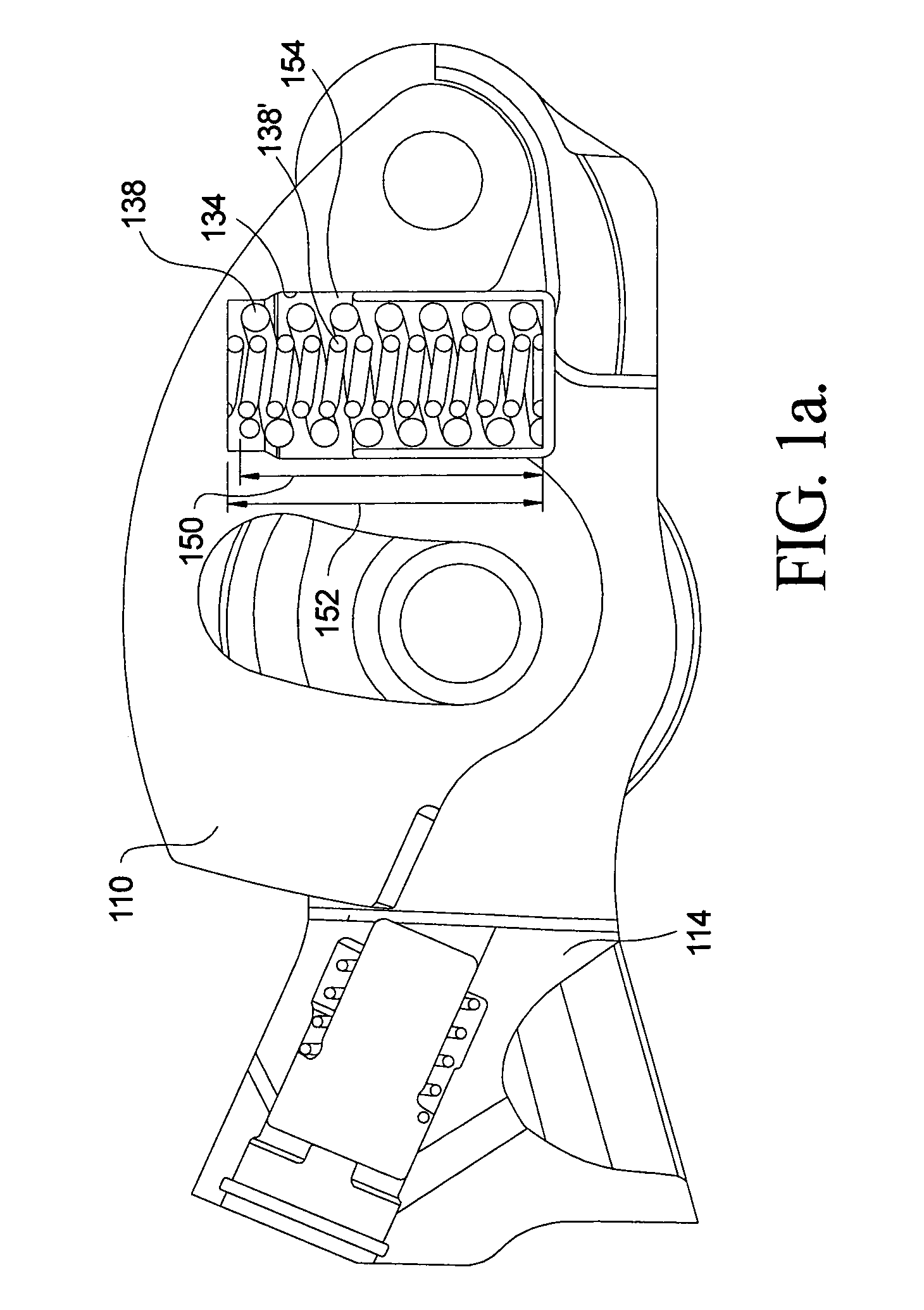

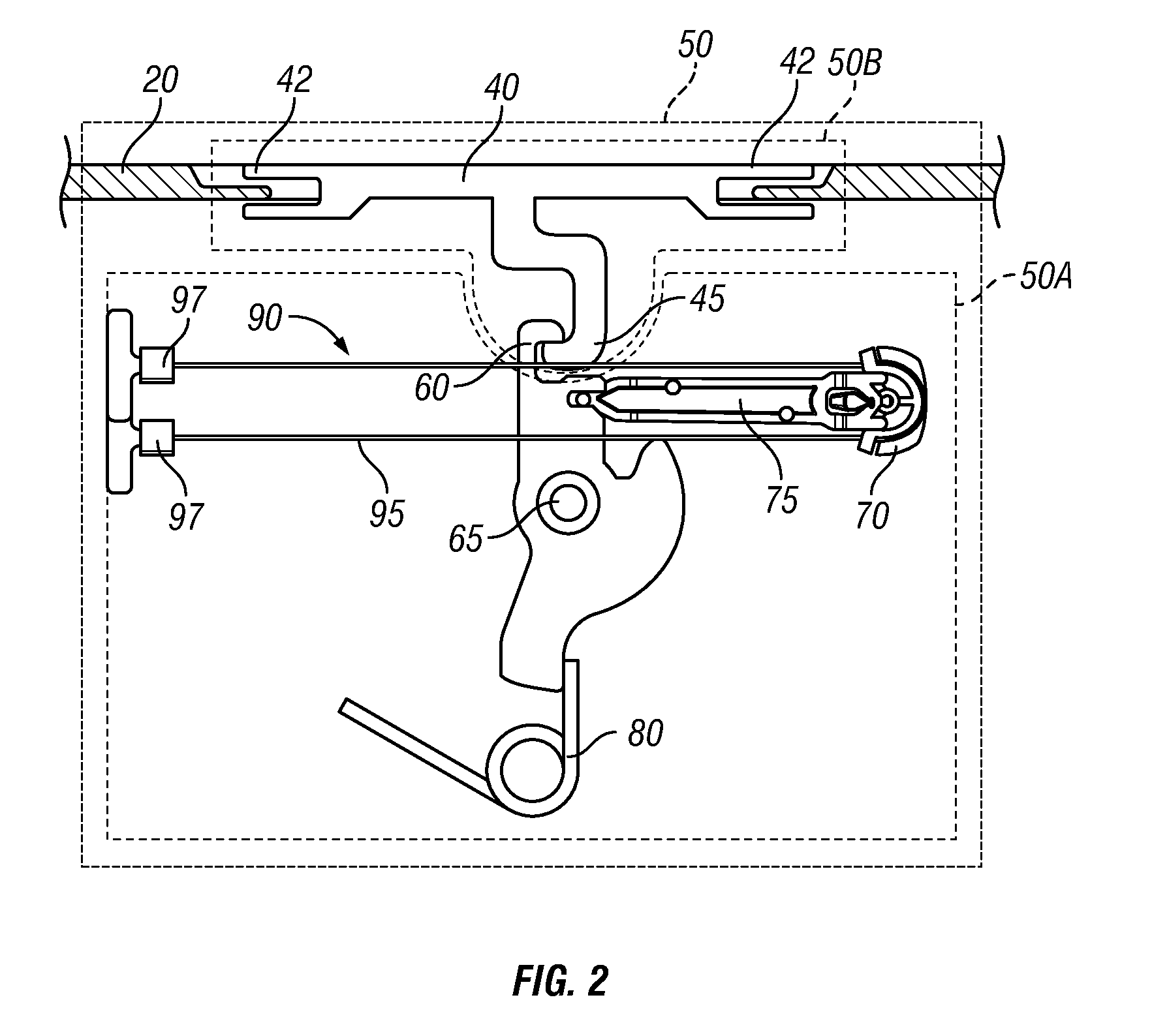

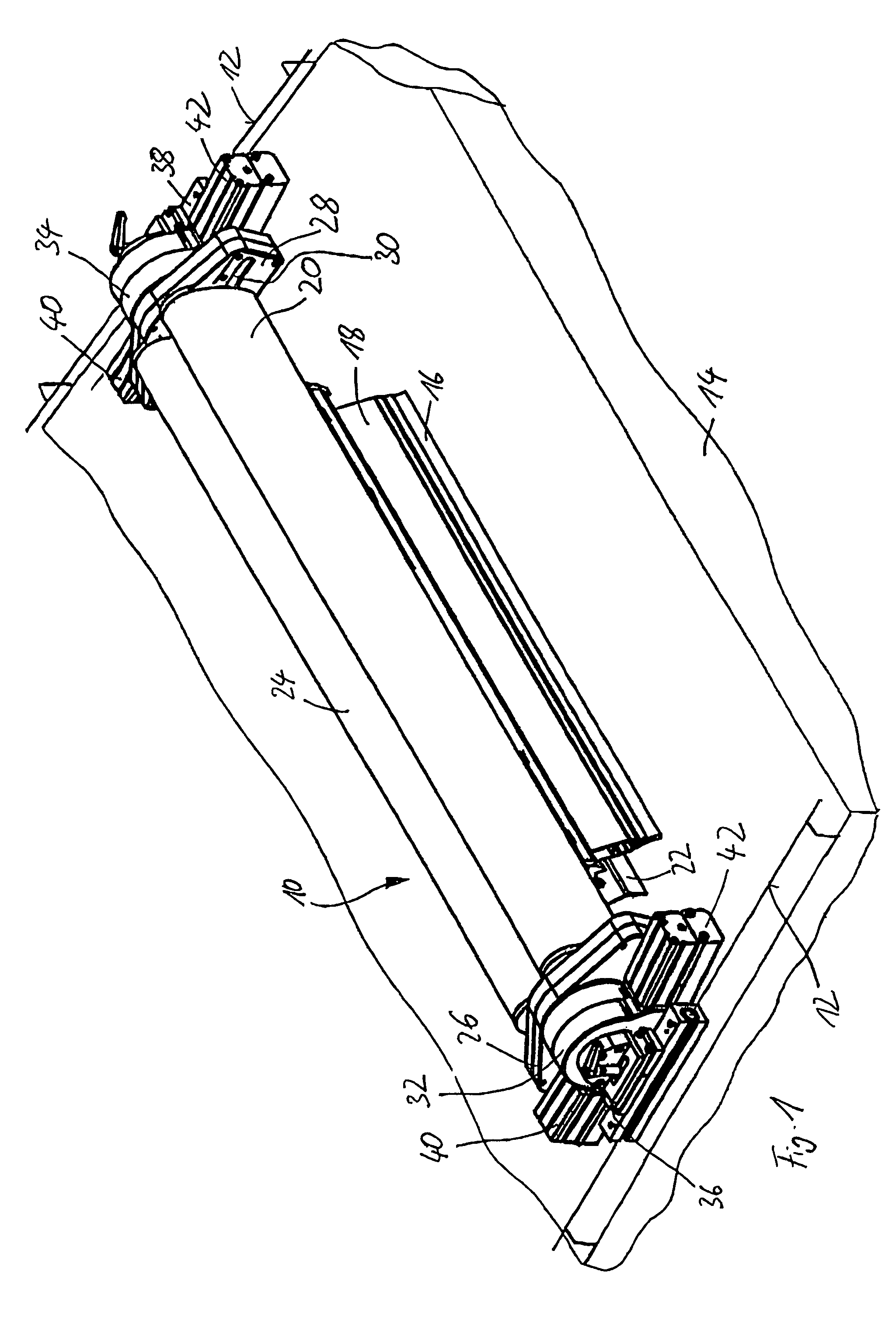

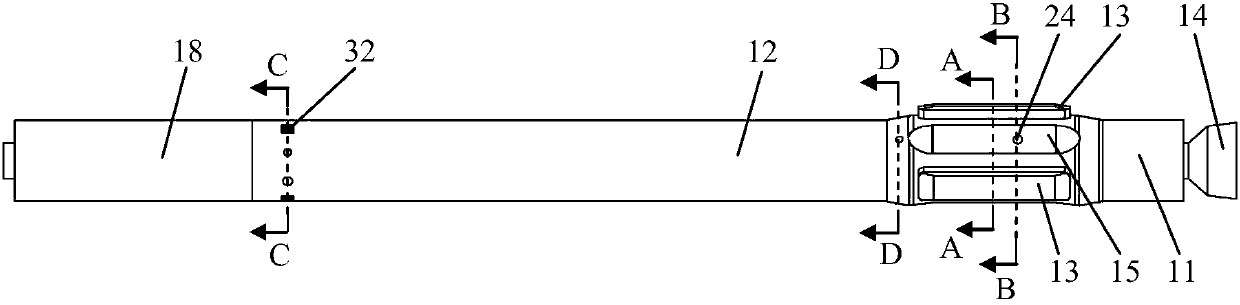

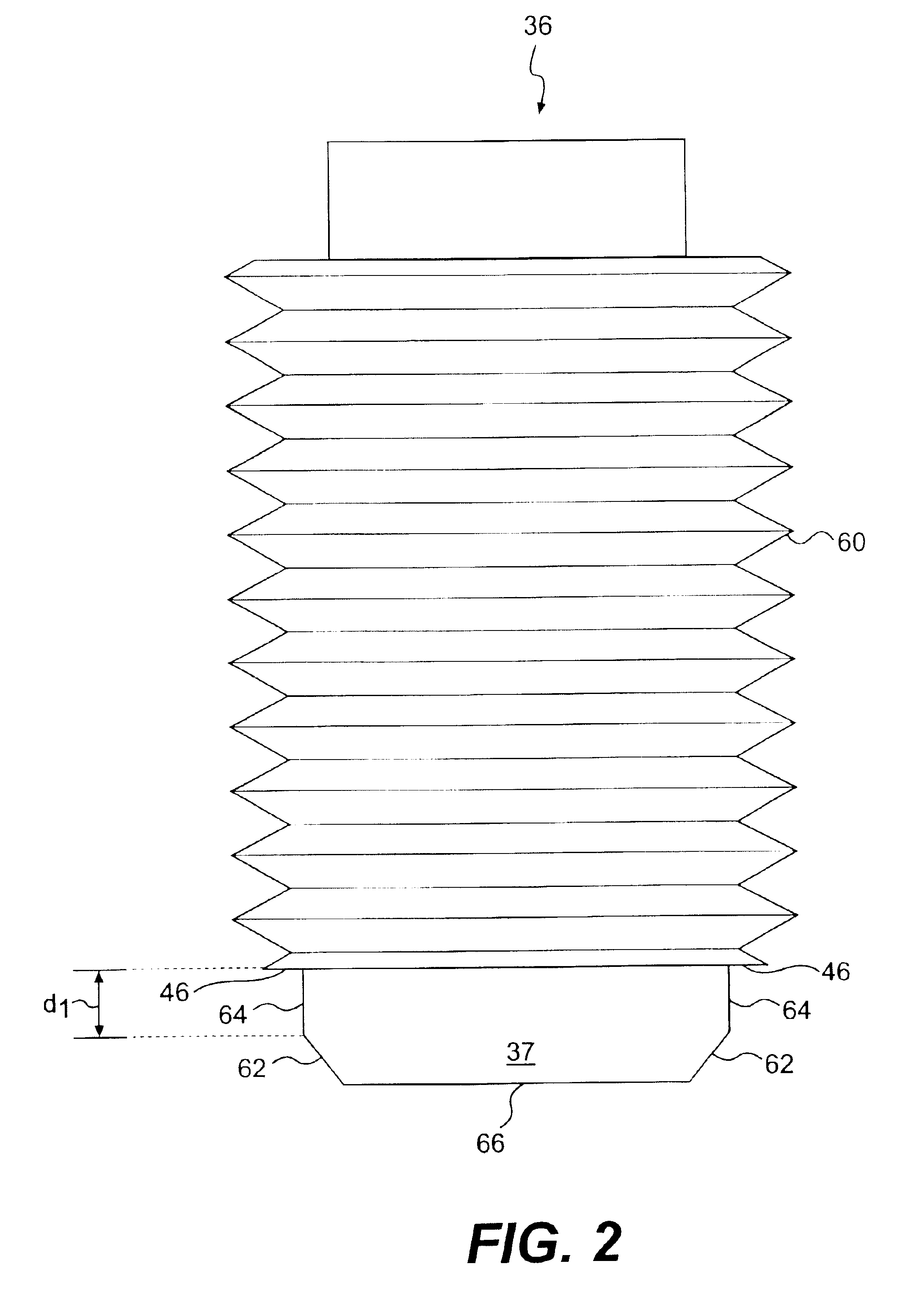

Two-step roller finger follower

A two-step roller finger follower having a high-lift follower portion that rotates relative to a low-lift follower portion about a pivot shaft, including a lost-motion compression spring disposed in a linear bore formed in the high-lift portion to exert force against an curved pad on the back side of the valve pallet of the low-lift portion. The spring is retained and guided in its bore by a spring retainer having a planar bottom for engaging the curved pad. Preferably the retainer is a cup positioned in the spring bore such that the stroke of the cup is limited, to prevent leak-down of the associated hydraulic lash adjuster. Driving the spring by a linear-acting retainer in a linear bore causes the spring to be compressed linearly, resulting in a highly stable and predictable spring rate.

Owner:DELPHI TECH IP LTD

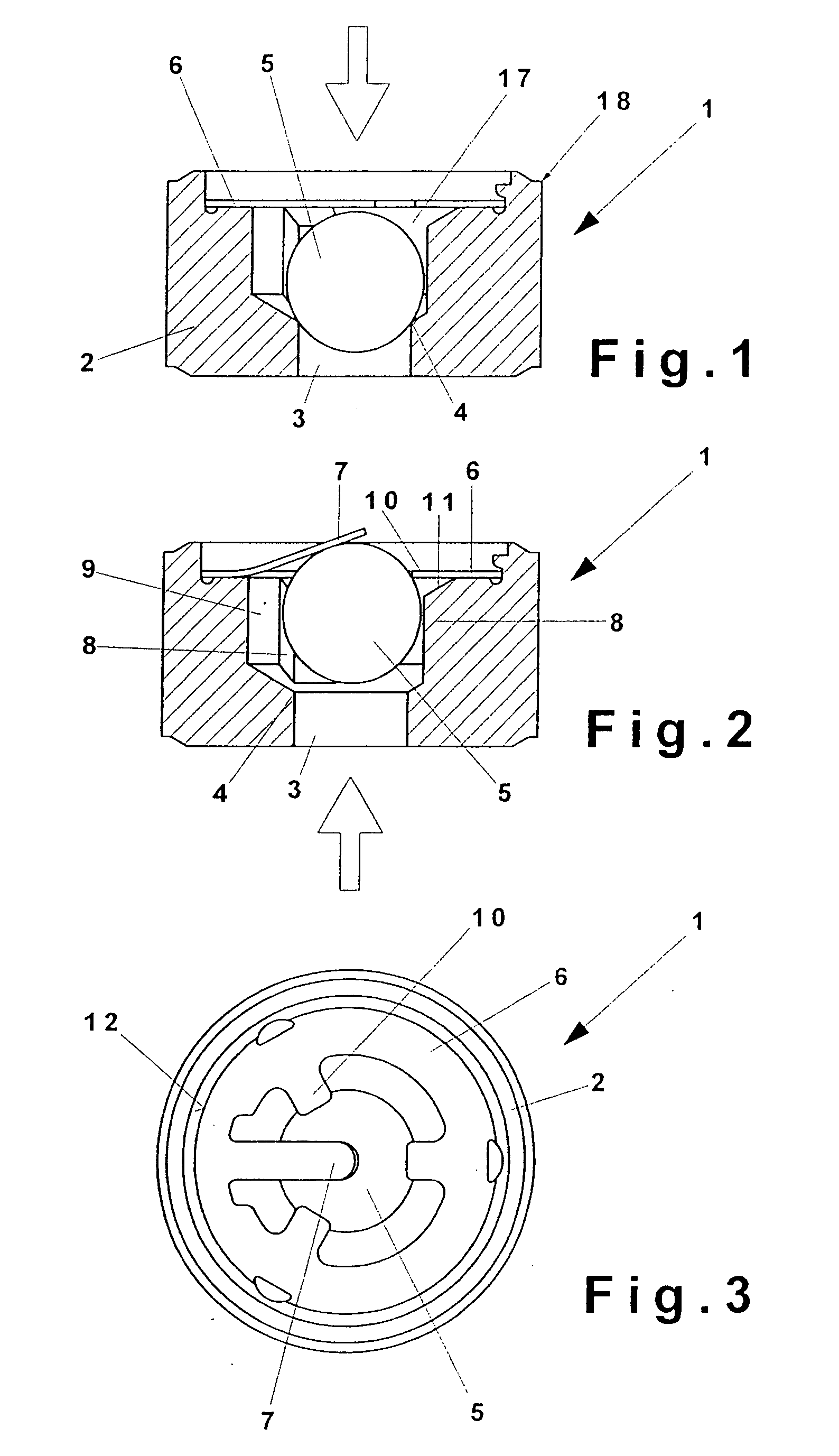

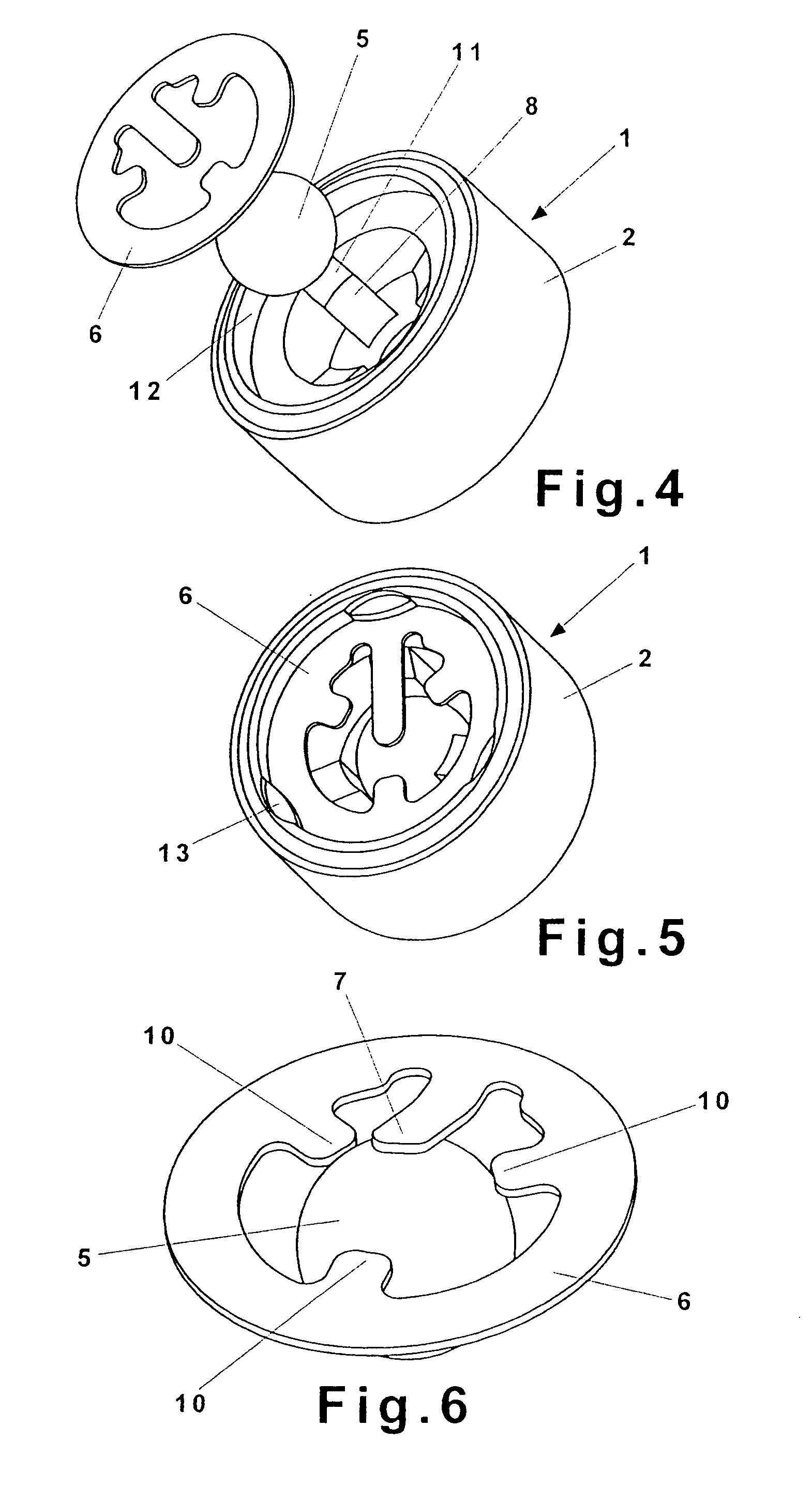

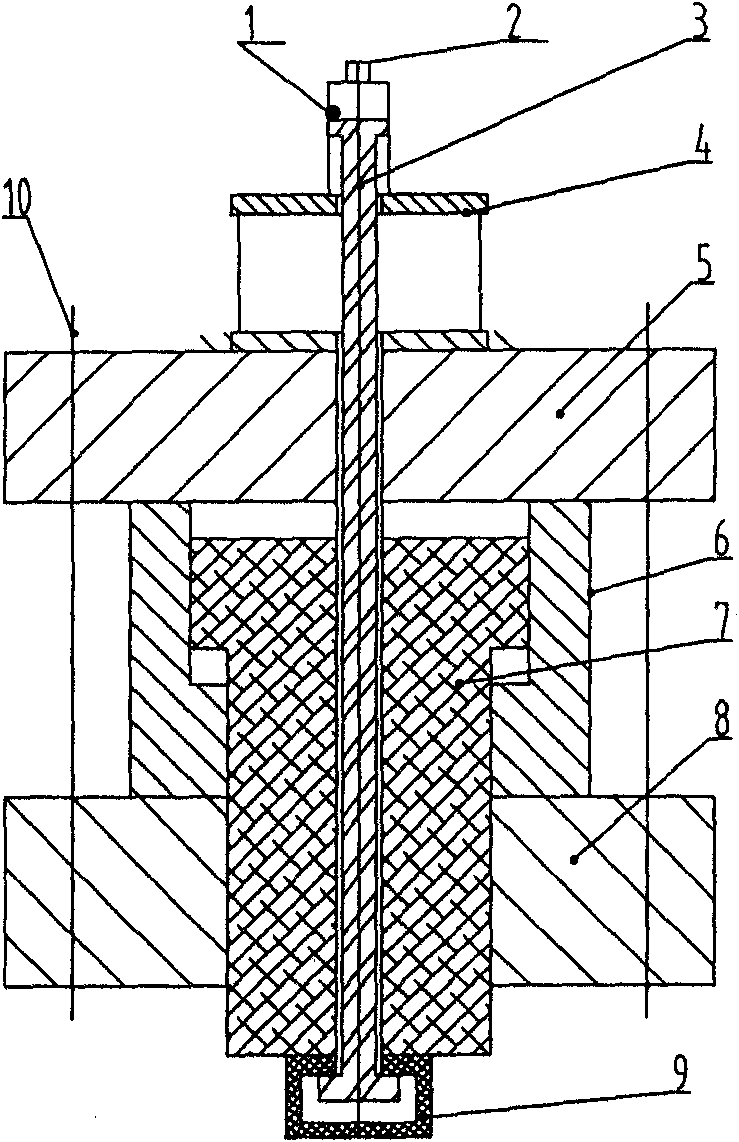

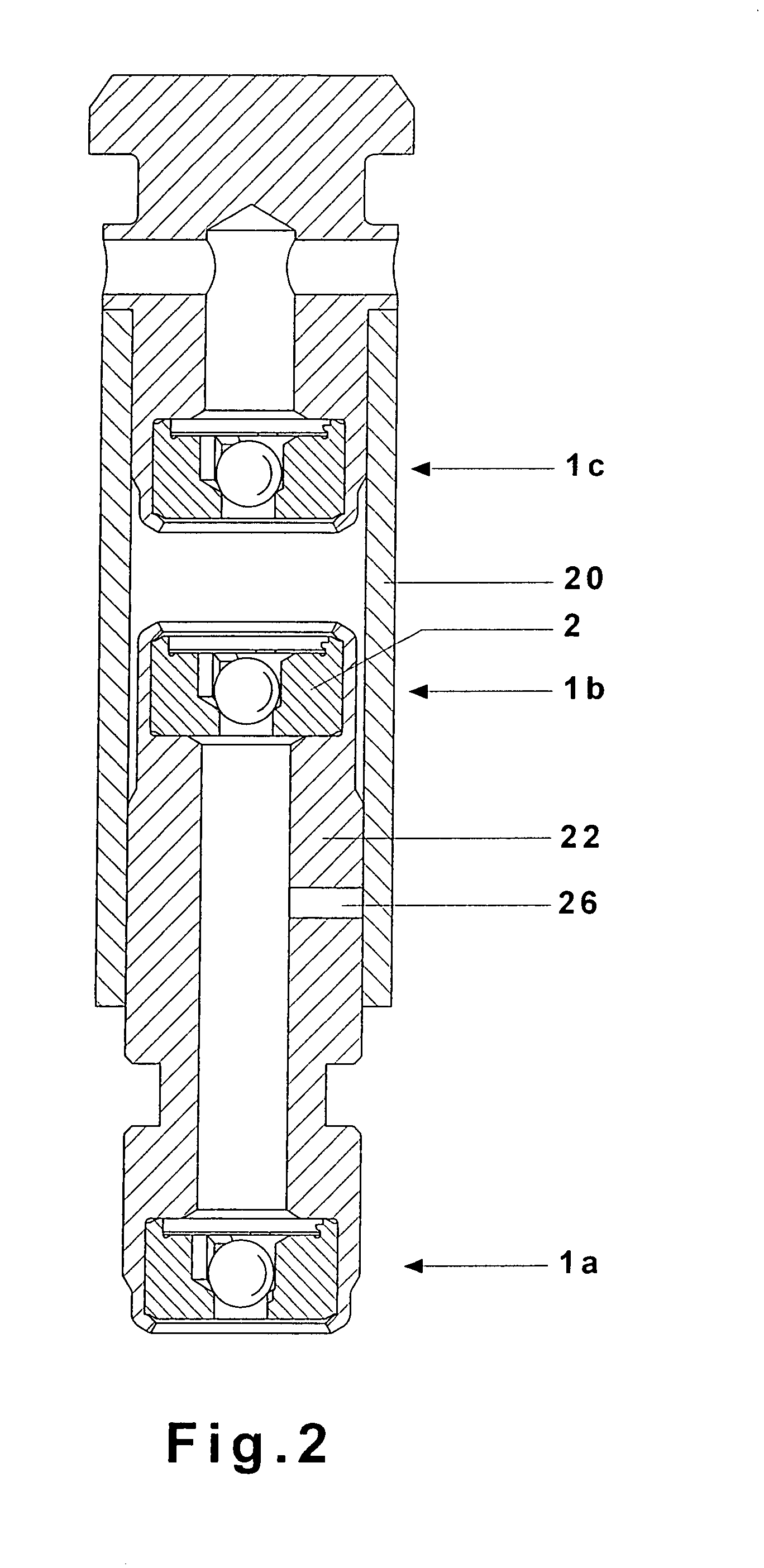

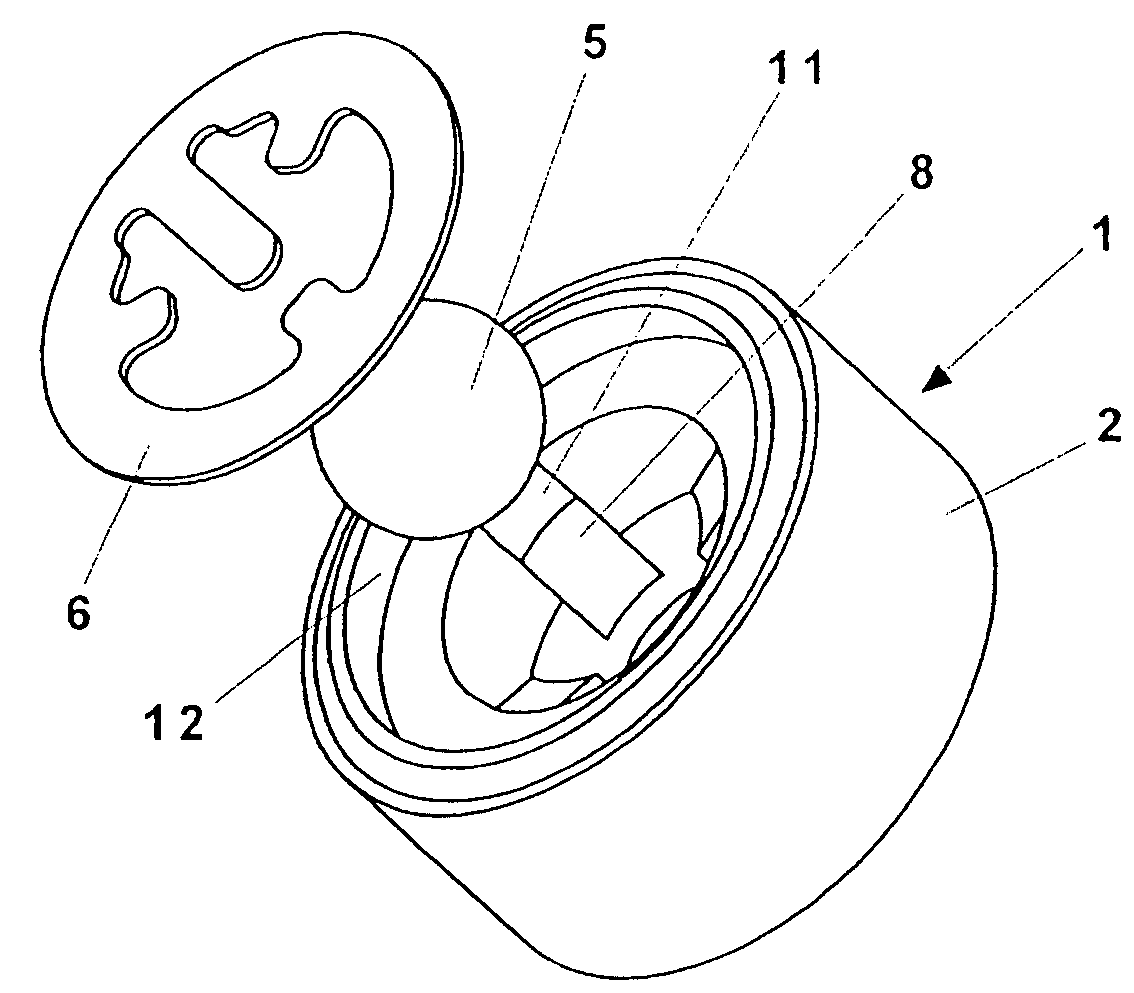

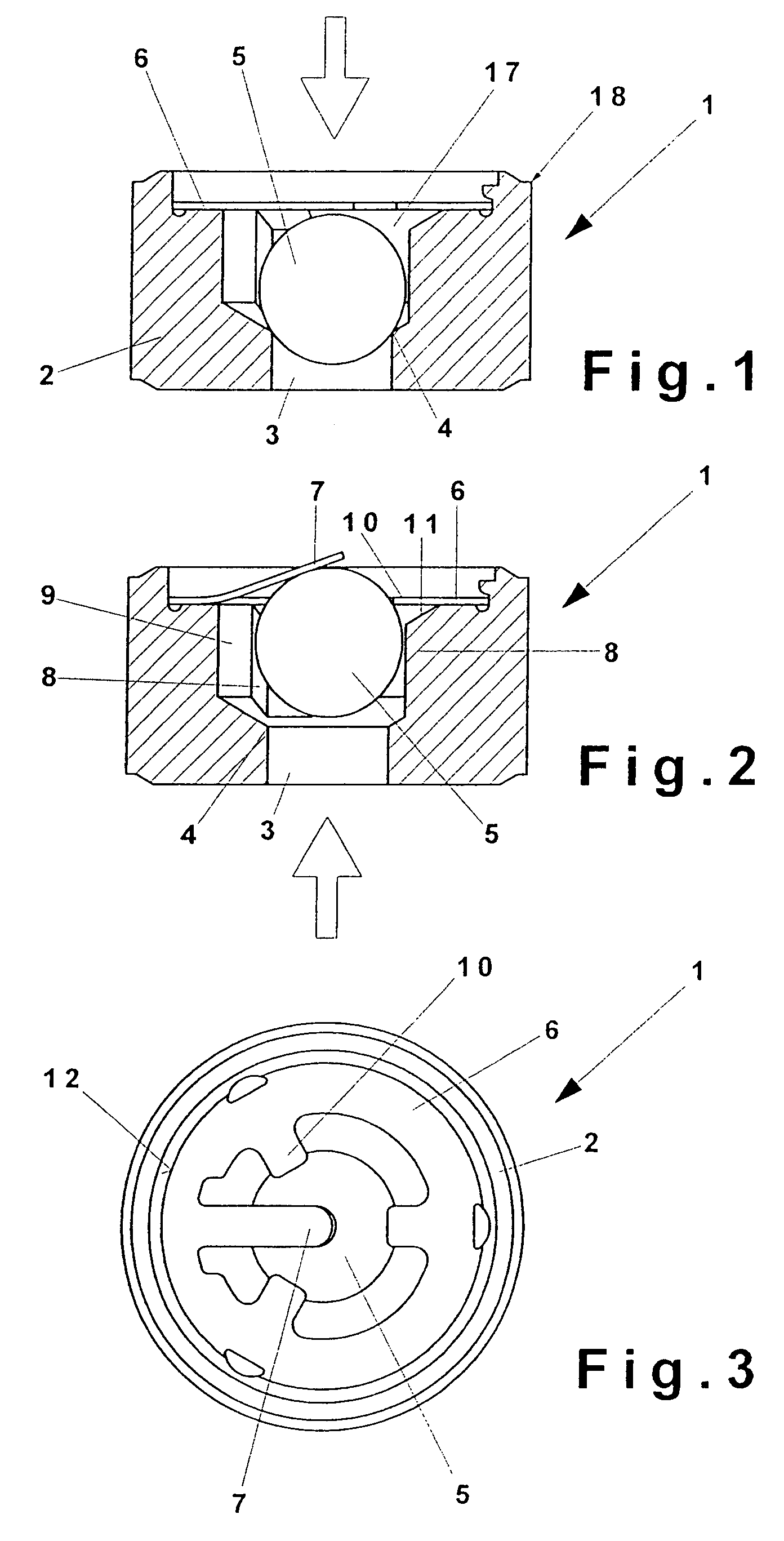

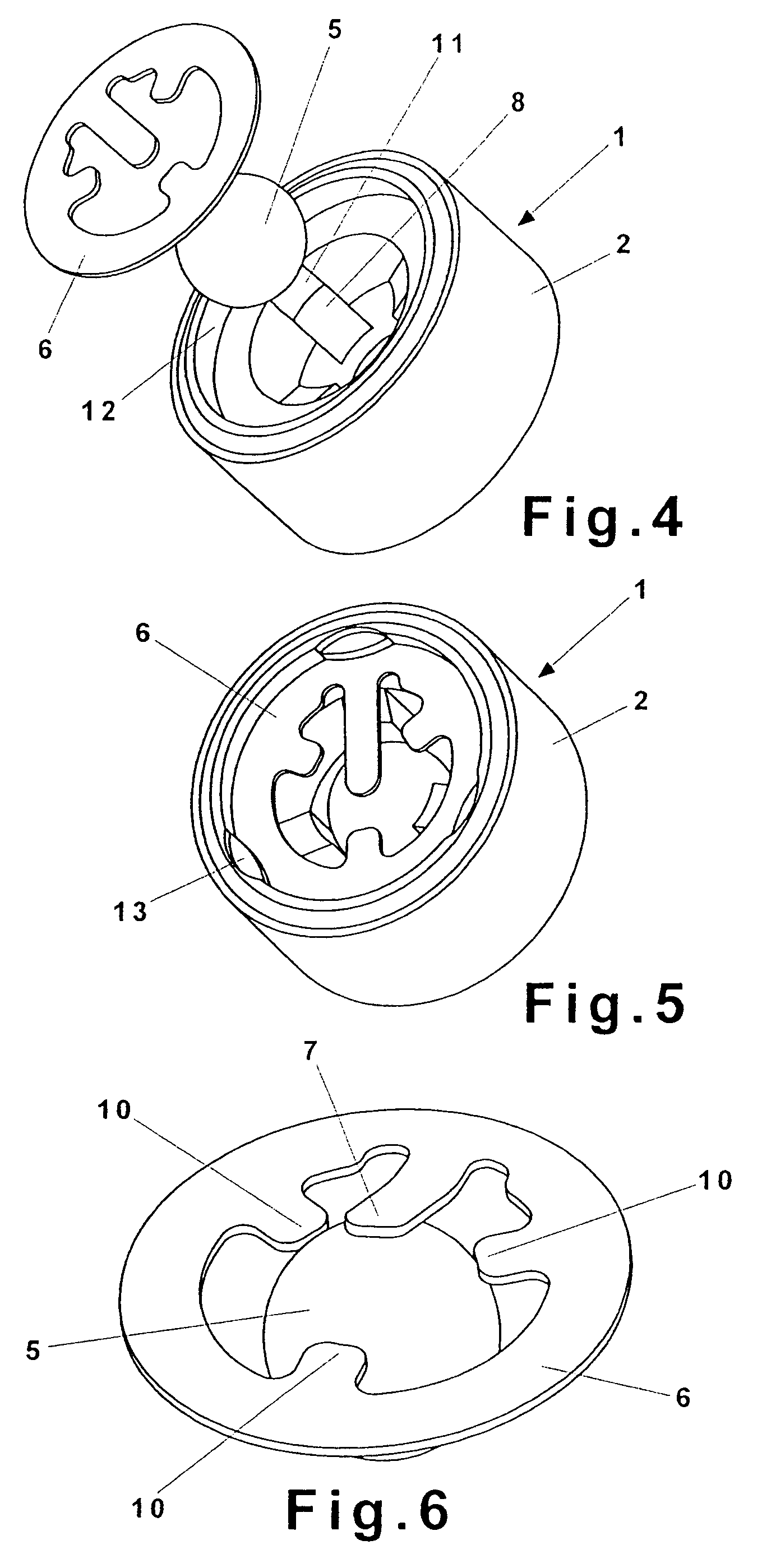

Check valve

Check valve includes a housing, a bore, and a movable valve body, which is spring-loaded and rests with a sealing action on a valve seat, where the bore is designed as a stepped bore, where the bore with the smaller diameter has the valve seat, and where the bore with the larger diameter holds the movable valve element. The valve body is designed as a ball, which is guided in the bore by at least two guide ribs, and a retaining element in the terminal area of the bore captures the ball and simultaneously spring-loads it.

Owner:ZF FRIEDRICHSHAFEN AG

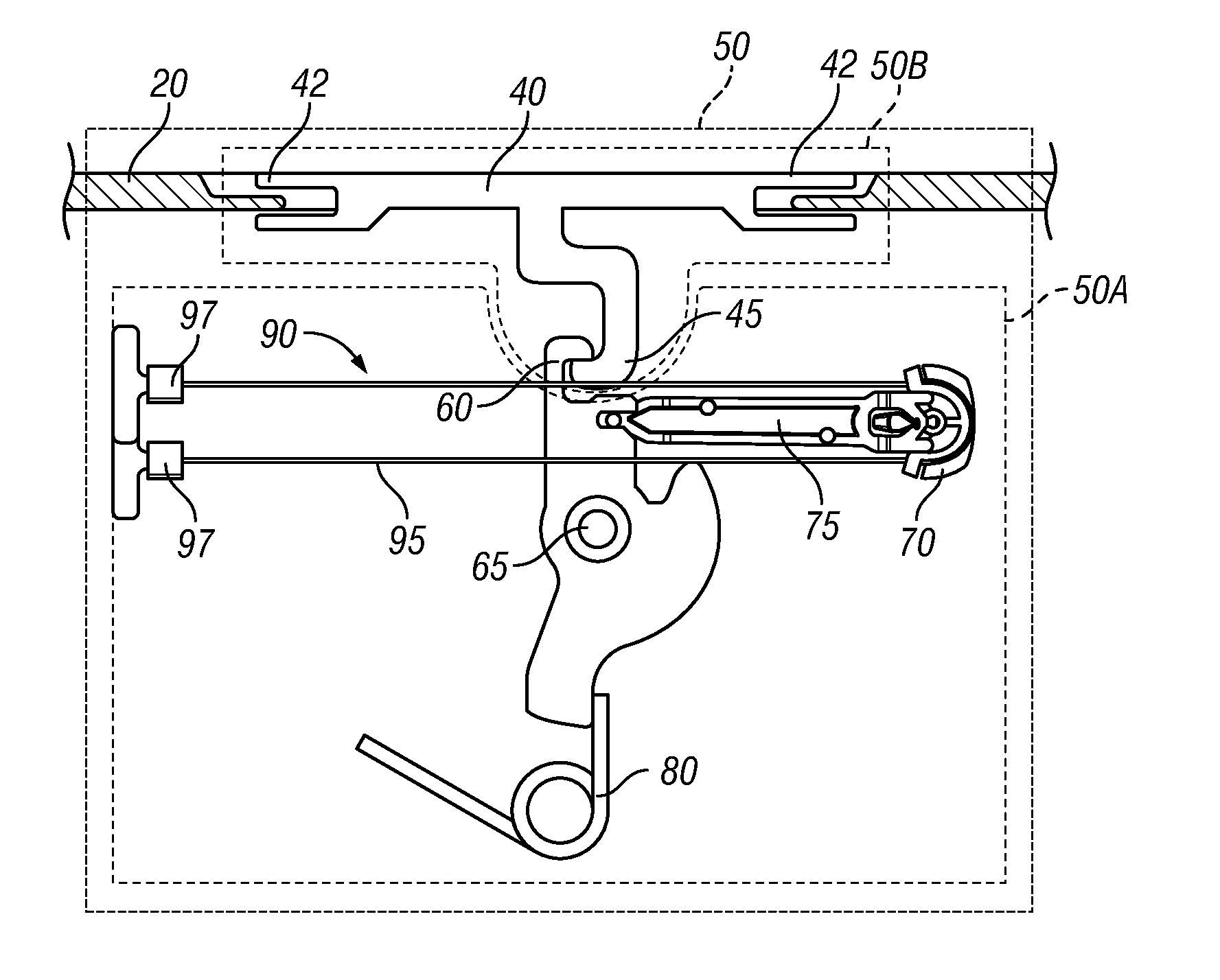

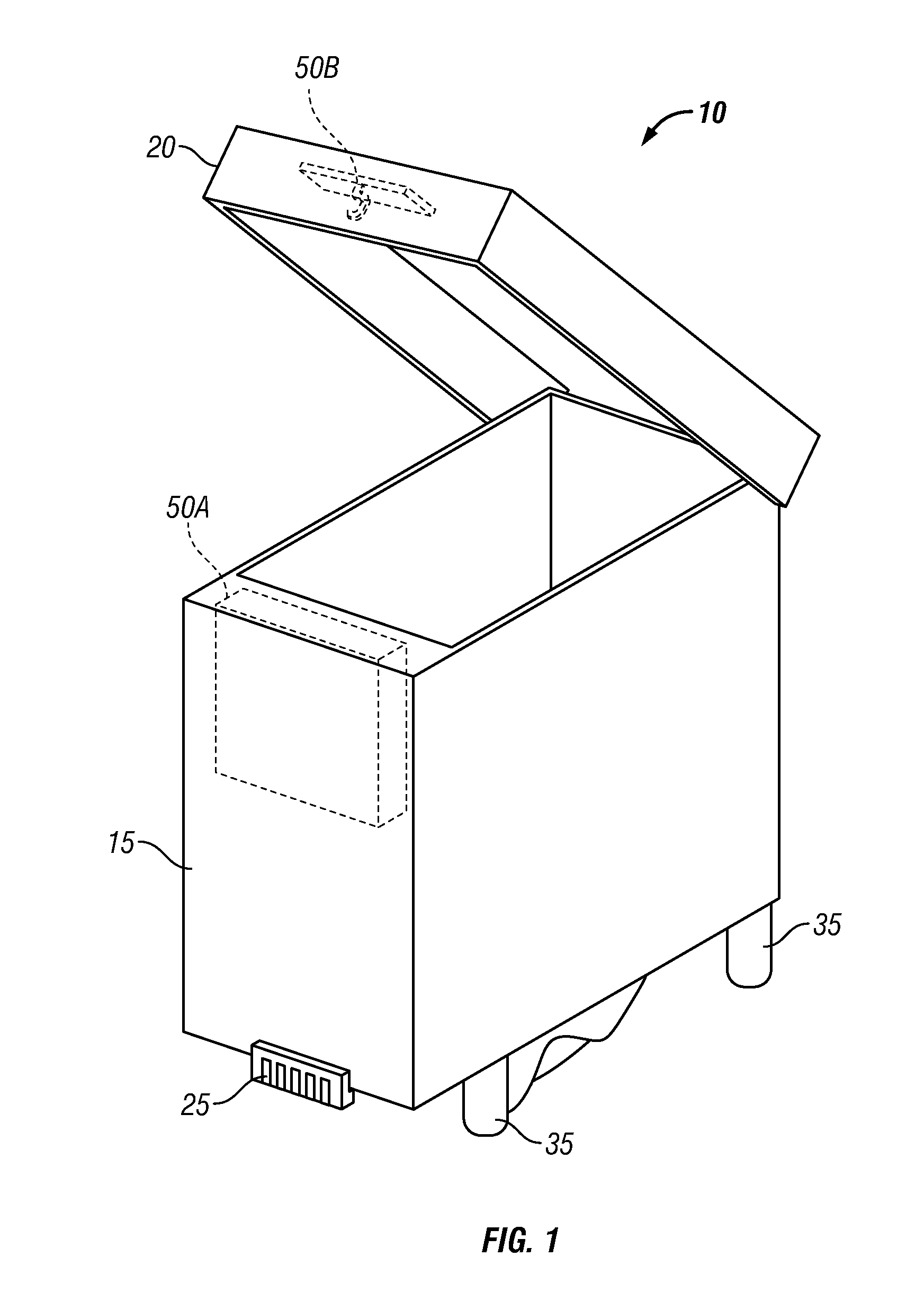

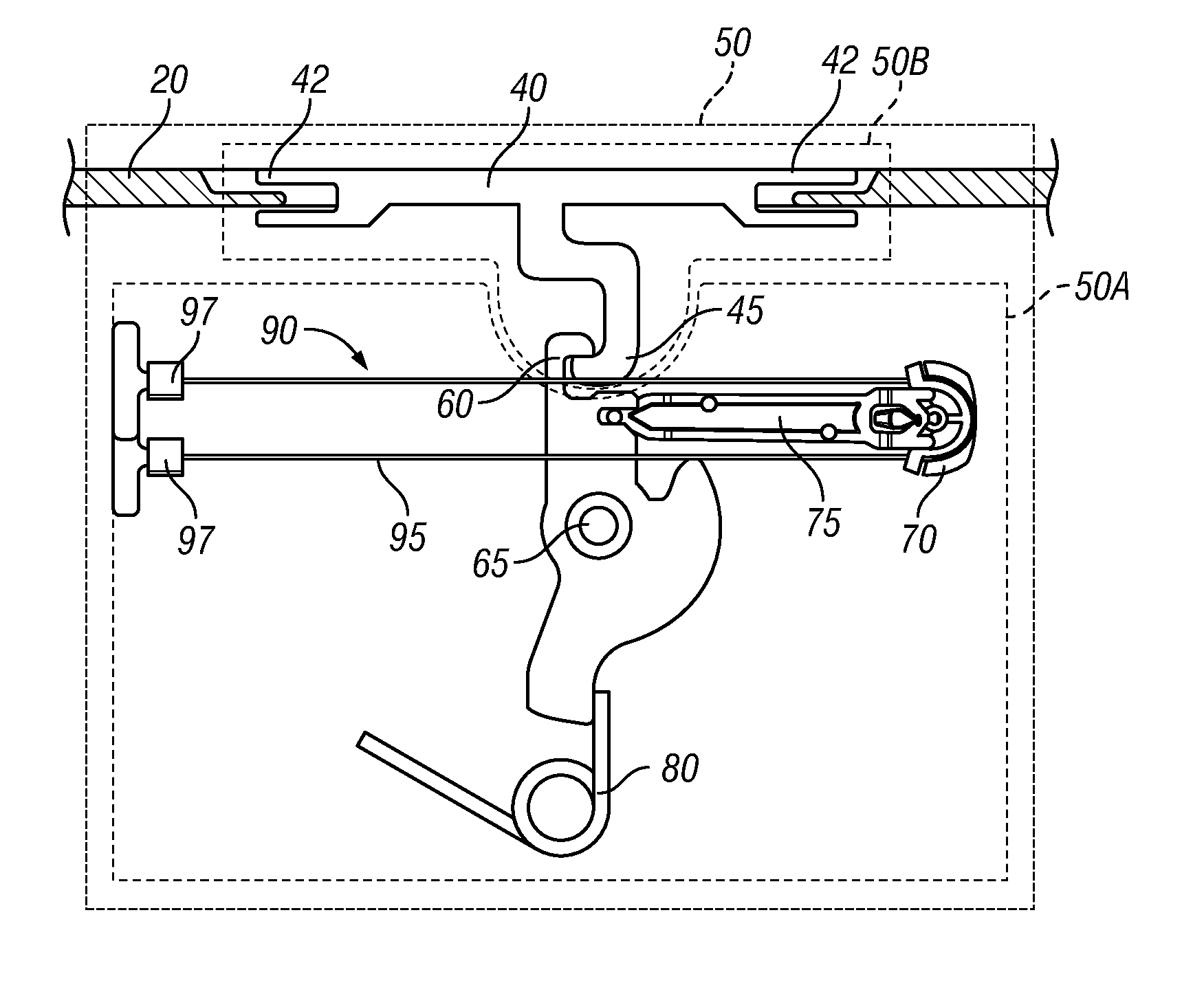

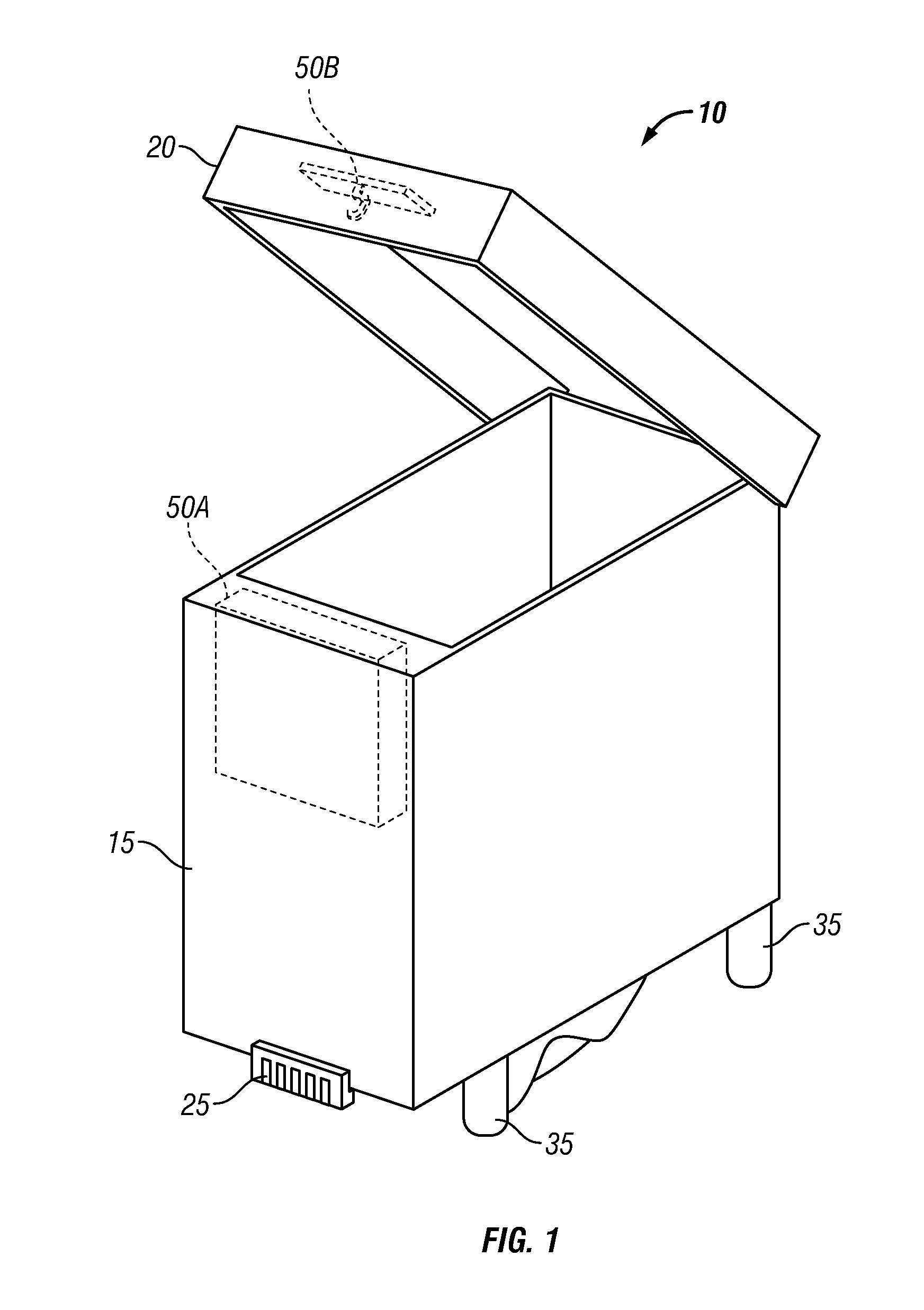

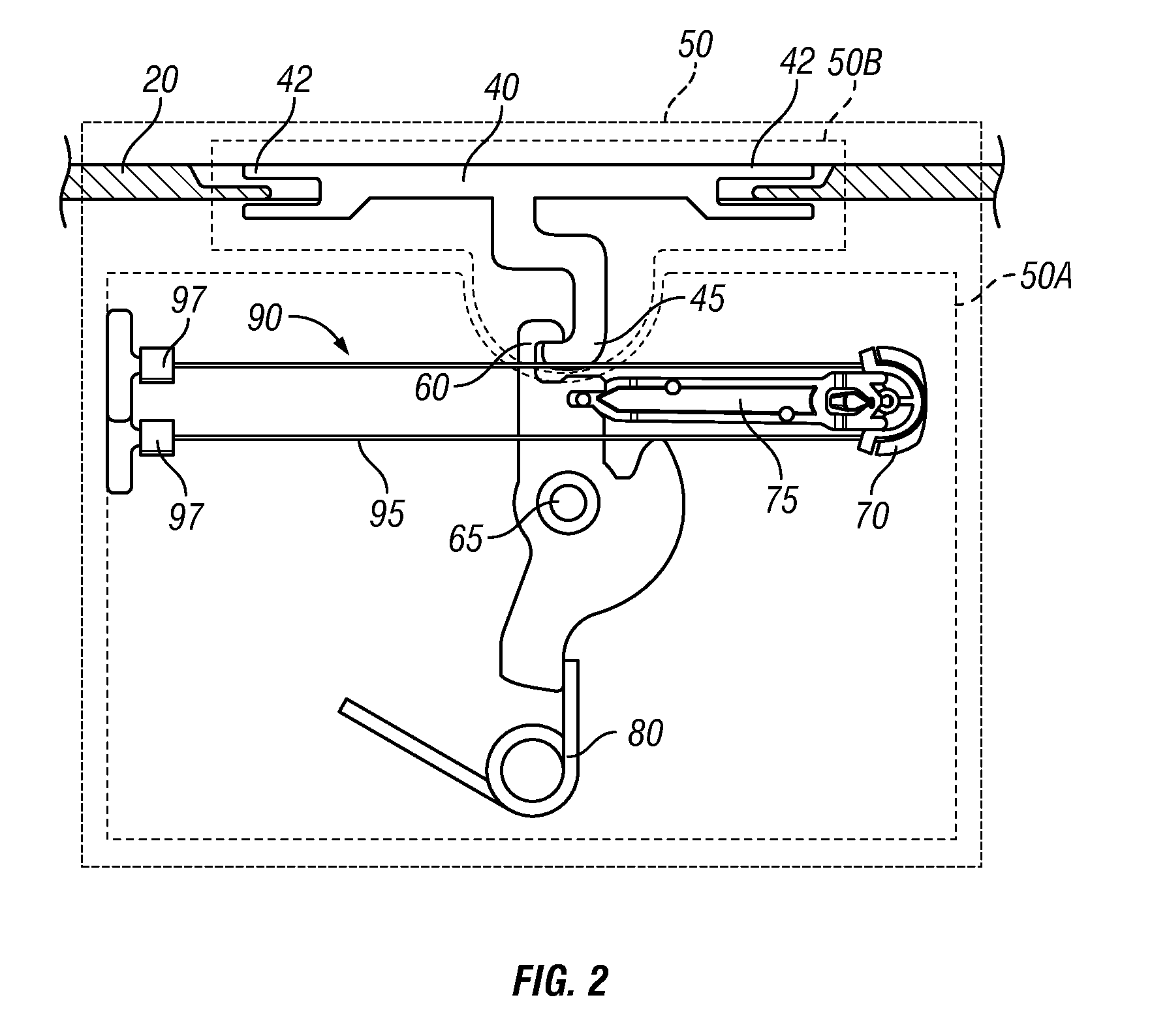

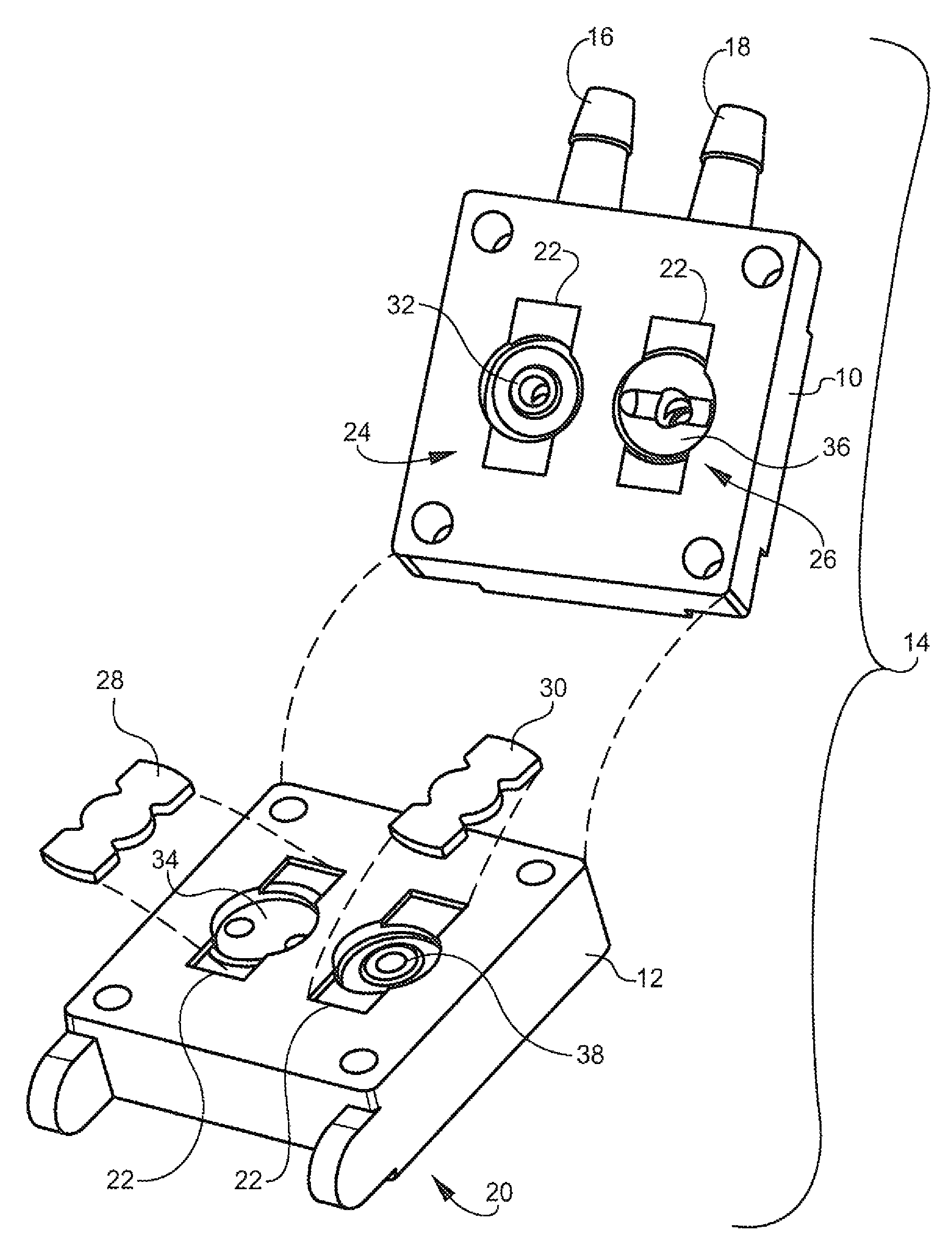

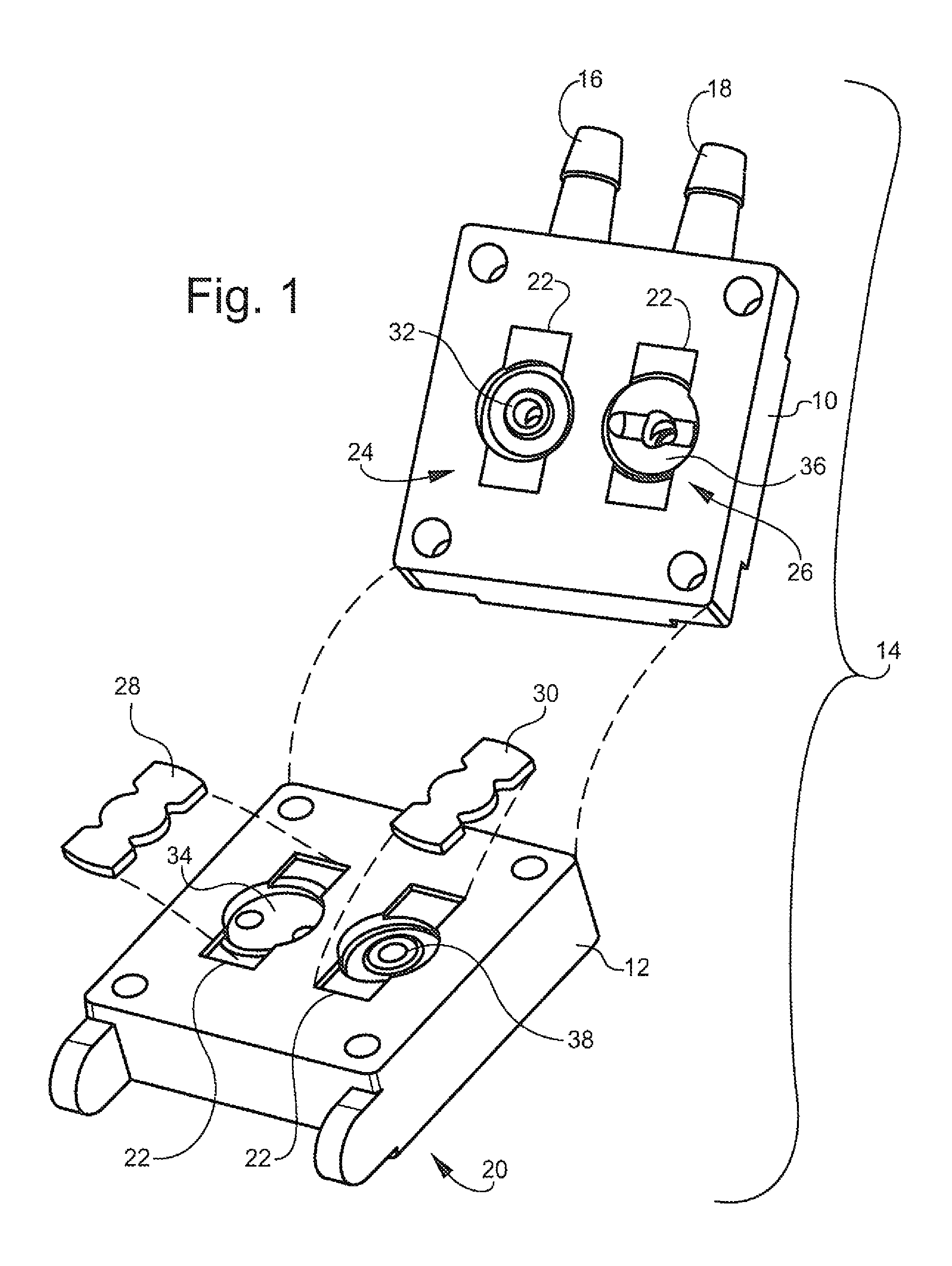

Self-aligning modular latch

ActiveUS20120187128A1Tight toleranceAdd partsVehicle locksNon-mechanical controlsFastenerEngineering

A container is disclosed that has a housing and a lid. The lid has a planar portion and a latch that is freely movable parallel to the planar portion of the lid. The latch has a retention feature and a first reference surface that is perpendicular to the planar portion of the lid. There is a latch mechanism coupled to the housing that has an engagement element configured to engage the retention feature of the latch and a first alignment feature having a first alignment surface. The first alignment feature is configured to laterally displace the latch in a first direction such that the first reference surface aligns with the first alignment surface when the lid is brought together with the housing with the fastener laterally displaced away from the engagement element in a second direction that is opposite to the first direction.

Owner:CAREFUSION 303 INC

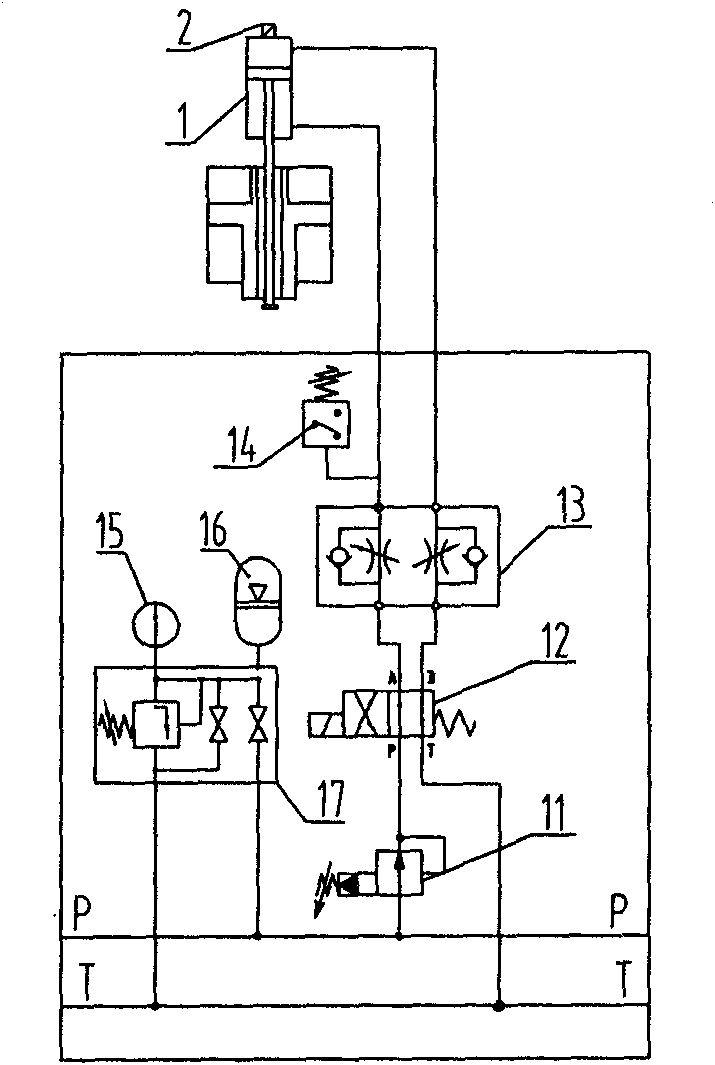

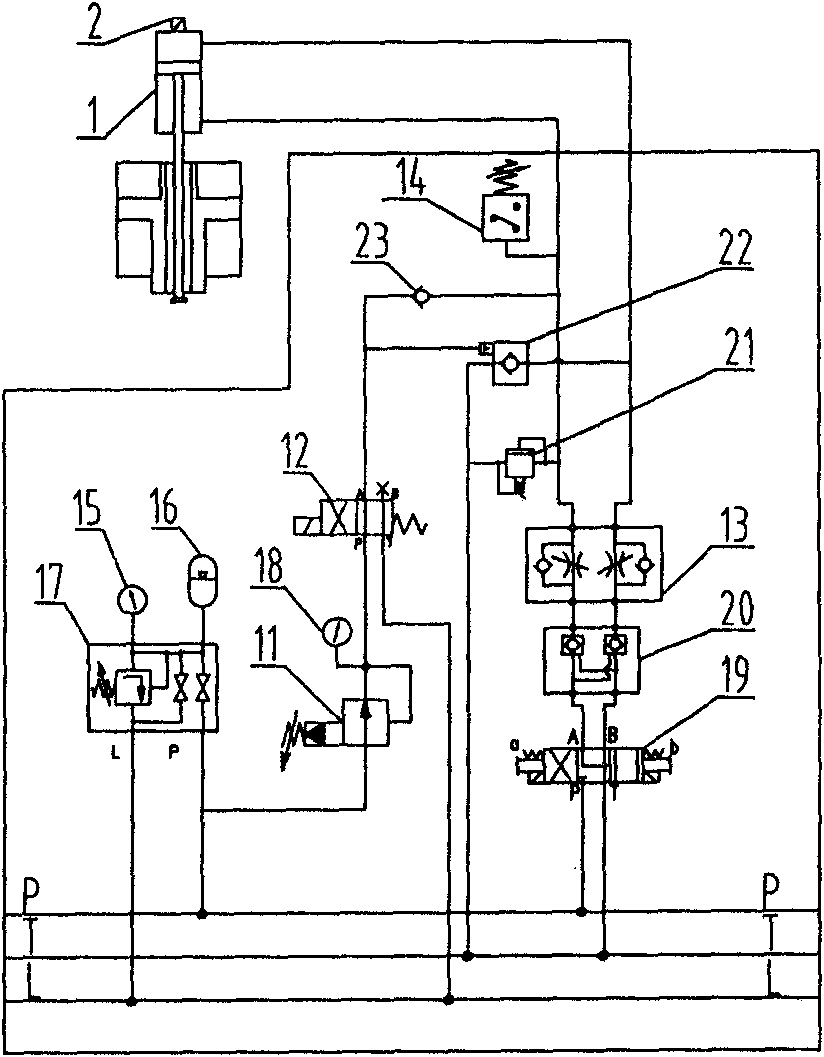

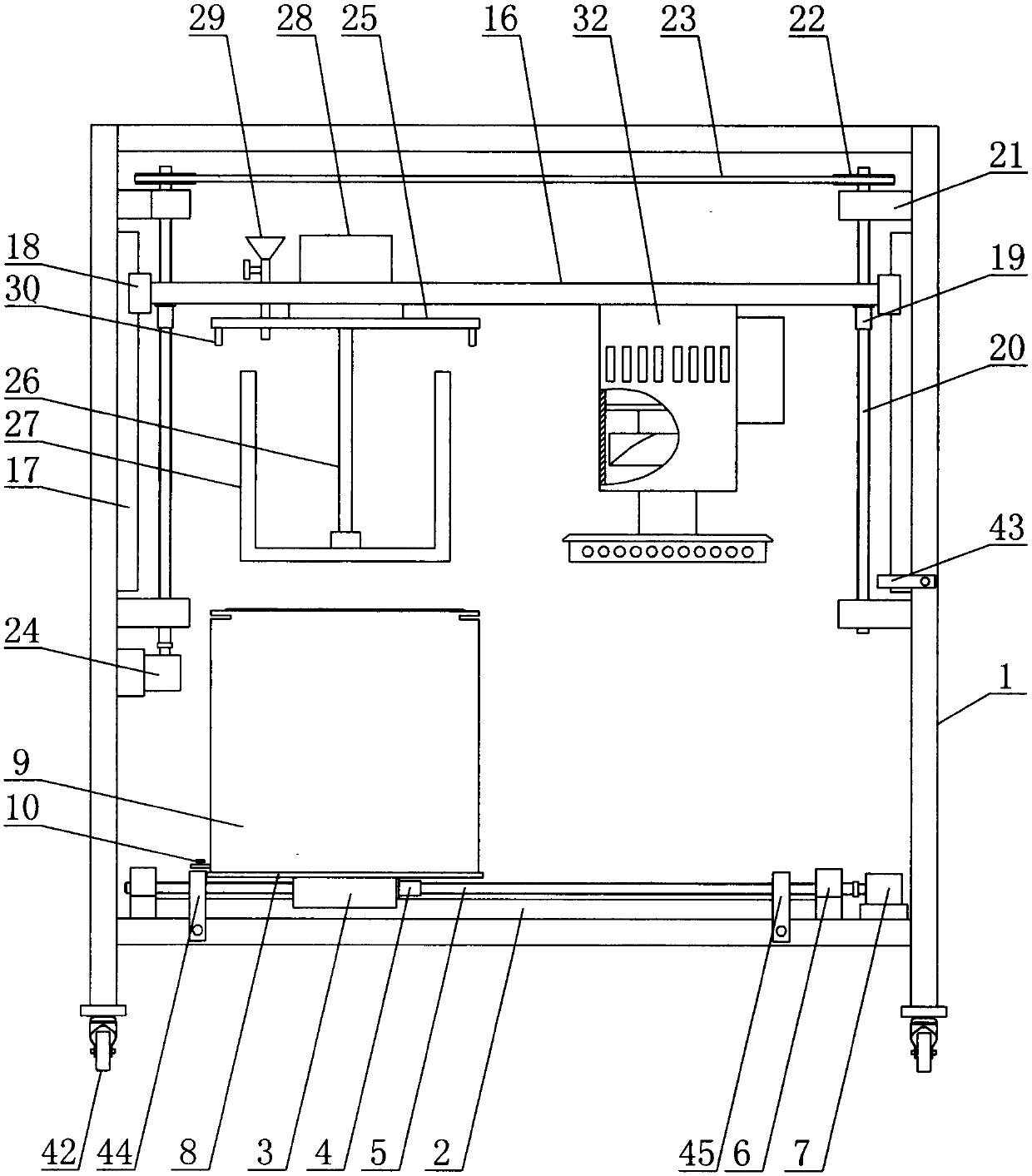

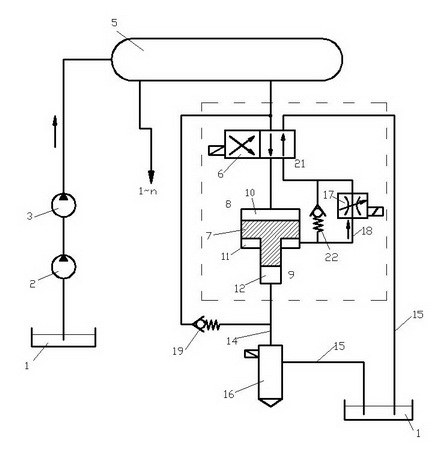

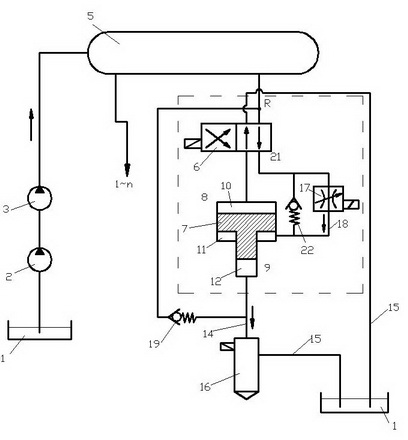

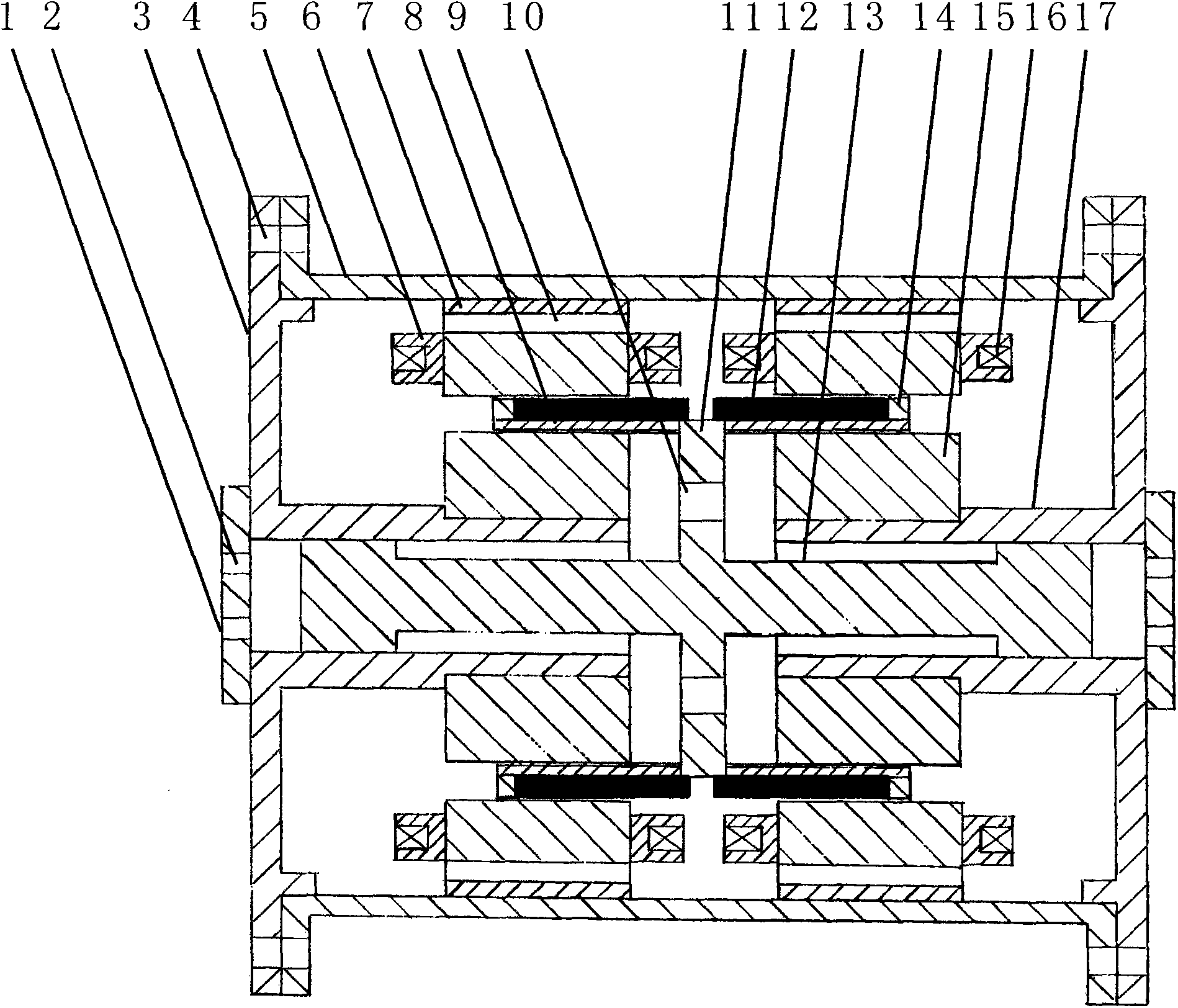

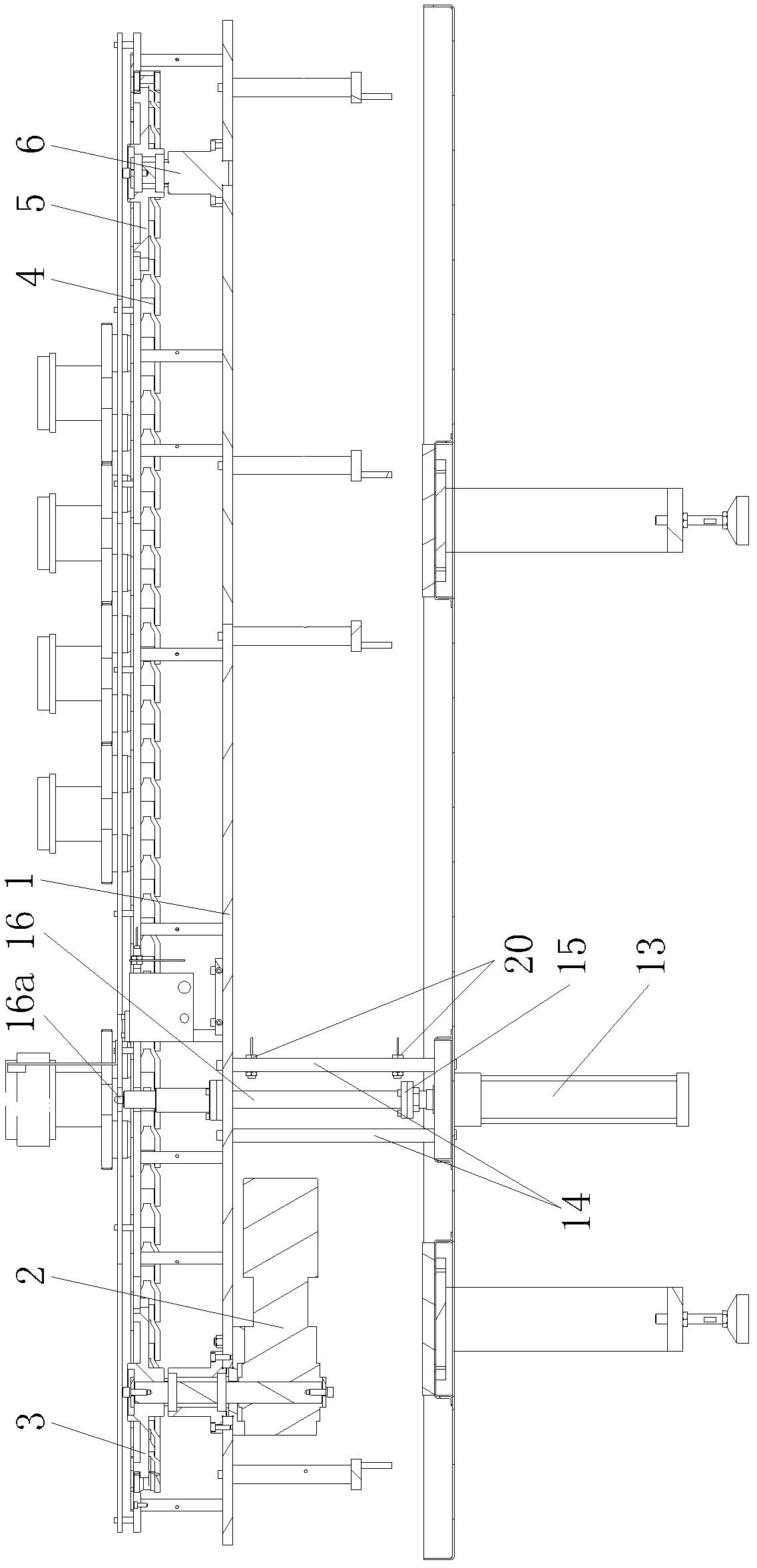

Pressure-maintaining and regulating hydraulic control system of roll balance gear

InactiveCN101869912AMonitor packing and packing pressureRegulate securityMetal rolling stand detailsMetal rolling arrangementsControl systemSafety valve

The invention discloses a pressure-maintaining and regulating hydraulic control system of a roll balance gear and relates to a hydraulic control system of a steel rolling machine. The pressure-maintaining and regulating hydraulic control system solves the problems of unreliable pressure maintenance, inconvenient equipment debugging and no pressure protection of a control loop in the prior art. The pressure-maintaining and regulating hydraulic control system is characterized in that: a hydraulic control loop comprises a pressure-maintaining loop of the roll balance gear and an adjusting loop of the roll balance gear; the pressure-maintaining loop is formed by connecting a pressure-reducing valve 11, an I-number electromagnetic directional valve 12, an energy accumulator 16, a safety valve 17, an I-number pressure meter 15, an II-number pressure meter 18 and a hydraulic oil pipe according to the conventional connecting method; the adjusting loop is formed by connecting an II-number electromagnetic directional valve 19, a one-way throttle valve 13, a pressure relay 14, a hydraulic locking valve 20, an overflow valve 21 and the hydraulic oil pipe according to the conventional connecting method; and the pressure-maintaining loop and the adjusting loop are separated and associated by using a hydraulic one-way valve 22 and a one-way valve 23.

Owner:TAIYUAN HEAVY IND

Self-aligning modular latch

A container is disclosed that has a housing and a lid. The lid has a planar portion and a latch that is freely movable parallel to the planar portion of the lid. The latch has a retention feature and a first reference surface that is perpendicular to the planar portion of the lid. There is a latch mechanism coupled to the housing that has an engagement element configured to engage the retention feature of the latch and a first alignment feature having a first alignment surface. The first alignment feature is configured to laterally displace the latch in a first direction such that the first reference surface aligns with the first alignment surface when the lid is brought together with the housing with the fastener laterally displaced away from the engagement element in a second direction that is opposite to the first direction.

Owner:CAREFUSION 303 INC

Chemical material mixing device

InactiveCN105536613AReduce manufacturing costIncrease productivityRotary stirring mixersTransportation and packagingElectromagnetic inductionEngineering

The invention discloses a chemical material mixing device and mainly relates to the technical field of chemical material mixing. The device comprises a machine frame, wherein a first guide rail is horizontally arranged on the lower portion of the machine frame, a first sliding block is arranged on the first guide rail, a first nut is arranged on the first sliding block, and a first lead screw is arranged in the first nut; a connecting plate is arranged on the first sliding block, a mixing cylinder is arranged on the connecting plate, a heat insulation cotton layer is arranged on the side wall of the mixing cylinder, and an electromagnetic induction heating coil is arranged on the heat insulation cotton layer; a movable supporting frame is horizontally arranged above the mixing cylinder, a cover is arranged on the movable supporting frame, a rotary shaft is arranged in the middle of the cover, a stirring paddle is arranged on the rotary shaft, and a cleaning device is arranged on the movable supporting frame. The device has the advantages that materials can be dried while being mixed, so that production cost is reduced and production efficiency is improved; materials left in the mixing cylinder can be cleared automatically, so that the labor intensity of workers is relieved.

Owner:HENAN INST OF SCI & TECH

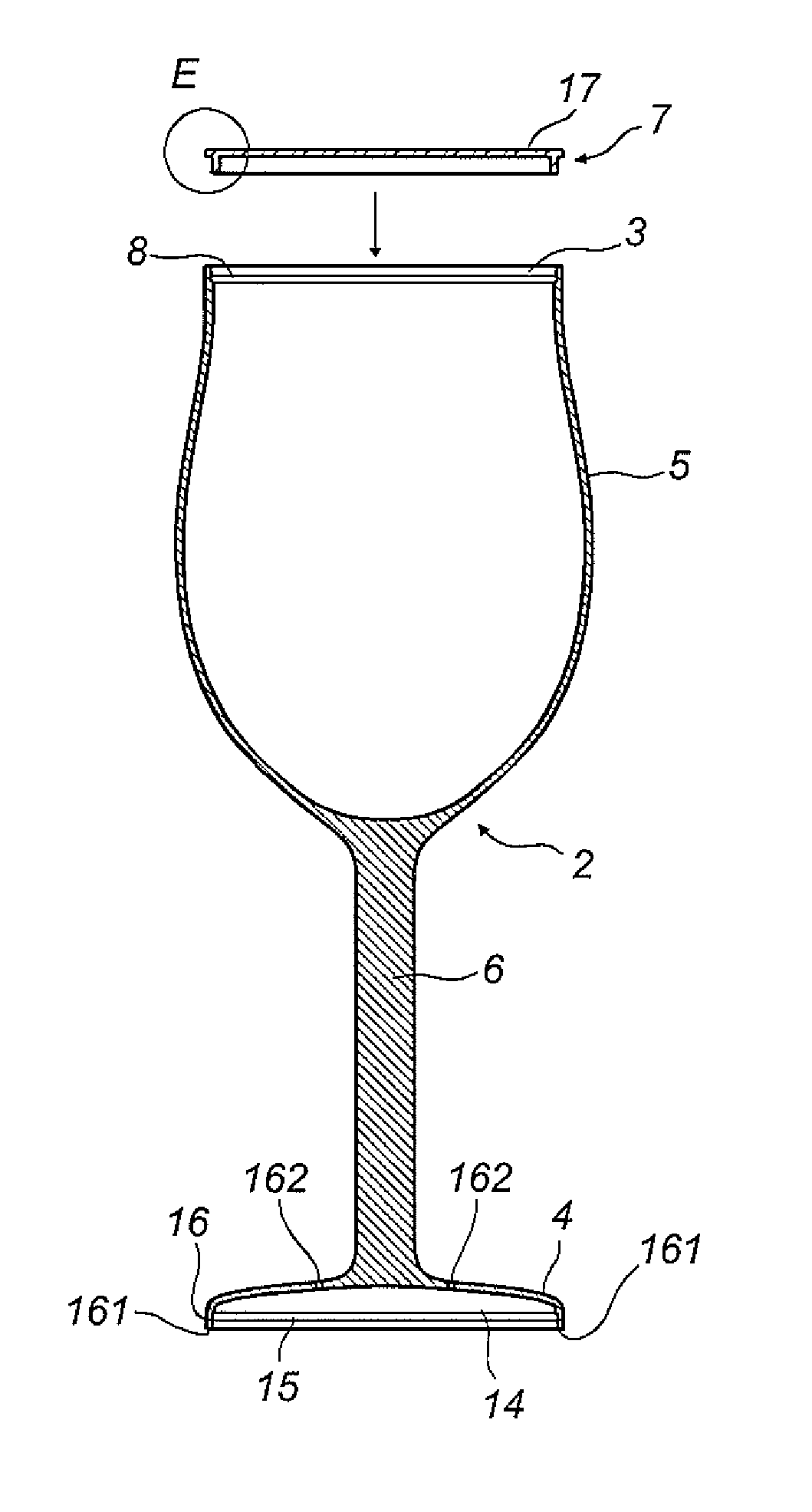

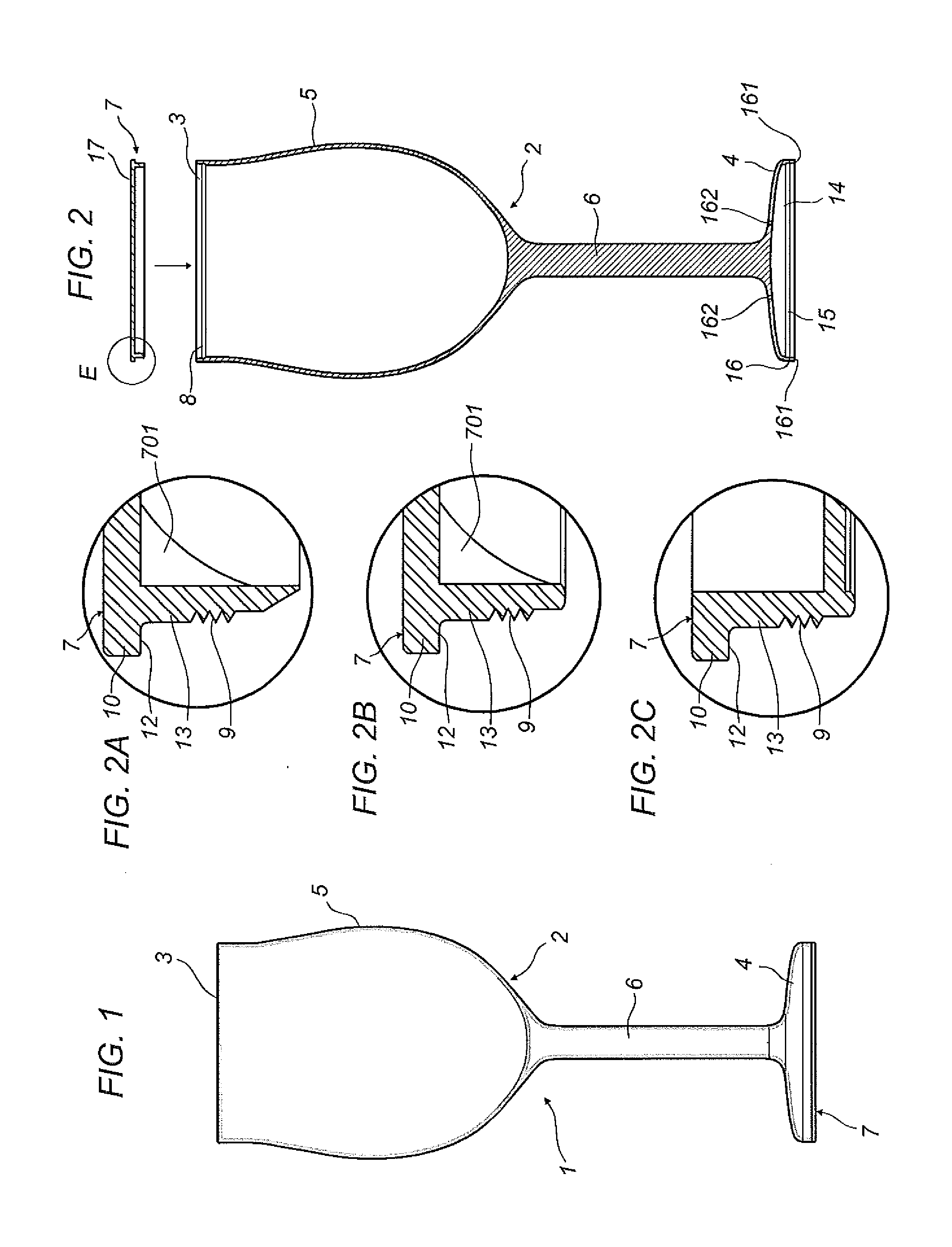

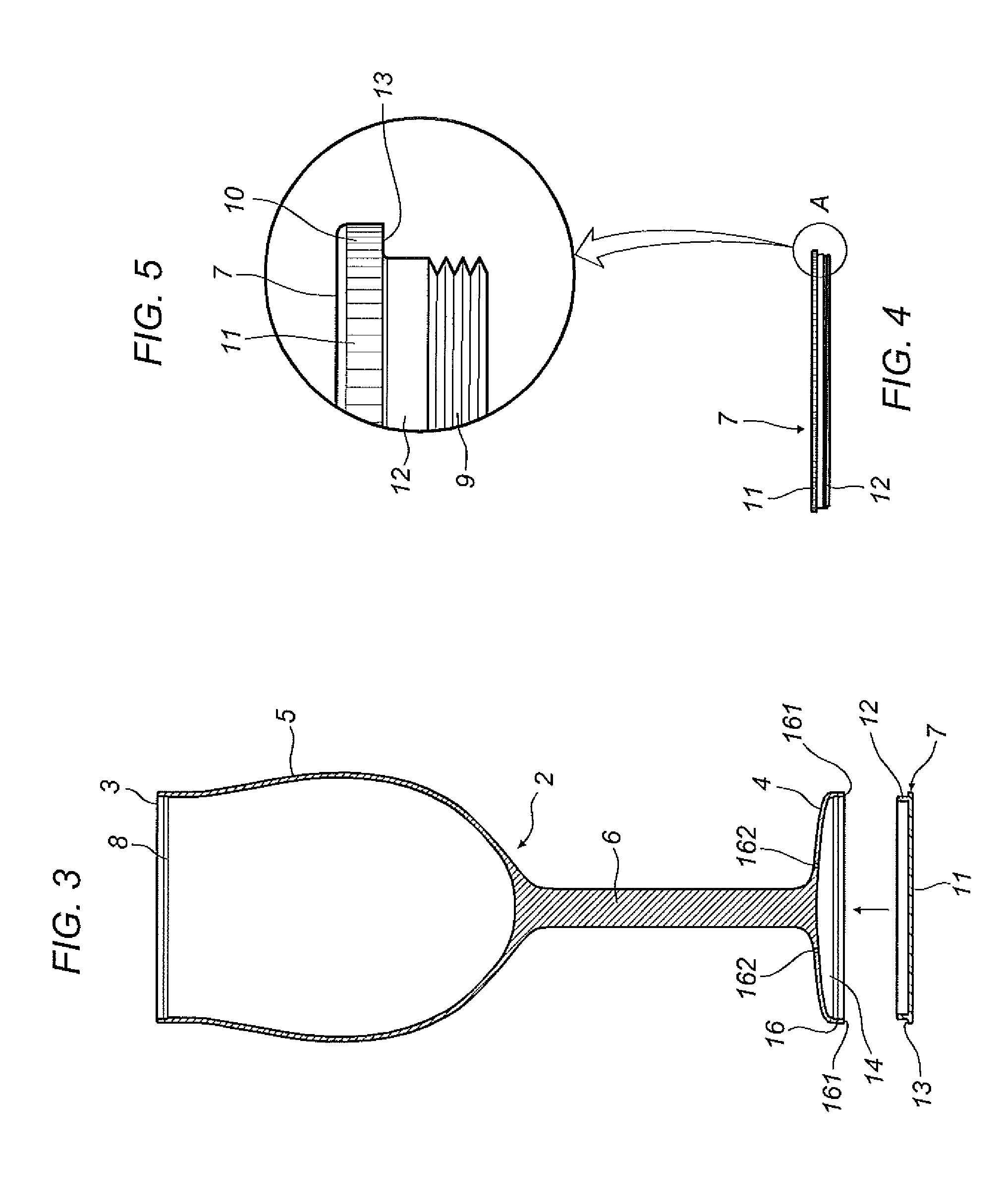

Container for drinking drinks

A container (1) for drinking drinks, equipped with a body (2) made of shatterproof material comprising a broad opening (3) for forming a glass, a goblet or a tankard, comprises a lid (7) which can be removably associated with the opening (3) and with the base (4) of the container (1) by means of a threaded coupling.

Owner:CHALICE

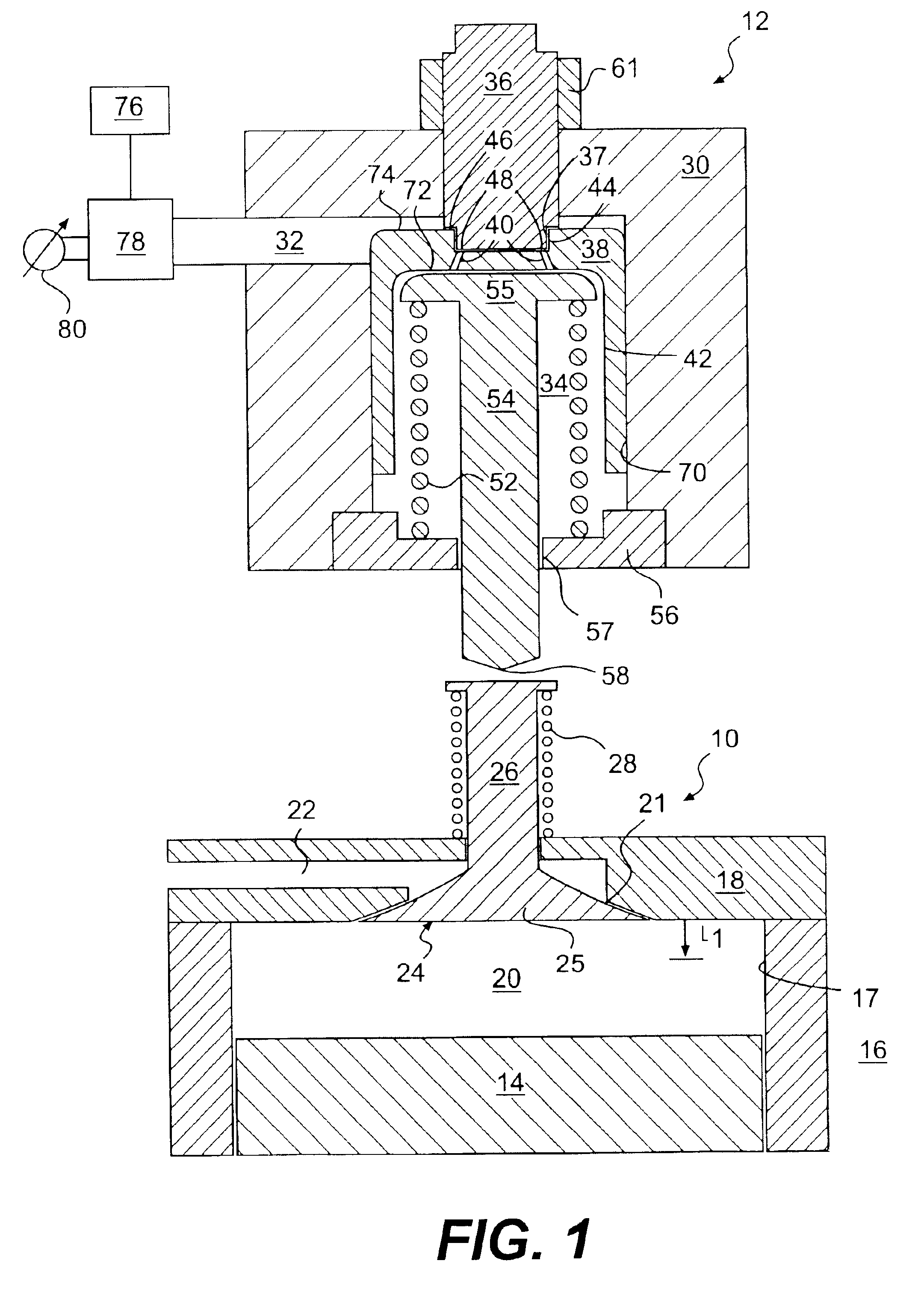

Engine valve actuator

InactiveUS20050274337A1Limit movement of pistonControl strokeOutput powerMachines/enginesActuatorEngine valve

An engine valve actuator for an internal combustion engine is provided. The engine valve actuator includes a housing having an opening and a first fluid passageway leading to the opening. An adjustment member is disposed in the housing and includes a protrusion that extends into the opening of the housing. A piston is disposed in the opening of the housing and has a bore adapted to receive the protrusion, a chamber, and a second fluid passageway that connects the bore with the chamber. The piston is adapted to move in a first direction relative to the housing in response to an introduction of pressurized fluid into the first fluid passageway. The piston moves in the first direction until the protrusion substantially withdraws from the bore. A push rod is operatively engaged with the piston such that movement of the piston in the first direction causes a corresponding movement of the push rod to thereby engage and open the engine valve.

Owner:CATERPILLAR INC

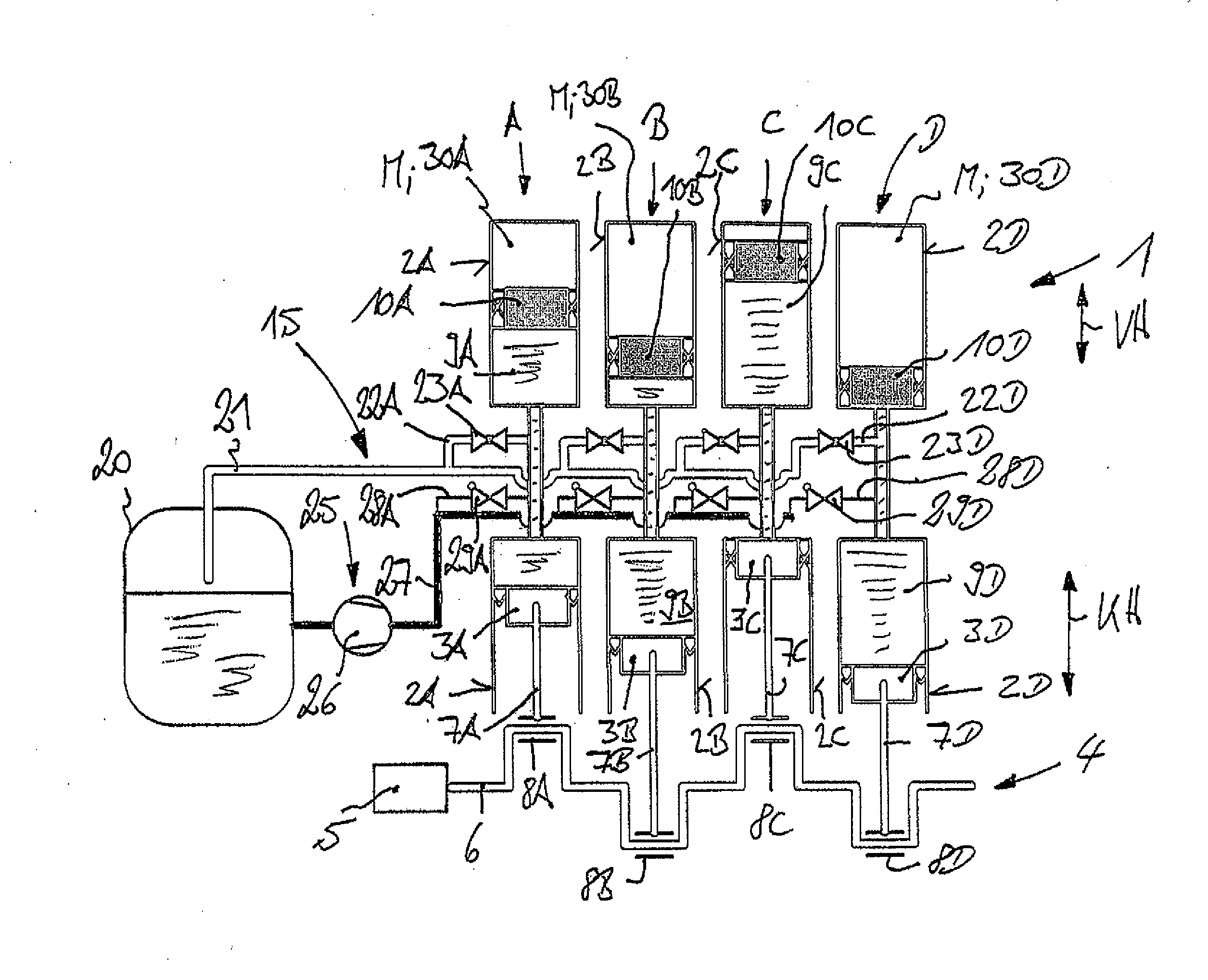

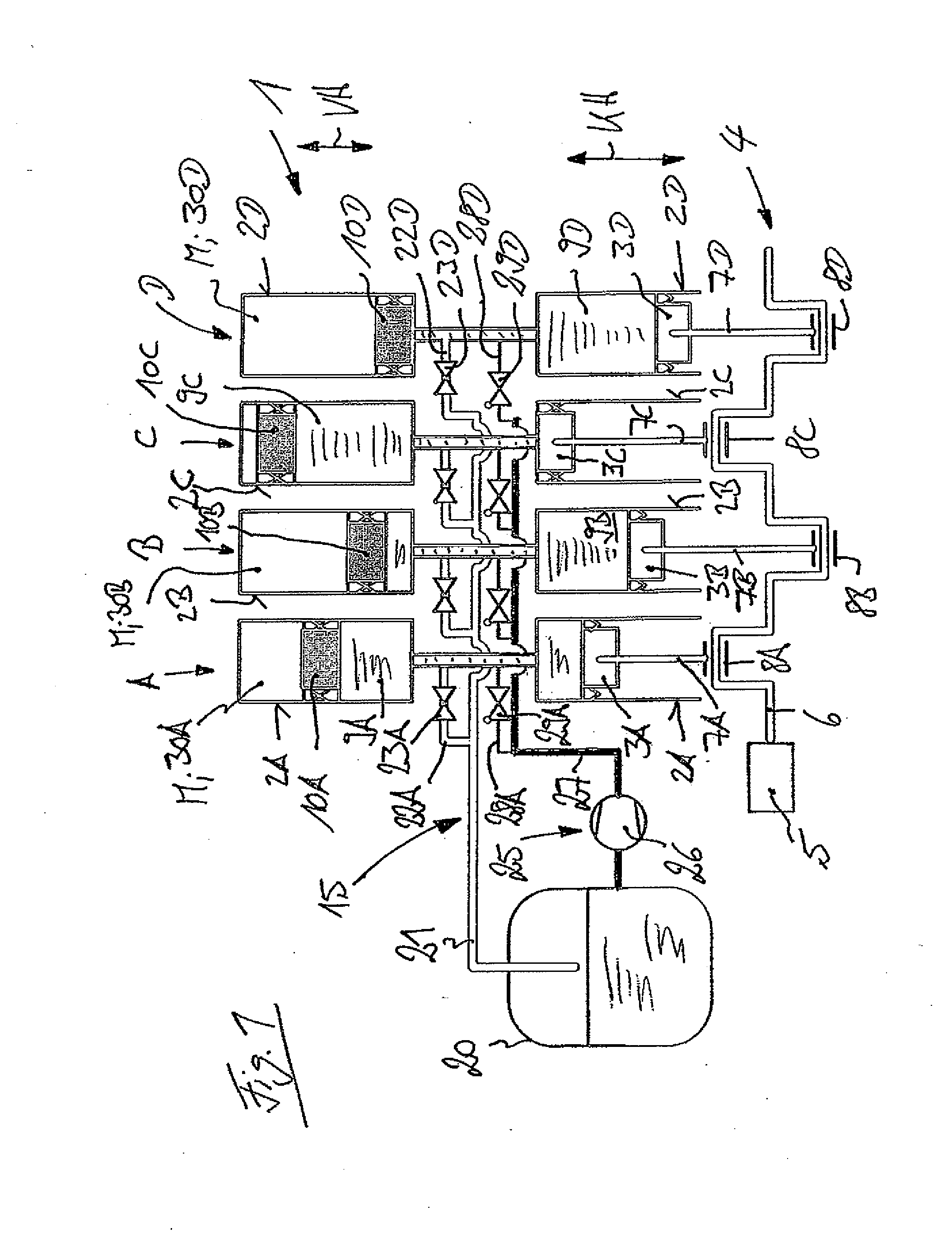

Multistage piston compressor

ActiveUS20120301328A1Improve energy efficiencyEasy to wearPositive displacement pump componentsWorking fluid for enginesControl theoryPiston

A multistage piston compressor for a gaseous or cryogenically liquefied medium with at least two compressor stages, which operatively interact with a shared drive train for purposes of joint powering, wherein each compressor stage exhibits a piston that is mechanically connected with the drive train, and arranged in a compressor cylinder so that it can longitudinally shift.

Owner:LINDE AG

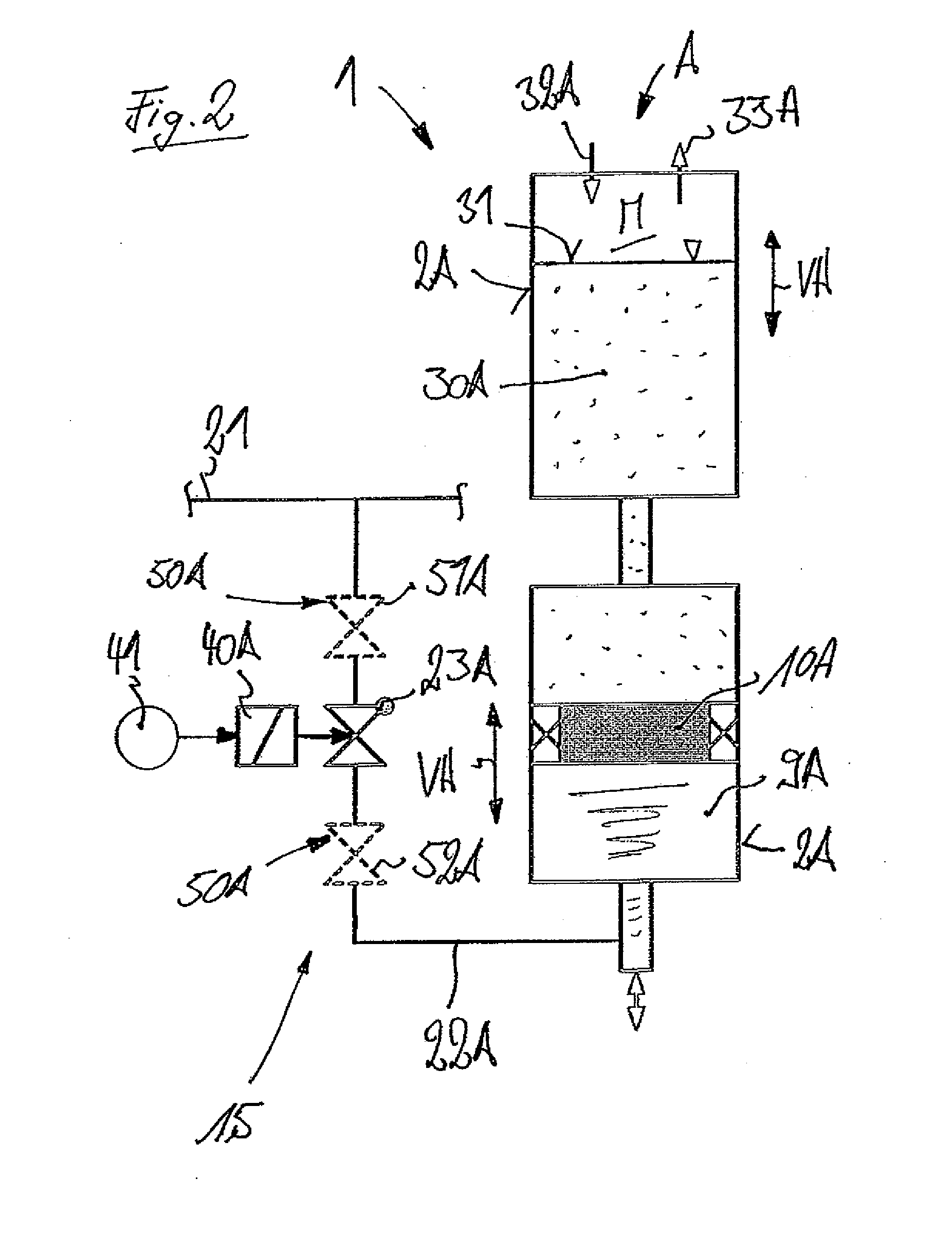

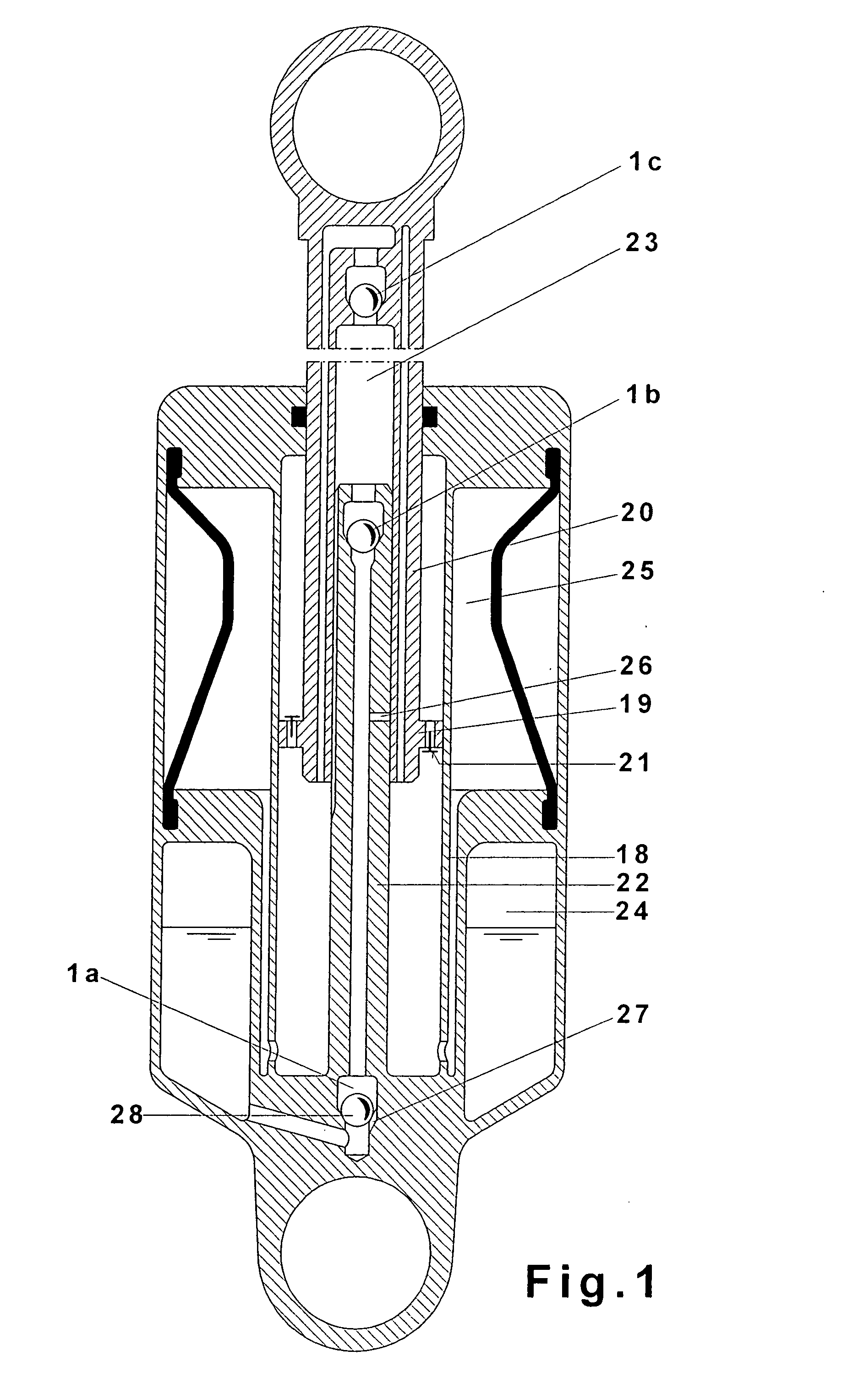

Self-pumping hydropneumatic spring strut with internal level control

InactiveUS20080029939A1Minimal spaceLow costSpringsLiquid based dampersReciprocating motionEngineering

An oil-filled working cylinder is divided into first and second working spaces by a working piston, the first working space being connected to a high pressure chamber. A piston pump includes a pump rod received in a pump cylinder formed by the hollow piston rod, the pump rod having a bore connected to a low pressure chamber via a discharge valve, a distal end provided with a suction valve, and a down-regulating opening connecting the bore to the first working space as a function of the position of the working piston, the pump cylinder being connected to the first working space by an outlet valve. At least one of the valves is a check valve including a housing having a bore, a ball reciprocably guided in the bore by guide ribs, and a resilient retaining element capturing the ball in the bore and spring-loading the ball toward a valve seat.

Owner:ZF FRIEDRICHSHAFEN AG

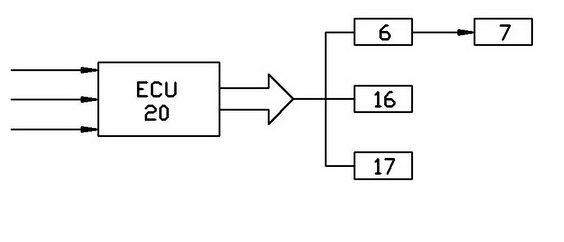

Pressurizing common-rail oil injection system

InactiveCN101984247AControl strokeEmission reductionFuel injection apparatusMachines/enginesCommon railDieseling

The invention provides a pressurizing common-rail oil injection system, relating to an oil injection system of a diesel. The invention provides the pressurizing common-rail oil injection system with a pressurizing valve and a common-rail pipe arranged together. The system comprises a high-pressure oil supply pump, the common-rail pipe, a high-pressure oil pipe and an oil return pipe, and is characterized by further comprising a control valve, the pressurizing valve, an electric control unit and a plurality of electric control injectors, wherein the pressurizing valve is arranged behind the common-rail pipe and each control valve, and the pressurizing valve, the common-rail pipe and the control valves are connected by the high-pressure oil pipe one another. In the system, lower injection pressure is adopted in pre-injection and after-injection, the exhaust and energy consumption are reduced, stroke of a pressurizing plunger can be controlled, and unnecessary oil return loss can be reduced.

Owner:FAW GROUP

Check valve

Check valve includes a housing, a bore, and a movable valve body, which is spring-loaded and rests with a sealing action on a valve seat, where the bore is designed as a stepped bore, where the bore with the smaller diameter has the valve seat, and where the bore with the larger diameter holds the movable valve element. The valve body is designed as a ball, which is guided in the bore by at least two guide ribs, and a retaining element in the terminal area of the bore captures the ball and simultaneously spring-loads it.

Owner:ZF FRIEDRICHSHAFEN AG

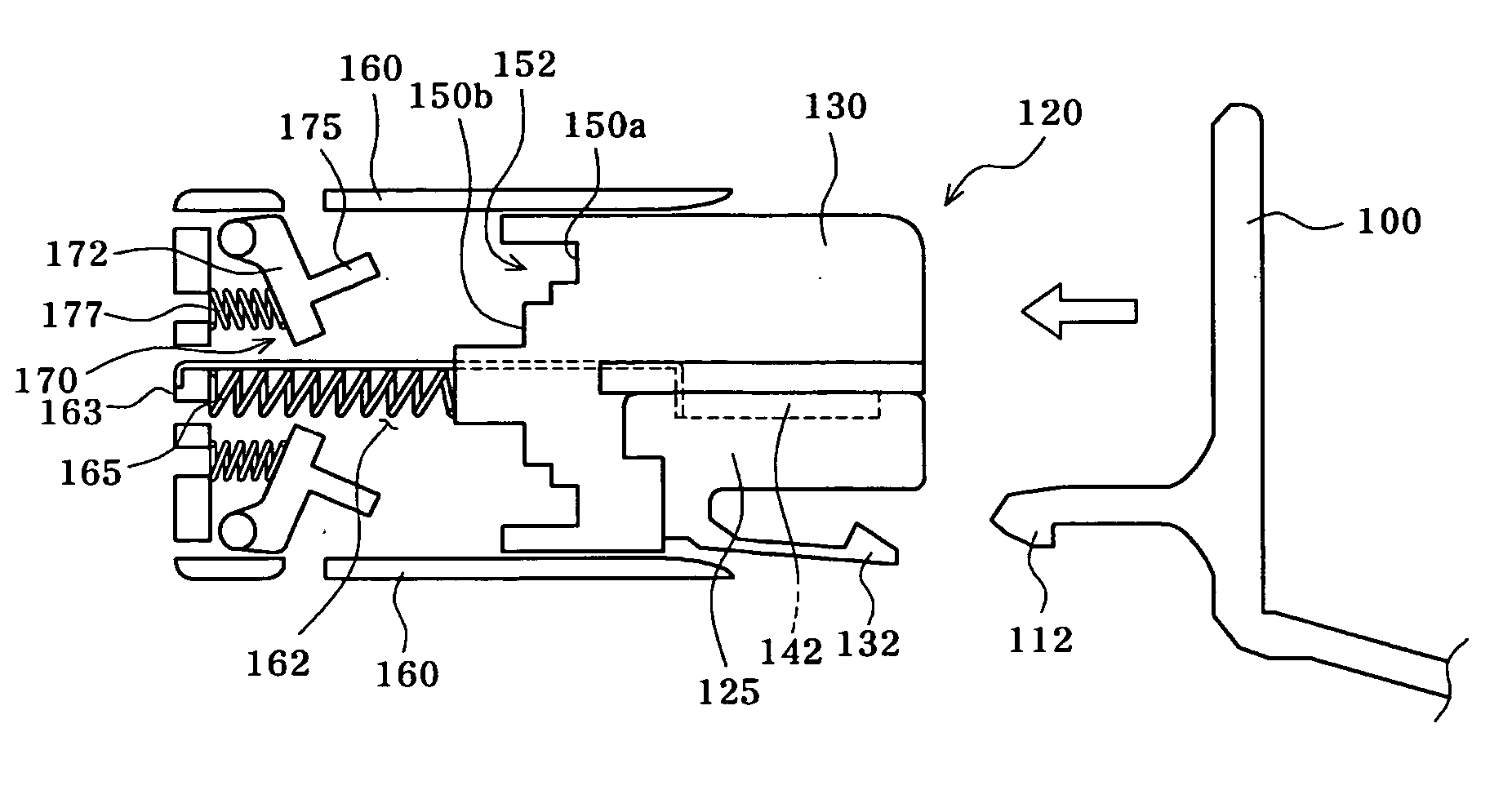

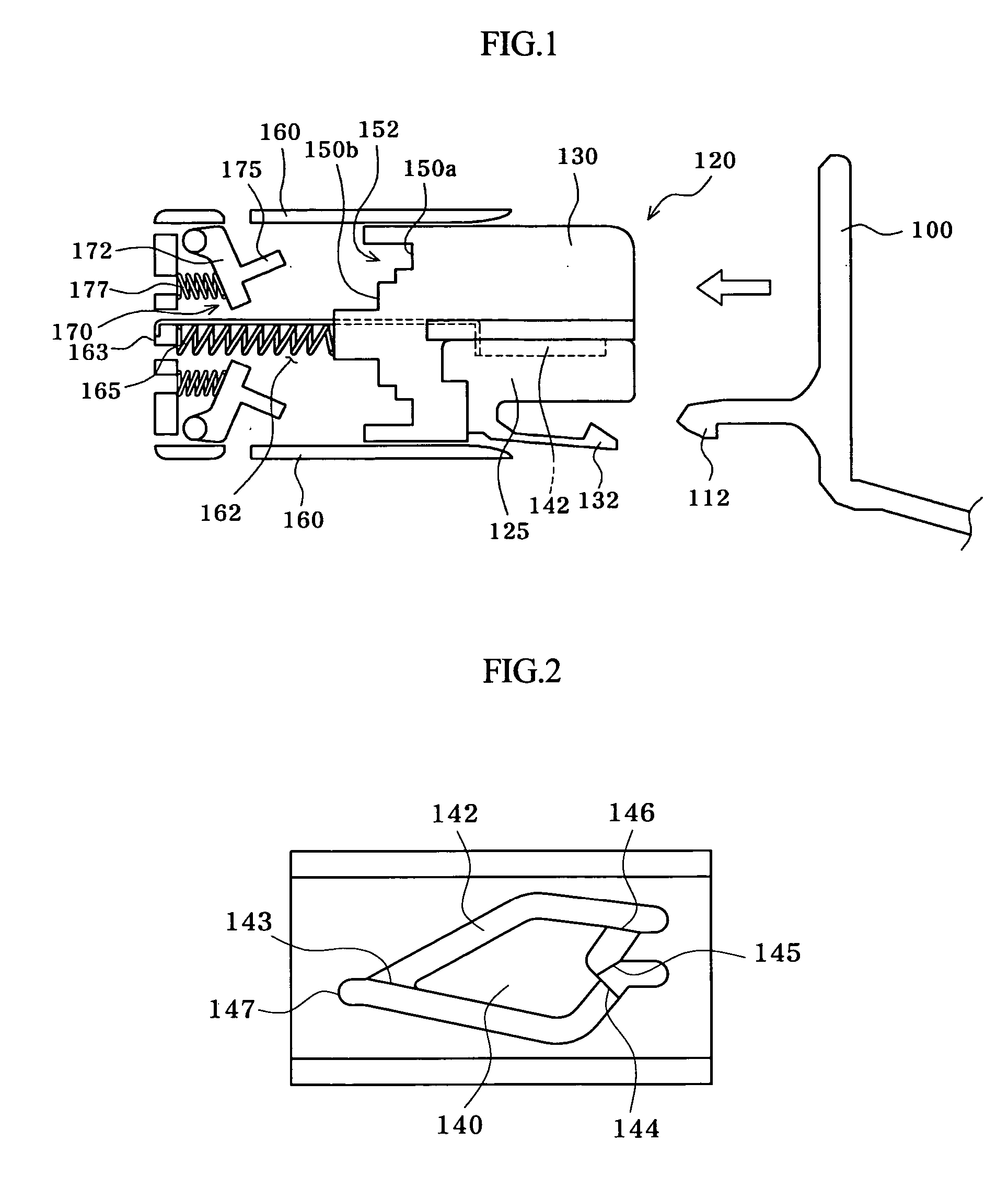

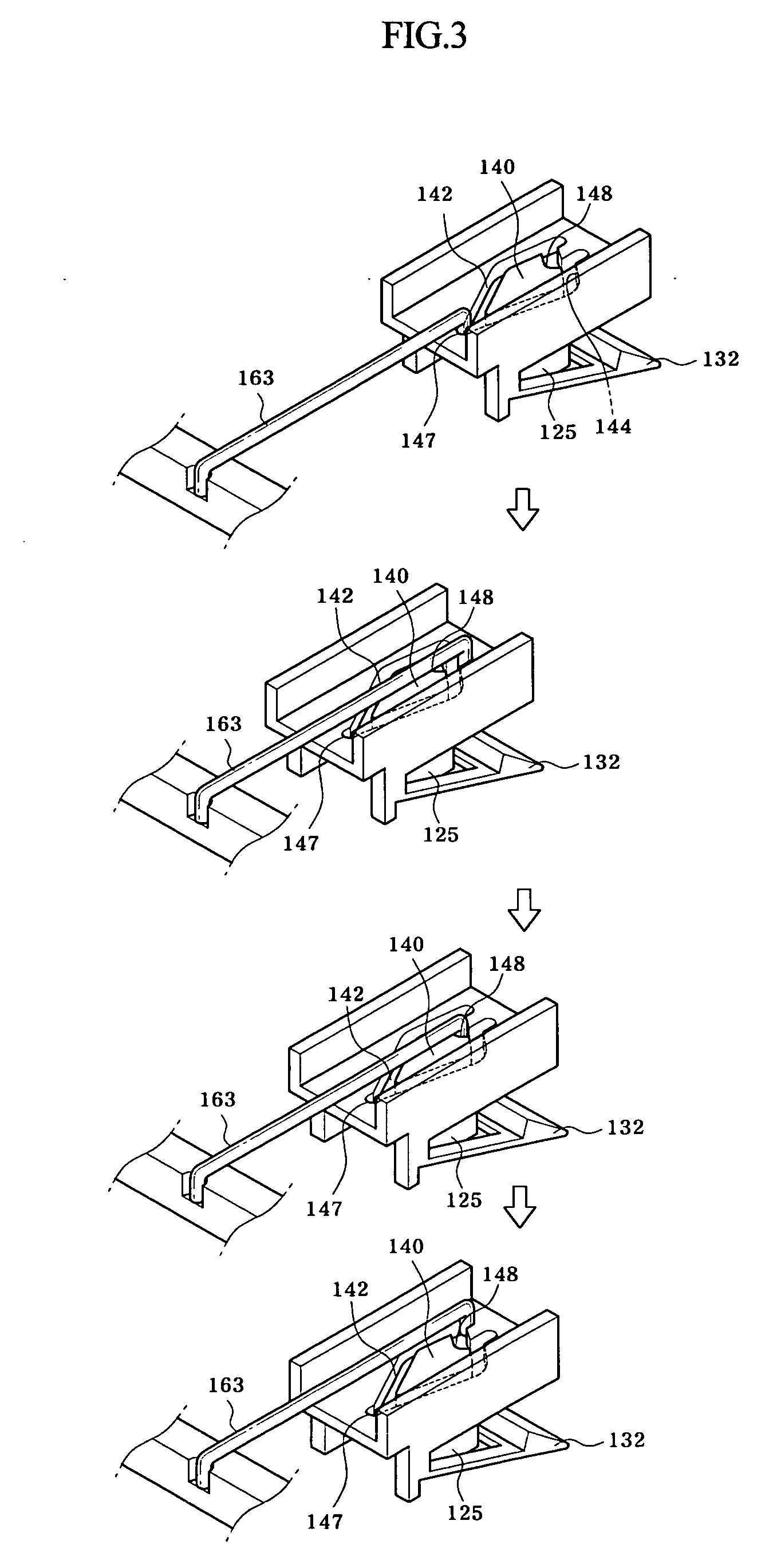

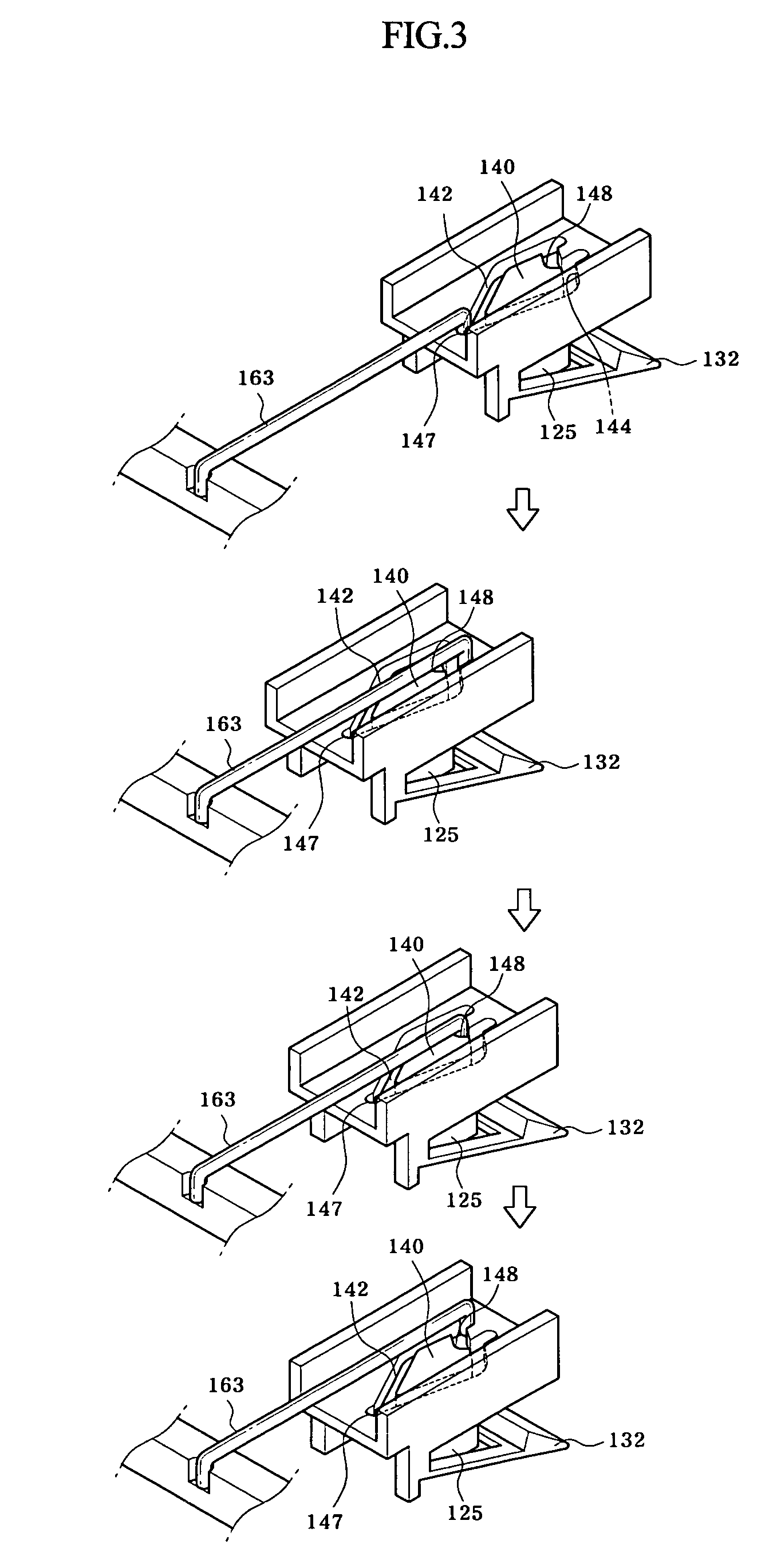

Tray latching device

Disclosed herein is a tray latching device. The tray latching device includes a latch, which has a passage for the insertion of a clasp panel that protrudes from a side of an automobile tray, and a plurality of supporting indentations each formed with a plurality of stepped supporting portions. If a predetermined stroke is applied to the latch and the latch moves along a housing, a heart cam of the latch acts to release a hook panel of the latch from the clasp panel of the tray. The tray latching device further includes a plurality of inertial sensors, which are arranged so that extensions thereof support desired ones of the stepped supporting portions provided in the supporting indentations of the latch. This configuration prevents the inertial sensors from being separated from the latch in the event of an automobile collision, eliminating a risk of unintentional opening of the tray.

Owner:HYUNDAI MOBIS CO LTD

Double-cylinder linear compressor

InactiveCN103696934AReached the bufferReach the positionPiston pumpsDynamo-electric machinesPower flowReciprocating motion

The invention discloses a double-cylinder linear compressor. Rotators of the double-cylinder linear compressor are in cylinder shapes; distance is formed between two stators axially; two pairs of permanent magnets are axially arranged. Radial alternating magnetic fields with different polarities are generated through the two stators when winding coils are electrified with alternating currents and the stator magnetic fields and rotator permanent magnetic fields are interacted, so that the stators perform reciprocating motion along an axial suspension state. Purposes of buffering, positioning and controlling strokes of the rotators are effectively achieved meanwhile the stator magnetic fields generate the suction and the pushing force to the permanent magnetic fields. The double-cylinder linear compressor has the advantages of being simple and compact in structure, low in cost, light in weight and convenient to machine due to the facts that a positioning spring is saved and positioning is performed through electromagnetic fields.

Owner:安鲁荣

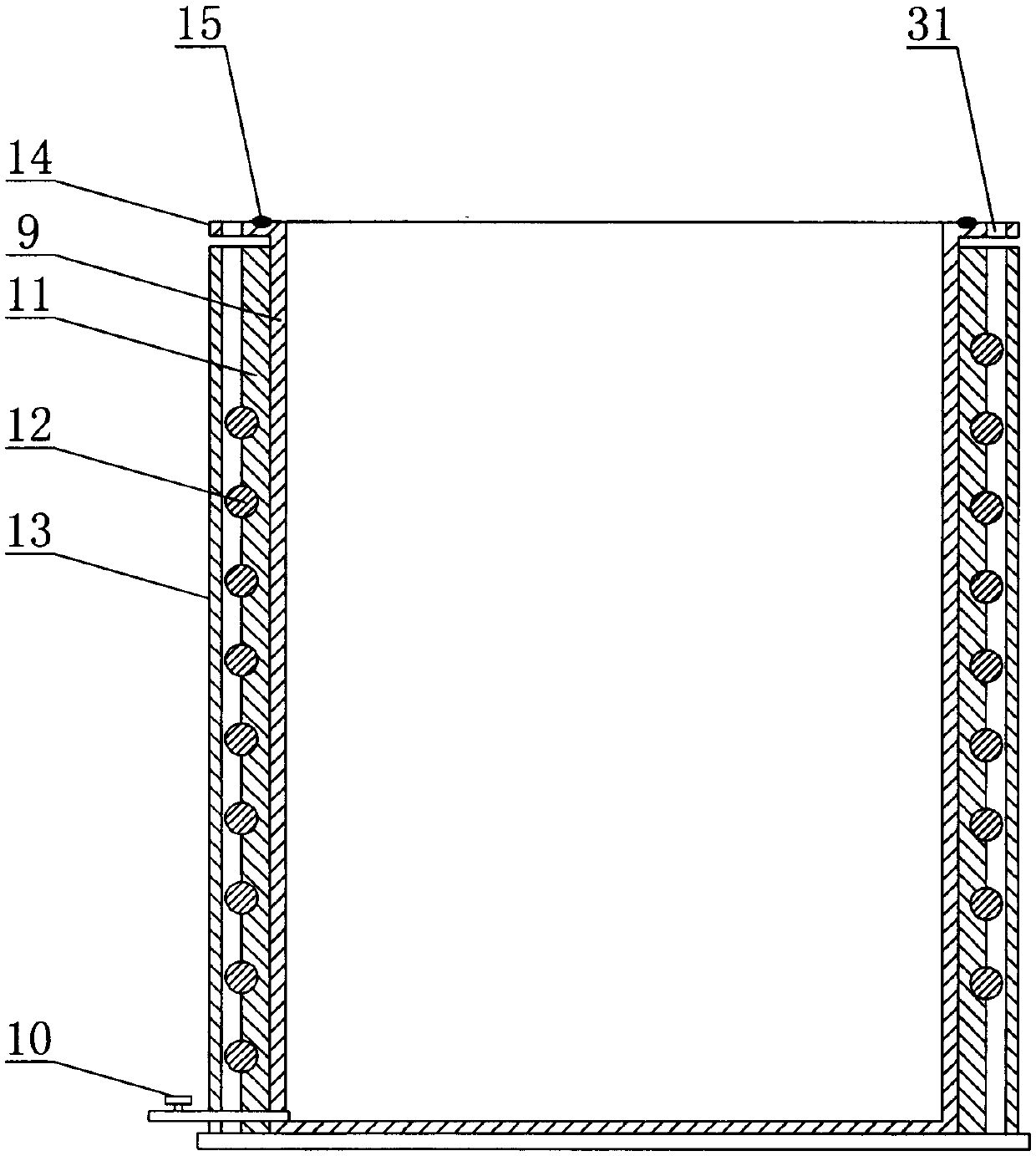

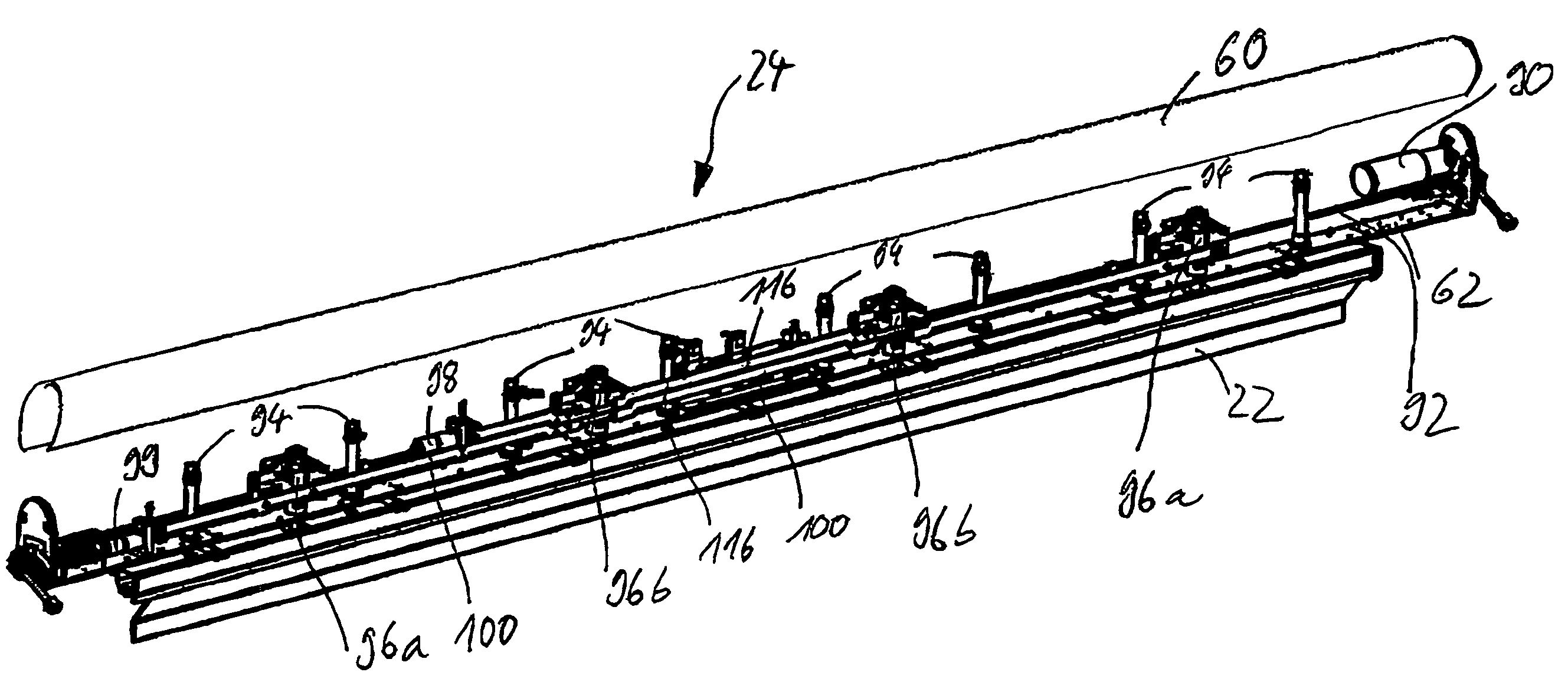

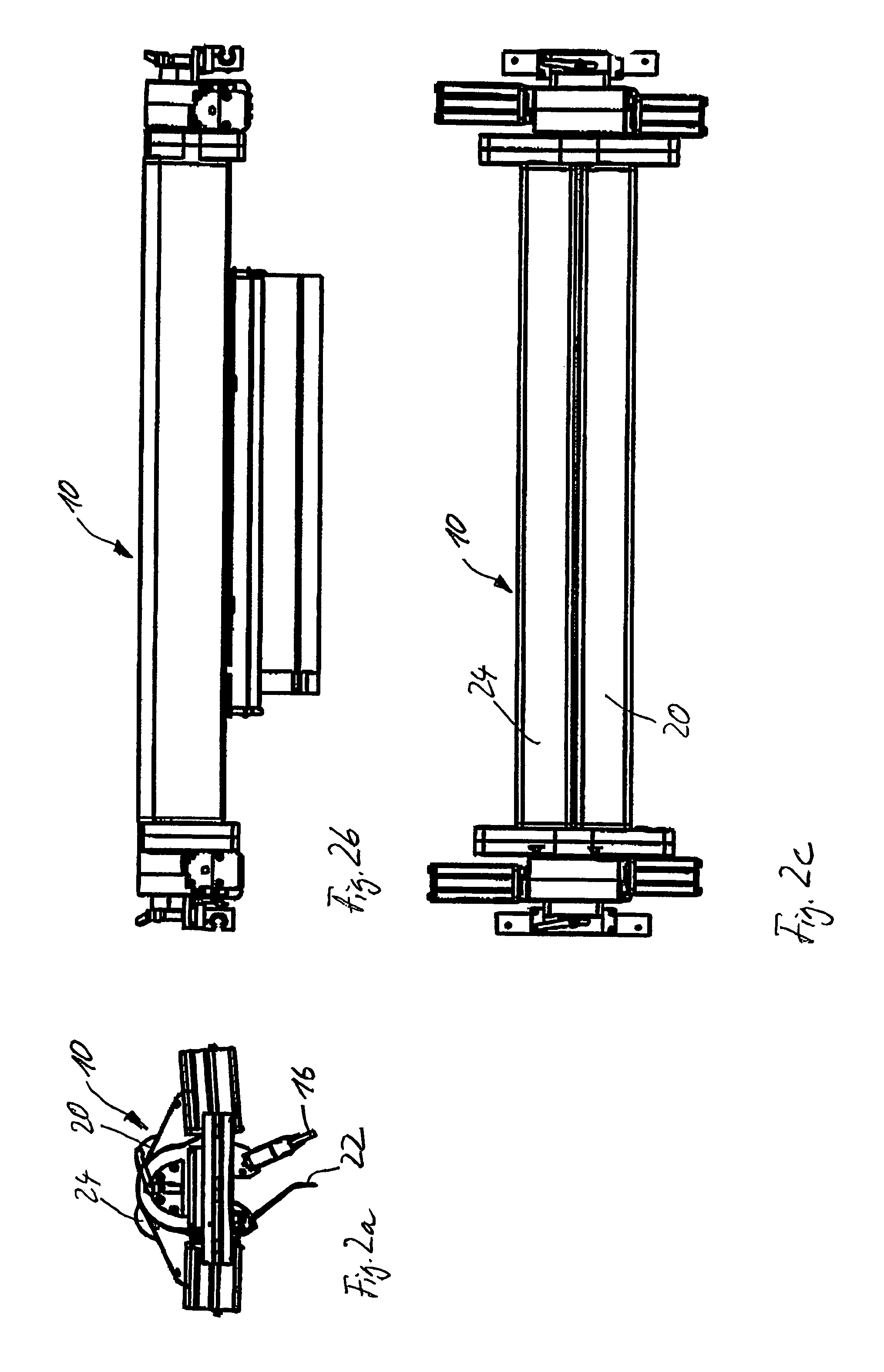

Squeegee device with U-shaped carriage

InactiveUS7503255B2High precision adjustmentLarge counterforcesInking apparatusLiquid surface applicatorsEngineeringPrinting press

Squeegee assembly for a screen printing machine with a printing table, wherein the squeegee assembly has at least one squeegee, one squeegee holder and at least one support displaceable across the printing table, wherein the squeegee is held on the support by means of the squeegee holder and can be pressed against the printing table by pressure cylinders, characterized in that the support has a U-shaped profile, and at least the cylinder sections of the pressure cylinders are accommodated within the U-shaped profile.

Owner:THIEME GMBH & CO KG

Tray latching device

A tray latching device includes a latch including a hook panel to catch an end of a clasp panel that protrudes from a side of an automobile tray, a heart cam to release the clasp panel of the tray from the hook panel when a predetermined stroke is applied thereto by the clasp panel of the tray, and a plurality of supporting indentations each formed with a plurality of stepped supporting portions. The tray further includes a housing and a plurality of inertial sensors each including a supporting portion to be coupled to the housing via a shaft, and an extension that protrudes from the supporting portion to support an innermost supporting portion of one of the indentations of the latch.

Owner:HYUNDAI MOBIS CO LTD

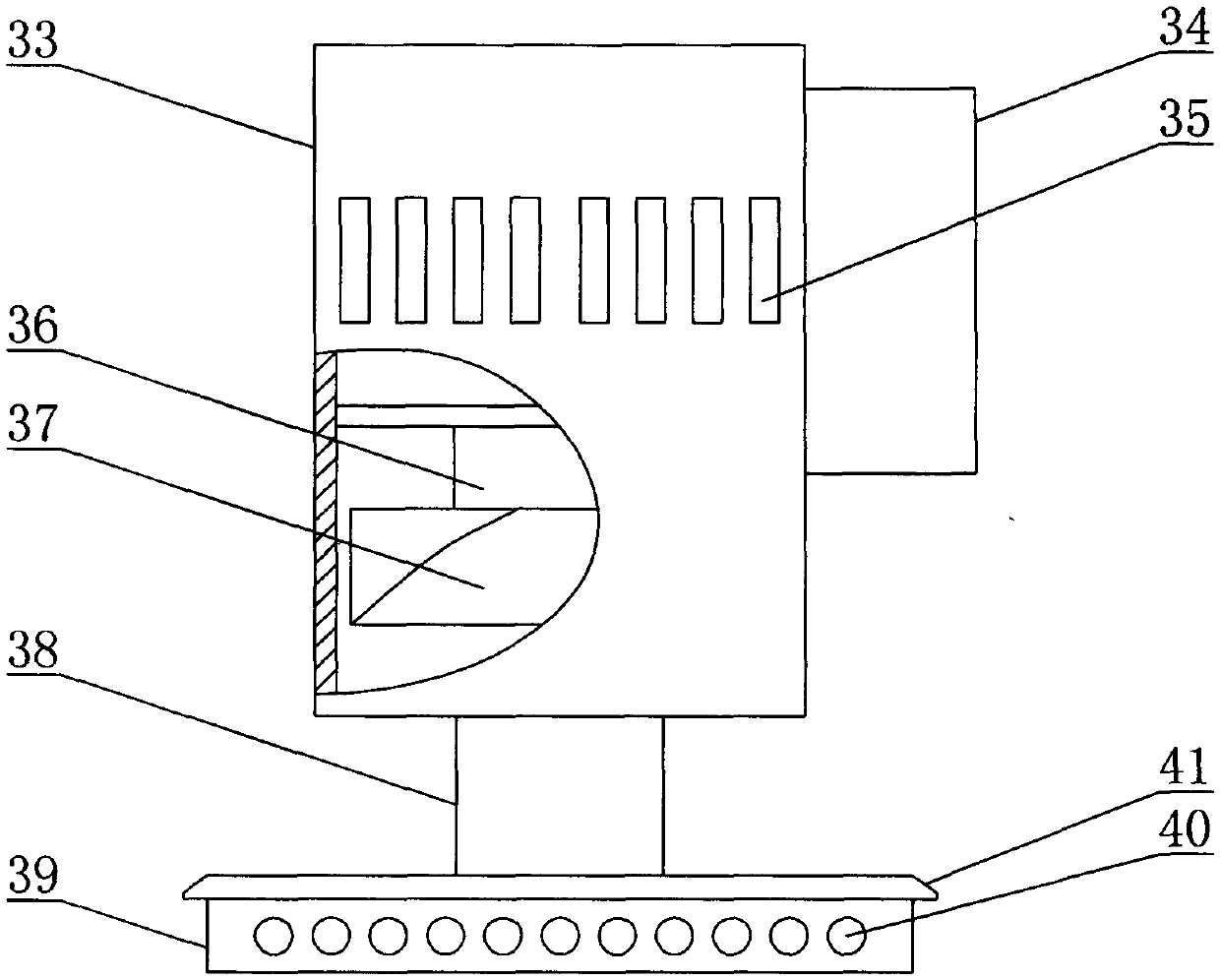

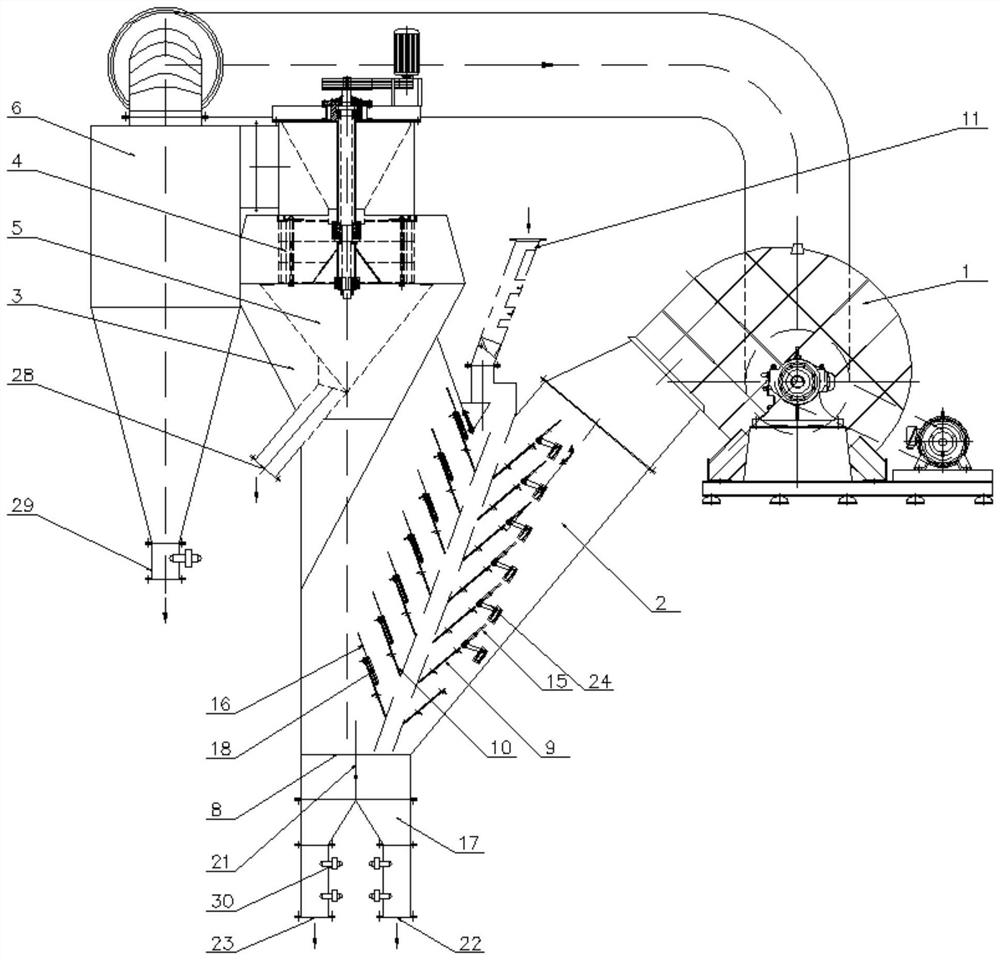

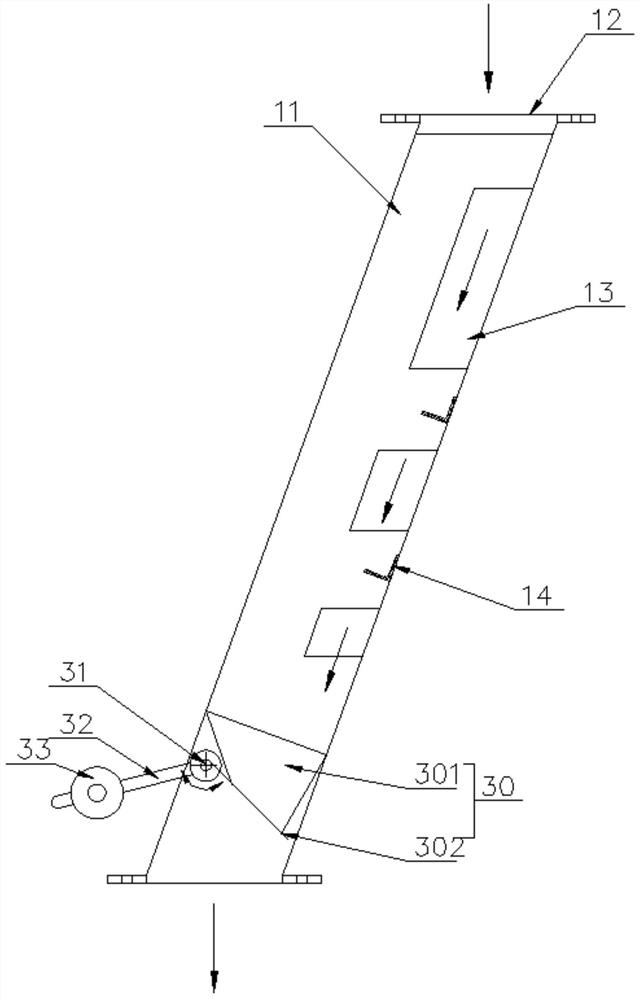

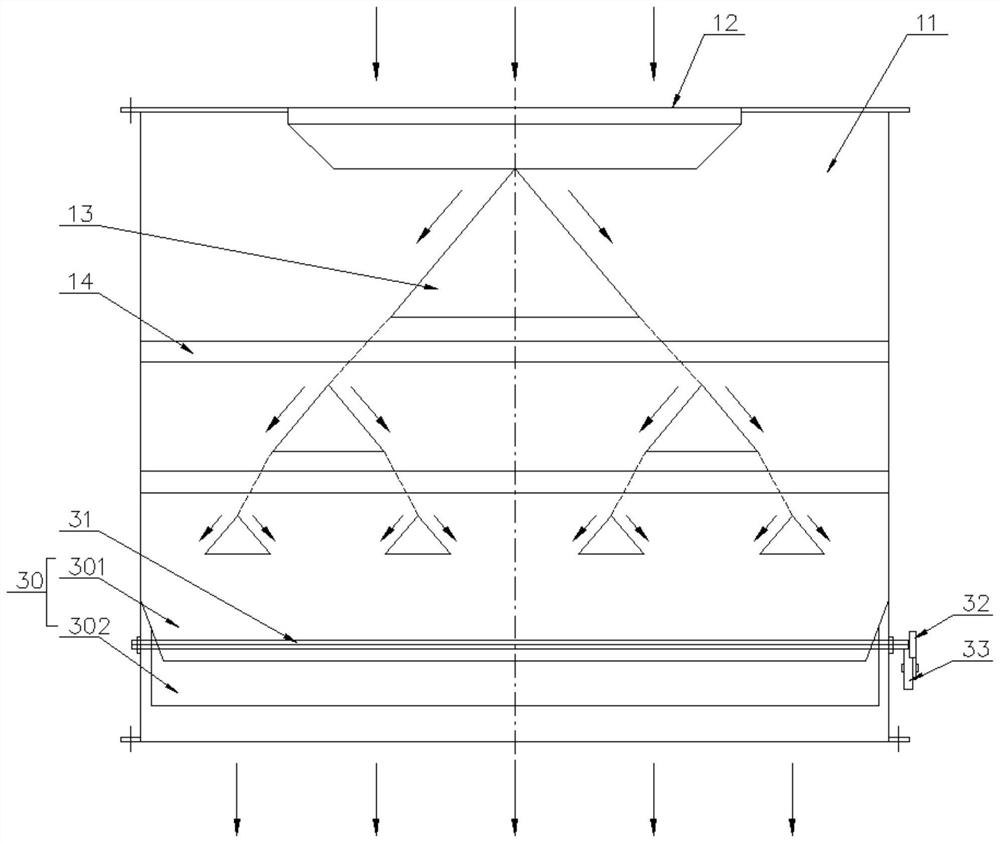

Composite sandstone powder concentrator

PendingCN112387592ALarge amount of processingImprove sorting efficiency and effectGas current separationVortex flow apparatusPhysicsEngineering

The invention relates to a composite sandstone powder concentrator. The composite sandstone powder concentrator comprises a fan, a V-shaped separation device, a medium sand conical hopper, a cage rotor, a fine sand conical hopper and a cyclone separator, wherein a feeding port of the V-shaped separation device is obliquely communicated with a distribution device; multiple stages of scattering blocks with the number of the scattering blocks being increased stage by stage are arranged on one side of the interior of the distribution device; deflection blades capable of being adjusted in a deflection mode are arranged at the ends of first fixed scattering blades of the V-shaped separation device; telescopic blades capable of being adjusted in a parallel front-back displacement mode are arranged on the side portions of second fixed scattering blades of the V-shaped separation device; and a discharging port is communicated with the bottom of the medium sand conical hopper and provided with amaterial segregation device. Coarse sand, medium sand, fine sand and powder in sandstone are separated and collected in an environment-friendly manner by adopting composite powder separation, the distribution device scatters materials to form a uniform material curtain, and sand molds with different particle sizes and specified gradings in machine-made sand are accurately separated out by adjusting and controlling the movement time and stroke of the materials in the powder concentrator, so that accurate grading meeting specified requirements is achieved, the treatment capacity can be remarkably increased, and the separation efficiency and effect of a composite sandstone separator are improved.

Owner:盐城市盐富环保设备有限公司

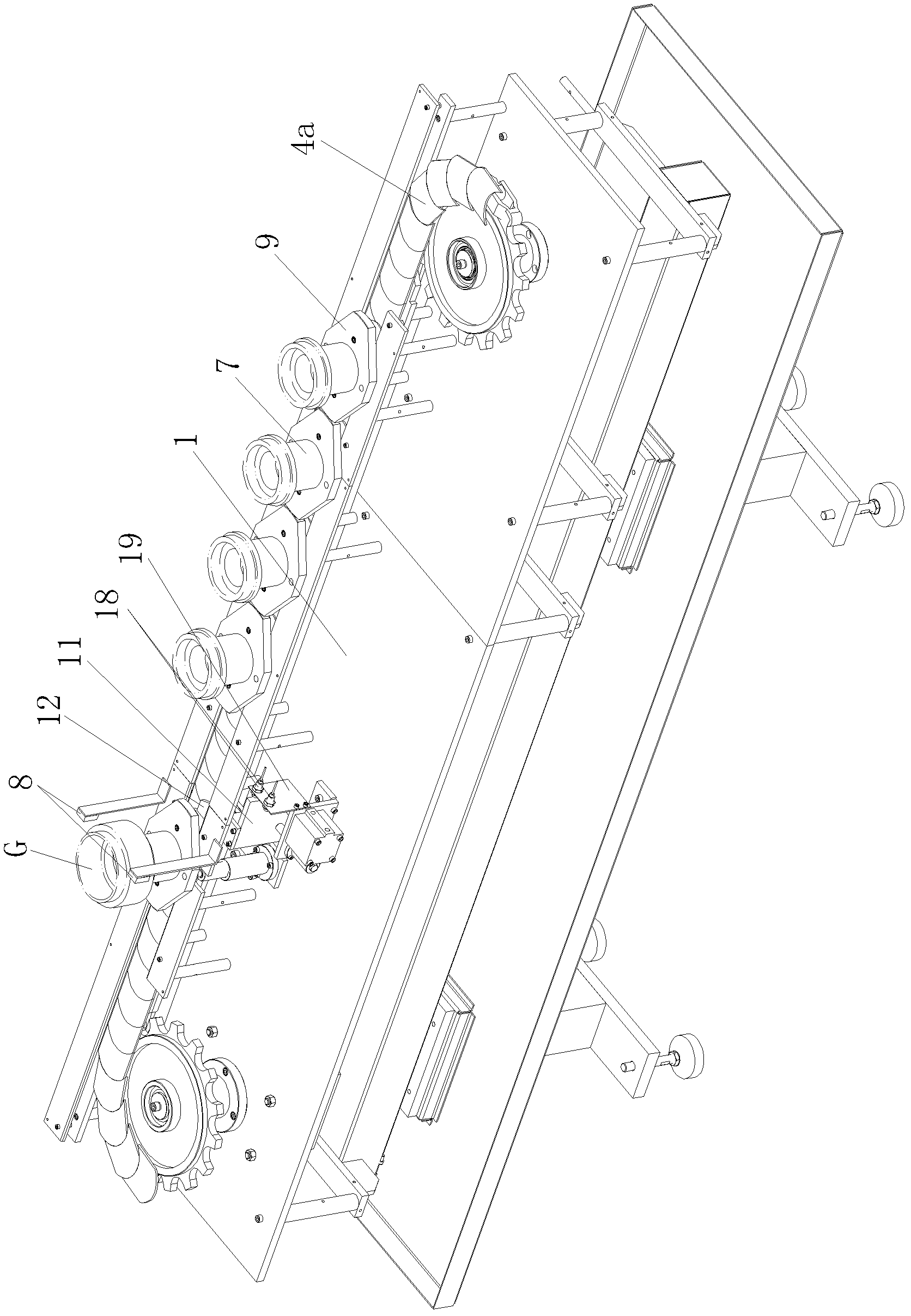

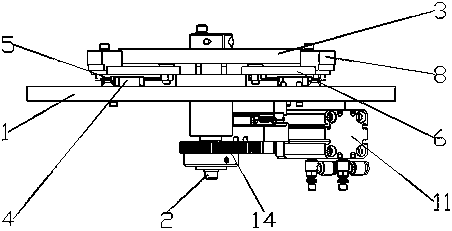

Loading and unloading transmission device for machine tool

The invention discloses a loading and unloading transmission device for a machine tool. The loading and unloading transmission device comprises a speed reducer on the left part of an intermediate plate, wherein a driving chain wheel on the upper end part of an output shaft of the speed reducer is connected with a driven chain wheel by a chain; a pair of correlation switches for acquiring signals of a workpiece bracket reaching a grabbing position is arranged above the chain; a tray is arranged on a support top plate of the chain; the workpiece bracket is arranged on an upper tray; an air cylinder is arranged on the intermediate plate from front to back; and the rear end part of an air cylinder extension bar is provided with a horizontal baffle capable of blocking the tray by a vertical plate. According to the loading and unloading transmission device, a workpiece is driven by friction force to move with the chain and is blocked reliably by the horizontal baffle, and the retention position of the workpiece is fixed and accurate, so that a bunker device is matched with a feed claw of the machine tool to load and unload; and the workpiece is jacked by the loading and unloading transmission device according to requirements to reduce the integral height of the bunker device effectively, so that the workpiece is put on the workpiece bracket by workers, and the loading and unloading transmission device has a simple structure and is convenient to manufacture.

Owner:CHONGQING MACHINE TOOL GROUP

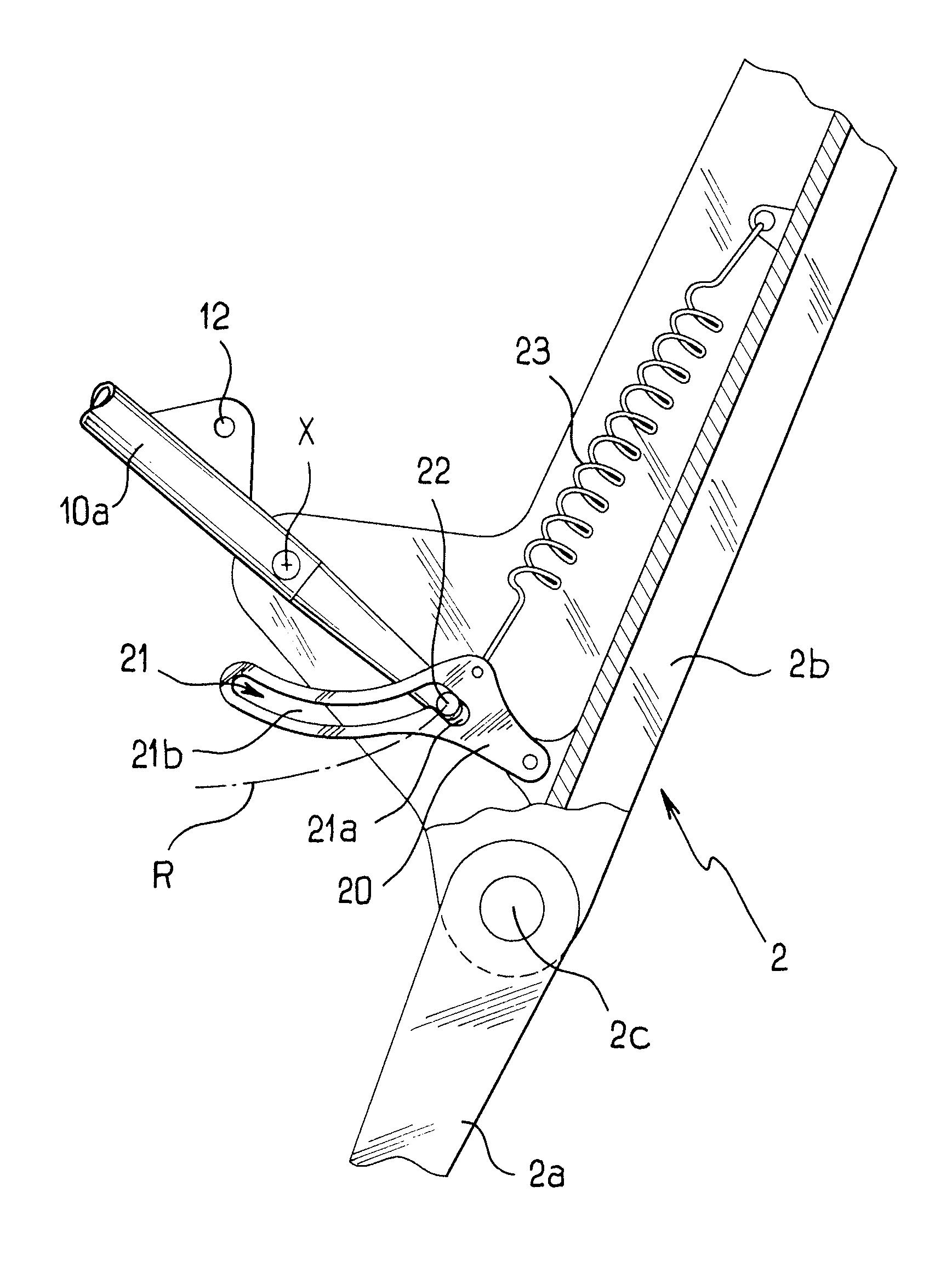

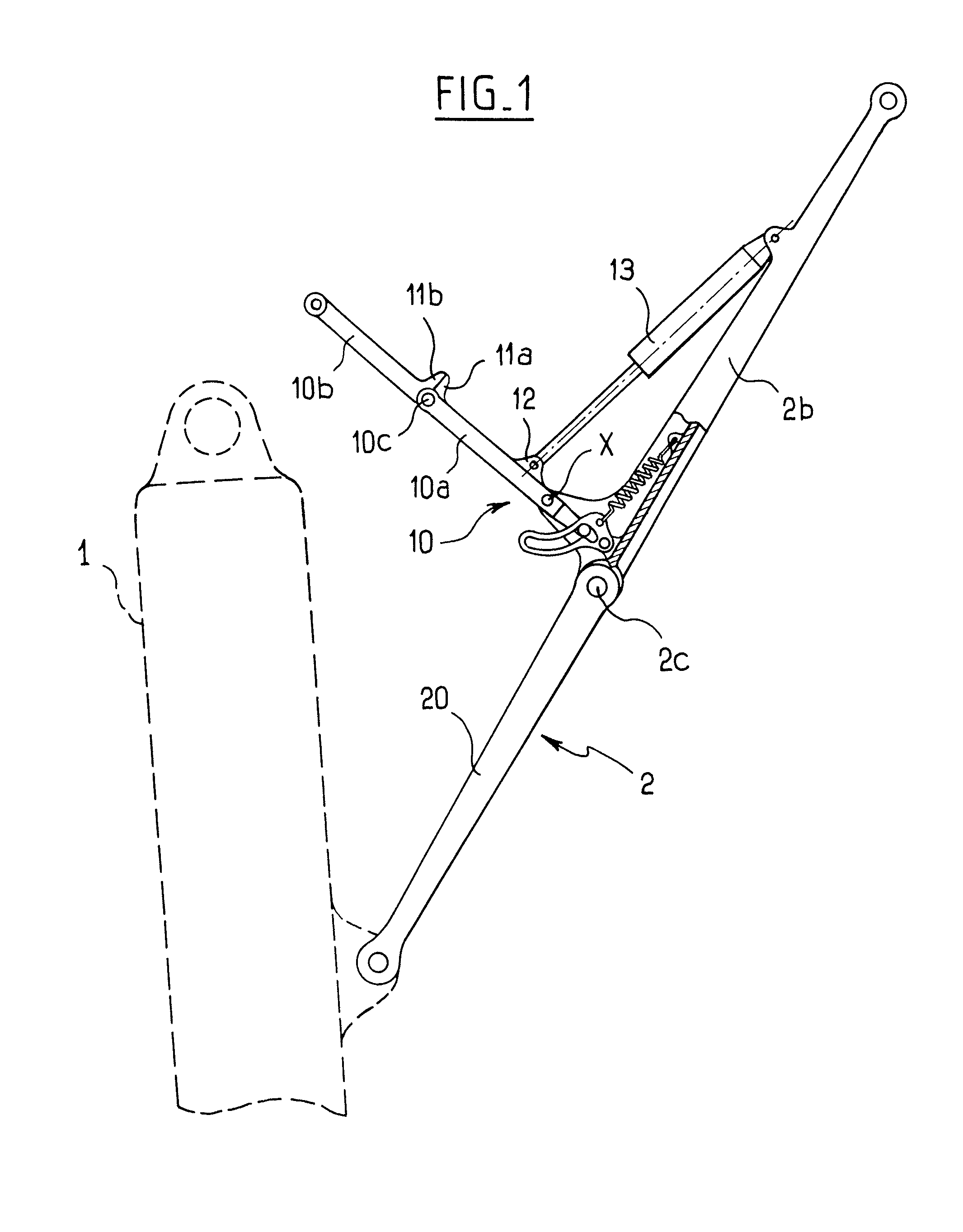

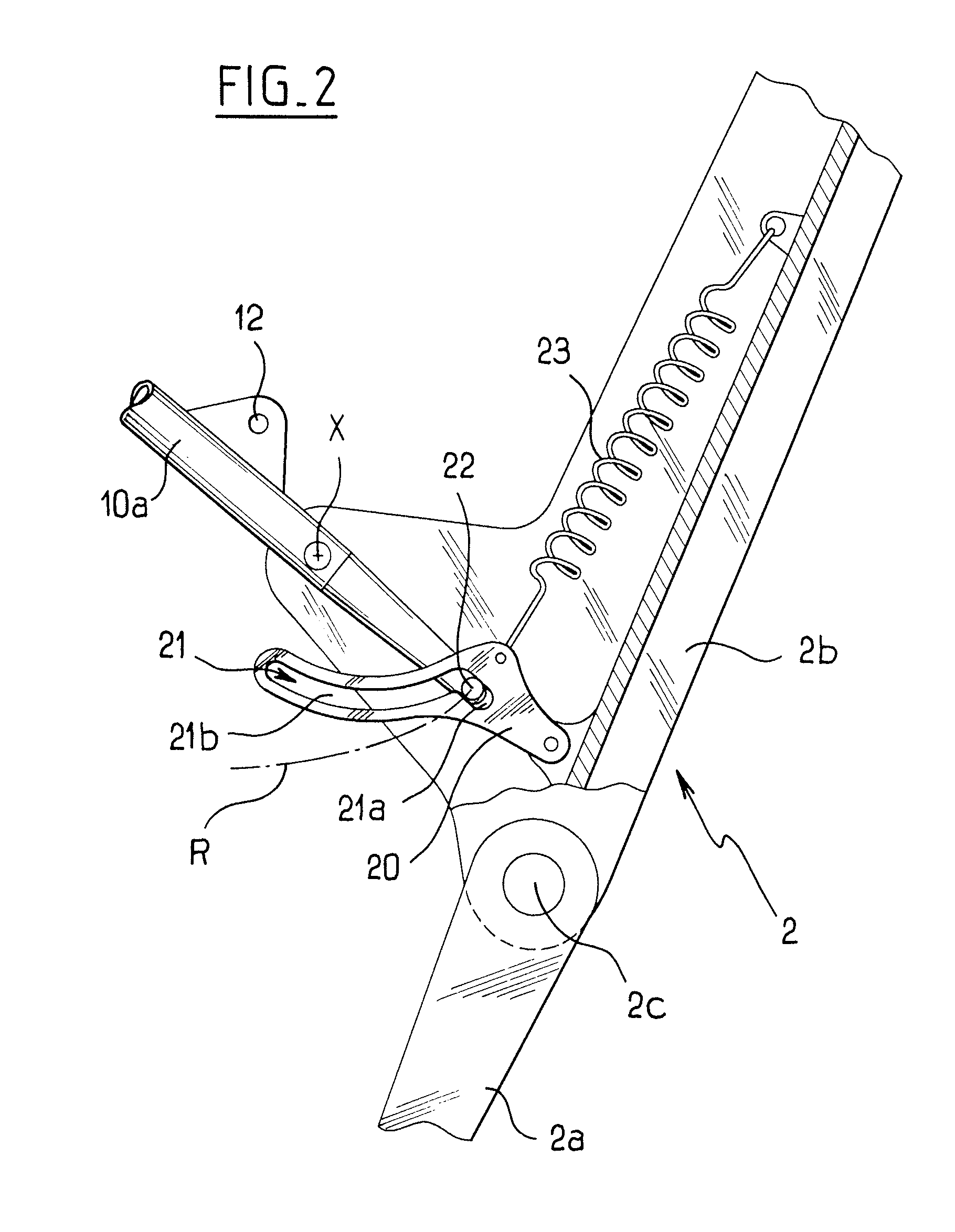

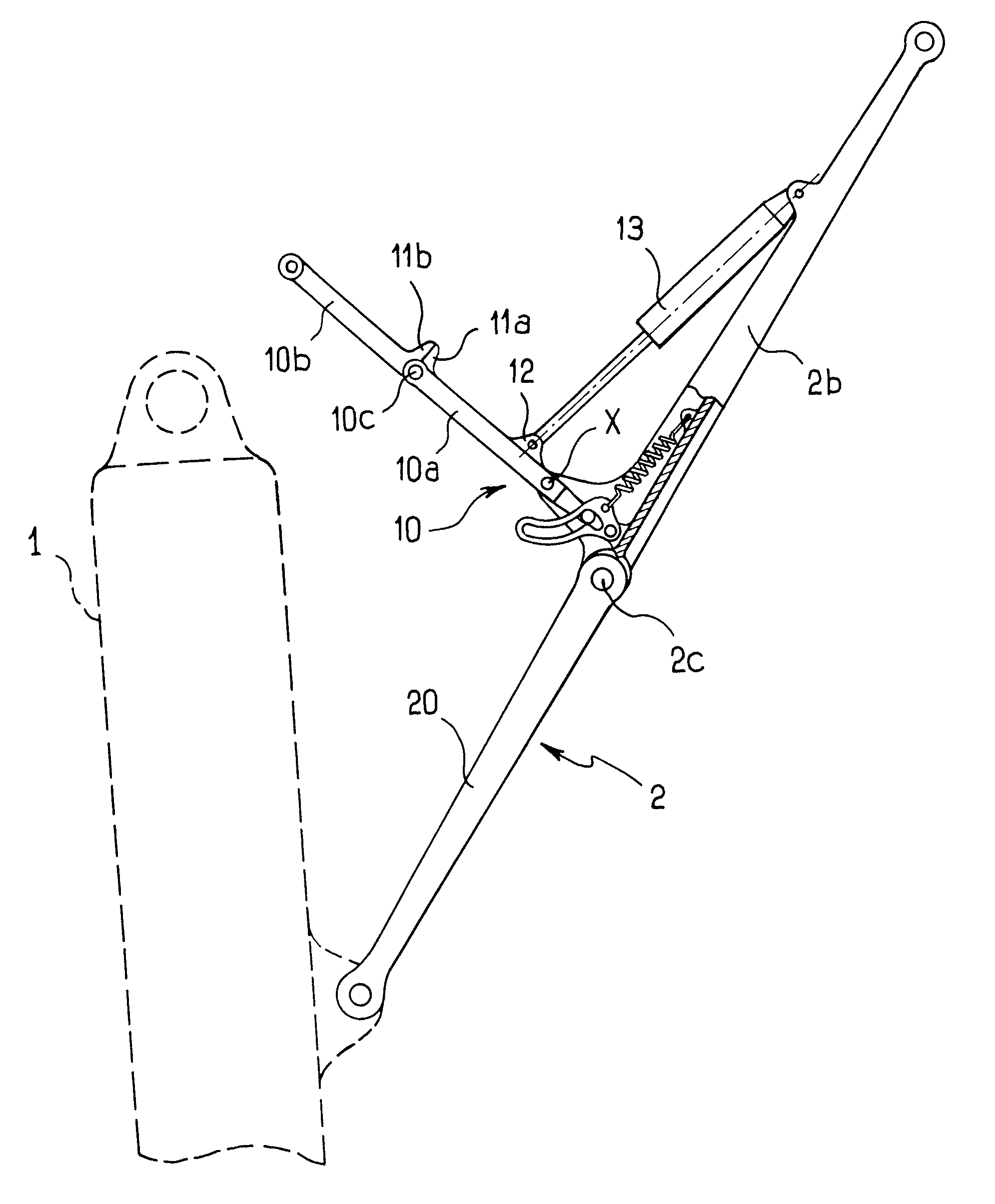

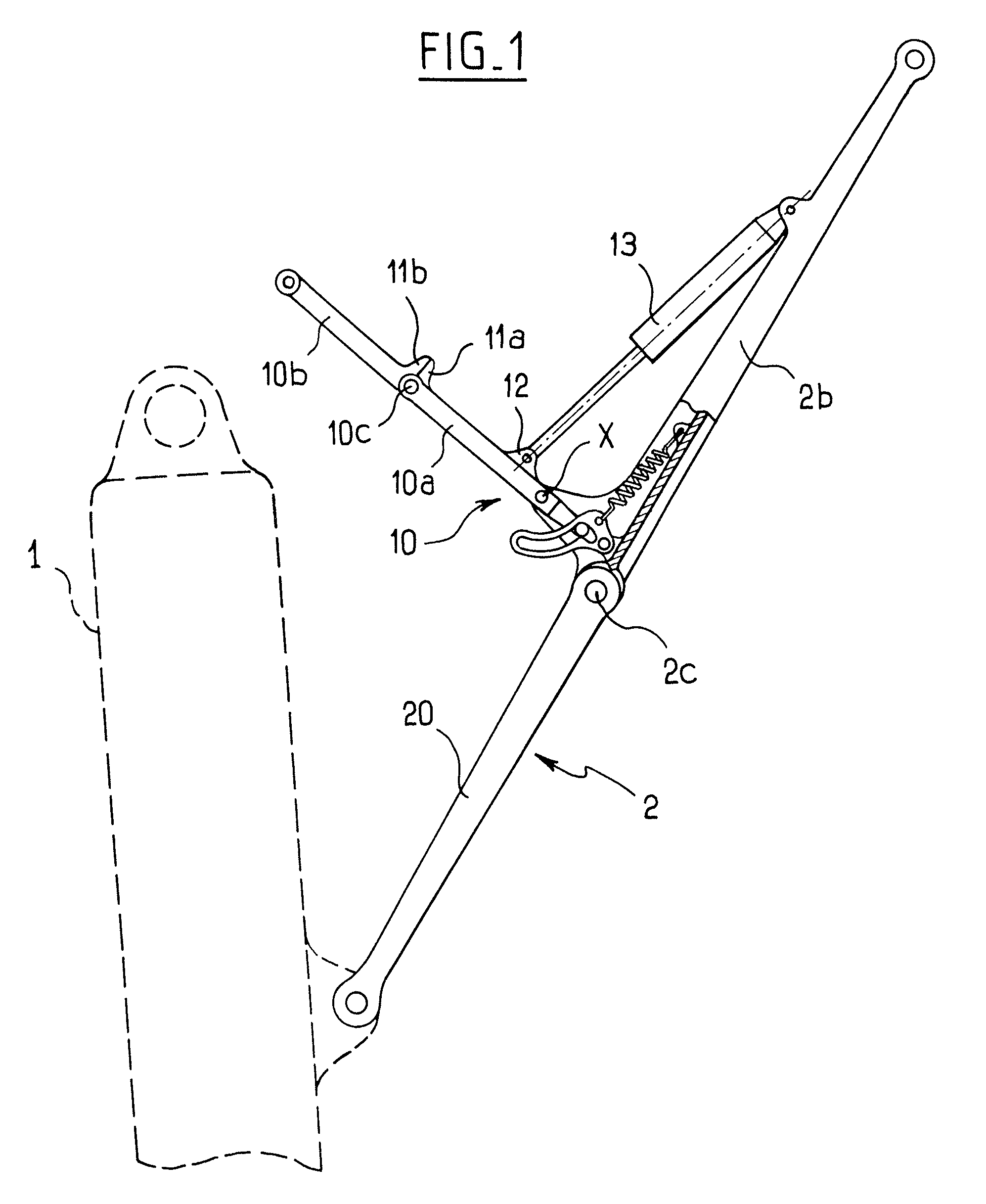

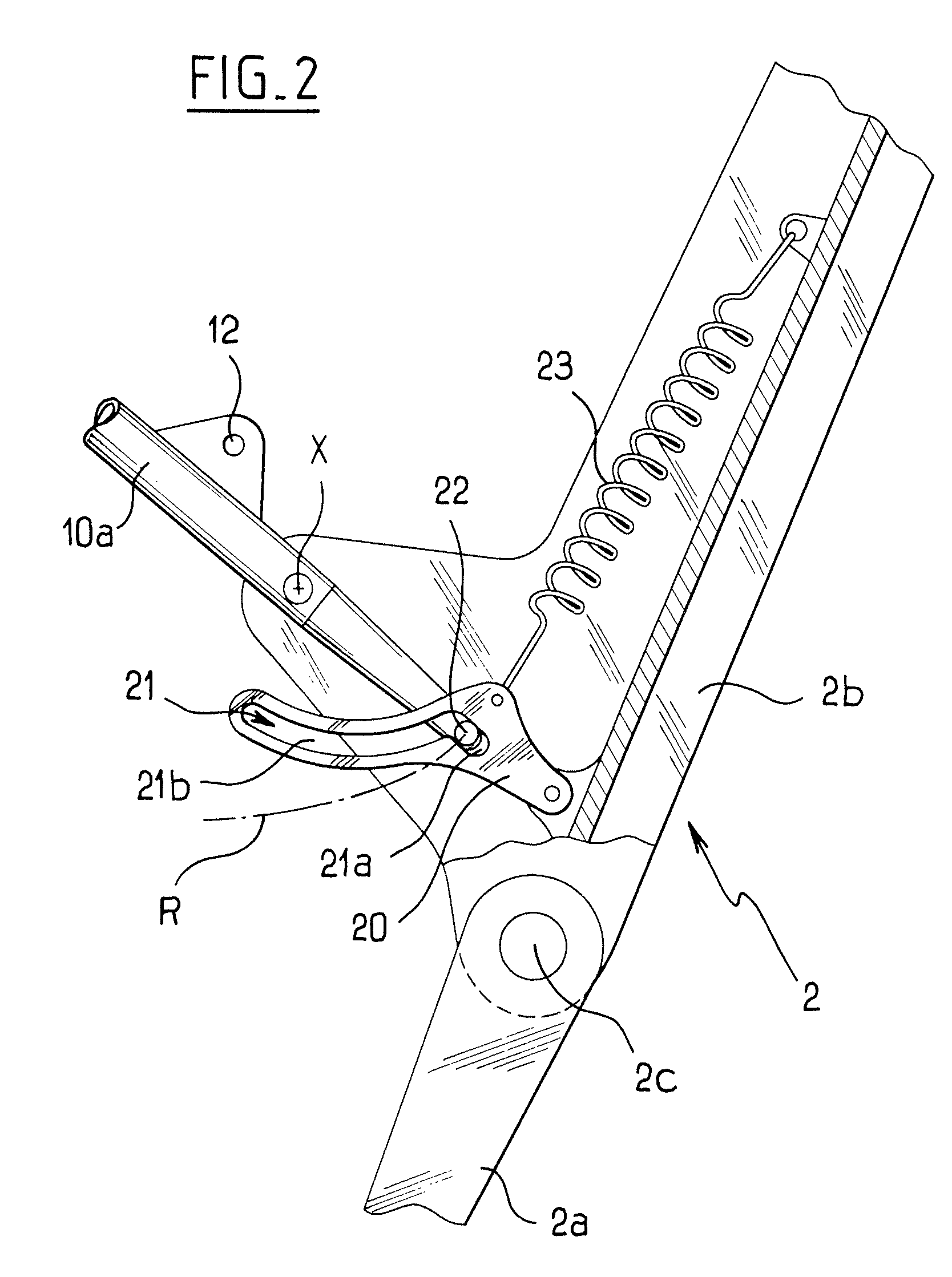

Brace-locking device for an aircraft undercarriage

Owner:SAFRAN LANDING SYSTEMS

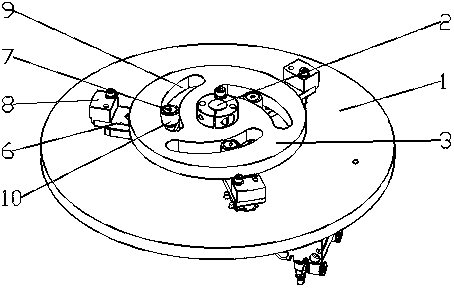

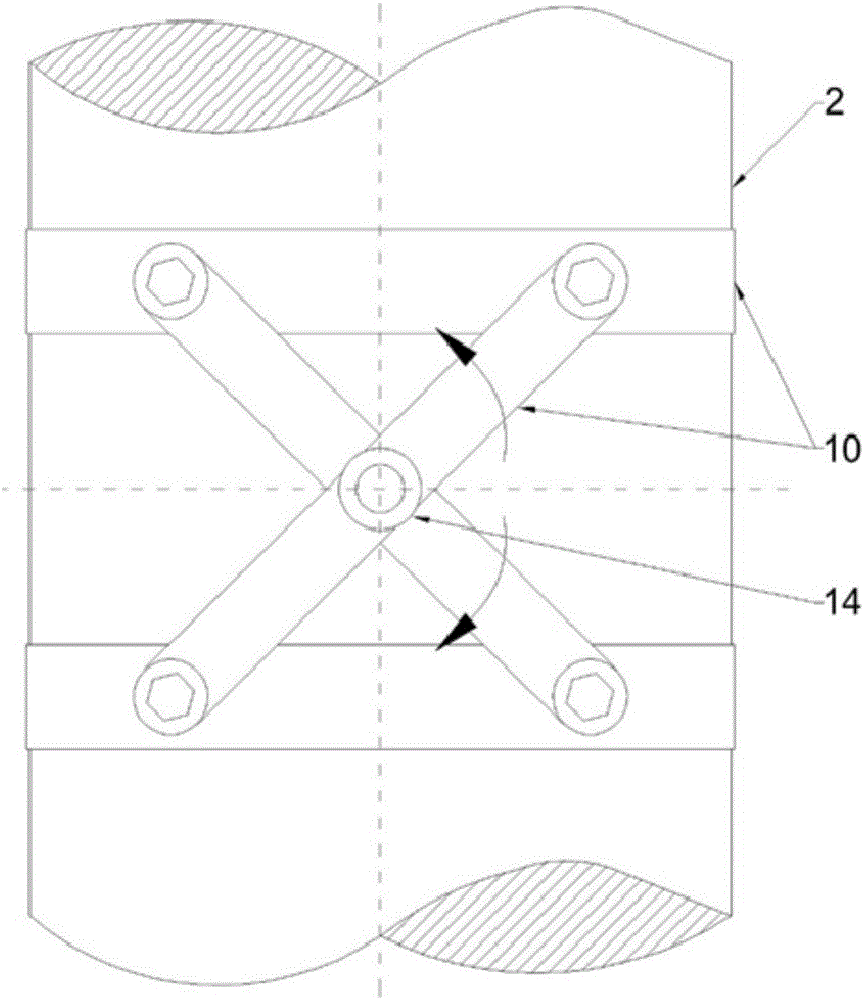

Self-adaption inner cylinder clamping manipulator

The invention discloses a self-adaptive inner cylinder clamping manipulator, which includes a chassis, a rotating shaft cooperating with the rotating shaft is arranged in the center of the bottom plate, a control disk is set on the rotating shaft, and at least three clamps are evenly arranged in a ring between the control disk and the chassis. holding unit; the clamping unit includes a radial slide seat fixedly installed on the chassis, a slide rail is provided on the radial slide seat for sliding cooperation with it, a connecting block is fixedly installed on the slide rail, and one end of the connecting block radially inward There is a sliding shaft, and the radially outward end of the connecting block is provided with a clamping head. The axis of the sliding shaft is parallel to the axis of the rotating shaft. The control panel is provided with a stroke groove corresponding to the sliding shaft, and the sliding shaft extends into the stroke groove. and cooperate with the stroke groove; the distance y between the centerline of the stroke groove and the axis of the rotating shaft satisfies: y=aθ+b, θ is the radial direction of any point on the centerline of the stroke groove relative to the axis of the rotating shaft and the distance between the stroke groove The angle between the point where the centerline is closest to the shaft axis and the radial direction of the shaft axis.

Owner:WENZHOU POLYTECHNIC

Brace-locking device for an aircraft undercarriage

Owner:SAFRAN LANDING SYSTEMS

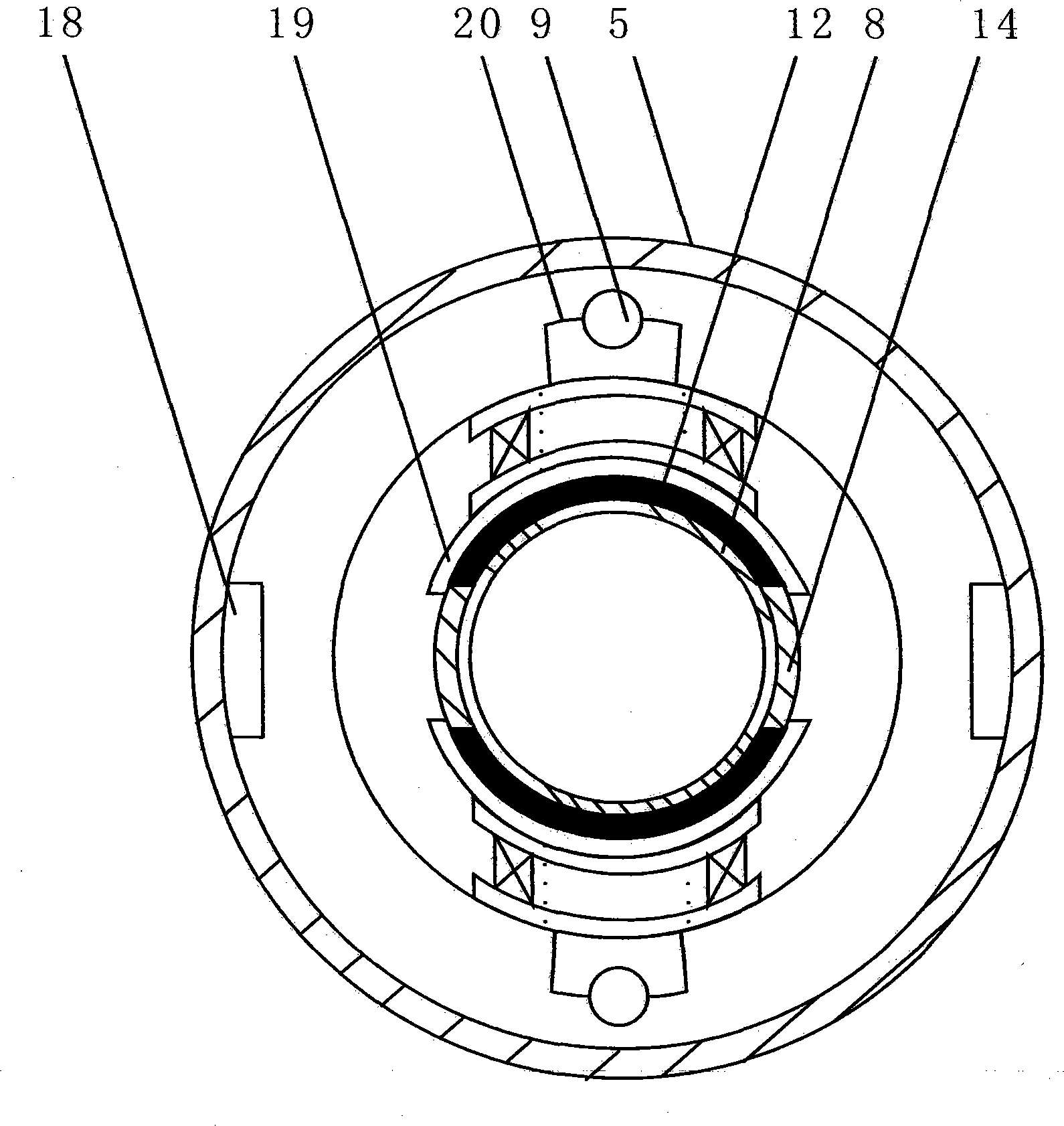

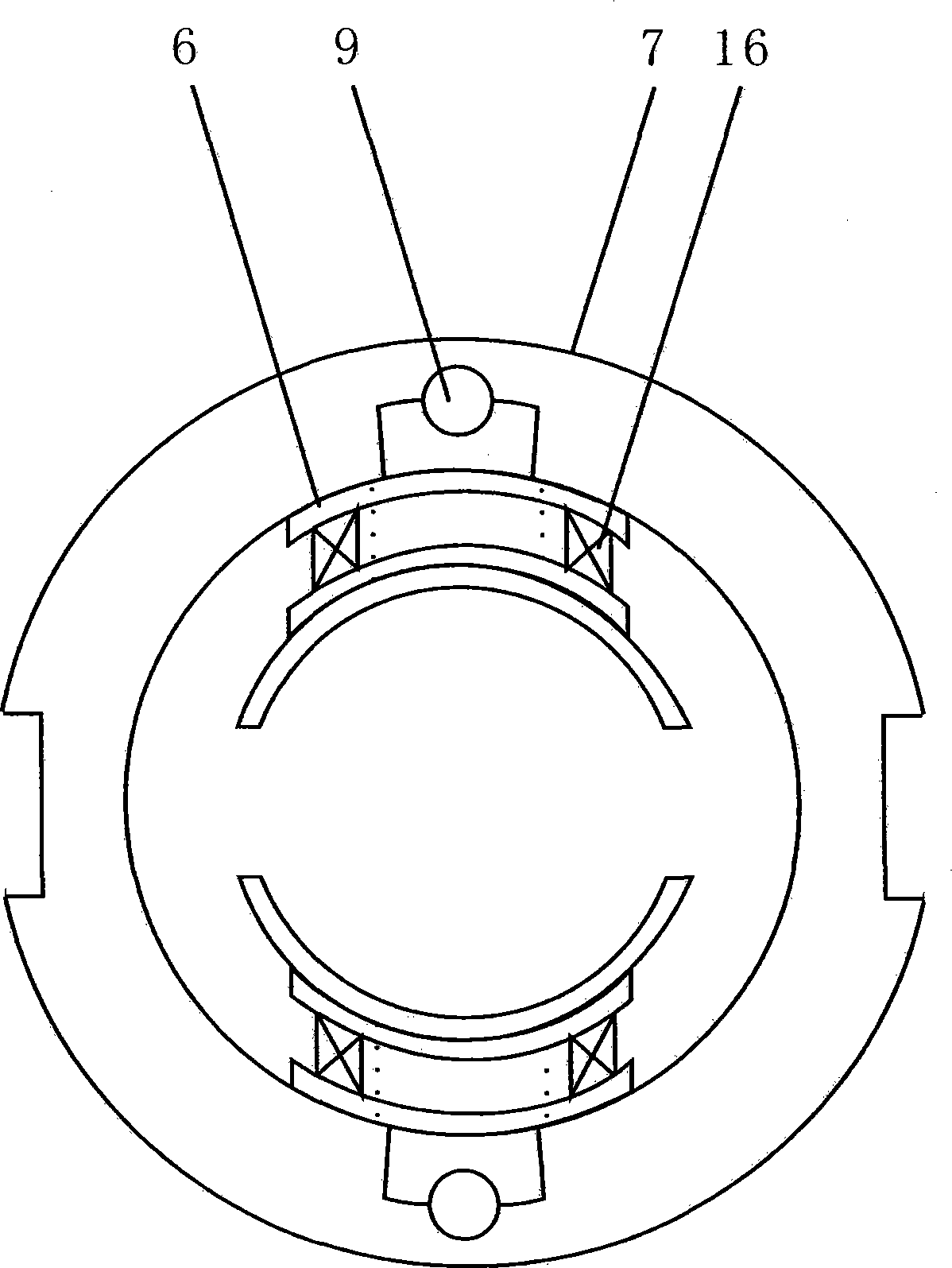

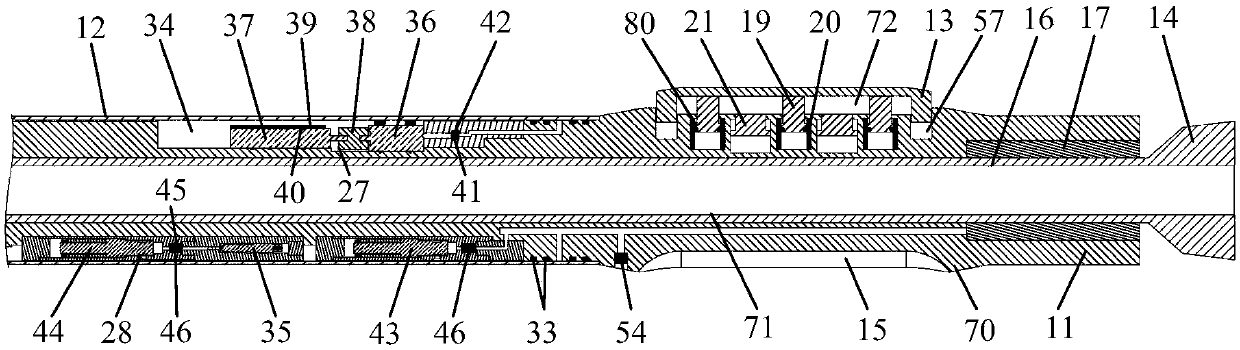

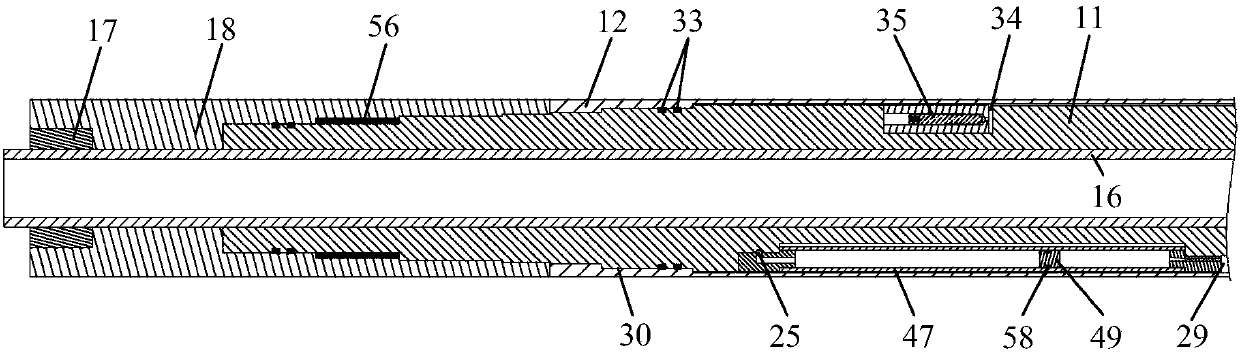

Push-lean type rotational guide device

ActiveCN109763777ASimple structureReduce energy consumptionDrilling rodsDirectional drillingControl systemDrill

The invention provides a push-lean type rotational guide device which comprises a drill collar body, wing ribs, an outer cylinder and a hydraulic control system, wherein the wing ribs are mounted on the outer circumference of the drill collar body; the drill collar body is sleeved by the outer cylinder; the outer cylinder is kept static relative to the drill collar body; the hydraulic control system comprises an oil storage cavity and an execution mechanism; the execution mechanism comprises an oil cylinder communicated with the oil storage cavity and a piston acting on the wing ribs; the hydraulic control system is capable of conveying hydraulic oil between the oil storage cavity and an oil cylinder, and then the wing ribs can make radial telescopic movement under the action of the piston.

Owner:CHINA PETROLEUM & CHEM CORP +1

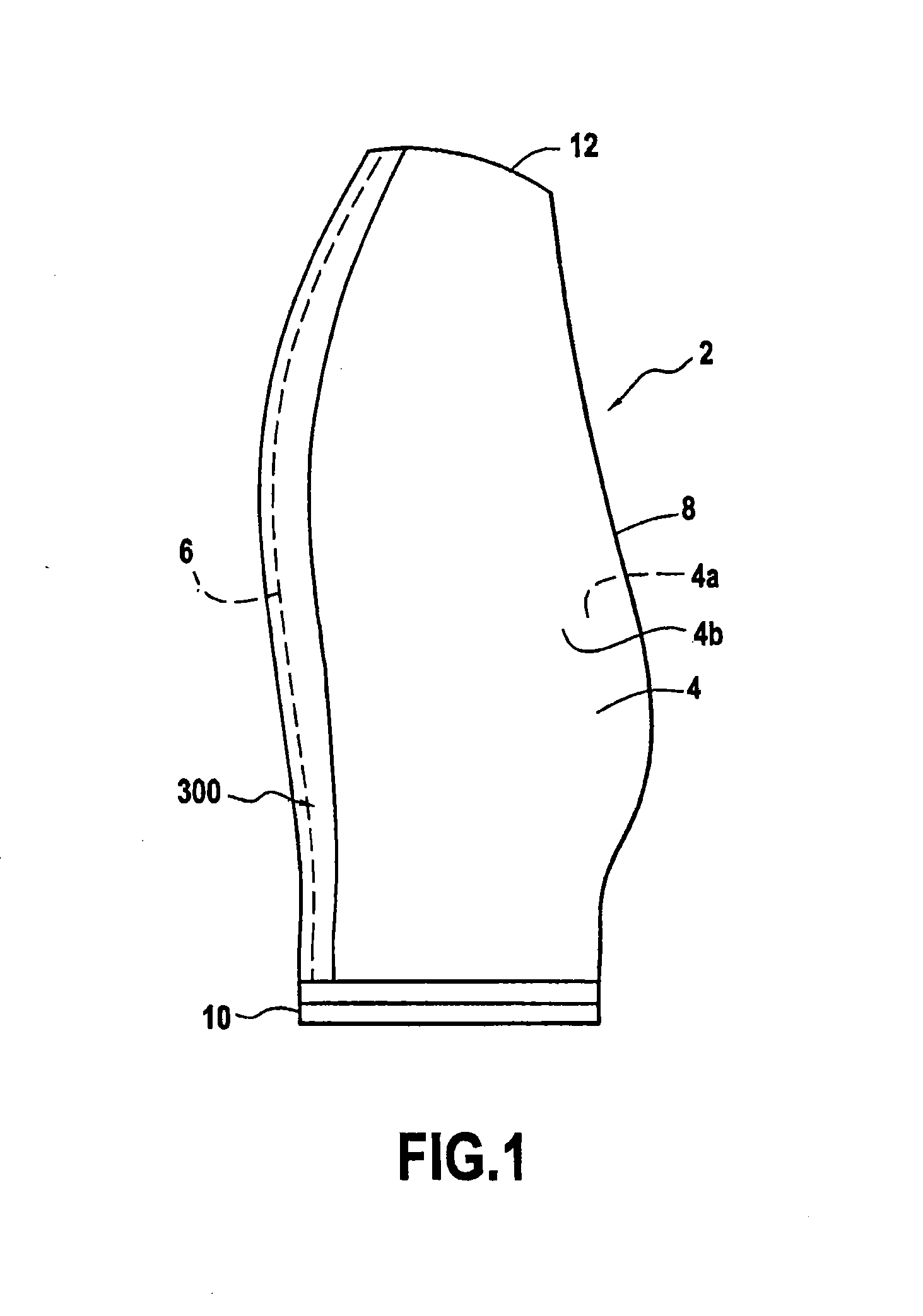

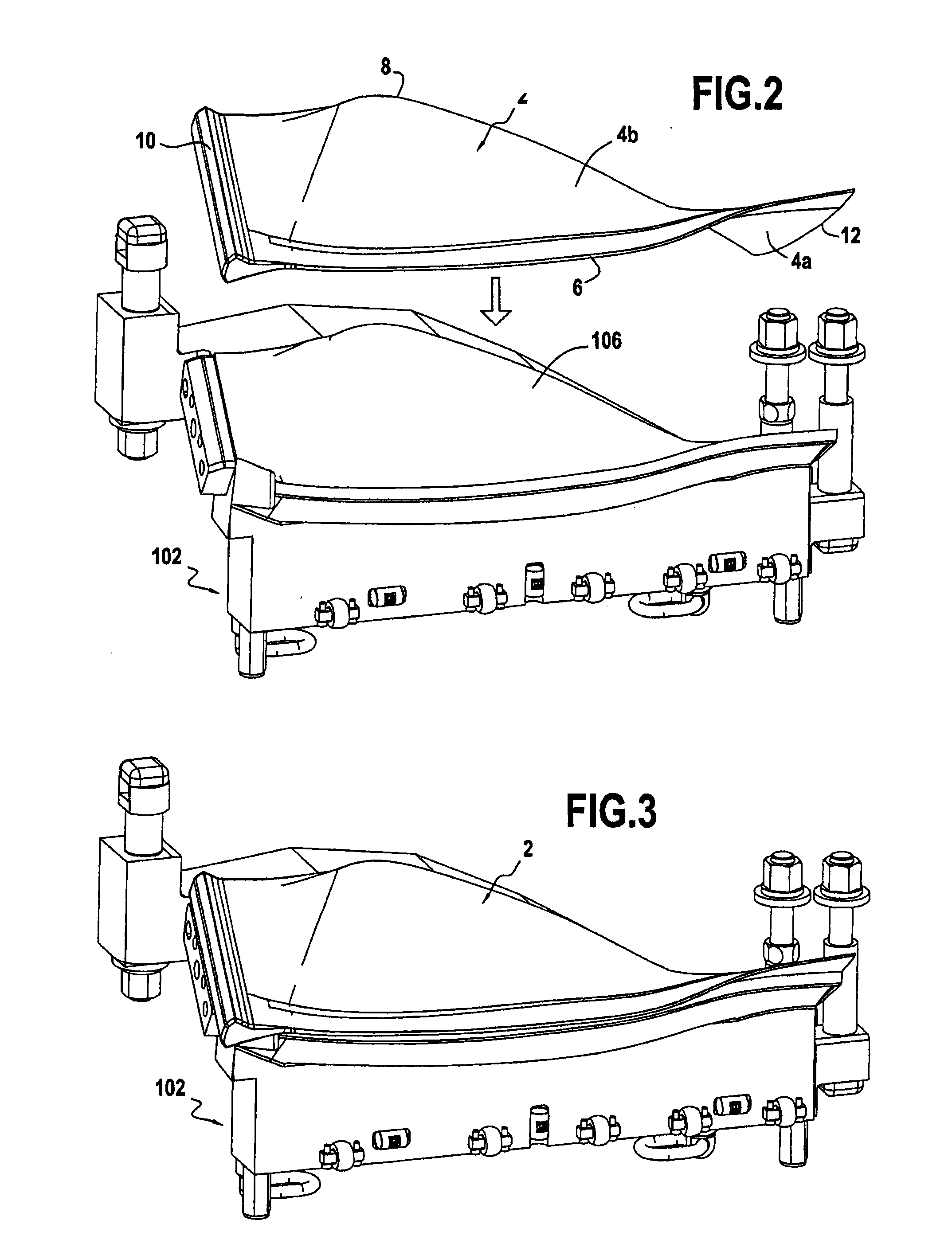

Tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, and a method using such tooling

ActiveUS20160076387A1Avoid defectsReduce heat fatiguePump componentsBlade accessoriesLeading edgeTurbine

A tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, the tooling including a blade support for receiving a blade while leaving surfaces of the leading edge of the blade disengaged; and a leading edge reinforcement support on which the blade support is designed to be mounted, and including two lateral wedges between which the metal reinforcement for the leading edge of the blade is positioned, the wedges being suitable for being capable of moving towards each other and apart from each other and each of them being provided with a suction grid for gripping the metal reinforcement, the leading edge reinforcement support further including heater elements for polymerizing an adhesive film applied on the leading edge surfaces of the blade.

Owner:SAFRAN +1

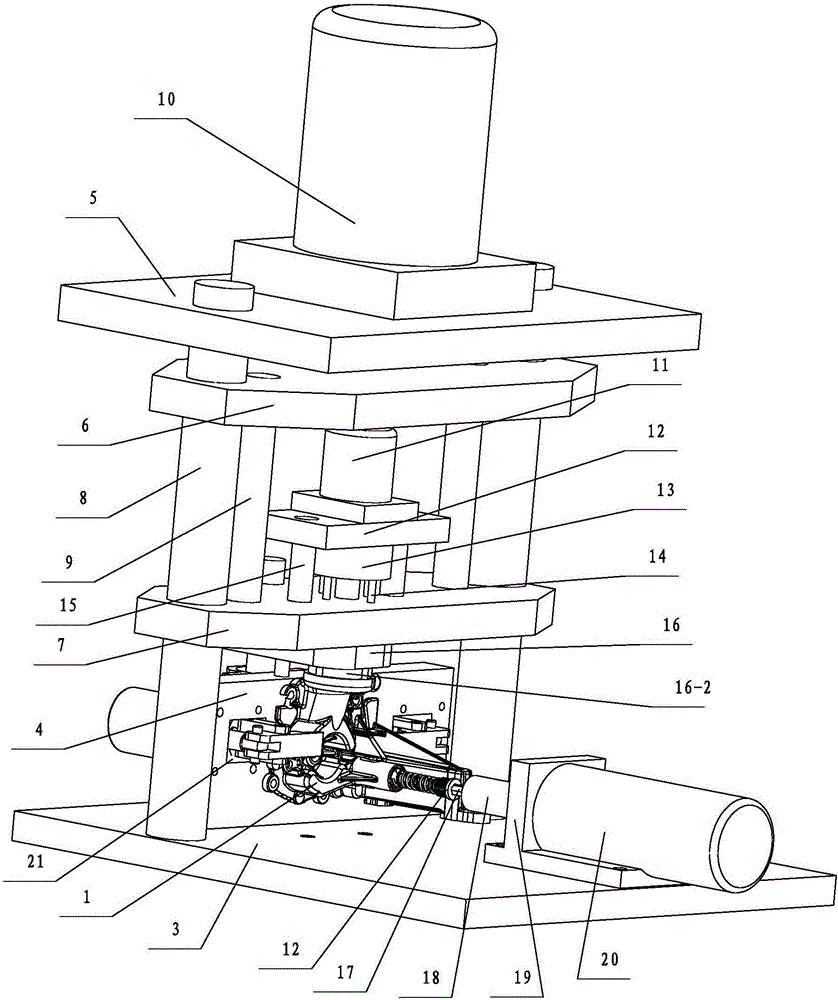

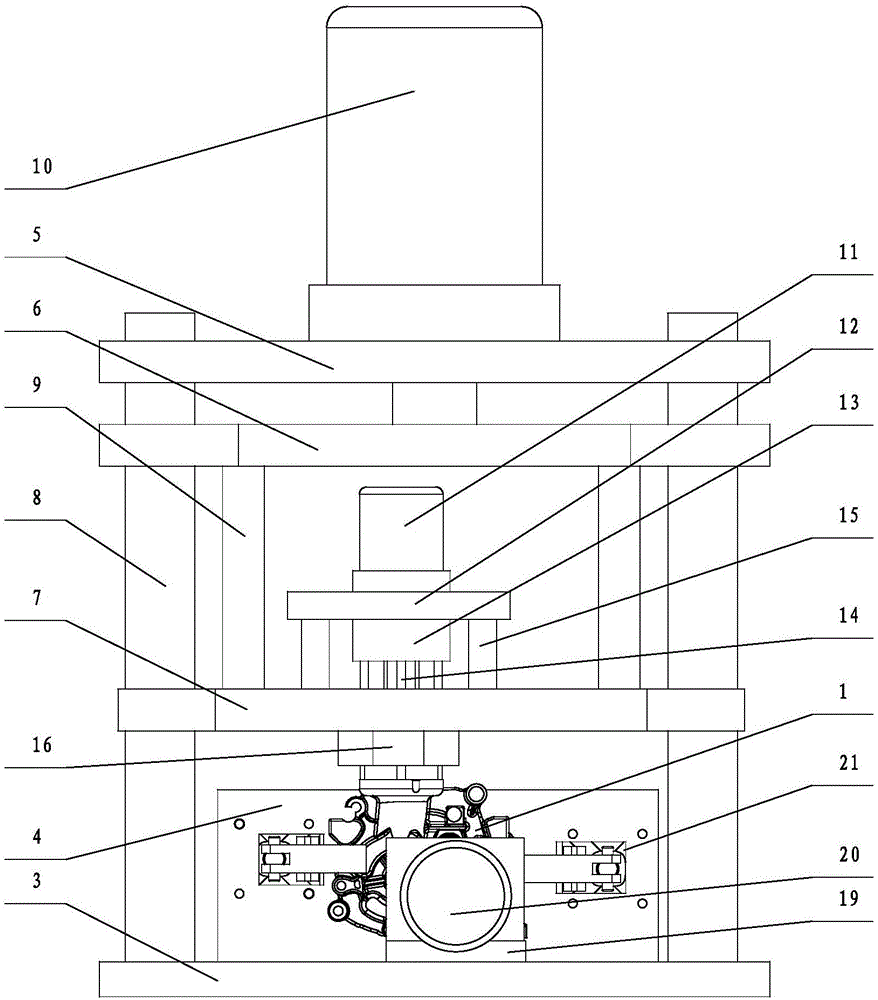

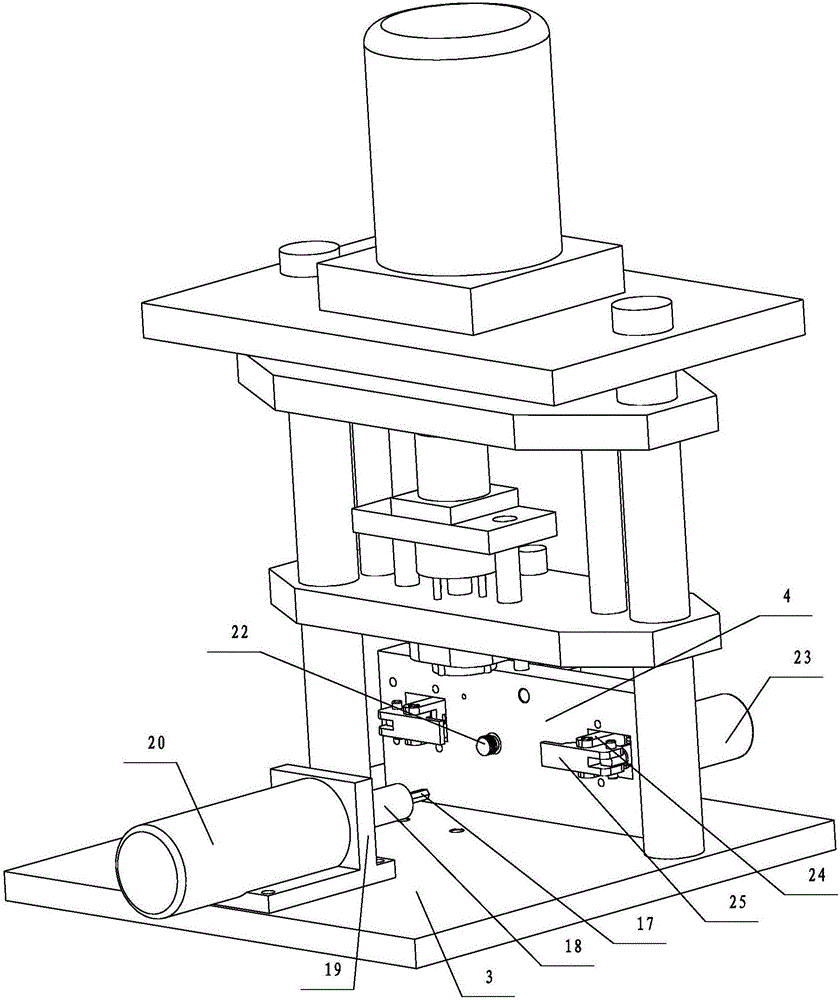

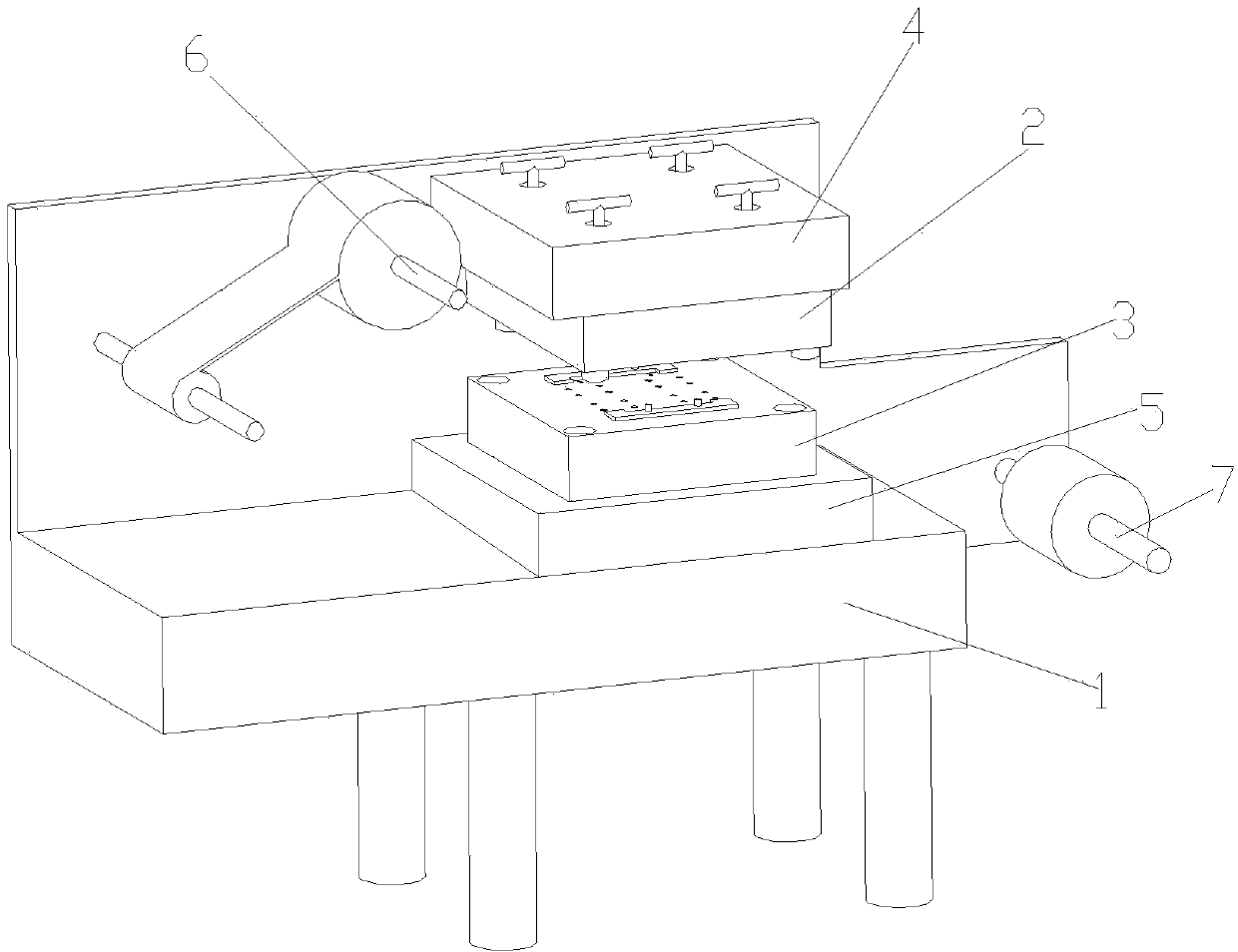

Installation tool for filtering net of oil pump

ActiveCN106312514AImprove assembly efficiencyImprove assembly qualityAssembly machinesMetal working apparatusEngineeringPressure release

The invention discloses an installation tool for a filtering net of an oil pump. The installation tool comprises a bottom plate (3), a positioning plate (4), a pressing device, a filtering net press mounting device and a pressure release valve installation device. The positioning plate (4) is vertically connected to the bottom plate (3) which is horizontally arranged. The filtering net press mounting device is connected to the bottom plate (3) through a support assembly, and a pressing head plate (16) in the filtering net press mounting device is located over an oil inlet of a pump body. The pressure release valve installation device is connected to the bottom plate (3), and the movement direction of the movable end of the pressure release valve installation device is the horizontal direction consistent with the direction of the axis of an installation opening of the pump body. After the above structure is adopted, the pump body of the oil pump does not need to be secondarily clamped, and therefore the assembling efficiency is greatly improved; and in addition, the benchmark does not need to be found again during assembling, and therefore the assembling quality of a product is better ensured.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

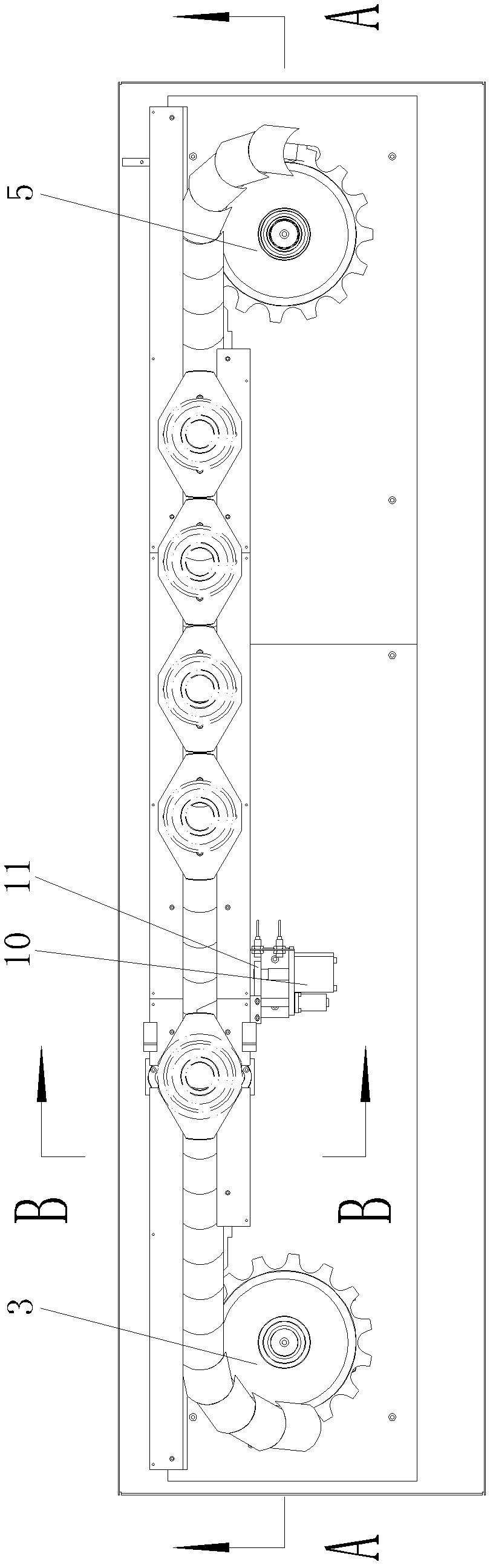

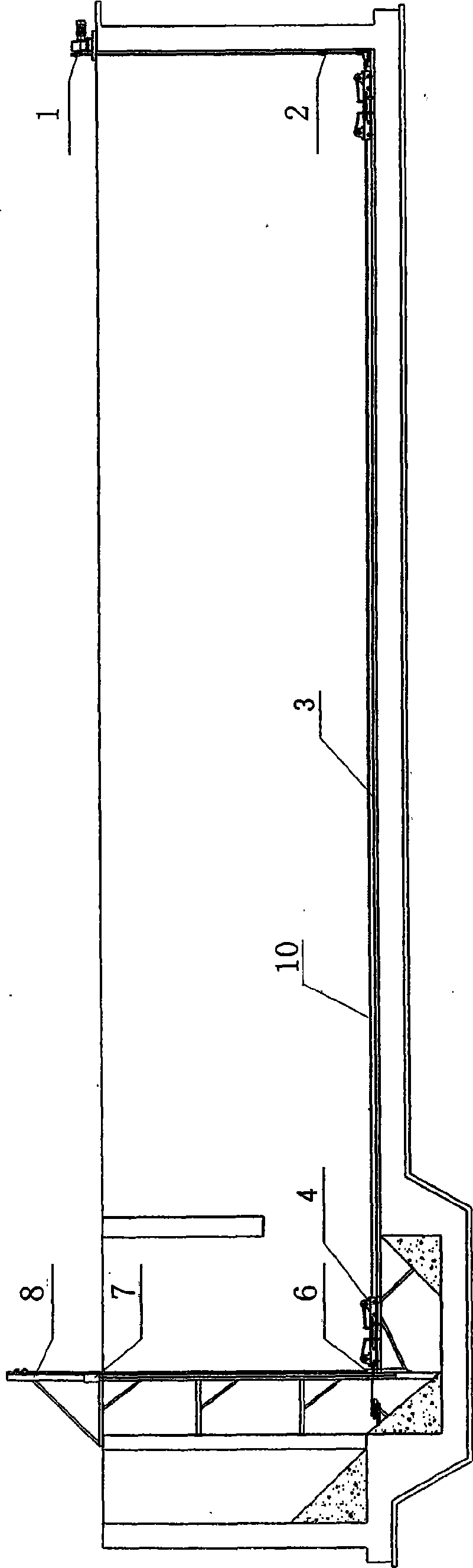

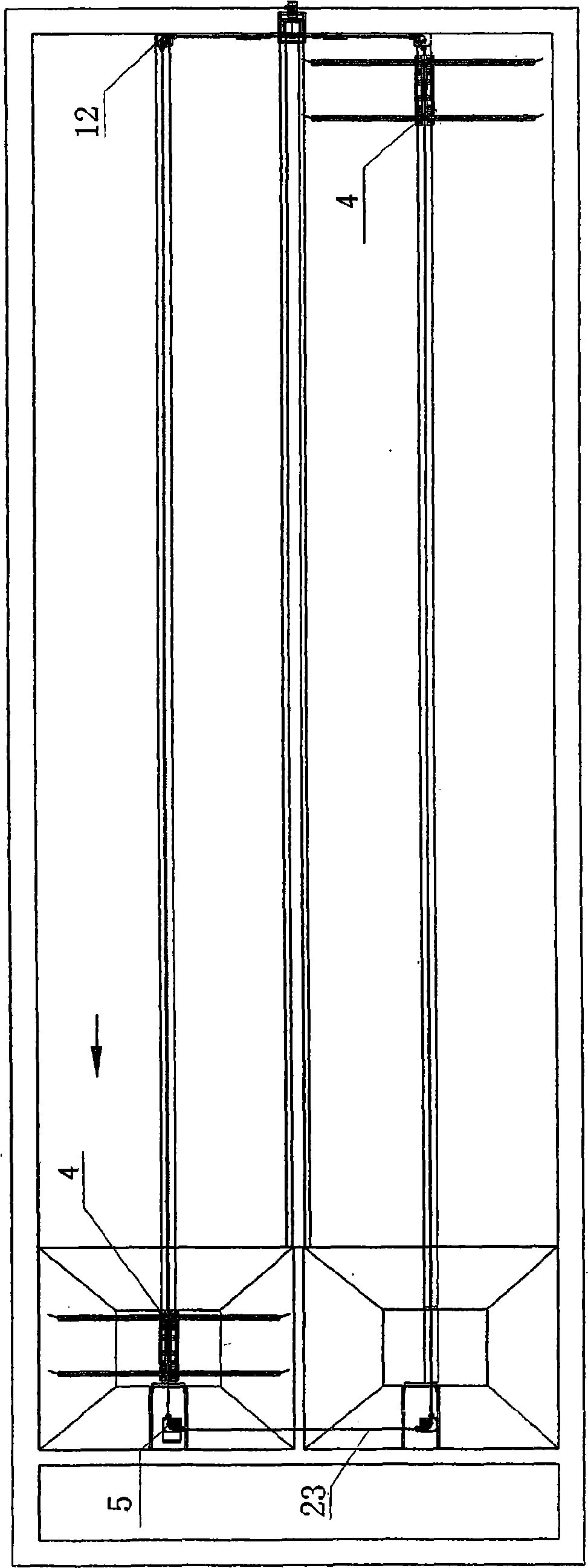

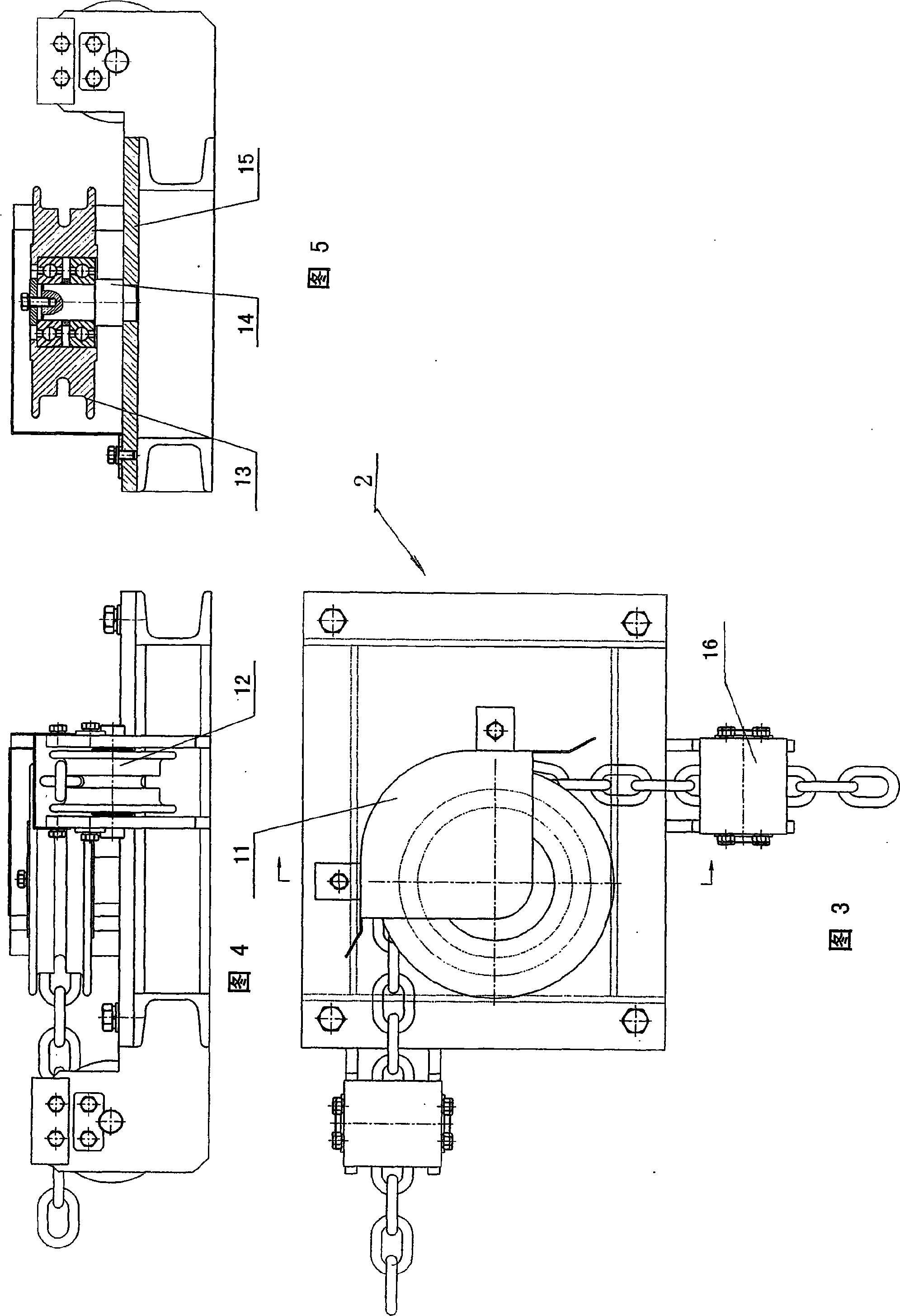

Trolley-type chain mud scraper

ActiveCN101530682ASimple structureReasonable structureSedimentation settling tanksRotation functionVehicle frame

The invention relates to a trolley-type chain mud scraper. A main structure of the chain mud scraper consists of a driving device, a guiding device, a guide rail component, a mud scraping trolley, a hoisting device and a safety protection device; the driving device consists of an electric motor with positive and negative rotation functions, a decelerator and a driving chain sprocket; the guiding device consists of a drag chain guiding device, a tension device and a drag rope guiding device; the guide rail component consists of a rail and an embedded plate; the mud scraping trolley consists of a frame, a running idler wheel, a lateral turning prevention idler wheel, a derailment prevention idler wheel, a link drive mechanism, a large mud scraping plate and a small mud scraping capable of turning, a mud scraping arm, a mud scraping arm bearing block and a trolley enclosure; and the hoisting device consists of a portal frame, an idler wheel and a hoisting mechanism. The trolley-type chain mud scraper can be widely used for removing mud out of a horizontal sedimentation (clarification) tank.

Owner:ZHEJIANG SUNLAND ENVIRONMENTAL TECH CO LTD

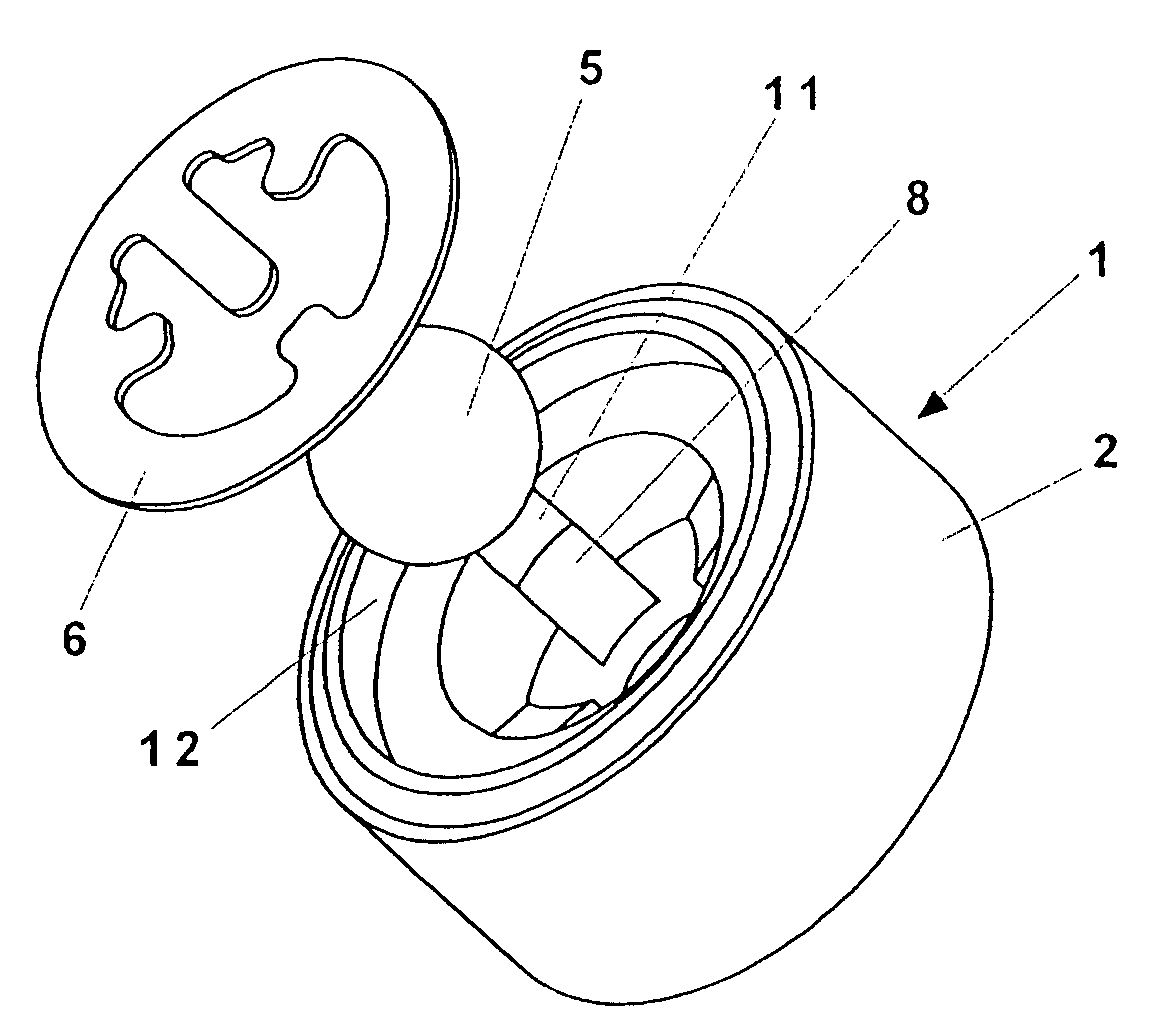

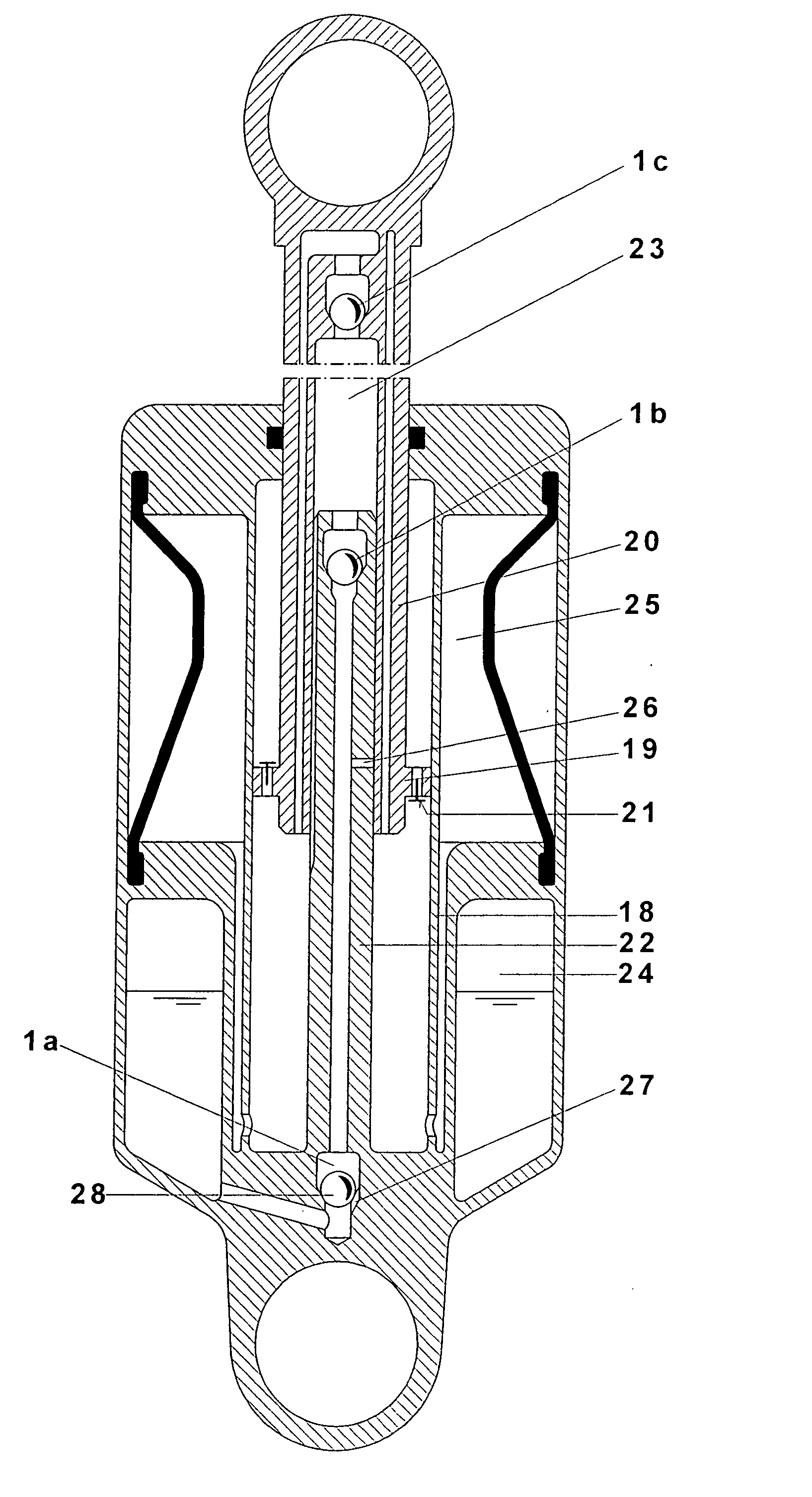

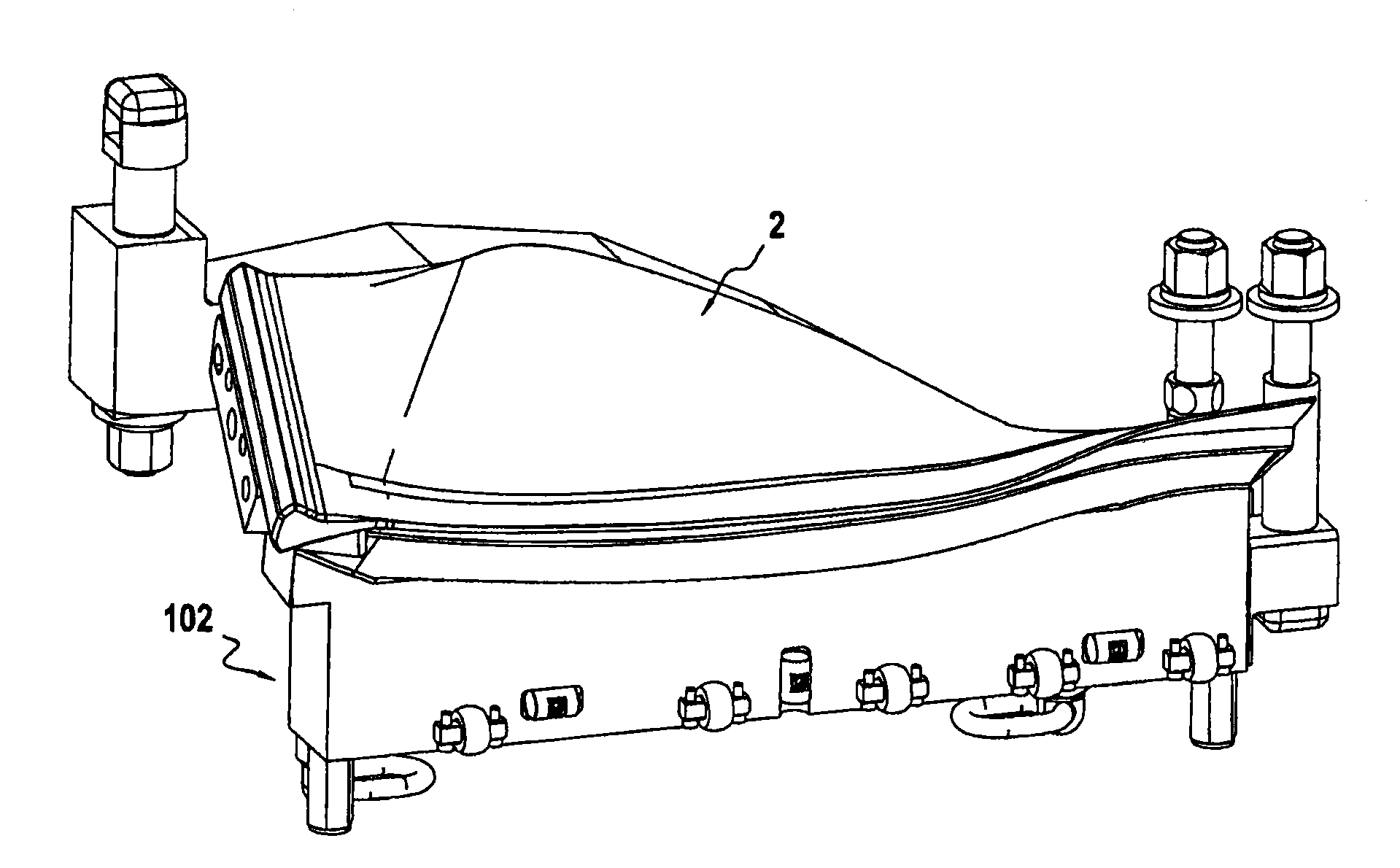

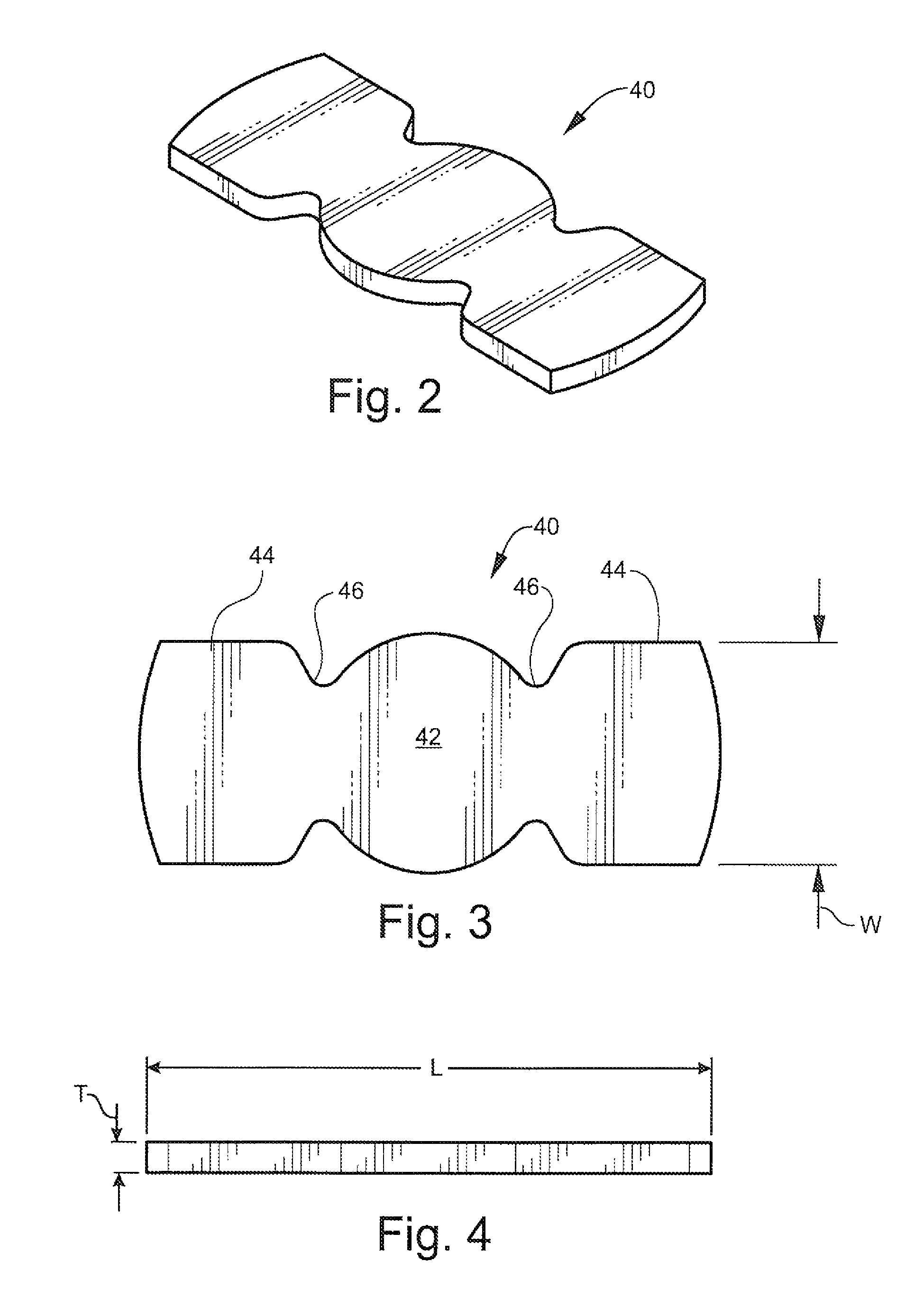

Pump valve with controlled stroke

ActiveUS7762796B2Avoid excessive noiseControl strokeDiaphragm valvesPositive displacement pump componentsPump chamberEngineering

A valve assembly for a pump includes a pump chamber and a pump head having complementary recesses formed therein which cooperate to define a valve compartment including a pocket and an opposed seat. A flexible valve element is disposed between the recesses and adapted to move between a closed position against the seat which prevents fluid flow and an open position away from the valve seat which permits fluid flow. The dimensions of the valve compartment are selected to limit the movement of the valve element in the open position, which increases the pump efficiency and prevents damage to the valve element and / or valve overlap.

Owner:PARKER INTANGIBLES LLC

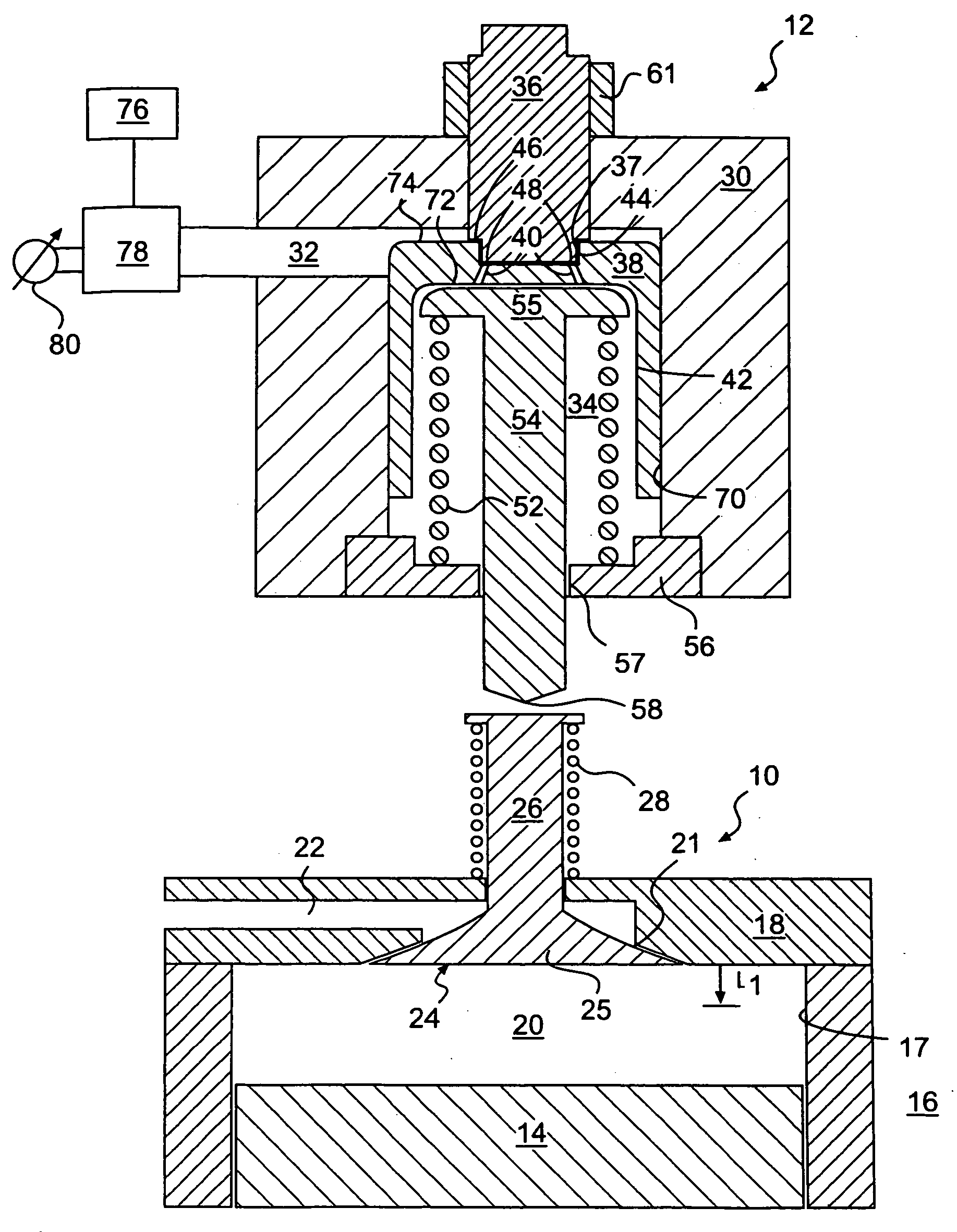

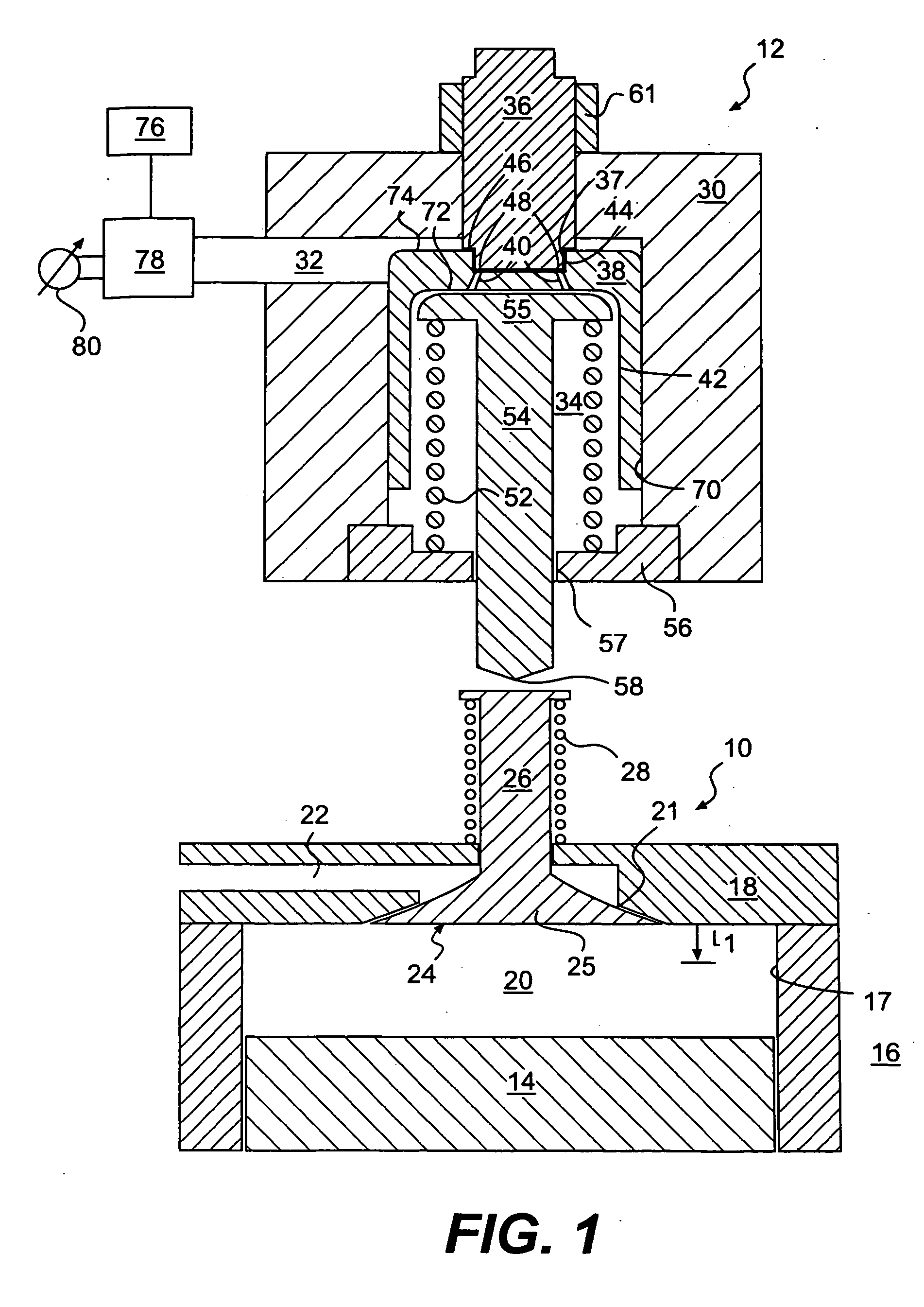

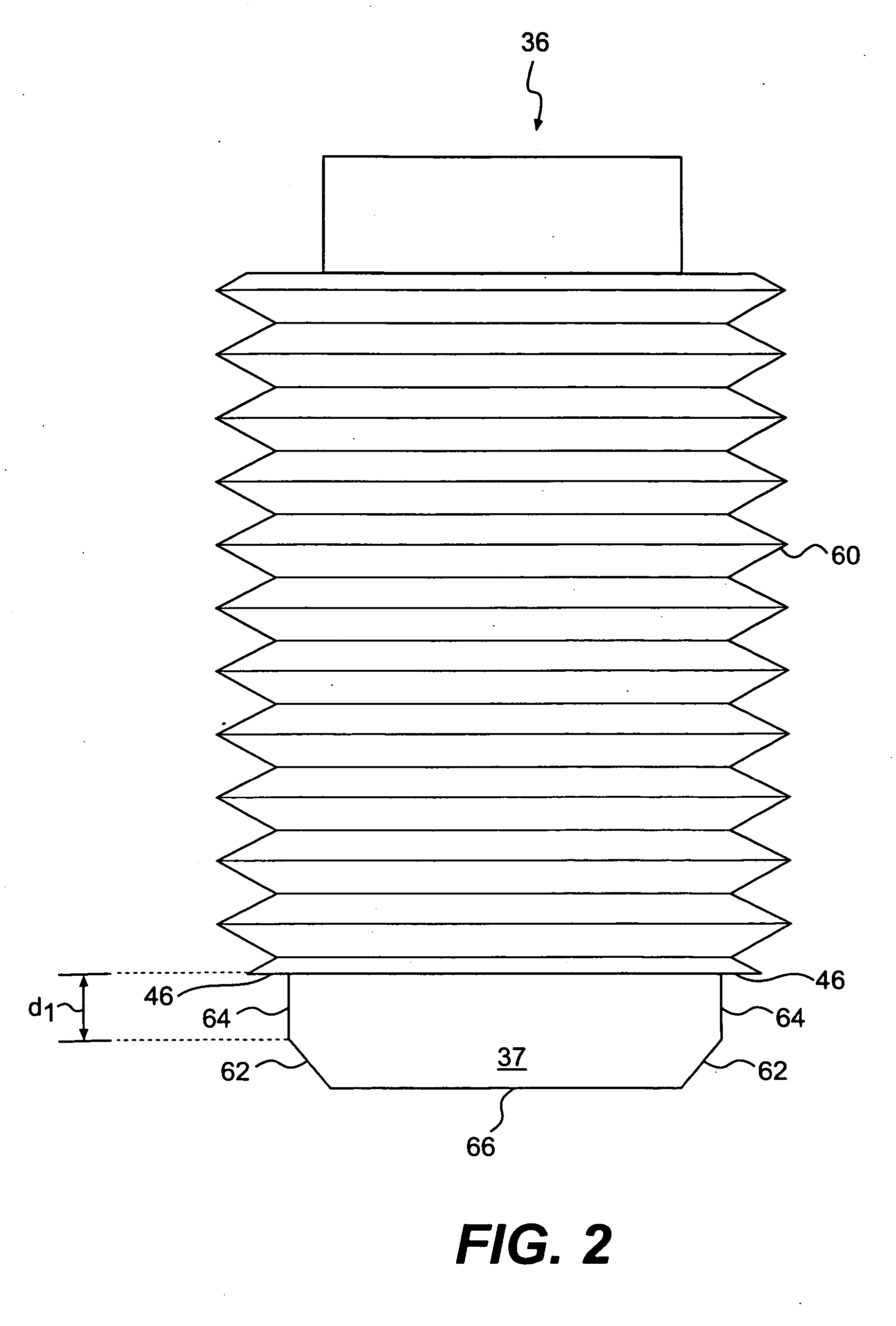

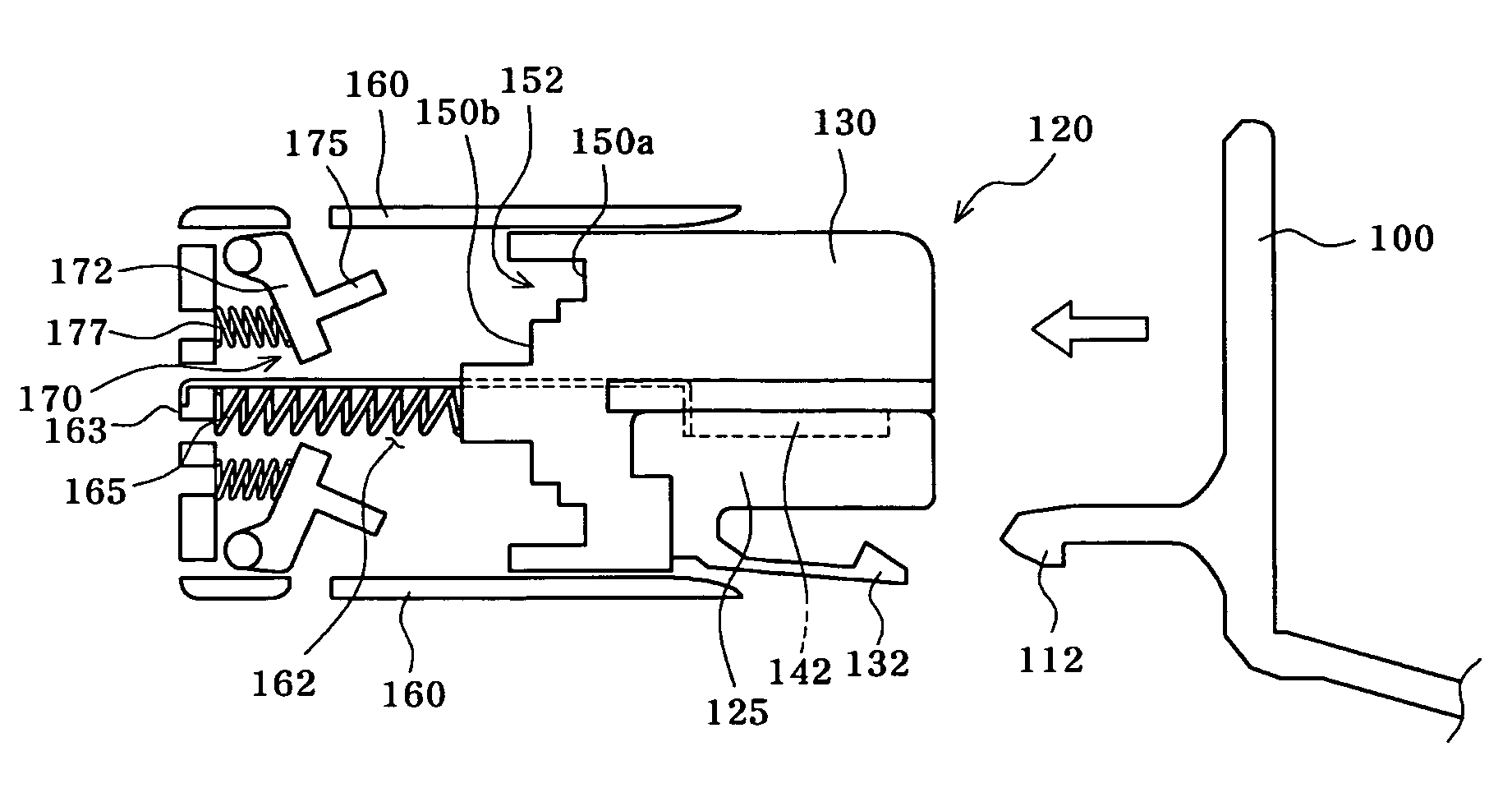

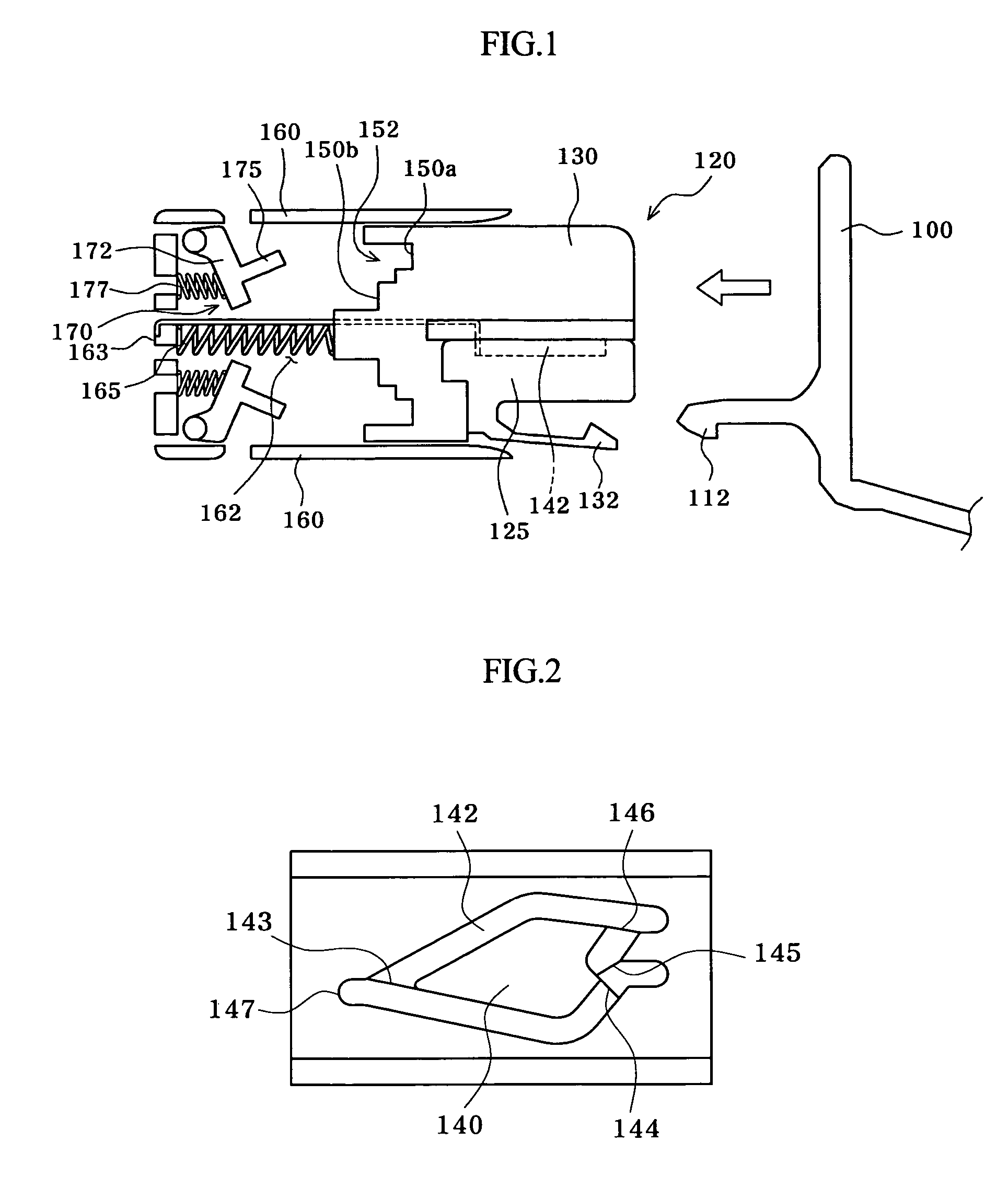

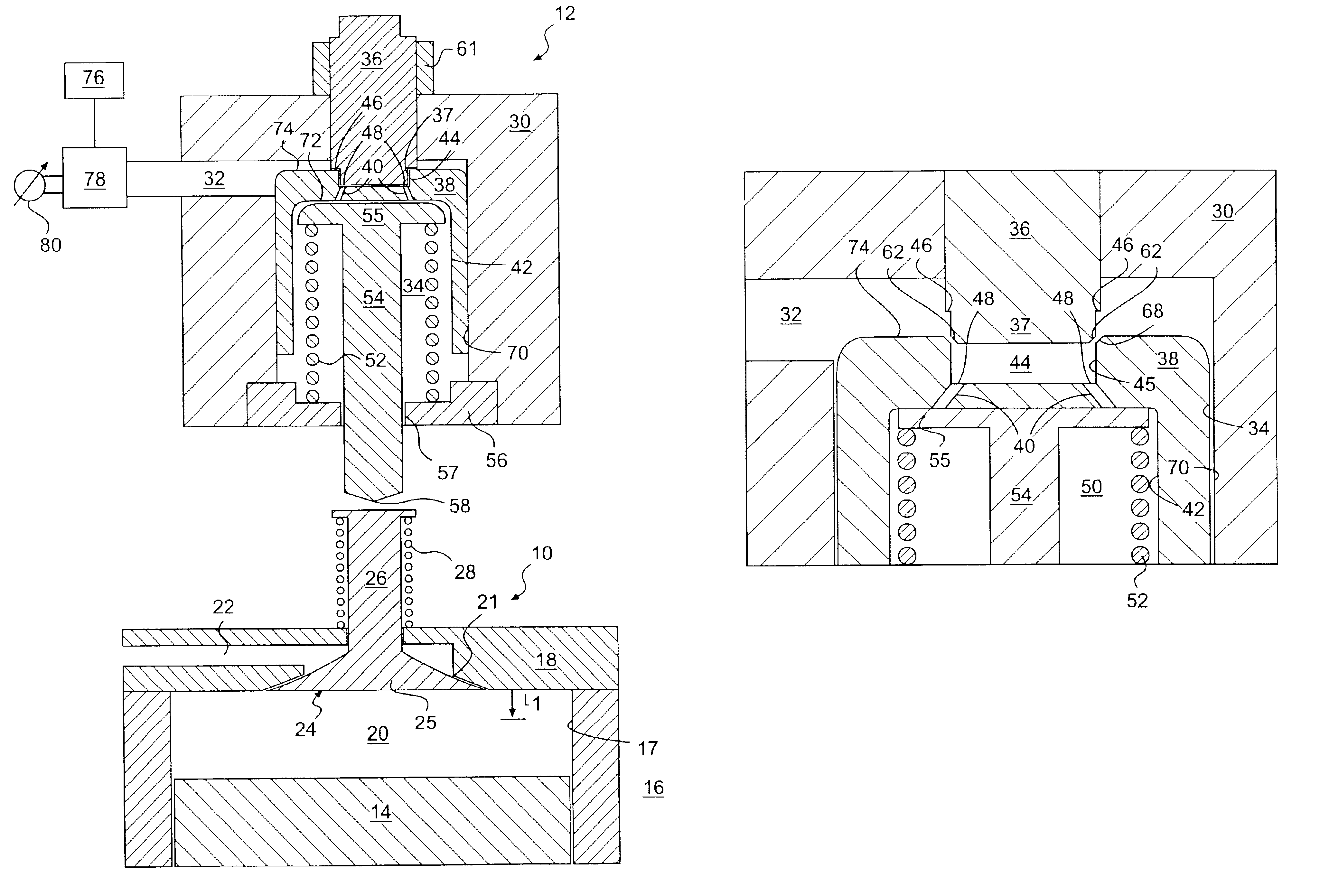

Engine valve actuator

InactiveUS6957634B2Limit movement of pistonControl strokeMachines/enginesNon-mechanical valveValve actuatorEngineering

An engine valve actuator for an internal combustion engine is provided. The engine valve actuator includes a housing having an opening and a first fluid passageway leading to the opening. An adjustment member is disposed in the housing and includes a protrusion that extends into the opening of the housing. A piston is disposed in the opening of the housing and has a bore adapted to receive the protrusion, a chamber, and a second fluid passageway that connects the bore with the chamber. The piston is adapted to move in a first direction relative to the housing in response to an introduction of pressurized fluid into the first fluid passageway. The piston moves in the first direction until the protrusion substantially withdraws from the bore. A push rod is operatively engaged with the piston such that movement of the piston in the first direction causes a corresponding movement of the push rod to thereby engage and open the engine valve.

Owner:CATERPILLAR INC

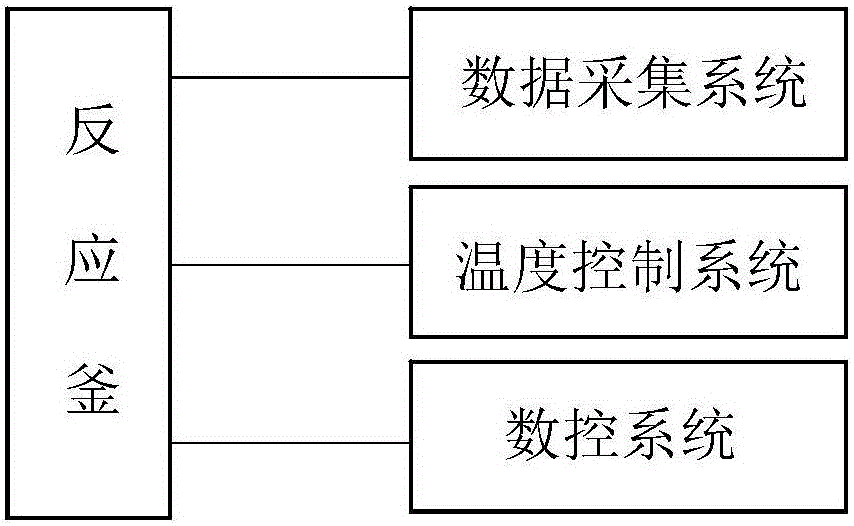

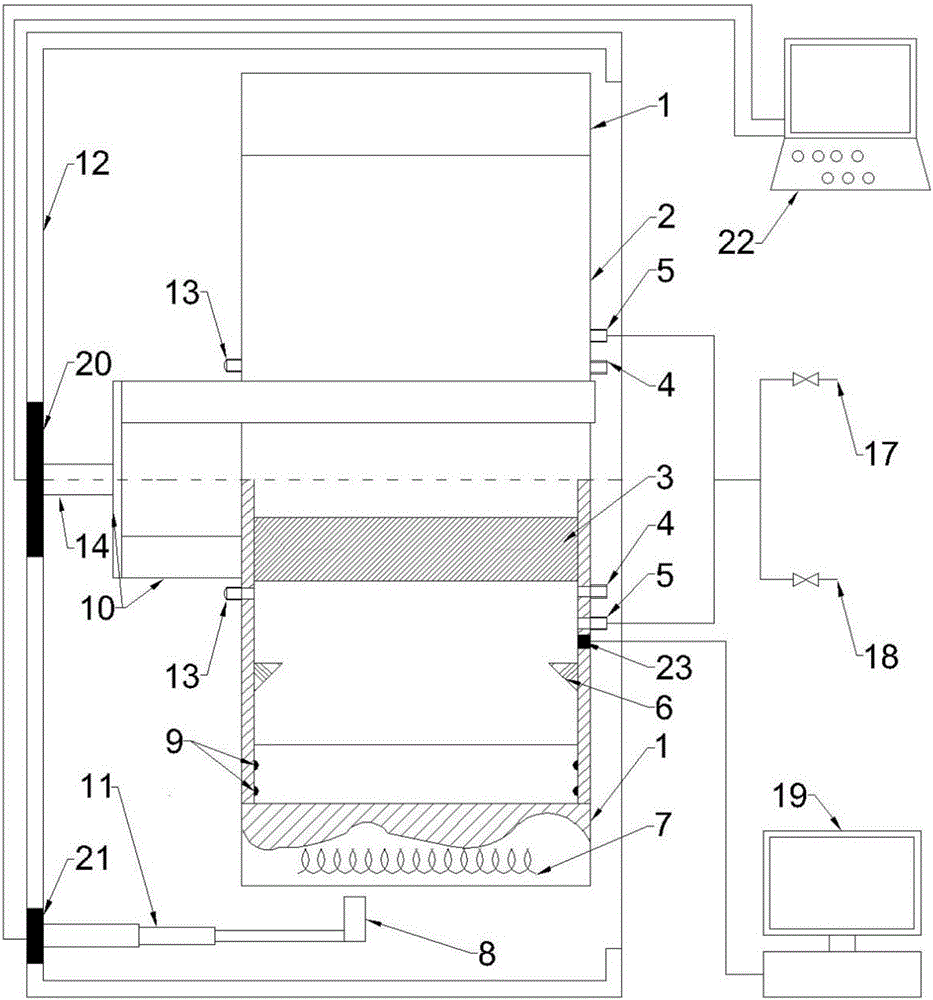

Semi-continuous piston type hydrate cake generating device

ActiveCN105107429APromote generationTemperature controlPressure vessels for chemical processReal time analysisGas phase

The invention relates to a semi-continuous piston type hydrate cake generating device, and belongs to the field of hydrate technology applications. The semi-continuous piston type hydrate cake generating device comprises a reaction kettle, a temperature control system, a numerical control system and a data collection system. A piston is installed in the reaction kettle, and the piston which does reciprocating motion can compress generated hydrates to be in the shape of a round cake; the temperature control system can precisely control the temperature of an air-bath operation desk and then control the temperature in the reaction kettle; the data collection system can collect temperature and pressure signals in real time and perform real-time analysis; the numerical control system controls a liquid source and a high-pressure gas source to inject quantificational liquid and gas into the reaction kettle and enables the pressure of the reaction kettle to reach a set value; in addition, the numerical control system controls a rotation-shaft motor to enable the reaction kettle to clockwise and anticlockwise rotate for 180 degrees at a certain rate, and therefore a gas phase and a liquid phase are fully mixed to promote generation of the hydrates; furthermore, the numerical control system can control a telescopic rod and a rotary telescopic type disassembly head to be conveniently disassembled.

Owner:DALIAN UNIV OF TECH

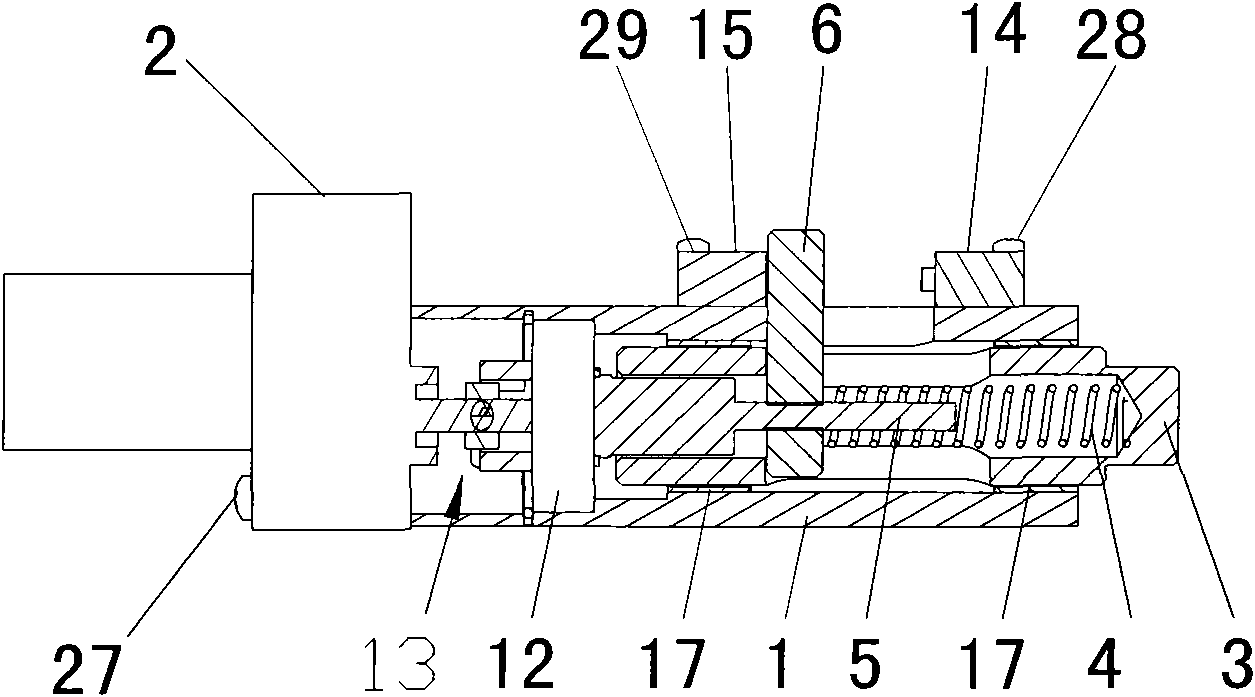

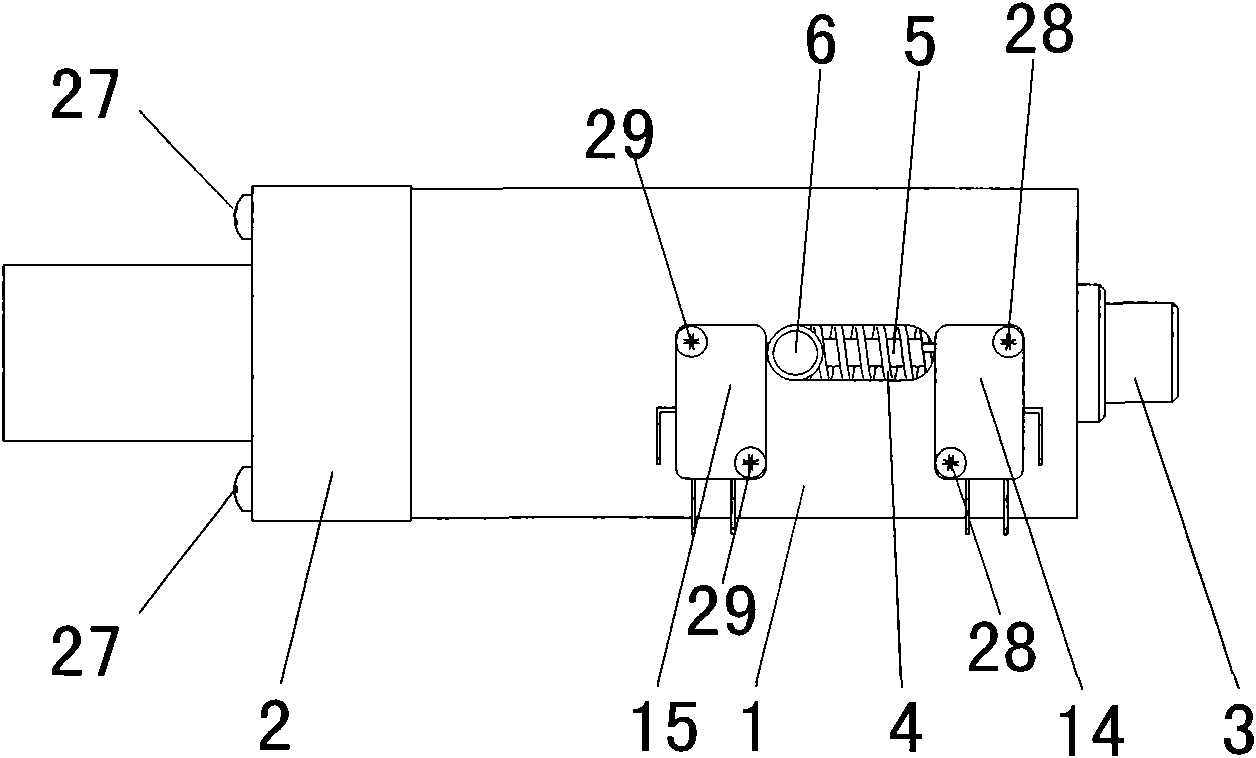

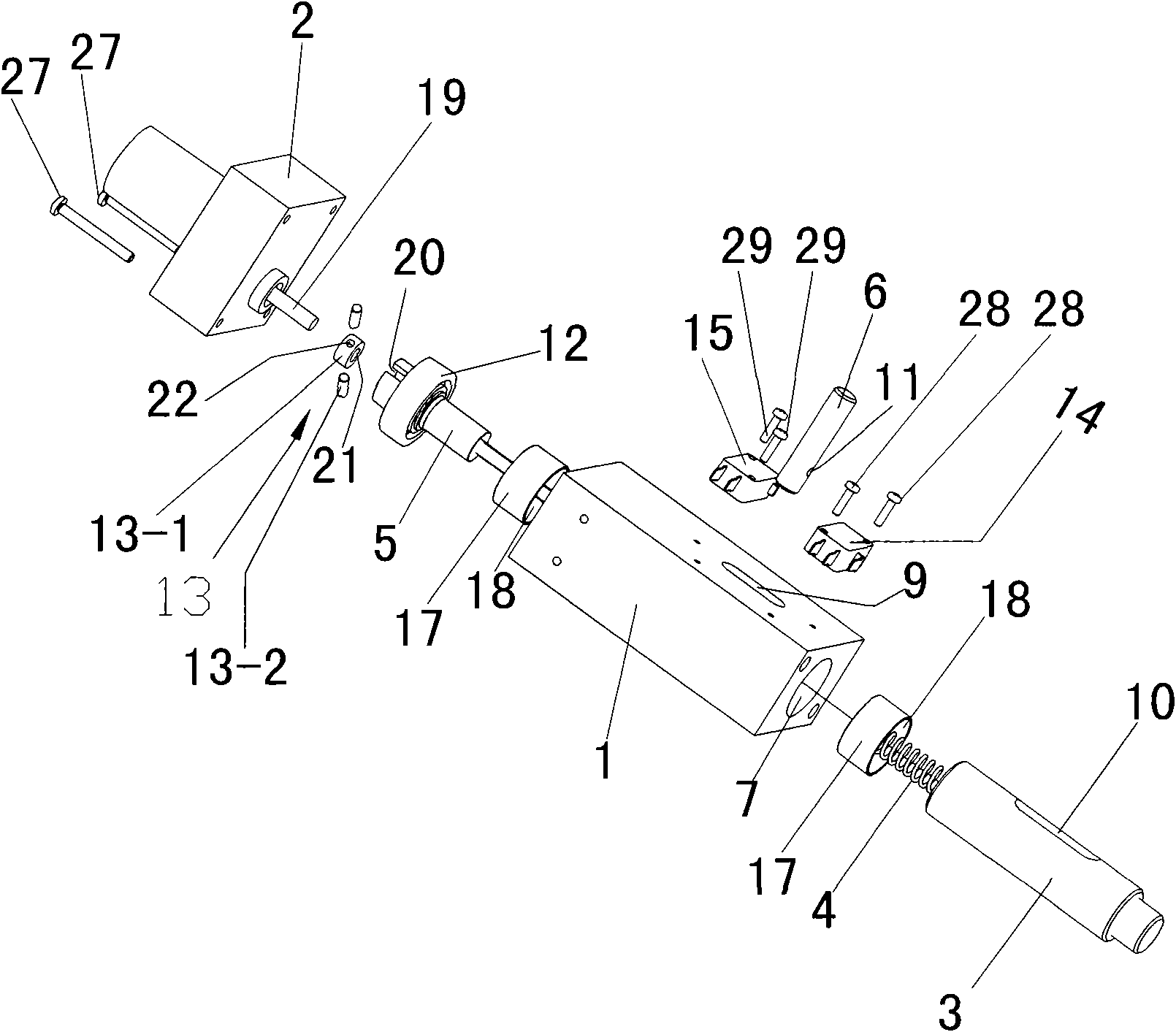

Electric lock

ActiveCN101560851APlay a buffer rolePlay a protective effectNon-mechanical controlsEngineeringMicro motor

The invention relates to an electric lock named as an electric lock and aims at solving the technical problem that as no buffer gear exists between a bolt and a guide screw of the existing electric lock, the guide screw or a micro motor is easy to be damaged. The technical scheme of the invention is as follows: the electric lock comprises a lock body 1, a motor 2 and a bolt 3 which can extend outof or retract into the lock body. The output shaft of the motor 2 is connected with a driving device, and a spring 4 is arranged between the driving device and the bolt 3. If the bolt 3 is obstructedwhen extending out of the lock body 1, the spring 4 has buffer effect, thus protecting the motor 2 and the driving device from being damaged.

Owner:青岛博宁福田通道设备股份有限公司

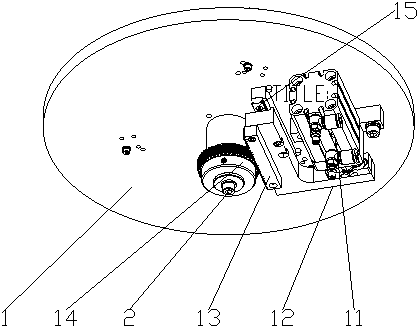

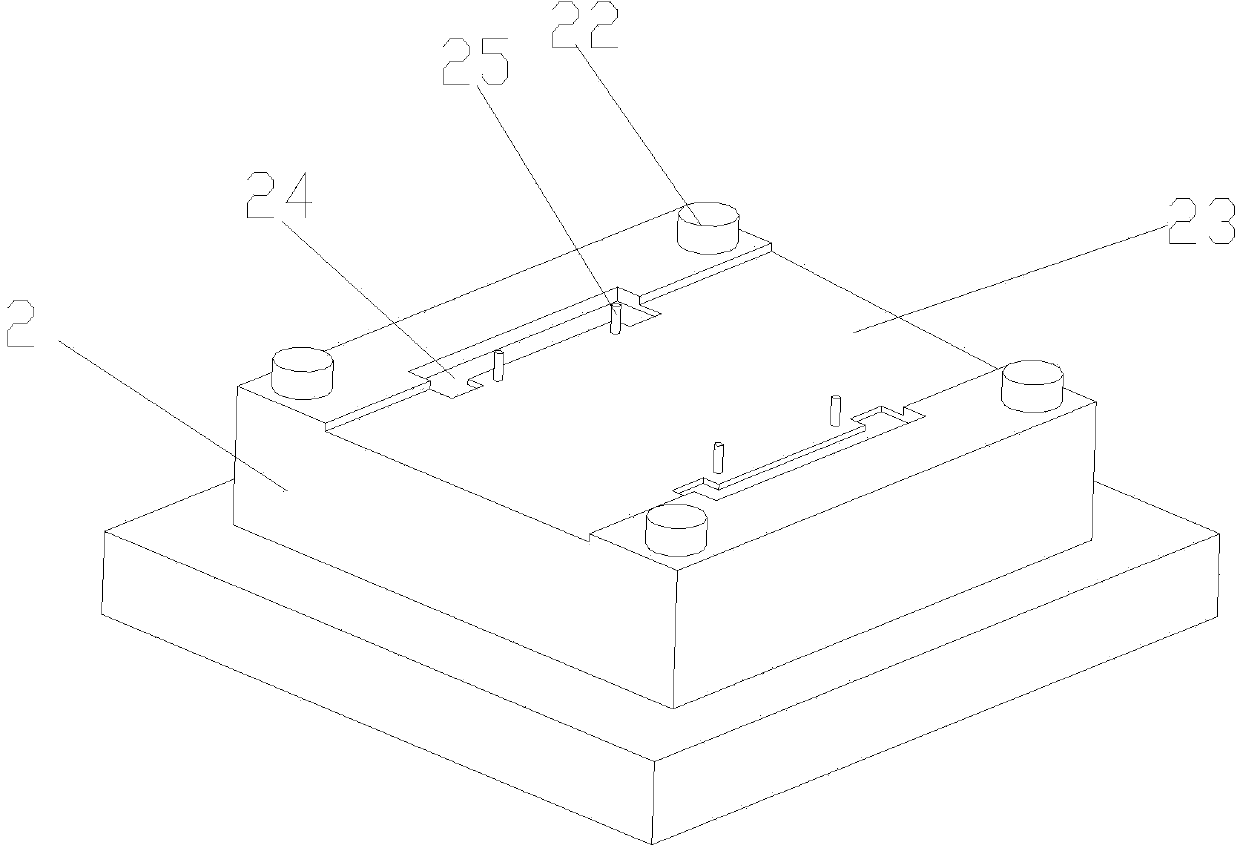

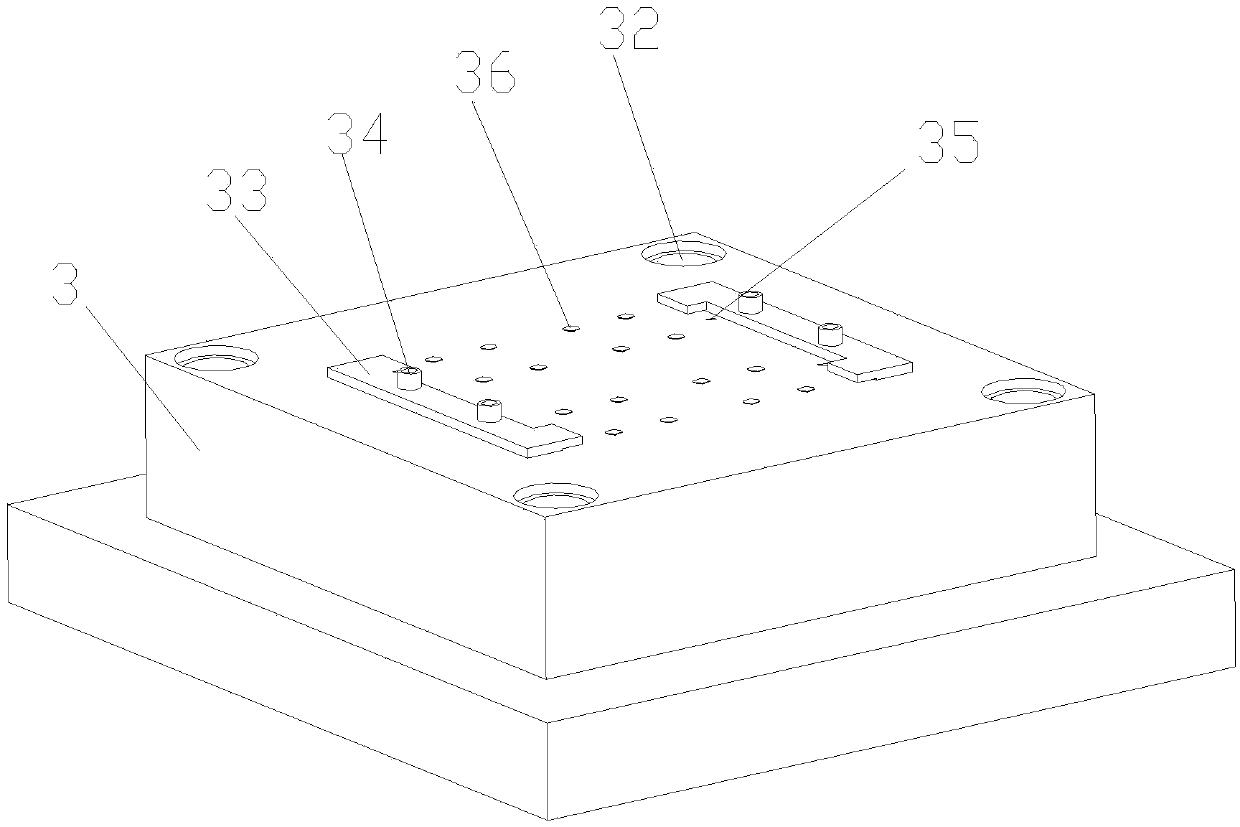

Die-cutter

InactiveCN103692487APrecise positioningEffective positioningMetal working apparatusStructural engineeringMechanical engineering

Owner:SUZHOU DONGFU ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com